Patents

Literature

221results about How to "Realize automatic handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

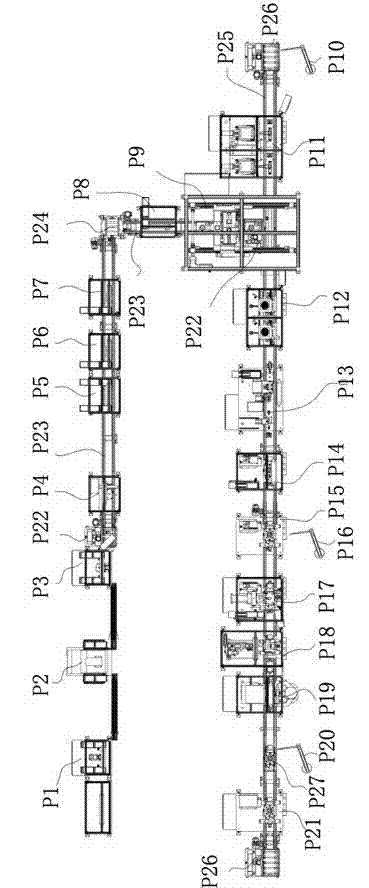

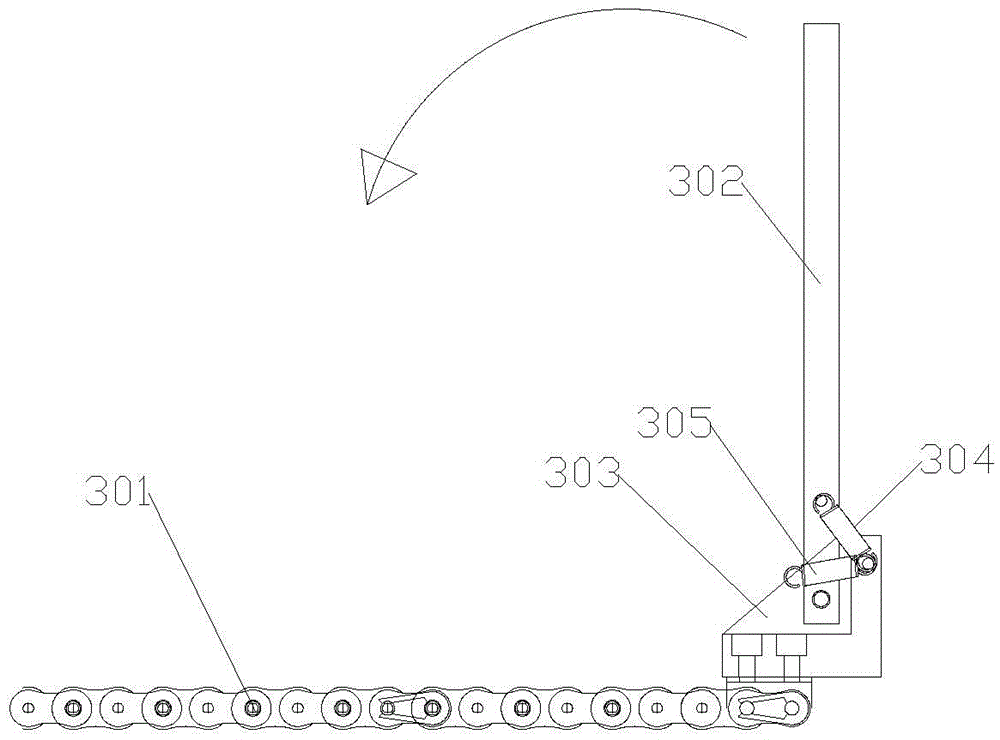

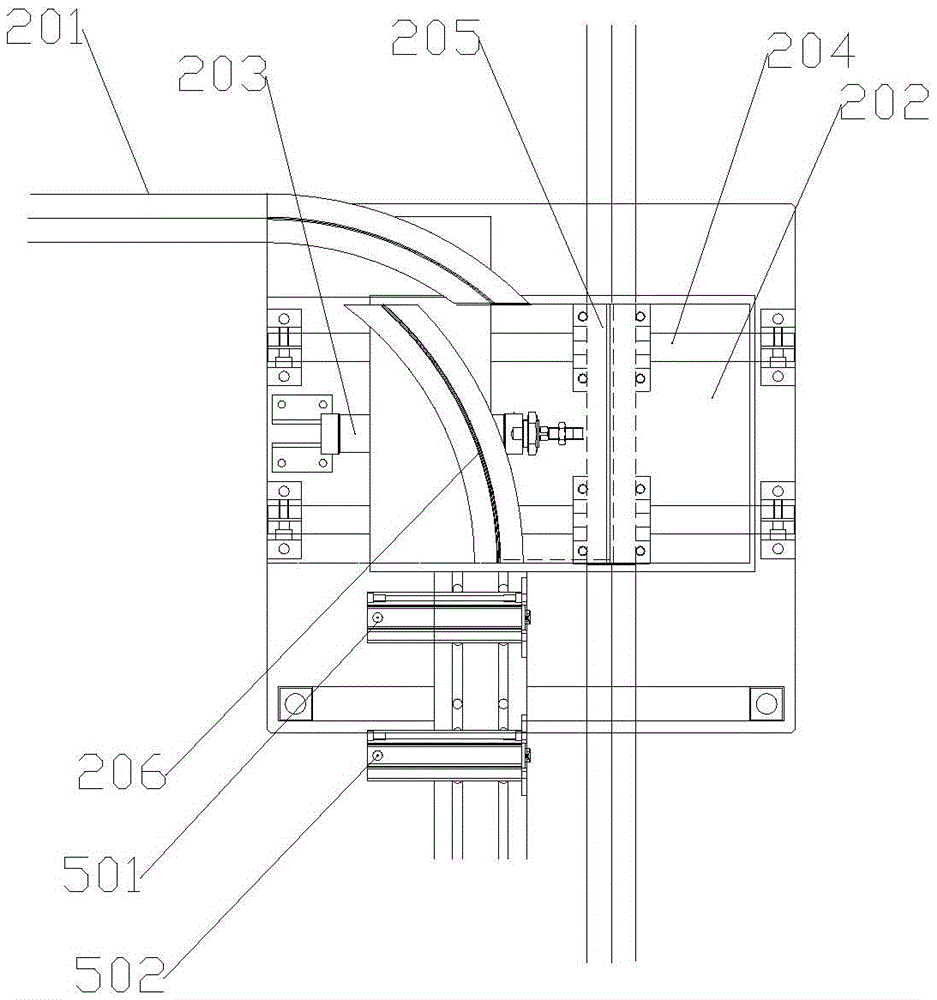

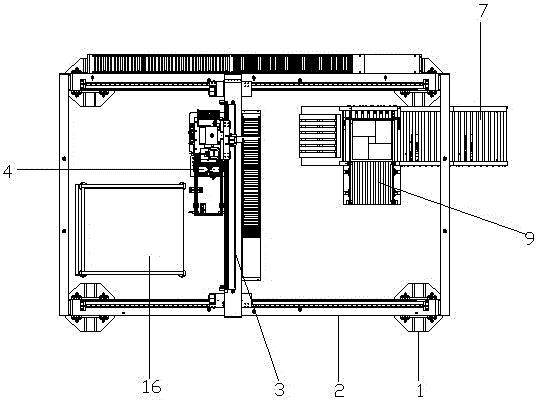

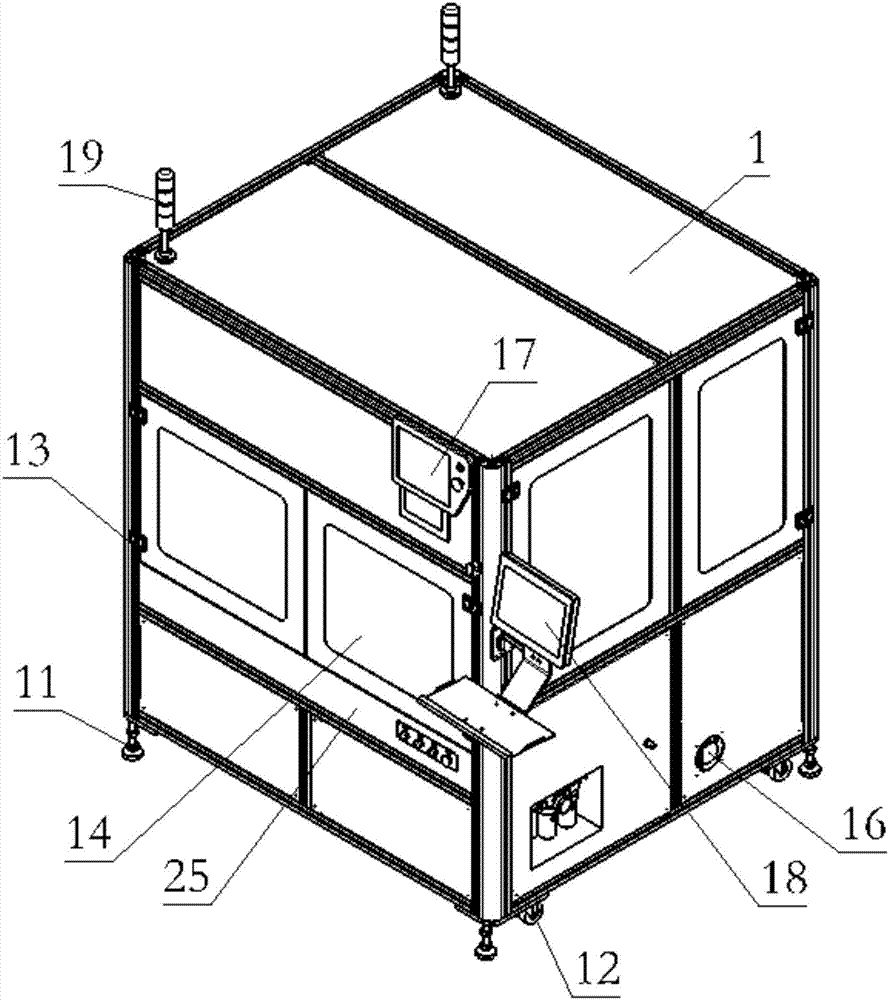

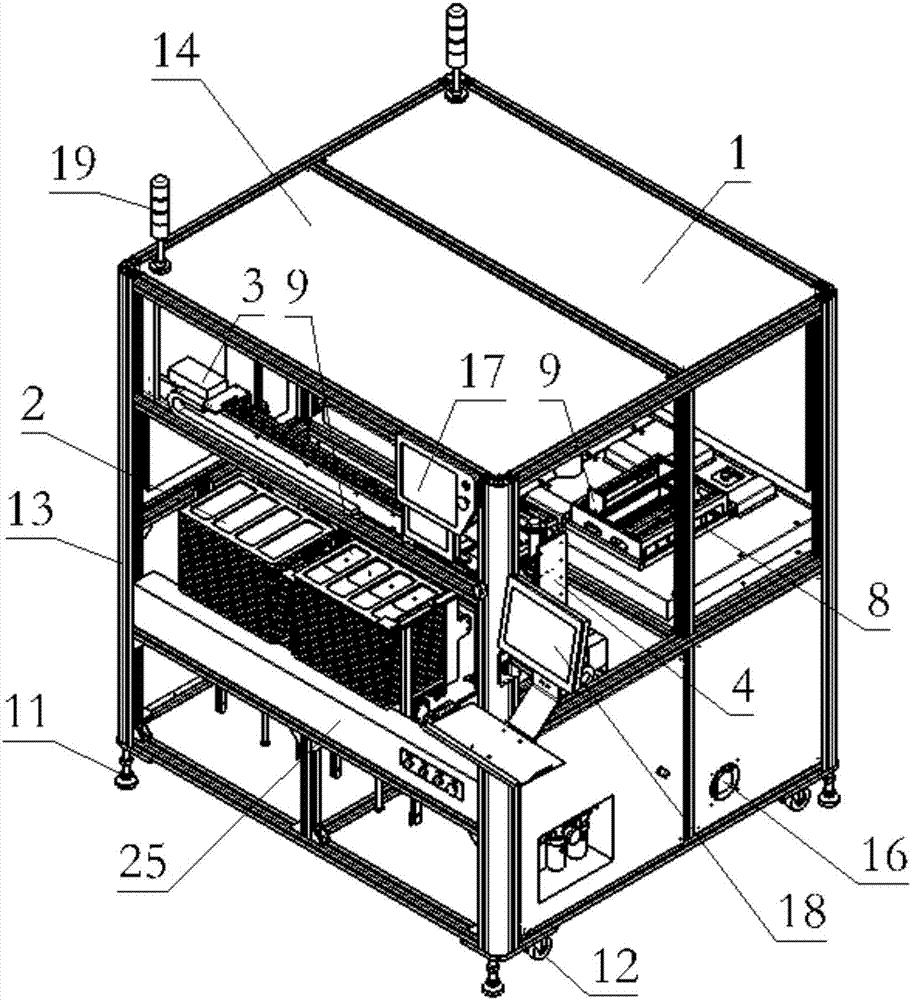

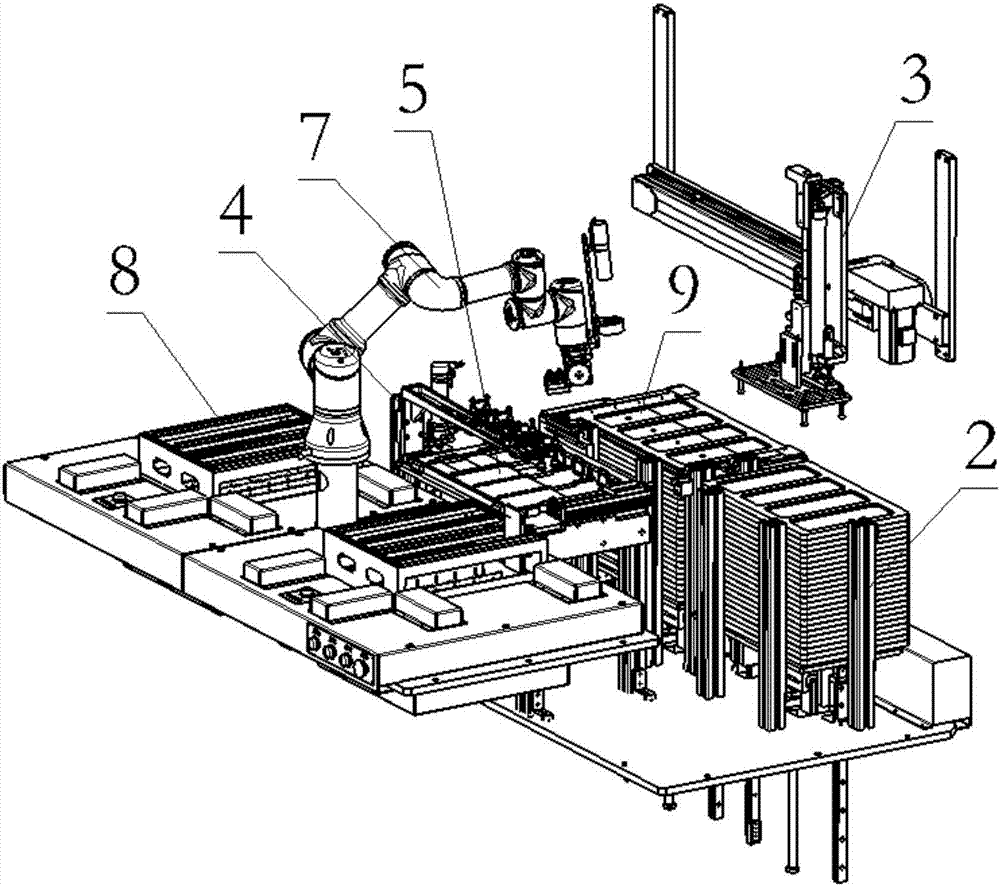

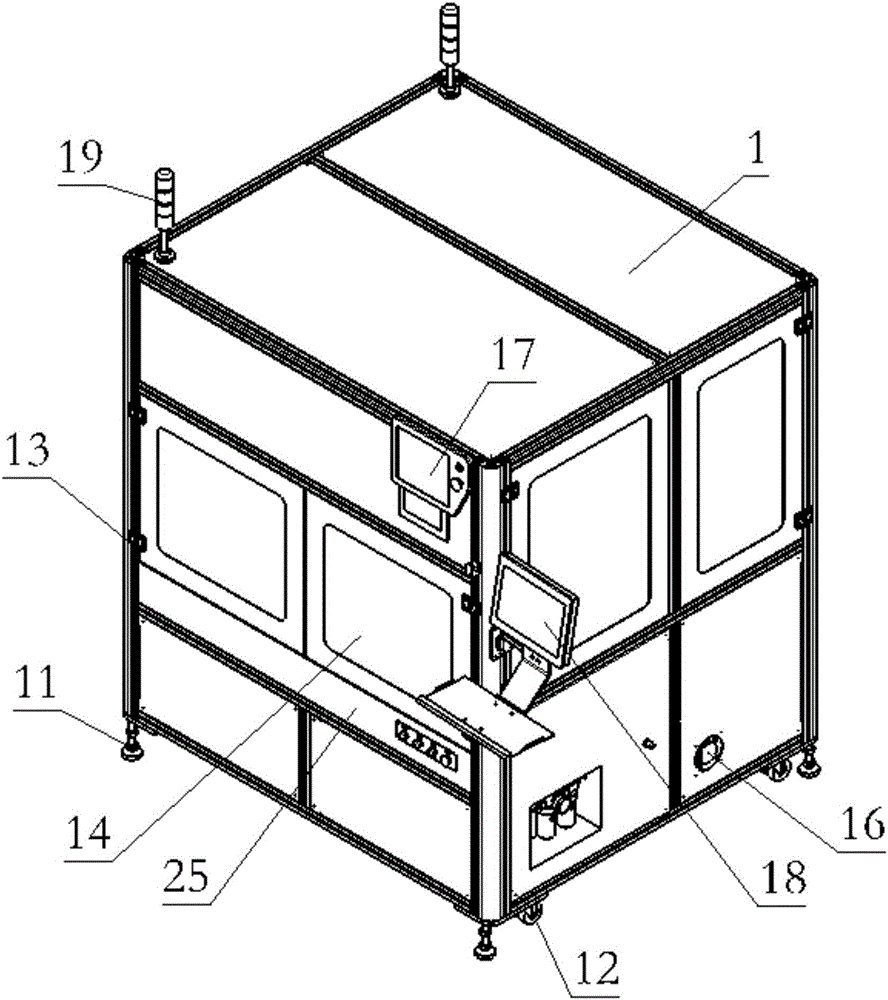

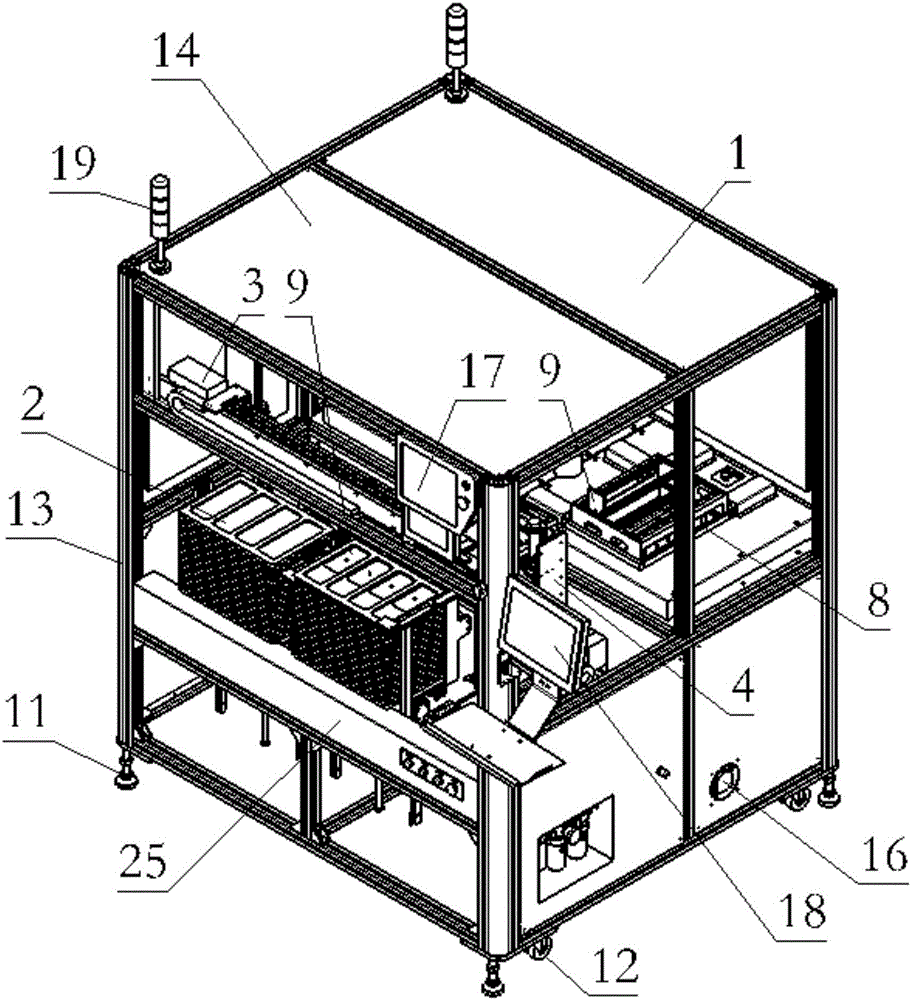

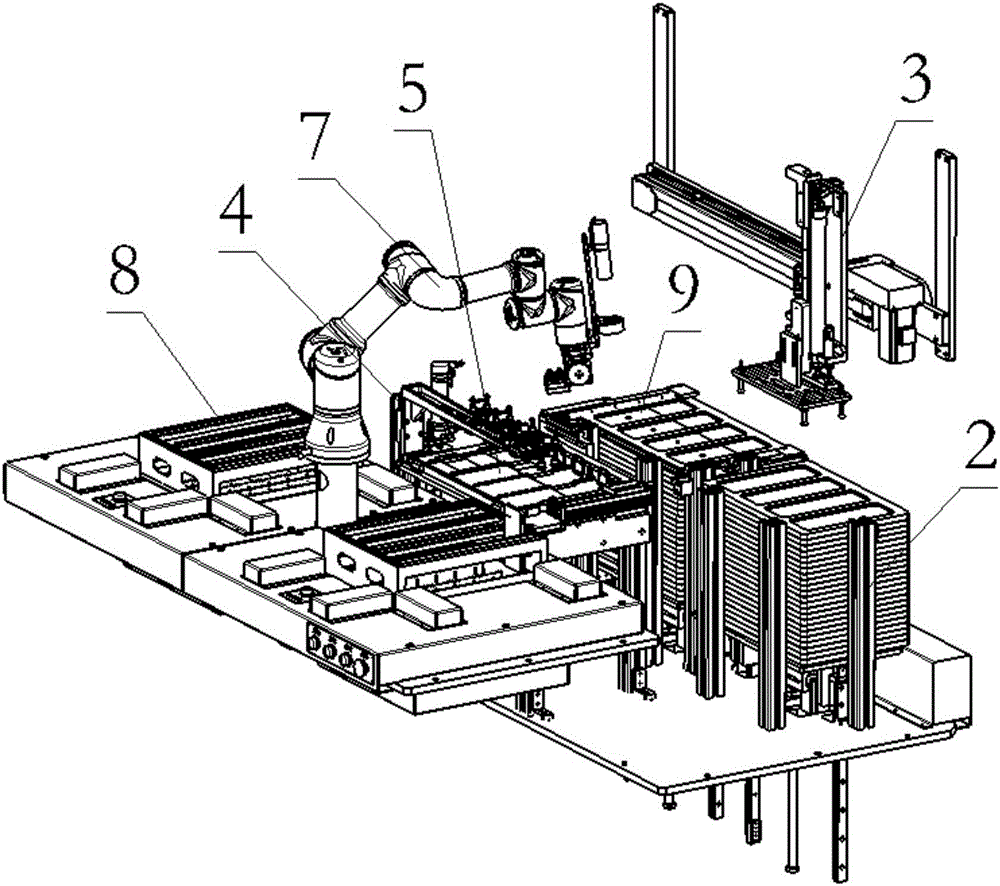

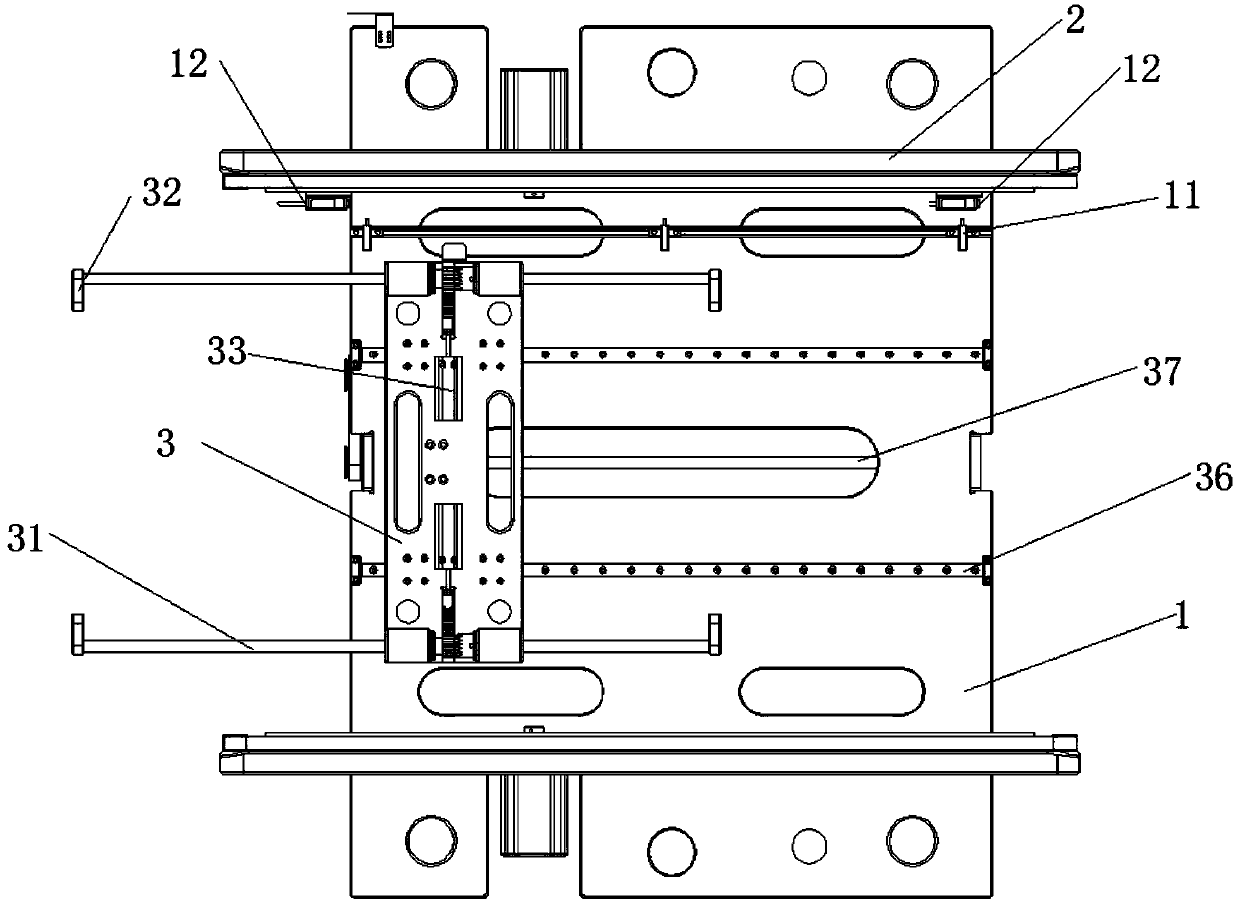

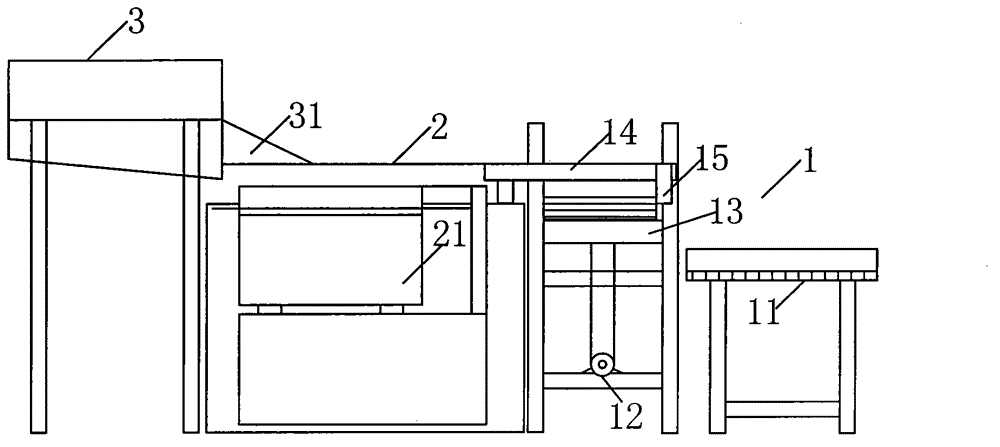

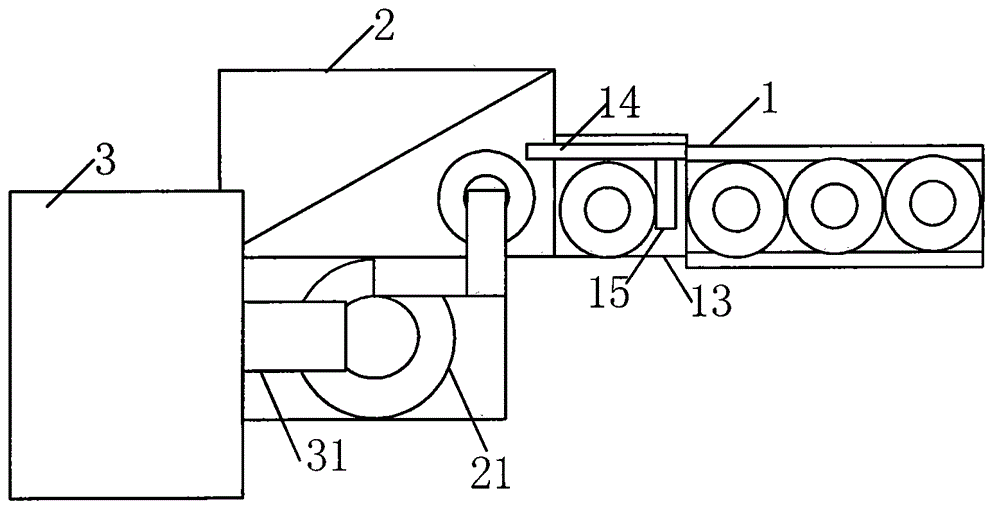

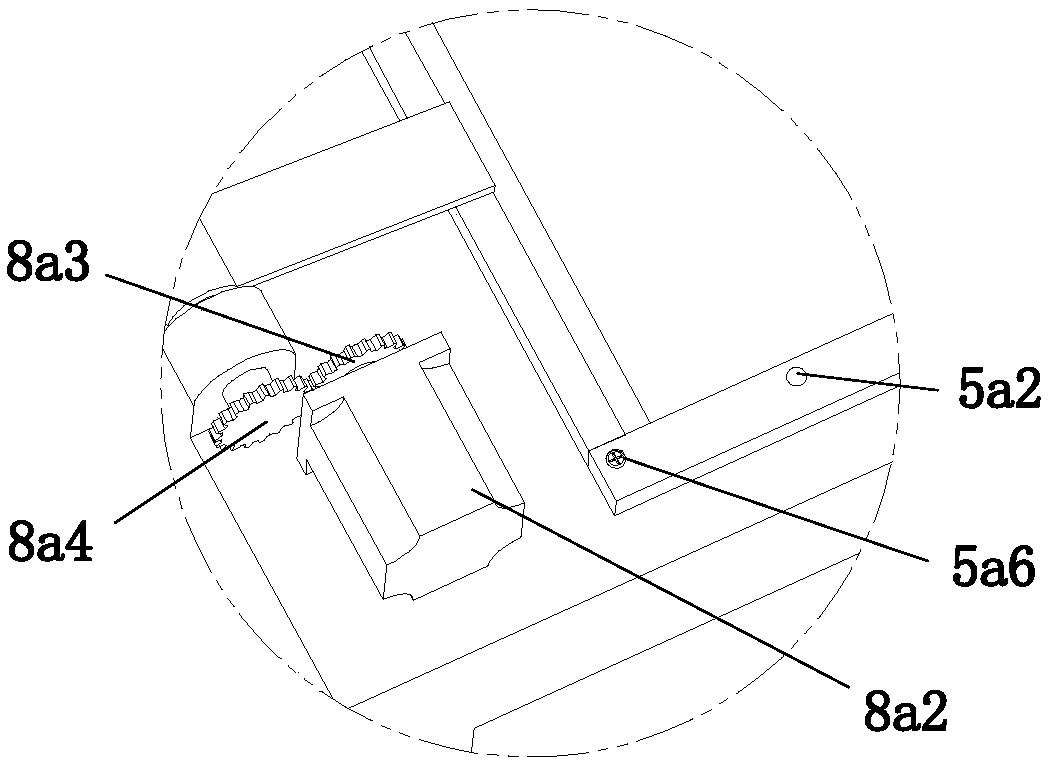

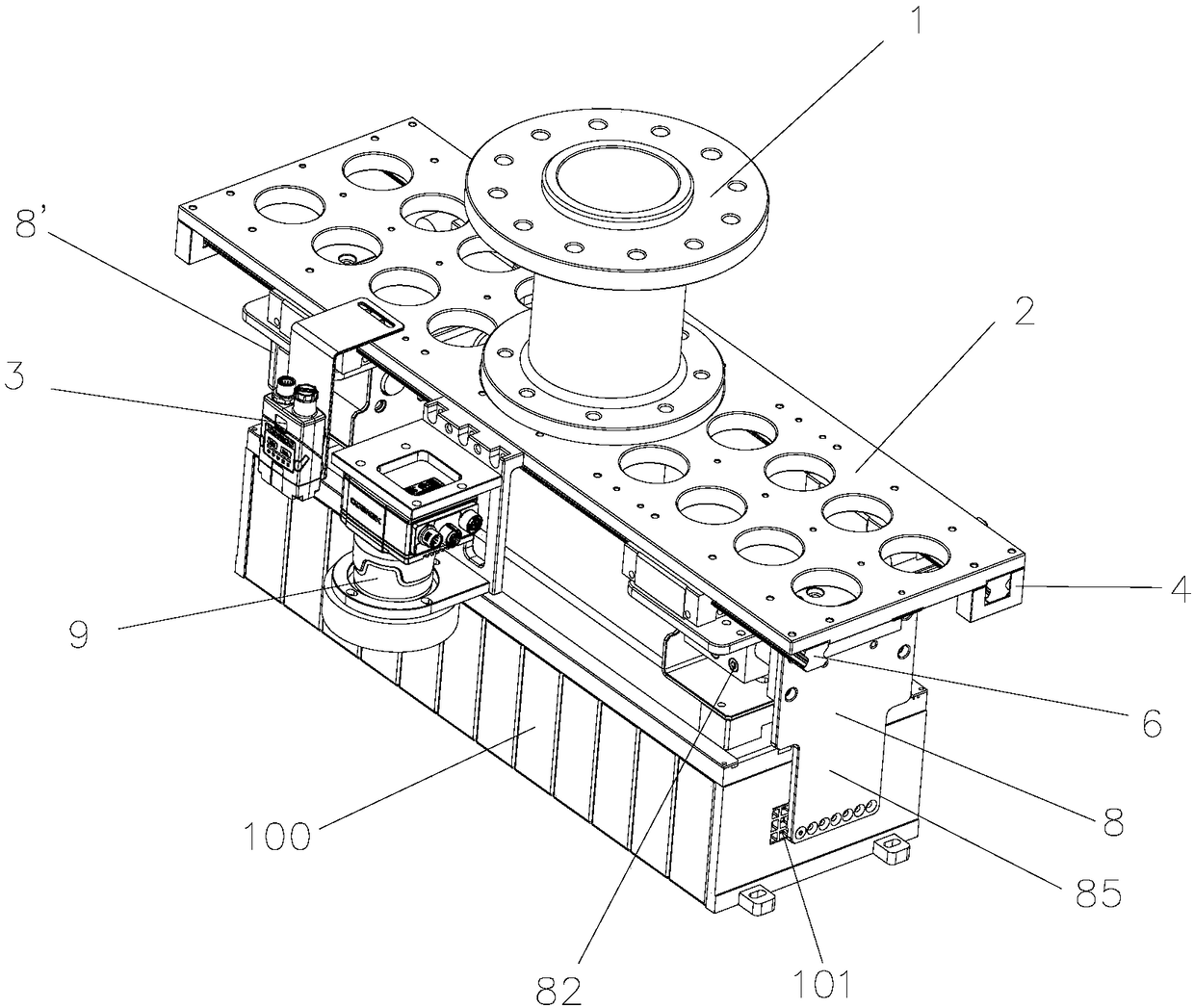

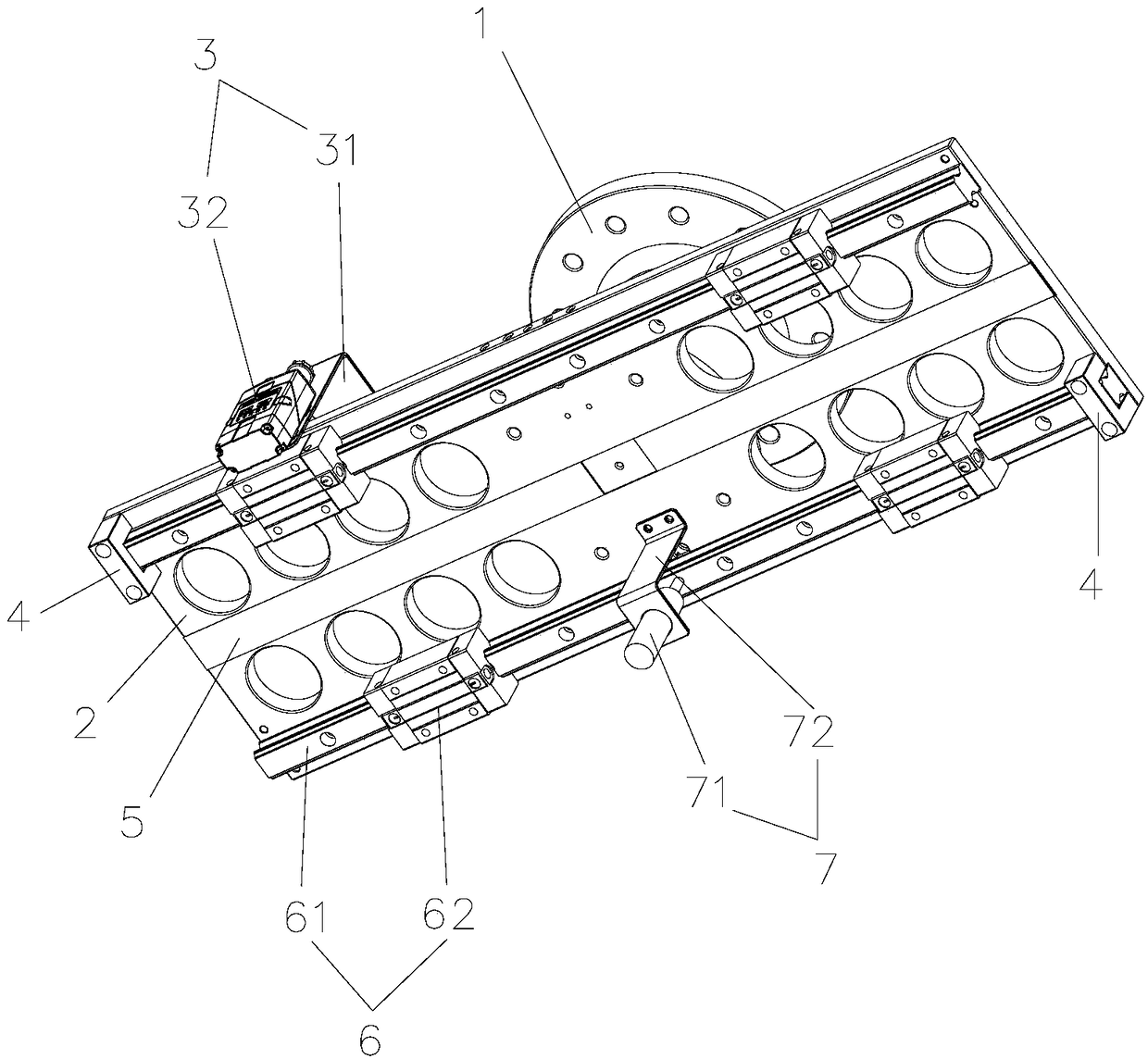

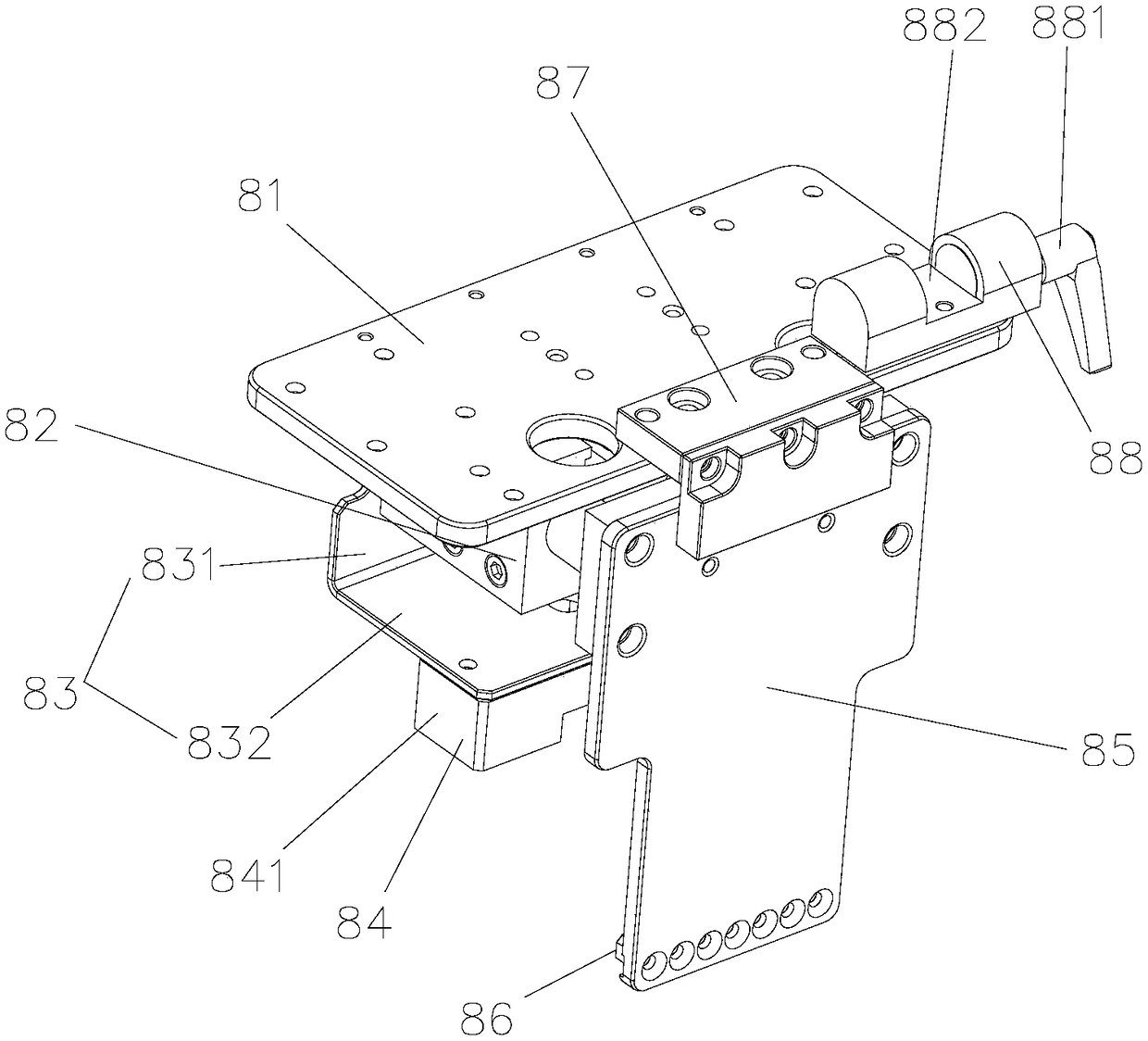

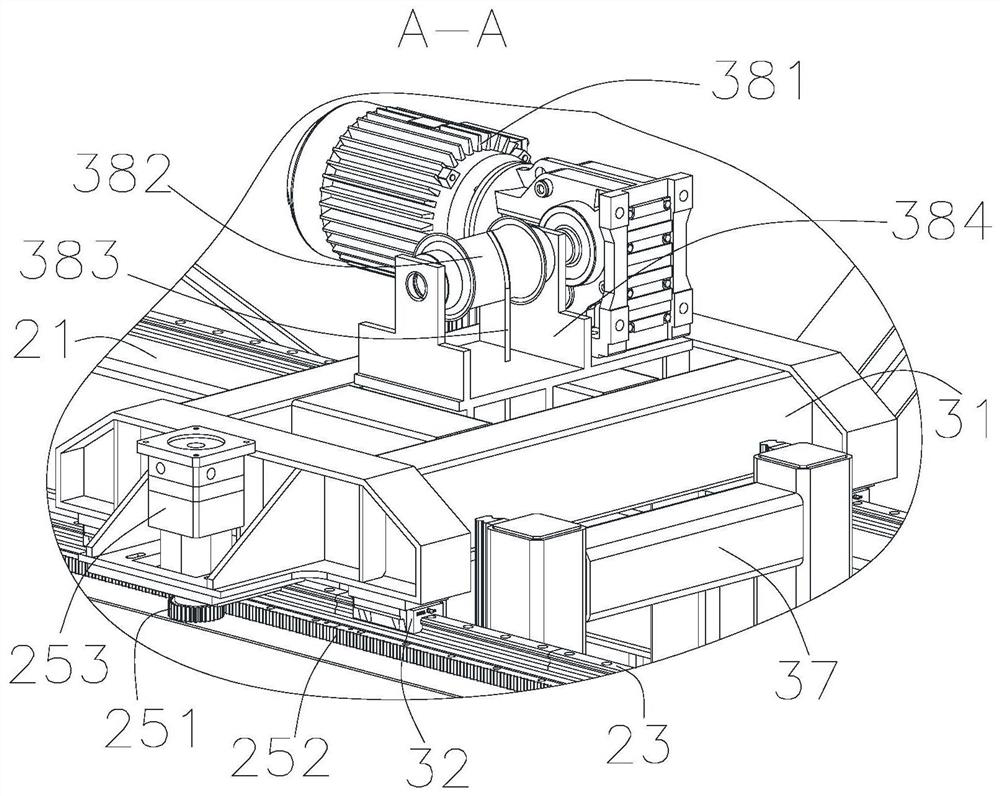

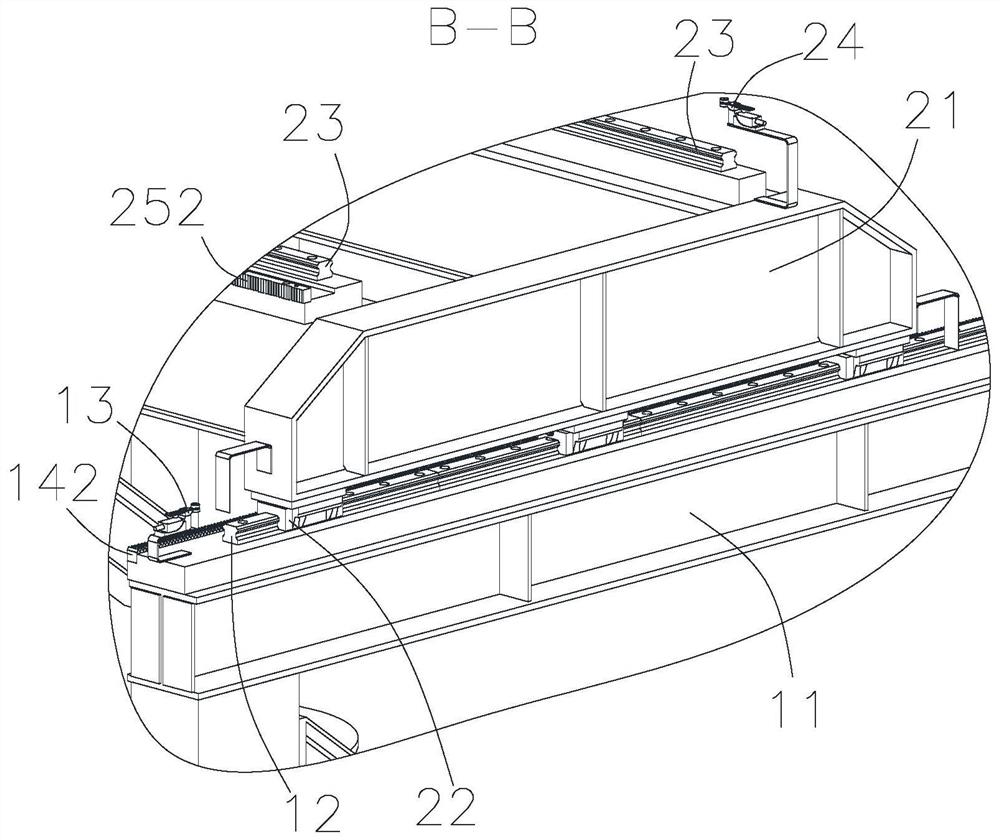

Intelligent assembly testing production line of hydraulic plunger pump

ActiveCN102922282ARealize automatic cycle transportationImprove work efficiencyAssembly machinesAssembly lineManufacturing line

The invention discloses an intelligent assembly testing production line of a hydraulic plunger pump. The intelligent assembly testing production line of the hydraulic plunger pump is characterized by comprising a branch line assembly line and a main line assembly line, wherein the branch line assembly line comprises a branch line conveyer line and assembly tables which are orderly arranged on the branch line conveyer line, and the main line assembly line comprises a main line conveyer line and assembly tables which are orderly arranged on the main line conveyer line. Compared with the prior art, the intelligent assembly testing production line of the hydraulic plunger pump has the following advantages and effects that the structure design is more reasonable; automatic transportation of a workpiece is achieved; automatic detection and automatic assembly are achieved; a computer is adopted to measure and control; the systematization and the datamation of the assembly lines are achieved; the data of an accepted product and an rejected product can be traced; the production efficiency is improved; the labor intensity is reduced; the labor cost is reduced; the production efficiency is improved, and assembly and production of 2-3 similar standardized products can be achieved.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

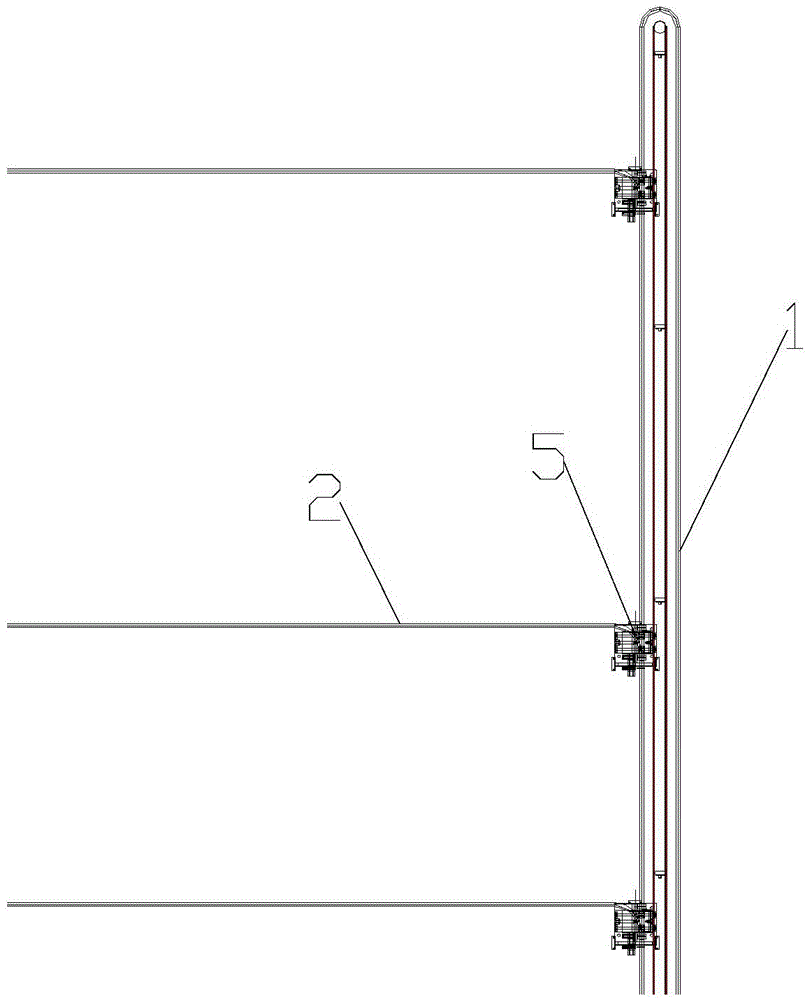

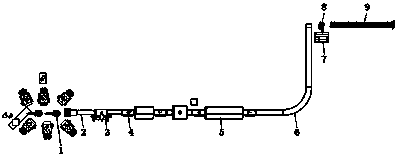

Intelligent suspension system and suspension distribution control method

ActiveCN105600294ARealize automatic handlingExact searchConveyorsControl devices for conveyorsDistribution controlEngineering

An intelligent suspension system comprises a main transportation circulating passage and a plurality of branch passages forked from the main transportation circulating passage, and a track changing mechanism is arranged at a fork position of the main transportation circulating passage and every branch passage. Different radio frequency identification cards are allocated to suspensions which are fed from a feeding end of the main transportation circulating passage and are distributed to different branch passages before feeding. When every suspension runs to the fork position of the corresponding branch passage, a card reading device reads radio frequency identification information to judge whether the suspension enters the branch passage or not, and if the suspension is allowed to enter the branch passage, the track changing mechanism is communicated with the branch passage and the suspension enters the suspension passage; if the suspension is not allowed to enter the branch passage, the track changing mechanism is communicated with the main transportation circulating passage and the suspension continues moving on the main transportation circulating passage circularly. If a specific branch alarms, directional distribution of the suspensions can be adjusted through terminal control, and if all the branches alarm, the main transportation circulating passage stops running.

Owner:青岛酷特智能股份有限公司

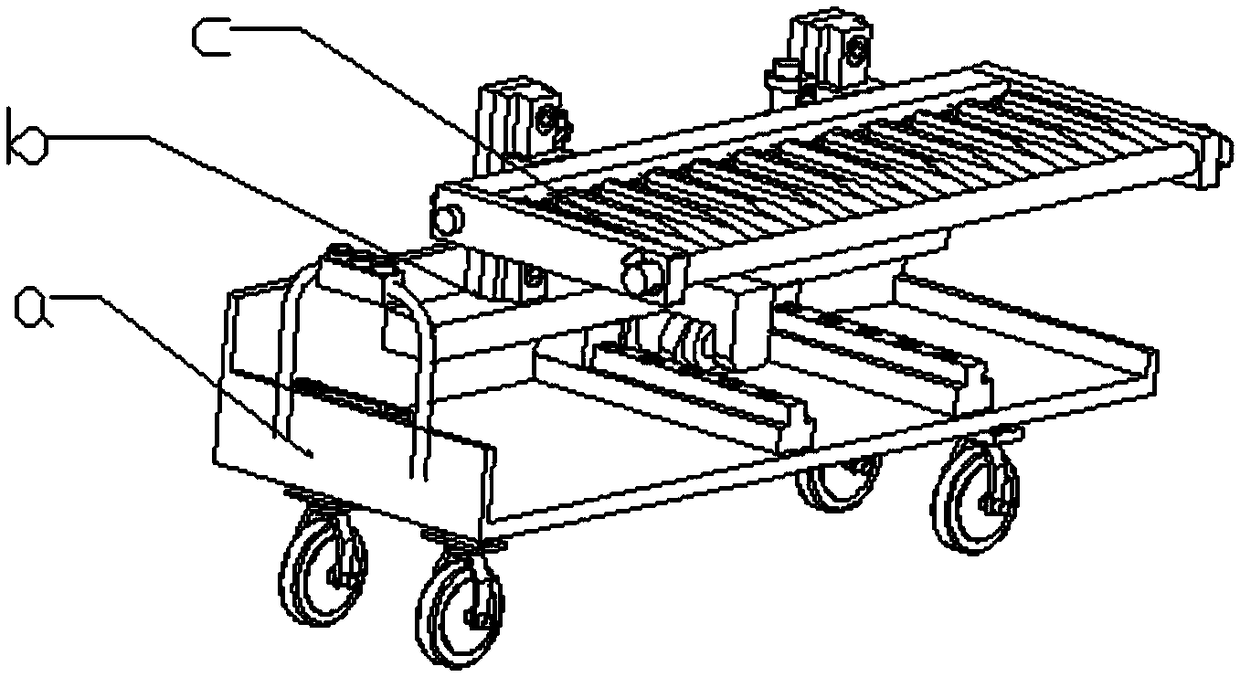

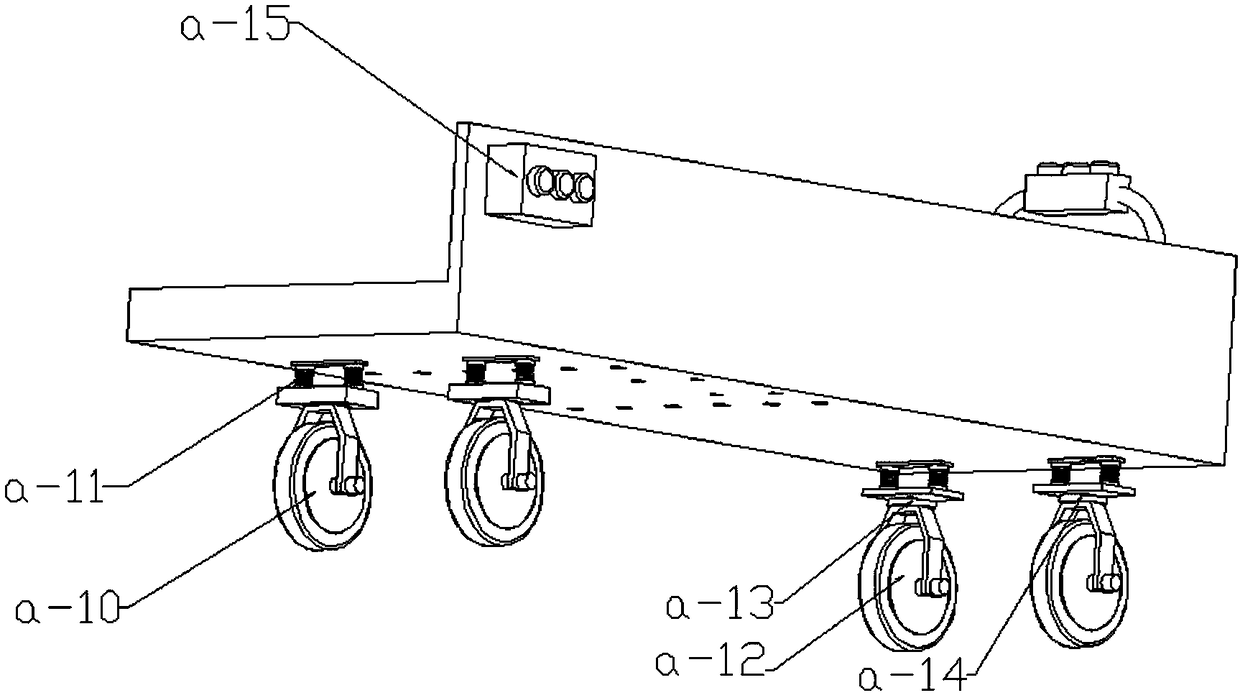

Movable adjustable transporting device

ActiveCN105947660ASimple structureEasy to operatePackagingConveyor partsEngineeringMechanical engineering

Owner:JIANGSU AEROSPACE POWER ELECTRIC

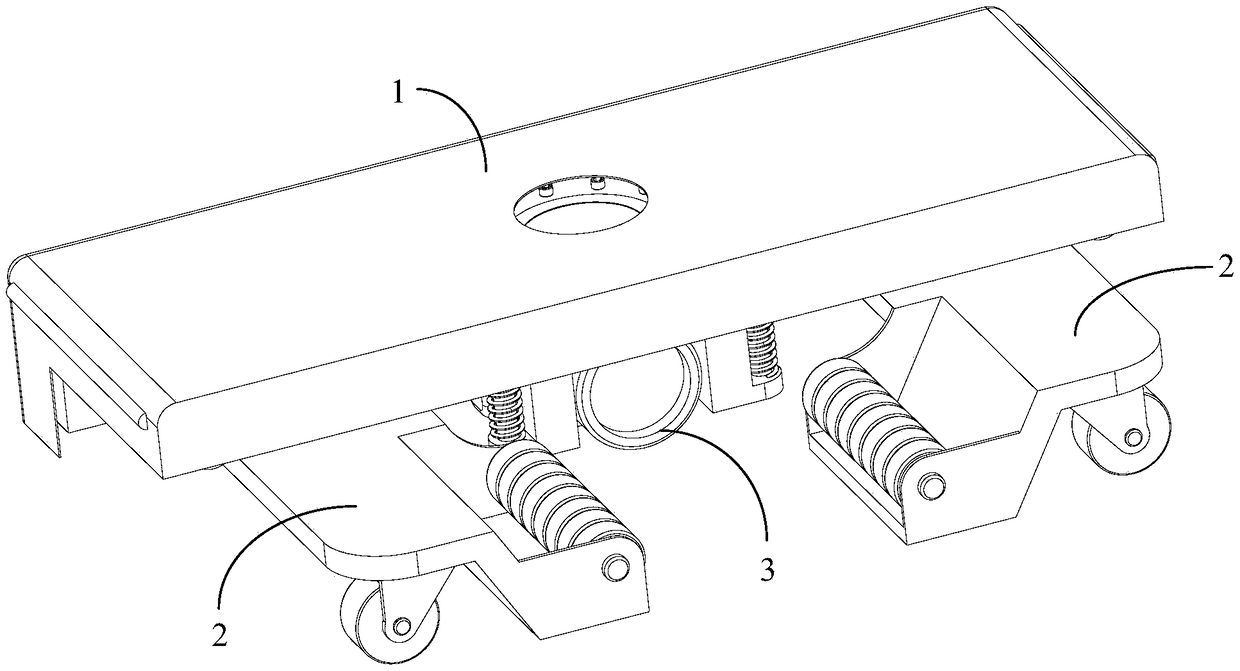

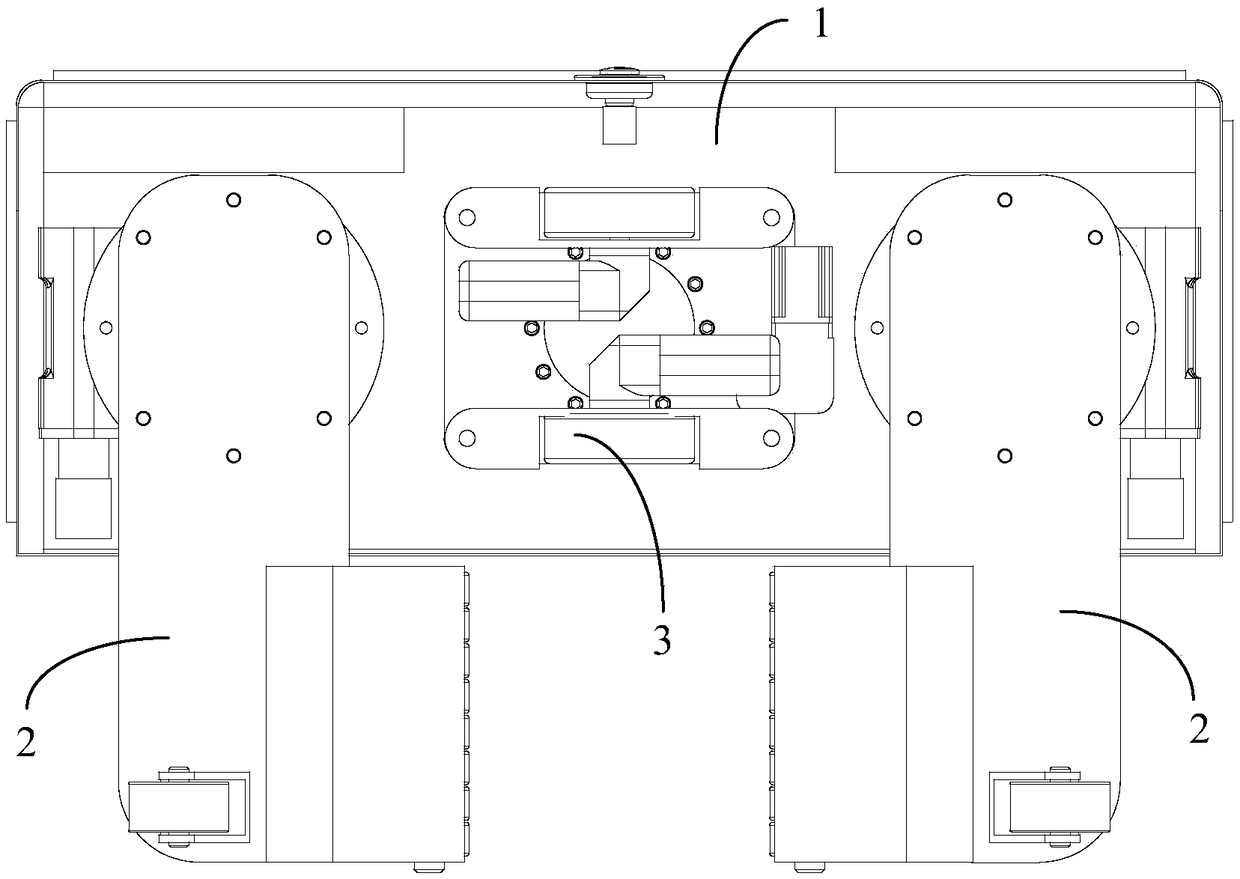

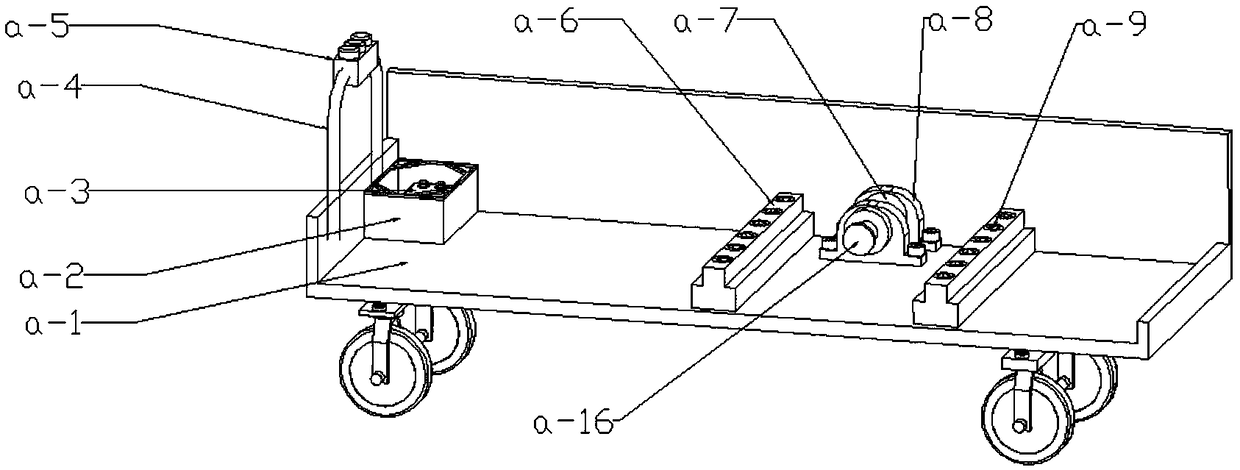

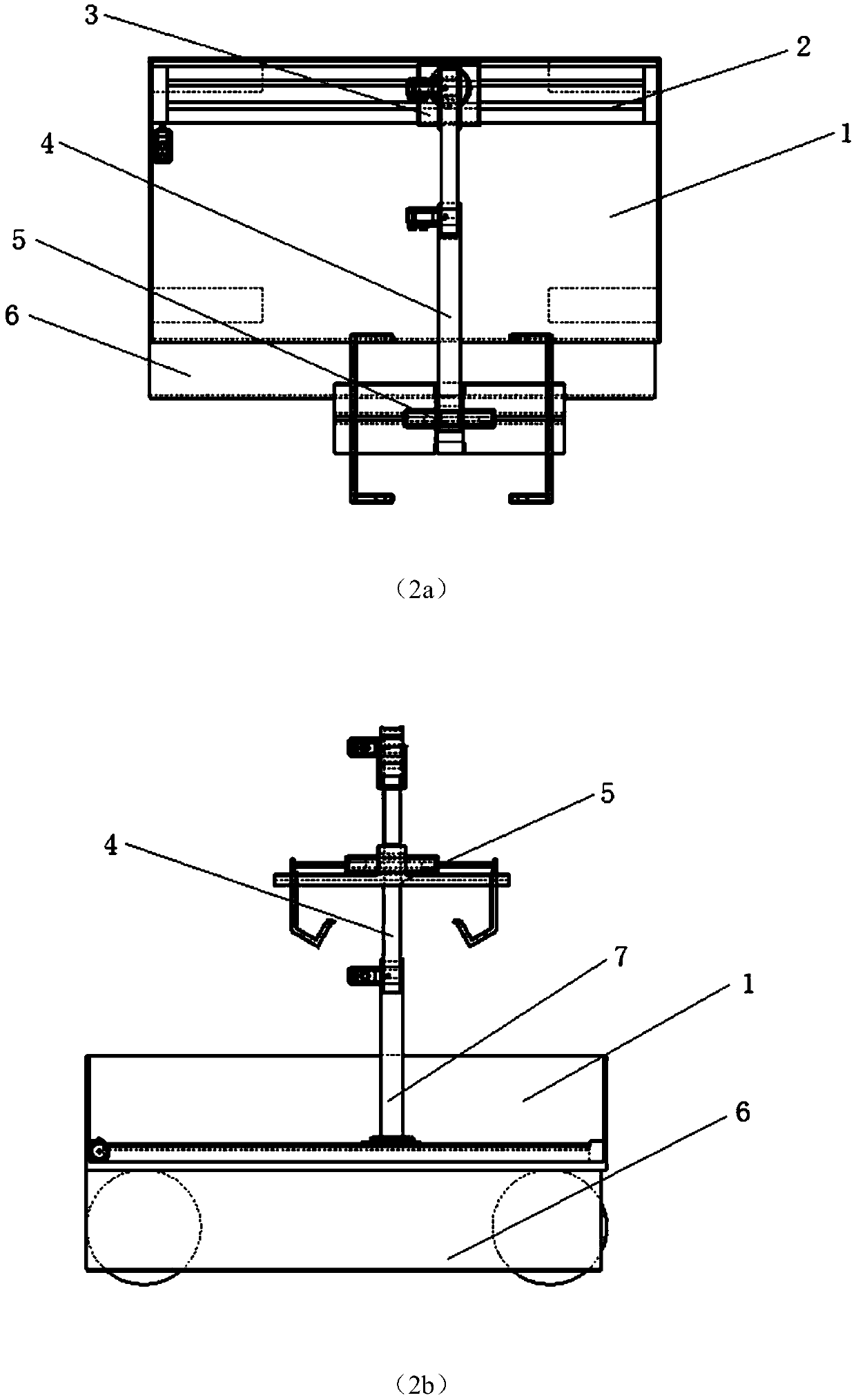

Intelligent carrying vehicle system adopting screw rod for jacking

ActiveCN105712249ARealize automatic handlingAvoid collisionLifting framesAutomotive engineeringEngineering

The invention provides an intelligent carrying vehicle system adopting a screw rod for jacking. The intelligent carrying vehicle system comprises a vehicle body, a first driving mechanism for driving the vehicle body and changing the moving direction of the vehicle body, an auxiliary supporting mechanism for providing auxiliary support for the vehicle body, a guide mechanism for identifying the forwarding path of the vehicle body and a position of an object to be carried, a screw rod transmission mechanism arranged on the vehicle body, a second driving mechanism for driving the screw rod transmission mechanism to rotate, and a tray which is fixed on the screw rod transmission mechanism and can move up and down along with the rotation of the screw rod transmission mechanism, wherein the tray does not rotate relative to the ground in the moving process. According to the intelligent carrying vehicle system adopting the screw rod for jacking, when the vehicle body steers, the tray does not rotate relative o the ground, so that the stability of the object to be carried during steering of the vehicle body is guaranteed, and collision of the object to be carried during rotation is avoided; and therefore, warehoused objects can be automatically carried, and the collision caused by rotation of the carried object can be avoided during steering.

Owner:BEIJING JIZHIJIA TECH CO LTD

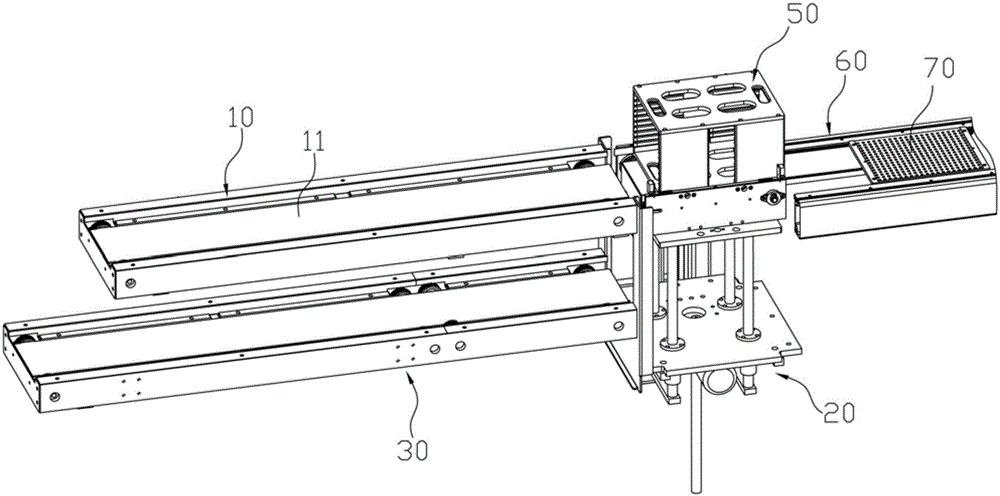

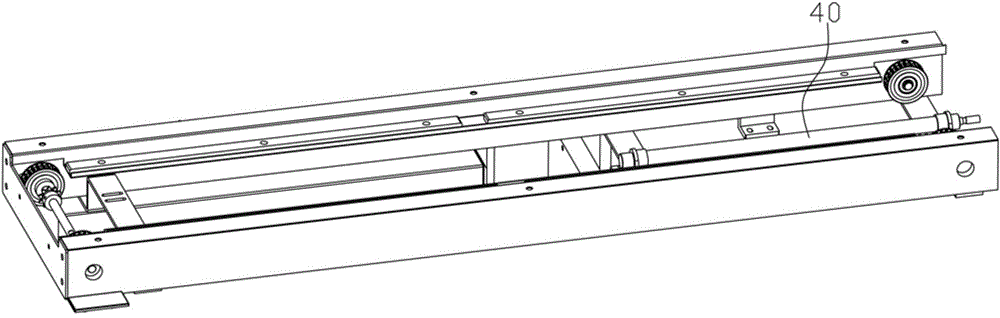

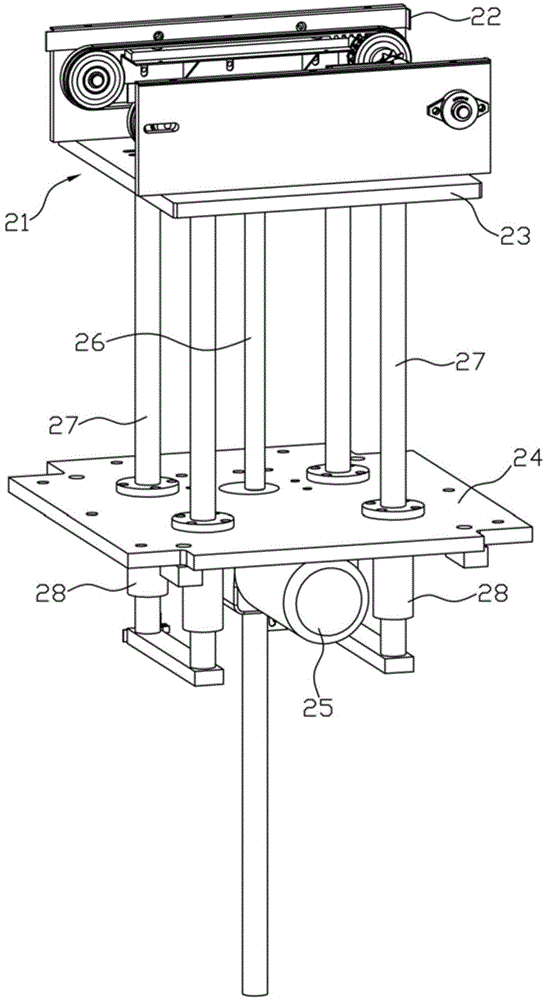

Mechanism for transporting electronic device support plates and recovering support plate baskets

InactiveCN104816926ARealize automatic handlingImprove production and processing efficiencyDe-stacking articlesMechanical conveyorsProduction lineEngineering

The invention discloses a mechanism for transporting electronic device support plates and recovering support plate baskets. The mechanism comprises a basket transporting rail, a lifting device and a basket recovering rail, wherein a cylinder is mounted on the basket transporting rail; the basket transporting rail is positioned above the basket recovering rail; the lifting device is positioned at one end side of the basket conveying rail leveled with the basket recovering rail; the lifting device comprises a transporting rail mounted at the top; and separation strips are vertically arranged on the inner side surface of a basket side plate. Support plates layered in baskets are operated to the transporting rail on the lifting device through the basket transporting rail; the lifting device is descended by a certain height; the cylinder pushes the support plates onto the transporting rail of a production line one by one; and then, the lifting device enables the transporting rail thereon to be joined with the basket recovering rail to recover empty baskets. The mechanism realizes automatic transportation of the support plates to the production line and automatic recovery of the empty baskets after the transportation, so that the production efficiency is improved.

Owner:KUNSHAN DEYOU MACHINERY EQUIP

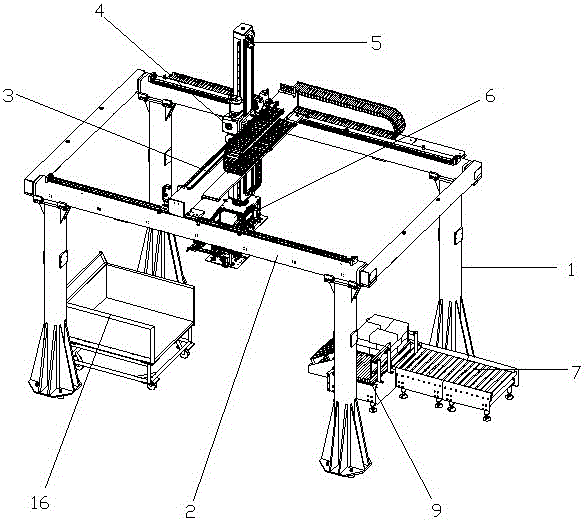

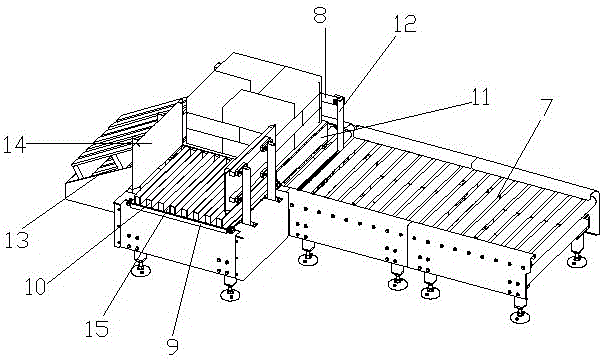

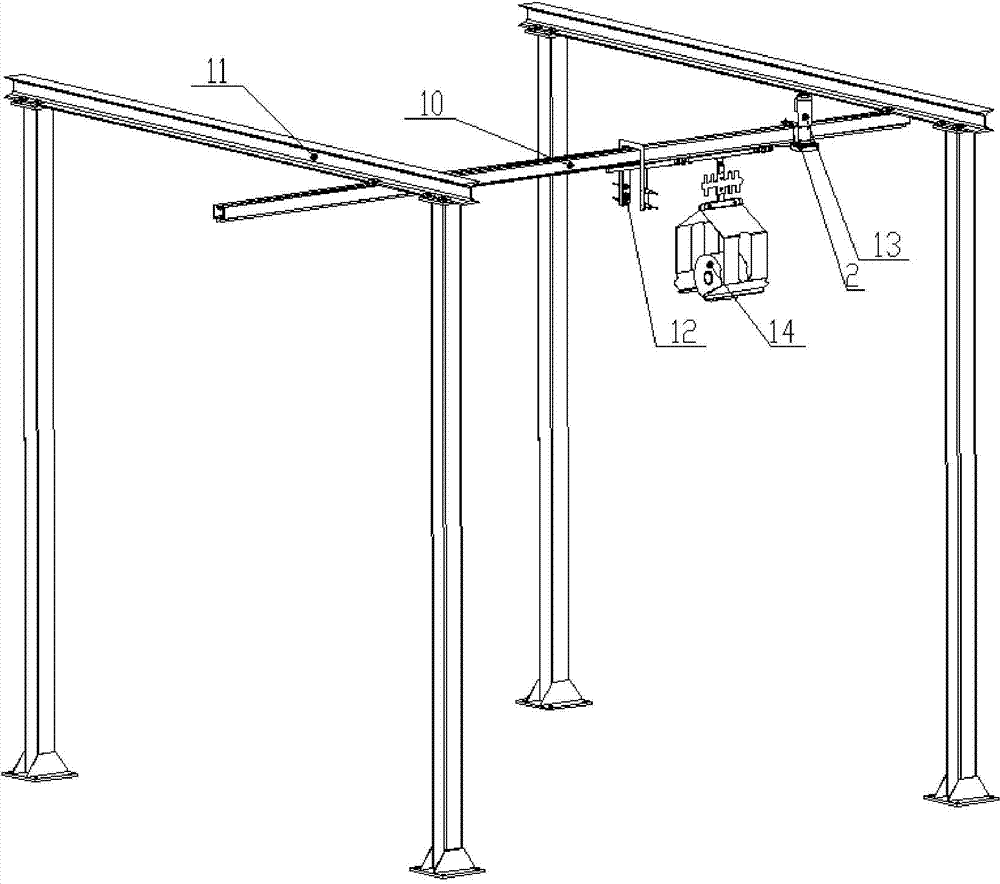

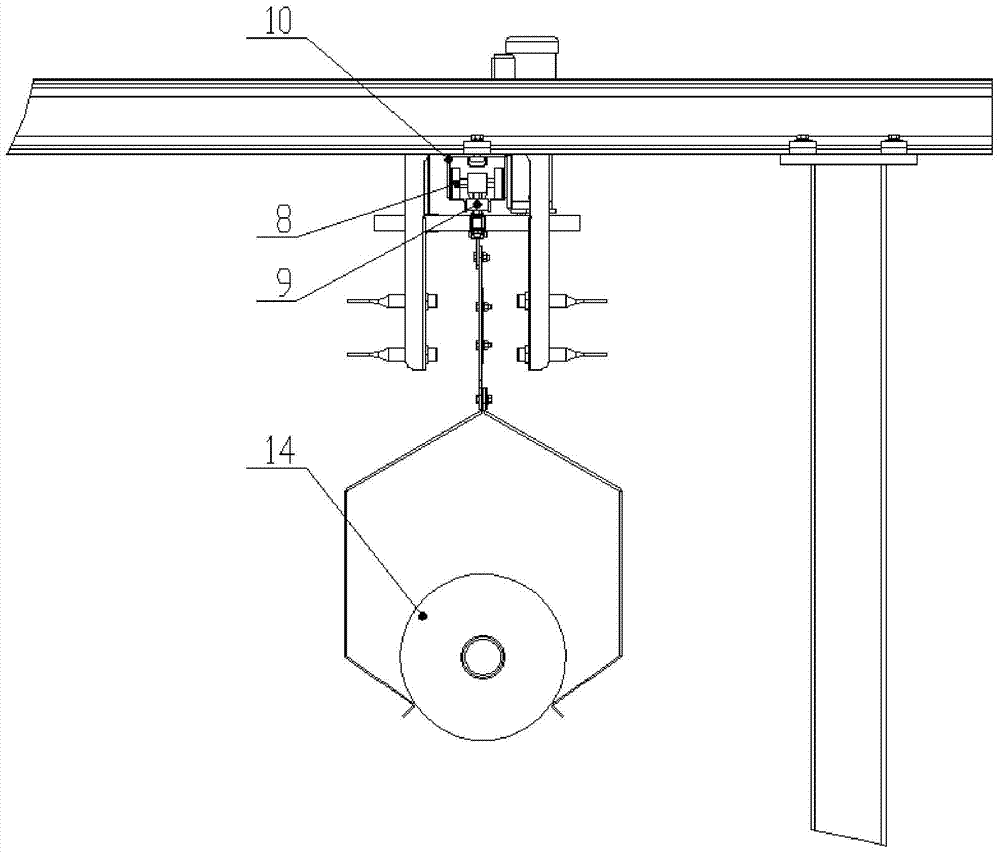

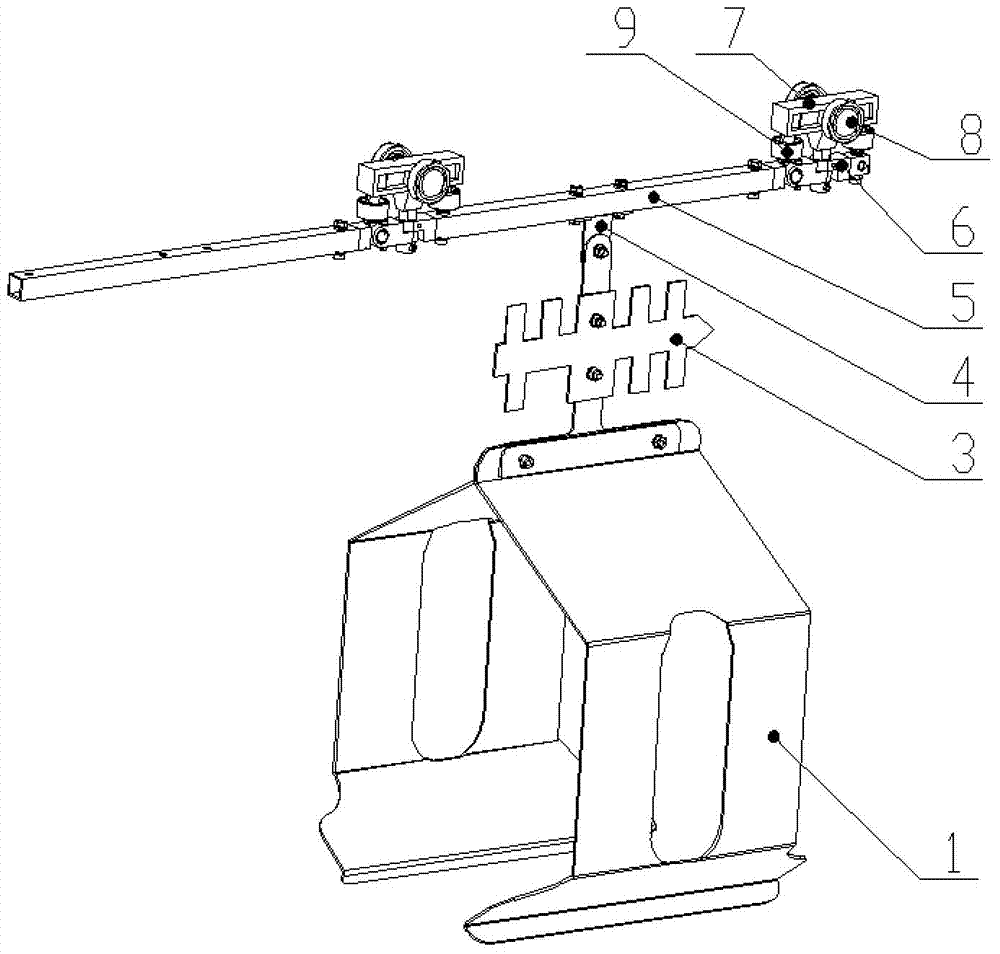

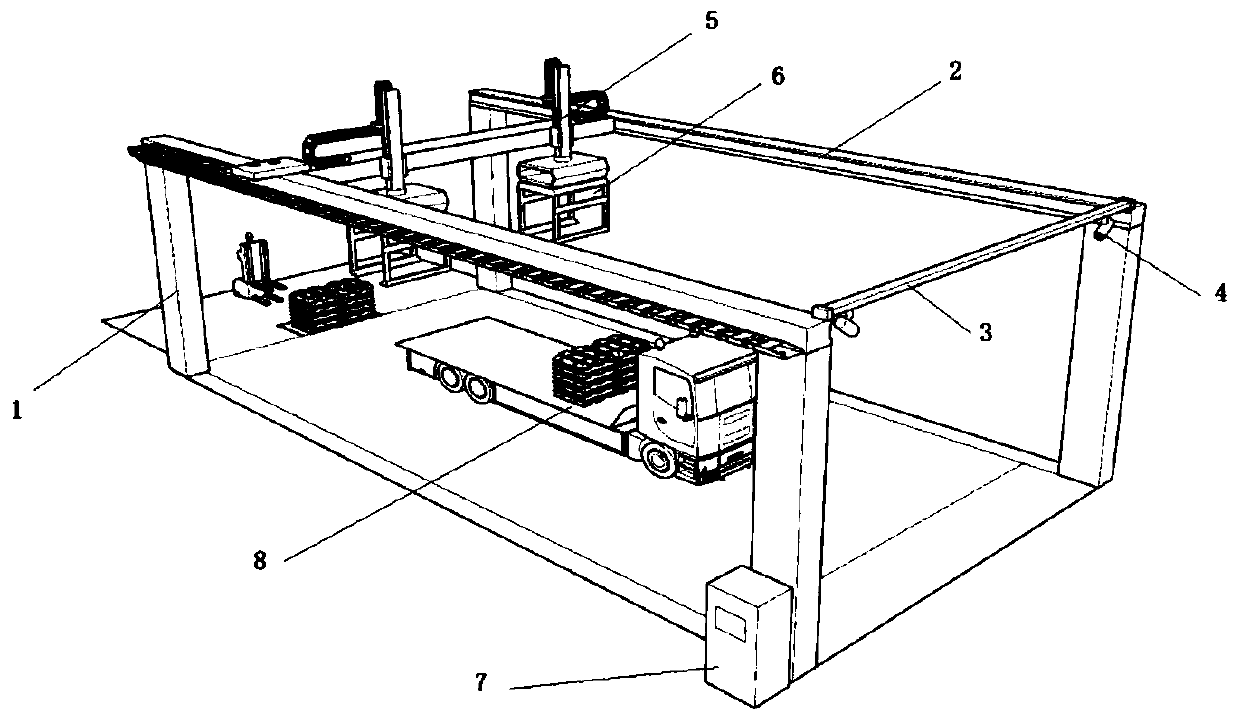

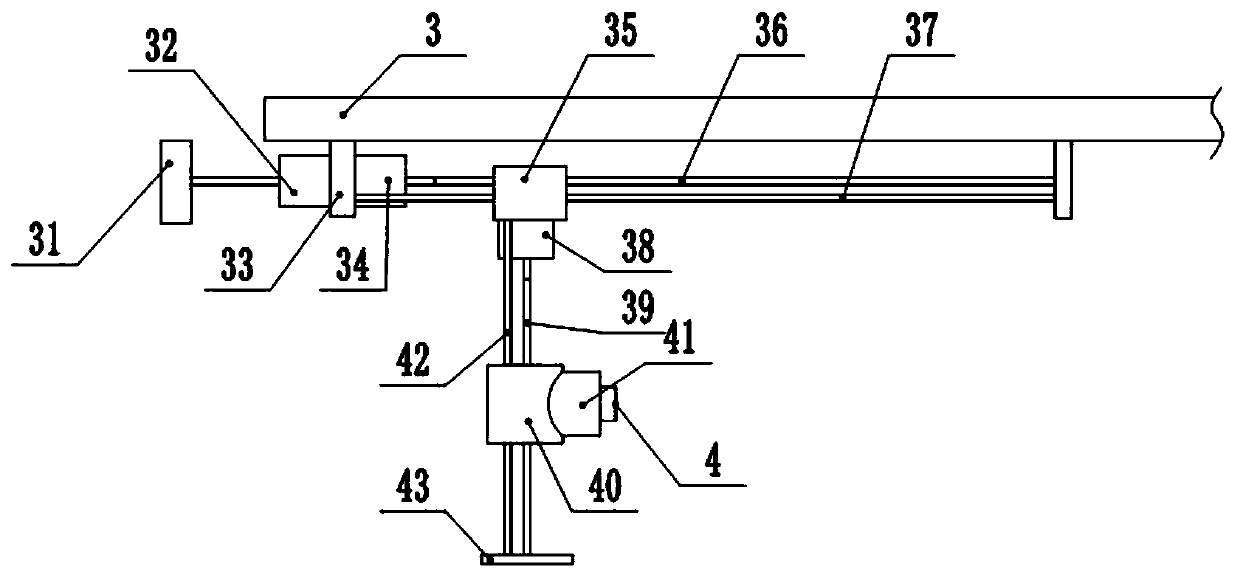

Synchronous and automatic loading system for whole stack of boxes and using method of synchronous and automatic loading system

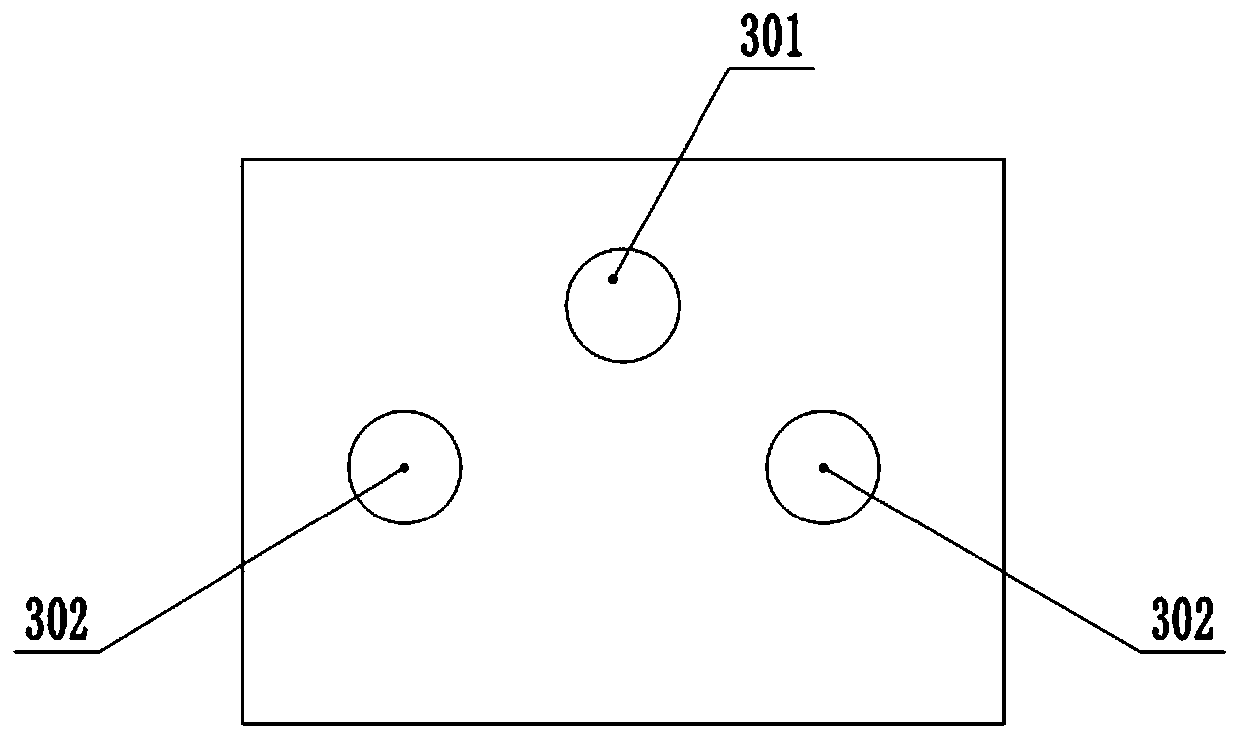

ActiveCN106629138ARealize automatic handlingReduce manual labor intensityConveyorsLoading/unloadingEngineeringMechanical engineering

The invention relates to the technical field of box carrying, and discloses a synchronous and automatic loading system for a whole stack of boxes. The synchronous and automatic loading system comprises a plurality of stand columns fixed to the ground, transverse beams are arranged between the upper ends of the stand columns, a longitudinal beam is arranged between the two transverse beams and is provided with a sliding base capable of sliding along the longitudinal beam, a lifting base is arranged on the sliding base, and a grabbing device is arranged at the lower end of the lifting base; a conveying belt is arranged at the position, at one ends of the transverse beams, of the ground, a push plate is arranged on one side of the tail end of the conveying belt, and a box positioning platform is arranged on the other side of the tail end of the conveying belt; and a plurality of parallel supporting strips are arranged on the top face of the box positioning platform, the top faces of the supporting strips are higher than the top face of the conveying belt and are lower than the top faces of trays on the conveying belt, a plurality of avoiding grooves are formed between the supporting strips, and insertion rods capable of extending into the avoiding grooves in a one-to-one correspondence manner are arranged at the lower end of the grabbing device. By means of the synchronous and automatic loading system, automatic carrying and automatic unloading of the whole stack of boxes can be achieved, the hand labor intensity is greatly reduced, and the carrying efficiency is improved.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

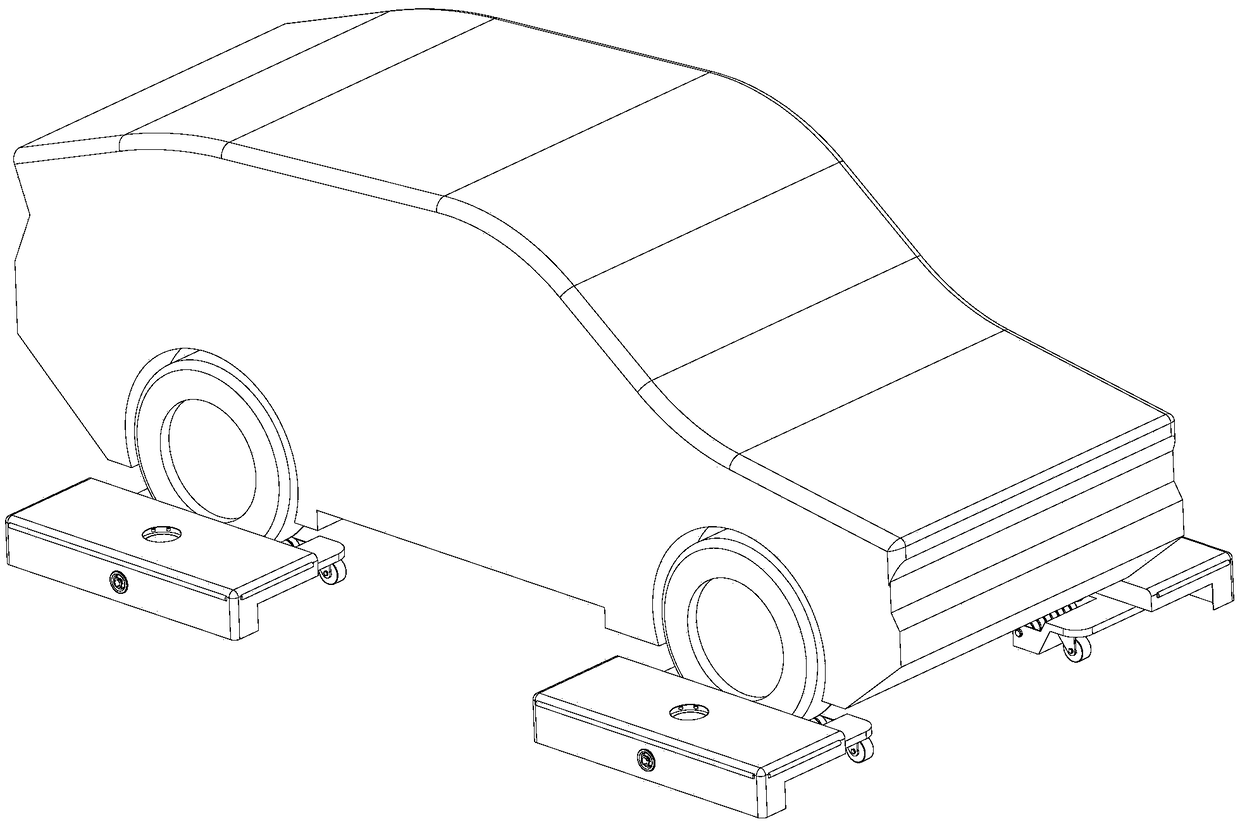

Intelligent parking lot and cluster carrying robot

PendingCN109339535ARealize automatic handlingReduce construction costsVehicle manoeuvring devicesItem transportation vehiclesEngineeringMechanical engineering

The invention discloses a cluster carrying robot, which comprises a body, two clamp arms and a first driving mechanism, wherein the two clamp arms are arranged at the bottom of the body; the first driving mechanism comprises a main moving wheel used for driving the carrying robot to walk; each clamp arm comprises a second driving mechanism and a rotating foot assembly connected with the second driving mechanism; the rotating foot assembly comprises rotating arms and support wheels; the rotating arms are rotationally connected with the body; the support wheels are arranged on the rotating armsand are used for supporting the carrying robot; each rotating arm is provided with a clamping part used for clamping a wheel; the clamping parts of the two rotating arms are in opposite arrangement; and the two clamping parts approach to each other so as to form a space for clamping the wheel. The cluster carrying robot has the advantage that the building cost of an intelligent parking lot can beeffectively reduced. In addition, the invention also discloses the intelligent parking lot.

Owner:GUANGZHOU DABO INTELLIGENT TECH CO LTD

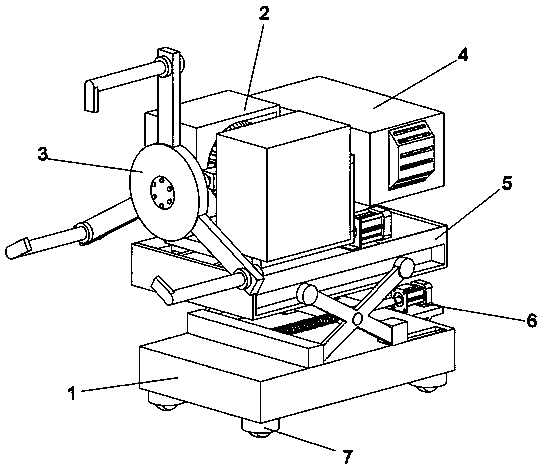

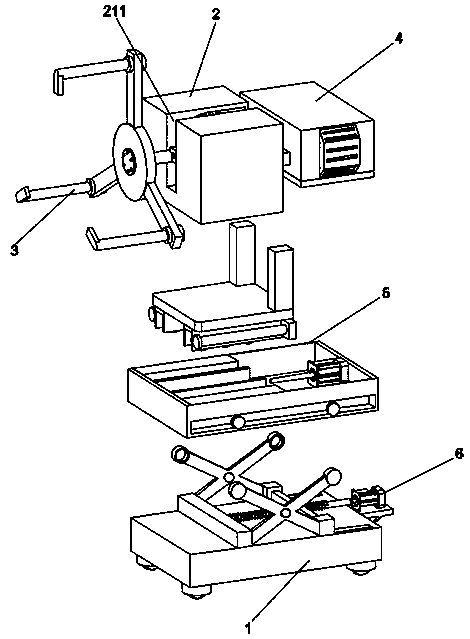

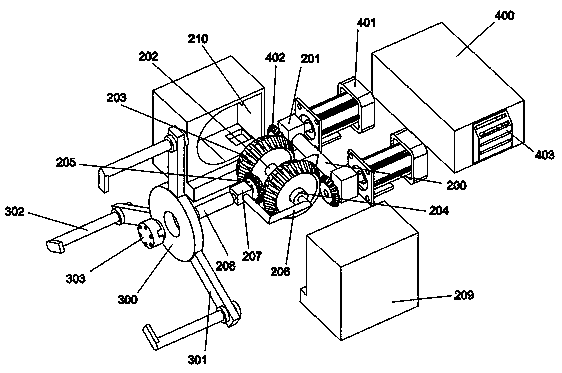

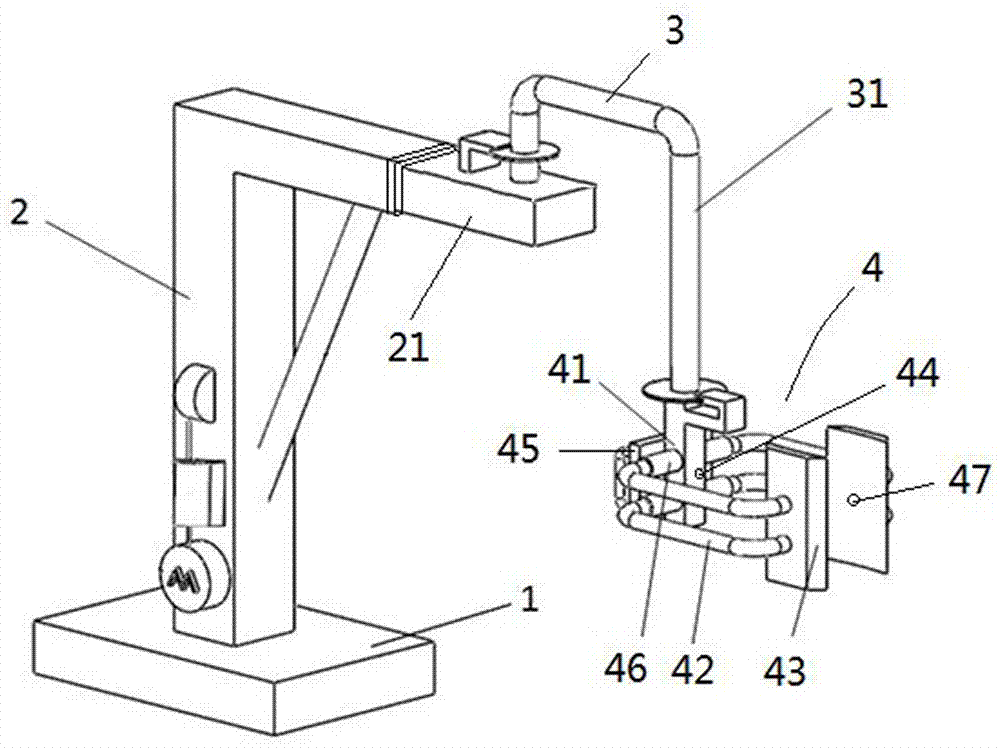

Automobile tire rapid maintenance and correction device

ActiveCN109515063AEasy to carryEasy to installWheel mounting apparatusTyre repairingTire maintenanceEngineering

The invention discloses an automobile tire rapid maintenance and correction device and belongs to the technical field of automobile maintenance. The automobile tire rapid maintenance and correction device comprises a mobile base, a Y-axis rotating mechanism, a tire clamping component, a power output mechanism, a Z-axis adjusting mechanism and a lifting component. According to the automobile tire rapid maintenance and correction device, as the lifting component is arranged on the top surface of the mobile base, the clamping height of the tire clamping component to an automobile tire can be adjusted by using the lifting component to enable the automobile tire to be conveyed or mounted conveniently; and moreover, the power is output by using the power output mechanism above the lifting component so that the Y-axis rotating mechanism operates; and finally, a wheel clamped by the tire clamping component is pushed to a wheel assembly direction by using the Z-axis adjusting mechanism to finish docking of the automobile tire and a wheel assembly. According to the automobile tire rapid maintenance and correction device, the labor intensity of maintenance worker is effectively reduced, a multi-dimension correction demand is also provided for automobile tire rapid maintenance so as to realize automobile tire automatic conveying and tire maintenance and correction, and therefore, the working efficiency is enhanced.

Owner:HUNAN ELECTRICAL COLLEGE OF TECH

Full-automatic plastic pallet transferring machine

ActiveCN107399608AFast automated sortingRealize automatic handlingConveyor partsCleaning processes and apparatusImage contrastMachine

The invention provides a full-automatic plastic pallet transferring machine. The full-automatic plastic pallet transferring machine comprises a mechanical arm; a detection camera assembly and a mechanical arm sucking disc assembly are arranged on the mechanical arm; a reference zero point is established on the mechanical arm; the detection camera assembly positions and records the positions of cleaning frames and workpieces to be cleaned; and the mechanical arm drives the mechanical arm sucking disc assembly to convey the workpieces to be cleaned to the cleaning frames. According to the full-automatic plastic pallet transferring machine, automation and image contrast and recognition are combined, and therefore pre-positioning of the multiple workpieces and automatic lifting of material pallets can be realized, and the automatic carrying of the material pallets can be realized through the coordination of an automatic material pallet carrying device; and rapid automatic sorting of the workpieces to be cleaned can be realized through the automatic mechanical arm. The full-automatic plastic pallet transferring machine has the advantages that positioning is rapid and accurate, the production efficiency is high, the safety and the reliability can be achieved, the practicability is high, and the automation degree is high.

Owner:深圳眼千里科技有限公司

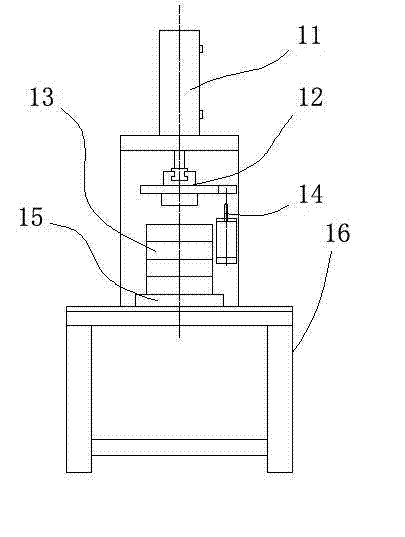

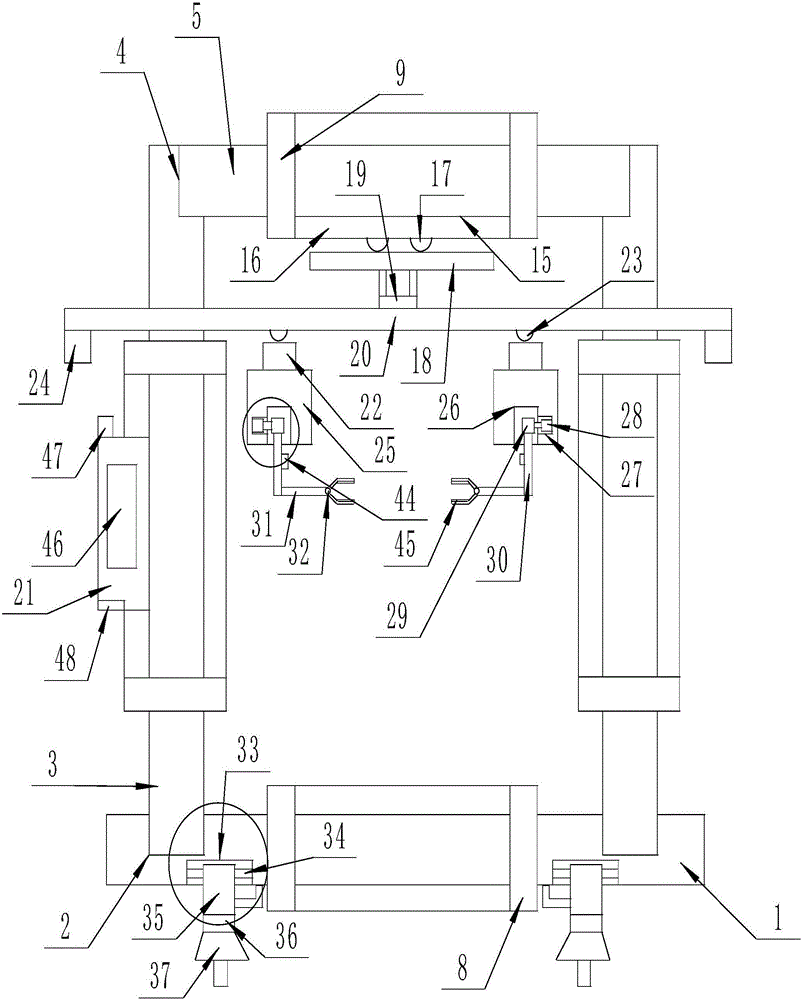

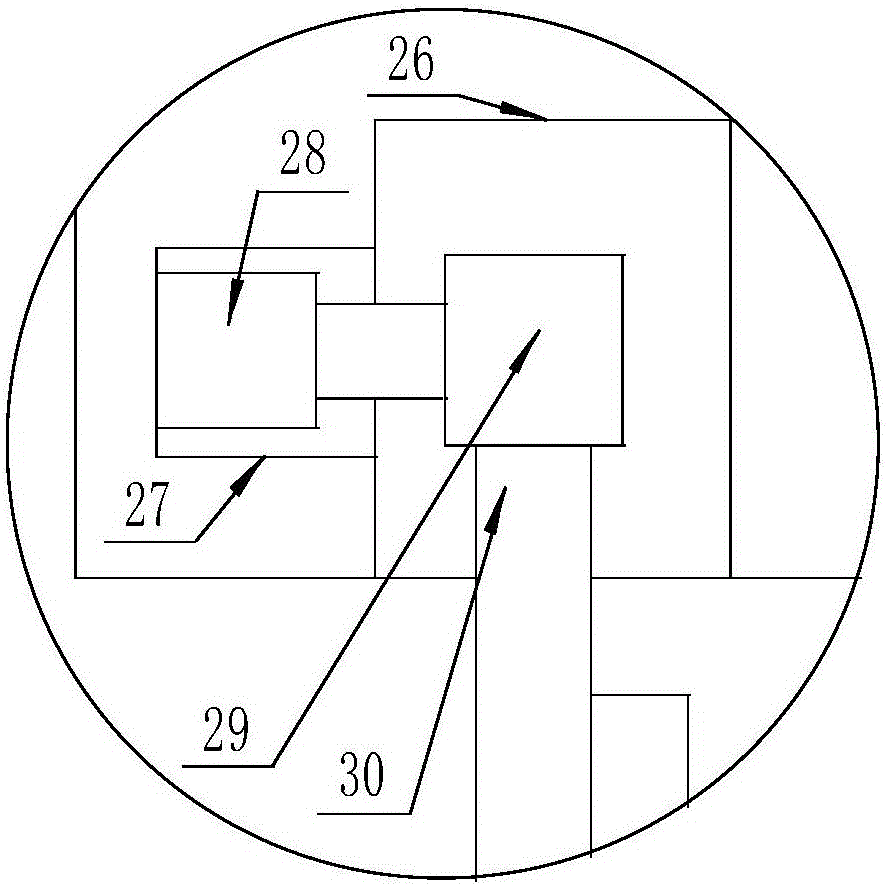

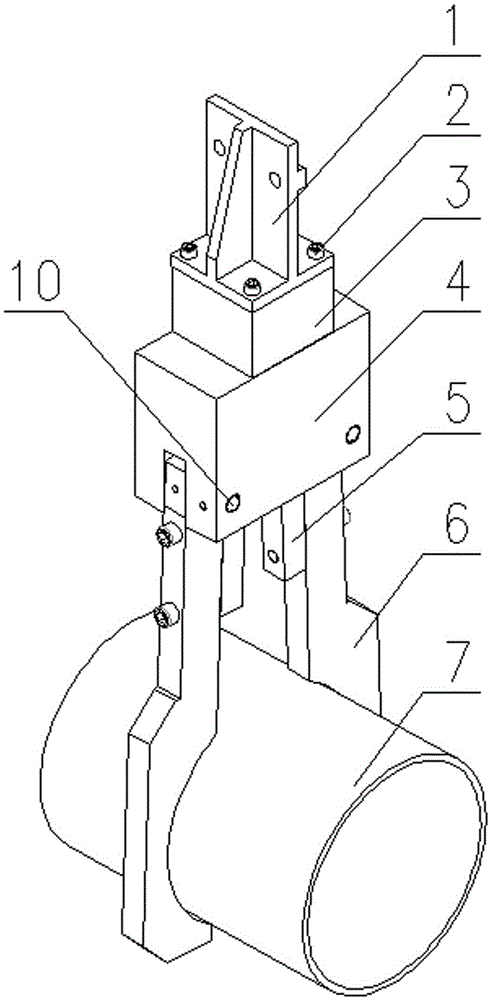

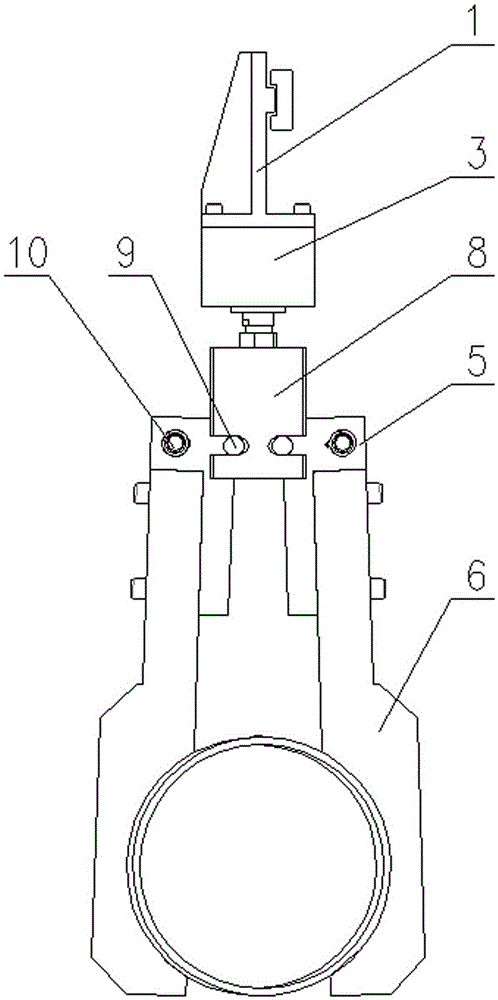

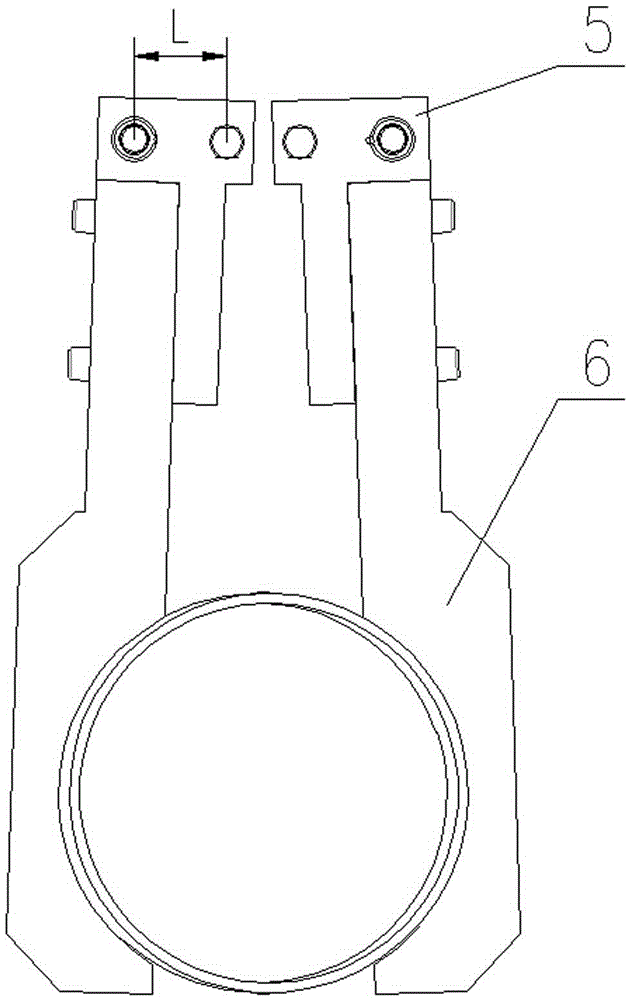

Grabbing manipulator for carrier roller

InactiveCN105414961ALabor savingImprove efficiencyGripping headsAssembly machinesManipulatorRoller bearing

The invention belongs to the technical field of assisting equipment for carrier roller production lines, and aims at solving the problems of high labor cost, high labor intensity and low working efficiency caused by manual up-down transferring of the carrier roller in the press-fitting process of a carrier roller bearing, a seal, and a retainer ring of a shaft. The grabbing manipulator for the carrier roller comprises a power cylinder, a manipulator arm pulling block, and two grabbing mechanisms which are symmetrically arranged through a gap, wherein each grabbing mechanism comprises a manipulator arm and a manipulator finger which are connected to form an upper-lower structure; the top part of the manipulator arm pulling block is connected to a piston rod at the output end of the power cylinder; the inner ends of the two manipulator arms are correspondingly connected to the manipulator arm pulling block through sliding shafts. According to the grabbing manipulator for the carrier roller, the power cylinder reciprocates up and down, and a connecting rod mechanism is used in match, so as to open and close the manipulator fingers to grab the carrier roller; a plurality of manipulators are used for forming a three-dimensional multi-station translating manipulator for carrying the carrier roller among a plurality of press-fitting device stations, so that the carrying efficiency can be improved, and meanwhile, the working intensity of workers can be reduced.

Owner:SHANXI GUDE BAOFENG HEAVY IND MACHINERY

Full-automatic plastic tray transferring machine

InactiveCN106514675AFast automated sortingRealize automatic handlingProgramme-controlled manipulatorGripping headsImage contrastEngineering

The invention provides a full-automatic plastic tray transferring machine. The machine comprises a mechanical arm, the mechanical arm is provided with a detection camera assembly and a mechanical arm suction cup assembly, the mechanical arm establishes a standard zero point, the detection camera assembly locates and records positions of a cleaning frame and work-pieces to be cleaned, and the mechanical arm drives the mechanical arm suction cup assembly to convey the work-pieces to be cleaned to the cleaning frame. According to the machine, automation and image contrast recognition are combined, pre-locating of the multiple work-pieces and automatic lifting of material plates are realized, the material plates are automatically transferred through an automatic material plate carrying device, and the work-pieces to be cleaned can be fast and automatically sorted through the automatic mechanical arm. The machine has the advantages that locating is fast and accurate, the production efficiency is high, the safety and the reliability are high, the practicality is high and the automation degree is high.

Owner:深圳眼千里科技有限公司

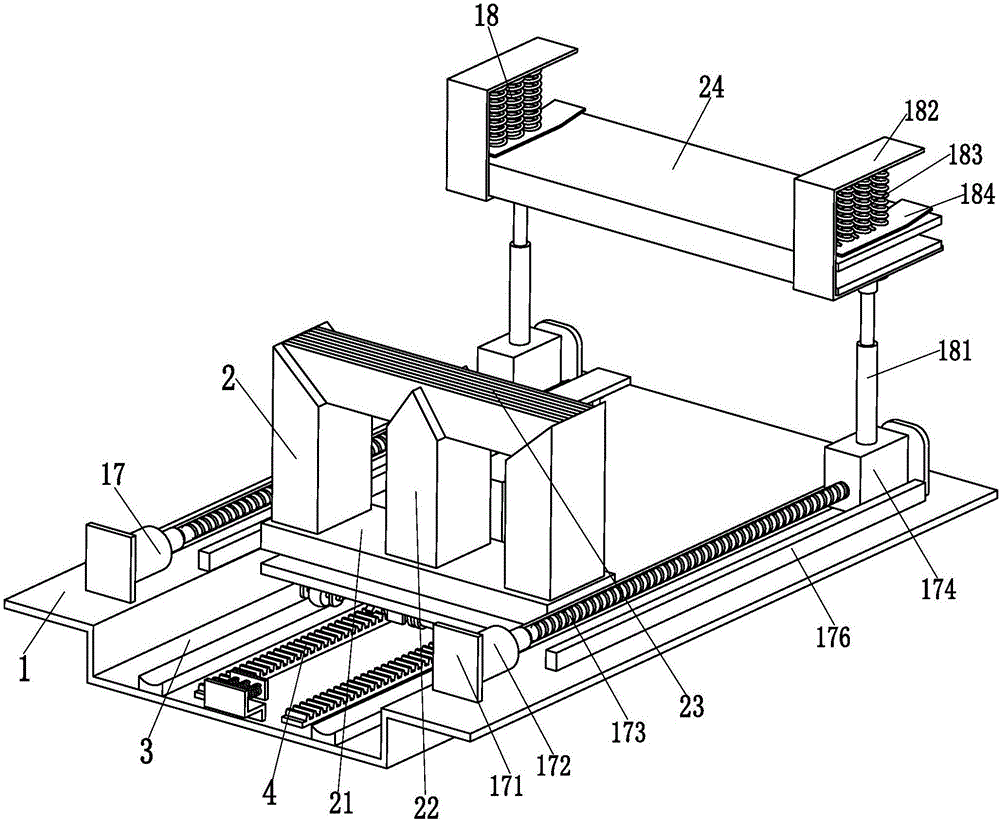

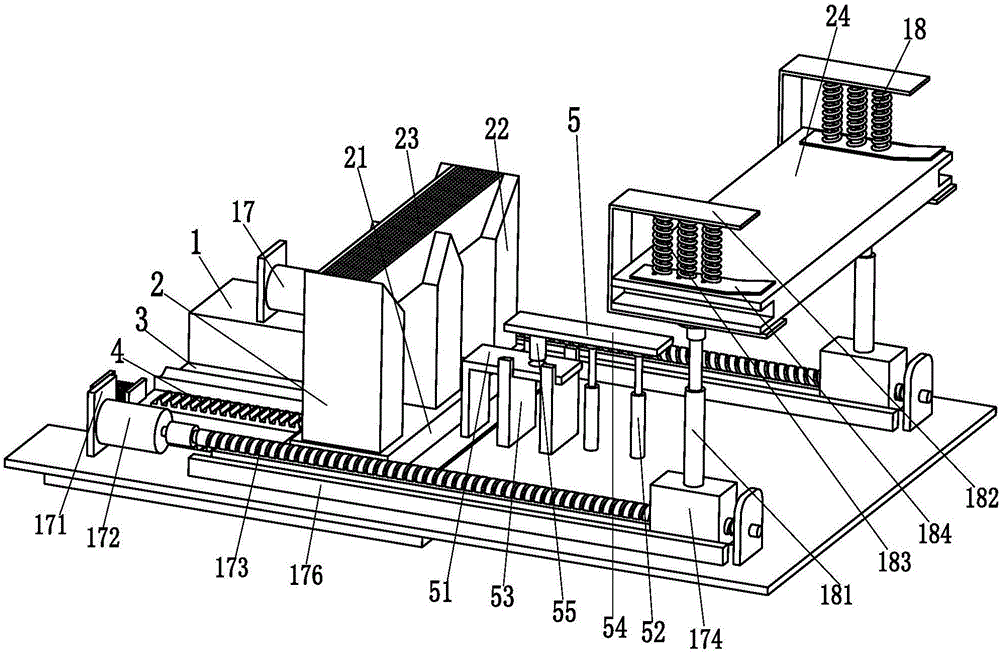

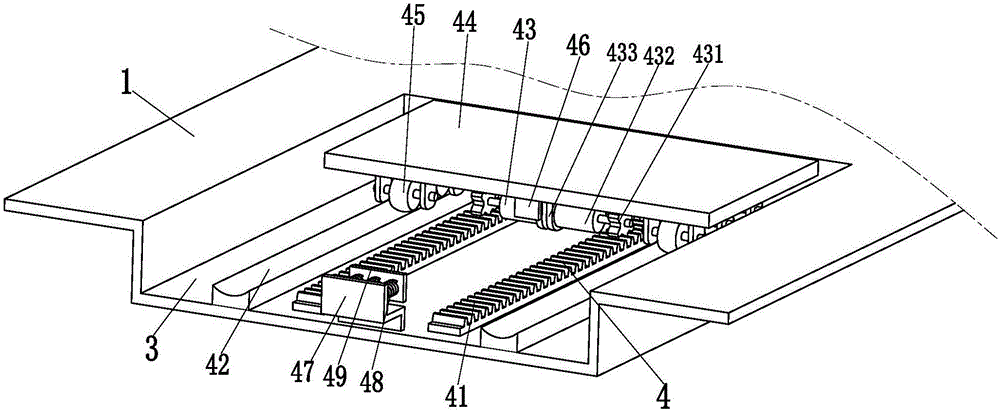

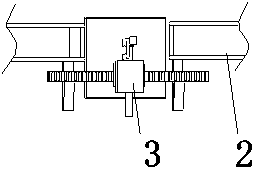

Upper clamp assembly and disassembly device with automatic carrying function for dry-type transformer

ActiveCN106548862ASmooth transmissionGood transmission effectInductances/transformers/magnets manufactureConveyor partsTransformerEngineering

The invention relates to an upper clamp assembly and disassembly device with an automatic carrying function for a dry-type transformer. The upper clamp assembly and disassembly device comprises a bottom plate and an iron core, wherein a concave installation groove is arranged in the front side of the upper end surface of the bottom plate; a sliding carrying mechanism is arranged on the upper end surface of the installation groove; the iron core is put on the upper end of the sliding carrying mechanism and a limiting mechanism is arranged in the middle of the bottom plate; after the sliding carrying mechanism automatically carries the iron core to a specified position, the iron core is locked through the limiting mechanism, so that the iron core does not move when the transformer is manufactured, and the condition that the iron core moves to affect the manufacturing efficiency of the transformer is avoided; two power mechanisms are symmetrically arranged at the left side and the right side of the upper end surface of the bottom plate; each power mechanism is provided with a clamping branch chain for clamping an upper clamp; and the two clamping branch chains are driven to move back and forth through the two power mechanisms. According to the upper clamp assembly and disassembly device, automatic carrying of the iron core of the transformer and the automatic assembly and disassembly function on the upper clamp can be achieved and manual operation is not needed.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER

Cone yarn fetching delivery wagon

PendingCN104843547AImprove production and transportation efficiencyLabor savingFilament handlingYarnEngineering

The invention discloses a cone yarn fetching delivery wagon. The cone yarn fetching delivery wagon comprises a rail, a driving device, a conveying mechanism, cone yarn holders, a marking card and a sensing identifying device; the rail crosses through the position where a cone yarn production process and a packaging process locate; the conveying mechanism is moved and positioned on the rail along the extending direction of the rail, and the driving device drives the conveying mechanism to move; several cone yarn holders are installed on the conveying mechanism, a holding space for stopping and storing the cone yarn is formed on the cone yarn holders; the marking card is installed on the cone yarn holder, and a mark corresponding to the cone yarn held by the cone yarn holders is arranged on the marking card; the sensing identifying device can identify the mark on the marking card and send it to a controller; the controller controls the movement of the driving device. The cone yarn fetching delivery wagon realizes the automatic conveying, variety identification, classified storage, and full-automatic operation of the cone yarn; besides, the cone yarn fetching delivery wagon improves the production and conveying efficiency, saves labor work, and avoids the classifying mistake.

Owner:苏州智尊智能科技有限公司

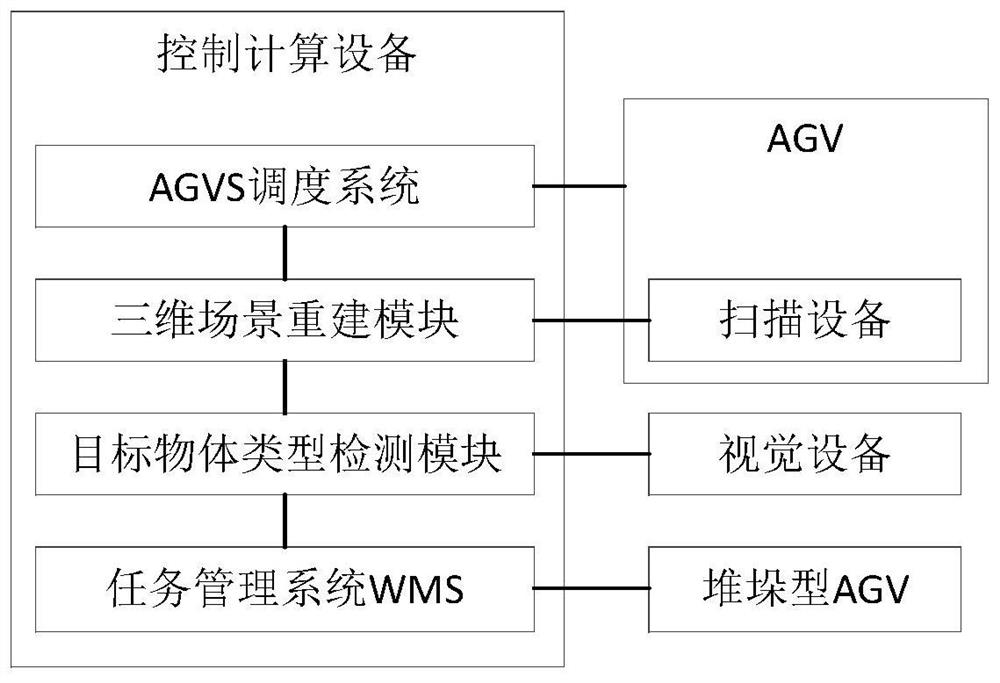

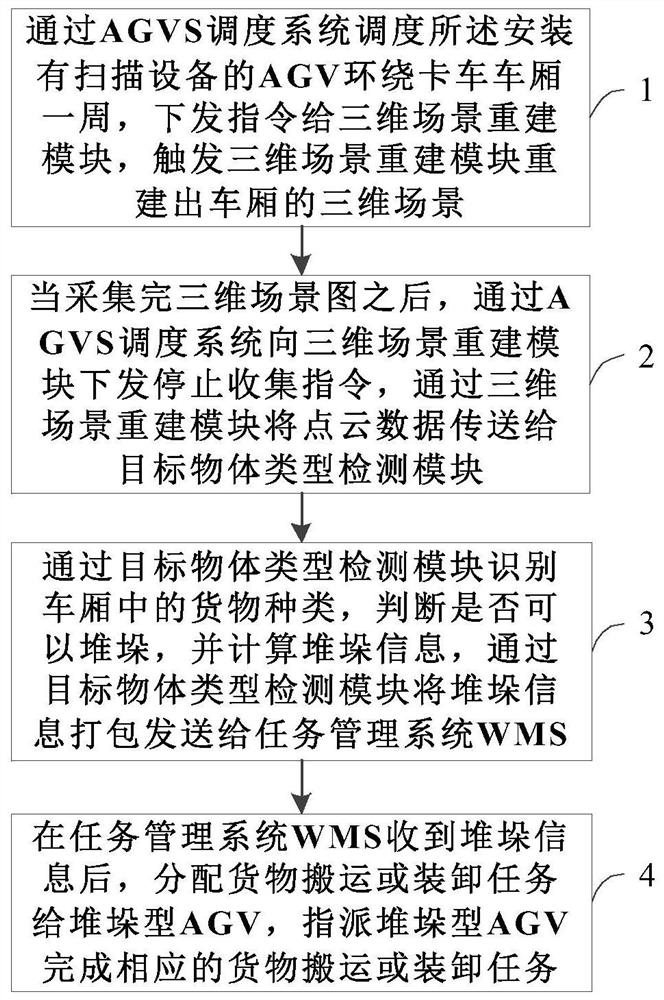

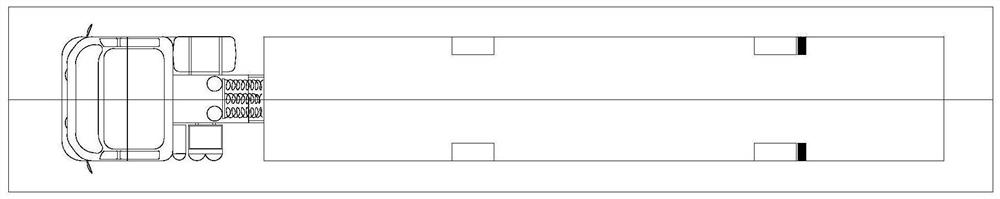

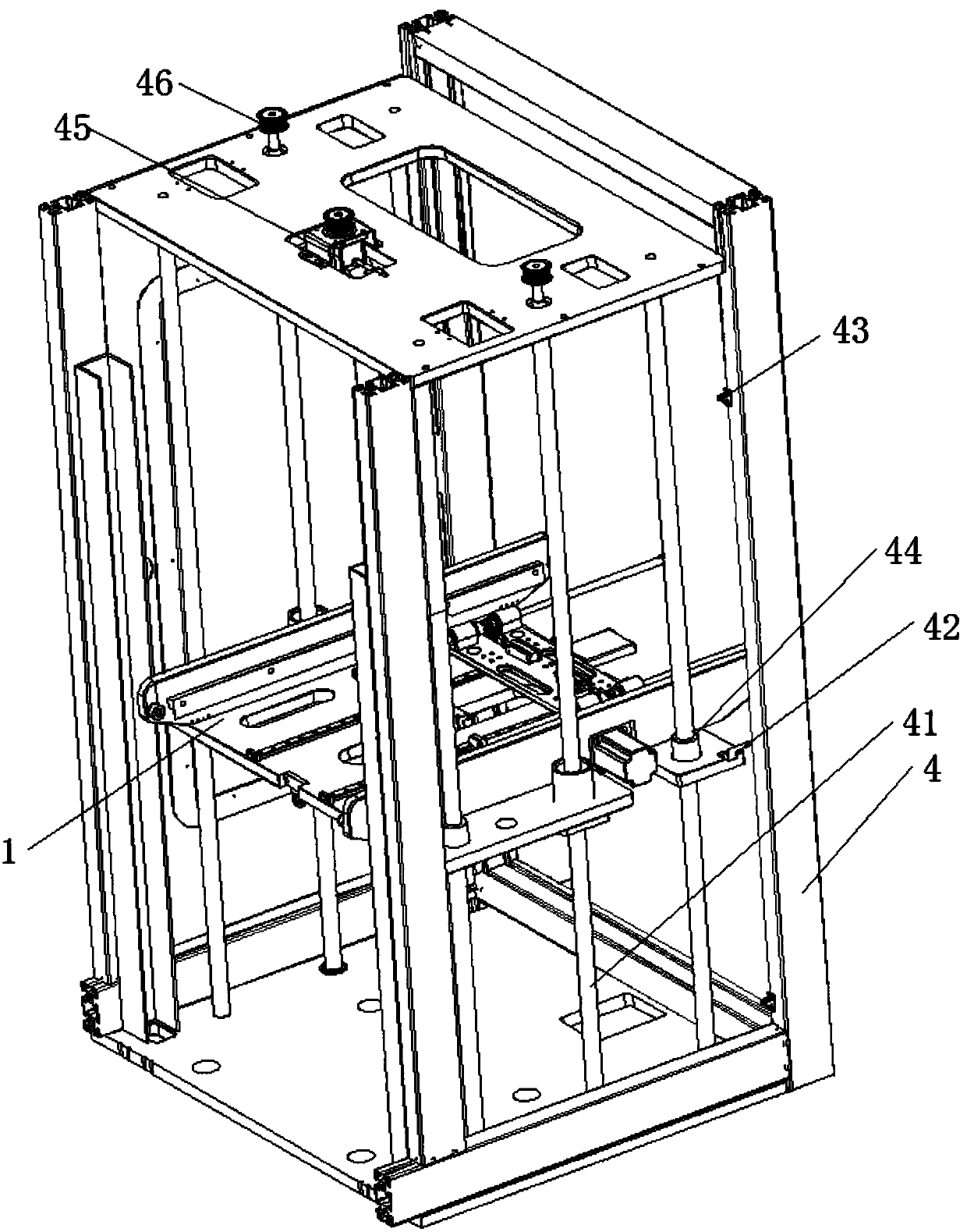

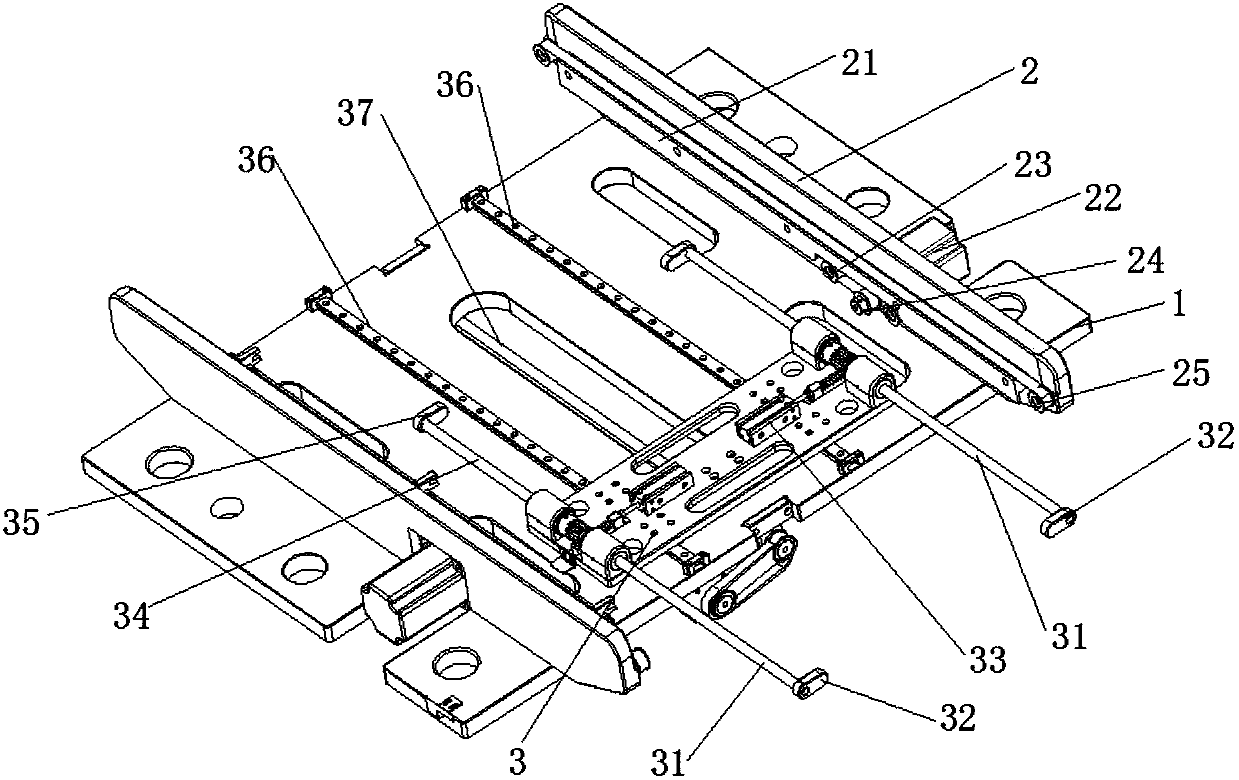

AGV automatic loading method

PendingCN112767540ASolve the problem of stacking type confusionReduce workloadDetails involving processing stepsCharacter and pattern recognitionPoint cloudTruck

The invention discloses an AGV automatic loading method, and the method comprises the steps that an AGVS scheduling system schedules an AGV provided with scanning equipment to surround a truck compartment for a circle, an instruction is issued to a three-dimensional scene reconstruction module, and the three-dimensional scene reconstruction module reconstructs a three-dimensional scene of the compartment; after the three-dimensional scene graph is collected, the three-dimensional scene reconstruction module transmits the point cloud data to the target object type detection module; the target object type detection module identifies the type of goods in a compartment, judges whether the goods can be stacked or not, calculates stacking information, packages the stacking information and sends the stacking information to the task management system WMS; and after the task management system WMS receives the stacking information, cargo carrying or loading and unloading tasks are distributed to the stacking type AGVs. The workload of manual loading and unloading is reduced, the problem of confusion of goods stacking types is solved, meanwhile, goods information can be obtained for unified management, automatic carrying is achieved, and the carrying efficiency is improved.

Owner:SUZHOU AGV ROBOT CO LTD

Material box conveying mechanism

PendingCN107857123AReduce manufacturing costImprove efficiencyConveyorsDe-stacking articlesElectric machineryConveyor belt

The invention relates to the technical field of conveying equipment, in particular to a material box conveying mechanism. According to the material box conveying mechanism, lifting screw rods are driven by a lifting motor to rotate, so that a base plate is driven to move up and down; a box pull assembly can grab material boxes which are stacked high; the material boxes can be picked and deliveredautomatically; manpower is saved; labor intensity is lowered; and accidents are effectively avoided. The material boxes are delivered to the next procedure through a conveying belt on a first materialdelivery assembly and a second material delivery assembly. Meanwhile, the structure is safe and reliable; automatic carrying of the material boxes can be achieved; workers for operating a machine tool are effectively reduced; box carrying efficiency is improved; and production cost of products of an enterprise is lowered. By means of the material box conveying mechanism, box pulling can be conducted smoothly; and the material box conveying mechanism is high in precision of box pulling of each time, high in efficiency, ingenious in concept, practical and suitable for being popularized.

Owner:嘉孚朗机器人设备(苏州)有限公司

Indoor plug valve automatic production line

PendingCN108788756ARealize automated productionTo achieve linkageOther manufacturing equipments/toolsProduction lineFire protection

The invention discloses an indoor plug valve automatic production line. The indoor plug valve automatic production line comprises a dedicated machining machine tool, a first conveying belt, a truss robot and an automatic spraying unit; a valve body semi-finished product is placed on the top of the first conveying belt, the dedicated machining machine tool is located at the head end of the first conveying belt, the dedicated machining machine tool is provided with two robots capable of achieving valve loading, carrying, turnover and discharging, the truss robot is located on the second stationof the first conveying belt, the automatic spraying unit is located on the third station of the first conveying belt, a second conveying belt is arranged on the tail end of the first conveying belt, and an SCARA robot and a machining platform are arranged at the tail end of the second conveying belt. The full-automatic production line is achieved, work efficiency is improved, labor intensity of aworker is reduced, the annual output can reach 600000 valves, and the problems that an existing fire protection plug valve is complex in production process, in the prior art, automation production cannot be achieved, production efficiency is low, and labor intensity of a worker is large are solved.

Owner:福建天广消防有限公司

Intelligent carrying device

InactiveCN105883372ARealize automatic handlingHigh positioning accuracyConveyor partsElectric machineryEngineering

The invention relates to the field of automatic production, and discloses an intelligent carrying device. The device comprises a first station, a second station and a third station, wherein the first station comprises a belt line, a servo motor, a lifting tray, a rodless cylinder and a shifting fork; the second station comprises a vibrating conveying plate; the third station comprises a stock box; the servo motor can drive the lifting tray to lift up and down through the belt; the rodless cylinder can drive the shifting fork to move to push a workpiece to the second station; the vibrating conveying plate can be used for conveying a wall pipe to the middle of the workpiece. With the adoption of the intelligent carrying device, line pipes can be automatically carried; the positioning accuracy is high; the product quality can be improved.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

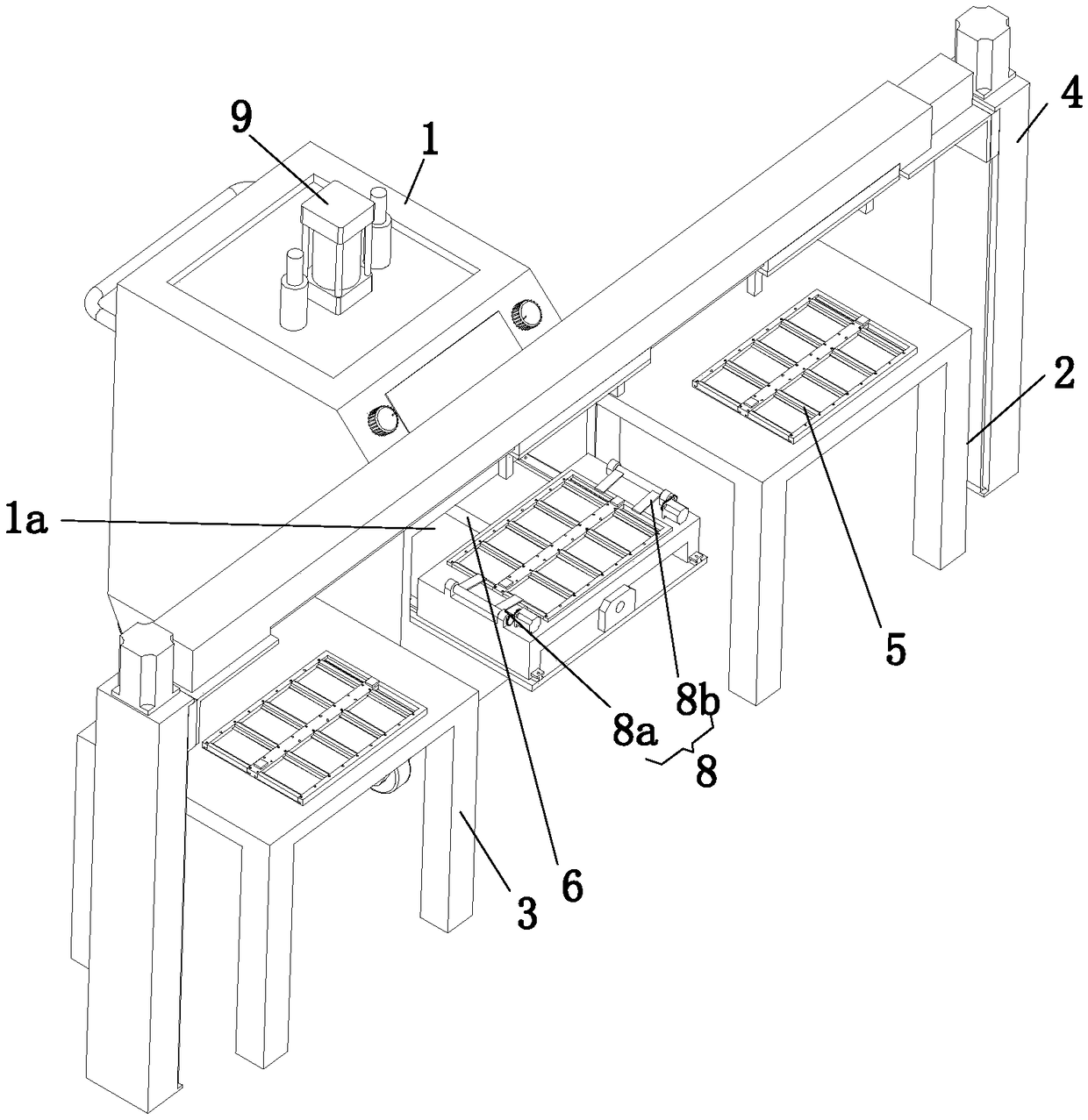

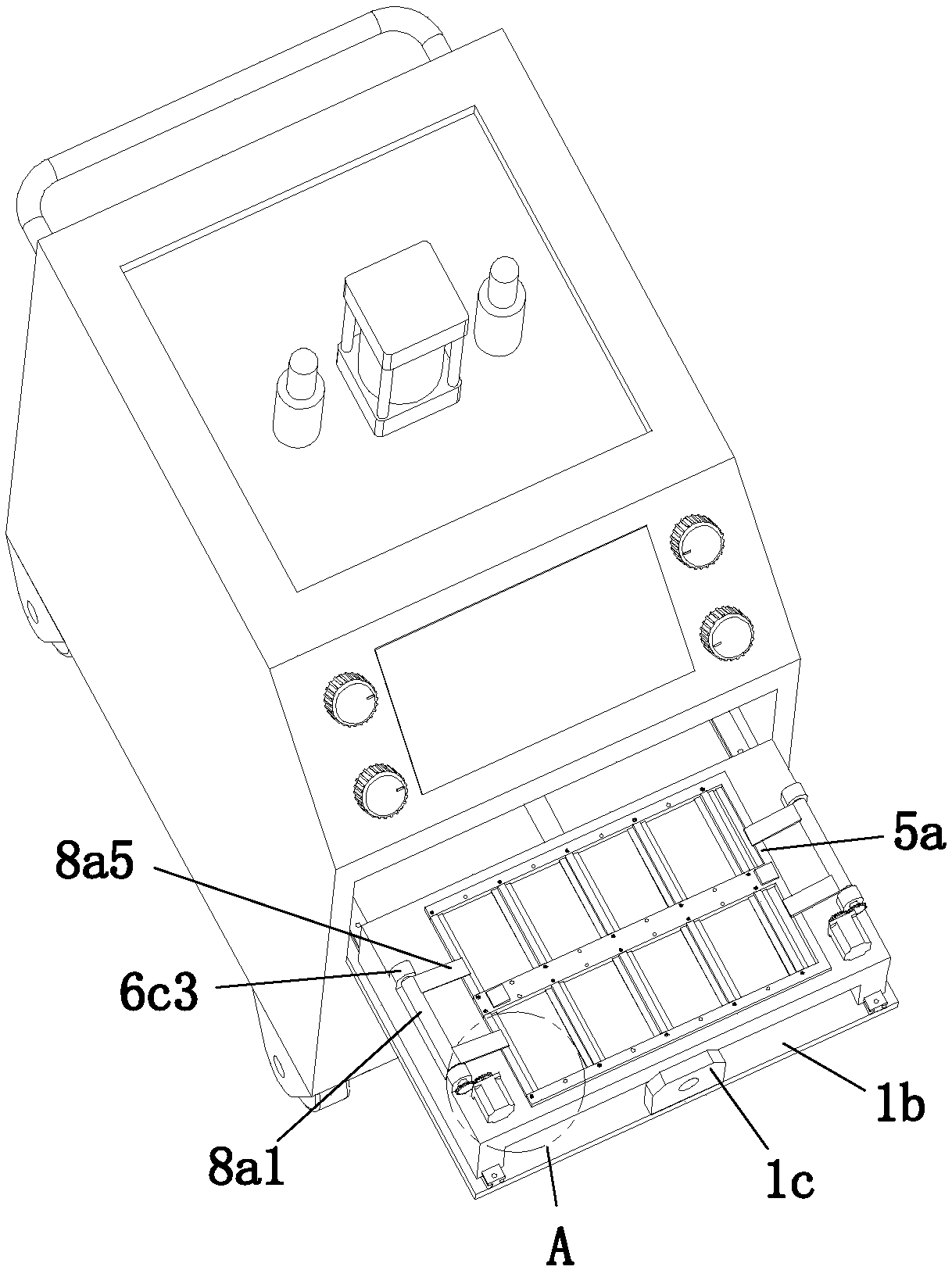

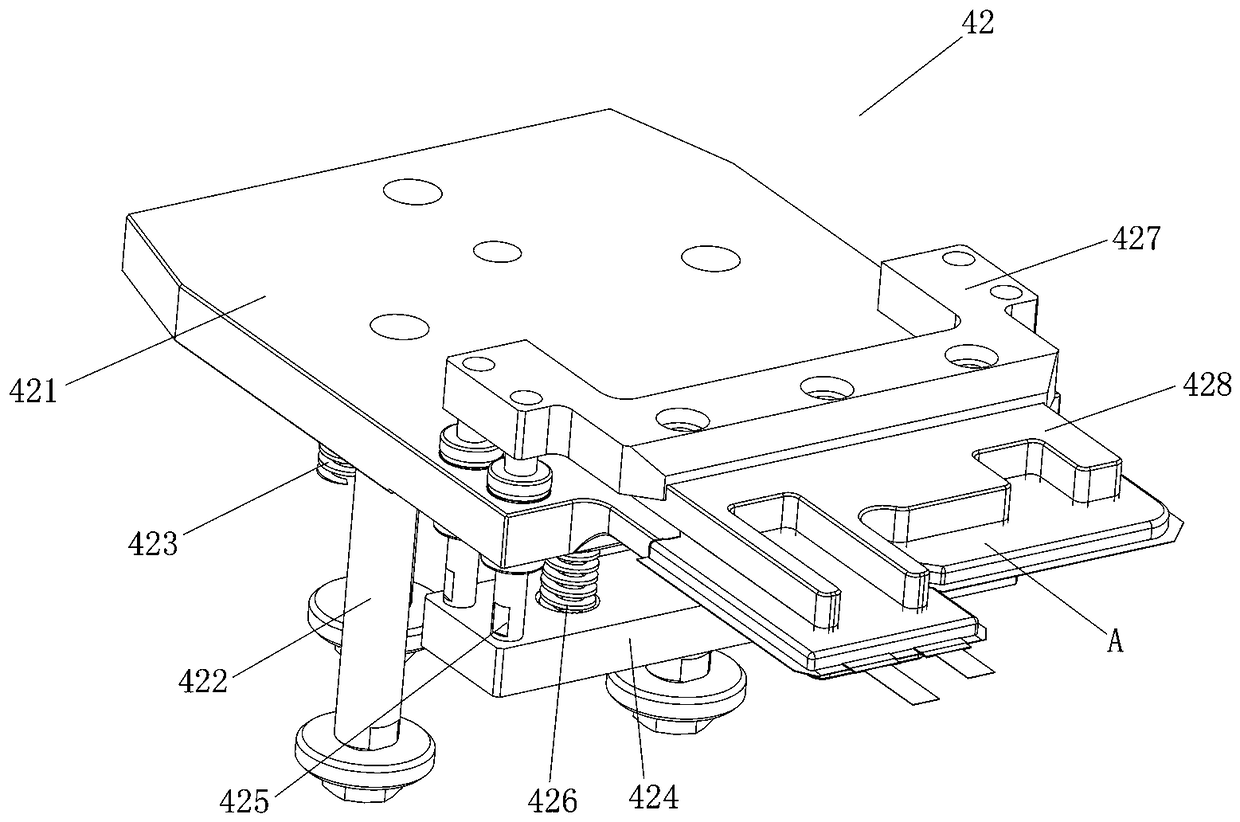

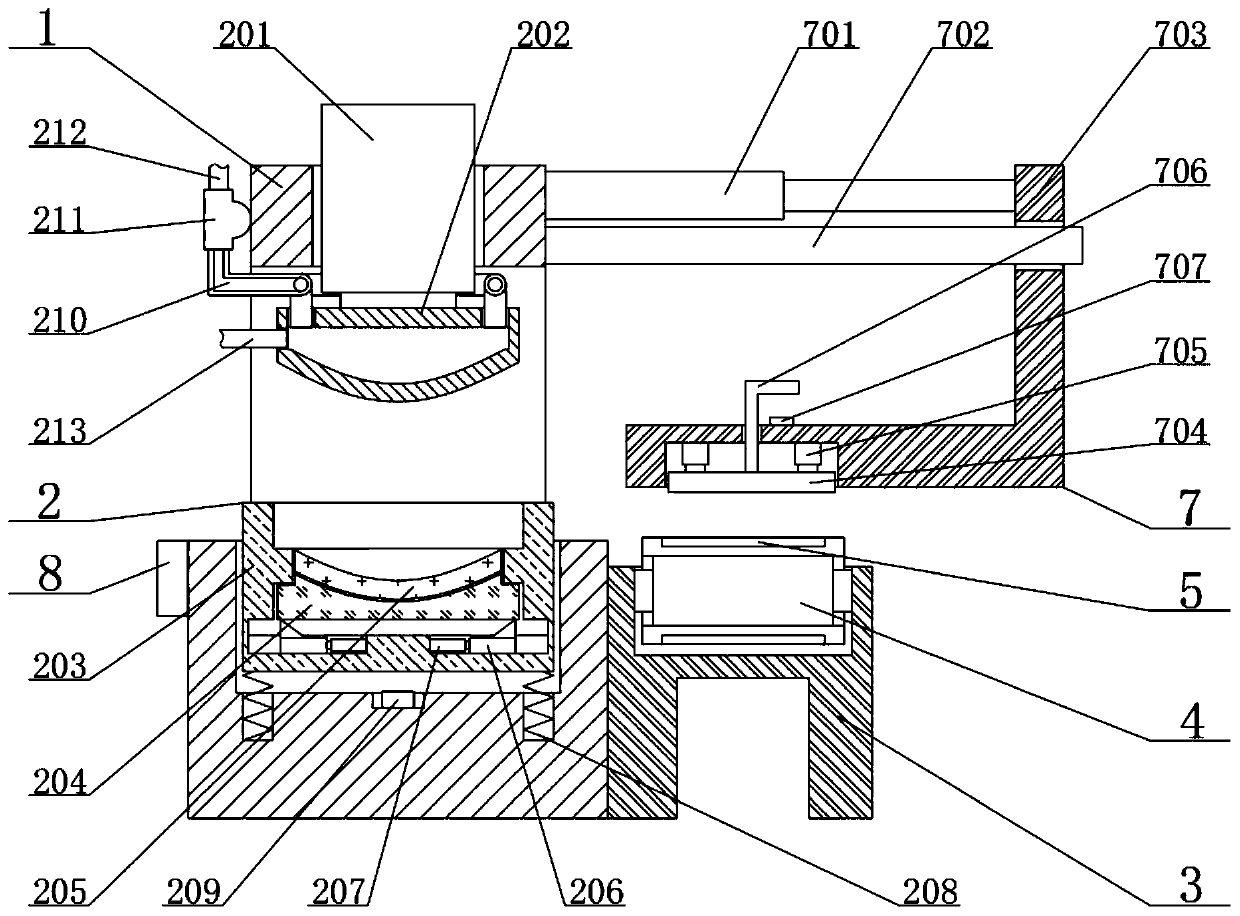

Device for testing circuit board of electronic equipment

ActiveCN109164375AAutomatic detection and automatic handlingImprove detection efficiencyElectronic circuit testingTesting equipmentTest fixture

The invention relates to the field of circuit board testing equipment, in particular to a device for testing a circuit board of electronic equipment. The device comprises a detecting platform, a feeding support platform, a blanking support platform and a carrying device, wherein the carrying device is installed on the ground, the feeding support platform and the blanking support platform are respectively located on left and right sides of the detecting platform, and are both located directly below the carrying device; the detecting platform, the feeding support platform and the blanking support platform are respectively provided with positioning fixtures for fixing the circuit board; the detecting platform is provided with a receiving slot, the receiving slot is internally provided with atranslation driving device for driving the positioning fixtures to perform translation, the translation driving device is provided with a buffering device and a limit device for limiting both ends ofthe positioning fixtures, the detecting platform is provided with a lifting device on the top, and the lifting device is mounted with a plurality of detecting needle plates. The device provided by theinvention realizes automatic carrying and automatic detection of the circuit board, improves the number and types of the detected circuit board, and improves the detection efficiency.

Owner:HARBIN UNIV

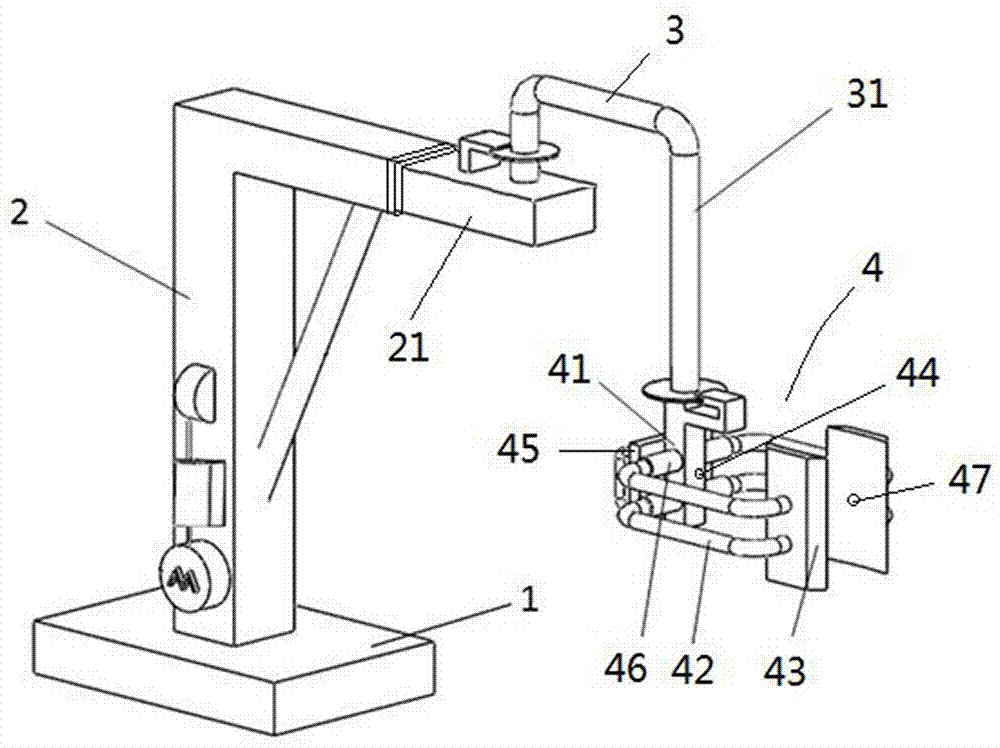

Displacement mechanical arm with vision system

InactiveCN107414805AReduce labor intensityReduce labor costsProgramme-controlled manipulatorEngineeringPressure sensor

The invention discloses a displacement mechanical arm with a vision system. The displacement mechanical arm comprises a control module, a base, a support, a carrying main shaft and a carrying clamping device. A horizontal stretching and contacting device is arranged at the end portion of the support, and the end portion of the support is connected with the carrying main shaft through the horizontal stretching and contracting device. The end portion of the carrying main shaft is provided with a vertical stretching and contracting device and is connected with the carrying clamping device through the vertical stretching and contracting device. The carrying clamping device comprises a rotating shaft, a pair of clamping arms, a pair of suckers, a vision device and an operation plate, wherein the pair of clamping arms, the pair of suckers, the vision device and the operation plate are arranged on the rotating shaft. The pair of clamping arms are connected with an opening and closing driving system, and the pair of suckers are connected with a grabbing driving system. Pressure sensors are arranged on the surfaces of the pair of suckers. By means of the displacement mechanical arm with the vision system, the production efficiency is improved, operation is simple, automatic carrying is achieved through the vision system, positioning is accurate, and the use safety coefficient is high.

Owner:苏州昌田机械设备制造有限公司

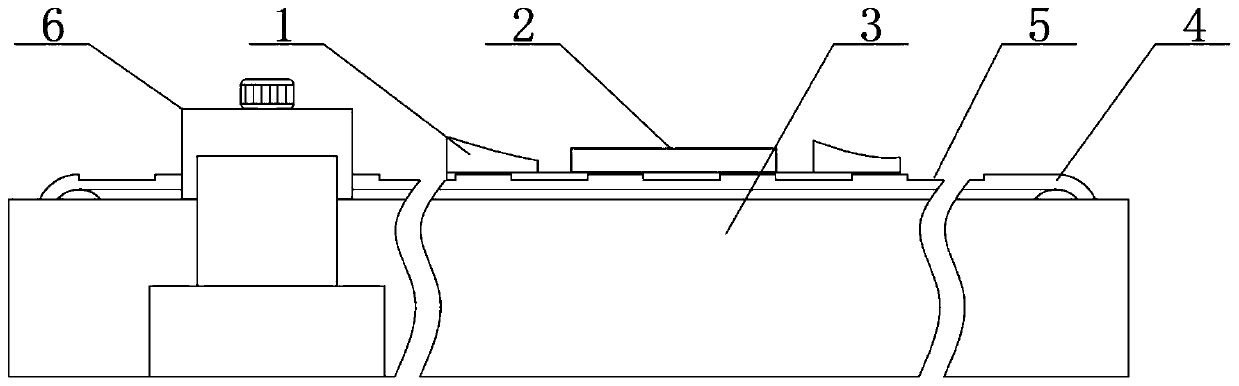

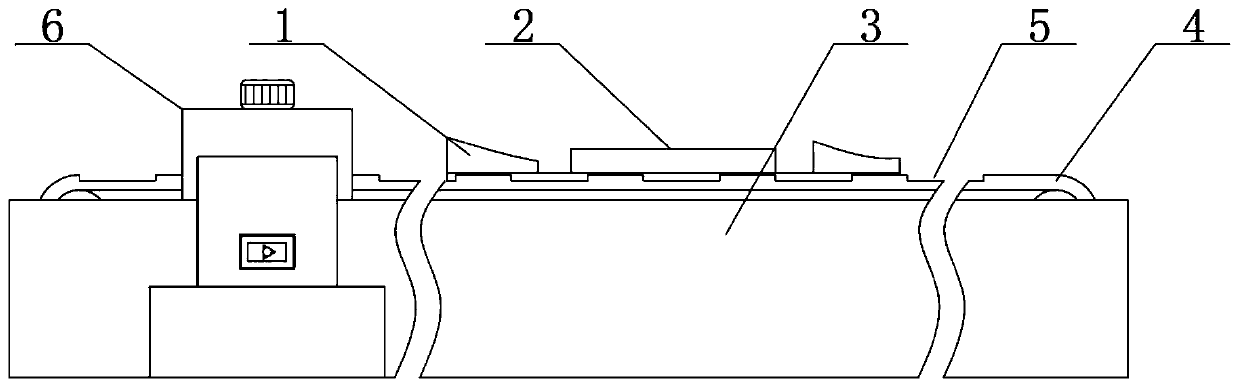

Automatic film cutting line for battery

PendingCN108199074ARealize automatic fixationRealize automatic handlingFinal product manufactureSecondary cells manufactureProduction lineOccupancy rate

The invention discloses an automatic film cutting line for a battery. The automatic film cutting line for the battery comprises a feeding belt, a feeding mechanism, a rotating disc mechanism, a firstpositioning mechanism, a first hot pressing mechanism, a first film cutting mechanism, a second positioning mechanism, a second film cutting mechanism, a third positioning mechanism, a third film cutting mechanism, a fourth positioning mechanism, a fourth film cutting mechanism, a second hot pressing mechanism, a discharging mechanism and a discharging belt, and the feeding belt and the discharging belt are arranged on the first machine frame and a second machine fame respectively; the rotating disc mechanism is arranged on the first machine frame; the feeding mechanism, the first positioningmechanism, the first hot pressing mechanism, the first film cutting mechanism, the second positioning mechanism, the second film cutting mechanism, the third positioning mechanism, the third film cutting mechanism, the fourth positioning mechanism, the fourth film cutting mechanism, the second hot pressing mechanism and the discharging mechanism are correspondingly arranged on the outer side of arotating disc. According to the automatic film cutting line for the battery, the space occupancy rate of the production line is effectively reduced, and automatic fixation of the battery, automatic joining between battery fixation and feeding and discharging and automatic positioning before battery film cutting are achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Automobile tailgate inner plate forming process

ActiveCN110899540AAvoid crackingEnsure stamping deformation accuracyShaping toolsDispersed particle filtrationStructural engineeringConveyor belt

The invention relates to the technical field of automobile tailgate inner plate processing, in particular to an automobile tailgate inner plate forming process. The automobile tailgate inner plate forming process comprises a fixed frame, a stamping device, a cleaning device and a handling device, the inner side of the fixed frame is provided with the stamping device, the bottom end of the right end face of the fixed frame is fixedly connected with a positioning frame, the inner side of the positioning frame is fixedly connected with a conveyor, the outer side of a conveyor belt of the conveyoris provided with a limiting groove, the front end of the outer side of the positioning frame is provided with the cleaning device, the top end of the right end face of the fixed frame is provided with the handling device, and the handling device is fixedly connected with the fixed frame. In the automobile tailgate inner plate forming process, an electric heating plate and an adapter tube are arranged, the arrangement cooperates with the fixed connection of a heating plate and a supporting block, the spring force of a spring to a lower pressing mold, the sliding connection of the supporting block and the lower pressing mold and a sliding block, and the communication of a water pump with the adapter tube and a water inlet pipe; and when processing an automobile tailgate inner plate is carried out, the phenomenon of the occurrence of cracking is avoided when the automobile tailgate inner plate is stamped, and the stamping deformation accuracy of the automobile tailgate inner plate is ensured.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Battery module grasping finger and battery module assembling robot with same

PendingCN108381580AReduce labor intensityRealize automatic handling and automatic assemblyGripping headsMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses a battery module grasping finger and a battery module assembling robot with the same. The battery module grasping finger is used for grasping the side surface of a battery module and comprises a first grasping assembly and a second grasping assembly, the first grasping assembly and the second grasping assembly are oppositely arranged below the base plate, each of the firstgrasping assembly and the second grasping assembly comprises a grasping part and a driving part, and the driving parts are used for driving the grasping parts to move so as to carry out grasping operation. The battery module grasping finger can conveniently grasp the battery module, so that the work of manually conveying the battery module can be avoided, the labor intensity of workers can be lowered, meanwhile, automatic conveying and automatic assembling can be realized, and therefore the assembling efficiency of the battery module can be improved.

Owner:天津格力钛新能源有限公司 +1

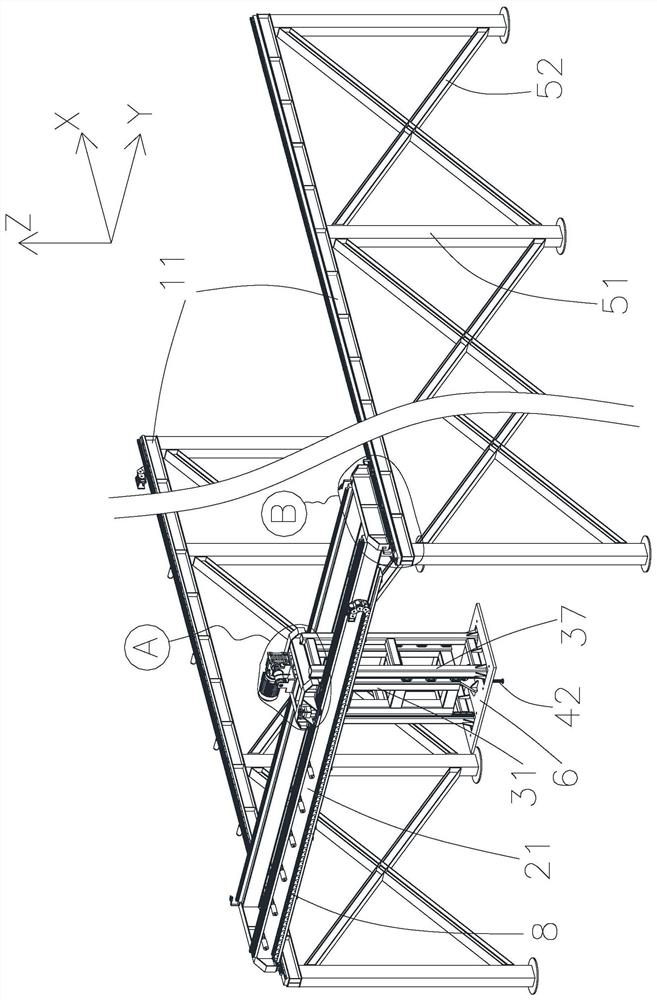

Heavy load intelligent carrying traveling crane

PendingCN111847261AGuaranteed connection strengthAccurately calculate moving distanceBase supporting structuresBraking devices for hoisting equipmentsHeavy loadServo

The invention belongs to the technical field of traveling crane carrying, and in particular relates to a heavy load intelligent carrying traveling crane. The heavy load intelligent carrying travelingcrane comprises an X-direction rail beam, a Y-direction rail beam and a Z-direction rail beam vertical to each other, wherein the Y-direction rail beam is driven by a first driving mechanism to move along the Y-direction rail beam, the Z-direction rail beam is driven by a second driving mechanism to move along the Y-direction rail beam, a lifting rack is slidably arranged on the Z-direction rail beam, and the lifting rack is driven by a third driving mechanism to move along the Z-direction rail beam. The third driving mechanism comprises a roller, a pendant chain and a third servo motor arranged on the Z-direction rail beam. The roller is in transmission connection to the third servo motor, one end of the pendant chain winds the roller and the other end of the pendant chain is fixedly connected to the lifting rack. A down-moving limiting switch and a down-moving trigger matched with each other are arranged at the bottom end of the lifting rack, the down-moving trigger moves close to orfar away from the down-moving limiting switch, and the down-moving limiting switch is electrically connected to the third servo motor.

Owner:江苏金猫机器人科技有限公司

Full automatic carrying trolley and use method thereof

ActiveCN108715423AReduce collisionReduce shipping damageLifting framesVehicular energy storageDegrees of freedomSingle vehicle

The invention discloses a full automatic carrying trolley and relates to the field of carrying equipment. The full automatic carrying trolley comprises a trolley body assembly, a lifting sliding mechanism and a yoke assembly; the trolley body assembly comprises a carriage, a power control device and a running mechanism; the lifting sliding mechanism comprises horizontal guide rails, horizontal sliding blocks, a cross beam, vertical guide rails, vertical sliding blocks and upright columns; the horizontal sliding blocks are matched with the horizontal guide rails; the vertical sliding blocks andthe upright columns are matched with the vertical guide rails; and the yoke assembly comprises a yoke cross beam, a bracket, a cylinder cross beam and goods forks. Automation carrying is realized tosome extent; five-degree-of-freedom fixing of shared bicycles on the carrying trolley is realized, and in addition with the gravity of shock absorbing springs and the carrying trolley, when the carrying trolley runs on a bumpy road, collision between the shared bicycles and between the shared bicycles and the carrying trolley can be reduced, and transport damage to the shared bicycles is lowered to some extent.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

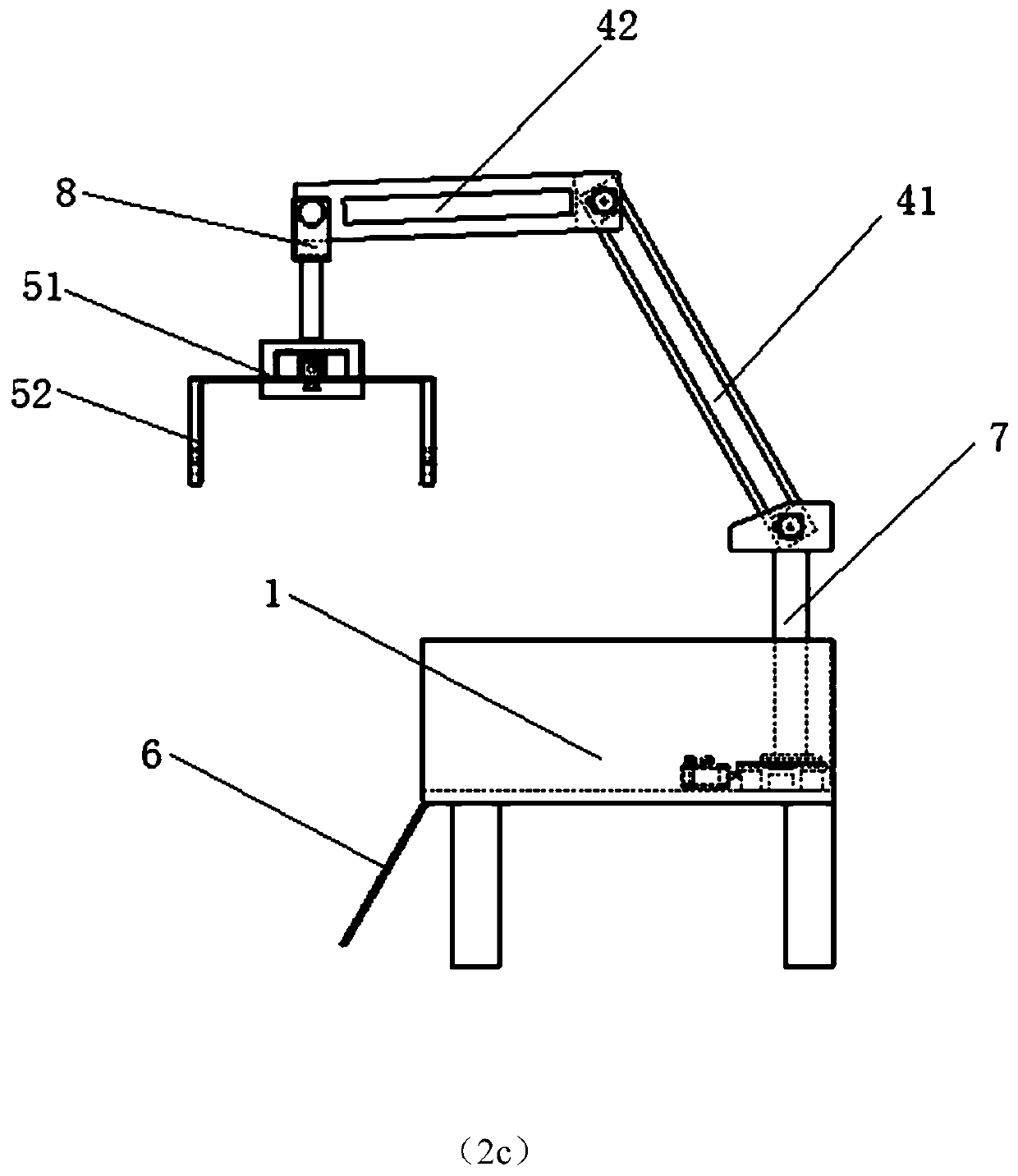

Three-dimensional warehousing system

InactiveCN104443991ARealize automatic handlingImprove work efficiencyStorage devicesConveyor partsEngineeringManipulator

The invention relates to a three-dimensional warehousing system which is arranged in a warehouse. The three-dimensional warehousing system comprises a conveying line and a mechanical arm. The conveying line and the mechanical arm are arranged in the warehouse. The conveying line is distributed in the X direction of the warehouse, and the mechanical arm is arranged on one side of the conveying line. The mechanical arm comprises a lifting device and a picking up device, wherein the lifting device moves along the Y axis of the warehouse, and the picking up device is arranged on the lifting device and moves along the Z axis of the warehouse. According to the system, the conveying line arranged in the X-axis direction and used for conveying materials and the mechanical arm capable of moving in the Y axis and the Z axis are arranged in the warehouse, so that the storage position is made to have coordinates, automatic carrying is achieved, and work efficiency is improved. In addition, because the three-dimensional warehousing system does not need a route line, compared with the prior art, the whole occupied area is smaller, and a warehouse space is reasonably used.

Owner:江苏华厦电力成套设备有限公司

High-speed carrying robot system for photovoltaic panels

ActiveCN106927244AReduce labor intensityAvoid shattering and crackingConveyorsFinal product manufactureAutomatic controlRobotic systems

The invention discloses a high-speed carrying robot system for photovoltaic panels, and relates to panel automatic carrying work. The system is composed of a photovoltaic panel separation system, a photovoltaic panel transport system, a photovoltaic panel thickness adjusting mechanism and a control system. Through the automatic control technology, automatic carrying of the panels can be achieved, and labor intensity of workers is reduced. The photovoltaic panels are output in the tangent direction through a friction wheel, suction by a suction cup is not needed, the photovoltaic panel separation type bonding problem caused by the air pressure is solved, and therefore high-speed carrying is achieved; meanwhile, when the photovoltaic panels fall down, mutation-free impact falling can be achieved, and defects of breaking, subfissure and the like can be overcome. A herringbone guide device is arranged, the photovoltaic panels can be carried in two directions at the same time, and the two-station photovoltaic panel carrying requirement can be met at the same time. The photovoltaic panel thickness adjusting mechanism is arranged, adjustment can be carried out according to specifications of the different photovoltaic panels, and the system is suitable for output of the photovoltaic panels of different specifications.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Working method for automatic shifting mechanical arm

ActiveCN107572250AReduce labor intensityReduce labor costsControl devices for conveyorsSuction forceEngineering

The invention discloses a working method for an automatic shifting mechanical arm. The working method comprises the following steps that automatic mode is started; a carrying clamping device is movedto a first station according to a set path; a pair of suction discs is opened to a set position; a visual device feeds back detected image information to a controlling module; the controlling module calculates and sends commands, micro adjusting of the position is conducted to enable the pair of suction discs to reach a target position; the pair of suction discs is closed and clamped and fixes a workpiece through suction force; the workpiece is carried to a second station; and the pair of suction discs is loosened and separated from the workpiece. According to the working method for the automatic shifting mechanical arm, the production efficiency is improved, and operation is simple, automatic carrying is achieved through the visual system, and accurate positioning and high using safety factor are achieved.

Owner:太仓市广聚德科技有限公司

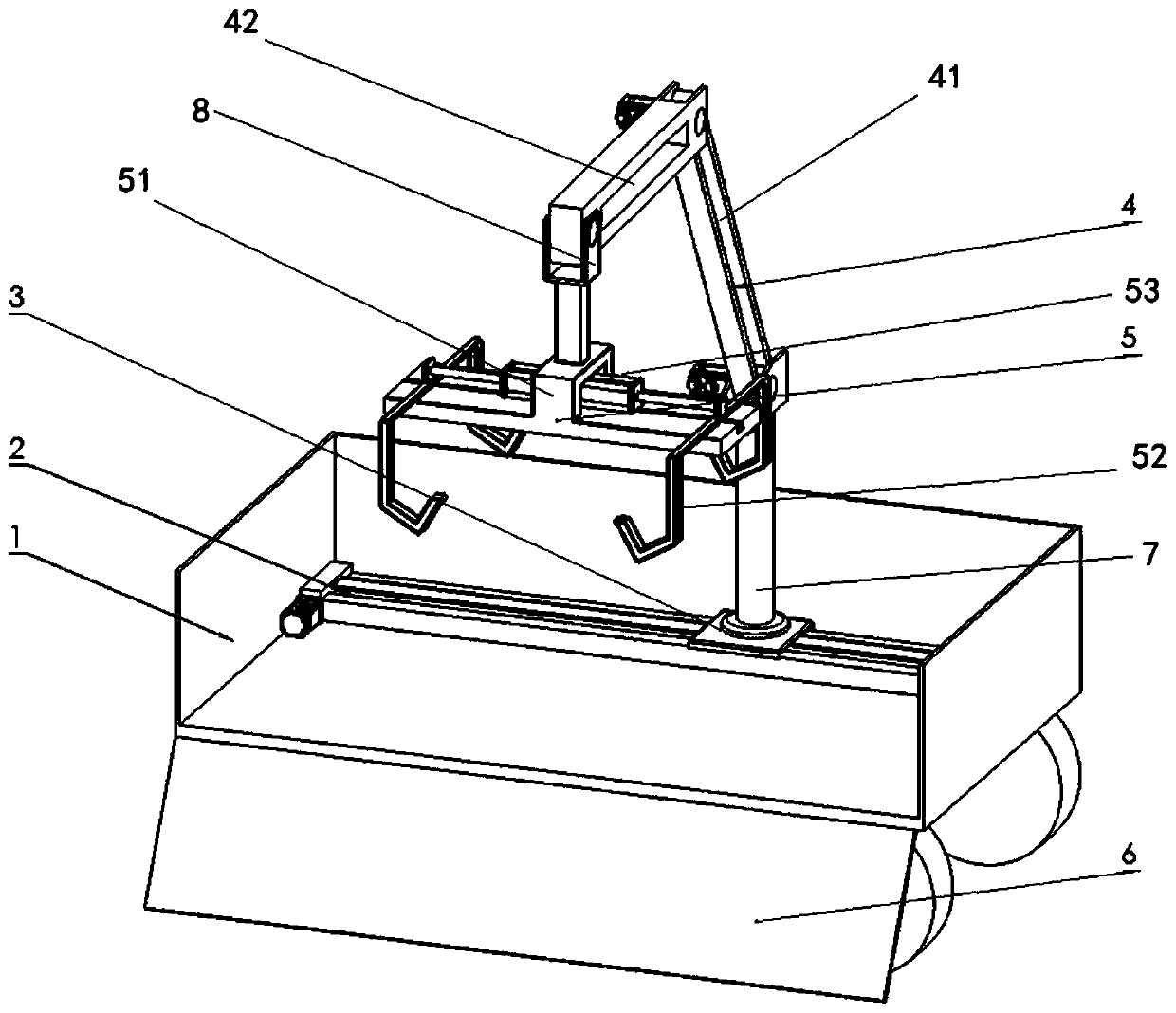

Aluminum ingot fully-automated loading system and method

PendingCN110155751ARealize automatic handlingImprove handlingConveyorsLoading/unloadingReciprocating motionLaser scanning

The invention discloses an aluminum ingot fully-automated loading system and method. The loading system comprises a support frame, two tracks, a moving member arranged on the two tracks, a laser scanning device arranged on the moving member, a three-axis linear sliding table arranged on the two tracks in a sliding manner, a clamp arranged on the three-axis linear sliding table and used for clamping an aluminum ingot and a control center electrically connected with a driving mechanism of the moving member, a laser scanning device, the three-axis linear sliding table and the clamp; after a carrying vehicle is driven in, the control center controls the moving member to move along the two tracks, and the laser scanning device is driven to move and scan the carrying vehicle to obtain a cargo loading area; and the control center controls the three-axis sliding table to do reciprocated motion so that the clamp can clamp the aluminum ingot stacked at the specified position and place the aluminum ingot on the cargo loading area. The aluminum ingot fully-automated loading system and method can solve the technical problems that the aluminum ingot is manually taken out of a warehouse and loaded to the vehicle, consequently the labor intensity is large, the work efficiency is low, and potential safety hazards exist.

Owner:贵阳振兴铝镁科技产业发展有限公司

Transit transport vehicle for automatic garbage classification box

ActiveCN111422535ARealize automatic handlingSolve the situation of manual handlingRefuse vehiclesWorking environmentCarriage

The invention relates to a transit transport vehicle for an automatic garbage classification box. The transit transport vehicle comprises a carriage, a movable guide rail assembly, a mechanical arm and a clamp, wherein the mechanical arm is installed on the movable guide rail assembly; the movable guide rail assembly is installed in the carriage and drives the mechanical arm to move linearly; theclamp comprises a support connected with the mechanical arm, a drive air cylinder and a clamping jaw, wherein the drive air cylinder and the clamping jaw are installed on the support and connected with each other; the clamping jaw is matched with a groove in the top of the garbage classification box; and when the garbage box is grabbed, the clamping jaw is clamped in the groove in the top of the garbage classification box. Compared with the prior art, the transit transport vehicle has the beneficial effects that the work environment of sanitation workers is improved, the work efficiency is improved, and safety and reliability are achieved.

Owner:SHANGHAI UNIV OF ENG SCI

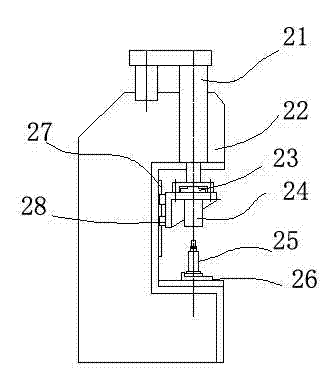

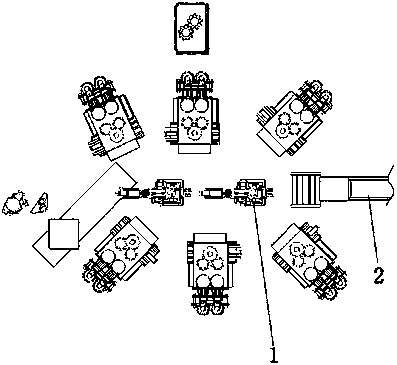

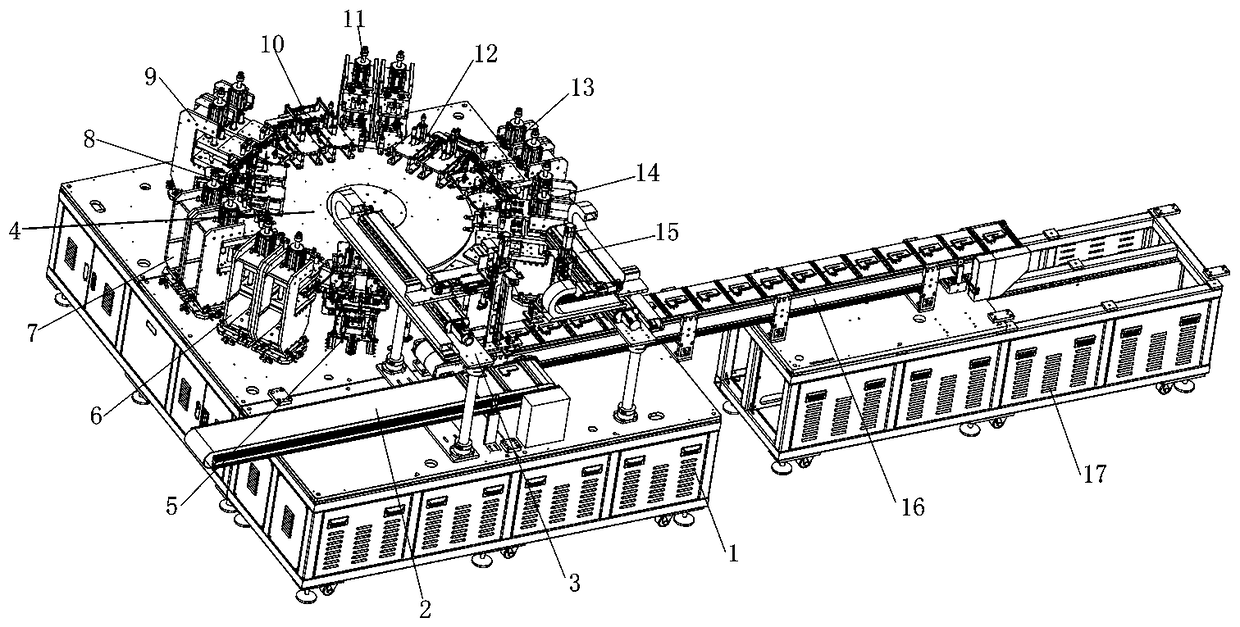

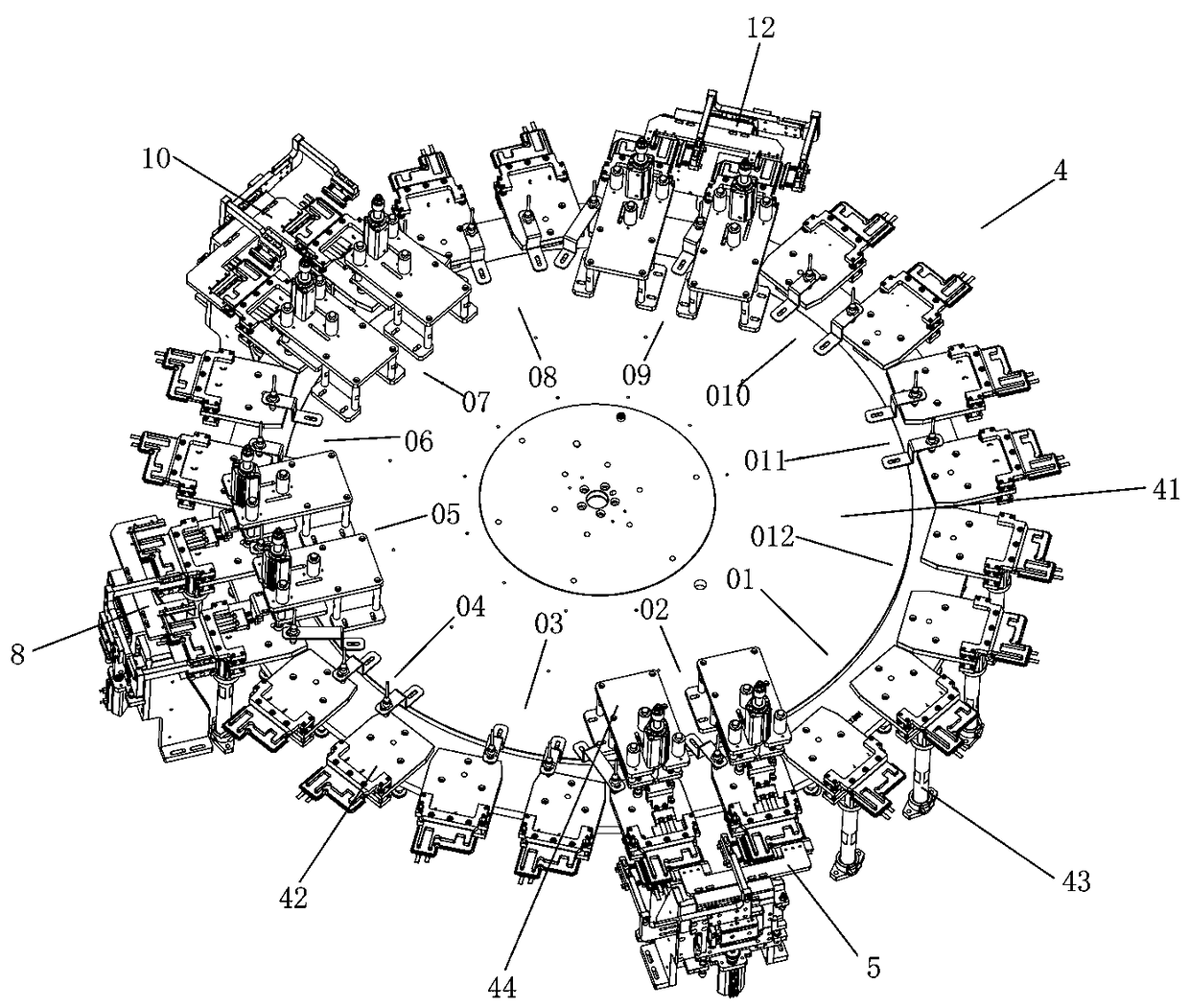

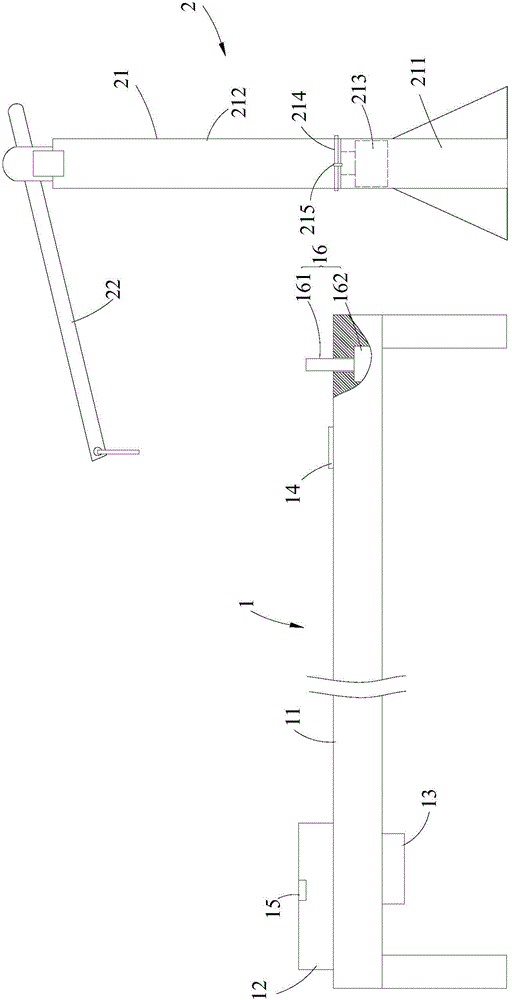

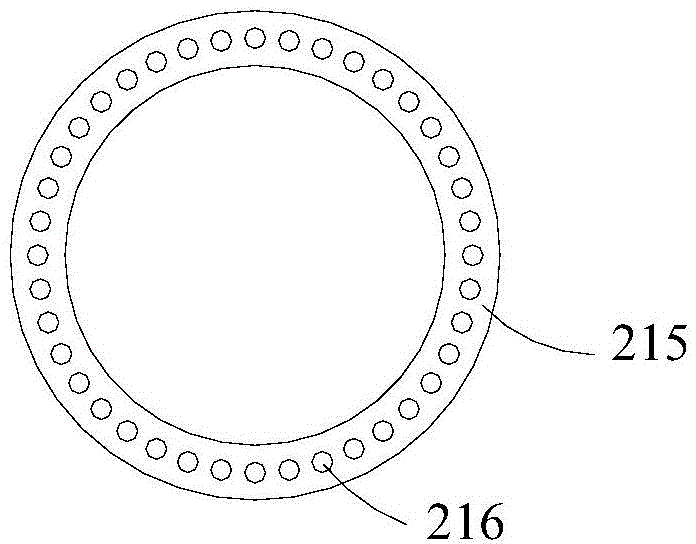

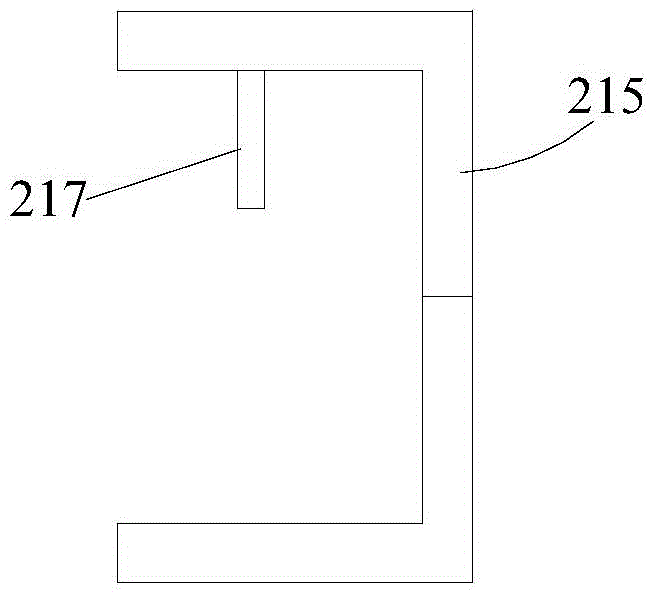

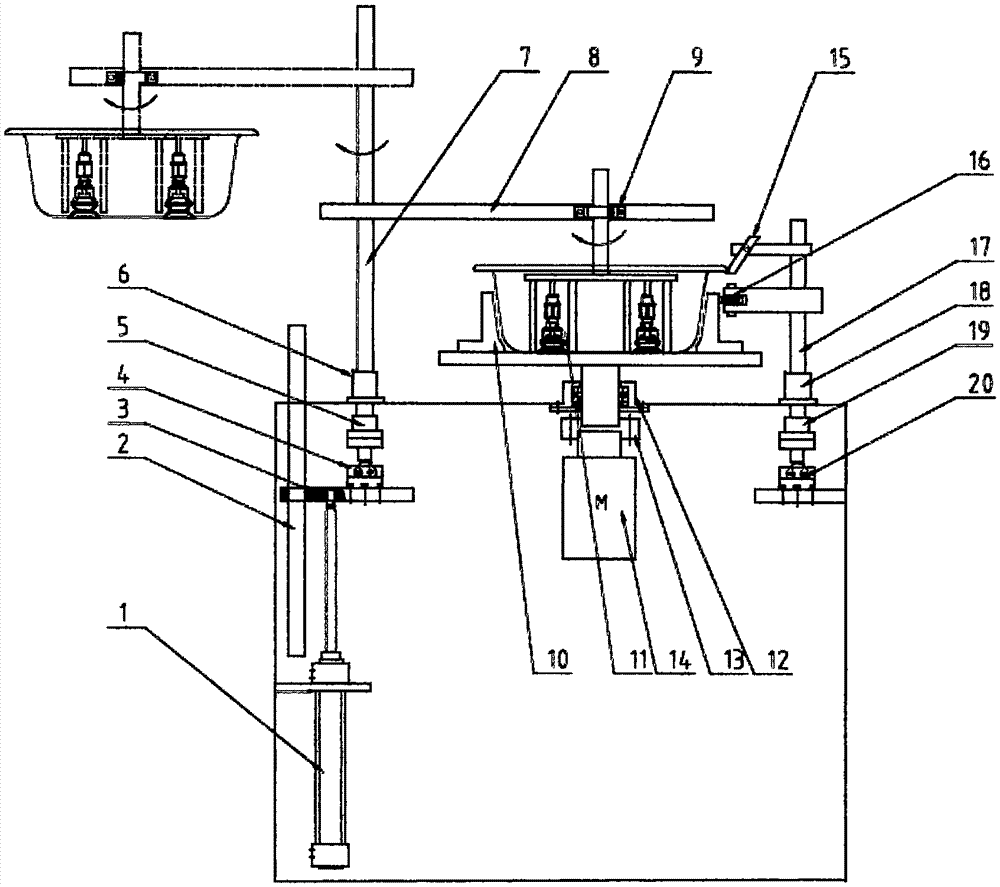

Plastic basin edge trimmer

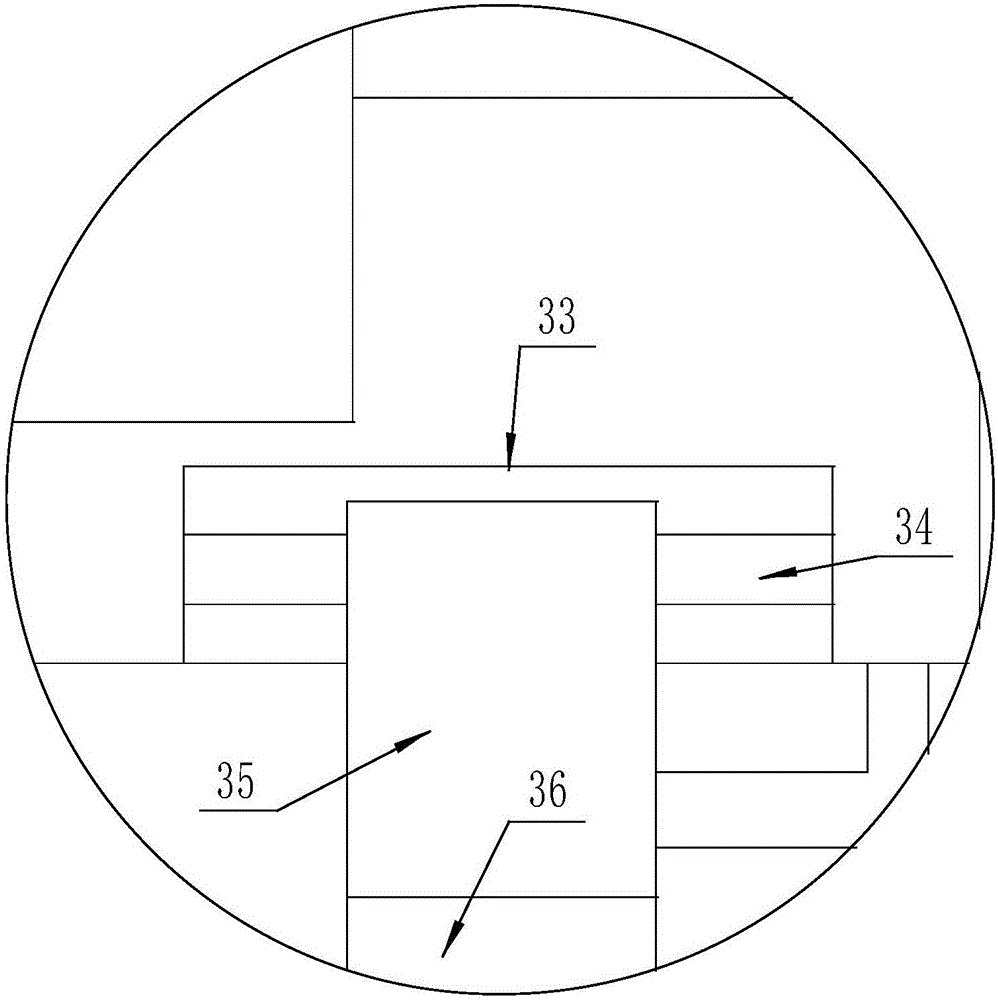

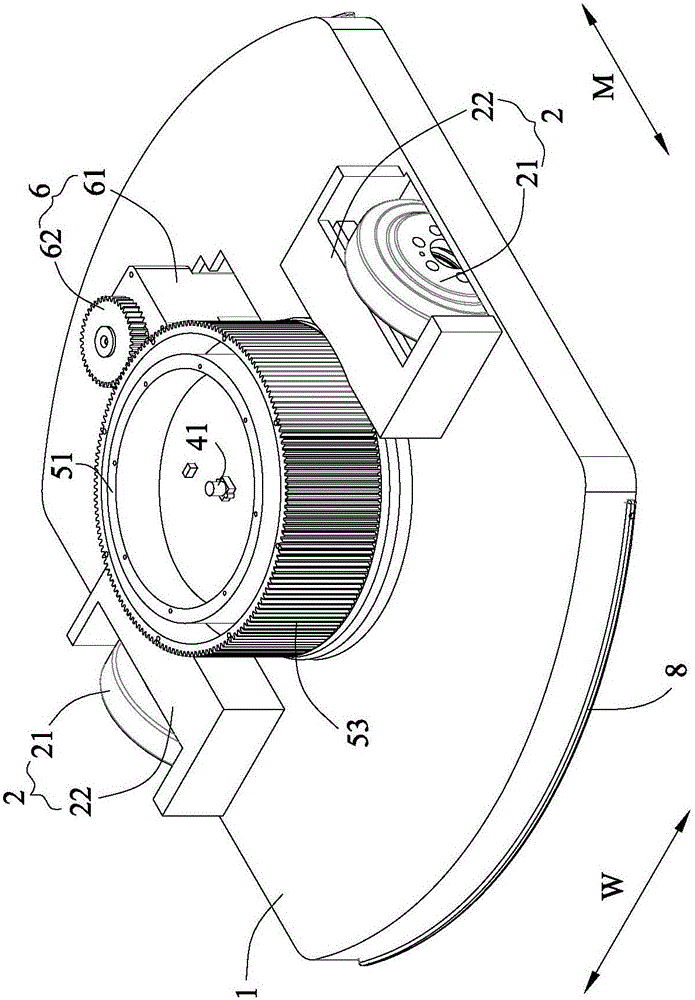

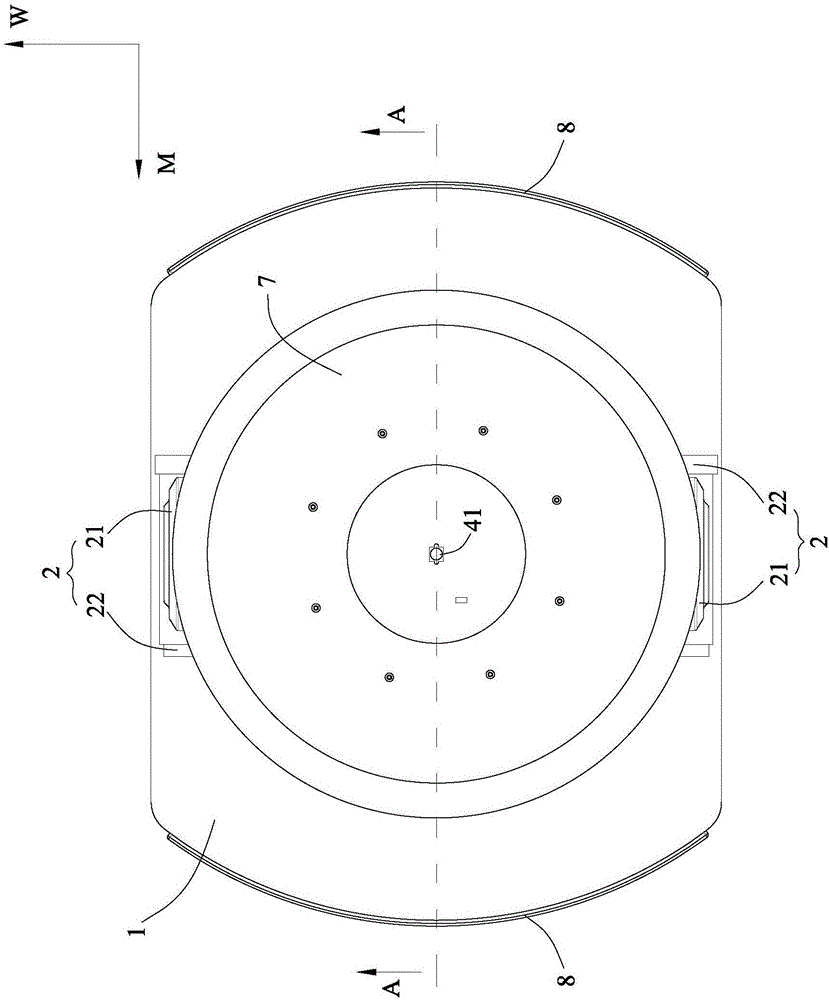

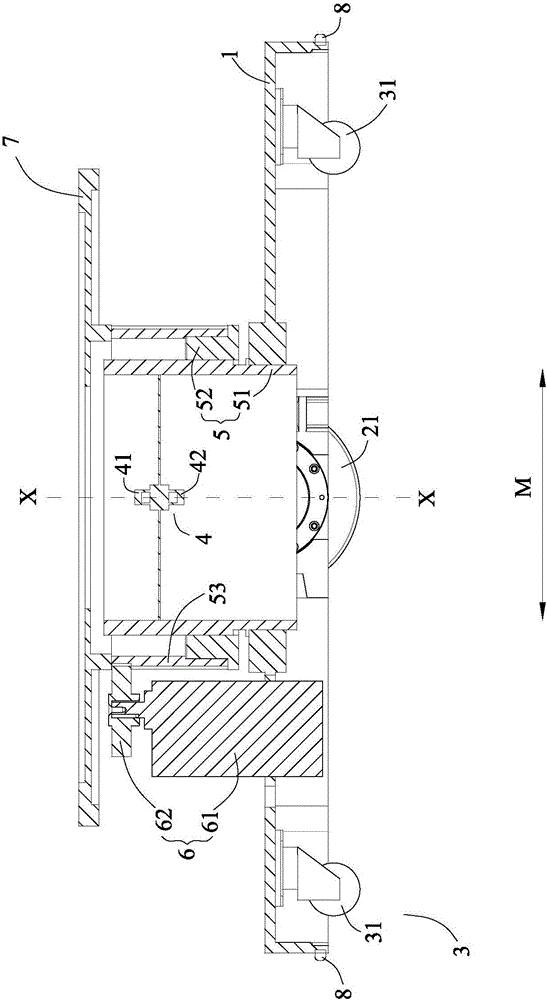

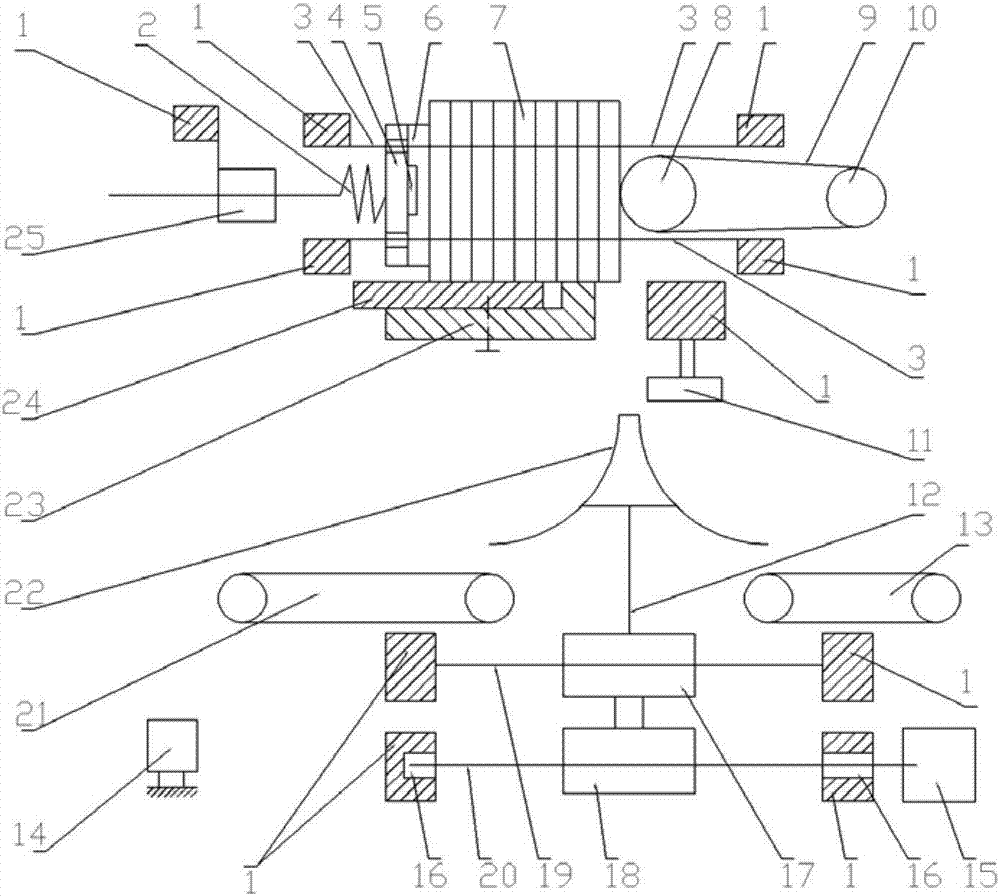

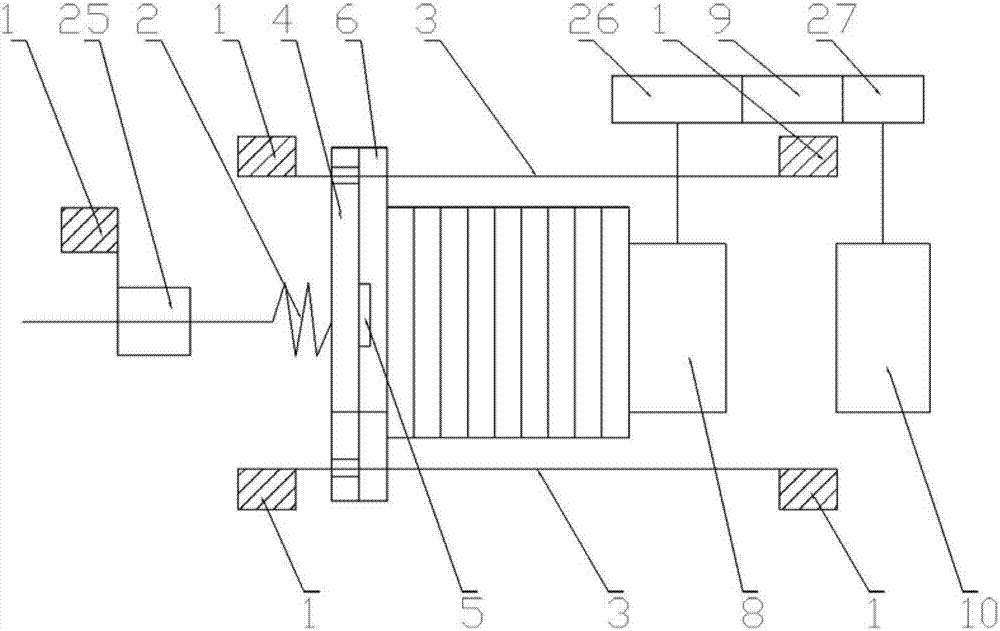

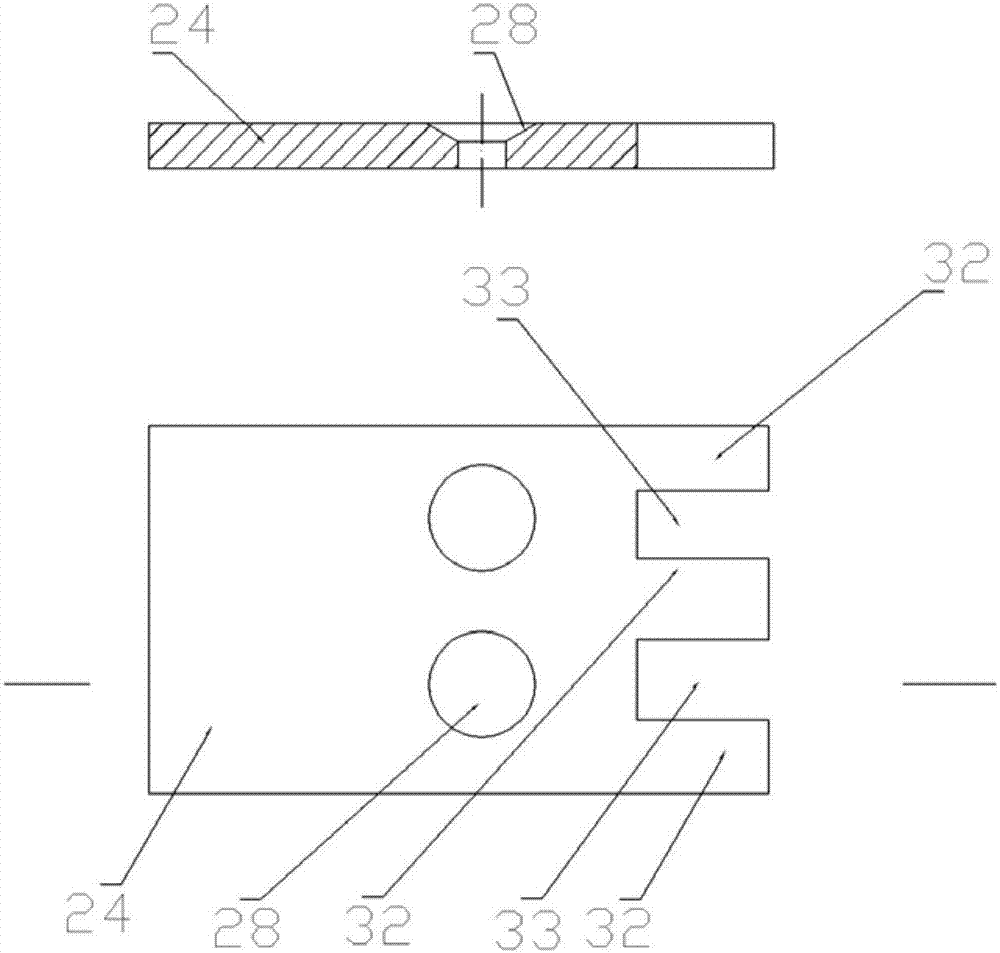

The invention provides a plastic pot edge machine, which includes a frame, 10 turntables to rotate plastic pots and 14 motors connected together through 13 for plastic pot fixation and rotation mechanisms. Labels 1 to 9, 11 are used for plastic basins to compress suction and transport mechanisms. Numbers 15 to 20 are used for trimming knives and knives oscillating mechanisms. The plastic pot edge trimming machine of the present invention can automatically trim and move circular and square plastic pots to realize full-automatic edge trimming and handling. The plastic basin edge trimming machine of the present invention can be matched with the injection molding machine take-out machine, and can realize the automatic unmanned operation production of the plastic basin. Improve quality, reduce production costs and reduce manual labor.

Owner:李伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com