Patents

Literature

9695results about How to "Avoid offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

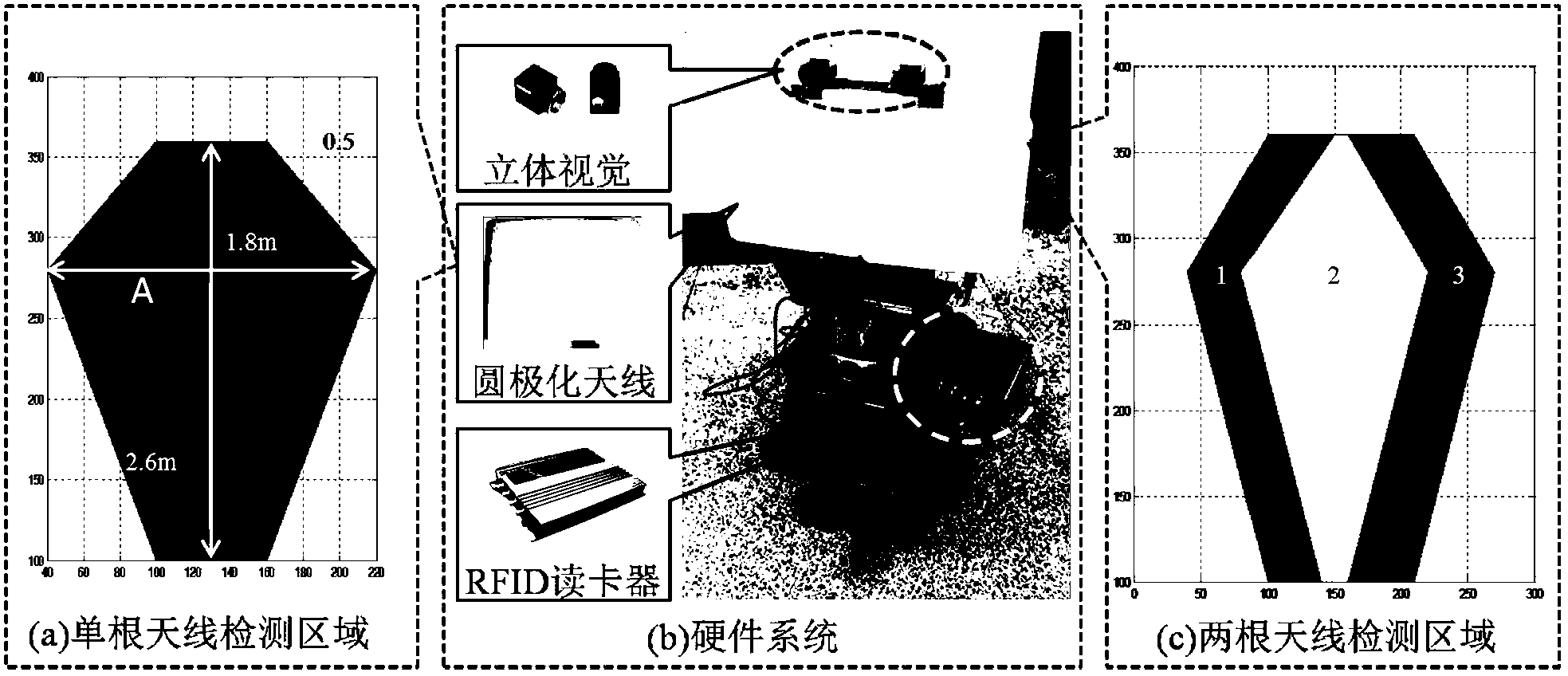

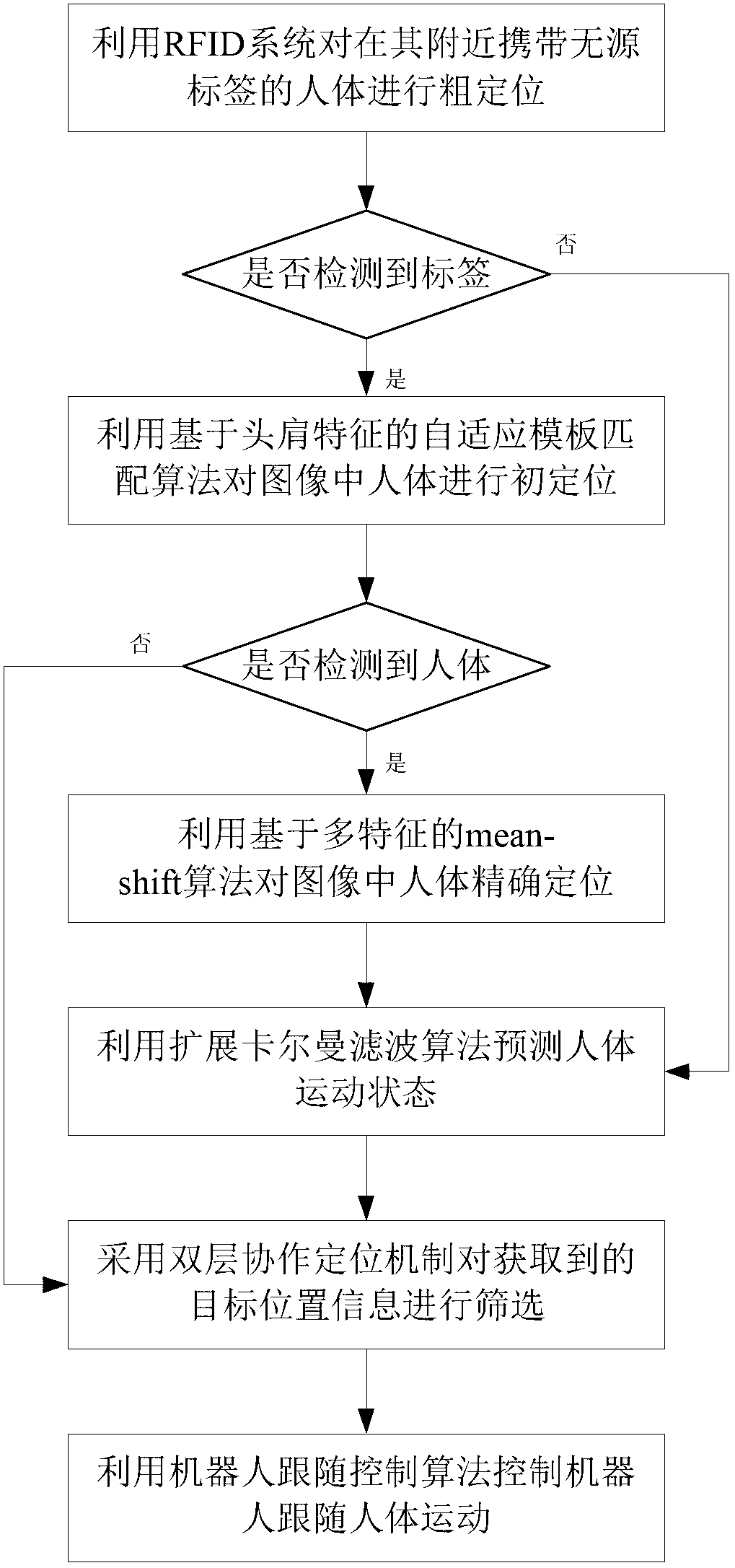

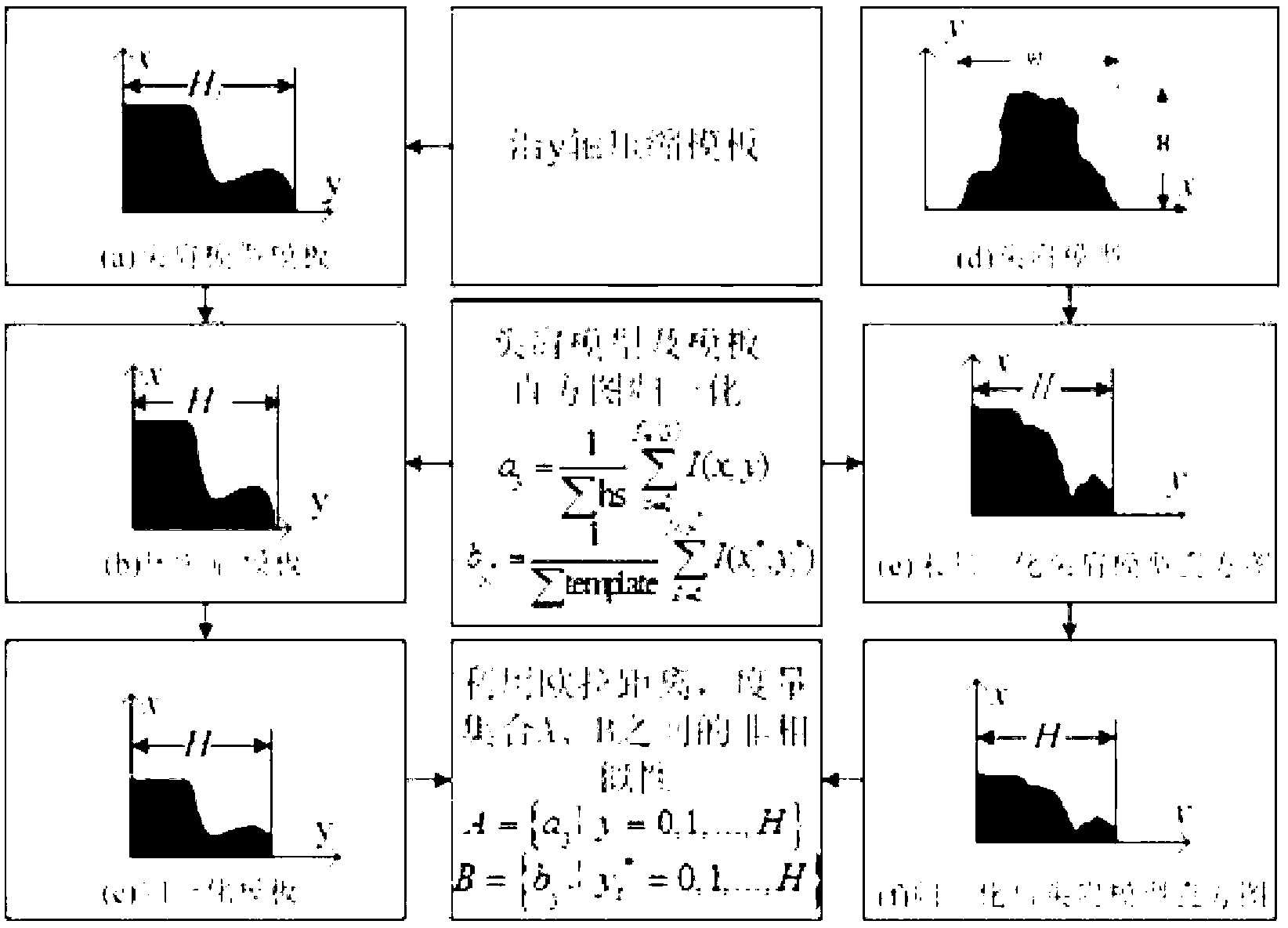

Multi-feature multi-sensor method for mobile robot to track moving body

InactiveCN103268616AEliminate the effects ofEnhanced description abilityImage analysisHuman motionVisual perception

The invention belongs to the crossing field of computer vision and intelligent robot, and discloses a new multi-feature multi-sensor method for a mobile robot to track a moving body. The method comprises the following steps: 1, coarsely positioning a body carrying a passive tag around a radio frequency identification (RFID) system by using the RFID system; 2, initially positioning the body in an image by using an adaptive template matching algorithm based on head and shoulder features; 3, accurately positioning the body in the image by using a multi-feature-based mean-shift algorithm; 4, predicting the moving state of the body by using a extended Kalman filter algorithm; 5, screening the acquired target position information by using a double-layer collaboration positioning mechanism; and 6, controlling the robot to move along with the body by using a robot following control algorithm. By the method, bodies with different poses can be tracked, the problem that the tracking is influenced when a target suddenly turns and is shielded is solved, and the robot can accurately, stably and continuously track the moving body.

Owner:BEIJING UNIV OF TECH

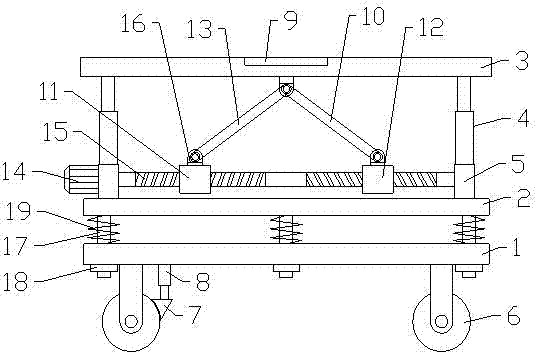

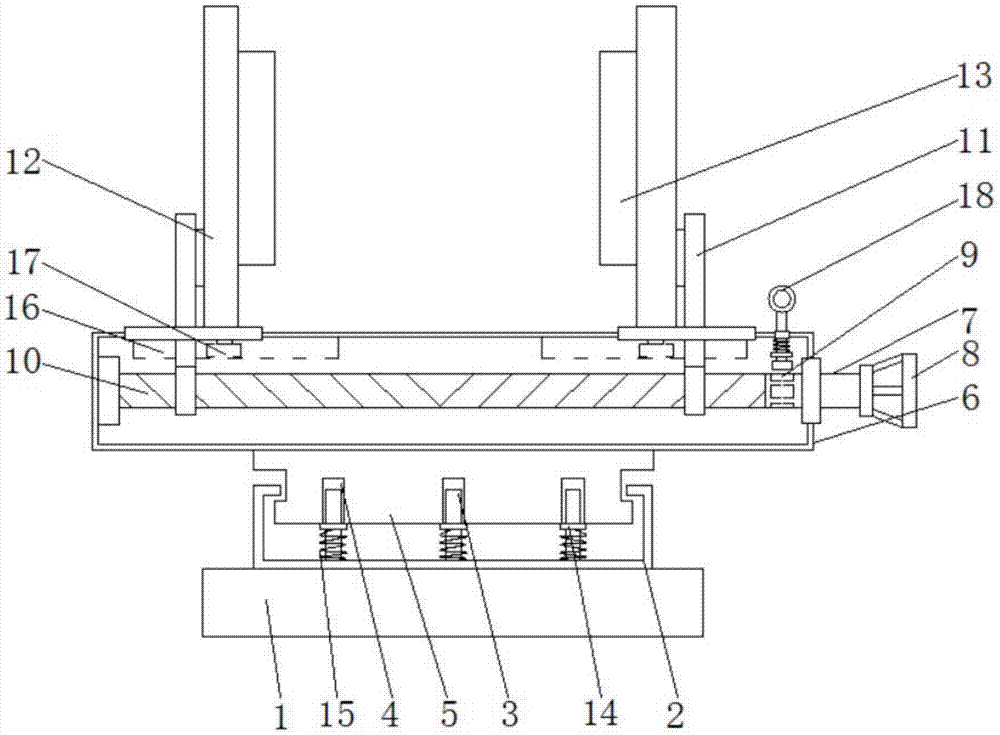

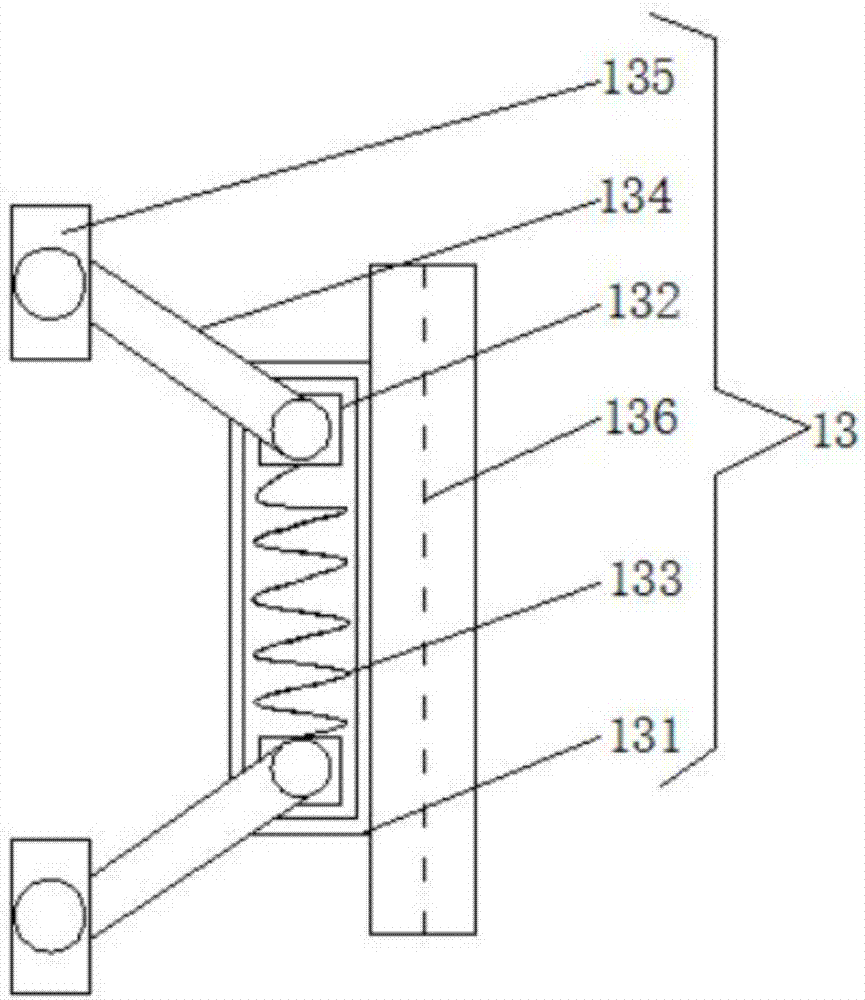

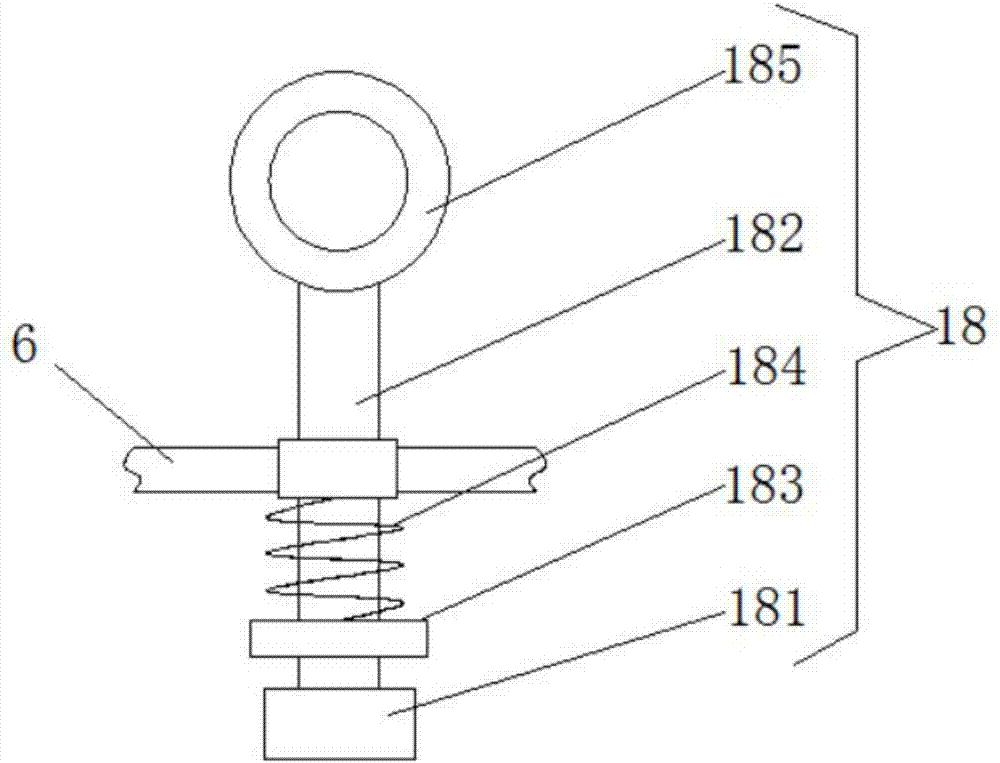

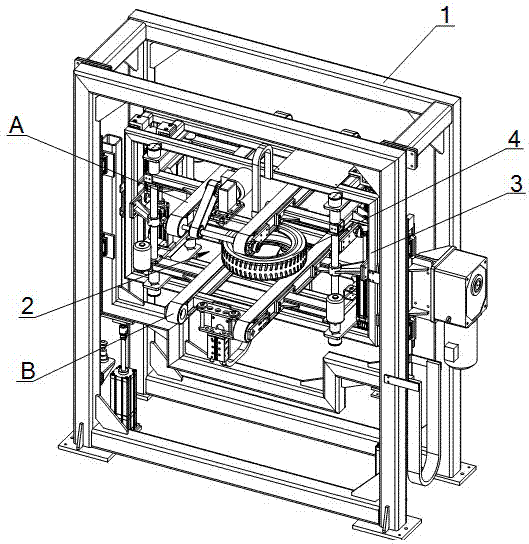

Textile machine supporting device

InactiveCN107327661AGuaranteed stabilityAvoid offsetPortable framesNon-rotating vibration suppressionHinge angleTextile

The invention discloses a textile machinery supporting device, which comprises a supporting base, a supporting plate, a workbench, a supporting sleeve rod, a No. 1 connecting rod, a No. 2 sliding block, a No. 1 sliding block, a No. 2 connecting rod, a hinge seat and shock The upper surface of the support plate is symmetrically fixed with a support vertical plate, the rotating frame on the two support vertical plates is provided with a screw, the upper surface of the support vertical plate is symmetrically fixed with a support sleeve rod, and the workbench is fixed on the support sleeve rod. At the top, the No. 2 slider is set on the outer ring of the left end of the lead screw by thread connection, the No. 1 slider is set on the right end outer ring of the lead screw by thread connection, and the lower surface of the middle part of the workbench is connected to the outer ring of the No. 2 slider. The upper surfaces are connected through the No. 2 connecting rod, and the middle lower surface of the workbench is connected with the upper surface of the No. 1 slide block through the No. 1 connecting rod. The invention can adjust the height according to the use requirements of the textile machine, and at the same time solves the problems of inconvenient movement, poor shock absorption and the like.

Owner:黄忠南

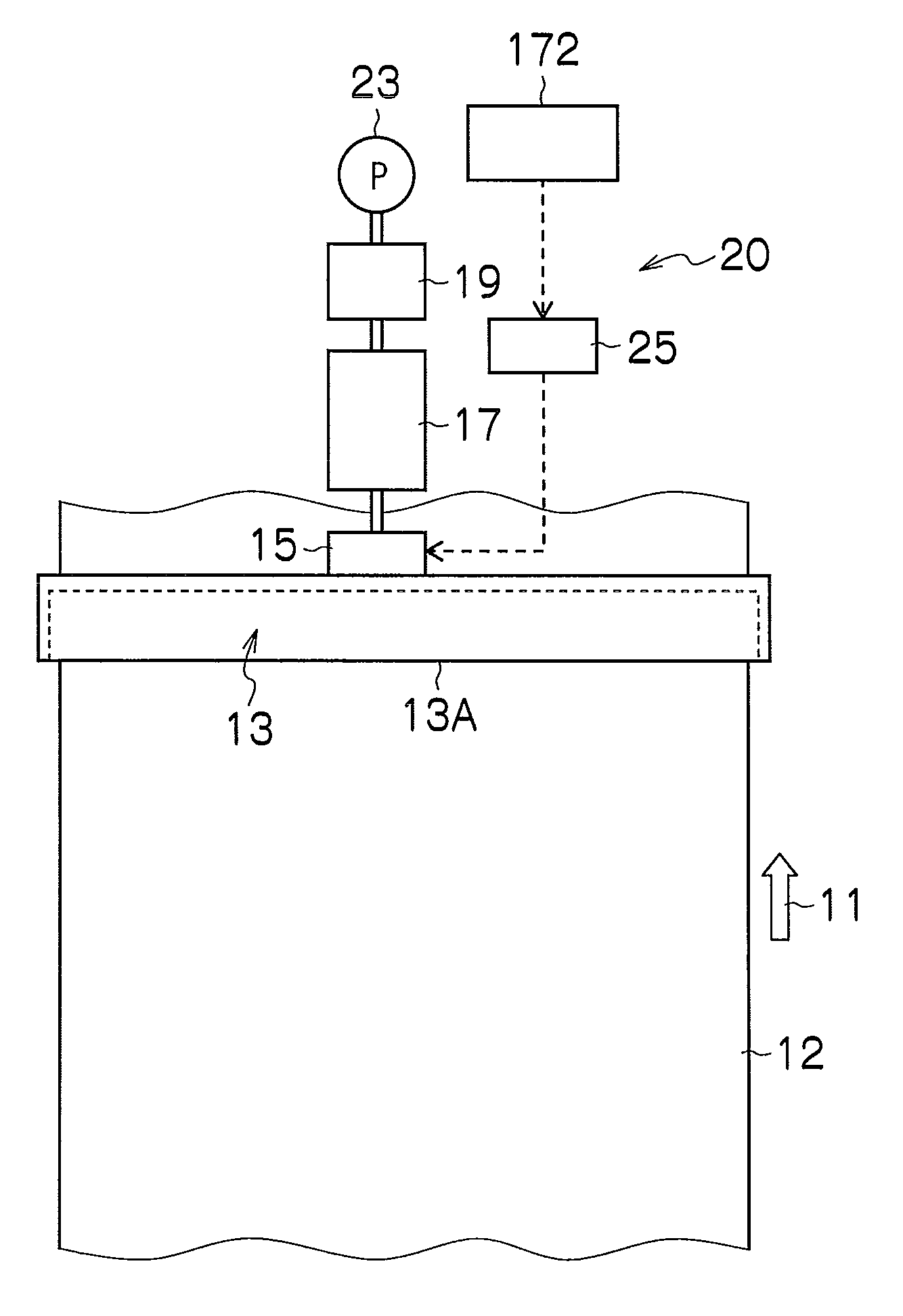

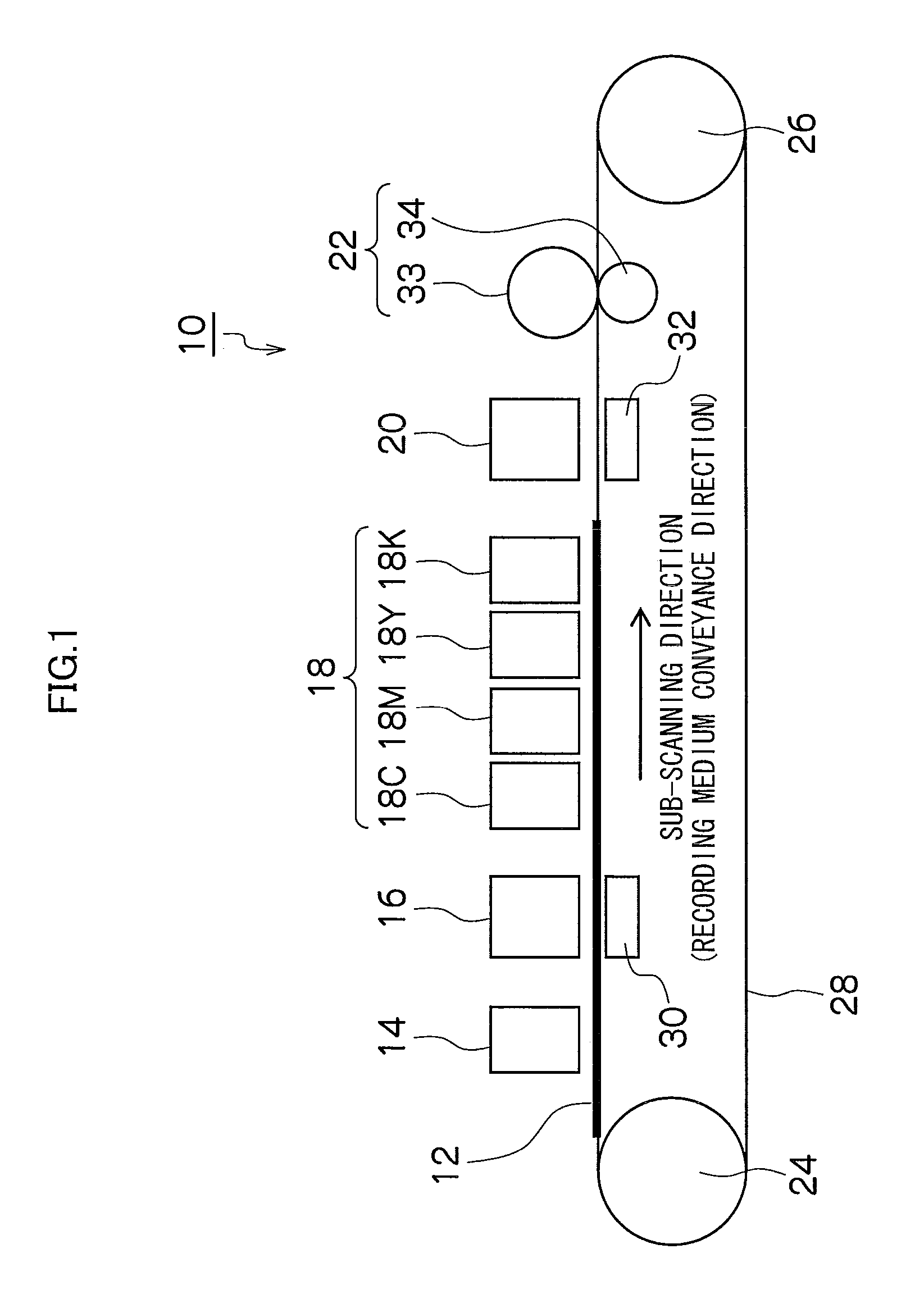

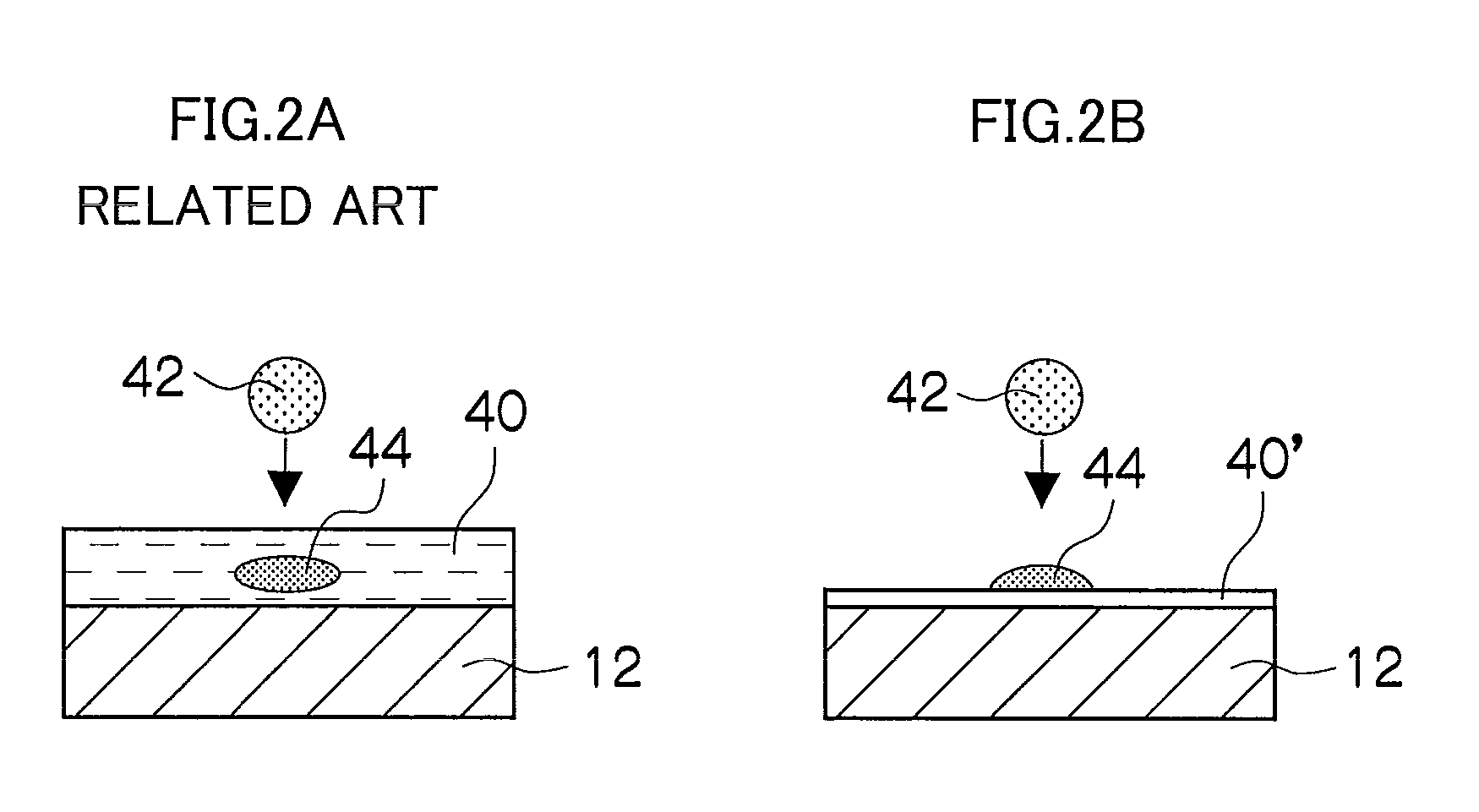

Image forming method and apparatus

InactiveUS20090315926A1Avoid offsetAvoid curlDuplicating/marking methodsOther printing apparatusEngineeringImage formation

The image forming method forms an image on a recording medium by using aqueous ink and treatment liquid. The ink contains coloring material, and the treatment liquid contains a component which reacts with the coloring material. The image forming method includes: a treatment liquid deposition step of depositing the treatment liquid onto the recording medium; an ink deposition step of ejecting and depositing droplets of the aqueous ink in accordance with image information, onto the recording medium on which the treatment liquid has been deposited in the treatment liquid deposition step; an ink drying step of drying an ink layer which has been formed on the recording medium by reaction between the treatment liquid deposited in the treatment liquid deposition step and the aqueous ink deposited in the ink deposition step, such that an amount of water originating from the aqueous ink and still remaining on the recording medium after the ink drying step is not more than 4.0 g / m2; and a fixing step of fixing the ink layer which has been dried in the ink drying step on the recording medium by applying heat and pressure to the ink layer.

Owner:FUJIFILM CORP

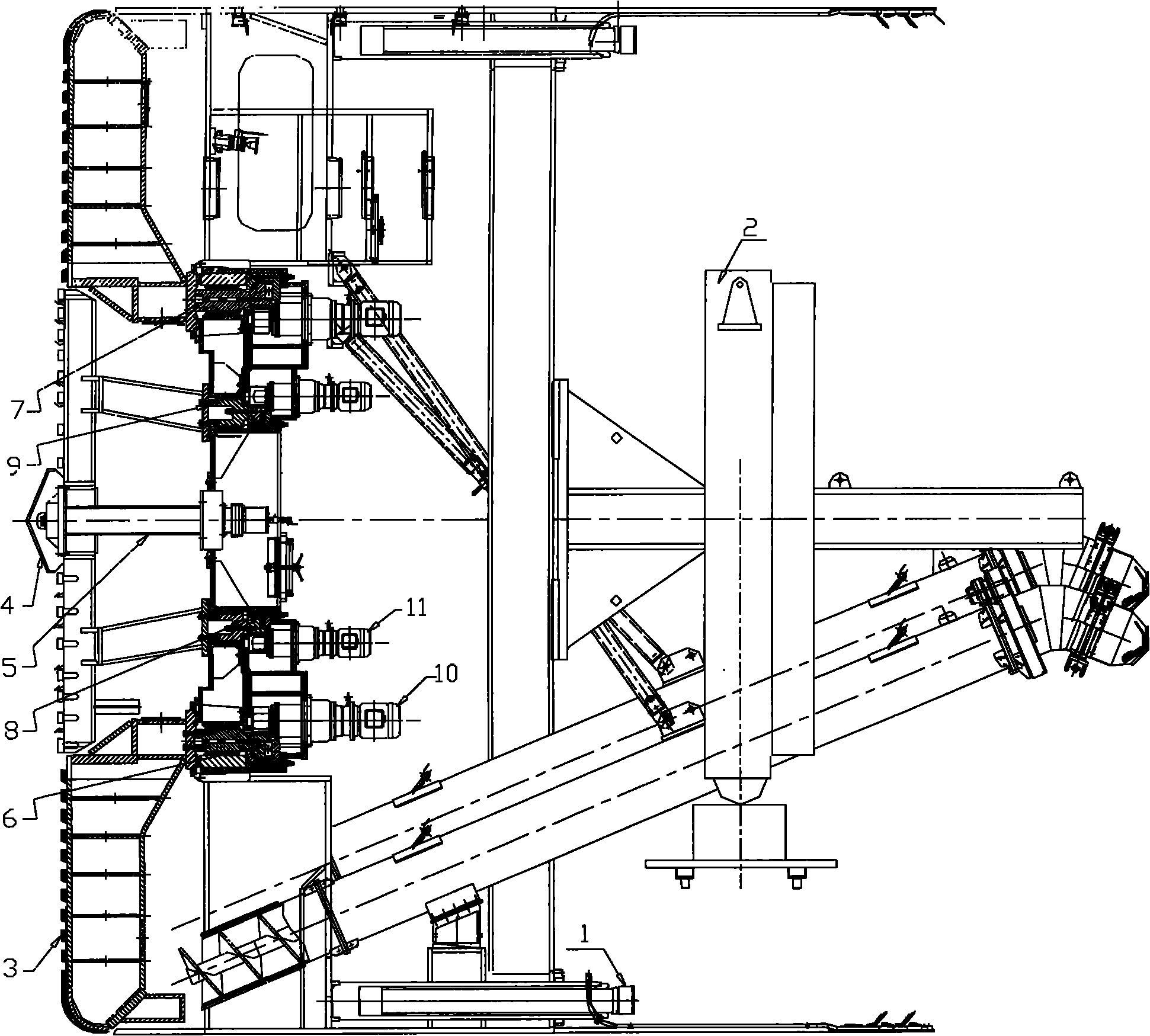

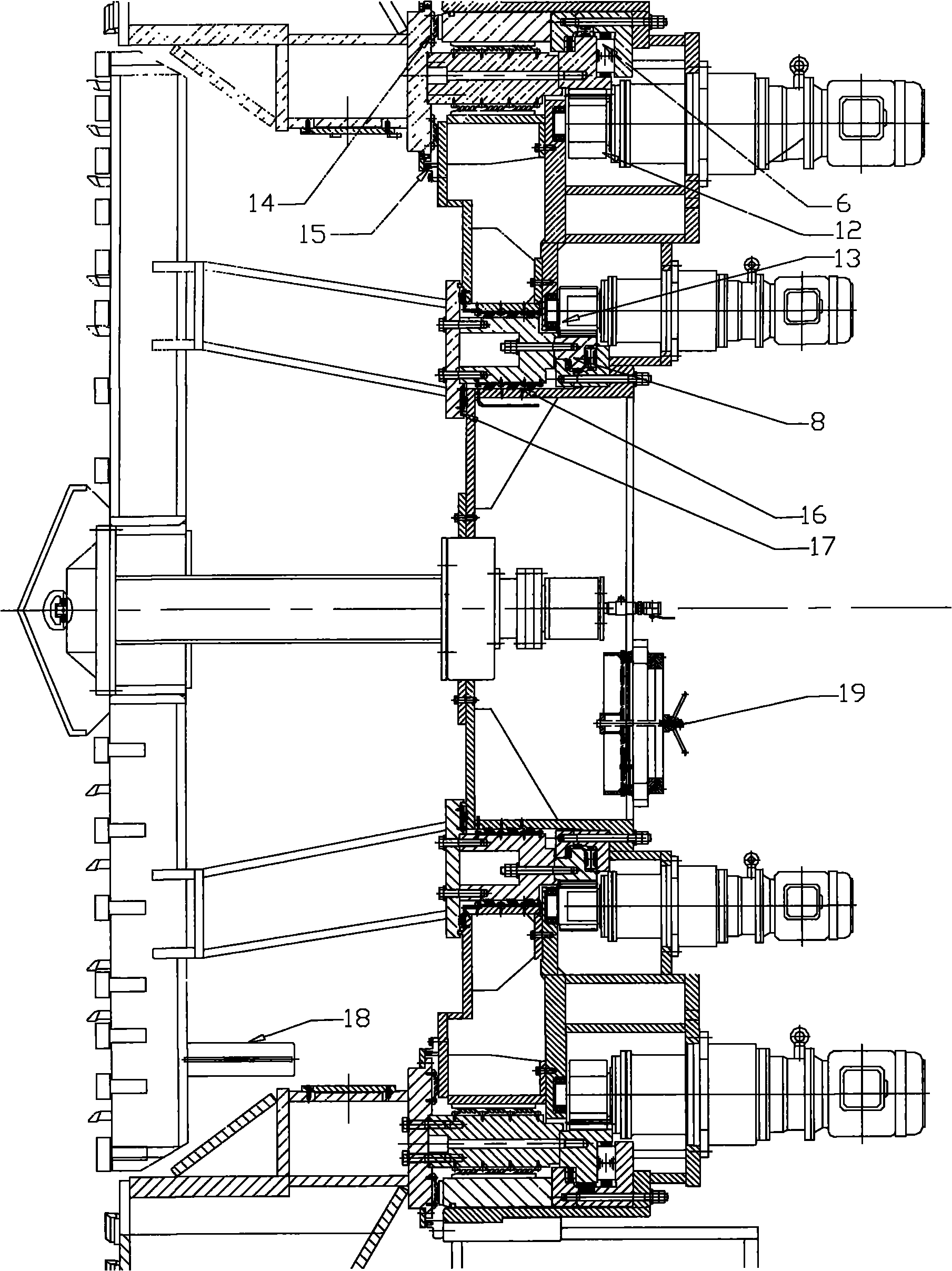

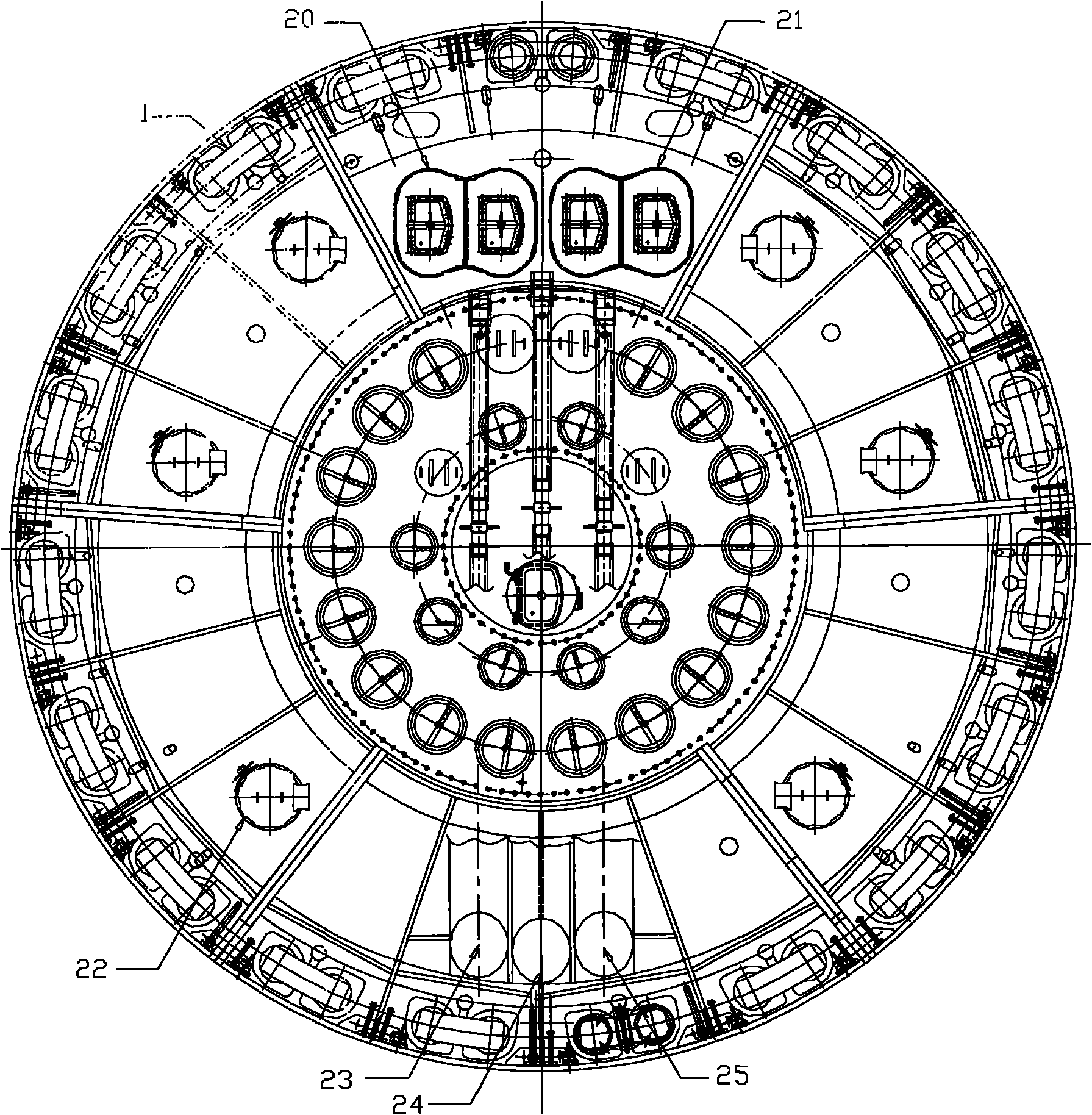

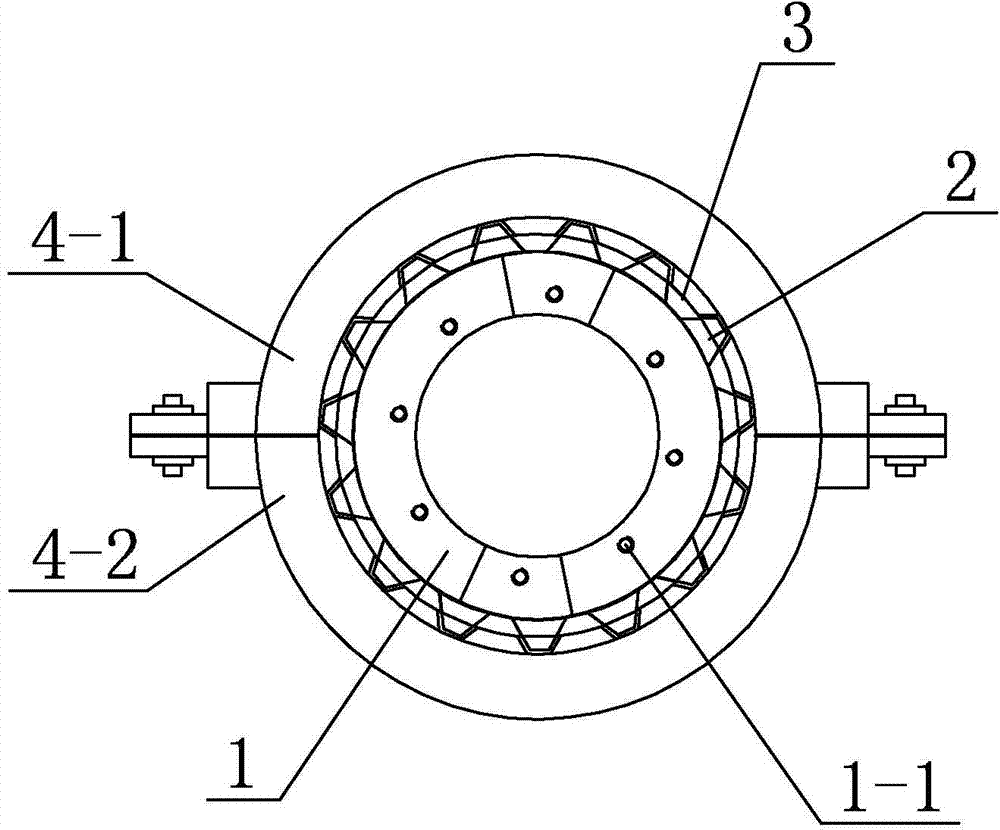

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

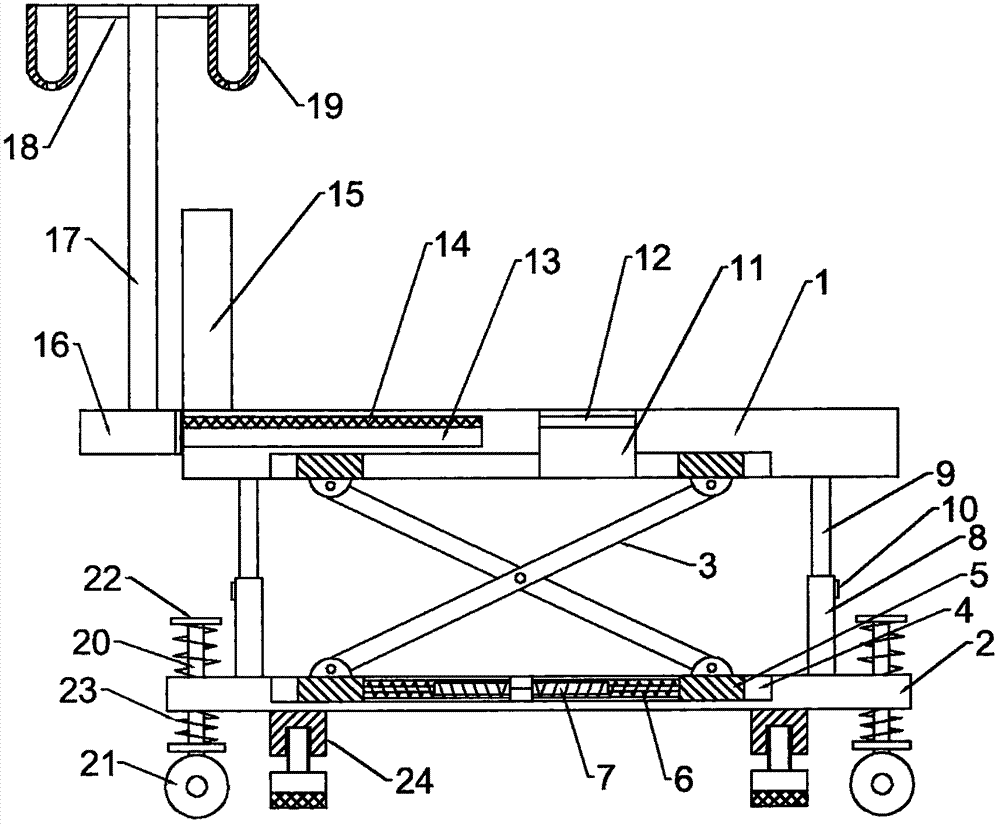

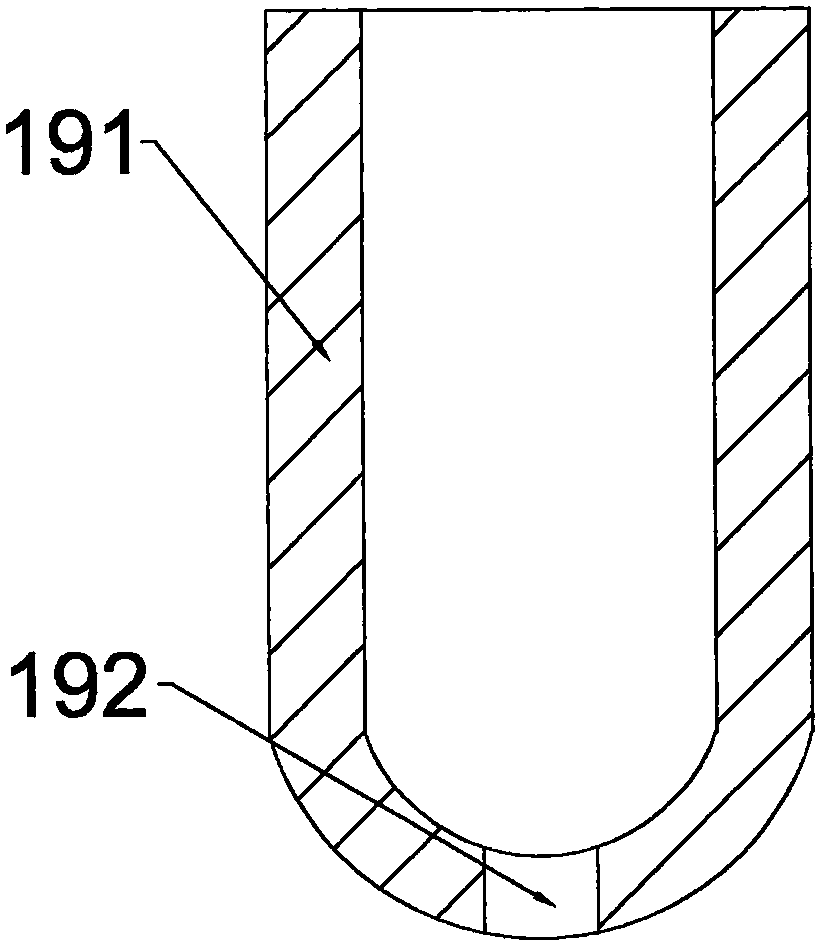

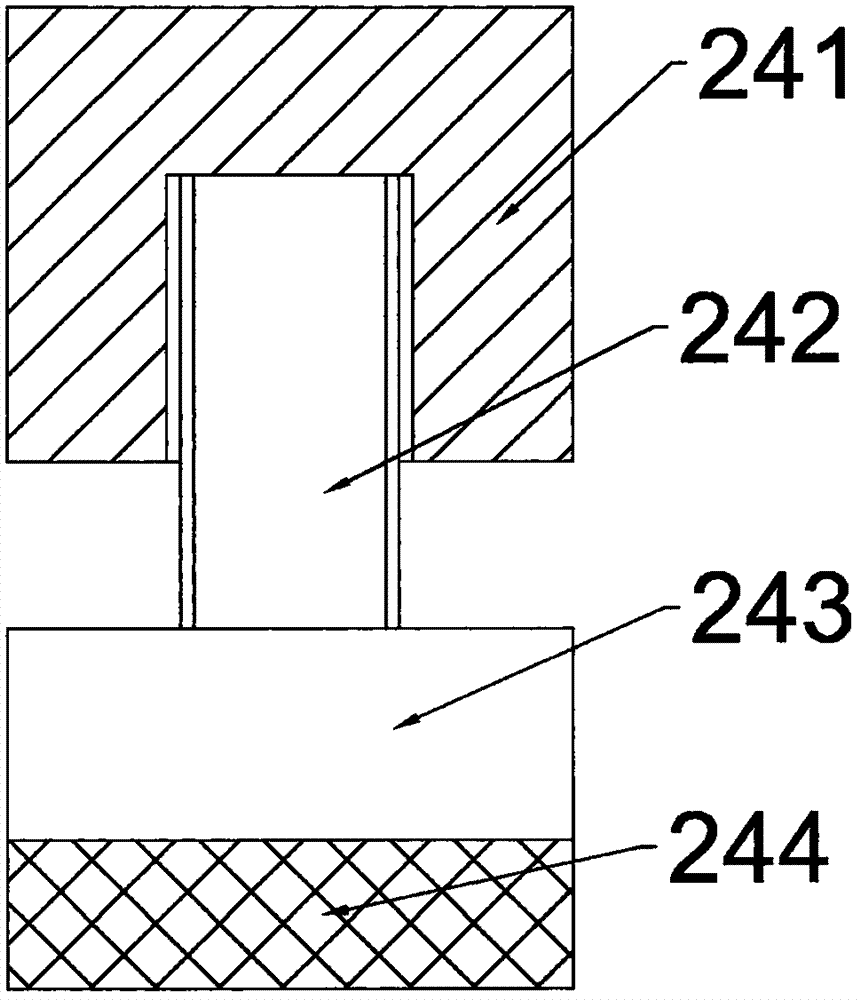

Nursing bed for gastroenterology department of hospital

InactiveCN107157675AGood for getting in and out of bedReduce manufacturing costNursing bedsStable stateEngineering

The invention discloses a nursing bed for the gastroenterology department of the hospital. The nursing bed comprises a bed board, a base, support frames, sliding chutes, sliders, telescopic booms, extension springs, support barrels, support rods, a through hole, a movable baffle plate, an arc-shaped support plate, a backrest, a fixing block and a telescopic rod, wherein a connecting rod is arranged on the top of the telescopic rod, infusion bottle racks are arranged on the connecting rod, vertical rods are arranged at four corners of the base in a penetrating manner, rolling wheels are mounted at the lower ends of the vertical rods, limiting boards are arranged at the upper and lower ends of the vertical rods, and damping springs are arranged at the positions, on the outer parts of the upper and lower sides of the base, of the vertical rods; stabilizing devices are further mounted at the lower part of the base, and each stabilizing device comprises a connecting block, a screw rod and a cushion block. The nursing bed is reasonable in structure, convenient to use, and stable in height adjustment, the conversion between the moving state and the stable state of the bed body can be conveniently realized, a patient can relieve the bowels without the need of getting out of bed, the damping effect is good, the pressure born by the rolling wheels can be alleviated, and in addition, friction cushions can prevent the deviation of the nursing bed.

Owner:刘云海

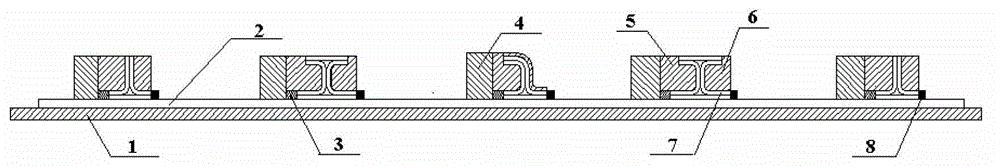

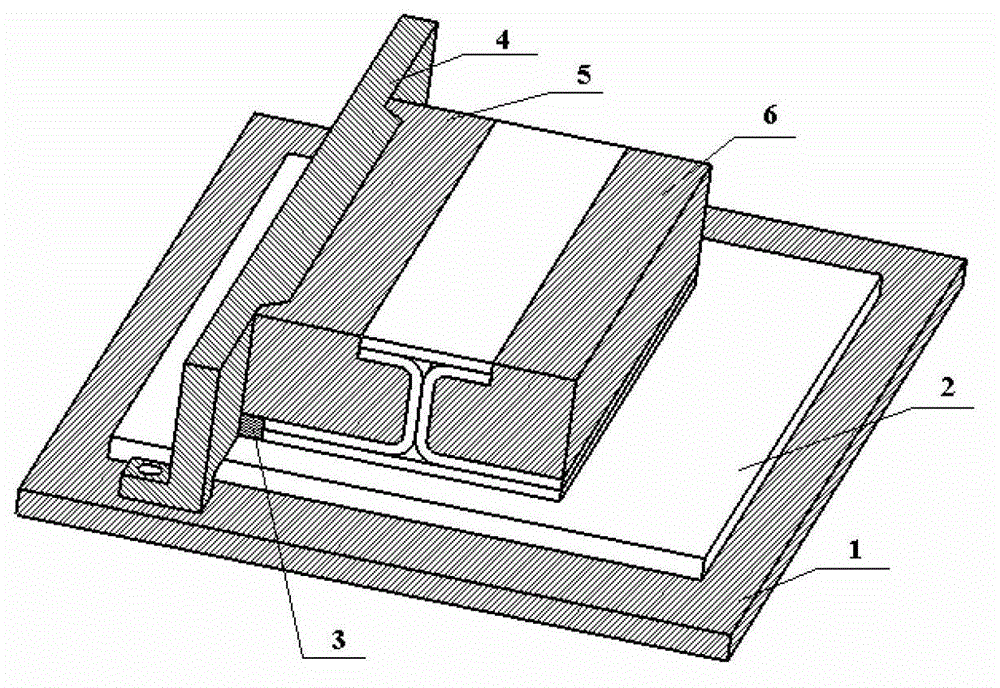

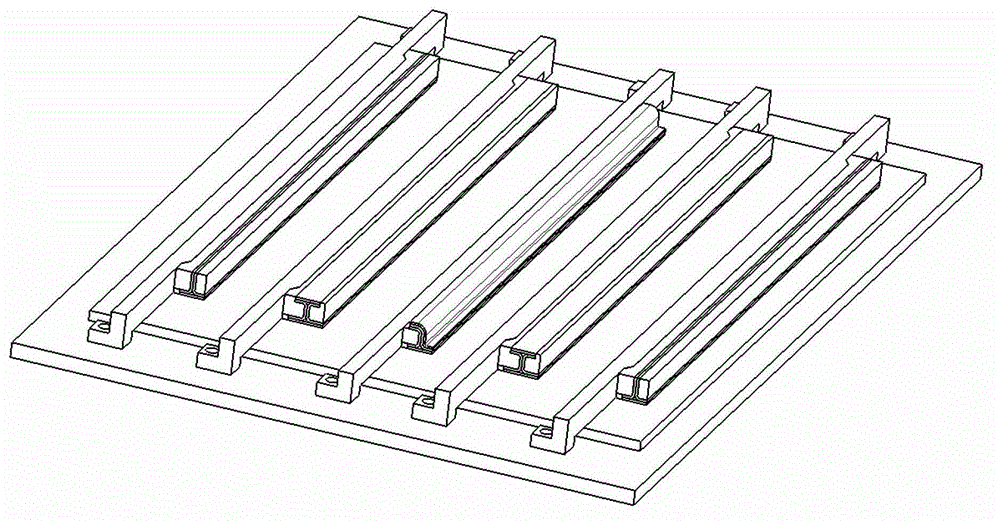

Method for forming control of long joist axial line of composite material stiffened wall panel

The invention belongs to technologies of composite material forming, and relates to a method for forming control of a long joist axial line of a composite material stiffened wall panel in an aviation aircraft. The method is a fixture method suitable for forming control of long joist axial lines of various types, such as a T shape, an I shape, a J shape and the like, of long joist composite material stiffened wall panels. A forming fixture mainly comprises a long joist forming mold A and a long joist forming mold B, a skinned curing mold, a cushion block and an axial line positioning mold. The two ends of the long joist forming mold A are designed to be dovetail-shaped and are closed matched with the axial line positioning mold to control the deviation of a long joist in the length direction of the axial line; and the axial line positioning mold is fixed on the skinned curing mold through positioning pins to control left and right deviations of the long joist axial line. By the forming fixture method, the molding surface quality and the position accuracy of a long joist product are effectively improved, and the long joist axial line is prevented from deviation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

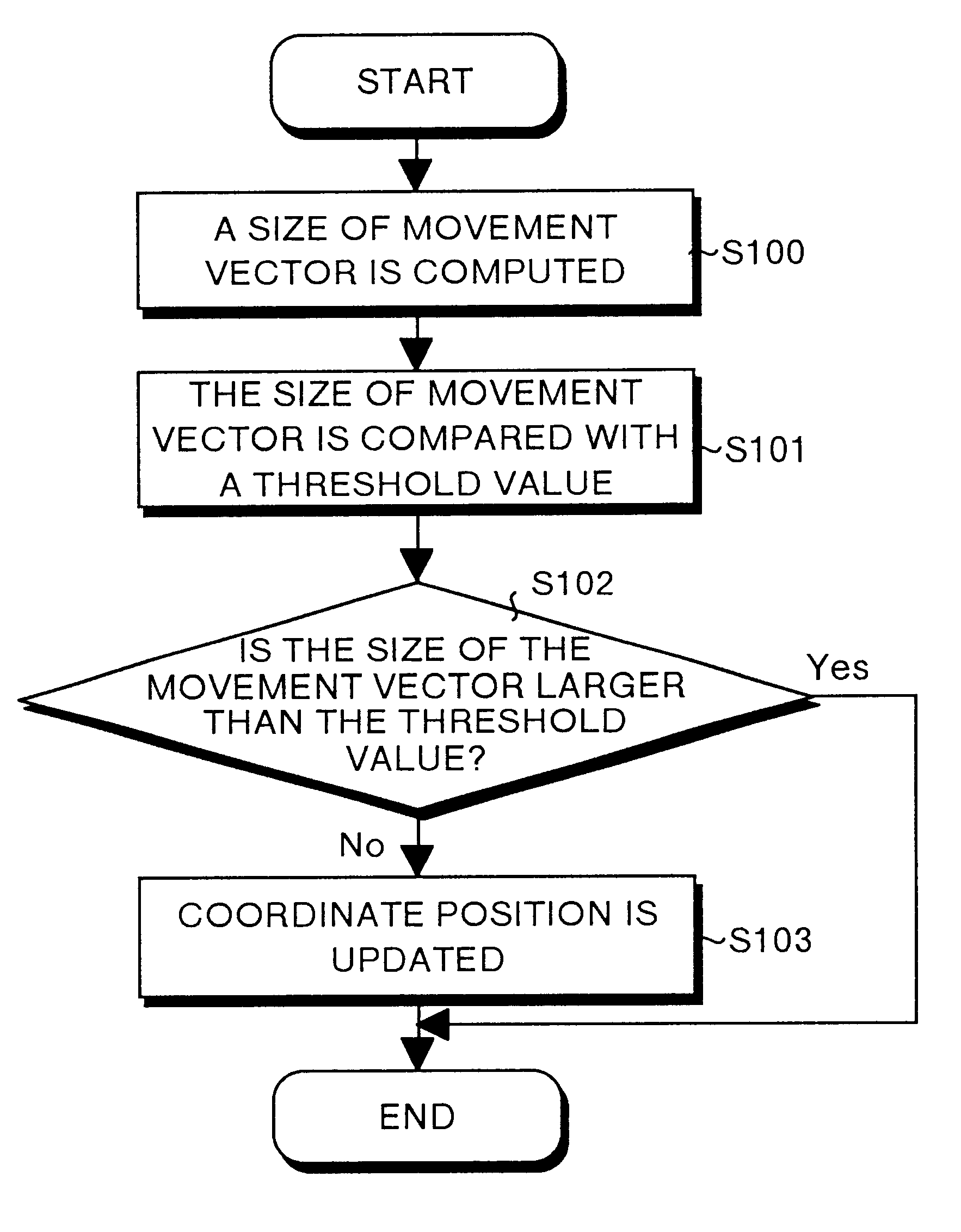

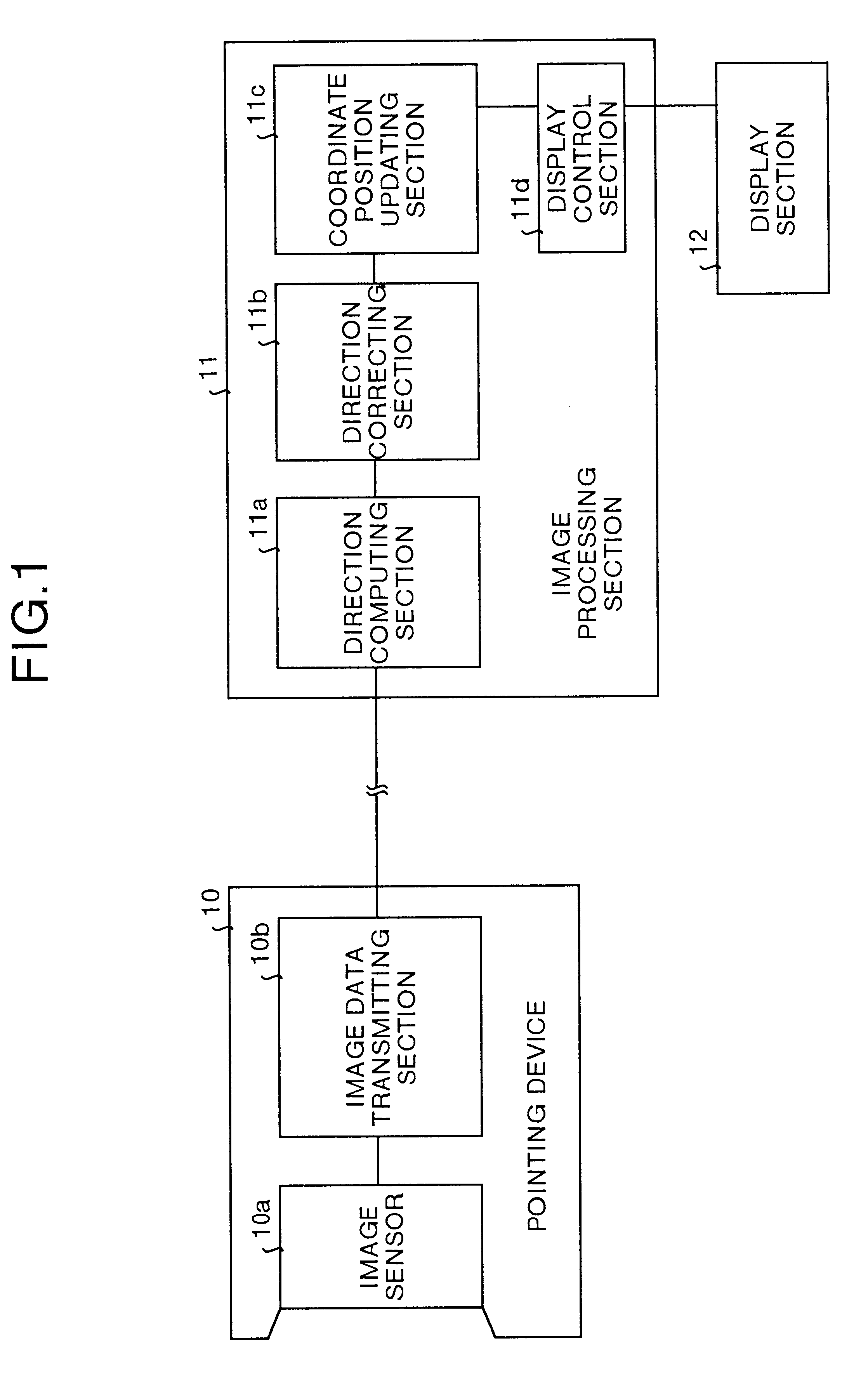

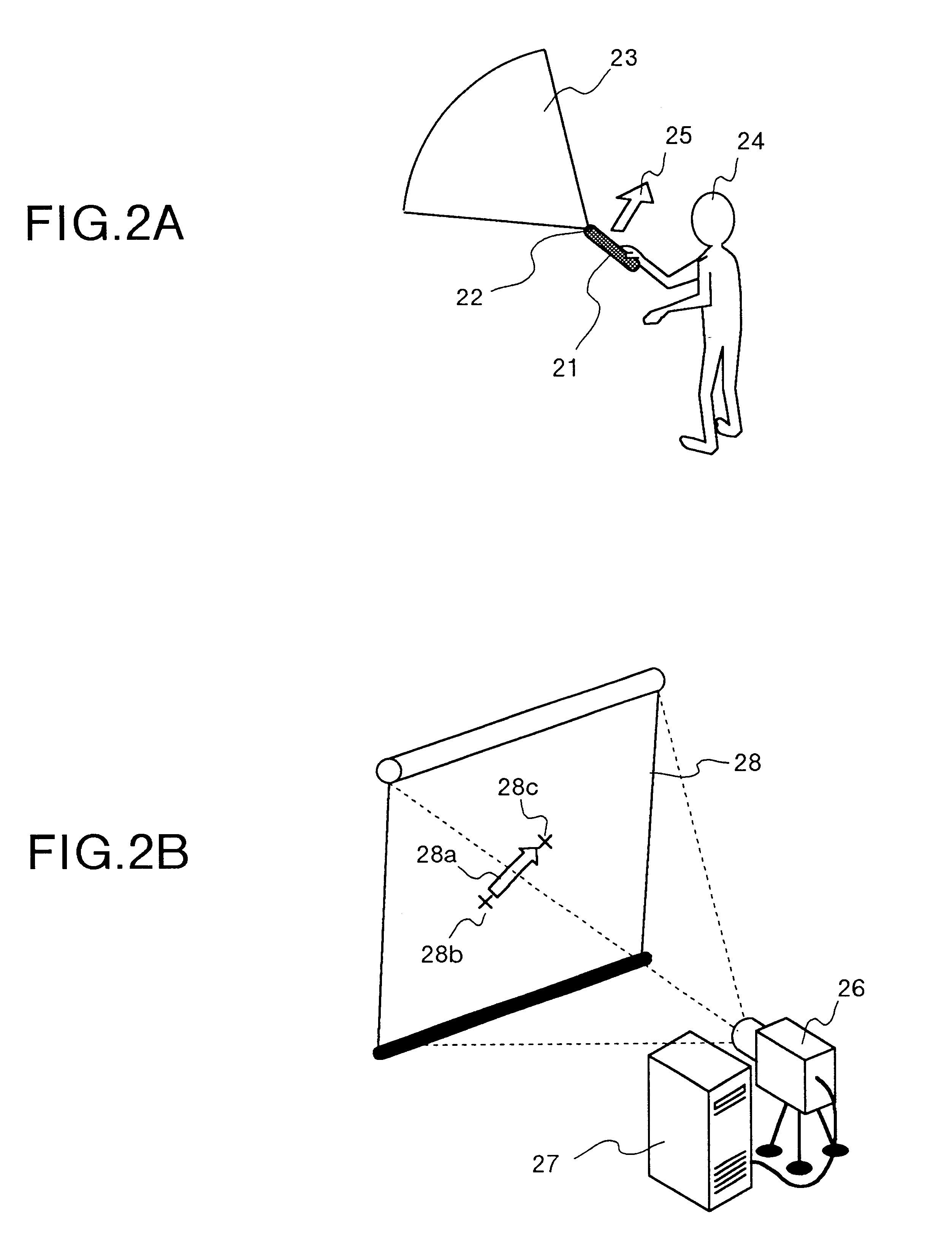

Coordinated position control system, coordinate position control method, and computer-readable storage medium containing a computer program for coordinate position controlling recorded thereon

InactiveUS6411278B1Easy to operateAvoid offsetImage analysisTransmission systemsImage sensorPosition control system

When an operator operates a pointing device, a direction computing section computes a movement vector from an image photographed by an image sensor, and when the movement vector is larger than a threshold, a direction correcting section determines the movement vector as invalid based on the recognition that the movement vector was caused by an abrupt change in the illumination or other conditions, and outputs only movement vectors that are smaller than the threshold to a coordinate position updating section.

Owner:MITSUBISHI ELECTRIC CORP +1

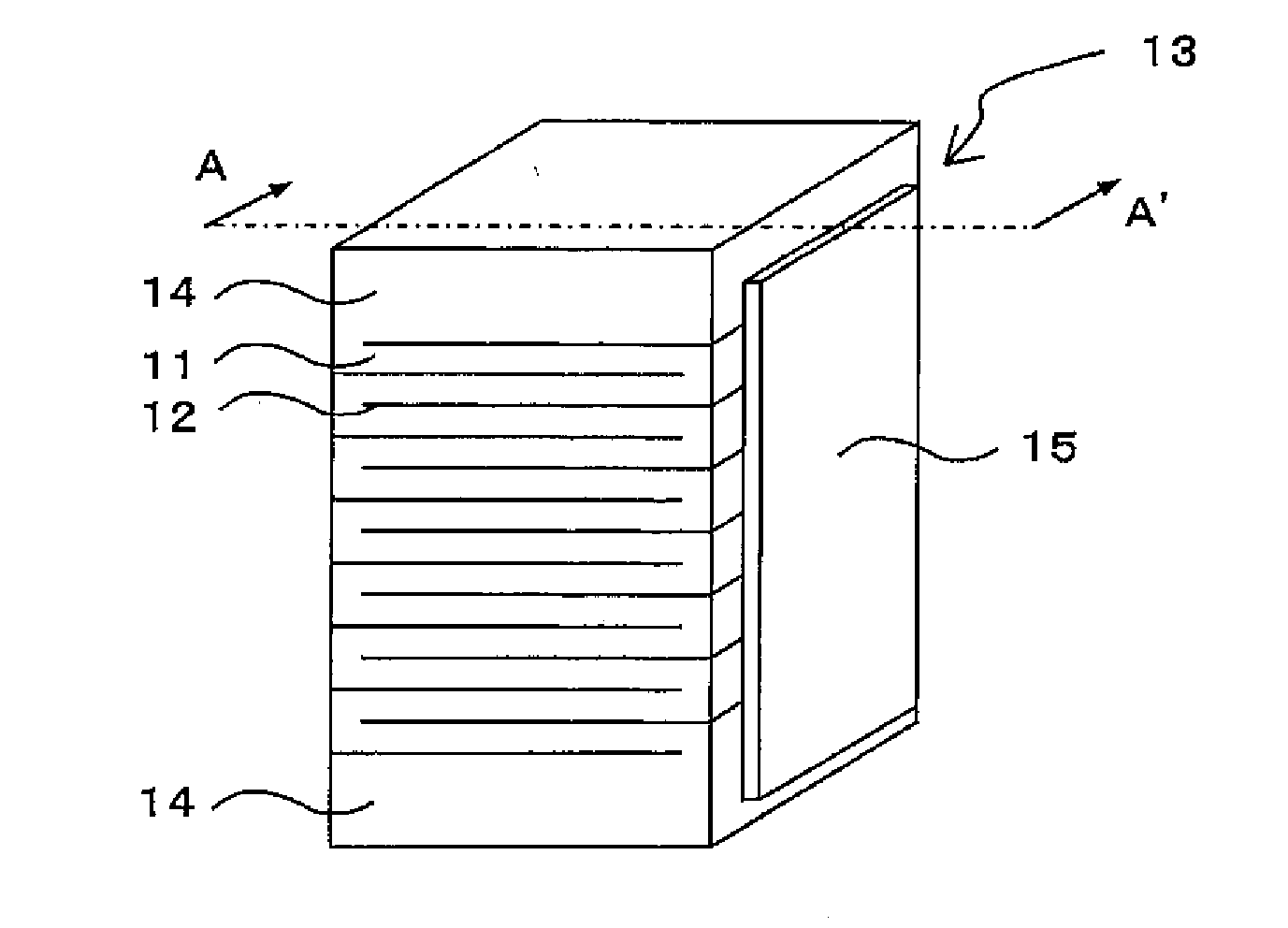

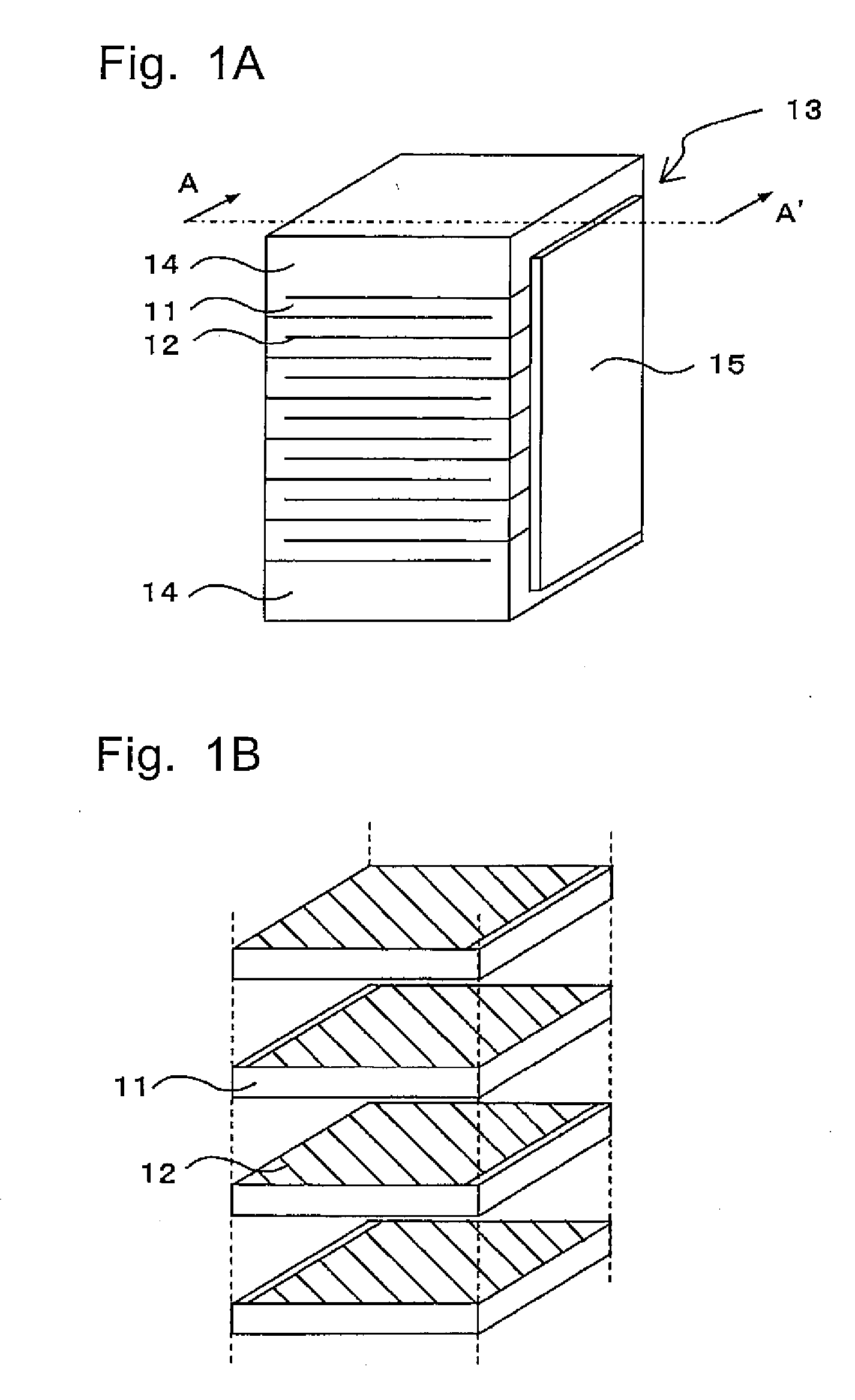

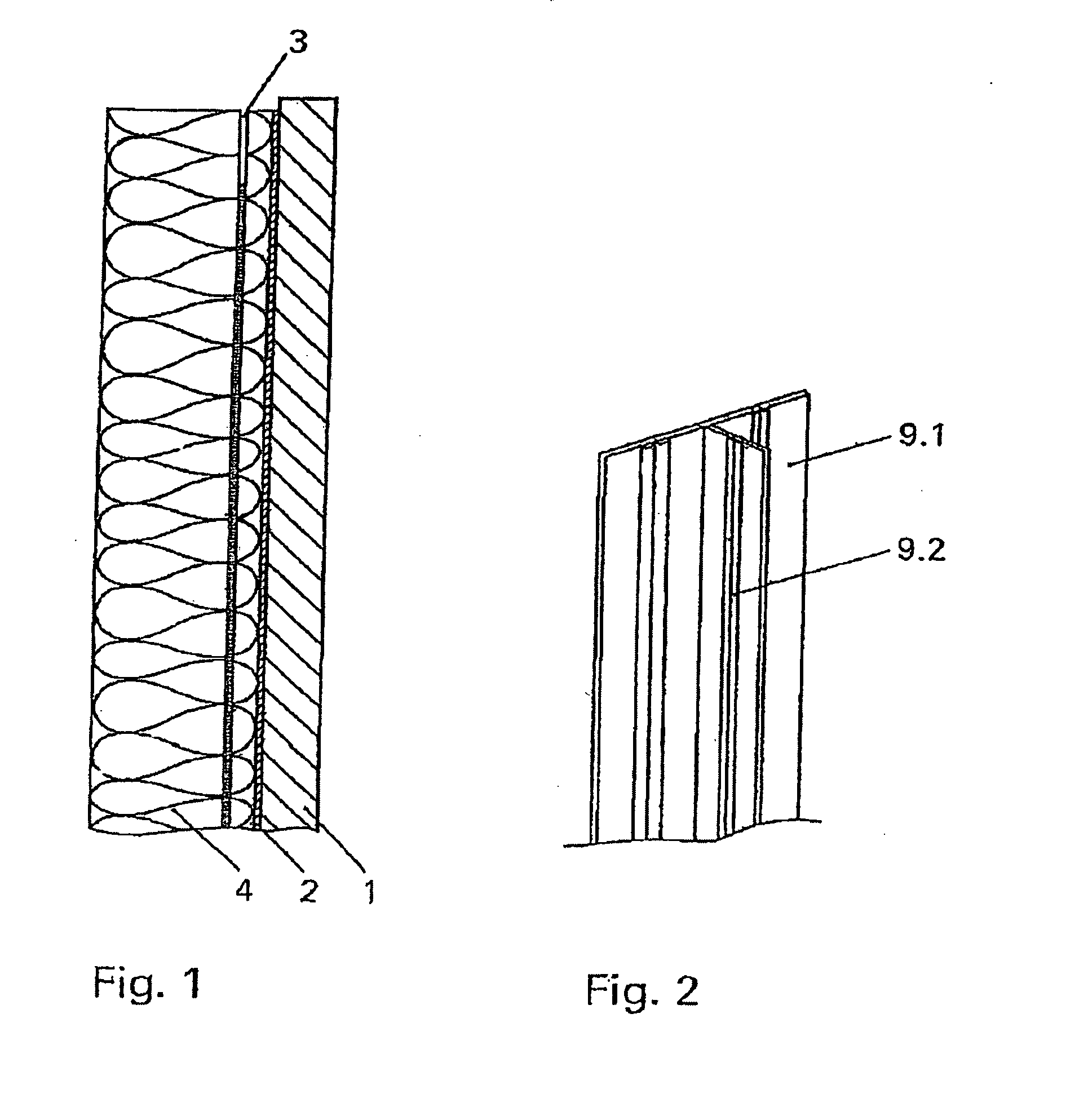

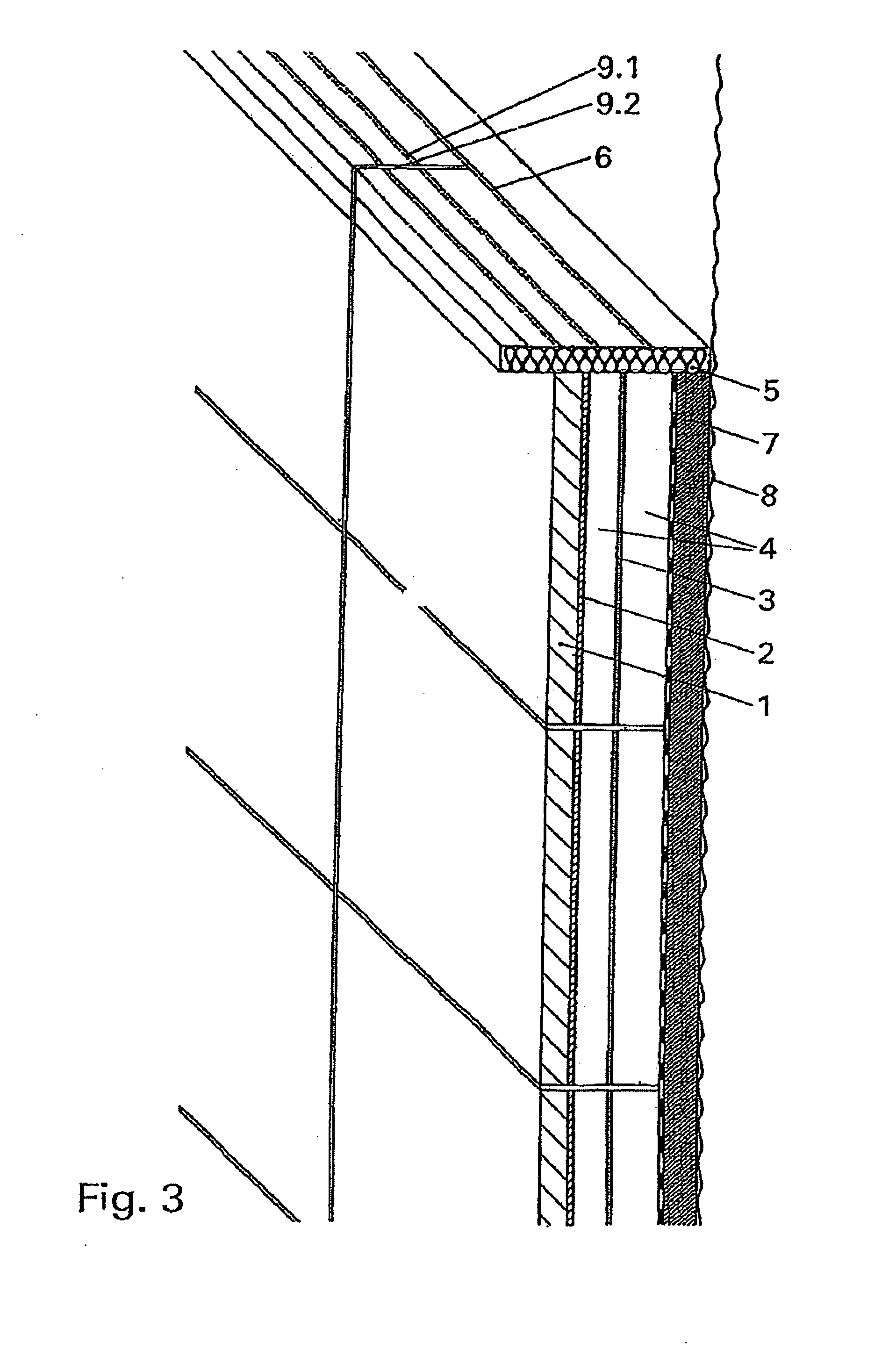

Multi-Layer Piezoelectric Element and Method for Manufacturing the Same

ActiveUS20070278907A1Increase displacementIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsFlexural strength

A multi-layer piezoelectric element having high durability which allows it to increase the amount of displacement of a piezoelectric actuator under high voltage and high pressure and does not undergo a change in the amount of displacement during continuous operation in a high electric field and under a high pressure over a long time period is provided. The multi-layer piezoelectric element comprises a stack of at least one piezoelectric layer and a plurality of internal electrodes consisting of first and second internal electrodes placed one on another, a first external electrode formed on a first side face of the stack and connected to the first internal electrode and a second external electrode formed on a second side face of the stack and connected to the second internal electrode, wherein the bonding strength between the piezoelectric layer and the internal electrode is weaker than the bending strength of the piezoelectric layer.

Owner:KYOCERA CORP

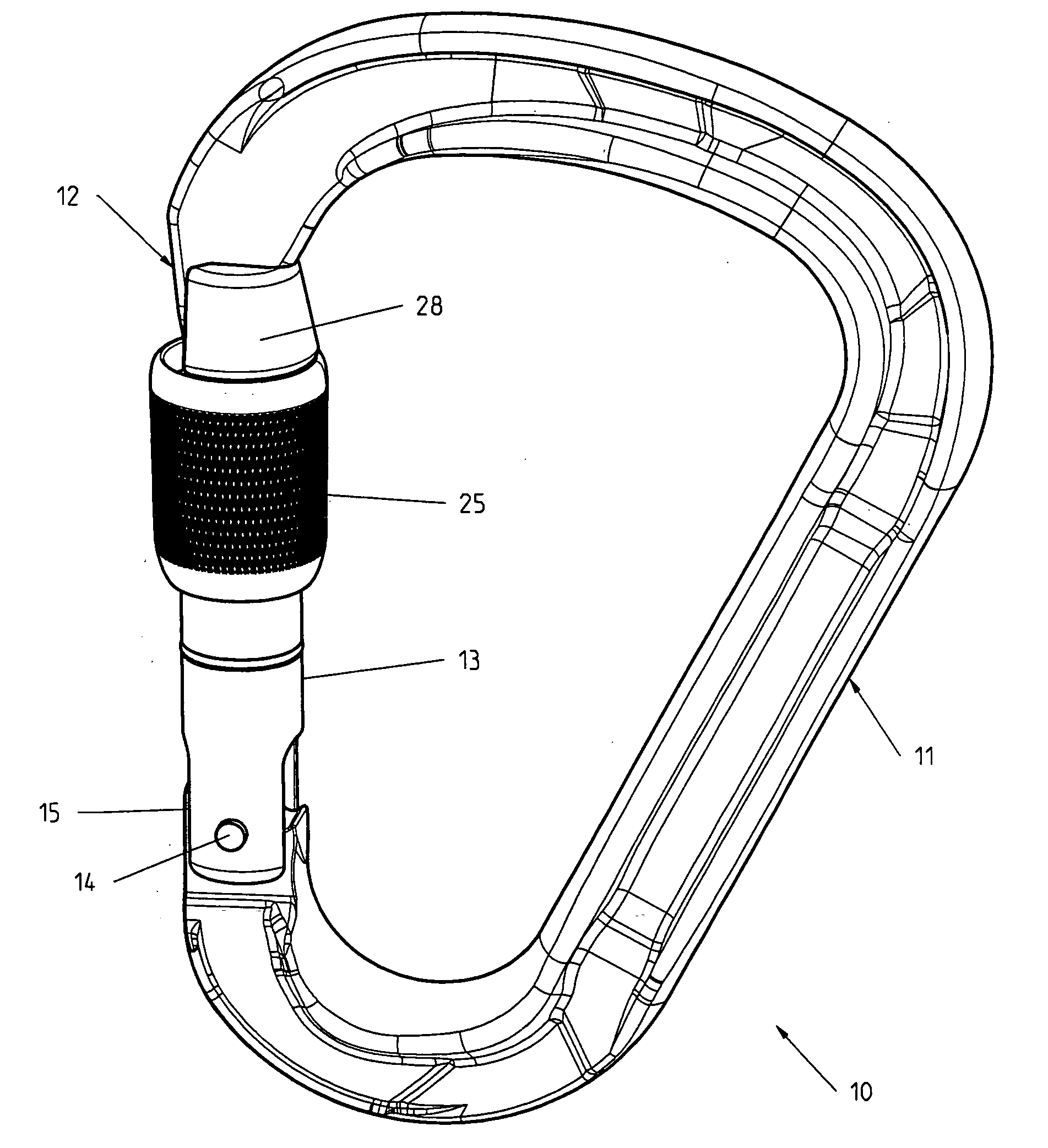

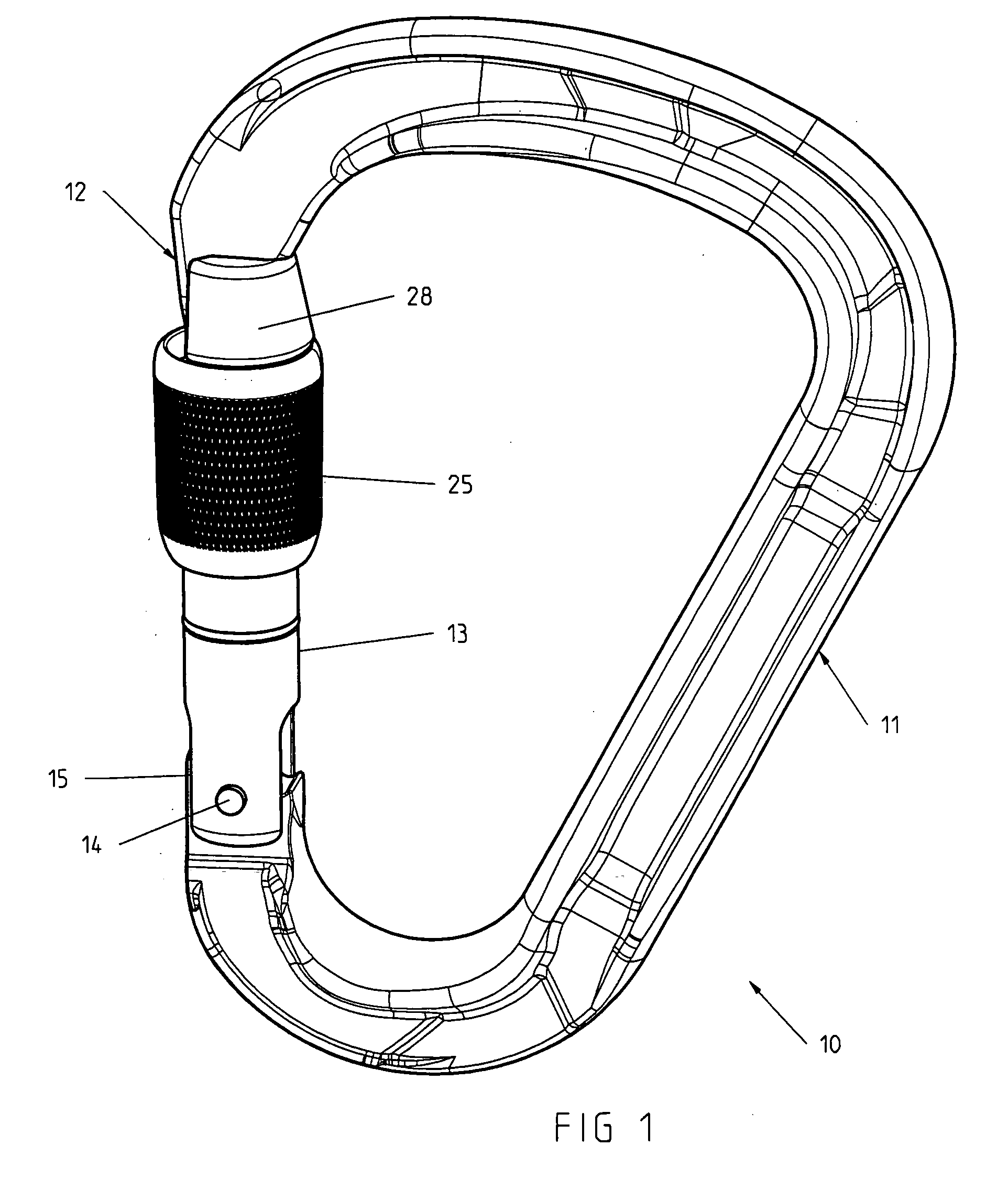

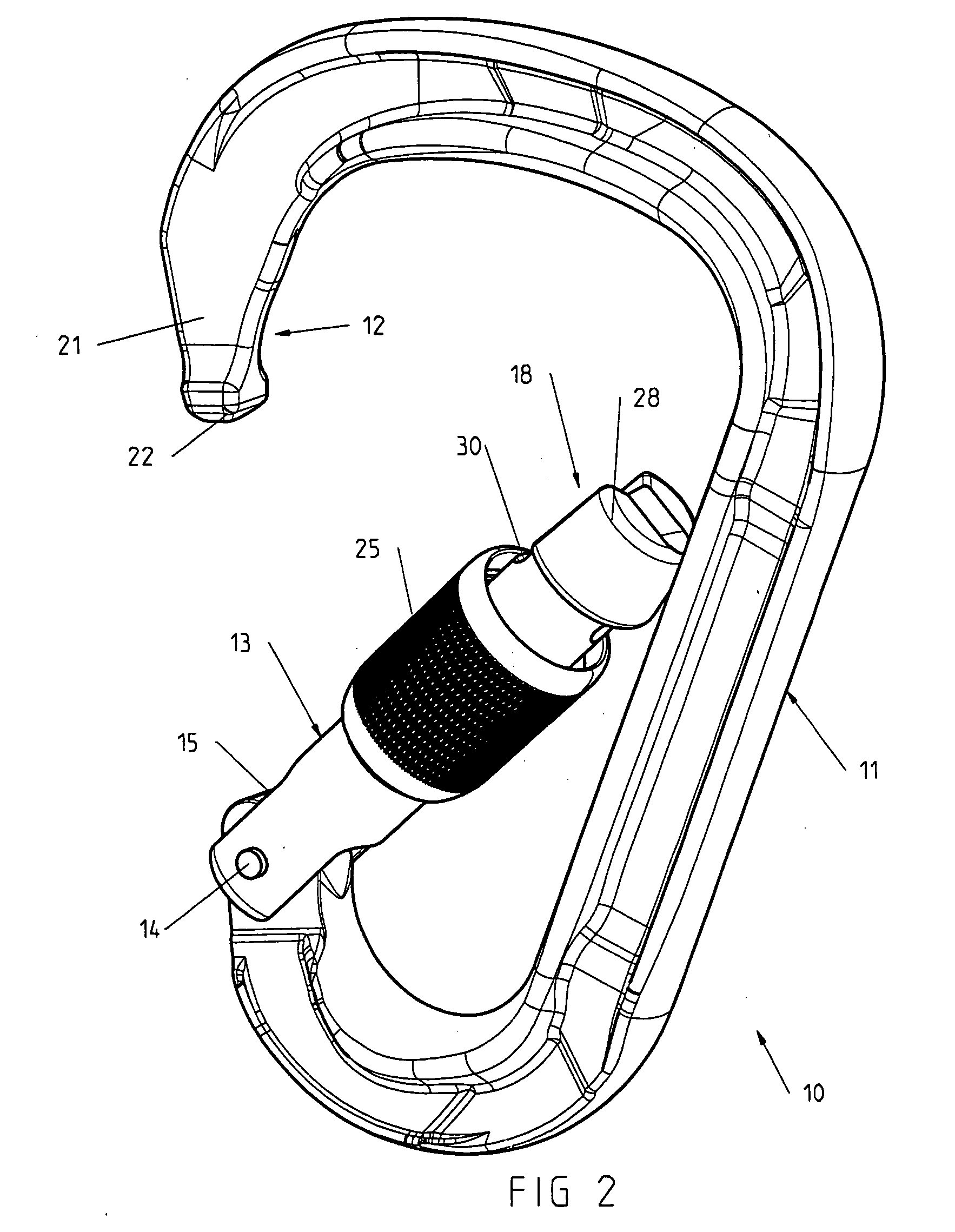

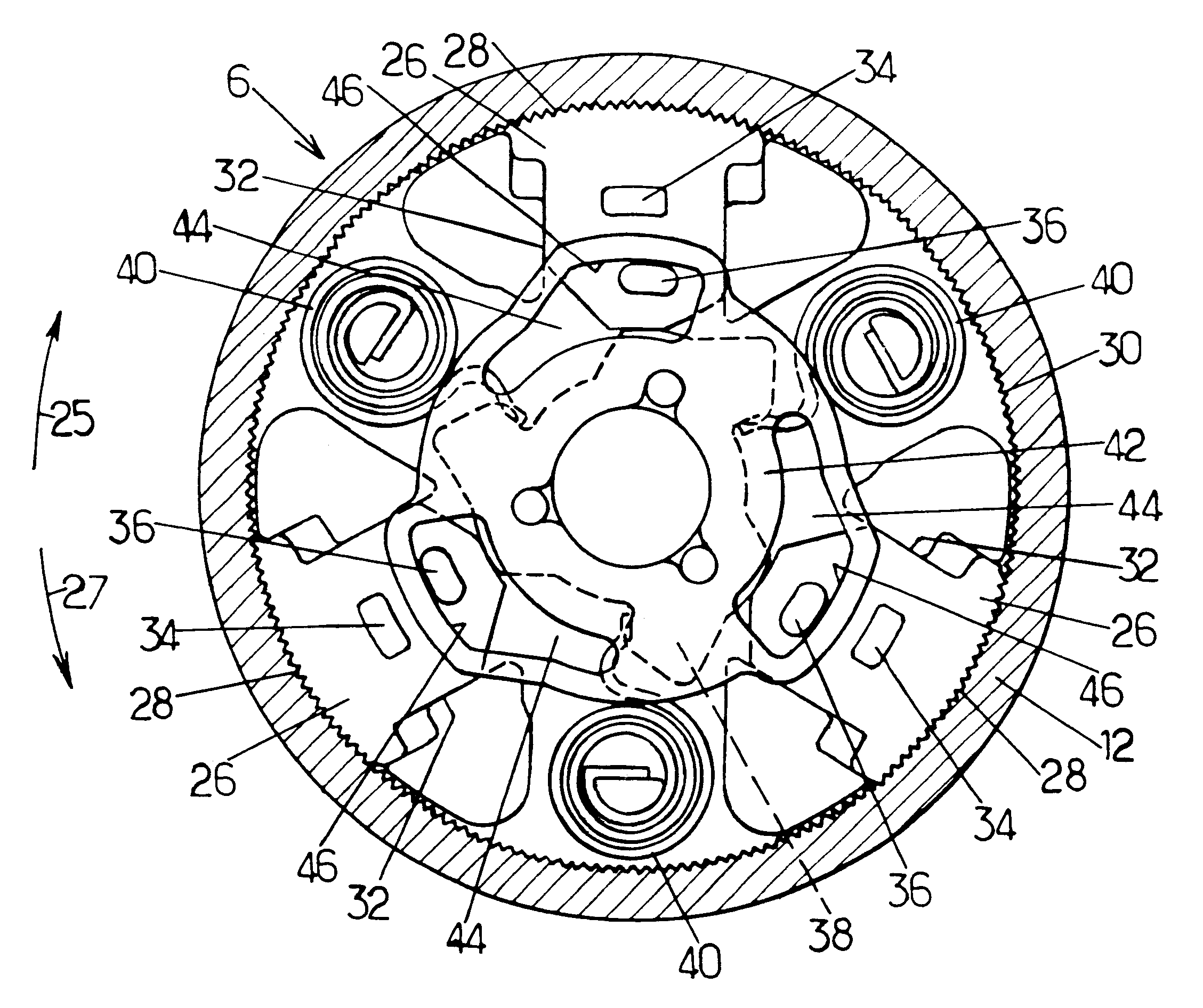

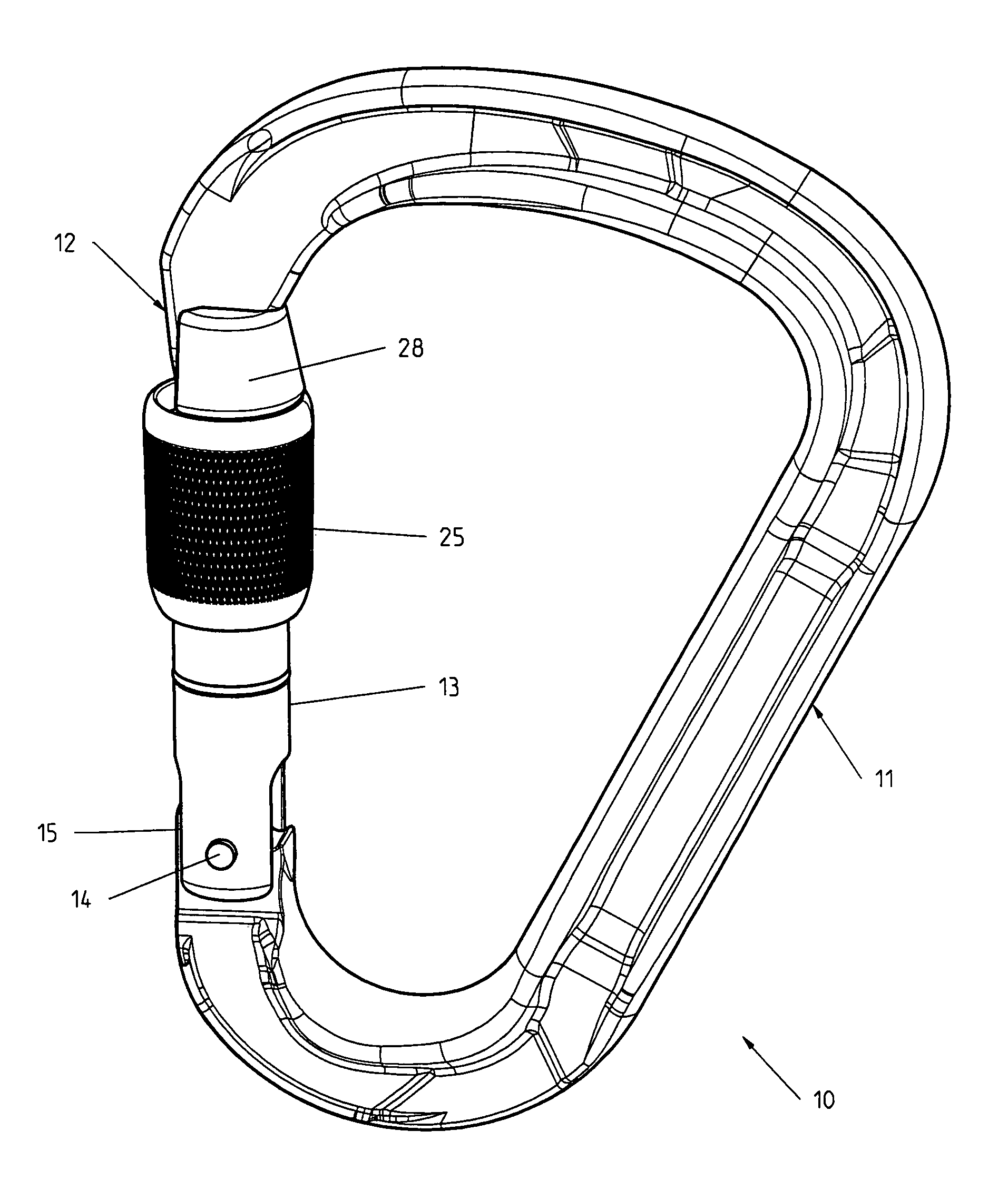

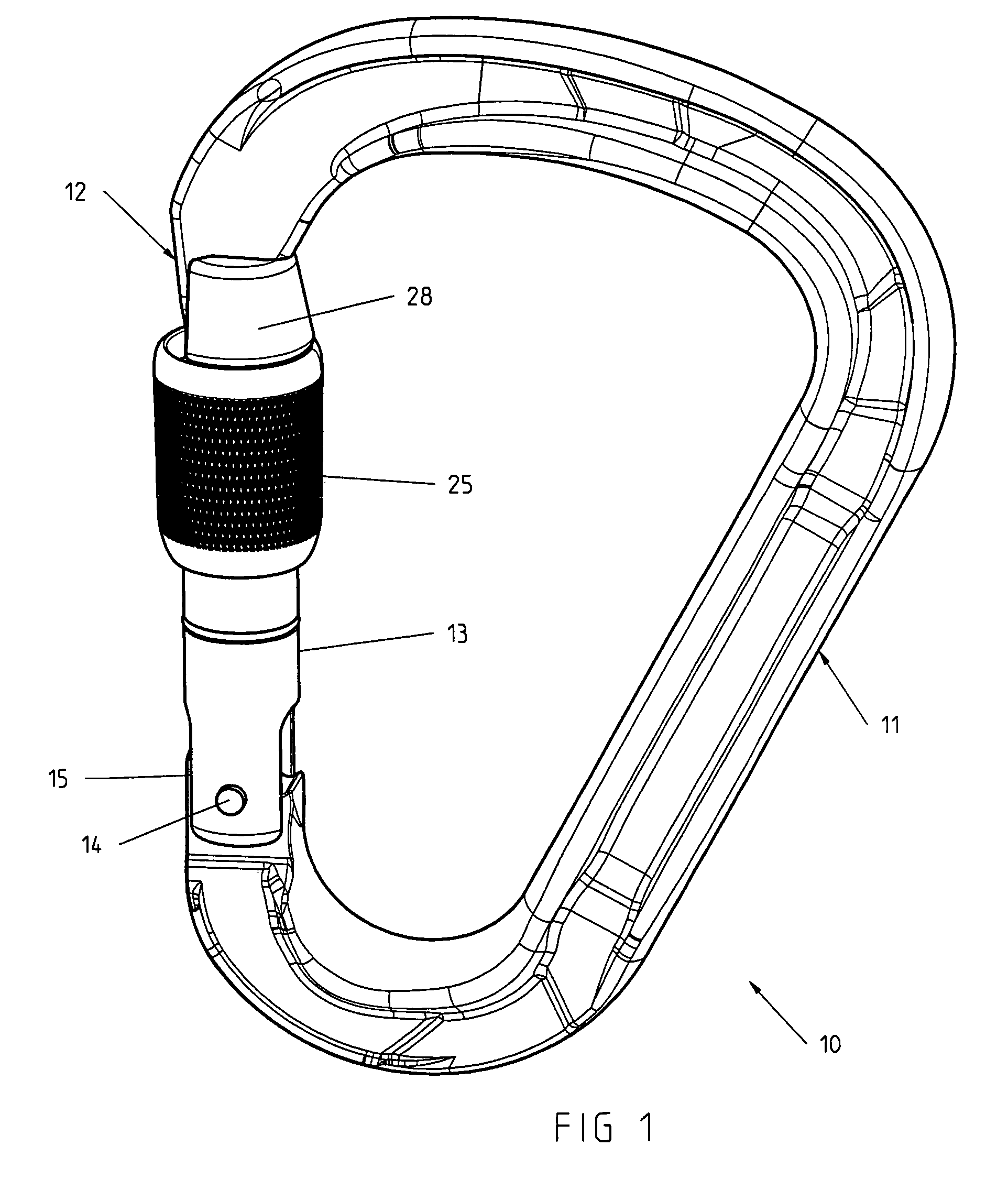

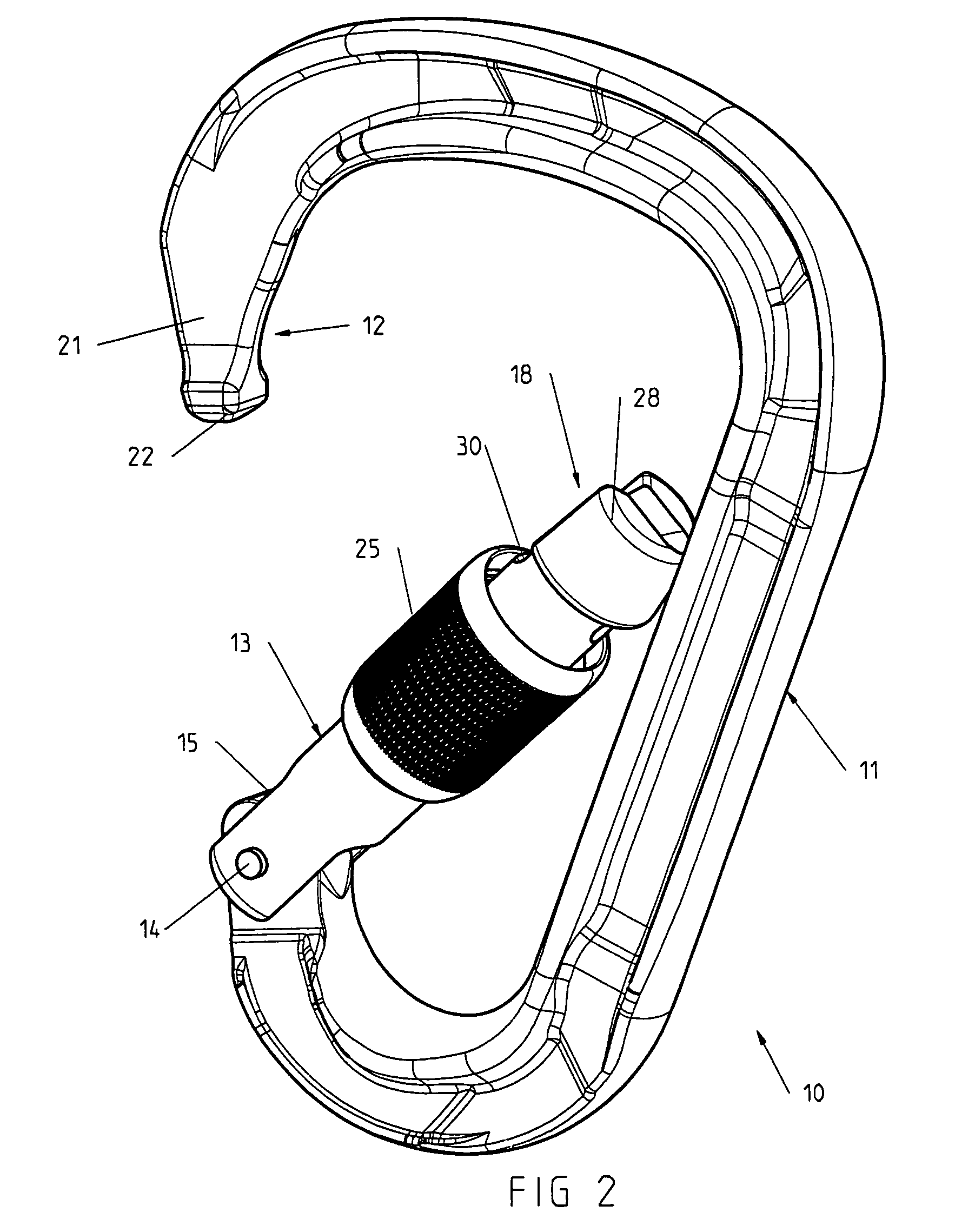

Carabiner with pivoting gate equipped with a locking ring

InactiveUS20090056088A1Controlling the riskAvoid offsetHook fastenersEye fastenersElectrical and Electronics engineering

Owner:ZEDEL CORP

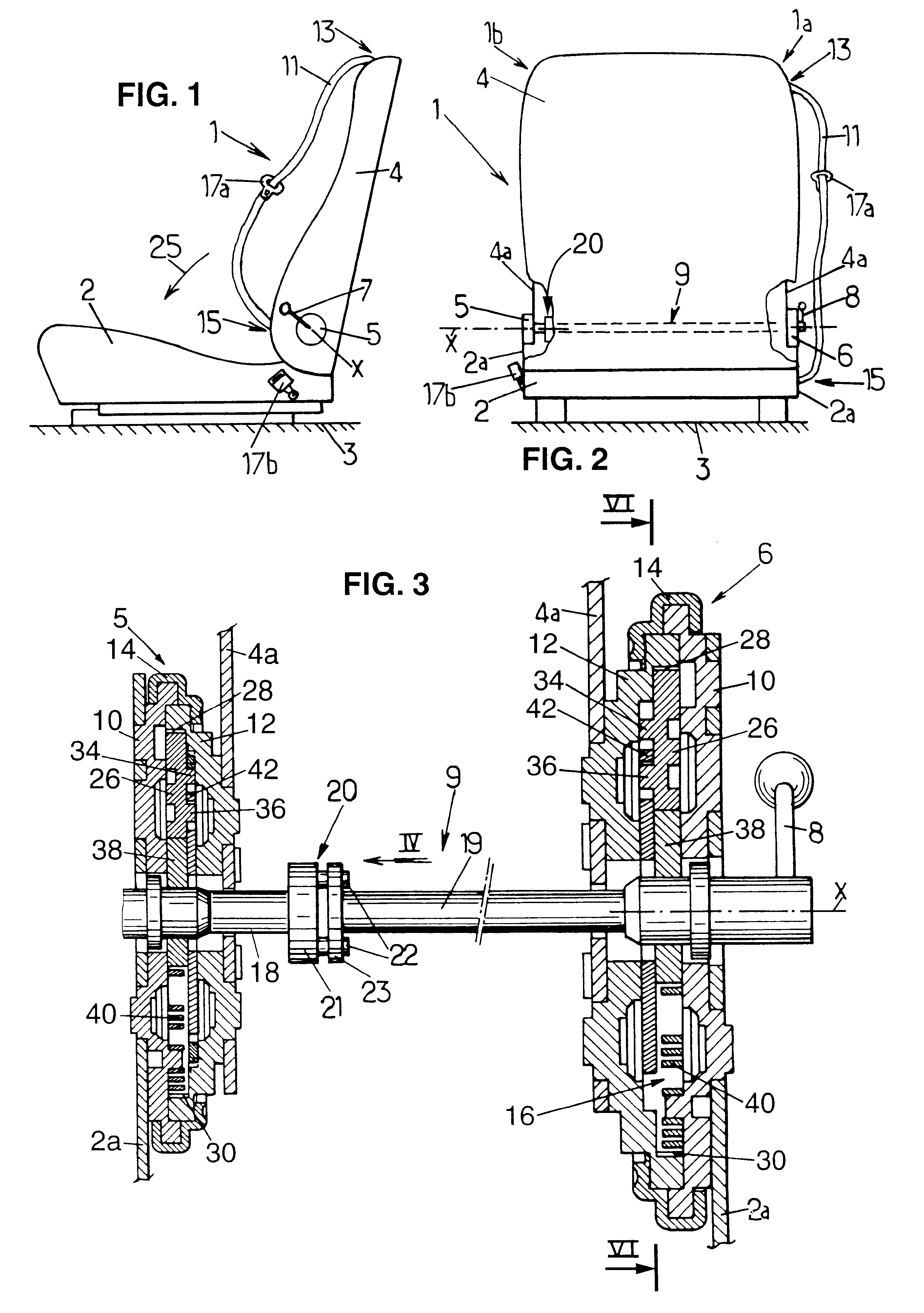

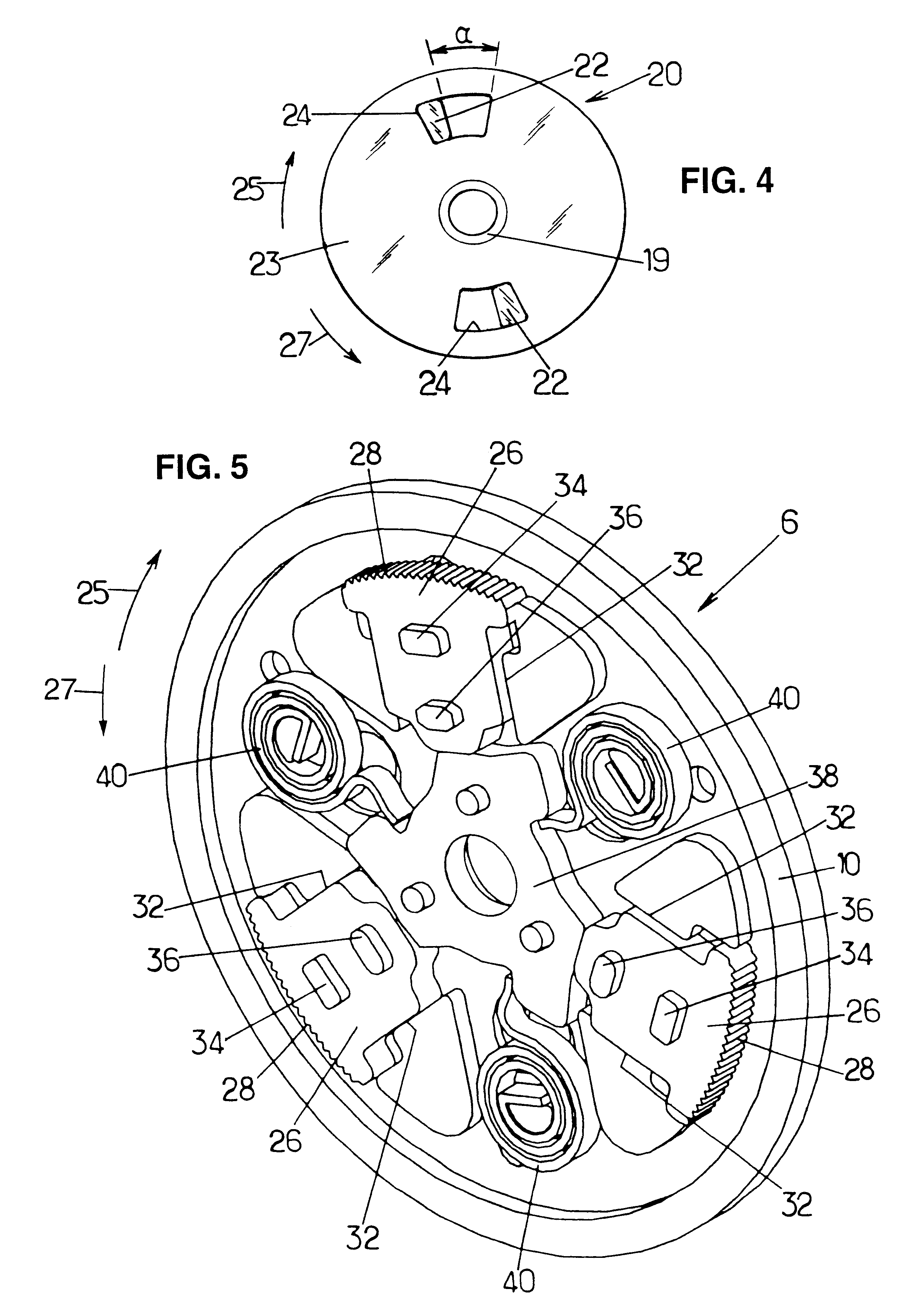

Vehicle seat equipped with a hinge mechanism

InactiveUS6726281B2Mitigate such drawbackGuarantees proper engagementMovable seatsReclining chairsEngineeringCam

A vehicle seat comprising a seat back mounted to pivot on a seat proper by means of first and second hinges, each of which is made up of two pivotally-mounted cheek plates that can be locked by slugs controlled by a rotary cam so that they are caused to come to mesh in a fixed set of teeth. The cams of the two hinges are connected together via a lost motion mechanism, and the fixed set of teeth of one of the hinges has truncated teeth, each of which forms a flat.

Owner:FAURECIA +1

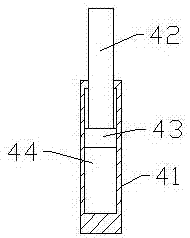

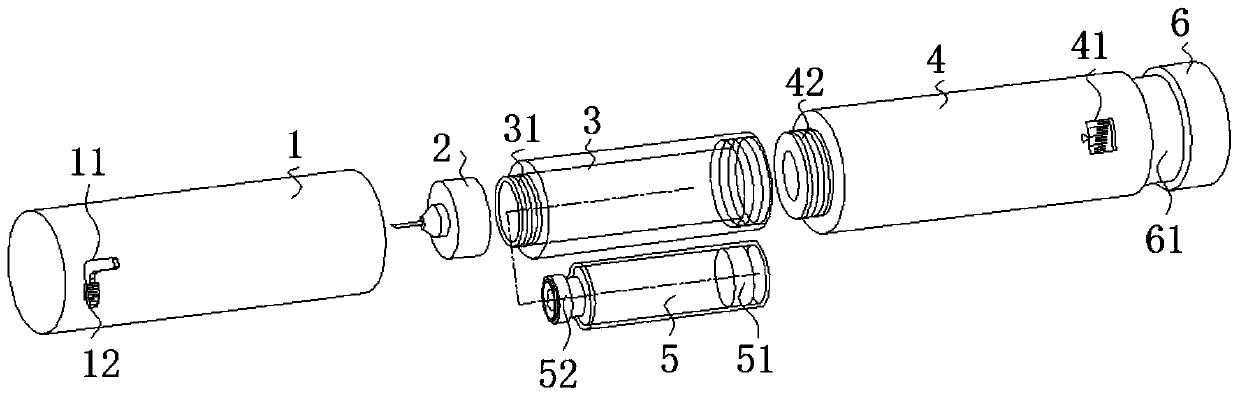

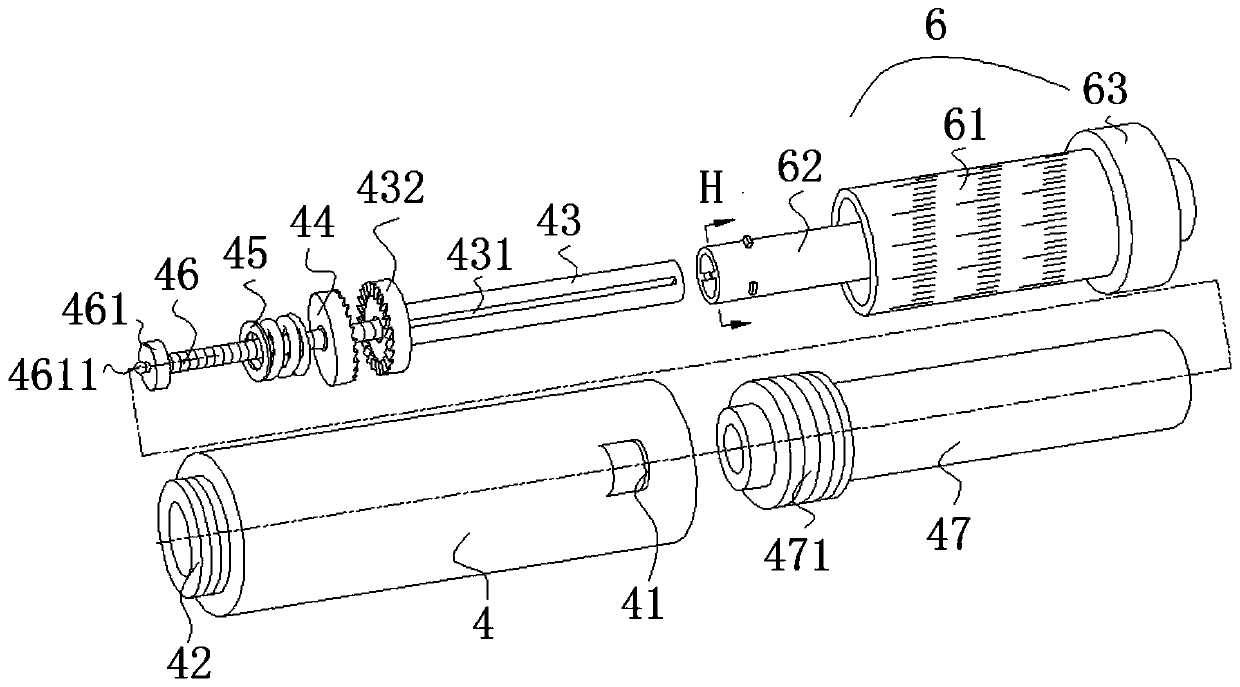

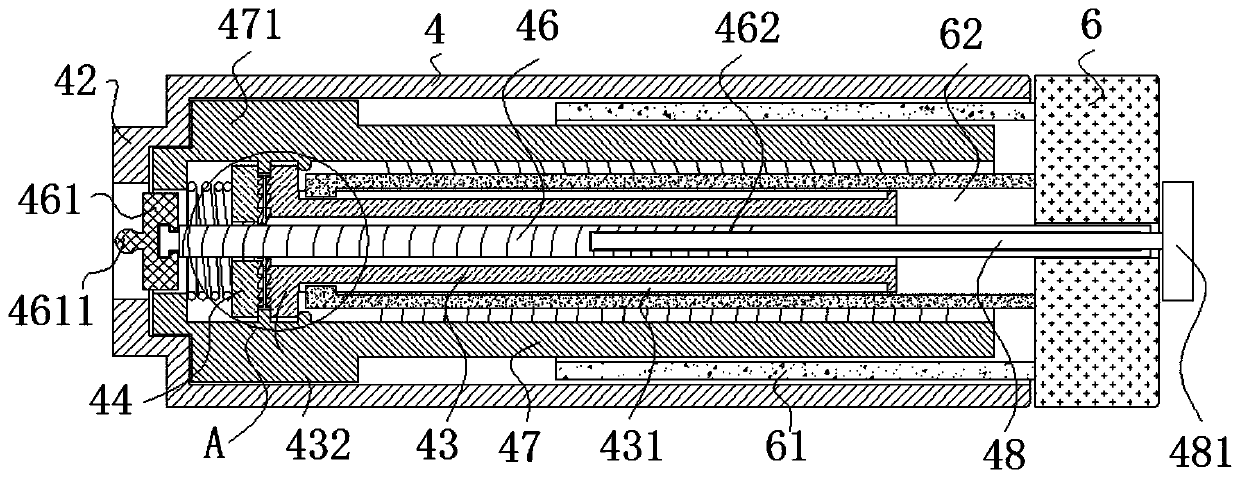

Disposable adjustable injection device for insulin injection

ActiveCN109999272AAvoid wastingImprove securityInfusion syringesInfusion needlesInsulin injectionEngineering

The invention discloses a disposable adjustable injection device for insulin injection. The device comprises a protection cover, a disposable syringe needle, an injection refill sleeve, a main deviceshell, an injection refill and an adjusting assembly, a second boss is arranged at one end of the main device shell, and the injection refill sleeve is installed on the outer portion of the second boss; a threaded groove is formed in one end of the injection refill sleeve, an outer thread of the second boss is in mutual threaded connection with the threaded groove, and a first boss is arranged atthe other end of the injection refill sleeve; the outer portion of the first boss is in threaded connection with the disposable syringe needle, a steel needle is inserted in the disposable syringe needle, and the injection refill is installed in the injection refill sleeve; the protection cover sleeves the outer portion of the injection refill sleeve, the adjusting assembly is arranged at the other end of the main device body shell, a fixed sleeve is installed in the main device body shell, and one end of the fixed sleeve protrudes outward to form a flange part. The device has the advantages that the operation is simple, the waste is avoided, and the safety performance is good.

Owner:甘李药业山东有限公司

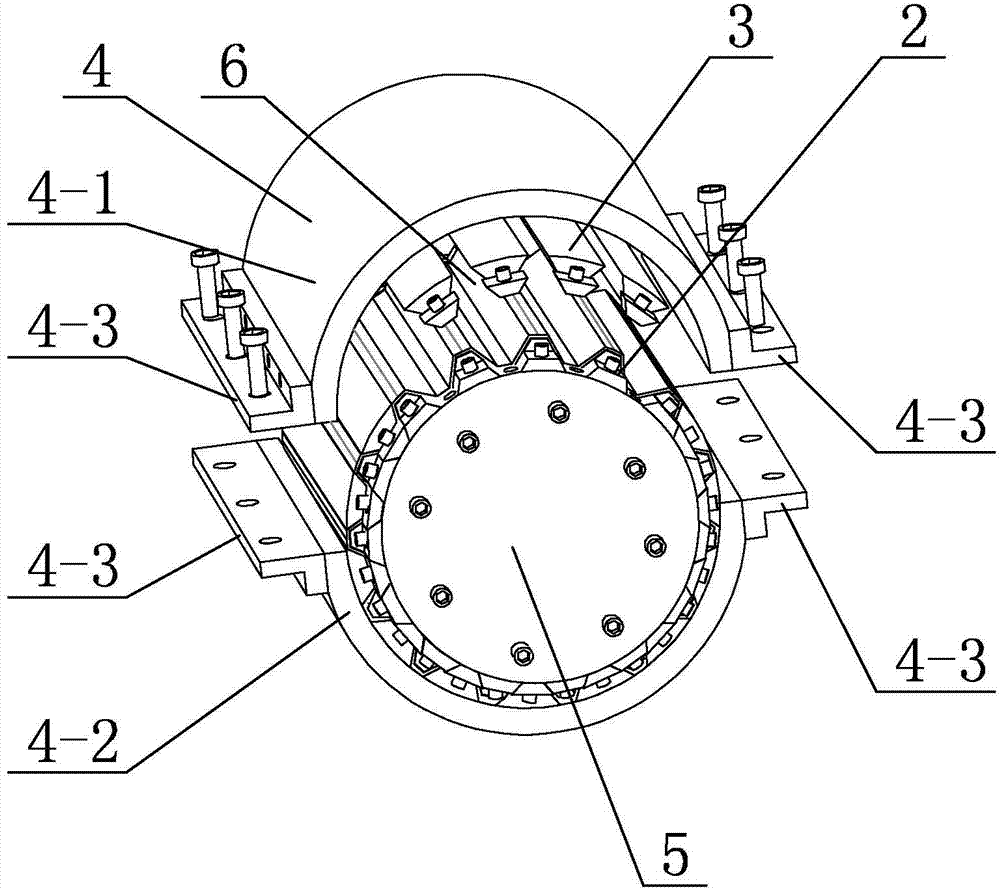

Assembling mold for all-composite corrugated sandwich cylindrical shells

InactiveCN104723579AGuaranteed to be stable and not deformedPrevent fiber entanglementEngineeringFilament winding

The invention discloses an assembling mold for all-composite corrugated sandwich cylindrical shells and relates to the assembling mold with an aim to overcome shortcomings about lack of special mold during production of existing all-composite corrugated sandwich cylindrical shells, skins and plates are not easy to be connected during production of other sandwich cylindrical shell, filament winding cannot be avoided, and the production process is complicated and not easy to for mass production. A core column is a split-type hollow column, two end caps are respectively detachably connected to the top surface and the bottom surface of the core column, multiple inner core strips and multiple outer core strips are alternatively arranged on the outer periphery of the core column along the axial direction of the core column, each inner core strip and each outer core strip are arranged at an interval, and a clamping fixture sleeves the core column provided with the inner core strips and the outer core strips. The cylindrical shells different in thickness can be produced, and mass production can be realized. The assembling mold is used for production of the all-composite corrugated sandwich cylindrical shells.

Owner:HARBIN INST OF TECH

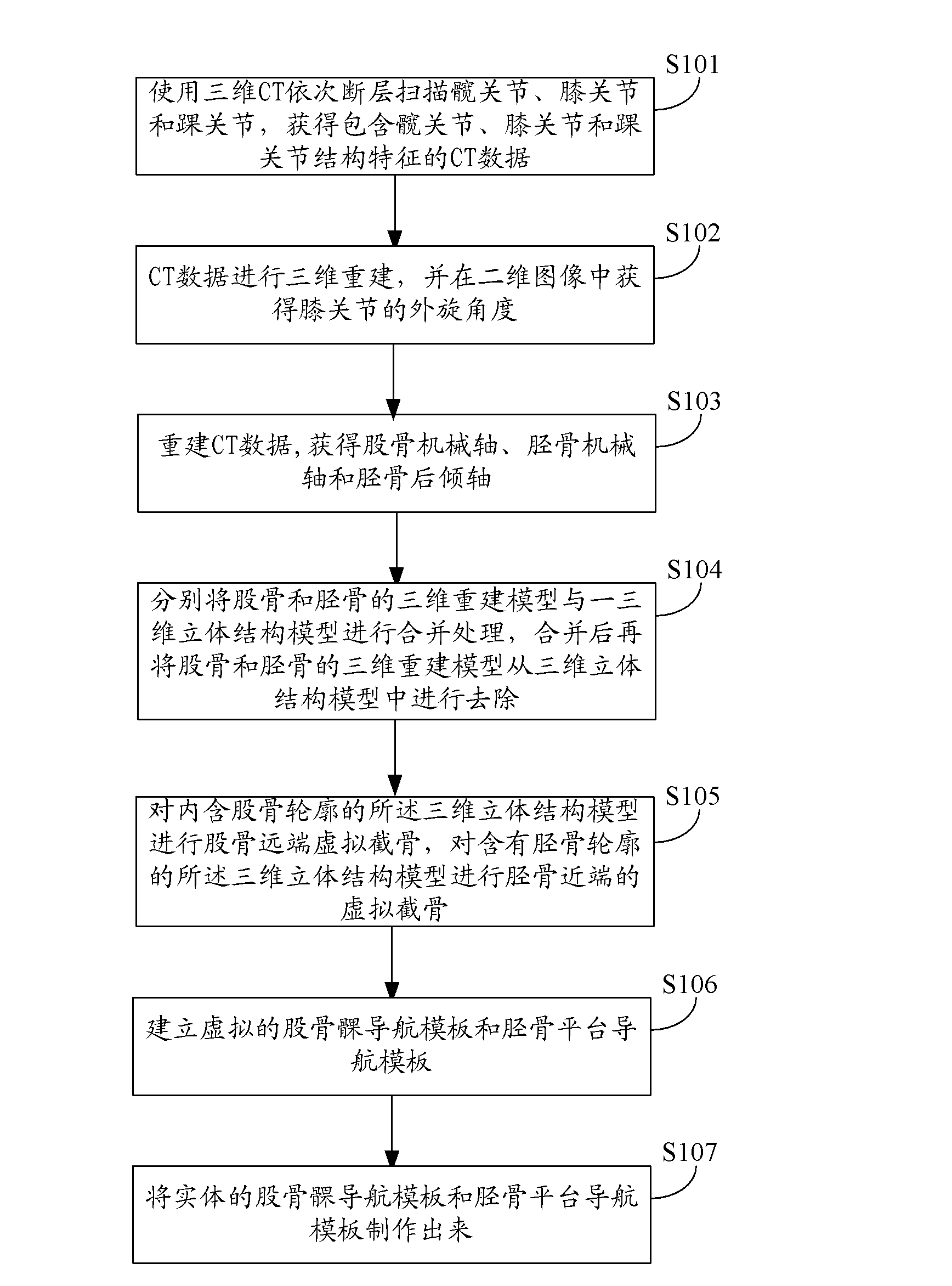

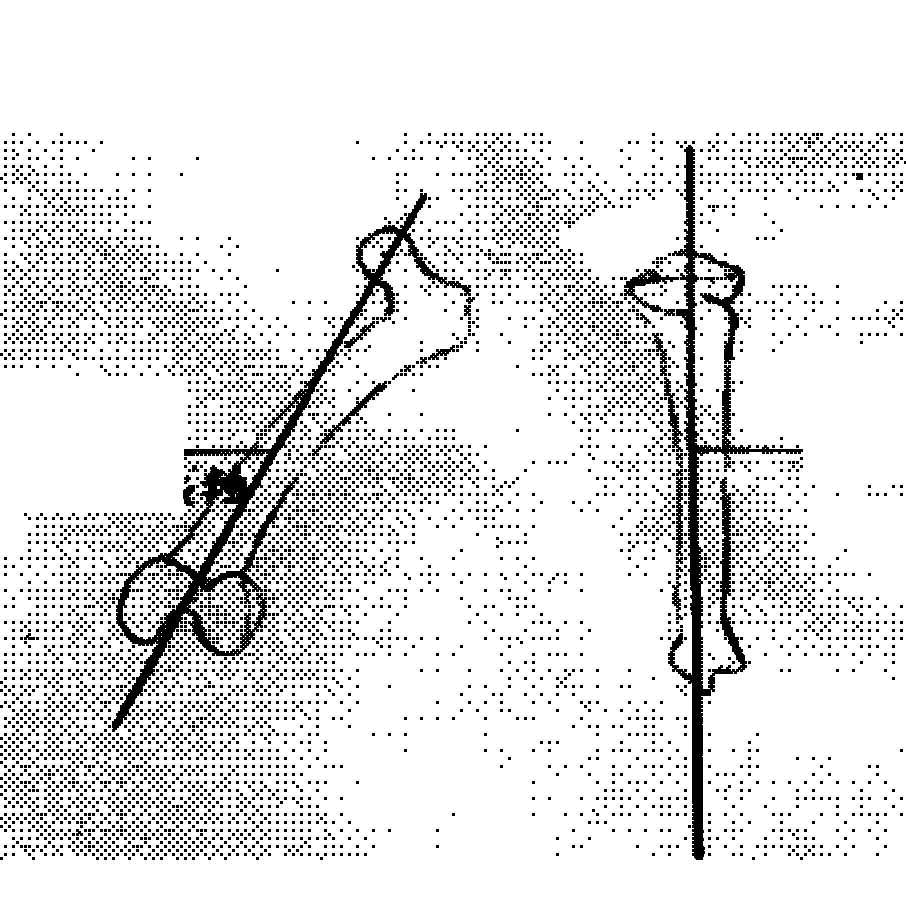

Method for manufacturing navigation template for knee replacement, and navigation template

ActiveCN102760199AAvoid offsetImprove the effect of long-term follow-upDiagnosticsSurgeryThighComputing tomography

The invention relates to a method for manufacturing a navigation template for knee replacement. The method comprises the following steps of: scanning a hip joint, a knee joint and an ankle joint through computed tomography (CT) to obtain CT data, and establishing three-dimensional reconstruction models of femur and tibia according to the CT data; respectively carrying out combination on the three-dimensional reconstruction models of thigh bone and shin bone with a three-dimensional structure, and respectively removing the three-dimensional structure models of femur and tibia from the three-dimensional structure; according to the knee replacement process, carrying out distal femoral virtual osteotomy on the three-dimensional structure model containing the femur contour, and carrying out proximal tibia virtual osteotomy on the three-dimensional structure model containing the tibia contour; and establishing virtual femur condyle navigation template and a virtual tibia platform navigation template, and manufacturing an entity condyle navigation template and an entity tibia platform navigation template. The individual navigation template manufactured by the invention be used for carrying out positioning of osteotomy and a rotating axis on the affected knee femur condyle and tibia platform, thus realizing individual precise osteotomy.

Owner:中国人民解放军联勤保障部队第九二〇医院

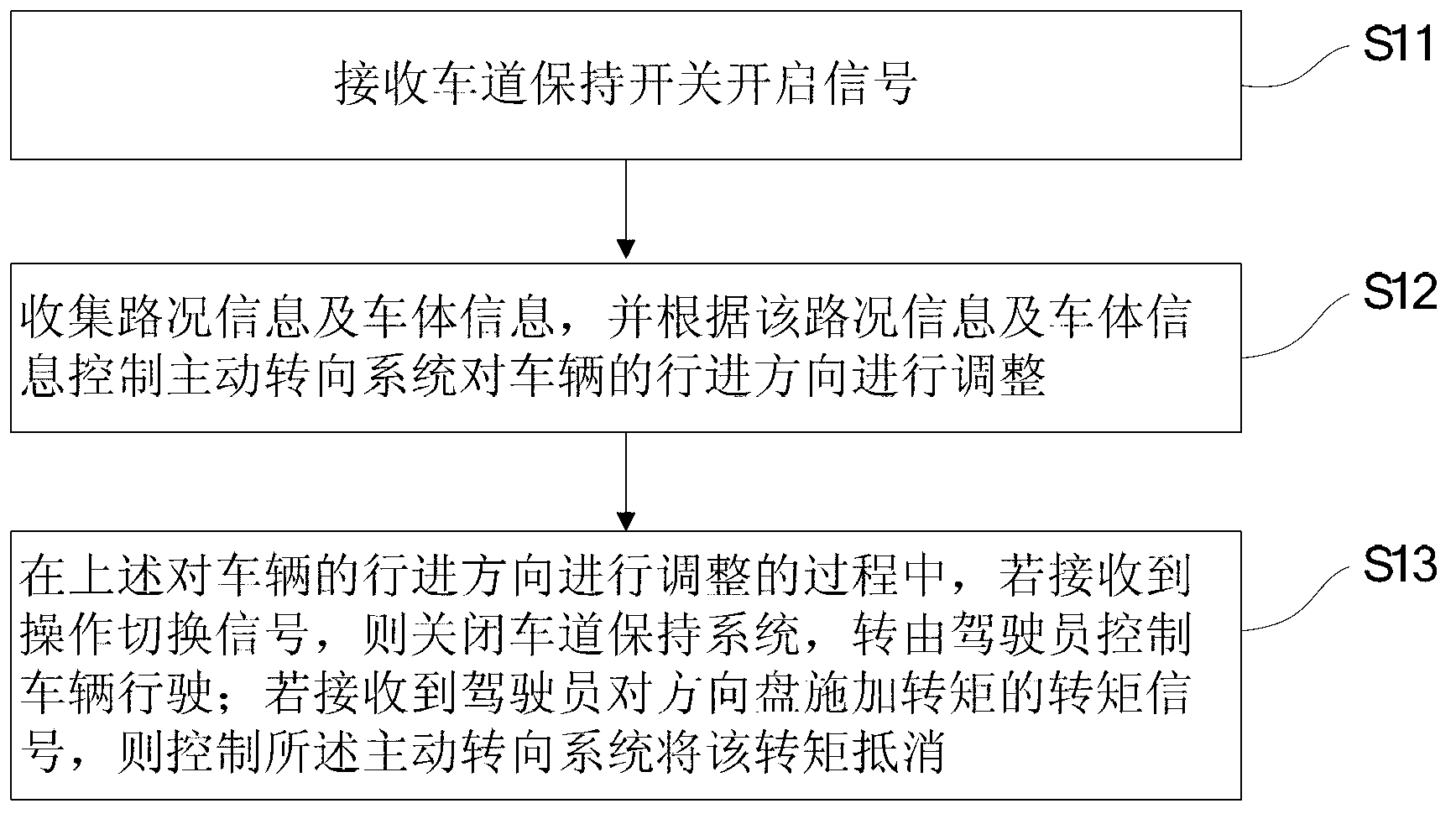

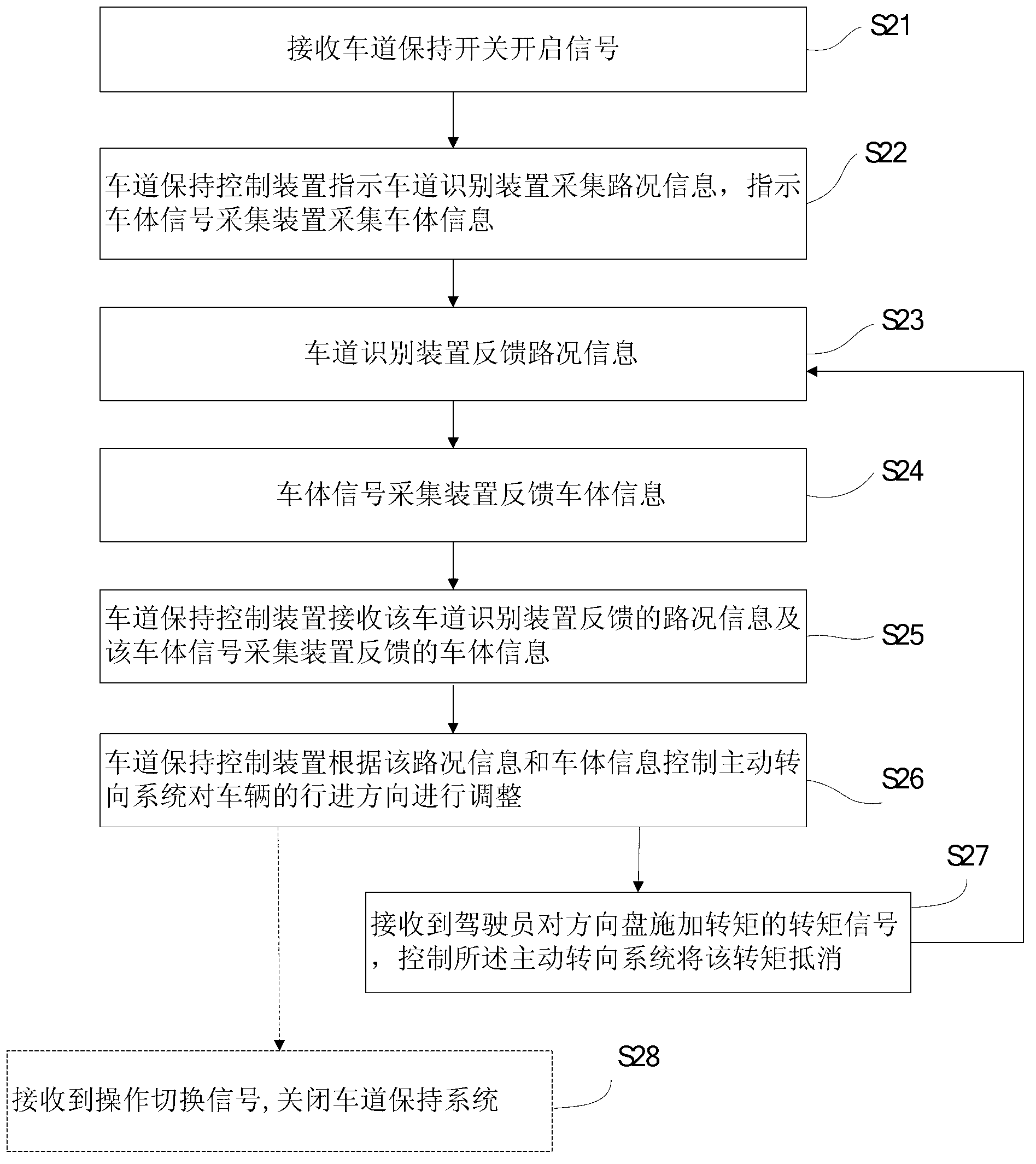

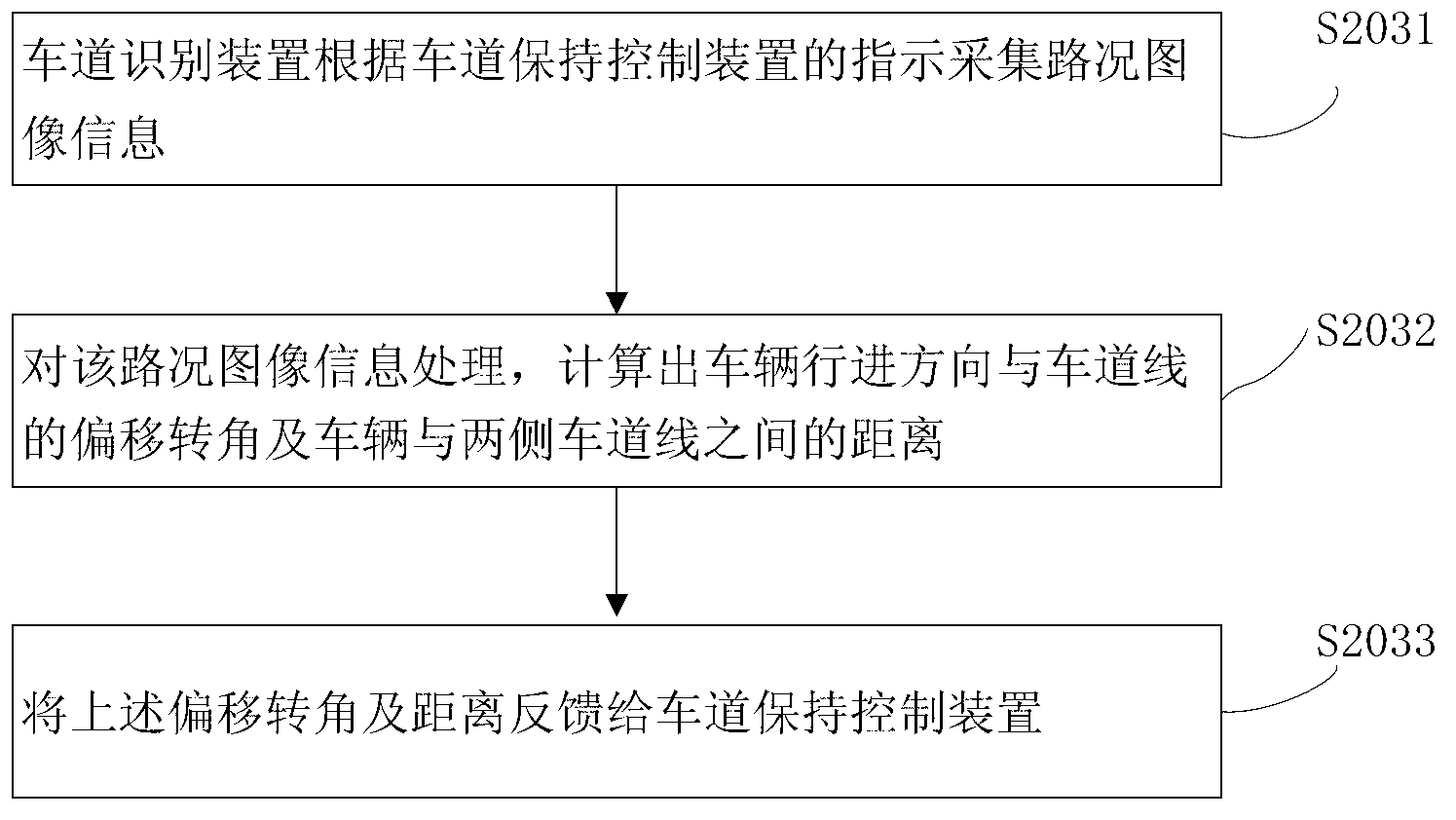

Lane-keeping system and lane-keeping control method

The invention provides a lane-keeping control method and a lane-keeping system. After the lane-keeping system receives opening signals of a lane-keeping switch, a lane identifying device collects road information, a car body information collecting device collects car body information, and a lane-keeping control device controls an initiative steering system to adjust the traveling direction of a car according to the road information and the car body information. In the process of adjusting the traveling direction of the car, if the lane-keeping control device receives operation switching signals, the lane-keeping system is turned off, and a driver controls traveling of the car; if the lane-keeping control device receives torque signals of applying torque on a steering wheel, the lane-keeping control device controls the initiate steering system to offset the torque. The lane-keeping system conducts analysis treatment on the operation of the driver in the process of adjusting the traveling direction of the car and can conduct corresponding treatment on drivers' different operation motions on the car.

Owner:深圳中智卫安机器人技术有限公司

Hole reserving construction method for tightly-fixed steel sleeve

ActiveCN102121315AEasy to installAvoid offsetForms/shuttering/falseworksBuilding material handlingLaserBuilding construction

The invention discloses a hole reserving construction method for a tightly-fixed steel sleeve, which adopts a hole-reserved steel sleeve to replace a PVC sleeve which is adopted in the traditional reserving step, has the characteristics of recyclability, no nail remaining at a reserved hole, nice appearance and remarkable economical benefit, and is easy in assembly. According to the construction drawing and a structure datum point, the center of the hole is determined and used as the central position for a fixed screw, and the reserved sleeve is fixed through the tightening effect of the fixed screw. In the method, the deflection of the center of the vertical hole is adjusted by utilizing a plumb line or a laser plummet apparatus every other 5 to 8 layers, and the center of the bottom hole is led to the bottom of an upper formwork to position an upper hole, so that the deflection of the centers of two holes which are symmetric up and down caused by errors of a civil support formwork can be effectively avoided. According to the invention, a reserved hole of a finished product sleeve can be fixed by a screw so as to achieve the aims of time conservation and rapidness in assembly.

Owner:中建五局第三建设有限公司

Carabiner with pivoting gate equipped with a locking ring

InactiveUS8060994B2Controlling the riskAvoid offsetHook fastenersEye fastenersElectrical and Electronics engineering

Owner:ZEDEL CORP

Display base wide in application range

ActiveCN107366804AAvoid offsetPrevent the situationDigital data processing detailsStands/trestlesBased wideDisplay device

The invention discloses a display base wide in application range, and relates to the related technical field of computers. The display base comprises a bottom plate. A base is fixedly connected to the top of the bottom plate. Bottom rods are fixedly connected to the bottom of the inner wall of the base. The tops of the bottom rods are movably connected with a movable plate through groove holes. A lead screw groove is fixedly connected to the top of the movable plate. A rotation rod penetrates one side of the lead screw groove, the end, located outside the lead screw groove, of the rotation rod is fixedly connected with a rotation handle, a clamping groove is formed in the surface of the end, located in the lead screw groove, of the rotation rod, and a clamping device is movably connected in the clamping groove. According to the display base wide in application range, the rotation rod is driven to rotate through rotation of the rotation handle, the rotation rod is used for driving a lead screw to rotate, then the movable rod is driven to move left and right, a vertical plate is driven to move, and fixing of displays different in size is achieved; and through the clamping device, the rotation rod is tightly clamped, loosening is avoided, the fixing effect is good, and universality is high.

Owner:湖北华涛显示科技有限公司

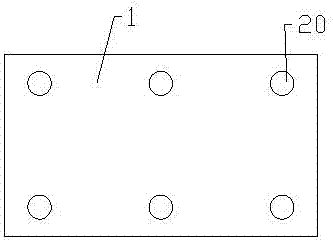

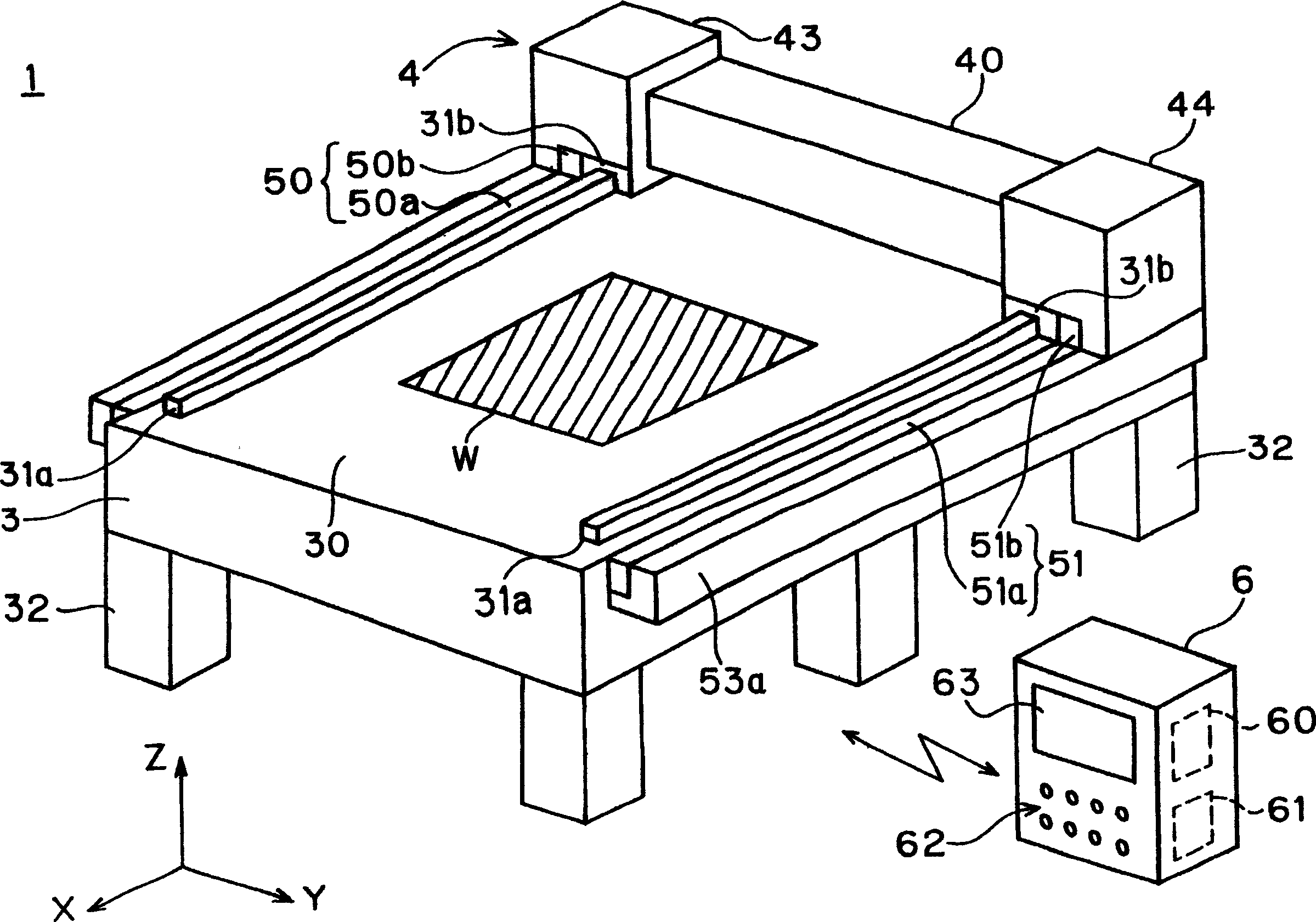

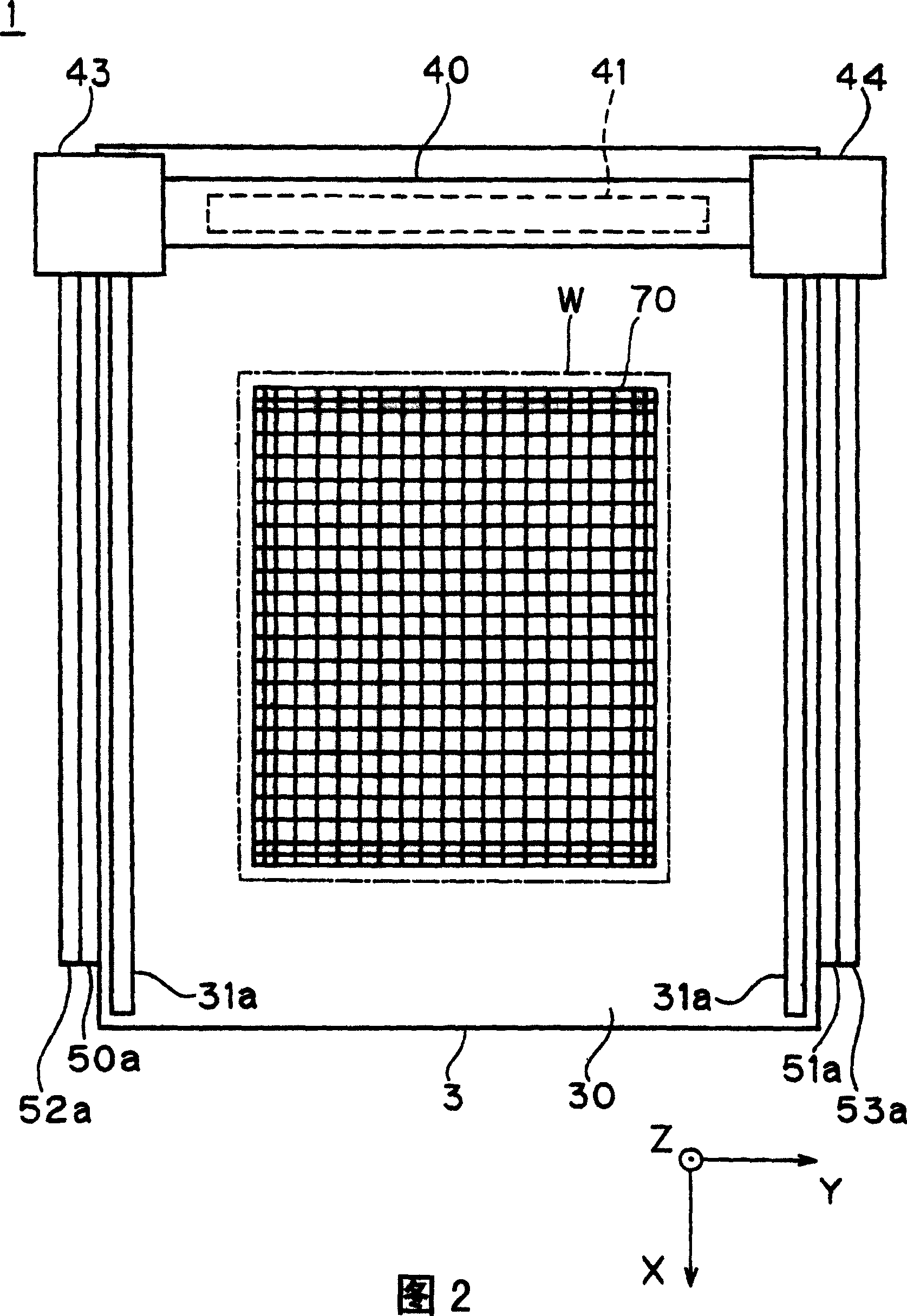

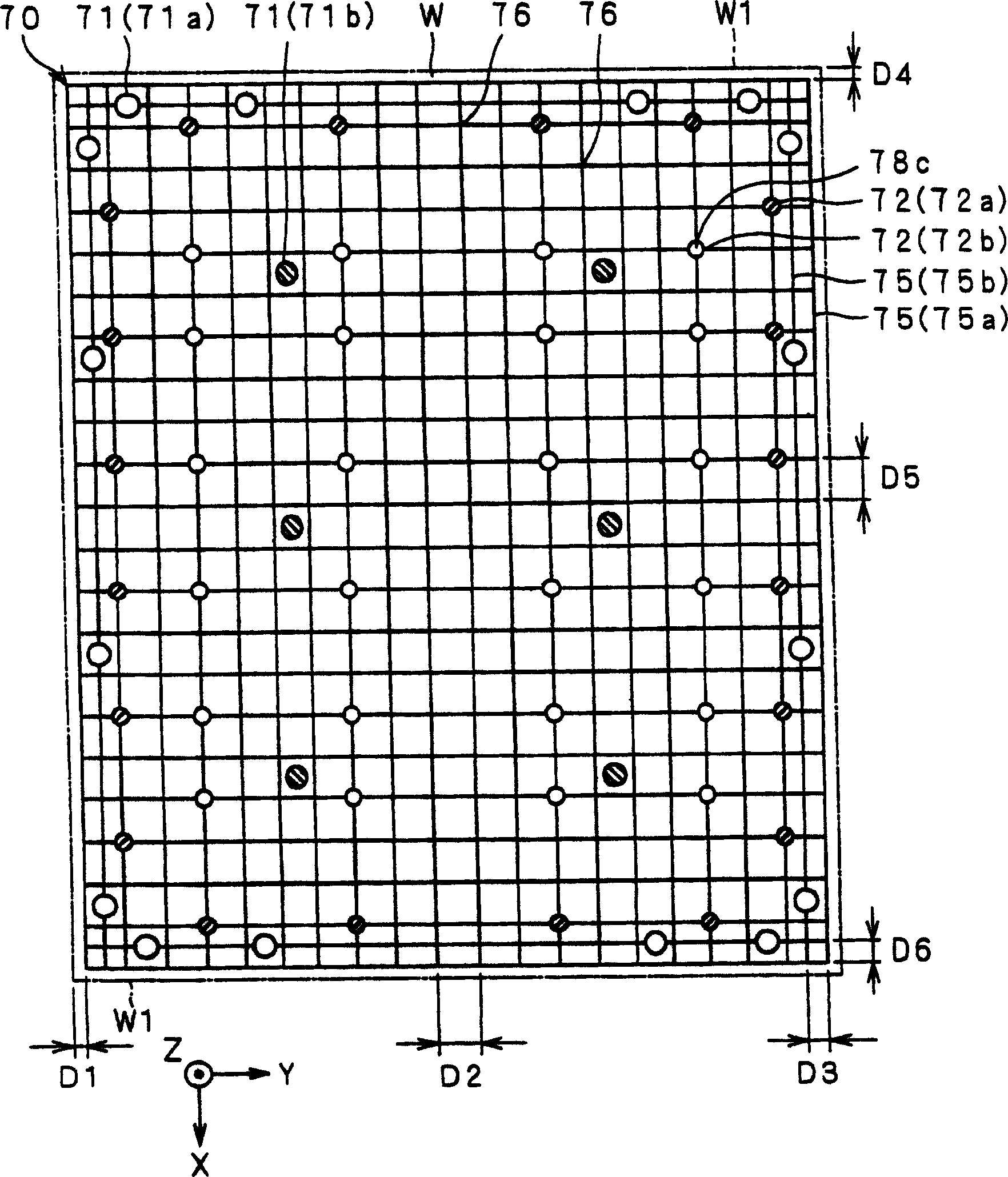

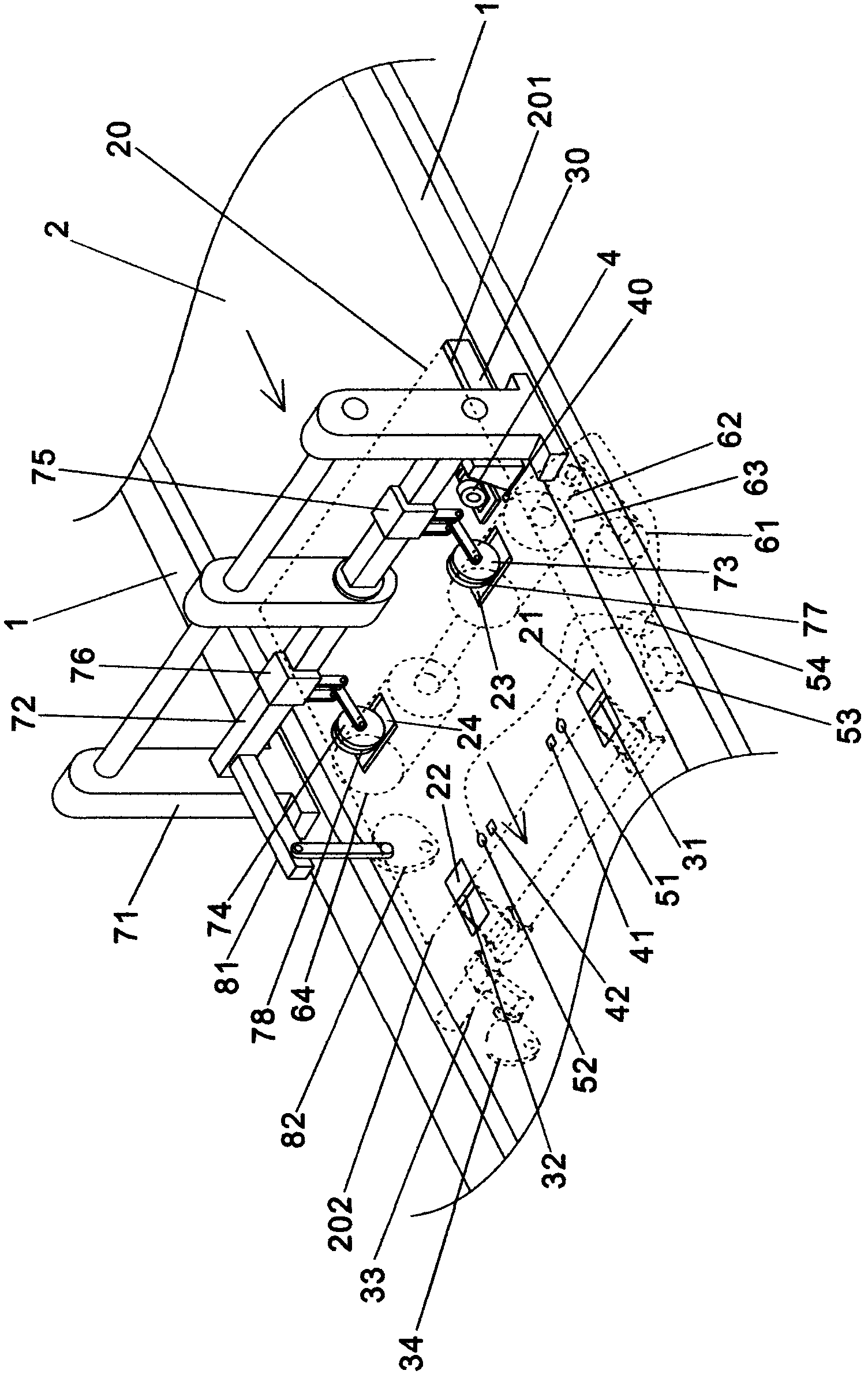

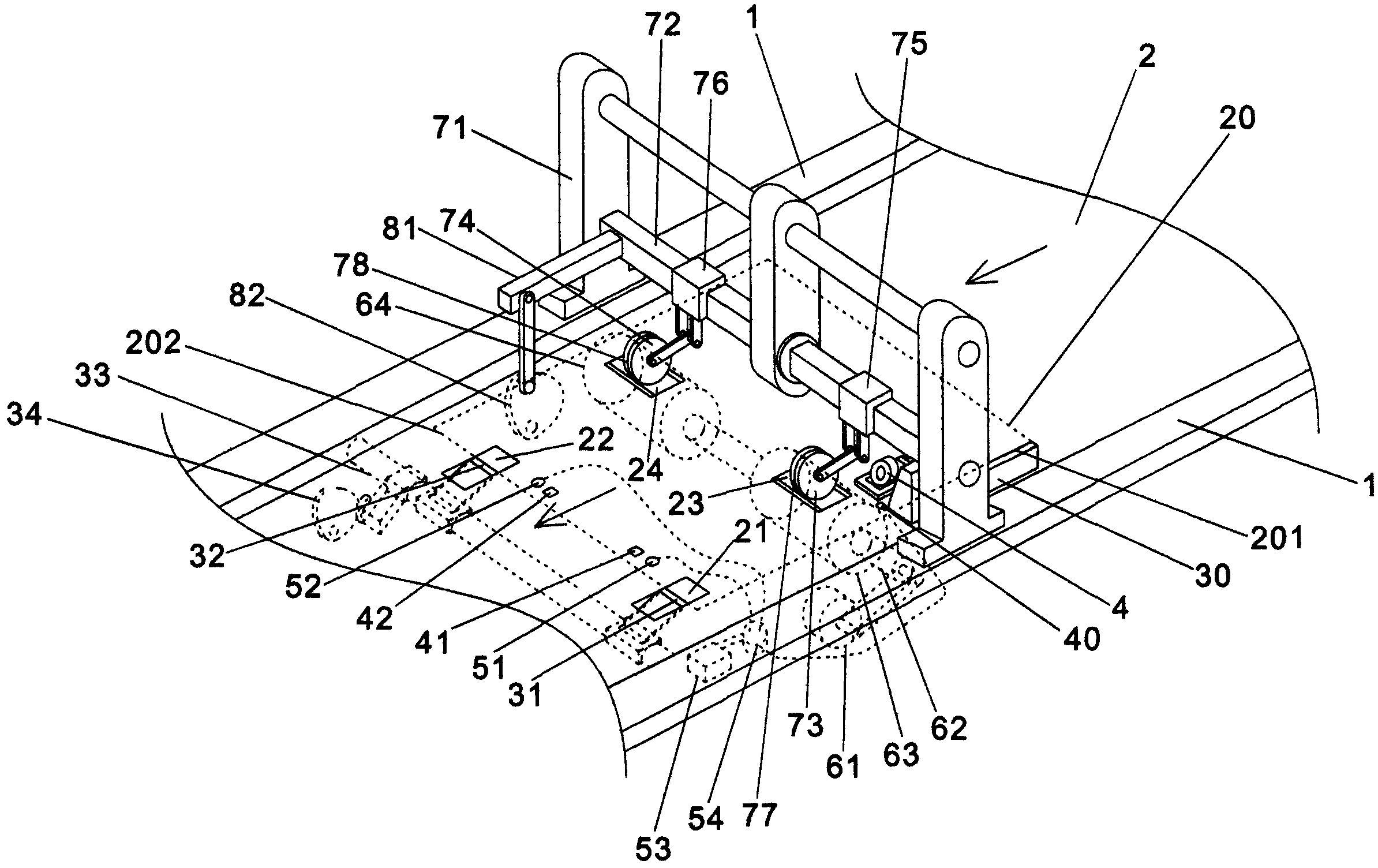

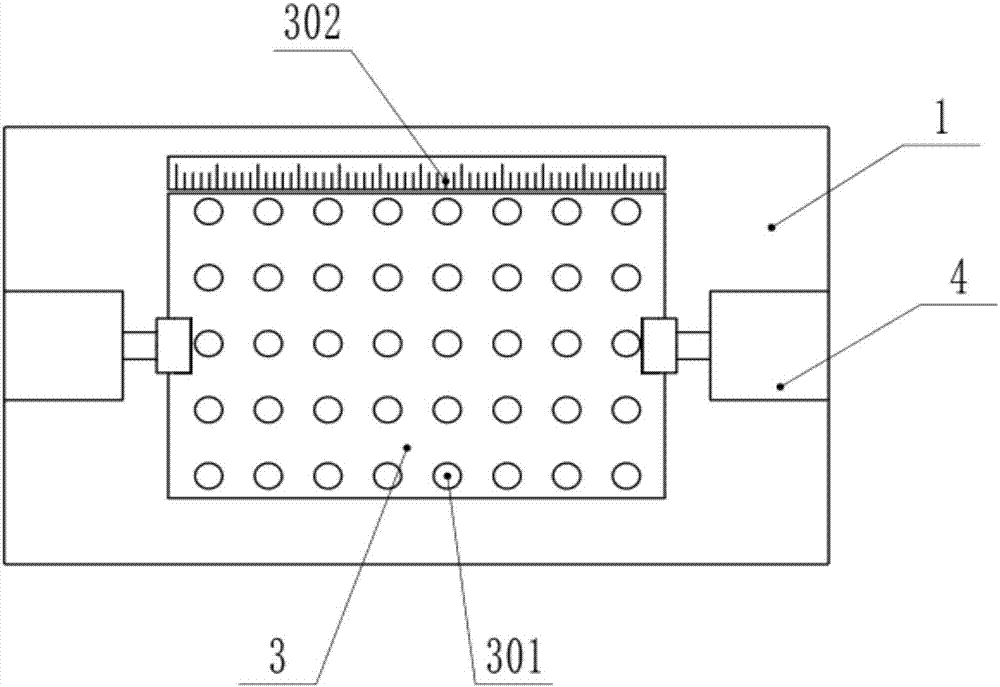

Substrate treater and treating method

ActiveCN1591816AImprove adsorption capacityReduce manufacturing costGripping headsSemiconductor/solid-state device manufacturingEngineeringVacuum pump

This invention is to provide a substrate treating device which can satisfactorily attract a substrate to its substrate placing part and, at the same time, from which the substrate attracted to the substrate placing section can be removed satisfactorily even when the size of the substrate is increased. A plurality of adsorption grooves 75 formed on the holding surface of the substrate treating device in a grid-like state are connected to each other at grid points 76. A part of the grid points 76 communicates with suction holes 72. The suction holes 72 are connected to a vacuum pump in communicating states through piping. End-section lifter pins 71a and central-part lifter pins 71b are independently provided in vertically movable states. Consequently, (1) the substrate treating device can attract the whole bottom surface of an angular substrate W even when the device does not have many attraction holes in the holding surface and (2) can attract the angular substrate W to the holding surface from the vicinity of the central part of the substrate W to the end section of the substrate W.

Owner:DAINIPPON SCREEN MTG CO LTD

Paper conveying device

InactiveCN102431818AGuaranteed accuracyReliable feedingArticle feedersPaper sheetPulp and paper industry

A paper conveying device comprises a framework, a paper conveying platform, a paper deviation correcting and limiting mechanism, a paper detecting mechanism, a paper absorbing and positioning mechanism and a batch type paper feeding mechanism. The paper deviation correcting and limiting mechanism, the paper detecting mechanism, the paper absorbing and positioning mechanism and the batch type paper feeding mechanism are arranged on the paper conveying platform, the paper deviation correcting and limiting mechanism forms a paper limiting area on the paper conveying platform, the paper detecting mechanism, the paper absorbing and positioning mechanism and the batch type paper feeding mechanism are respectively arranged in the paper limiting area, and the paper detecting mechanism is electrically connected with the paper absorbing and positioning mechanism. The paper conveying device is capable of preventing slanting or deviating of paper by deviation correcting and position limiting of the paper deviation correcting and limiting mechanism and absorbing and positioning of the paper absorbing and positioning mechanism, so that paper can be stably reliably conveyed, accuracy of printing and processing of paper printing and processing equipment and accuracy of printed matter quality detection and code spraying equipment detection are guaranteed.

Owner:陈晓滨

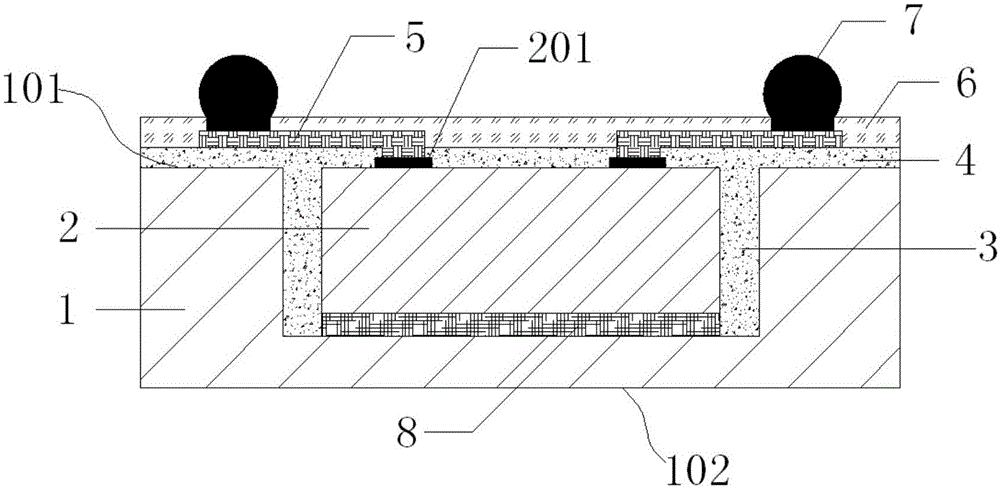

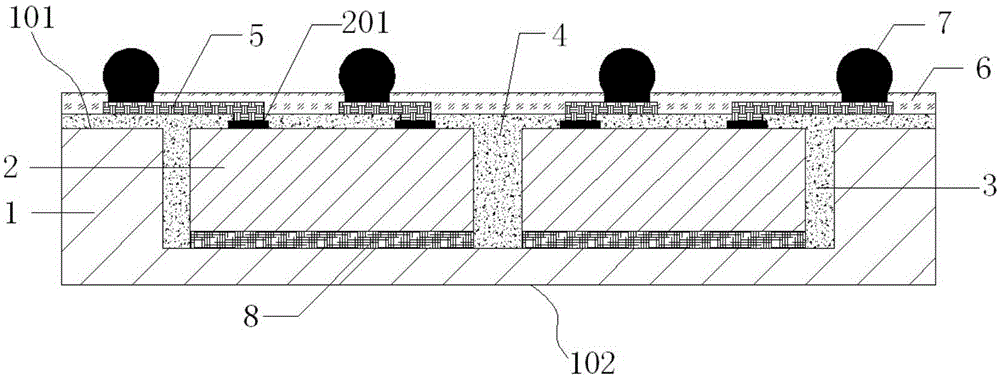

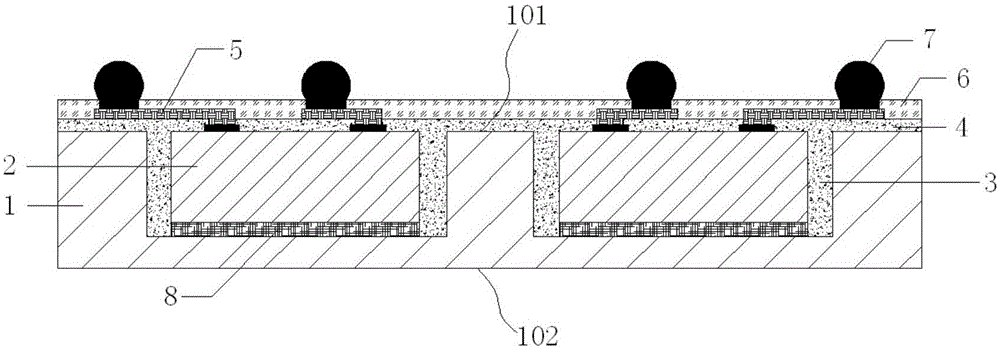

Embedded silicon substrate fan-out type packaging structure and manufacturing method thereof

InactiveCN105023900AImprove cooling effectAvoid offsetSemiconductor/solid-state device detailsSolid-state devicesSilicon matrixPolymer adhesive

The invention discloses an embedded silicon substrate fan-out type packaging structure and a manufacturing method thereof. A silicon matrix is adopted to replace molding material to act as a fan-out matrix, and fine wiring can be manufactured by fully utilizing the advantages of the silicon matrix. Holes, grooves and other structures can be accurately etched by utilizing a mature silicon etching technology. Chips are embedded in the grooves on the silicon matrix, the gaps between the chips and the side walls of the grooves are filled by polymer glue and partial welded balls are welded at the surface of the silicon matrix in a fan-out way so that packaging reliability can be enhanced, the technology is simple and cost is low. The silicon matrix has great heat radiation and lower warping so that enhancement of packaging heat radiation is facilitated, adverse warping can be overcome and smaller wiring line width can be acquired, and thus the structure is suitable for high-density packaging. `Wafer plastic packaging and the de-bonding technology can be eliminated as for the aspect of technology so that technology difficulty can be reduced, and thus cost can be substantially reduced and yield rate can be enhanced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

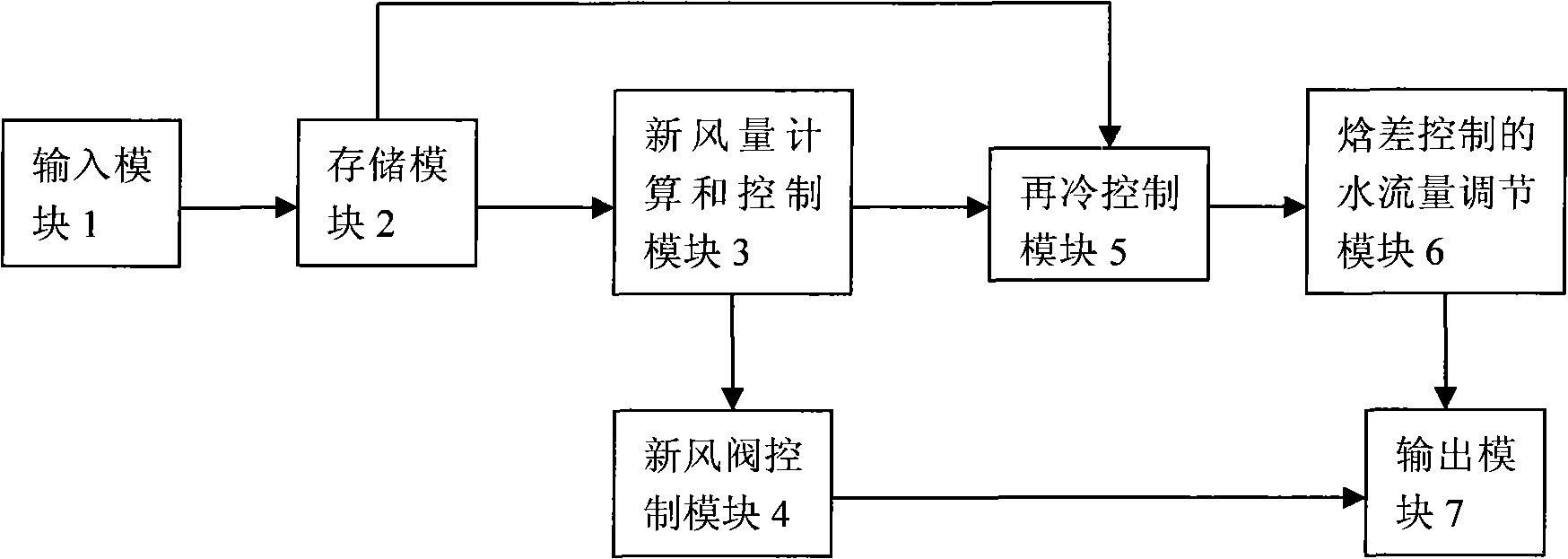

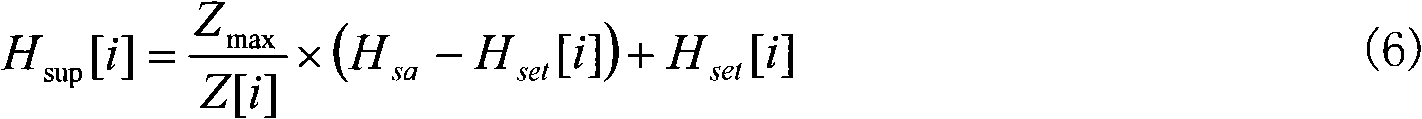

Controller based on VAV air conditioner fresh air optimized dispensing

InactiveCN101266464ABoth qualityReduce air volumeSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeIndoor air quality

A controller based on VAV air conditioner fresh air optimizing allocation belongs to the building surroundings equipment as well as control technique field. In the invention, the input module captures required data to transmit to the storage module, the storage module stores the desired data, the fresh air calculation and control module calculates the total fresh air amount of the system and fresh air amount of each area and their ratio, the maximum fresh air requirement ratio is found out to be the fresh air ratio setting value for system air blow. The fresh air valve control module takes the total fresh air amount as the setting value, and the results are transmitted to the fan valve executor according to PID control. A double cold control module calculates the air blow setting enthalpy value of each area terminal, which is transmitted to a water flow regulate module controlled by the enthalpy difference, and the module transfers the valve position information to the water valve executor according to PID control based on the air blow setting enthalpy value and sampling value passing through the termini serpentinepipe. The invention not only does not increase thee fresh air load, but also avoids cold-hot counteract, meanwhile compromises indoor air quality.

Owner:SHANGHAI JIAO TONG UNIV

Deviation-prevention-type cutting device for building ceramic tiles

InactiveCN107322445ACutting stabilityAvoid offsetWorking accessoriesGrinding machinesMotor driveDrive motor

The invention discloses an anti-offset cutting device for architectural tiles, which comprises a base, a casing, a cutting table, a clamping device, a driving motor, a cylinder, a cutting motor, a cutting wheel and a fan. The upper surface of the cutting table is provided with several Through holes, a fan is fixedly installed inside the base, a foam collection box is connected to the air outlet of the fan, a clamping device is fixedly installed on the upper surface of the base, the output shaft of the driving motor is horizontal to the left and connected with a screw, the screw A sliding sleeve is installed on the upper thread, and a cutting motor is fixedly connected to the piston rod of the cylinder. Set the clamping device to clamp the tiles to prevent the tiles from shifting during the cutting process and improve the cutting accuracy; by using the drive motor to drive the screw to cooperate with the sliding sleeve, the cutting wheel can move left and right, so that the tiles can be cut stably, saving It saves time and effort, improves production efficiency, and at the same time, compared with manual cutting, it has higher precision and higher safety.

Owner:黄娜茹

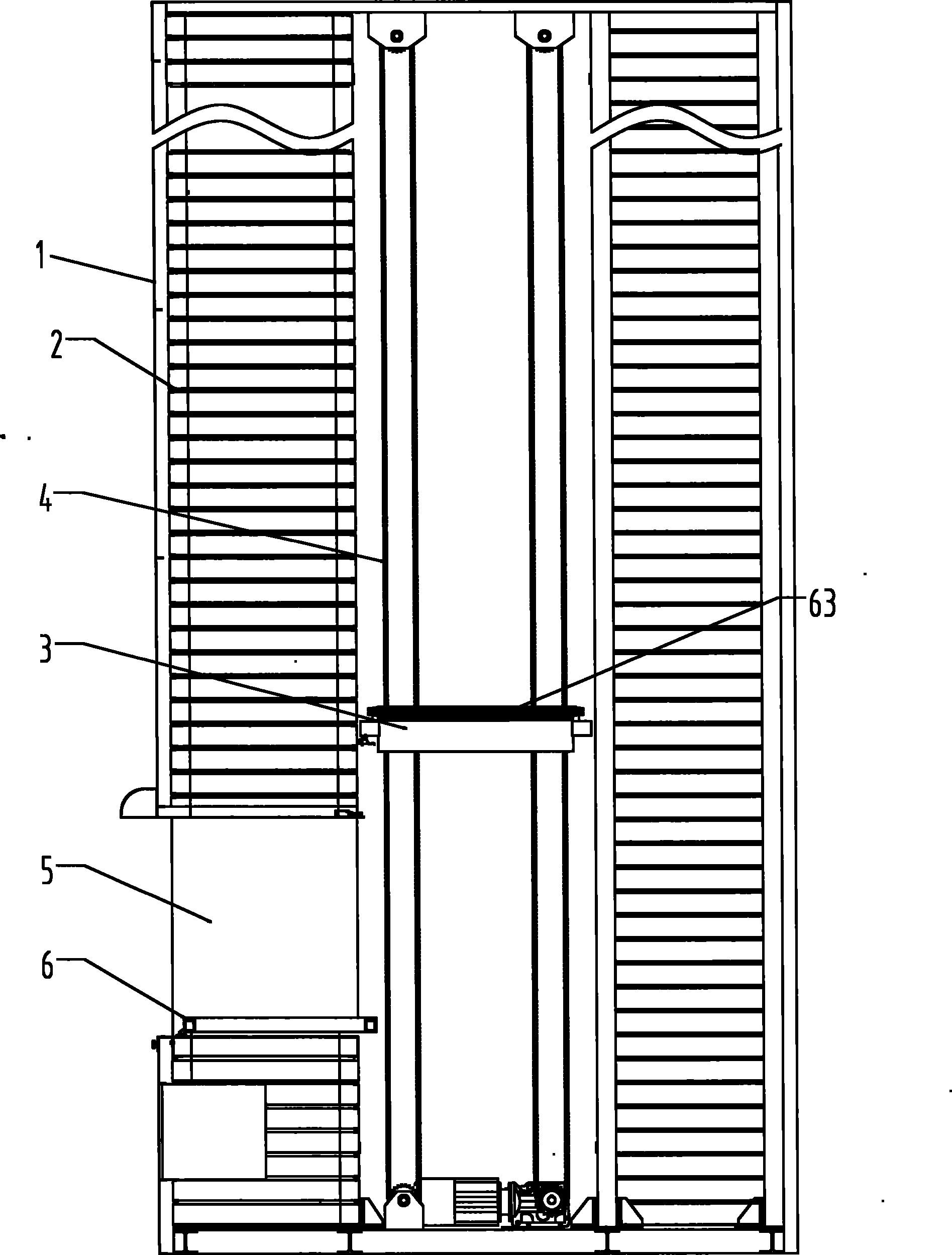

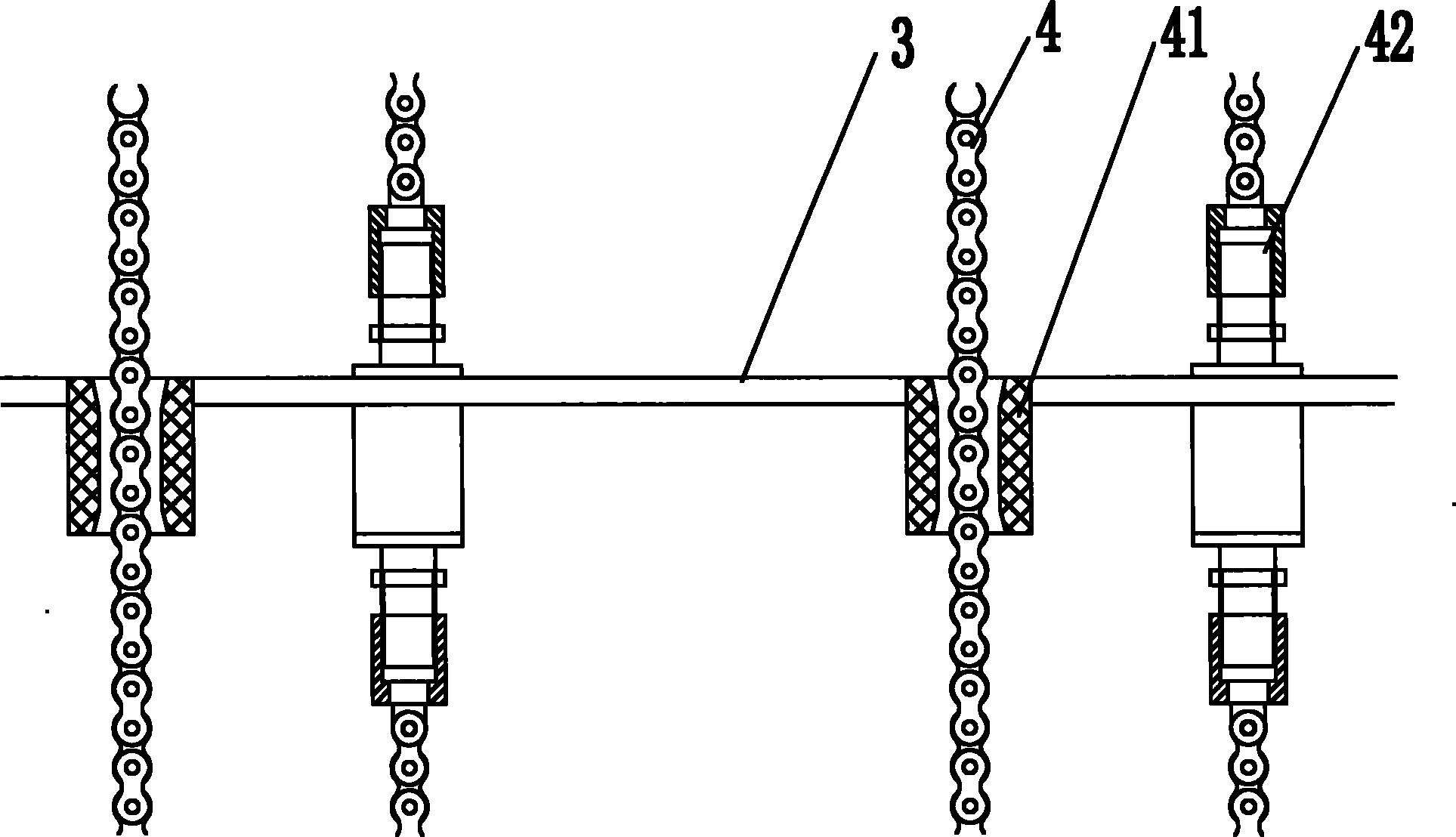

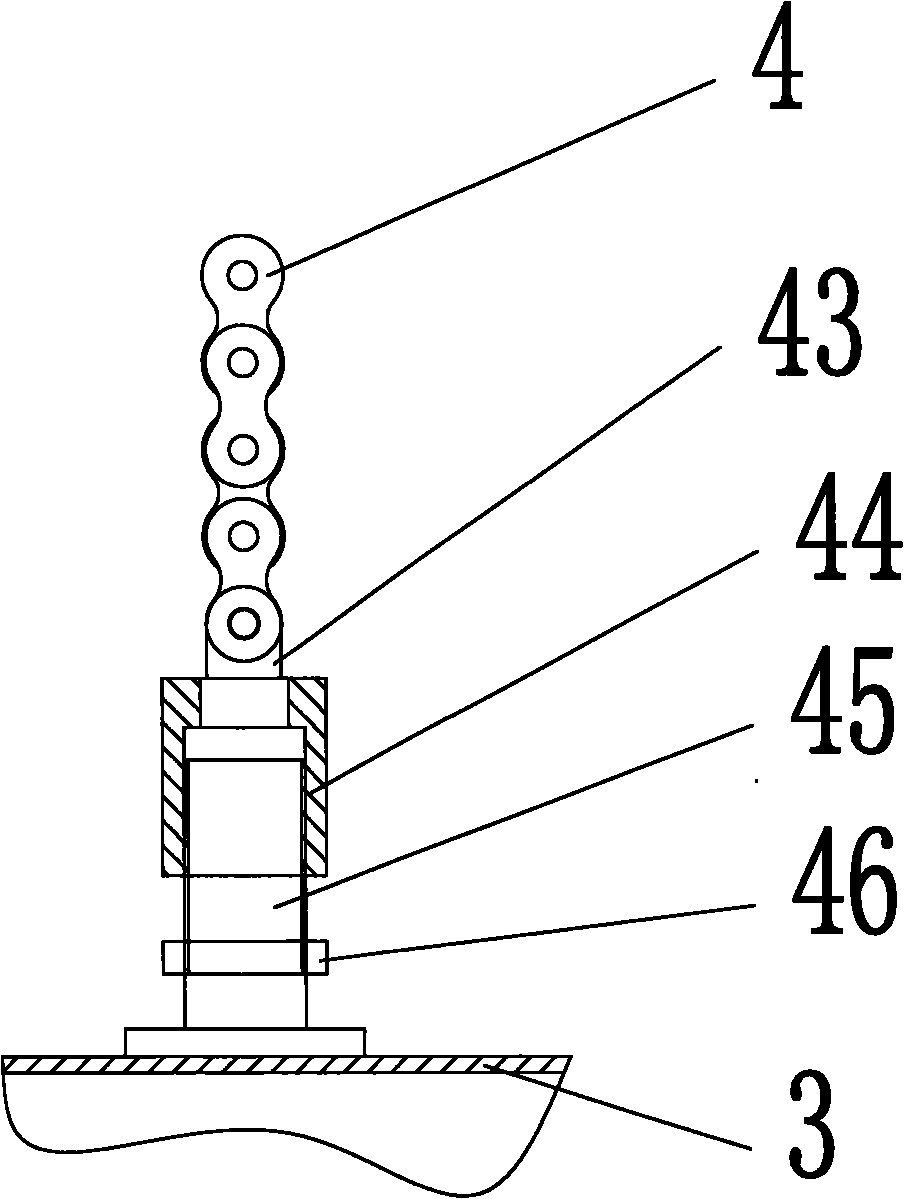

Vertical lifting container

ActiveCN101850884AGuaranteed smoothnessImprove shipping efficiencyStorage devicesSprocketEngineering

The invention discloses a vertical lifting container, which comprises a container body, a corbel for holding a pallet is respectively on the two sides of the container, a passage for the lifting platform to run from top to down is left between the cornels on the two sides of the container body, a lifting platform is hung in the passage through a lifting chain, one side of the container is provided with a goods outlet, the pallet for transporting into or out the goods is arranged in the goods outlet, and a drive device drives the pallet to translate. In the vertical lifting container of the invention, the pallet device is driven by a chain wheel device to smoothly and stably run, a guide device is arranged to further guarantee the smoothness of the pallet during the processes of drawing and withdrawing, so as to improve the operating efficiency of the goods and reduce running noise, and a chain tensioner can adjust the tension of the chain to avoid the swaying phenomenon and to enable the adjustment of the horizontal position of the lifting platform to be convenient. Since a guide upright similar to a guide rail is arranged, the vertical lifting platform can ensure the smoothness of the lifting platform and prevent the surface of the lifting platform from being oblique and shifted.

Owner:南京音飞储存设备(集团)股份有限公司

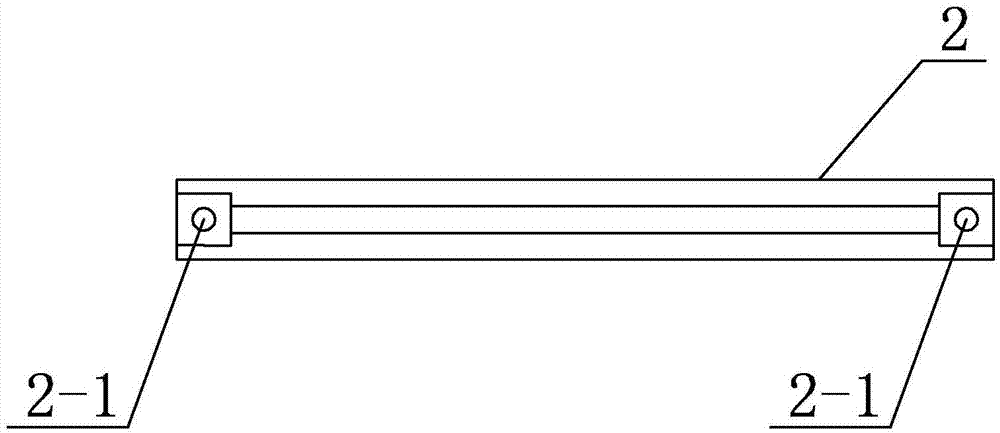

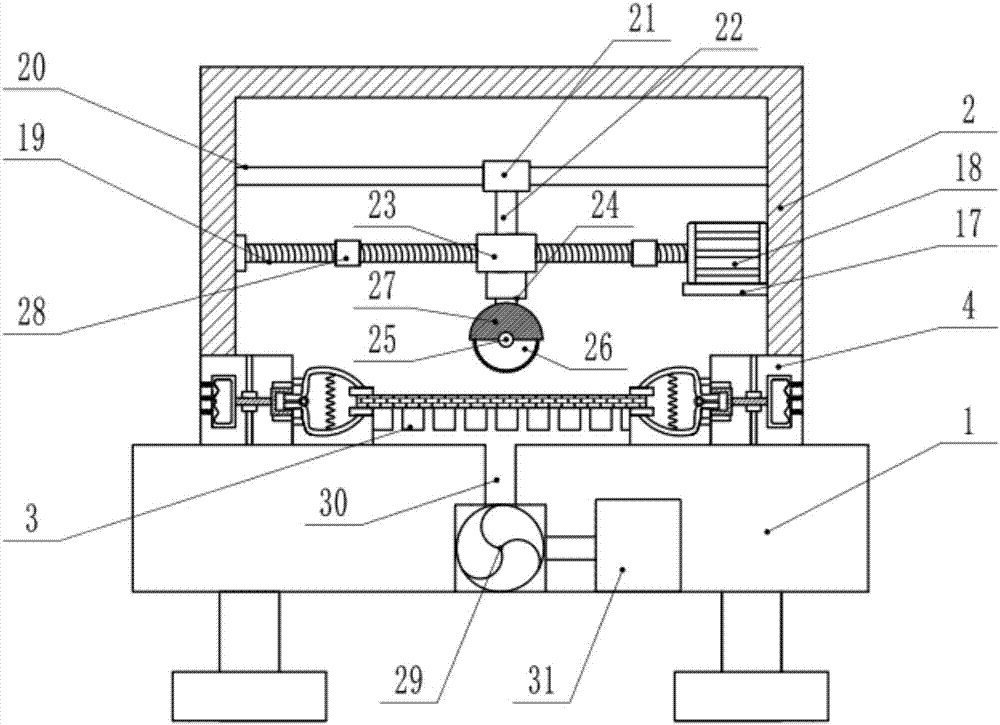

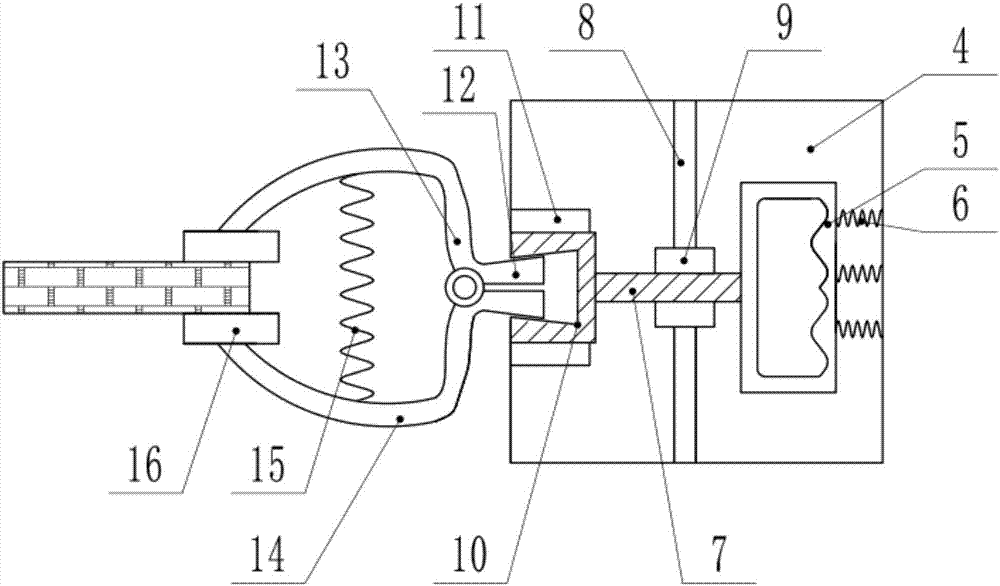

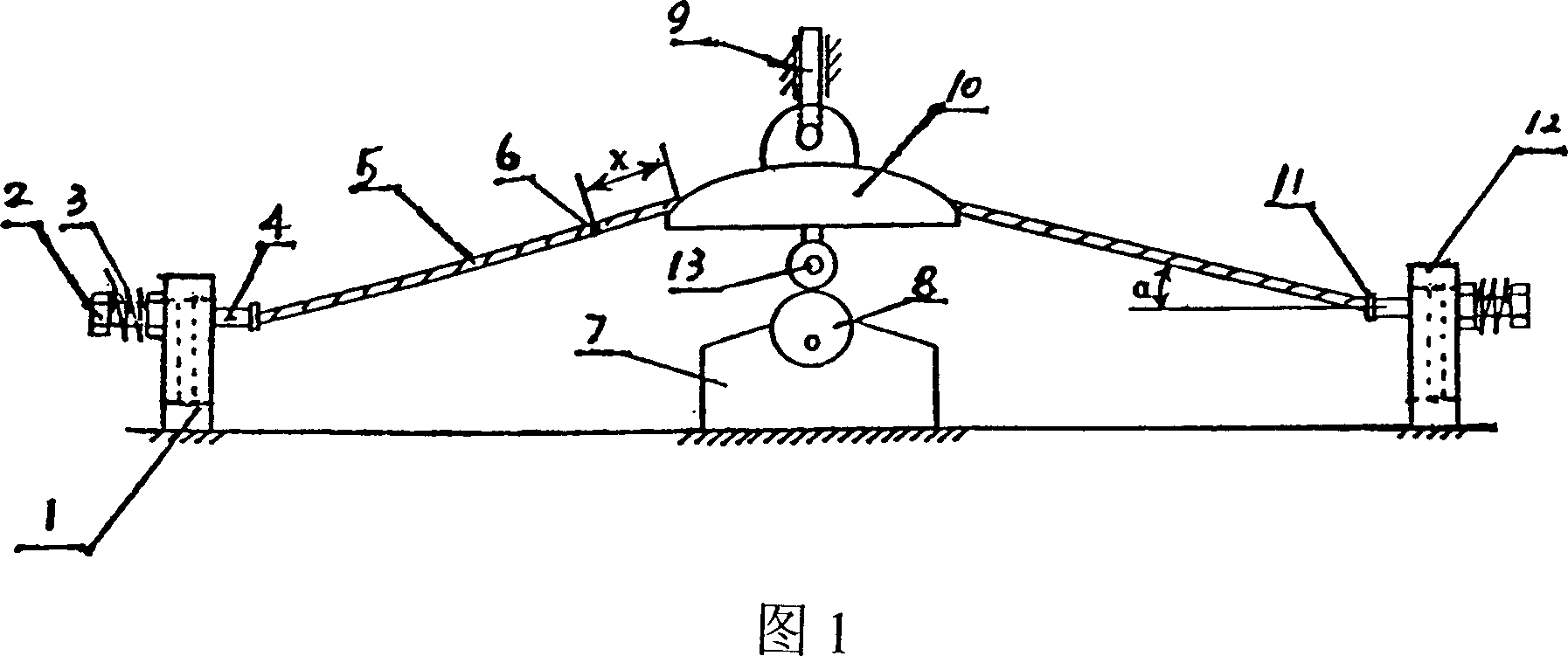

Multi-parameter adjustable cable fretting fatigue device

InactiveCN101017715AAdjustable vibration frequencyAvoid offsetStructural/machines measurementCoupling light guidesButt jointRelative motion

The invention relates to a multi-parameter adjustable cable fretting fatigue device. Wherein, the current wire vibration test bench mainly aims at the macroscopical wire vibrating or weaving; while for research on wire breaking, it is hard to adjust multiple parameters for vibrating frequency and amplitude, loading, and angle. This invention comprises a vibration source device, a tension device, a fixing slot base, a vertical location device, an overhanging-line clamp, some wires, a vibration detector, and a stress-strain detector. This invention completes the test by means of relative motion between the cam on motor shaft and flow butt-joint wheel fixed under the overhanging-line.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

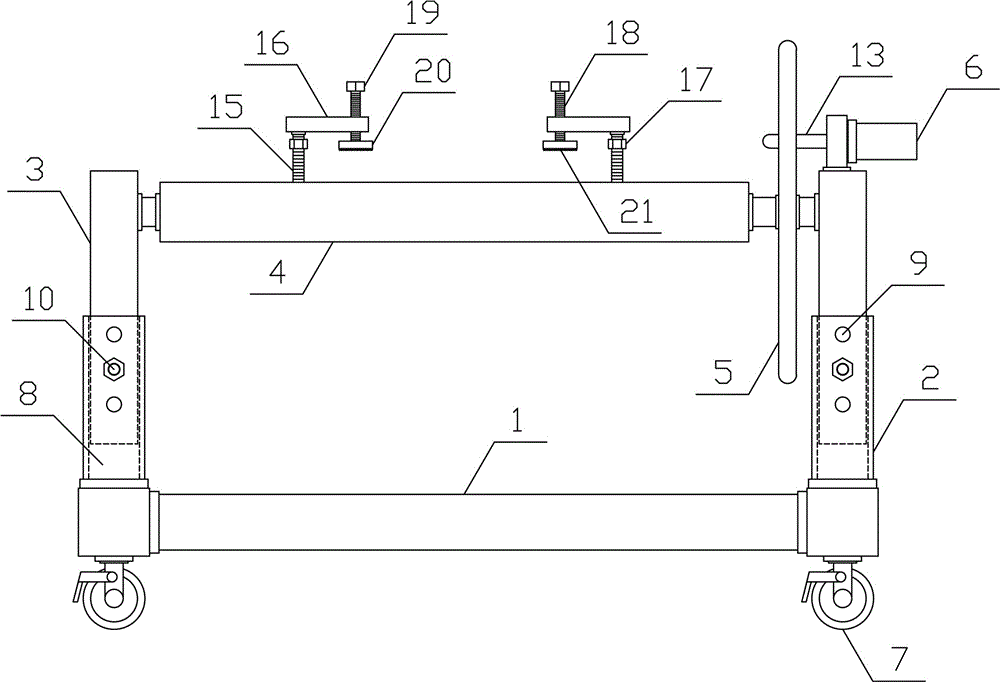

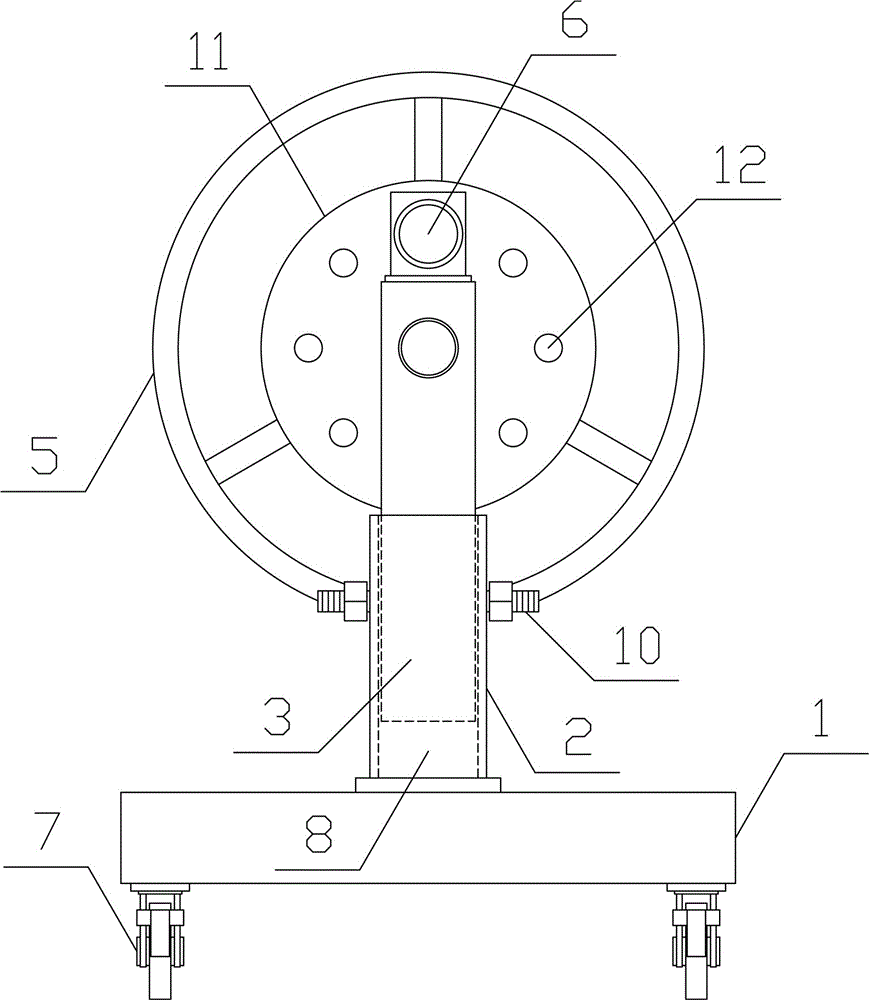

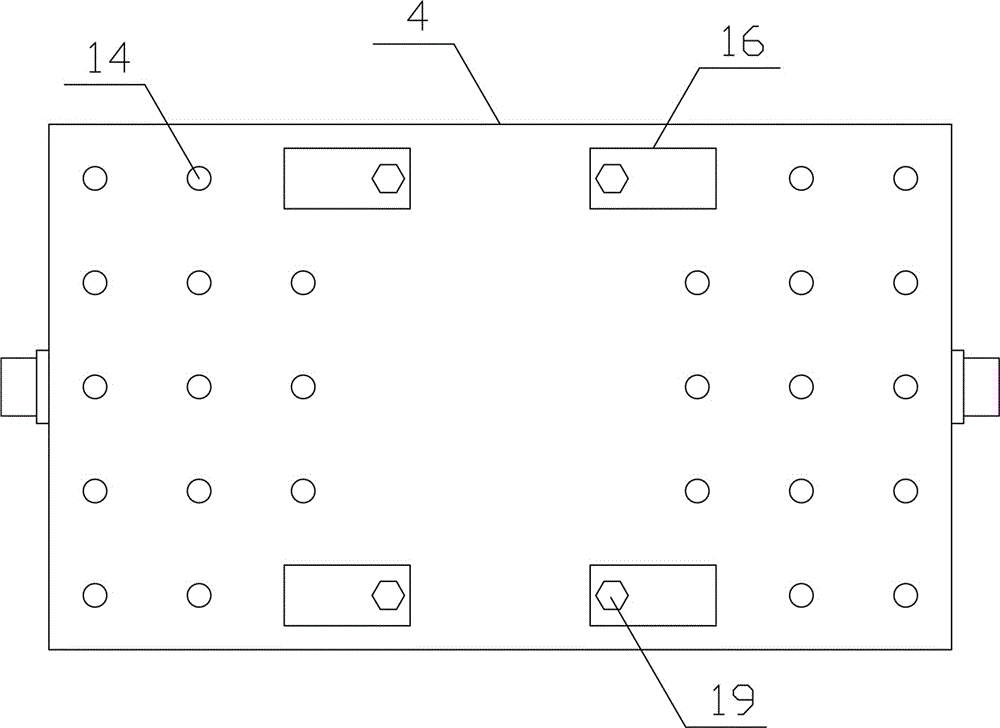

Plate machining turnover mechanism

InactiveCN106217328AAvoid offsetImprove processing efficiencyWork holdersWork benchesEngineeringMachining

The invention discloses a plate machining turnover mechanism, and belongs to the field of machining equipment. The plate machining turnover mechanism comprises a translation base, a lifting sleeve, lifting plates, a plate fixed plate, a rotating wheel disc and a fixed cylinder; multiple brake universal wheels are uniformly arranged on the lower side of the translation base; the lifting plate is vertically arranged in the lifting sleeve; the middle parts of two sides of the plate fixed plate are rotationally connected to the lifting plates on two sides above the translation base; the rotating wheel disc is vertically arranged between one side of the plate fixed plate and the lifting plates; multiple plate locking holes are uniformly formed in the upper side of the plate fixed plate; the lower end of a fixed lead screw is in threaded connection with the plate locking holes; one end of a support plate is in threaded connection with a lifting lead screw; and a plate clamping plate is arranged at the lower end of the lifting lead screw. The plate machining turnover mechanism is reasonable in structure design, can firmly press and fix plates with multiple size specifications, can overturn the plates according to the plate machining demands, and satisfies the plate machining demands.

Owner:屠明州

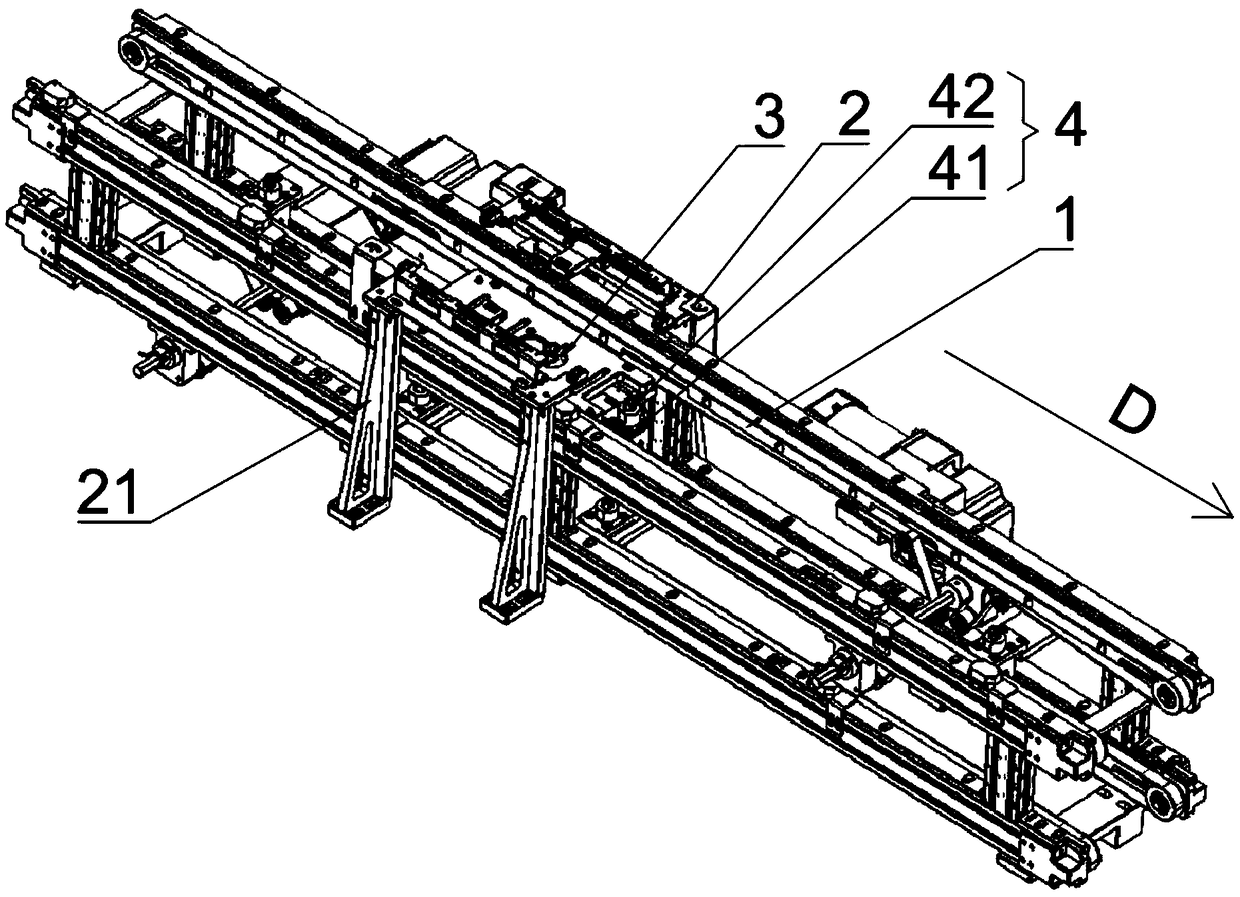

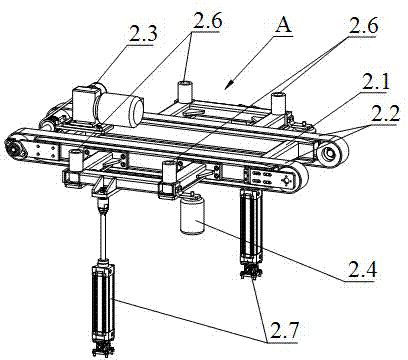

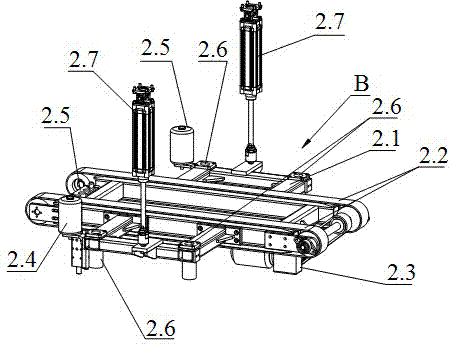

Carrier positioning device, material conveying device and full-automatic production line

ActiveCN109132405ARealize processing operationsEasy loading and unloadingControl devices for conveyorsMechanical conveyorsProduction lineEngineering

The invention provides a carrier positioning device which comprises a jacking mechanism and a blocking mechanism and further comprises positioning mechanisms. The jacking mechanism is arranged betweenconveying belts which conduct conveying in parallel, can move vertically relative to the conveying belts and is used for jacking a carrier to make the carrier disengaged from the conveying belts andmove to the work position. The blocking mechanism is arranged on the downstream part of the jacking mechanism in the conveying direction and is provided with a lifting blocking rod which is used for preventing the carrier from moving. The positioning mechanisms are symmetrically arranged on the two sides of the conveying belts in the conveying direction. Each positioning mechanism comprises a detecting device and a carrier unlocking device, wherein the detecting device is used for detecting the position of the carrier and the position of a workpiece in the carrier, and the carrier unlocking device is used for unlocking the workpiece in the carrier when the carrier is in the working position so as to achieve unloading of the workpiece. By means of the carrier positioning device, the position of the workpiece can be detected in the unloading process. The invention further provides a material conveying device with the carrier positioning device and a full-automatic production line.

Owner:SUZHOU RS TECH

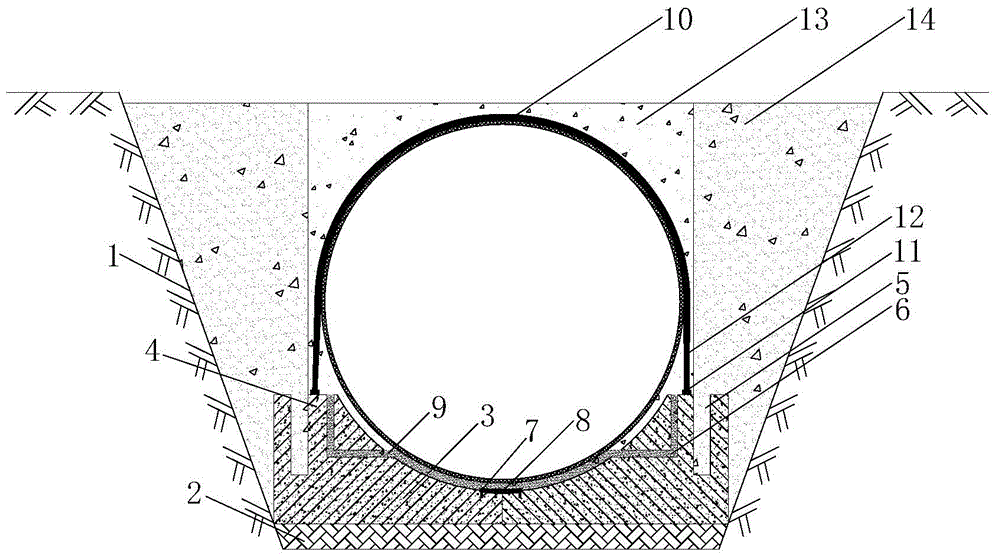

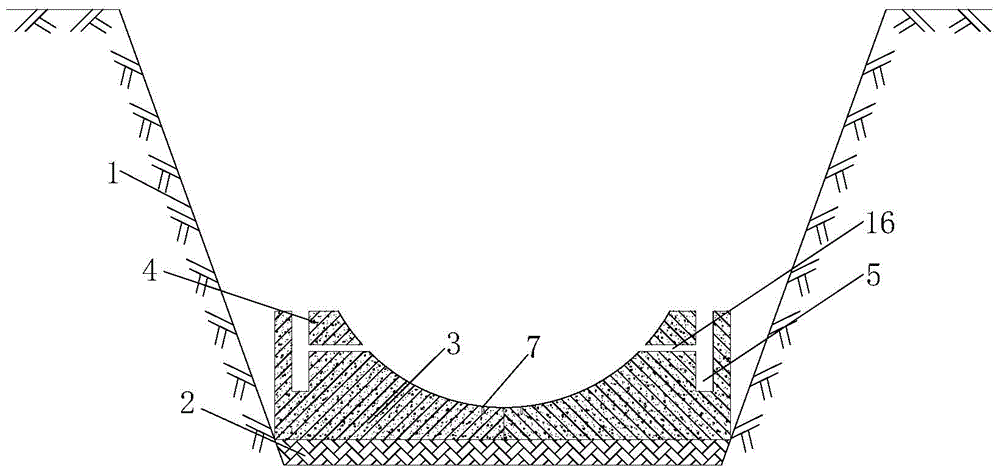

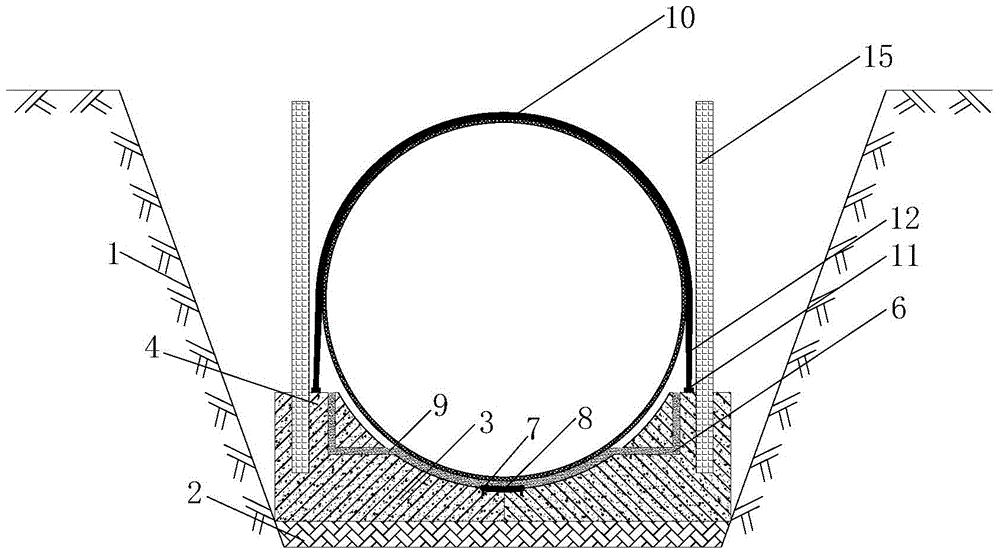

Construction method of large-diameter rain sewage pipeline assembling type component structure

The invention relates to a large-diameter rain sewage pipeline assembling type component structure. The large-diameter rain sewage pipeline assembling type component structure is characterized in that a shallow curing cement layer is disposed at the bottom of the groove of a pipeline, a prefabricated pipeline base is disposed on the upper portion of the shallow curing cement layer, the pipeline base is provided with hoisting holes, rear grouting holes, form board grooves and positioning fasteners, the pipeline is supported on the pipeline base, rear grouting sealing bodies are formed in the gaps between the pipeline and the pipeline base by grouting through the rear grouting holes, separated annular positioning bands are evenly disposed on the pipeline, two ends of the separated annular positioning bands are respectively connected with the positioning fasteners on two sides of the pipeline base, a concrete backfill layer is disposed on the periphery of the pipeline, and gravel backfill layers are disposed on two sides of the pipeline. The large-diameter rain sewage pipeline assembling type component structure has the advantages that the prefabricated pipeline base is used, pipeline mounting integrity and stability are effectively enhanced by a series of reinforcing measures, and the structure is convenient in hoisting and good in economic and technological benefits.

Owner:神州建设集团有限公司

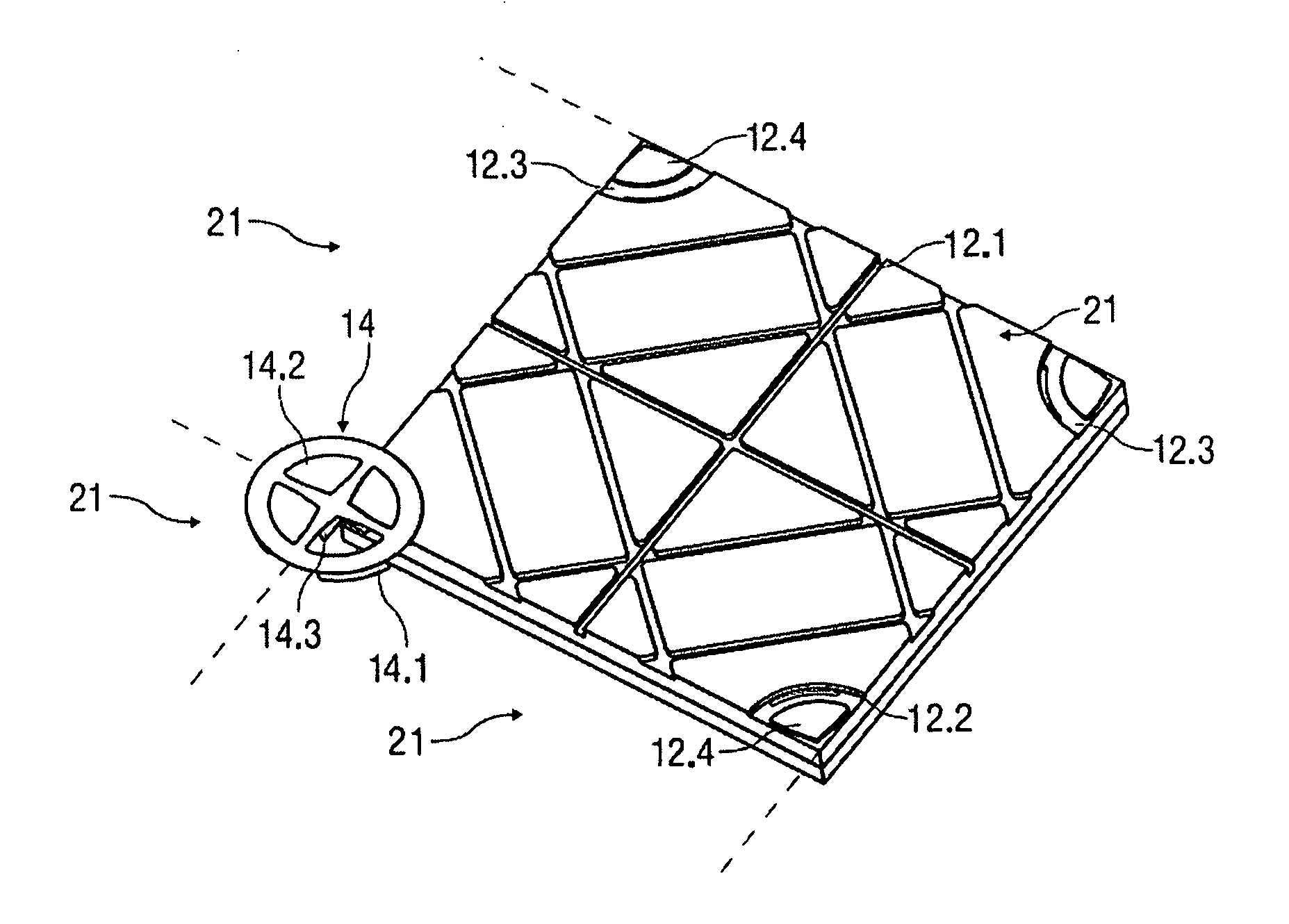

Floor made from individual elements

InactiveUS20090313915A1Easy to transportEasy to disassembleConstruction materialWallsVertical edgeWear resistant

Owner:KELLNER PETER

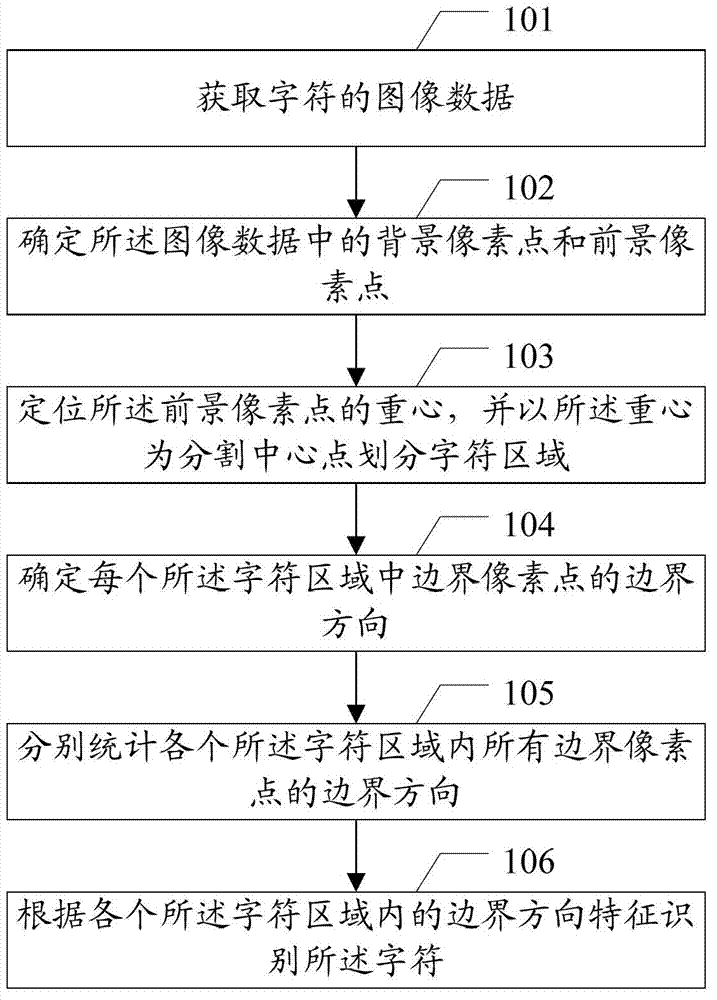

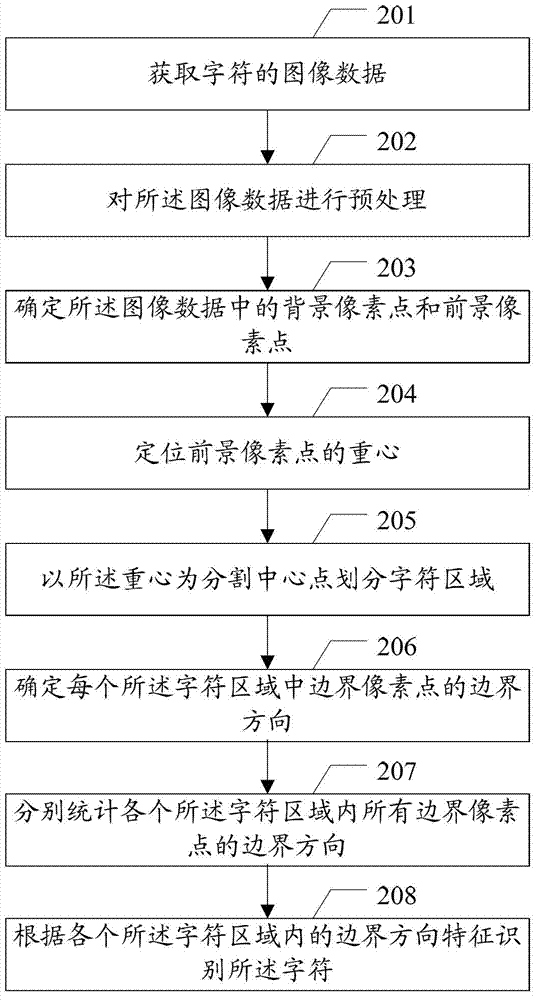

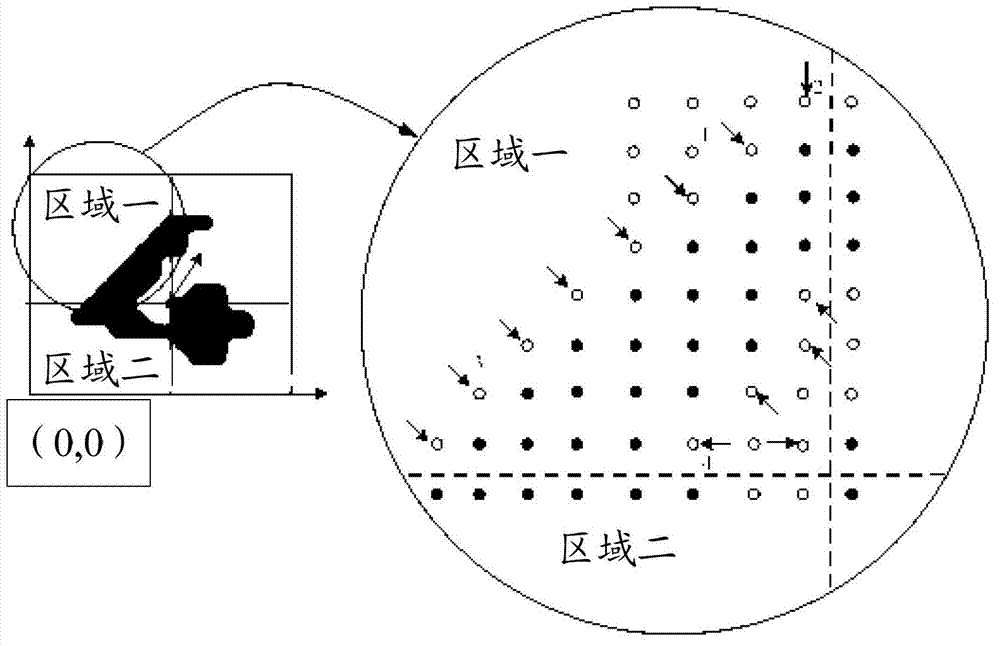

Character identification method and relevant device

InactiveCN102831416AAvoid offsetAdaptableCharacter recognitionComputer graphics (images)Imaging data

The embodiment of the invention discloses a character identification method and a relevant device, applied to efficient and rapid identification of characters. According to the embodiment of the invention, the character identification method comprises the steps of: obtaining image data of a character; determining a background pixel point and a foreground pixel point in the image data; positi0oning the center of gravity of the foreground pixel point and dividing character regions by regarding the center of gravity as a cutting central point; determining a border direction of a border pixel point in each character region; respectively counting the border directions of all the border pixel points in each character region to obtain border direction characteristics of each character region; and identifying the character based on the border direction characteristics in each character region.

Owner:GRG BAKING EQUIP CO LTD

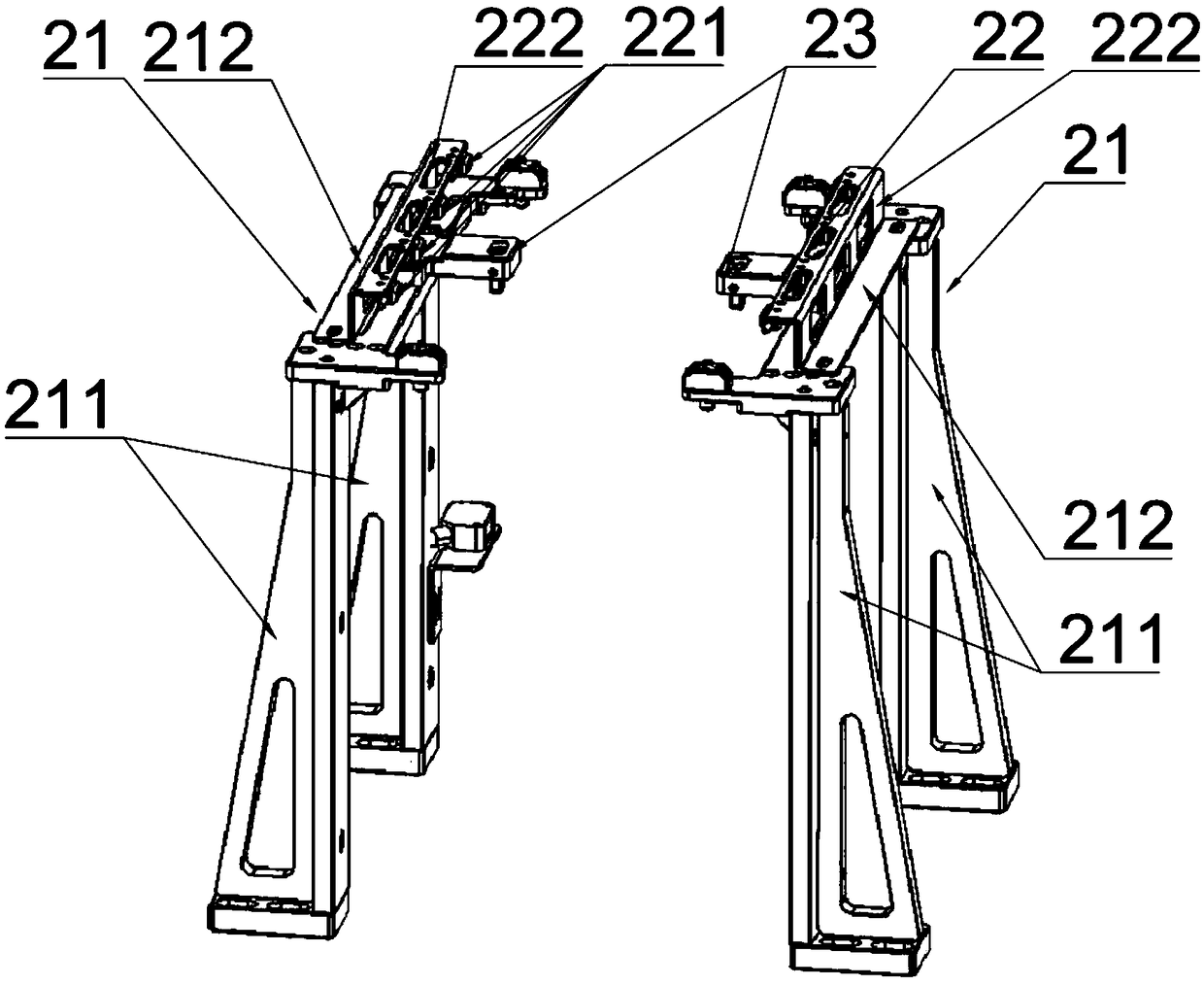

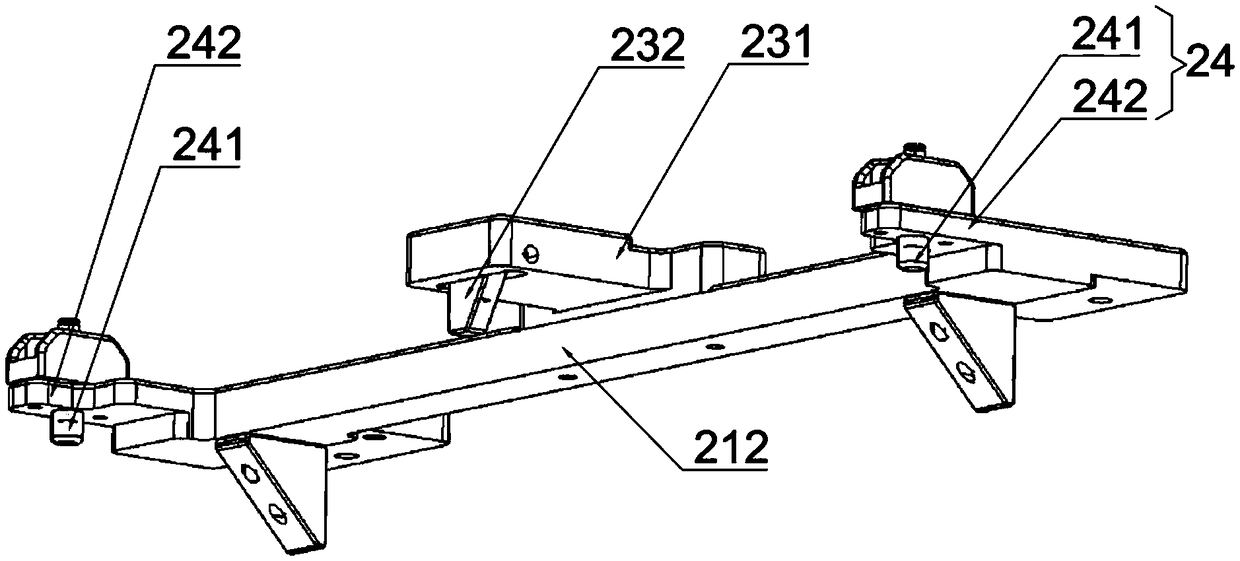

Tire overturning device

InactiveCN103569644ANot prone to travel deviationReduce distortionConveyor partsDynamic balanceEngineering

The invention provides a tire overturning device difficult to generate tire traveling deviation, guaranteeing influence uniformity and dynamic balance marking precision and having precisely controlled overturning angle and little tire deformation. The tire overturning device comprises a frame, an overturning mechanism and a clamp conveying mechanism, wherein the clamp conveying mechanism comprises upper and lower conveying clamp devices, which both comprise main body brackets, conveying mechanisms, clamp driving parts and first guiding parts; the overturning mechanism comprises an overturning frame, an overturning motor, an overturning bracket and second guiding parts; the main body brackets are mounted on the overturning frame; the first guiding parts are in sliding fit with the second guiding parts. The overturning mechanism of the invention is the upper and lower clamp conveying devices with clamping and conveying functions; tires are passed in the station from a previous station and directly conveyed to the center part for clamping to realize 180 degrees of overturning, so that the tire traveling deviation is difficultly generated, and the uniformity and the dynamic balance marking precision are guaranteed; as the clamped surfaces are the sides of the tires, the deformation of the tires is little.

Owner:MESNAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com