Patents

Literature

333 results about "Gap width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gap Width is a jargony name that simply refers to the size of the spacing or gap in between the columns. Excel’s default setting is typically around 150%. Reduce the Gap Width from 150% to 30 to 50% for regular bar charts and from 150% to 5 to 15% for histograms.

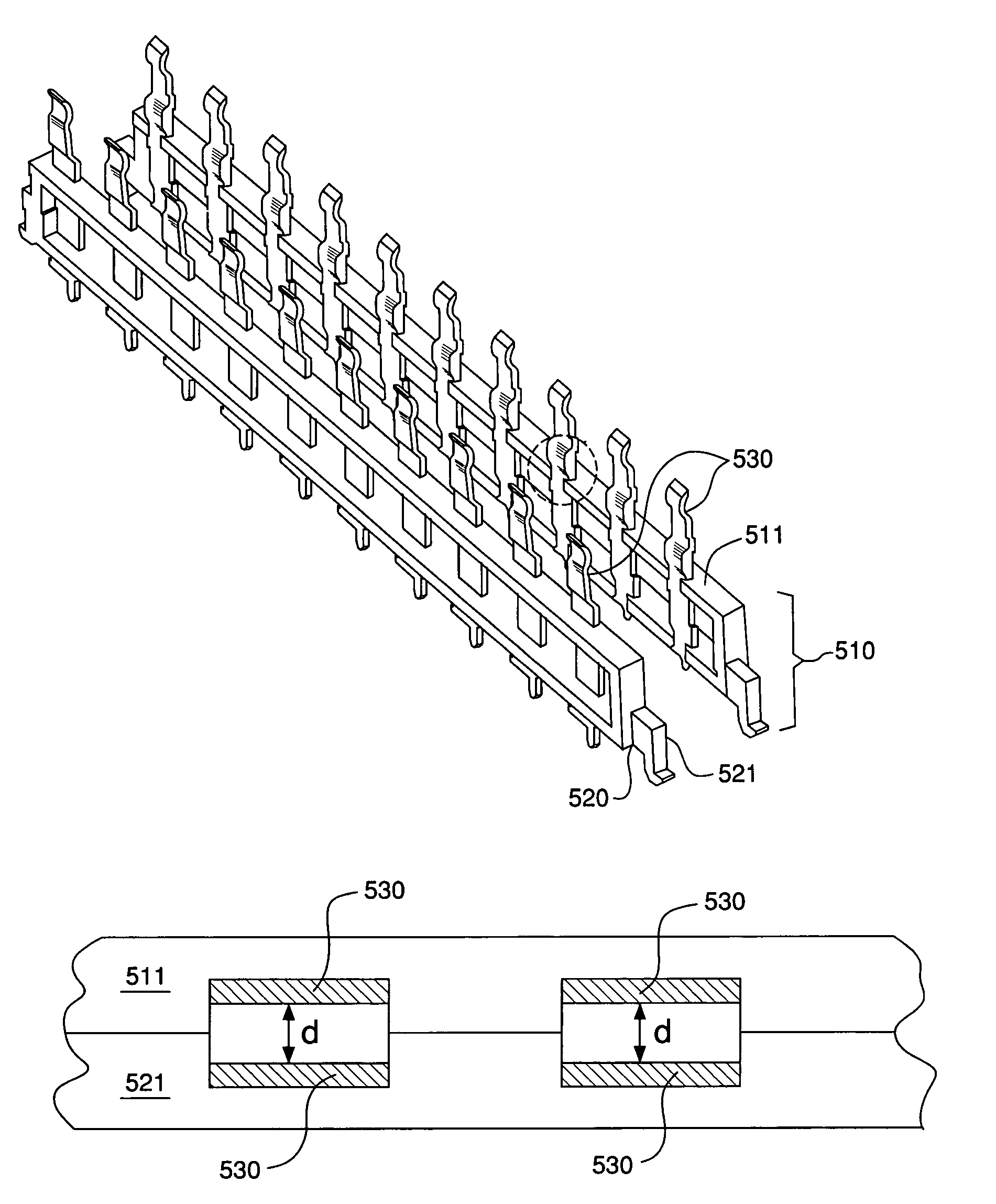

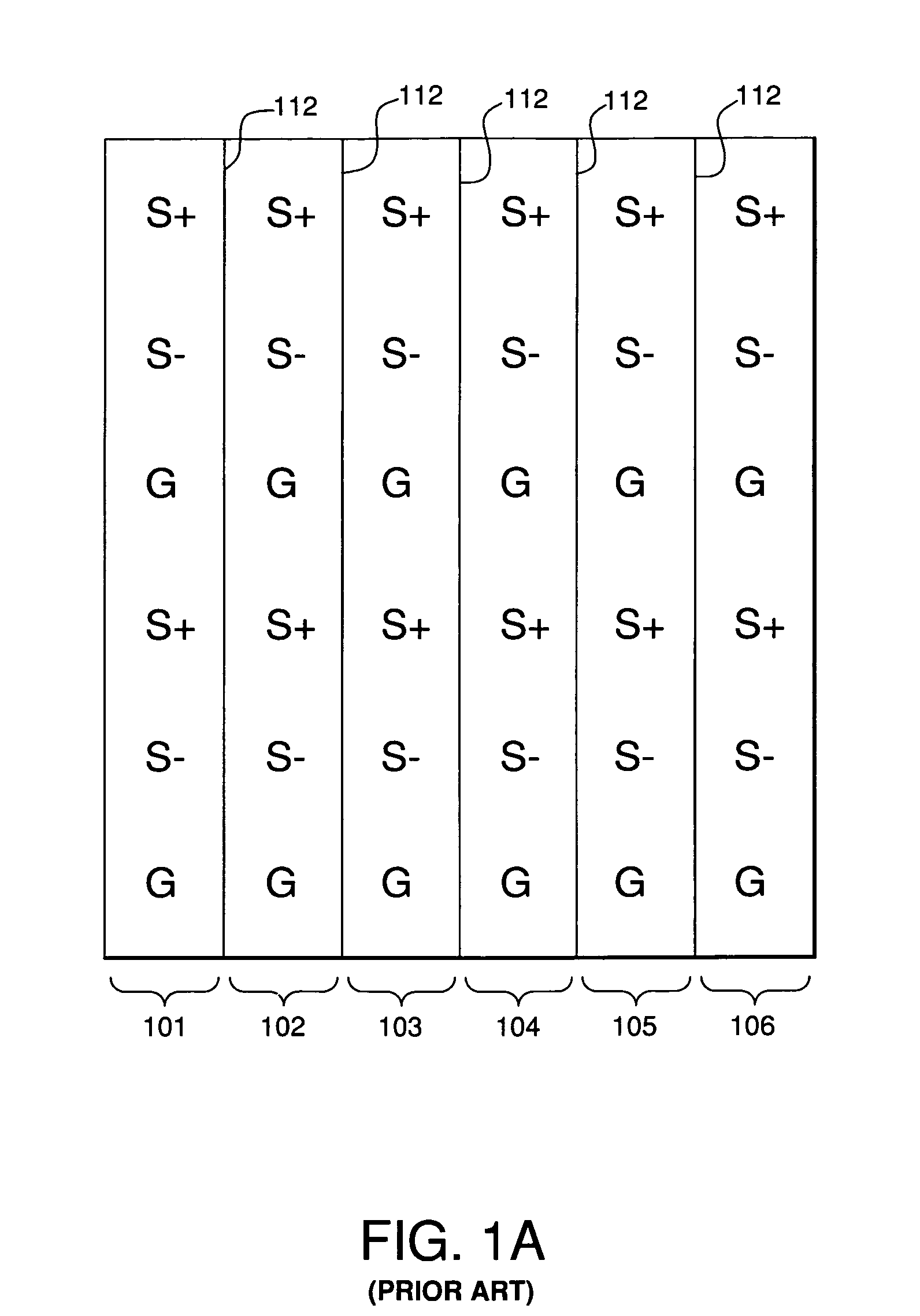

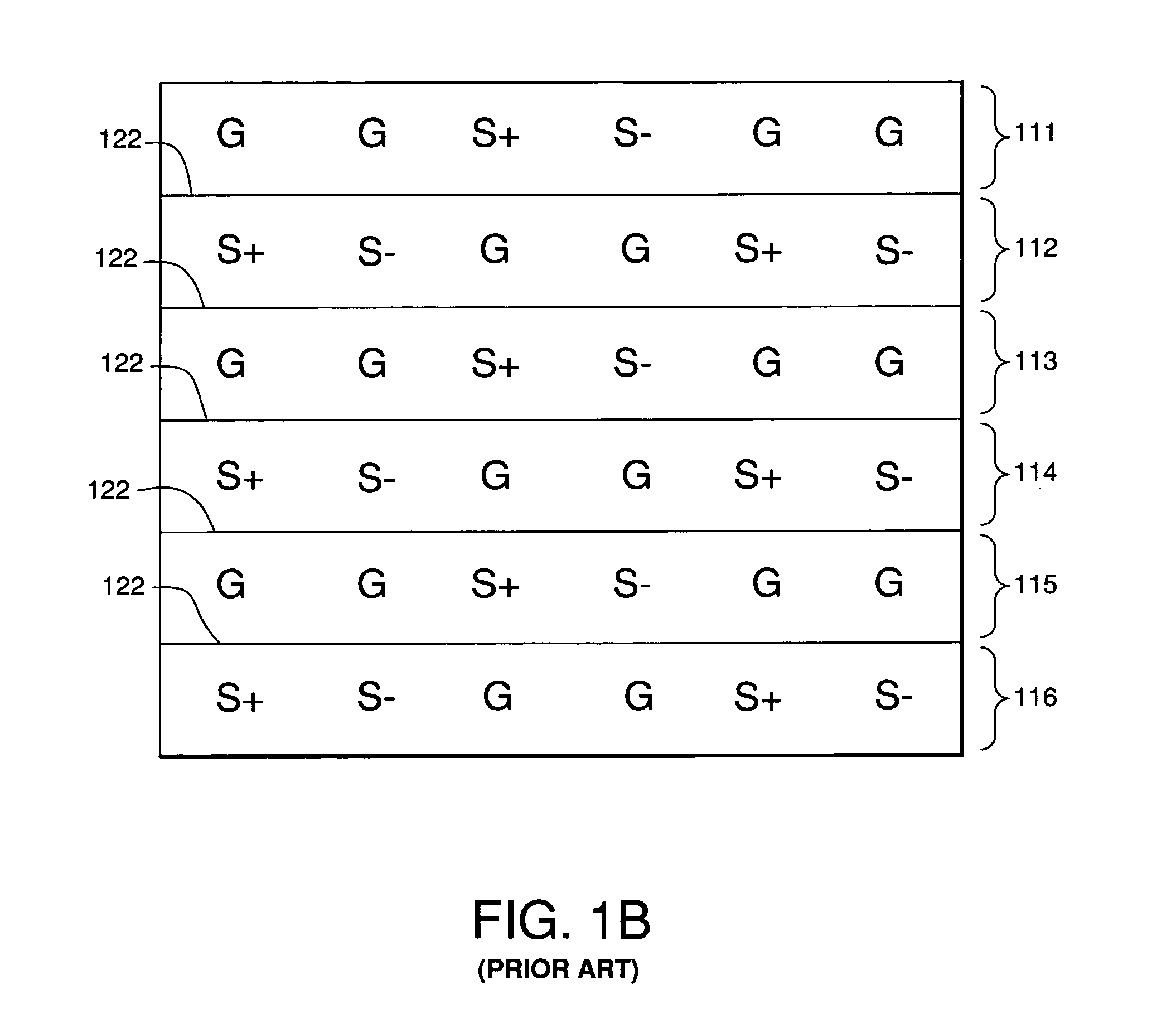

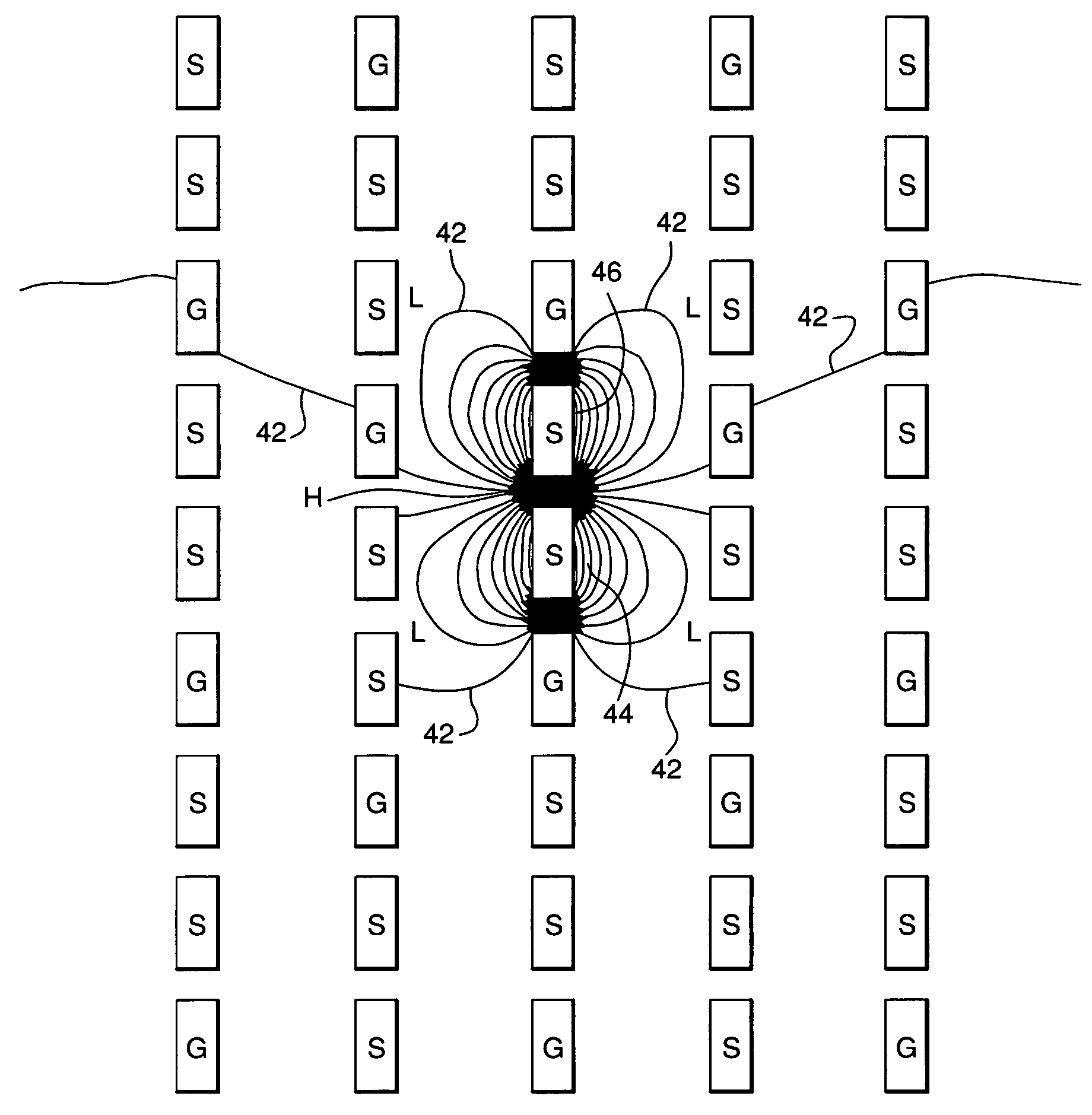

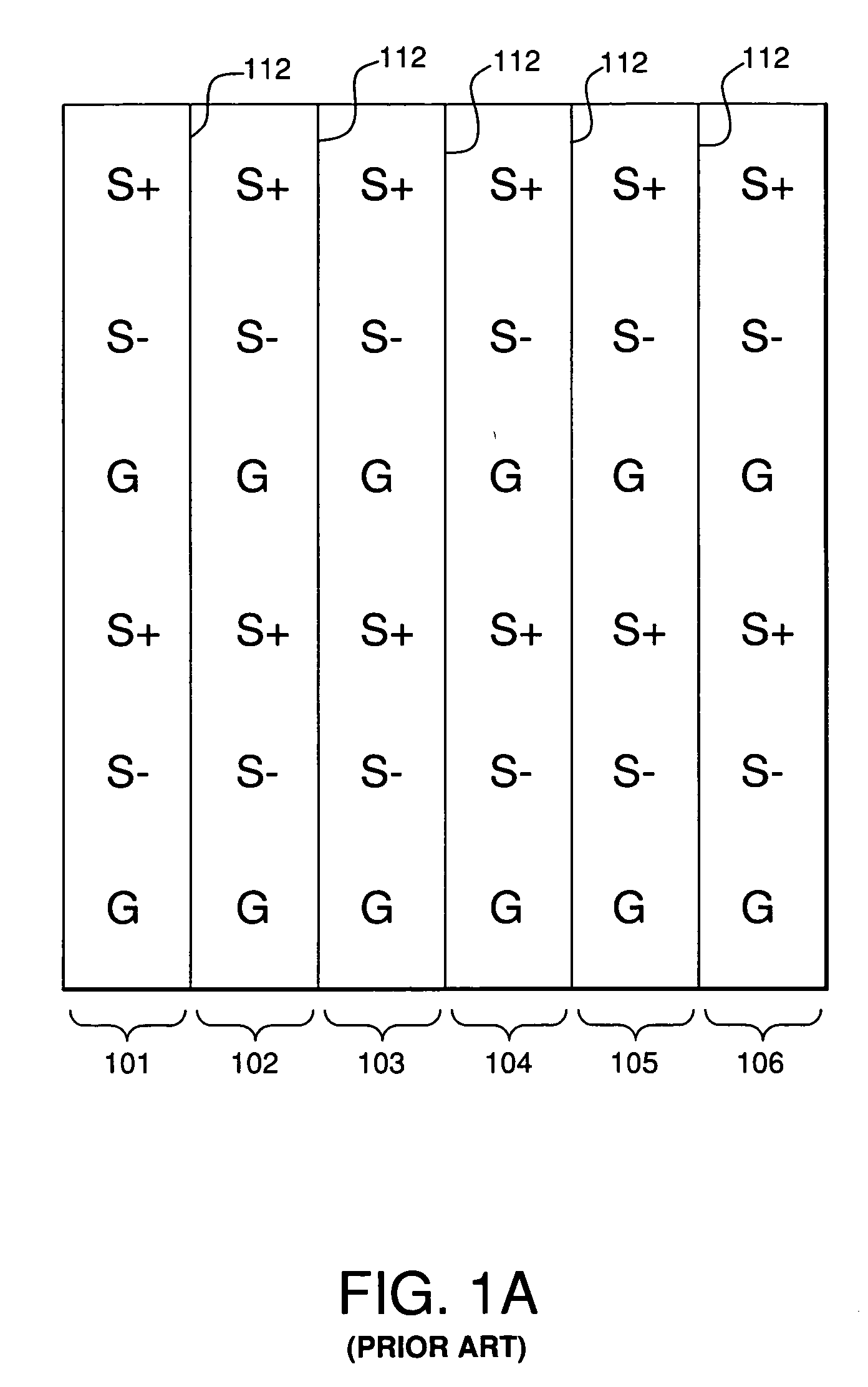

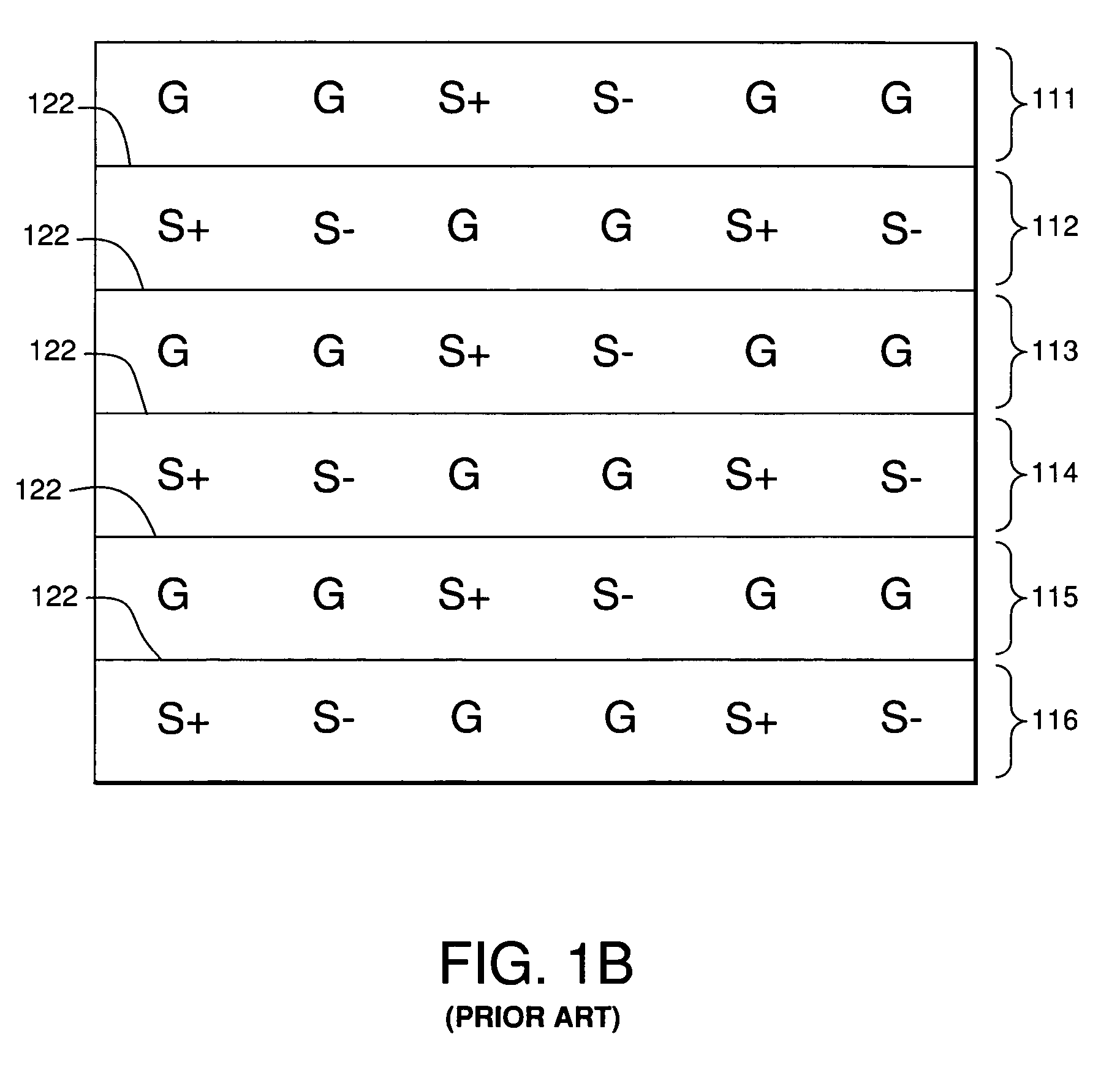

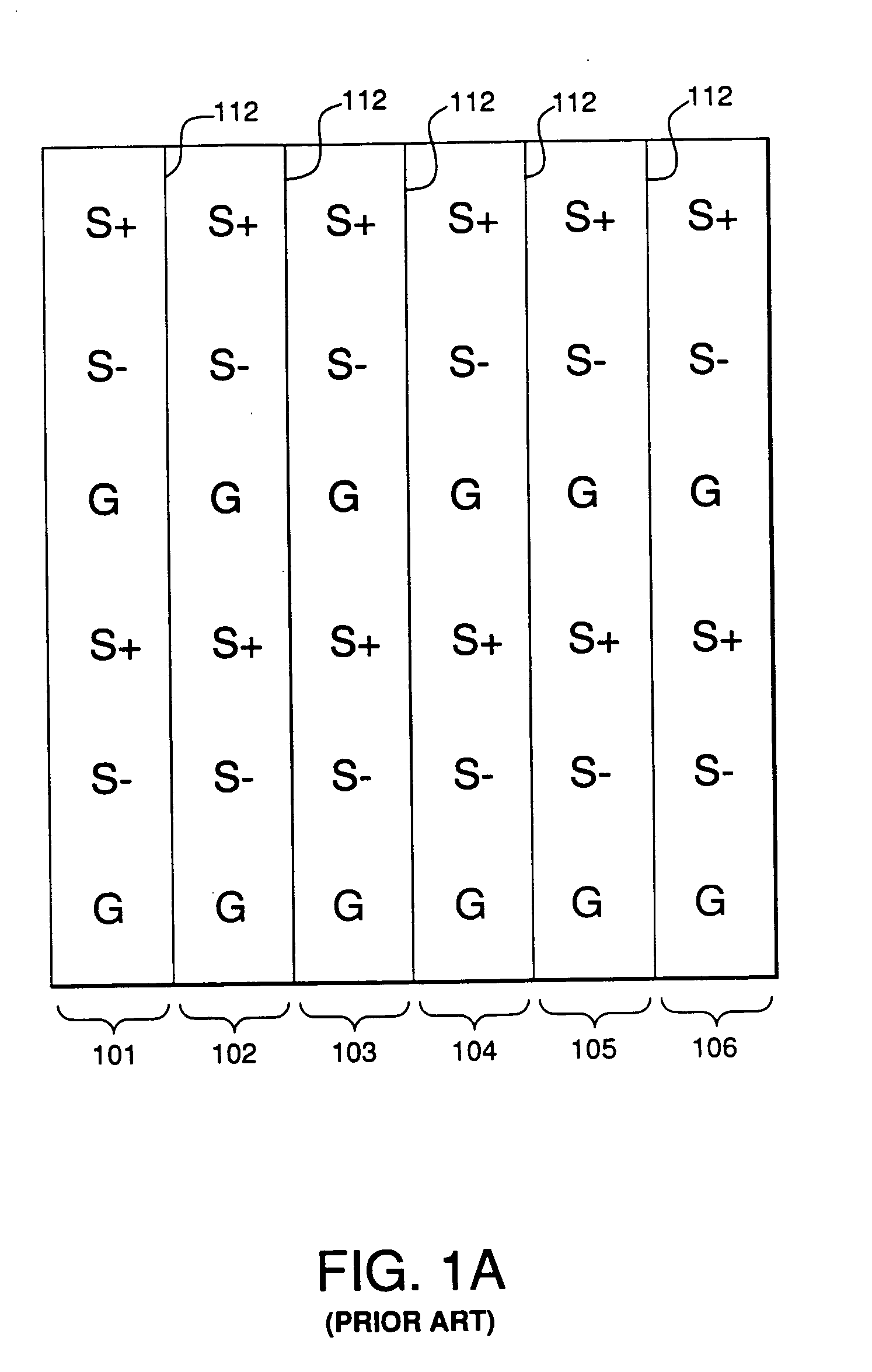

Impedance control in electrical connectors

InactiveUS6981883B2Coupling contact membersTwo-part coupling devicesDifferential signalingElectrical connector

The invention provides a high speed connector wherein differential signal pairs are arranged so as to limit the level of cross talk between adjacent differential signal pairs. The connector comprises lead frame assembly having a pair of overmolded lead frame housings. Each lead frame housing has a respective signal contact extending therethrough. The lead frame housings may be operatively coupled such that the signal contacts form a broadside-coupled differential signal pair. The contacts may be separated by a gap having a gap width that enables insertion loss and cross talk between signal pairs to be limited.

Owner:FCI AMERICAS TECH LLC

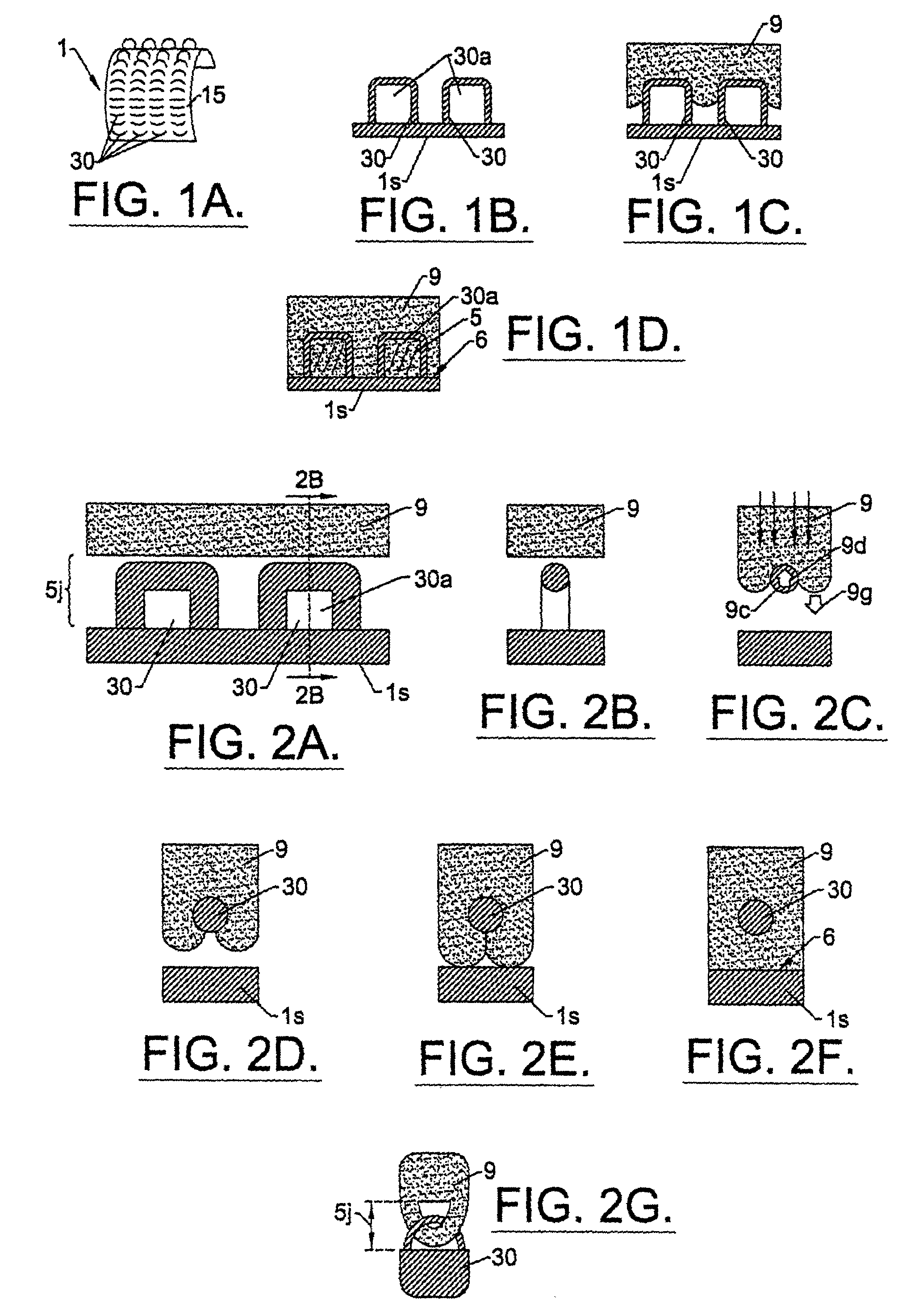

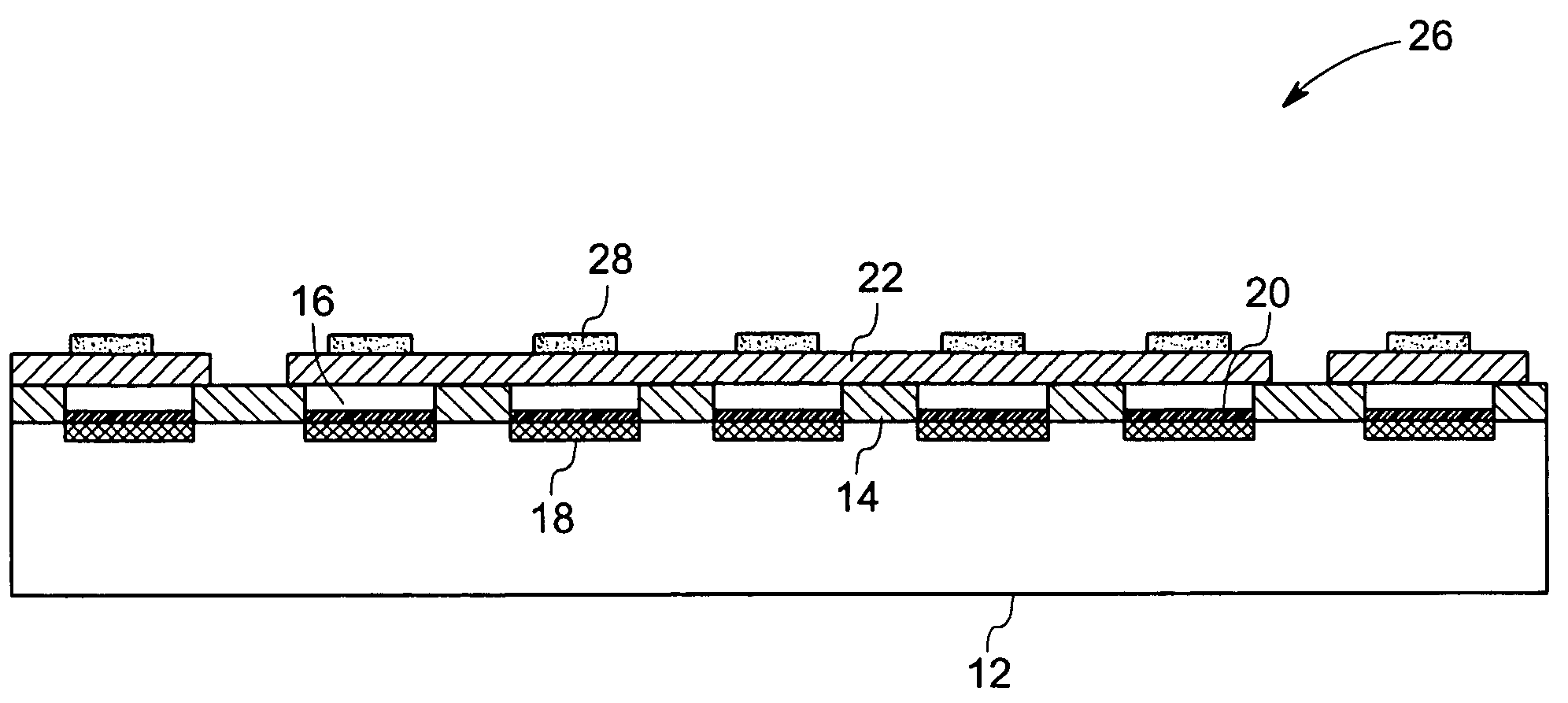

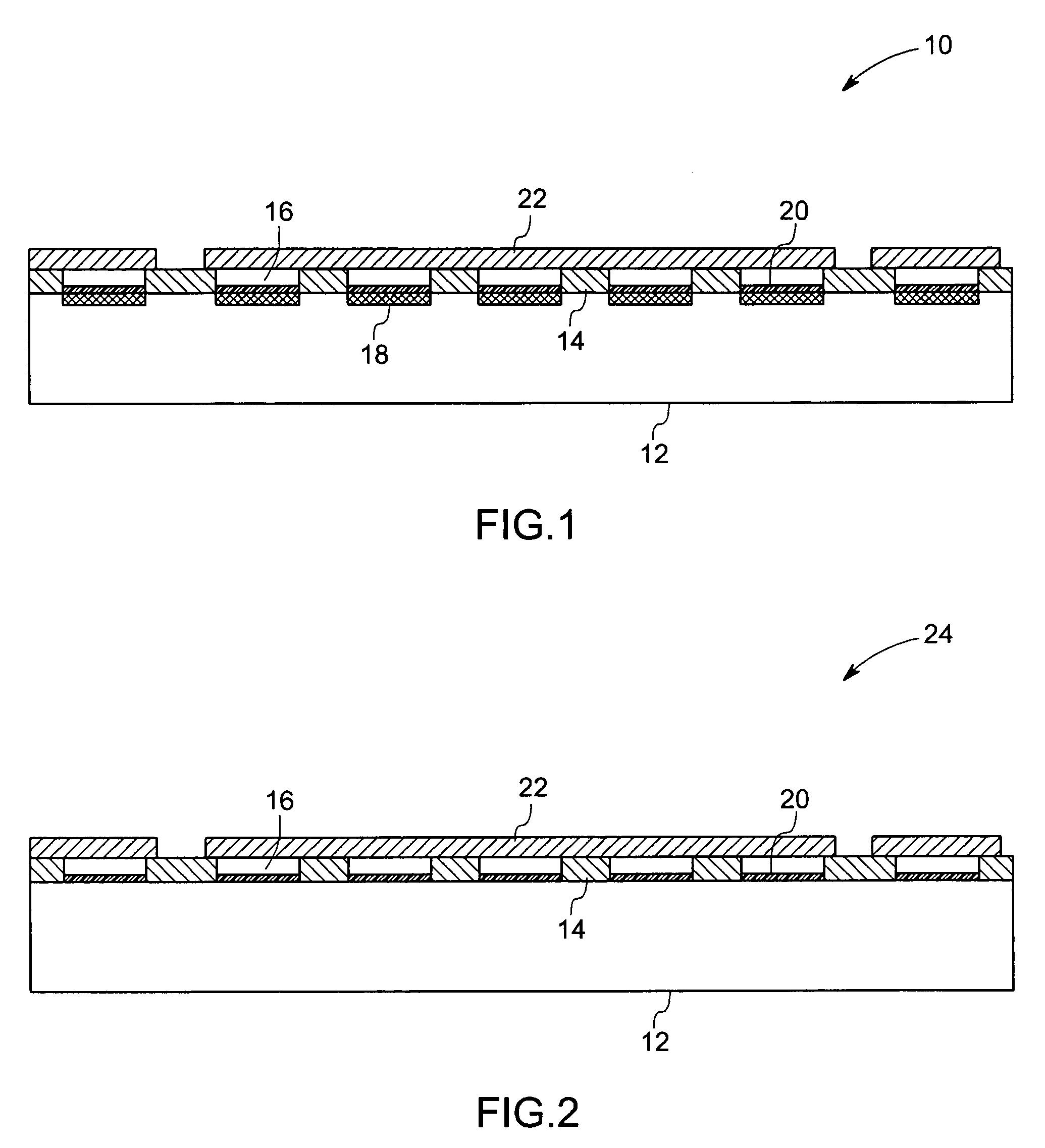

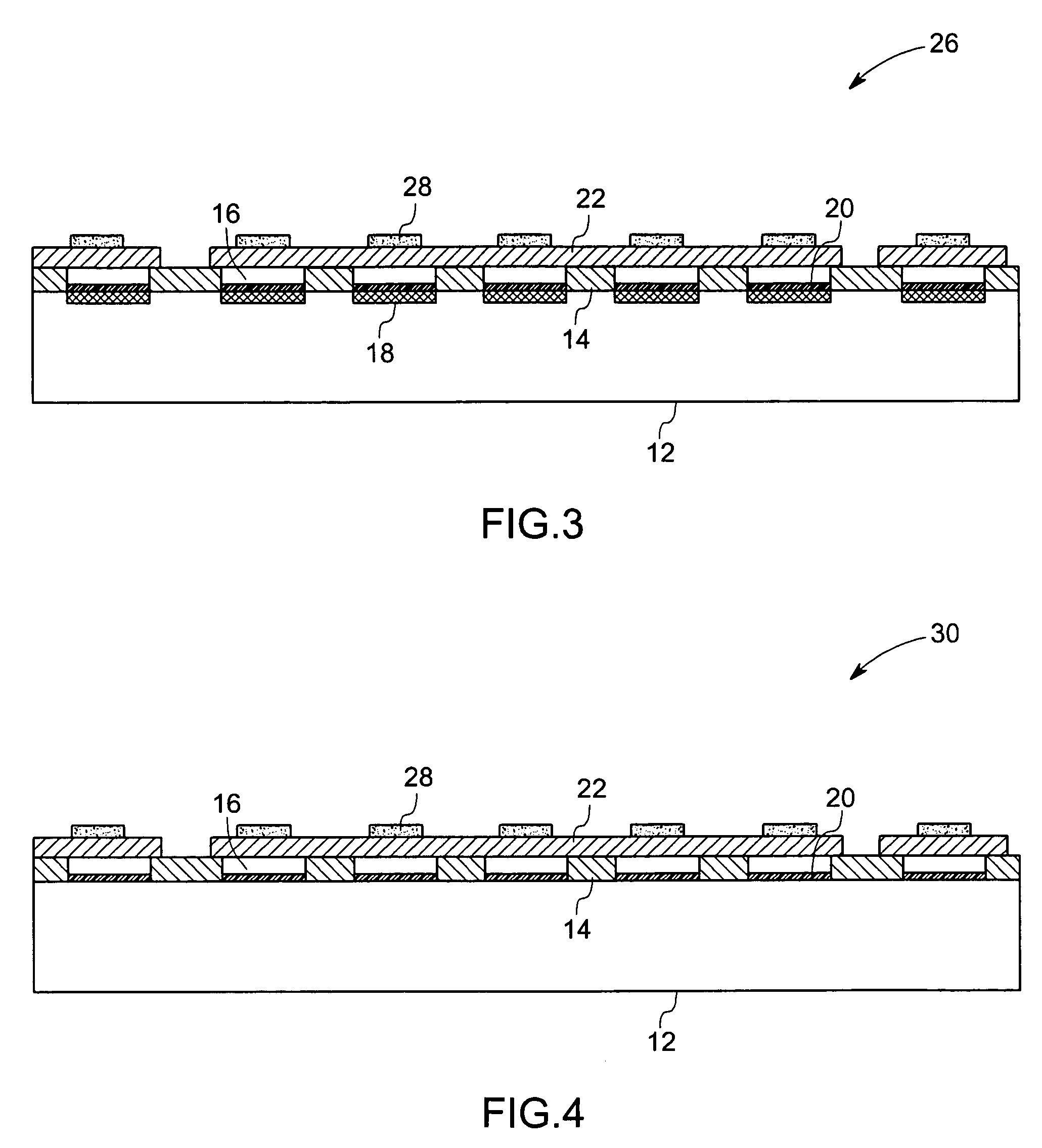

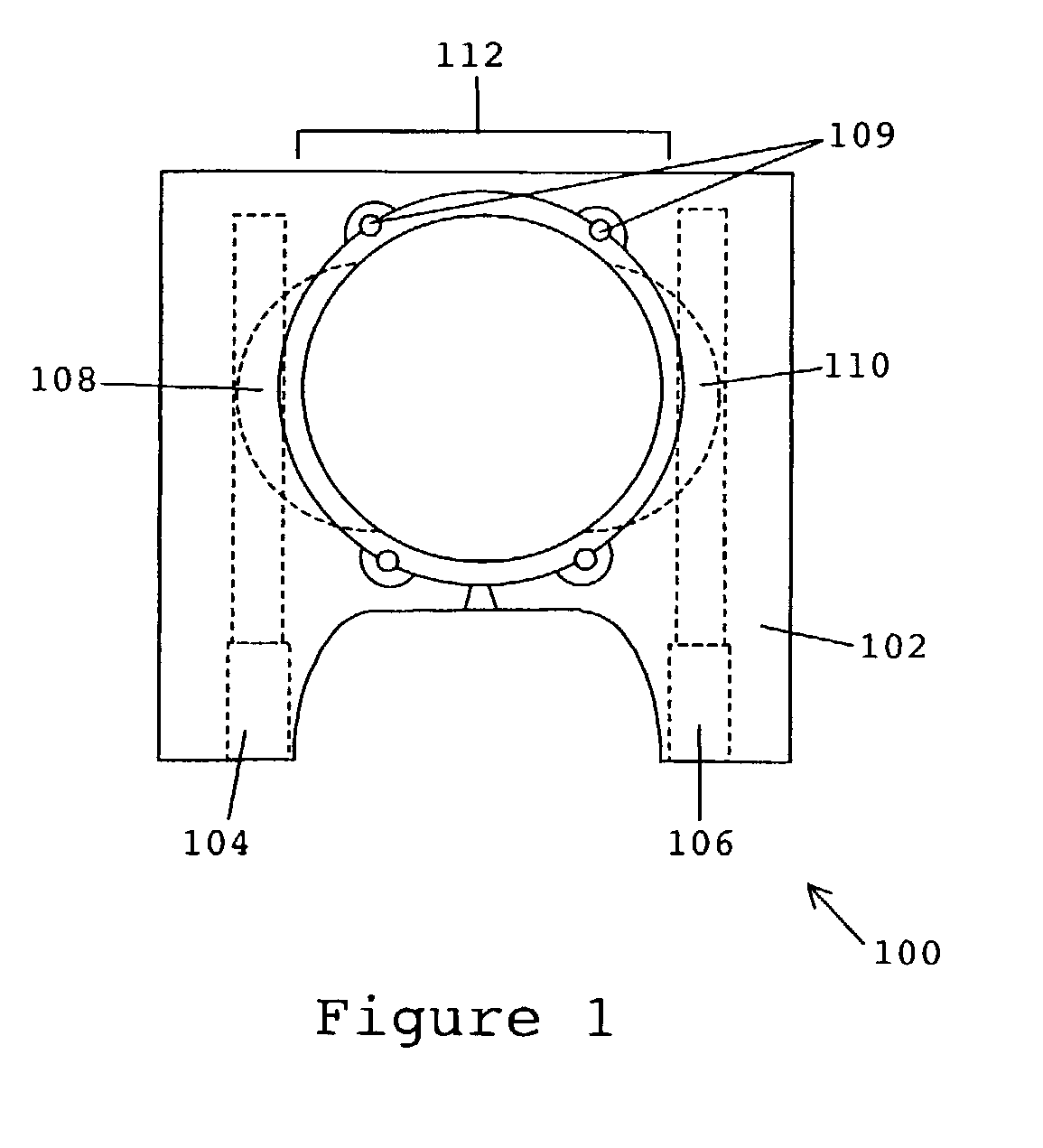

Tissue lockable connecting structures

InactiveUS7083648B2Strengthen the mechanical connectionInhibits tissueDental implantsSkin implantsSoft tissue infectionSubcutaneous tissue

Percutaneous skin access devices include a plurality of locked connecting units mounted to the exterior surface of an implantable medical object which, in position, is configured to penetrate the skin of a subject. The locked connecting units may be mounted directly onto the desired surface of the exterior of the device or may be held on a substrate sheet, which is mounted to the exterior surface of the device. In position, the locked connecting units engage with soft tissue which can include the skin to form a bio-junction layer which includes mechanical and bio-sealing connection between the device body and the soft tissue. The configuration at the bio-junction layer secures the medical object in location in the subject even for long-term indwelling applications in a manner, which inhibits soft tissue infection.The locked connecting units may be rigid or semi-rigid for longer-term indwelling applications, and semi-rigid and / or resilient for shorter term indwelling applications. The locked connecting units may take on the form of rings, hooks, or loops having aperture or gap width / length sizes of from about 0.2–4 mm. The rings, loops, or hooks may connect with any soft tissue including skin as well subcutaneous tissue. The rings, hooks, or loops may be released from the skin / tissue without requiring surgical cutting procedures.The locked connecting units may be configured as a semi-rigid mesh collar arranged about the primary body providing access to the subject such that it resides in the subject and engages with the skin (epidermal / dermal layer). The mesh collar can be described as a particular type of ring or loop structure as the mesh defines the gap provided in individual loop configurations. The mesh collar may be used alone, or in combination with the loops, rings, or hooks. A skin stop collar having increased rigidity may be disposed under the mesh collar.

Owner:EAST CAROLINA UNIVERISTY

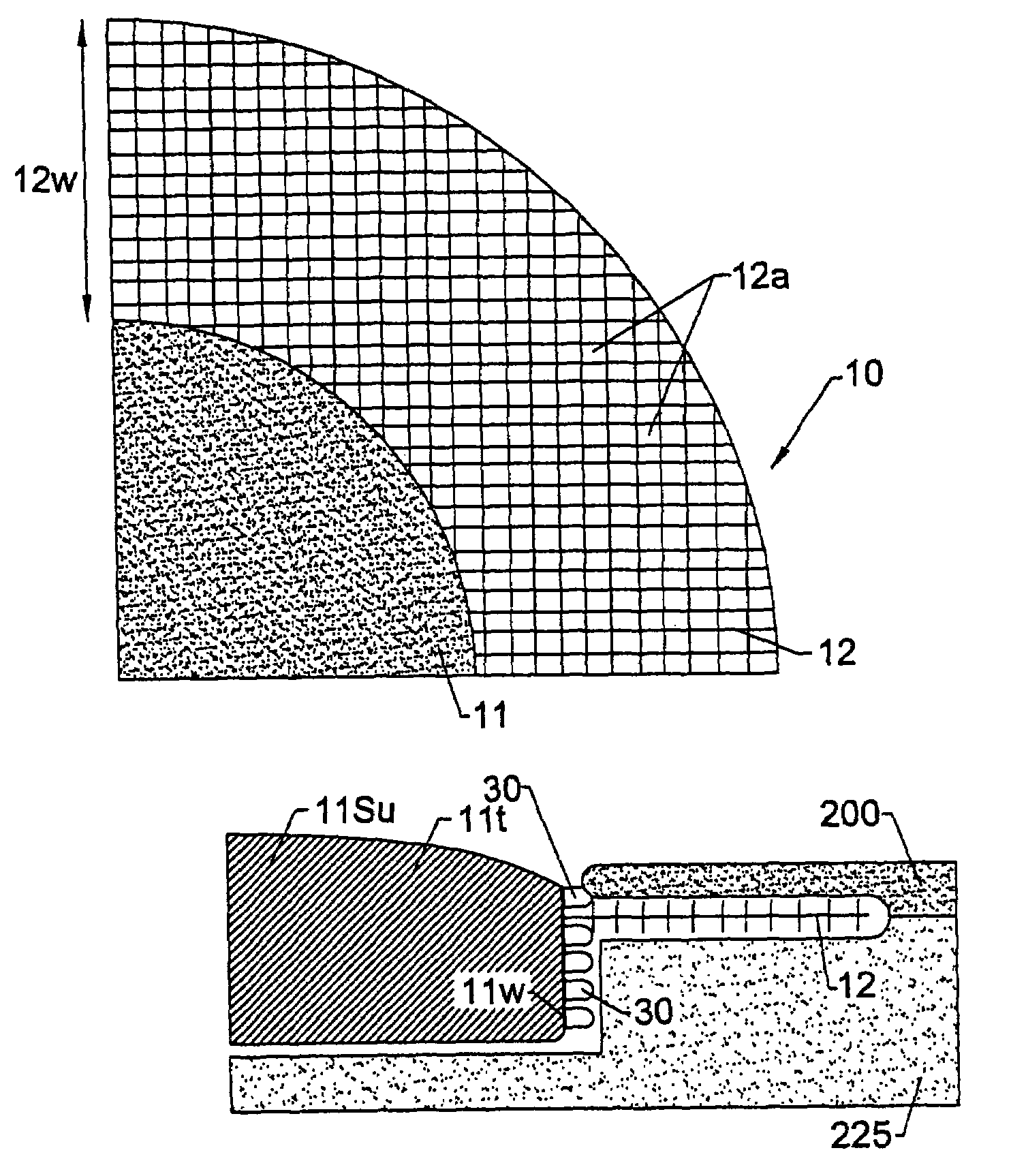

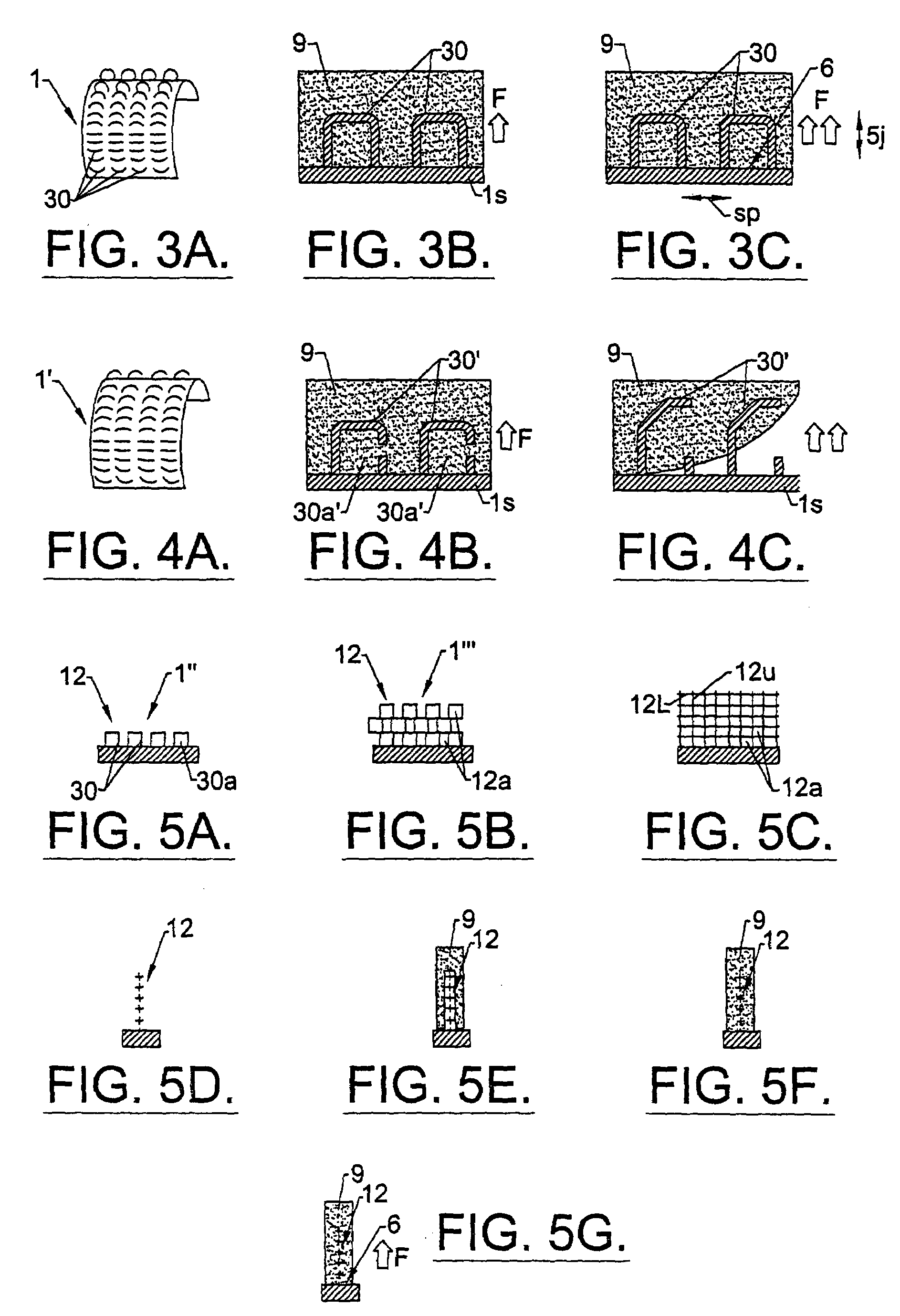

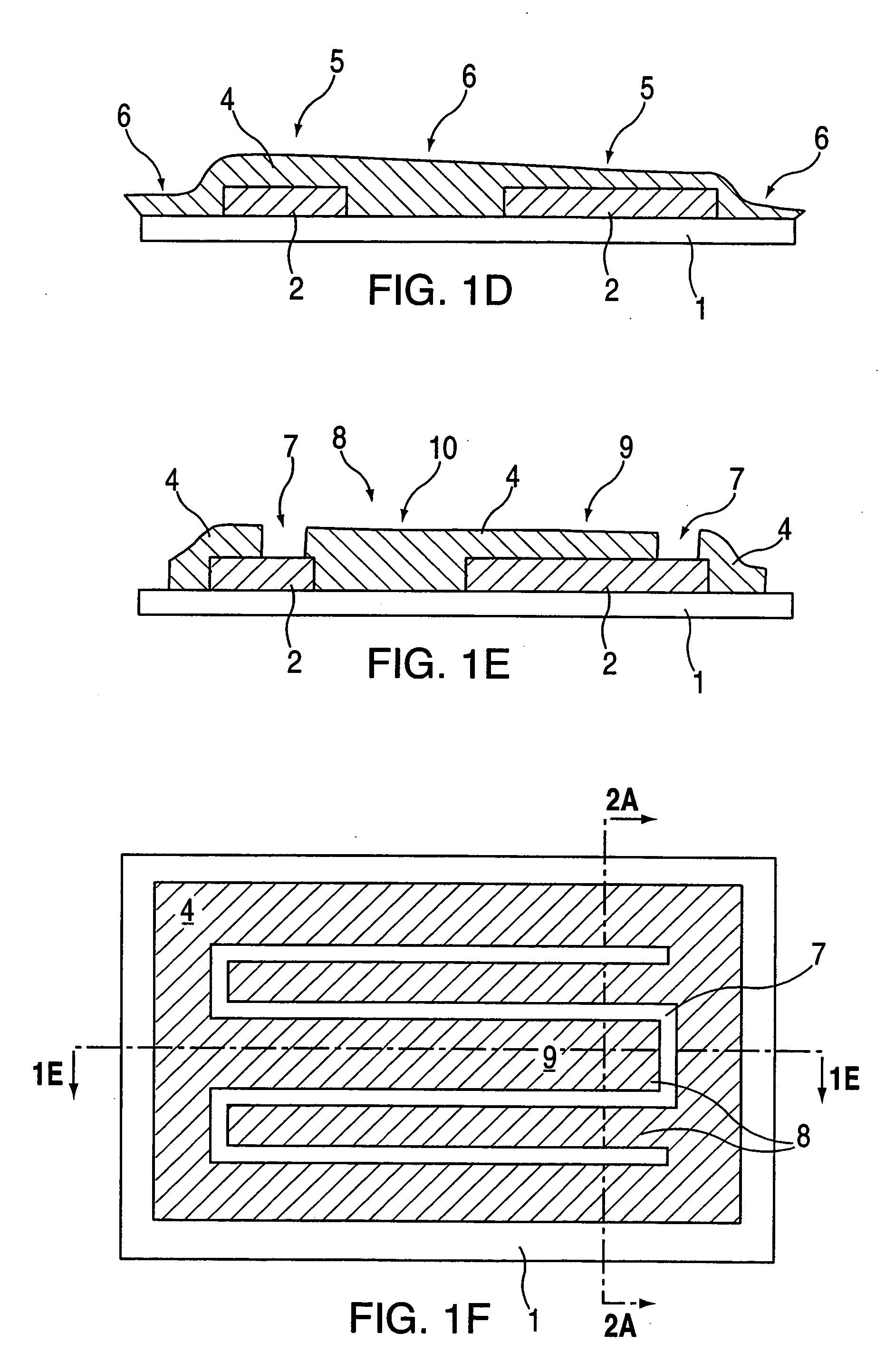

Gap tuning for surface micromachined structures in an epitaxial reactor

InactiveUS20050014374A1Increase chanceIncrease deposition rateDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringSilicon dioxide

A method for adjusting with high precision the width of gaps between micromachined structures or devices in an epitaxial reactor environment. Providing a partially formed micromechanical device, comprising a substrate layer, a sacrificial layer including silicon dioxide deposited or grown on the substrate and etched to create desired holes and / or trenches through to the substrate layer, and a function layer deposited on the sacrificial layer and the exposed portions of the substrate layer and then etched to define micromechanical structures or devices therein. The etching process exposes the sacrificial layer underlying the removed function layer material. Cleaning residues from the surface of the device, then epitaxially depositing a layer of gap narrowing material selectively on the surfaces of the device. The selection of deposition surfaces determined by choice of materials and the temperature and pressure of the epitaxy carrier gas. The gap narrowing epitaxial deposition continues until a desired gap width is achieved, as determined by, for example, an optical detection arrangement. Following the gap narrowing step, the micromachined structures or devices may be released from their respective underlying sacrificial layer.

Owner:ROBERT BOSCH GMBH

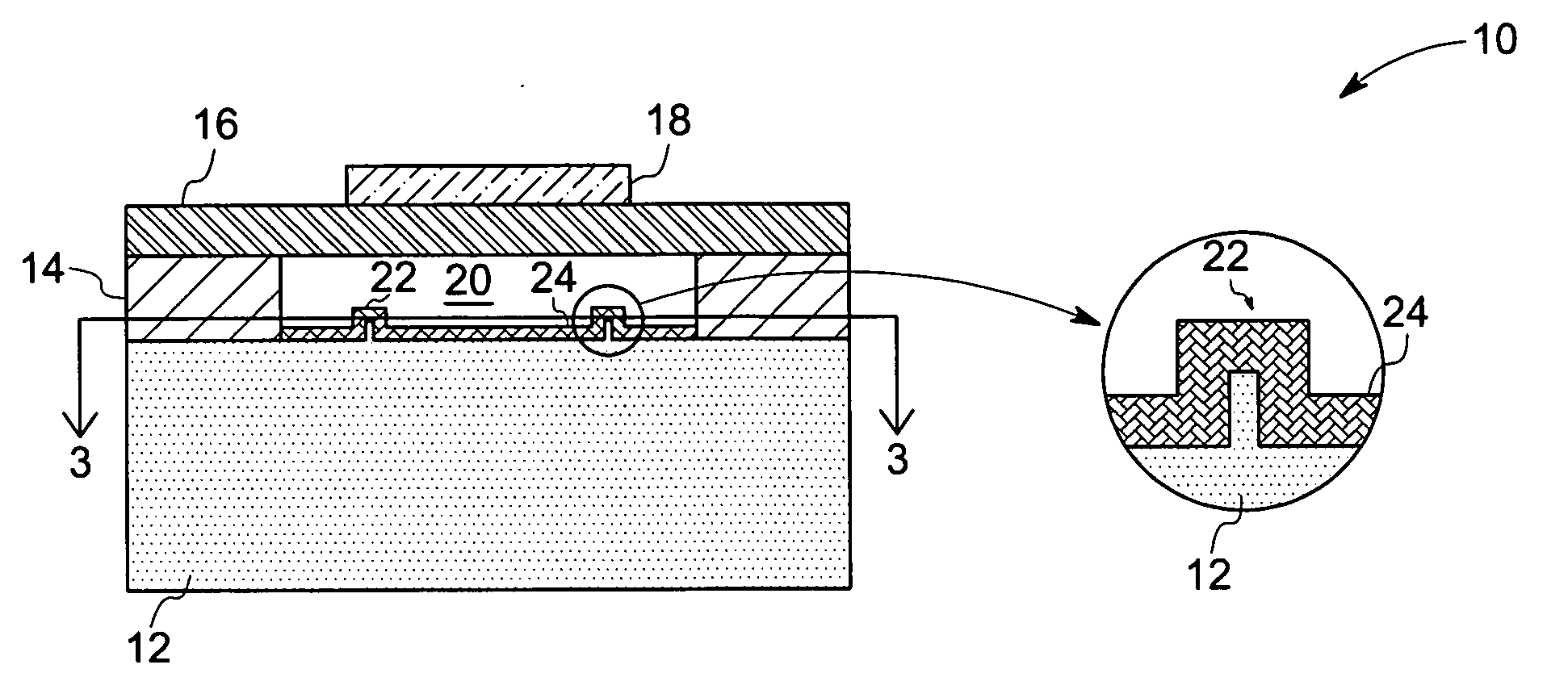

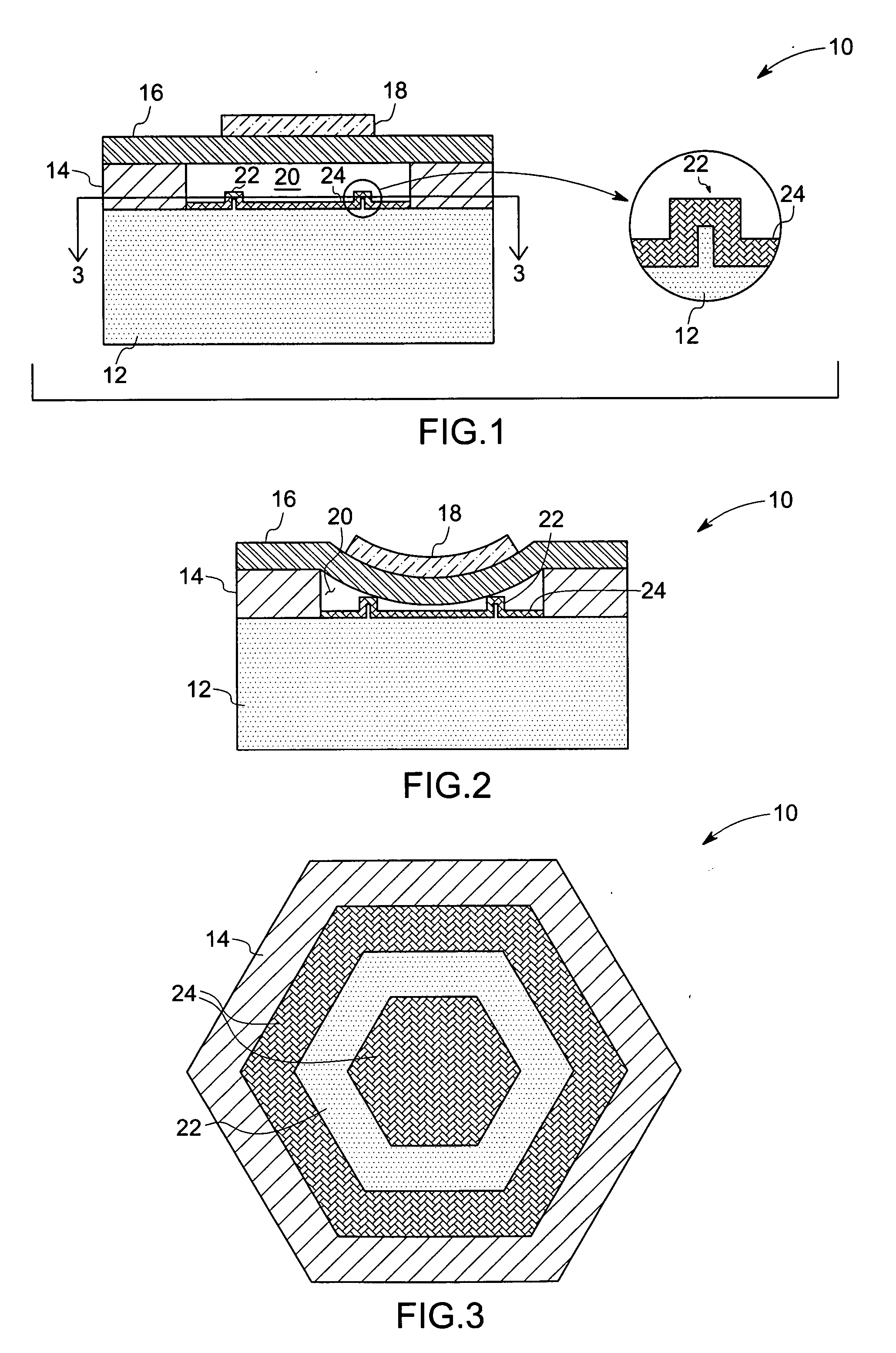

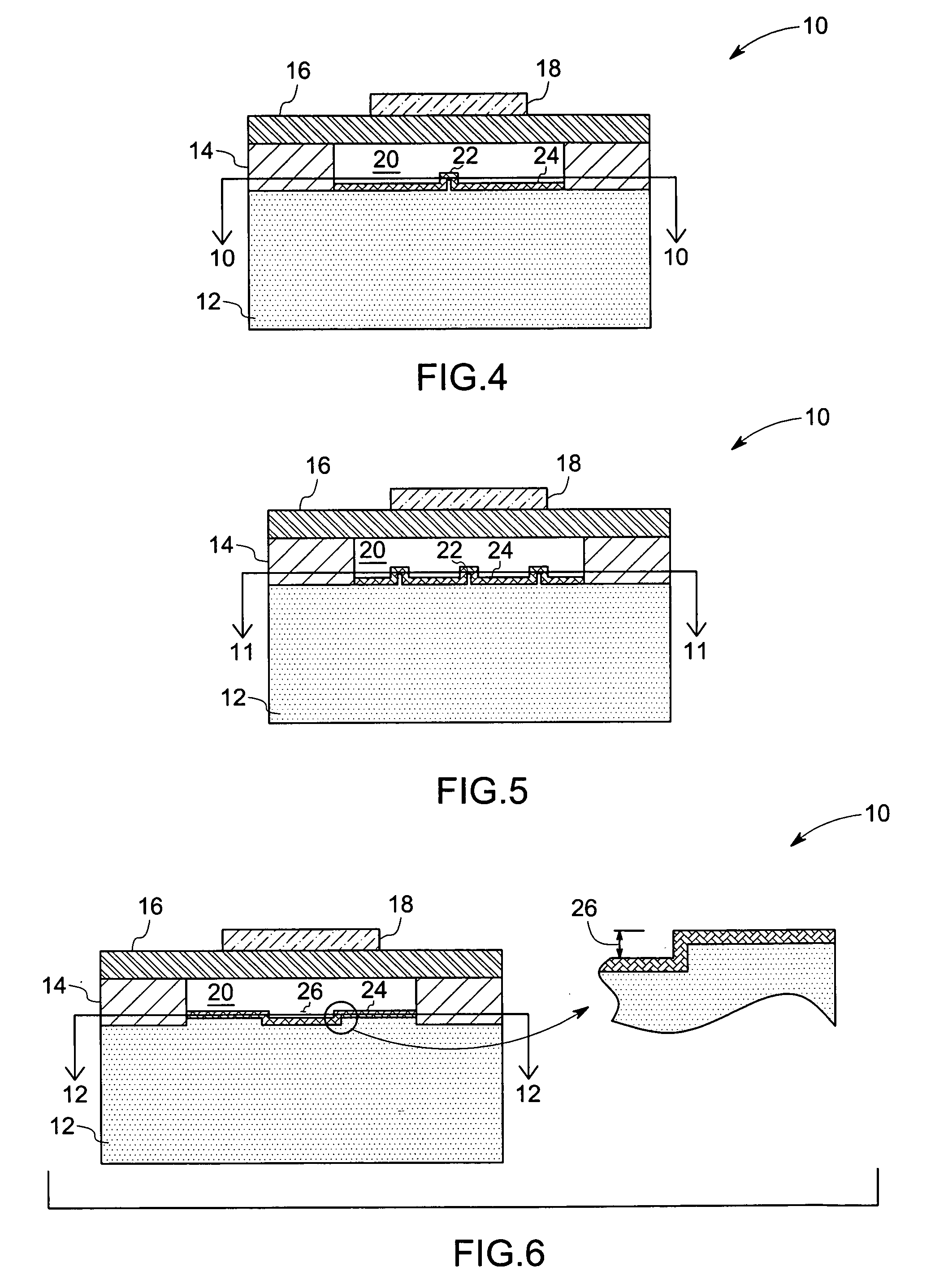

High sensitivity capacitive micromachined ultrasound transducer

InactiveUS20060004289A1Ultrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationCapacitanceUltrasonic sensor

A capacitive micromachined ultrasound transducer (cMUT) comprises a lower electrode. Furthermore, the cMUT includes a diaphragm disposed adjacent to the lower electrode such that a gap having a first gap width is formed between the diaphragm and the lower electrode. Additionally, the cMUT includes at least one element formed in the gap, where the at least one element is arranged to provide a second gap width between the diaphragm and the lower electrode.

Owner:GENERAL ELECTRIC CO

Capacitive micromachined ultrasound transducer fabricated with epitaxial silicon membrane

InactiveUS7037746B1Semiconductor/solid-state device manufacturingMechanical vibrations separationTransducerOptoelectronics

A capacitive micromachined ultrasound transducer (cMUT) cell is presented. The cMUT cell includes a lower electrode. Furthermore, the cMUT cell includes a diaphragm disposed adjacent to the lower electrode such that a gap having a first gap width is formed between the diaphragm and the lower electrode, wherein the diaphragm comprises one of a first epitaxial layer or a first polysilicon layer. In addition, a stress reducing material is disposed in the first epitaxial layer.

Owner:GENERAL ELECTRIC CO

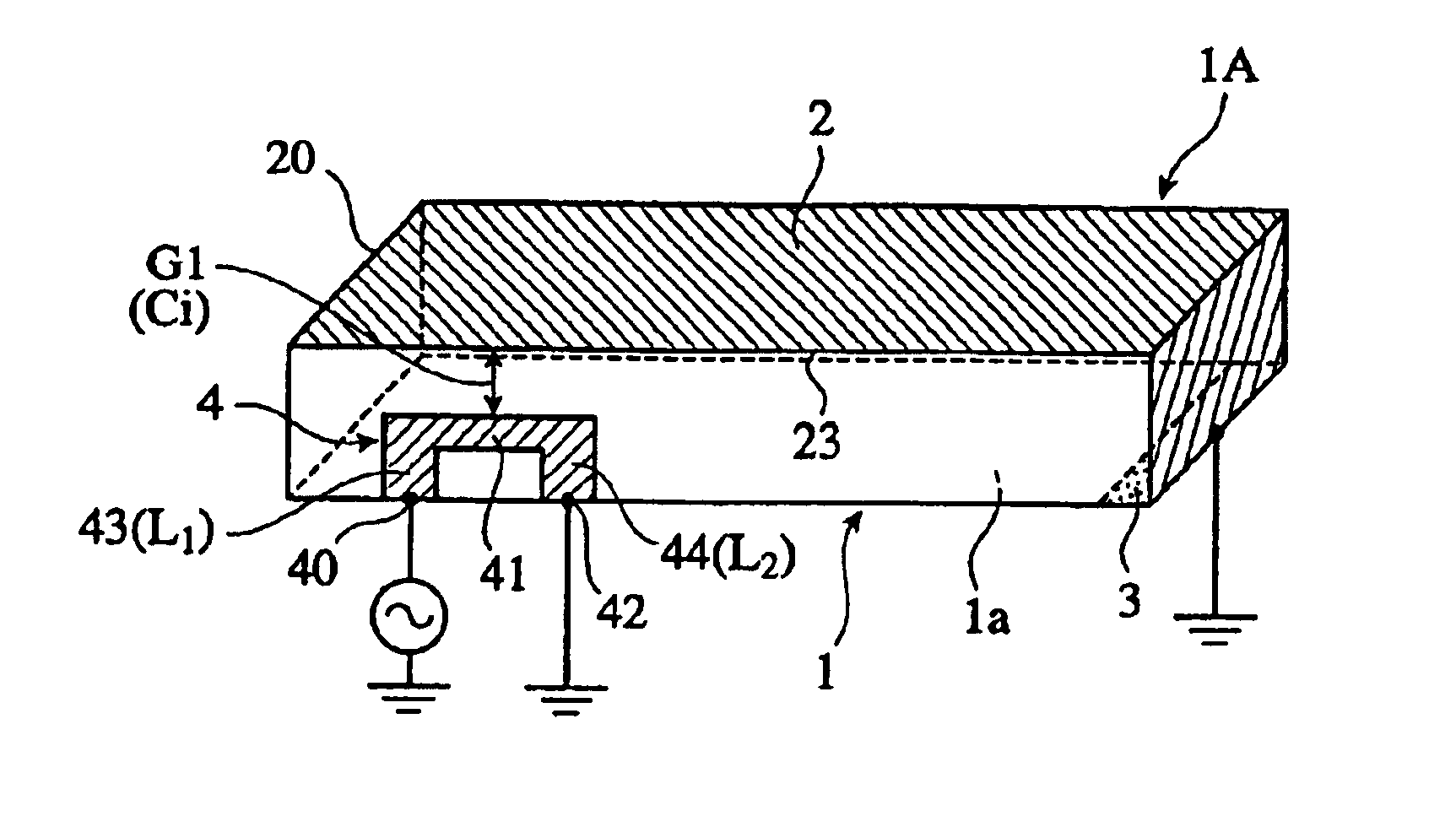

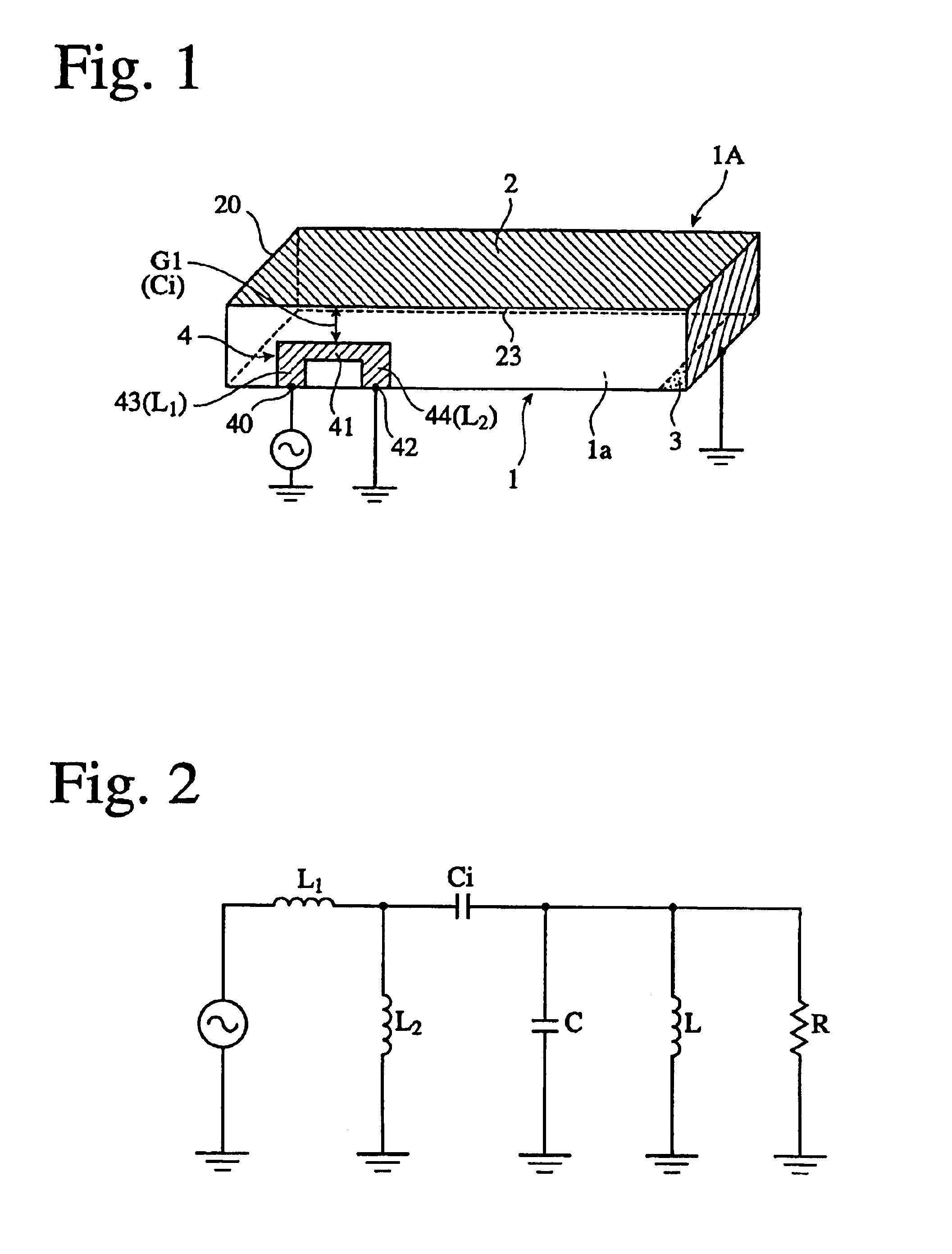

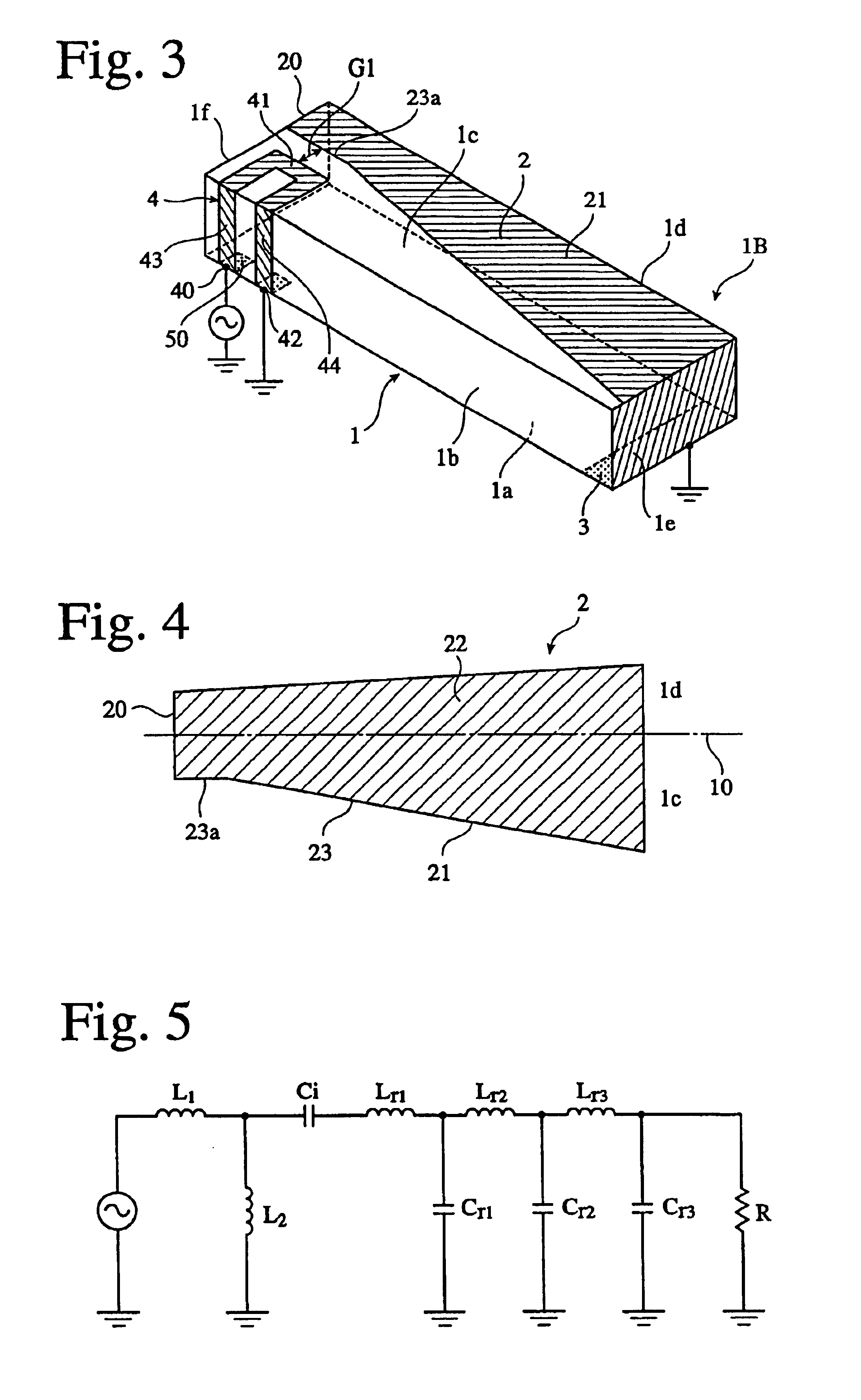

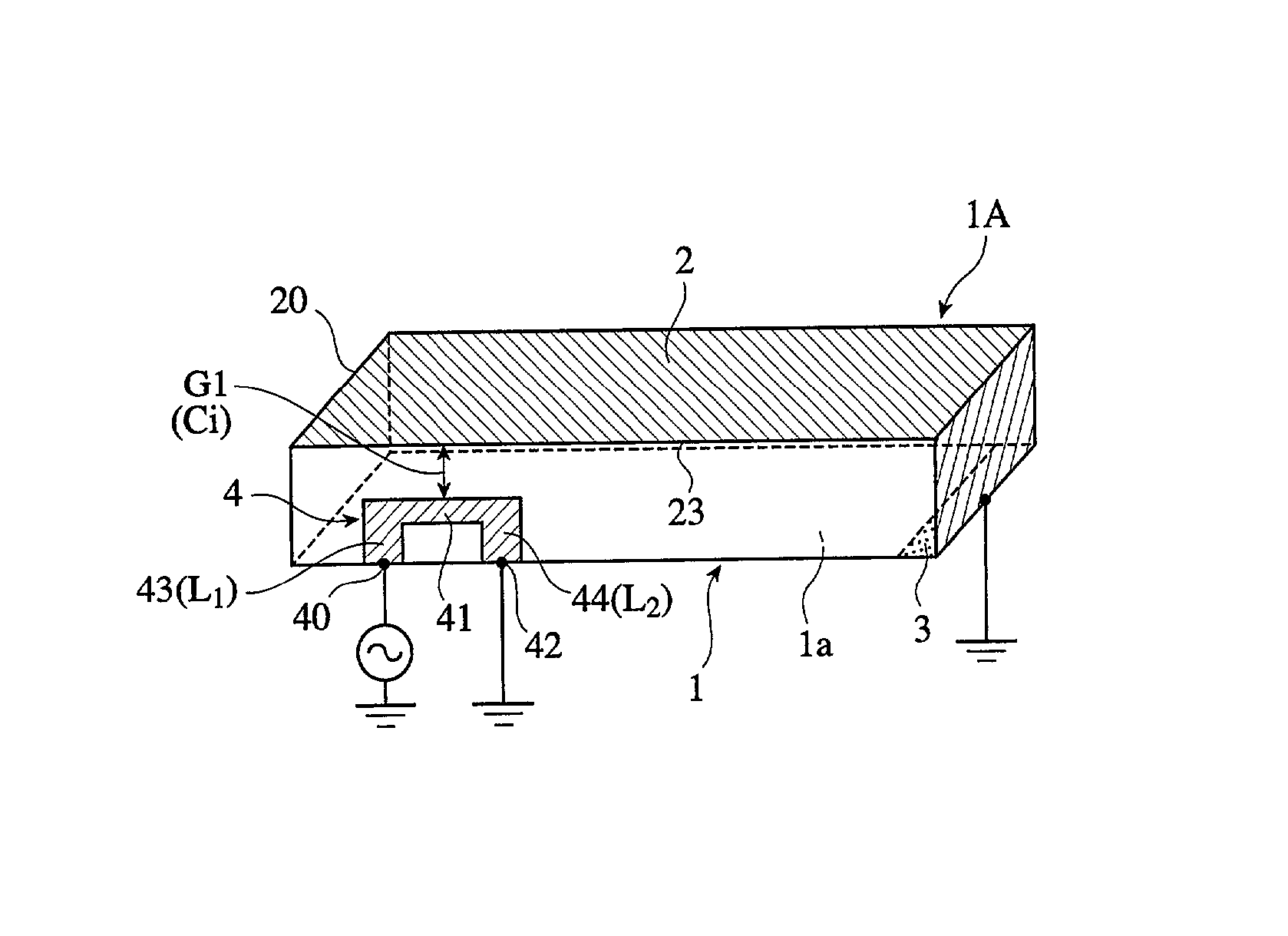

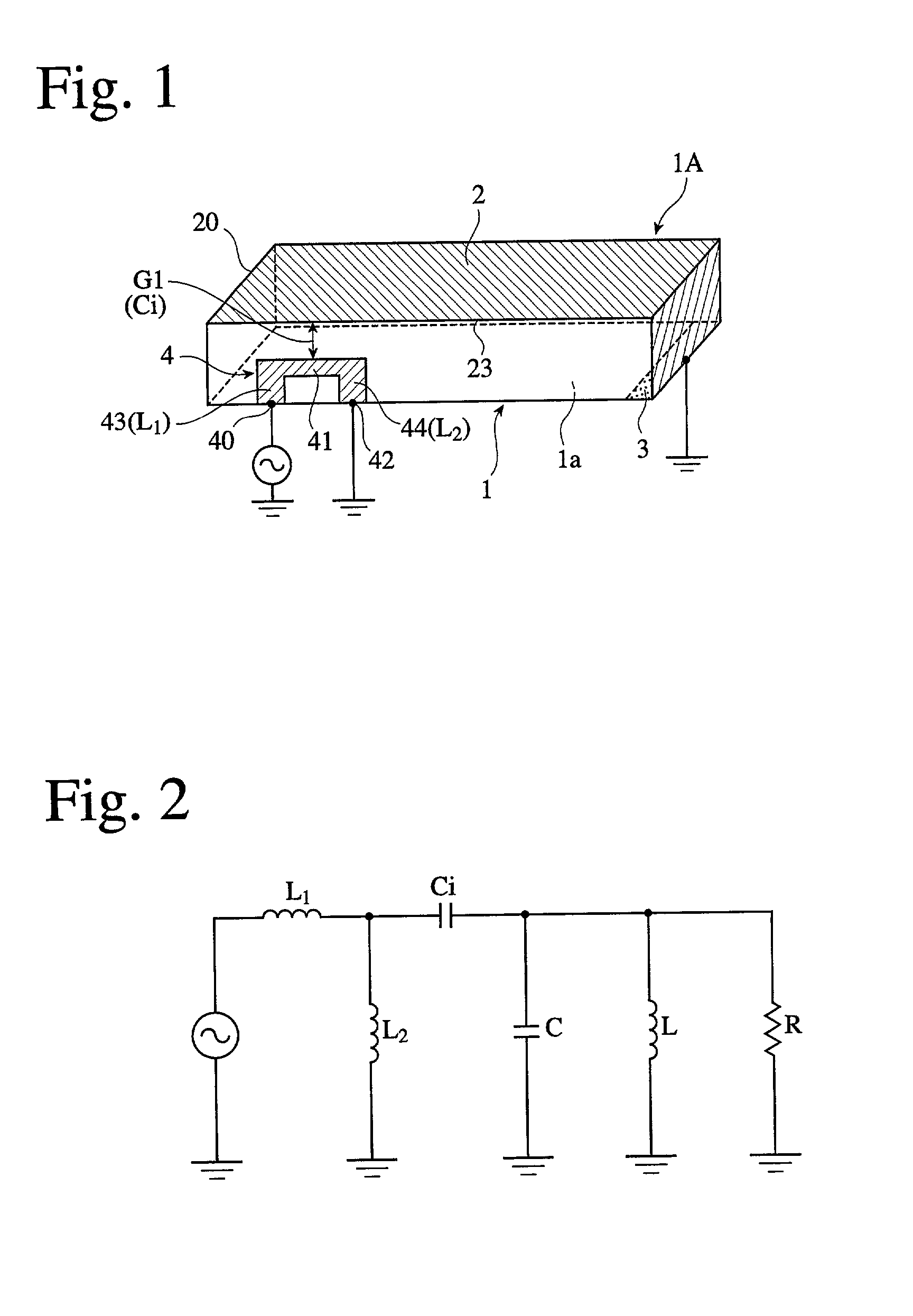

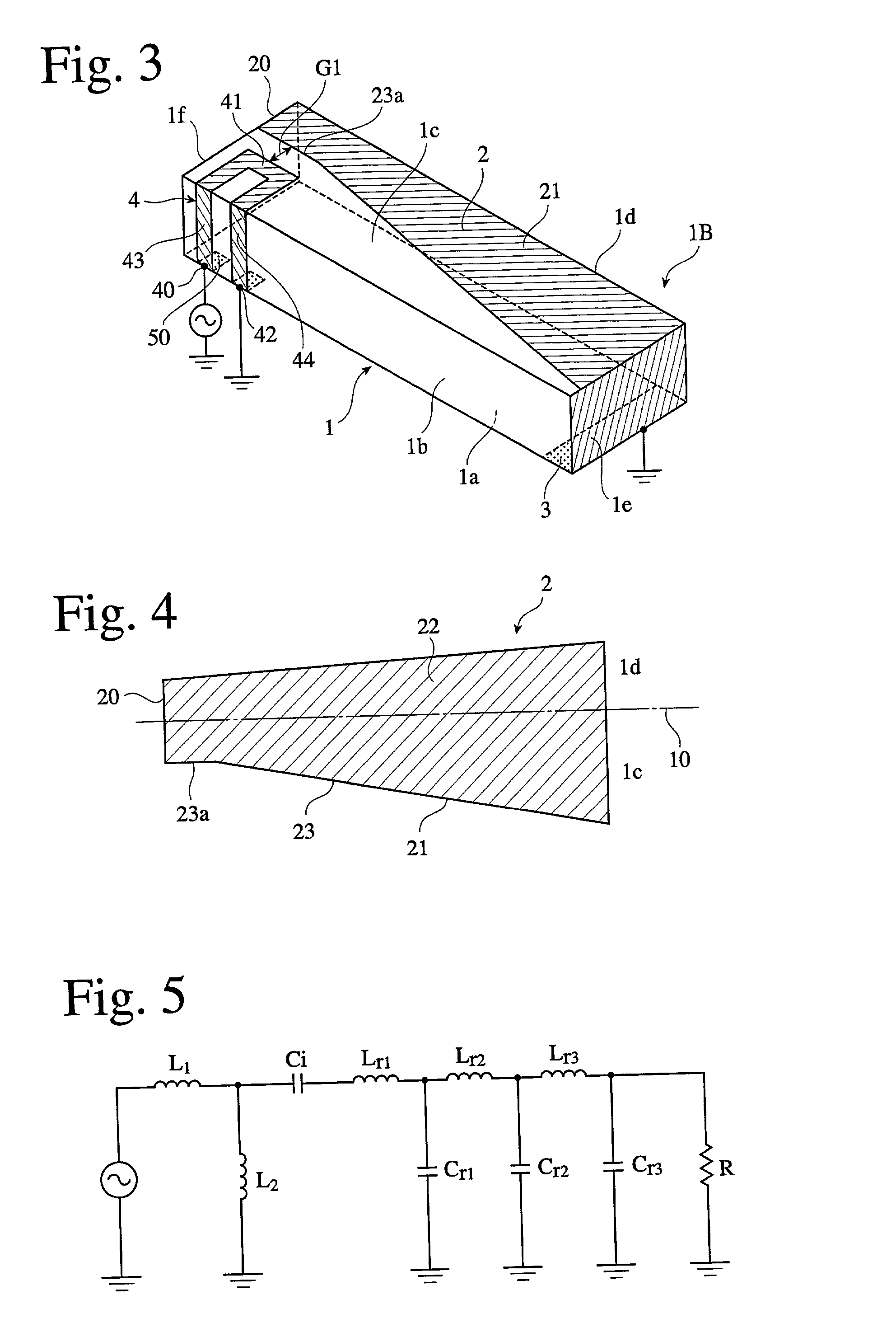

Surface-mounted antenna and communications apparatus comprising same

InactiveUS6873291B2High gainEasy impedance matchingSimultaneous aerial operationsMotorised scootersCapacitanceBand shape

A surface-mounted antenna comprising a substrate made of a high-dielectric constant material having a dielectric constant ∈r of 6 or more, a ribbon-shaped radiation electrode having one end which is grounded and the other end which is open, a grounding electrode connected or capacitance-coupled to one end of the radiation electrode, and a current-feeding electrode in a portal shape formed on a side surface separate from the radiation electrode with a gap; the current-feeding electrode having a current-feeding portion at one end, a grounding portion at the other end, and a portion substantially in alignment with the radiation electrode between them; and the length of the aligning portion, a gap width or a portal shape being able to be properly set such that capacitance owned by the current-feeding electrode and inductance can be adjusted for easily achieving impedance matching.

Owner:HITACHI METALS LTD

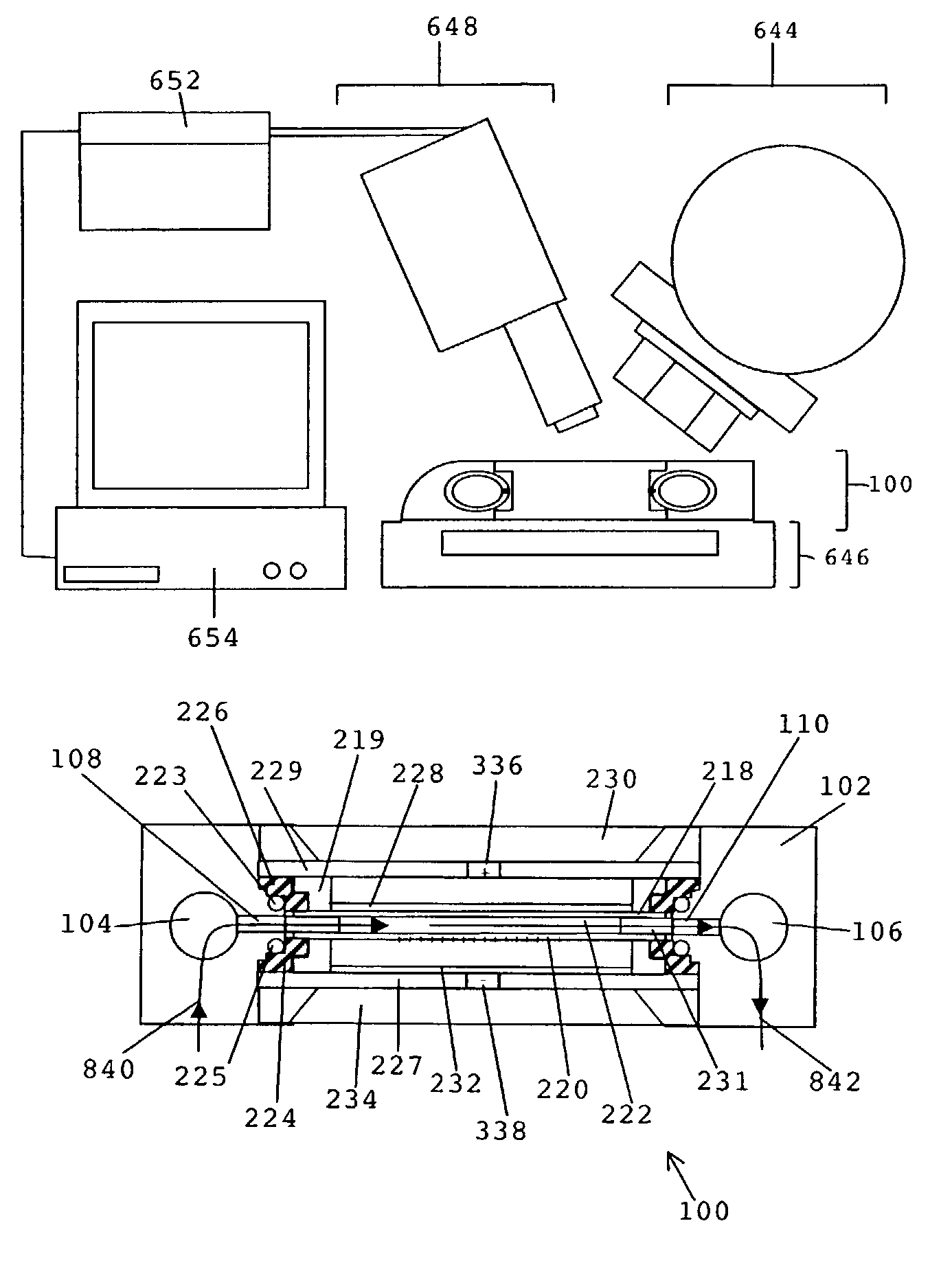

Ionic pre-concentration XRF identification and analysis device, system and method

InactiveUS7016462B1High sensitivityHinder full rangeMaterial analysis using wave/particle radiationX-ray spectral distribution measurementCapacitanceX-ray

A device, system and method for detecting and measuring concentrations of elements in fluids comprises: flowing a fluid through a central flow interelectrode gap of an ionic preconcentration cell separating an upper high specific surface area electrode from a lower high specific surface area electrode of the ionic preconcentration cell by a predetermined interelectrode gap width; and applying a voltage differential between the upper high surface area electrode and the lower high surface area electrode while the fluid is flowing through the central flow interelectrode gap. As such, this cell that utilizes its inherent capacitance for double layer formation to extract ultra-trace levels of ionic contaminants from fluids in order to enhance detection by x-ray fluorescence analysis.

Owner:INTERSCI +1

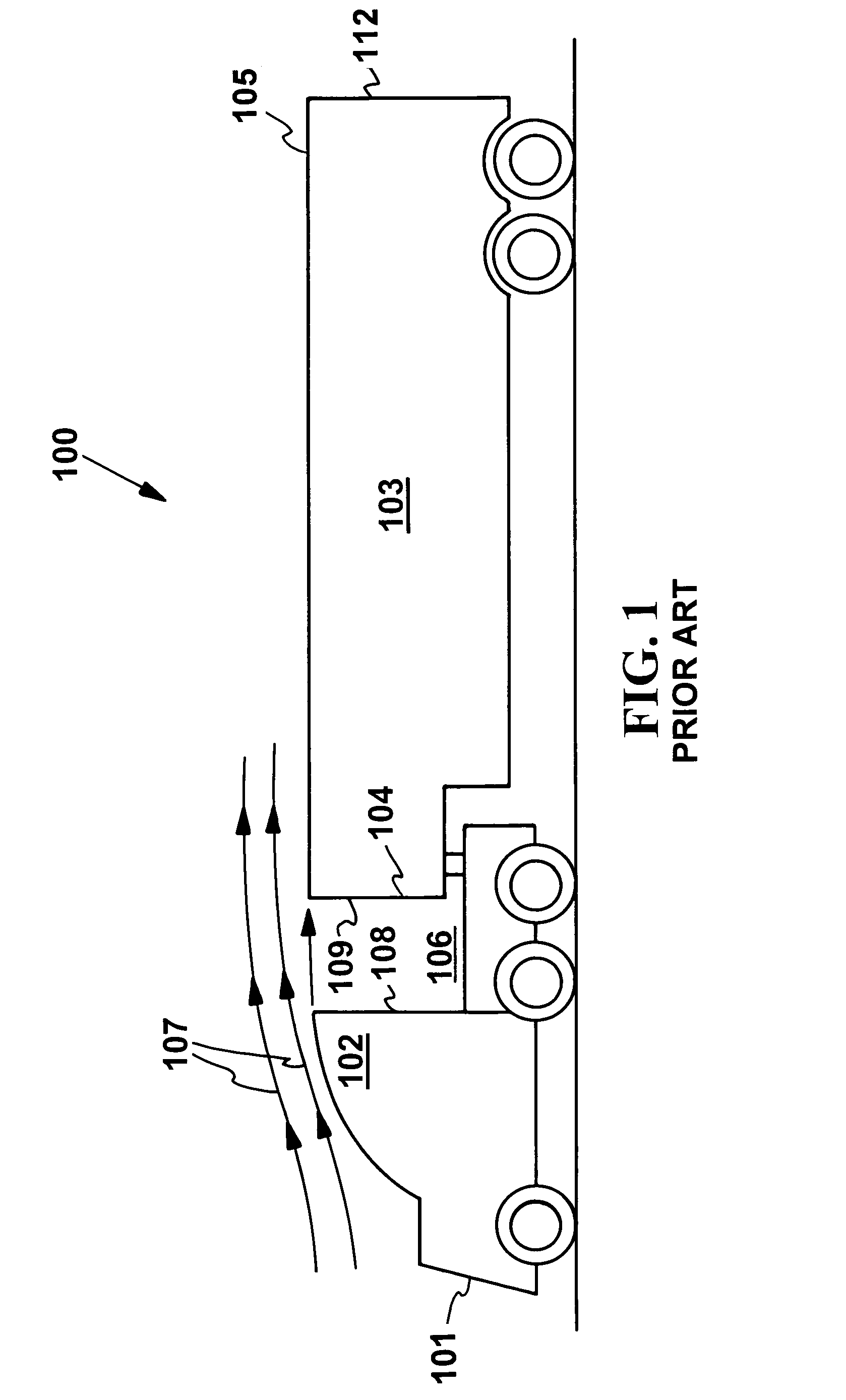

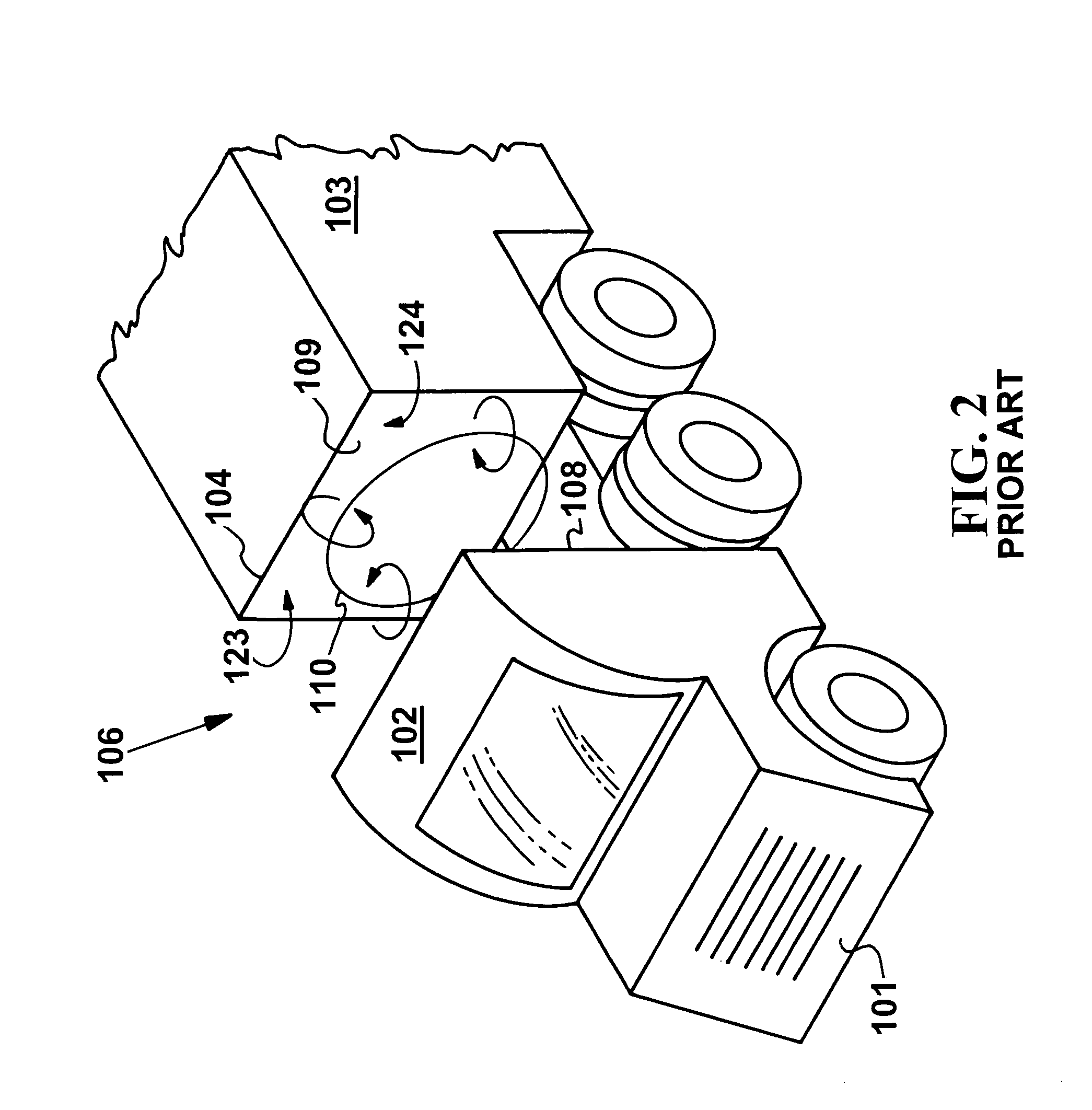

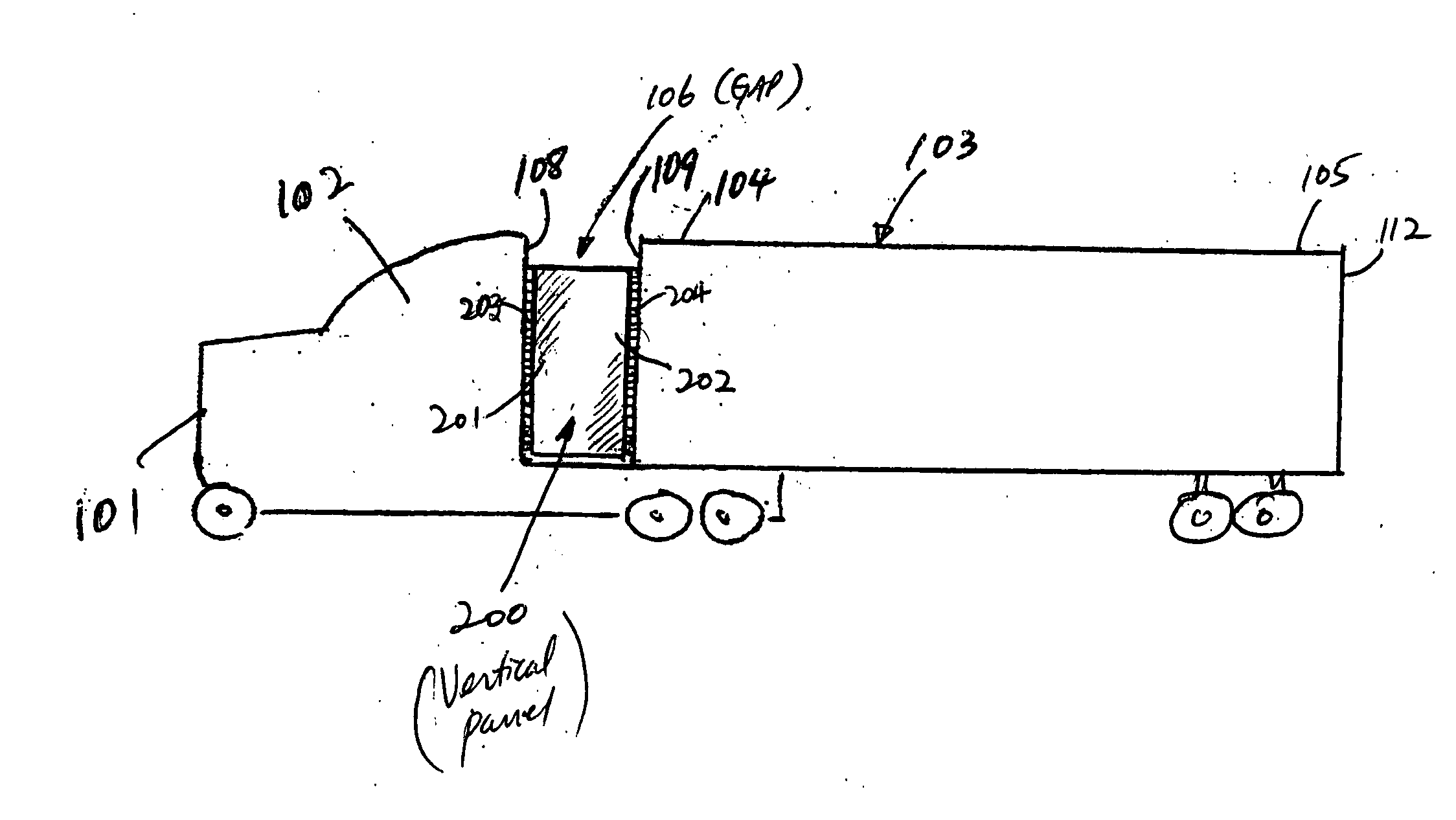

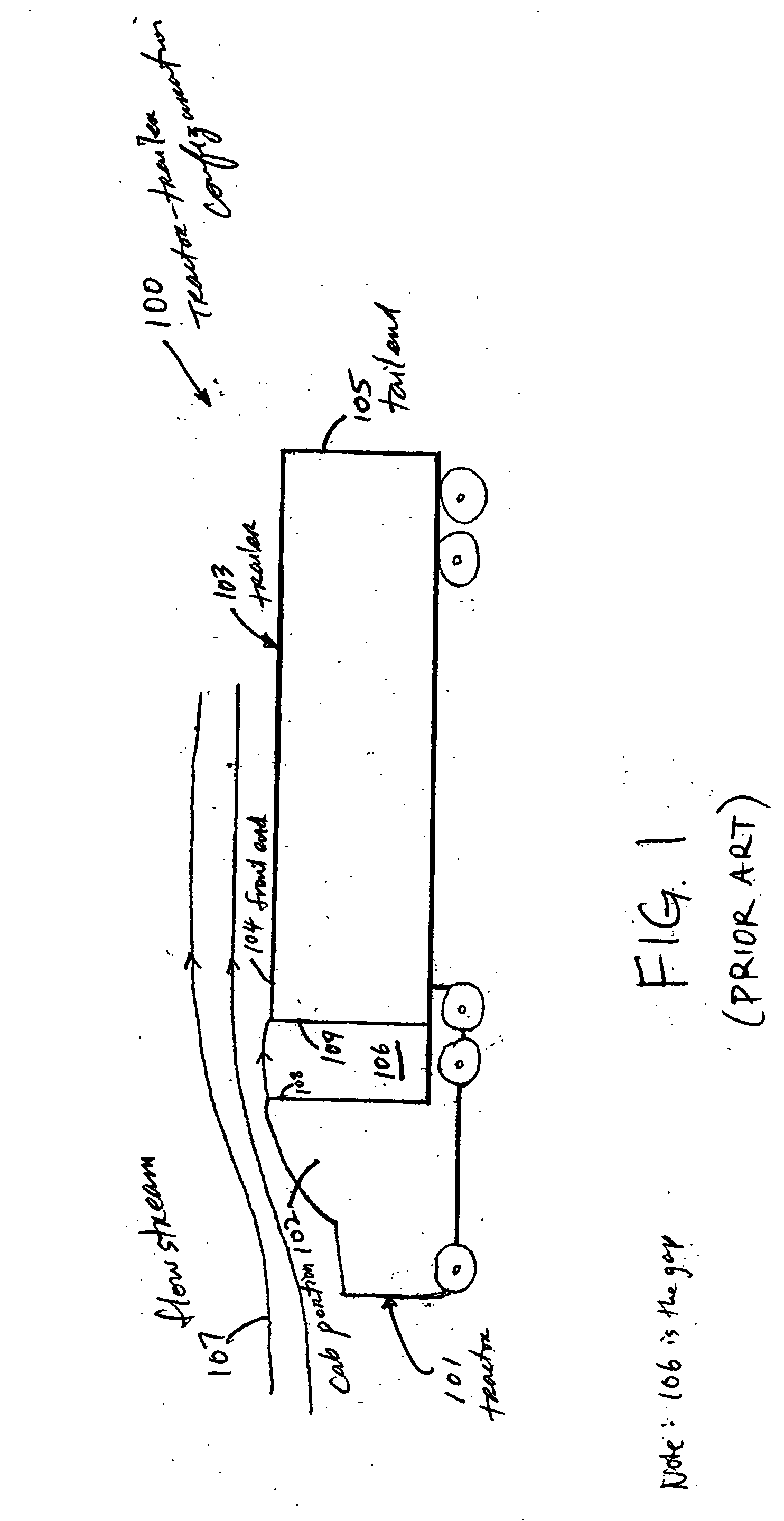

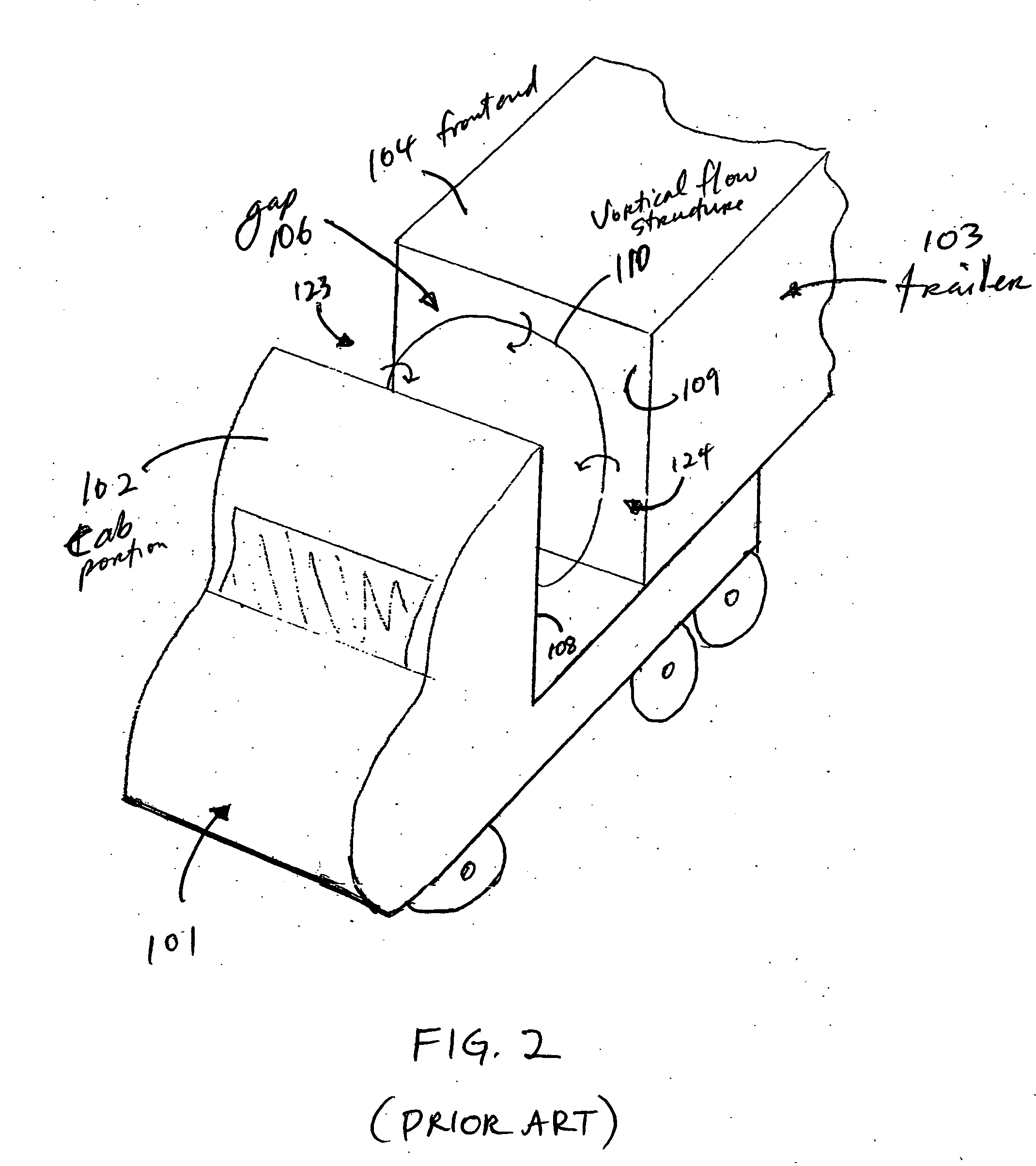

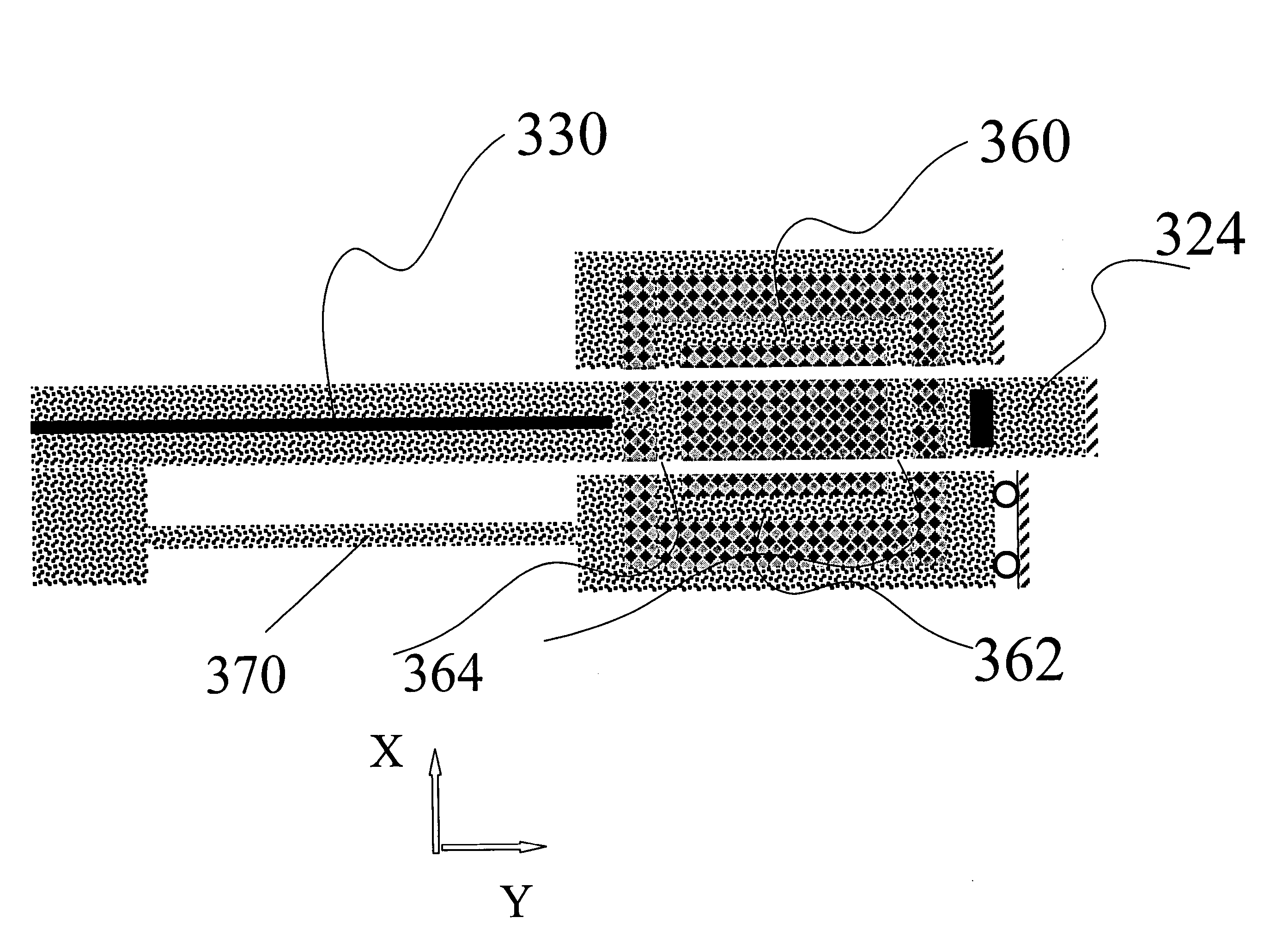

Aerodynamic drag reduction apparatus for gap-divided bluff bodies such as tractor-trailers

InactiveUS7073845B2Reducing the aerodynamic drag of a bluff-bodiedReducing the aerodynamic drag of a bluff bodyVehicle seatsWindowsAerodynamic dragEngineering

An apparatus for reducing the aerodynamic drag of a bluff-bodied vehicle such as a tractor-trailer in a flowstream, the bluff-bodied vehicle of a type having a leading portion, a trailing portion connected to the leading portion, and a gap between the leading and trailing portions defining a recirculation zone. The apparatus is preferably a baffle assembly, such as a vertical panel, adapted to span a width of the gap between the leading and trailing portions so as to impede cross-flow through the gap, with the span of the baffle assembly automatically adjusting for variations in the gap width when the leading and trailing portions pivot relative to each other.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

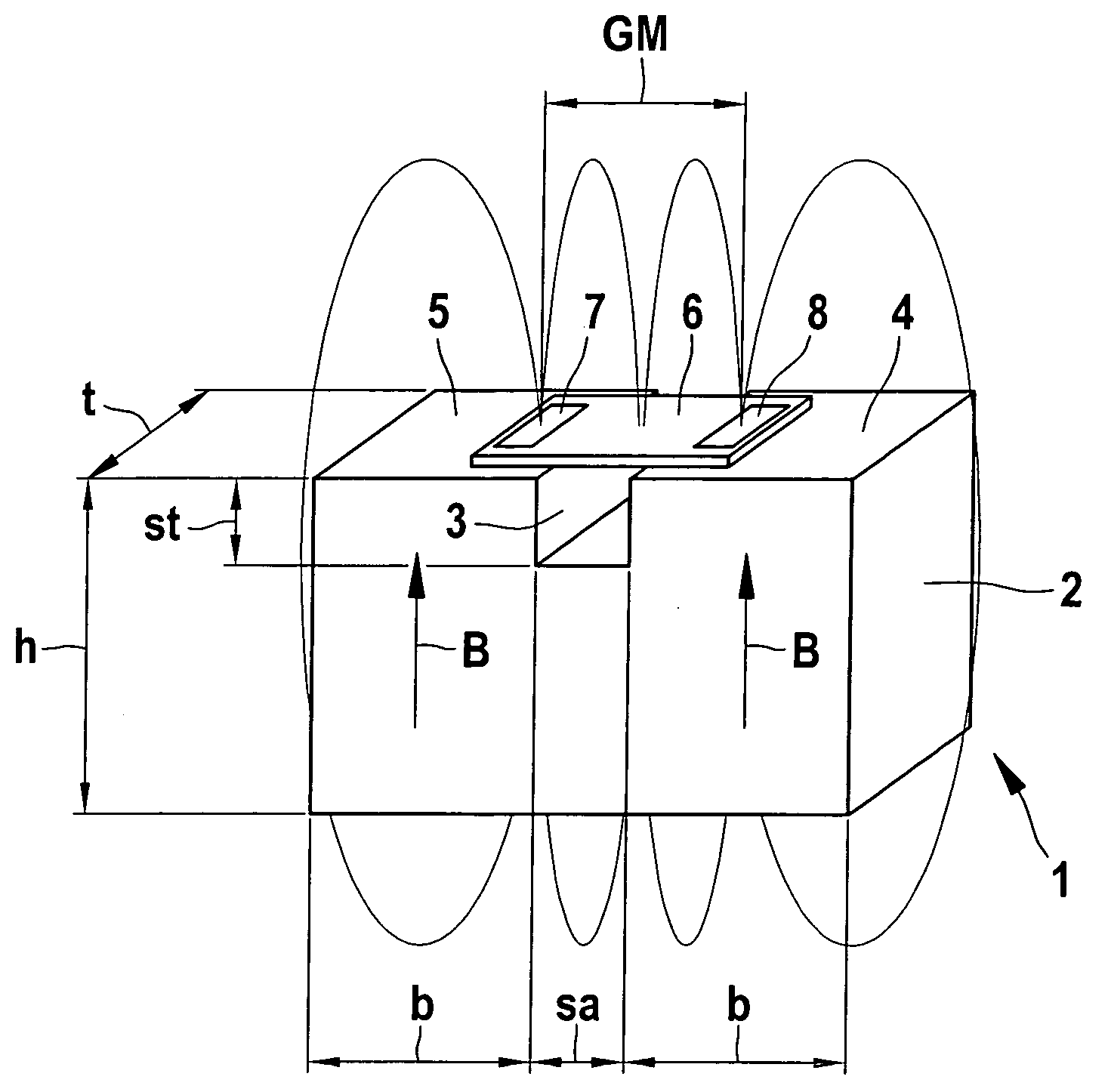

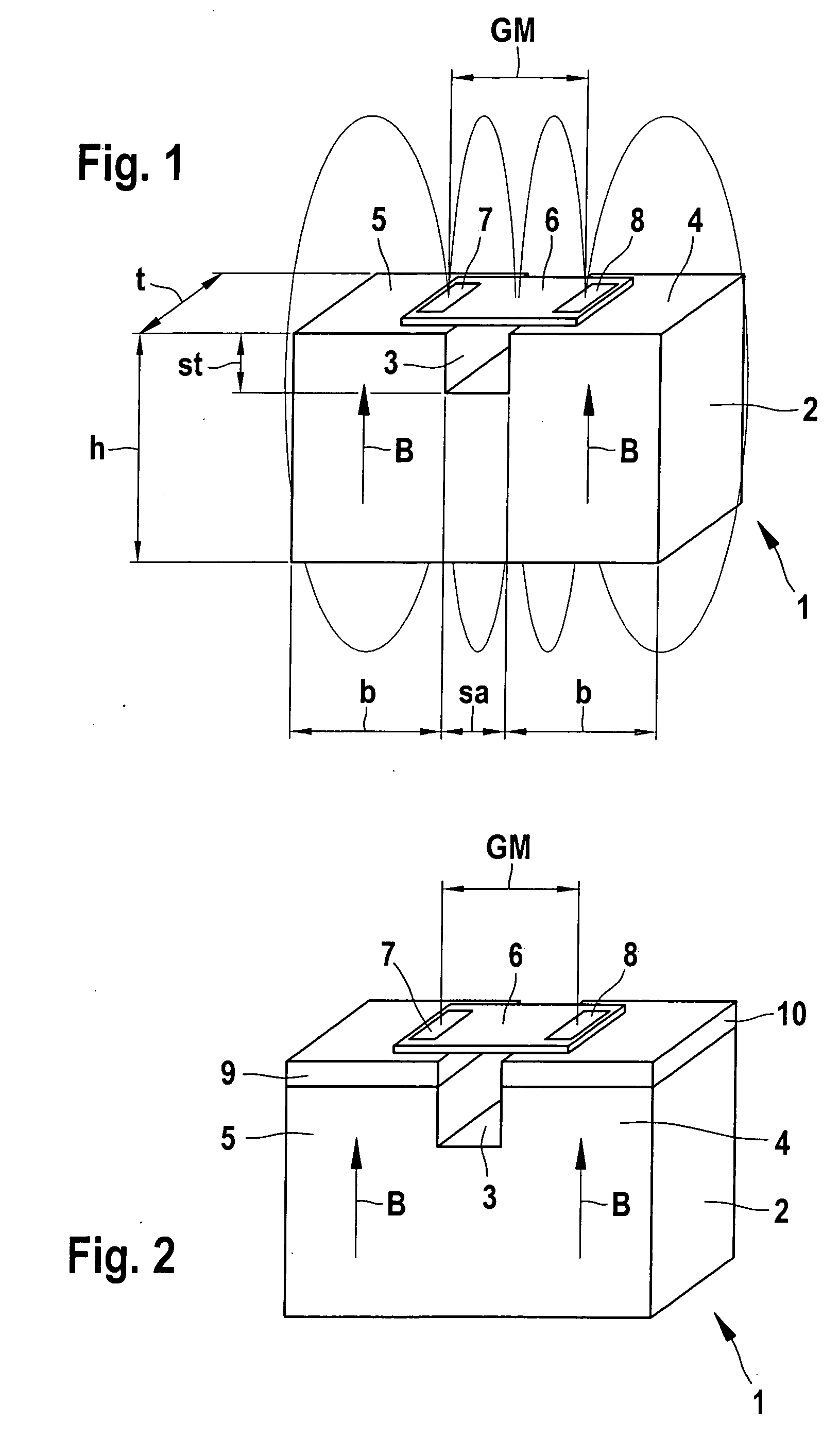

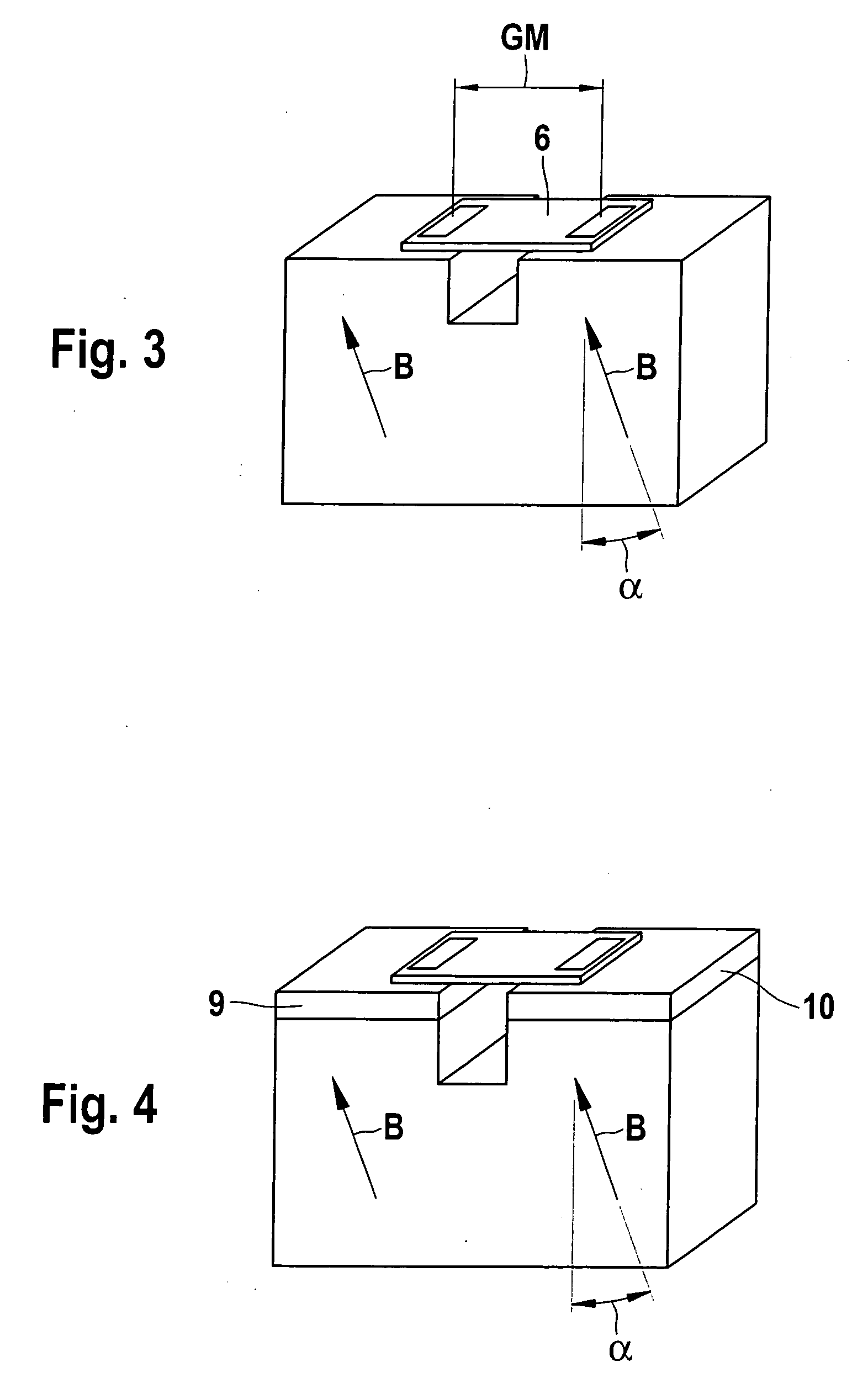

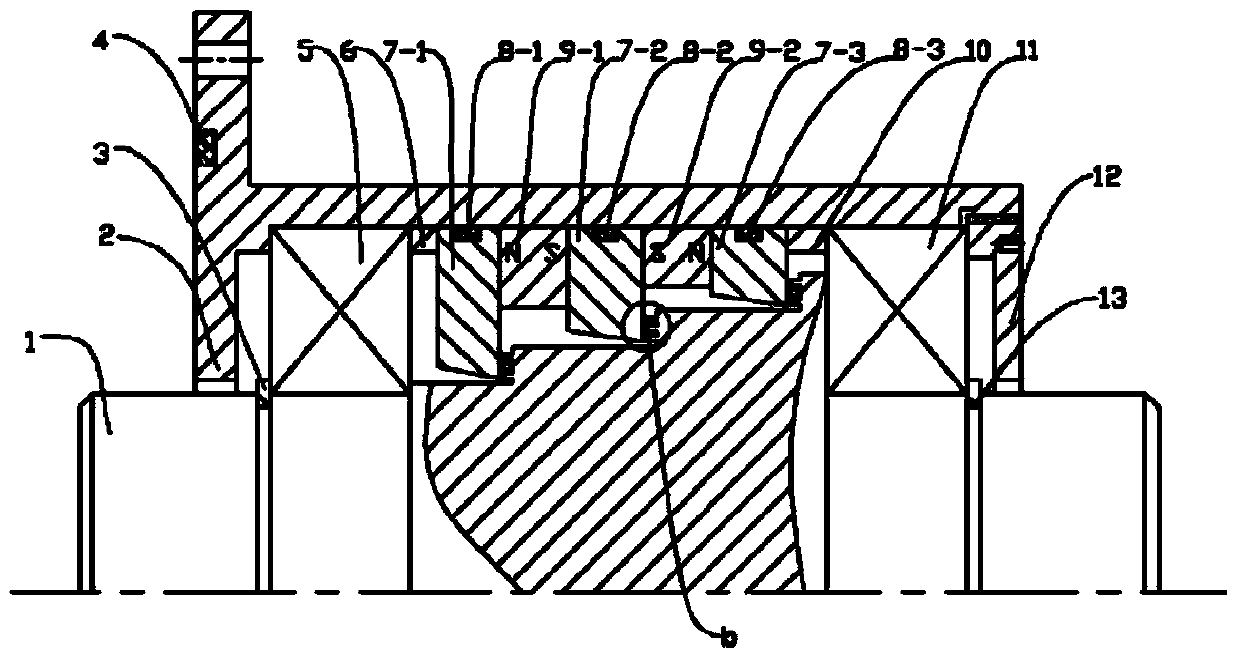

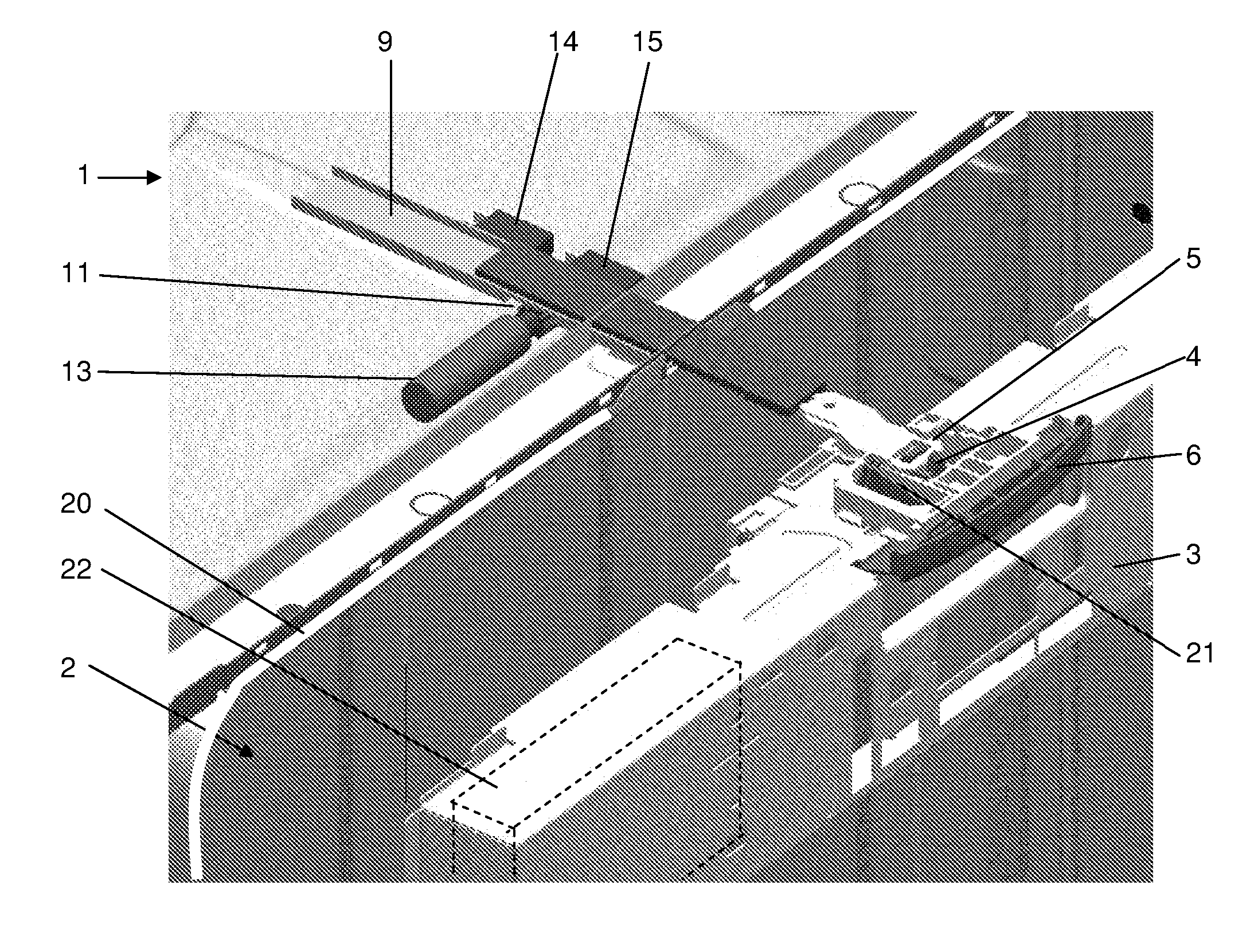

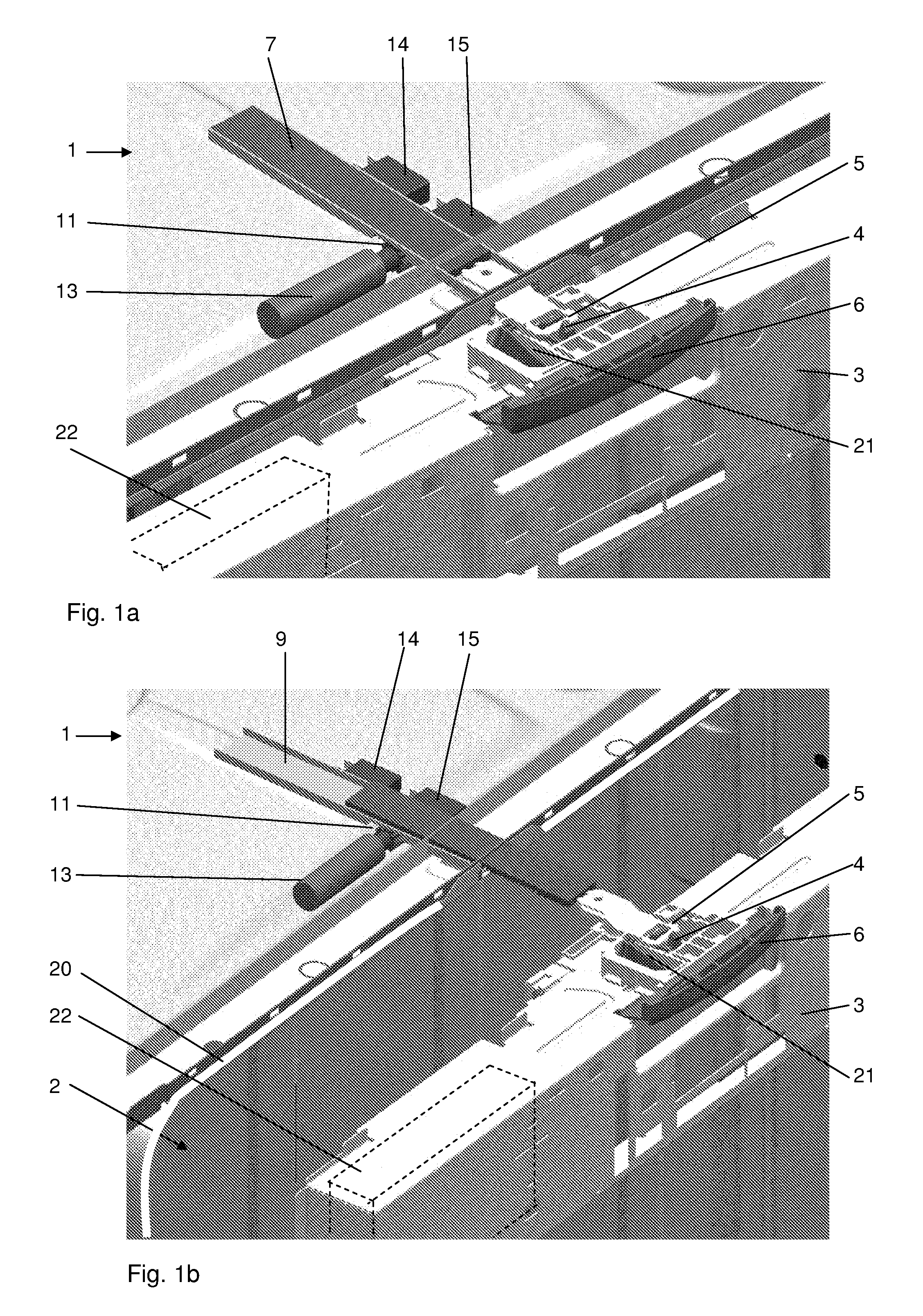

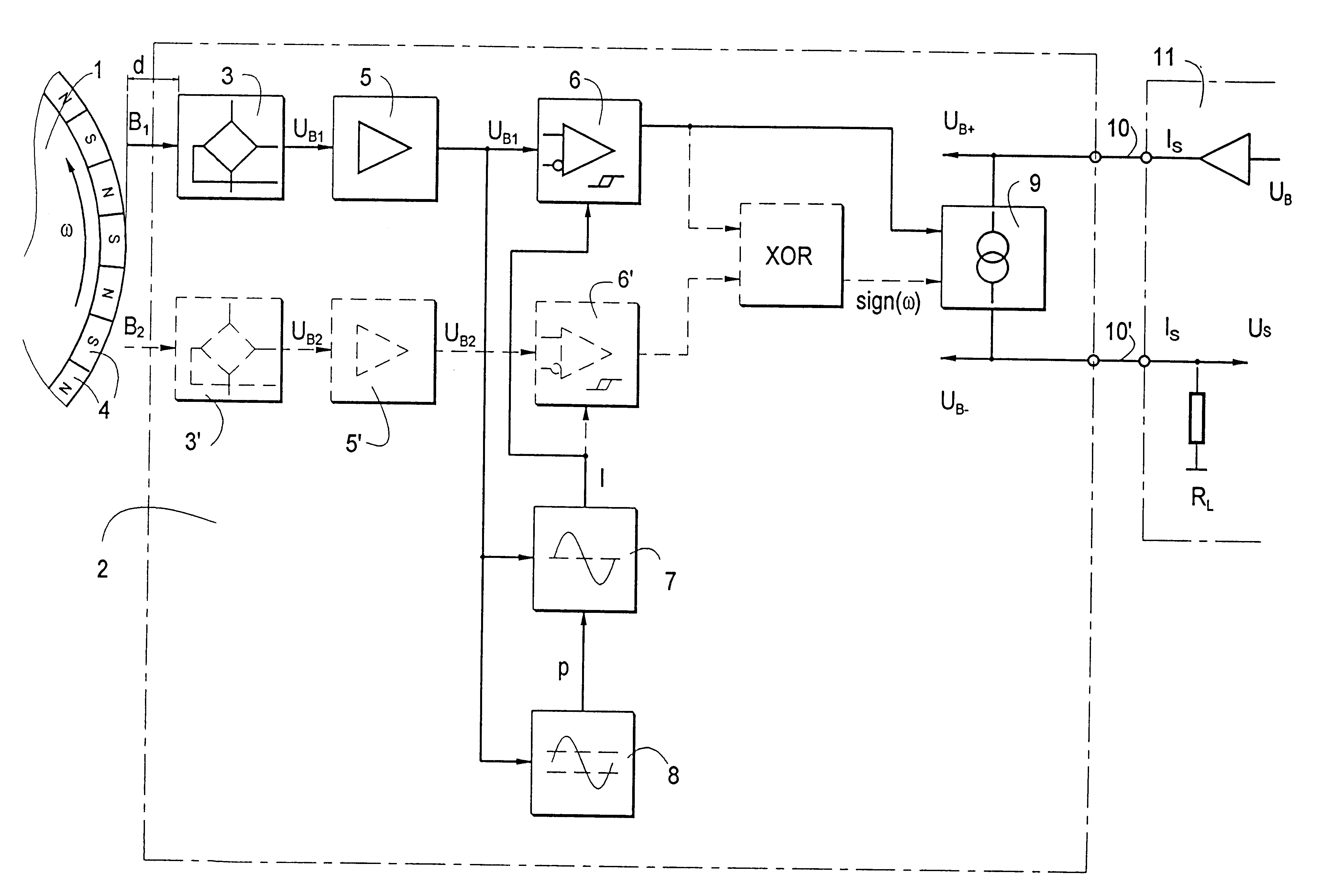

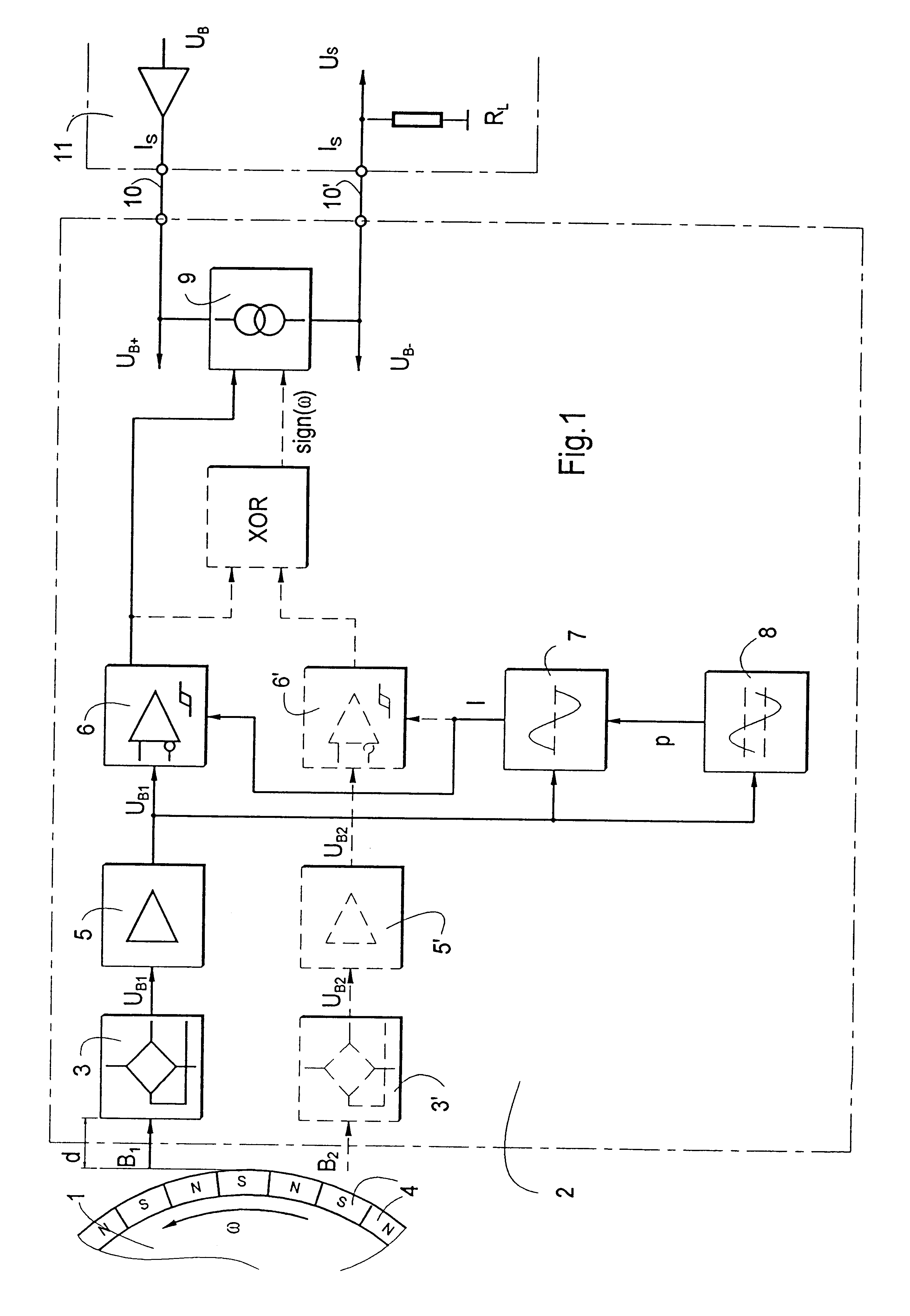

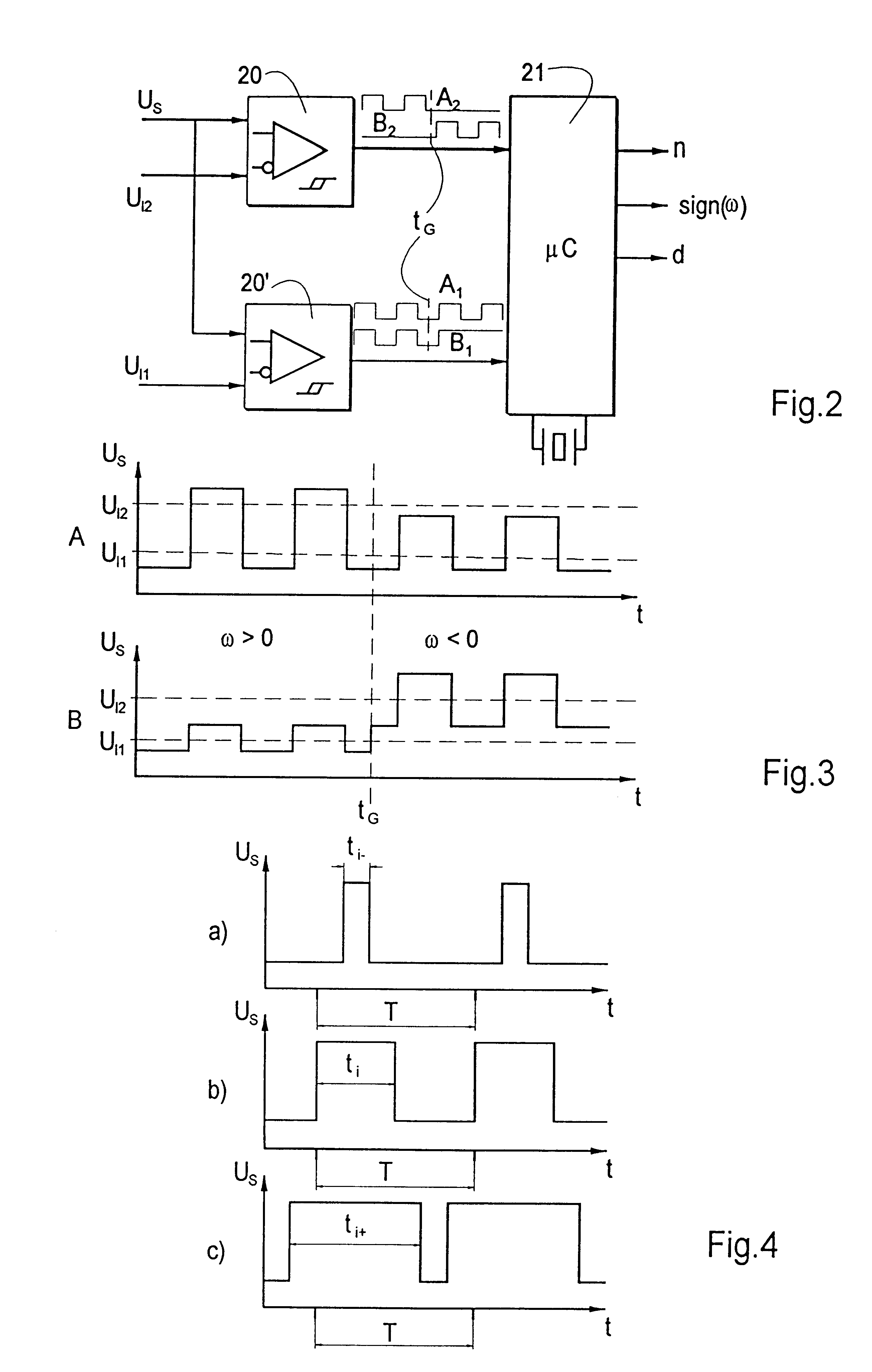

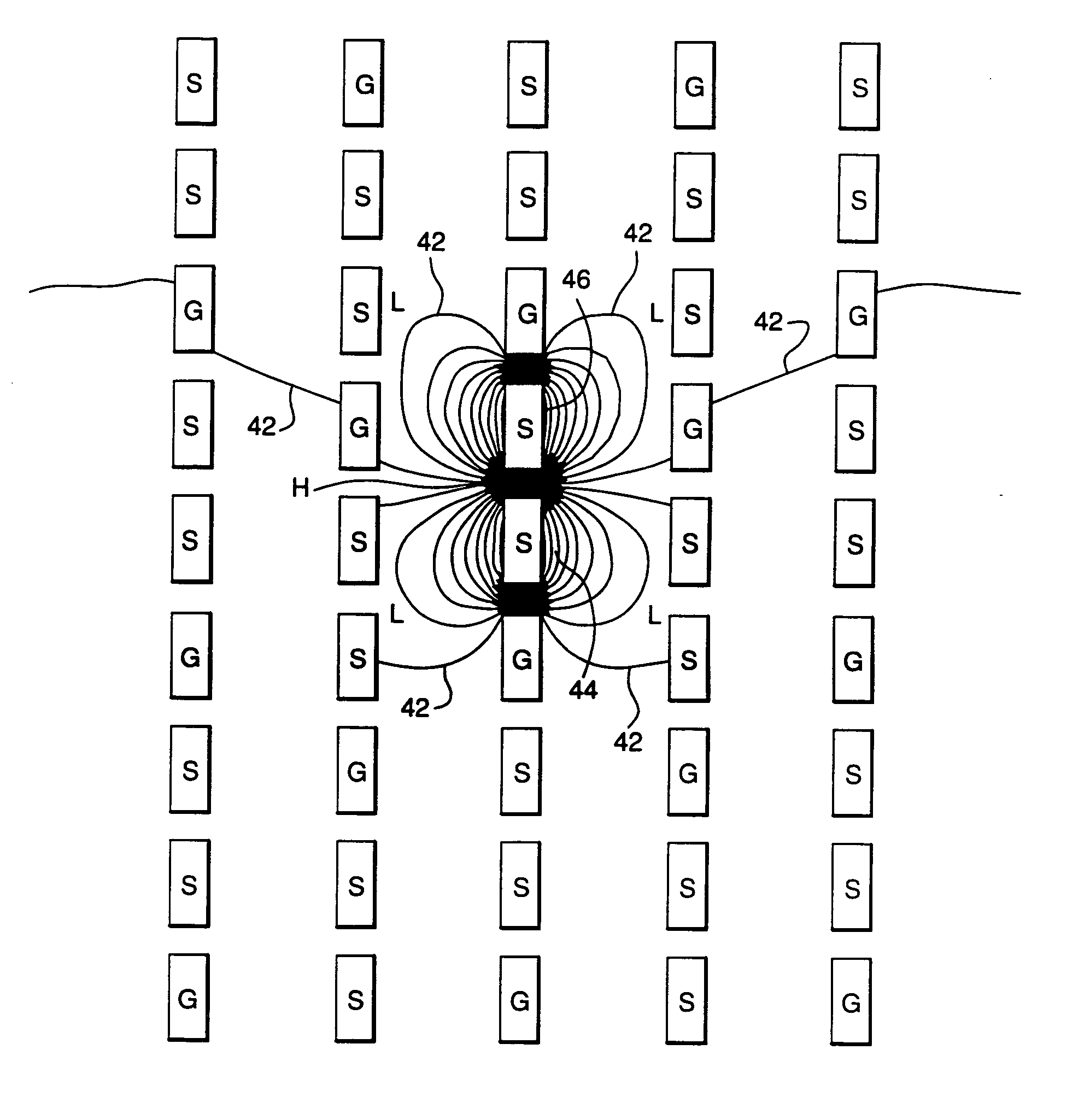

Magnet Sensor Arrangement

InactiveUS20080116884A1Magnetic-field-controlled resistorsMagnetic field measurement using flux-gate principleElectricityTransmitter

A magnetic sensor arrangement (1), having magnetically sensitive sensor elements (7, 8) whose electrical properties are changeable as a function of a magnetic field that a moving, passive transmitter element (11) is able to influence. The magnetic sensor arrangement (1) has two sensor elements (7, 8) in a gradiometer arrangement that are each respectively associated with one of two magnetic regions (4, 5) of a permanent magnet embodied in the form of a gap magnet (2; 20; 23), which regions are spaced apart from each other by a predetermined distance (sa). The regions (4, 5) and the gap magnet (2; 20; 23)—in terms of the for example wedge-shaped embodiment, the dimensions (h, b, t), the gap width (sa), the gap depth (st), and their positions in relation to the sensor elements (7, 8)—are situated so as to minimize the offset of the output signal of the sensor elements (7, 8) in the gradiometer arrangement.

Owner:ROBERT BOSCH GMBH

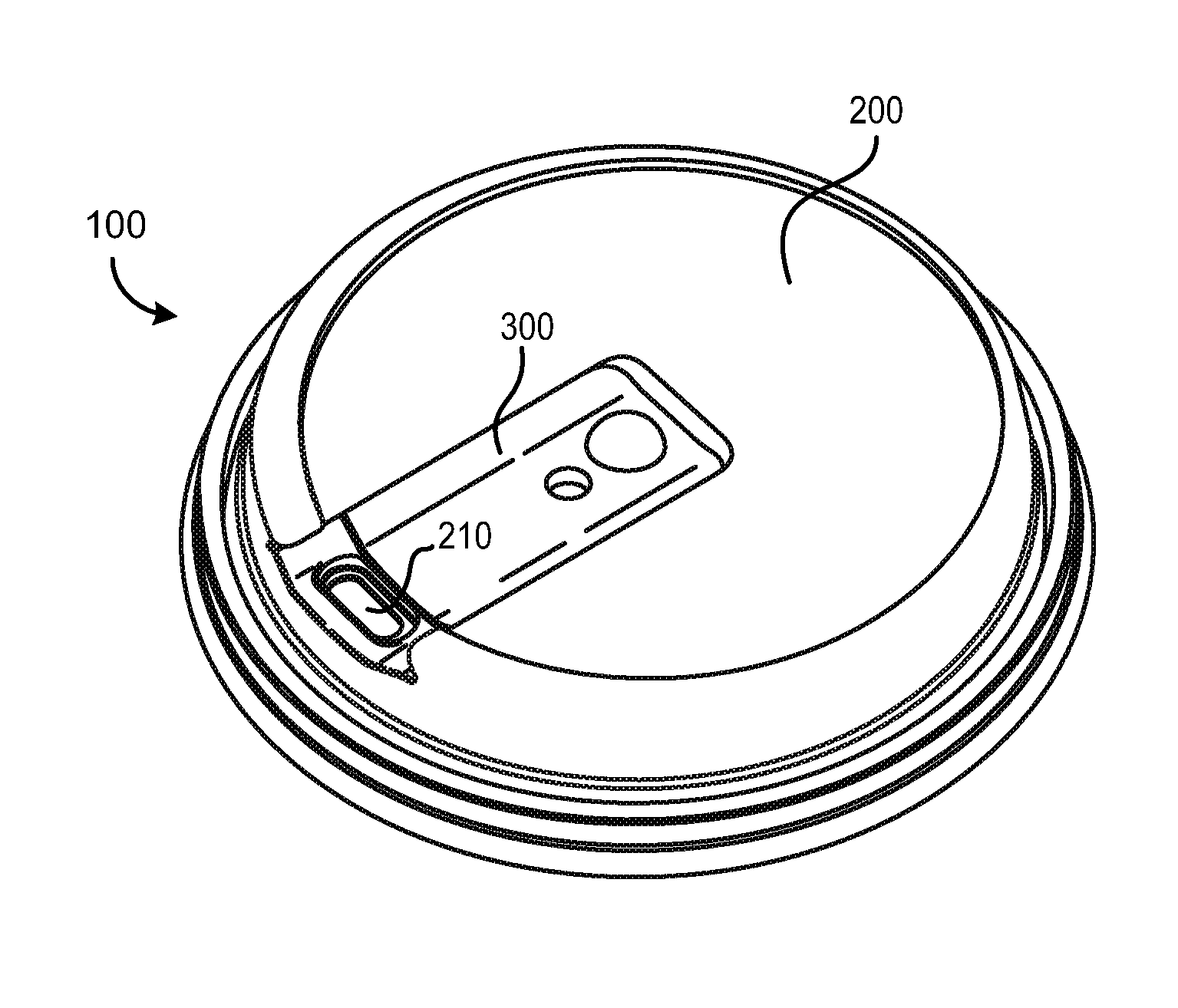

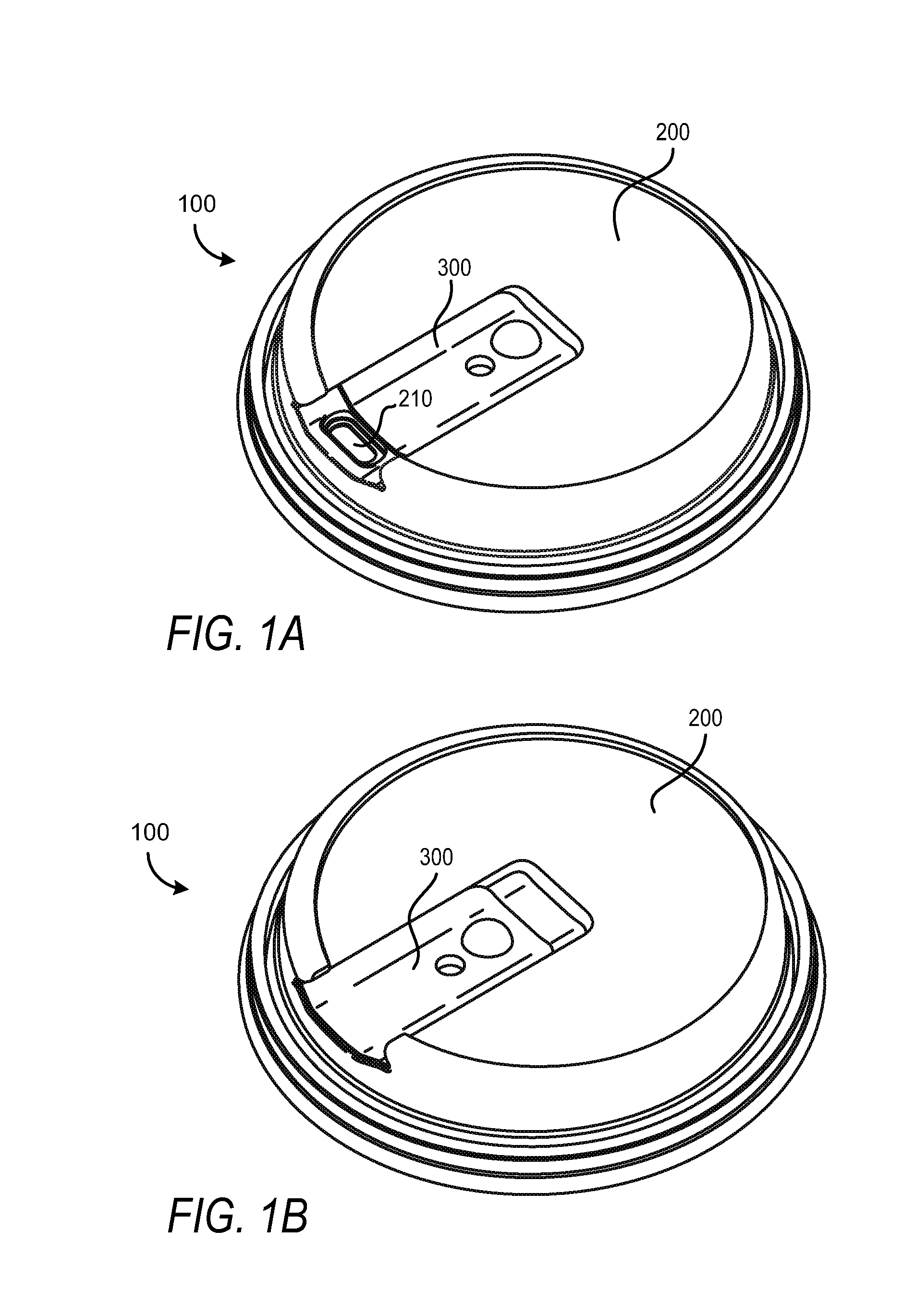

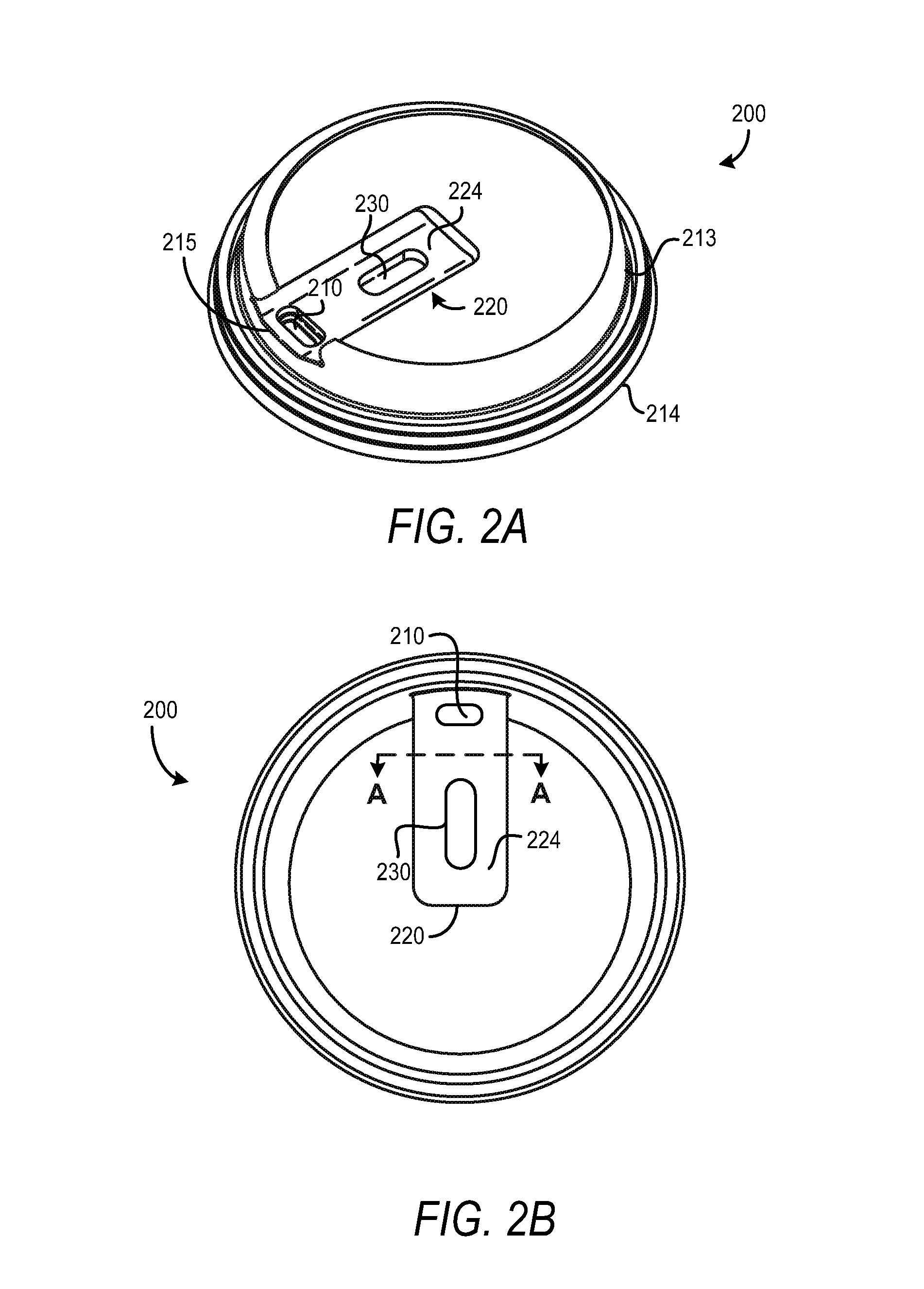

Drinking cup lid with self-securing sliding member

A disposable lid for a drinking cup includes a cover portion and a sliding member that is configured to slidably fit into a trench in the cover portion. The trench includes a drink opening on a floor of the trench and the sliding member is configured to cover and uncover the drink opening. In one embodiment, the sliding member includes side portions that extend longitudinally and upwardly from a central portion of the sliding member such that an outer edge of each side portion is located above the central portion of the sliding member. A gap width between the outer edges of the side portions of the sliding member is greater than a width of a mouth of the trench such that the side portions of the sliding member secure the siding member to the cover portion.

Owner:DOUBLE TEAM

Aerodynamic drag reduction apparatus for gap-divided bluff bodies such as tractor-trailers

InactiveUS20040239146A1Avoid cross flowReducing the aerodynamic drag of a bluff-bodiedVehicle seatsWindowsAerodynamic dragGap width

An apparatus for reducing the aerodynamic drag of a bluff-bodied vehicle such as a tractor-trailer in a flowstream, the bluff-bodied vehicle of a type having a leading portion, a trailing portion connected to the leading portion, and a gap between the leading and trailing portions defining a recirculation zone. The apparatus is preferably a baffle assembly, such as a vertical panel, adapted to span a width of the gap between the leading and trailing portions so as to impede cross-flow through the gap, with the span of the baffle assembly automatically adjusting for variations in the gap width when the leading and trailing portions pivot relative to each other.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Surface-mounted antenna and communications apparatus comprising same

InactiveUS20030006936A1MiniaturizationHigh bandwidthSimultaneous aerial operationsMotorised scootersCapacitanceBand shape

A surface-mounted antenna comprising a substrate made of a high-dielectric constant material having a dielectric constant is inr of 6 or more, a ribbon-shaped radiation electrode having one end which is grounded and the other end which is open, a grounding electrode connected or capacitance-coupled to one end of the radiation electrode, and a current-feeding electrode in a portal shape formed on a side surface separate from the radiation electrode with a gap; the current-feeding electrode having a current-feeding portion at one end, a grounding portion at the other end, and a portion substantially in alignment with the radiation electrode between them; and the length of the aligning portion, a gap width or a portal shape being able to be properly set such that capacitance owned by the current-feeding electrode and inductance can be adjusted for easily achieving impedance matching.

Owner:HITACHI METALS LTD

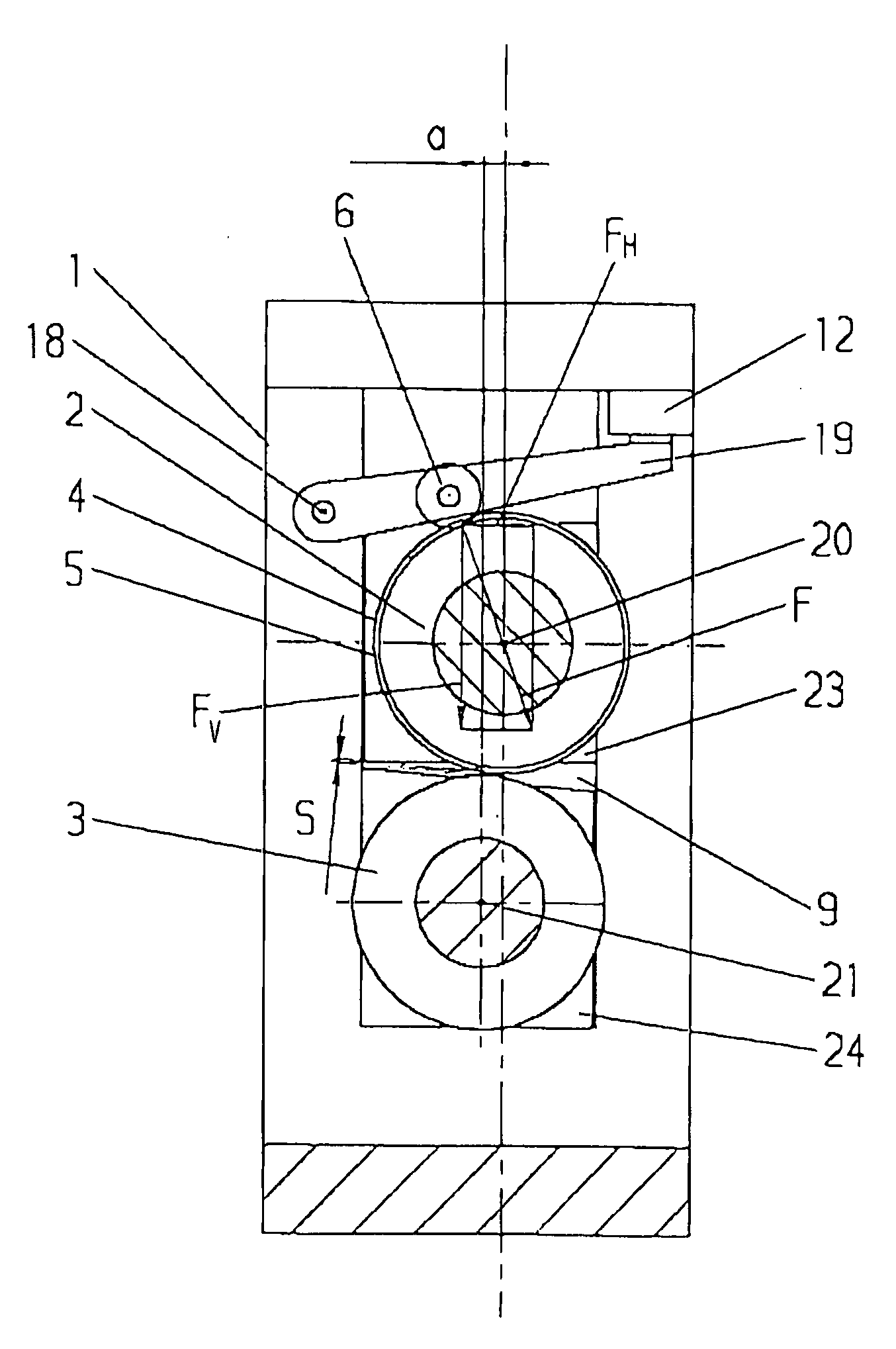

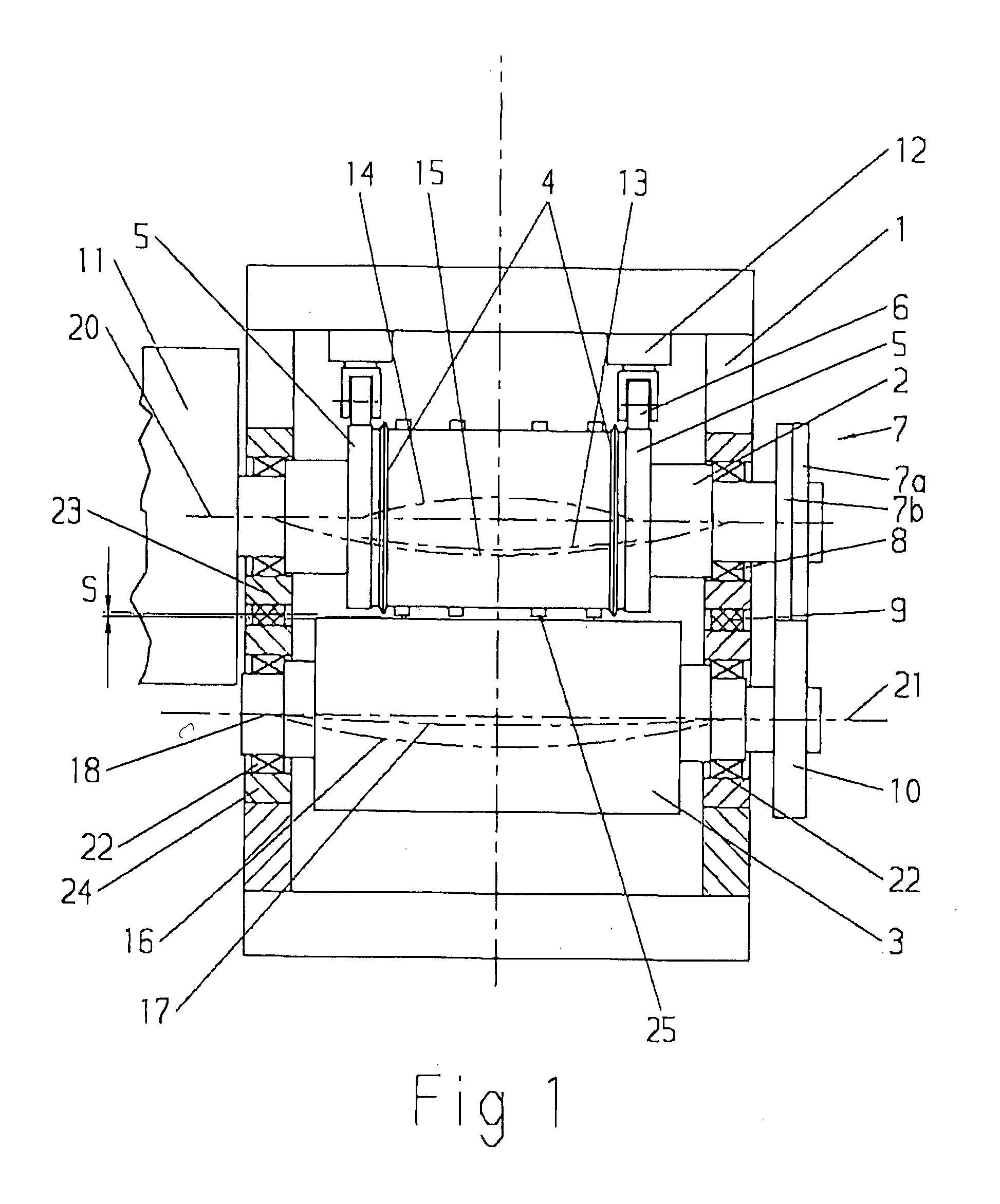

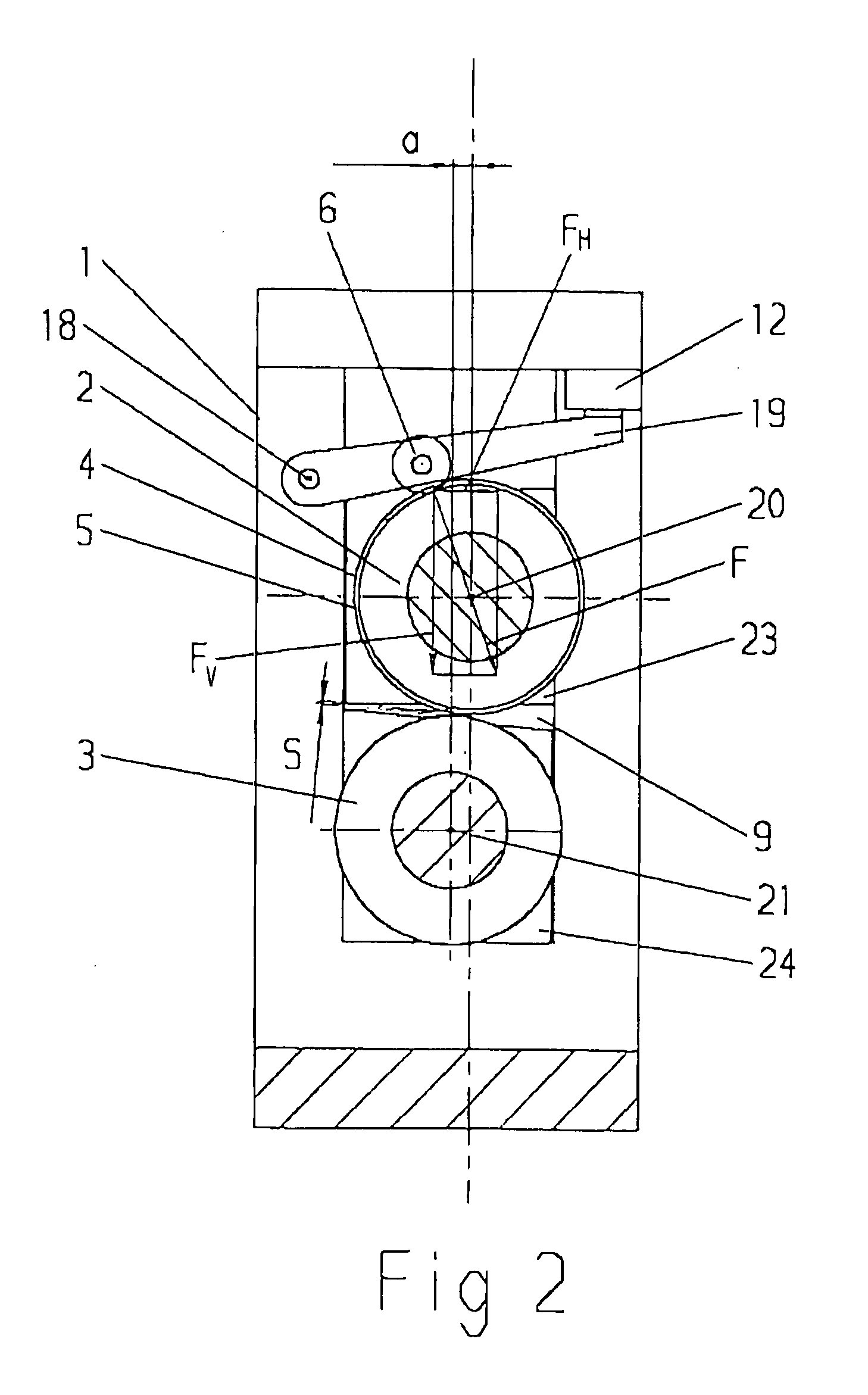

Device for cutting and/or embossing a pre-cut blank or a material web

InactiveUS20080066632A1Uniform widthBending of the counter-roller is advantageously reducedMechanical working/deformationRotary pressesEngineeringGap width

A device for cutting and / or embossing a sheet, a pre-cut blank, or a material web has a cutting and / or embossing roller having a longitudinal axis, which is mounted, at its two ends, in at least one bearing so as to rotate, a counter-roller that works together with the embossing roller and is mounted so as to rotate, and a force application device for applying a pressure force to a circumference surface of the cutting and / or embossing roller. This device makes it possible to set a uniform gap width of the gap between the cutting and / or embossing roller and the counter-roller, over its axial width. The pressure force applied to the circumference surface is diverted by the force application device into the at least one bearing by way of at least one part of the cutting and / or embossing roller, so that the pressure force is not applied to the counter-roller.

Owner:WINKLER DUNNEBIER GMBH

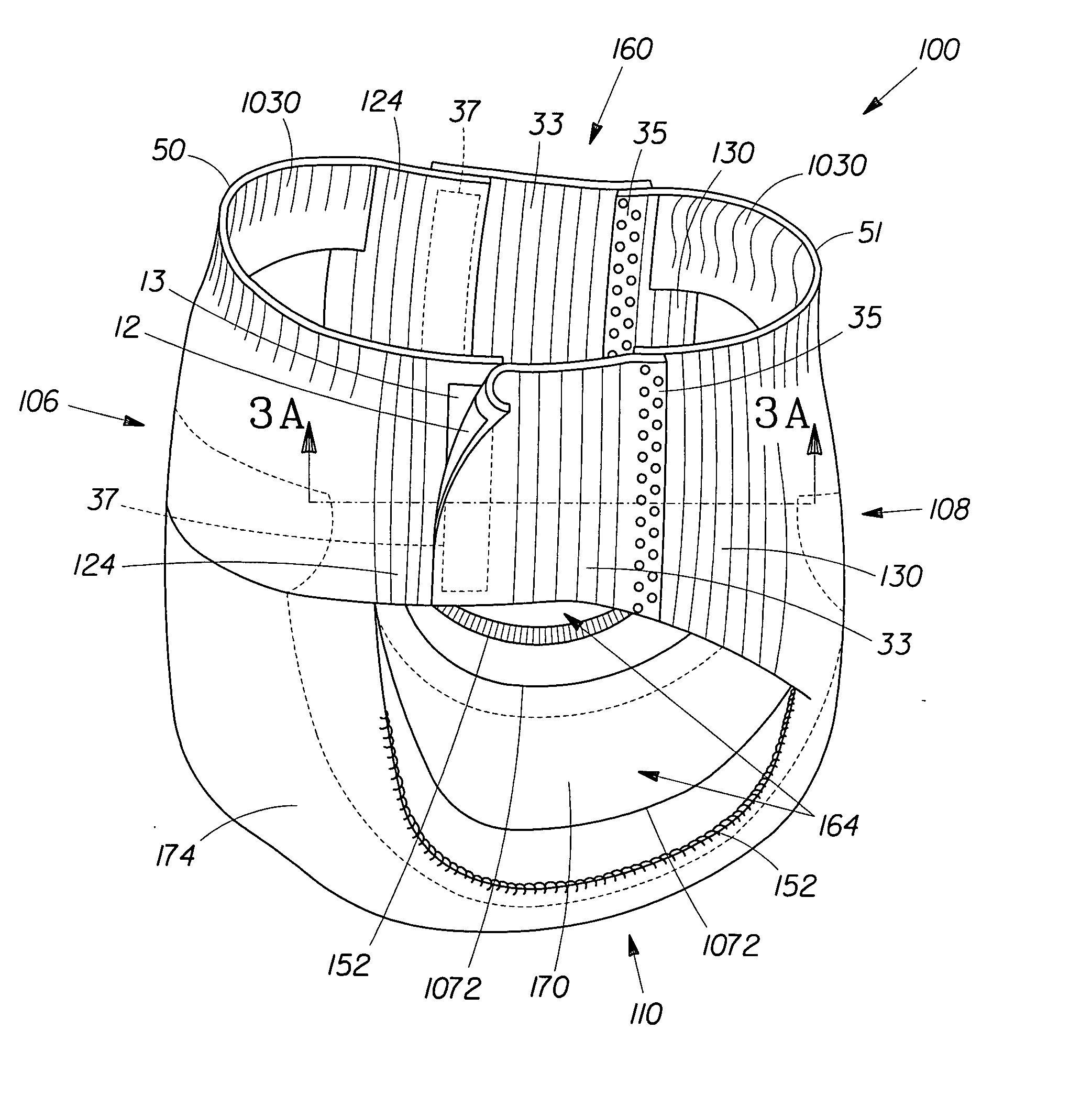

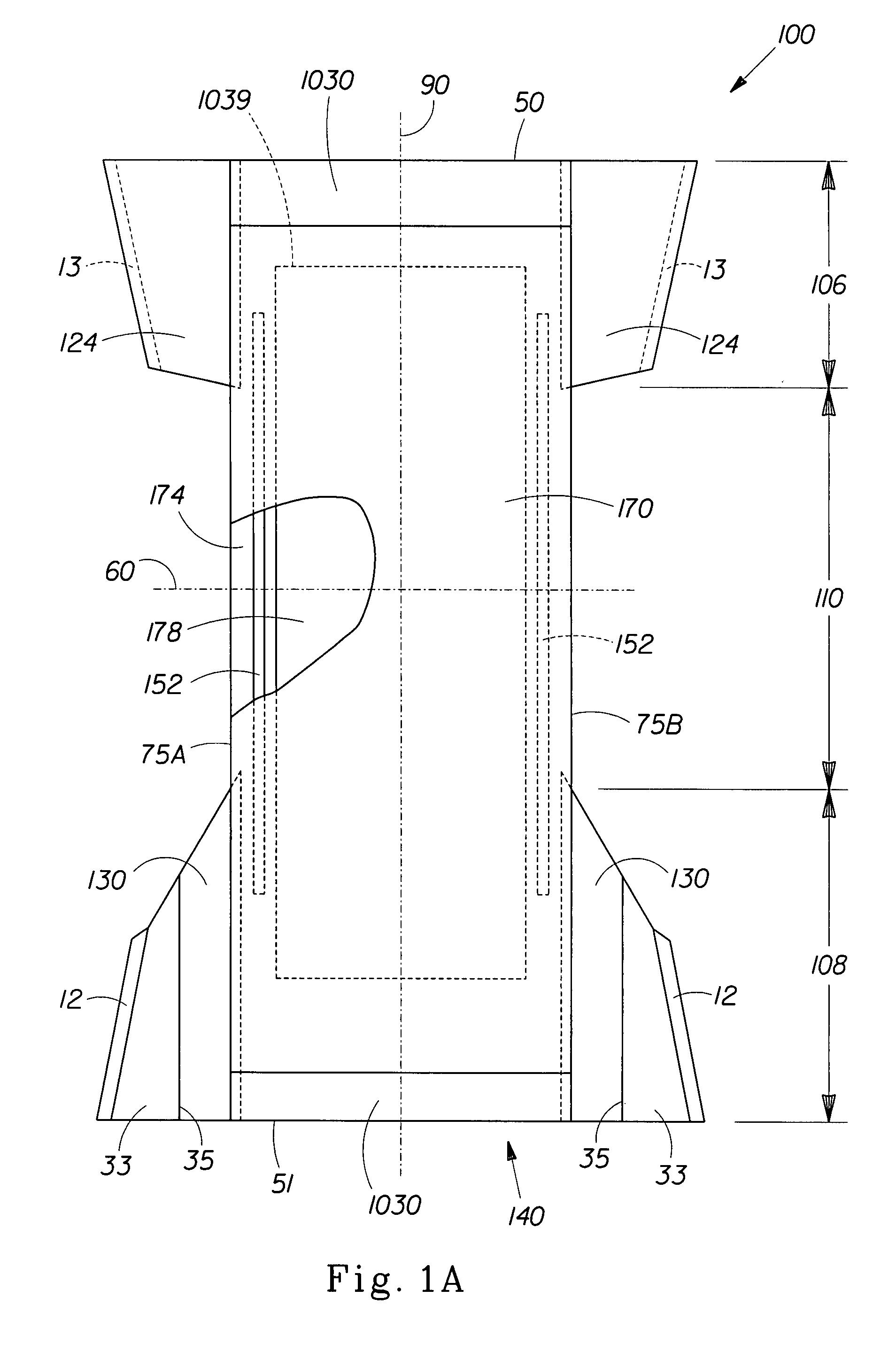

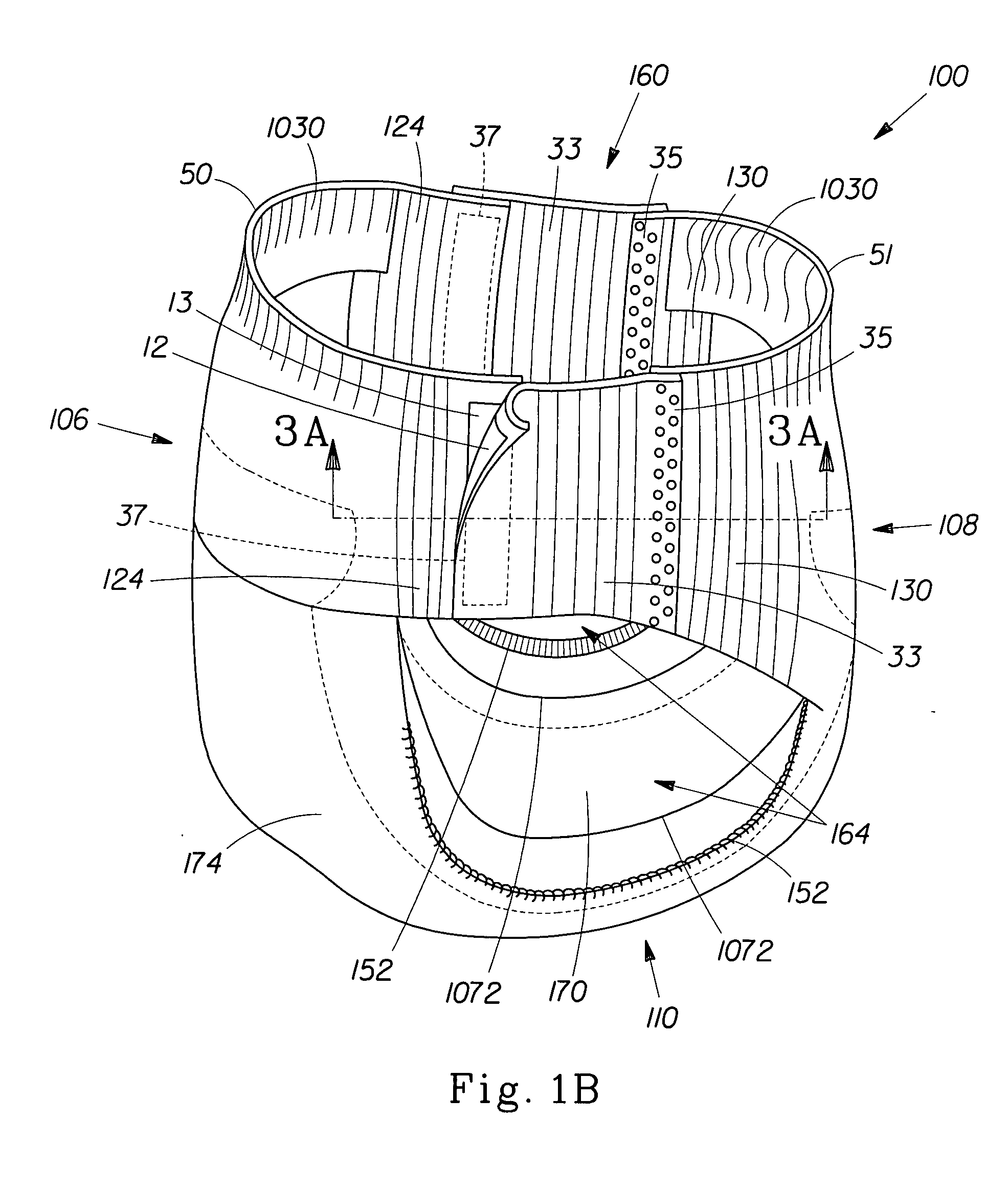

Absorbent article having refastenable and non-refastenable seams

A disposable absorbent article includes a first side panel, a second side panel, and an intermediate side panel. The first side panel is disposed in a first waist region, and the second side panel is disposed in a second waist region. Both the first and second side panels extend outward from a first longitudinal edge. The first side panel has a first stretchable width, and the second side panel has a second stretchable width. The intermediate side panel is joined to the second side panel thereby forming a non-refastenable seam and is joined to the first side panel thereby forming a refastenable seam. A gap disposed between the first side panel and non-refastenable seam having a gap width between about 1 percent to about 40 percent of the first stretchable width plus the second stretchable width.

Owner:THE PROCTER & GAMBLE COMPANY

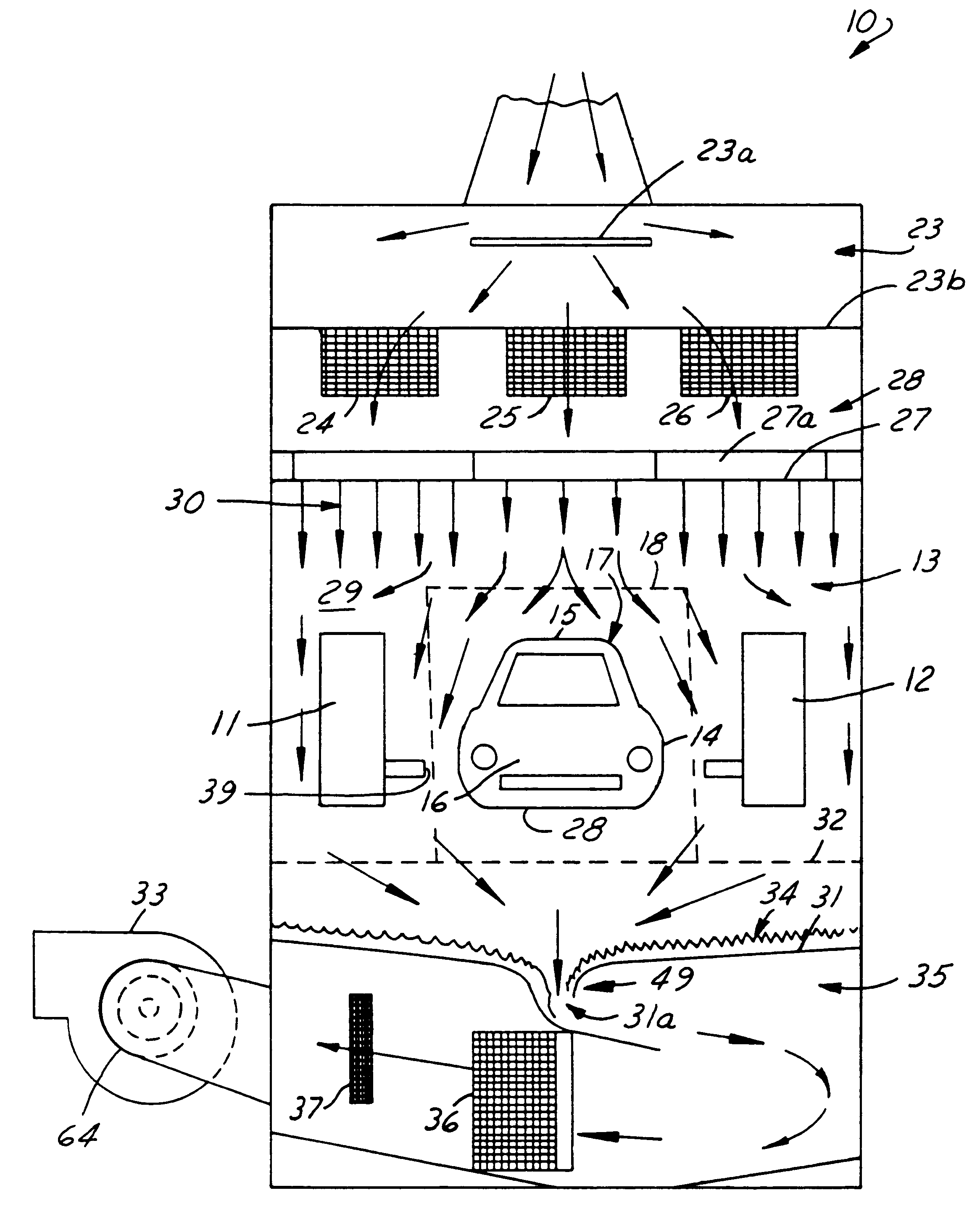

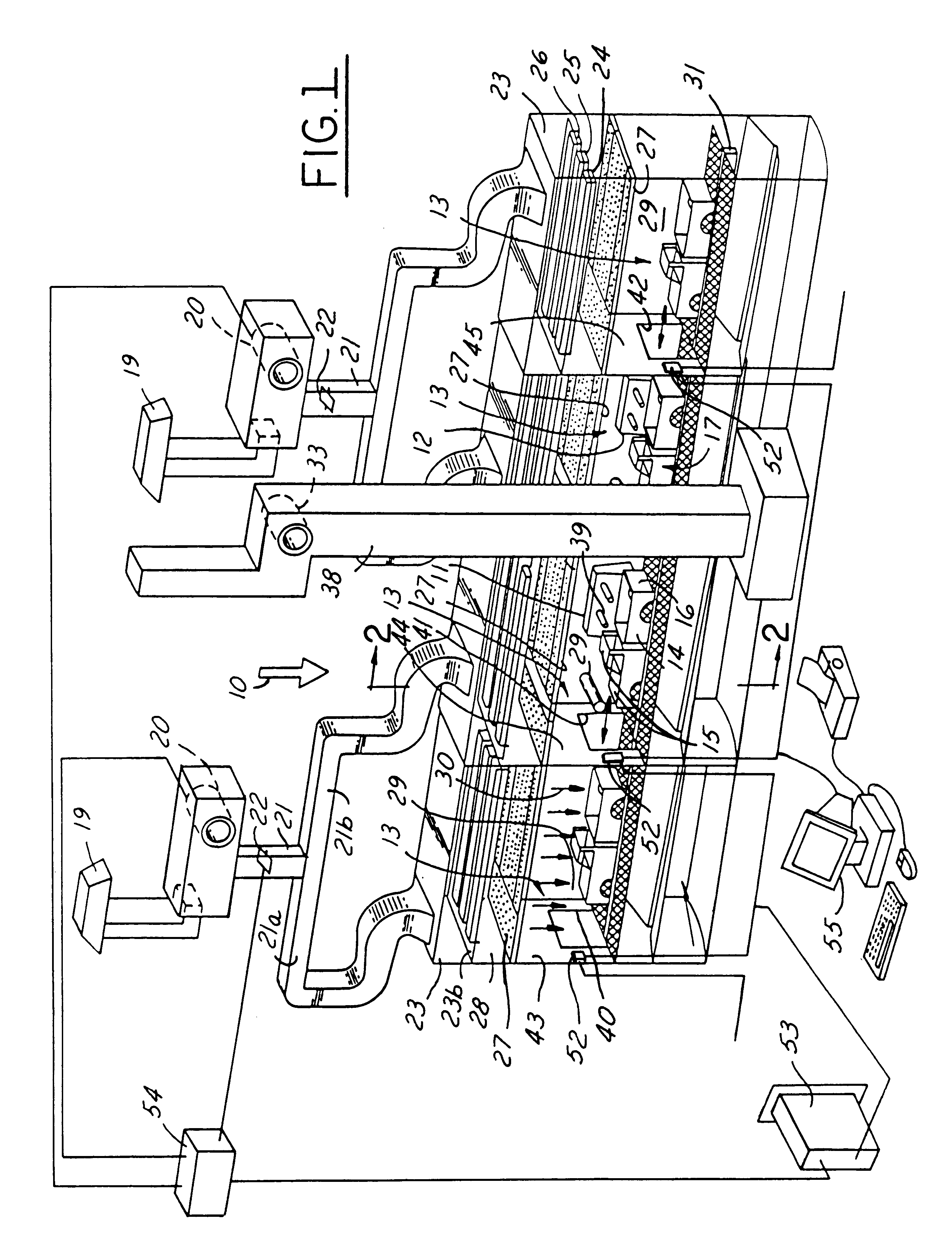

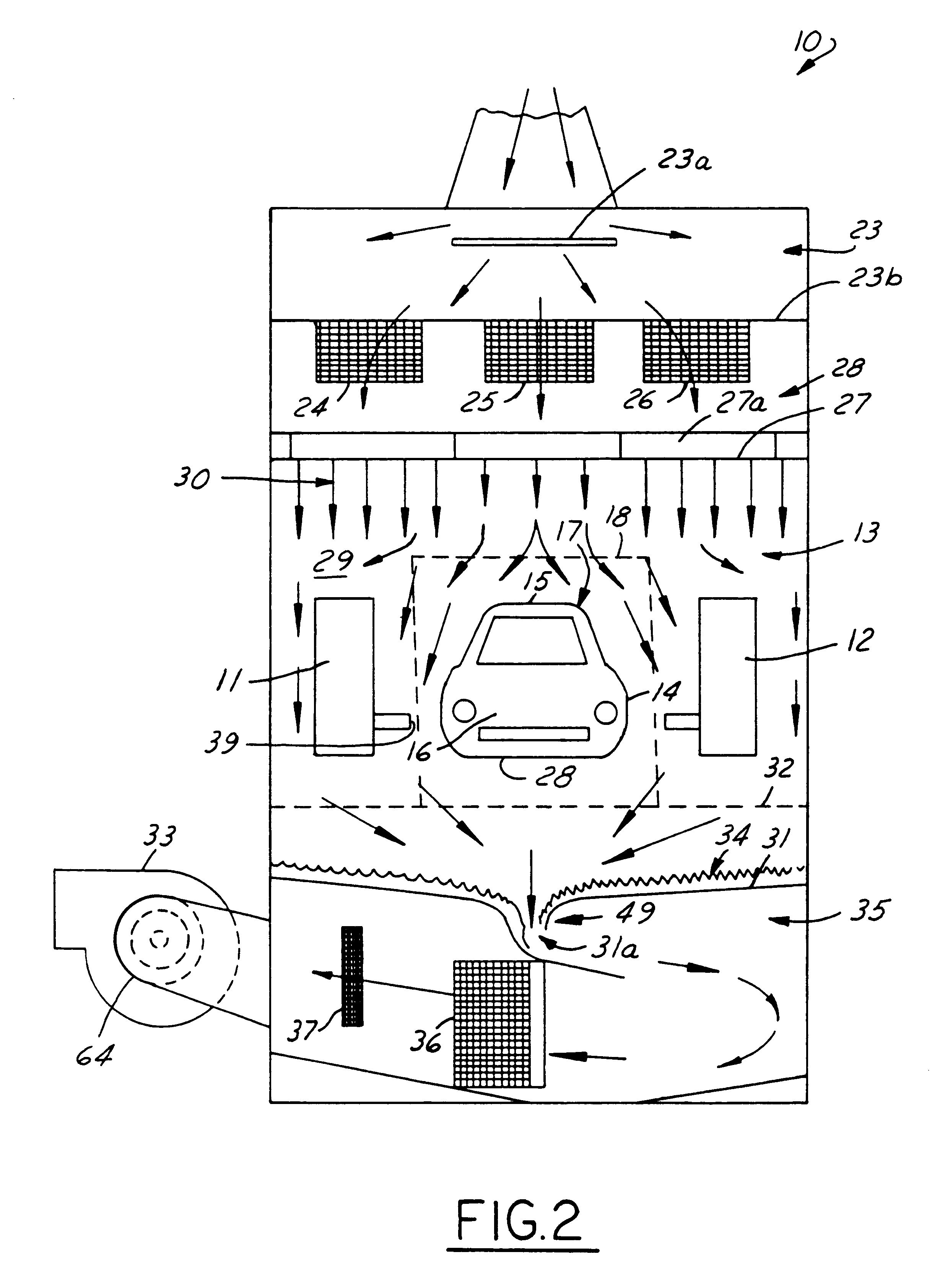

Method of balancing paint booth air flows

InactiveUS6226568B1Sampled-variable control systemsLiquid surface applicatorsControl theoryDischarge pressure

A method of rapidly balancing air flows in a complex paint spray booth having a series of cells supplied by a common air flow that is pushed by an adjustable speed supply fan and then divided into downdrafts for each of the said cells accompanied by cross-flows between said cells. The downdrafts and cross-flows converging into exhaust flows drawn by an adjustable speed exhaust fan, the system having control elements for changing the downdrafts and / or cross-flows, and further having means for passing the exhaust flow through a waste paint water scrubber having an adjustable venturi gap width. The method comprising (a) setting an exhaust an speed and venturi gap width by correlating perturbed exhaust air flow rate data with a desired exhaust air flow rate at a desired exhaust pressure drop to establish a target fan curve as a function of pressure drop and exhaust flow rate, the setting for the exhaust fan sped and venturi gap width being derived from such curve; and (b) setting a supply fan speed and control position for each cross-flow damper by solving an objective optimization function for the sum of the cross-flows by using perturbed supply fan speed values and cross-flow rate values that establish distinct optimum cross-flow velocities at a specific air supply velocity from which the supply fan speed and cross-flow speed damper positions can be derived.

Owner:FORD GLOBAL TECH LLC

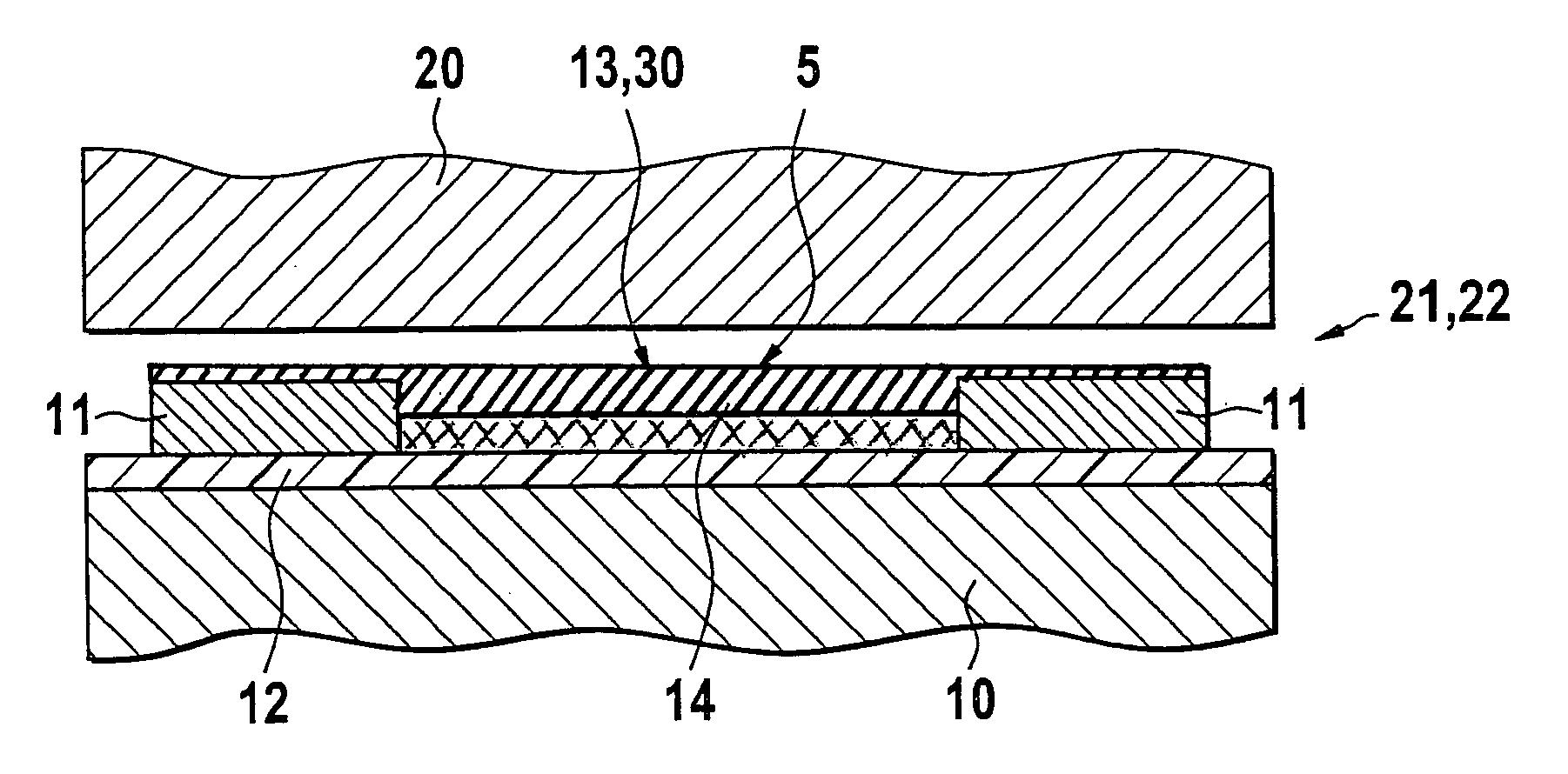

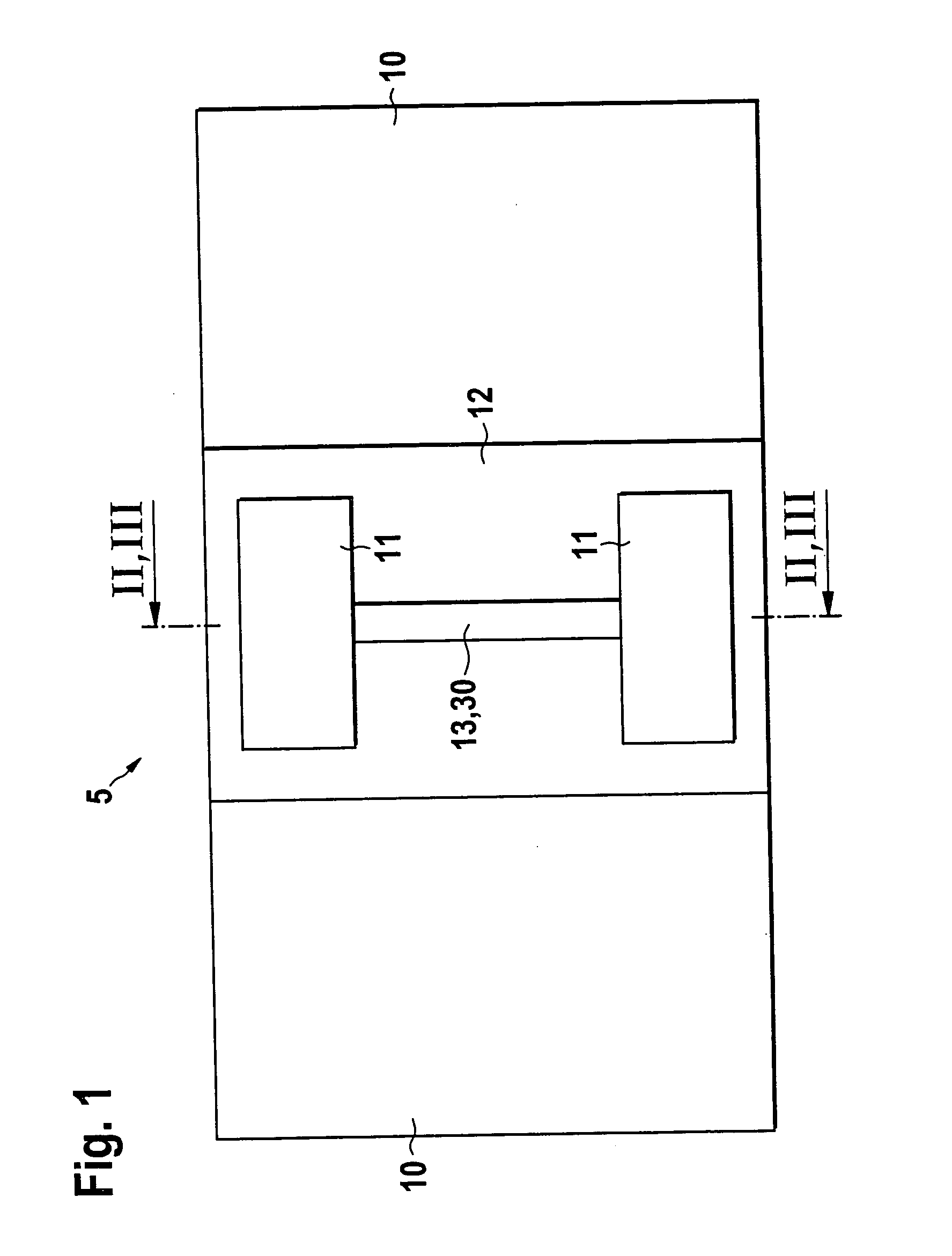

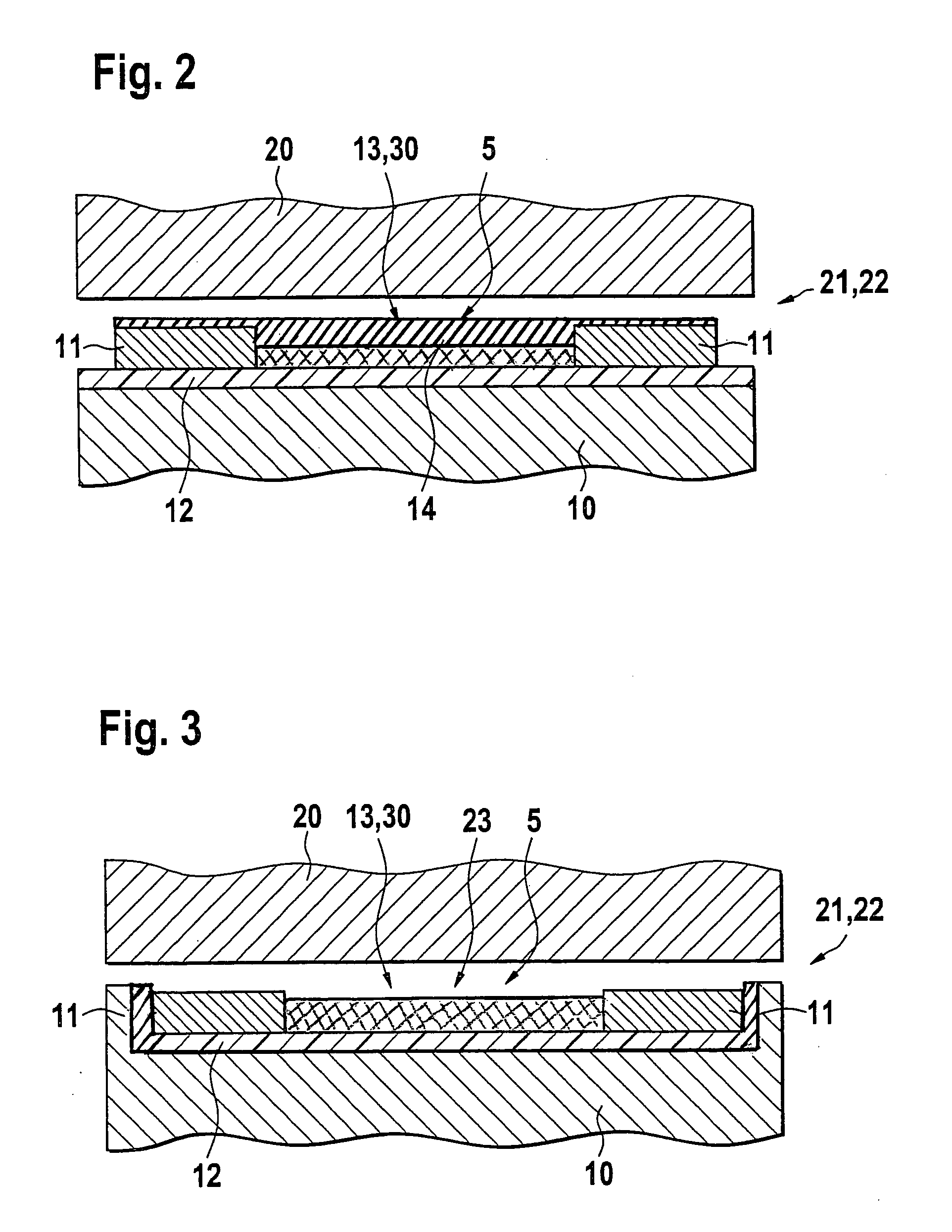

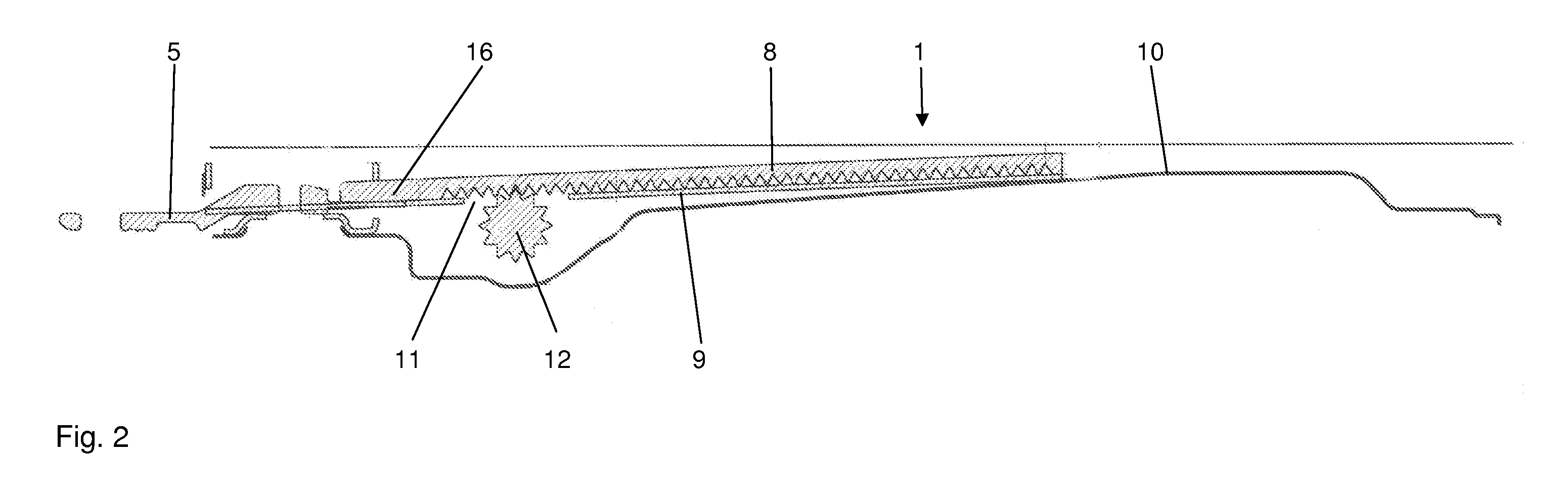

Sensor element for detecting a physical measuring variable between bodies exposed to high tribological strain

The invention proposes a sensor element (5) for detecting a physical measurement variable such as a pressure, a temperature, a capacitance, or a gap width between two bodies (10, 20) that move in relation to each other during operation and experience high tribological stress. In certain areas between the surfaces of the bodies (10, 20) that move in relation to each other, in a surface region of at least one of the bodies (10), a sensitive layer (13, 30), in particular a sensor segment (13), is provided, which is separated from the body (10) by an insulation layer (12). The insulation layer (12) has at least two component layers (31, 32), wherein one component layer (31) is a layer (31) with at least a low electrical conductivity in comparison to the sensitive layer (13) and wherein one component layer (32) is a layer with a higher tribological stress capacity in comparison to the component layer (31) with the comparatively low electrical conductivity and / or the insulation layer (12) is a layer that is at least essentially comprised of carbon, or contains carbon, oxygen, and silicon. The sensor element (5) proposed is primarily suited for detecting measurement variables in the contact region between lubricated components under high tribological stress.

Owner:ROBERT BOSCH GMBH

Method for producing metallic titanium plate using medium-wide strip hot rolling machine set

ActiveCN101412038ALow investment costRoll force/gap control deviceTemperature control deviceSocial benefitsProduction line

The invention discloses a method for producing a metallic titanium plate by adopting a medium-wide band heat rolling set. The method comprises the following steps: heating a titanium plate blank with a thickness of between 50 and 90 millimeters in a roller-hearth type soaking furnace to between 800 and 1,000 DEG C, controlling inlet temperature of the titanium plate blank entering the medium-wide band heat rolling set at a temperature of between 800 and 950 DEG C, controlling process temperature to between 700 and 950 DEG C, and keeping final rolling temperature at a temperature of between 700 and 800 DEG C after fine rolling for seven times; and well controlling roll gap width, depressing rate, roll force and roll (rolling) speed of each stander of the heat rolling set, controlling the rolling speed of the titanium plate rolled by the tail stander of the heat rolling set at between 4.0 and 8.0 meters per second, and coiling the titanium plate by a coiling machine after cooling the titanium plate by water, wherein the coiling temperature is between 550 and 680 DEG C. The method uses a CSP production line to produce the non-ferrous metallic titanium plate (coil) for domestic initiation, and has extremely great economic and social benefits.

Owner:湖南湘投金天钛金属股份有限公司 +1

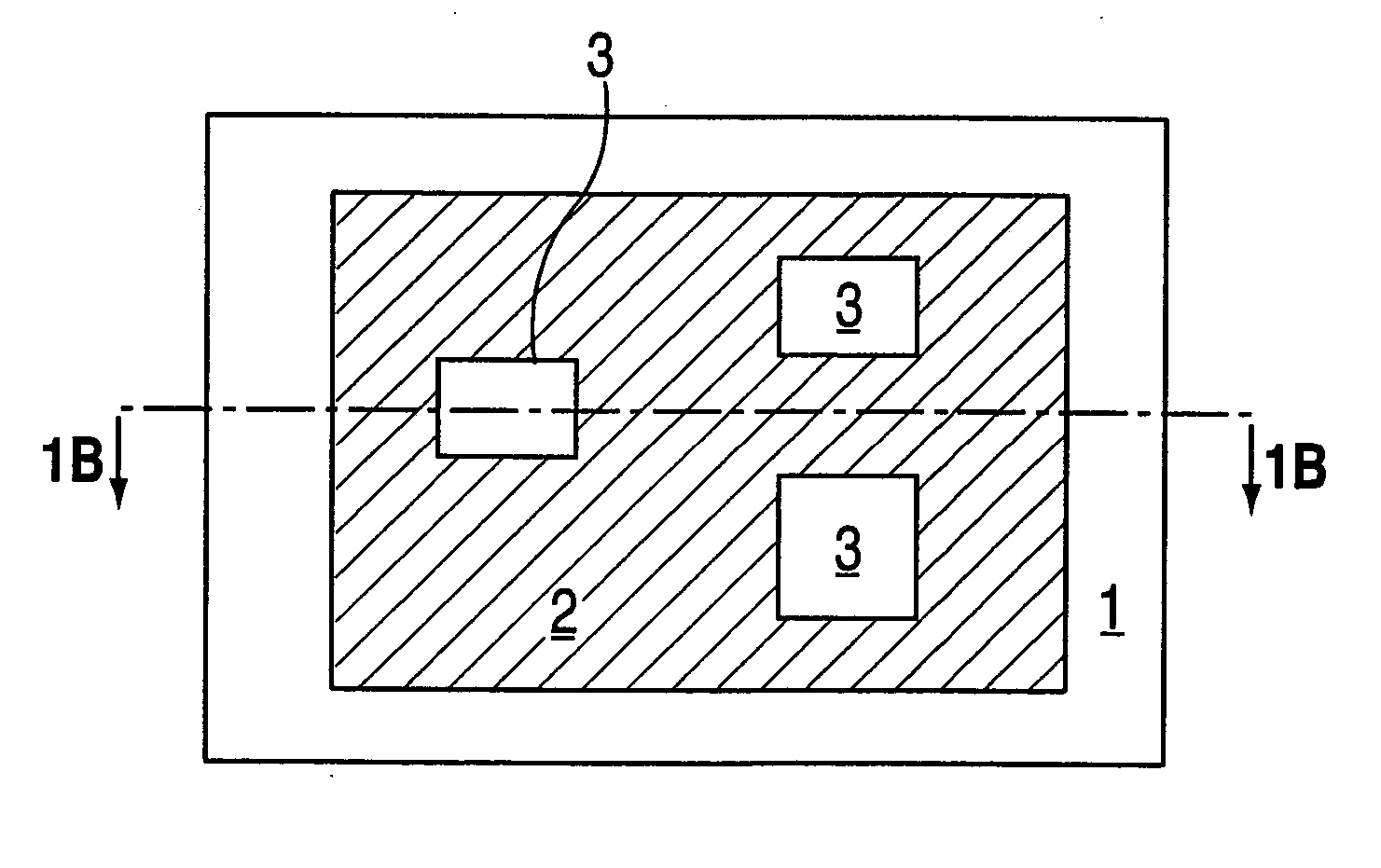

High capacitance density vertical natural capacitors

InactiveUS20070279835A1Increase capacitance densityEffective gap distanceTransistorThin/thick film capacitorDielectricCapacitance

Disclosed are embodiments of a capacitor with inter-digitated vertical plates and a method of forming the capacitor such that the effective gap distance between plates is reduced. This gap width reduction significantly increases the capacitance density of the capacitor. Gap width reduction is accomplished during back end of the line processing by masking connecting points with nodes, by etching the dielectric material from between the vertical plates and by etching a sacrificial material from below the vertical plates. Etching of the dielectric material from between the plates forms air gaps and various techniques can be used to cause the plates to collapse in on these air gaps, once the sacrificial material is removed. Any remaining air gaps can be filled by depositing a second dielectric material (e.g., a high k dielectric), which will further increase the capacitance density and will encapsulate the capacitor in order to make the reduced distance between the vertical plates permanent.

Owner:GLOBALFOUNDRIES INC

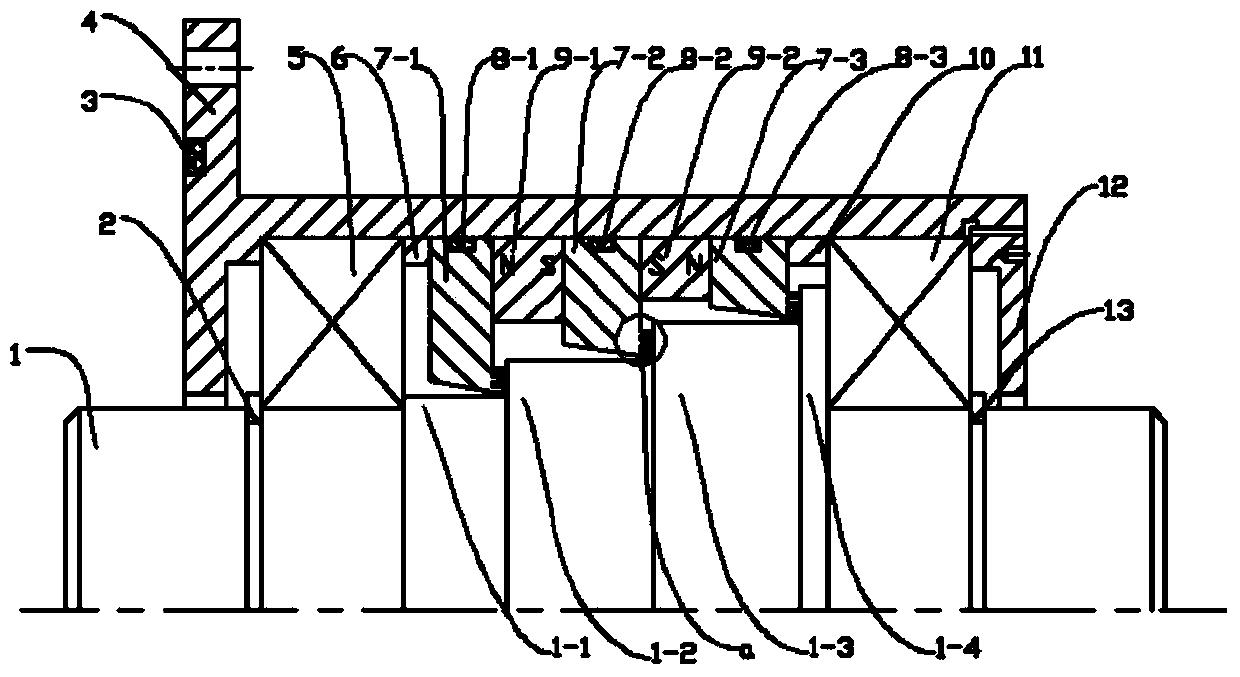

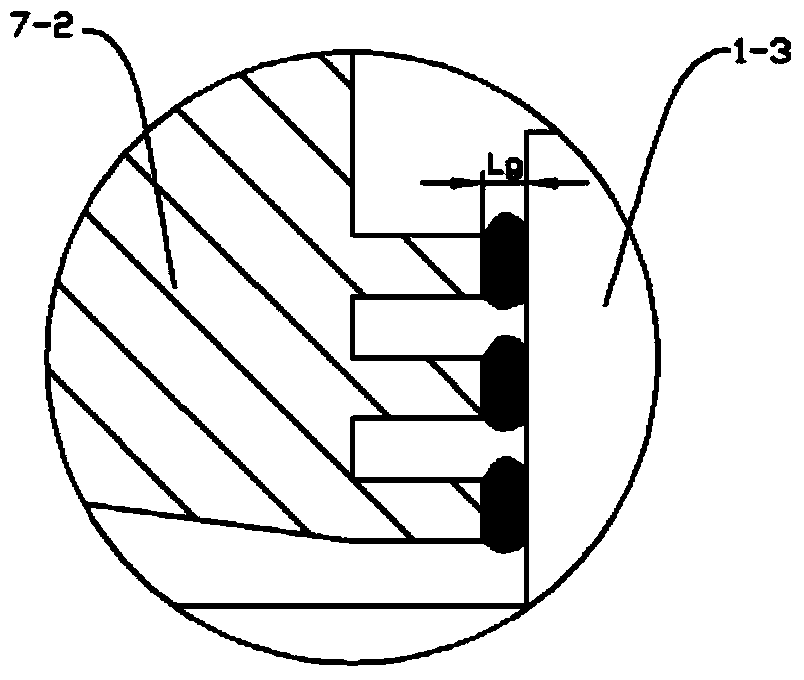

Sealing device for improving sealing anti-pressure capability and sealing reliability of magnetic liquid

InactiveCN103498939AOvercome the shortcomings of low sealing pressure resistanceImprove pressure resistanceEngine sealsMagnetic liquidsEngineering

The invention provides a sealing device for improving the sealing anti-pressure capability and the sealing reliability of magnetic liquid, and belongs to sealing devices of rotating shafts. The problems that large-gap sealing is low in anti-pressure capability and poor in reliability are solved. A shaft of the sealing device is a step shaft, the right side face of a first pole shoe, the right side face of a second pole shoe and the right side face of a third pole shoe, or shaft shoulders of steps from the second to the fourth are provided with pole teeth, the axial gap widths of the pole shoes and the shaft shoulders are smaller than the radial gap widths between the pole shoes and the step shaft, and the sealing device for improving the sealing anti-pressure capability and the sealing reliability of the magnetic liquid is achieved. The defect that the large-gap magnetic liquid is low in sealing anti-pressure capability is overcome, the transformation from an axial drainage channel to a radial drainage channel is achieved, the sealing anti-pressure capability and the sealing reliability of the magnetic liquid under the condition of large gaps are improved, and the safety working range is widened. Therefore, the sealing device is an ideal sealing device for solving the problems of being low in large-gap sealing anti-pressure capability and poor in reliability.

Owner:BEIJING JIAOTONG UNIV

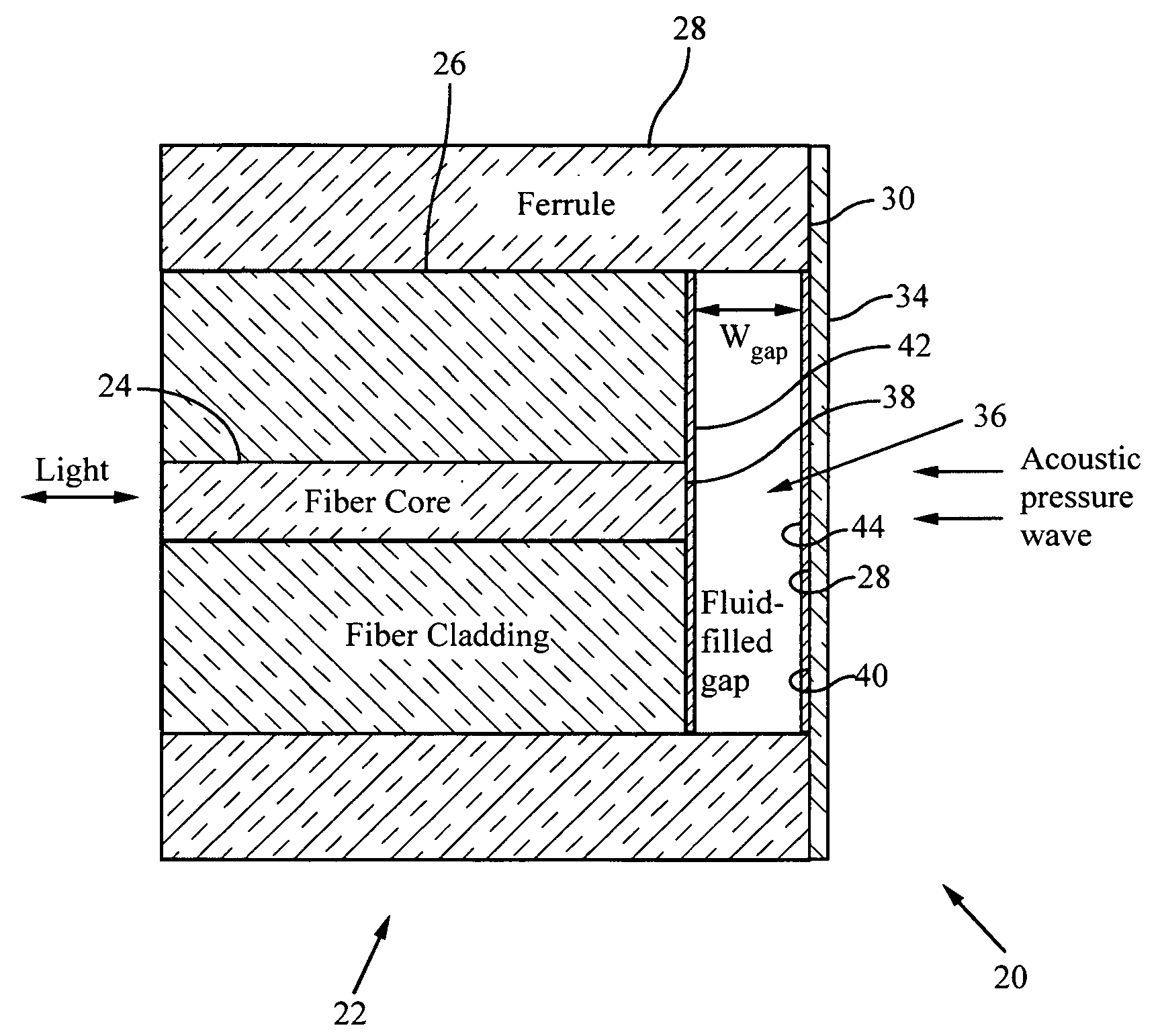

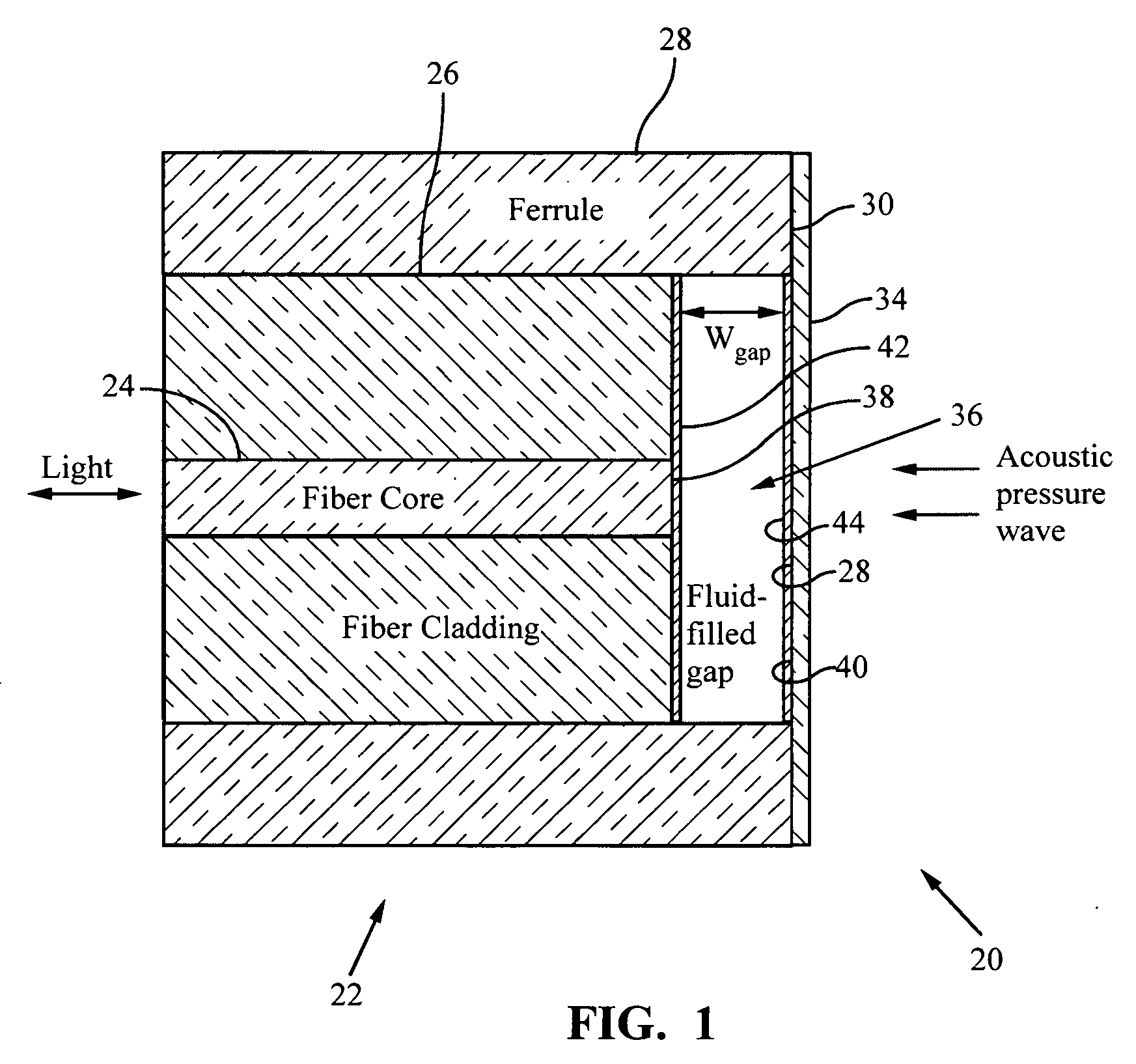

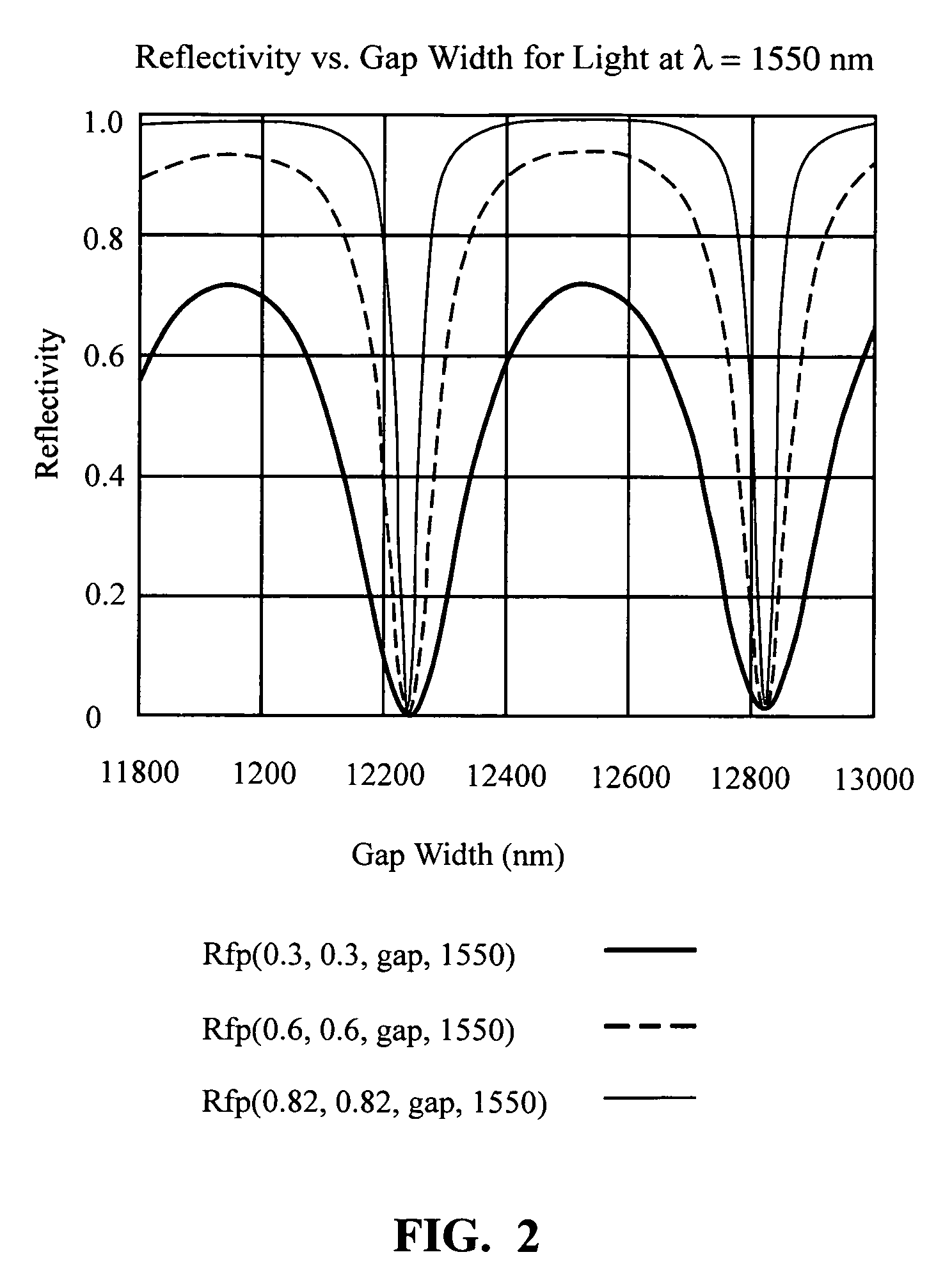

Push-pull two wavelength fabry perot sensor for fiber optic acoustic sensor arrays

Two optical wavelengths are used to interrogate a fiber optic Fabry-Perot sensor having a moveable diaphragm that changes the width of a gap between two reflective surfaces. By picking the right operating point for the gap, the power output for one wavelength increases as the gap width changes and the power for the other wavelength decreases. A ratio of the difference of the two powers over the sum of the two powers is formed to generate a detected signal independent of power and phase fluctuations in a fiber between signal sources and sensor and between sensor and detector. This ratio, which is called the visibility, has a response proportional to the pressure of acoustic disturbances that move the diaphragm. The push-pull sensor can be used with both TDM and CW fan-out array architectures.

Owner:NORTHROP GRUMMAN GUIDANCE & ELECTRONICS

Dishwasher having a flushing container with a lockable door and method for performing a dishwashing program in such dishwasher

ActiveUS20060283482A1Simplify operating proceduresSimple actionAutomatic washing/rinsing machine detectionWing accessoriesEngineeringGap width

A dishwasher includes a tub, a hinged door for closing the tub, a sealing gasket disposed between the tub and the door, a device control unit, a closing plate connected to the tub and movable by a motor, a latching element disposed on the door, and a closing tab disposed on the closing plate for engaging with the latching element for closing the door and enabling the device control unit to partially open the door. The closing plate is movable into first and second positions to bring the door into respective first and second partially open positions with respective first and second gap widths. The second gap width is larger than the first gap width.

Owner:MIELE & CO KG

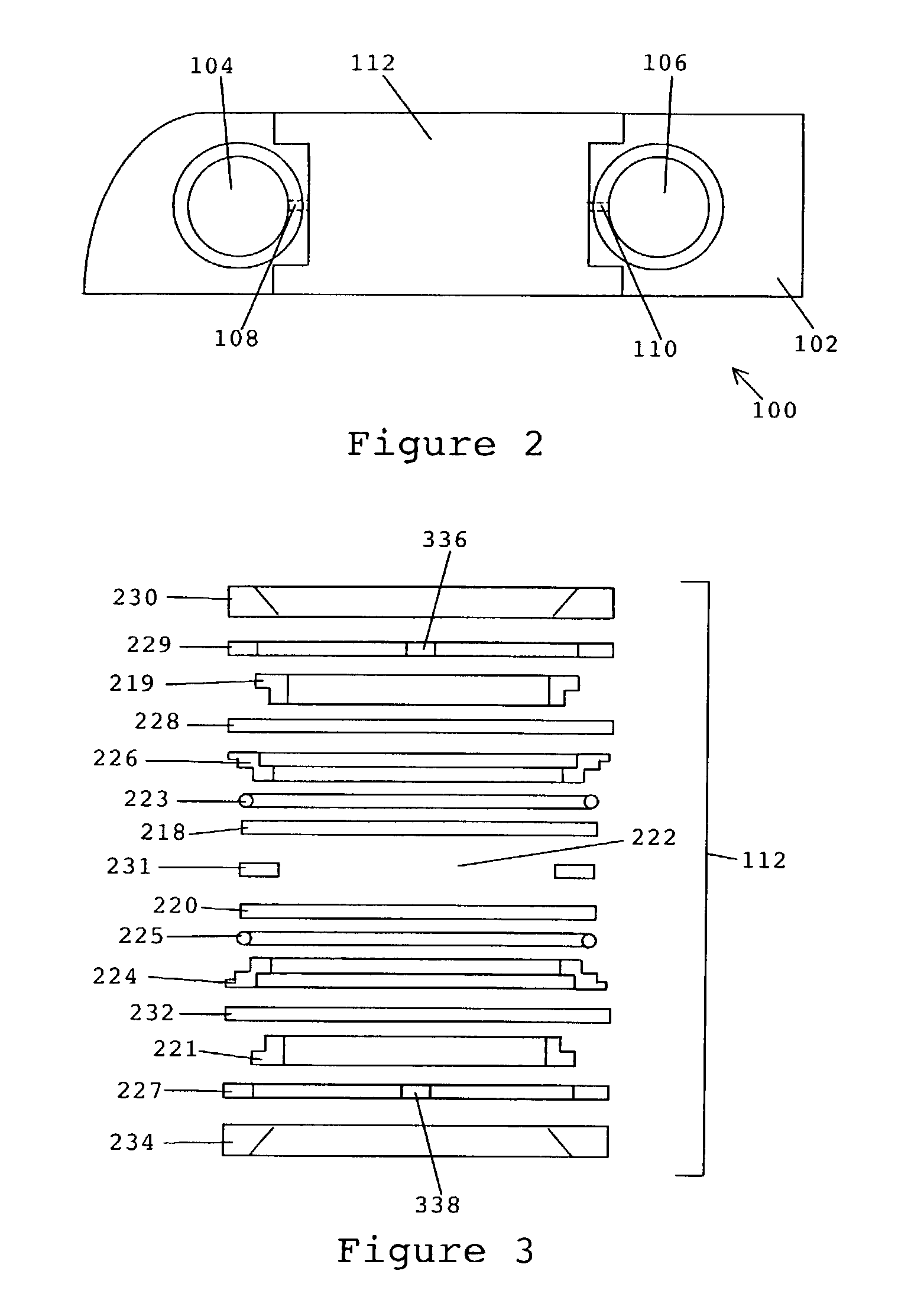

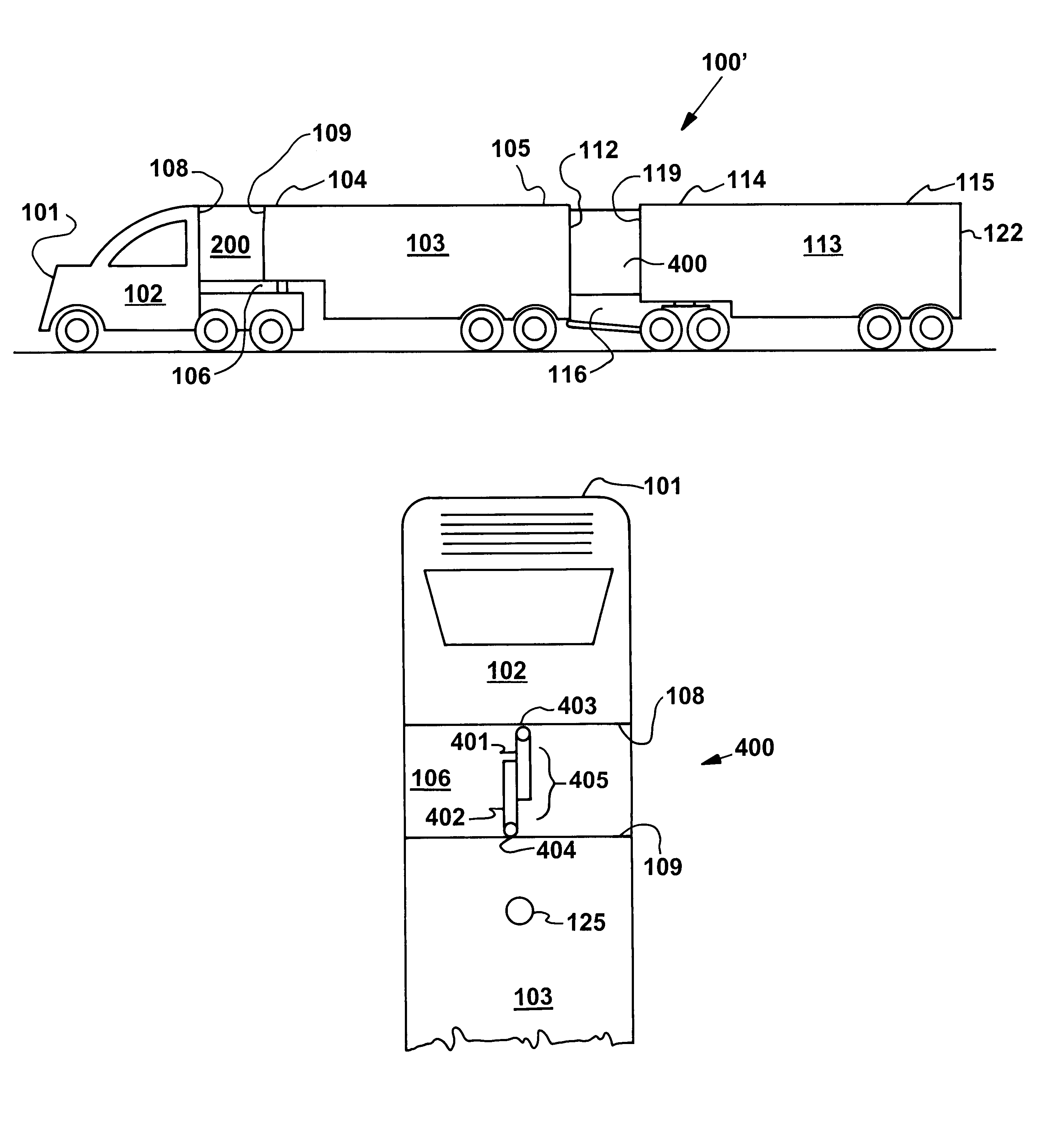

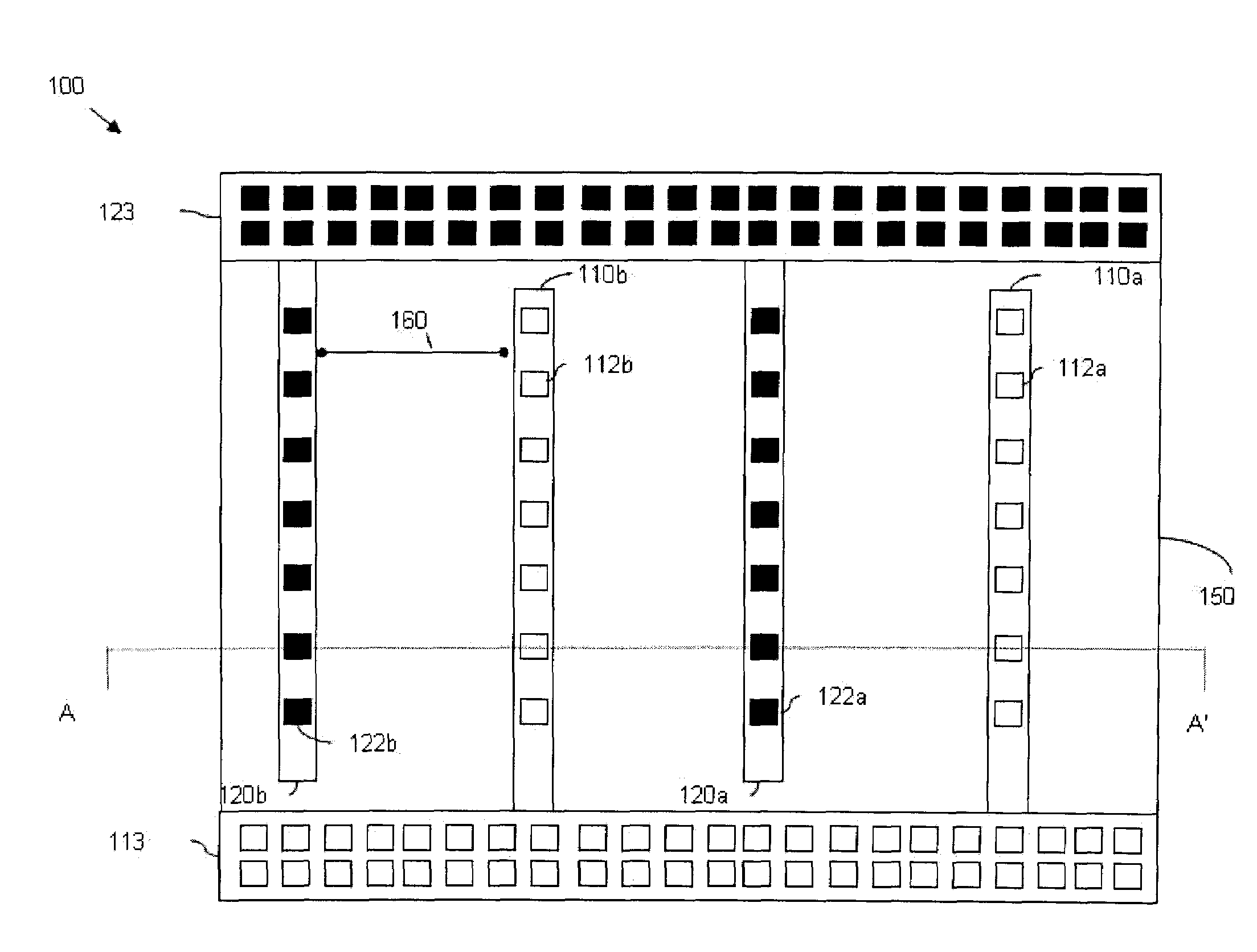

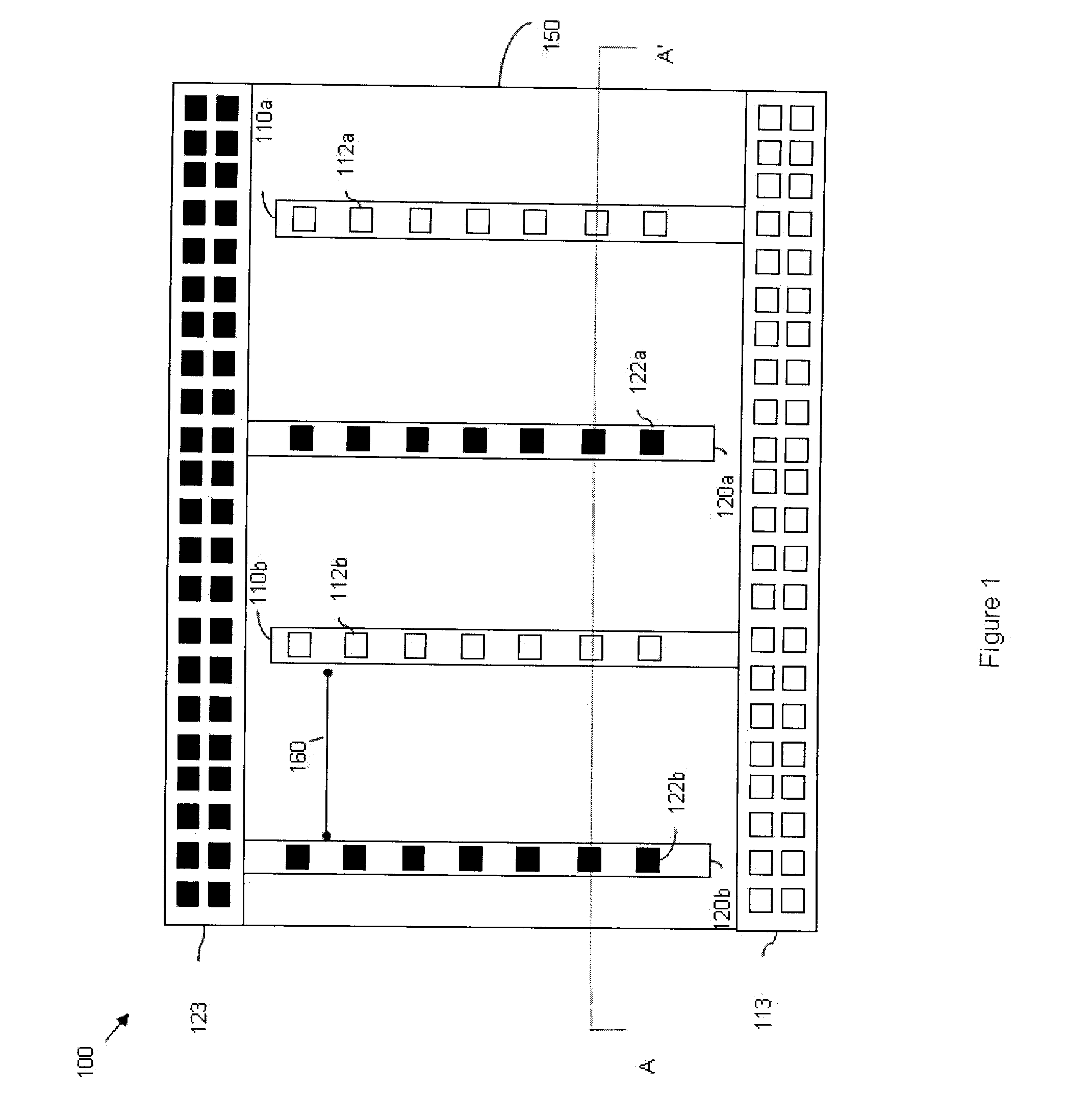

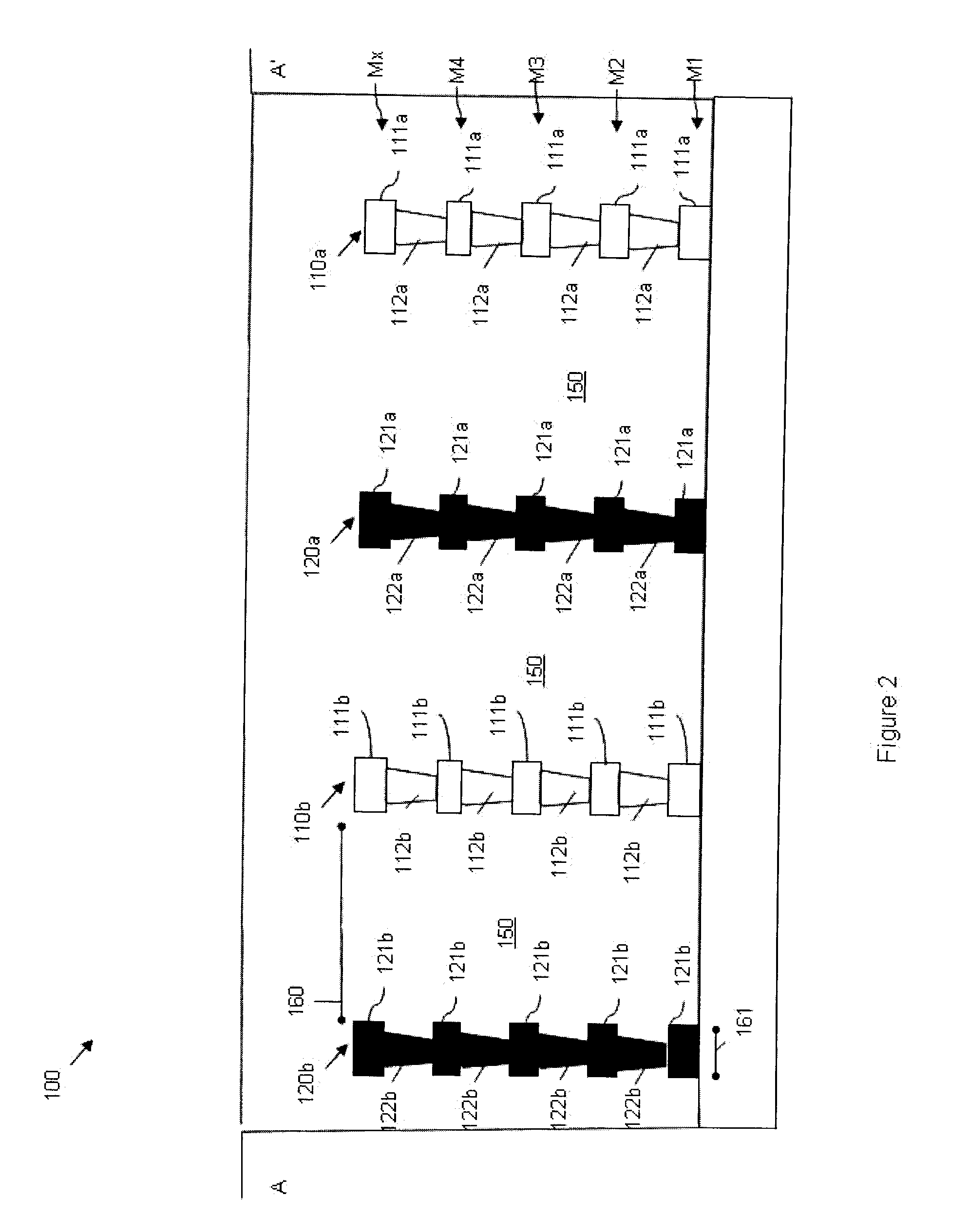

Impedance control in electrical connectors

InactiveUS20050020109A1Coupling contact membersTwo-part coupling devicesEngineeringElectrical connector

The invention provides a high speed connector wherein differential signal pairs are arranged so as to limit the level of cross talk between adjacent differential signal pairs. The connector comprises lead frame assembly having a pair of overmolded lead frame housings. Each lead frame housing has a respective signal contact extending therethrough. The lead frame housings may be operatively coupled such that the signal contacts form a broadside-coupled differential signal pair. The contacts may be separated by a gap having a gap width that enables insertion loss and cross talk between signal pairs to be limited.

Owner:FCI AMERICAS TECH LLC

Method and circuit for checking the width of the air gap in a speed sensor

In the case of a method for checking the width of the measuring air gap of a magnetic speed sensor, square-wave output signals are generated from the measurement signals of the sensor by means of at least one prescribable threshold value. The pulse duty factor of the output signals is held within a prescribed range in the case of an acceptable gap width. In the case of amplitudes of the measurement signal outside prescribed limits, the pulse duty factor deviates in a reliably measurable fashion from the prescribed range. A circuit has the means for carrying out this method.

Owner:CONTINENTAL AUTOMOTIVE GMBH

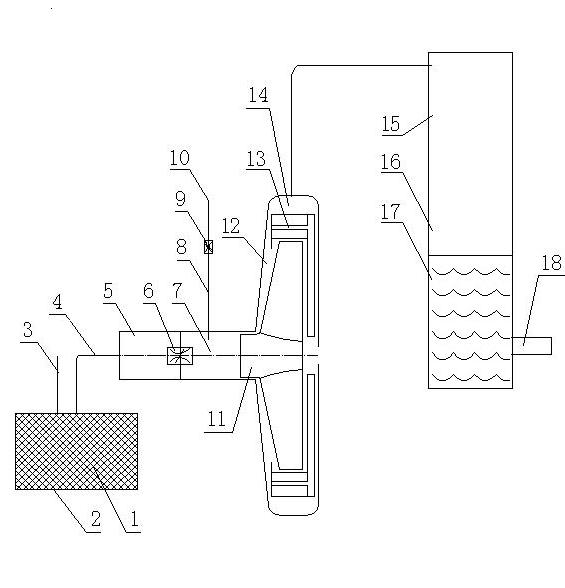

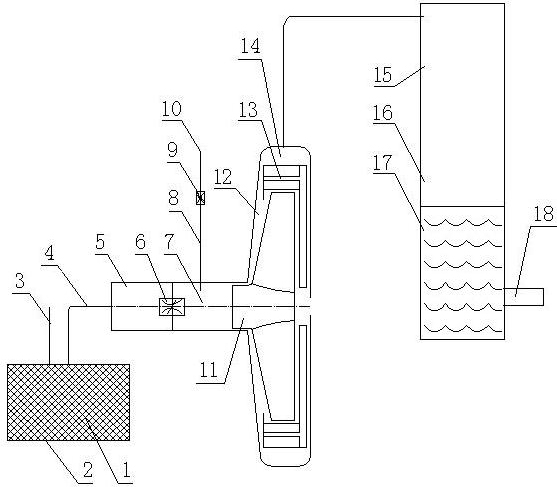

High-efficiency energy-saving submicron bubble aeration oxygenating device

InactiveCN102219315AEasy to handleEnergy saving treatmentWater aerationSustainable biological treatmentFilter systemSewage

The invention relates to a high-efficiency energy-saving submicron bubble aeration oxygenating device. The high-efficiency energy-saving submicron bubble aeration oxygenating device combines an air suction device, a centrifugal pump, a gas water mixed energy accumulator, a wide-gap submicron bubble spray head and a filtering system, wherein the centrifugal pump can work normally after gas enters the centrifugal pump; the filtering system can perform back wash; the air suction device is arranged on a water inlet of the centrifugal pump and is connected with the filtering system; an air suction pipe communicated with the outside is arranged on the side wall of the air suction device; the sucked gas is forcedly mixed into water under the high-speed rotation action of pump impellers to obtain gas water mixed liquid; the gas water mixed liquid is conveyed into the gas water mixed energy accumulator; the lower part of the gas water mixed energy accumulator is connected with the wide-gap submicron bubble spray head with the gap width of 2 to 3 mm; the wide-gap submicron bubble spray head is arranged at the bottom of sewage requiring aeration to manufacture submicron bubbles; and the submicron bubbles release the gas carried by the bubbles to the sewage to perform aeration and oxygenation, and the concentration of the dissolved oxygen in the sewage is maintained to be 2.5 to 5 mg / L.

Owner:DIBO PUMP IND MFG KUNMING

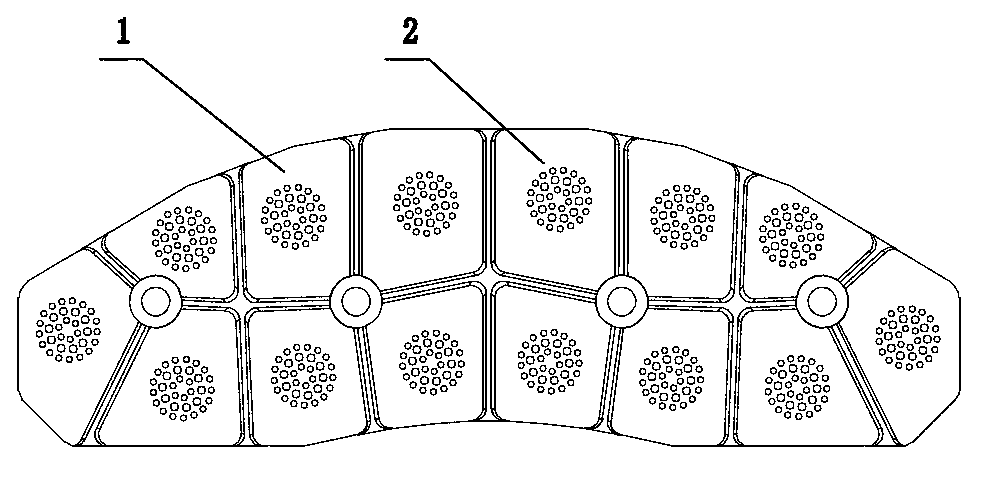

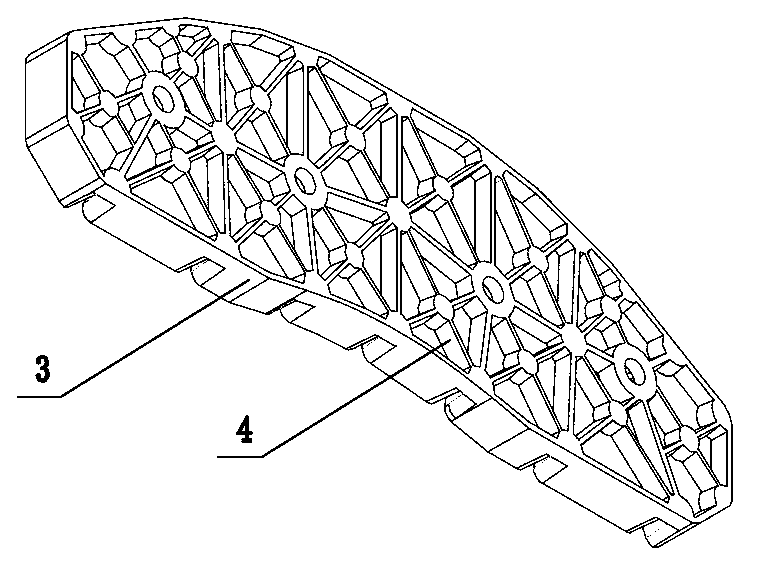

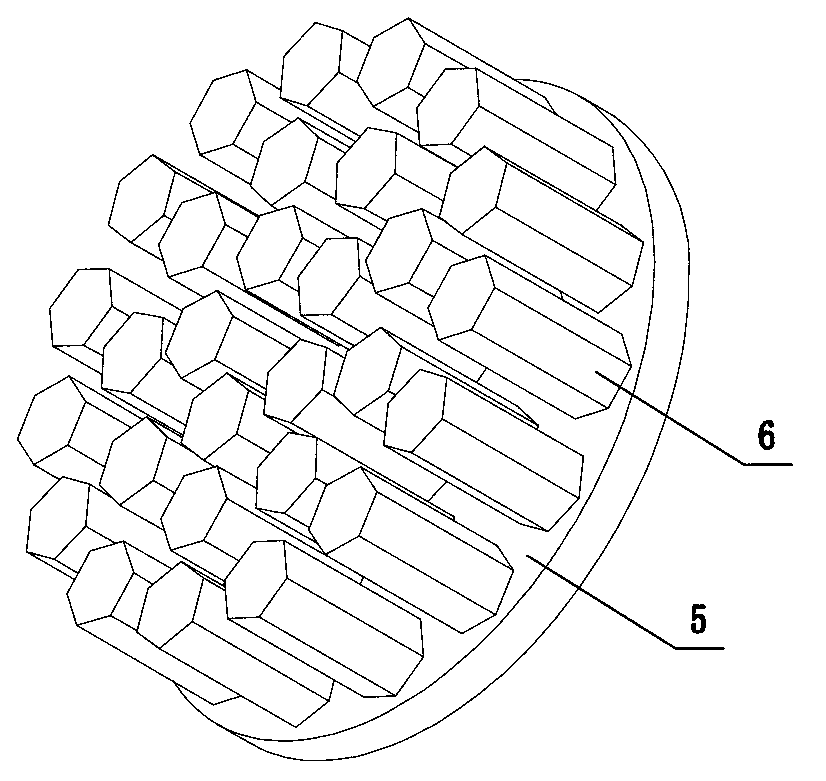

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

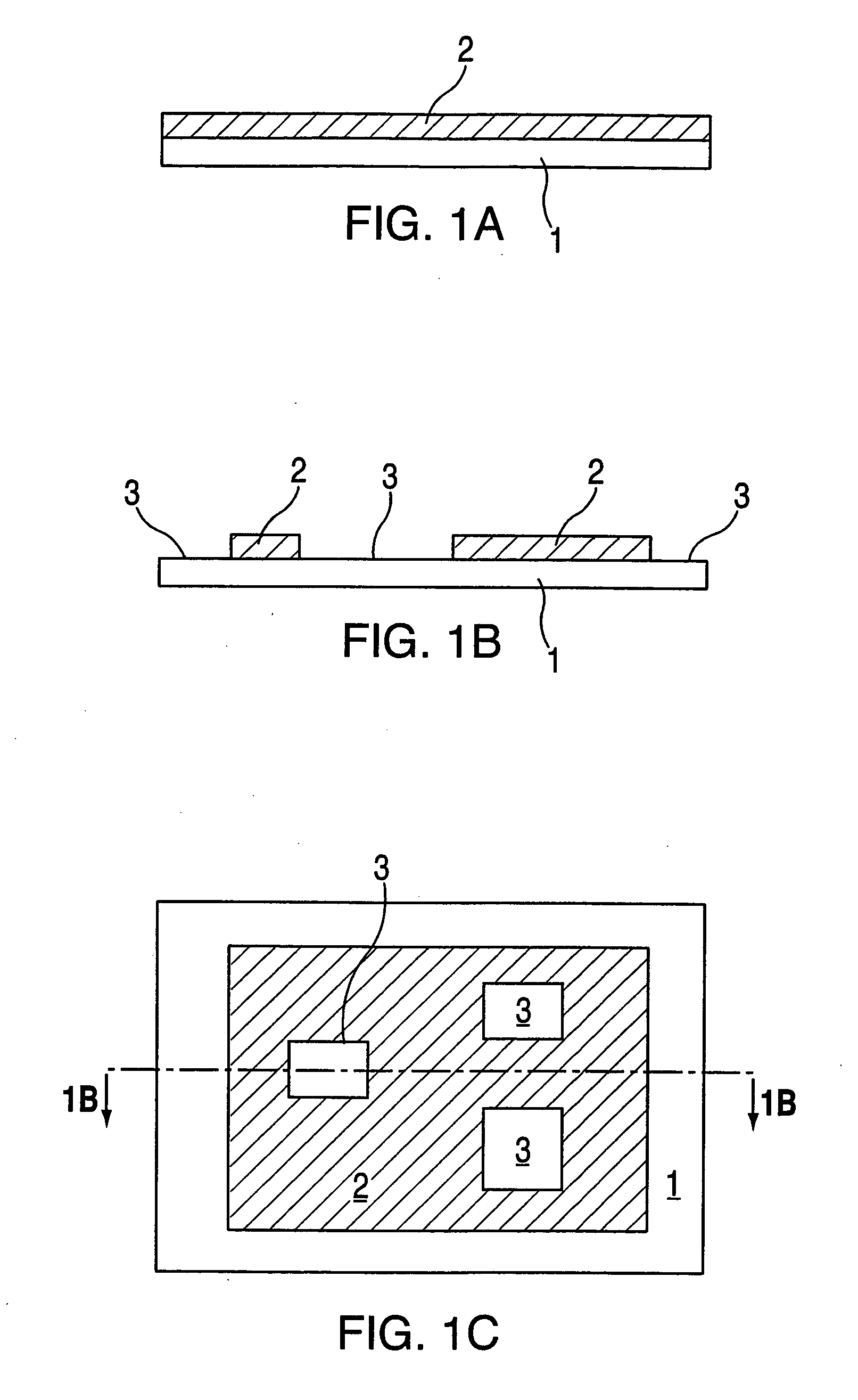

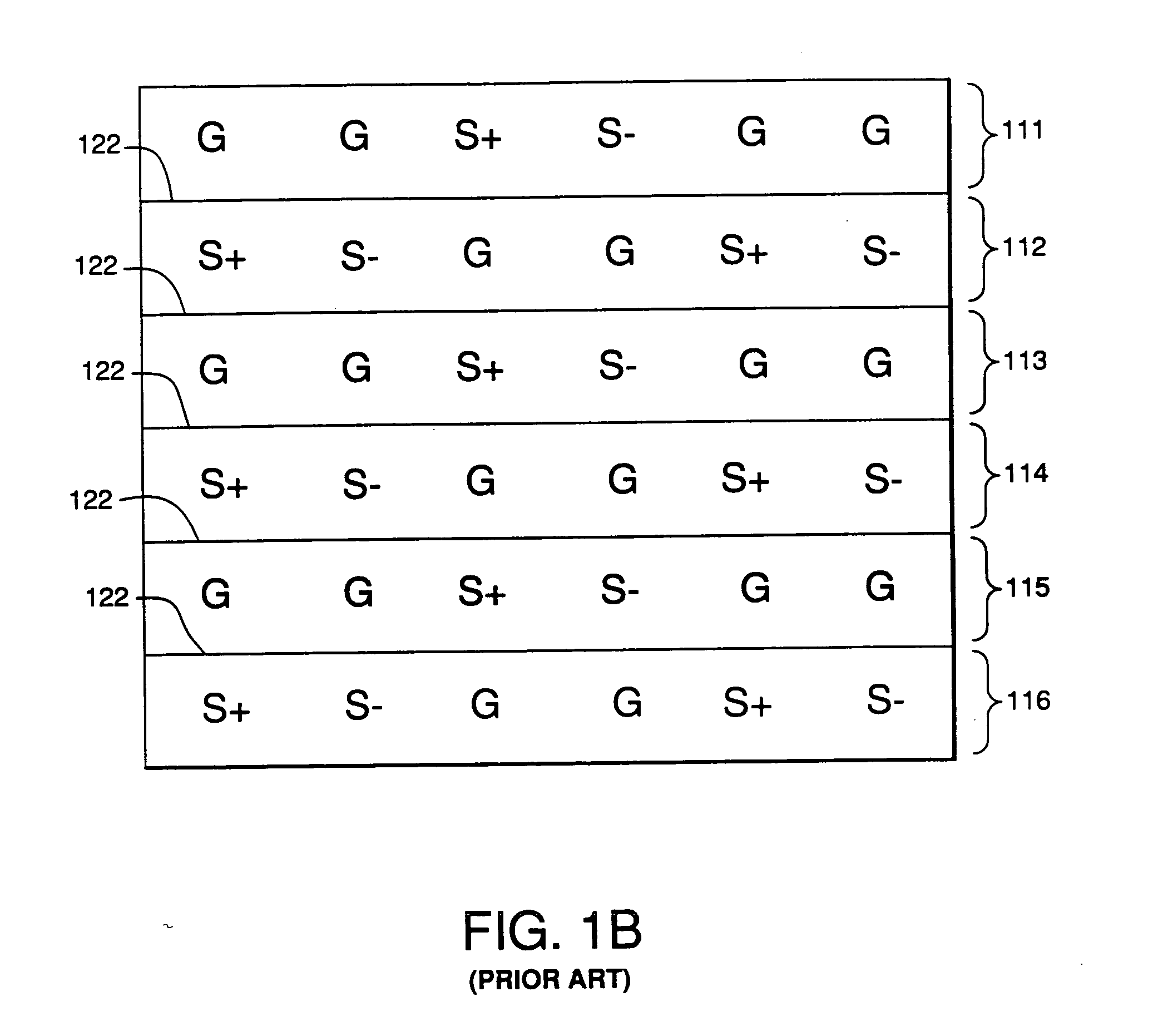

Electrical connectors having differential signal pairs configured to reduce cross-talk on adjacent pairs

InactiveUS20050287850A1Fixed connectionsCoupling protective earth/shielding arrangementsElectrical and Electronics engineeringGap width

An electrical connector according to the invention may include a first signal contact that defines a first side and a first edge, wherein the first side is greater in length than the first edge, the first edge having a first edge width, and a second signal contact that defines a second side and a second edge, wherein the second side is greater in length that the second edge, the second edge having a second edge width. The first signal contact and the second signal contact may be positioned edge-to-edge. A gap may be defined between the first edge of the first signal contact and the second edge of the second signal contact. The gap may have a gap width that is approximately equal to at least one of the first edge width and the second edge width. The connector may have a column pitch, and the gap width may be based on the column pitch. The gap width may be approximately 0.3-0.4 millimeters.

Owner:FCI AMERICAS TECH LLC +1

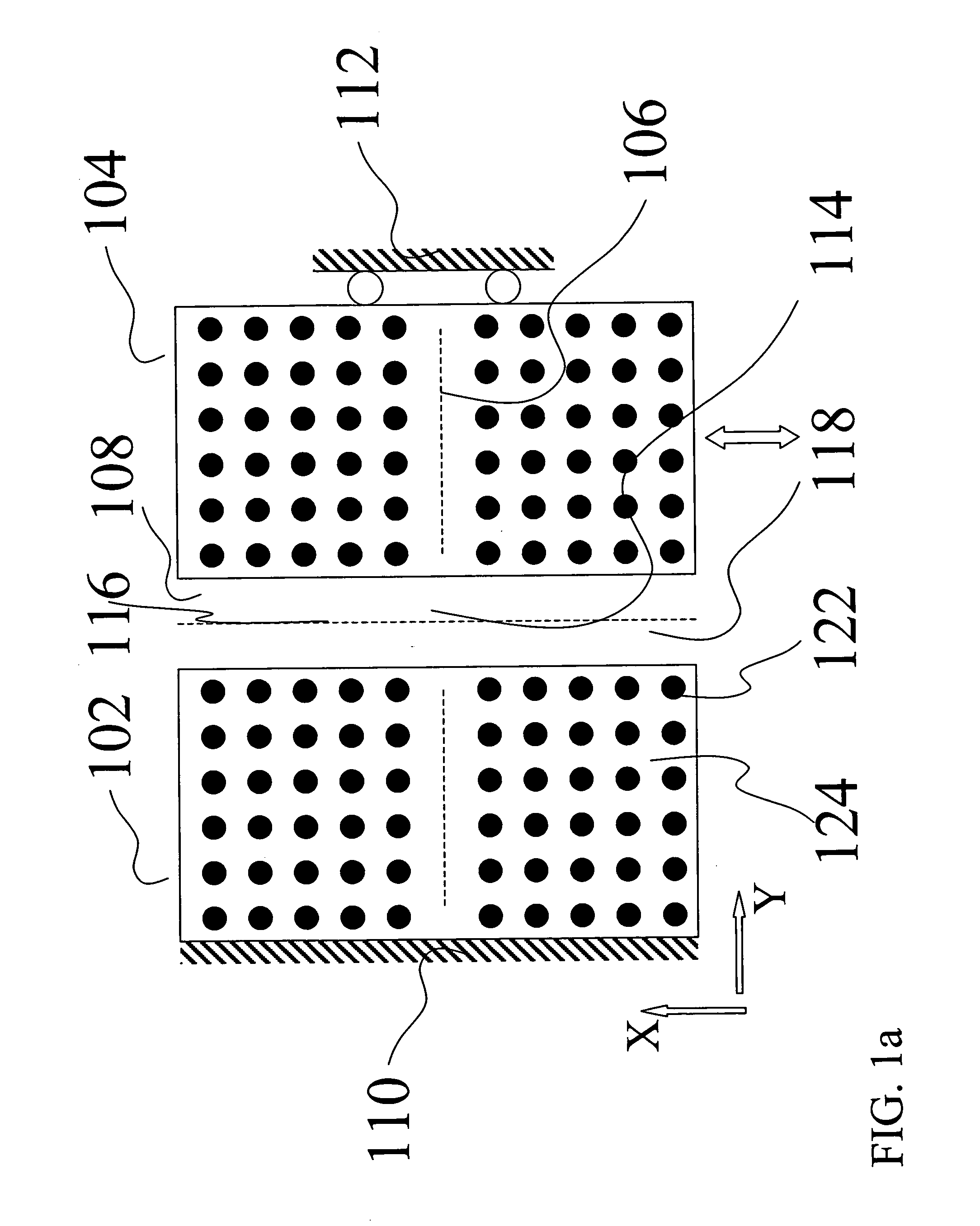

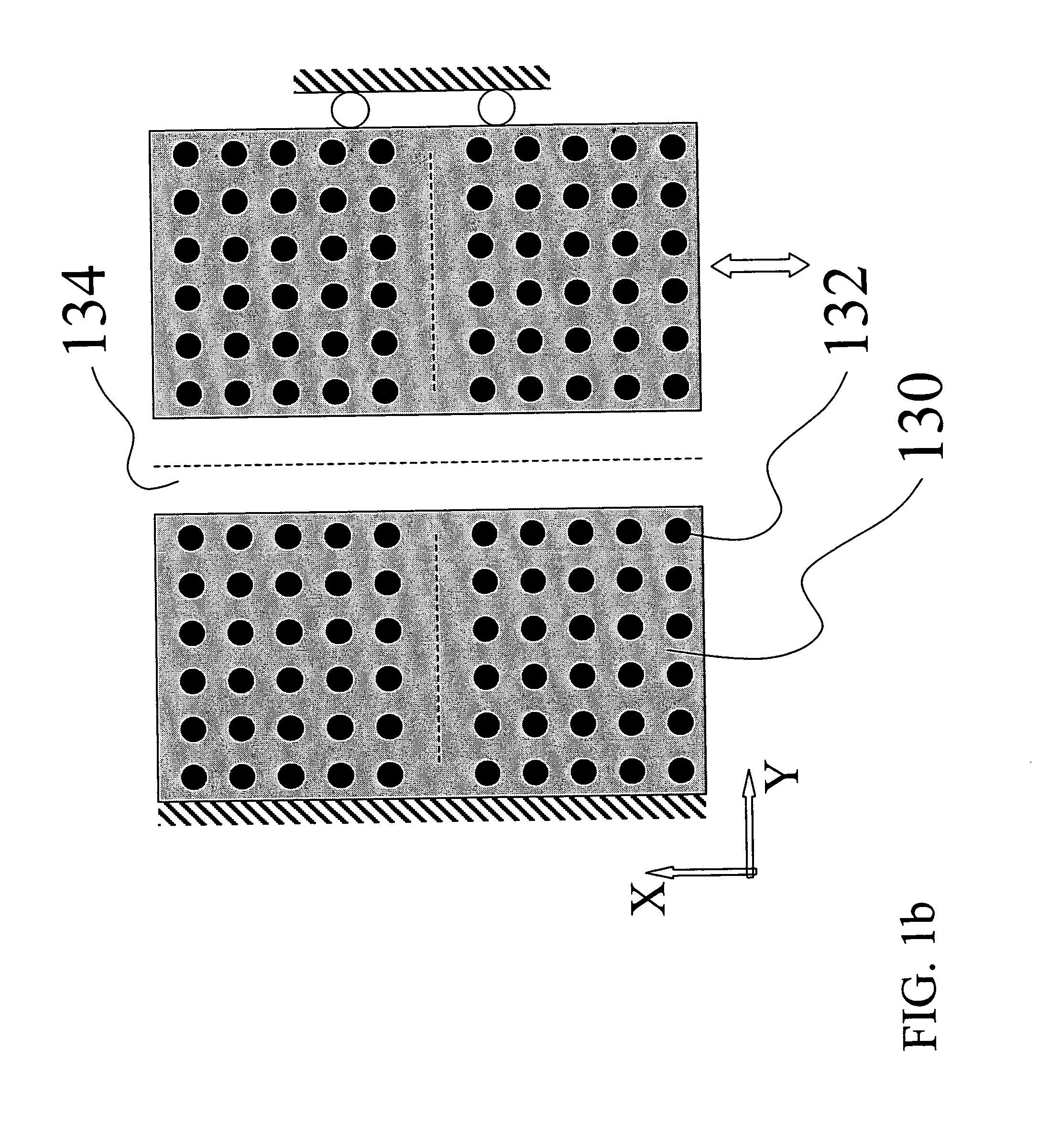

Displacement sensor based on photonic crystal waveguides

A displacement sensor comprising at least one pair of co-planar photonic crystal waveguide (PCWG) sections aligned along or parallel to a common axis and separated by a gap, one PCWG section of a pair operative to perform a displacement relative to the other section of the pair. In some embodiments, the sensor is linear, comprising two PCWG sections sperated by a gap that forms a cross PCWG, the displacement sensing performed preferrably differentially between two edges of the cross PCWG. In other embodiments, the sensor includes Mach Zehnder Interferometer (MZI) configurations with gaps between fixed and moving PCWG sections. Displacement induced changes in the gap widths are reflected in changes in an output parameter of the MZI.

Owner:RAMOT AT TEL AVIV UNIV LTD

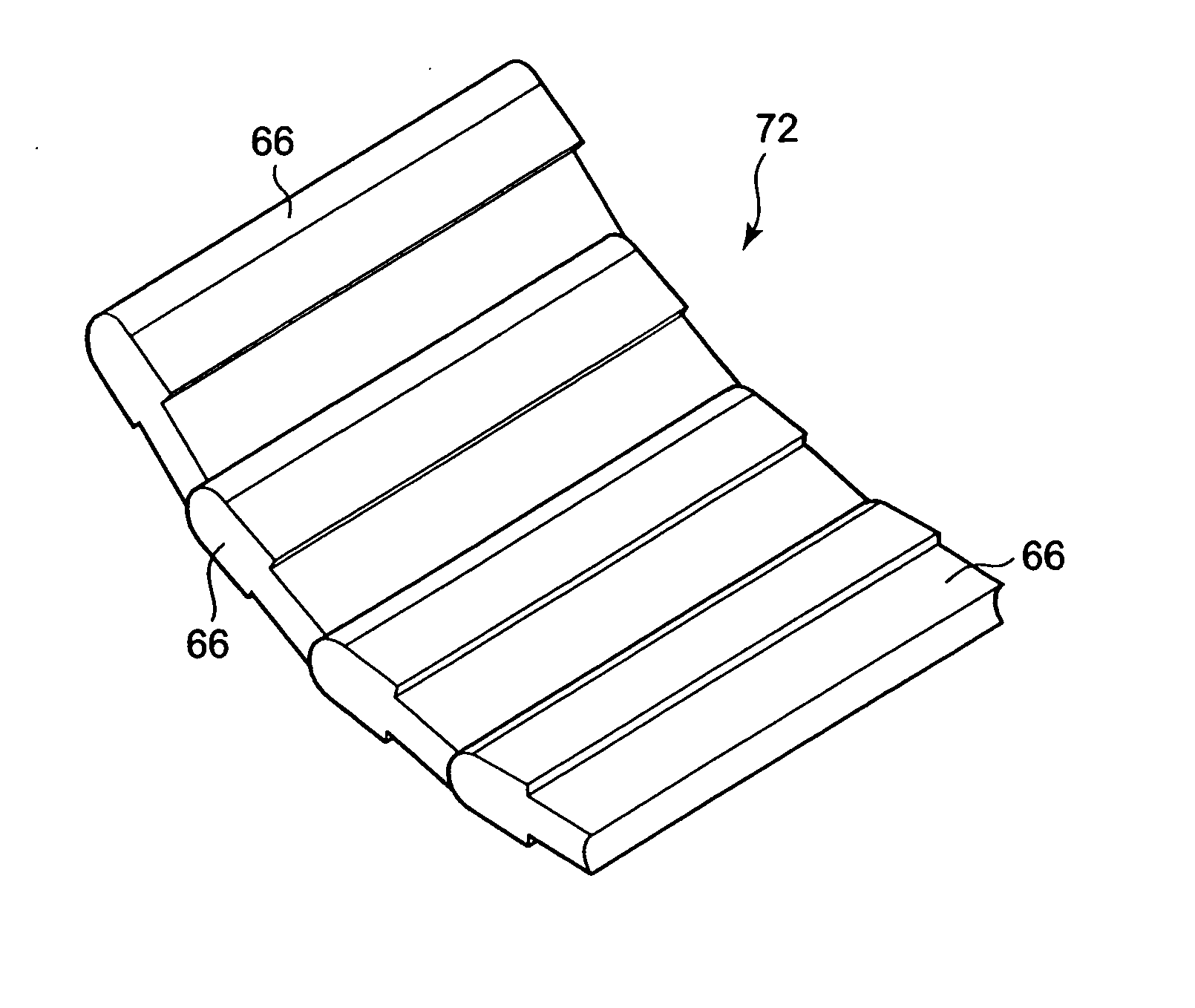

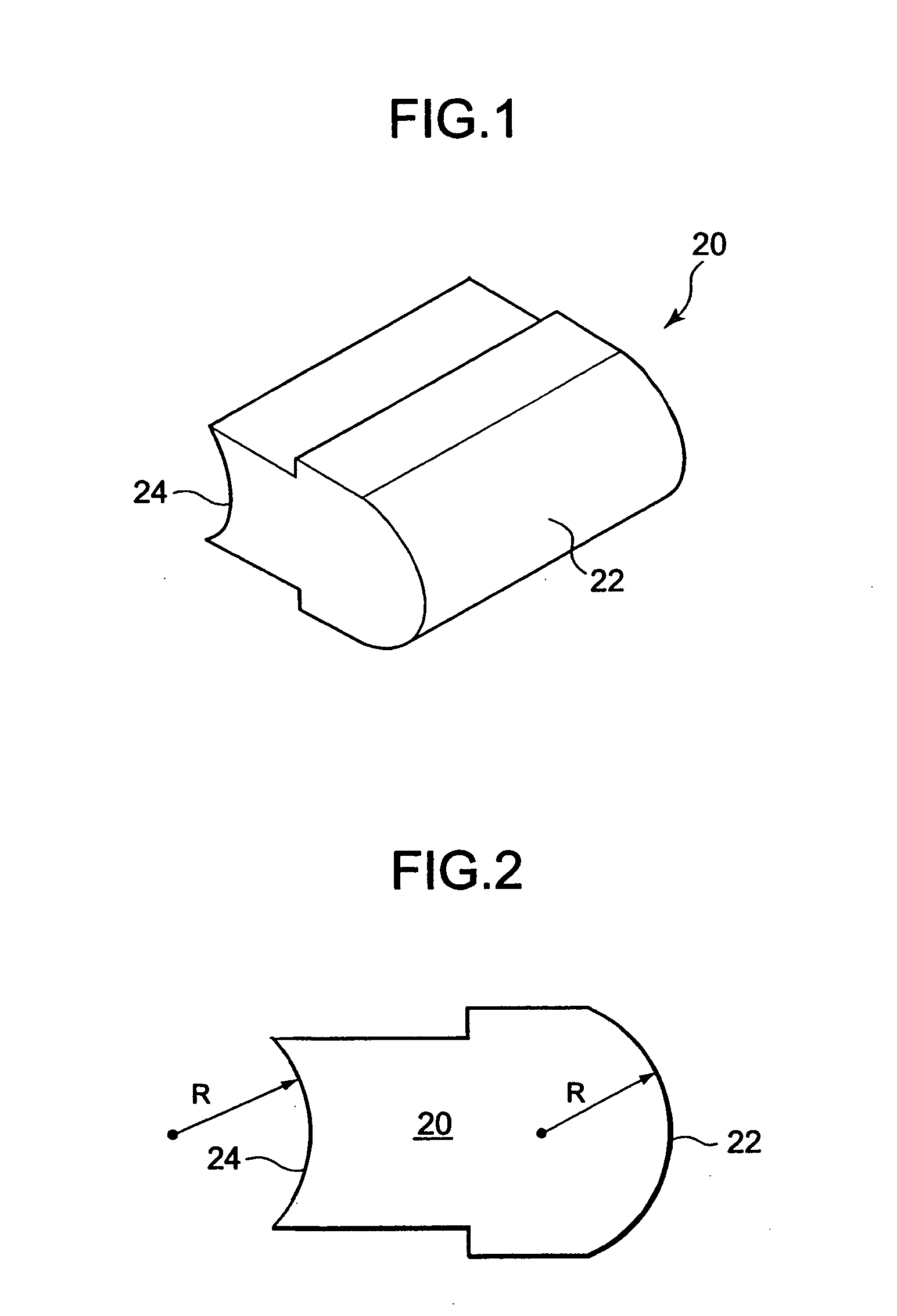

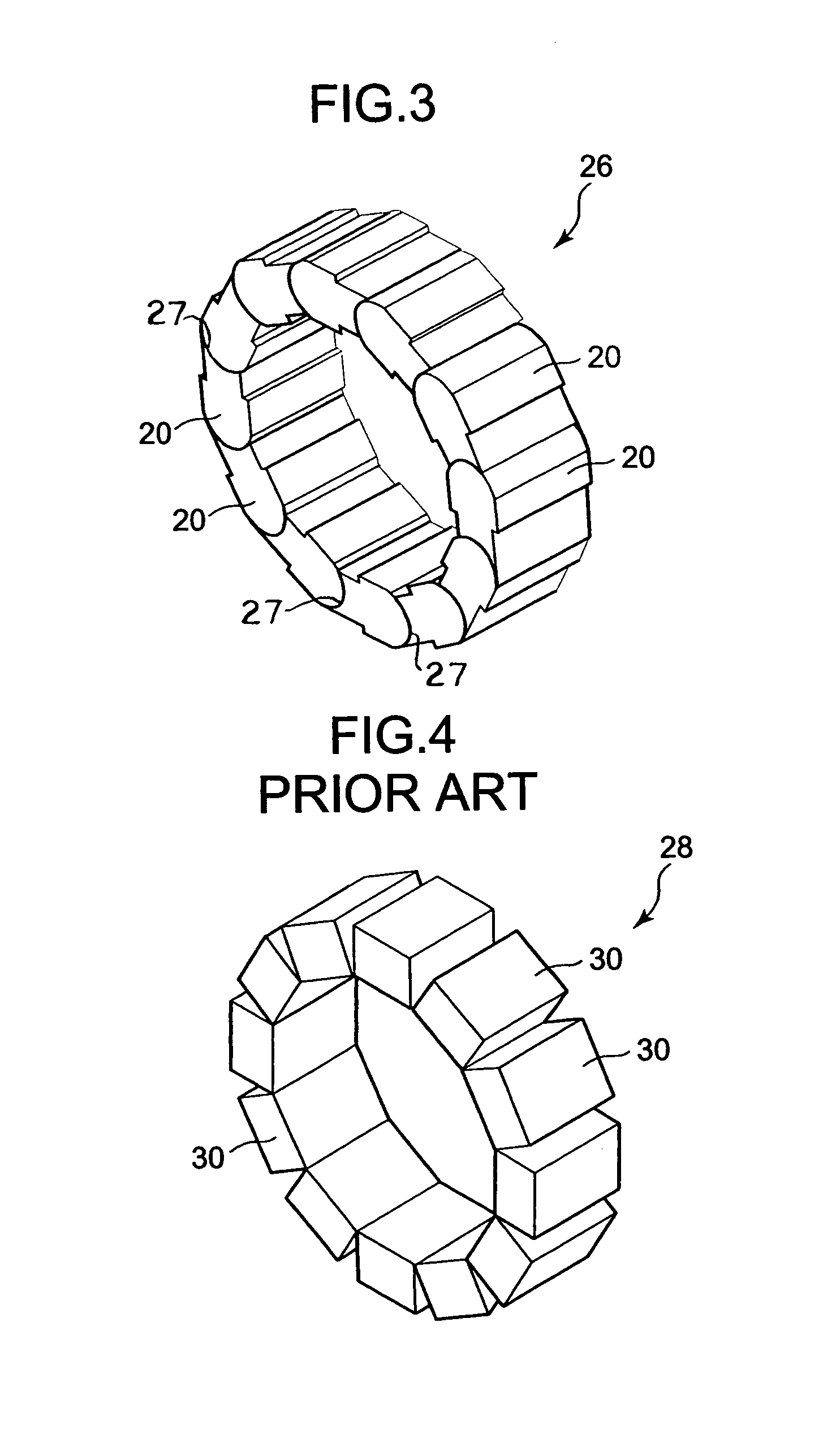

Ferrite core, and flexible assembly of ferrite cores for suppressing electromagnetic interference

InactiveUS20050285708A1EMI suppressionGap minimizationTransformers/inductances casingsTransformers/inductances magnetic coresElectromagnetic interferenceEngineering

Ferrite cores are provided with rounded, convex head ends and complimentary rounded, concave tail ends. The configuration of the head and tail ends permits a reduction in gap width between adjacent cores when they are joined together into a core assembly that suppresses electromagnetic interference emitted from a cable.

Owner:IBM CORP

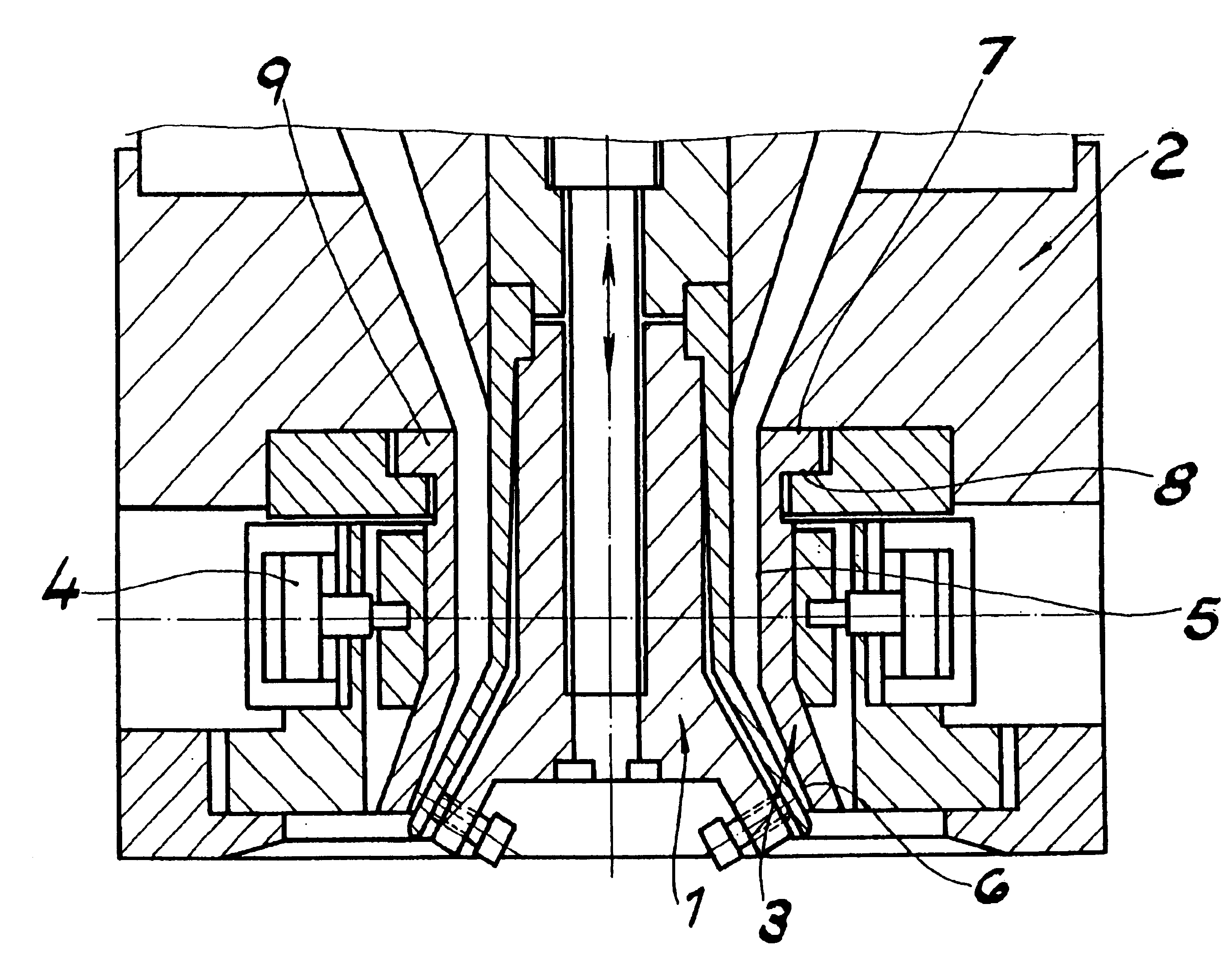

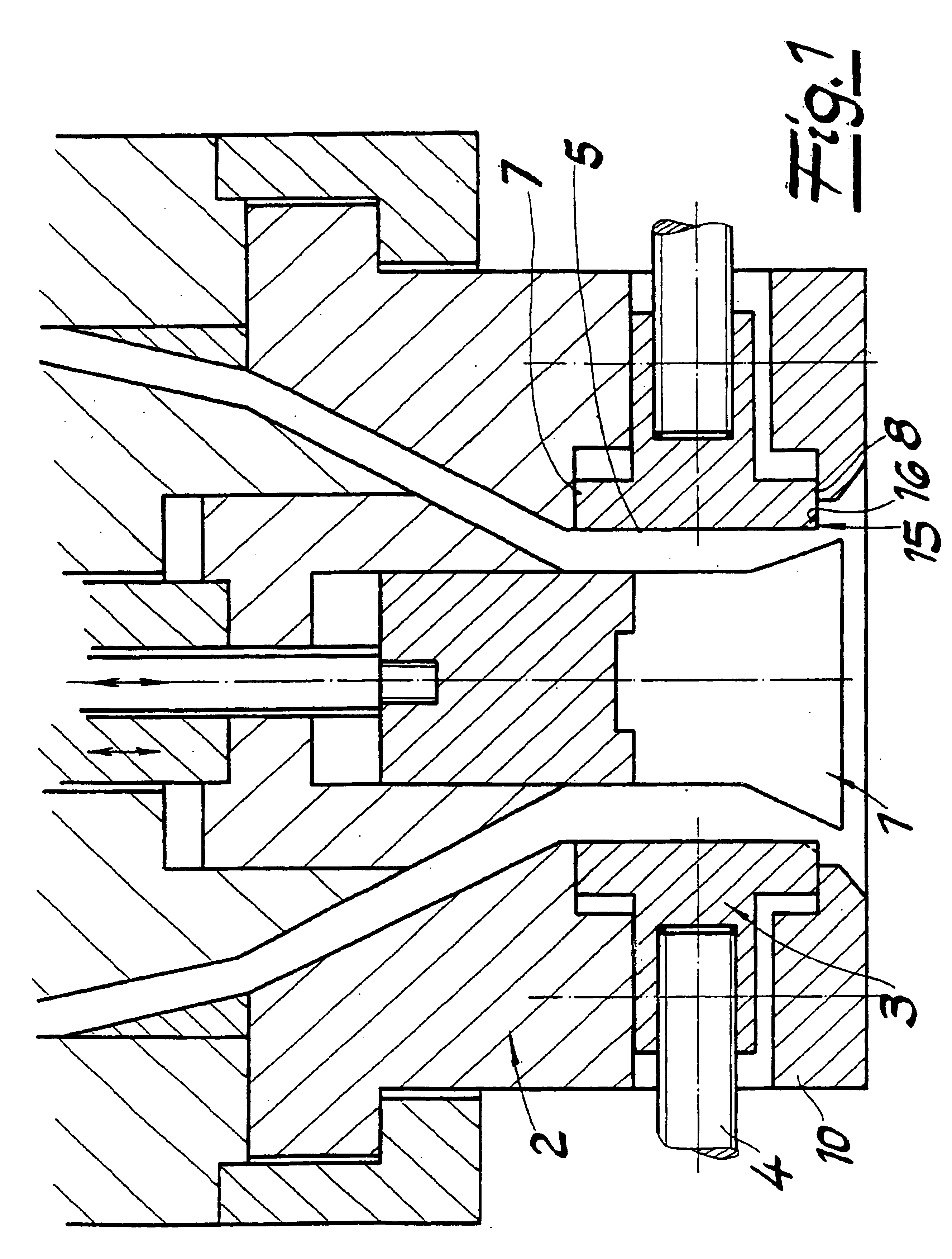

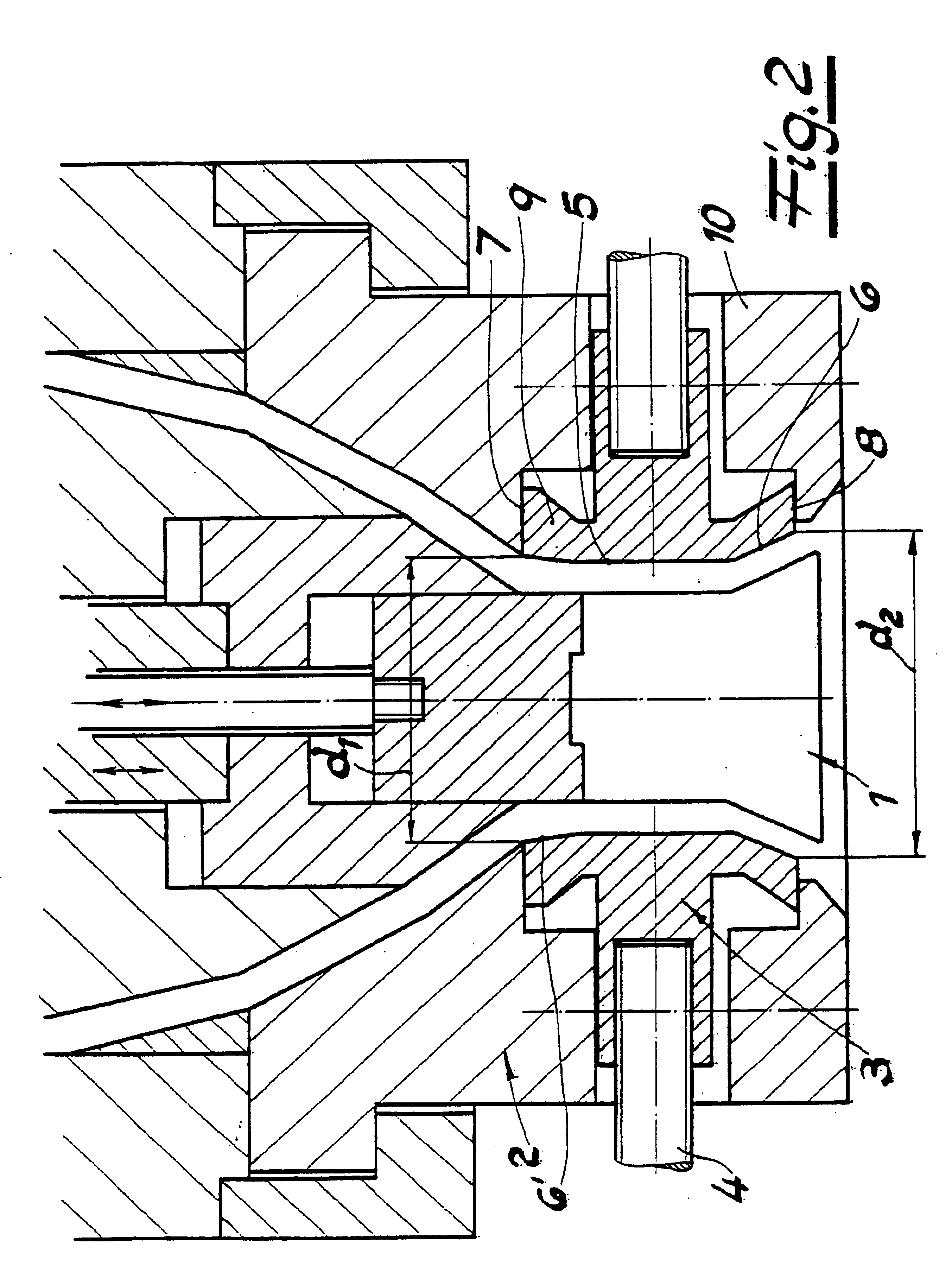

Extruder head

InactiveUS6953333B1Distortions on the upper face of the sleeve can be avoidedAvoid distortionConfectioneryMovable spraying apparatusBlow moldingEngineering

An extruder head for extrusion blow-molding plastic containers includes a ring gap nozzle with a mandrel and a ring-shaped nozzle body. An elastically deformable sleeve is arranged on an end of the nozzle outlet side and defines a gap width which can be varied by axial setting movements of the mandrel and / or the nozzle body. The geometry of the nozzle gap can be influenced by radially deforming the sleeve with setting devices during the extrusion of a hose-shaped preformed blank. The sleeve may be moved in a radial direction and is guided on sliding surfaces which support it in upward and downward directions. The sleeve may be in the form of a cylinder or tube. A lower edge of the sleeve shapes a cross-section of a melt stream exiting from the ring gap nozzle.

Owner:FEUERHERM MAX

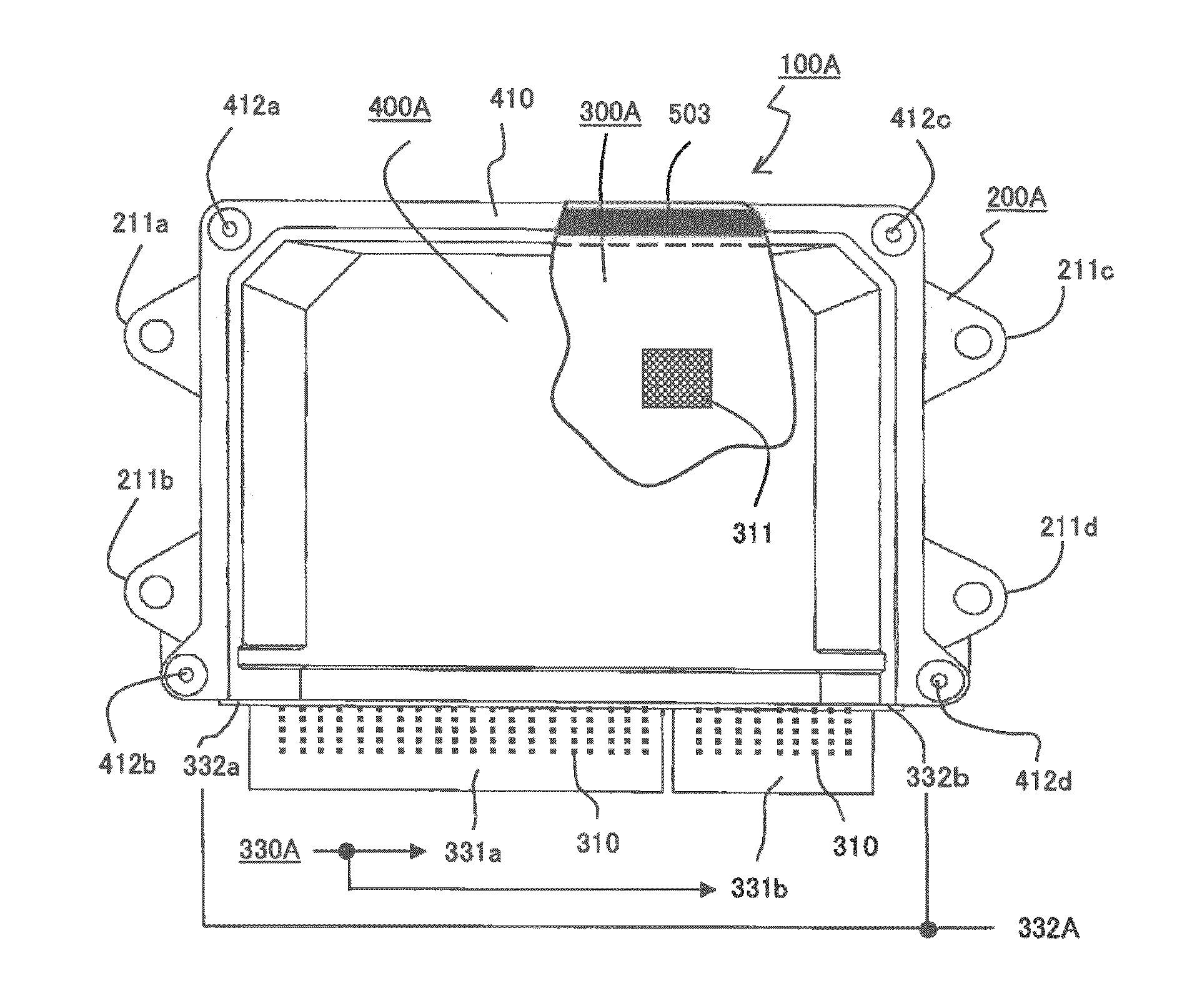

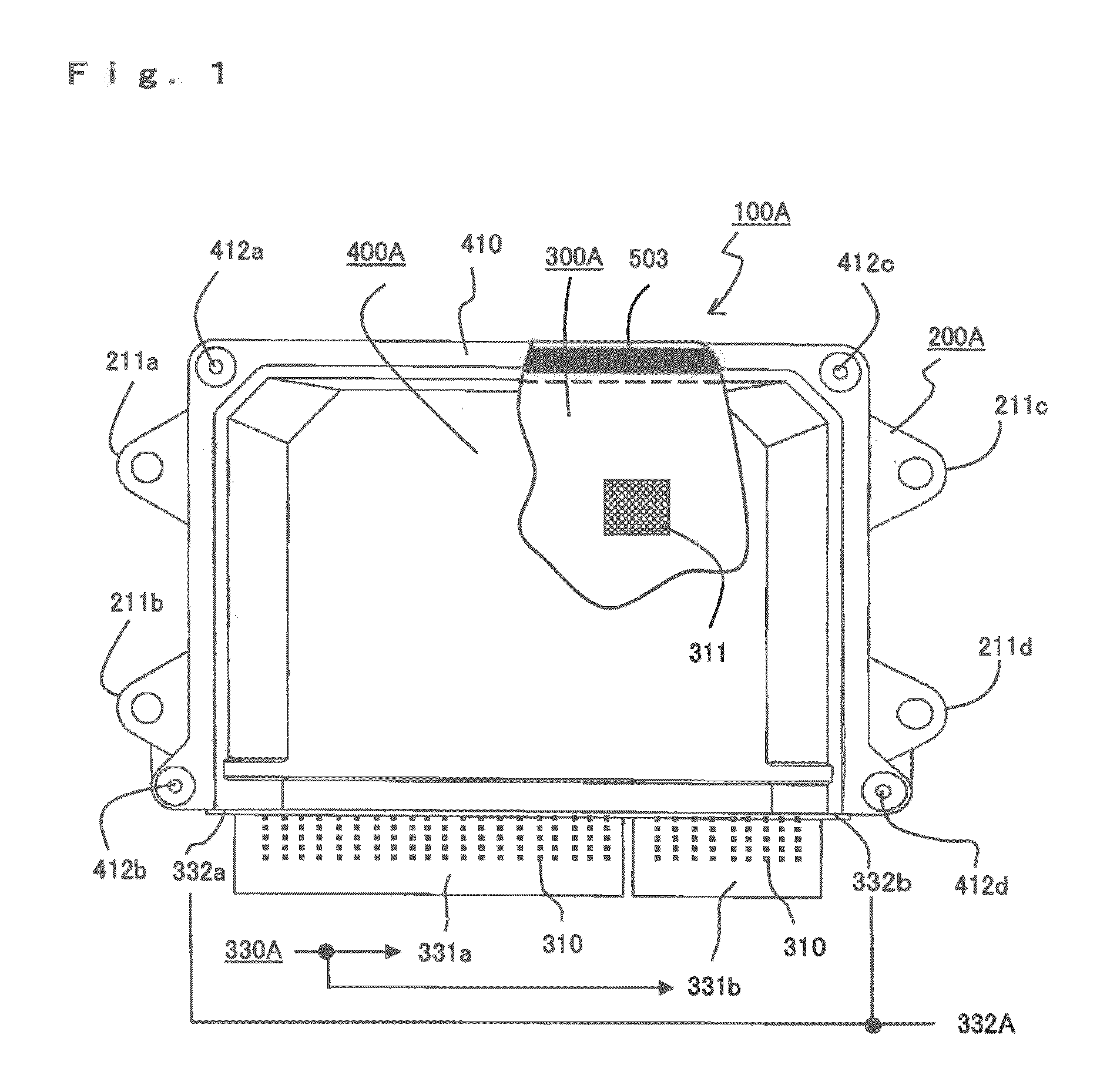

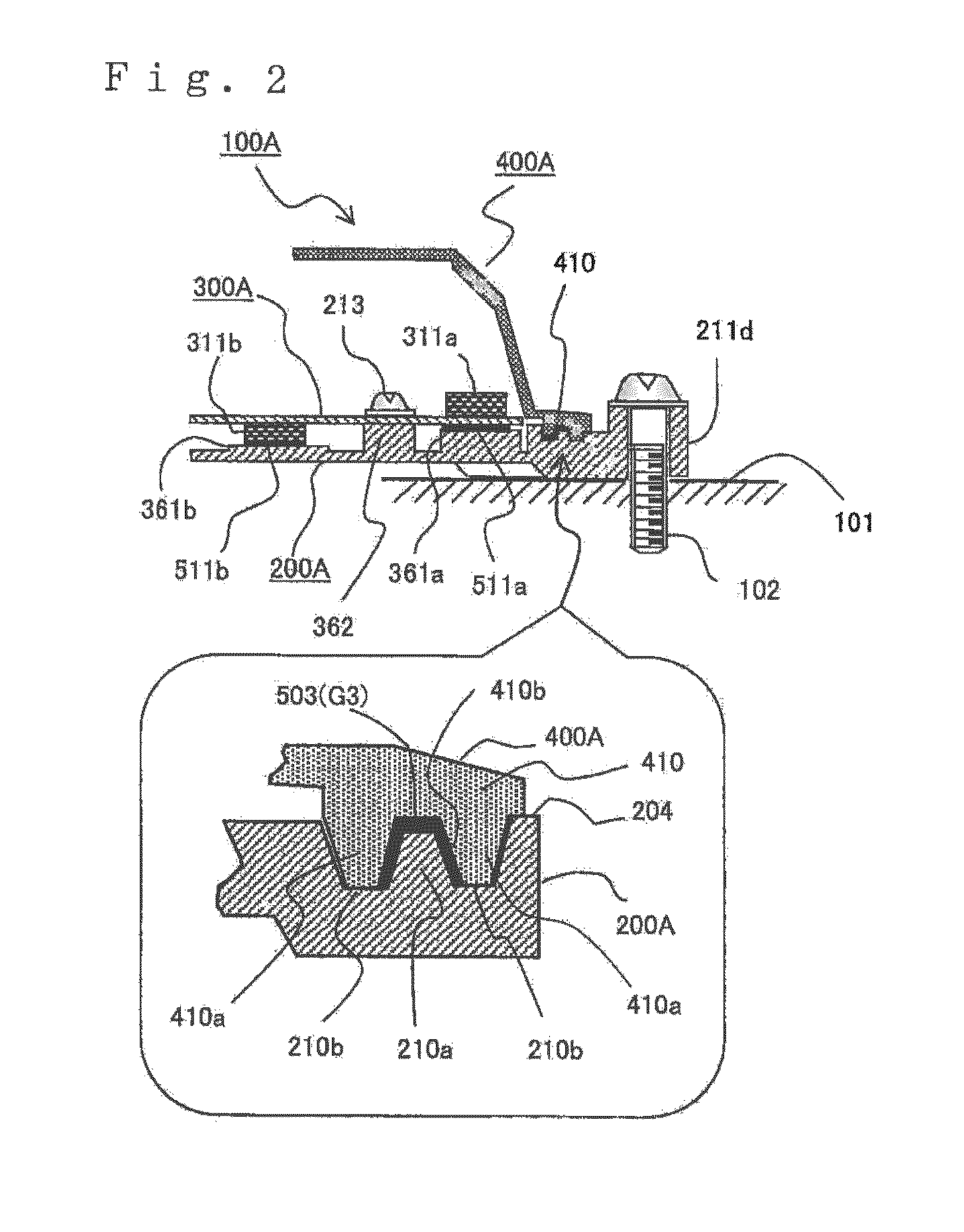

Waterproof control unit

ActiveUS20150282362A1Simple mold structureShort bodyElectrical apparatus contructional detailsHermetically-sealed casingsGap widthControl unit

A waterproof control unit is provided in which: connector housing is fixedly positioned onto circuit board that is mounted onto base; a first seal gap G1 formed of the connector housing and a cover, a second seal gap G2 formed of the connector housing and the base and a third seal gap G3 formed of the base and the cover are included; the first seal gap G1 is formed of a terrace slope portion gap G1b and an outer step flat portion gap G1a and an inner step flat portion gap G1c that are in communication with the terrace slope portion gap G1b; a gap setting protrusion for limiting the gap width is provided at least in the first seal gap G1; and, between the connector housing and the cover, a horizontal movement limitation member are provided for limiting the relative positional relationship between the connector housing and the cover.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com