Patents

Literature

1445results about How to "Improve production and processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

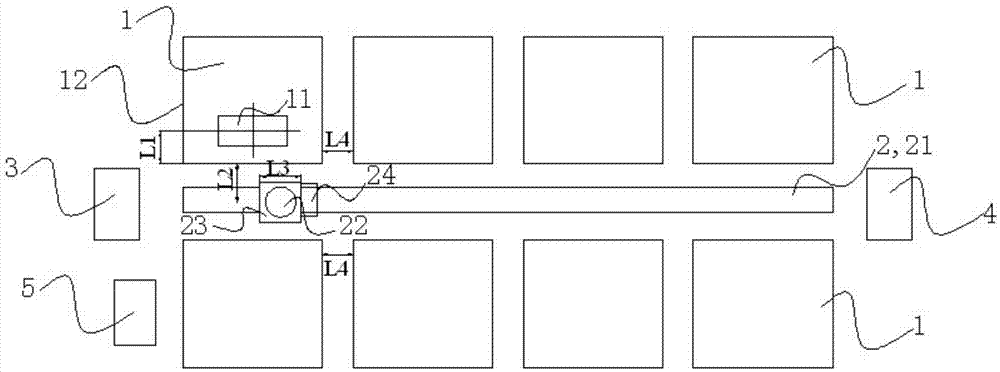

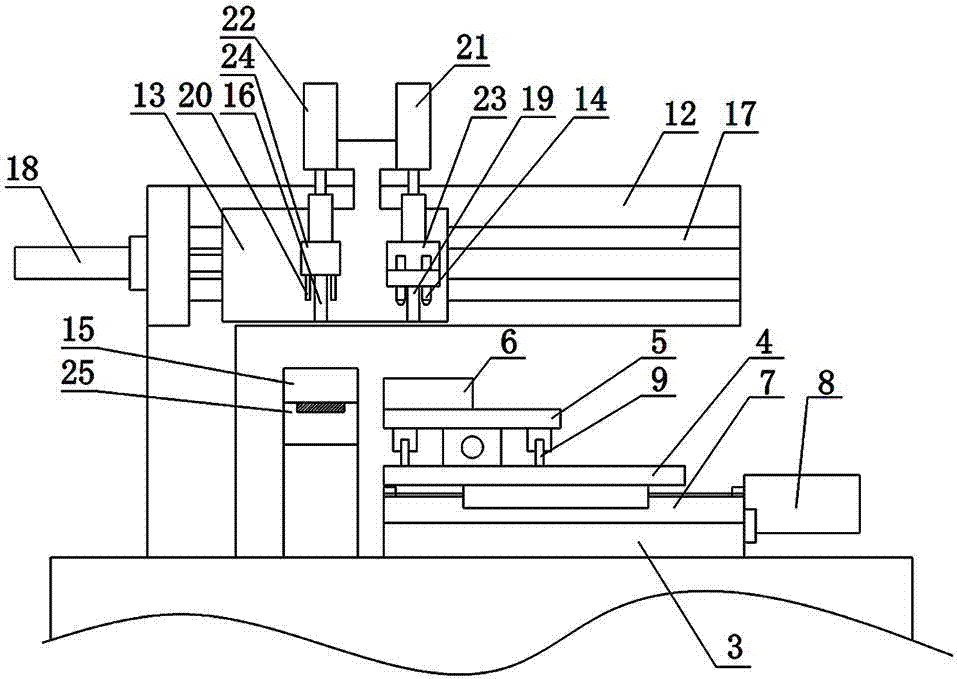

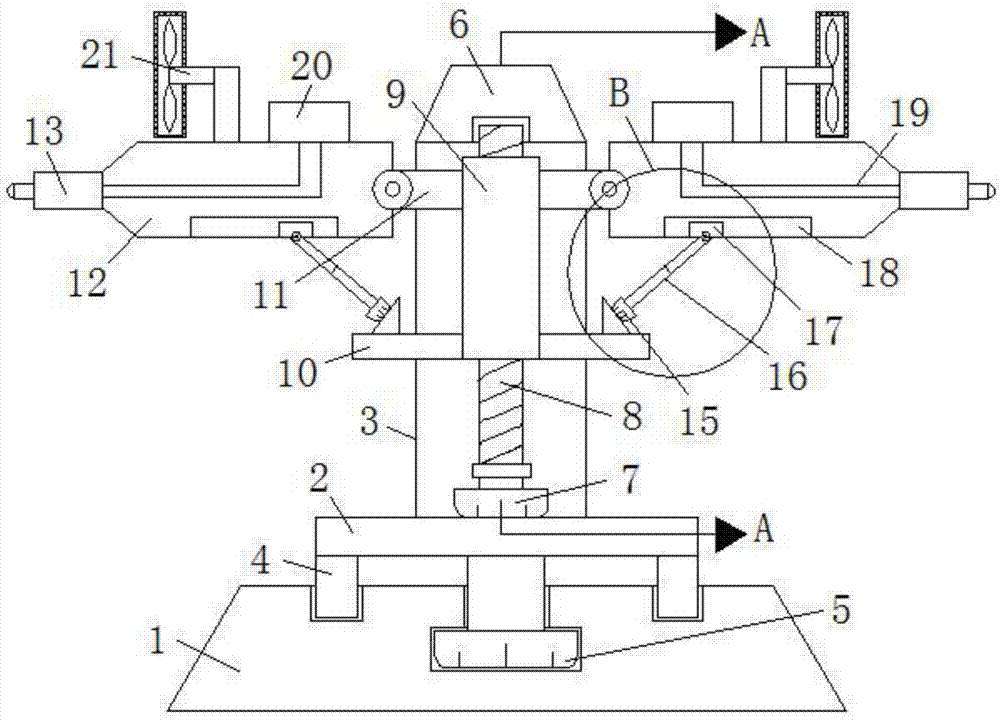

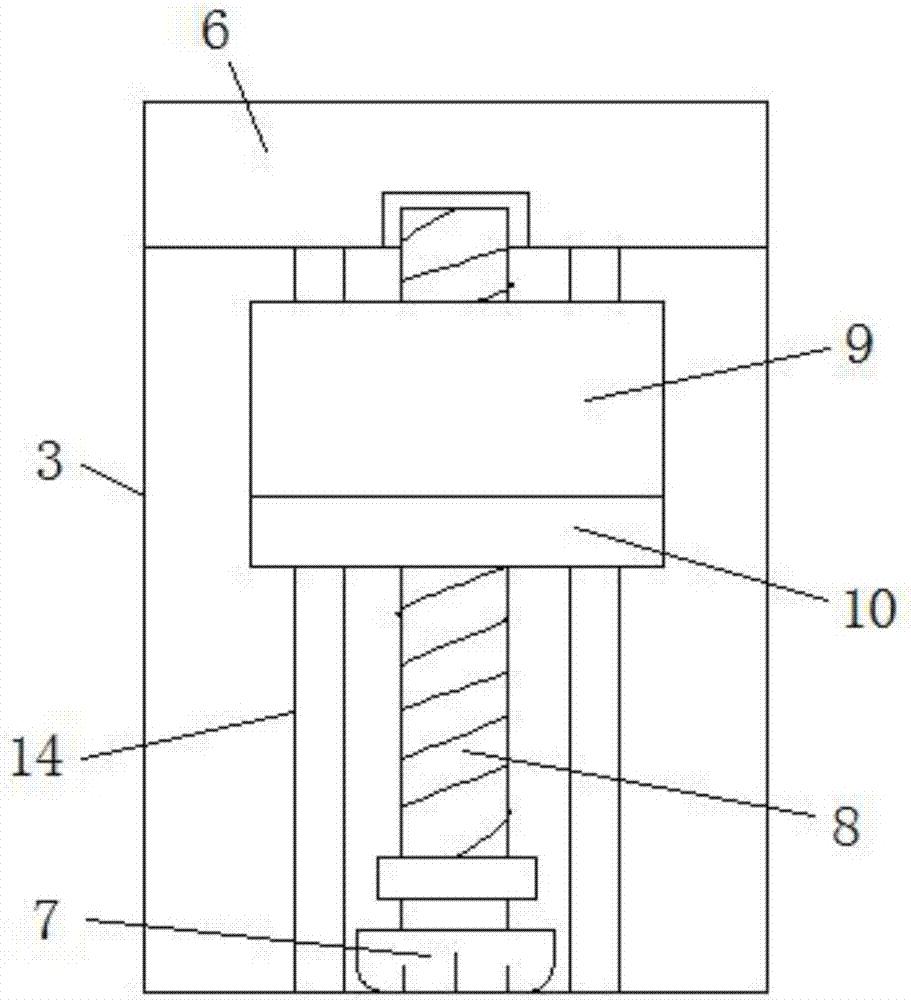

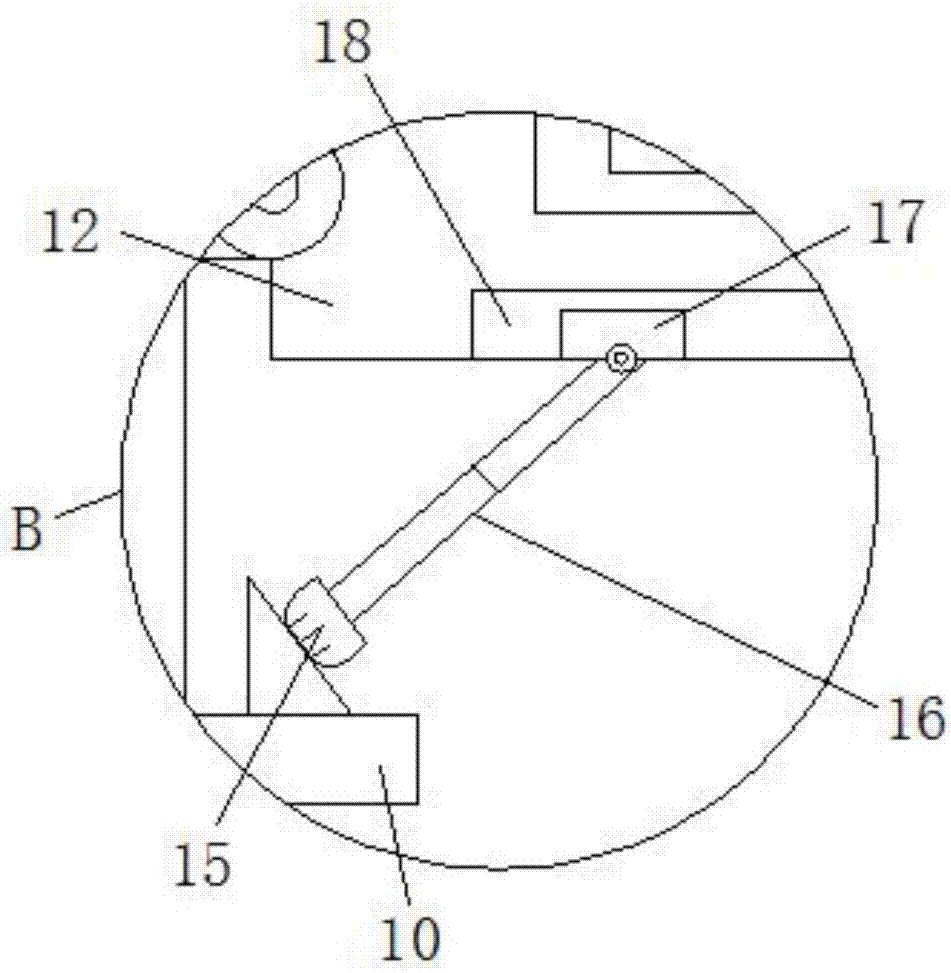

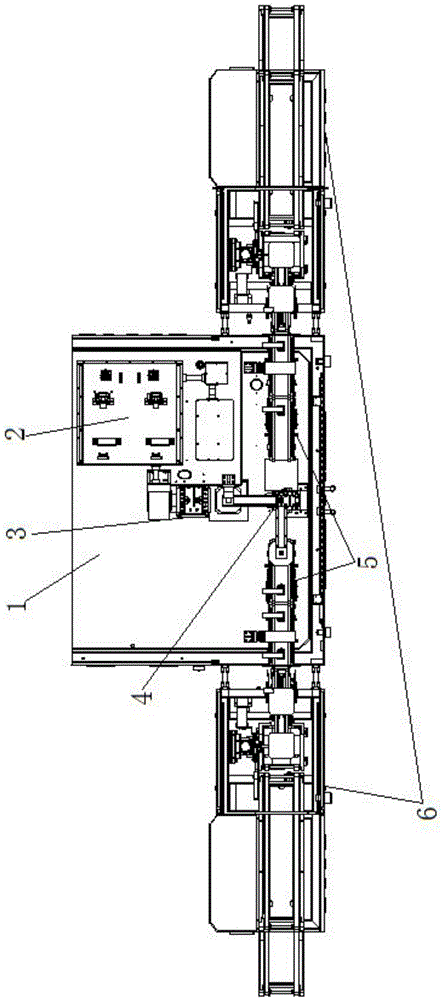

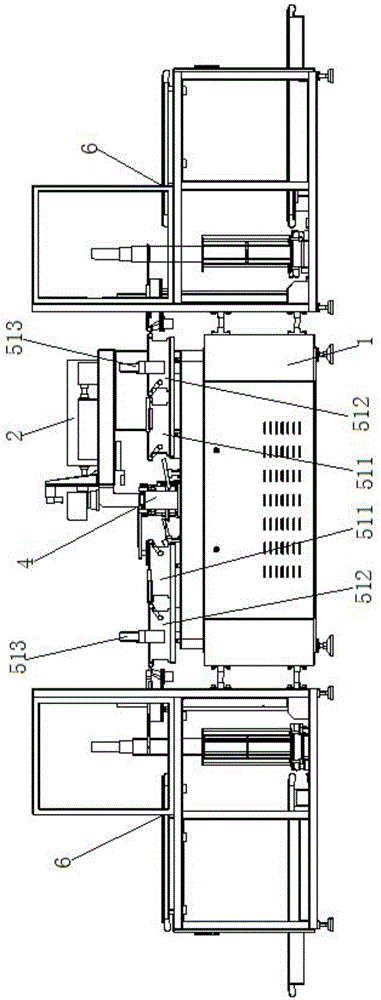

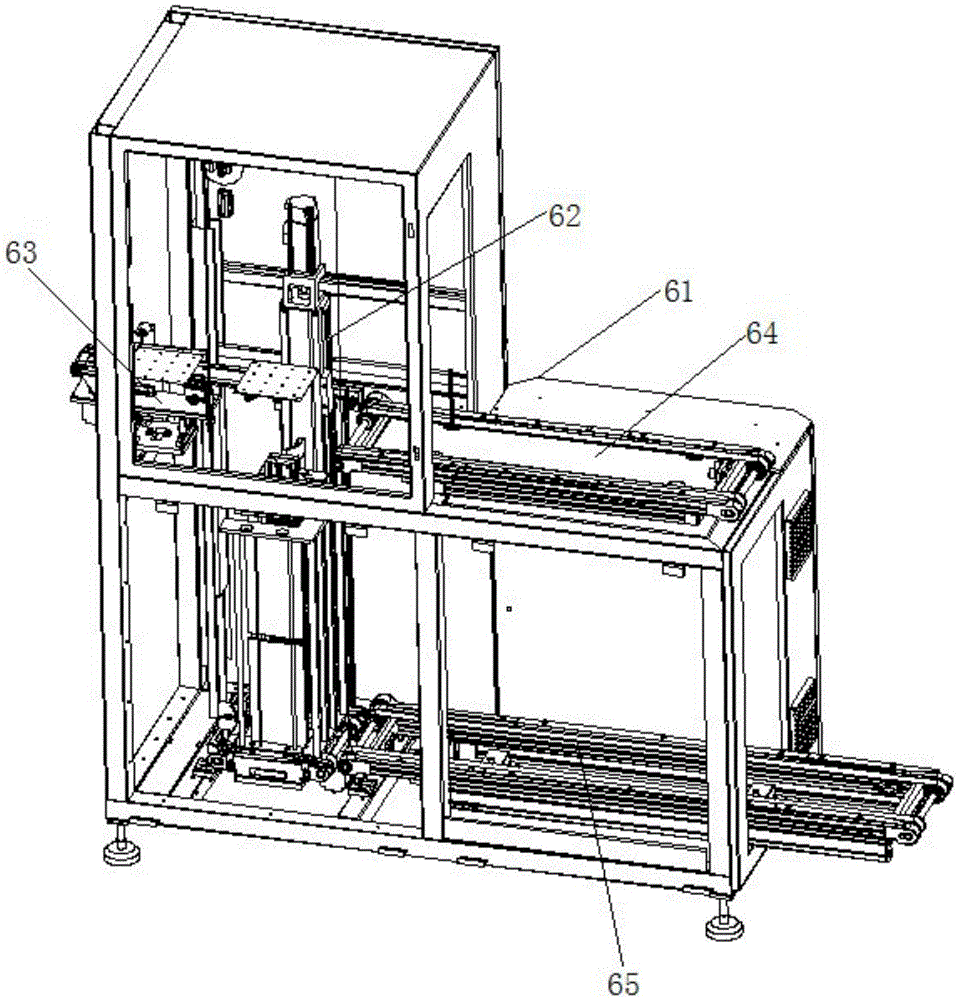

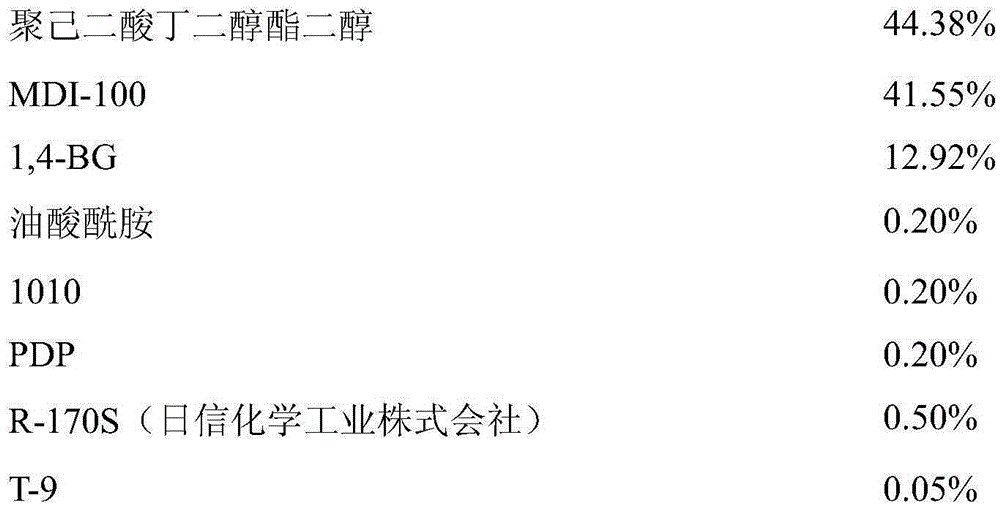

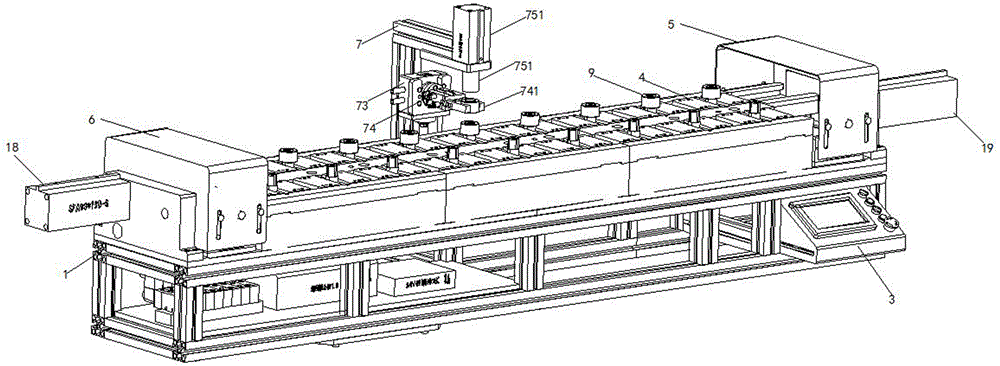

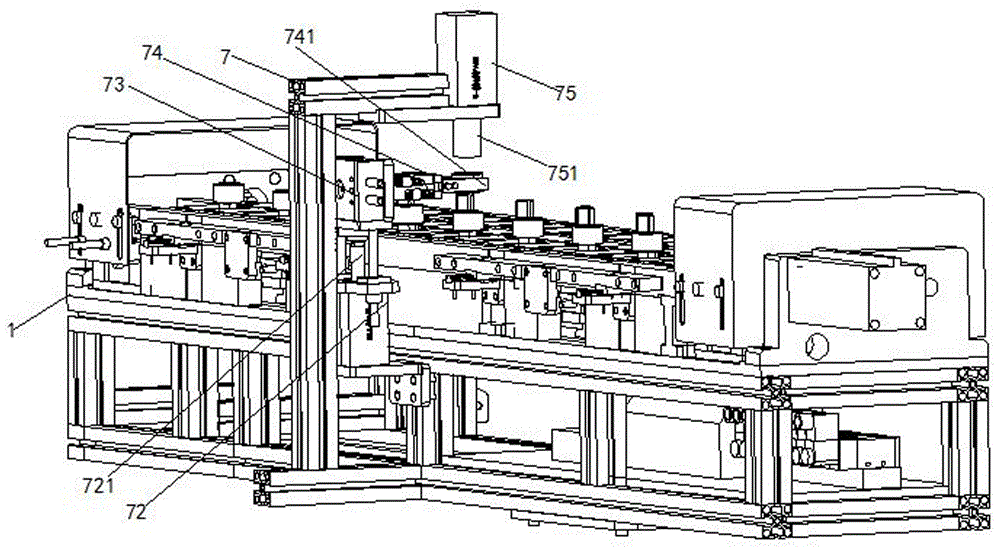

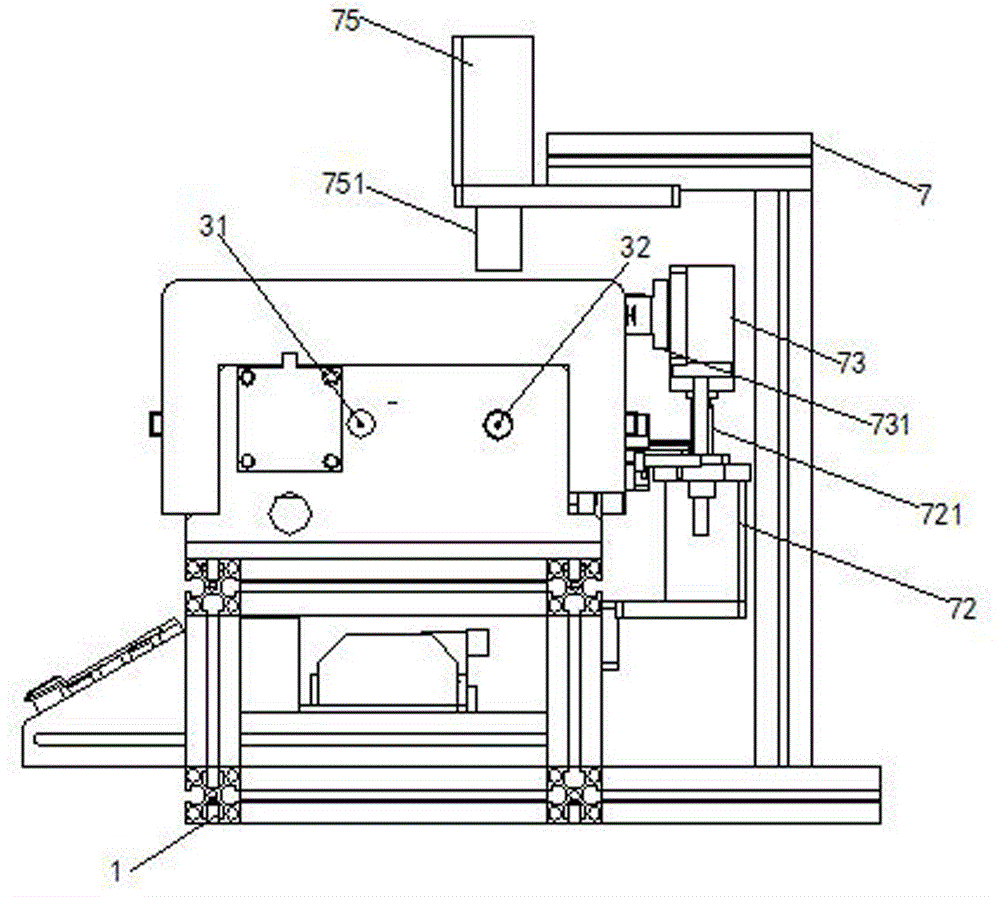

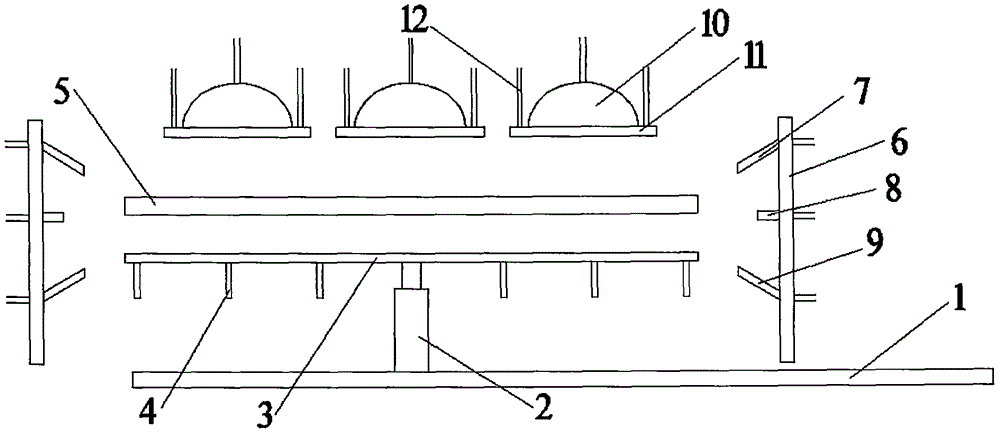

Full-automatic robot-assisted machining production line

InactiveCN104723115AShorten production timeImprove production and processing efficiencyOther manufacturing equipments/toolsMetal working apparatusNumerical controlProduction line

The invention relates to the field of machining, in particular to a full-automatic robot-assisted machining production line which comprises a plurality of numerical-control machine tools, a robot-assisted device and a robot control box. The numerical-control machine tools are divided into two rows, the two rows of numerical-control machine tools are opposite to each other, the robot-assisted device is positioned between the two rows of numerical-control machine tools, and a feeding table and a discharging table are respectively arranged at two ends of the robot-assisted device. The full-automatic robot-assisted machining production line has the advantages that materials can be automatically fed and discharged for the two rows of sequentially arrayed numerical-control machine tools by the robot-assisted device, so that the purpose of controlling a plurality of production lines by a single person can be achieved, the production time can be greatly shortened, the production and machining efficiency can be improved, the labor intensity and the labor cost can be lowered, and various problems due to human factors can be effectively solved.

Owner:CHANGZHOU TRANSCEND CNC MACHINE TOOL

Processing technique of Cui Ya tea

InactiveCN102907509AReduce dosageReduce manual labor intensityPre-extraction tea treatmentMachining processComputer science

The invention discloses a processing technique of Cui Ya tea and belongs to the field of tea processing. The technique includes the steps of picking, hierarchical piling, withering, fixing, spread-cooling, tiding and shaping, drying, aroma enhancing and preparing into tea. In order to overcome the defects that the requirement for staff is high, operation is heavy, palms and fingers are often scalded, production efficiency is low, and a large amount of requirements of market cannot be met, the processing technique of Cui Ya tea can guarantee product quality, manual labor is reduced, scald of fingers and palms in operators is reduced, and production efficiency is improved.

Owner:GUIZHOU MEITAN COUNTY YIYACUIPIAN TEA

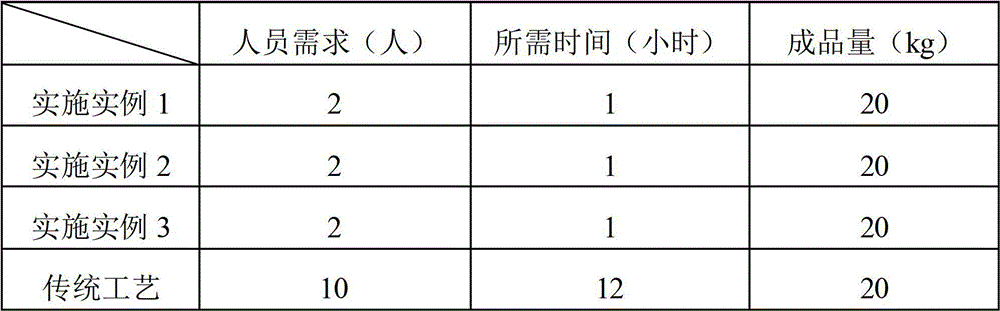

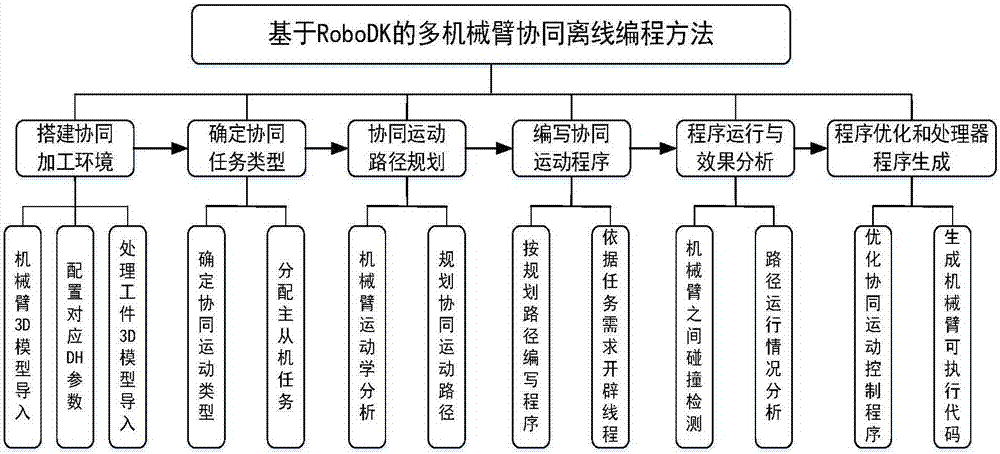

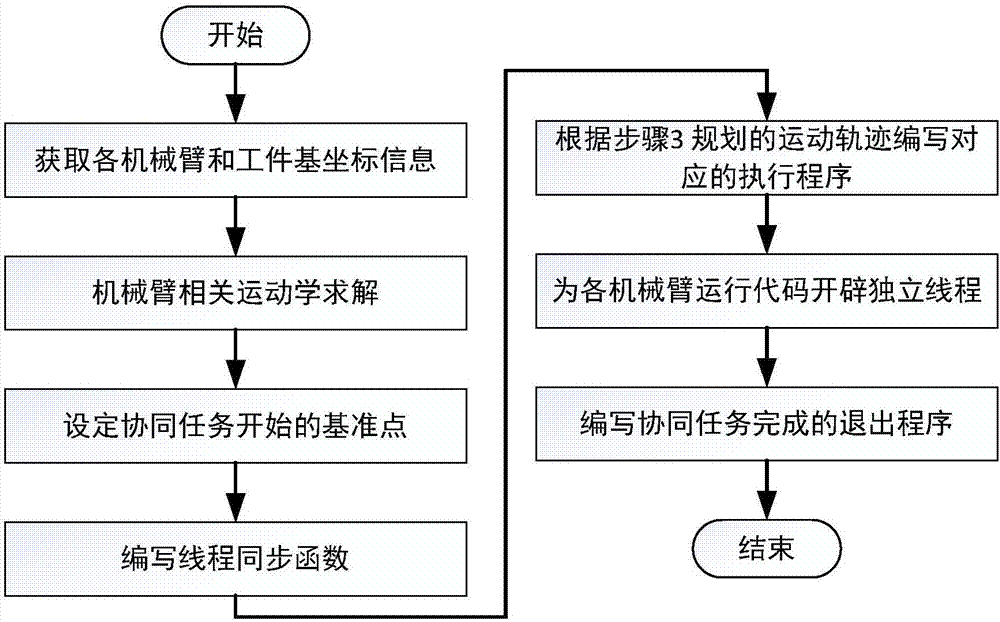

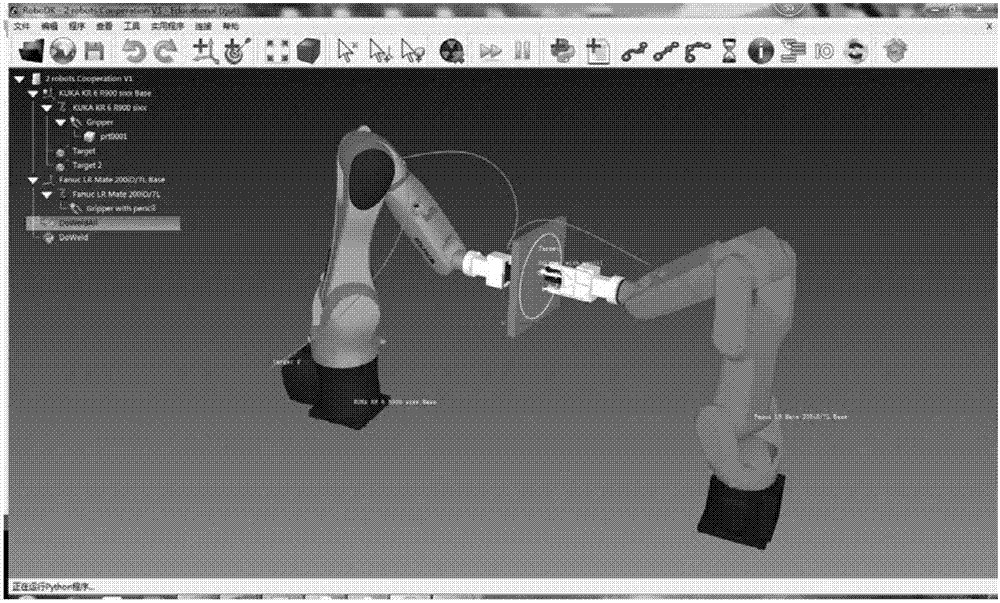

Multi-mechanical-arm collaborative offline programming method based on RoboDK

InactiveCN107486858AEasy to buildFunction increaseProgramme-controlled manipulatorKinematicsWork task

The invention discloses a multi-mechanical-arm collaborative offline programming method based on RoboDK. A multi-mechanical-arm collaborative machining work environment is built in a RoboDK visual interface; a collaborative motion type is determined and master and slave machine work tasks are allocated according to practical workpiece processing needs; mechanical arm kinematics analysis is completed, and a motion path is planned on the designated collaborative motion type; a collaborative work program is compiled with the combination of a RoboDK-API interface function and the planned motion path; the program runs, collision and path deviation conditions are detected, and corresponding are output; the collision and path deviation is processed according to output data, and therefore the planned motion path is adjusted, and the optimal running effect is achieved; and finally, a post processor program is compiled, and a multi-mechanical-arm collaborative practical executable code is generated. By means of the multi-mechanical-arm collaborative offline programming method based on RoboDK, the function of RoboDK is greatly expanded, a new technical scheme is provided for development of the mechanical arm offline programming field, the research and development cycle of multi-mechanical-arm collaborative machining is shortened, and the producing and machining efficiency is greatly improved.

Owner:ZHEJIANG UNIV OF TECH

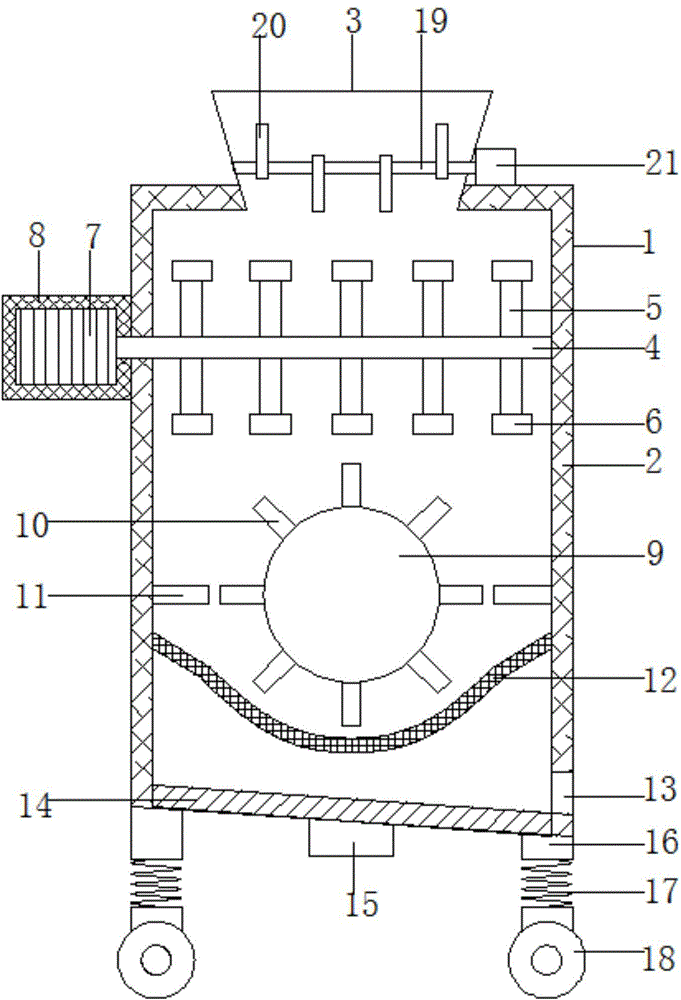

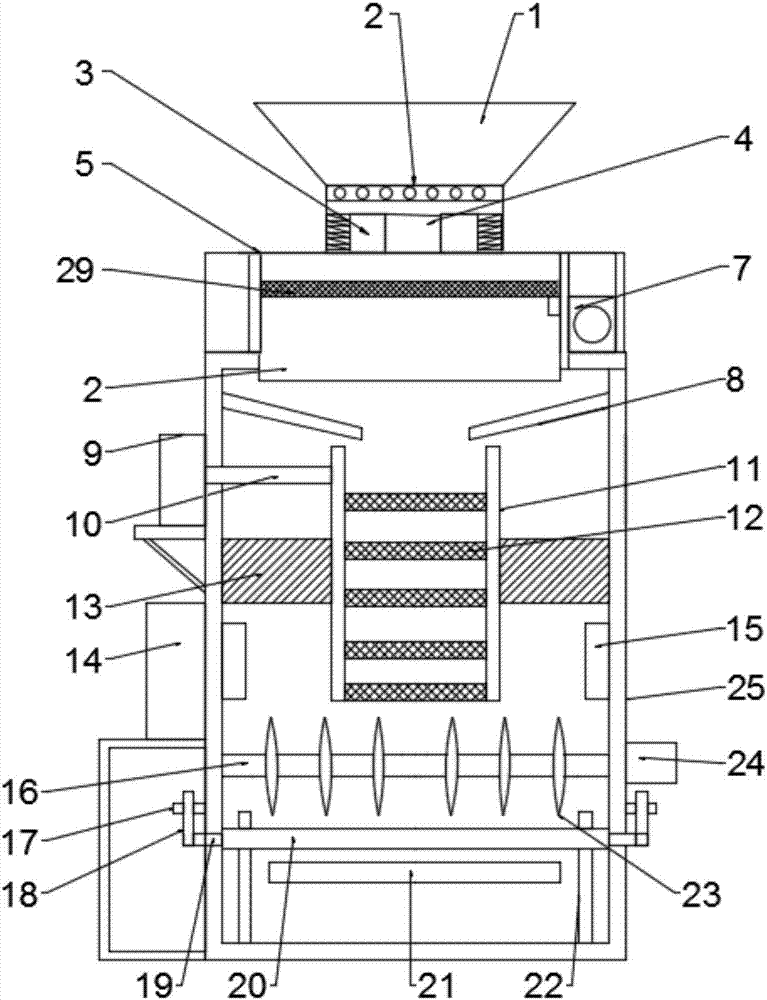

Movable anti-blocking pulverizer for ceramic production

InactiveCN104923344AAvoid cloggingImprove crushing effectGrain treatmentsElectric machineryDrive motor

The invention discloses a movable anti-blocking pulverizer for ceramic production. The movable anti-blocking pulverizer for ceramic production comprises a pulverizer body, a rotary shaft and eccentric wheels, wherein an electric heating layer evenly covers the outer wall of the pulverizer body, a feeding funnel is connected to the upper side of the pulverizer body, the rotary shaft is horizontally arranged in the feeding funnel, the eccentric wheels are evenly arranged on the rotary shaft, the centers of the eccentric wheels are evenly distributed around the rotary shaft, and the right end of the rotary shaft extends out of the feeding funnel to be connected with a driving motor. The movable anti-blocking pulverizer for ceramic production adopts two pulverizing mechanisms to pulverize a material, can fully pulverize the material, the working efficiency of the pulverizer is improved, the pulverizing effect is ensured, the material is heated and dried in the pulverizing process, material production efficiency is improved, vibration can be effectively reduced through the arranged eccentric wheels, material blockage in the feeding funnel can be prevented, and continuous feeding is ensured. In addition, noise of the pulverizer during working is small, the pulverizer can be freely and conveniently moved, and practicability and convenience are high.

Owner:顾广才

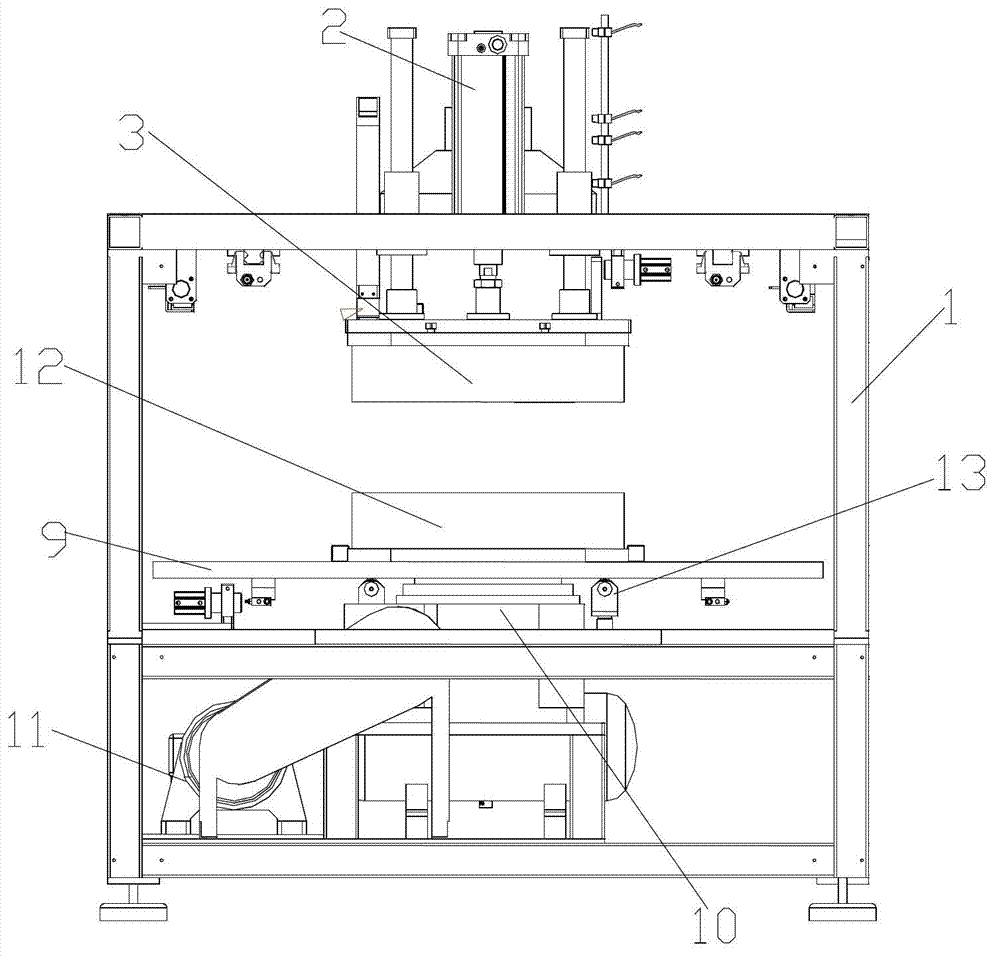

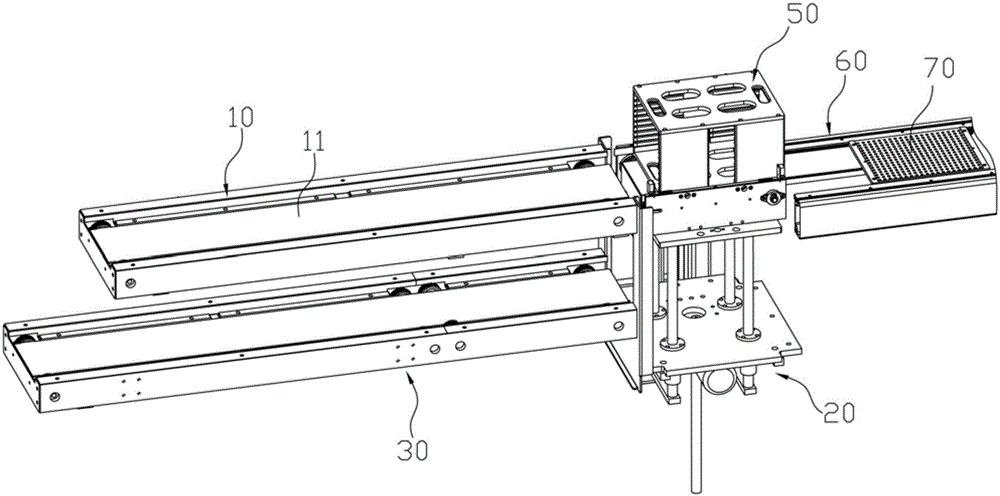

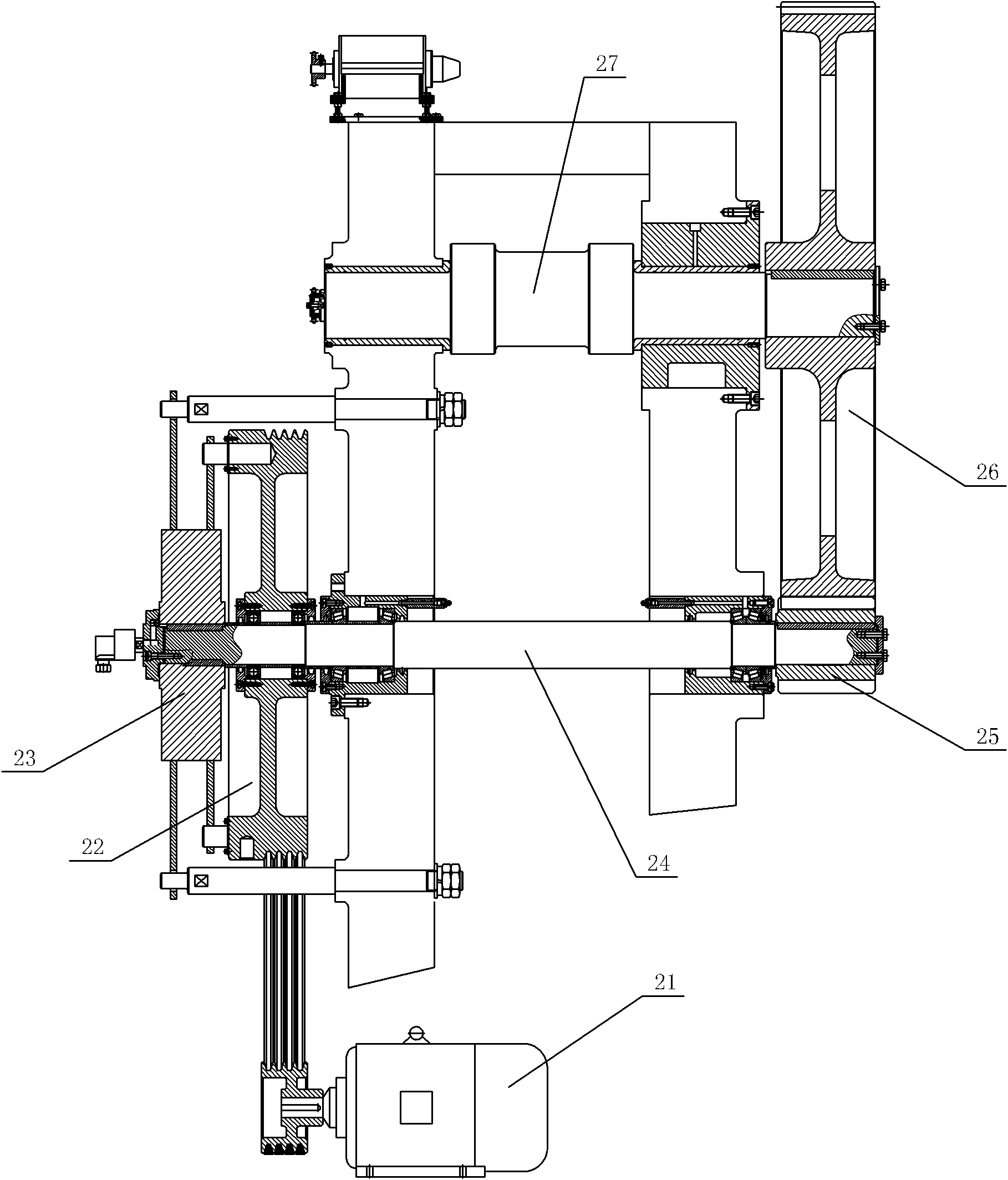

Double-station rotation type gimbal hot plate welding machine

The invention discloses a double-station rotation type gimbal hot plate welding machine which comprises a machine frame and a hot die transmitting device, wherein a main cylinder is arranged at the top end of the machine frame, a piston end of the main cylinder is connected with an upper die clamp, and the hot die transmitting device comprises a hot template and a horizontal cylinder controlling the hot template to move horizontally. The double-station rotation type gimbal hot plate welding machine further comprises a rotating working table located below the machine frame. A clearance separator is arranged below the rotating working table, driven by a speed reducer and provided with two lower die clamps, and the two lower die clamps are evenly distributed at an interval of 180 degrees with a rotating shaft of the rotating working table. According to the technical scheme, by designing the rotating working table, the traditional gimbal processing feeding process is changed, the two lower die clamps alternately performs processing, the production processing efficiency is greatly improved, unnecessary switching efficiency in the machine production processing process is also greatly reduced, and energy is saved.

Owner:SUZHOU KEBER PRECISION MACHINERY

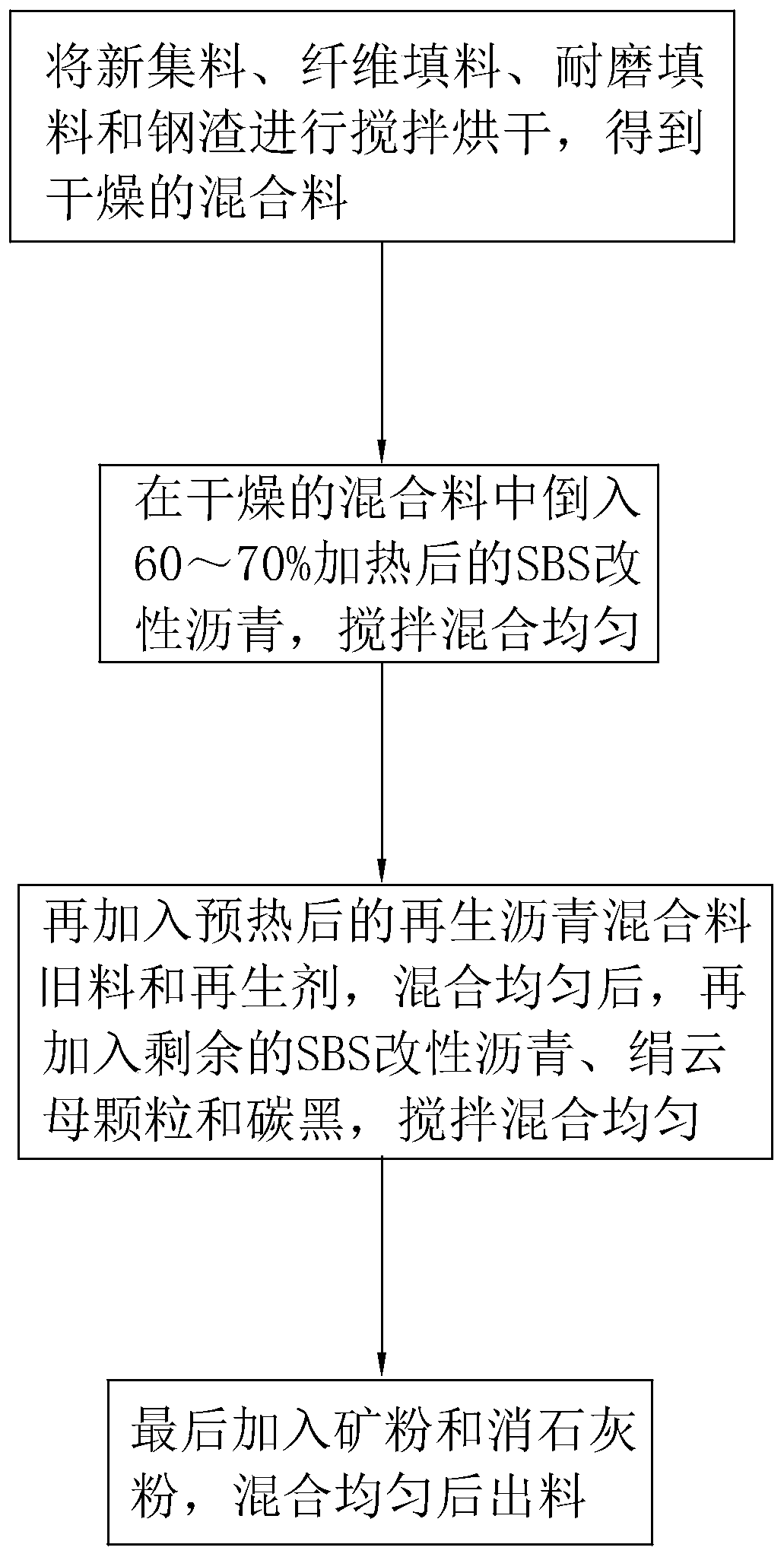

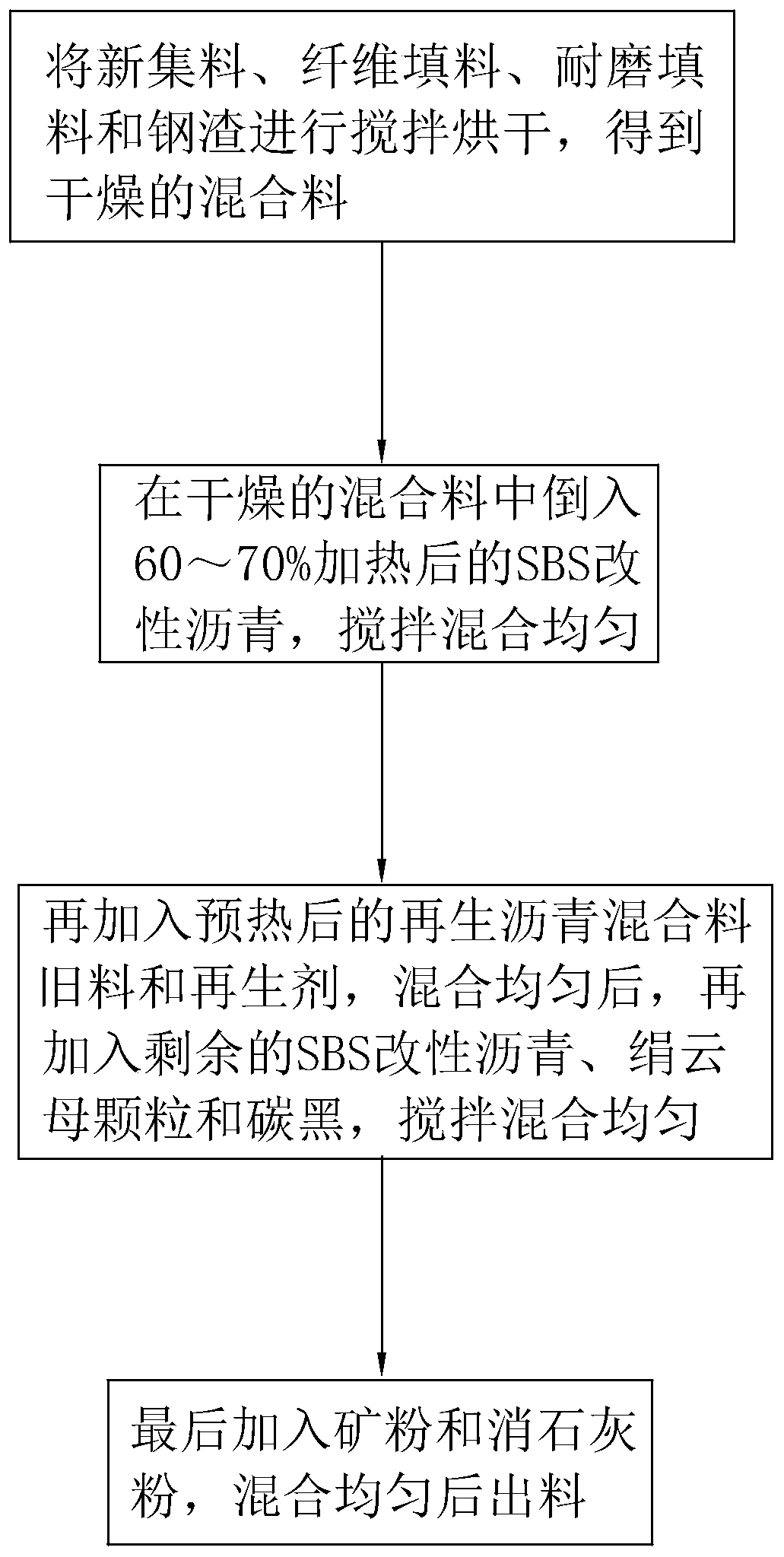

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

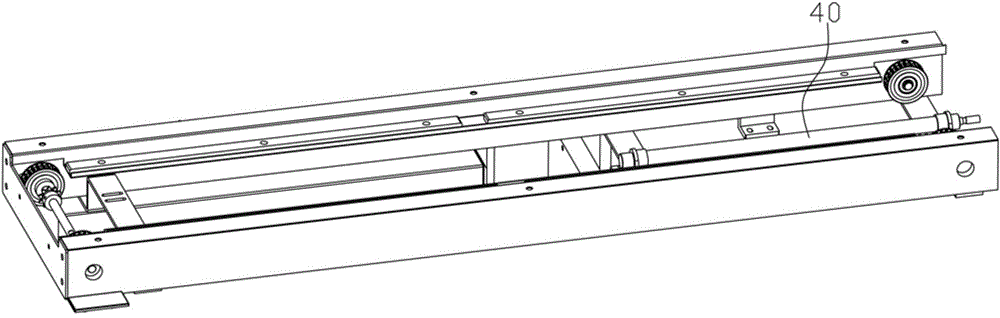

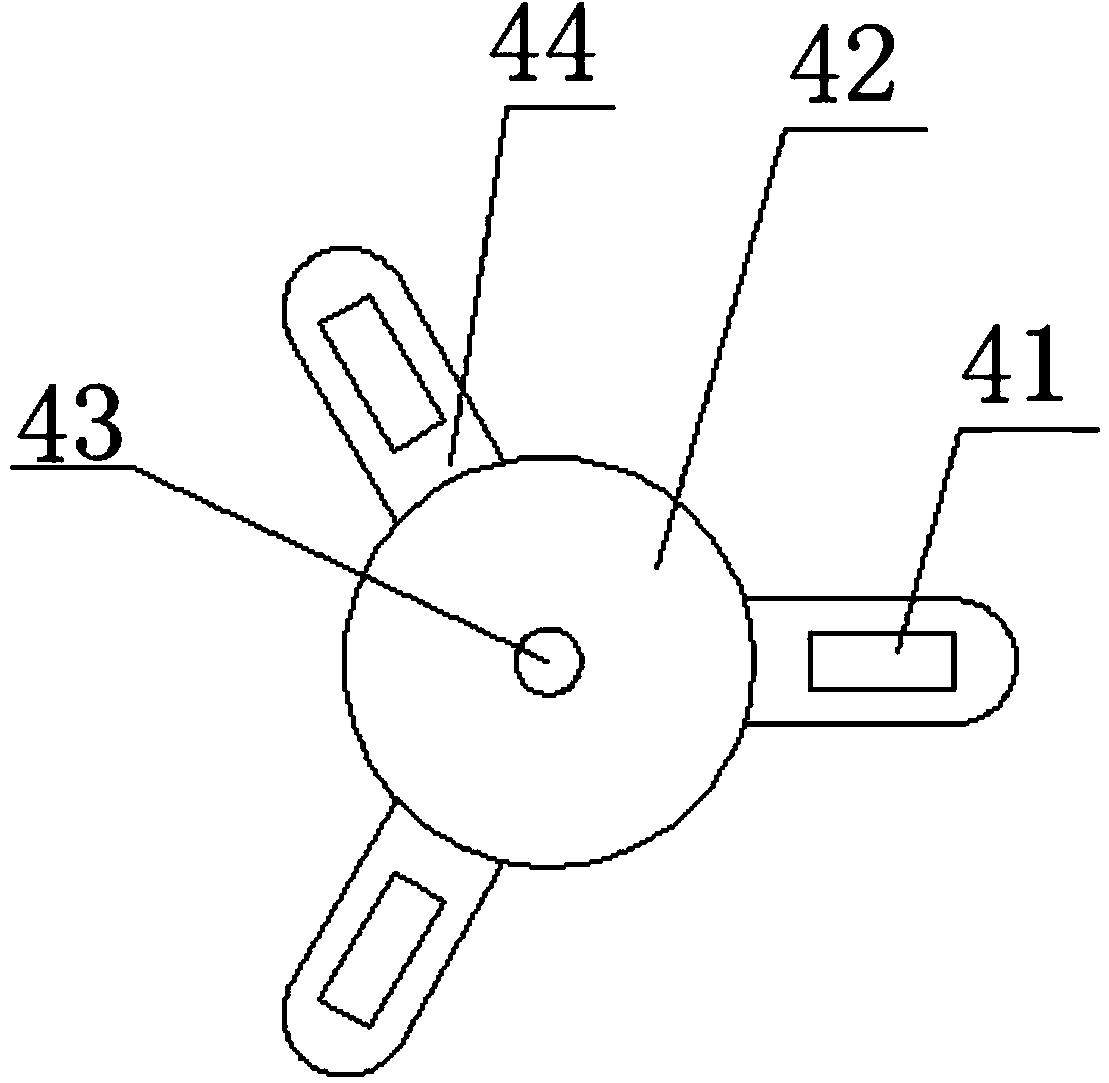

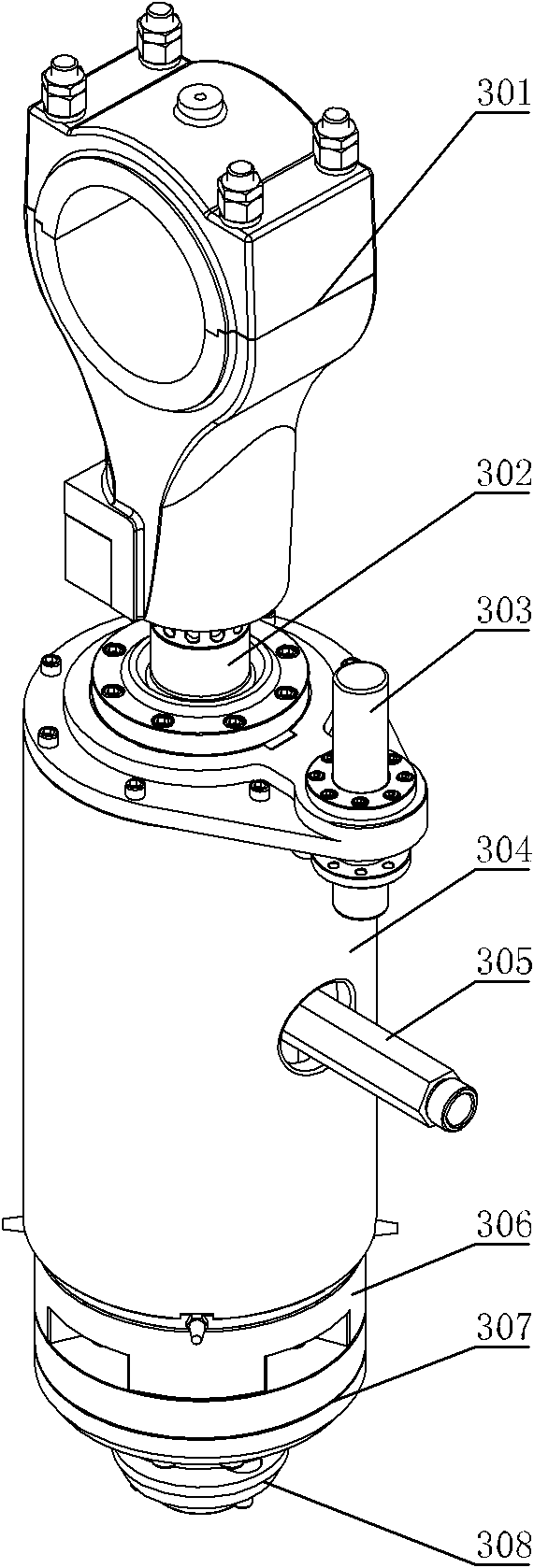

Automatic riveting device

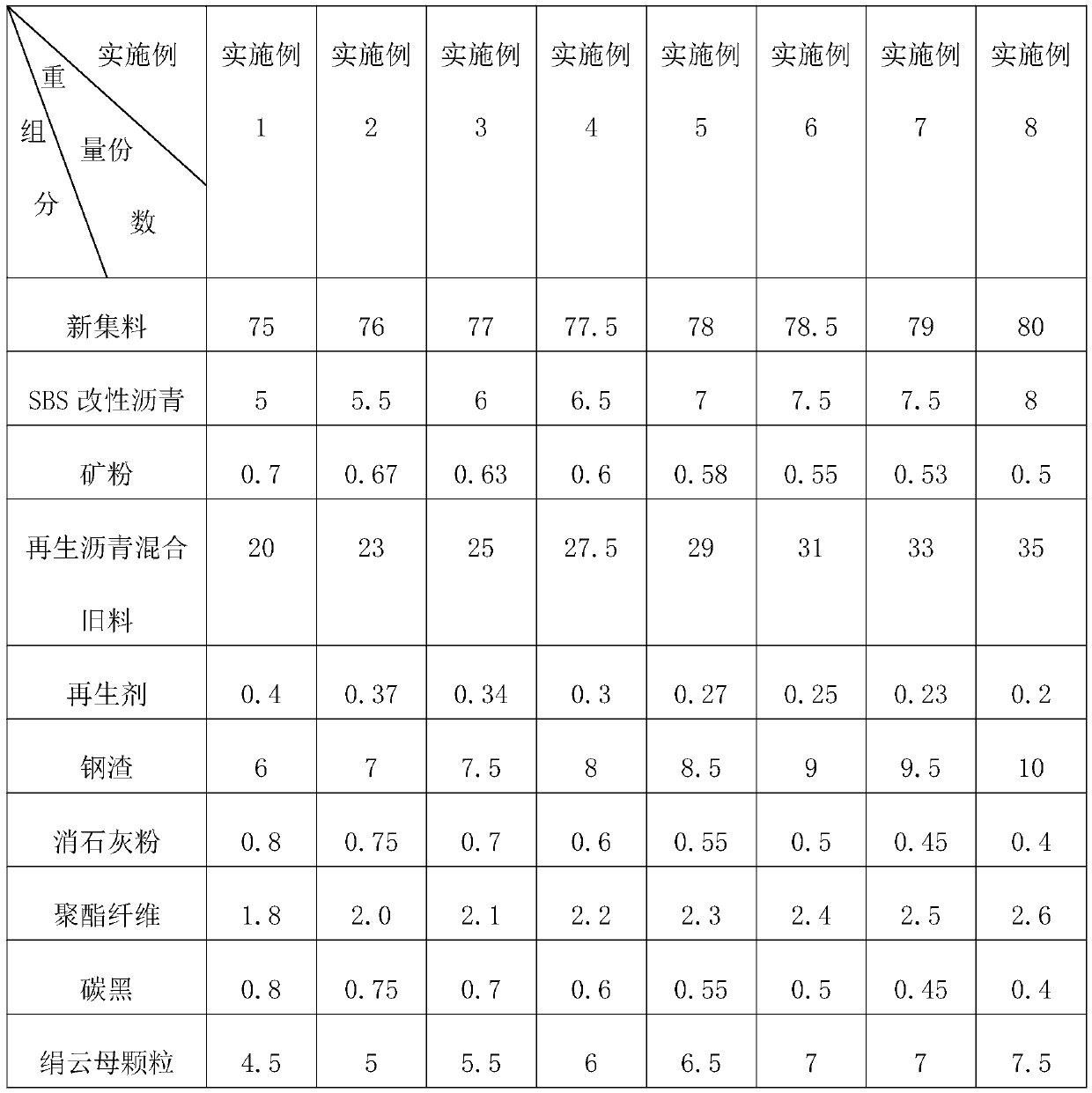

The invention discloses an automatic riveting device which comprises a rack (1), a material belt placing disk (2), a rivet loading device, a riveting and pressing device, a material dragging device and a cutting device. The material belt placing disk (2), the rivet loading device, the riveting and pressing device, the material dragging device and the cutting device are sequentially arranged on the rack (1), the material belt placing disk (2) is installed on the rack (1) through a rotating shaft, the rivet loading device comprises a rivet feeding device and a rivet installing device, a material storing groove (42) is further arranged on the rack (1) at a discharging end of the cutting device, and a discharging guide rail (43) is arranged between the cutting device and a discharging groove and fixedly installed on the rack (1). The automatic riveting device has the advantages of being simple in structure, convenient to use and capable of saving labor costs, reducing labor intensities of operators, achieving full automatic production of loading, installing, riveting and cutting, greatly improving production and processing efficiencies and guaranteeing uniform processing qualities.

Owner:CHENGDU HOMIN TECH

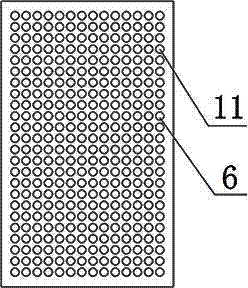

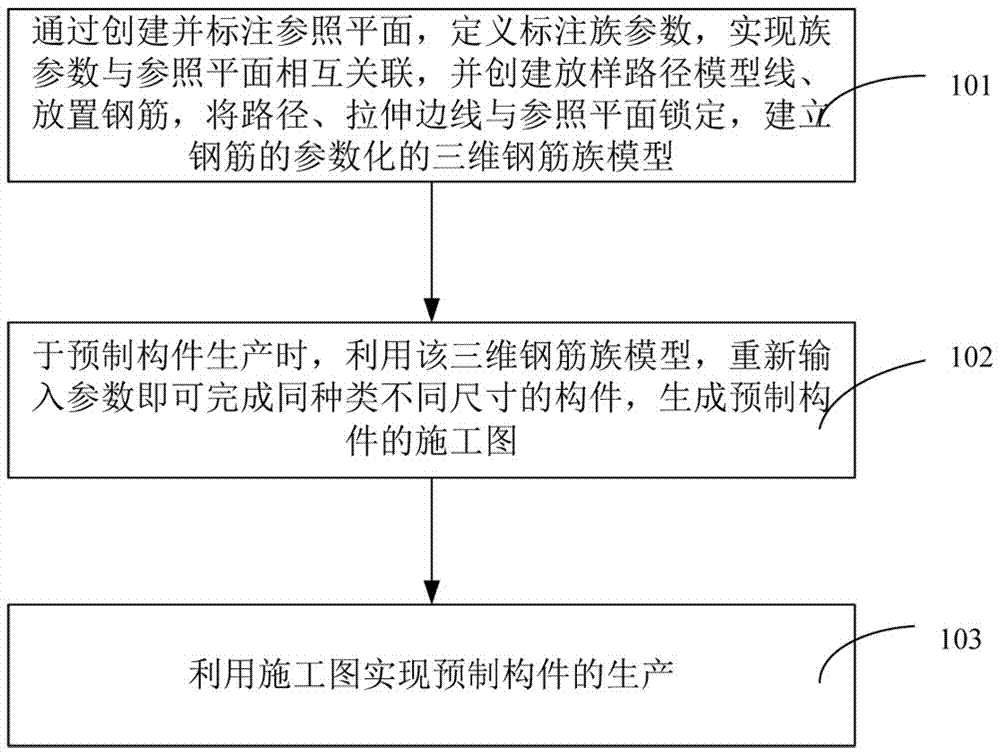

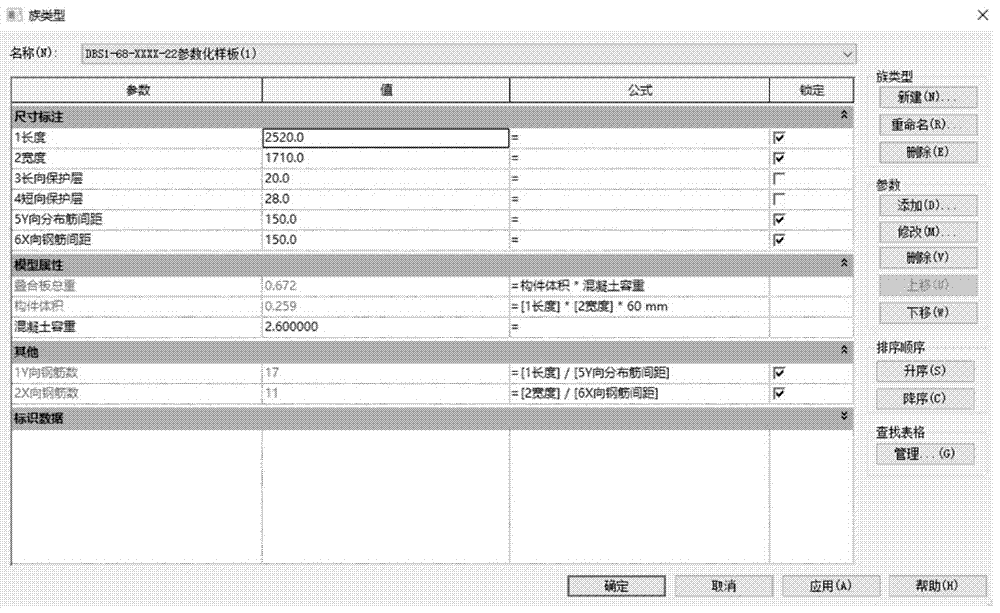

Production method and production system for parameterized steel bars applied to prefabricated components

ActiveCN107220462AImprove production and processing efficiencyRealize fine controlDesign optimisation/simulationSpecial data processing applicationsRebarProduction drawing

The invention discloses a production method and a production system for parameterized steel bars applied to prefabricated components. The production method includes: by means of establishing and labelling a reference plane and defining labelled family parameters, realizing interrelation between the family parameters and the reference plane, establishing lofting path model lines and steel bar placement, locking paths and extension edge lines with the reference plane, and establishing a parameterized three-dimensional steel bar family model for the steel bars; during production of the prefabricated components, by the aid of the three-dimensional steel bar family model, re-inputting parameters to complete size change of same types of the components, and generating a production drawing; by the aid of the production drawing, realizing large-scale and refined production for the prefabricated components. The production method and the production system have the advantages that shape and size of the needed steel bars can be generated quickly by only modifying a few parameters, refined controlling of the steel bars is realized, constraints of inflexible freehand sketching for the steel bars by AutoCAD (automatic computer-aided design) are ridded of, the parameters of the steer bars can be input into various steel bar fabricating facilities directly, and convenience is brought to production and fabrication.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

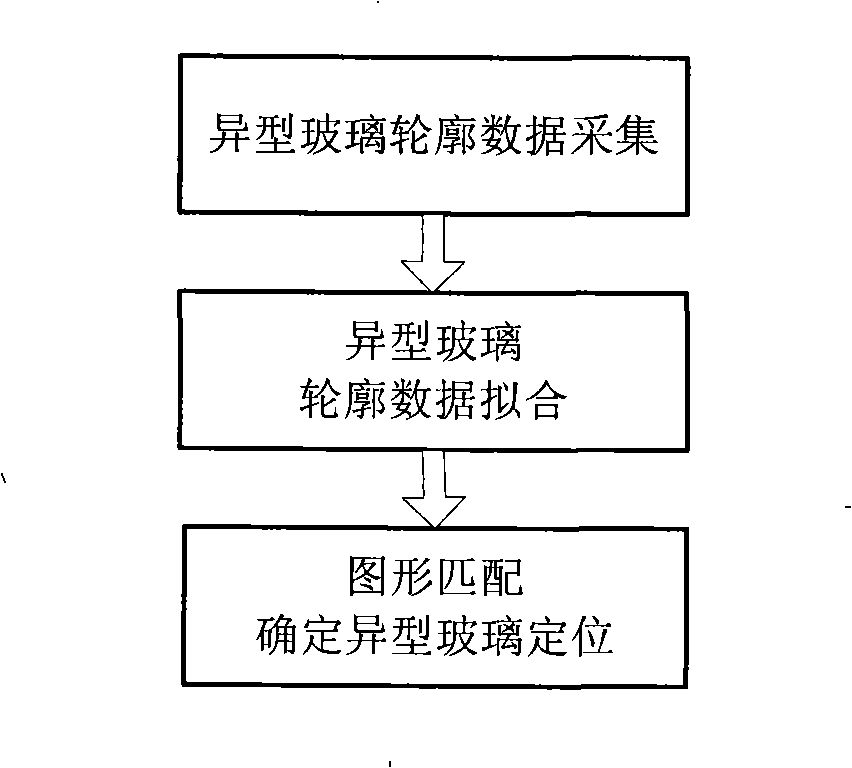

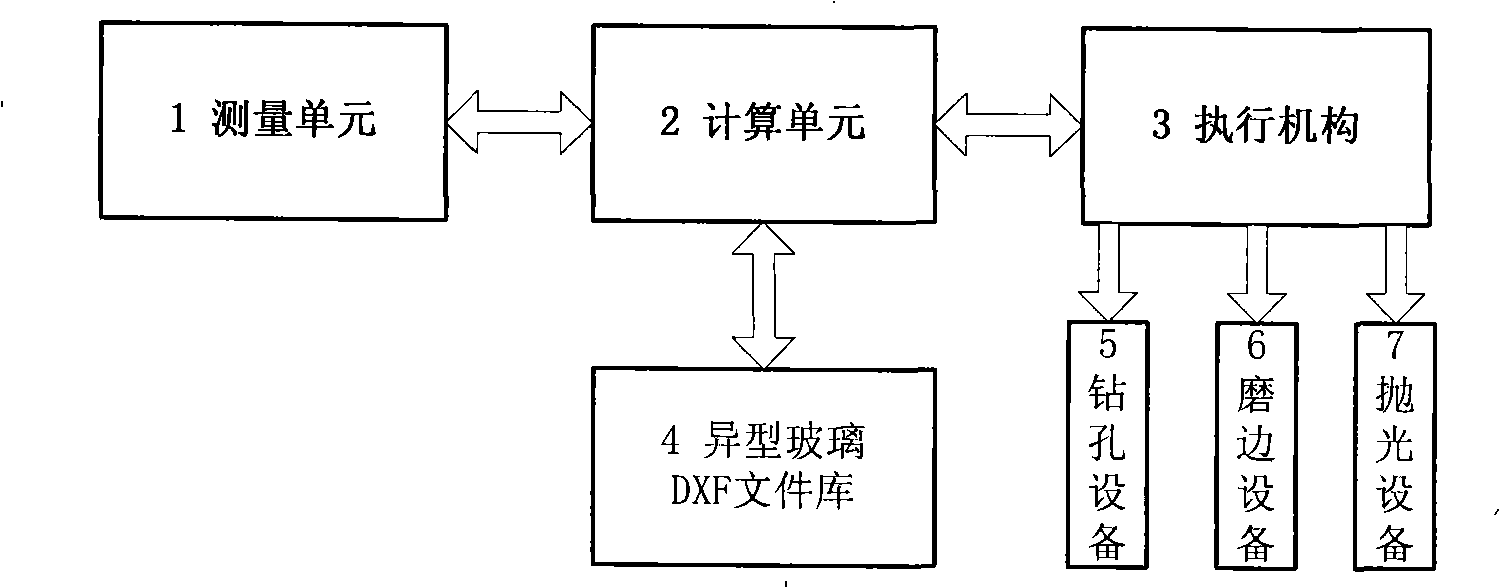

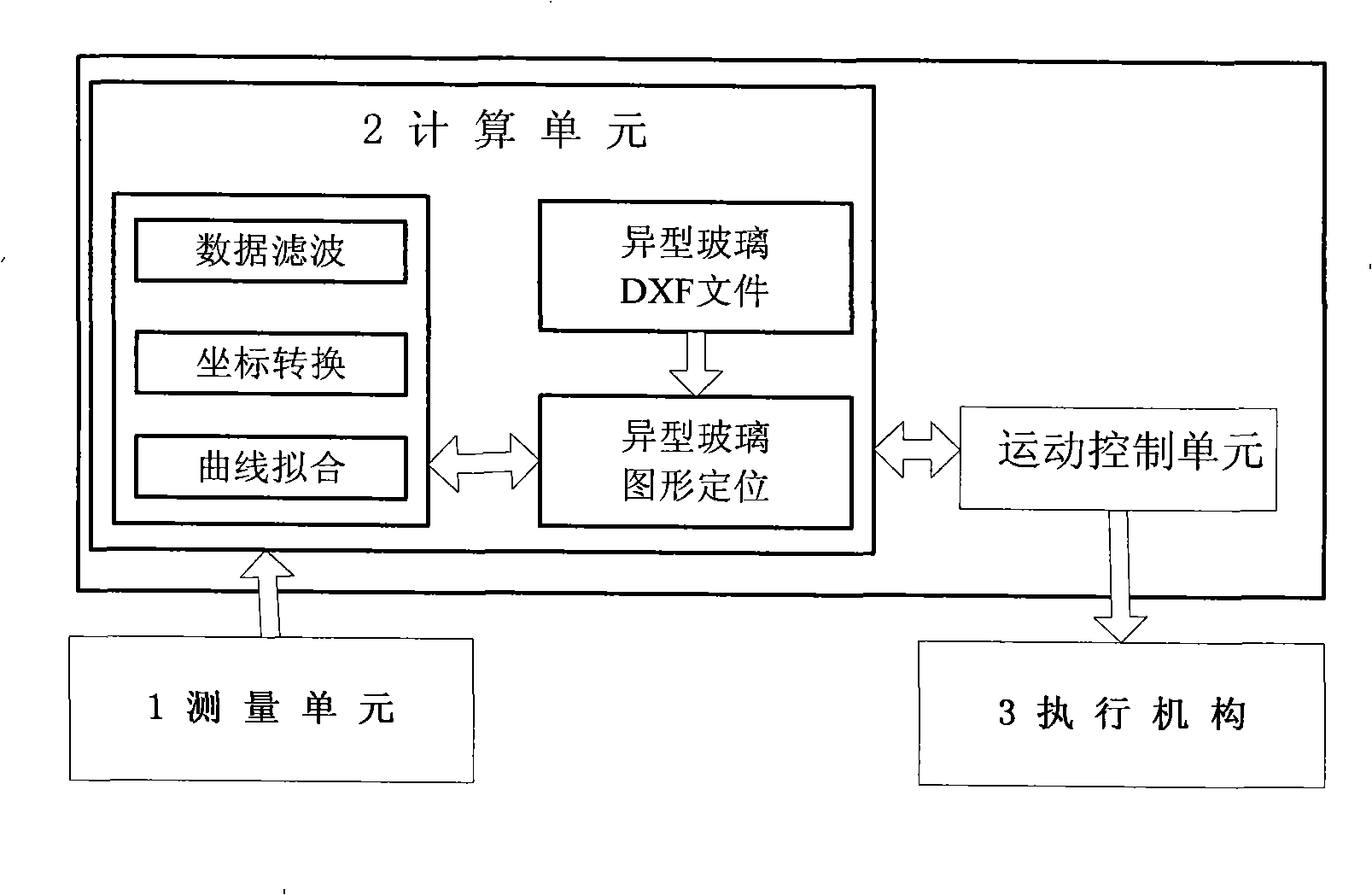

Method and system for positioning special-shaped glass processing pattern

InactiveCN101281403AAccurate detectionRapid positioningProgramme controlComputer controlGraphicsSystem hardware

This invention refers to a processing image positioning method and system for special-shaped glass. The operation steps of this method are: (1) collecting outline data of the special-shaped glass through a method of scanning practical outline of the special-shaped glass; (2) fitting the practical outline data of the special-shaped glass, and reproducing the practical outline of the special-shaped glass: (3) comparing the practical outline of the special-shaped glass with the theoretical outline of the special-shaped glass through matching the image, determining the practical gesture of the special-shaped glass in the processing system, and finishing the positioning. This system is: a measuring unit is connected with an execution mechanism through a computing unit which is connected with a DXF file base of the special-shaped glass; the execution mechanism is connected with a drilling implement, an edger unit and a polishing device. The automatic positioning function of the special-shaped glass can be realized through adopting the method and system provided by this invention on the current processing system and configuring (glass drilling implement, glass edger unit and a plurality of combined processing units) to the current system hardware structure based on the processing need.

Owner:SHANGHAI UNIV

Spraying type industrial robot

InactiveCN107321534AEasy to sprayThe turntable turns smoothlySpraying apparatusPretreated surfacesCouplingEngineering

The invention discloses a spraying type industrial robot. The spraying type industrial robot comprises a base; annular clamping blocks are arranged on the base through annular clamping grooves, a rotary table is fixedly connected to the annular clamping blocks, the center of the bottom of the rotary table is connected with a first driving motor through a first rotary shaft, the first driving motor is fixed in an inner cavity of the base, a fixing frame is fixedly connected to the rotary table, a second driving motor is arranged at the bottom of the fixing frame, the second driving motor is connected with a coupler through a second rotary shaft, a threaded rod is arranged at the end, far away from the second rotary shaft, of the couple, the external of the threaded rod is screwed with a movable part, and connecting rods are symmetrically and fixedly connected to the two sides of the outer wall of the movable part; a mechanical arm is rotationally connected with the end, far away from the movable part, of each connecting rod; a spraying gun is arranged on the end, away from the corresponding connecting rod, of each mechanical arm, the end portion of each spraying gun communicates with a spraying pipeline, each spraying pipeline penetrates through the inner wall of the corresponding mechanical arm and extends outwards to communicate with a spraying box, fixing plates are symmetrically arranged on the two sides of the outer wall at the lower end of the movable part, an inclined block is fixedly connected to each fixing plate, a third driving motor is arranged on the outer side of each inclined block, each third driving motor is rotationally connected with a sliding block through a telescopic rod, and the lower side of the outer wall of each mechanical arm is provided with a sliding groove corresponding to the corresponding sliding block.

Owner:SUZHOU INST OF INDAL TECH

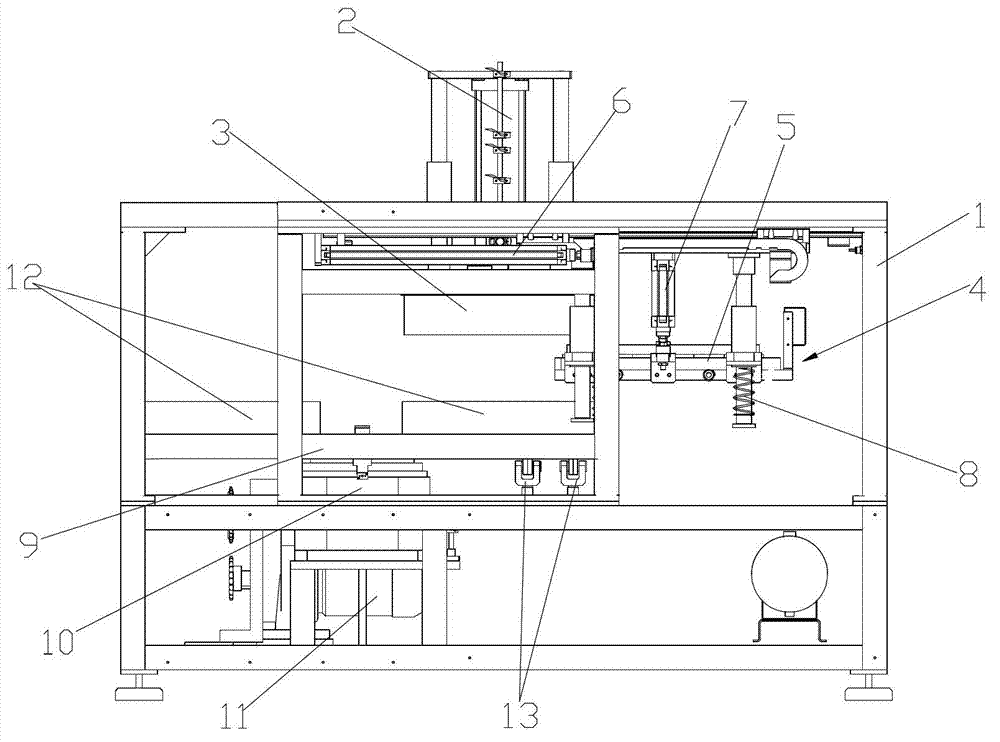

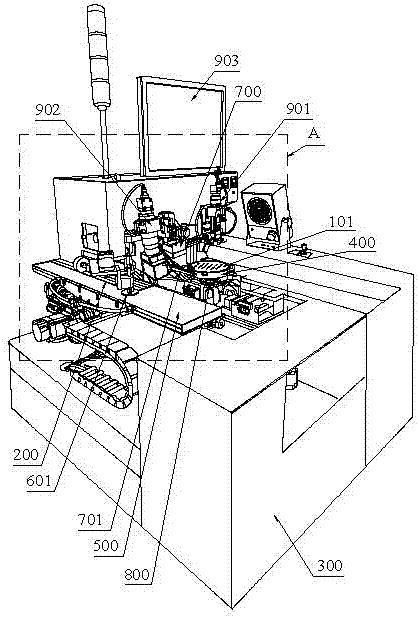

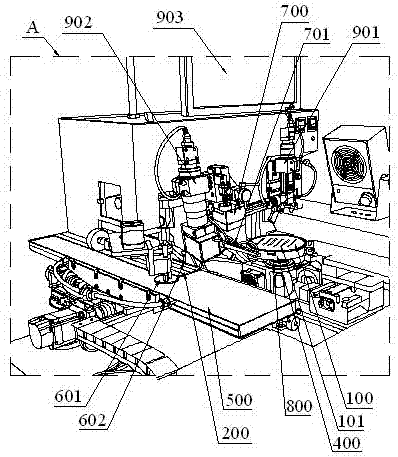

Laser processing equipment for full-automatic solar battery piece

ActiveCN105618934ASimple structureEasy to useManipulatorLaser beam welding apparatusLaser processingEngineering

The invention relates to laser processing equipment for a full-automatic solar battery piece. The laser processing equipment comprises a workbench, a laser processing host, a battery piece processing table, a rotary mechanical arm assembly, left and right battery piece caching and transferring components and left and right battery piece connection assemblies, wherein the laser processing host and the battery piece processing table are both installed on the workbench; the battery piece processing table is arranged below a laser processing head of the laser processing host; the rotary mechanical arm assembly is installed on the workbench on one side of the battery piece processing table; the left and right battery piece caching and transferring components are installed on the workbench on the two sides of the rotary mechanical arm assembly; in the rotation process of the rotary mechanical arm assembly, the free end of the rotary mechanical arm assembly can rotate to the positions above the battery piece processing table and above the left and right battery piece caching and transferring components on the two sides of the rotary mechanical arm assembly respectively; and the left and right battery piece connection assemblies are installed on the two sides of the workbench. The laser processing equipment has the advantages of simple structure, convenience in use, high production efficiency and strong processing stability.

Owner:WUHAN DR LASER TECH CORP LTD

Textile fabric processing system and processing method

InactiveCN110004695AImprove flatnessImprove cleanlinessMechanical cleaningPressure cleaningEngineeringMachining system

The invention relates to the field of textile fabric processing, in particular to a textile fabric processing system and a processing method. The textile fabric processing system comprises a servo motor, a fabric dust removal mechanism, a fabric guide roller, a dust removal chamber, a sliding door, tensioning pressure rollers, linkage frames, ironing rollers, a dust collection mechanism, a frame board and supporting legs. The servo motor is fixedly connected to the frame board through a motor seat and is in transmission connection with the fabric dust removal mechanism, and the fabric dust removal mechanism is rotationally and fittingly connected to the inner middle of the dust removal chamber which is fixedly connected to the frame board. By the textile fabric processing system, spreading, dust removal and ironing processing of textile fabrics can be realized, smoothness and cleanness of the textile fabrics can be improved conveniently, and product quality is further improved. The textile fabric processing method is scientific and reasonable, excellent in process and beneficial to improvement of textile fabric production and processing efficiency.

Owner:深圳市盛鸿医疗科技有限公司

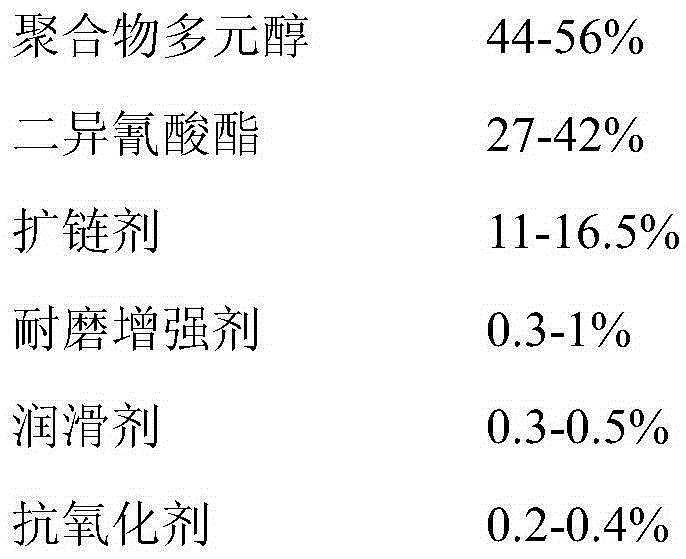

TPU (Thermoplastic Polyurethane Elastomer) material and preparation method thereof

The invention belongs to the technical field of TPU (Thermoplastic Polyurethane Elastomer), and in particular relates to a TPU material and a preparation method thereof. The TPU material is prepared from the following raw materials in percentage by weight: 44 to 56 percent of polymer polyol, 27 to 42 percent of diisocyanate, 11 to 16.5 percent of chain extender, 0.3 to 1 percent of wear-resistant fortifier, 0.3 to 0.5 percent of lubricating agent, 0.2 to 0.4 percent of antioxidant and 0.02 to 0.05 percent of catalyst. According to the preparation method provided by the invention, a continuous process is adopted, the quality of a product is stable, and a higher production efficiency is realized in comparison with that of a casting TPU; the polymer polyol is adopted as a raw material, the high cost of a PTMG type polyurethane material is reduced and meanwhile, the elastomer is endowed with good mechanical properties.

Owner:SHANDONG INOV POLYURETHANE

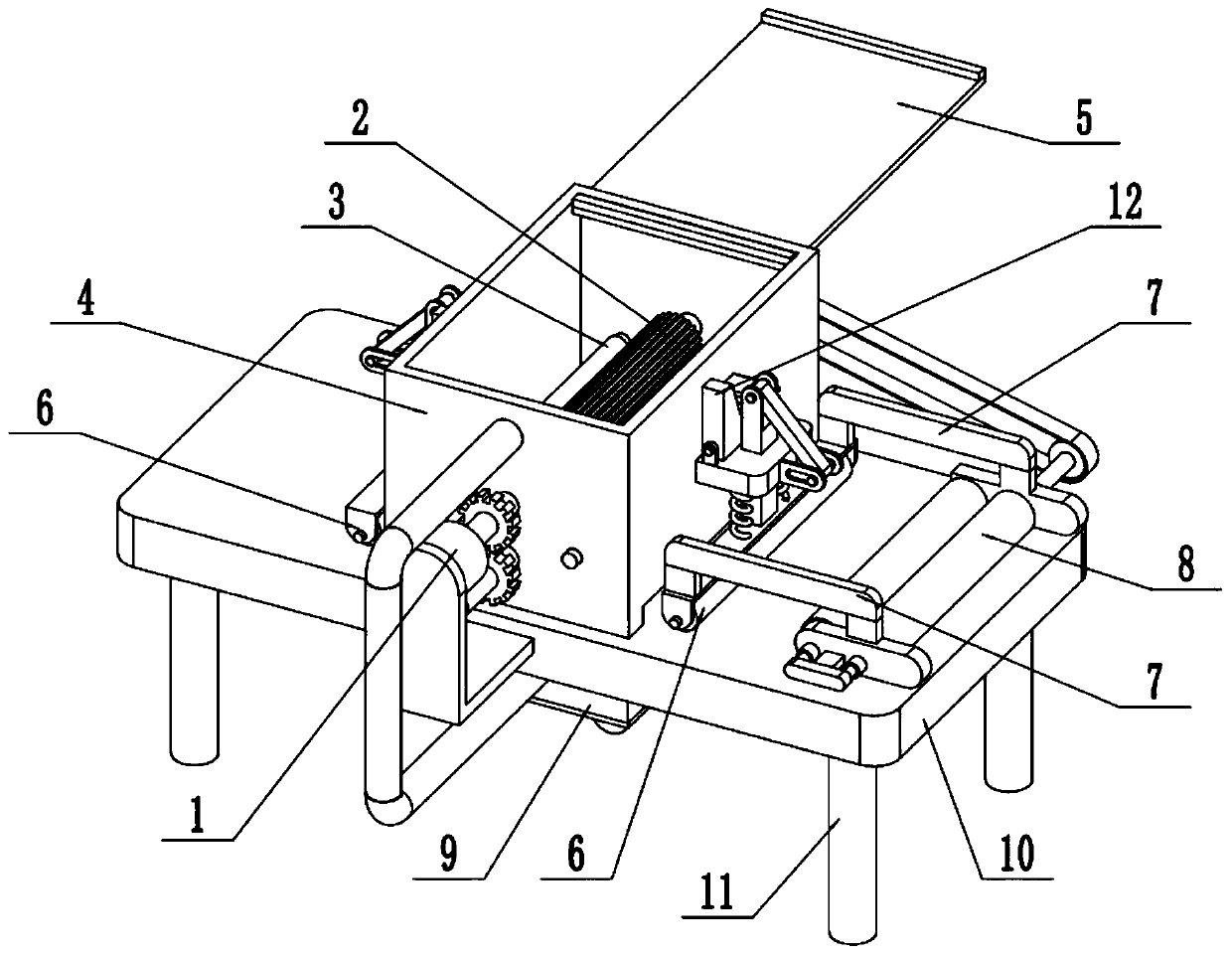

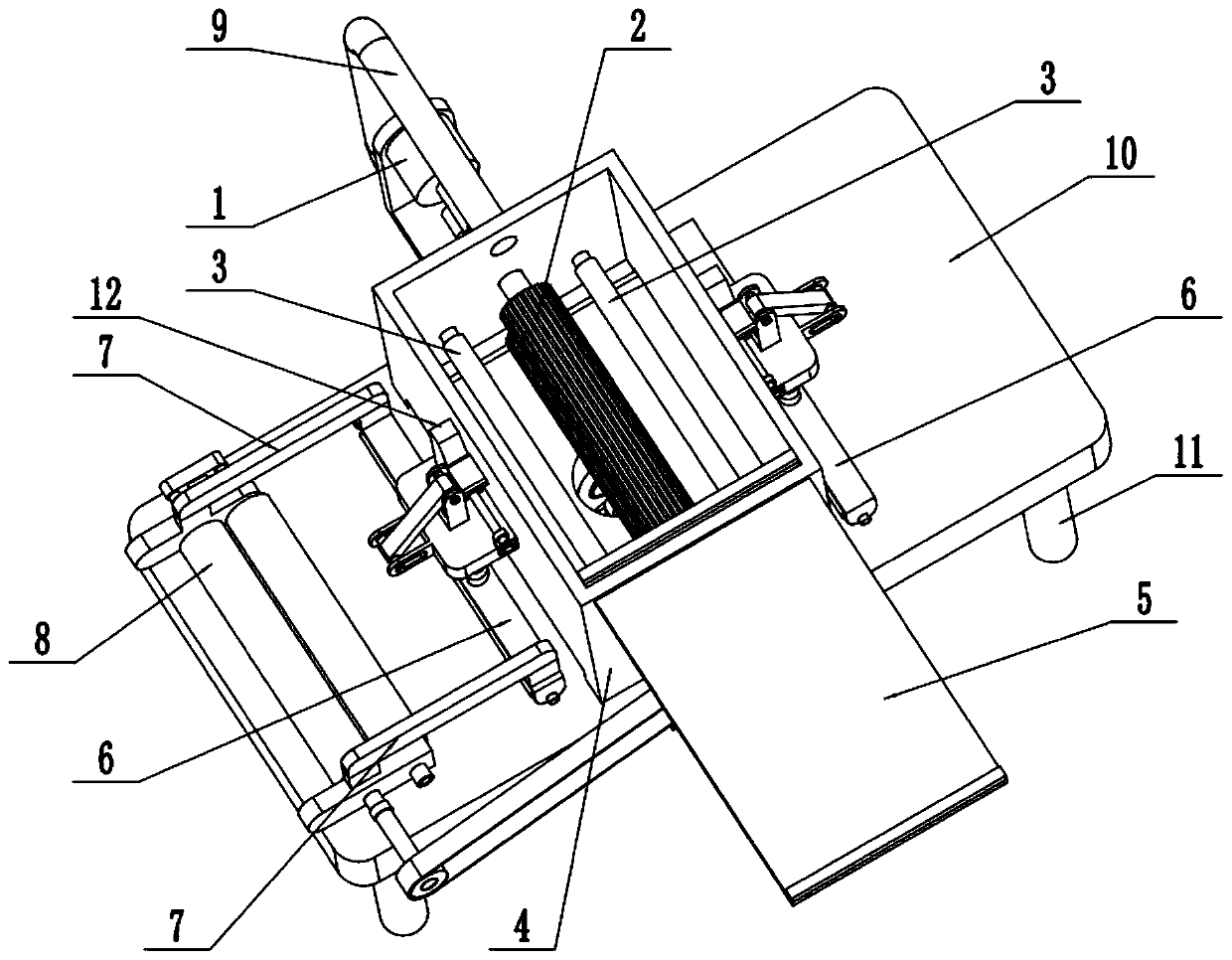

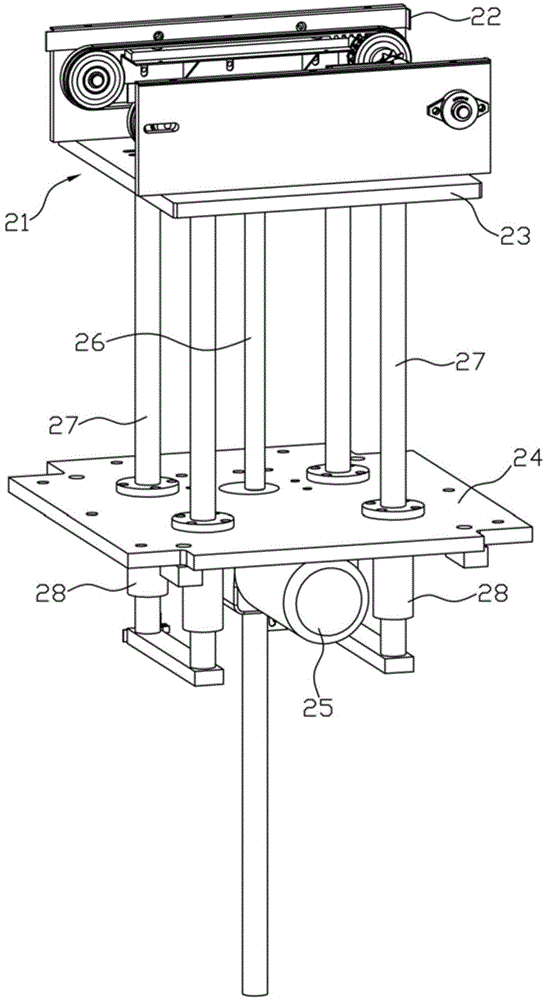

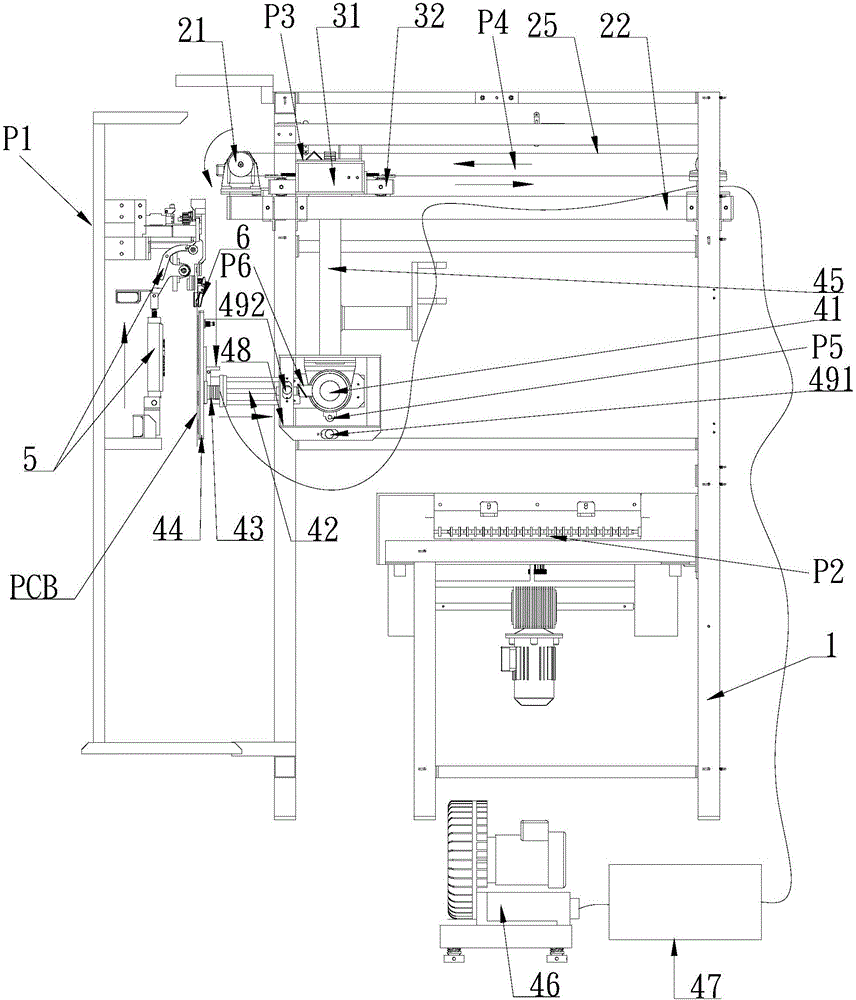

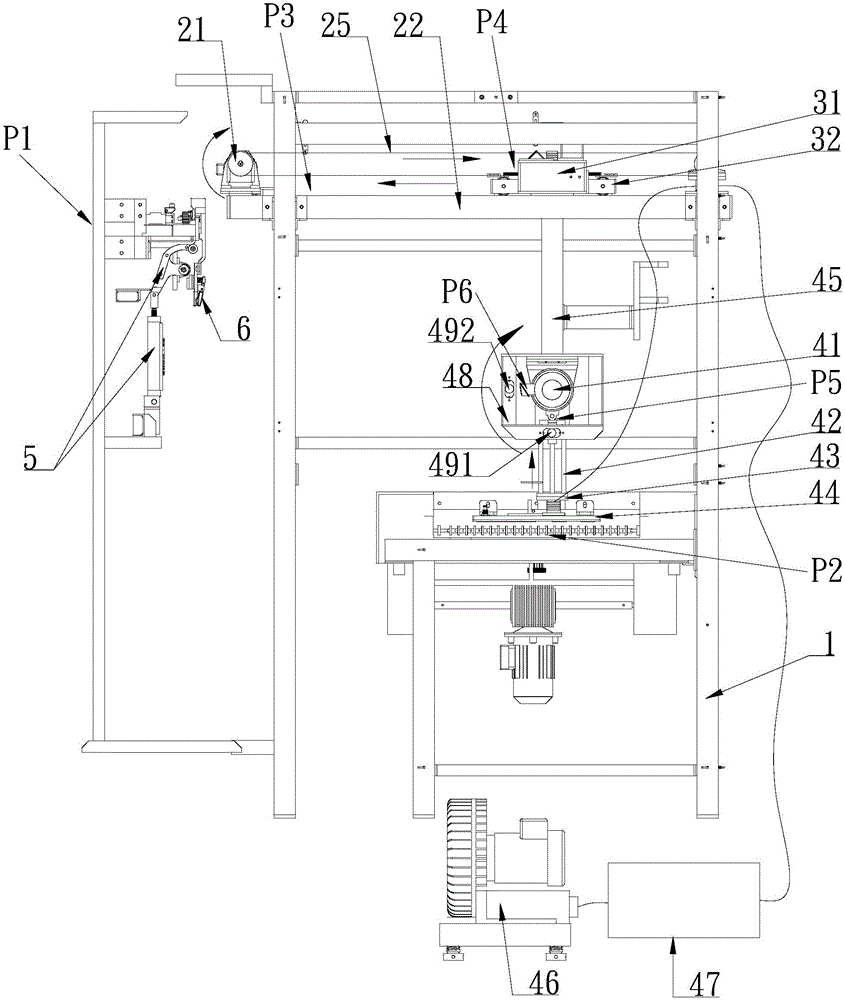

Mechanism for transporting electronic device support plates and recovering support plate baskets

InactiveCN104816926ARealize automatic handlingImprove production and processing efficiencyDe-stacking articlesMechanical conveyorsProduction lineEngineering

The invention discloses a mechanism for transporting electronic device support plates and recovering support plate baskets. The mechanism comprises a basket transporting rail, a lifting device and a basket recovering rail, wherein a cylinder is mounted on the basket transporting rail; the basket transporting rail is positioned above the basket recovering rail; the lifting device is positioned at one end side of the basket conveying rail leveled with the basket recovering rail; the lifting device comprises a transporting rail mounted at the top; and separation strips are vertically arranged on the inner side surface of a basket side plate. Support plates layered in baskets are operated to the transporting rail on the lifting device through the basket transporting rail; the lifting device is descended by a certain height; the cylinder pushes the support plates onto the transporting rail of a production line one by one; and then, the lifting device enables the transporting rail thereon to be joined with the basket recovering rail to recover empty baskets. The mechanism realizes automatic transportation of the support plates to the production line and automatic recovery of the empty baskets after the transportation, so that the production efficiency is improved.

Owner:KUNSHAN DEYOU MACHINERY EQUIP

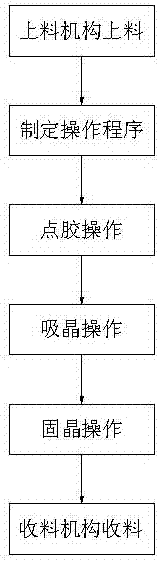

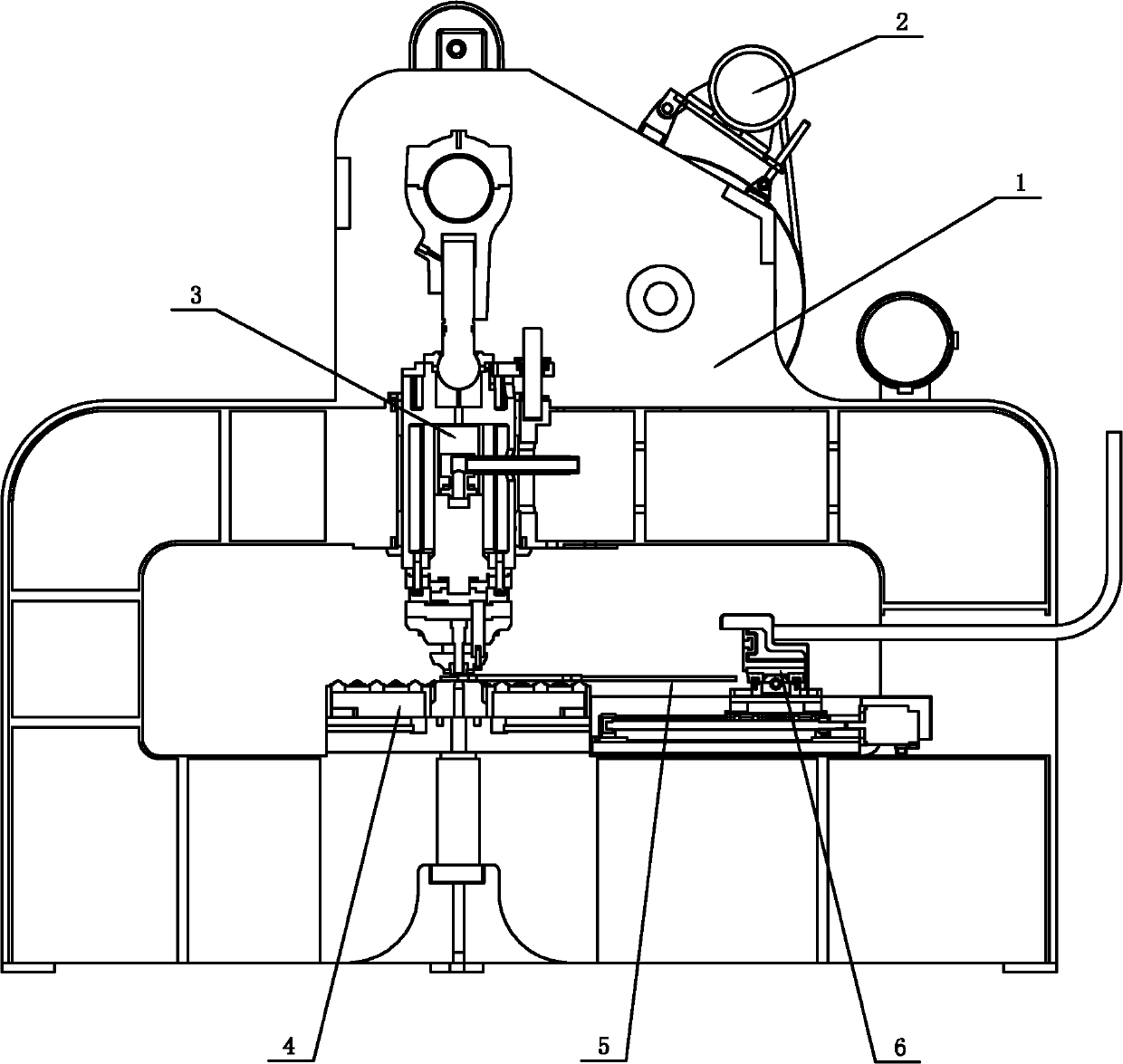

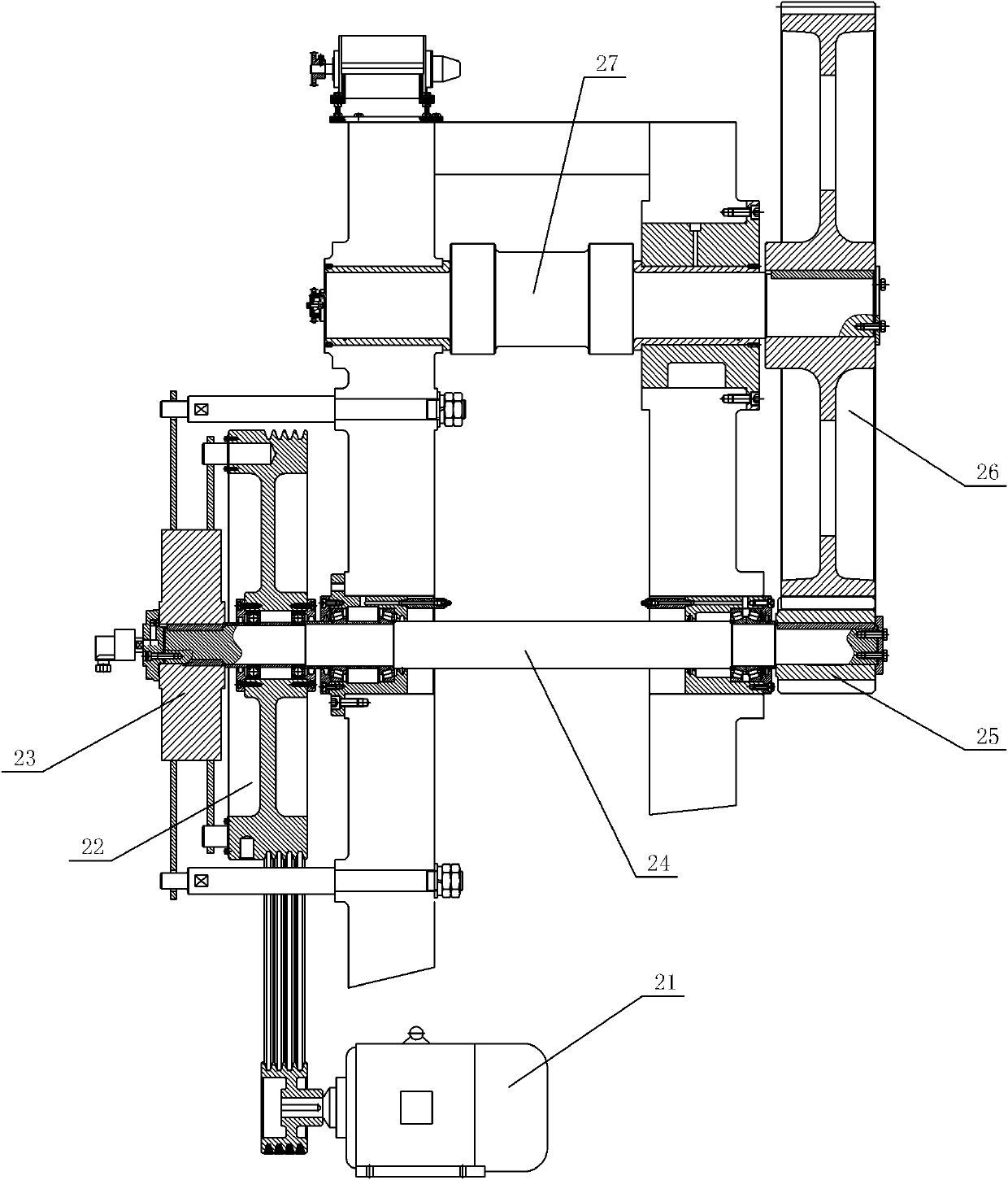

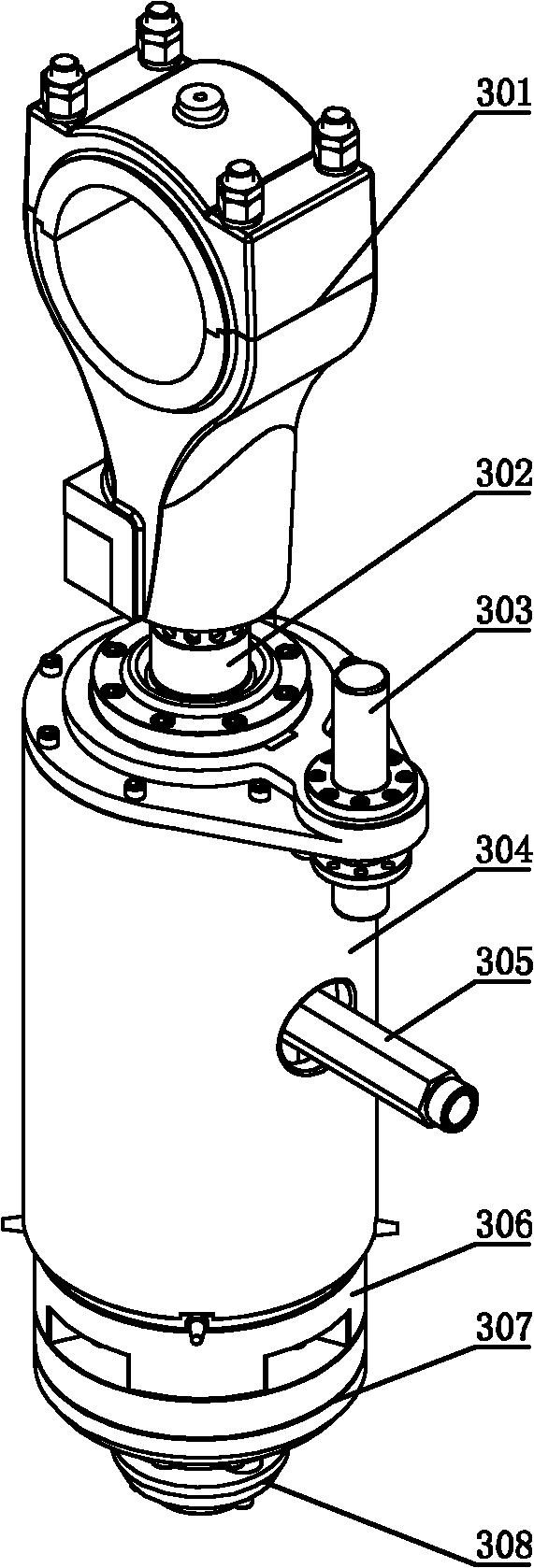

Chip mounter for CSP LEDs, and processing process for chip mounter

InactiveCN107305916AImprove production yieldImprove production and processing efficiencySemiconductor devicesAdhesiveEngineering

The invention discloses a chip mounter for CSP LEDs, and a processing process for the chip mounter. LED chips arranged and attached on a blue film in an array mode can be directly welded and fixed on a substrate; the chip mounter comprises a machine frame, a crystal adsorption table arranged on the machine frame and capable of being equipped with the blue film, a movable crystal fixing worktable arranged on the machine frame and used for bearing the substrate, and an adhesive dispensing mechanism capable of performing adhesive dispensing operation on a corresponding bonding pad of the substrate; the chip mounter further comprises a crystal adsorbing and fixing mechanism with a swing arm capable of performing vacuum adsorption on the LED chips on the blue film on the crystal adsorption table and directly welding and fixing the LED chips to the bonding pad subjected to adhesive dispensing, and an ejector mechanism capable of ejecting the LED chips to facilitate the crystal adsorbing and fixing mechanism to perform adsorption operation on the LED chips; the chip mounter further comprises an image identification control apparatus; the image identification control apparatus consists of an optical crystal adsorption apparatus and an optical crystal fixing apparatus; the chip mounter further comprises an intelligent control apparatus capable of controlling each part of the chip mounter to work; and the chip mounter further comprises a feeding mechanism and a discharging mechanism.

Owner:ZHONGSHAN HONGCHANG ELECTRIC & LIGHTING TECH

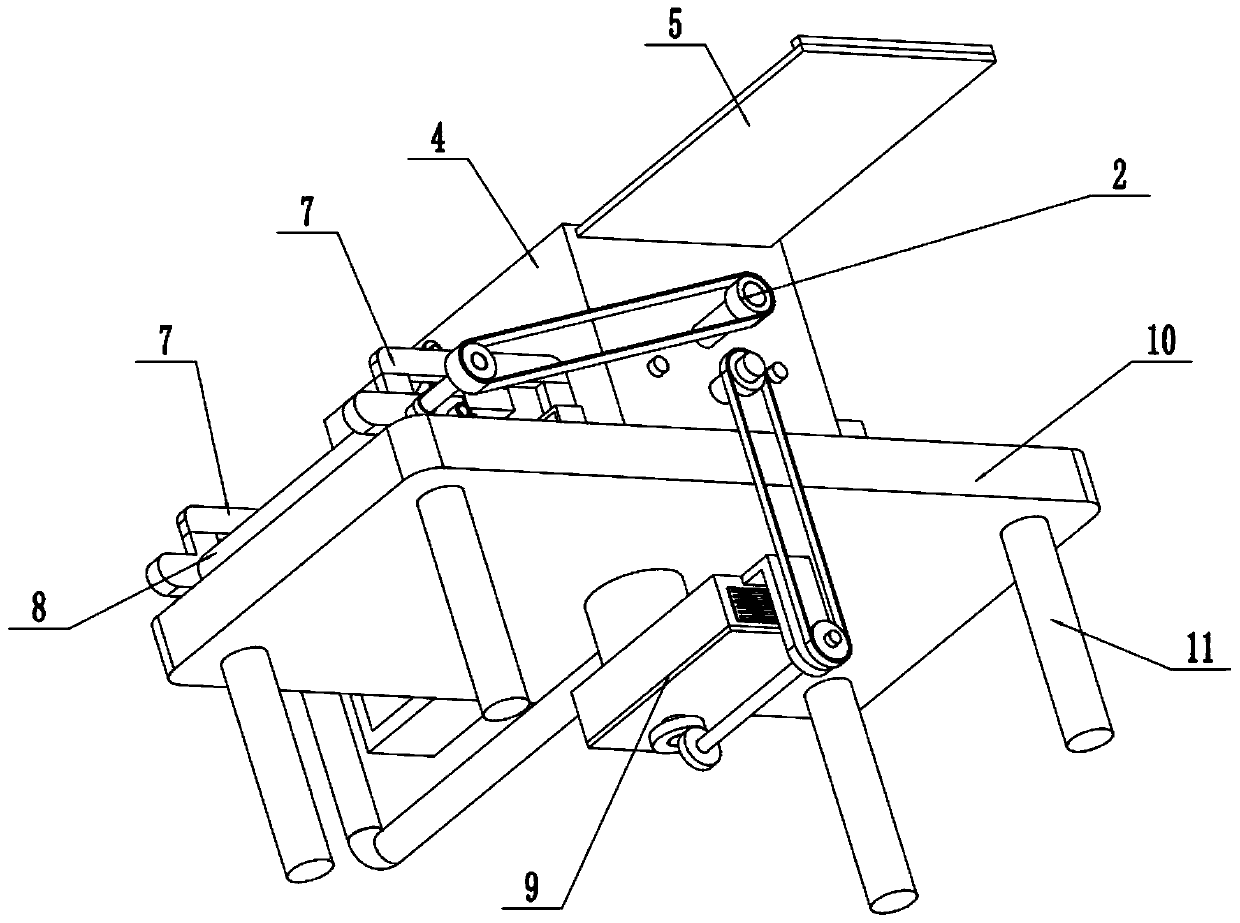

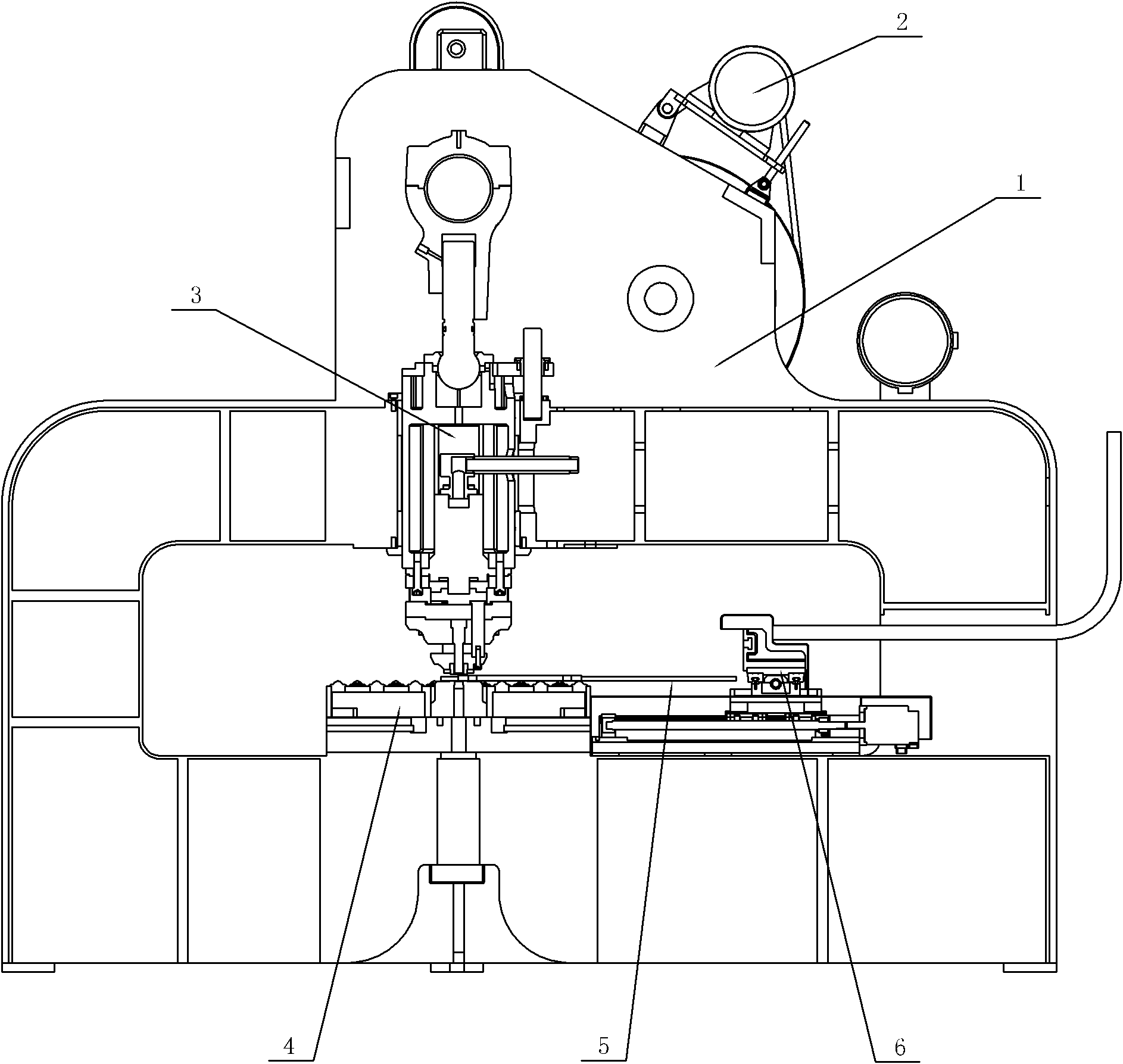

Punching machine tool

InactiveCN102233374AImprove production and processing efficiencyReduce labor costsPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses a punching machine tool. The punching machine tool comprises a gantry type machine body, wherein the machine body is provided with a punch mechanism for punching, a power transmission mechanism for providing punching power to the punch mechanism, a feeding mechanism for clamping and transferring a plate to be processed and a material platform mechanism arranged below the punch mechanism and used for placing the plate to be processed. The punching machine tool has the following beneficial effects: the punching machine tool can not only be used for realizing punching of a thicker small plate but also ensure the punching precision and quality, thus improving the processing efficiency of holes on the small plate and lowering the processing cost.

Owner:浙江博雷重型机床制造有限公司

Automatic conveying production line applied to part spraying

PendingCN105834038AHigh degree of automationBe precise and consistentLiquid surface applicatorsCoatingsRotary machineProcess engineering

The invention relates to the field of toy models, in particular to an automatic conveying production line applied to part spraying. According to the technical scheme, the automatic conveying production line comprises a rectangular rack body, a conveying rail, a transfer printing bottom die and a workpiece rotation mechanical arm used for driving workpiece reversing; and a workpiece is installed on the transfer printing bottom die in a separated manner, a transmission device arranged on the rack body drives the transfer printing bottom die to do reciprocating motion along the conveying rail of the rack body, and the conveying rail comprises a first rail for conveying the transfer printing bottom die in a forward manner and a second rail for conveying the transfer printing bottom die in a backward manner. The automatic conveying production line has the beneficial effects that the automatic degree is high, too-much manual intervention is not needed, the accuracy and the consistency of part spraying are effectively kept, and the production and machining efficiency is improved.

Owner:DONGGUAN SUMS MODEL GIFTS CO LTD

Piece dyeing method of cotton binding textiles

InactiveCN101864677AUniform surfaceUniform colorBleaching apparatusDyeing processShrinkage rateEngineering

The invention discloses a piece dyeing method of cotton binding textiles, which is characterized in that the invention has the concrete processing process comprising the steps of singeing, desizing, light scouring and bleaching, pre-setting, rendering, color fixation soap washing, forming and preshrinking. The invention has the advantages that the cotton binding textiles obtained through being processed by the method have the advantages of uniform cloth surface color, good luster, high intensity and low washing shrinkage rate, and in addition, the production processing efficiency of the method is high. In addition, the mixed alkali treatment is adopted in the light scouring and bleaching process, so the invention ensures that the processed cotton binding textiles have certain whiteness and water absorption performance, in addition, the plant intensity of the textiles can not be damaged to the furthest extent, and the narrow width of the textiles caused by shrinkage in the following processing work procedure can be avoided through improving the hydrophilicity of the textiles and widening the width of the textiles via the pre-setting process.

Owner:浙江盛泰服装集团股份有限公司

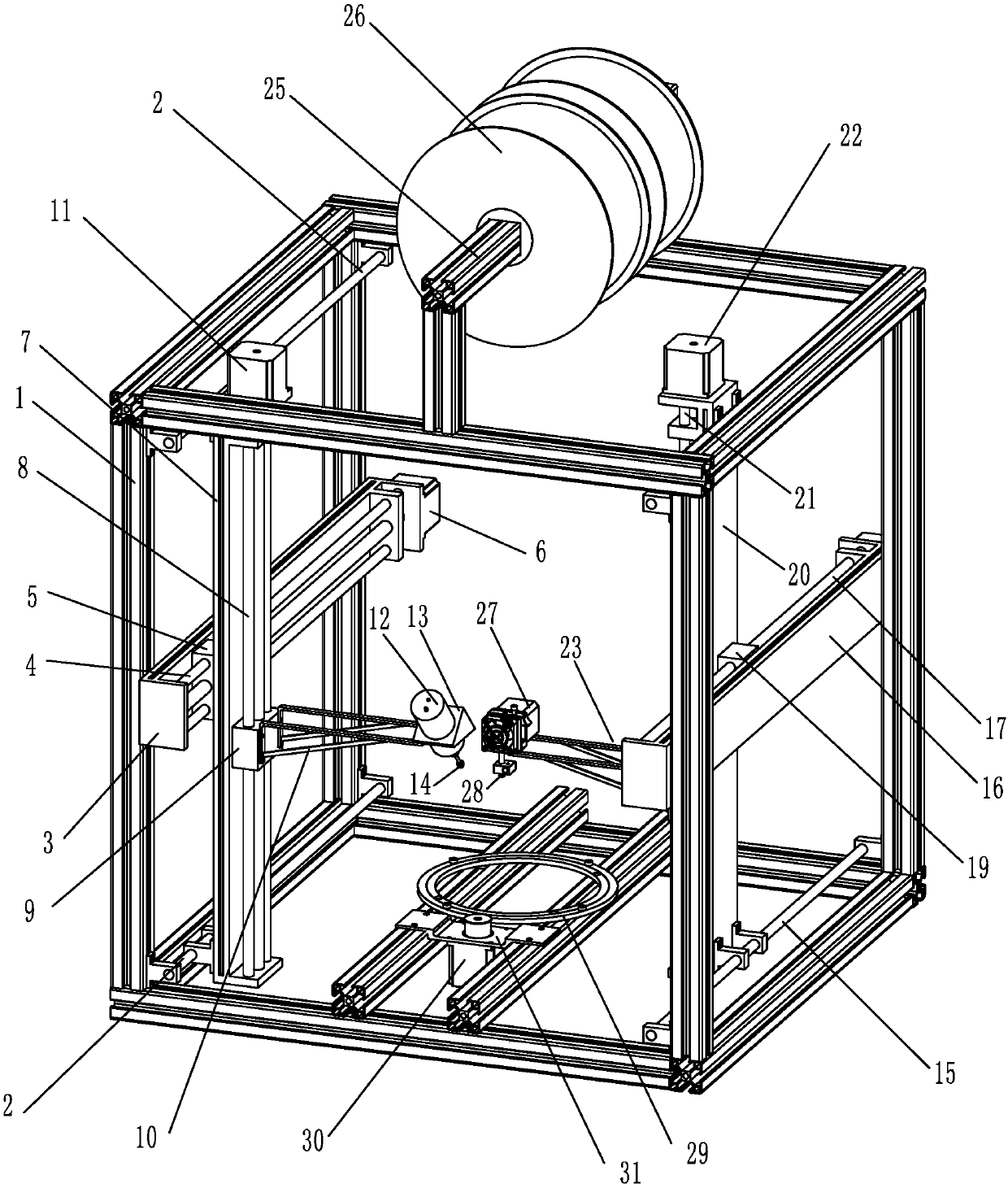

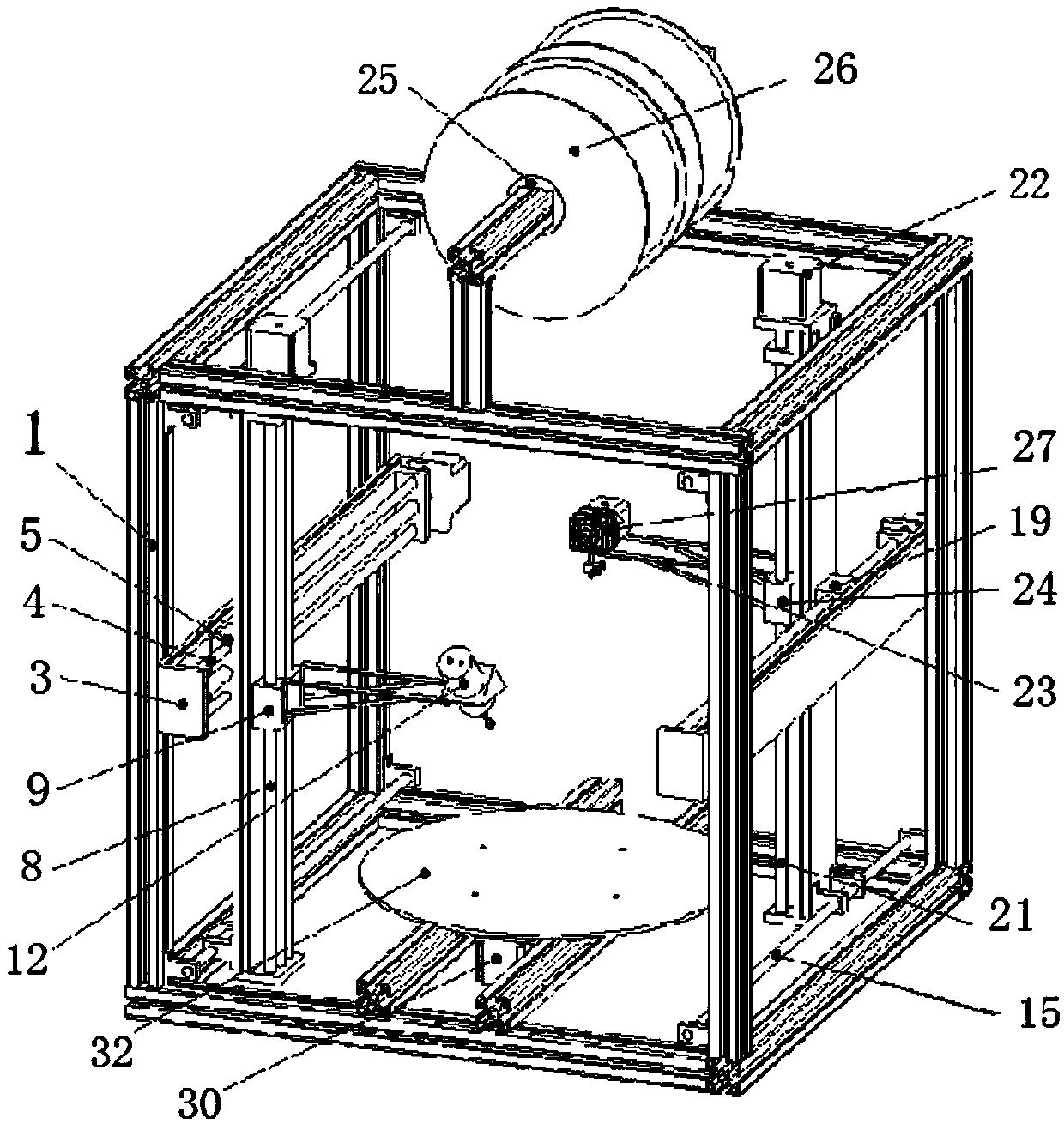

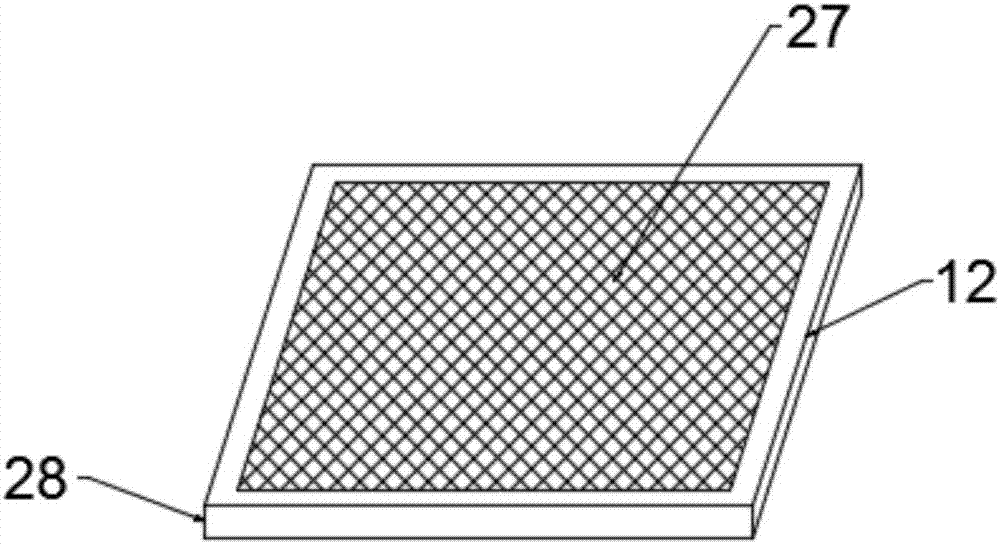

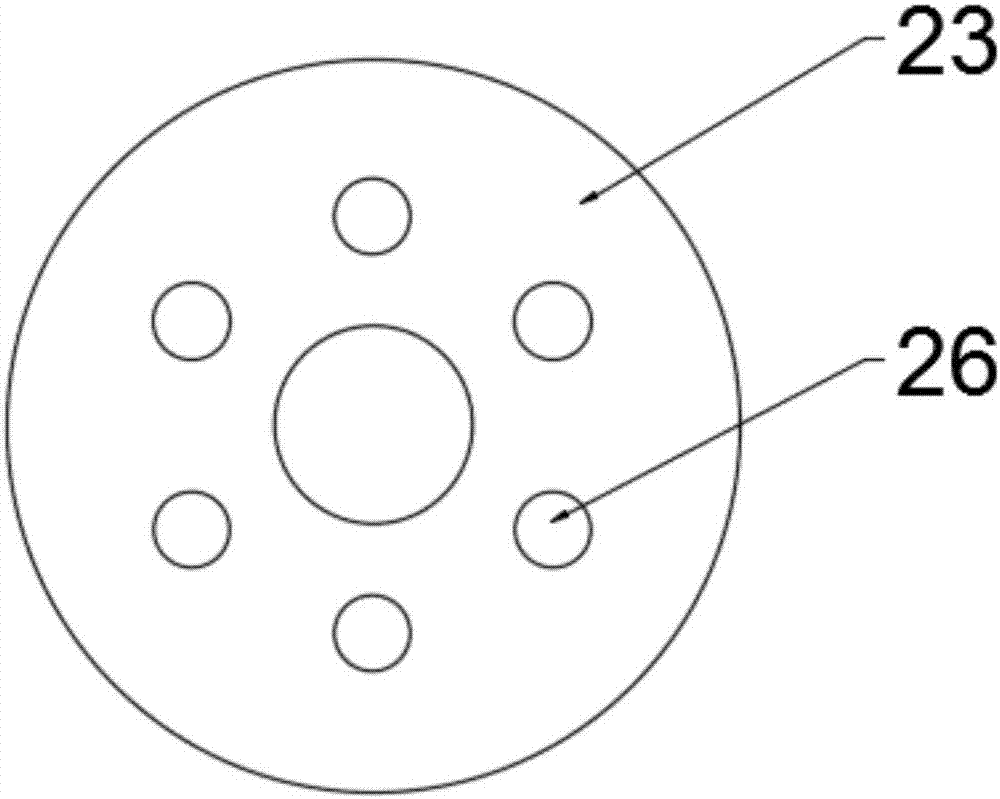

Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

PendingCN107672162AImprove flexibilityShorten the timeEdge grinding machinesAdditive manufacturing apparatusWear particleSurface roughness

The invention discloses a table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function, and relates to table top material increasing and decreasing wood-plastic composite 3D printers. In order to solve the problem that the shape accuracy, dimensional accuracy, surface quality and the like of parts are both limited by the single-layer printingthickness and plane printing accuracy in an existing 3D printing layer-by-layer stacking manufacturing mode, the table top material increasing and decreasing wood-plastic composite 3D printer comprises a rectangular frame (1) and further comprises a material decreasing assembly, a material increasing assembly and a material increasing and decreasing working platform. The material increasing and decreasing working platform is installed at the lower end of the rectangular frame (1) in a rotating mode. The material decreasing assembly and the material increasing assembly are installed on the rectangular frame (1). According to the table top material increasing and decreasing wood-plastic composite 3D printer, the wood-plastic composite is used as a manufacturing raw material to be stacked layer by layer, so that the material increase manufacturing technology is implemented; and a grinding wheel serves as a cutter in abrasive machining, and grinding wheel abrasive particles serve as cutting blades so that the size and shape accuracy and surface roughness needs required can be met. The table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function is used for wood-plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

Agricultural drying machine for rice type small-size particle grain

InactiveCN107062872AEasy dischargeTake advantage ofDrying gas arrangementsSeed preservation by dryingRubber ringAgricultural engineering

The invention discloses an agricultural rice grain small-diameter grain dryer, which comprises a machine shell, and a first-stage sieve-shock feeding mechanism is arranged at the top of the machine shell; The bottom of the screening cavity is connected to the discharge port, a screen is arranged in the inner cavity of the screen, a vibration motor is provided at the bottom of the screen, and the discharge port is located below the screen; the bottom of the discharge port is surrounded by The inner side wall of the casing is provided with a circle of material guide plates, and a deceleration device is arranged below the material guide plate. The deceleration device includes a deceleration cylinder, a rubber ring and a deceleration frame; the lower end of the deceleration cylinder is provided on the side wall of the casing corresponding to the A circle of hot air cavity; a stirring shaft is horizontally arranged below the reduction drum, and the outer end of the stirring shaft passes through the casing and is fixedly connected to the second drive motor, and a stirring blade is fixedly installed on the stirring shaft. The bottom wall of the body is provided with a discharge channel.

Owner:段华勇

Graphene sheet paint spraying and drying device

InactiveCN106179839AImprove production and processing efficiencyAvoid blind spotsSpraying apparatusPretreated surfacesSpray nozzleEngineering

The invention discloses a graphene sheet paint spraying and drying device which comprises a sliding rail, a placement table, paint spraying racks and vacuum chucks. A telescopic supporting rod is installed inside a slide of the sliding rail; the upper end of the telescopic supporting rod is fixedly connected with the bottom center portion of the placement table; drying openings of an inverted-circular truncated cone structure are formed in the placement table in an evenly penetrating mode; first hot air pipes communicating with the drying openings are arranged on the lower portion of the placement table; a graphene sheet is arranged on the placement table; the paint spraying racks are symmetrically arranged on the two sides of the placement table; an upper paint spraying nozzle, a middle paint spraying nozzle and a lower paint spraying nozzle are arranged on each paint spraying rack at intervals from top to bottom; and the upper paint spraying nozzles align with the upper side face of the graphene sheet. The graphene sheet paint spraying and drying device integrates paint spraying and drying, paint spraying and drying can be completed in one procedure, the production machining efficiency of the graphene sheet is improved, dead corners of paint spraying are avoided, and the situation that a paint face is destroyed to cause flaws after paint spraying is prevented.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

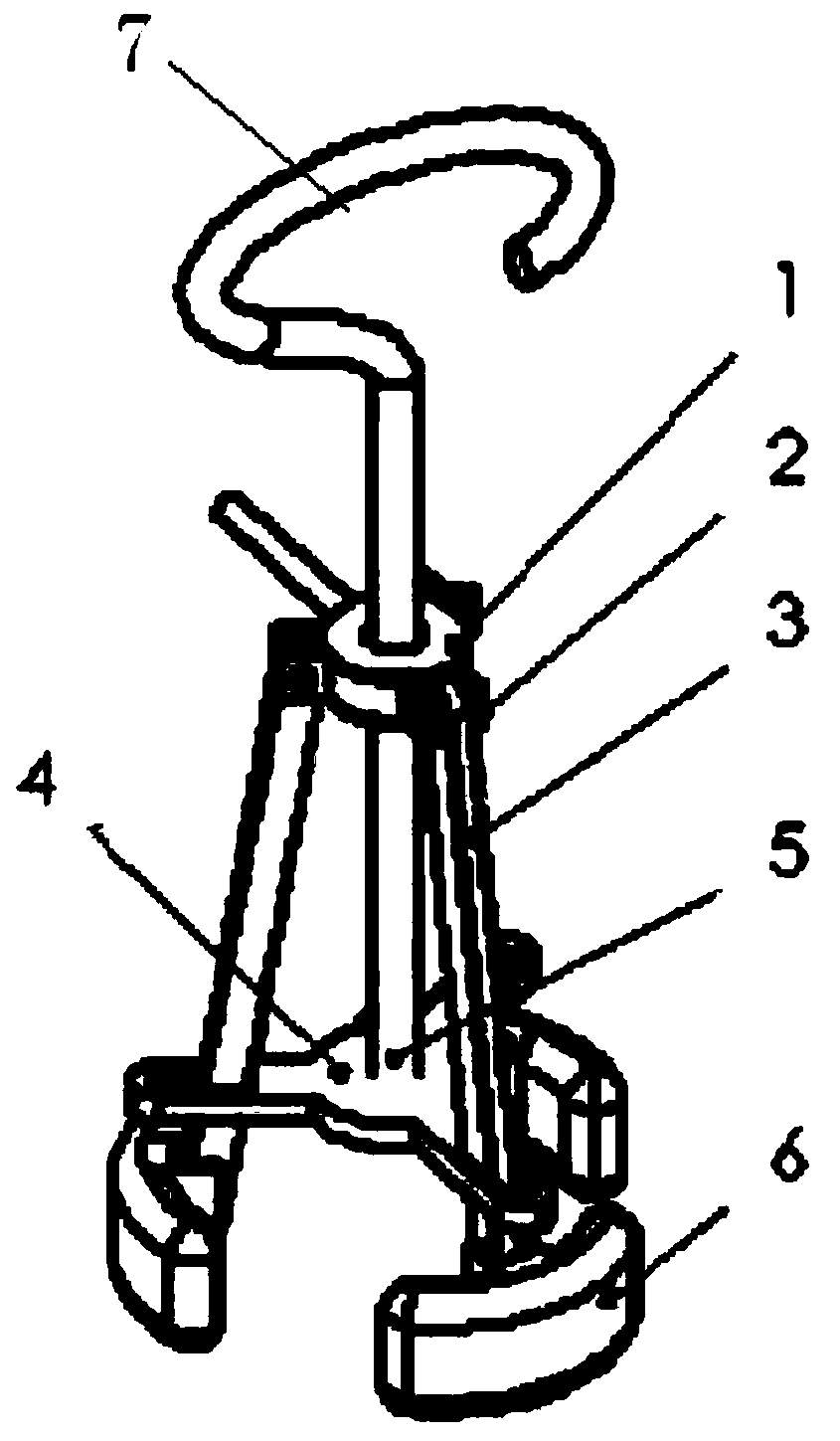

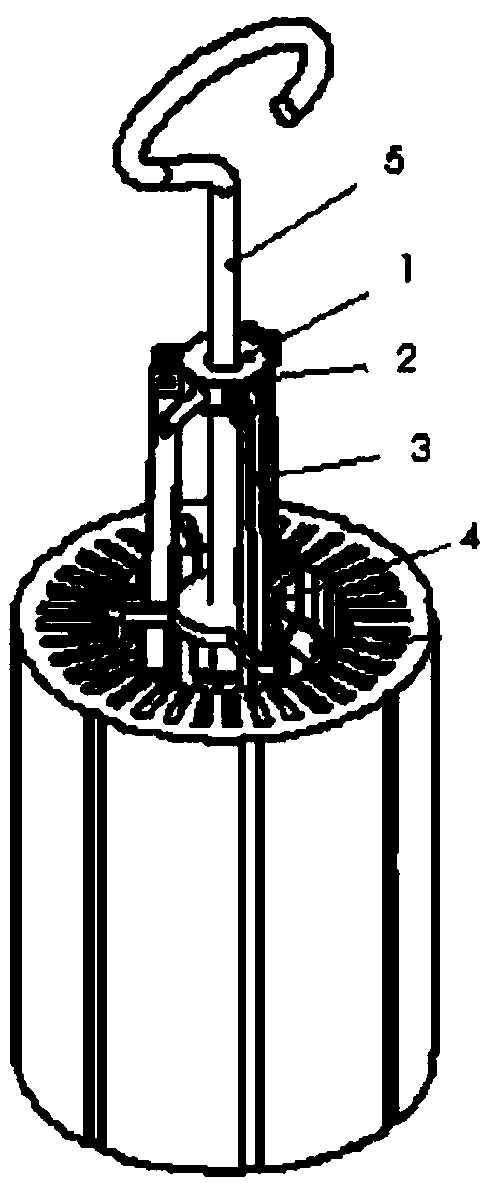

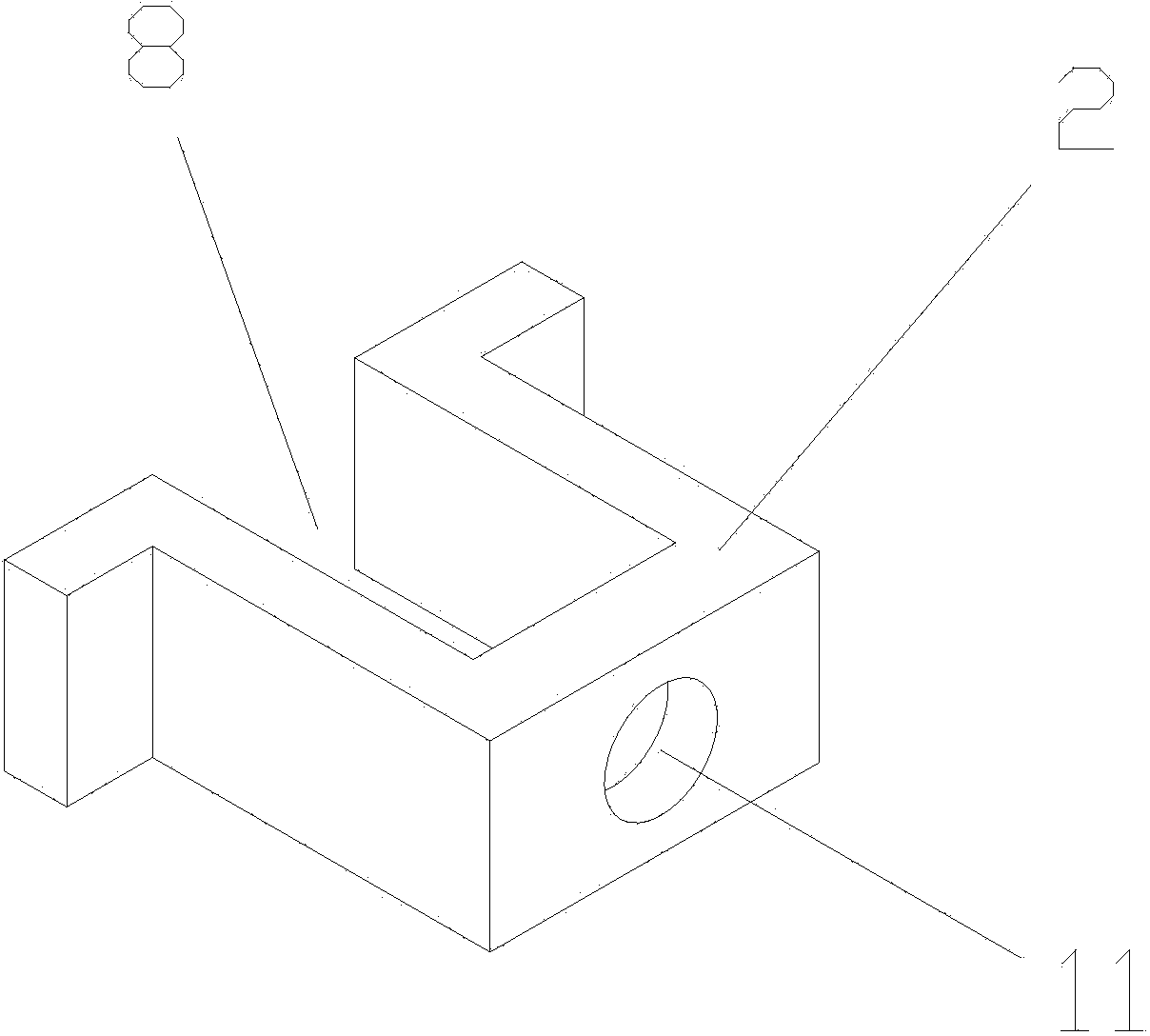

Special hoisting device for hollow cylindrical piece

InactiveCN103466439ASolve the non-destructive lifting operationSimple structureLoad-engaging elementsStructural engineeringMachining

The invention relates to a special hoisting device for a hollow cylindrical piece. The special hoisting device comprises a fixing ring (1), a plurality of claw bars (3) and a handle (5), wherein the handle (5) vertically passes through the middle of the fixing ring (1) to be connected with the middle of a supporting plate (4), the claw bars (3) are uniformly distributed around the fixing ring (1), the upper ends of the claw bars (3) are hinged with the fixing ring (1), the claw bars (3) pass through a square slot (41) in the supporting plate (4) and can slide in the square slot (41), the lower ends of the claw bars (3) are hinged with a claw pad (6) which is arc-shaped, and the top end of the arc surface is outwards. The special hoisting device is simple in structure and convenient to operate, can realize quick damage-free hoisting of a hollow cylinder, and improves the production and machining efficiency.

Owner:颜从均

Numerical control punching machine tool

InactiveCN102139308AImprove production and processing efficiencyReduce labor costsPerforating toolsMetal-working feeding devicesNumerical controlThick plate

The invention discloses a numerical control punching machine tool, which comprises a portal frame machine body, wherein a punch mechanism for punching, a power transmission mechanism for providing punching power for the punch mechanism, a feed mechanism for clamping and conveying plates to be machined and a material platform mechanism which is positioned below the punch mechanism and is used for placing the plates to be machined. By the technical scheme, small thick plates which are relatively thick can be punched, and the punching accuracy and punching quality can be ensured, so the machining efficiencies of holes on the small thick plates are improved, and the machining cost is reduced.

Owner:浙江博雷重型机床制造有限公司

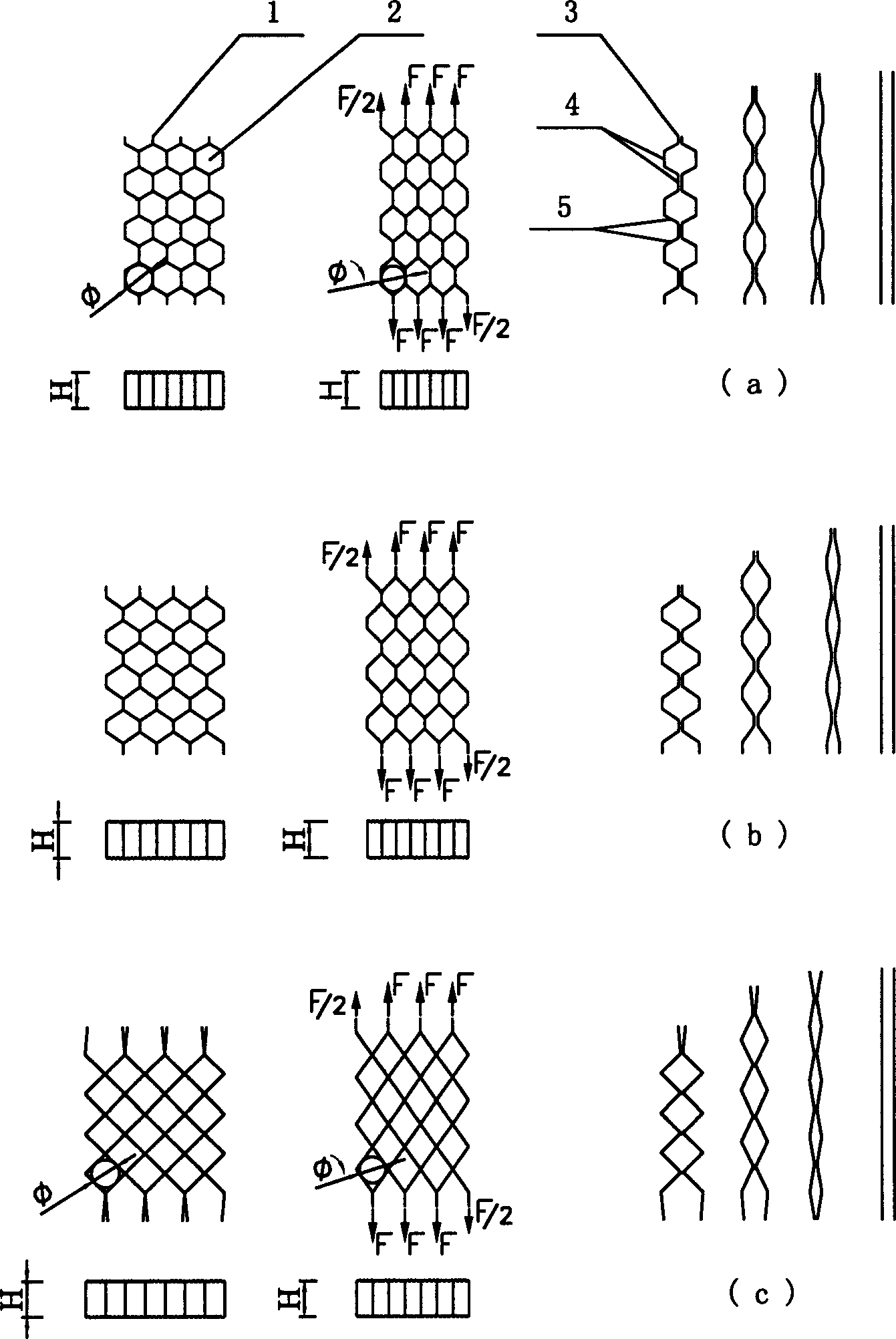

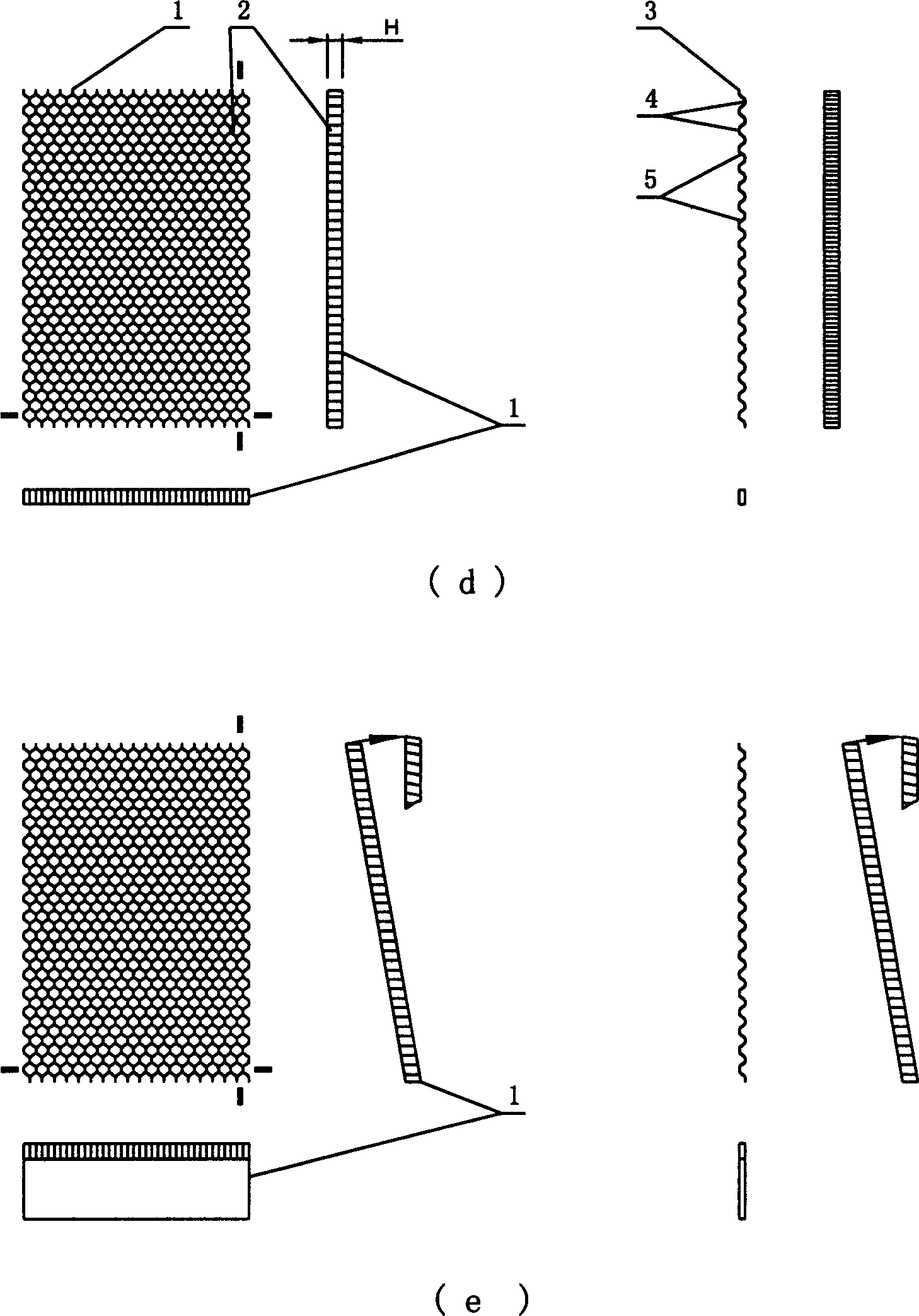

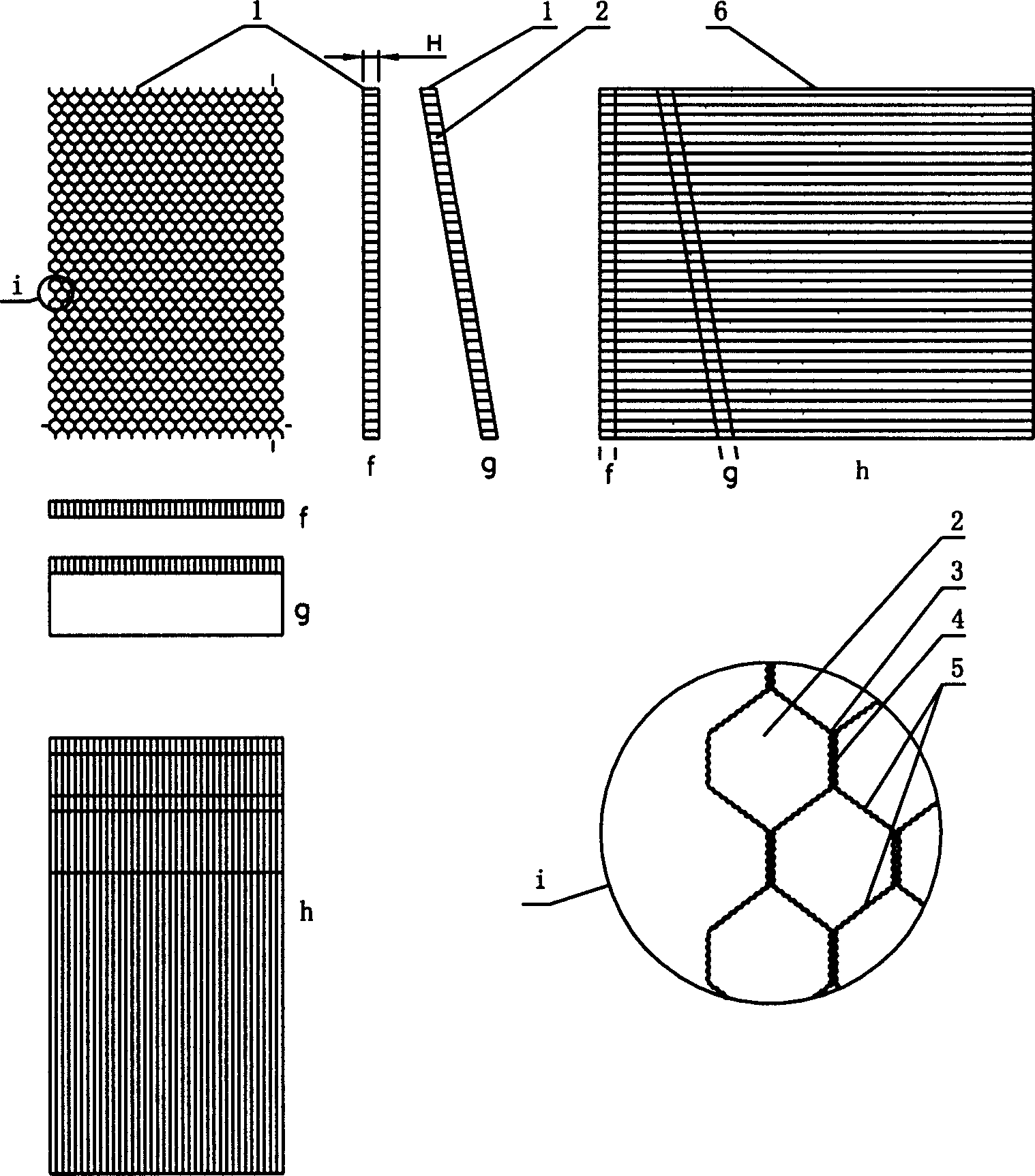

Multipurpose plastic honeycomb bundle

InactiveCN1596634ASignificant comprehensive benefitsRemarkable effectAnimal husbandryAquatic animalAquatic product

A multi-purpose plastic cellular bundle for raising silkworms, storage of grains, culture of aquatic animals, etc is made up of non-toxic plastics or composite material.

Owner:黄海芳

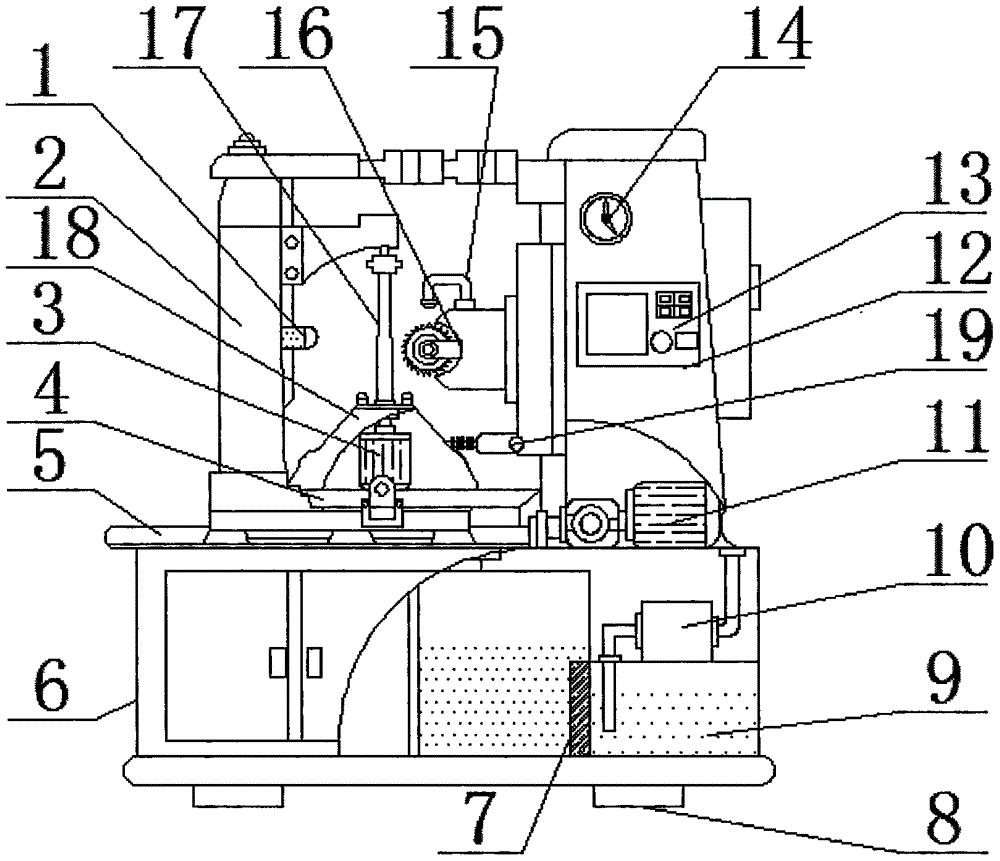

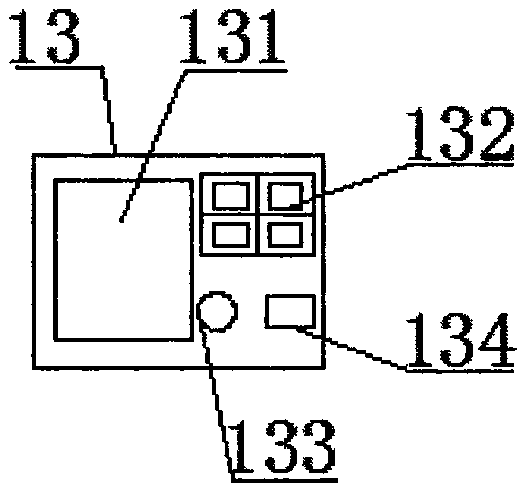

Efficient, energy-saving and high-precision gear hobbing machine applied to mechanical processing field

InactiveCN105817718AHigh precisionScientific and reasonable structureWorm wheelsGear-cutting machinesGear wheelSprayer

The invention discloses an efficient, energy-saving and high-precision gear hobbing machine applied to a mechanical processing field. The machine comprises uprights, a machine case and supporting legs, wherein the uprights are installed on slide rods; a working table is disposed under a work piece mandrel; a control panel is disposed under a pressure meter; the machine case is installed under a machine body; and an electric hydraulic pump and a displacement sensing movable device are electrically connected to the control panel. The machine disclosed by the invention has the advantages that the structure is scientific and rational; use and operations are safe and convenient; work is efficient; comprehensive functions are provided; an infrared distance measuring sensor is disposed, so that errors generated to a pitch of a processed gear can be detected; a prompt lamp is turned on to send out a prompt; consumption of time and materials is reduced; an emulsified oil sprayer and a circulating oil pump are disposed, so that lubrication, cooling and iron scrap removal can be implemented to the processed gear, and production and processing efficiency can be effectively increased; emulsified oil can be recycled, so that consumption of resources is reduced; and the displacement sensing movable device is disposed, so that the gear can be processed precisely according to processing requirements.

Owner:XINCHANG COUNTY QIXING STREET JINYUAN MACHINE TOOL FITTING SALES DEPT

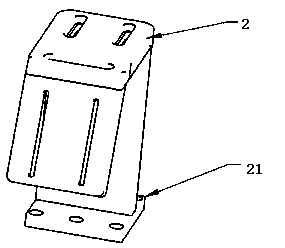

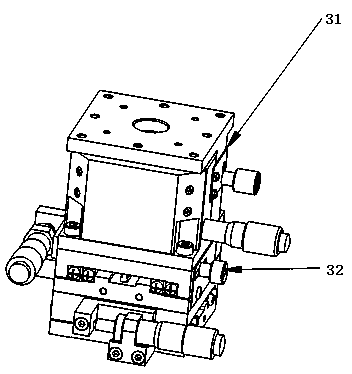

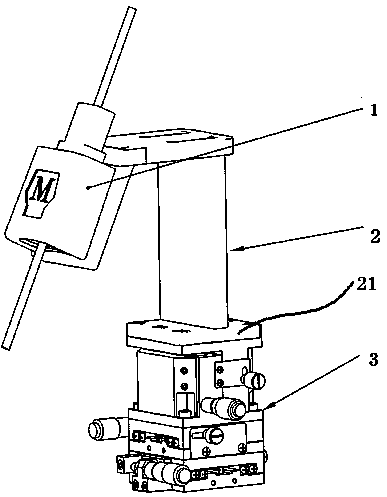

Two-dimension code scanning mechanism for mobile phone module

InactiveCN104376294AShort transition timeImprove production and processing efficiencyTelephone set constructionsSensing by electromagnetic radiationMachineMechanical engineering

The invention discloses a two-dimension code scanning mechanism for a mobile phone module. The two-dimension code scanning mechanism comprises a machine table, an inductor, a scanning gun, scanning gun fixing supports, a scanning gun fixing base and product fixing bases, the multiple scanning gun fixing supports and the multiple product fixing bases are arranged on the machine table, the scanning gun fixing supports are of inversed-U-shaped structures, the ends, where the scanning gun is fixed, of the scanning gun fixing supports are slope, and the scanning gun fixing base is fixedly connected the other ends of the scanning gun fixing supports. The scanning gun fixing base sequentially comprises a horizontal plane XYZ axis platform and a two-dimensional displacement table from top to bottom, and the product fixing bases are of rounded rectangle structures. By means of the two-dimension code scanning mechanism, the scanning gun can move upwards, downwards, leftwards and rightwards effectively through the horizontal plane XYZ axis platforms and the two-dimensional displacement tables on the product fixing bases, and two-dimension code data of to-be-tested products can be rapidly obtained; meanwhile, a sliding rail is arranged on the machine table, after two-dimension code scanning on the products to be measured is stopped, the products can be moved to a next work procedure through the sliding rail, the transition time between work procedures is effectively shortened, and the production and machining efficiency is improved.

Owner:KUNSHAN Q TECH CO LTD

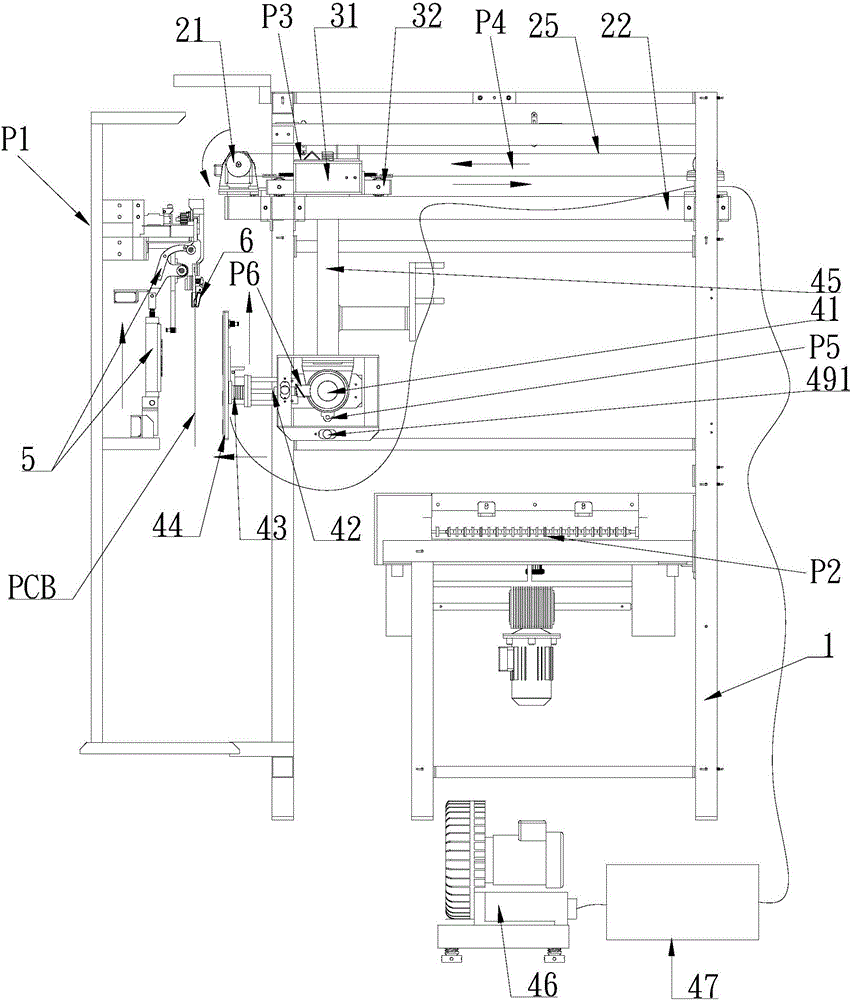

Automatic board unloader for electroplating device

ActiveCN106087015AImprove production and processing efficiencySave human effortElectrolysis componentsSensory controlEngineering

The invention discloses an automatic board unloader for an electroplating device. The automatic board unloader comprises a rack, a linear driving device, a transfer device, a suction cup device, an inductive control device and a board unloading sensory control device, wherein the linear driving device, the transfer device, the suction cup device, the inductive control device and the board unloading sensory control device are installed on the rack. The linear driving device can drive the transfer device to make linear movement between a taking position close to a board unloading position and a discharging position close to a board loading position. The suction cup device is provided with a rotary motor, a first cylinder, a second cylinder, a suction cup and a suction cup driving mechanism. According to the automatic board unloader for the electroplating device, a PCB which stops at the board unloading position can be automatically taken down from a clamp of the electroplating device and sent to the board loading position of a conveying face of an electroplating post treatment device; full-automatic operation can be conducted without manpower; and accordingly, the PCB production and processing efficiency is improved, manpower is reduced, and the cost is lowered.

Owner:GREAT CHIEFTAIN ELECTRONICS MACHINERY

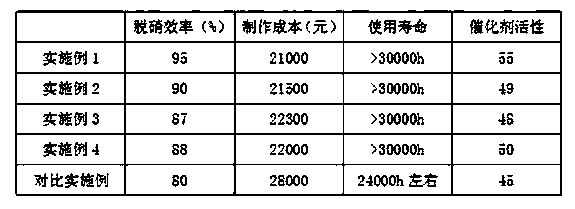

Plate-type denitration catalyst

ActiveCN103706409AHigh strengthFlat surfaceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberAmmonium heptamolybdate

The invention relates to a plate-type denitration catalyst, and belongs to the technical field of a selective catalytic reduction (SCR) catalyst. The catalyst is prepared from a base material, titanium dioxide, vanadium pentoxide, ammonium heptamolybdate, lactic acid, a glass fiber and silicon dioxide, wherein the base material is coated with the titanium dioxide, the vanadium pentoxide, the ammonium heptamolybdate, the lactic acid, the glass fiber and the silicon dioxide and then is sintered to form the plate-type denitration catalyst. The plate-type denitration catalyst is applied to a denitration treatment process, so that the plate-type denitration catalyst has the advantages of being high in mechanical strength, durable and high in denitration efficiency, can be recycled, and the like.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

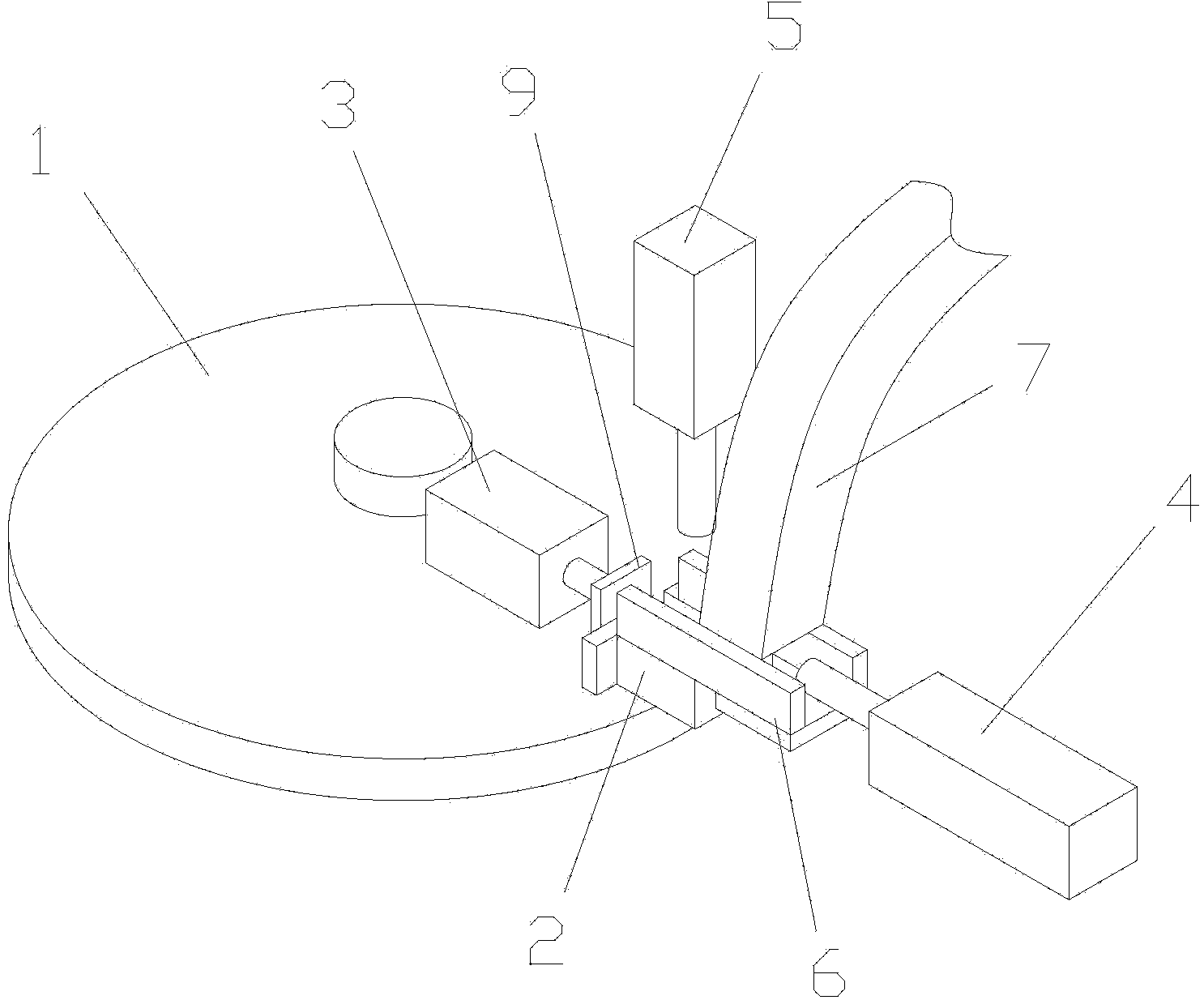

Feeding and positioning device for use in processing of box car lock

InactiveCN104044007AImprove production and processing efficiencyReasonable structureMetal working apparatusMechanical engineering

The invention discloses a feeding and positioning device for use in processing of a box car lock, and relates to the technical field of production and processing equipment for box car locks. The feeding and positioning device is characterized by comprising a rotating disk, a trough plate, a back positioning cylinder, a front positioning cylinder, an upper positioning cylinder, a block inlet groove and a feeding groove, wherein the trough plate is arranged on the upper side edge of the rotating disk; a trough is formed in the trough plate; the back positioning cylinder is arranged on the rotating disk; a positioning plate is arranged at the output end of the back positioning cylinder; the block inlet groove is positioned in the upper part of the trough plate and extends to the upper side of the front side of the trough plate; the front positioning cylinder is arranged on the front side of the block inlet groove; the upper positioning cylinder is positioned above the block inlet groove, and is positioned over the trough; the feeding groove is formed above the front part of the block inlet groove. The feeding and positioning device has the advantages of reasonable structure, convenience in use, high automatic degree, high feeding speed and high positioning accuracy, and the production and processing efficiency of the box car lock can be increased greatly.

Owner:安徽中铁施封锁有限公司

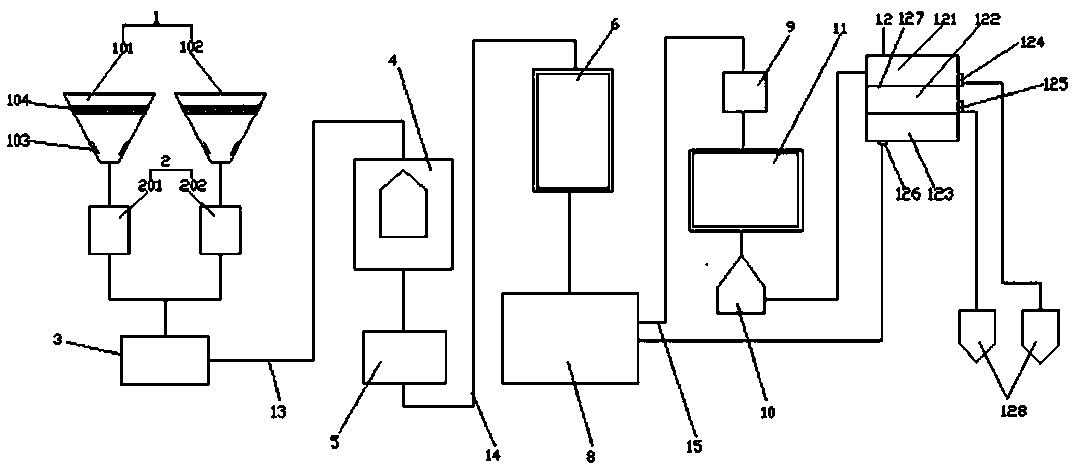

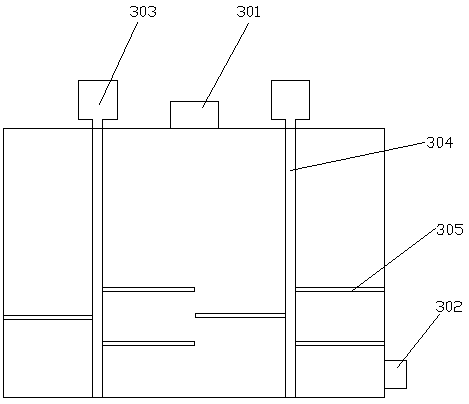

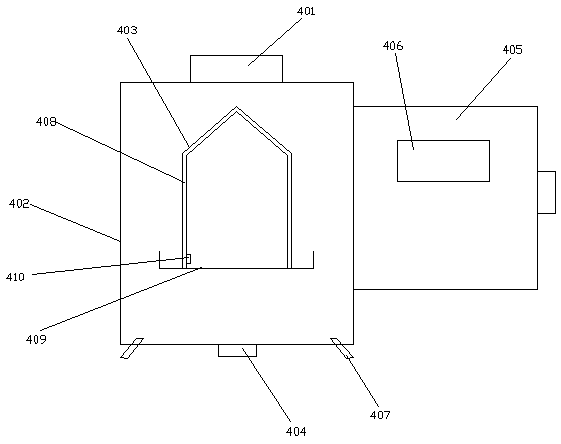

Granulated feed producing and processing equipment and method

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com