Large offshore platform split-type conduit frame structure suitable for shallow-water marine float-over mounting, and mounting method thereof

A technology for offshore platforms and jackets, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems that threaten the long-term safe and stable operation of platforms, significant dynamic effects on upper platforms, and restrict equipment layout schemes, etc. The force is reasonable, the construction is convenient and accurate, and the effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

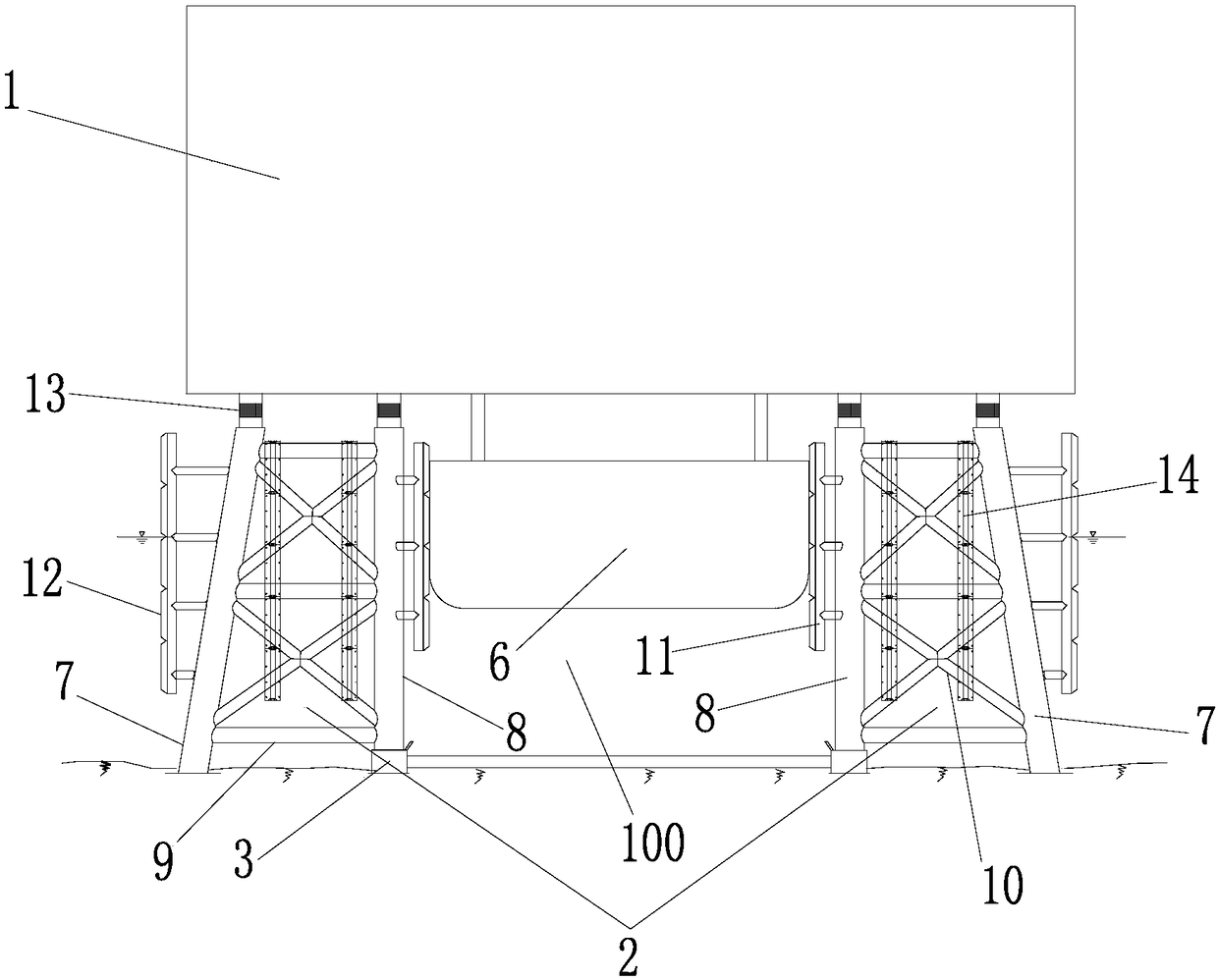

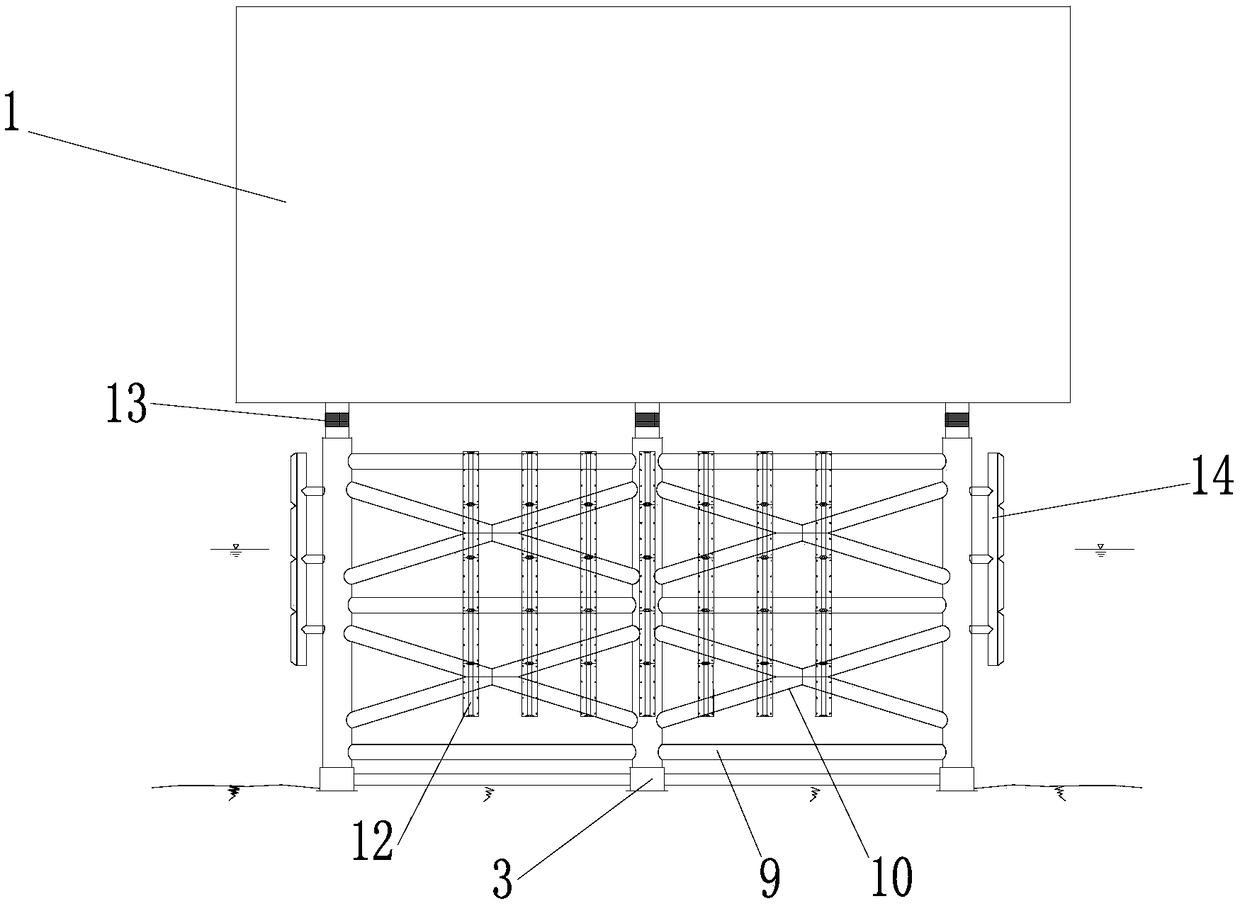

[0042] Such as Figure 1~Figure 7 As shown, this embodiment is an offshore electrical platform 1 with a capacity of 1100 MW, and the water depth of the sea area of the wind farm is 14 m. The upper platform 1 is an integral closed structure, its size is 88m×72m×36m, and the total weight of the upper platform 1 is about 20000t. The overall construction of the large offshore electrical platform 1 is completed on land, and then transported to the sea area of the wind farm for float-over installation.

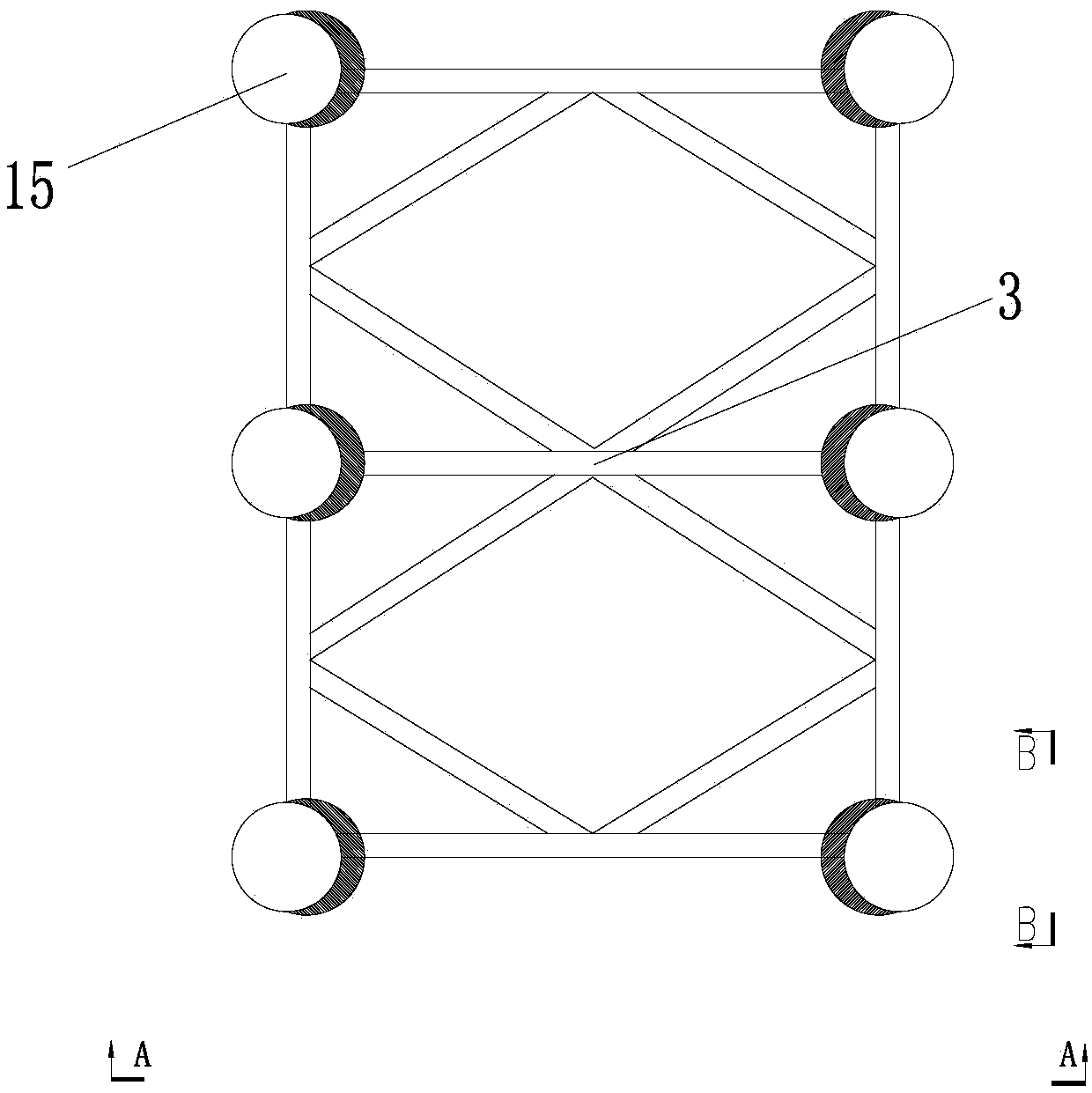

[0043] Such as Figure 1~Figure 2 As shown, the split jacket structure of this embodiment is provided with two jackets 2 and their associated components, a positioning frame 3 and twelve steel pipe piles 4,5. Two independent jackets 2 are arranged on the two wings along the longitudinal direction (longitudinal direction) of the platform 1, and a certain hollow area 100 is reserved between the two jackets 2 to ensure the entry and exit of the barge 6 during float-over installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com