Patents

Literature

2385results about How to "Cool evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

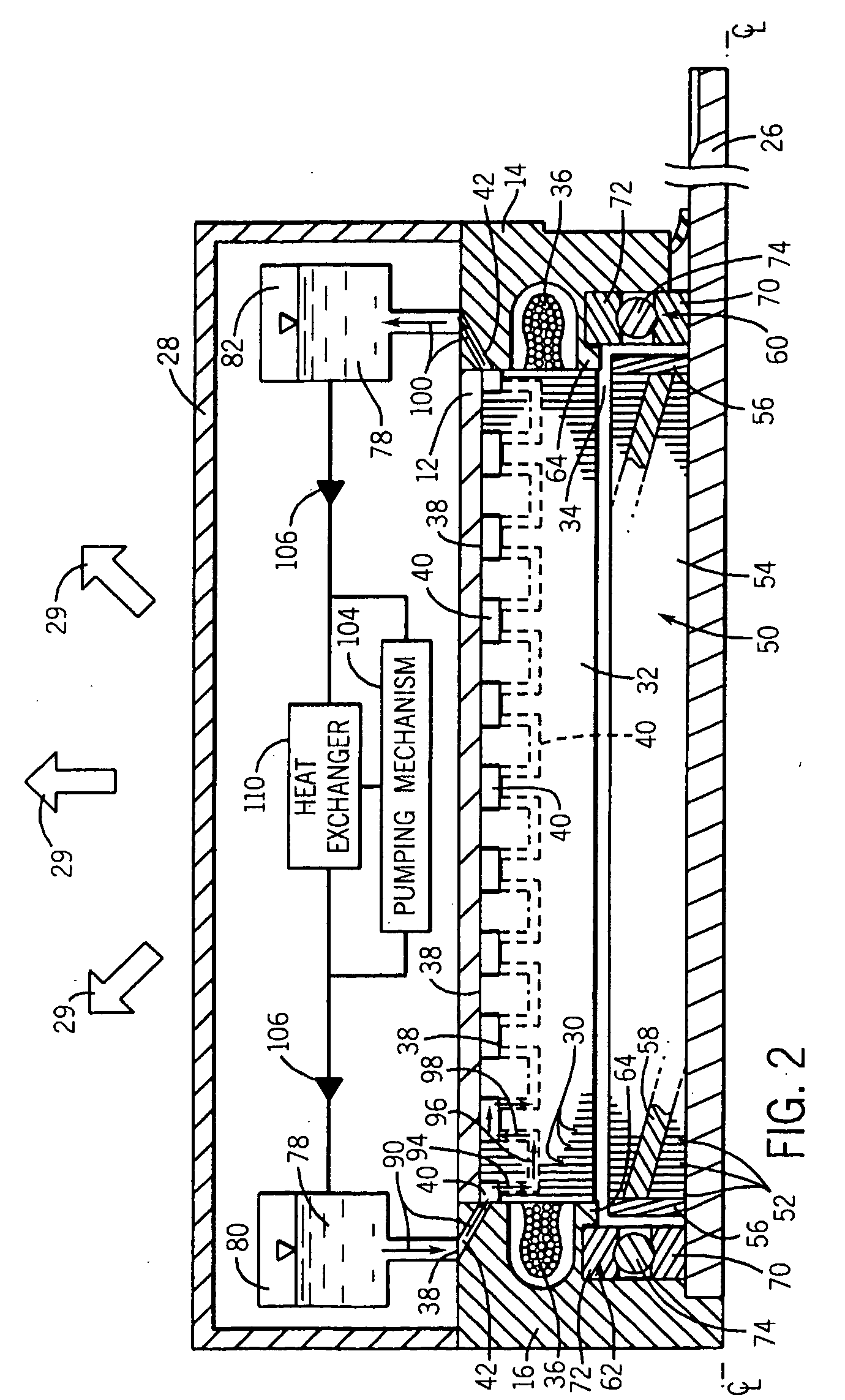

Unit for varying a temperature of a test piece and testing instrument incorporating same

ActiveUS7115838B2Easy to control temperatureUniform temperature distributionDrying solid materials with heatDomestic cooling apparatusInstrumentationCoolant

Owner:ESPEC CORP

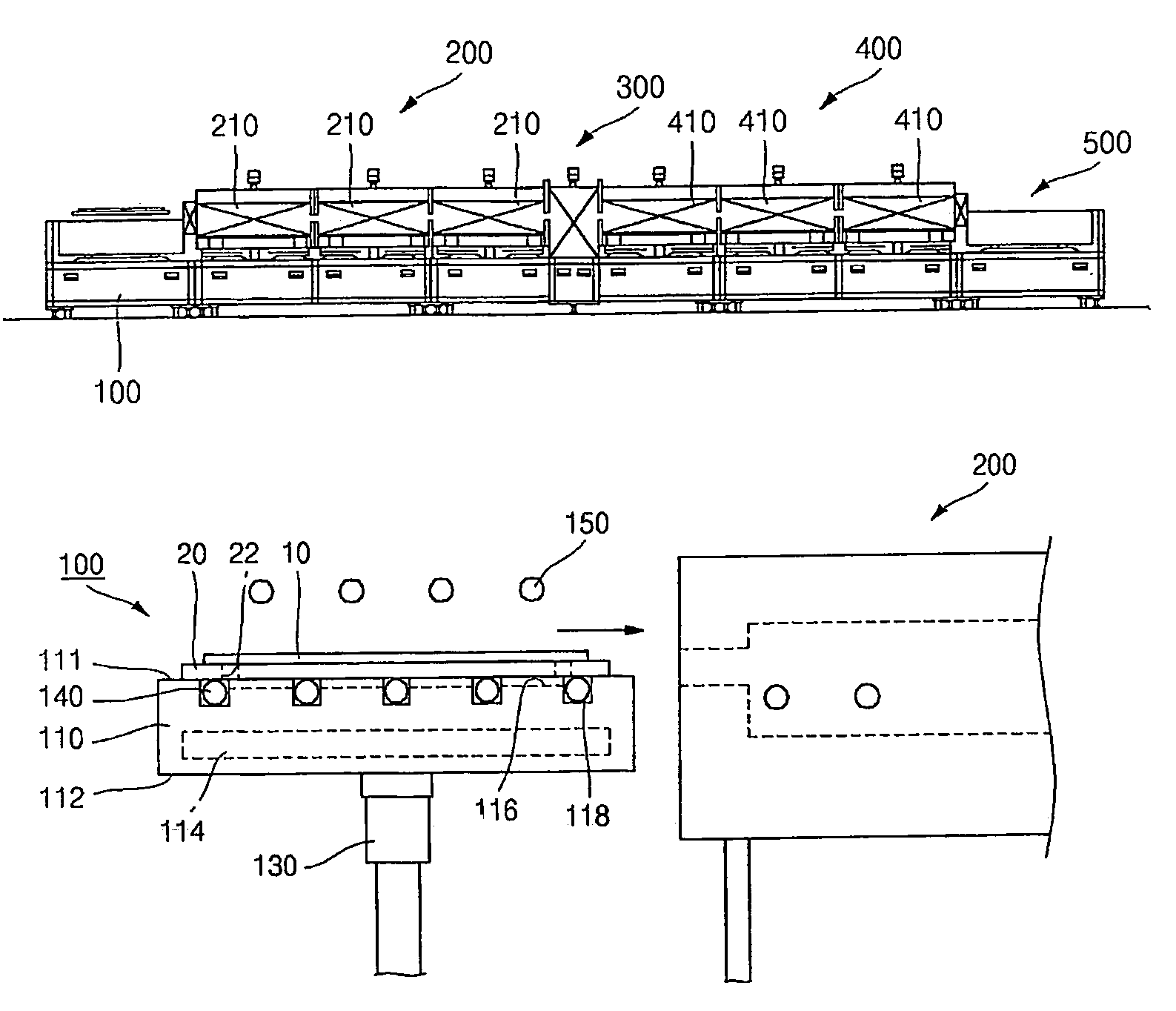

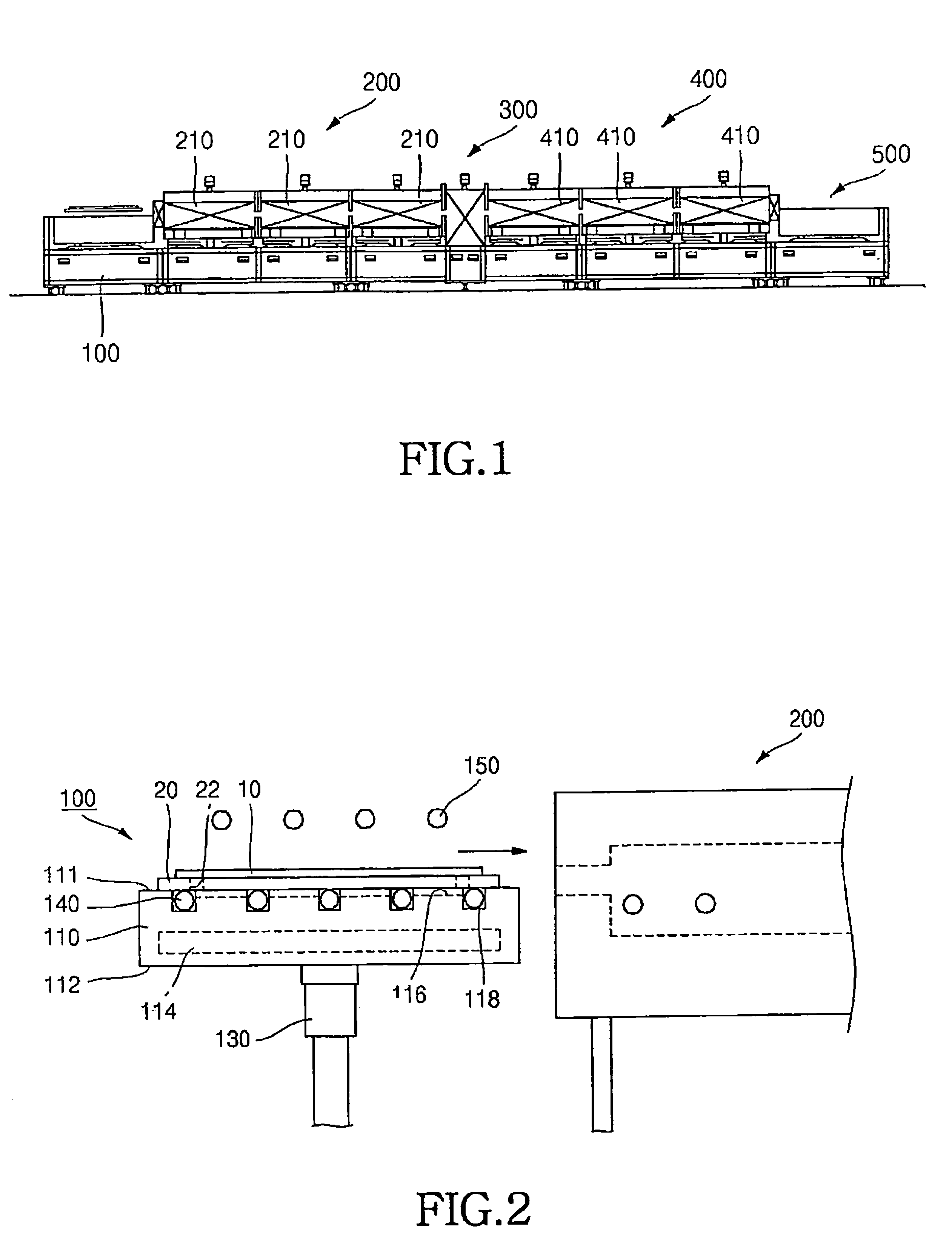

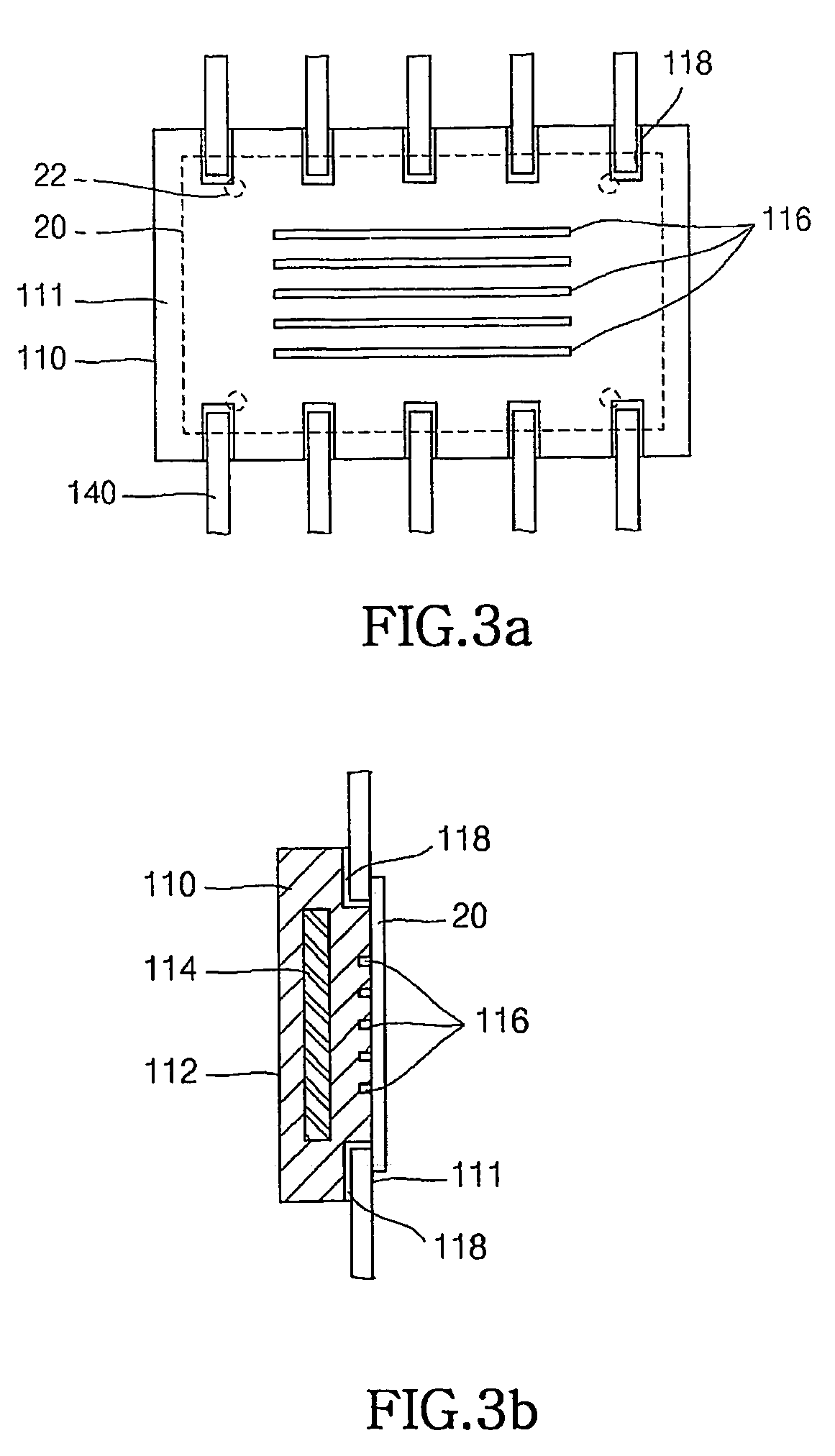

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

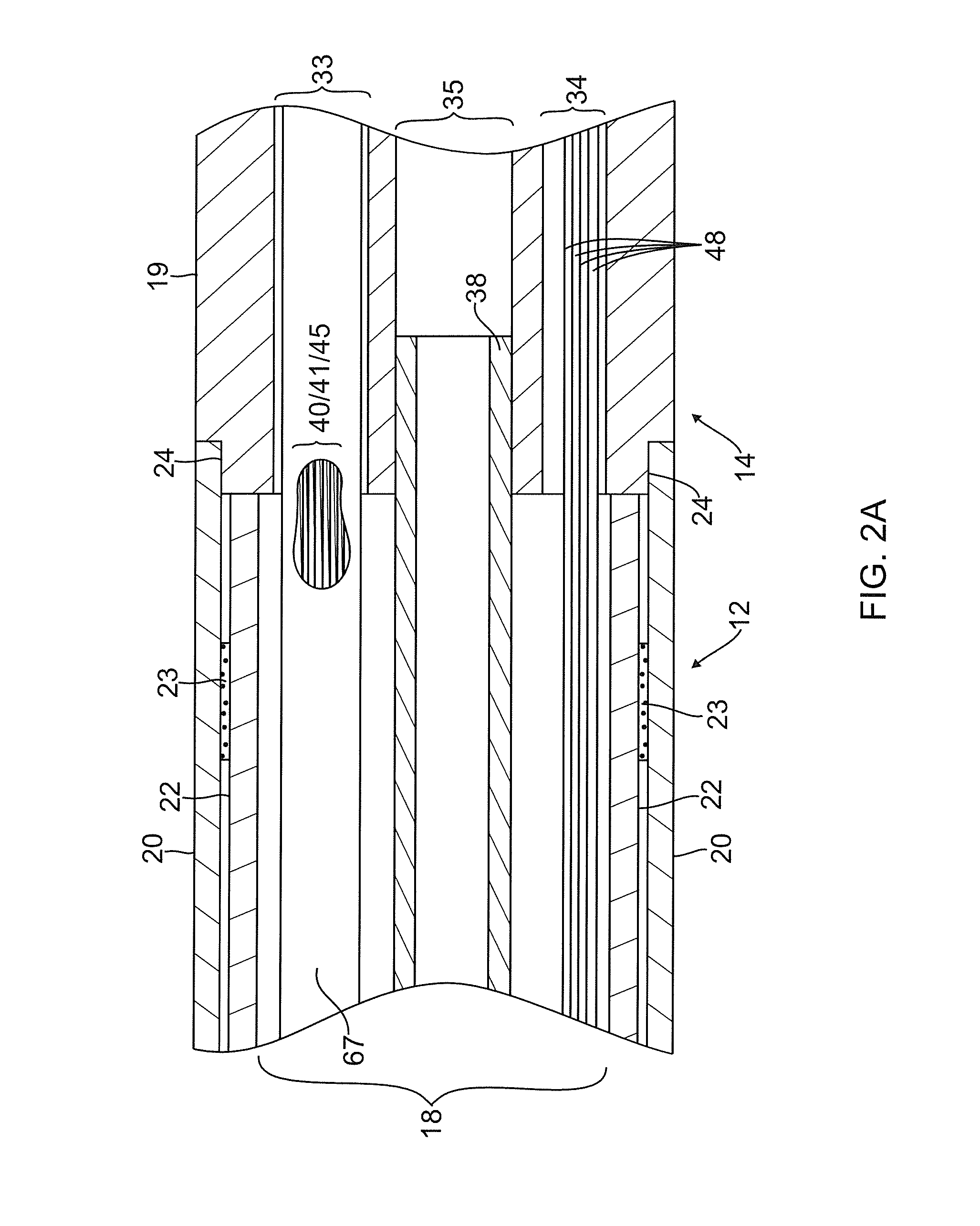

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

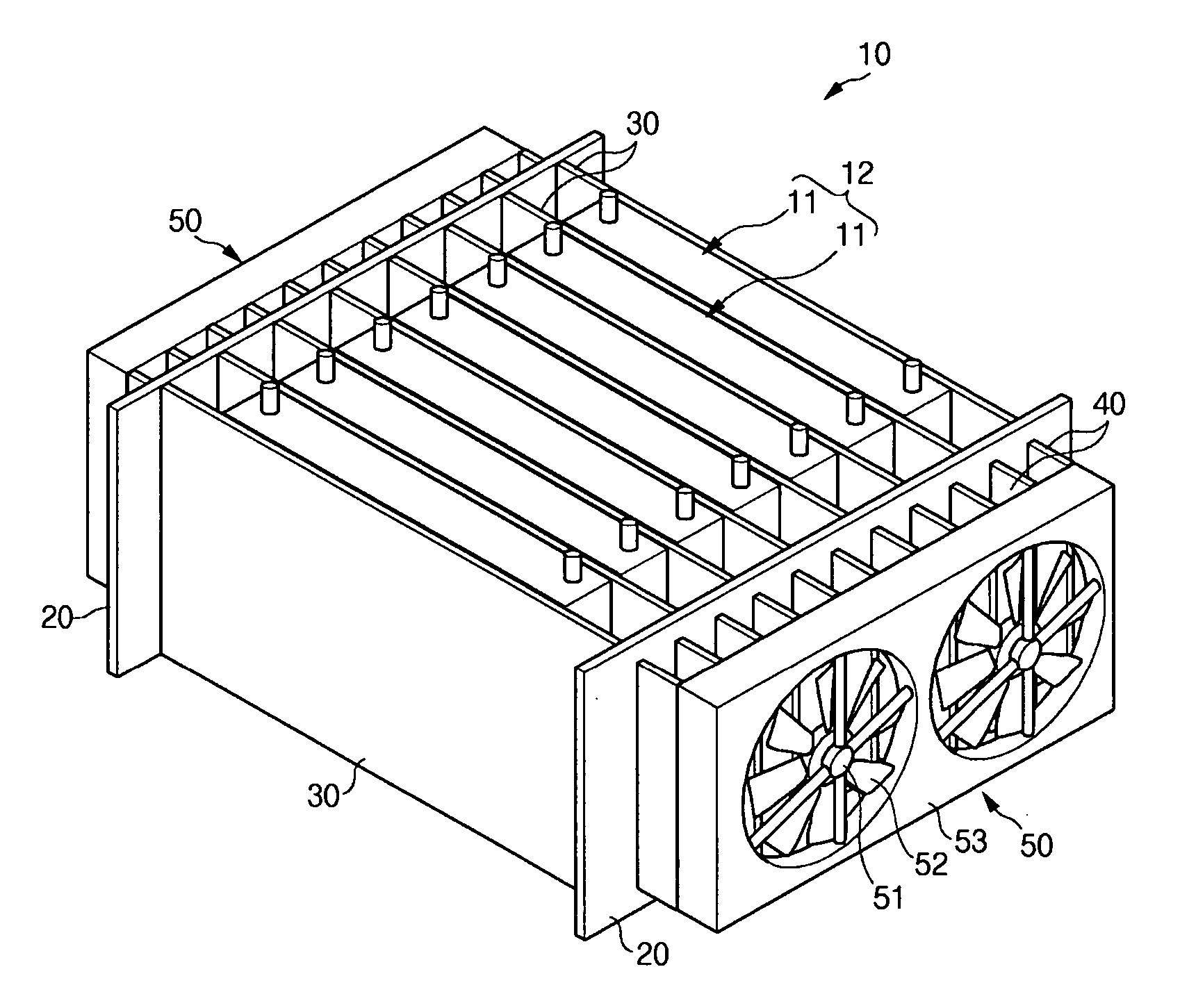

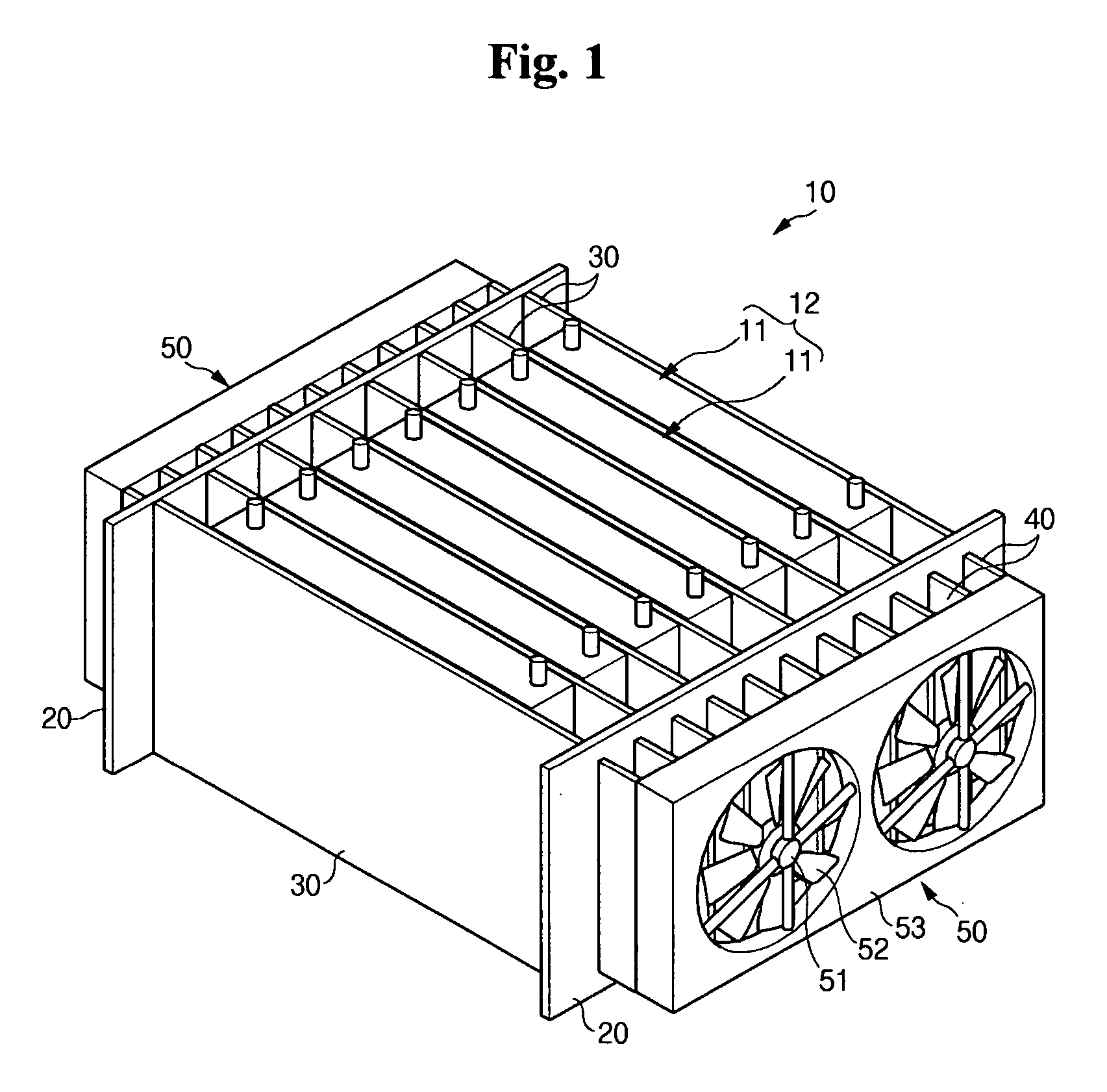

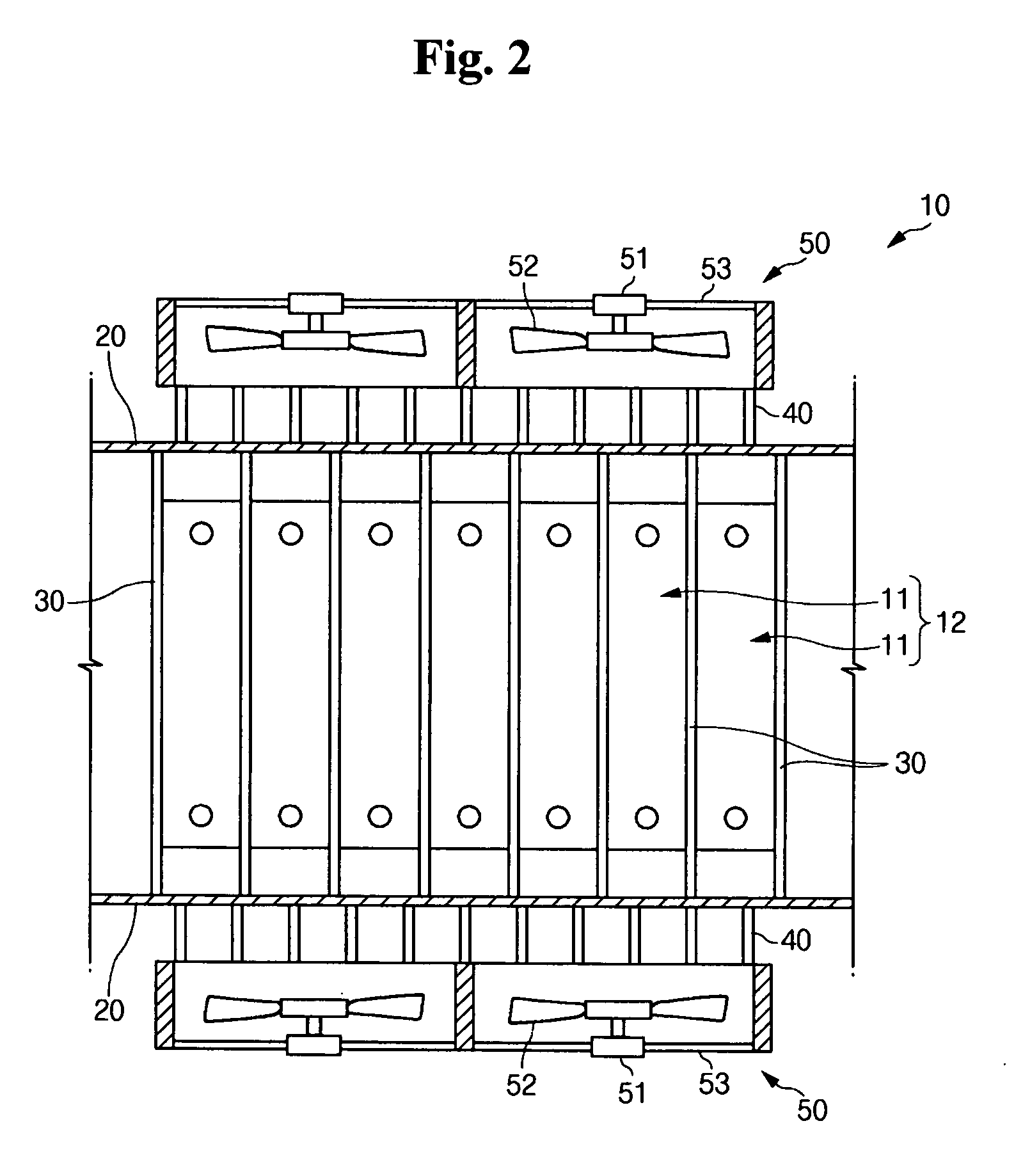

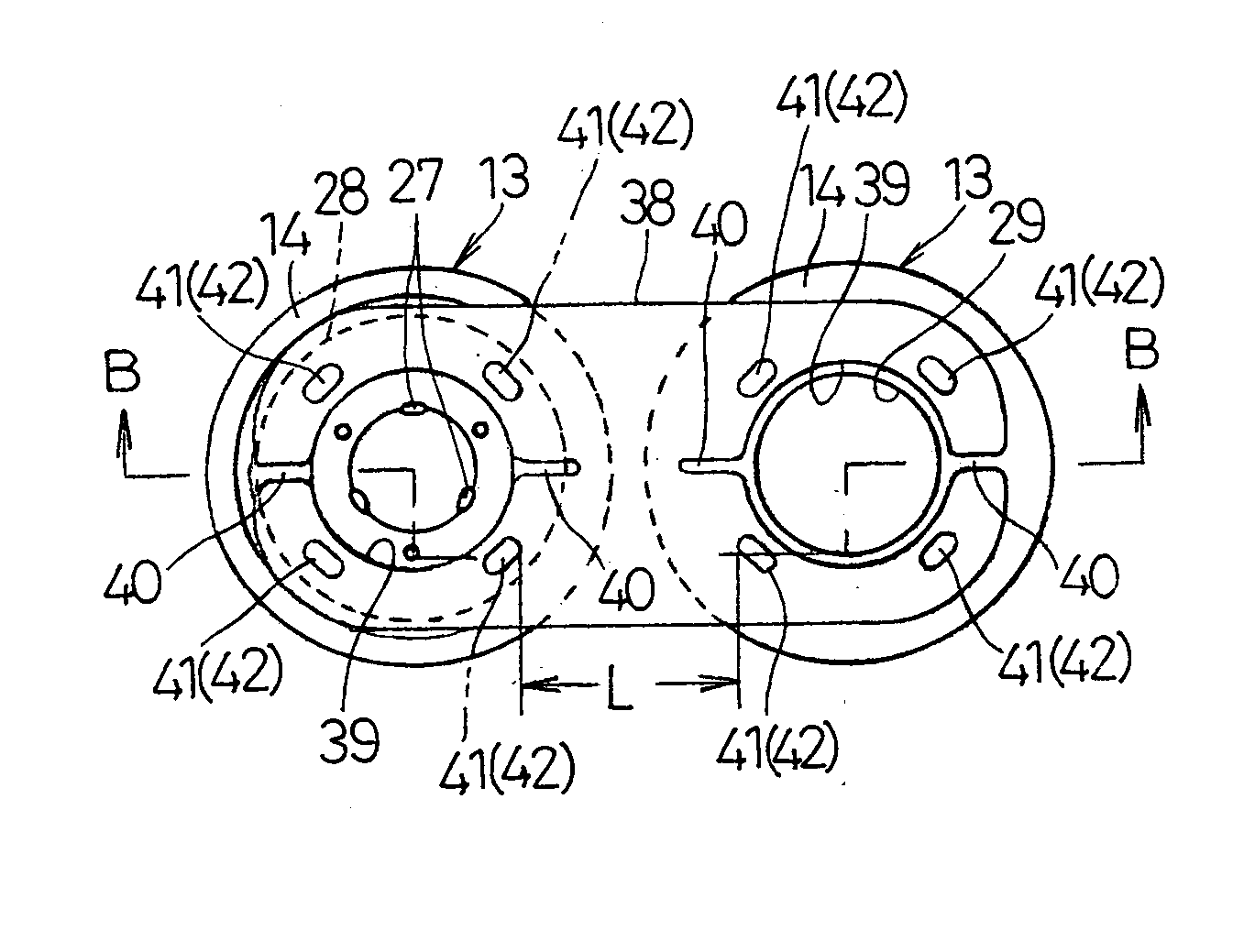

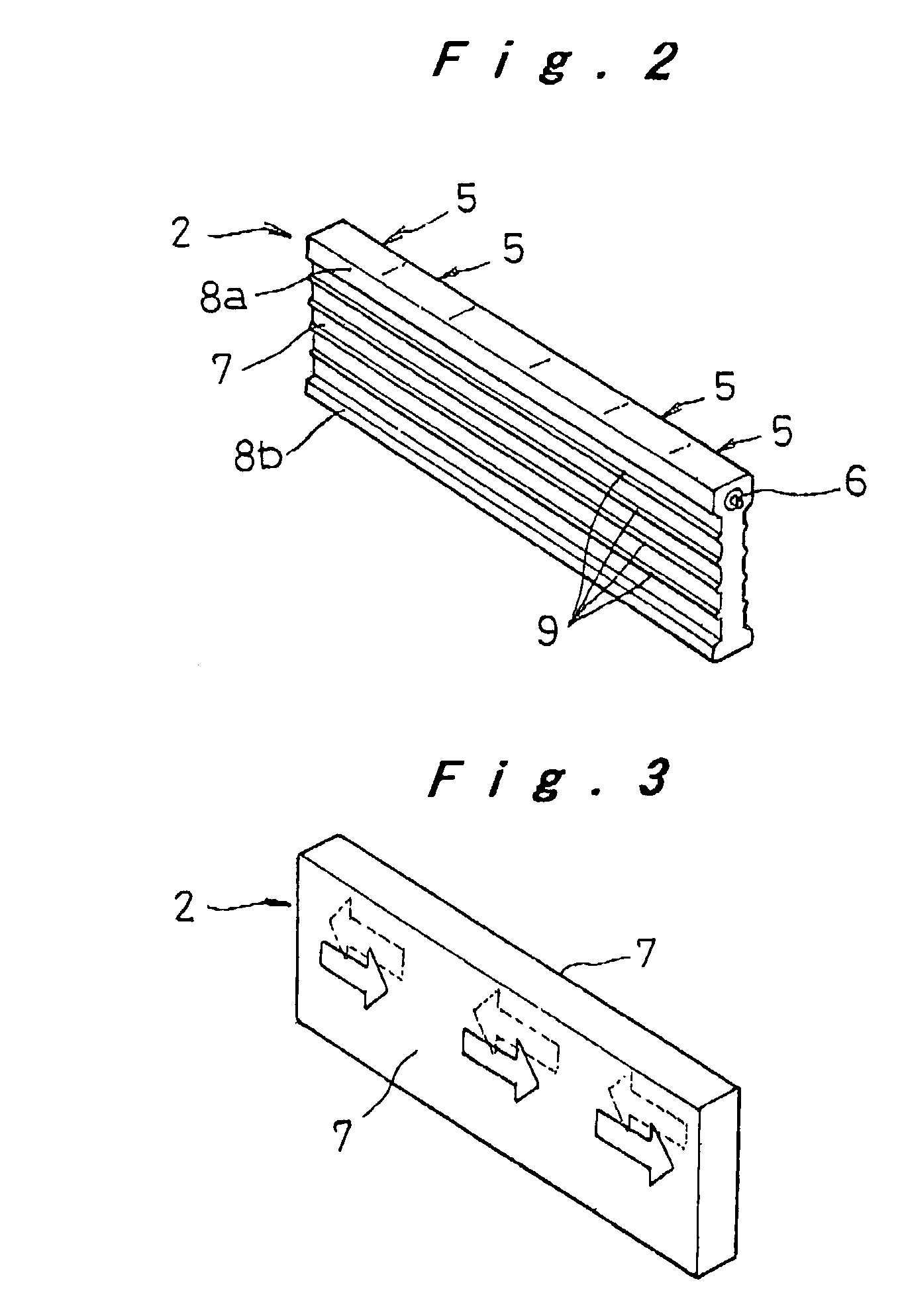

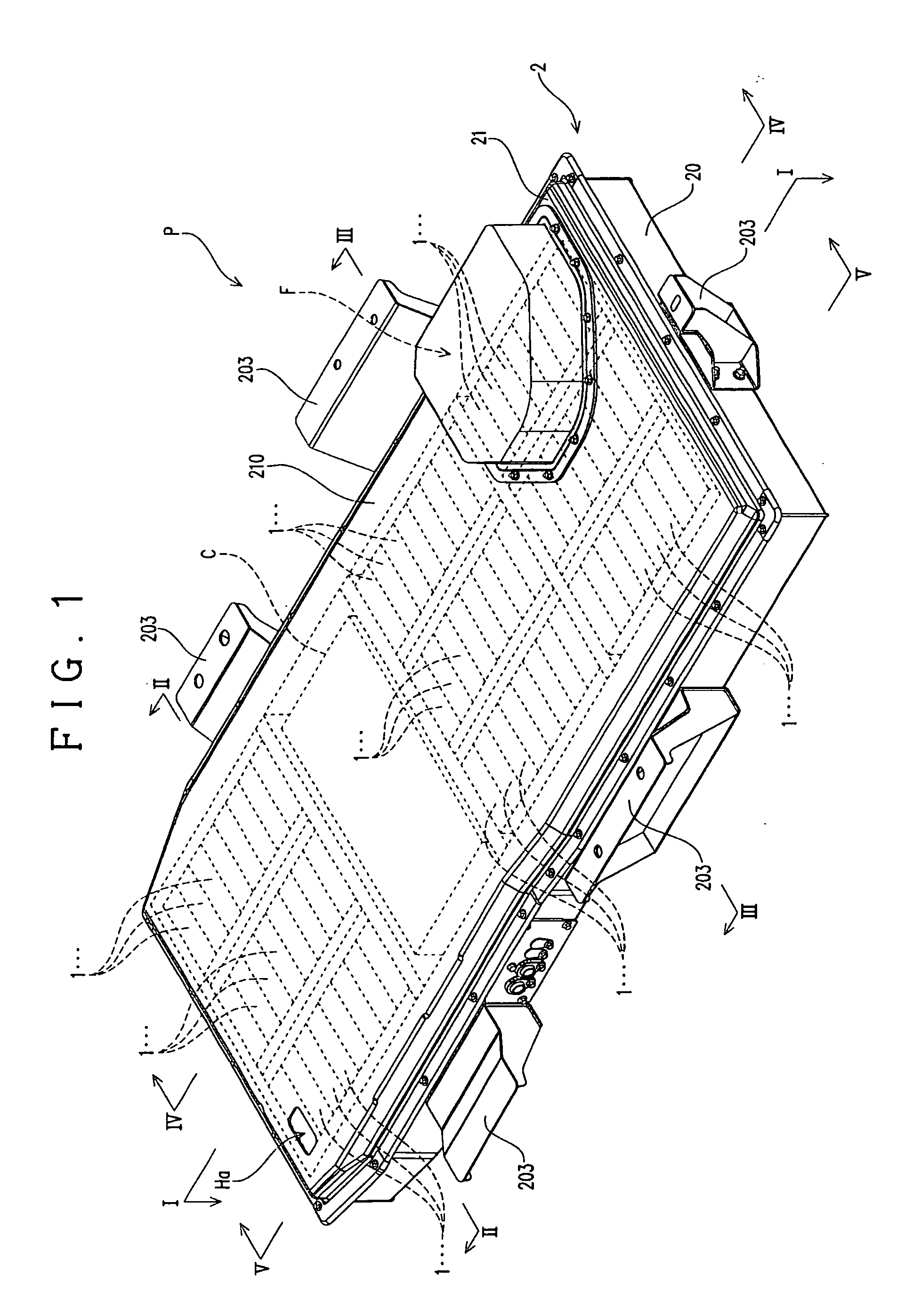

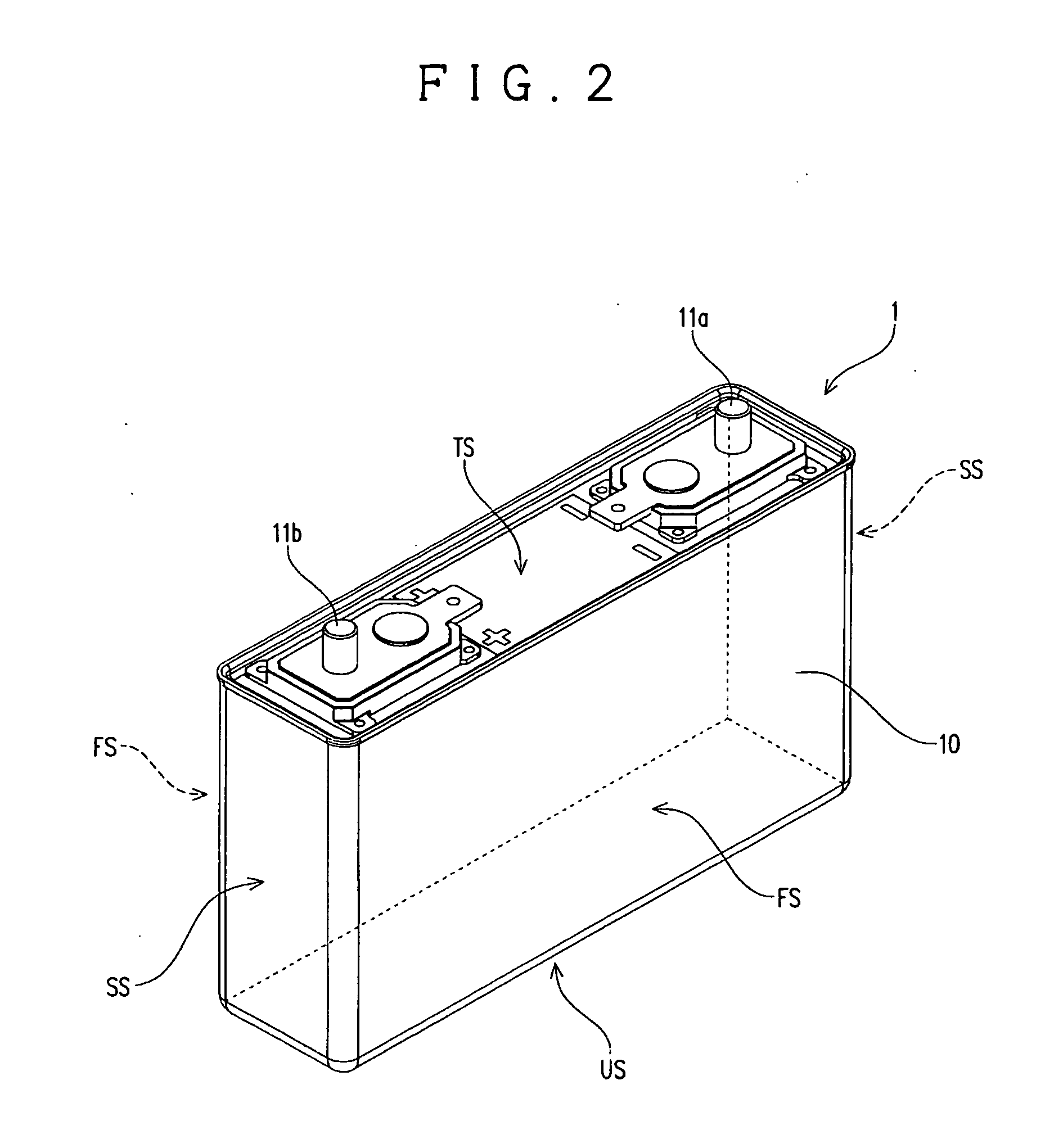

Secondary battery module

ActiveUS20060216582A1Improve cooling efficiencyCool evenlyPrimary cell to battery groupingCell temperature controlElectrical and Electronics engineeringHeat transfer

A secondary battery module includes a plurality of unit batteries, a housing receiving the unit batteries, a cell barrier plate disposed between the unit batteries to transfer heat generated from the unit batteries, a cooling plate disposed in contact with an end of the cell barrier plate, and a heat dissipation assembly disposed proximate to the cooling plate to dissipate heat transferred to the cooling plate.

Owner:SAMSUNG SDI CO LTD

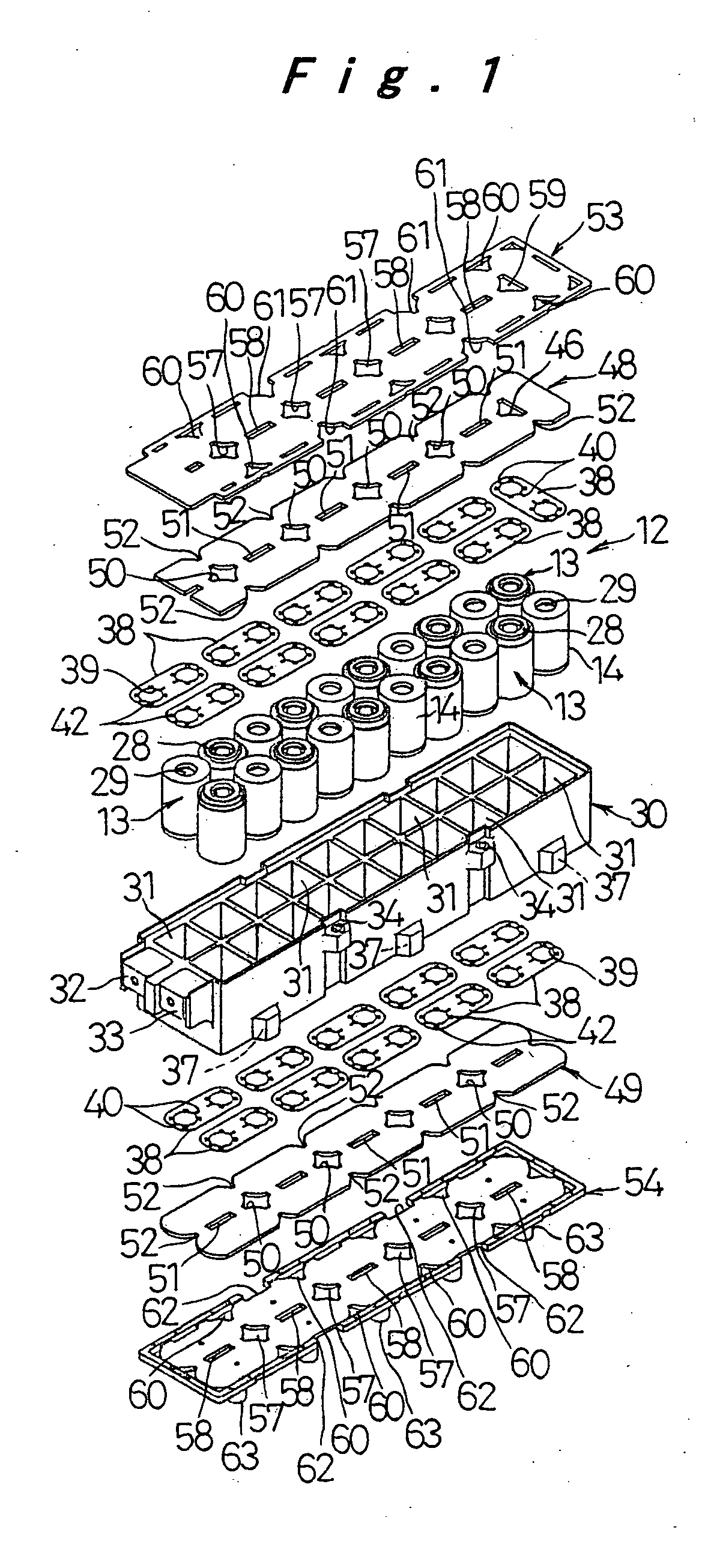

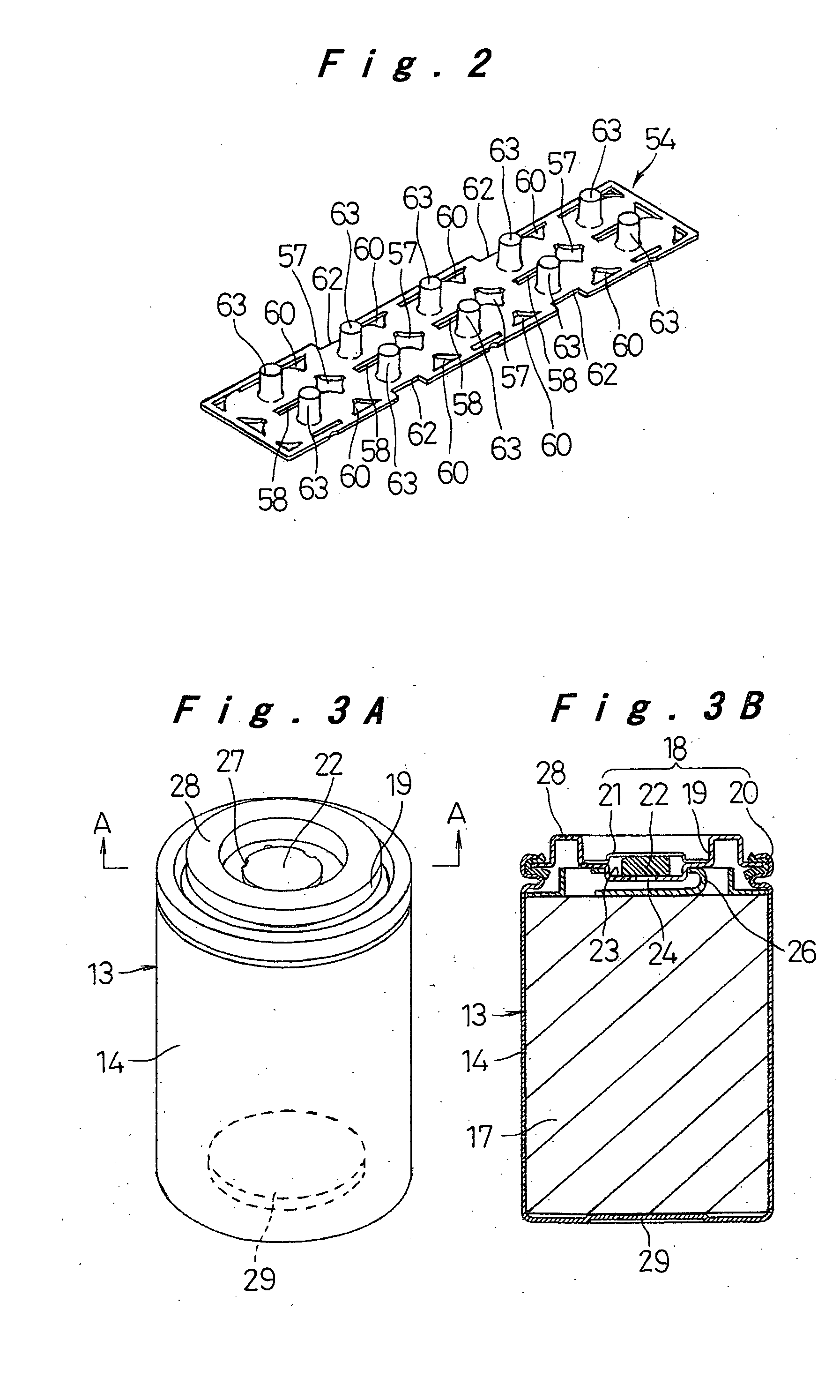

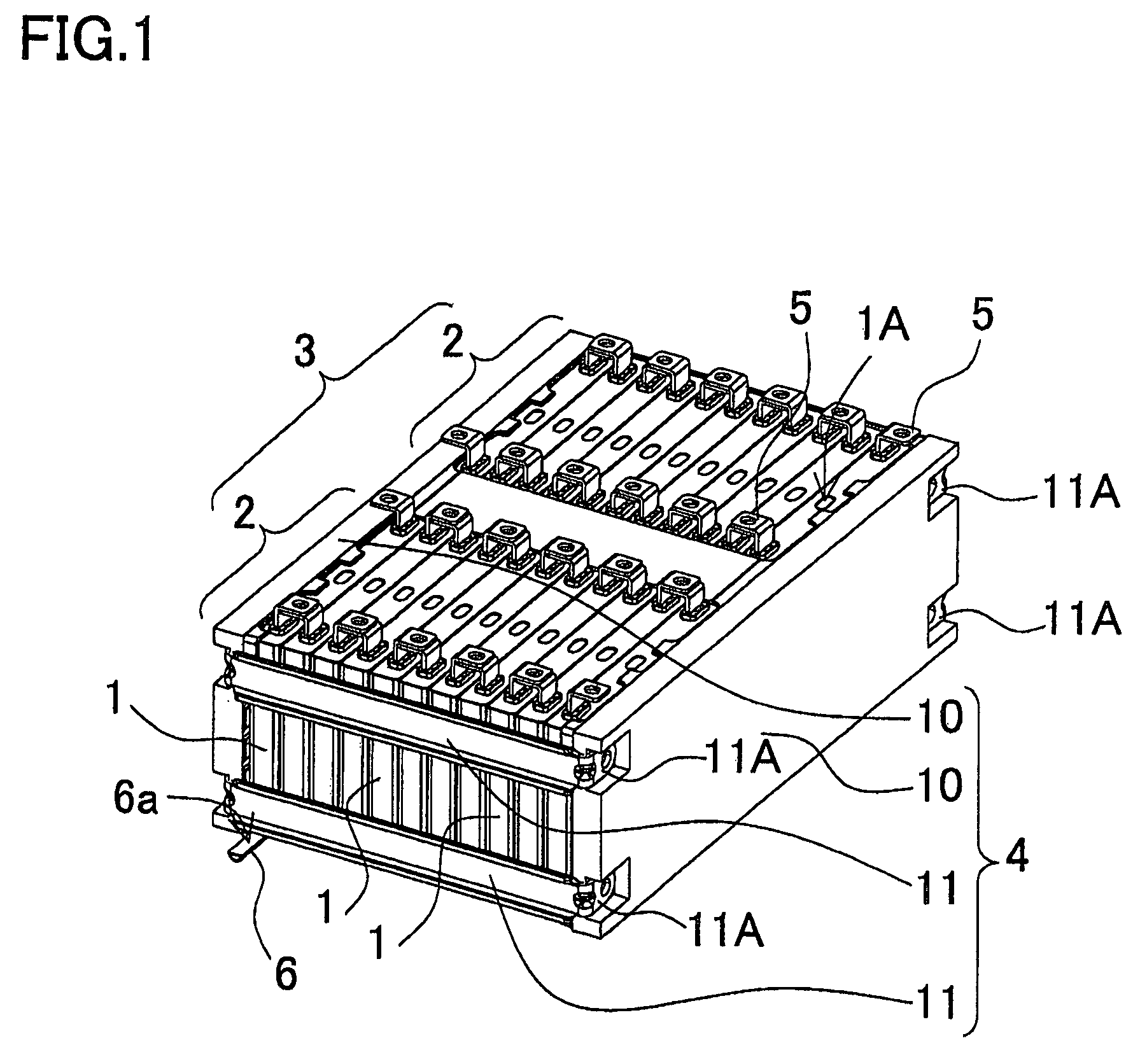

Battery connection structure, battery module, and battery pack

InactiveUS20050079408A1Increase productionReduce in quantityPrimary cell to battery groupingElectric propulsion mountingElectrical resistance and conductanceSolid structure

A connection plate in form of flat plate is welded to be connected to portion that are close to each other, i.e., a connection-electrode portion of one of two adjacent cells and a bottom of a cell case of the other cell, while being bridged between the connection-electrode portion and the bottom of the cell case, thereby forming an inexpensive connecting structure between cells, that reduces the electric resistance, by simple processes. A battery module having a solid structure impervious to vibration or shock is formed by accommodating cylindrical cells in cell-accommodating portions, each of which has a square shape seen from the front, of a holder case made of synthetic resin with their cell axes arranged in parallel, and by closing both sides of the holder case with cover members having radiation holes. Then, a battery pack is formed by attaching outer plates to a plurality of such battery modules that are arranged and integrating them.

Owner:PANASONIC CORP

Computer rack heat extraction device

InactiveUS6412292B2More revenueExcessive coolingDucting arrangementsDigital data processing detailsAppliance componentEngineering

An air conditioning cooling apparatus and method which includes the steps of supplying cooling air generated from a cooling apparatus into an air passageway formed below a floor; guiding the cooling air within the air passageway into an equipment assembly disposed on the floor through an opening located in the floor; communicating the cooling air introduced into the equipment assembly into a plenum and introducing the air released from within the equipment into the plenum and communicating the released air through the cooling apparatus for cooling the released air. The method permits temperature differential between the air supplied to the air passageway and the air introduced into the plenum from the equipment assembly to be 45.degree. F. to substantially 40.degree. F. so as to reduce the power necessary for operating on the fan of the blowing apparatus. The equipment assembly utilizes an air flow control mechanism so as to substantially evenly distribute cooling air to the equipment.

Owner:EATON INTELLIGENT POWER LIMITED

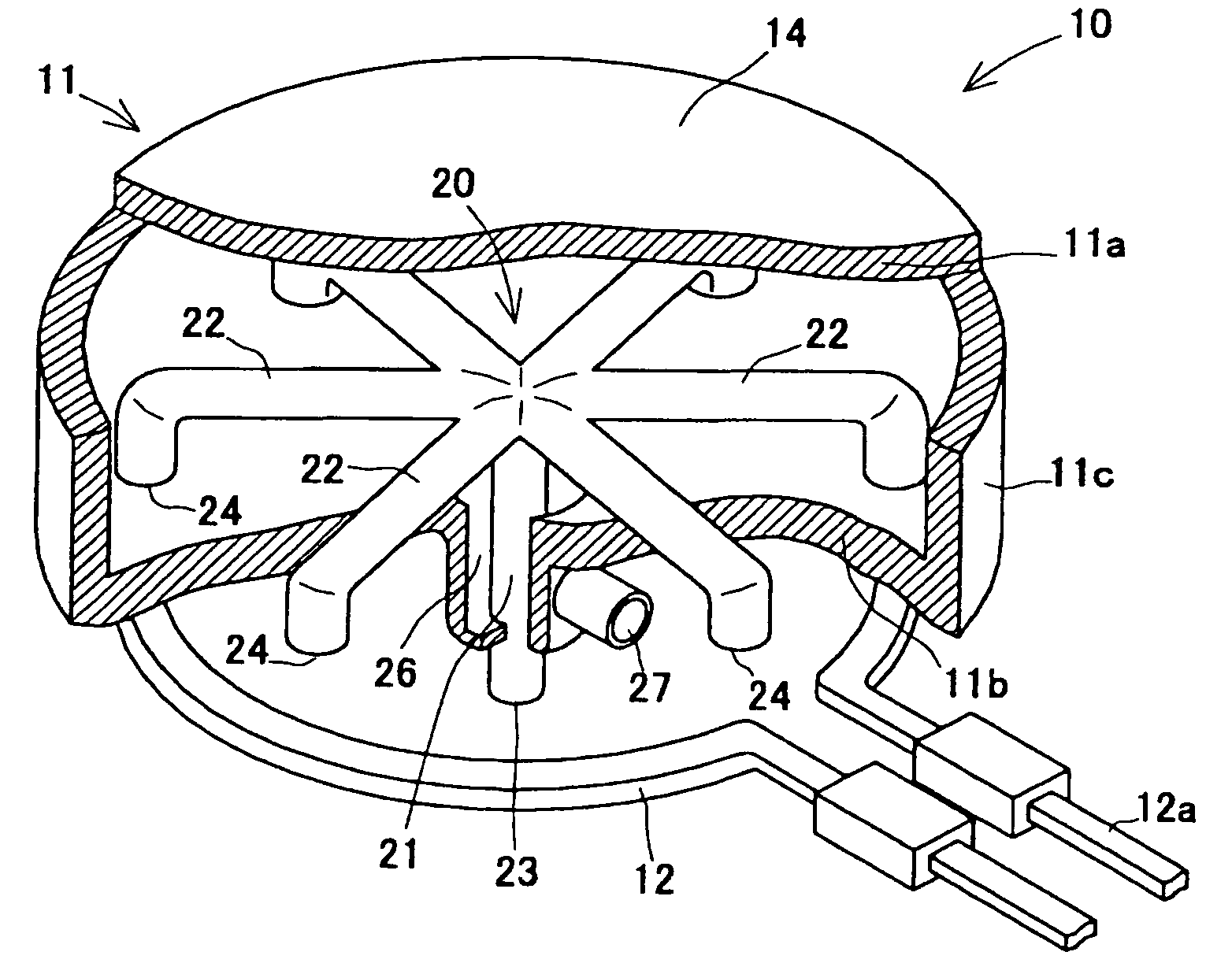

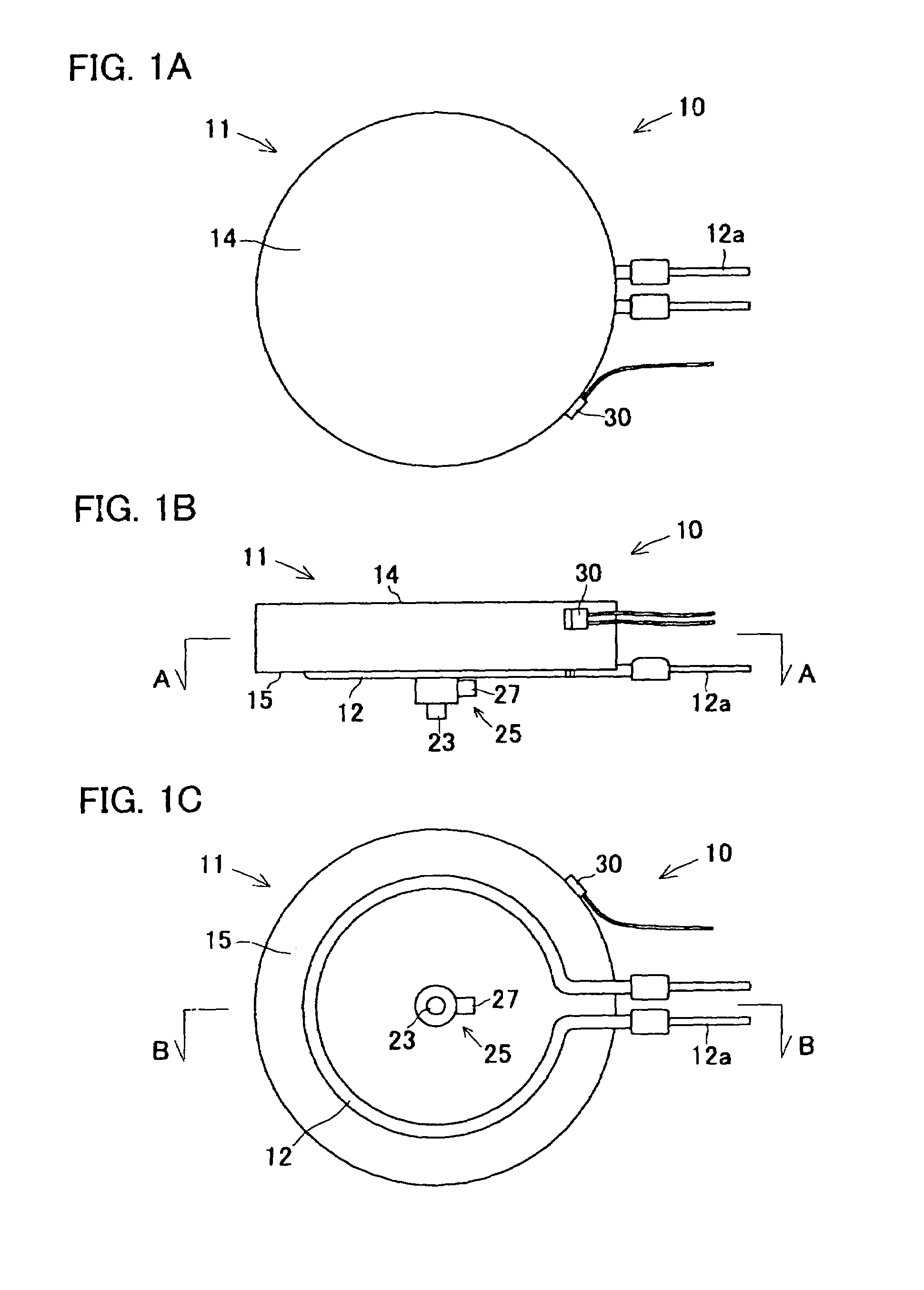

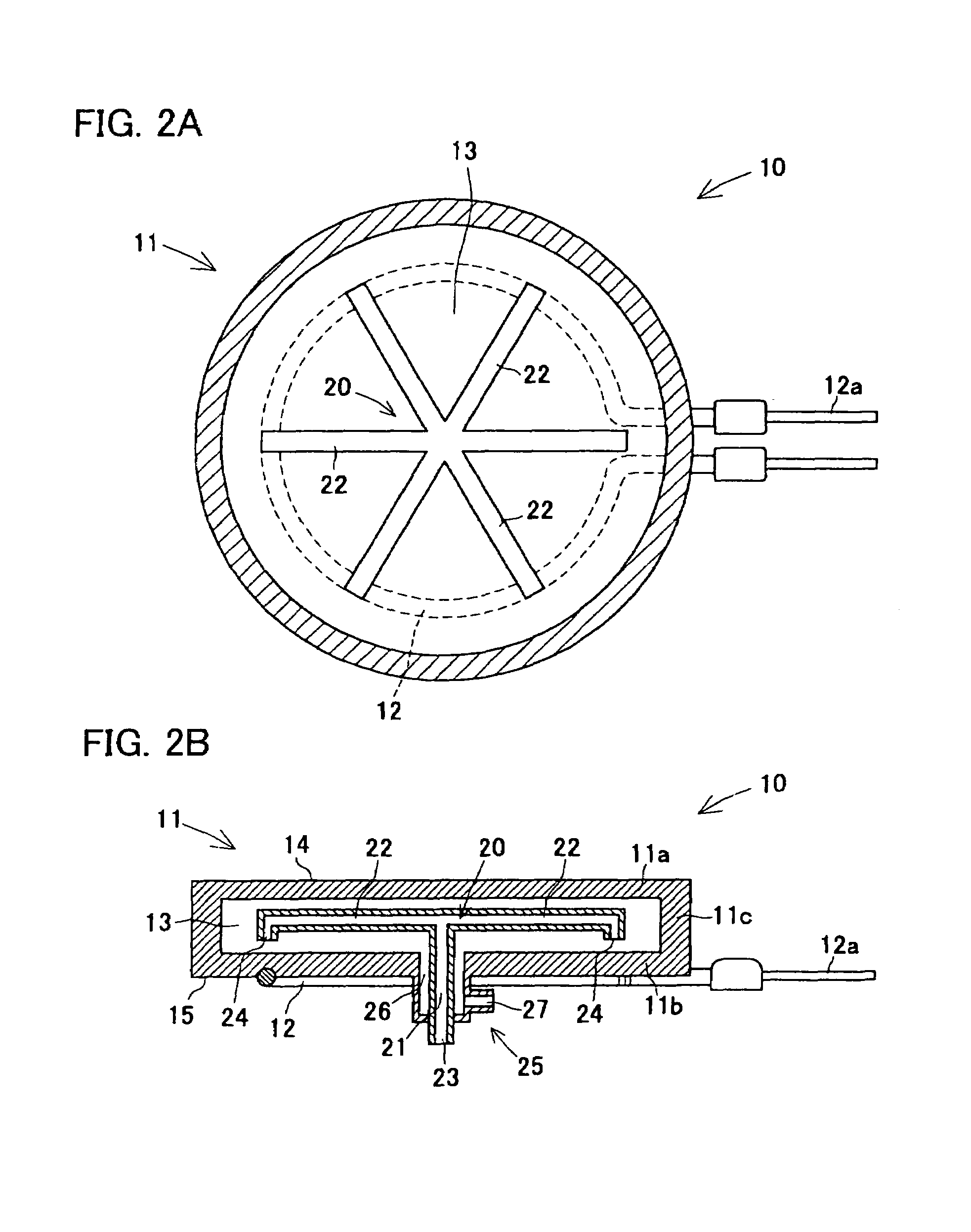

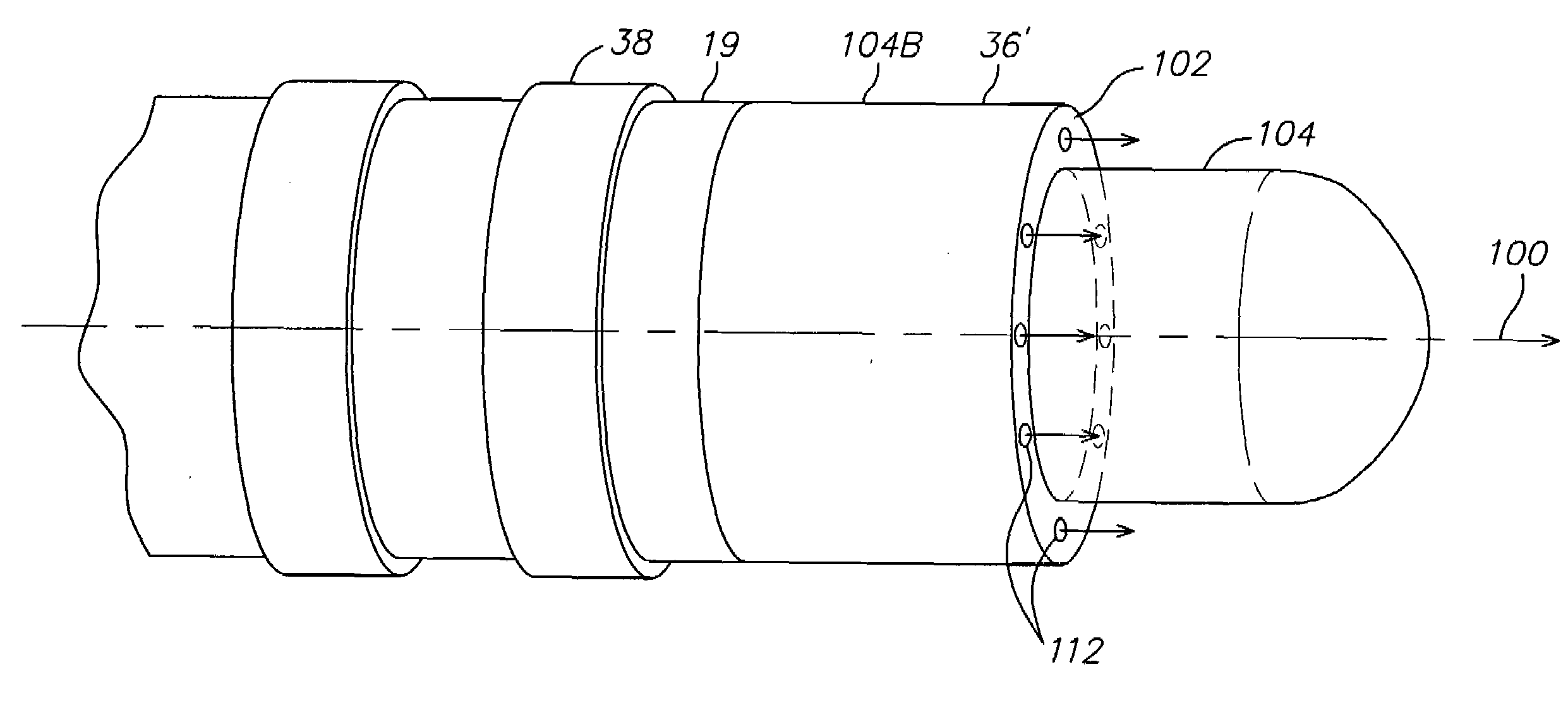

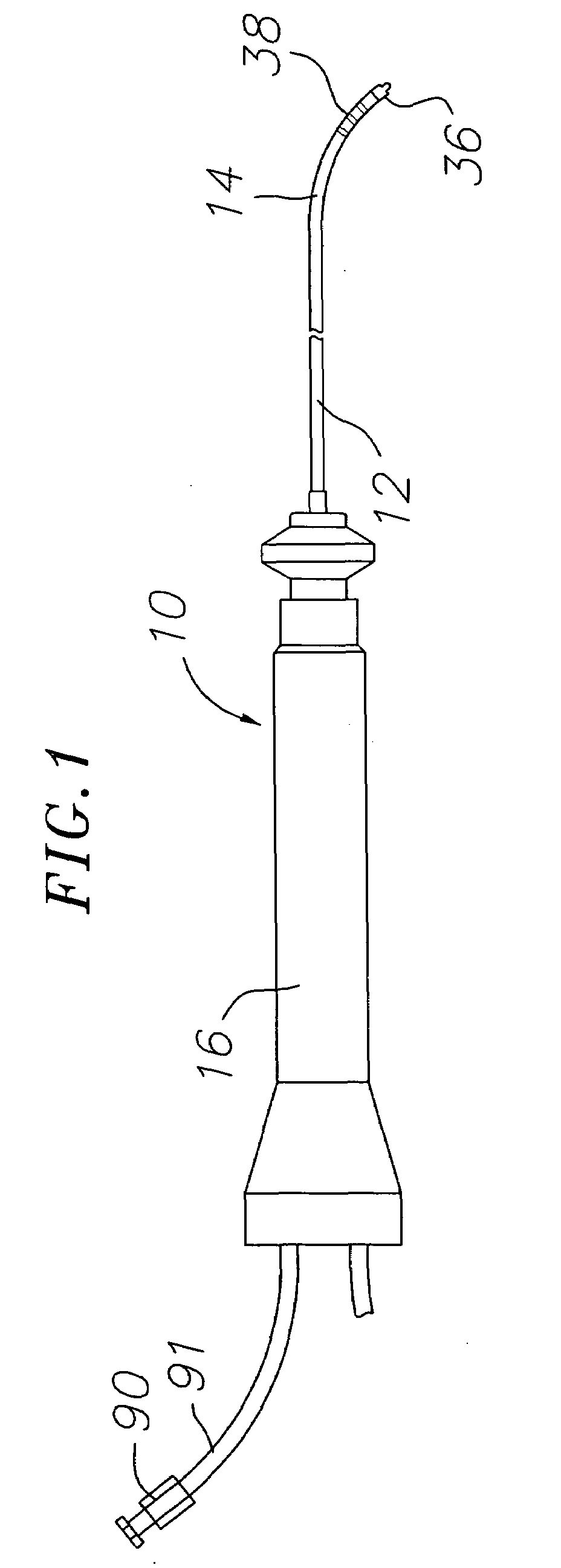

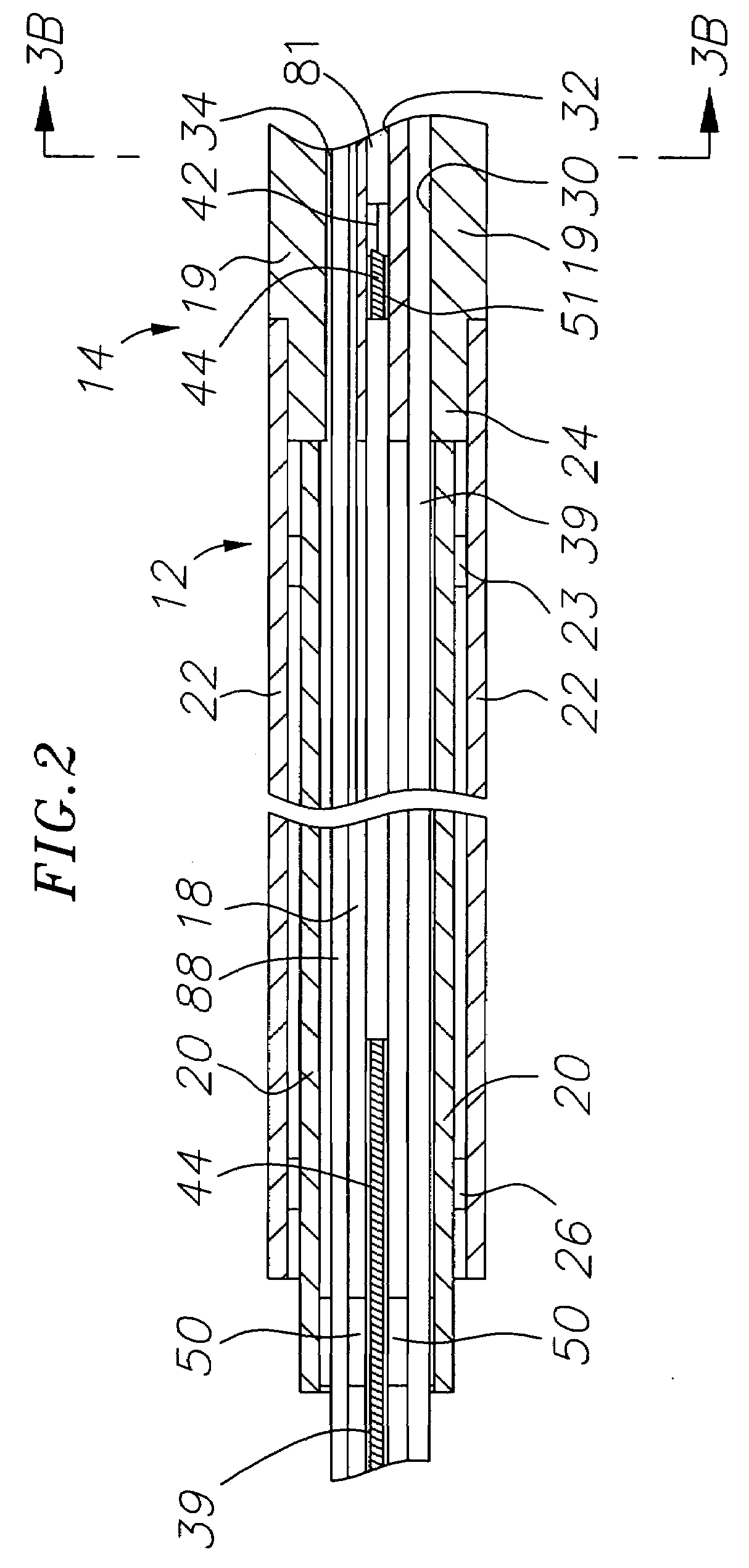

Irrigated catheter with internal position sensor

ActiveUS20110264089A1Promotes fluid diffusion and dispersionEasy feedingElectrocardiographySurgical navigation systemsDistal portionCatheter

A catheter carries a position sensor in a distal, on-axis position in an irrigated ablation tip electrode. The tip electrode has a shell wall that defines a cavity through which fluid flows and exits via fluid ports formed in the shell wall. The cavity is sealed by an internal member extends into the cavity with a baffle portion and a distal portion. The distal portion safely houses the position sensor and the baffle portion diffuses and disperses fluid entering the tip electrode for a more uniform flow through the cavity. The distal portion is configured to provide an annular region that runs along the length of the tip electrode to better feed fluid to the more distal fluid ports on the tip electrode for more uniform cooling at all locations on the tip electrode.

Owner:BIOSENSE WEBSTER INC

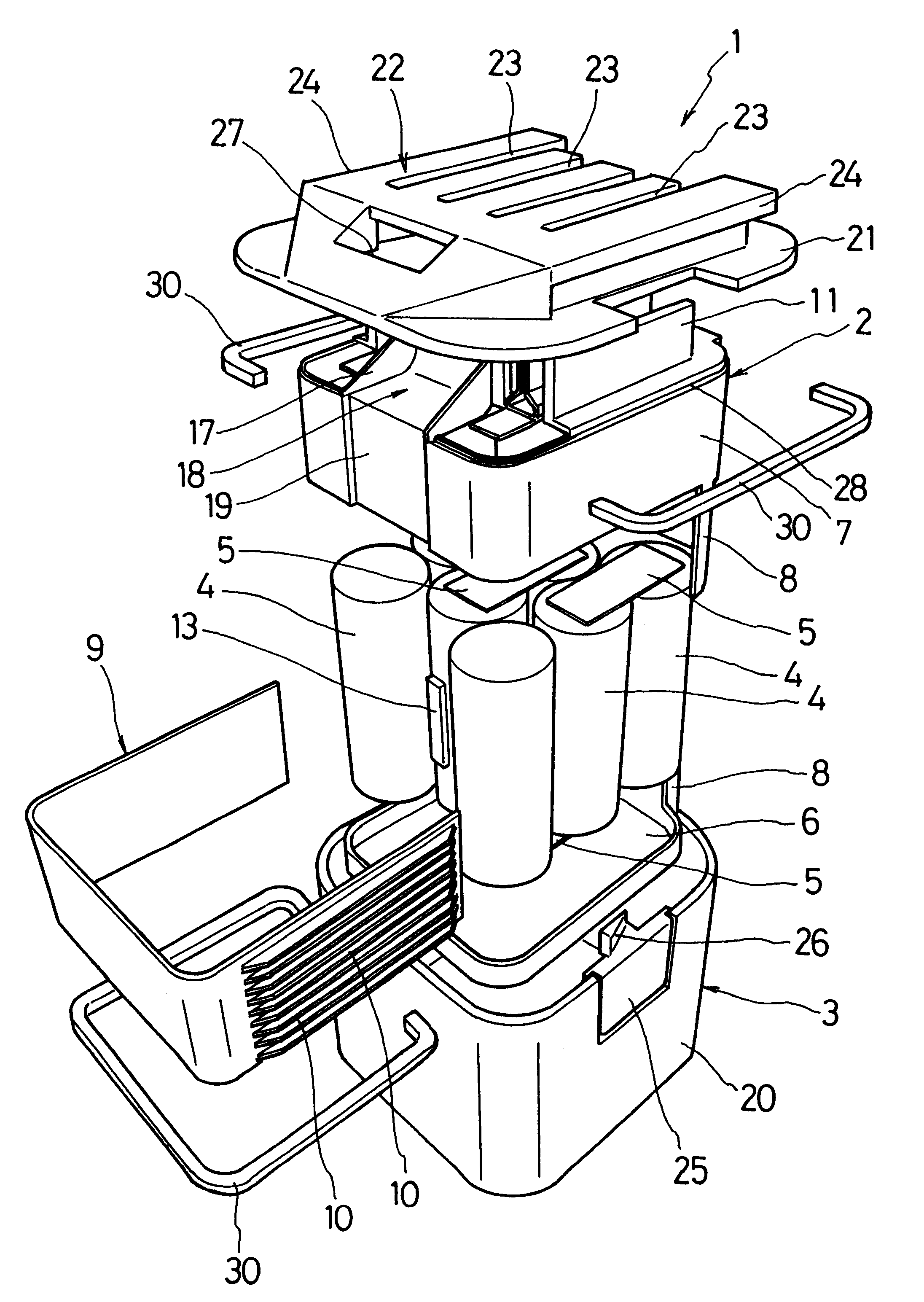

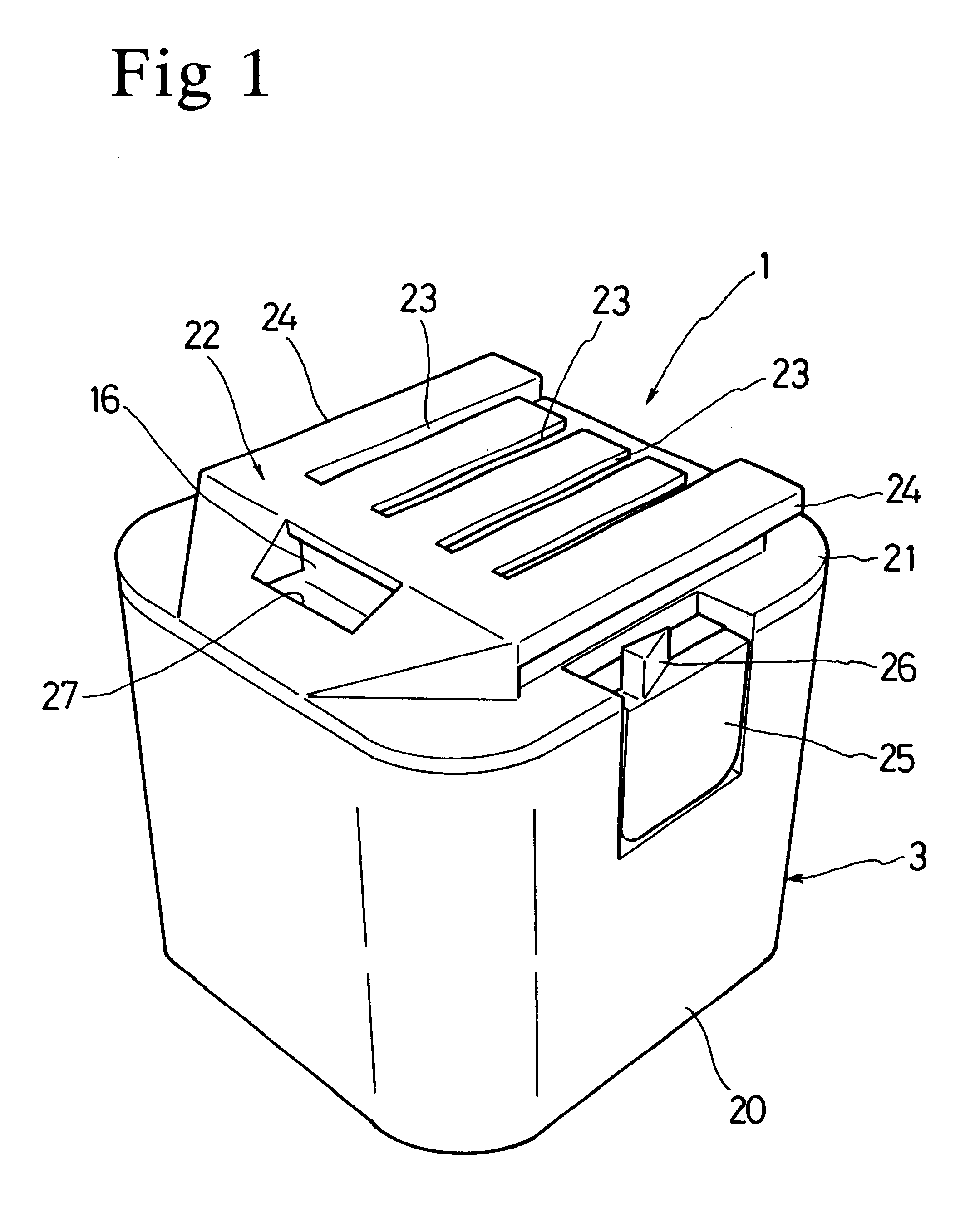

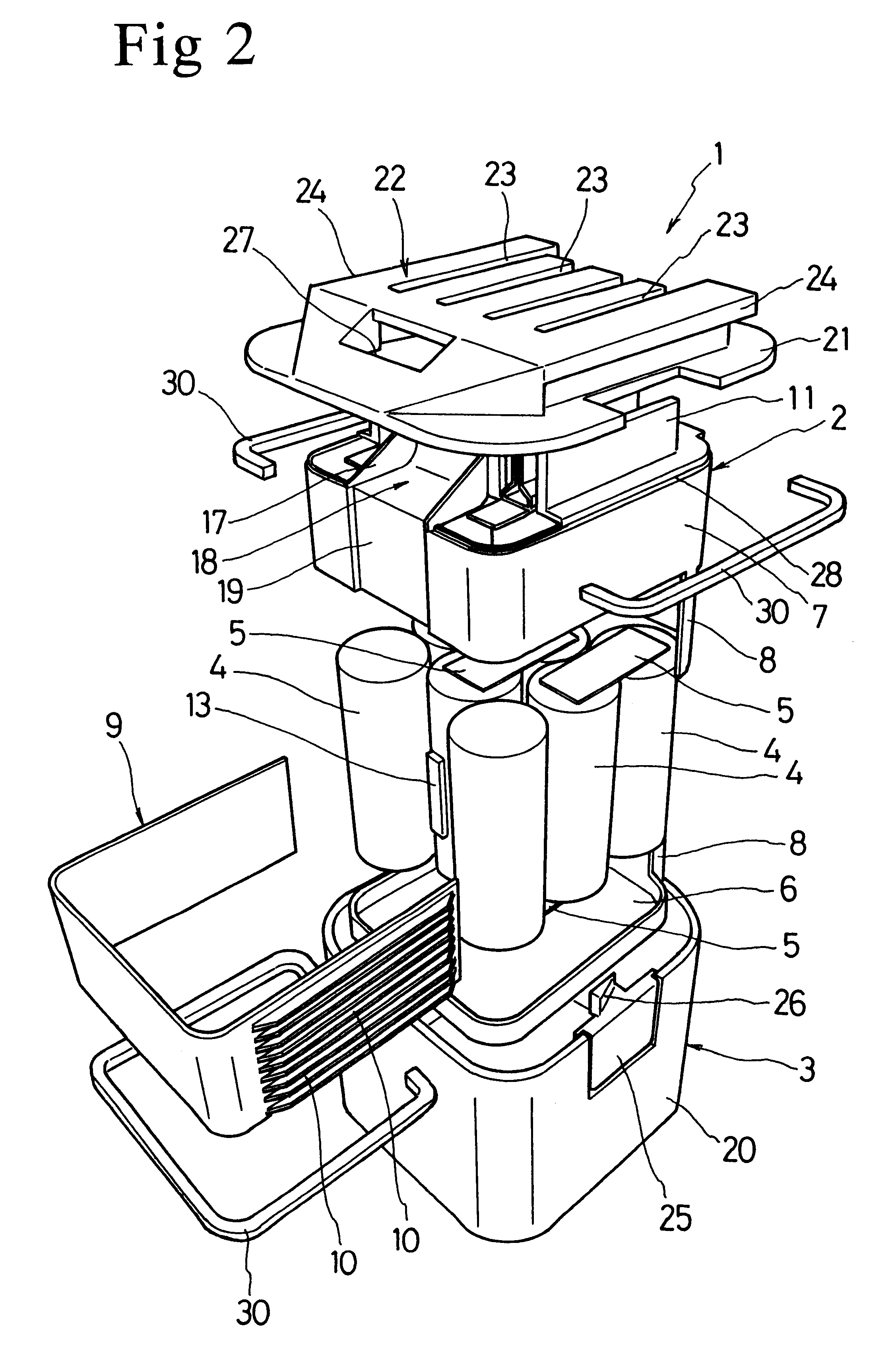

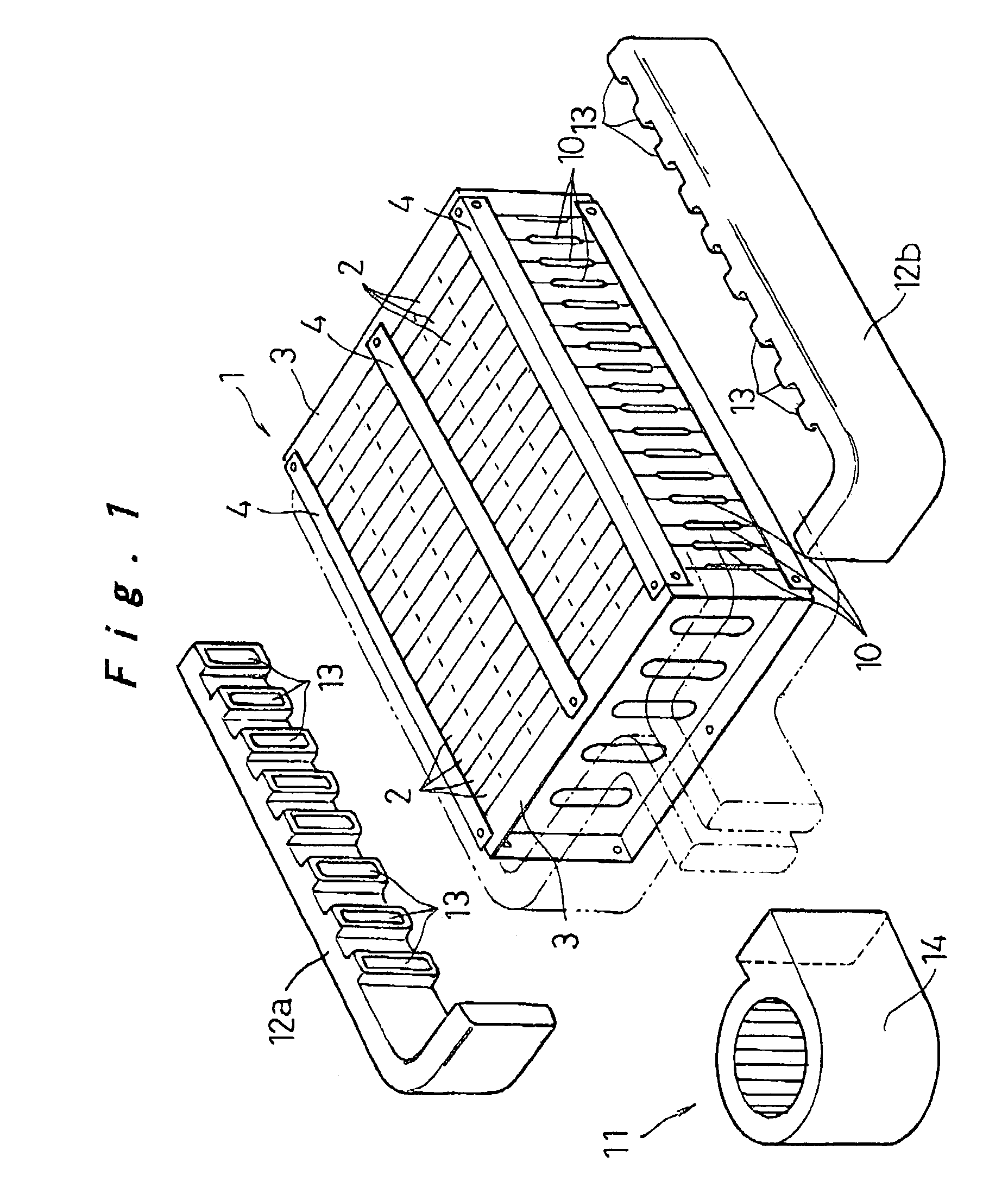

Battery pack with improved heat radiation and sealing

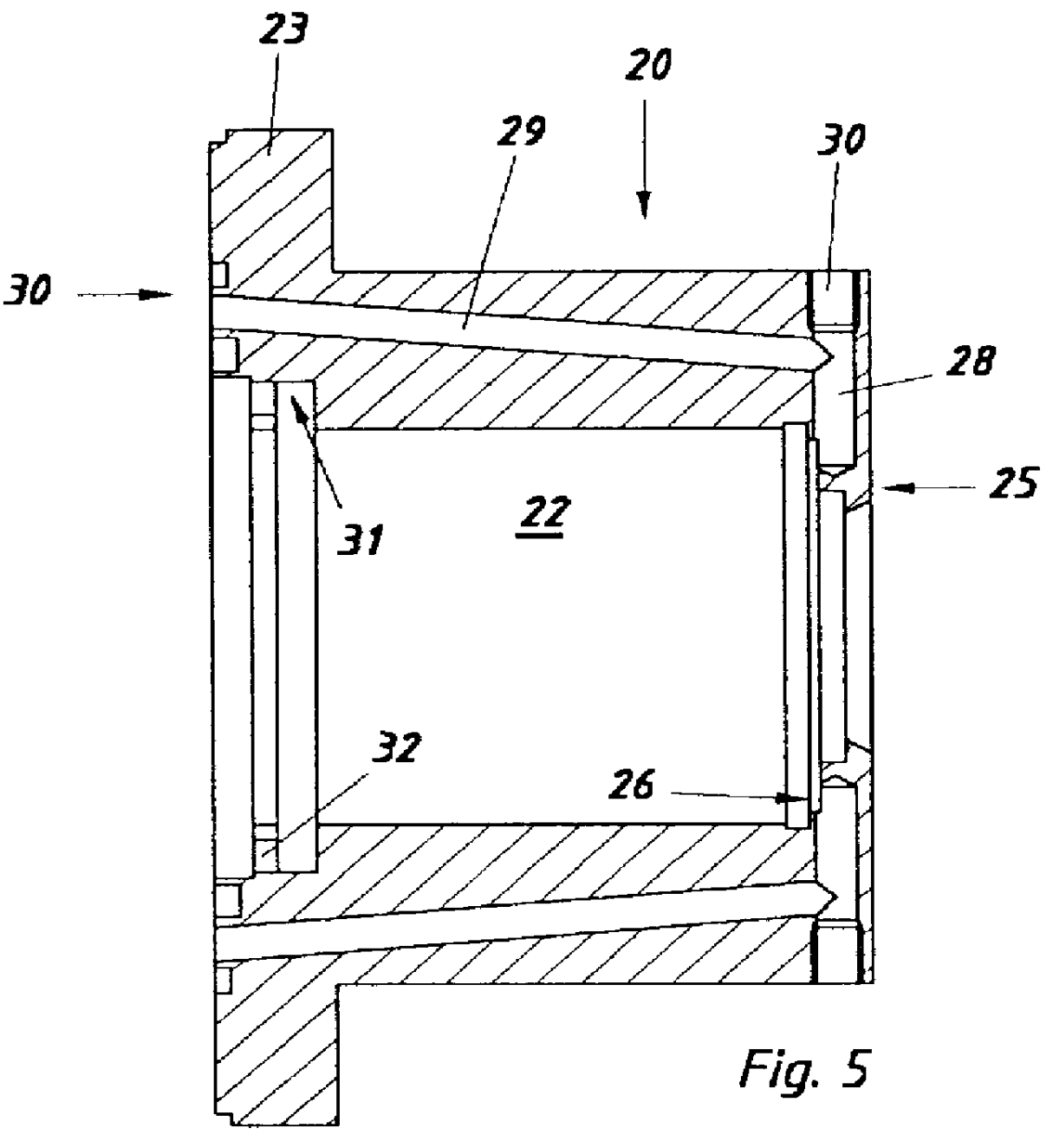

InactiveUS6537694B1Increased durabilityReduce vibrationBatteries circuit arrangementsCell temperature controlEngineeringBattery cell

A battery pack (1) has a double casing structure, including an inner case (2) disposed inside an outer case (3). The inner case (2) includes a radiator plate (9) that is in contact with the side walls of battery cells (4) disposed within the battery pack (1). A forked air passage (32) extends from an air inlet (27) and is defined between the inner case (2) and the outer case (3) and along the outer surface of the radiator plate (9) until reaching a pair of air outlets (31).

Owner:MAKITA CORP

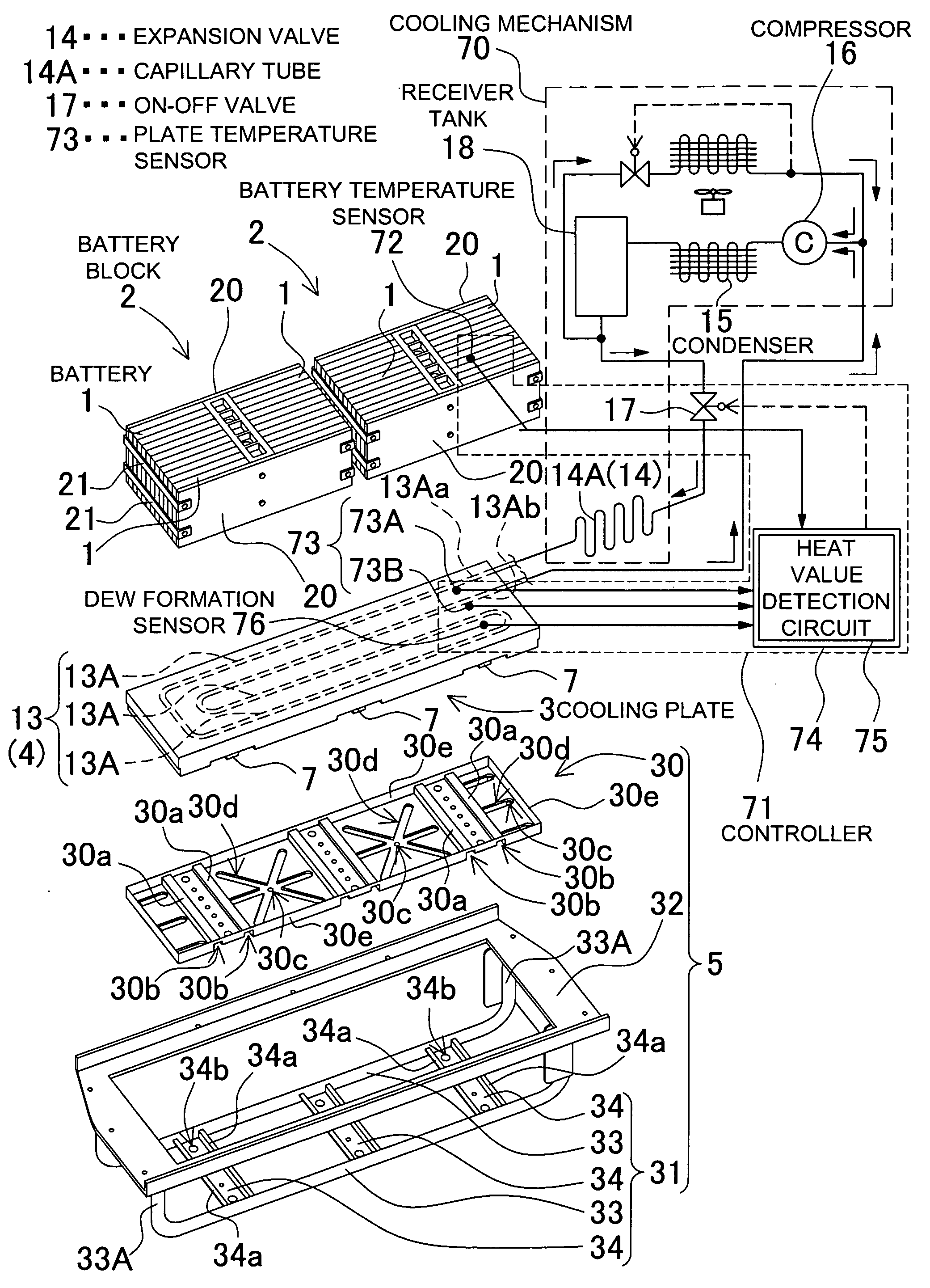

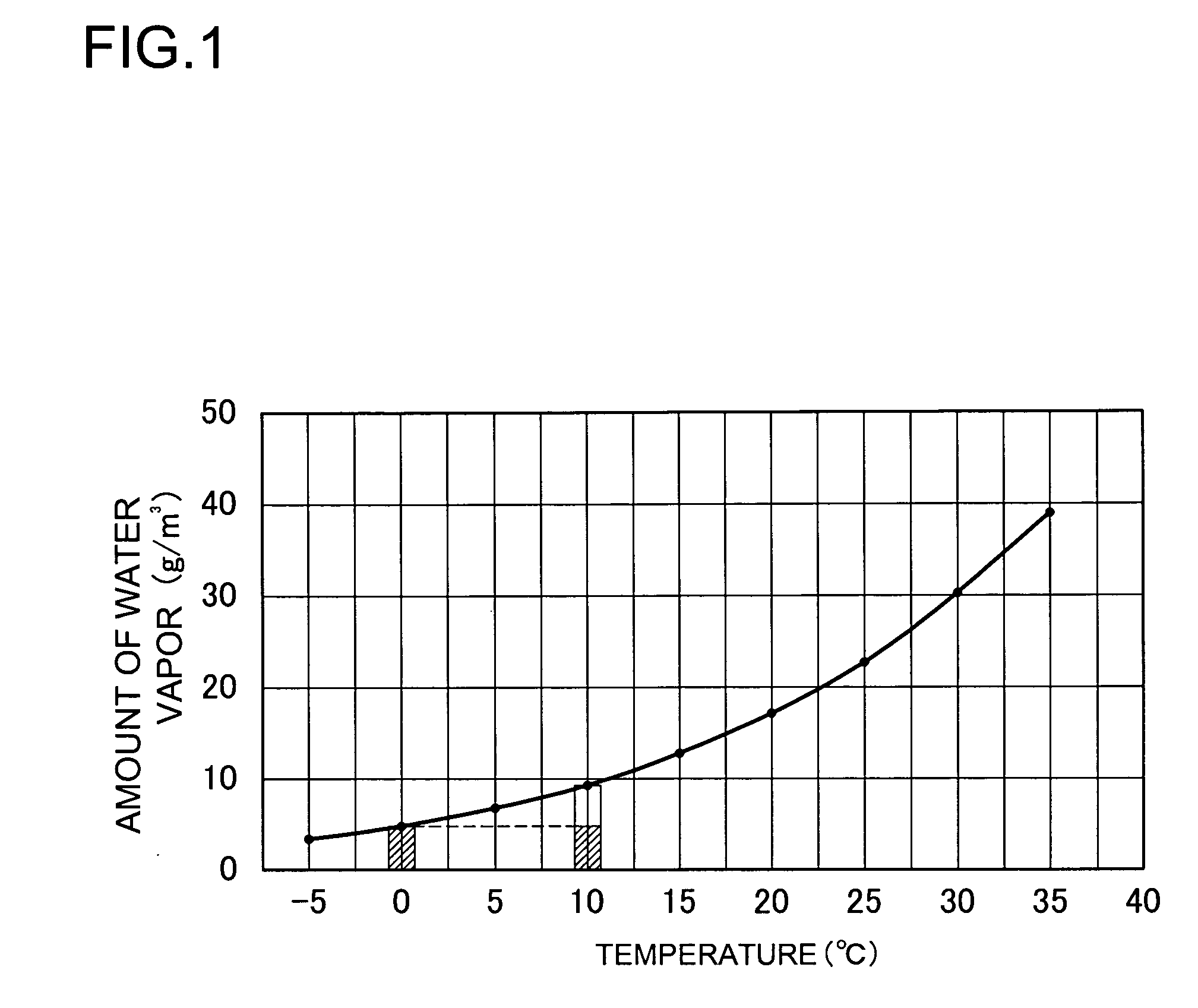

Electric power source used with vehicles

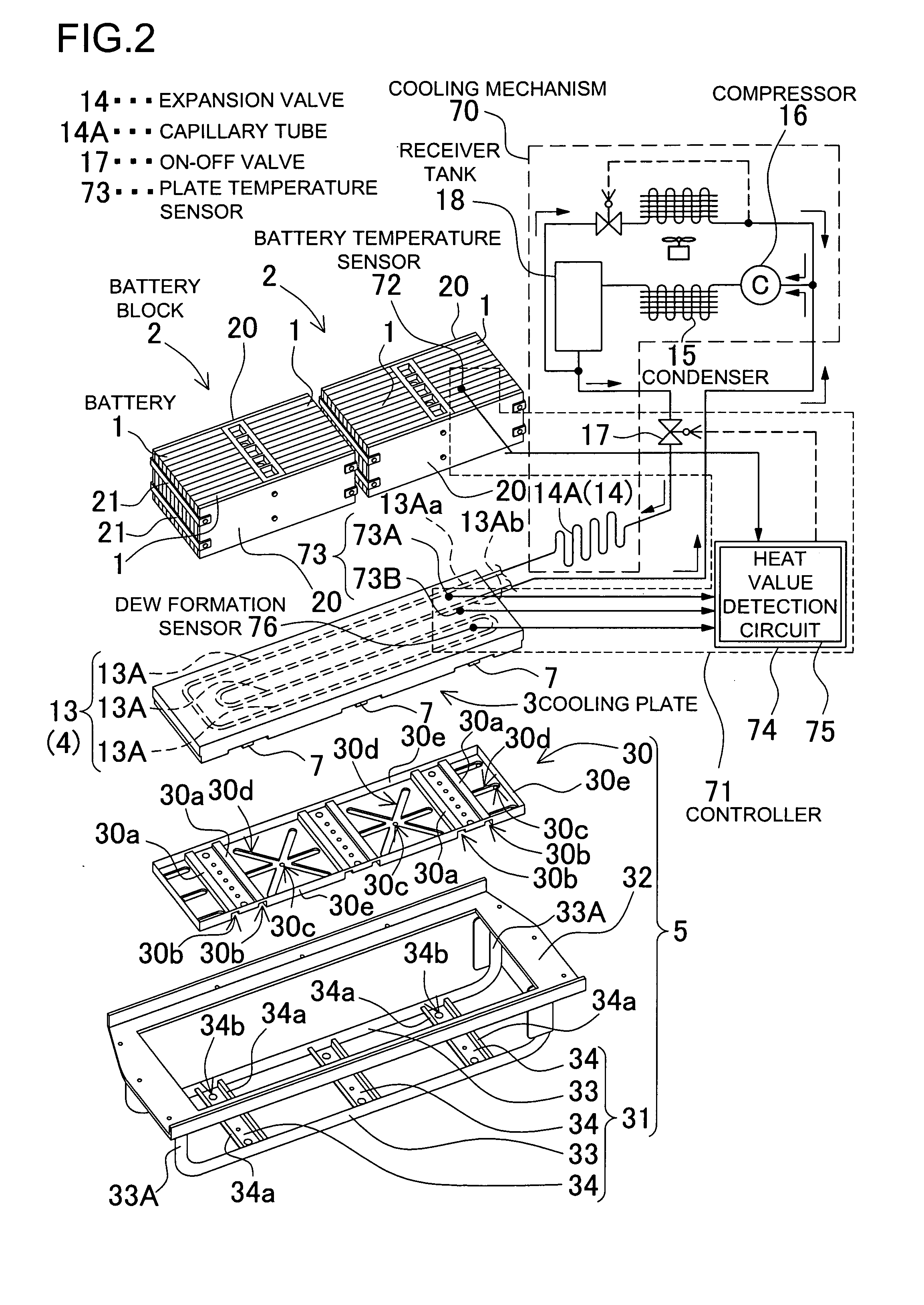

InactiveUS20090246606A1Temperature elevation can be reducedAvoid condensationCell temperature controlCell component detailsElectric power systemRechargeable cell

An electric power source used with a vehicle includes: a battery block composed of a rechargeable battery; a cooling plate thermally coupled with the battery block to cool the battery; a cooling mechanism for cooling the cooling plate; and a controller for controlling the cooling mechanism to switch the cooling plate into a cooled state and an uncooled state. The controller controls the cooling mechanism both in accordance with temperature of the battery block and temperature of the cooling plate, and switches the cooling plate into the cooled state and the uncooled state.

Owner:SANYO ELECTRIC CO LTD

Electric power source

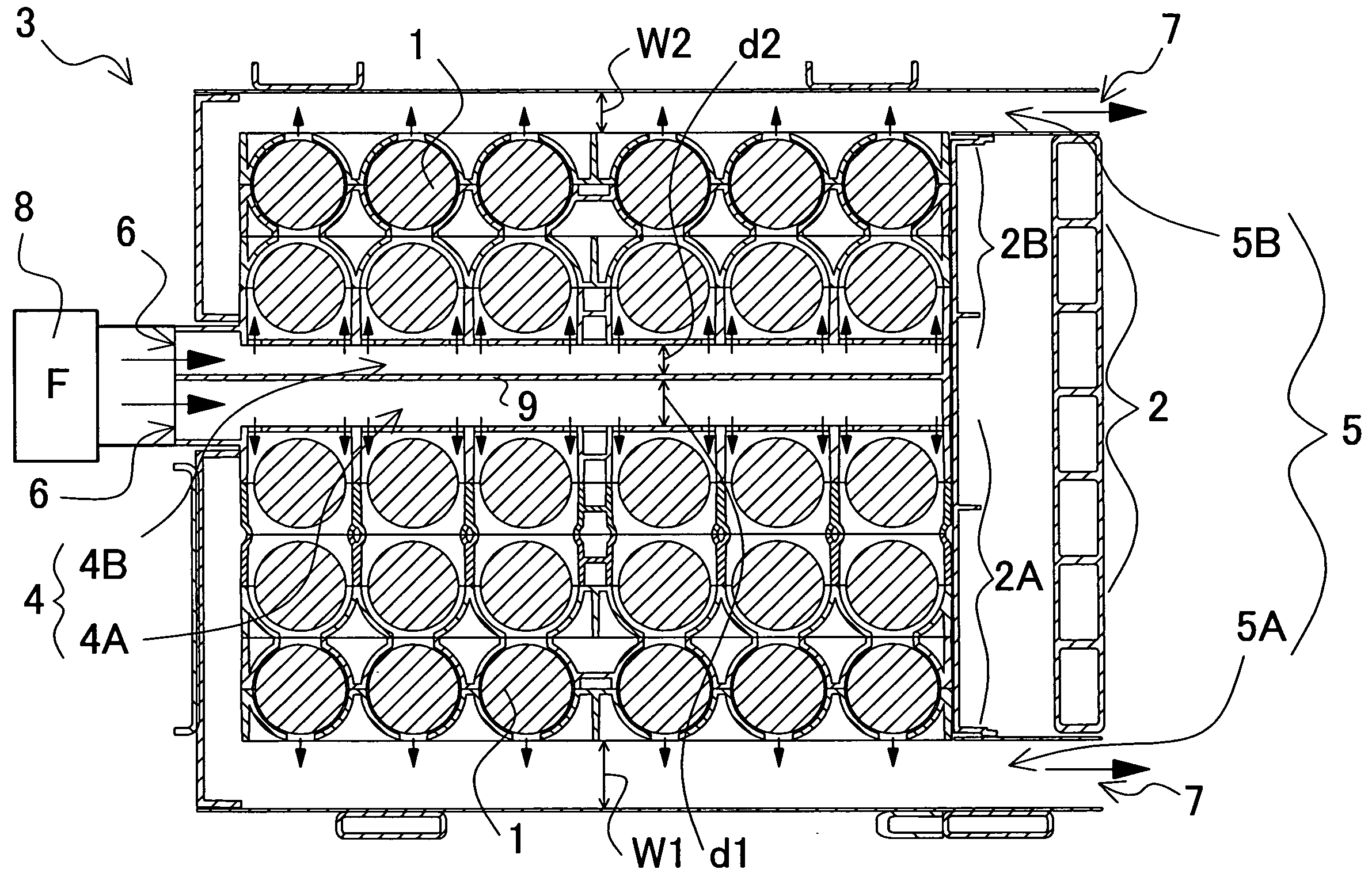

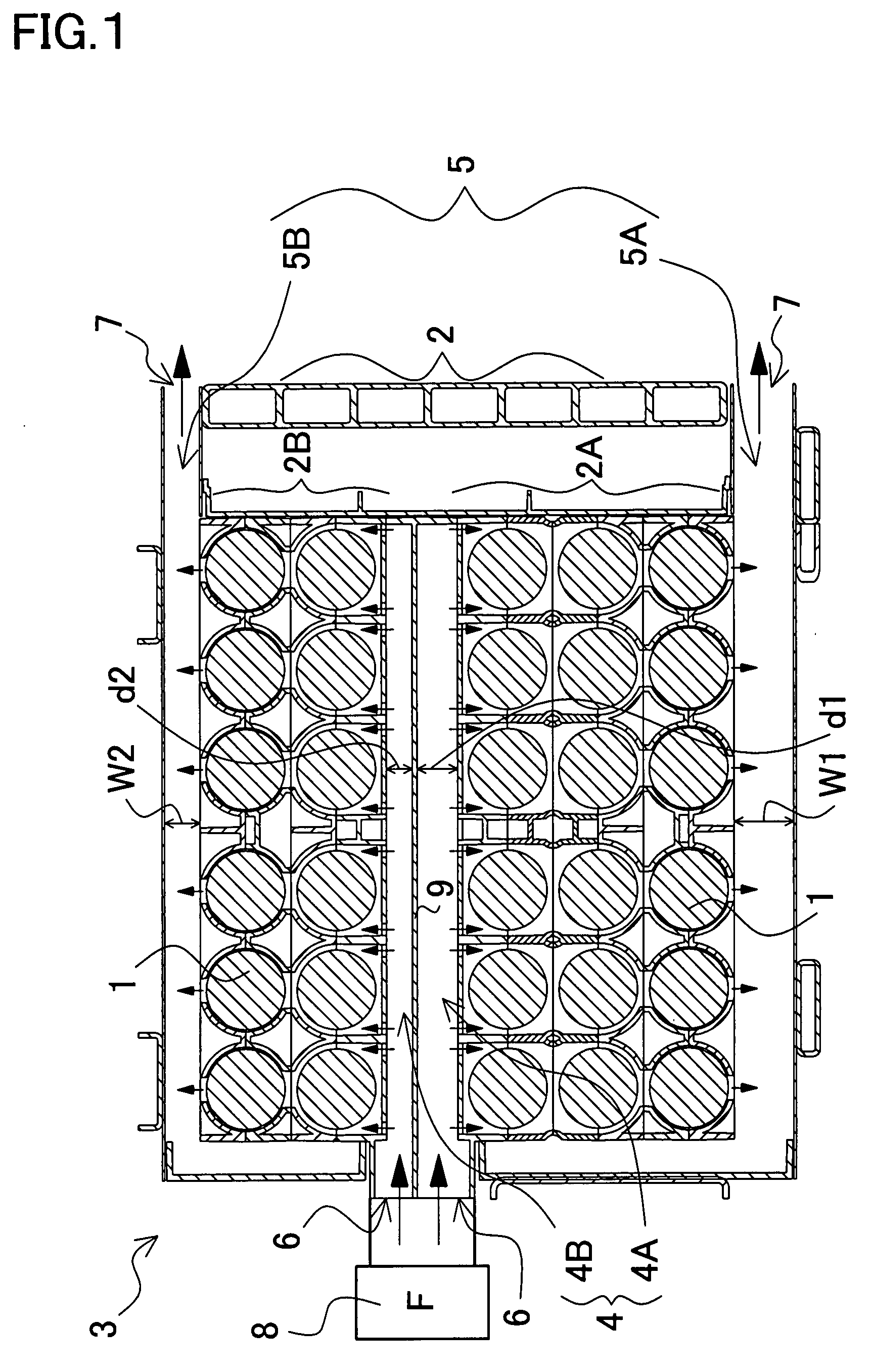

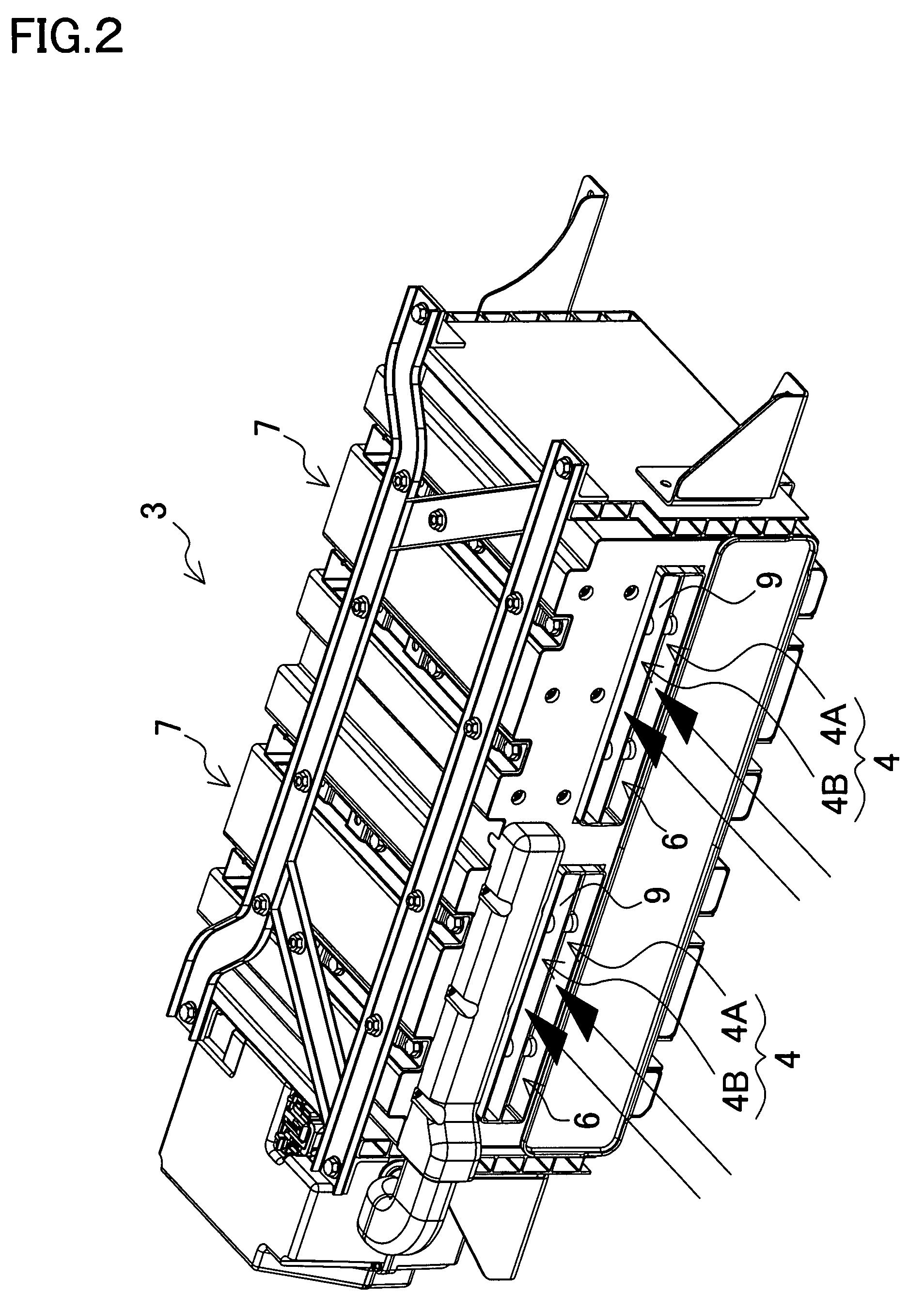

InactiveUS20080026284A1Cool performance less efficientHigh temperatureCell temperature controlCells cooling/heatingEngineeringElectric power system

The electric power source contains a plurality of batteries stacked in two or more tiers in a battery case which is provided with an intermediary duct placed between the first sub holder case and second sub holder case. A first outer duct is outside the first sub holder case and a second outer duct is outside the second sub holder case. The power source is so designed that cooling air is blown to the intermediary duct, the holder case and the outer duct, thus cooling the batteries in the holder case. Further, the power source has a partition disposed inside the intermediary duct, with the first intermediary sub duct being connected to the first sub holder case and the second intermediary duct being connected to the second sub holder case.

Owner:SANYO ELECTRIC CO LTD

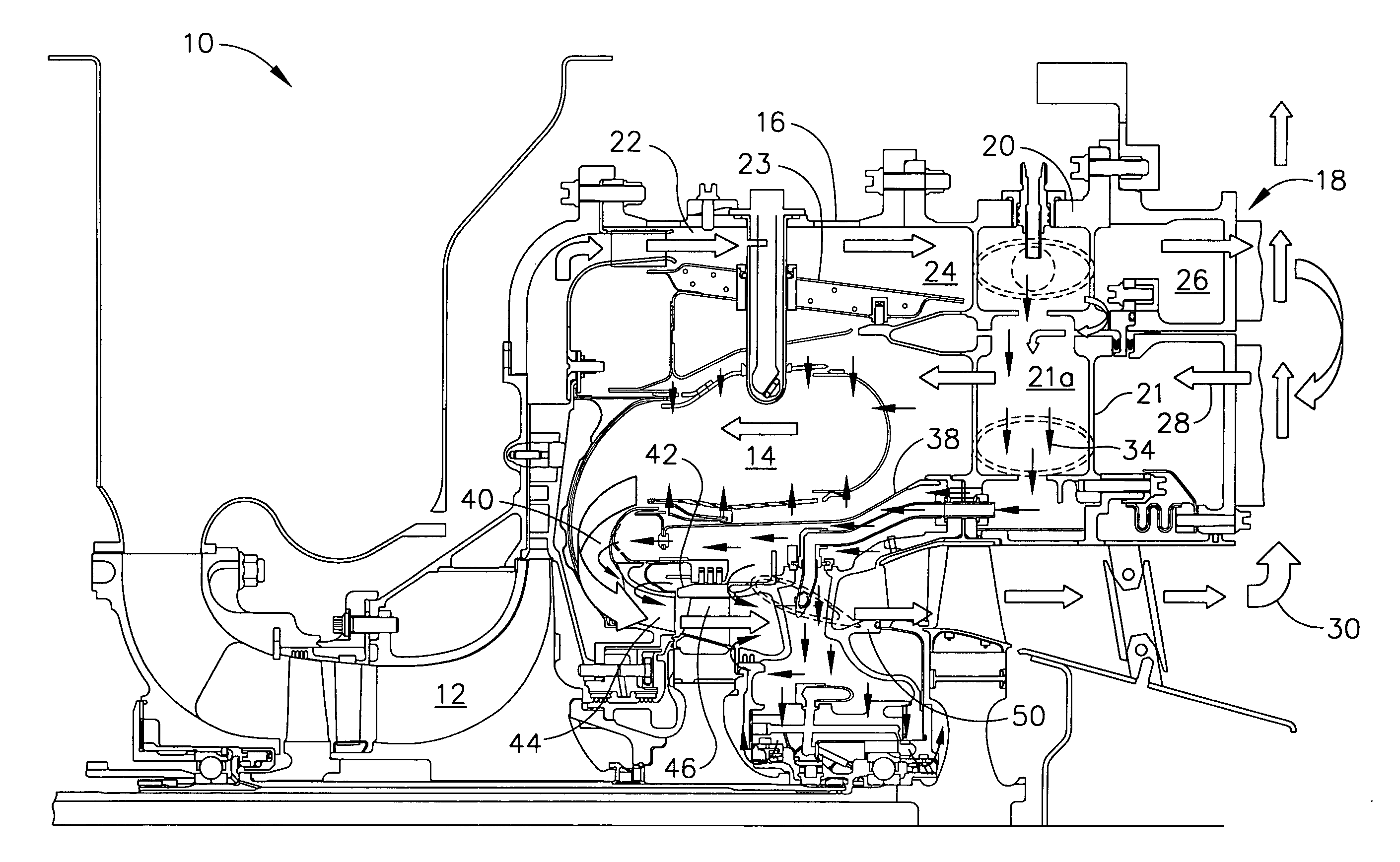

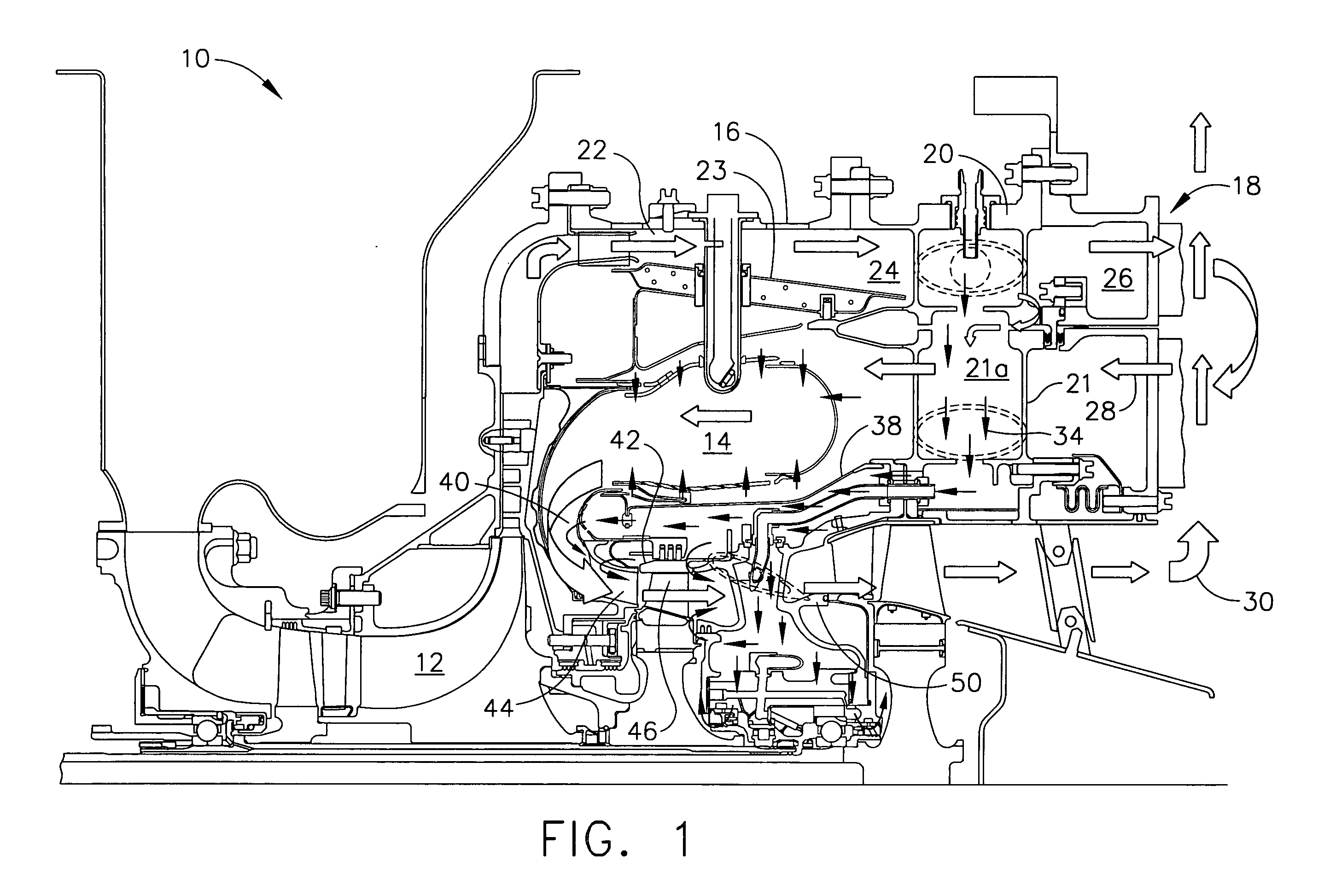

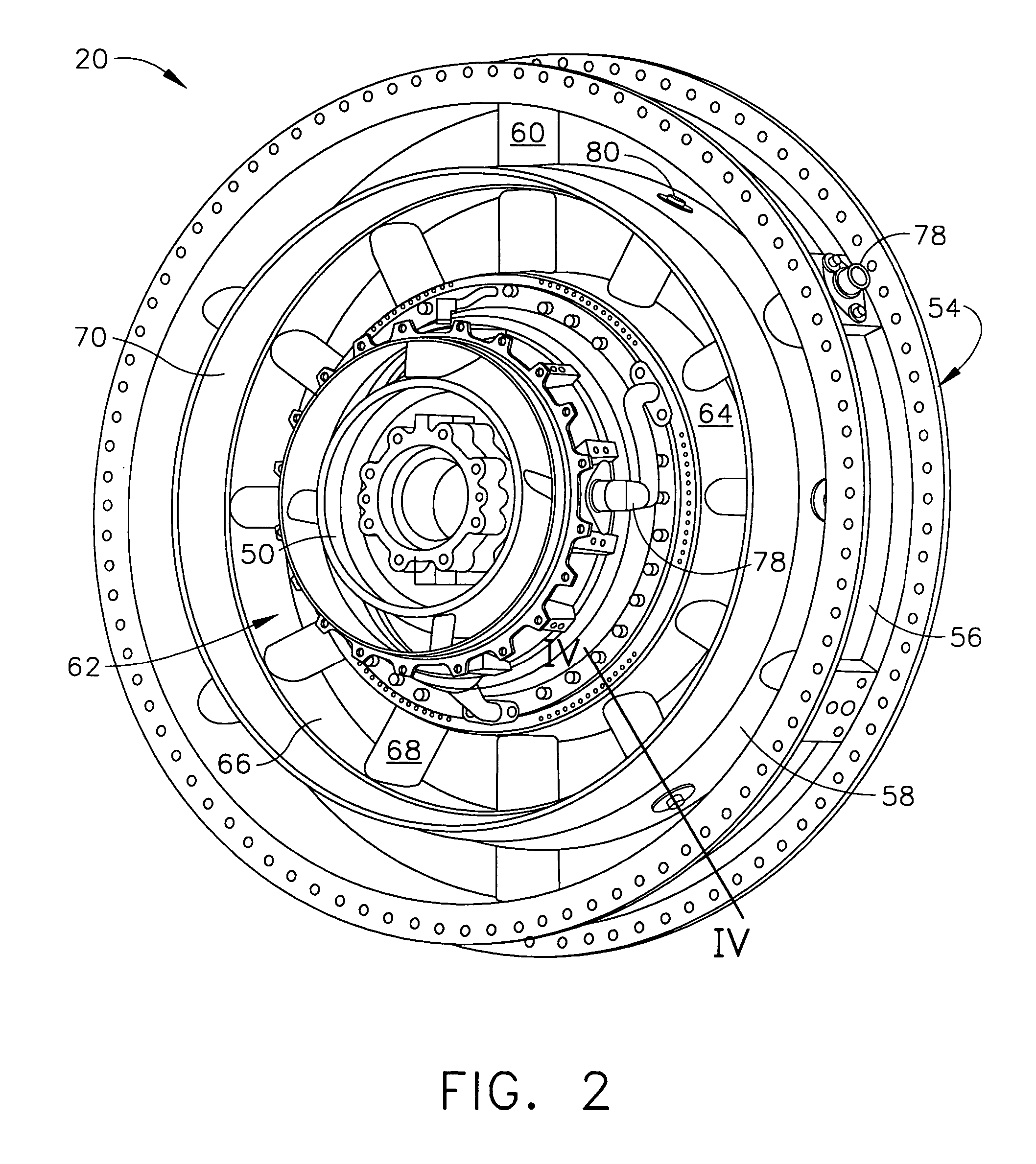

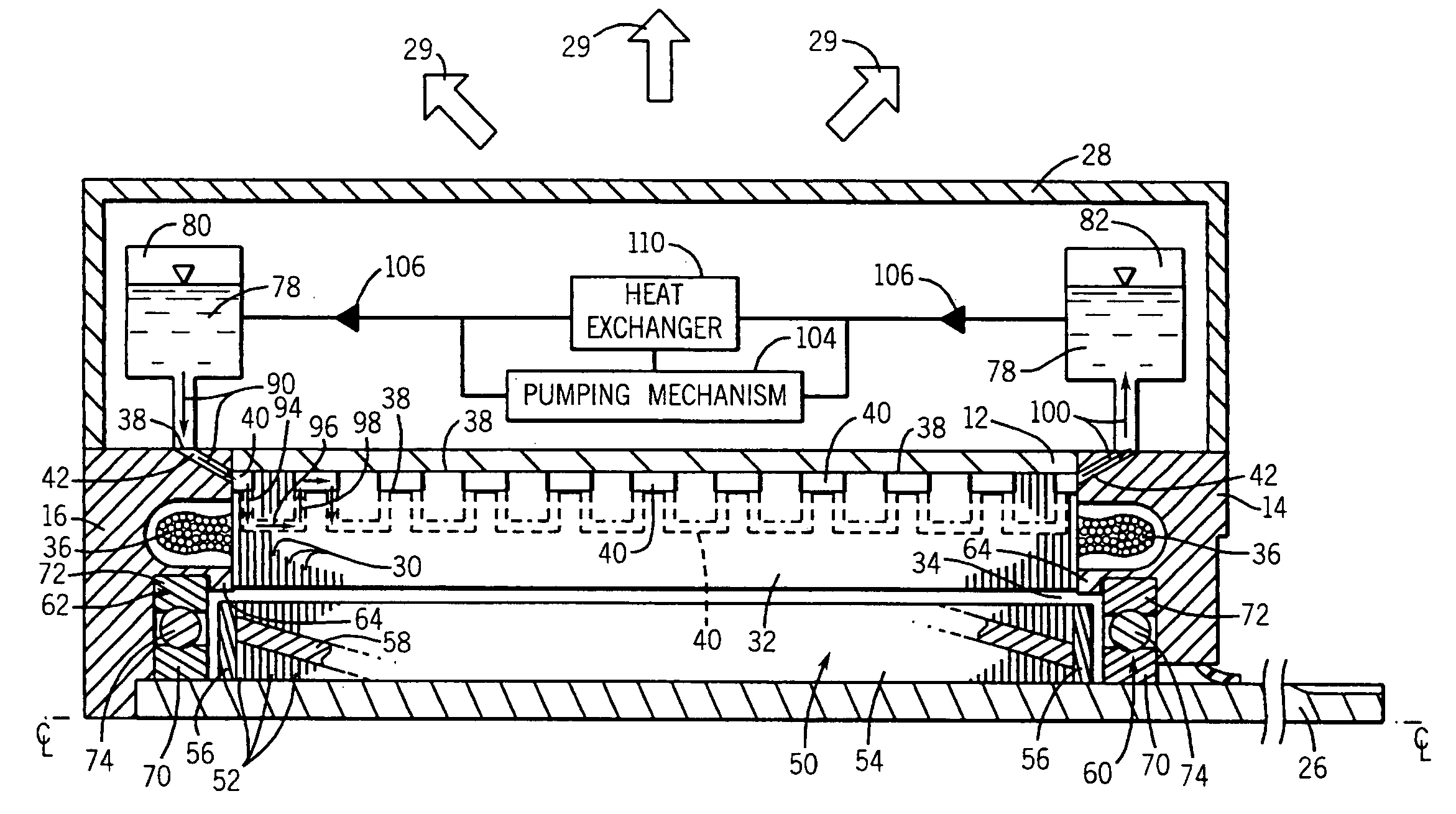

Secondary flow, high pressure turbine module cooling air system for recuperated gas turbine engines

InactiveUS20060123796A1Cool evenlyTurbine/propulsion engine coolingGas turbine plantsTurbine bladeHigh pressure

A secondary flow, turbine cooling air system for the uniform cooling of high pressure turbine module components such as the turbine shroud, turbine blade tips, turbine nozzle, transion liner, and turbine bearing support housing in a recuperated gas turbine engine is provided. The secondary flow turbine cooling system provides uniform cooling air having a similar pressure and temperature in a recuperated gas turbine engine as the compressor discharge air of a non-recuperated gas turbine engine. A method for uniform cooling of high pressure turbine module components using the secondary flow turbine cooling air system is also provided.

Owner:HONEYWELL INT INC

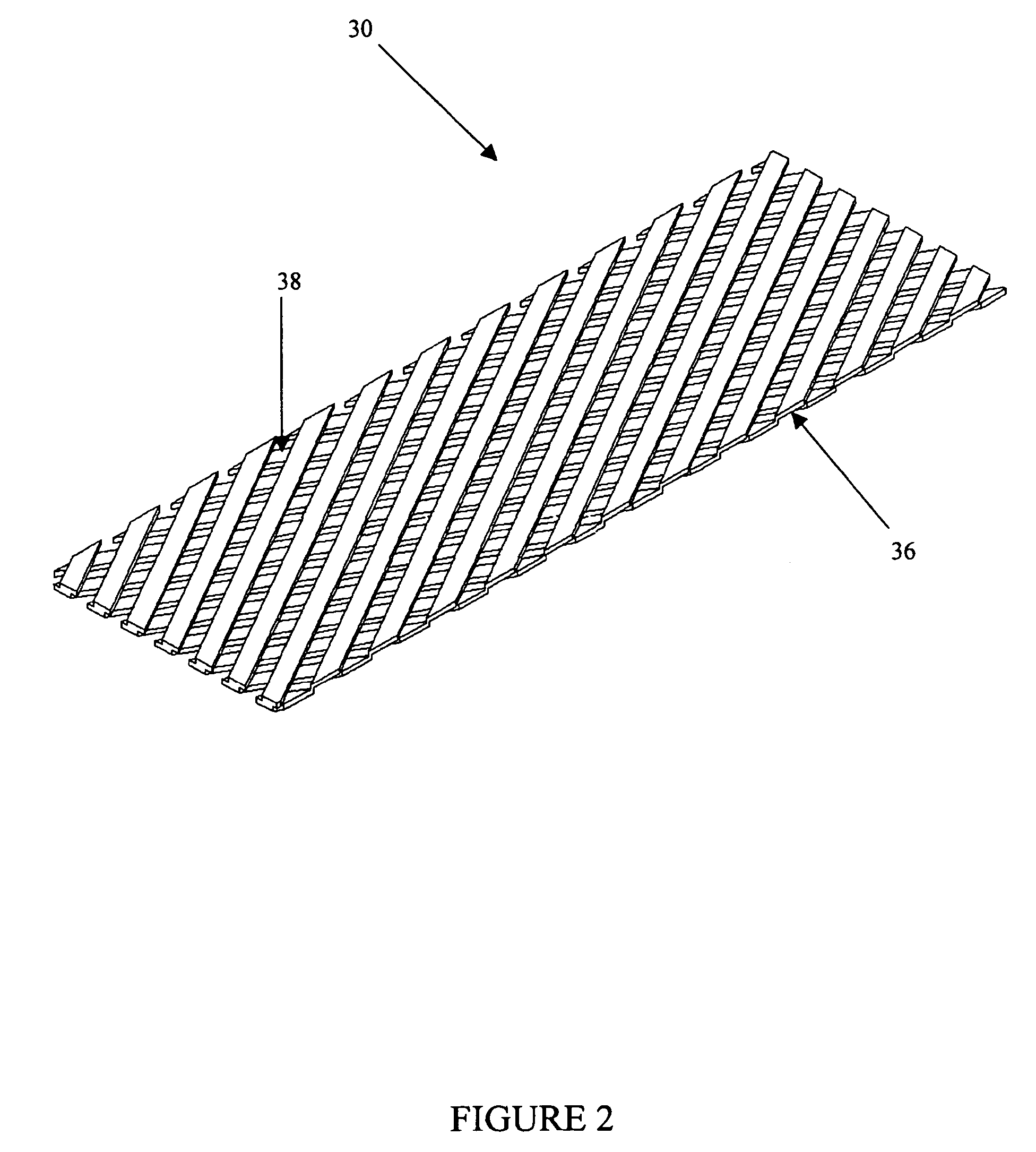

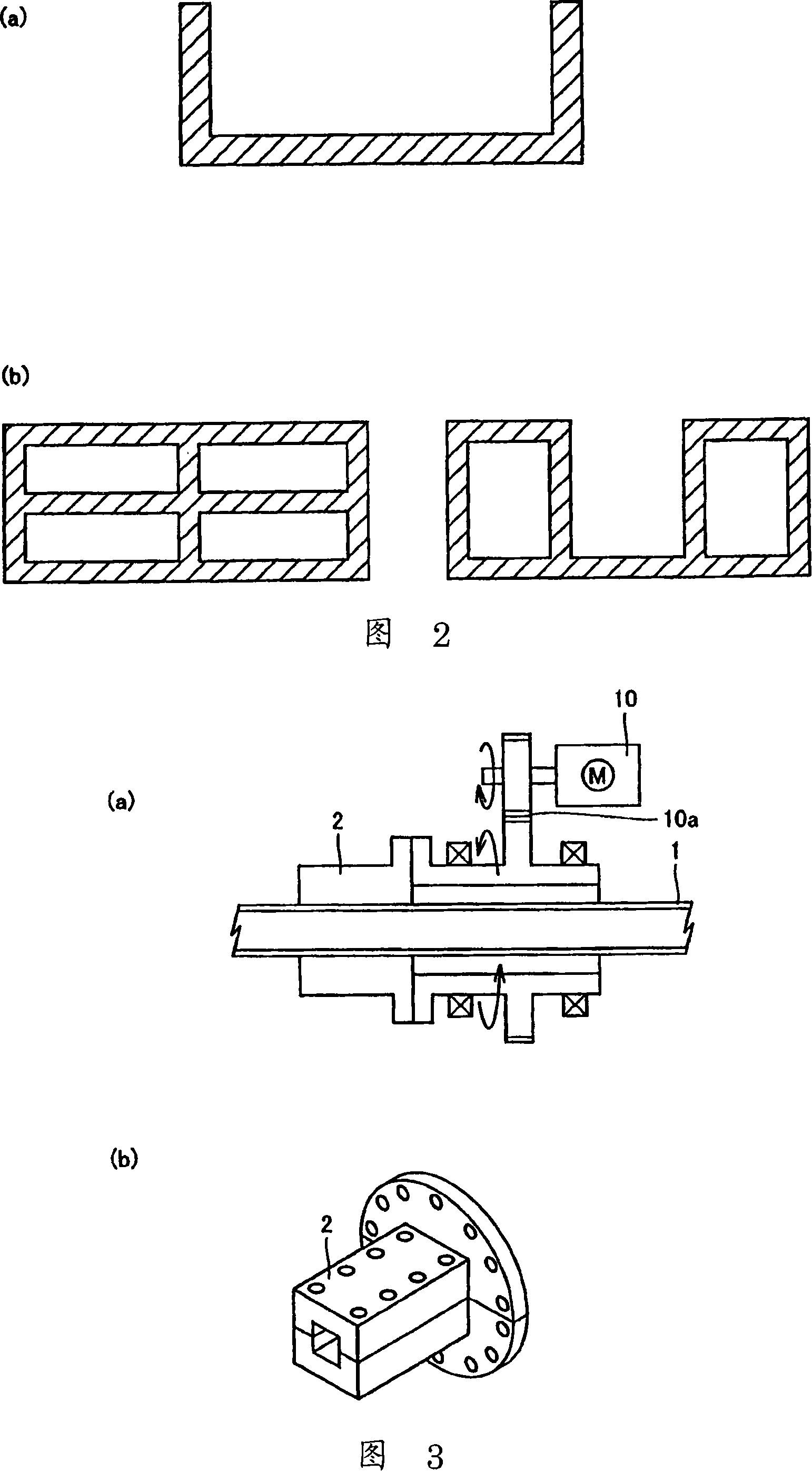

Lamination stack cooling path

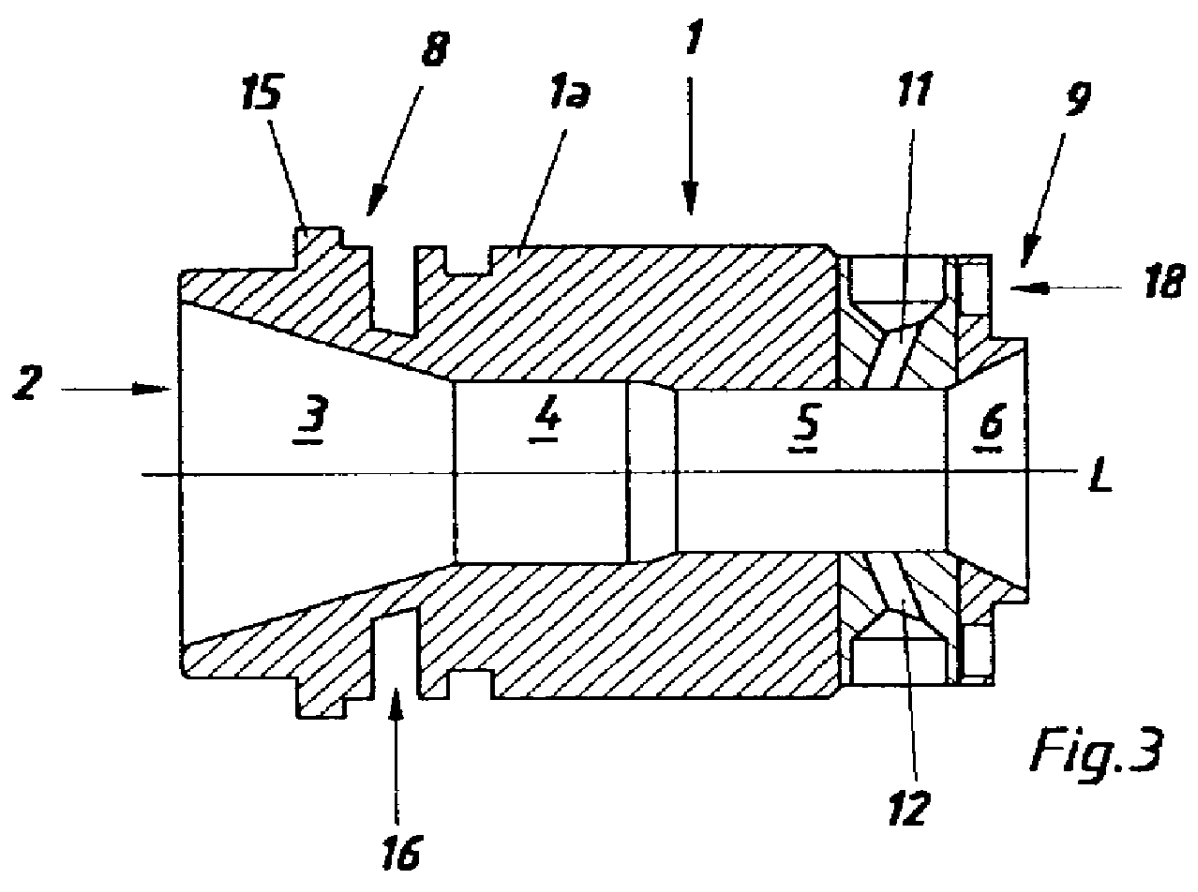

InactiveUS20070013241A1Increase cooling efficacyLarge surface areaMagnetic circuit rotating partsManufacturing dynamo-electric machinesStatorElectrical and Electronics engineering

According to one embodiment, the present invention provides a motor having a stator core disposed in a motor frame. The stator core is formed of a plurality of substantially identical laminations. Each lamination of the stator core comprises at least one recessed section, which, in cooperation with the frame, defines an incremental segment of closed passageway for routing a fluid along a perimetric surface of the stator core. Accordingly, the closed passageway provides a mechanism by which the outer regions of the stator core may be more effectively cooled. Furthermore, the laminations of the stator core may be oriented at varied orientations with respect to one another to form a labyrinthine path along the surface of the stator core through which coolant is routed.

Owner:RELIANCE ELECTRIC TECH

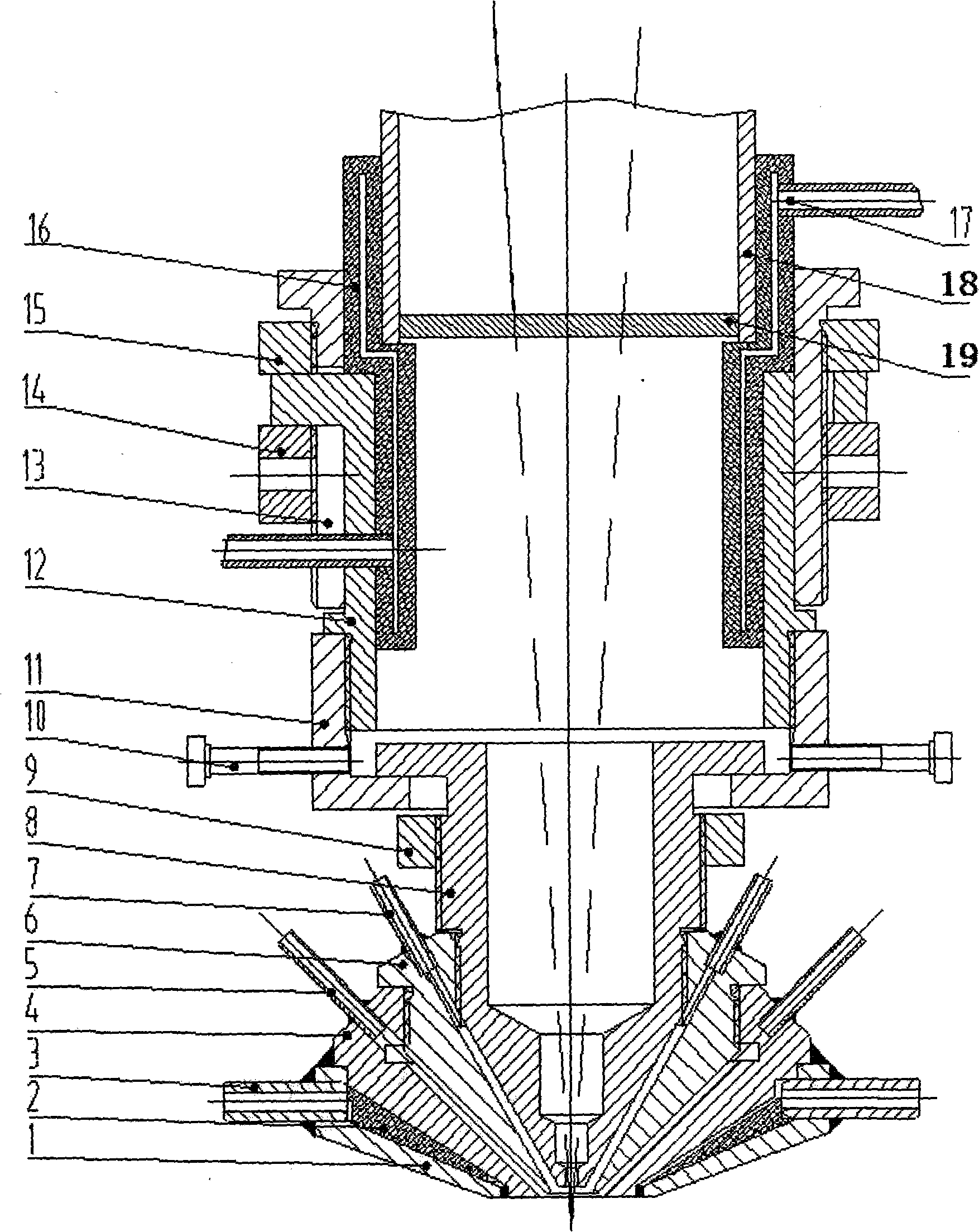

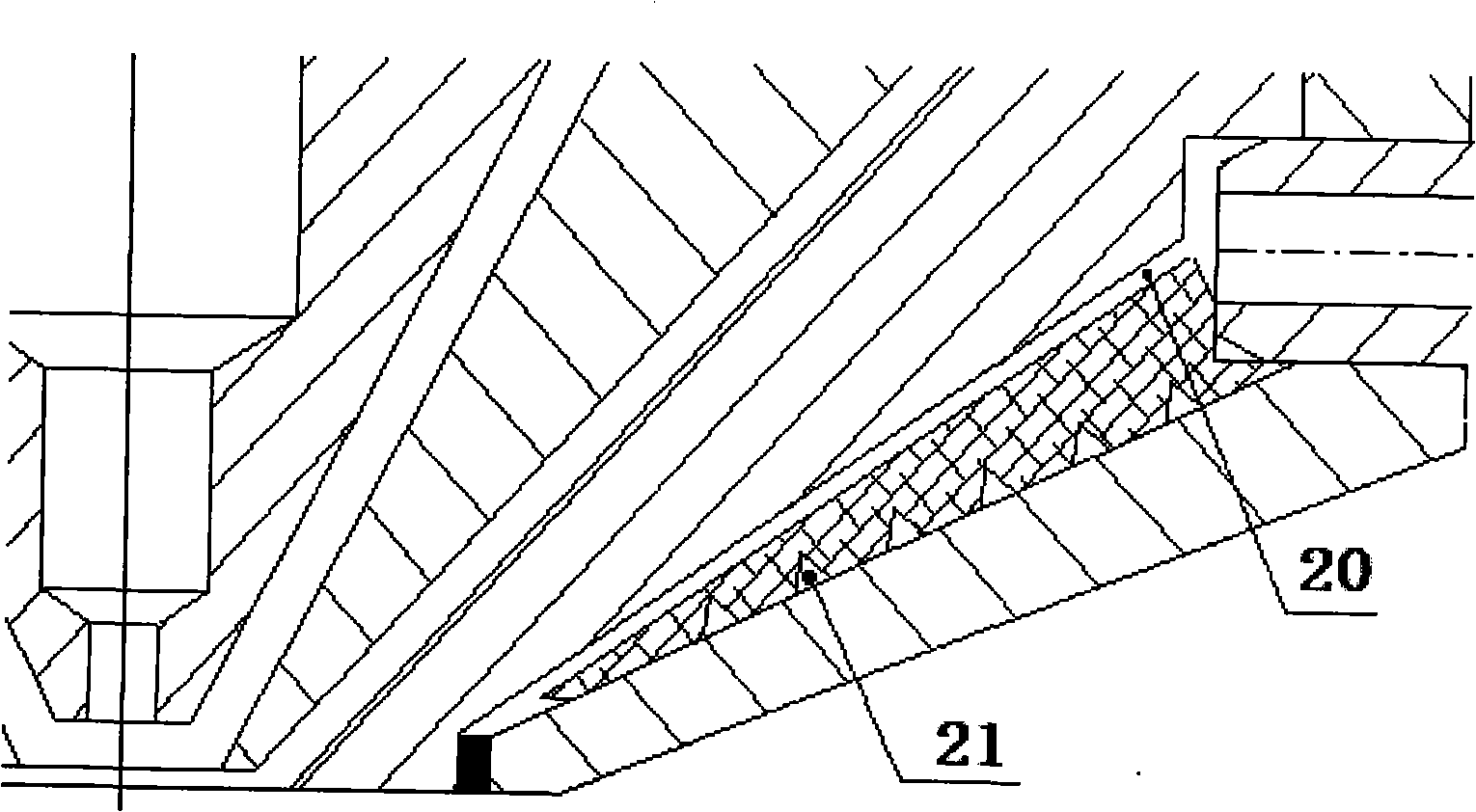

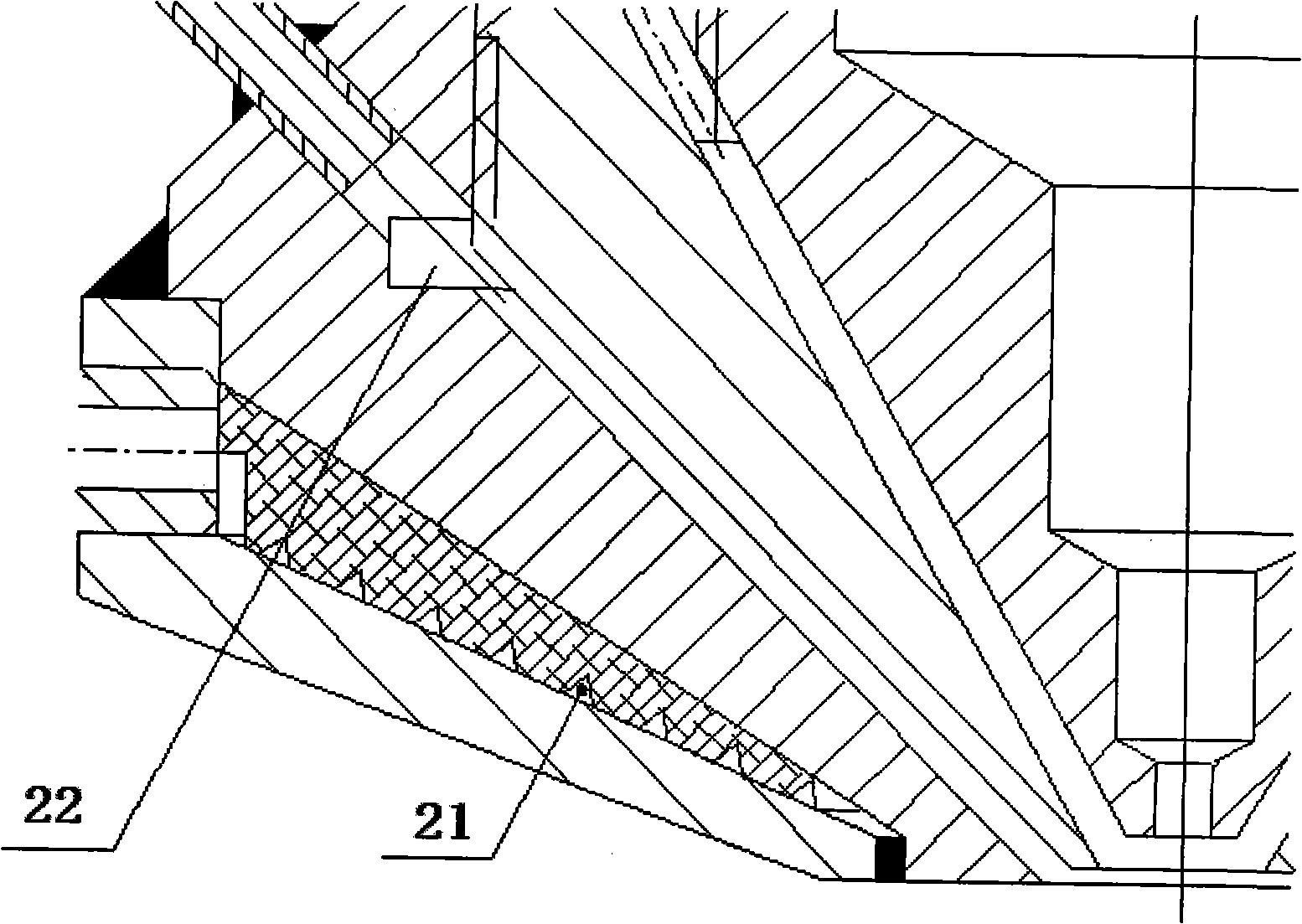

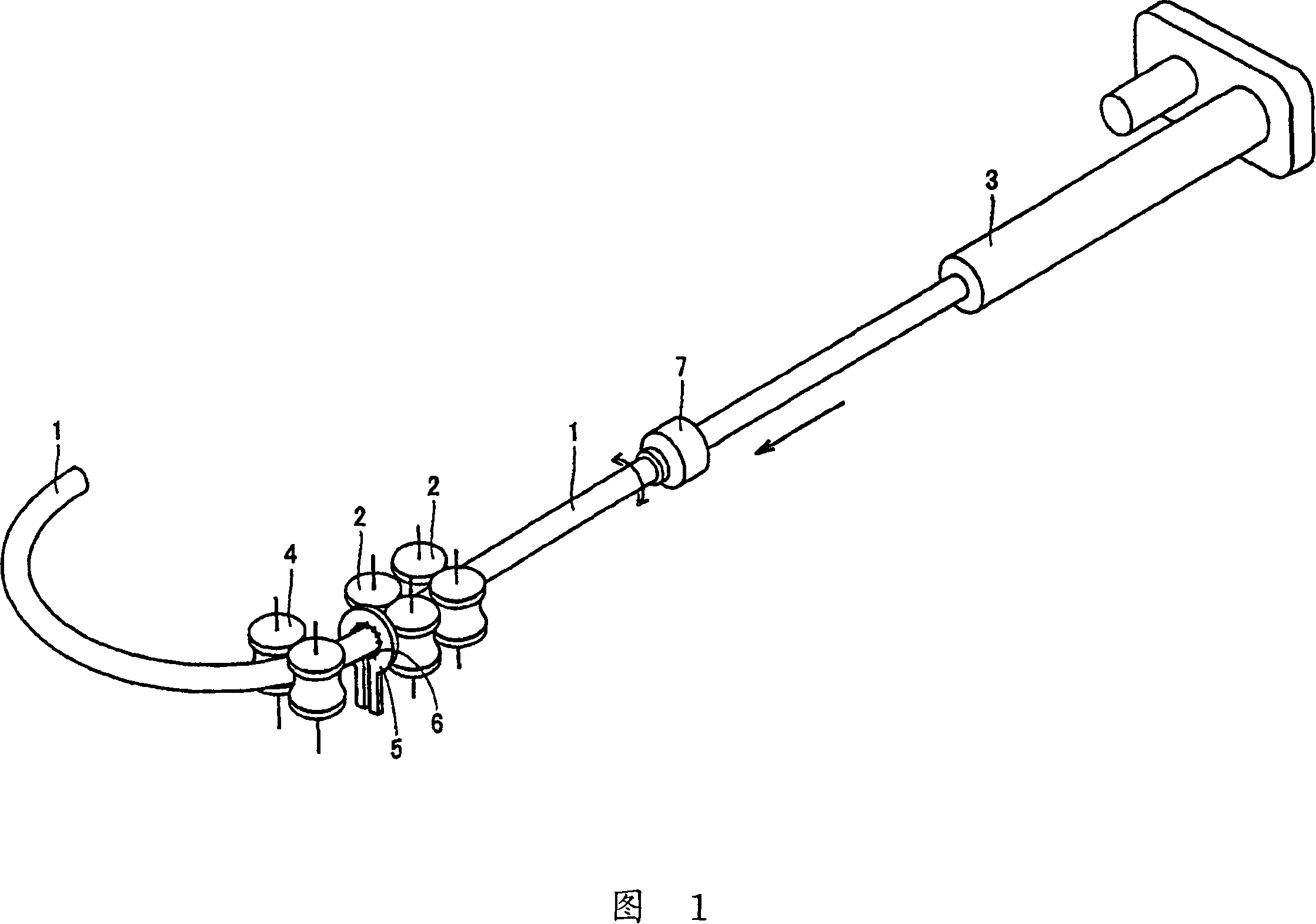

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

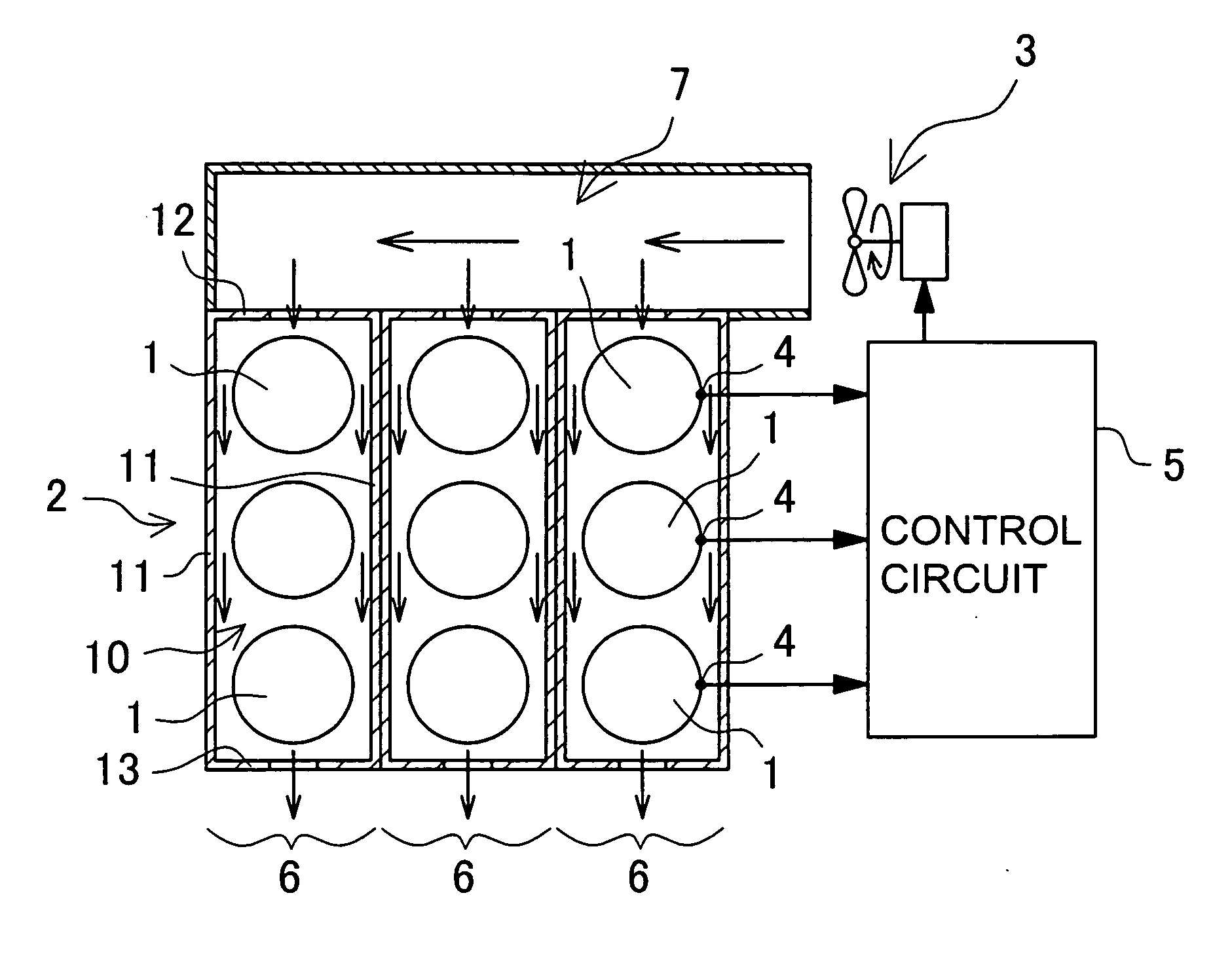

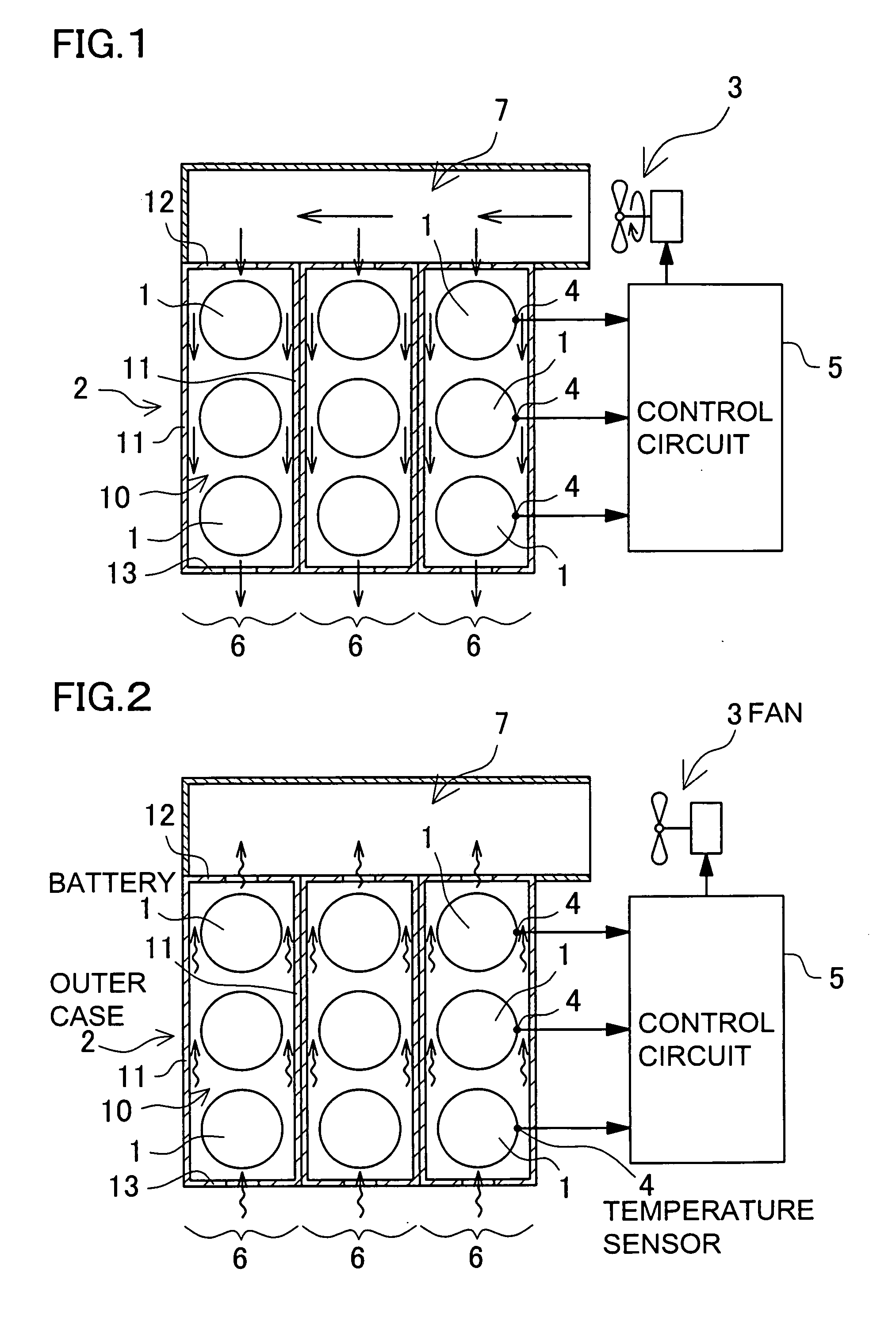

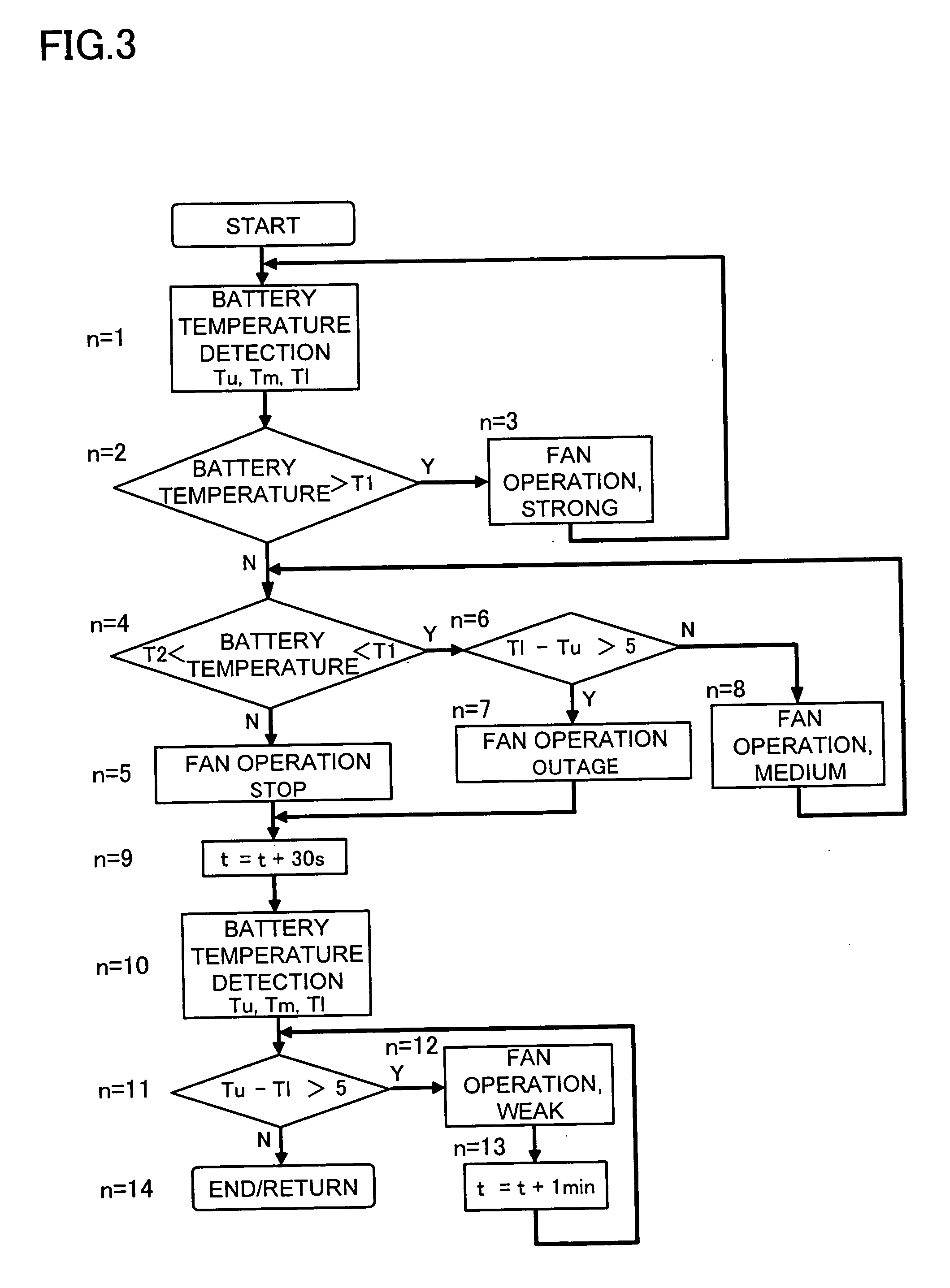

Power supply unit and method for cooling battery contained therein

InactiveUS20070072061A1Improve cooling effectLess effectiveSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical batteryEngineering

A method for cooling a battery is disclosed, in which a power supply unit includes a plurality of batteries disposed up and down (in a multi-tier manner) within a case, a fan for cooling the batteries by forcibly blowing cooling air from top to bottom within the case, a temperature sensor for detecting temperatures of the batteries, and a control circuit for controlling operation of the fan by means of a signal fed out of the temperature sensor. In the battery cooling method, when a battery temperature difference between the upper battery and the lower battery reaches above a set value as detected by the temperature sensor while the fan is in operation, the control circuit stops operation of the fan to cool the batteries through natural heat radiation.

Owner:SANYO ELECTRIC CO LTD

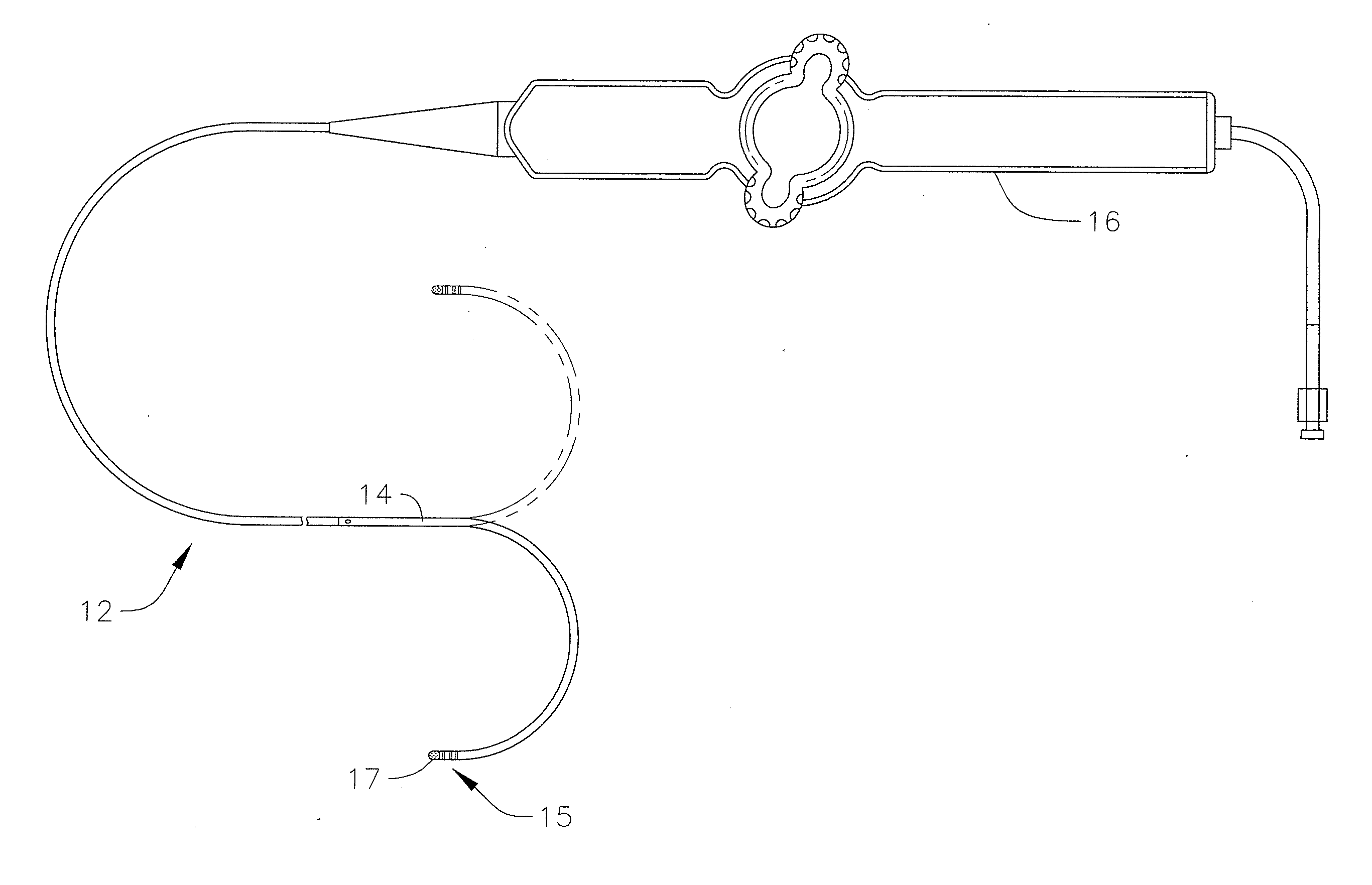

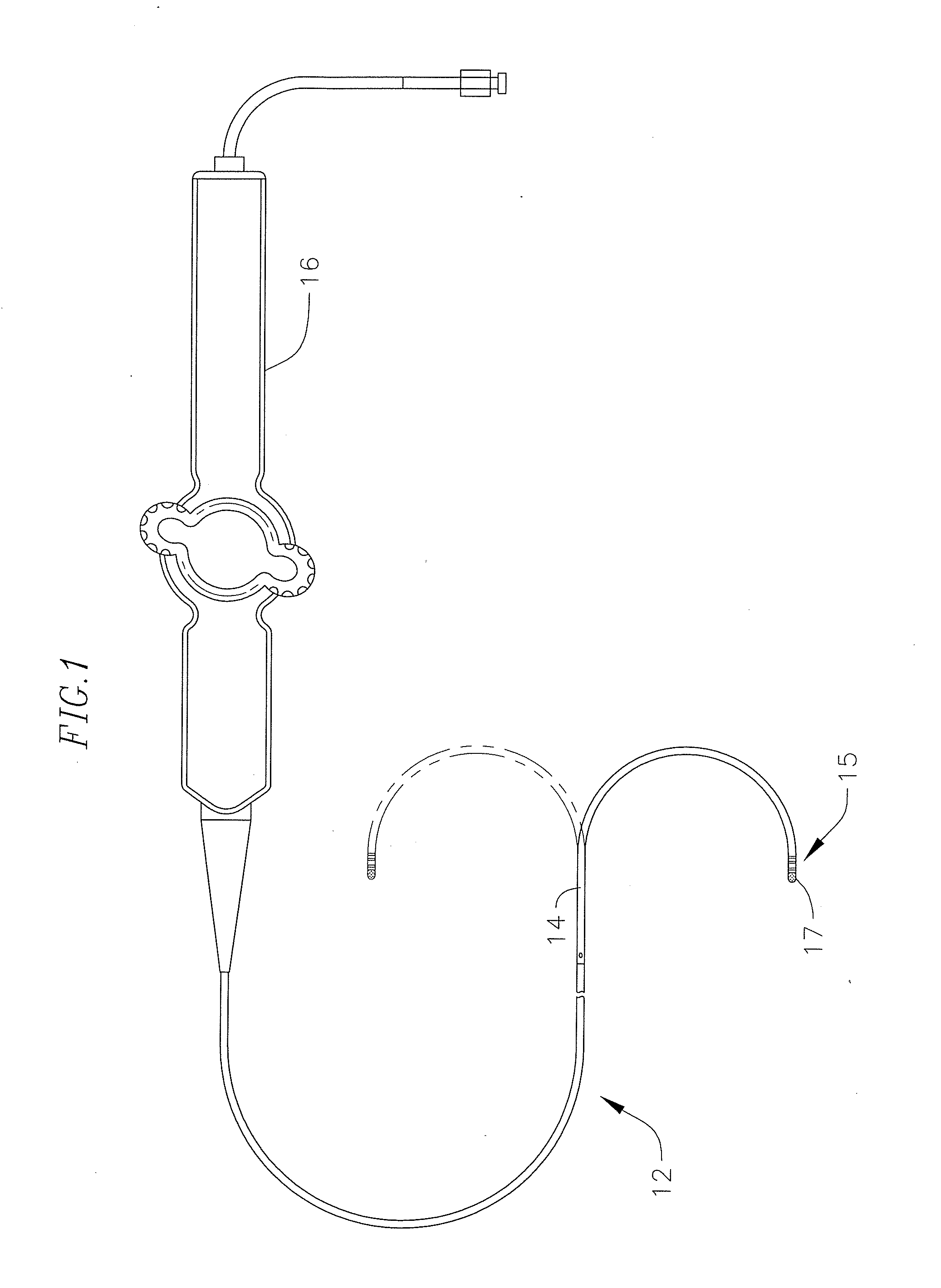

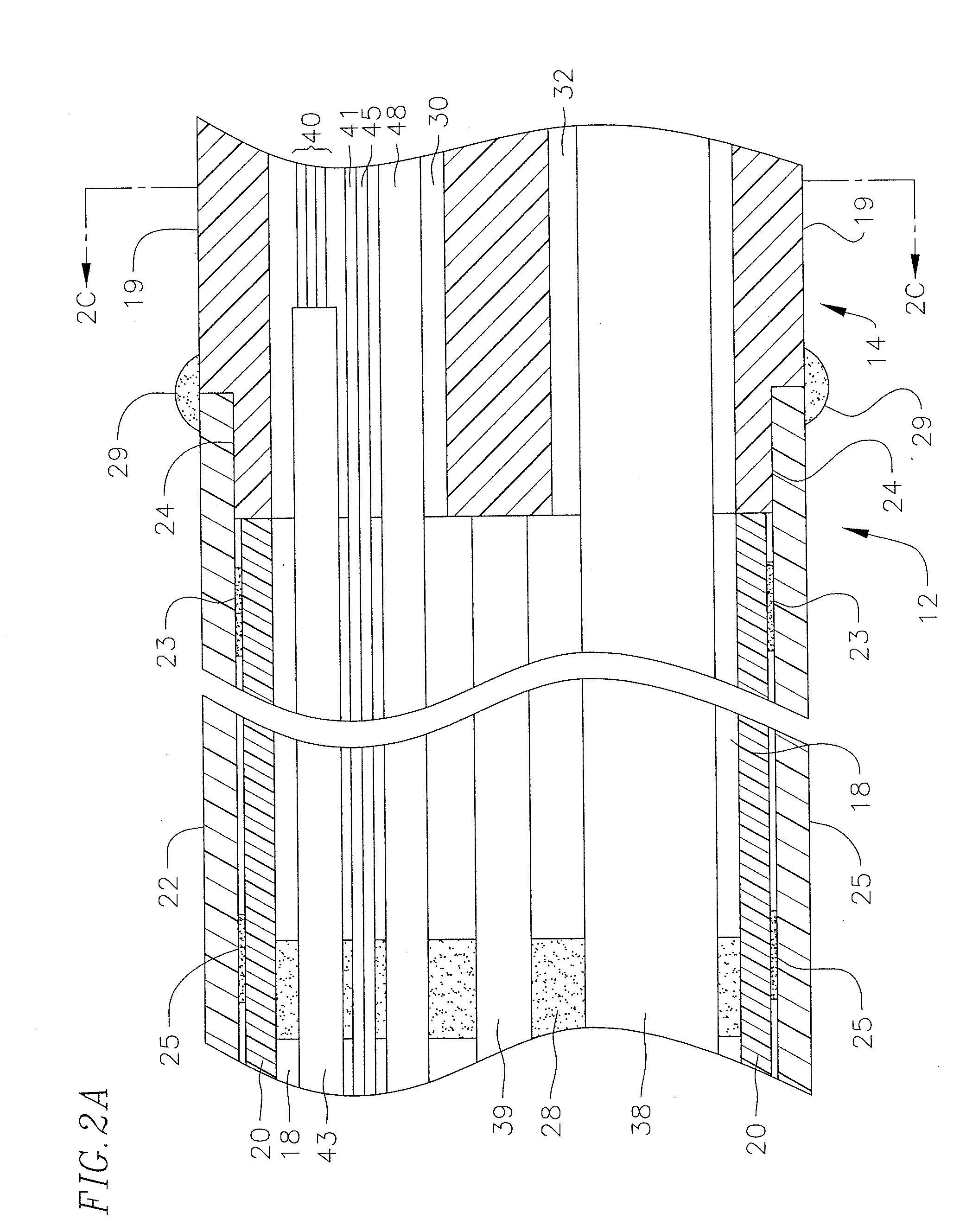

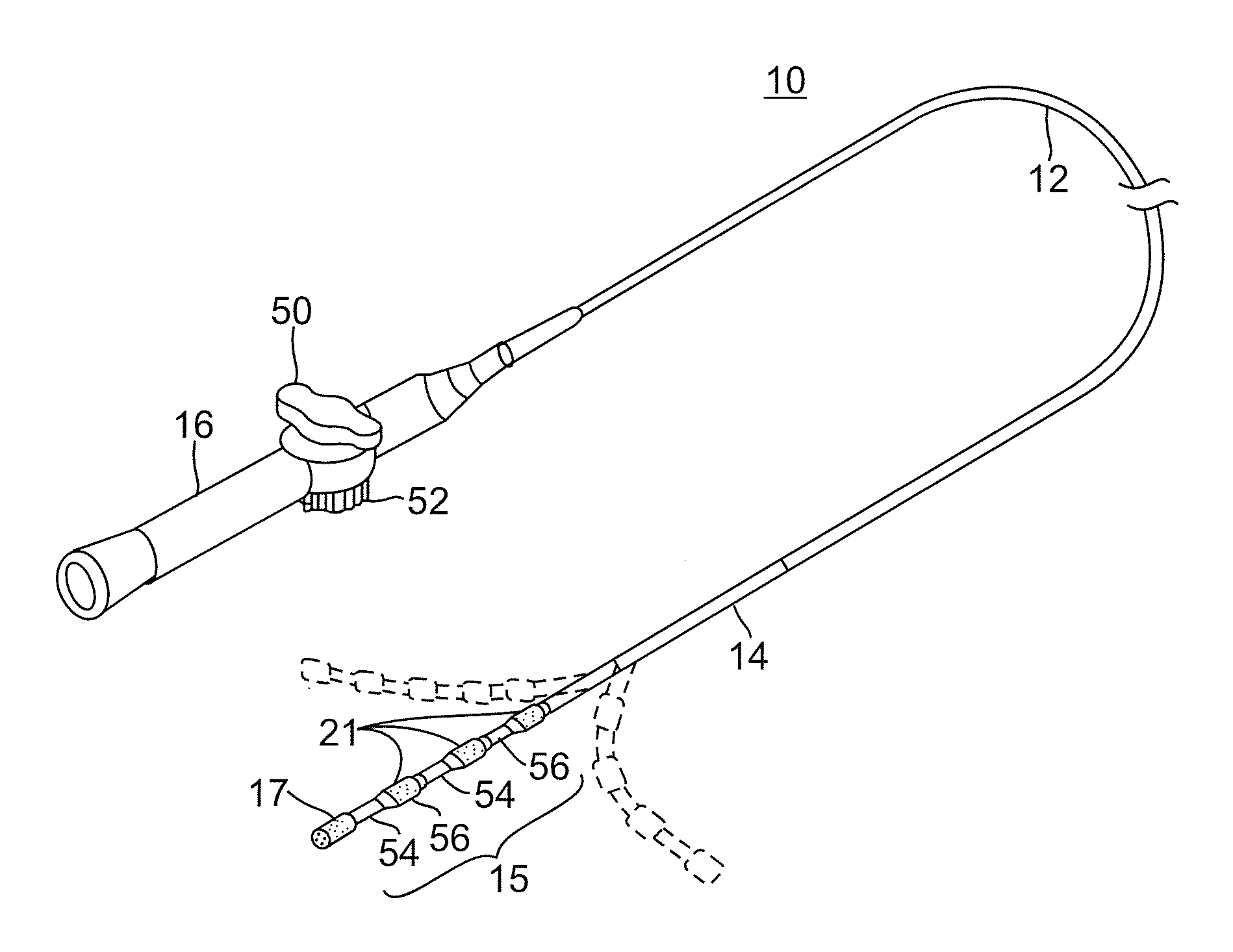

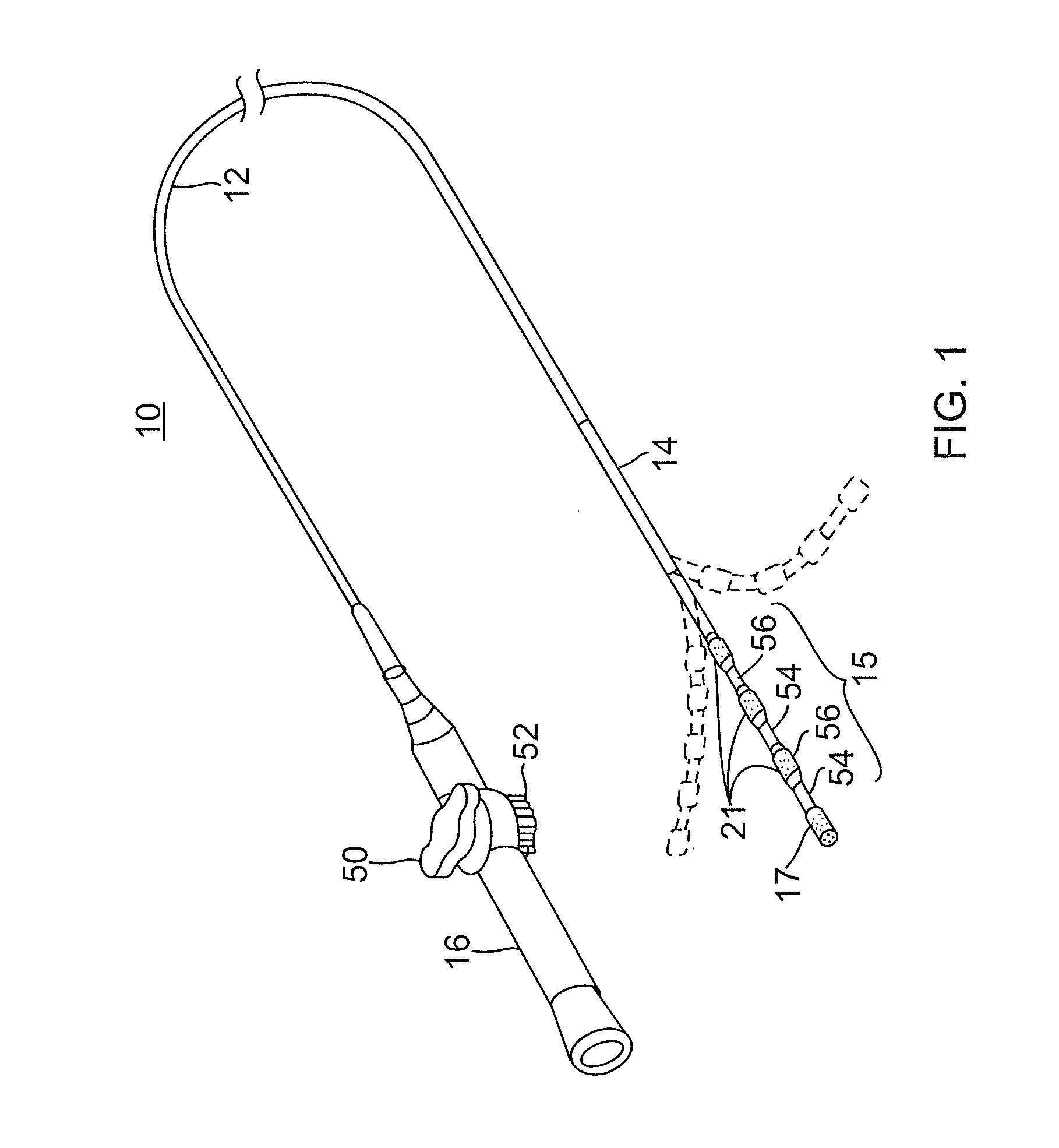

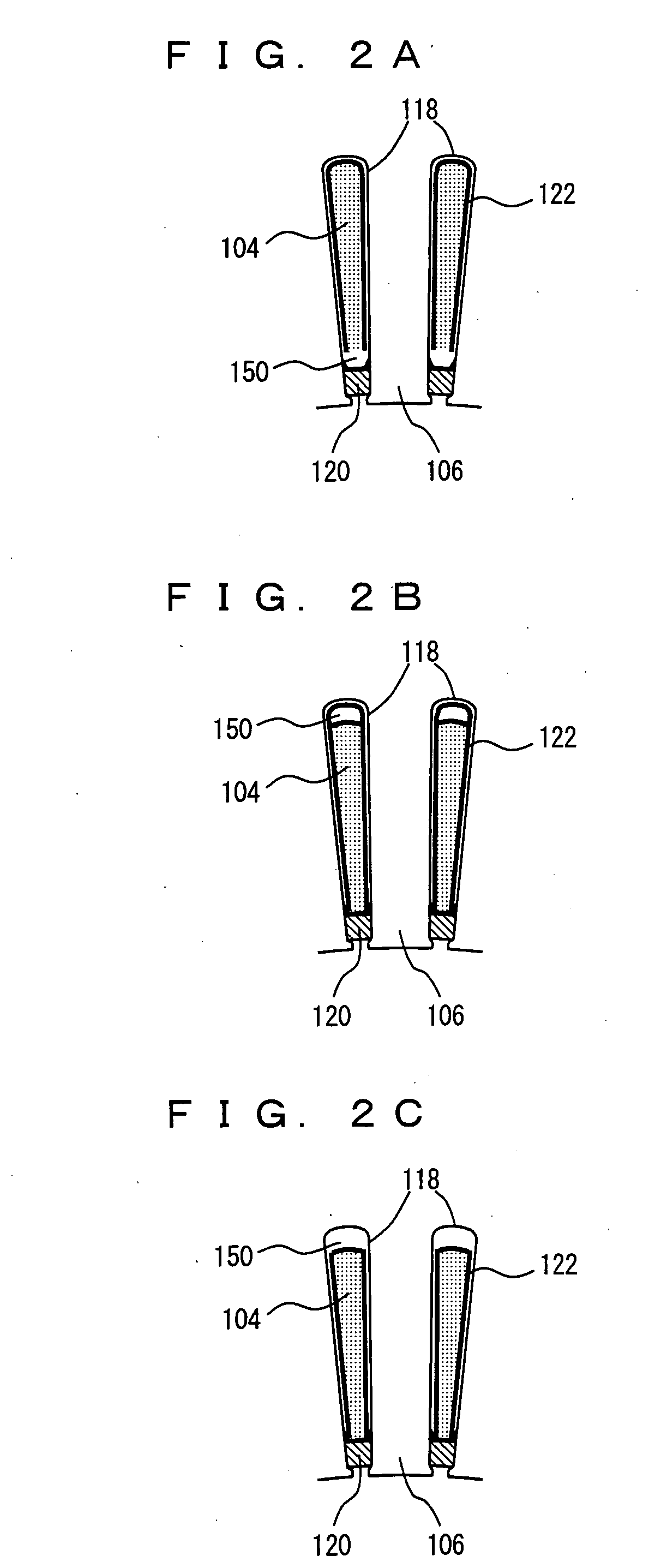

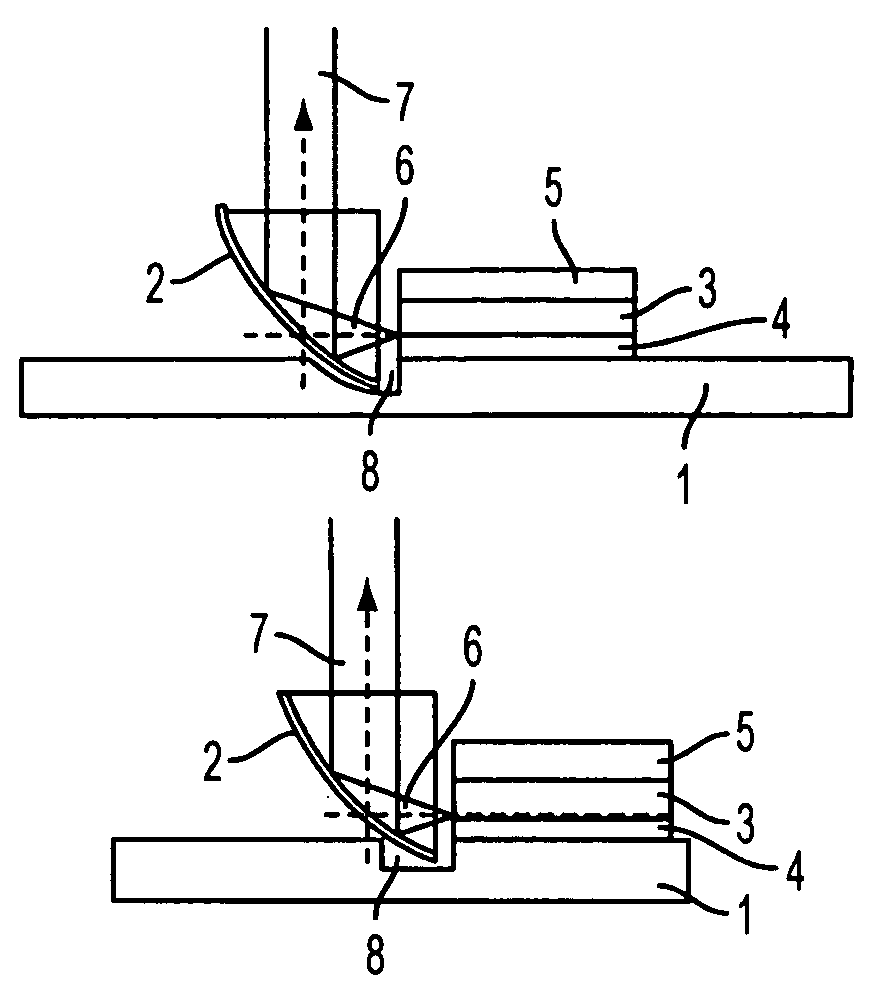

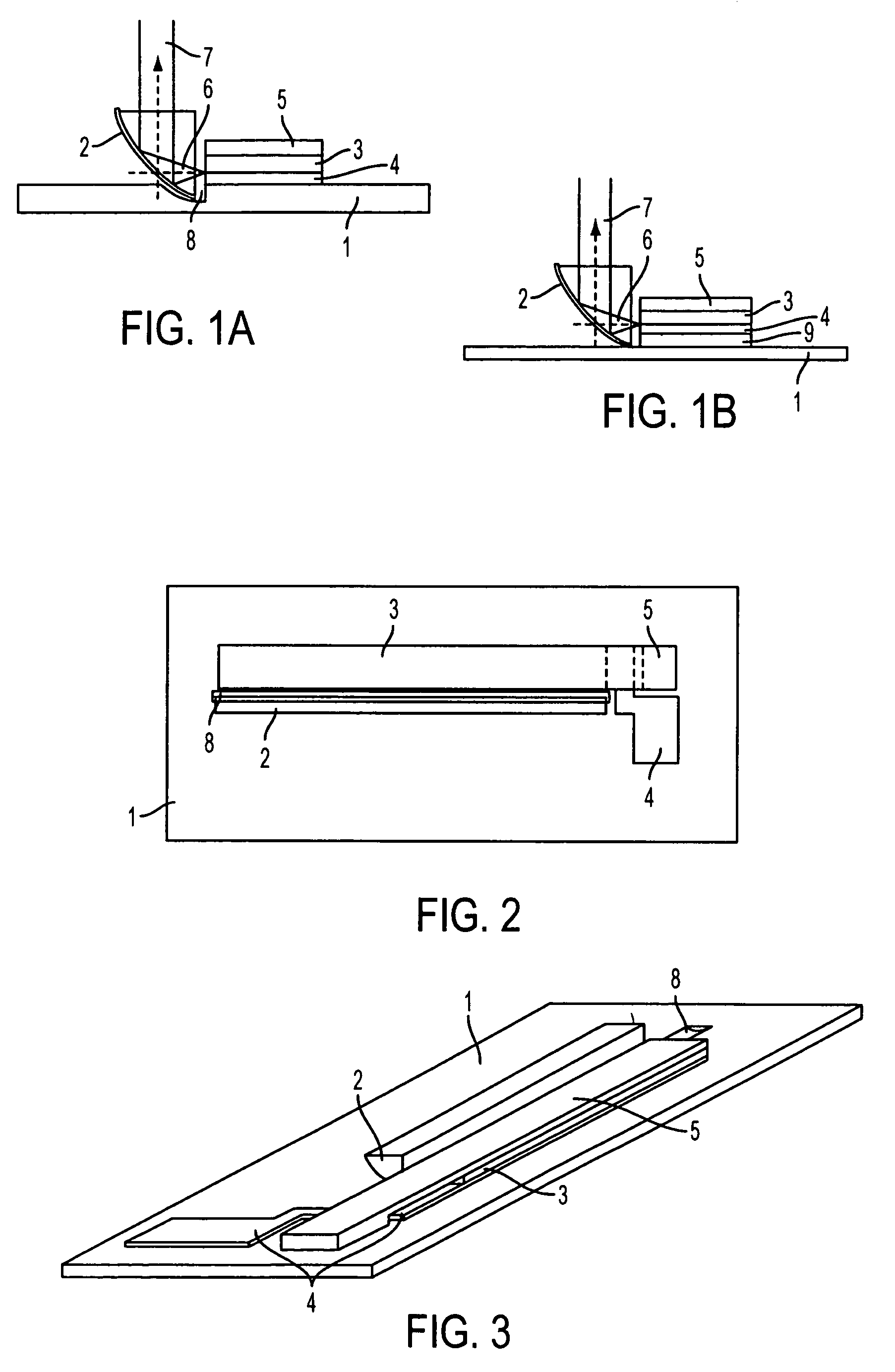

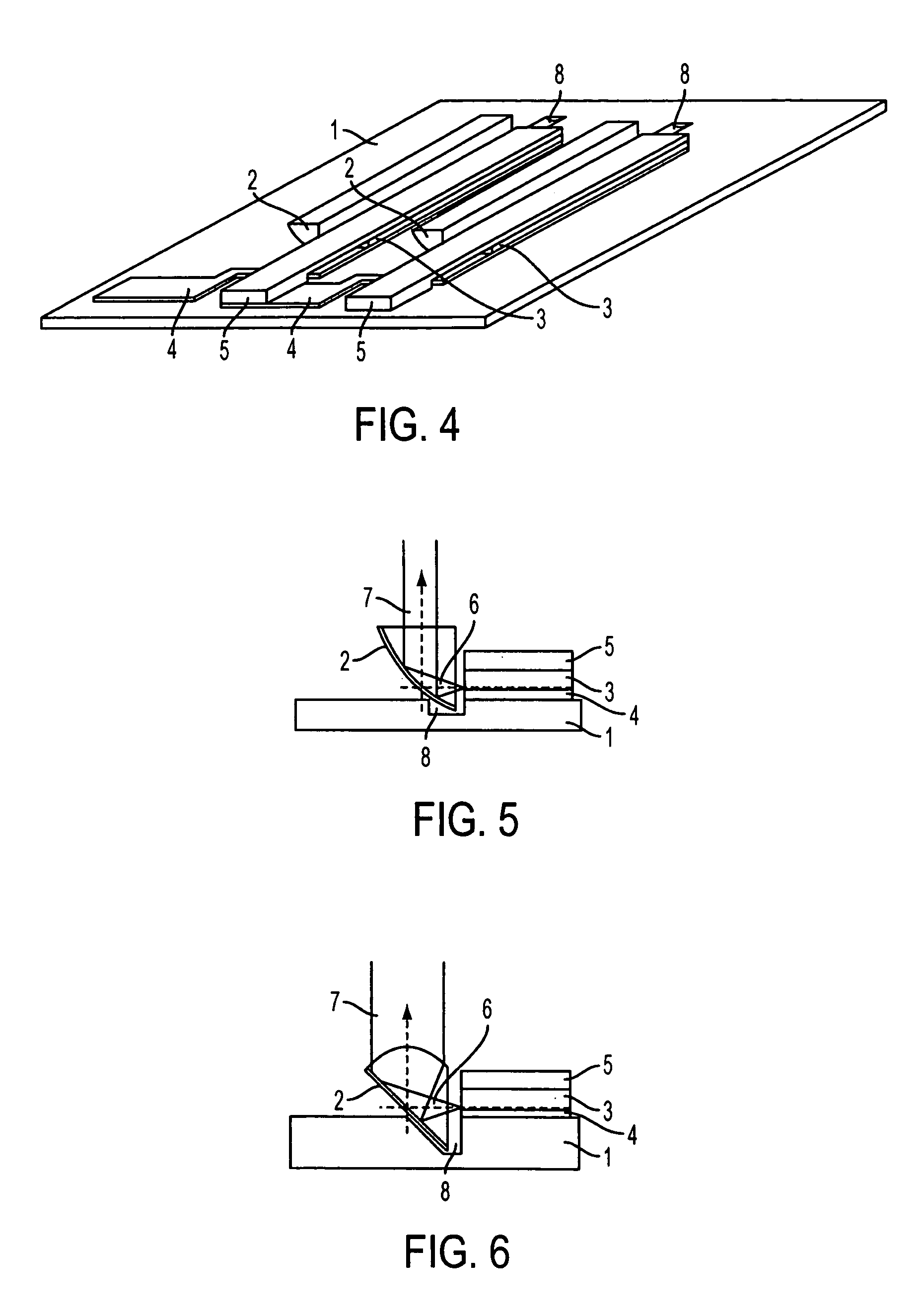

Ablation catheter with improved tip cooling

ActiveUS20070156131A1Cool evenlyMinimizing turbulent flowSurgical instruments for heatingSurgical instruments for irrigation of substancesWater irrigationCooling fluid

A catheter has a catheter body having an outer wall, proximal and distal ends, and at least one lumen extending therethrough. A tip section distal the catheter body includes an irrigated tip electrode and a segment of flexible tubing with at least one lumen therethrough. The tip electrode has a stepped profile which provides laminar flow (or at least minimizes turbulent flow and eddies) of irrigation / cooling fluid over its surface, which in turn provides more uniform cooling of the tip electrode, particularly where the tip electrode is elongated. In one embodiment, the tip electrode has a longitudinal axis, an outer ring surface generally perpendicular to the longitudinal axis, and an outer cylindrical surface extending distally from the outer ring surface along the longitudinal axis. Openings are provided in the outer ring surface to permit fluid (e.g., saline) to pass from an interior of the tip electrode to the outer ring surface and flow in a laminar manner over the cylindrical surface.

Owner:BIOSENSE WEBSTER INC

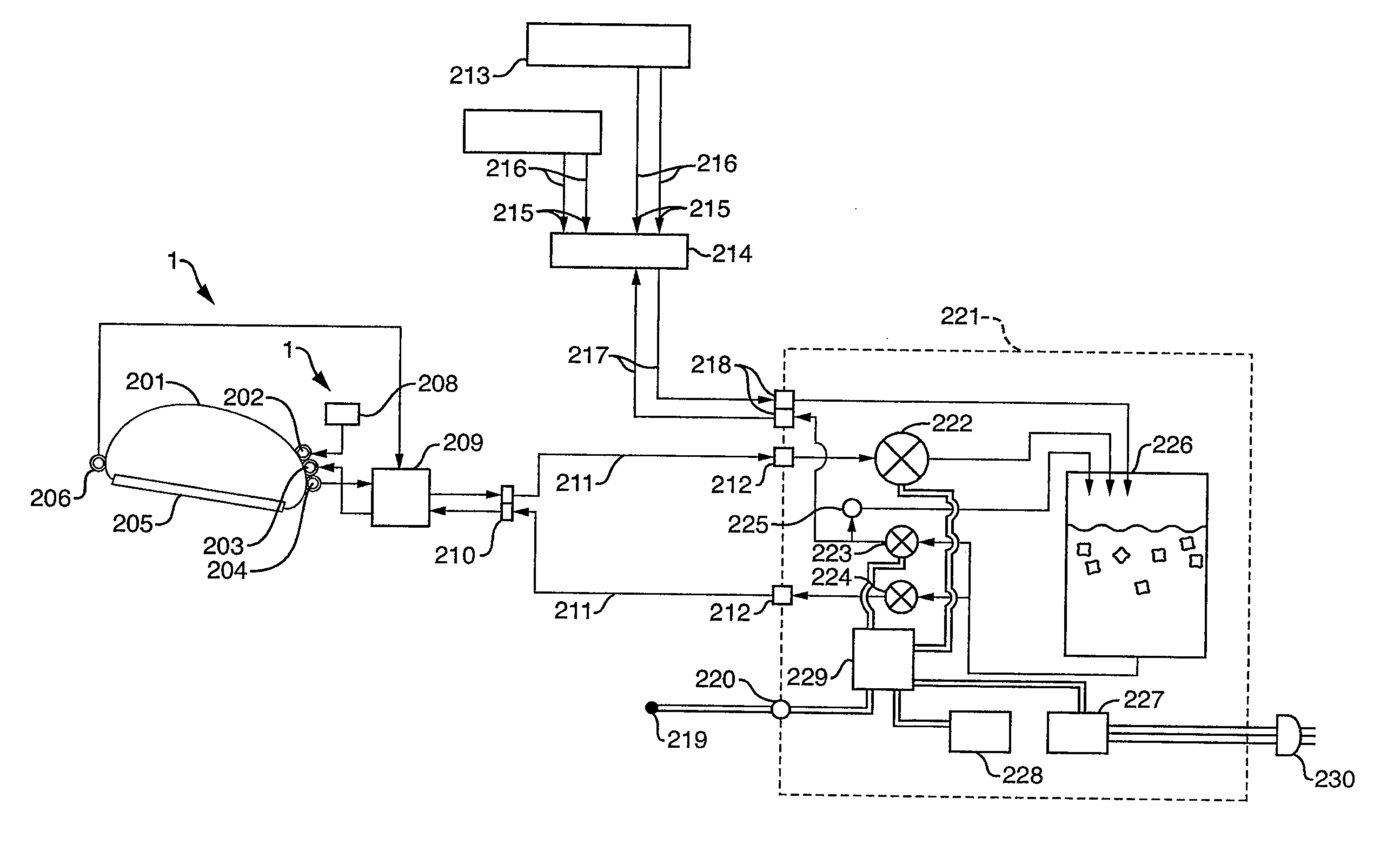

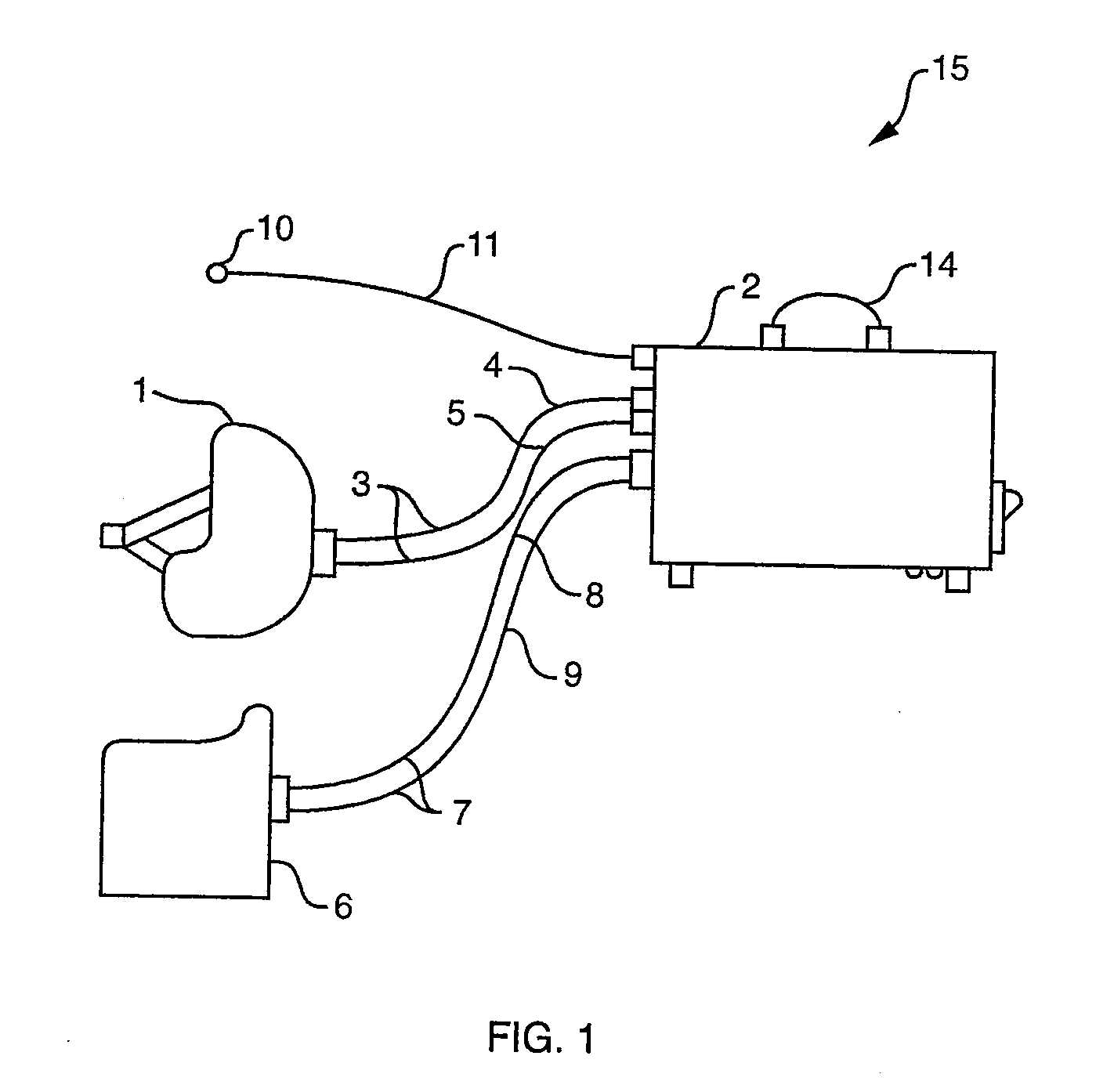

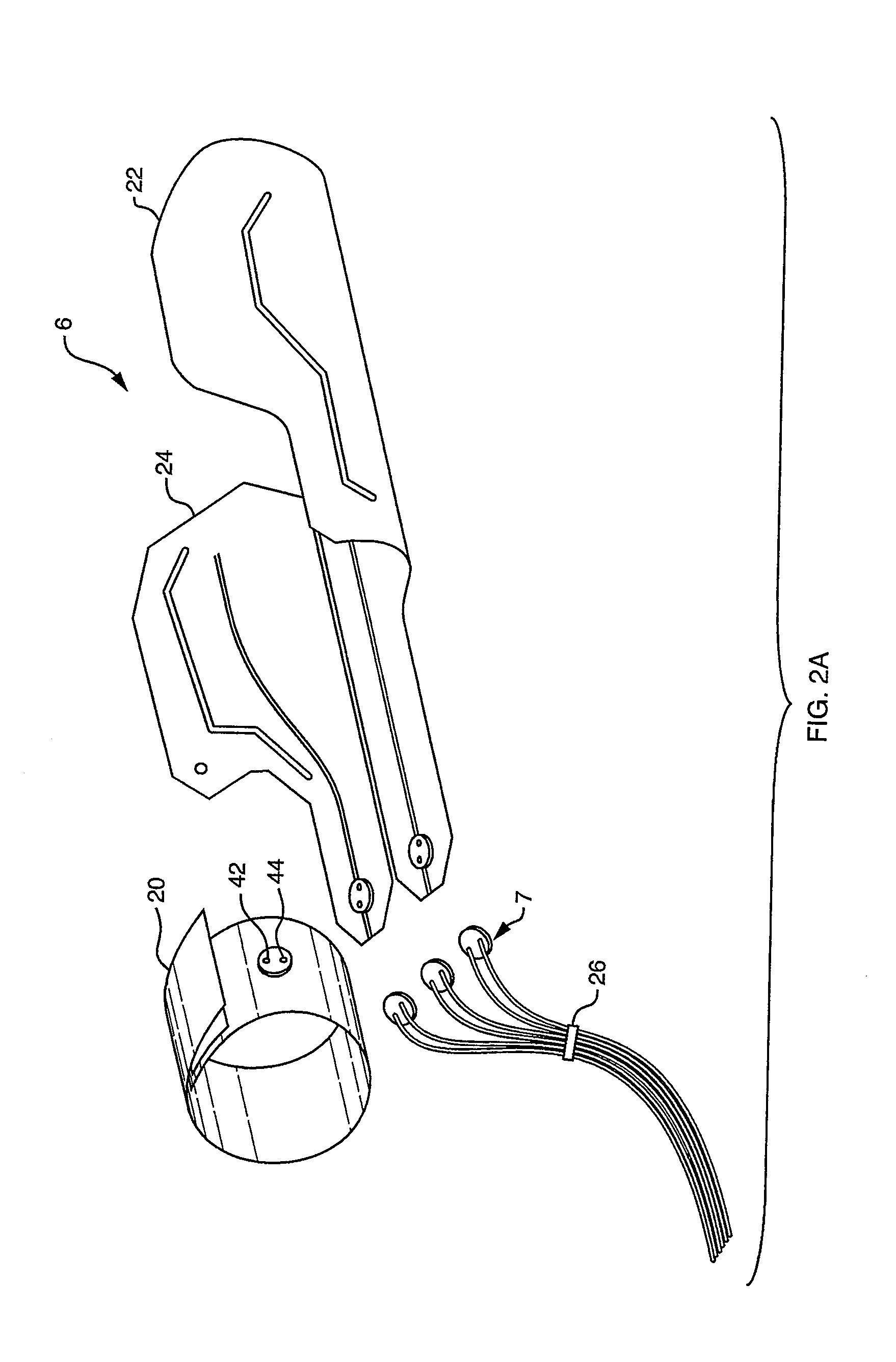

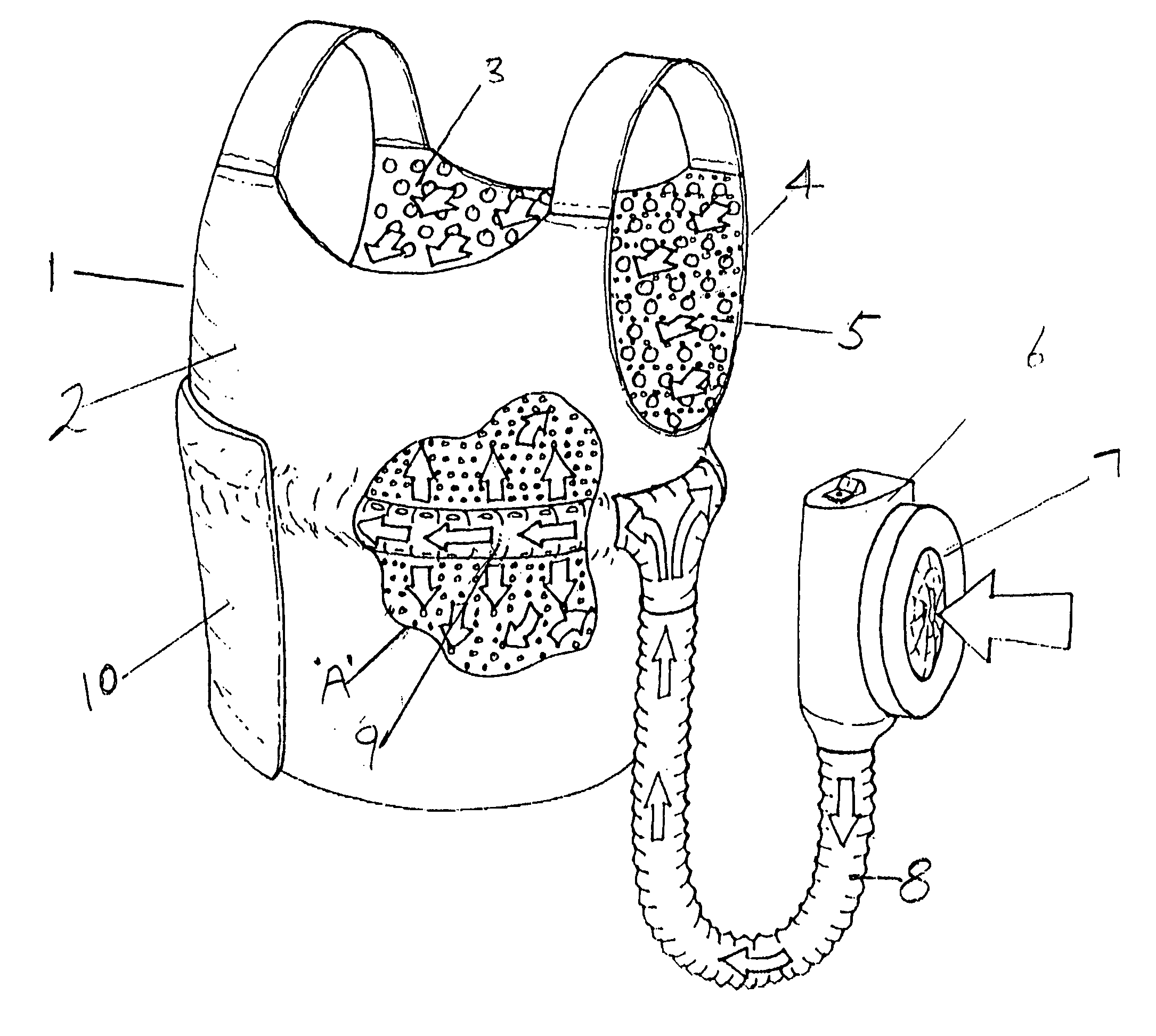

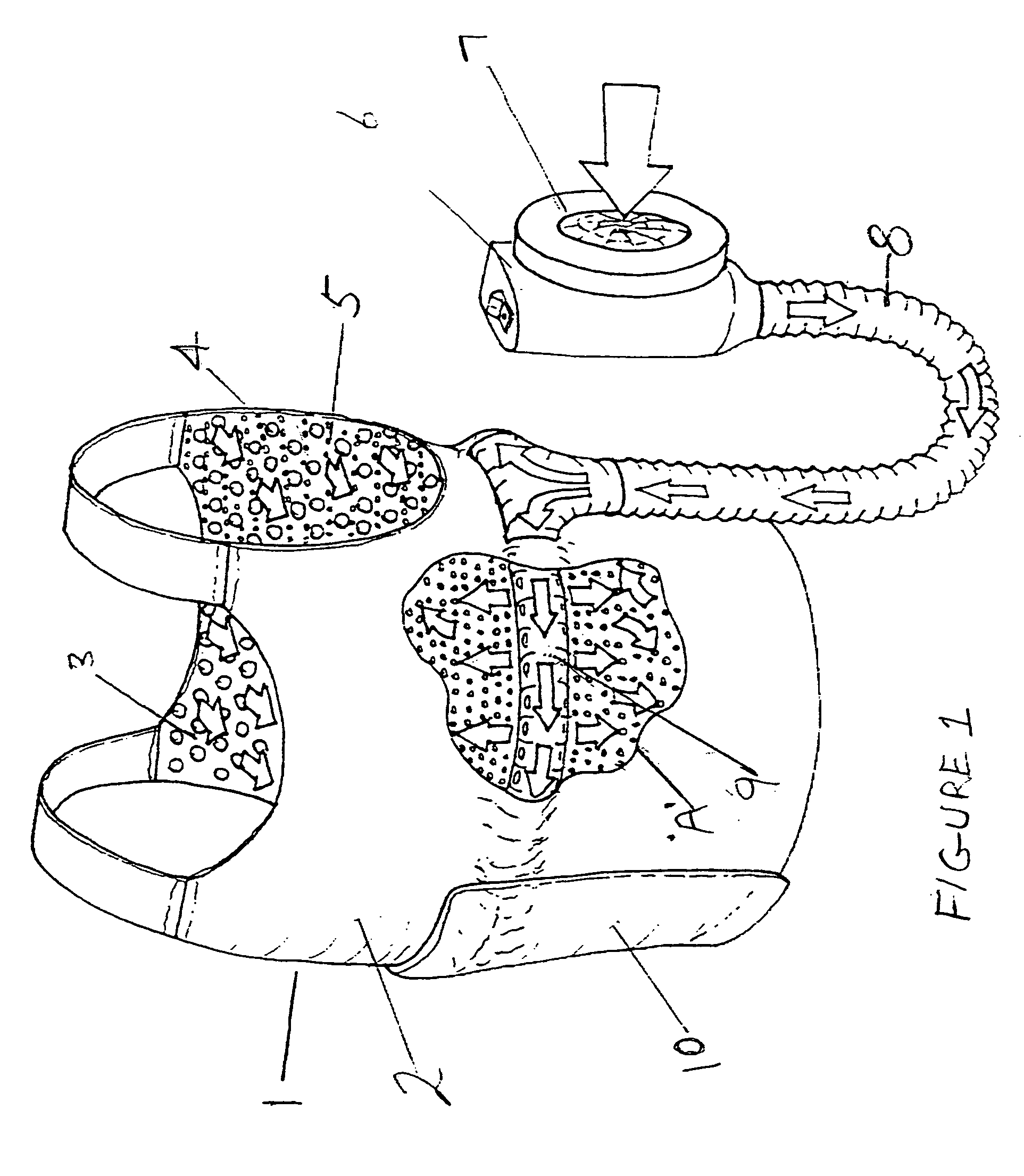

Methods and Apparatus for Thermal Regulation of a Body

InactiveUS20080269852A1Stress minimizationLimit over inflationTherapeutic coolingTherapeutic heatingSurgeryBody region

A thermal regulation system includes a thermal exchange collar for application to a neck of a patient, a thermal regulation pad for application to a body region, such as an axilla region of the patient, and a thermal regulation cap for application to a head of the patient.

Owner:MEDCOOL

Catheter with composite construction

ActiveUS20130253505A1Increase catheter sizeLess spaceDiagnosticsSurgical navigation systemsComposite constructionEngineering

A catheter has a composite and segmented construction in a distal section that includes deflectable members and support member arranged in alternating sequence, with each support member carrying a ring electrode and the deflectable members being flexible to allow deflection of the distal section as a whole. Carried on an outer surface of the support member is a coil location sensor. The distal section is configured with a distal irrigation fluid path extending axially through the deflectable members and the support members to deliver irrigation fluid to the ring electrode and the tip electrode. A method of constructing a catheter includes building a section of the catheter from the inside out by mounting the support members on a tubing at predetermined locations and filling gaps in between with a more flexible material to form the deflectable members by extrusion segments or injection molding over assembled components internal to the catheter.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Nozzle for use in a torch head of a plasma torch apparatus

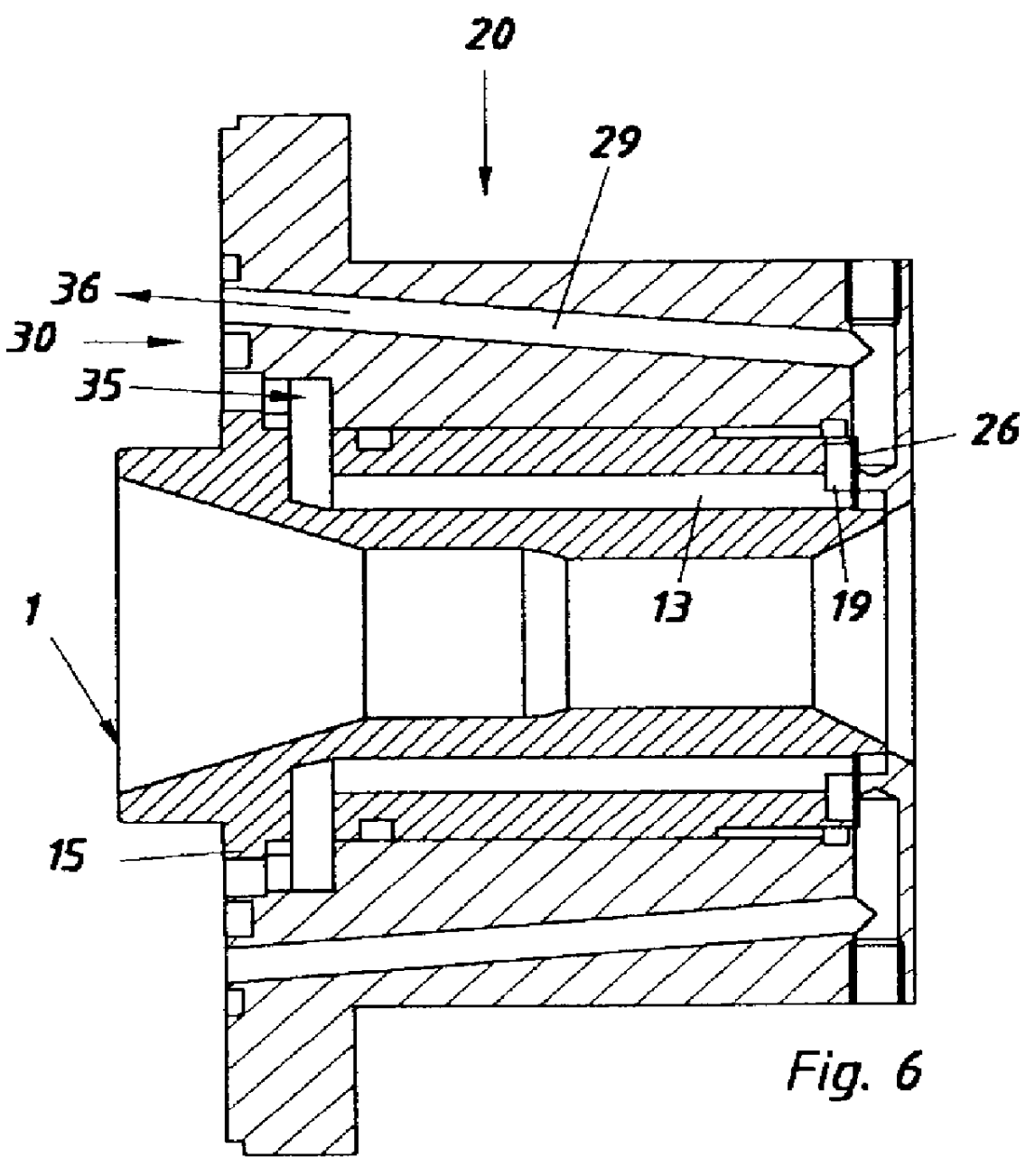

InactiveUS6137078AImproved an more homogenous cooling of the nozzle body memberCool evenlyArc welding apparatusPlasma welding apparatusEngineeringTorch

The nozzle is provided with a plurality of cooling channels running from an annular channel located in an inlet region of the nozzle through the nozzle in longitudinal direction up to an outlet region of the nozzle. The powder supply channels provided for the supply of coating material are led between the cooling channels. A nozzle support member adapted for receiving the nozzle is provided with cooling ducts that are hydraulically connected to the cooling channels of the nozzle and constitute therewith a nozzle cooling circulation system. The advantages of this design can be seen in the facts that the nozzle is homogeneously and efficiently cooled up to its outlet end and that the danger of building-up molten deposits within the nozzle is substantially avoided.

Owner:SULZER METRO AG

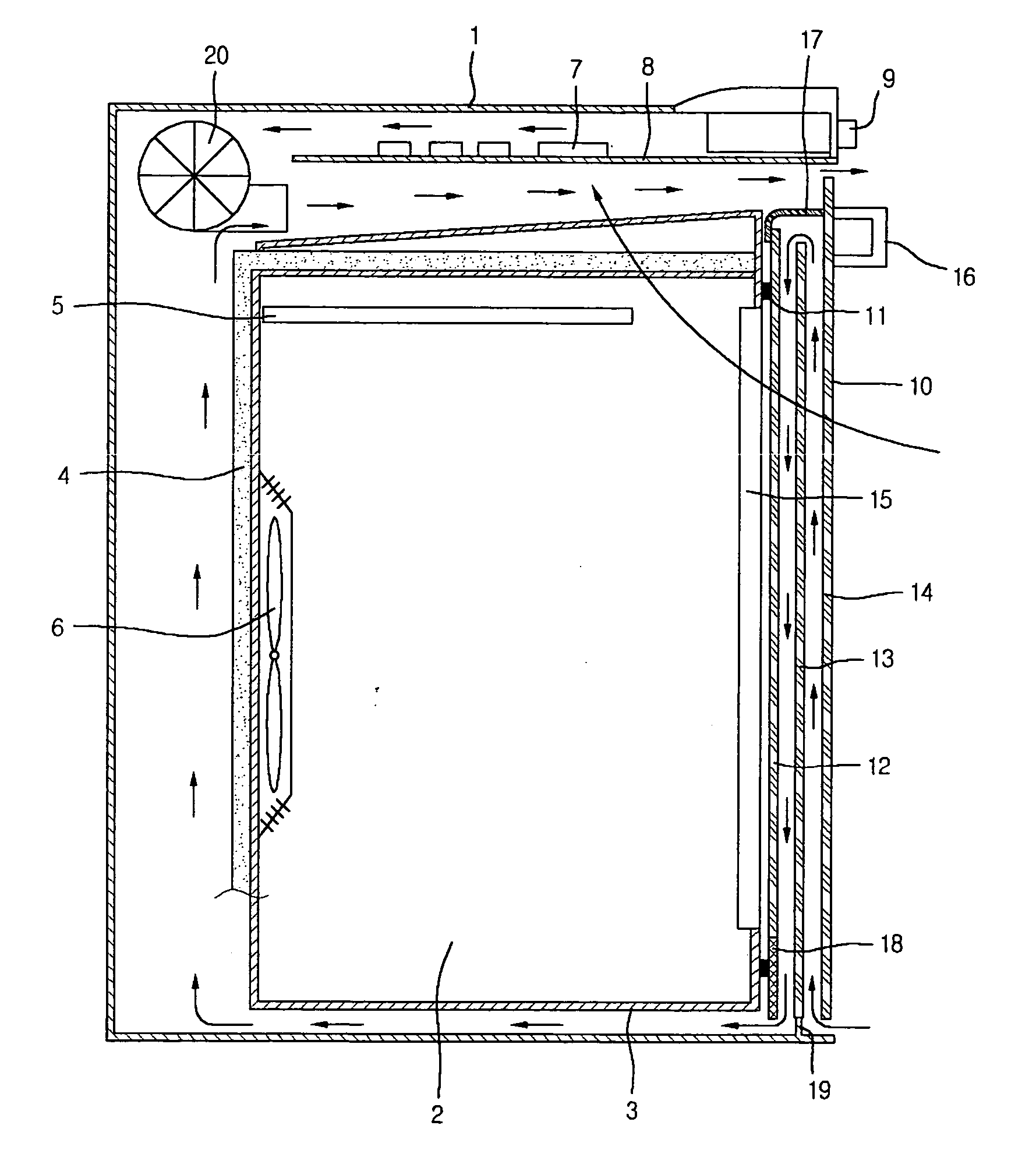

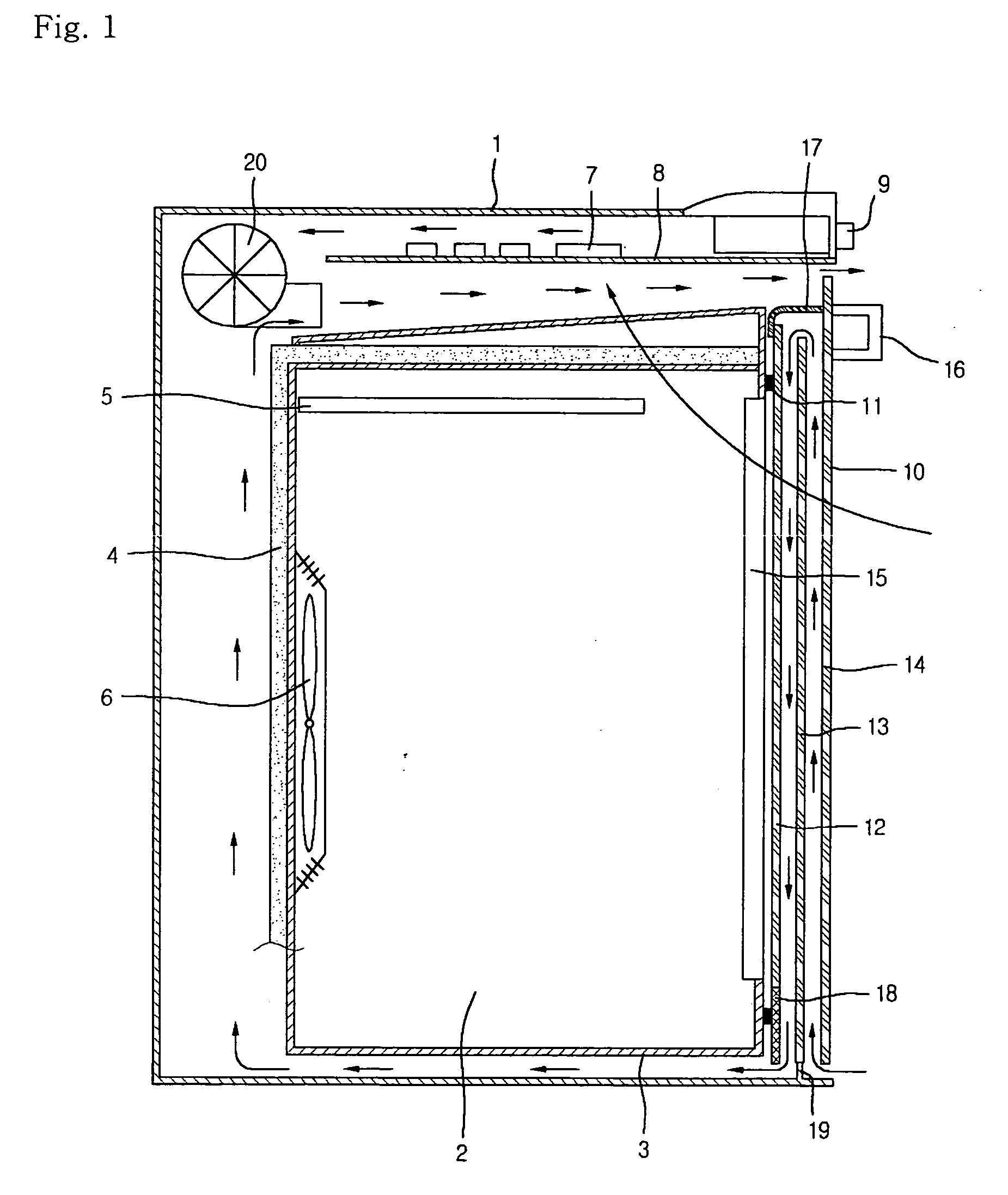

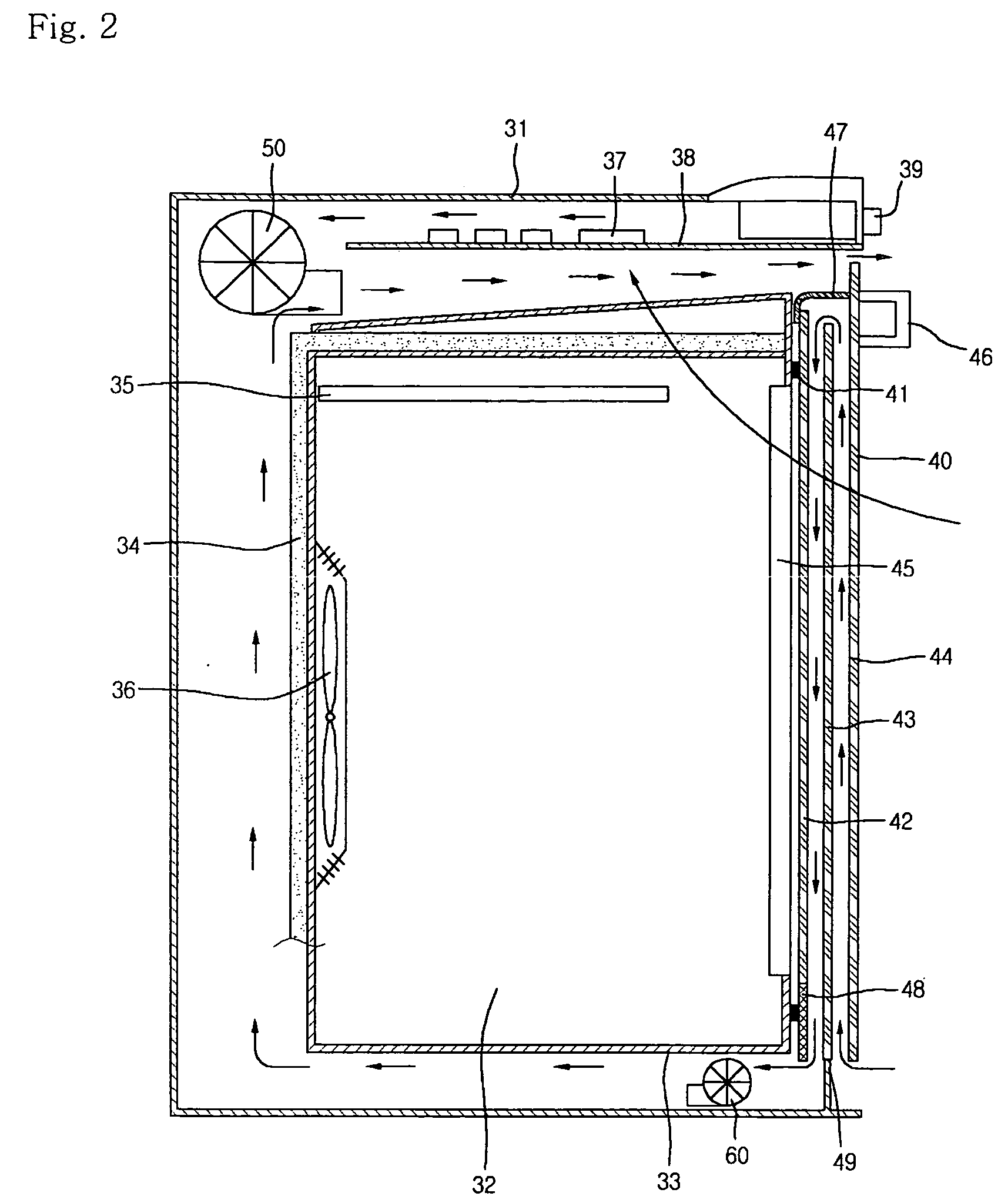

Electric oven with door cooling structure

InactiveUS20050133019A1Avoid damageQuickly sufficiently cool downDomestic stoves or rangesDoors for stoves/rangesEngineeringElectrical and Electronics engineering

An electric oven with a door cooling structure includes a cavity formed in the case to provide a high temperature environment, a door for selectively opening and closing the cavity, inner, intermediate and outer panels provided in the door; an airflow shielding panel for blocking a space formed below the intermediate panel to guide introduced air upward; a door cover for blocking a top of the door, which is defined between the inner and outer panels, and a fan for applying negative pressure to gaps defined between the inner, intermediate and outer panels so that the panels can be cooled by the air flowing upward and downward in the gaps.

Owner:LG ELECTRONICS INC

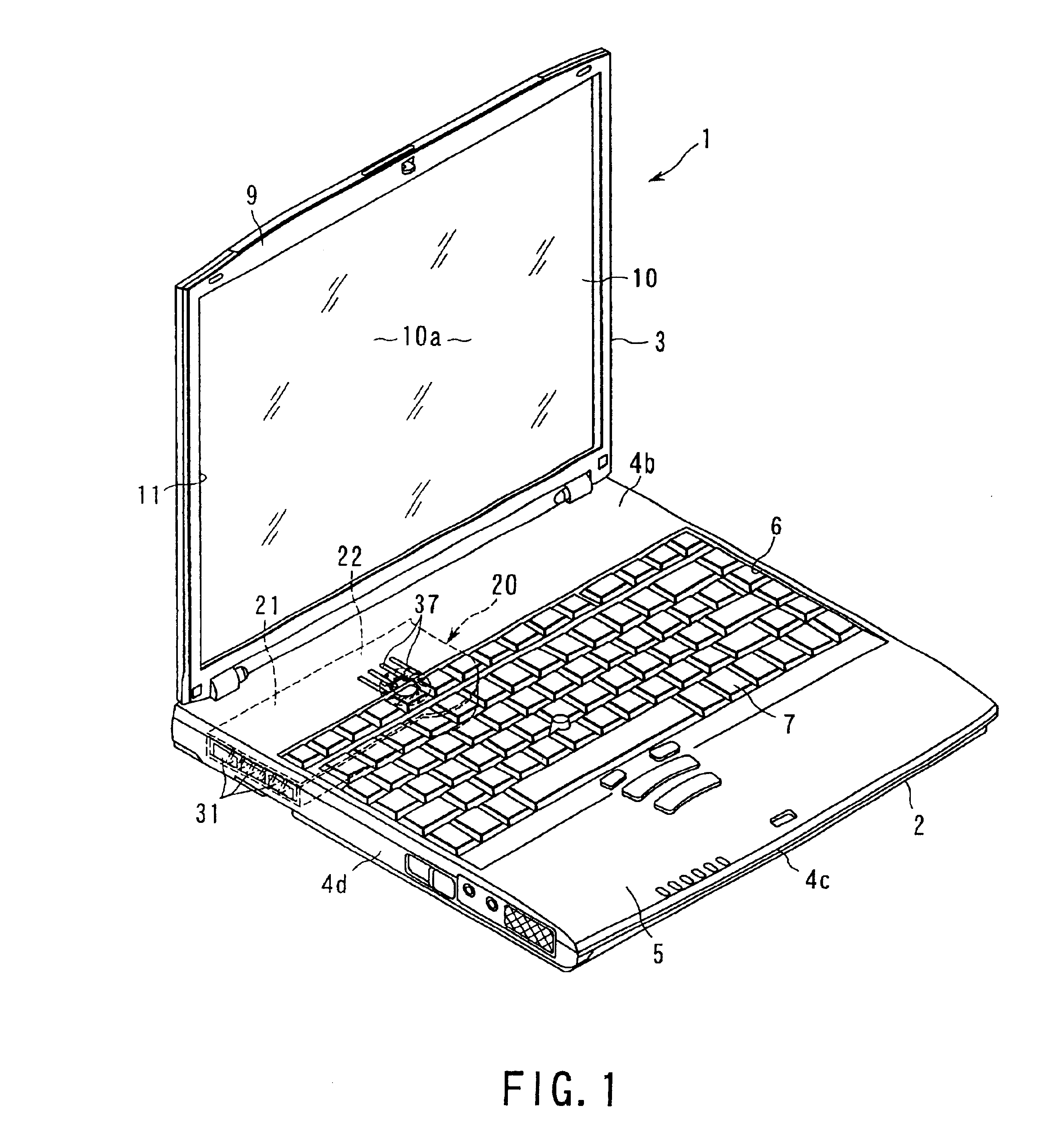

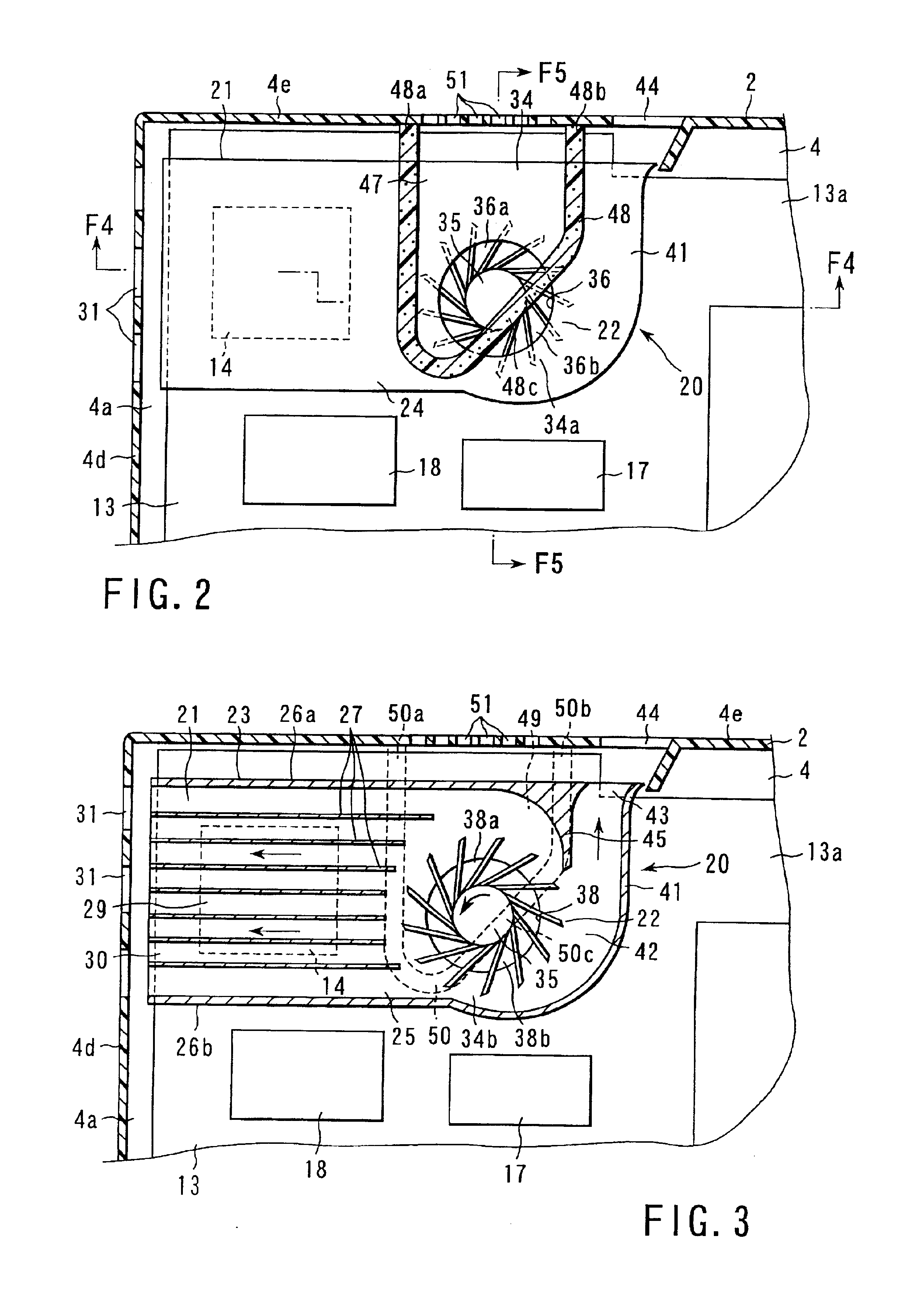

Electronic apparatus having cooling unit for cooling heat-generating component

InactiveUS6847524B2Improve cooling effectCool evenlyDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

An electronic apparatus comprises a housing containing a heat-generating component, and a cooling unit. The cooling unit includes a heat sink thermally connected to the heat-generating component, a first air passage for guiding air outside the housing to the heat sink and guiding air heated by heat exchange with the heat sink to the outside of the housing, and a second air passage for guiding air within the housing to the outside of the housing.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

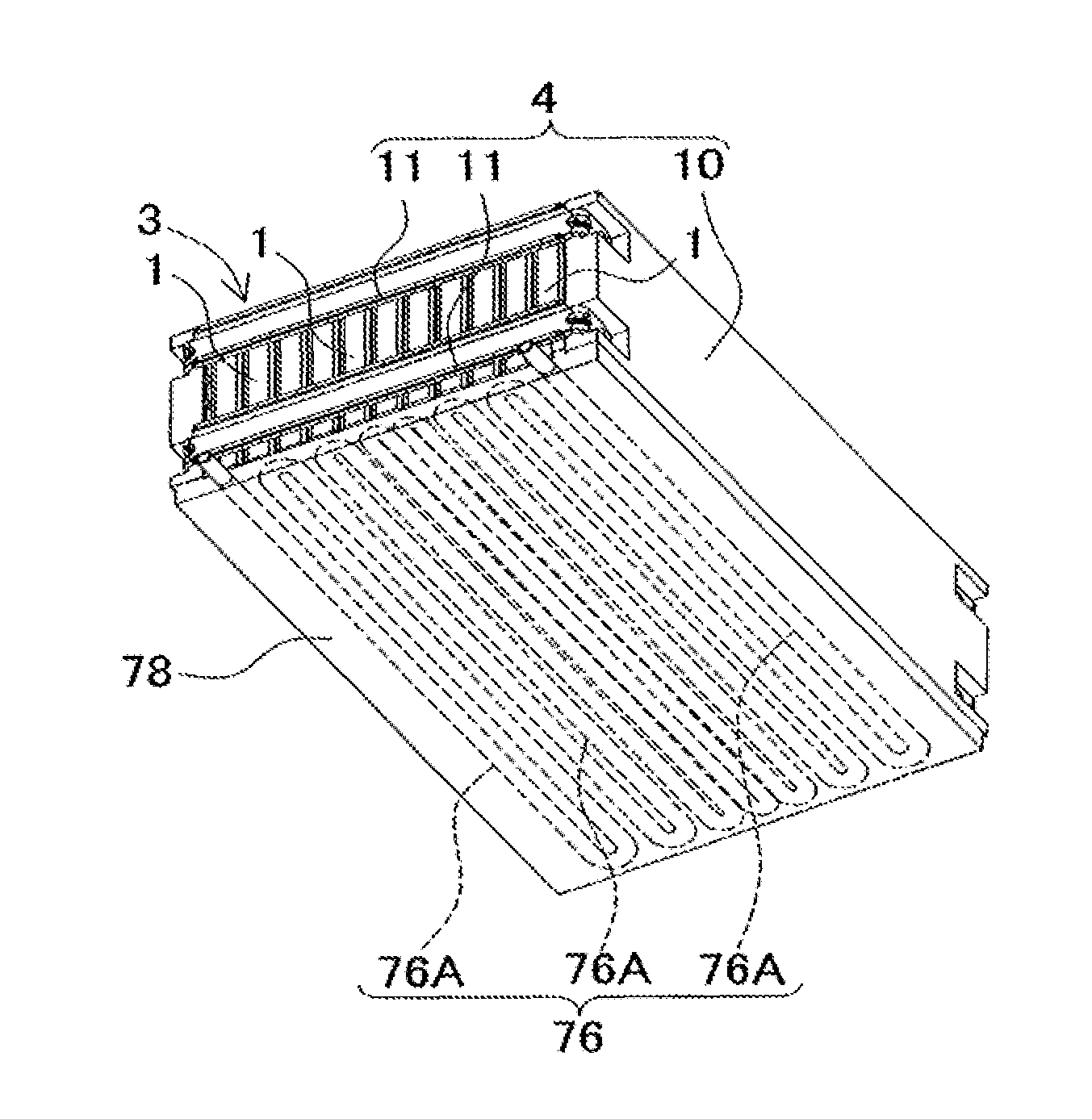

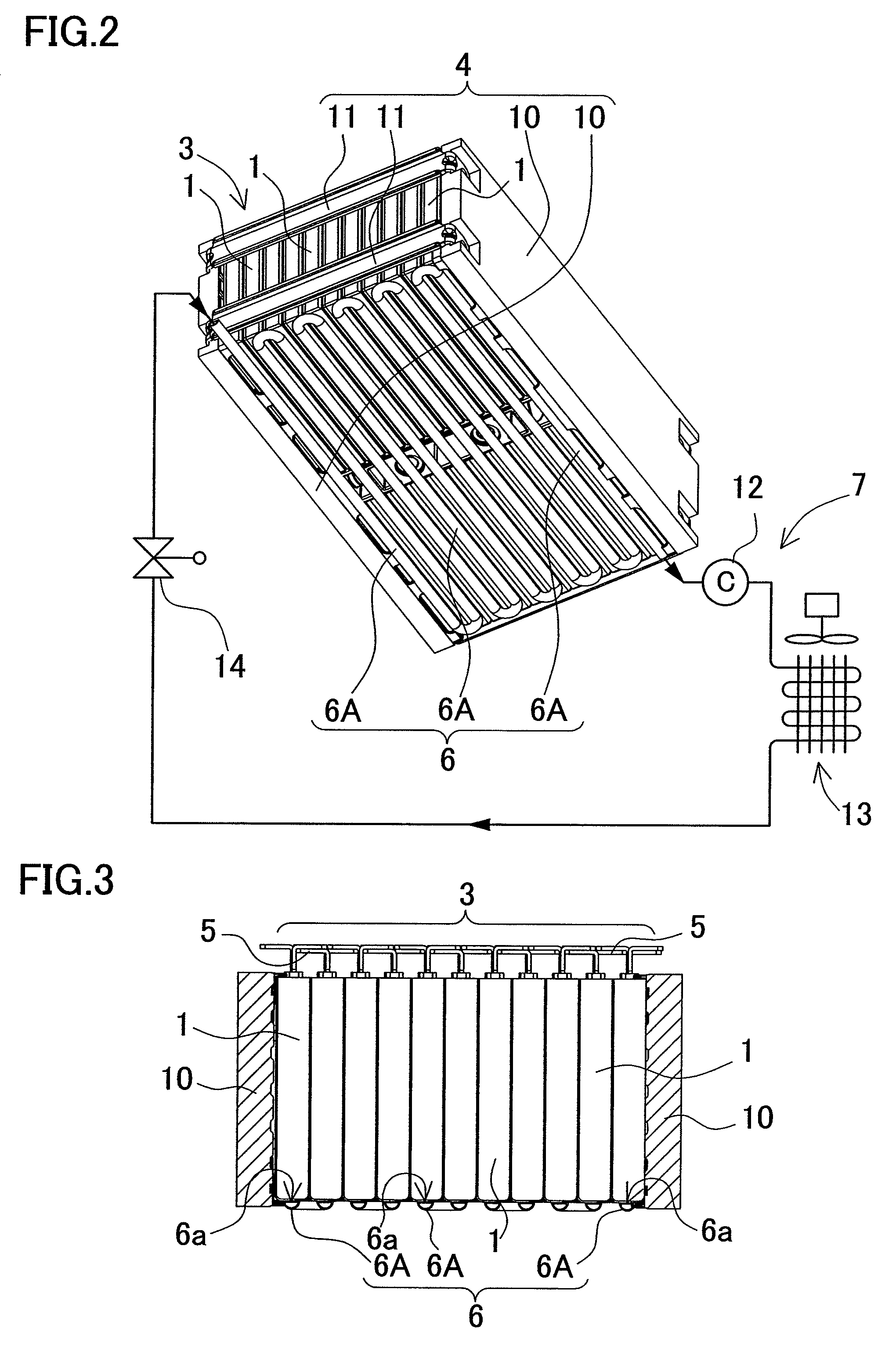

Battery system with battery cells arranged in array alignment

ActiveUS8409743B2Improve cooling effectConvenient ArrangementPrimary cell to battery groupingCell temperature controlEngineeringCooling pipe

A battery system includes a battery block, a cooling pipe, and a coolant feeding device. The battery block includes a plurality of rectangular batteries that have a width greater than a thickness and are securely arranged in array alignment by a battery holder. The cooling pipe cools the rectangular batteries of the battery block. The coolant feeding device feeds coolant to the cooling pipe. In the battery system, the cooling pipe is arranged on the surface of the battery block in a thermally-coupled state so that the rectangular batteries are cooled by the coolant, which is circulated through the cooling pipe.

Owner:SANYO ELECTRIC CO LTD

Motor for vehicle

InactiveUS20050151429A1Avoid introducingPrevent leakageCooling/ventillation arrangementPropulsion coolingOil supplyElectric machine

A motor having a rotation shaft extending in a horizontal direction and efficiently cooling stator portion includes a cooling oil inlet provided in a lower portion of the motor in order to introduce the cooling oil supplied from an oil pump through a supply pipe, a coil end cover for immersing a stator portion of the motor in order to discharge the cooling oil from the motor, and a discharge pipe connected to the cooling oil discharge outlet for discharging the cooling oil to an oil pan.

Owner:TOYOTA JIDOSHA KK

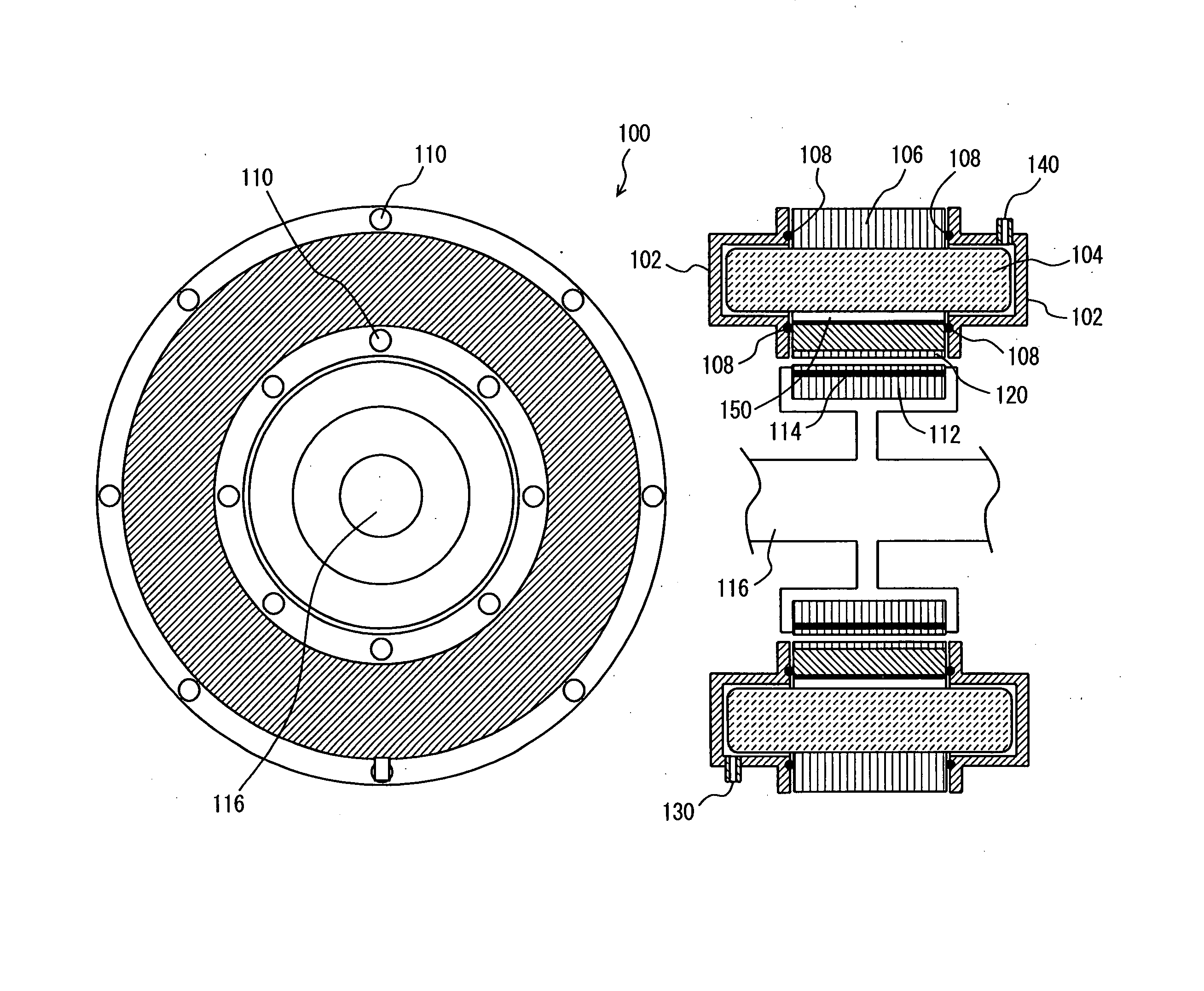

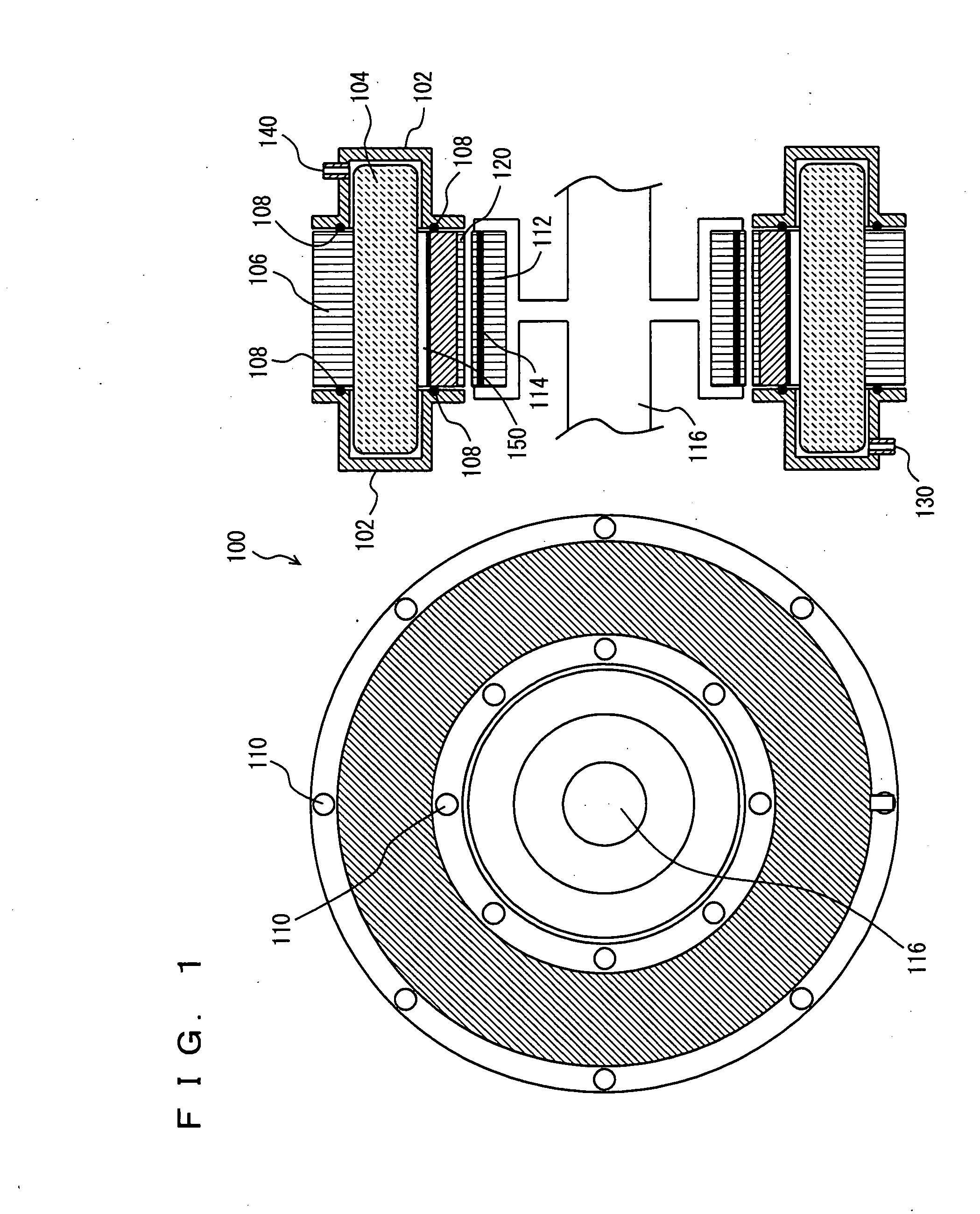

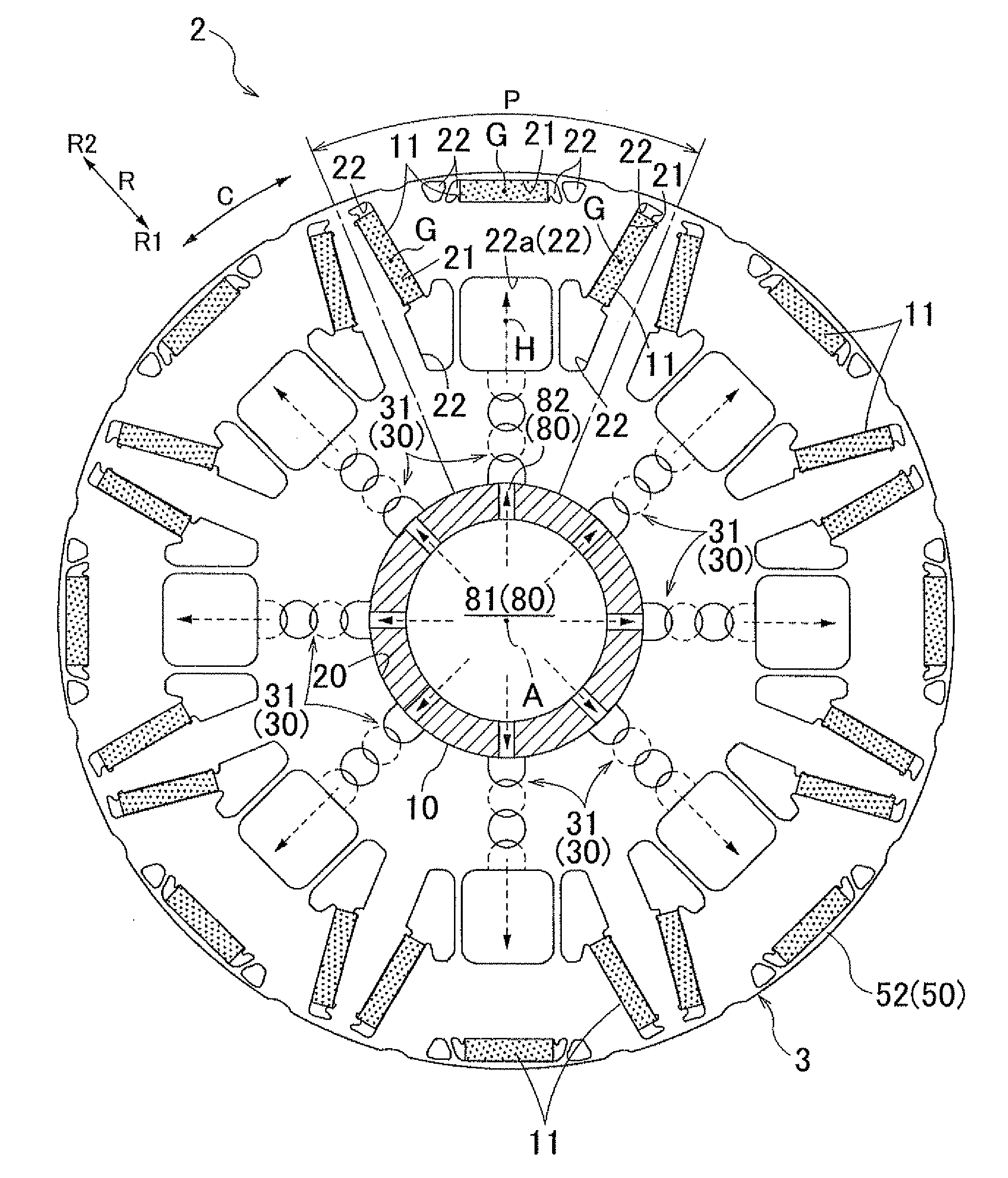

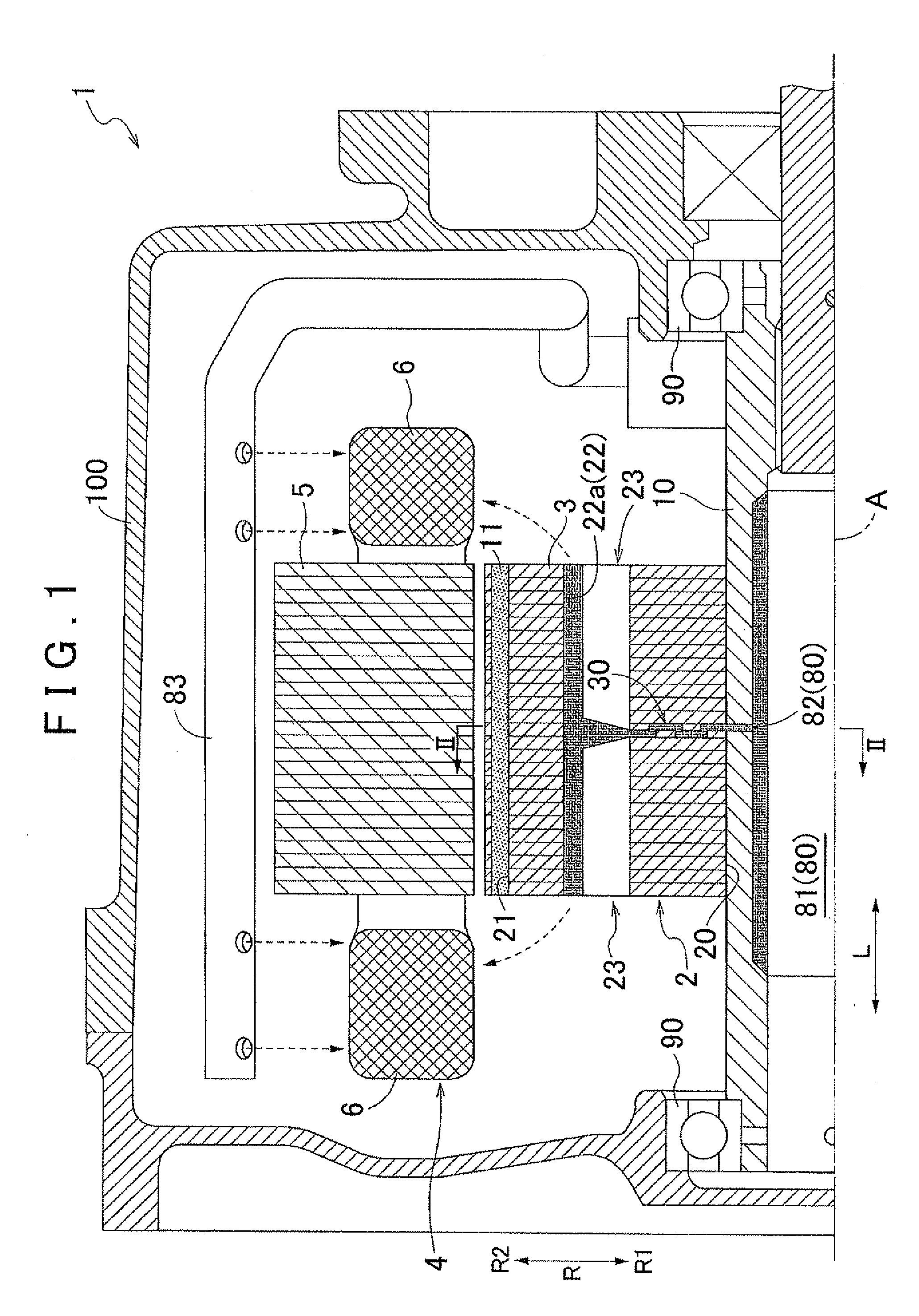

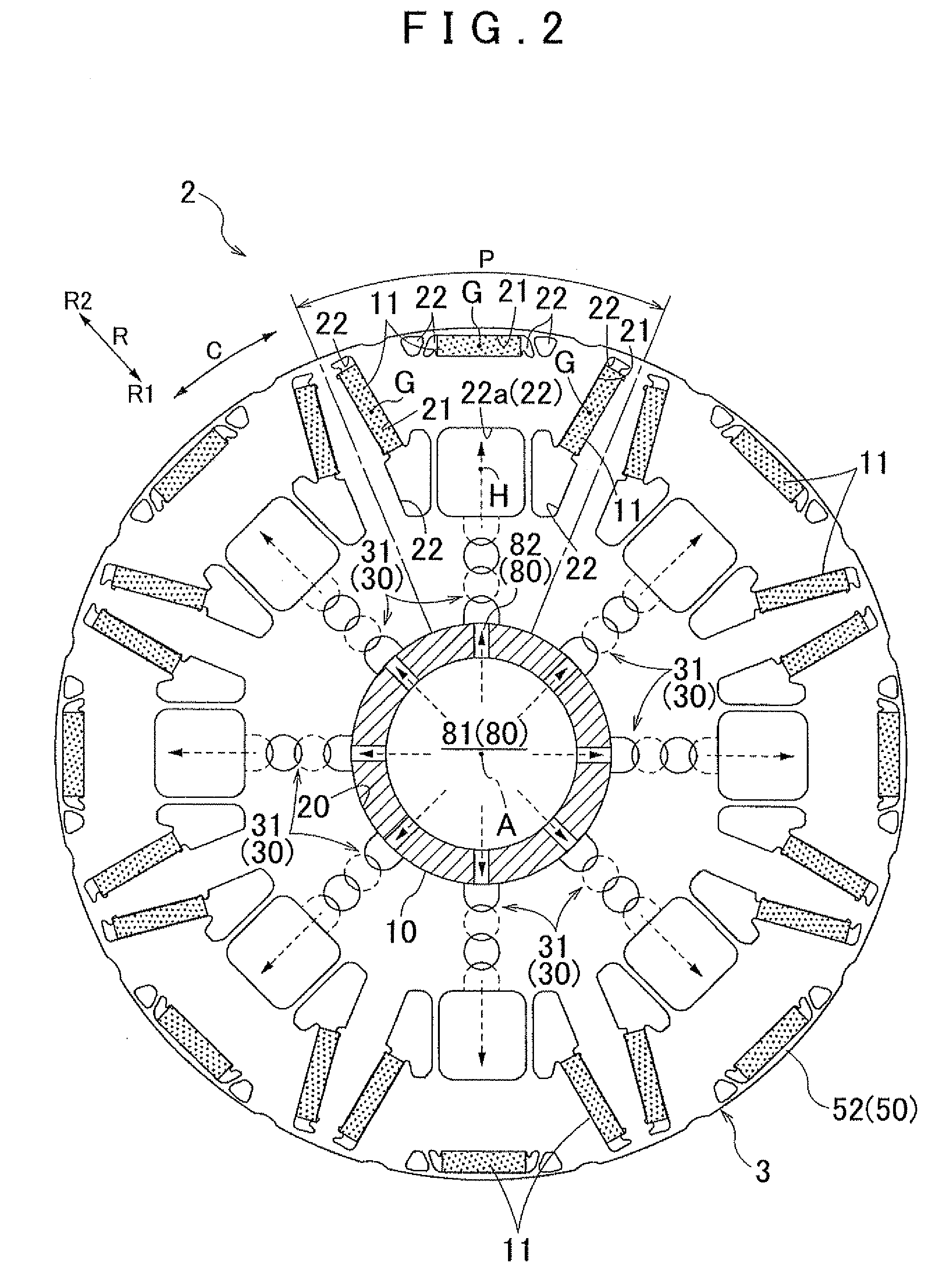

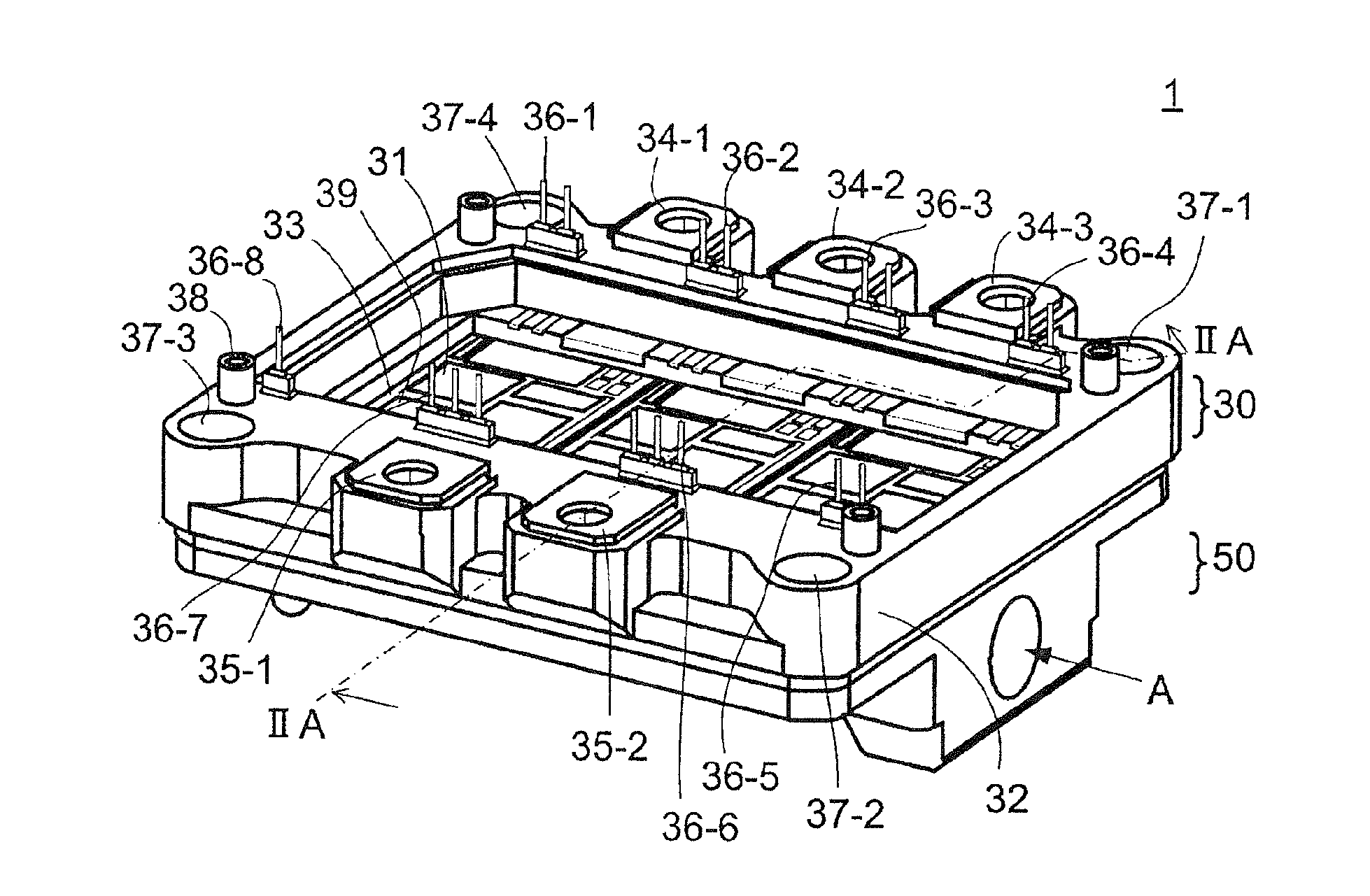

Rotating electrical machine

ActiveUS20130020889A1Improve cooling effectSecure performanceMagnetic circuit rotating partsCooling/ventillation arrangementRadial positionElectric machine

A rotating electrical machine includes a rotor which has a rotor core formed by stacking magnetic plates having an annular plate shape in an axial direction, a permanent magnet is inserted into a magnet insertion hole formed in the rotor core, and a rotor shaft is inserted into a shaft insertion hole surrounded by an inner peripheral surface of the rotor core; and a stator. A radial communication passage is formed by a communication penetration hole group that is formed by sequentially communicating a plurality of the penetration holes from a shaft insertion hole to a magnetic resistance hole in the radial direction. The plurality of the penetration holes are divided into at least two specific magnetic plates and formed such that the radial positions of the penetration holes are different from each other and the penetration holes partially overlap each other when viewed in the axial direction.

Owner:AISIN AW CO LTD

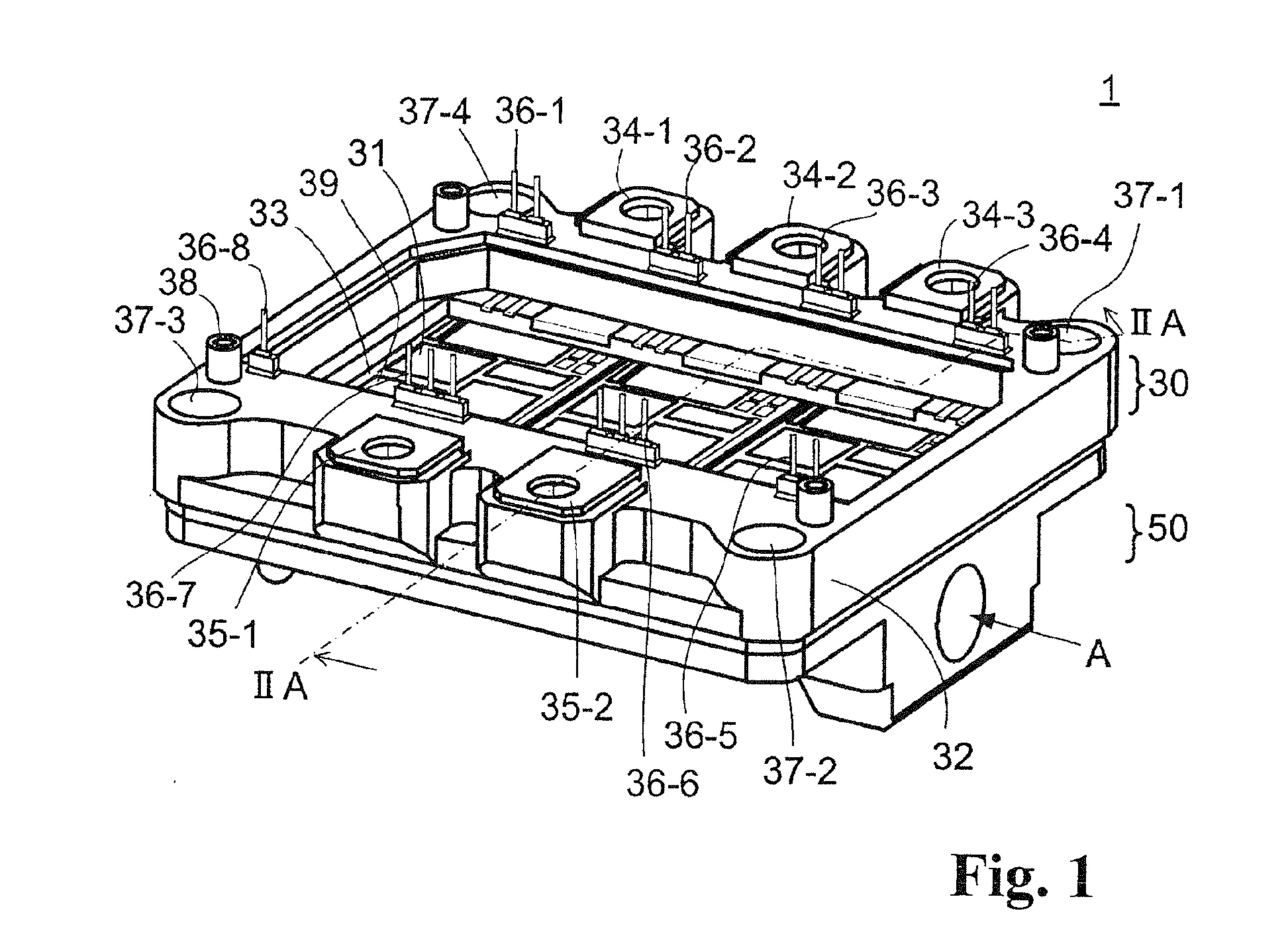

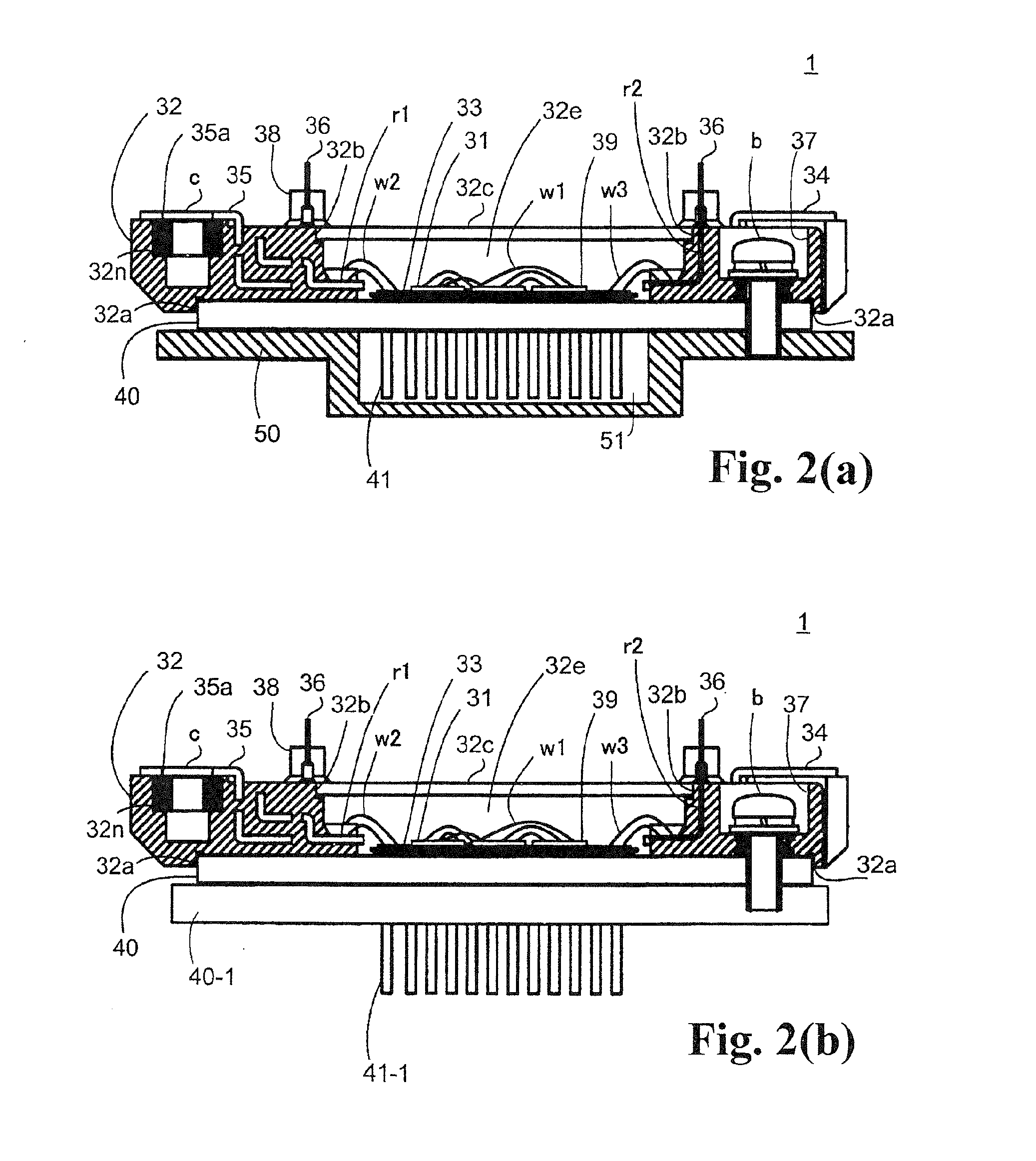

Semiconductor device and cooler thereof

ActiveUS20140376184A1Reduce pressure lossReduce power lossSemiconductor/solid-state device detailsSolid-state devicesHeat sinkCooling Units

A semiconductor device exhibits low pressure loss and is capable of cooling a plurality of power semiconductor chips evenly. This semiconductor device includes a semiconductor module and a cooler for cooling a power semiconductor element mounted in the semiconductor module. A cooling unit of the cooler has a first header part that has a first bottom surface disposed between a coolant inlet and an end portion of a first substrate on the coolant outlet side and inclined toward a bottom plane of cooling fins so that a coolant supplied from the coolant inlet flows toward the cooling fins; and a second header part that has a second bottom surface inclined from an end portion of the bottom plane of the cooling fins on the coolant outlet side so that the coolant discharged from the cooling fins flows to the coolant outlet.

Owner:FUJI ELECTRIC CO LTD

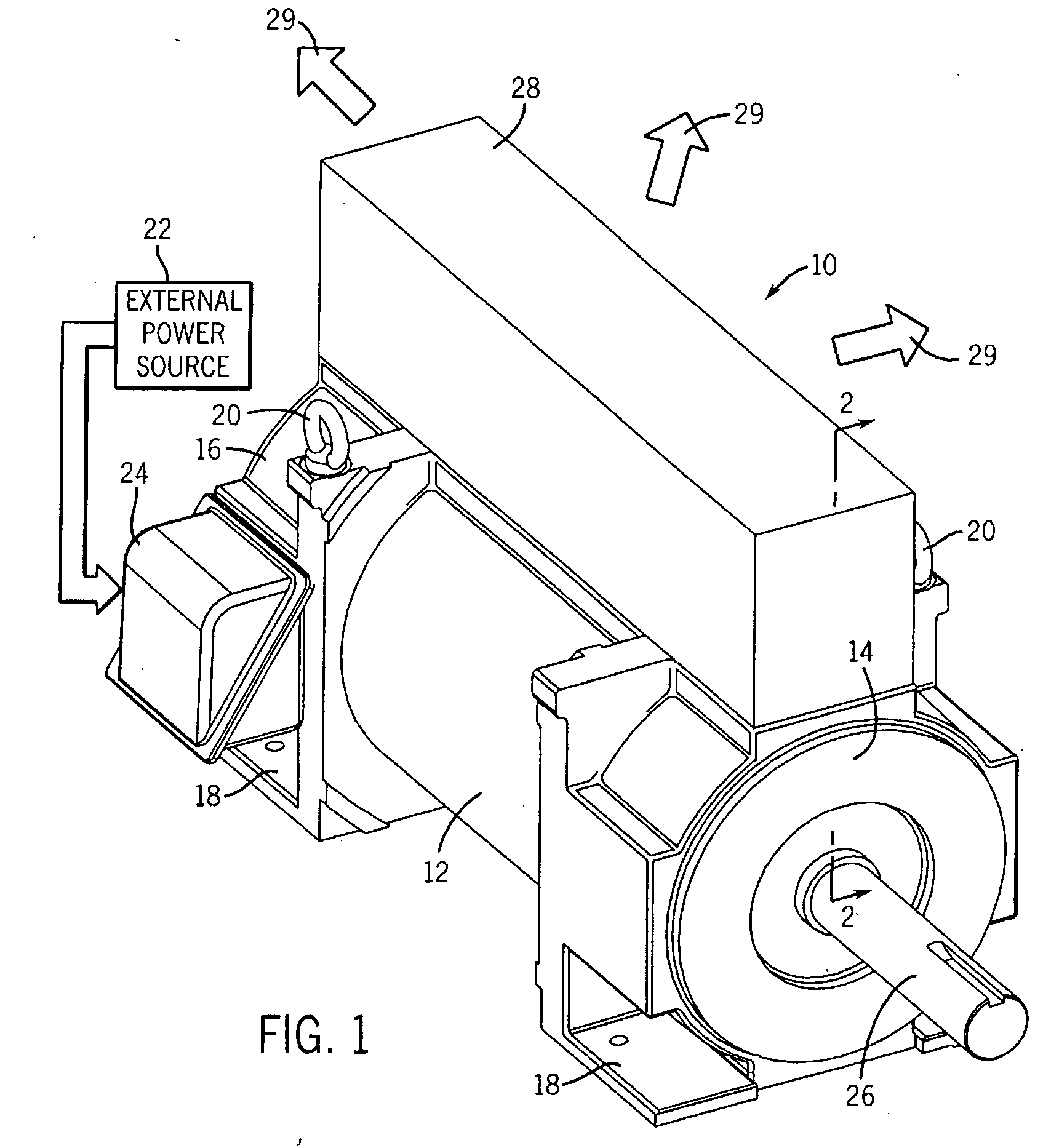

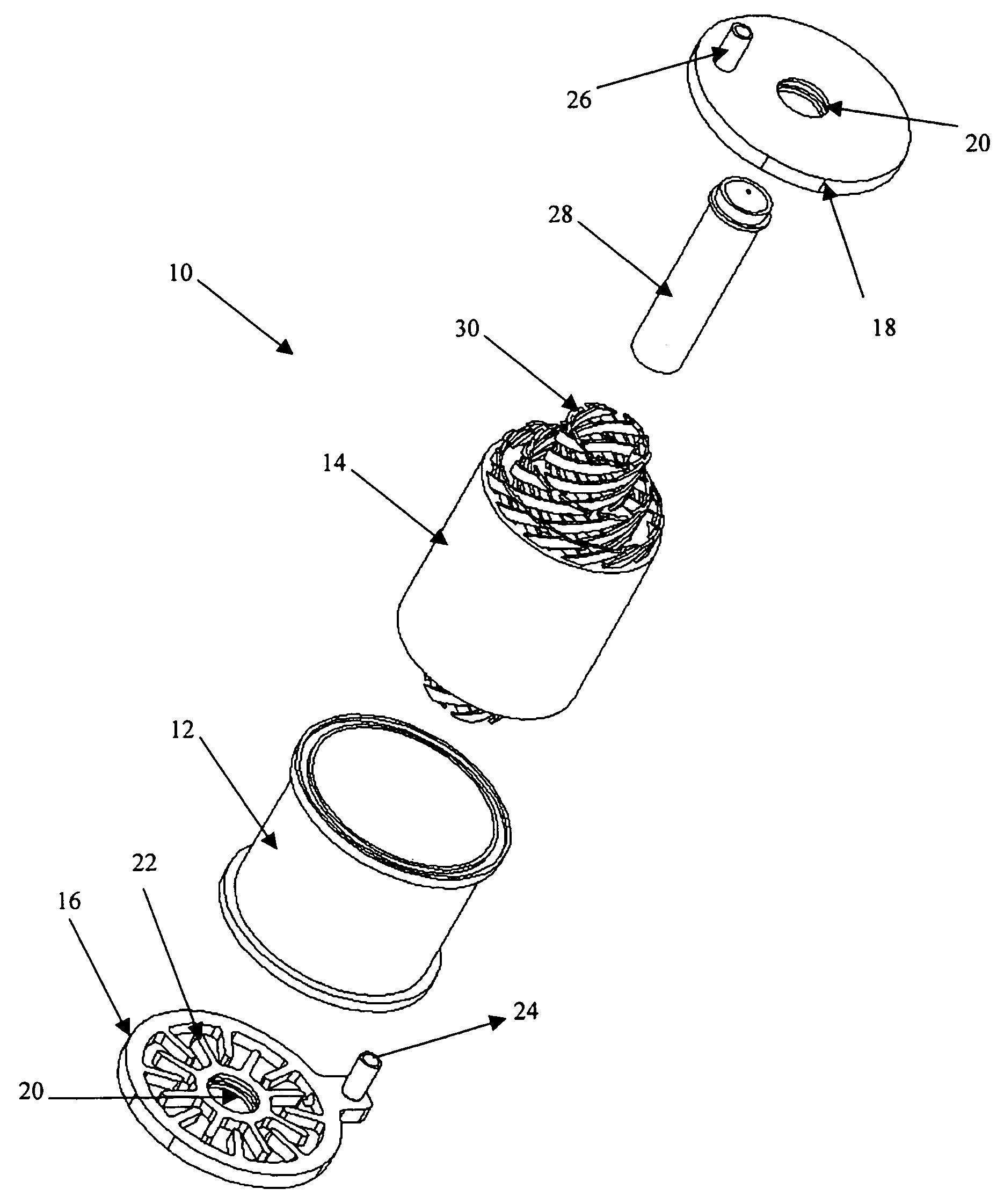

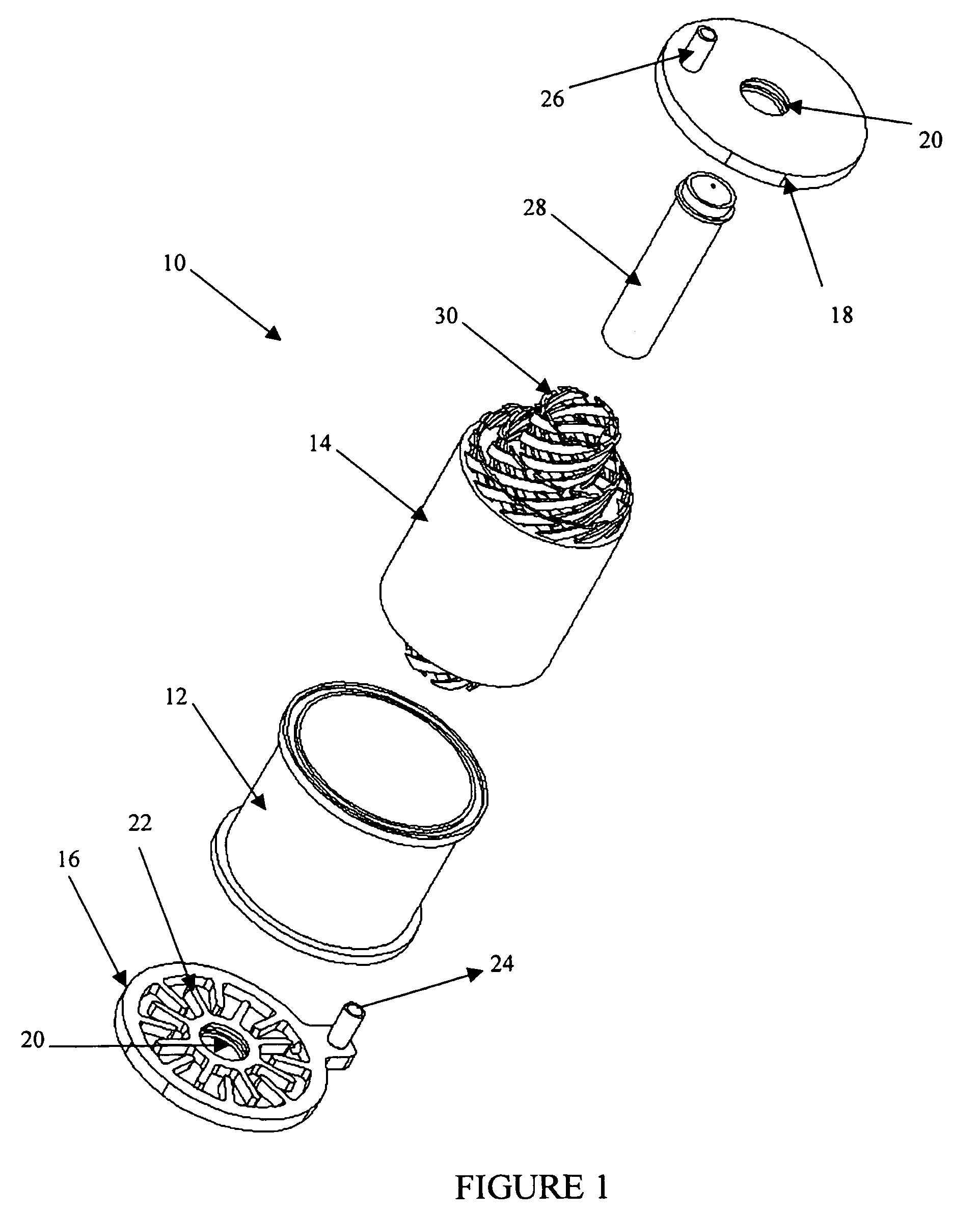

Electromagnet having spacer for facilitating cooling and associated cooling method

ActiveUS7088210B2Increase loopImpart different cooling propertyTransformers/inductances coolingTransformers/inductances coils/windings/connectionsNuclear engineeringConductor Coil

An electromagnet and associated apparatus and method are provided. The electromagnet includes a core and at least one winding disposed circumferentially about the core such that the winding extends at least one revolution around the core. The electromagnet further includes at least one spacer having channels defined therein and disposed circumferentially about the core and adjacent to the at least one winding. The channels facilitate cooling by directing fluid about the windings of the coil as fluid is introduced into the electromagnet.

Owner:THE BOEING CO

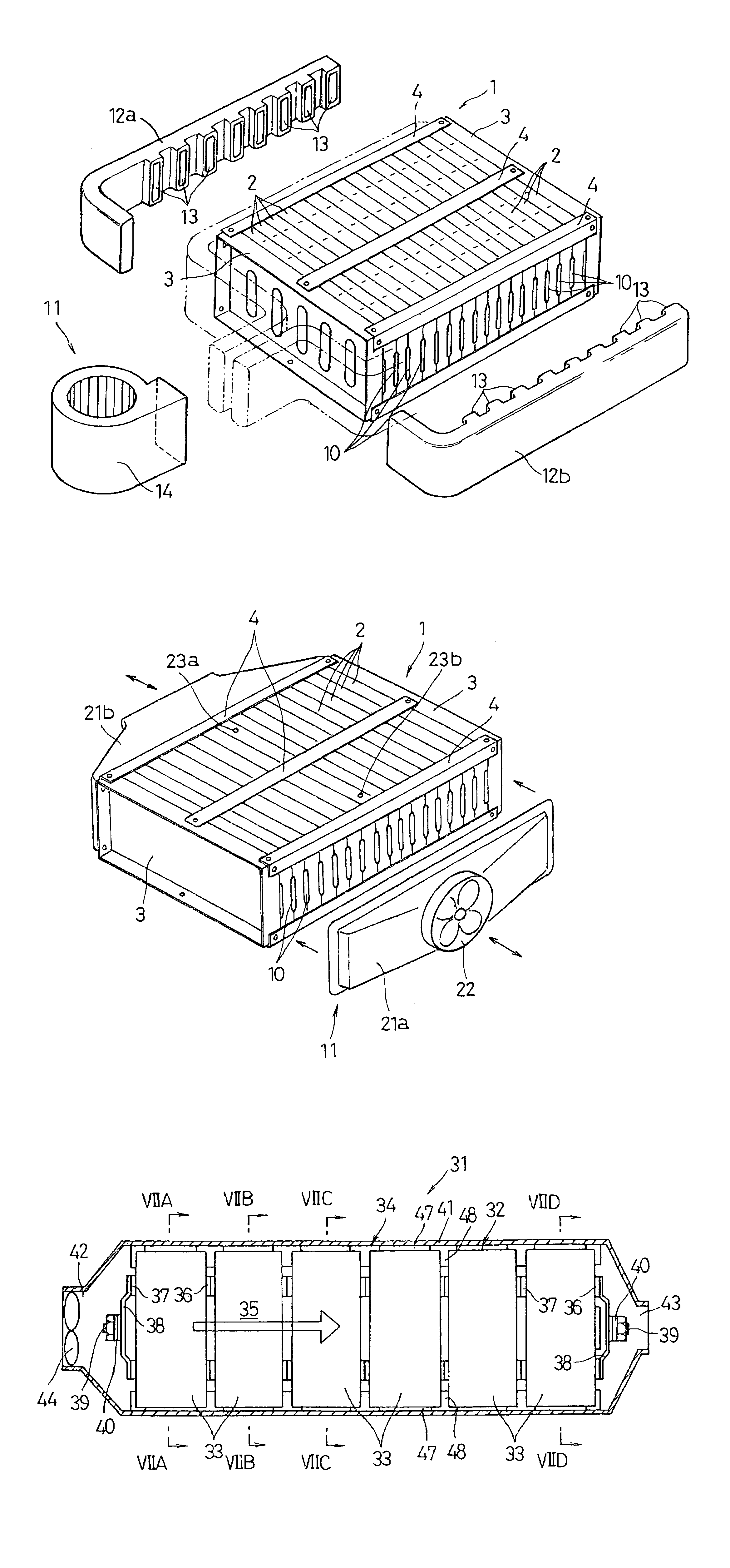

Cooling device for battery pack and rechargeable battery

InactiveUS7150935B2Reduce the overall heightEfficient and uniform coolingPrimary cell to battery groupingCell temperature controlRechargeable cellEngineering

In a battery pack including rechargeable batteries arranged in parallel, a cooling medium path for allowing a cooling medium to horizontally flow be formed between the rechargeable batteries. A cooling medium delivery device for delivering the cooling medium to the cooling medium path is provided so as to reduce a height of the battery pack including a cooling device. The cooling medium delivery device is constituted by a pair of cooling medium introduction ducts provided on both right and left sides of the battery pack, each having delivery ports for delivering the cooling medium alternately in horizontally opposed directions to each of the cooling medium paths, and a cooling medium compression transport device for supplying the cooling medium to both of the cooling medium introduction ducts.

Owner:PANASONIC CORP +1

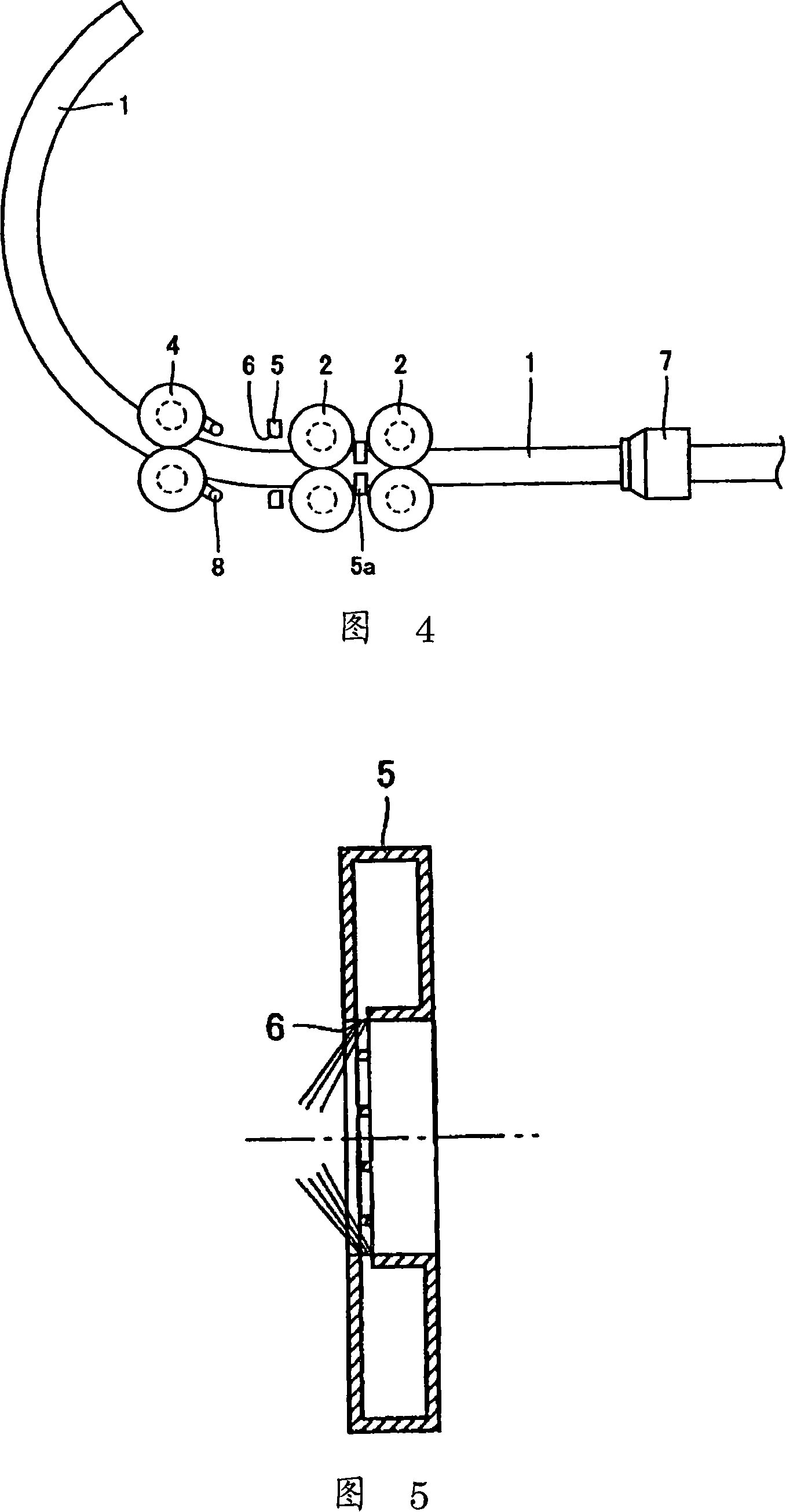

Method for bending metal material, bending machine, bending-equipment line, and bent product thereof

A method of push-through bending processing for a metal material, comprising, while sequentially or continuously extruding a material to be processed from the upstream side, carrying out bending processing thereof on the downstream side, wherein the metal material is clamped by means of mobile roller dies and under controlling of the position and / or moving speed of the mobile roller dies, heated at a temperature range permitting local plastic deformation and permitting quench hardening by means of heating means and cooling means disposed on the periphery of the metal material, followed by application of a bending moment and quenching. Further, there are provided a relevant bending processing apparatus and bending processing equipment line. Even in the event of processing to achieve continuous bending involving two-dimensionally different bending directions, or continuous bending involving three-dimensionally different bending directions, of the metal material, and even in the event of requirement of bending processing for a metal material with greater strength, a metal material with high shape fixability and uniform hardness distribution can be obtained efficiently at low cost. Accordingly, wide application thereof can be found as an increasingly sophisticated automobile part bending processing technology.

Owner:NIPPON STEEL CORP +1

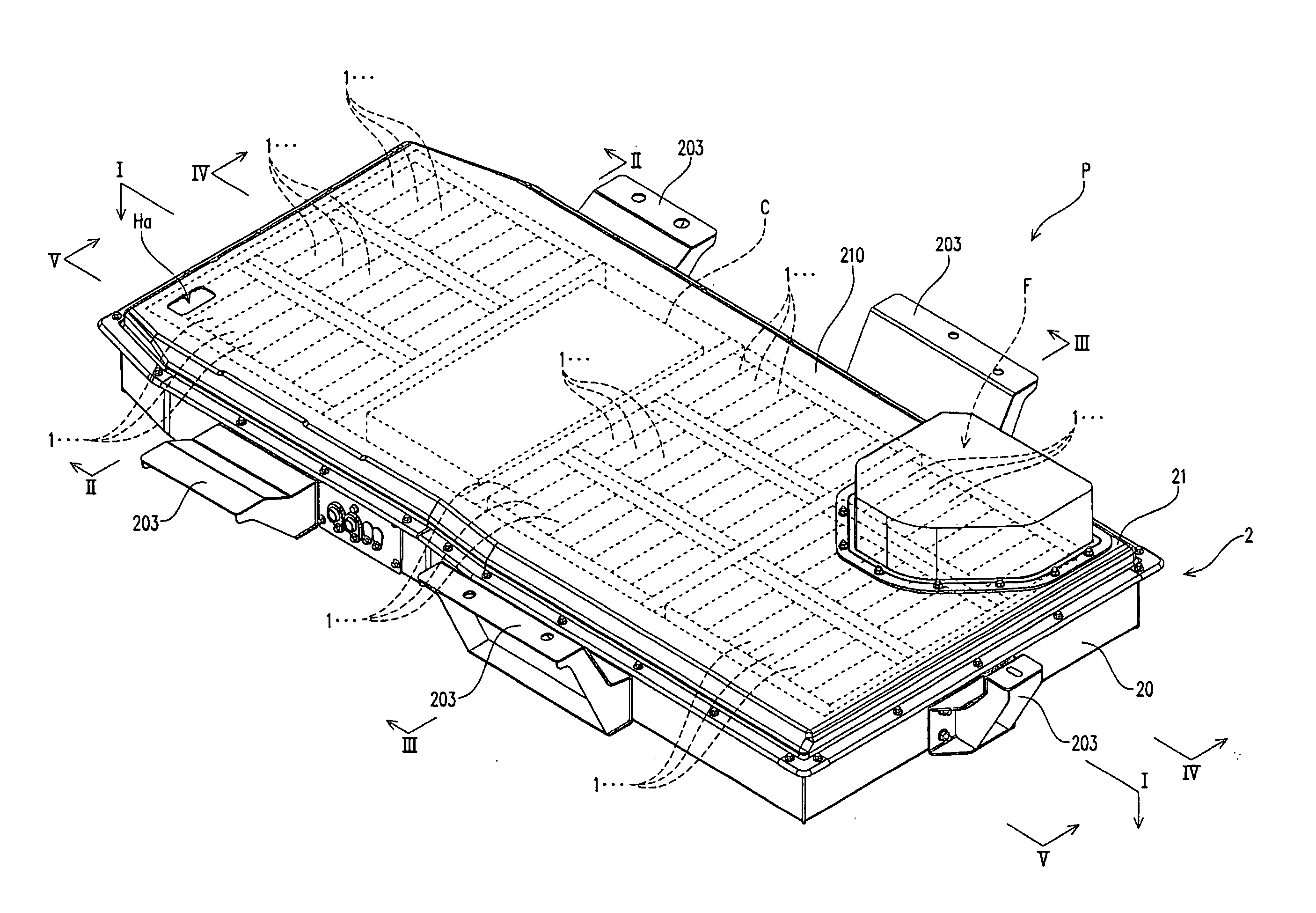

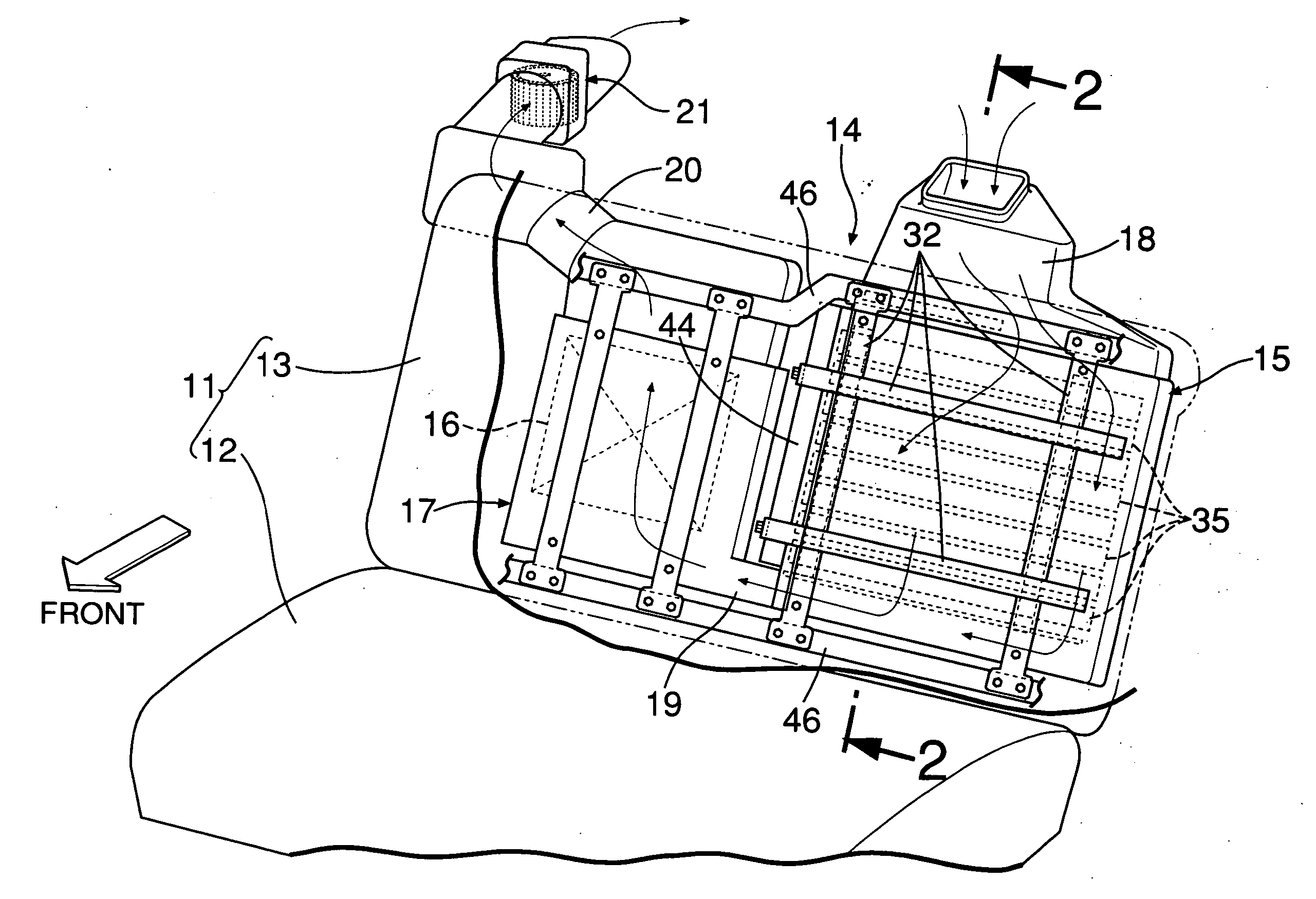

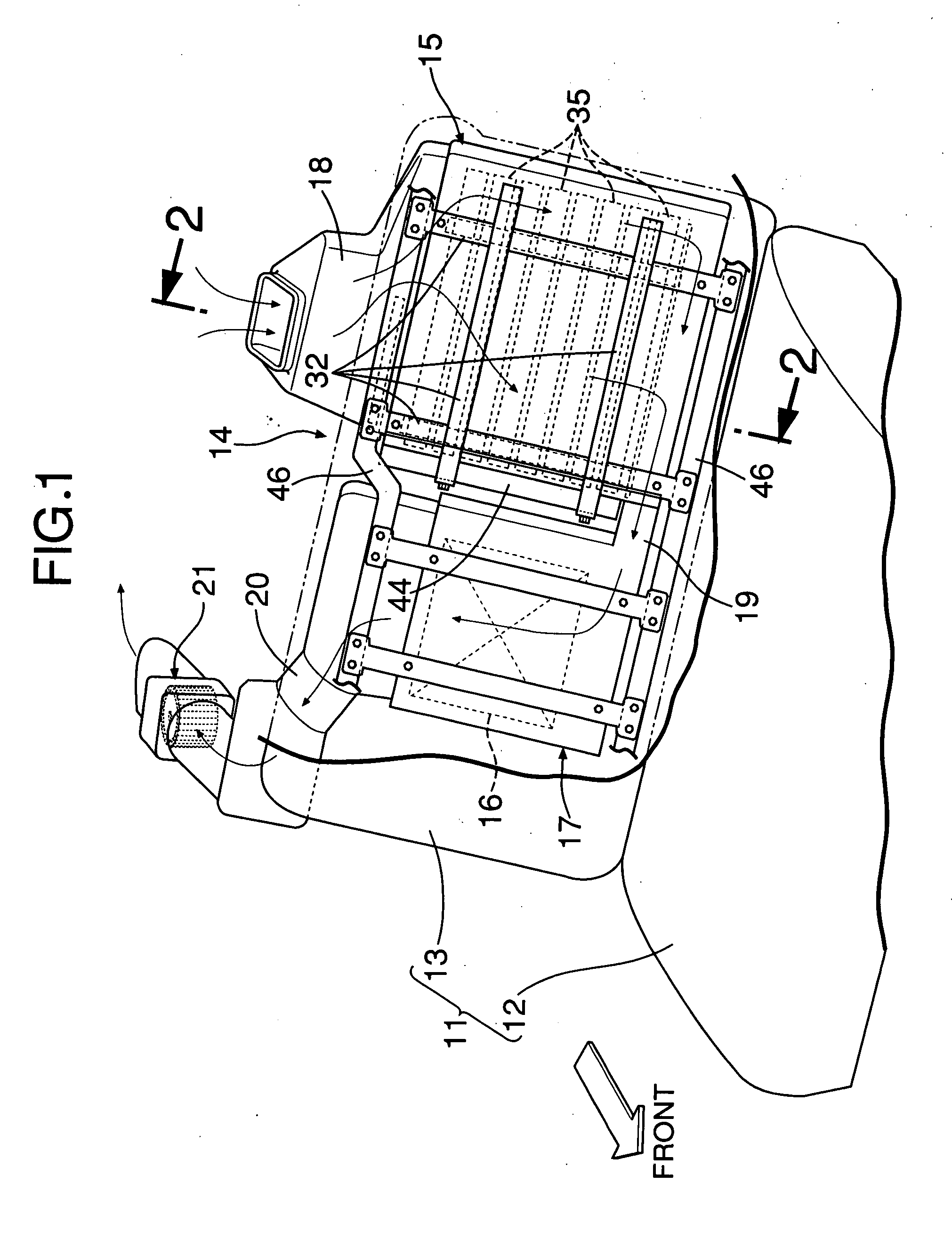

Battery pack and electrically powered vehicle including the battery pack

ActiveUS20120082875A1Prevent breakdownSufficient performanceElectrolyte moving arrangementsCell temperature controlTraffic volumePlenum space

Provided is a battery pack that can uniformly cool a plurality of electric cells, prevent a breakdown of the electric cells, and provide high performance of all electric cells. The battery pack includes a packaging case in which: each adjacent ones of a plurality of electric cells in the first direction define a ventilation space; first and second passages are defined that extend in the first direction and that are arranged to have the plurality of electric cells located between the first and second passages in a second direction intersecting the first direction, wherein gas supplied to the first passage flows through the ventilation spaces to the second passage; and a flow rate limitation device is provided that is arranged in an upstream area of the first passage and that limits a flow rate of the gas flowing through one of the plurality of ventilation spaces, which leads to the upstream area of the first passage, to a predetermined flow rate.

Owner:GS YUASA INT LTD

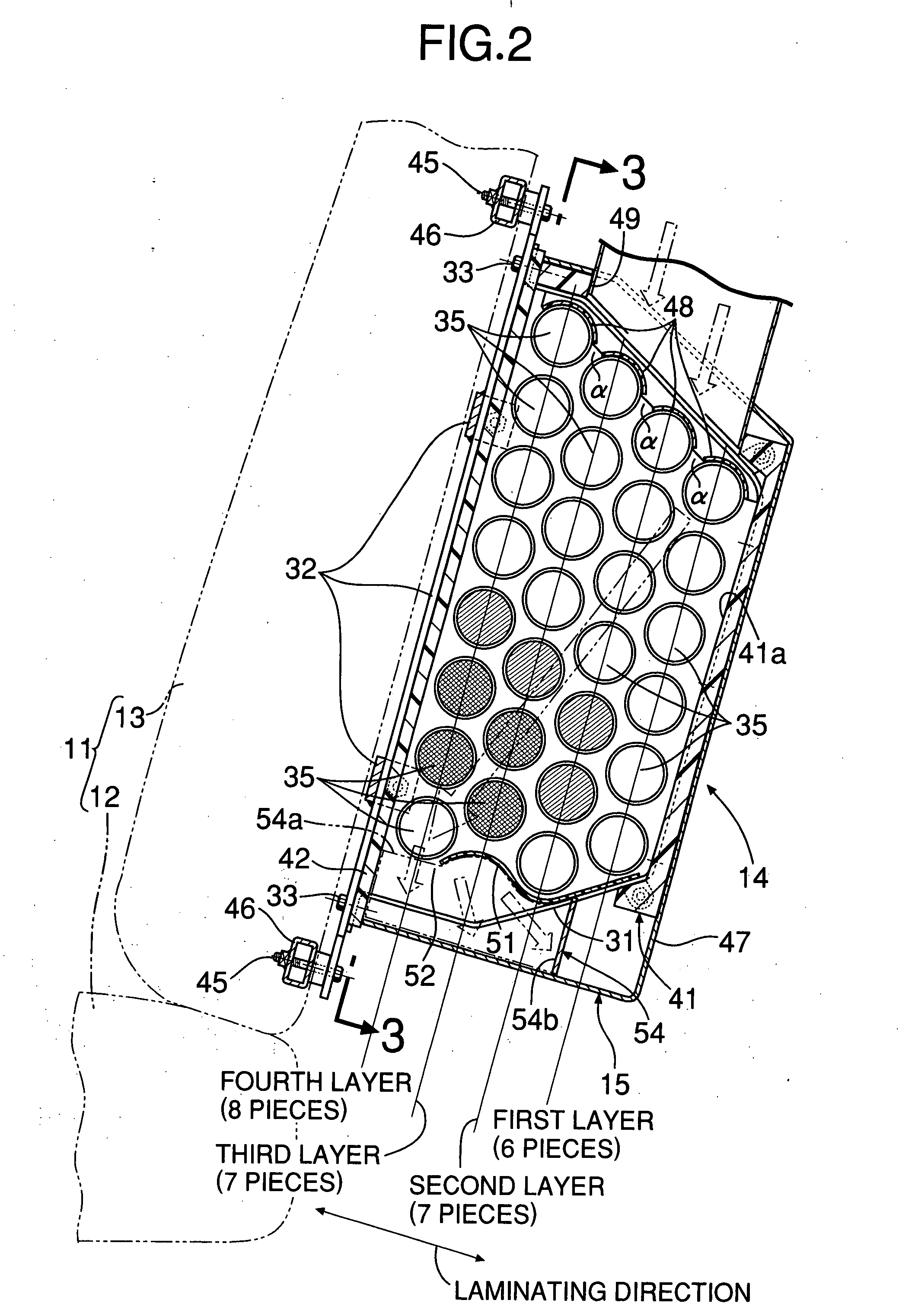

Vehicular power source device

InactiveUS20070238015A1Improve cooling effectCool evenlyCell temperature controlPropulsion by batteries/cellsEngineeringElectrical and Electronics engineering

A vehicle power source includes a number of battery modules in a first layer on one end side in a battery module laminating direction which is smaller than the number of battery modules in a fourth layer on an other end side. A cooling-air supply port is opened over the entire region in the laminating direction of the battery modules, an air-introduction guide is provided on the downstream side in the cooling-air flow direction, and a coolant discharge port is opened at a position closer to the fourth layer side. A flow from the first layer side to the fourth layer side is formed on the downstream side in the cooling-air flow direction so as to efficiently cool the battery modules difficult to be cooled.

Owner:HONDA MOTOR CO LTD

Method and apparatus for use of beam control prisms with diode laser arrays

InactiveUS6975465B1Shorten physical lengthHigh densityPrismsLaser optical resonator constructionLaser arrayPrism

The subject invention relates to beam control prisms and the use of a beam control prism to modify the beam properties of light emitted from an edge emitting diode laser. The subject invention can utilize a beam control prism placed next to a diode laser bar. The subject beam control prism can have, for example, a curved surface and / or a high reflective coated surface for a diode laser wavelength. The curved surface can collimate the fast axis divergence and the mirror surface can change the beam direction. The subject curved surface beam control prisms can incorporate one or more features, such as parabolic reflecting surface, elliptical exit surface with flat reflecting surface, and a hyperbolic entrance surface with flat reflecting surface.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

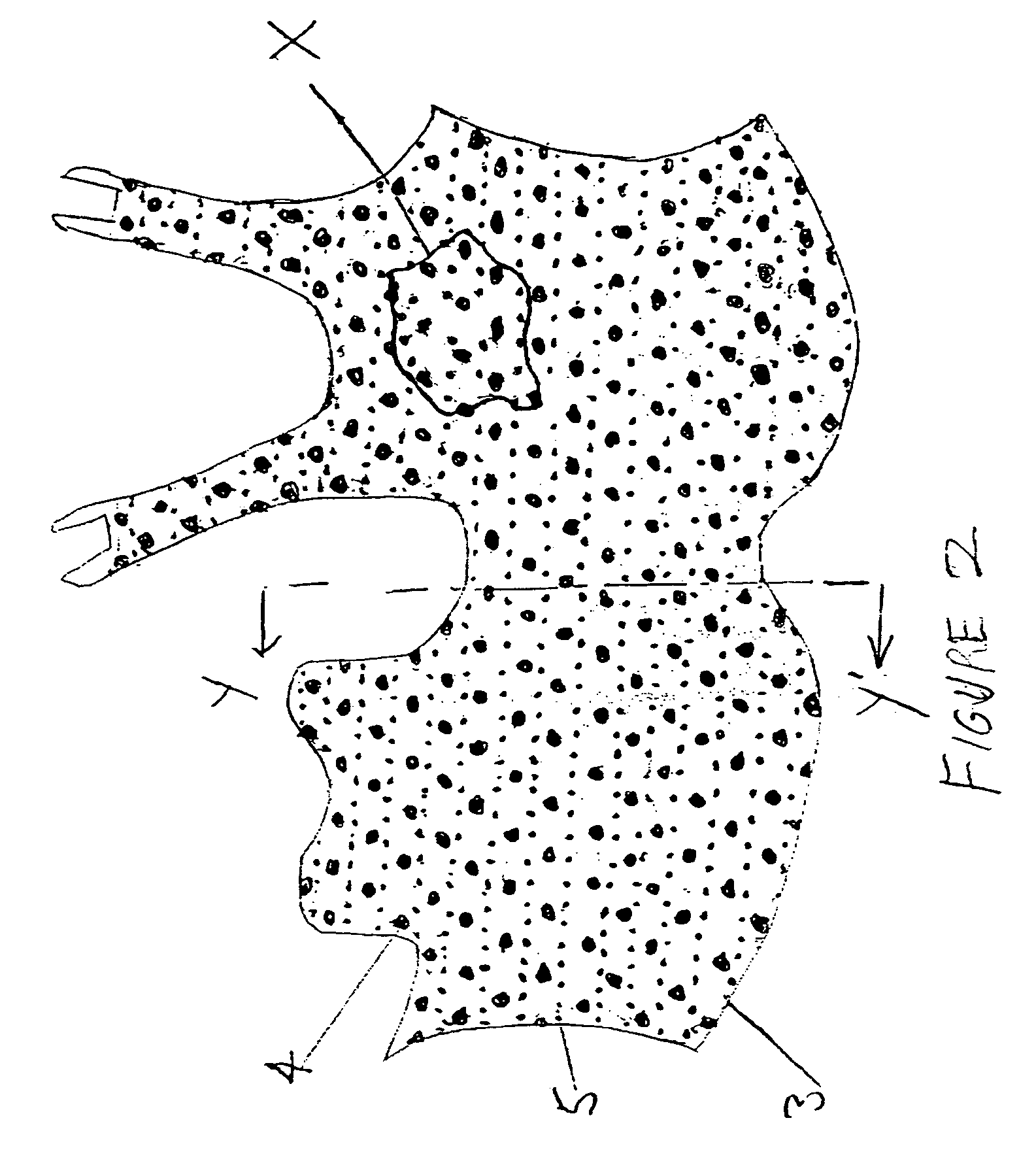

Gas distribution garment

InactiveUS20060026743A1Good cooling efficiencyImprove cooling efficiencyChemical protectionHeat protectionBiomedical engineeringGas supply

A garment for cooling the body of a wearer is described which comprises a substantially gas impermeable first substrate and a gas-permeable second substrate attached to form a cavity. At least one of the first and second substrates comprising a plurality of raised protrusions on a surface within the cavity, and the gas permeable second substrate comprising a plurality of raised protrusions on the surface external to the cavity and proximate to the body of the wearer. The cavity is adapted to be connected to a gas supply such that the gas flows into the cavity and exits the cavity through the gas permeable second substrate. The cooling garment is light weight and conformable, and may be non-tethered for portability.

Owner:WL GORE & ASSOC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com