Patents

Literature

5792results about How to "Place stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

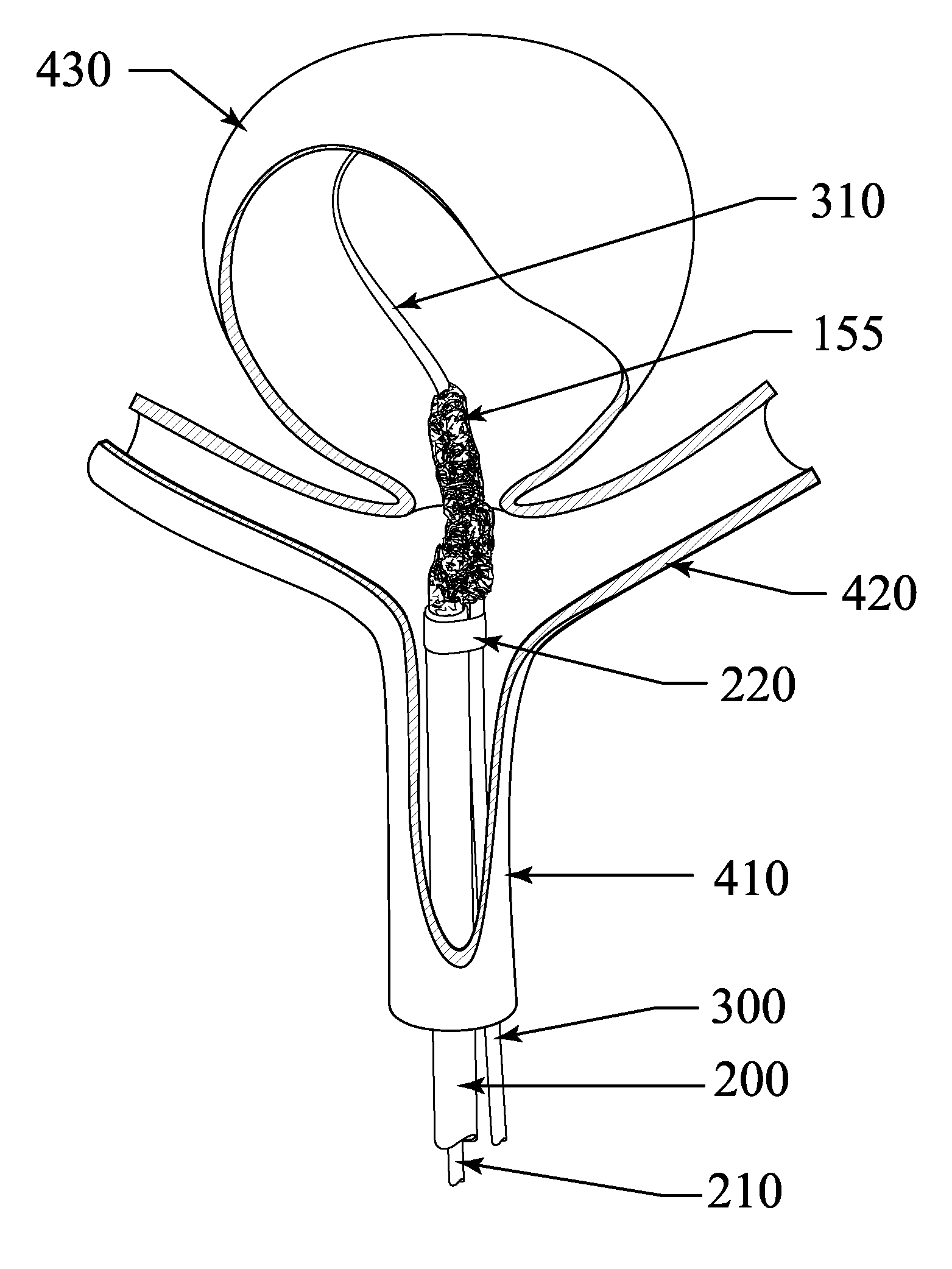

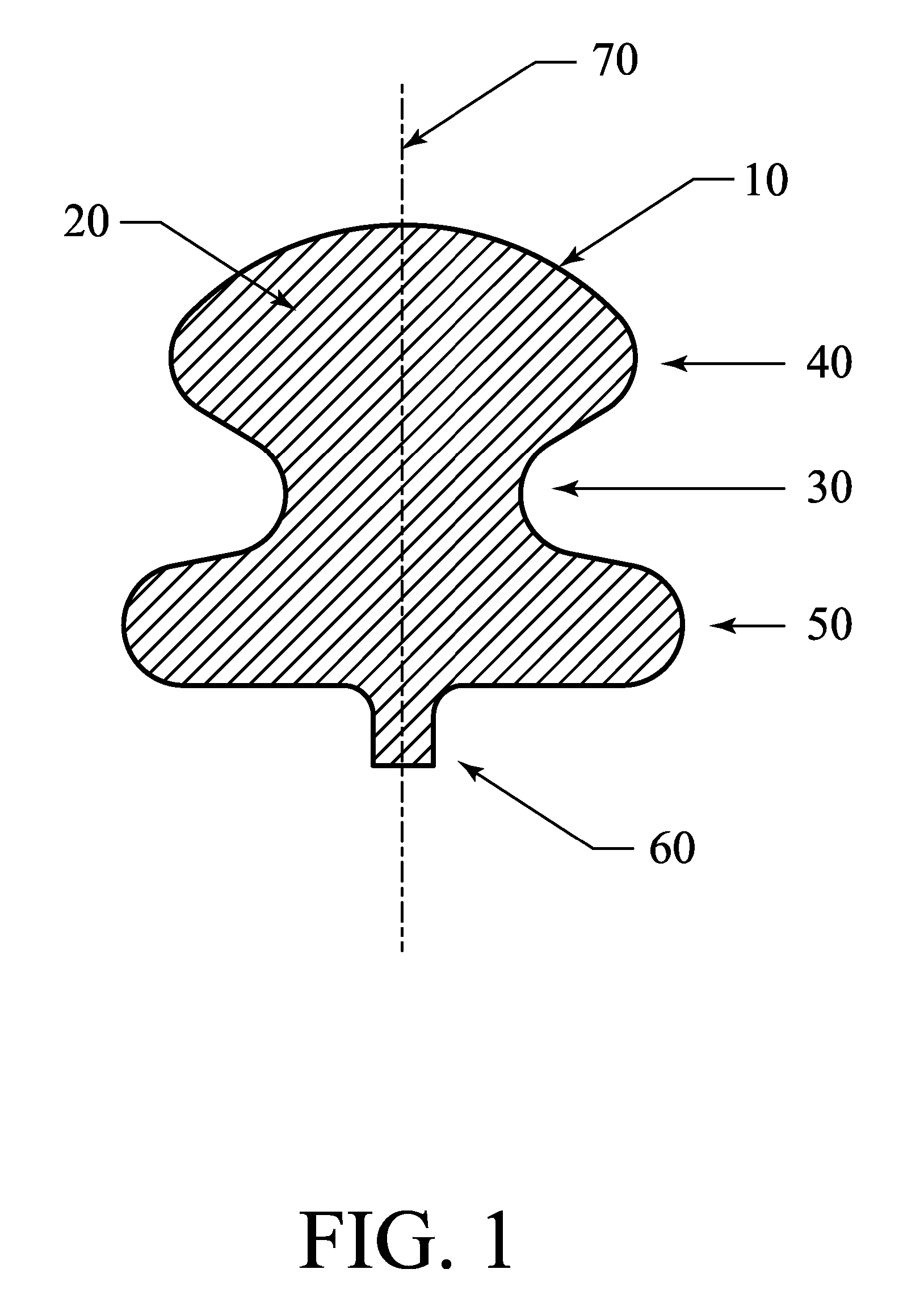

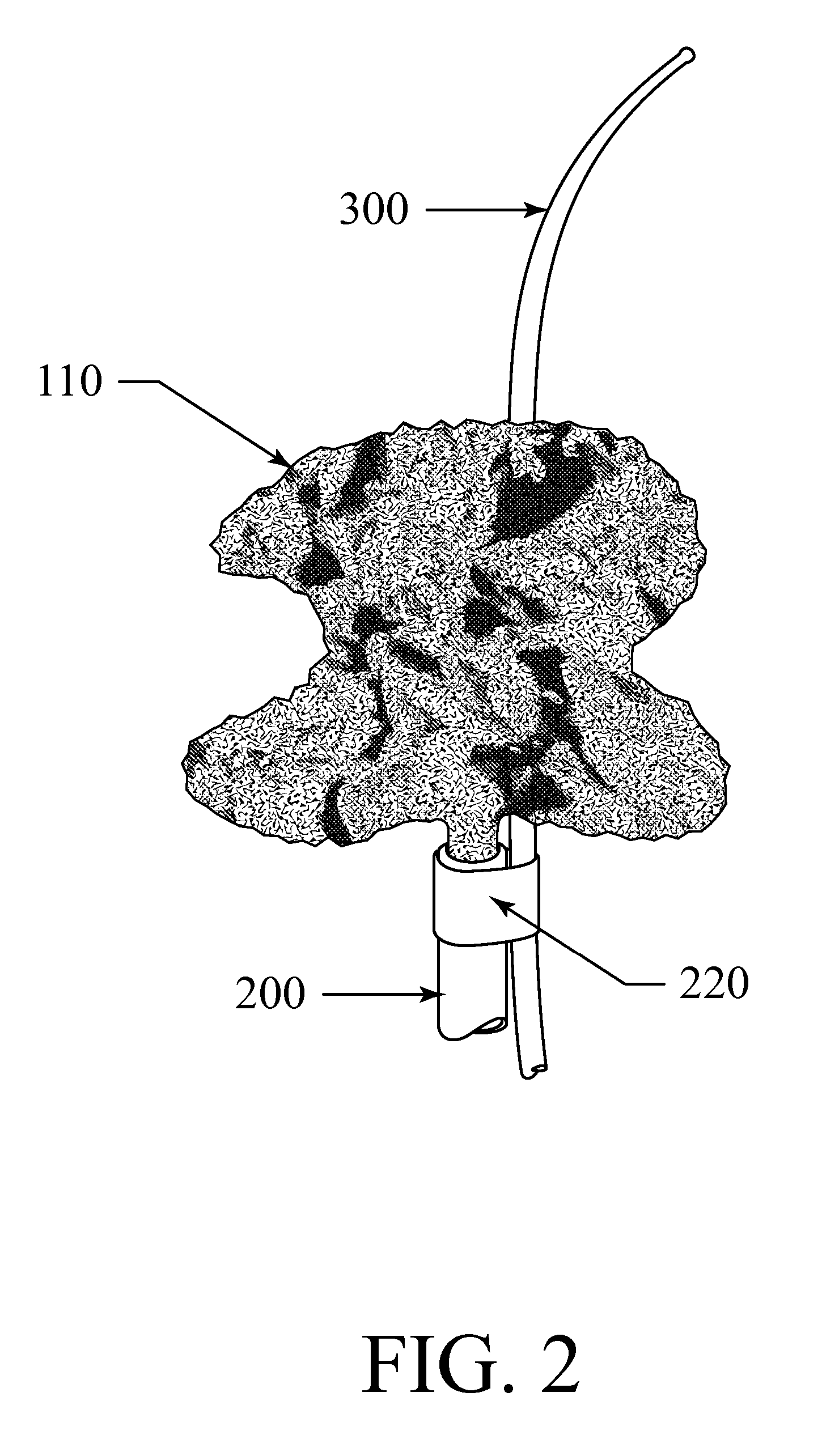

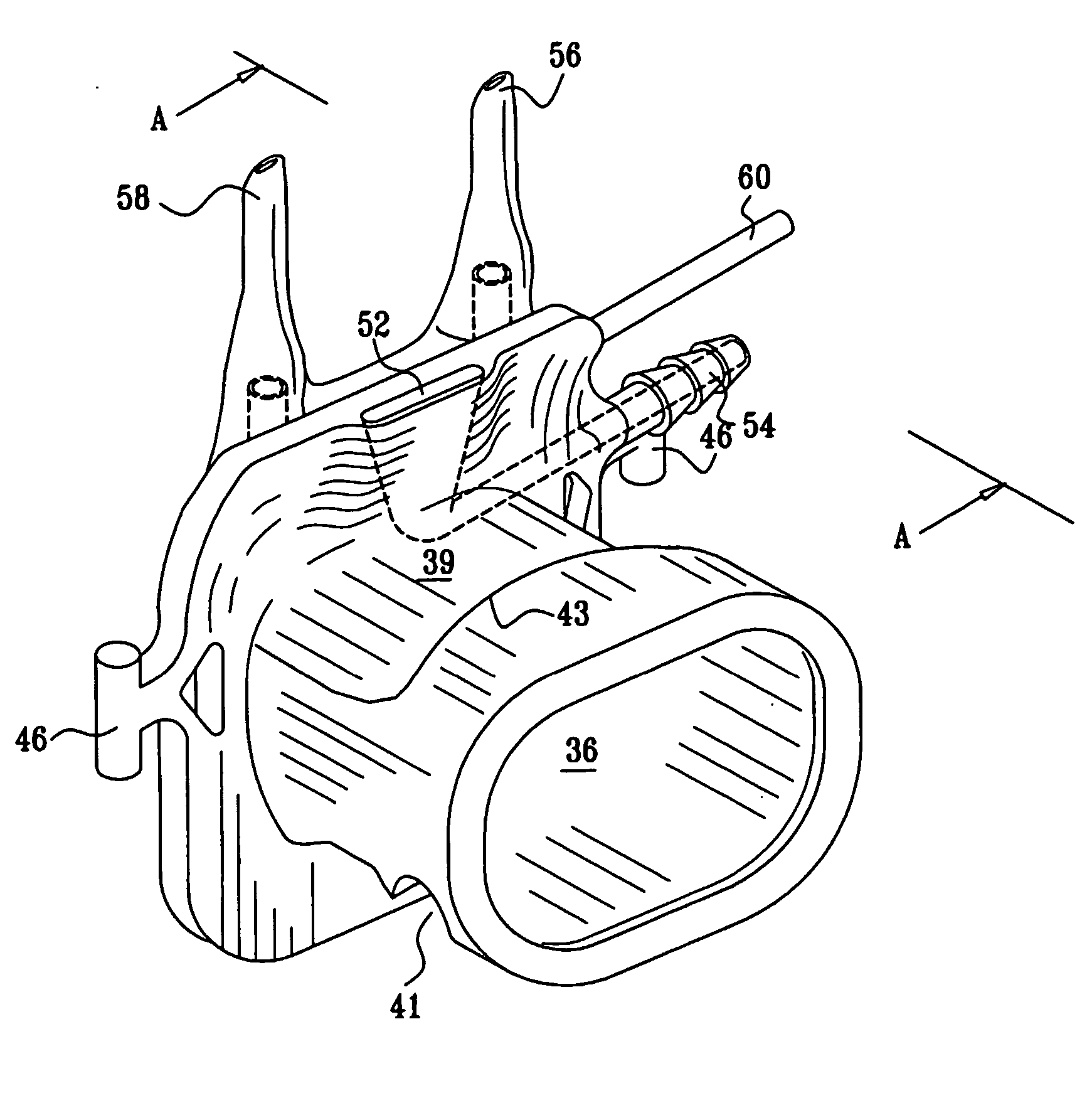

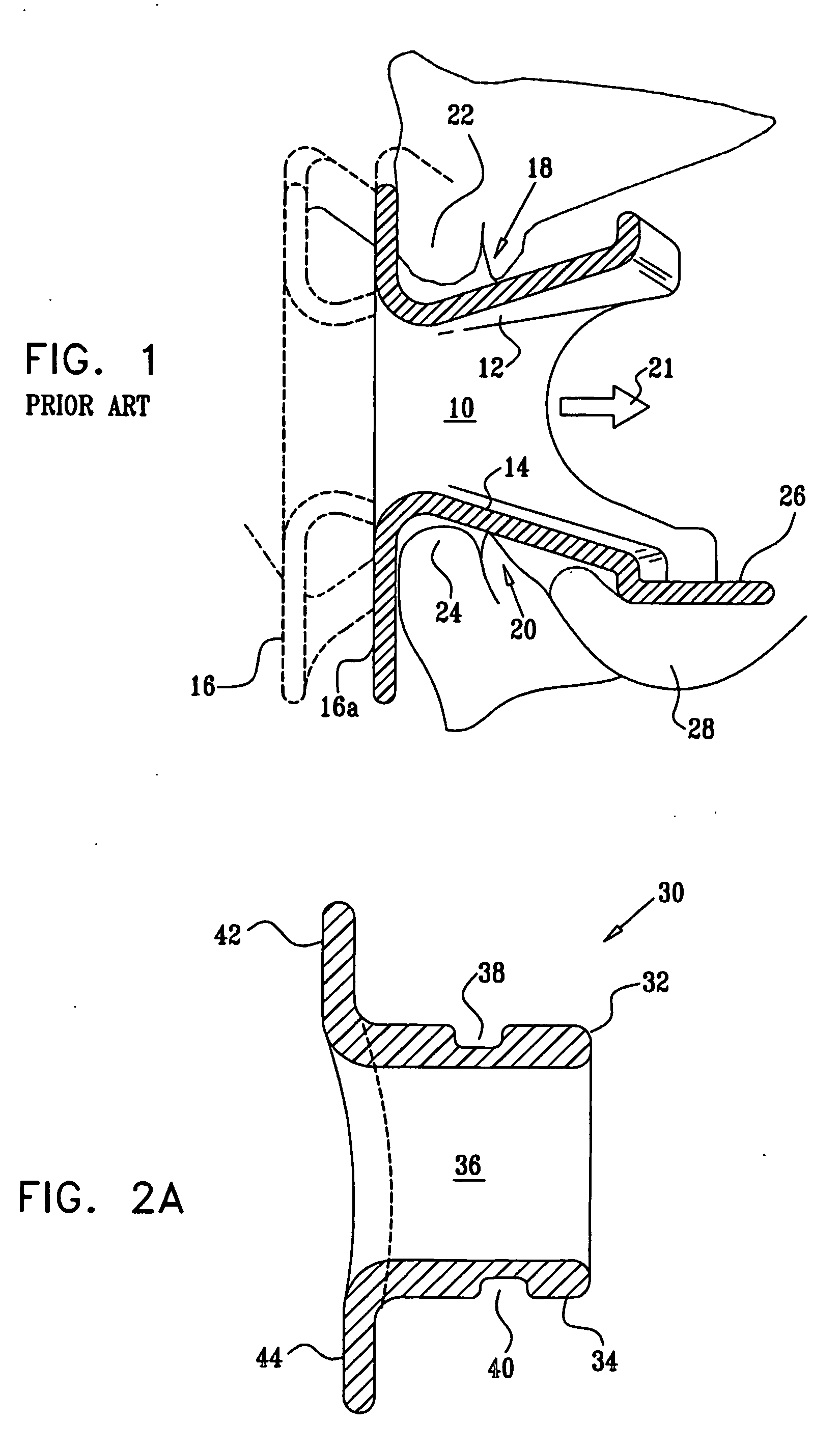

Exclusion Device and System For Delivery

InactiveUS20070288083A1Reduce flowReduce blood flowPretreated surfacesOcculdersAnterior Cerebral Artery AneurysmNeck of pancreas

A medical flow restrictor that may be used to exclude a saccular aneurysm from the circulatory system. The device, a thin walled, foil-like shell, is compacted for delivery. The invention includes the device, electroforming fabrication methods, delivery assemblies, and methods of placing, and using, the device. A device with an aneurysm lobe and an artery lobe self-aligns its waist at the neck of an aneurysm as the device shell is pressure expanded. Negative pressure is used to collapse both the aneurysm lobe and the artery lobe, captivating the neck of the aneurysm and securing the device. The device works for aneurysms at bifurcations and aneurysms near side-branch arteries. The device, unlike endovascular coiling, excludes the weak neck of the aneurysm from circulation, while leaving the aneurysm relatively empty. Unlike stent-based exclusion, the device does not block perforator arteries. This exclusion device can also limit flow through body lumens or orifices.

Owner:ELECTROFORMED STENTS

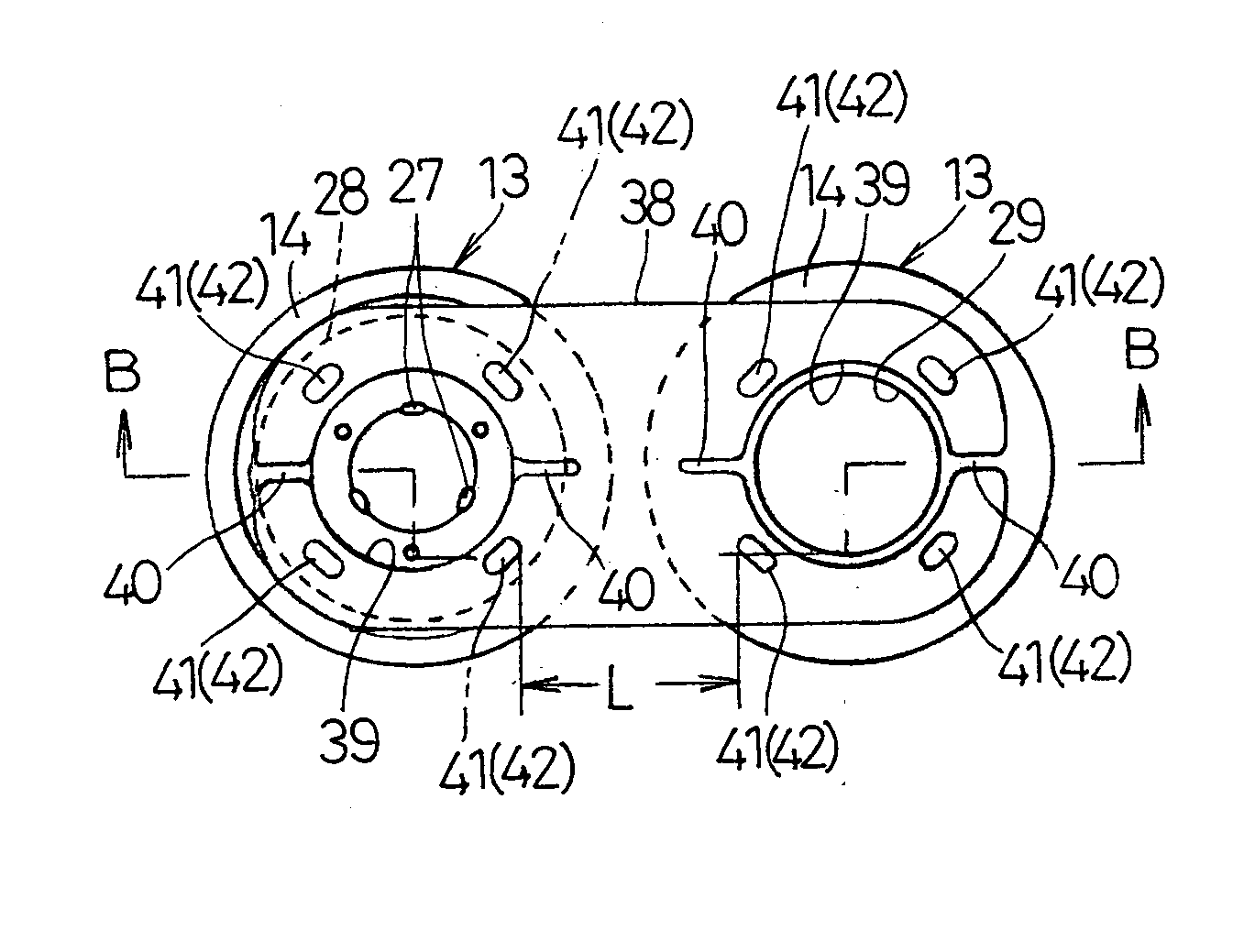

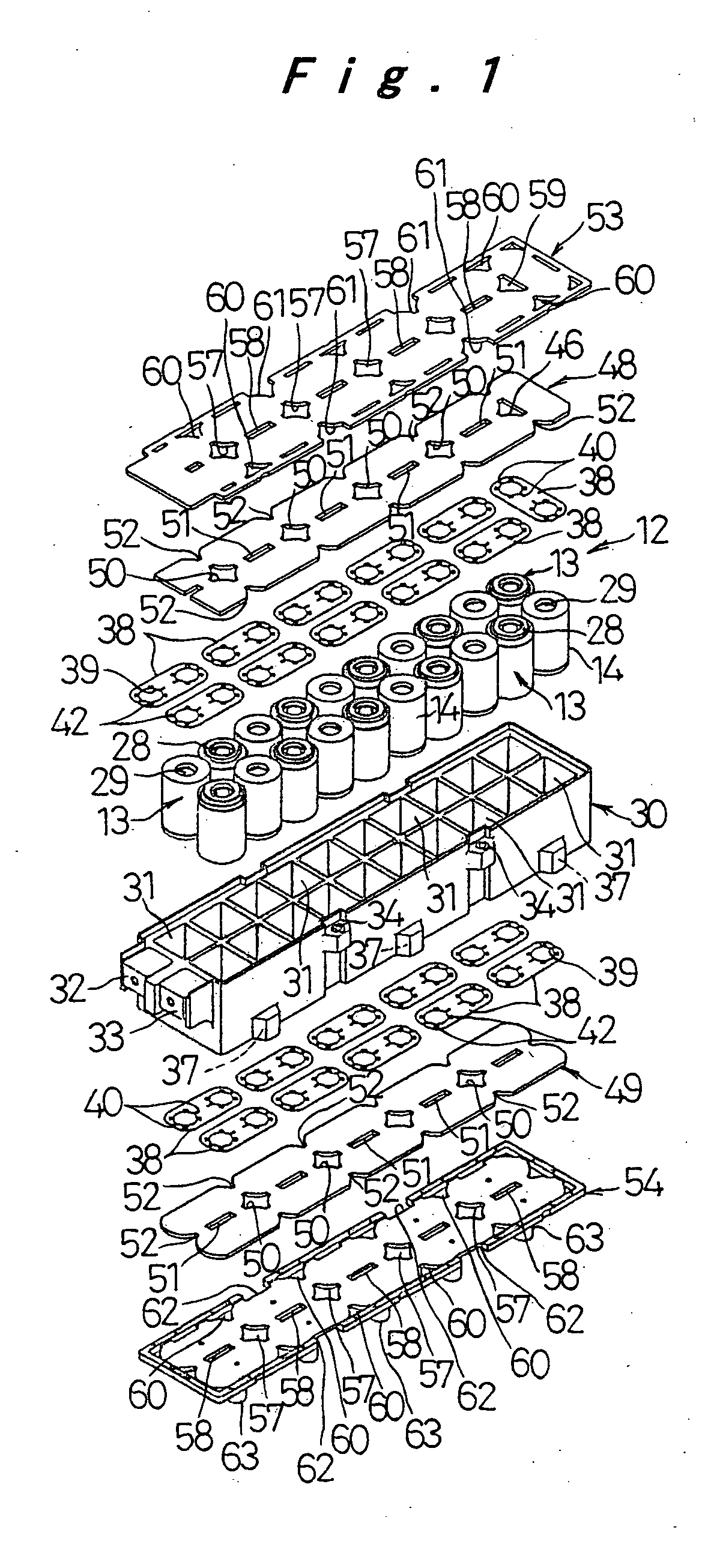

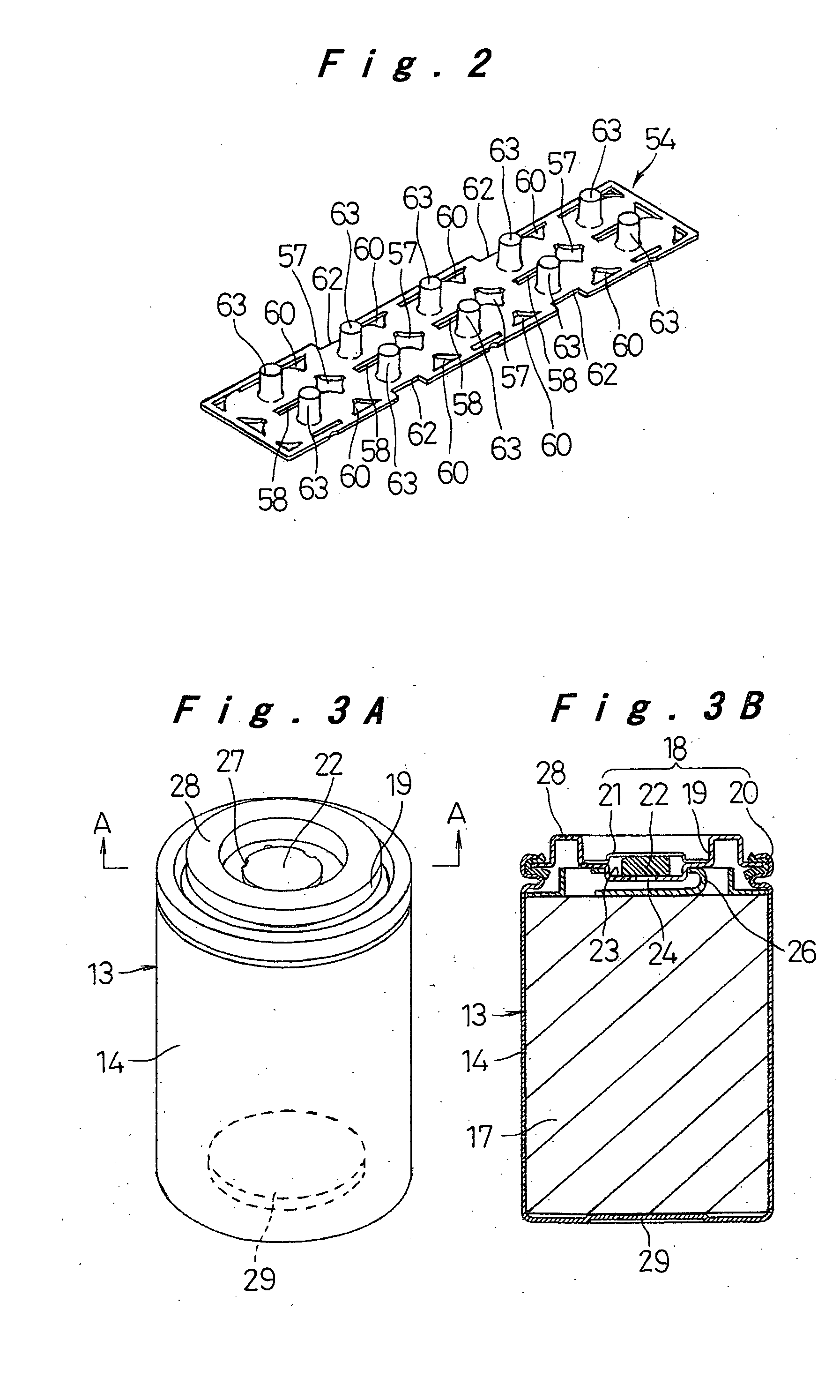

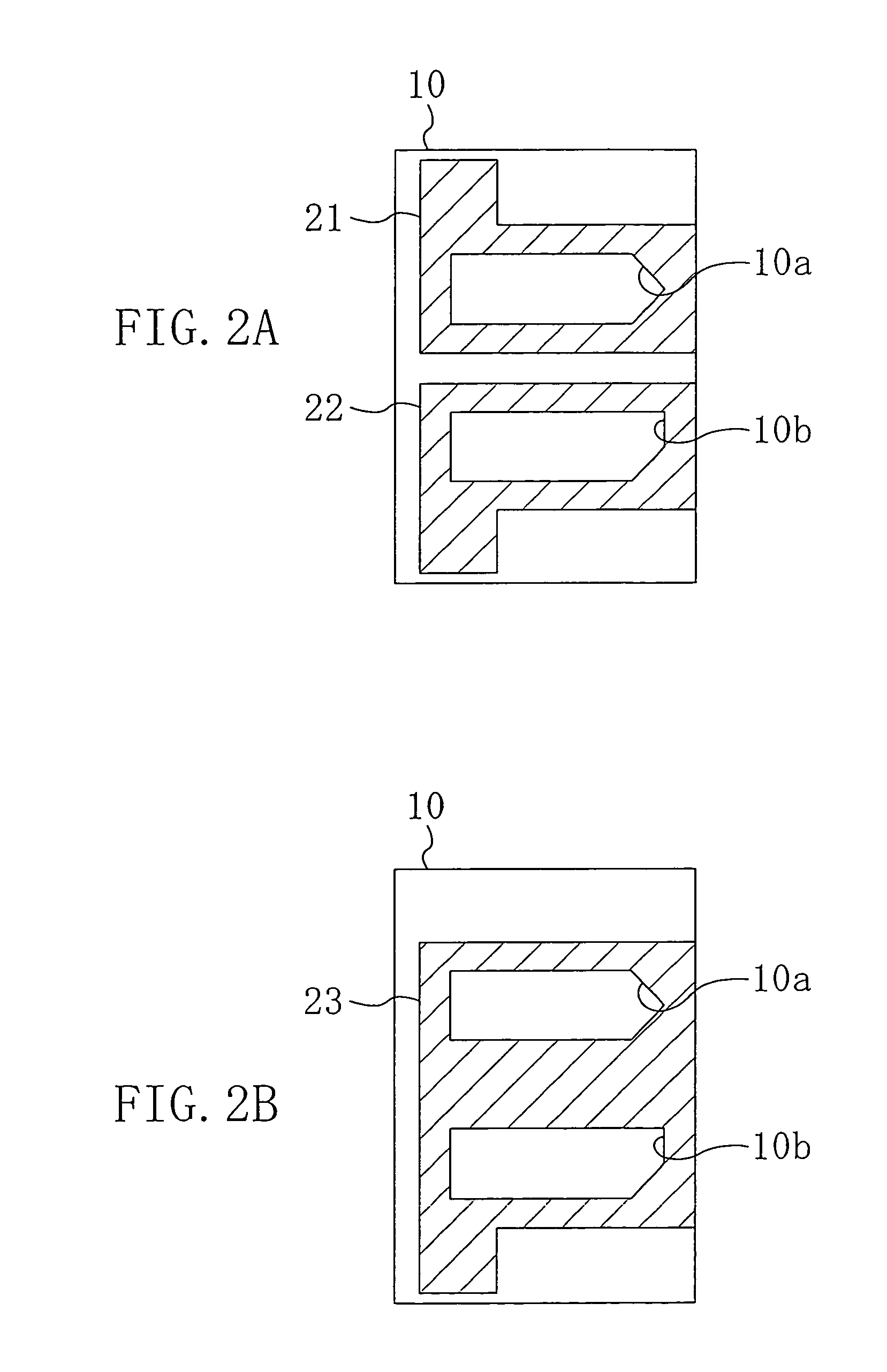

Battery connection structure, battery module, and battery pack

InactiveUS20050079408A1Increase productionReduce in quantityPrimary cell to battery groupingElectric propulsion mountingElectrical resistance and conductanceSolid structure

A connection plate in form of flat plate is welded to be connected to portion that are close to each other, i.e., a connection-electrode portion of one of two adjacent cells and a bottom of a cell case of the other cell, while being bridged between the connection-electrode portion and the bottom of the cell case, thereby forming an inexpensive connecting structure between cells, that reduces the electric resistance, by simple processes. A battery module having a solid structure impervious to vibration or shock is formed by accommodating cylindrical cells in cell-accommodating portions, each of which has a square shape seen from the front, of a holder case made of synthetic resin with their cell axes arranged in parallel, and by closing both sides of the holder case with cover members having radiation holes. Then, a battery pack is formed by attaching outer plates to a plurality of such battery modules that are arranged and integrating them.

Owner:PANASONIC CORP

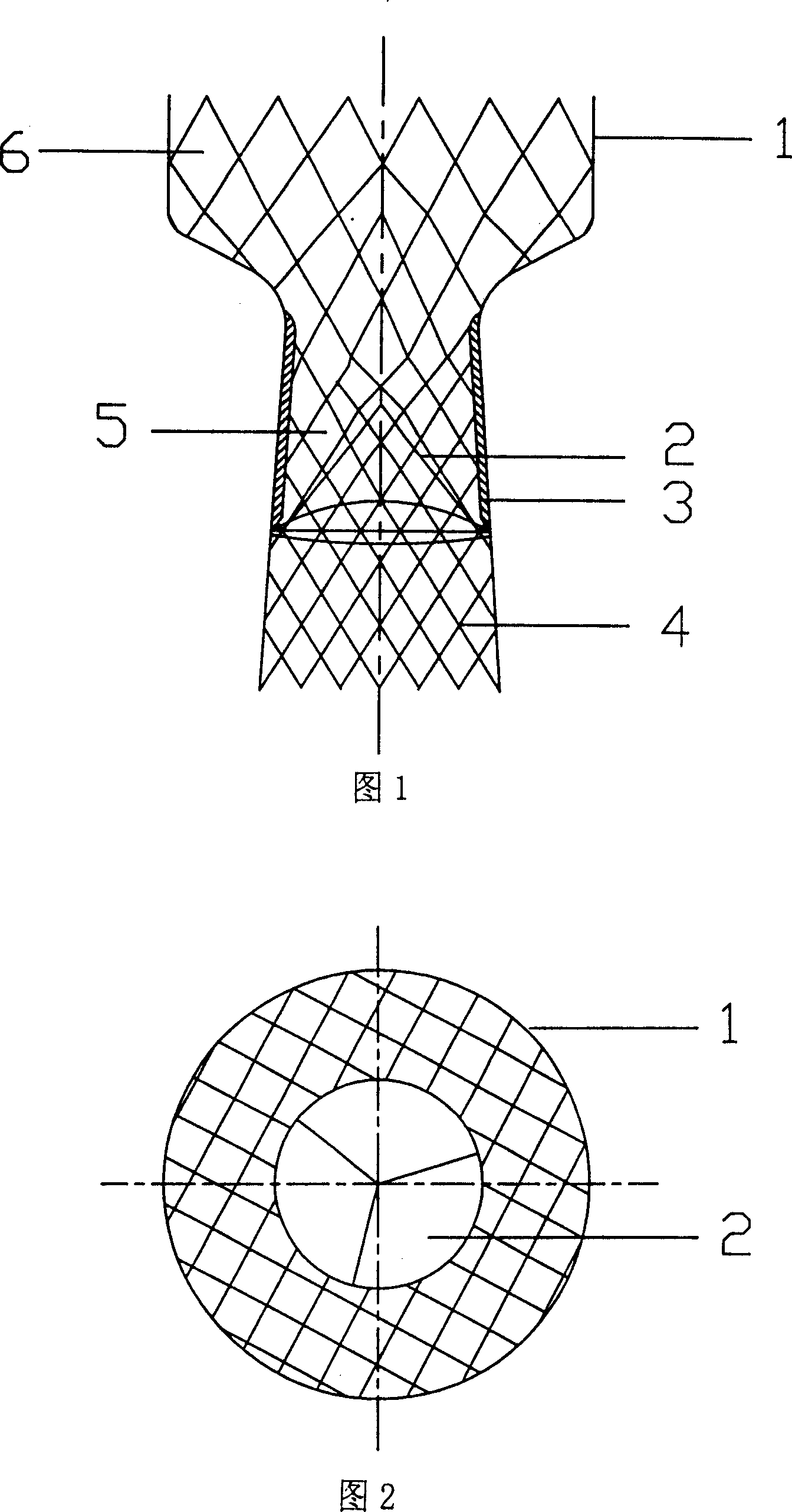

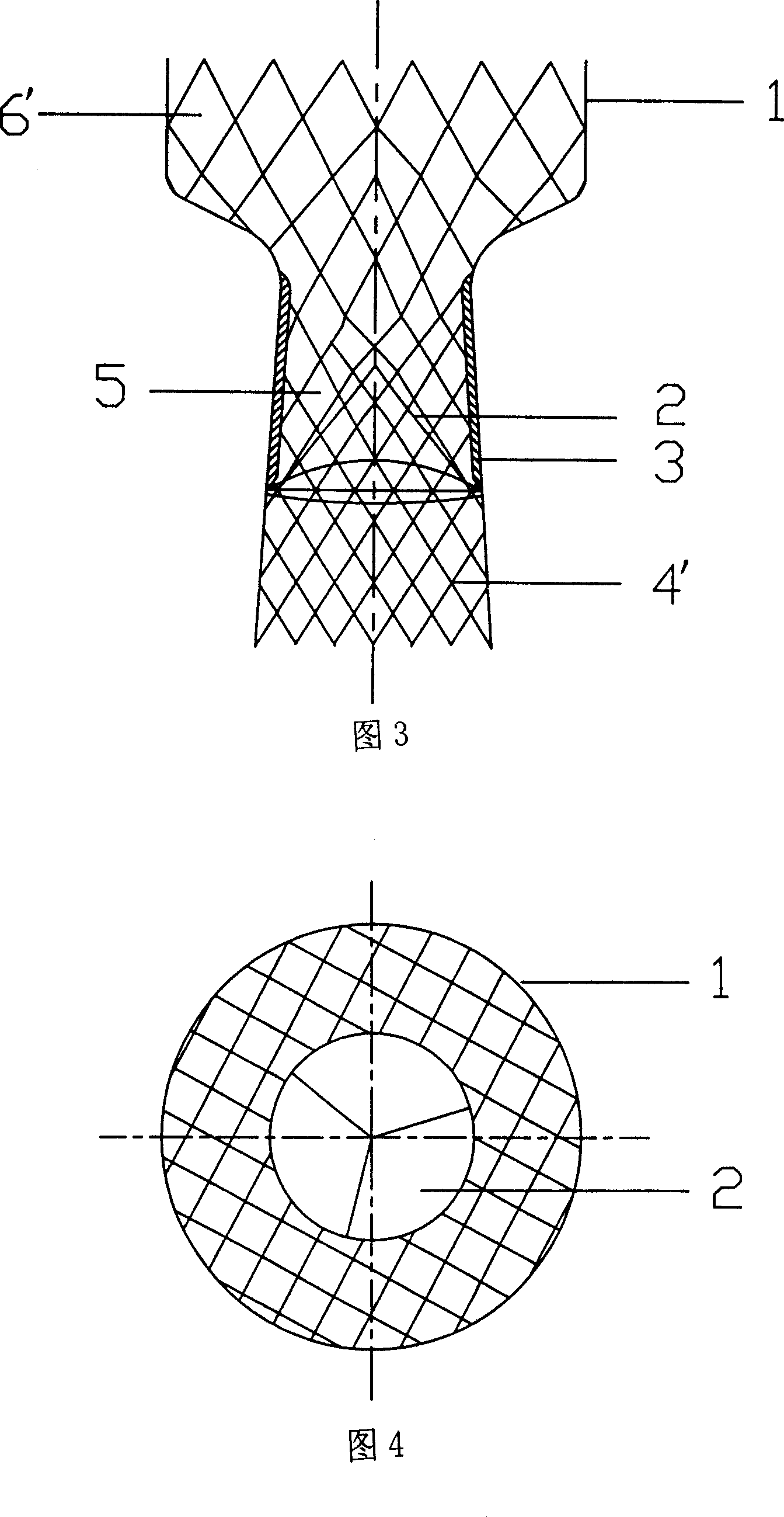

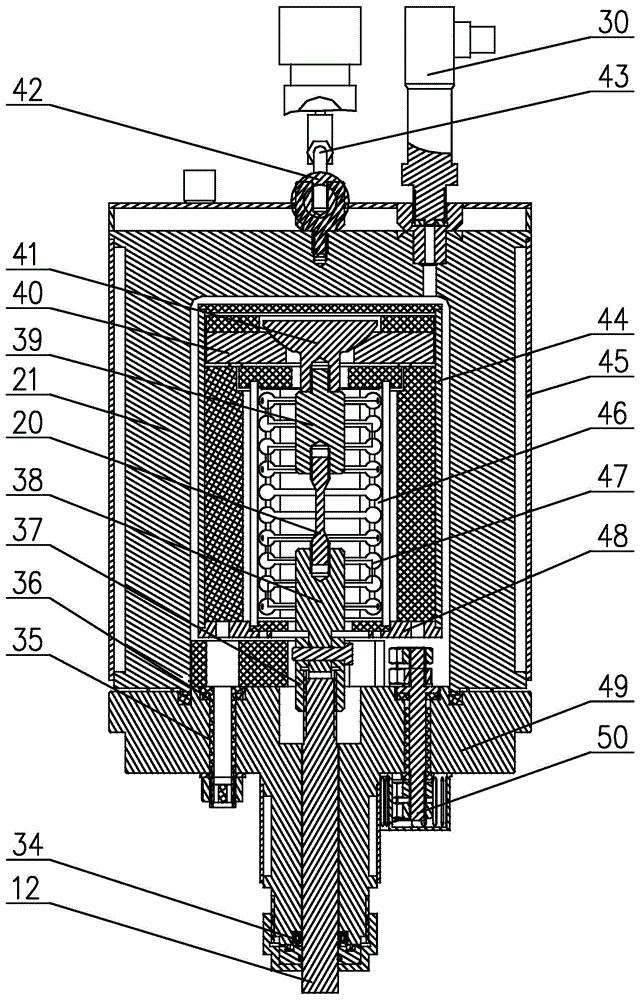

Device for replacing aortic valve membrane or pulmonary valve membrane percutaneously

The invention relates to a novel percutaneous aortic valve and pulmonary valve exchanger, which is a self-expand support with biological valve, formed by the support in special shape and made from nickel titanium alloy skeleton and the three-blade one-way opening valve formed by pig heart, wherein, the support has fixing and supporting functions, and the pig heart forms three valves fixed in the support. The invention has little hurt, high safety and reduced complication.

Owner:孔祥清

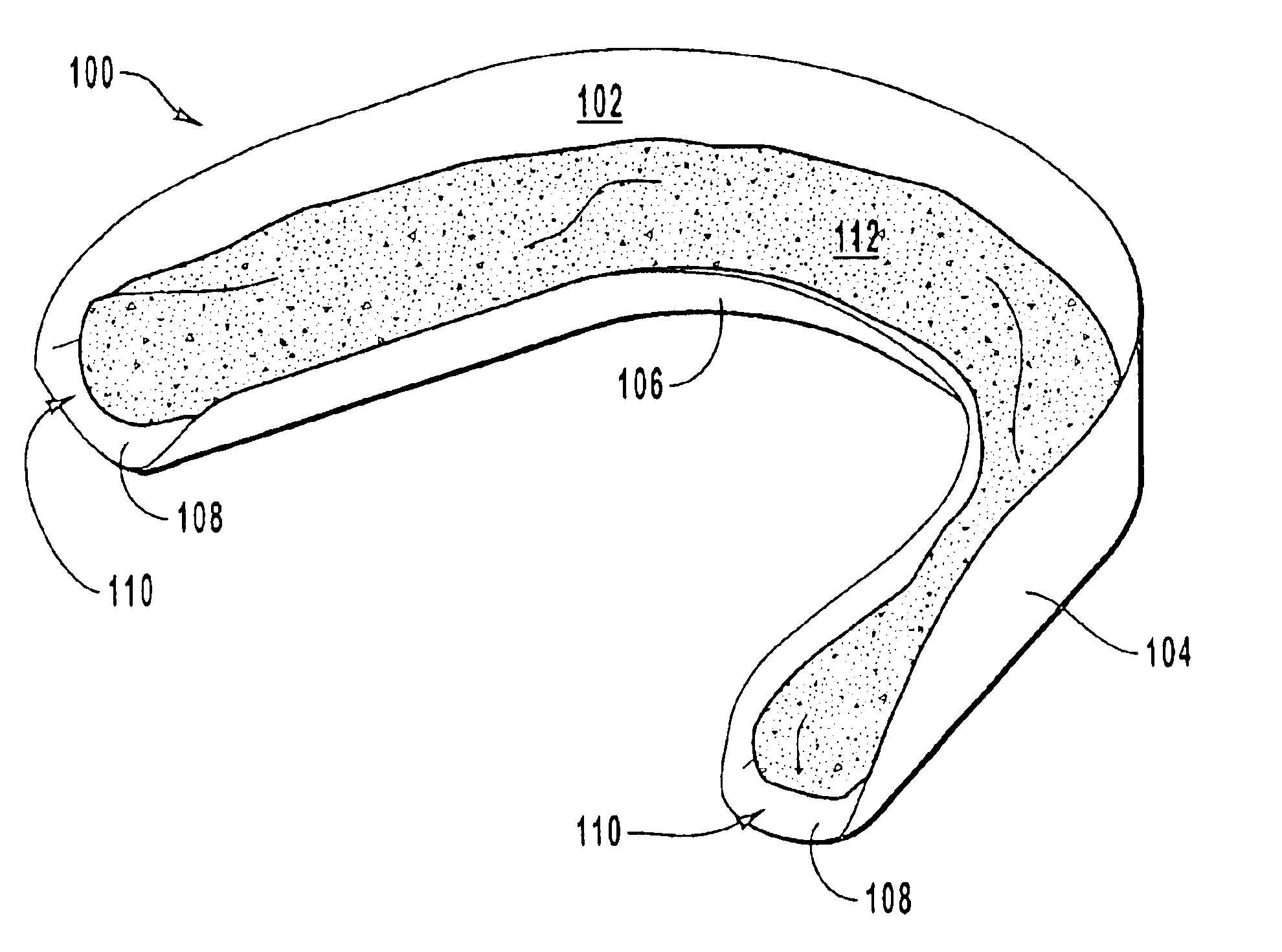

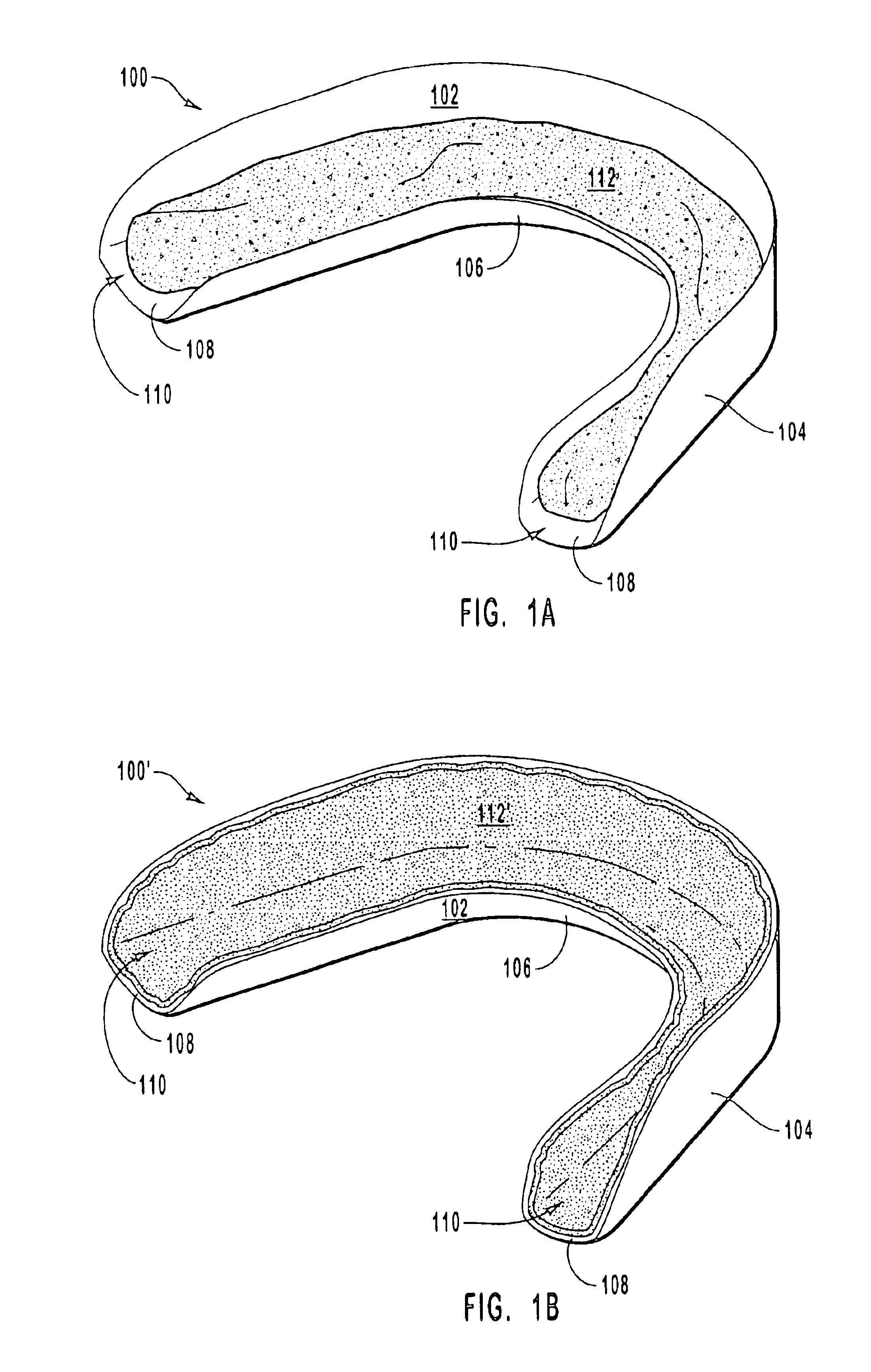

Oral treatment devices that include a thin, flexible barrier layer and an endoskeleton treatment or adhesive composition

InactiveUS6860736B2Prevent, minimize or lessen their diffusion into the user's mouthPlace stableTeeth fillingCoffinsOral treatmentDentistry

Oral treatment devices include a barrier layer and an oral treatment composition, and optionally an auxiliary adhesive composition, that acts as an endoskeleton so as to at least partially contribute to maintaining the barrier layer in the shape of a dental tray, or in a tray-like configuration, prior to use. The barrier layer protects the oral treatment and / or adhesive composition from saliva or moisture during use. The treatment and / or auxiliary adhesive compositions can have a consistency ranging from a sticky, viscous gel or a solid. They preferably include a tissue adhesion agent comprising a hydrophilic polymer.

Owner:ULTRADENT PROD INC

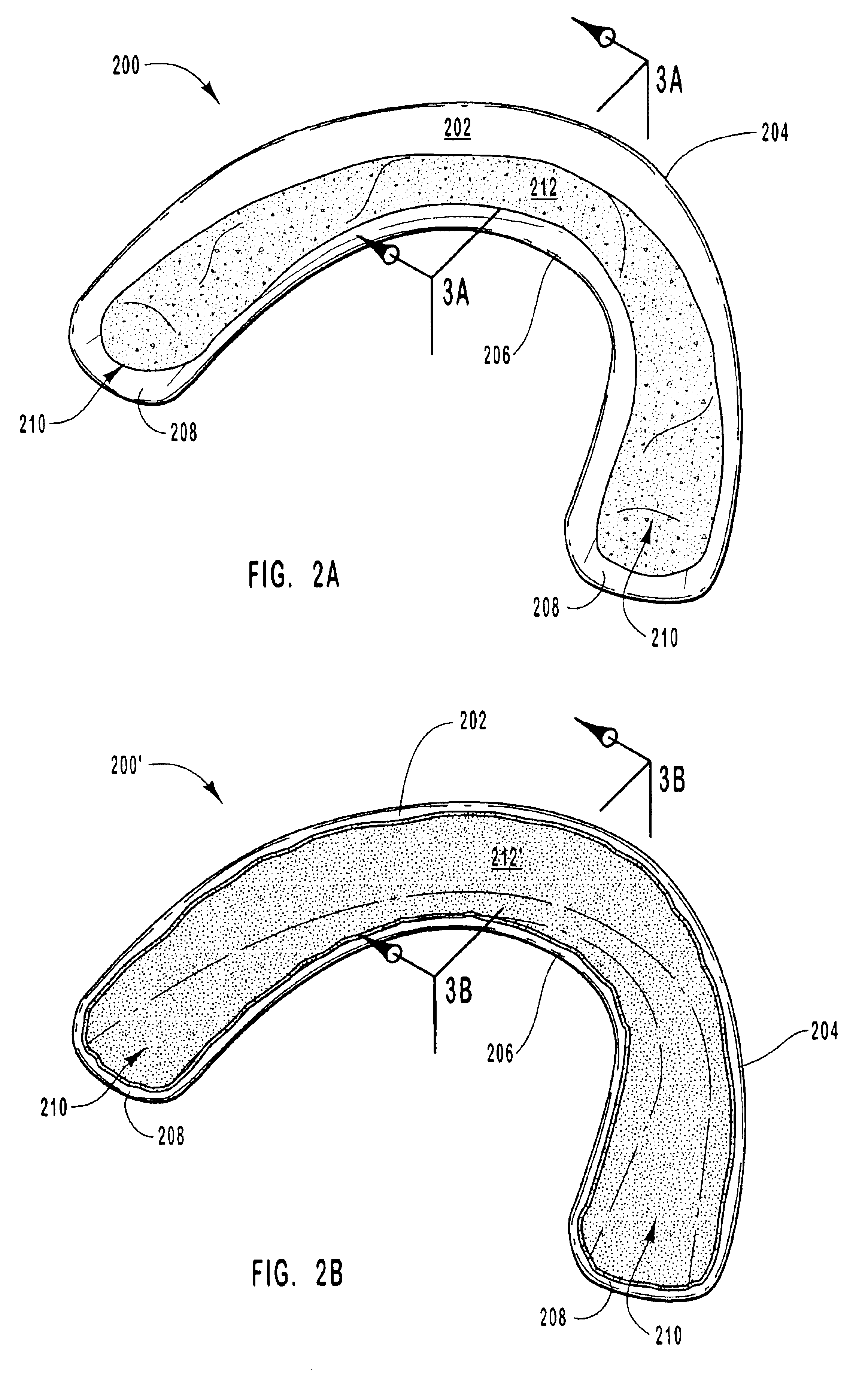

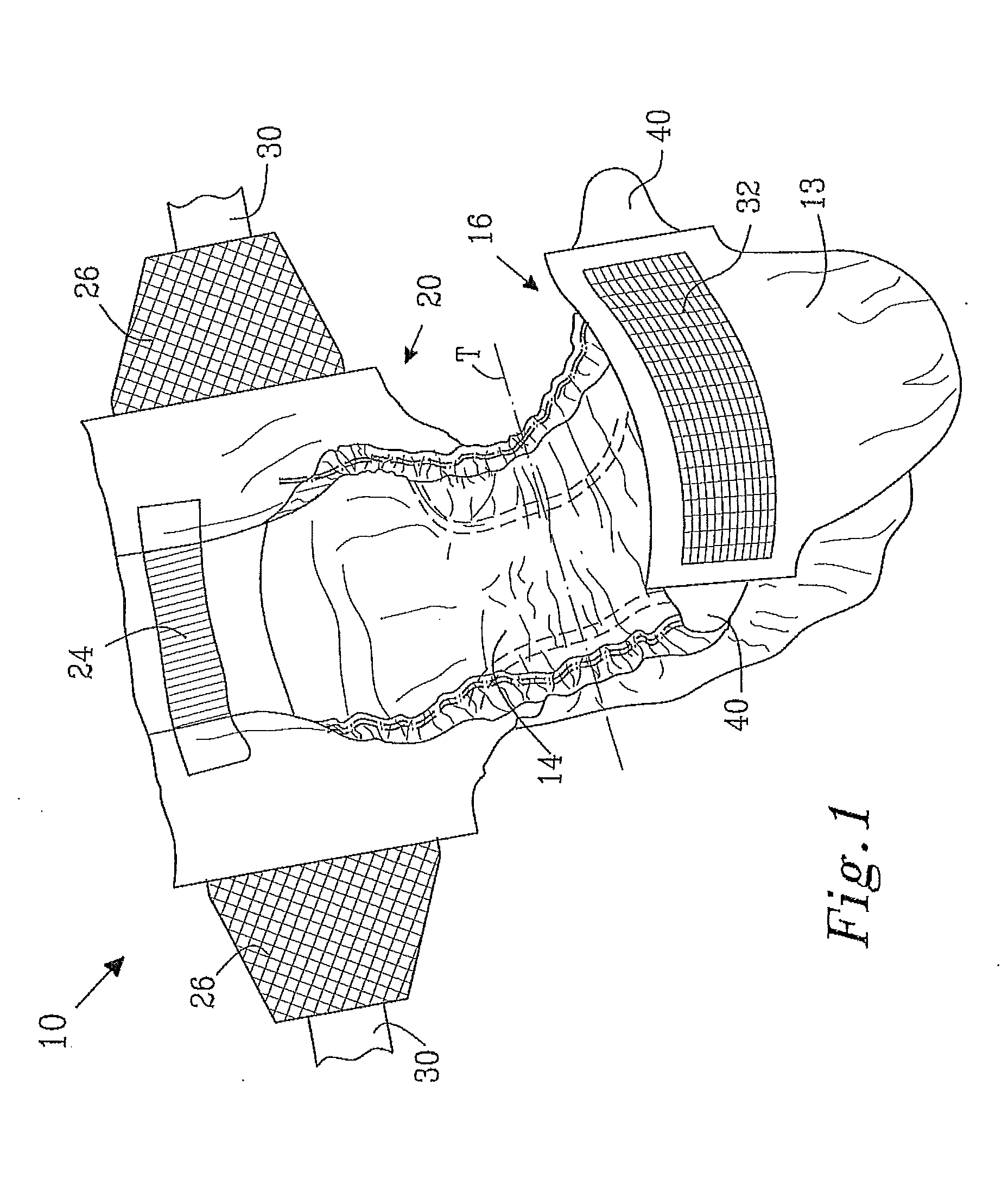

Absorbent article with improved fit

An absorbent article includes a chassis extending about a longitudinal axis and having a topsheet, a backsheet and an absorbent structure disposed between the topsheet and the backsheet. The chassis has a first transverse axis dividing the absorbent structure into a front body panel terminating in a front waist region and a rear body panel terminating in a rear waist region. The rear waist region has a first elastic region. The chassis is delimited by opposed longitudinal edges and opposed transverse edges. In the rear waist region, the absorbent structure terminates at a first distance from the transverse edge and the first elastic region extends substantially parallel to the transverse edge and spaced therefrom by a second distance and spaced from the absorbent structure by a third distance. The third distance is greater than said second distance or substantially equal thereto.

Owner:ESSITY HYGIENE & HEALTH AB

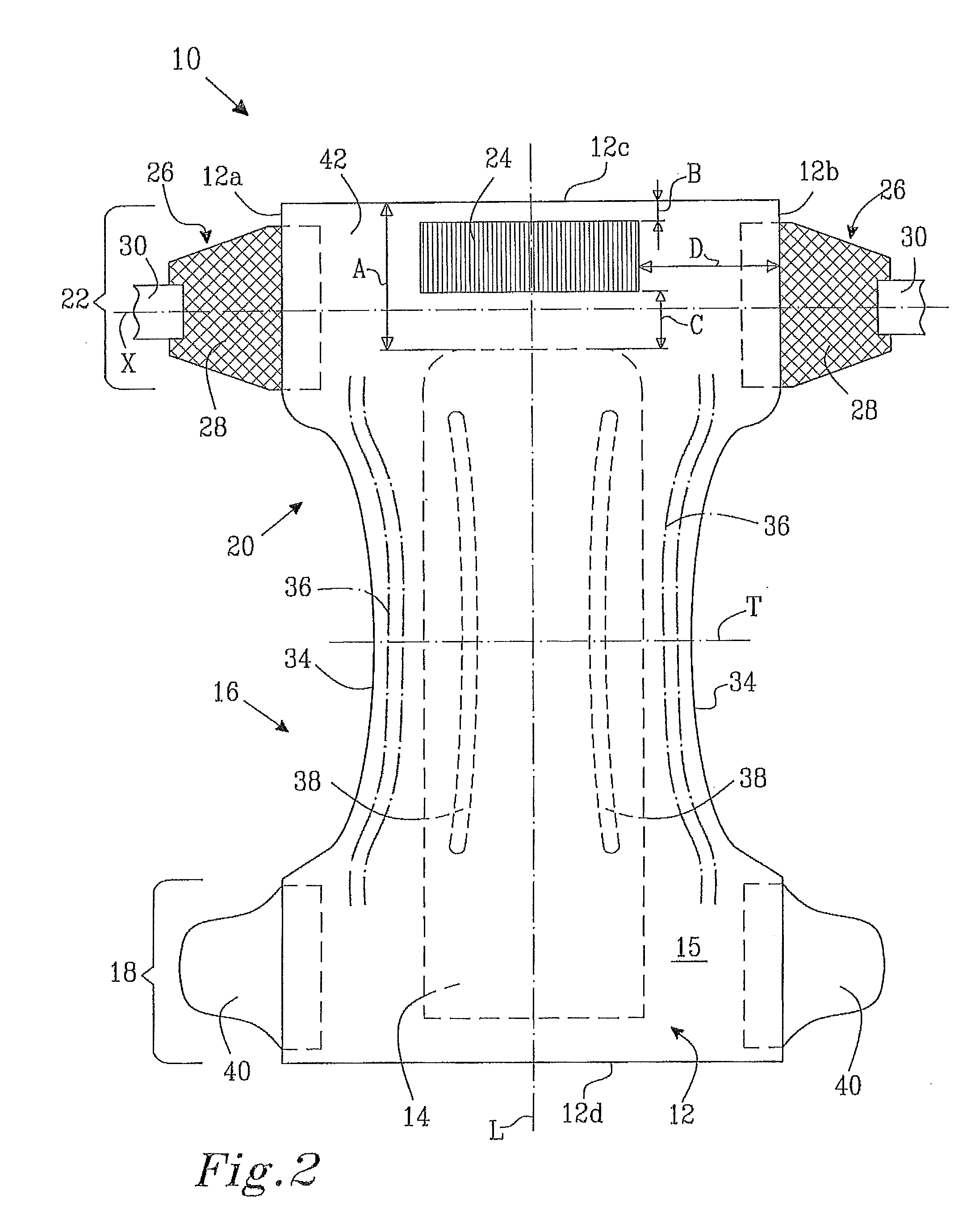

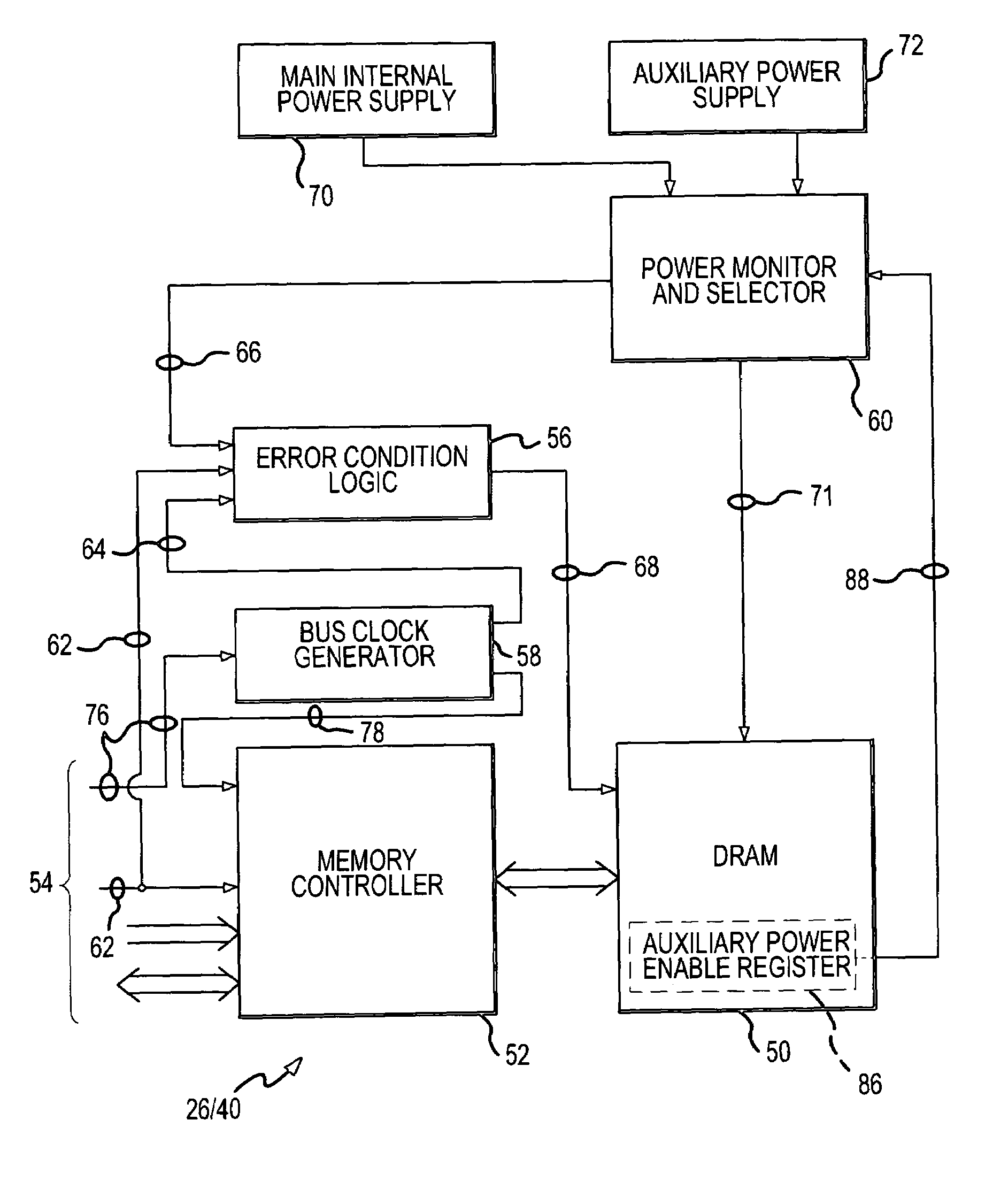

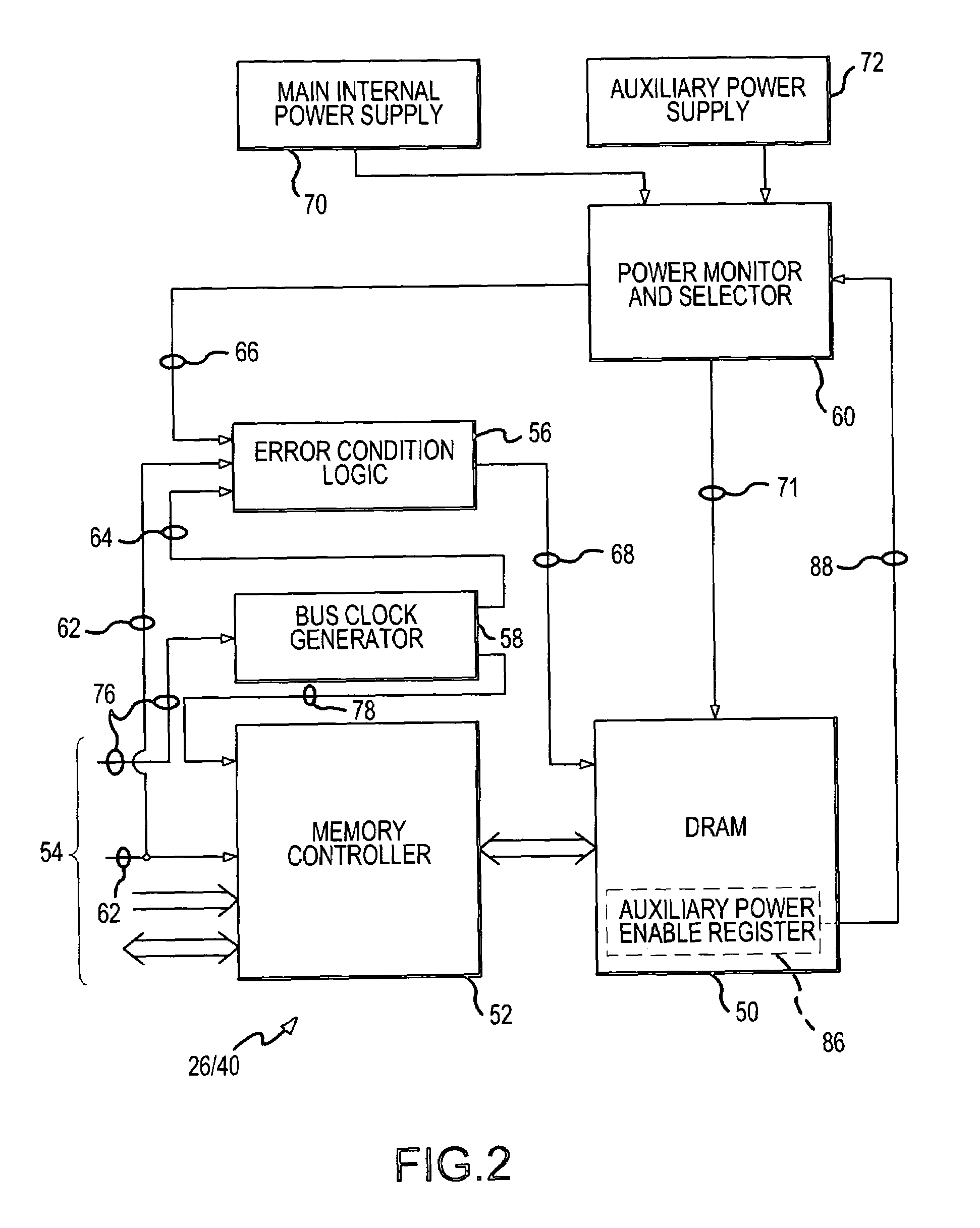

Method and apparatus to establish safe state in a volatile computer memory under multiple hardware and software malfunction conditions

ActiveUS7139937B1Avoid data lossImprove abilitiesError detection/correctionDigital data processing detailsSignal onSoftware failure

Volatile memory is placed into a data-preserving safe state in a computer system in response to any one of a reduction in power applied to the volatile memory, a bus reset signal on a data communication bus of the computer system, and an absence of a bus clock signal on the bus. The volatile memory is powered from an auxiliary uninterruptible power supply in response to the reduction in power. The volatile memory is also placed into the data-preserving safe state in response to a cessation in executing software instructions by a CPU of the computer system. Placing the volatile memory into the safe state in response to and under these conditions enhances the opportunity to preserve data in response to error and malfunction conditions.

Owner:NETWORK APPLIANCE INC

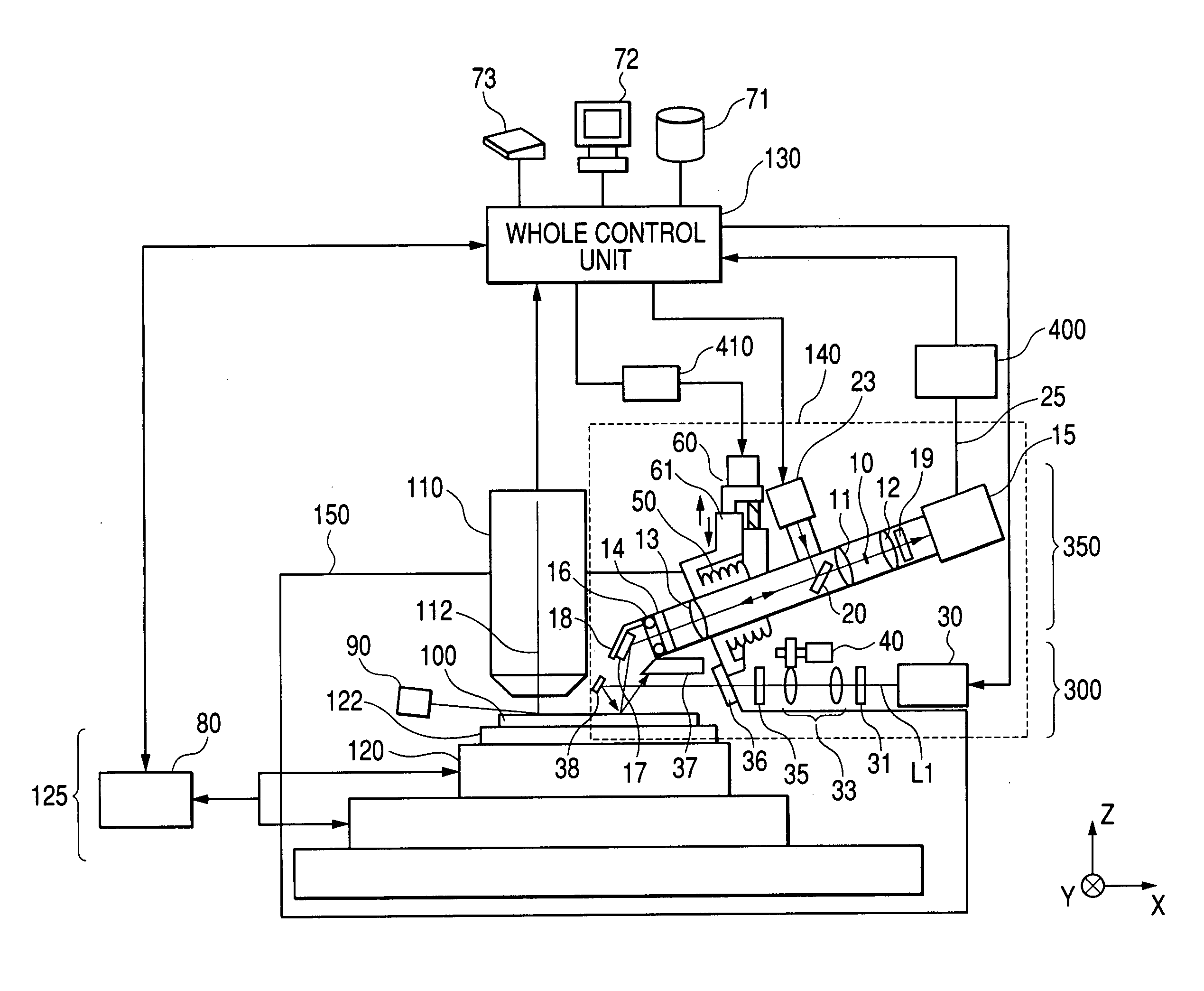

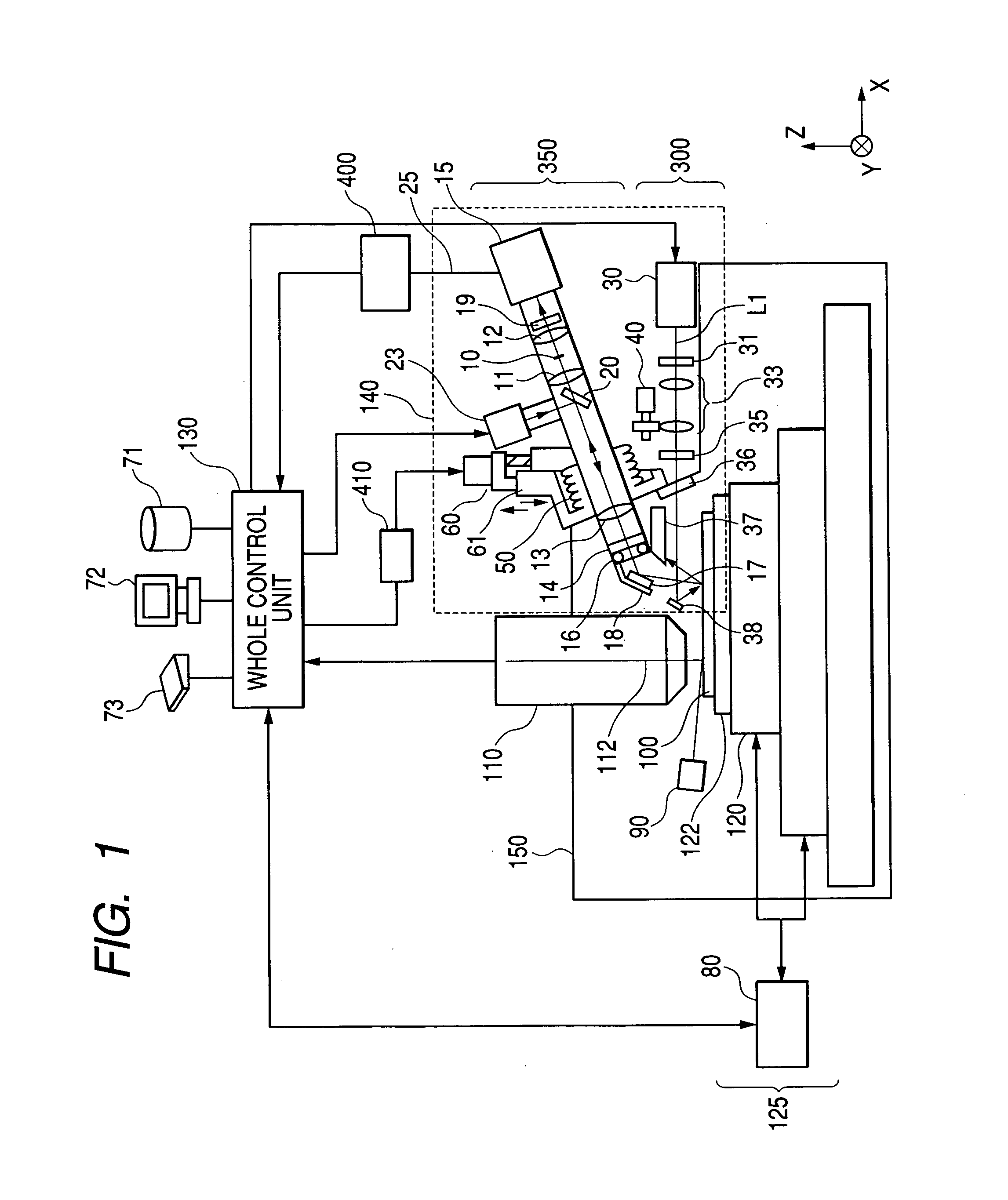

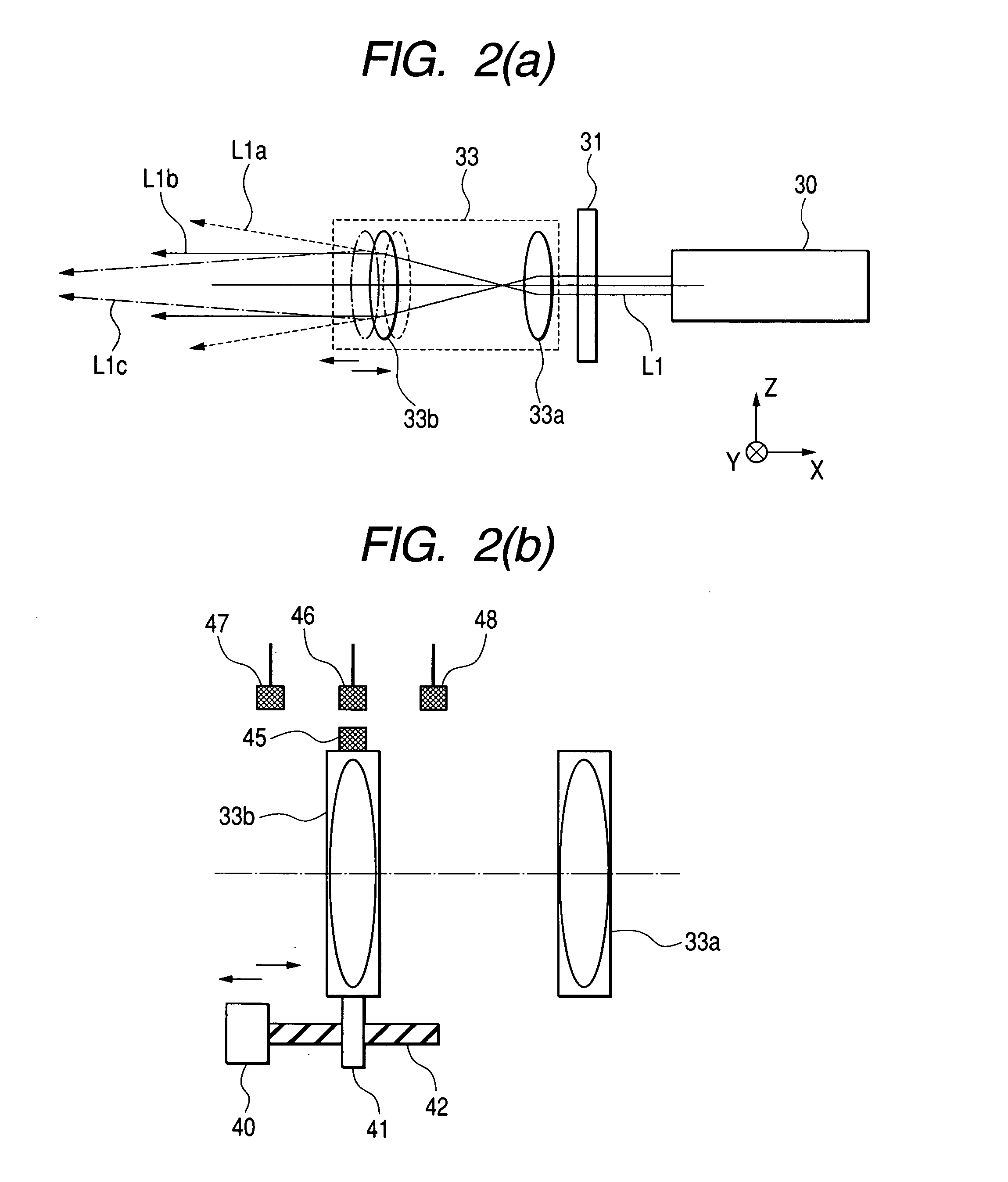

Method and apparatus for reviewing defects

InactiveUS20050122508A1Improve throughputReliably movedMaterial analysis using wave/particle radiationElectric discharge tubesForeign matterScanning electron microscope

The present invention provides an apparatus capable of, and a method for, inspecting at high speed and with high accuracy the super minute foreign particles and pattern defects occurring during device-manufacturing processes in which circuit patterns are to be formed on a sample such as a substrate of semiconductor devices and other elements: in the invention, the sample is illuminated in a dark field from multiple directions each of a different incident angle, the light scattered from the sample during the dark-field illumination is detected in each of the multiple directions, and the signals obtained by detecting the scattered light in each direction; thus, defects present on the surface of an optically transparent film of the sample, and defects present in or under the transparent film are discriminated from each other and both types of defects are discriminatively reviewed using a scanning electron microscope.

Owner:HITACHI HIGH-TECH CORP

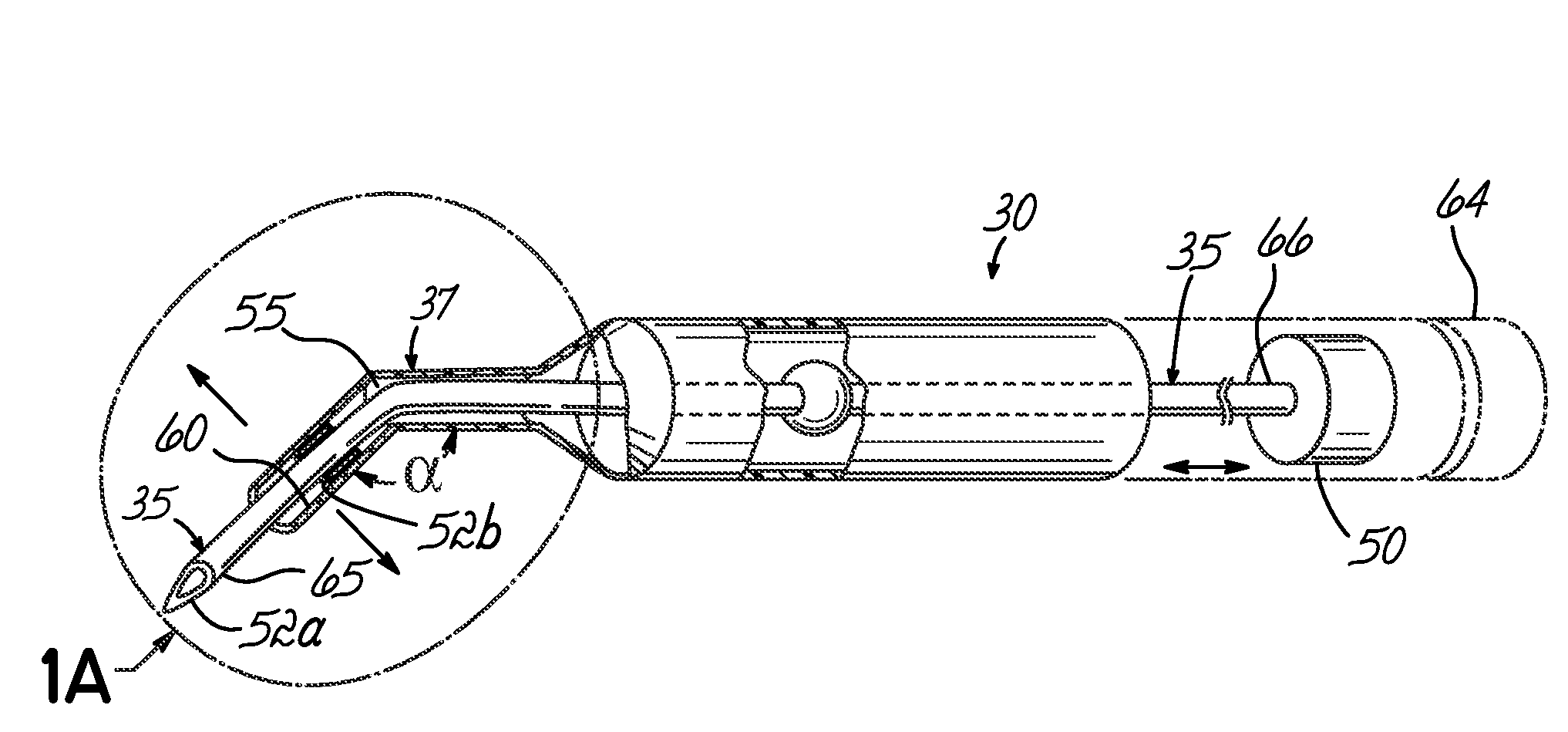

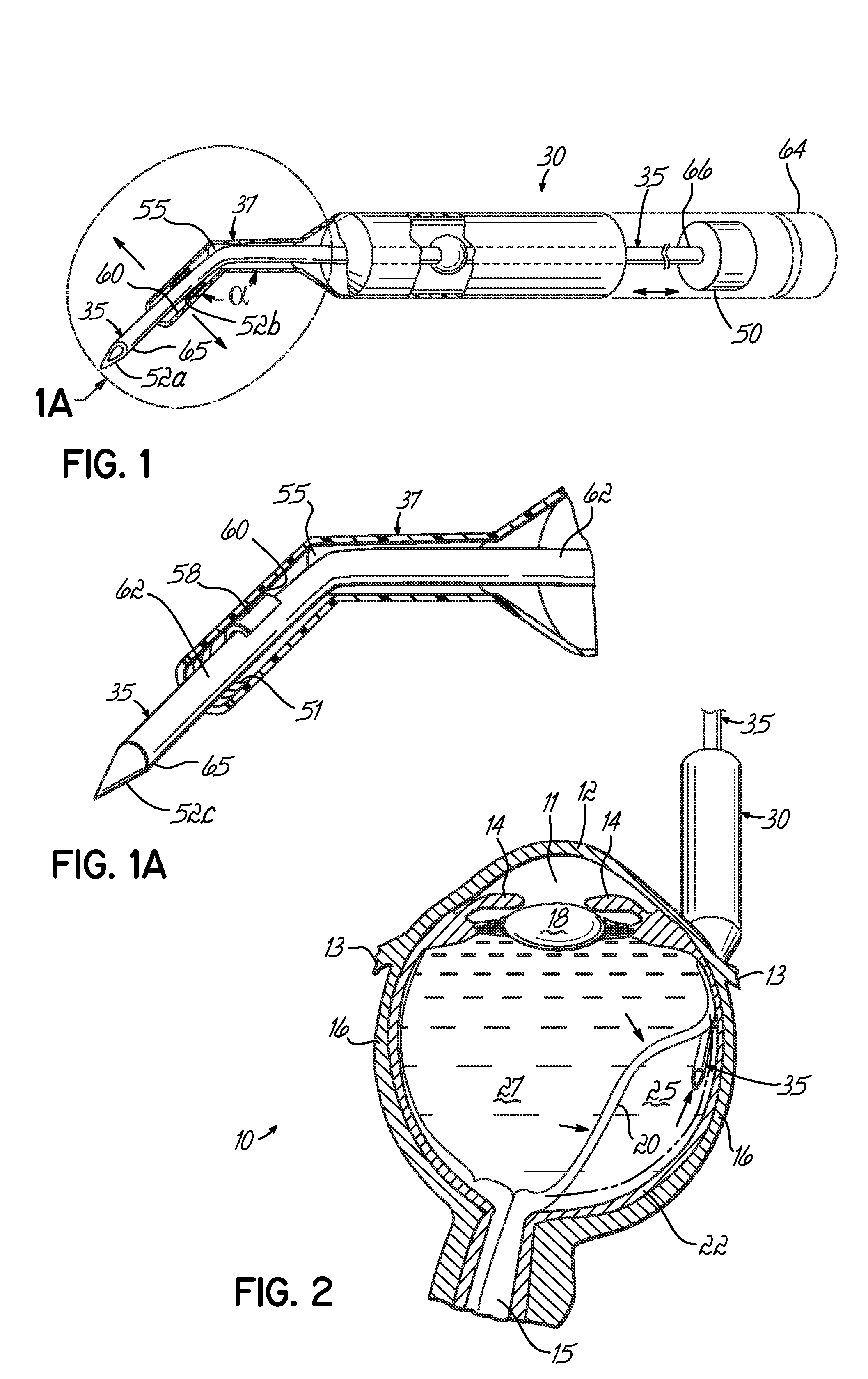

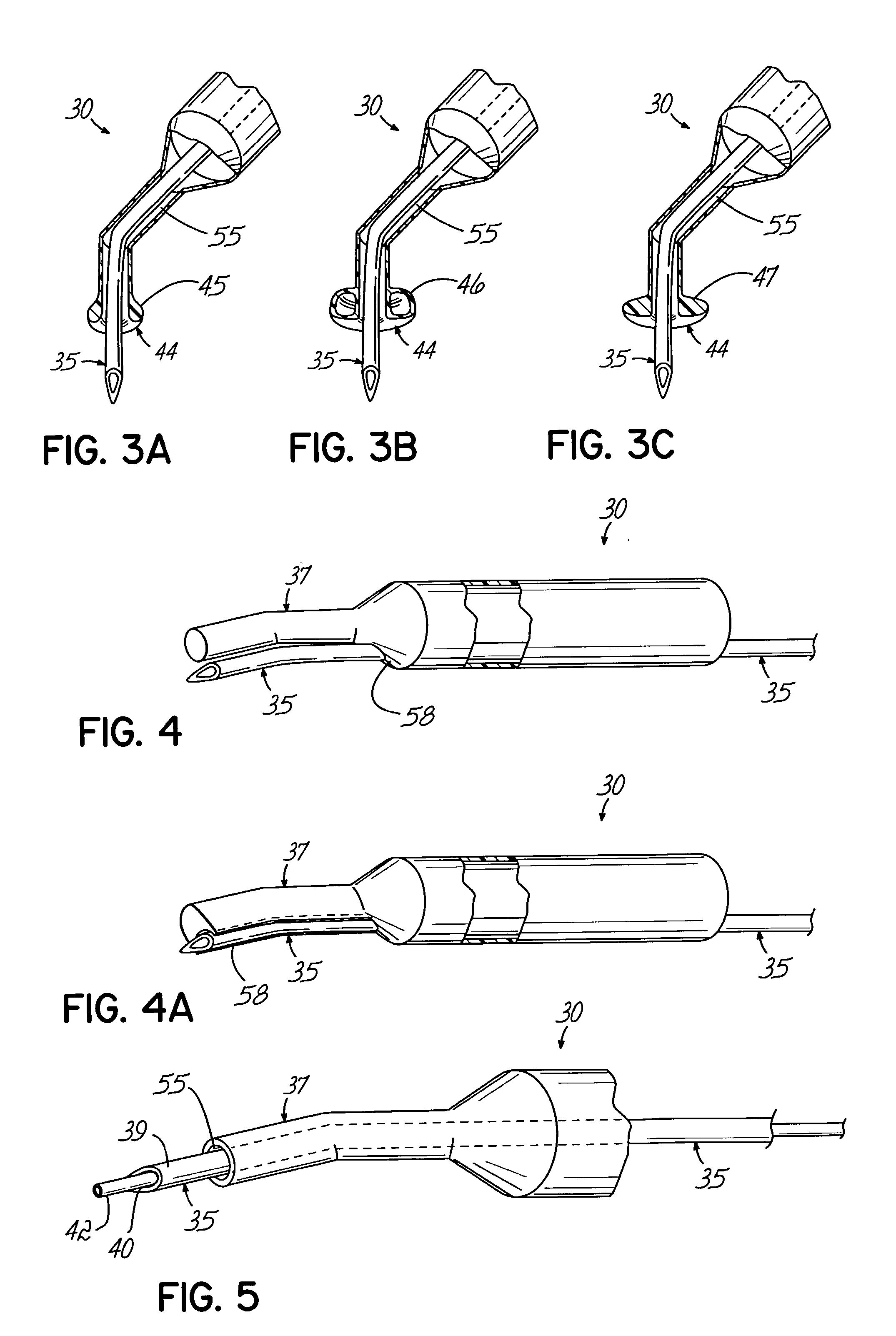

Treatment of retinal detachment

An apparatus and minimally invasive method for removing fluid from a subretinal space to allow a detached retina to flatten. An apparatus, comprising a fluid withdrawal device and a guide for advancing and placing the device, is positioned on the exterior eye surface at the detachment site. Various embodiments of the apparatus are disclosed. Using the guide, the surgeon advances the device into the fluid-filled space and drains fluid, allowing the retina to flatten. Additional injection of saline or gas into the vitreous cavity normalizes intraocular pressure, and the patient is ambulatory immediately afterward. Unlike other retinal attachment techniques, in the inventive procedure the patient receives only a local anesthetic, and has no restraint on head movement.

Owner:PEYMAN GHOLAM A

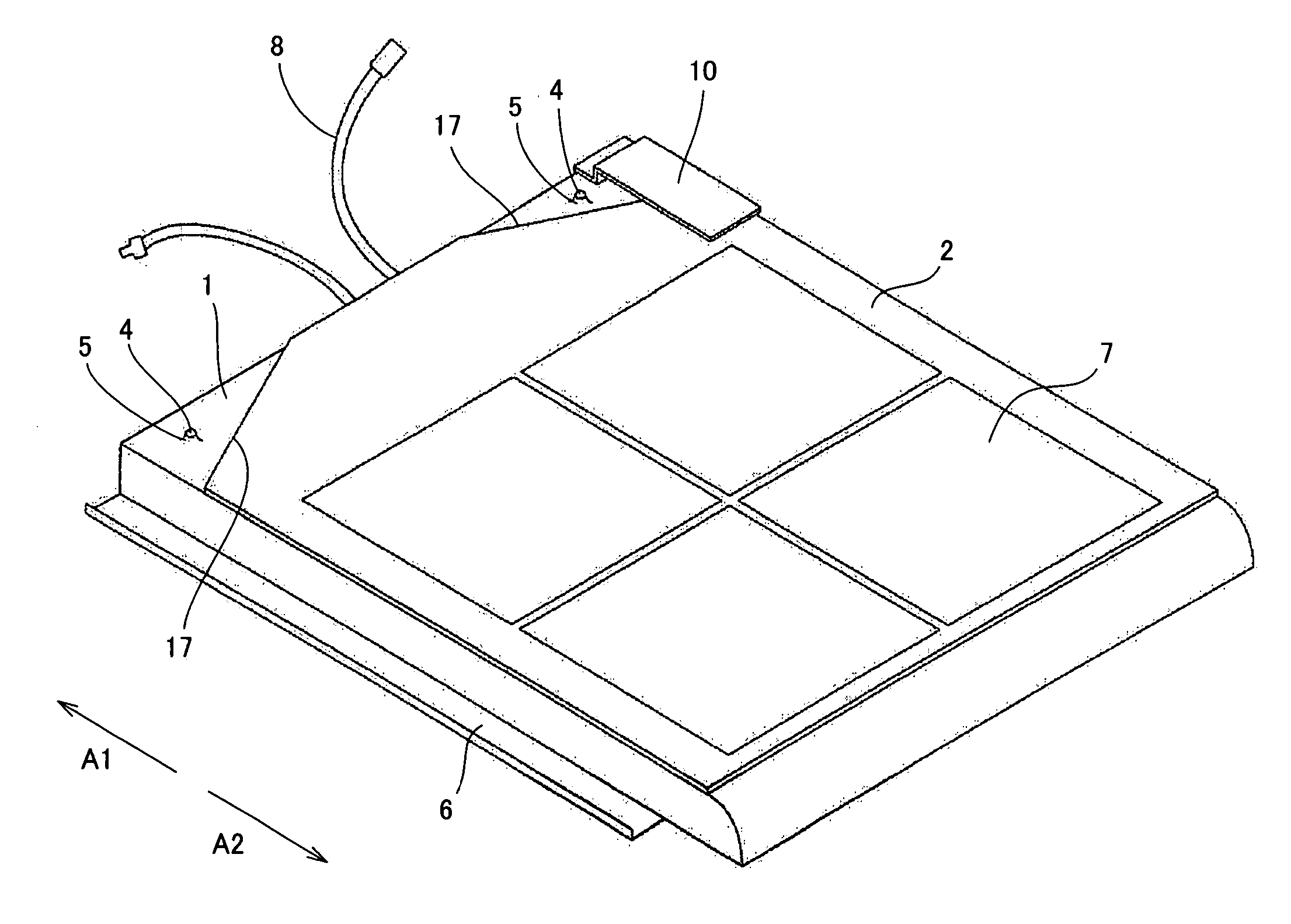

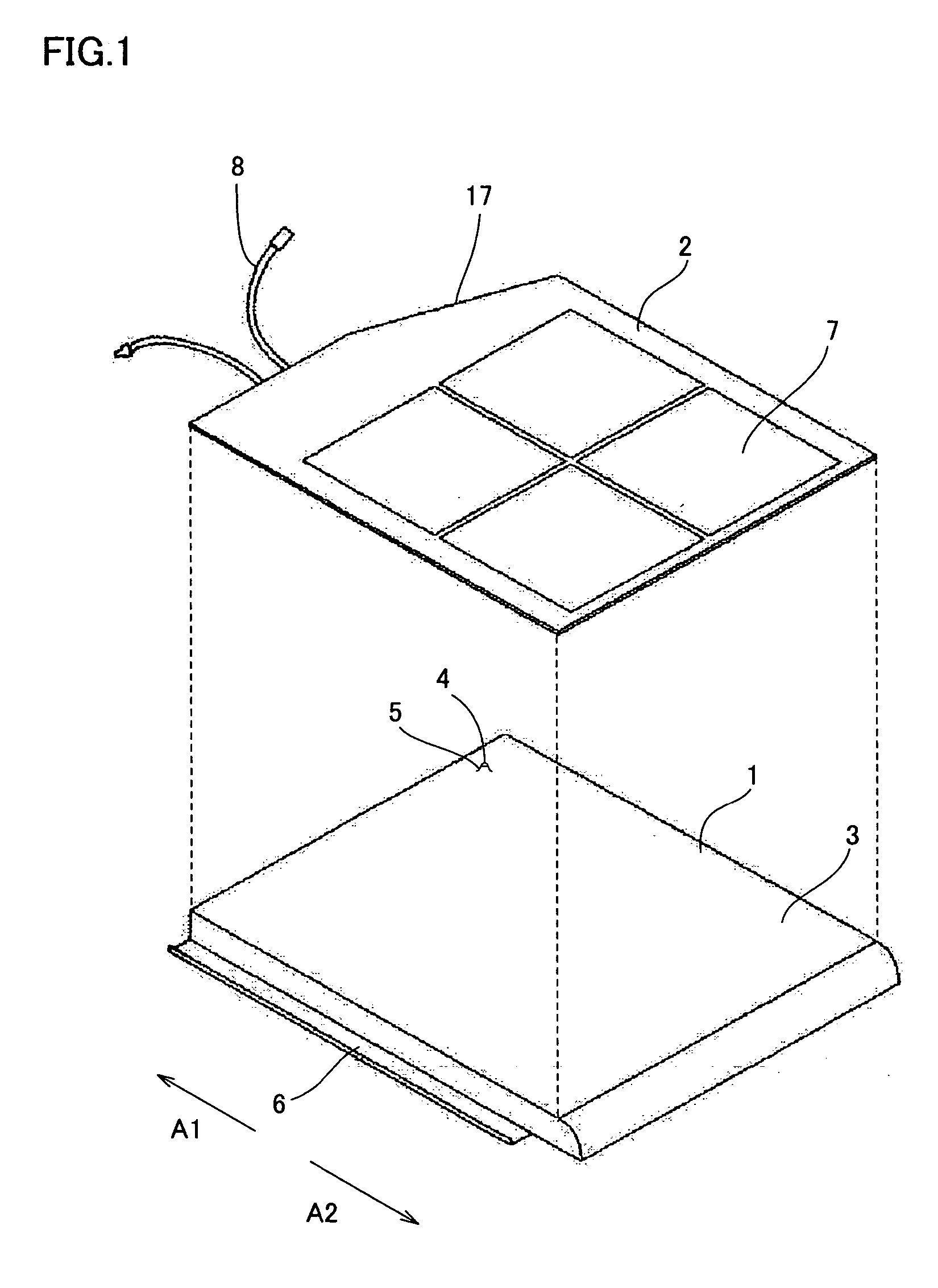

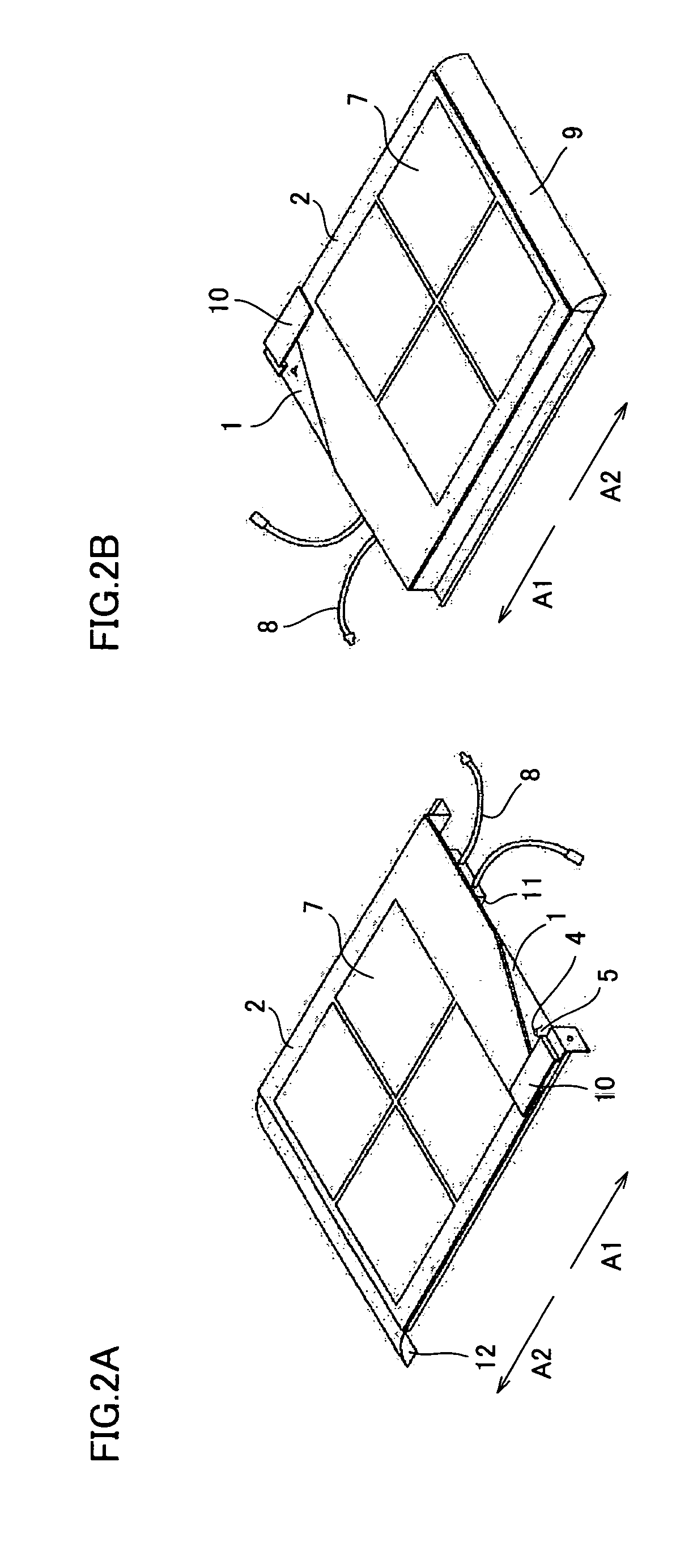

Roof cover type solar cell module

InactiveUS7138578B2Place stableMaintain good propertiesPhotovoltaic supportsRoof covering using slabs/sheetsWeather resistanceElectrical battery

A roof cover type solar cell module includes a roof cover base member and a power generating unit. The roof cover base member has a mounting surface to which the power generating unit is mounted, and an underlap that can mate with an adjacent roof cover. The power generating unit is mounted to the mounting surface, leaving a part of the mounting surface uncovered. Thus, a roof cover type solar cell module for which a variety of materials can be used for the roof cover base member, which can be produced at low cost, and which is excellent in stability when placed on the roof surface, and also excellent in workability, weather resistance and design property, is provided.

Owner:SHARP KK

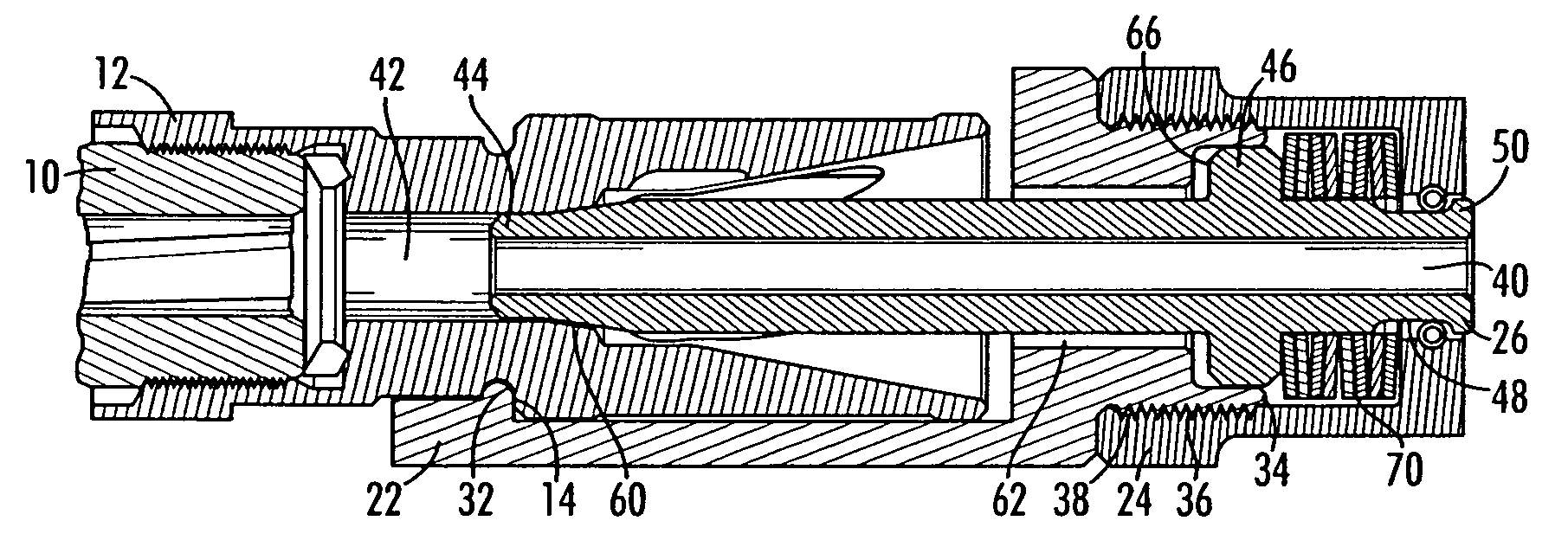

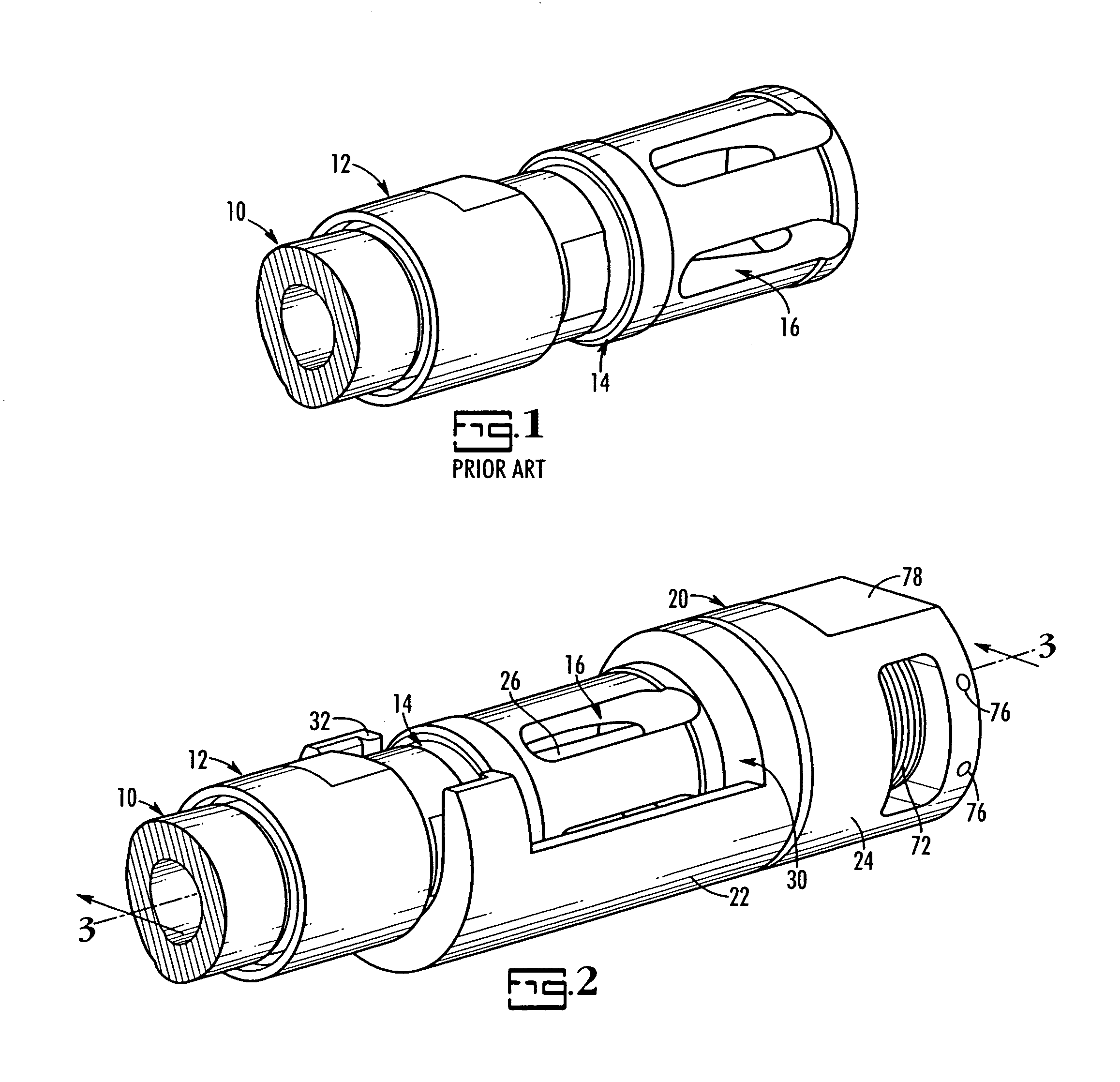

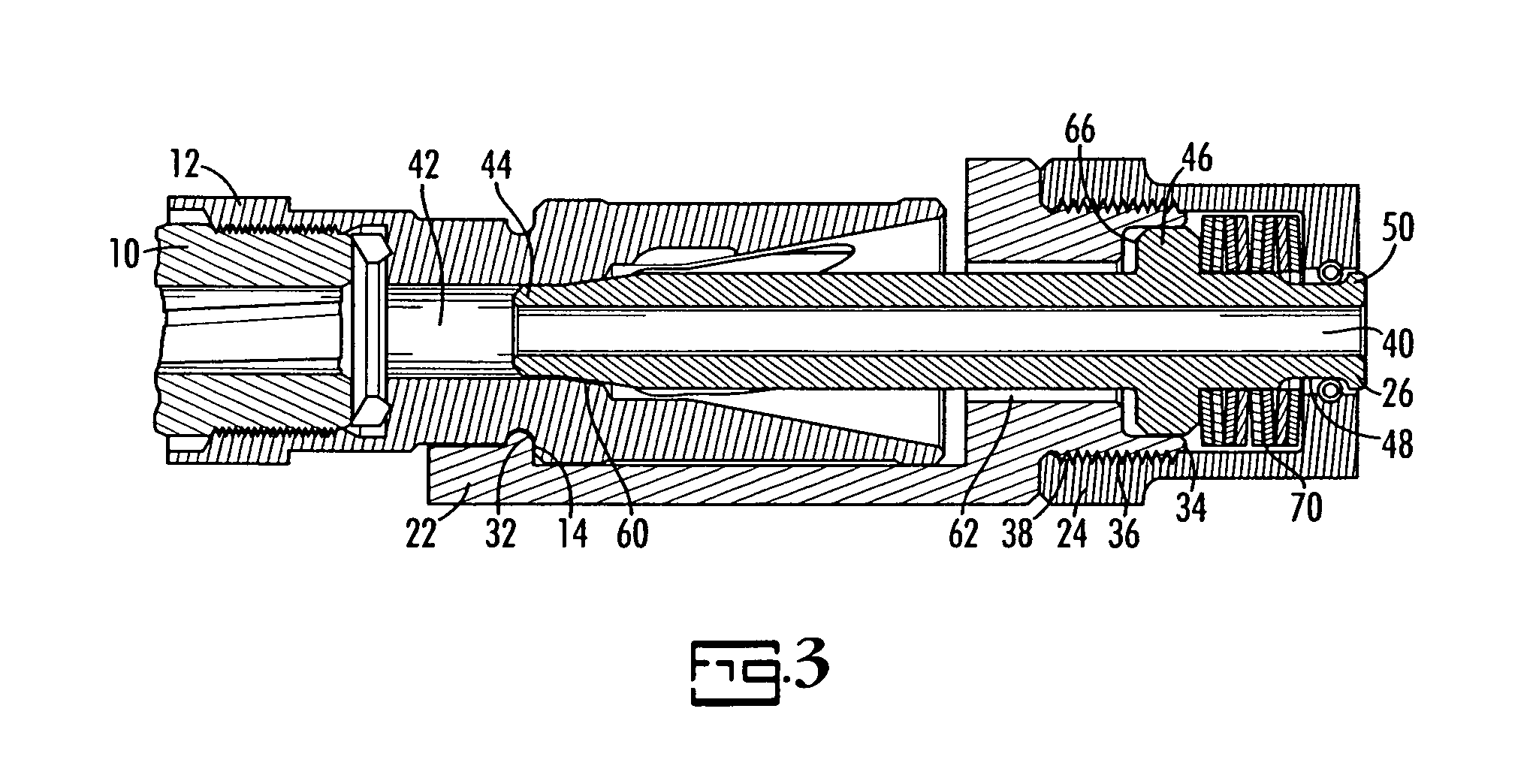

Adaptor for firing blank ammunition

An adaptor for use with a flash suppressor on a gun barrel in order to allow the gun to repeatedly fire blank rounds of ammunition. The adaptor has a stem that chokes the flow of gases from an exploding round in order to create a back pressure. A body is used to couple the stem to the flash suppressor and permit a cap to be threaded to the body. The cap urges the stem into the throat of the flash suppressor when tightened to the body while the body grips the flash suppressor to hold the stem and cap in place. Belleville washers in the cap pre-loaded and urge the stem into the throat and hold it there securely during repeating firing of the gun.

Owner:FN HERSTAL +1

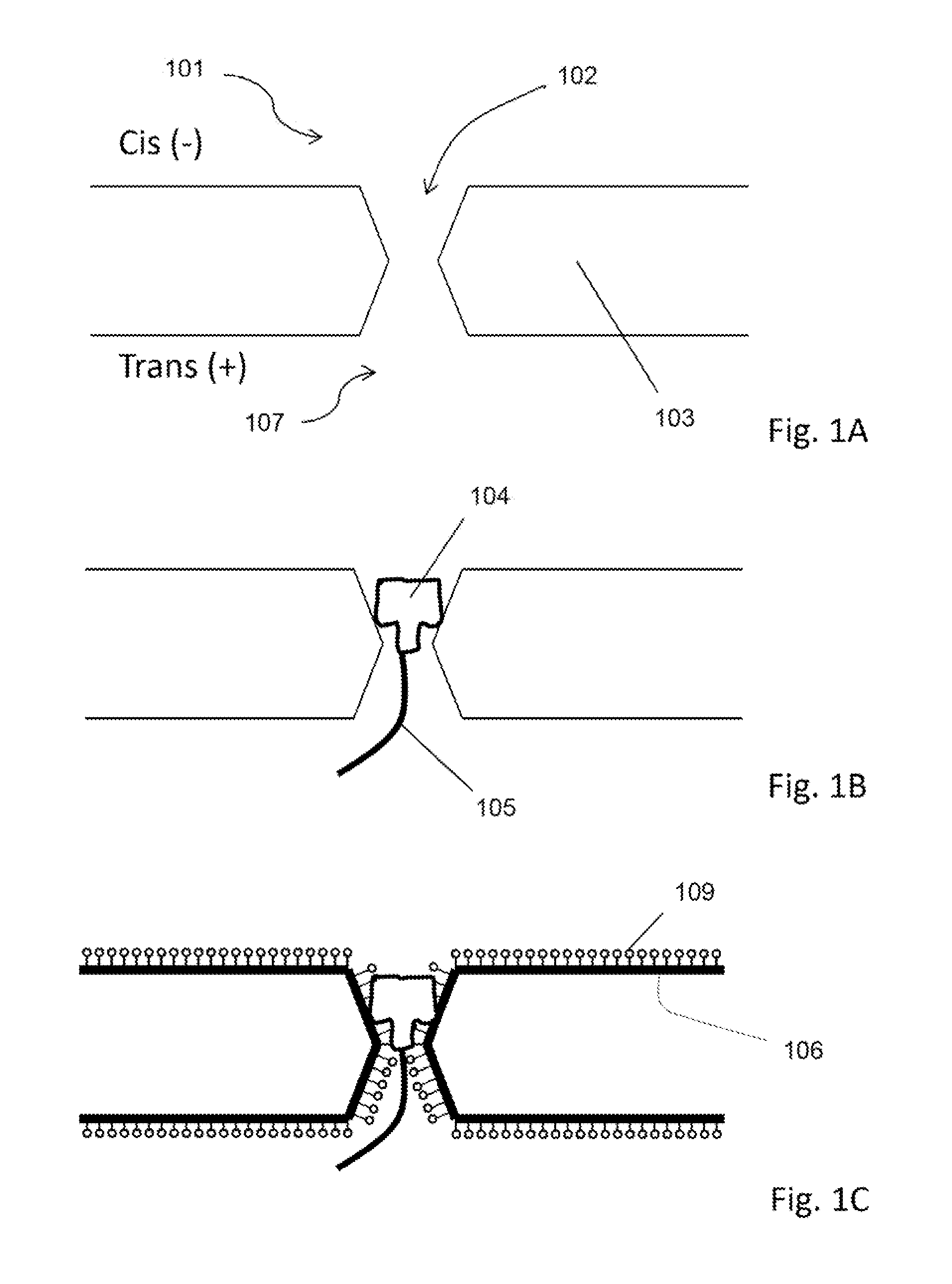

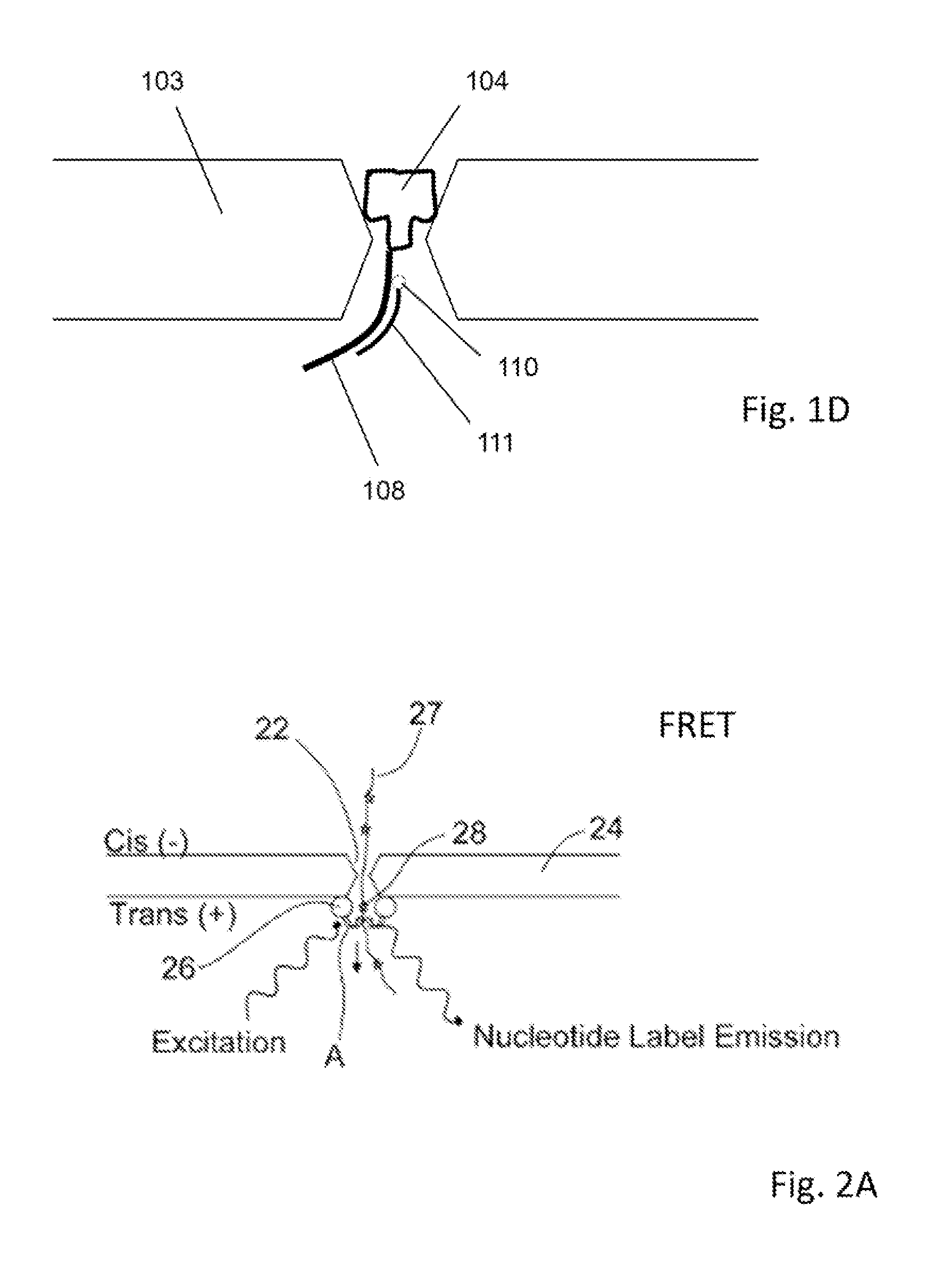

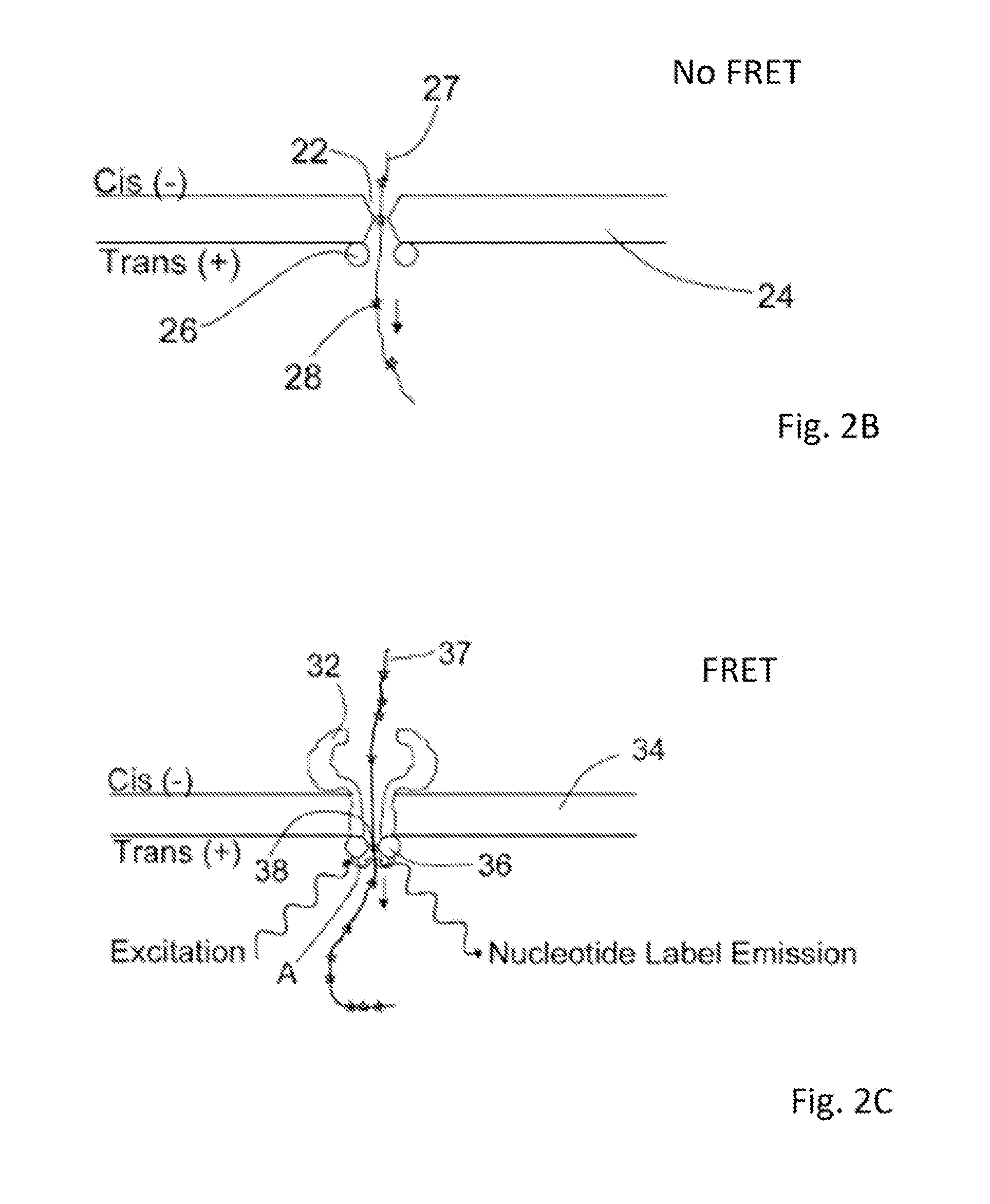

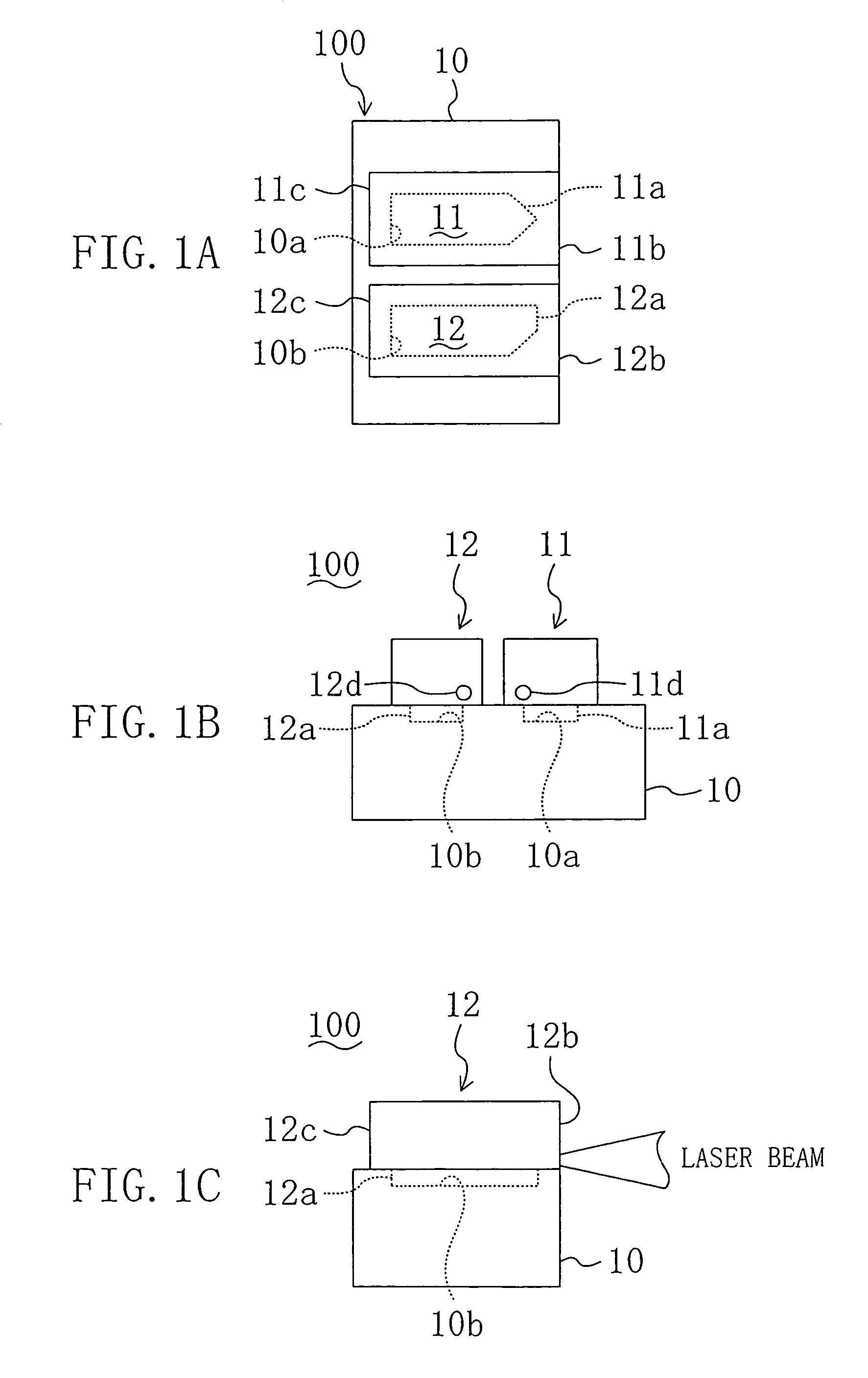

Hybrid nanopore device with optical detection and methods of using same

InactiveUS20130203050A1Place stableBioreactor/fermenter combinationsBiological substance pretreatmentsLipid formationAnalyte

The invention is directed to a device comprising a protein nanopore immobilized in a lipid layer within an aperture of a solid phase substrate, which provides a stable platform for using first and second members of one or more FRET pairs to generate optical signals as a labeled analyte translocates through the bore of the protein nanopore. In another aspect, the invention is directed to the use of the device to determine the nucleotide sequence of a polynucleotide analyte.

Owner:QUANTAPORE

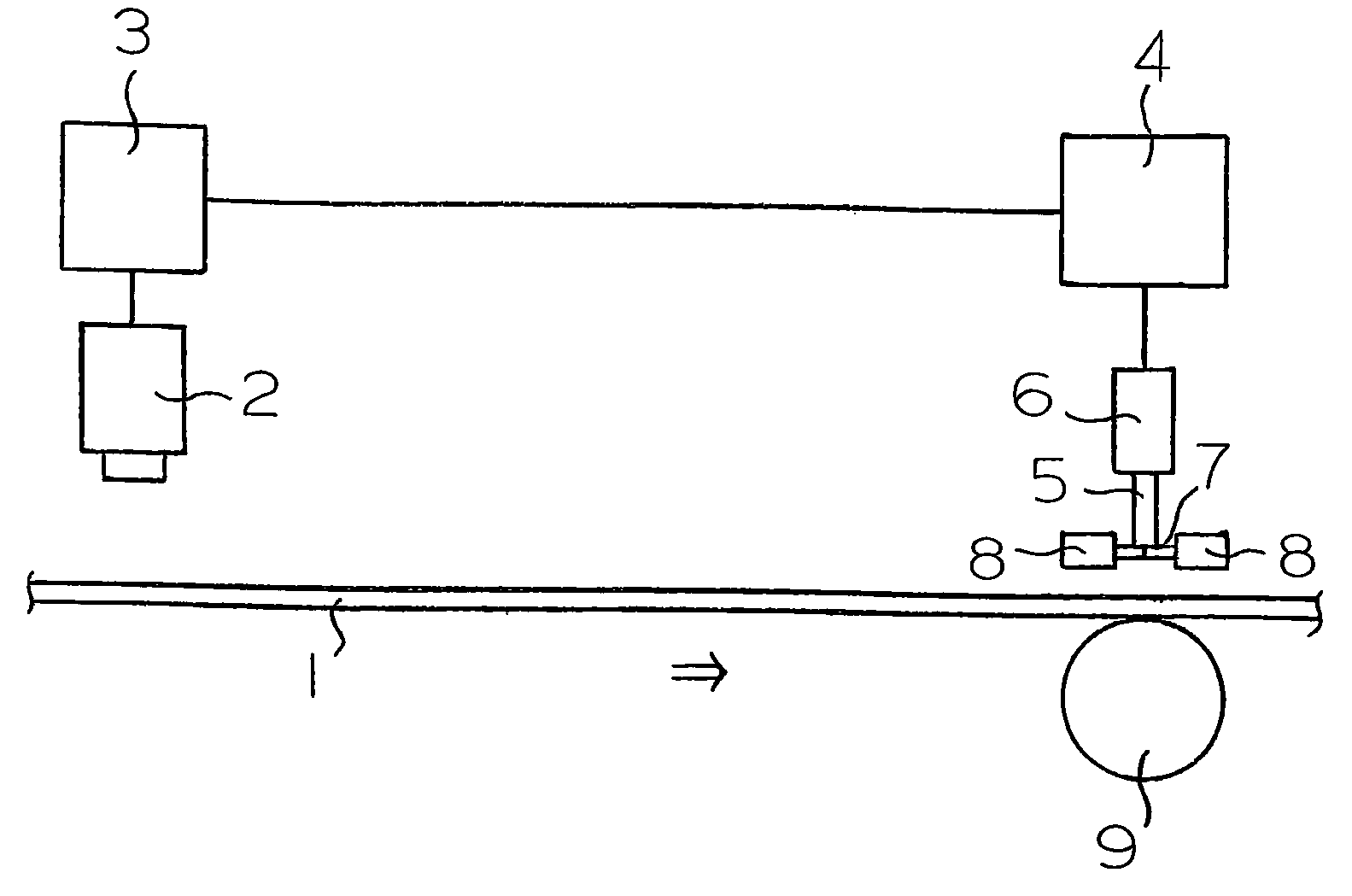

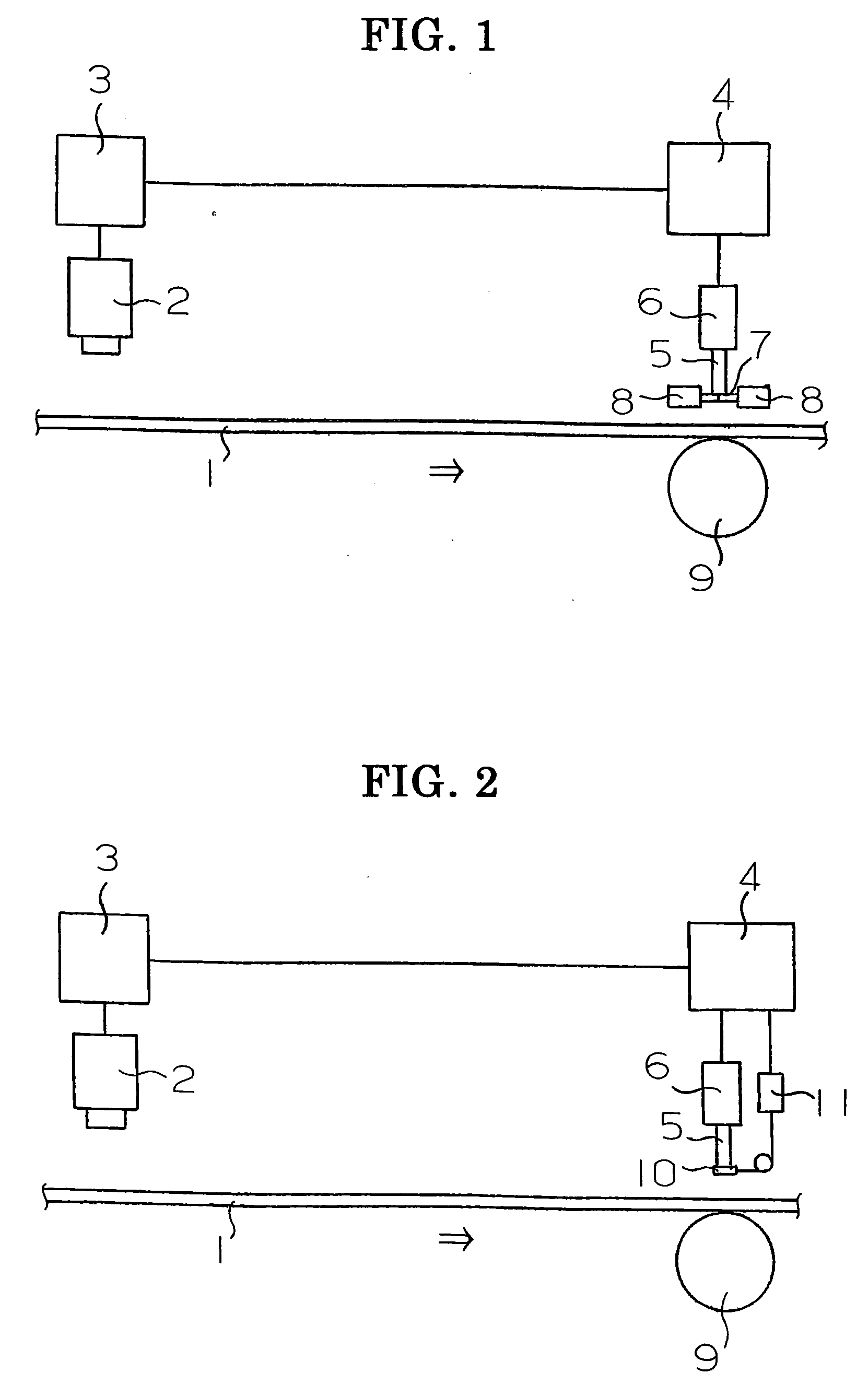

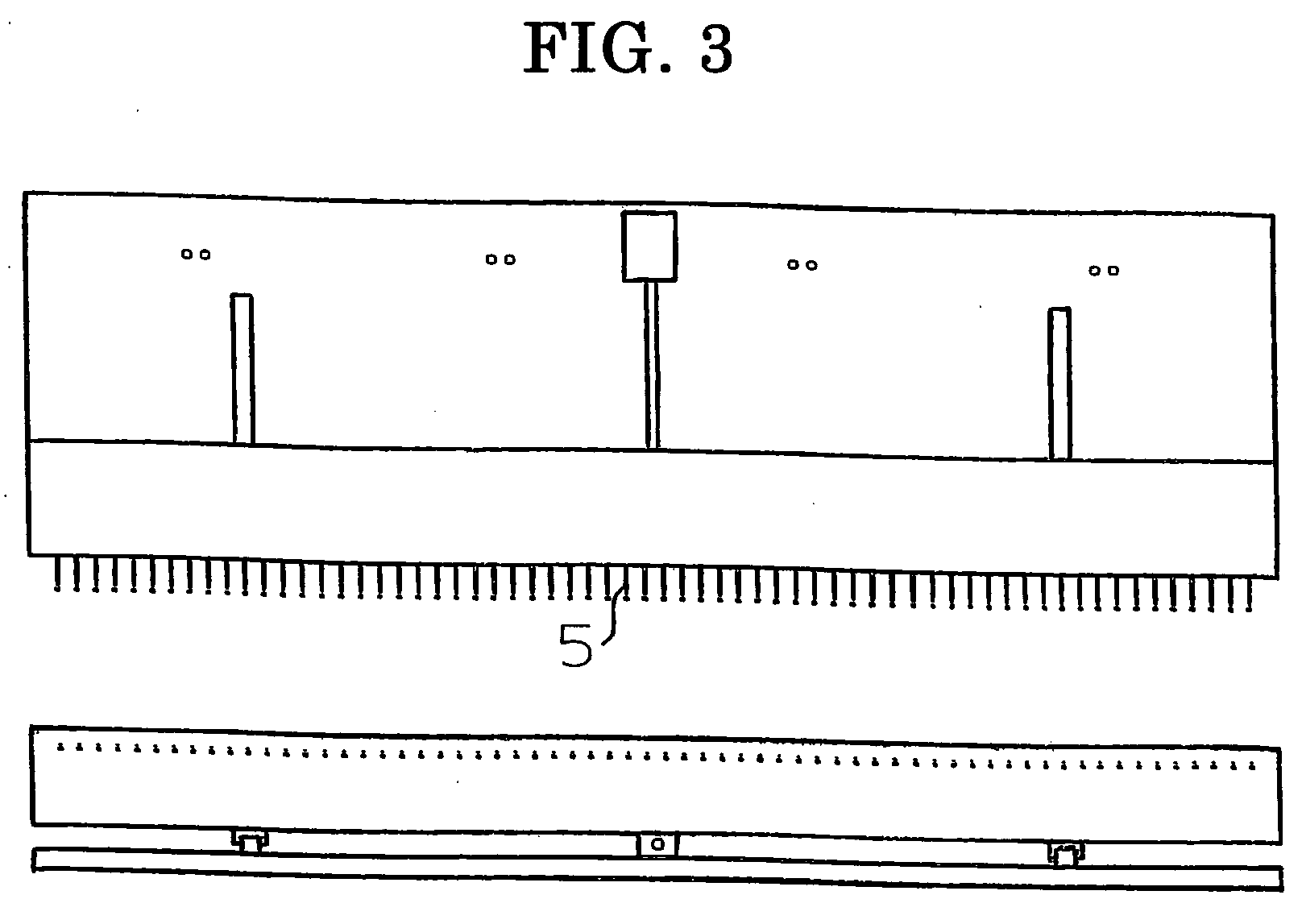

Apparatus for marking a defect

InactiveUS20060164647A1Effective placementEfficient use ofCharacter and pattern recognitionOptically investigating flaws/contaminationEngineeringBiomedical engineering

An apparatus for marking a defect detects a defect in a long sheet product transferred in a longitudinal direction by an inspection apparatus and places a mark at the defect at a position downstream of the inspection apparatus. An oil-based marking pen is contained in a container tube having a shutter for closing the tip of the pen. The shutter is opened based on a signal sent from the inspection apparatus, a mark is placed at the defect in the long sheet product by the tip of the pen pushed out of the container tube, the pen is pulled back into the container tube after the marking is completed, and the shutter is closed. The mark can be placed at the portion of the detected defect by an oil-based marking pen without causing a decrease in the marking property due to drying of the tip of the pen.

Owner:NAGASE & COMPANY

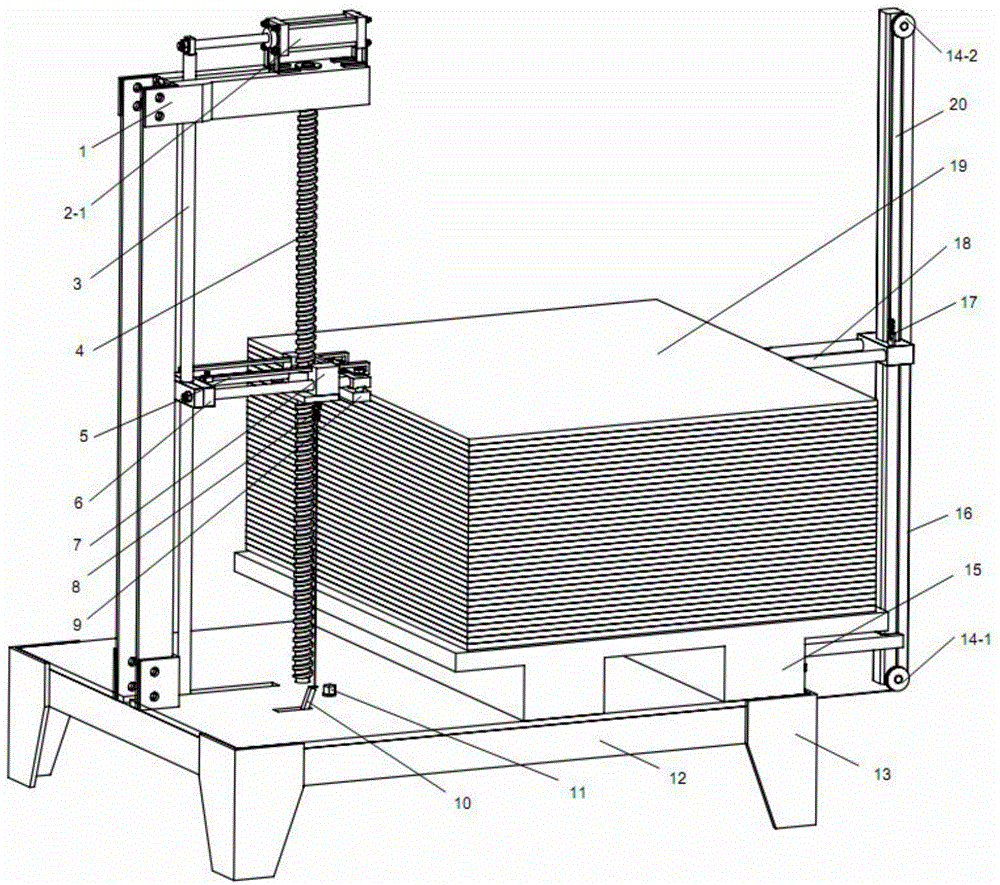

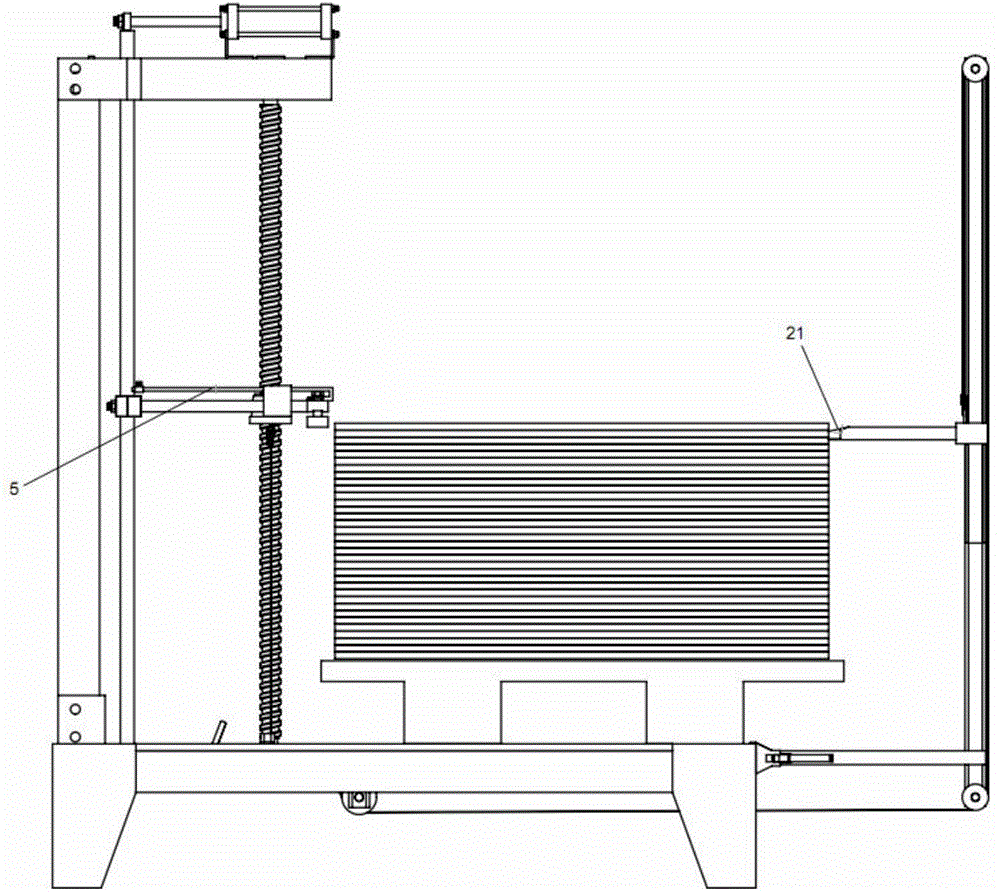

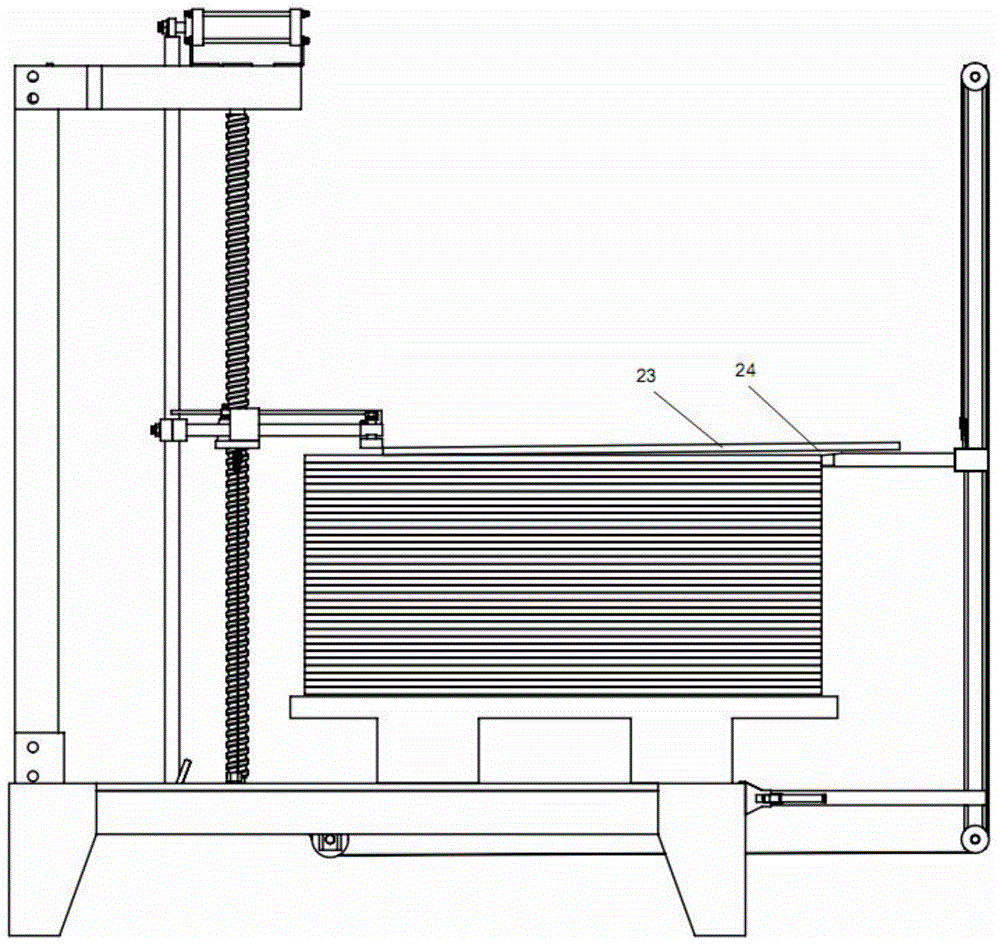

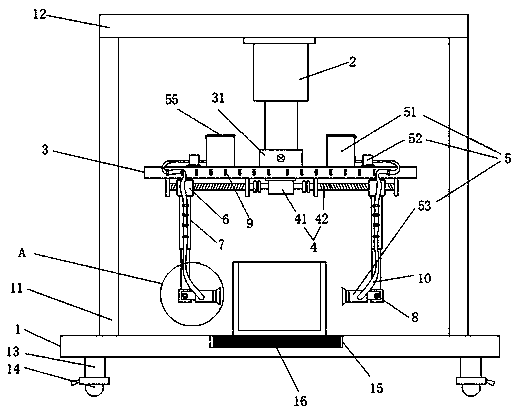

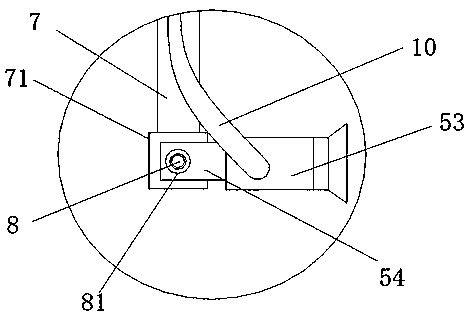

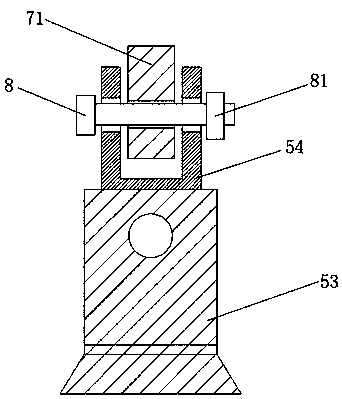

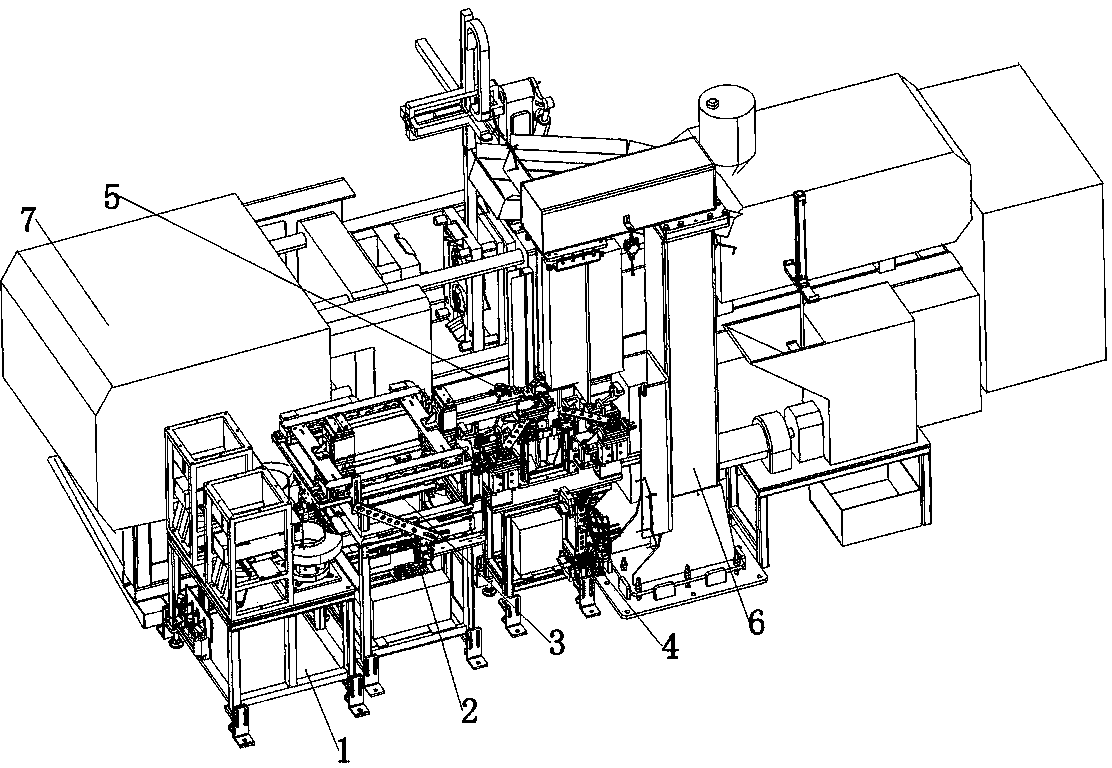

Separation device for detaching and stacking stamped sheet metal

A separation device for detaching and stacking stamped sheet metal comprises a driving mechanism, a pushing mechanism, a lifting mechanism, a separating mechanism and a sheet metal supporting base. The sheet metal supporting base is used for supporting the other mechanisms and stacking the sheet metal. The pushing mechanism allows a pushing assembly to slide linearly in the horizontal guide direction of a guide support through a vertical slide rod connected with a cylinder so that the effect of pushing out the sheet metal on the top layer can be achieved. The lifting mechanism controls the guide support to rise and fall by adjusting the number of rotation circles of a screw so that a push block can always keep aligned with the sheet metal on the top layer when starting to work. The separating mechanism is connected to the lifting mechanism when a steel wire rope is wound around a pulley so that the separating mechanism can synchronously rise and fall together with the lifting mechanism under the influences of the gravity of the separating mechanism. A separating rod can prevent the sheet metal on the top layer from absorbing the sheet metal on the lower layer and sliding together with the sheet metal on the top layer, and a separating inclined block makes a gap formed between the sheet metal on the top layer and a sheet metal stack. The intermittent movement of the pushing mechanism and the lifting mechanism is achieved through double ratchets by means of the driving device. The separation device is easy to operate, high in efficiency, good in separation effect, high in flexibility and wide in applicability.

Owner:GUANGXI UNIV

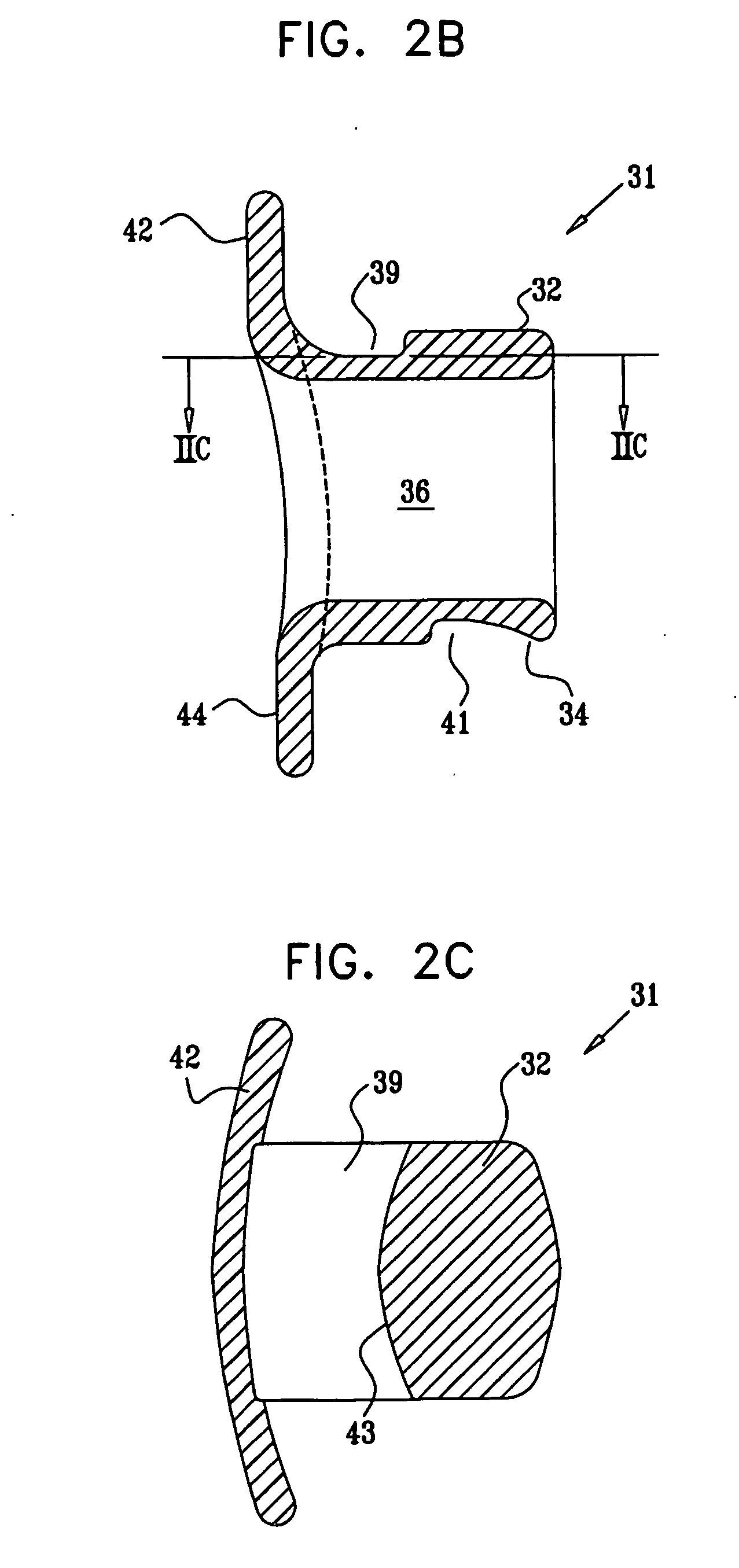

Endoscopic bite block

An endoscopic bite block, with teeth position defining regions which guide the subject's teeth to grip the bite block in their natural position, with the teeth of the upper jaw positioned further out than the lower jaw teeth. These teeth position defining regions are also preferably curved to match the curved shape of the jaw. The upper and lower parts of the front plate of the bite block may also be positioned at different distances out, so that upper and lower lip regions both contact the front plate snuggly. The bite block may be used with separate oral / nasal cannulae, or may incorporate breath sampling or gas supply cannulae. A flexible flapped curtain at the outer end of the bite block may be provided to largely enclose the inner volume of the bite block to enable more accurate capnographic sampling under conditions of wide-open mouth breathing.

Owner:ORIDION MEDICAL 1987

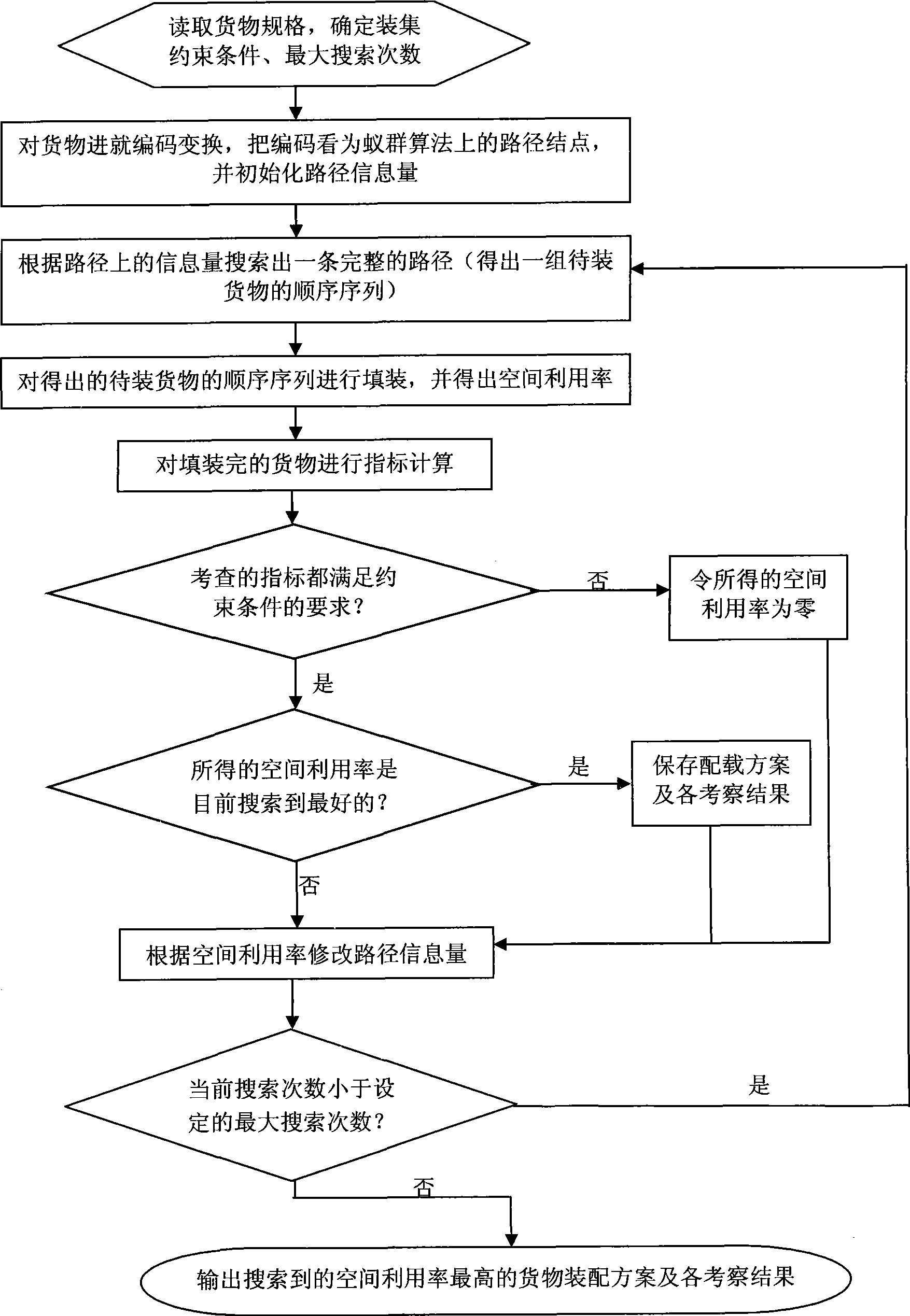

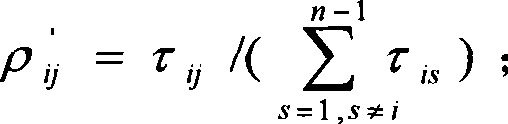

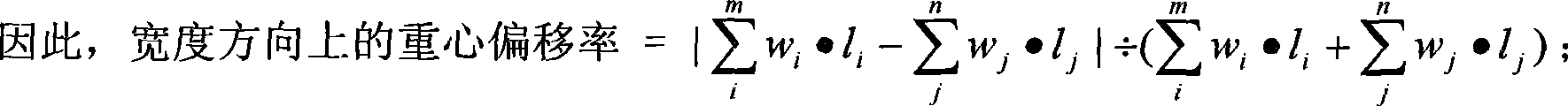

Container loading method based on ant colony algorithm

InactiveCN101381033AReduce operating costsImprove space utilizationBiological modelsLoading/unloadingLoad capacityStowage

The invention discloses a container loading method based on an ant colony algorithm. The method takes into consideration overall constraints such as the load capacity of a container, the stability of cargo placement, the convenience of loading and unloading and so on, and introduces the ant colony algorithm for a group of goods to be loaded in order to search for a stowage solution allowing for high space utilization rate. The specific proposal of the method is as follows: firstly, searching for the sequence of the goods to be loaded which allows the goods after being loaded to meet the constraints and get good space utilization rate; and secondly, loading goods according to the searched stowage solution allowing for high space utilization rate, wherein the stowage solution contains information on how goods to be placed. The container loading method of the invention has high use value.

Owner:JIANGSU UNIV OF SCI & TECH

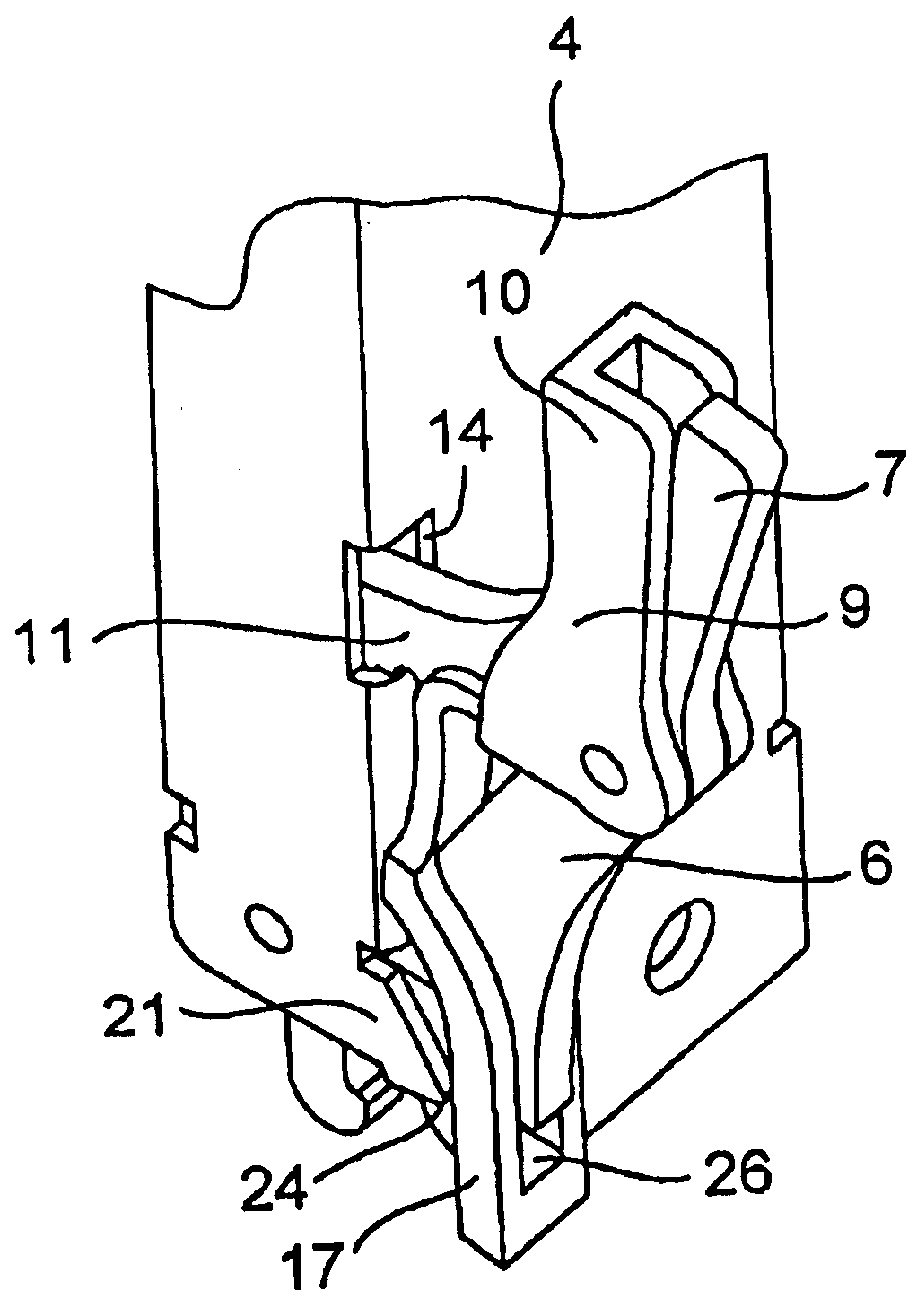

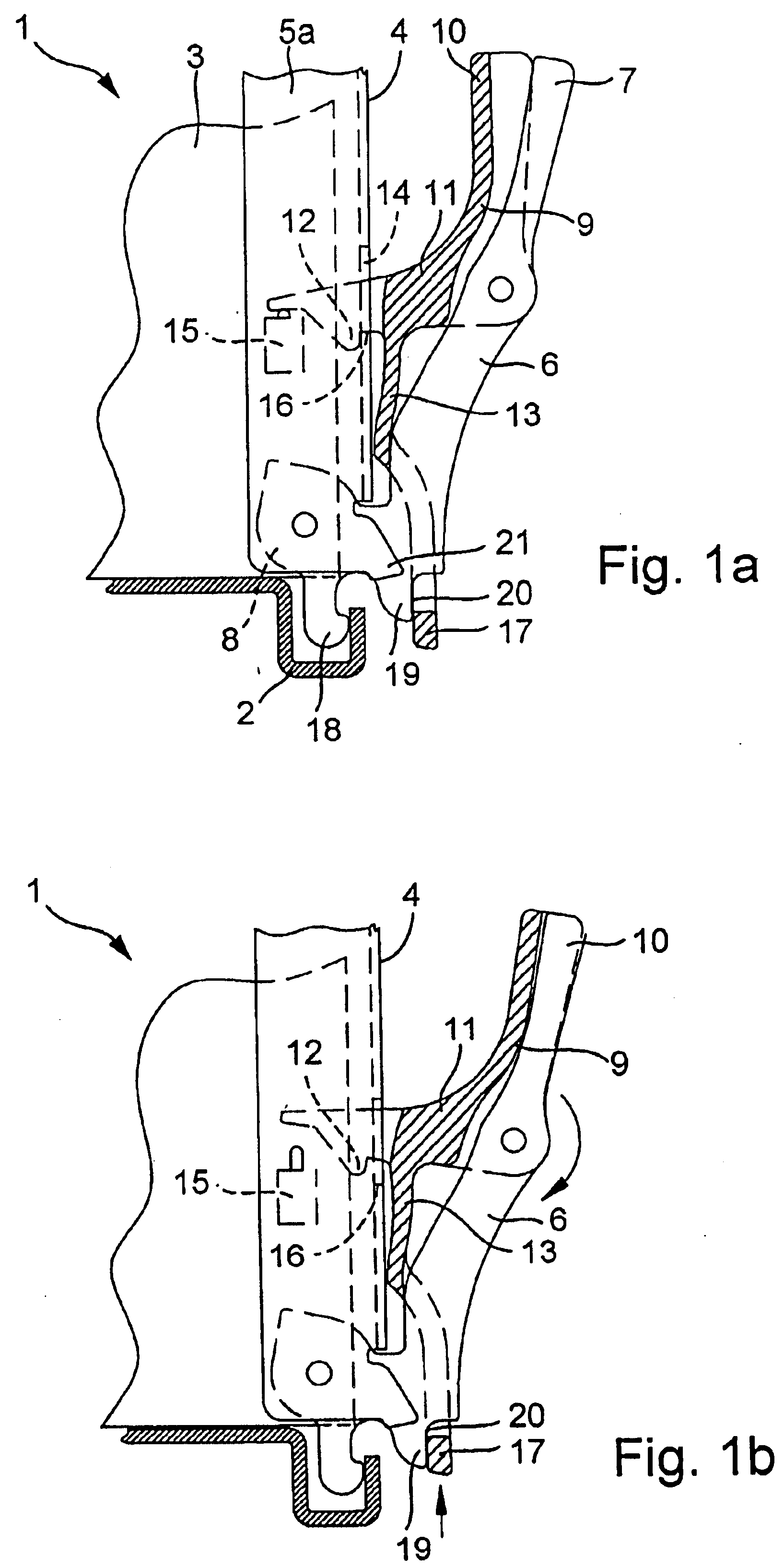

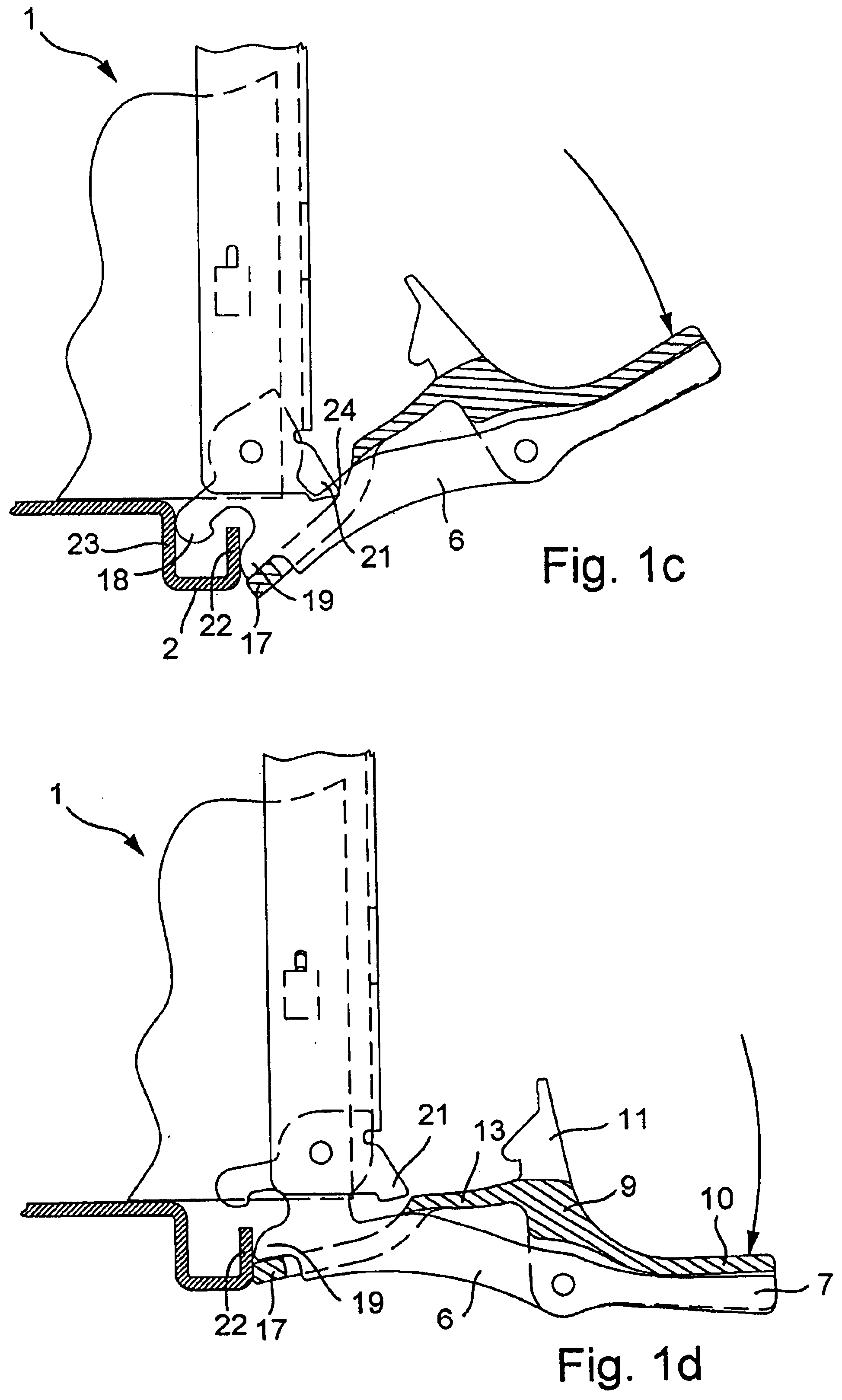

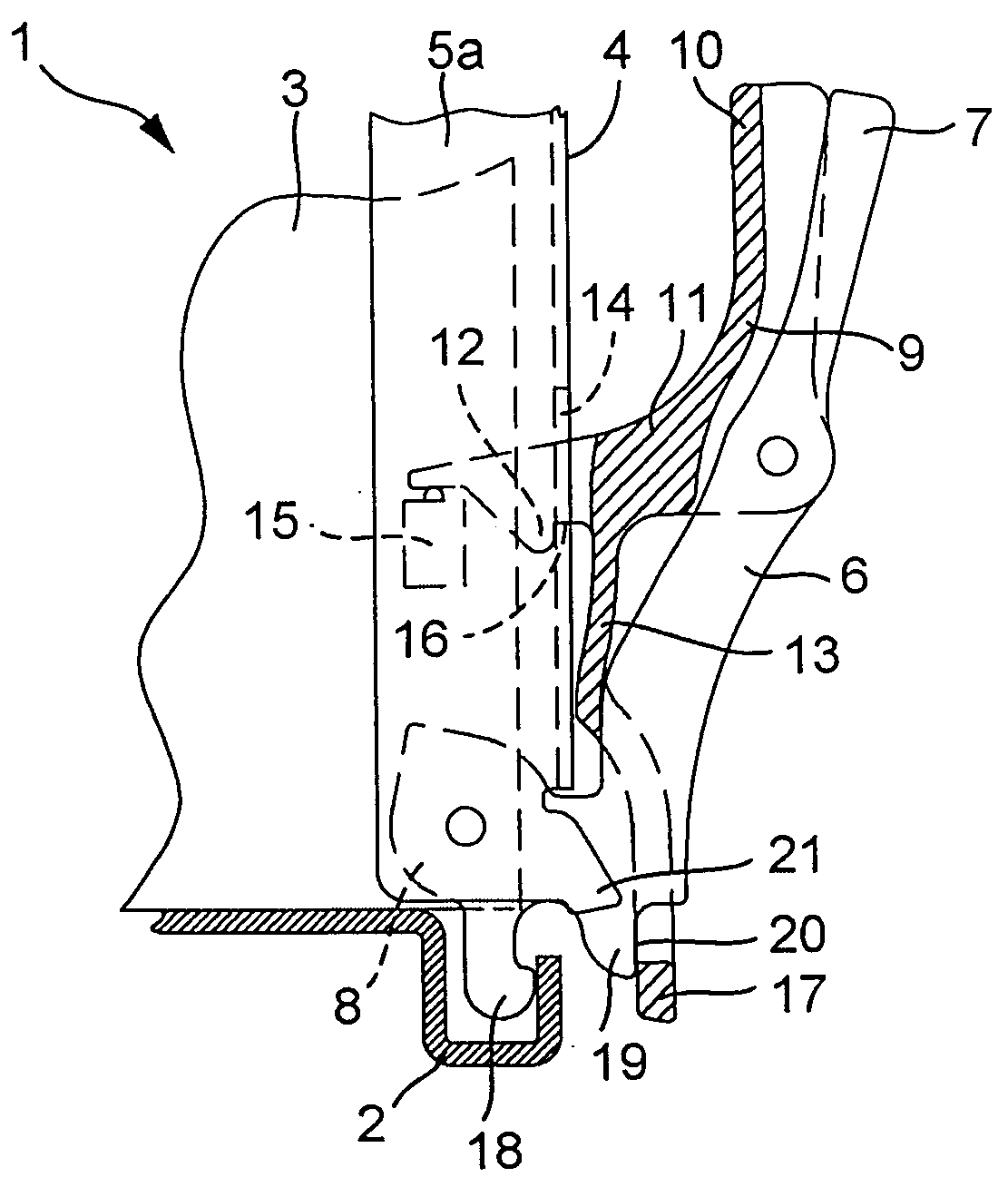

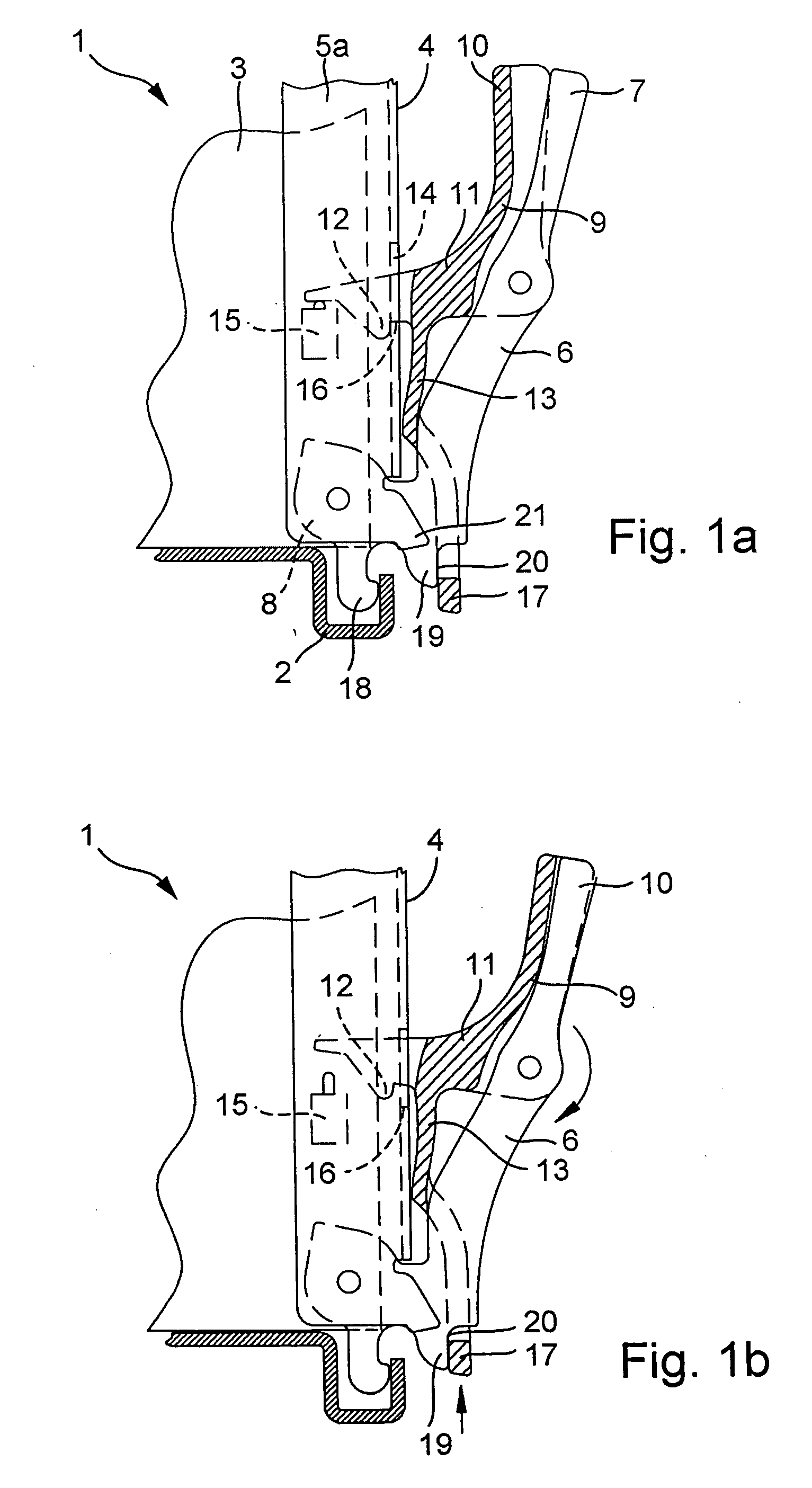

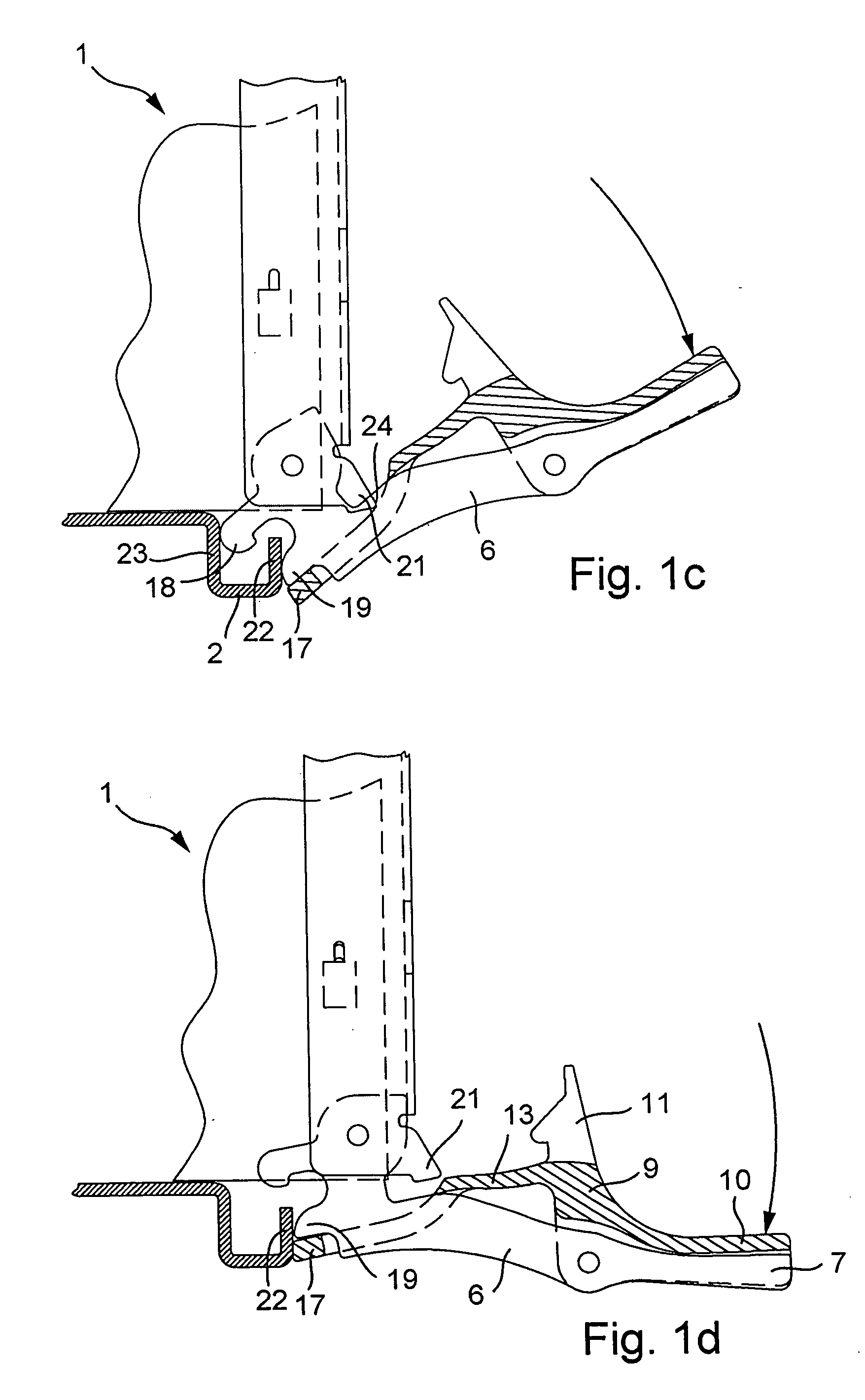

Plug-in module for plugging in and/or pulling out of a module rack

InactiveUS6916190B2Simple mechanical meanEasily and without problemEngagement/disengagement of coupling partsClamping/extracting meansFrontal regionsEngineering

A plug-in module to be plugged in and / or pulled out of a module rack provided with at least one front stop edge, comprising a lever pull with handle arm and lever arm which is positioned pivoting in the frontal region of the plug-in module. A locking lever is attached articulated and such that it can rotate to the handle arm of lever pull. The locking lever turns an elastic locking tab. A corresponding locking profile is arranged in the frontal region of the plug-in module, wherein the locking tab engages behind the locking profile if the lever pull is pivoted out completely and thus prevents the lever pull from pivoting.

Owner:SCHROFF GMBH

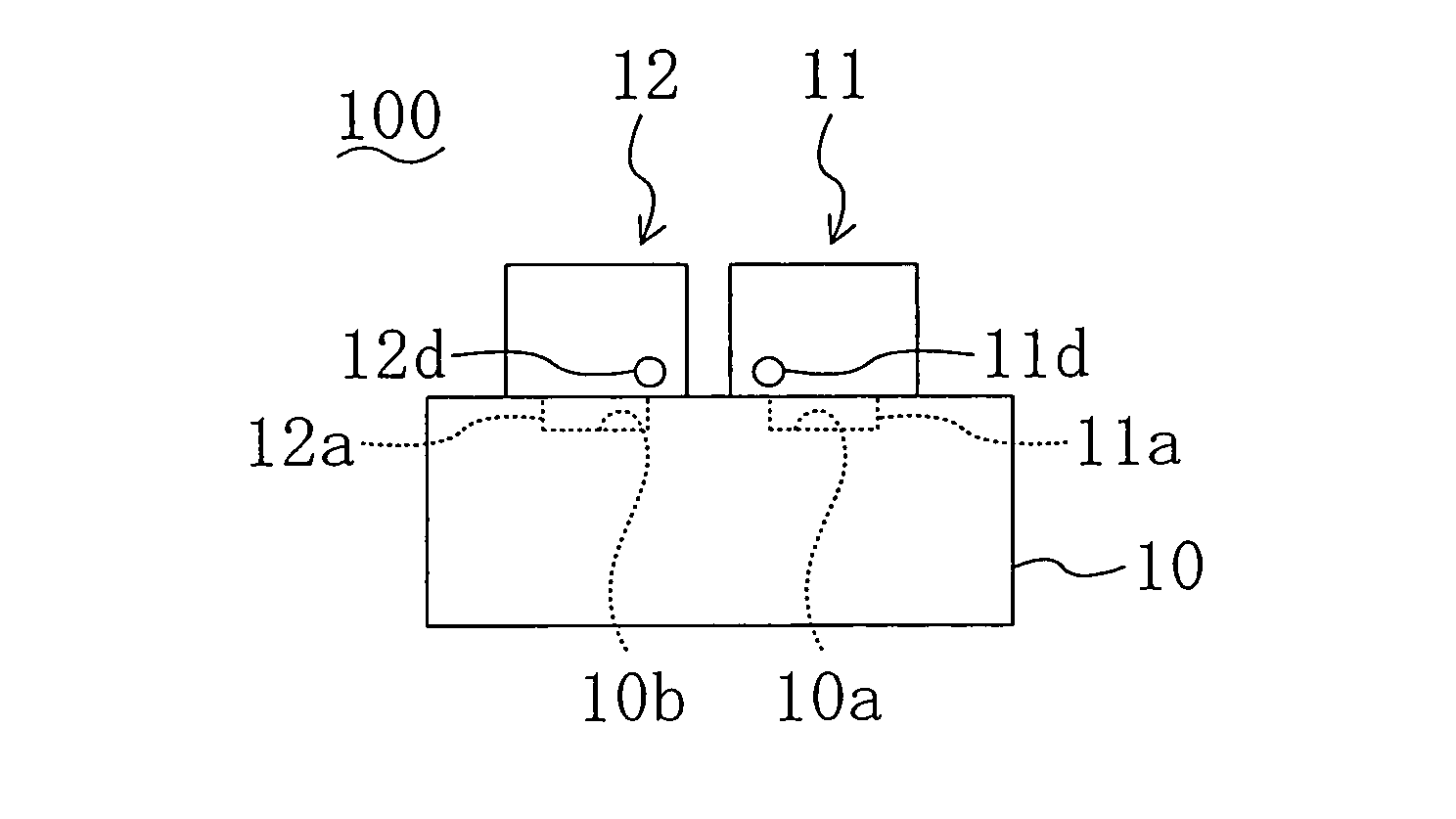

Semiconductor device fabrication method

InactiveUS7045446B2Easily and reliably mounted onto substrateEasy to placeLaser detailsLight-sensitive devicesEngineeringSelf-assembly

Owner:PANASONIC CORP

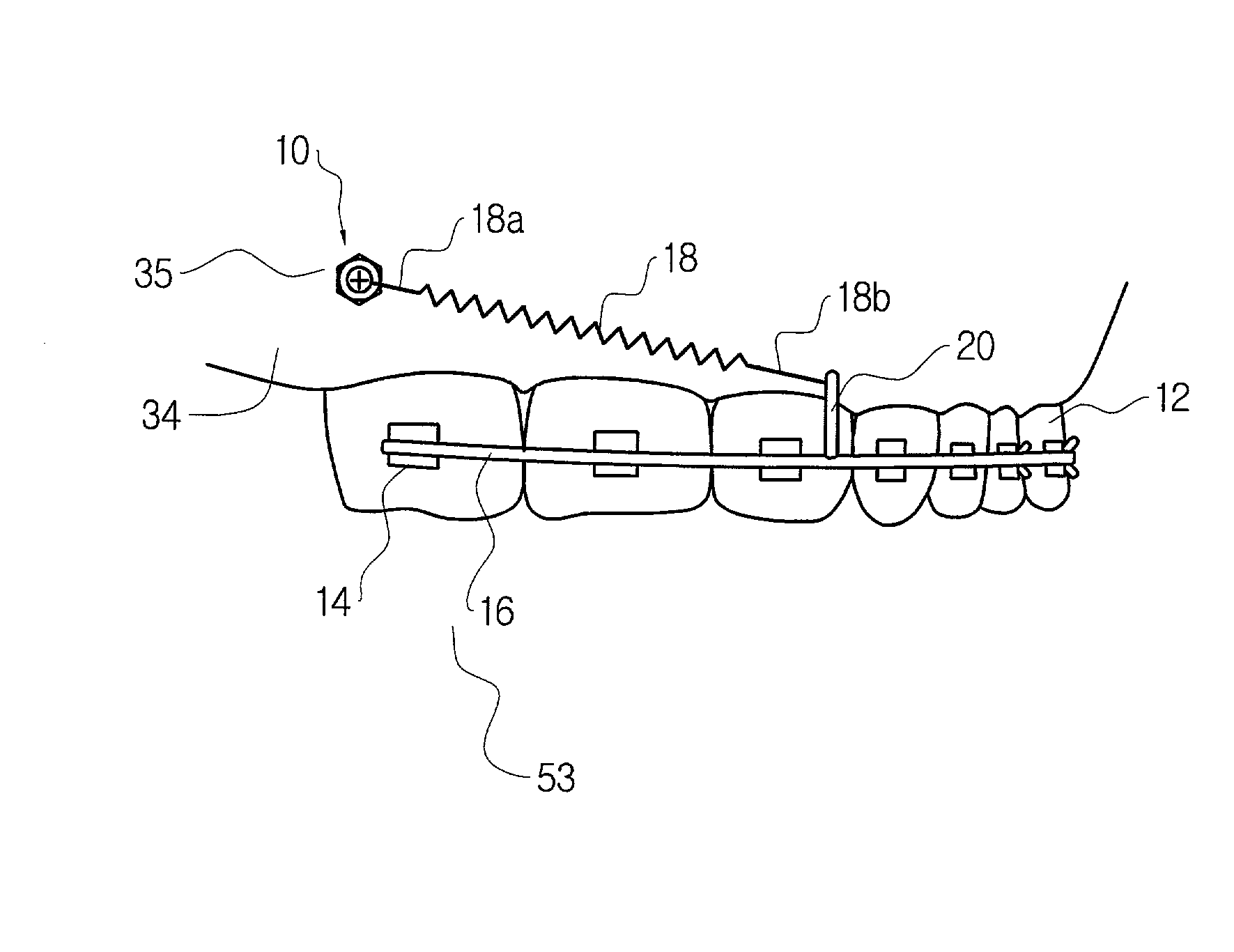

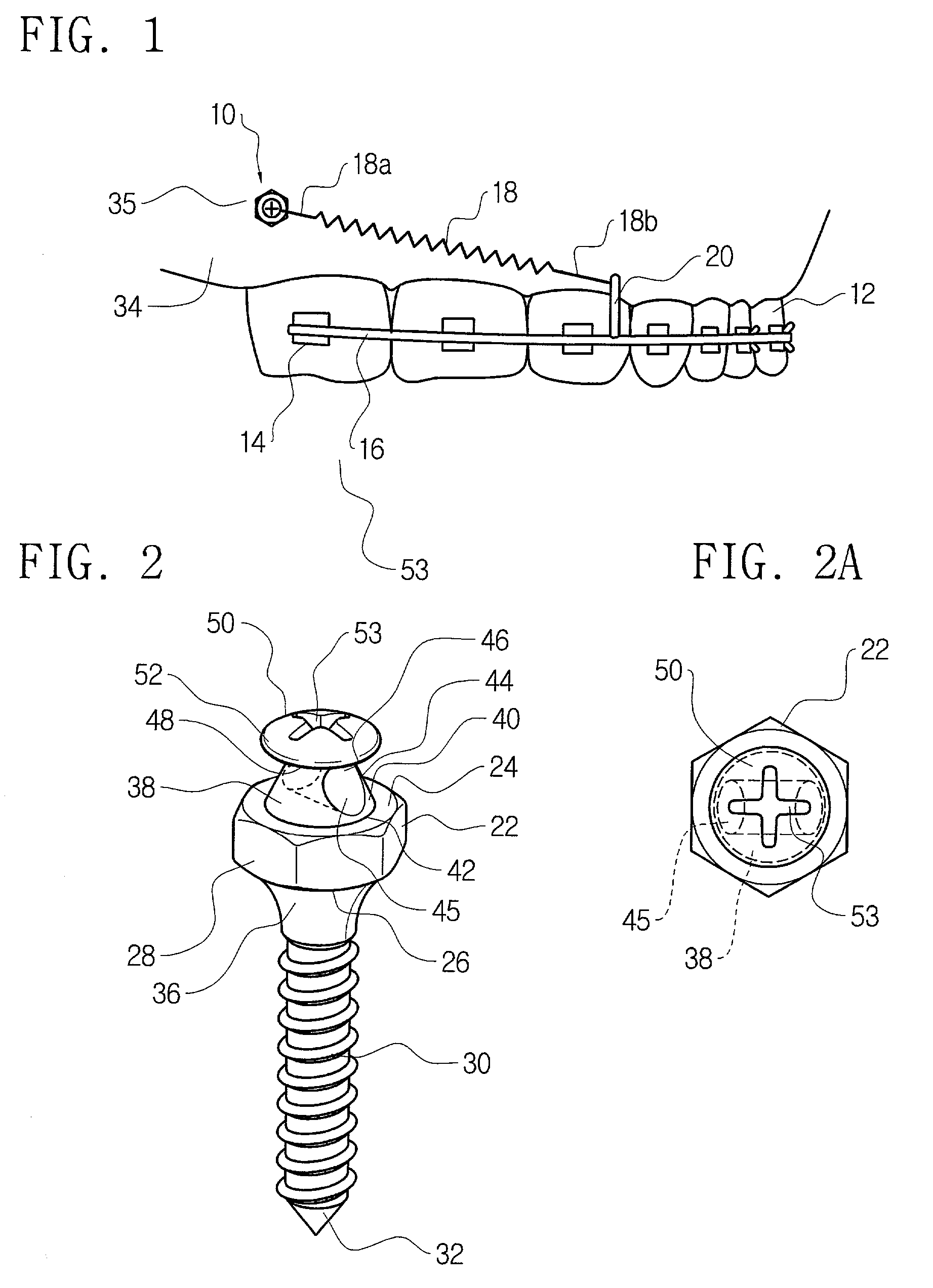

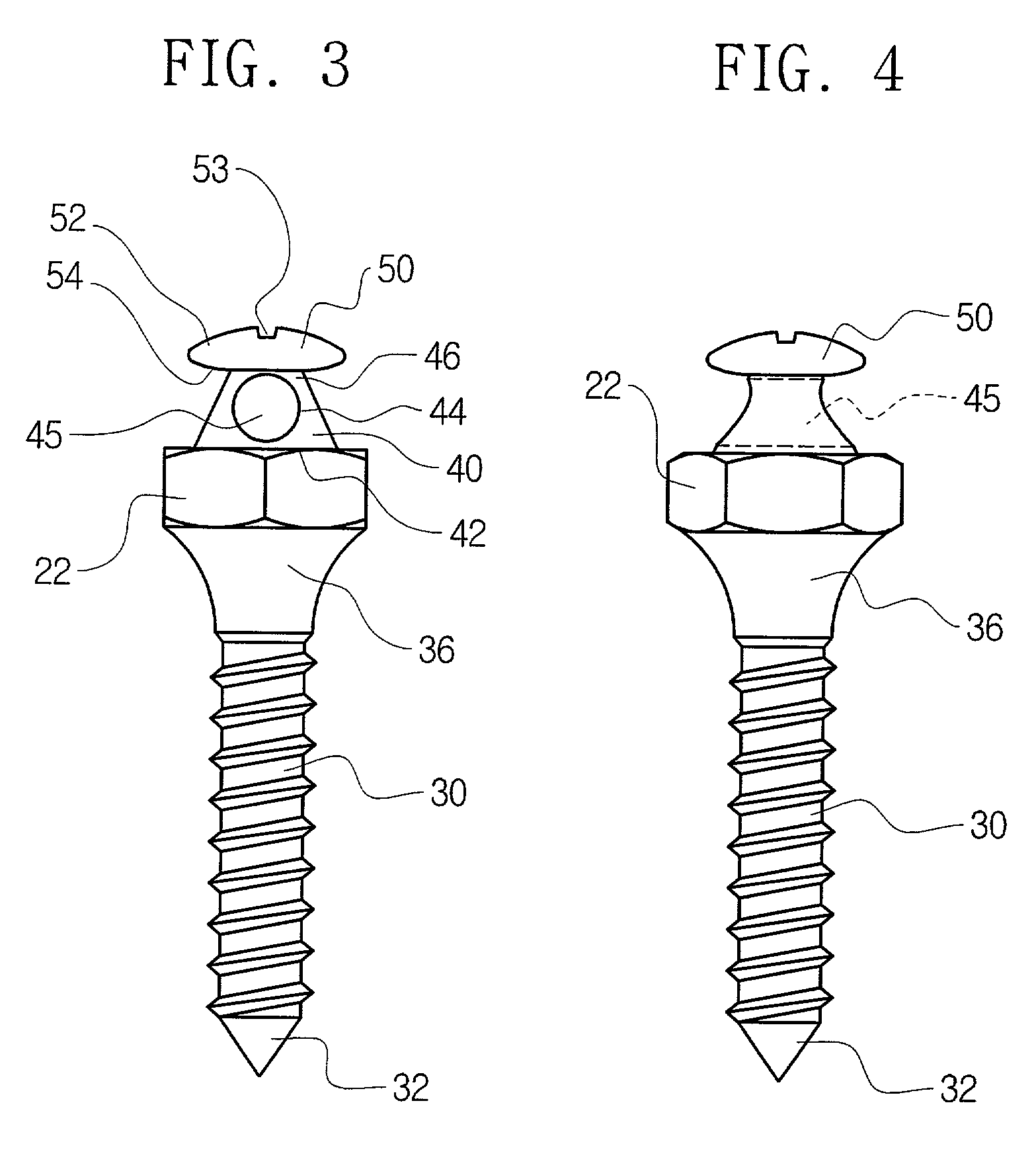

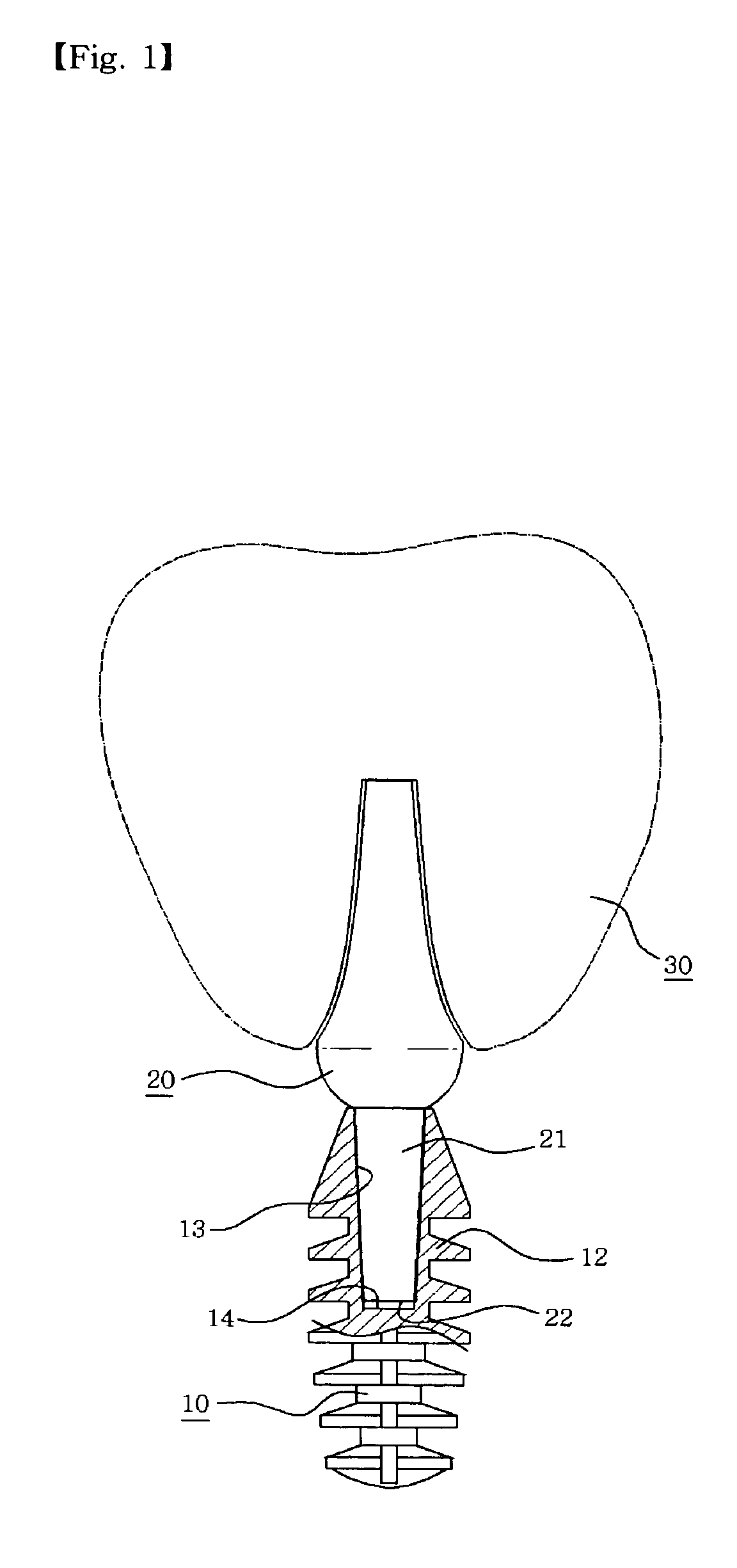

Osteogenic support device for orthodontic treatment

InactiveUS20020127510A1Minimize contactImprove efficiencyDental implantsBracketsOrthodontic wireLower upper

An osteogenic support device for an orthodontic treatment comprises a platform, lower and upper projections extending downwardly and upwardly from the platform. The upper projection is substantially tapered from the platform toward a cap. The upper protection has a through opening substantially perpendicular to an axis of the lower projection. A first end of the elastic wire is hooked between the cap and the platform, and a second end of the elastic wire is hooked with an orthodontic wire which links each bracket attached on teeth of the orthodontic patient.

Owner:KYUNG HEE MOON +2

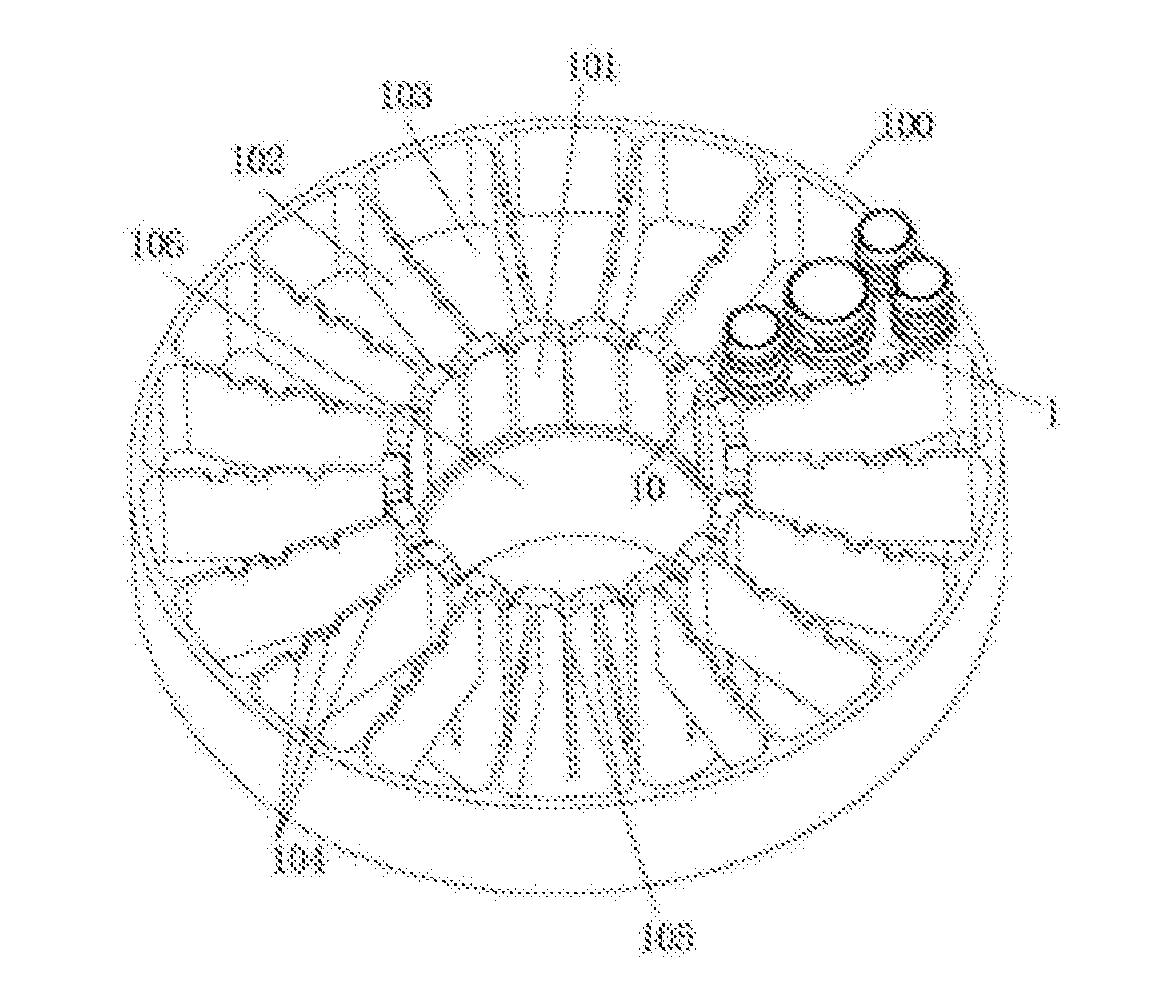

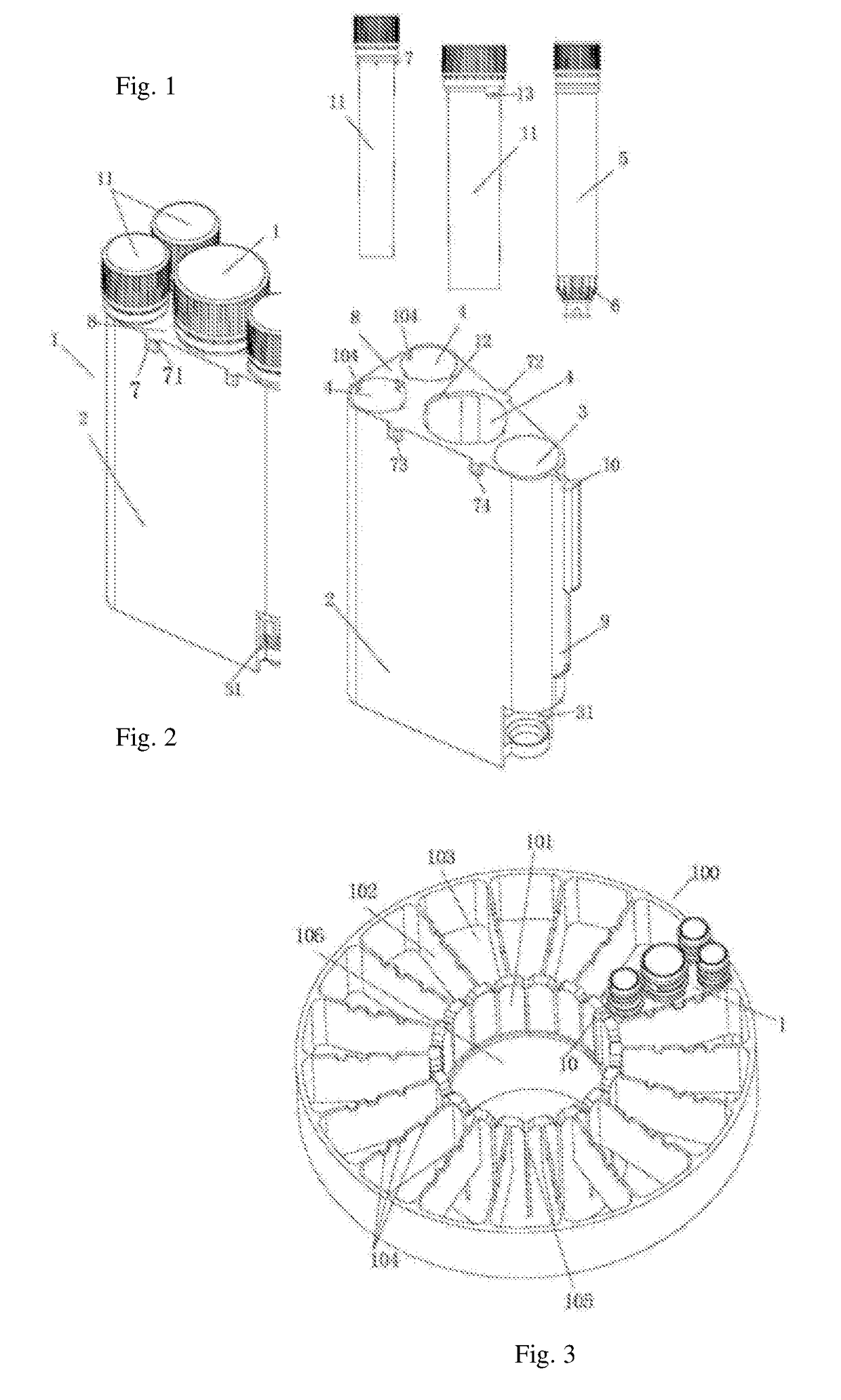

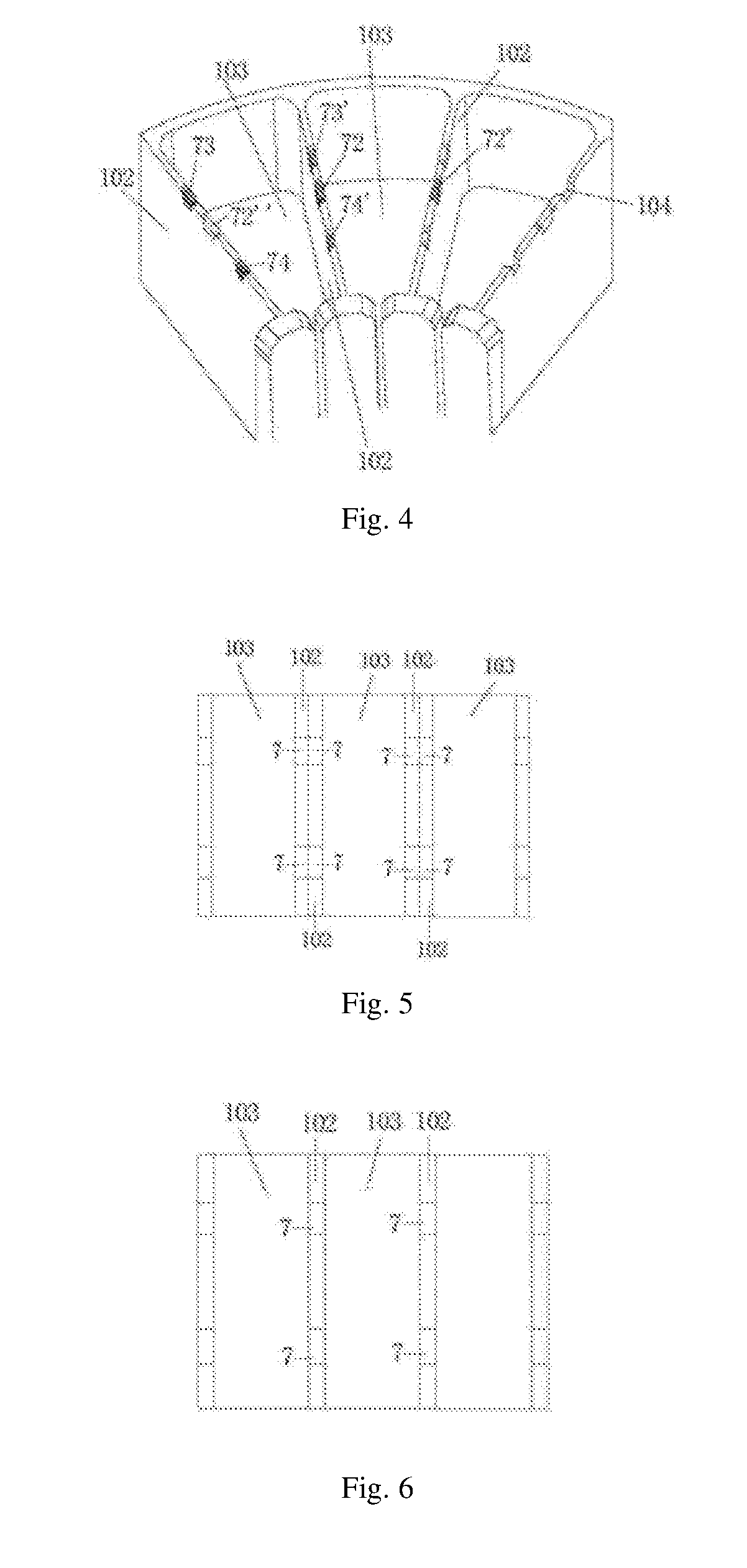

Reagent mixing and conveying device and reagent mixing method

ActiveUS20180252707A1Small sizeSmart structureRotating receptacle mixersTransportation and packagingMechanical engineeringChemiluminescence immunoassay

The present invention provides a reagent mixing device, which comprises a driving device, a transport device and a rotating part, wherein the transport device comprises a conveying mechanism for conveying a reagent kit and a mixing mechanism for mixing a reagent; the conveying mechanism is driven by the driving device to move relative to the mixing mechanism; the rotating part and mixing mechanism are in transmission matching; the conveying mechanism and the mixing mechanism are sleeved with each other to form a bearing structure. The present invention further provides a reagent mixing method. The reagent mixing device is small in size, smart in structure, easy to assemble and low in manufacturing cost. The reagent mixing method provided by the present invention is simple and reliable, high in overall operation reliability, and has very high application values in such analysis and test fields as full-automatic chemiluminescence immunoassay analyzers and biochemical analyzers.

Owner:LEADWAY HK

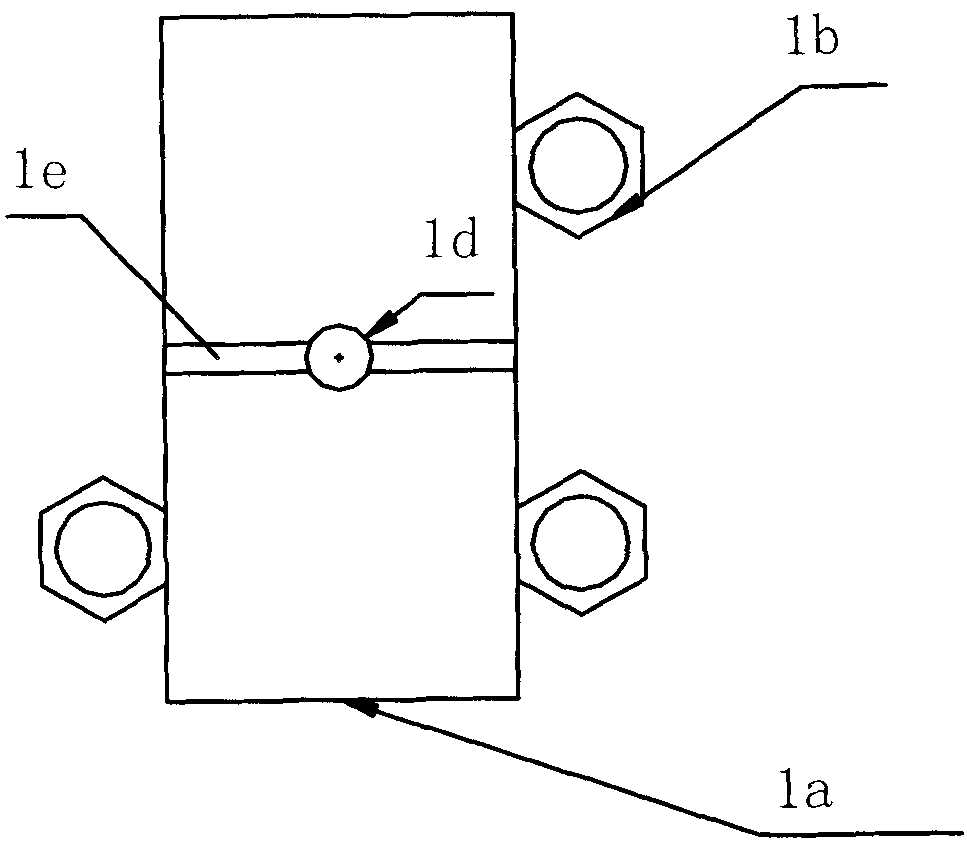

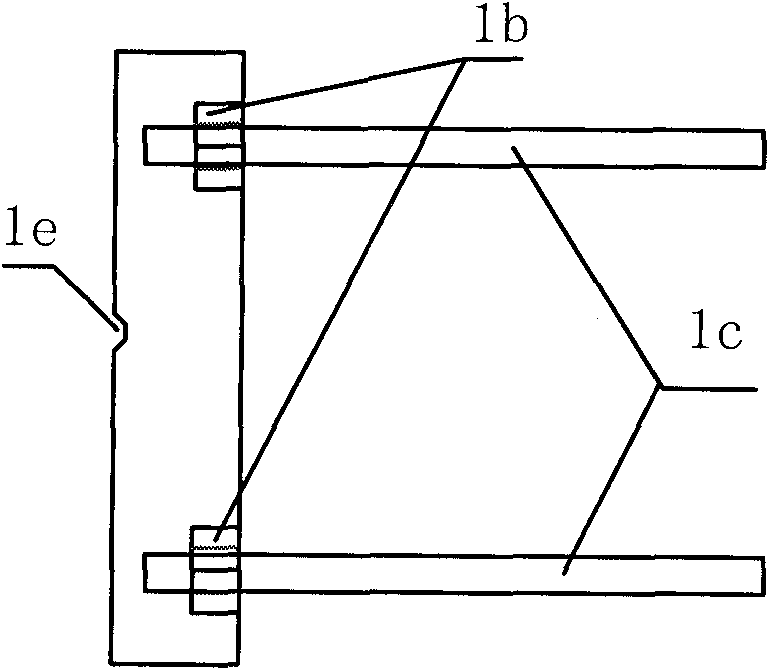

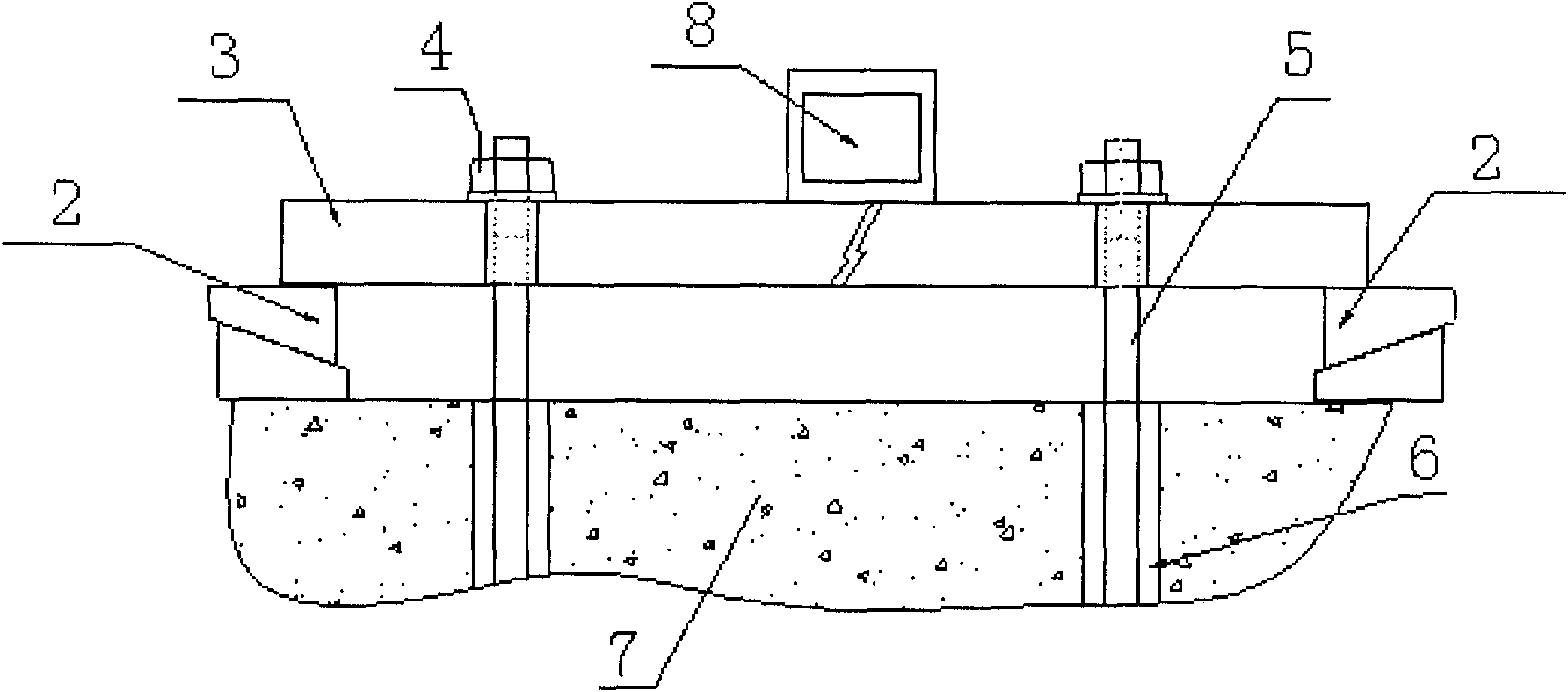

Mounting construction method of liner plates during mounting large-scale precision equipment

ActiveCN101831917AGuaranteed levelnessIncrease contactFoundation engineeringSpot weldingUltimate tensile strength

The invention provides a mounting construction method of liner plates during mounting large-scale precision equipment, which comprises the following steps of: (1) processing an equipment base; (2) setting temporary liner plates, arranging hoisting equipment, mounting the equipment base on the temporary liner plates, adjusting the coordinate position, the height and the levelness of the equipment; (3) mounting liner plates: necessarily arranging liner plates at both sides of an anchor bolt of the equipment, supporting the liner plates on the bolt which is directly supported on the equipment base, adjusting the liner plates to support the bolt so that the horizontal plate and the equipment base are stably and firmly attached and monitoring the central line, the elevation and the levelness of the equipment in a liner plate mounting process; (4) primarily grouting: making an anchor bolt die on the periphery of the anchor bolt of the equipment, grouting and fastening the anchor bolt of the equipment after grouting reaches the strength requirement; and (5) secondarily grouting: spot-welding the anchor bolt and a screw cap of the equipment when the strength of primarily grouted concrete reaches over 75 percent, dismounting the temporary liner plates, making an equipment base die below the equipment base and grouting integrally.

Owner:武汉武钢绿色城市技术发展有限公司

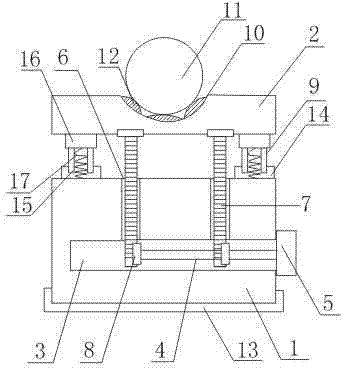

Shock-resistant petroleum pipeline fixing base

InactiveCN104728525AHeight adjustablePlay a shock absorbing rolePipe supportsNon-rotating vibration suppressionPetroleumPetroleum engineering

The invention discloses a shock-resistant petroleum pipeline fixing base. The shock-resistant petroleum pipeline fixing base comprises a base body and a supporting seat which is located above the base body. A groove is formed in the side wall of the base body. The shock-resistant petroleum pipeline fixing base further comprises an adjusting screw rod arranged in the groove, at least three holes are formed in the upper surface of the base body, and the lower ends of the holes are communicated with the groove. The shock-resistant petroleum pipeline fixing base further comprises racks fixed at the bottom of the supporting seat. The shock-resistant petroleum pipeline fixing base further comprises gears which are sequentially fixed on the adjusting screw rod, and the gears are meshed with rack bodies on the racks. The shock-resistant petroleum pipeline fixing base further comprises elastic devices arranged on the two sides of the upper surface of the base body, one ends of the elastic devices are connected with the upper surface of the base body, and the other ends of the elastic devices are connected with the lower surface of the supporting seat. A semicircular groove is formed in the upper surface of the supporting seat. The shock-resistant petroleum pipeline fixing base further comprises a petroleum pipeline arranged in the semicircular groove. According to the shock-resistant petroleum pipeline fixing base, due to the arrangement of the racks and the adjusting screw rod, the height of the base body can be adjusted; the elastic devices with one ends connected with the upper surface of the base body and the other ends connected with the lower surface of the supporting seat achieve a certain damping effect on the base body.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

Iron barrel paint spraying device for environmental protection machinery

The invention discloses an iron barrel paint spraying device for environmental protection machinery. The iron barrel paint spraying device comprises a base, a rotating motor, a mounting plate, an adjusting device and paint spraying devices. The rotating motor is arranged on the lower end face of a transverse plate, and the end of an output shaft of the rotating motor is fixedly arranged at the upper end of the mounting plate. The adjusting device comprises a double-shaft motor and two screw rods, sliding blocks are arranged on the screw rods, electronic telescopic rods are arranged at the lower ends of the sliding blocks, and the two paint spraying devices are symmetrically arranged on two sides of the mounting plate. Each paint spraying device comprises a paint barrel, a pump body and a paint spraying head, wherein the paint spraying head is hinged to the lower end of the corresponding electronic telescopic rod, and an inlet and an outlet of the pump body are connected with the paintbarrel and the paint spraying head separately. According to the diameter of an iron barrel, the positions of the paint spraying devices can be adjusted from two sides, the directions of the spraying heads can be adjusted, and thus paint spraying can be conveniently carried out on the outer wall and the inner wall of a barrel body; in combination with the rotating motor and the telescopic rods, therequirement for different-depth paint spraying on the interior and exterior of the barrel body can be met; and rotatable paint spraying is adopted, so that uniformity and practicality are higher.

Owner:彭翠芳

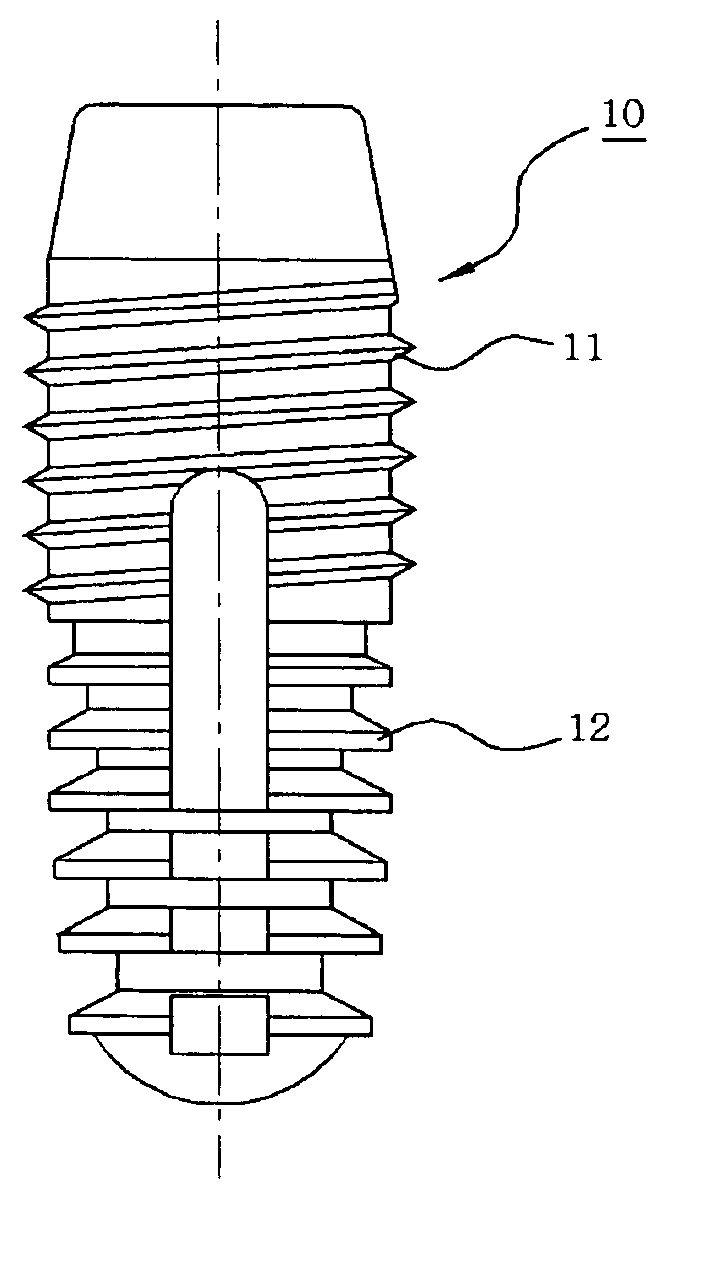

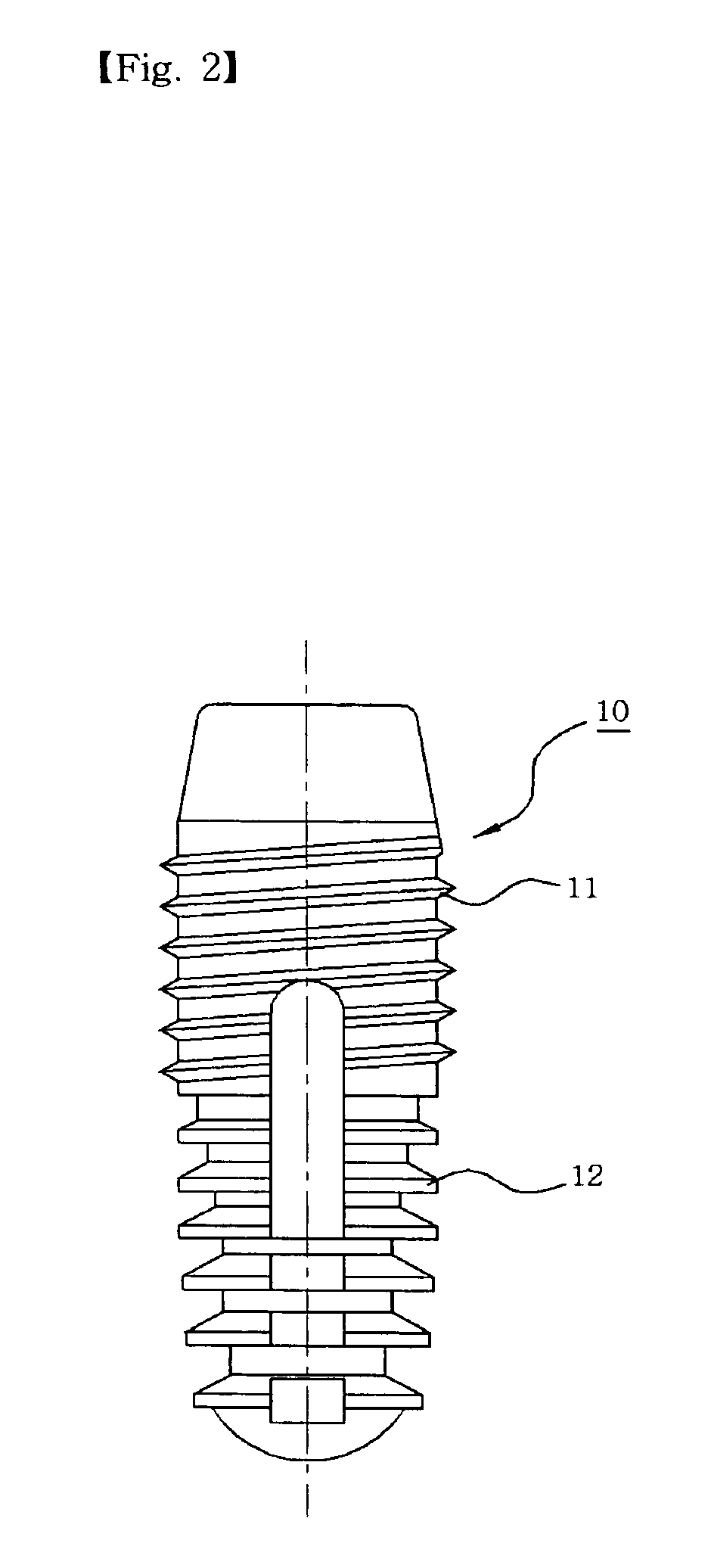

Dental implant fixture

InactiveUS20050147943A1Eliminate the problemEasy to engageDental implantsBridge structural detailsSurgical operationAir compression

The present invention relates to dental implant fixture capable of achieving an easier engagement and disengagement operations using a screw by forming a threaded portion and a circular plate pin portion in an external cylindrical surface of an fixture and preventing a screw from being loosened by using a circular plate pin, thereby achieving a stable placement and easier implant surgical operation. The improved dental implant fixture comprises a threaded portion formed in an upper external cylindrical surface of the fixture for achieving an easier and convenient engagement and disengagement; and a plurality of circular plate pins provided in a lower external cylindrical surface for enhancing a stability when an alveolar bone is grown, wherein the hole has a deeper space at a bottom end for preventing an air compression problem when the post portion of the abutment is assembled.

Owner:NORTHERN ENG IND PLC +1

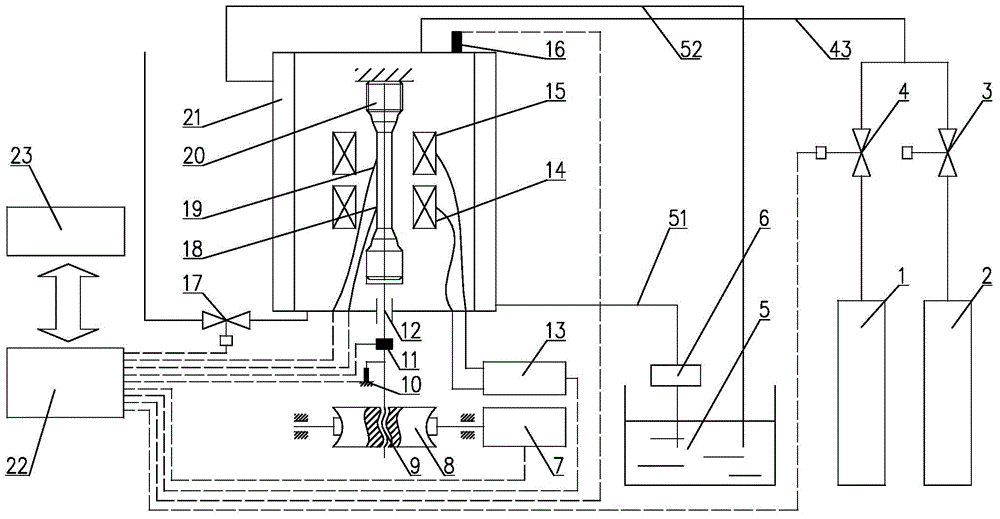

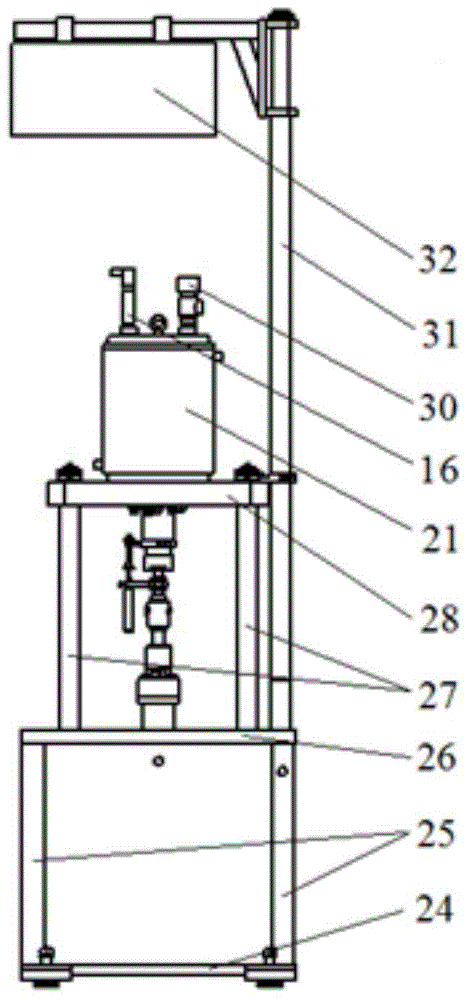

Device for testing material properties in high-temperature hydrogen environment

ActiveCN104897476AReasonable and reliable device structureShort heat transfer chainWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesProcess engineeringHydrogen supply

The invention relates to a device for testing material properties in a high-temperature hydrogen environment. The device comprises a hydrogen environment box and a host machine loading framework, wherein a test sample is arranged in the hydrogen environment box; a pull rod is mounted on the host machine loading framework; the hydrogen environment box is arranged on the host machine loading framework; an upper clamping part, a lower clamping part and an electrical heating component are arranged in the hydrogen environment box; the pull rod penetrates through the hydrogen environment box and is fixedly connected with the lower clamping part; the hydrogen environment box is connected with a hydrogen supply pipe; an air-relief solenoid valve is arranged on the hydrogen environment box. The device further comprises sensors and a control component, wherein the sensors are used for monitoring test sample stress load, test sample deformation, test sample environment temperature and test sample ambient hydrogen pressure; the control component is used for monitoring and processing the information collected by the sensors. The device can be used for testing the creep property, stress rupture property and tension-tension alternating load fatigue property of a metal material in the hydrogen environment, can ensure the accuracy of testing results, works reliably and stably and has high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST +1

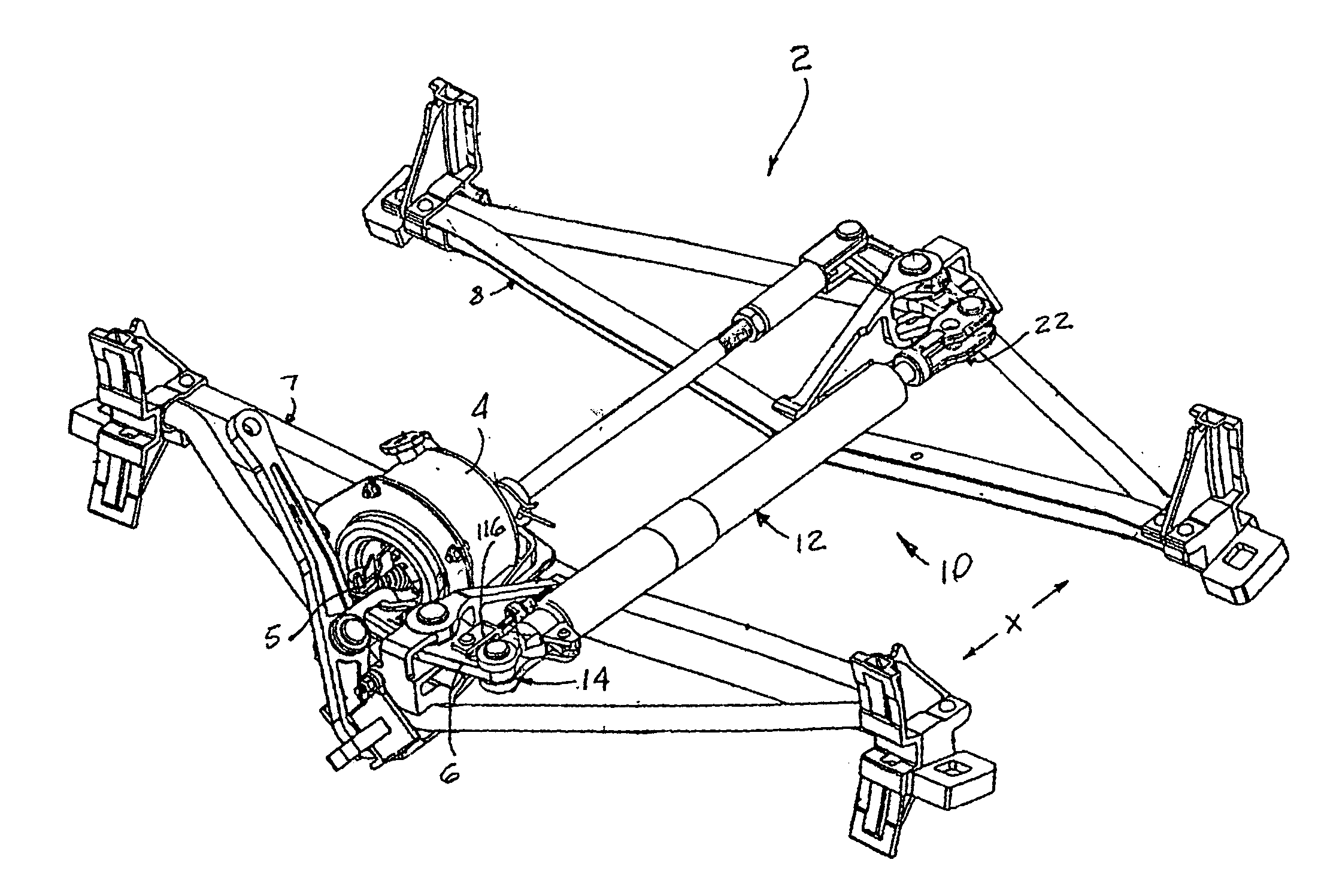

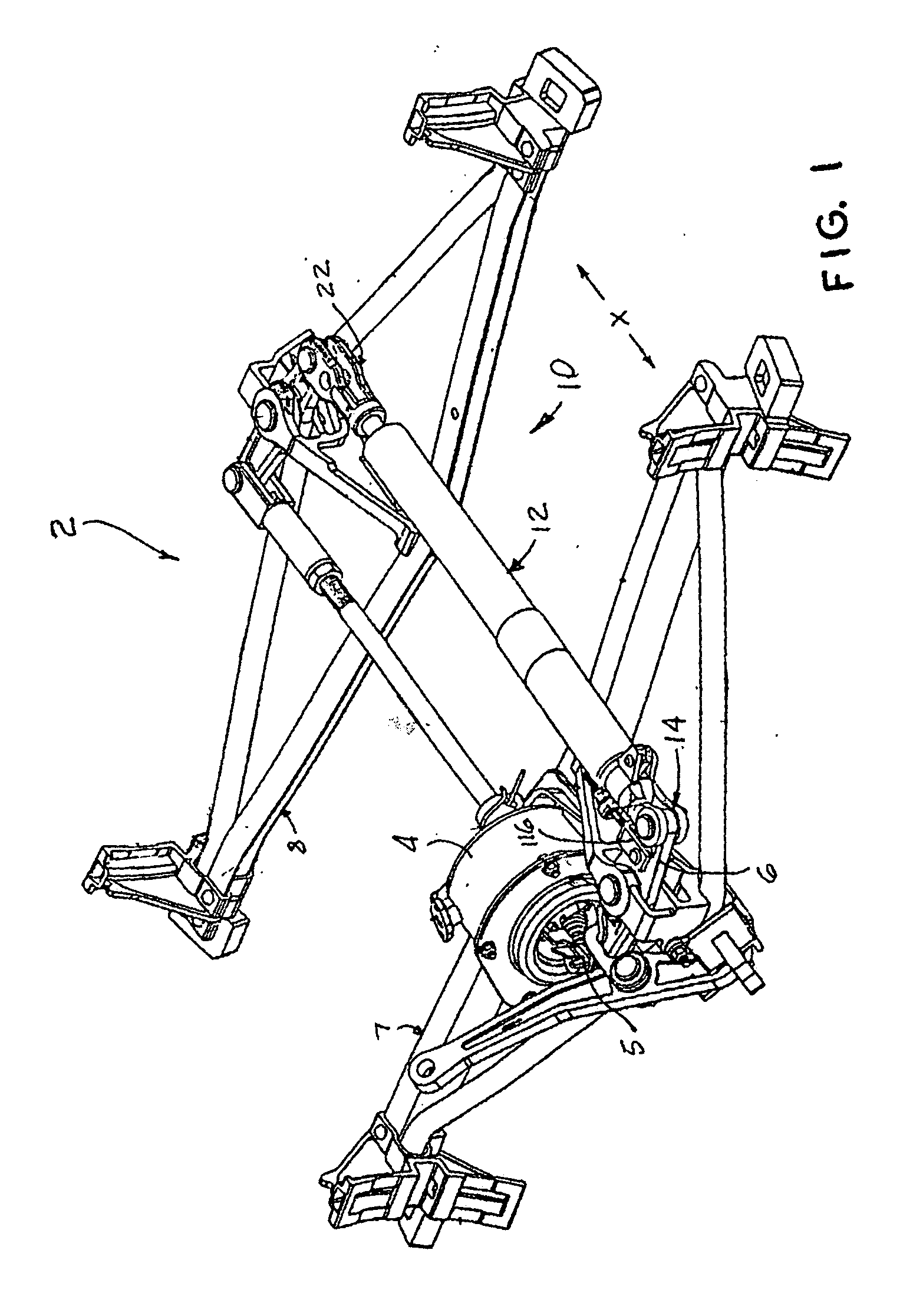

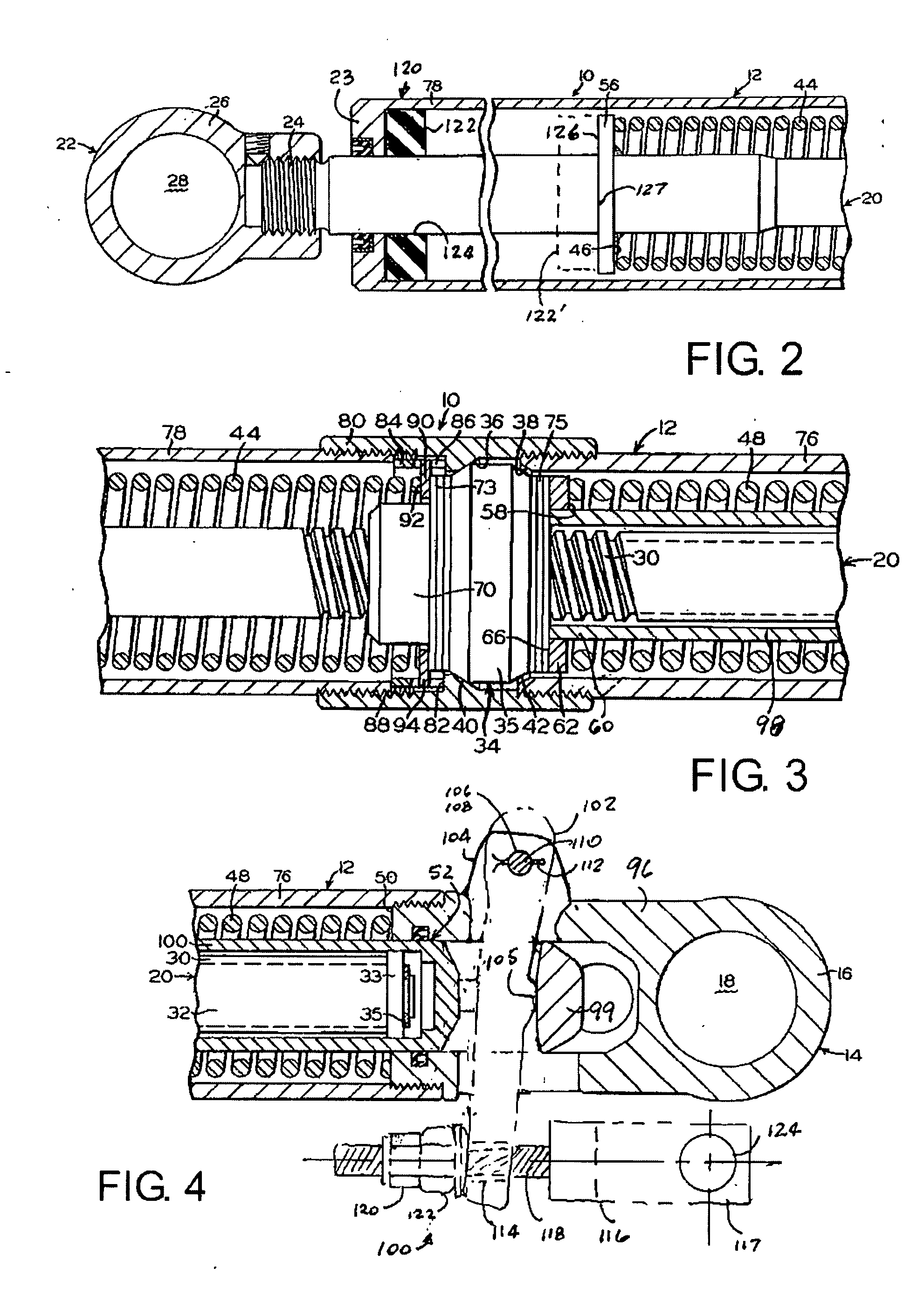

Slack adjuster for railway vehicle brake rigging

ActiveUS20090065312A1Slow changeAvoid interferenceBrake wear compensation mechanismRail brake actuationEngineeringMechanical engineering

The present invention teaches a double-acting compression actuatable slack adjuster to adjust the slack in the brake rigging of a railway vehicle which includes a pair of elongated members movable with respect to each other in a longitudinal direction. A positioning device carrying a pair of opposed abutting surfaces is threadedly engaged with a threaded portion of the elongated rod. Pair of opposite facing abutment surfaces are positioned within the hollow housing. A first urging device is positioned to urge the positioning device into a disengaged position. A second urging device overcomes the force of the first urging device and urges an abutting surface on the positioning device into engagement with an adjacent abutment surface. A first overtravel control device is provided which is activated by a trigger device. A second overtravel control device is provided to prevent jamming condition of the positioning device with one of the abutment surfaces when the elongated rod is fully extended.

Owner:WABTEC HLDG CORP

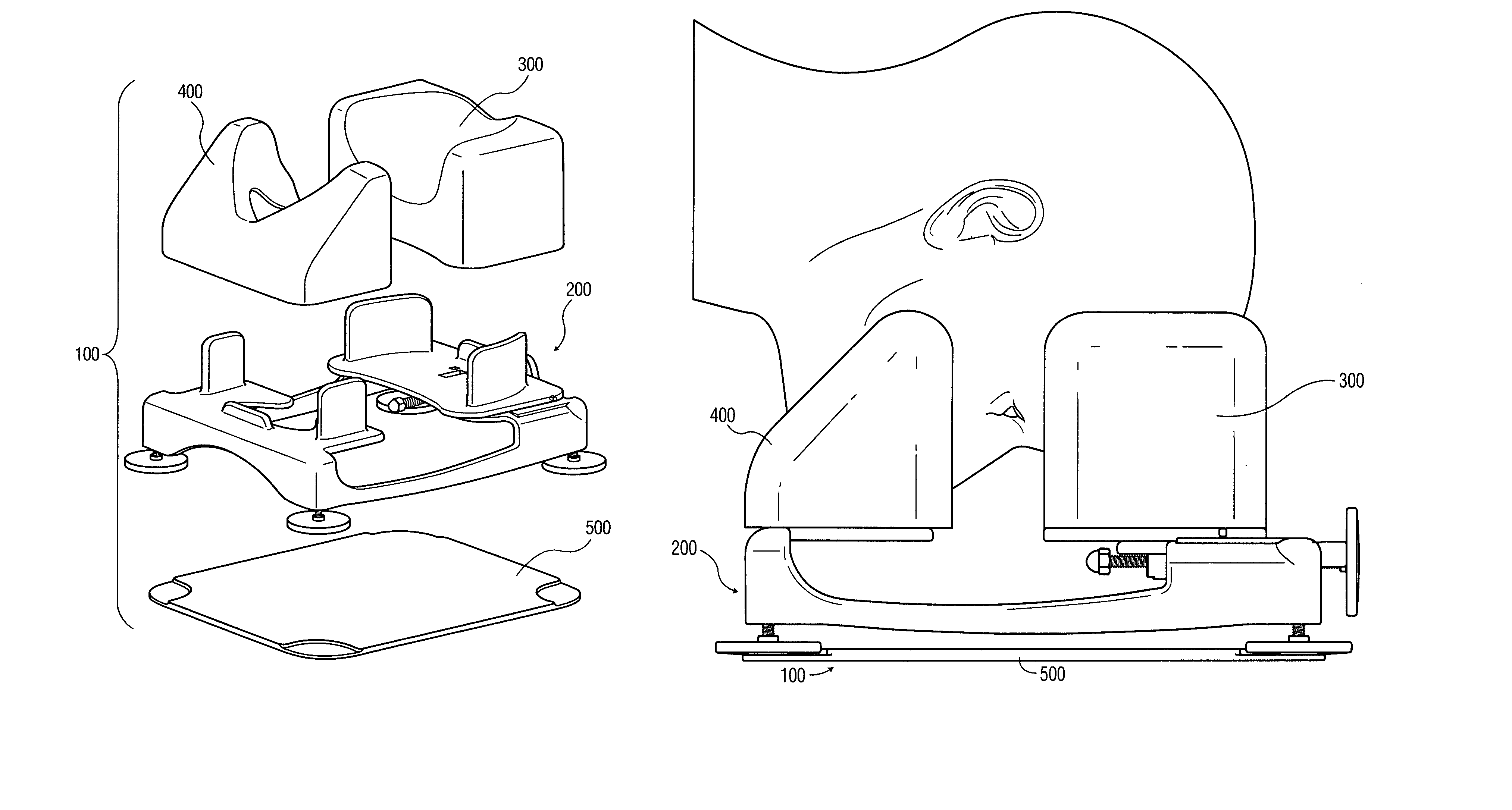

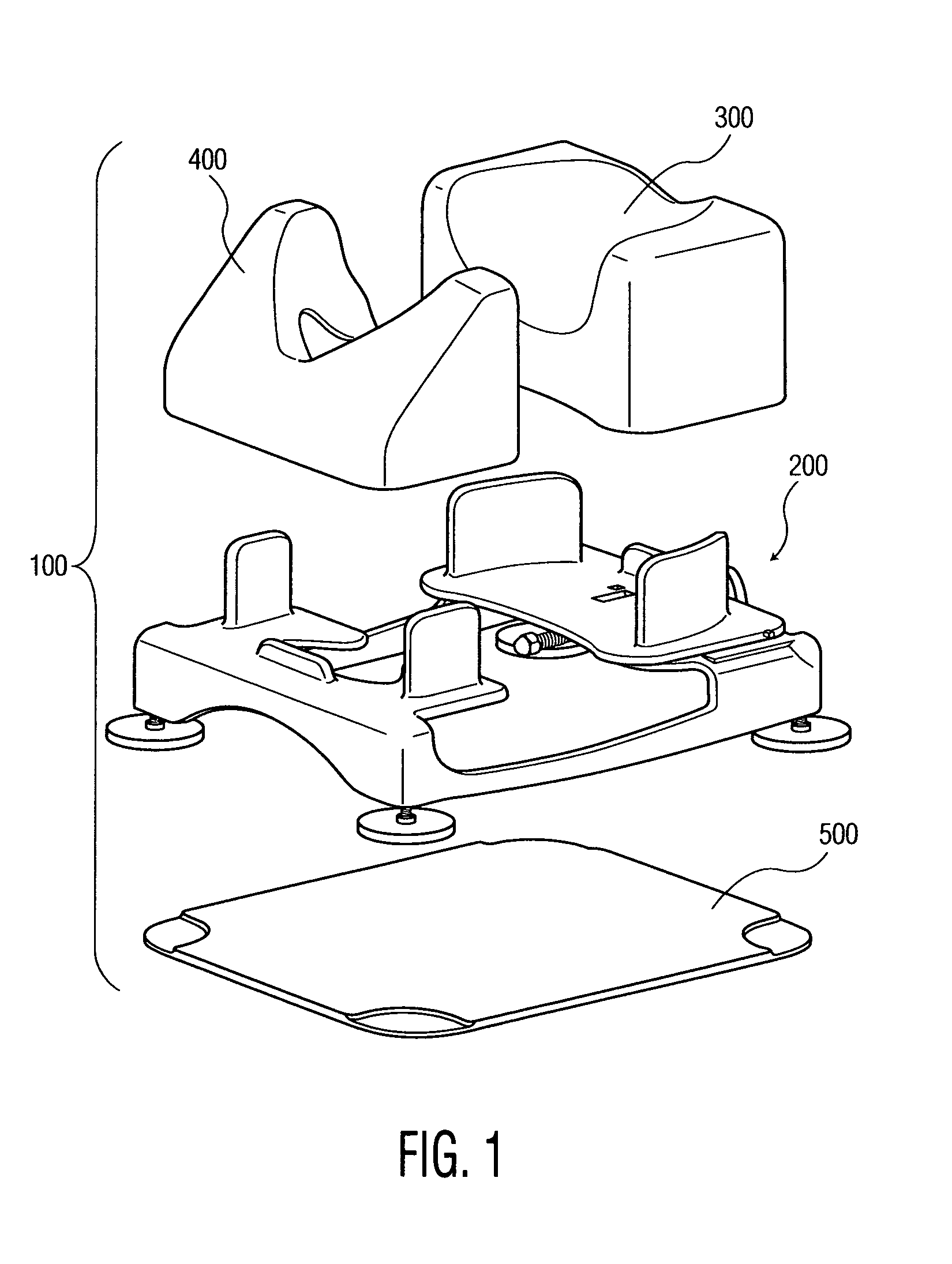

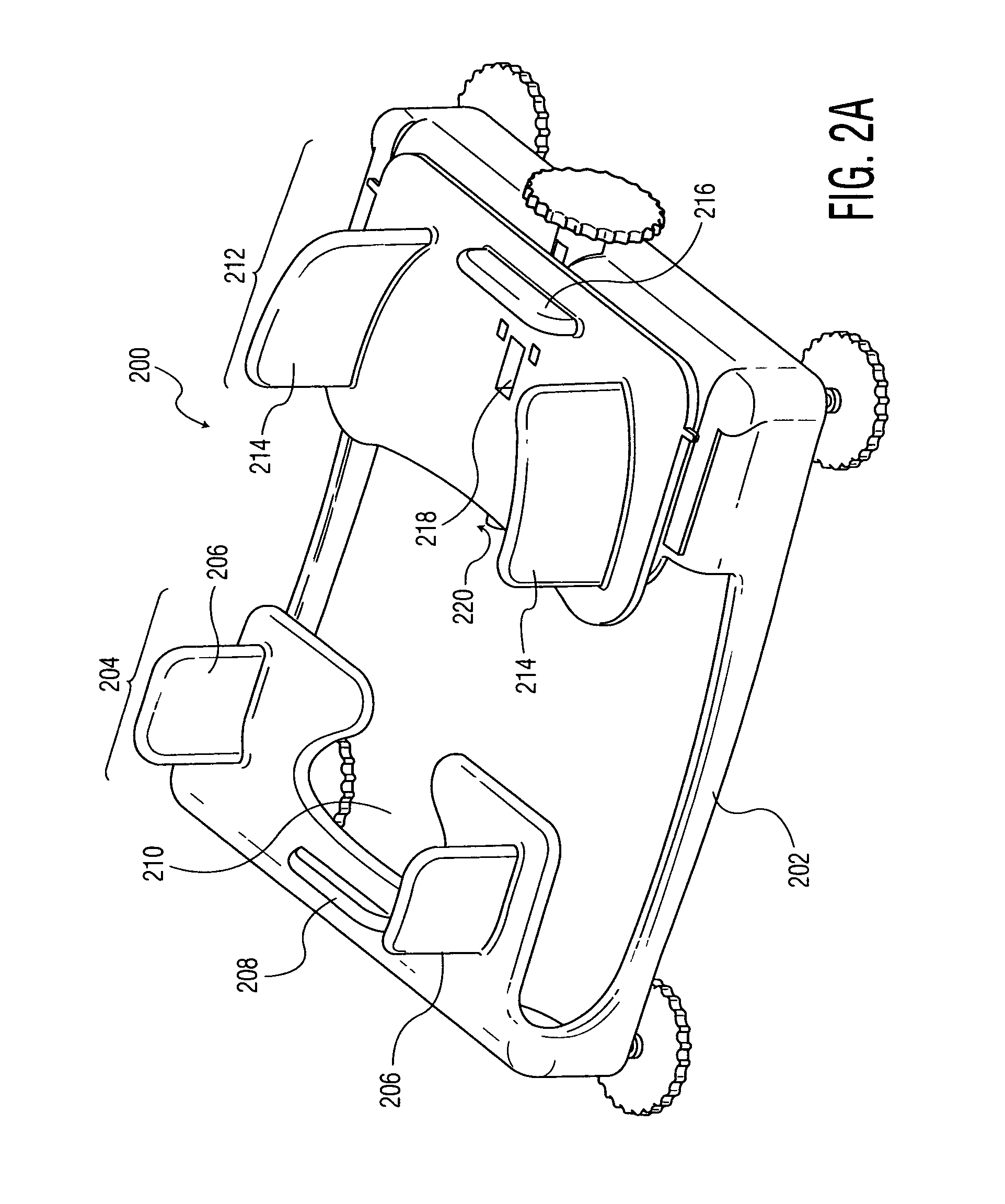

Surgical head support

ActiveUS8549683B2Limited visibilityPlace stableOperating chairsOperating tablesDuring procedureMedical device

Owner:MERCURY ENTERPRISES

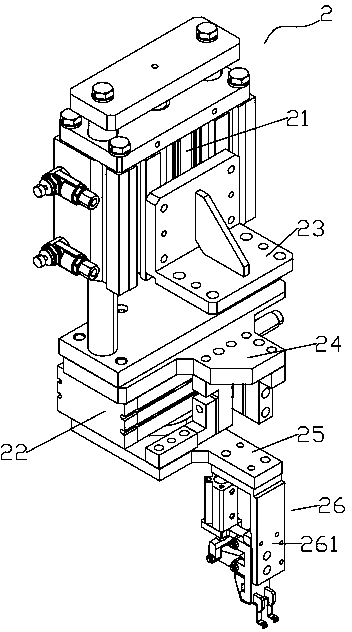

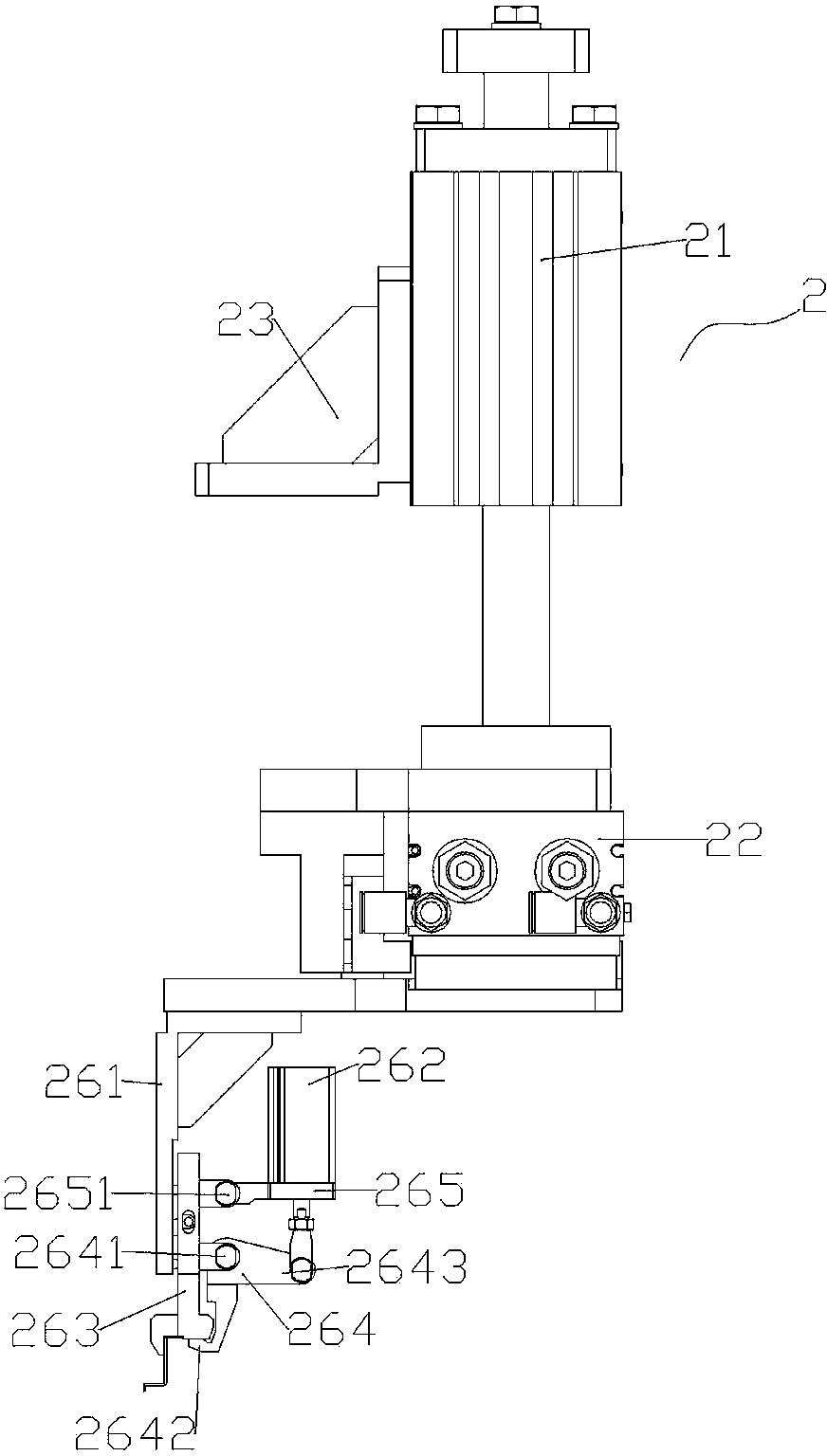

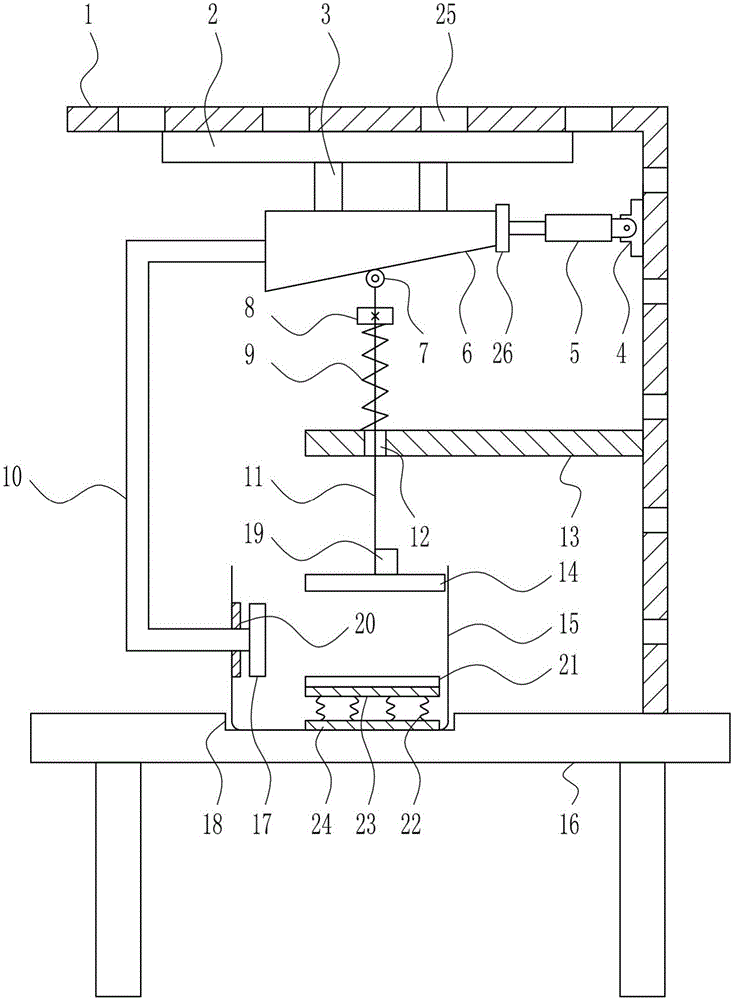

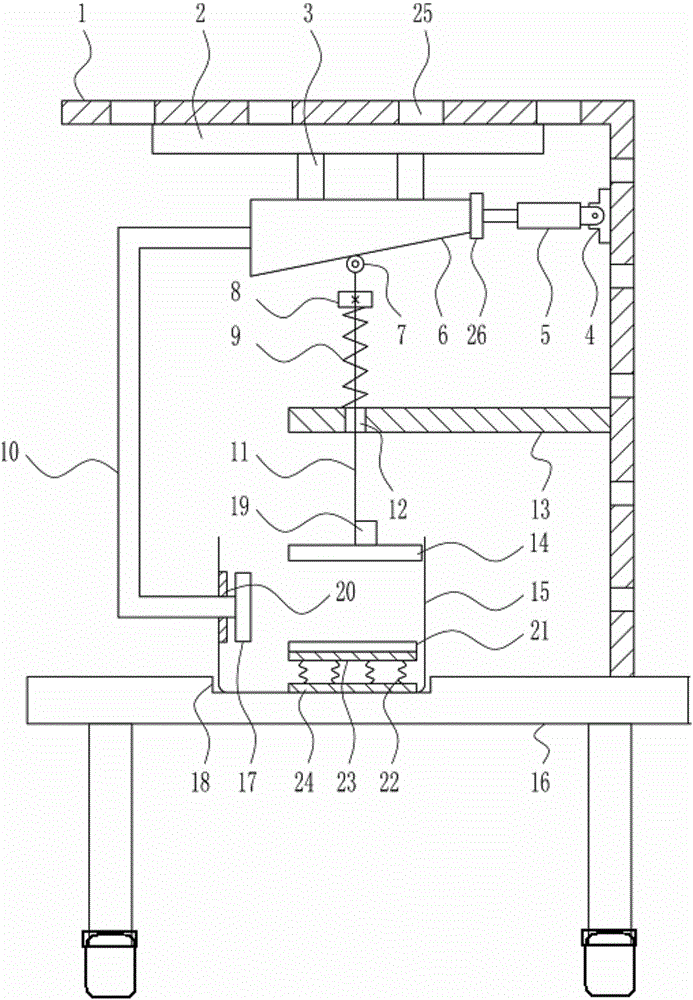

Automatic control method of workpiece-carrying injection molding and robot handling system

The invention discloses an automatic control method of workpiece-carrying injection molding. Automatic control of workpiece-carrying injection molding is completed through a rotor handling system, wherein a robot arm handling system is arranged near the side of an injection molding machine in a hanging manner, and automatic feeding of an embedded member of the injection molding machine and procedures of automatic grabbing and automatic placing of a finished injection molding workpiece are realized through a pneumatic control system and a program control system, wherein the robot arm handling system is provided with a grabbing mechanism which is composed of an air cylinder-controlled horizontal extending mechanism, and an air cylinder-controlled finished injection molding workpiece grabber mechanism, a small air cylinder-controlled embedded member compacting mechanism and a small air cylinder-controlled embedded member extending and compacting mechanism. The invention further discloses a robot handling system. The robot handling system is an automatic system which is high in automation degree, high in production efficiency and strong in universality, and is capable of lightening the labor intensity of manual operation, and realizing the automatic feeding of the embedded member of the injection molding machine and automatic grabbing and automatic placing of the finished injection molding workpiece.

Owner:GUANGZHOU RUISONG INTELLIGENT TECH CO LTD

Plug-in module for plugging in and/or pulling out of a module rack

InactiveUS20050014403A1Simple mechanical meanEasily and without problemEngagement/disengagement of coupling partsClamping/extracting meansFrontal regionsFrontal region

A plug-in module to be plugged in and / or pulled out of a module rack provided with at least one front stop edge, comprising a lever pull with handle arm and lever arm which is positioned pivoting in the frontal region of the plug-in module. A locking lever is attached articulated and such that it can rotate to the handle arm of lever pull. The locking lever turns an elastic locking tab. A corresponding locking profile is arranged in the frontal region of the plug-in module, wherein the locking tab engages behind the locking profile if the lever pull is pivoted out completely and thus prevents the lever pull from pivoting.

Owner:SCHROFF GMBH

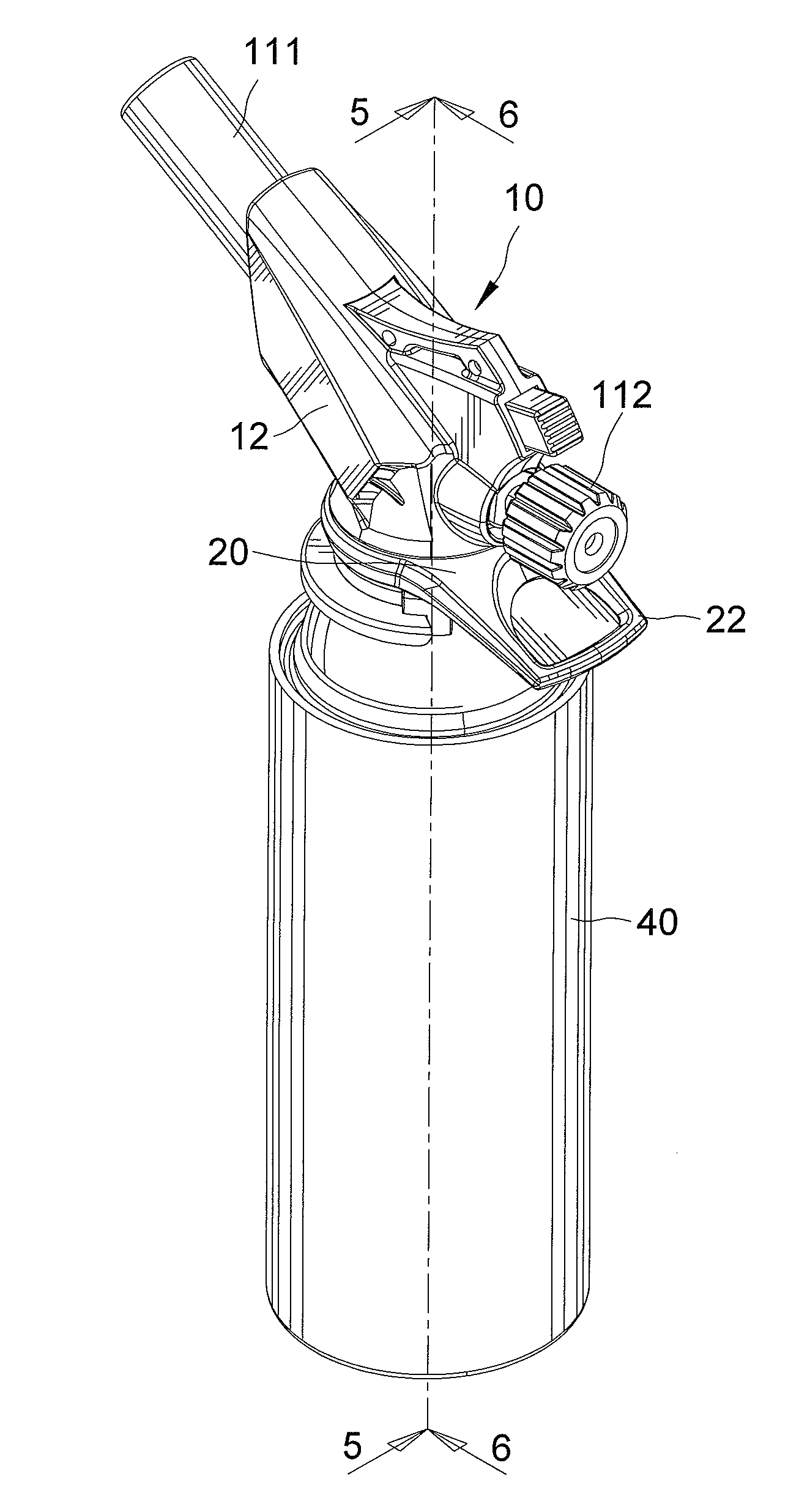

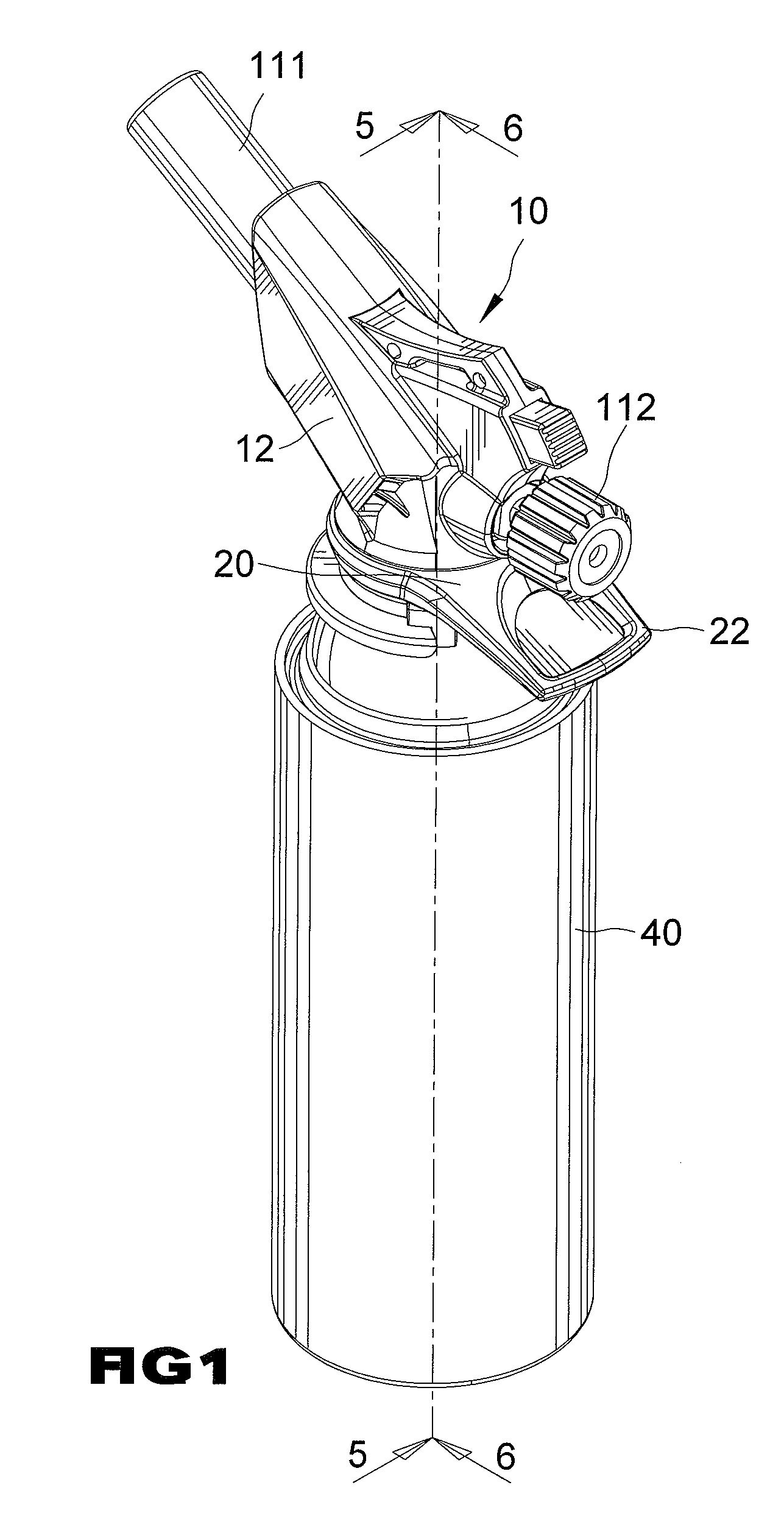

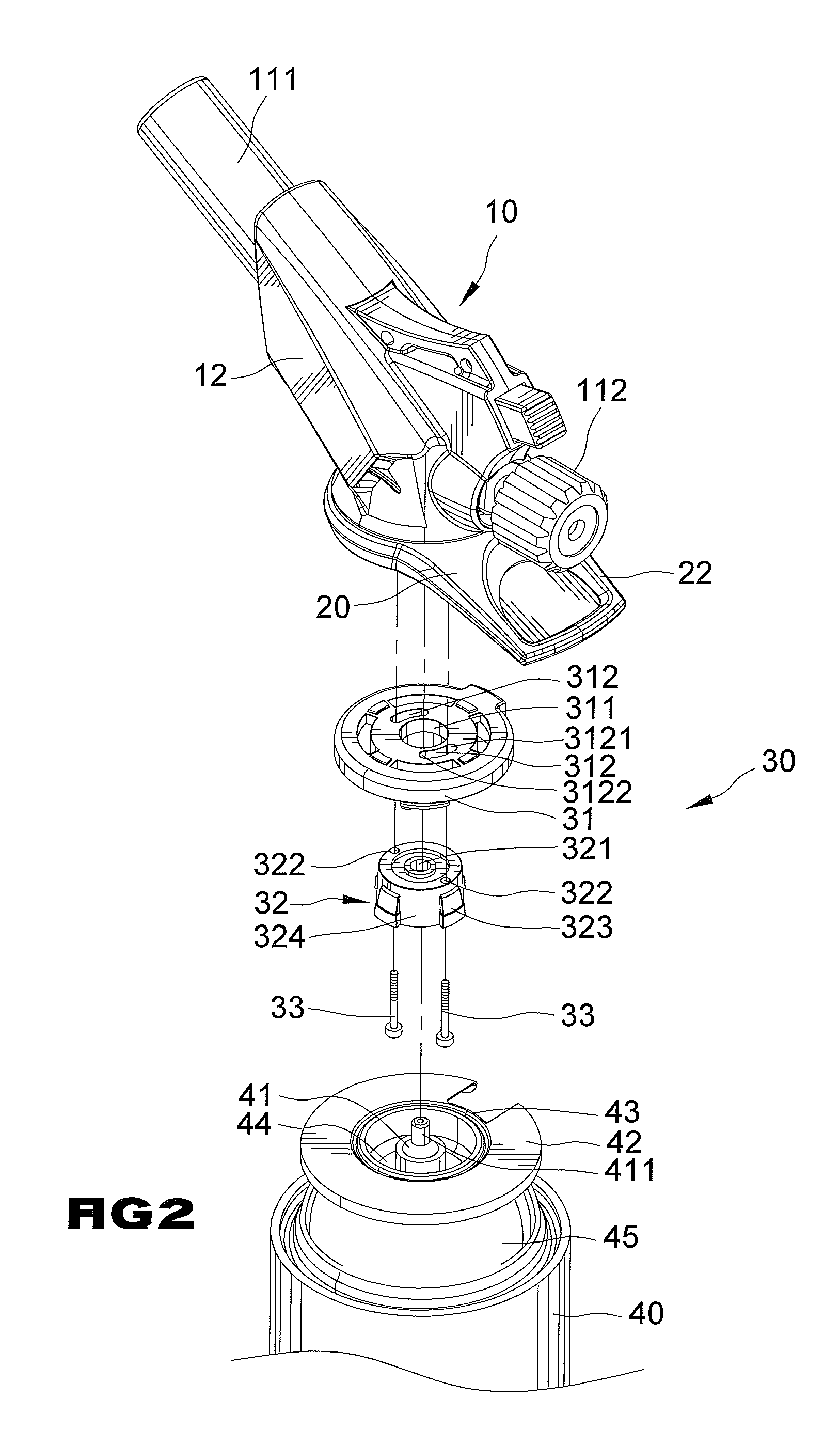

Gas Torch

ActiveUS20100261129A1Place stablePrevent fallingFuel lightersFlame-throwing apparatusTorchEngineering

A gas torch comprises a torch head assembly including a coupled base and a connected portion coupled to the outer periphery of the coupled base; and a joint assembly, which is coupled to the coupled base and adapted for connecting to a nozzle of a bottled gas tank, includes a first joint member and a second joint member communicating with the first joint member; wherein two fasteners are inserted through the first and second joint members and engaged with the coupled base of the torch head; wherein the joint assembly enables to connect the torch head assembly to different kinds of gas tanks.

Owner:PRO IRODA INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com