Automatic conveying production line applied to part spraying

An automatic conveying and production line technology, applied to the surface coating liquid device, coating, spray booth, etc., can solve the problems of low processing efficiency, increased processing cost, and inability to meet the needs of enterprises, so as to improve efficiency and automation High, precise and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

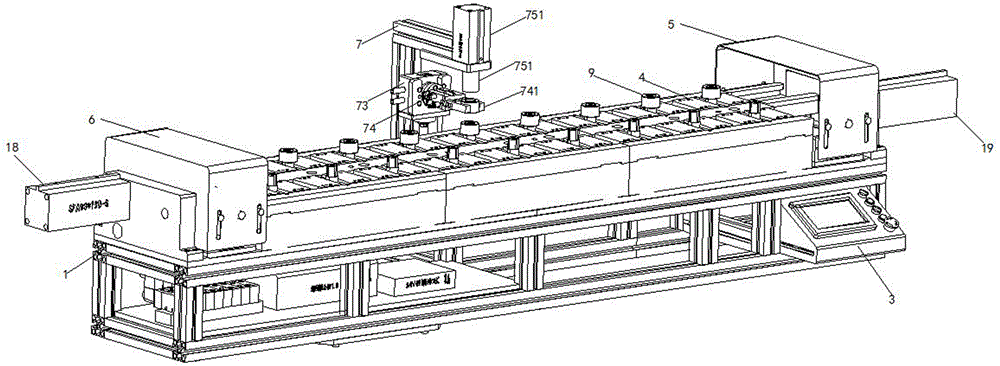

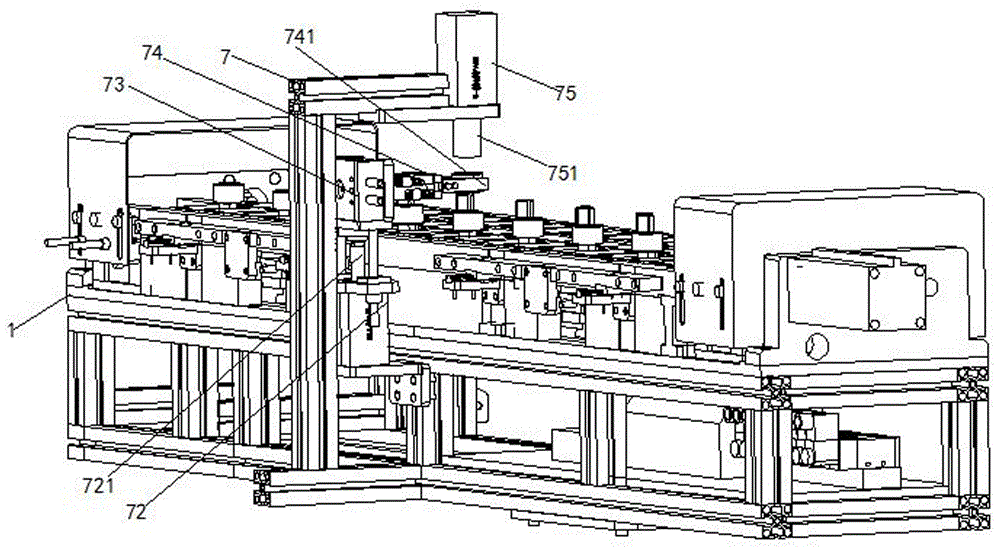

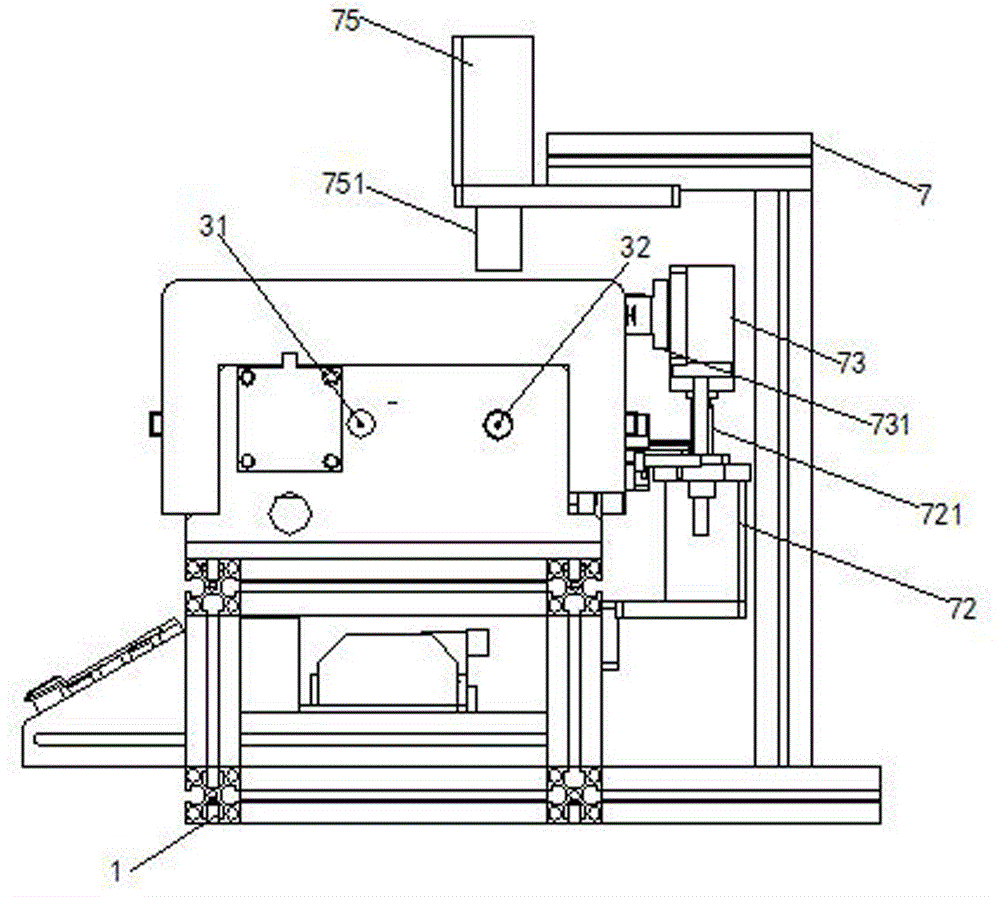

[0027] Embodiment 1: refer to Figure 1-3 , an automatic conveying production line applied to parts spraying, including a rectangular frame body 1, a conveying track, a pad printing bottom mold 4, a workpiece rotating manipulator for driving the workpiece to change direction, and the workpiece is detachably installed on the pad printing bottom mold 4, the transmission device arranged on the frame body 1 drives the pad printing bottom mold 4 to reciprocate along the conveying track of the frame body 1, and the conveying track includes: the first track 11 for forwardly conveying the pad printing bottom mold 4, the reverse direction The second track 12 for conveying the pad printing bottom mold 4 .

[0028] The transmission device includes: a first rail changing device for switching the pad printing bottom mold 4 from the first track 11 to the second track 12; a second switching device for switching the pad printing bottom mold 4 from the second track 12 to the first track 11; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com