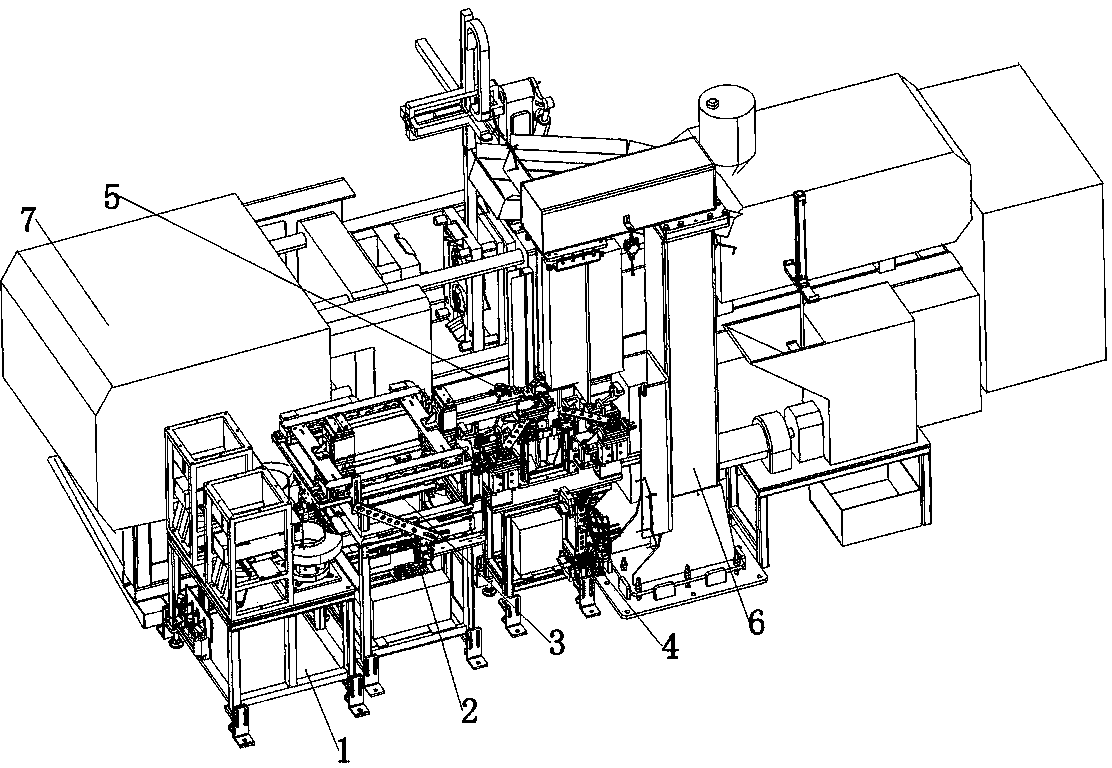

Automatic control method of workpiece-carrying injection molding and robot handling system

A handling system and injection molding technology with parts, applied in the direction of coating, etc., can solve the problems of labor cost waste and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

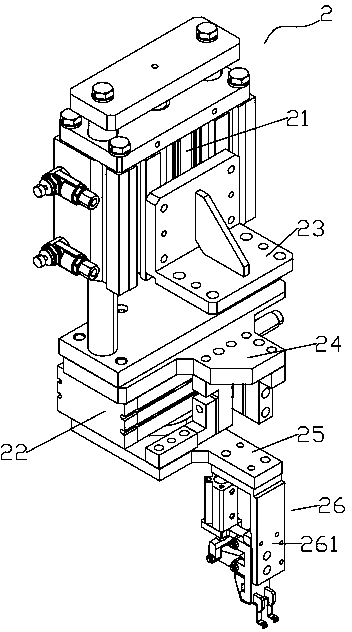

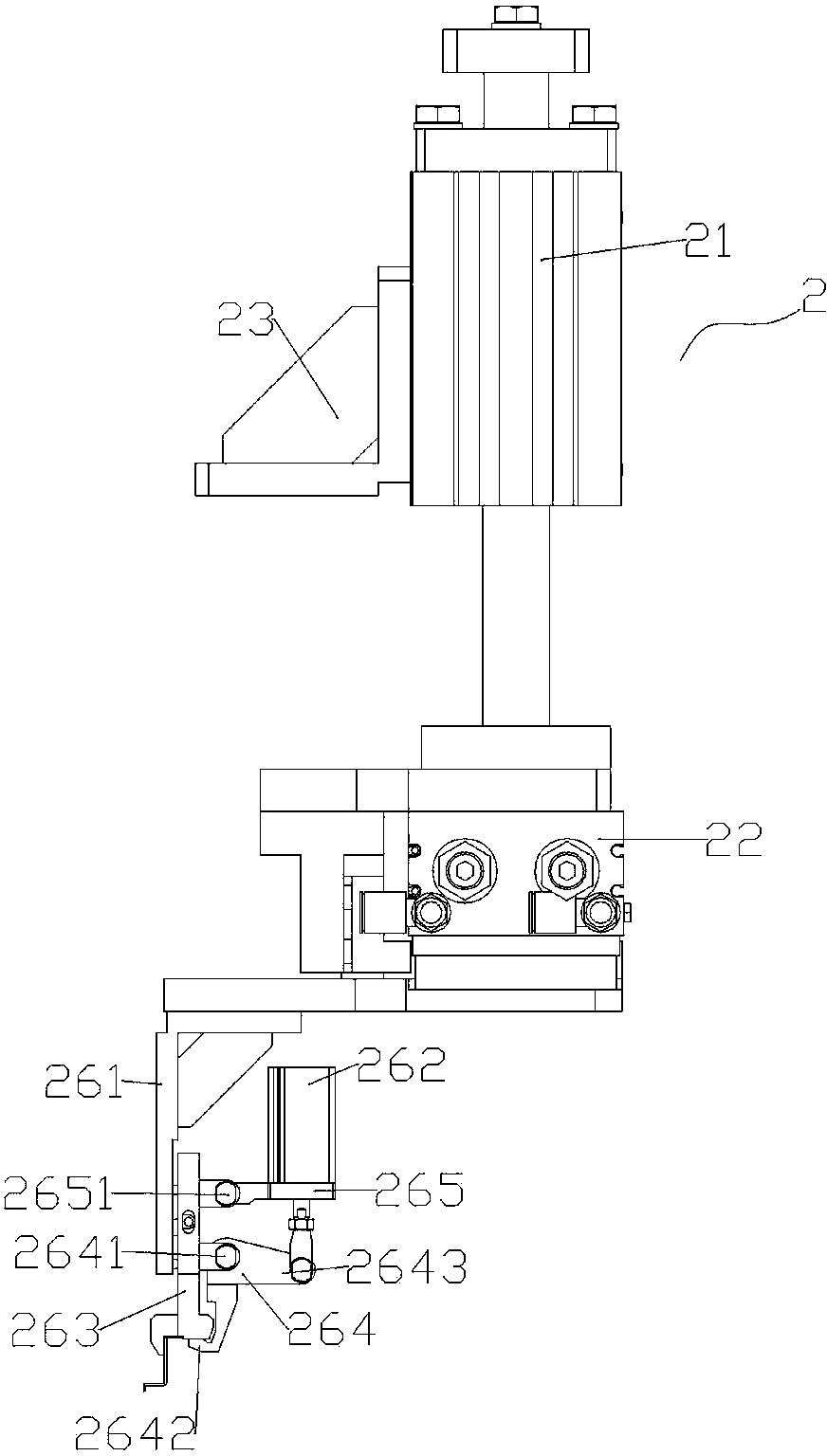

[0036] The present invention will be further described below:

[0037] The automatic control method of belt injection molding of the present invention, wherein the belt product in the belt injection molding is a pre-embedded part, and the product after the belt injection molding is an injection-molded finished product, and the aforementioned pre-embedded parts are generally finished products, such as metal hardware Terminals made of parts, injection molded finished parts are injection molded parts, injection molding machine 7 puts the embedded parts into the mold cavity in advance, and then molds are closed for injection molding to obtain products, such as speaker products, injection molded speaker products , The terminals on the speaker are buried in the speaker body and are directly fixed and connected together through the adhesive force of the plastic, which requires good electrical conduction performance of the terminals.

[0038] Taking the terminal as the embedded part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com