Patents

Literature

752results about How to "Reduce handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

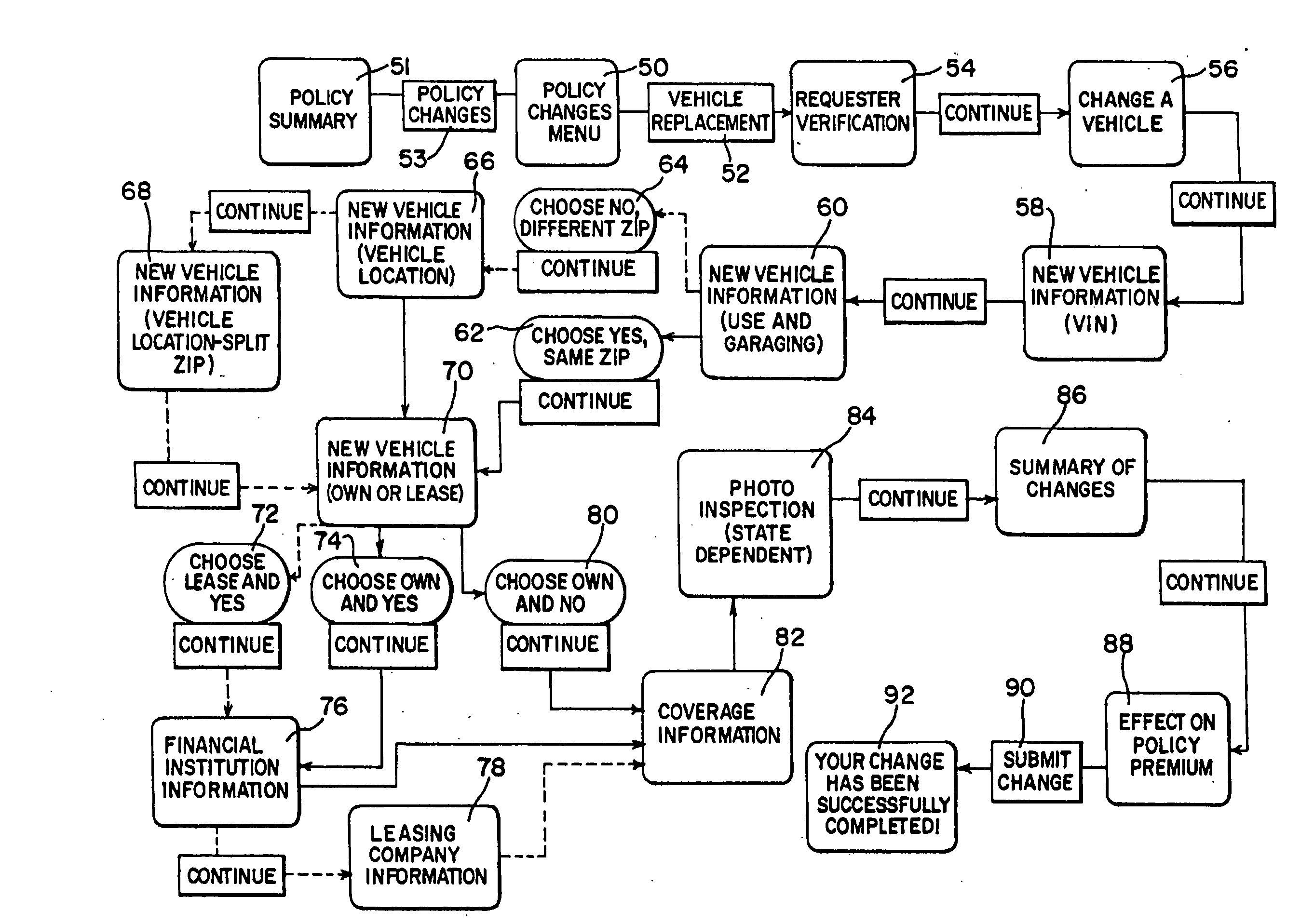

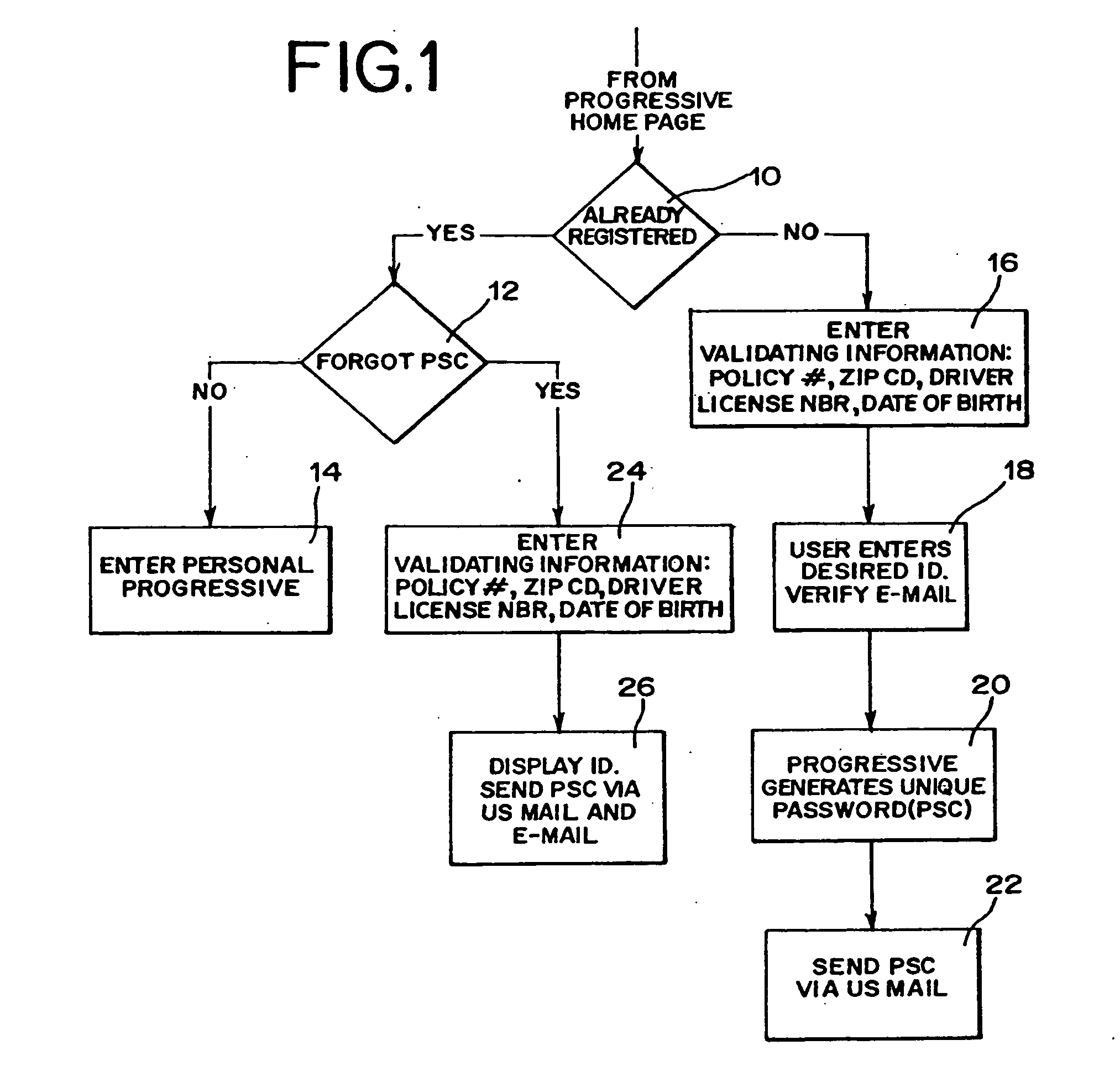

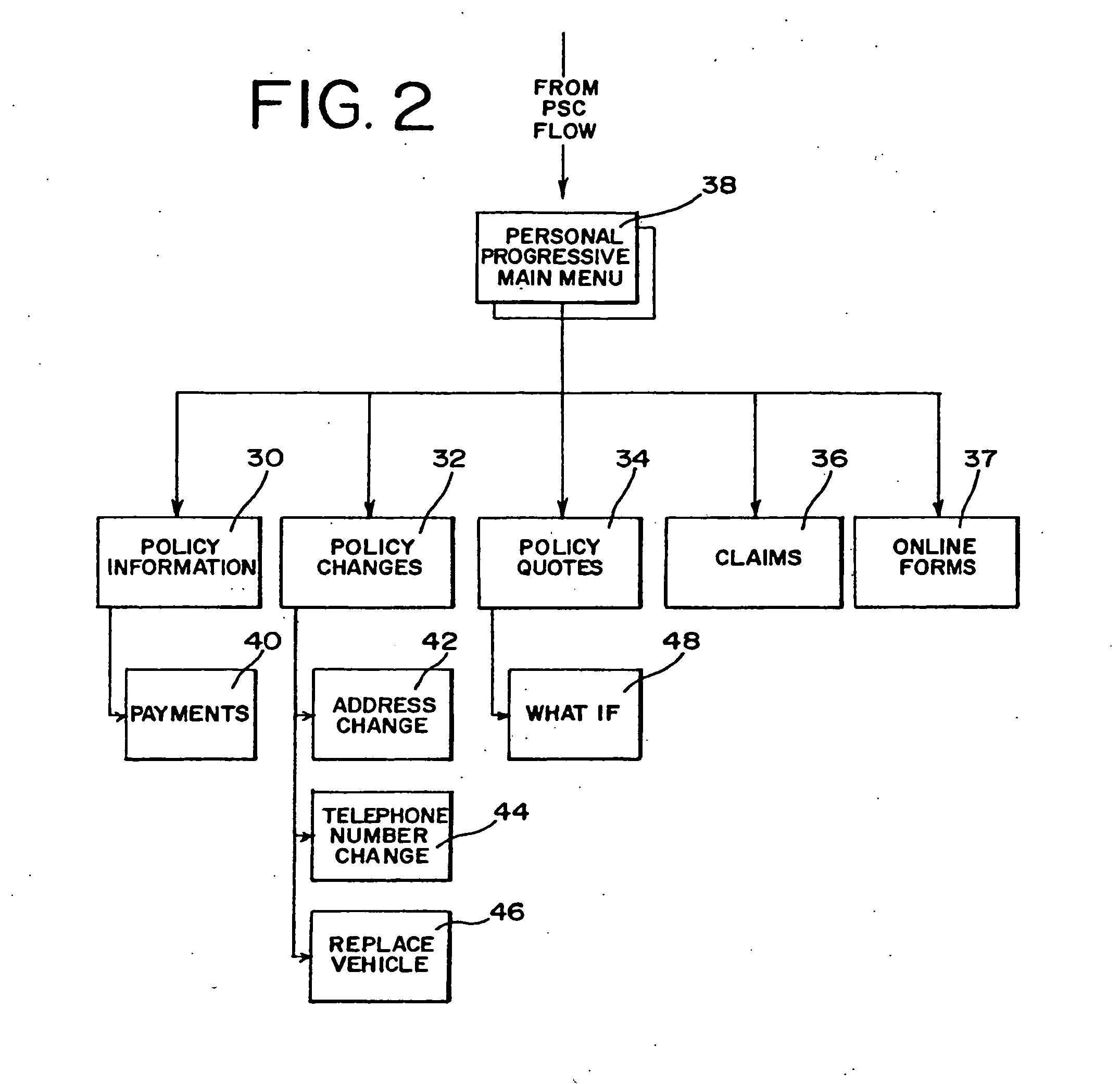

Method and apparatus for internet on-line insurance policy service

InactiveUS20070038488A1Easy to handleReduce inconvenienceFinanceOffice automationThe InternetComputer science

An Internet on-line insurance policy service system that facilitates real-time automated communication of policy information, adjustment of policy parameters, calculation and communication of resulting policy quotes, and implementation of policy changes, while obviating insurer personnel involvement and supervision of the communication. The system comprises a plurality of software modules relating to on-line real-time communication of existing policy information, testing of a wide range of variations in policy parameters, computing and communicating changes in policy premiums that would result from such variations, communicating desired changes in policy parameters and implementing desired policy changes. Other modules relate to communication of claims information and the providing of on-line forms.

Owner:PROGRESSIVE CASUALTY INSURANCE

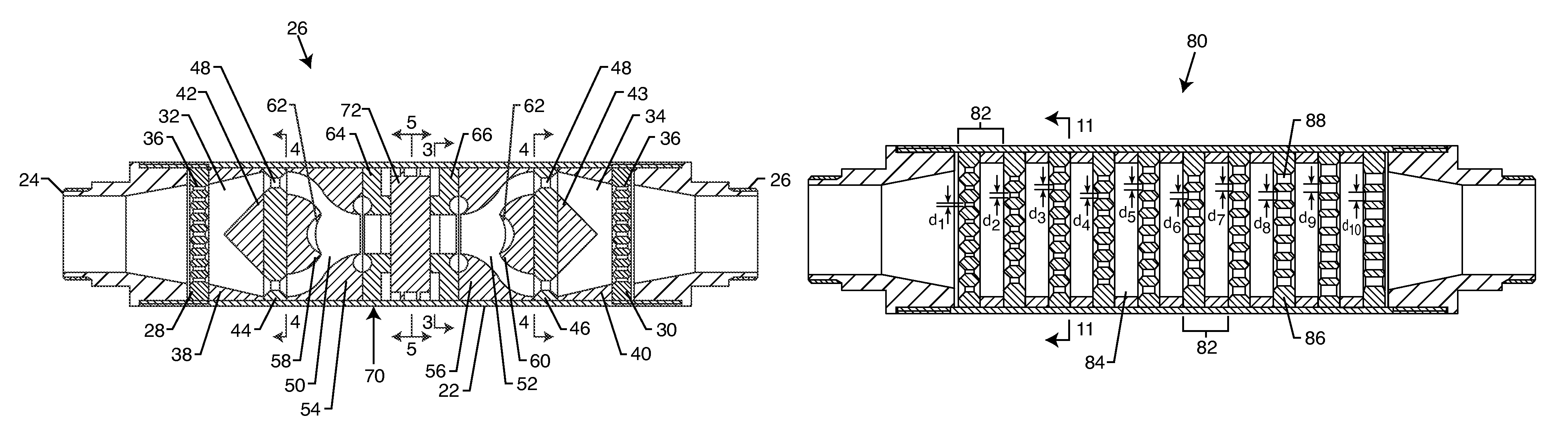

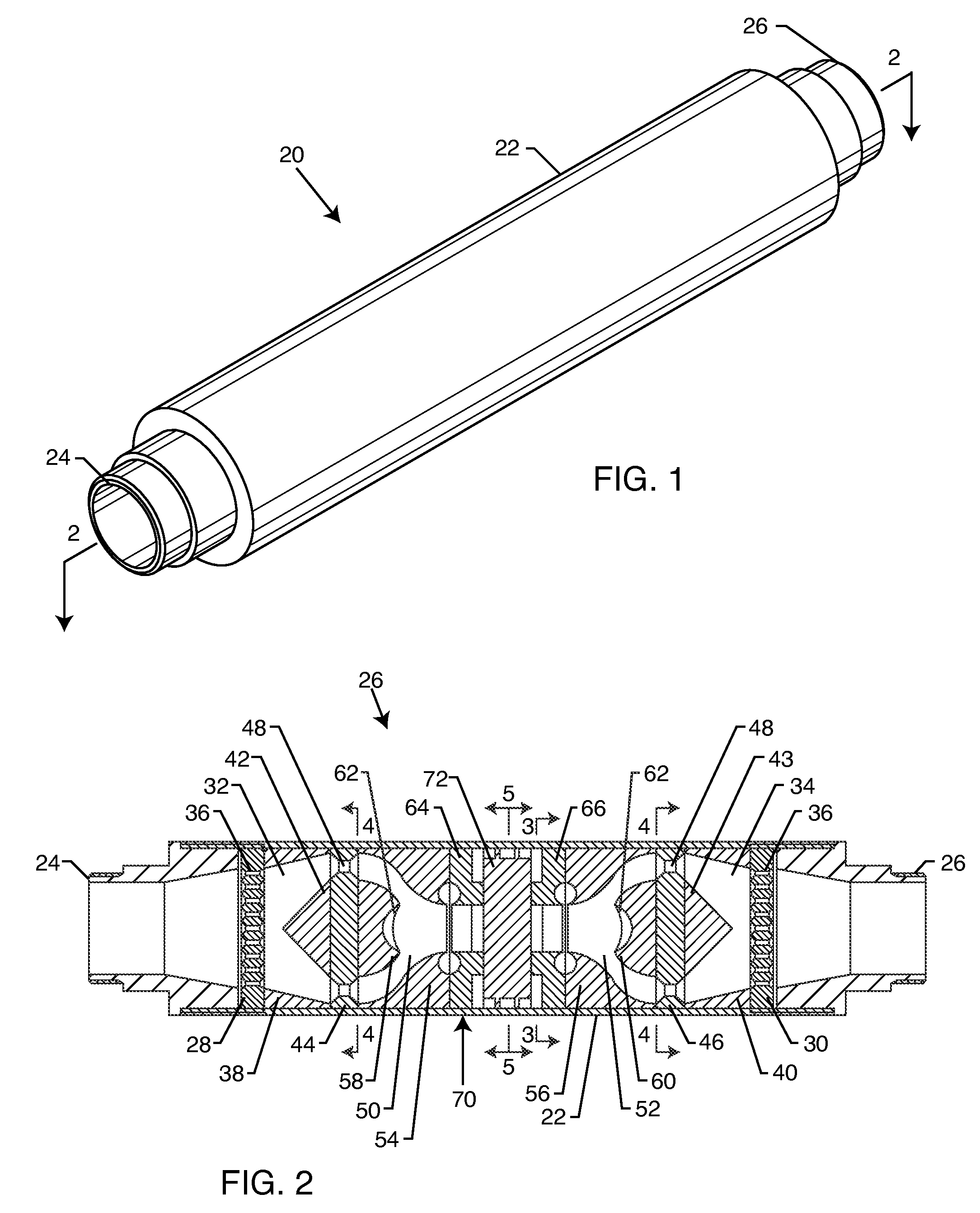

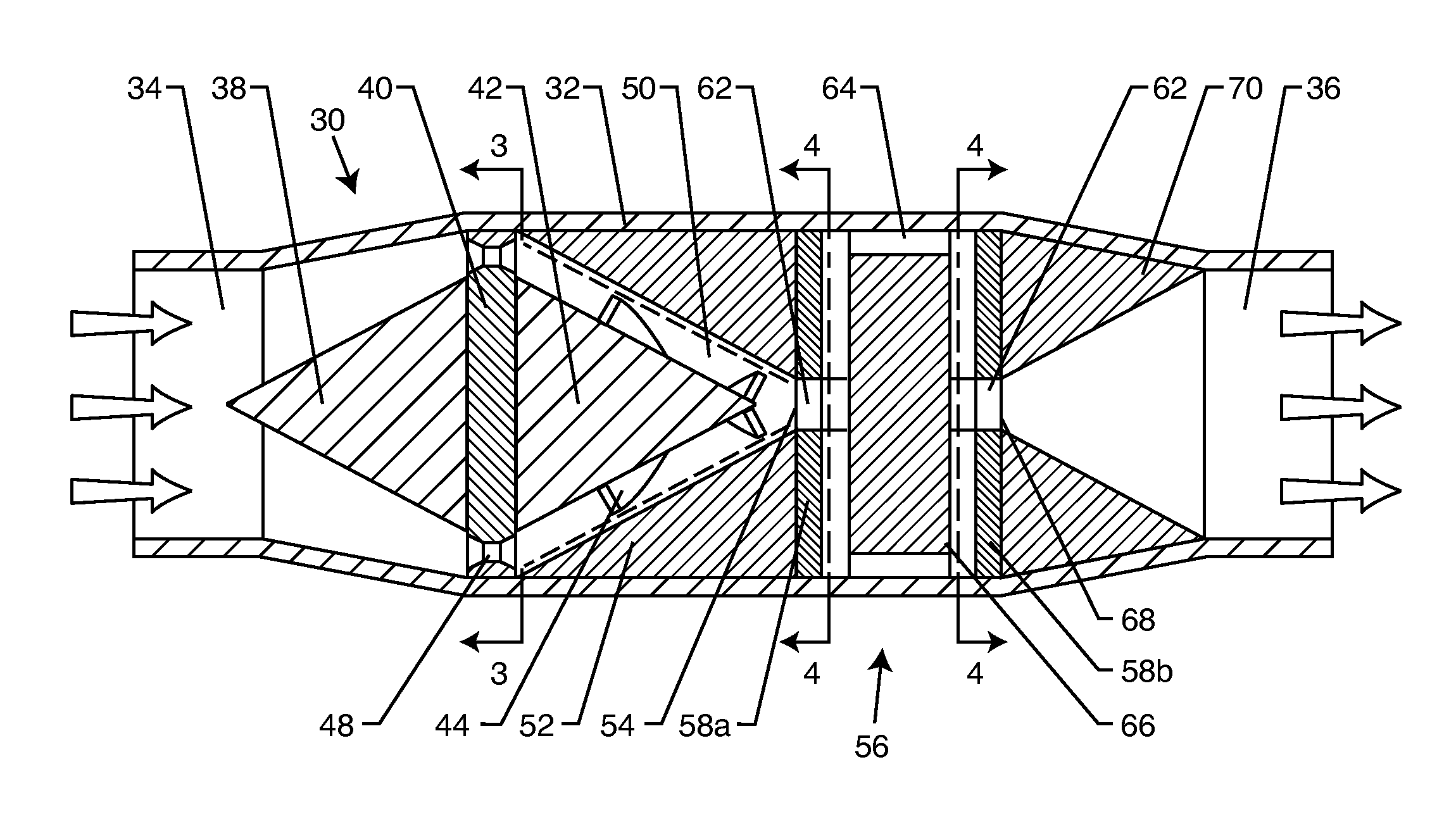

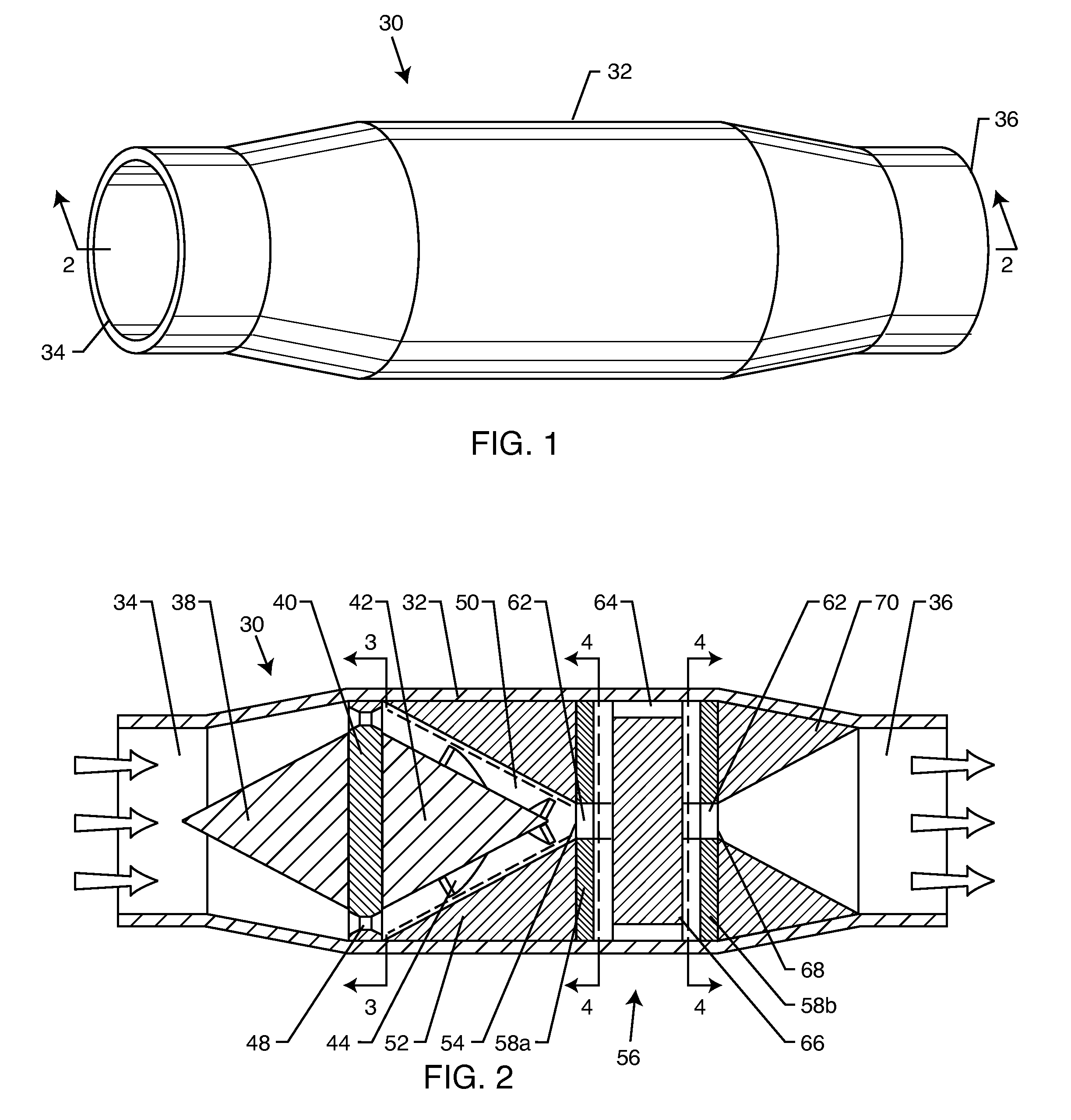

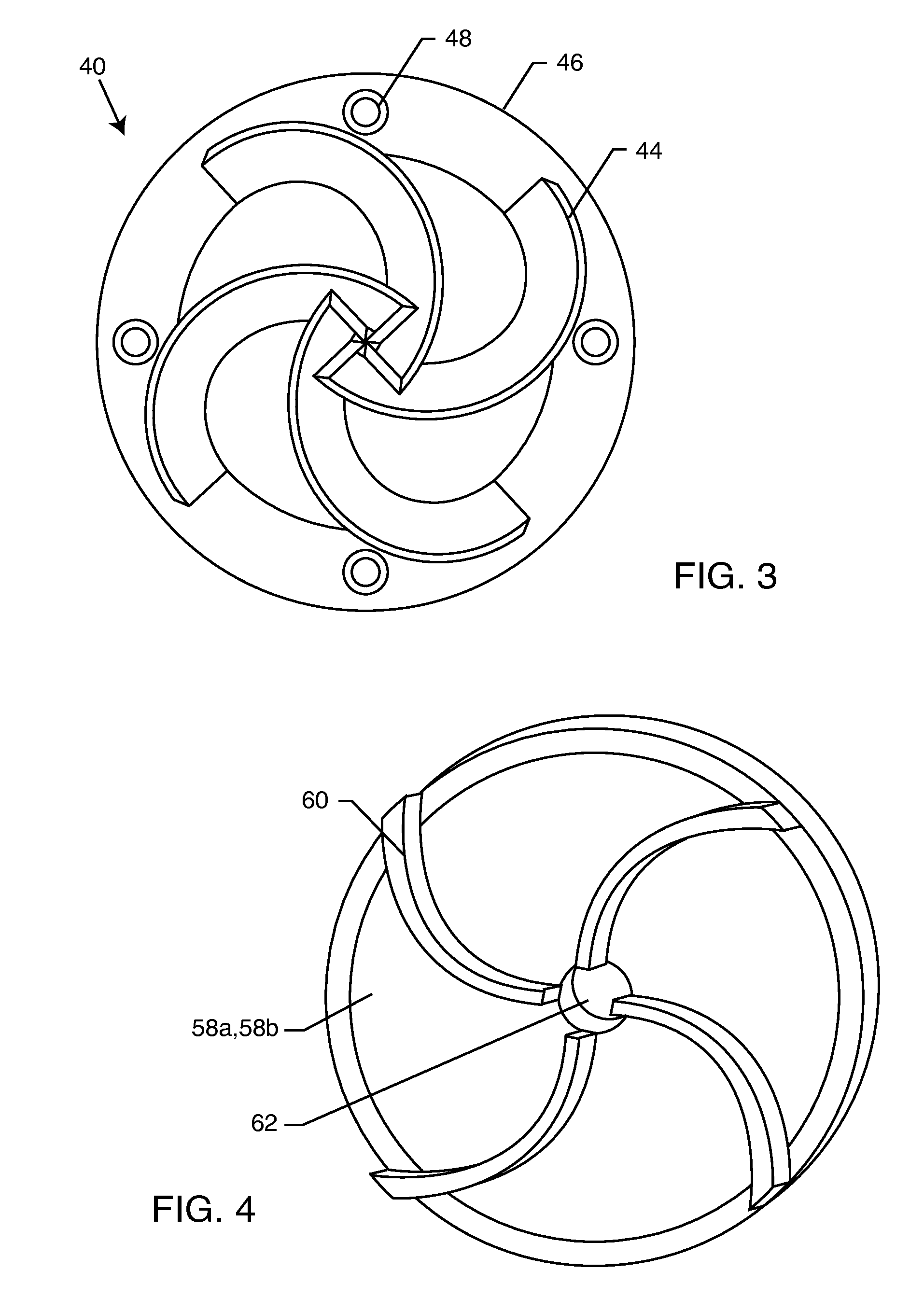

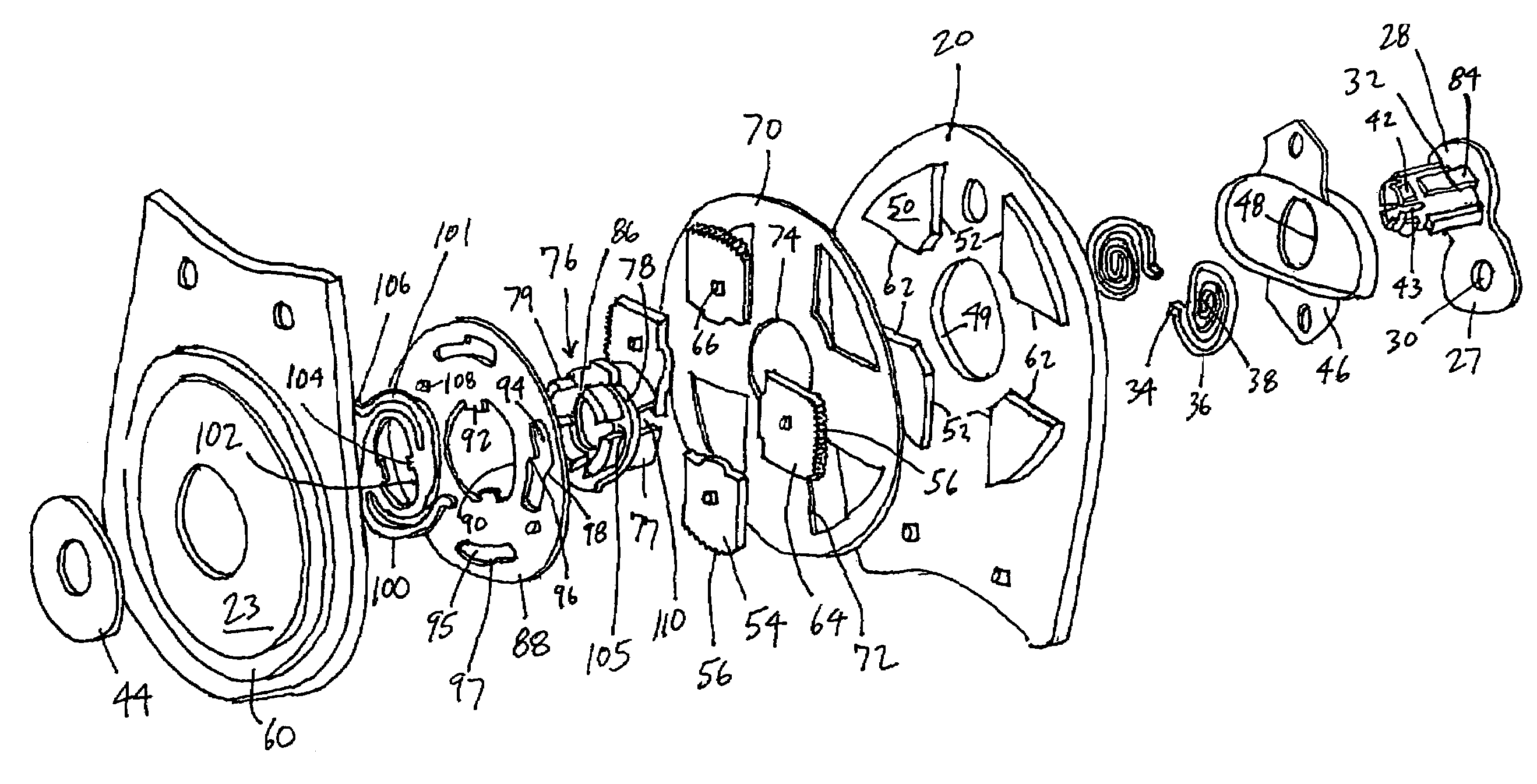

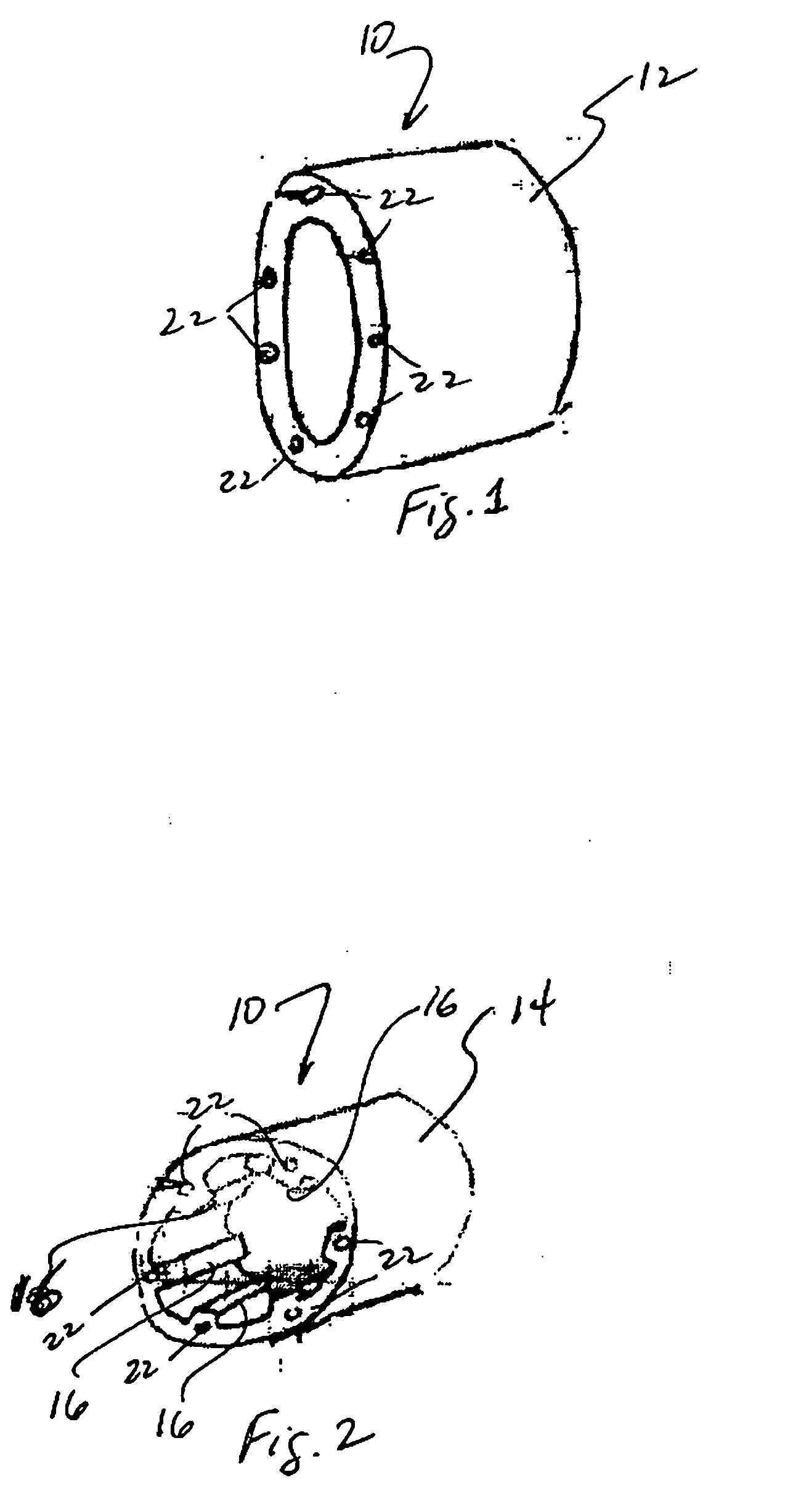

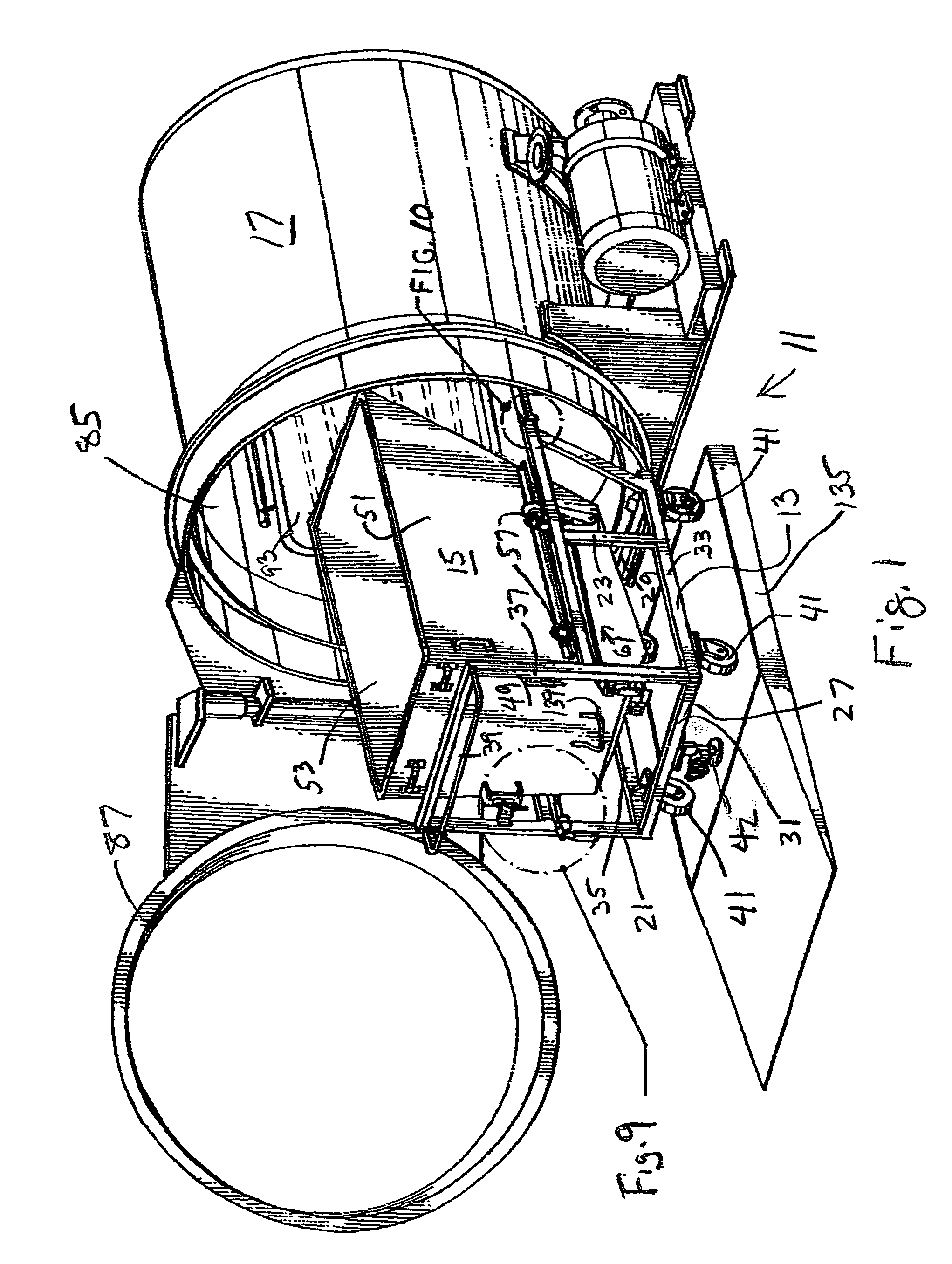

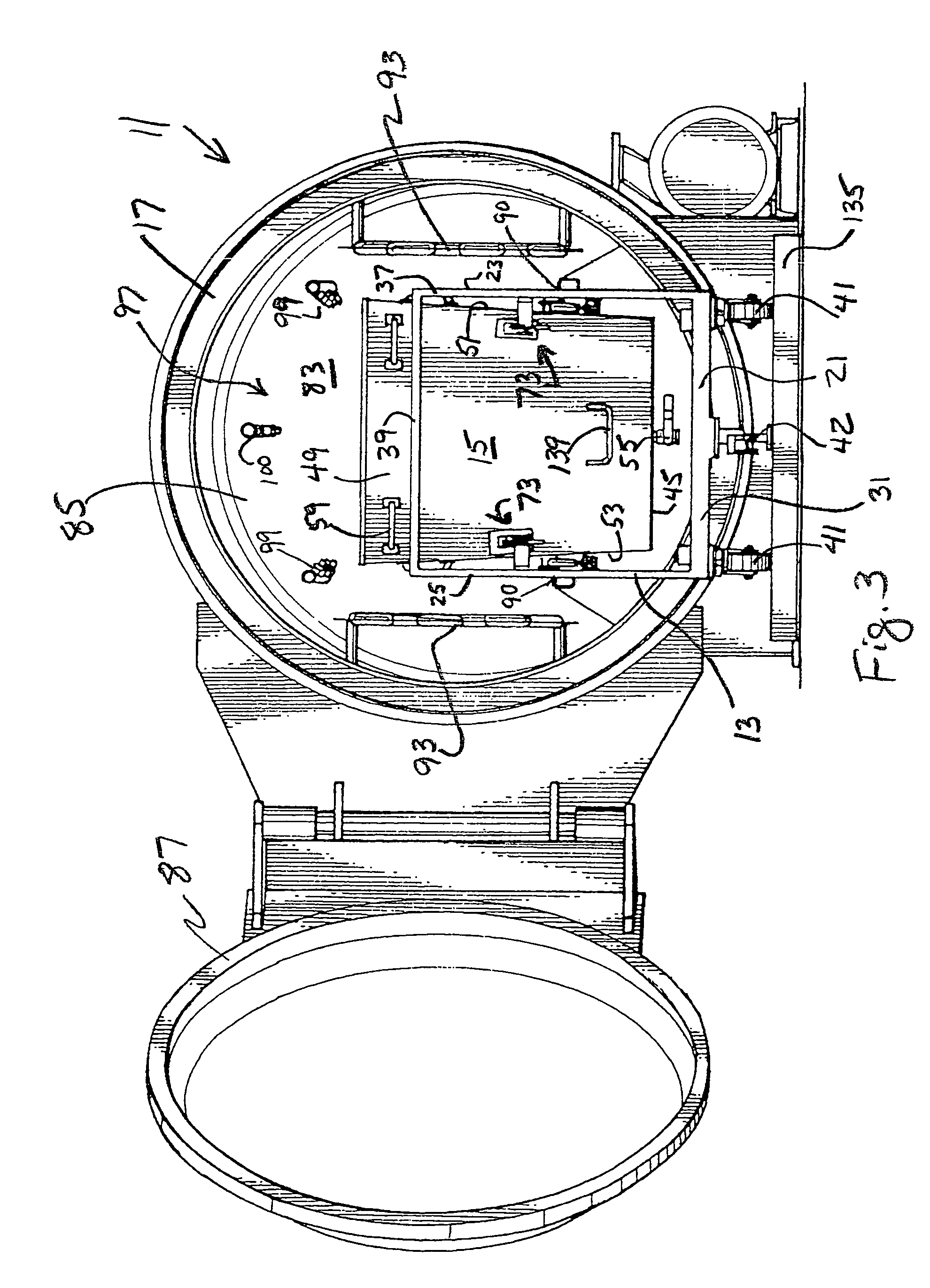

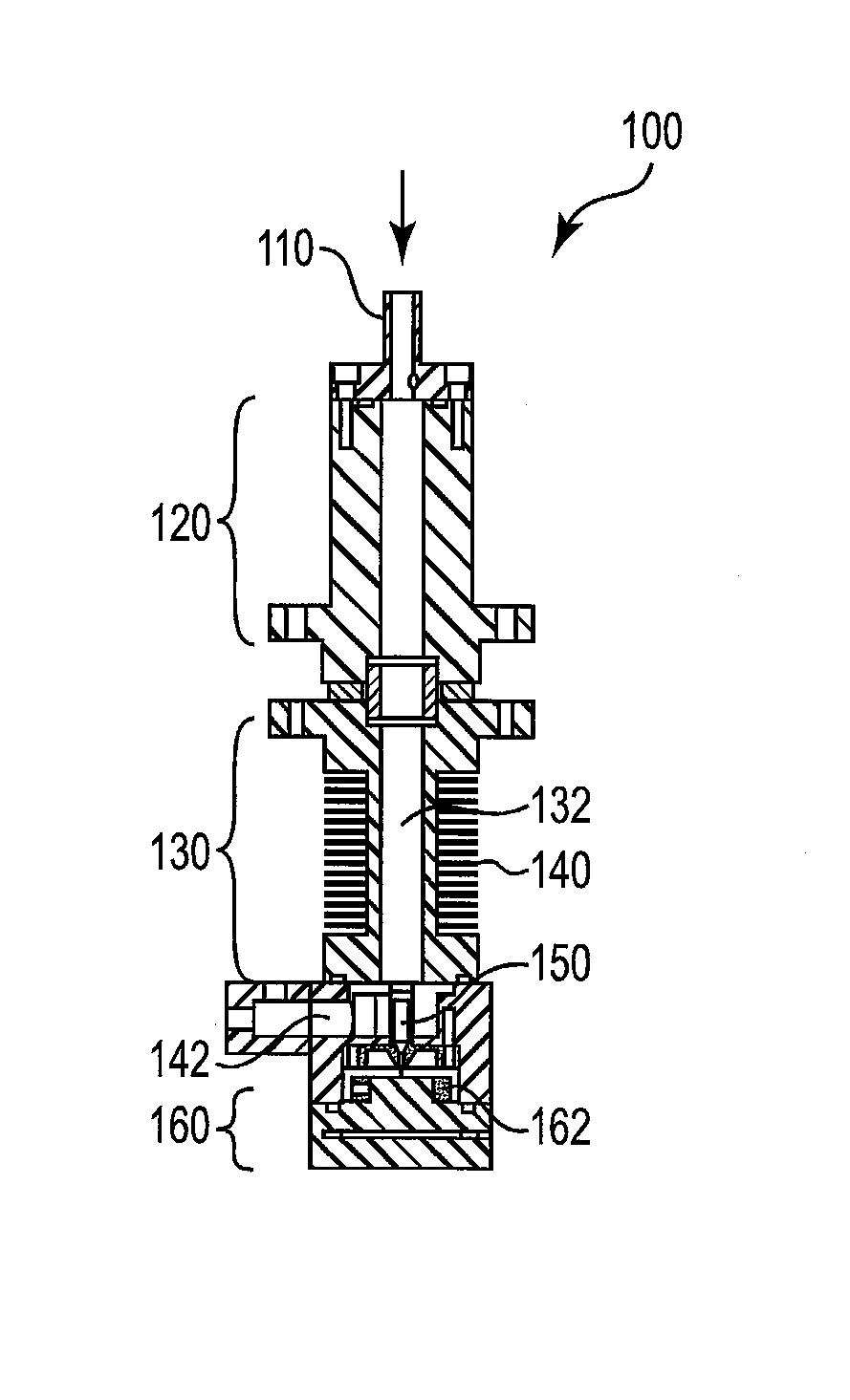

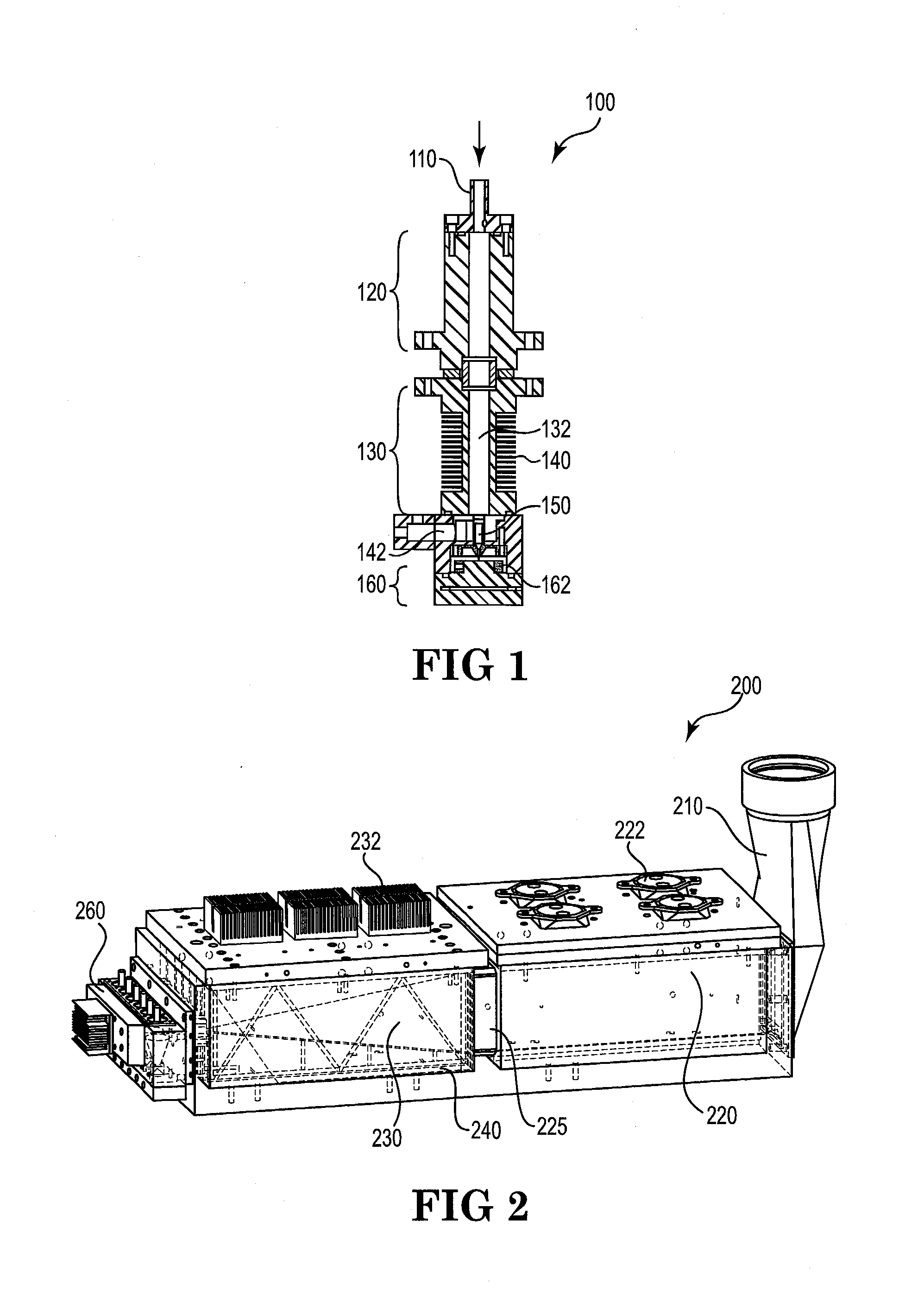

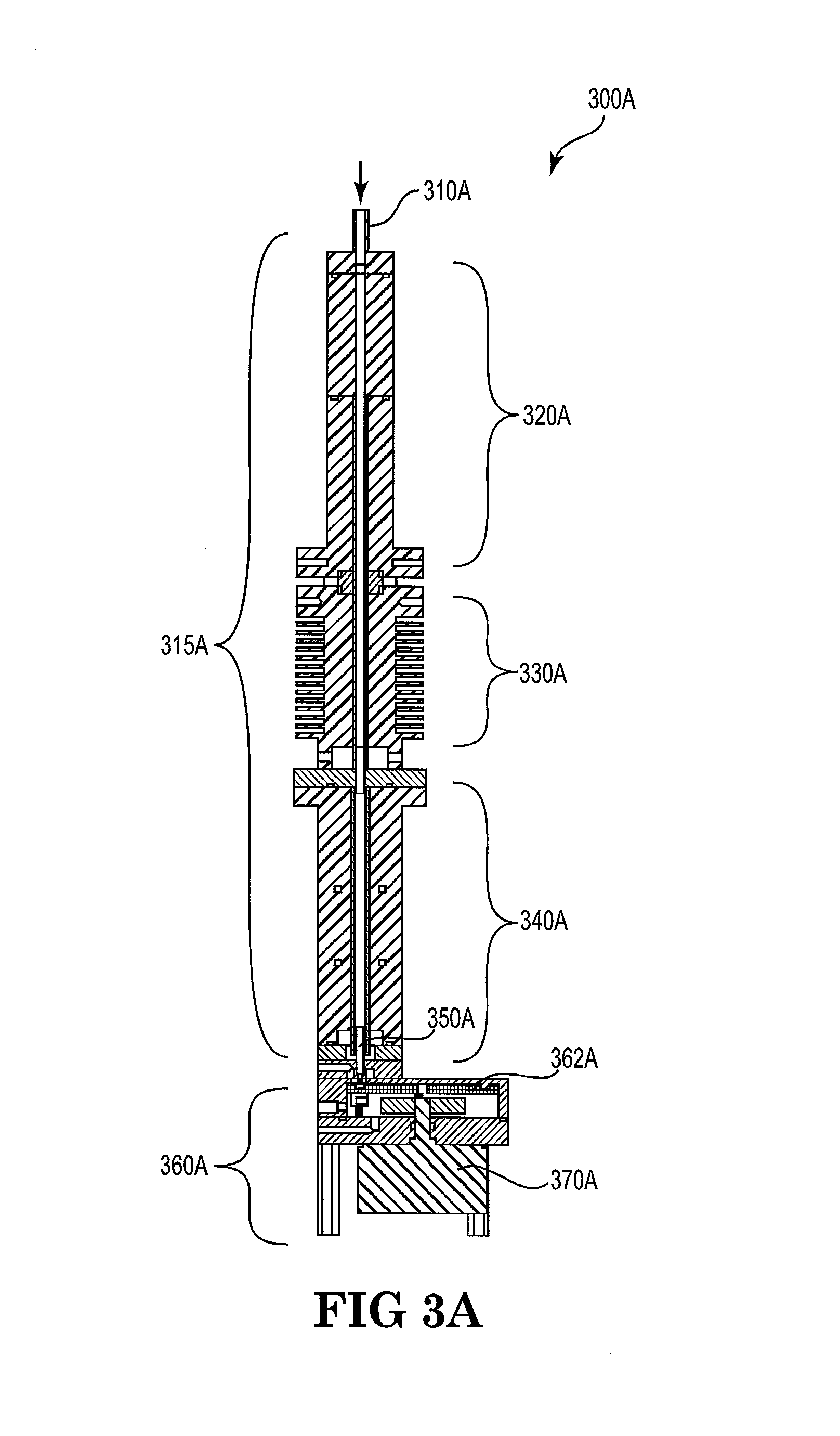

Multi-stage cavitation device

ActiveUS8042989B2Improve productivity and efficiencyWeaken energyThermal non-catalytic crackingFlow mixersSpray nozzleCavitation bubble

A method for processing a fluidic mixture in a multi-stage hydrodynamic cavitation device is disclosed. The fluidic mixture is introduced to an inlet and passed through a flowpath having at least ten cavitation zones. The fluidic mixture is exposed to cavitation inducing features in each of the at least ten cavitation zones to induce cavitation bubbles, which bubbles are then collapsed between every two adjacent of the at least ten cavitation zones. The multi-stage hydrodynamic cavitation device for processing the fluidic mixture has a generally cylindrical housing with an inlet, an outlet, a flowpath therebetween, and a plurality of cavitation zones along the flowpath. Two or more of the cavitation zones along the flowpath comprise a disk multi-jet nozzle having a plurality of through channels disposed across the surface thereof, wherein each channel includes expansions and contractions of its cross-sectional area along its length.

Owner:CAVITATION TECH

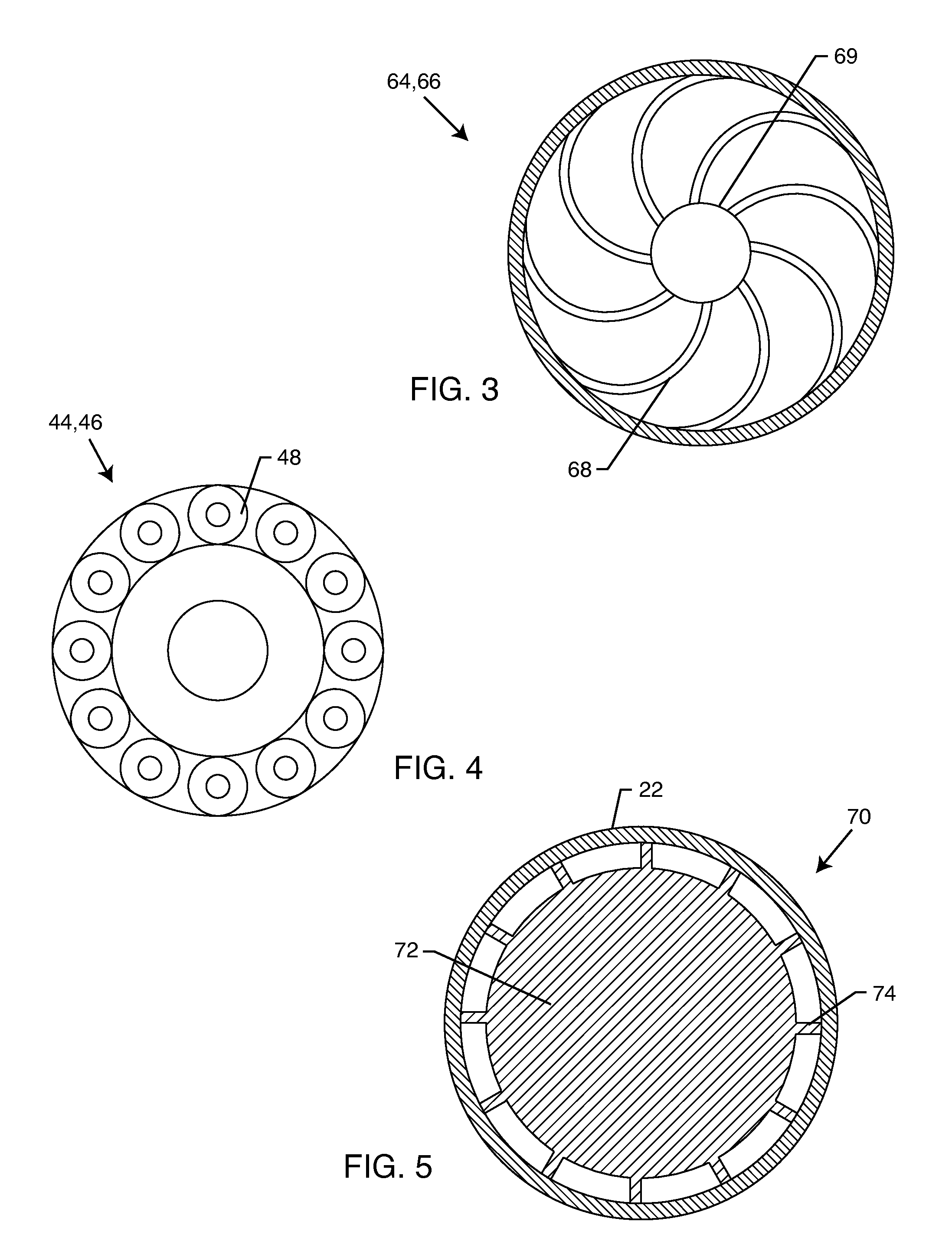

Modular blades and methods for making same

ActiveUS7393184B2Reduce weightImprove structural performancePropellersFinal product manufactureEngineeringKnife blades

Owner:GE INFRASTRUCTURE TECH INT LLC

Powder injection molding feedstock preparing method and powder injection molding method

Disclosed are a powder injection molding feedstock preparing method and a powder injection molding method. The powder injection molding feedstock preparing method includes: stirring and heating 80% to 94%, preferably 85% to 94%, by percent, of forming powder in an internal mixer, adding 6% to 20%, preferably 6% to 15%, by percent, of binder component when the forming powder is heated to 180 DEG C to 200 DEG C, and continuing stirring for 60min to 120min according to the mixing temperature 175 DEG C to 195 DEG C, preferably at the mixer speed 10rpm to 30rpm, thus obtaining evenly mixed feedstock. The powder injection molding method includes performing injection molding and degreasing sintering with the feedstock. The powder injection molding feedstock preparing method and the powder injection molding method have the advantages that degreasing efficiency is high, the process is simple and easy to control, blank quality is good and the methods are sanitary and environment friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Flow-through cavitation-assisted rapid modification of beverage fluids

ActiveUS20100104705A1Smooth tasteReduced adverse after-effectsMilk preparationMilk preservationFlavorCavitation

A method and device for manipulating alcoholic and non-alcoholic beverages to obtain desirable changes in the beverages, comprising subjecting said beverages to a flow-through hydrodynamic cavitation process and continuing the application of such process for a period of time sufficient to produce a consumable product. In the case of wine, the method includes altering the composition and accelerating the conversion of ingredients to obtain wine with a superior homogeny, an extended shelf life and a mouth feel, flavor, bouquet, color and body resembling those of wine that was subjected to a traditional oak barrel maturation. The system provided implements the described method.

Owner:CAVITATION TECH

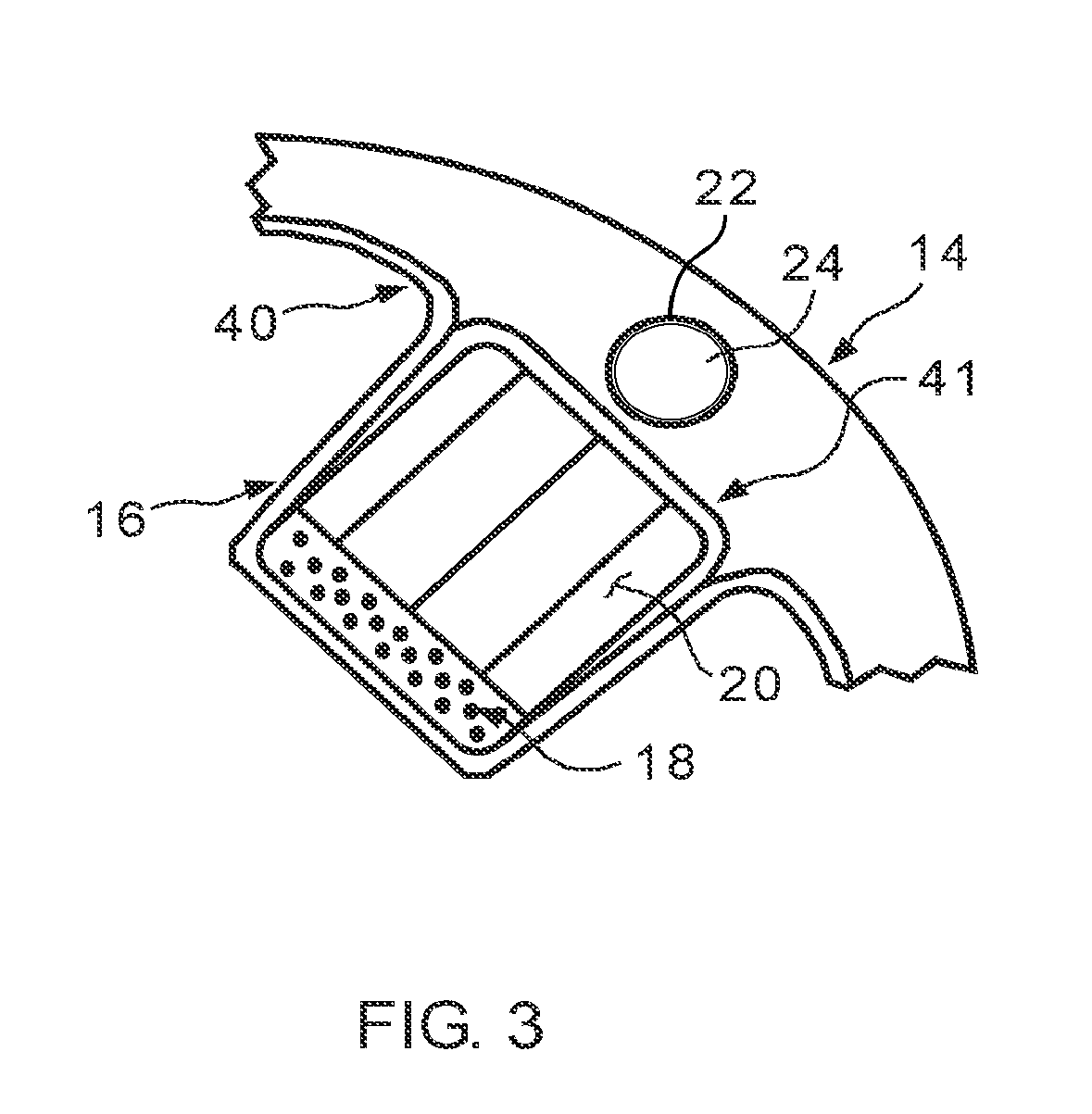

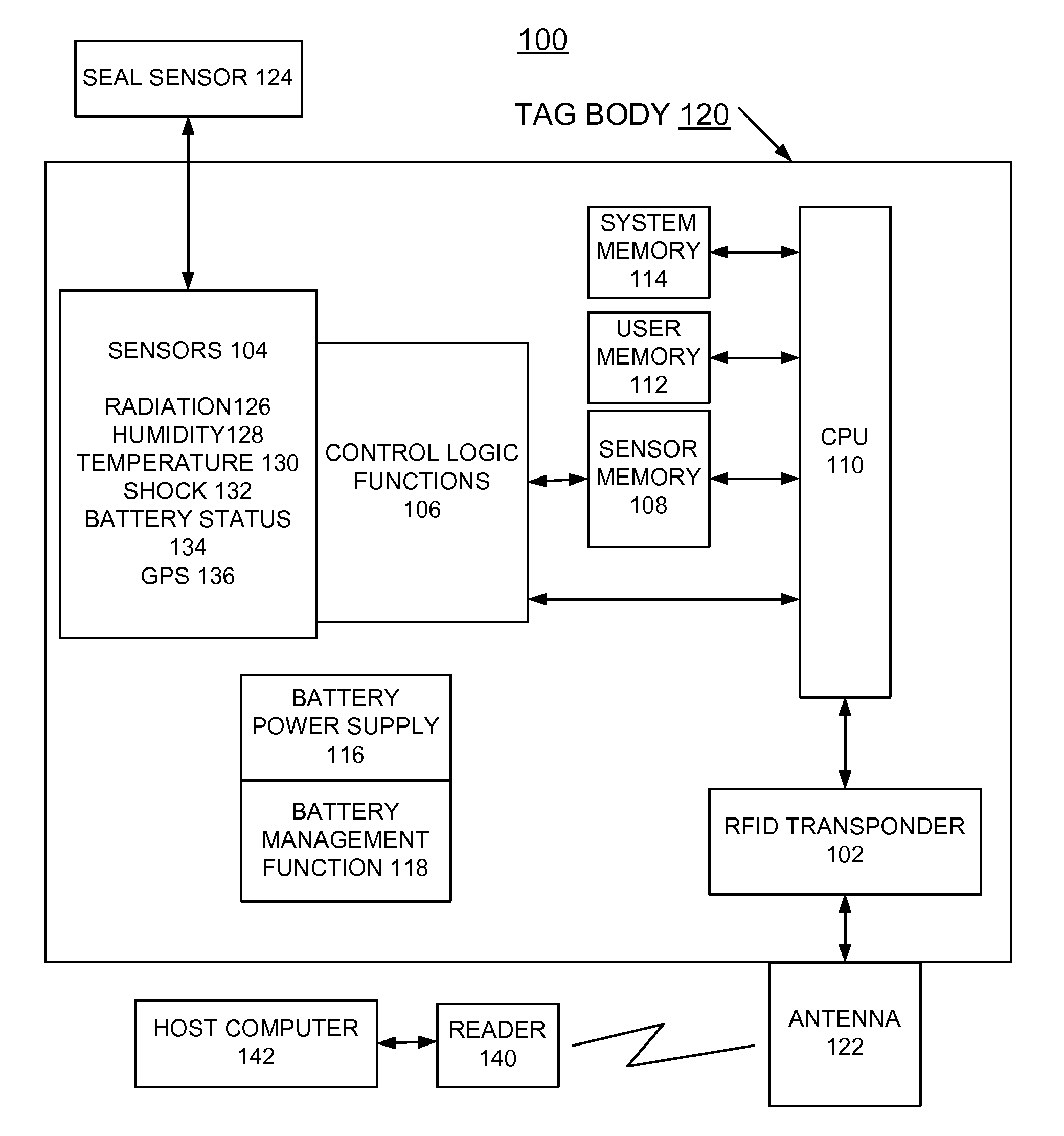

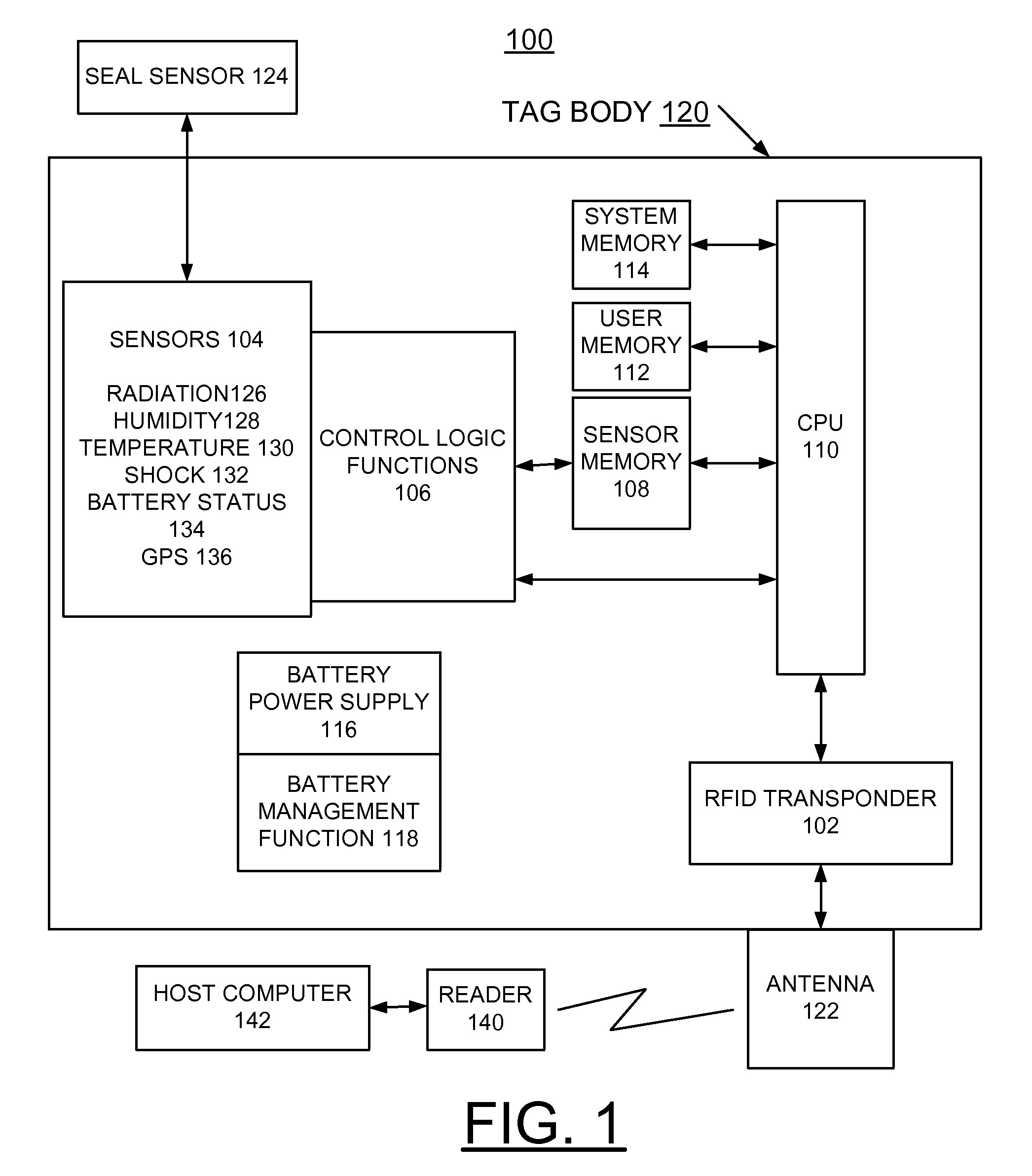

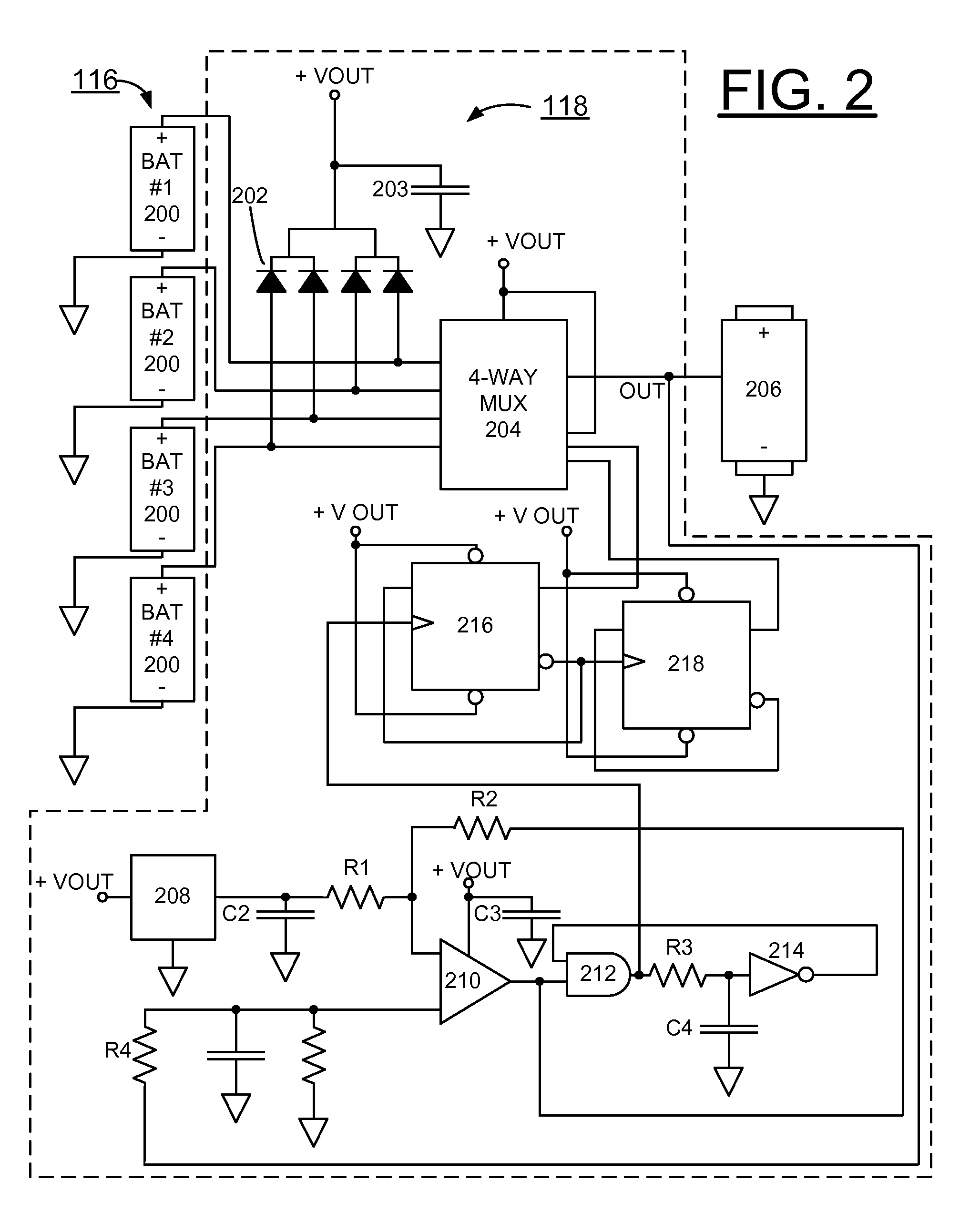

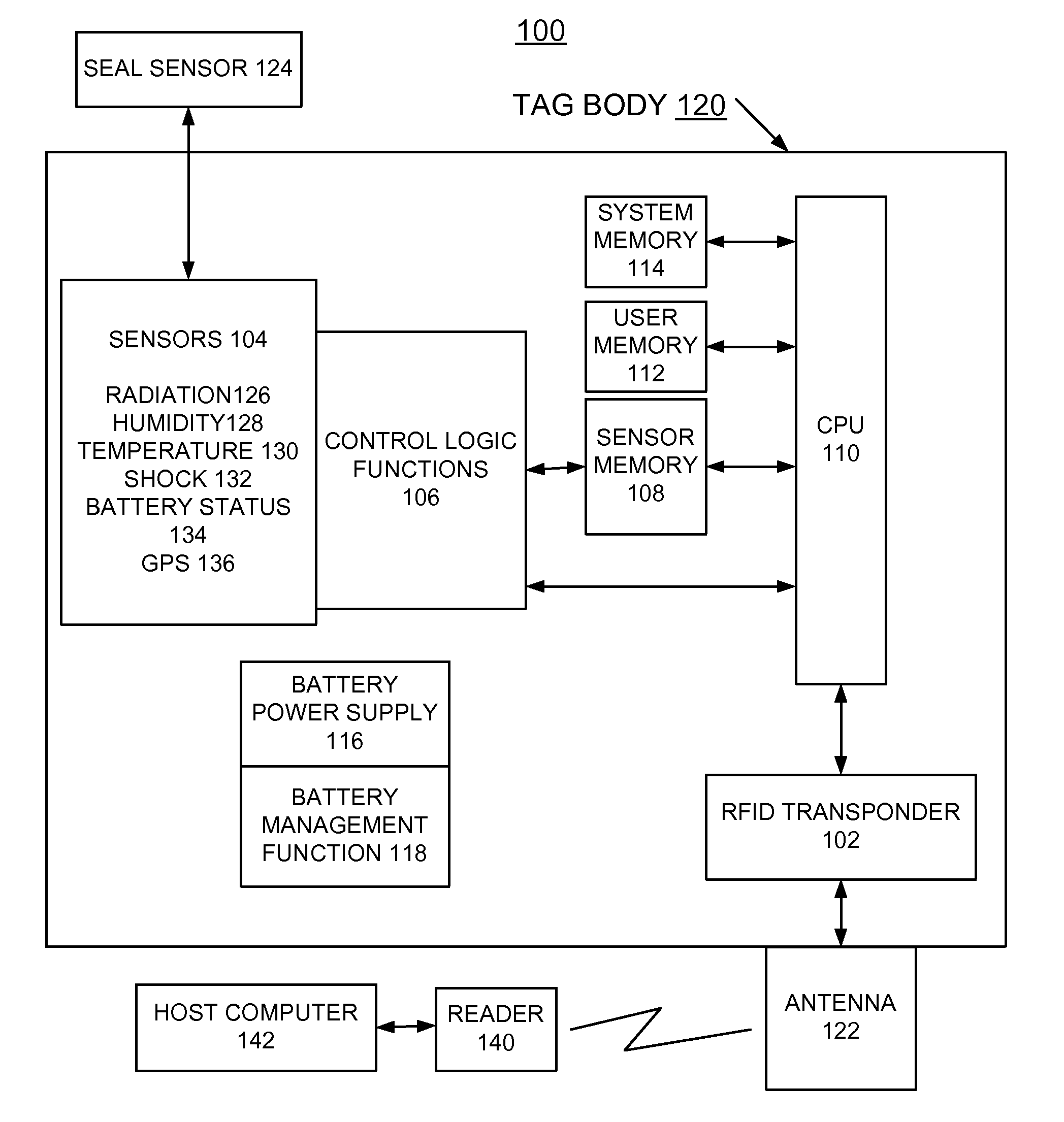

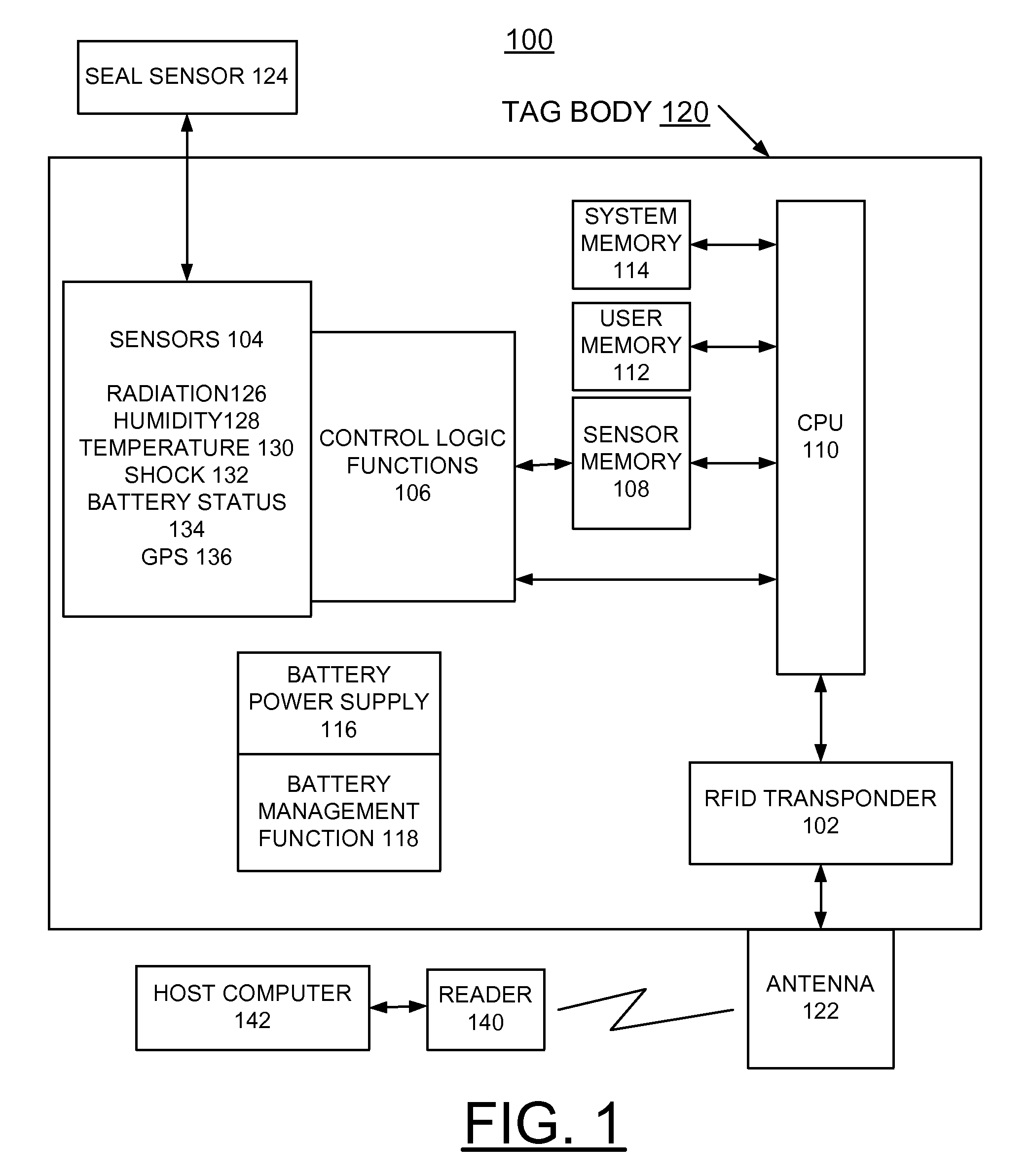

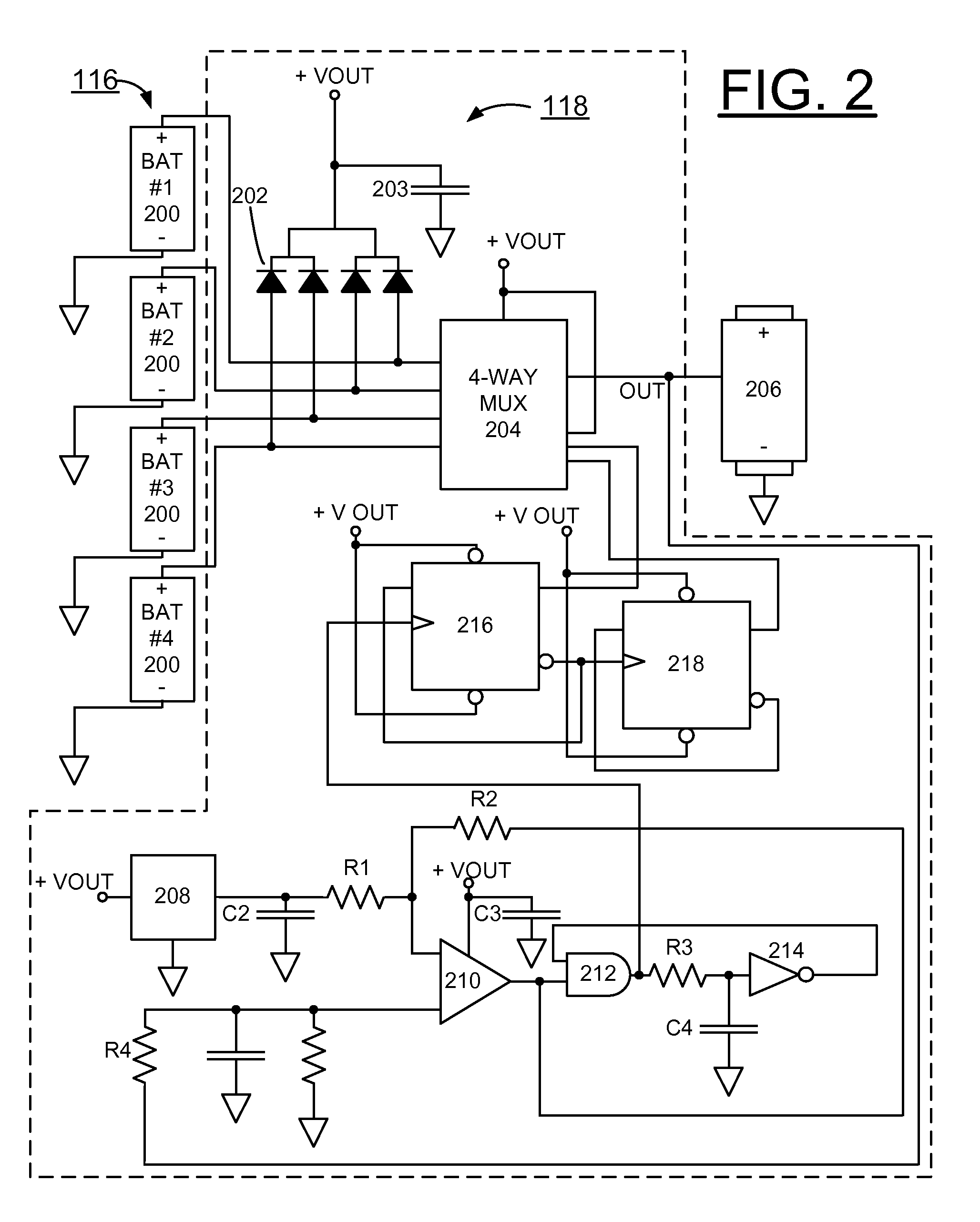

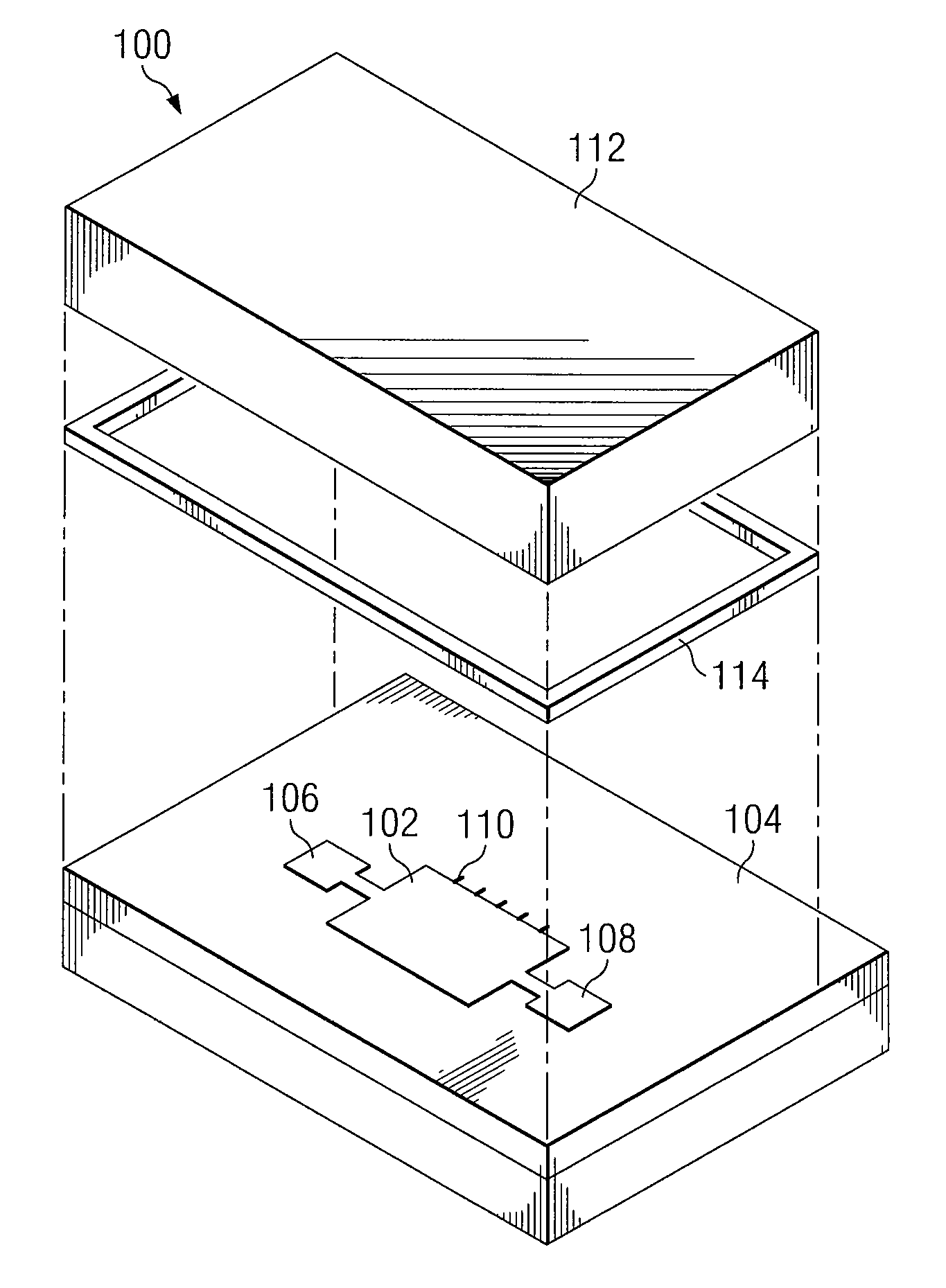

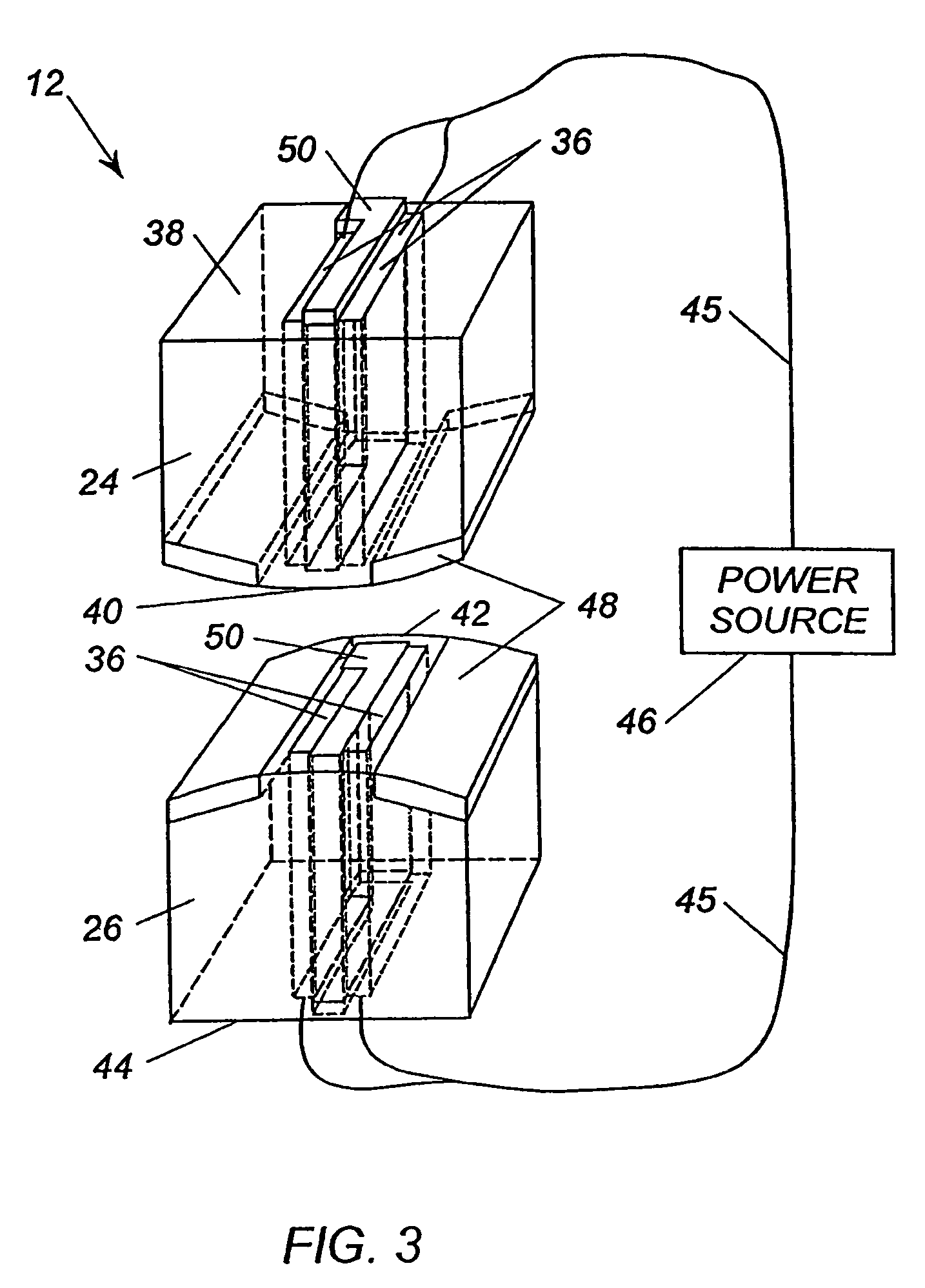

Radio frequency identification (RFID) surveillance tag

ActiveUS20100033323A1Reduce handlingReduced likelihoodSensing detailsElectric signalling detailsEngineeringRadio frequency

An enhanced method and apparatus are provided for tracking and managing a plurality of packagings, particularly packagings containing radioactive and fissile materials. A radio frequency identification (RFID) surveillance tag is provided with an associated packaging. The RFID surveillance tag includes a tag body and a back plate including predefined mounting features for mounting the surveillance tag to the associated packaging. The RFID surveillance tag includes a battery power supply. The RFID surveillance tag includes a plurality of sensors monitoring the associated packaging including a seal sensor. The seal sensor includes a force sensitive material providing a resistivity change responsive to change in a seal integrity change of the associated packaging. The resistivity change causes a seal integrity tag alarm. A tag memory stores data responsive to tag alarms generated by each of the plurality of sensors monitoring the associated packaging.

Owner:UCHICAGO ARGONNE LLC

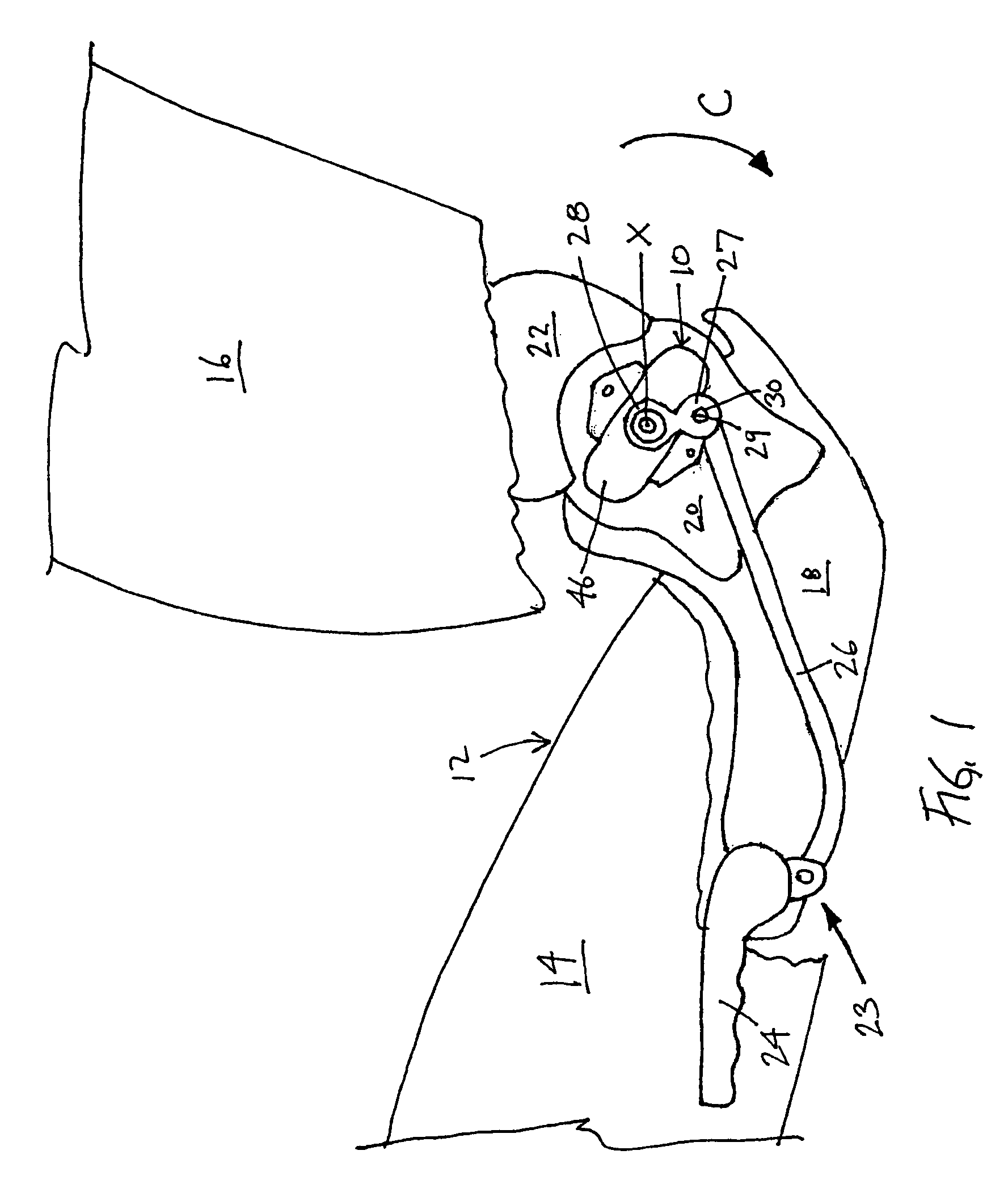

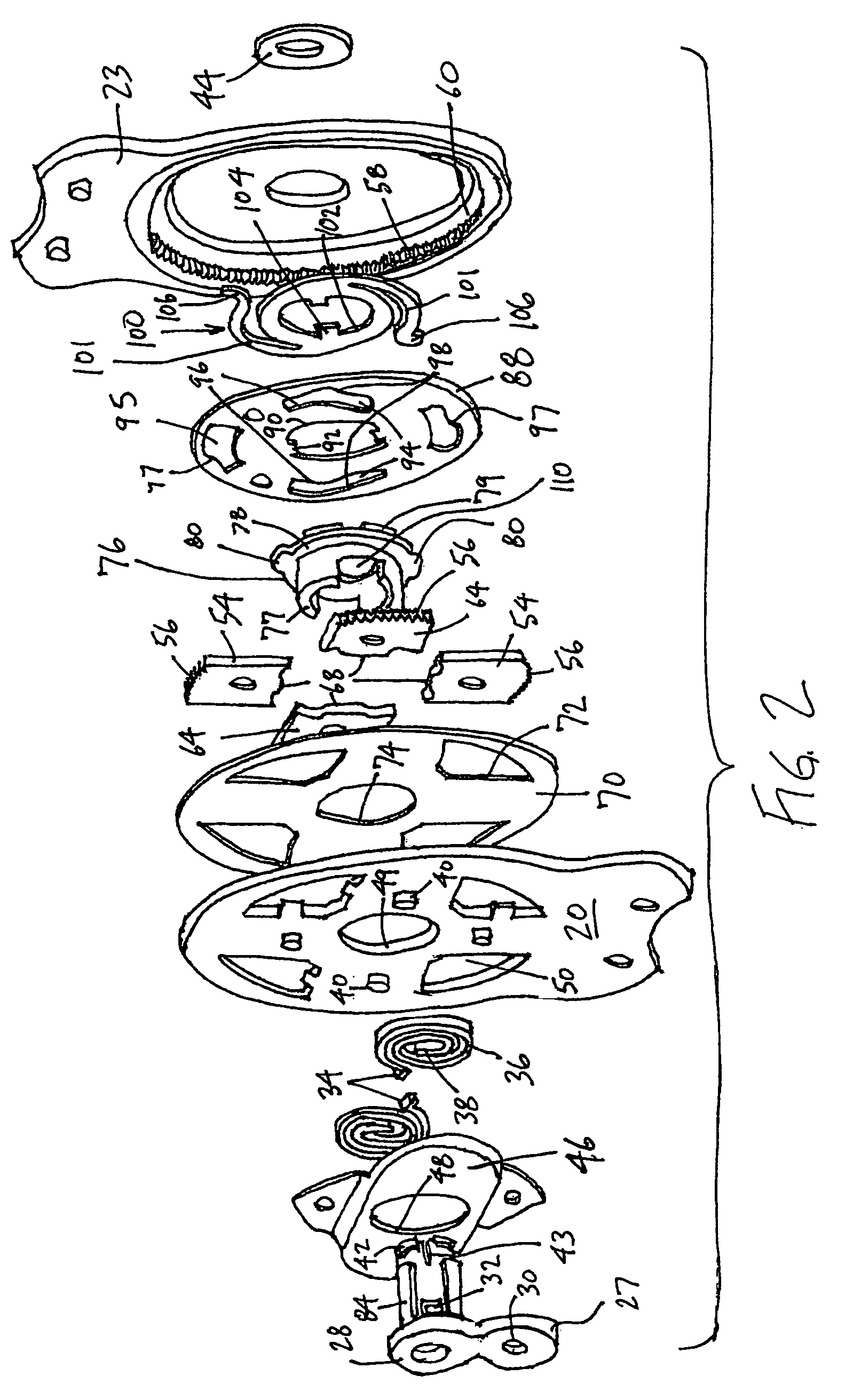

Reclining vehicle seat hinge assembly

Owner:DURA GLOBAL TECH

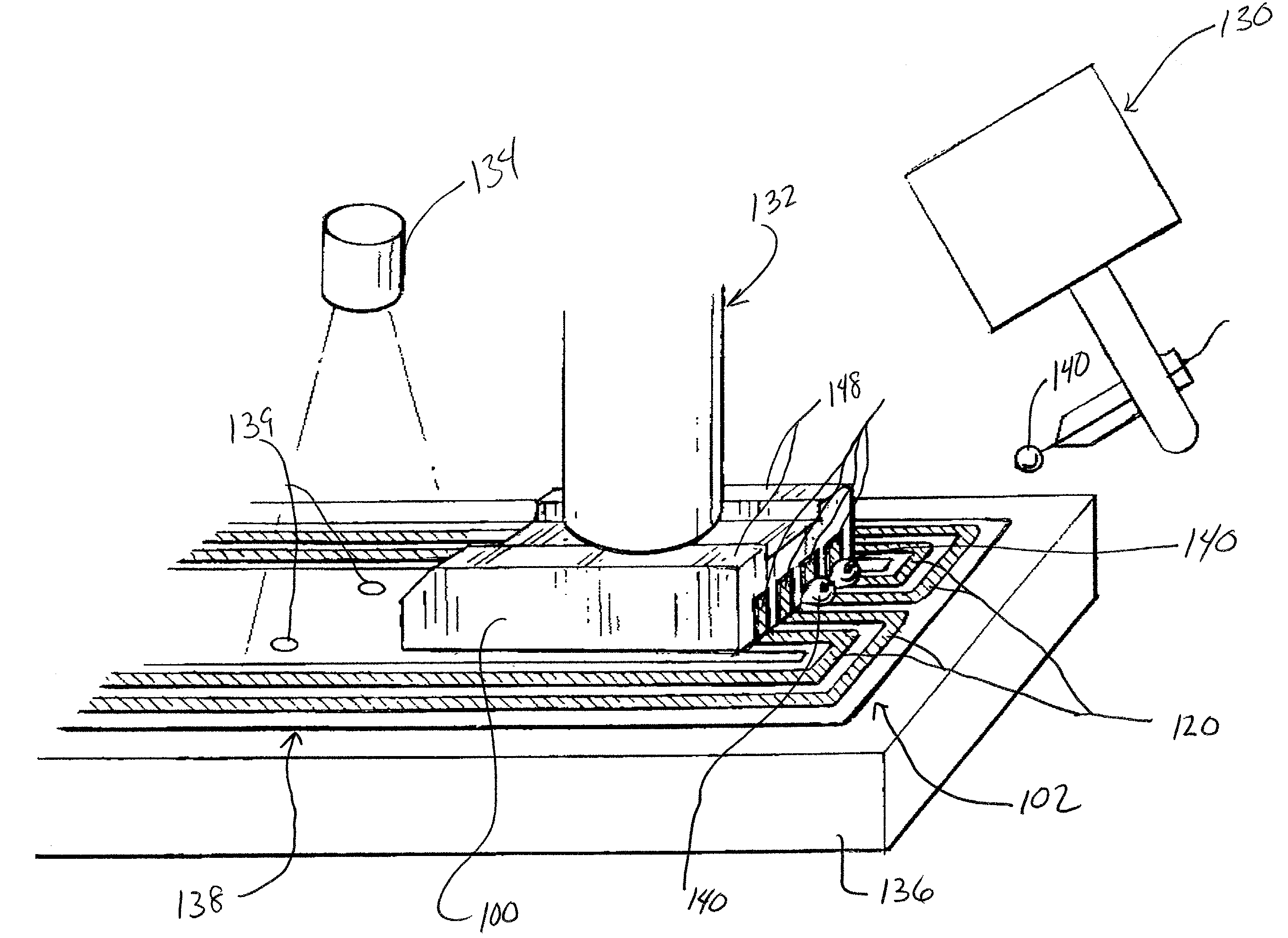

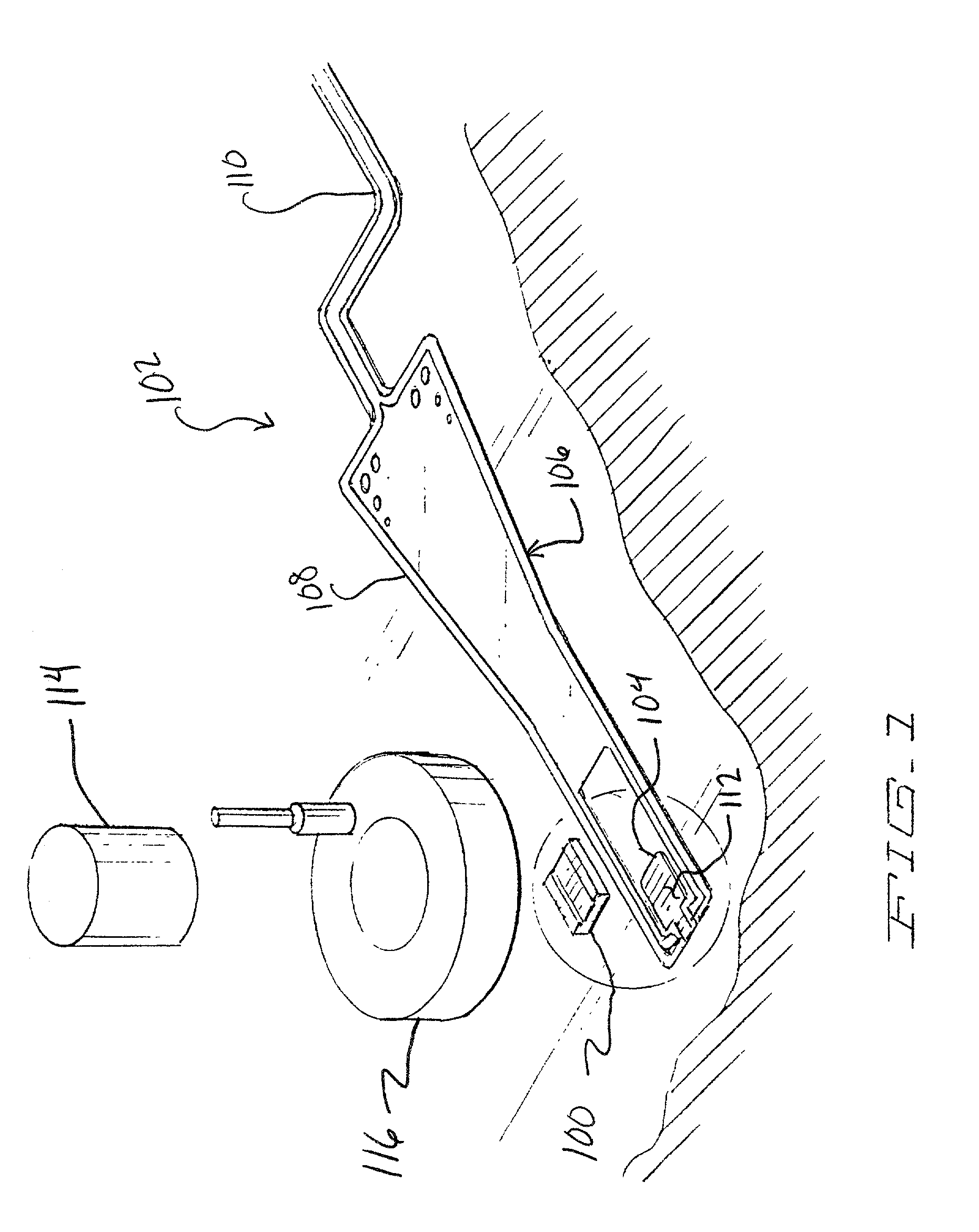

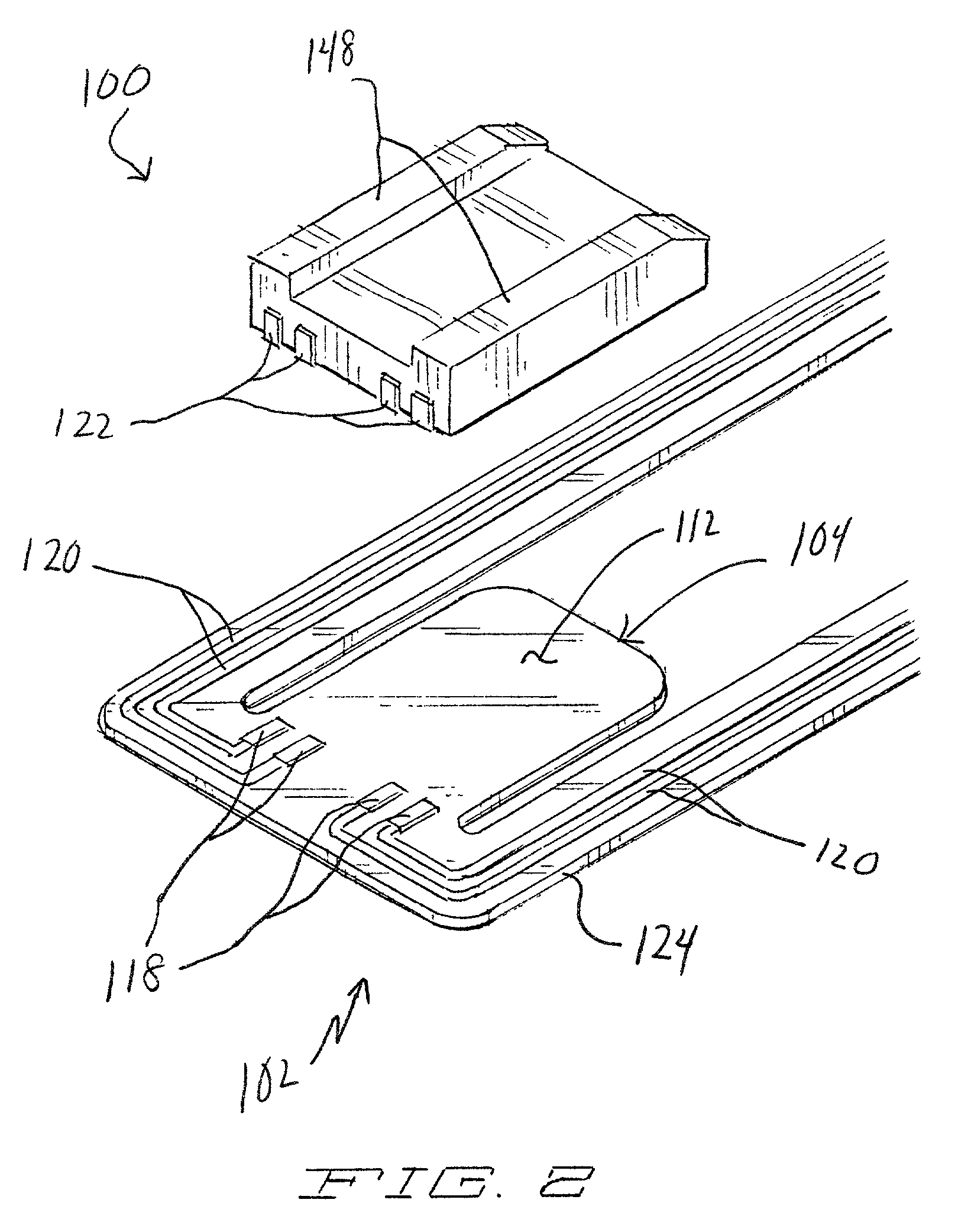

Head gimbal assembly method

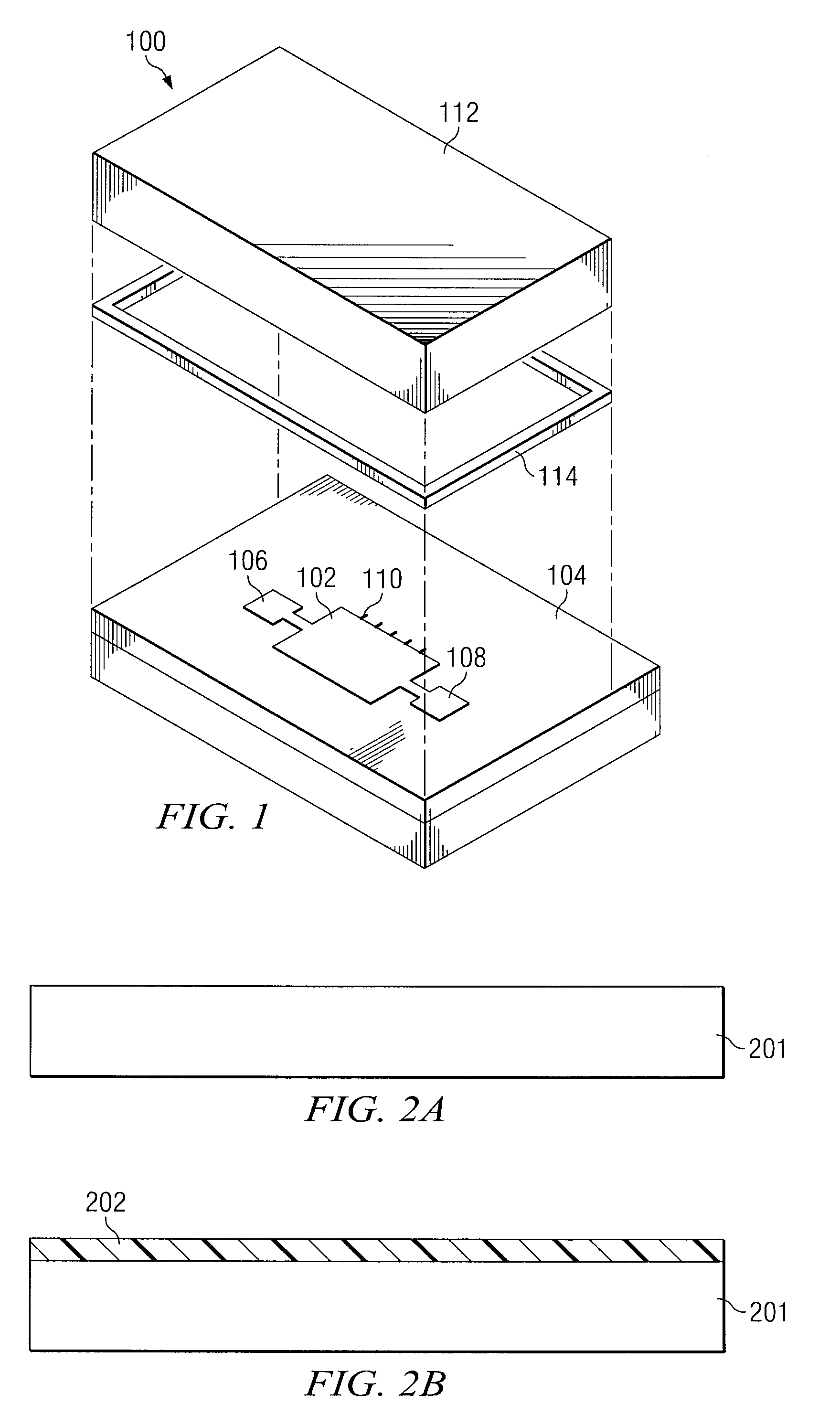

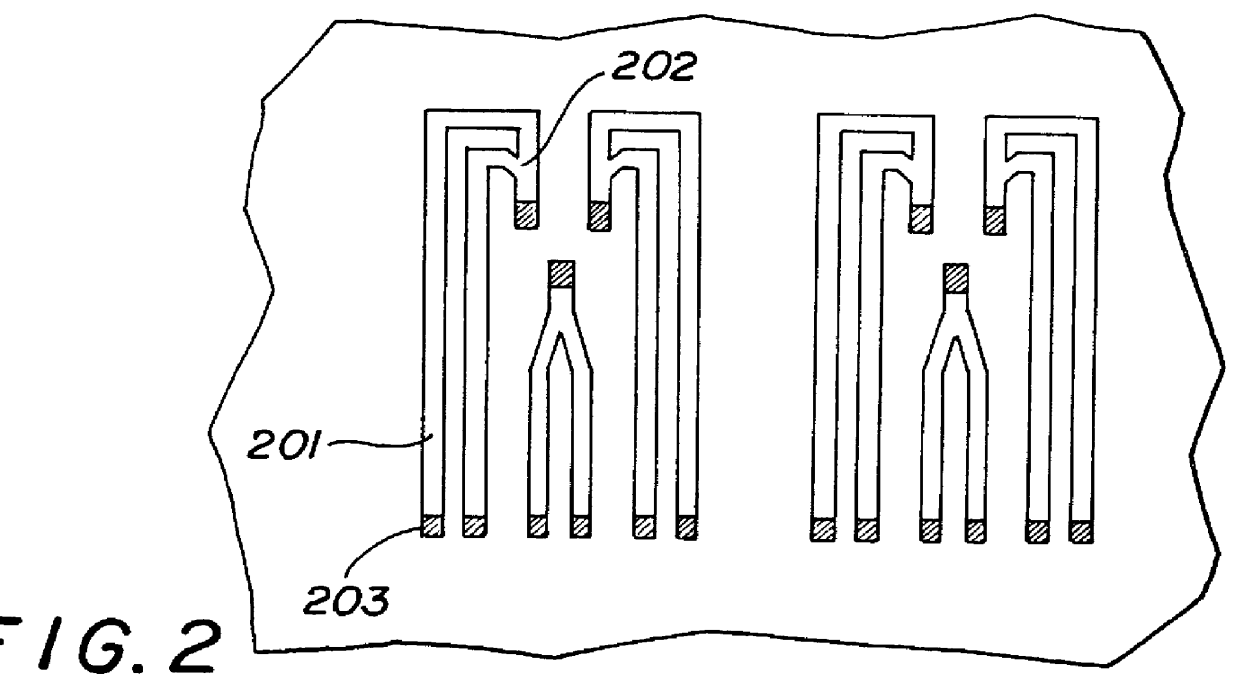

InactiveUS7127799B2Free from damageEasy alignmentPrinted circuit assemblingElectrical transducersHard disc driveEngineering

The present invention provides a method for assembling a head gimbal assembly useful in a hard disk drive and for testing such an assembly. In a method in accord with the present invention a head / slider is mounted to a circuited gimbal in an automated assembly machine. Following this step the head / slider circuited gimbal assembly will be subjected a dynamic electrical test with those head / slider circuited gimbal assemblies not passing being sorted from the lot. Following this step the head / slider circuited assembly will be attached to a suspension.

Owner:APPLIED KINETICS

Modular blades and methods for making same

ActiveUS20070105431A1Reduce weightImprove structural performancePropellersFinal product manufactureEngineeringElectrical and Electronics engineering

Owner:GENERAL ELECTRIC CO

Radio frequency identification (RFID) surveillance tag

ActiveUS8013744B2Reduce handlingReduced likelihoodSensing record carriersElectric signalling detailsEngineeringRadio frequency

Owner:UCHICAGO ARGONNE LLC

Hermetic packaging of integrated circuit components

ActiveUS20100224980A1Reduce and eliminate laborReduce individual handlingSemiconductor/solid-state device detailsSolid-state devicesEngineeringHermetic packaging

A method for forming an integrated circuit includes transforming at least a portion of a first substrate layer to form a conductive region within the first substrate layer. An integrated circuit device is provided proximate an outer surface of the first substrate layer. The integrated circuit device transmits or receives electrical signals through the conductive region. A second substrate layer is disposed proximate to the outer surface of the first substrate layer to enclose the integrated circuit device in a hermetic environment.

Owner:RAYTHEON CO

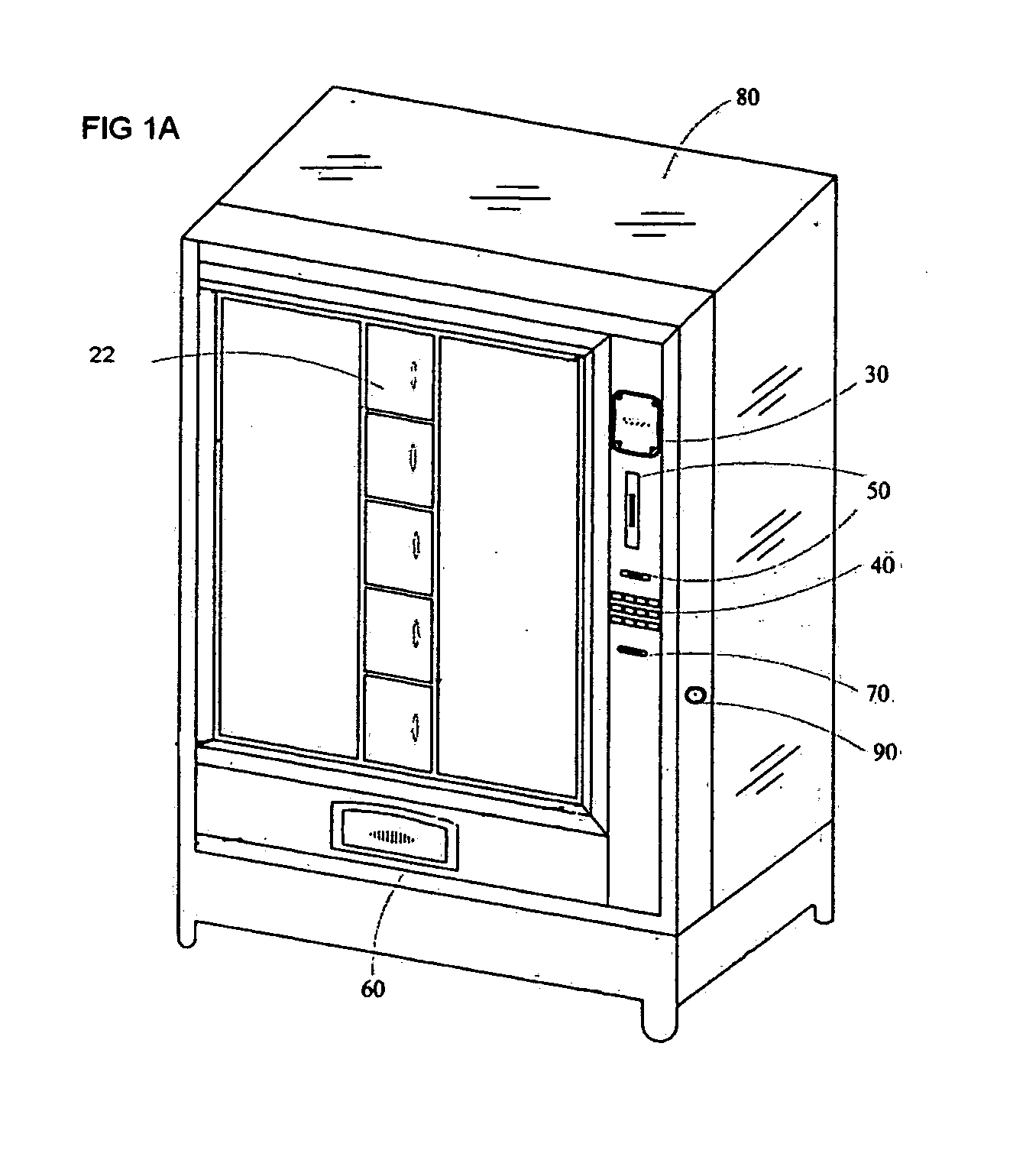

Vending distribution system

InactiveUS20080058985A1Reduce delayReduce handlingAcutation objectsApparatus for meter-controlled dispensingDistribution systemEngineering

A vending distribution system having an enclosure capable of housing a storage assembly containing a plurality of actual and sample items. Access to and controls for the storage assembly are separate from the access area thus creating a system with potential for two distinct areas. Interaction with the system determines the ability exclude items from vending without staff intervention thus providing usage for drive up unattended vending.

Owner:ALCOV NICHOLAS

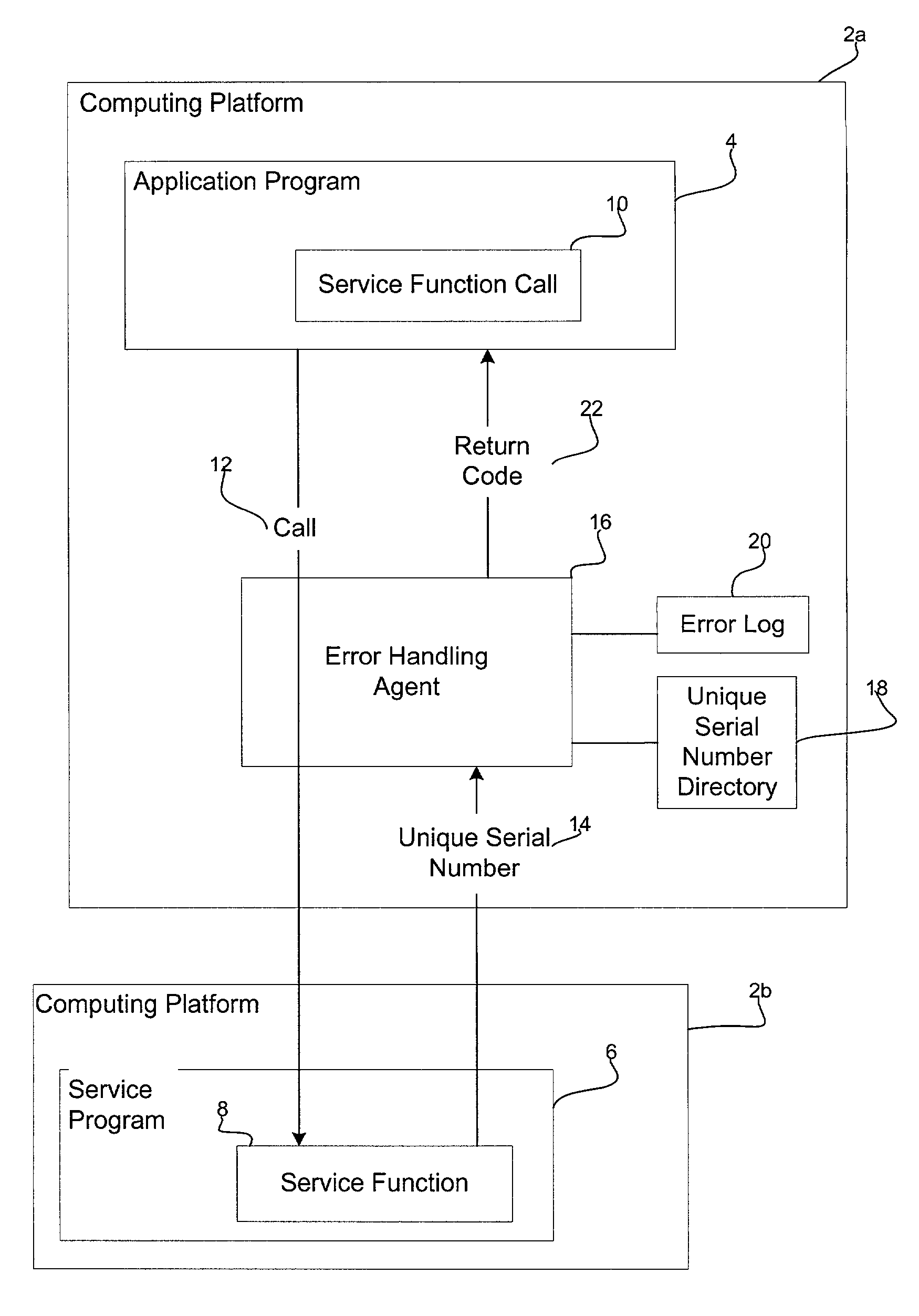

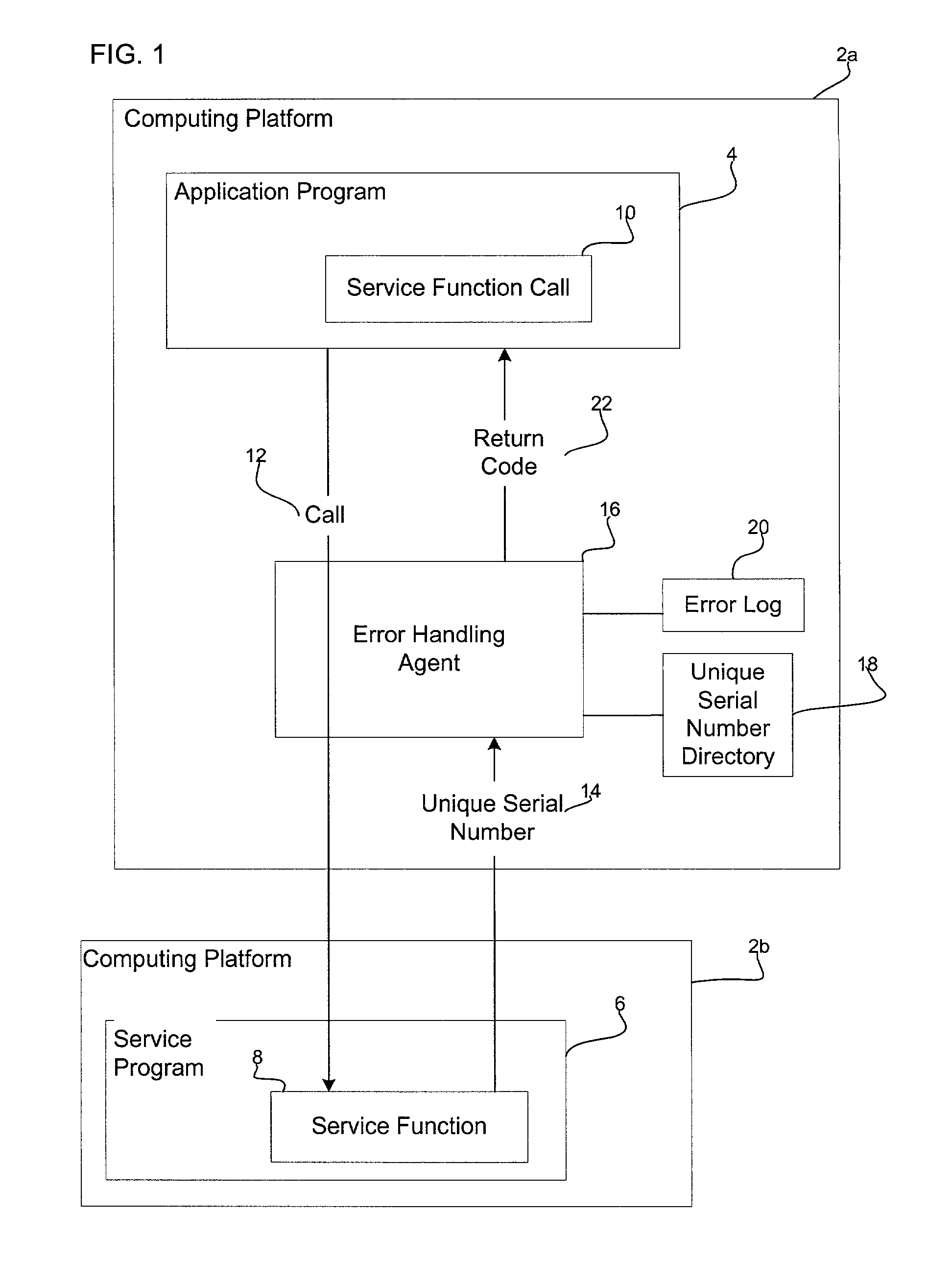

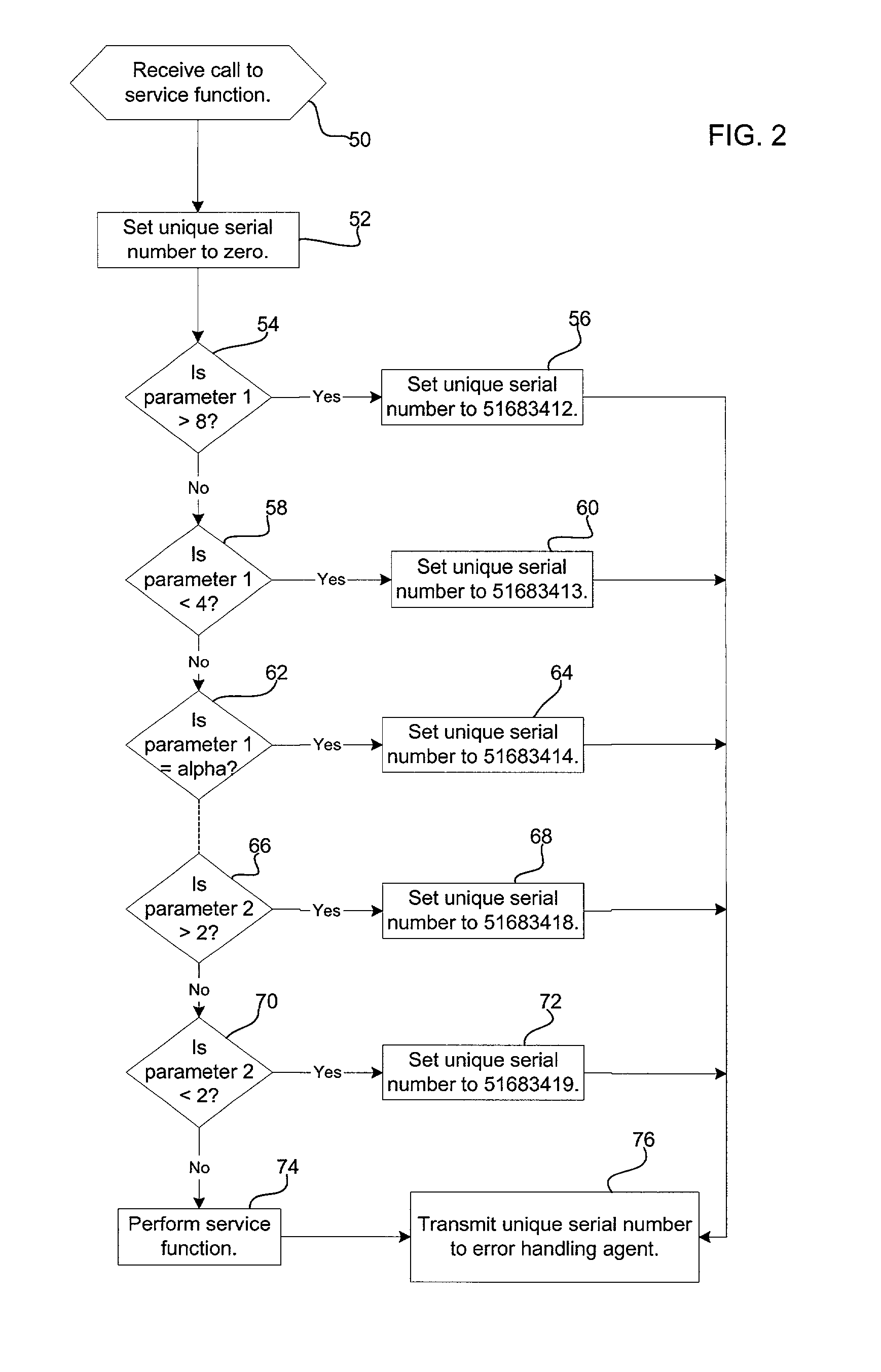

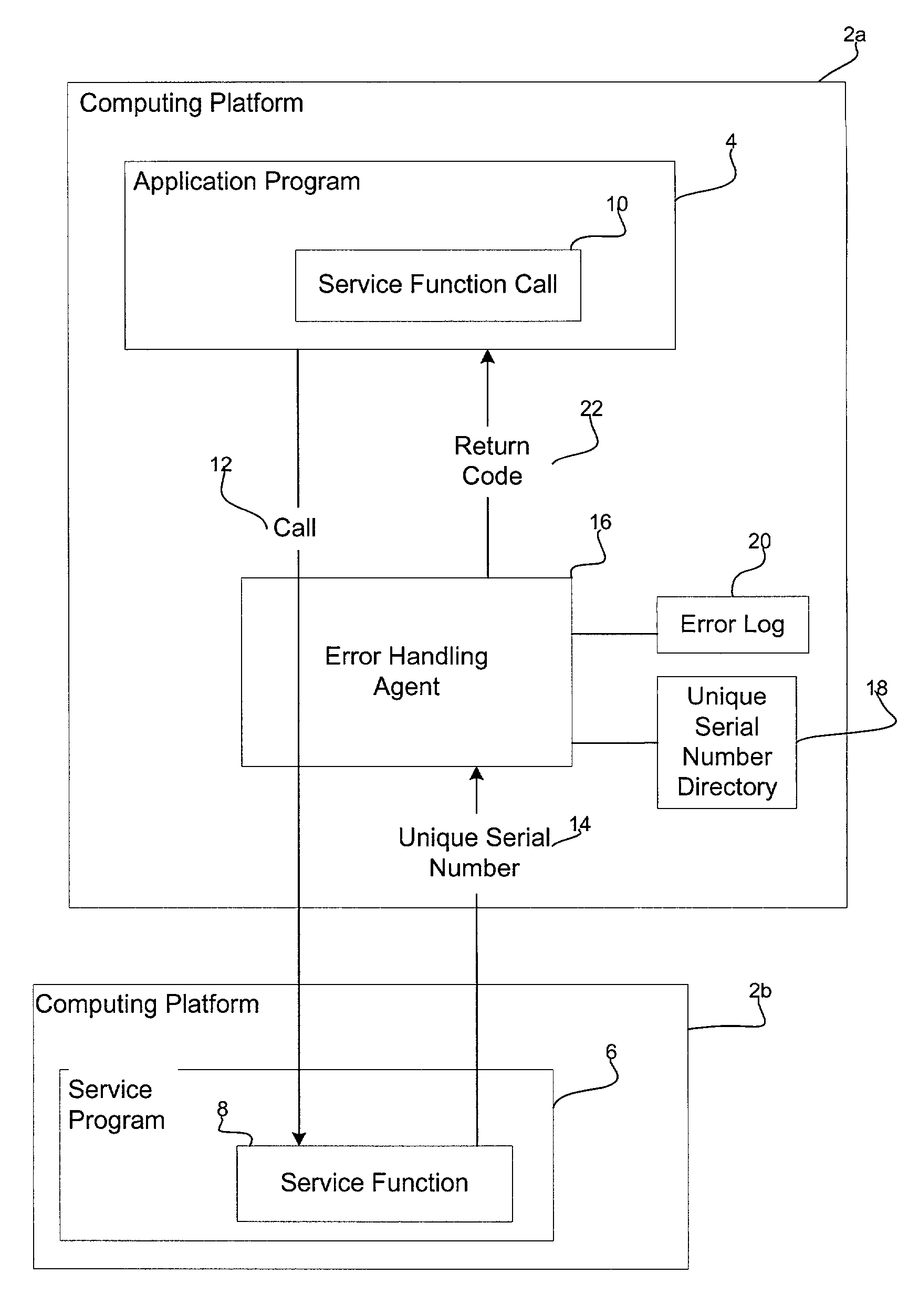

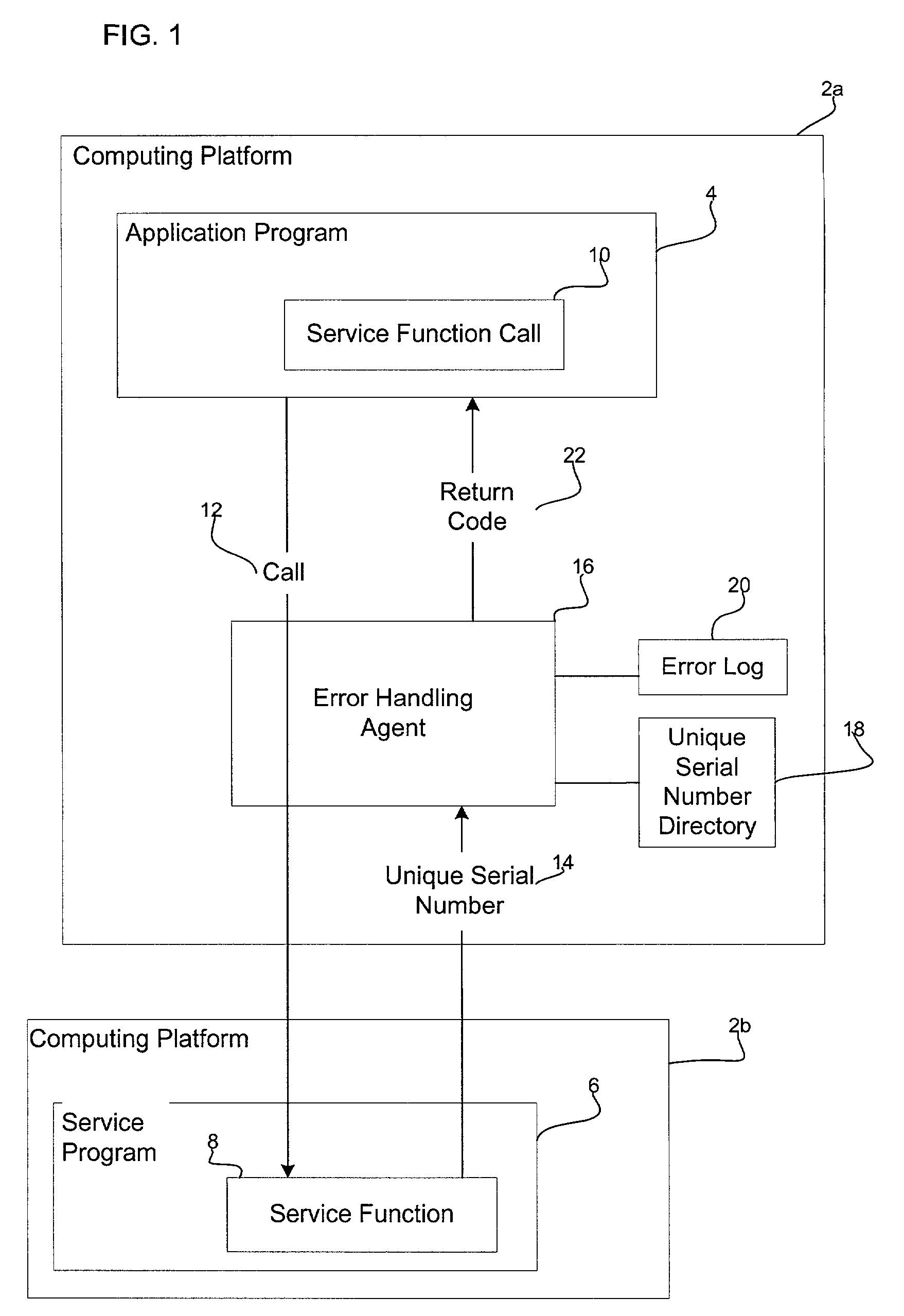

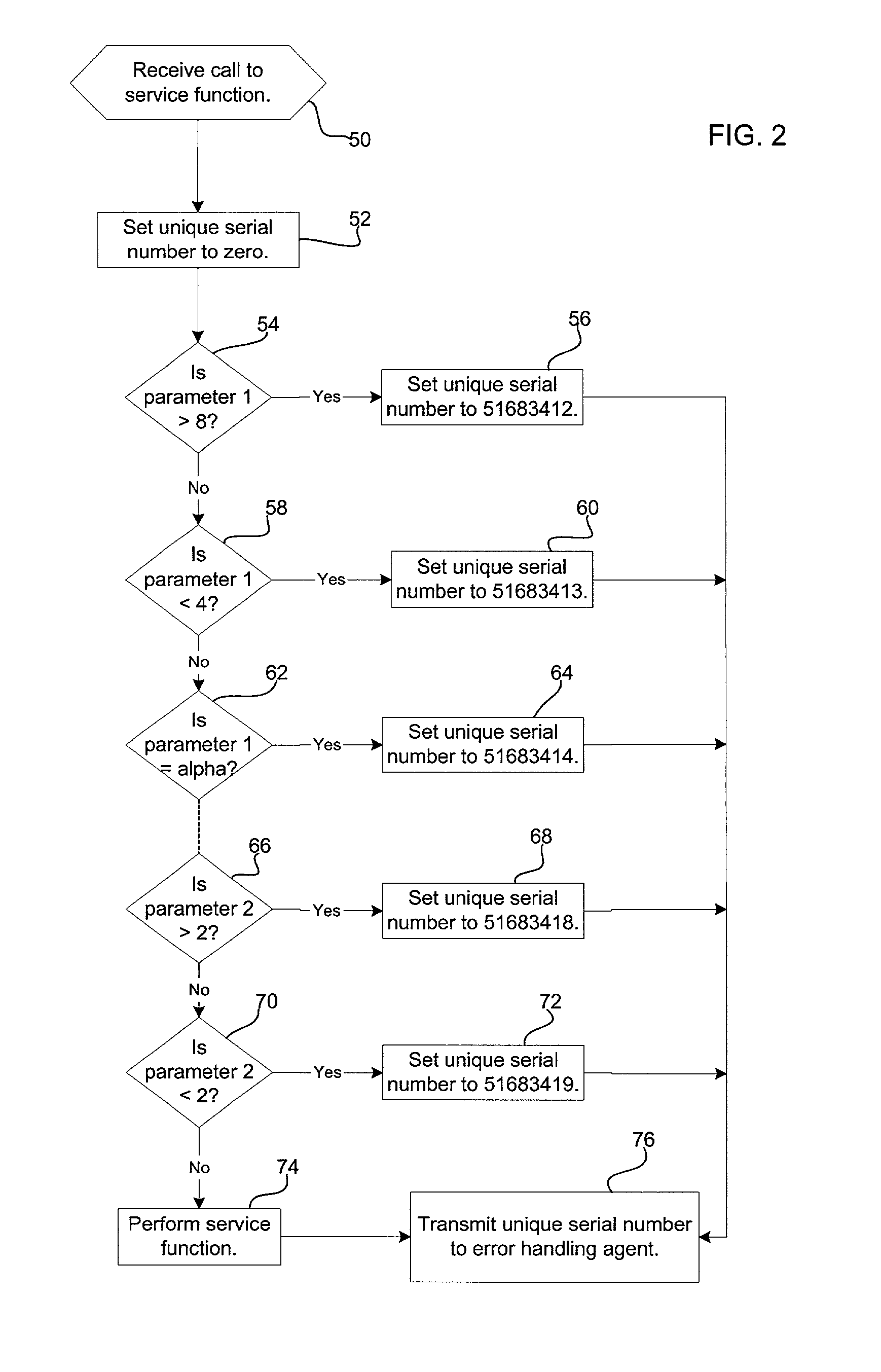

Method, system and program for handling errors occurring in function calls

InactiveUS20030037291A1Efficiently and effectively diagnose and correctReduce handlingFault responseHardware monitoringApplication procedureOperating system

Provided is a method, system, and program for handling errors in a service program including service functions capable of being called from application programs. A call is received for one service function from a service function call within one application program. A series of test operations are performed when executing the service function call. Each test operation returns an identifier if the test operation failed where each identifier is associated with one error state. If one test operation failed, then the identifier for the failed test operation is transferred to an error handling agent, wherein the error handling agent accesses error information associated with the identifier and generates error information describing a specific cause of the error that caused the test operation to fail and then returns to the application program with a generic return code.

Owner:IBM CORP

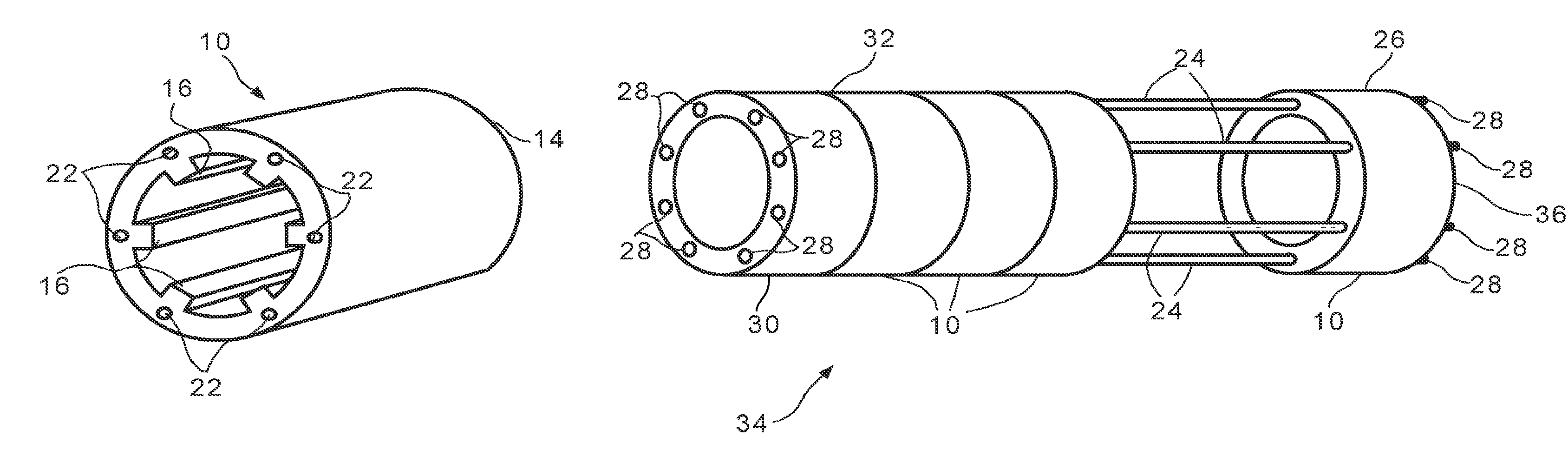

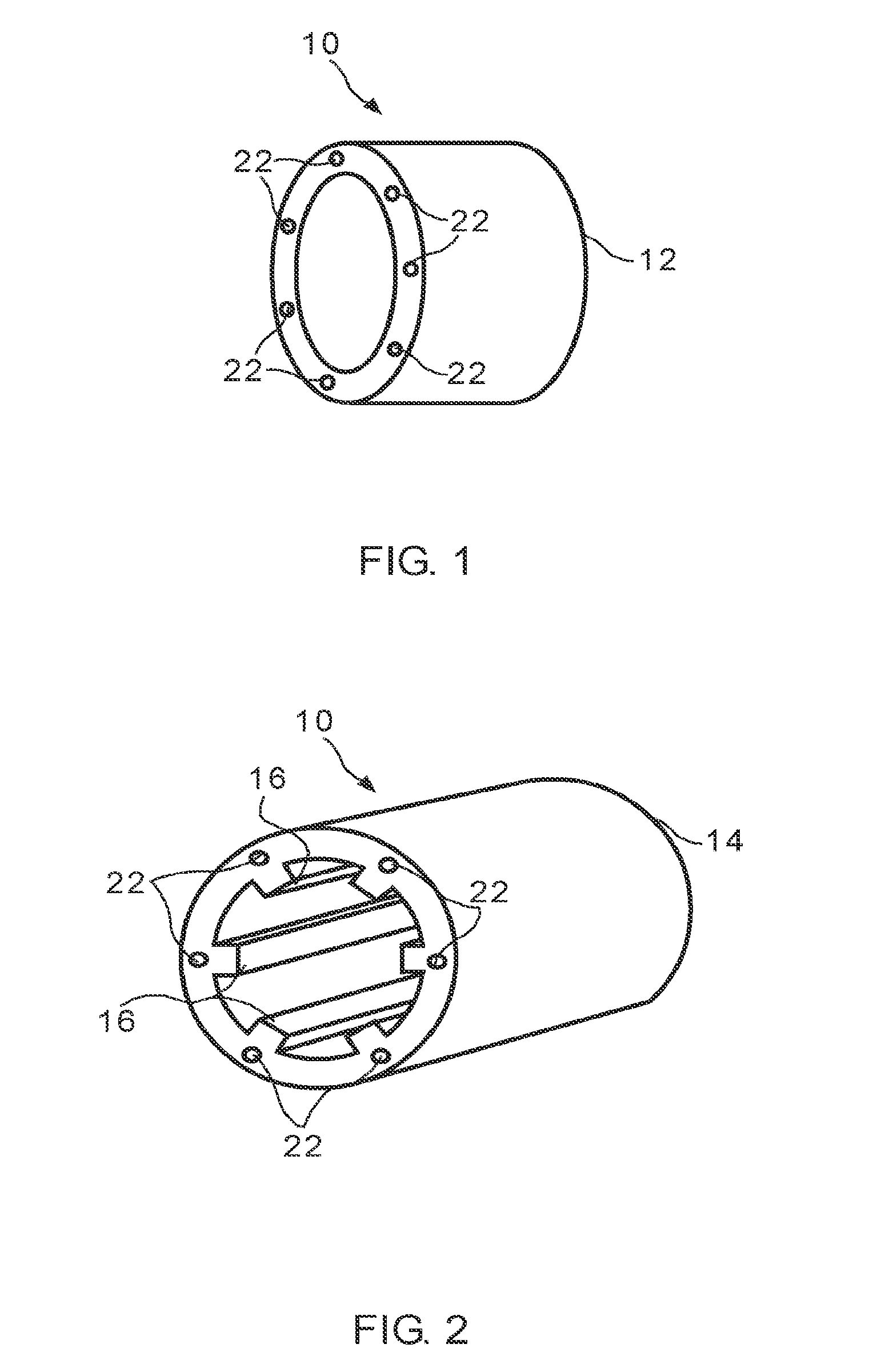

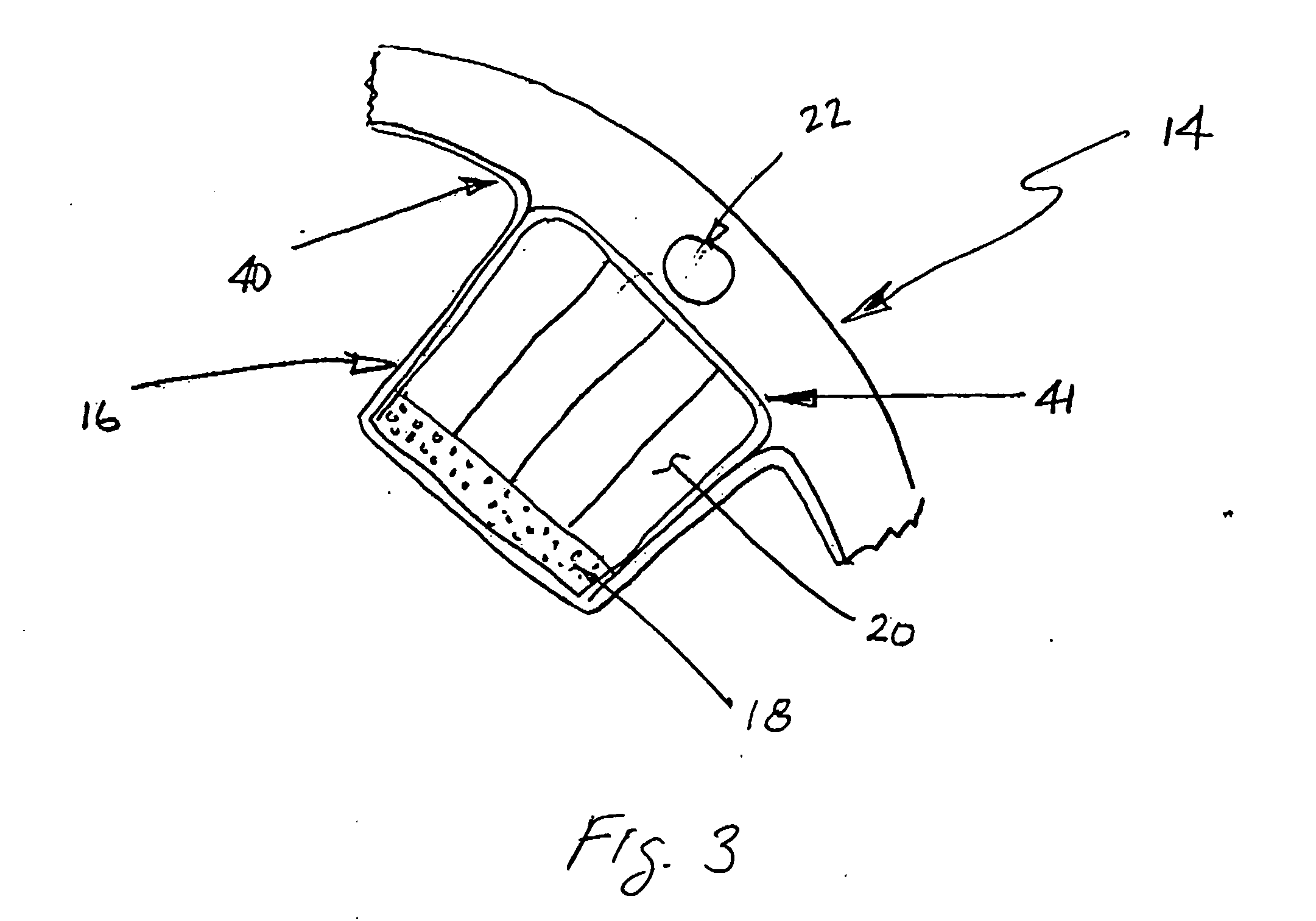

In ovo delivery of an immunogen containing implant

InactiveUS20070098733A1Relieve pressureReduces vaccine reactionSnake antigen ingredientsGranular deliveryIn ovoPrimary immune response

The disclosure provides a method for administering an agent to an avian species by in ovo delivery of an implant releasably containing the agent. In one embodiment, the method is particularly advantageous for stimulating an immune response in a bird by in ovo administration of a biocompatible implant releasably containing an immunogen. The implant can provide for sustained or delayed release of the immunogen or both. The amount of immunogen that is released from the implant into the bird is preferably sufficient to effectively stimulate a primary immune response to the immunogen. Other agents which can be administered according to the method of the invention are disclosed.

Owner:EPITOPIX LLC

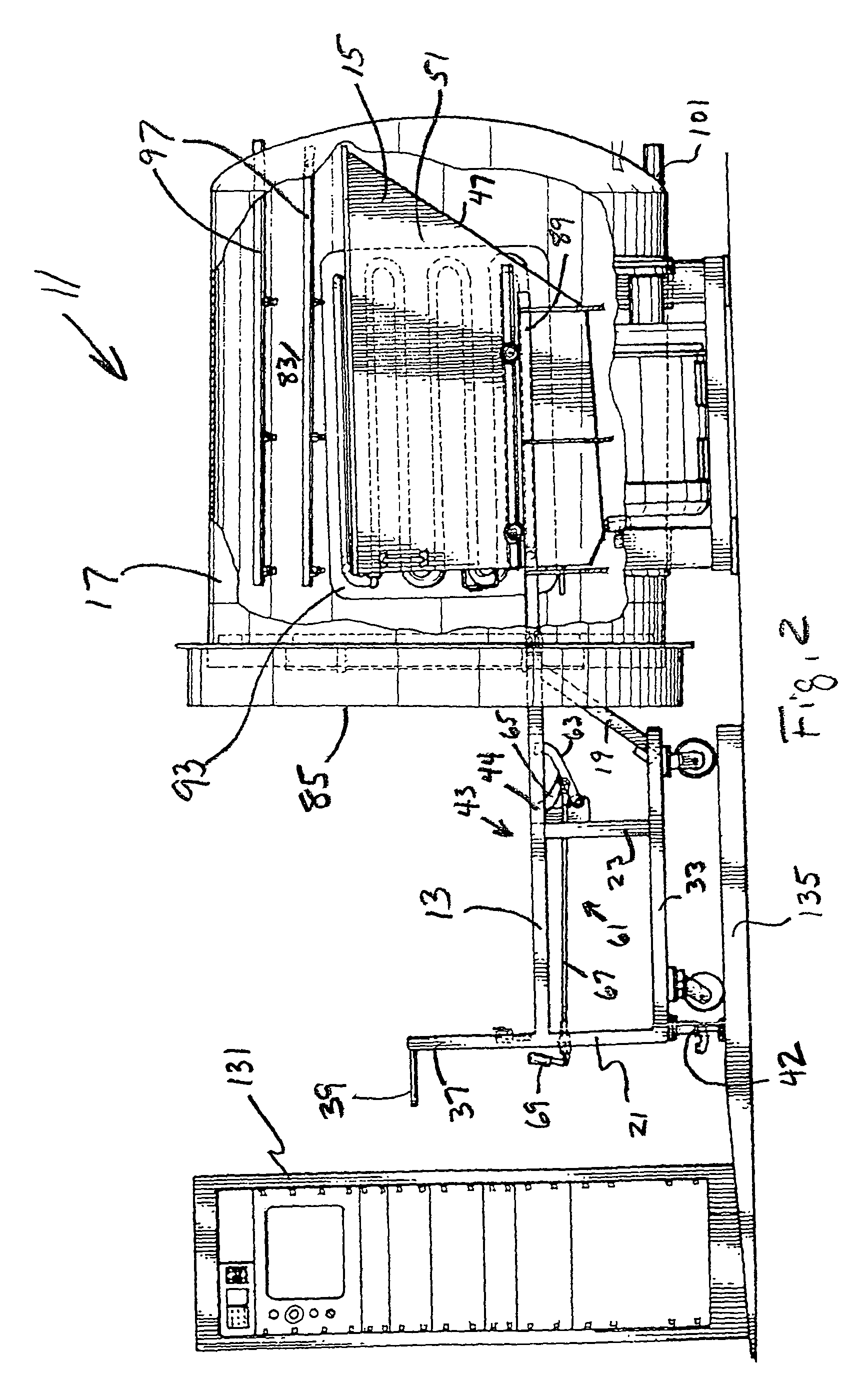

Steam sterilization system for sterilizing medical waste

InactiveUS7815851B1Reduce handlingReducing pathogen exposureLavatory sanitoryHeatThermal energyMedical waste

An integrated sterilization and materials handling system for sterilizing and handling items such as medical waste, paper, or other things comprises a cart for carrying a removable bin for holding the items to be sterilized, and a sterilization chamber that receives the bin when it is removed from the cart. The various embodiments include a bin that is dumpable with the cart using existing dumping apparatus, a bin that pivots on the cart to permit dumping of the items from the bin by tilting the bin, and a bin used primarily in a dry heat sterilization process of the invention when sterilizing items that are not to be discarded after sterilization to facilitate loading and unloading of the bin. The system has thermal energy booster plates mounted in the sterilization chamber for providing dry radiant heat to the chamber, and the system may vary process times, process pressures, and process temperatures to predetermine settings that correlate to the weight of the items to be sterilized.

Owner:ASSURED WASTE SOLUTIONS LLC

Method, system and program for handling errors occurring in function calls

InactiveUS6973643B2Efficiently and effectively diagnose and correctReduce handlingFault responseError identificationError processingApplication software

Provided is a method, system, and program for handling errors in a service program including service functions capable of being called from application programs. A call is received for one service function from a service function call within one application program. A series of test operations are performed when executing the service function call. Each test operation returns an identifier if the test operation failed where each identifier is associated with one error state. If one test operation failed, then the identifier for the failed test operation is transferred to an error handling agent, wherein the error handling agent accesses error information associated with the identifier and generates error information describing a specific cause of the error that caused the test operation to fail and then returns to the application program with a generic return code.

Owner:INT BUSINESS MASCH CORP

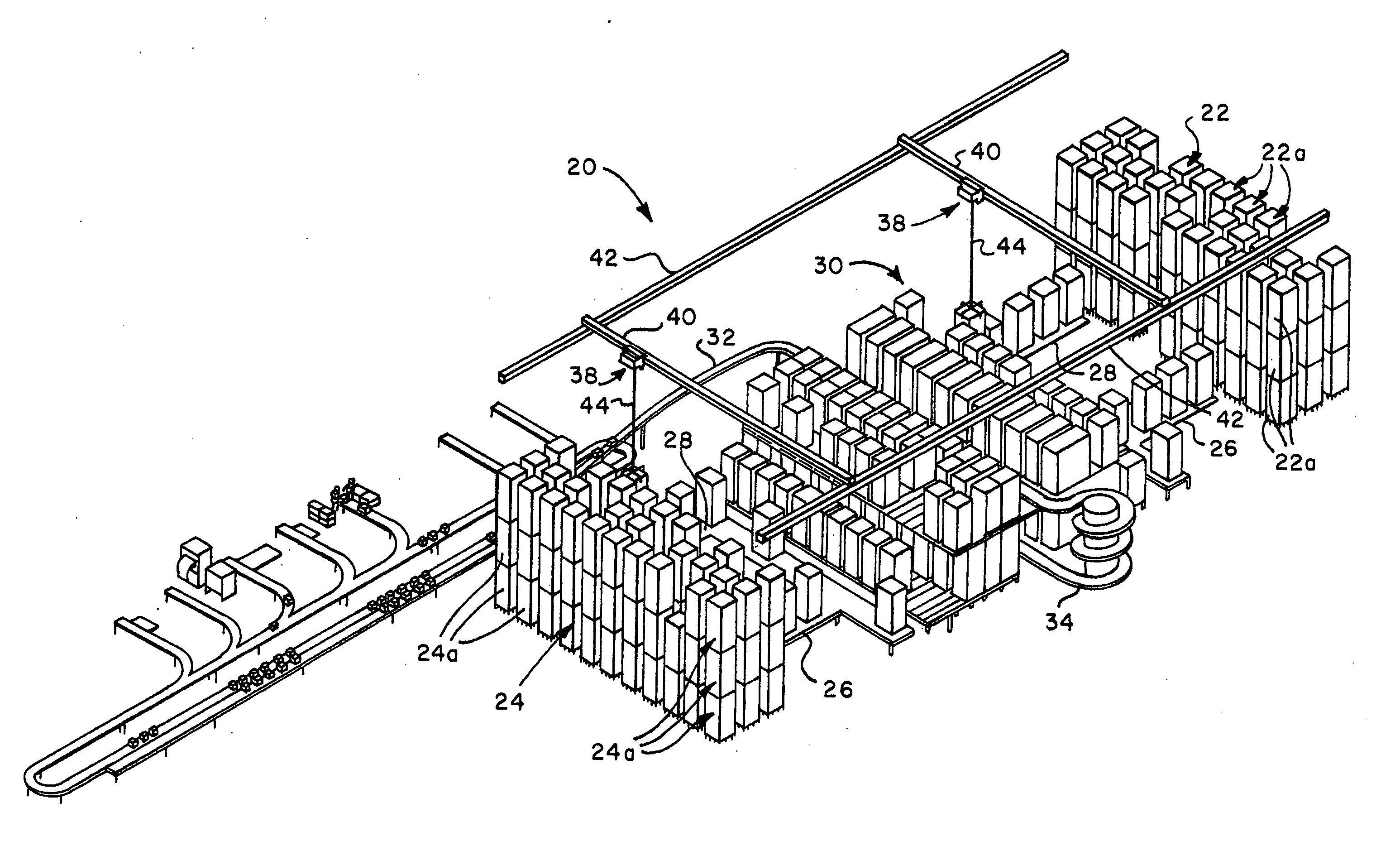

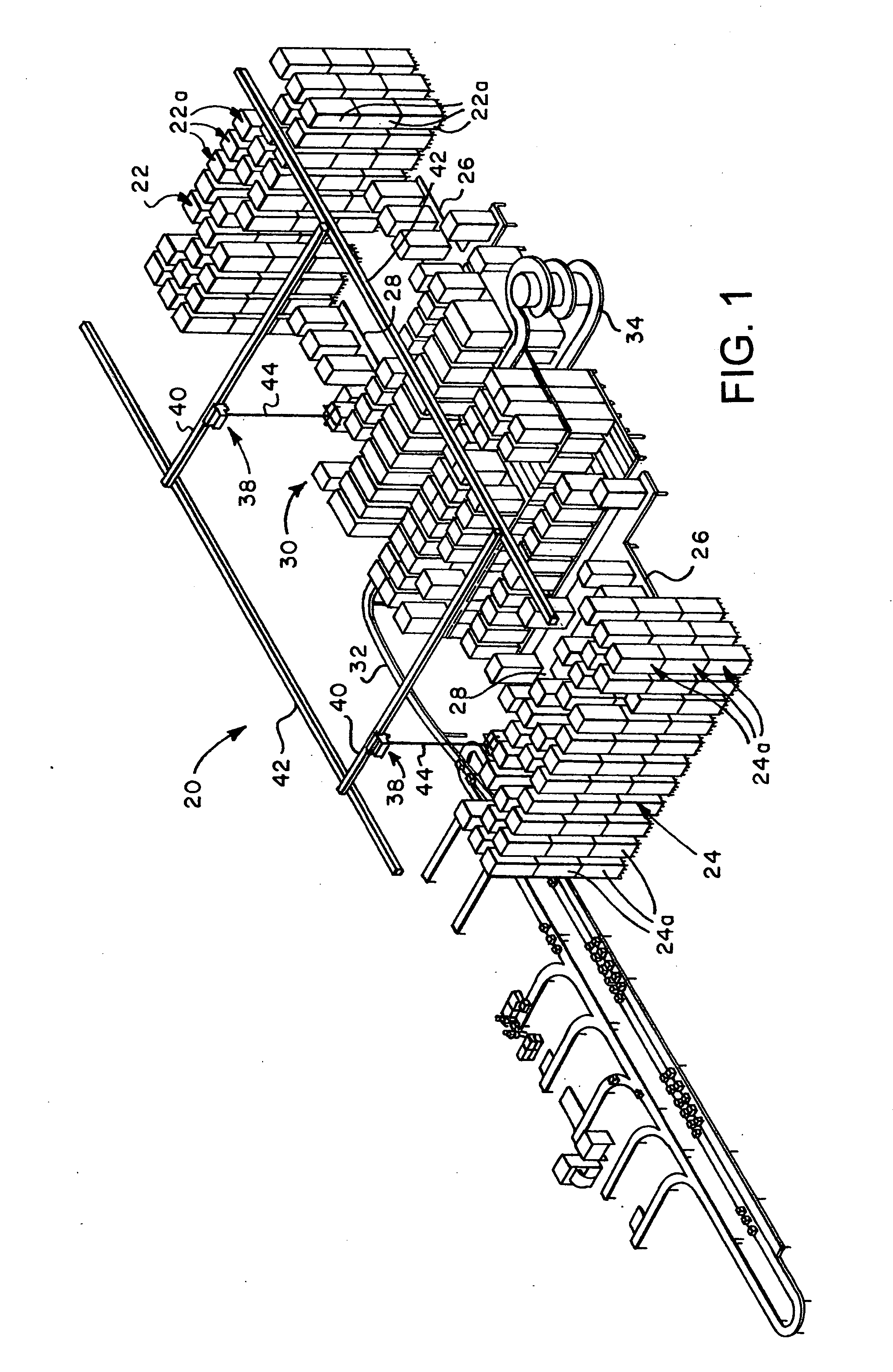

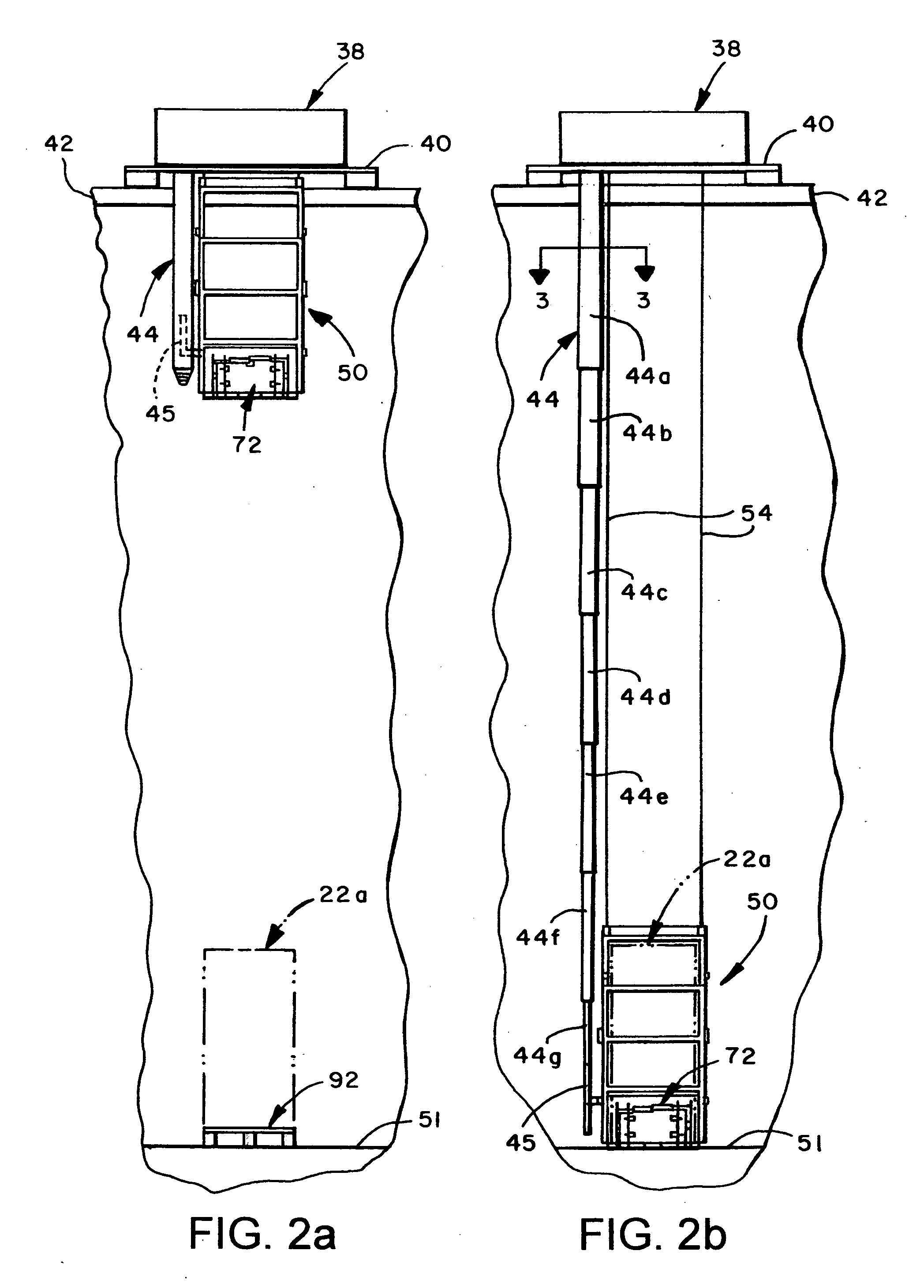

Material handling system

InactiveUS20060056951A1High density storageReduced activityLifting devicesStorage devicesEngineeringOverhead crane

A material handling system for placing and retrieving palletized loads in densely spaced storage areas utilizing an overhead bridge crane connected to a pallet load handling device by way of lifting cables and a stabilizing mast assembly. The pallet handling devices may include vertically or horizontally movable pallet engaging fork mechanisms mounted on a generally rectangular frame which is operable to be lowered over a pallet load and engaged therewith by way of the fork mechanisms. The pallet handling device frame may be split and interconnected by actuator mechanisms to facilitate ease of placing the handling devices over a pallet load and releasing the load from the handling device.

Owner:WILLIAMSON JEFFREY TODD

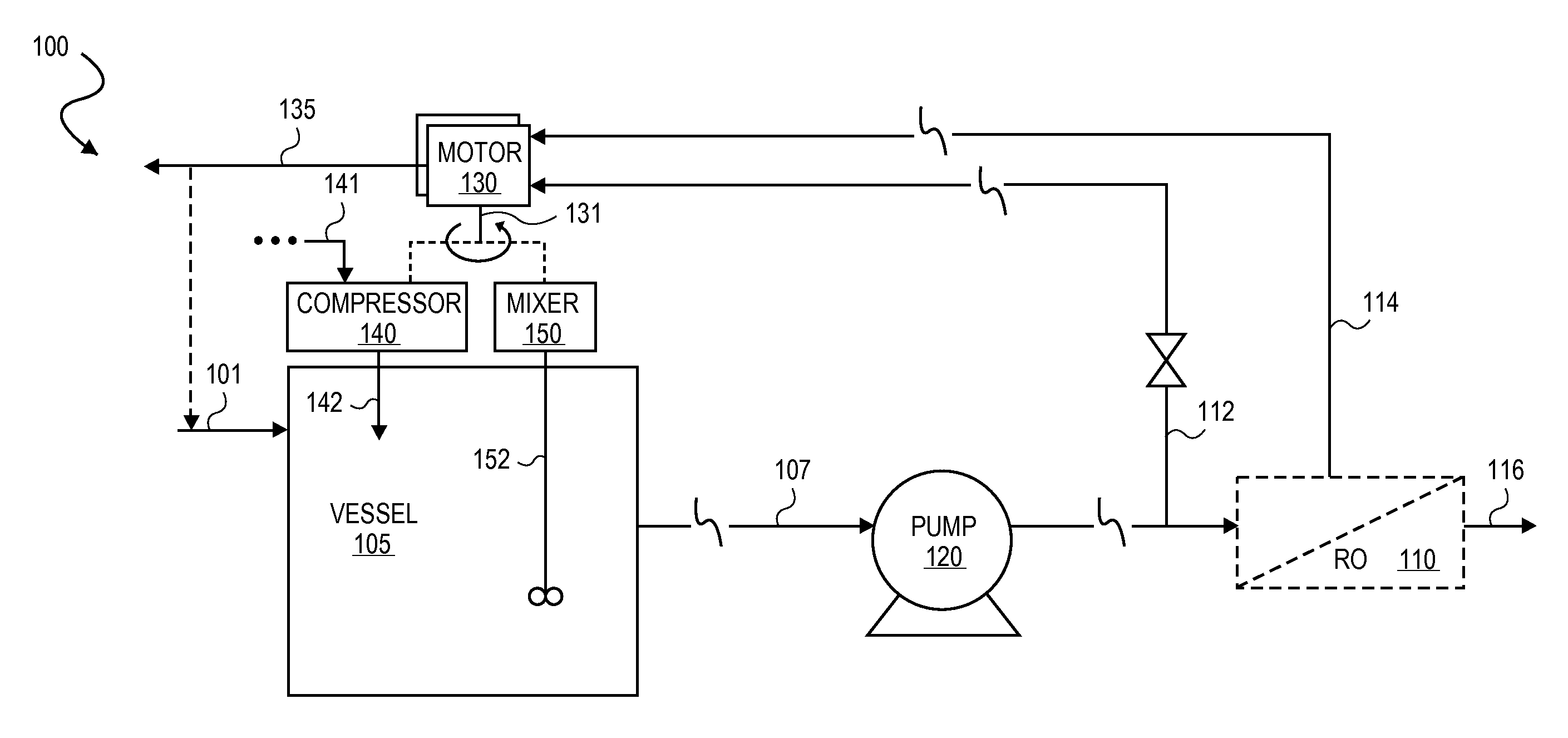

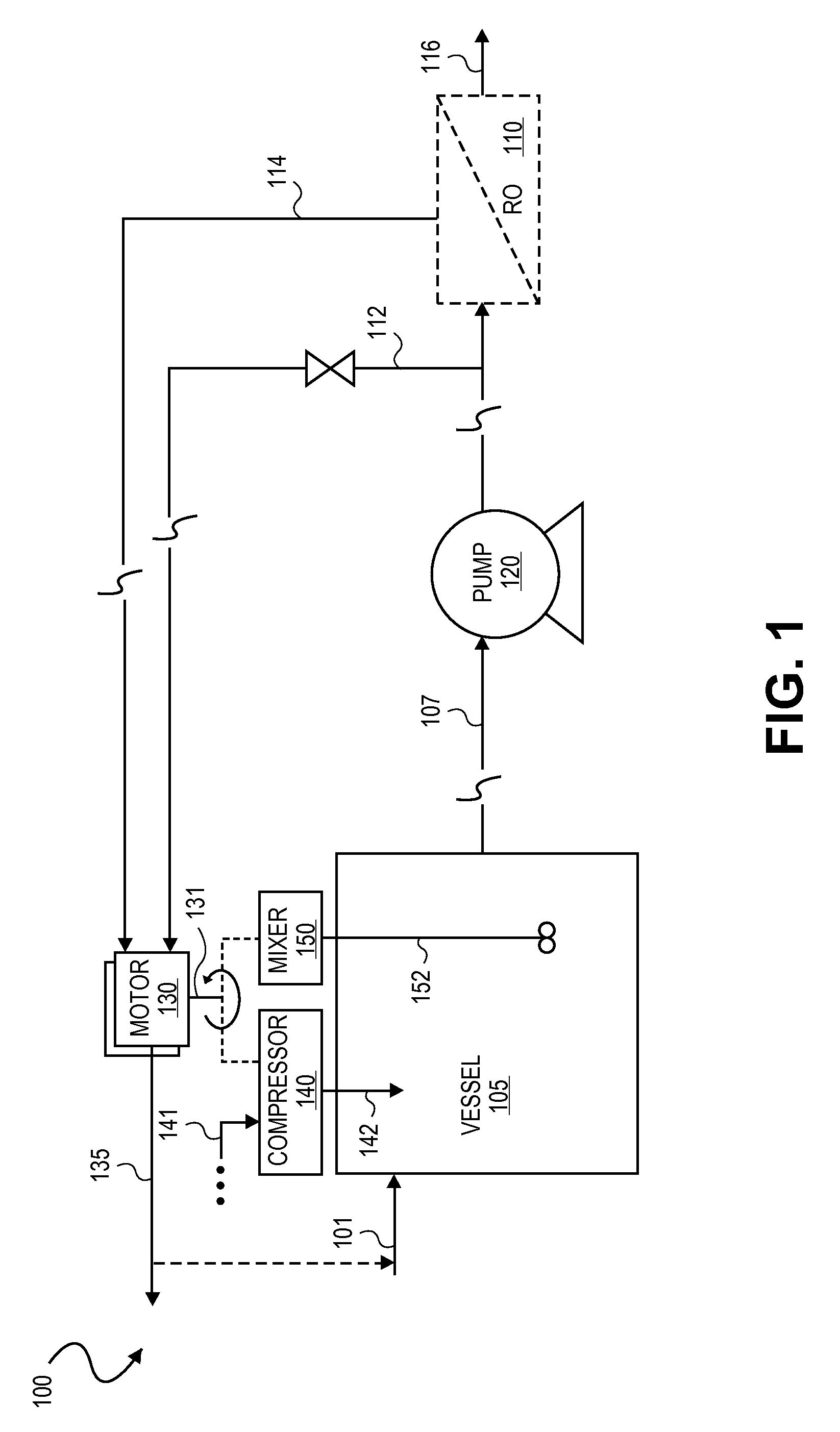

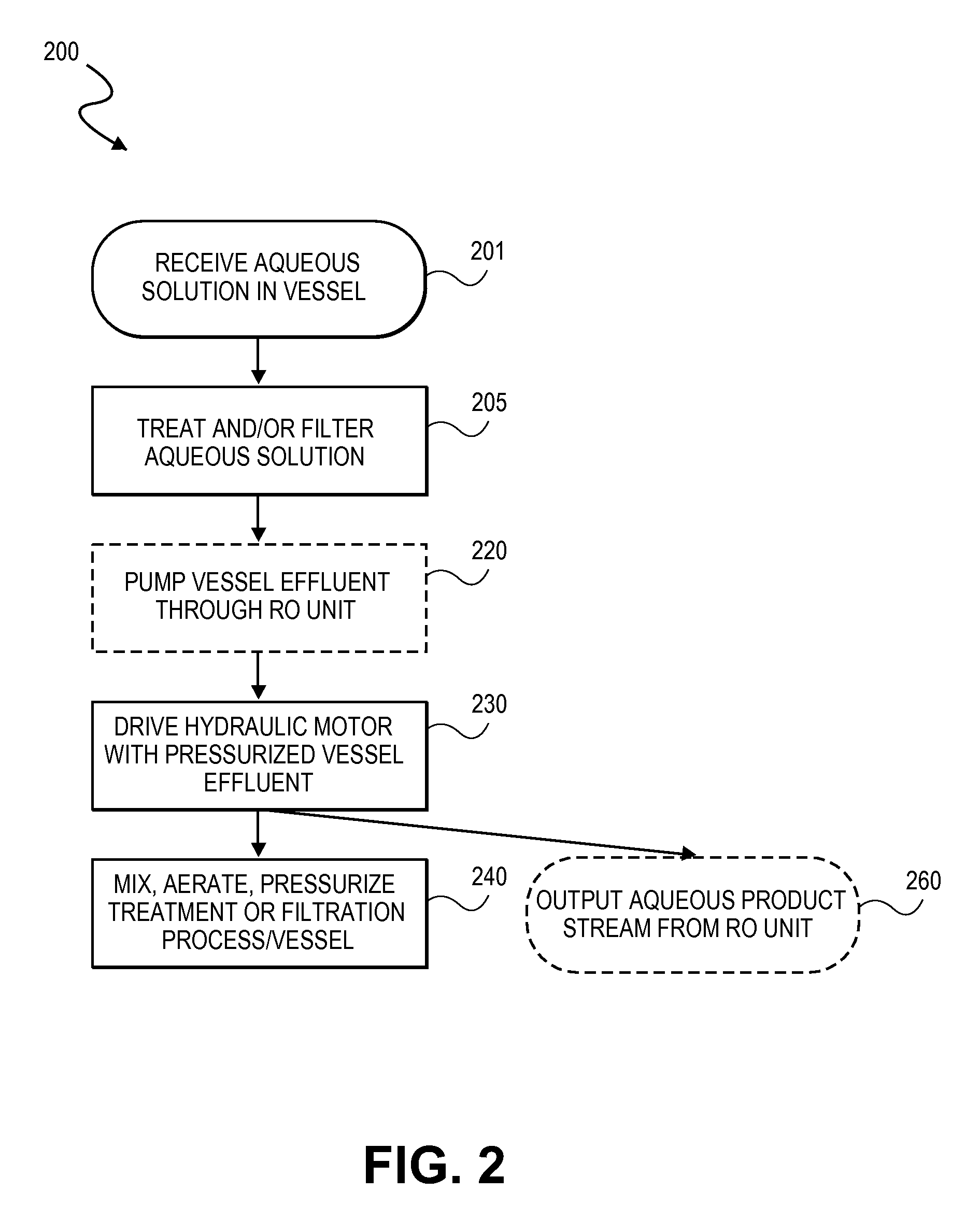

Integrated membrane system for distributed water treatment

InactiveUS20130032533A1Easy to operateLess-effectiveTreatment using aerobic processesTreatment by combined electrochemical biological processesChloramine BPh control

Integrated membrane treatment systems for treatment of an aqueous solution. In embodiments, components, such as an MBR, are integrated with means to recover energy from the system, for example from an RO concentrate, to operate the other components. In embodiments including biological treatment, RO is integrated with other components, such as an MBR with the ROs ability to remove inorganic nitrogen enabling biological treatment to be performed with only partial nitrification and the MBR operated without active pH control. In embodiments, RO is integrated with a chlorine generator to convert chlorides present in the RO concentrate for an in-situ source of oxidizing biocides for disinfection purposes. Chloramines may be generated in-situ from residual ammonia and chlorides in the RO reject. In embodiments, carrier media is employed in a membrane tank to enhance removal of residual organics by the MBR and to also improve effectiveness of membrane scouring.

Owner:ENVEERA

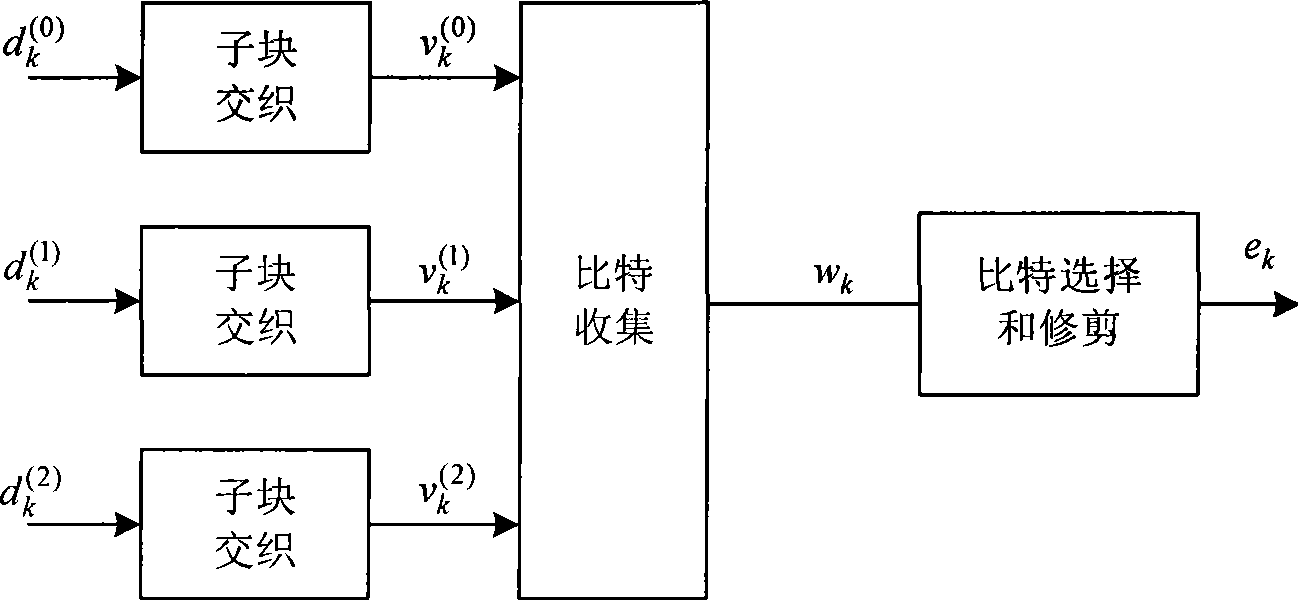

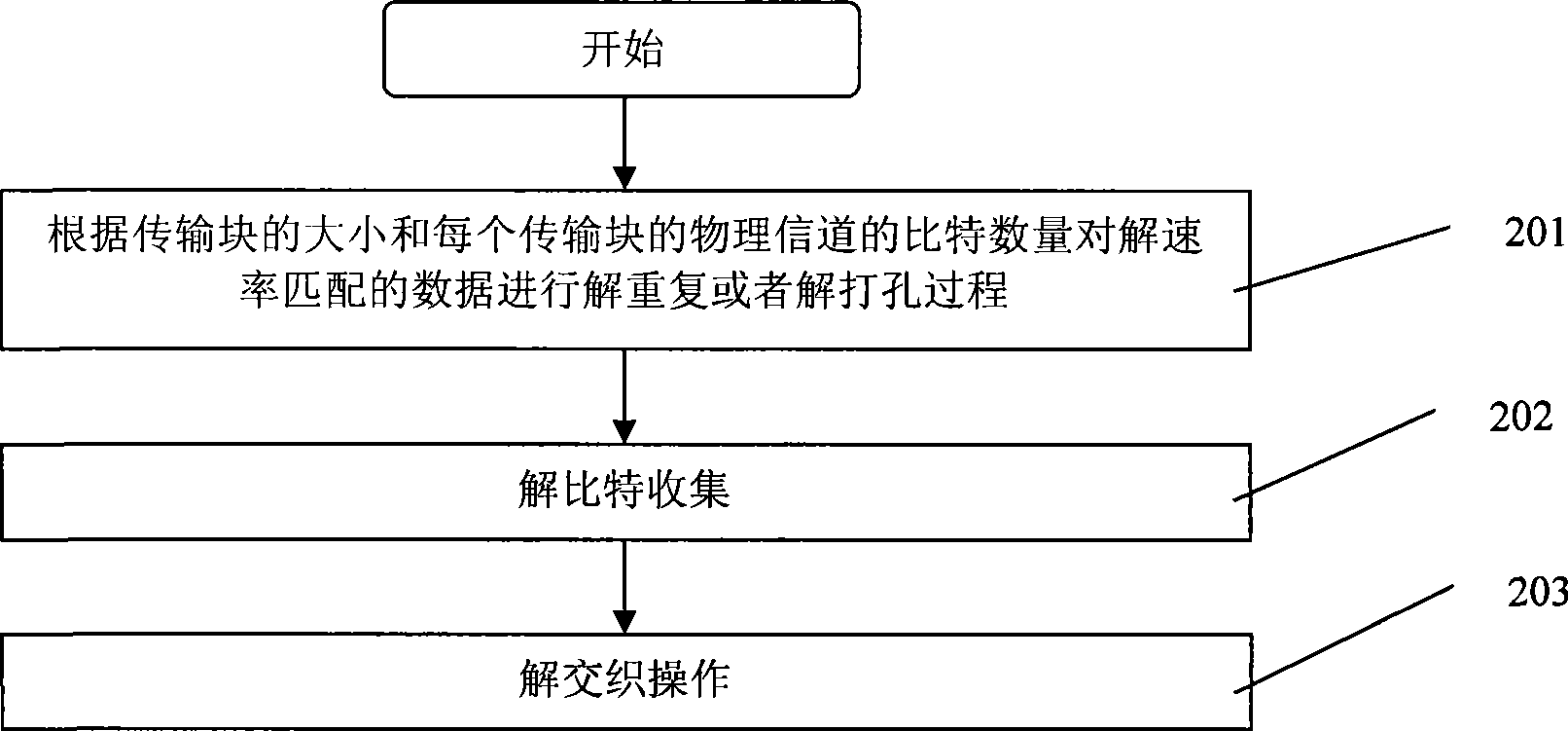

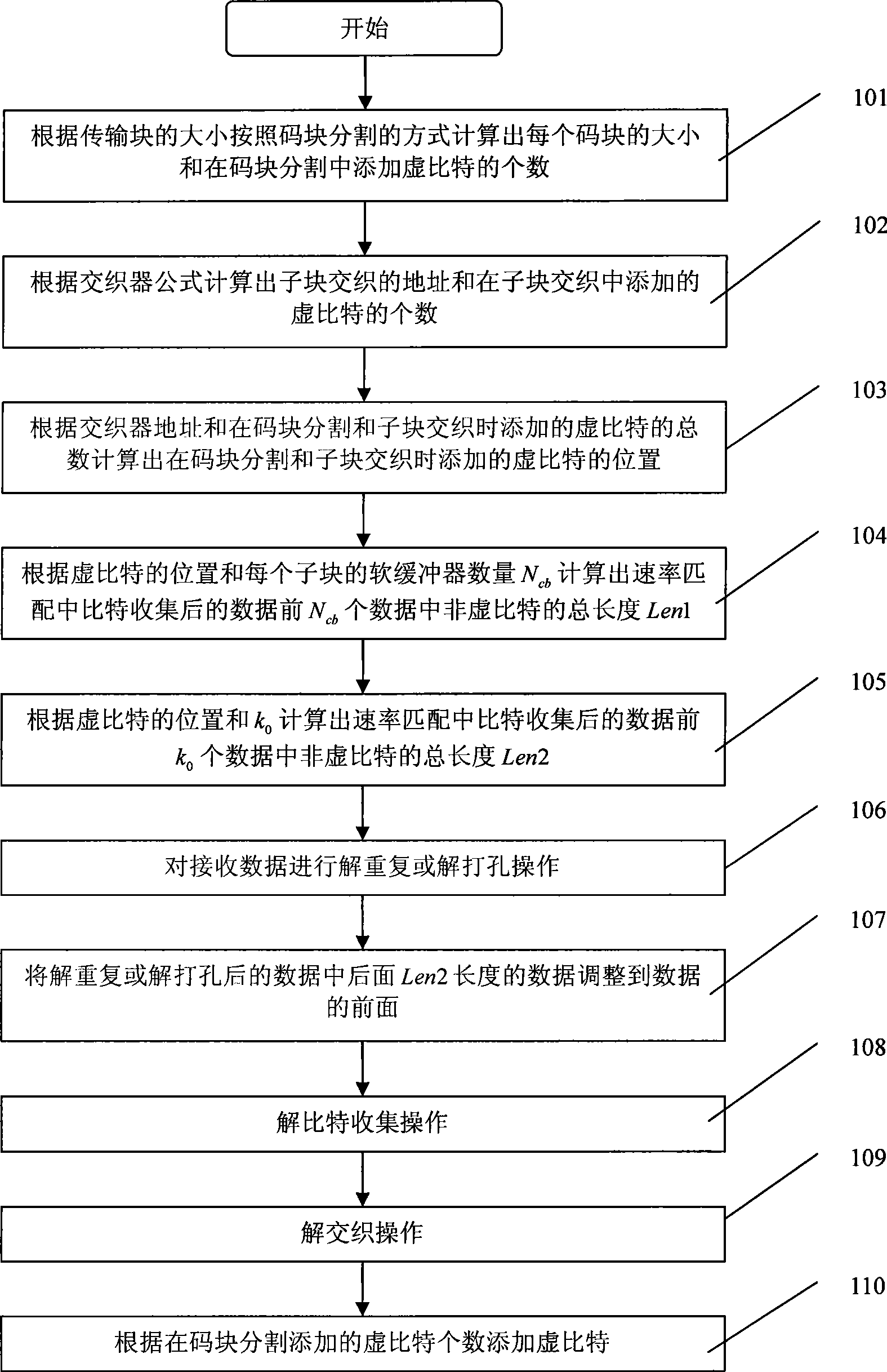

Rate de-matching method

ActiveCN101388751AReduce handlingEasy to implementError preventionData switching networksCoding blockComputer science

The invention provides a method for solving rate matching, which comprises the following steps: without inserting dummy bits into receiving data, which are added during the dividing of code blocks and the interweaving of sub-blocks before the de-repeating operation or the de-drilling operation, directly carrying out the de-repeating operation or the de-drilling operation to the receiving data, then carrying out the de-bit-collecting and the de-interweaving, wherein for the rate de-matching of Turbo codes, the process of inserting the dummy bits into the receiving data, which are added during the dividing of the code blocks and the interweaving of the sub-blocks, is concealed, and the de-repeating operation or the de-drilling operation can be carried out only through calculating the length of non-dummy bits in the former Ncb of data and the former k0 of data in the data after the collection of bits in the rate matching, and for the rate de-matching of convolution codes, the method is more simplified, namely the de-repeating operation or the de-drilling operation can be directly carried out to the receiving date according to the size of transmission blocks. Compared with the prior art, the method simplifies the de-rate matching process, reduces the data transmitting process, greatly reduces the processing time, reduces the data quantity which needs to be processed and improves the processing efficiency.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

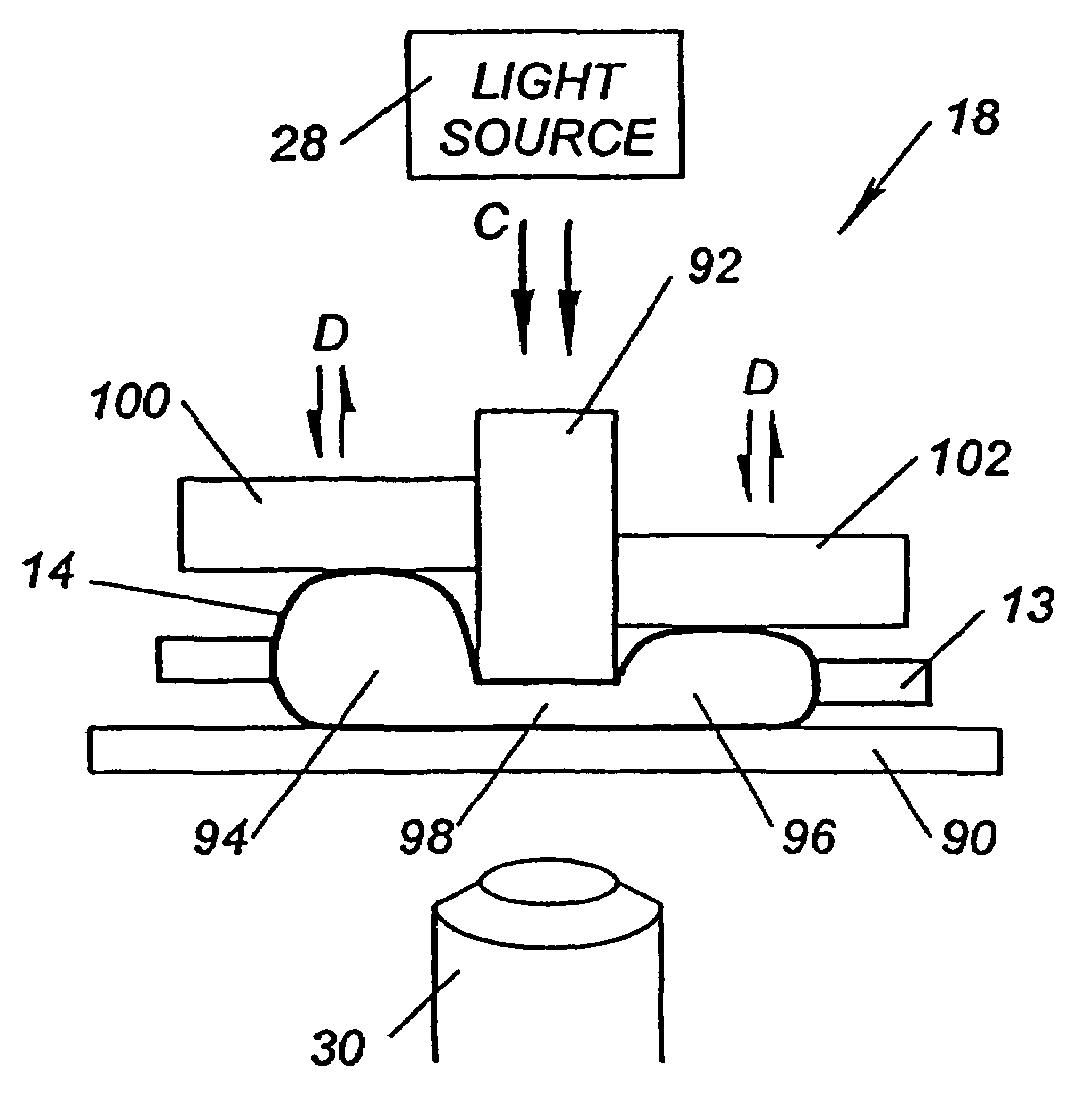

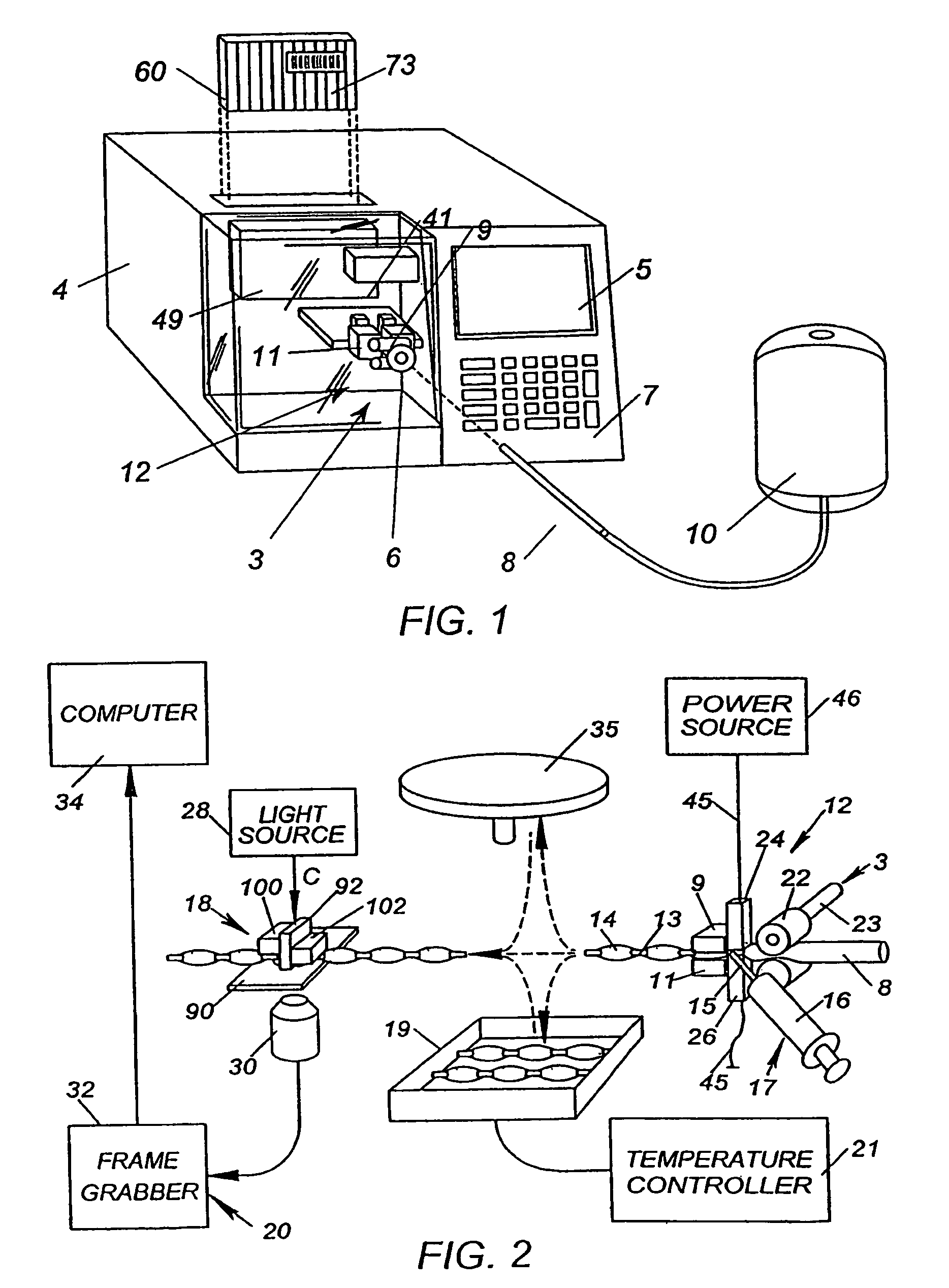

Fluid sample testing system

InactiveUS7337072B2Improve efficiencyCost reductionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringElectrical and Electronics engineering

A sample testing system may include a housing, a cavity in the housing to receive a chamber, two contact members, and a sensor. The contact members may be positioned to be engageable with respective portions of the chamber inserted in the cavity, and to compress those respective portions, thereby driving fluid flow. A sample testing system may include a housing, a cavity in the housing to receive a chamber, at least one contact member, and a sensor. The at least one contact member may be positioned to be engageable with a first segment of the chamber when the chamber is in the cavity, and to compress the first segment, thereby defining a gap of the first segment of the chamber and a reservoir in at least a second segment of the chamber.

Owner:ROCHE MOLECULAR SYST INC

Method for concentration of gold in copper sulfide minerals

ActiveUS20100242681A1Efficient separationEffective recoveryPhotography auxillary processesGold compoundsEnrichment methodsHydrometallurgy

Disclosed herein is a method for concentrating gold contained in a leach residue obtained in a copper hydrometallurgical process for recovering copper from a copper sulfide mineral to efficiently separate and recover gold from the leach residue. According to the method, a gold-bearing copper sulfide mineral is subjected to pressure leaching with sulfuric acid at a temperature higher than 102° C. and 112° C. or lower to obtain a leach residue, and the leach residue is subjected to flotation to separate it into a float fraction and a sink fraction. The float fraction obtained by flotation is desulfurized by heating at a temperature of 250 to 800° C. under an inert atmosphere to obtain a desulfurized product. The desulfurized product is subjected to oxidative roasting by heating at a temperature of 600 to 800° C. under an atmosphere of flowing oxygen or air to obtain an oxidatively-roasted product. The oxidatively-roasted product is dissolved in a sulfuric acid solution to obtain a copper solution, and a gold-bearing residue is separated and recovered from the copper solution.

Owner:SUMITOMO METAL MINING CO LTD

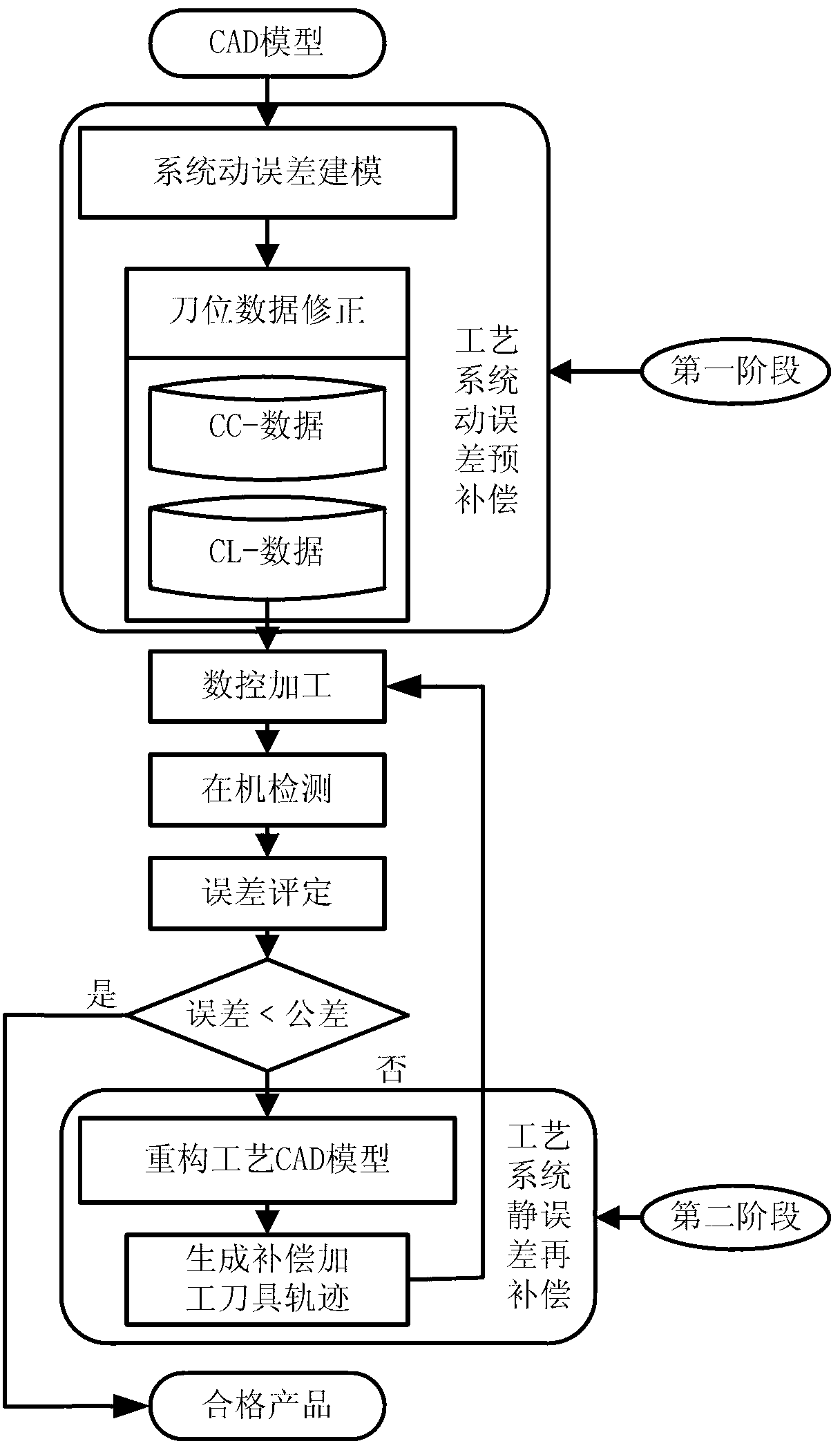

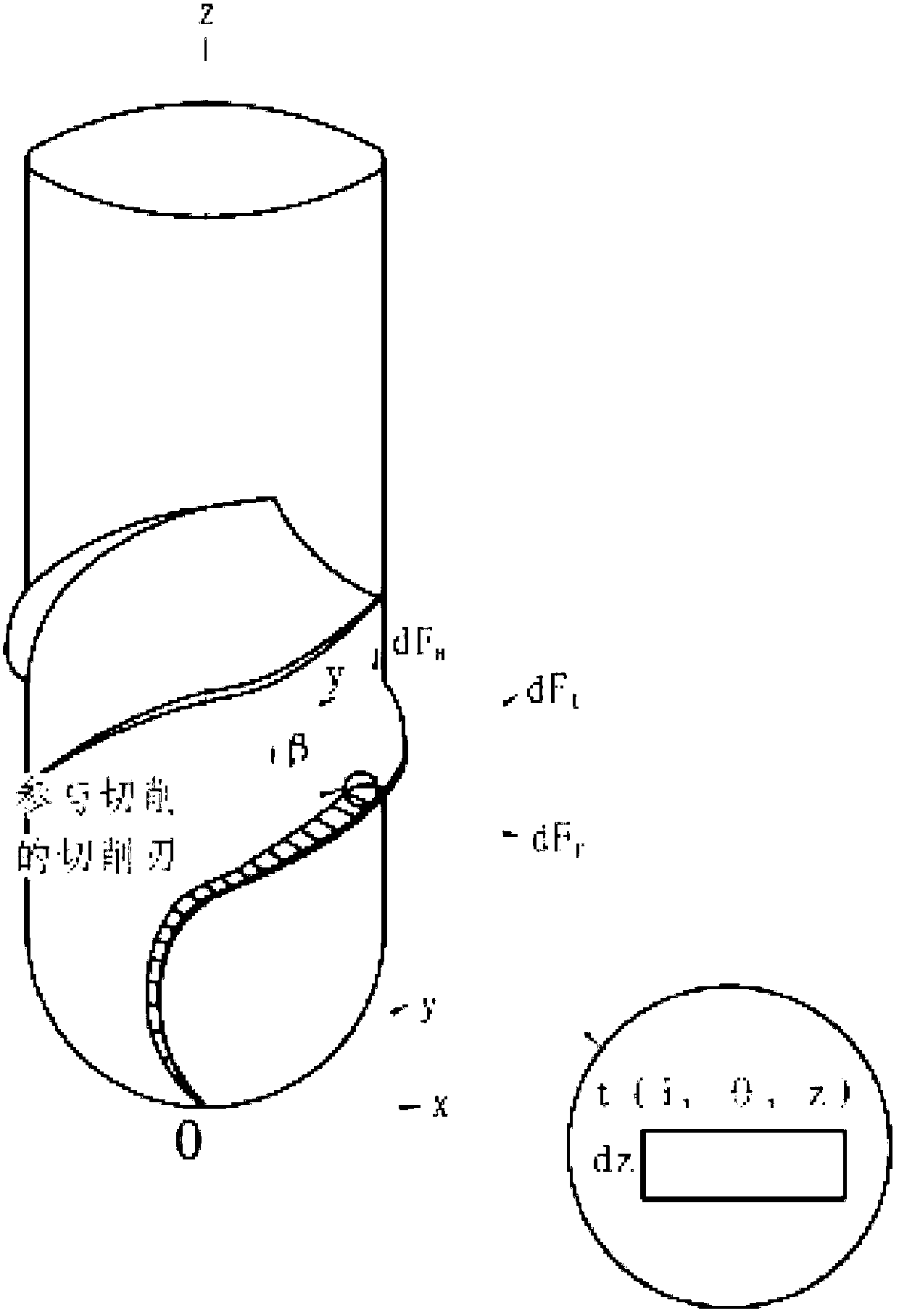

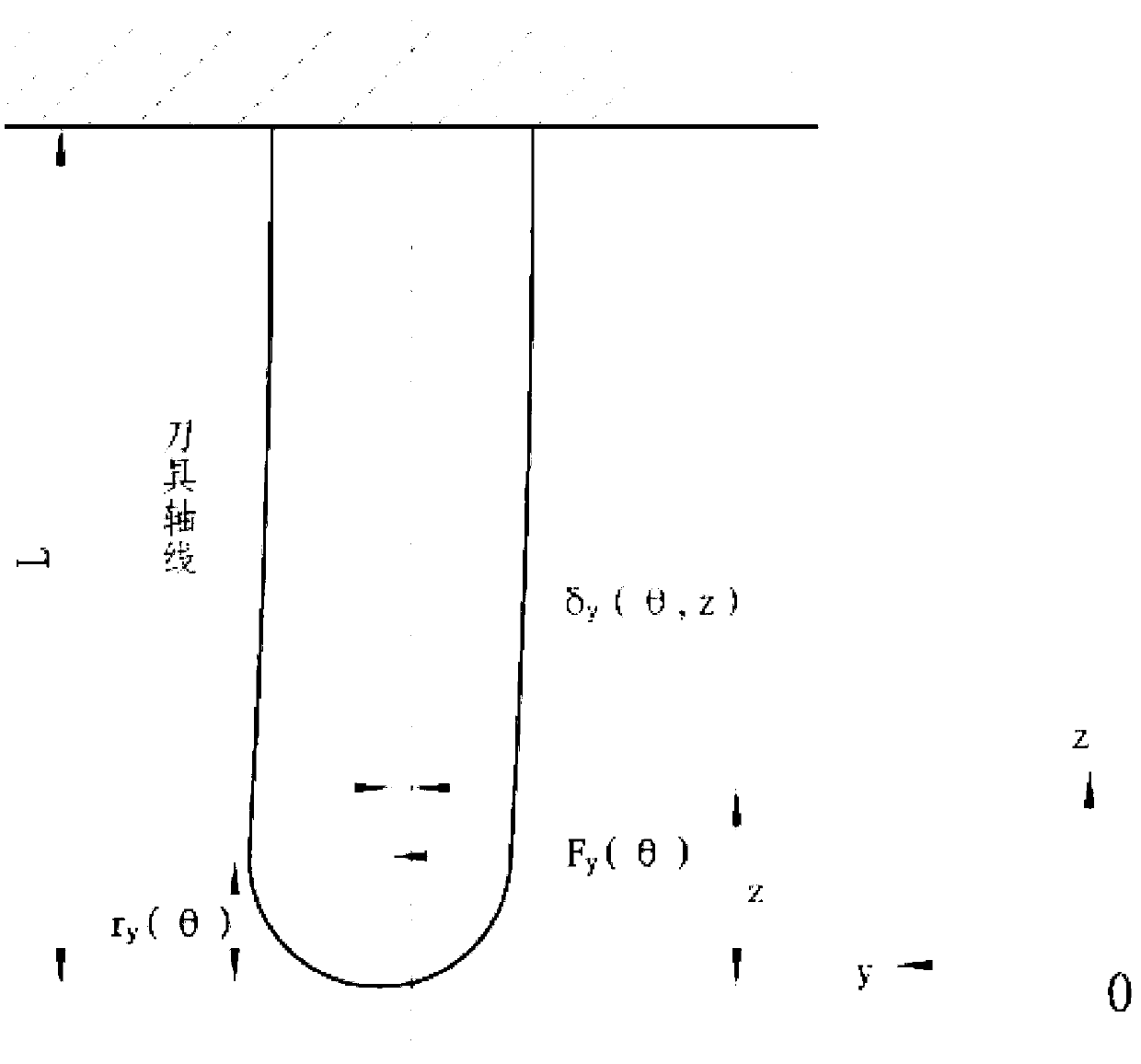

In-process evaluation based complex spatial surface error feedback compensating method

ActiveCN103218475AAvoid repeated positioning errorsReduce handlingSpecial data processing applicationsComputer Aided DesignCutter location

The invention discloses an in-process evaluation based complex spatial surface error feedback compensating method. The method comprises the following steps of processing a complex surface cutting force module through a ball-end cutter, performing dynamic compensation for a target cutter location point for workpiece pre-processing; performing in-process detection for the pre-processed workpiece to obtain geometrical information of an actual contour; evaluating error for the pre-processed workpiece through a contour degree error evaluation model; when the contour error is greater than tolerance, determining a compensation point position U1 corresponding to each contact point; guiding the compensation point position corresponding to each contact point to three-dimensional CAD (Computer-Aided Design) to obtain a compensating process contour to generate a compensating processing tool track; and performing static compensation and processing for the pre-processed workpiece and finishing the flow. Under the premise of ensuring the processing precision of part surface, the processing precision of the part is detected in process without investing fund to purchase more detection devices, so that the conveying and loading time of workpieces is shortened.

Owner:TIANJIN SAIXIANG TECH

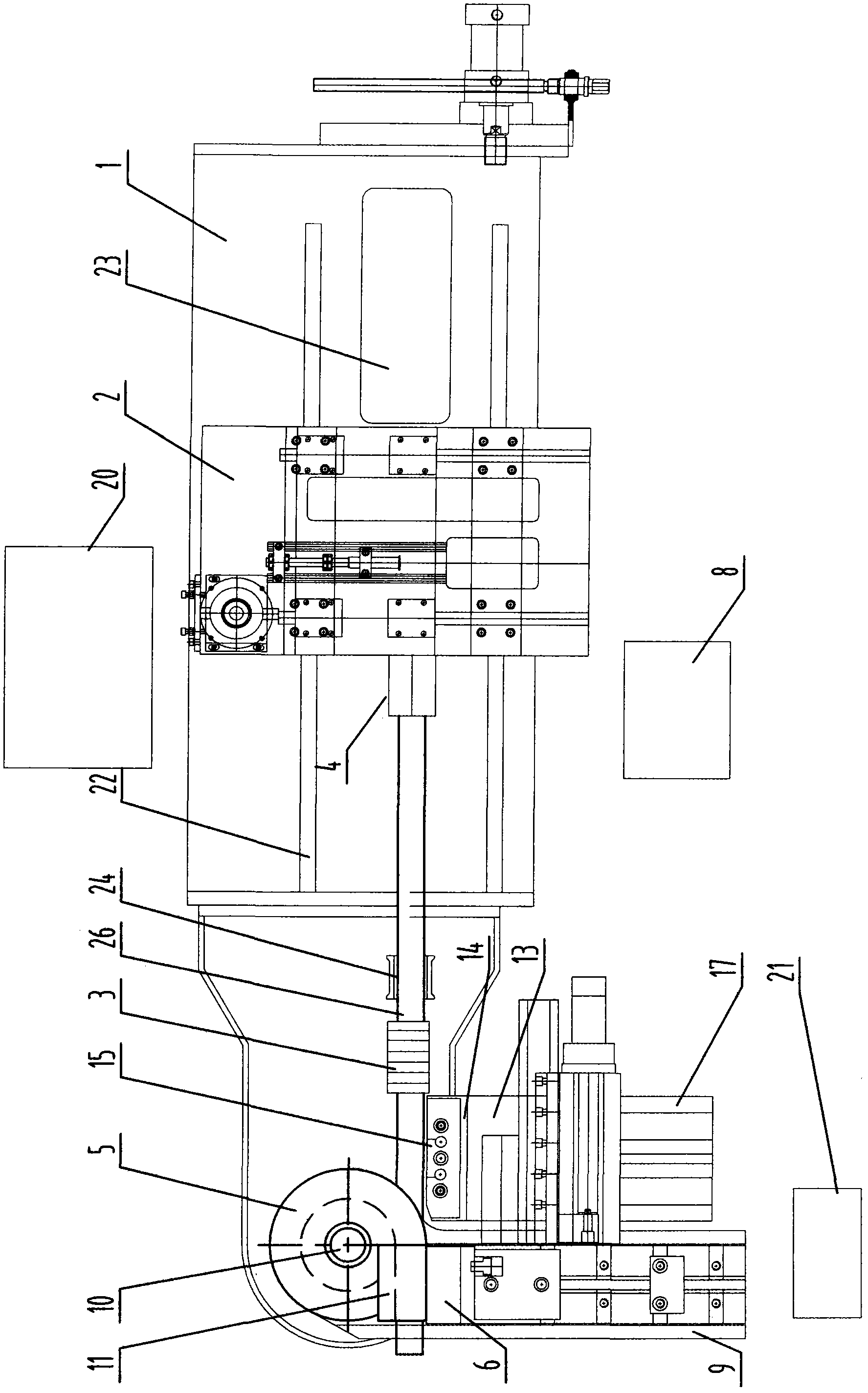

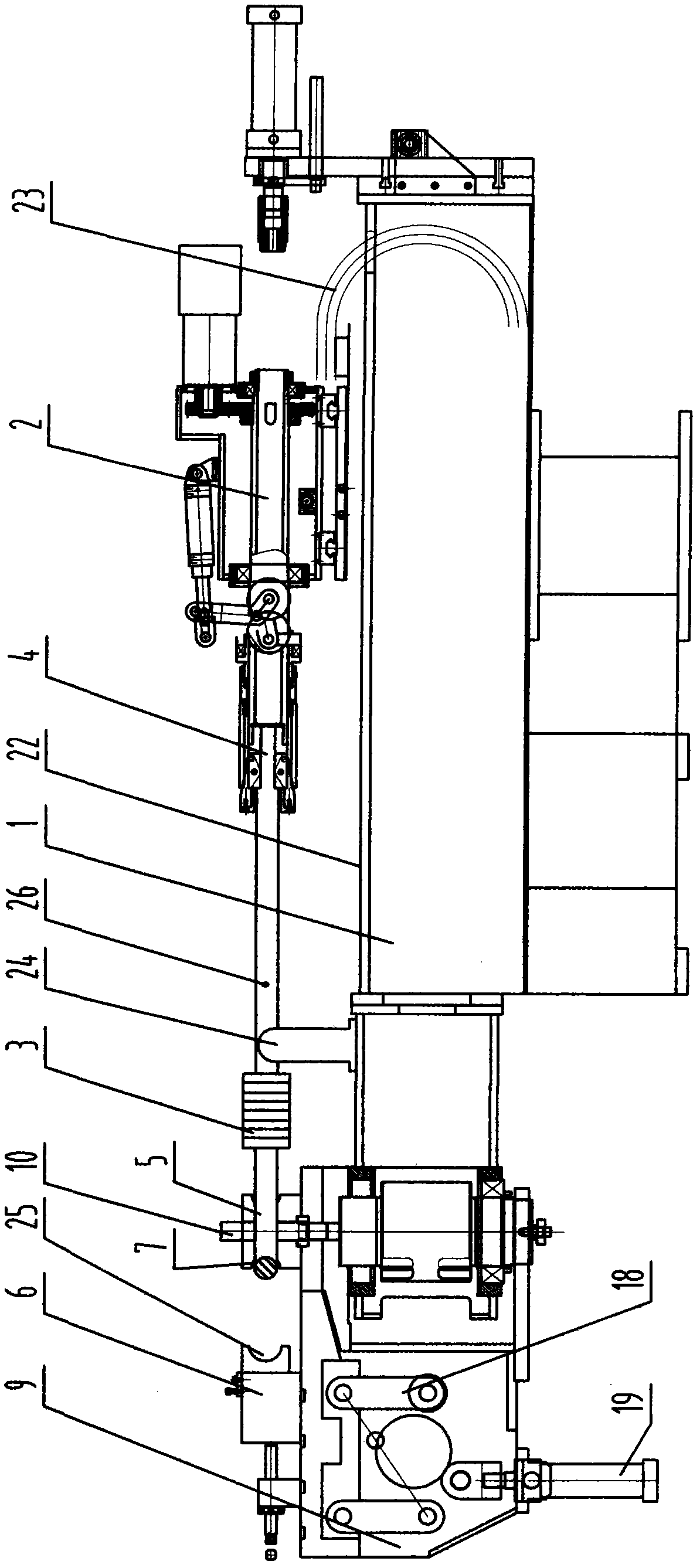

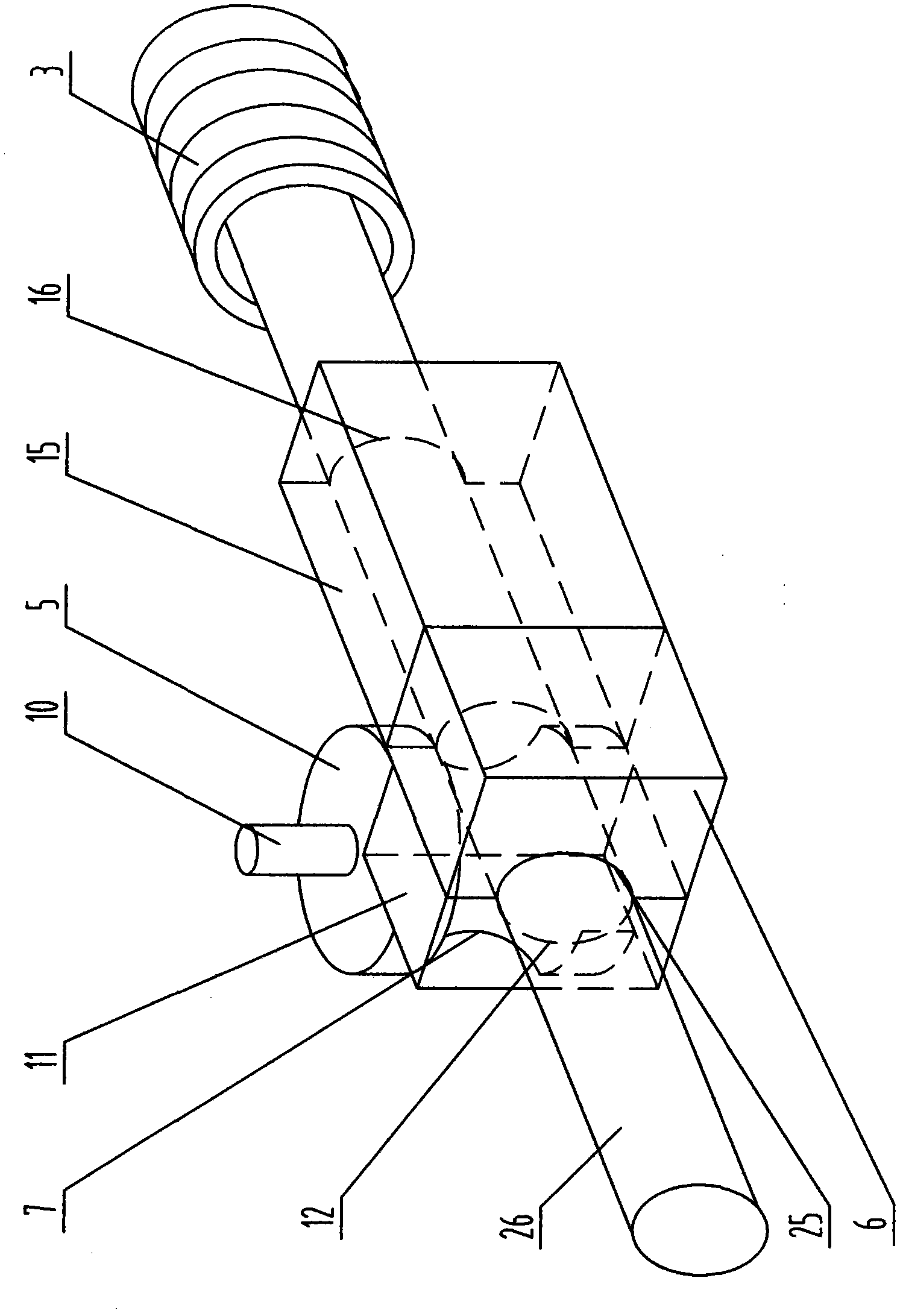

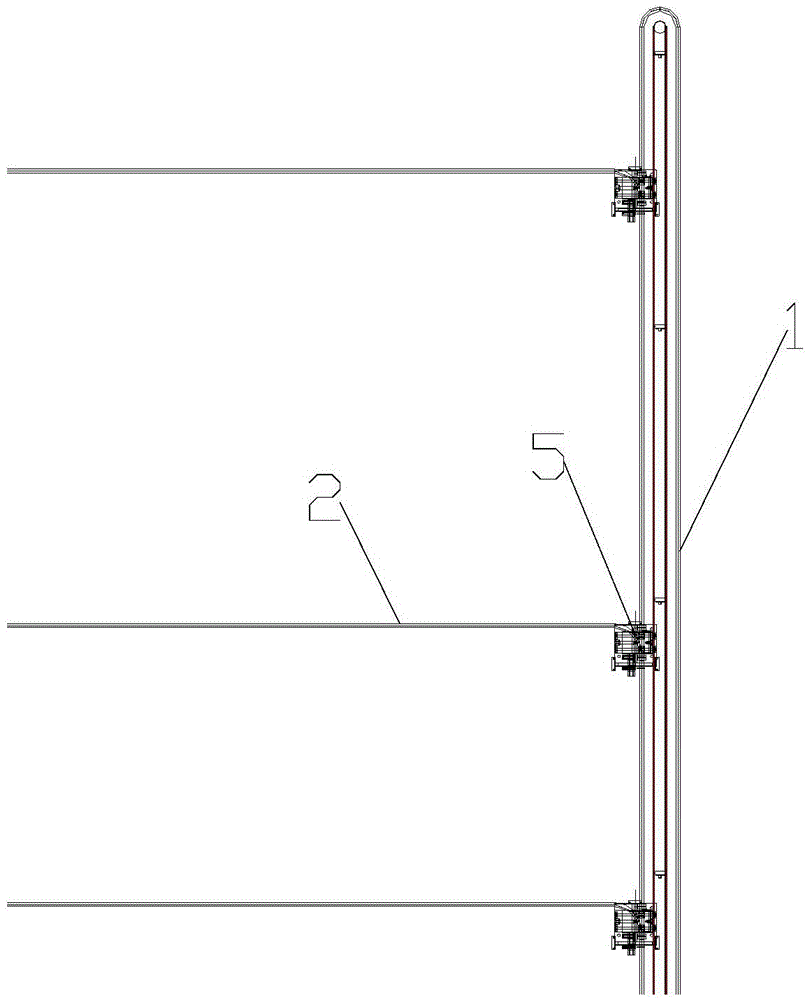

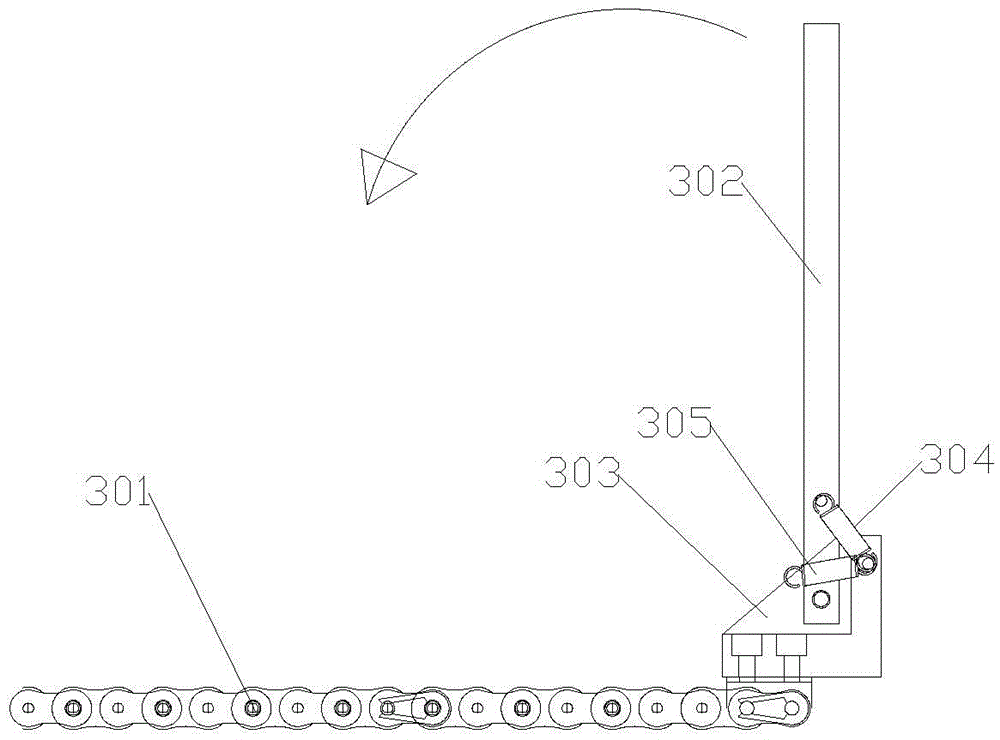

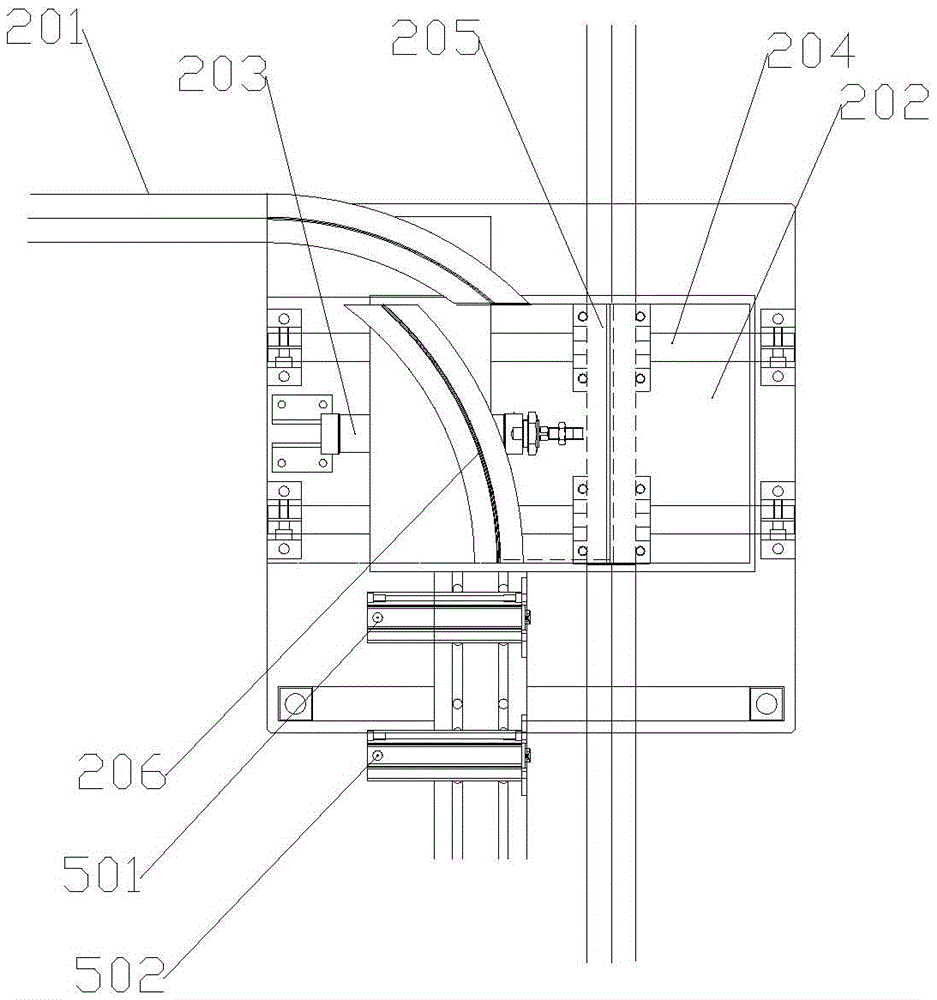

Automatic pipe bending device and pipe bending process thereof

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

System and method for the concentrated collection of airborne particles

ActiveUS20140060155A1Simplifying chain of custodyReducing data handlingWithdrawing sample devicesSolid surfaceAnalytical technique

A system and a method is described herein for the collection of small particles in a concentrated manner, whereby particles are deposited onto a solid surface or collected into a volume of liquid. The collected samples readily interface to any of a number of different elemental, chemical, or biological or other analysis techniques.

Owner:AEROSOL DYNAMICS INC +1

Processes Using Multifunctional Catalysts

InactiveUS20190076834A1Cost reductionLow costMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsProtein carbonylEpoxide

The present invention is directed to catalysts and processes for catalyzing two or more chemical reactions with a multifunctional catalyst in a reaction vessel. The processes include steps for introducing one or more reagents to a reaction vessel containing a multifunctional catalyst; contacting the one or more reagents with a first portion of the multifunctional catalyst to produce an intermediate; contacting the intermediate with a second portion of the multifunctional catalyst to produce a product; and removing the product from the reaction vessel. In certain embodiments, the multifunctional catalyst may have a first portion with carbonylation functionality for catalyzing the production of a beta-lactone intermediate from an epoxide reagent and a carbon monoxide reagent. In certain embodiments, the multifunctional catalyst may have a second portion with a functionality suitable for polymerization, co-polymerization, and / or modification of a beta-lactone intermediate. In preferred embodiments, the first portion and second portion are bonded to a heterogenous support.

Owner:NOVOMER INC

Intelligent suspension system and suspension distribution control method

ActiveCN105600294ARealize automatic handlingExact searchConveyorsControl devices for conveyorsDistribution controlEngineering

An intelligent suspension system comprises a main transportation circulating passage and a plurality of branch passages forked from the main transportation circulating passage, and a track changing mechanism is arranged at a fork position of the main transportation circulating passage and every branch passage. Different radio frequency identification cards are allocated to suspensions which are fed from a feeding end of the main transportation circulating passage and are distributed to different branch passages before feeding. When every suspension runs to the fork position of the corresponding branch passage, a card reading device reads radio frequency identification information to judge whether the suspension enters the branch passage or not, and if the suspension is allowed to enter the branch passage, the track changing mechanism is communicated with the branch passage and the suspension enters the suspension passage; if the suspension is not allowed to enter the branch passage, the track changing mechanism is communicated with the main transportation circulating passage and the suspension continues moving on the main transportation circulating passage circularly. If a specific branch alarms, directional distribution of the suspensions can be adjusted through terminal control, and if all the branches alarm, the main transportation circulating passage stops running.

Owner:青岛酷特智能股份有限公司

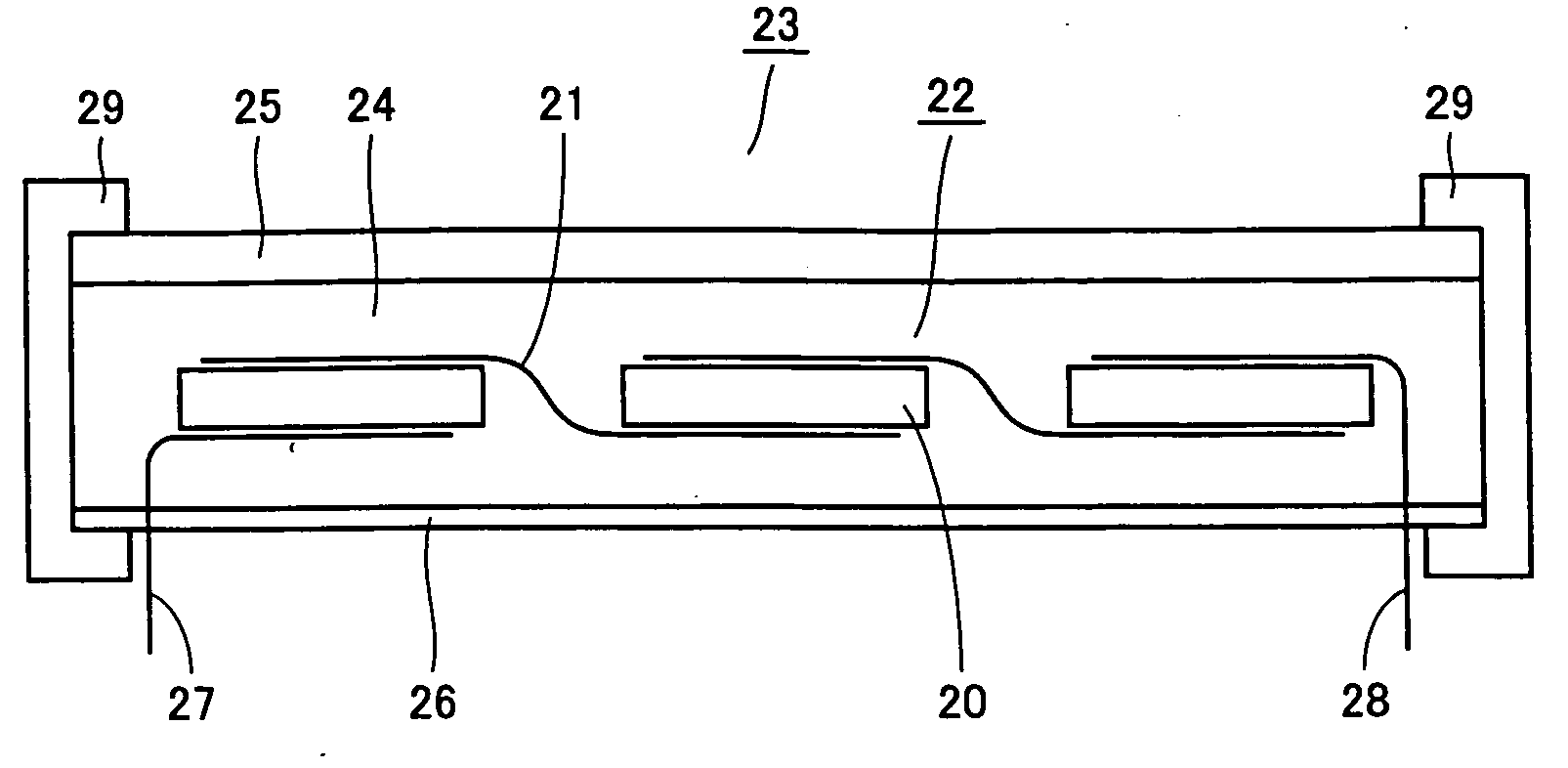

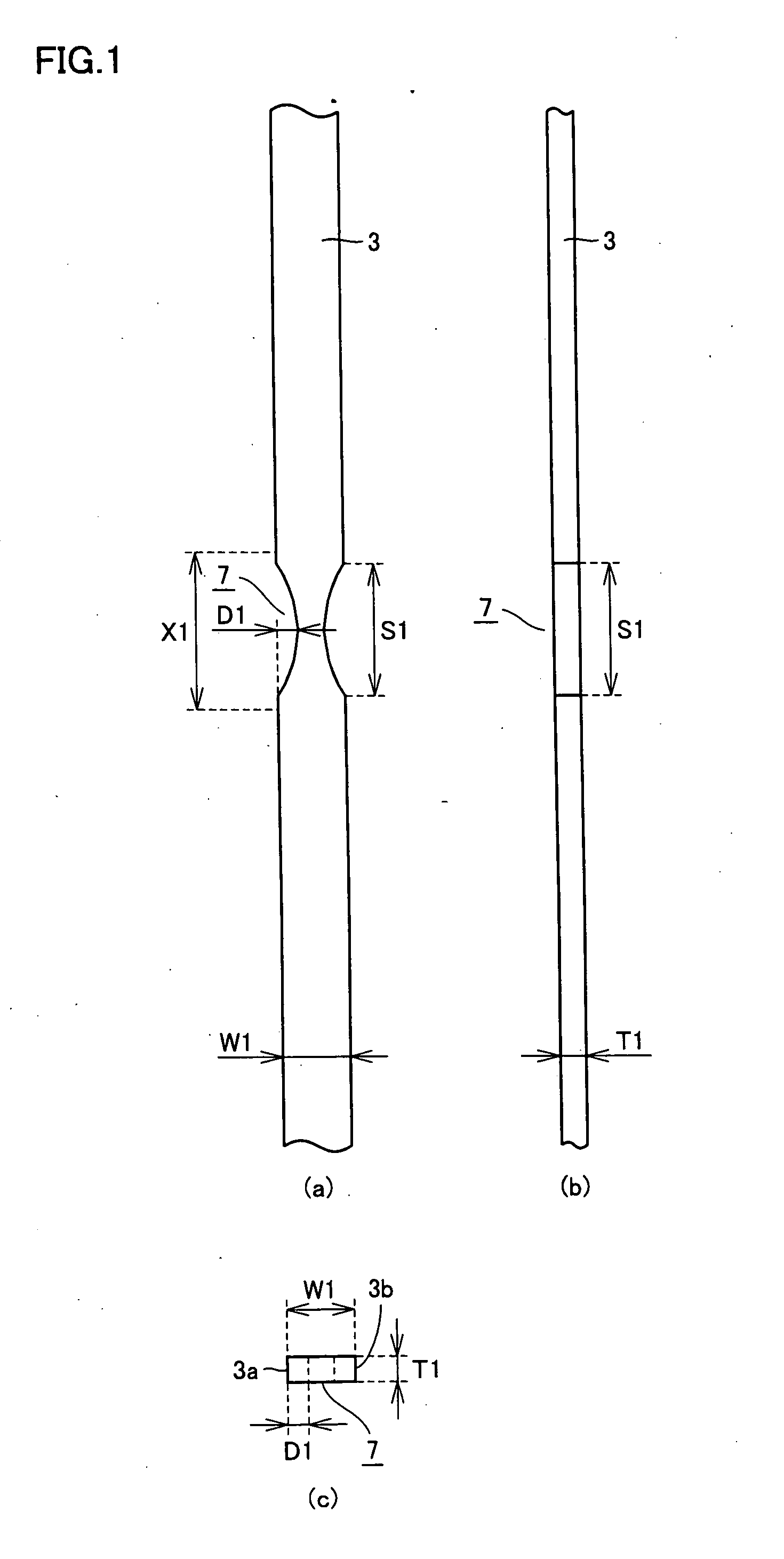

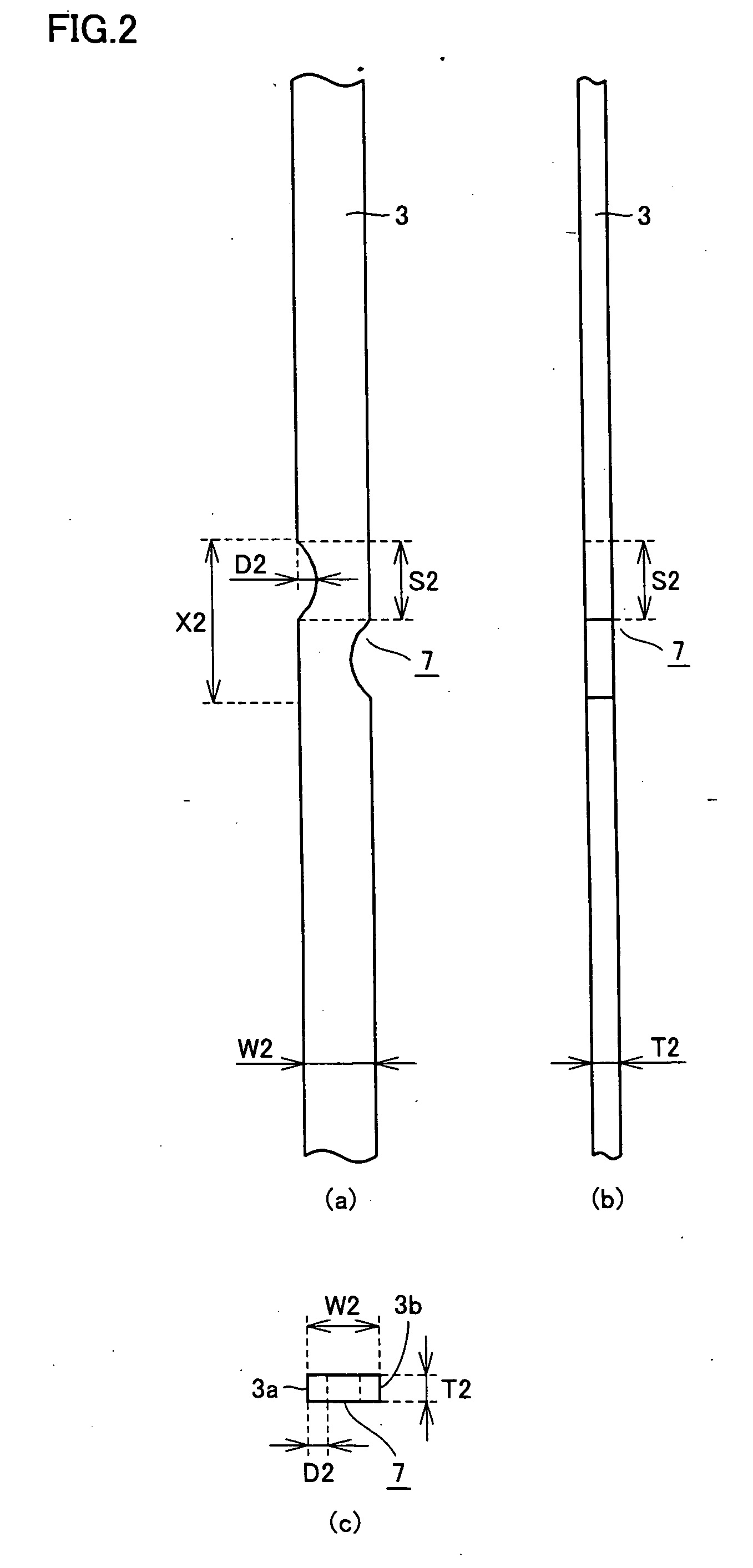

Interconnector, Solar Cell String Using the Interconnector and Method of Manufacturing Thereof, and Solar Cell Module, Using The Solar Cell String

InactiveUS20100116323A1Difference in stressFirmly connectedNon-insulated conductorsPV power plantsElectricityInterconnector

An interconnector includes a strip-shaped and electrically conductive member electrically connecting respective electrodes of adjacent solar cells, the conductive member includes a plurality of planar stress relief parts and the stress relief parts are formed at equal pitches. With this structure, a stress due to a difference in thermal expansion coefficient between the interconnector and the solar cell is uniformly alleviated, so that the warp occurring to the solar cell is reduced and the reliability of the connection between the interconnector and the solar cell is improved.

Owner:SHARP KK

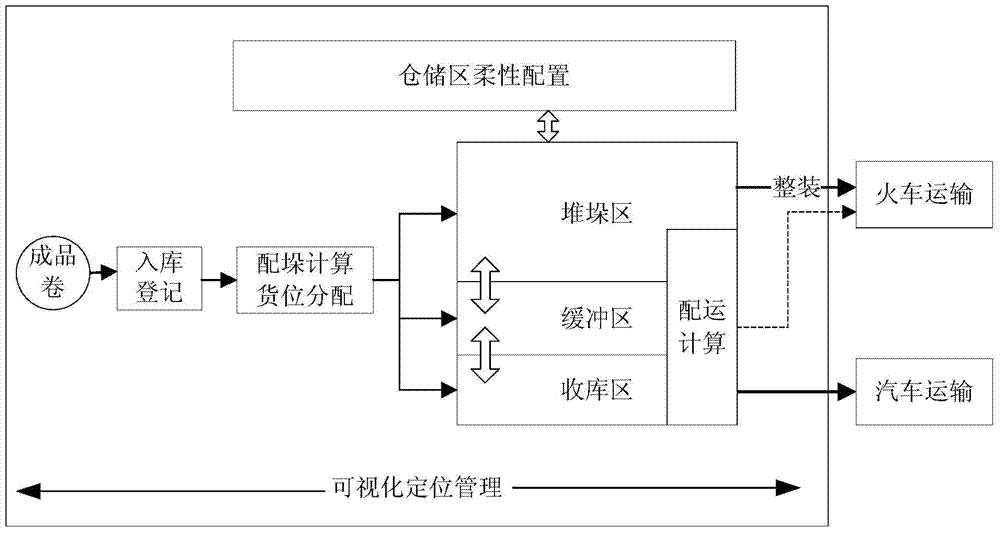

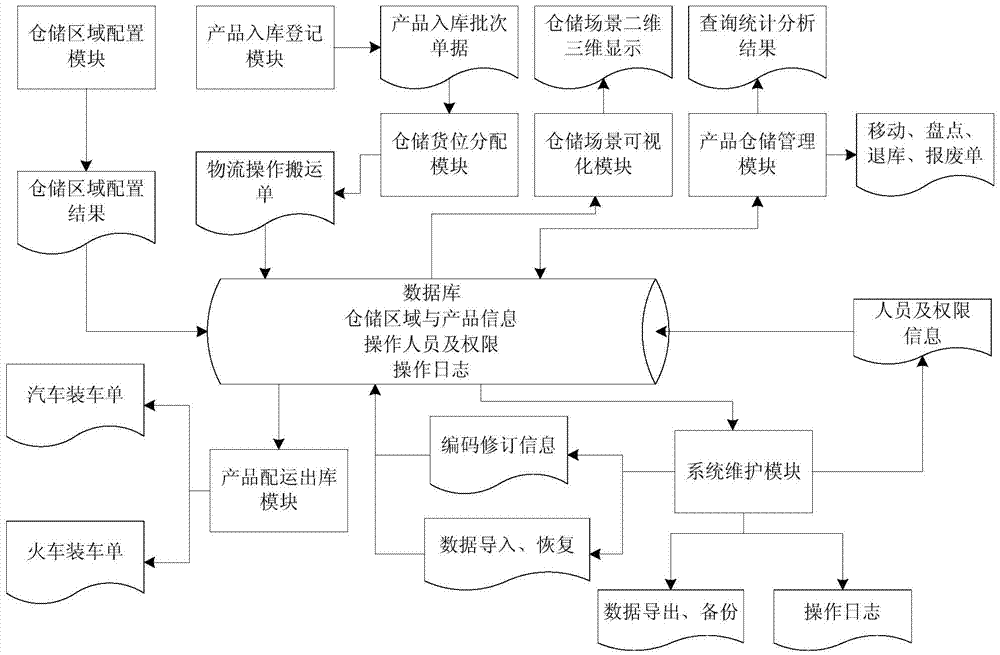

Steel strand finished product storage and distribution system and method

ActiveCN103942670ARealize visual monitoringRealize intelligent managementLogisticsLogistics managementDistribution system

The invention discloses a steel strand finished product storage and distribution system and method. The system comprises a storage area configuration module, a product warehouse-in registration module, a storage space allocation module, a product distribution warehouse-out module, a product storage management module and a storage scene visualization module. The method includes the steps: setting storage area function partitions and designing shapes and sizes of different storage stack types; dividing and numbering cargo spaces; registering steel strand finished product warehouse-in information in real time or in batch; allocating the steel strand finished product cargo spaces, generating a steel strand finished product cargo space carrying scheme and carrying steel strand finished products; calculating distribution of the steel strand finished products according to different transport means and generating a steel strand finished product distribution scheme when the steel strand finished products need to be transported; discharging the steel strand finished products from a warehouse, loading the steel strand finished products into the transport means and finishing distribution. By considering bulk shipment, storage stack type design and storage area configuration are restrained, storage and distribution are integrated and optimized online, and storage logistics multi-dimensional visualization is realized.

Owner:NORTHEASTERN UNIV

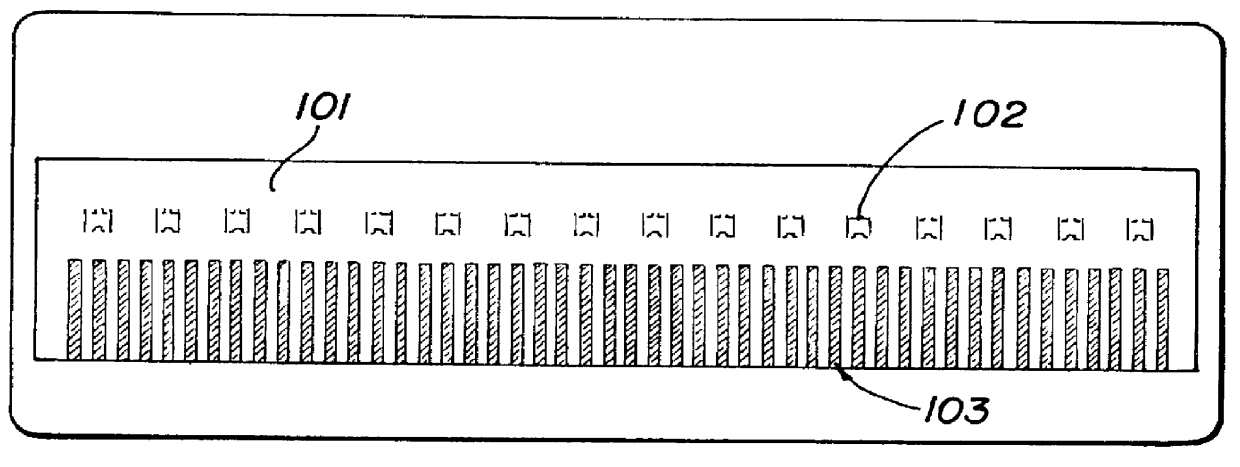

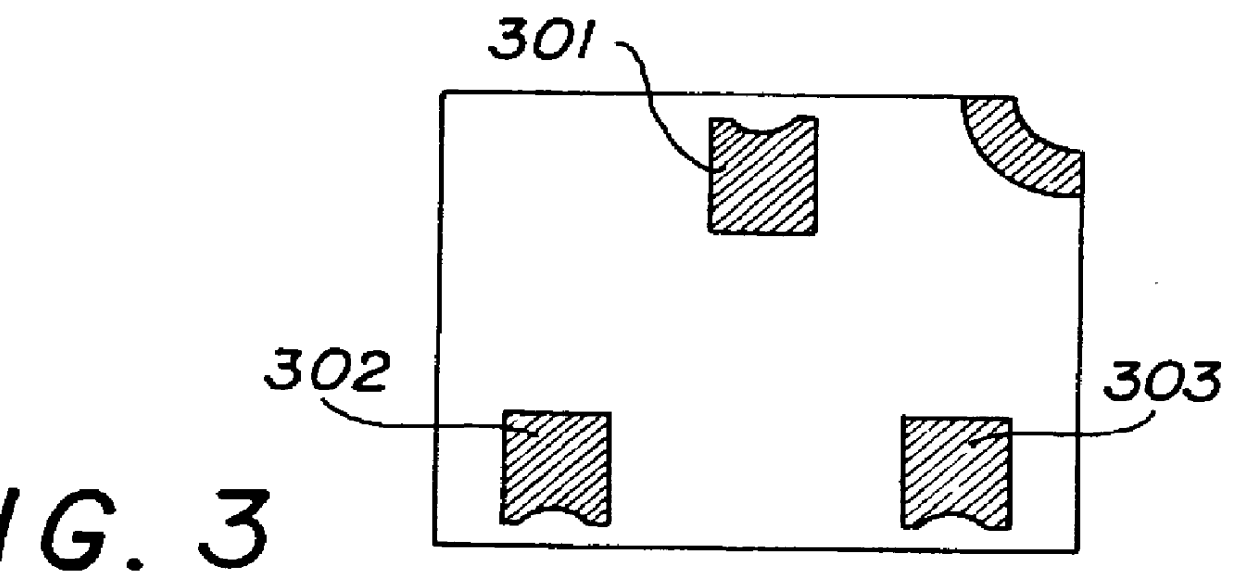

Method of batch testing surface mount devices using a substrate edge connector

InactiveUS6020745AReduce processingLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSurface mountingCeramic substrate

The present invention is used with single devices mounted on a ceramic substrate. The devices are broken out of the sheet, after all testing, electrical conditioning, and screening, as small surface mount devices. Conductive strips are formed on the ceramic substrate and are spaced to match a standard circuit board edge connector. These strips are electrically connected to the devices to allow testing and burn-in in sheet form rather than testing each device individually. The design reduces handling of the individual devices. The invention allows all of the testing and assembly to be done in a "batch" fashion. The board that is used to test the devices is separated to create the package for the individual components. The technique of the invention reduces cost and handling damage.

Owner:SEMICOA CORP

Ceramic part and production method thereof

PendingCN106977184AHigh densityImprove uniformityCeramic shaping apparatusInjection molding machineHigh heat

The invention relates to the technical field of powder metallurgy and particularly relates to a ceramic part and a production method thereof. The production method comprises (1) mixing granulation: putting ceramic powder into a mixer, heating the ceramic powder, adding a binder into the ceramic powder, carrying out mixing, and carrying out granulation through an extruder to obtain feed, (2) injection molding: placing the feed in an injection molding machine and carrying out injection molding to obtain an injected blank, (3) degreasing: placing the injected blank into an air furnace, carrying out hot degreasing, carrying out heating pre-sintering, carrying out furnace cooling and taking out a blank, and (4) sintering: putting the blank in a sintering furnace, carrying out sintering, and carrying out grinding and polishing to obtain a ceramic part. Through powder injection molding process and final degreasing and high temperature sintering, a fine ceramic part having a complex shape is obtained, the product has high compactness and good uniformity and is obtained by one step molding, the operation and control are simple, product quality is stable, production efficiency is high, a production cost is low and large-scale industrial production is realized.

Owner:深圳市星迪伟业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com