Patents

Literature

7480results about "Spray booths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for coating implantable devices

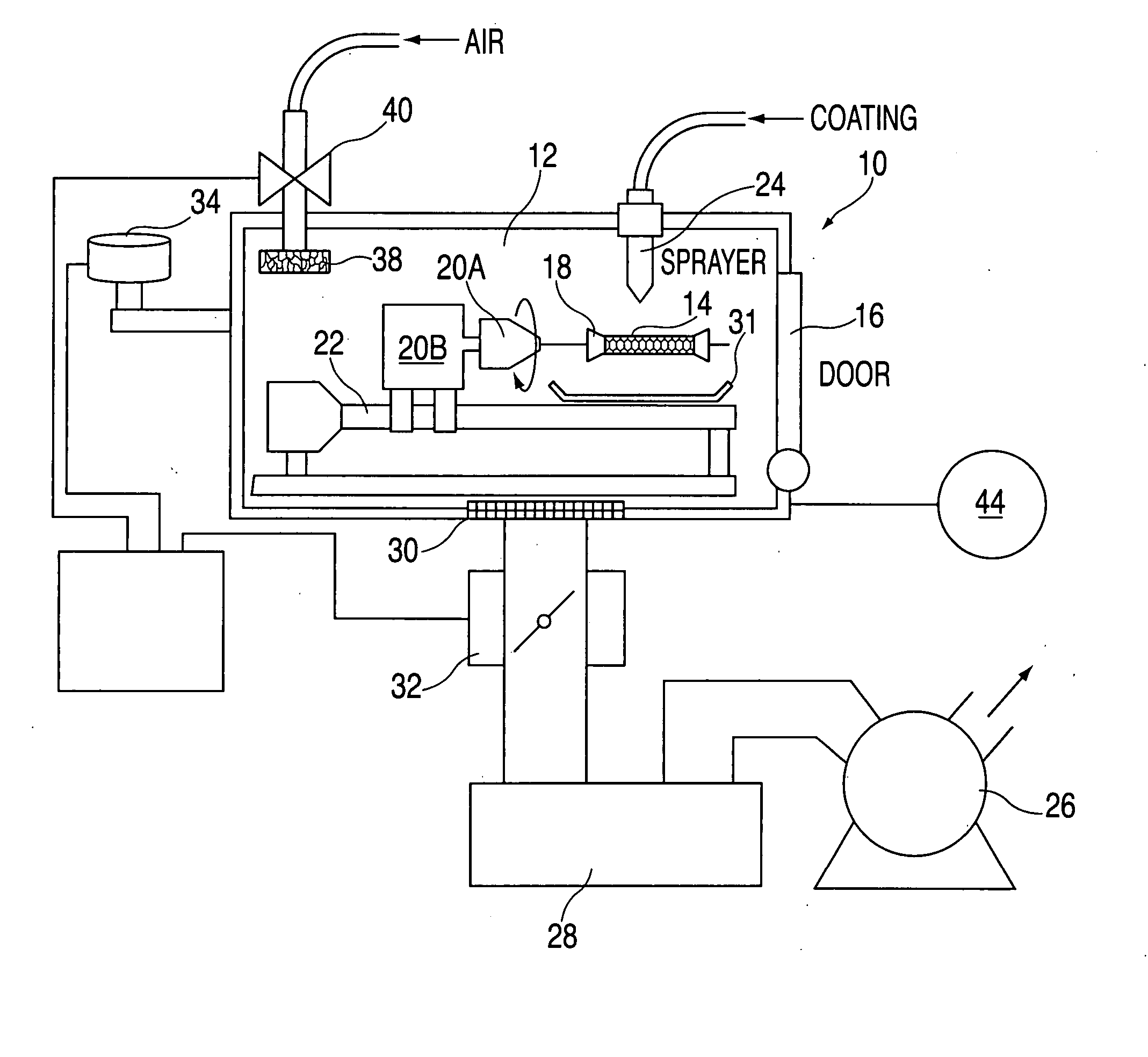

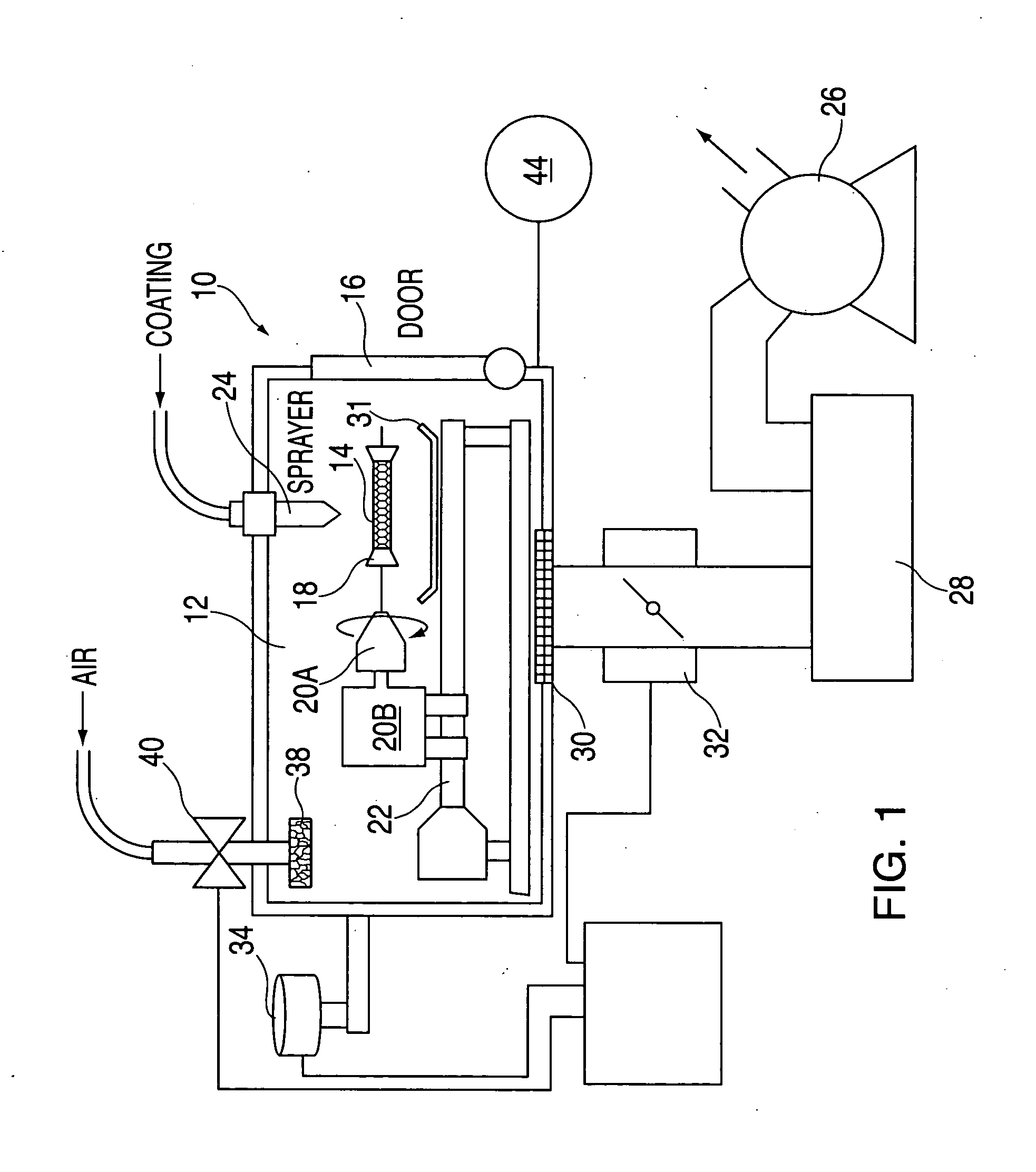

A method of forming a coating for an implantable medical device, such as a stent, is provided which includes applying a composition to the device in an environment having a selected pressure. An apparatus is also provided for coating the devices. The apparatus comprises a chamber for housing the device wherein the pressure of the chamber can be adjusted during the coating process.

Owner:ABBOTT CARDIOVASCULAR

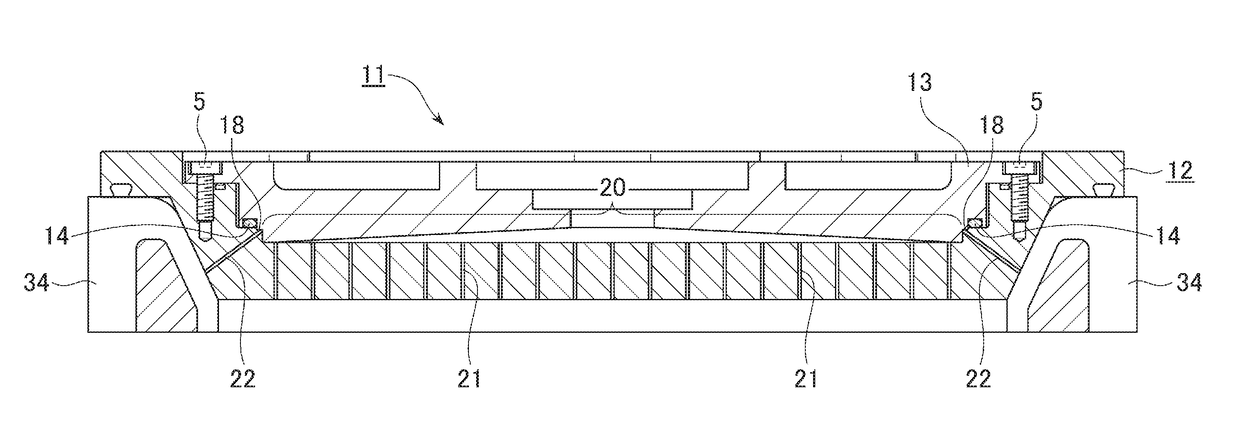

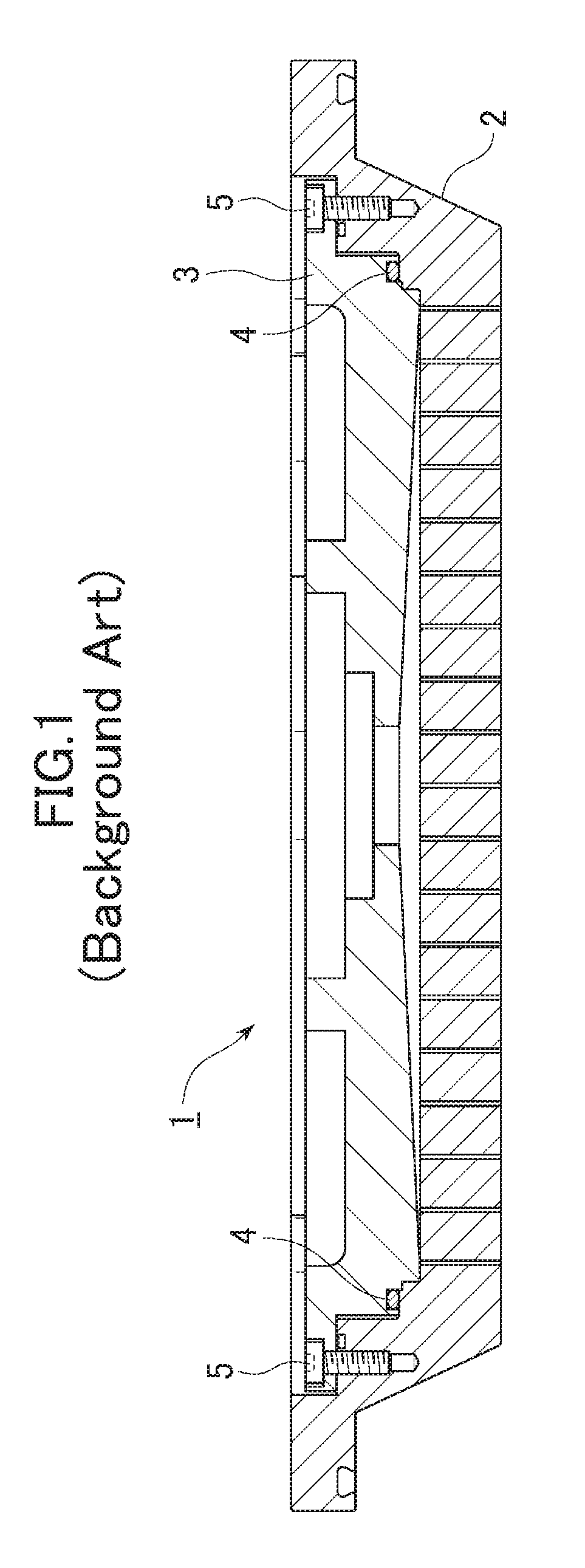

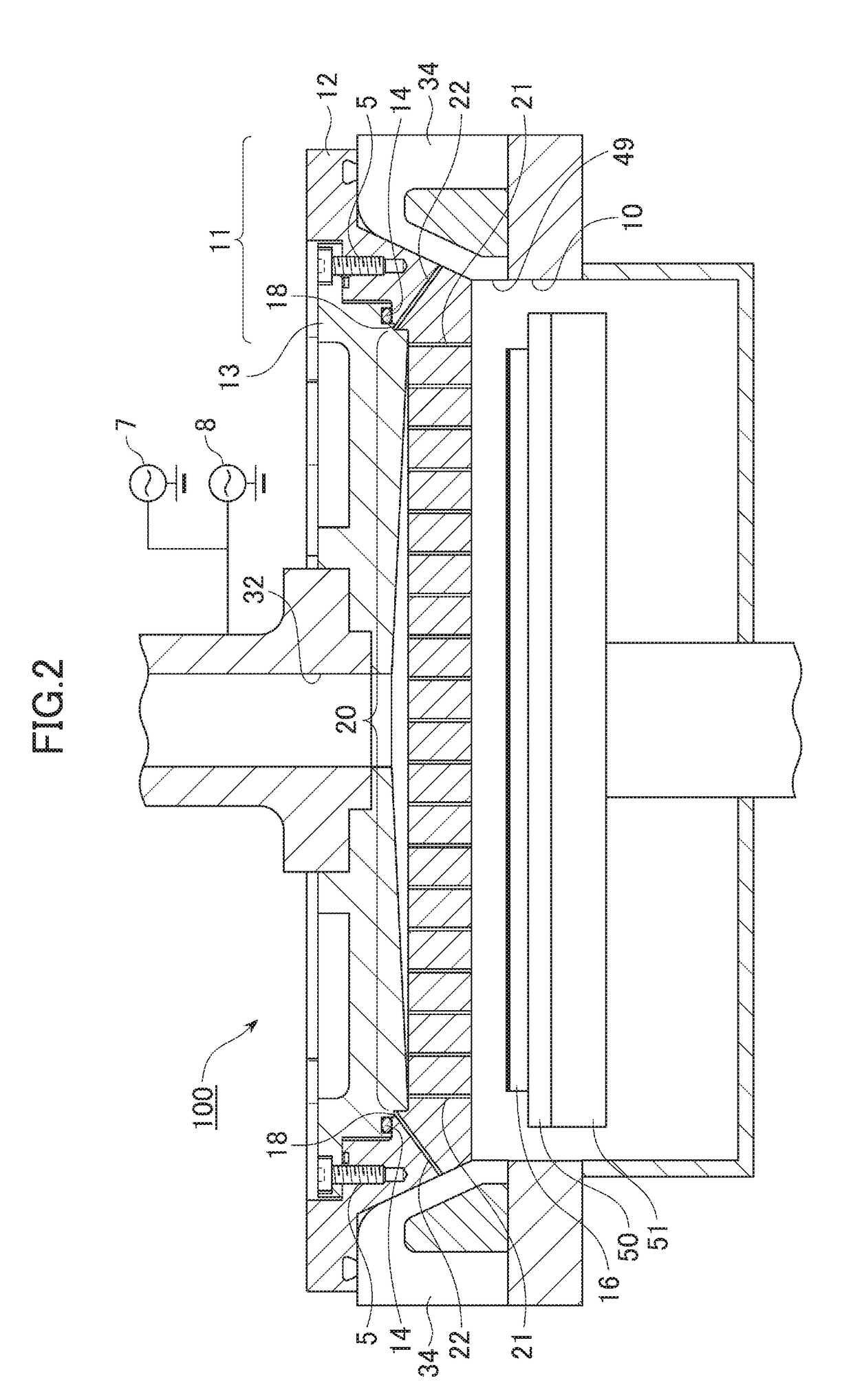

Shower plate structure for exhausting deposition inhibiting gas

ActiveUS20180171472A1Simple structureGood film uniformityLiquid surface applicatorsElectric discharge tubesPlasma depositionEngineering

A shower plate adapted to be installed in a plasma deposition apparatus including a gas inlet port, a shower head, a reaction chamber and an exhaust duct, the shower plate being adapted to be attached to the showerhead and having: a front surface adapted to face the gas inlet port; and a rear surface opposite to the front surface, wherein the shower plate has multiple apertures each extending from the front surface to the rear surface, and wherein the shower plate further has at least one aperture extending from the front surface side of the shower plate to the exhaust duct.

Owner:ASM IP HLDG BV

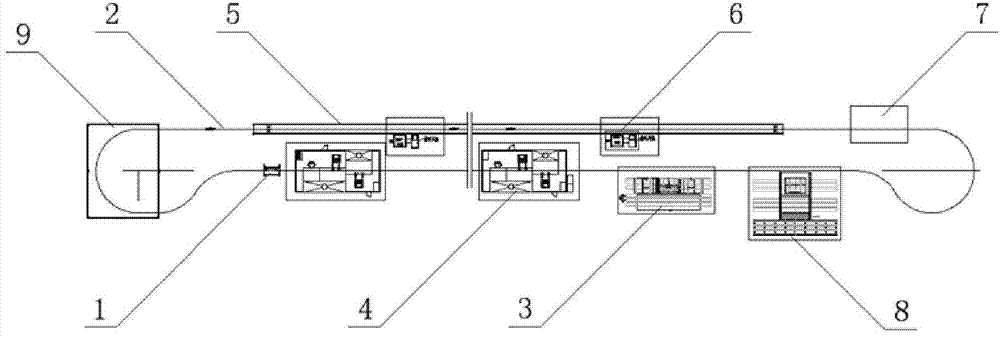

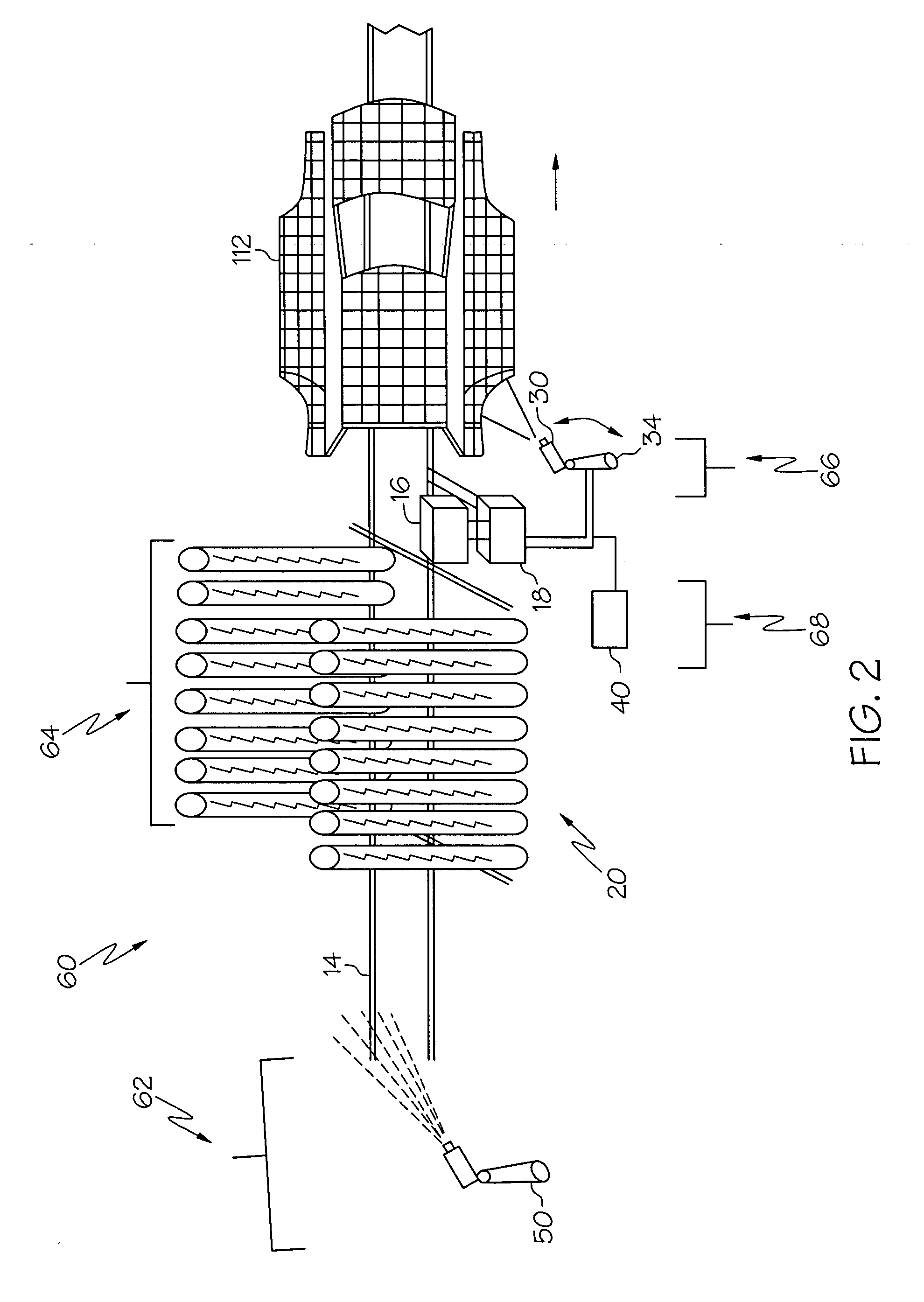

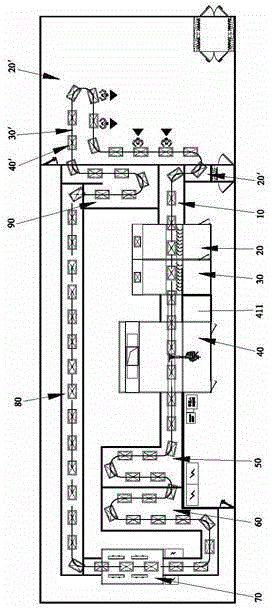

Production line for automatically coating profile steel and coating method thereof

ActiveCN104759383ASolve puzzlesFully automatedLiquid spraying plantsPretreated surfacesProduction lineIndustrial engineering

The invention discloses a production line for automatically coating a profile steel and a coating method thereof, wherein a suspension conveying line (2) runs through the central axis of a coating chamber (4). A loading mechanism (3) is installed on the front end of the coating chamber (4); and the suspension conveying line (2) on the back end of the coating chamber (4) is provided with a drying channel (5). A back output end of the drying channel (5) is connected with a cooling area (7); and an unloading mechanism (8) is installed behind the cooling area (7). By utilizing the head-to-tail closed loop suspension conveying line and the tandem type hanging manner of hanging multiple workpieces on one hanger, procedures such as loading, finishing coat spraying, priming paint spraying, drying, cooling, unloading and storing are all finished automatically, accordingly achieving the automatic spraying of the profile steel having a long length, and optimizing the conventional profile steel coating technology. By utilizing electrostatic spraying in association with the position and the angle of the spraying gun, the coating problem of coating dead angle at inside corners of the profile steel is solved better, accordingly improving the coating quality of the entire profile steel.

Owner:HUBEI ABSOLUTE SINCERITY STEEL STRUCTURE +1

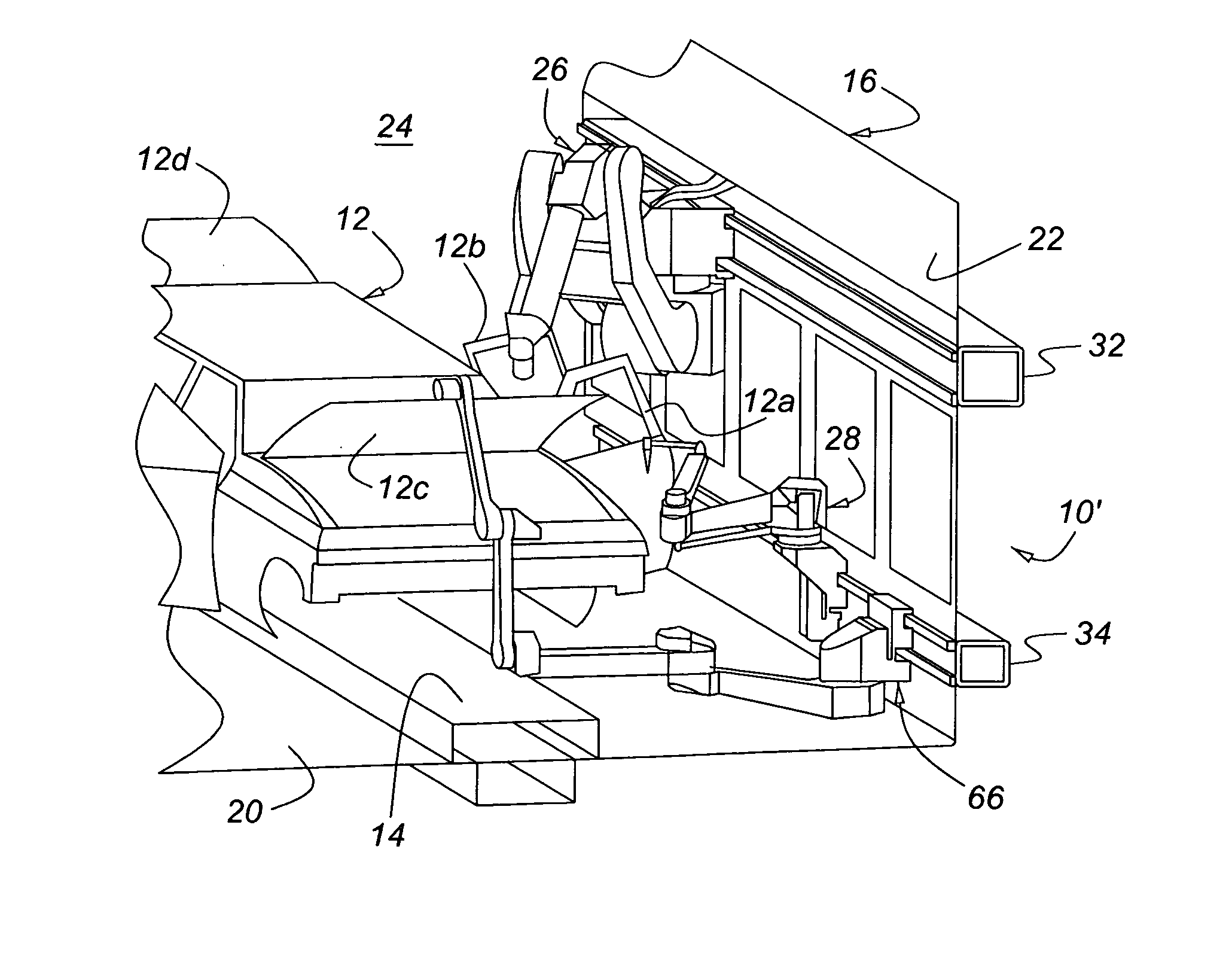

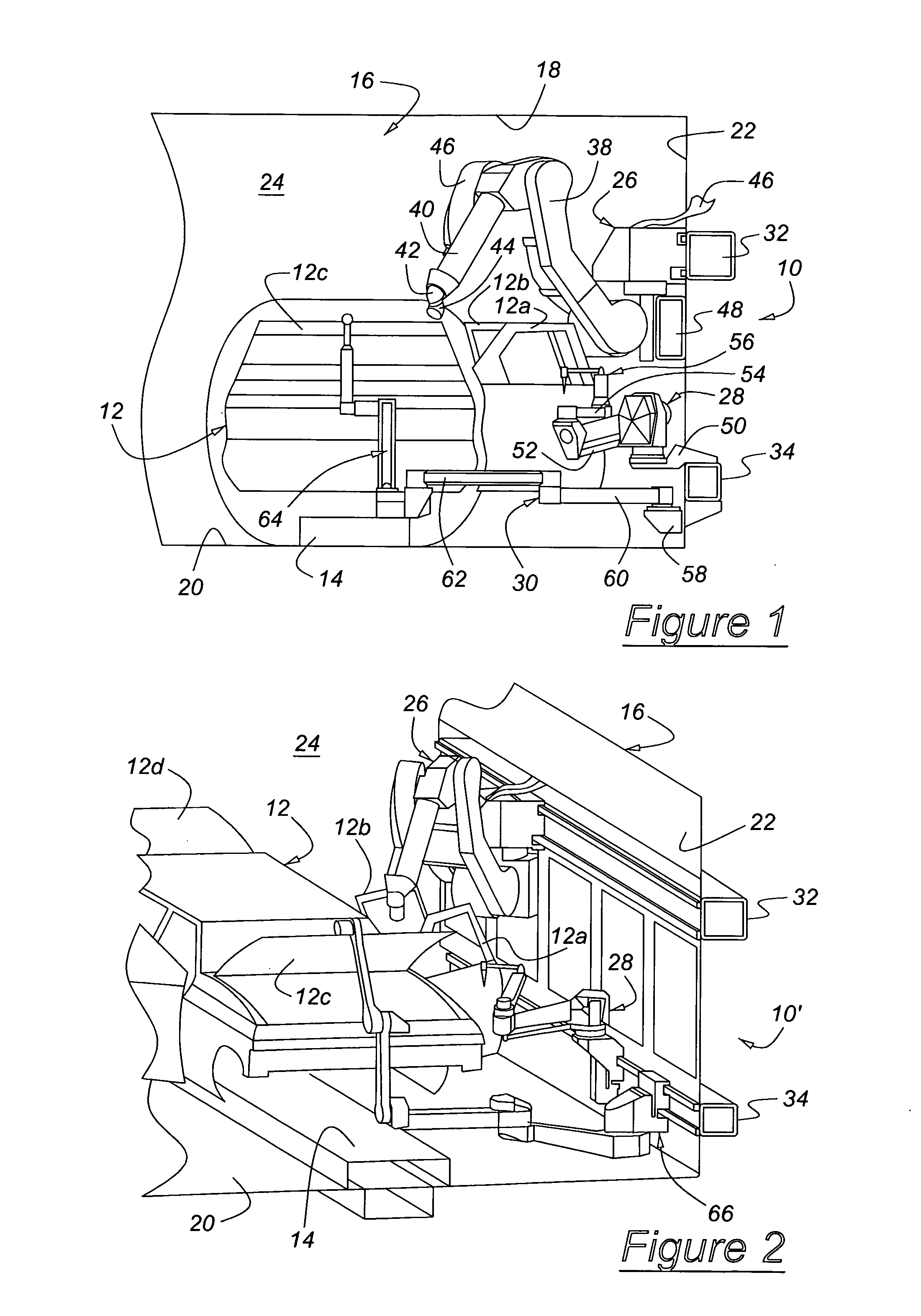

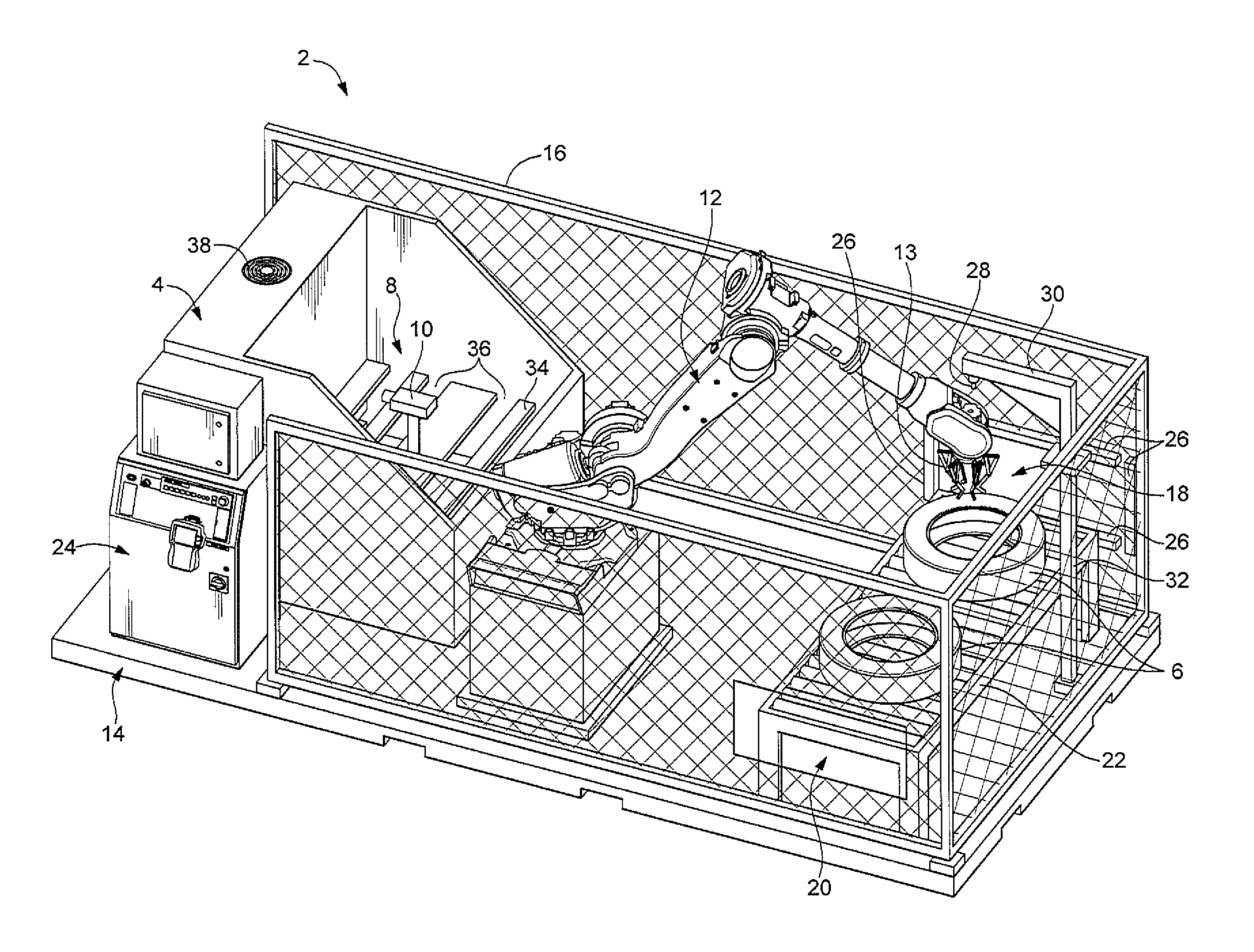

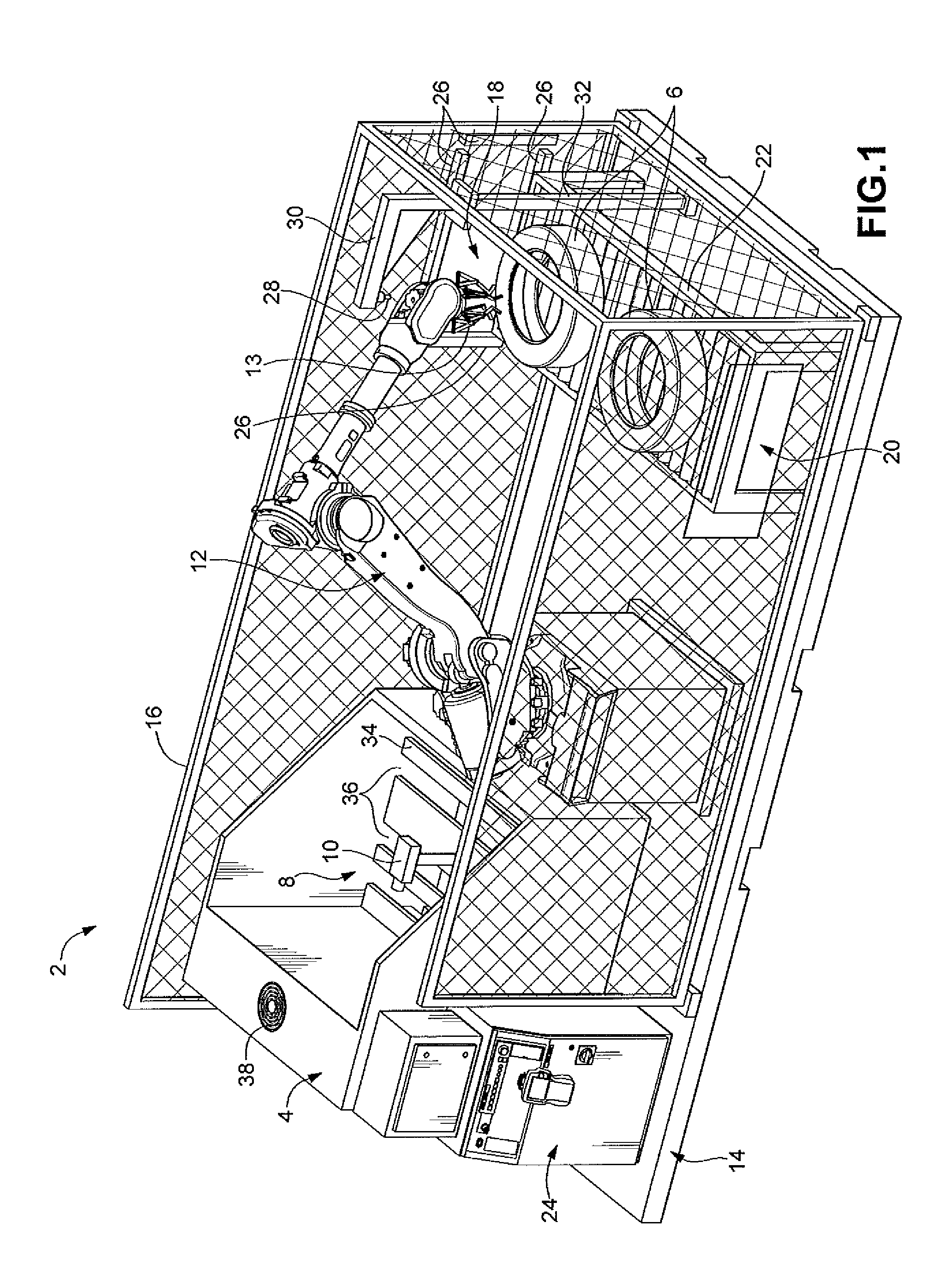

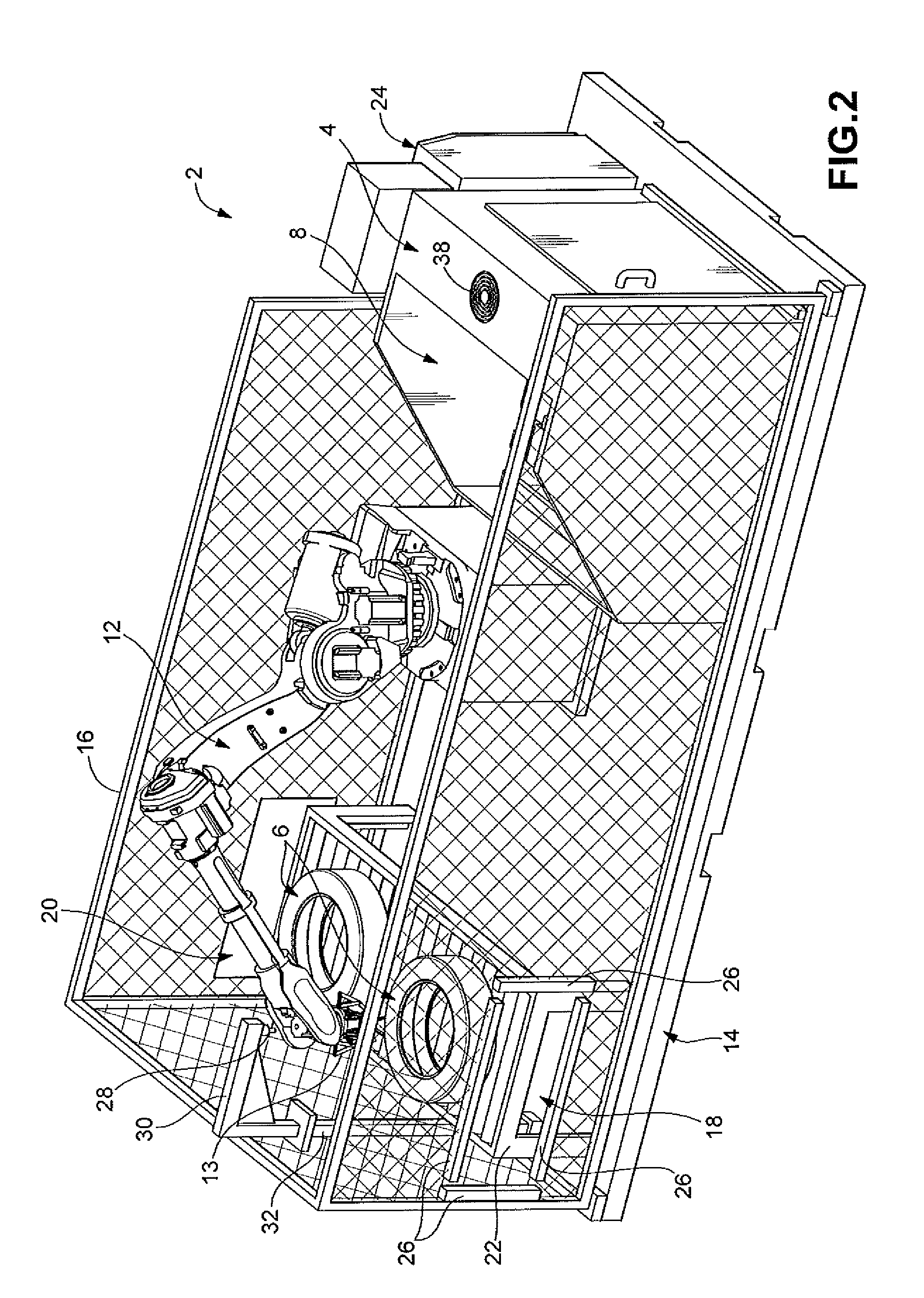

Compact robotic painting booth

ActiveUS20060292308A1Save spaceMinimize paint over-build-upProgramme controlProgramme-controlled manipulatorPaint robotEngineering

A system for painting an article, such as an automotive vehicle body, includes a painting booth, a conveyor for transporting articles through the painting booth, a first rail located beside and extending along the conveyor, a second rail located beside and extending along the conveyor at a lower elevation than an elevation of the first rail, a paint robot including an articulating arm mounted on the first rail for displacement along the first rail, a panel opener robot mounted on the second rail for displacement along the second rail such that the paint robot and the panel opener robot can move past each other on the rails without interference.

Owner:FANUC ROBOTICS NORTH AMERICA

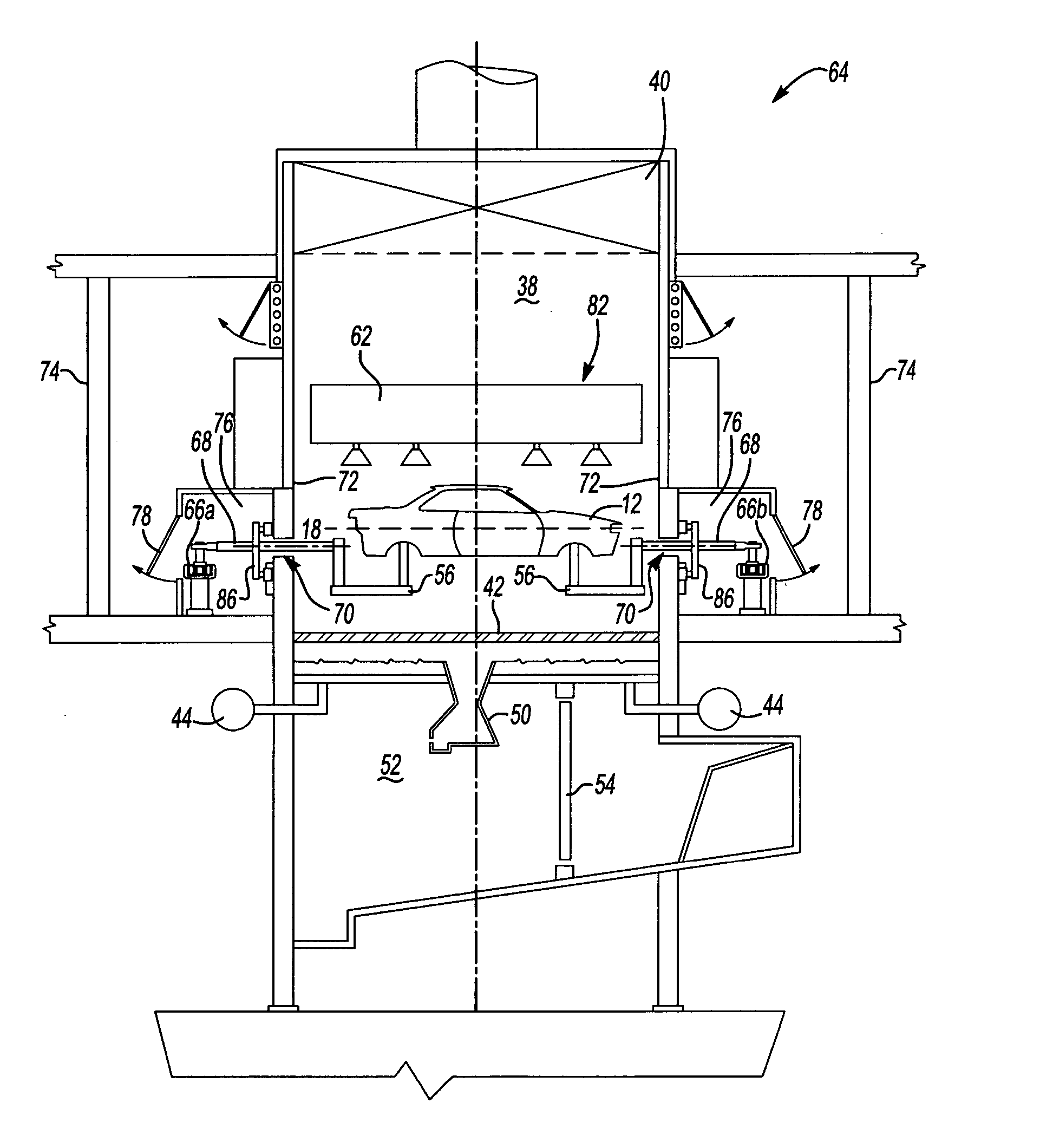

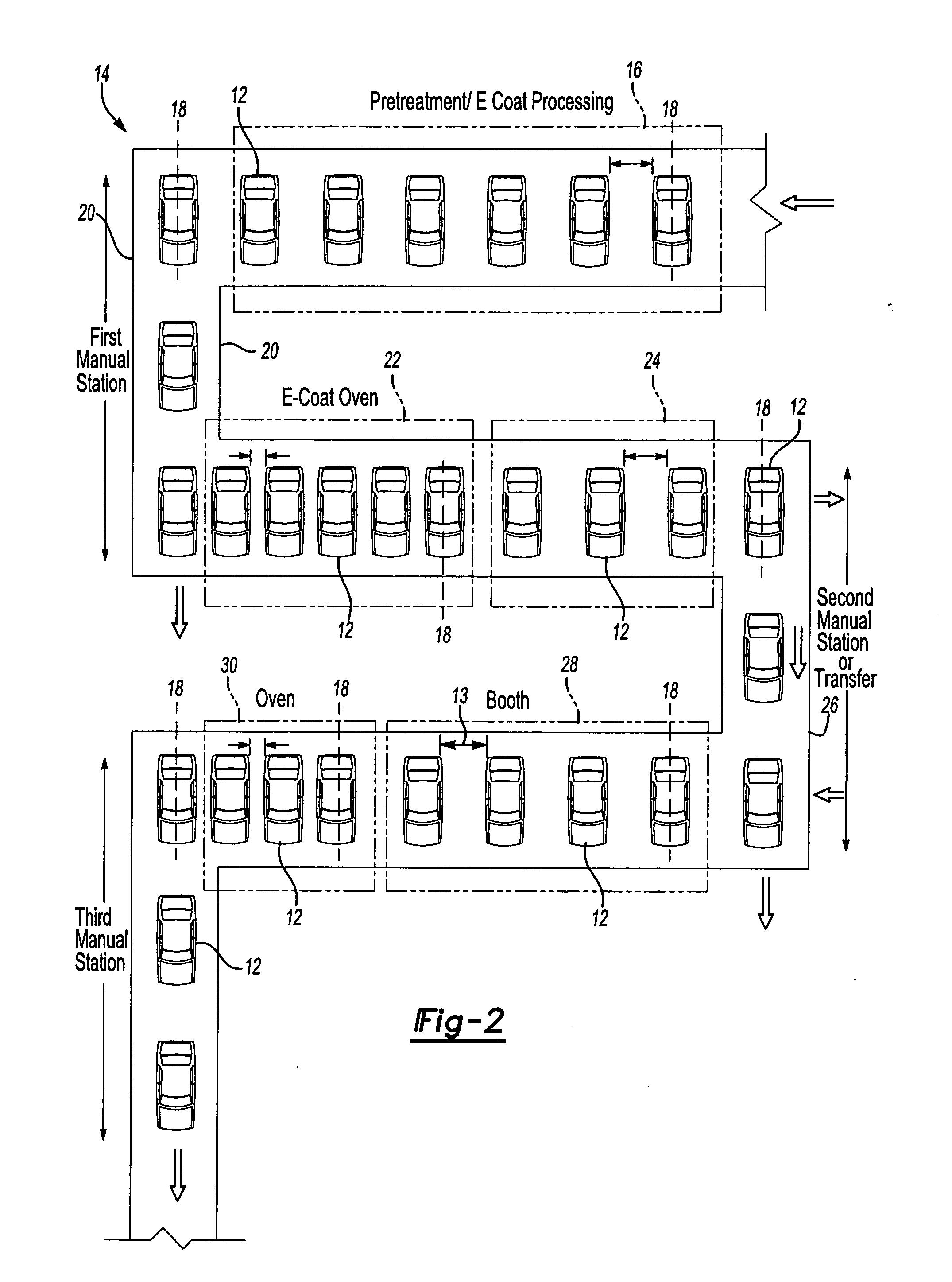

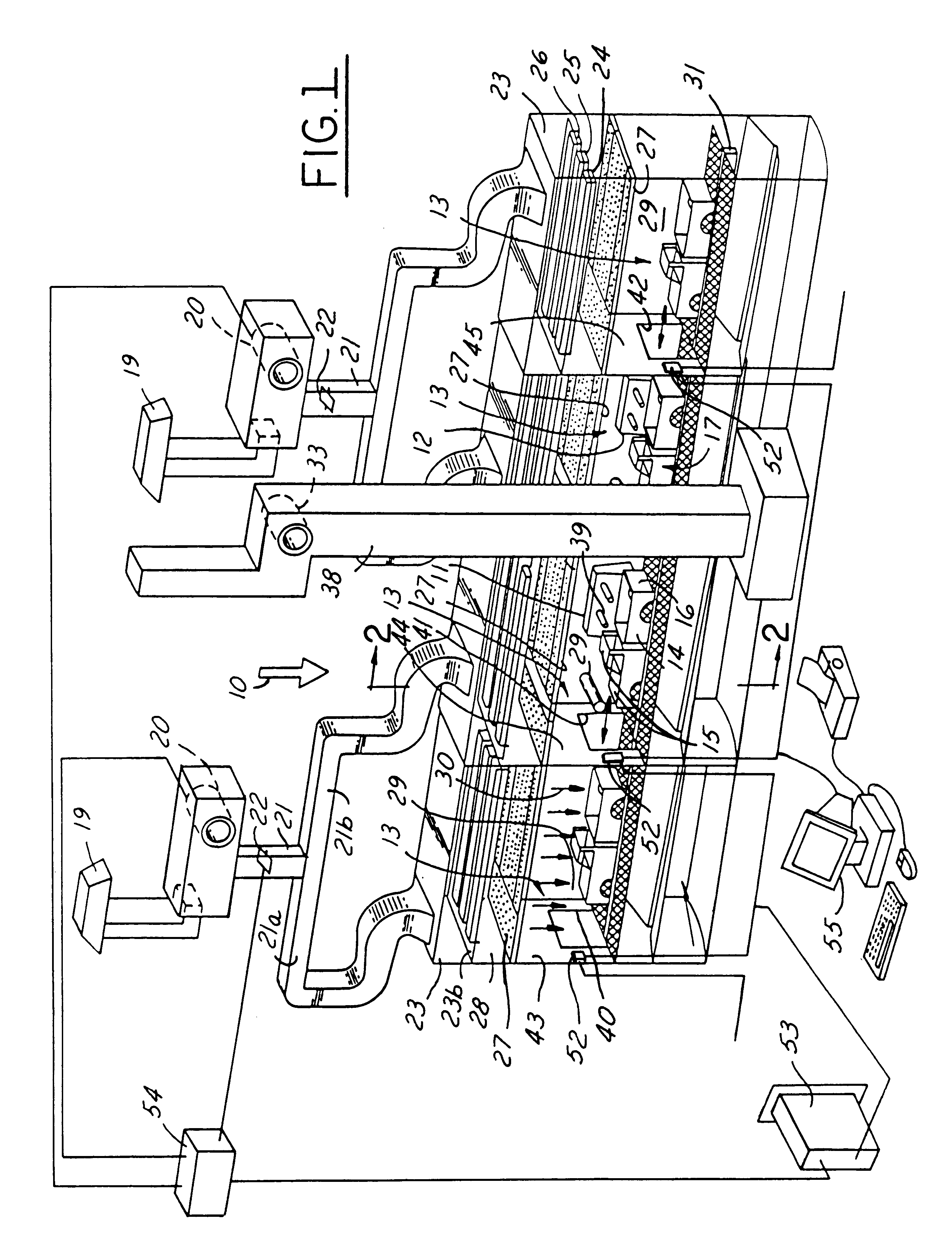

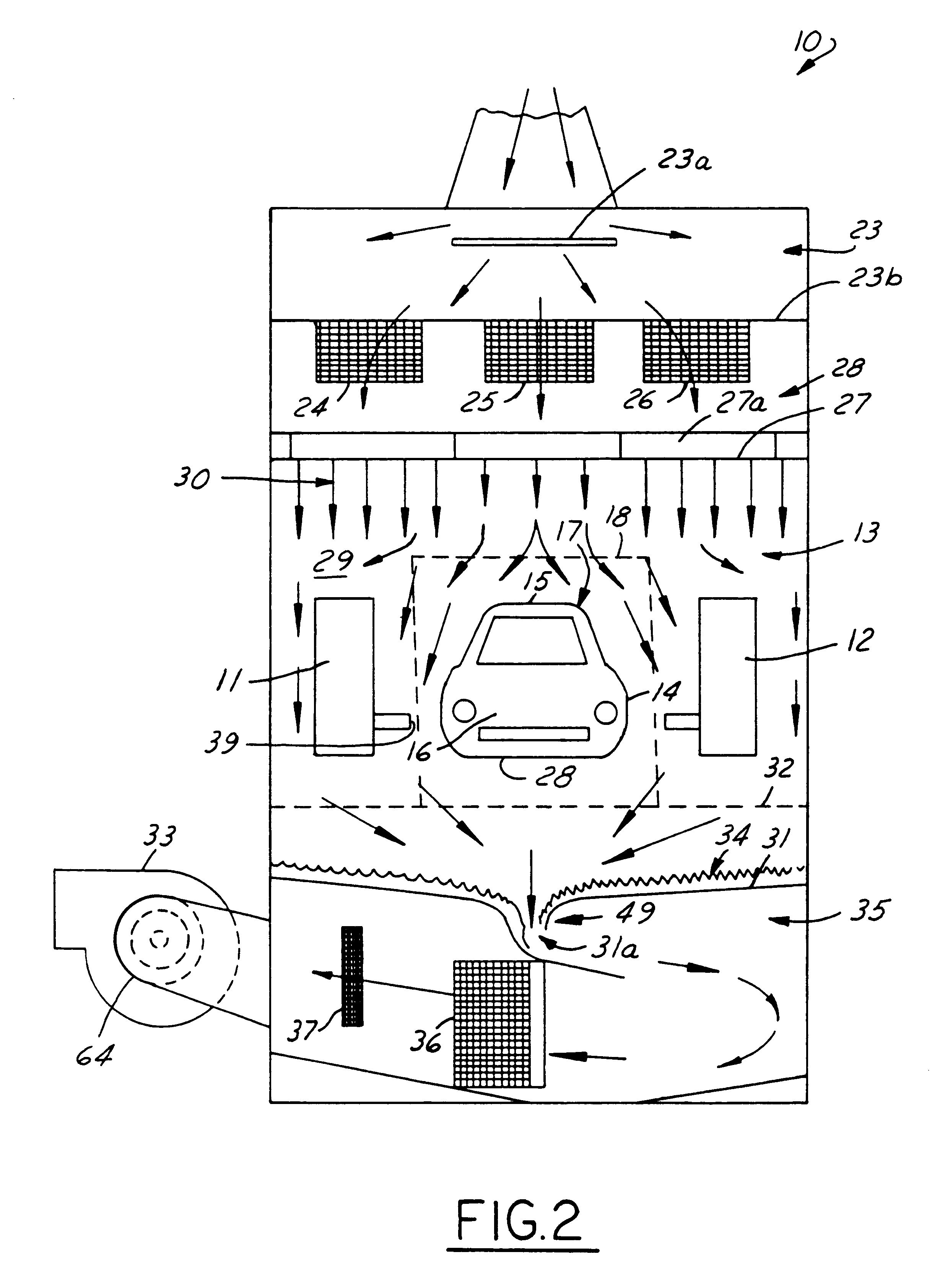

Production paint shop design

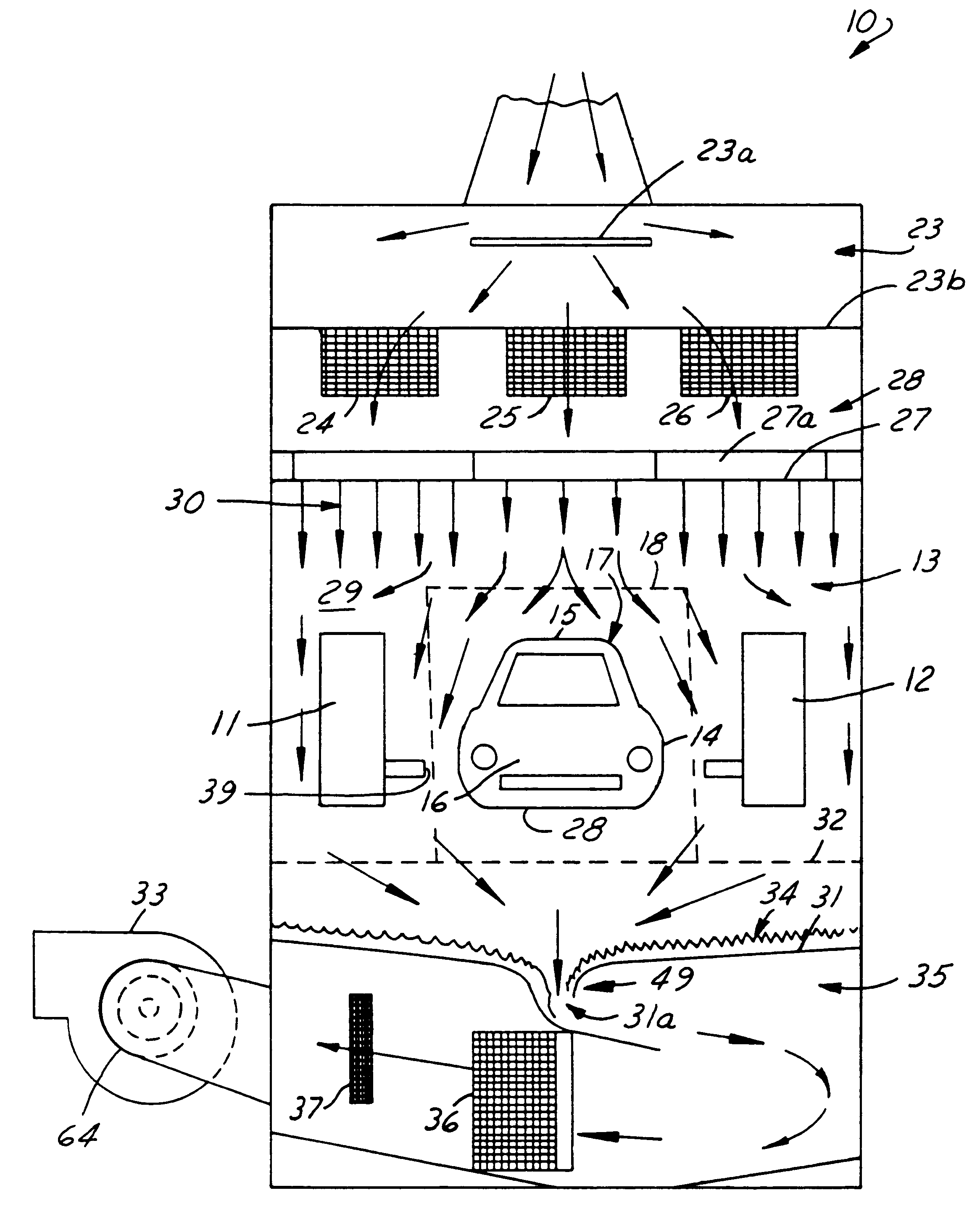

InactiveUS20060068094A1Improve paint qualityReduce flow rateConveyorsSpray nozzlesMotorized vehicleMechanical engineering

A paint application facility including a paint booth assembly for applying paint to automotive vehicles each defining a longitudinal axis includes a carrier adapted to serially move a plurality of automotive vehicles through the booth assembly in a direction generally perpendicular to the longitudinal axis of the vehicle.

Owner:FUJIFILM HEALTHCARE CORP +1

Systems and methods for inspecting coatings, surfaces and interfaces

InactiveUS7220966B2Efficient detectionMinimization requirementsRadiation pyrometryPretreated surfacesThermodynamicsTemporal change

Owner:TOYOTA MOTOR CO LTD +1

Rotary wall board paint spraying bracket

ActiveCN106000729AEasy to operateEasy to useLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a rotary wall board paint spraying bracket. The rotary wall board paint spraying bracket comprises a door fixture, wherein a bearing platform is arranged below a cross beam of the door fixture; a rectangular slideway 1 is machined on the lower surface of the cross beam of the door fixture; a slide rail 1 is arranged inside the rectangular slideway 1; an electric trolley 1 is arranged on the slide rail 1; a telescopic cylinder 1 with a downward telescopic end is arranged on the lower surface of the electric trolley 1; a mounting box is arranged at the telescopic end of the telescopic cylinder 1; a circular through hole is formed in the center of the lower surface of the mounting box; a spray head is embedded into the circular through hole; a controller is arranged on the front surface of the bearing platform; a storage battery is arranged inside the controller; the storage battery is electrically connected with the controller; and the controller is electrically connected with the electric trolley 1, the telescopic cylinder 1, electric trolleys 2, telescopic cylinders 2, rotary motors and clamping claws. The rotary wall board paint spraying bracket has the beneficial effects of simple operation, convenience in use, automatic rotary paint spraying treatment, high working efficiency, high convenience and practicality.

Owner:江苏凯蒂家居用品有限公司

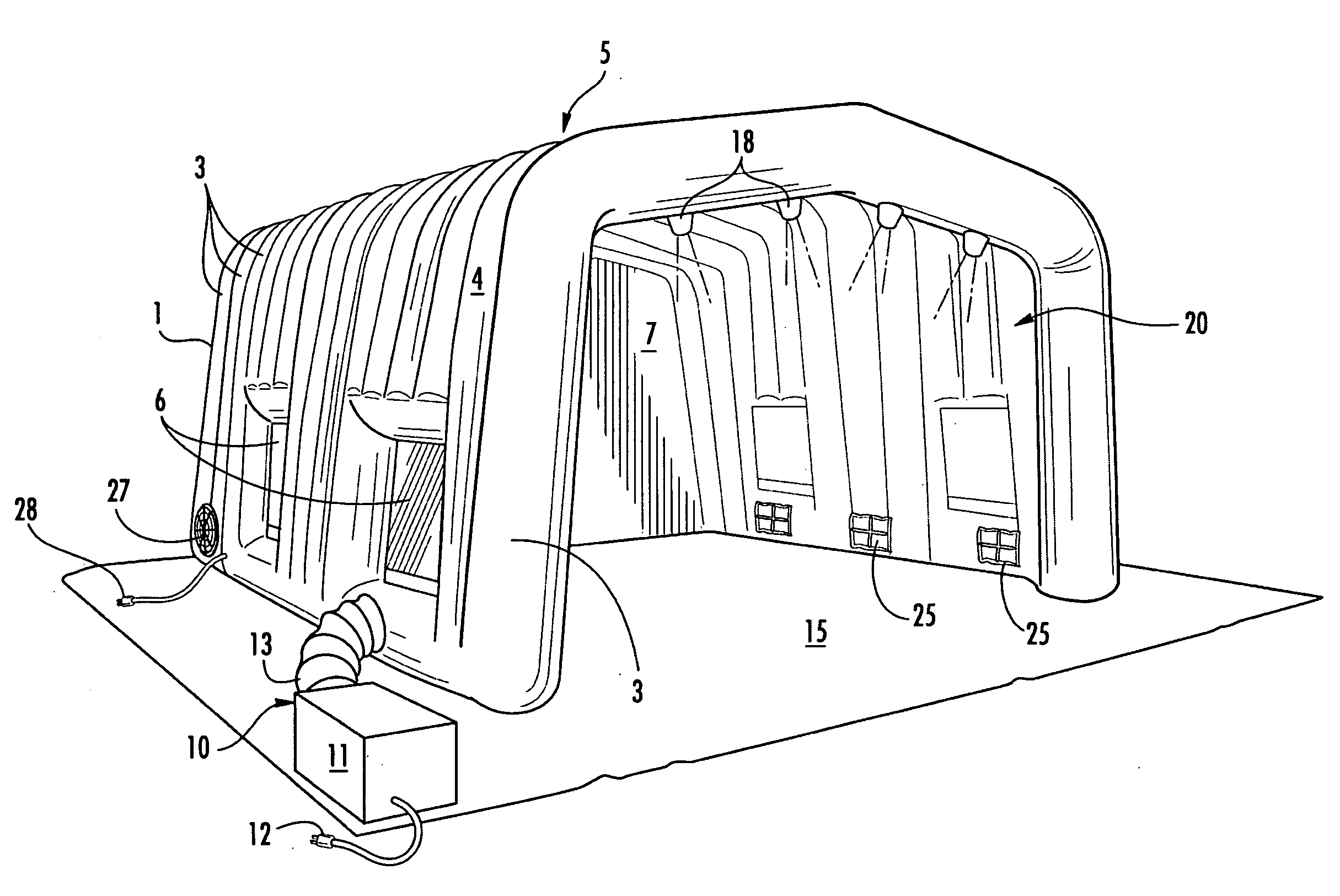

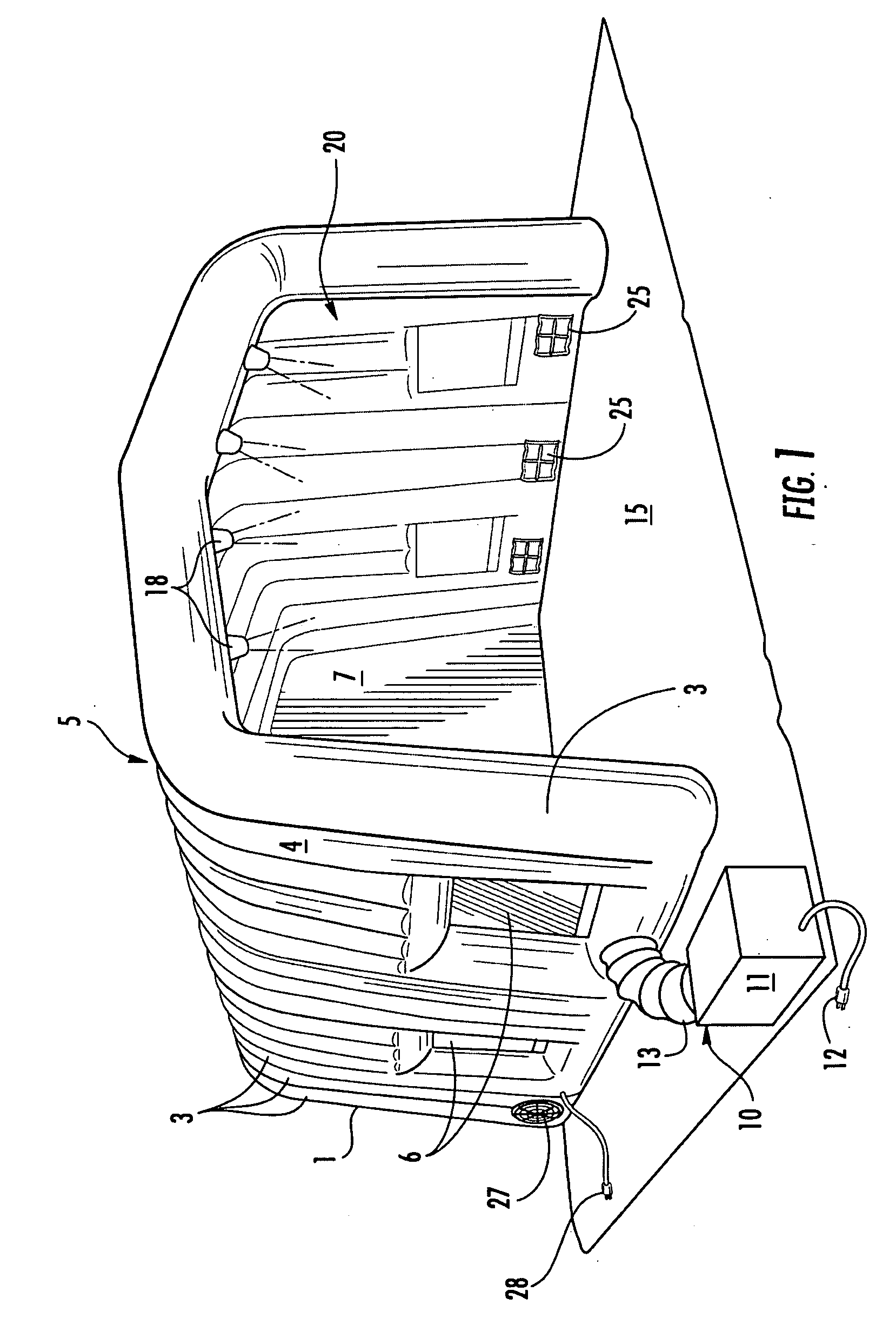

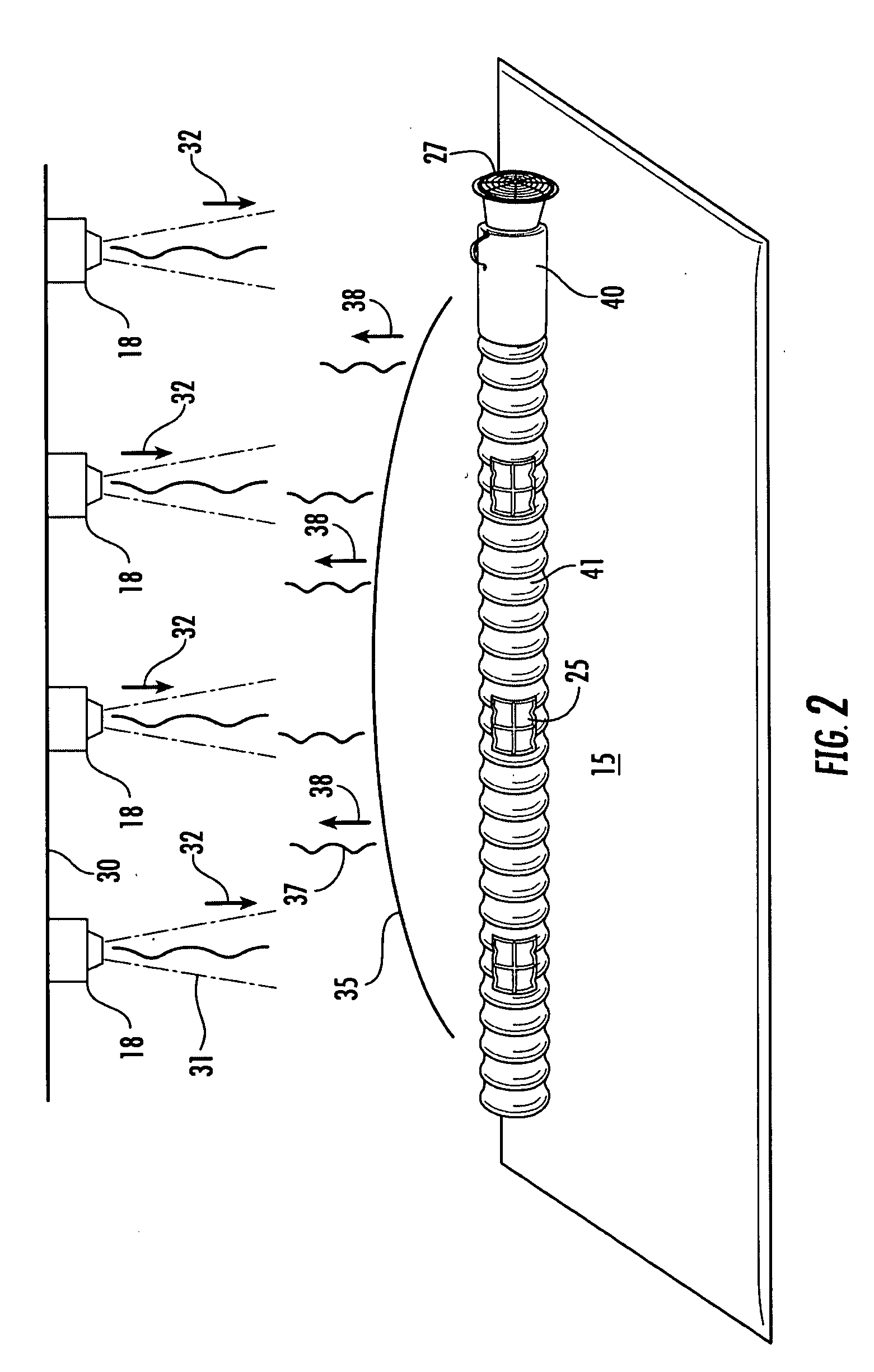

Portable spray booth with air handling system

InactiveUS20100272915A1Liquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingAtmospheric pressureHandling system

The present invention discloses a paint spray booth which consists of an inflatable structure. The structure comprises downdraft jets powered by the same air pressure that inflates the building. The downdraft air jets blow volatile paint fumes toward the bottom portion of the paint booth where one or more ventilation exhaust jets extract the volatile gases and filter the volatile gases out before ejecting clean air to the environment.

Owner:LAWS SETH ANTHONY

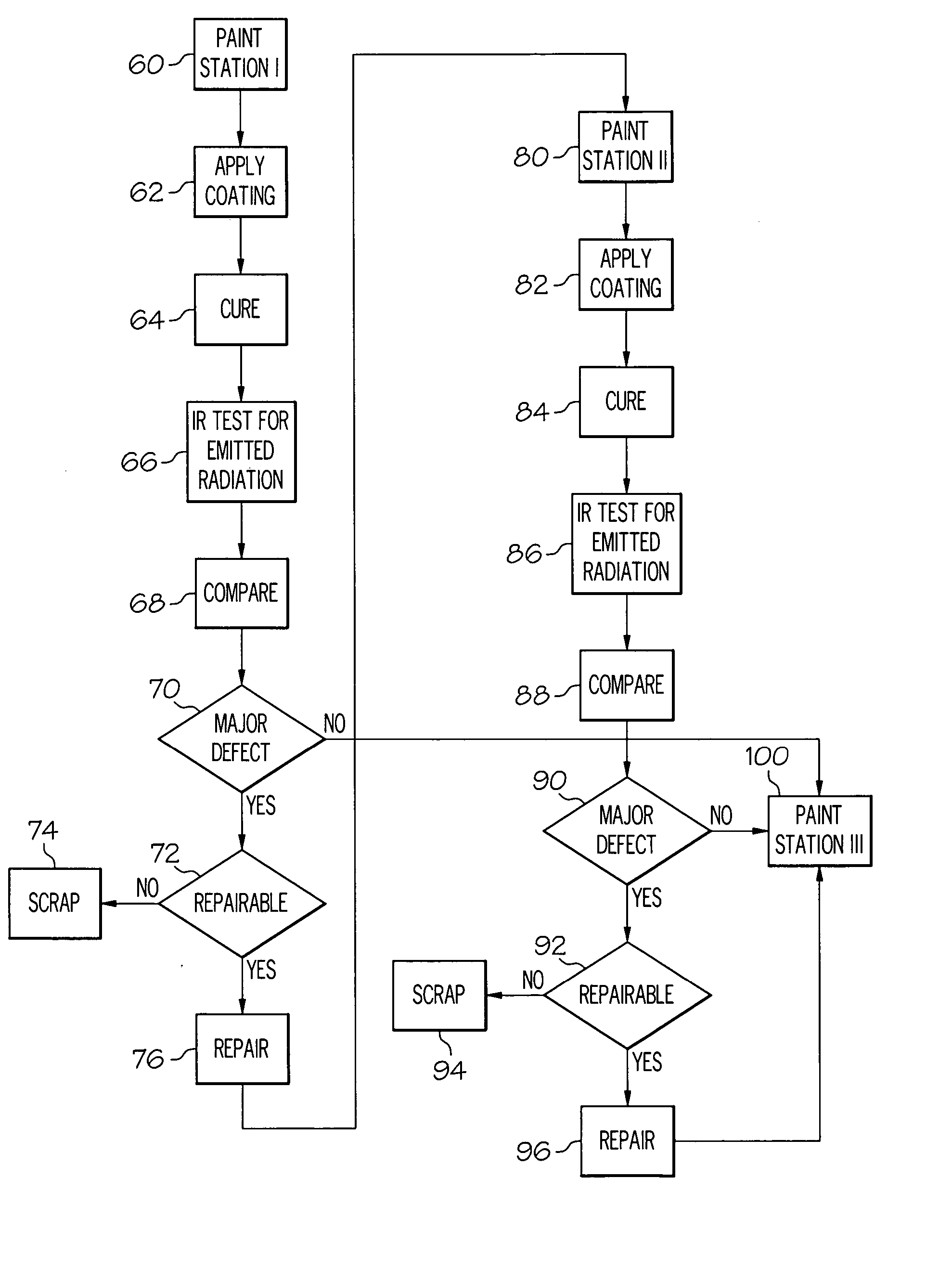

Systems and methods for inspecting coatings, surfaces and interfaces

InactiveUS20050186327A1Efficient detectionMinimization requirementsRadiation pyrometryPretreated surfacesThermodynamicsCoating

A system for detecting defects in paint coatings includes a temperature manipulation apparatus configured to change the temperature of a surface and a coating applied to the surface. The system may further include an infrared sensor for measuring the change in temperature (over time) of the surface and coating and a processor to compare the measured change in temperature of the surface and coating to an expected change of temperature (over time) in order to determine anomalies in the coatings. A self-referencing method of determining defects is also disclosed, wherein surrounding pixels are utilized as a reference in the detection process for calculating the change in temperature of each pixel. In addition, application of the inventive aspects to inspection of adhesion interfaces is also disclosed.

Owner:TOYOTA MOTOR CO LTD +1

Vacuum painting head and relative painting method

InactiveUS7022189B2Prevent leakagePreventing the paint from leaking out of the containerVacuum evaporation coatingSpray nozzlesEngineeringAtmospheric pressure

A vacuum painting head to paint objects, including a container having an inlet aperture and an outlet aperture for the object to be painted, wherein the outlet aperture has a transverse section substantially equal to that of the object to be painted, wherein a suction pump is provided to create inside the container a determinate depression with respect to atmospheric pressure, and wherein paint is continuously introduced into the container. A stopper element is inserted into one of the apertures and is selectively movable to move away from or closer to the other aperture to open or close it.

Owner:DELLE VEDOVE LEVIGATRICI

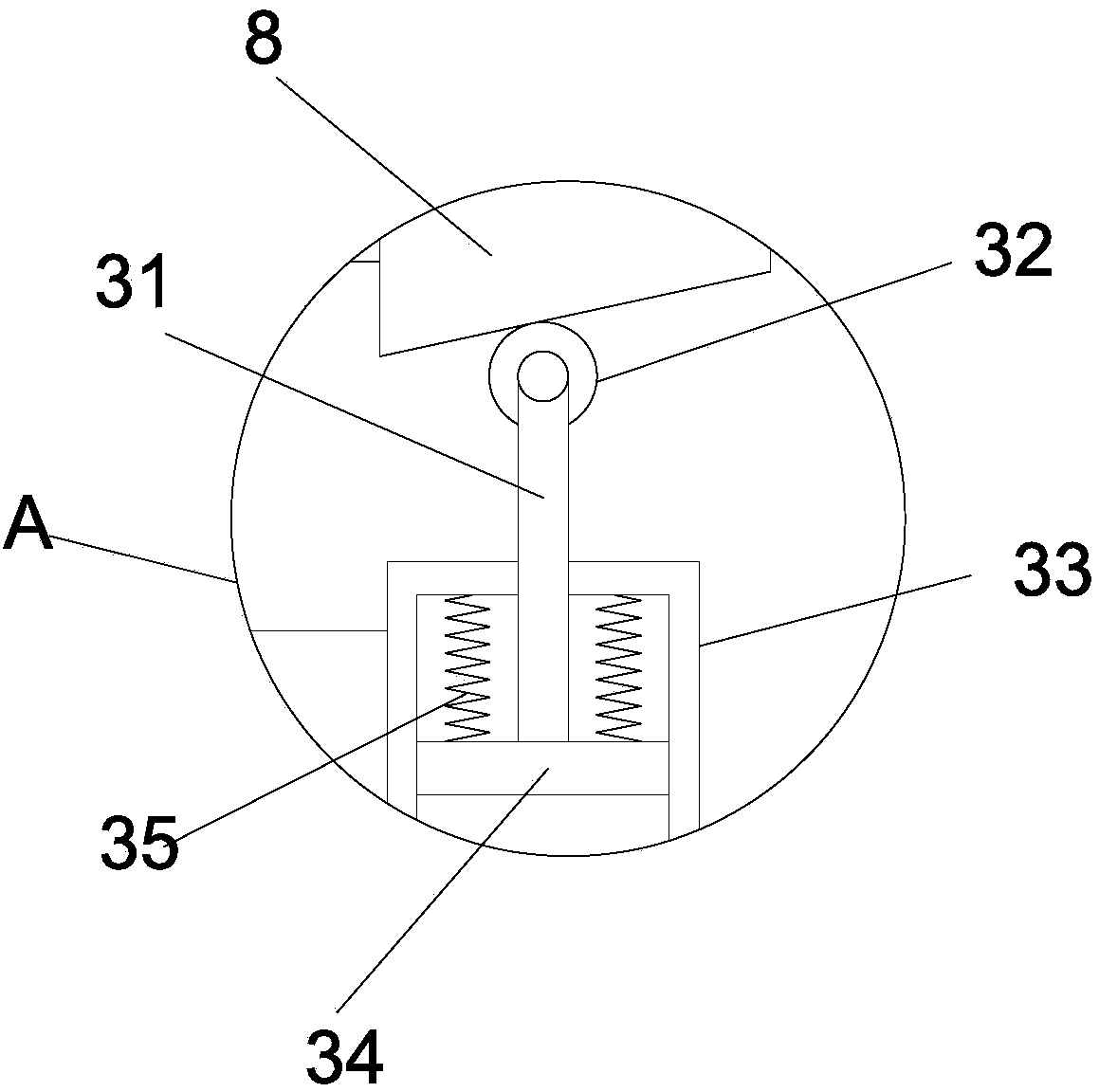

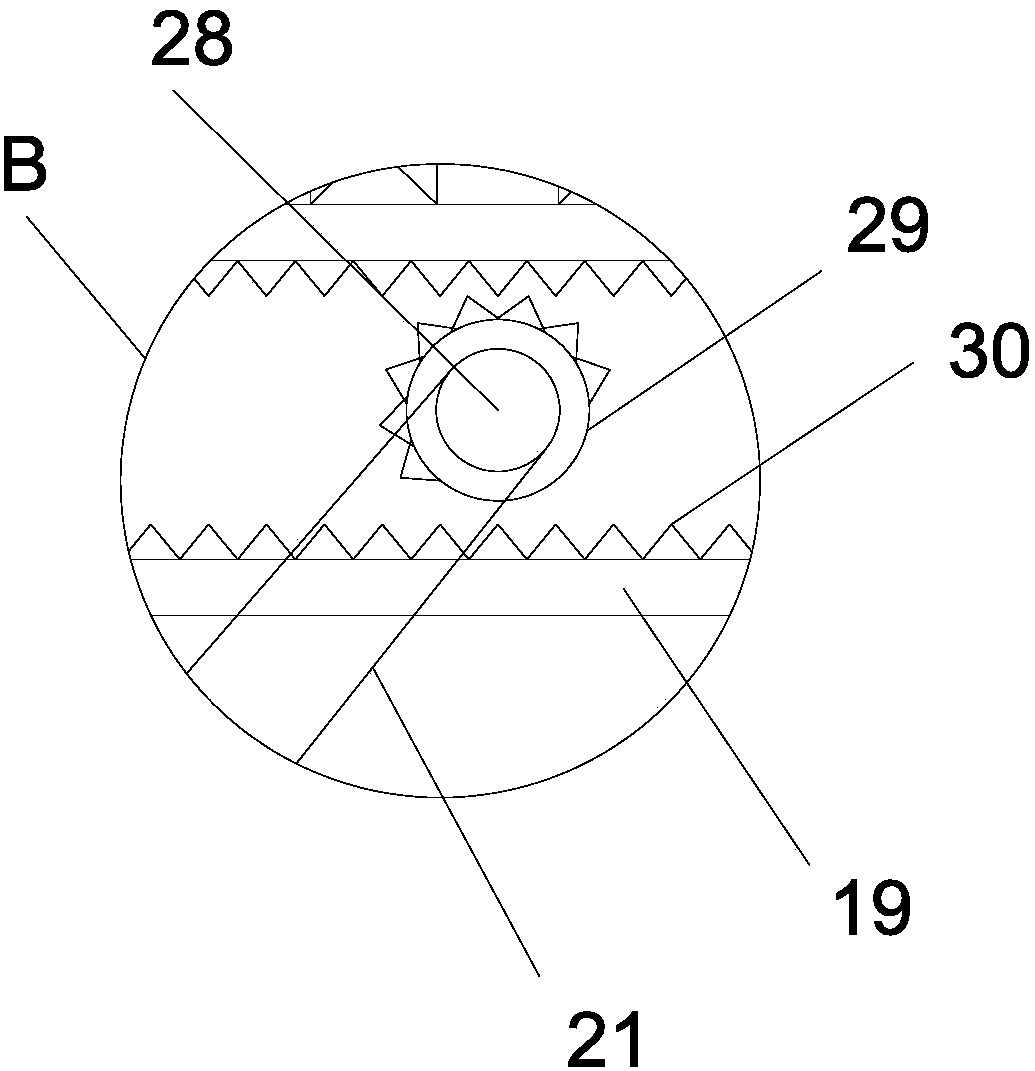

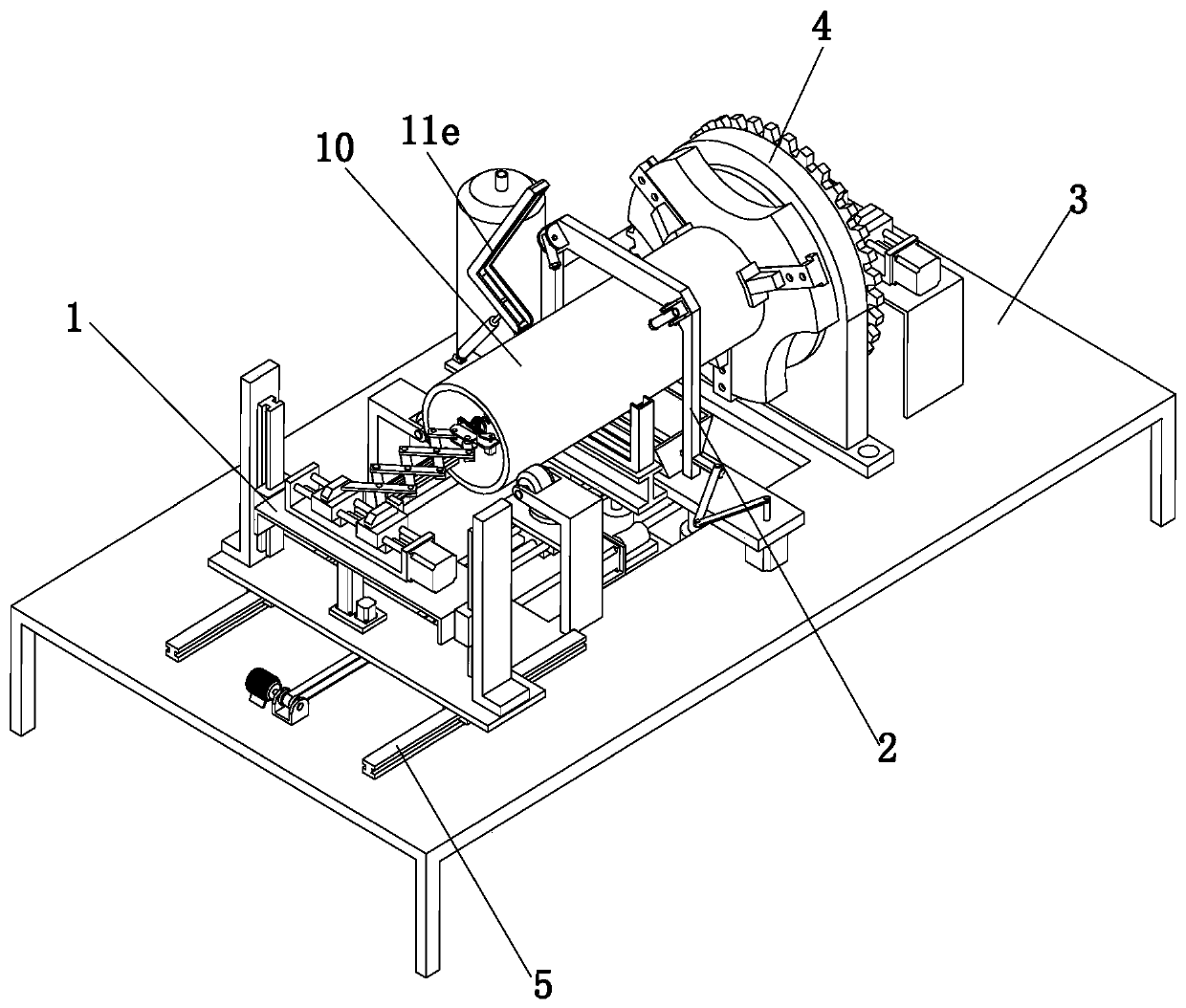

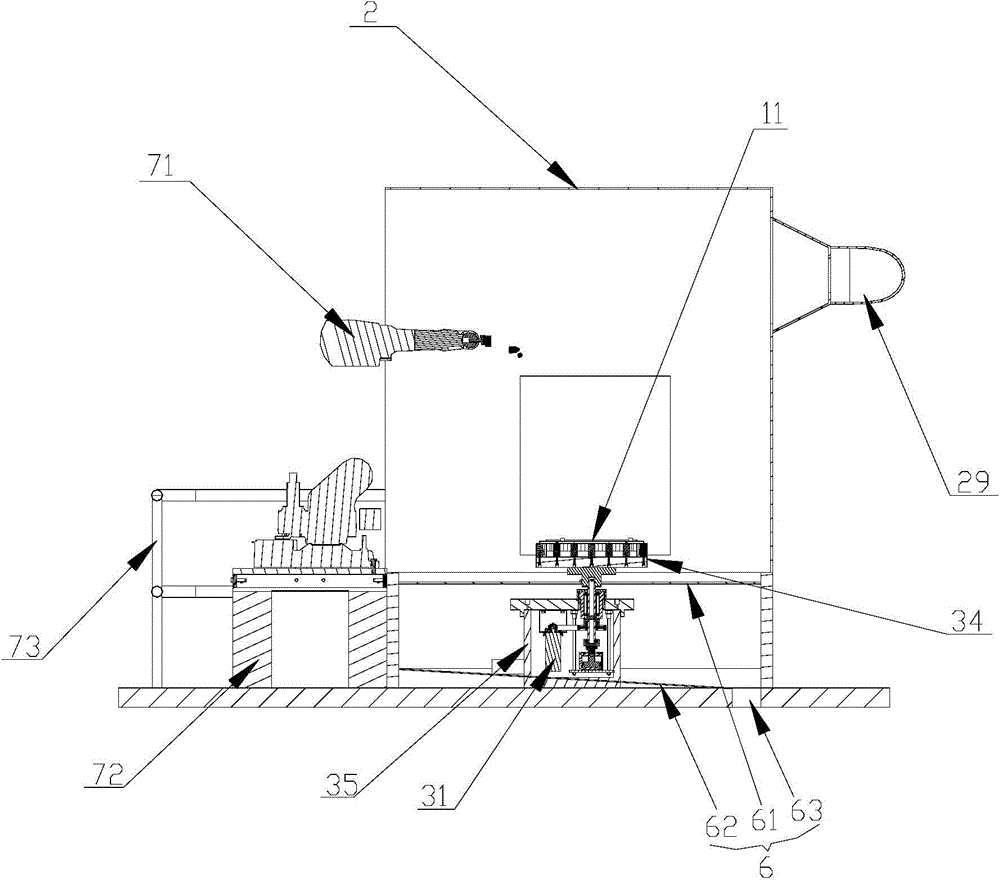

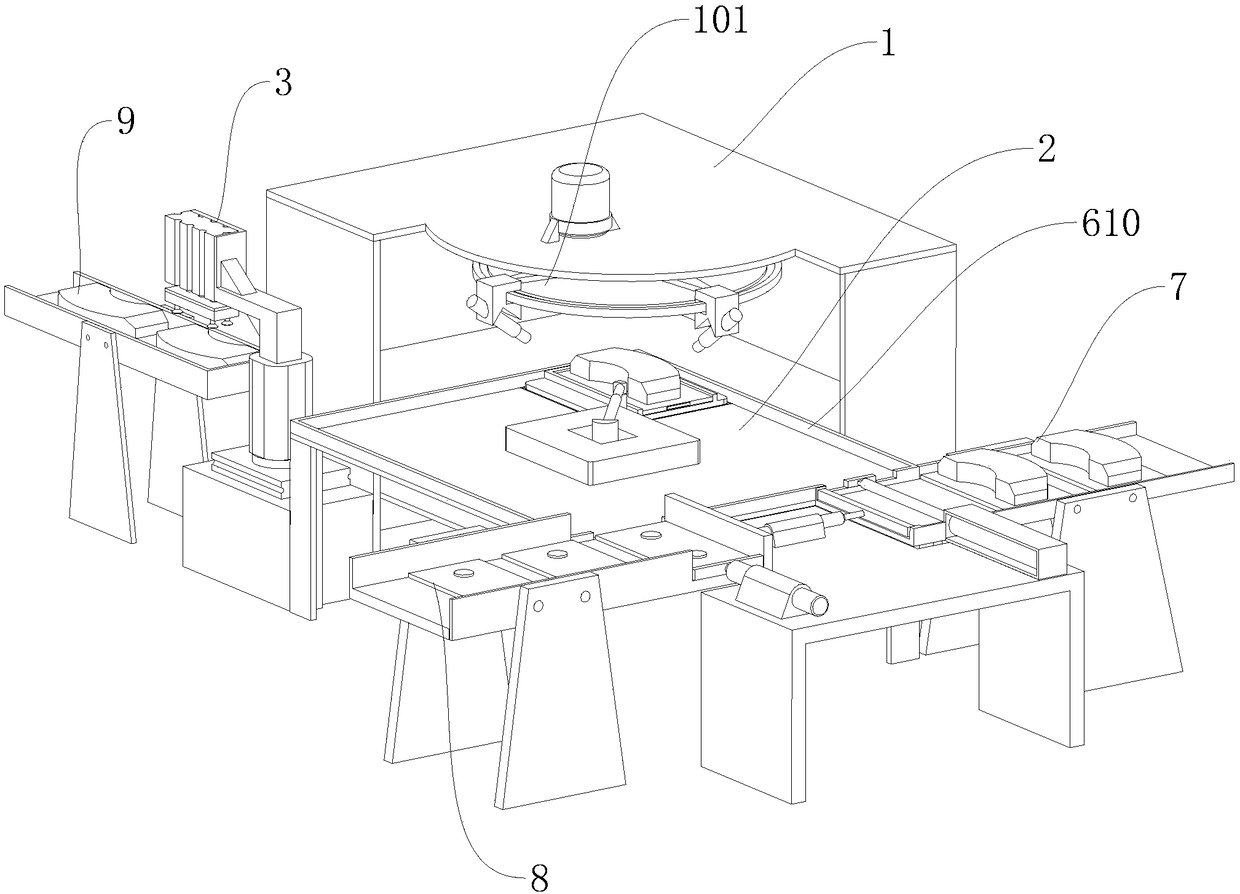

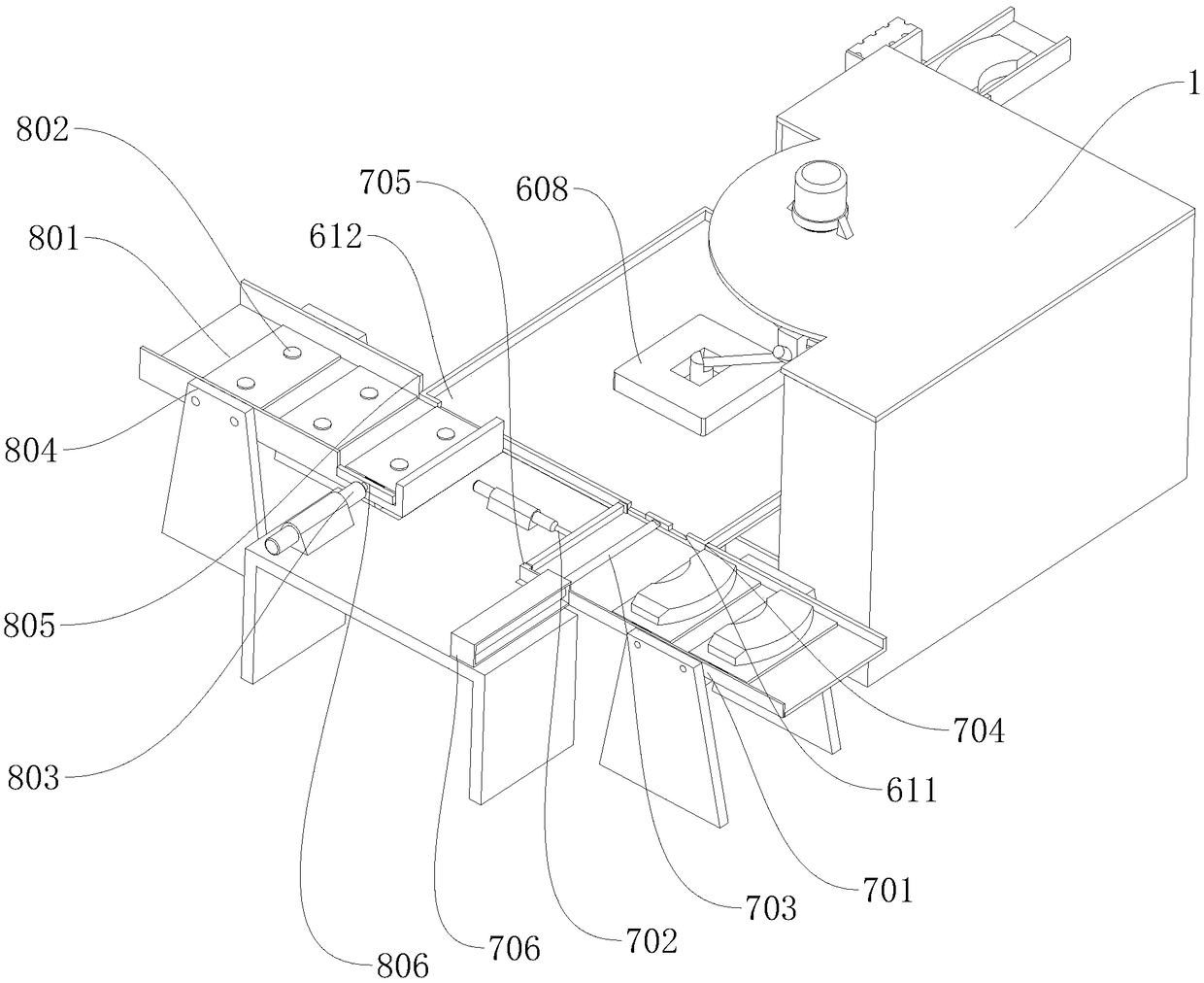

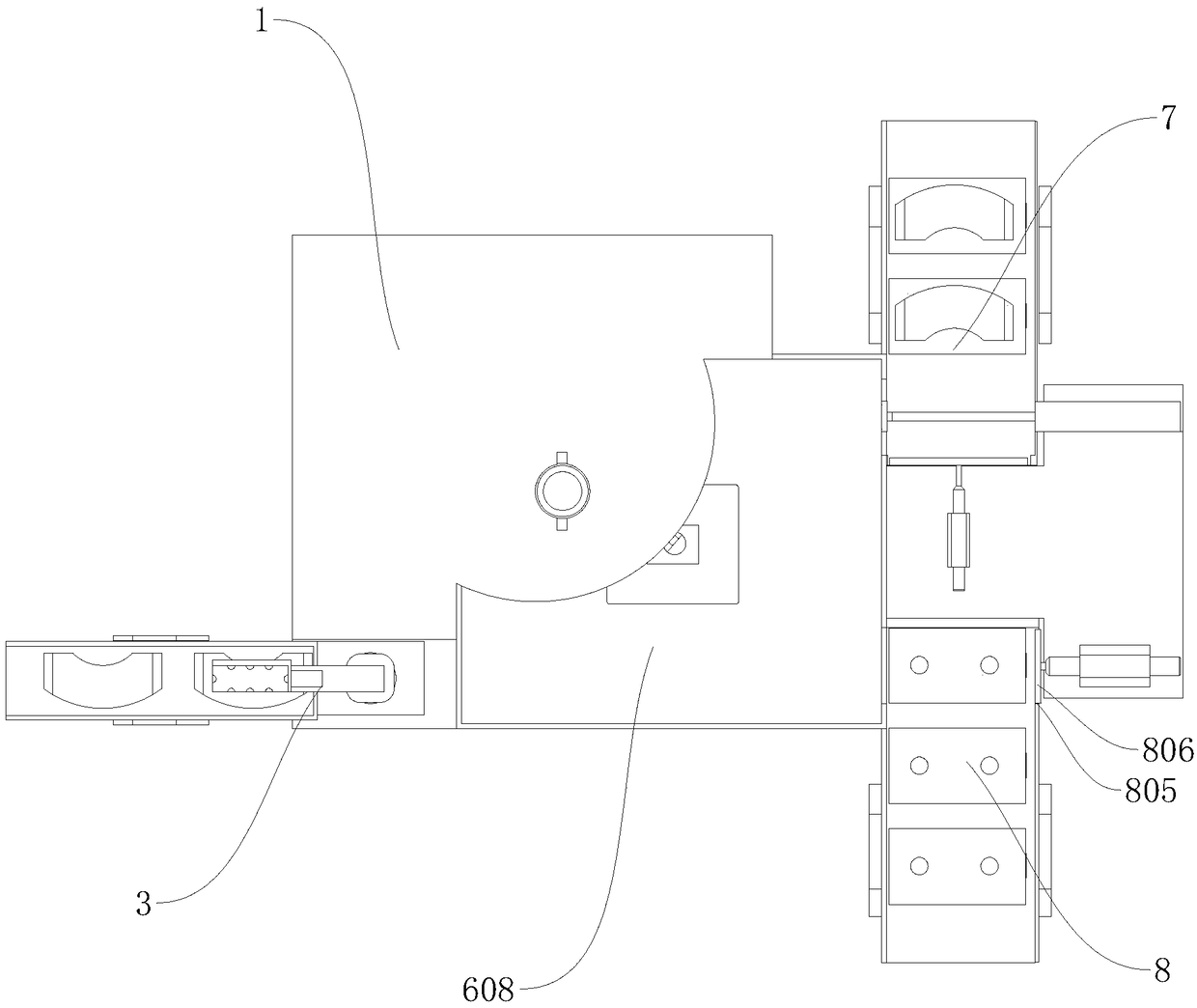

Working method of steel pipe inner wall and outer wall automatic spraying machine

ActiveCN109513544AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipeSpray boothsEngineeringSteel tube

The invention discloses a working method of a steel pipe inner wall and outer wall automatic spraying machine and belongs to the field of steel pipe spraying equipment. The steel pipe inner wall and outer wall automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, a working table and a rotating mechanism. The inner wall spraying mechanism comprisesa first spraying assembly, a second spraying assembly and a material shifting assembly. The first spraying assembly and the second spraying assembly respectively comprise an extending and feeding part and a rotary spraying part. The material shifting assemblies comprise lifting parts, material shifting boards and material shifting parts. The lifting parts are arranged at the tops of the materialshifting boards. The inner wall spraying mechanism can extend into a steel pipe and automatically perform uniform spraying operation on the inner wall of the steel pipe, so that the situation that thelocal inner wall of the steel pipe is not sprayed is avoided; and moreover, the outer wall of the steel pipe can be automatically sprayed through the outer wall spraying mechanism, so that the automation degree is high, and workers do not need to manually carry out spraying operation on the outer wall of the steel pipe.

Owner:德高金属制品宿迁有限公司

Masking solutions comprising siloxane-based surfactants for using in painting operations

This invention provides a masking material that can be used to protect an underling surface (e.g. an automobile surface) during an overcoating (e.g. painting) operation. The masking material in one embodiment includes a thickener and a pH control agent and water. The masking material can be applied to a surface that is to be protected from paint overspray or other coating processes, allowed to dry, and the surface then coated (e.g. with paint). After drying of the paint, or other coating, the masking material can removed by water washing.

Owner:CAL WEST SPECIALTY COATINGS

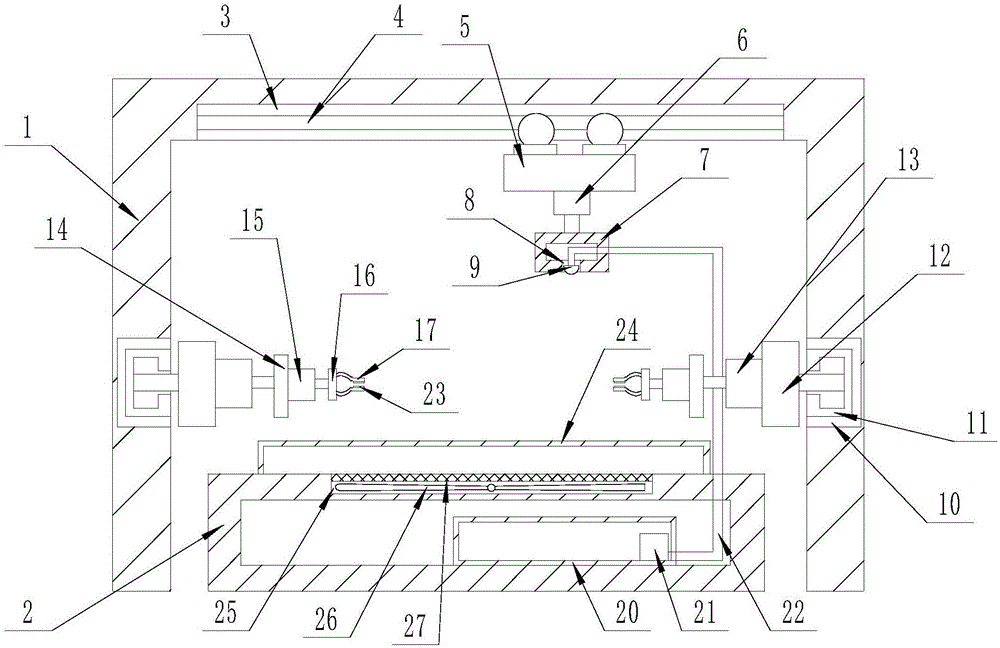

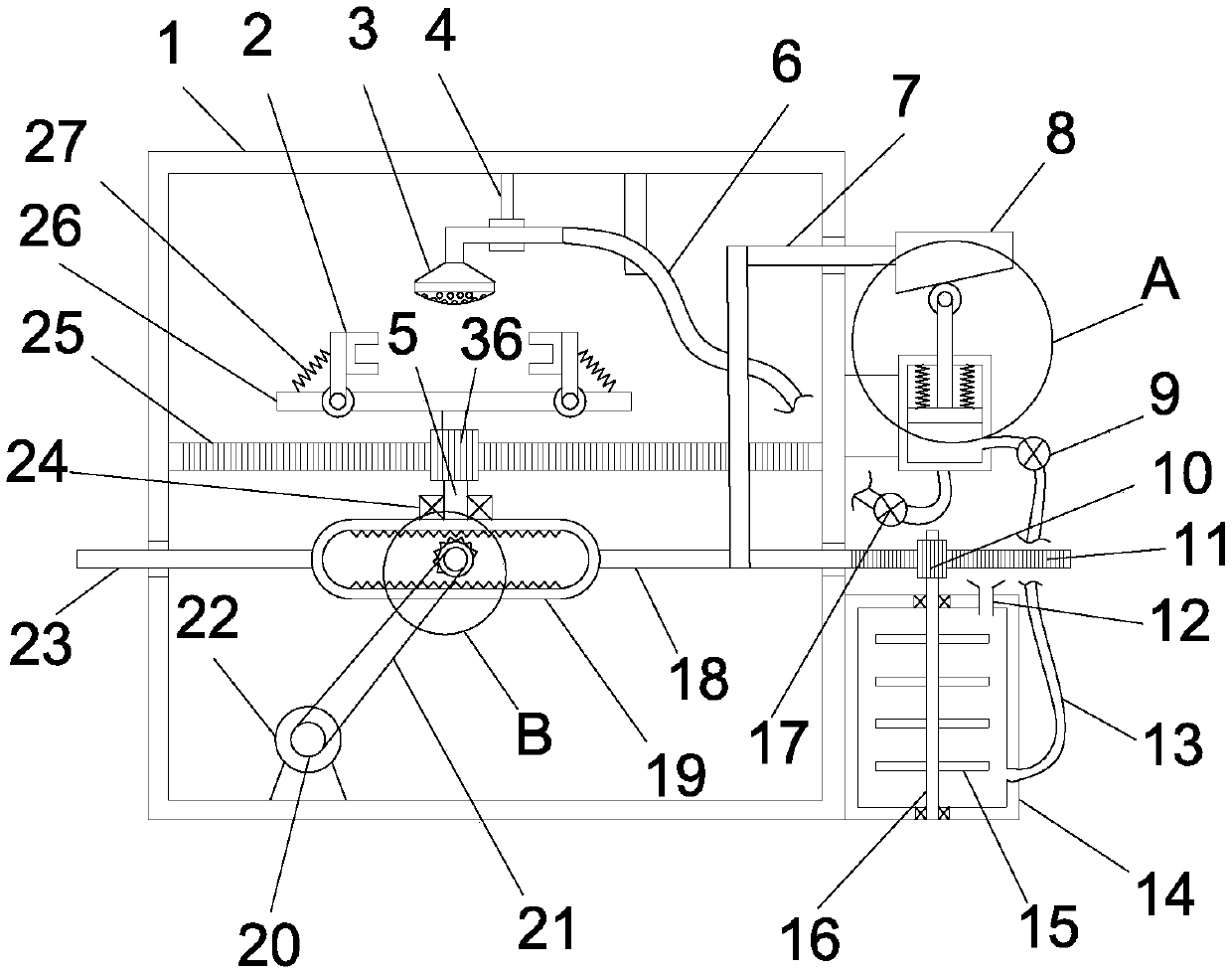

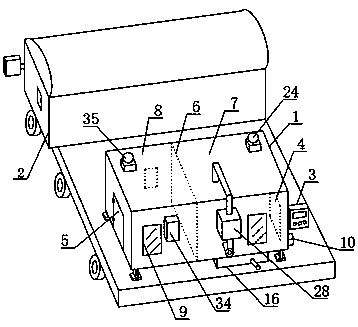

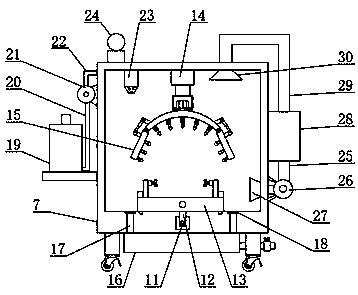

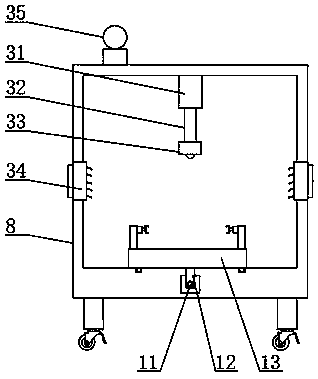

Plate surface paint spraying device for machining

InactiveCN107899826AImprove spraying efficiencyAvoid stickingSpray boothsReciprocating motionEngineering

The invention discloses a plate surface paint spraying device for machining. The plate surface paint spraying device for machining comprises an operation box; a first guide rod and a second guide rodare transversely and slidingly arranged in the operation box; the first guide rod slidingly penetrates through the right side wall of the operation box; an L-shaped push rod slidingly penetrates through the right side wall of the operation box; a wedged block with a wedged surface butting against a roller is fixedly mounted at the right end of the L-shaped push rod; and a discharge hose communicates between a paint nozzle and a piston cylinder, and is from the piston cylinder to the paint nozzle. A bearing plate drives plates to rotate; meanwhile, a return frame performs a left-right reciprocating motion to realize a left-right reciprocating motion of the bearing plate; paint sprayed by the paint nozzle can be uniformly sprayed to different positions of the surfaces of the plates so as toimprove the paint spraying efficiency; and a stirring shaft, arranged in a paint box, drives stirring blades to rotate to rotationally stir the paint in the paint box, so that the bonding of the paintis prevented, the paint is sprayed from the paint nozzle more uniformly, and the paint spraying quality is improved.

Owner:石瑞敏 +1

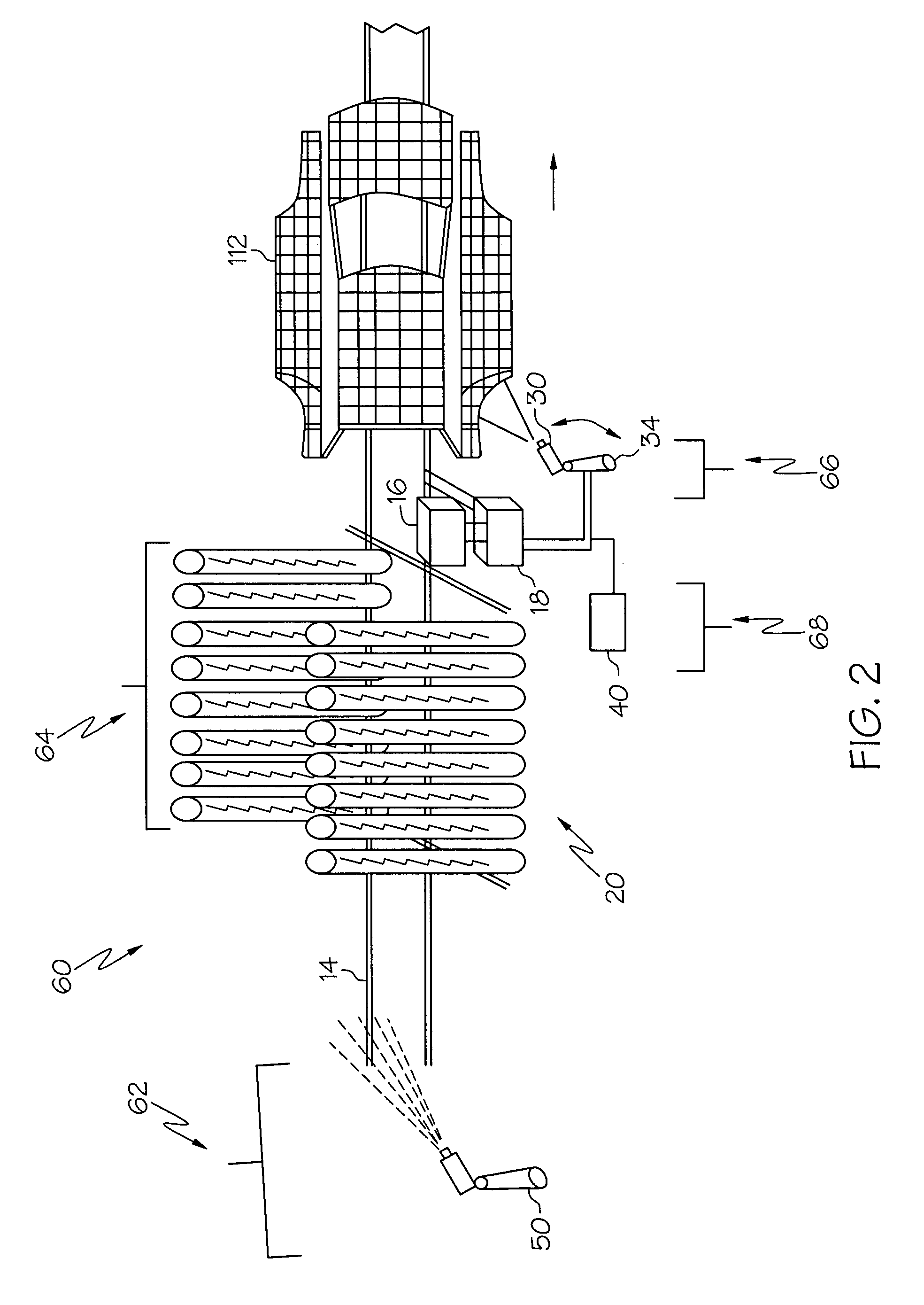

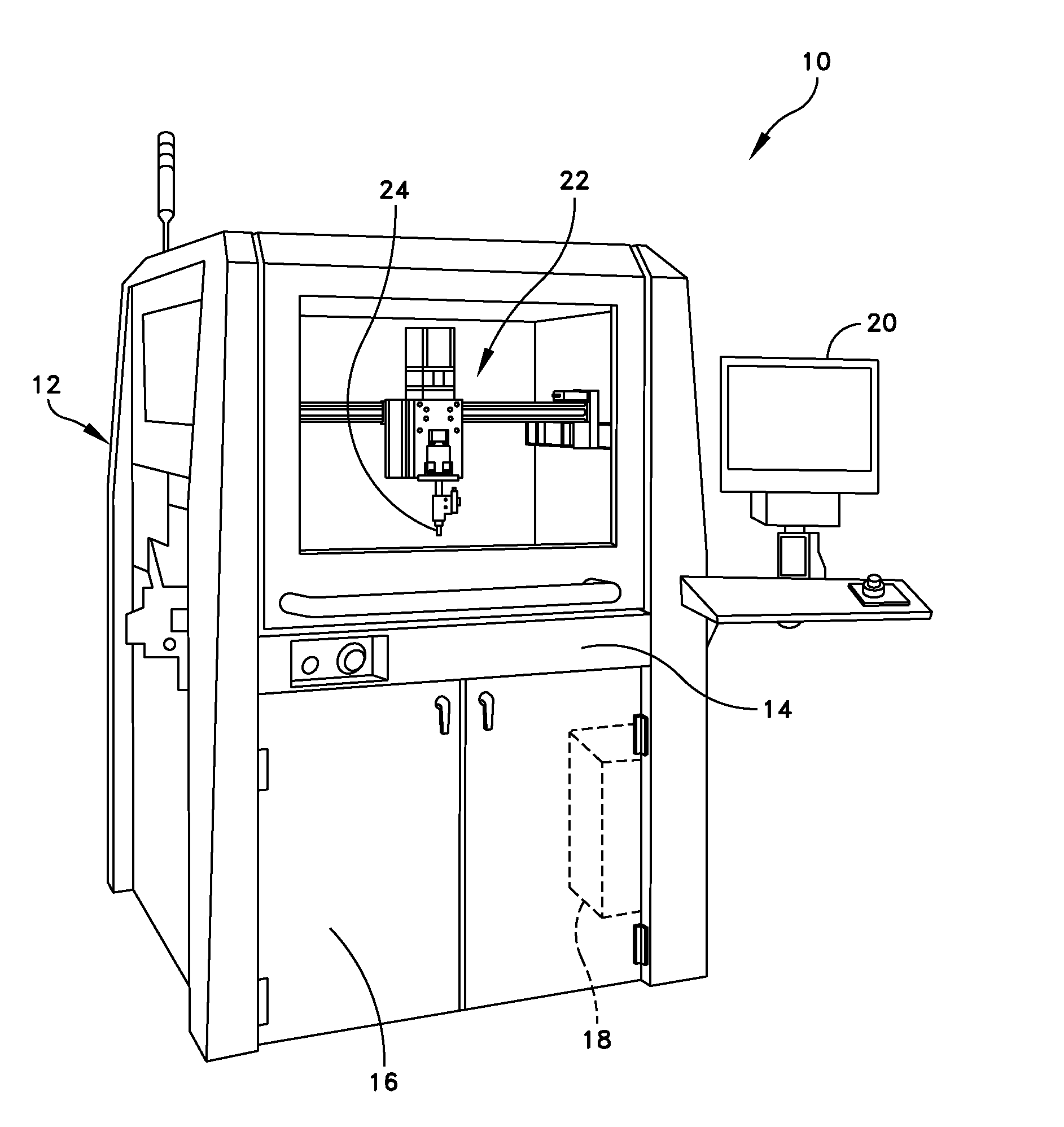

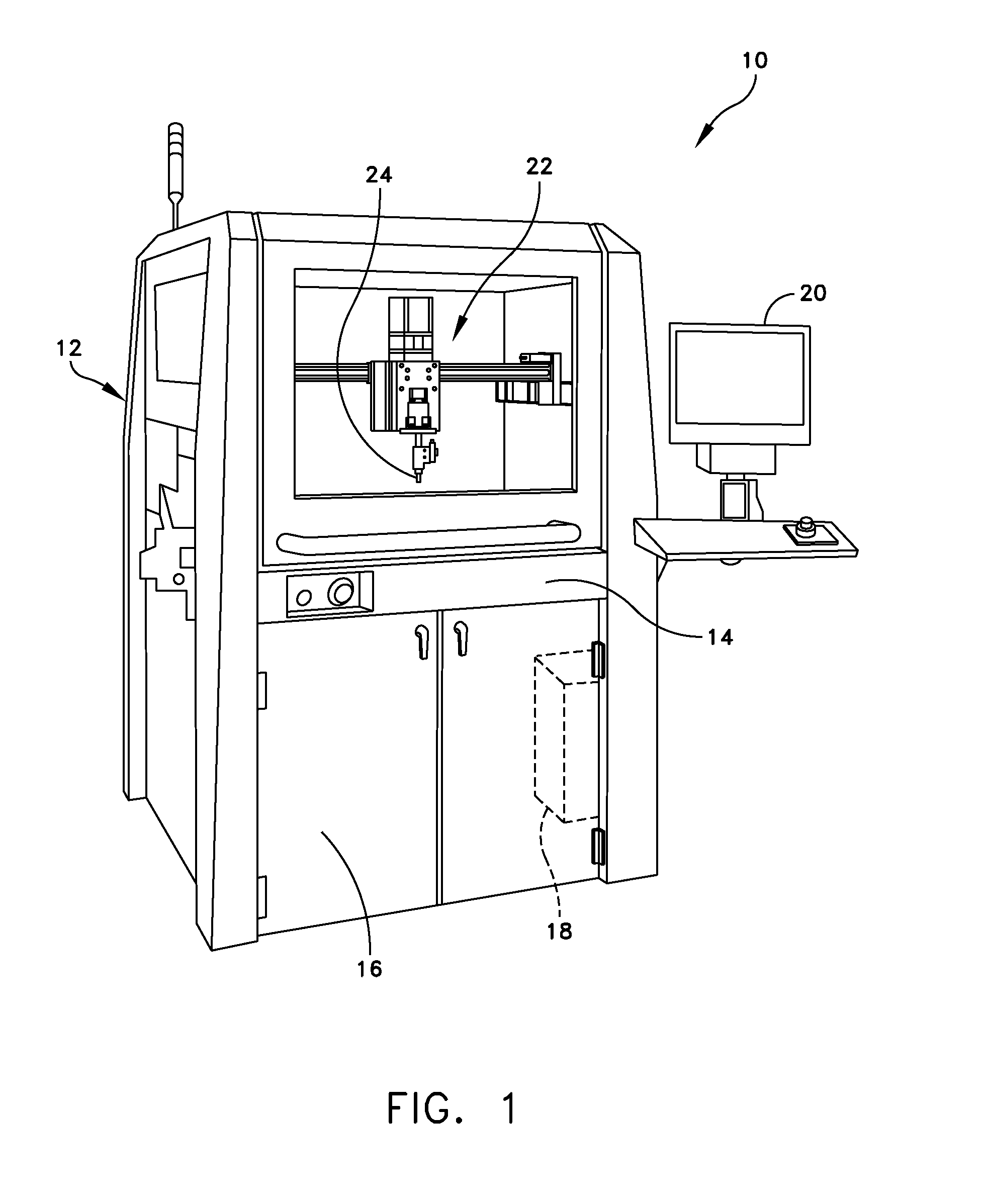

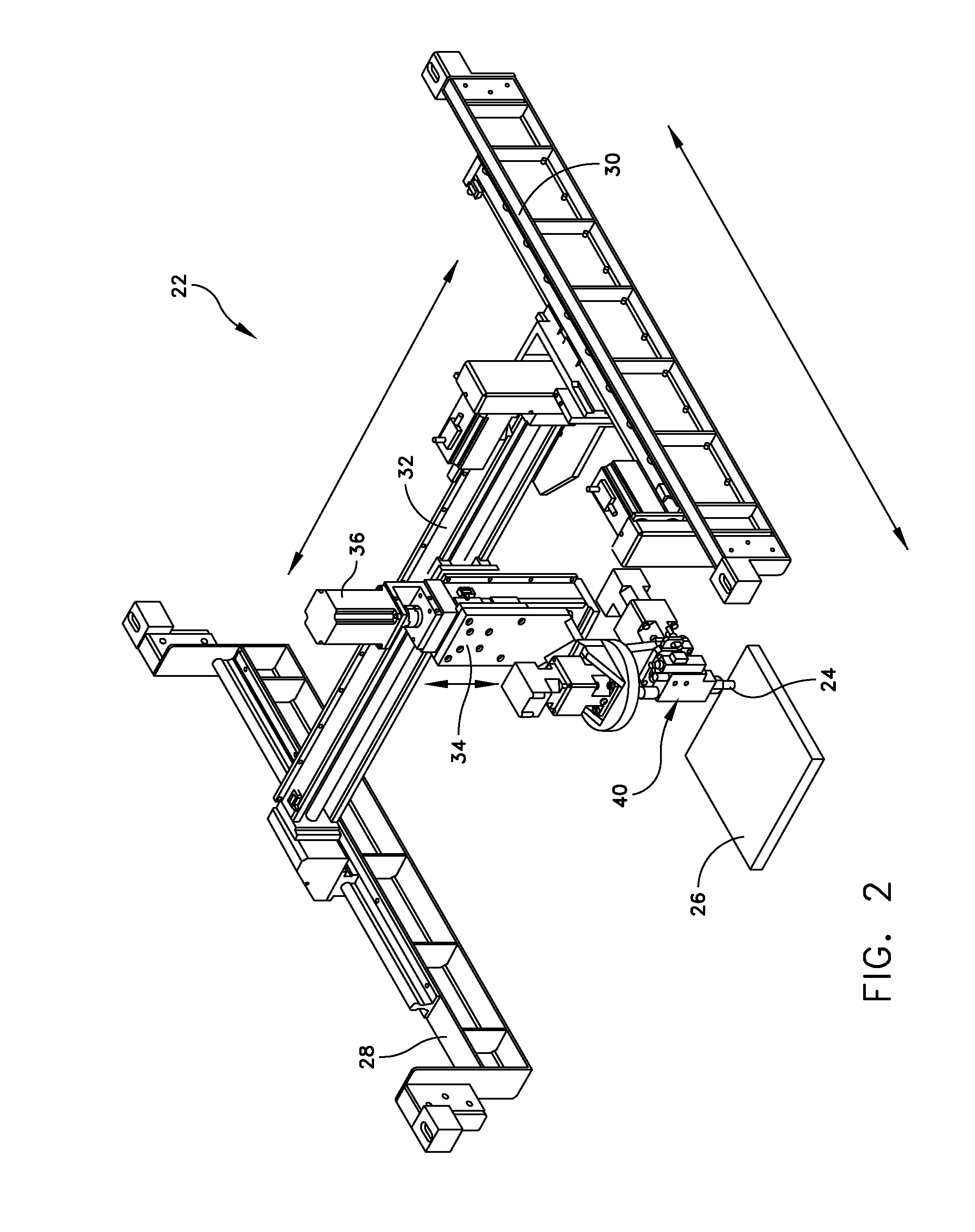

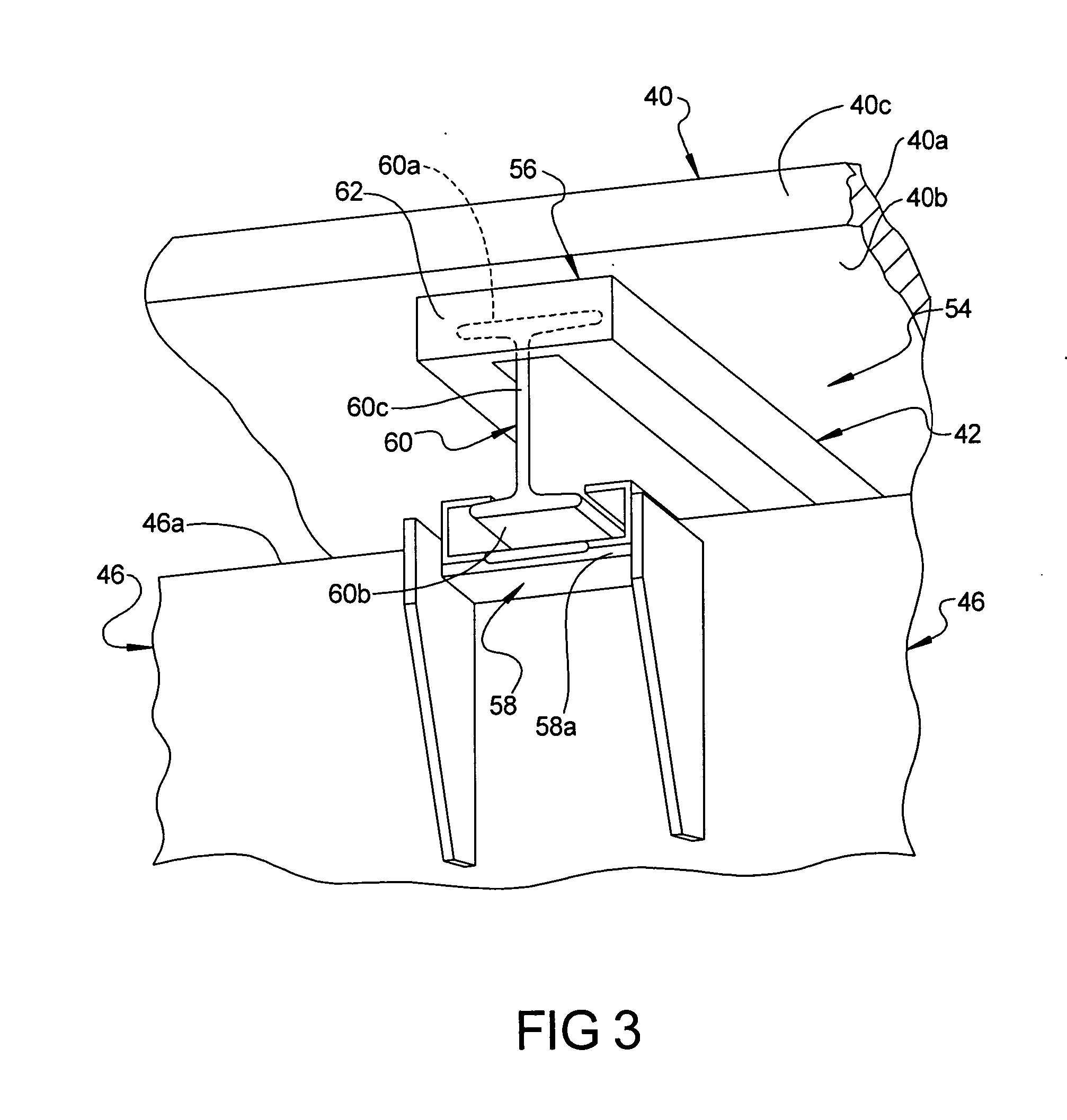

Apparatus and method for spray coating

InactiveUS20090317554A1Programme-controlled manipulatorLiquid/solution decomposition chemical coatingSpray coatingEngineering

A spray coating apparatus for spraying material on a substrate includes a frame and a gantry coupled to the frame. The gantry may be configured to provide x-axis, y-axis and z-axis movement. A device is coupled to the gantry. The device may be configured to rotate about the z-axis and pivot about a point on the z-axis. A spray head is coupled to the device. A controller is coupled to the gantry and the spray head. The controller may be configured to control the automated movement of the gantry to provide x-axis, y-axis and z-axis movement and rotational and pivoting movement of the spray head. Other embodiments of the spray coating device and related methods are further disclosed.

Owner:SPECIALTY COATING SYST

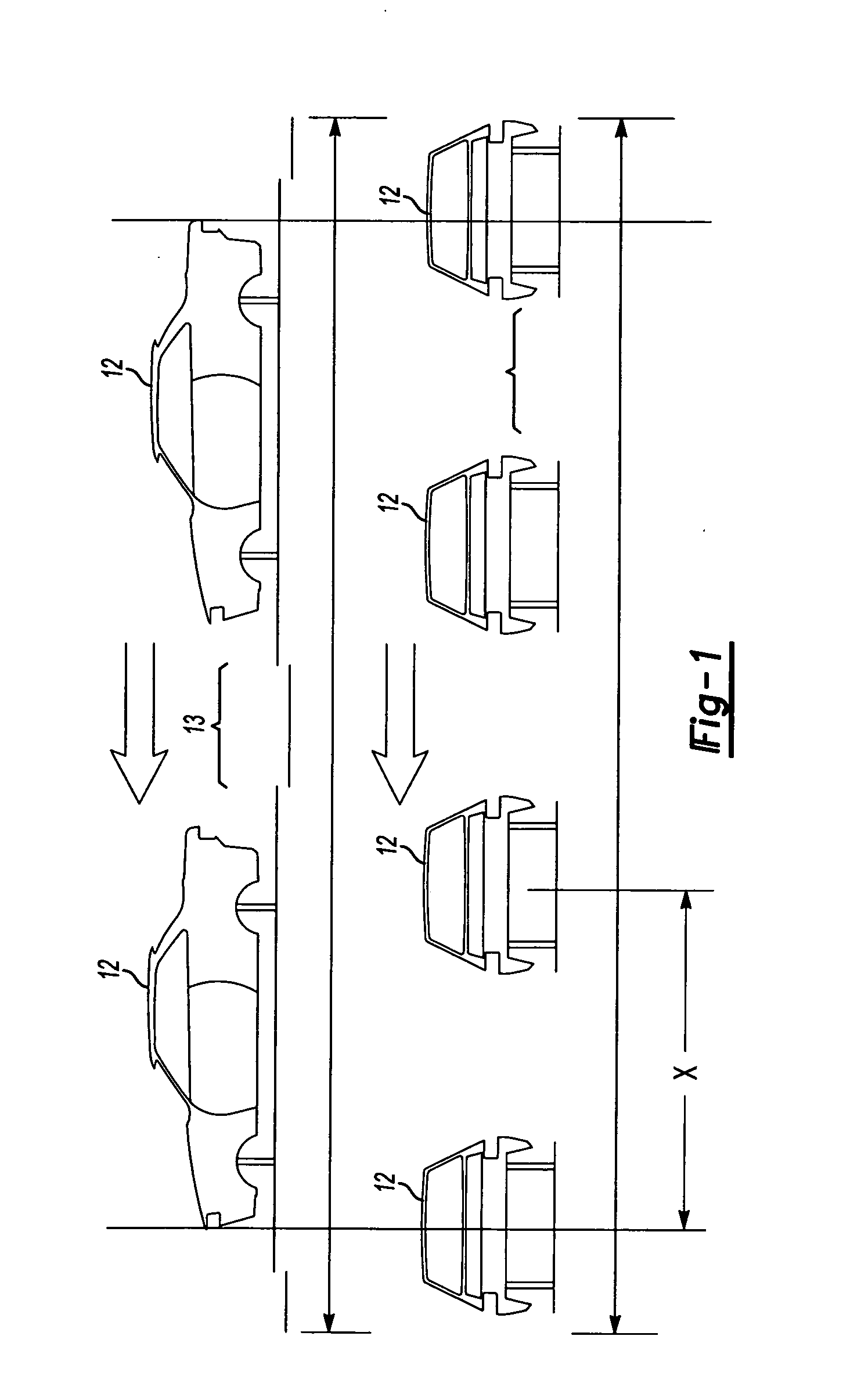

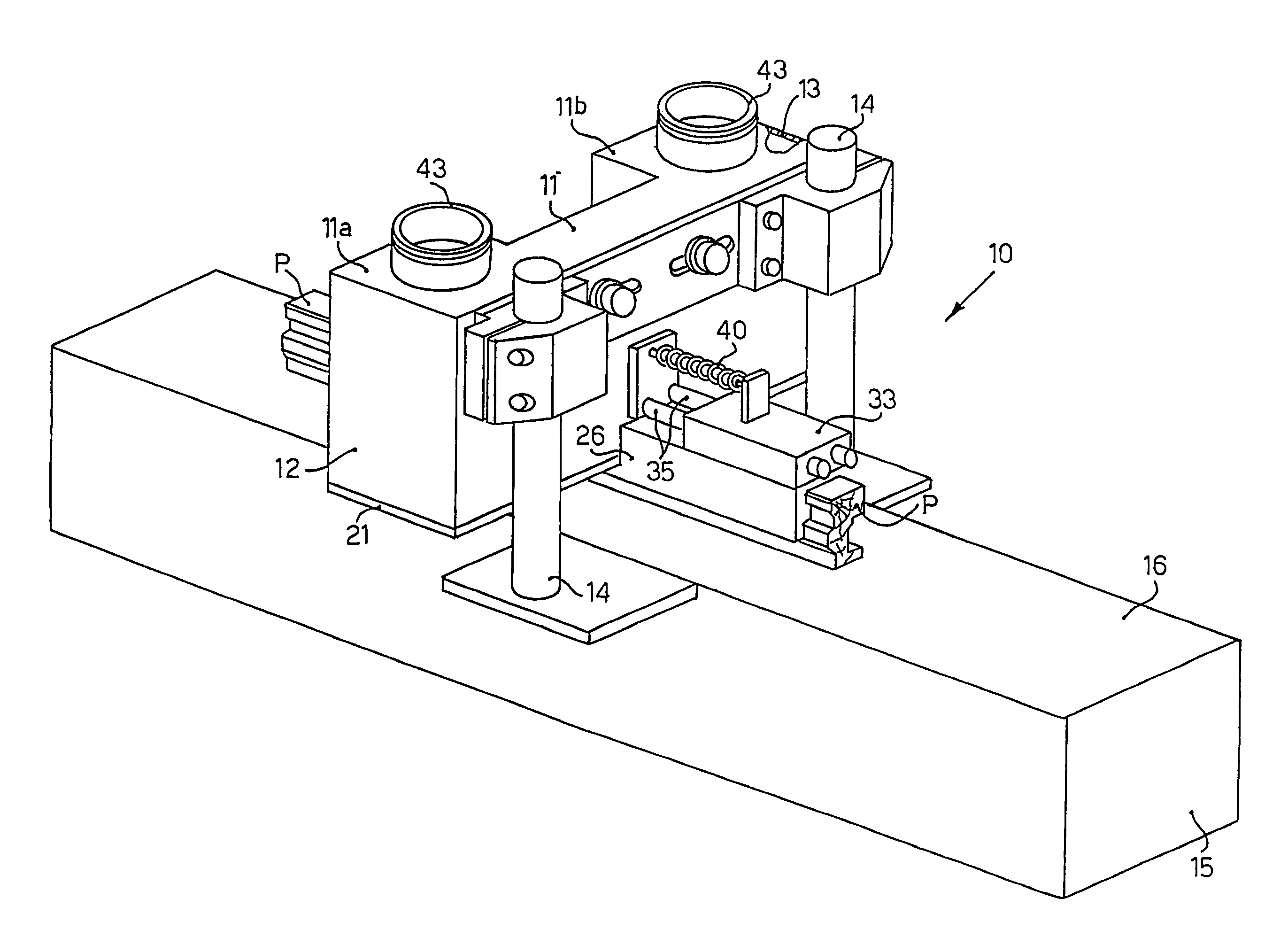

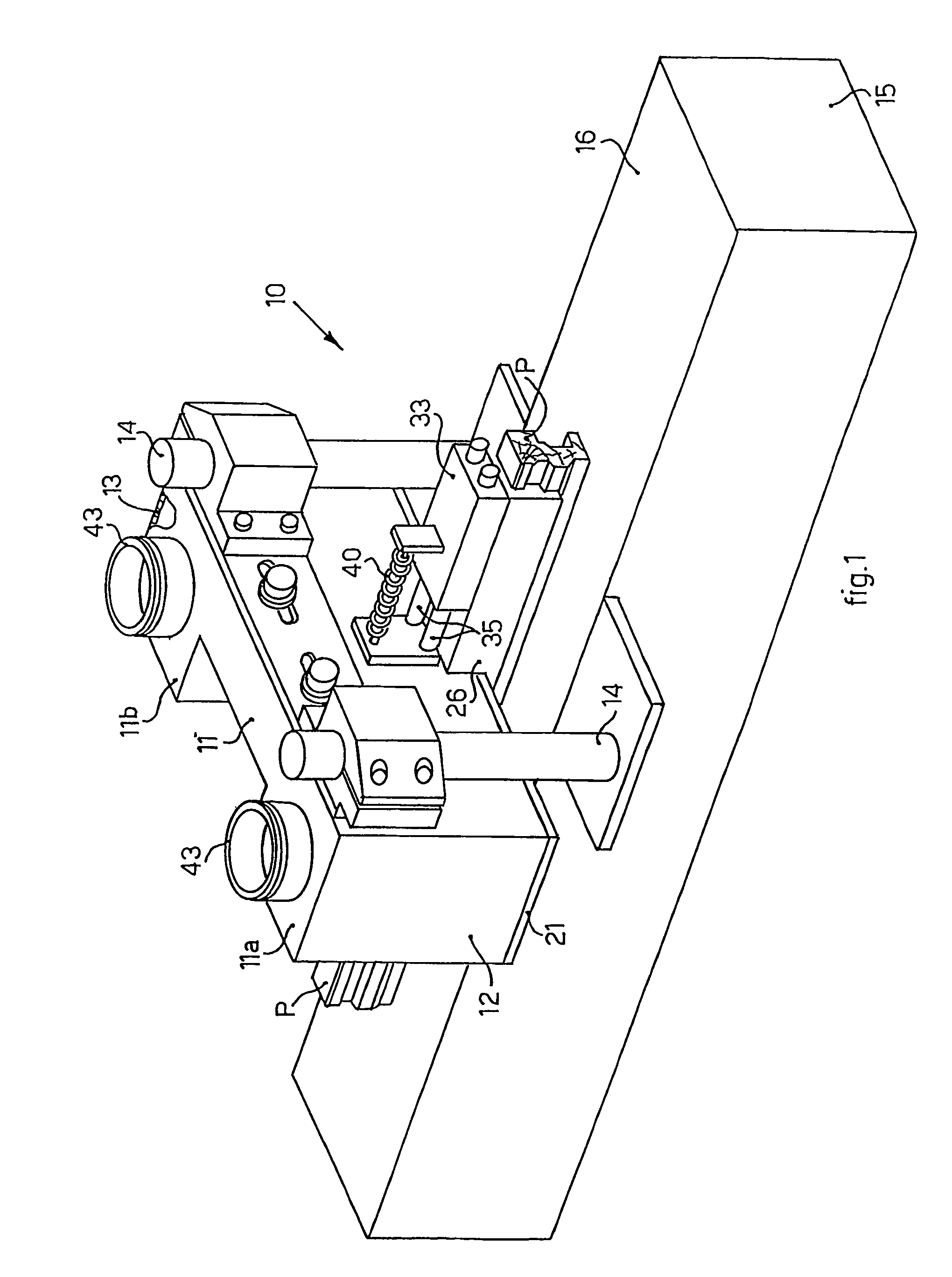

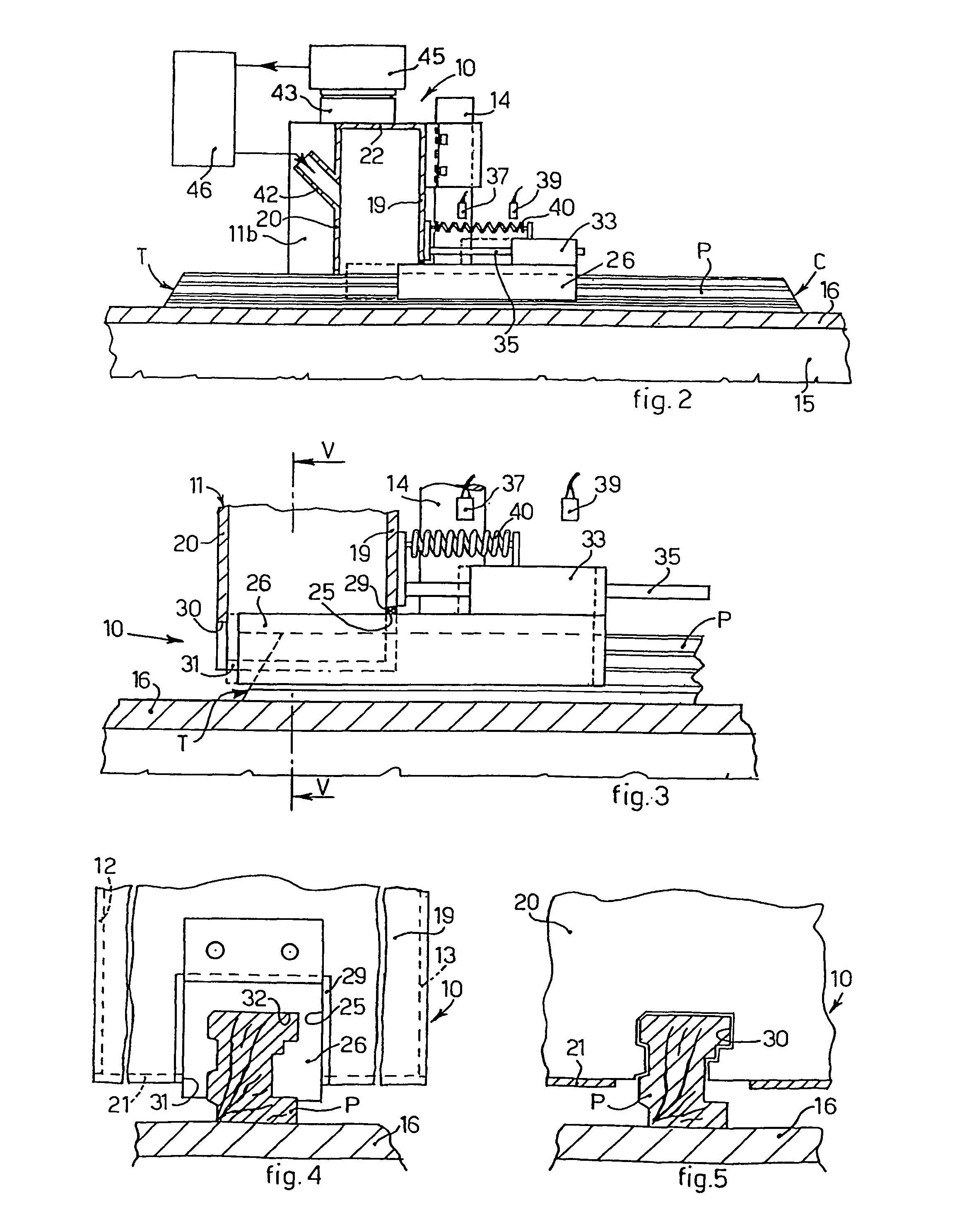

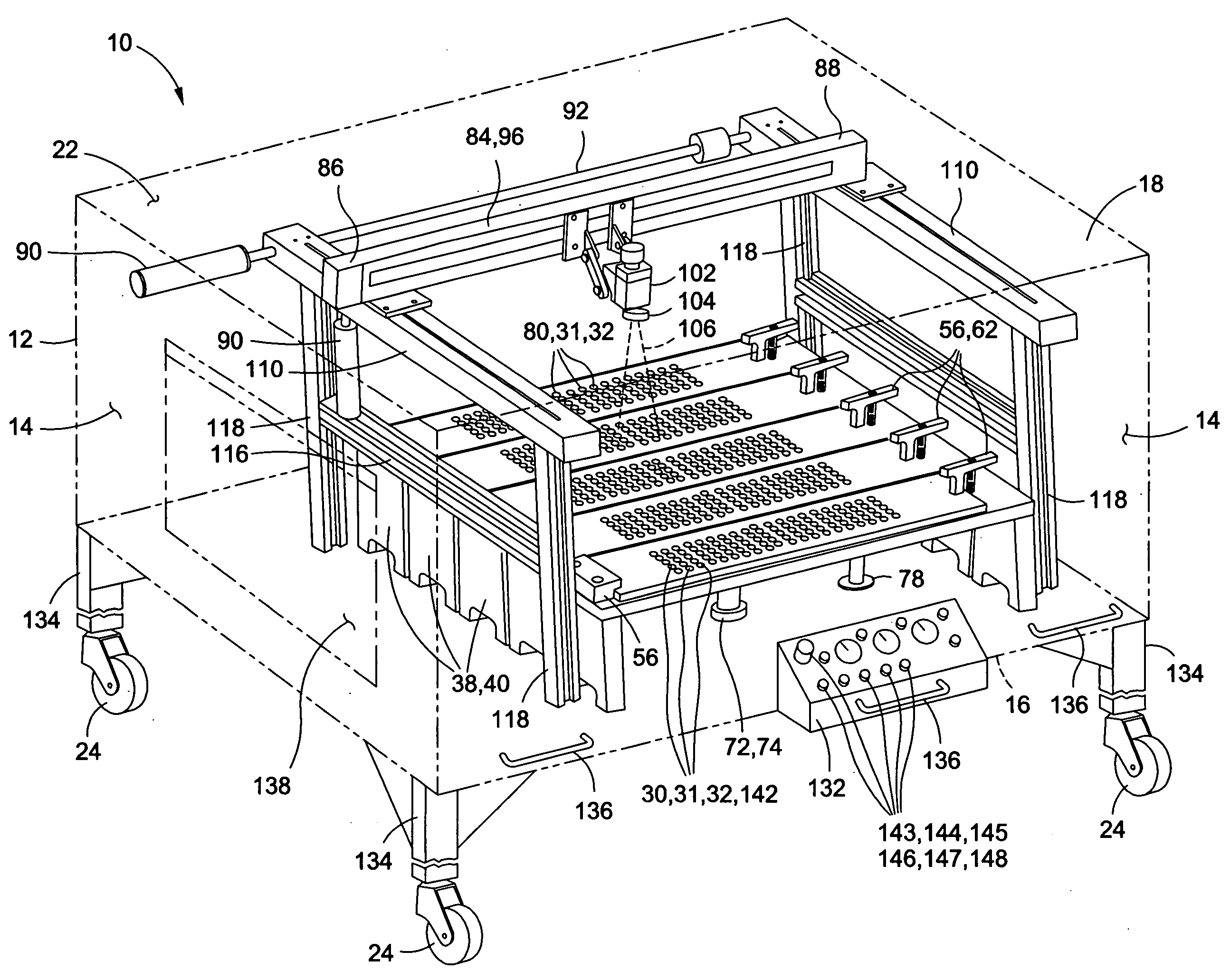

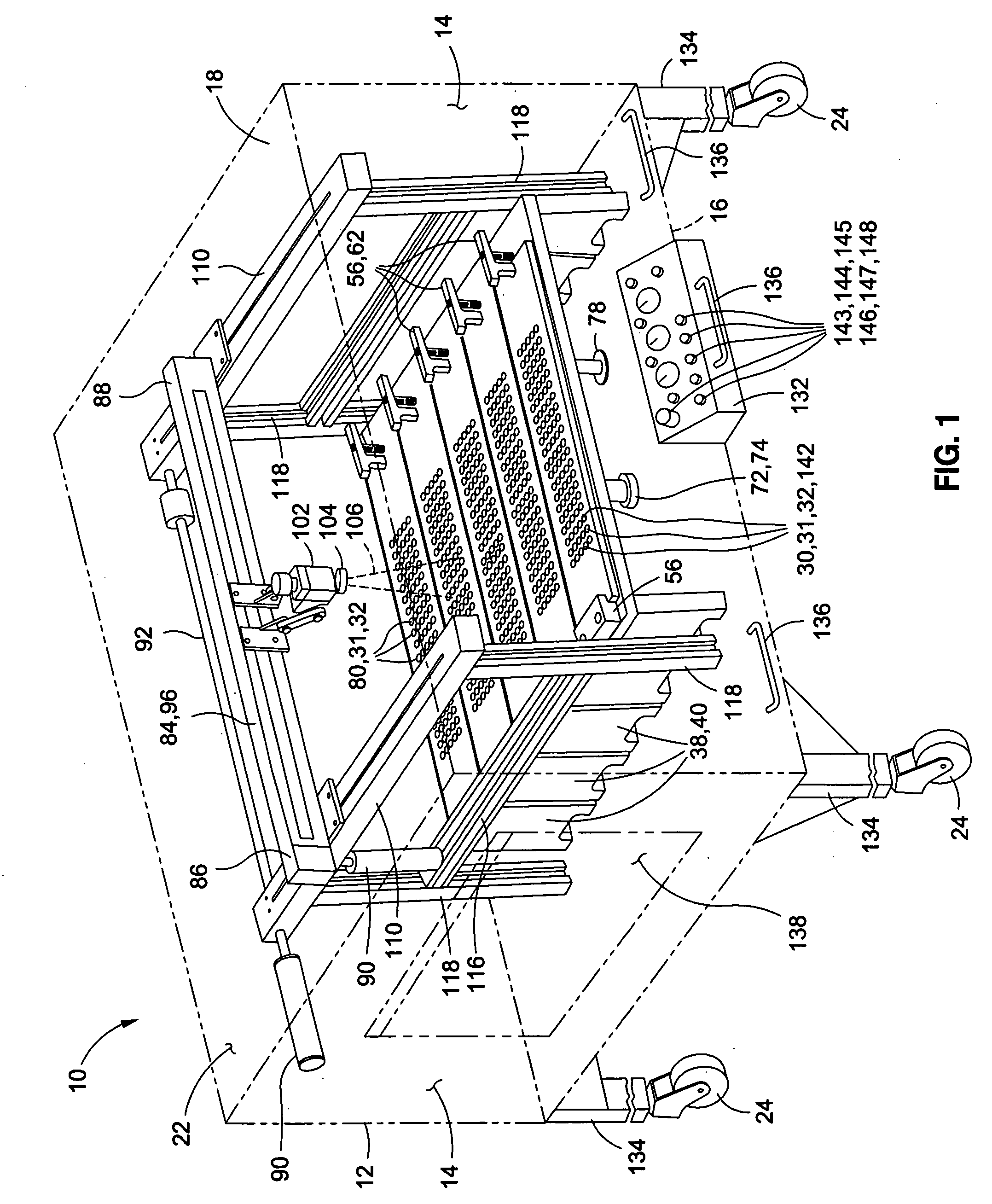

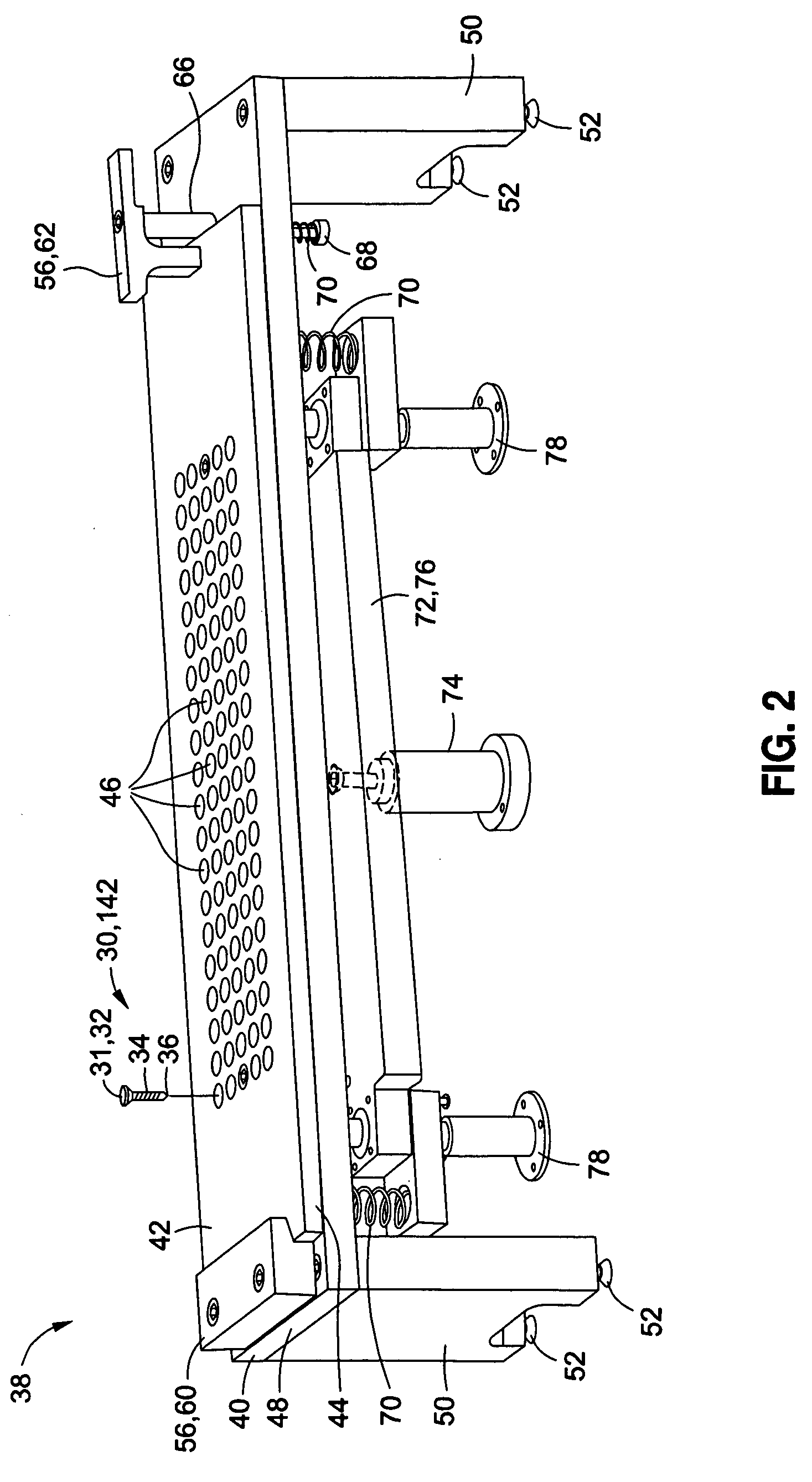

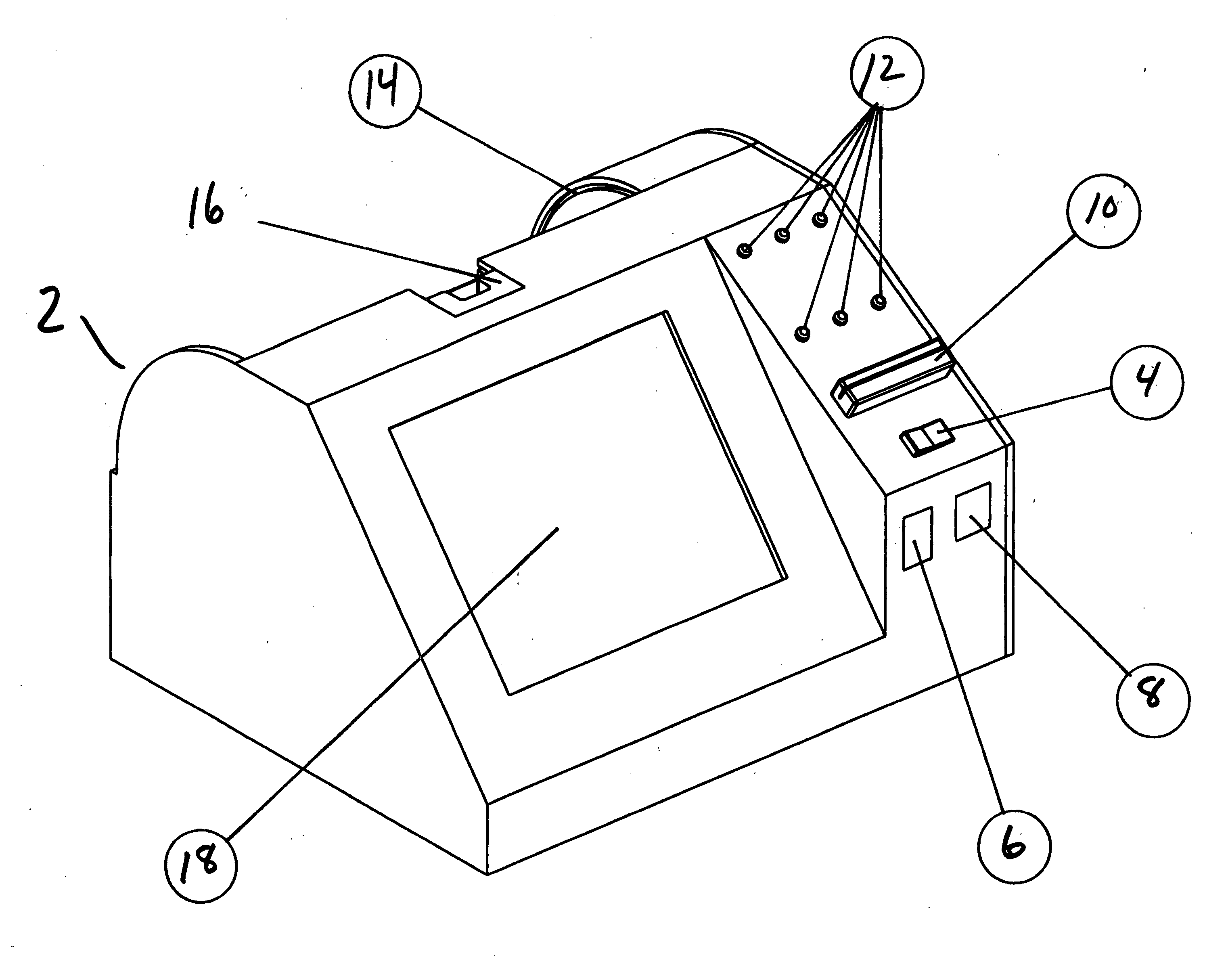

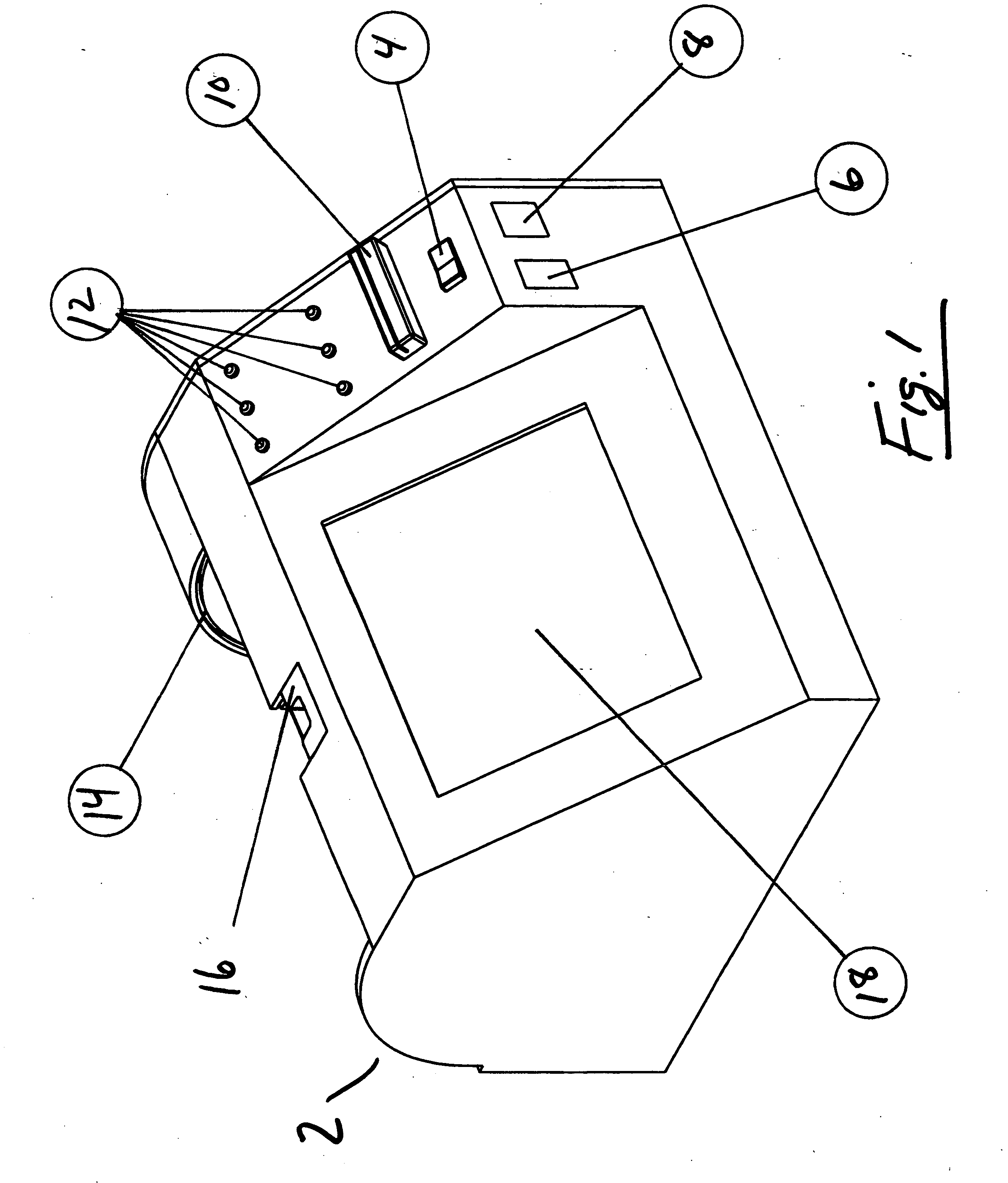

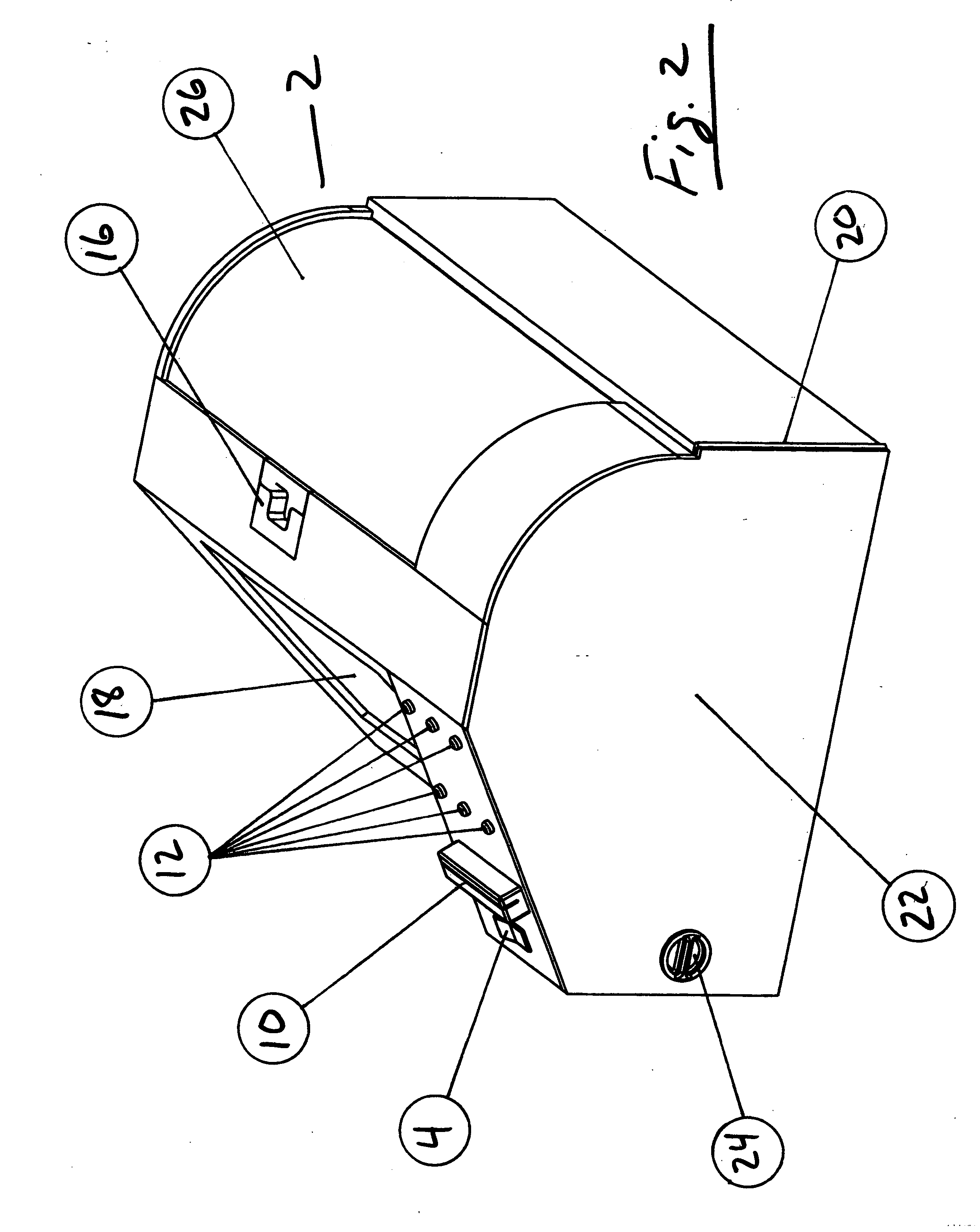

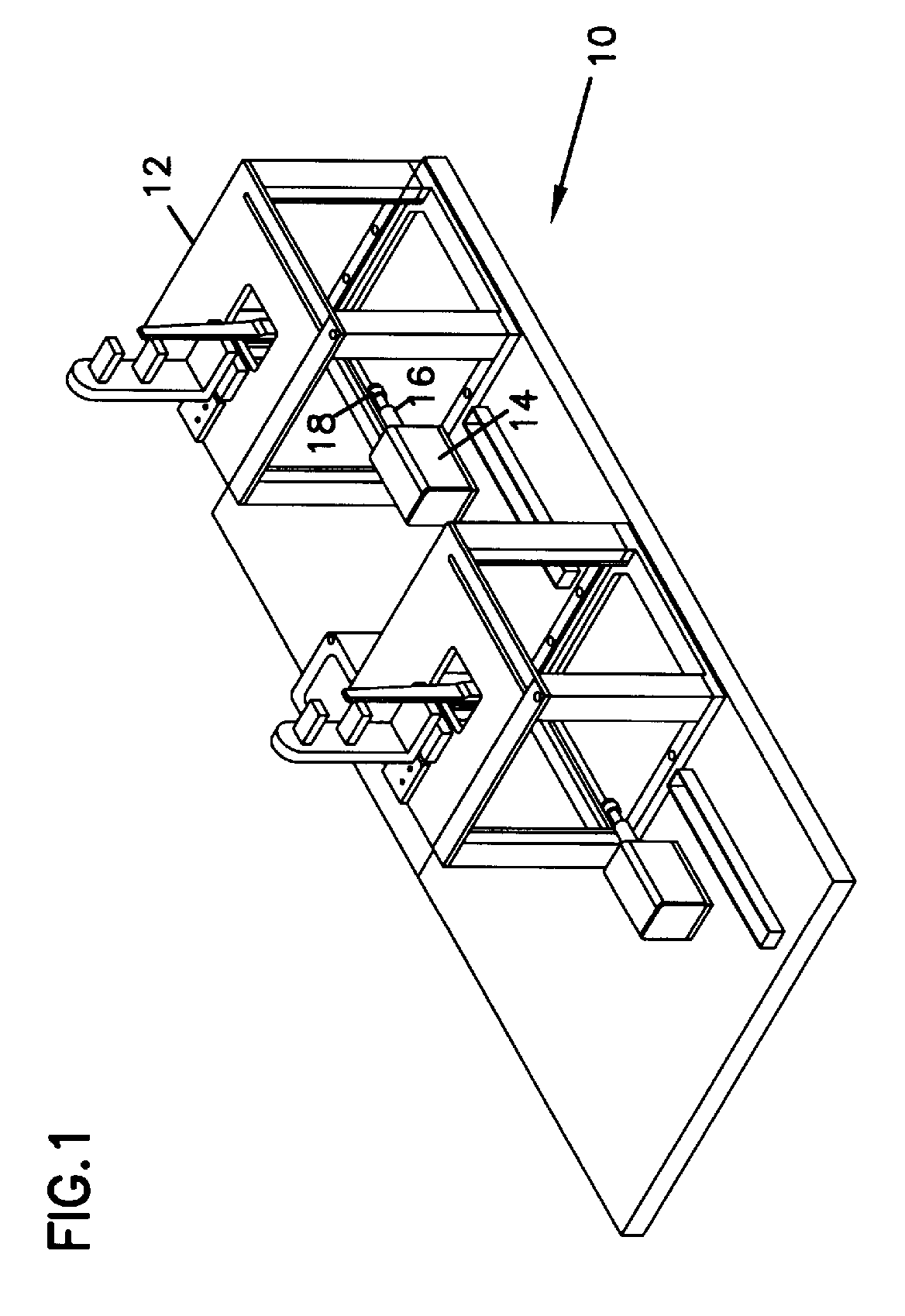

Controlled environment fastener head painting device and method

ActiveUS20100173090A1Small sizeEasy to controlWire articlesSlide fastenersEngineeringMechanical engineering

A painting apparatus for applying a coating material to a member surface of a member comprises a housing, at least one slide rail, a rack assembly, a cross beam and a spraying device. The slide rail may be mountable within the housing and may have a plurality of rack positions. The rack assembly is mountable within the housing at one of the rack positions. The rack assembly is configured to support the member such that the member surface is exposed. The cross beam may be coupled to the slide rail. The cross beam is movable along the slide rail and is positionable at the rack positions. The spraying device is mountable on the cross beam and is configured to move along the cross beam while spraying the coating material onto the member surface.

Owner:THE BOEING CO

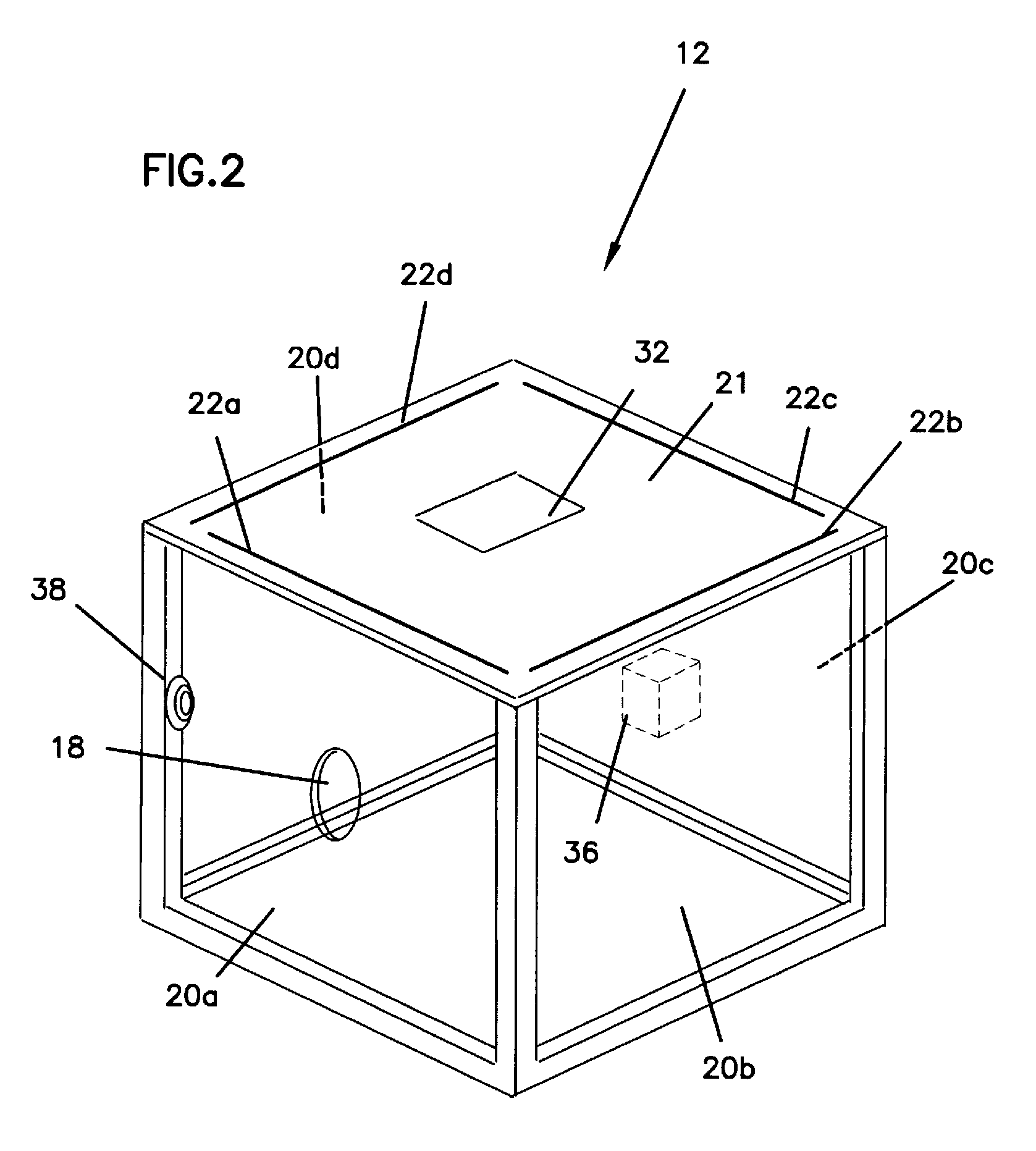

Apparatus for coating medical devices

An apparatus for coating medical devices at the point of care with a polymer and / or therapeutic agent comprising an environmentally controlled device coating chamber in which the device may be delivered by the manufacturer as the device packaging, or the device may be placed into the chamber at the point of care. The environmentally controlled chamber can provide a sterile enclosure in which the polymer and / or a therapeutic agent can be applied to an uncoated or previously coated device and converted to another form (such as a liquid to a film or gel) if desired, under controlled and reproducible conditions. The environmentally controlled chamber can accommodate and provide for coating the device by immersion, spray and other methods of covering the device surface with a liquid or powder. The chamber can provide for energy sources, both internally, such as heat produced by film heaters, and externally, such as UV light or microwave passing through the enclosure. The chamber may allow for changes in atmosphere to affect the coating, such as the introduction of certain gases and introducing pressure or vacuum.

Owner:LARSON +1

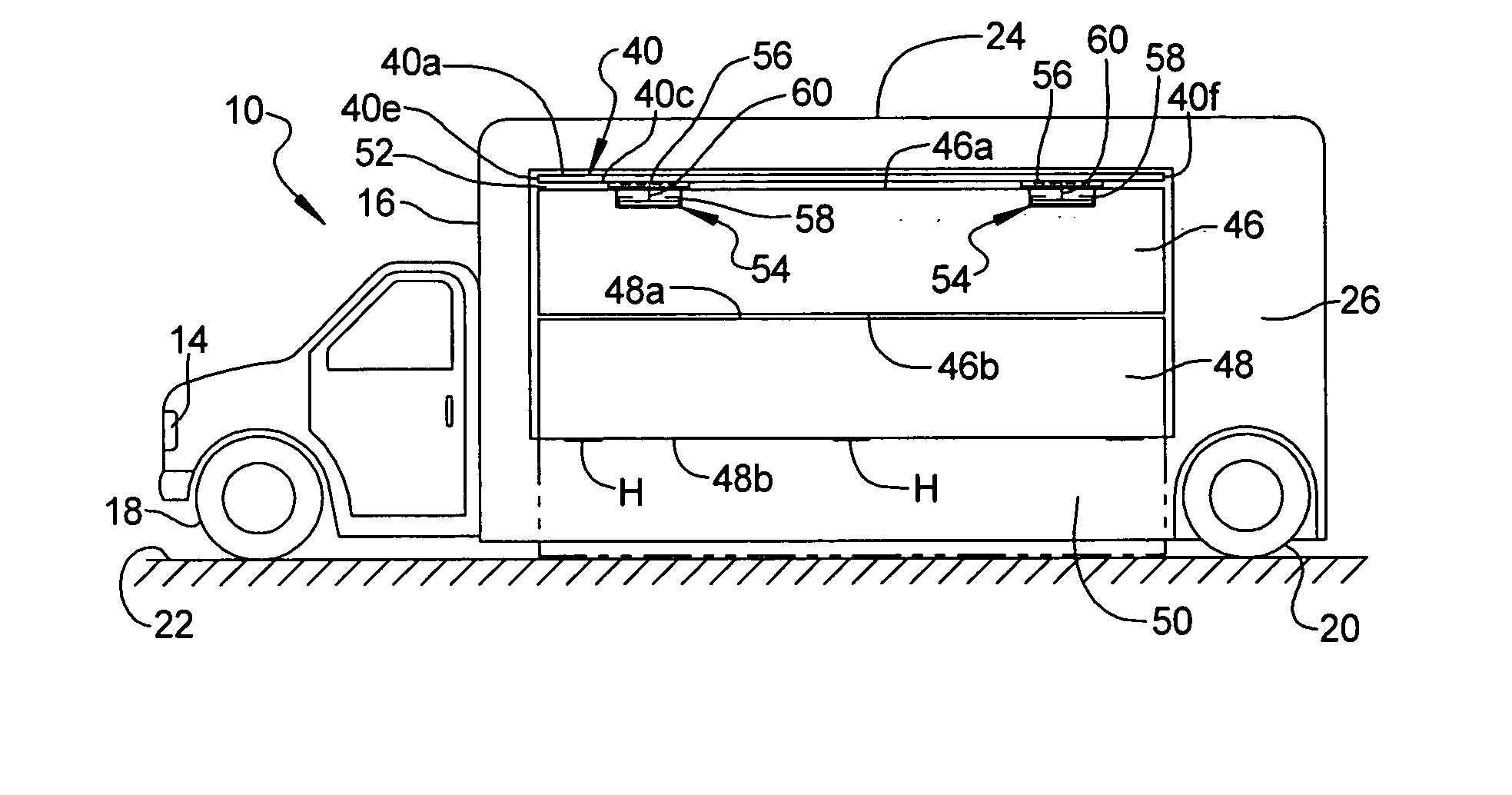

Portable paint booth

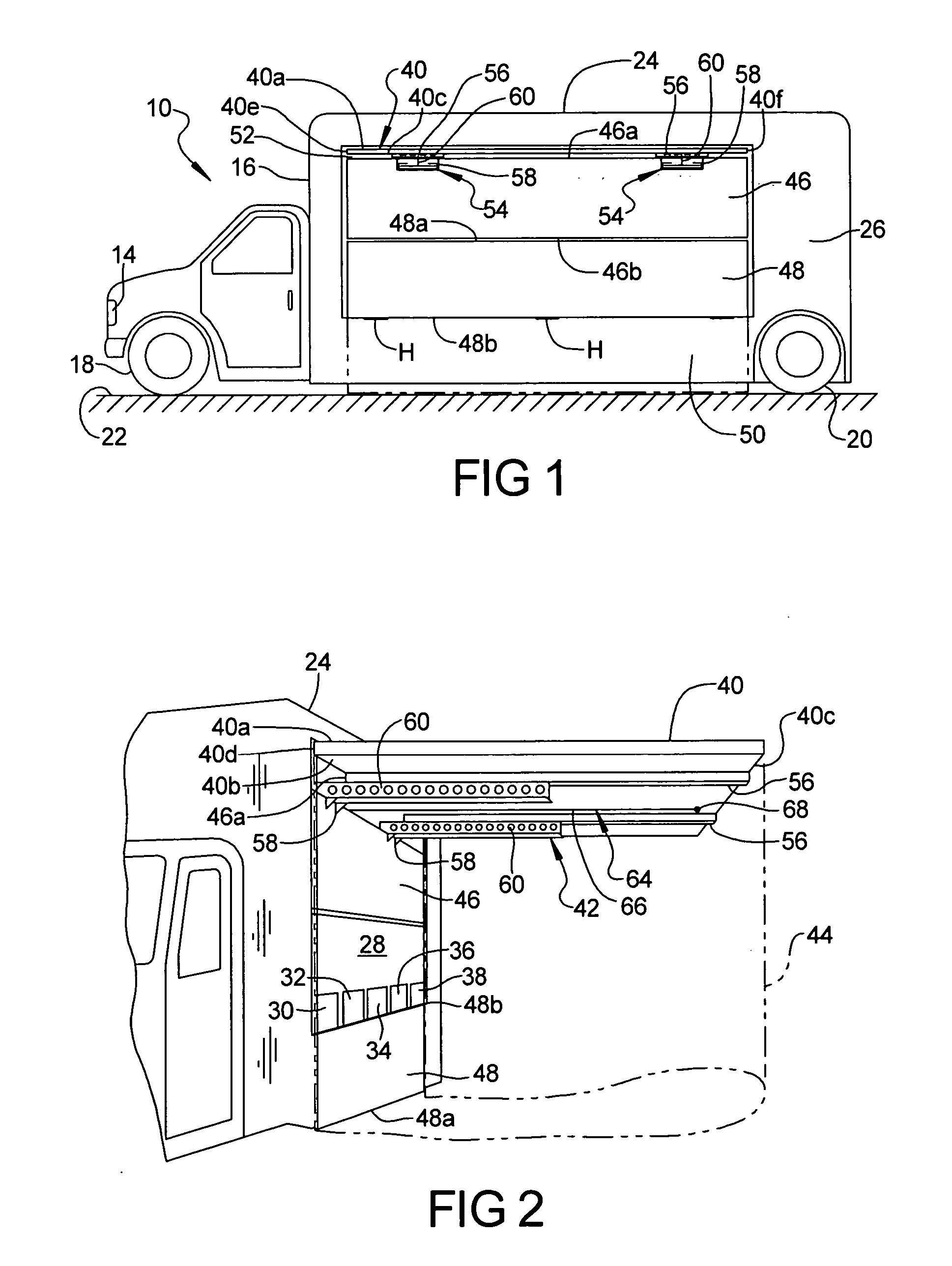

InactiveUS20070056510A1Reduce pressureQuick configurationLiquid surface applicatorsSpray nozzlesMobile vehicleStructural engineering

A mobile booth system, carried by a truck or like mobile vehicle, creates a portable, temporary in situ booth or enclosure at a remote location. A pair of side by side slide assemblies are formed by respective nests of C-channels and I-beams, each assembly extending and retracting through an opening in a sidewall of the truck wherein to deploy and retract a roof section outwardly from the truck. The roof section is deployed through a dedicated opening in the sidewall, which opening may be closed by a closure panel but opened by deployment of the roof section. When deployed, an enclosure is formed by attaching a drop cloth to the roof section. The enclosure when used as a paint booth enables rapid deployment of a drop cloth about irregular or difficult surfaces to be painted, as well as to contain overspray and fumes created by the spraying operation.

Owner:ANTAYA BRUCE C

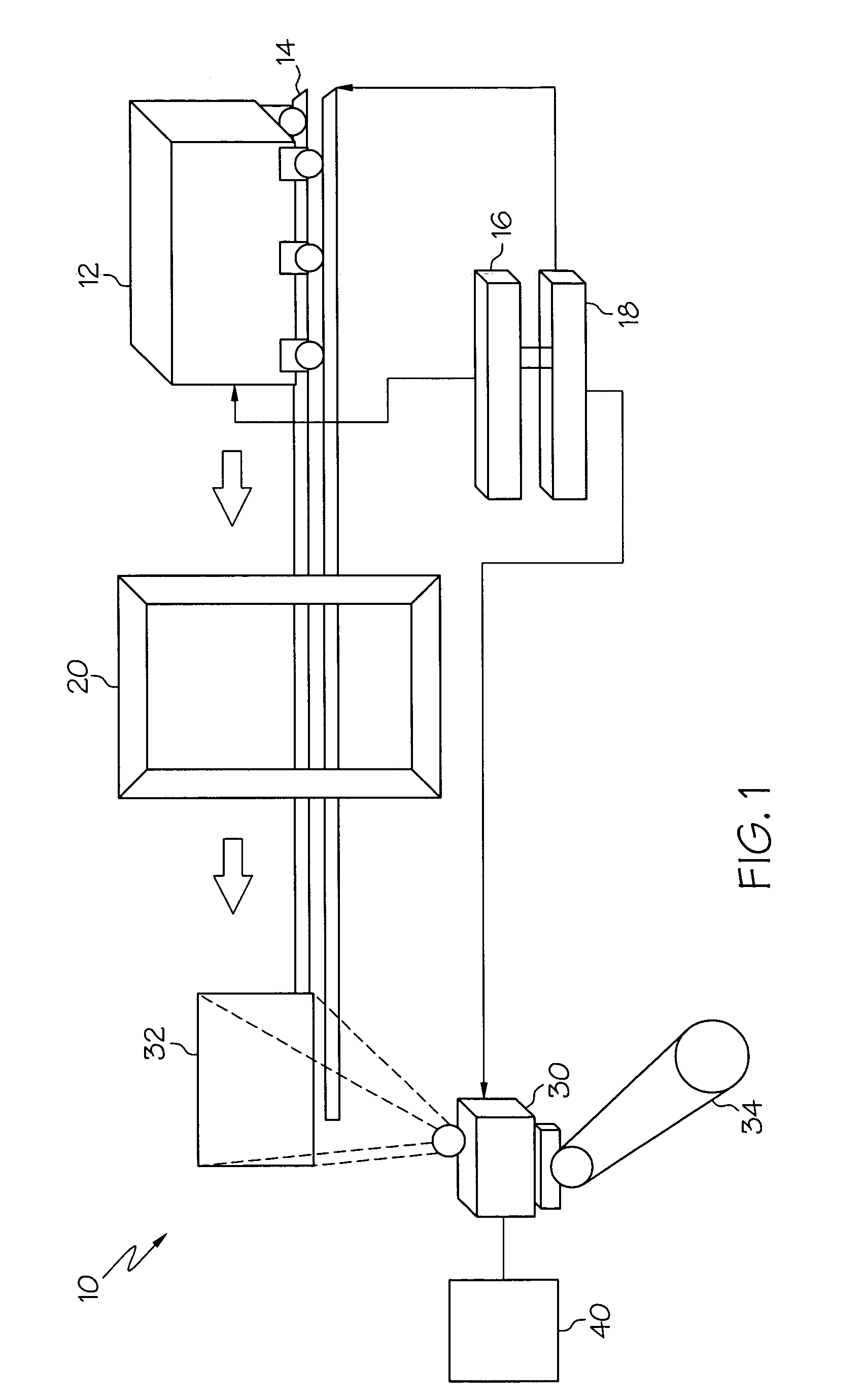

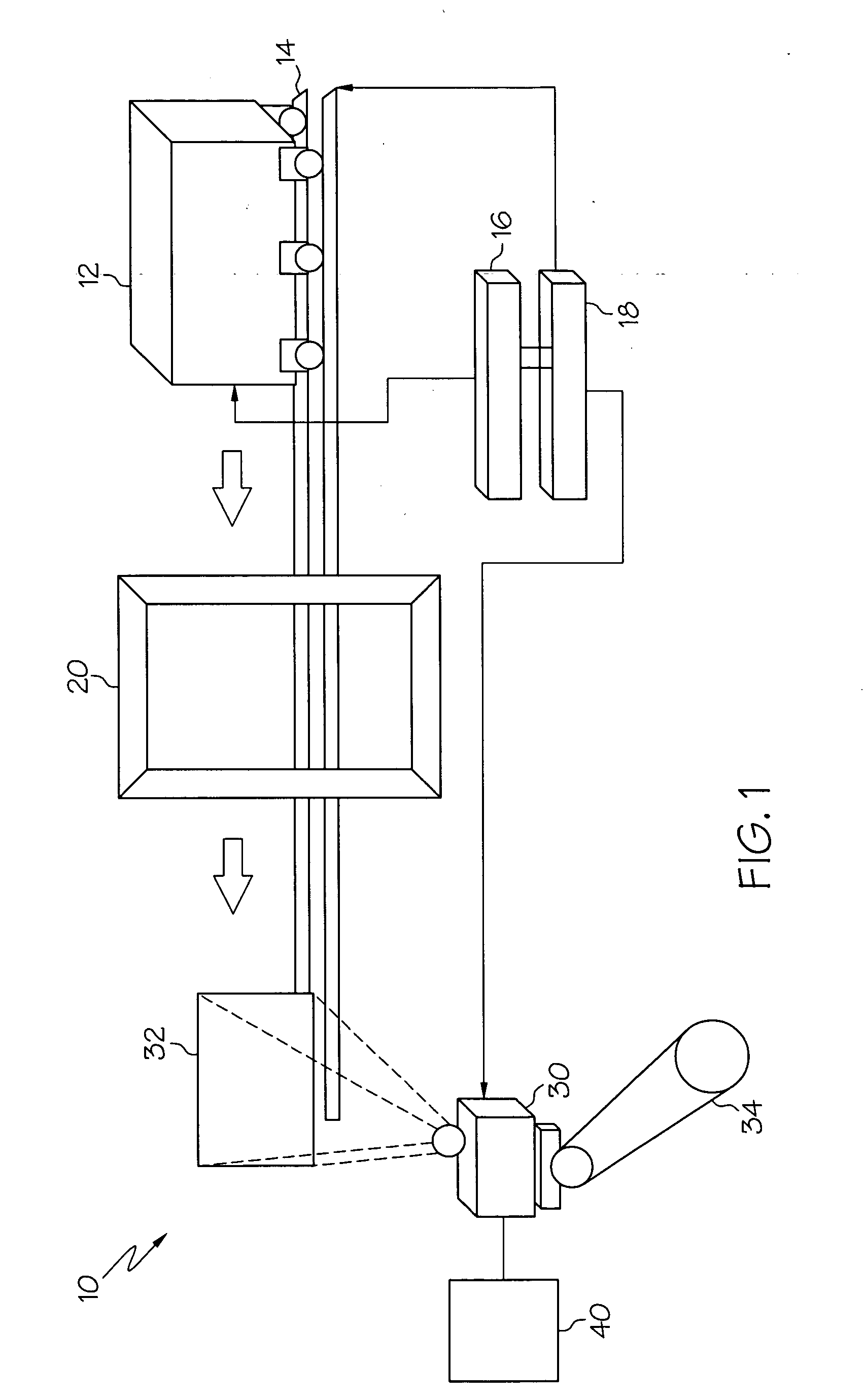

Linear Rail Coating Apparatus and Method

InactiveUS20060210701A1Reduce humidityEliminates human factorStentsPharmaceutical containersBiomedical engineeringHumidity

The invention provides an apparatus for coating a device comprising a coating chamber and a device rotator having at least one device mount wherein the apparatus allows insertion and retraction of the device on the device mount into and out of the coating chamber. In another aspect, the invention provides a method of applying a substantially uniform coating on a device comprising the steps of providing an apparatus for coating a device, mounting the device onto the device mount, purging the coating chamber to reduce humidity in the coating chamber, maintaining a reduced humidity content in the coating chamber, inserting the device into the coating chamber, disposing a coating material on the device and rotating the device mounts about the device axis.

Owner:SURMODICS INC

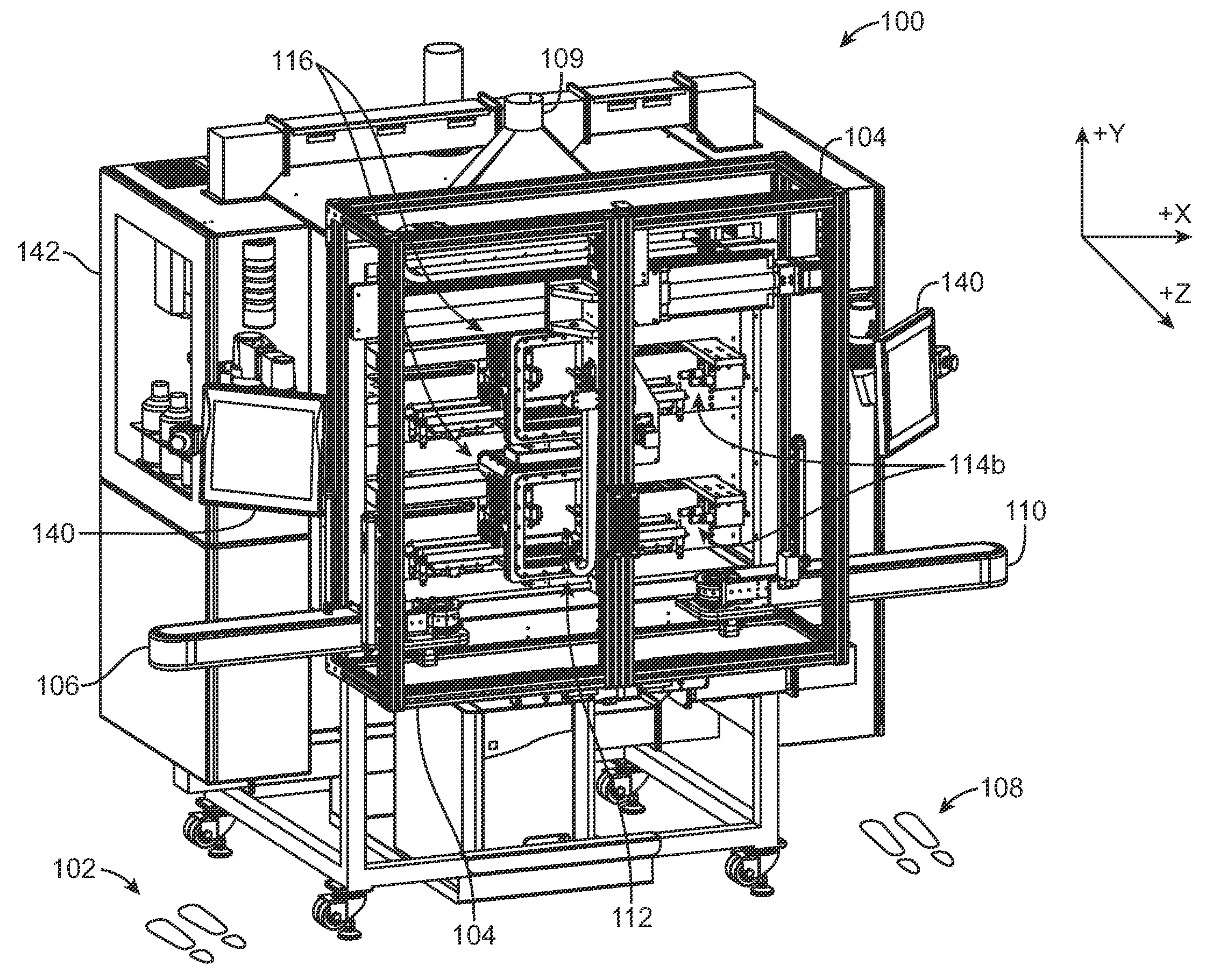

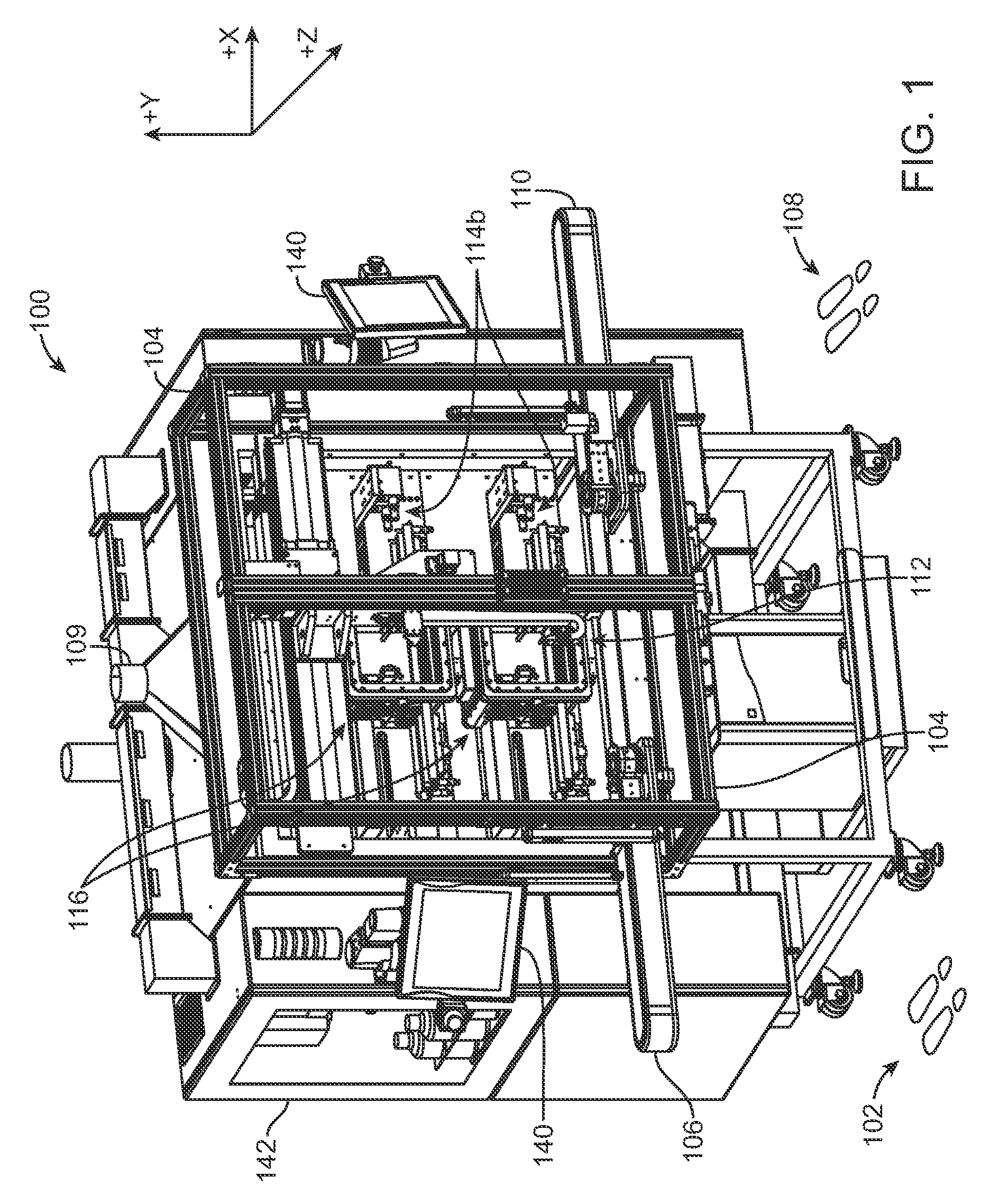

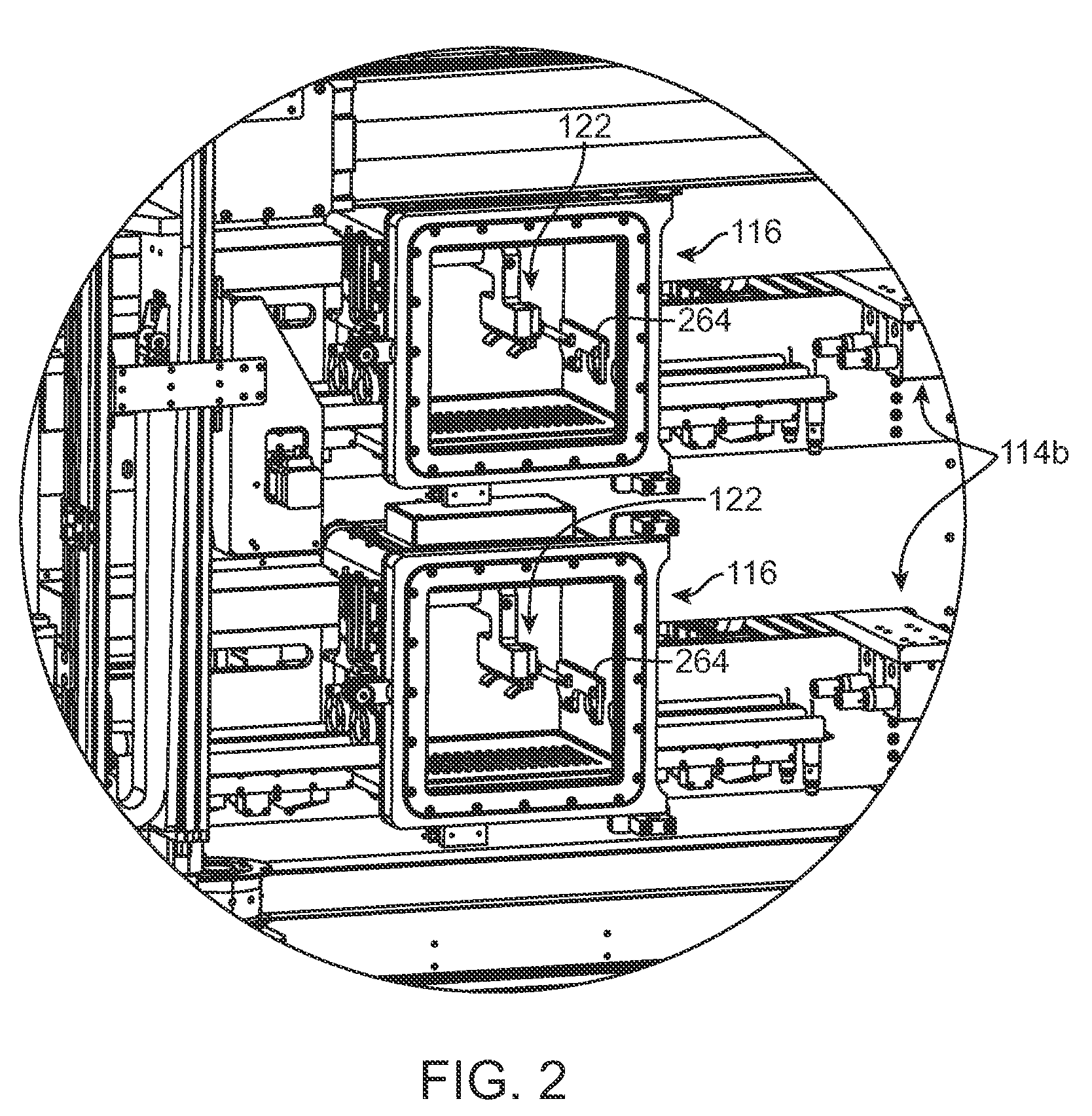

System and Method for Coating a Medical Device

A system and method allows for processing of two groups of medical devices, both groups being alternatingly spray coated within the same enclosure. The two groups repeatedly move back and forth between a spray area and a drying area which is isolated from the spray area. One group moves into the spray area as the other group moves out and into the drying area. Thereafter, the group in the spray area moves out and into the drying area and the other group moves back into the spraying area for a second coating. The alternating process may be repeated any number of times. The spray area may be located inside a sealed spray isolator enclosure and surrounded by gas discharge nozzles.

Owner:ABBOTT CARDIOVASCULAR

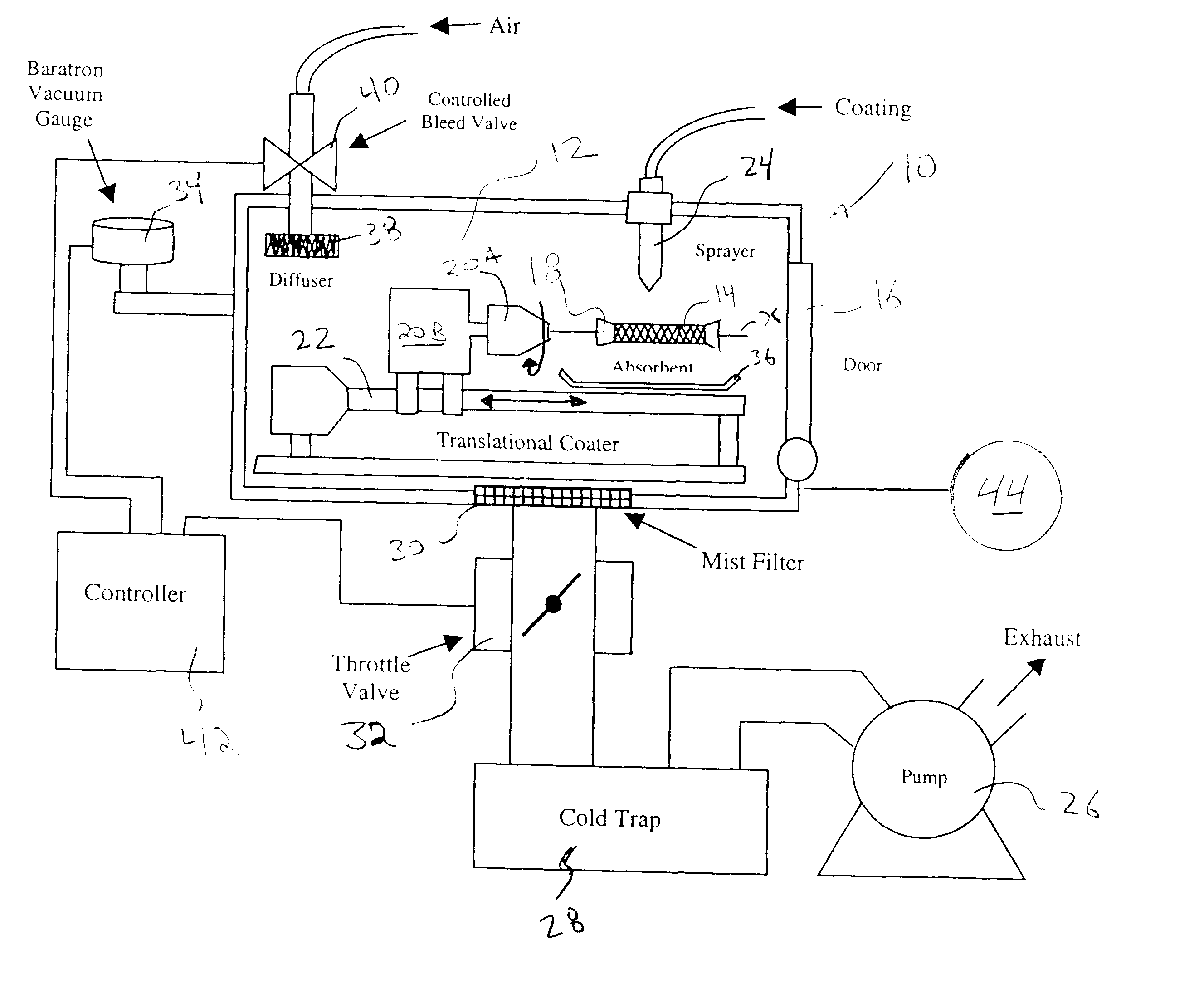

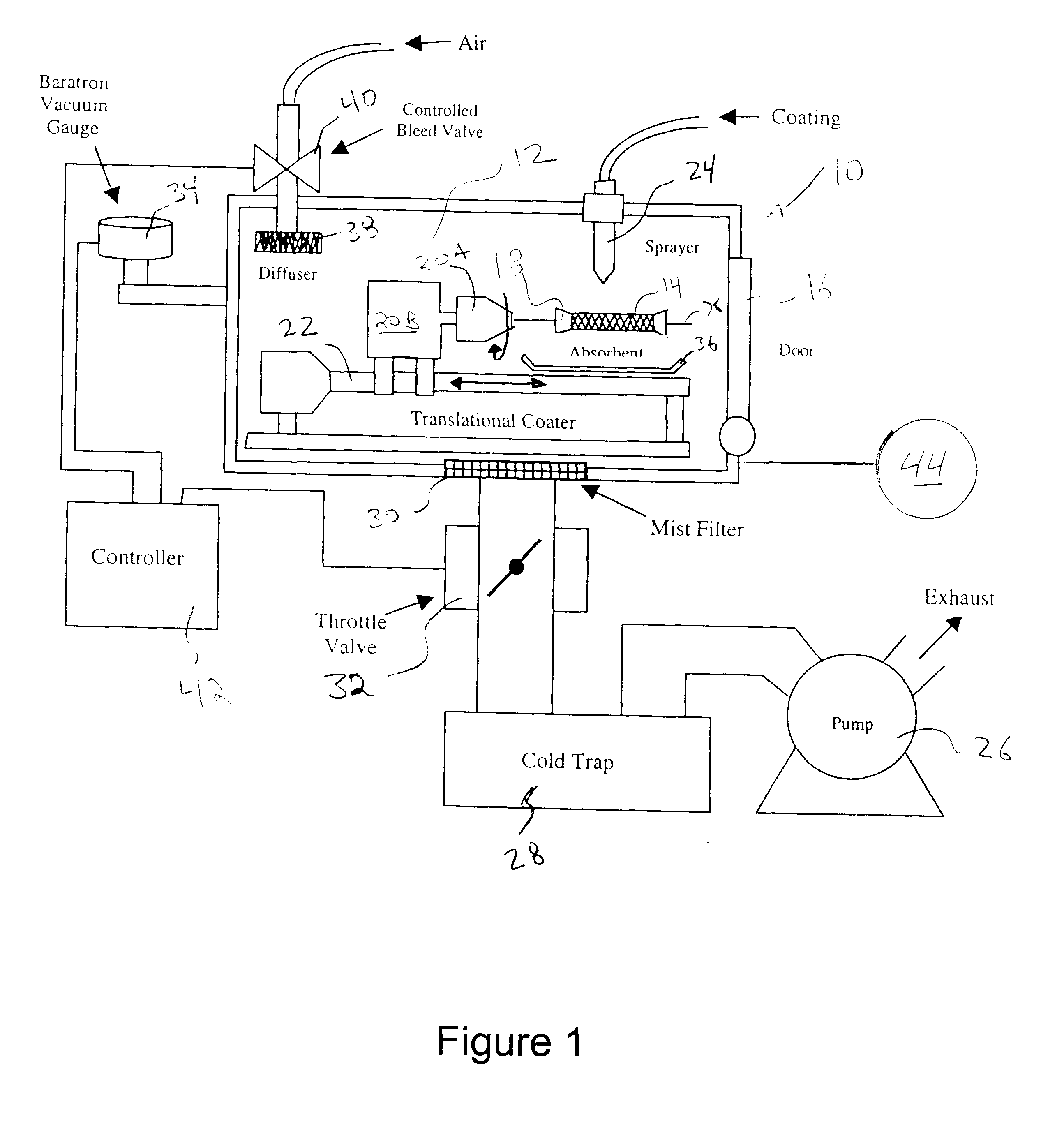

Apparatus and method for coating implantable devices

A method of forming a coating for an implantable medical device, such as a stent, is provided which includes applying a composition to the device in an environment having a selected pressure. An apparatus is also provided for coating the devices. The apparatus comprises a chamber for housing the device wherein the pressure of the chamber can be adjusted during the coating process.

Owner:PACETTI STEPHEN D

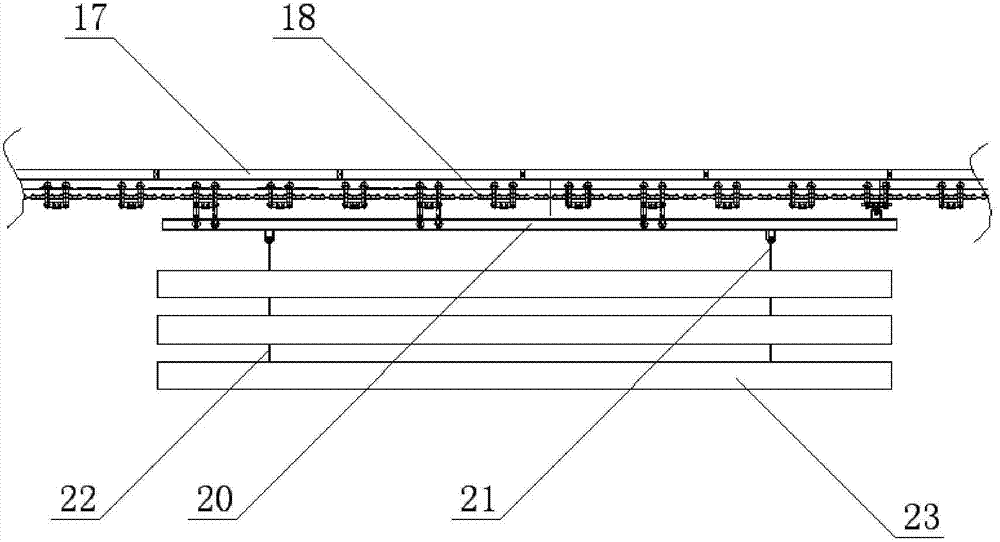

Production system of hub bearing

ActiveCN106050920ANo need for manual operationFast productionLiquid surface applicatorsGrinding carriagesThrust bearingEngineering

The invention provides a production system of a hub bearing, in order to solve the technical problems that the hub bearing is to be carried manually and the production speed is low because the structure of the conventional processing device is too simple. The production system of the hub bearing comprises a workbench, wherein an outer ring grinding device for grinding an outer ring of the hub bearing, an inner ring grinding device for grinding an inner ring of the hub bearing, a cleaning device for cleaning the hub bearing, a spraying device for spraying the hub bearing, and a detection device for detecting the hub bearing are sequentially arranged on the workbench. The production system has the advantage of high production speed.

Owner:嘉兴福可吉精密机械有限公司

Anticorrosive paint spraying device for metal panel

The invention discloses an anti-corrosion paint spraying device for metal plates, which comprises an operating room. The bottom of the operating room is horizontally slidably provided with a slider, the right end of the first limiting spring is fixed on the side wall of the operating room, and the left end of the second limiting spring is fixed. On the right side wall of the sliding sleeve, the right end of the second limit spring is fixed on the left inner wall of the operating room; the output shaft of the forward and reverse motor is coaxially fixed with a first winding wheel and a second winding wheel; The end of the first pull cord away from the first winding wheel is fixed on the left side wall of the sliding sleeve; the structure of the invention is ingenious, and the reciprocating movement of the collecting pipe realizes that the spray head evenly and reciprocally sprays paint on the metal plate clamped between the blocks. The range of spraying is wider, and the efficiency of painting is greatly improved. During the spraying process of the nozzle, the slider drives the blower to reciprocate left and right, so that the blower can dry the metal sheet from top to bottom, which promotes the rapid drying of the paint and improves the spraying efficiency. s efficiency.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

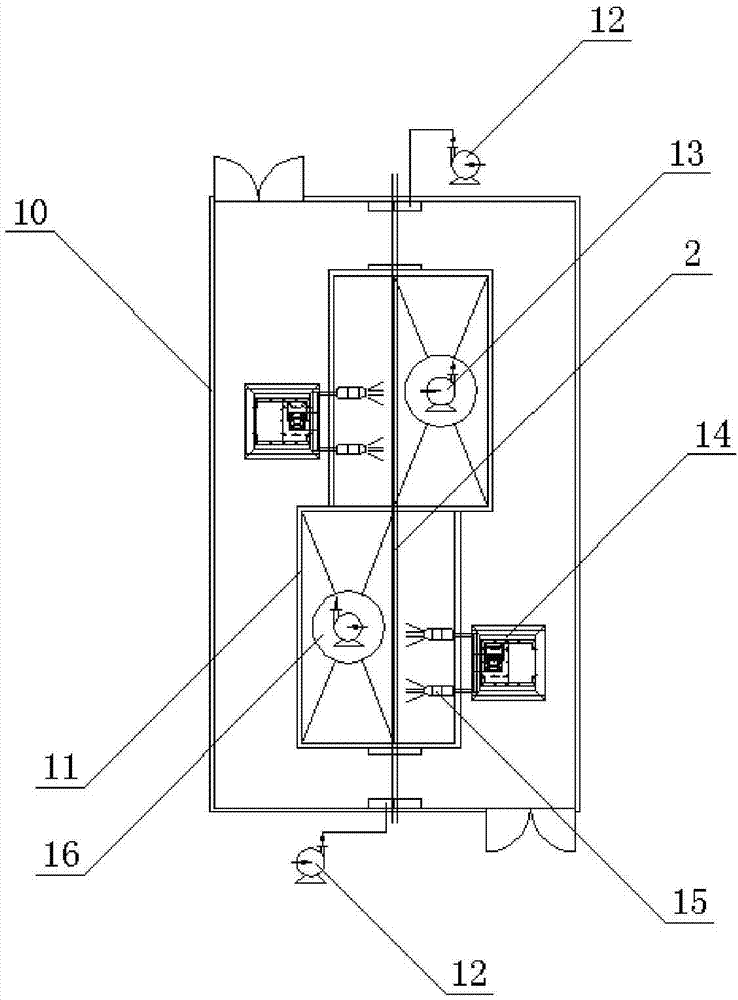

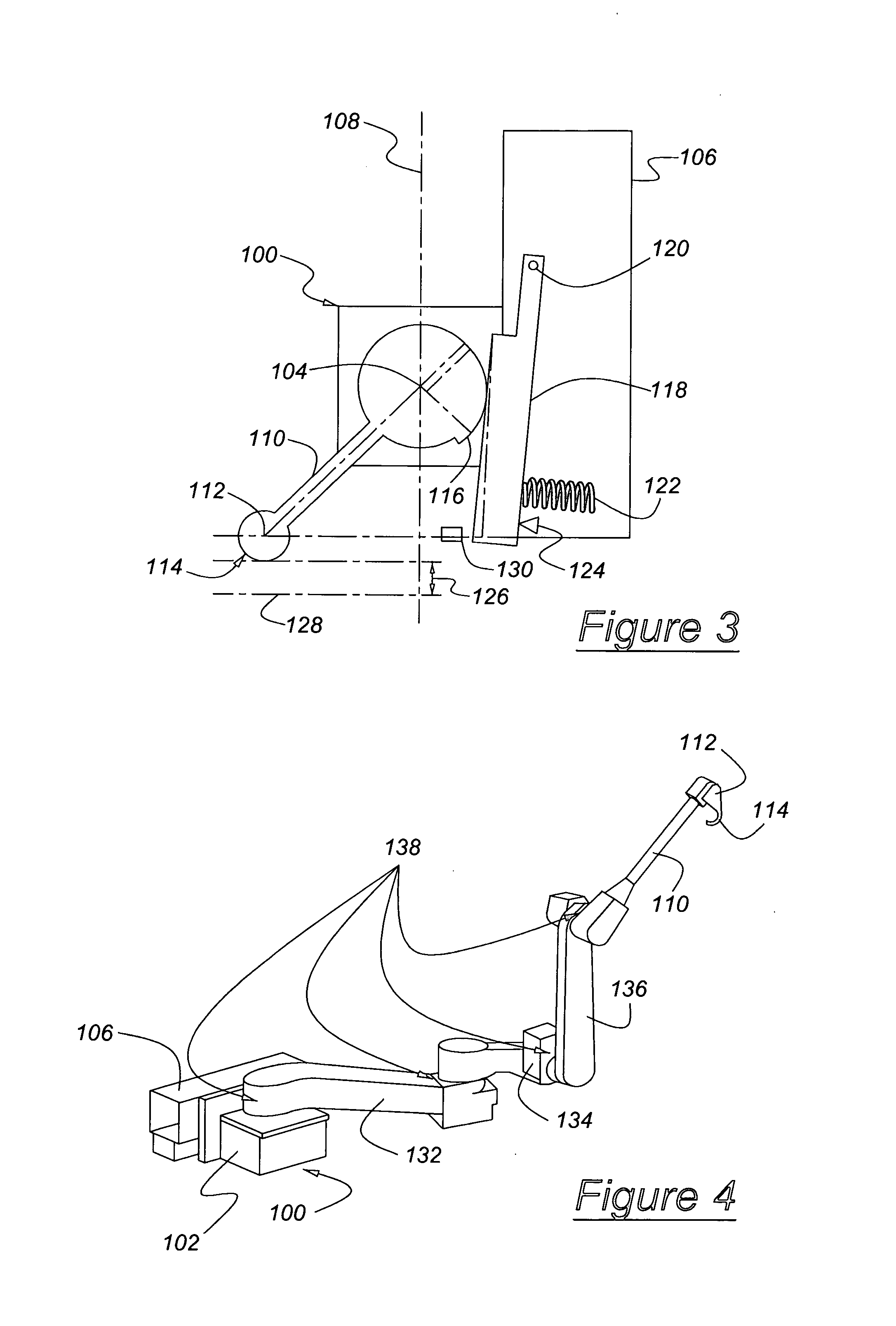

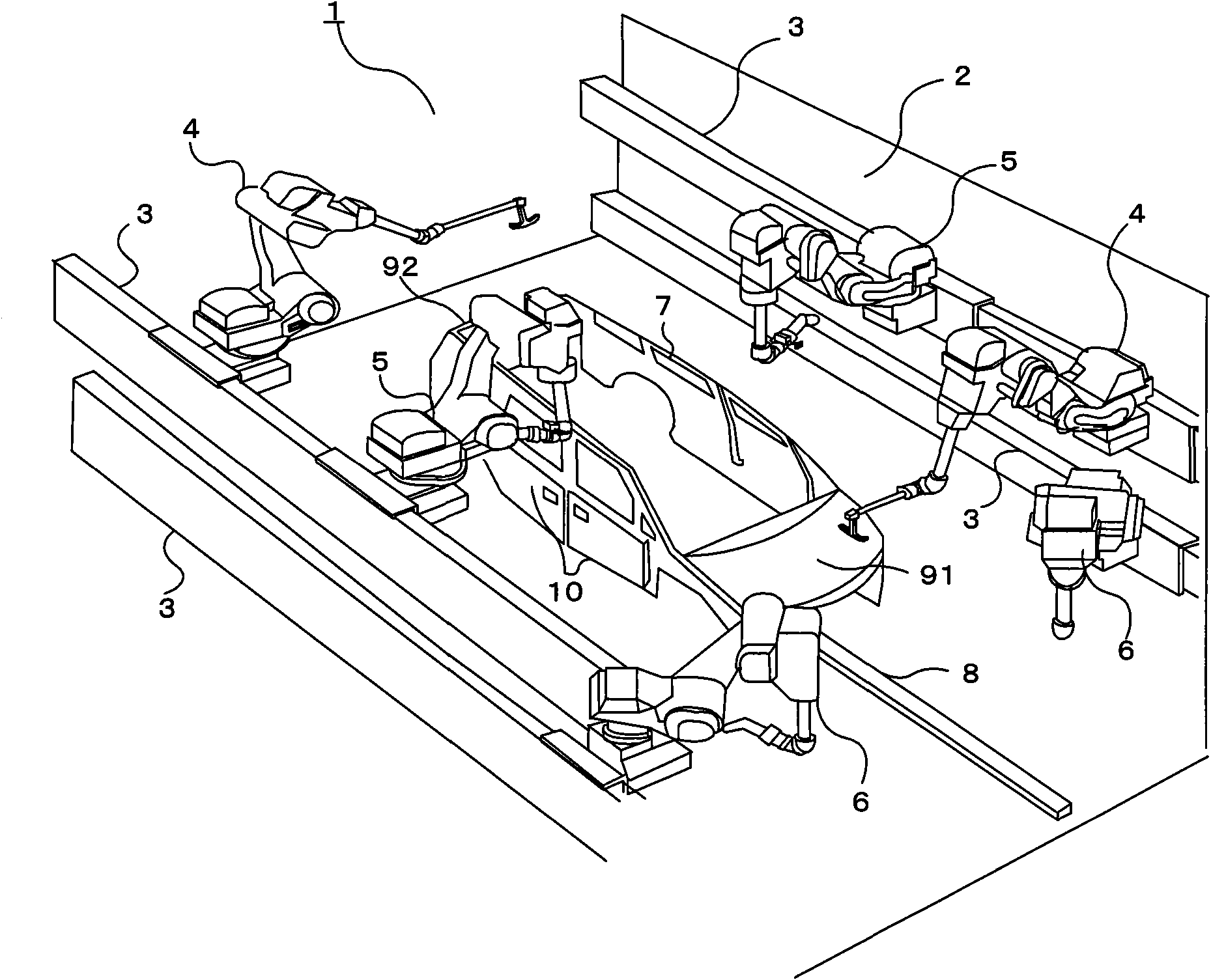

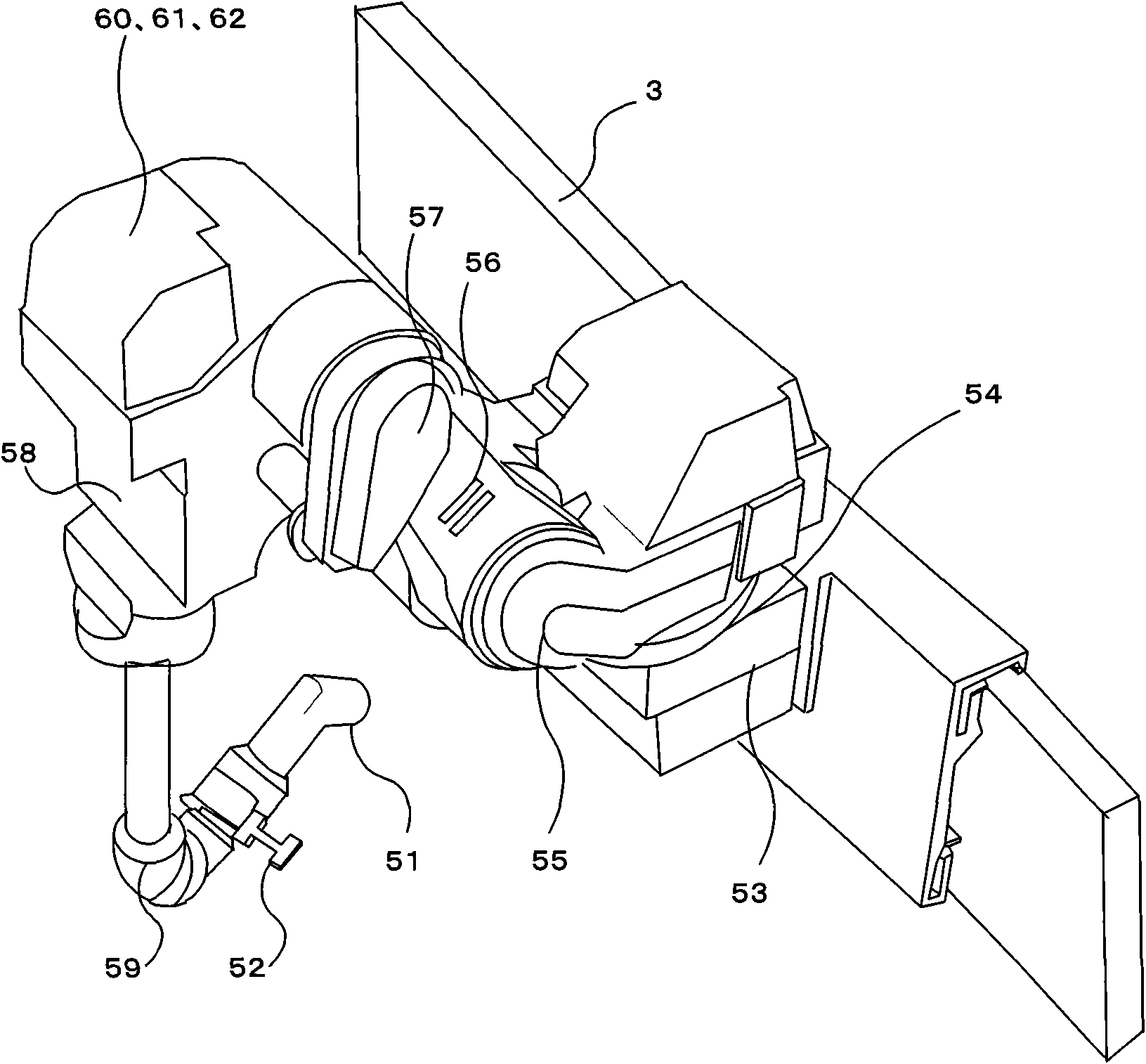

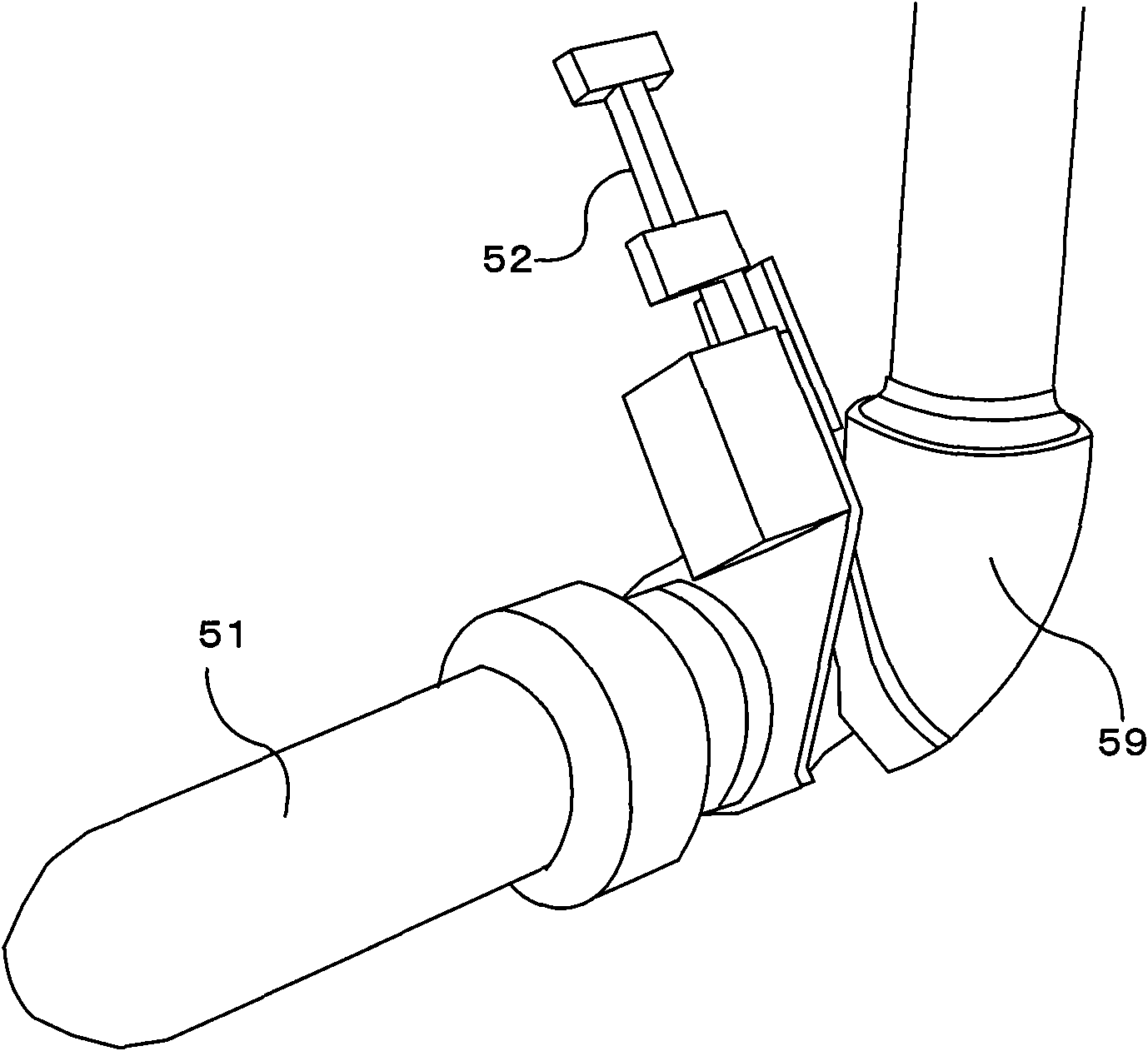

Painting system

ActiveCN101657264AAbnormal color does not occurRealize continuous coatingProgramme-controlled manipulatorSpray boothsControl theoryRobot

The present invention relates to a painting system having improved productivity achieved by optimizing the number and arrangement of robots in a painting booth. A painting system (1) in which a painting robot (6) and an opener robot (4) can pass each other without interference on a first travel guide rail (3) and a second travel guide rail (3). The first travel guide rail (3) is placed at a lower position than the second travel guide rail (3). The painting robot (6) is placed on the first travel guide rail (3), and the opener robot (4) is placed on the second travel guide rail (3).

Owner:YASKAWA DENKI KK +1

Mobile environment-friendly paint spraying booth

InactiveCN109604101AEasy to paintImprove painting efficiencyPretreated surfacesCoatingsHydraulic cylinderInternal cavity

The invention discloses a mobile environment-friendly paint spraying booth in the technical field of paint spraying. The paint spraying booth comprises a paint spraying booth body and a transport vehicle; an inner cavity of the paint spraying booth body is divided by a dividing plate into a paint spraying chamber located on the right side and a drying chamber located on the left side; a driving mechanism is mounted in the center of the inner wall of the top of the paint spraying chamber; a dust sensor is mounted on the back side of the inner wall of the top of the paint spraying chamber; the top end of a filtering box is connected with the bottom end of an air inlet pipe; the top end of the air inlet pipe extends to the top of an inner cavity of the paint spraying chamber; an air inlet cover is mounted at the top end of the air inlet pipe; and the bottom of a hydraulic cylinder I is connected with a detecting mechanism through a telescopic rod I. According to the paint spraying booth,an upper paint spraying pipe cooperates with side paint spraying devices on two sides, clamped workpieces are rotated by 180 degrees by two rotation motors, and two-side paint spraying is performed onthe workpieces, so that the paint spraying efficiency for the workpieces is improved effectively; and the workpieces after paint spraying are dried by the aid of a fan with heat produced by a heatingresistance wire II during working, so that environmental pollution caused by waste gas and waste liquids which are produced during paint spraying is avoided.

Owner:袁大力

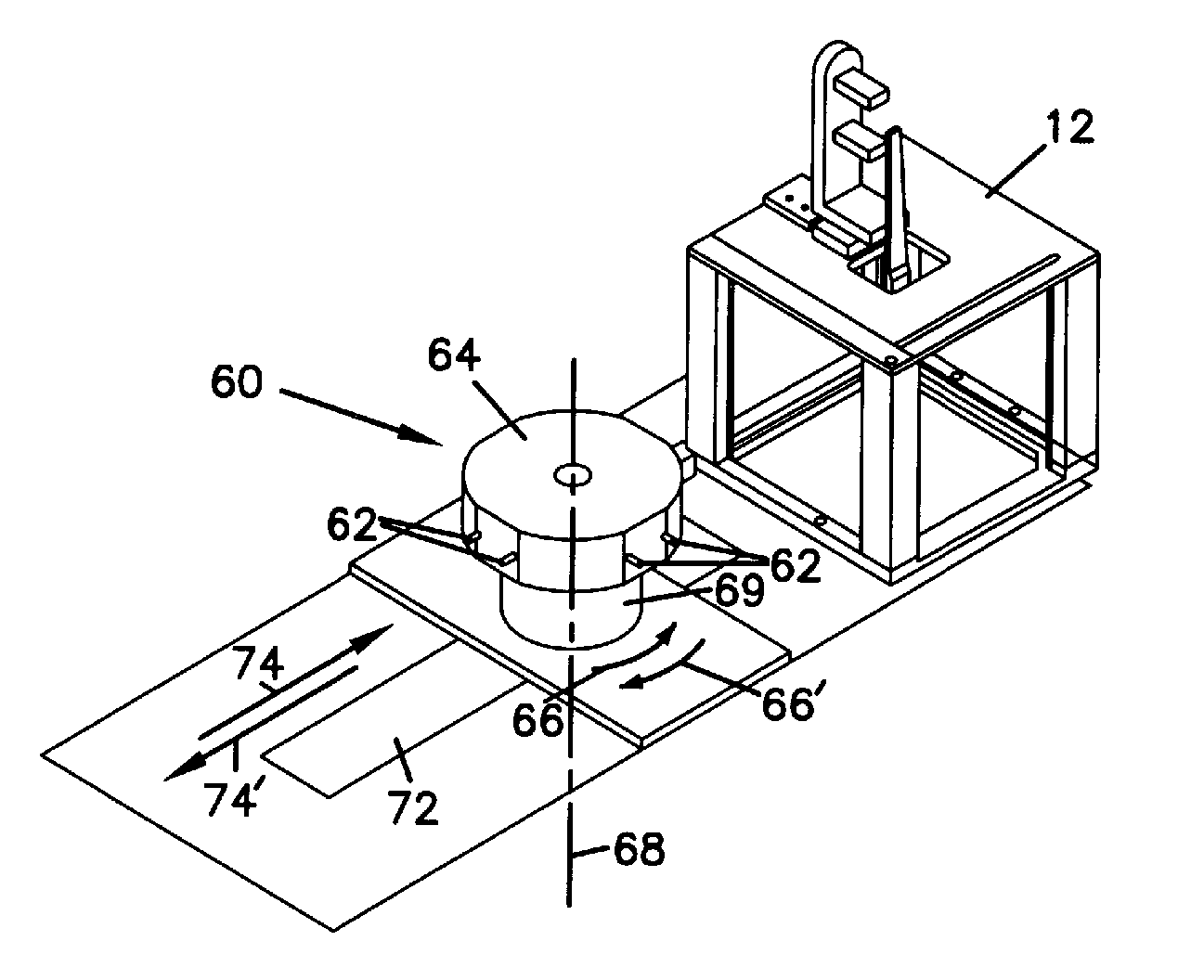

Modular tire spraying system

ActiveUS20130078385A1Use minimizedUniform coverageLiquid surface applicatorsTyresAgricultural engineeringDelivery system

A modular tire spraying system includes a downdraft spray booth for receiving a tire, a fluid delivery system disposed in the spray booth, a robot for transporting the tire to the spray booth, and a platform on which each of the spray booth, the fluid delivery system, and the robot is disposed. The fluid delivery system includes at least one spray gun for delivering a coating to the tire.

Owner:PIONEER IND SYST

Fully-automatic dust-free painting line of plastic component

ActiveCN104588247AHigh degree of automationReduce manpower consumptionLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses a fully-automatic dust-free painting line of a plastic component. The painting line comprises a preheating furnace, a first dust-removing cabinet, a second dust-removing cabinet, a spraying room, a leveling device, an IR (infrared) furnace, a UV (ultraviolet) light curing machine, a PU (polyurethane) curing oven, a cooling device and a component loading and unloading area, wherein the preheating furnace, the first dust-removing cabinet, the second dust-removing cabinet, the spraying room, the leveling device, the IR furnace and the UV light curing machine are sequentially and transversely connected and are positioned on the front side of the PU curing oven. Operation procedures, such as continuous dust removal, paint spraying, baking, drying and cooling, are sequentially finished by matching and using each device, the automation degree is high, labor consumption is reduced, the production efficiency is effectively improved, and meanwhile, the painting quality is improved; intelligent control is realized, and the aims of energy conservation, emission reduction, waste removal, production cost reduction and the like are fulfilled by arranging each electric sensor; the painting line is reasonable in structural layout, can be used for painting a UV paint and a PU paint to a workpiece, and is strong in function and wide in application range.

Owner:东莞市慧江平成机械有限公司

Method of balancing paint booth air flows

InactiveUS6226568B1Sampled-variable control systemsLiquid surface applicatorsControl theoryDischarge pressure

A method of rapidly balancing air flows in a complex paint spray booth having a series of cells supplied by a common air flow that is pushed by an adjustable speed supply fan and then divided into downdrafts for each of the said cells accompanied by cross-flows between said cells. The downdrafts and cross-flows converging into exhaust flows drawn by an adjustable speed exhaust fan, the system having control elements for changing the downdrafts and / or cross-flows, and further having means for passing the exhaust flow through a waste paint water scrubber having an adjustable venturi gap width. The method comprising (a) setting an exhaust an speed and venturi gap width by correlating perturbed exhaust air flow rate data with a desired exhaust air flow rate at a desired exhaust pressure drop to establish a target fan curve as a function of pressure drop and exhaust flow rate, the setting for the exhaust fan sped and venturi gap width being derived from such curve; and (b) setting a supply fan speed and control position for each cross-flow damper by solving an objective optimization function for the sum of the cross-flows by using perturbed supply fan speed values and cross-flow rate values that establish distinct optimum cross-flow velocities at a specific air supply velocity from which the supply fan speed and cross-flow speed damper positions can be derived.

Owner:FORD GLOBAL TECH LLC

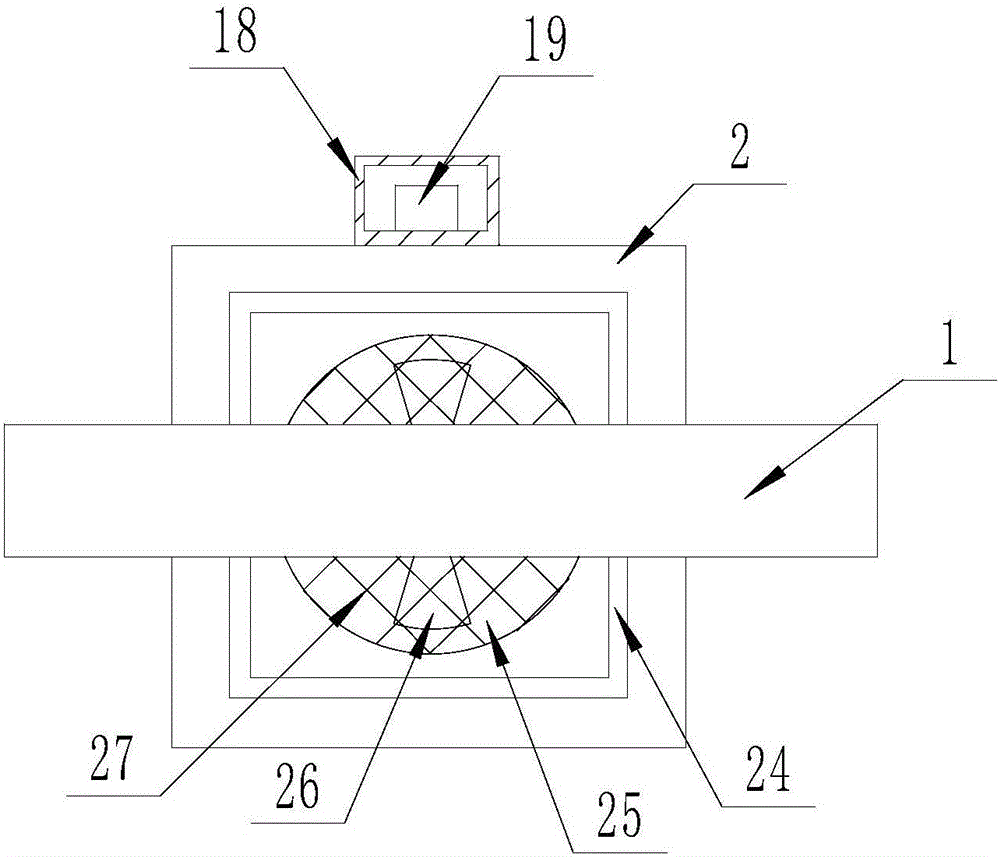

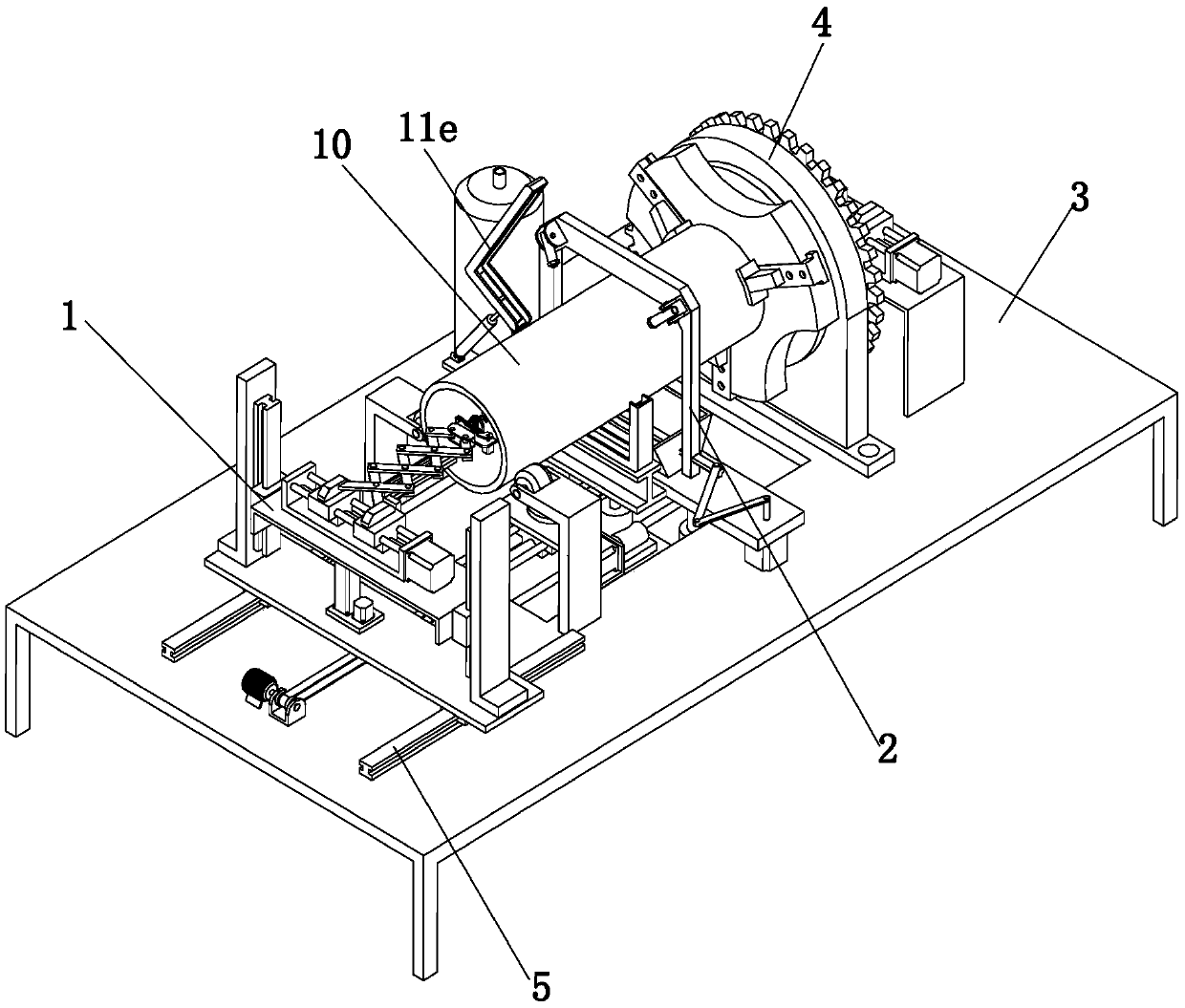

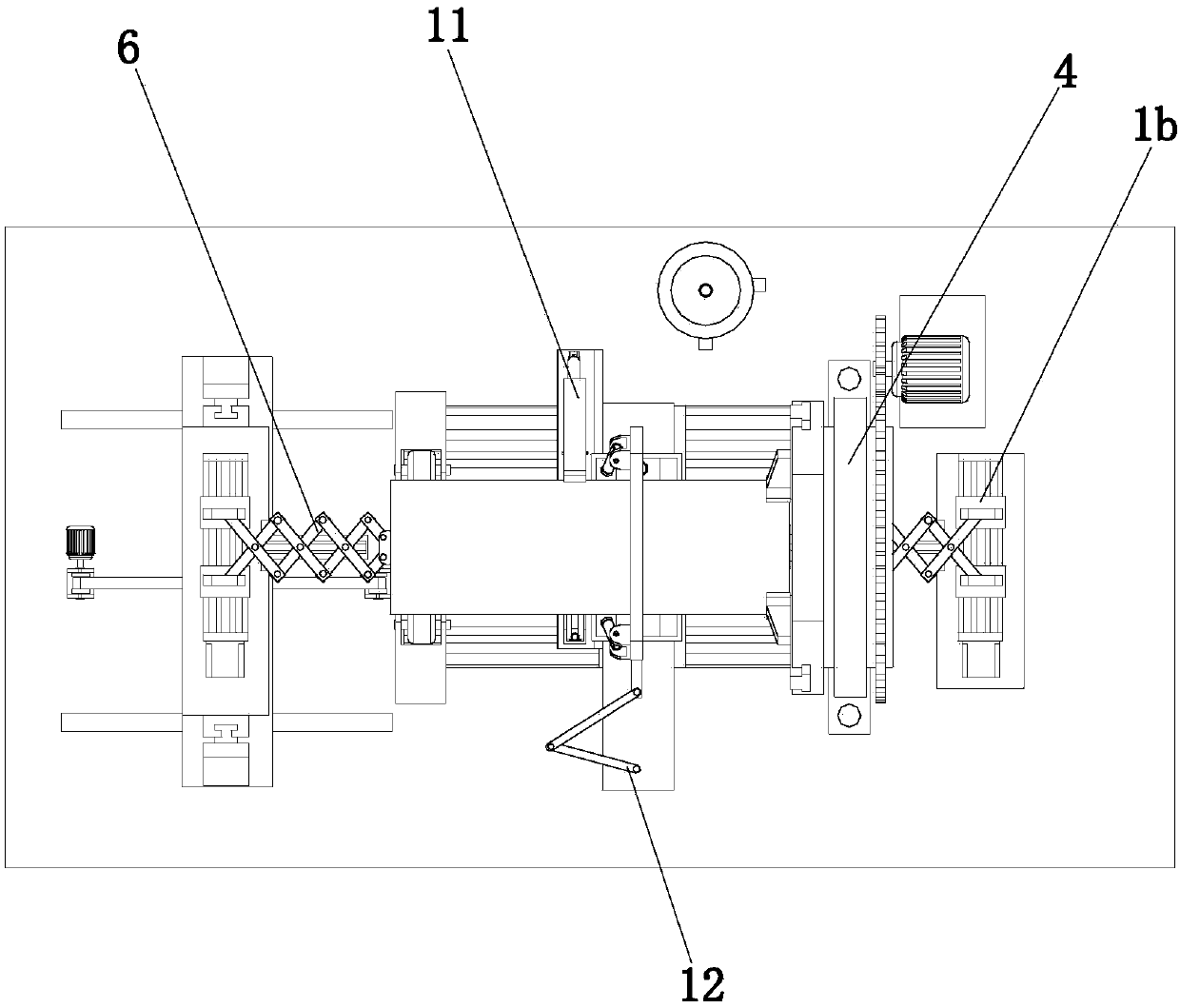

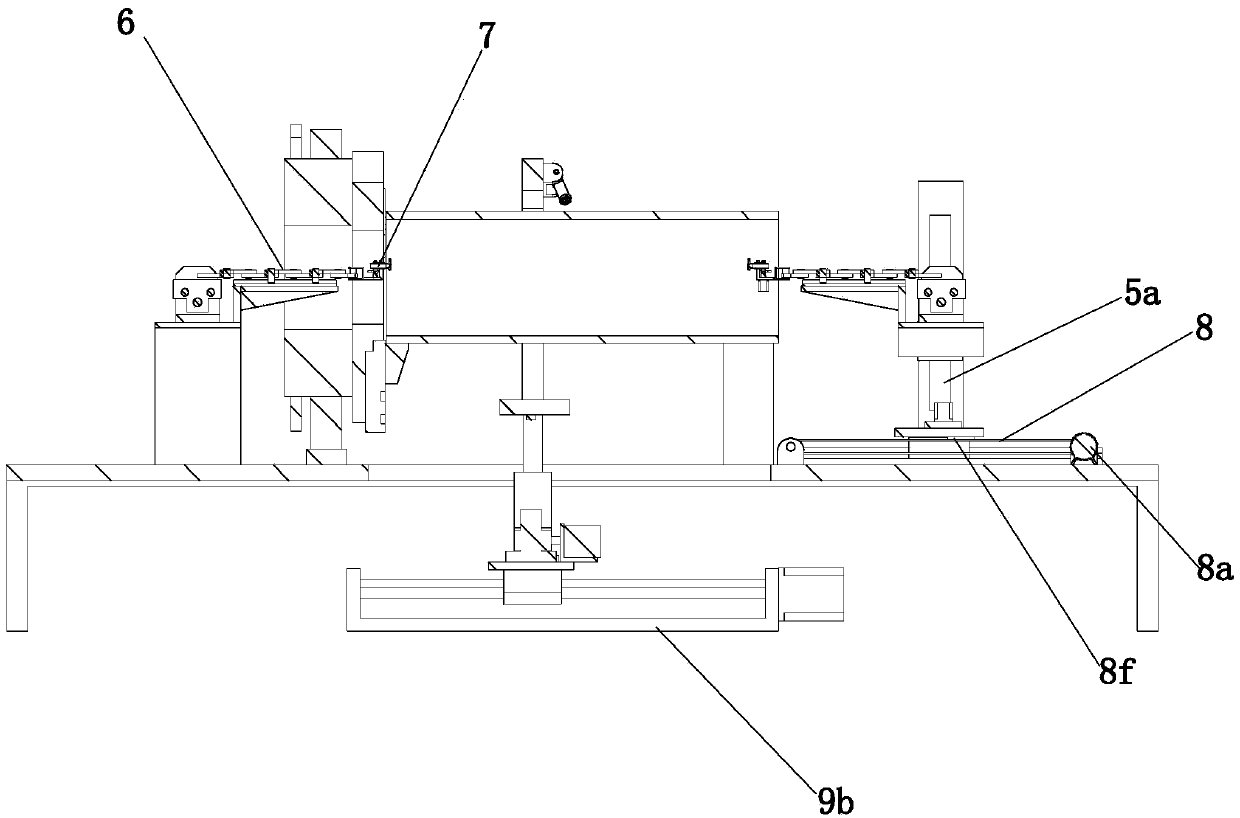

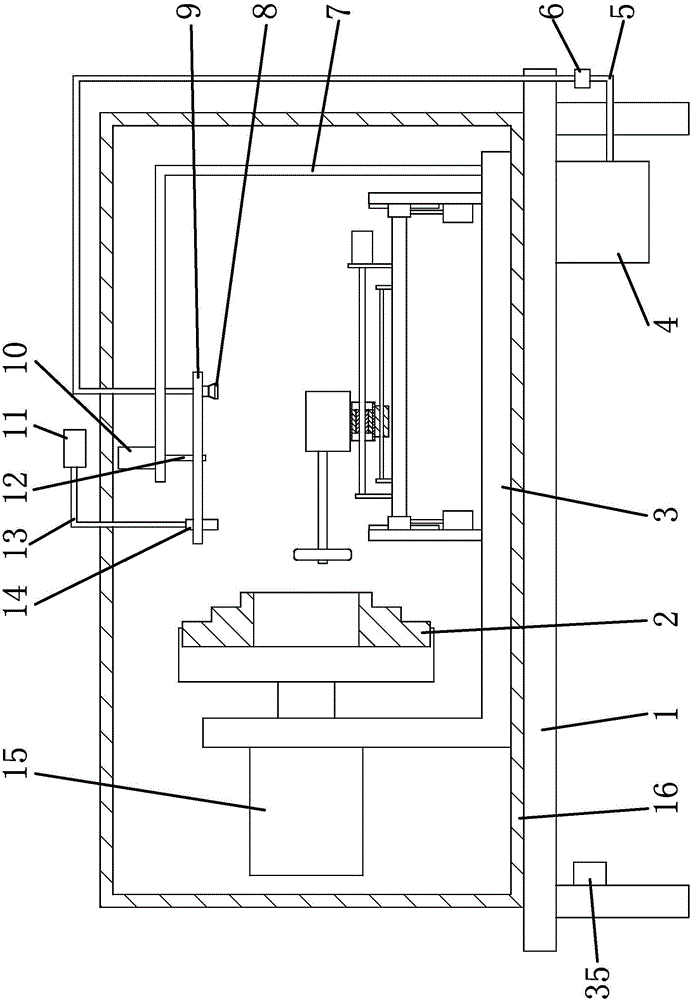

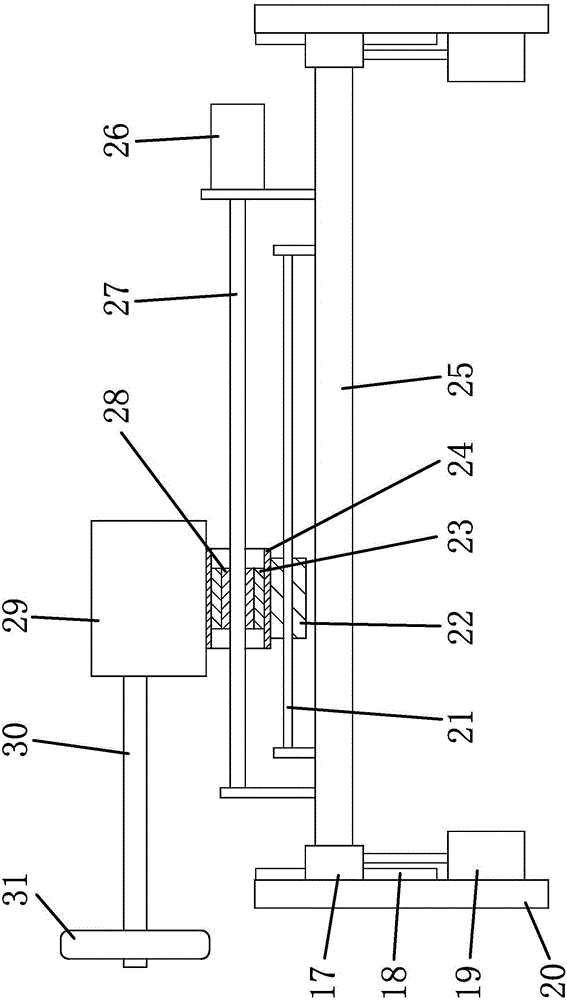

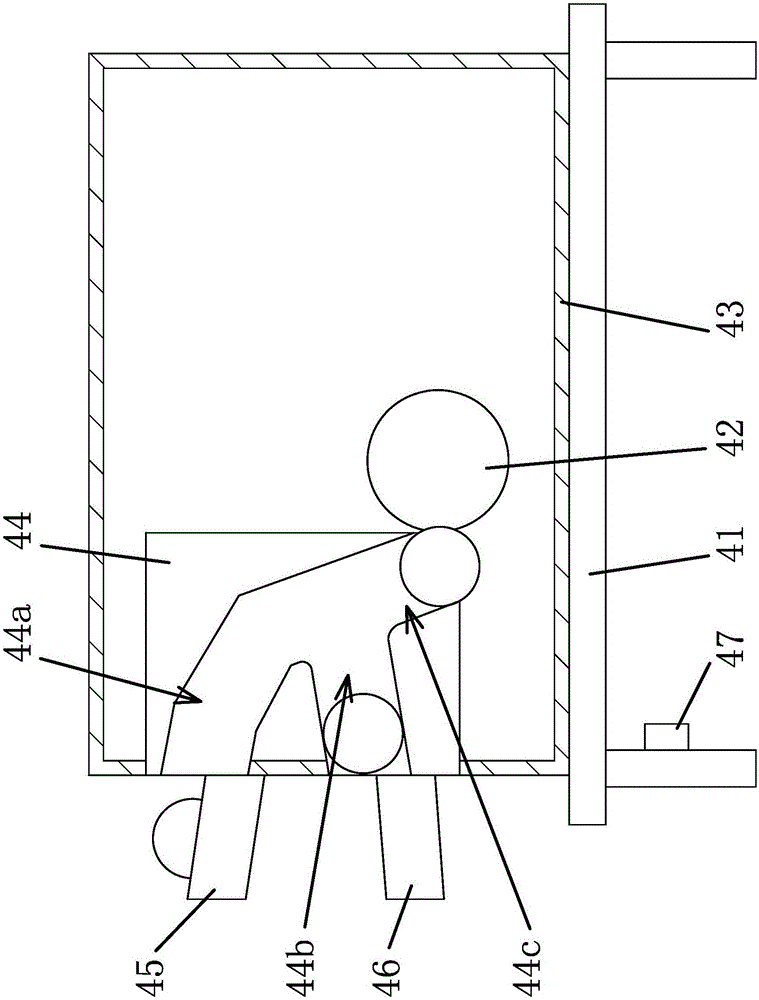

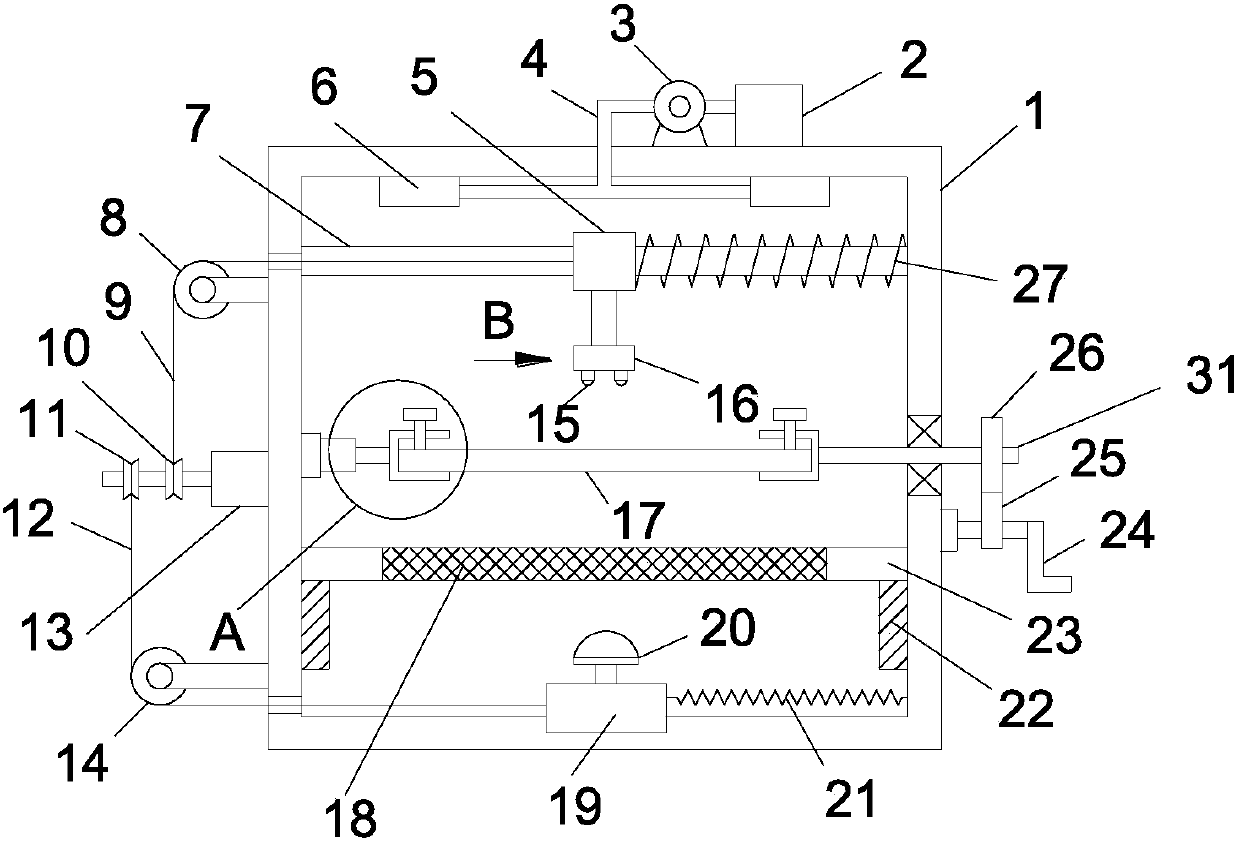

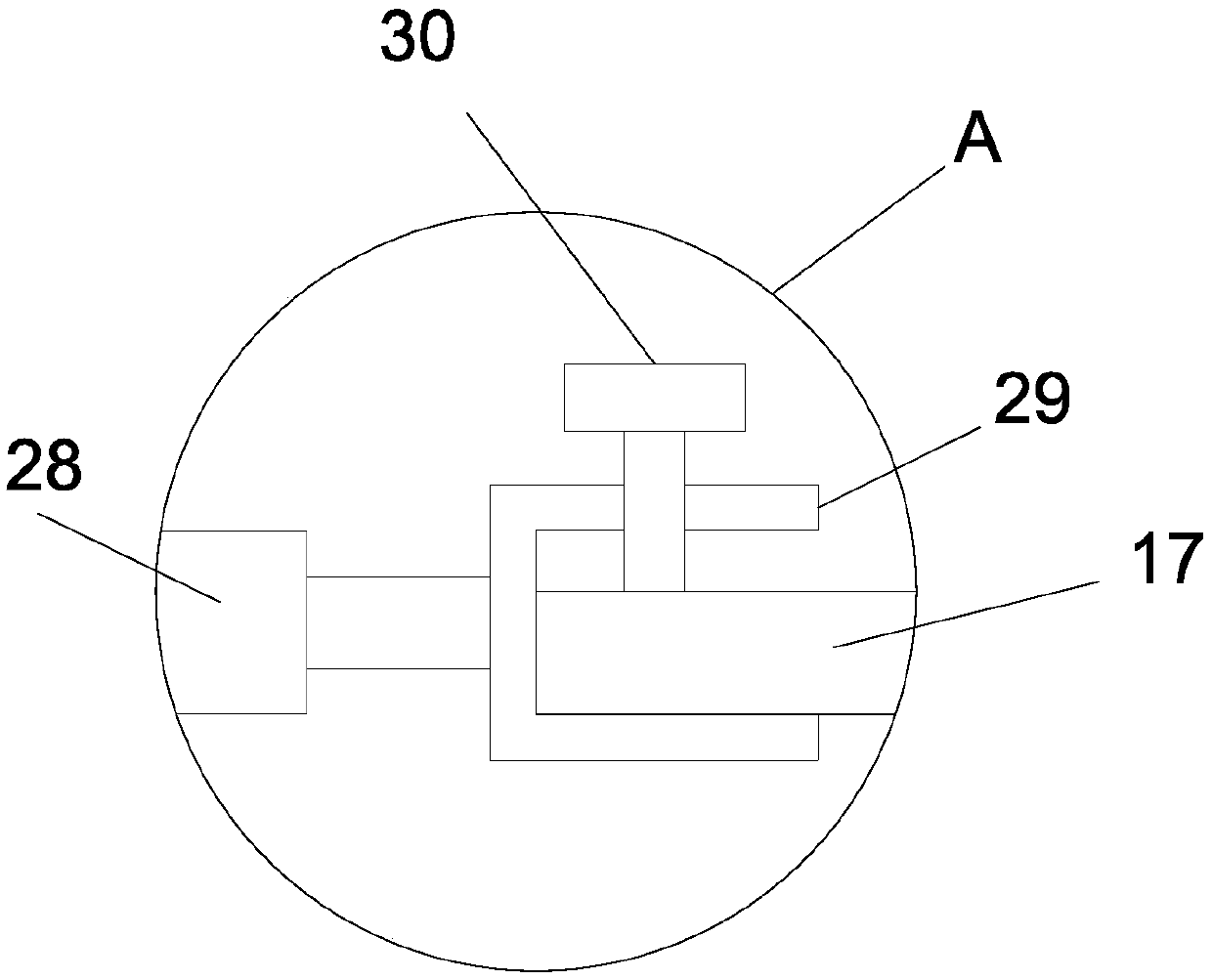

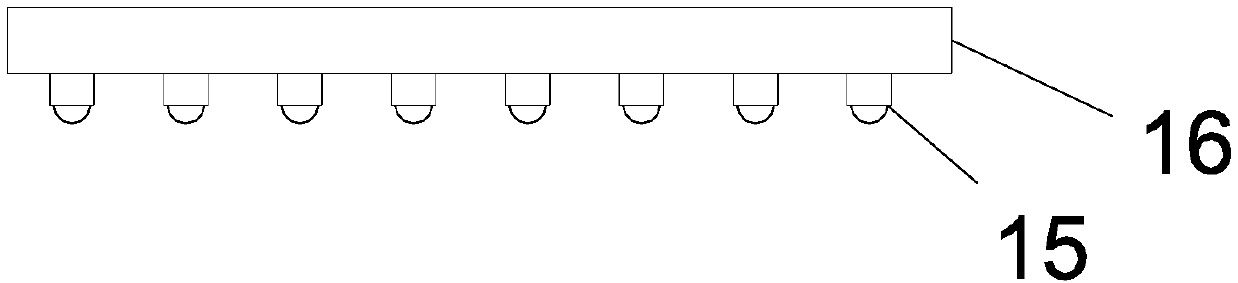

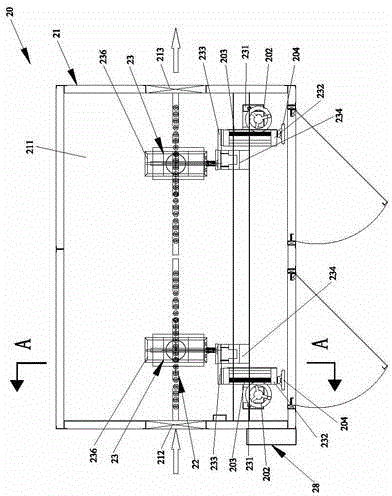

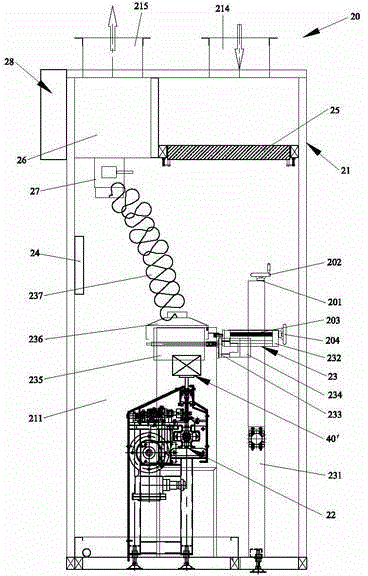

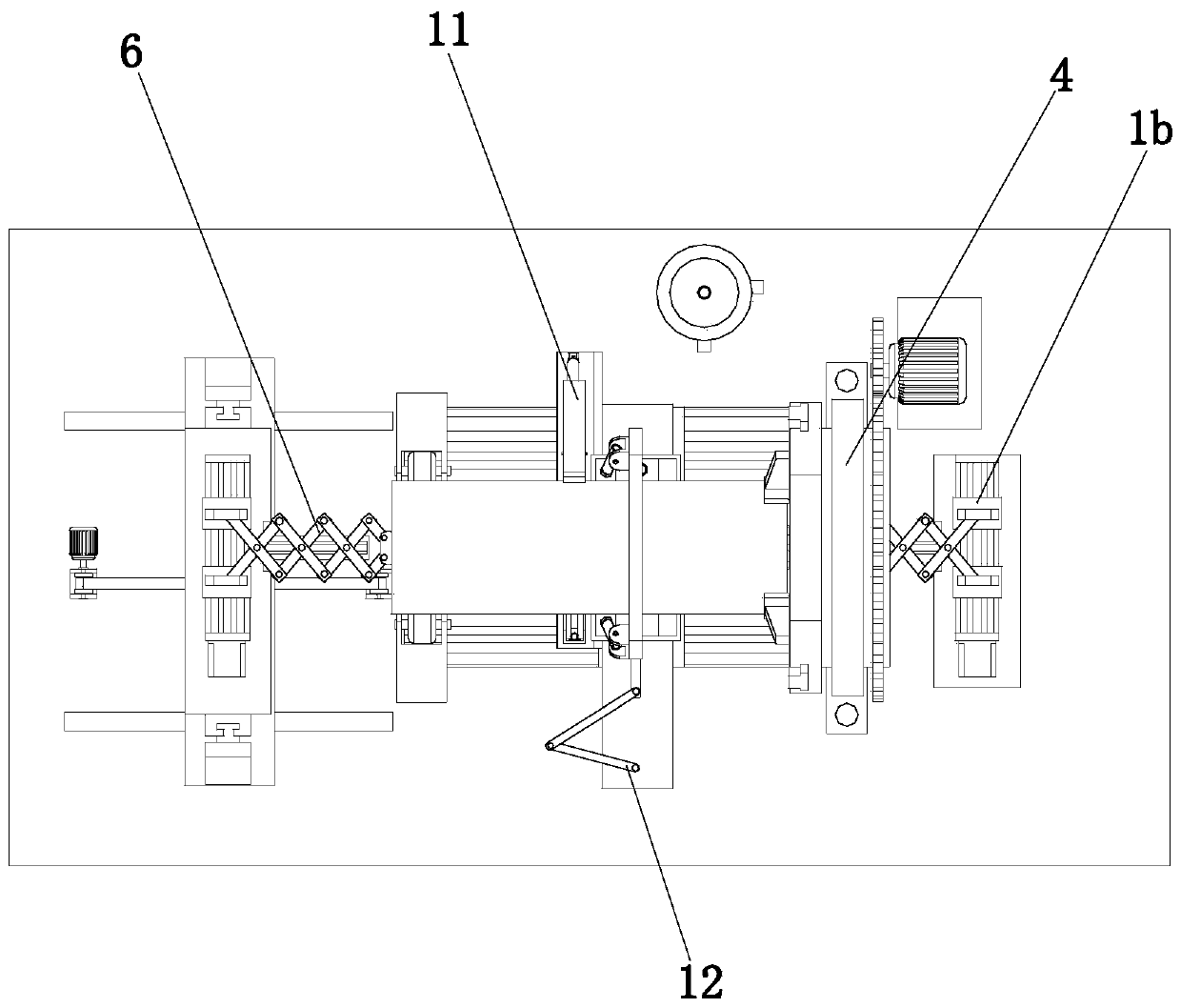

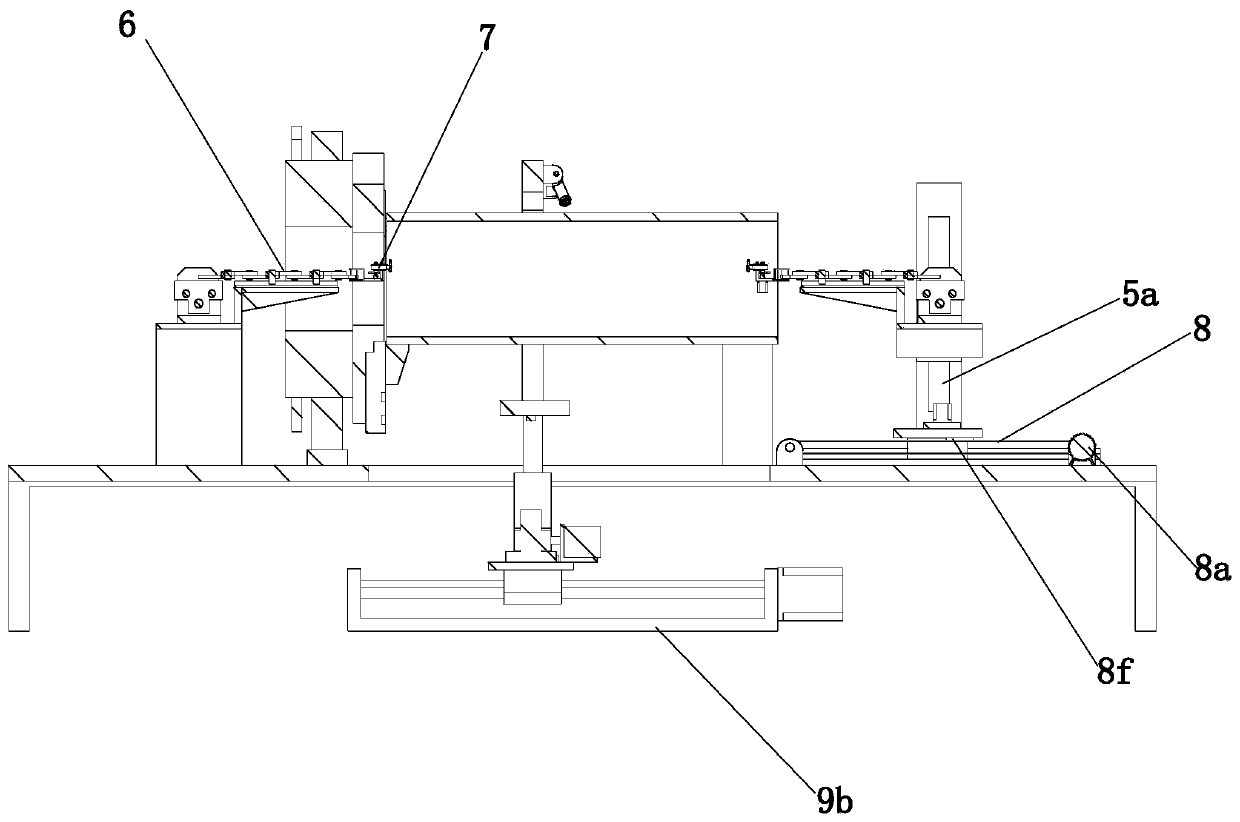

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

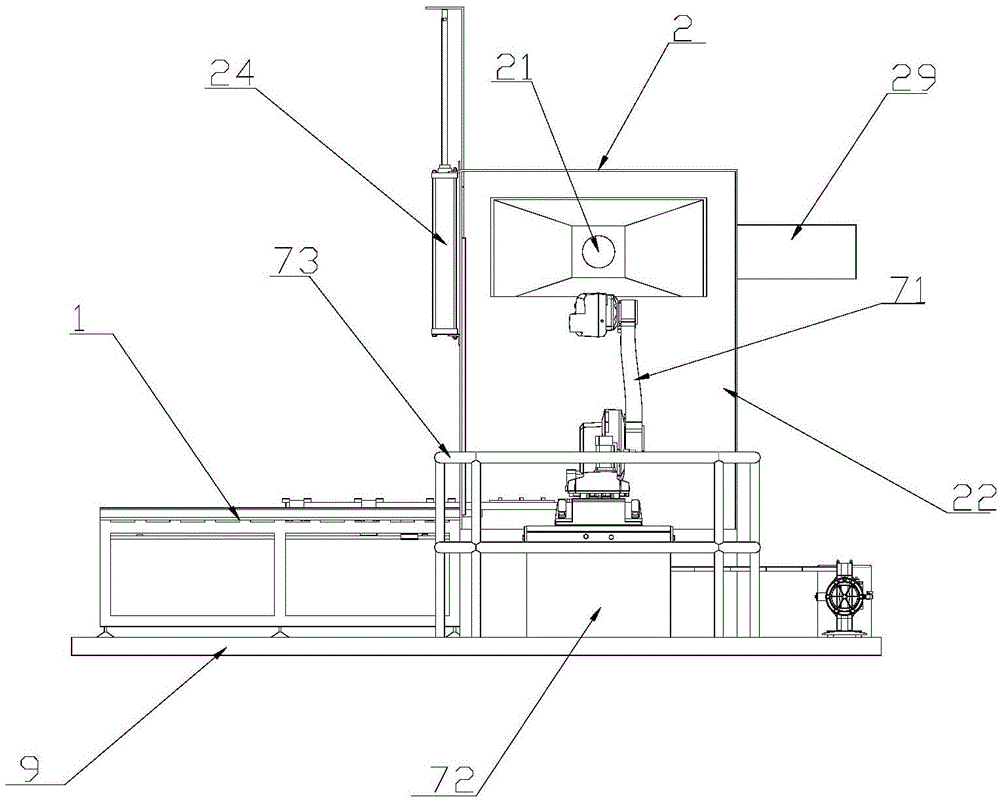

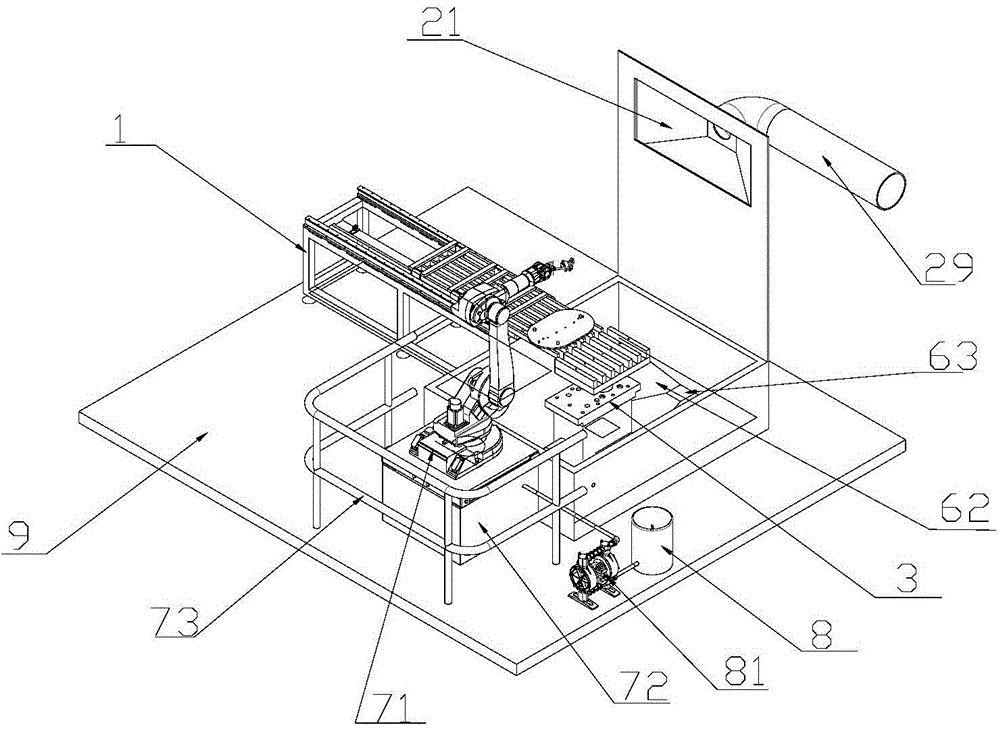

Automatic single-station glaze spraying device and method

ActiveCN104959255AImprove working environmentEasy to collect and centralizeLiquid surface applicatorsCoatingsSingle stationAutomatic testing

The invention discloses an automatic single-station glaze spraying device. The automatic single-station glaze spraying device comprises a spraying room, a feeding mechanism, a working rotary table and a robot body. The spraying room is a semi-closed space with the front end face provided with an opening. The feeding mechanism is arranged outside the spraying room. The working rotary table is installed inside the spraying room and matched with the end, stretching into the spraying room, of the feeding mechanism so that an object on which glaze spraying needs to be carried out can be taken down from the feeding mechanism. The robot body is arranged at the opening, a spray gun of the robot body stretches into the spraying room so that the glaze spraying operation can be carried out on the object on which glaze spraying needs to be carried out on the working rotary table. The invention further discloses an automatic single-station glaze spraying method. Glaze aerial fog produced in the spraying room is exhausted out of a workshop through a ventilation channel through the structure of the semi-closed spraying room and a suction opening and processed, and the operating environment of the workshop is improved.

Owner:广东金马领科智能科技有限公司

Automatic vehicle brake plate painting equipment

ActiveCN109332067AAchieve the effect of automatic painting processingEvenly paintedSpray boothsAssembly lineEngineering

The invention discloses automatic vehicle brake plate painting equipment. A rotating painting assembly is located above a working platform. A bearing jig is arranged at the top of the working platformby a rail moving mechanism. The rail moving mechanism comprises a telescopic rod rotating on the horizontal surface and a limiting frame used for the bearing jig to move in an attaching mode. A lifting assembly is located below the bearing jig. The rotating painting assembly is located right above a lifting receding opening. A filling assembly is provided with an iron workpiece disc. A feeding assembly is located outside a workpiece feeding opening and is horizontally arranged. The filling mechanism and the feeding mechanism are symmetrically arranged on two sides of the working platform. A loading assembly is provided with a material conveying arm used for moving brake plates. During operation, the brake plates are positioned at an assembly line, the brake plates are automatically conveyed to the jig of the equipment by the material conveying arm arranged beside the assembly line, the rotating painting assembly and the lifting assembly are arranged at the equipment, and therefore theuniform painting effect can be achieved during painting. The feeding assembly is arranged, and therefore the automatic painting effect is achieved, and production efficiency is improved.

Owner:山东高新创达科技创业服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com