Patents

Literature

1629results about How to "Guaranteed installation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

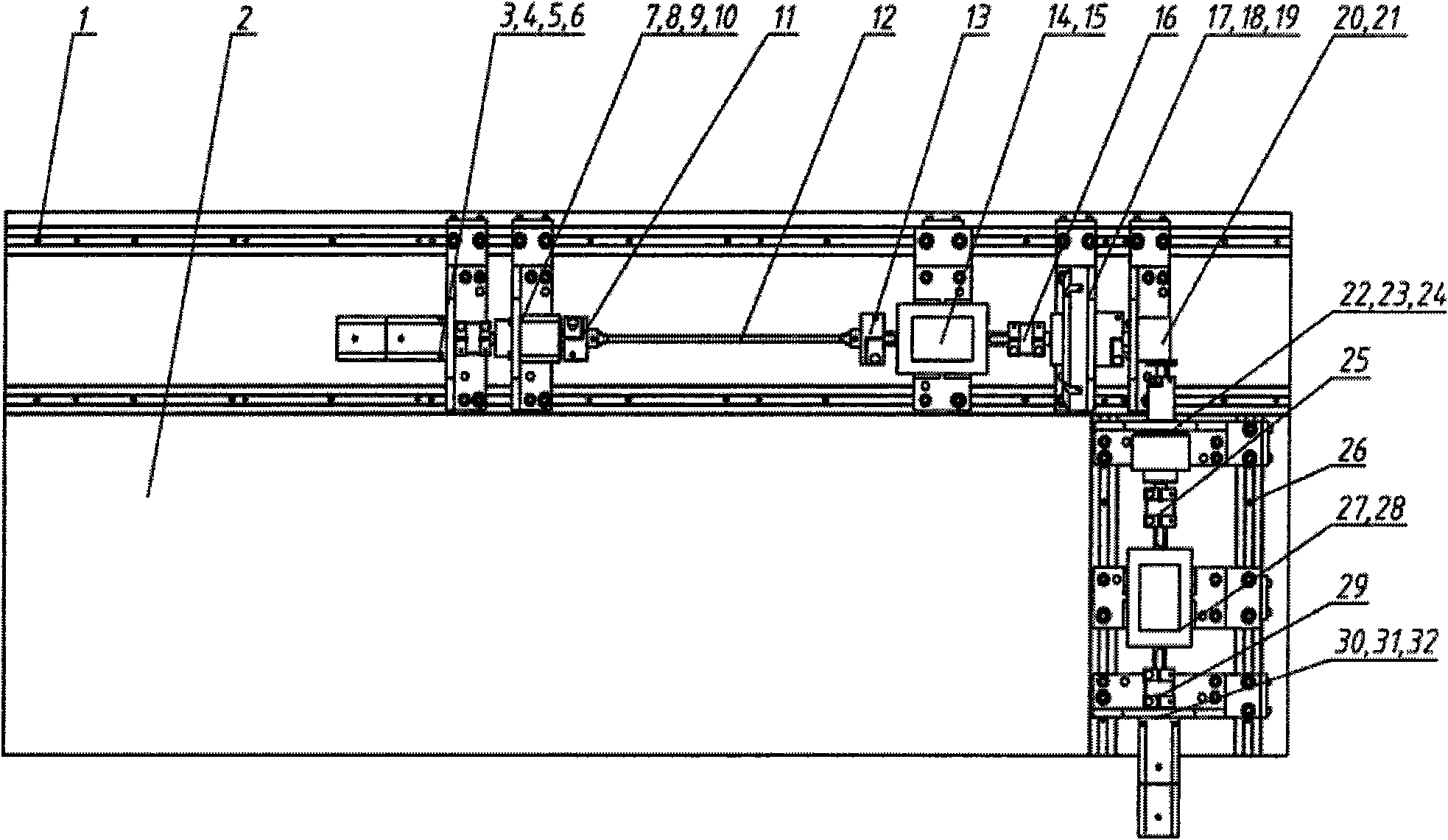

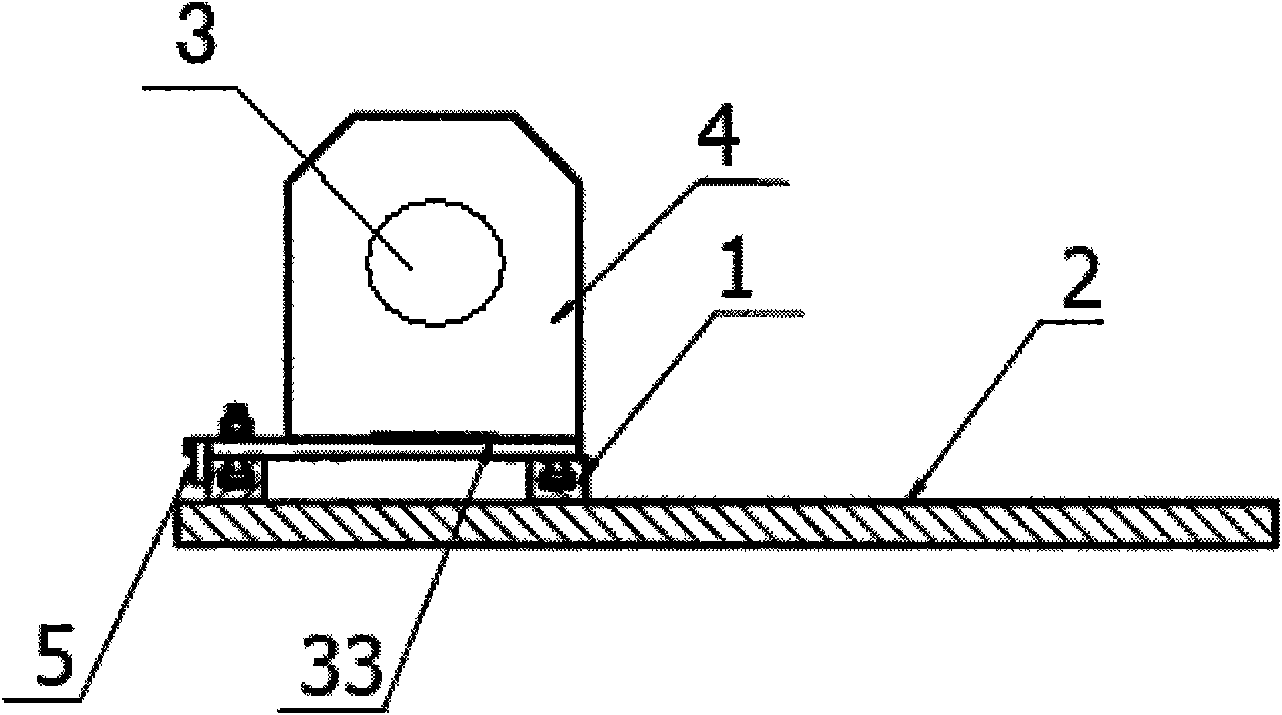

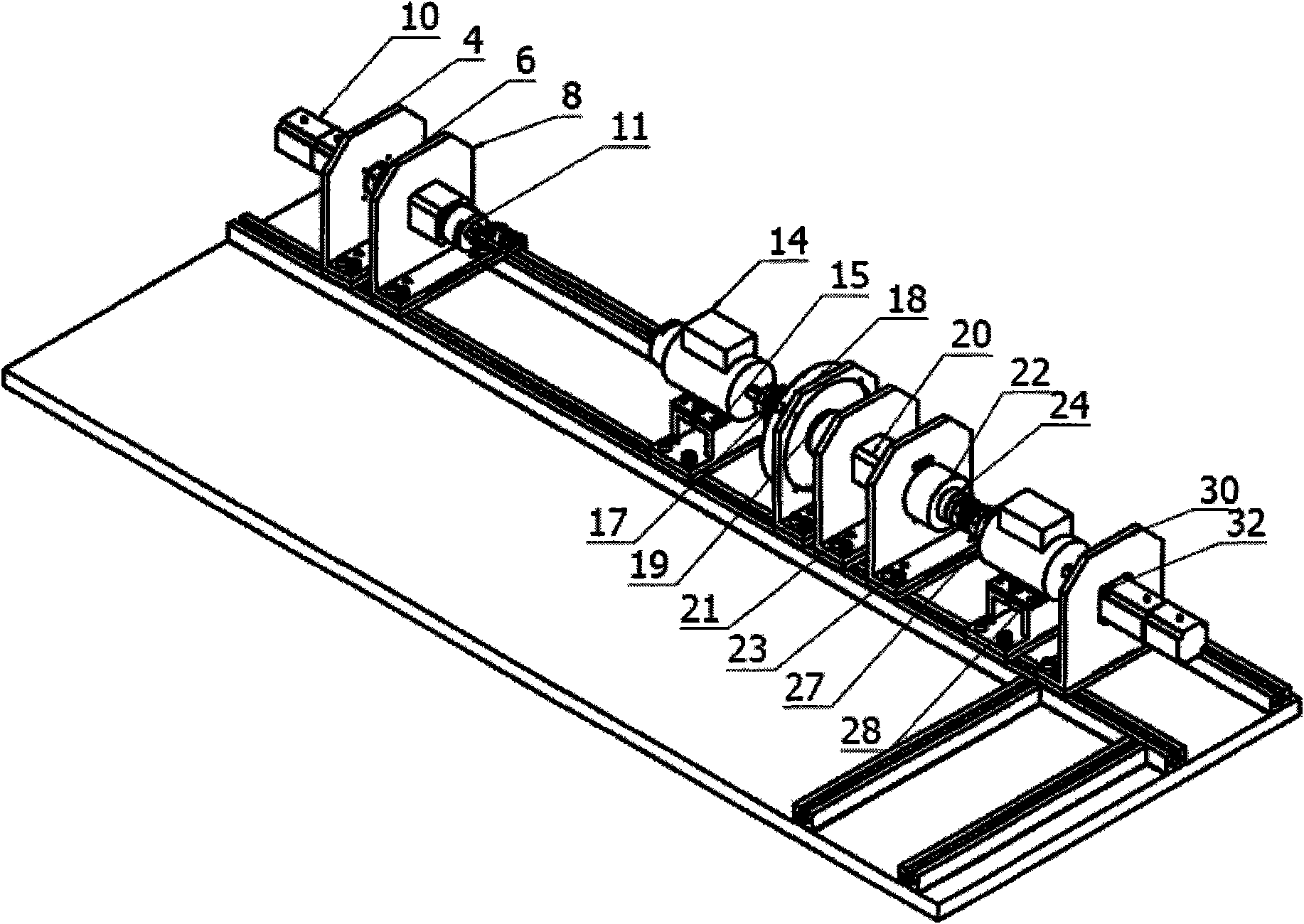

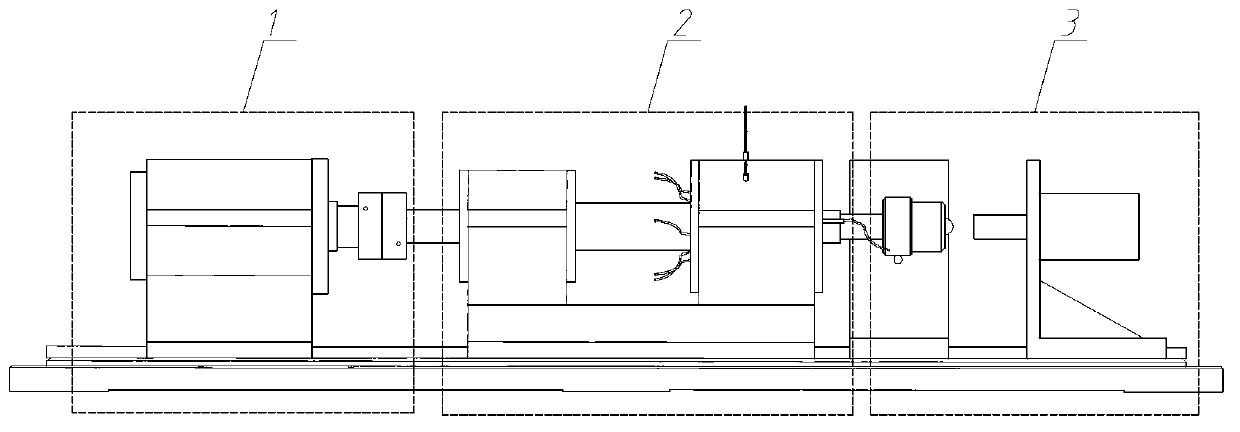

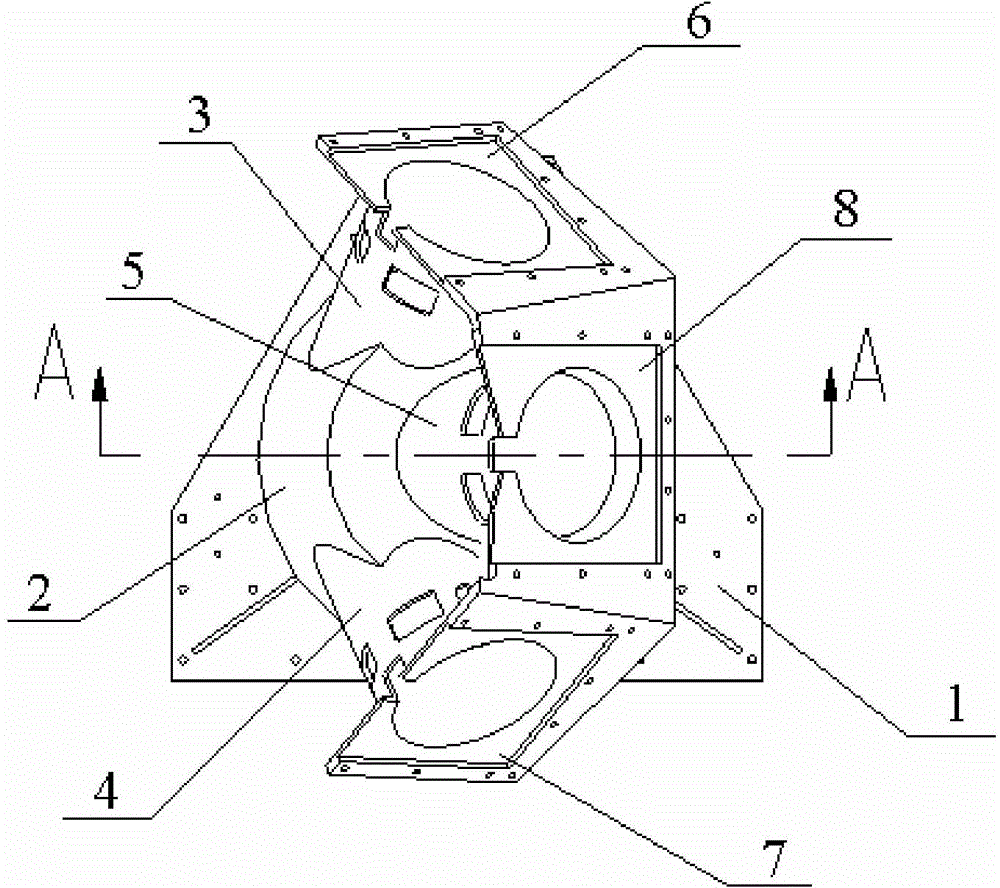

Experiment table for detecting dynamic characteristics of harmonic reducers

InactiveCN101587015AImprove versatilityWide range of test modelsMachine gearing/transmission testingHarmonicReduction drive

The invention discloses an experiment table for detecting dynamic characteristics of harmonic reducers, which comprises an X guide rail arranged on a bottom plate, as well as a first servo motor, wherein the first servo motor is fixed on the X guide rail and is axially connected with a follow-up harmonic reducer; the follow-up harmonic reducer is fixed on the X guide rail and is axially connected with a first torque sensor through a first torsion bar; the first torsion bar sensor is axially connected with a first angle measuring device; the first angle measuring device is connected with a first connecting shaft; and a detected harmonic reducer is arranged on the X guide rail through a mounting bracket and a positioning piece. The experiment table is characterized in that a Y guide rail perpendicular to the X guide rail is arranged on the bottom plate; when the detected harmonic reducer is a right-angled reducer, a second angle measuring device is arranged on the Y guide rail and is axially connected with a second torque sensor; and the second torque sensor is axially connected with a second servo motor. The experiment table has the advantages of good universality and capability of completing the task of testing the dynamic characteristics of a plurality of detected harmonic reducers on one experimental device.

Owner:XI AN JIAOTONG UNIV

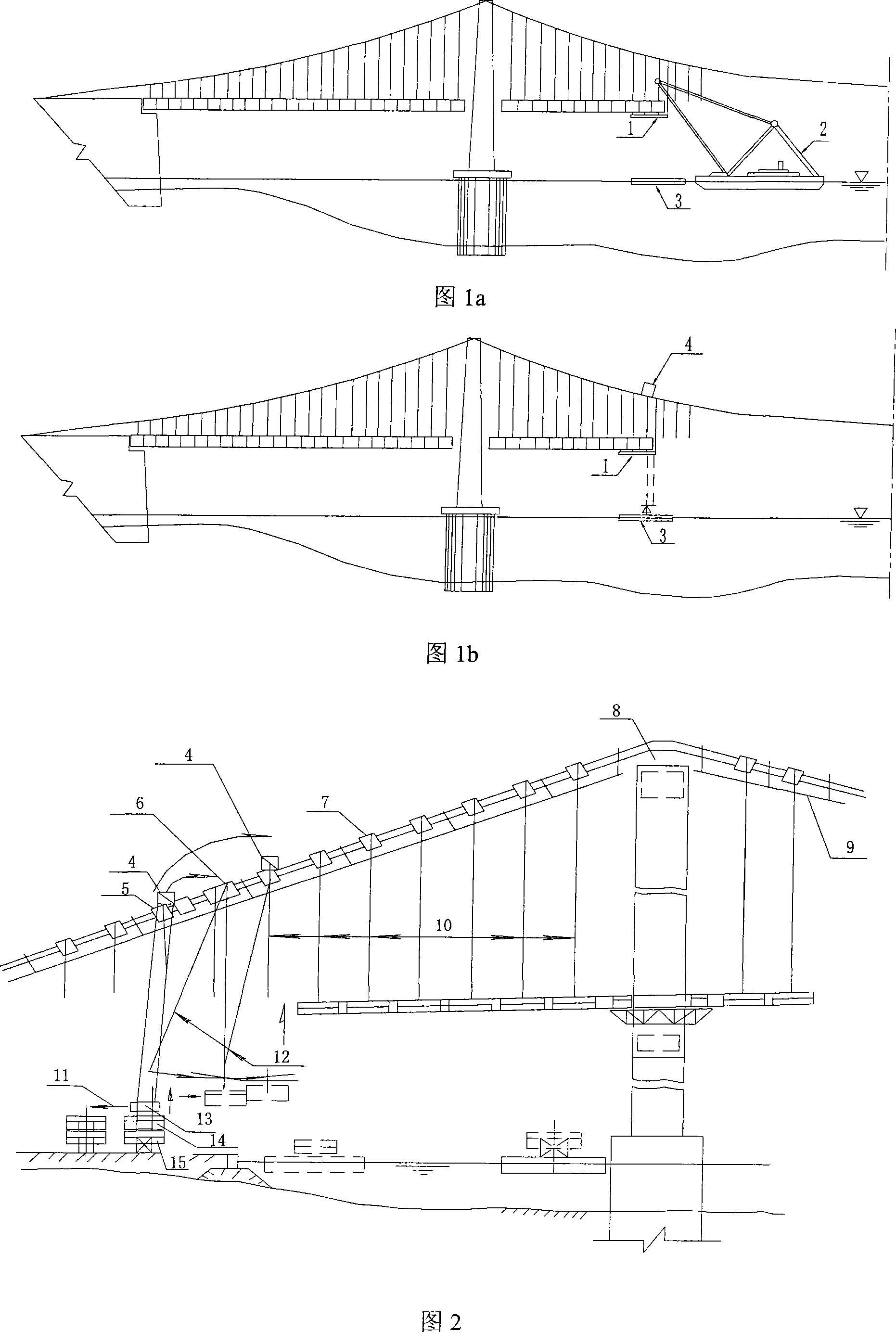

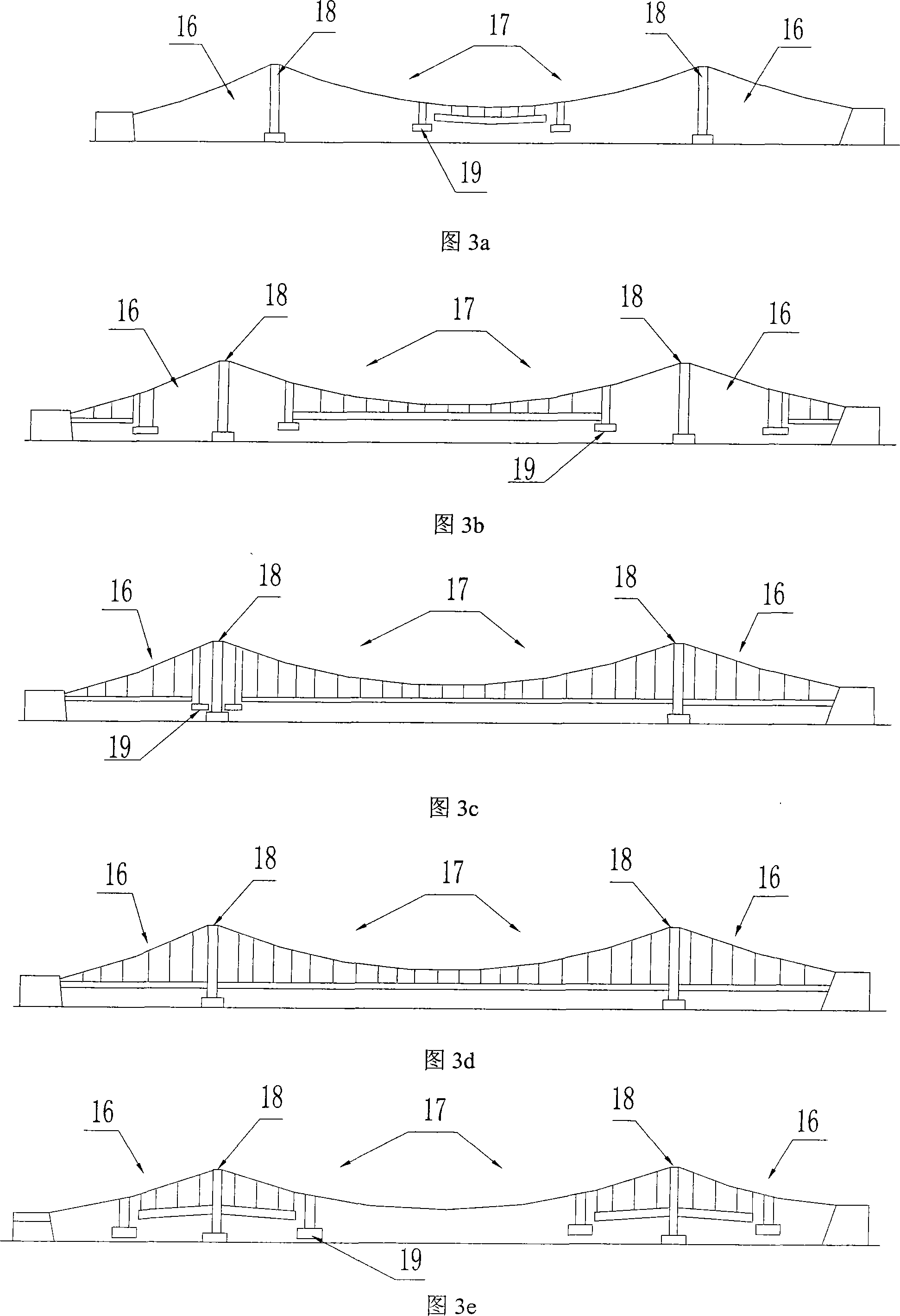

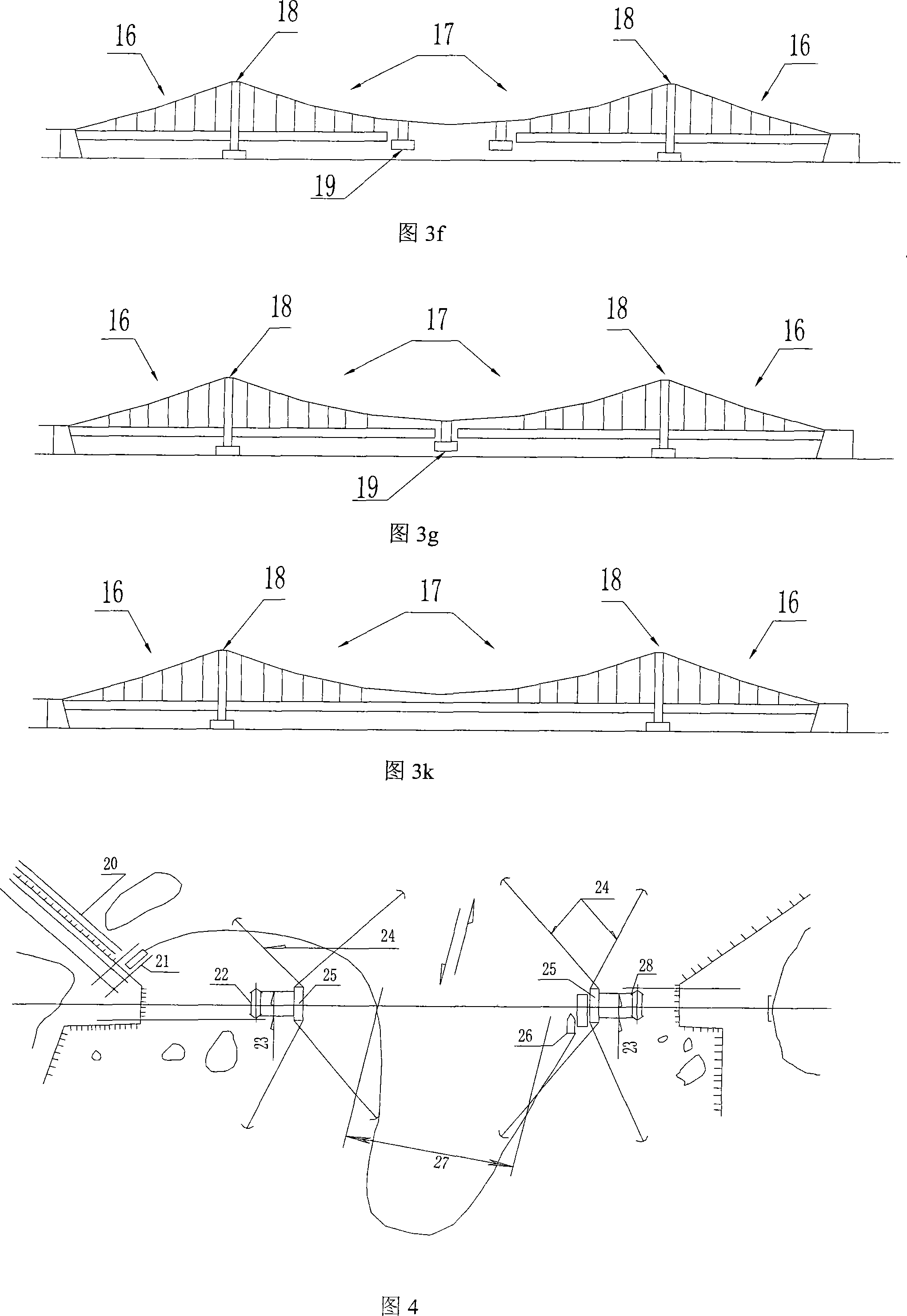

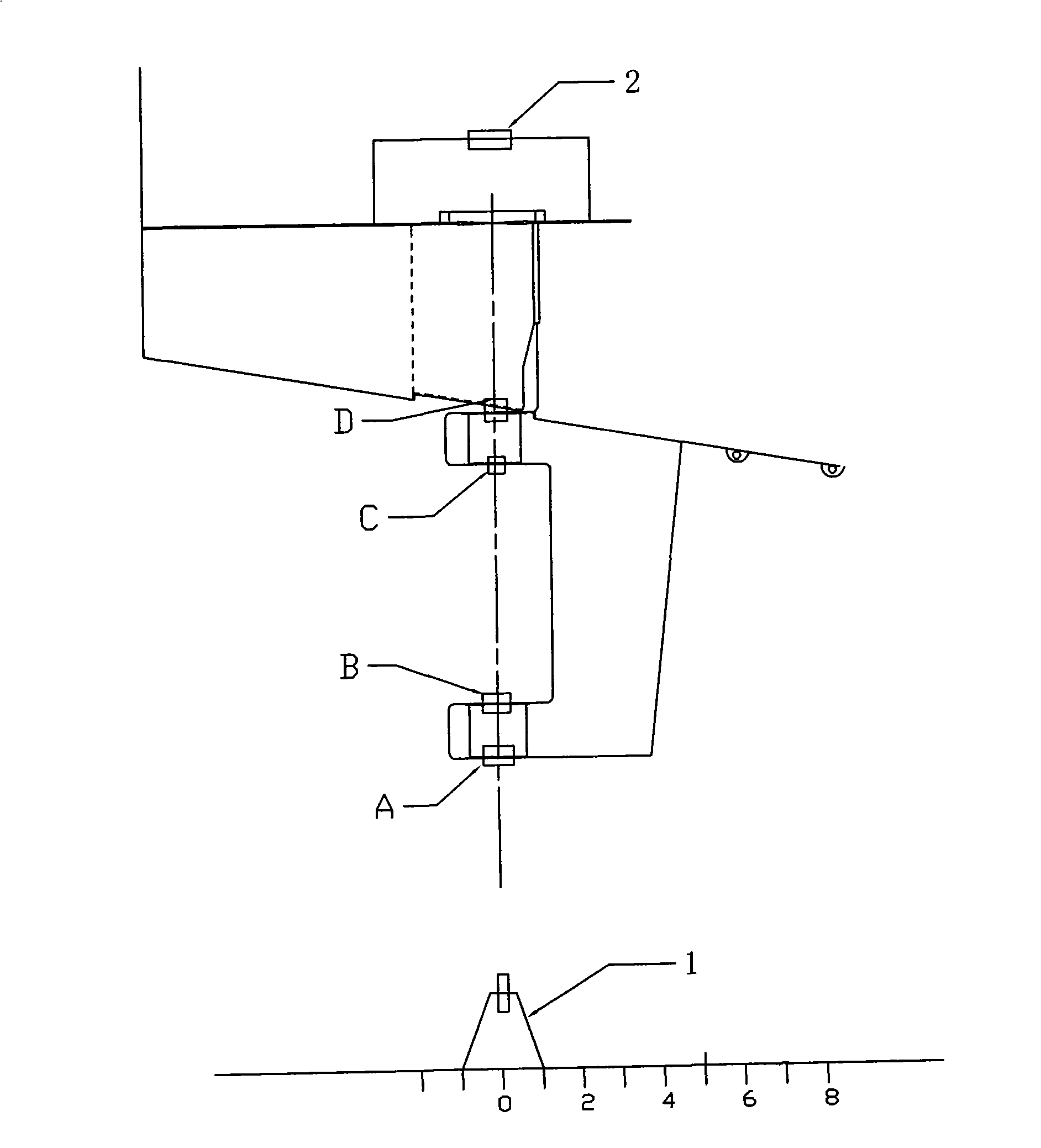

Method for mounting ground anchor type suspension bridge prestressed concrete stiffening box girder

InactiveCN101225638AImprove linearityGuaranteed installation accuracyBridge erection/assemblyEngineeringEarth anchor

The invention discloses an installation method of prestressed concrete stiffened box girder for an earth-anchored suspension bridge, relating to an installation method of stiffened box girder for suspension bridge. The installation procedure is that: symmetrically pushing from the segment at mid-span to the main towers at the two sides or pushing from the segment near the main towers to the mid-span and the abutments, the steps are that: the concrete structure stiffened box girder is erected by hoisting, lifting or oscillating-shifting method, the erection of the concrete structure stiffened box girder comprises the pre-assembly of the stiffened girder, the installation of cable clamp and suspender cable, the slung load of catwalks, carrying the stiffened girder to the construction site, the girder erection crane at the position, hoisting, floating and positioning, moving the stiffened girder to the hoisting point and raising perpendicularly, connecting with the segment by drawing off, after the stiffened girder in position, adjusting the alignment of the beam segment, completing the temporary connecting installation between the beam segments, penetrating the longitudinal prestressed steel strands, loading the top surface of the beam blocks, wet connection between the segments, incrementally launching the cable saddle on the top of the tower, locking the cable saddle. The installation method of prestressed concrete stiffened box girder for an earth-anchored suspension bridge has the advantages of ensuring the installation precision and good alignment of the bridge.

Owner:CHINA MAJOR BRIDGE ENG

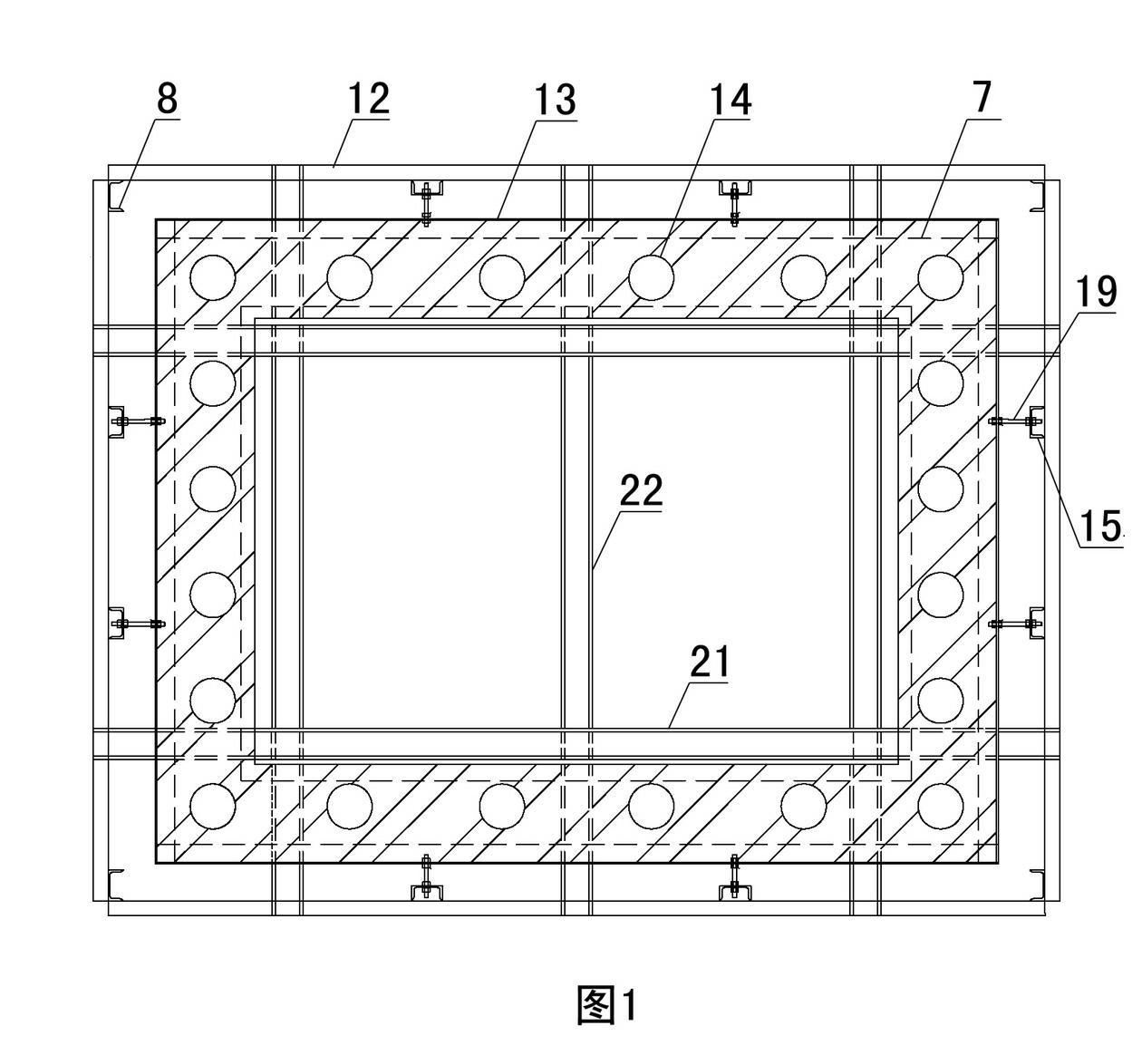

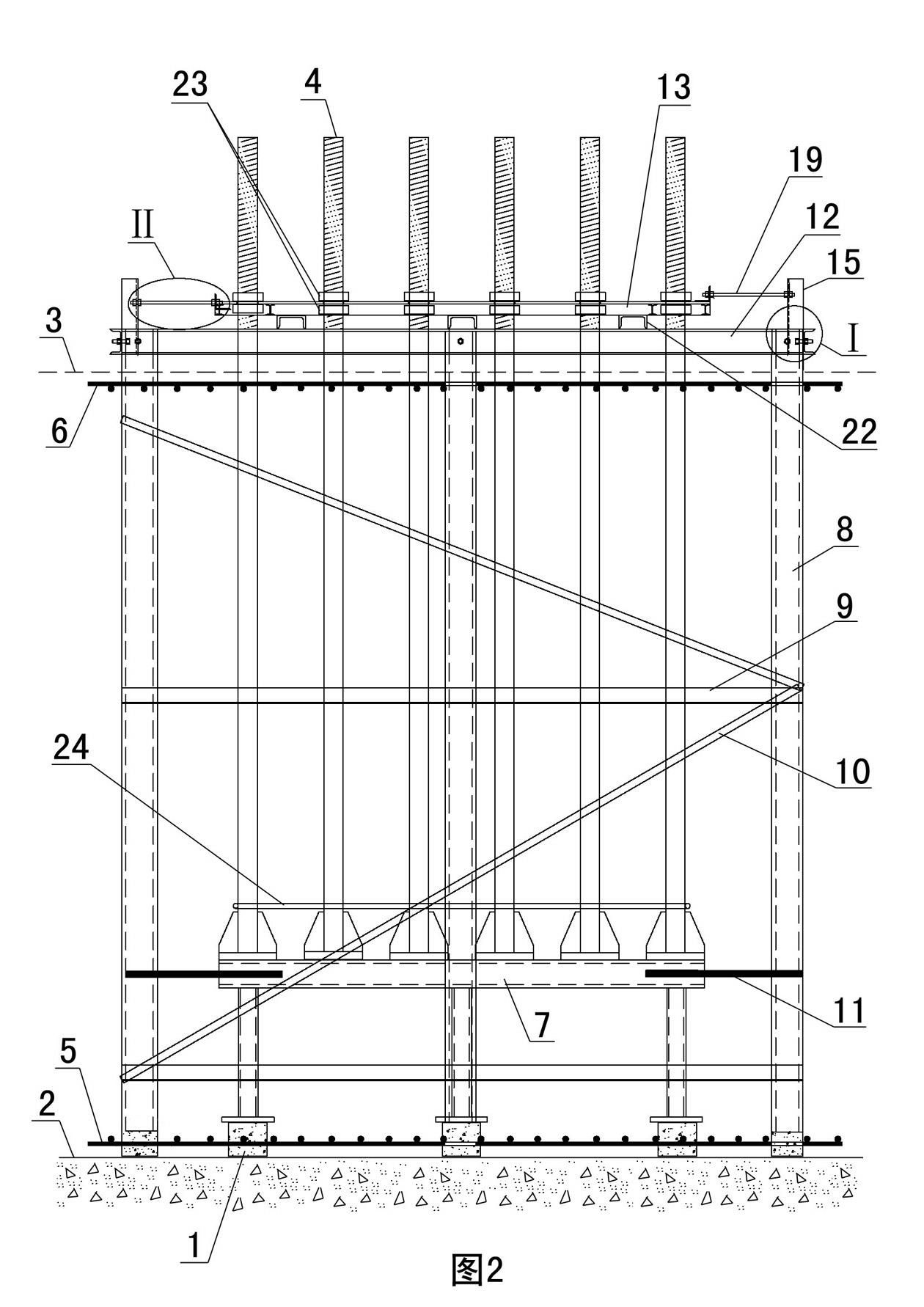

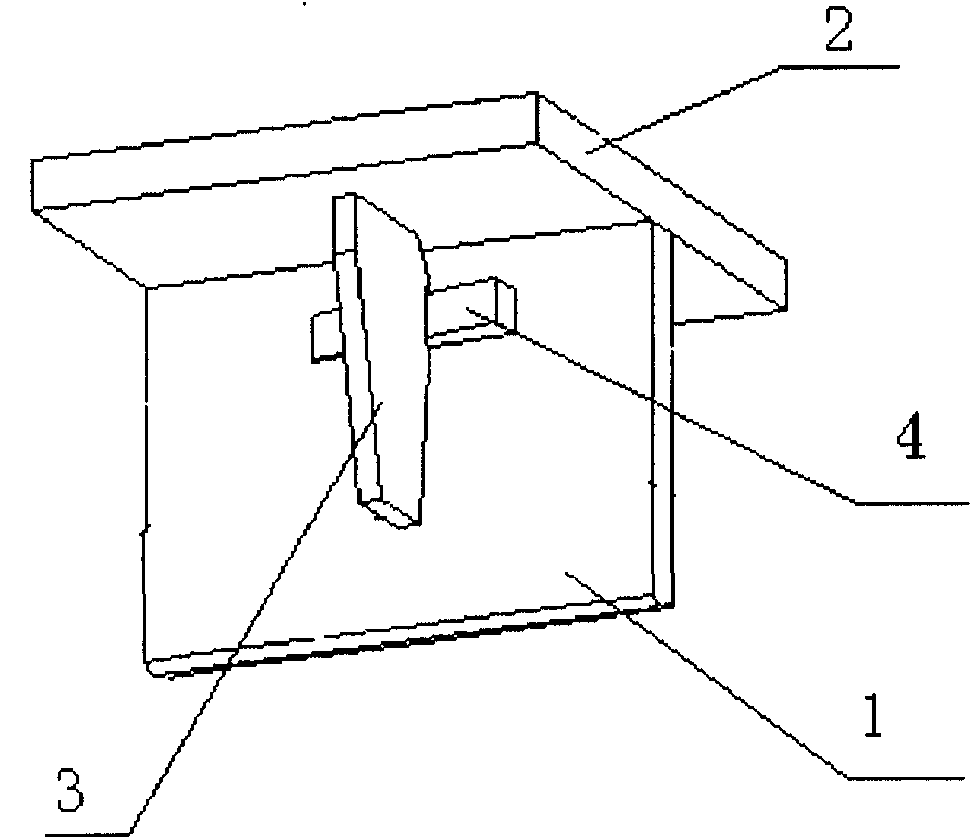

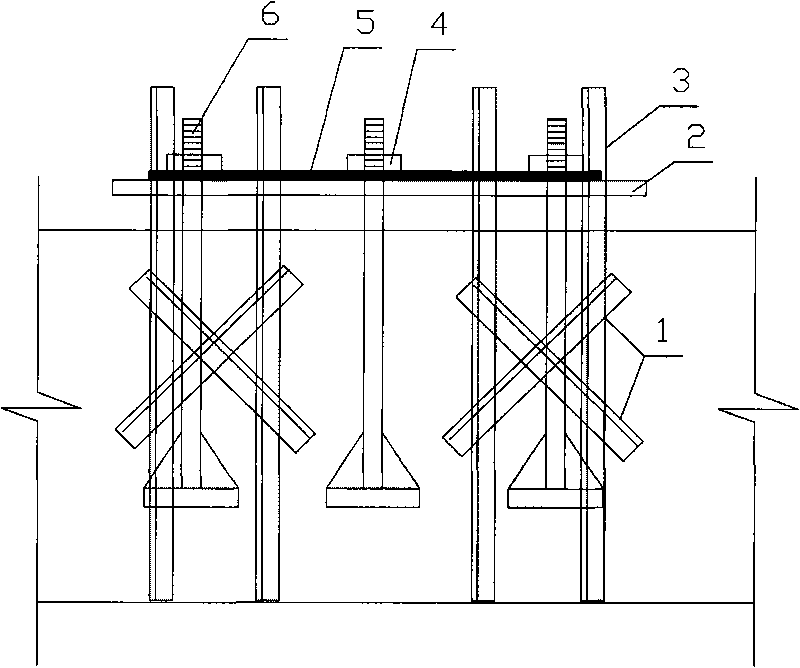

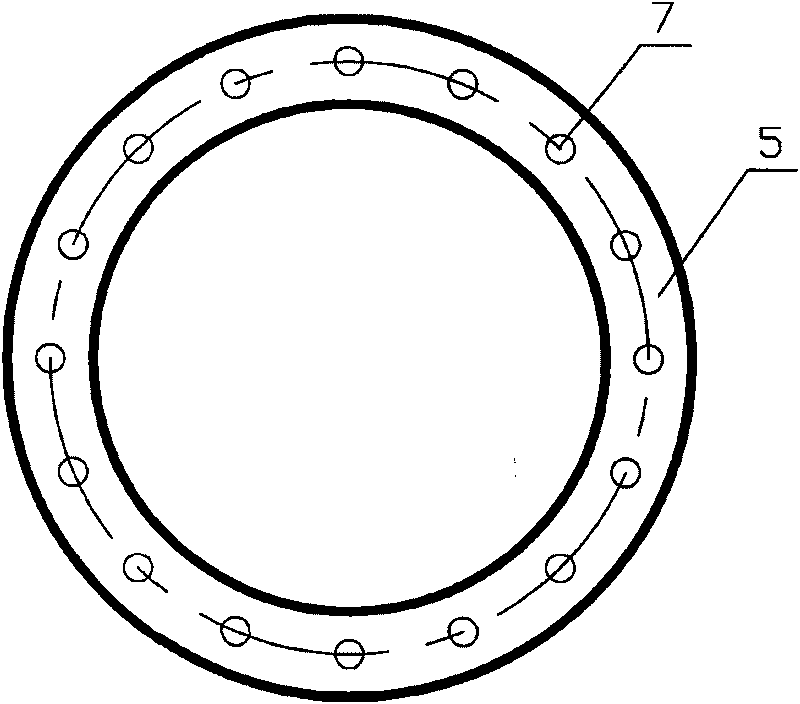

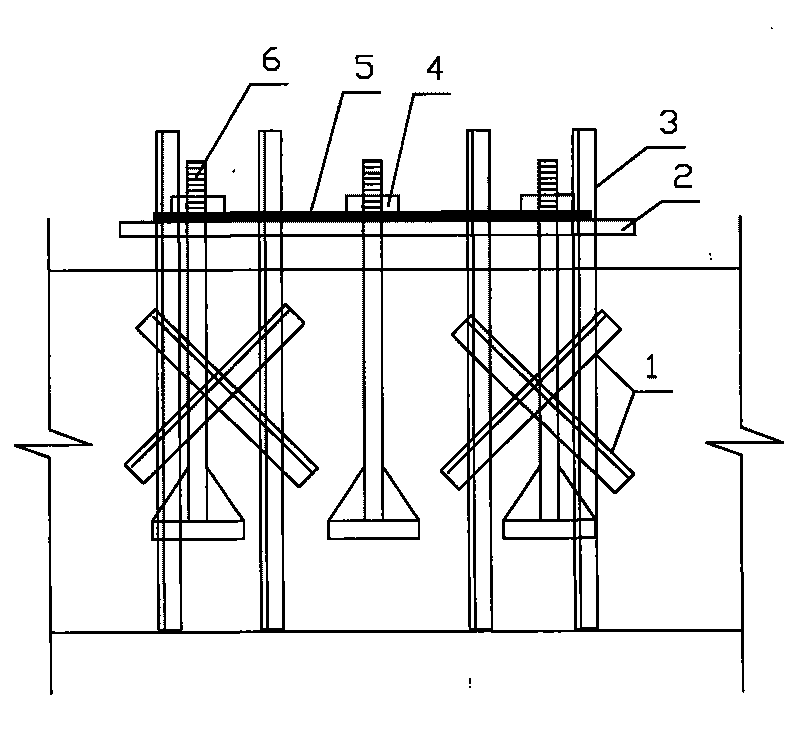

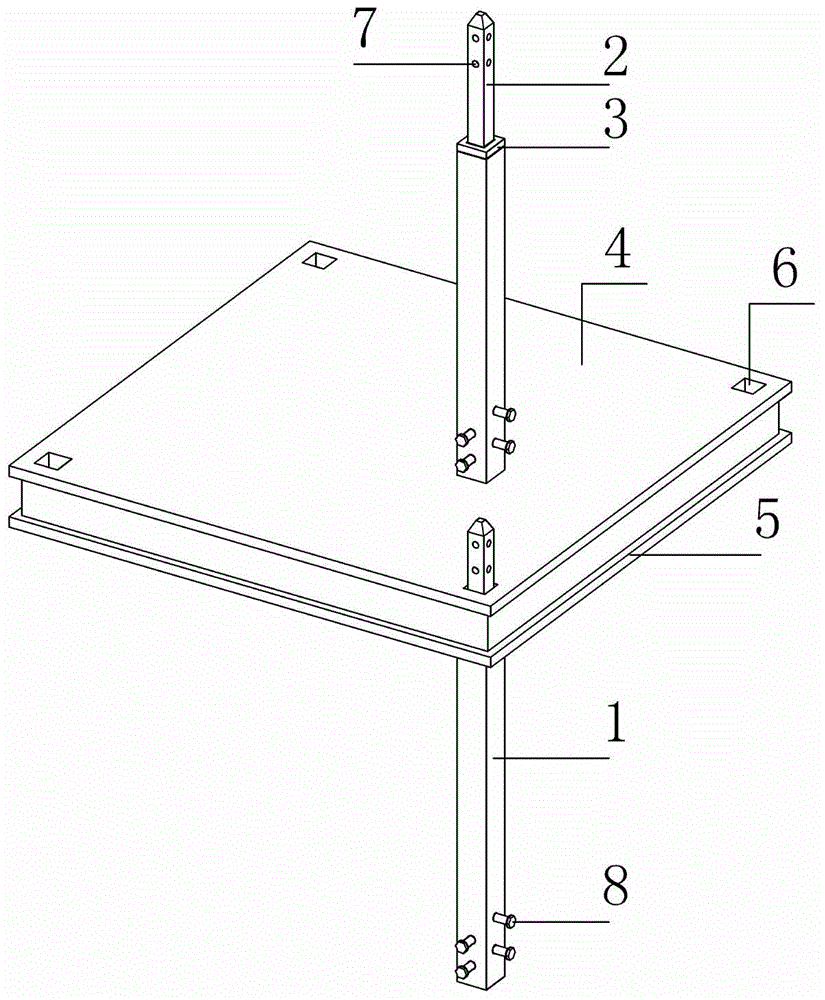

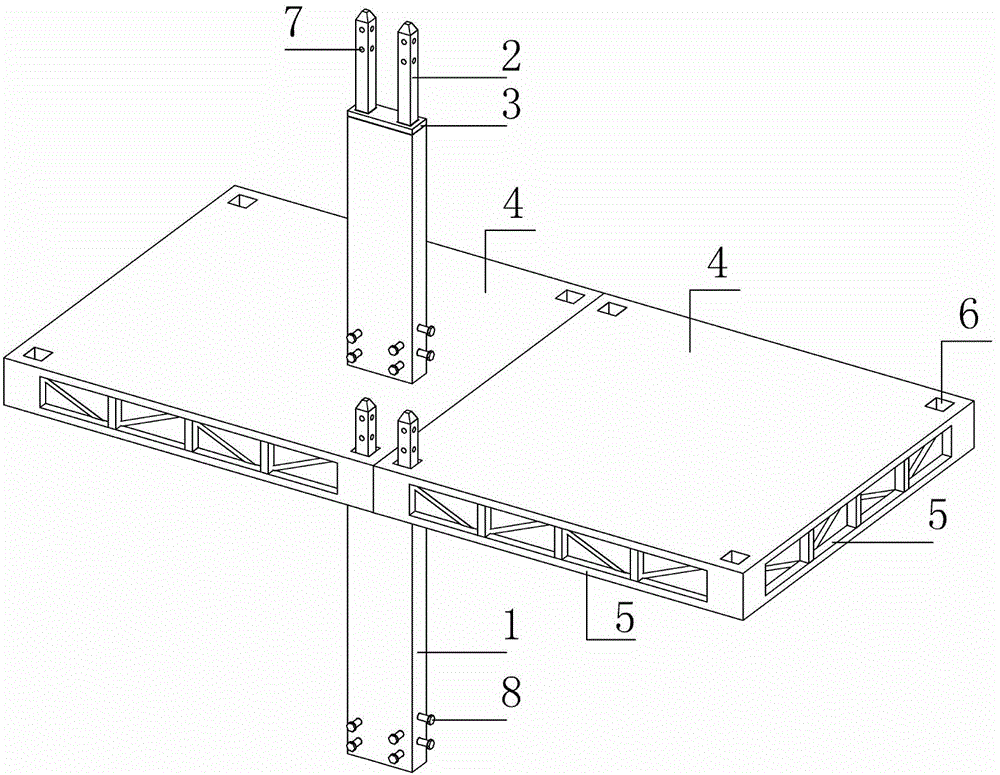

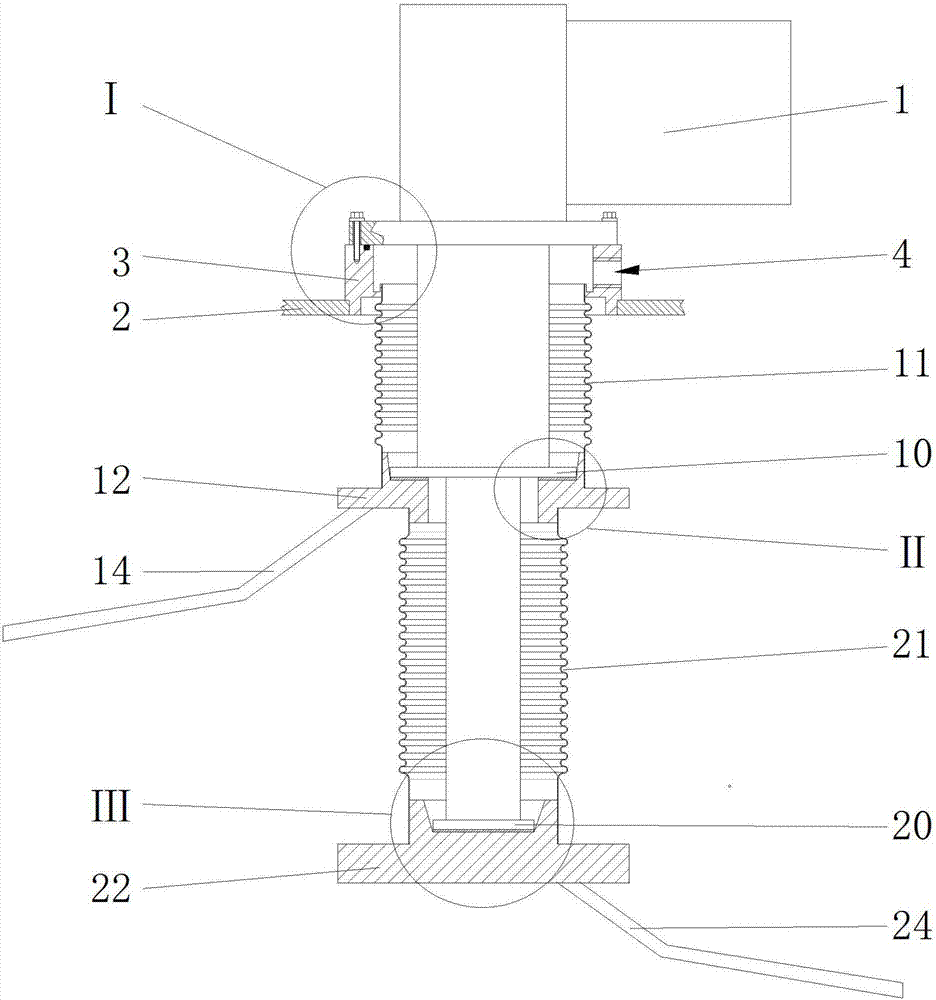

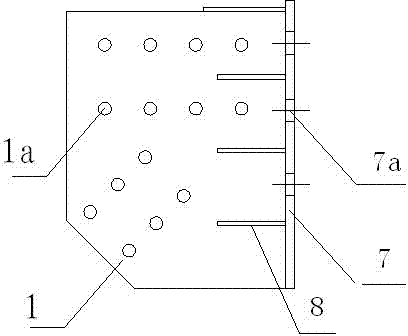

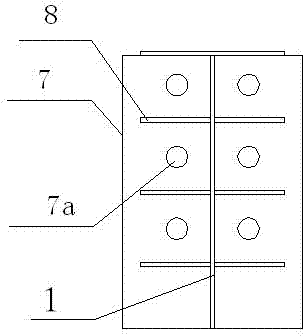

Precise positioning frame for large steel columns and equipment foundation fixing bolts and construction method of precise positioning frame

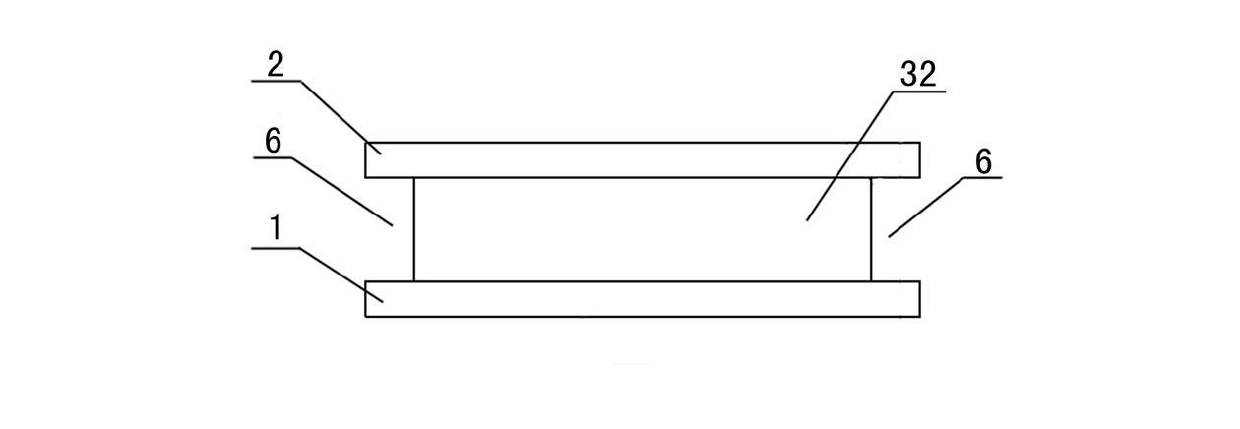

InactiveCN102561712AEasy to installGuaranteed installation accuracyFoundation engineeringBuilding material handlingBraced frameSteel columns

The invention discloses a precise positioning frame for large steel columns and equipment foundation fixing bolts and a construction method of the precise positioning frame. The precise positioning frame comprises a supporting frame for placing the fixing bolts; a profile steel bracket is surrounded at the outer side of the supporting frame; the profile steel bracket comprises vertical rods, connecting rods, a profile steel bracket top frame and a positioning sleeve frame placing platform, wherein the vertical rods are distributed at intervals, each connecting rod is connected between every two adjacent vertical rods, the profile steel bracket top frame is detachably connected between upper end parts of the vertical rods through a connecting bolt, and the positioning sleeve frame placing platform is connected on the profile steel bracket top frame; the fixing bolt positioning sleeve frame is laid on the positioning sleeve frame placing platform; and a positioning hole is arranged on the fixing bolt positioning sleeve frame. The positioning frame ensures that large steel structure column bolts or large equipment foundation fixing bolts are more precise to install, the defect that bolts can be adjusted and fixed only before concrete is cast and cannot be precisely adjusted during the casting of concrete in the traditional process is avoided, moreover, the positioning frame can be partly turned over to be operated, so that the construction cost is saved, and the construction progress is accelerated.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

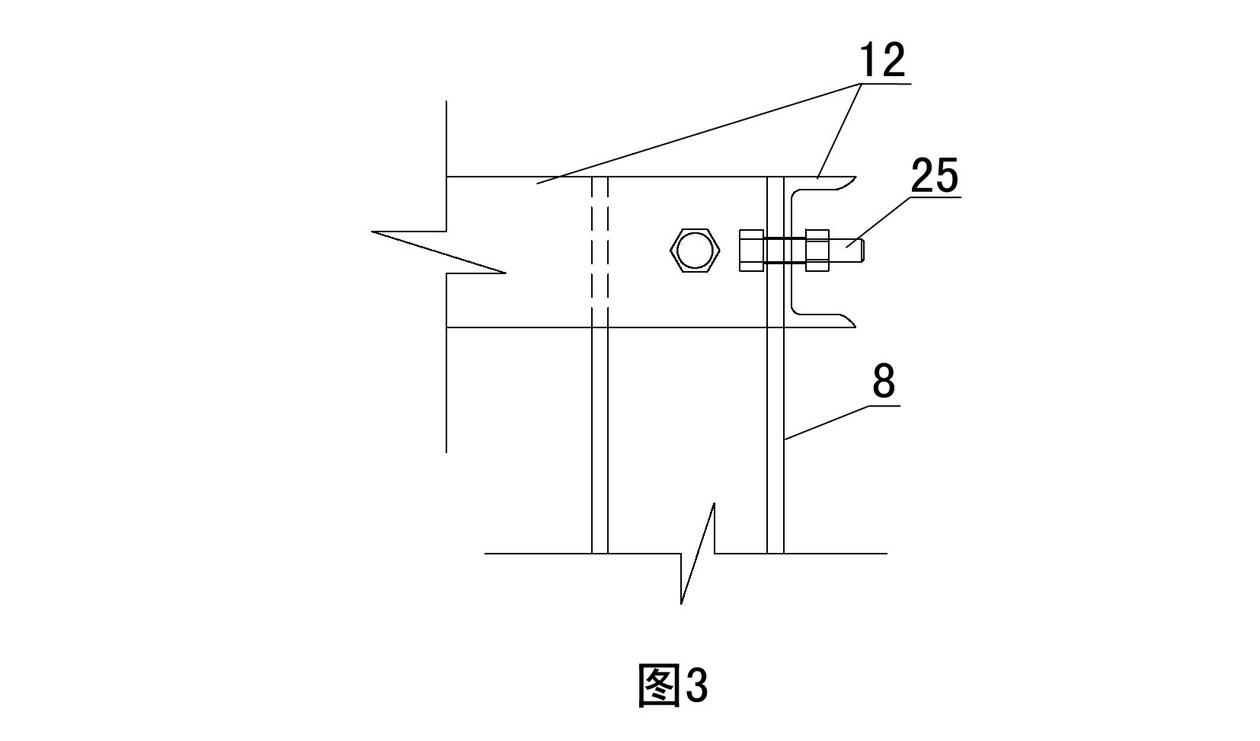

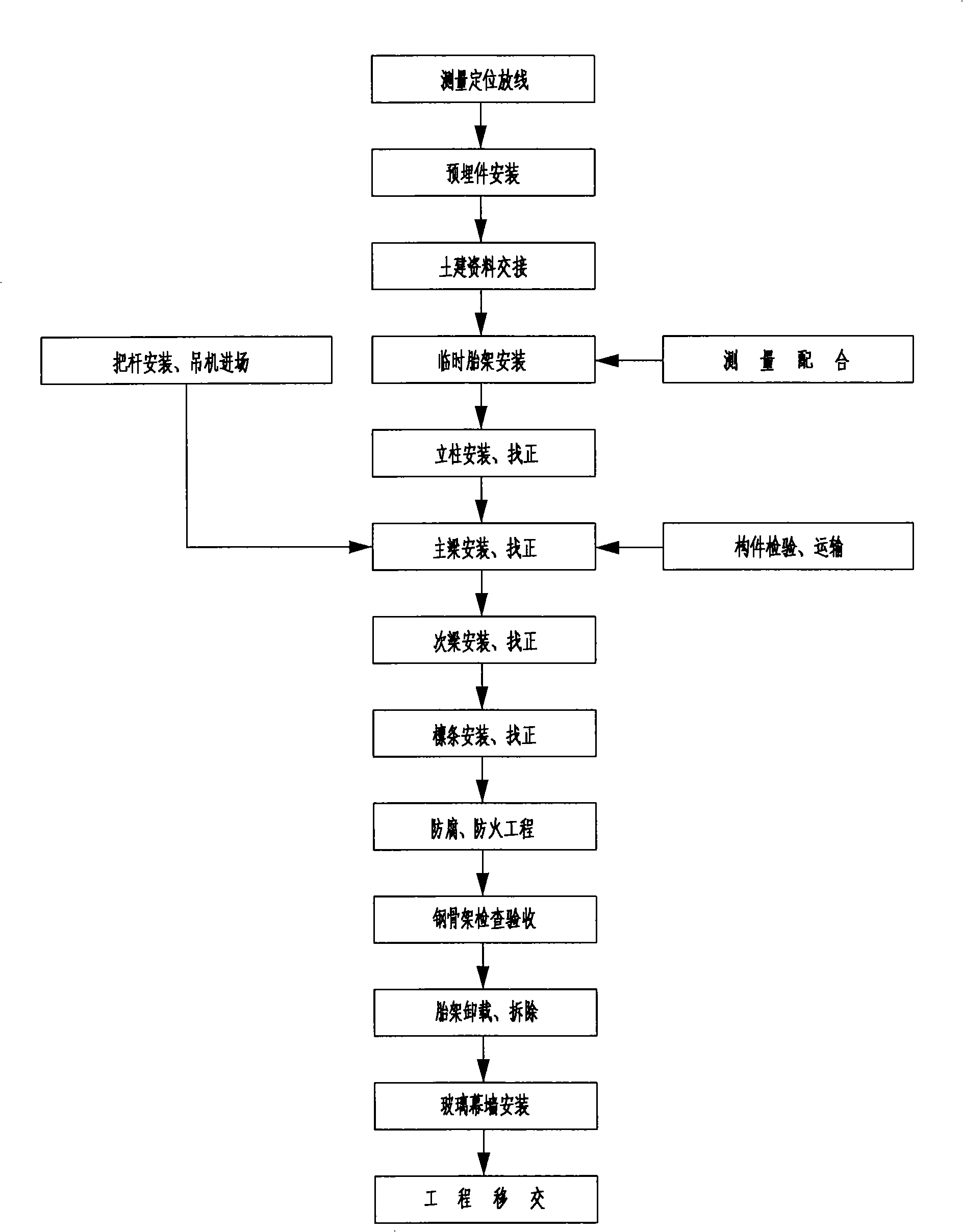

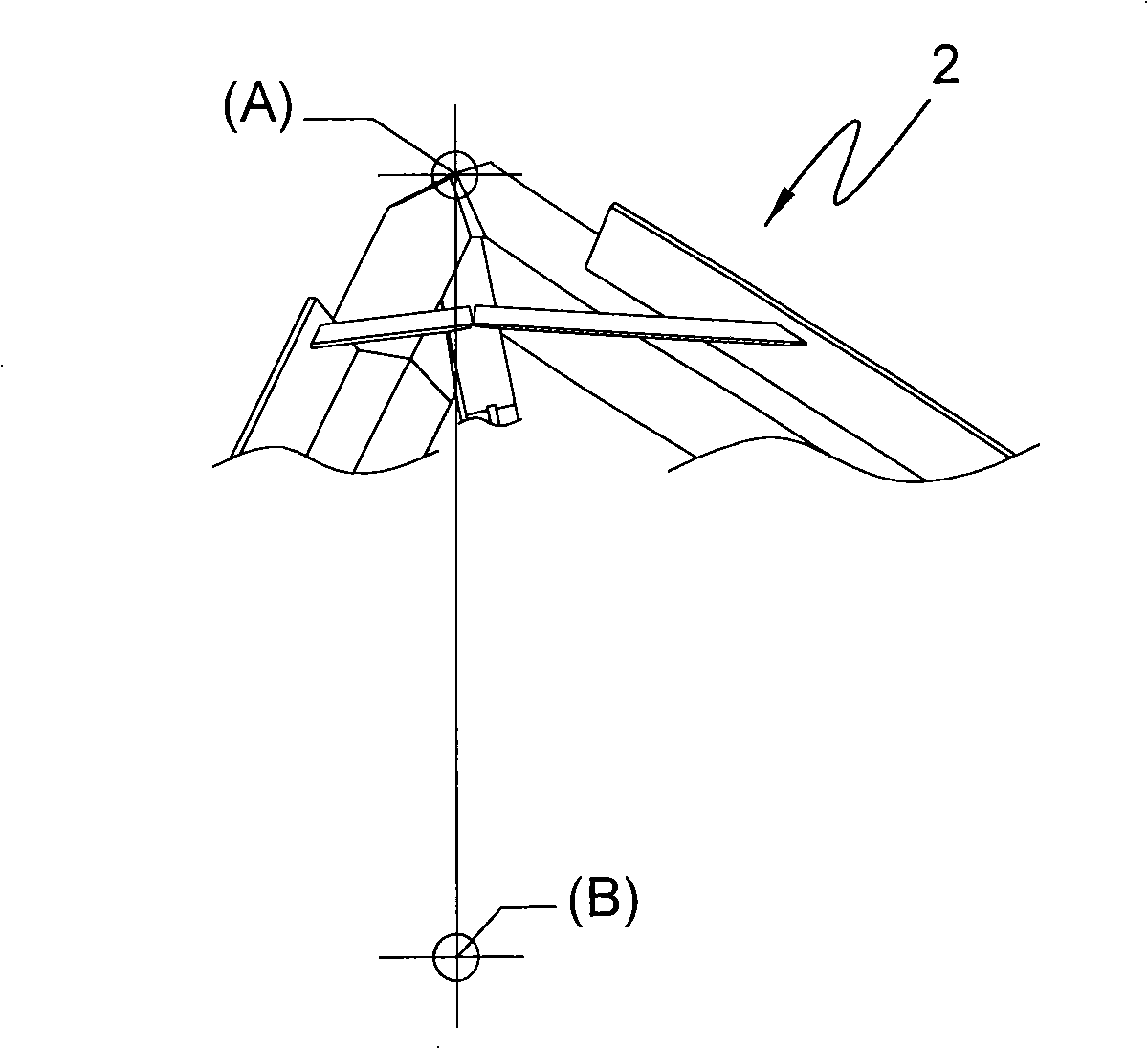

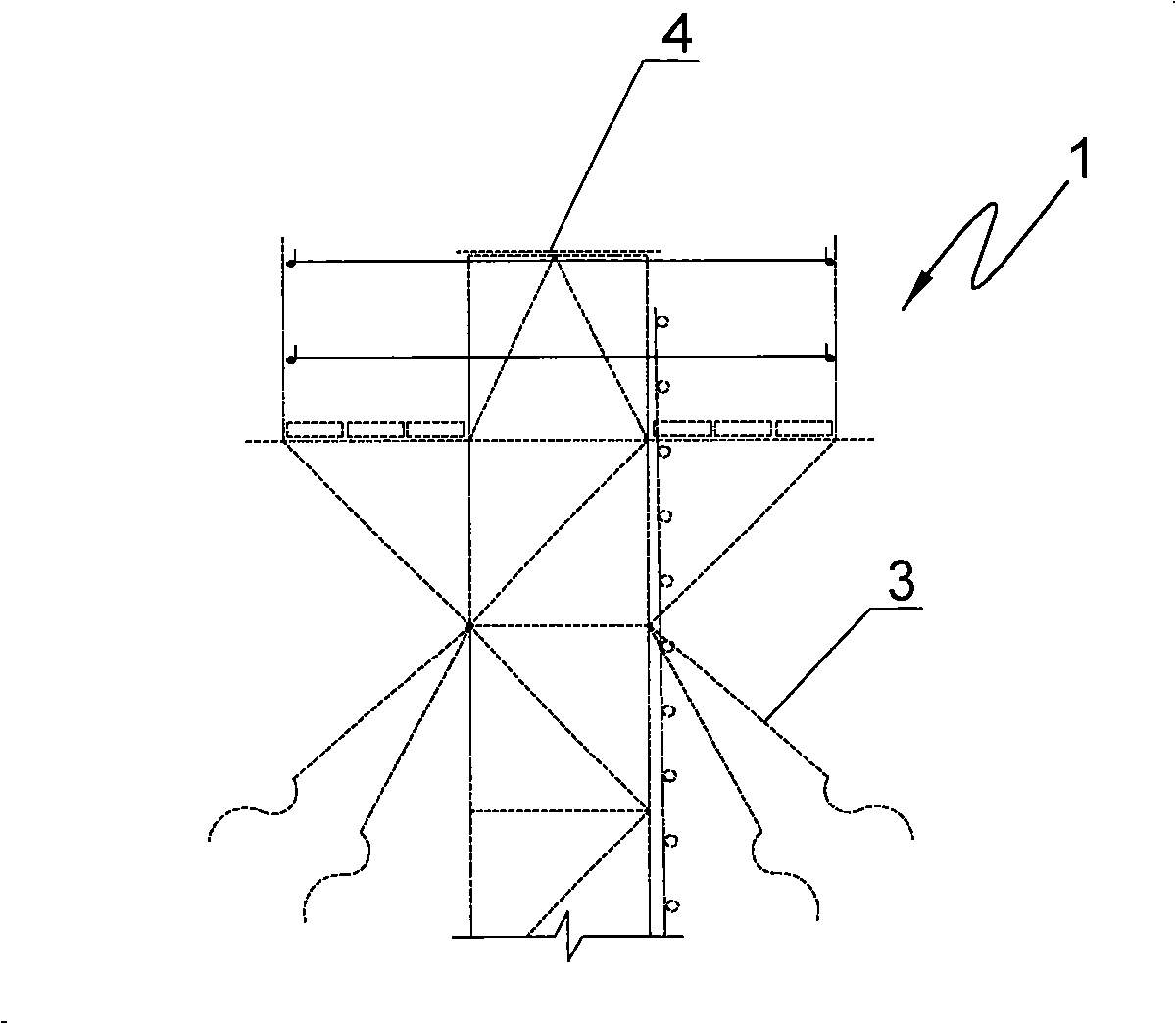

Steel structure high altitude mounting method

InactiveCN101328746AGuaranteed manufacturing accuracyAccurate modelingBuilding roofsBuilding material handlingEngineeringWelding

The invention provides a method for installing an overhead steel structure high, which belongs to a method for constructing a fixed structure. The prior installation method has defects that precise positioning is hard to realize and installation precision is hard to guarantee. The method comprises the following steps of: accurately modeling and correctly lofting and cutting, correctly paying off and accurately positioning; installing embedded parts, a temporary assembly jig and an upright post according to the paying-off position; positioning and fixing a joint on the temporary assembly jig; orderly lifting a main girder, a secondary girder and a purline; and unloading and dismounting the temporary assembly jig. The method is easy to guarantee manufacture precision of each component and installation precisions of the embedded parts, the temporary assembly jig, and the joint; the on-site lofting and cutting is unnecessary to undergo, and the on-site lifting and connection (welding) of each component are convenient.

Owner:ZHEJIANG ZHANCHENG CONSTR GROUP

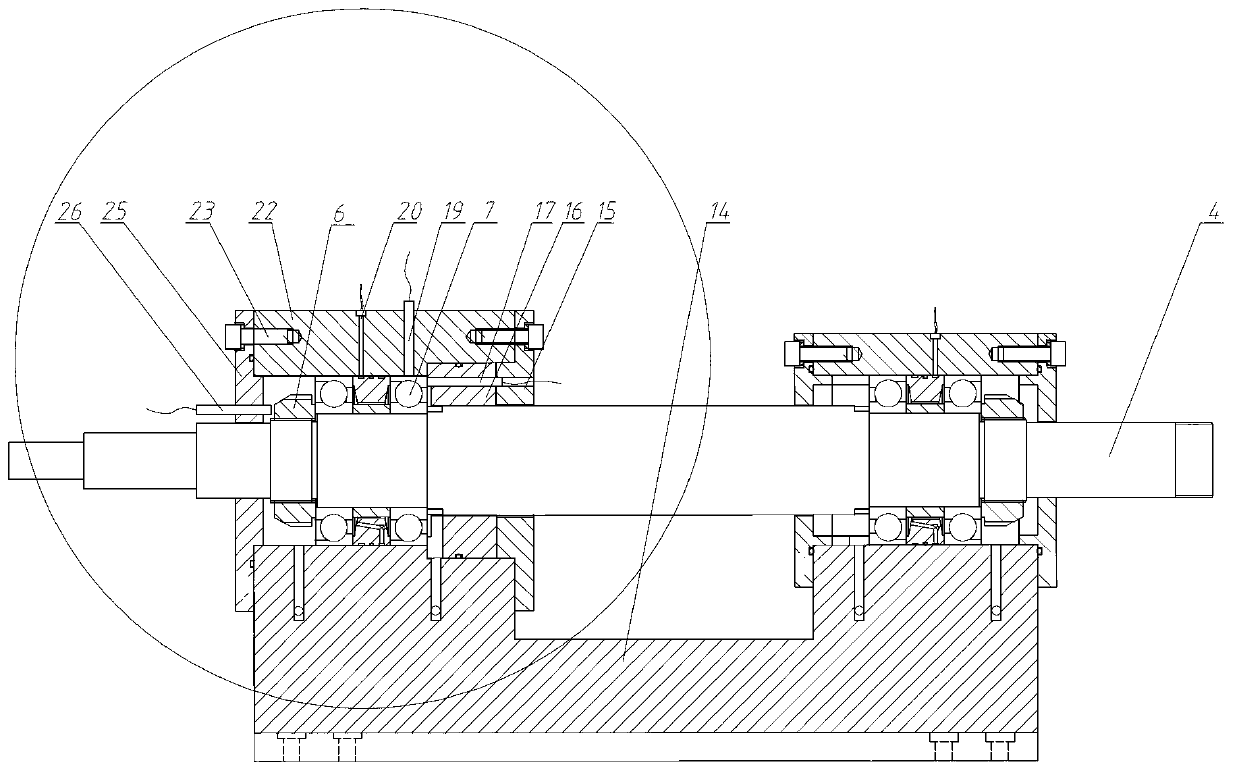

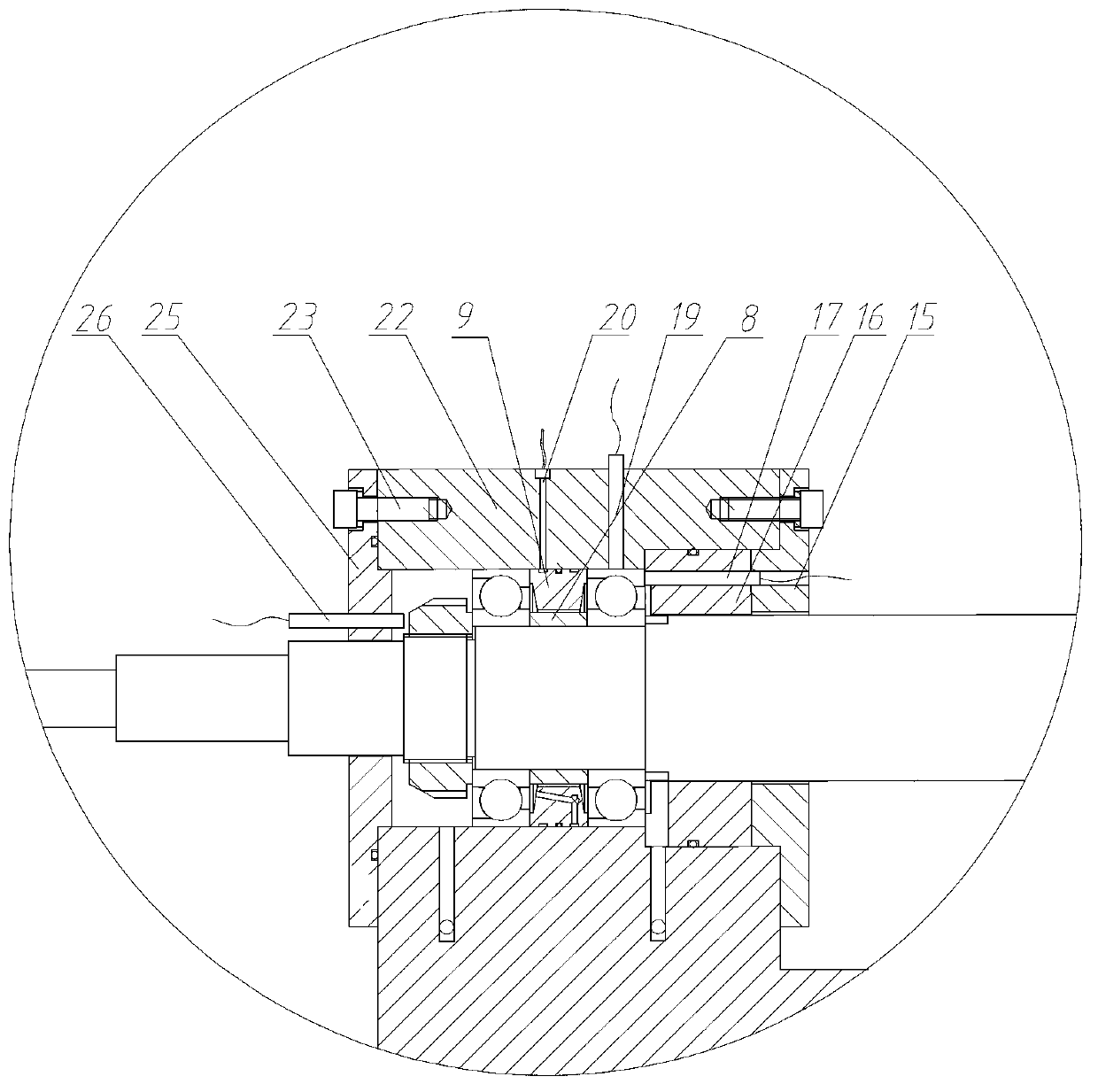

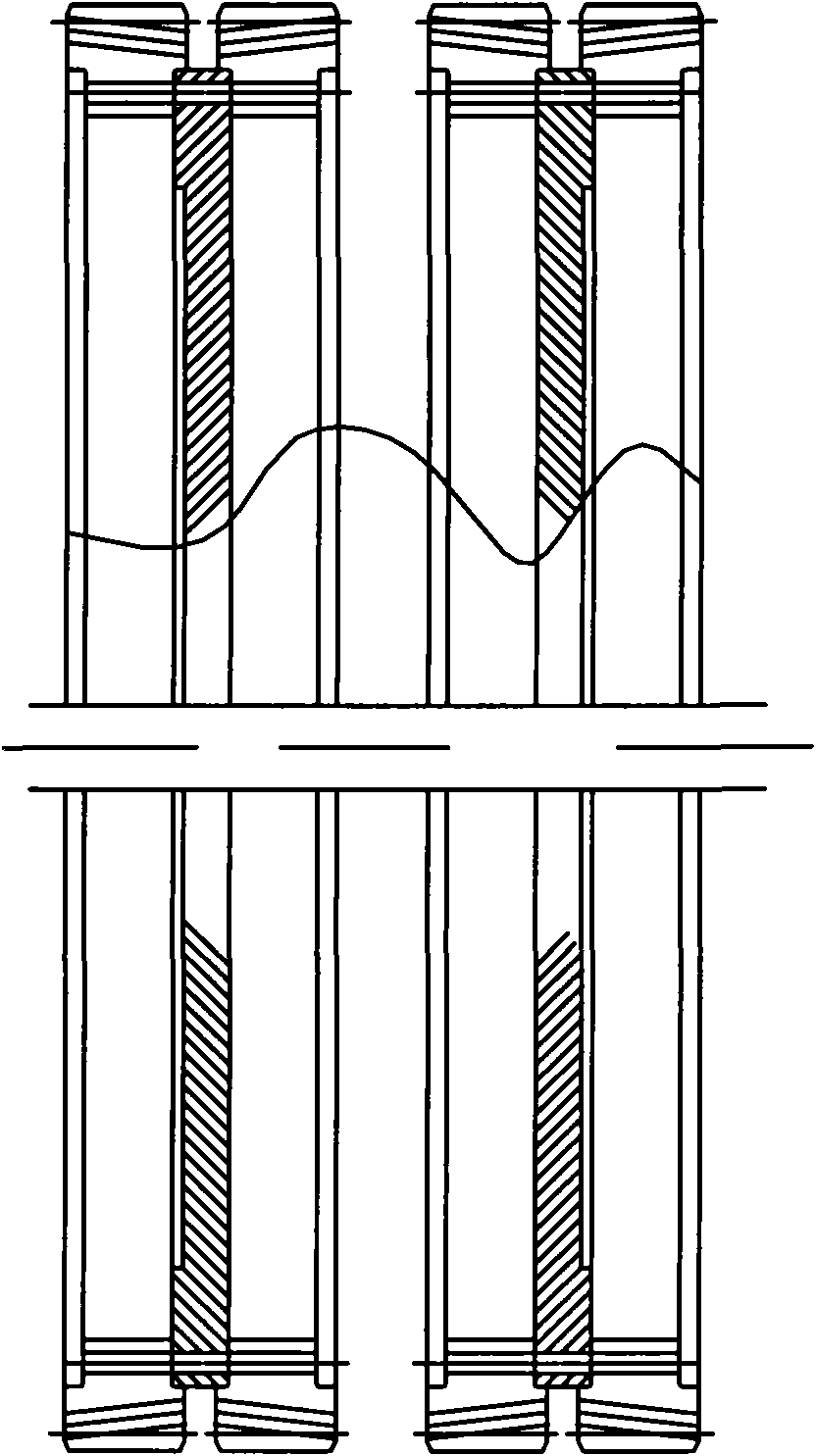

Strong-generality comprehensive experiment table for testing dynamic and static properties of spindle system

InactiveCN102866006ARealize the experimentVerify service performanceMachine bearings testingBall bearingPiezoelectric actuators

The invention discloses a strong-generality comprehensive experiment table for testing dynamic and static properties of a spindle system. The experiment table mainly comprises a driving electric spindle module, a mechanical spindle module and a hydraulic loading module, wherein the mechanical spindle module comprises a spindle, a bearing, a bearing pedestal, a pre-tightening force self-adaptive adjustment device, a temperature sensor, a displacement sensor, a pressure sensor and an air-oil lubrication device. The pre-tightening force self-adaptive adjustment is completed by six evenly distributed piezoelectric actuators, so as to realize the accurate control of the pre-tightening force of an angular contact ball bearing in the spindle system. According to the experiment table, different bearing configuration manners and different lubrication manners can be used, so that the properties of the experiment table are greatly expanded. Through controlling the rotation speed of an electric spindle, property test data such as temperature rise, rigidity and the like of the spindle under different configuration and pre-tightening conditions can be obtained by using the temperature sensor, the displacement sensor and the pressure sensor.

Owner:XI AN JIAOTONG UNIV

High precision welding method for rudder horn, propeller shaft bracket and intermediate shaft bracket of long shaft ship

InactiveCN102059461AImprove construction conditionsGuaranteed installation accuracyVessel partsWelding apparatusPropellerControl theory

The invention discloses a high precision welding method for a rudder horn, a propeller shaft bracket and an intermediate shaft bracket of a long shaft ship, belonging to the field of ship welding. In the high precision welding method, a shaft center line of the ship is firstly pulled out according to design requirements when the ship is assembled and installed; after the shaft center line is examined, the following three steps are synchronously carried out: firstly, welding of the rudder horn; secondly, the welding of the propeller shaft bracket; and thirdly, the welding of the intermediate shaft bracket. Compared with the prior art, because installation phases of the propeller shaft bracket and the intermediate shaft bracket are advanced to the assembling phase, the construction condition is improved, and the installation precision is ensured; and because the complete cross section of a ship body is horizontally assembled (the complete cross section is the propeller shaft bracket which is reversely placed, and the intermediate shaft bracket is over the intermediate shaft bracket), the installation position can be adjusted by fully utilizing a crane when the ship body is installed, the working efficiency is improved, and the utilization time of a dock is greatly reduced.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

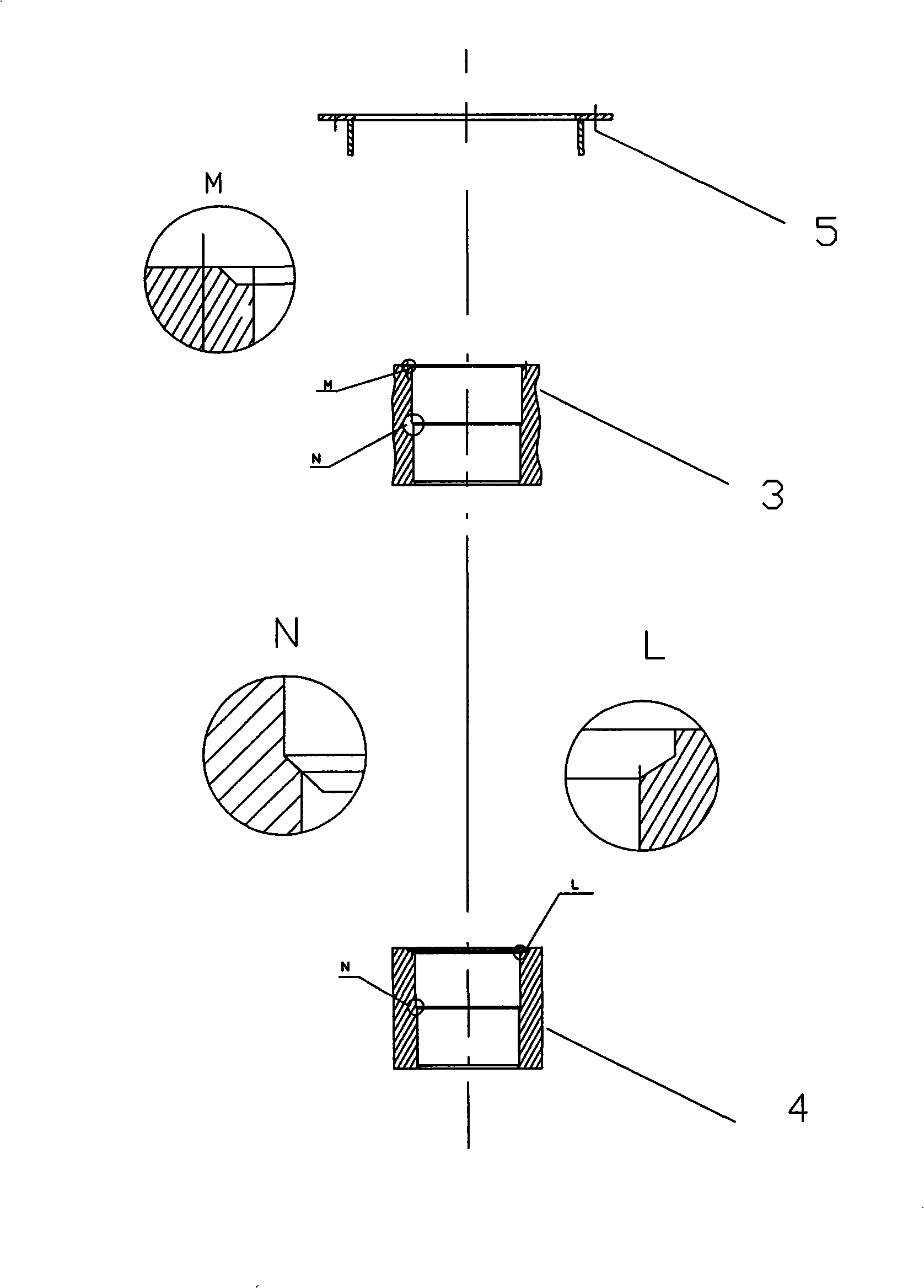

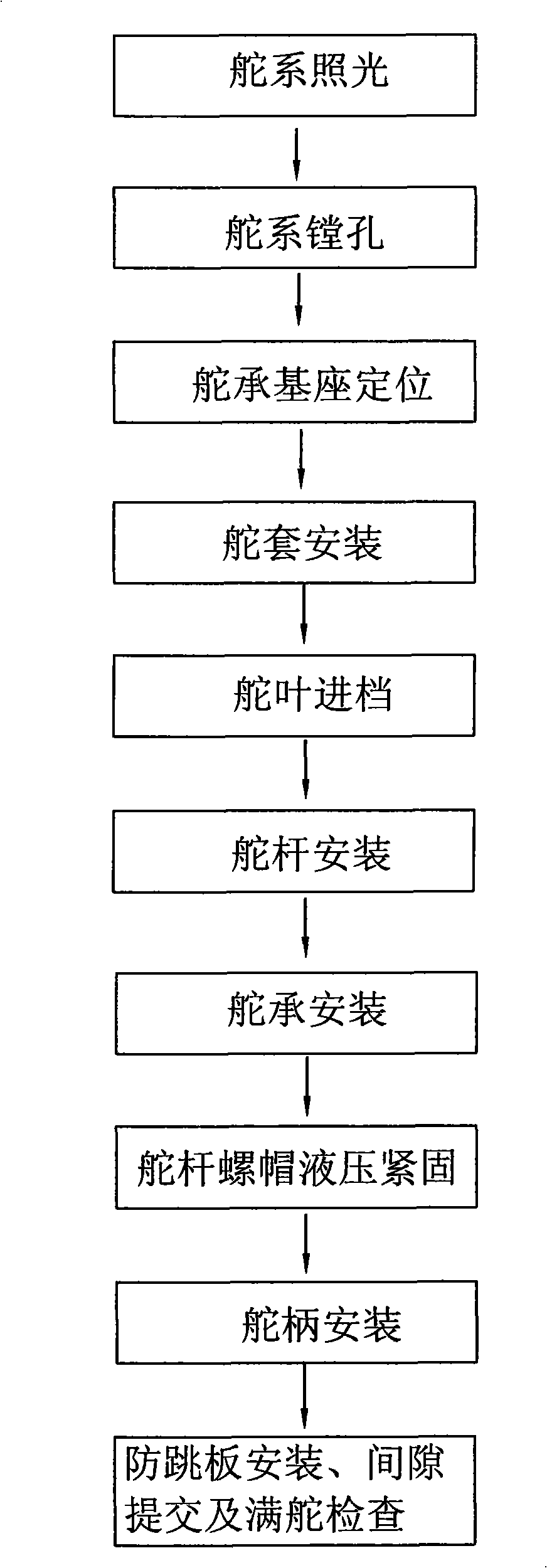

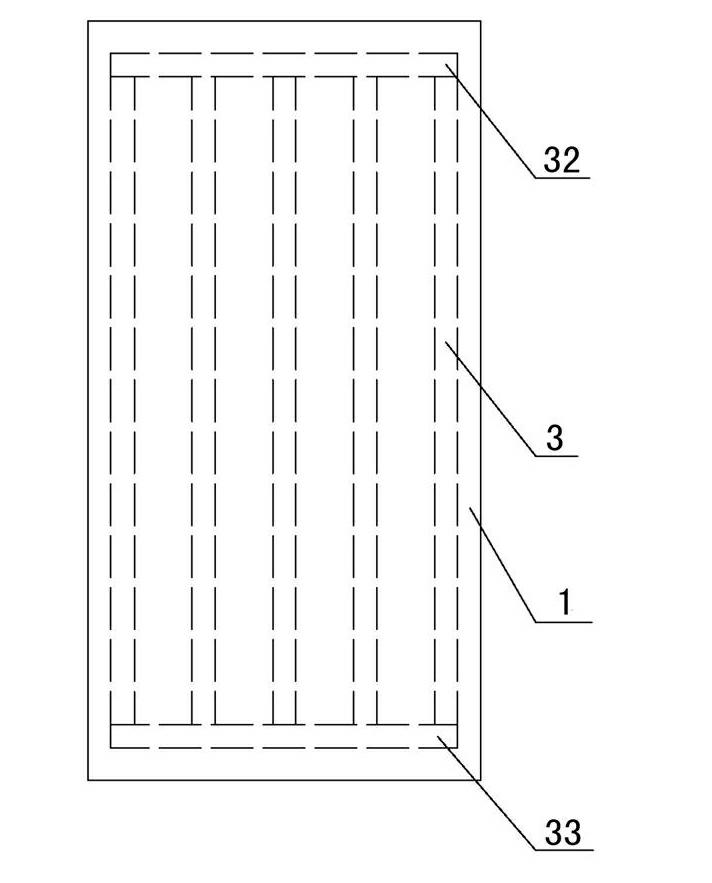

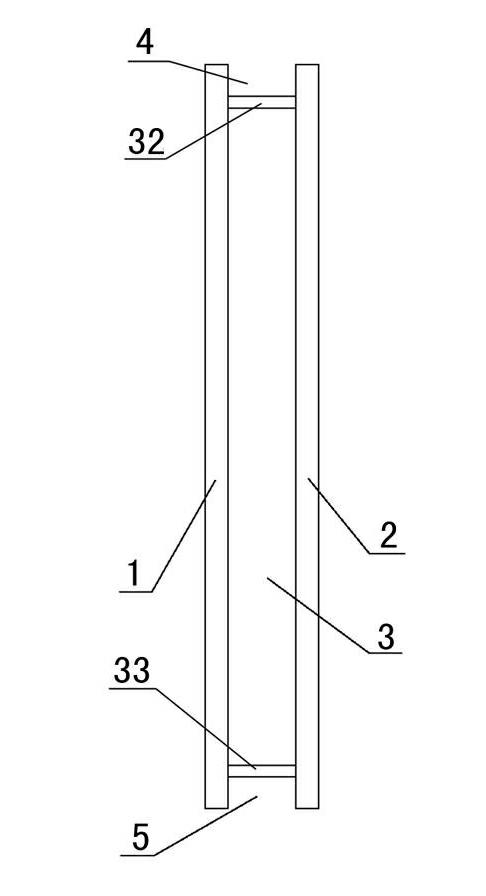

Shipping rudder system lighting and mounting method

ActiveCN101323351AGuaranteed design sizeGuaranteed installation accuracyVessel partsMaterial resourcesIrradiation

The invention relates to an irradiation and installation method of a ship rudder system, which comprises the following steps: (1)the irradiation of a rubber system; (2)the borings of the rubber system; (3) the location of a rubber bearing base; (4)the installation of a rubber set; (5)the clutchless-shifting of rudder blades; (6)the installation of a rubber stock; (7)the installation of a rubber bearing; (8) the hydraulic fastening of a rubber stock screw cap; (9)the installation of a rubber handle; (10)the installation of the anti-skip block of the rubber blades, gap submission and examination of a full rubber. By using the method of the invention, construction must be fulfilled according to maps at the construction field of the ship building to guarantee the precision of the installation and avoids the waste of human and material resources caused by the installation failure of related components of the rubber system.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Two-storey modular villa building and construction method thereof

ActiveCN102587693ASimple installation and constructionNo pollution in constructionBuilding material handlingDwelling buildingSeismic resistanceGable

Disclosed is a two-storey modular villa building and a construction method thereof. The villa building comprises a foundation, structural upright columns, a gable wall, longitudinal walls, floors and a roof. The structural upright columns are connected with the foundation, the gable wall and the longitudinal walls are connected with the structural upright columns, the floors and the roof are connected with the gable wall and the longitudinal walls, the gable wall comprises a first-storey gable wall and a second-storey gable wall, modular square plate walls are pieced together to form the first-storey gable wall, modular square plate walls and modular triangular plate walls are pieced together to form the second-storey gable wall, each longitudinal wall comprises a first-storey longitudinal wall and a second-storey longitudinal wall, modular square plate walls are pieced together to form the first-storey longitudinal walls and the second-storey longitudinal walls, each modular square plate wall comprises a square external inorganic plate, a square internal inorganic plate and vertical inorganic plate strips parallelly distributed between the square external inorganic plate and the square internal inorganic plate. The modular square plate walls are pieced together to form the first-storey walls and the second storey walls of the villa building, the first-storey walls and the second-storey walls are connected with the floors, so that a firm integral frame is formed and has quite high seismic resistance, and the integral weight of the villa building is greatly reduced.

Owner:沈汉杰

Method for manufacturing superlarge spherical seal head

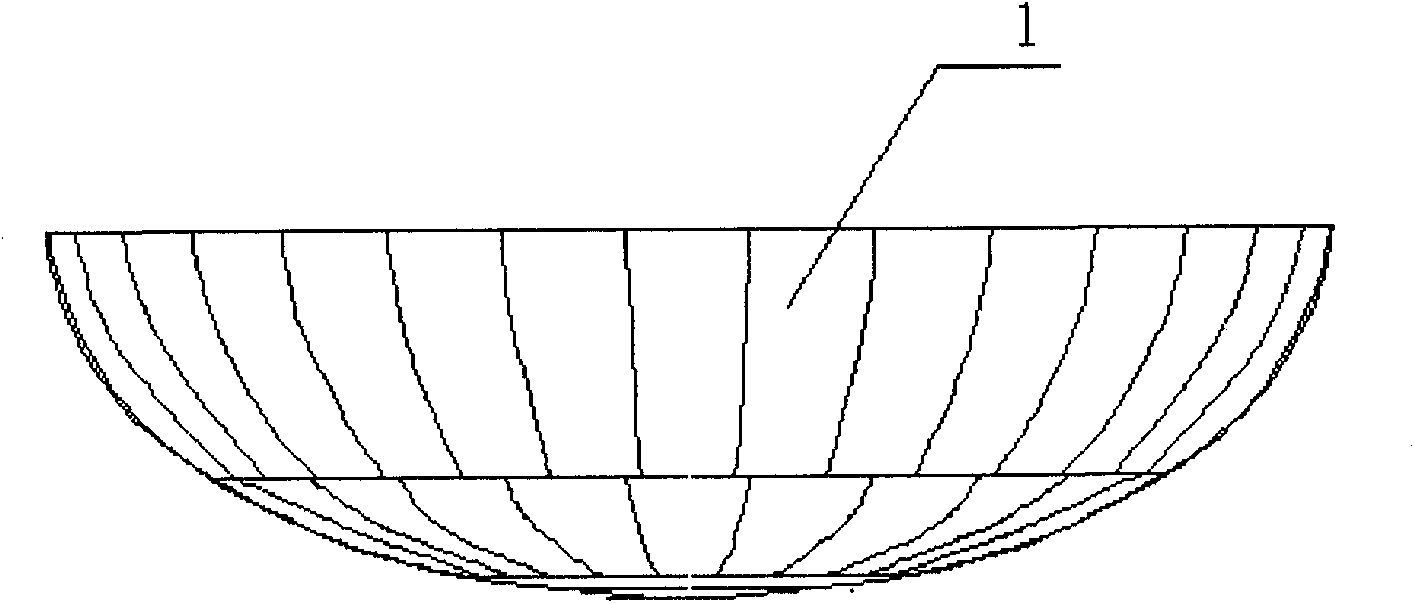

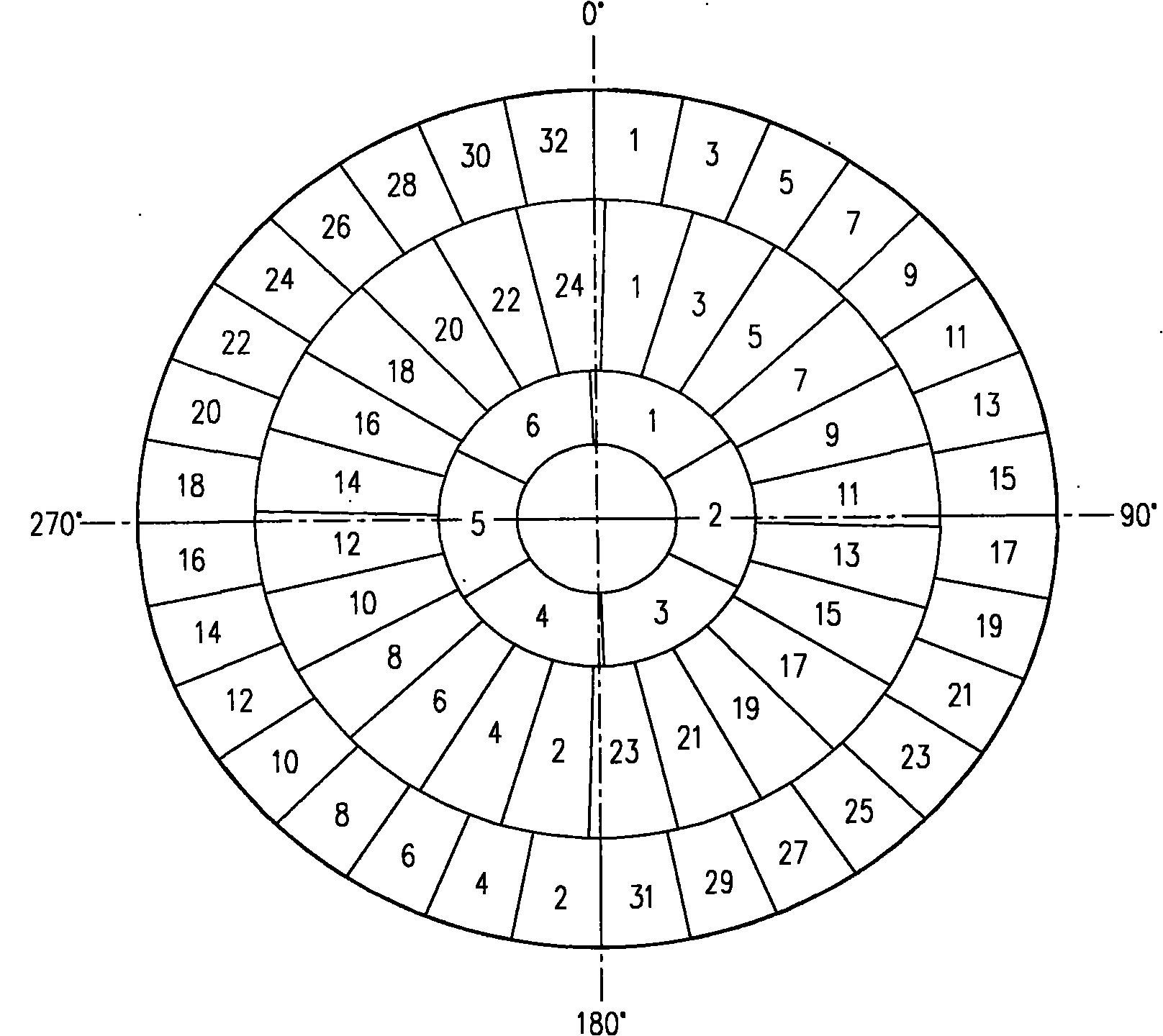

ActiveCN101829856ARealize formingUniform deformationNuclear energy generationContainmentSheet steelEngineering

The invention provides a method for manufacturing a superlarge spherical seal head, which comprises the steps of: providing a first group of steel plates to form a first ring part of a spherical seal head, wherein the closed end of the spherical seal head is formed by the first ring part; providing at least one group of steel plates to form at least one middle ring part of the spherical seal head; and providing the last group of steel plates to form an outmost ring part of the spherical seal head, wherein the open end of the spherical seal head is formed by the outmost ring part. Corresponding steel plates of adjacent groups and adjacent steel plates of each group of steel plates are finally interconnected through welding. A sectional forming method is applied to the spherical seal head, the seal head is formed step by step through deformation of each area, and larger deformation is dispersed and localized, therefore, the deformation of each area can be even to effectively avoid defects, such as crinkles and the like.

Owner:CHINA NUCLEAR IND 23 CONSTR

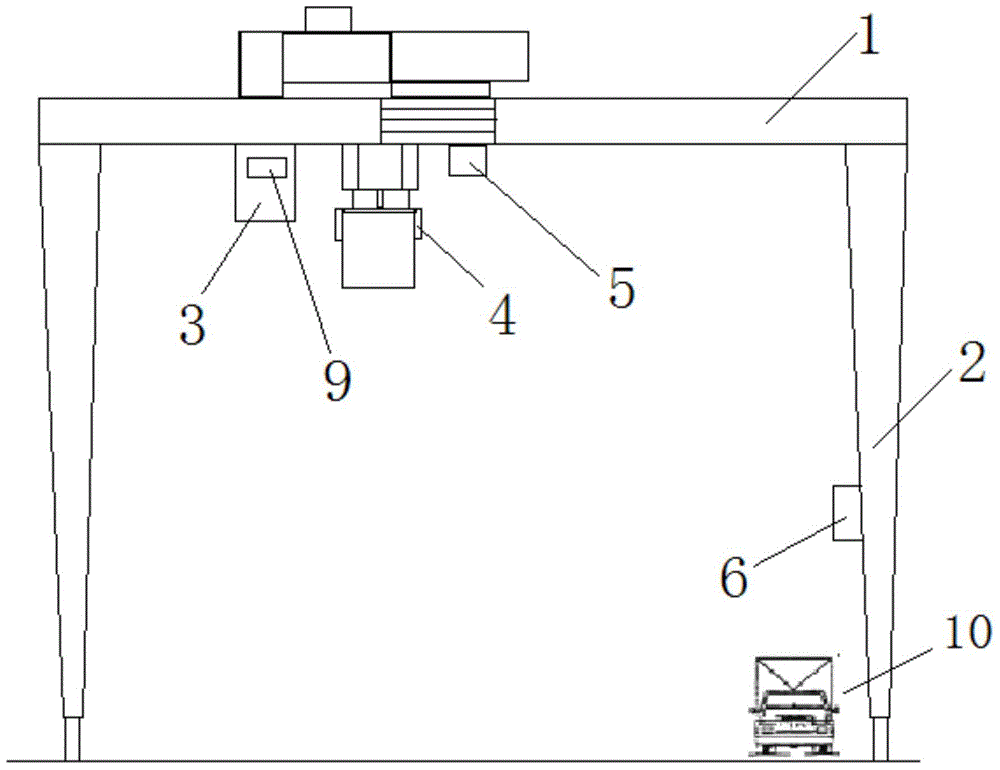

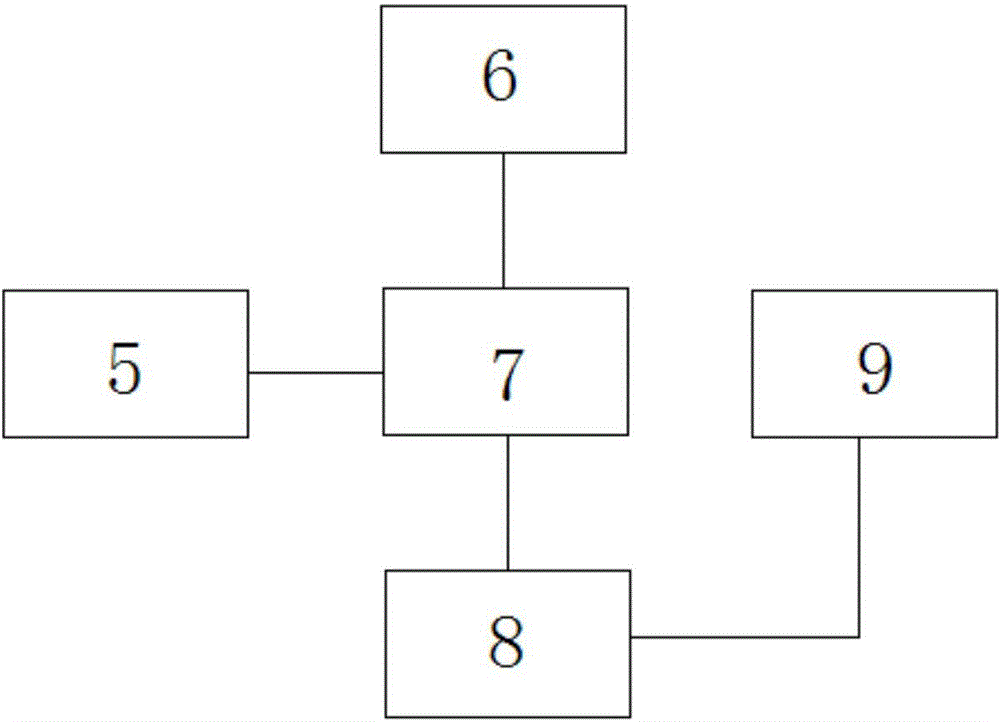

Container wharf RTG and RMG lower container truck alignment guide system and method

The invention discloses a container wharf RTG and RMG lower container truck alignment guide system and method. A laser scanning rangefinder, an LED display screen, a loudspeaker, a high-speed embedded controller and other components are adopted, and automatic precise guide of alignment of an RTG / RMG lower container truck is achieved. The high-speed embedded controller carries out conversion, calculation and contour recognition on measured data obtained through two-dimensional scanning on a container truck frame or a container on the frame through the laser scanning rangefinder in the direction parallel to the central line of a container lane, the position of the container truck and the deviation distance between the container truck and the benchmark hoisting point of a gantry crane are accordingly judged, meanwhile, the hoisting direction and distance information of the container truck deviating the hoisting point are displayed on the LED display screen, and a driver of the container truck is prompted to adjust the parking position of the container truck in advance.

Owner:CATHAY NEBULA SCI & TECH CO LTD

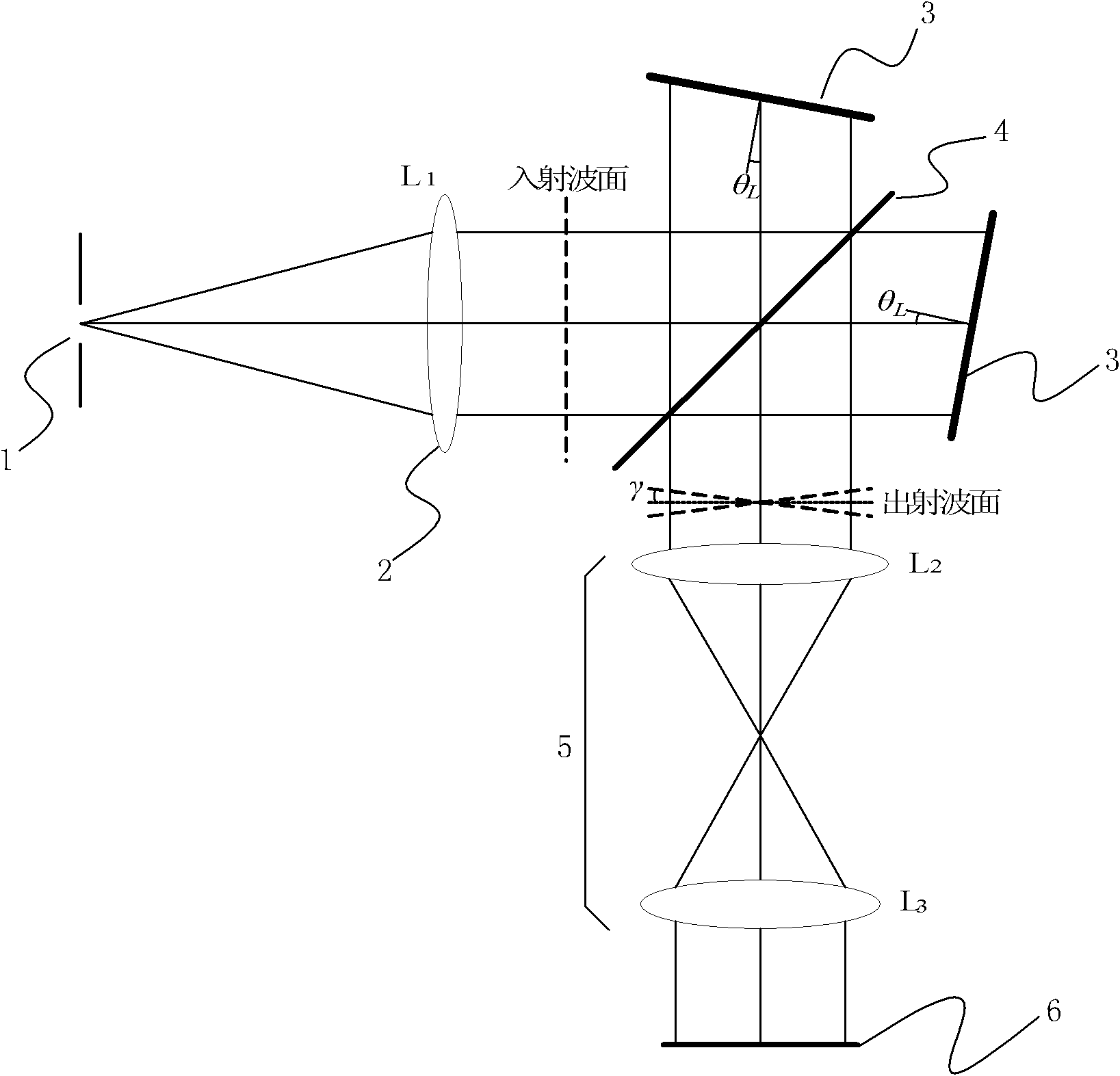

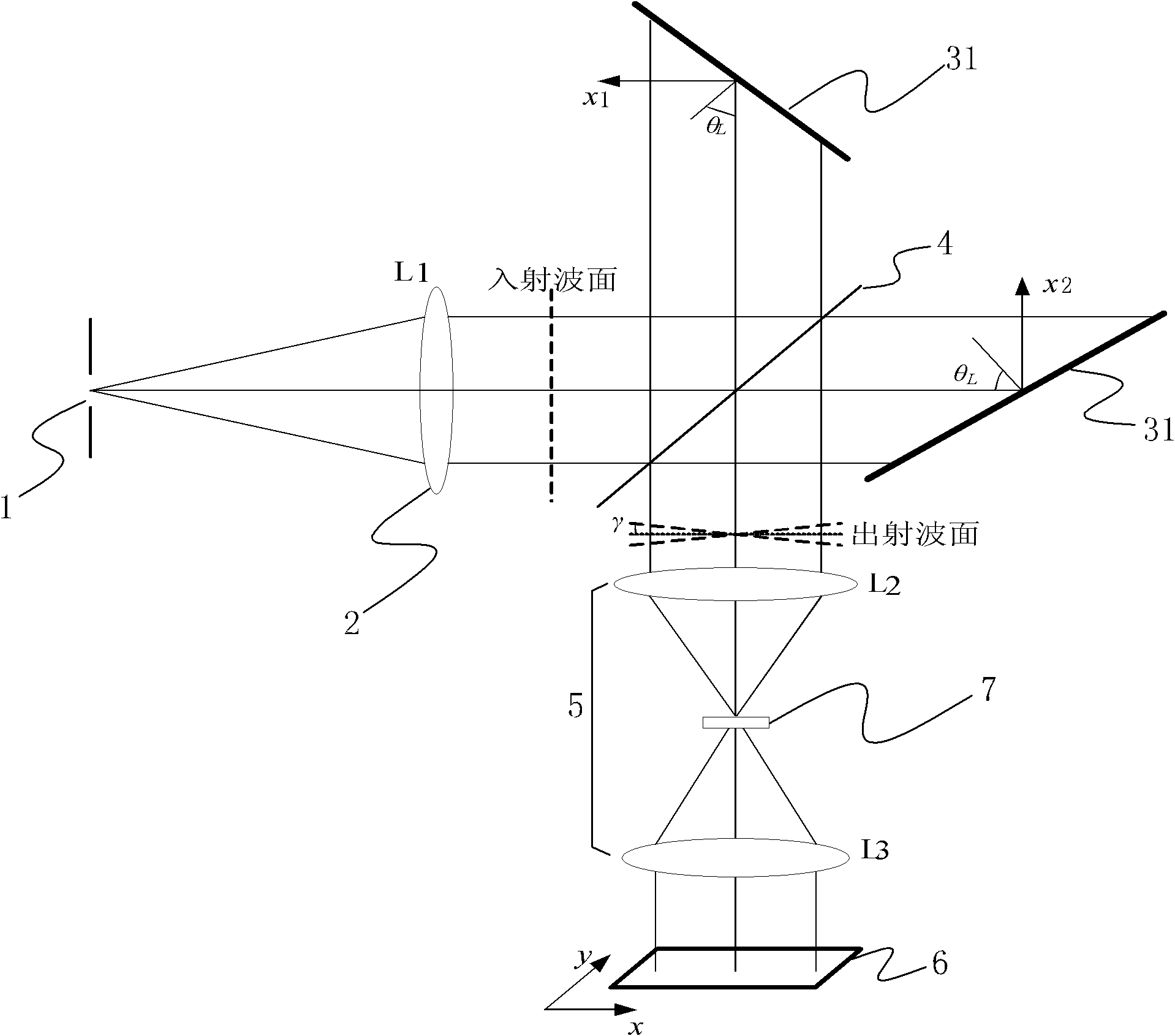

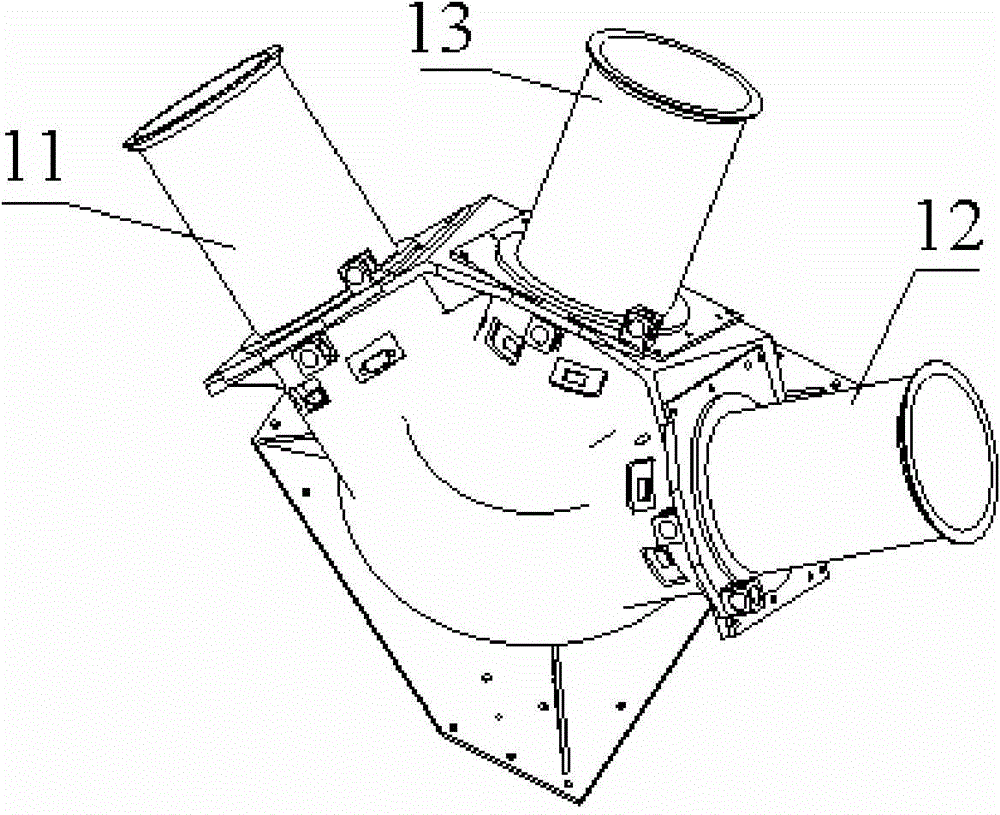

Wide-spectrum spatial heterodyne spectrometer

ActiveCN102052968AOvercome the defect of very narrow spectrumGuaranteed installation accuracyInterferometric spectrometryGratingBeam splitting

The invention discloses a wide-spectrum spatial heterodyne spectrometer, which overcomes the defect that the conventional spatial heterodyne spectrometer has a narrow spectrum in the prior art. A blazed grating component consists of a first echelle grating and a second echelle grating which are respectively positioned on a reflection light path and a transmission light path formed by a beam splitting element for the first time; an angle relationship and a position relationship between the two echelle gratings are that: (1) a reflection beam and a transmission beam which are split by the beam splitting element for the first time are transmitted to the two echelle gratings at a Littrow angle; and (2) by taking the conventional position relationship between the blazed grating component and the beam splitting element as the standard, the first echelle grating rotates alpha / 4 degrees around a first rotating shaft, and the second echelle grating rotates -alpha / 4 degrees around a second rotating shaft; and a controllable optical shutter serving as a hierarchy selection mask is arranged at a superposed position of focal planes of a fringe imaging system. The wide-spectrum spatial heterodyne spectrometer has the advantages of high stability, high spectral resolution and wide-spectrum coverage, and is very suitable for satellite-borne spatial environment remote sensing and atmospheric sounding.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

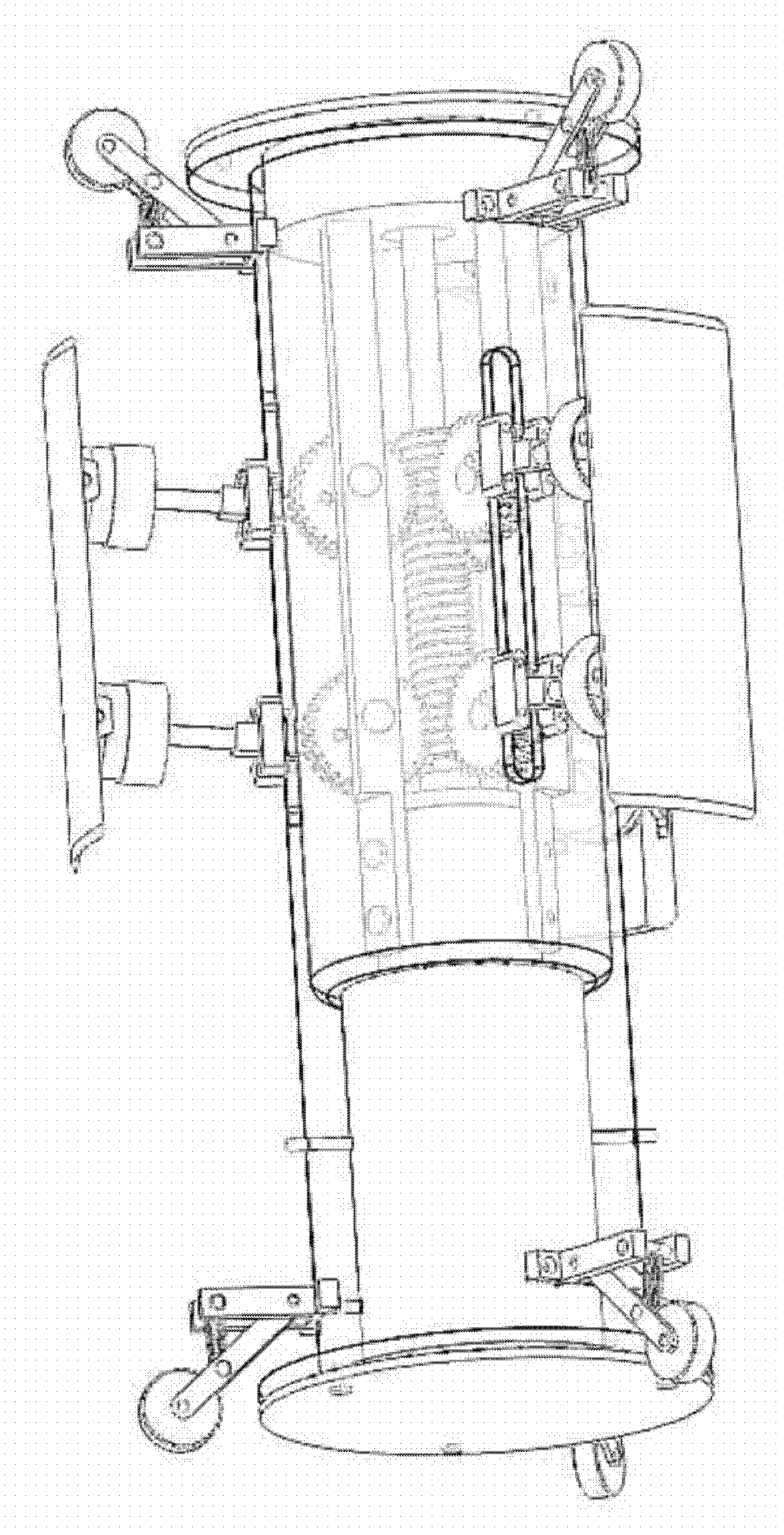

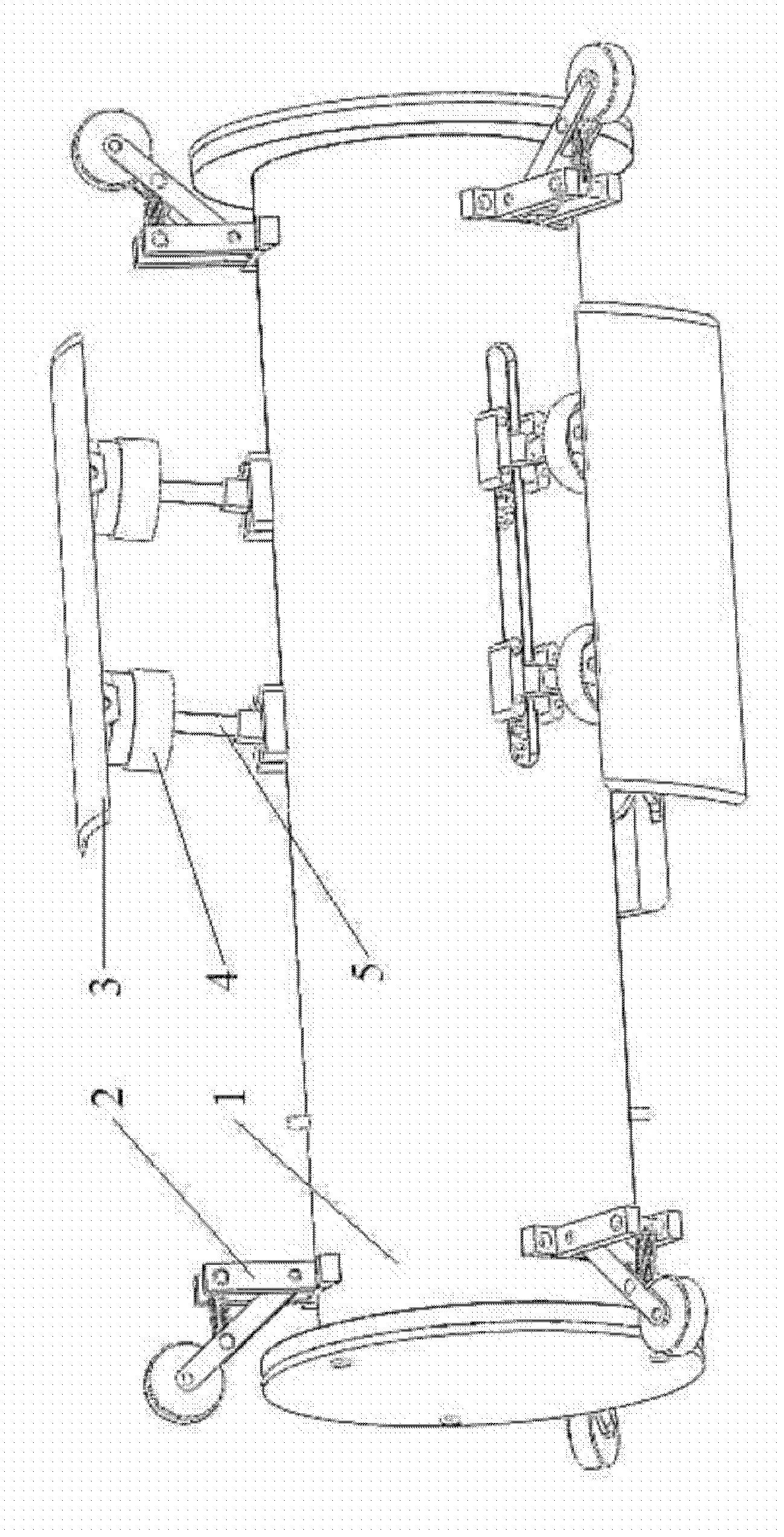

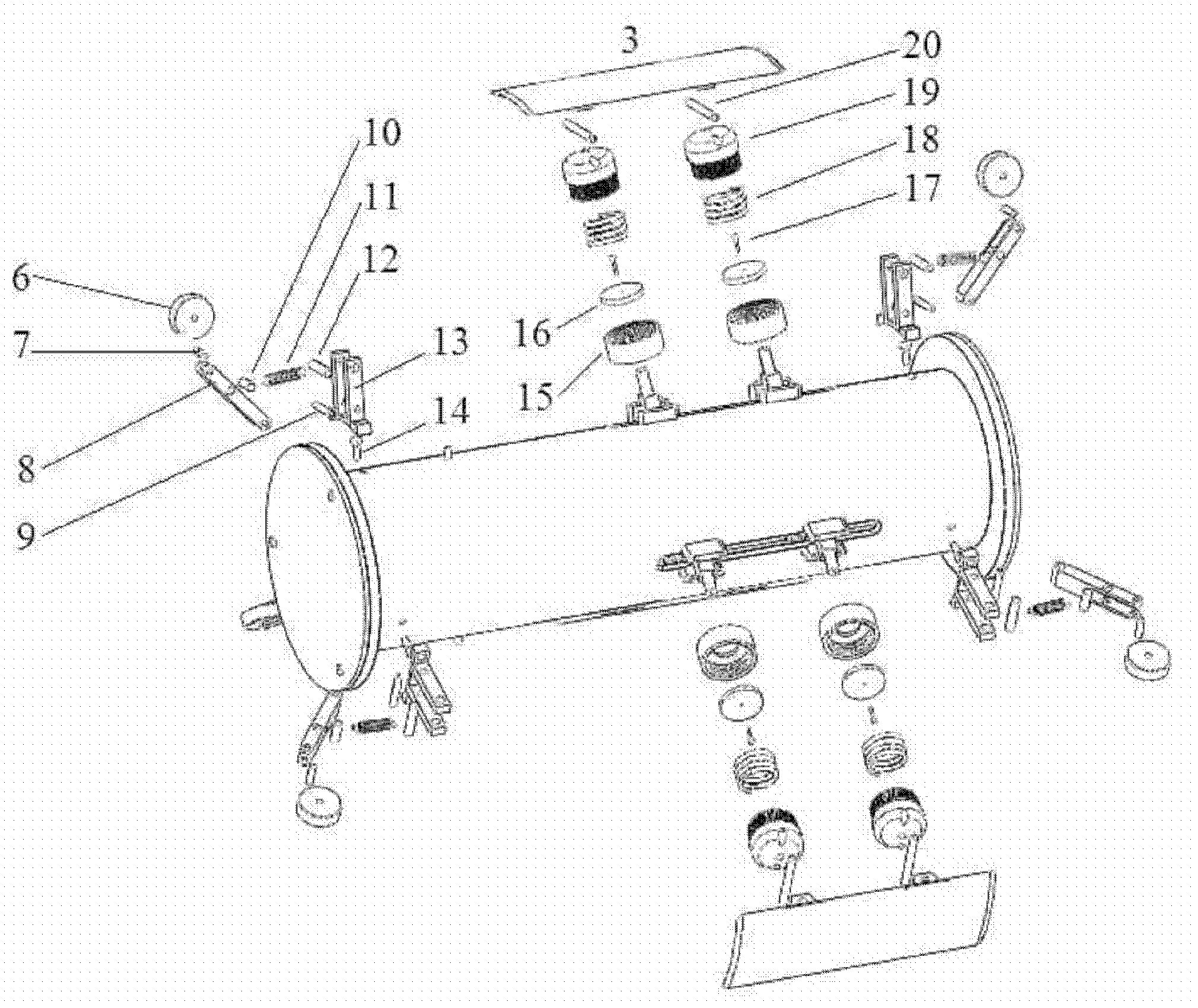

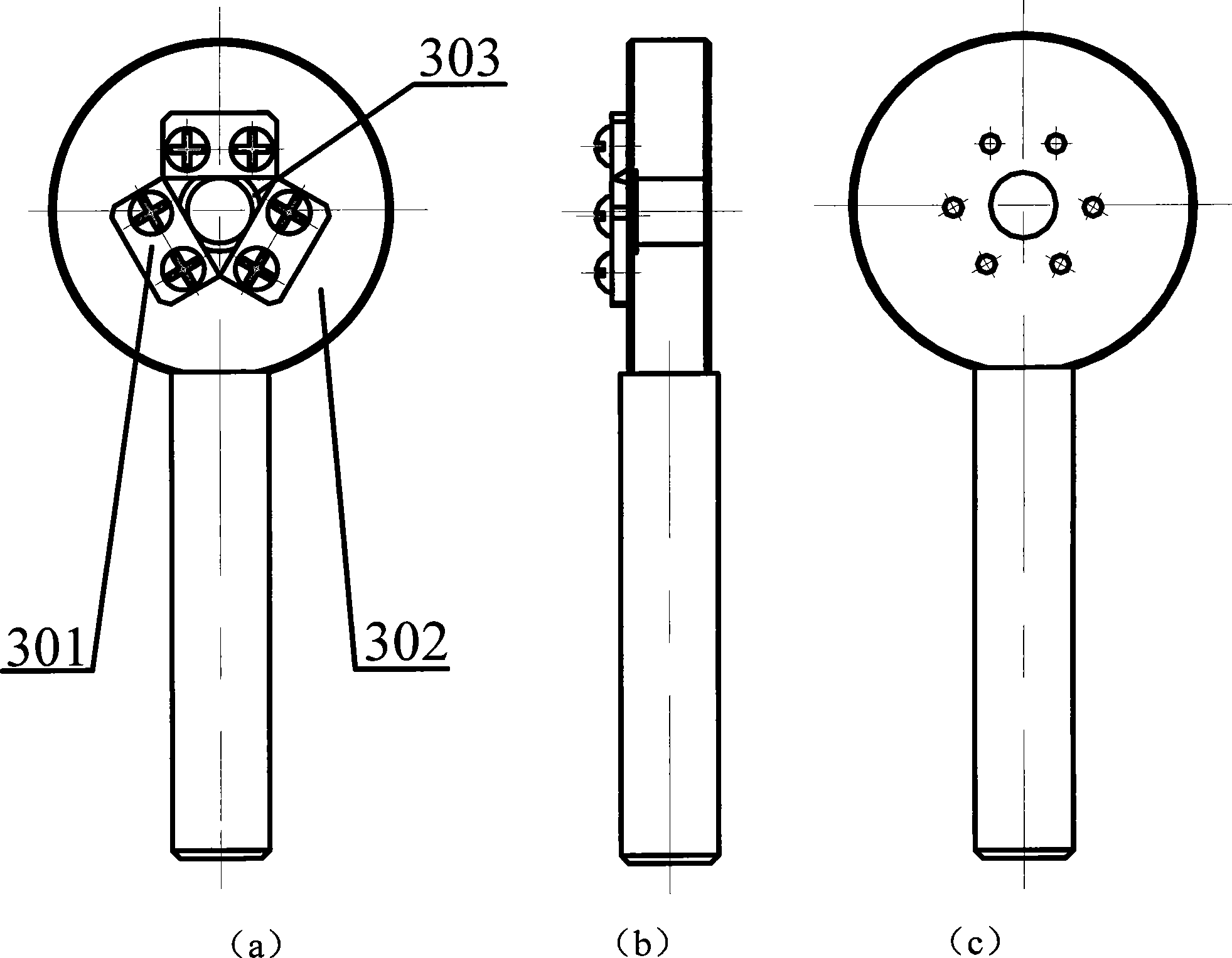

Drive travelling mechanism of peristaltic pipeline robot

A drive traveling mechanism of a peristaltic pipeline robot mainly solves the problem that existing pipeline internal drive travelling mechanism are lower in driving force and hard to drive robots to run for long distance in pipelines. The drive traveling mechanism of the peristaltic pipeline robot is characterized in that the drive traveling mechanism consists of two crank-and-rocker mechanisms and a worm-and-gear mechanism which share a robot body as a framework, a connecting rod of one crank-and-rocker mechanism is of an elastic connecting rod structure, and the elastic connecting rod penetrates through a rocker which swings around the robot body to be further connected with a gear rotating around the robot body so as to form one crank-and-rocker mechanism. The two crank-and-rocker mechanisms identical in structure are respectively arranged from front to back. When a motor drives the worm to drive the gear to rotate, traveling legs connected to the two crank-and-rocker mechanisms arranged from front to back realize translational motion. The two crank-and-rocker mechanisms serving as components of the drive traveling mechanism are distributed along the radial direction of the worm by 120 degrees and are driven by the same worm. The drive traveling mechanism has the advantages that traveling legs can contact with walls of pipelines sufficiently to generate higher dragging force so that the robot can travel by a long distance in the pipelines.

Owner:NORTHEAST GASOLINEEUM UNIV

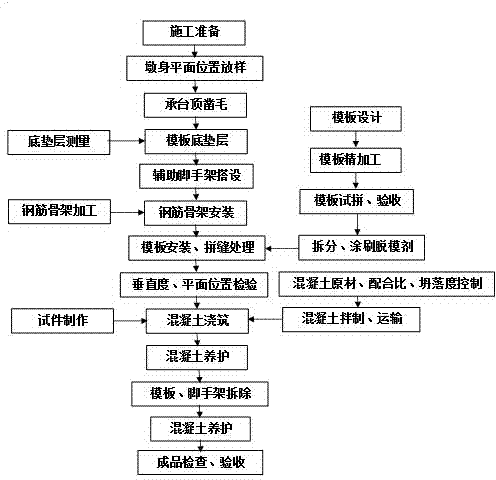

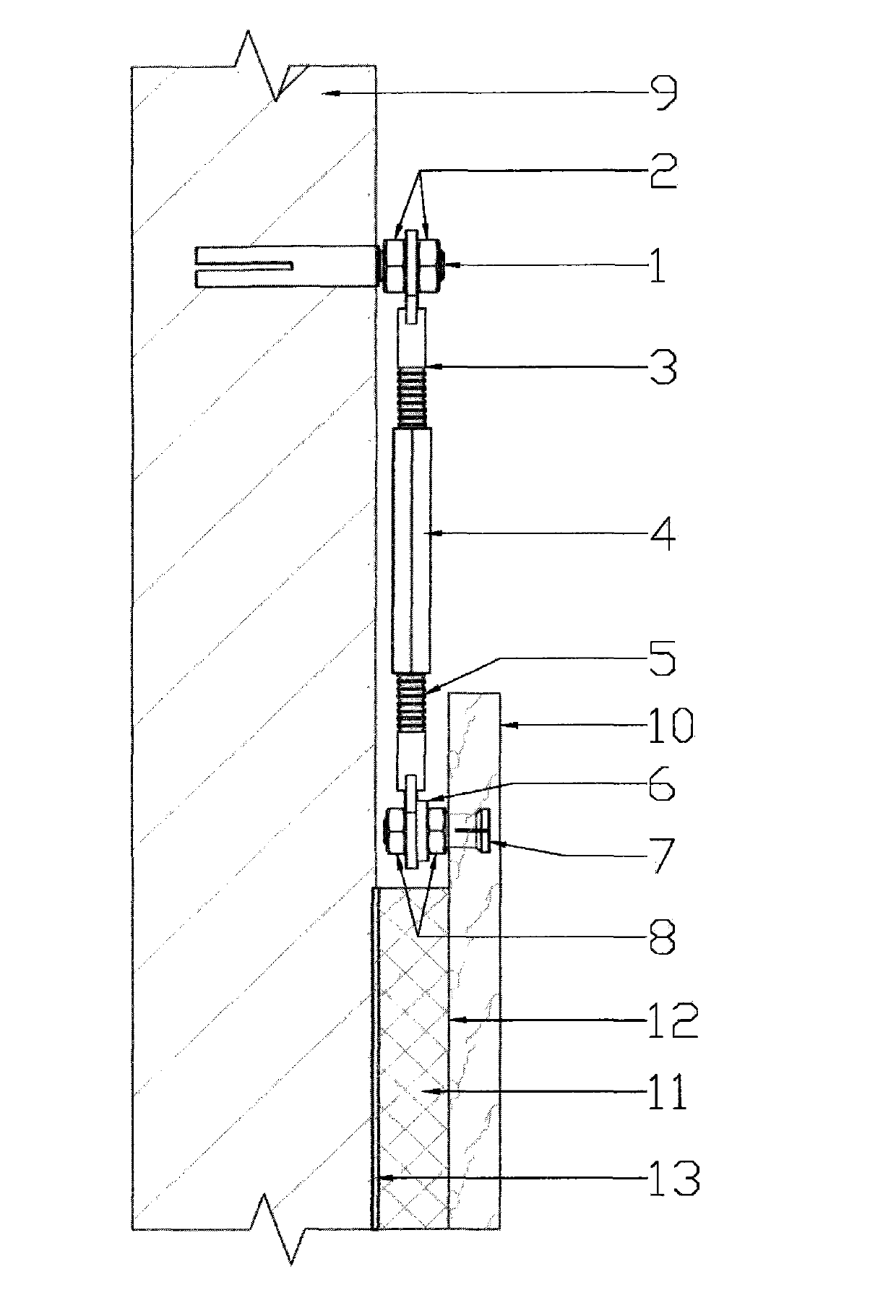

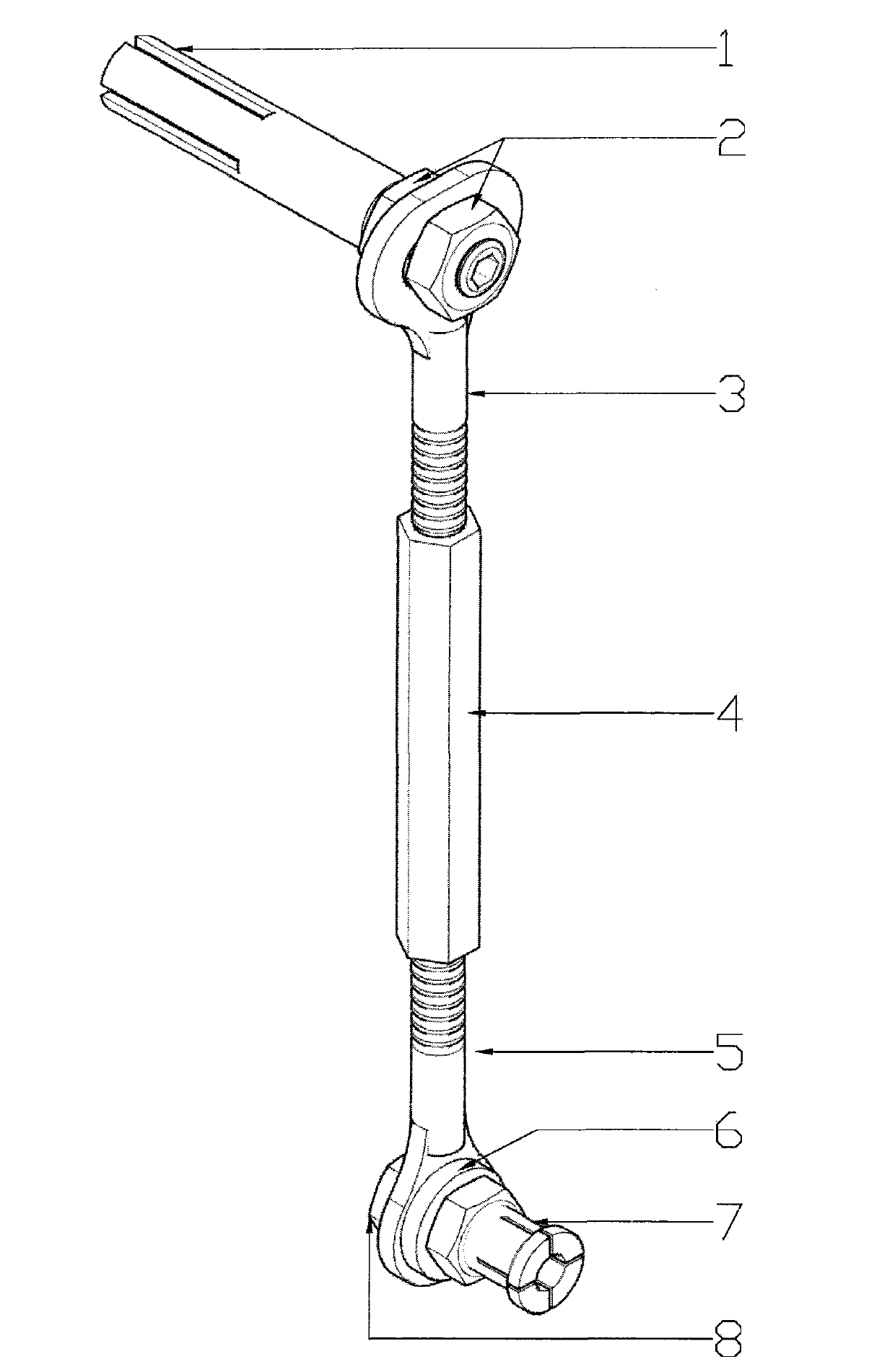

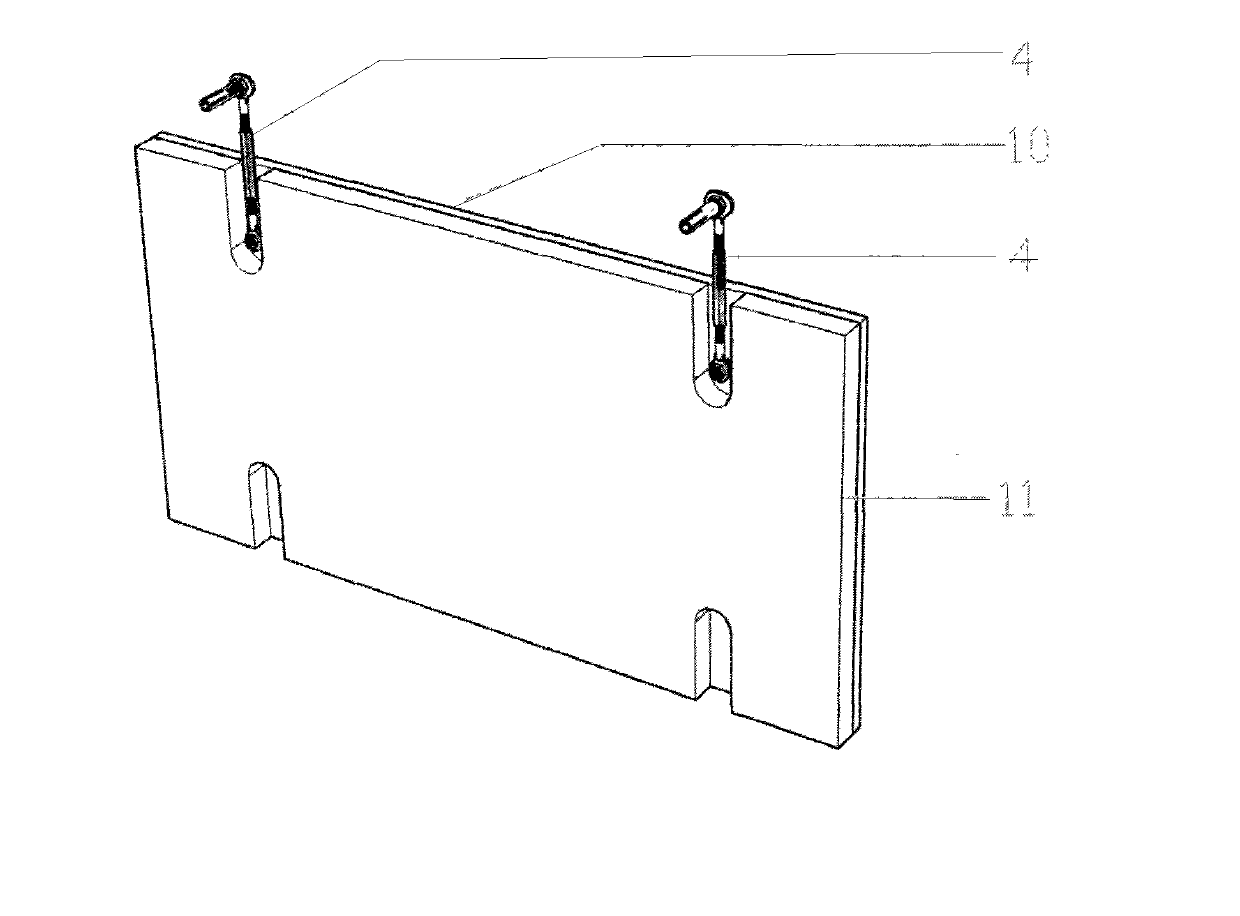

Construction method for pouring and forming urban viaduct curve type pier stud in one-off mode

InactiveCN104846744AQuality improvementHigh precisionBridge structural detailsBridge erection/assemblyFalseworkPile cap

The invention discloses a construction method for pouring and forming an urban viaduct curve type pier stud in a one-off mode. The construction method includes the following steps of 1 positioning pier stud pre-buried main reinforcement, 2 chiseling the combined portion of a pier body and a pile cap, 3 staking out in survey, 4 putting up a scaffold, 5 machining and installing reinforcement, 6 machining and installing a formwork, 7 pouring concrete, 8 disassembling the formwork and curing, and 9 removing the scaffold. According to the construction method for pouring and forming the urban viaduct curve type pier stud in the one-off mode, the pier stud has the advantages of being fast to construct, reasonable in structure, economical, practical and the like and is widely applicable to an urban high-pier bridge, particularly an urban high-pier landscape bridge.

Owner:NANTONG UNIVERSITY

Method for paving and sticking stone materials or ceramic tiles

The invention provides a construction method for paving and sticking stone materials or ceramic tiles on a wall or floor. The construction method comprises the following steps: sticking an extruded sheet on the back of a plate to be paved and stuck in advance and mounting stainless steel back bolts; sticking and hanging materials to be paved and stuck on the wall by using adhesive and hanging pieces so as to achieve a firm paving and sticking effect.

Owner:陈晓通

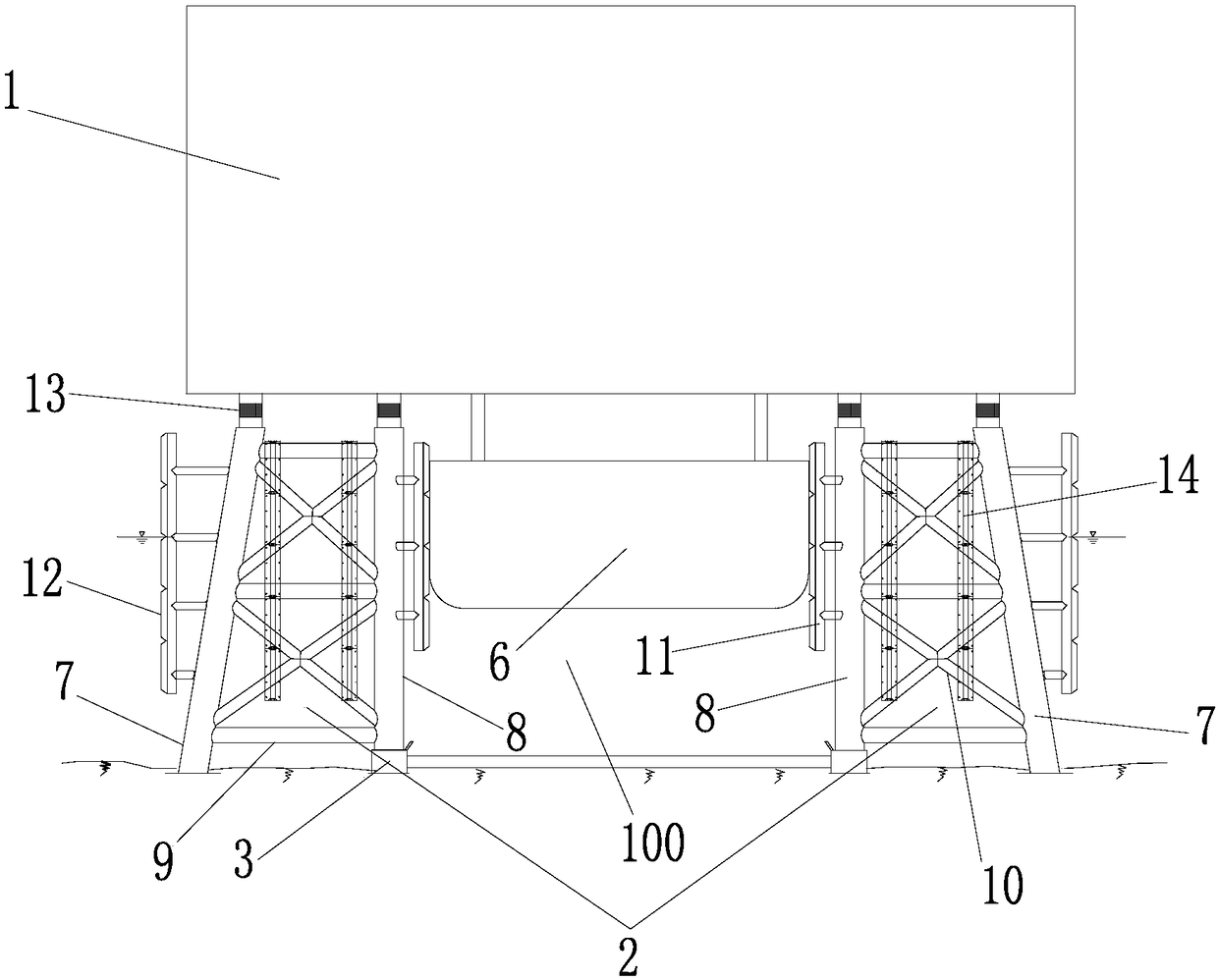

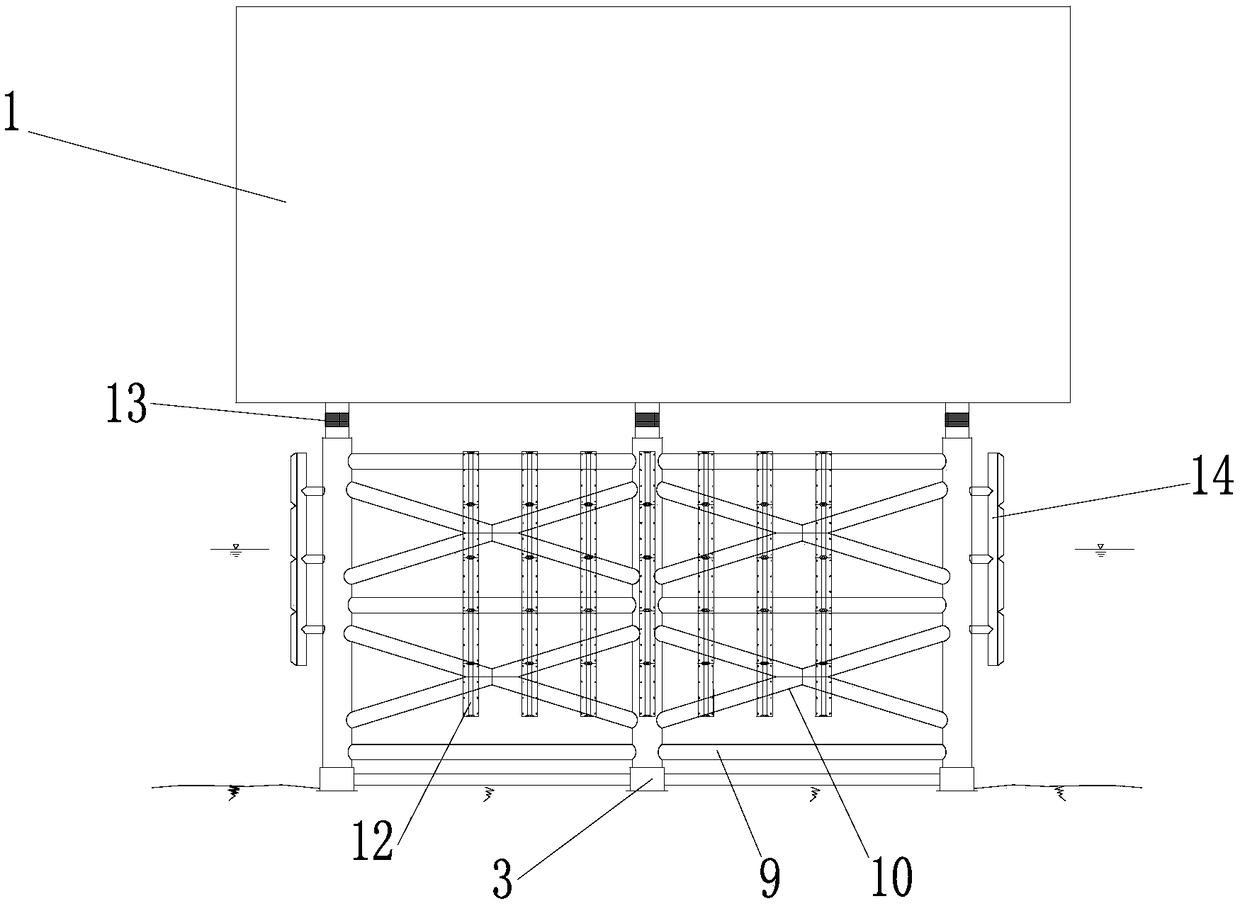

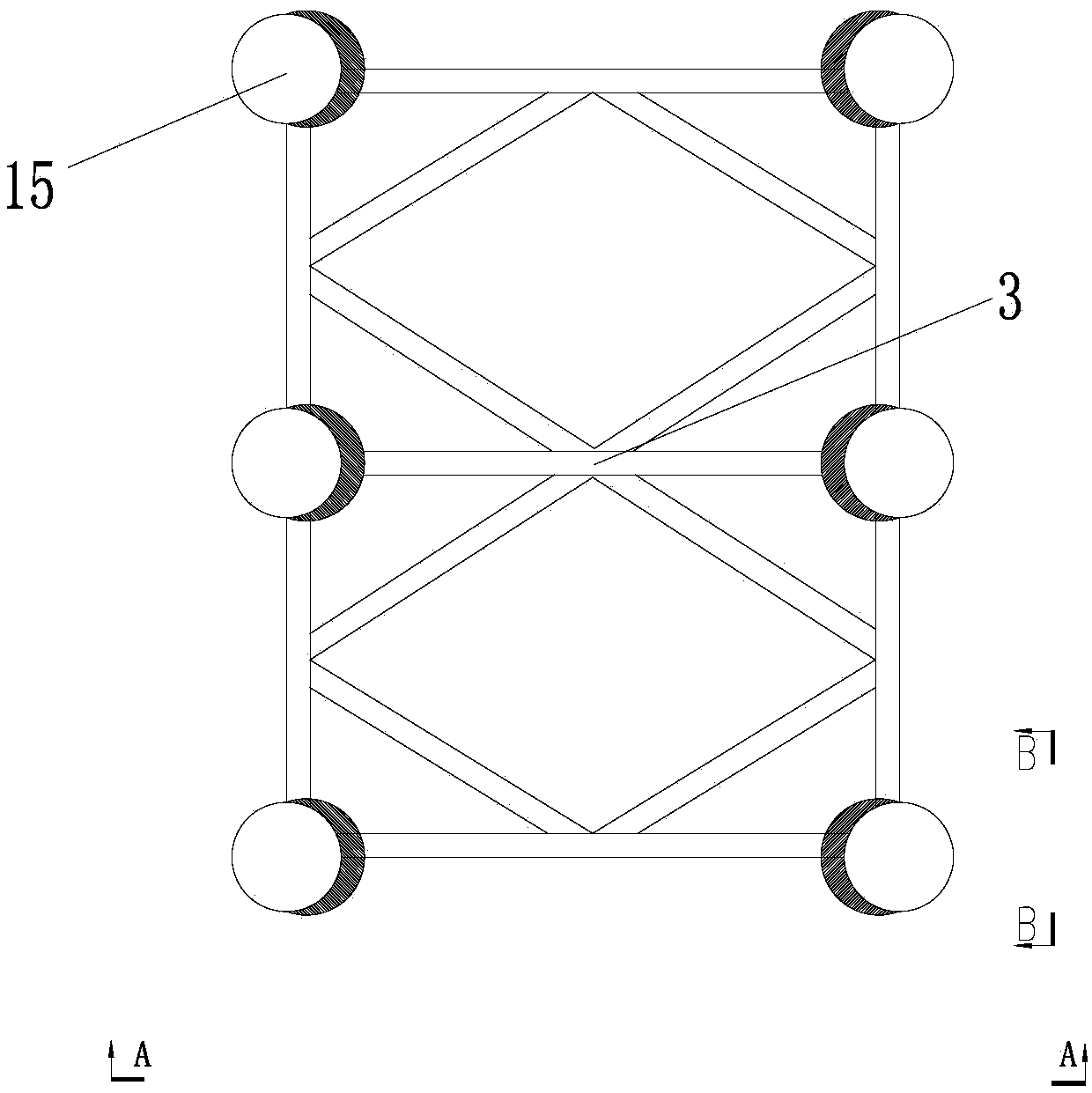

Large offshore platform split-type conduit frame structure suitable for shallow-water marine float-over mounting, and mounting method thereof

PendingCN109056684ASmall sizeReduce weightArtificial islandsUnderwater structuresMarine engineeringBuilding construction

The invention provides a large offshore platform split-type conduit frame structure suitable for shallow-water marine float-over mounting, and a mounting method thereof. The split-type conduit frame structure is provided with two split conduit frames which are arranged in the longitudinal direction of a platform, and a certain hollow area is reserved between the two split conduit frames to serve as a float-over ship entering area; the conduit frames are connected into a whole by inner side main conduits, outer side main conduits, steel pipe piles, transverse struts and inclined struts, and thesteel pipe piles are arranged in the inner side main conduits and the outer side main conduits; each split conduit frame transversely adopts a structure with multiple rows of piles and multiple trusses of conduit frame bodies, the steel pipe piles in the inner side main conduits adopt vertical piles, and the steel pipe piles in the outer side main conduits adopt inclined piles; and the main conduits in the two conduit frames are in positioning fit at the bottom through a positioning frame. The large offshore platform split-type conduit frame structure is structurally safe and reliable, convenient and precise in construction and can be used for shallow-water marine float-over mounting of the large offshore platform.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

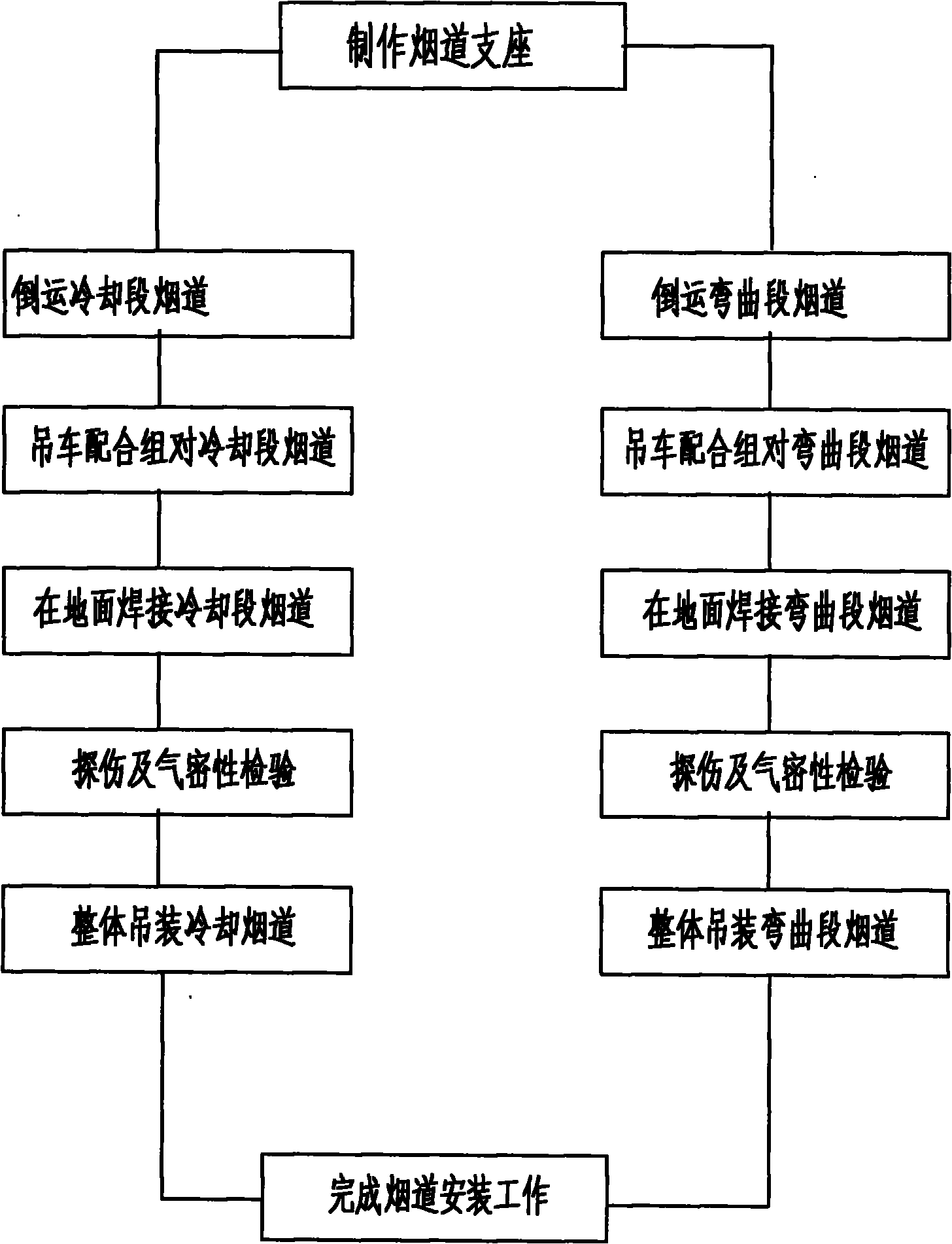

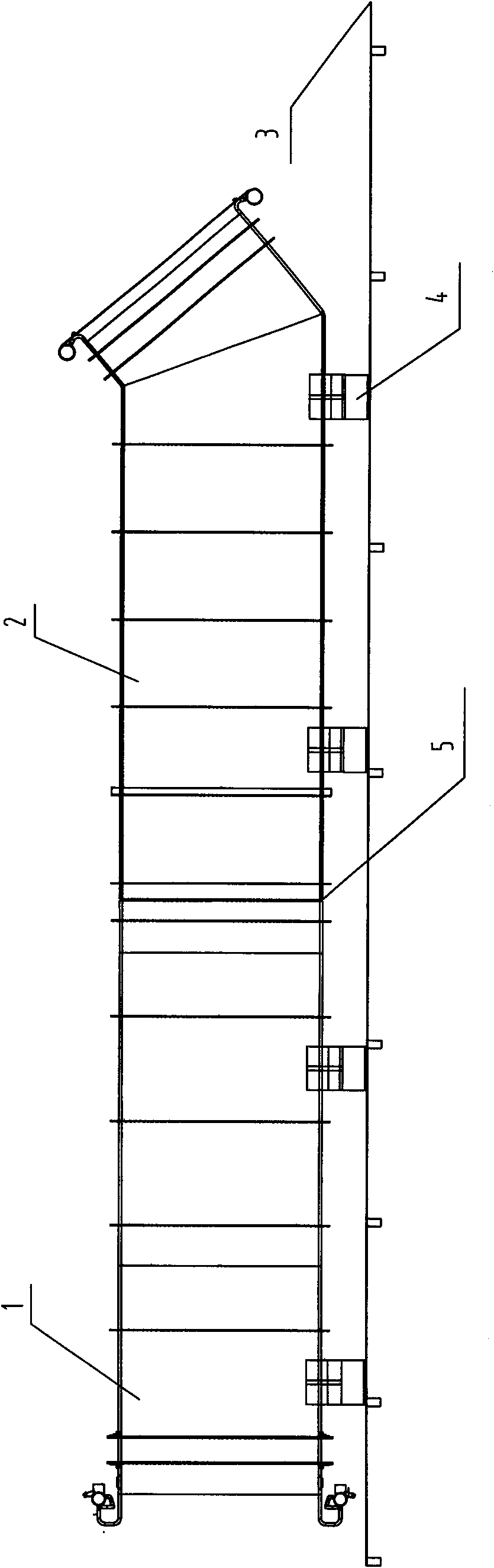

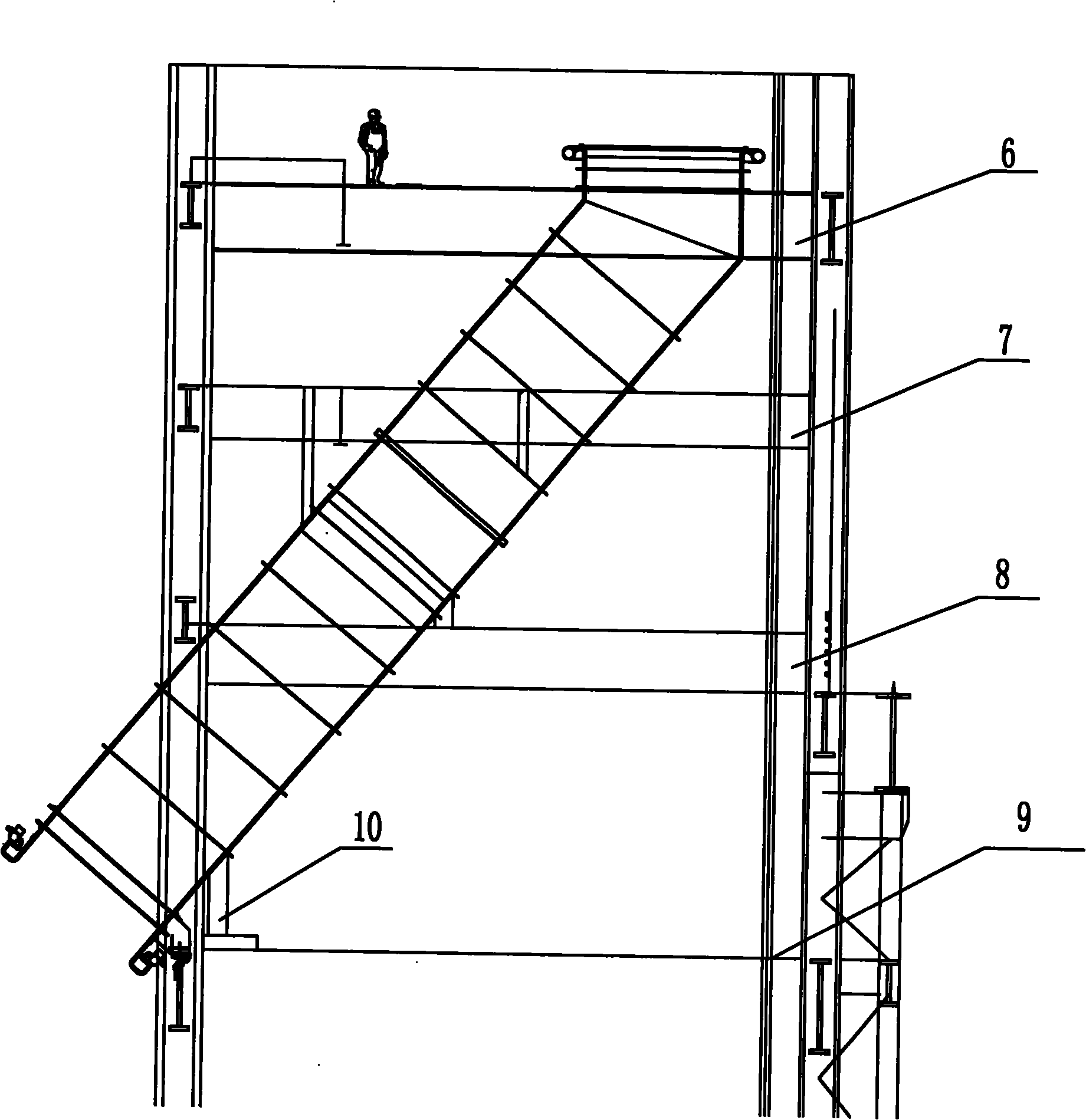

Ground assembling and welding integral installation and construction technology for vaporization-cooling chimney

ActiveCN101804501AImprove construction qualityExtended service lifeArc welding apparatusManufacturing convertersArchitectural engineeringVaporization

The invention relates to installation project construction of a vaporization-cooling chimney of a large converter, in particular to ground assembling and welding integral installation and construction technology for the vaporization-cooling chimney. The technology comprises the following steps: laying a steel platform and making a chimney support by using steel plates; transporting a cooling chimney to an installation site by using a large-tonnage flat truck; assembling the cooling chimney by using a large-tonnage crane; performing all-position ground welding on the vaporization-cooling chimney by adopting argon tungsten arc welding; performing 25 percent of radiographic detection and a corresponding airtight test on the welded chimney according to construction specifications; hoisting the chimney integrally; and fixing chimney system equipment according to the following sequence: curved chimney, cooling chimney and movable chimney so as to complete the installation of the chimney. The technology ensures the welding quality of the vaporization-cooling chimney, reduces the workload of overhead construction, reduces potential safety hazard during the construction, greatly improves the working efficiency of the installation of the vaporization-cooling chimney, reduces the duration of the construction, and increases the service life of the vaporization-cooling chimney.

Owner:CHINA 22MCC GROUP CORP

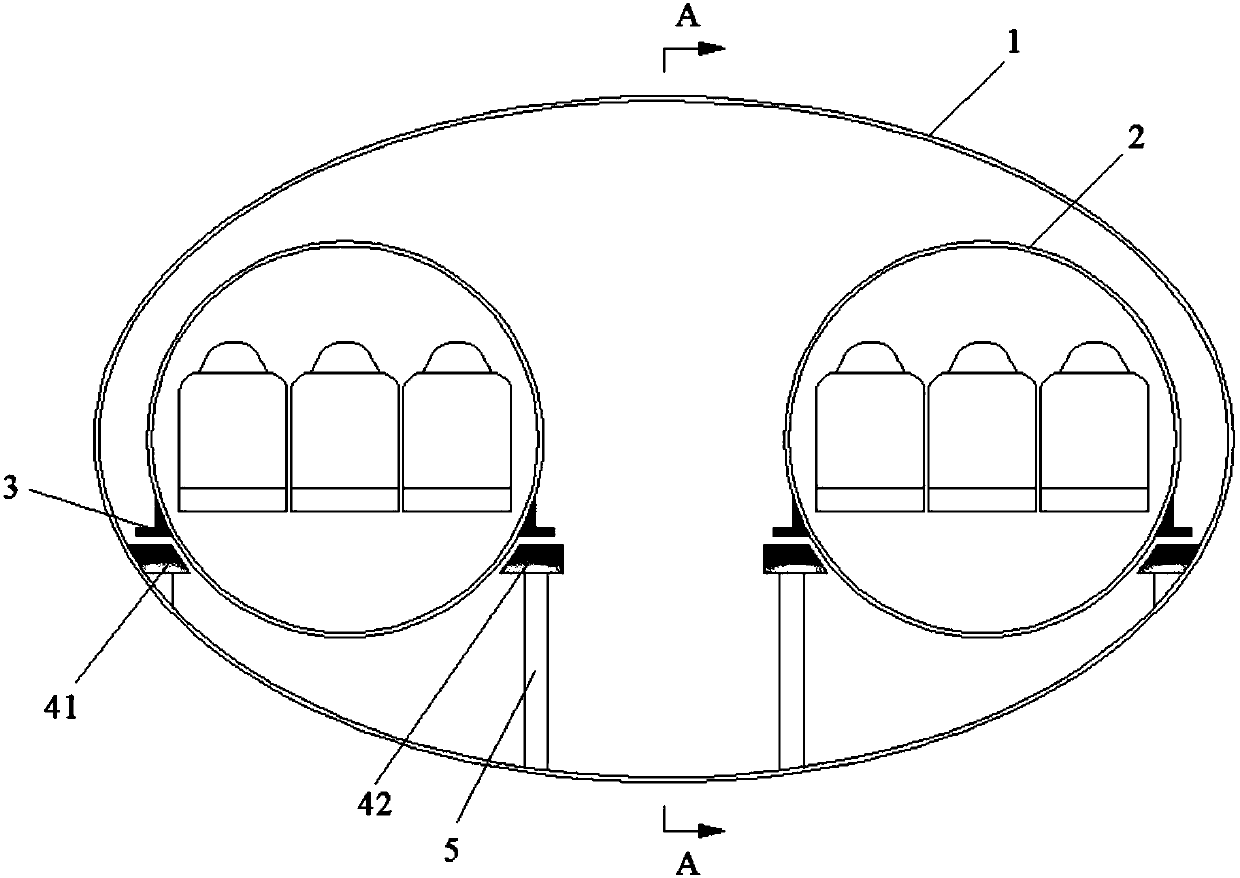

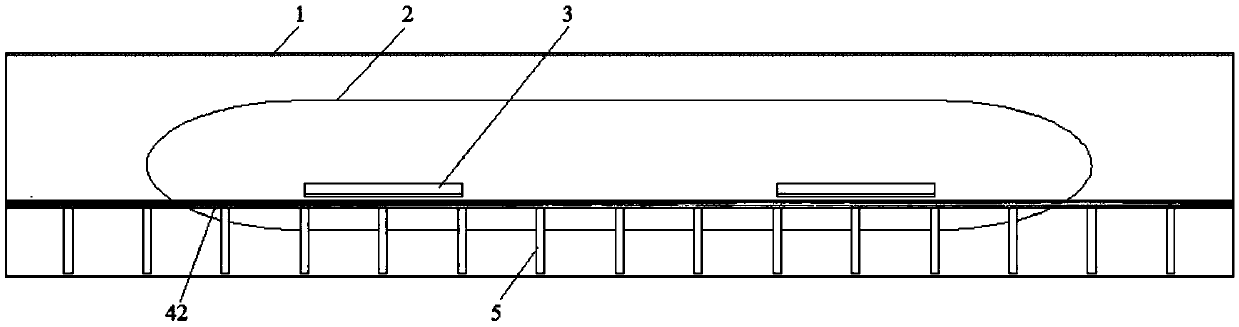

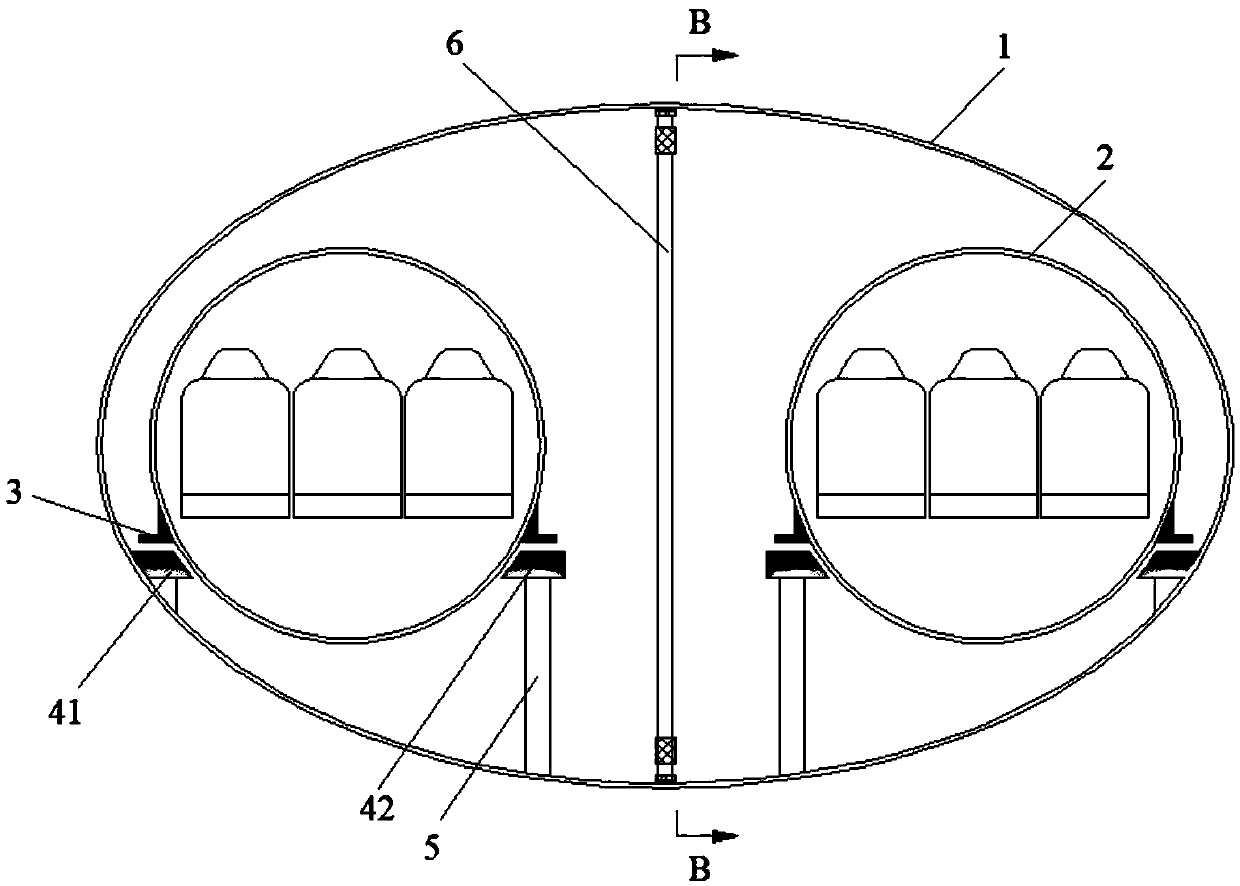

Oval single-tube two-way vacuum pipeline traffic system

An oval single-tube two-way vacuum pipeline traffic system comprises an oval pipeline. The oval pipeline is internally provided with a two-way travelling vehicle, vehicle upward suspension magnetic poles are arranged on the two sides of the travelling vehicle and matched with an outer suspension track and an inner suspension track correspondingly, and the outer suspension track is connected to theinner wall of the oval pipeline. The inner suspension track is supported on the inner wall of the oval pipeline through a track first support. A support rod is arranged at the position of a short shaft of the oval section of the oval pipeline, a semi-oval groove-shaped support seat is arranged along the exterior of the oval pipeline, and tight-pushing clamps are arranged on the position, on the horizontal positions of the two sides of the exterior of the pipeline, of the upper portion of the groove-shaped support seat along the long axis of the section of the oval pipeline. Adjusting and fixing are conducted through adjusting bolts. As for a vehicle with the same section, the blockage ratio in two-way double pipelines is slightly decreased, and the train travelling pneumatic resistance isreduced; and pipeline manufacturing materials are reduced, the pipeline erecting work procedure is reduced, the cost is reduced, the effective clearance in the pipeline is greatly increased, and mounting, examining and maintaining are conveniently facilitated.

Owner:BEIJING JIUZHOU ARTERY TUNNEL TECH CO LTD

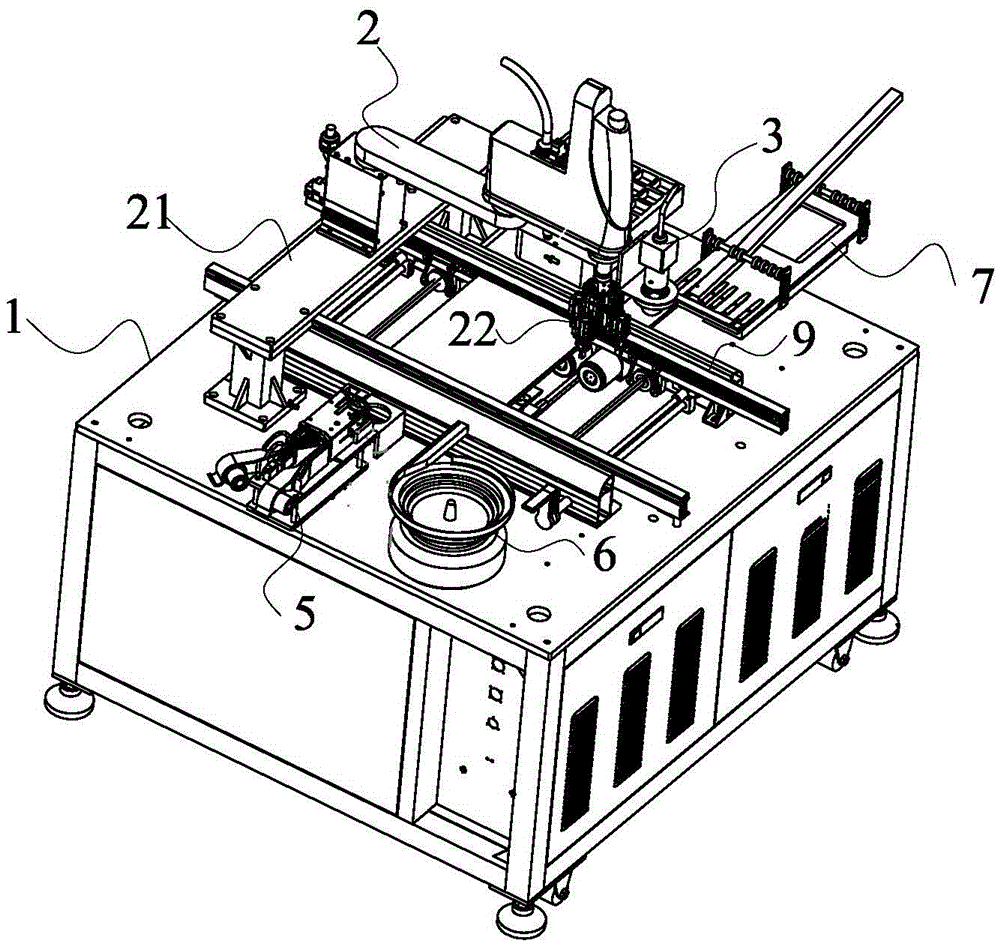

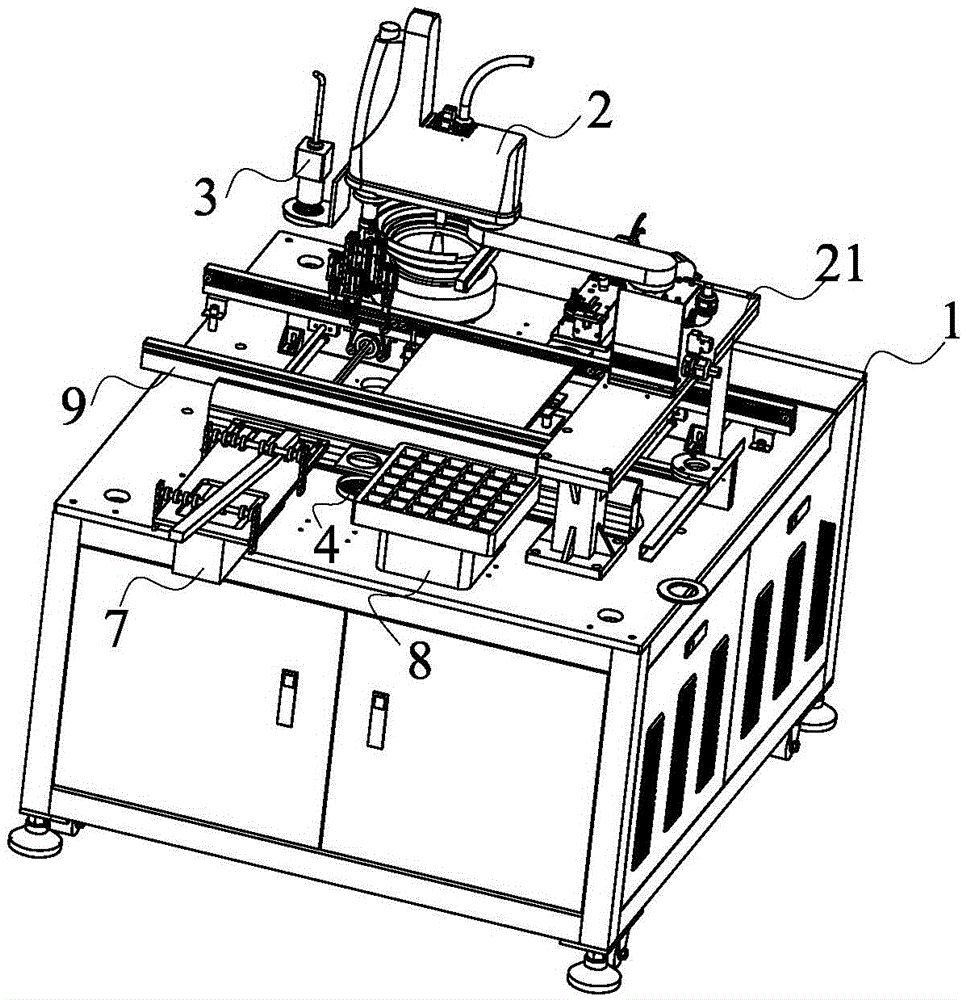

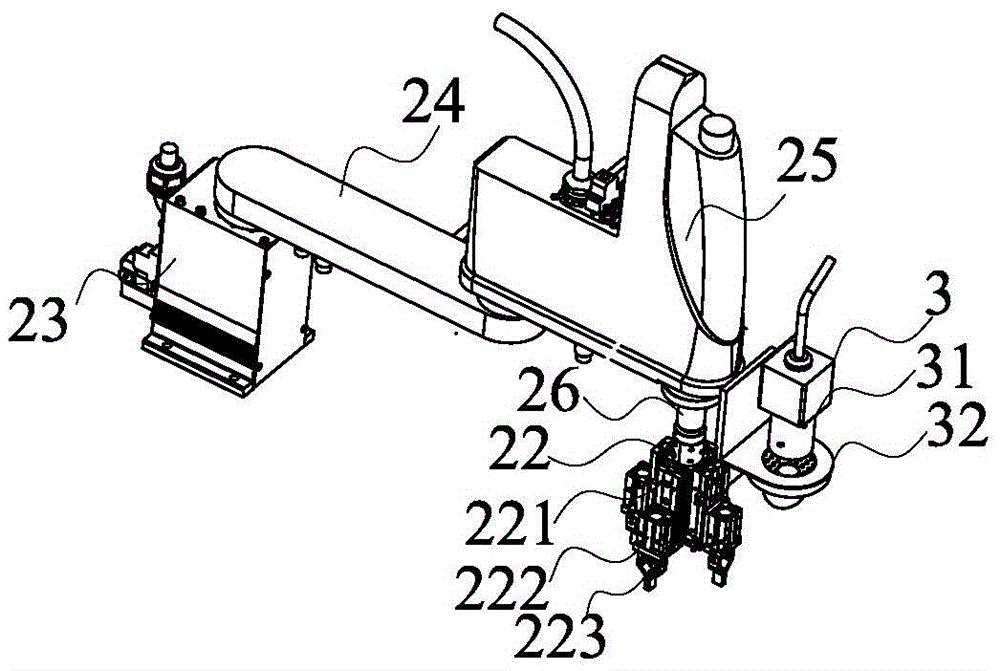

Automatic plug-in machine

ActiveCN105636427ALow positioning accuracy requirementsGuaranteed installation accuracyPrinted circuit assemblingElectrical componentsElectronic componentPrinted circuit board

The invention provides an automatic plug-in machine. The automatic plug-in machine comprises a machine seat and a printed circuit board (PCB) transmission device, a mechanical arm, a first charge coupled device (CCD) recognition device and a component feeding mechanism which are arranged on the machine seat, the first CCD recognition device is used for pin recognition of an electronic component, the mechanical arm comprises a fixed end and a free end, the fixed end is used for installing and fixing, the free end is used for acquiring the component and a plug-in, a transmission mechanism is arranged between the free end and the fixed end, a component fixture and a second CCD recognition device are arranged at the free end of the mechanical arm, and the second CCD recognition device is used for recognizing and positioning a PCB. The automatic plug-in machine provided by the invention can be suitably used for automatic plug-in operation of a large amount of electronic components, manual labor is completely substituted, and the production cost is saved; and with the dual and automatic compensation of the component and PCB, the installation accuracy is high, and the reject ratio is reduced.

Owner:SHENZHEN KUNQI XINHUA

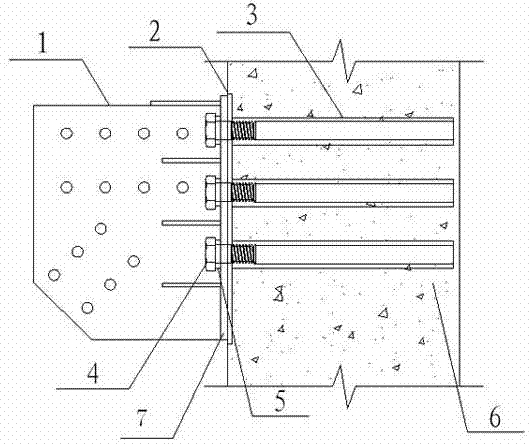

Method for integrally fixing and installing foundation bolts with large diameter

InactiveCN101705693AImprove installation qualityGuaranteed installation accuracyFoundation engineeringAnchor boltTransverse beam

The invention discloses a method for integrally fixing and installing foundation bolts with large diameter, which comprises the following steps of: (1), manufacturing a supporting steel plate in a partition way; (2), determining the central positions of bolt positioning holes on the supporting steel plate; (3), processing the bolt positioning holes on the partitions of the supporting steel plate; (4), installing an upright post and a transverse beam of a fixing rack in situ; (5), splicing the partitions of the supporting steel plate on the transverse beam of the fixing rack, fixing the partitions of the supporting steel plate with the transverse beam of the fixing rack after regulating to enable the positions of the bolt positioning holes on the partitions of the supporting steel plate to be consistent with the design positions of bolts, and welding all the partitions of the supporting steel plate into a whole; (6), installing the bolts in a hung way, enabling the bolts to penetrate through the positioning holes from the lower part of the supporting steel plate, installing nuts on the bolts and centring the elevations of the bolts by utilizing the nuts; and (7), after centring the elevations of all the bolts completely, fixing the bolts with the fixing rack by knot pulling bars and welding the fixing rack firmly. The bottoms of the bolts are fastened by one-time regulation and centring so as to complete the integral fixation and installation of the bolts, and the invention has high efficiency and low cost.

Owner:TIANJIN 20 CONSTR

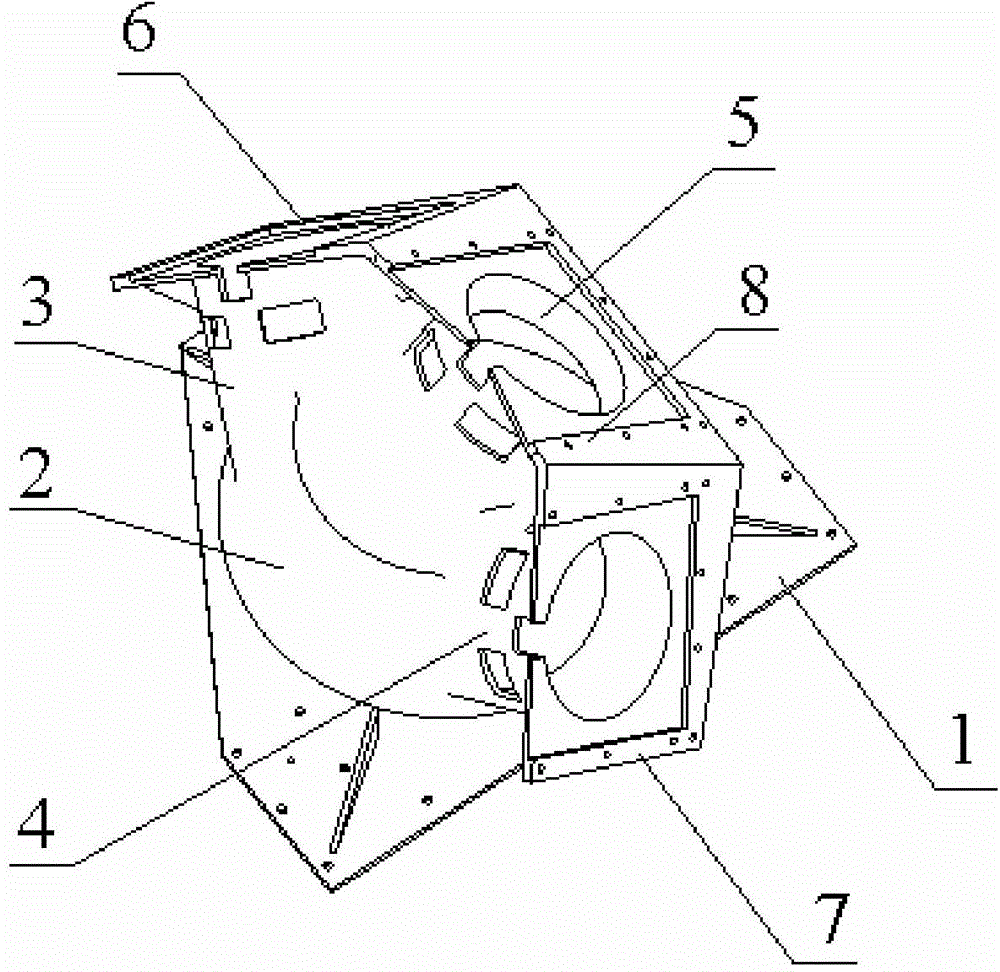

Integrated mounting bracket for star sensors

InactiveCN104859866AAll-in-one installationAvoid inconsistencyMachine supportsSpacecraft guiding apparatusEngineeringOrbit

The invention provides an integrated mounting bracket for star sensors. The mounting bracket comprises a mounting bottom plate, an overall support platform, a plurality of support barrels and mounting flanges, wherein the mounting bottom plate is fixedly connected with a satellite platform; the overall support platform is fixedly connected with the mounting bottom plate; the plurality of support barrels are connected with the overall support platform respectively; the mounting flanges are arranged at the top ends of the support tubes and used for mounting the star sensors. According to the integrated mounting bracket for the star sensors, integrated mounting of three star sensors is realized according to a satellite attitude and orbit control subsystem scheme and the mounting requirements of the star sensors, and conditions of non-uniform bracket forms, complicated design and processing procedures and longer period occurring when the star sensors are separately mounted are avoided.

Owner:AEROSPACE DONGFANGHONG SATELLITE

Lead-connecting device

InactiveCN101841117AHigh coincidenceImprove connection qualityLine/current collector detailsFixed frameElectric power system

The invention relates to a lead-connecting device in a power system. The device comprises a hydraulic press binding clip and a hydraulic system matched with the same and is characterized in that a guide rail is fixed on a worktable, a trolley which can move along the guide rail and is provided with the hydraulic press binding clip is mounted on the guide rail, the hydraulic press binding clip is fixed on a fixed plate on the trolley, a lifting device and a guiding device for moving the fixed plate up and down are mounted between the fixed plate and the trolley, a fixed frame is mounted on the worktable at one end of the trolley and provided with a lead-clamping device, a lead-clamping trolley which can move along the guide rail is mounted on a guide rail at the other end of the trolley and is provided with a lead-clamping device, and the lifting device, the guiding device and a tension device which pulls the lead-clamping trolley to move along the guide rail are mounted on the lead-clamping trolley. The invention has the advantages of reasonable structure, convenient use and high working efficiency and lead-connecting quality.

Owner:宁夏送变电工程有限公司

Prefabricated slab and column mortise and tenon type connecting joint and installation method

ActiveCN104947803AEnsure structural safetyGuaranteed structural qualityBuilding material handlingFloor slabMortise and tenon

The invention discloses a prefabricated slab and column mortise and tenon type connecting joint and an installation method. The connecting joint comprises a composite frame column, a floor slab and a high-strength bolt. A column end sealing plate is welded to the top end of a column body, and the bottom end of a column tenon is welded to the column end sealing plate. Frame beams on the periphery are structural steel or structural steel combination trusses. Tenon holes are hollow steel members connected with the frame beams, the cross section shape of the tenon holes is the same as that of the column tenon, and the cross sections of the tenon holes are larger than the cross section of the column tenon but small than the cross section of a body of the composite frame column. Composite frame columns and floor slabs are sequentially connected and fixed through bolt holes and high-strength bolts. By means of tenon and mortise type connection of slabs and columns prefabricated in a factory, the structure form and the installation mode are greatly simplified, the structural safety and quality of a building can be guaranteed better, the field workload is reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

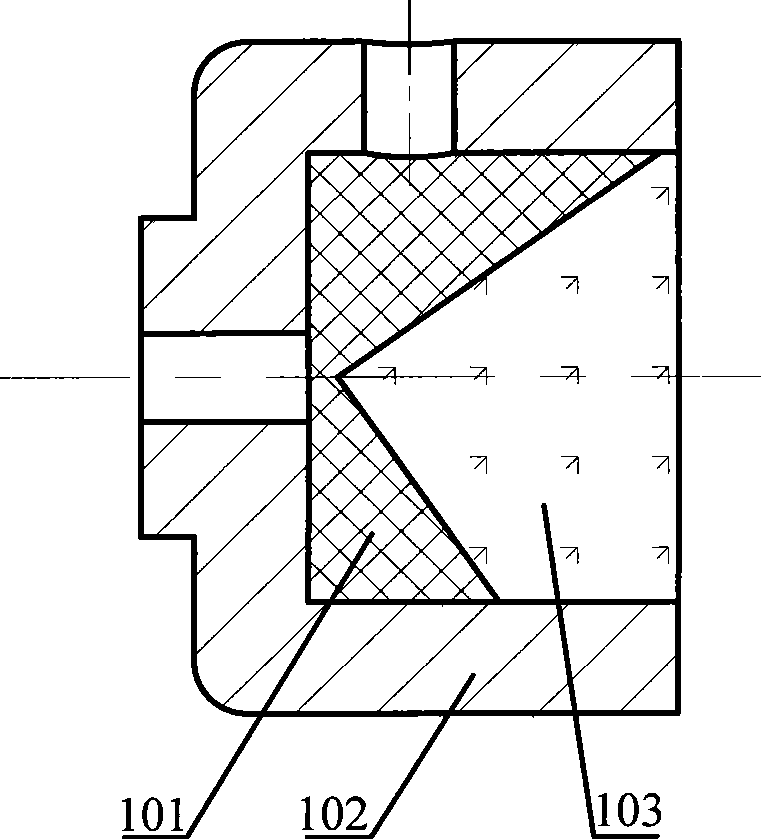

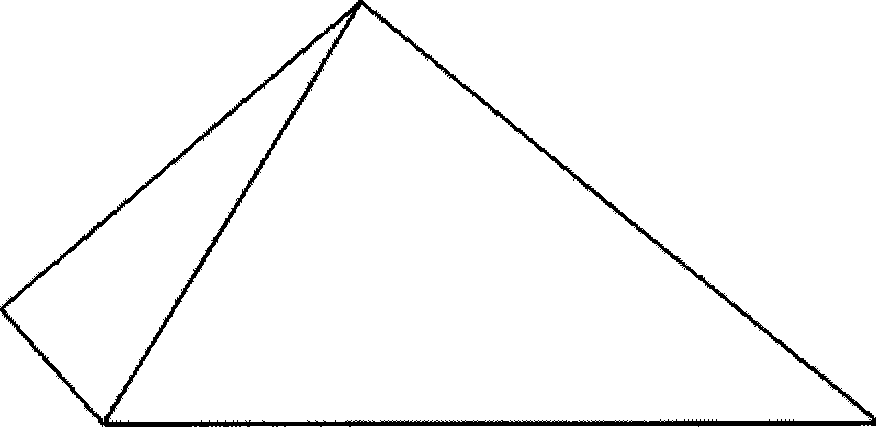

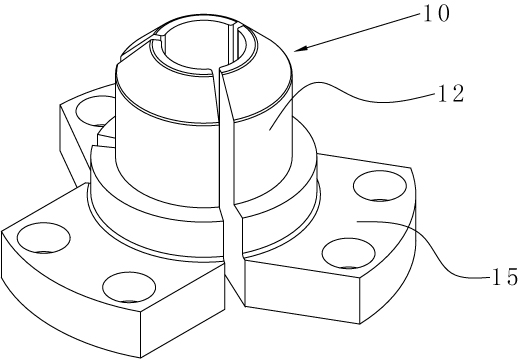

Pyramid prism fixing device and method

The invention discloses a fixing device and a fixing method for a prism of corner cube. The fixing device comprises a clamp, an apron, a base, a lock nut and a holding screw. A hollow hole with a circum-circle diameter less than a bottom diameter of the prism of corner cube is arranged in the clamp and is used for placing the prism of corner cube. A hollow hole with an opening containing inner screw threads is arranged in the base and is used for placing the prism of corner cube and the clamp. The inner hole diameter of the lock nut is slightly less than the circum-circle diameter at the bottom of the prism of corner cube. The gap between the whole length of the hollow hole of the base and the length of the assembled prism of corner cube and clamp is less than the inner screw thread length of the base. The lock nut matches with the base through the inner and exterior screw threads and tightly locks the prism of corner cube in axial direction. The holding screw is screwed in the screw holes in the exterior wall of the base to tightly hold the clamp and prevent the clamp from rotating in the axial direction. The fixing device and a fixing method fully make use of the three orthogonal seamed edges of the prism of corner cube, adopts the three contact styles containing point contact, line contact and surface contact to realize the precisely-fixed prism of corner cube, and has the advantages of simple structure, convenient installation and detachable installation.

Owner:王利强 +1

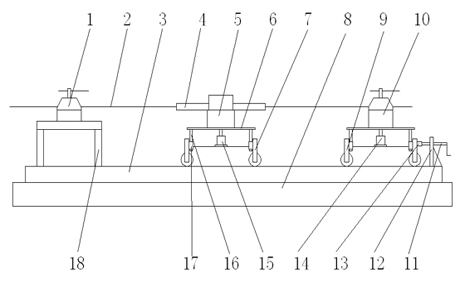

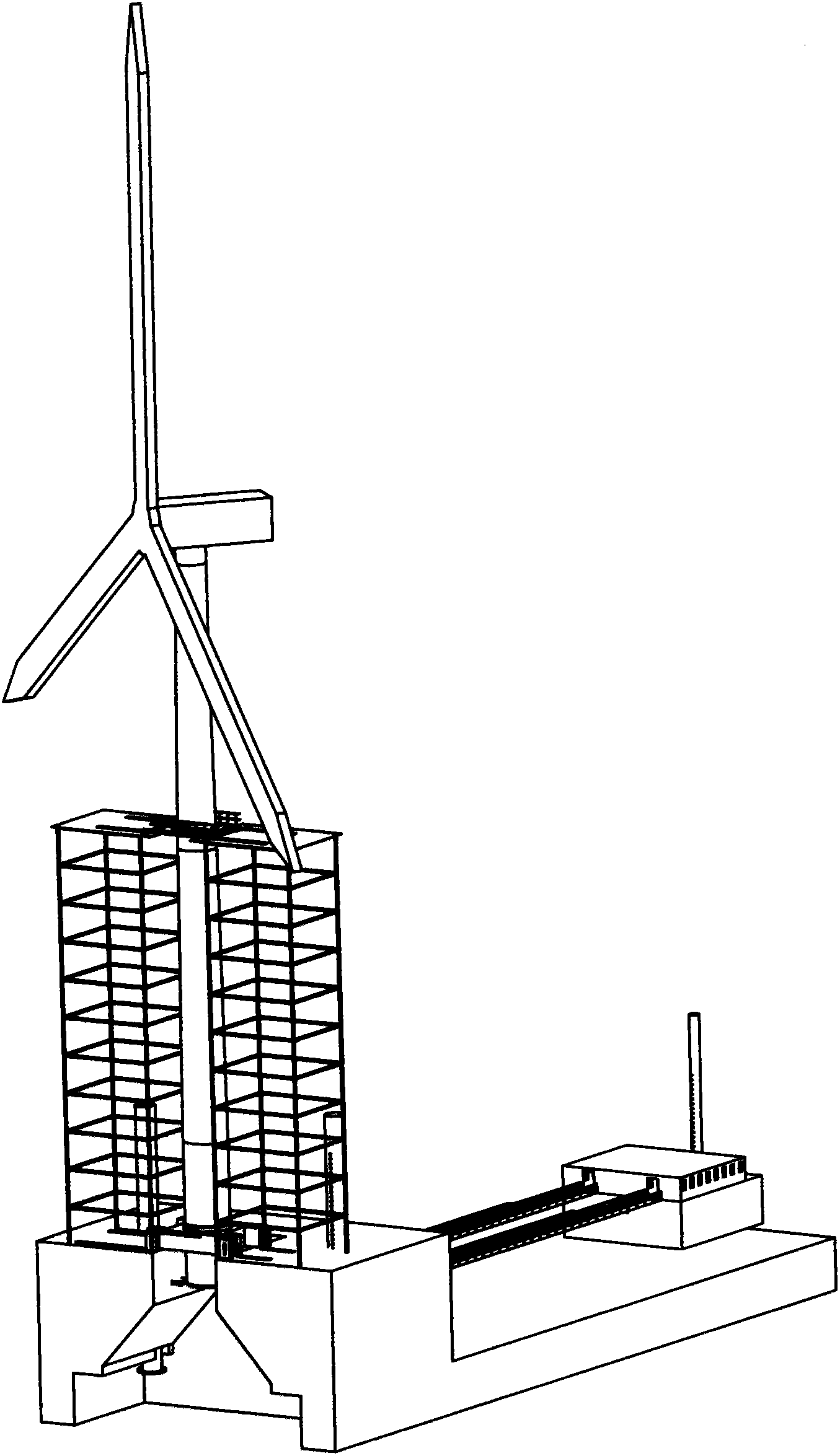

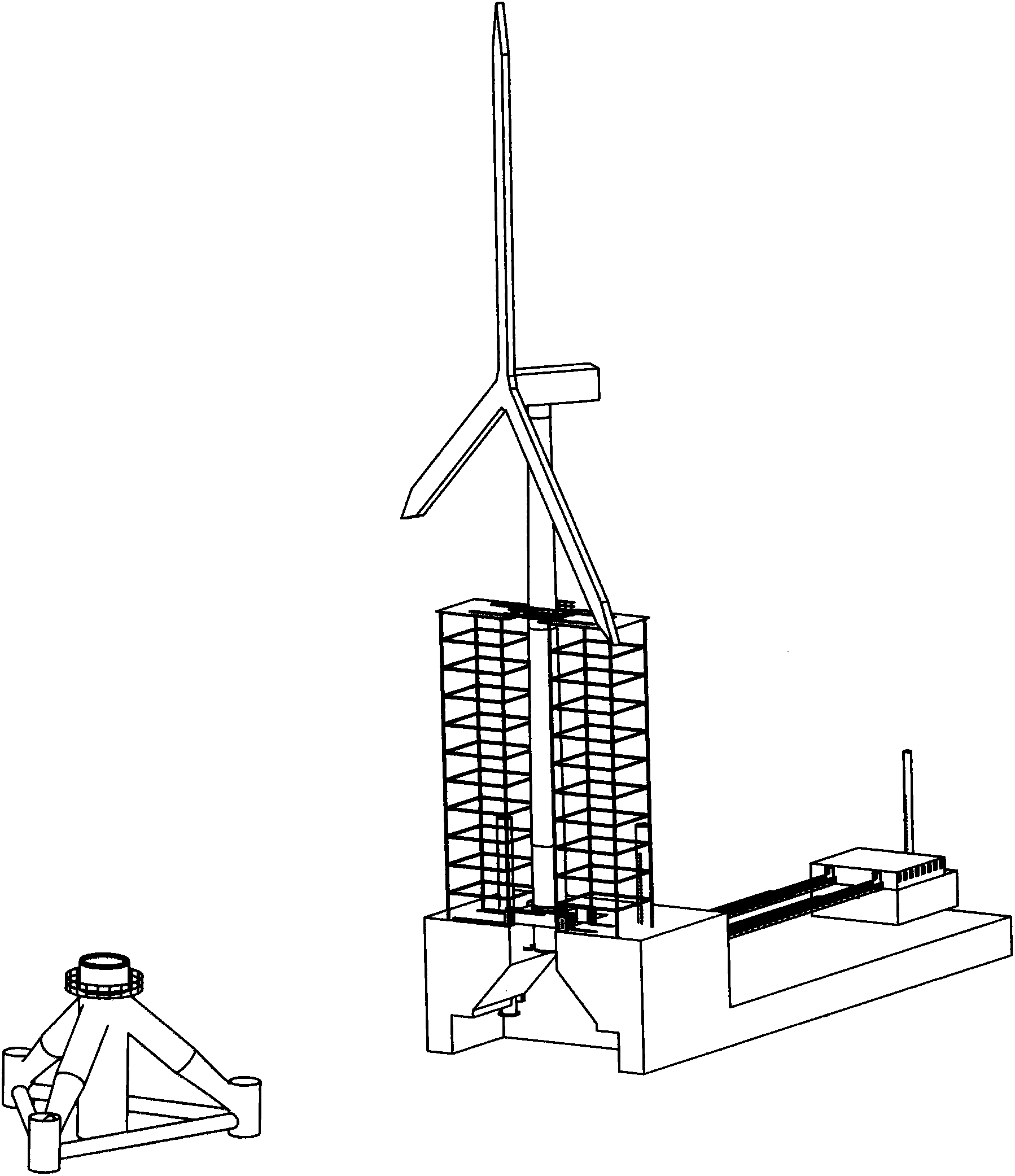

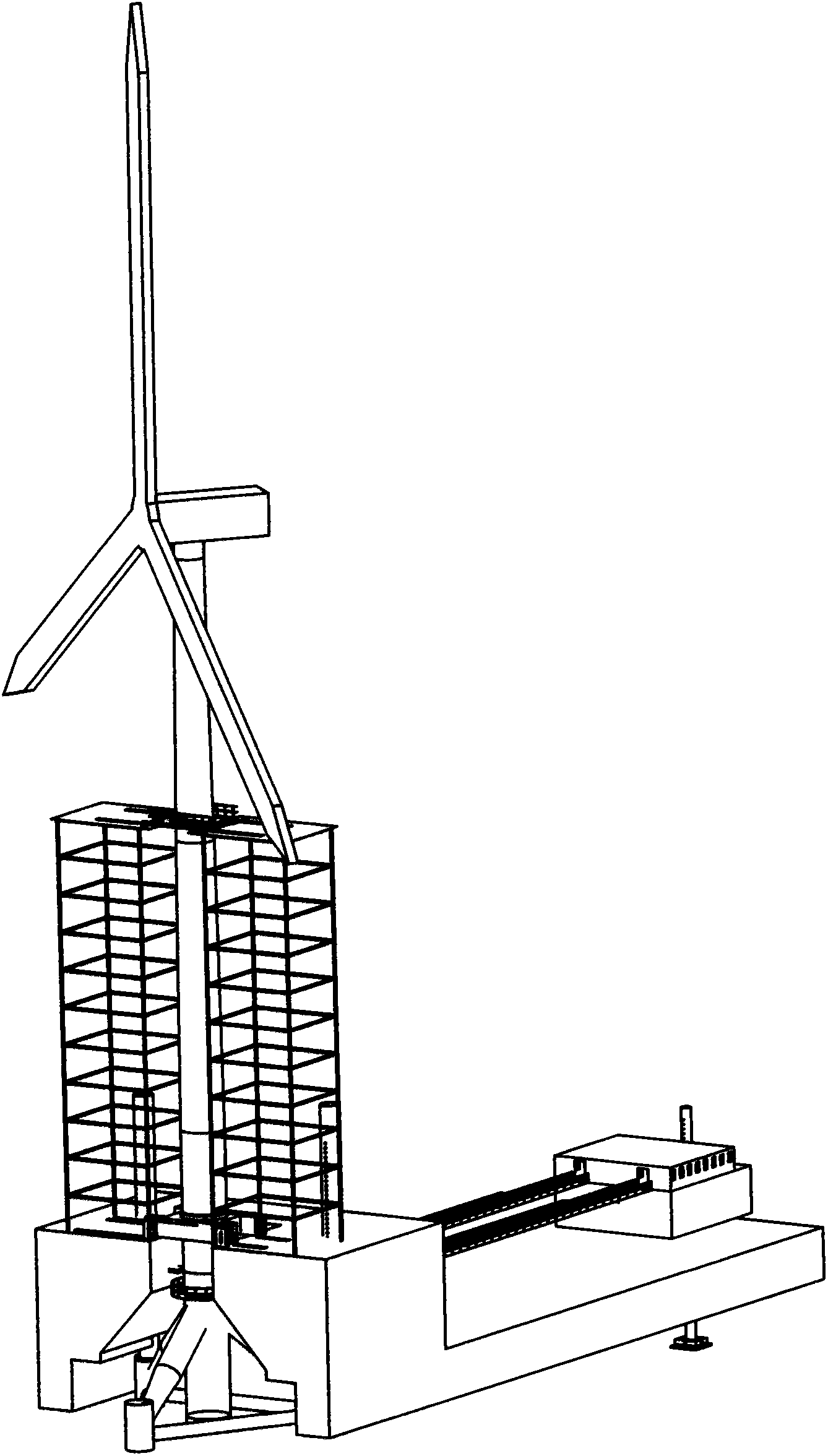

Construction method and special transport and installation ship for marine transport and installation of wind-driven generator

ActiveCN102278291APrecise positioningGuaranteed installation accuracyWaterborne vesselsWind energy generationWind drivenWind force

The invention relates to a construction method and a special transport and installation ship for the marine transport and installation of a wind-driven generator. The special transport and installation ship adopted in the construction method comprises a ship body, wherein the stem of the ship body is provided with an installation system and a ship body stem overlapping device; the installation system comprises an installation platform, a mounting bracket arranged on the installation platform and a jacking and fine tuning device, and the mounting bracket used for fixing the wind-driven generator in transport and installation processes; and the jacking and fine tuning device is used for positioning the wind-driven generator. According to the invention, the transport and installation ship isadopted to perform installation and integrates the functions of the marine transport and installation of the whole wind-driven generator, thus the marine transport and installation of the whole wind-driven generator can be directly performed without influences caused by wind waves; and a special transport ship is not required to be used for transporting the wind-driven generator to an installation site, and a marine platform or a giant hoisting machine on a special crane ship is not required to be used for installation thus the construction and use cost is low.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

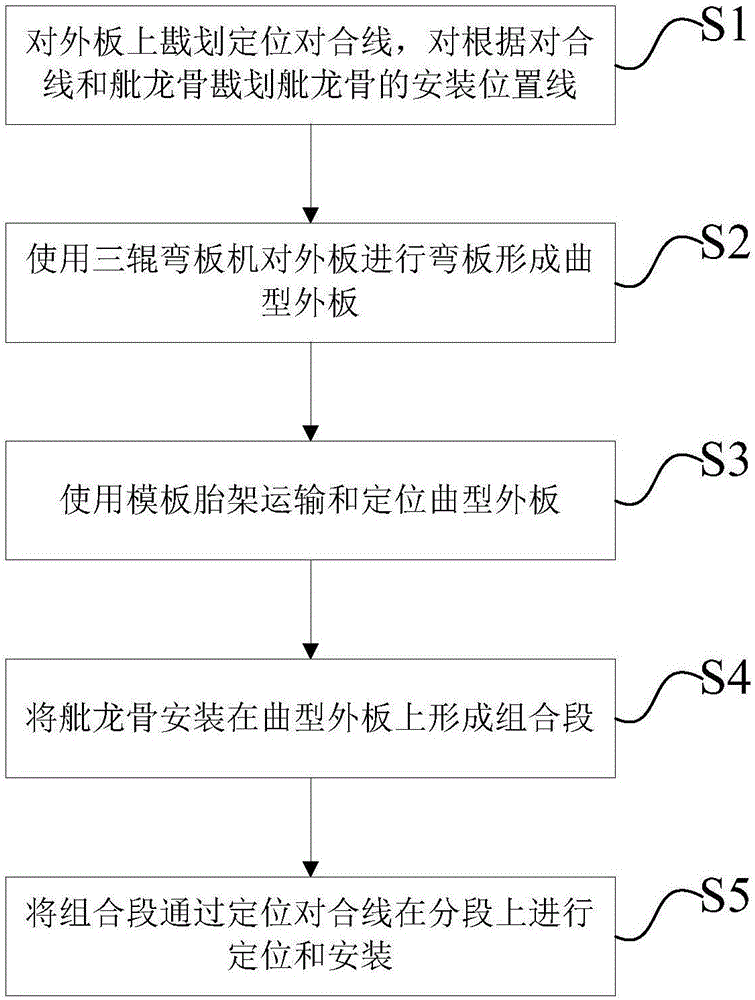

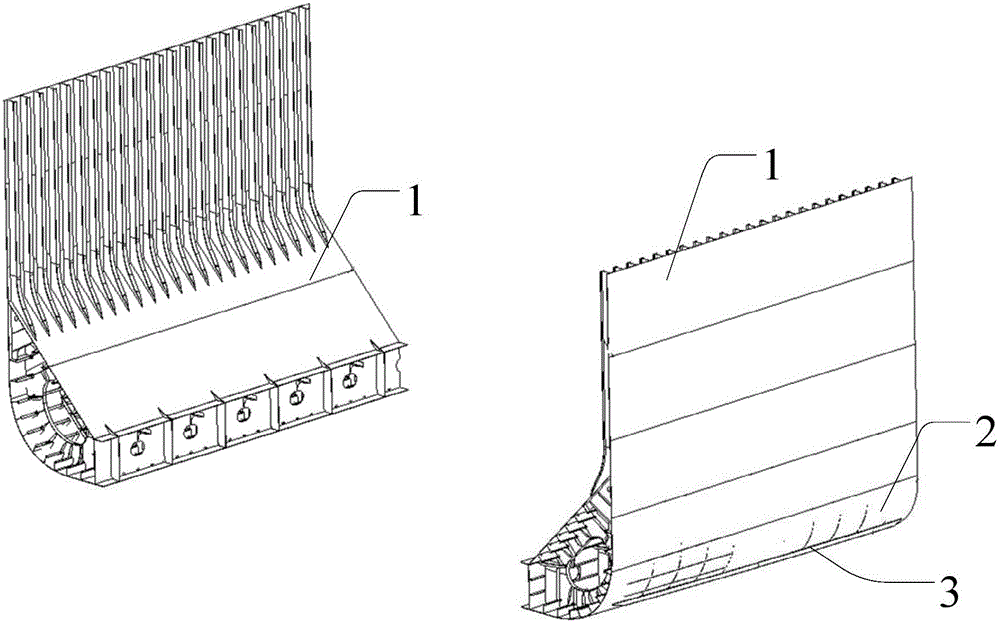

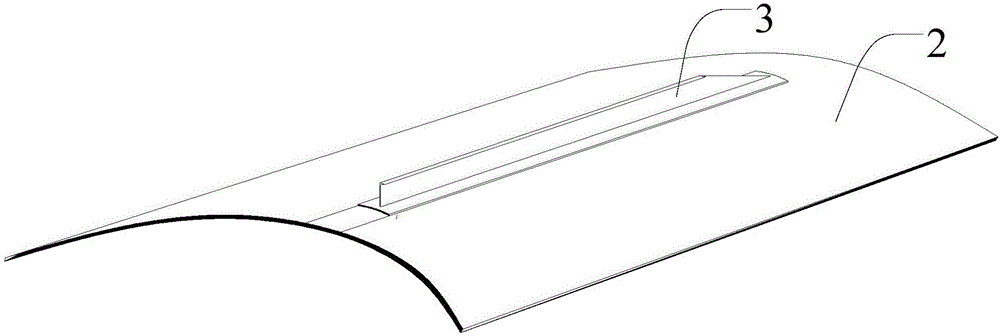

Ship bilge keel positioning and mounting method

ActiveCN106516001AOptimize the segmented construction processReduce installation difficultyVessel designingBilgeKeel

The invention provides a ship bilge keel positioning and mounting method. A bilge keel is mounted on an outer curved plate which is positioned in a bilge section. The method includes steps: S1, marking a positioning joining line on the outer plate, and marking a bilge keel mounting position line according to the positioning joining line and the bilge keel; S2, adopting a three-roll plate bending machine for linear curvature processing of the outer plate to form the outer curved plate; S3, using a moulding bed for transporting and positioning the outer curved plate; S4, mounting the bilge keel on the outer curved plate to form a combined section; S5, positioning and mounting the combined section on the bilge section according to the positioning joining line. At a bilge keel mounting stage, after completion of a large section group, curvature processing of the outer plate of the bilge section is performed before mounting of the bilge keel. A normal-posture faceup installation way of the bilge keel is optimized into a horizontal faceup installation way to lower installation difficulty. Bilge keel installation precision is optimized from rough installation to accuracy control, subsequent reworking is avoided due to angle control of the bilge keel, and the moulding bed guarantees linear precision of the outer curved plate in a placement and transport process to avoid subsequent reworking.

Owner:JIANGNAN SHIPYARD GRP CO LTD

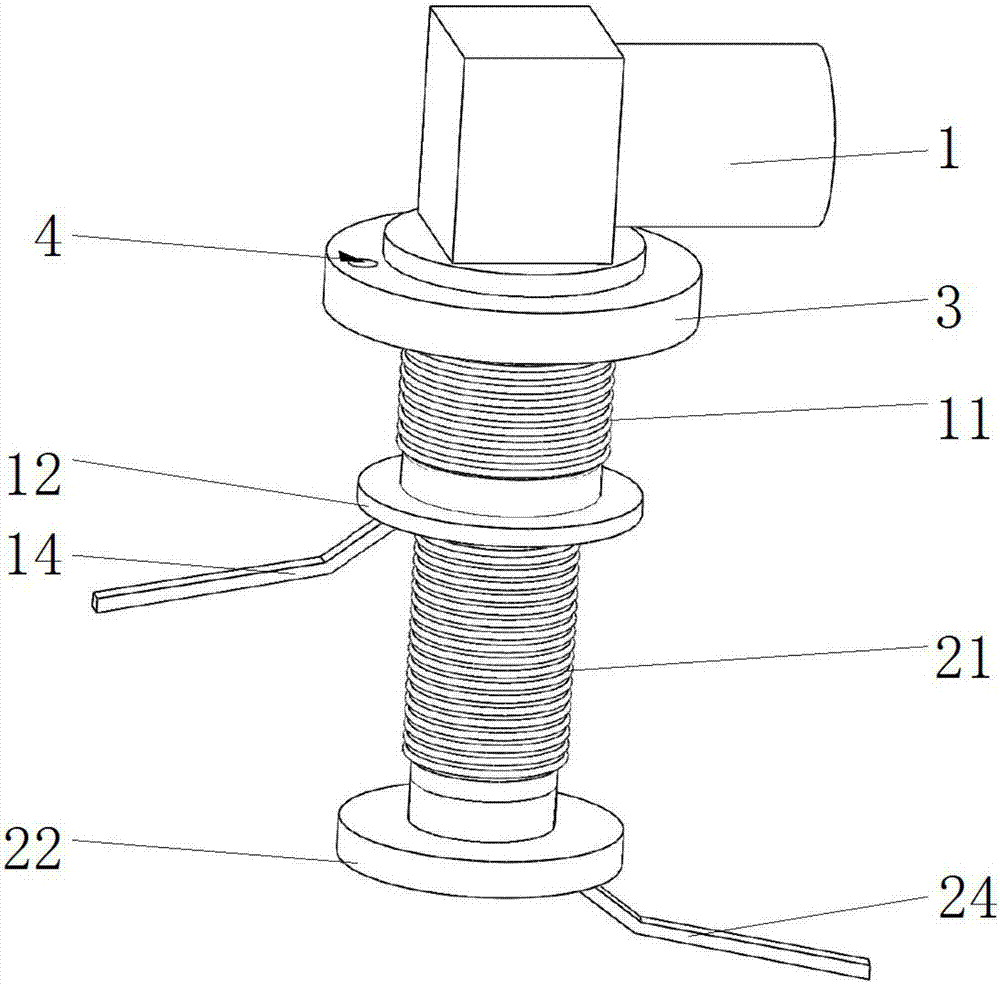

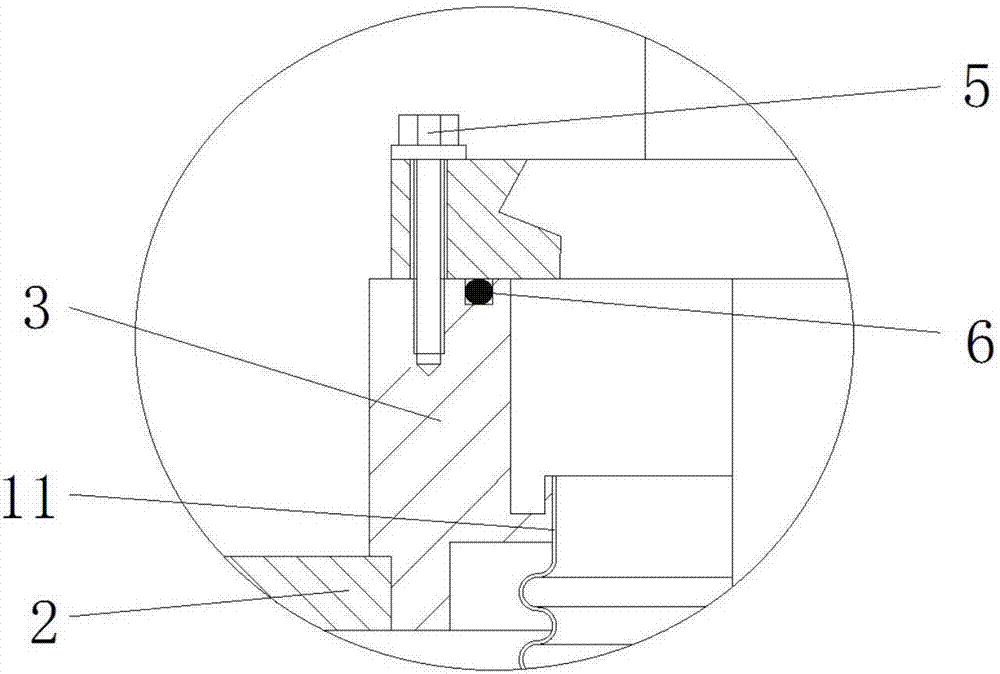

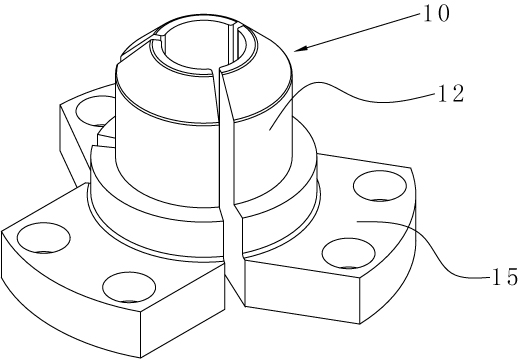

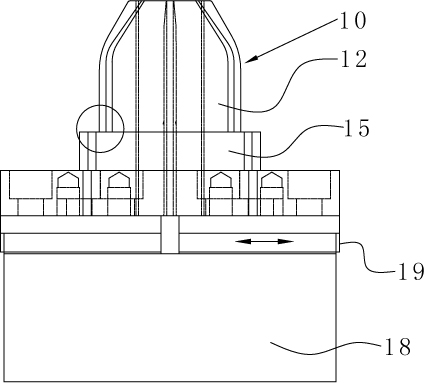

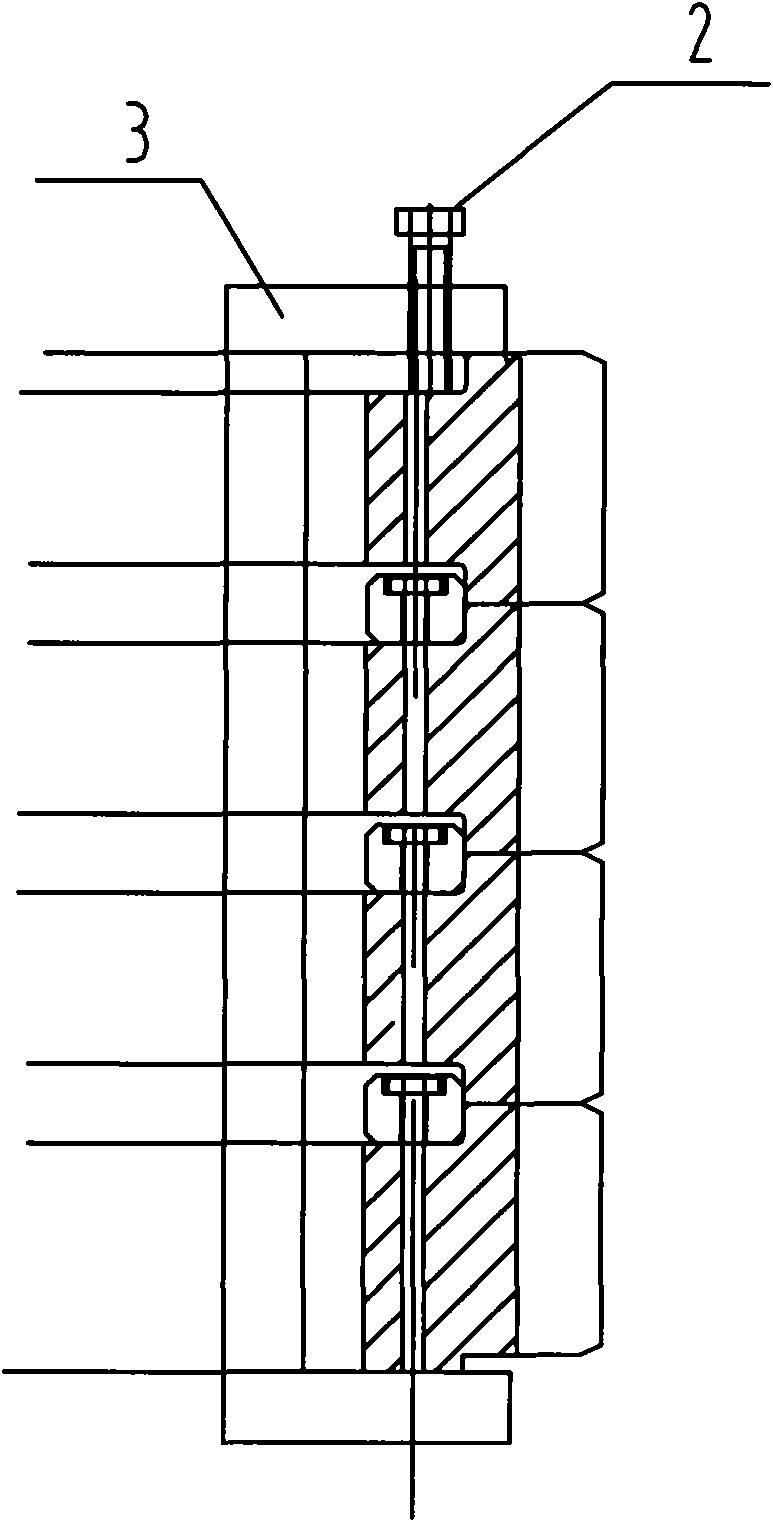

Refrigerating machine jacket structure for superconduction magnet and installation and disassembly method of refrigerating machine jacket structure

ActiveCN106960713AGuaranteed vacuum tightnessGuaranteed conduction heat leakageSuperconducting magnets/coilsFlangeMagnet

A refrigerating machine jacket structure for a superconduction magnet and an installation and disassembly method of the refrigerating machine jacket structure relate to the technical field of low-temperature engineering and superconduction magnets. The refrigerating machine jacket structure sequentially comprises a refrigerating machine flange seat (3), a primary corrugated pipe (11), a primary flange seat (12), a secondary corrugated pipe (21) and a secondary flange seat (22) from top to bottom, wherein thermal connection is formed between a cold screen and the primary flange seat 12), thermal connection is formed between a superconduction coil and the secondary flange seat (22), the refrigerating machine flange seat (3) and the primary flange seat (12) are connected by the primary corrugated pipe (11), and the primary flange seat (12) and the secondary flange seat (22) are connected by the secondary corrugated pipe (21). The refrigerating machine jacket structure has the characteristics of low conduction thermal leakage, high vacuum tightness, high thermal connection efficiency and long lifetime of a refrigerating machine.

Owner:杭州图锐科技有限公司

Round pin-inserted positioning device and tensioning and positioning round pin thereof

ActiveCN102121496AGuaranteed positioning accuracyGuaranteed positional stabilityWelding/cutting auxillary devicesBoltsEngineeringCar door

Owner:GUANGQI HONDA

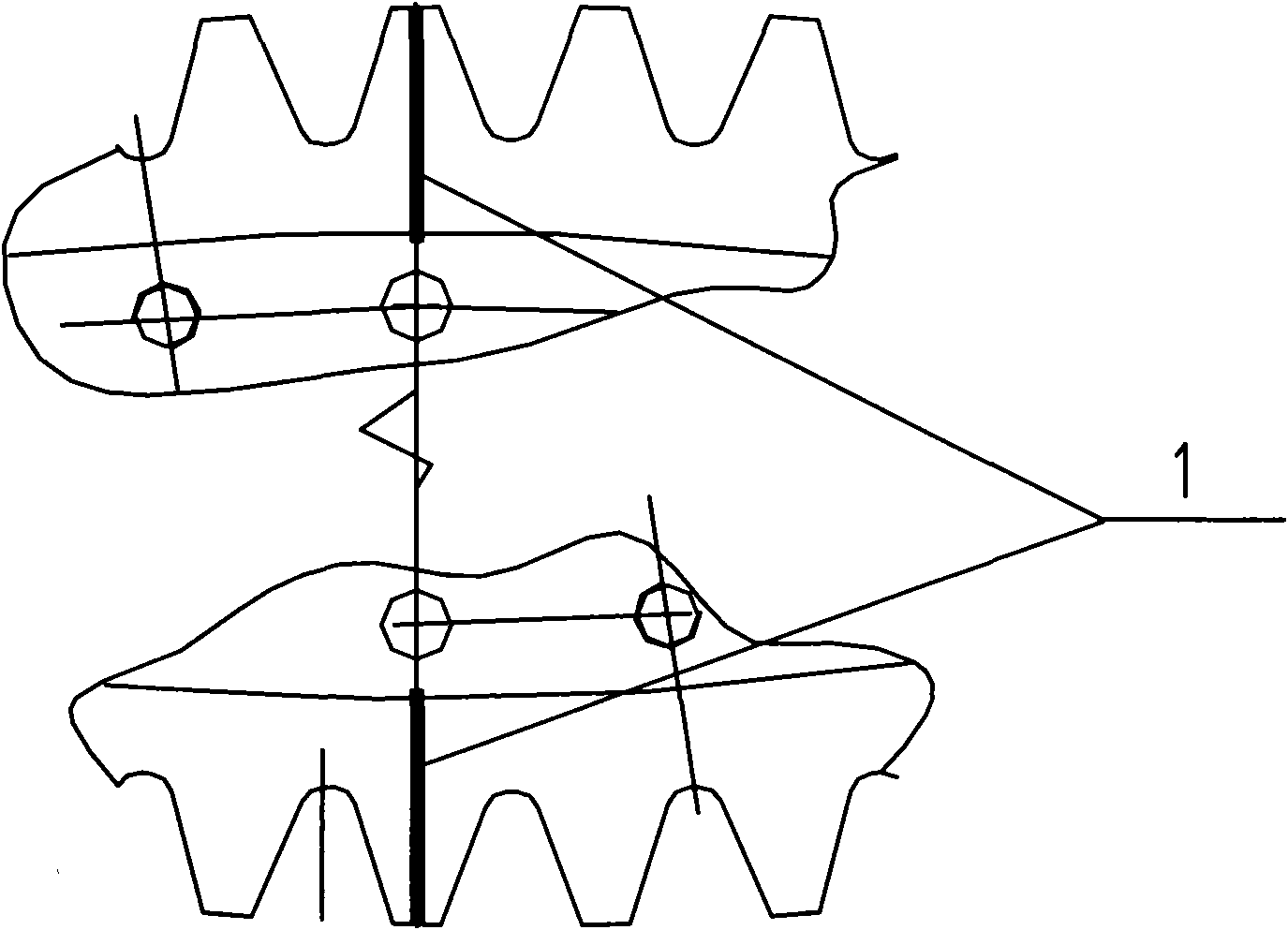

Method for processing large combination type herringbone gear

ActiveCN101862945ASave materialShorten the timeTransportation and packagingTrepanning drillsGear grindingHobbing

The invention discloses a method for processing a large combination type herringbone gear, which comprises the following steps of: forging; carrying out rough processing of the end surface, an incircle and an excircle on a processed workpiece by utilizing a lathe; drilling a hoisting hole; carrying out rough gear hobbing on the workpiece by utilizing a gear hobbing machine; carrying out tempering processing on a gear; semifinishing an inner hole, the end surface and an addendum circle by utilizing the lathe; drawing any pair of end surface gear central lines based on the end surface of one side of a reference groove, making a reference groove mark on an addendum and drawing a position line of each hole; drawing and drilling each hole by using a drilling machine; finishing and lathing the inner hole and both end surfaces of the lathe to a preset size; positioning based on a reference surface, carrying out correcting gear grinding on the addendum circle ; chambering, drilling and articulating each hole on a gear ring; and screwing a bolt and hinging the bolt and combining two gears into a pair. The invention has the advantages of material saving, cost reduction and mechanical performance improvement of products.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

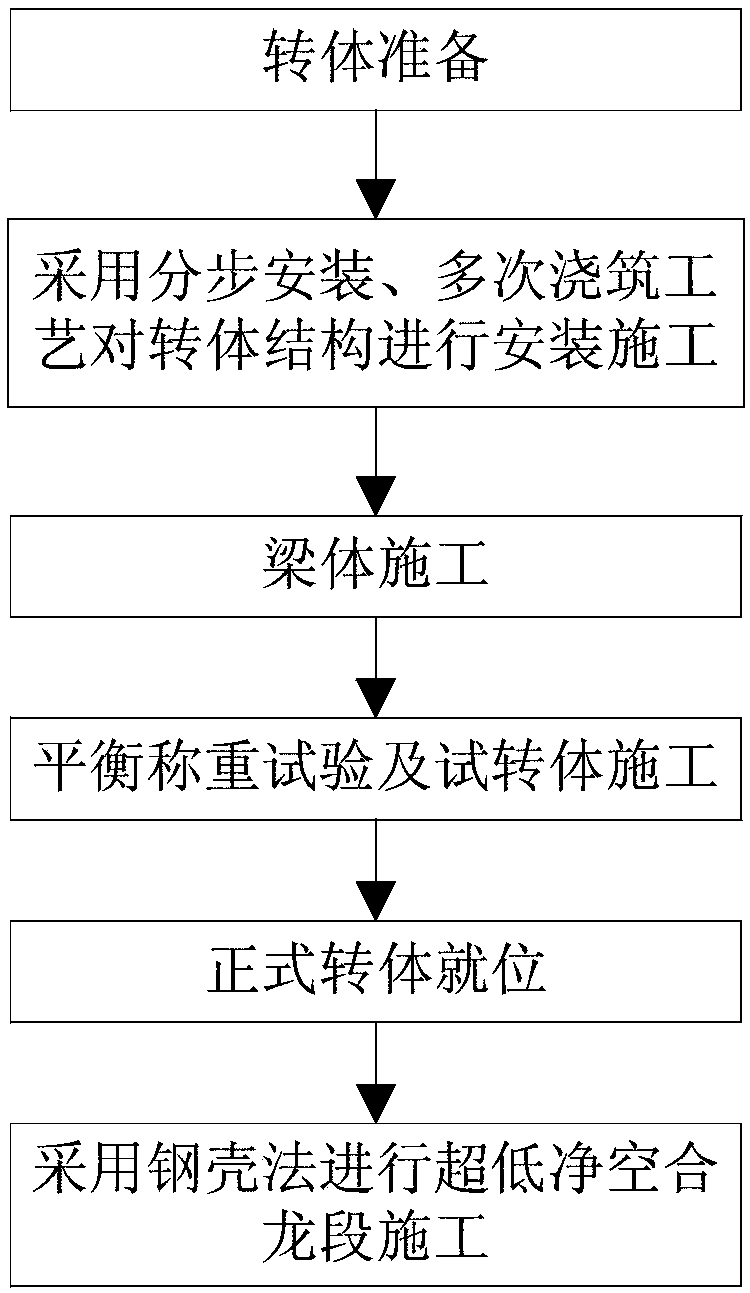

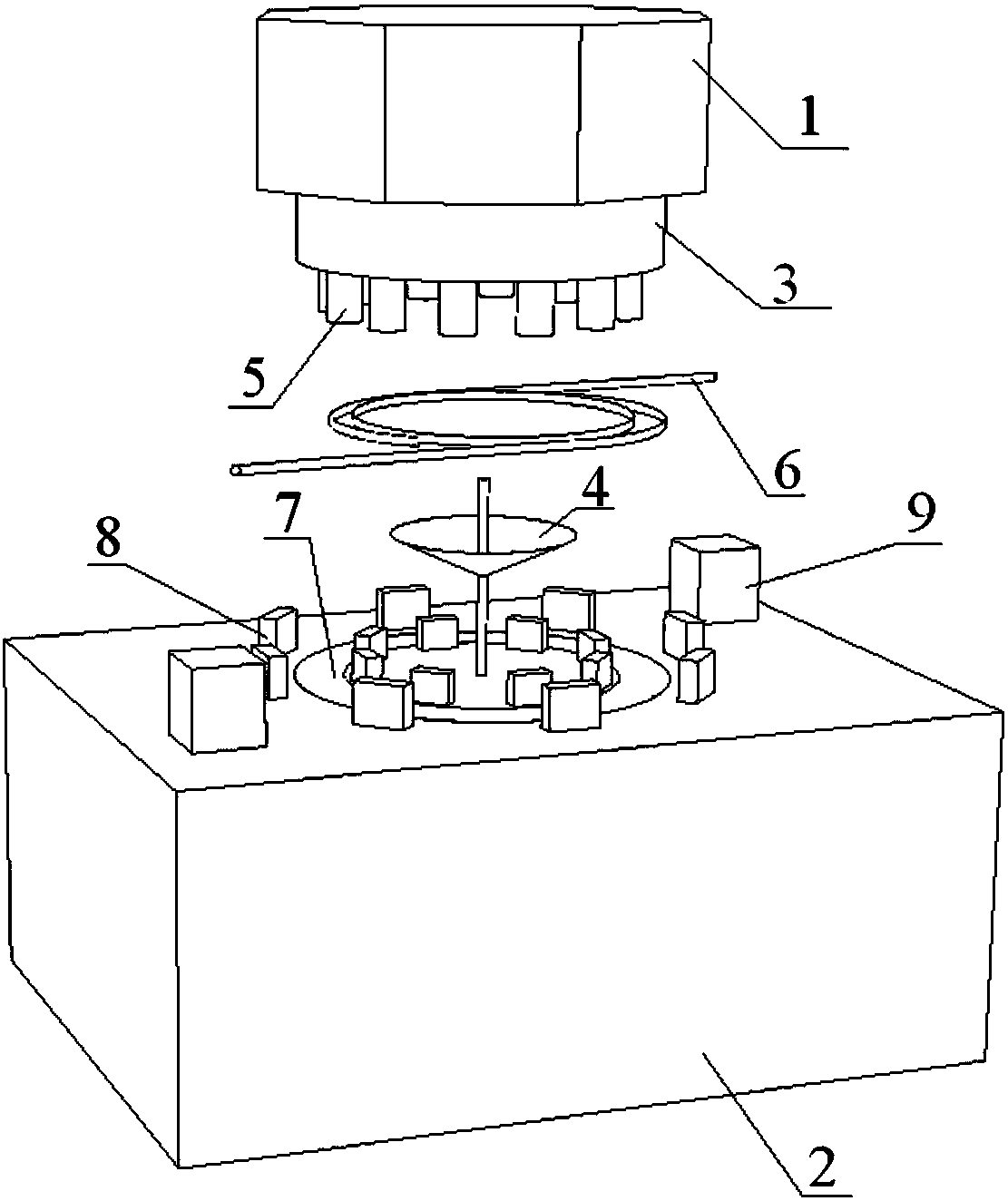

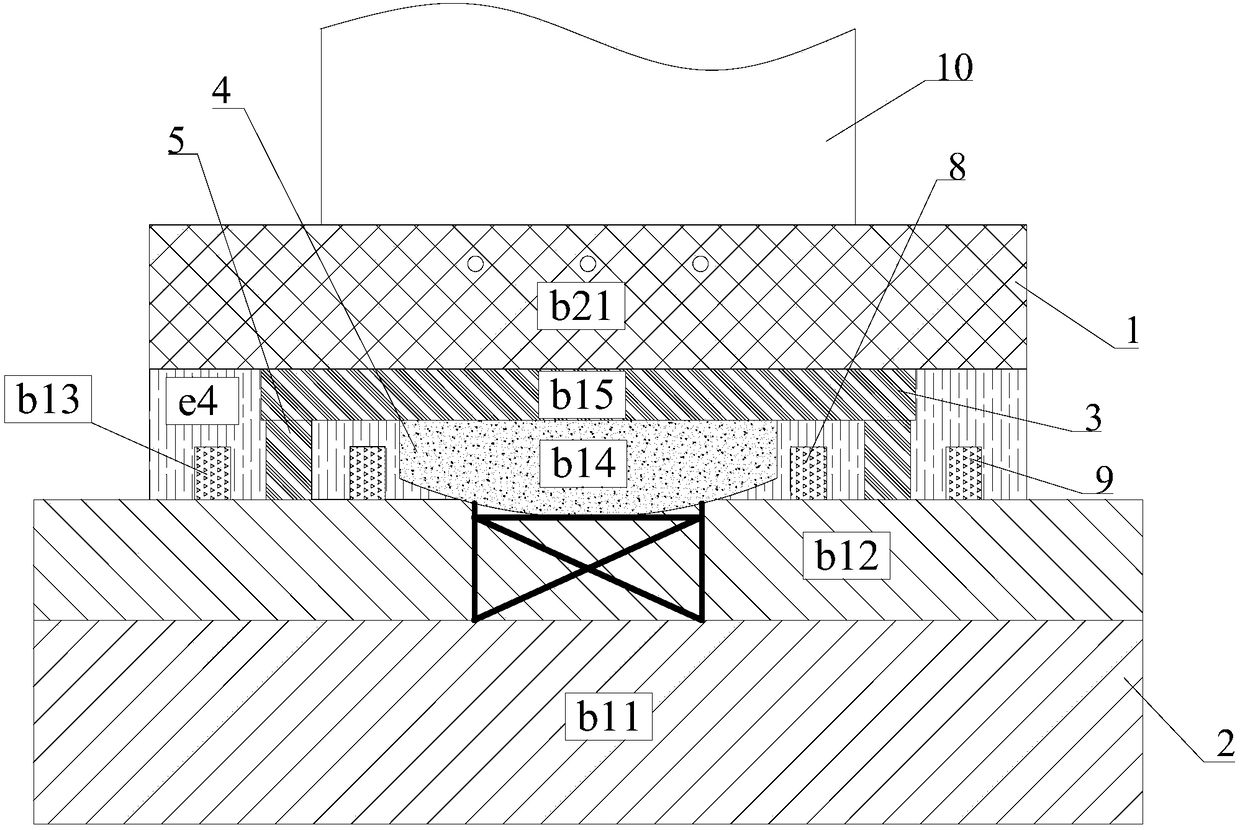

Construction method of low-clearance swing bridge across operational line

ActiveCN108589556AGuaranteed rotationReduce friction coefficientBridge erection/assemblySwing bridgeOperational amplifier

The invention discloses a construction method of a low-clearance swing bridge across an operational line. The construction method comprises the steps of preparing for swing, installing and constructing a swing structure by virtue of the techniques of step-by-step installation and multiple pouring, performing beam body construction, performing a balance weighing test and trial swing construction, allowing formal swing to be in place, and using a steel shell method to perform the construction of an ultra-low-clearance closure segment. The construction method of the low-clearance swing bridge across the operational line adopts a spherical hinge multistep installation precise control technique, a balance weighing test pre-weighting technique, a swing parameter correction and precise positioning technique and a closure segment ultra-low-clearance steel shell construction technique to meet specifications, precision of design drawings and quality requirements, and leads the way in swing spherical hinge installation precision, swing balance stability and precision control. The construction method solves the difficult problem of insufficient clearance under the bottom of the bridge, and ensures the safety of the operational line.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Universal member pre-buried node and installing method thereof

ActiveCN103205937AGuaranteed installation accuracyThe power transmission route is clearBridge erection/assemblyStructural engineeringSteel plates

The invention relates to a universal member pre-buried node. The universal member pre-buried node comprises a node plate, a plurality of screw rods and a plurality of locking bolts which are respectively in matching connection with the plurality of screw rods, wherein one end of each screw rod is provided with an inside thread, a plurality of via holes are formed in a locating steel plate, the plurality of screw rods respectively penetrate through the via holes in the locating steel plate and are welded with the locating steel plate together to be commonly pre-buried in concrete, the node plate is in a T shape and consists of a vertical straight plate and a horizontal straight plate, a plurality of first bolt holes for splicing a universal member are formed in the vertical straight plate, and a plurality of second bolt holes are formed in the horizontal straight plate, are correspondingly matched with the plurality of screw rods one by one and are respectively connected and fixed with a screw rod through a spring washer and a locking bolt. According to the universal member pre-buried node disclosed by the invention, the screw rods are stressed, a force transmission route is definite and reasonable, the stress performance is good, the safety and reliability are high, and the appearance of concrete can also be ensured without influence.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com