Patents

Literature

158results about How to "Simple mold structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

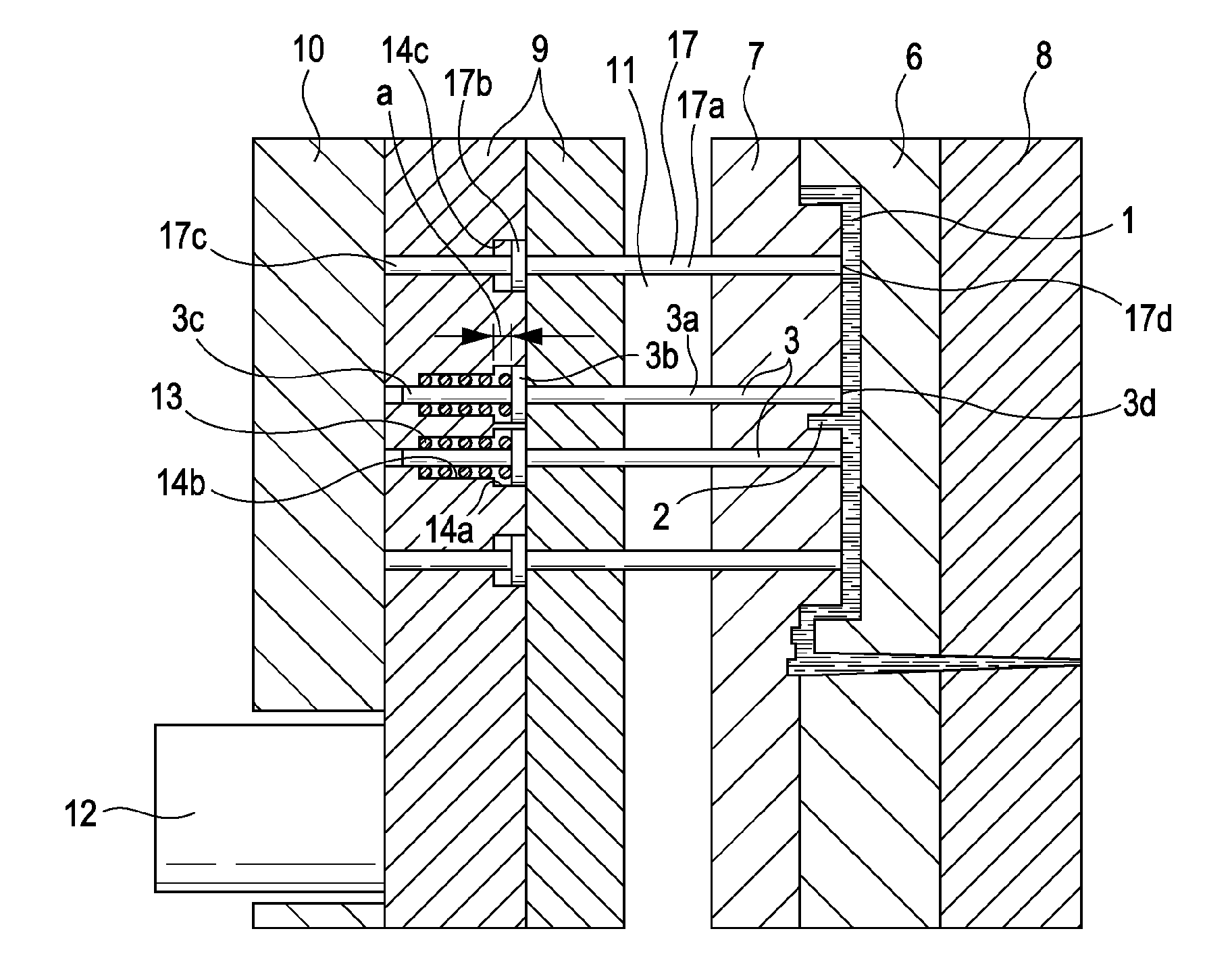

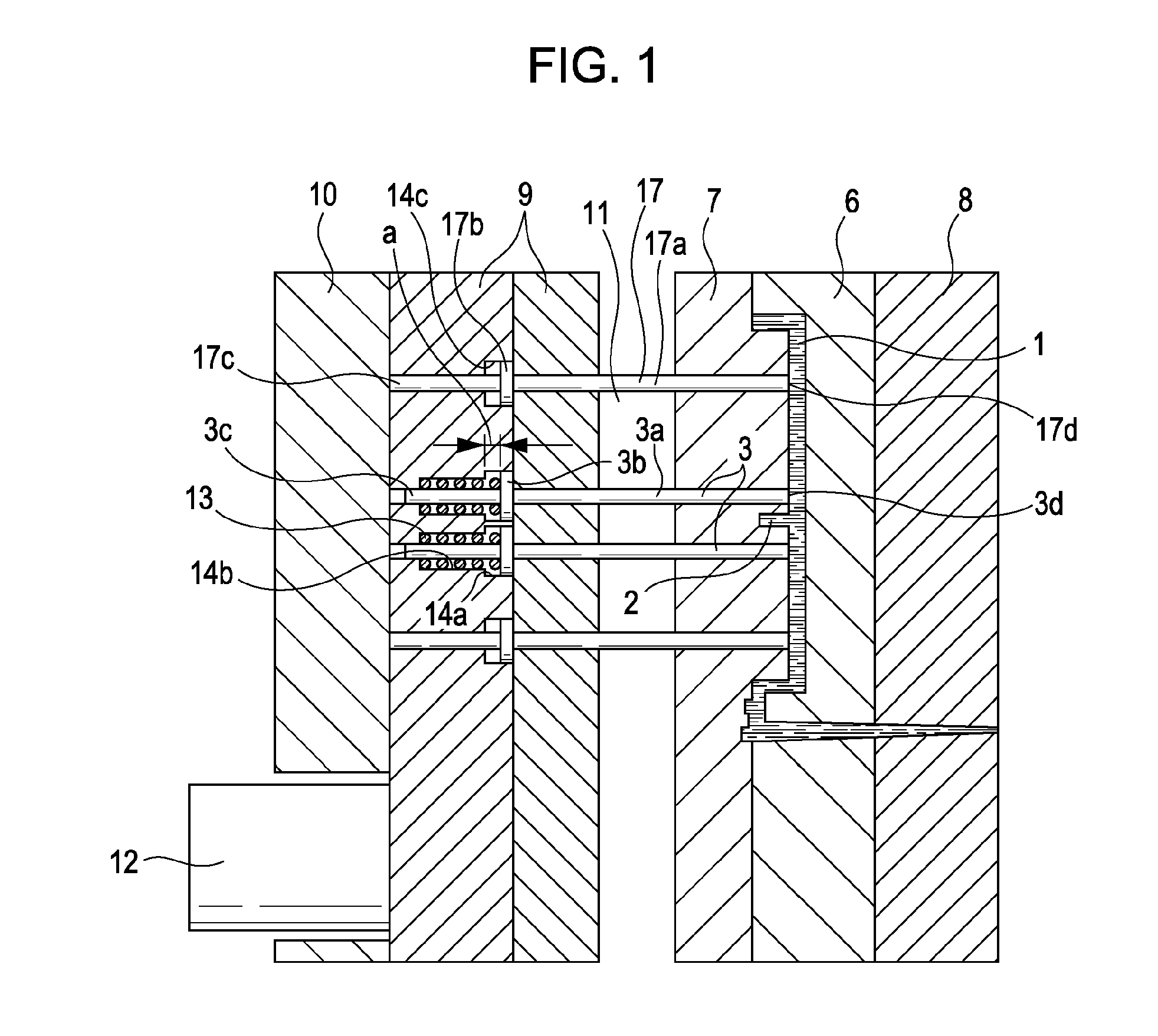

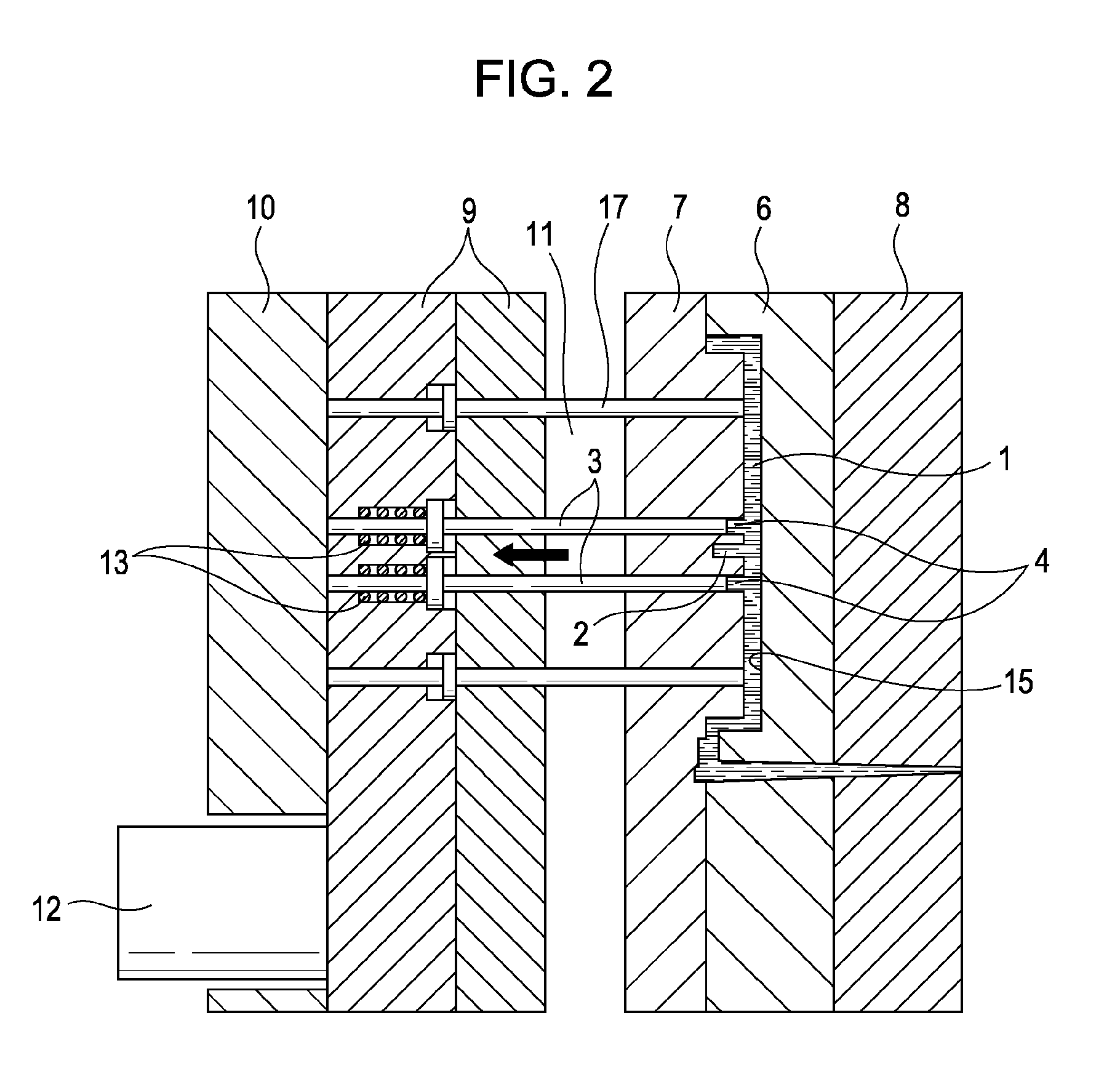

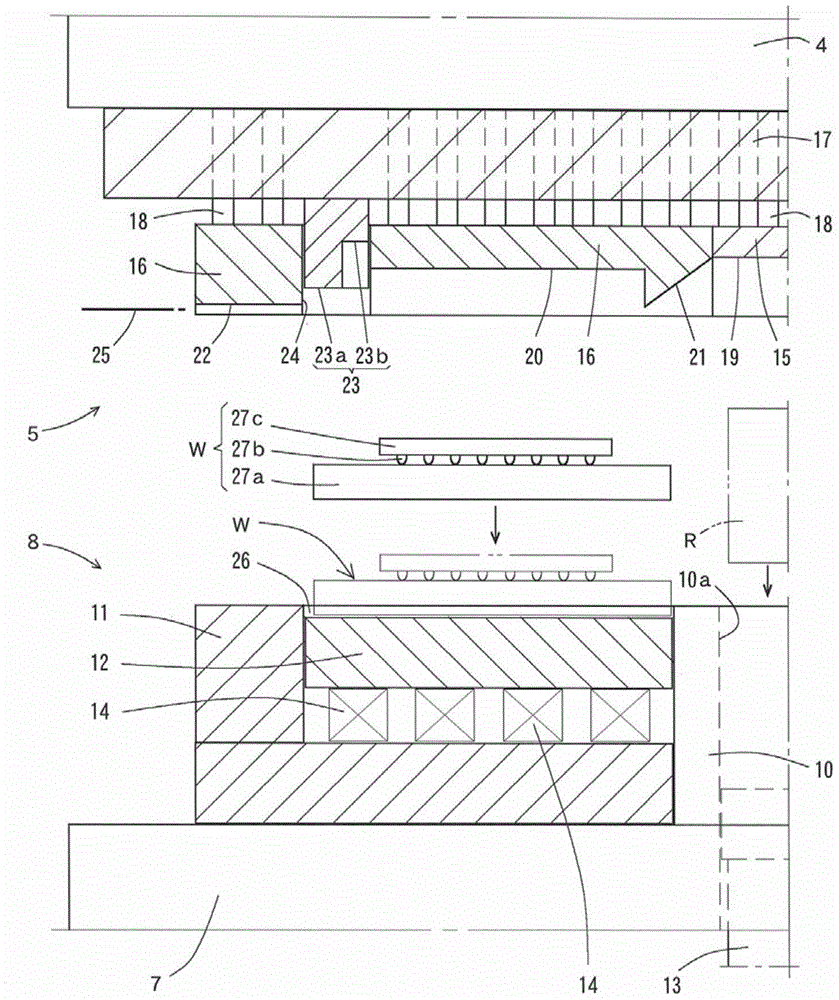

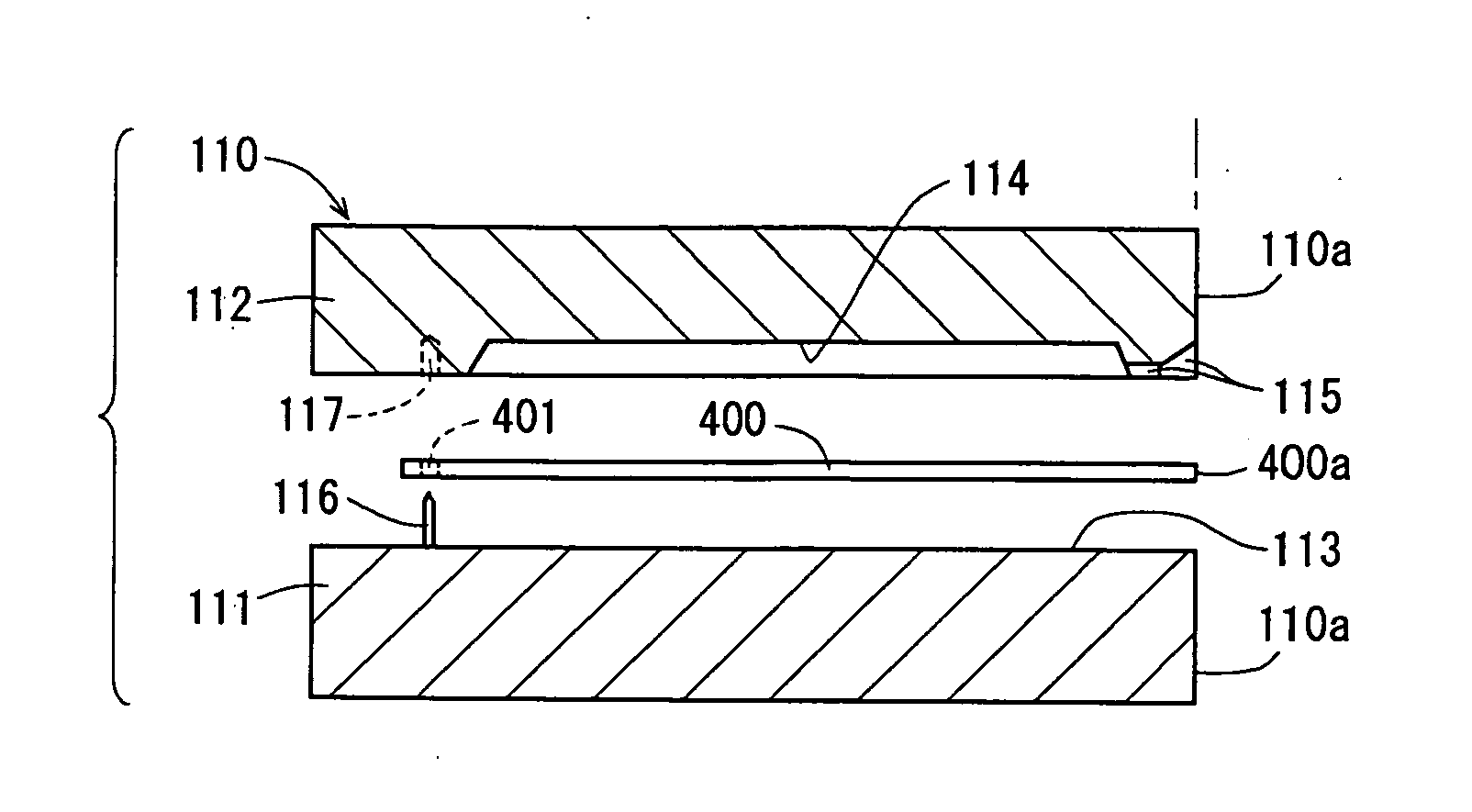

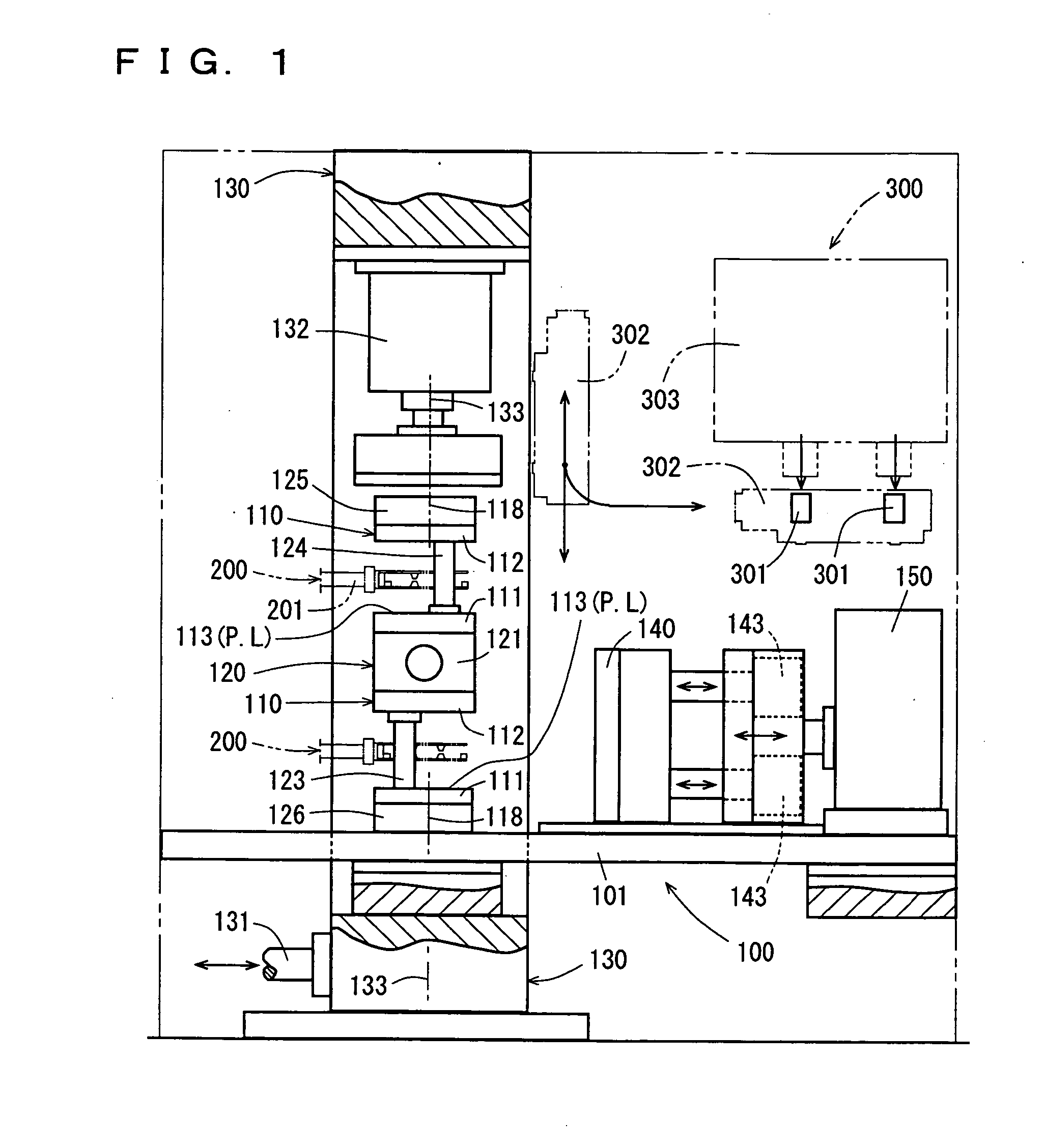

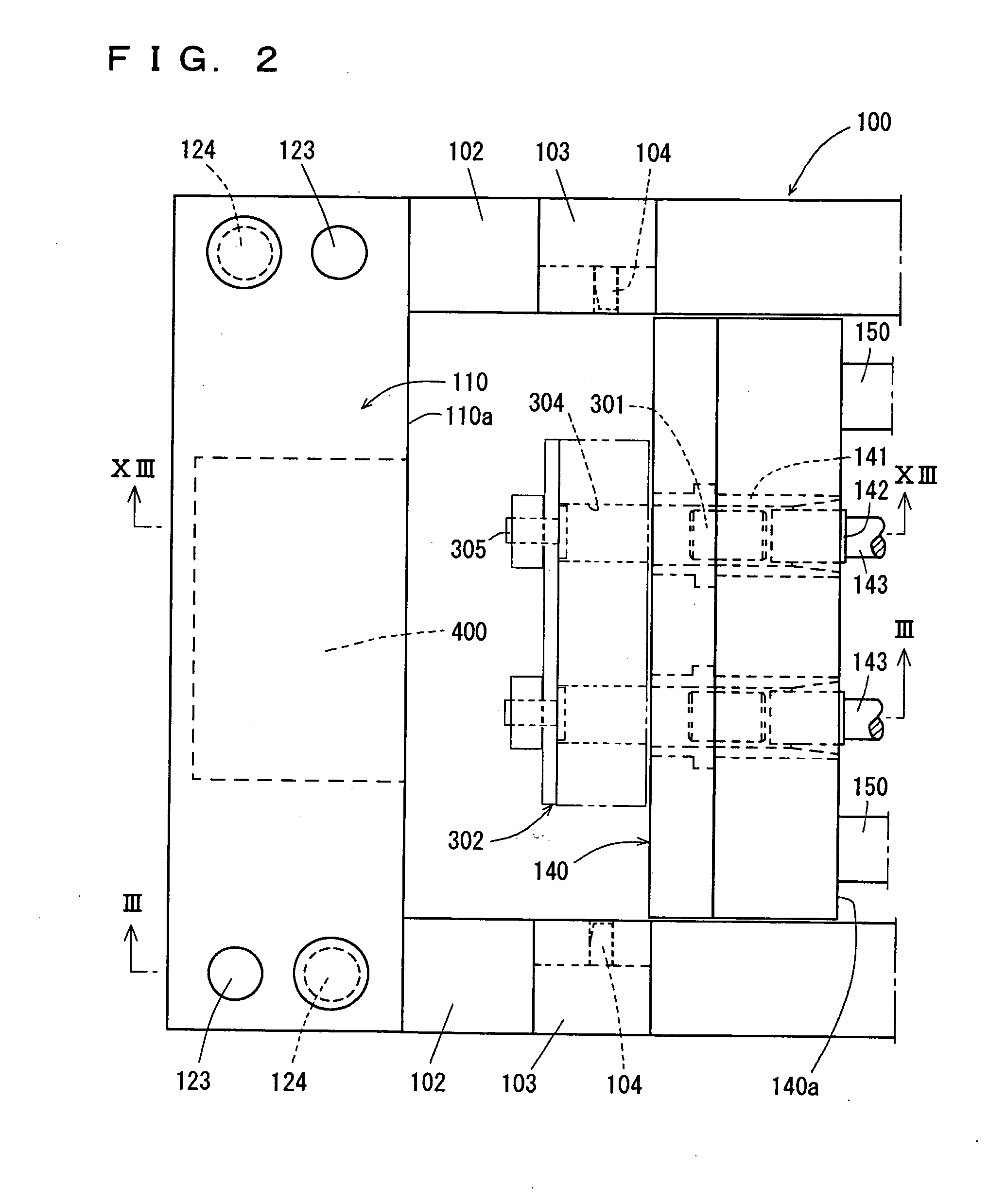

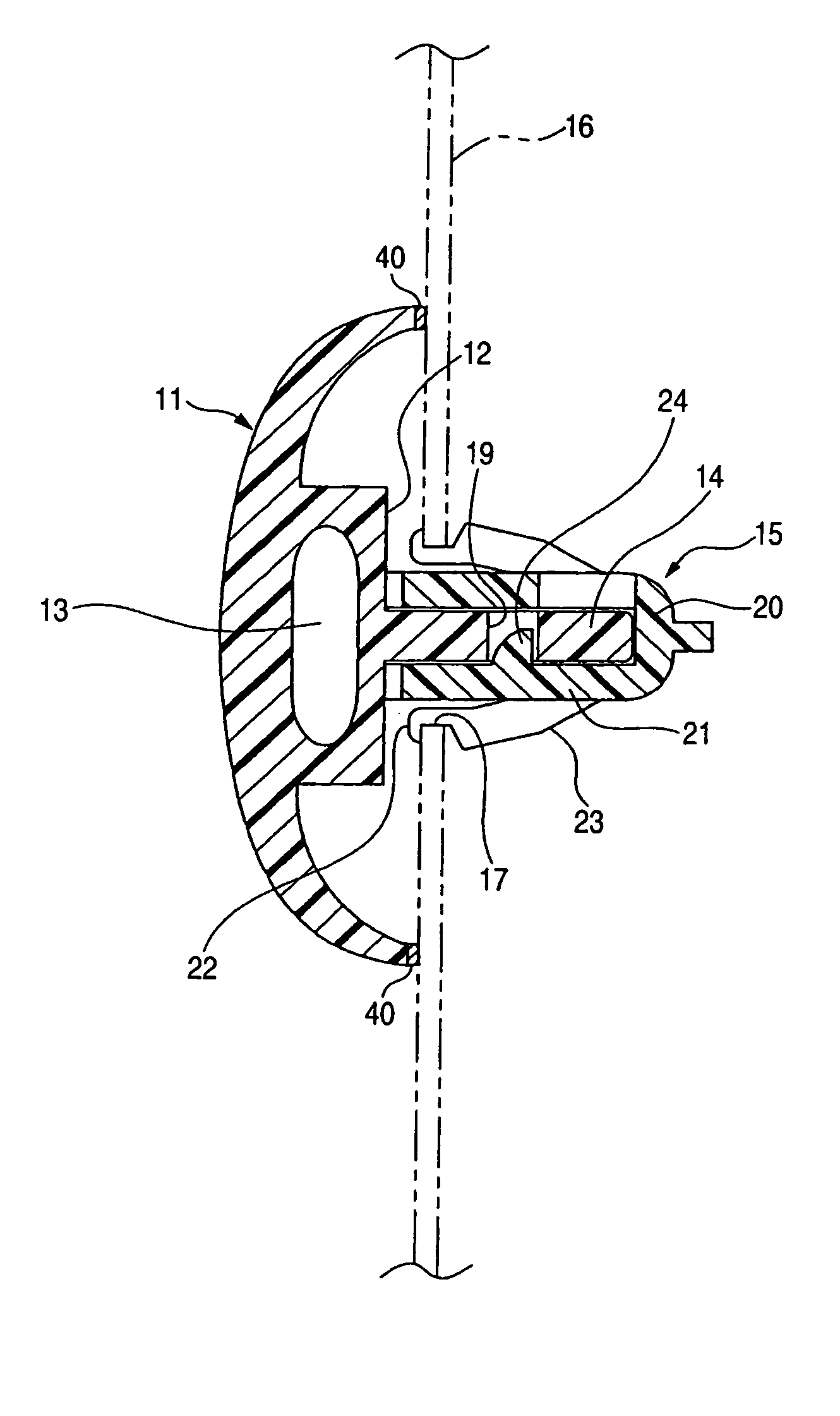

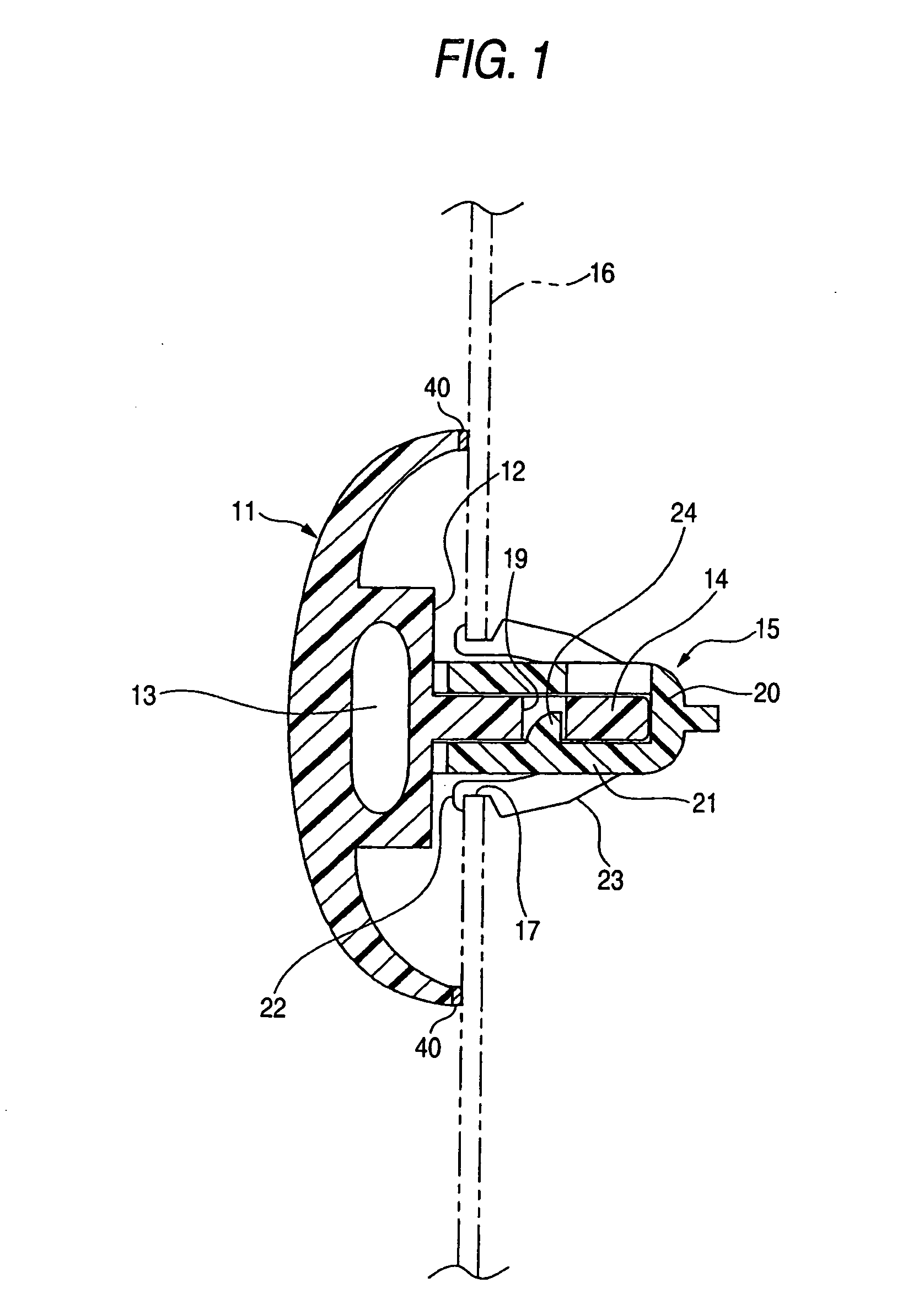

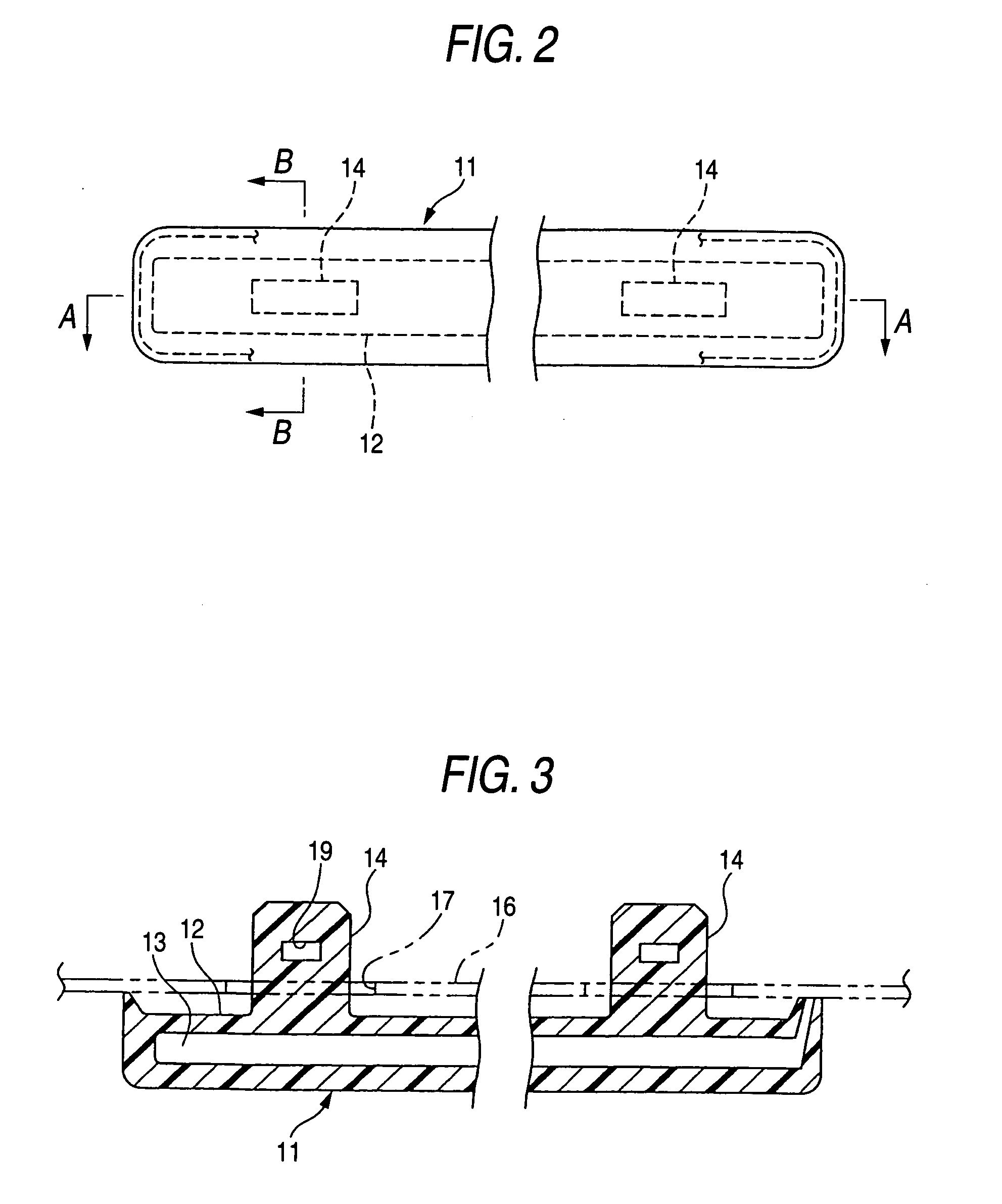

Injection mold and partial compression molding method

InactiveUS7722792B2Good lookingAvoid flowAuxillary shaping apparatusFood shapingCompression moldingShell molding

Owner:CANON KK

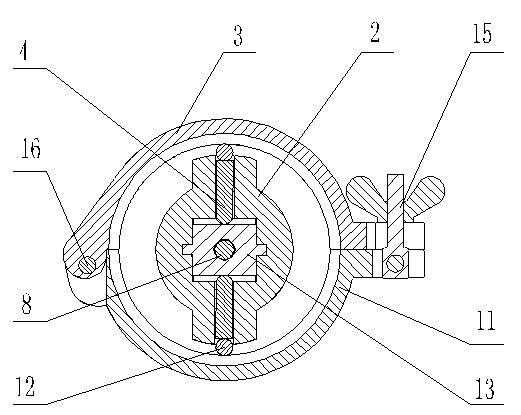

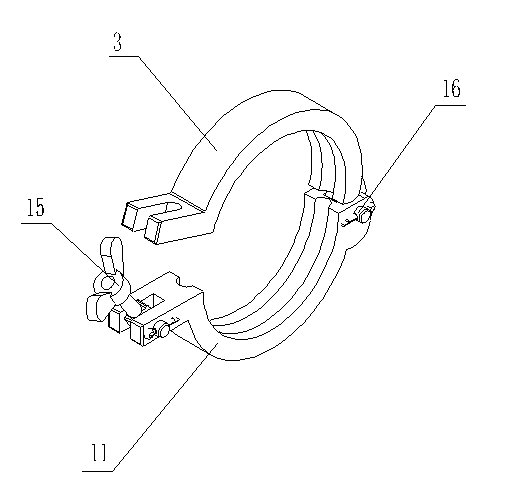

Rotary extrusion secondary forming die for novel pipe fitting for decoration and forming method thereof

InactiveCN104209404ASimple mold structureEasy to installShaping toolsTransmission mediumSurface shape

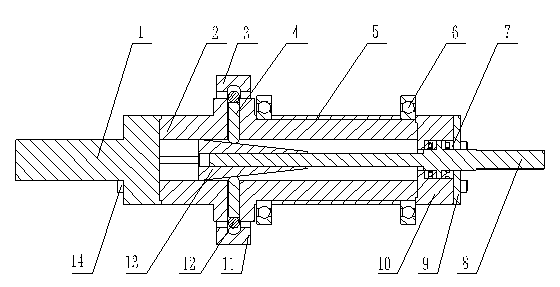

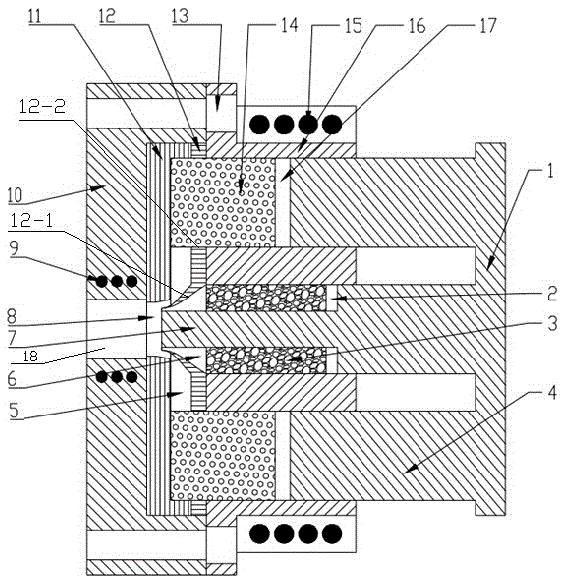

The invention provides a rotary extrusion secondary forming die for a novel pipe fitting for decoration. The rotary extrusion secondary forming die comprises an inner forming male die mechanism and an outer forming female die mechanism. The inner forming male die mechanism comprises a male die, a male die guiding mechanism, a balance mechanism and a rotation mechanism. The outer forming female die mechanism comprises at least two outer forming female die pieces and a locking mechanism. The male die guiding mechanism comprises a male die transmission medium, a male die stretching and retracting control mechanism and an end cover. The balance mechanism is a swing mechanism and arranged between the pipe fitting to be formed and the inner forming male die mechanism. The rotation mechanism and the male die guiding mechanism are coaxial and are connected through a fastening screw. The inner wall of each outer forming female die piece is provided with a groove matched with the outer surface of the male die in shape. The outer forming female die pieces are locked through the locking mechanism. The rotary extrusion secondary forming die for the novel pipe fitting for decoration is compact in structure, easy to install and stable in operation. The shape which is difficult to form by the adoption of the prior art can be formed on the pipe fitting. According to the rotary extrusion secondary forming die for the novel pipe fitting for decoration, a cold forming method is adopted, the pipe fitting does not need to be heated, and the working environment is good.

Owner:郑果

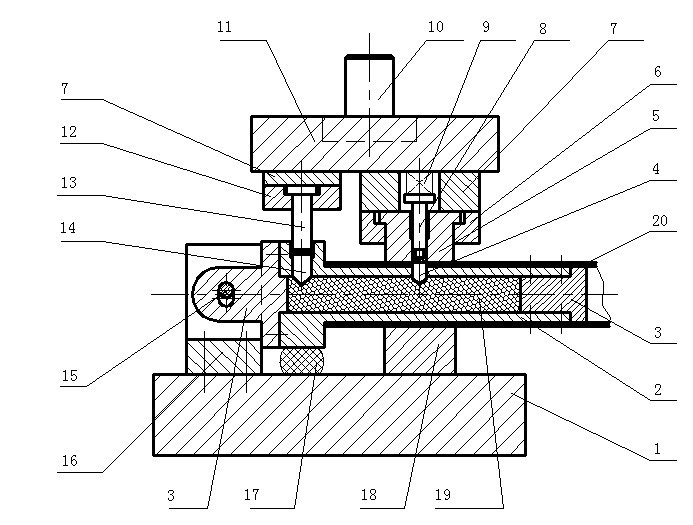

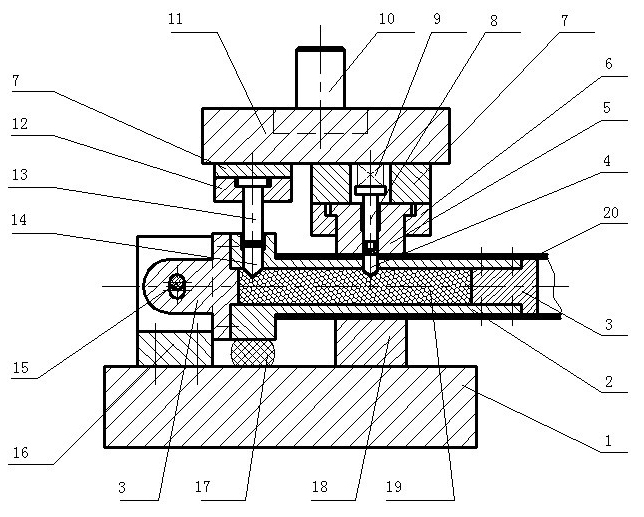

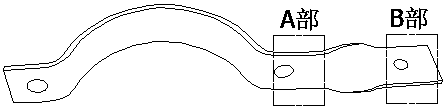

Pipe fitting punch die based on flexible slide block

InactiveCN101862788AEasy PickupSimple mold structurePerforating toolsStructural engineeringMechanics

The invention relates to a pipe fitting punch die based on a flexible slide block and a method. The die comprises a lower die holder, a position pipe, a drain plug, a terrace die, a die, a fixed plate, a base plate, a spring, a push rod, a die handle, an upper die holder, another fixed plate, a floating wedge, a supporting seat, polyamine, a filling block, solid particles and the like, wherein an inner cavity of the position pipe is internally provided with the solid particles, the terrace die vertically arranged is movably arranged in a radial hole of the position pipe, one end of the terrace die is positioned among the solid particles, the upper end of the floating wedge vertically arranged is connected on the upper die holder, the lower end thereof passes through the position pipe to be contacted with the solid particles, the filling block is arranged between the lower die holder and the position pipe to support the position pipe, and the position of the filling block corresponds to the position of the terrace die. The invention drives the terrace die to move outward to punch by taking the solid particles as the slide block, is particularly suitable for multi holes to simultaneously punch outward, has simple structure and high efficiency, and is easy to take pieces due to outward bristles of the punch.

Owner:CHONGQING UNIV OF TECH

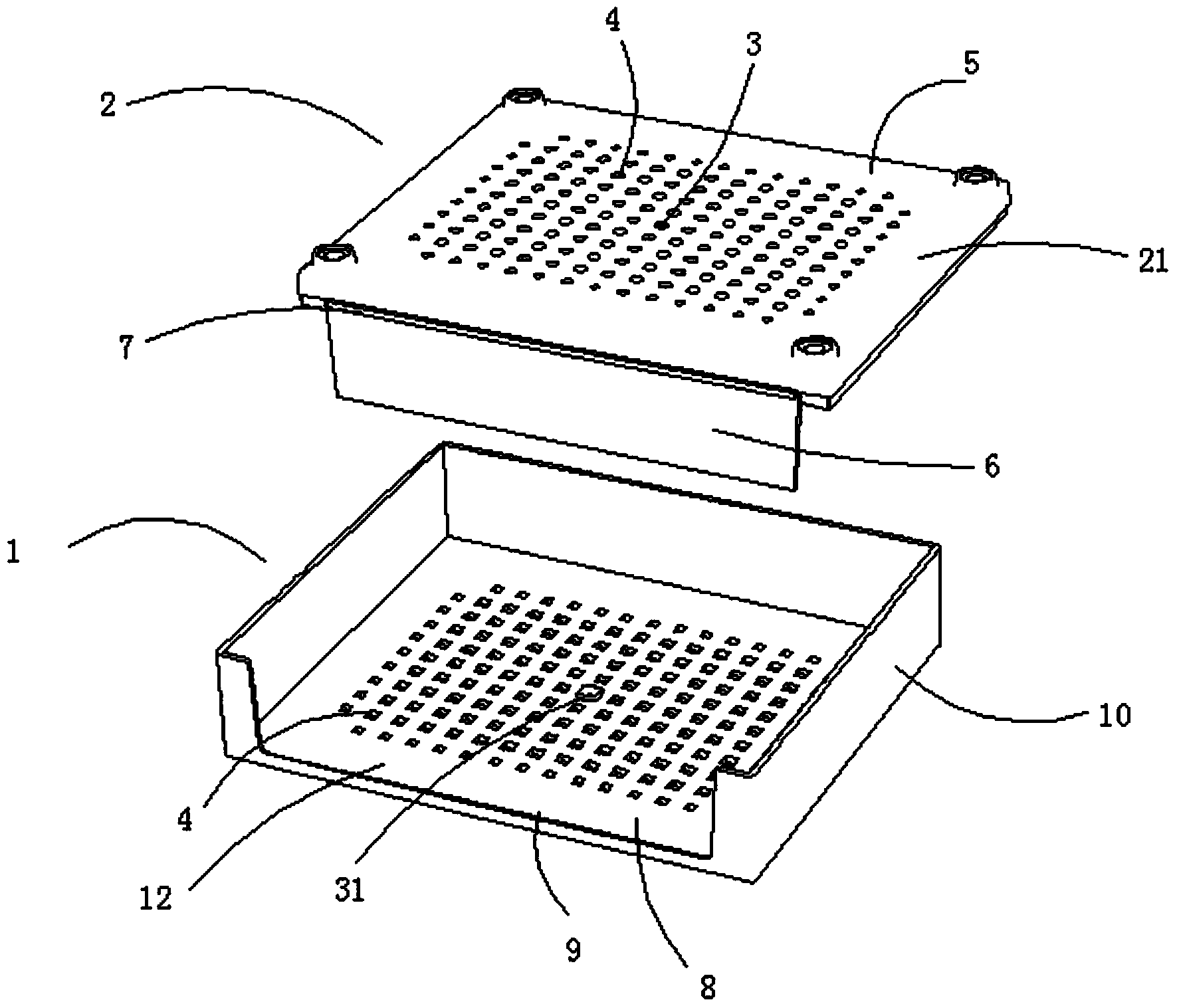

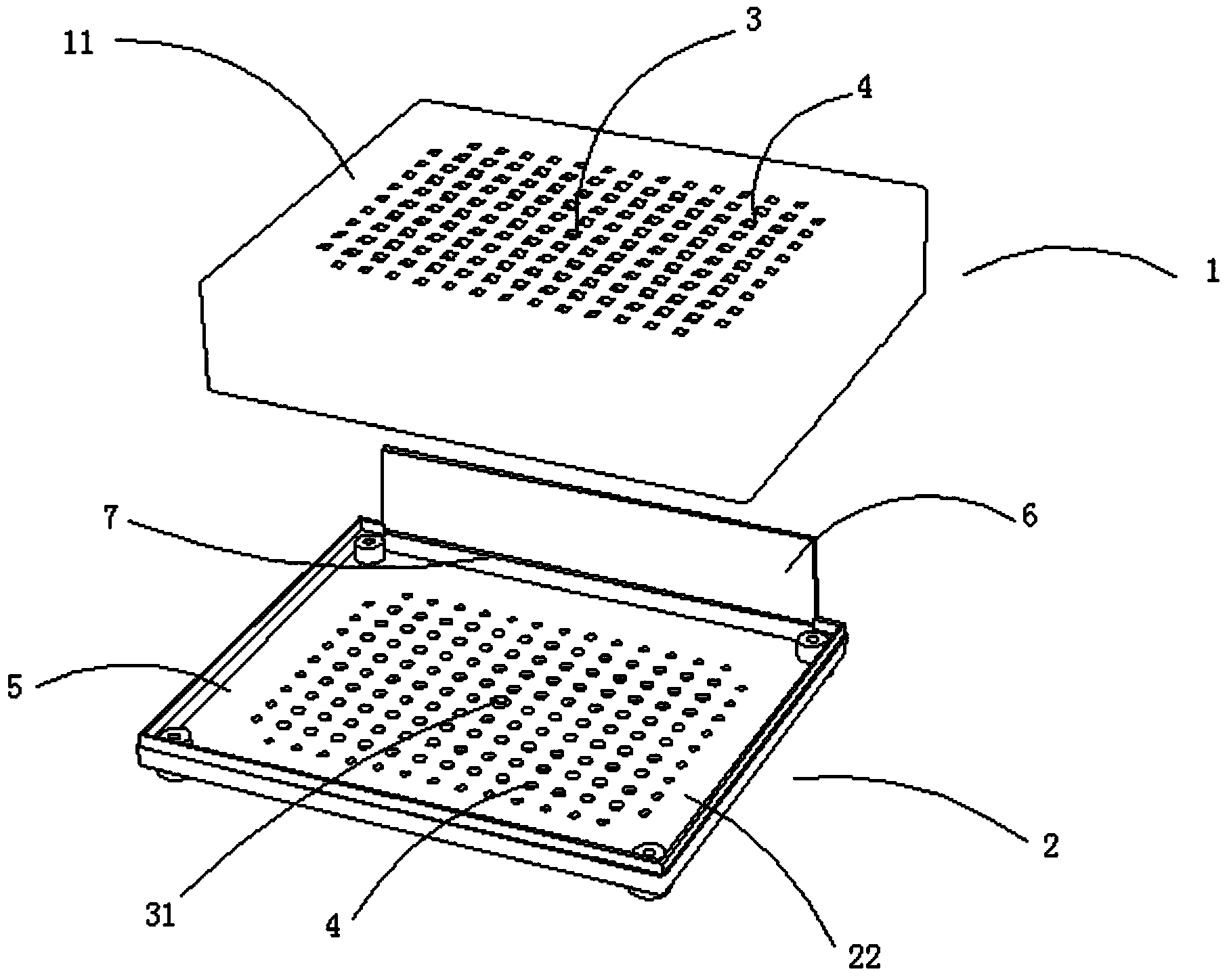

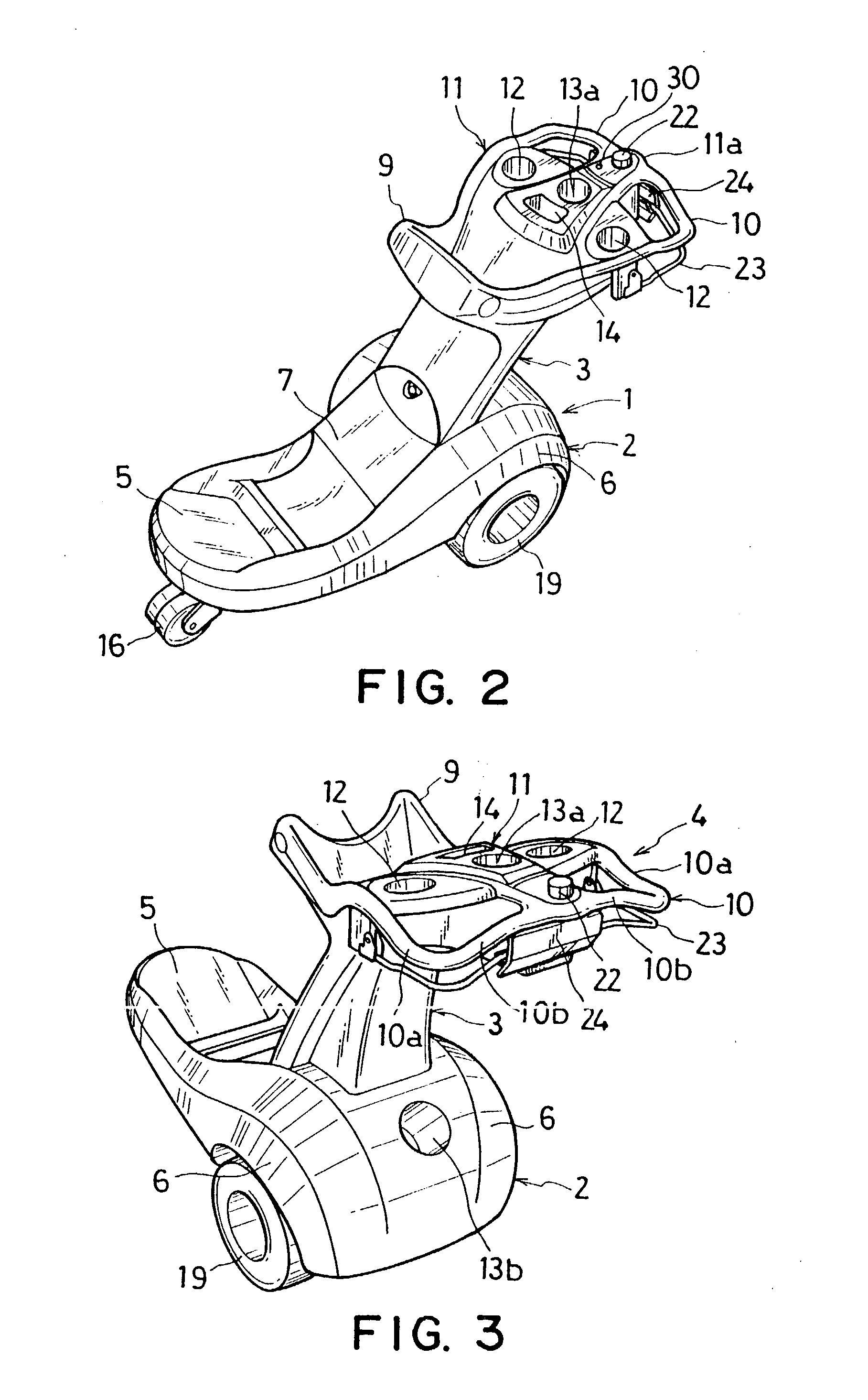

Set-top box and preparation method thereof

InactiveCN103716665ABeautiful productSimple mold structureSelective content distributionCooling/ventilation/heating modificationsEngineeringSet top box

The invention relates to a set-top box and a preparation method thereof. The set-top box includes a body with an accommodating space and a cover body which covers the body and is used for closing the accommodating space; the body is provided with a first outer surface; the cover body is provided with a second outer surface; the first outer surface and the second outer surface are arranged back to back; the central area of the first outer surface and / or the second outer surface is provided with a pouring entering opening which is formed in molding; and a plurality of heat dissipation holes which are communicated with the accommodating space are formed around the pouring entering opening. The invention also relates to a preparation method of the set-top box. According to the set-top box and the preparation method thereof of the invention, the array-shaped heat dissipation holes are formed around the pouring entering opening, and welding wires are covered through a surface texture etching technology, and therefore, the product can have a beautiful appearance, and the structure of required moulds can be greatly simplified, and production processing can be optimized, and cost for the moulds can be reduced, and unit cost of the product can be eventually decreased.

Owner:SHENZHEN JIUZHOU ELECTRIC

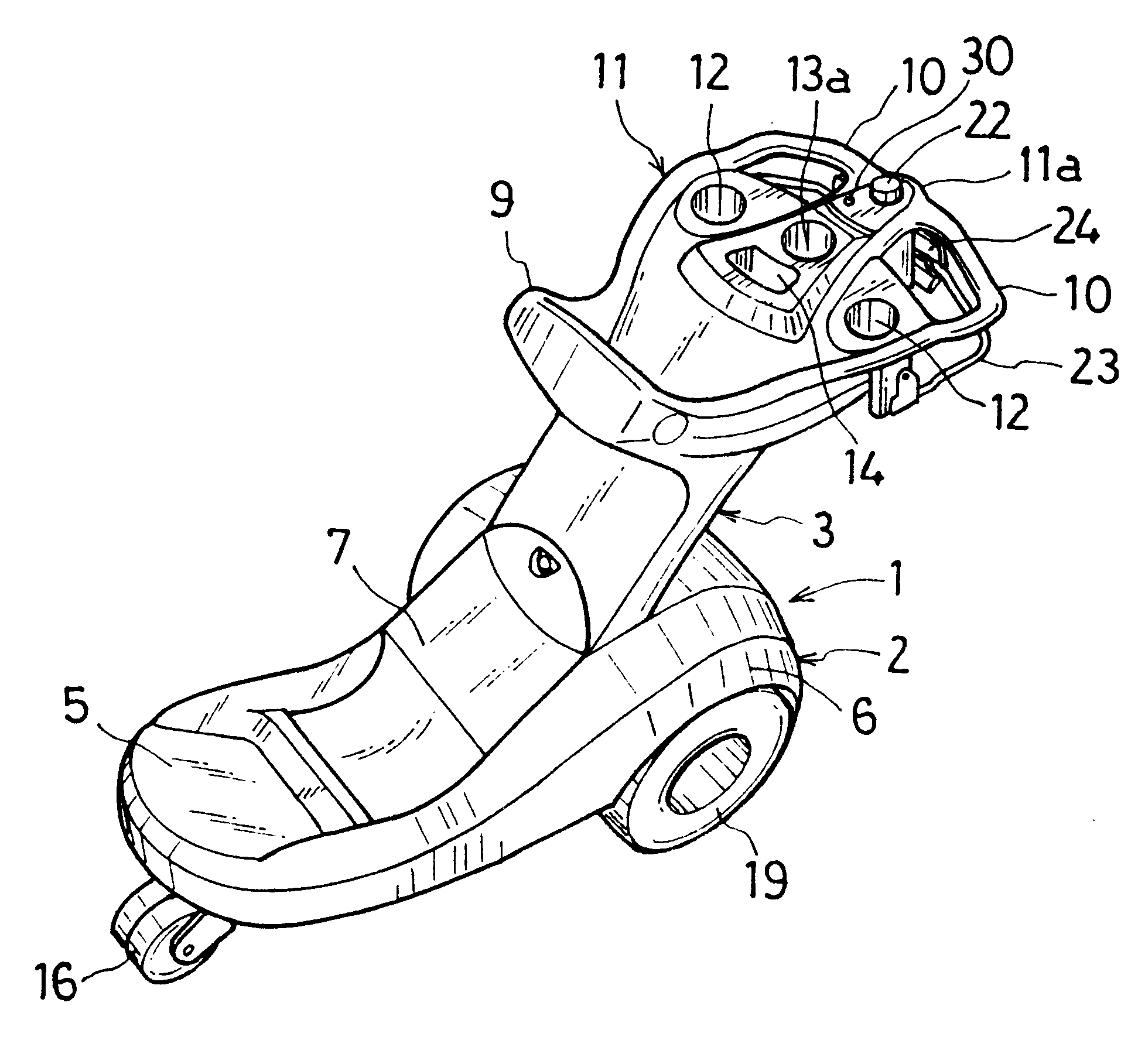

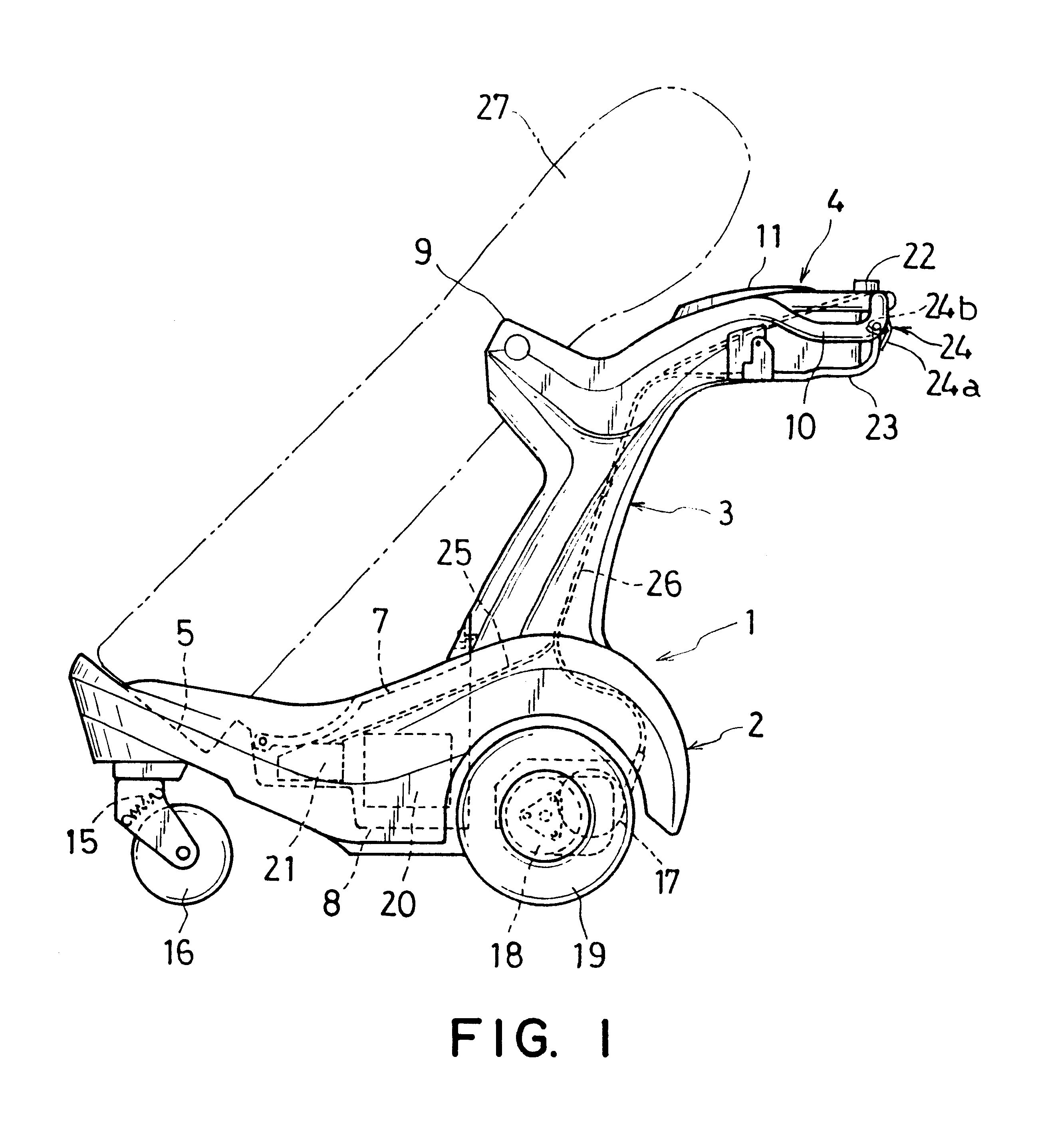

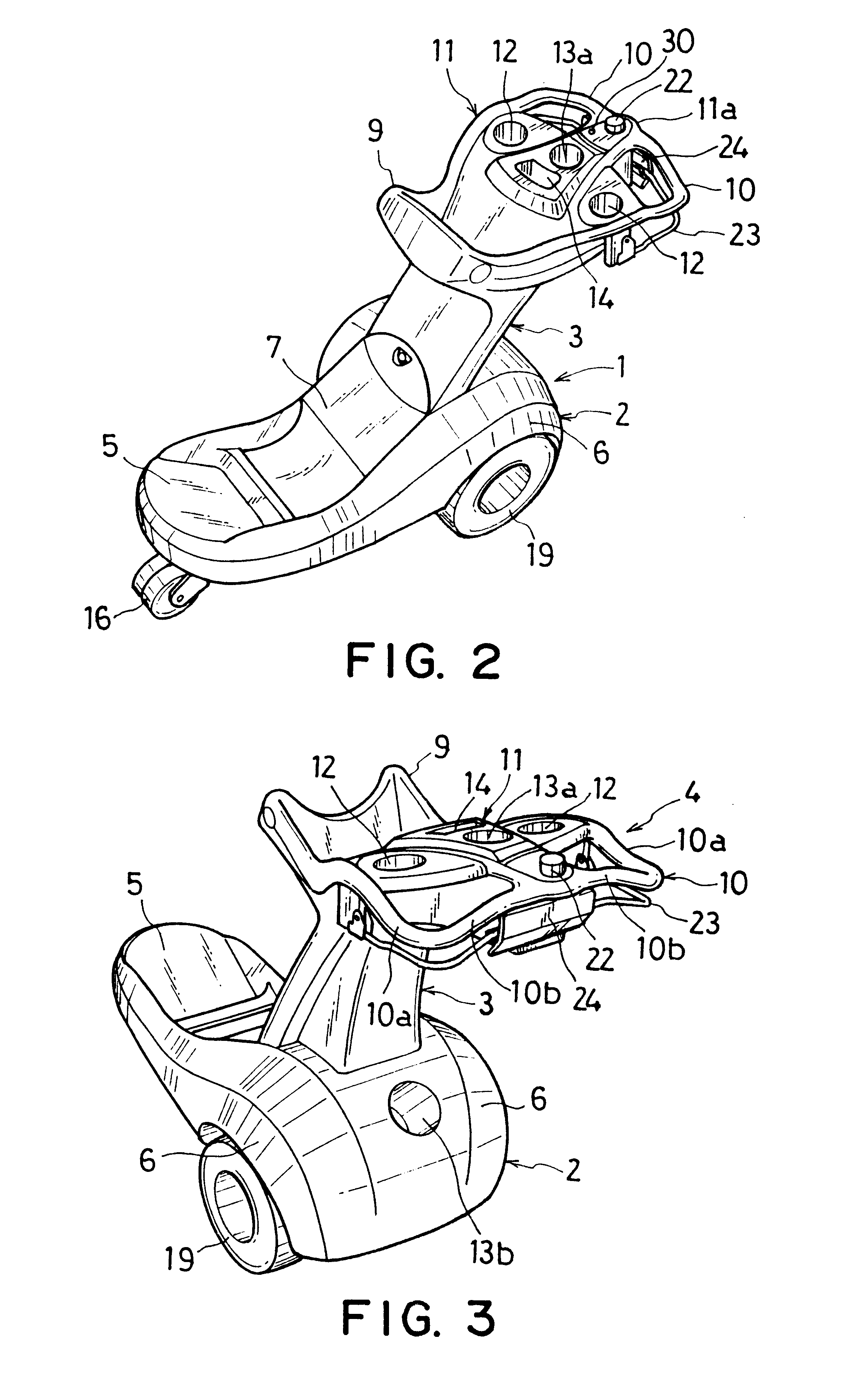

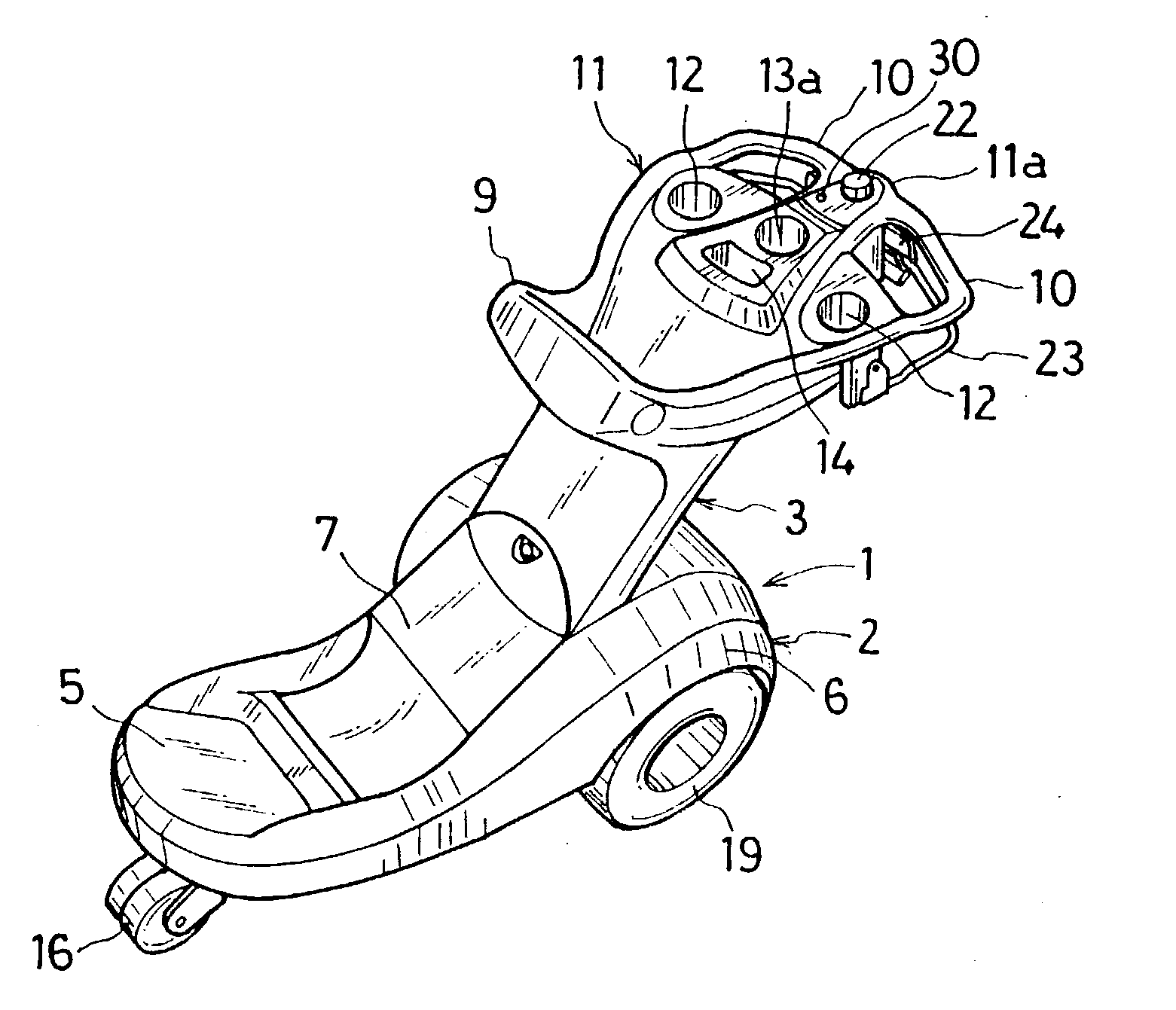

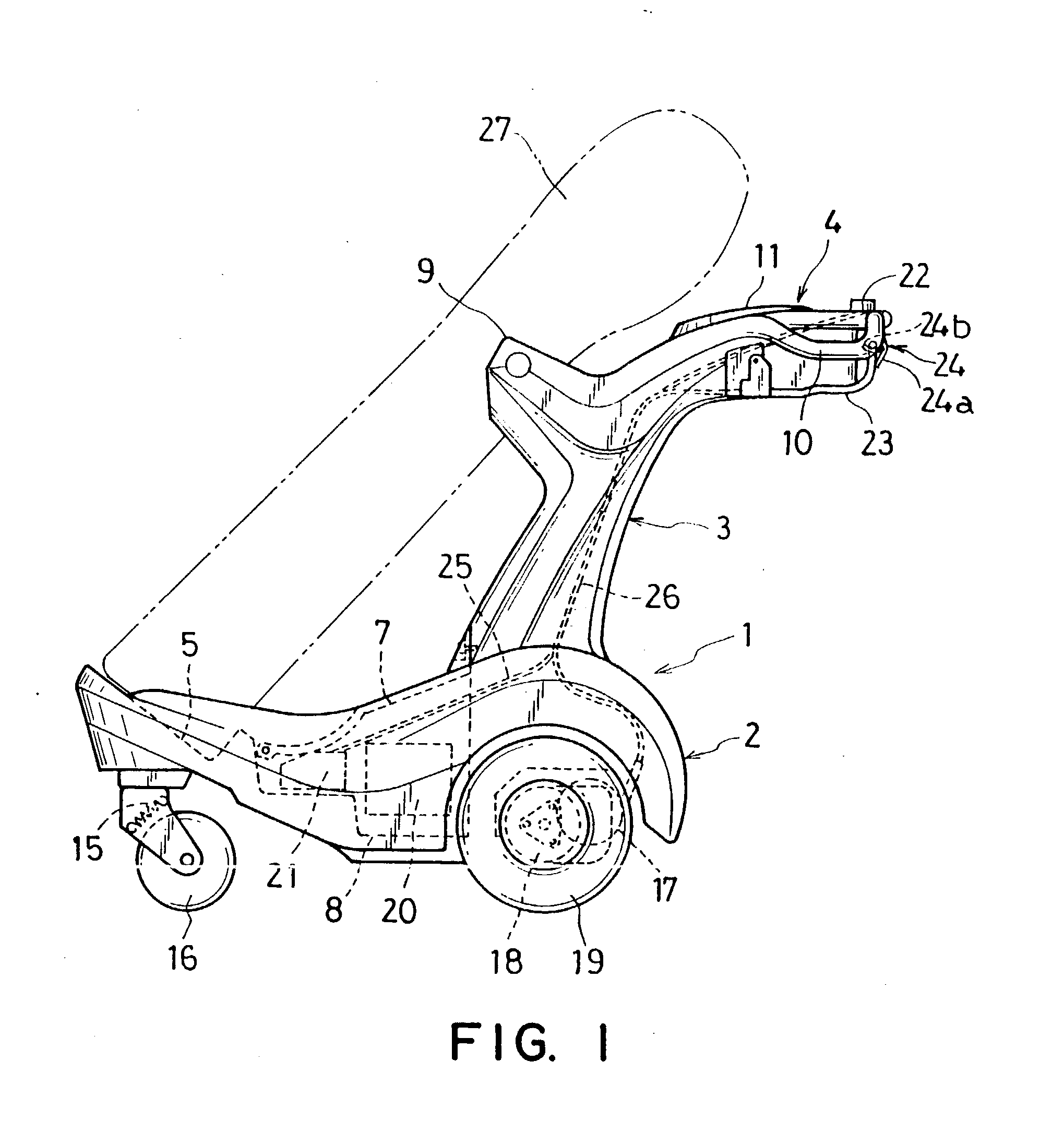

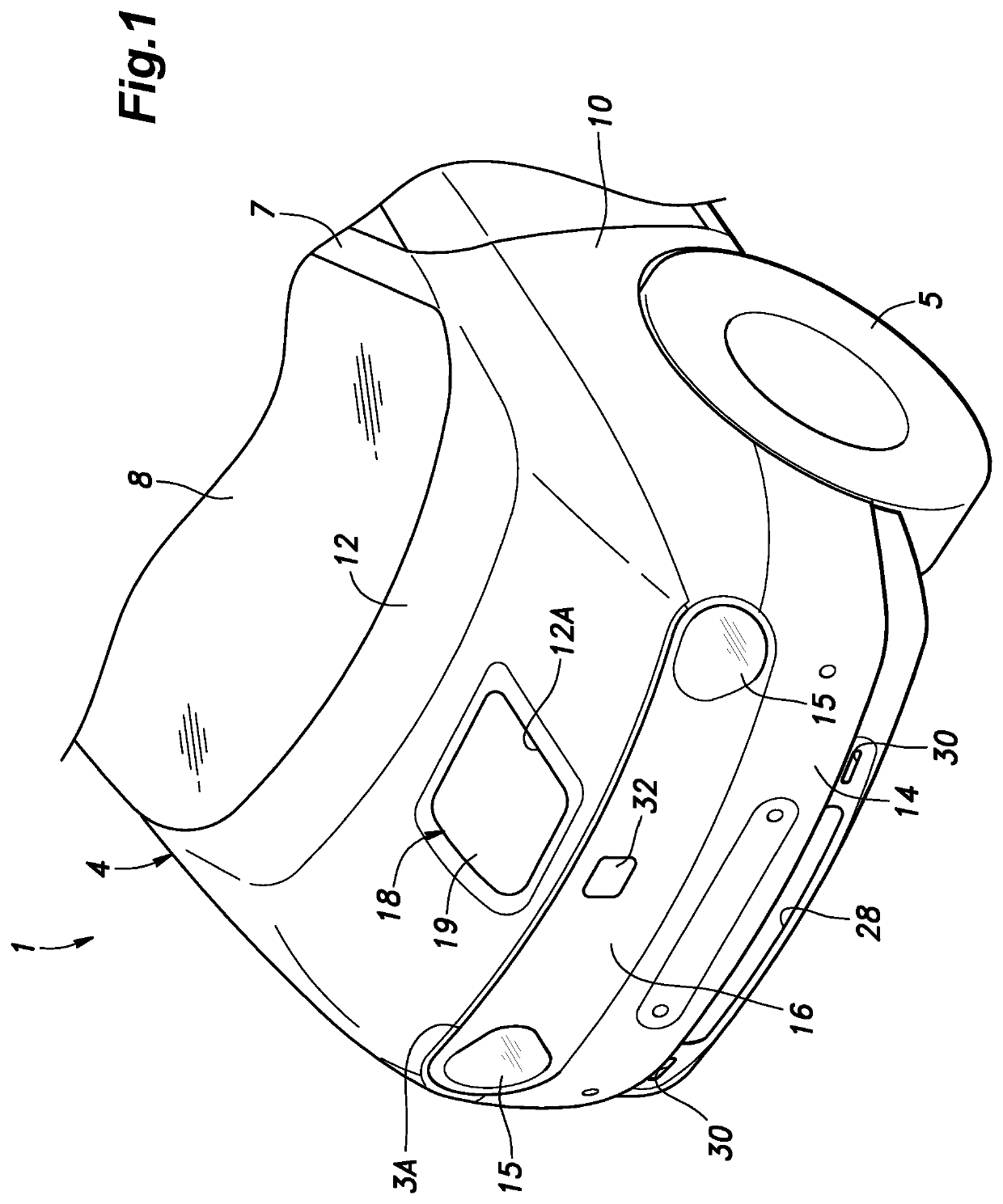

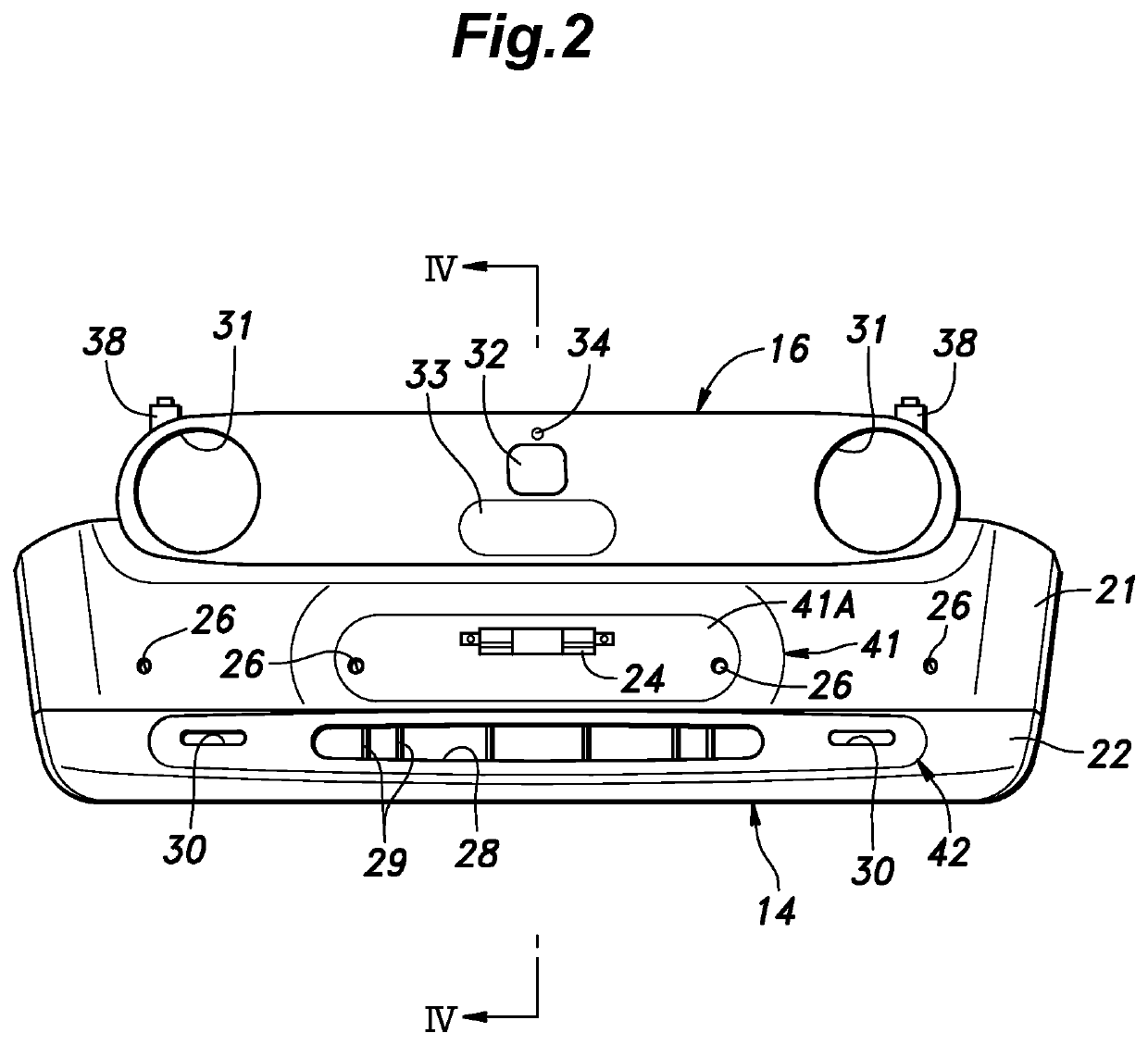

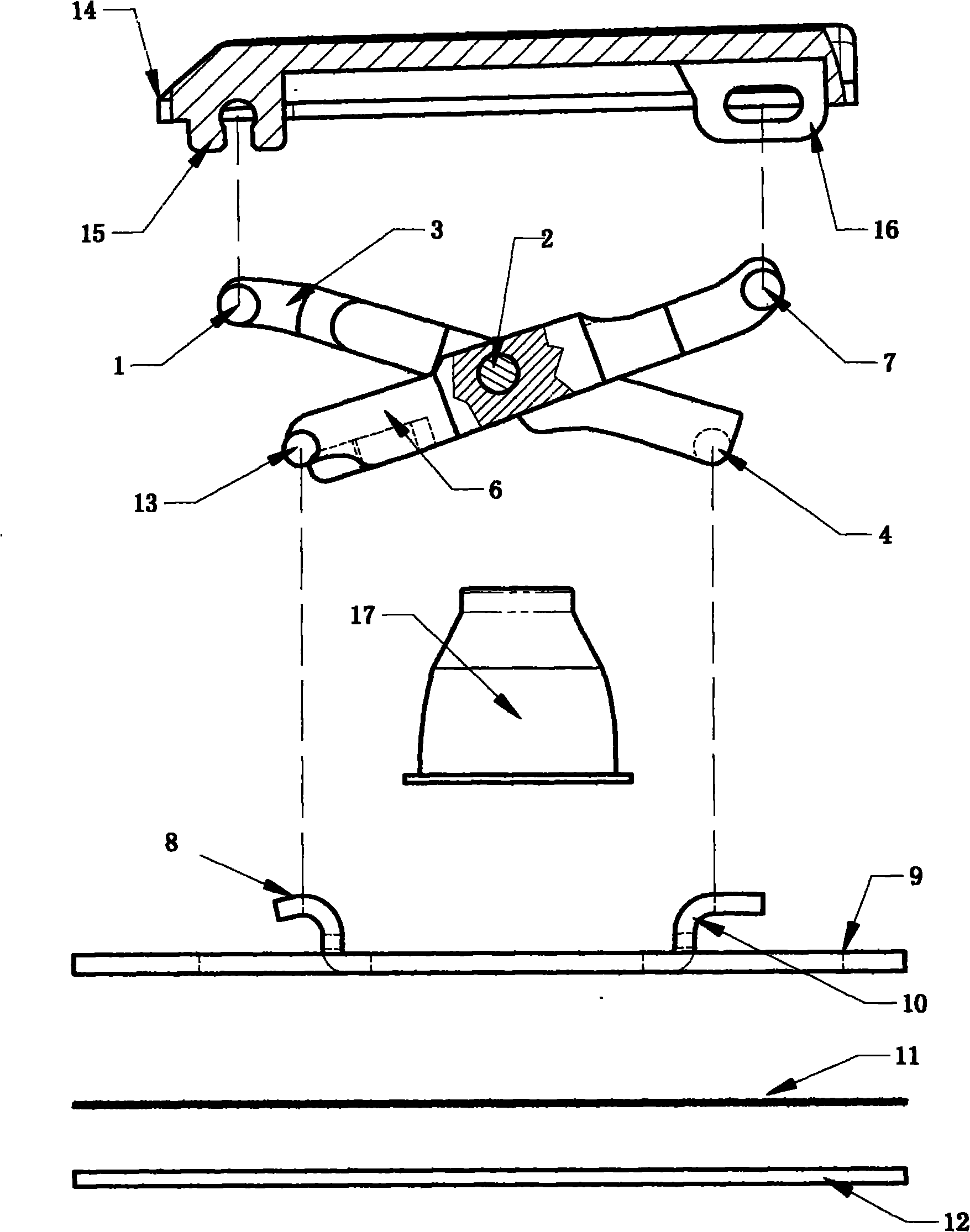

Electric one-bag golf cart

InactiveUS6732823B2Simple mold structureLow costCyclesElectric propulsion mountingDrive wheelGolf course turf

An electric one-bag golf cart that carries a single caddie bag for a player on a golf course is provided. The cart body, including a chassis part, a neck part and a steering device part, is formed as an integral hollow piece using the rotational molding method. The wheel system provided under the chassis consists of one front wheel and two rear wheels, with the front wheel being mounted pivotally on a suspension as a free wheel, while the rear wheels are driving wheels using a differential gear device driven by a motor. At the center of the handlebars, which are made of circular rods, a dial-type speed controller is located, and a brake lever is provided under the steering device, together with a lock mechanism.

Owner:BILLCON

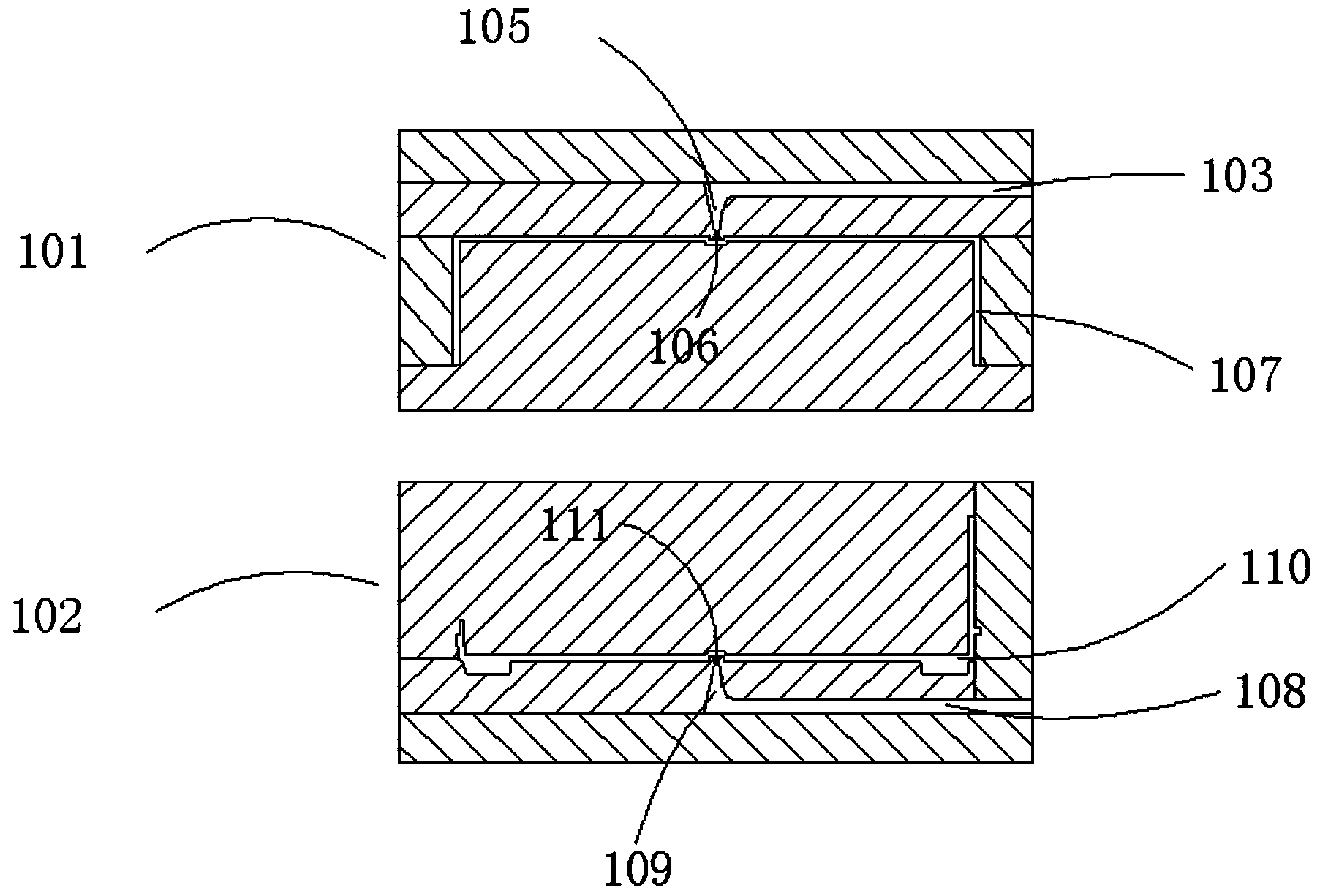

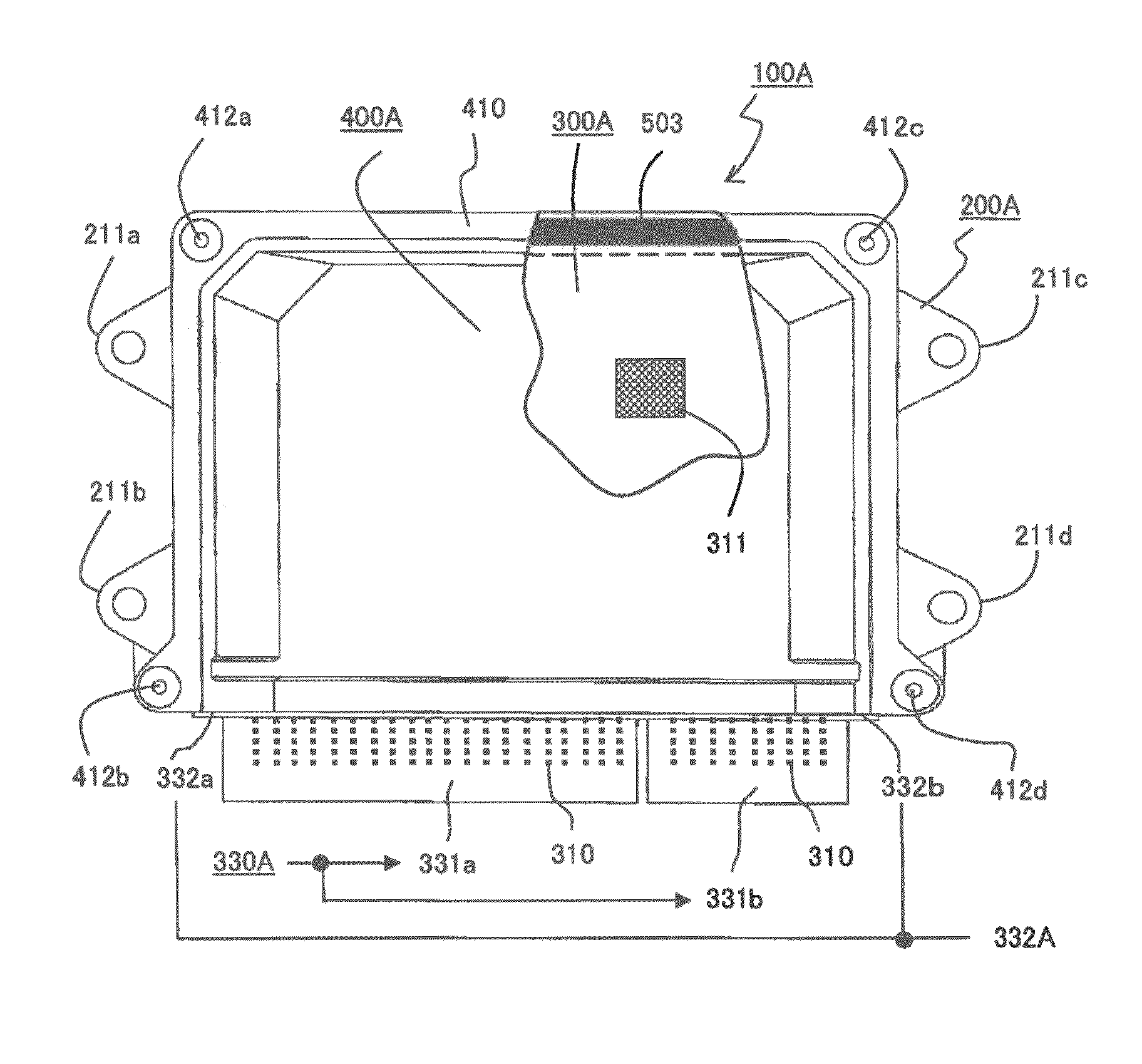

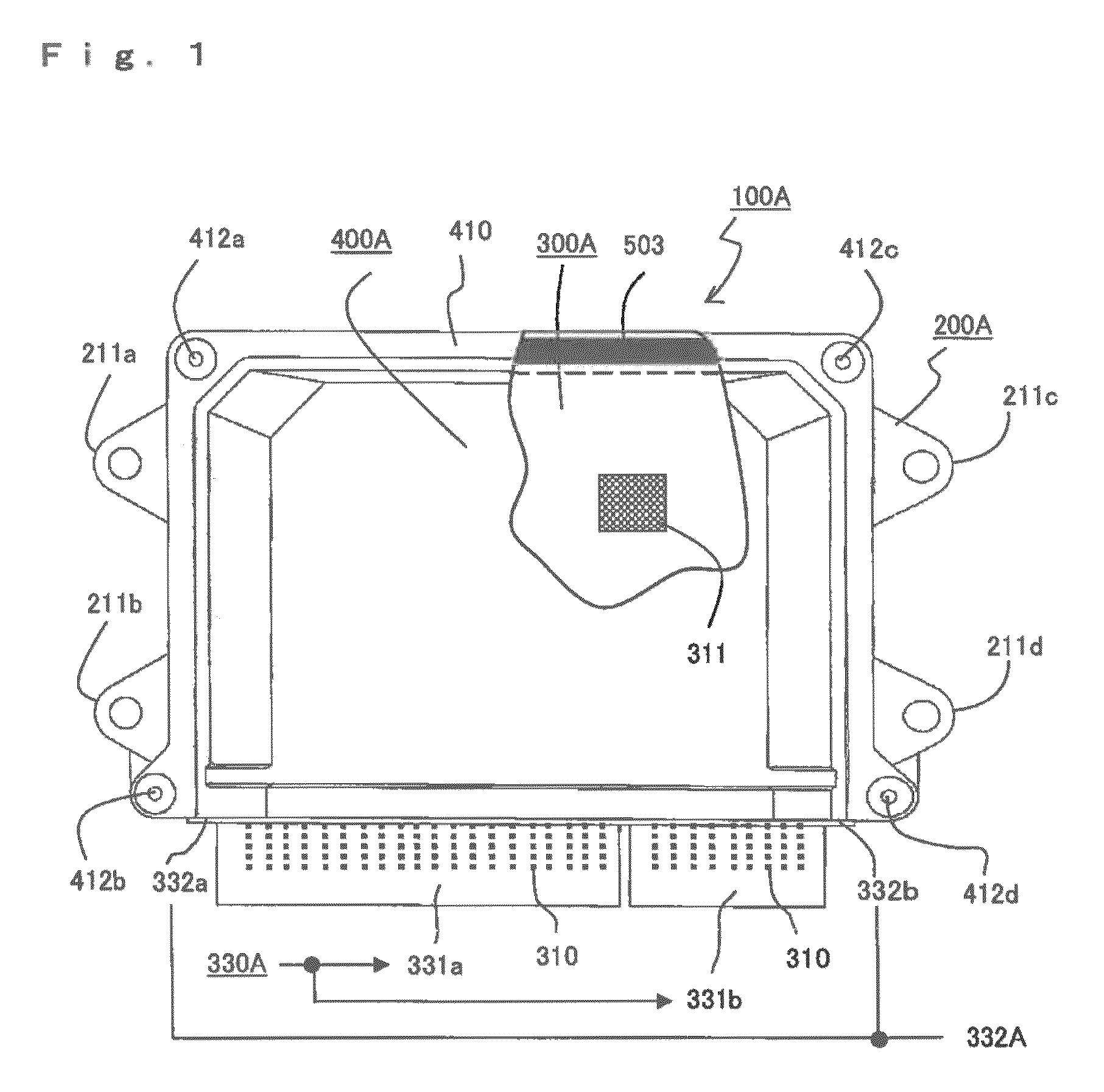

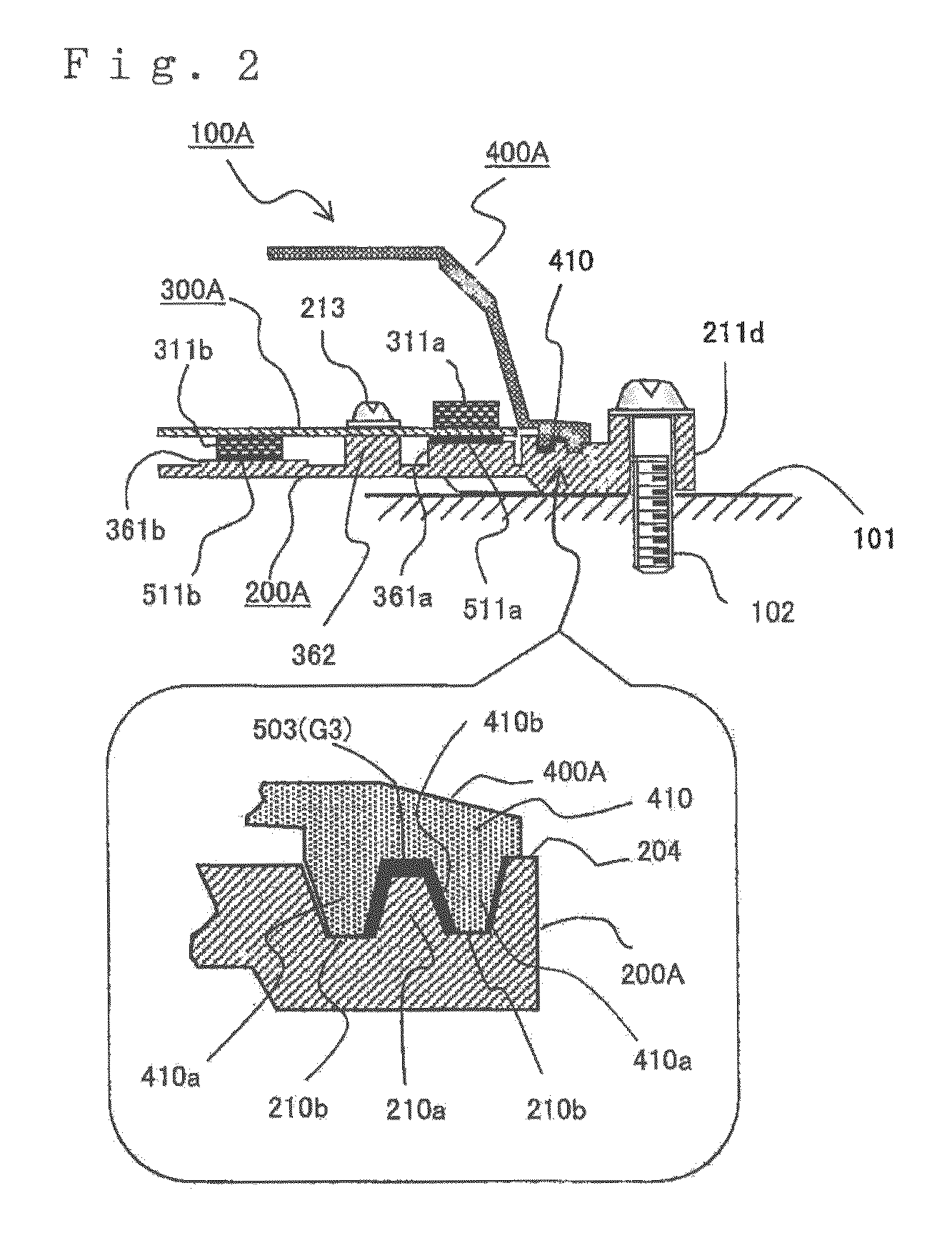

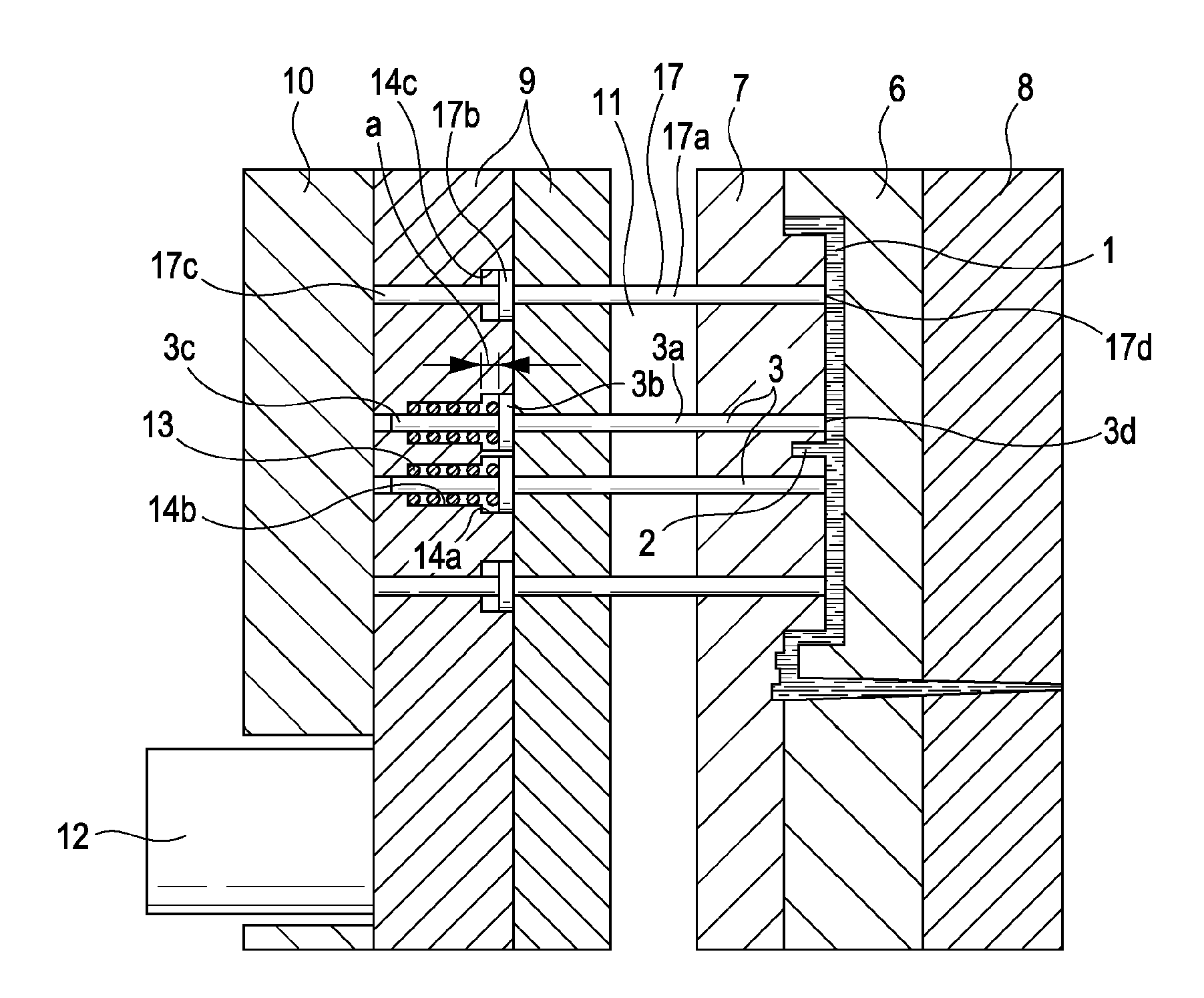

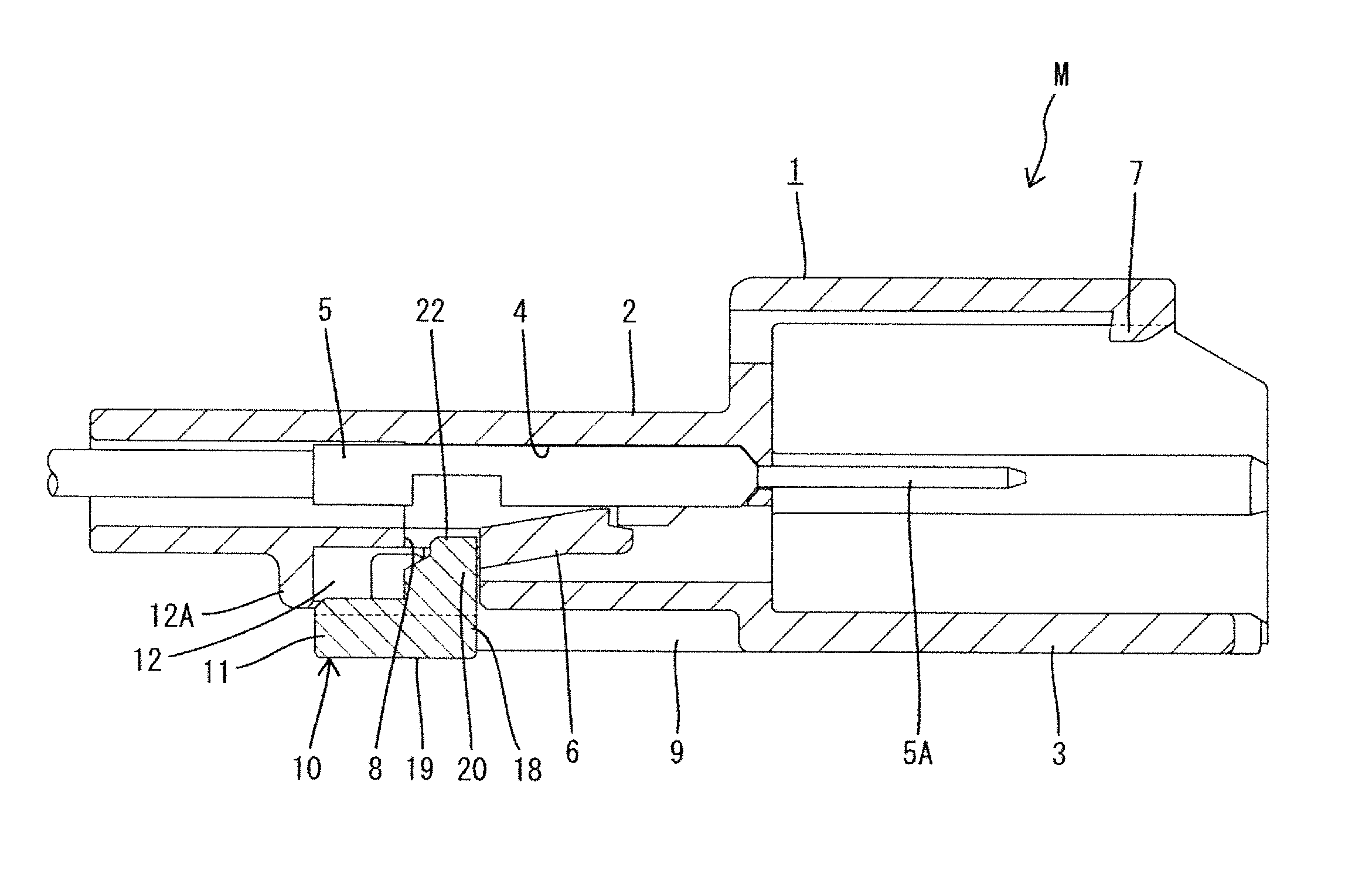

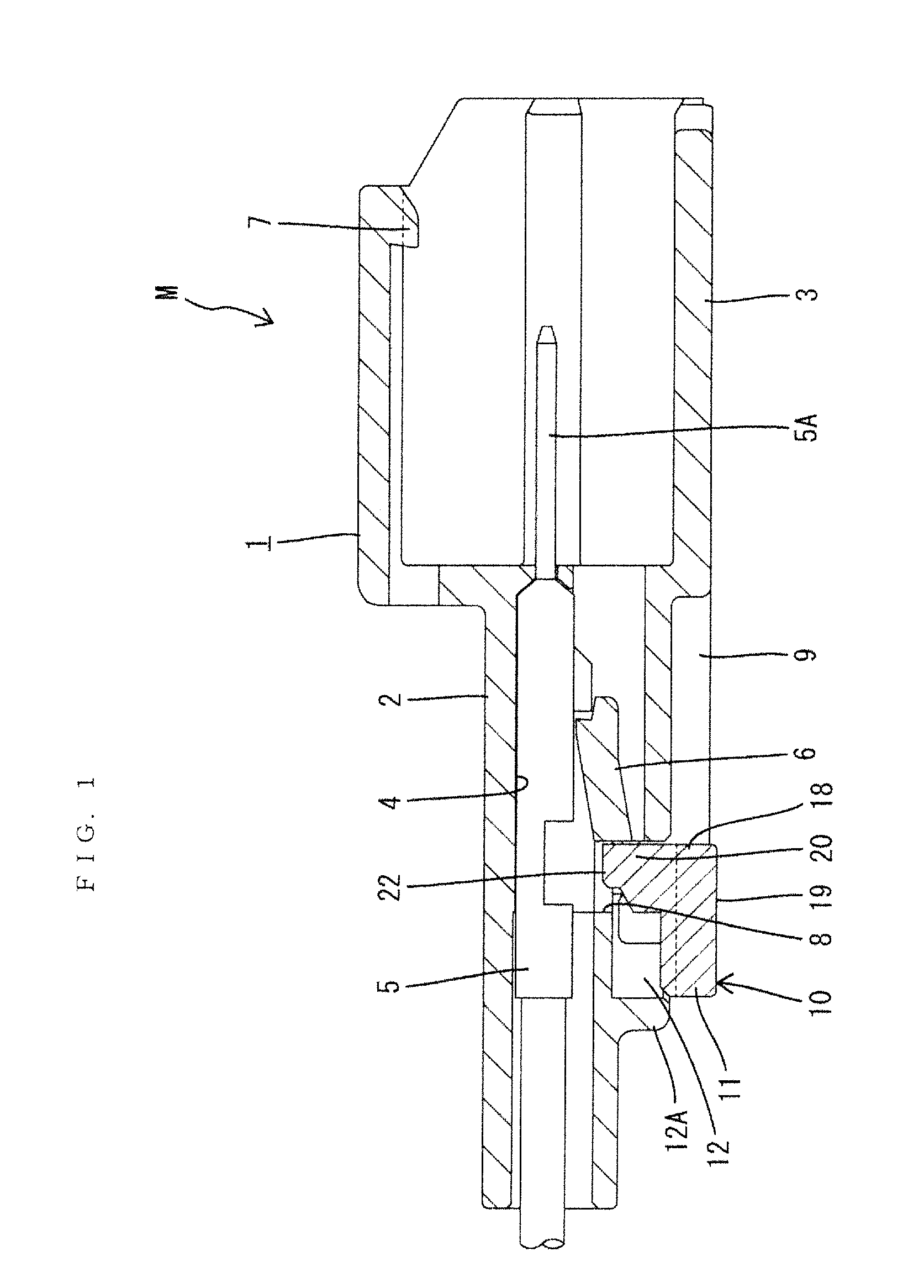

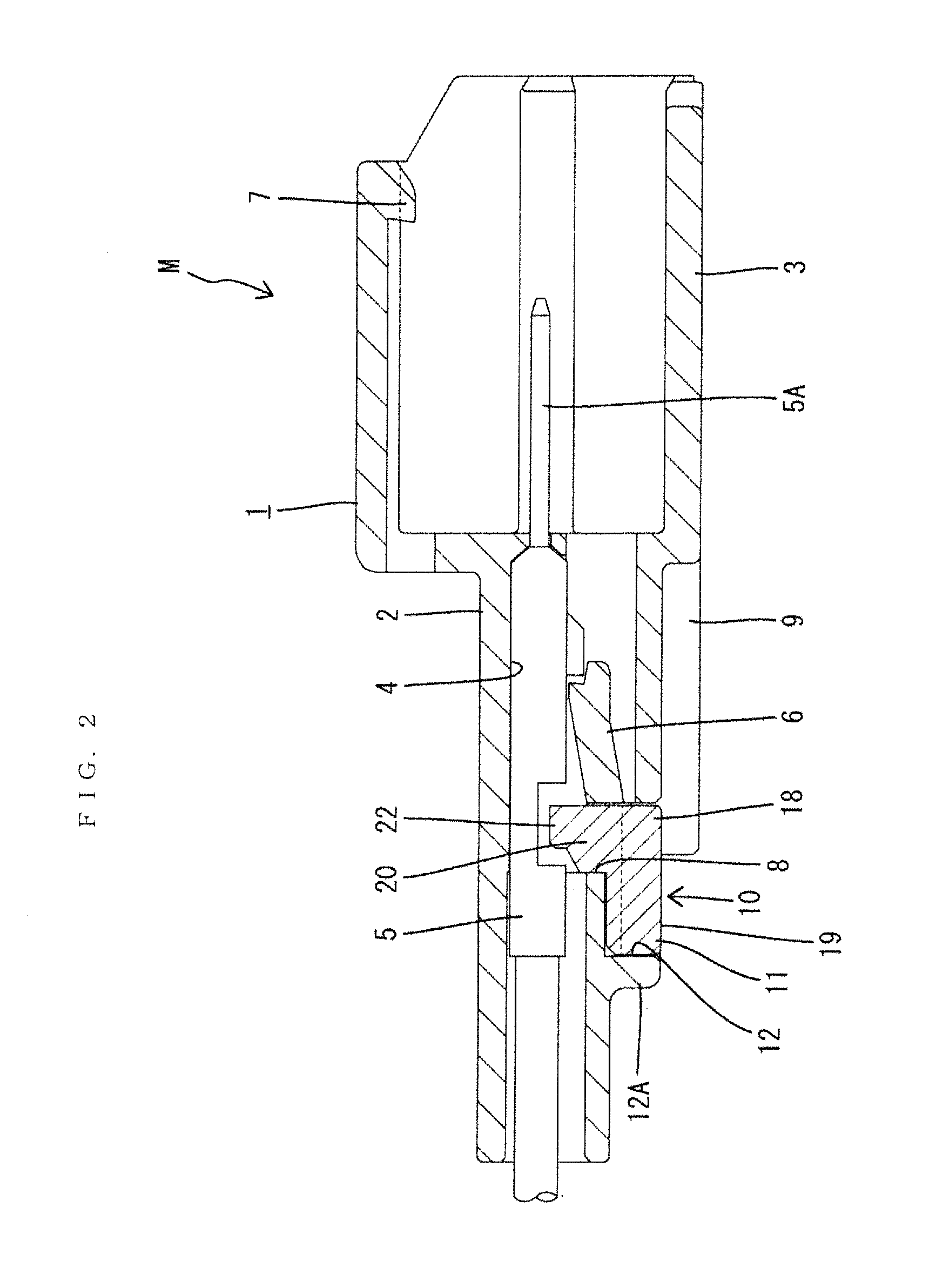

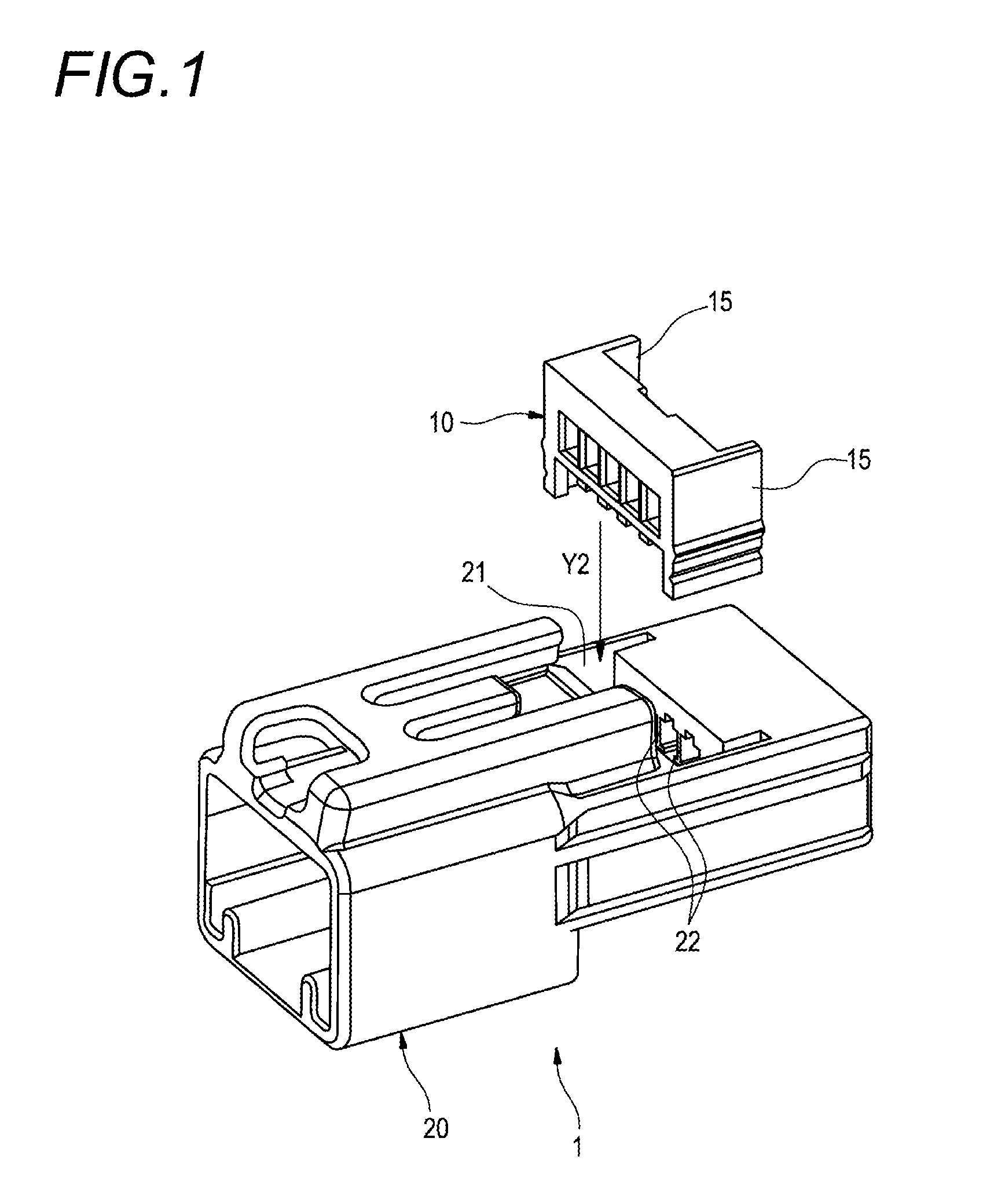

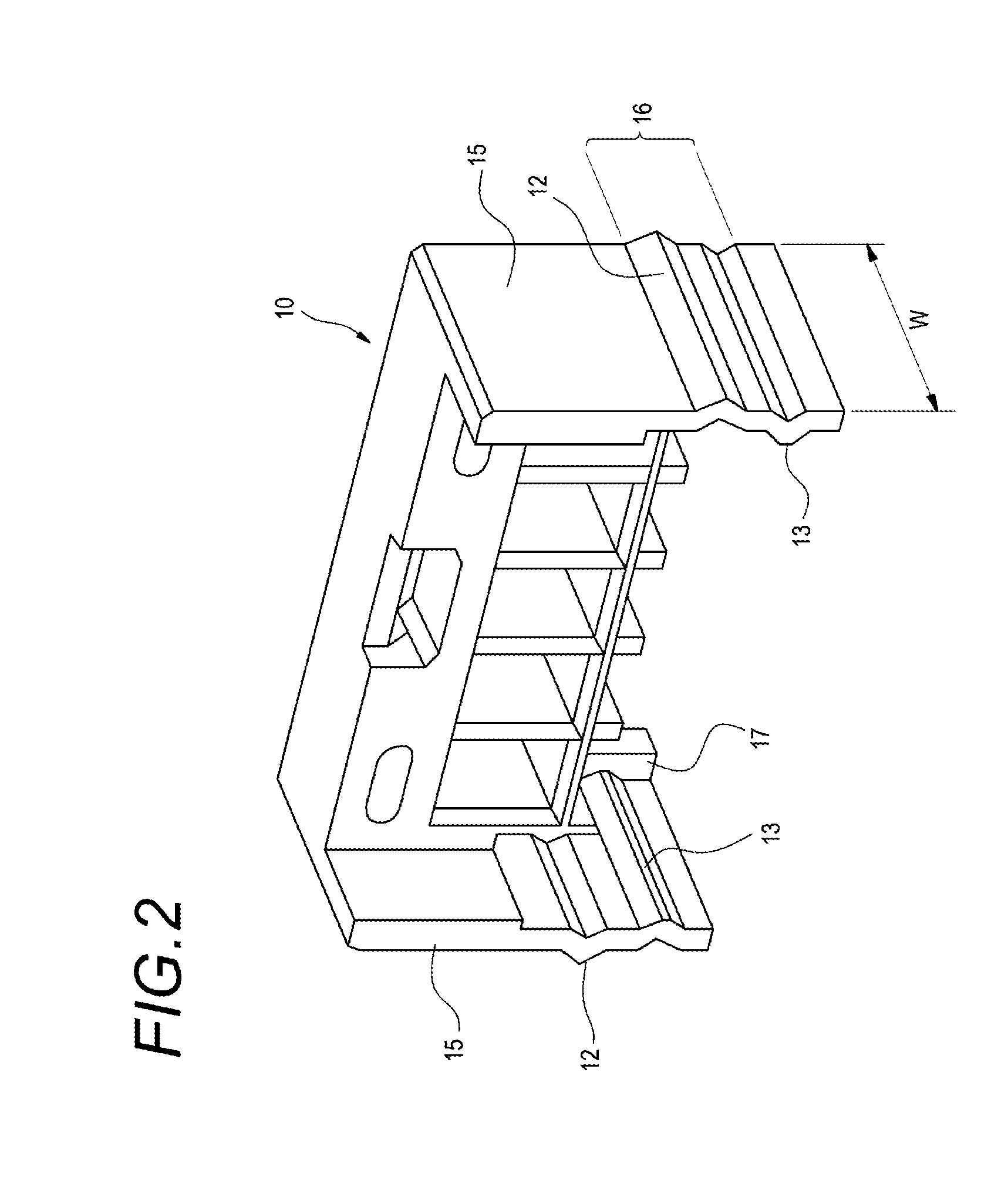

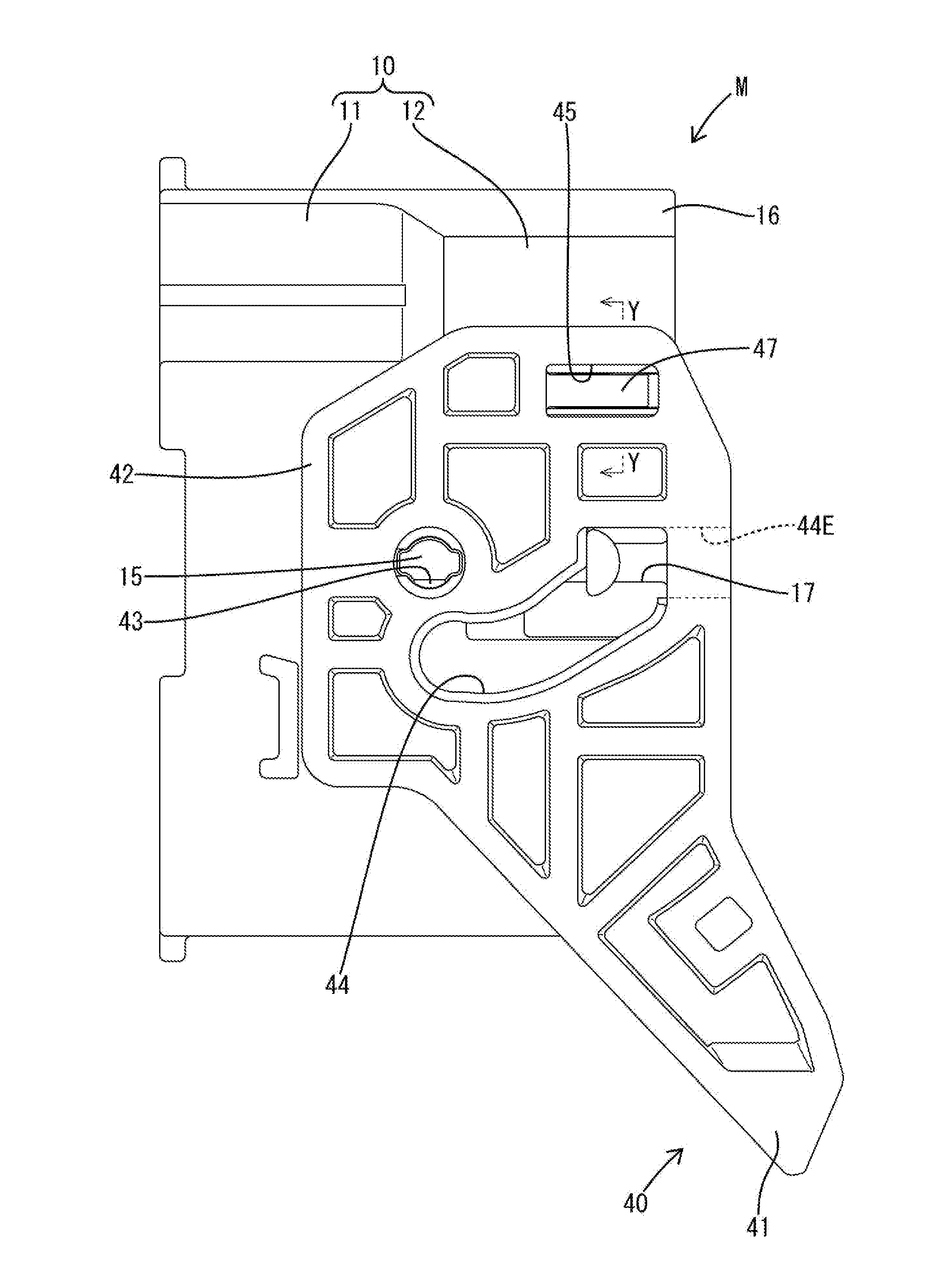

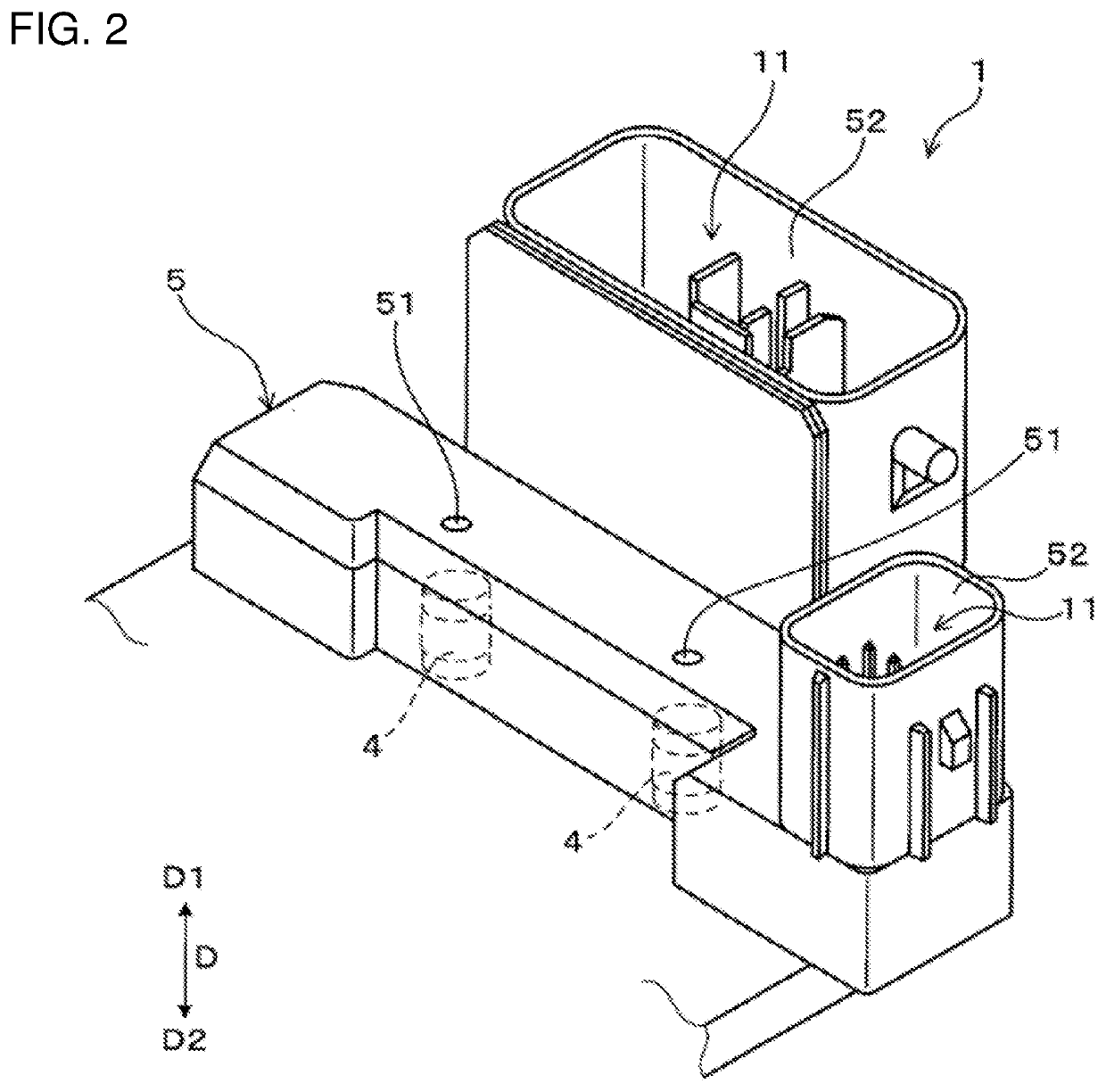

Waterproof control unit

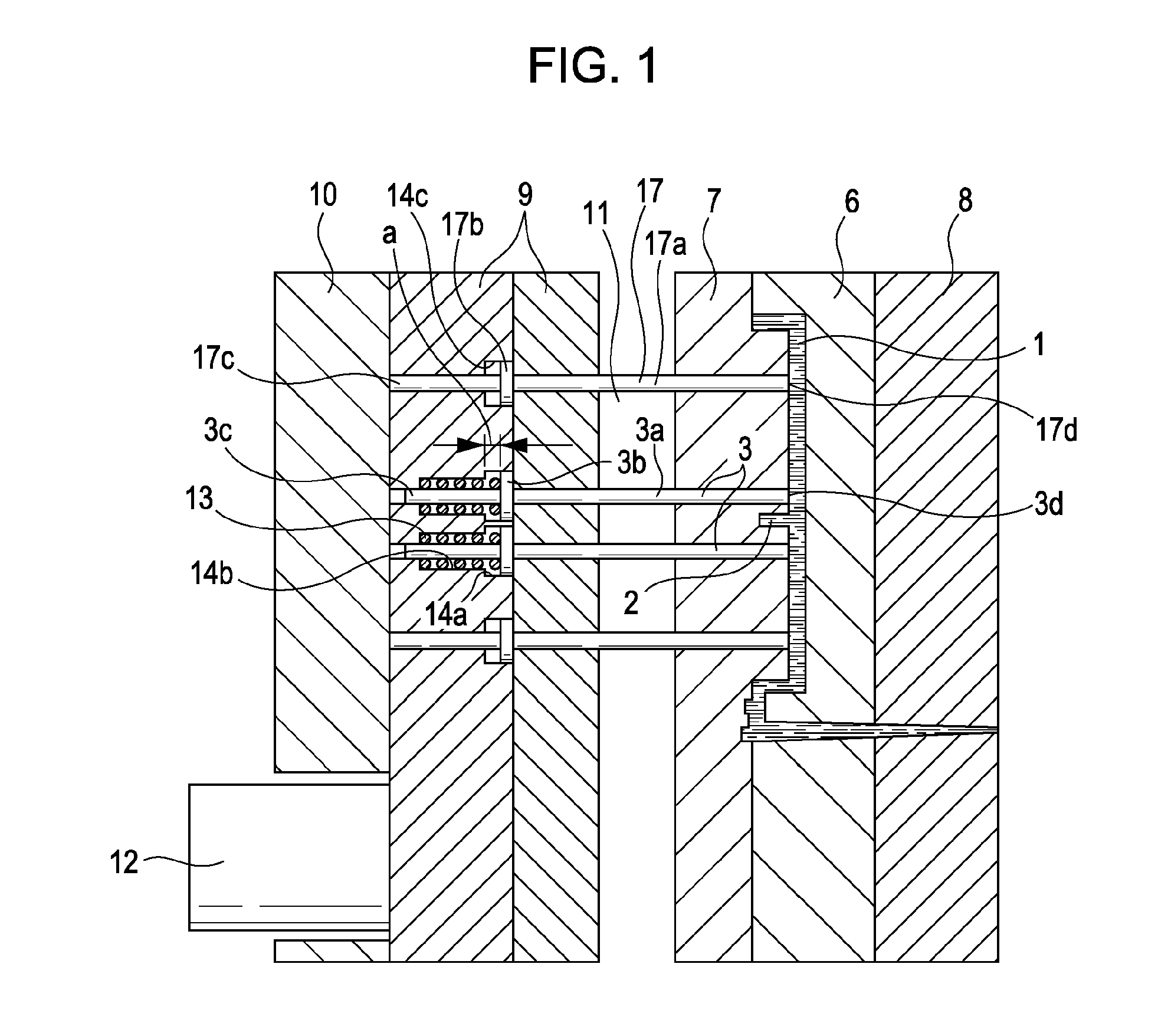

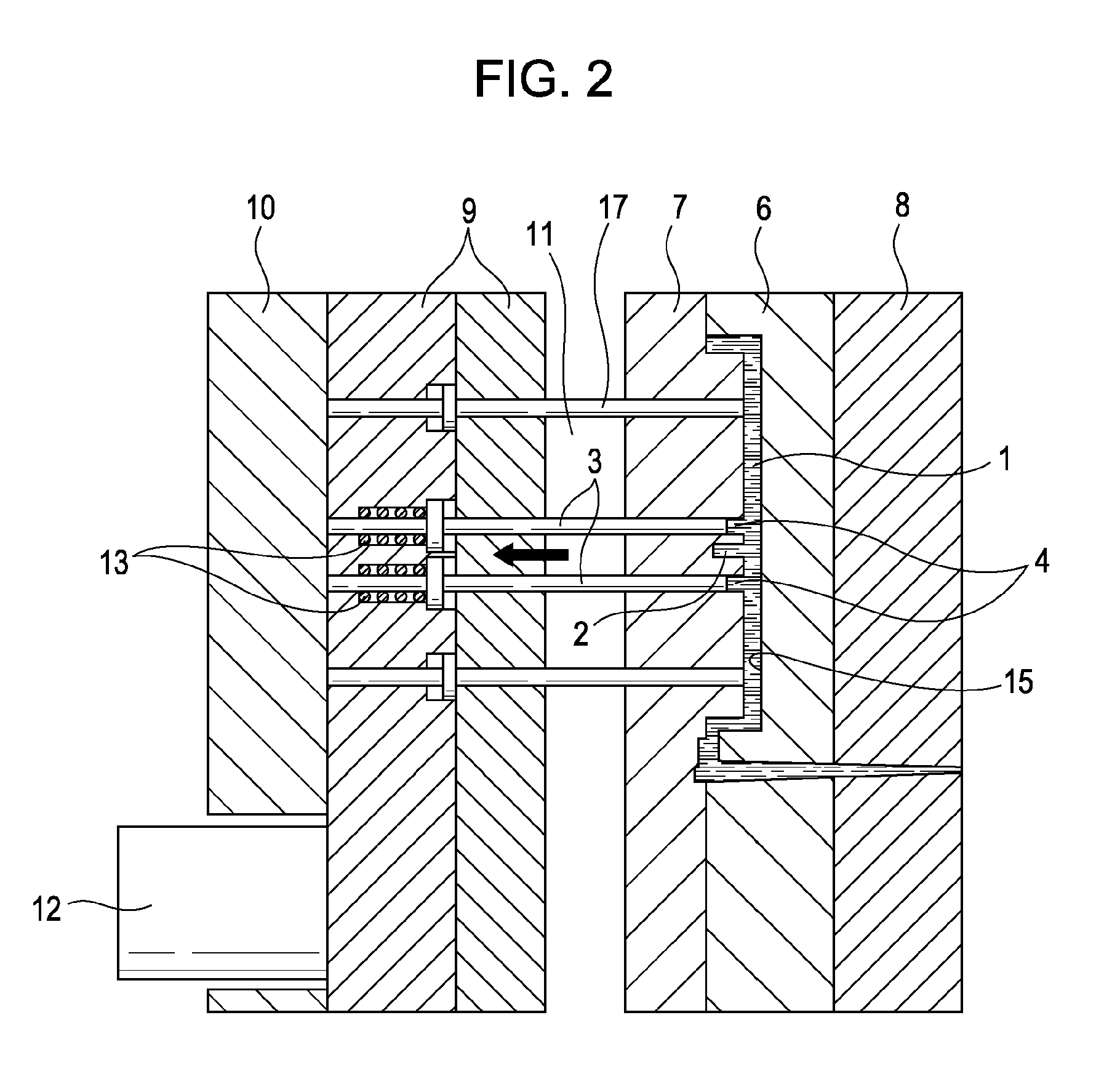

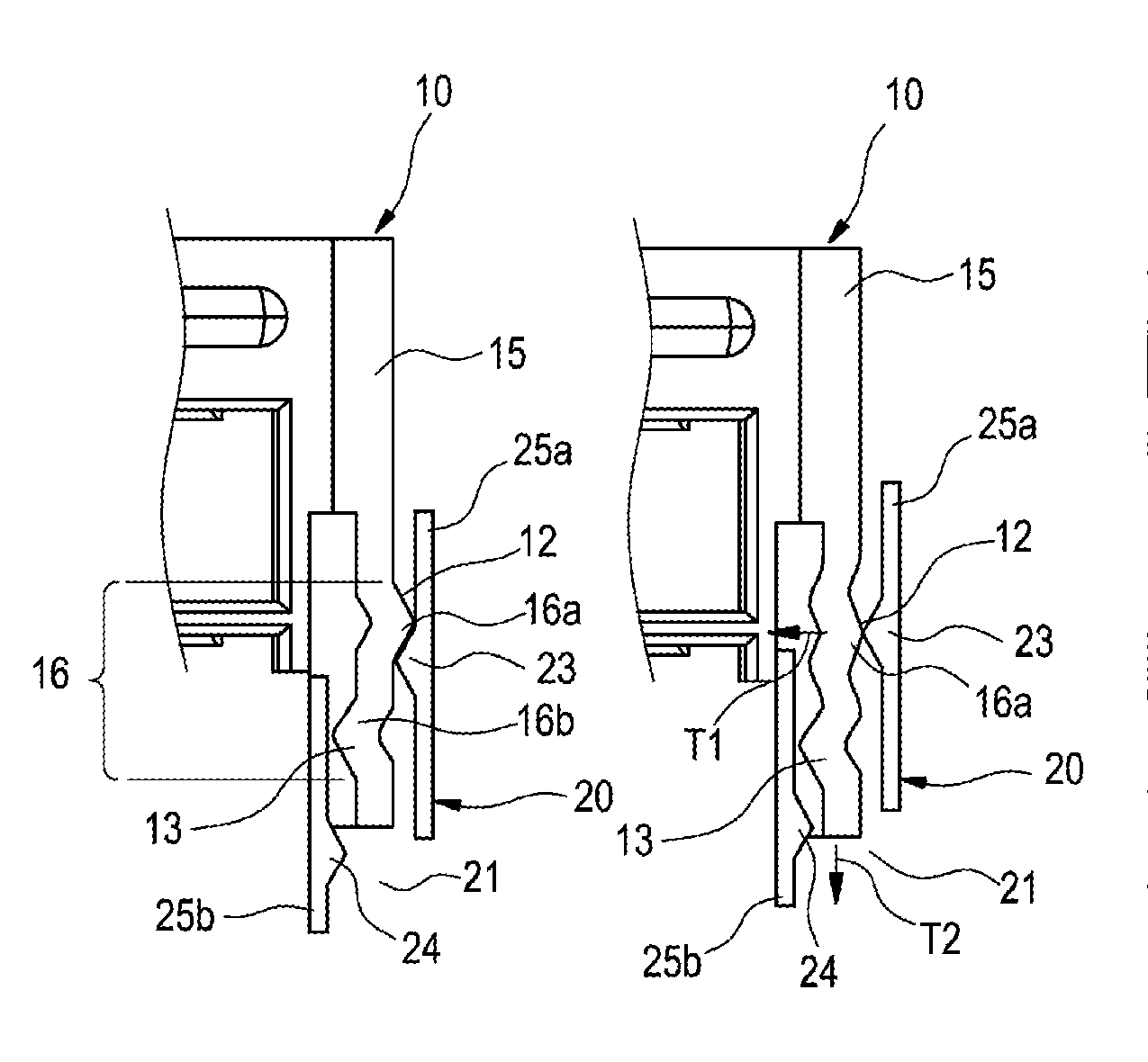

ActiveUS9462715B2Short bodySimple mold structureHermetically-sealed casingsElectrical apparatus contructional detailsEngineeringGap width

A waterproof control unit is provided in which: connector housing is fixedly positioned onto circuit board that is mounted onto base; a first seal gap G1 formed of the connector housing and a cover, a second seal gap G2 formed of the connector housing and the base and a third seal gap G3 formed of the base and the cover are included; the first seal gap G1 is formed of a terrace slope portion gap G1b and an outer step flat portion gap G1a and an inner step flat portion gap G1c that are in communication with the terrace slope portion gap G1b; a gap setting protrusion for limiting the gap width is provided at least in the first seal gap G1; and, between the connector housing and the cover, a horizontal movement limitation member are provided for limiting the relative positional relationship between the connector housing and the cover.

Owner:MITSUBISHI ELECTRIC CORP

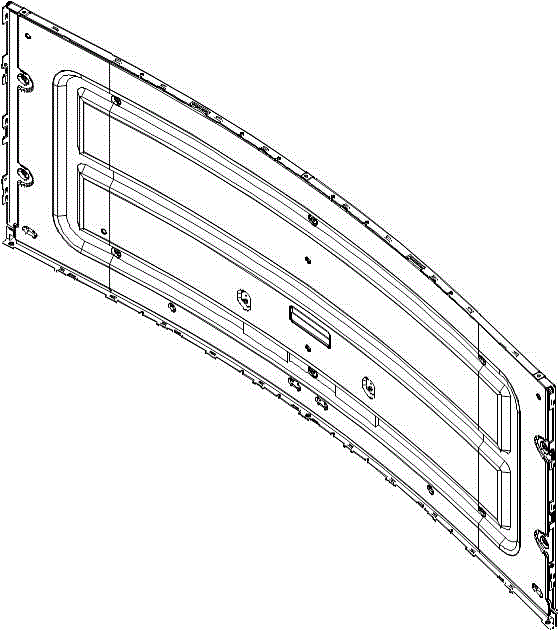

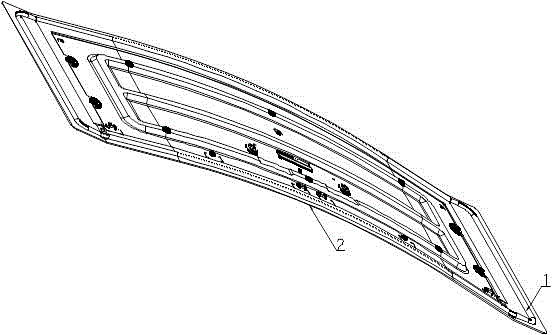

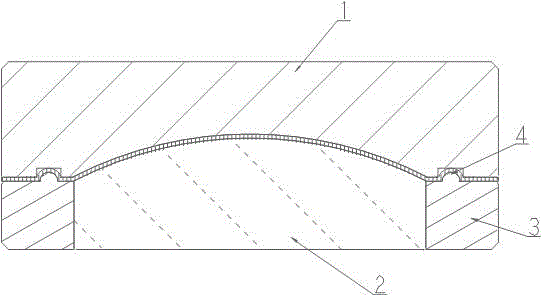

Curved-surface LED display backboard stamping die machining method

The invention relates to a curved-surface LED display backboard stamping die machining method. The method is characterized in that used raw materials are sheets, the sheets are formed into curved-surface sheet bodies on first project curved surfaces, and other subsequent processes such as trimming, convex hull shaping, clamp hook forming, hole stamping, engraving, burr pressing, little bending, engraving, sprouting and complete-cycle bending are all finished on the formed curved-surface sheet bodies. During curved-surface forming, a male die, a female die and a pressure plate are provided, the working surface is a curved surface, pressing ribs are arranged on the die pressure plate, stretching and curved-surface stabilization are facilitated, and accordingly production efficiency is increased, and waste is reduced.

Owner:JIANGSU FANRUN ELECTRONICS

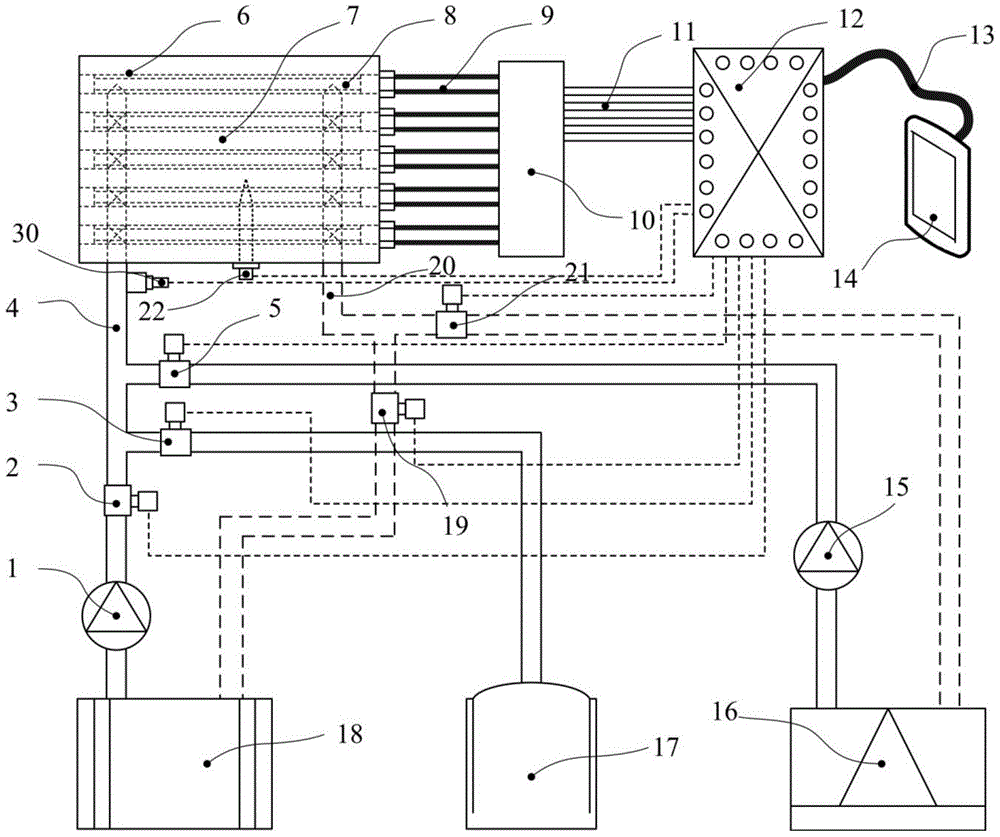

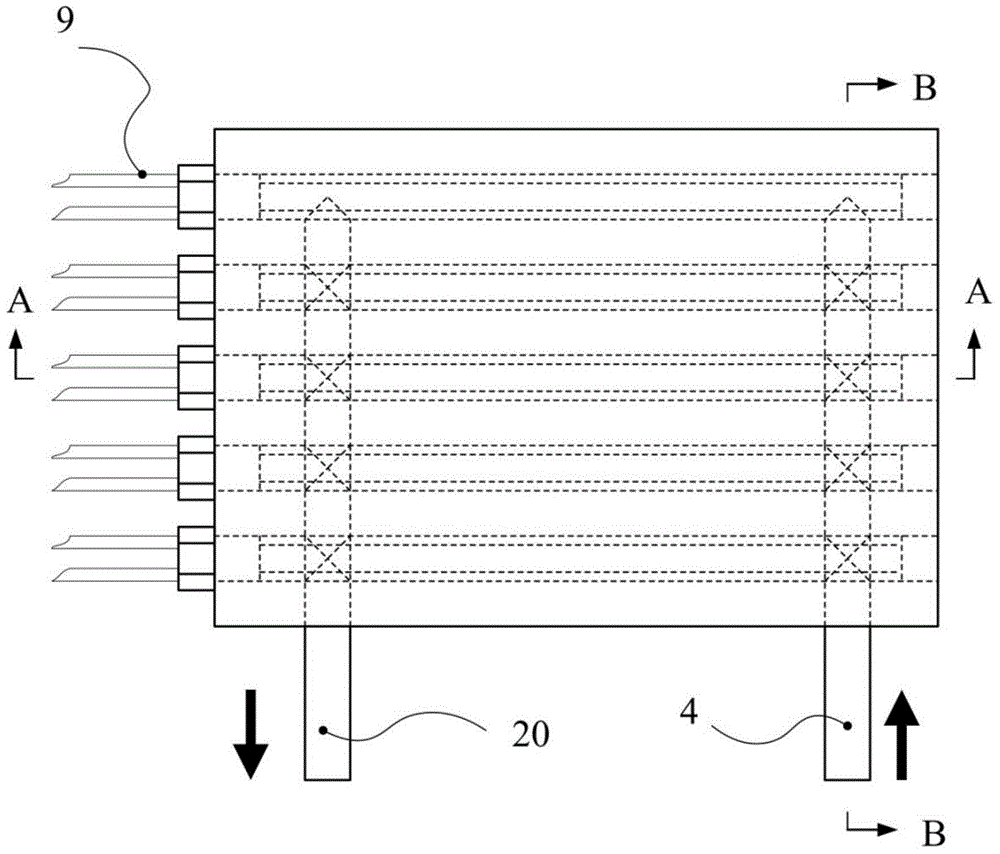

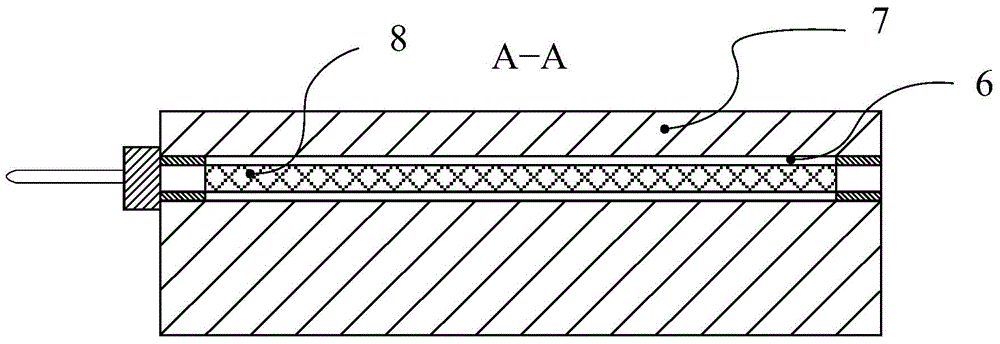

Rapid heating and cooling method and system of injection mould

ActiveCN103552223ASimple mold structureLow processing and manufacturing costsHeating coolingHeating element

The invention discloses a rapid heating and cooling system of an injection mould. The rapid heating and cooling system comprises four closed loops which can be independently controlled to be connected or disconnected, wherein the closed loops are respectively used for inputting / outputting a hot fluid medium for a mould cavity plate, and inputting / outputting a cold fluid medium for the mould cavity plate; the mould cavity plate comprises at least one fluid medium input main pipeline, a fluid medium output main pipeline and a plurality of branch pipelines for connecting the fluid medium input main pipeline with the fluid medium output main pipeline, the branch pipelines are internally provided with heating elements, and gaps are reserved between the heating elements and installing hole walls. The invention also provides a rapid heating and cooling method of the injection mould. The rapid heating and cooling method comprises a mould heating stage, an after heating stage, a cooling stage and an after cooling stage. The rapid heating and cooling system and device provided by the invention have the outstanding characteristics that the regulation and control range of the temperature of the mould is large, the heating cooling efficiency and energy use ratio are high, the structure is compact, the operation is reliable, the maintenance is convenient, and the cost is low.

Owner:SHANDONG UNIV

Injection mold and partial compression molding method

InactiveUS20080185747A1Good lookingAvoid flowAuxillary shaping apparatusFood shapingCompression moldingEngineering

Owner:CANON KK

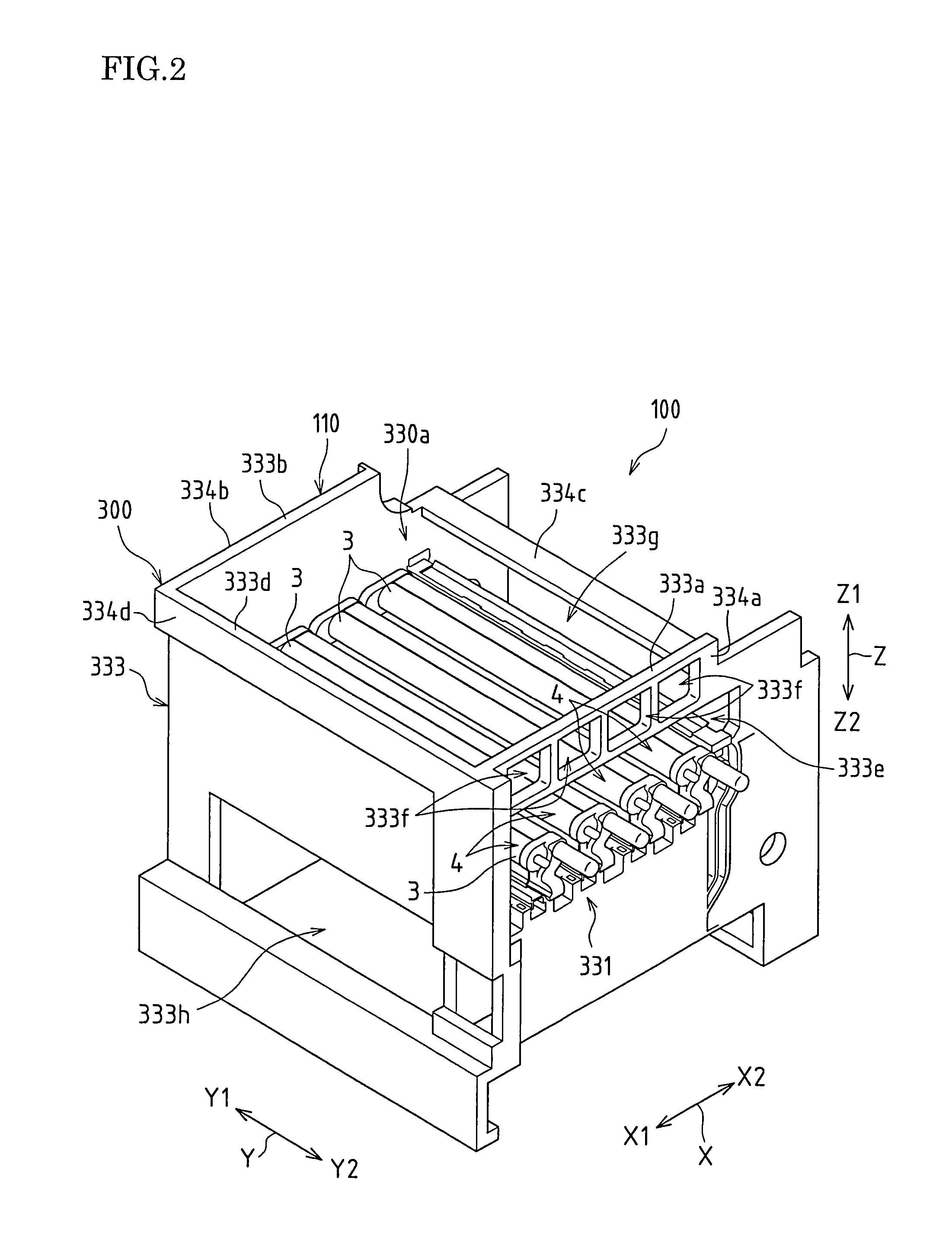

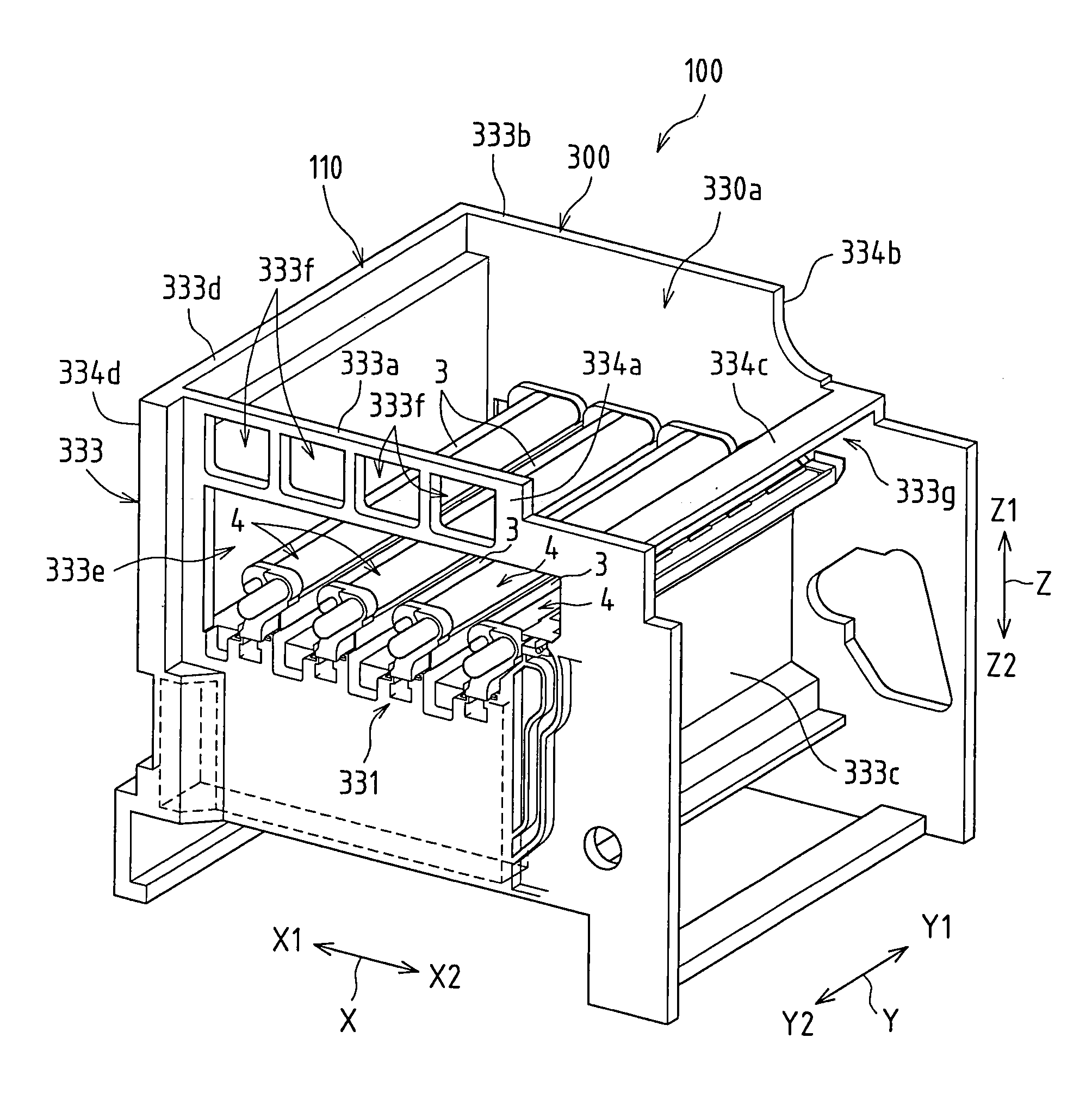

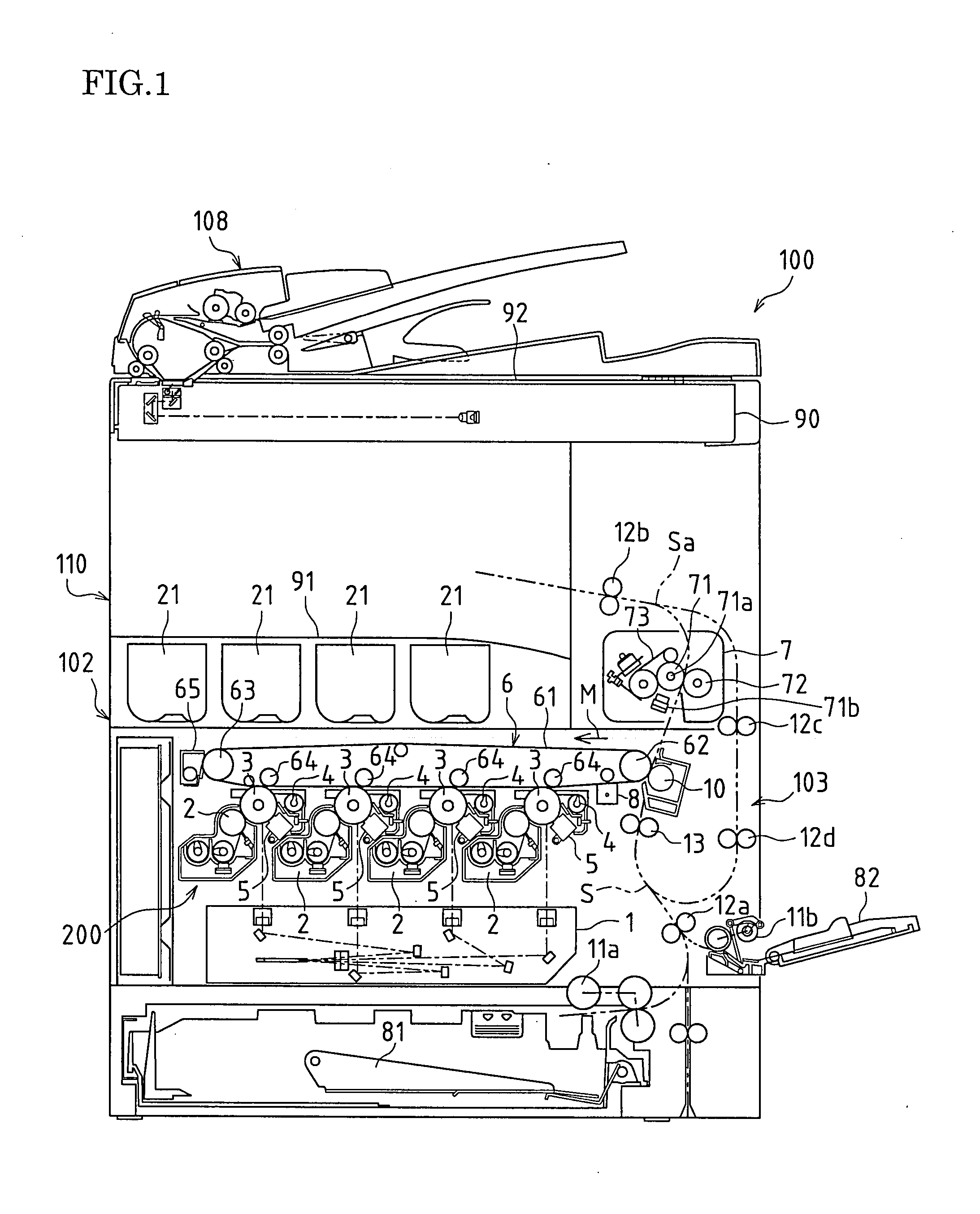

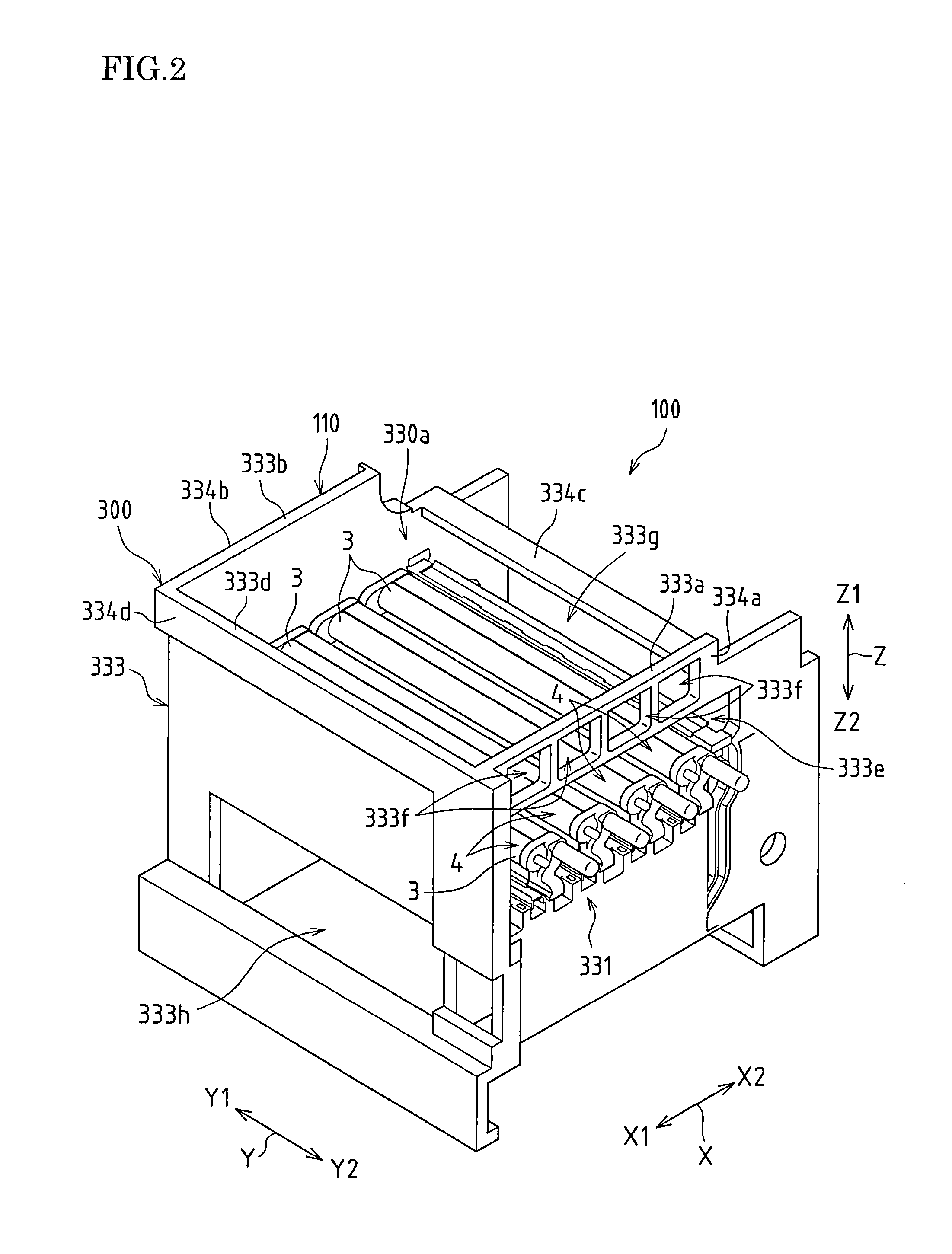

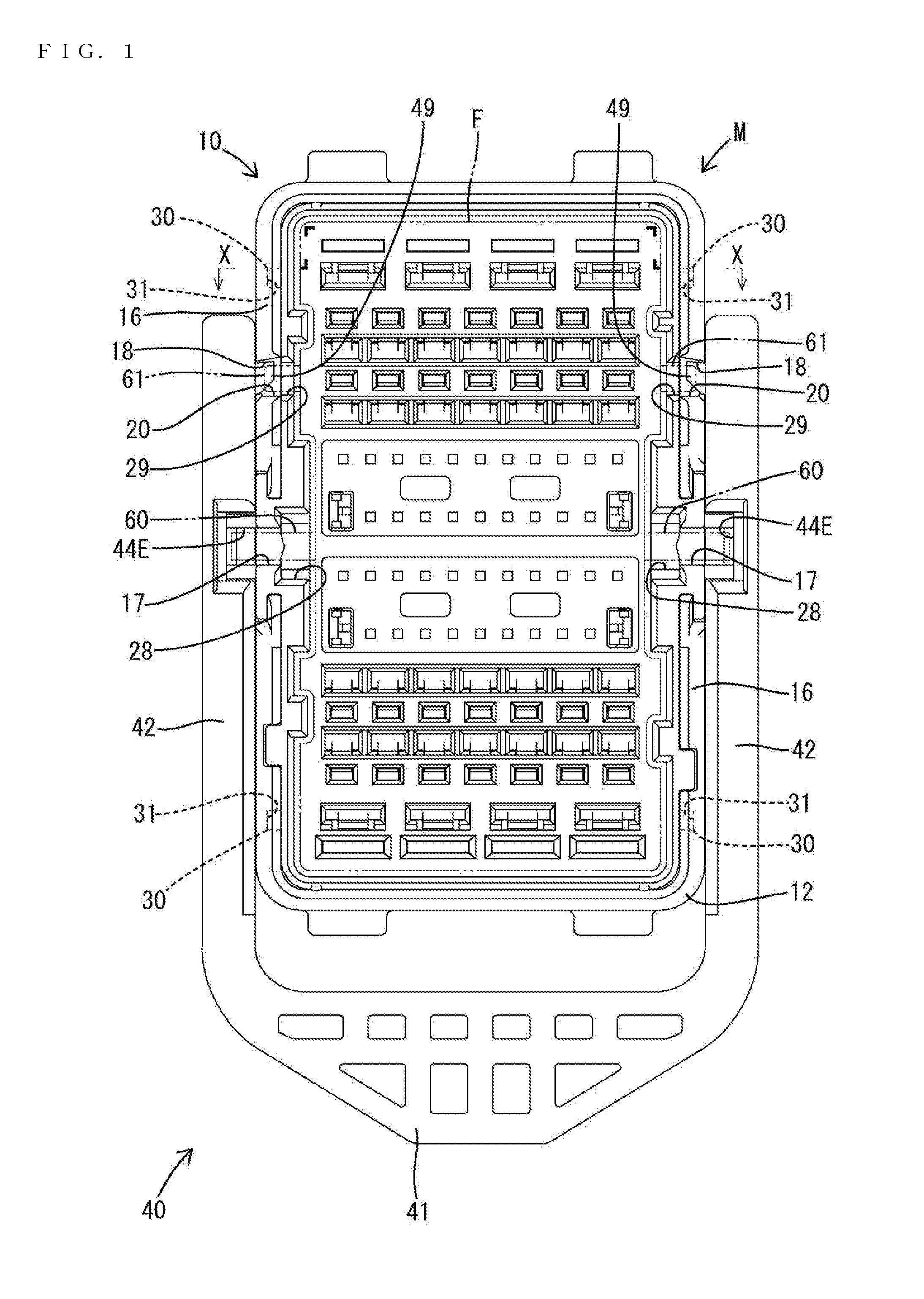

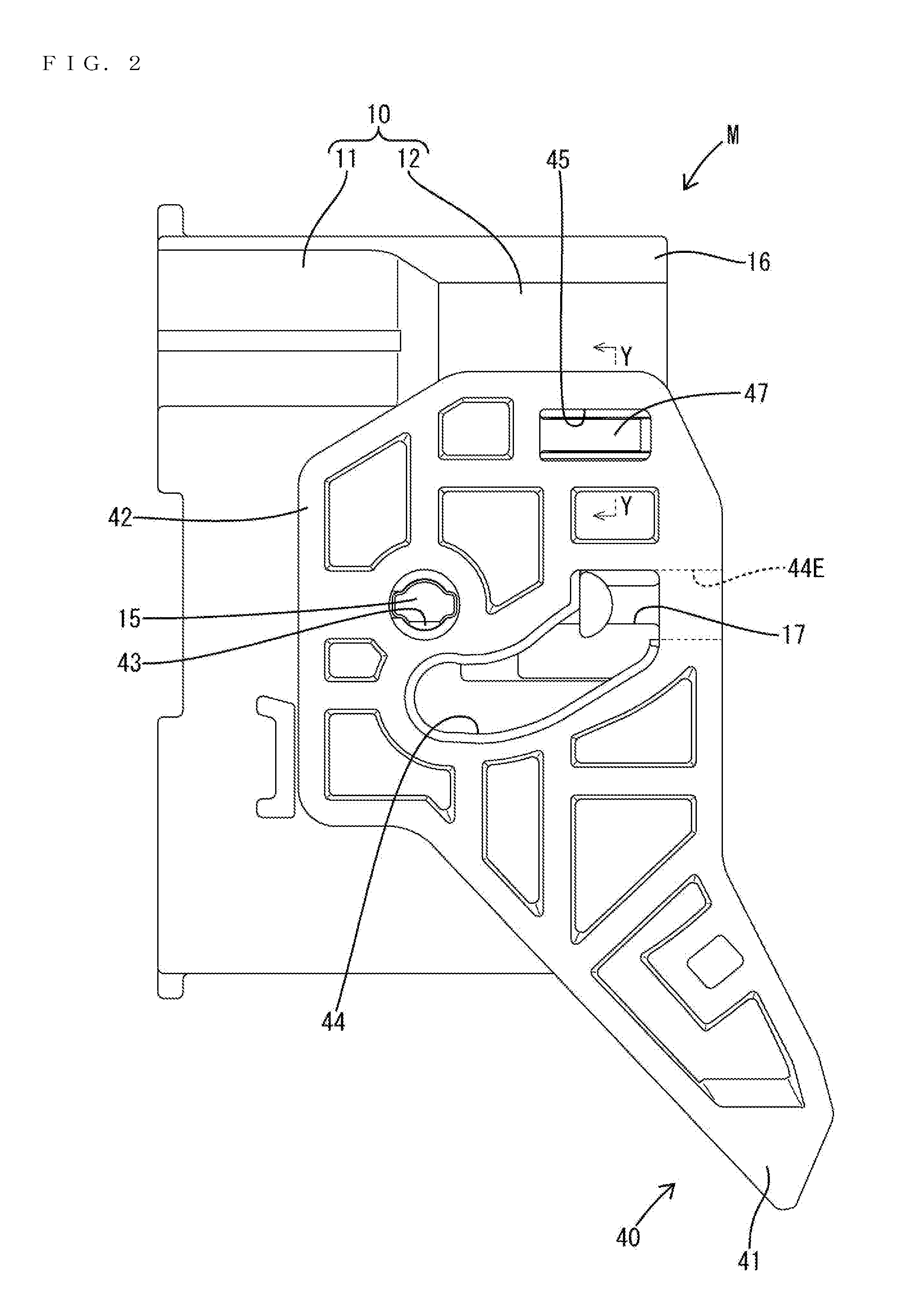

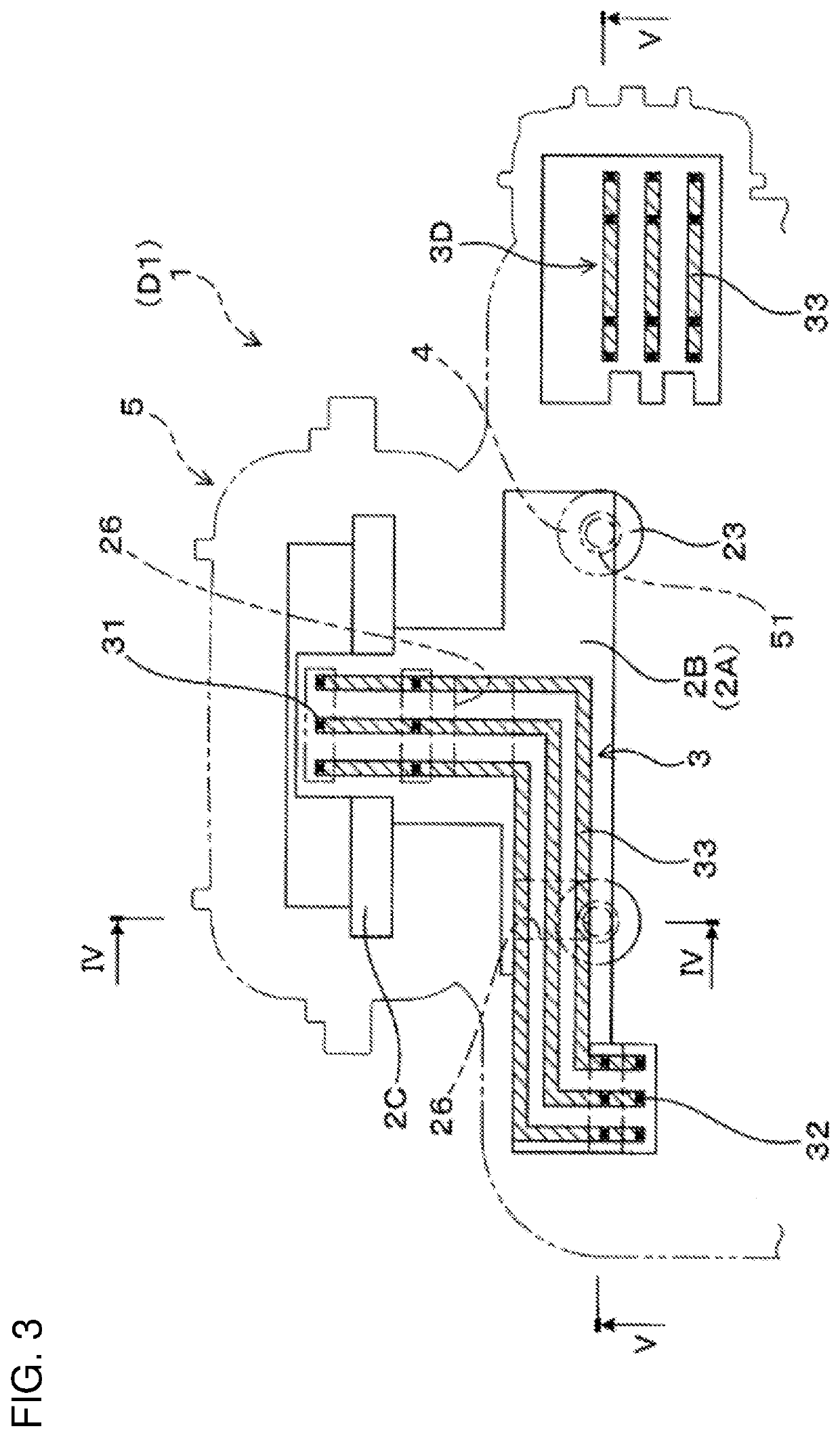

Image forming apparatus with resin frame and method for molding the resin frame

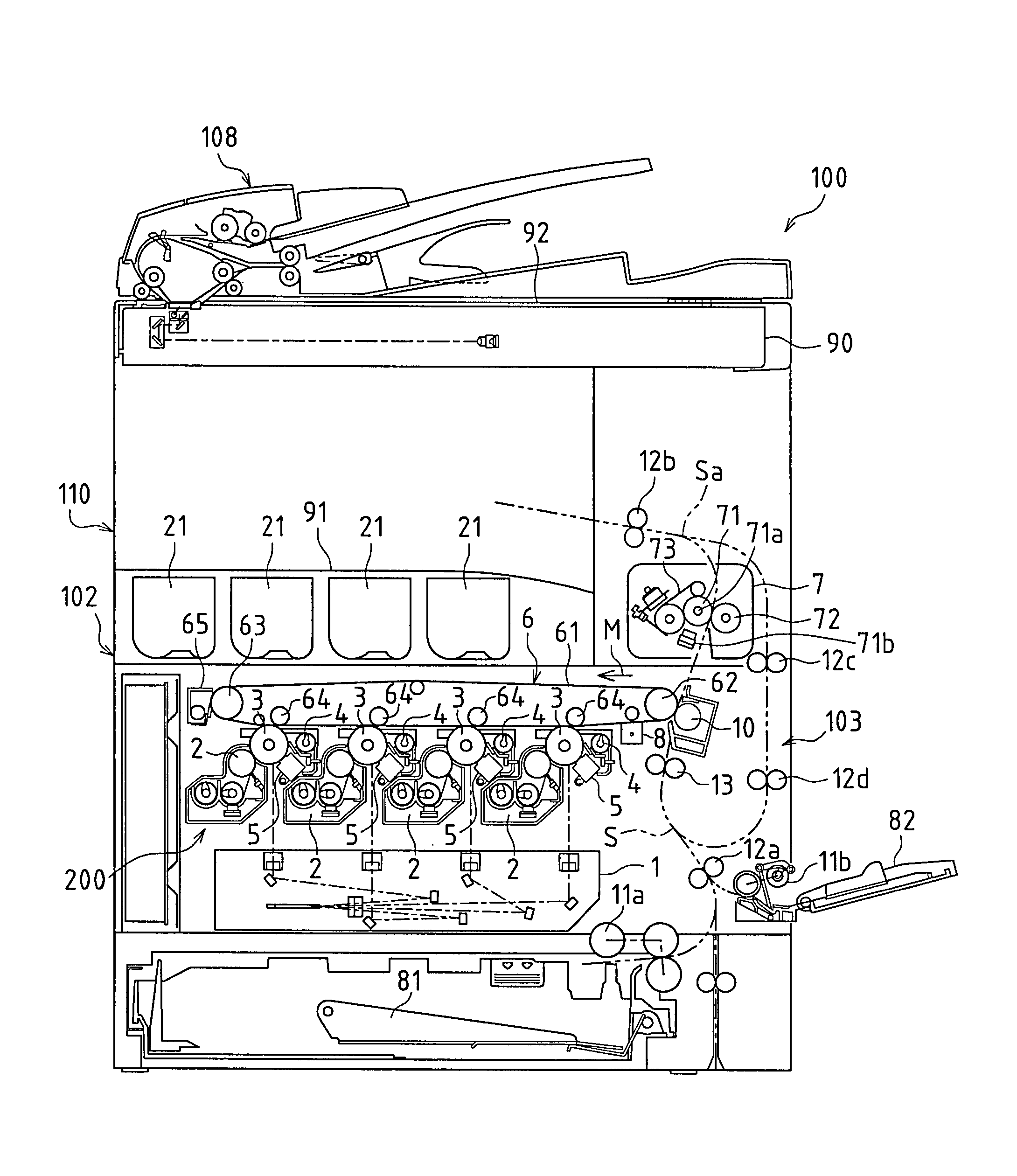

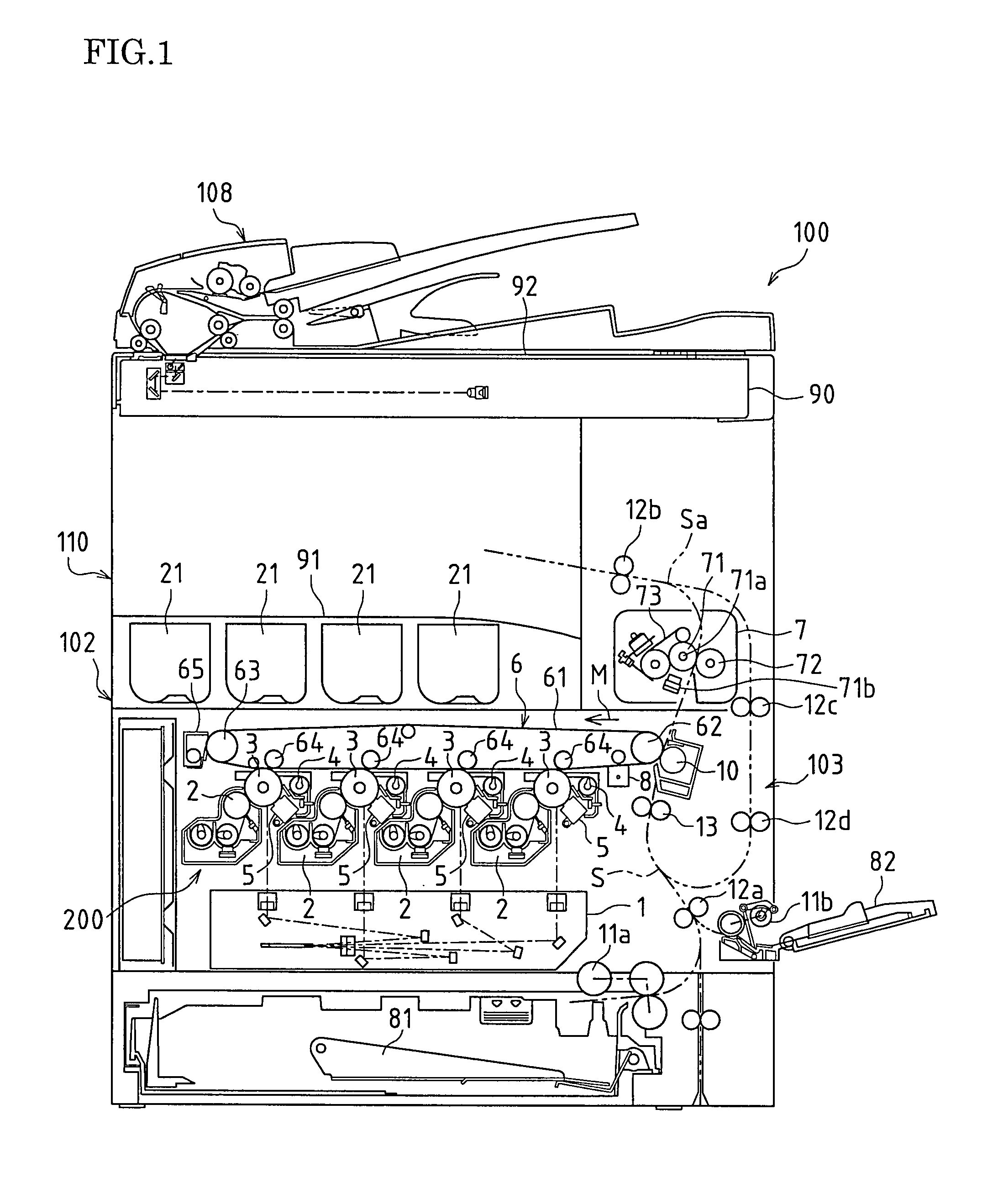

ActiveUS8706001B2Simple mold structureSecure strengthElectrographic process apparatusImage formationEngineering

An image forming apparatus of the present invention includes a resin frame composed of a resin and an image forming unit that is removably inserted in the resin frame. The resin frame includes a base having a supporting surface that supports the image forming unit, a guide portion that extends in the base in an insertion direction in which the image forming unit is inserted along the supporting surface and that guides the image forming unit in the insertion direction while limiting movement of the image forming unit in an orthogonal direction that is orthogonal to the insertion direction, and a side plate portion that is provided at a peripheral edge of the base so as to extend in a direction perpendicular to the supporting surface, the base, the guide portion, and the side plate portion being integrally molded from a resin. A mold opening direction of a mold for molding the guide portion is set to a direction parallel to the orthogonal direction, and downstream end portions of the side plate portion in the mold opening direction are integrally connected to each other and extend essentially parallel to the perimeter of the base.

Owner:SHARP KK

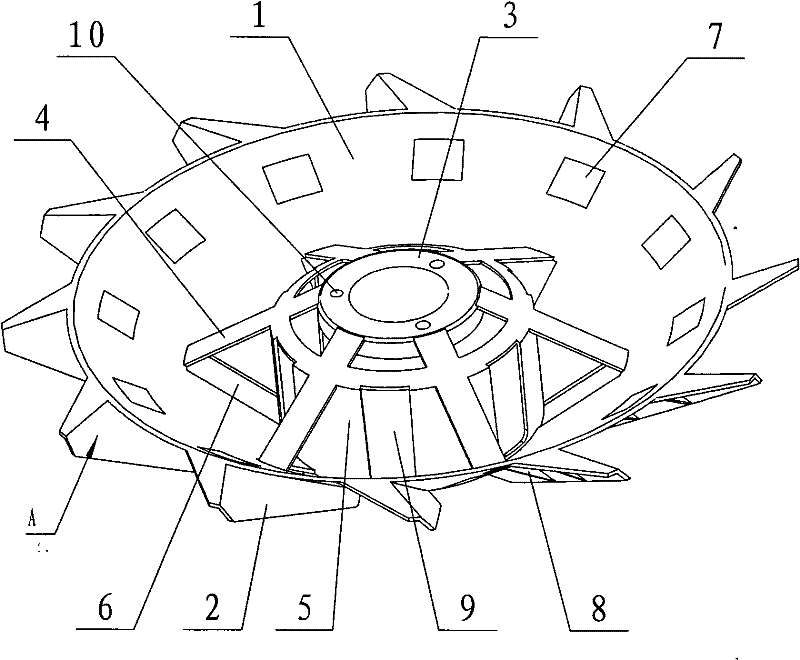

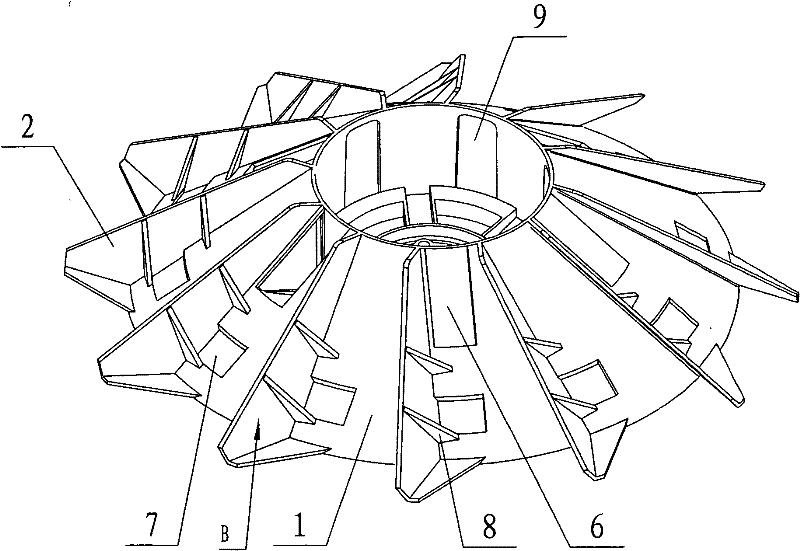

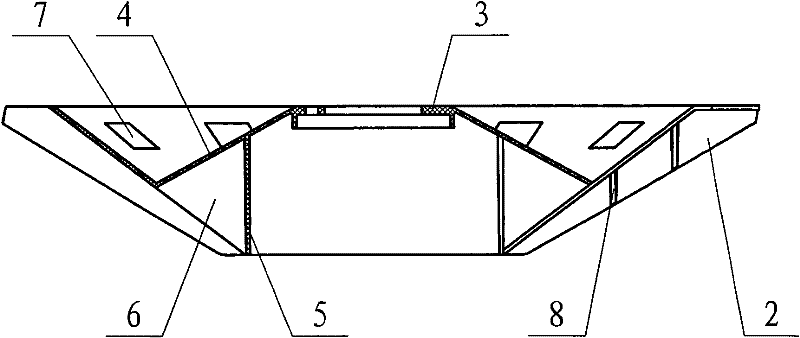

Injection molding impeller and mold of automatic aerator

ActiveCN102239820ASimple mold structureIncrease water exchange capacityPisciculture and aquariaPush outImpeller

The invention relates to an injection molding impeller of an automatic aerator. The injection molding impeller is mainly composed of a conical body, blades, a fixed plate, an upper support plate and a lower support plate and the like, wherein the fixed plate is provided with a connection hole; the fixed plate is connected with the conical body through the upper support plate and the lower supportplate; the outer conical surface of the conical body is connected with a plurality of blades; the back side B of each blade is provided with a reinforcing rib to support the blade; and a window is arranged in the space of the reinforcing ribs. The mold of the automatic aerator is mainly composed of a movable die, a stationary die and the like, wherein the movable die is provided with a main core and a plurality of subsidiary cores; the subsidiary cores enter the stationary die; the sides of the subsidiary cores are matched with the stationary die to form the upper support plate and the window; the main core is arranged in the mold; the cavity of each blade is provided with a movable block and a stationary block; the movable blocks are connected with an angle ejector rod; a workpiece and the angle ejector rod are pushed out together by a demoulding mechanism in demoulding; the movable block slides out obliquely by virtue of the angle ejector rod; and the workpiece is straightly pushed out under the guiding of the subsidiary core and is separated from the movable block.

Owner:ZHEJIANG FORDY MACHINERY

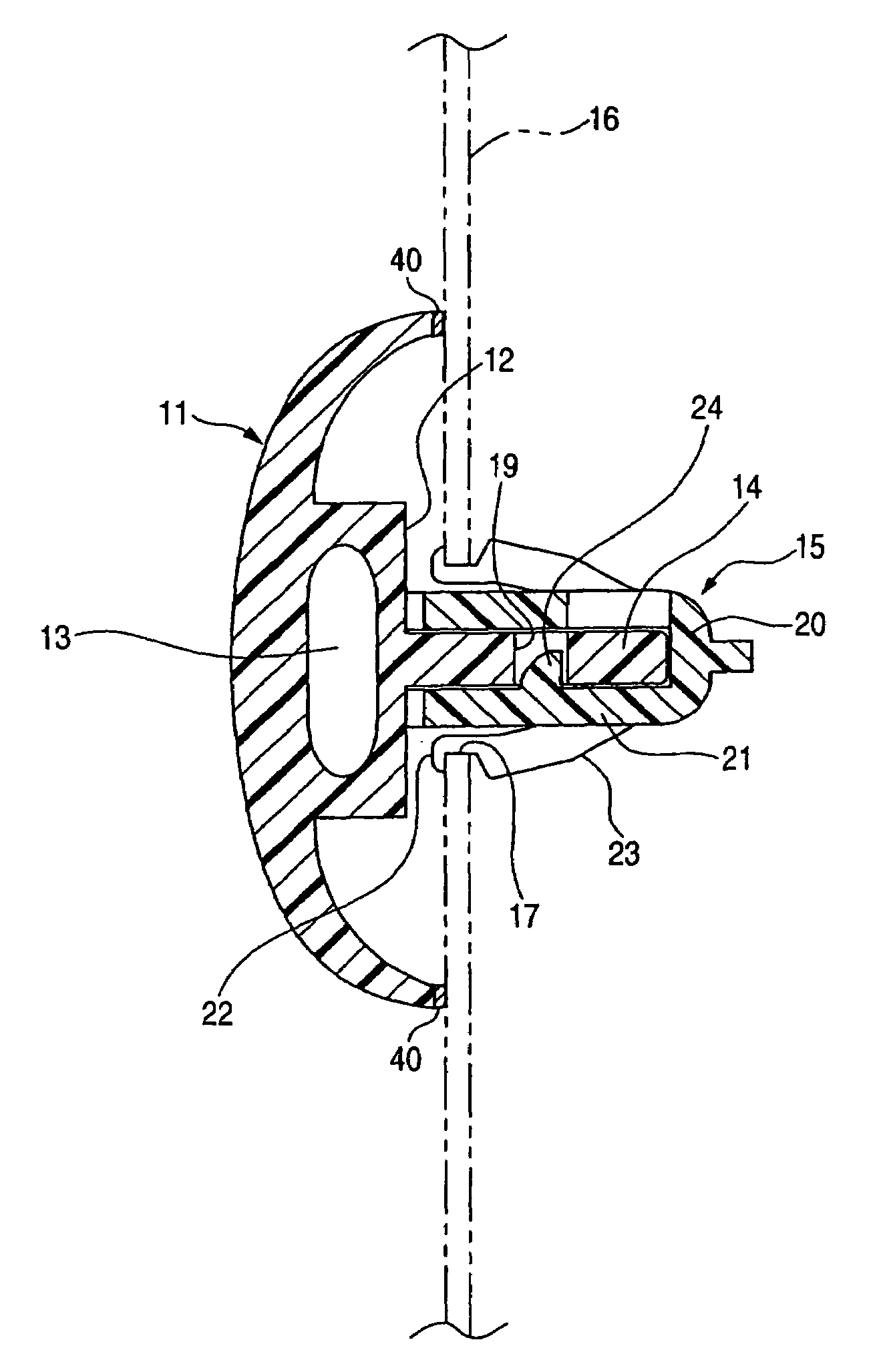

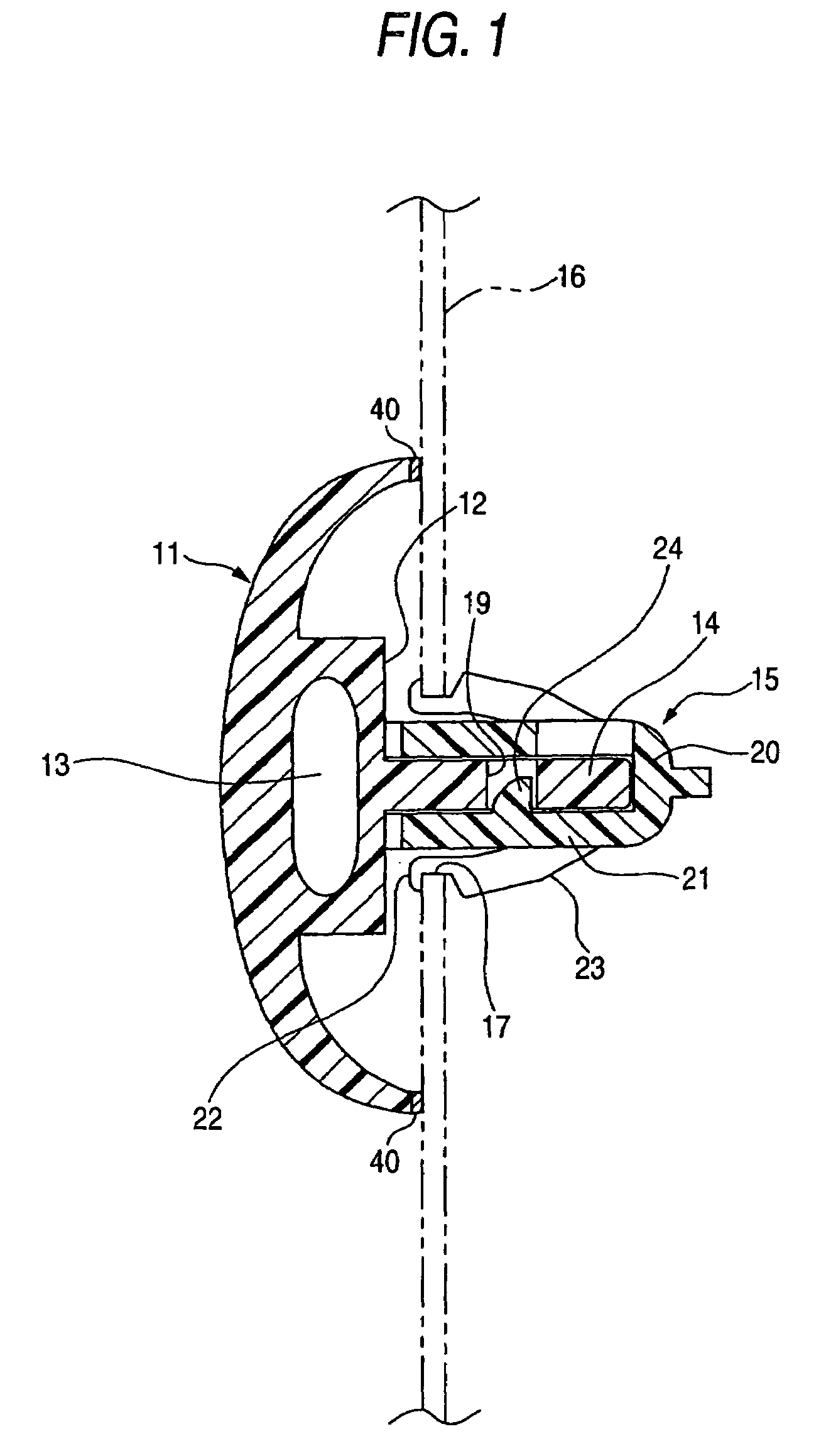

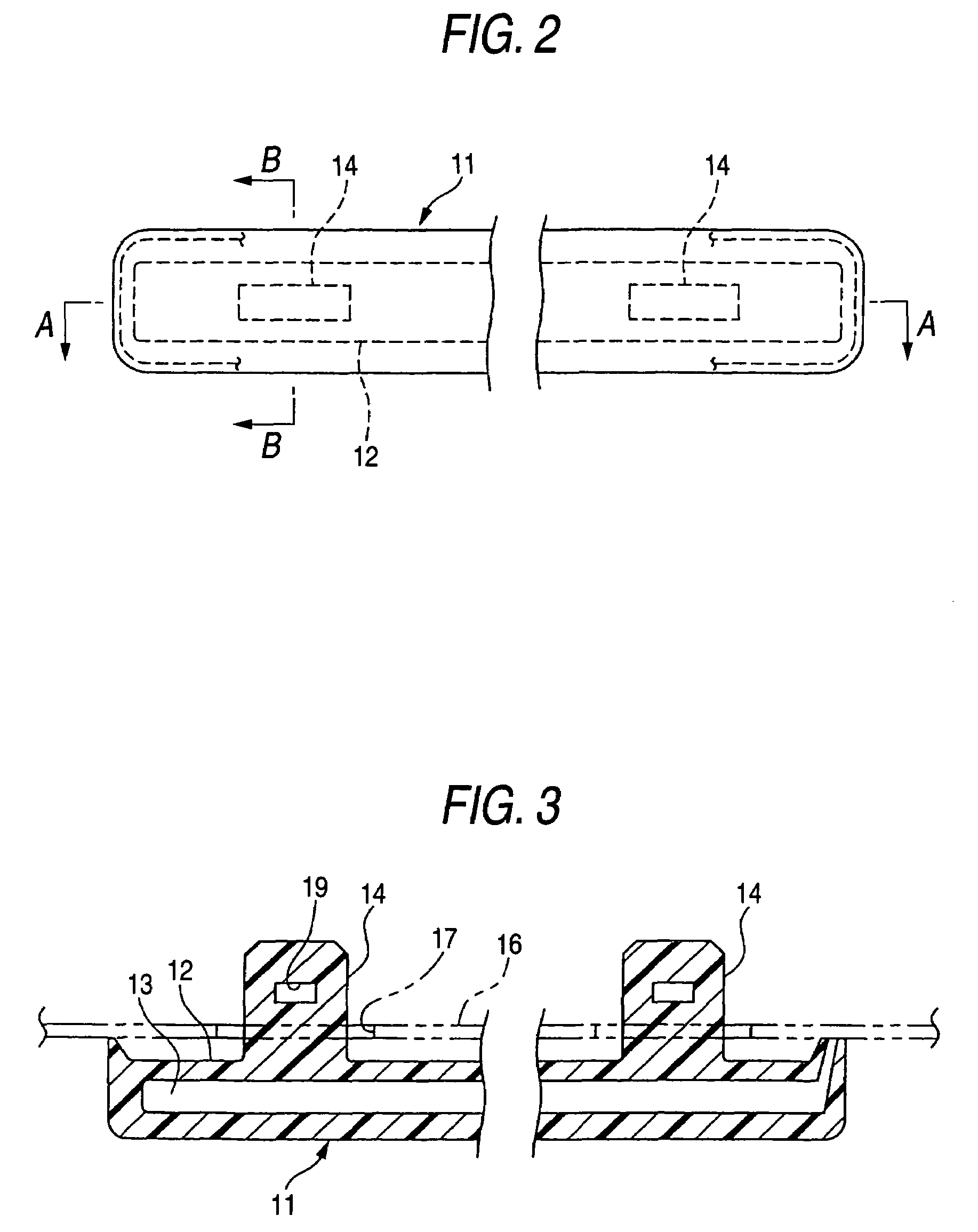

Coaxial connector with shielding shell

ActiveUS8317540B2Firmly connectedSimple mold structureElectrically conductive connectionsTwo pole connectionsEngineeringFront and back ends

Owner:CHEN SHIH CHIEH

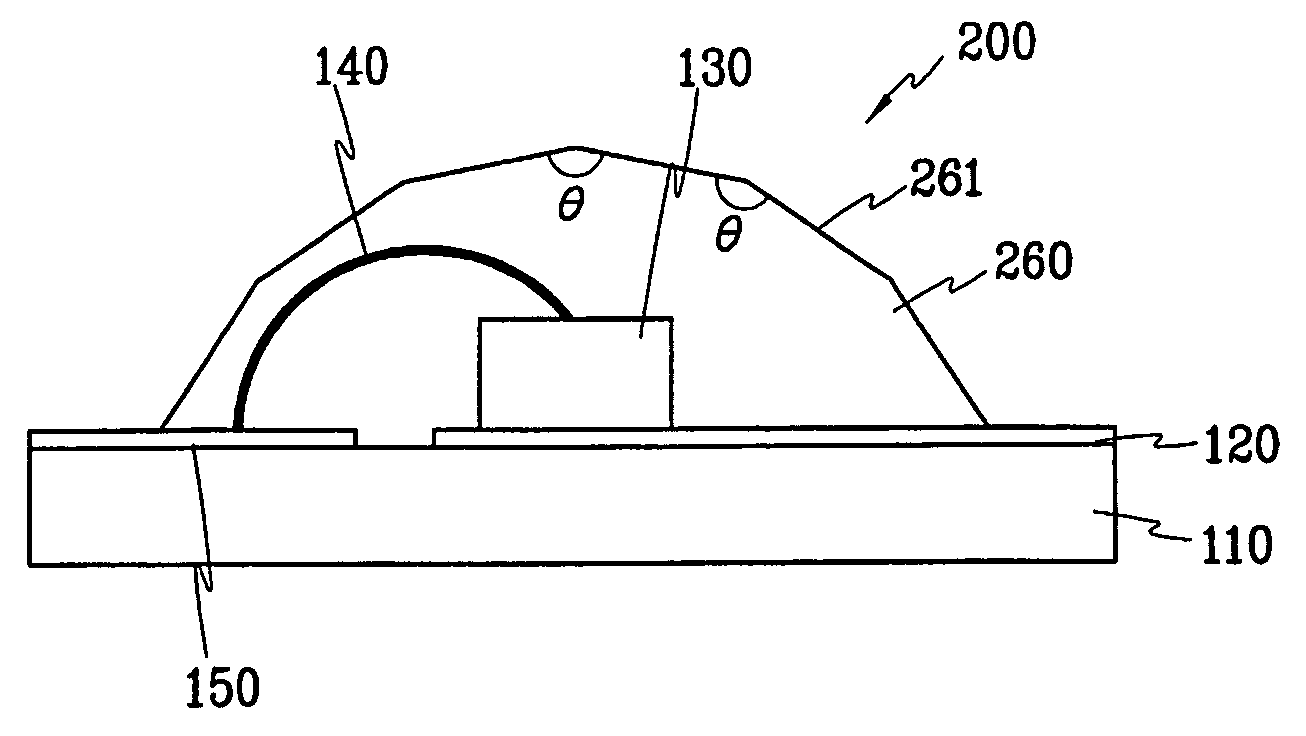

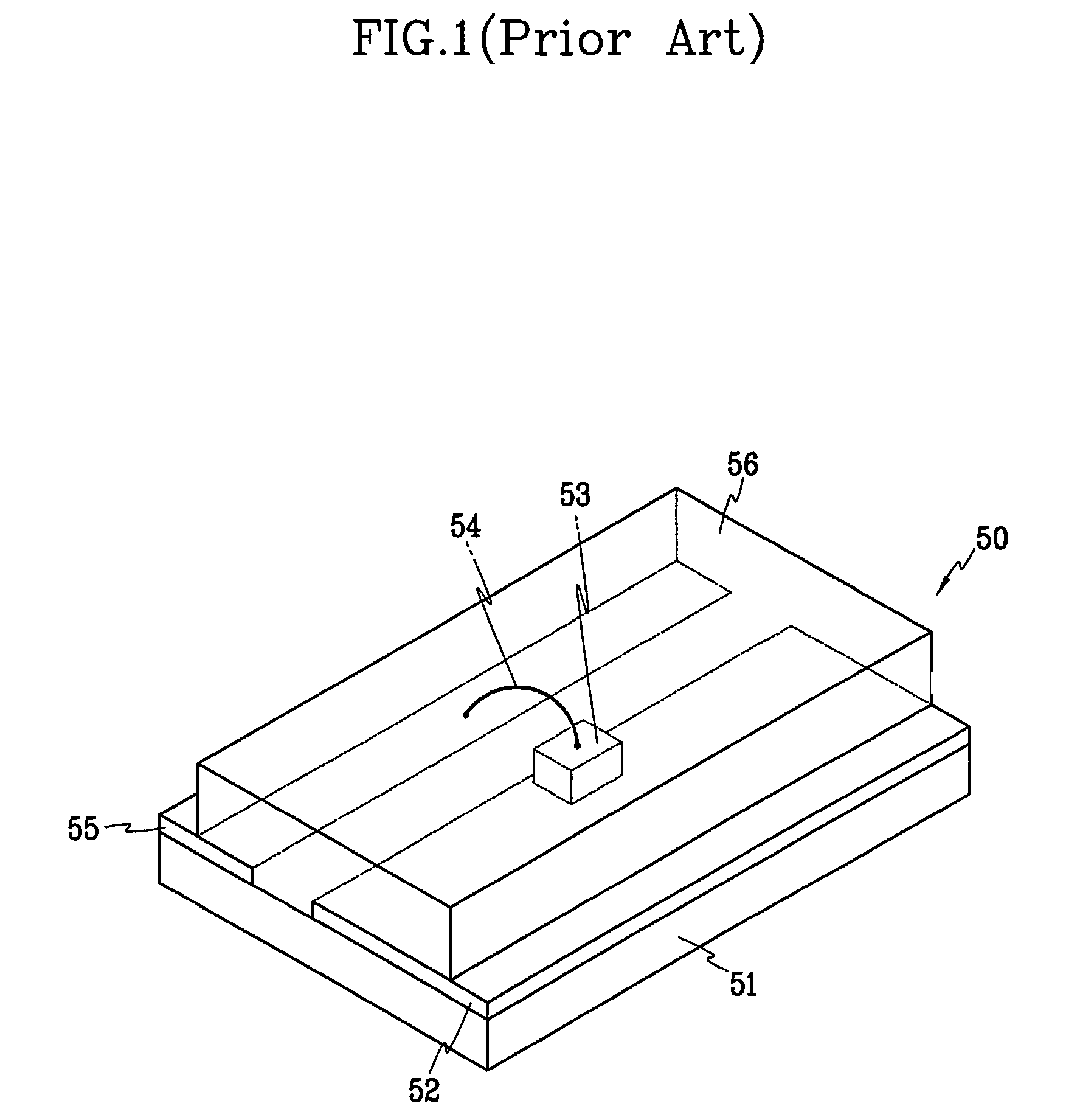

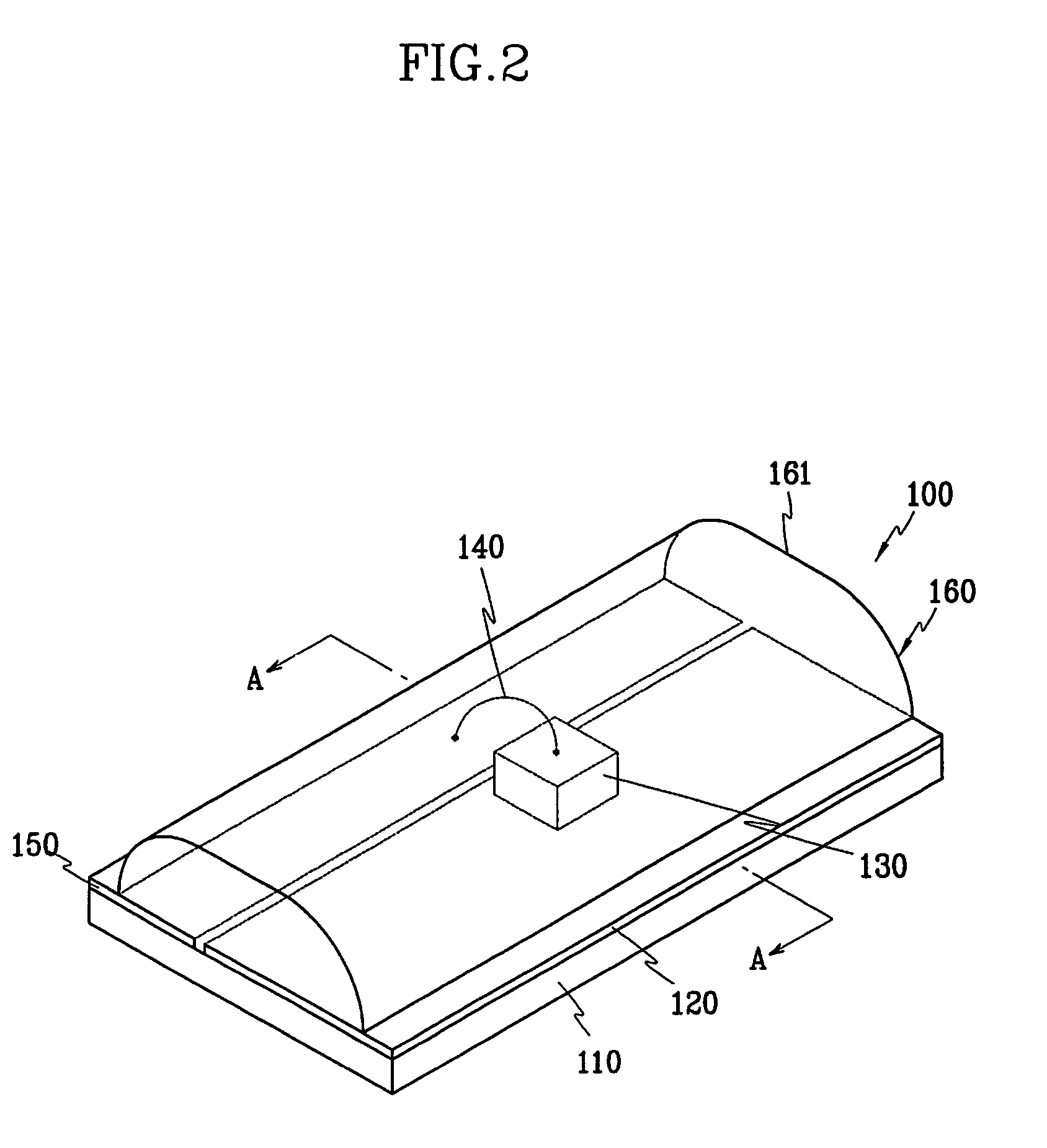

Chip light emitting diode and fabrication method thereof

ActiveUS7042022B2Relieve stressAvoid deformationSolid-state devicesSemiconductor devicesLight-emitting diodeDiode

A chip light emitting diode having a wide viewing angle, and a fabrication method thereof. The chip light emitting diode has a resin package sealing a light emitting chip which has at least one curved projecting part. The curved projecting part has a cross section which is substantially semicircular, or substantially or partially elliptical or parabolic. The curved projecting part preferably has a cross section which is comprised of a plurality of straight lines, an angle being formed between adjacent lines. The cross section is elongated to form a cylindrical outer surface of the resin package.

Owner:SEOUL SEMICONDUCTOR

Resin-sealing method and resin-sealing apparatus for electronic components

ActiveCN105280506AEfficient dischargePrevent outflowSemiconductor/solid-state device manufacturingElectronic componentMaterials science

Owner:TOWA

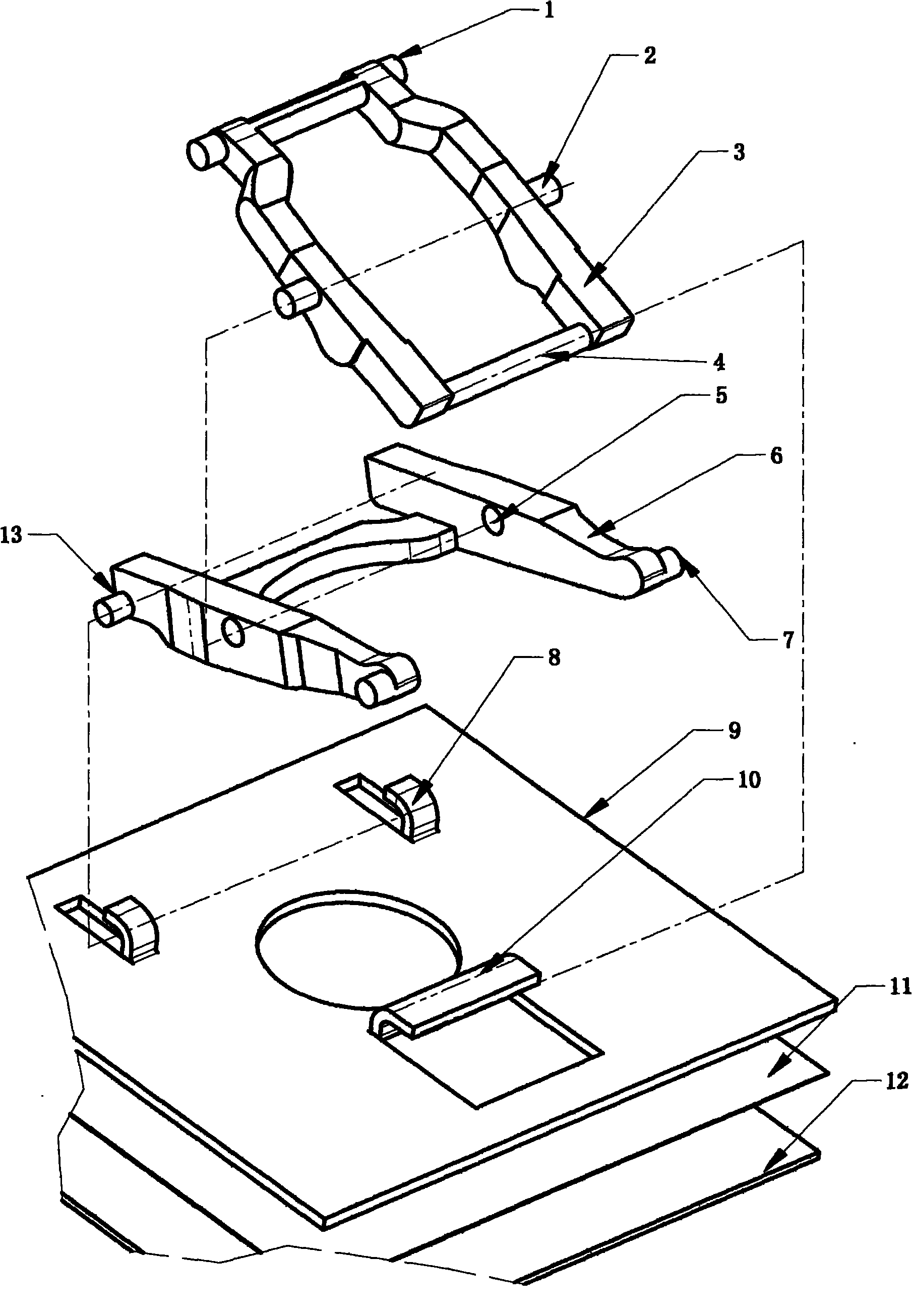

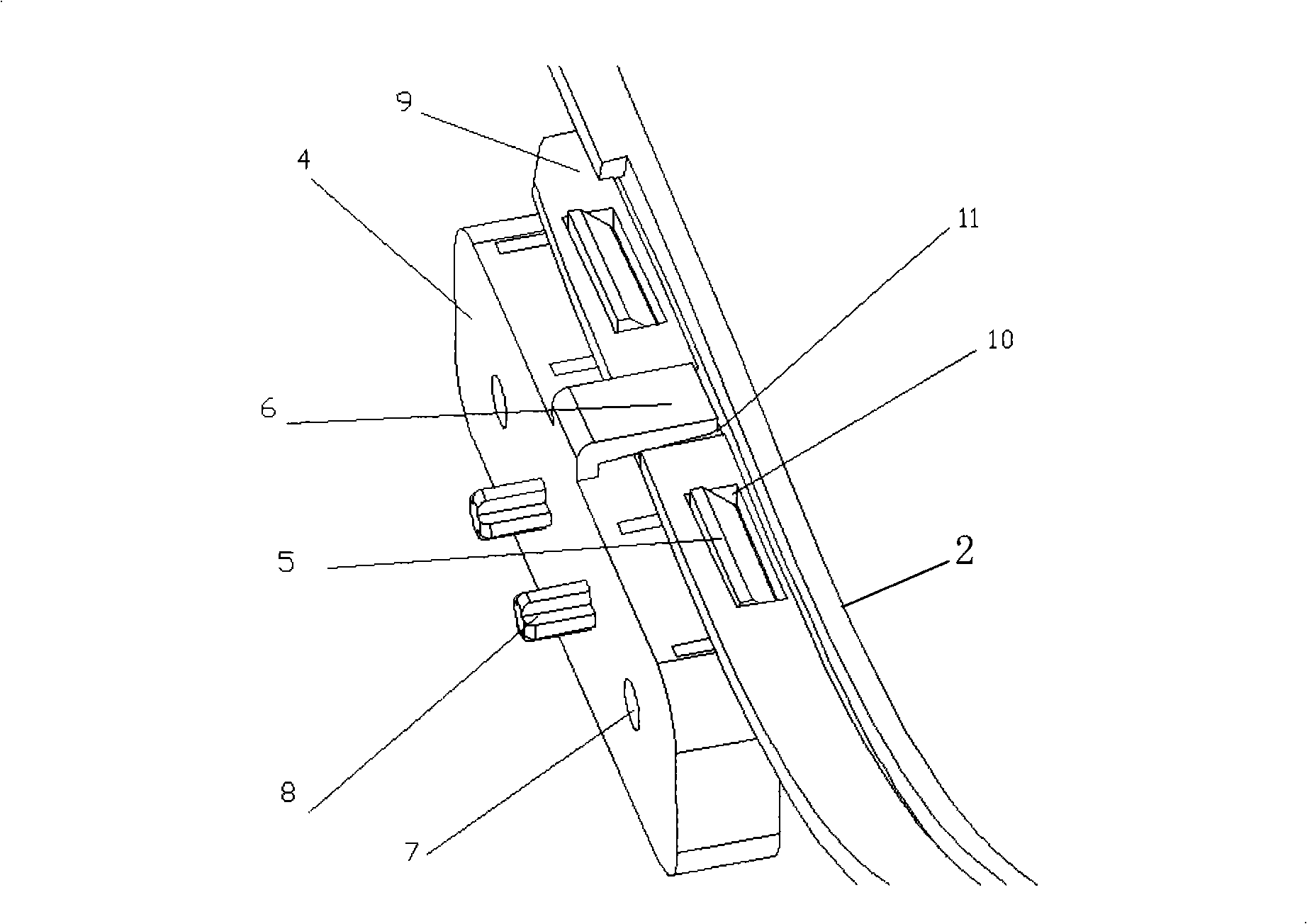

Molded product assembly and fastener

ActiveUS7344331B2Simple mold structureSave mold costSnap fastenersScaffold connectionsShell moldingEngineering

A molded product assembly includes a molded product being mountable to a body to be mounted having a mounting hole via a fastener. The molded product has a post projecting toward the mounting hole and disposed on a back surface of the molded product, at least a part of the post projecting through the mounting hole to a back surface side of the body to be mounted in mounting the molded product to the body to be mounted, and a holding portion disposed on the part of the post to hold the fastener. The fastener has a portion to be held that is held by the holding portion, and an elastic engagement leg being elastically deformable and having an engagement portion to be engaged with a peripheral edge of the mounting hole, the elastic engagement leg being located on the back surface side of the body to be mounted.

Owner:TOKAI KOGYO CO LTD

Image forming apparatus with resin frame and method for molding the resin frame

ActiveUS20110280614A1Low positioning accuracy requirementsImprove image qualityElectrographic process apparatusEngineeringMechanical engineering

An image forming apparatus of the present invention includes a resin frame composed of a resin and an image forming unit that is removably inserted in the resin frame. The resin frame includes a base having a supporting surface that supports the image forming unit, a guide portion that extends in the base in an insertion direction in which the image forming unit is inserted along the supporting surface and that guides the image forming unit in the insertion direction while limiting movement of the image forming unit in an orthogonal direction that is orthogonal to the insertion direction, and a side plate portion that is provided at a peripheral edge of the base so as to extend in a direction perpendicular to the supporting surface, the base, the guide portion, and the side plate portion being integrally molded from a resin. A mold opening direction of a mold for molding the guide portion is set to a direction parallel to the orthogonal direction, and downstream end portions of the side plate portion in the mold opening direction are integrally connected to each other and extend essentially parallel to the perimeter of the base.

Owner:SHARP KK

Electric one-bag golf cart

InactiveUS20030159864A1Simple mold structureLow costCyclesElectric propulsion mountingCartVelocity controller

An electric one-bag golf cart that carries a single caddie bag for a player on a golf course is provided. The cart body, including a chassis part, a neck part and a steering device part, is formed as an integral hollow piece using the rotational molding method. The wheel system provided under the chassis consists of one front wheel and two rear wheels, with the front wheel being mounted pivotally on a suspension as a free wheel, while the rear wheels are driving wheels using a differential gear device driven by a motor. At the center of the handlebars, which are made of circular rods, a dial-type speed controller is located, and a brake lever is provided under the steering device, together with a lock mechanism.

Owner:BILLCON

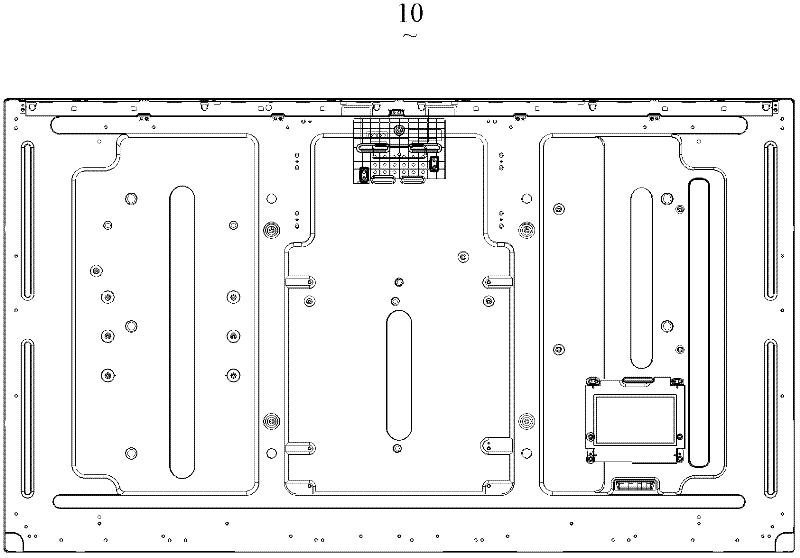

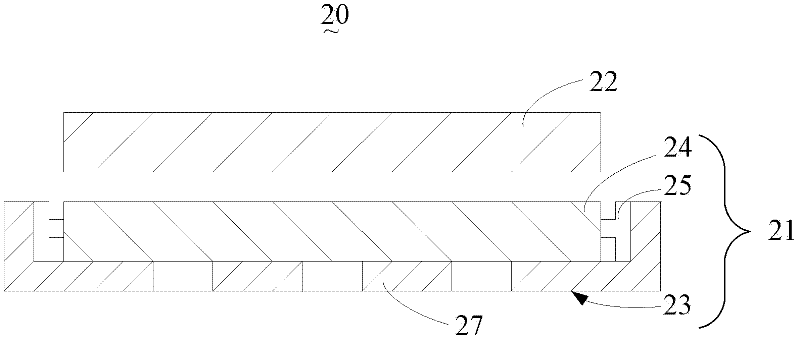

Flat-panel display device and stereoscopic display device

ActiveCN102376210ASimple mold structureLow costNon-linear opticsIdentification meansPrinted circuit boardEngineering

The invention provides a flat-panel display device which comprises a backlight system and a display panel, wherein the backlight system comprises an LED (Light Emitting Diode) light source, a back frame and a PCB (Printed Circuit Board), wherein the LED light source comprises an LED lamp and an LED substrate; the LED substrate comprises a first lead layer, a first insulating layer, an aluminum substrate, a second insulating layer and a second lead layer which are sequentially overlapped; and the LED lamp is arranged on the first lead layer. The back frame is used for bearing the LED light source and comprises at least two main splicing members which are spliced to form a main framework of the back frame; and the PCB is arranged on the second lead layer of the LED substrate. The invention also provides a stereoscopic display device. According to the flat-panel display device and the stereoscopic display device provided by the invention, the cost of a back frame die can be reduced; in addition, the material and the space of the back frame are saved, so that the cost of the flat-panel display device and the cost of the stereoscopic display device are reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

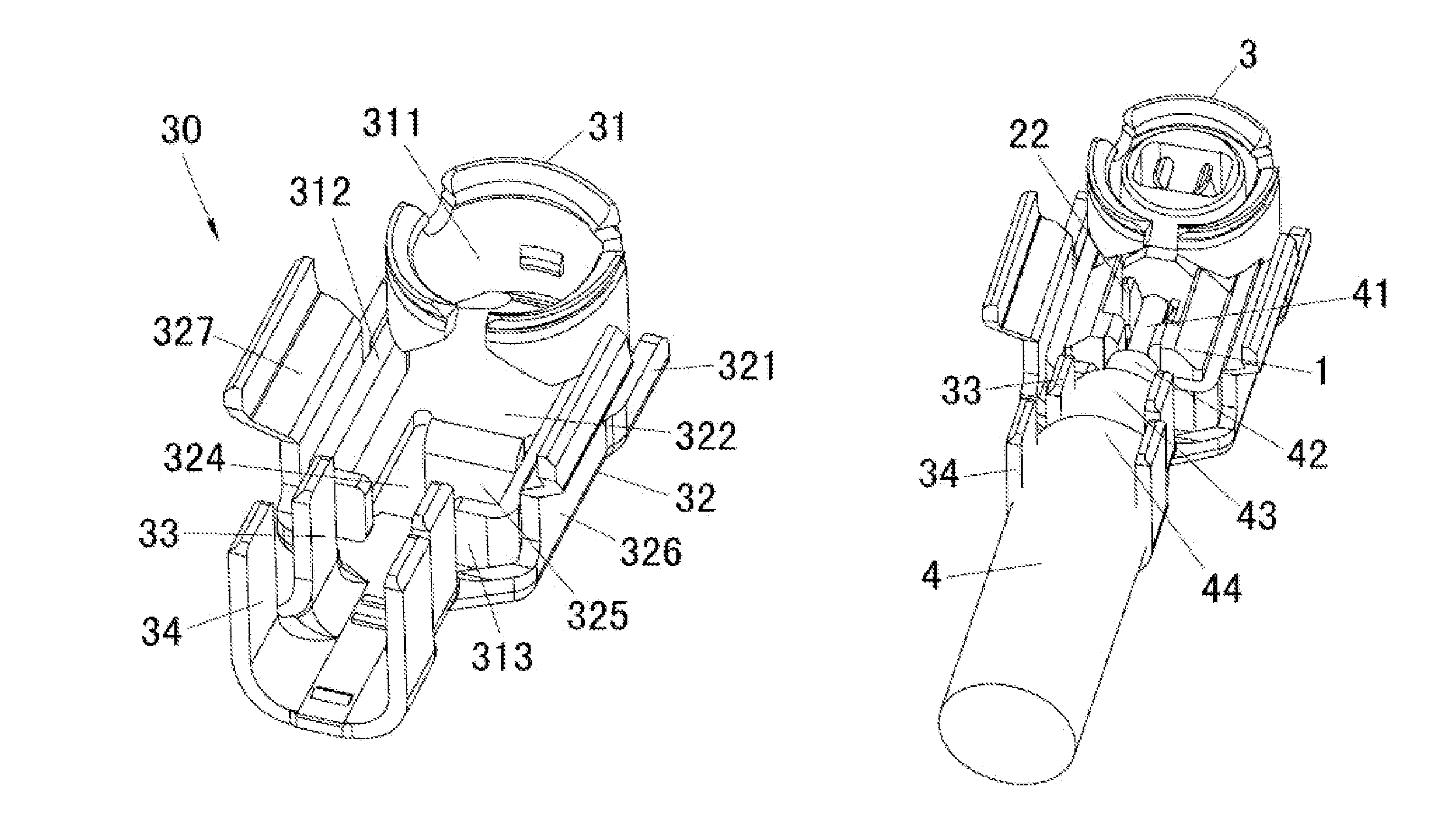

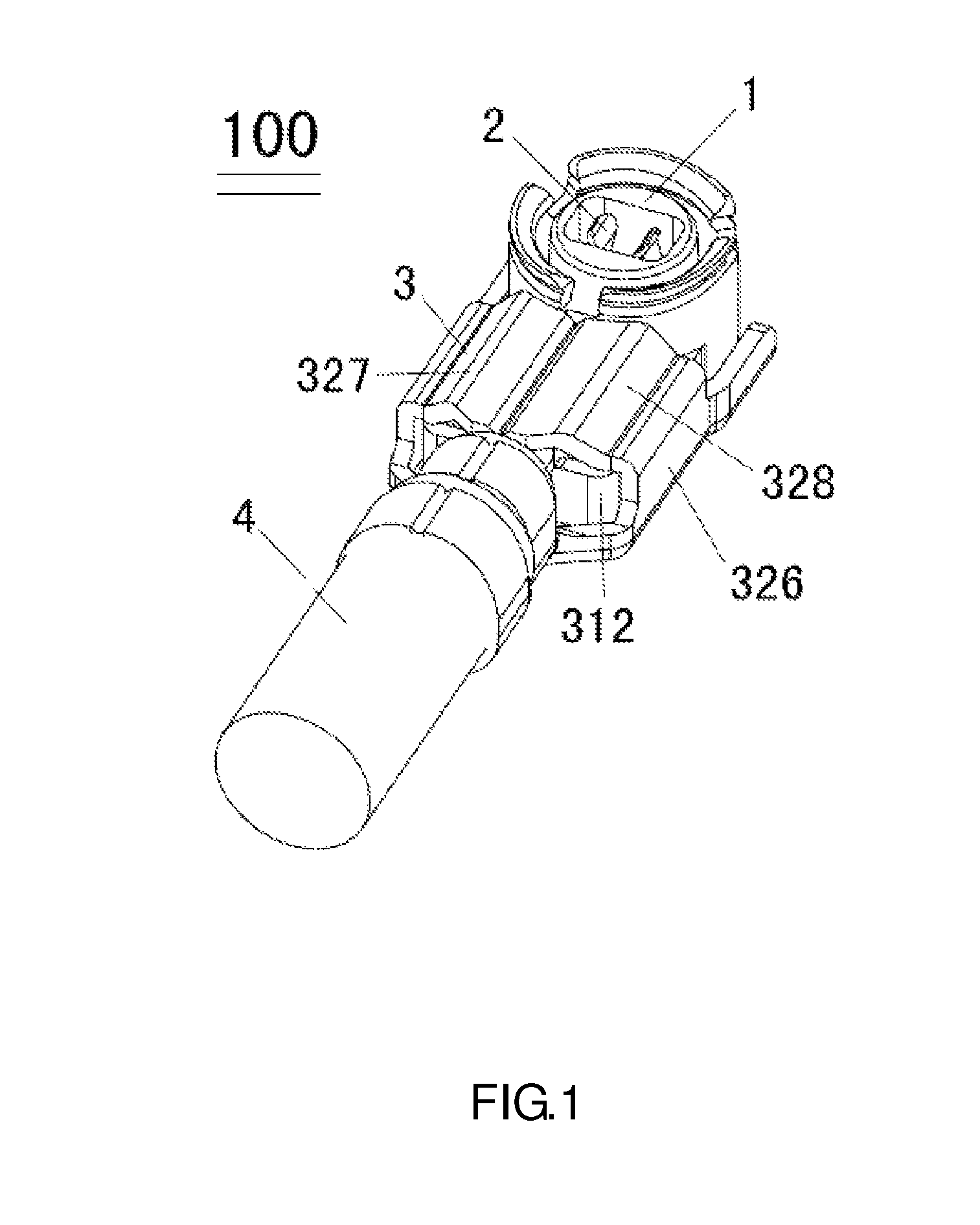

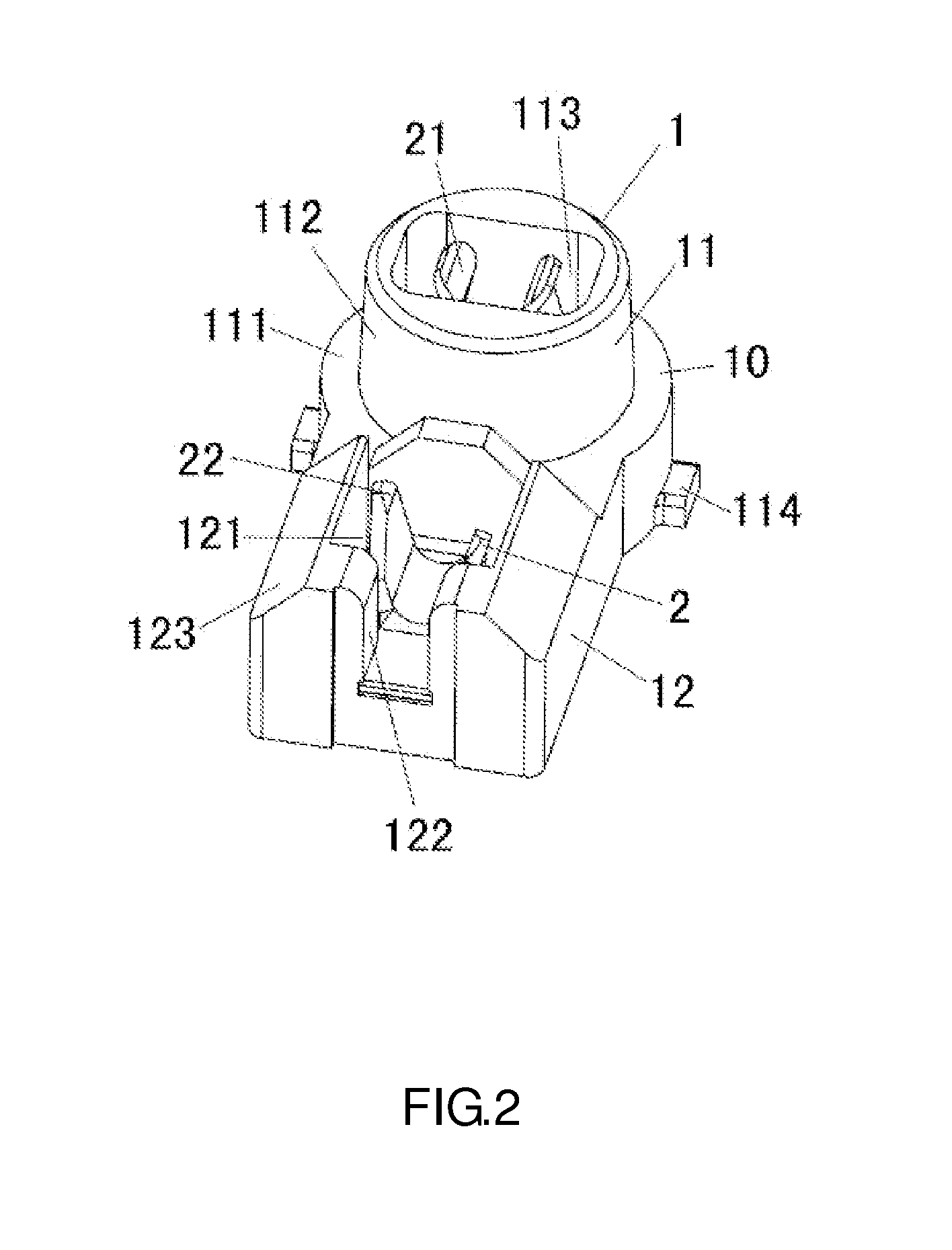

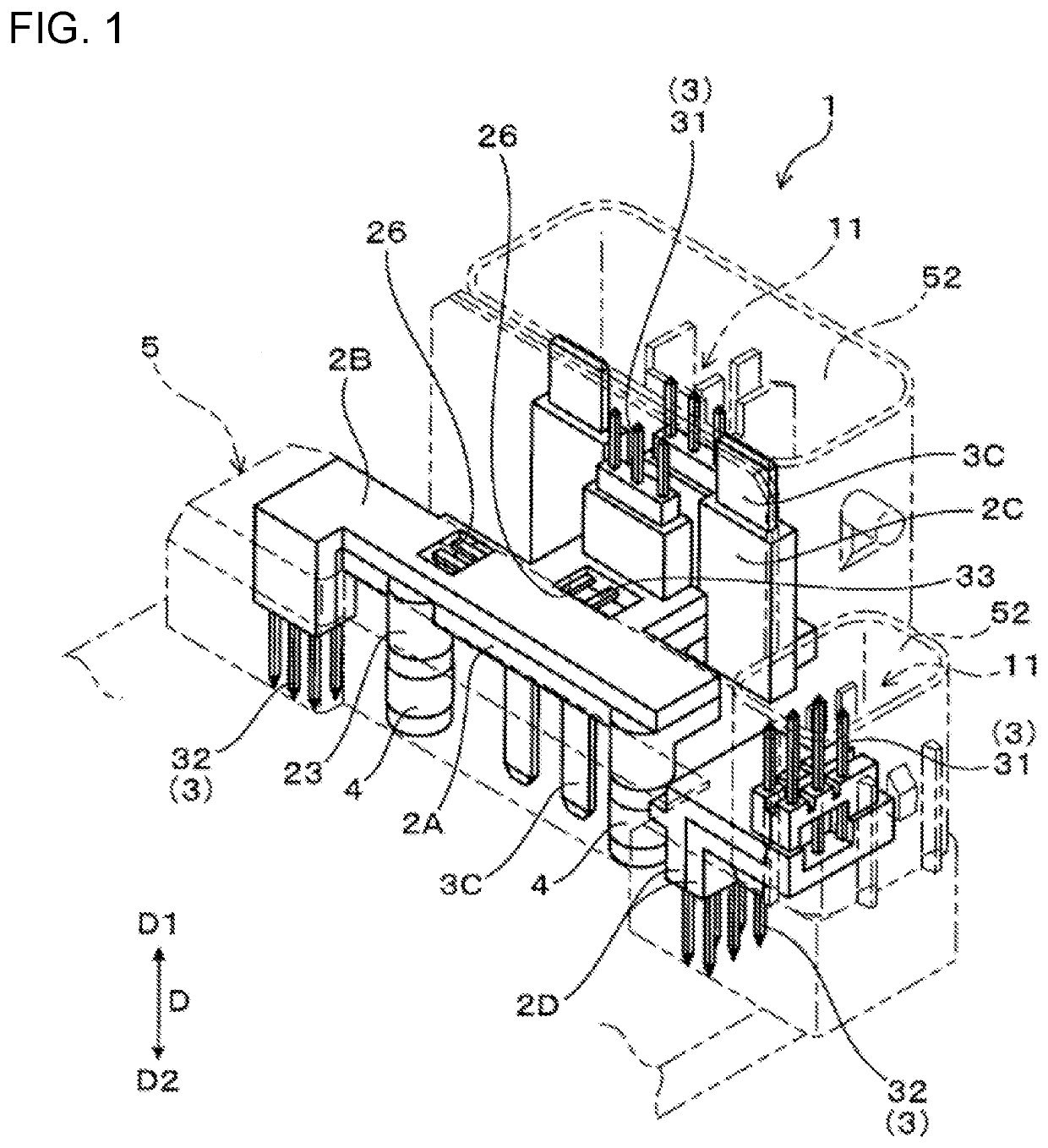

Connector

ActiveUS20150037998A1Simple mold structureCoupling device detailsEngineeringElectrical and Electronics engineering

A lock arm (33) is arranged on the upper surface of a female connector housing (27), and lock-arm protection walls (37) stand at opposite widthwise sides of the lock arm (33). Detector protection walls (38) are provided behind the lock-arm protection walls (37), and first and second lock receiving portions (43, 44) are formed on the inner surfaces thereof. Two inwardly deflectable locking arms (56) are formed on a detector (39) and locked to the first or second lock receiving portions (43, 44) to restrict a backward movement when the detector (39) is at an initial position and a detecting position. The locking arms (56) are arranged utilizing dead spaces behind the lock-arm protection walls (37).

Owner:SUMITOMO WIRING SYST LTD

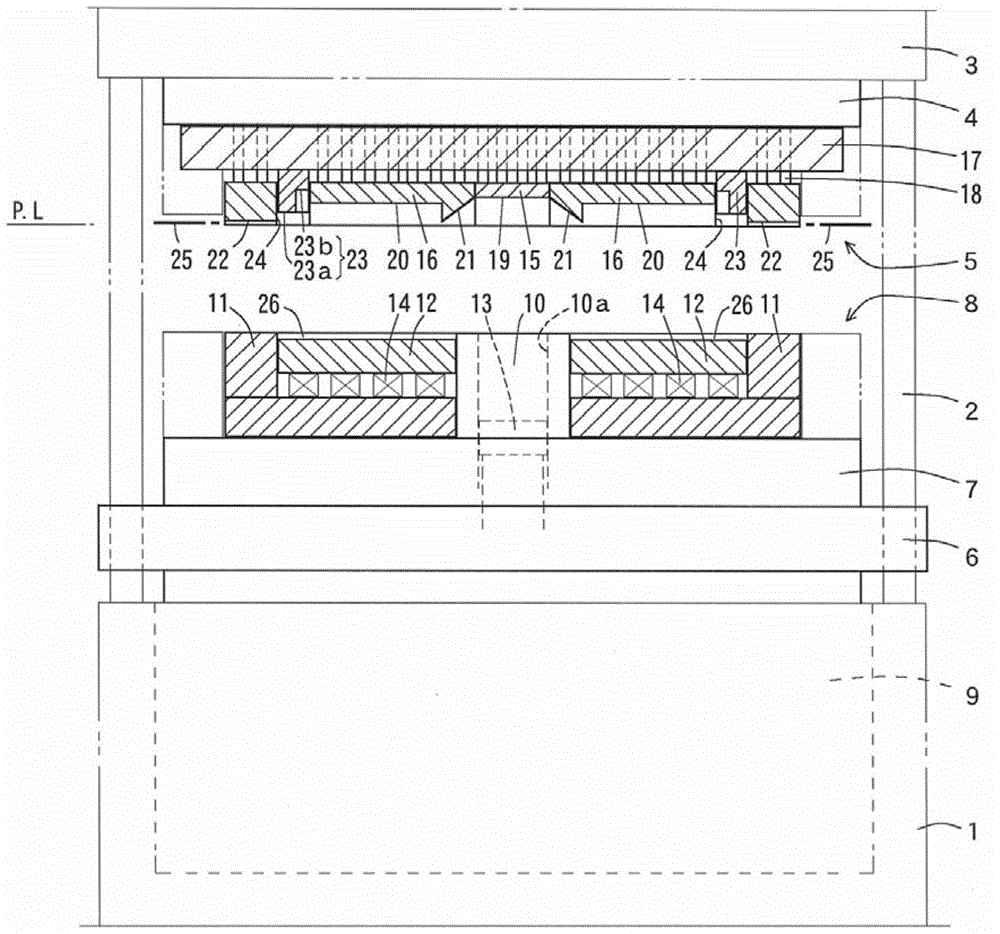

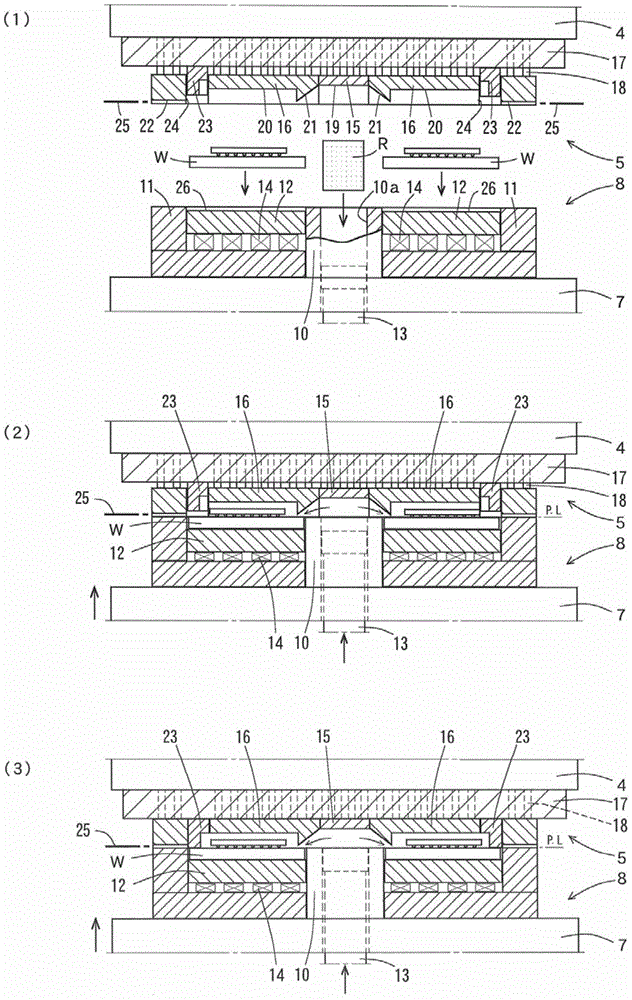

Method of resin-seal-molding electronic component and apparatus therefor

InactiveUS20070072346A1Simple mold structureSolve the real problemSolid-state devicesSemiconductor/solid-state device manufacturingElectronic componentSubstrate surface

A mold for resin-seal-molding an electronic component is constituted by a first mold and a second mold. At a mold face (PL face) of the molds, a substrate supply-set surface having a flat shape without a step is provided. A pot block is joined with and separated from a side position of the mold intersecting perpendicularly with the mold face (PL face) of the molds. In a state where the mold face and the pot block are joined, a molten resin material in the pot block is injected into a cavity. The overall structure of the mold for resin-seal-molding an electronic component mounted on the substrate is simplified. Additionally, when resin-seal-molding the electronic component, a problem of variation in the thicknesses of the substrates is solved. Thus, resin flash formation on the substrate surface is prevented.

Owner:TOWA

Connector

InactiveUS20140169871A1Simple mold structureReduce manufacturing costCoupling device detailsRod connectionsWave shapeBiomedical engineering

A connector includes a housing body and an attachment component that is inserted in a component containing space of the housing body. The attachment component has a side wall extending in an insertion direction of the attachment component into the component containing space. The housing body includes a provisionally retaining portion and a completely retaining portion. The attachment component has a first projection portion which is retained to the provisionally retaining portion at a provisionally retaining position. The attachment component has a second projection portion which is retained to the completely retaining portion at a completely retaining position. The side wall includes a wave shaped plate section having elasticity, and the wave shaped plate section has the first and second projection portions which are formed in a shape of a wave progressing along the insertion direction.

Owner:YAZAKI CORP

Lever-type connector

ActiveUS20160336686A1Simplify structure of moldReliable holdCoupling device detailsEngineeringCantilever

A lever (40) is formed with resilient arms (48) cantilevered in a direction substantially perpendicular to rotary shafts (15) of the lever (40) and intersecting with a circumferential direction about the rotary shafts (15), and locking projections (49) projecting from extending end parts of the resilient arm pieces (48) and configured to hold the lever (40) at an initial position by entering locking holes (20) and being locked. The locking hole (20) is formed with a locking edge part (21) located on a surface of a housing (10) facing the lever (40) and configured to lock the locking projection (49) and a recess (23) formed by recessing an inner surface part on a deeper side than the locking edge part (21), and the locking projection (49) is formed with a hooking portion (53) configured to enter the recess (23) while being locked to the locking edge part (21).

Owner:SUMITOMO WIRING SYST LTD

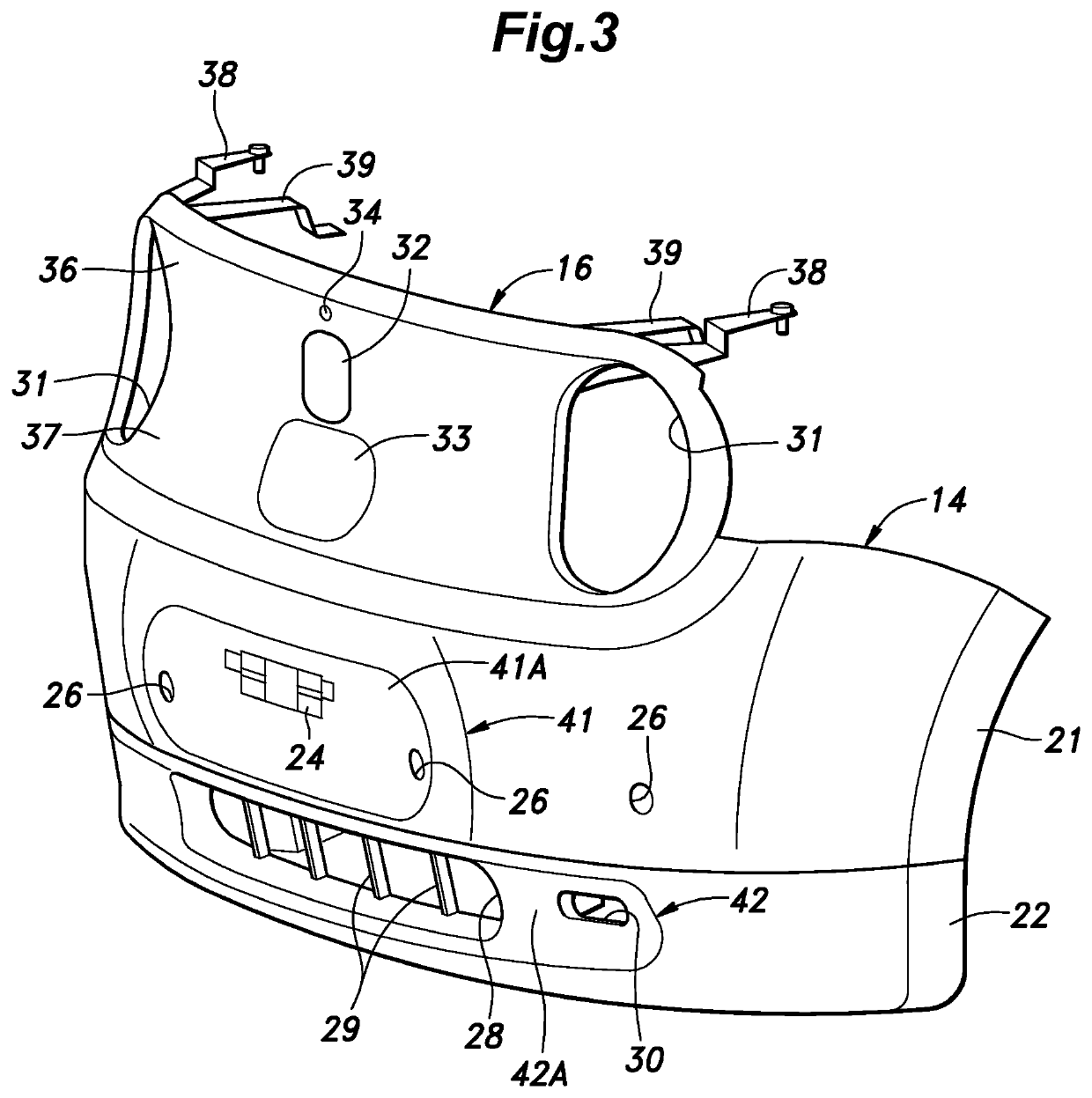

Vehicle body front structure

ActiveUS20200094759A1Simple mold structureHigh level of freedomSuperstructure subunitsBumpersClassical mechanicsMechanical engineering

A vehicle body front structure includes a front bumper face positioned in front of a front bumper beam, wherein the front bumper face includes an upper face member provided with a license plate mounting portion, and a lower face member provided with an external air introduction opening. The vehicle body front structure further includes a front panel positioned above the upper face member.

Owner:HONDA MOTOR CO LTD

Molded product assembly and fastener

ActiveUS20050095064A1Easy to fixSimple mold structureSnap fastenersScaffold connectionsEngineeringFastener

A molded product assembly includes a molded product being mountable to a body to be mounted having a mounting hole via a fastener. The molded product has a post projecting toward the mounting hole and disposed on a back surface of the molded product, at least a part of the post projecting through the mounting hole to a back surface side of the body to be mounted in mounting the molded product to the body to be mounted, and a holding portion disposed on the part of the post to hold the fastener. The fastener has a portion to be held that is held by the holding portion, and an elastic engagement leg being elastically deformable and having an engagement portion to be engaged with a peripheral edge of the mounting hole, the elastic engagement leg being located on the back surface side of the body to be mounted.

Owner:TOKAI KOGYO CO LTD

Semi-solid horizontal extrusion mold for double-layer composite pipes and application thereof

InactiveCN105665463ASimple mold structureEasy to make and useExtrusion diesContinuous productionHigh intensity

The invention discloses a semi-solid horizontal extrusion mold for double-layer composite pipes and application thereof, and relates to the technical field of production of double-layer metal composite pipes. The mold comprises a base, an extrusion sleeve, an extrusion rod, an inner extrusion mold and an outer extrusion mold. The mold, providedby the invention, is simple in structure and convenient for manufacturing and use, can be applied to continuous production of metal composite pipes with different inner and outer materials, and is low in energy consumption, short in flow, flexible in structure and excellent in reusability, interfaces can reach high strength of metallurgical bond,and high-quality and high-efficiency semi-solid extrusion molding can be realized.

Owner:扬州宏福铝业有限公司

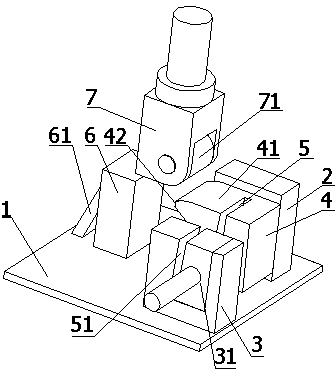

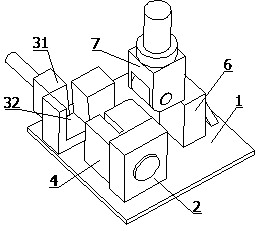

Twisting mold of fat steel and flat steel twisting method

InactiveCN103480737ASimple mold structureHigh accuracy of torsion formingShaping toolsEngineeringUltimate tensile strength

The invention discloses a twisting mold of flat steel and a flat steel twisting method. The twisting mold of the flat steel comprises a base, a supporting seat I, a supporting seat II and a rotating block, the supporting seat I and the supporting seat II are fixedly arranged on the upper surface of the base in a face-to-face mode, the rotating block is arranged between the supporting seat I and the supporting seat II, and the rotating block is rotatably and movably connected with the supporting seat I; the rotating block is provided with an inserting groove I, the supporting seat II is provided with an inserting groove II, the inserting groove I and the inserting groove II are arranged in a fact-to-face mode, and the shape and the size of the inserting groove I and the inserting groove II are matched with the size and shape of the portion to be clamped of the flat steel to be processed; a rotating and driving unit drives the rotating block to rotate relative to the supporting seat I; a distance which matches with the length of the flat steel is reserved between the rotating block and the supporting seat II. The twisting mold of the flat steel has a simple structure and guarantees the twisting accuracy through the structure of the twisting mold of the flat steel. According to the flat steel twisting method, a mechanical cold working mode is utilized, material damage caused by uneven heating is avoided, meanwhile, the labor intensity of workers is reduced and the processing efficiency is improved.

Owner:浙江恒瑞金属科技有限公司

Connector and manufacturing method therefor

ActiveUS20200350723A1Simple mold structureSimple structureVehicle connectorsContact member assembly/disassemblyEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

X-shaped support structure device

InactiveCN102054602ASimple mold structureLow manufacturing costContact operating partsMembrane switchCircular surface

The invention discloses an X-shaped support structure device, which comprises a rubber elastic ring 17, a membrane switch sheet 11 and an inner frame connecting rod 3, wherein the upper end and the lower end of an outer frame connecting rod 6 are connected with the membrane switch sheet 11, a keycap 14 and a support plate 9. The device is characterized in that: a sliding middle shaft fitting part 29 on a sliding middle shaft 28 which is positioned on a connecting rod and a rotating pivot shaft fitting surface 30 on a rotating pivot shaft 31 are in sliding fit with a pivot groove sliding circular surface 20 on another connecting rod and in running fit with a pivot groove arc surface 25; and the pivot groove sliding circular surface 20 shares a circle center with the pivot groove arc surface 25. The X-shaped support structure device greatly simplifies a mold structure, greatly lowers mold manufacturing cost, greatly enhances the intensity and rigidity of a pivot shaft of an X-shaped support structure, greatly enhances the durability, overcomes the influence of sticky liquid on the X-shaped support structure device, further enhances product quality and can be widely applied to computer keyboards and key switch devices for key pressing operation.

Owner:王淑君

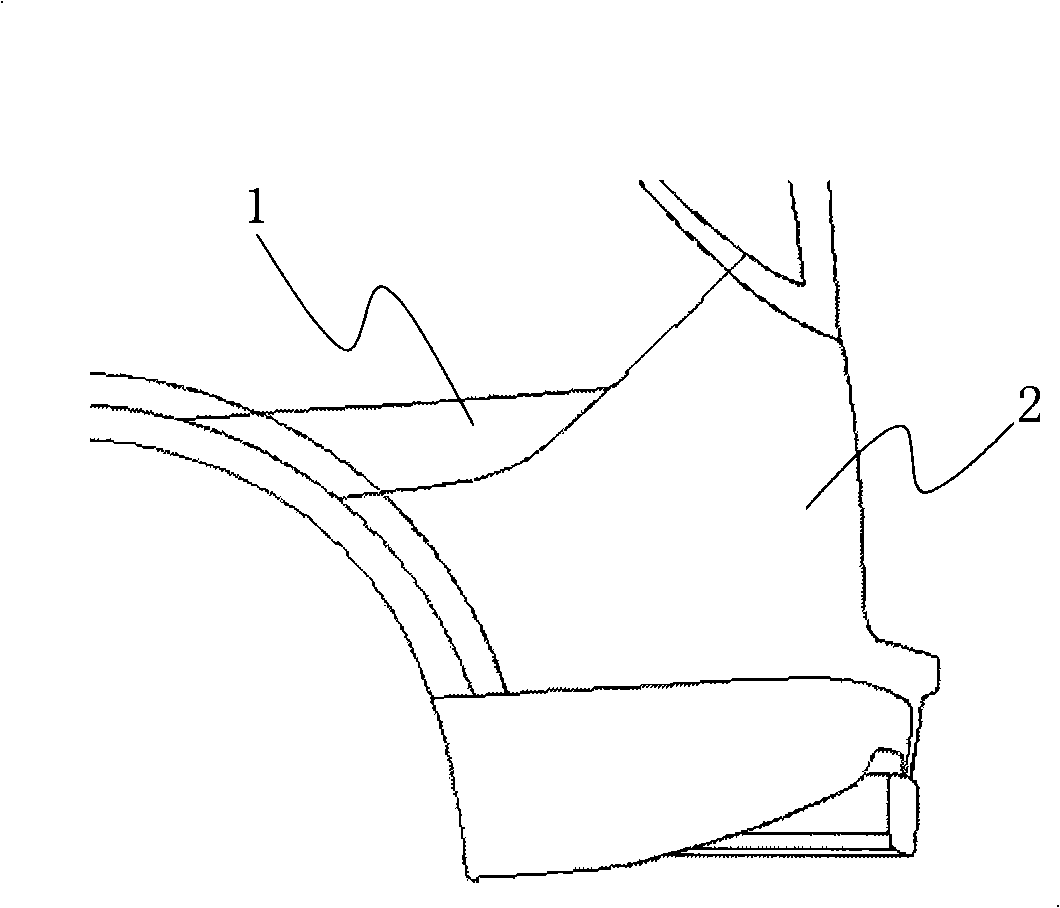

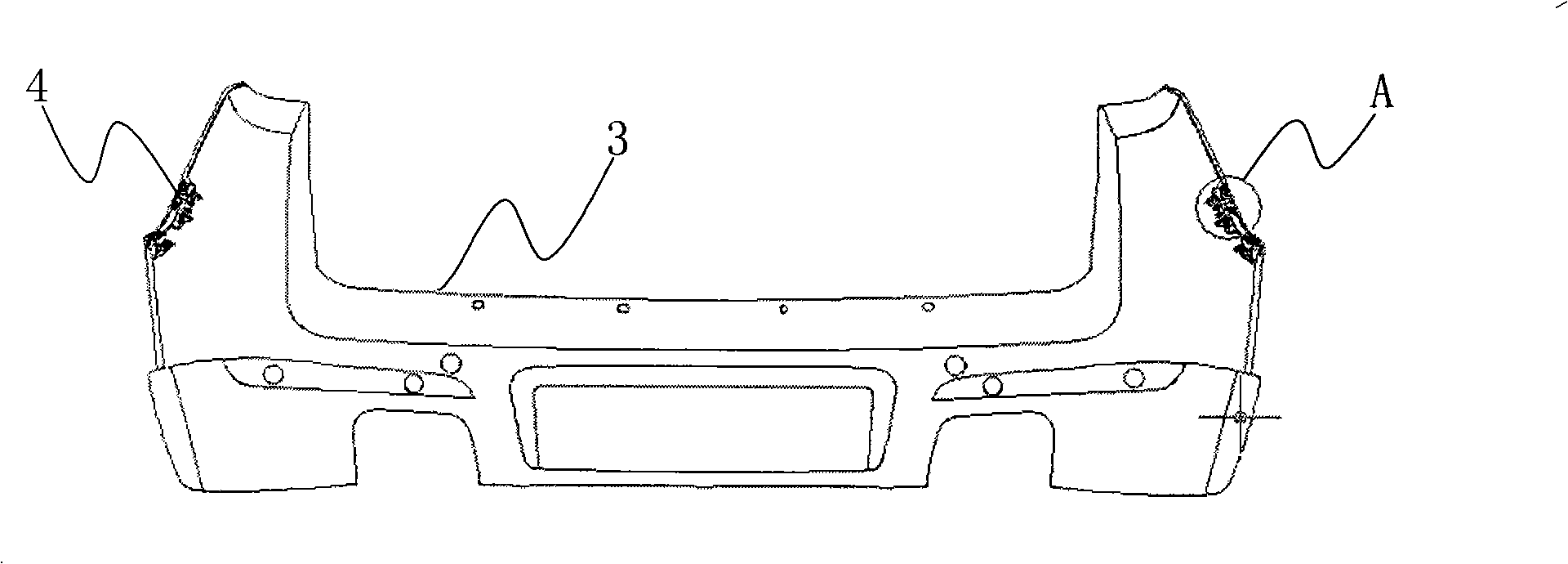

Fender-guard mounting structure

InactiveCN101318490AAvoid direct connectionSimple mold structureBumpersEngineeringHorizontal and vertical

The invention belongs to the mounting field of bumpers, in particular relating to a bumper mounting structure. The invention includes a connector which is fixedly connected with a vehicle body; a limiting part which limits the horizontal and vertical movement of the bumper is arranged on the connector; the bumper is combined with the vehicle body by the connector. The invention avoids the bumper being directly connected with the vehicle body by arranging the connector; besides, the limiting part on the connector firmly ensures the position of the bumper; the connector can be independently shaped, thus simplifying the die structure of the bumper and improving the mounting efficiency of the bumper.

Owner:CHERY AUTOMOBILE CO LTD

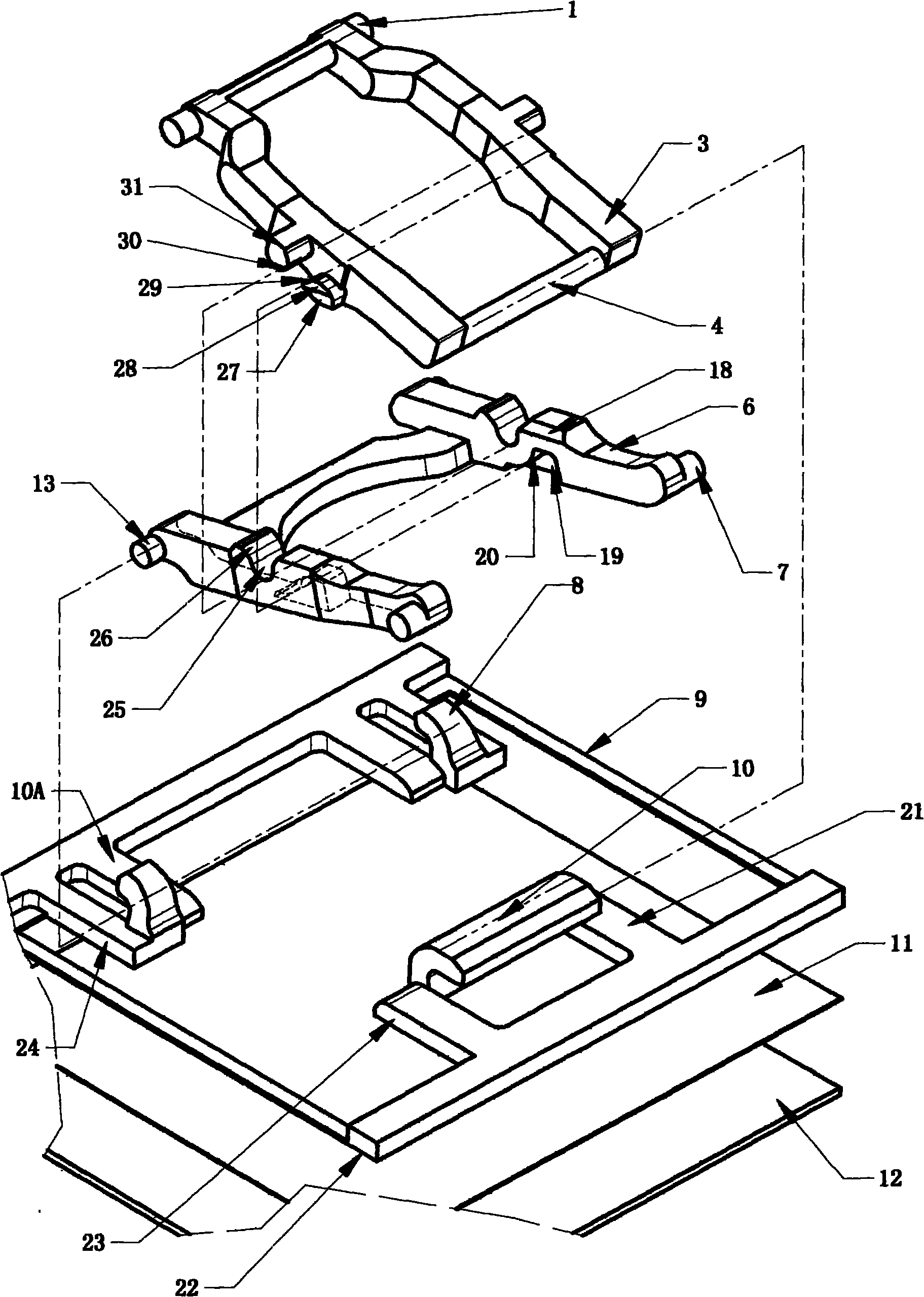

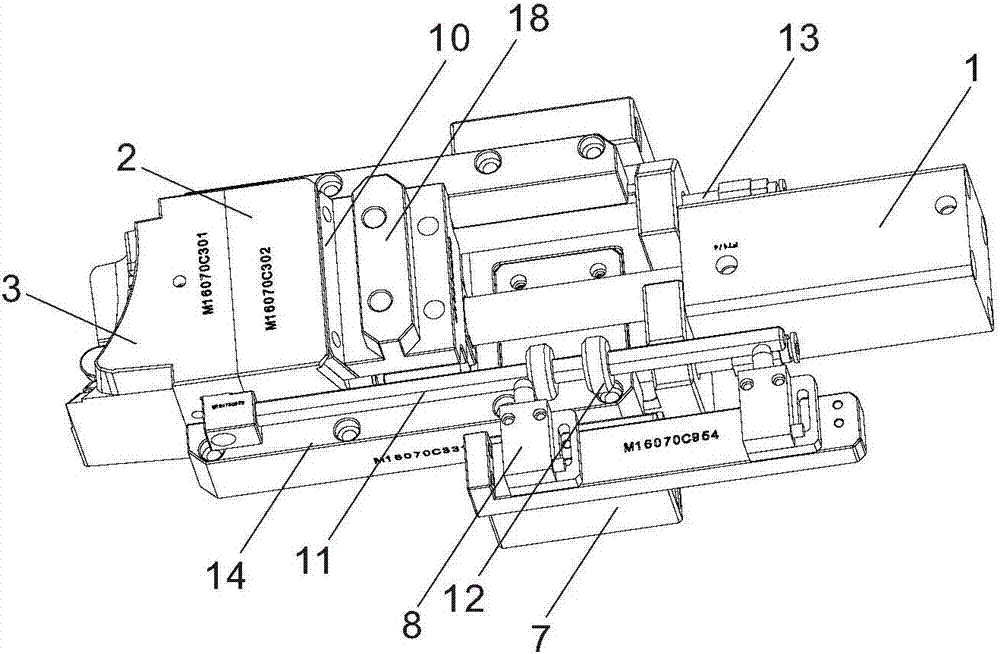

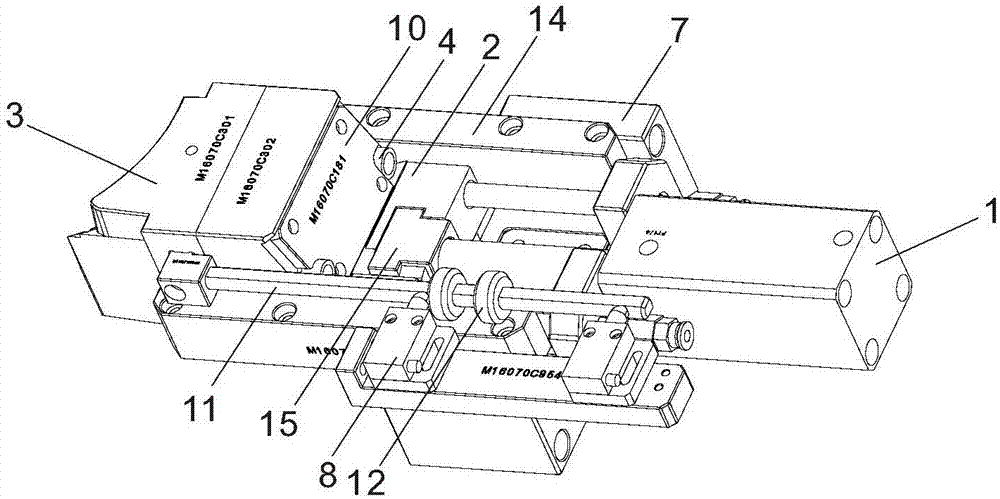

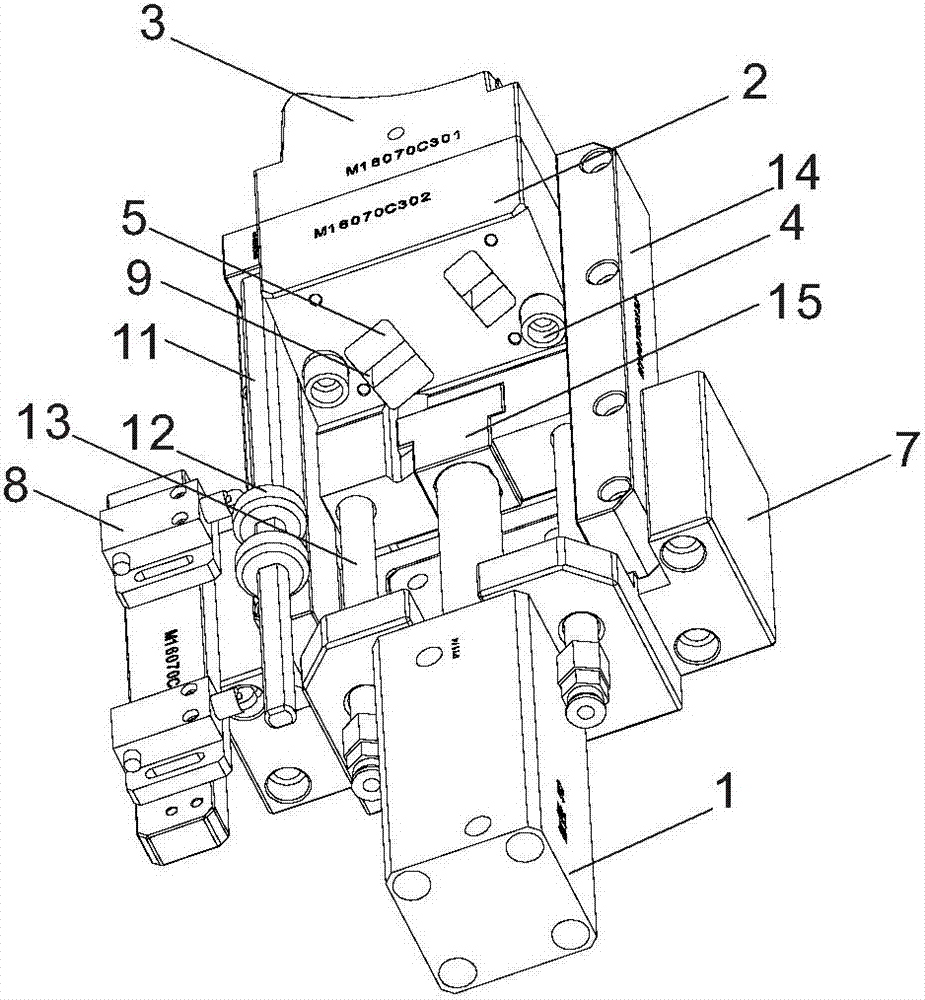

Mechanism capable of realizing two times of core pulling and forcible hole stripping operation by virtue of slide

PendingCN107053613ASimple mold structureReduce mold volumeStructural engineeringMechanical engineering

The invention discloses a mechanism capable of realizing two times of core pulling and forcible hole stripping operation by virtue of a slide. The mechanism is arranged on a mold and is characterized by comprising an oil cylinder, a slide body, a slide head, a threaded limiting sleeve, and U-shaped buckle lateral pins and a U-shaped buckle center pin which are capable of extending to a mold core of the mold, wherein a piston rod of the oil cylinder is connected to the slide body, the slide body and the slide head are slideably connected to a bottom frame, the U-shaped buckle lateral pins are fixedly arranged on the slide body and slideably penetrate through the slide head, and the U-shaped buckle center pin is fixedly arranged on the slide head; the U-shaped buckle center pin is provided with a protrusion part used for forming an inner undercut structure of an injection product; the threaded limiting sleeve is connected between the slide body and the slide head; a limited travel pull rod is slideably arranged inside the threaded limiting sleeve, and the end of the limited travel pull rod is fixed on the slide head; the slide head is provided with a U-shaped buckle forming hole leading to the mold core of the mold, and the U-shaped buckle center pin is arranged in the U-shaped buckle forming hole in a penetrating manner; and the bottom frame is fixedly provided with a travel switch used for detecting the moving travel of the slide head.

Owner:SHENTONG TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com