Set-top box and preparation method thereof

A set-top box and outer surface technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, selective content distribution, etc., can solve problems such as complex molds, achieve the effects of optimizing production processing, simplifying mold structure, and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a set-top box, the steps are as follows:

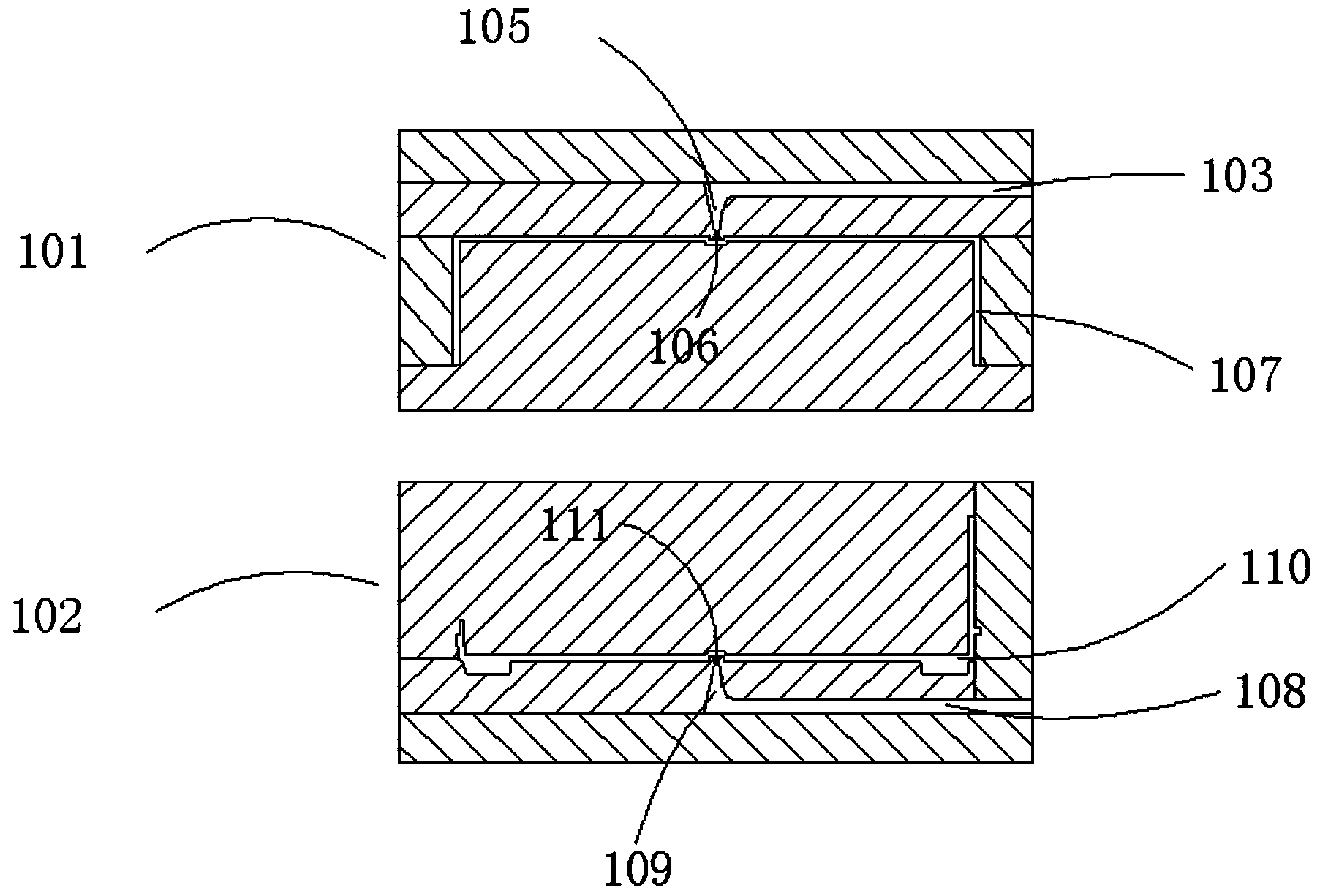

[0050] S1, use as image 3 The special mold with a central gate shown, the special mold includes an upper mold 101 for preparing the body 1 and a lower mold 102 for preparing the cover 2 that cooperate with each other, and the upper mold 101 includes an upper horizontal caster arranged in a horizontal direction. The channel 103 and the vertical upper gate 105 communicating with the upper runner 103, the upper runner 103 communicates with the upper cavity 107 through the upper gate 105; the lower mold 102 includes a lower runner arranged in the horizontal direction 108 and a vertical lower gate 109 communicating with the lower runner 108, and the lower runner 108 communicates with the lower cavity 110 through the lower gate 109;

[0051] S2, heating the upper mold 101 and the lower mold 102 to a working temperature of 75°C-85°C, which is preferably 80°C in this embodiment;

[0052] S3. Heat the ABS raw material...

Embodiment 2

[0064] The method steps of this method embodiment are the same as the method steps of method embodiment 1, and will not be repeated here. The difference is that the working temperature of the mold is 75°C. If it is less than 75°C, the rapid cooling caused by the injection of the ABS raw material into the upper and lower molds of the mold will not facilitate the flow of the raw materials, which will also adversely affect the filling. Correspondingly, the temperature of ABS is 220°C, in order to reduce the temperature difference between ABS and the mold, and the filling pressure needs to be set to 140MPa to promote the rapid flow of ABS. Under a filling pressure of 140 MPa, the height of the upper gate step 106 and the lower gate step 111 needs to be set to 1.5 mm to ensure the strength at the pouring point and the fluidity of the plastic.

Embodiment 3

[0066] The method steps of this method embodiment are the same as the method steps of method embodiment 1, and will not be repeated here. The difference is that the working temperature of the mold is 85°C. If it is greater than 85°C, the strength of the mold will decrease and may not be able to withstand the impact of injection molding. At this time, the ABS material needs to be heated to a temperature of 250°C and the filling pressure is as small as possible. The filling pressure is 100MPa to promote the normal flow of raw materials. Under 100 MPa, the height of the upper gate step 106 and the lower gate step 111 only needs to be set to 1.0 mm to ensure the strength at the pouring point and the fluidity of the plastic.

[0067] By setting the center gate on the front mold, the present invention makes full use of the advantages of the center gate, and adopts beautification methods to optimize the appearance of the product after the molding is completed; the special mold used has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com