LED backlight light bar and application thereof

A technology of LED backlight and backlight, which is applied in the field of optical devices, can solve the problems of waste of materials and unsightly appearance, and achieve the effect of material saving and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

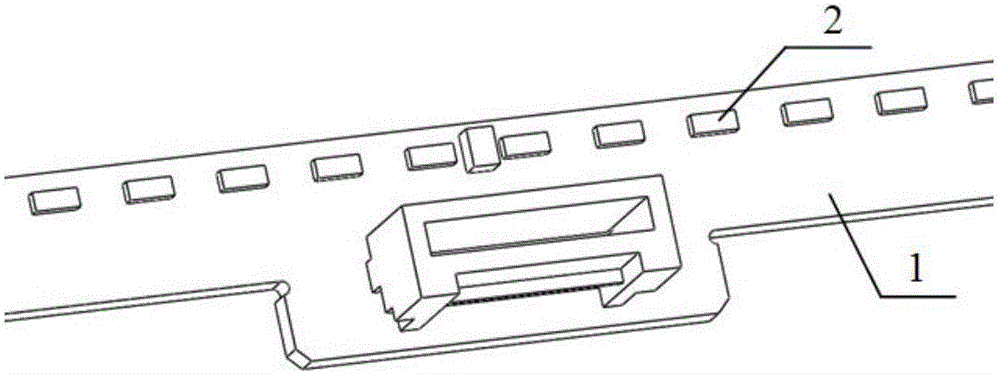

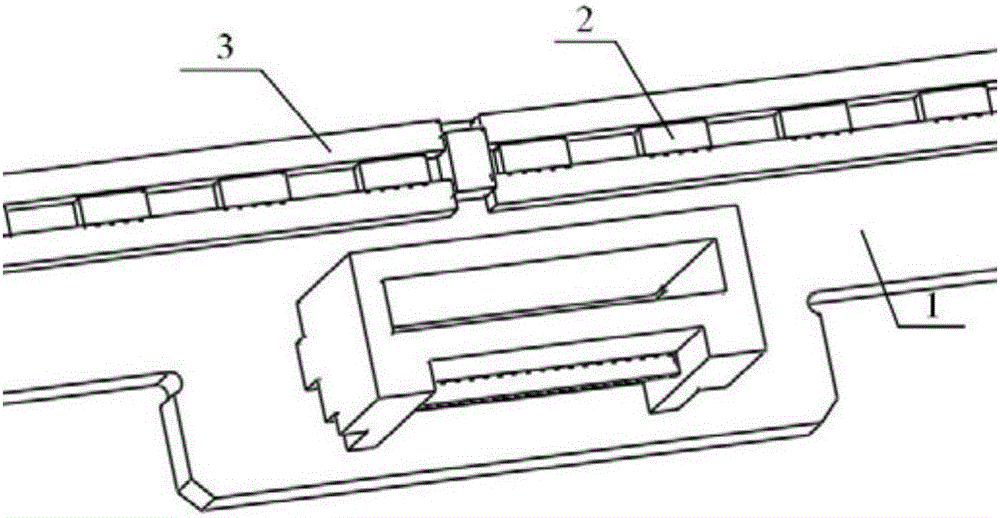

[0019] Such as figure 2 As shown, the present invention provides an LED backlight strip, which at least includes: a substrate 1, a light-emitting unit 2, and a light-shielding strip 3; The unit 2 is assembled in the U-shaped groove formed by the two shading strips 3 and the base plate 1 .

[0020] Preferably, the luminous groove surface of the U-shaped groove can be adjusted by adjusting the distance between the two light-shielding strips 3 .

[0021] Preferably, the light emitting unit 2 is an LED lamp bead.

[0022] Preferably, the shading strip 3 is bonded on the substrate 1 by means of double-sided adhesive or natural colloid curing.

[0023] In the LED backlight strip provided in this embodiment, since the light-emitting unit 2 is placed in the U-shaped groove formed by the two light-shielding strips 3 and the substrate 1, the arbitrary adjustment of the light-emitting groove surface of the backlight light strip is realized. Realize the ultra-narrow frame of liquid cr...

Embodiment 2

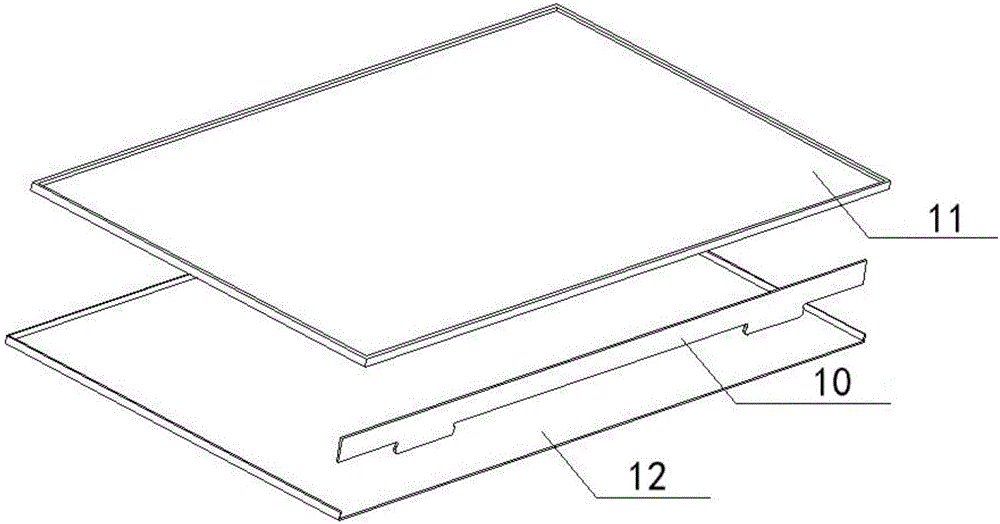

[0025] Such as image 3 As shown, the present invention also provides a liquid crystal display, including a backlight strip 10, a display screen 11, and a rear panel 12. The backlight strip is the LED backlight strip described in Embodiment 1, and the same parts will not be repeated.

[0026] In the liquid crystal display provided by this embodiment, since the light-emitting unit is placed in the U-shaped groove formed by the two light-shielding strips and the substrate, arbitrary adjustment of the surface of the light-emitting groove of the backlight light bar is realized, and the liquid crystal display device is realized under the condition of complete light-shielding. Ultra narrow bezels.

Embodiment 3

[0028] Such as Figure 4 As shown, the present invention also provides a panel light, including a backlight strip 10, a light-emitting panel 21, and a base plate 22. The backlight strip is the LED backlight strip described in Embodiment 1, and the same parts will not be repeated.

[0029] The panel light provided in this embodiment, because the light-emitting unit is placed in the U-shaped groove formed by the two light-shielding strips and the substrate, the surface of the light-emitting groove of the backlight light bar can be adjusted arbitrarily, and the panel-type lighting device can be realized under the condition of complete shading ultra-narrow bezel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com