Patents

Literature

2786 results about "Medical waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

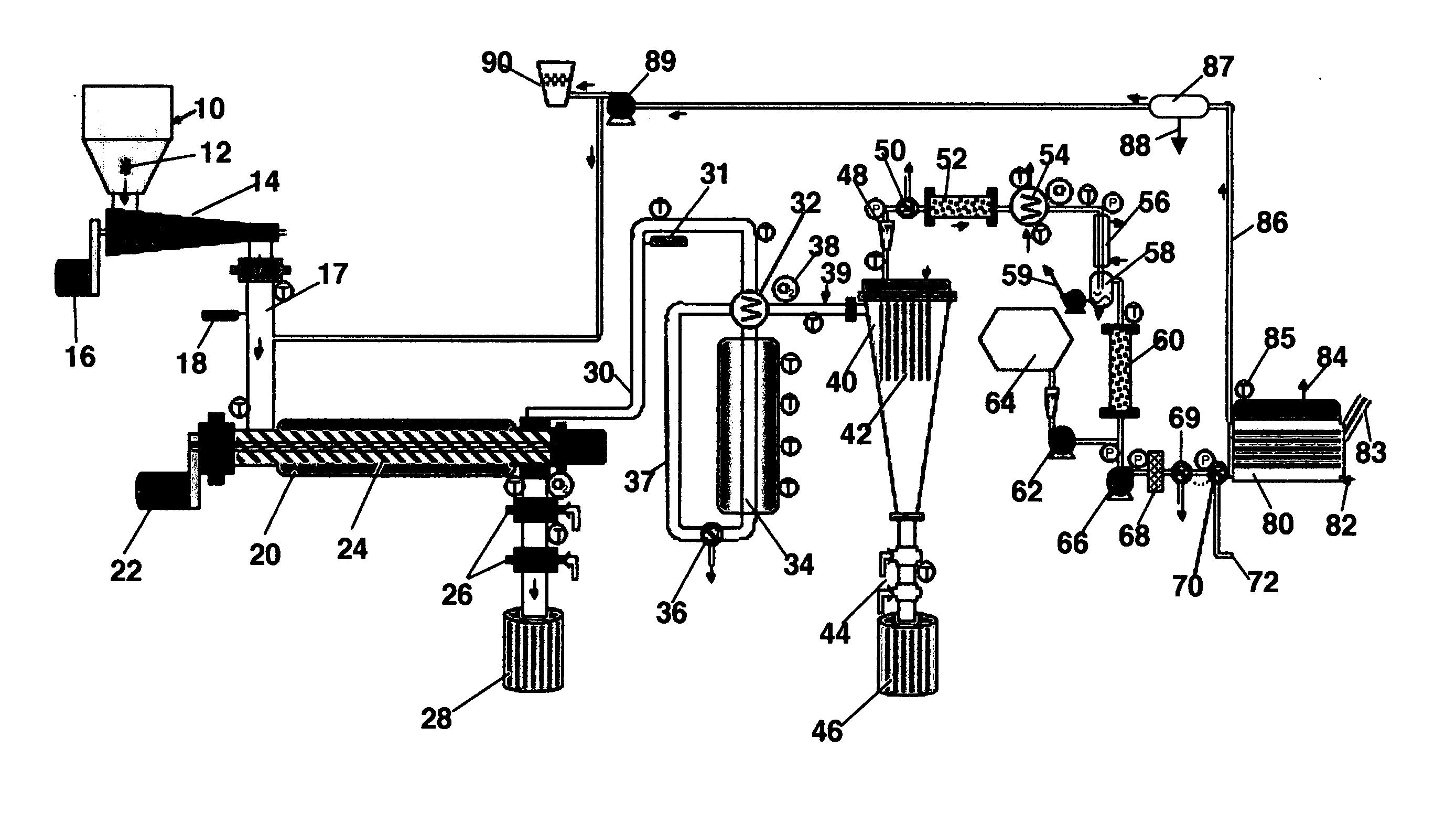

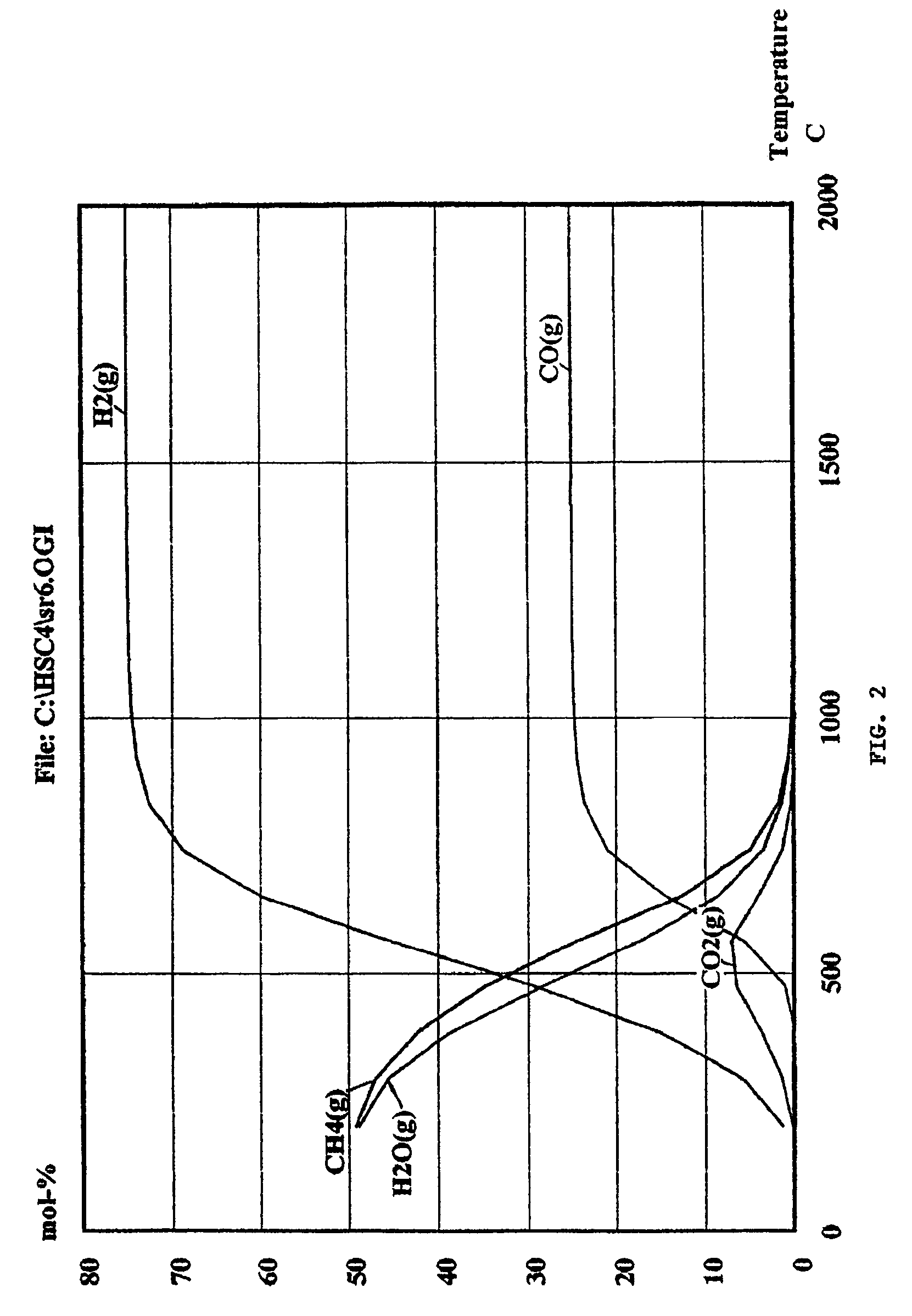

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

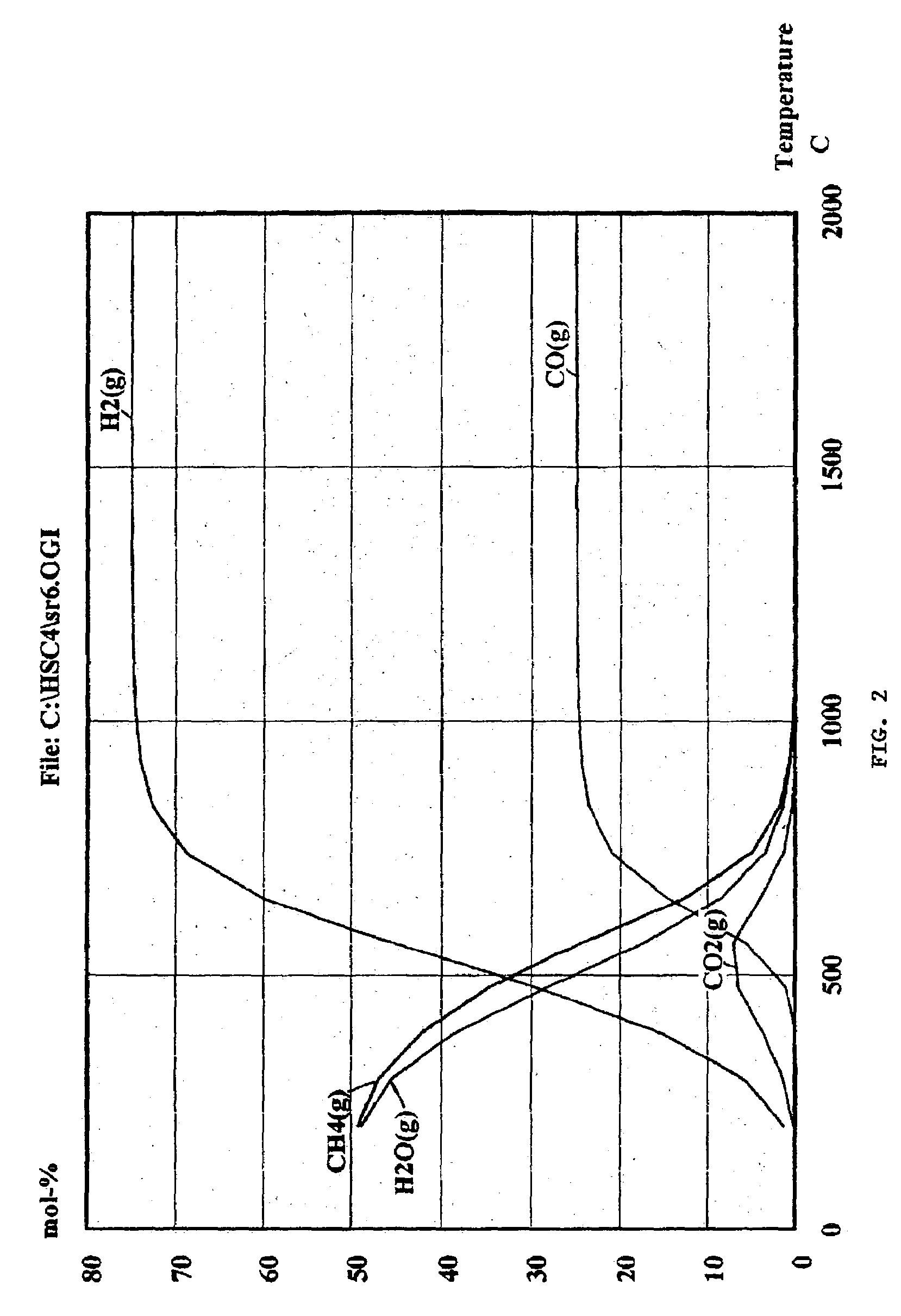

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

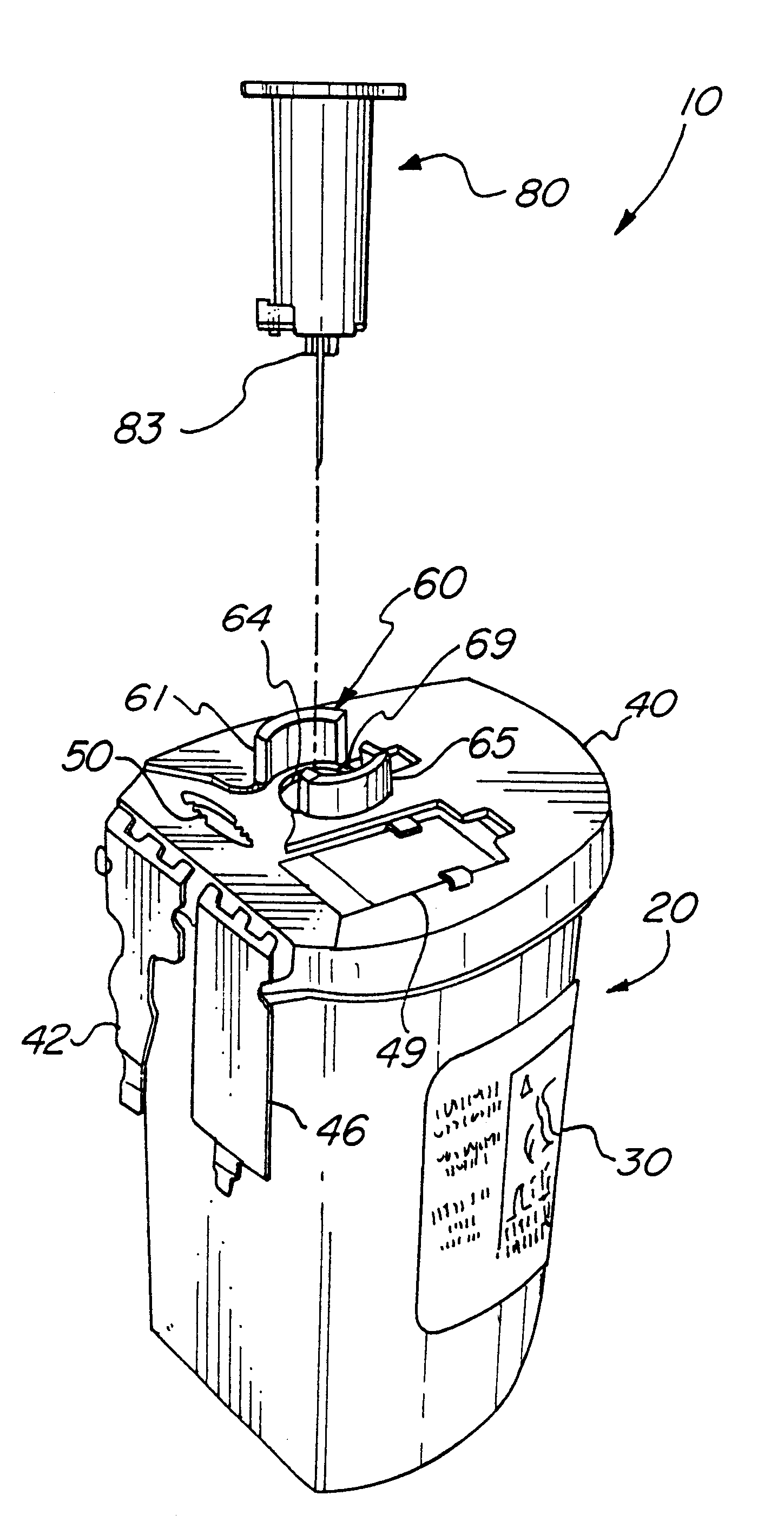

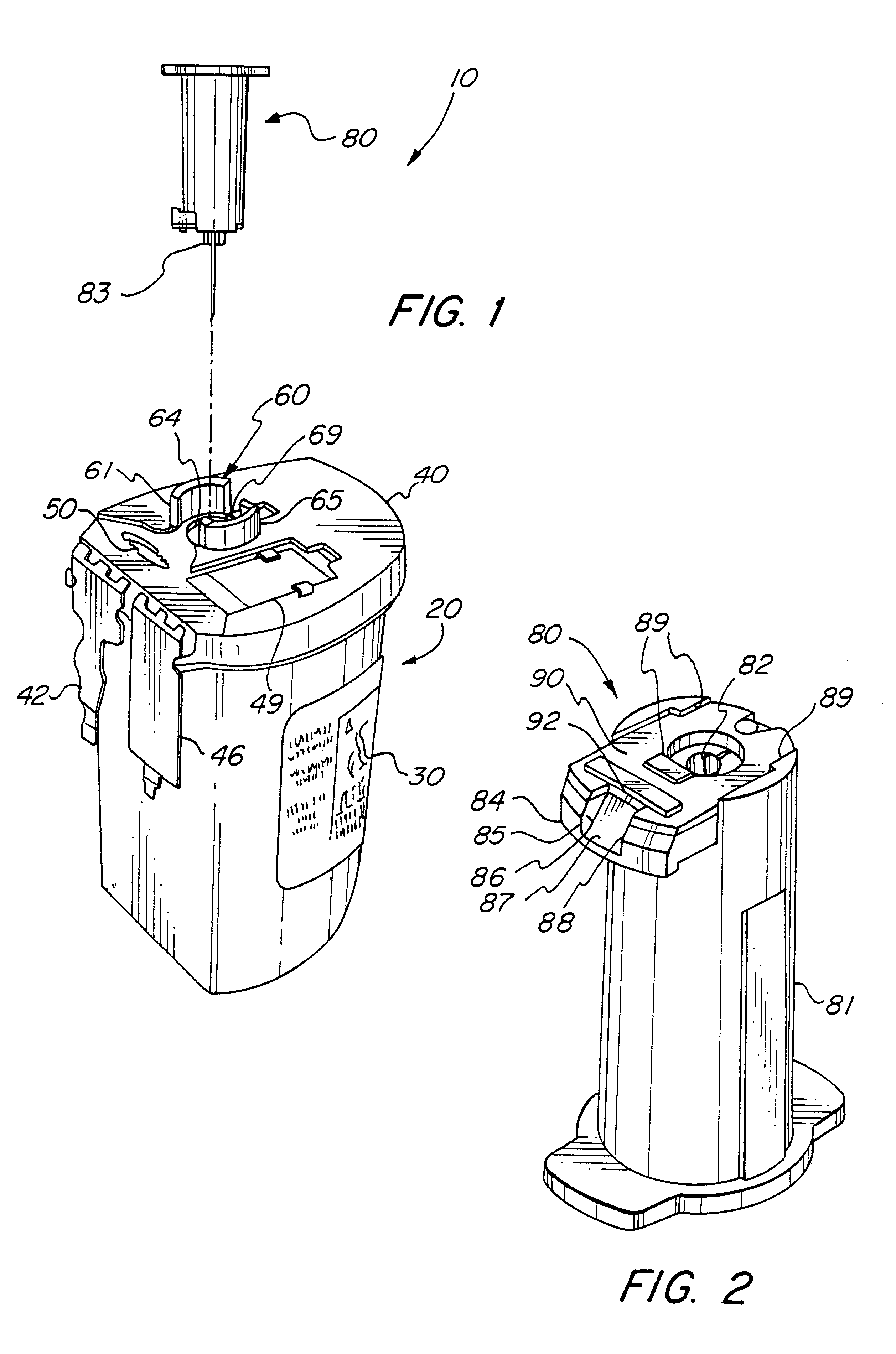

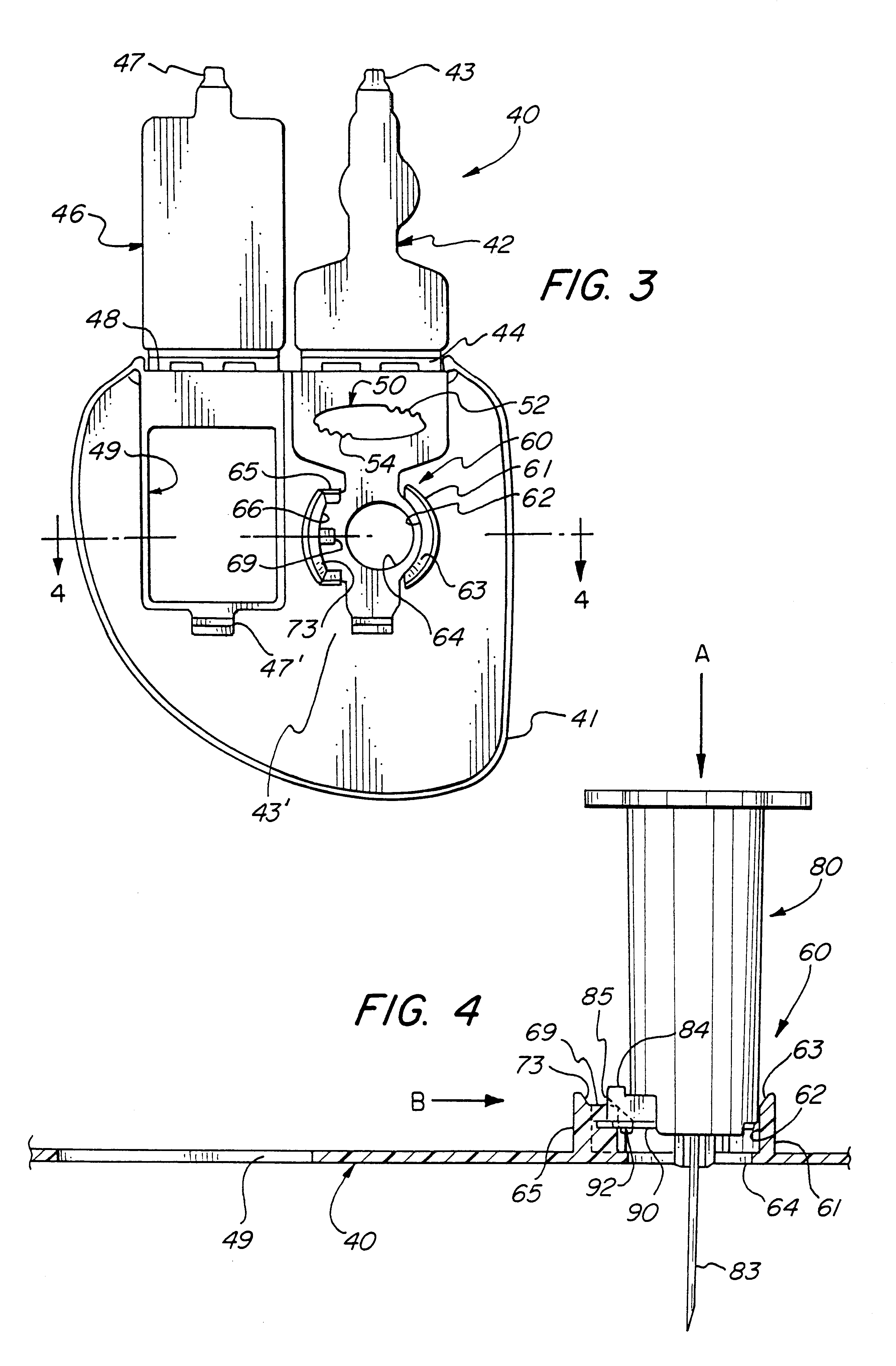

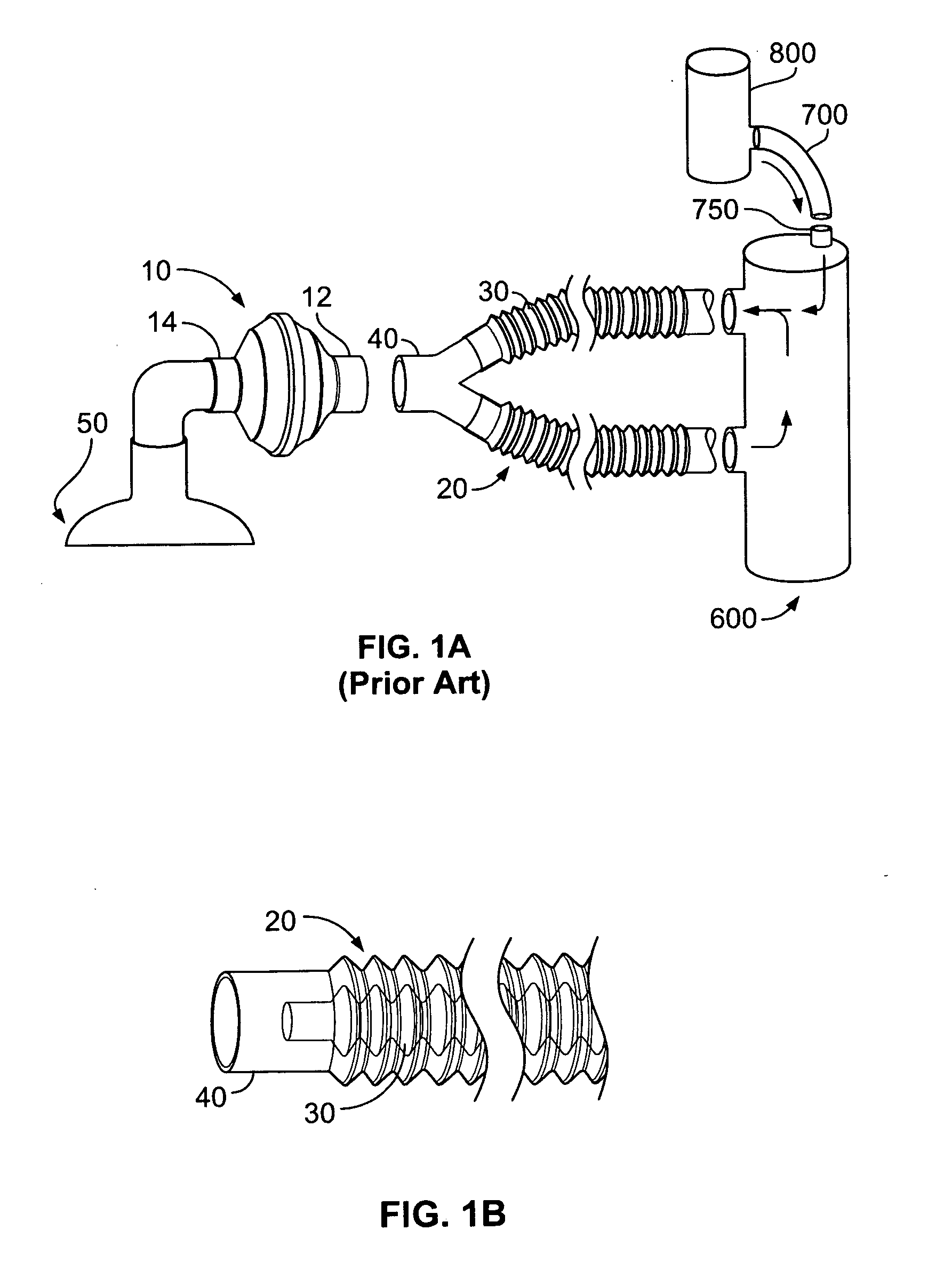

System for disposal of contaminated medical products

InactiveUS6247592B1Precise and reliable single-handedPrecise and reliable detachmentDispensing apparatusRefuse receptaclesMedical wasteMedical product

A disposed system for medical waste, and particularly sharp ended waste, includes a sharps receptacle and a companion needle holder. The needle holder has an actuation mechanism capable of detachably mounting an externally threaded hub of a needle assembly to the holder. The sharps receptacle has a top with an automatic release structure disposed thereon for engagement with the actuation mechanism of the needle holder. The automatic release structure cooperates with the actuation mechanism of the needle holder to automatically detach a mounted needle assembly from the holder into the sharps receptacle in response to placement of the holder into the automatic release structure.

Owner:ICU MEDICAL SALES +1

Method for sorting discarded and spent pharmaceutical items

ActiveUS7318529B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentDispensing apparatusMedical wasteWorkstation

Owner:CAREFUSION 303 INC

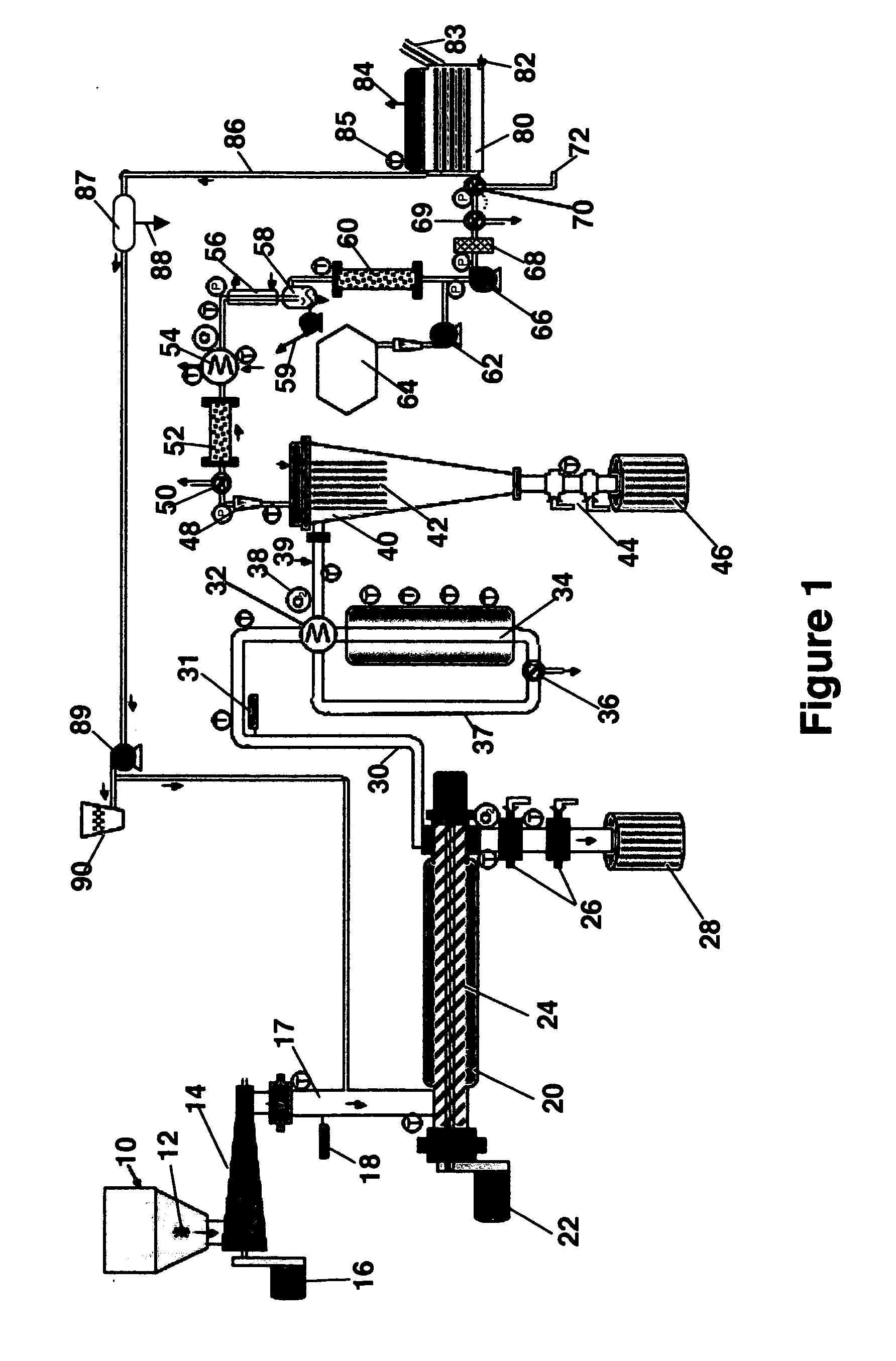

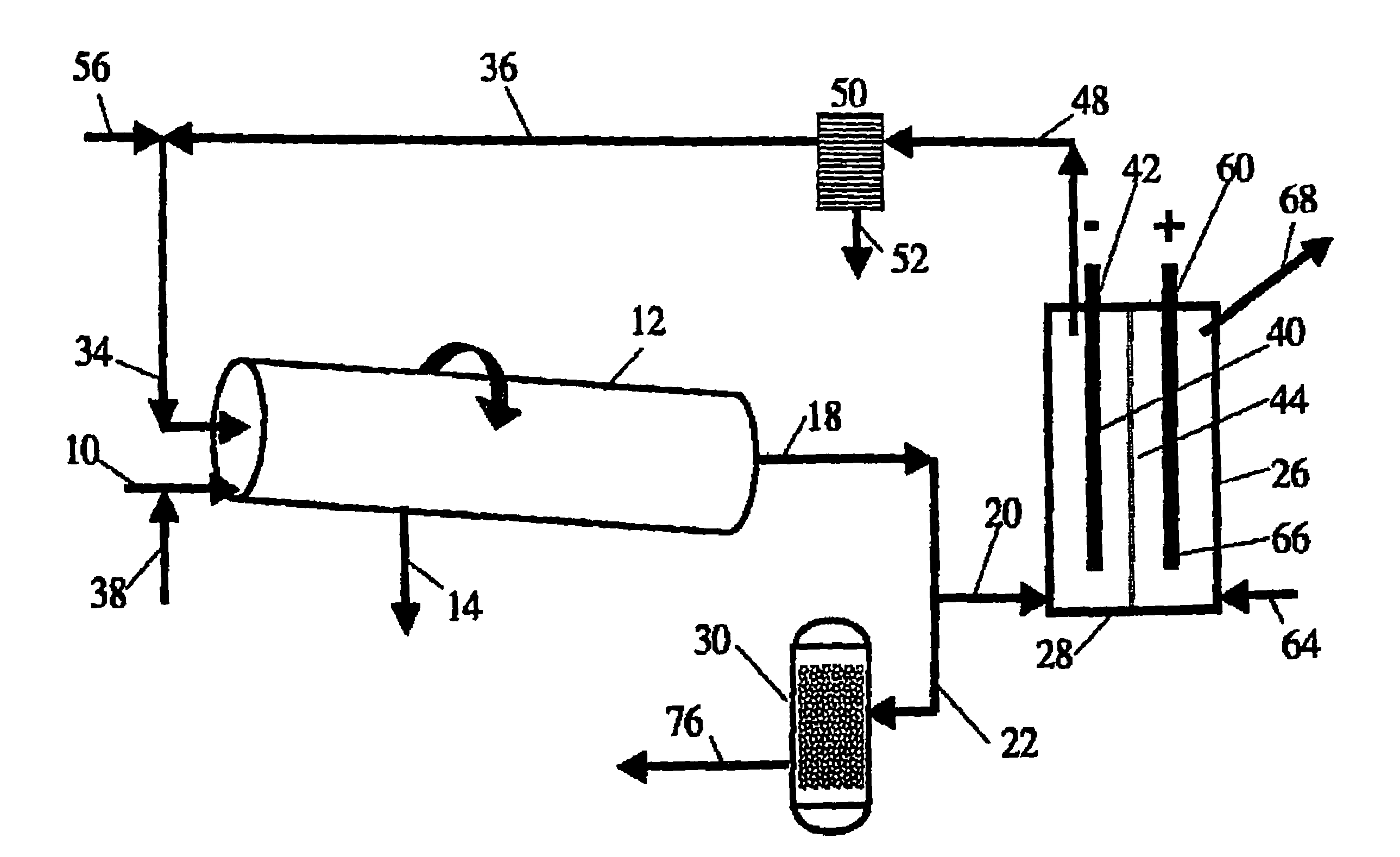

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

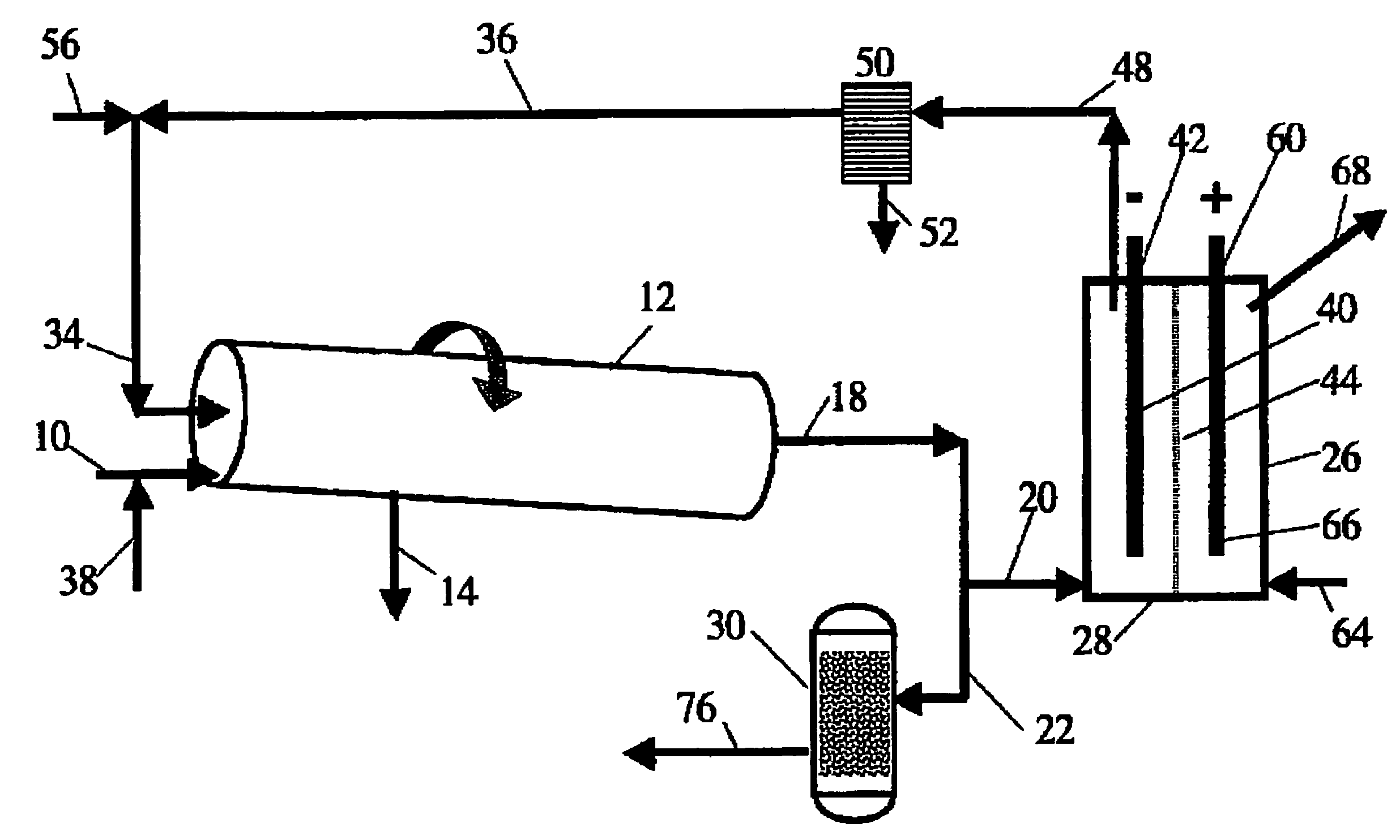

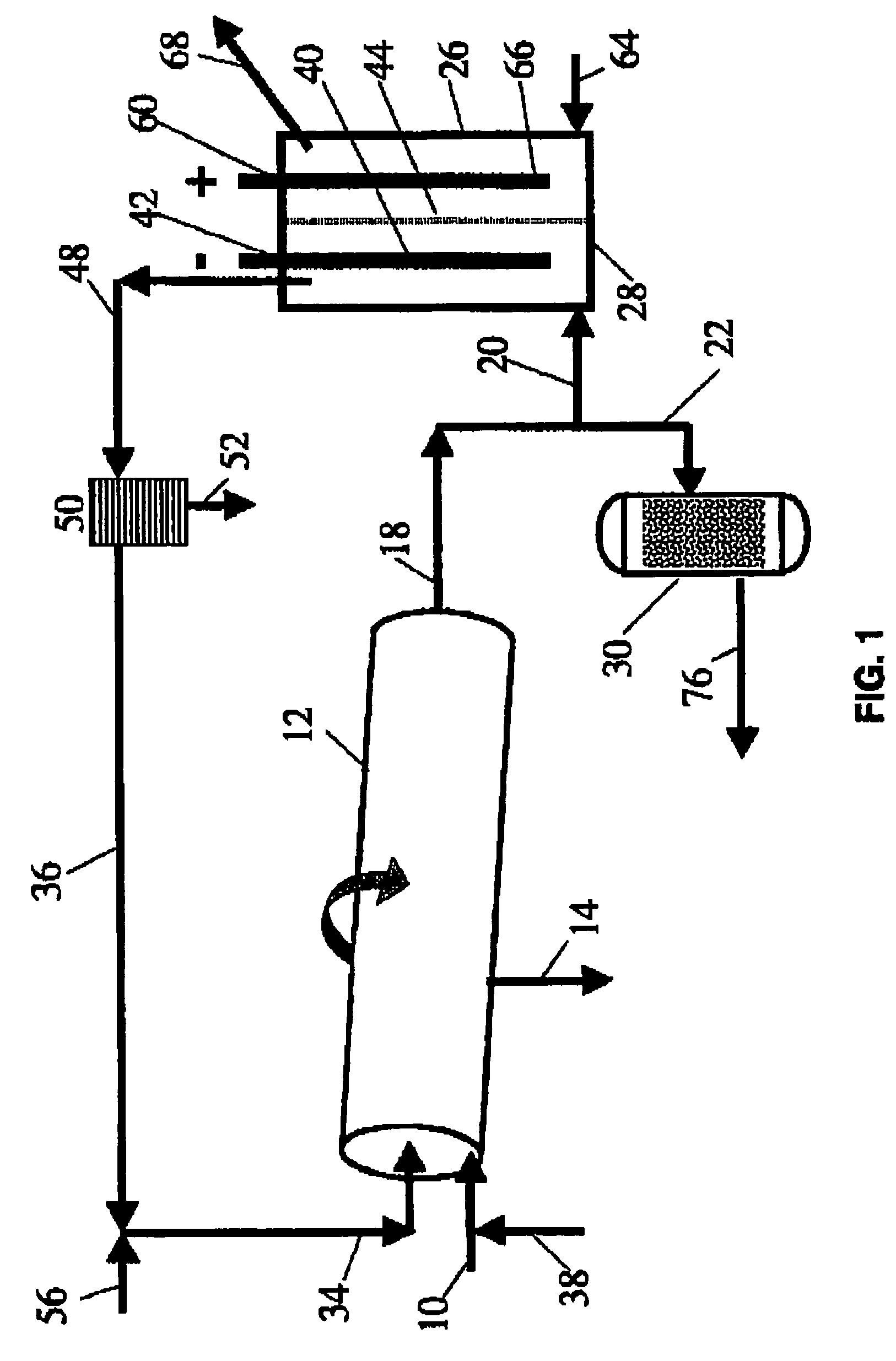

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

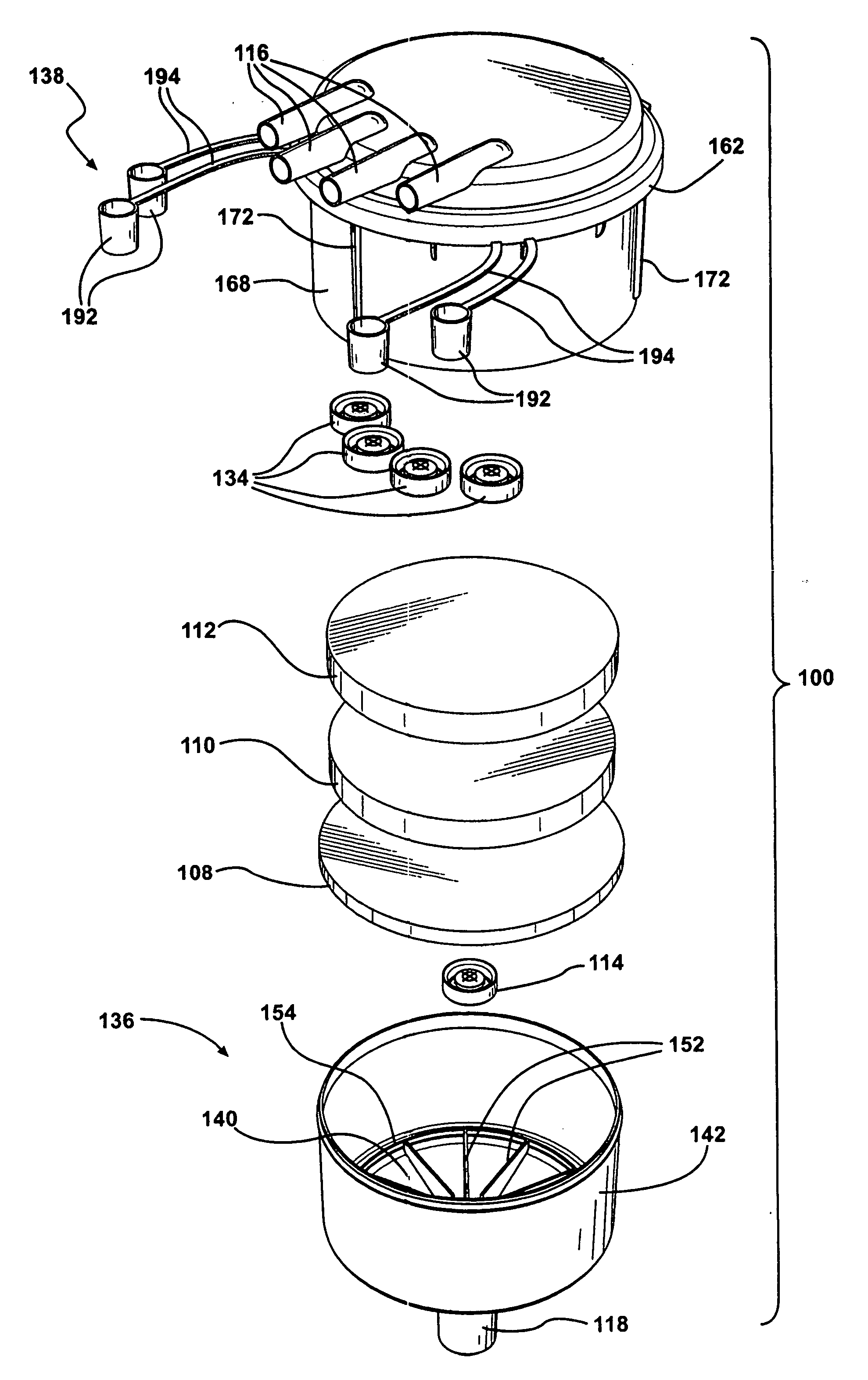

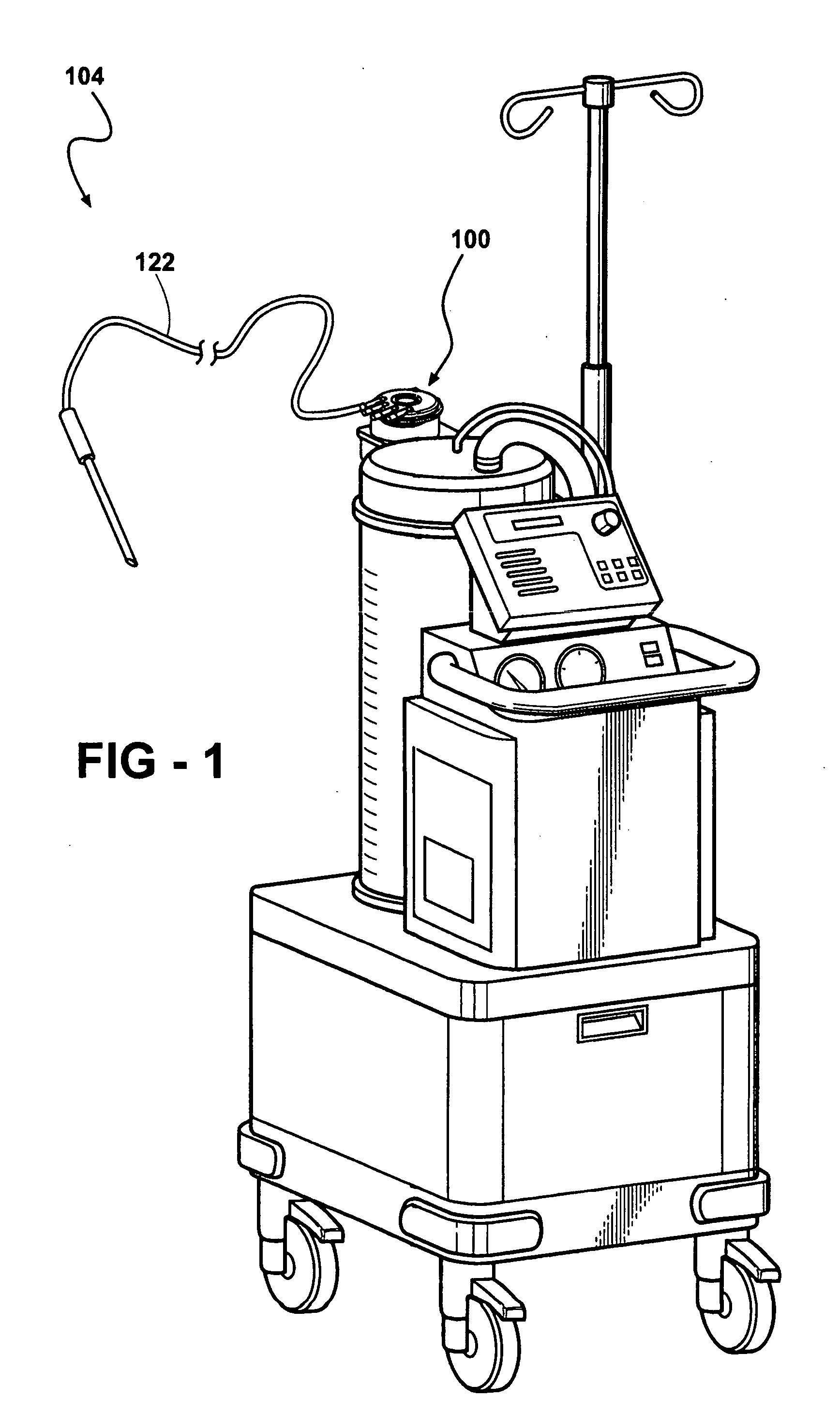

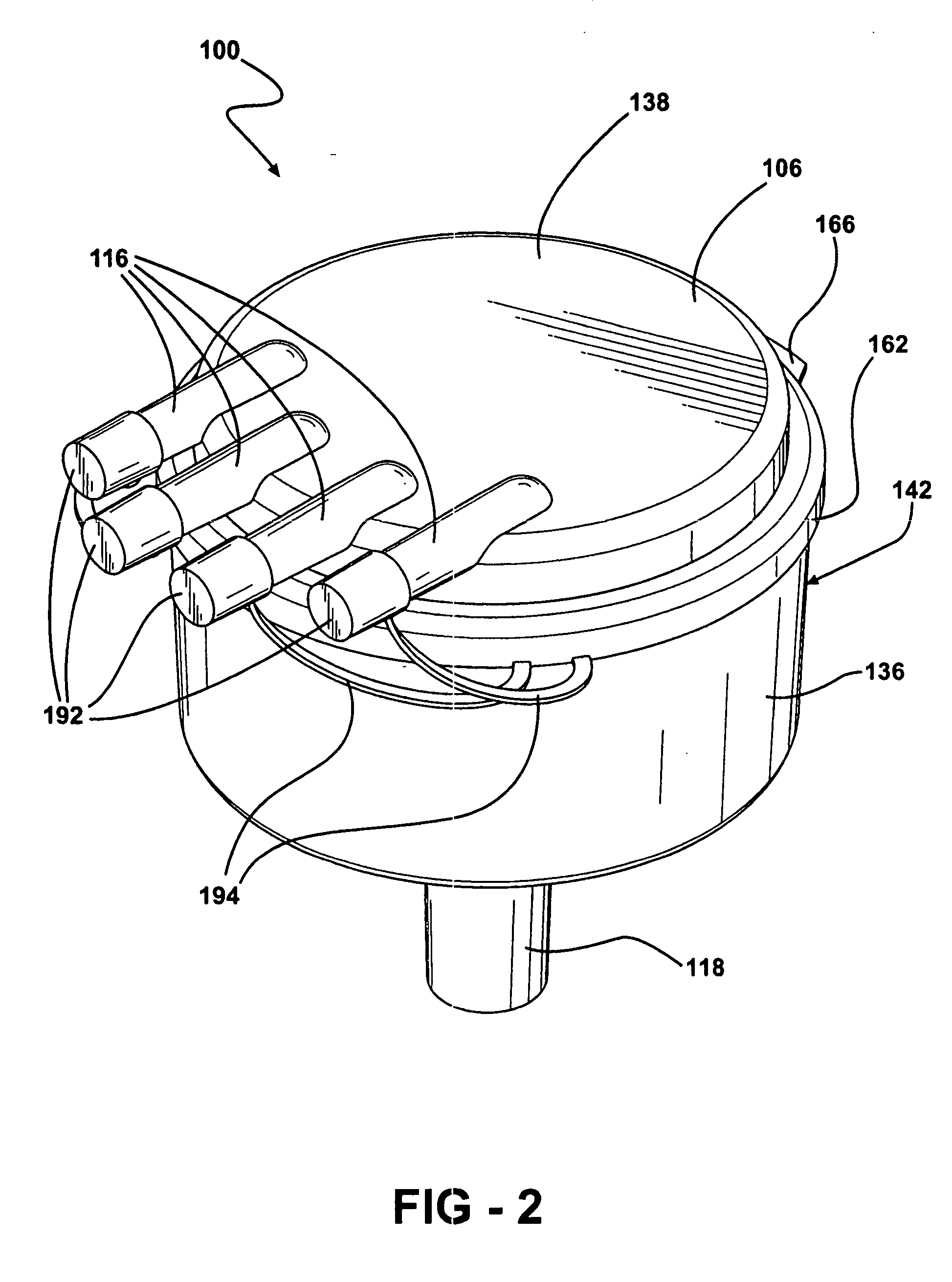

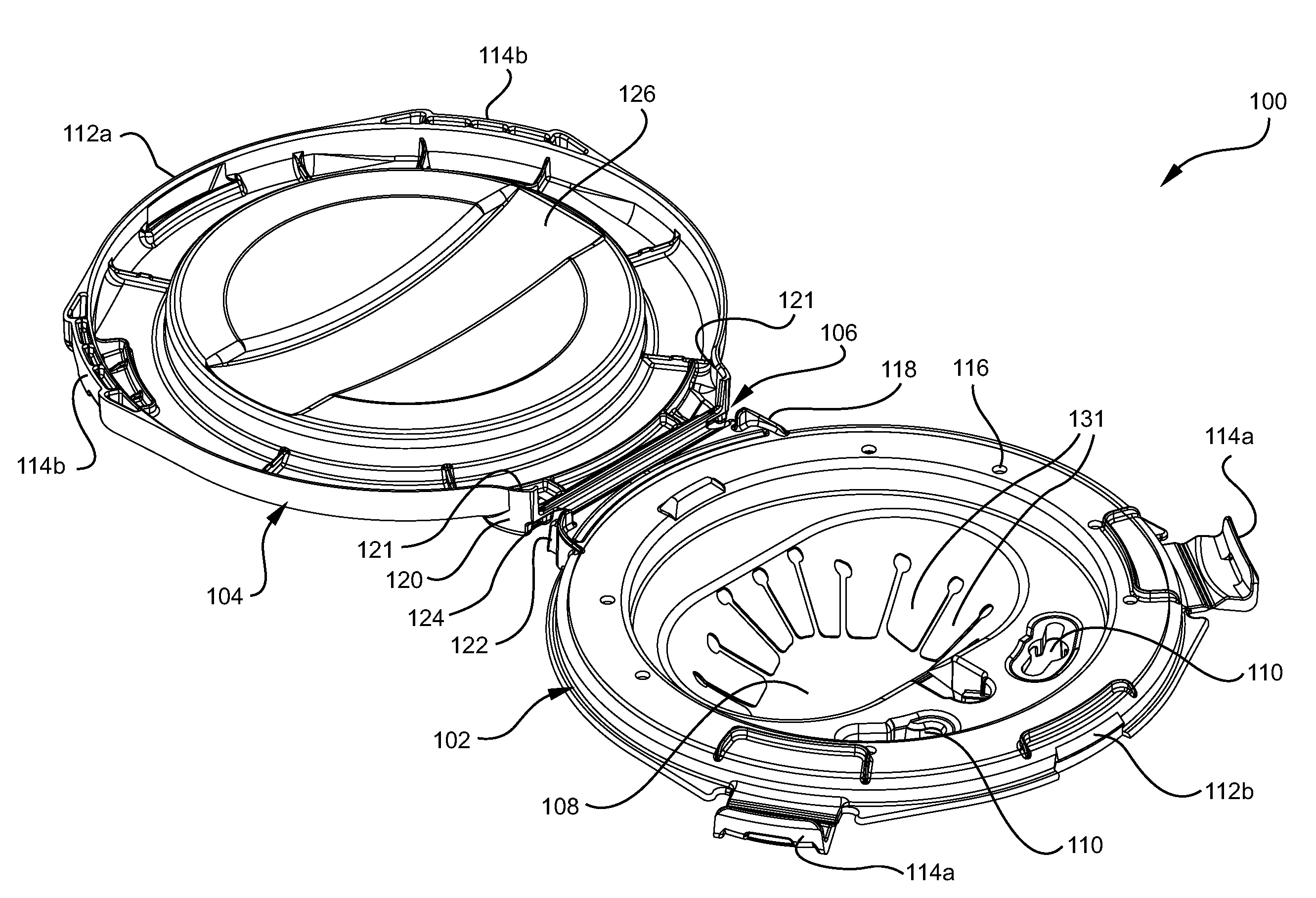

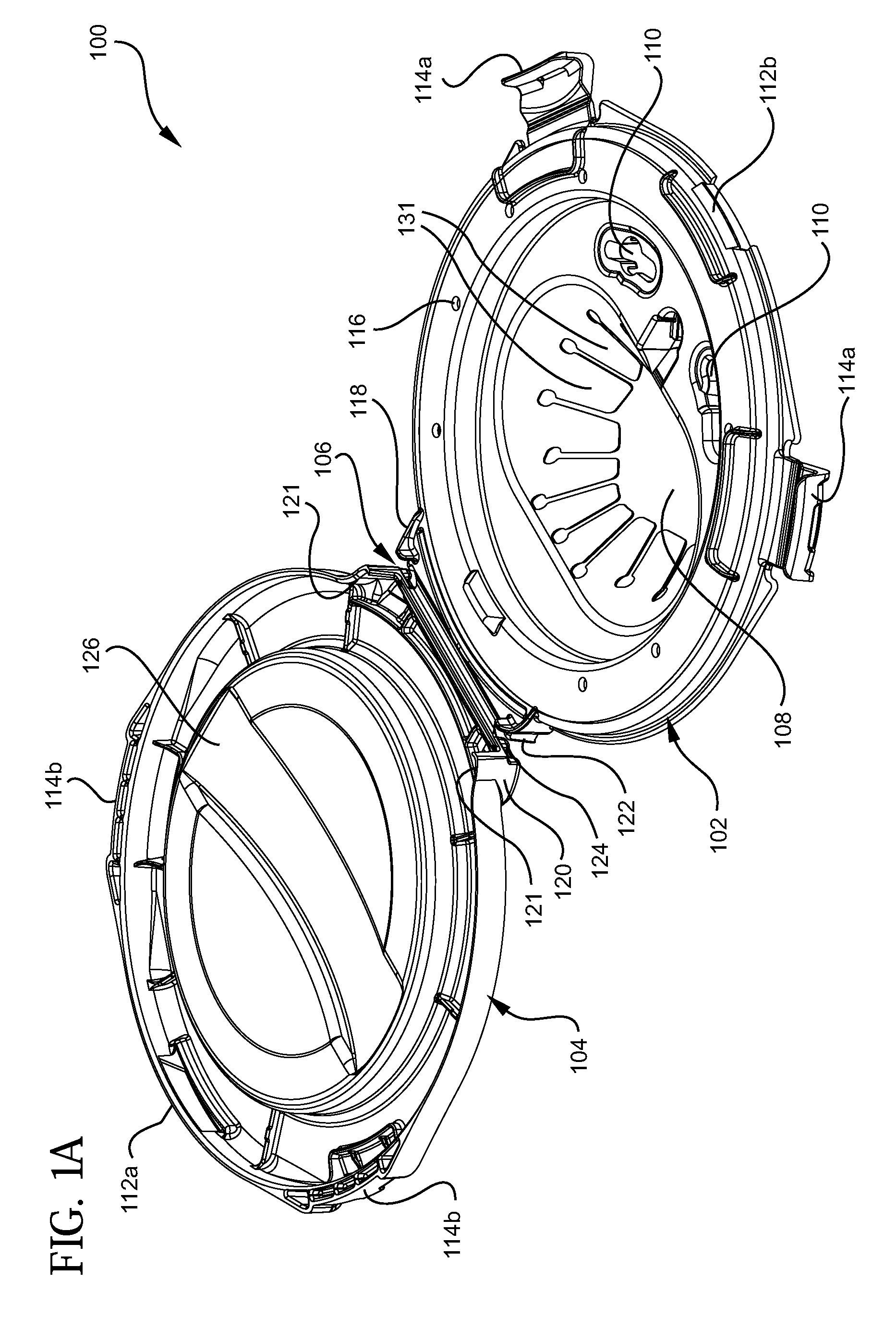

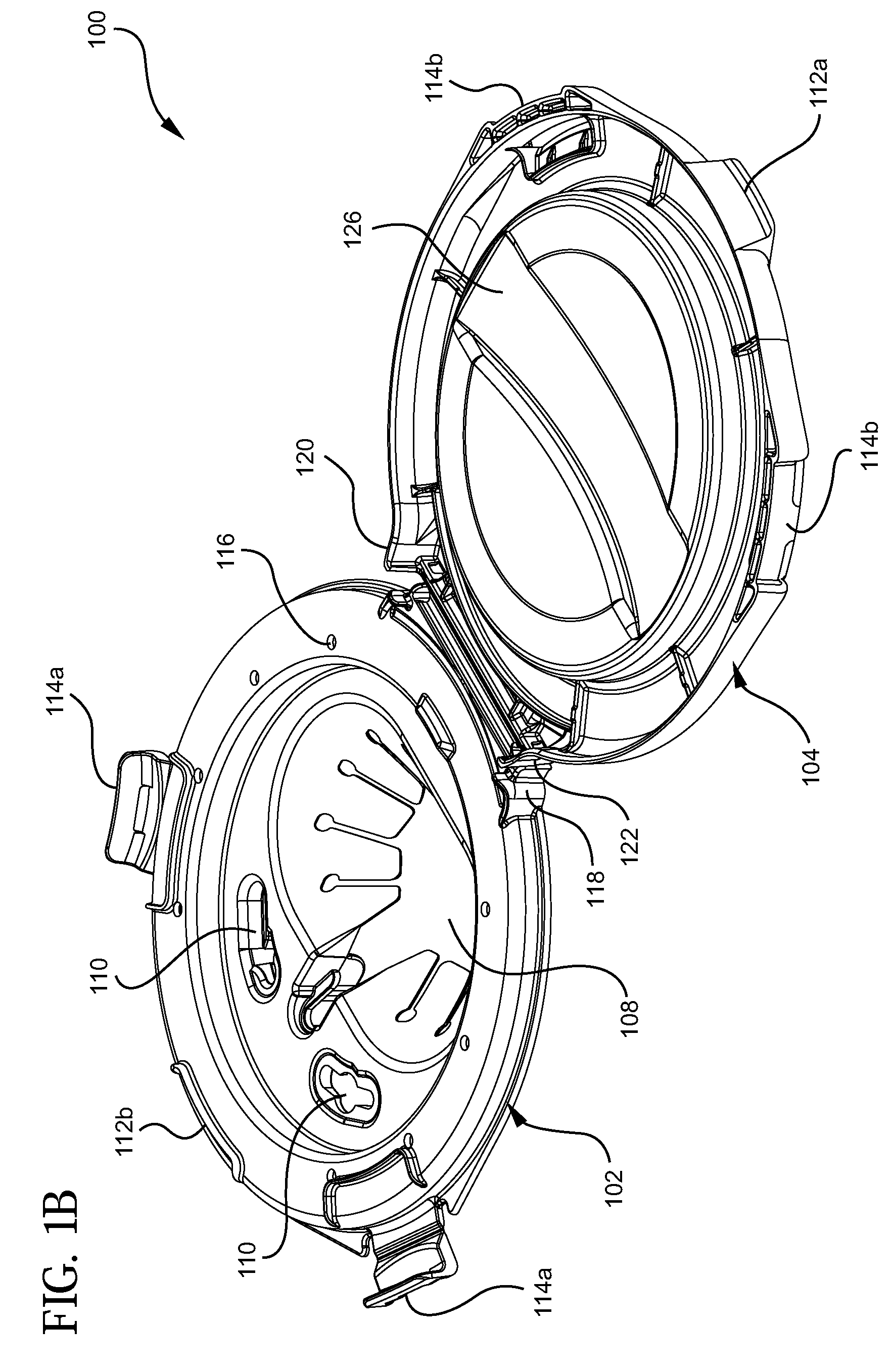

Manifold assembly

A manifold assembly (100) for directing and filtering material (102) from fluid flowing into a medical waste collection device (104) includes a plurality of inlet ports (116) and an outlet port (118) with a filter (108, 110, 112) disposed between the ports (116, 118) along a fluid path (120). An outlet check-valve (114) is disposed at the outlet port (118) for opening in response to a predetermined vacuum pressure applied to the outlet port (118) from the medical waste collection device (104).

Owner:STRYKER CORP

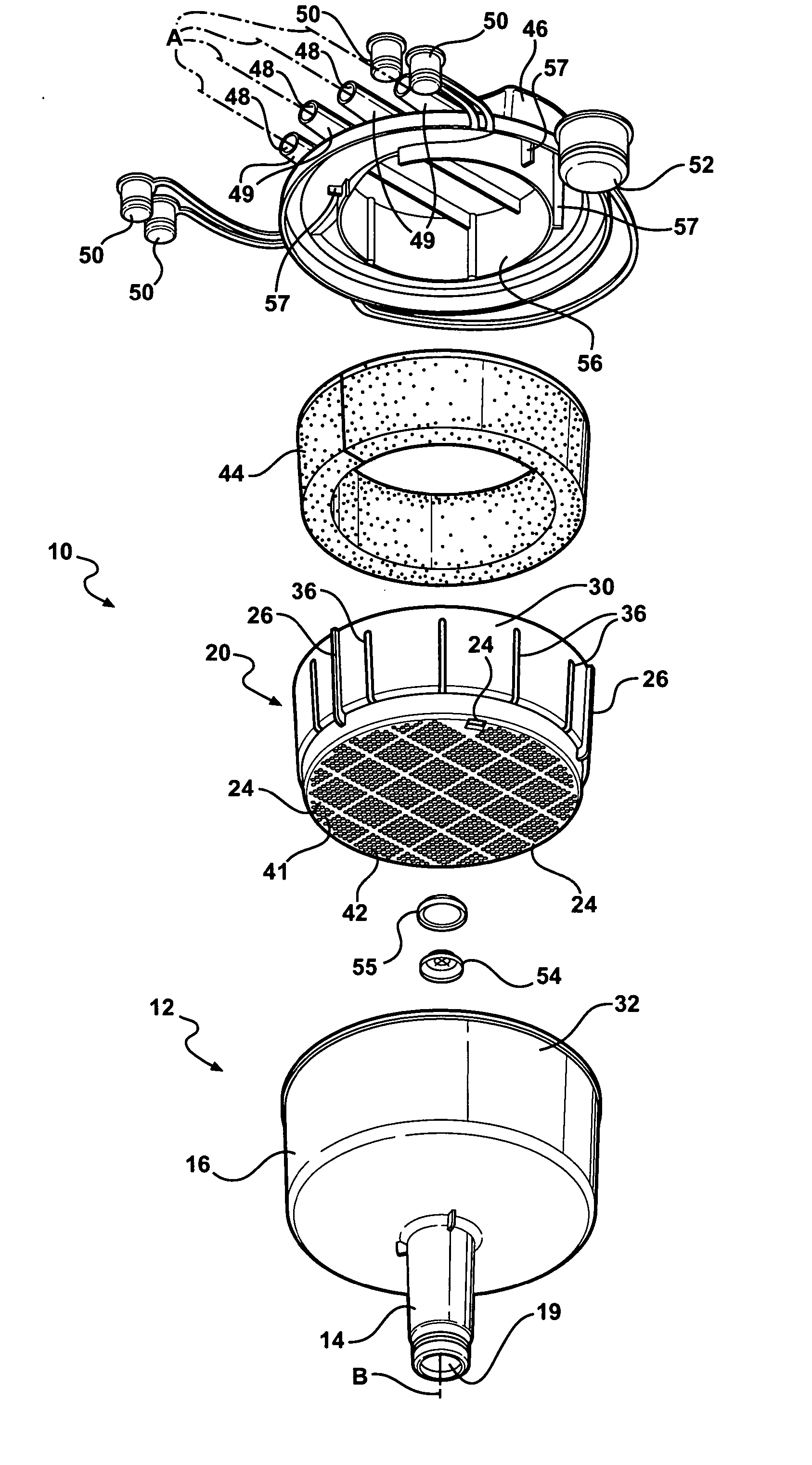

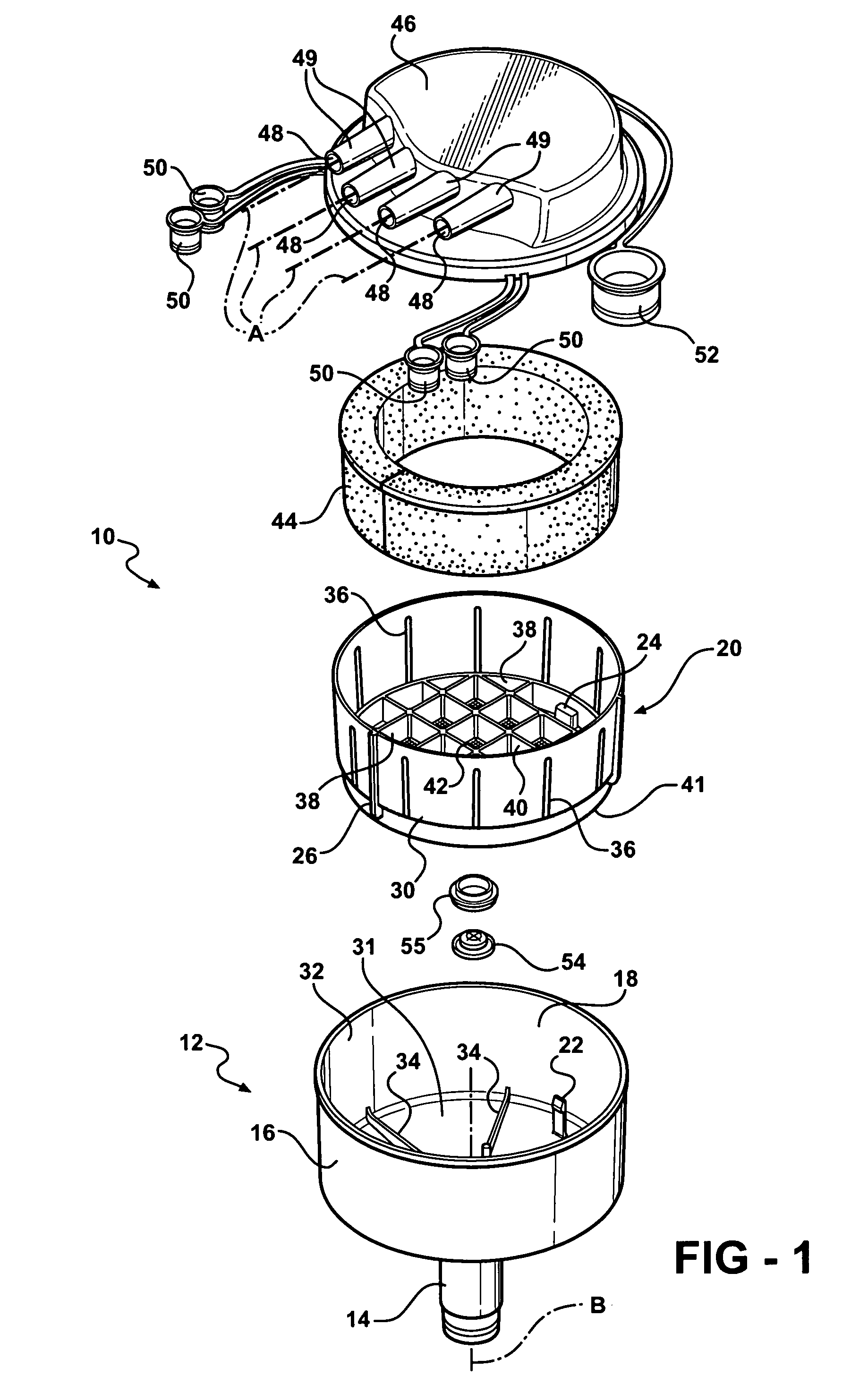

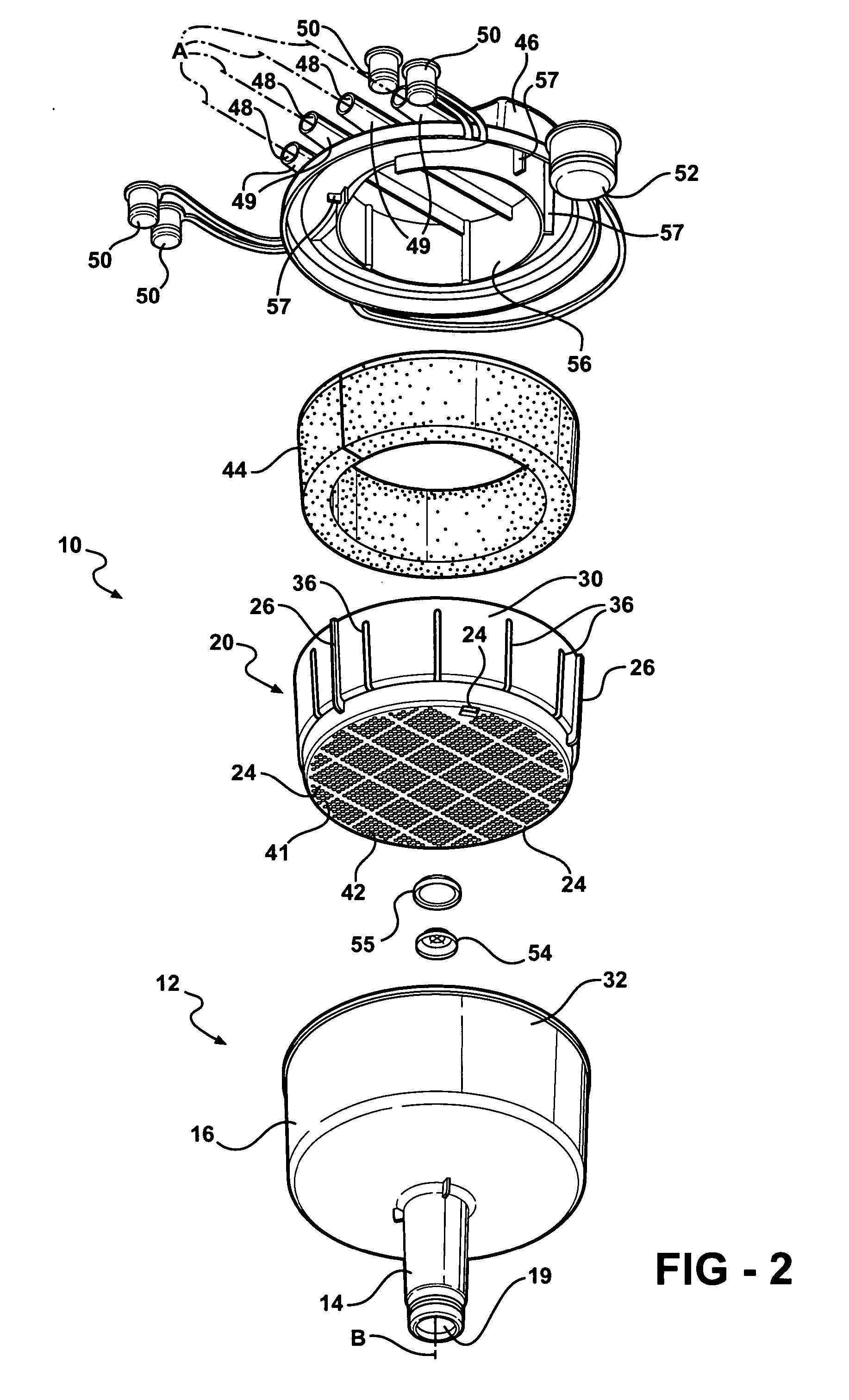

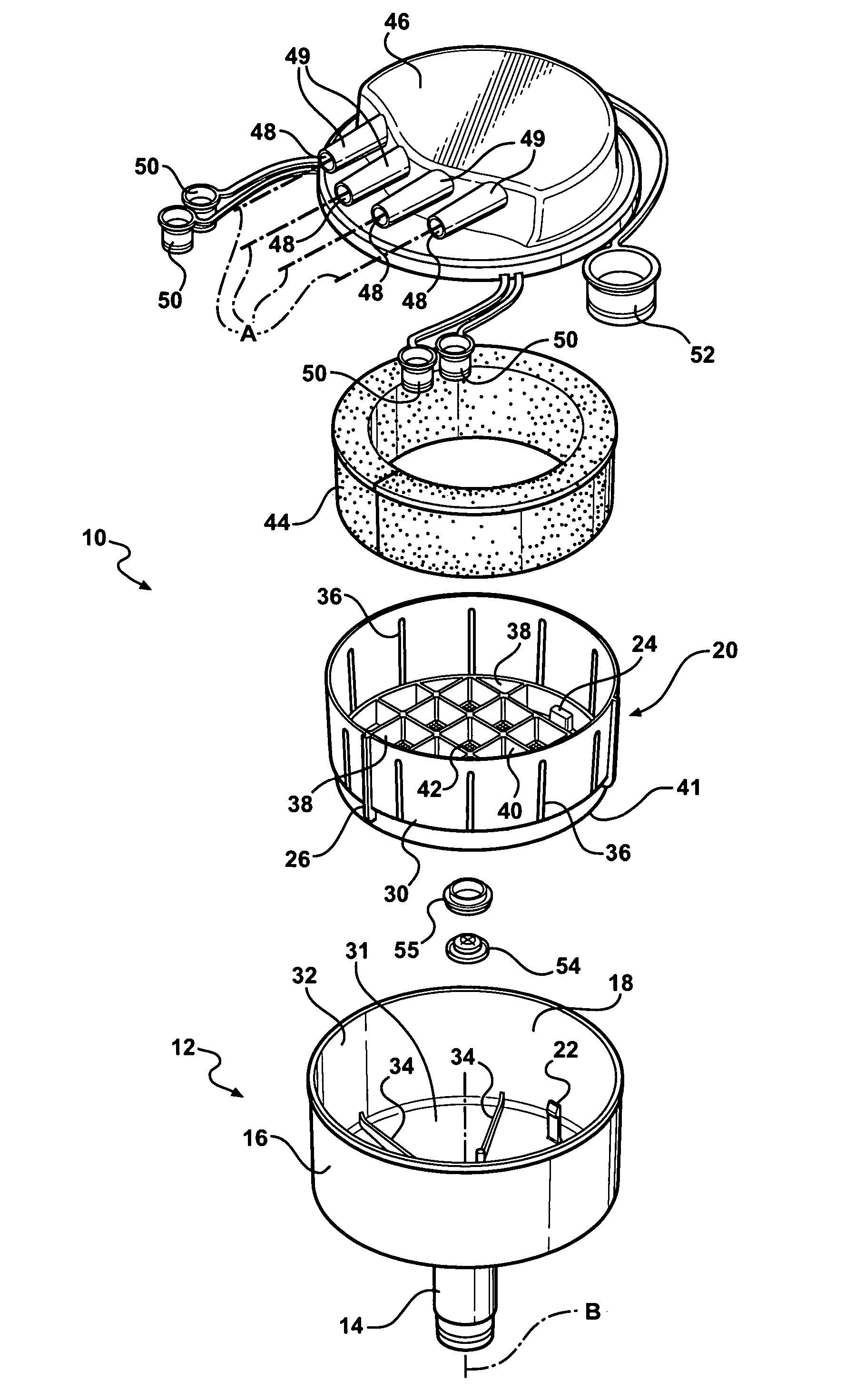

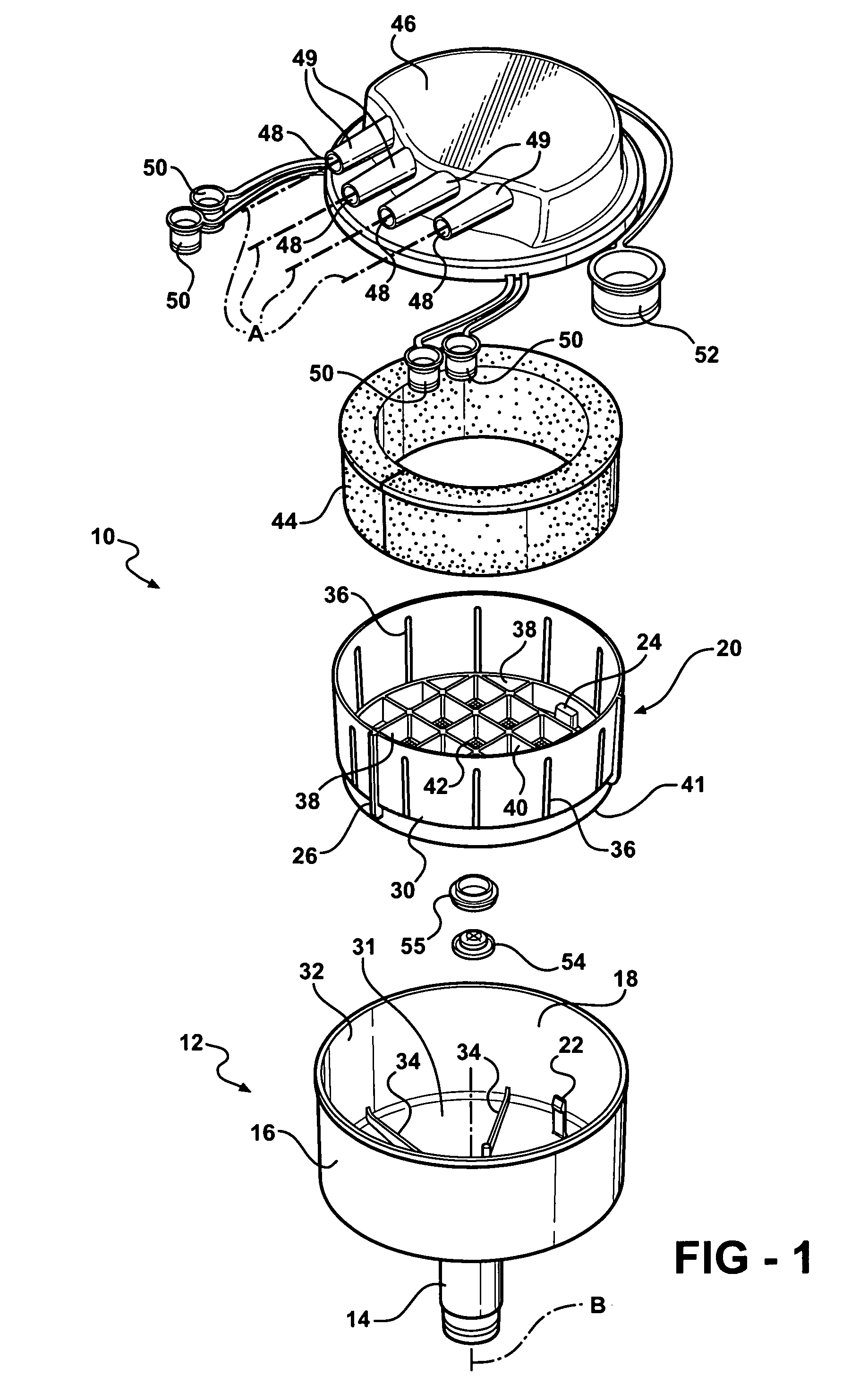

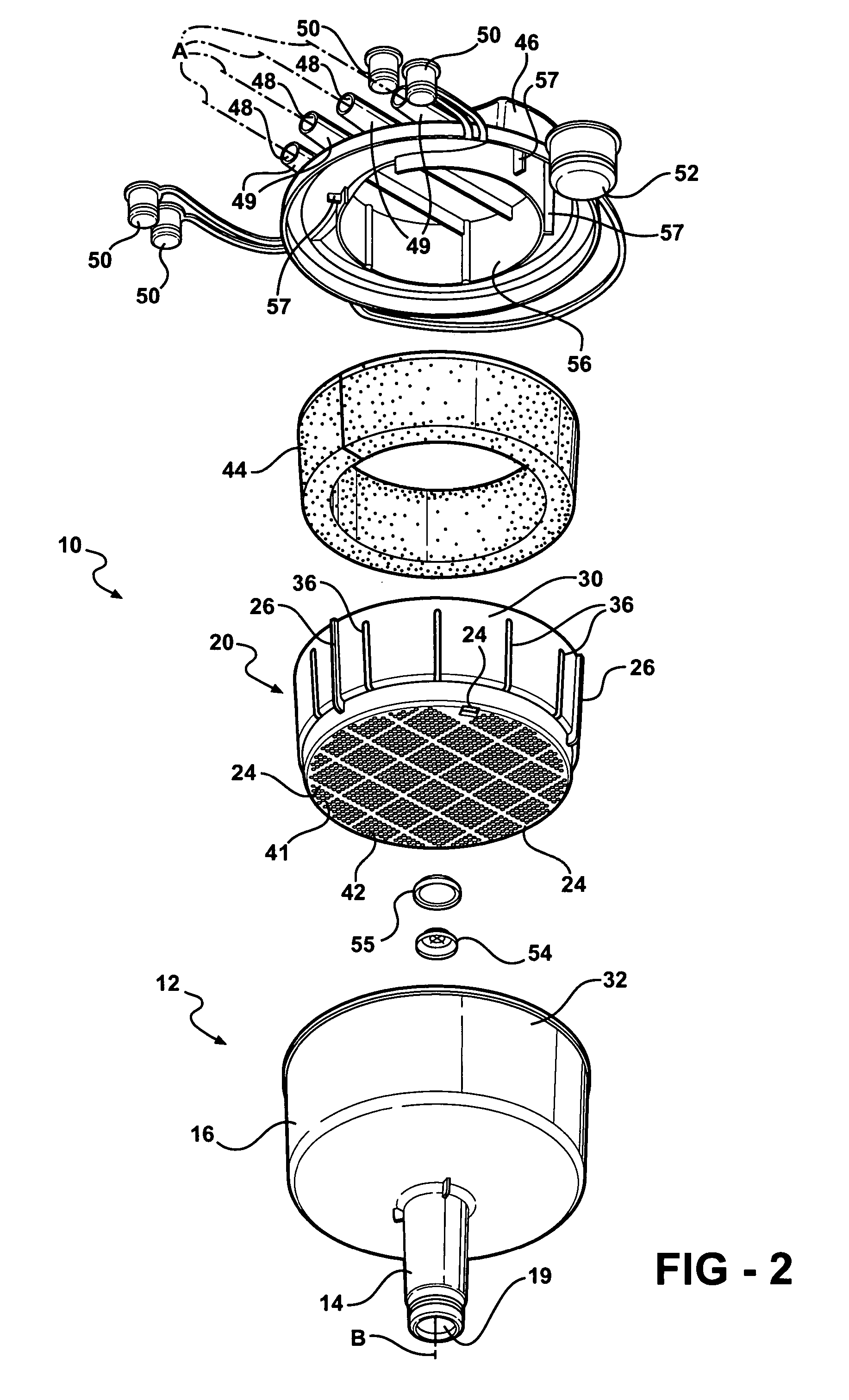

Manifold and filter assembly with filter basket

A manifold and filter assembly for use with a waste collection unit is provided. The manifold and filter assembly directs and filters medical waste flowing into the waste collection unit. The manifold and filter assembly comprises a manifold body defining a chamber and an outlet for directing the medical waste into the waste collection unit. A manifold cap is fitted to the manifold body to close the chamber. The manifold cap defines a plurality of inlets for receiving the medical waste. A filter basket having a bottom and a peripheral wall defining a plurality of openings is snap-locked to the manifold body. The filter basket is positioned such that a fluid bypass is formed between the filter basket and the manifold body and between the filter basket and the manifold cap. The fluid bypass is in fluid communication with the outlet whereby the medical waste can flow over the peripheral wall to the outlet through the fluid bypass.

Owner:STRYKER CORP

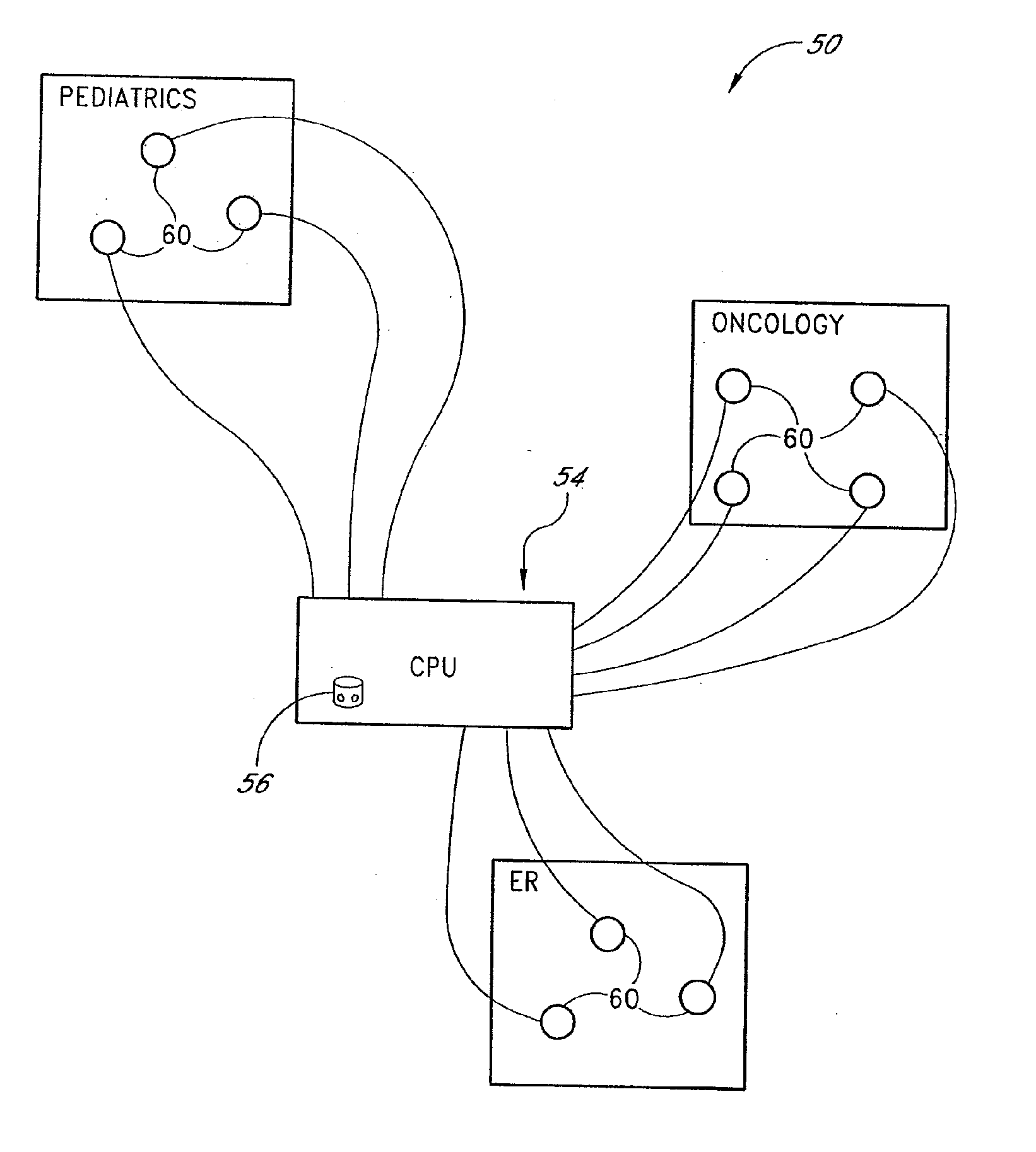

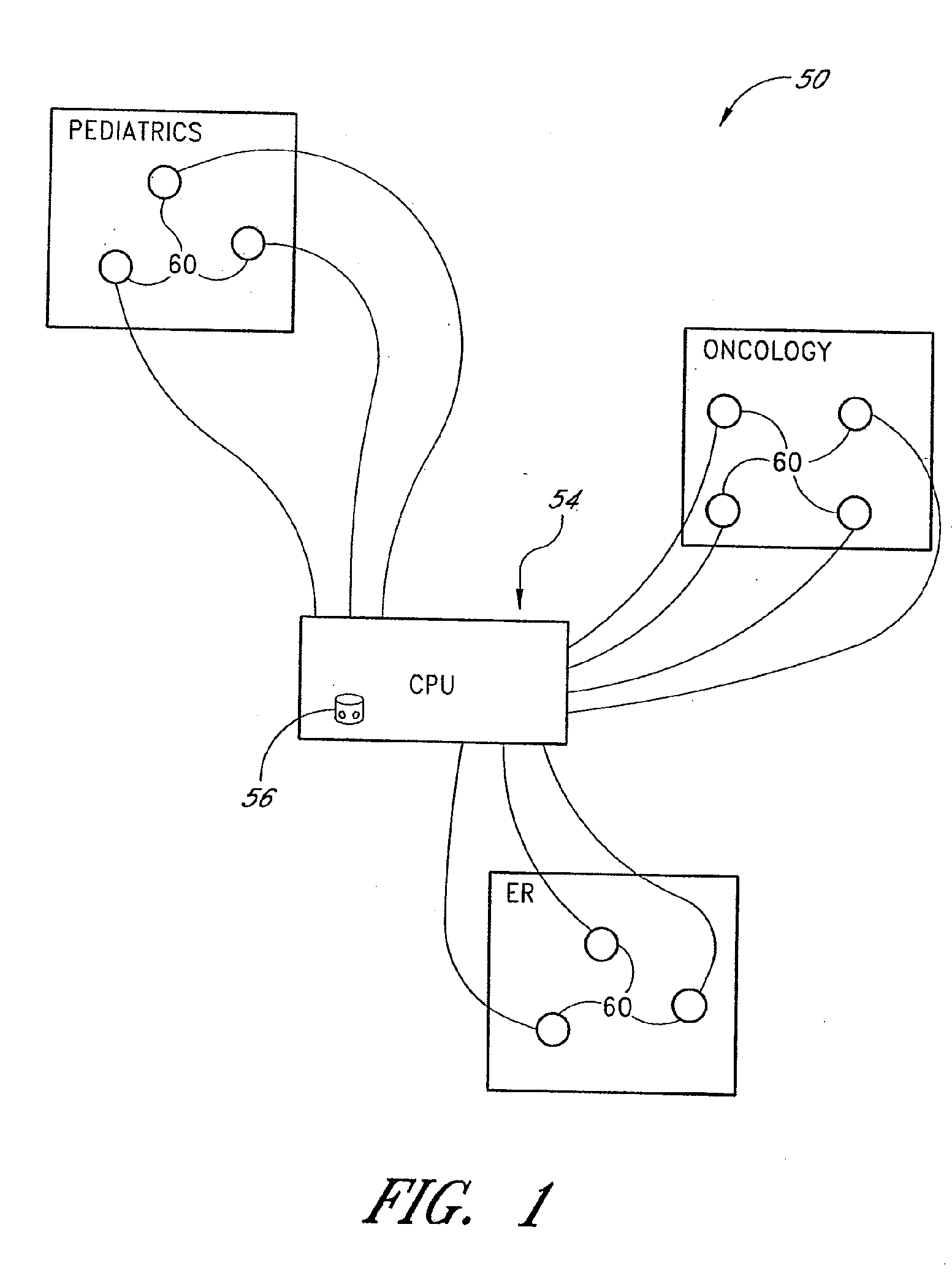

Restricted access waste sorting system

ActiveUS20070278140A1Easy to classifyEncourages and facilitates complianceSustainable waste treatmentData processing applicationsMedical wasteRestricted access

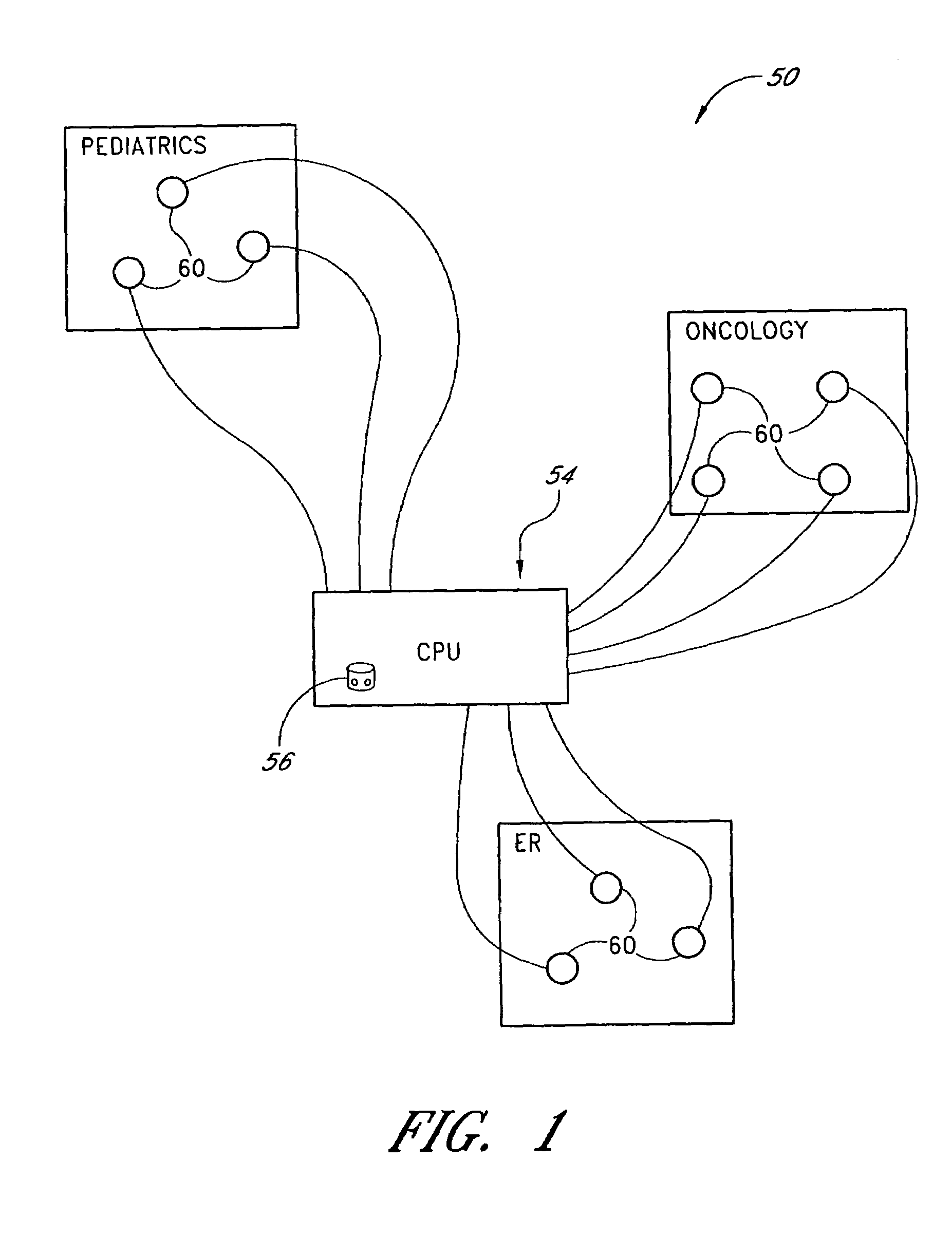

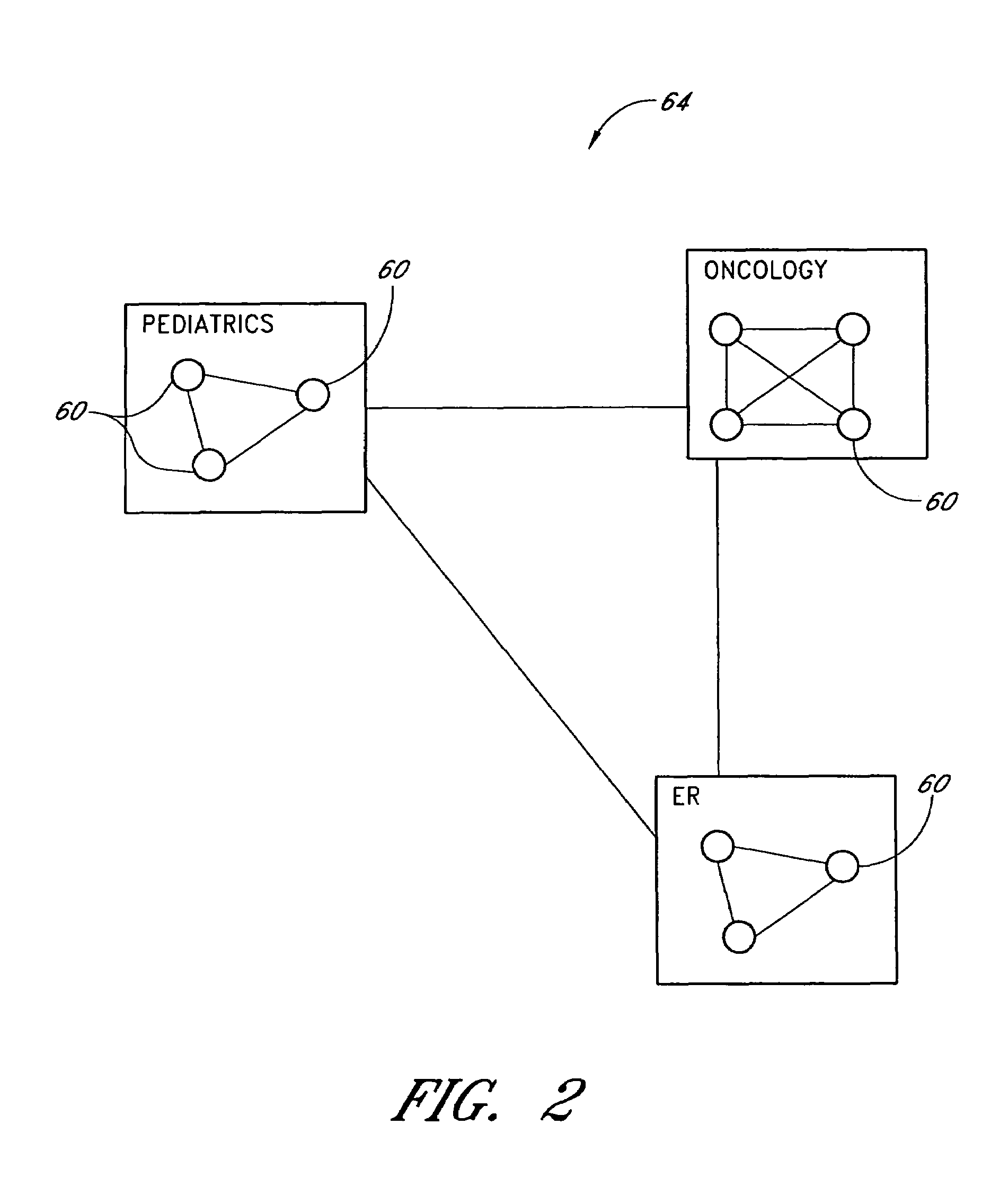

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a detection system for determining a presence and / or a quantity of waste items within a container is also provided. In some embodiments, access to discarded waste items is restricted once the waste items have been placed in a container.

Owner:CAREFUSION 303 INC

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

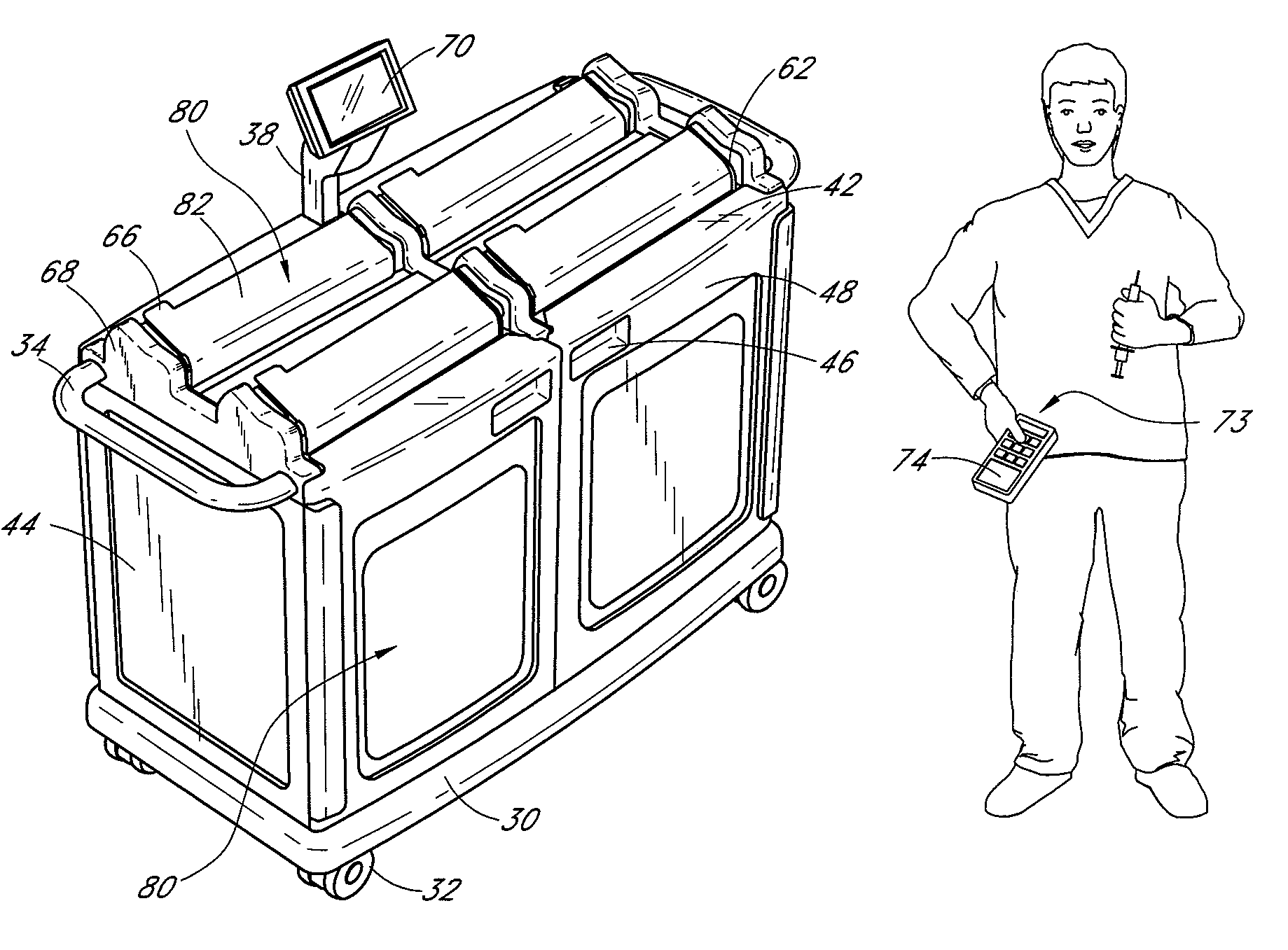

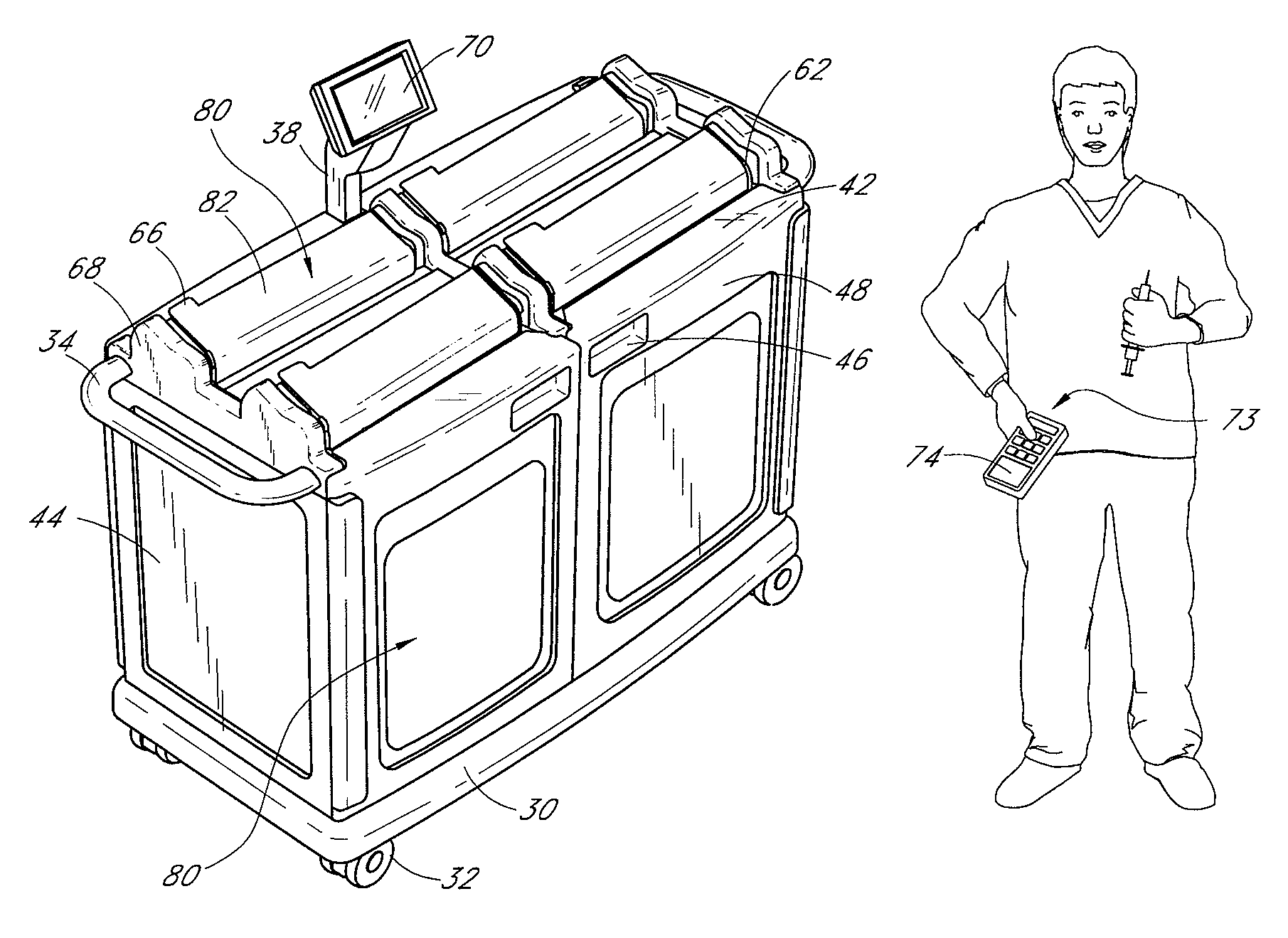

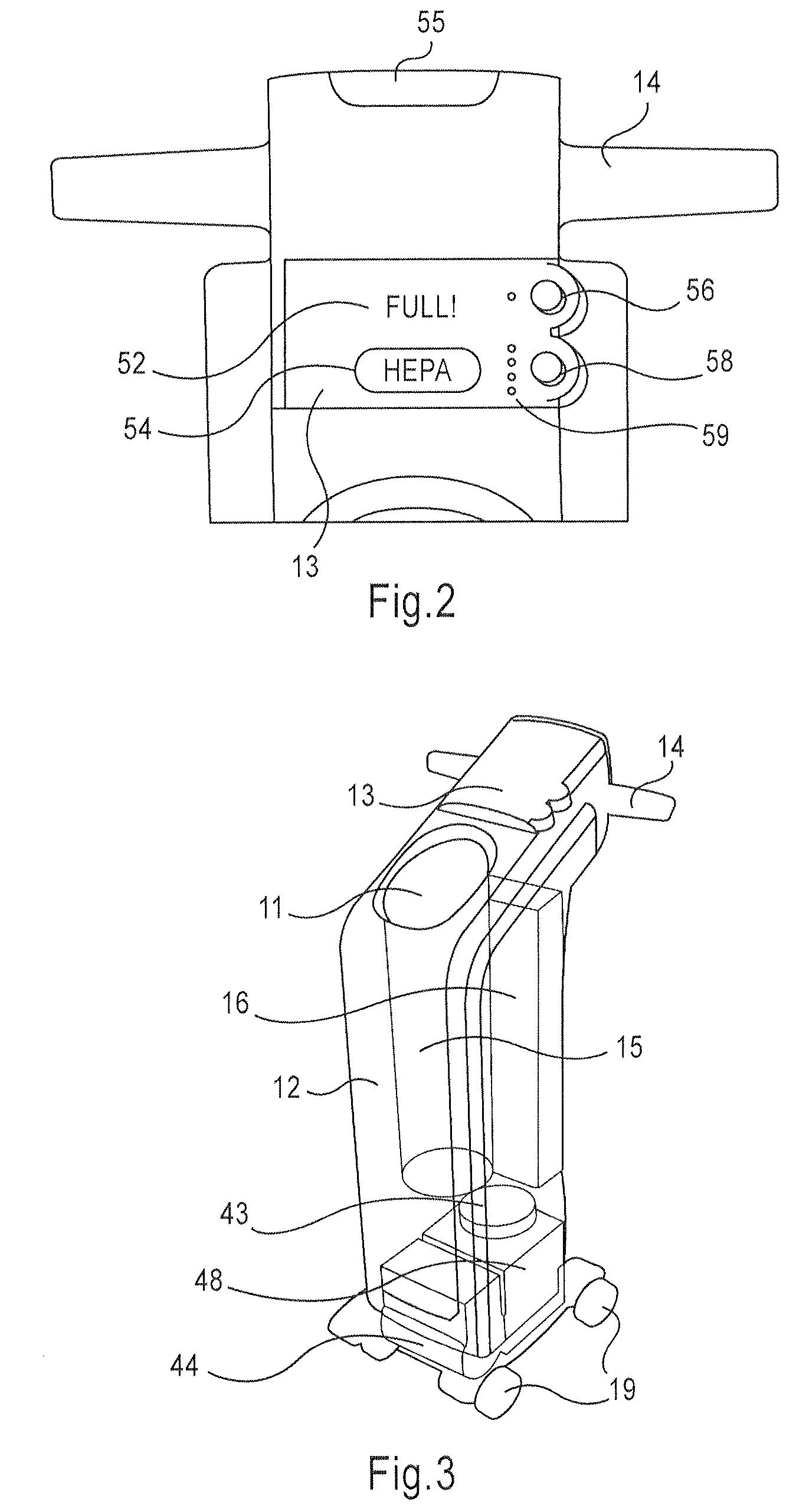

Methods of sorting waste

ActiveUS20050065640A1Easy to classifyEncourages and facilitates complianceSustainable waste treatmentSurgical furnitureClassification methodsMedical waste

A system for disposing of medical waste is generally configured to sort waste items into a plurality of disposable containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations, each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container.

Owner:CAREFUSION 303 INC

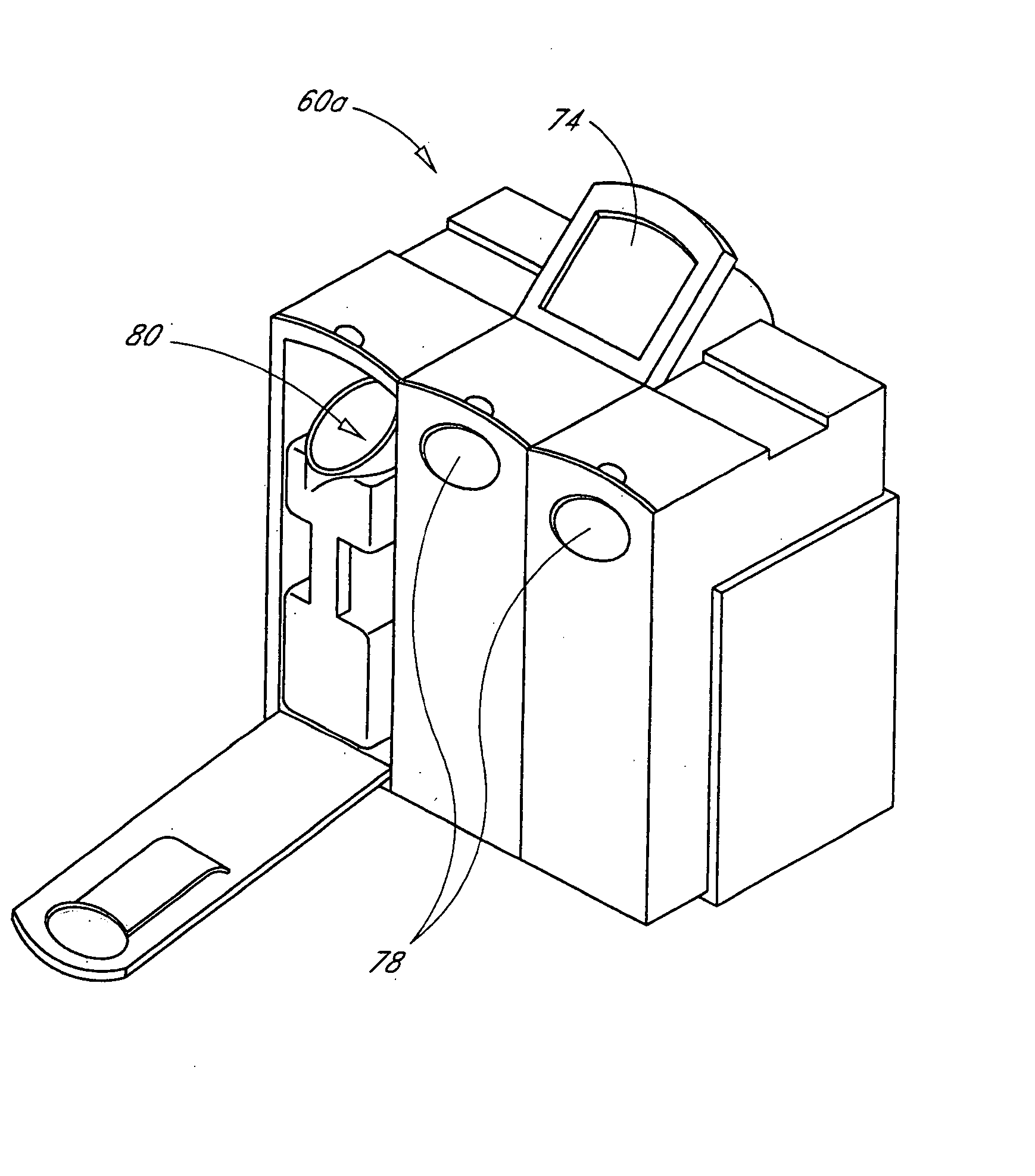

Handheld medical waste sorting device

ActiveUS7275645B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentSurgical furnitureMedical wasteWorkstation

Owner:CAREFUSION 303 INC

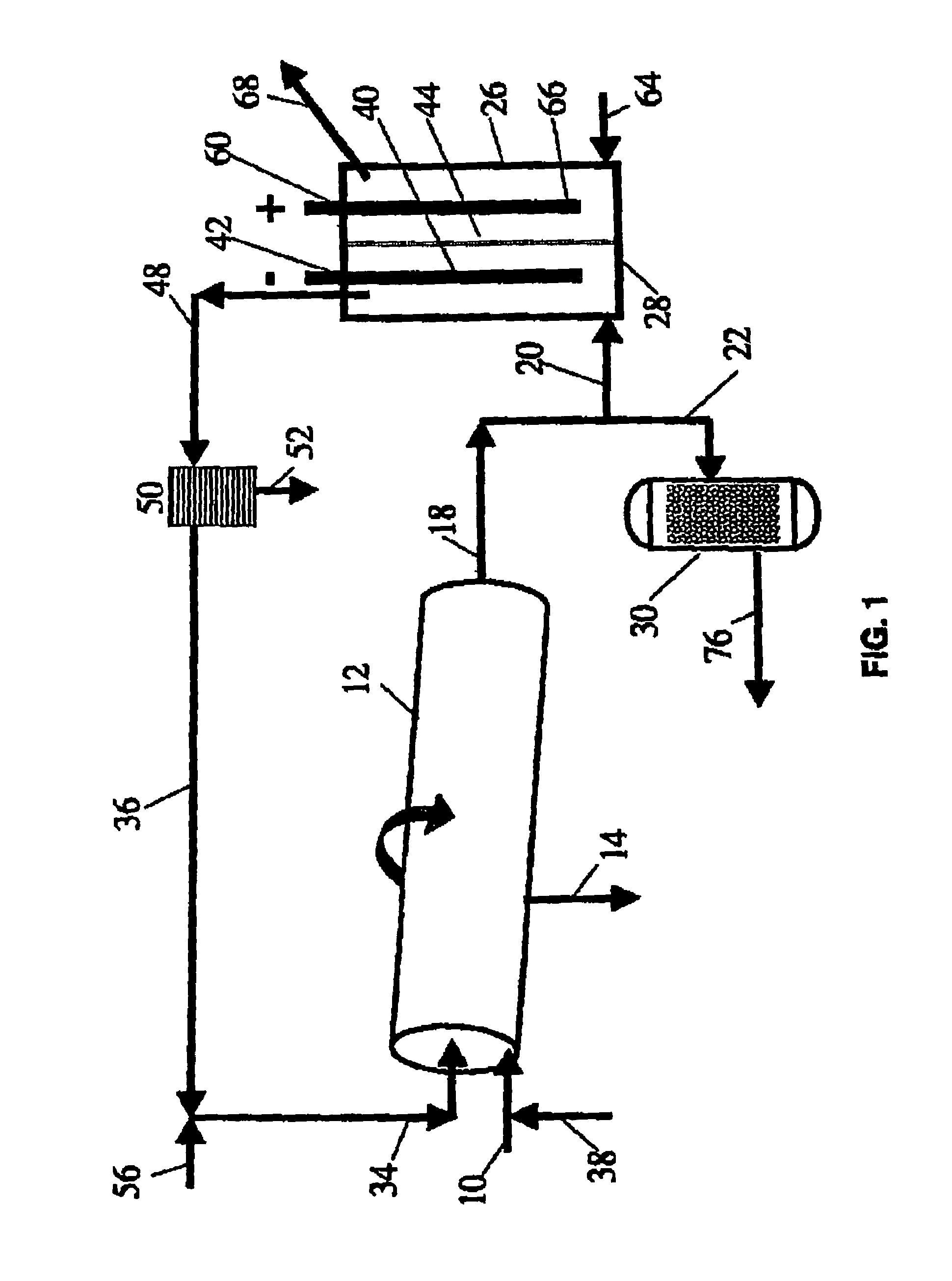

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

Manifold and filter assembly with filter basket

A manifold and filter assembly for use with a waste collection unit is provided. The manifold and filter assembly directs and filters medical waste flowing into the waste collection unit. The manifold and filter assembly comprises a manifold body defining a chamber and an outlet for directing the medical waste into the waste collection unit. A manifold cap is fitted to the manifold body to close the chamber. The manifold cap defines a plurality of inlets for receiving the medical waste. A filter basket having a bottom and a peripheral wall defining a plurality of openings is snap-locked to the manifold body. The filter basket is positioned such that a fluid bypass is formed between the filter basket and the manifold body and between the filter basket and the manifold cap. The fluid bypass is in fluid communication with the outlet whereby the medical waste can flow over the peripheral wall to the outlet through the fluid bypass.

Owner:STRYKER CORP

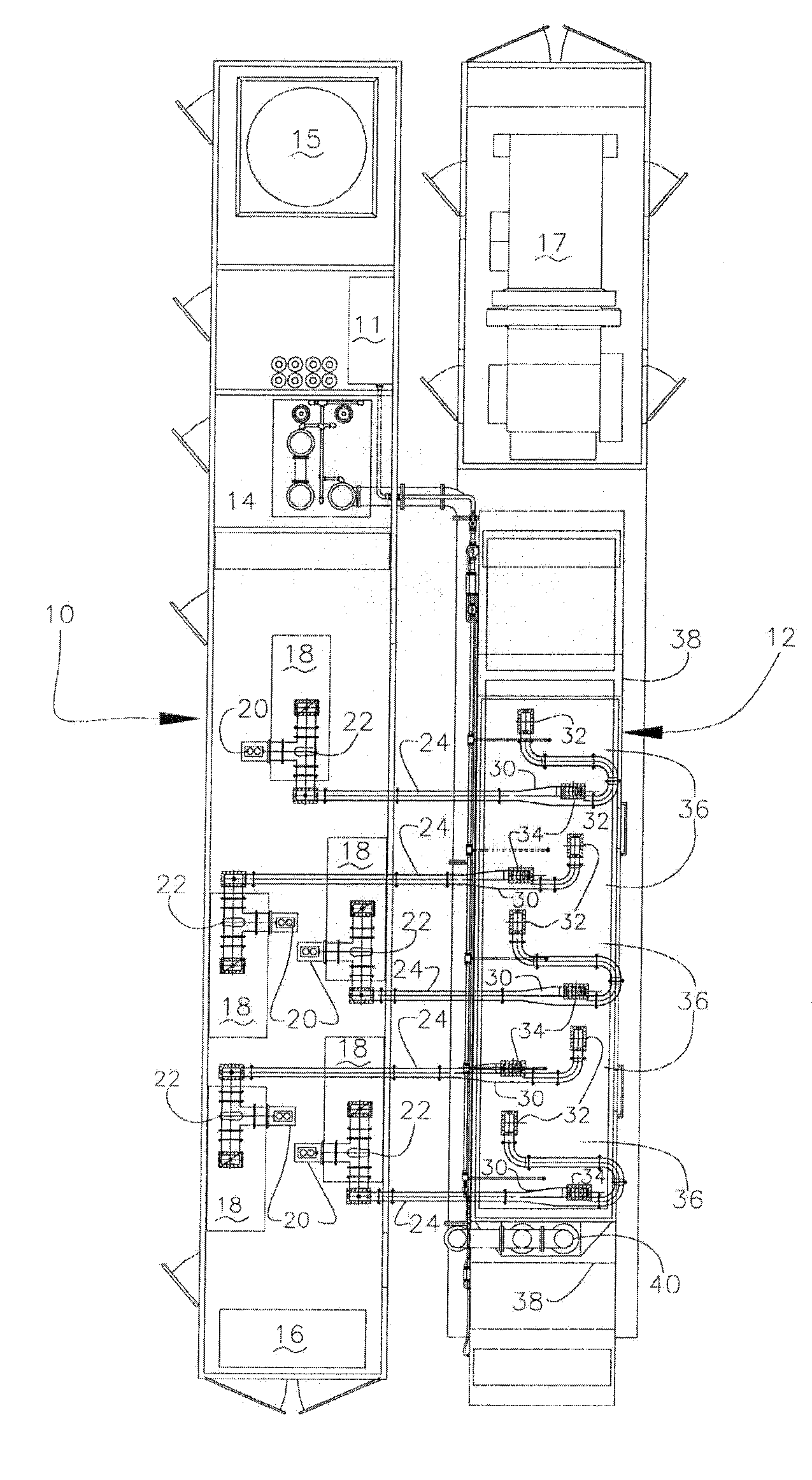

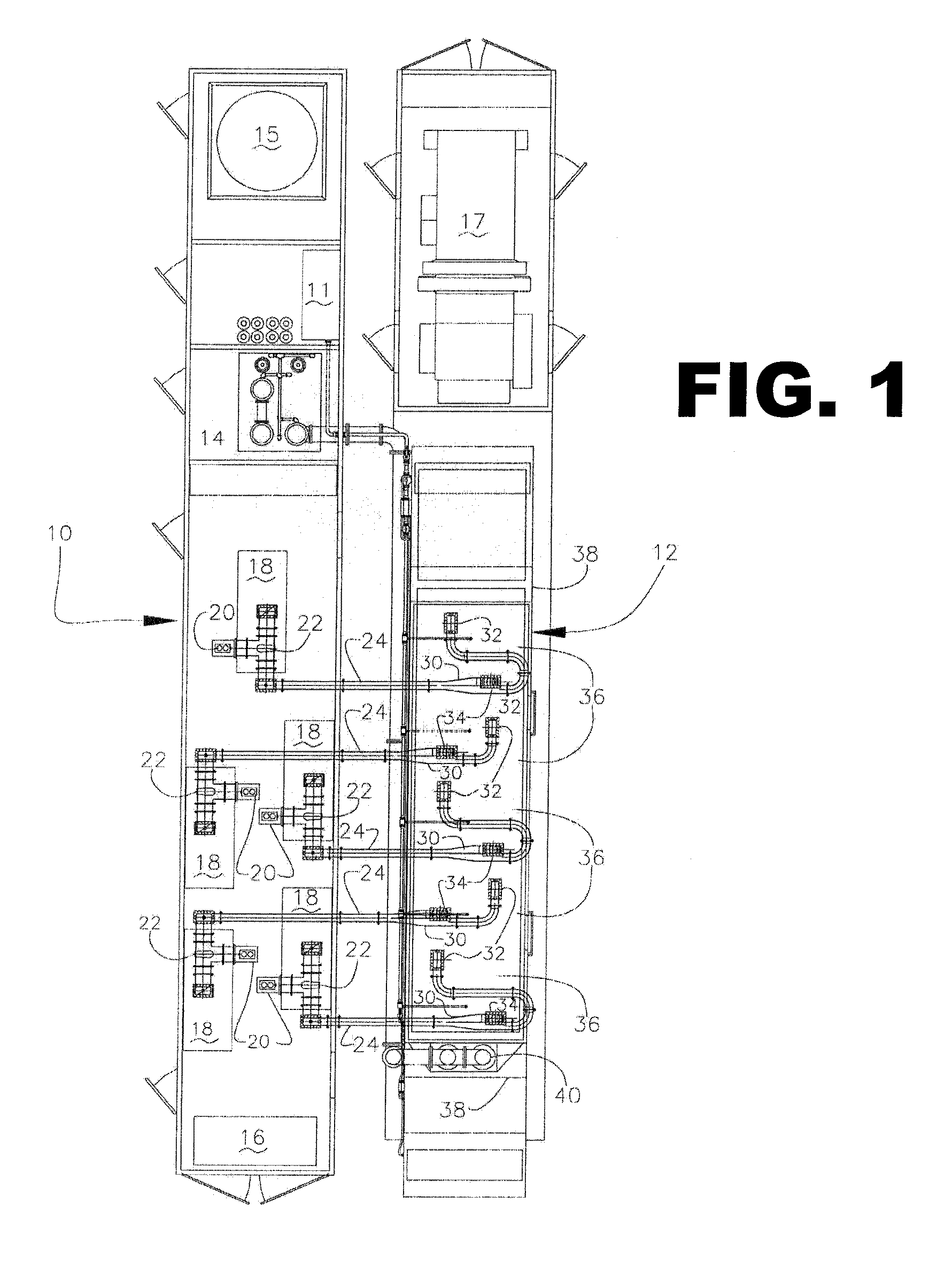

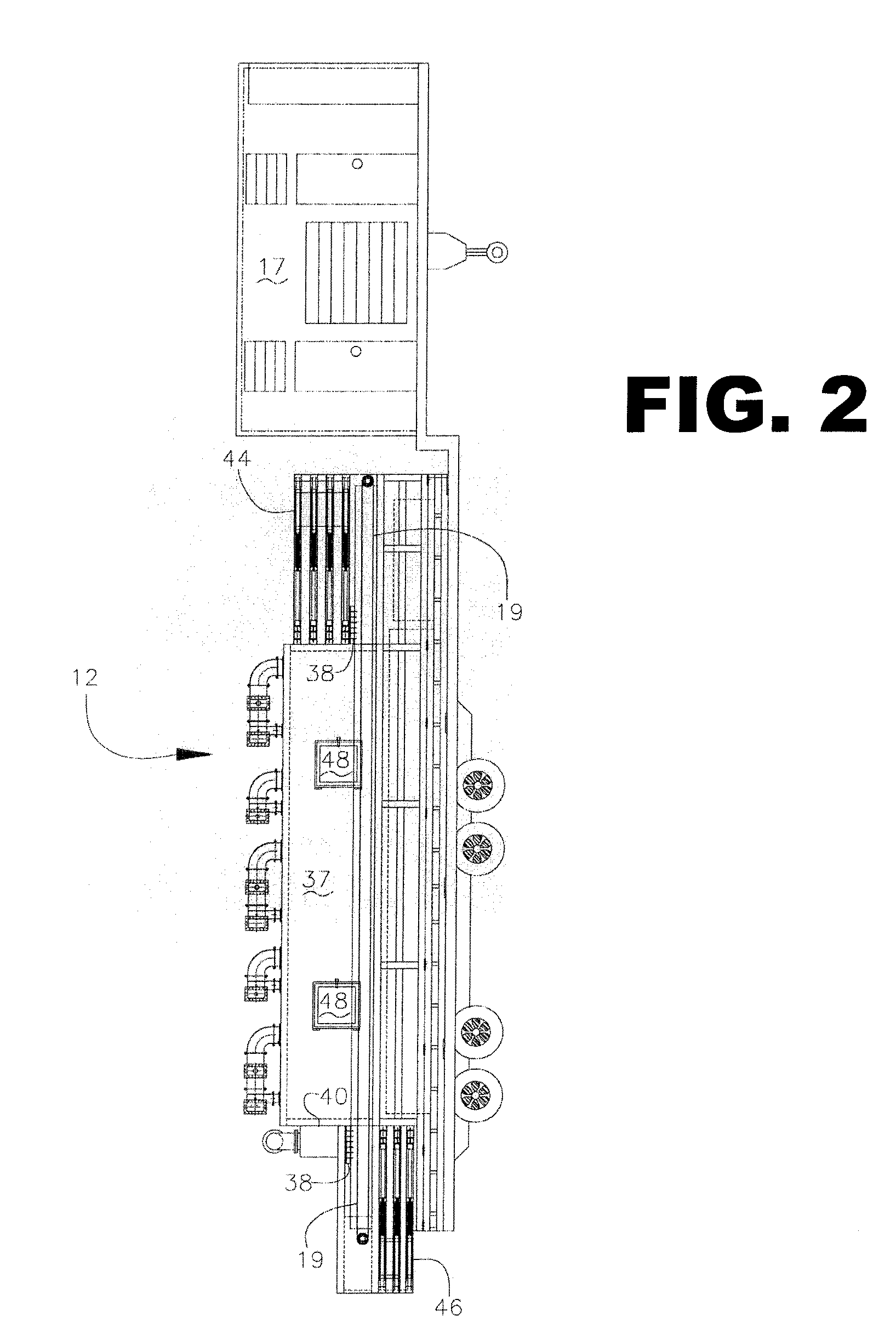

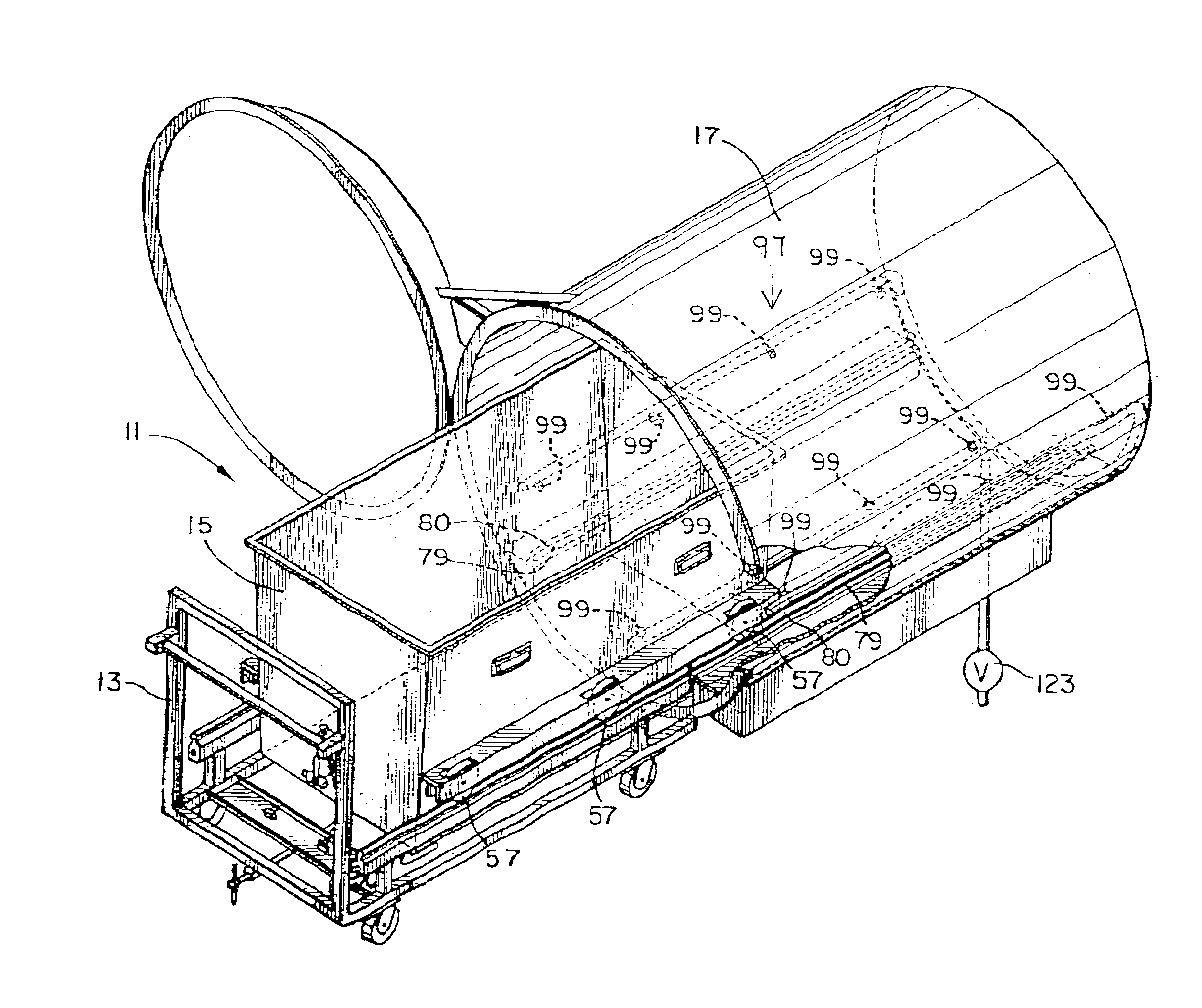

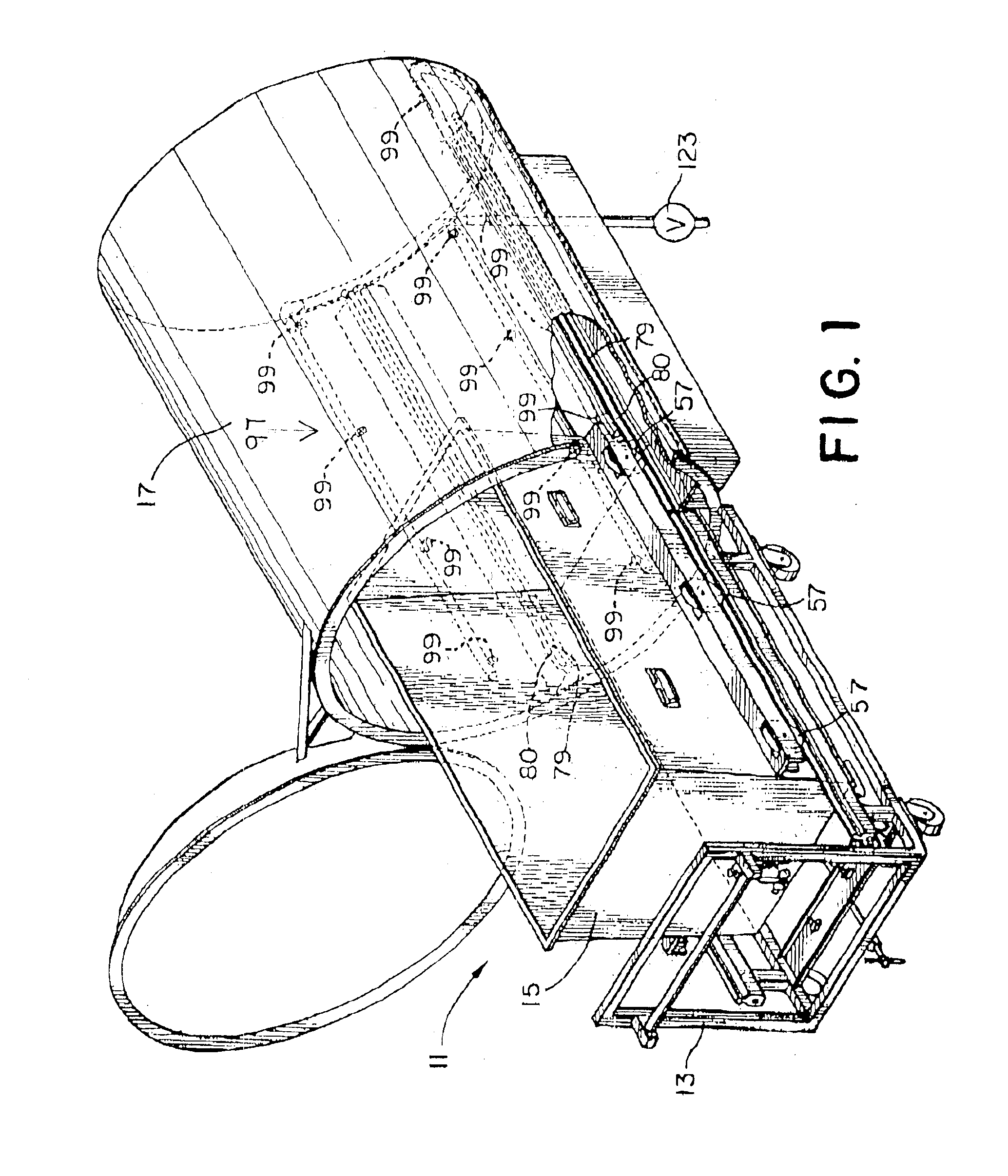

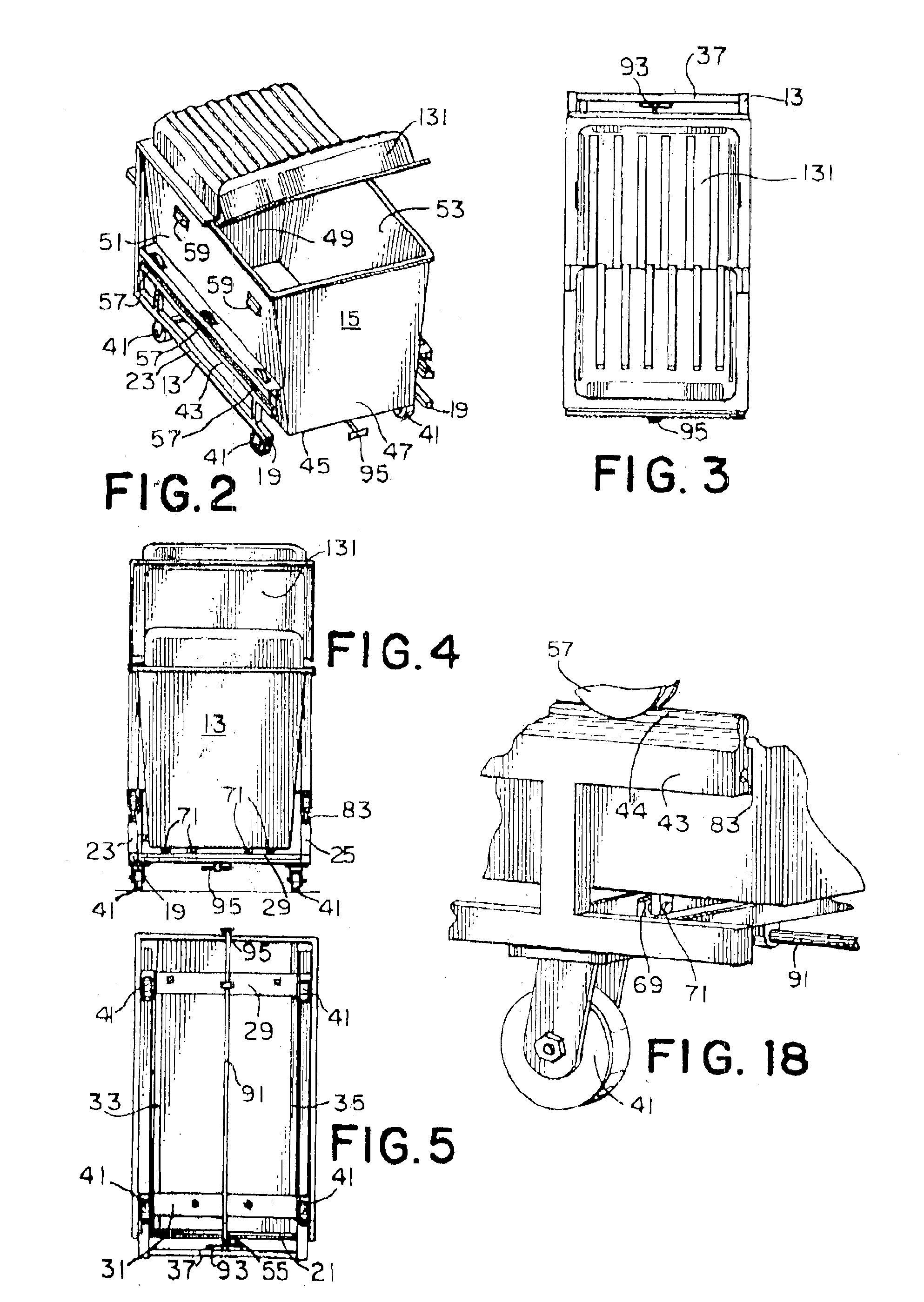

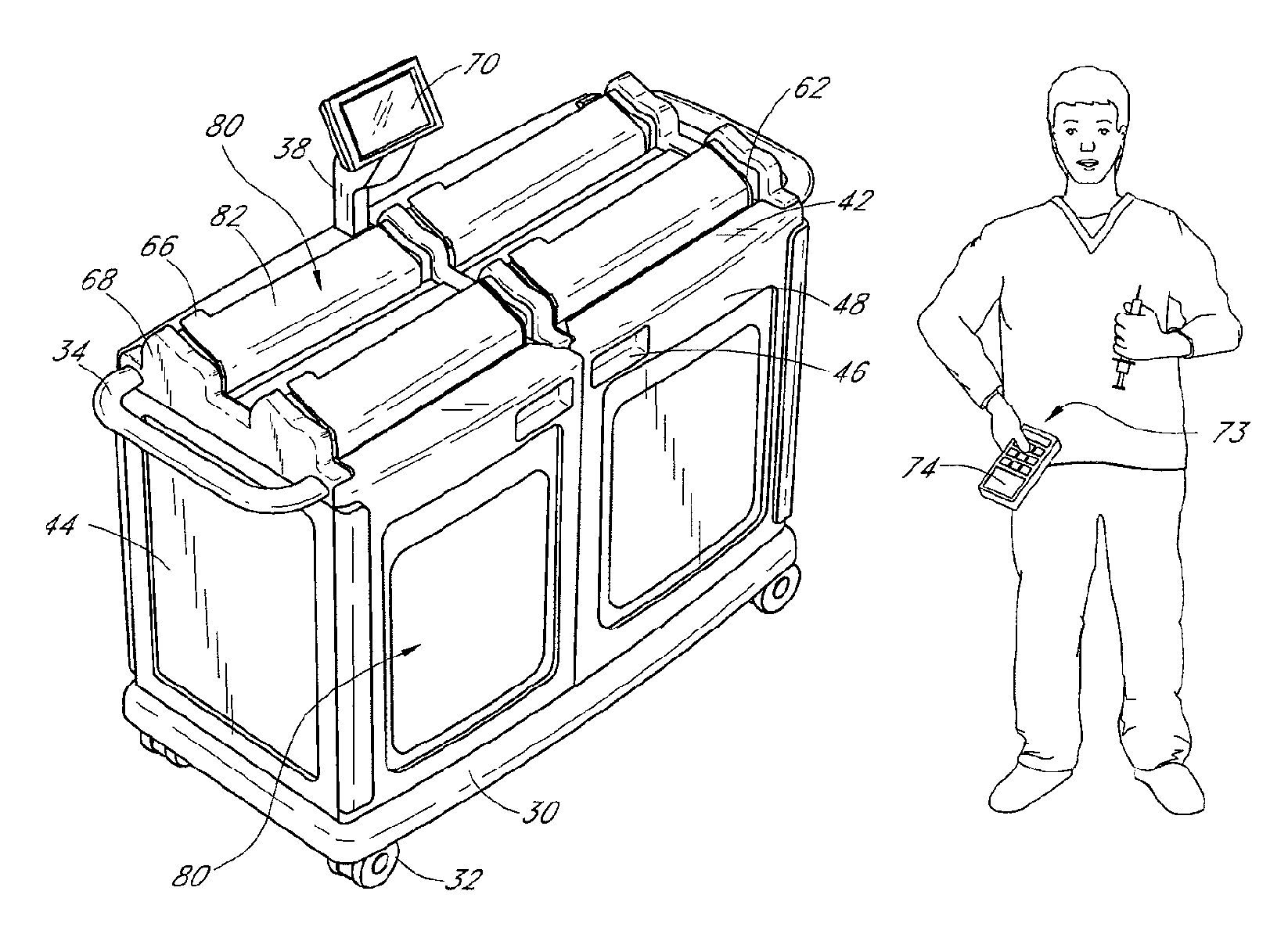

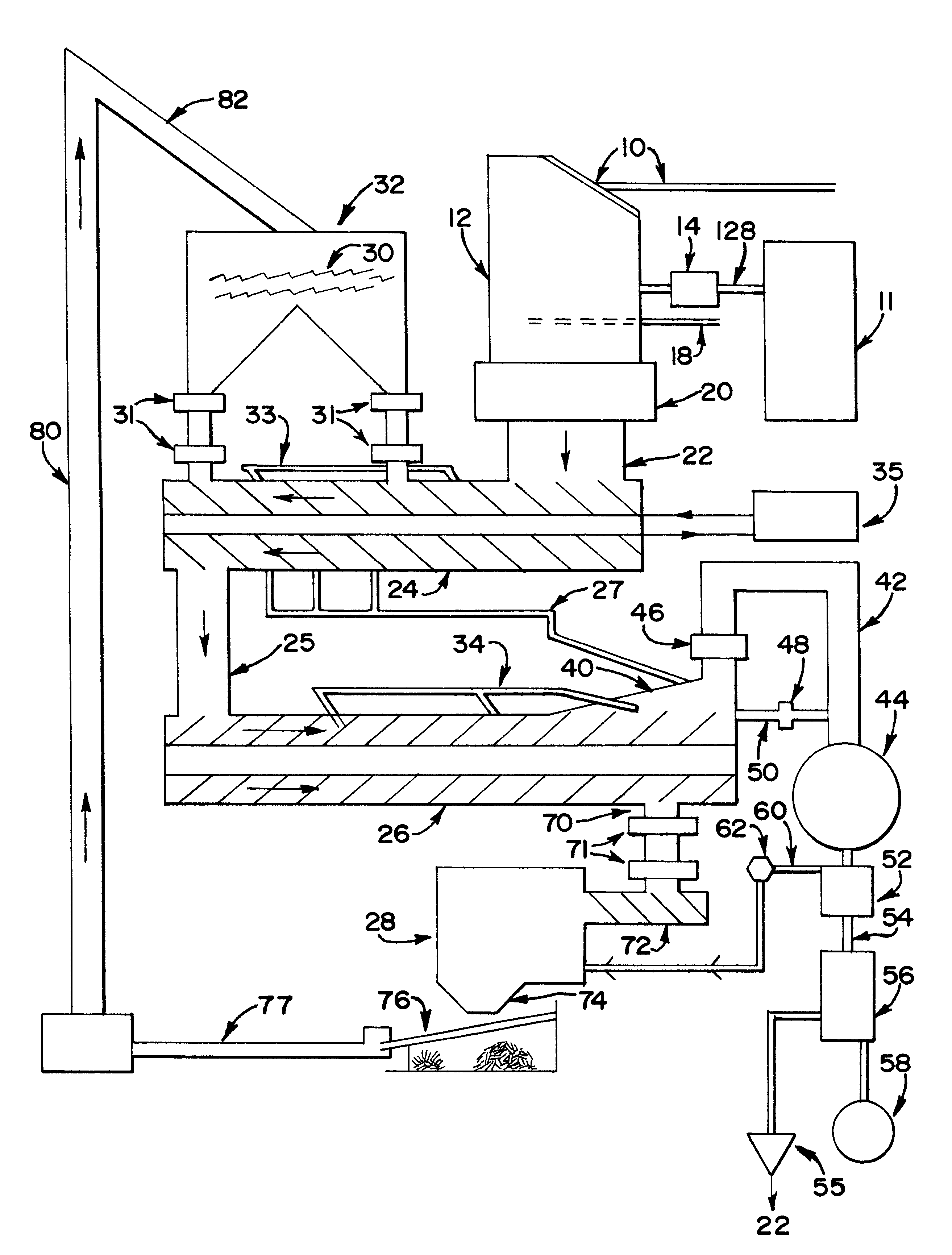

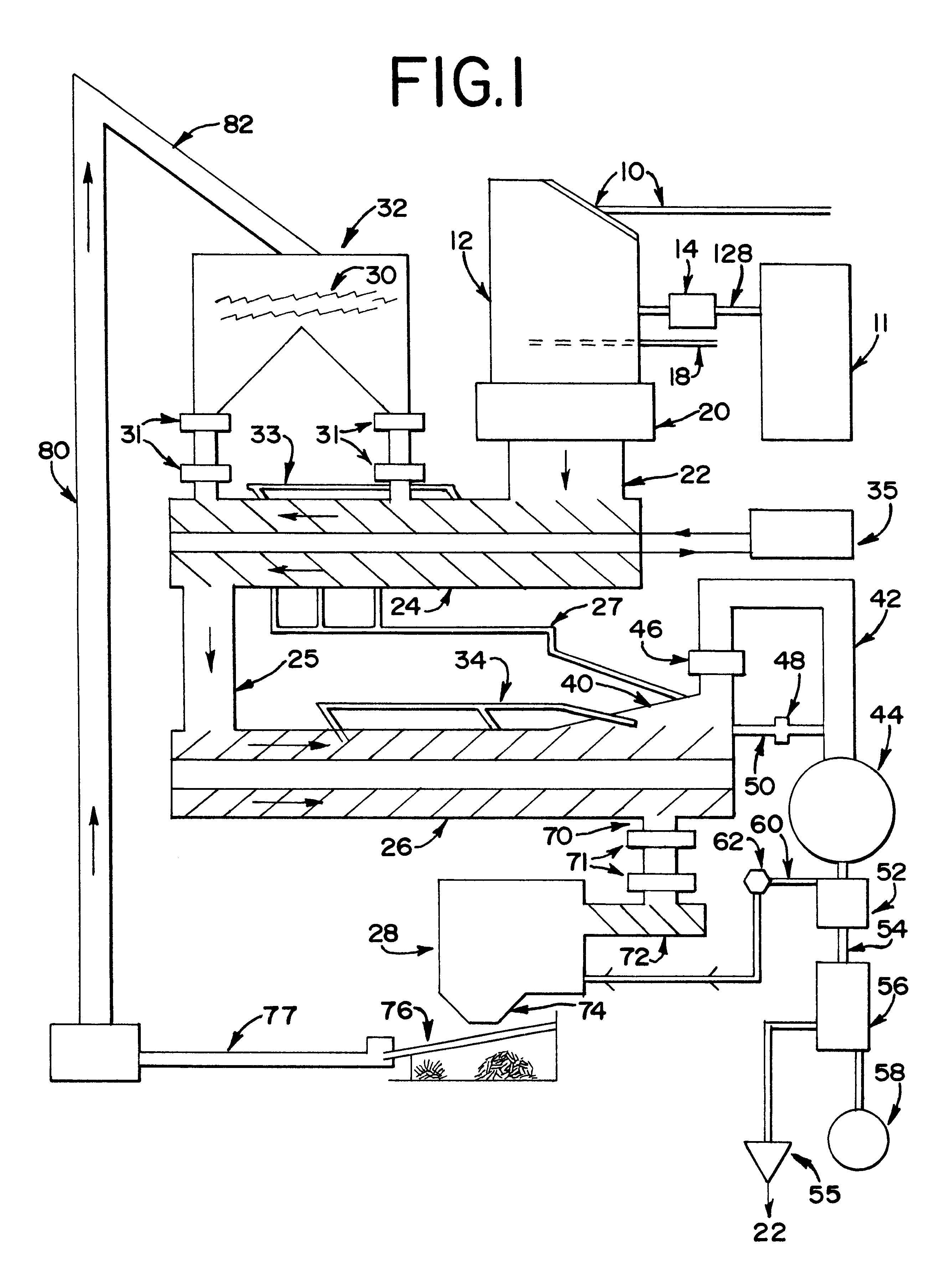

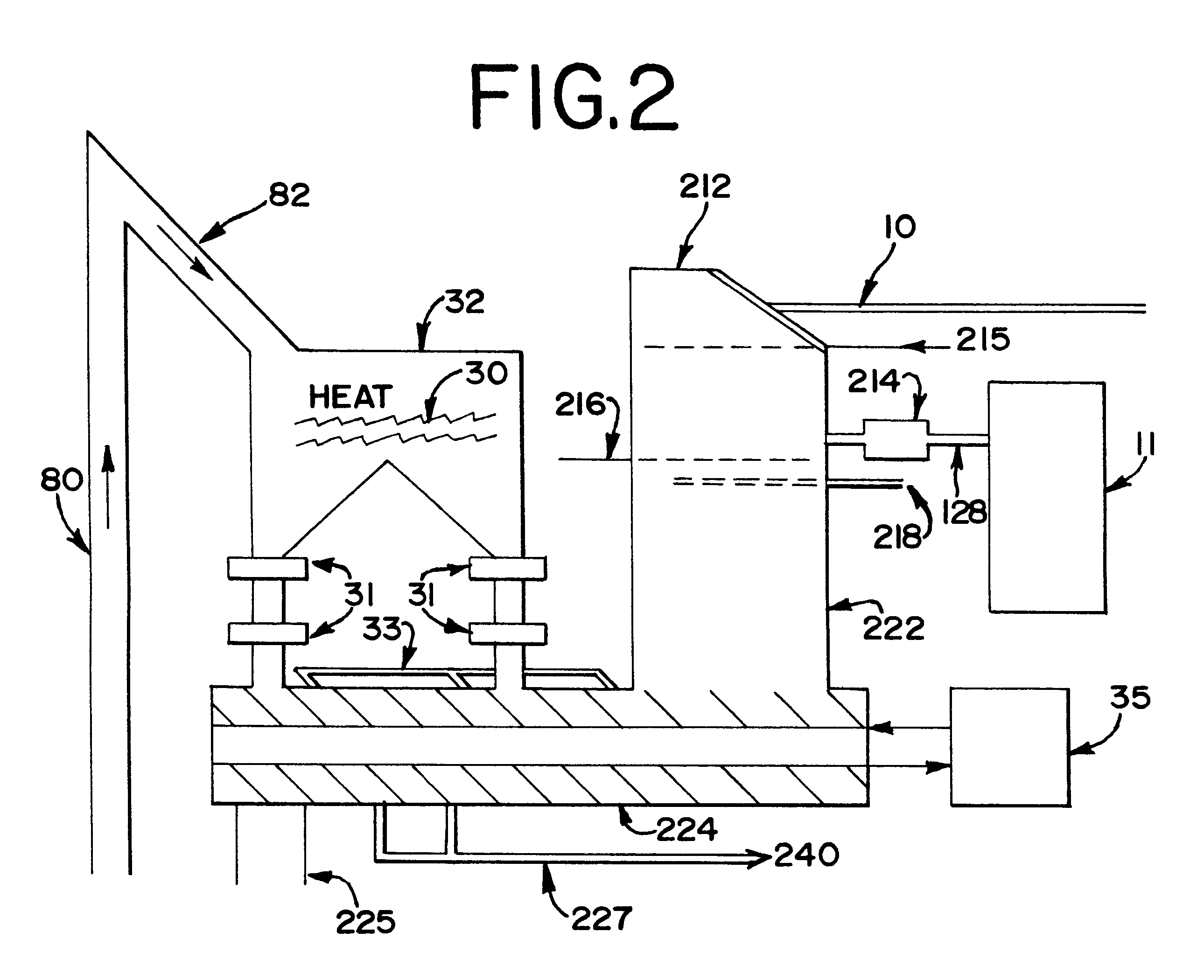

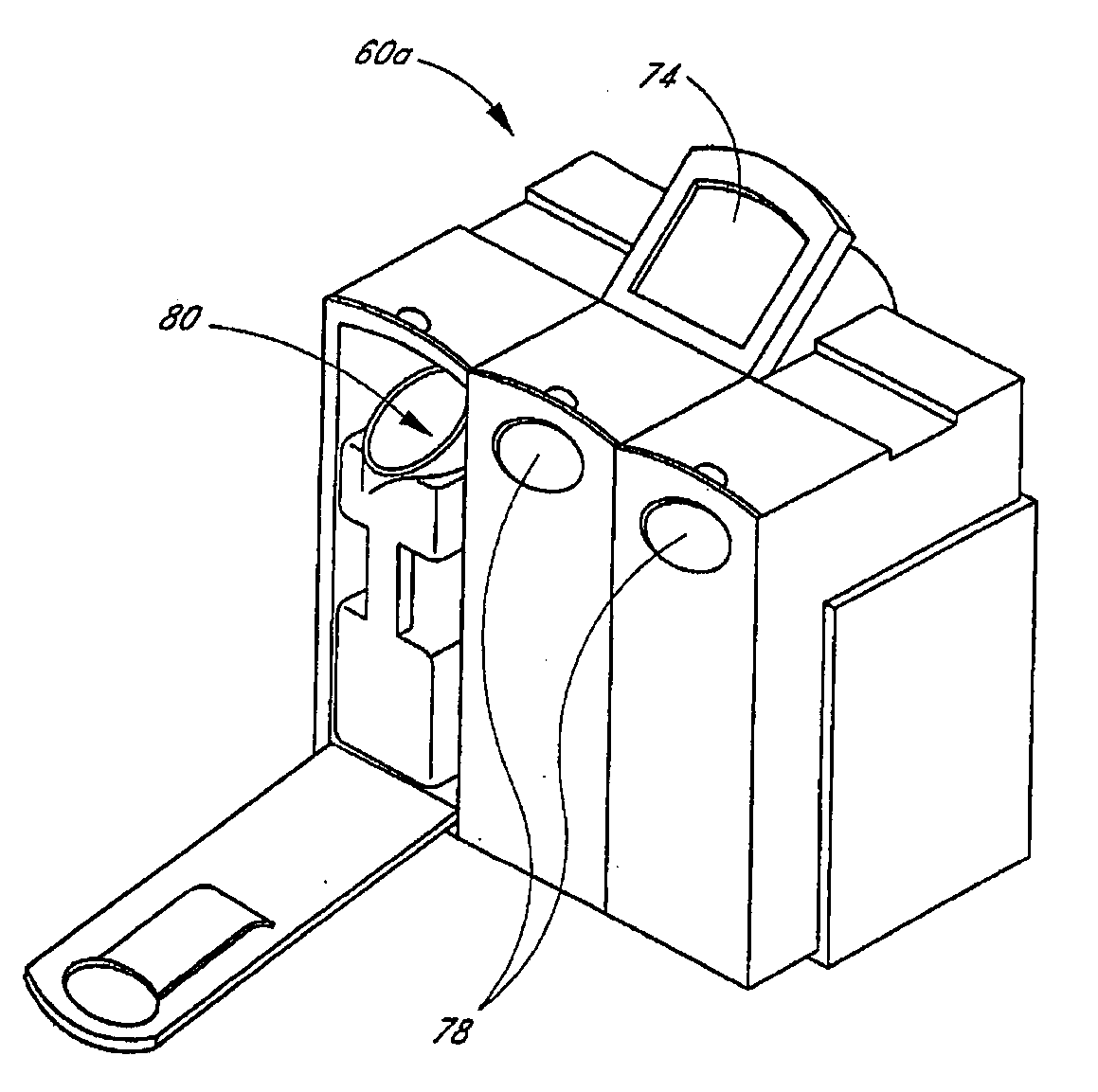

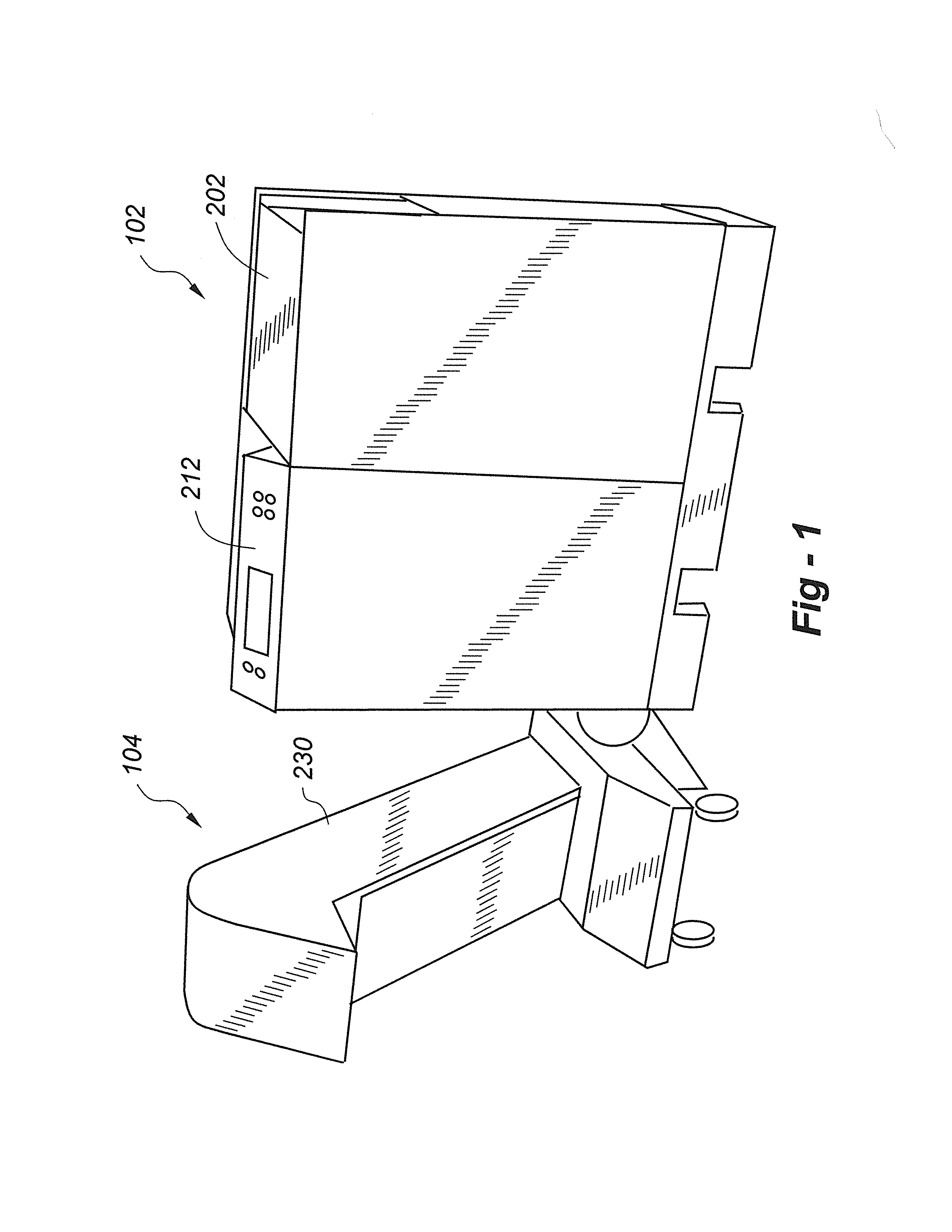

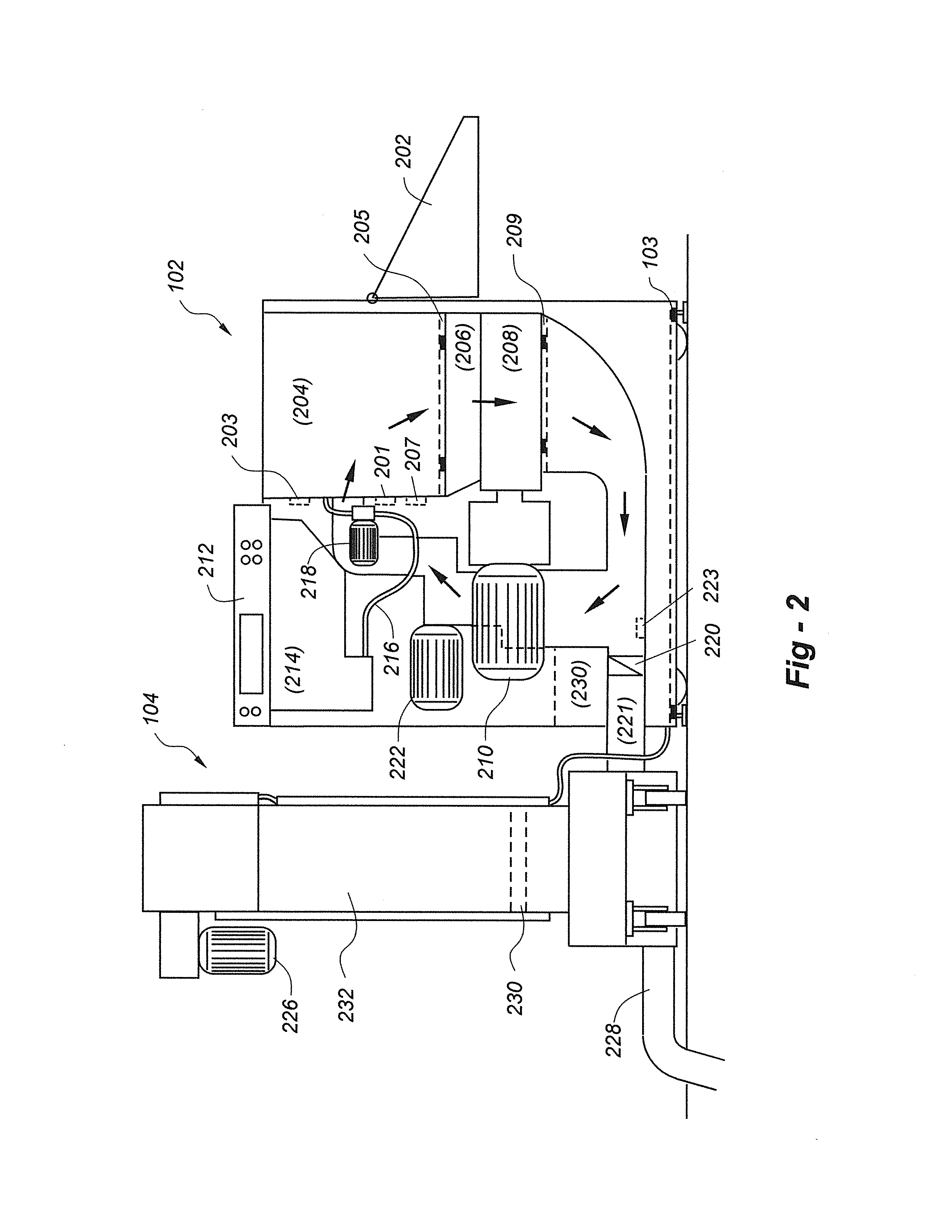

Steam sterilization system for sterilizing medical waste

ActiveUS6867393B1Reduce handlingReducing pathogen exposureMuffle furnacesBaking ovenMedical wasteEngineering

A steam sterilization system for sterilizing medical waste comprises a cart for carrying a removable bin for holding medical waste, and a sterilization chamber that receives the bin when it is removed from the cart. The cart has wheels mounted thereon to provide mobility to the cart, and the cart has a rail assembly positioned at each side end portion. The bin for holding medical waste the bin being removably mountable to the cart, and the bin has wheels mounted on each side wall of the bin and spaced such that the wheels engage the rail assemblies of the cart when the bin is being loaded onto the cart and such that the wheels engage the rail assemblies of the cart when the bin is being removed from the cart. The sterilization chamber has a rail assembly mounted in the interior of the chamber on which the wheels of the bin ride when the bin is inserted into the chamber from the cart prior to sterilization and on which the wheels of the bin ride when the bin is being removed from the chamber and rolled back onto the cart after sterilization. A steam valve is connected to the chamber for introducing steam when desired into the chamber, and a vacuum pump is connected to the chamber for evacuating air in the chamber when desired.

Owner:ASSURED WASTE SOLUTIONS LLC

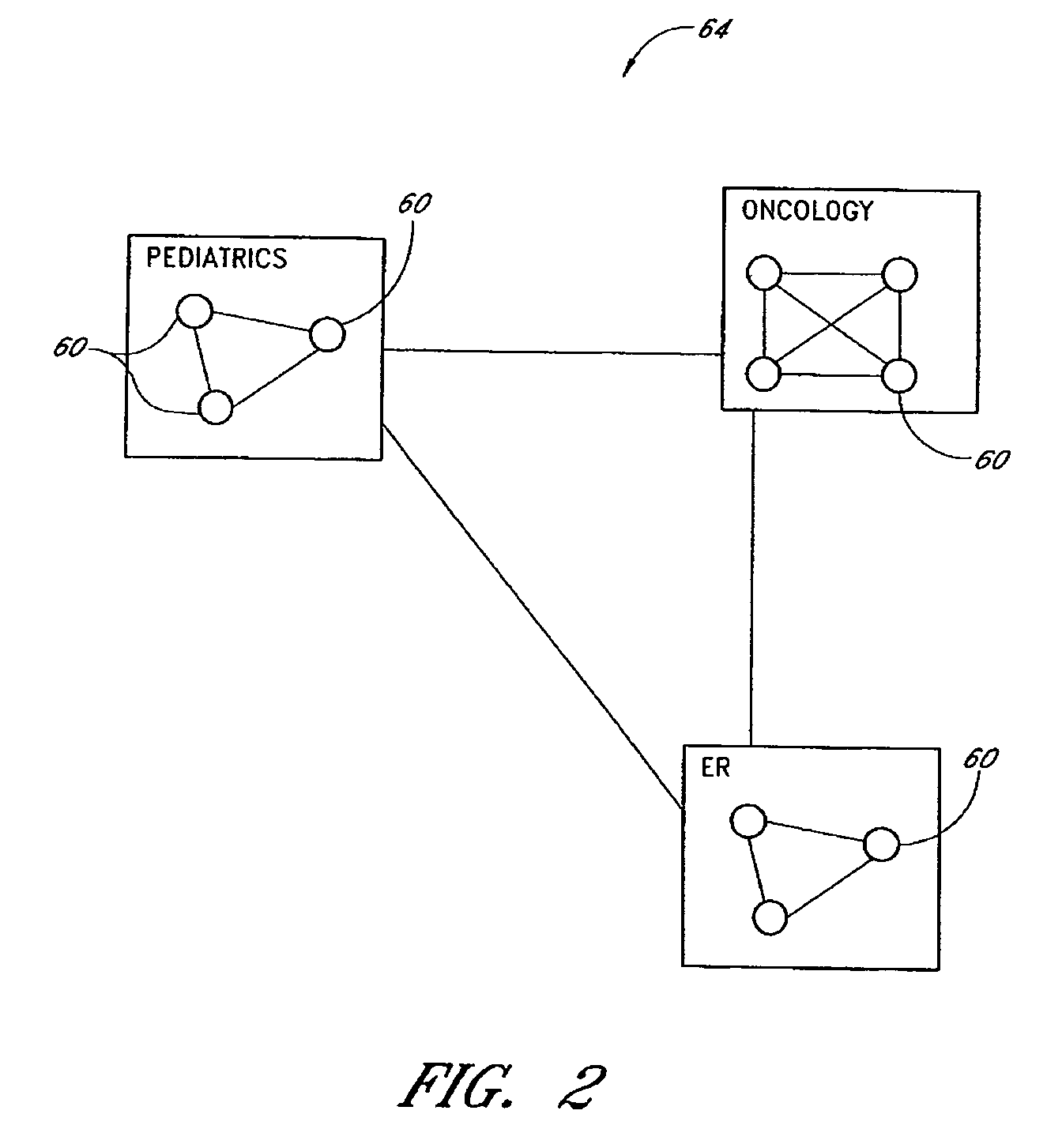

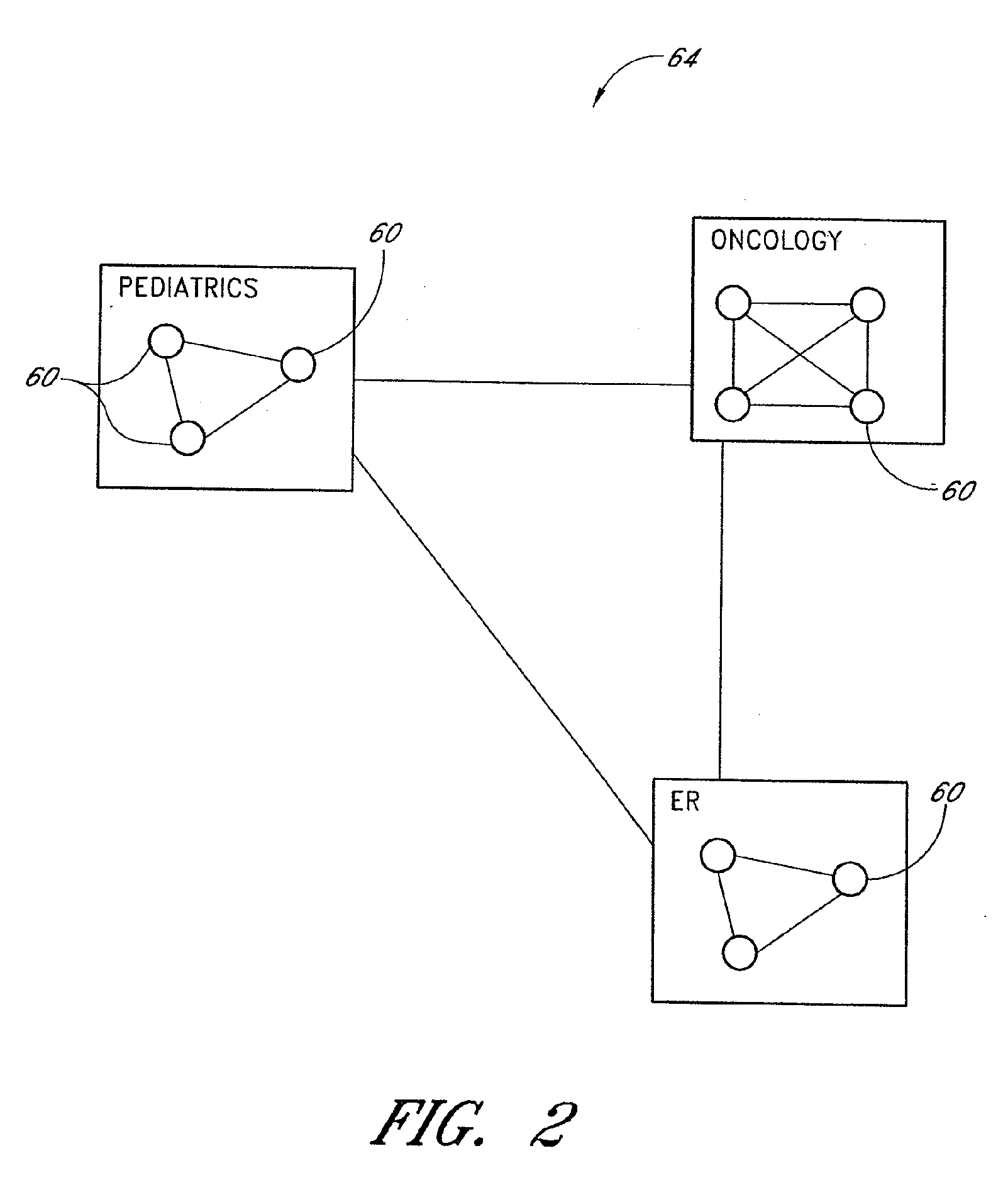

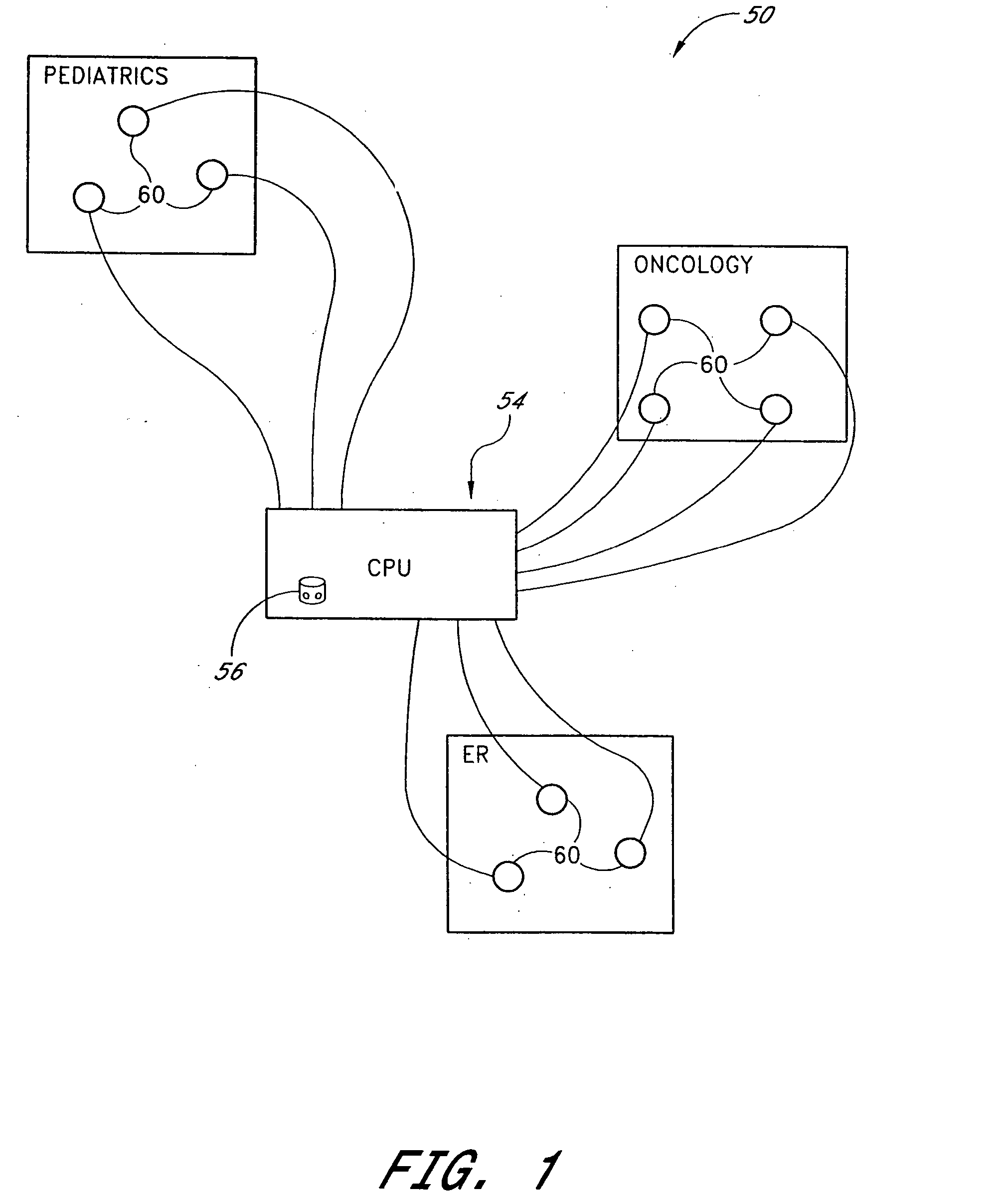

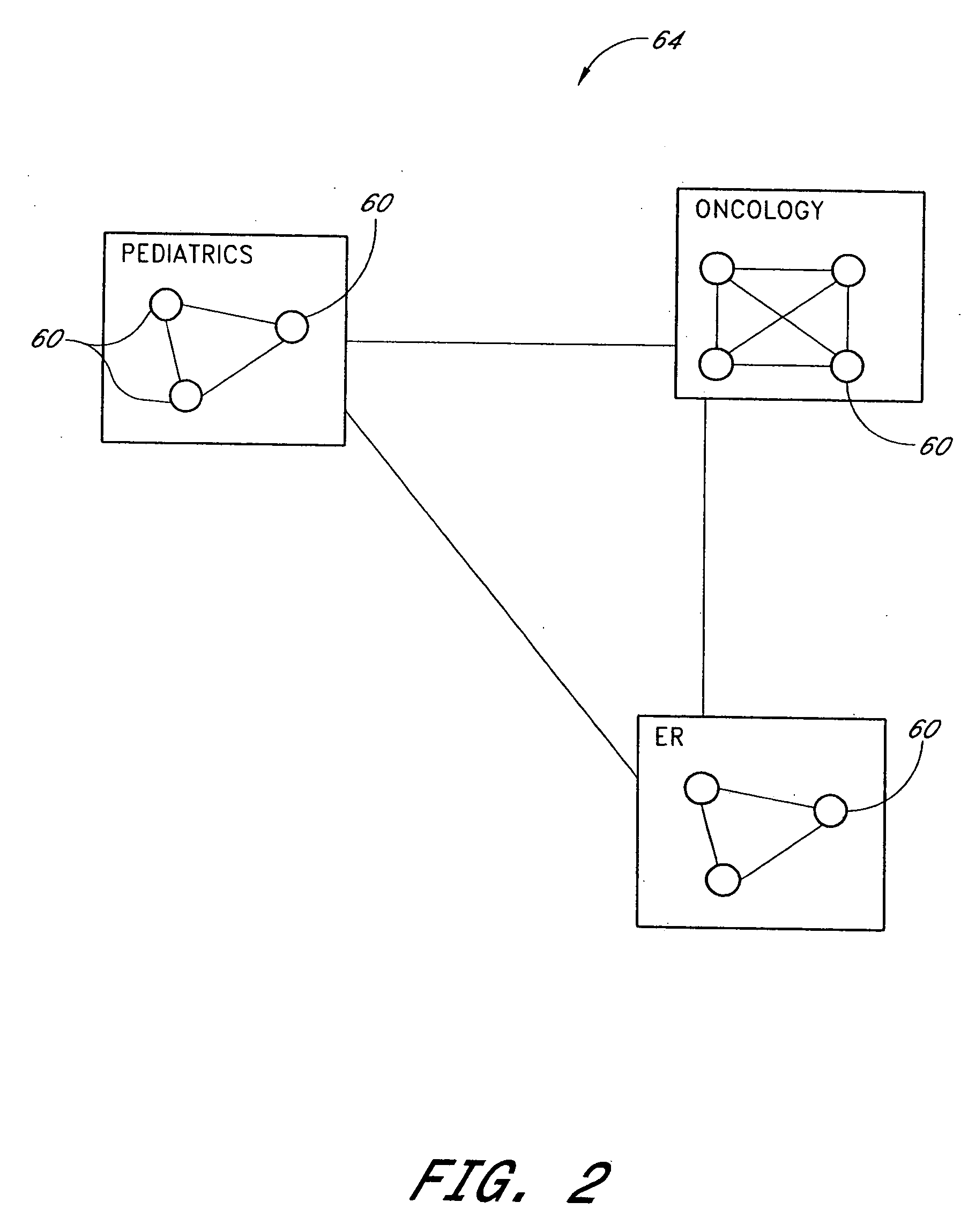

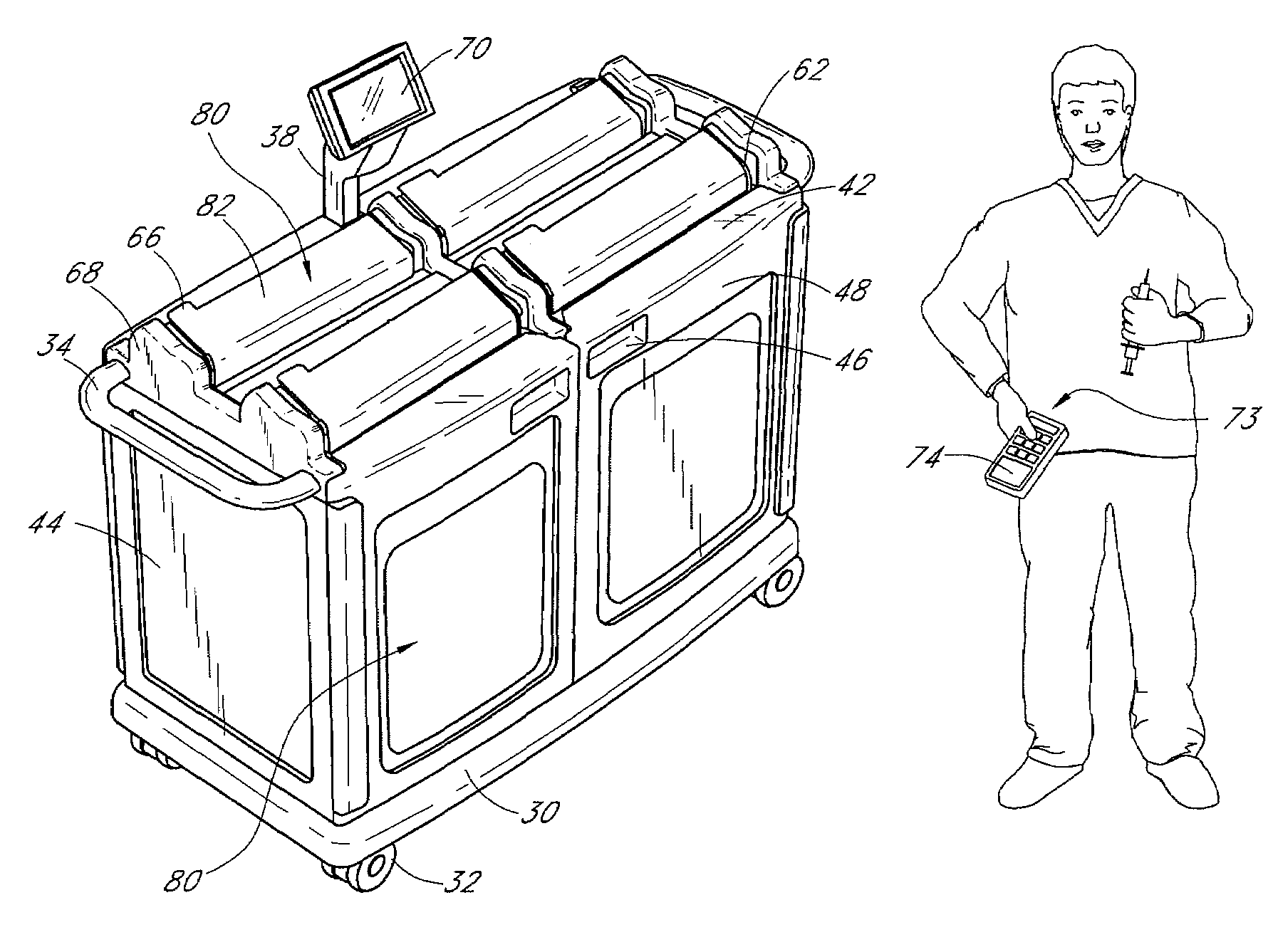

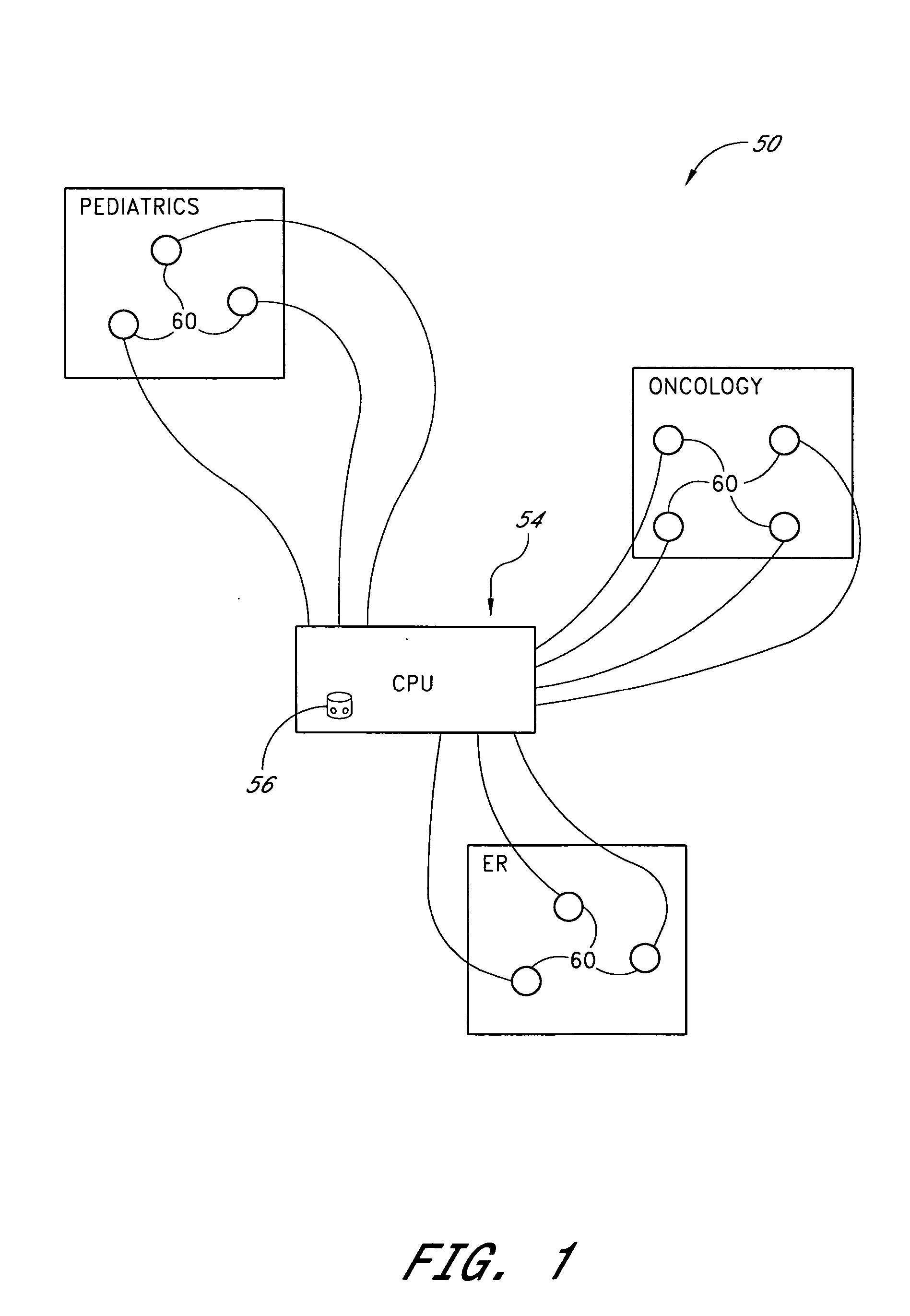

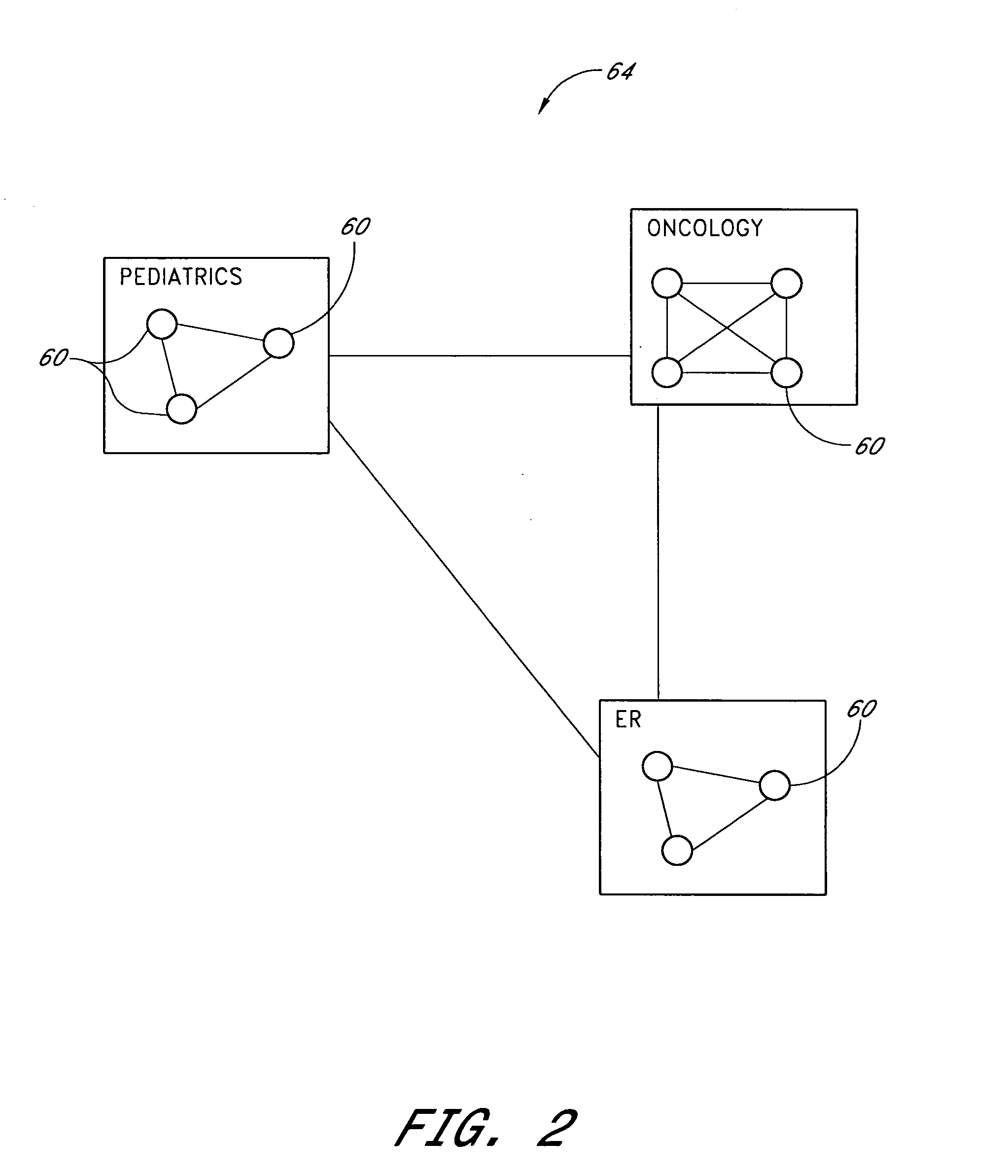

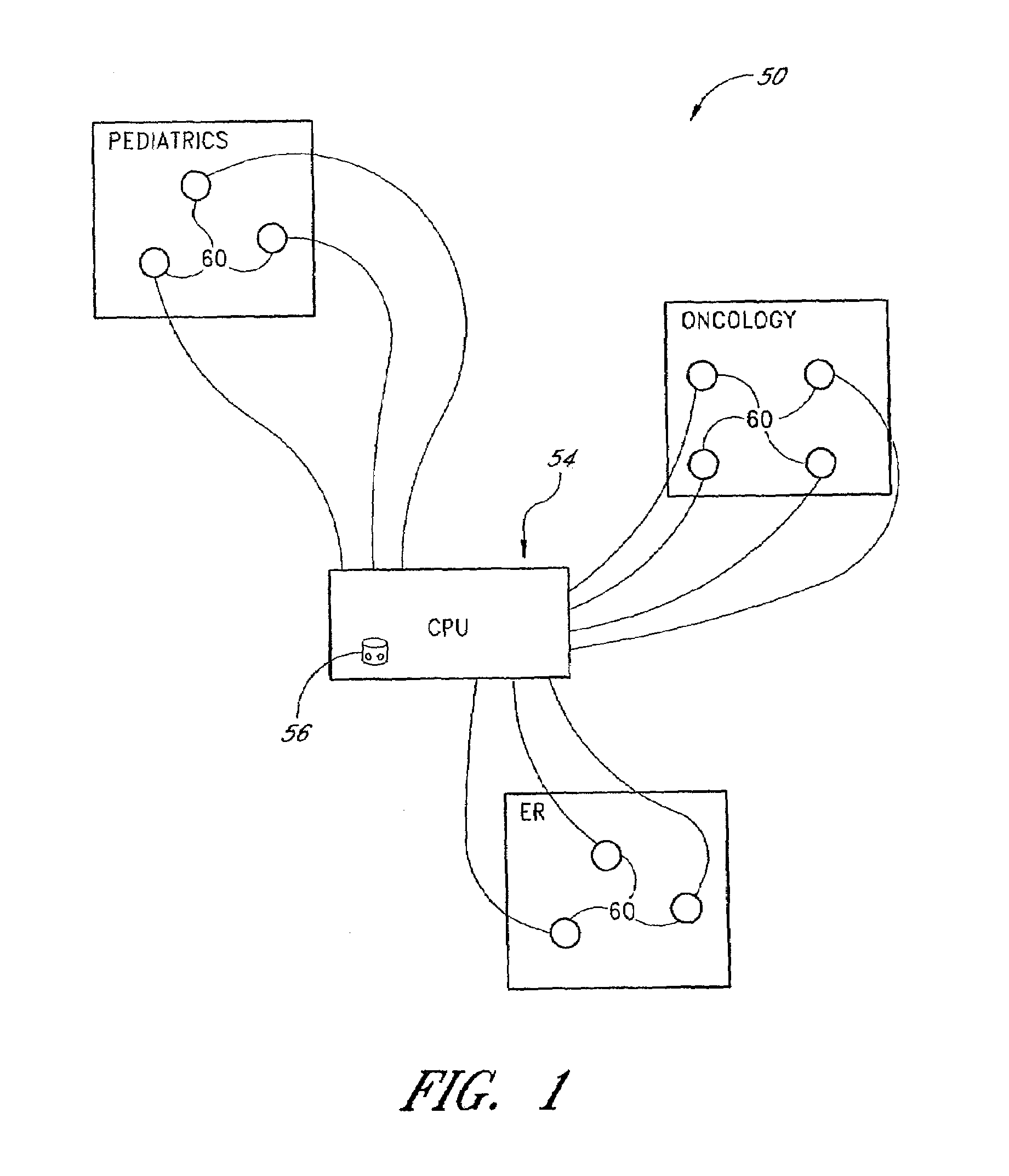

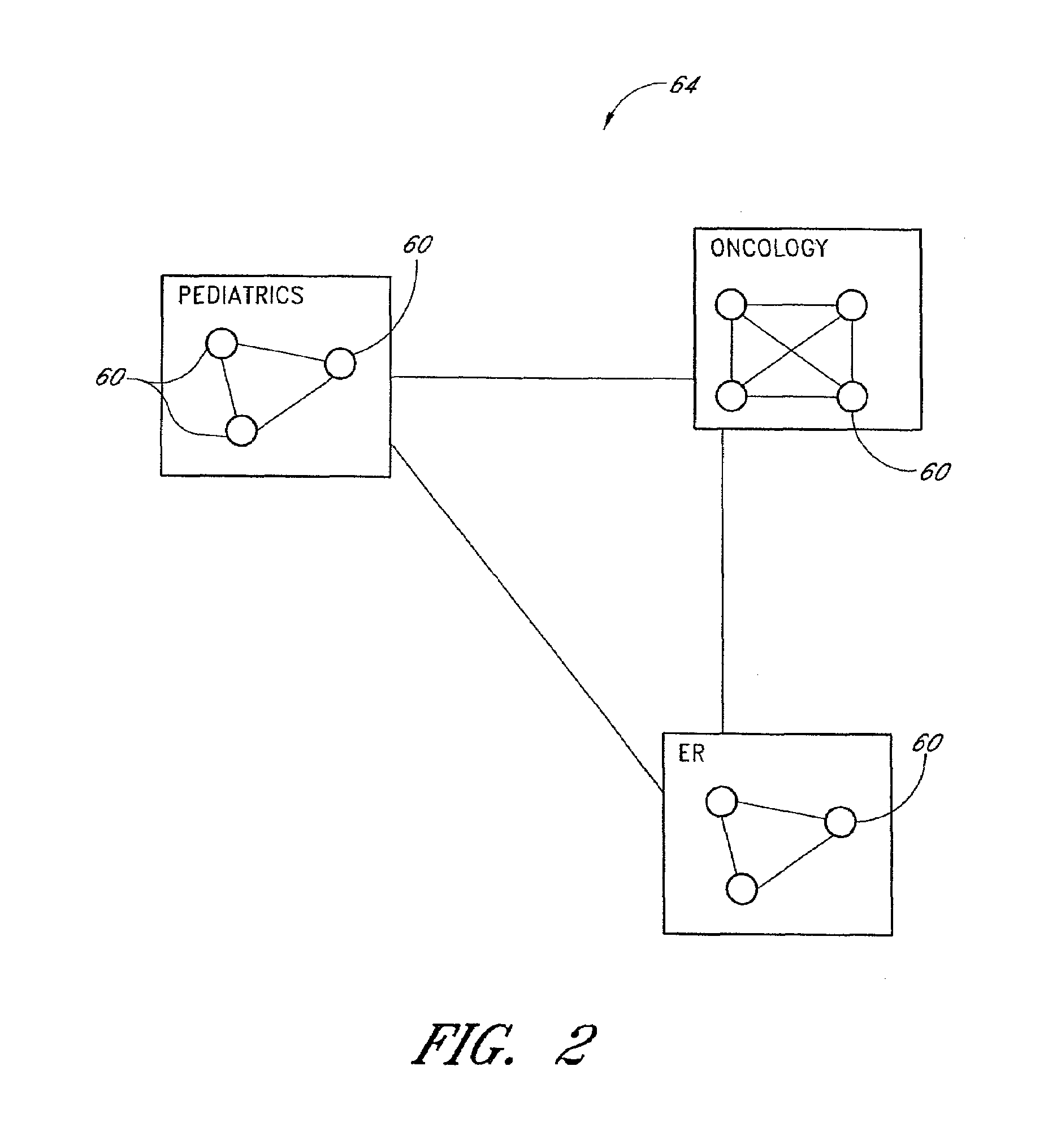

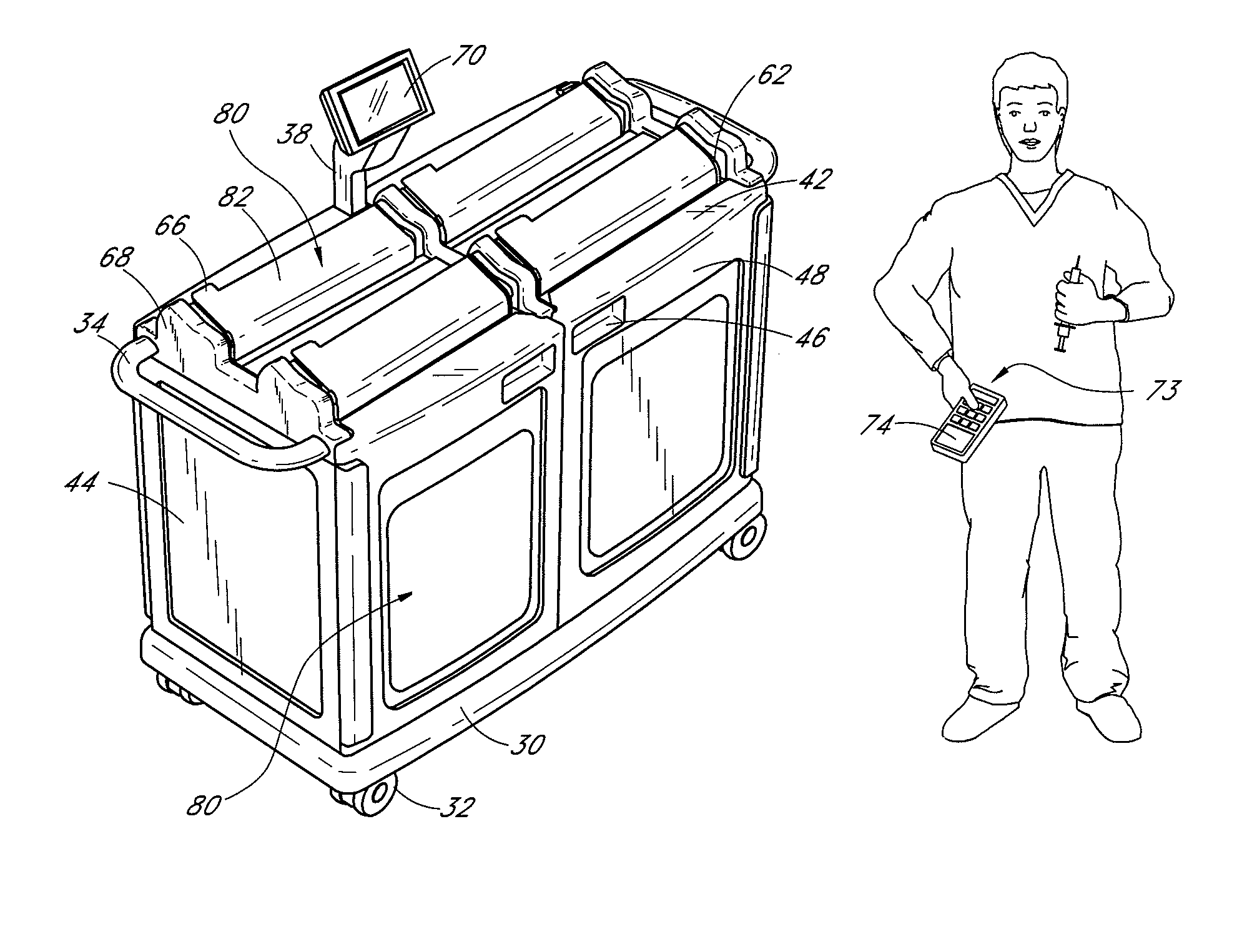

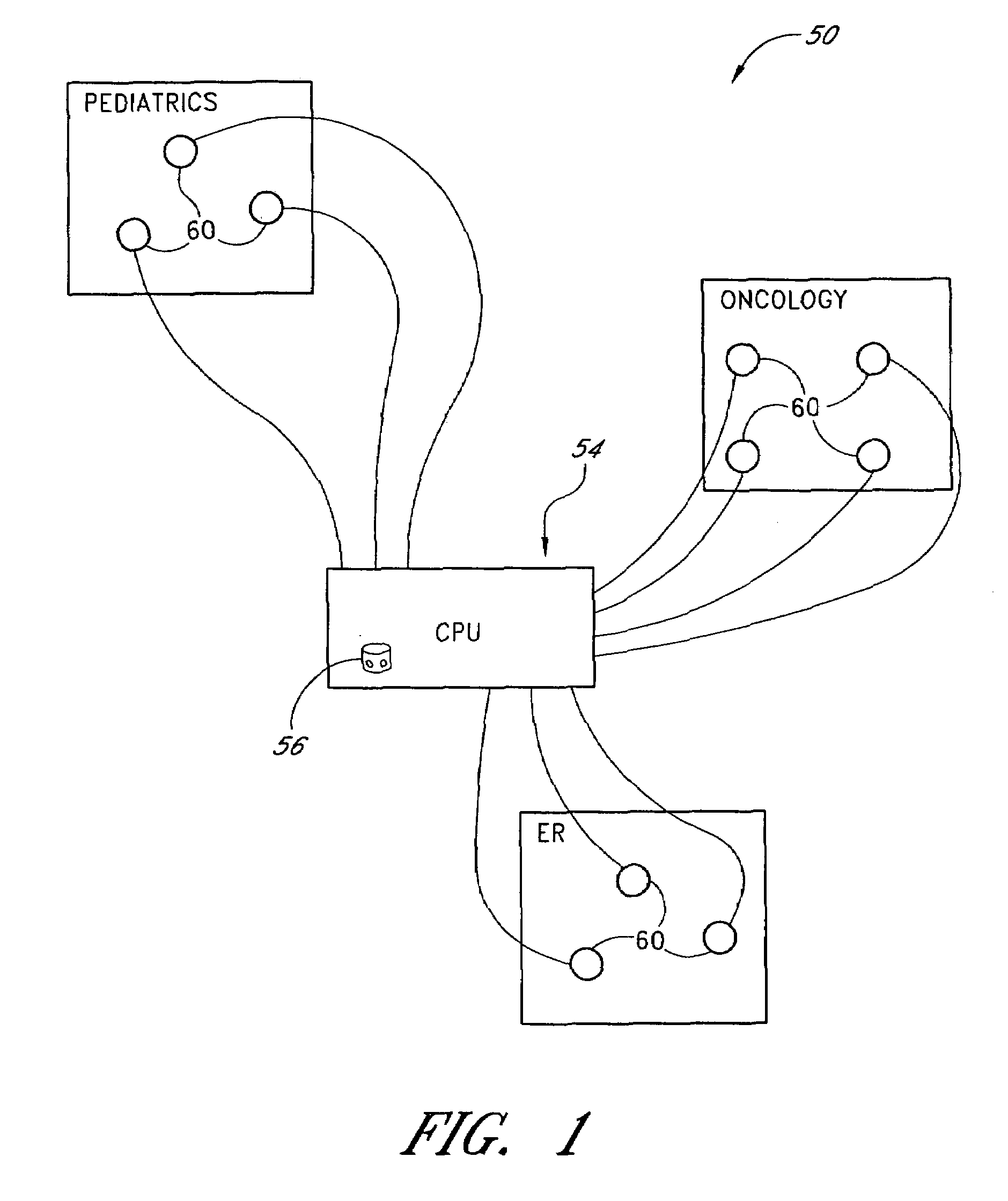

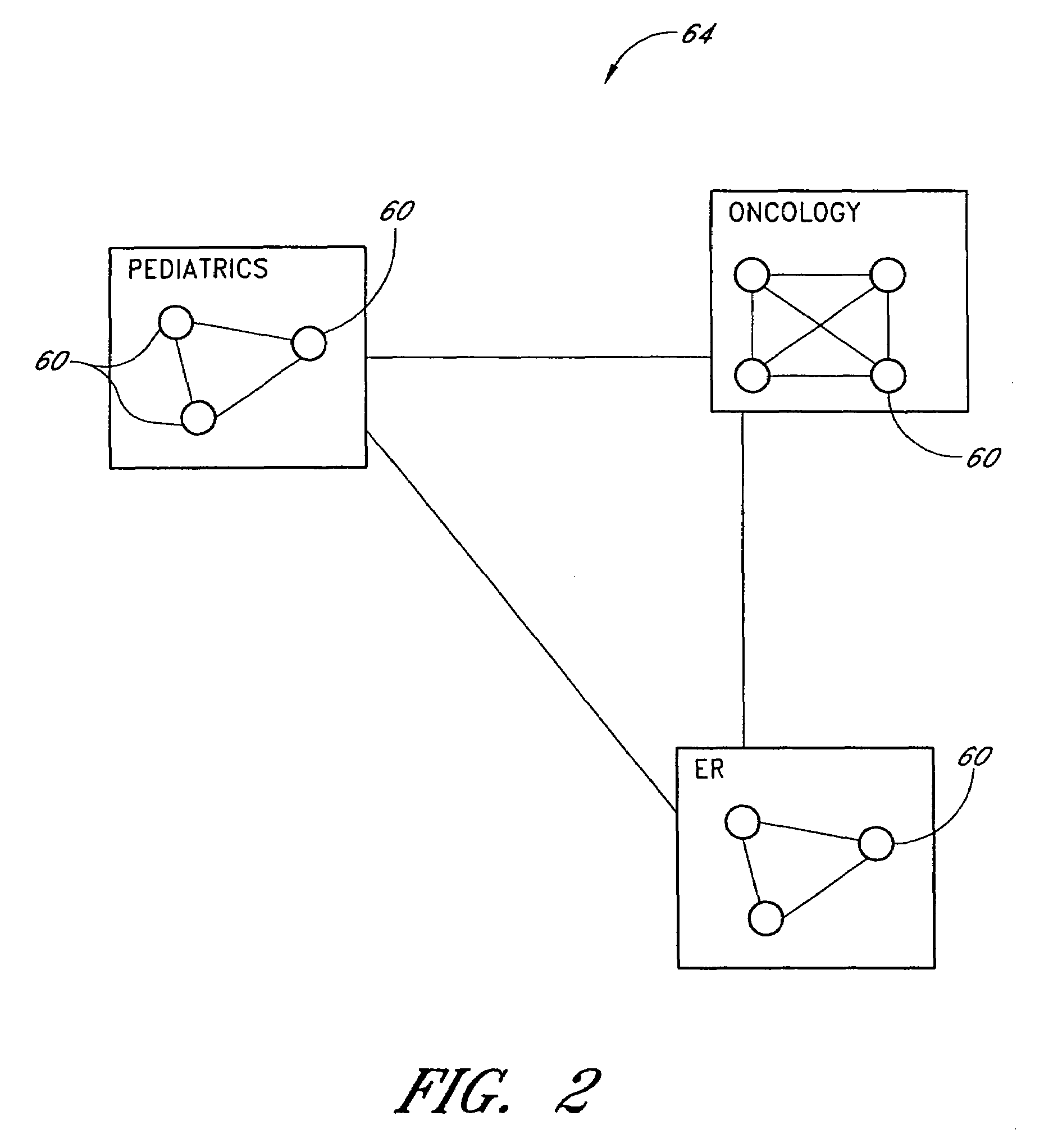

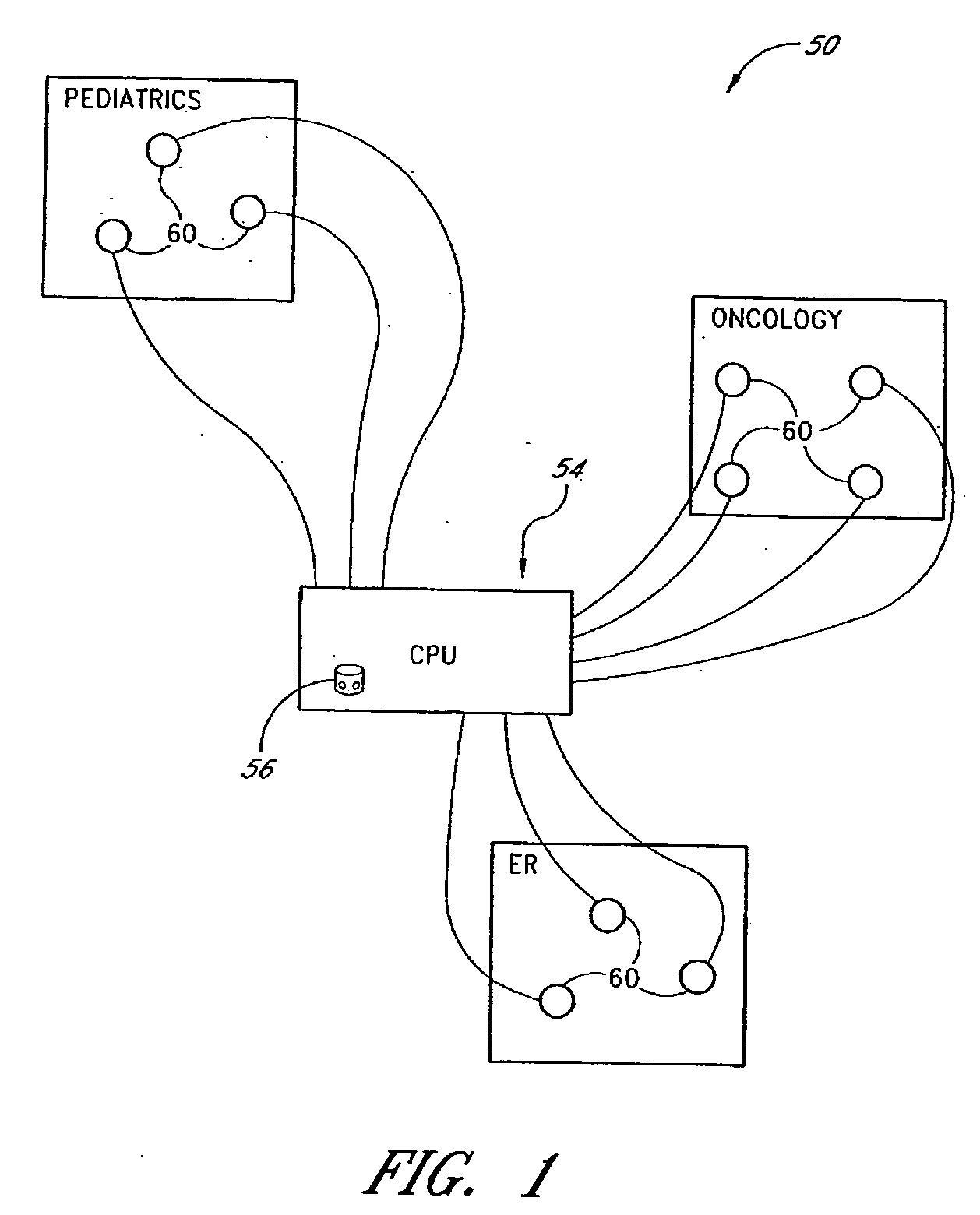

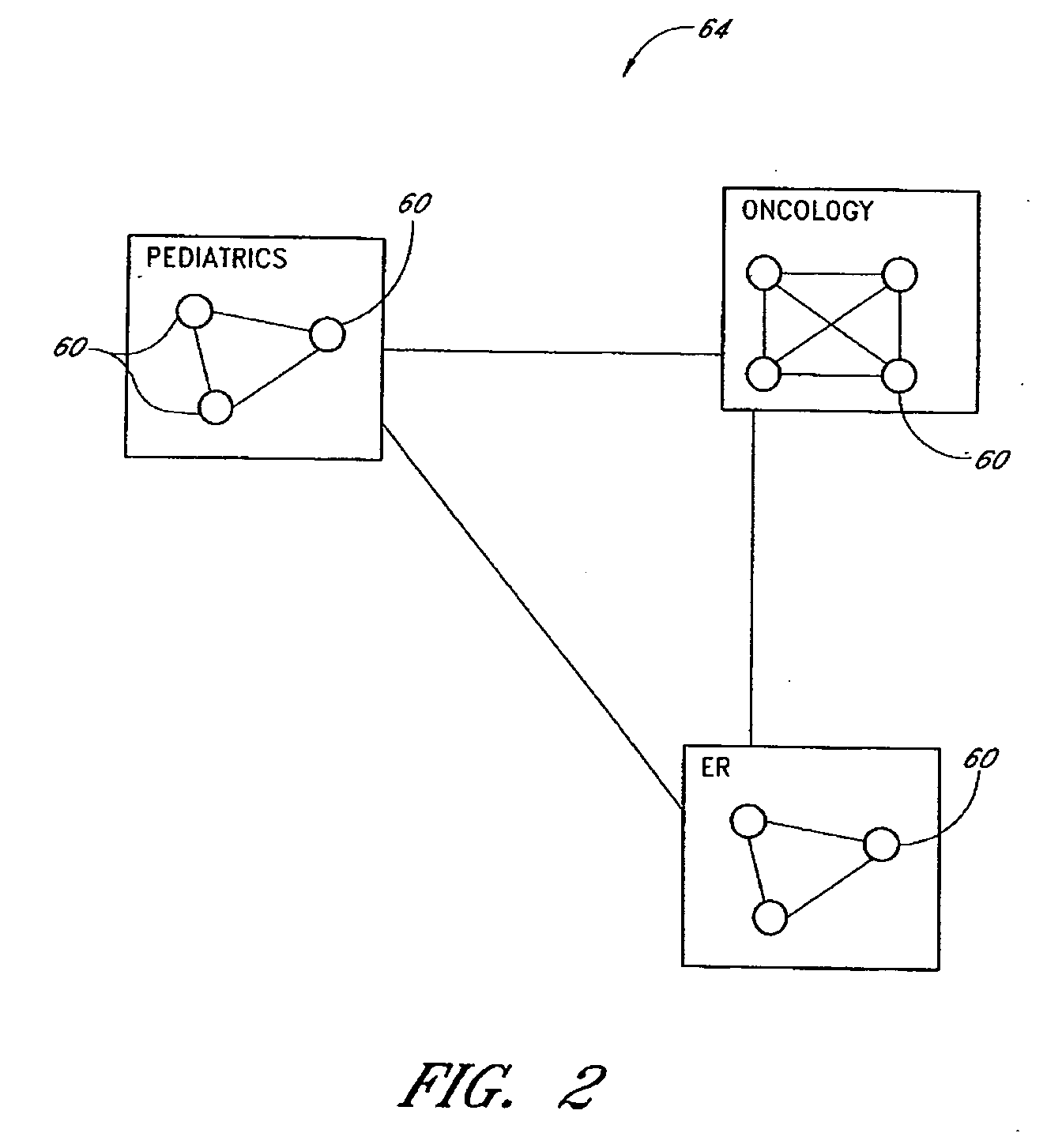

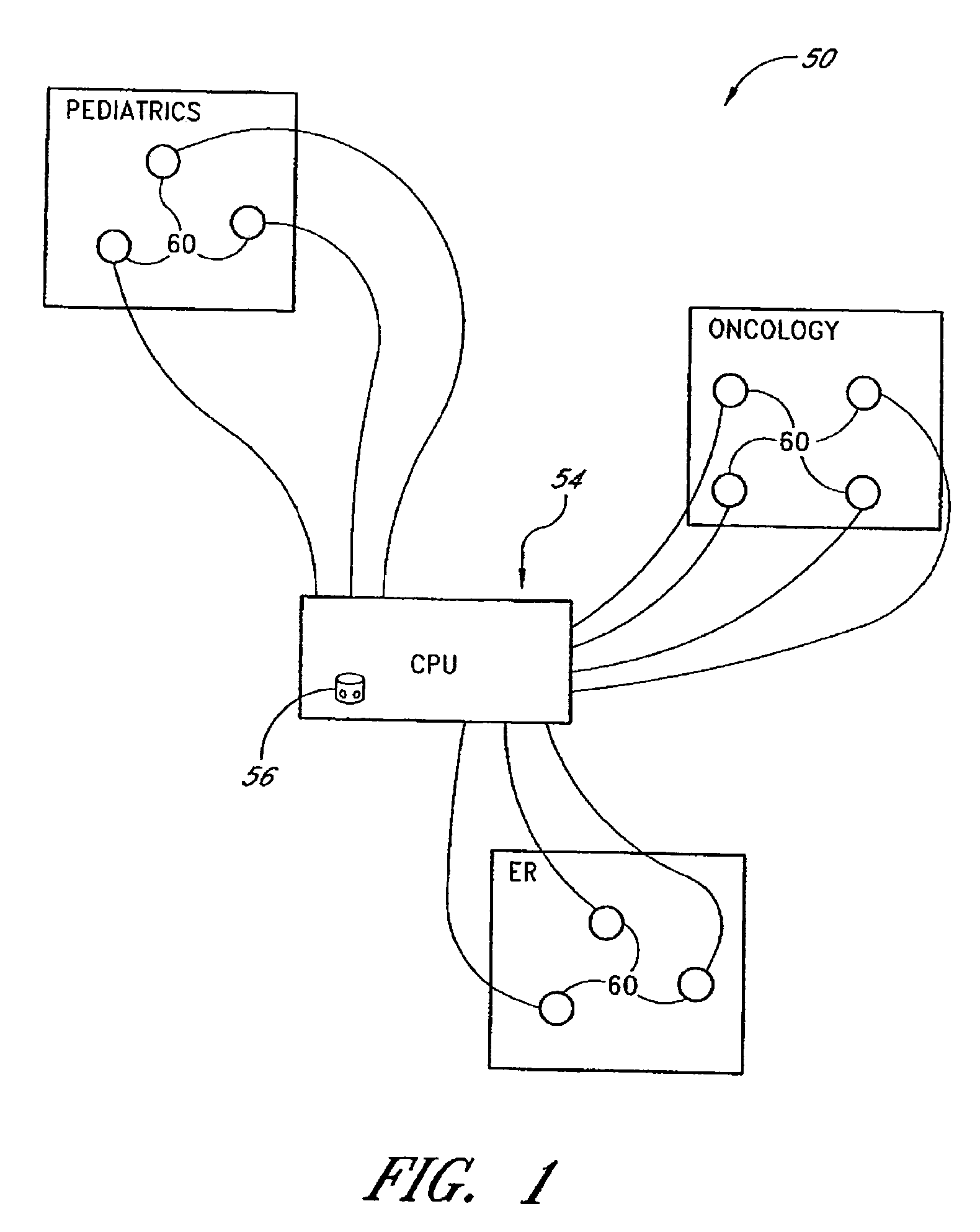

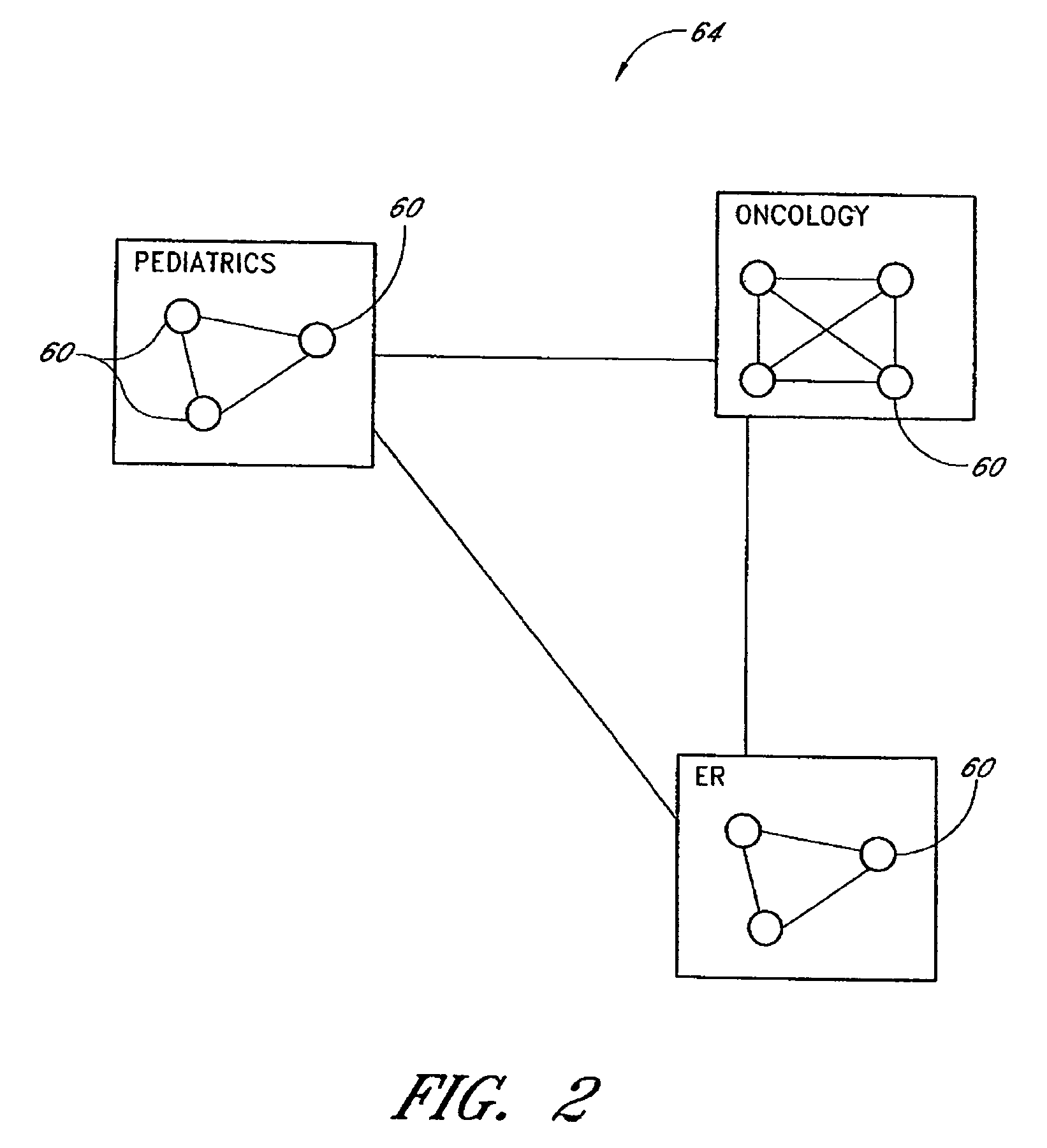

System and method for sorting medical waste for disposal

ActiveUS20050065820A1Easy to classifyEncourages and facilitates complianceSustainable waste treatmentSurgical furnitureMedical wasteMedical treatment

A system for disposing of medical waste is generally configured to sort waste items into a plurality of disposable containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations, each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container.

Owner:CAREFUSION 303 INC

Waste sorting system with query function, and method thereof

ActiveUS7562025B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentDispensing apparatusMedical wasteWorkstation

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a detection system for determining a presence and / or a quantity of waste items within a container is also provided. In some embodiments, access to discarded waste items is restricted once the waste items have been placed in a container.

Owner:CAREFUSION 303 INC

Handheld medical waste sorting method

ActiveUS7303081B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentSurgical furnitureMedical wasteClassification methods

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a detection system for determining a presence and / or a quantity of waste items within a container is also provided. In some embodiments, access to discarded waste items is restricted once the waste items have been placed in a container.

Owner:CAREFUSION 303 INC

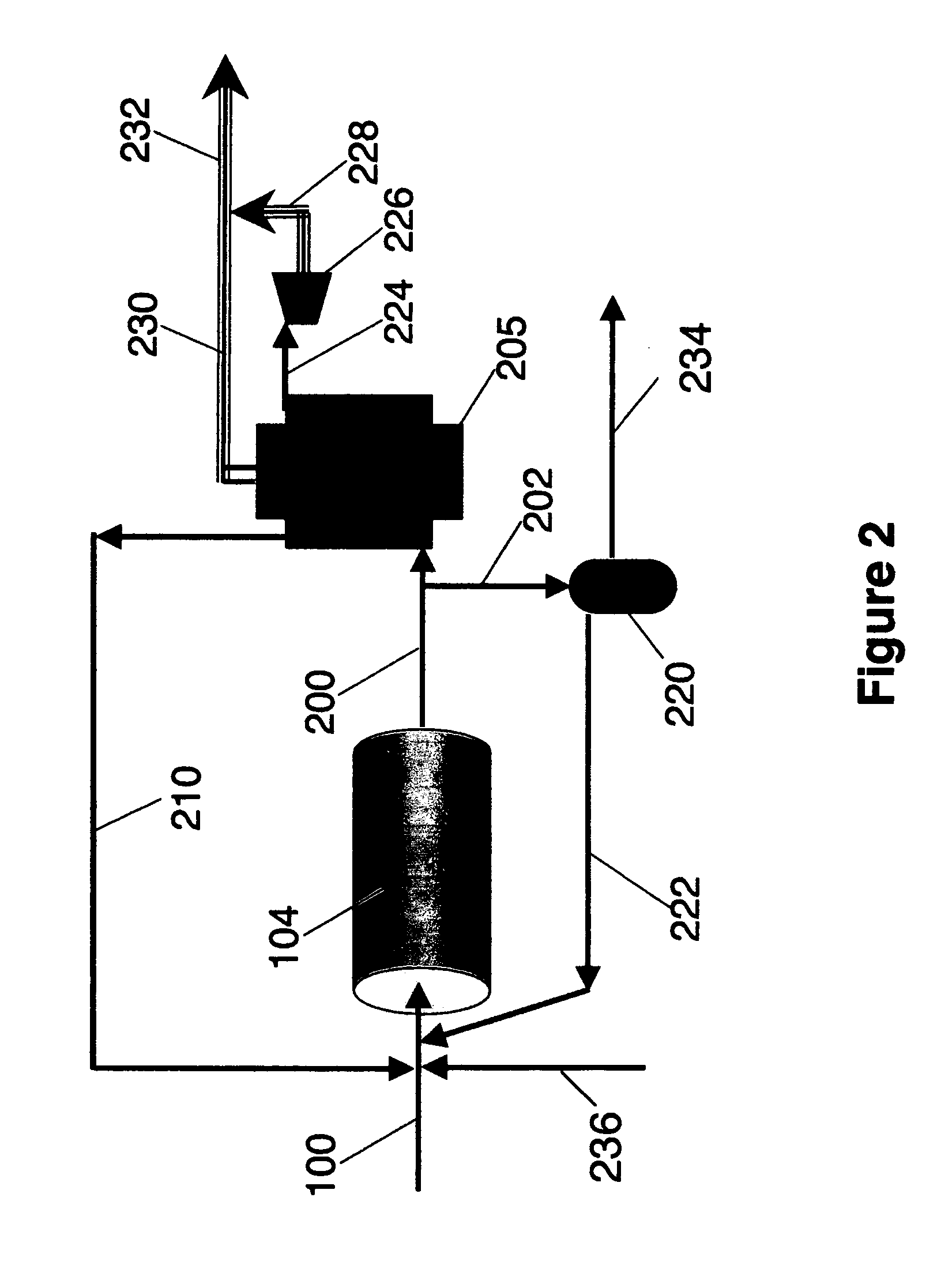

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

Method for sorting discarded and spent pharmaceutical items

ActiveUS20060253297A1Easy to classifyEncourages and facilitates complianceSustainable waste treatmentDispensing apparatusMedical wasteEngineering

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a detection system for determining a presence and / or a quantity of waste items within a container is also provided. In some embodiments, access to discarded waste items is restricted once the waste items have been placed in a container.

Owner:CAREFUSION 303 INC

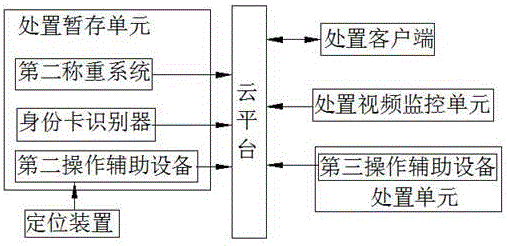

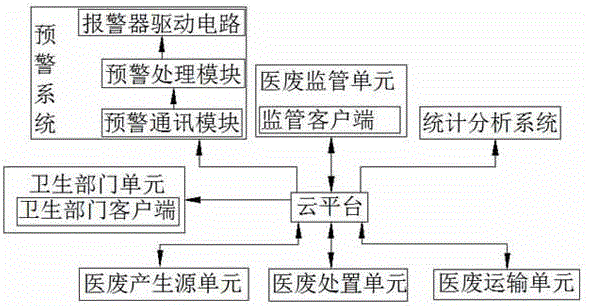

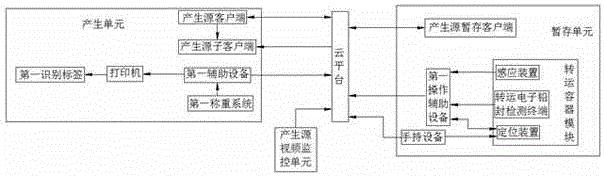

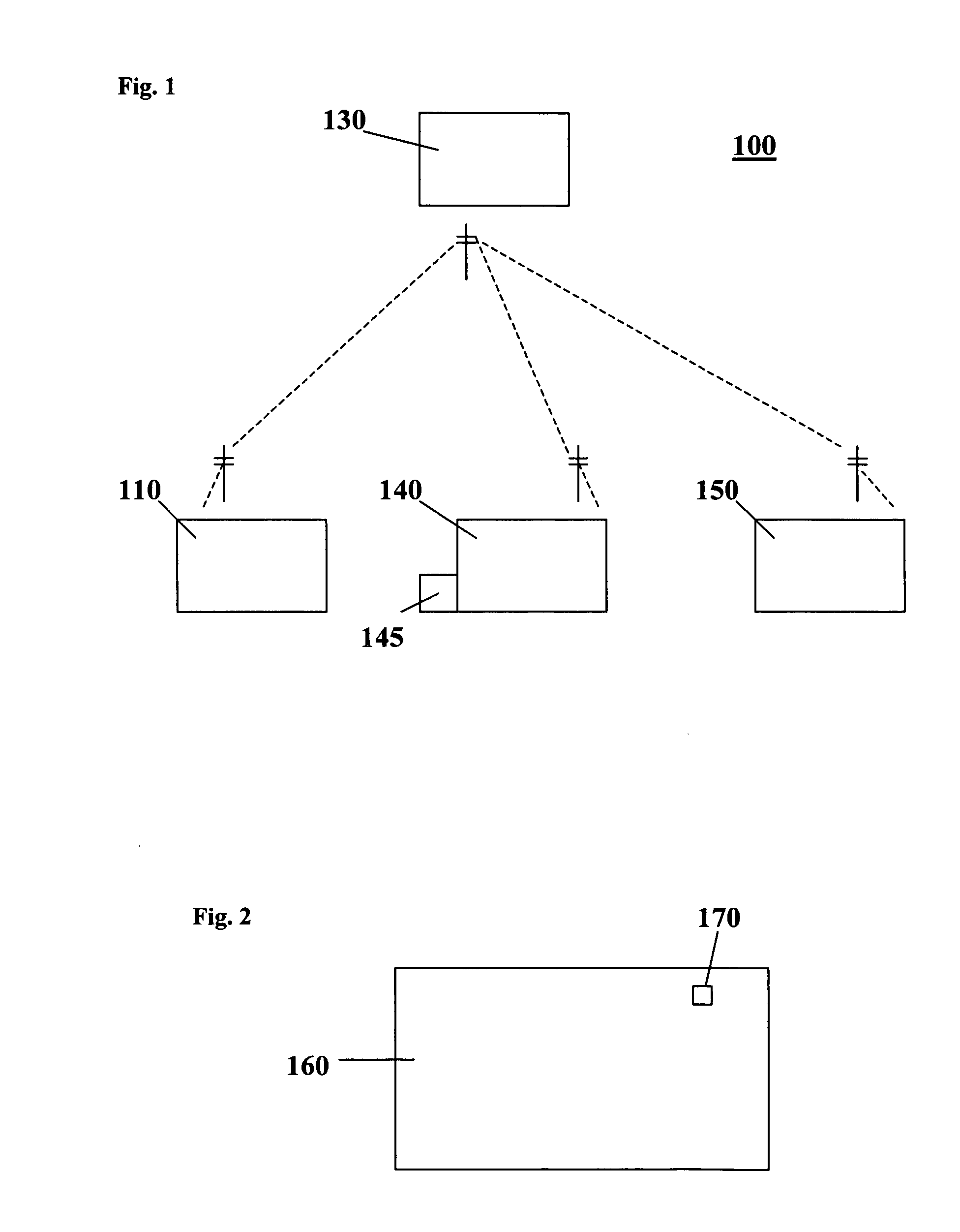

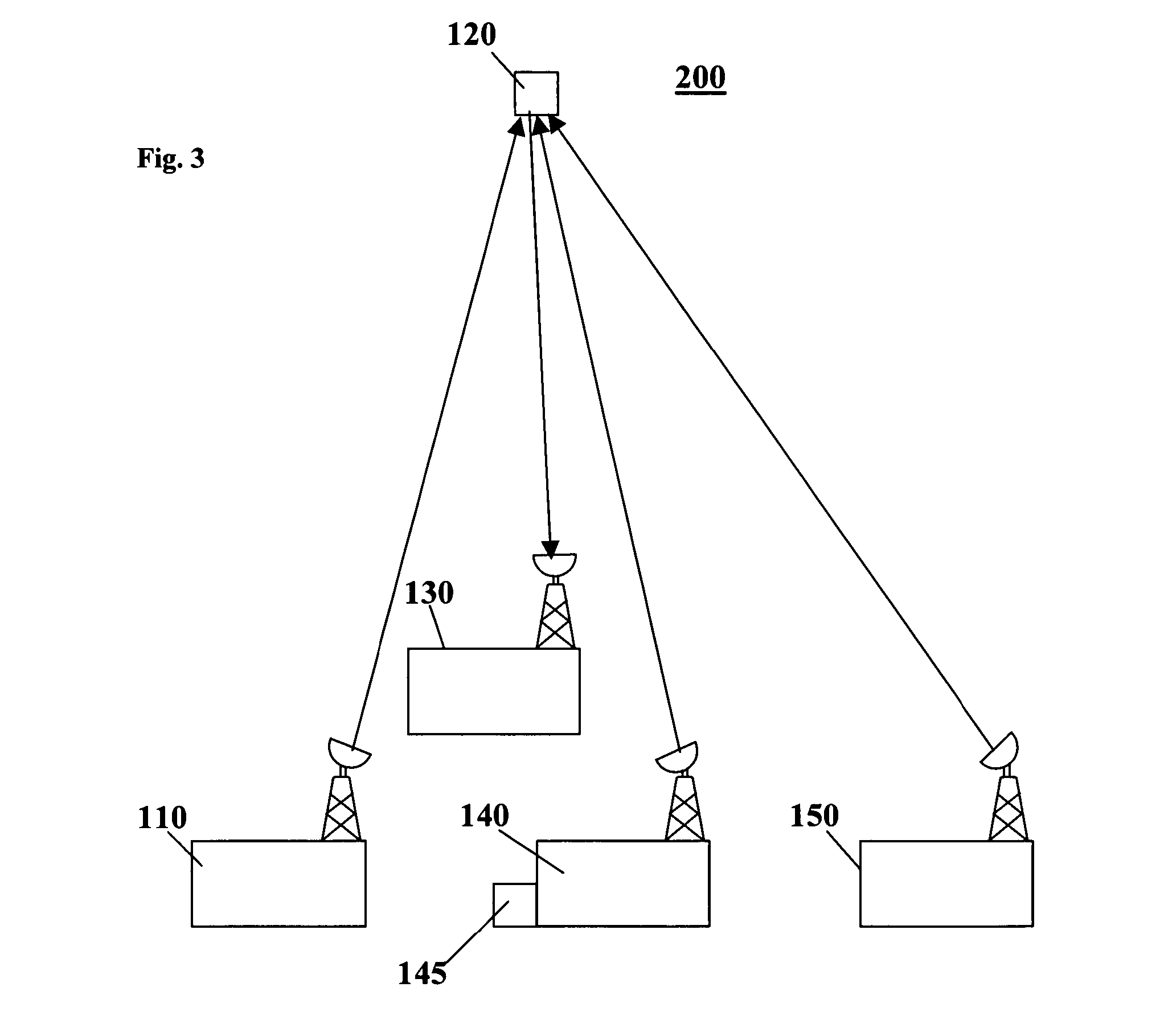

System and method for managing medical waste internet of things

ActiveCN105730935AEffective monitoringEffective reminderRefuse receptaclesVideo monitoringStatistical analysis

The invention discloses a system and a method for managing a medical waste internet of things. The system comprises a medical waste generation source unit, a health department unit, a medical waste transportation unit, a medical waste disposing unit, a medical waste supervising unit, a cloud platform, a video monitoring unit, a prewarning system and a statistic analysis system; the medical waste generation source unit, the medical waste transportation unit and the medical waste disposing unit all transmit information to the cloud platform so as to realize supervision of medical waste information; and when the cloud platform detects errors, signals are output to the prewarning system. The method comprises the following steps: medical wastes are transported to a temporary storage warehouse, a disposing temporary storage warehouse and a disposing room from a temporary storage point in sequence; and meanwhile, in the medical waste transportation process, information of the medical wastes and staff information are identified to prevent the mixing or missing phenomenon of the medical wastes. The system and the method realize acquisition of information in each phase of medical waste disposing, prevent the missing or mixing phenomenon of the medical wastes caused by human factors, and realize dynamic supervision of the medical wastes through the internet of things.

Owner:河南新辰环保科技有限公司

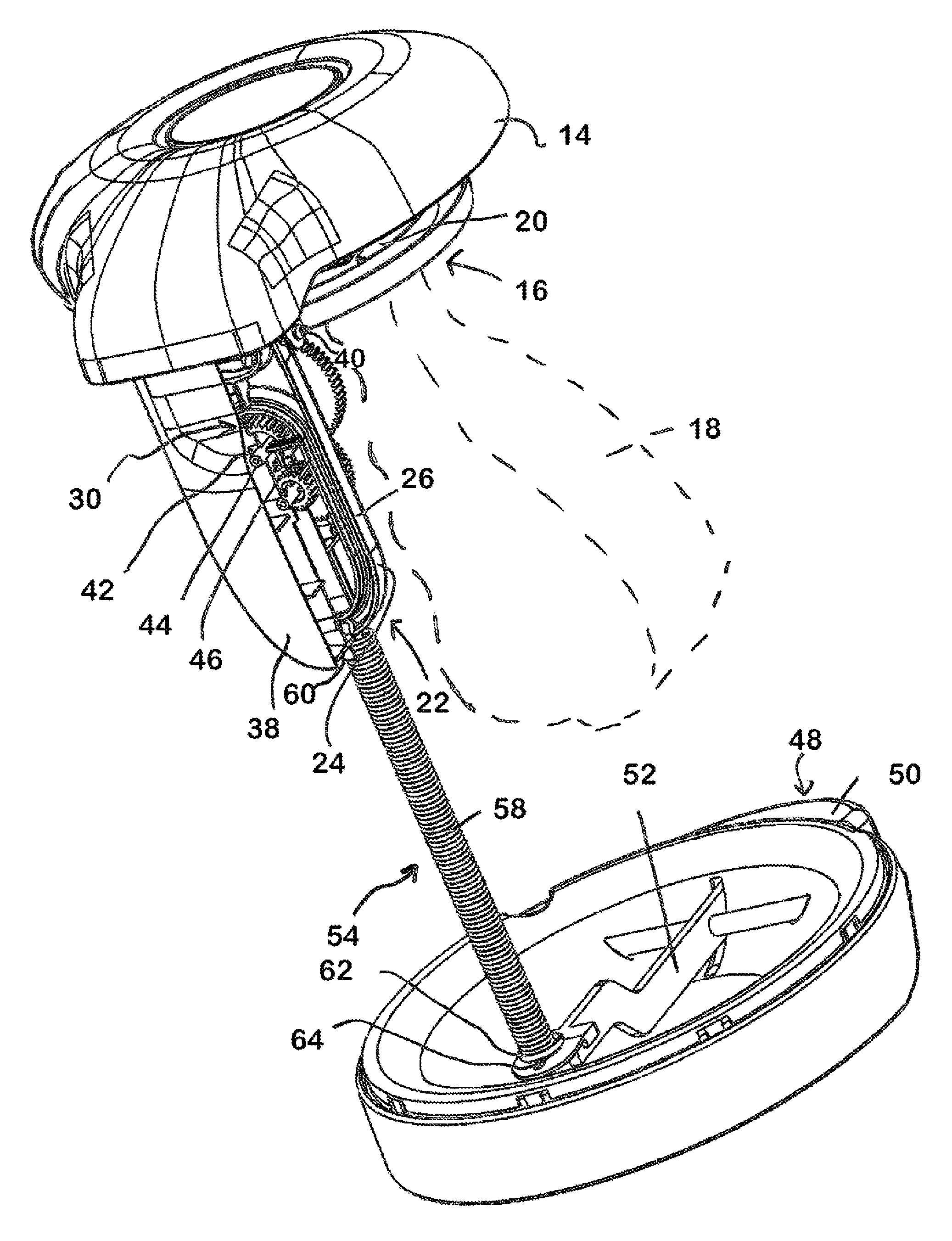

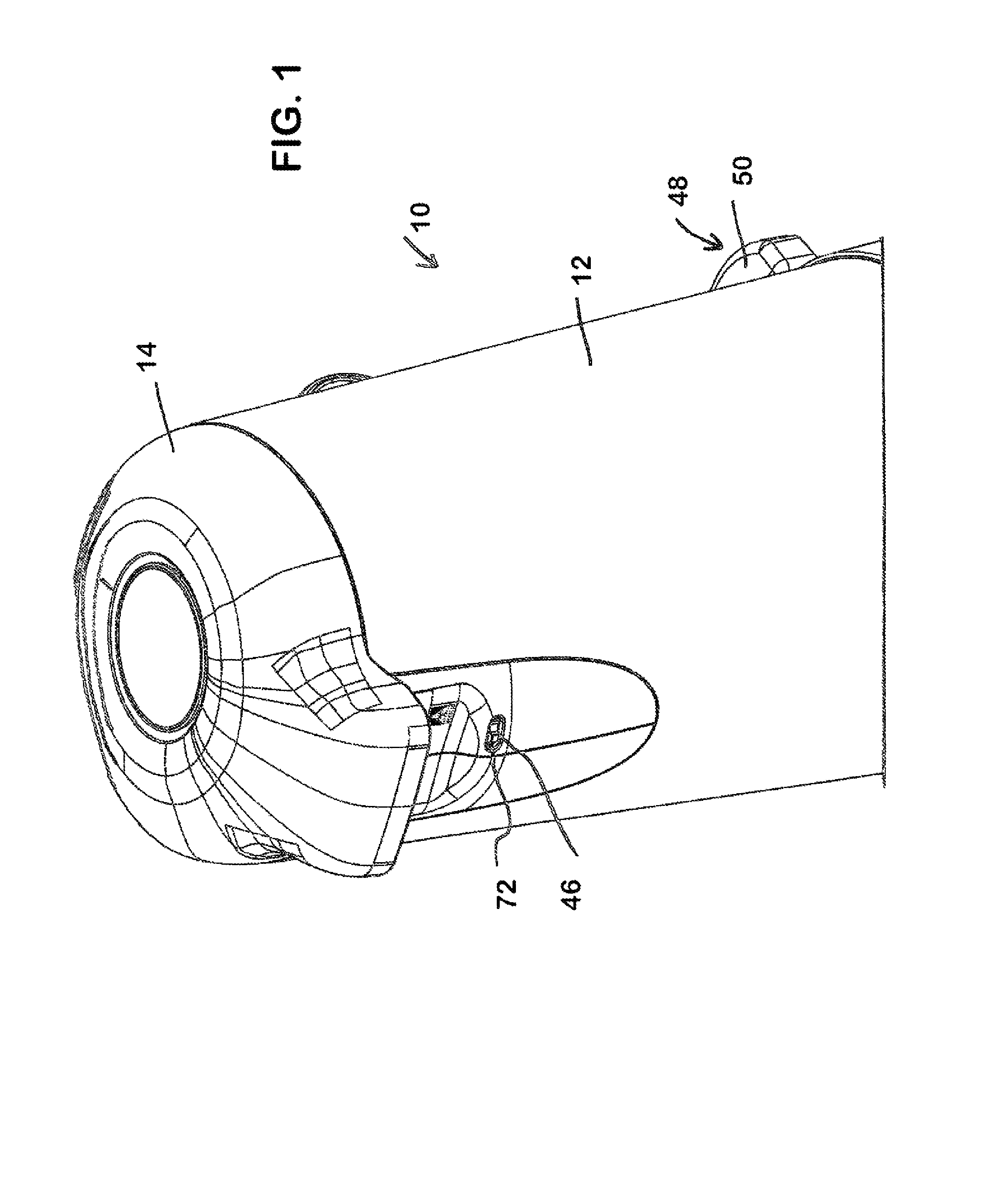

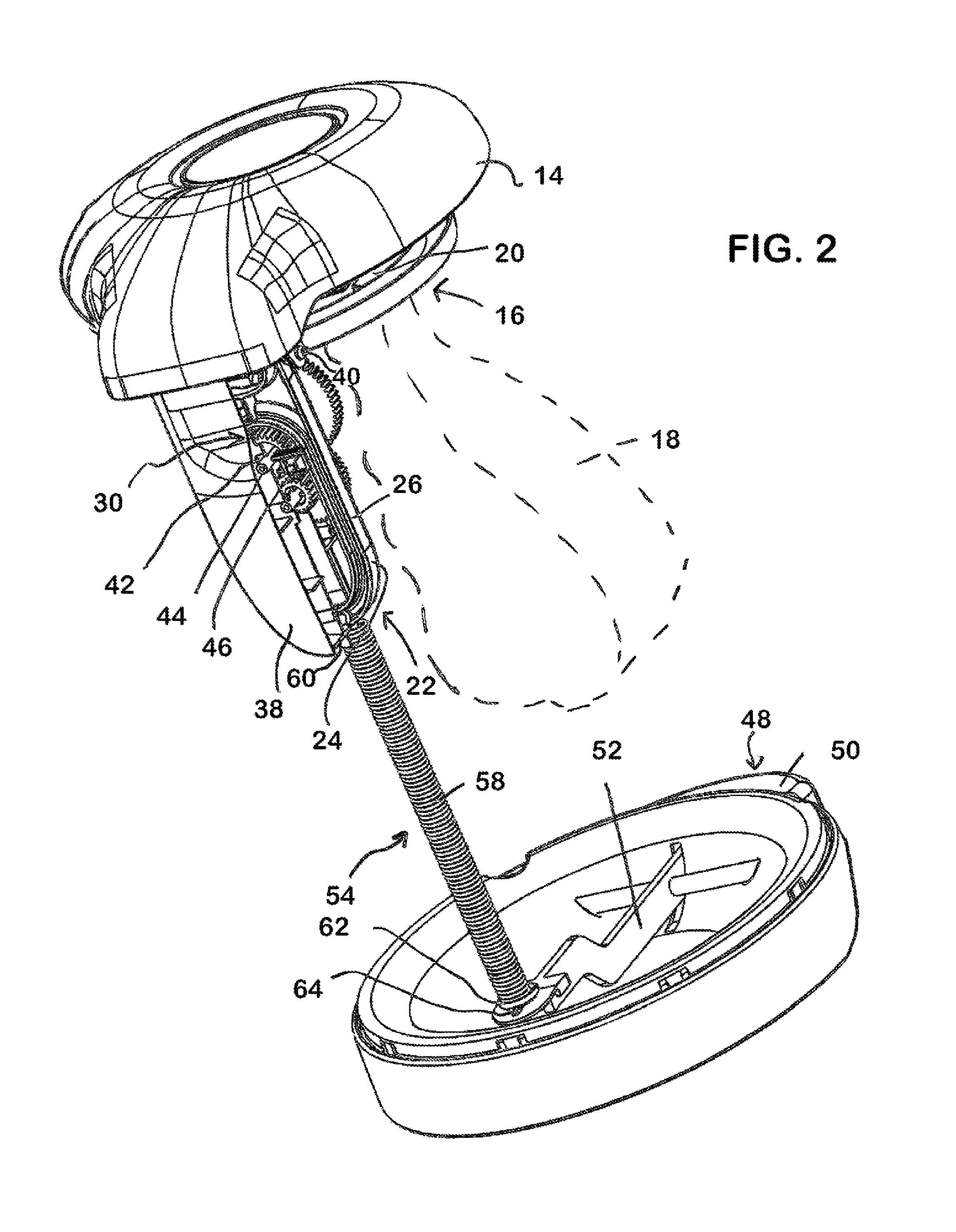

Medical waste disposal device with self-closing lid

ActiveUS8393489B1Easy to insertAvoids untwisting of the bag or tubingRefuse receptaclesWrapper twisting/gatheringCare personnelMedical waste

Waste disposal device includes a container, a lid, and a rotation mechanism that rotates a waste-containing member when present in the container. A slide mechanism enables opening movement of the lid to cause the rotation mechanism to rotate the waste-containing member or prevent the rotation mechanism from rotating the waste-containing member depending on its setting. A foot pedal assembly includes a foot pedal and a spring, and causes both opening of the lid when the foot pedal is depressed and closure of the lid when the pressing force is removed. The spring is moved against its bias upon depression of the foot pedal and returns to its original state when the pressing force is removed to cause closure of the lid and rotation of the waste-containing member. The device may be used for medical waste from hospitals, doctors' offices, home health care personnel and facilities, nursing homes, and biohazard laboratories.

Owner:DOOLI PROD LLC

Medical waste container hinged lid

ActiveUS8038025B2Increase stiffnessPrevent exitSurgical furnitureClosuresMedical wasteMedical treatment

Owner:BECTON DICKINSON & CO

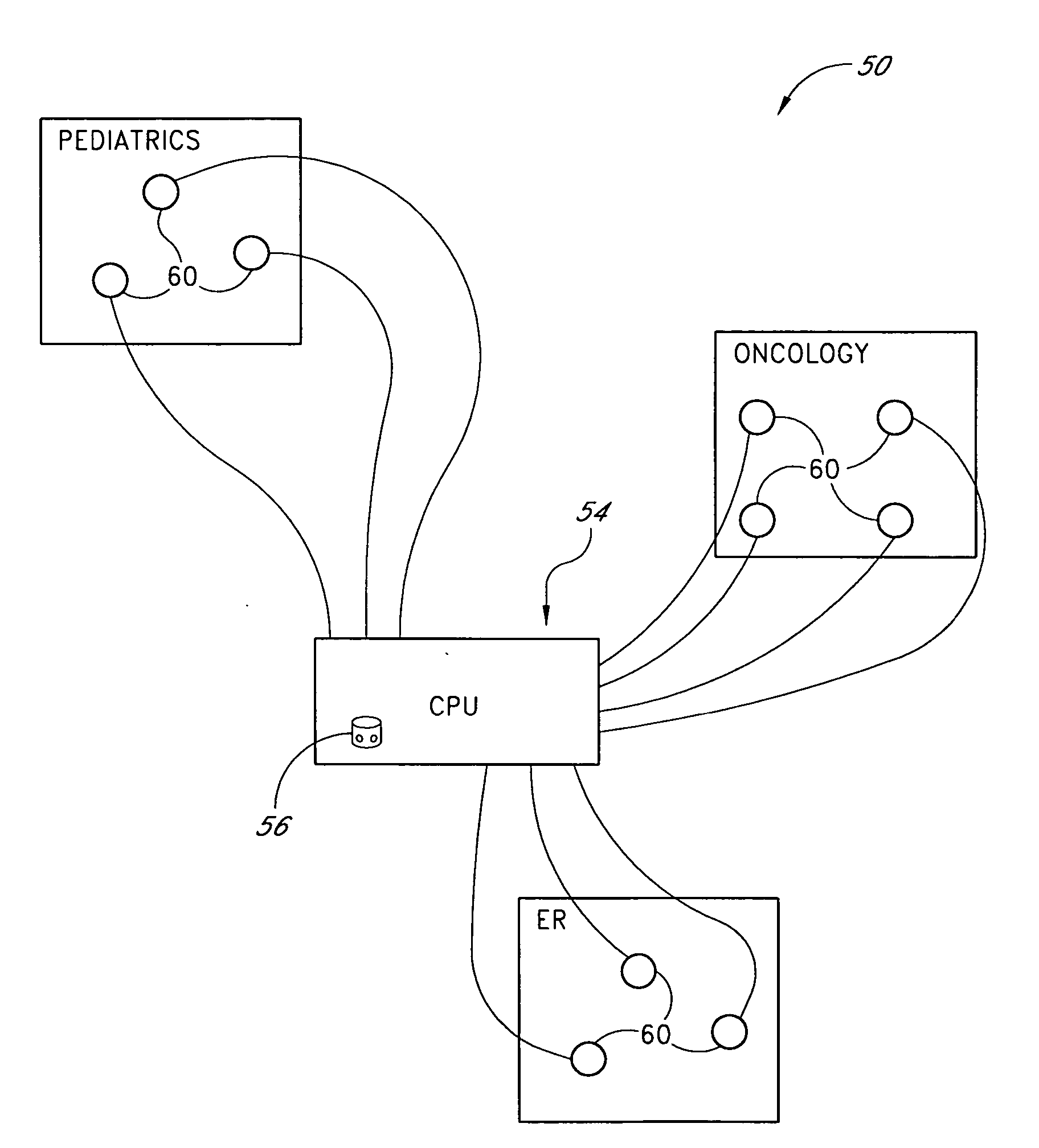

System for sorting discarded and spent pharmaceutical items

ActiveUS7311207B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentSurgical furnitureMedical wasteMedical treatment

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a detection system for determining a presence and / or a quantity of waste items within a container is also provided. In some embodiments, access to discarded waste items is restricted once the waste items have been placed in a container.

Owner:CAREFUSION 303 INC

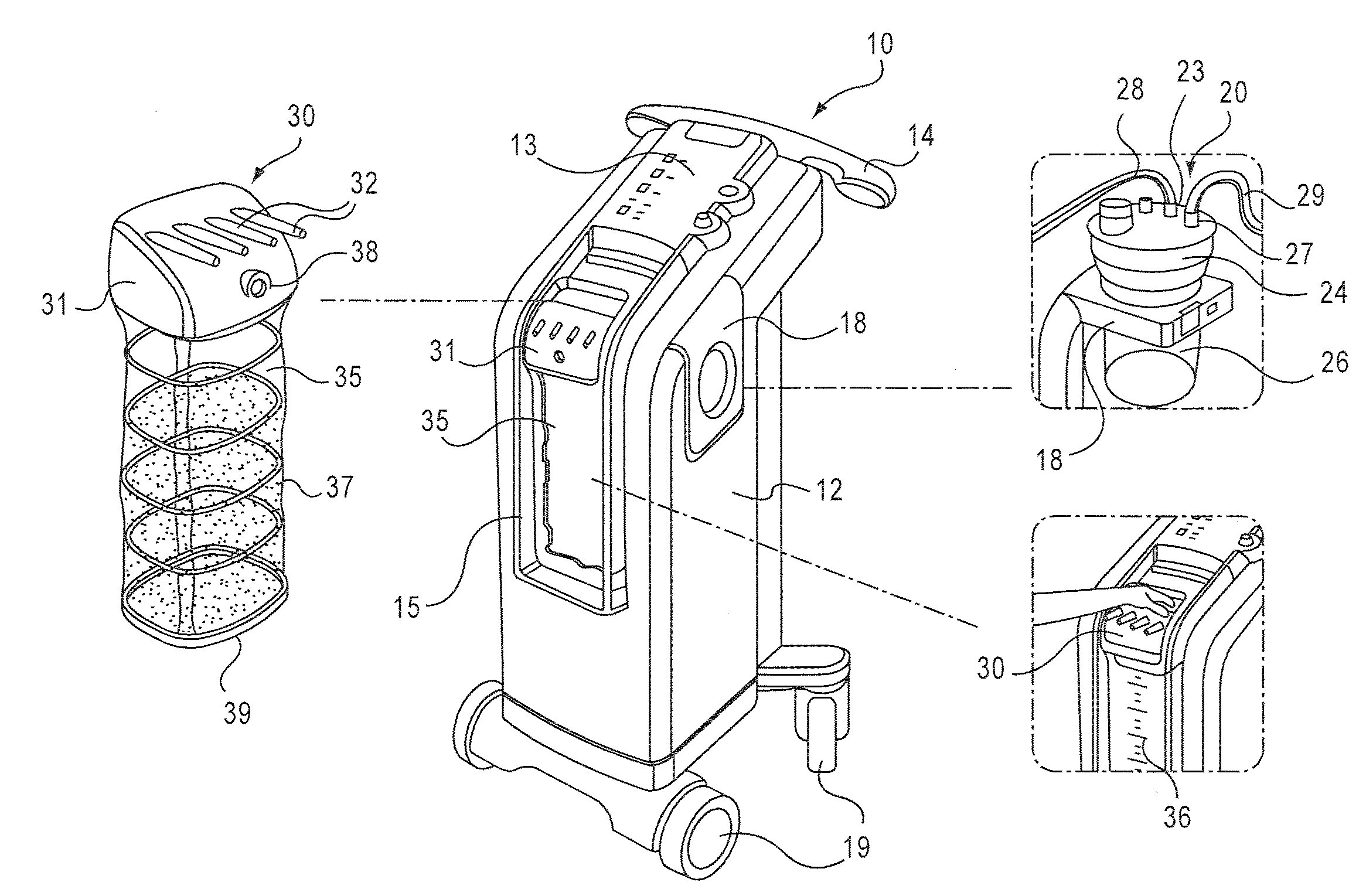

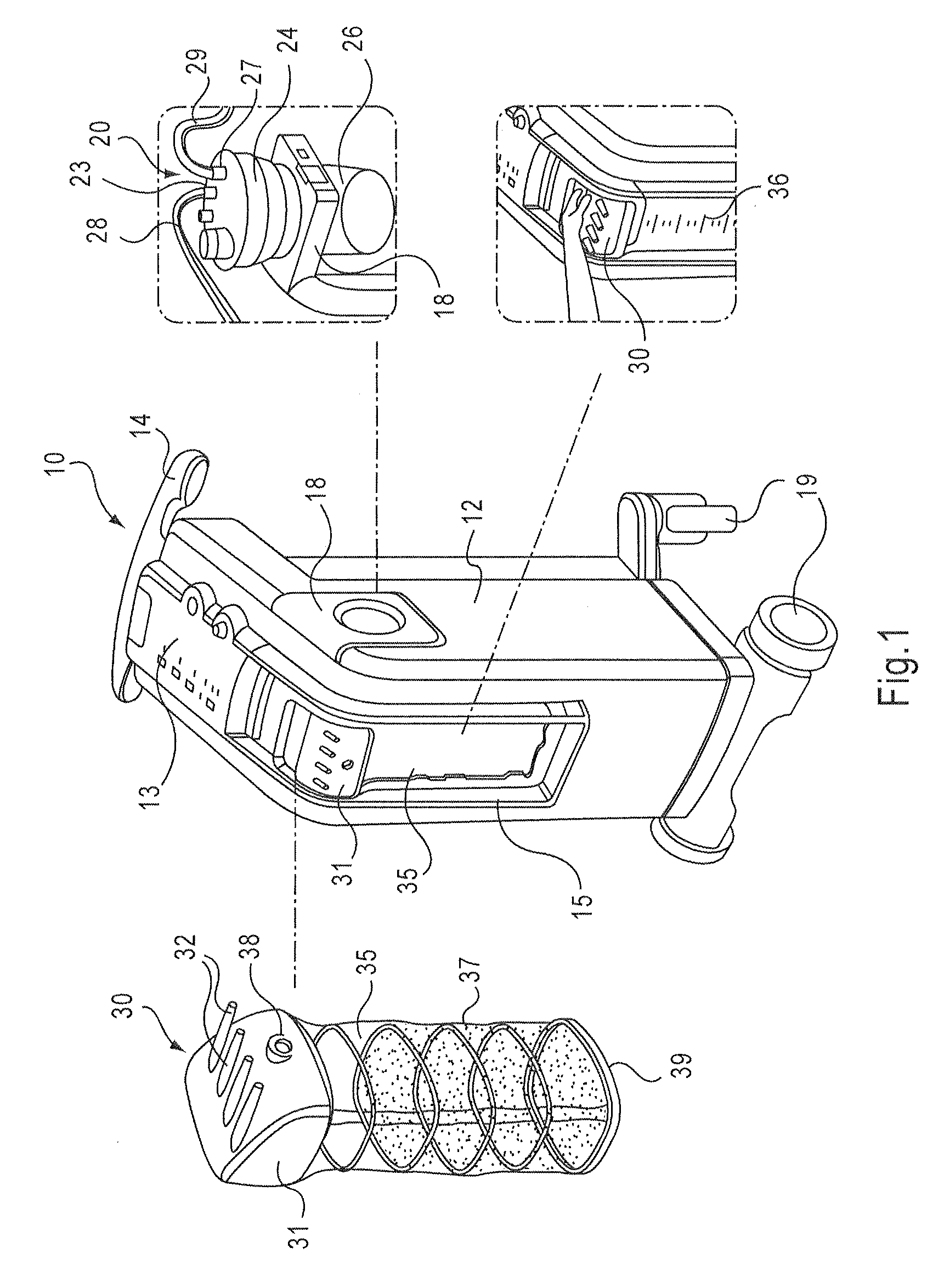

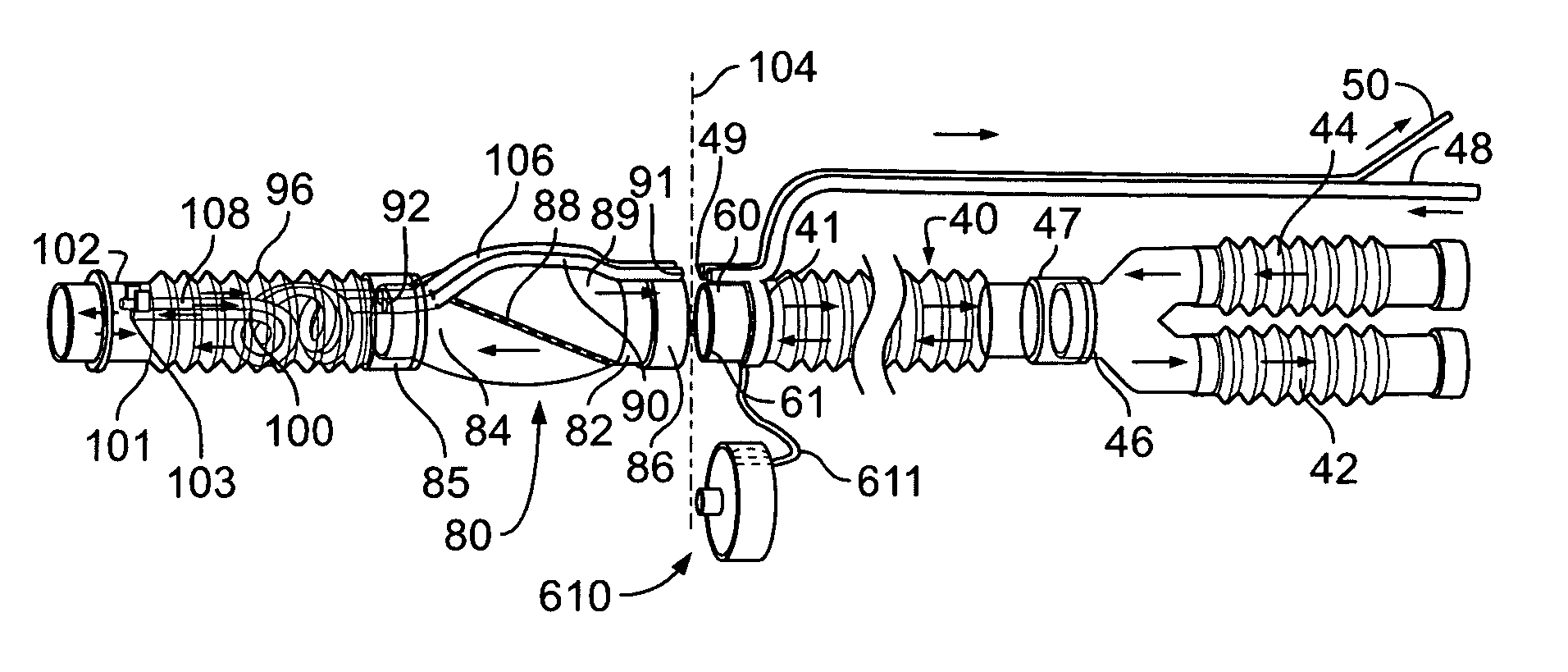

Fluid collection and disposal system having interchangeable collection and other features and methods relating thereto

InactiveUS20090005747A1Lower the volumeImprove convenienceHollow article cleaningMedical devicesBlood collectionCollection system

Various implementations of a fluid collection system having a flexible liner are disclosed. In one exemplary variation, the fluid collection system may include a flexible liner configured to collapse, a plurality of containers, back storage, specimen collection containers, and / or automatic connection to a suction source to reduce the volume of medical wastes, reduce the frequency of disposal cycles, reduce risk of exposure to potentially hazardous waste.

Owner:ALLEGIANCE CORP

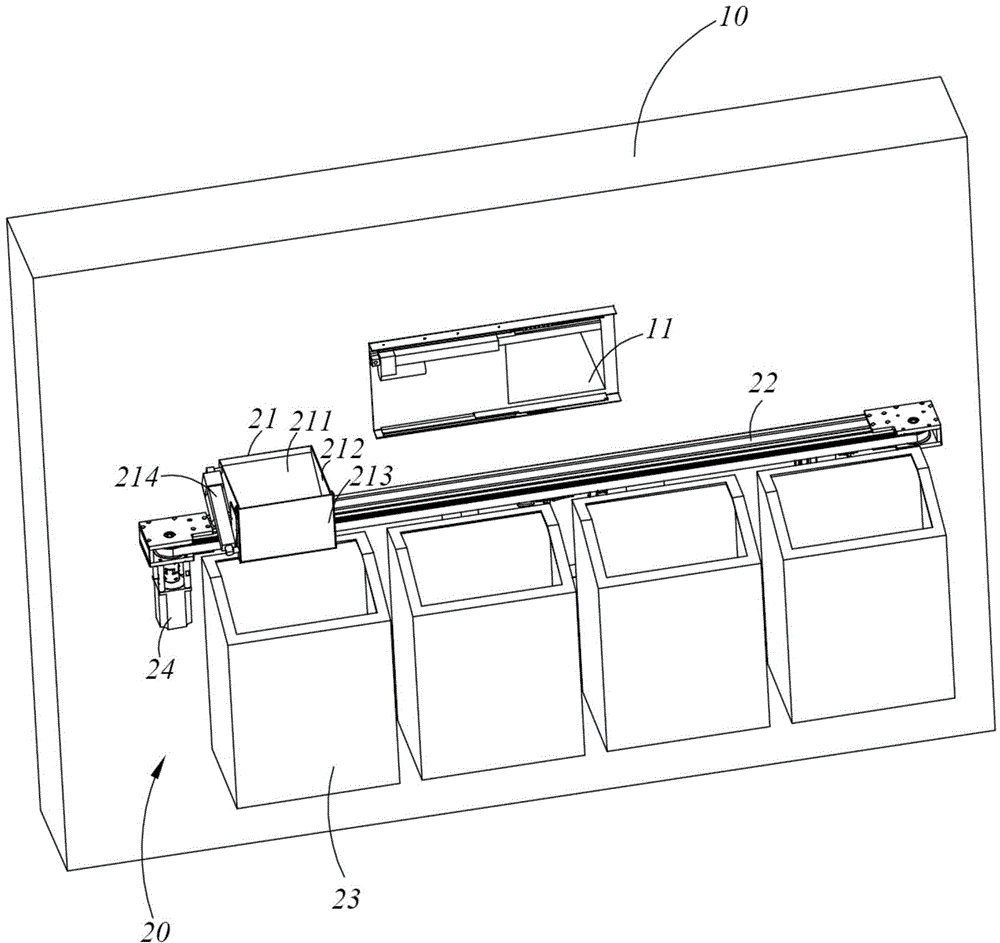

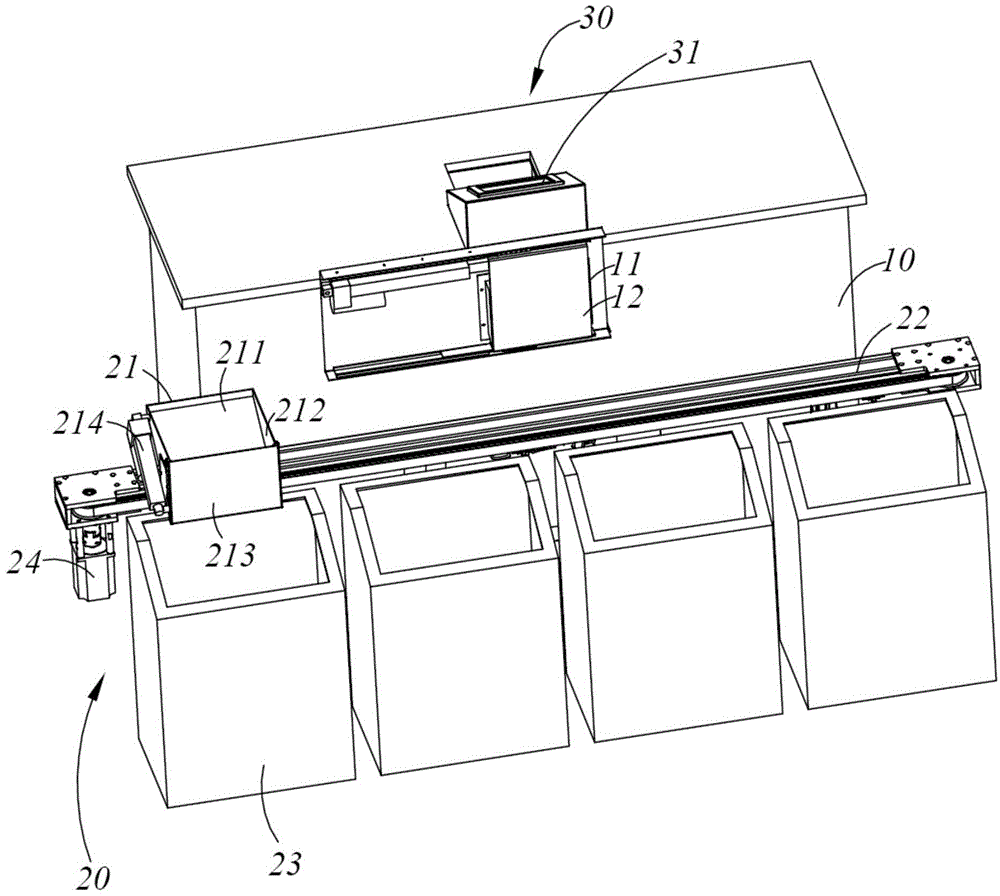

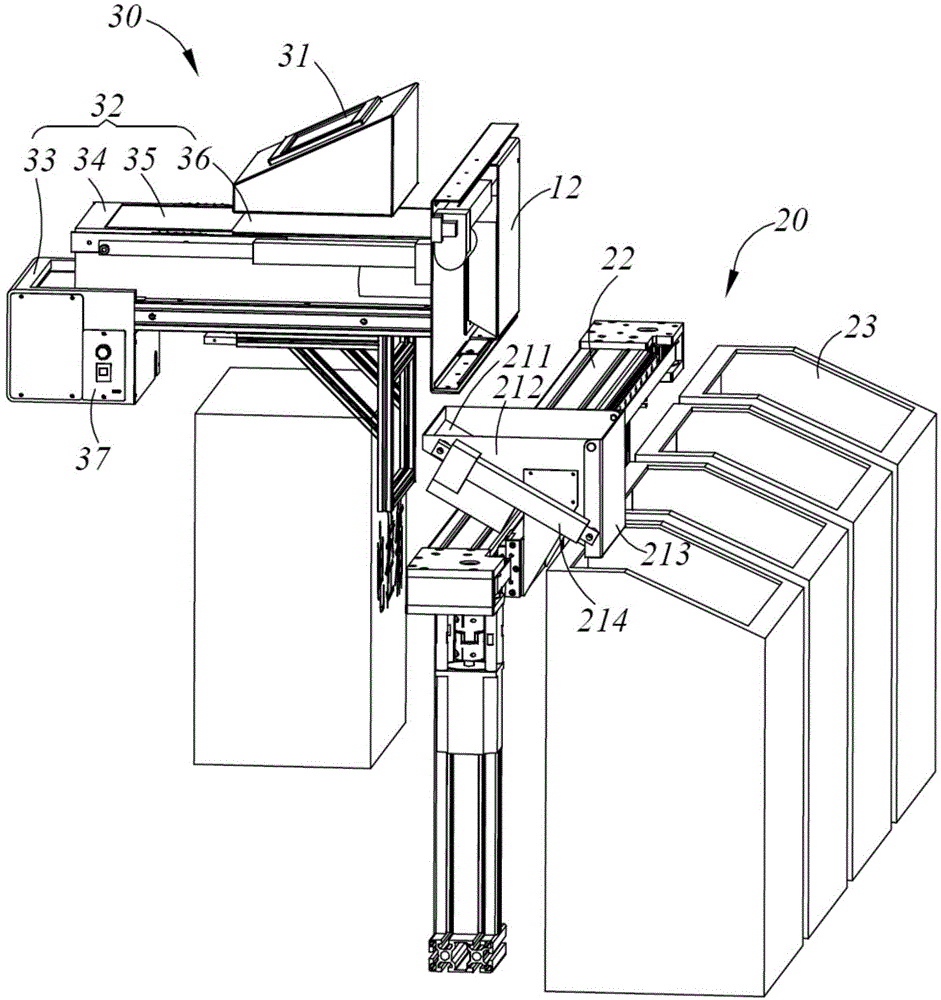

Intelligent classified recovery system of medical waste and control method of intelligent classified recovery system

InactiveCN104648865AImprove the environmentReduce work intensityWaste collection and transferRefuse receptaclesRefuse collectionMedical waste

The invention discloses an intelligent classified recovery system of medical waste and a control method of the intelligent classified recovery system. The intelligent classified recovery system of the medical waste comprises a separating wall, a window, a receiving device, an output device, a conveyor belt and a plurality of waste collection devices, wherein the separating wall is used for forming a first chamber and a second chamber, which are isolated from each other; the window penetrates through the separating wall; the receiving device is arranged in the first chamber, and the receiving device is used for receiving the medical waste and conveying the medical waste to the second chamber through the window; the output device is arranged in the second chamber, and the output device is used for receiving and conveying the medical waste; the conveyor belt is arranged in the second chamber, and the conveyor belt is used for driving the output device to move; a plurality of waste collection devices are arranged in the second chamber; the control device is used for distinguishing the types of the medical waste and controlling the output device to convey the medical waste to the corresponding waste collection device. By adopting the intelligent classified recovery system, a consulting room and a waste treatment room can be separated, the medical waste can be distributed to different waste collection devices, the environment of the consulting room is improved, and the working intensity is alleviated.

Owner:SUZHOU DERPIN MEDICAL SCI & TECH CO LTD

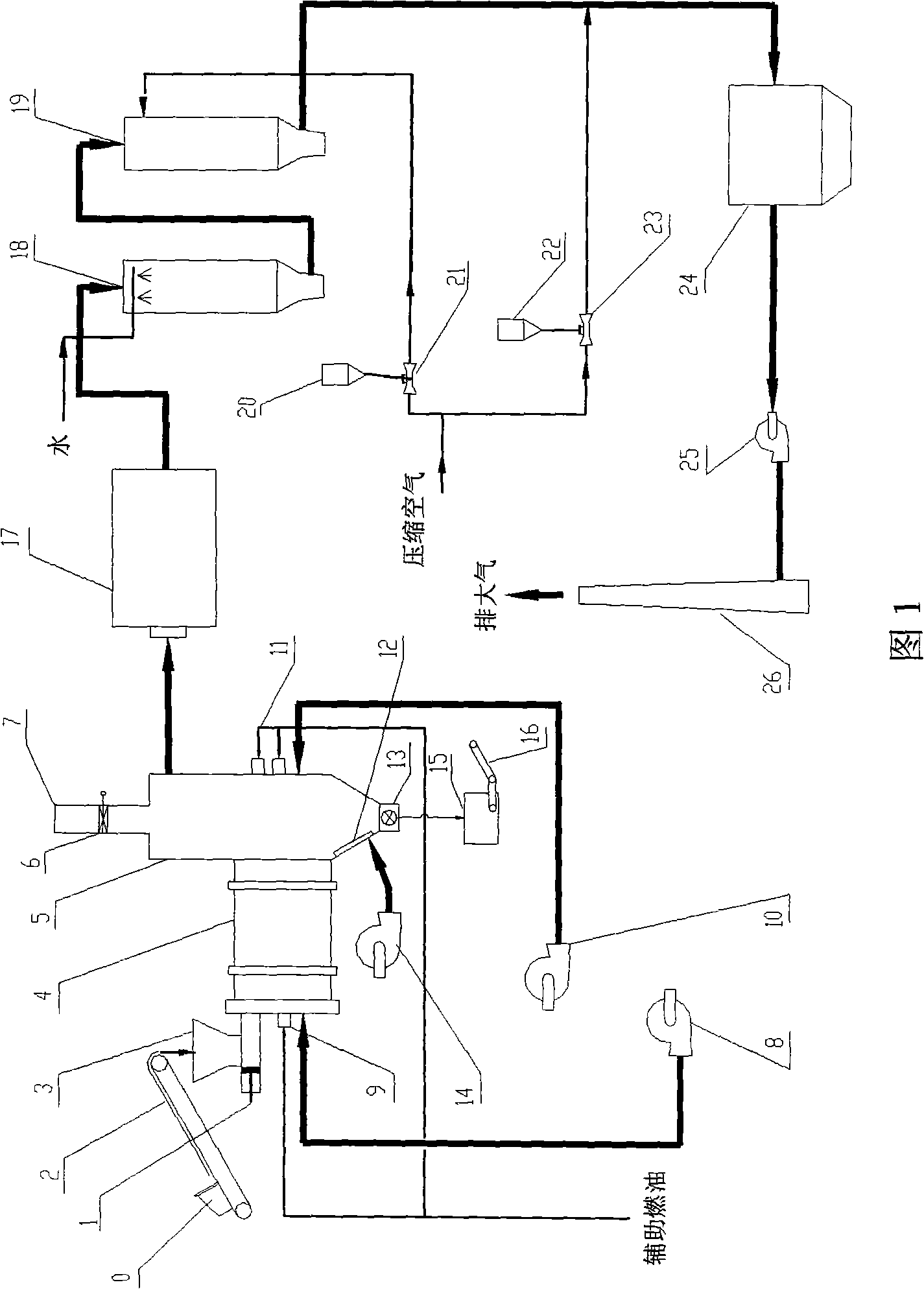

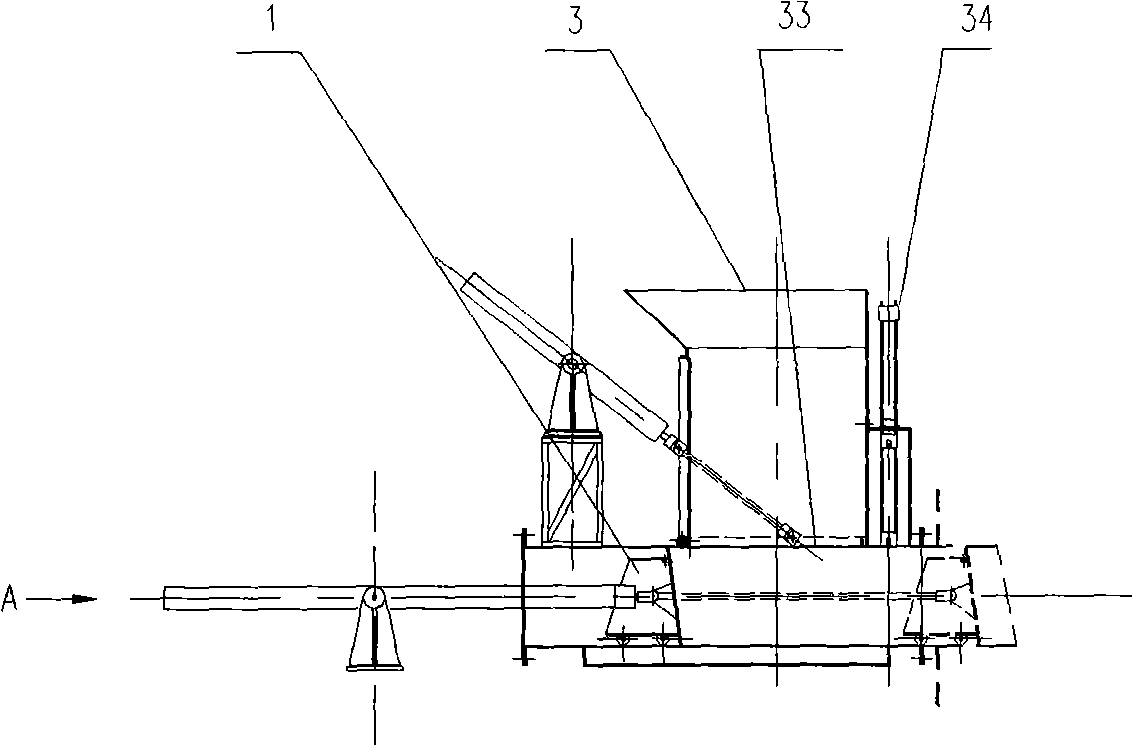

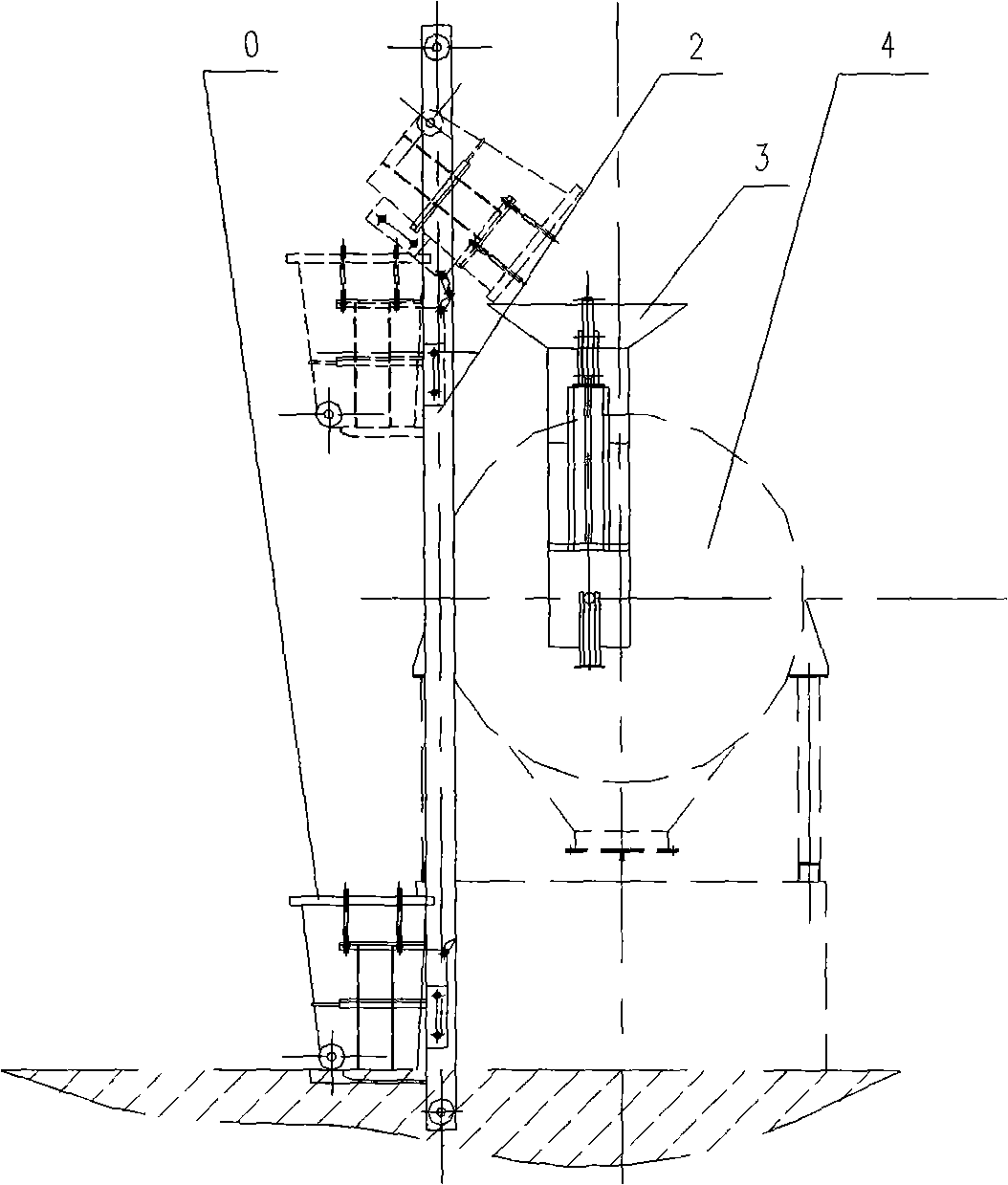

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

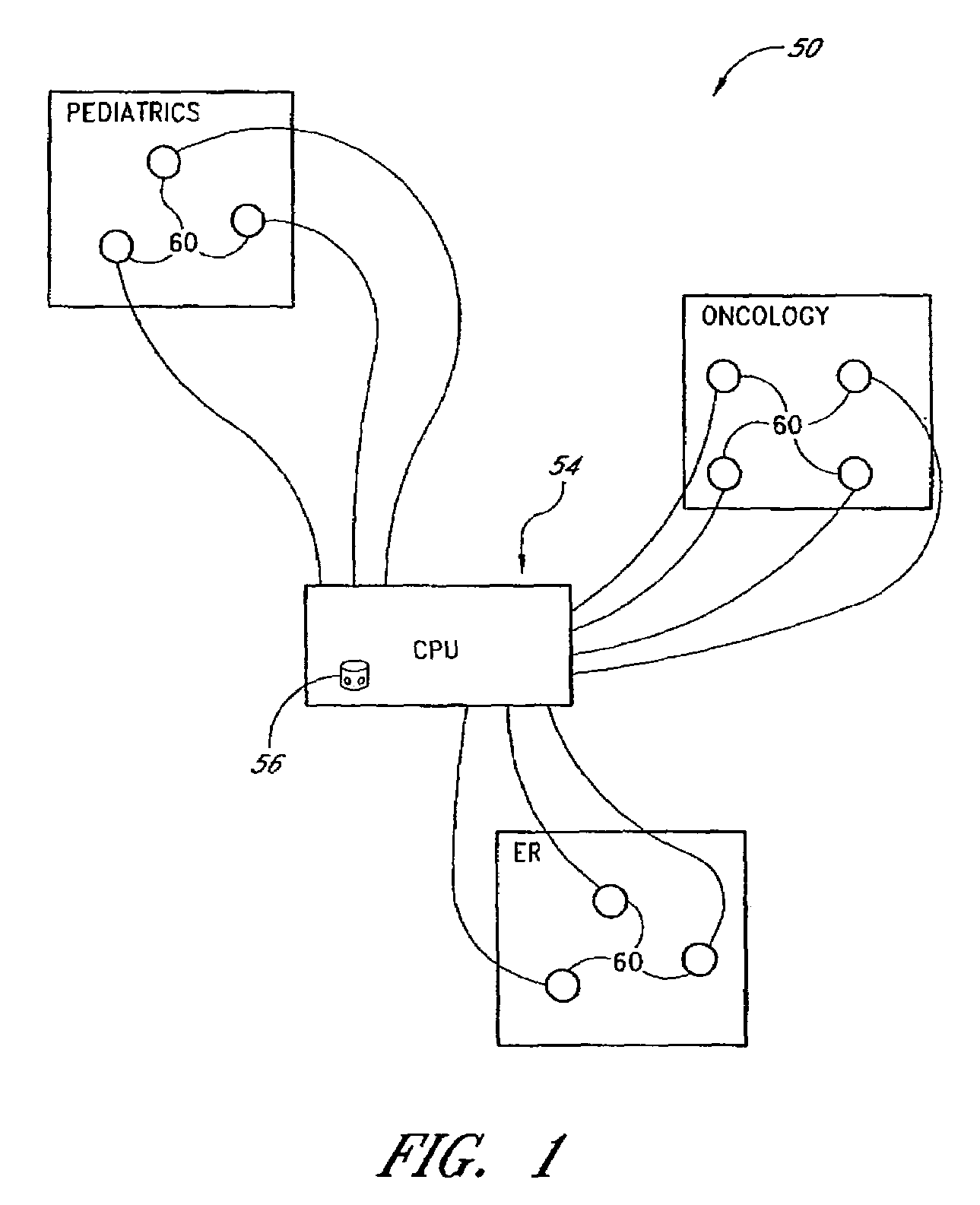

Method and system for tracking medical and other waste

InactiveUS20050228682A1Complete banking machinesSustainable waste treatmentMedical wasteToxic material

A system and method for tracking medical or toxic waste including a first container adapted to hold untreated medical waste, the container having a wireless tracking device attached thereto. The system also includes a tracking station capable of monitoring the movement of the medical waste by tracking the wireless tracking device.

Owner:SANITEC INDS

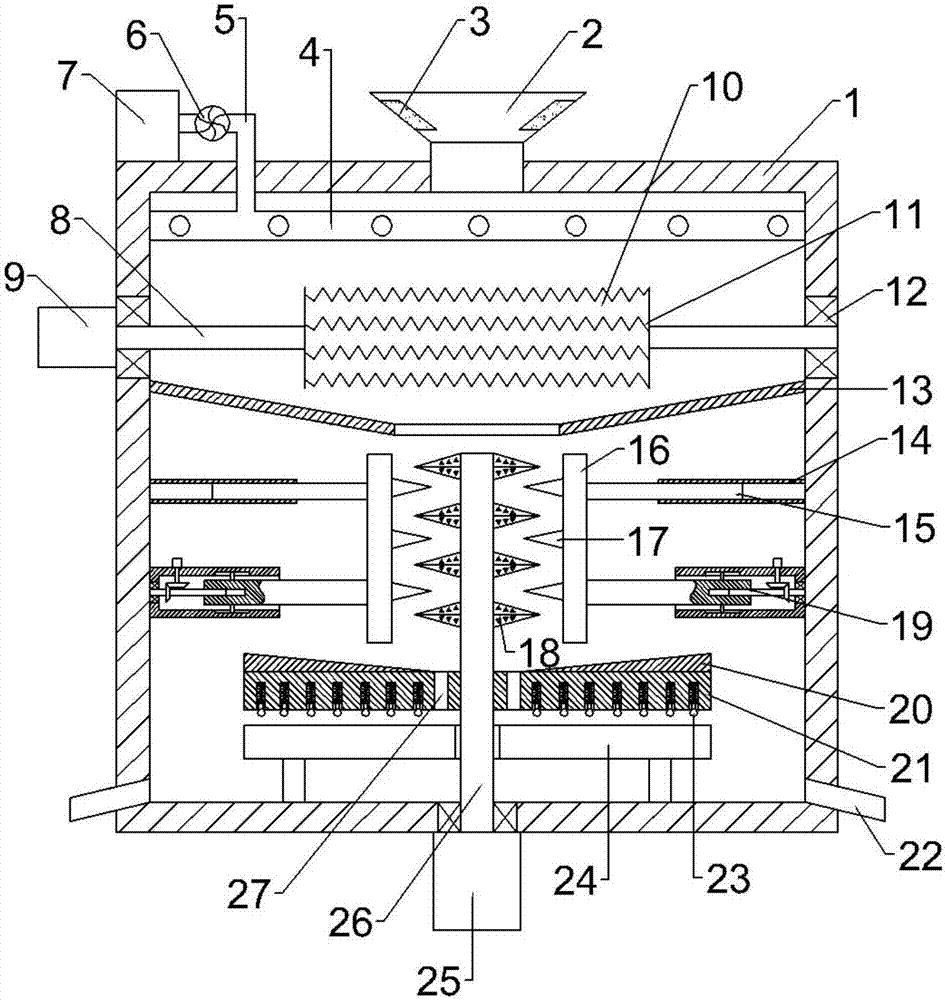

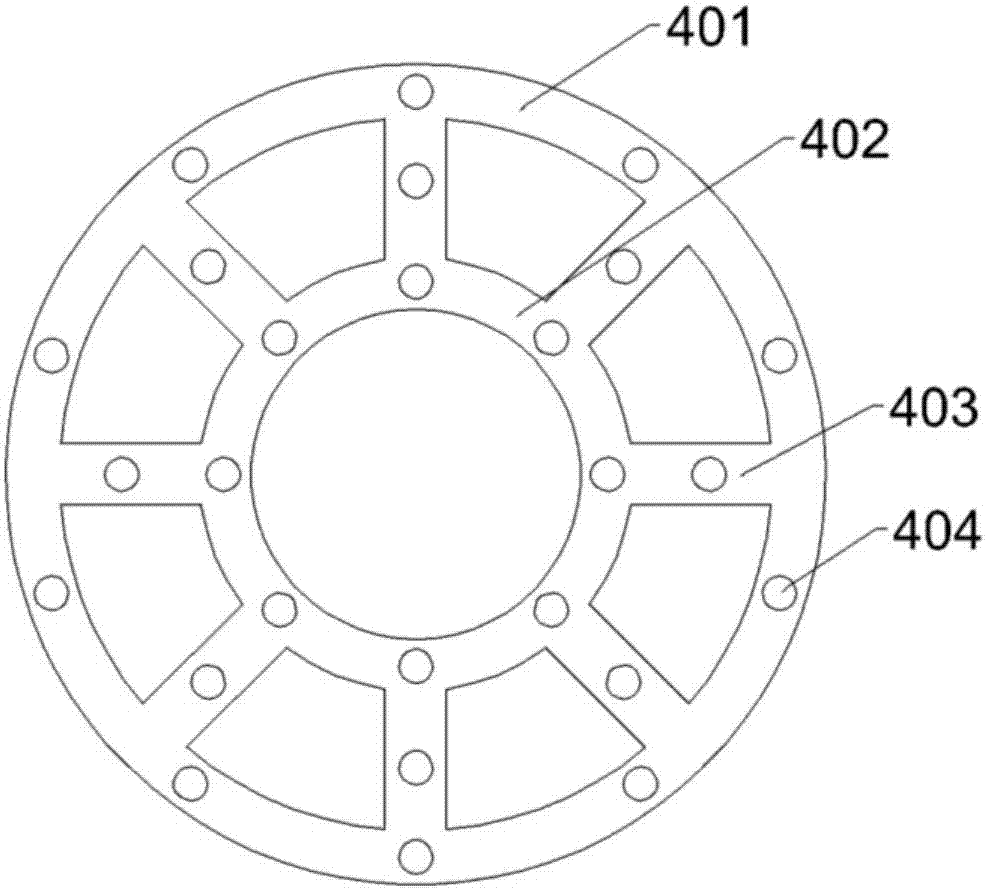

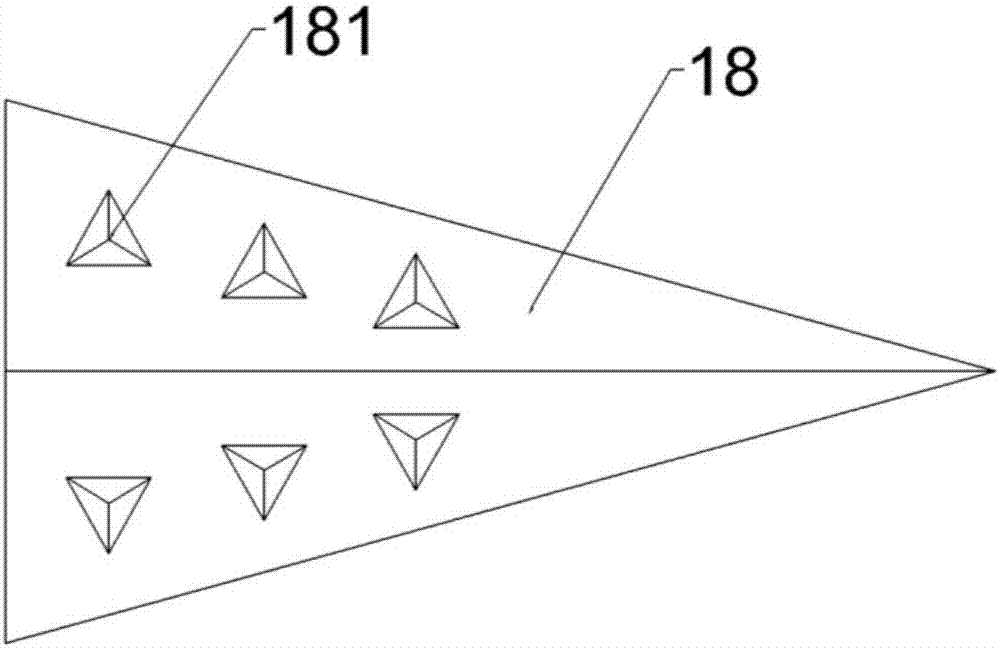

Medical waste crushing equipment based on crushing force adjusting principle

InactiveCN107051645ANo pollutionSmall particle sizeCocoaGrain treatmentsMedical wasteAgricultural engineering

A medical waste crushing device based on the principle of crushing force adjustment, comprising a casing, the top of the casing is provided with a feeding port, and a magnet block is provided on the side wall of the feeding port; the inner top of the casing is provided with a disinfection ring pipe , the disinfection ring pipe communicates with the disinfectant solution tank located above the housing through the liquid inlet pipe; a horizontal rotating shaft is arranged below the disinfection ring pipe, and the left end of the horizontal rotating shaft is fixedly connected with the output shaft of the first motor located on the left side wall of the housing. A crushing roller is arranged on the horizontal rotating shaft, and several screw teeth are evenly arranged on the outer surface of the crushing roller; a vertical rotating shaft is arranged below the horizontal rotating shaft, and the bottom end of the vertical rotating shaft is fixedly connected with the output shaft of the second motor located below the housing. The upper part of the vertical rotating shaft is fixedly connected with several pulverized bodies, and the side surfaces of the pulverized bodies are fixedly connected with several pulverized protrusions. The invention has the advantages of reasonable structural design, simple and convenient operation, good crushing effect, etc., and has certain popularization and application value.

Owner:王杰

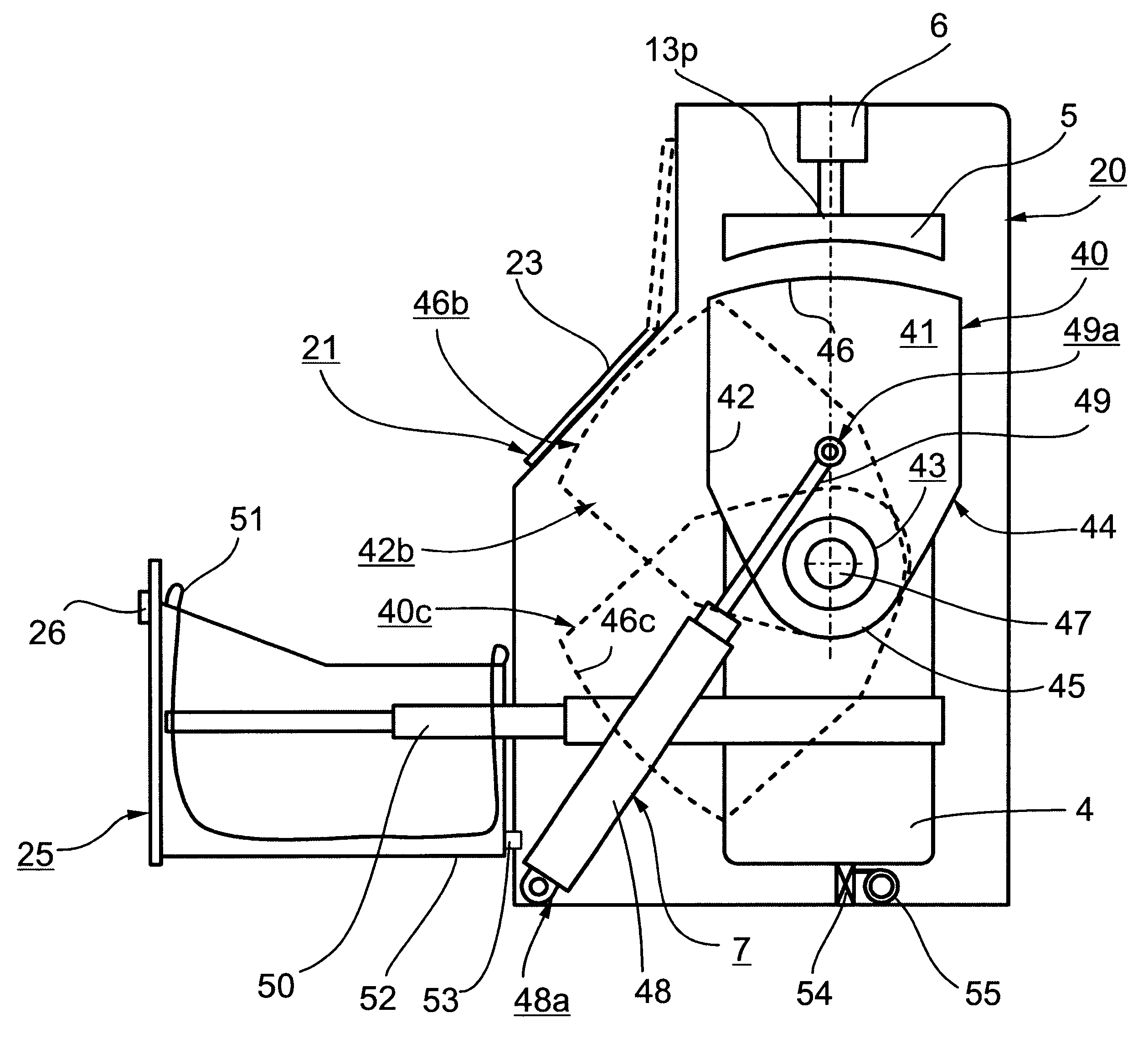

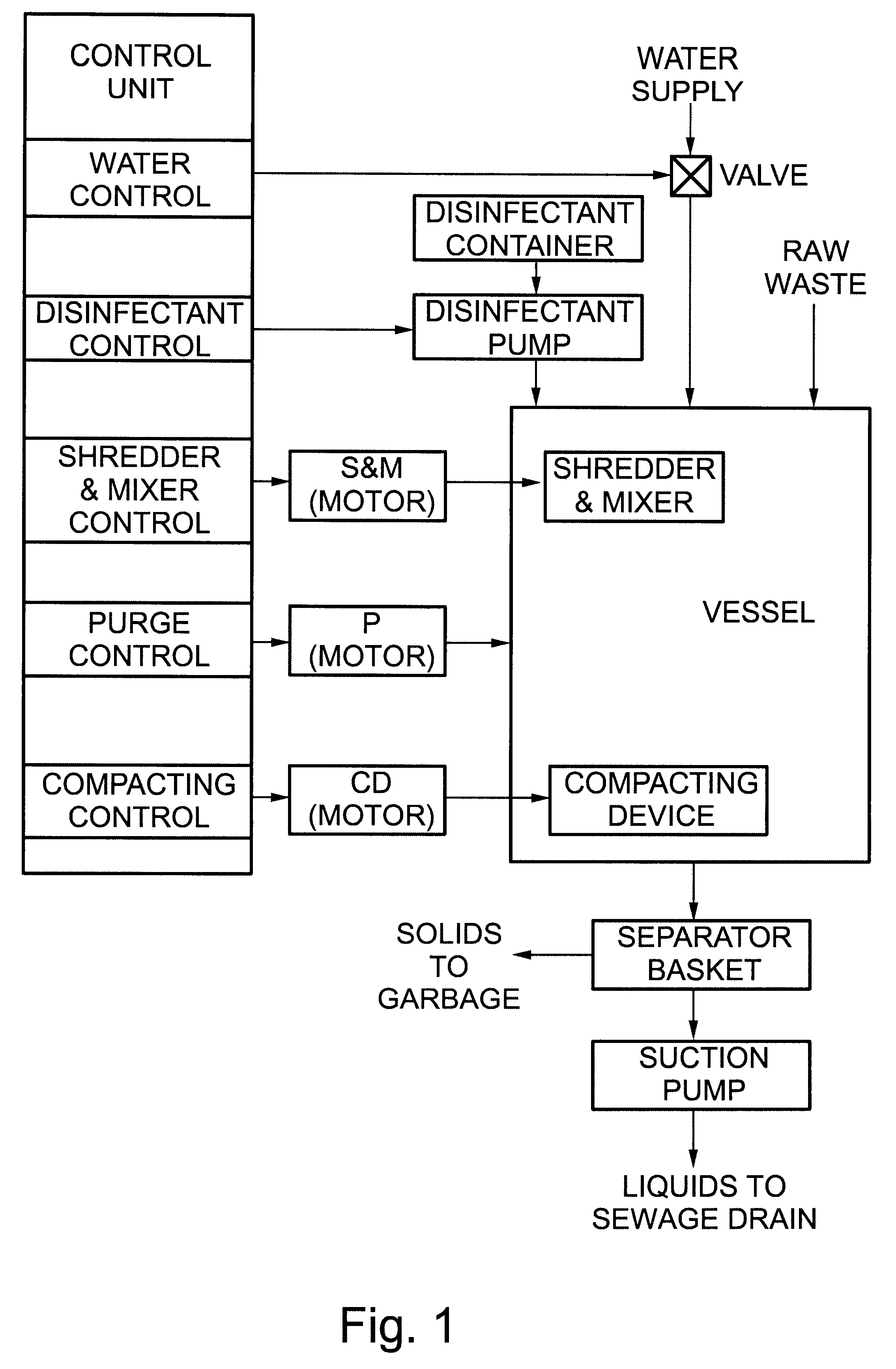

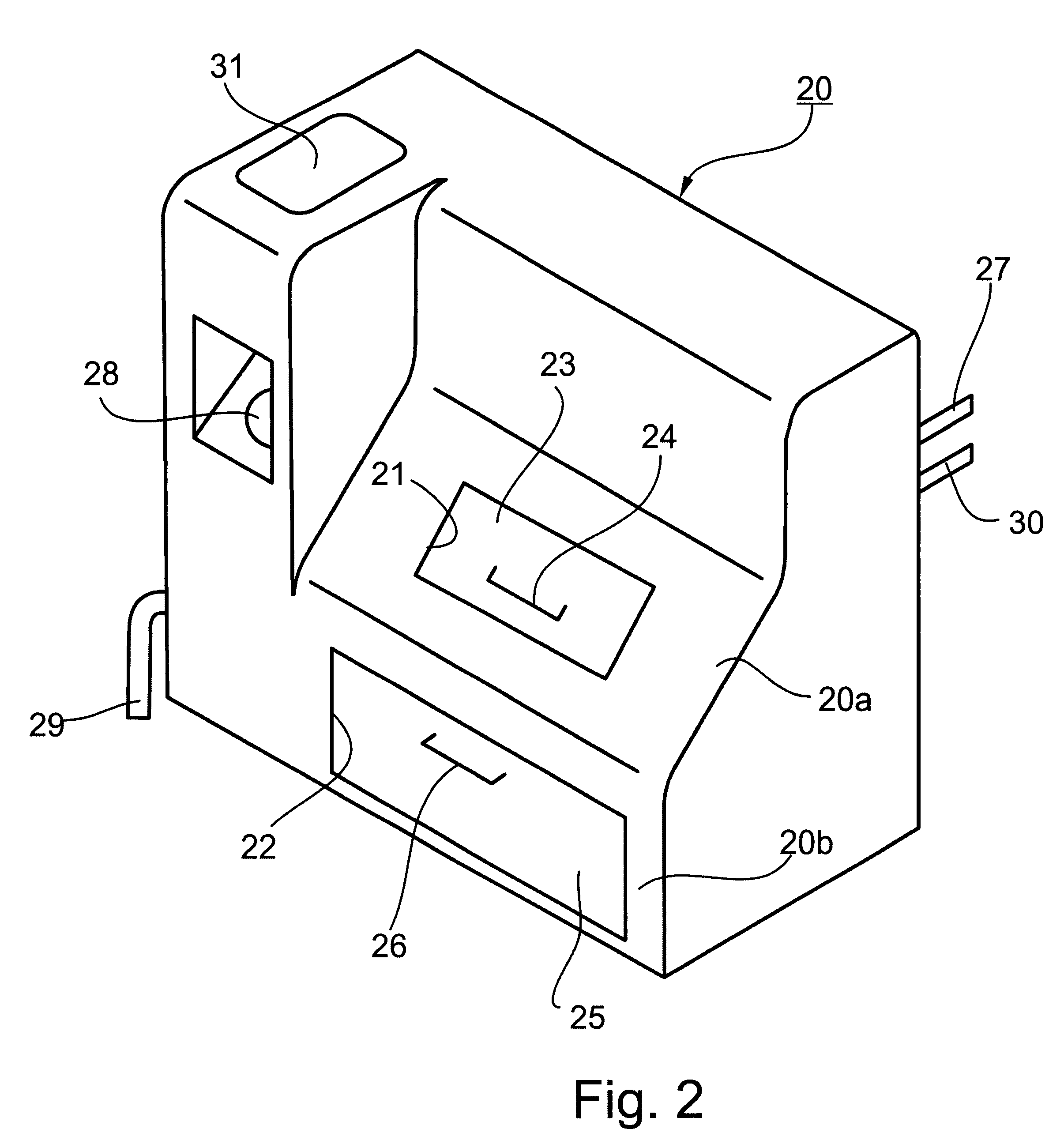

Apparatus for treating waste, particularly medical waste, to facilitate its disposition

InactiveUS6494391B2Simple and compactSuitable for useGrinding machine componentsGas current separationLine tubingDisinfectant

Apparatus for treating waste, particularly all types of medical waste, to facilitate its disposition includes a treatment vessel having an open top pivotal within a housing to a waste-loading position with its open top aligned with the housing inlet for receiving the waste, a waste-treating position for shredding the waste by a shredder unit disposed within the treatment vessel, and a waste-removing position with its open top aligned with the housing outlet for removing the shredded waste. The apparatus further include a compactor head for compacting the waste within the treatment vessel, a water feed line, and a disinfectant feed line, for feeding water and a disinfectant into the treatment vessel, for mixing with the waste while it is being compacted and shredded.

Owner:M C M ENVIRONMENTAL TECH INC

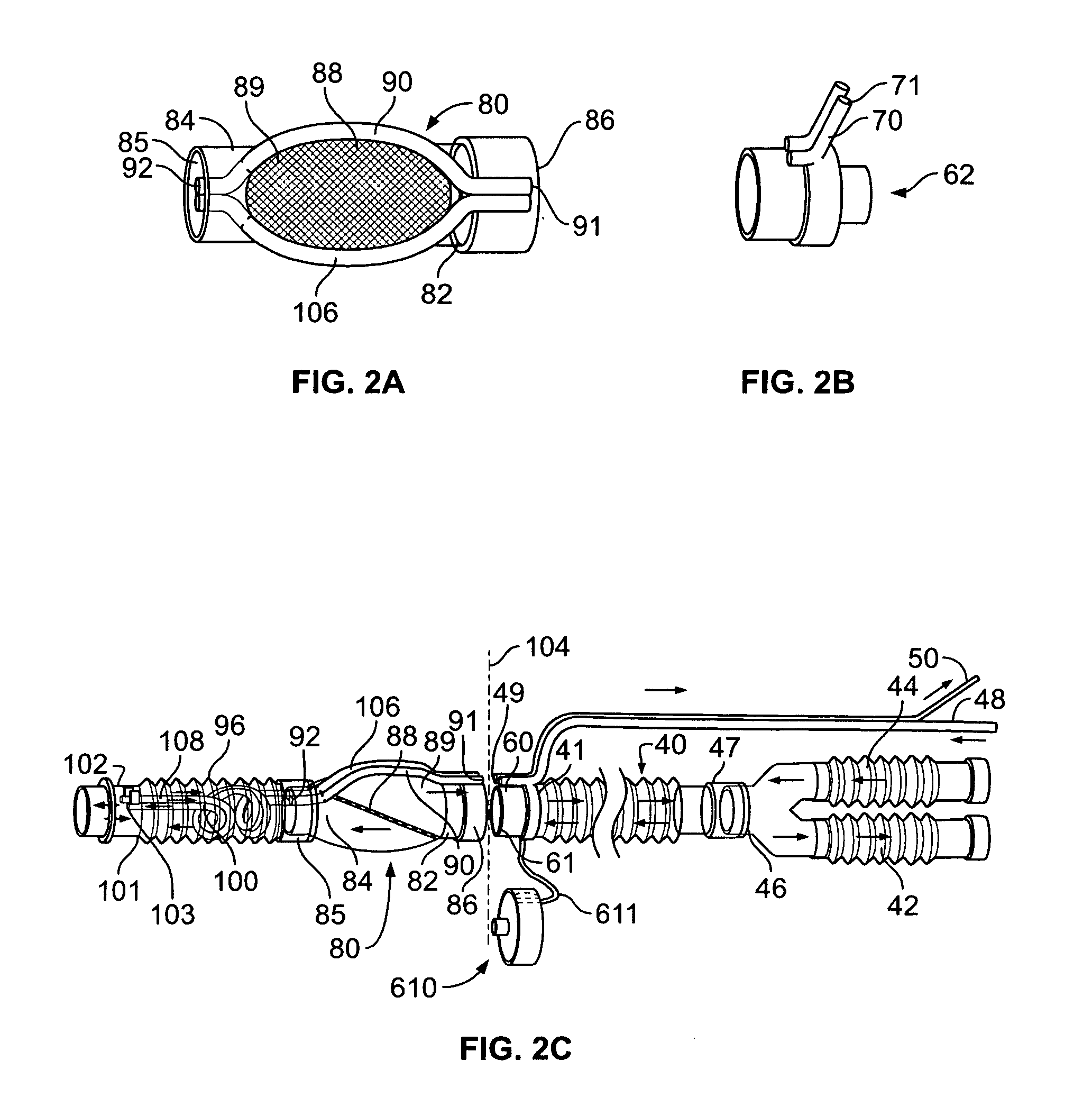

Multifunctional integrated filter and breathing conduit

InactiveUS20050188990A1Minimizing mixing spaceReduced dimensionRespiratorsBreathing filtersMedical wasteCatheter

A device for use in constructing a breathing circuit has at least a first tube and a filter; the filter has a proximal and a distal end; the first tube is attached to the filter distal end. A second tube can be attached to the filter proximal end, wherein the second tube can be detached from the filter for reuse in a breathing circuit formed with the foregoing components. The filter and the first tube may be disposed of after a single use. The first tube has a length sufficient to maintain the filter at a desired distance from a patient airway device when connected thereto. In a preferred embodiment, a fresh gas outlet is provided at the distal end of the first tube resulting in minimal or substantially no mixing space in the circuit, while the disposable first tube and filter create less medical waste than that created by prior art circuits. Mixing space refers to space distal of the fresh gas outlet into the circuit where the fresh gases can mix with recirculated or other gases. In embodiments, the mixing space is less than 15 cm3 or less than about 5 cm3, and the distal disposable filter and tube device is less than 50 cm in length.

Owner:FUKUNAGA ATSUO F +2

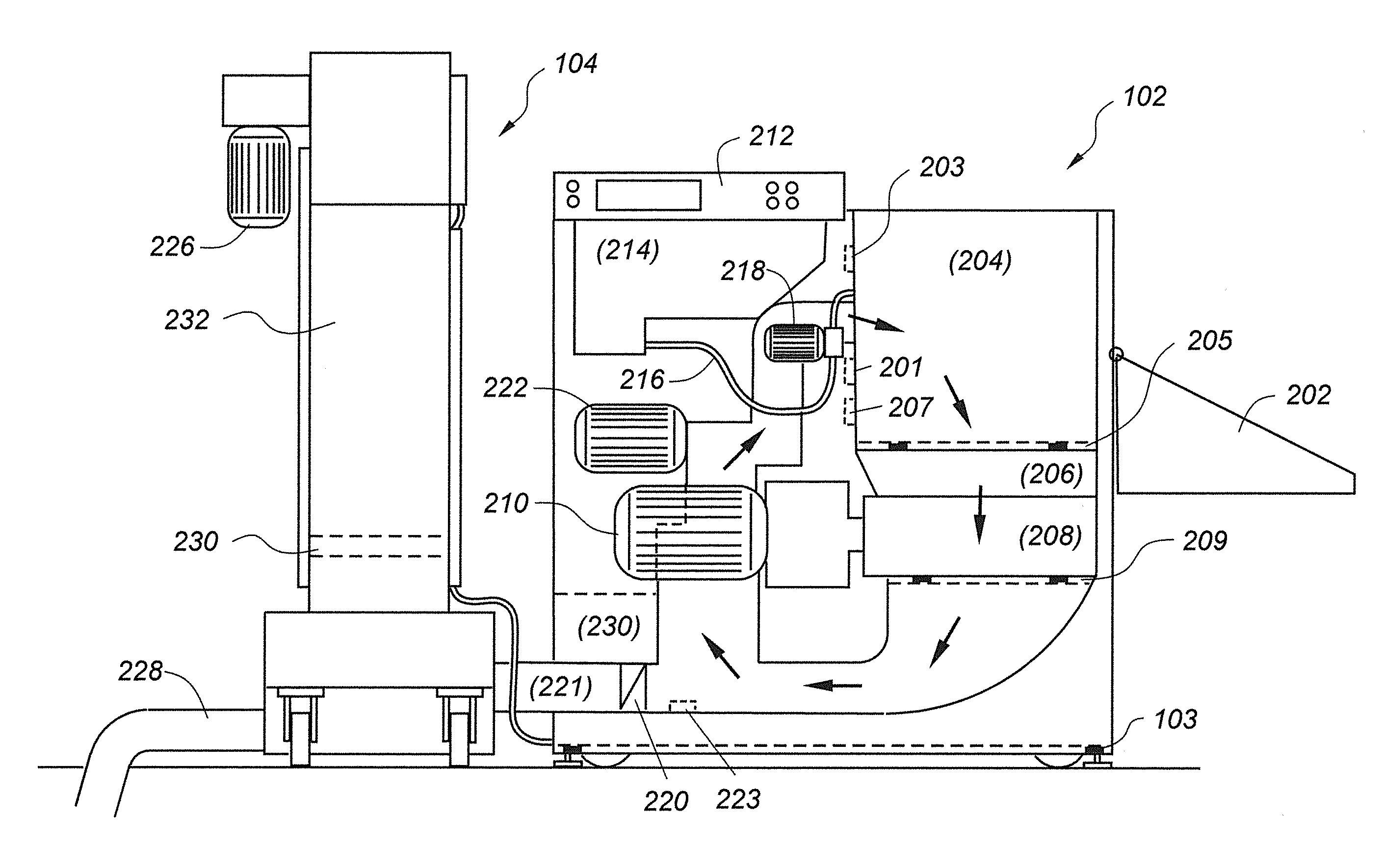

Integrated medical waste management system and operation

InactiveUS20130175373A1Promote degradationGas current separationSolid waste disposalTelecommunications linkDisinfectant

An integrated medical waste management and treatment system may include sensors, interlocks, communications links and / or other features for determining if the waste itself, the decontaminating disinfectant used in the process, or the status of the system are consistent with recommended or authorized system operation. System operation may be terminated if a condition inconsistent with recommended or authorized system operation is detected. Such compliance apparatus may include an electronic scale for determining the weight of the waste loaded into the receiver compartment, a metal detector, or a sensor for determining if the decontaminating disinfectant is a recommended or authorized disinfectant. A communications link may be provided one or more systems to transmit information to a central station to deliver updates or commands associated with the recommended or authorized operation of each system.

Owner:STERIMED MEDICAL WASTE SOLUTIONS UK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com