Heating closestool cover plate and preparation process thereof

A preparation process and toilet cover technology, which is applied in the field of heating toilet cover and its preparation, can solve the problems of shrinkage, gaps, cumbersome assembly, etc., and achieve the effect of ensuring the accuracy of installation, stable connection structure and fast heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

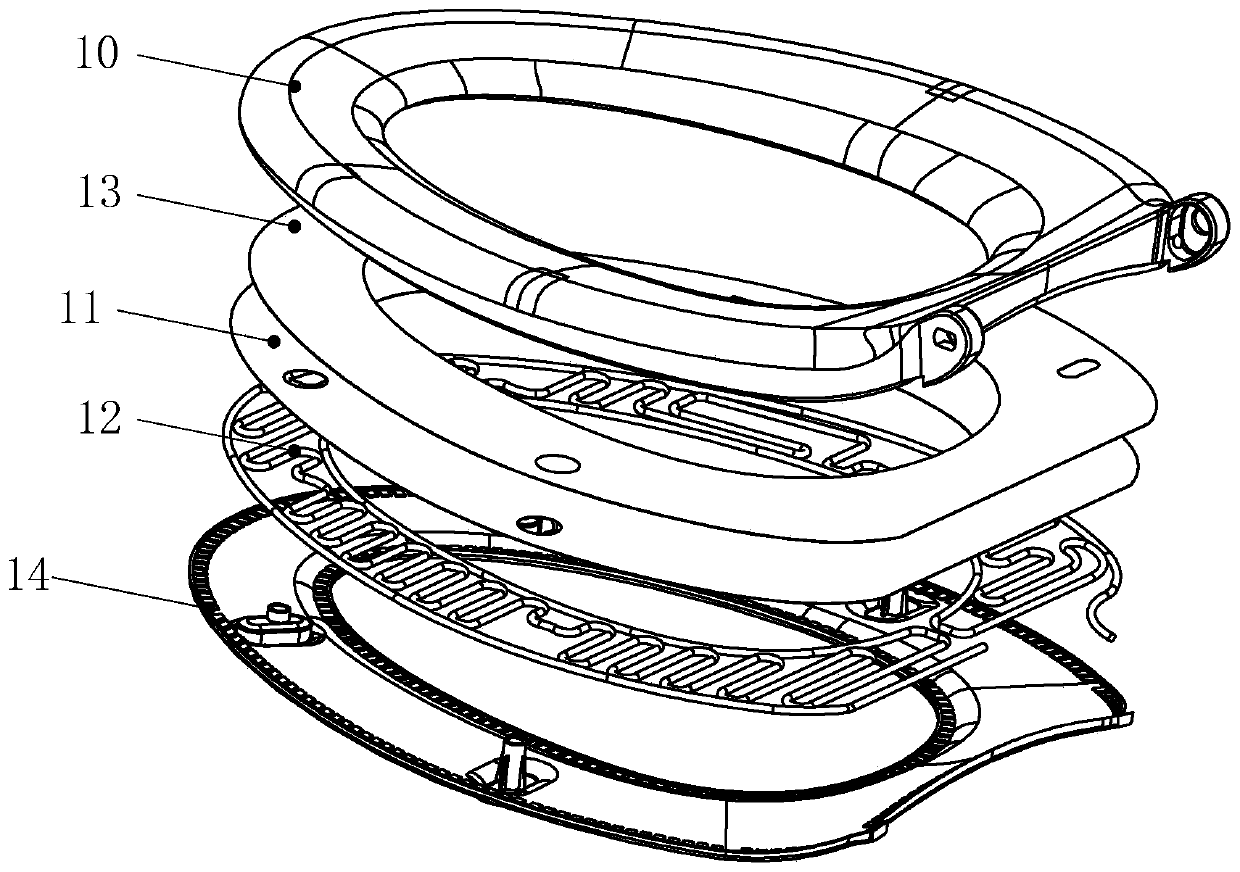

[0034] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

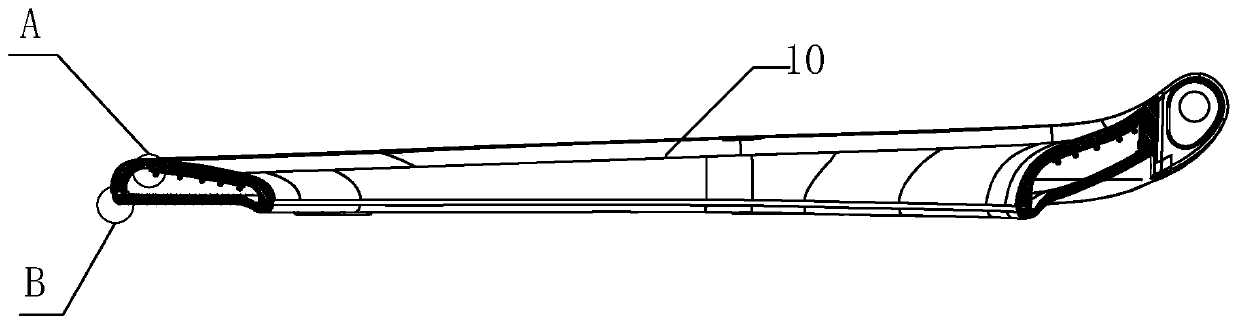

[0035] See attached Figure 5-13 , a heating toilet cover, including a panel 4, a seat ring 2 and a heating wire 3 in the seat ring 2, and one end of the seat ring 2 is hinged to the panel 4.

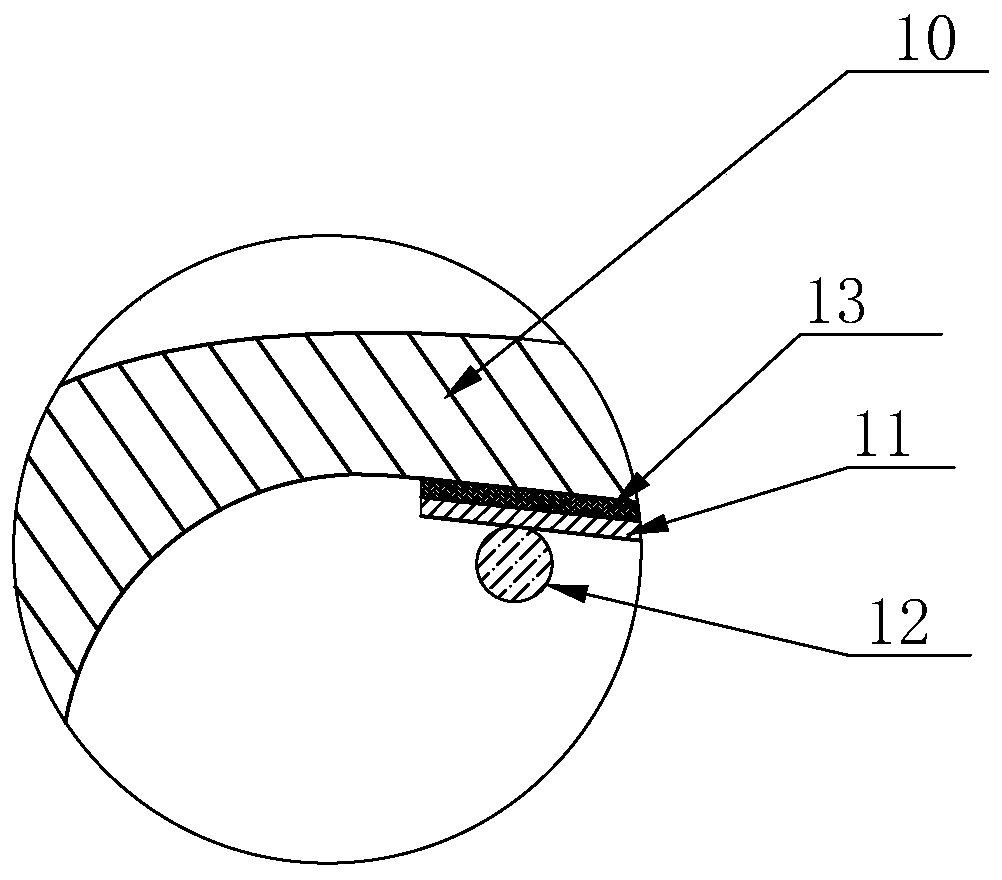

[0036] The seat ring 2 is made of urea-formaldehyde resin (UF) material by die-casting twice. The seat ring 2 includes a first ring body 21 and a second ring body 22 . The heating wire 3 is made of nickel-chromium alloy, which is located between the first coil body 21 and the second coil body 22 and embedded in the surface of the first coil body 21 . The heating wire 3 is curved and evenly distributed in a wave shape. Both ends of the heating wire 3 are connected with positioning copper points 31 , and the positioning copper points 31 are provided with transverse grooves 311 , and the ends of the heating wires 3 are embedded in the transverse grooves 311 and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com