Mechanism for transporting electronic device support plates and recovering support plate baskets

A technology for electronic devices and baskets is applied in the field of mechanisms for transporting electronic device carriers and recycling carrier boards and baskets, which can solve the problems of trouble, high labor intensity of operators, unfavorable production and processing efficiency, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

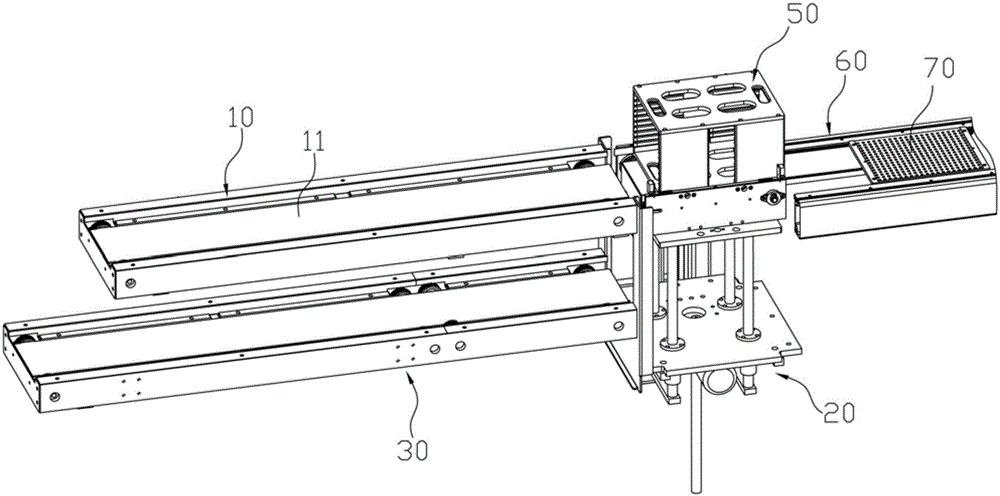

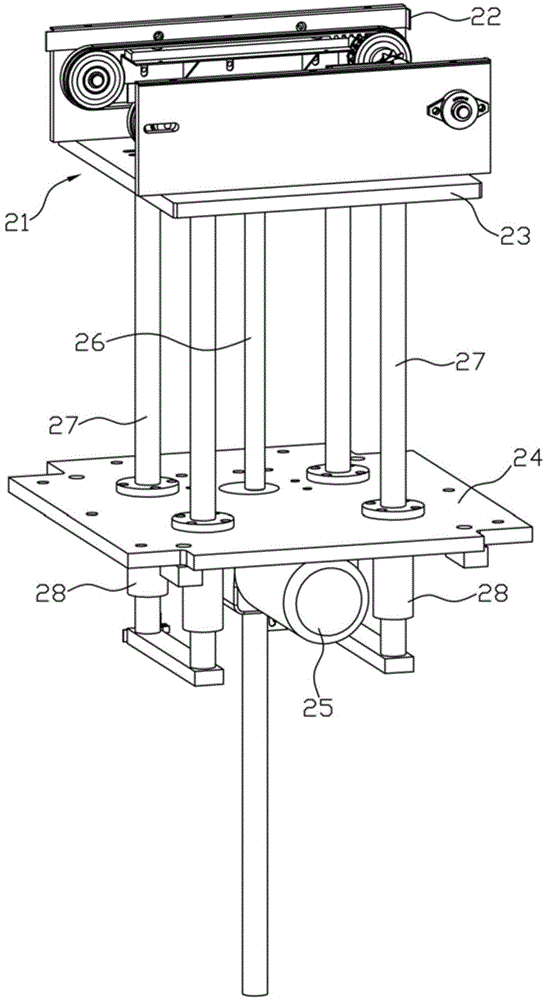

[0025] Such as figure 1 As shown, a mechanism for conveying electronic device carriers and recovering carrier baskets includes a basket conveying track 10 , a lifting device 20 , and a basket recovery track 30 .

[0026] Such as figure 1 As shown, the basket delivery track 10 is located above the basket recovery track 30, one end side of the basket delivery track 10 is flush with one end side of the basket recovery track 30, and the lifting device 20 is located on the basket delivery track 10 is flush with the one end side of basket recovery track 30.

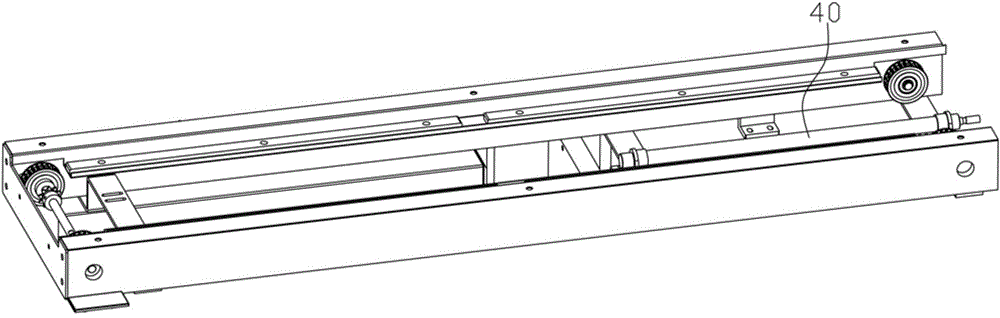

[0027] Such as figure 1 As shown, the basket conveying track 10 includes a conveyor belt and a cover plate 11 . Such as figure 2 As shown, a cylinder 40 is installed on the basket conveying track 10, and the cylinder 40 is located below the cover plate 11. The telescopic direction of the piston rod of the cylinder 40 is the same as the conveying direction of the basket conveying track 10. The cylinder The height of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com