Patents

Literature

7233results about How to "Easy loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

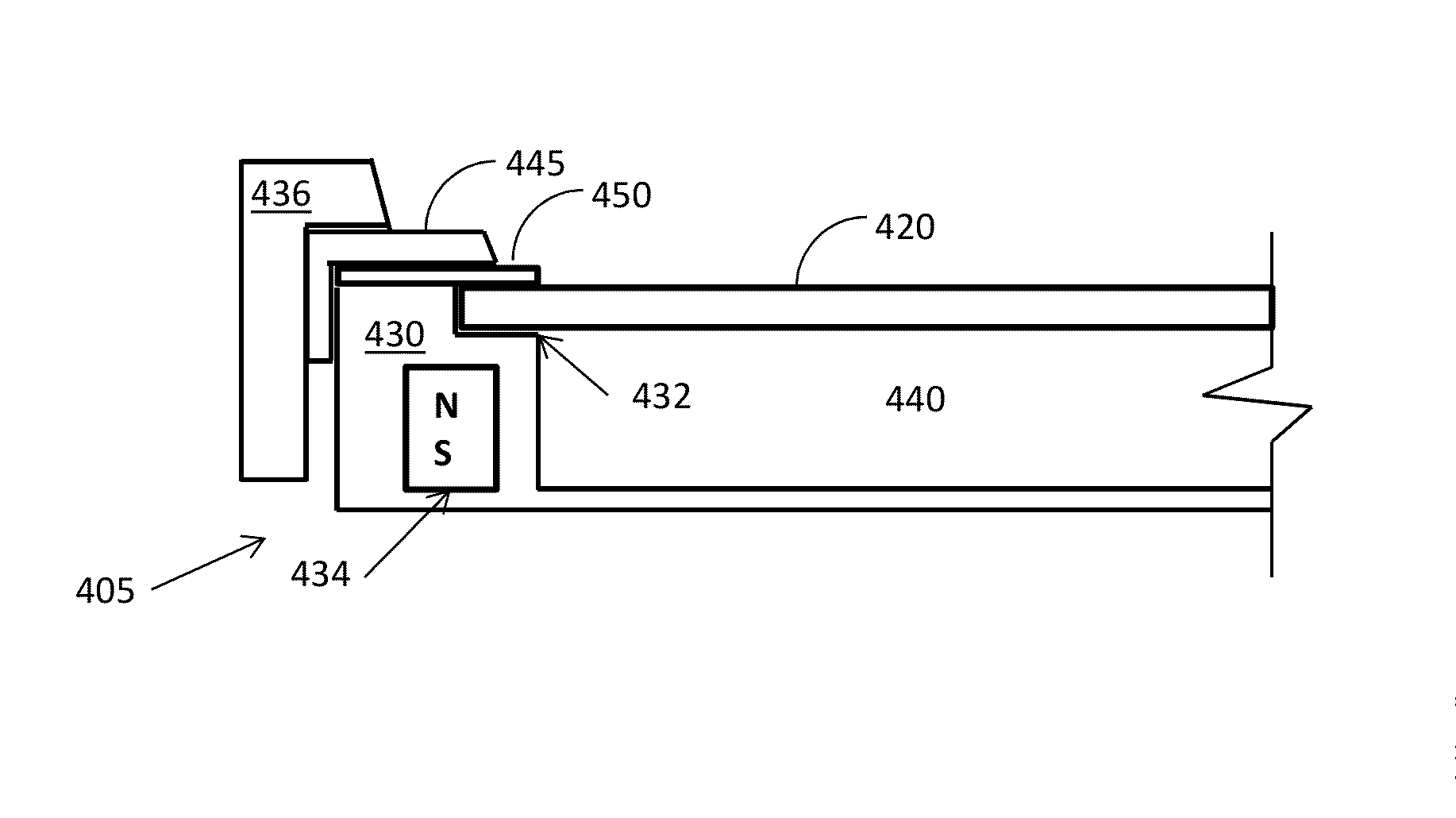

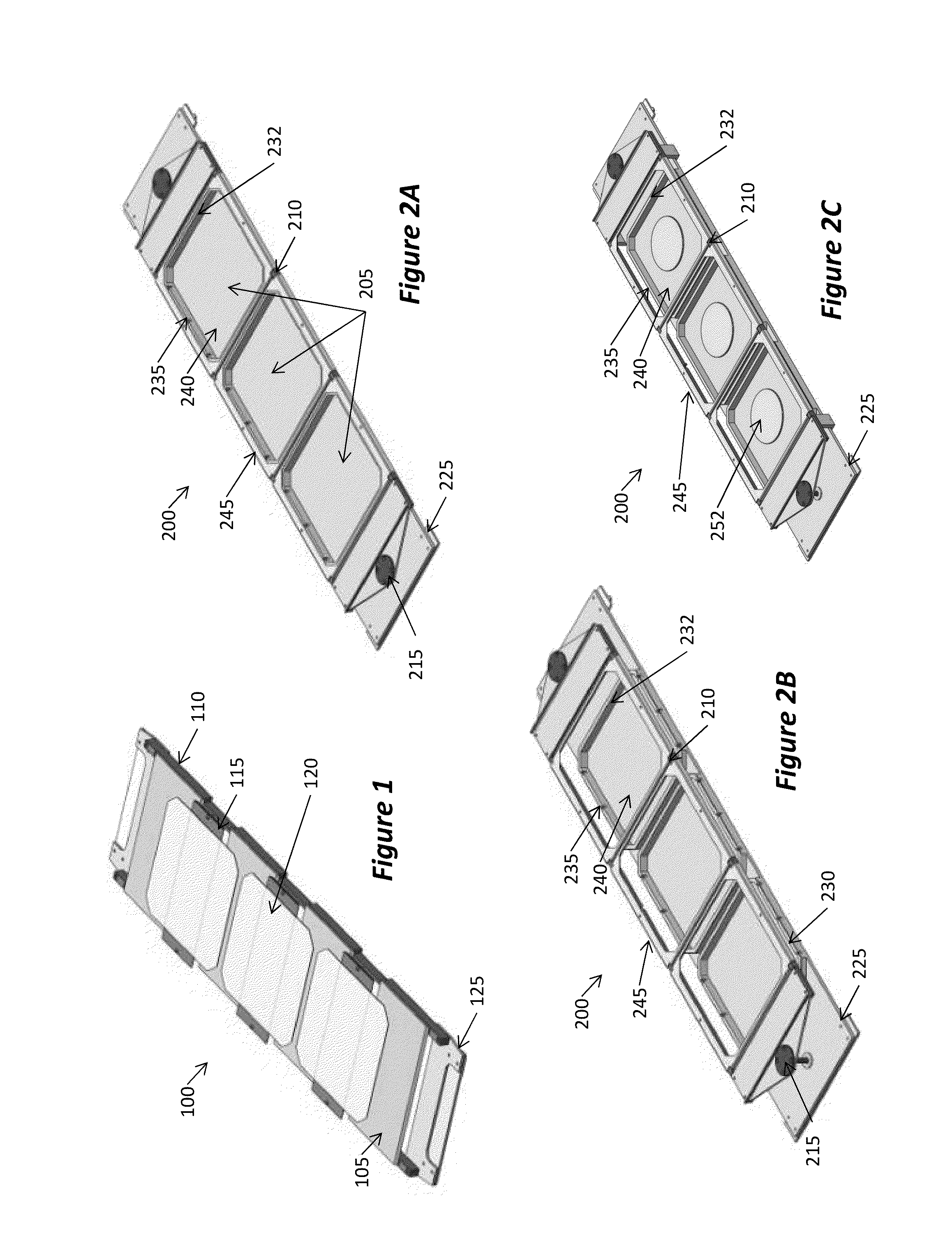

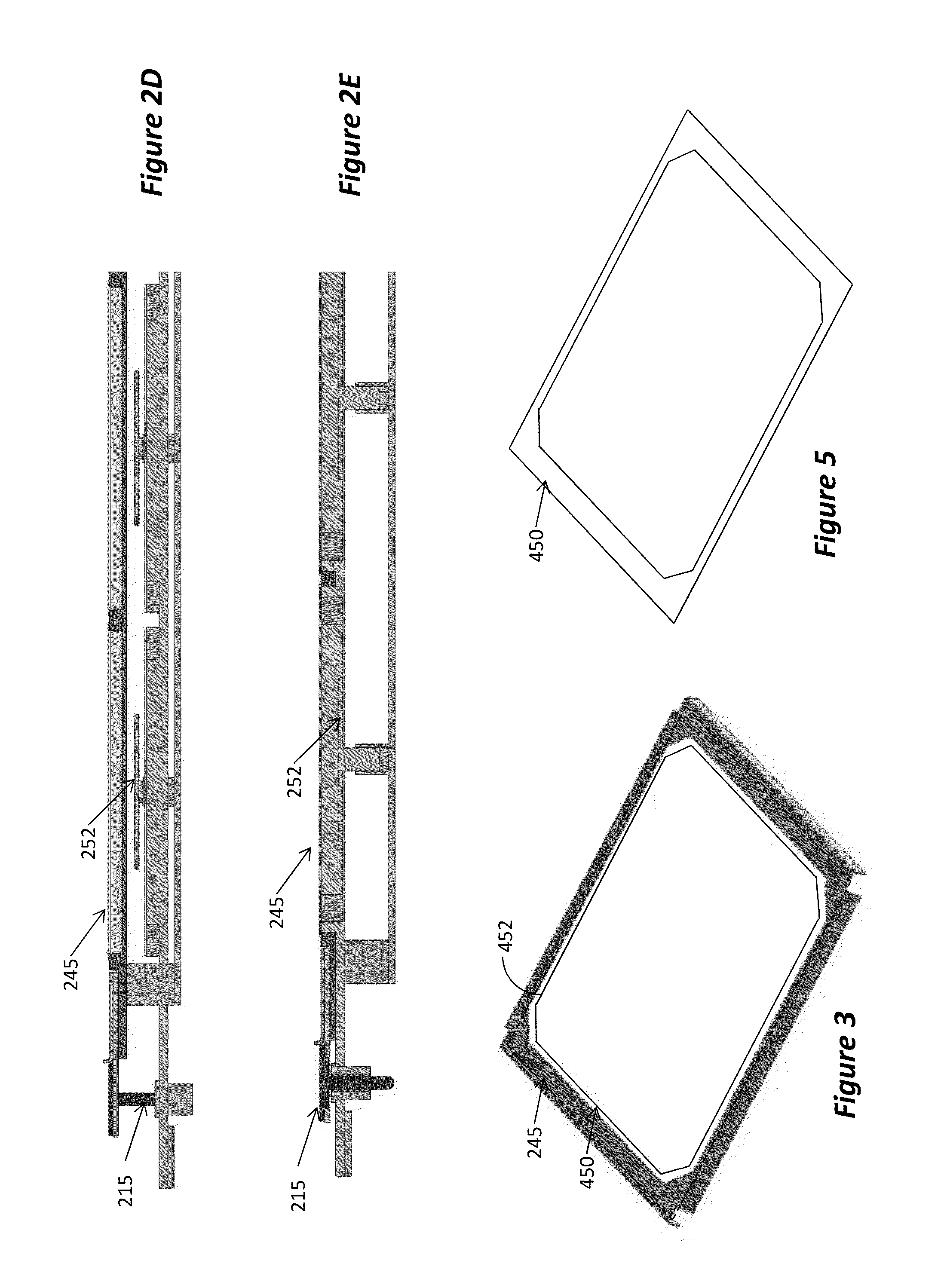

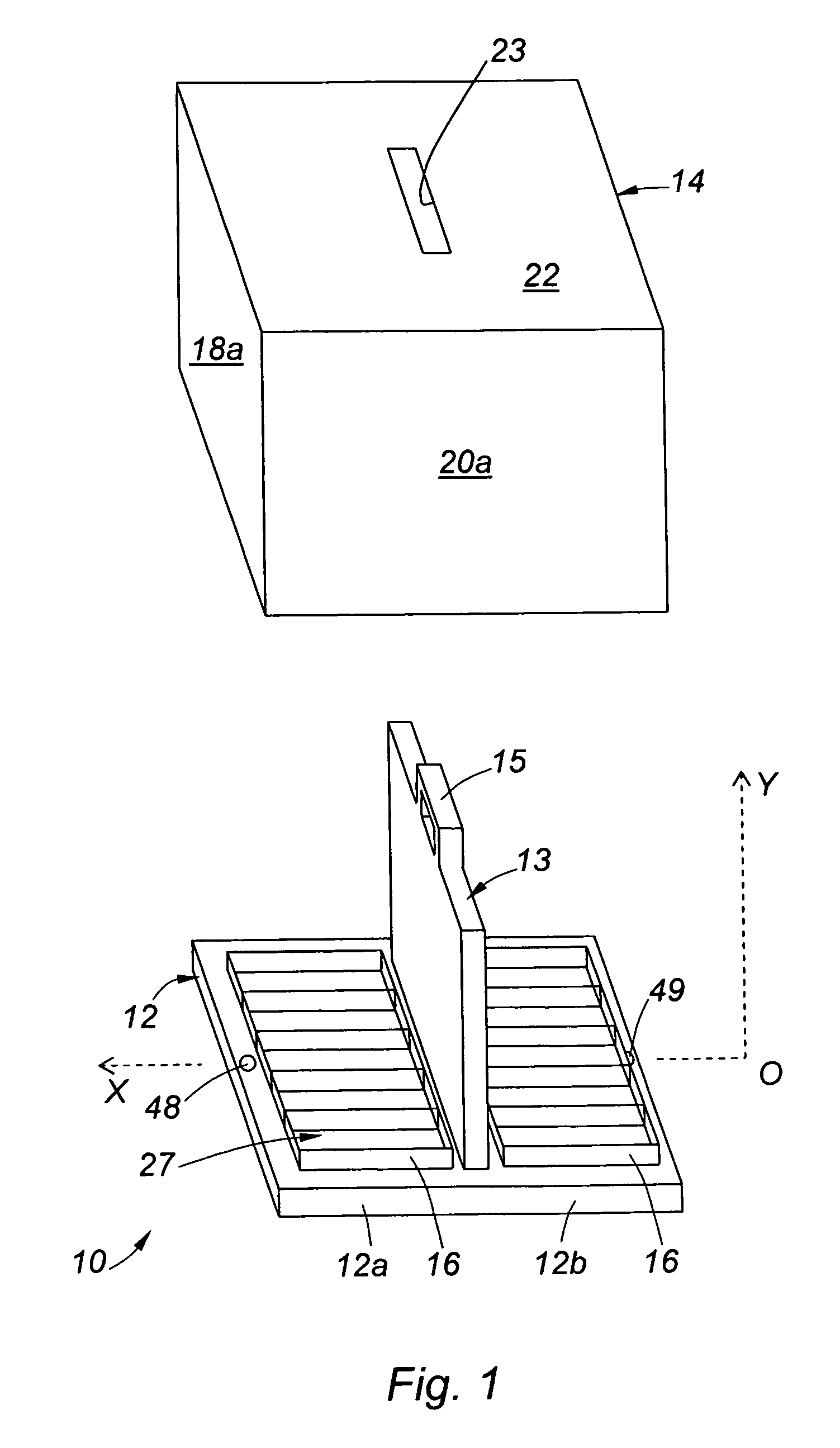

Dual-mask arrangement for solar cell fabrication

ActiveUS20130276978A1Easy and fast unloadingAvoid depositionLiquid surface applicatorsVacuum evaporation coatingSolar cell fabricationSolar energy

An arrangement for supporting substrates during processing, having a wafer carrier with a susceptor for supporting the substrate and confining the substrate to predetermined position. An inner mask is configured for placing on top of the substrate, the inner mask having an opening pattern to mask unprocessed parts of the substrate, but expose remaining parts of the substrate for processing. An outer mask is configured for placing on top of the inner mask, the outer mask having an opening that exposes the part of the inner mask having the opening pattern, but cover the periphery of the inner mask.

Owner:INTEVAC

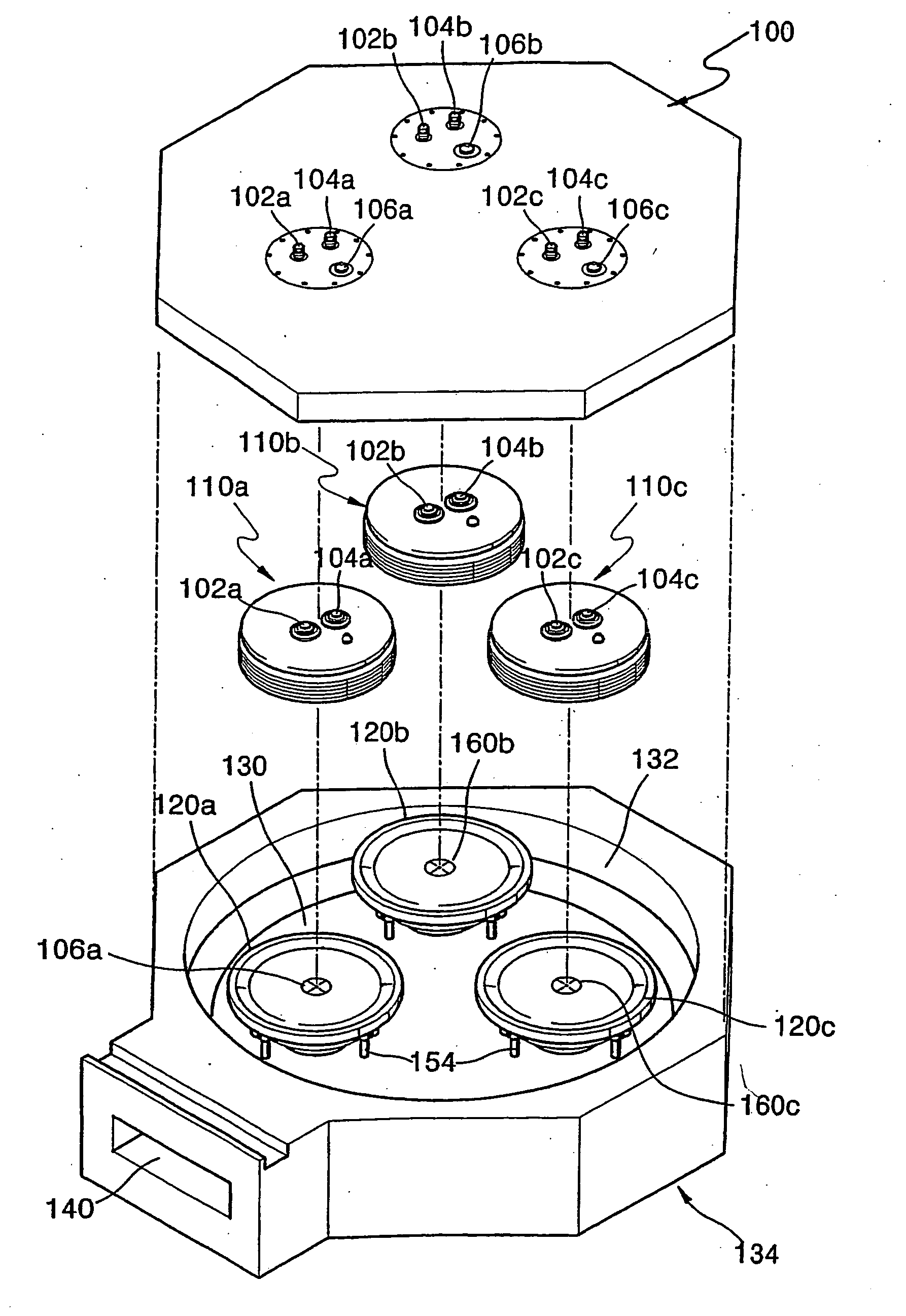

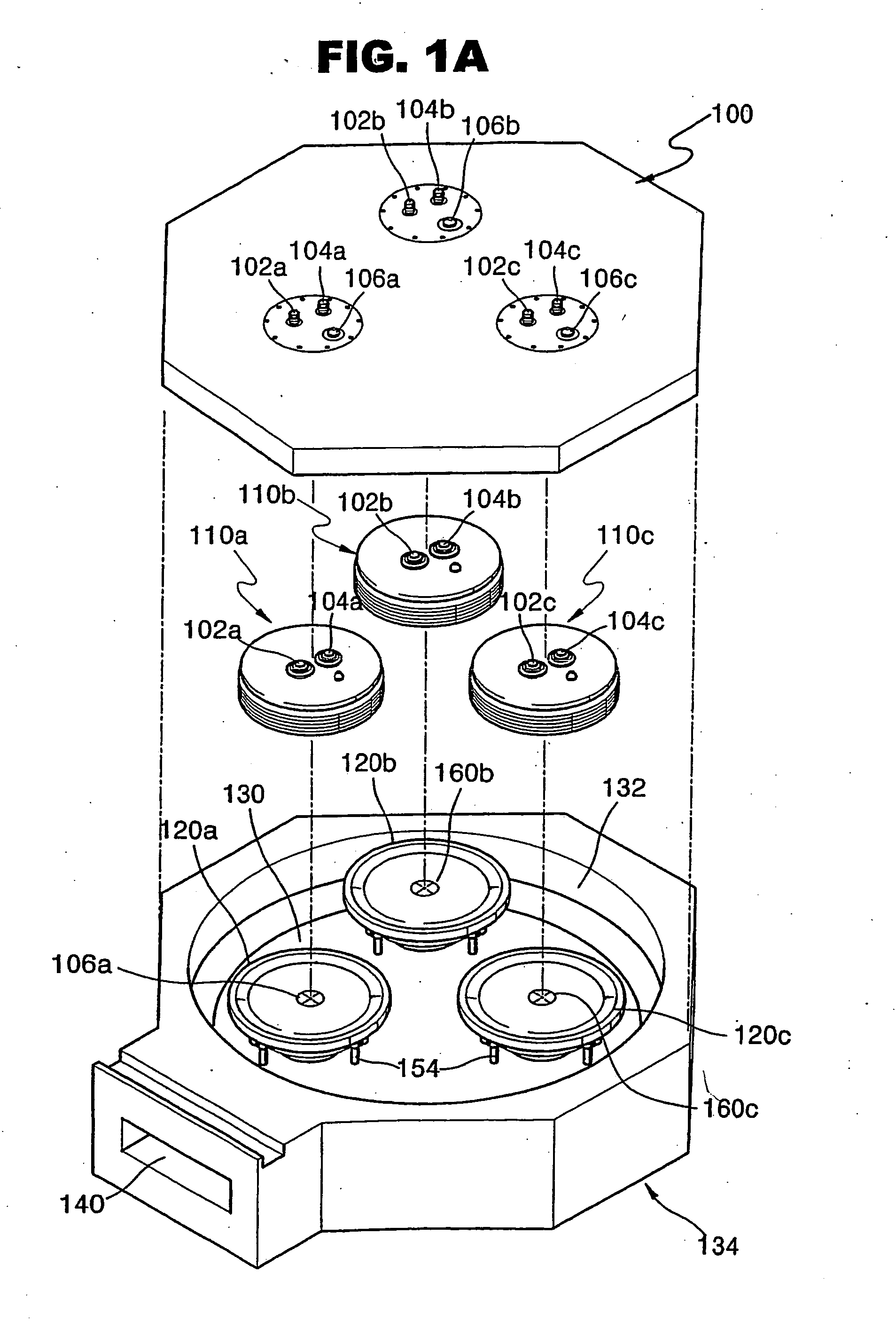

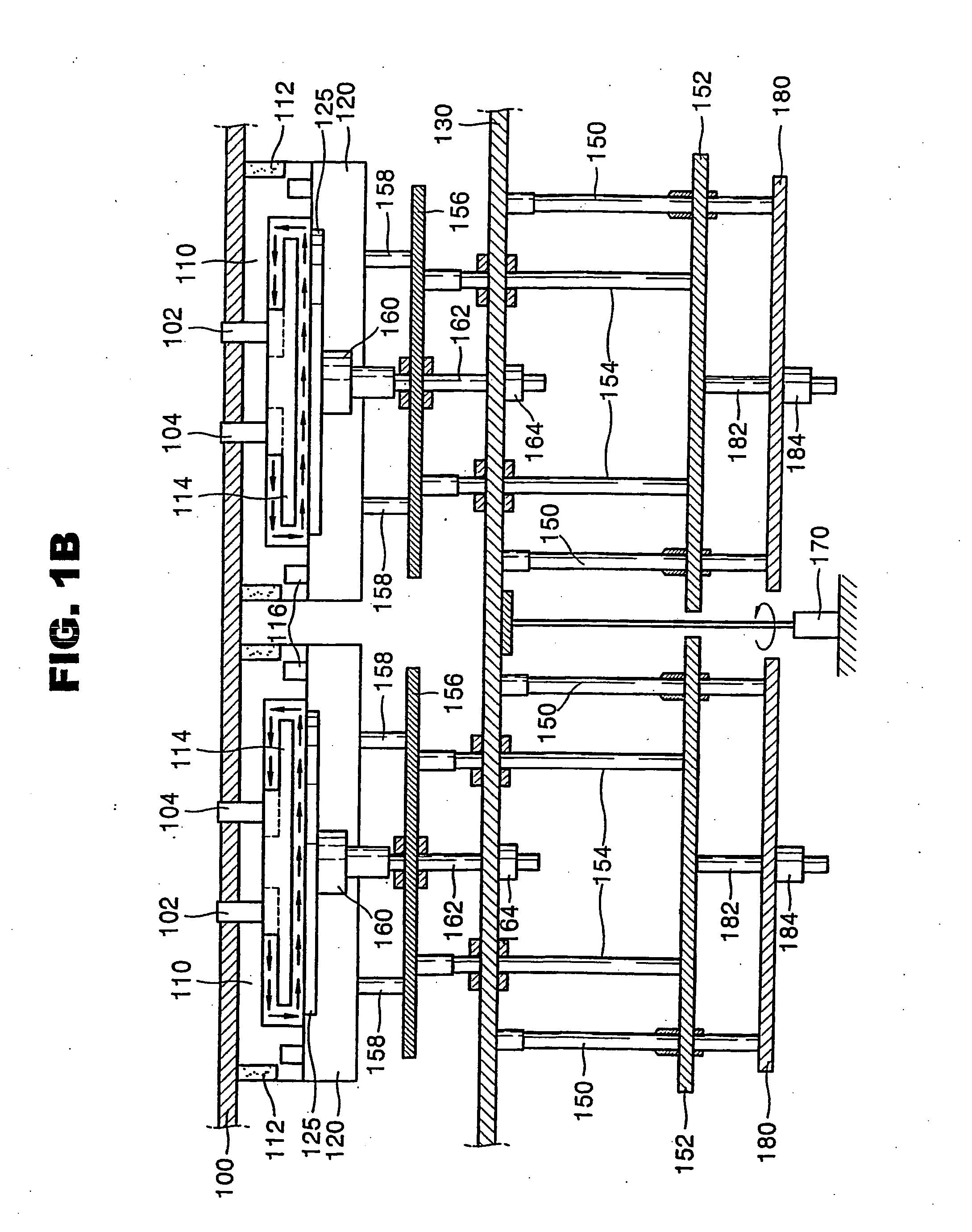

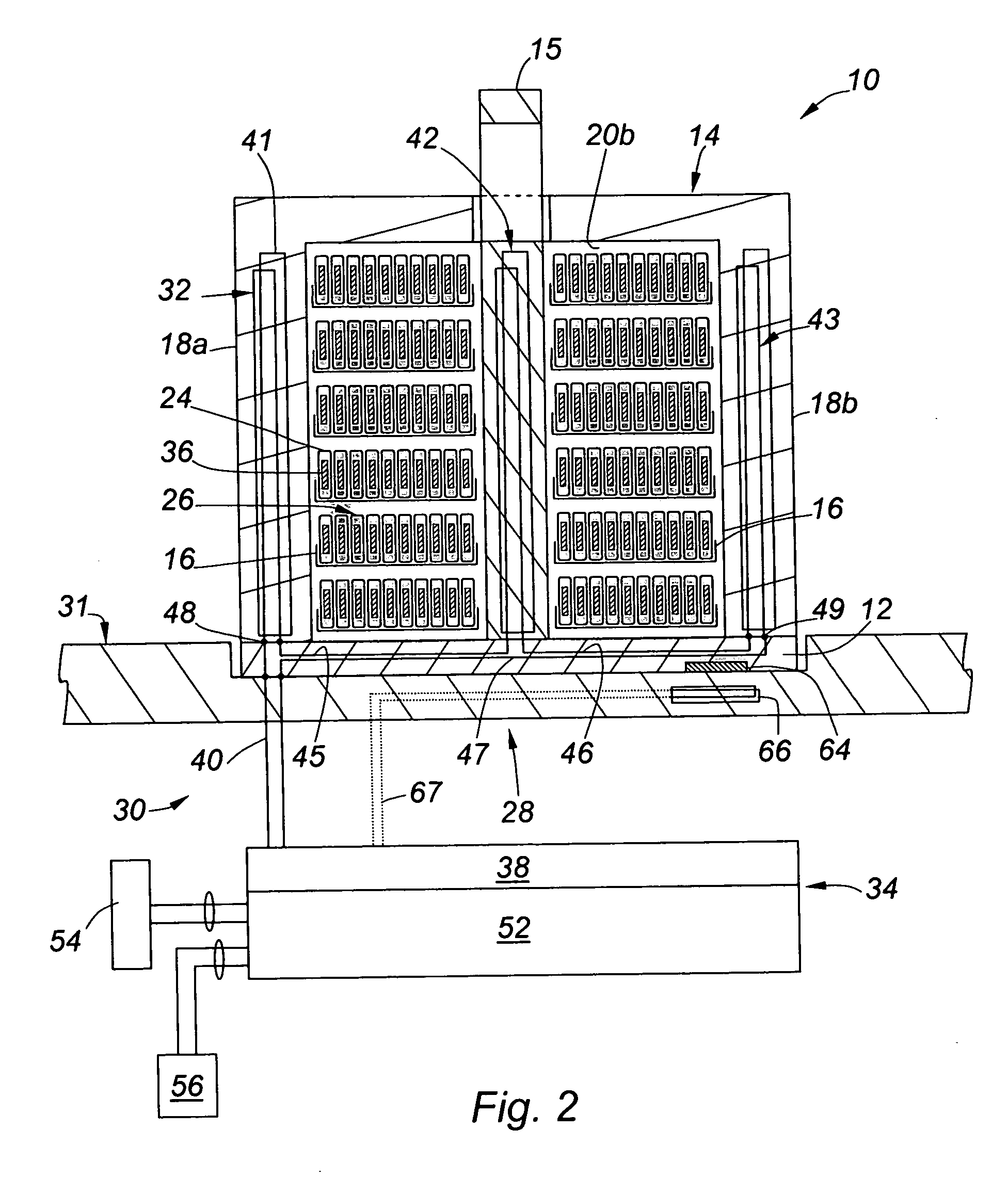

Apparatus for depositing

InactiveUS20050034664A1Easy to unloadEasy loading and unloadingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSubstrate typeNuclear engineering

An apparatus constructed with a plural of independent reactors for depositing thin films is provided. The apparatus includes a chamber consisting of a base plate, a chamber wall and a chamber cover. A plural of identical and independent reactors are mounted inside the chamber, and each reactor has two parts; a reactor lower body and a reactor upper body, where the reactor upper body is fixed to the chamber cover and the reactor lower body is fixed to the base plate and moves up and down, thereby the up position of the reactor lower body makes a contact with the reactor upper body and thus providing a vacuum-tight processing space. Since a plural of identical and independent reactors are used, the processing steps and conditions developed for a single substrate type of reactor can be used for multiple reactors with minor adjustments, by utilizing a relatively symmetrical process gas supply inlet tube and process gas inlet tube and process gas exhaust tube arrangements. Such an arrangement also leads to high throughput, low cost and compact designs with tight footprints.

Owner:ASM GENITECH KOREA

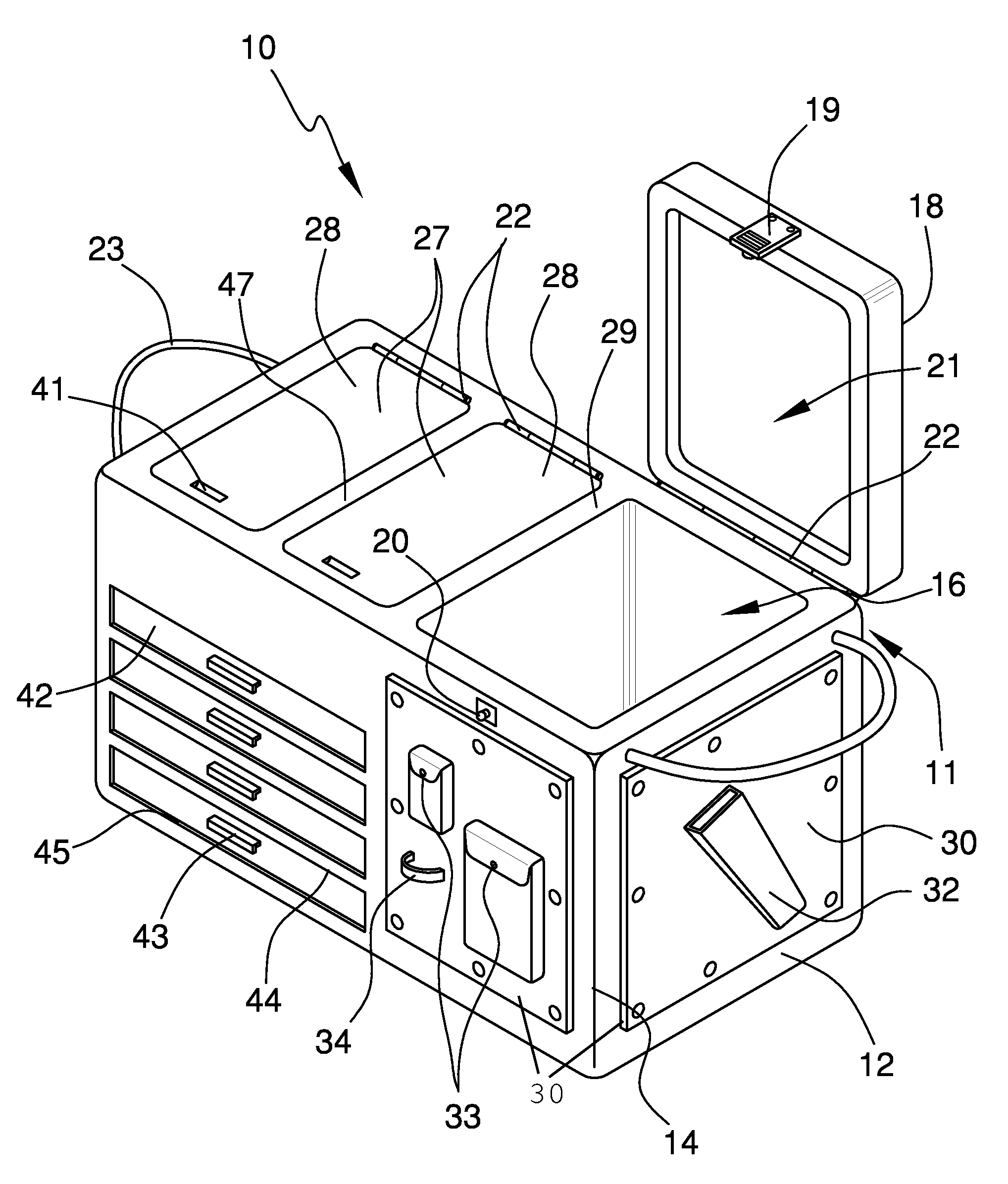

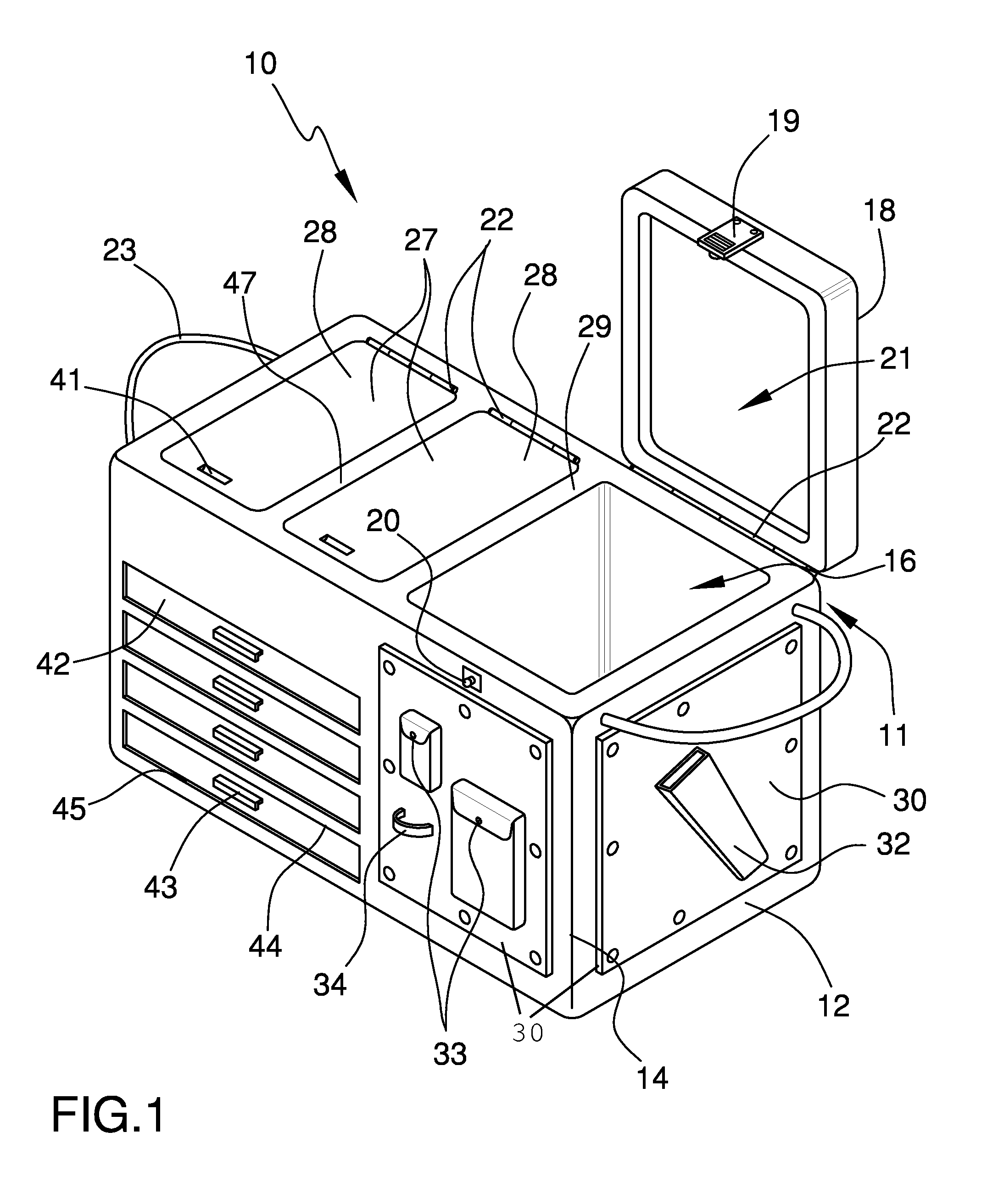

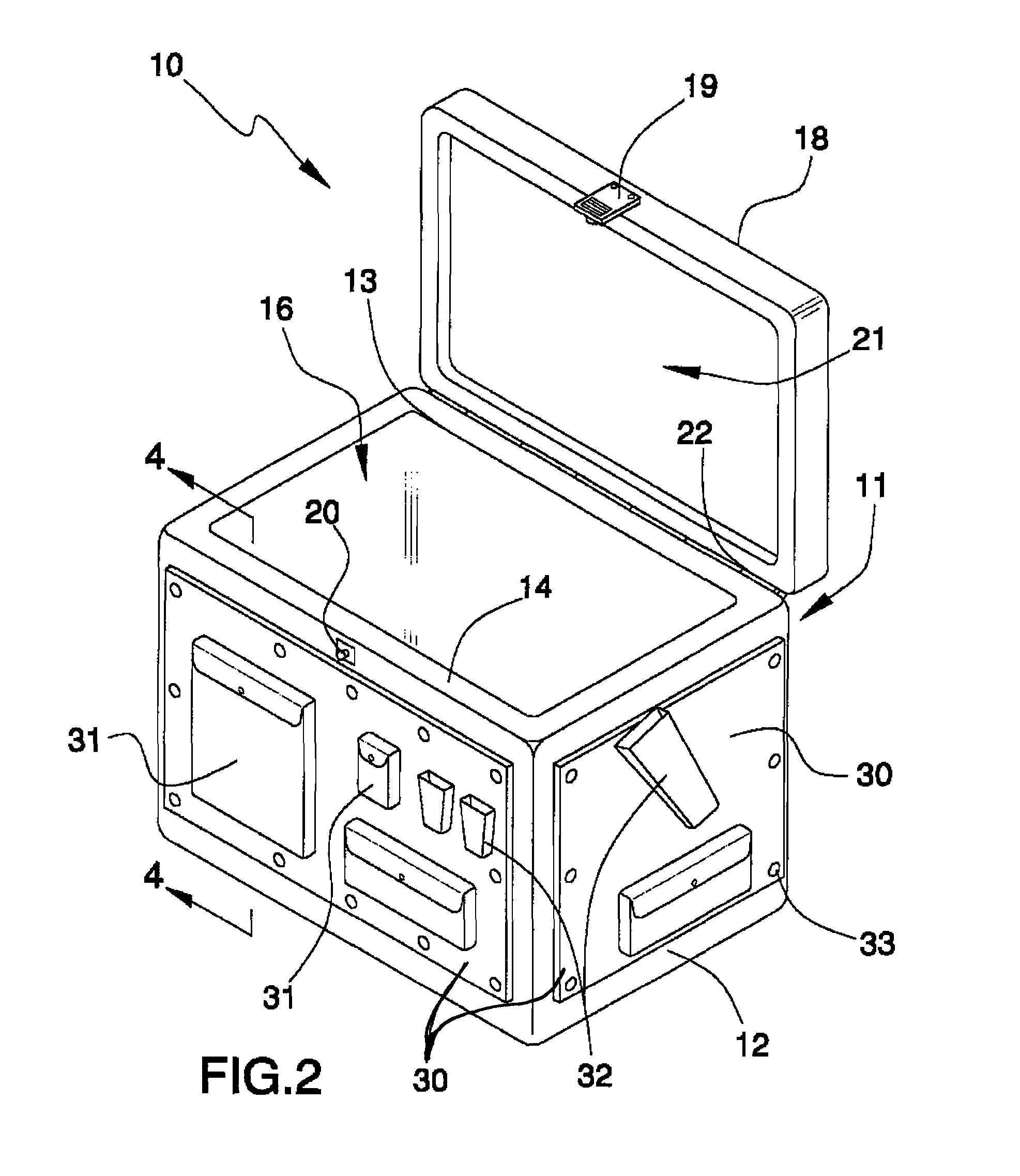

Portable cooler and tackle box

InactiveUS7415794B1Ease in unloadingSmall sizeDomestic cooling apparatusLighting and heating apparatusEngineering

A portable cooler and tackle box provided in sizes from about 5 gallon to about 60 gallon capacity with at least one wheel affixed on or proximally to the bottom and at least one handle affixed exteriorly, and insulation, and a pivotally attached cover. Aprons are removably attached to the exterior and are fitted with pockets, holders, and pouches for holding accessories, and at least one horizontal partition wall is within the main body. At least one tray is slideably contained within the lower interior. The main body interior may contain at least one permanent or removable compartment.

Owner:THOMPSON SCOTT M

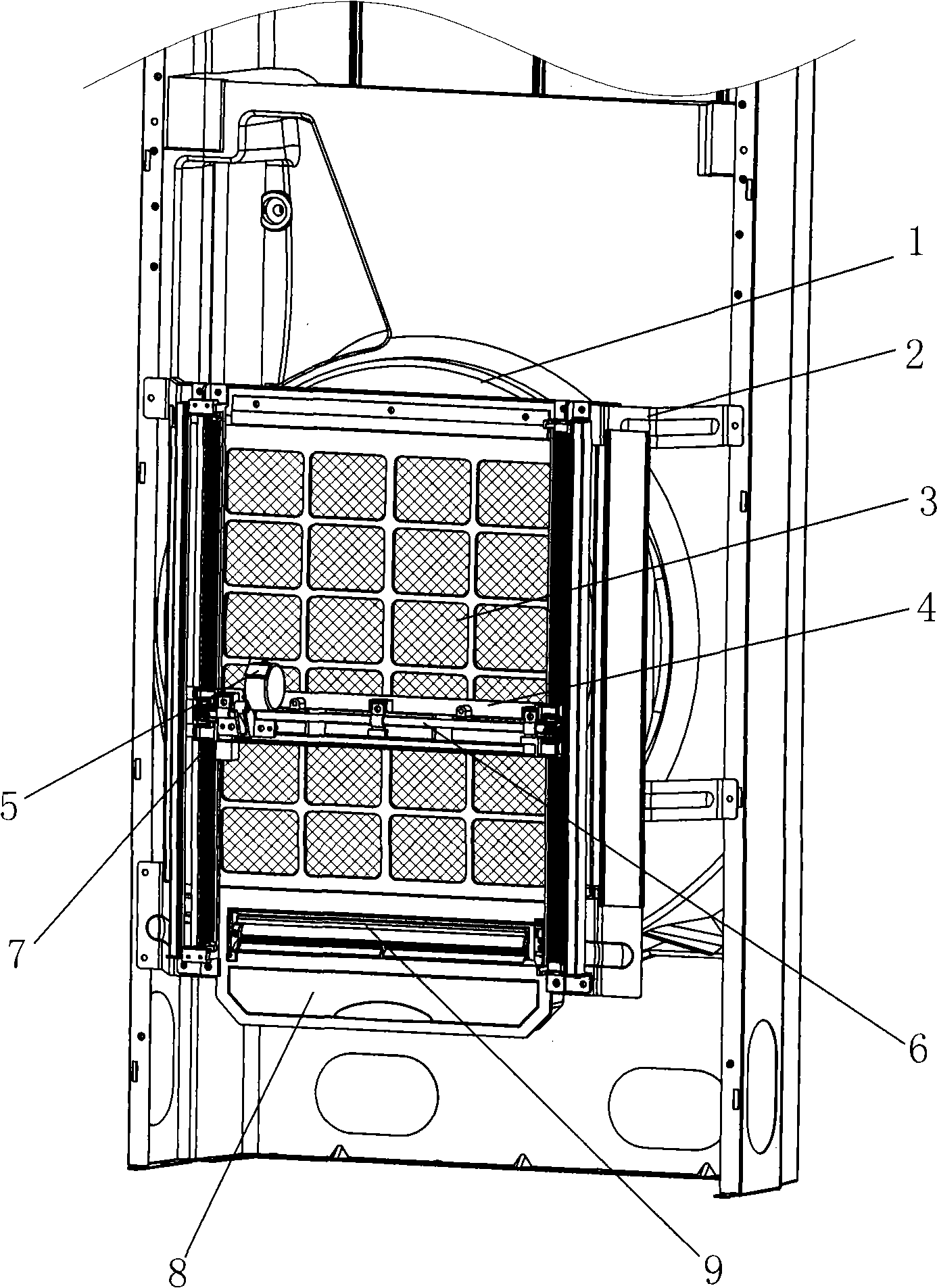

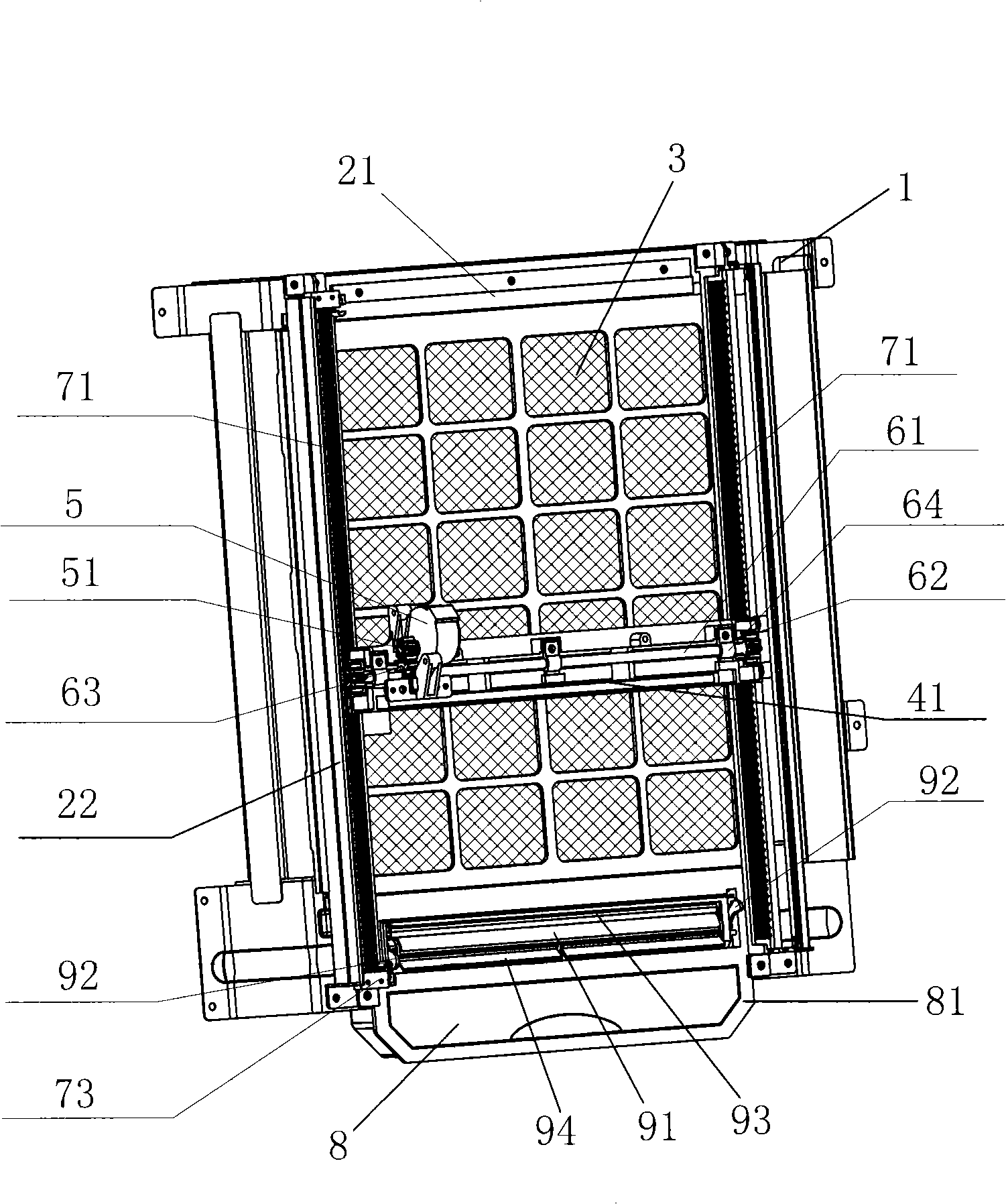

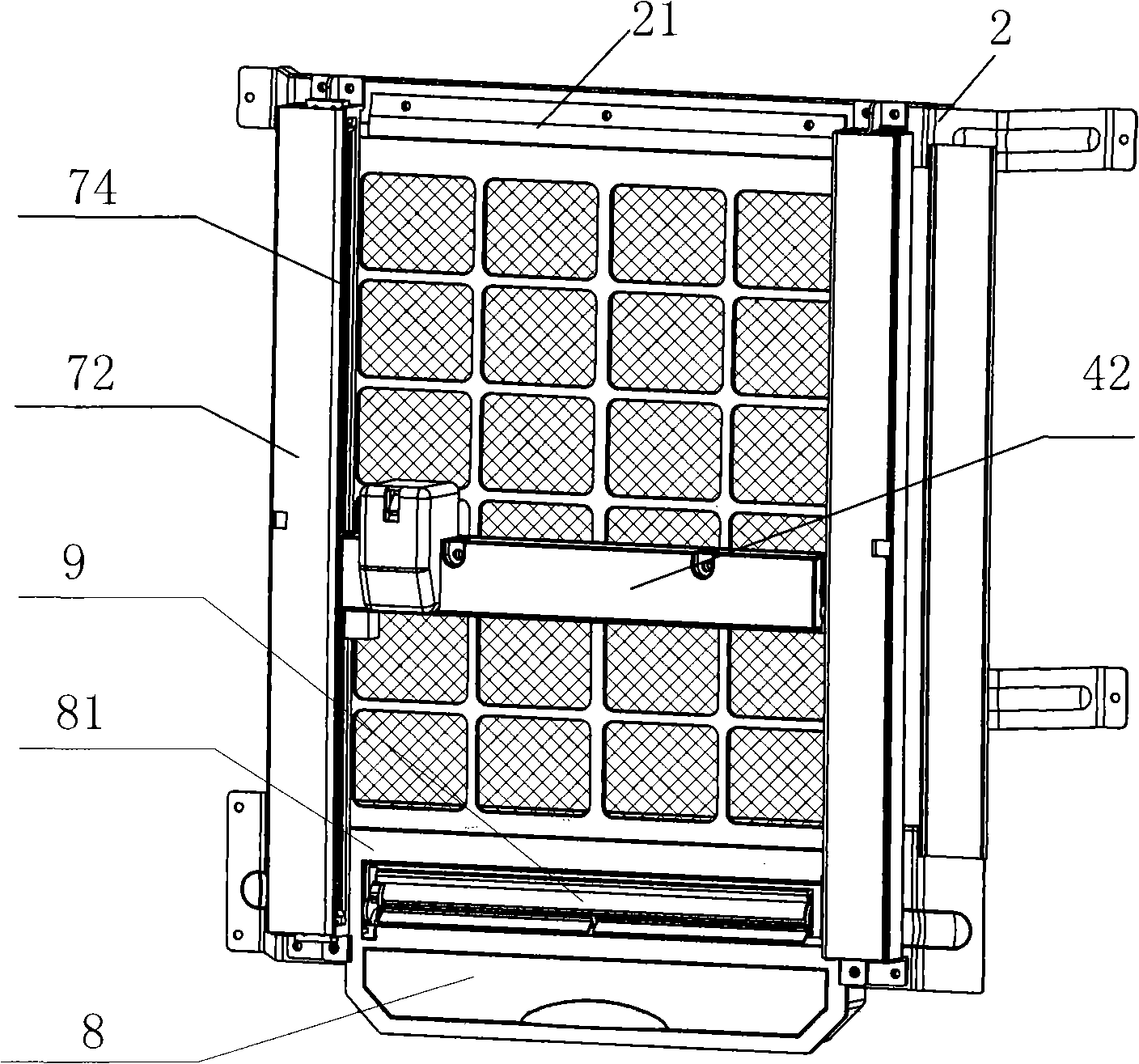

Air conditioner filter screen self-cleaning device

ActiveCN101290151AGuaranteed cleanlinessGuarantee the quality of workMechanical apparatusDispersed particle filtrationDrive motorSelf cleaning

The invention discloses a self-cleaning device for an air conditioner filter screen, which is arranged on filter screen brackets at an air passage spiral casing air inlet of a cabinet air conditioner and is arranged outside the filter screen, an upper bracket and a lower bracket are provided with filter screen guide rails with slots, the filter screen is fixed on the filter screen brackets through the slots of the guide rails, a filter screen cleaning device comprises a cleaning component with a brush, a drive motor fixed on the cleaning component, a driving mechanism connected with the drive motor, a rack set arranged at the left side part and the right side part of the filter screen and a dust box arranged under the filter screen and used for collecting dust; a dust exchange device is arranged between the dust box and the filter screen; the drive motor connected with the driving mechanism drives the cleaning component to slide up and down along the rack set adhering to the filter screen in order to enable the brush to clean dust down; the cleaning component slides down to pass through the dust exchange device and cleans the dust down in the dust exchange device, and then the dust exchange device pours the dust to the dust box. The self-cleaning device for air conditioner filter screen saves time and labor and can be cleaned at any time without disassembling.

Owner:HAIER GRP CORP +1

Method and apparatus for plating substrates

InactiveUS20050263401A1Easy loading and unloadingLoading and unloadingElectrolysis componentsLiquid/solution decomposition chemical coatingConductive materialsMechanical engineering

Owner:WD MEDIA +1

Equipment for transporting chips and chip carrier structure therefor

InactiveUS20070026949A1Improve reliabilityEasy loading and unloadingCoin countersApparatus for meter-controlled dispensingDocking stationRadio frequency

The equipment for transporting chips carrying coded information includes a movable structure carrying chips with an electronic circuit arranged in columns in stacked racks and a docking station for the carrier structure in the place of storage of the chips, for example the vault of the casino, or at their place of use, for example a gaming table. The carrier structure includes a plane base divided by a partition with a handle for carrying two stacks of racks of chips and a lid. The docking station integrates part of an RFID contactless radio-frequency reading station for reading the coded information carried by the chips of at least one column to determine or verify the content of at least one batch of chips present in the carrier structure, in particular to draw up or to check an inventory thereof. The read station includes a read unit with a digital section and an analog section provided with a wide-loop antenna with three loops respectively integrated into the walls of the lid and the median partition fixed to the plane base.

Owner:GAMING PARTNERS INTERNATIONAL CORPORATION

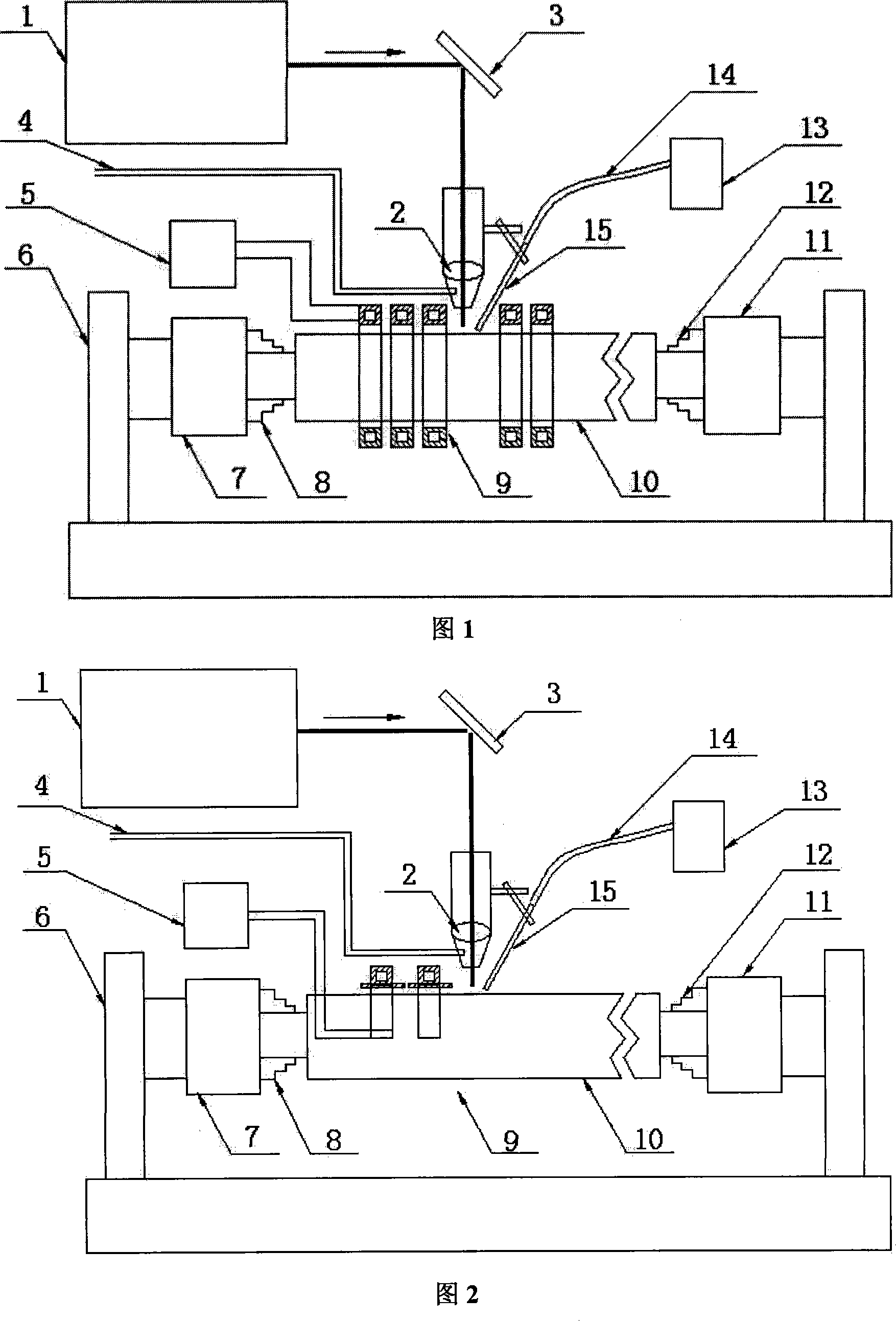

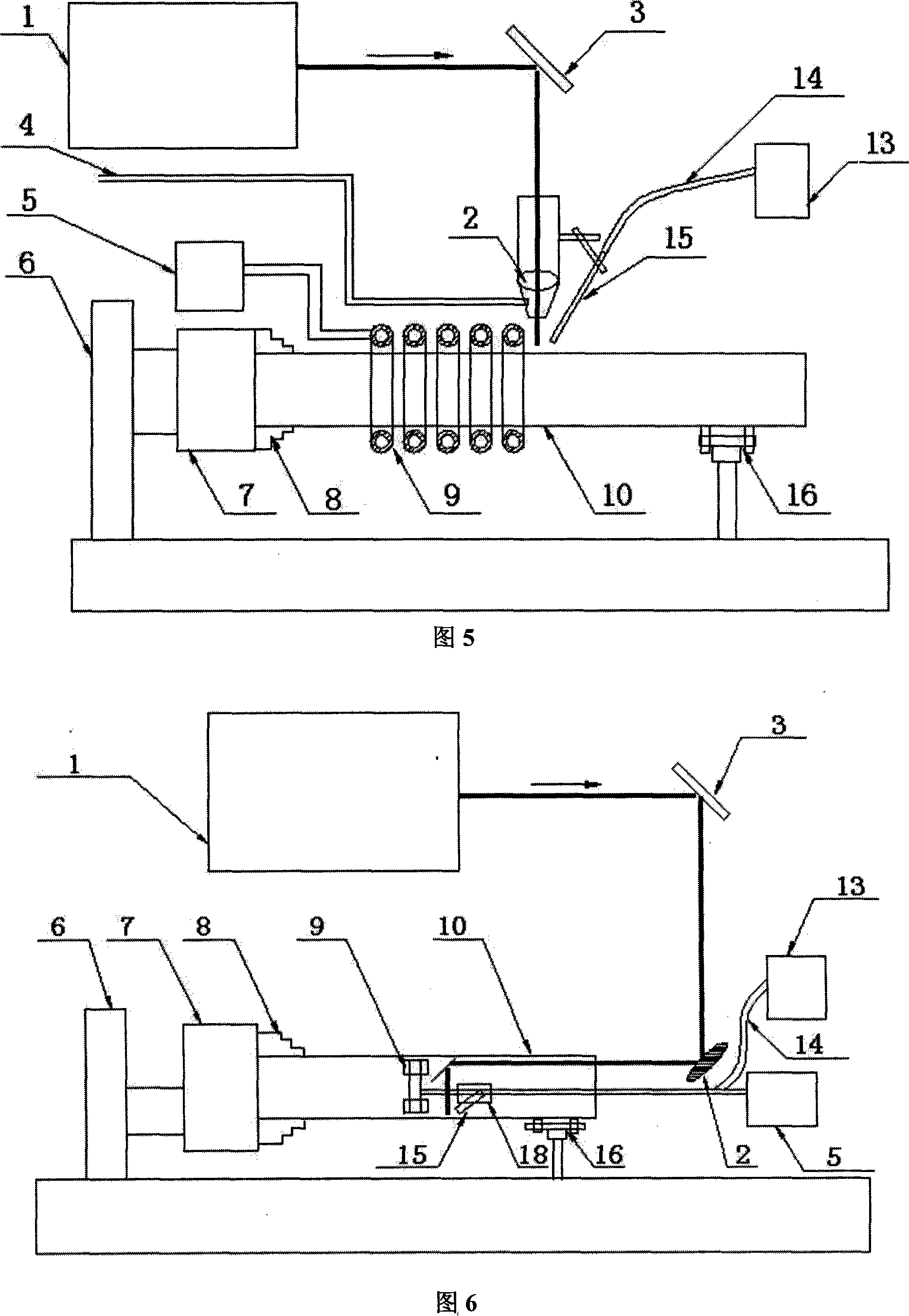

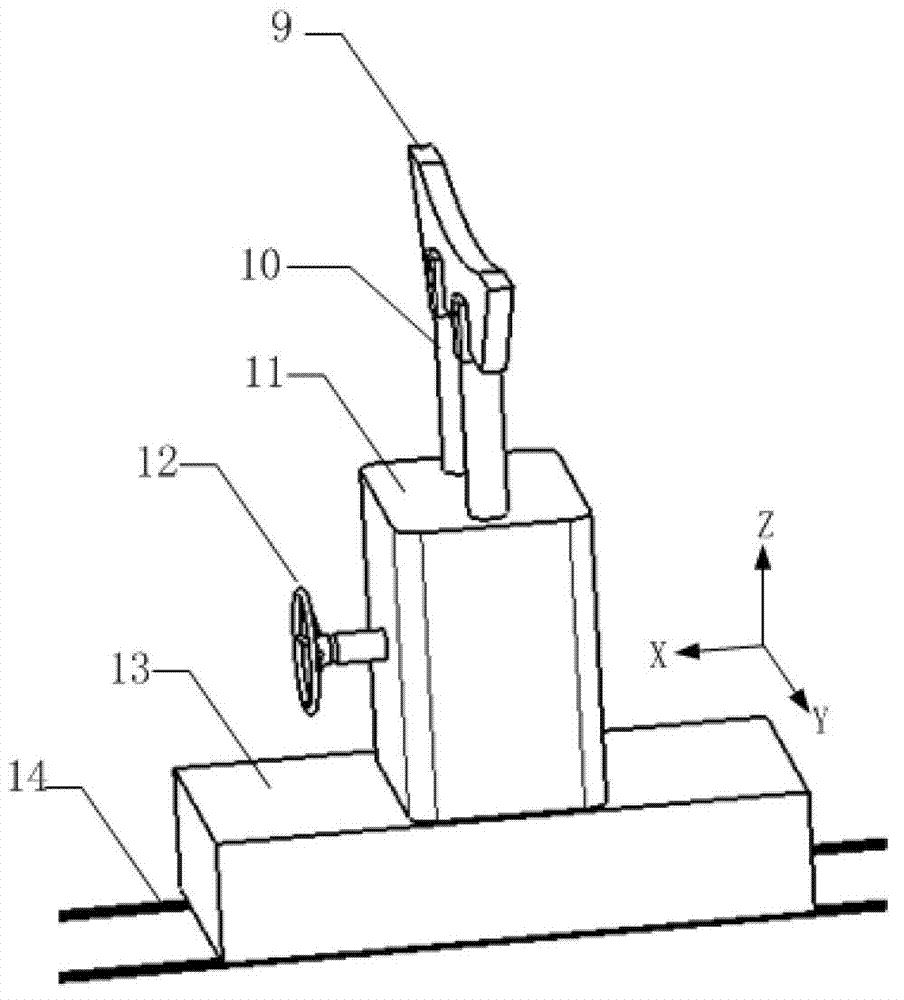

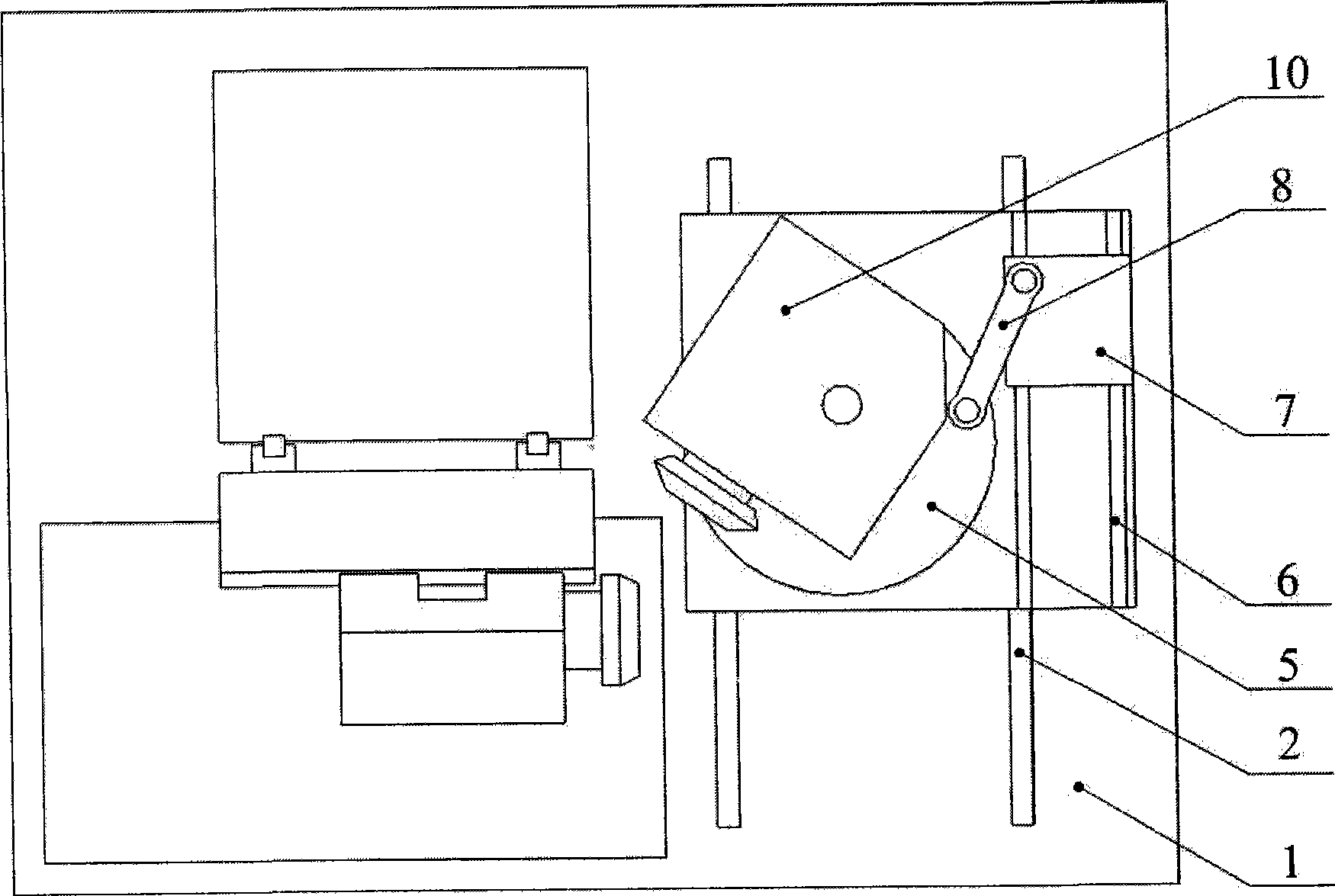

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

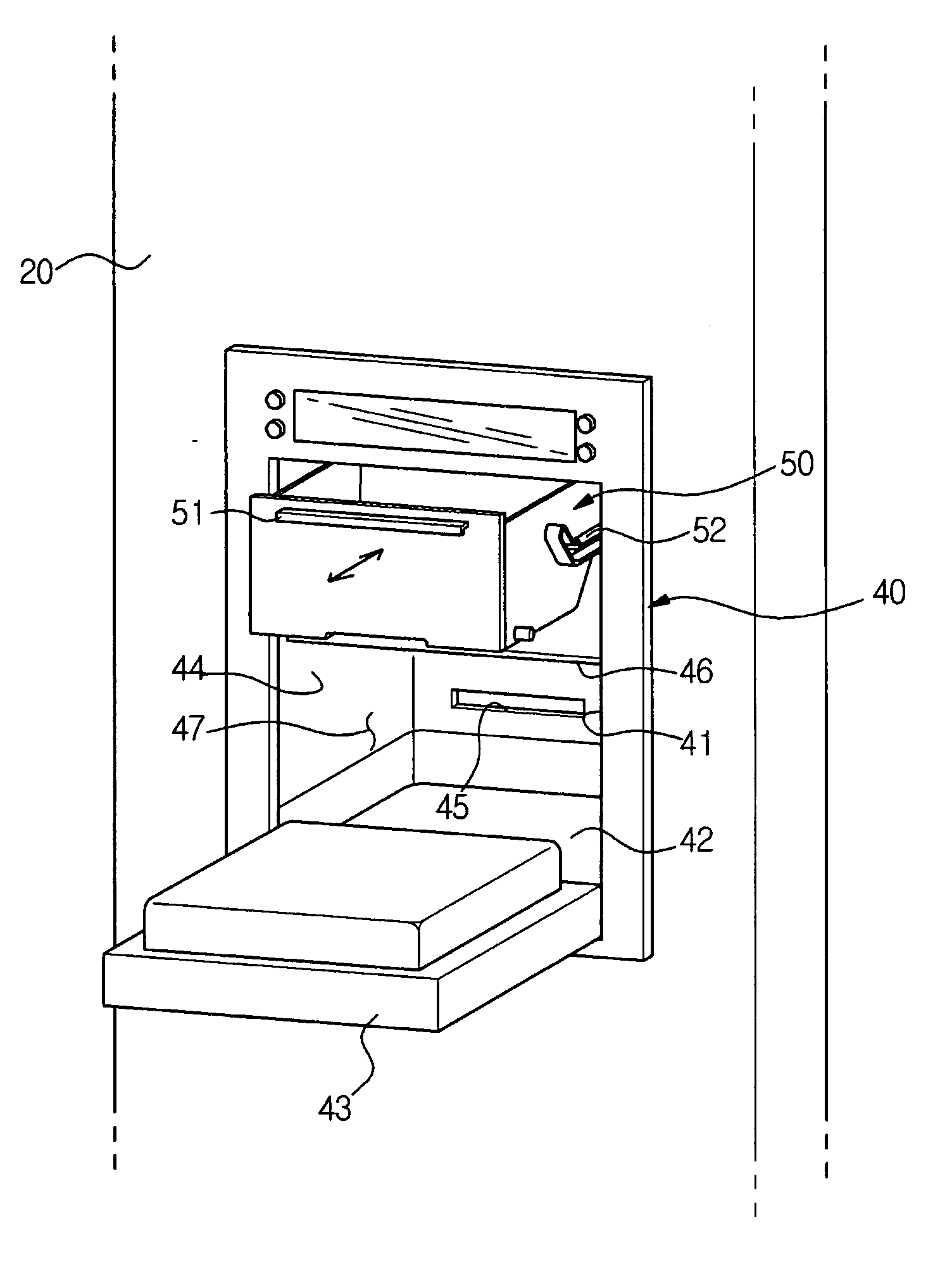

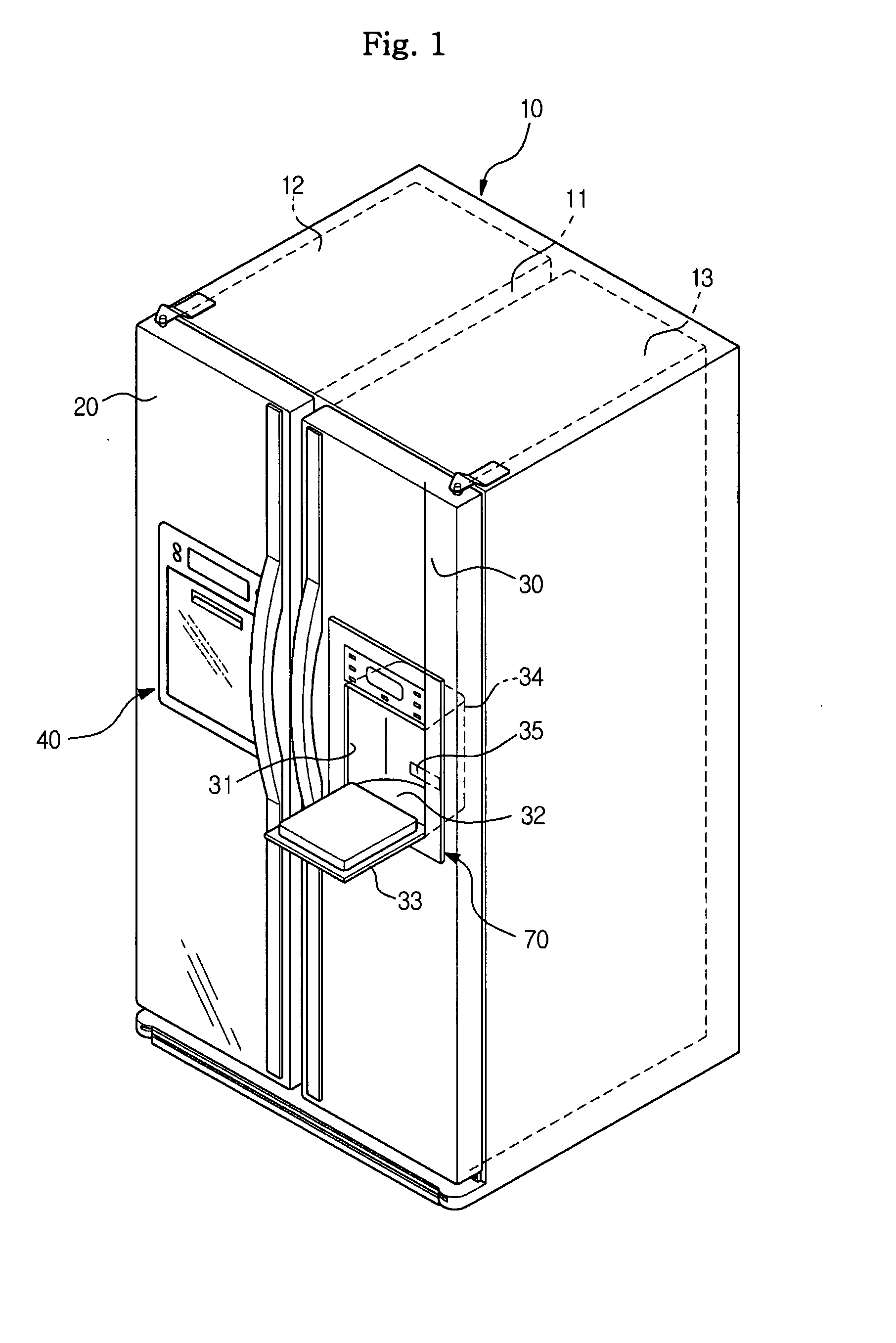

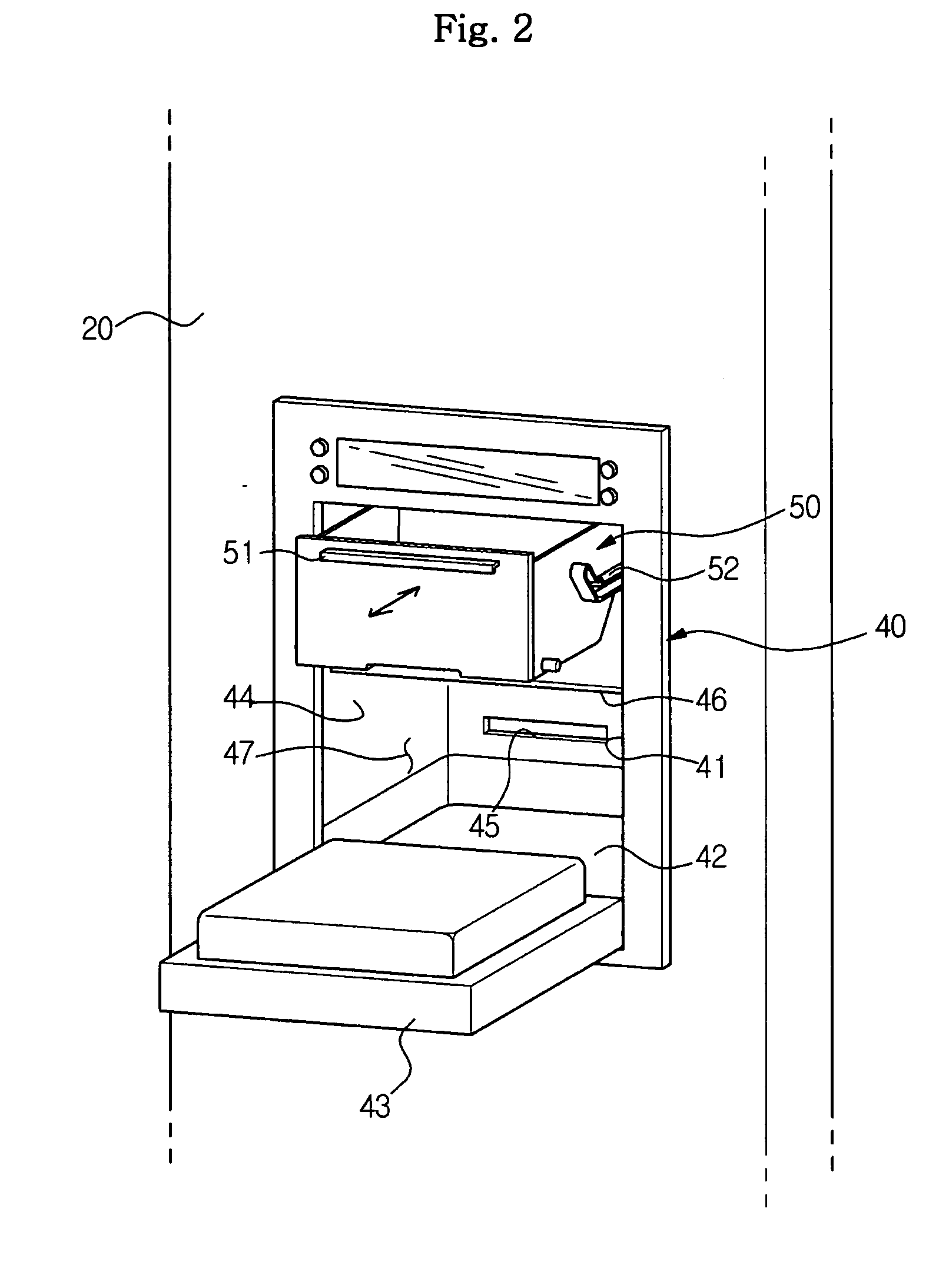

Refrigerator

InactiveUS20080168794A1Avoid excessive rotationImprove space efficiencyLighting and heating apparatusDomestic refrigeratorsAuxiliary memoryEngineering

A refrigerator including an auxiliary receiving chamber is disclosed. The refrigerator includes a main body having a storage chamber, and a door which opens or closes the storage chamber and has a receiving space formed at a back side of the door. The door includes an auxiliary storage area having an opening to store goods, an auxiliary receiving chamber disposed in the auxiliary storage area to move back and forth, an auxiliary door to open or close the opening, and an opening / closing member to extract or retract the auxiliary receiving chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

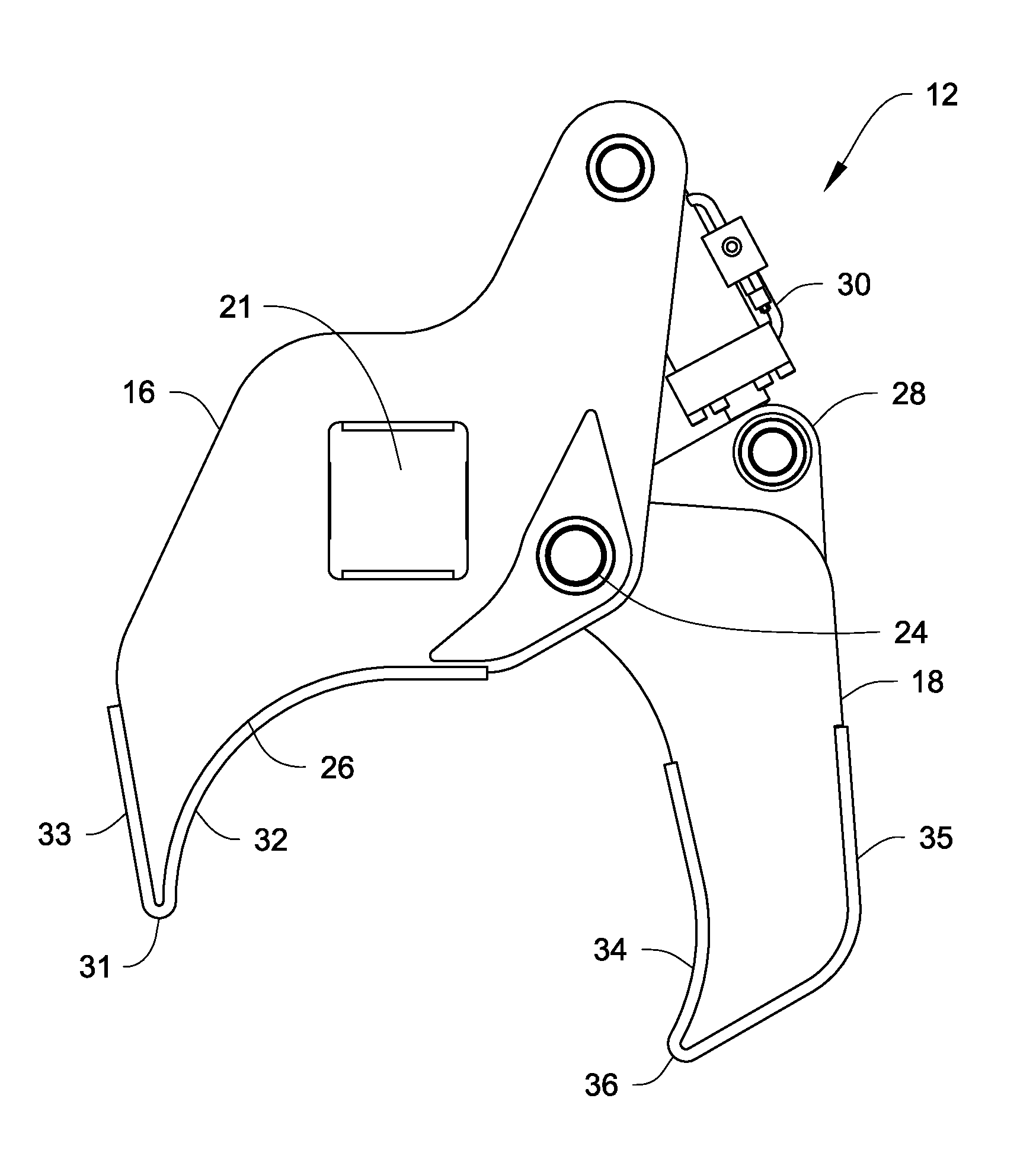

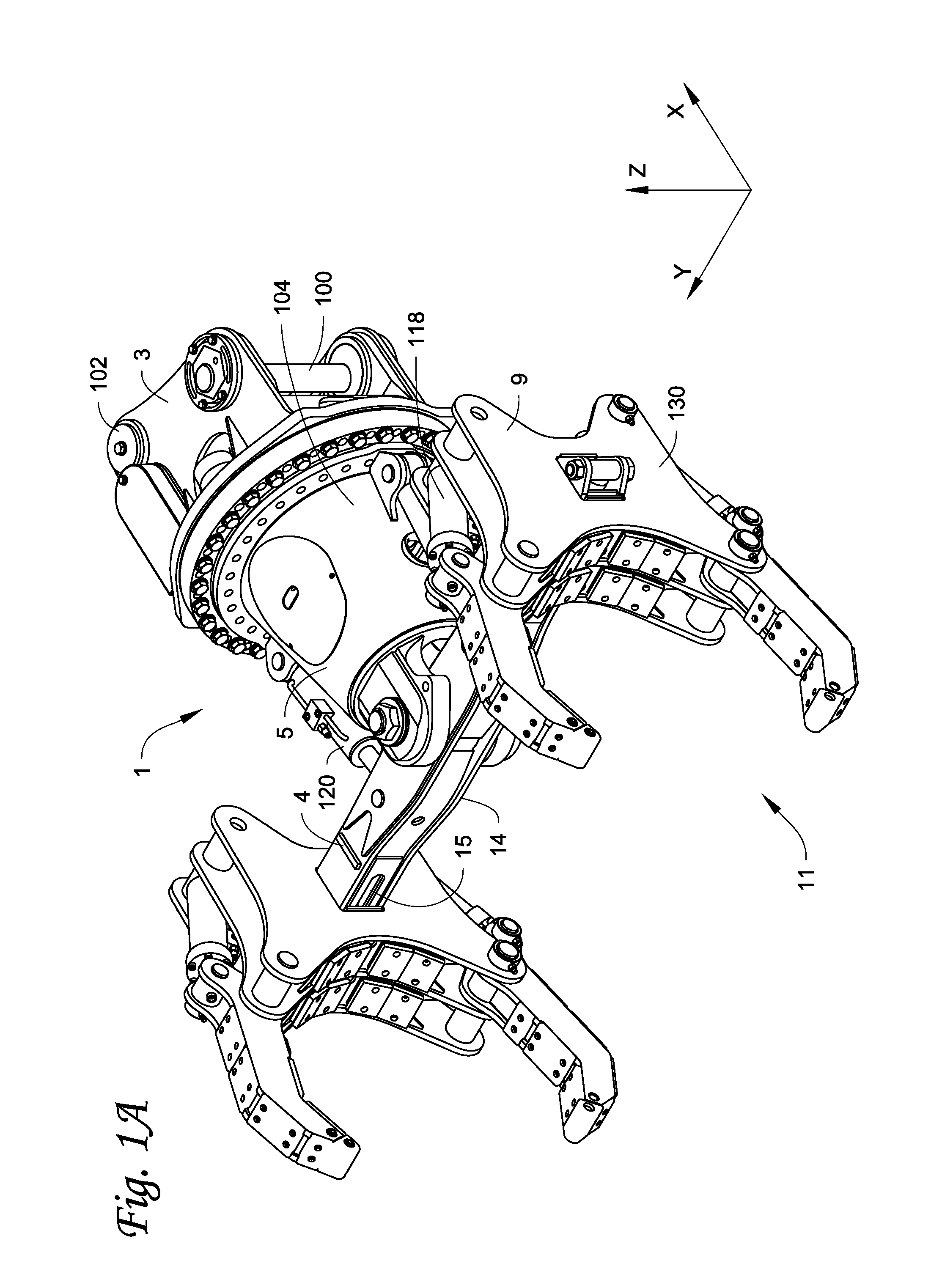

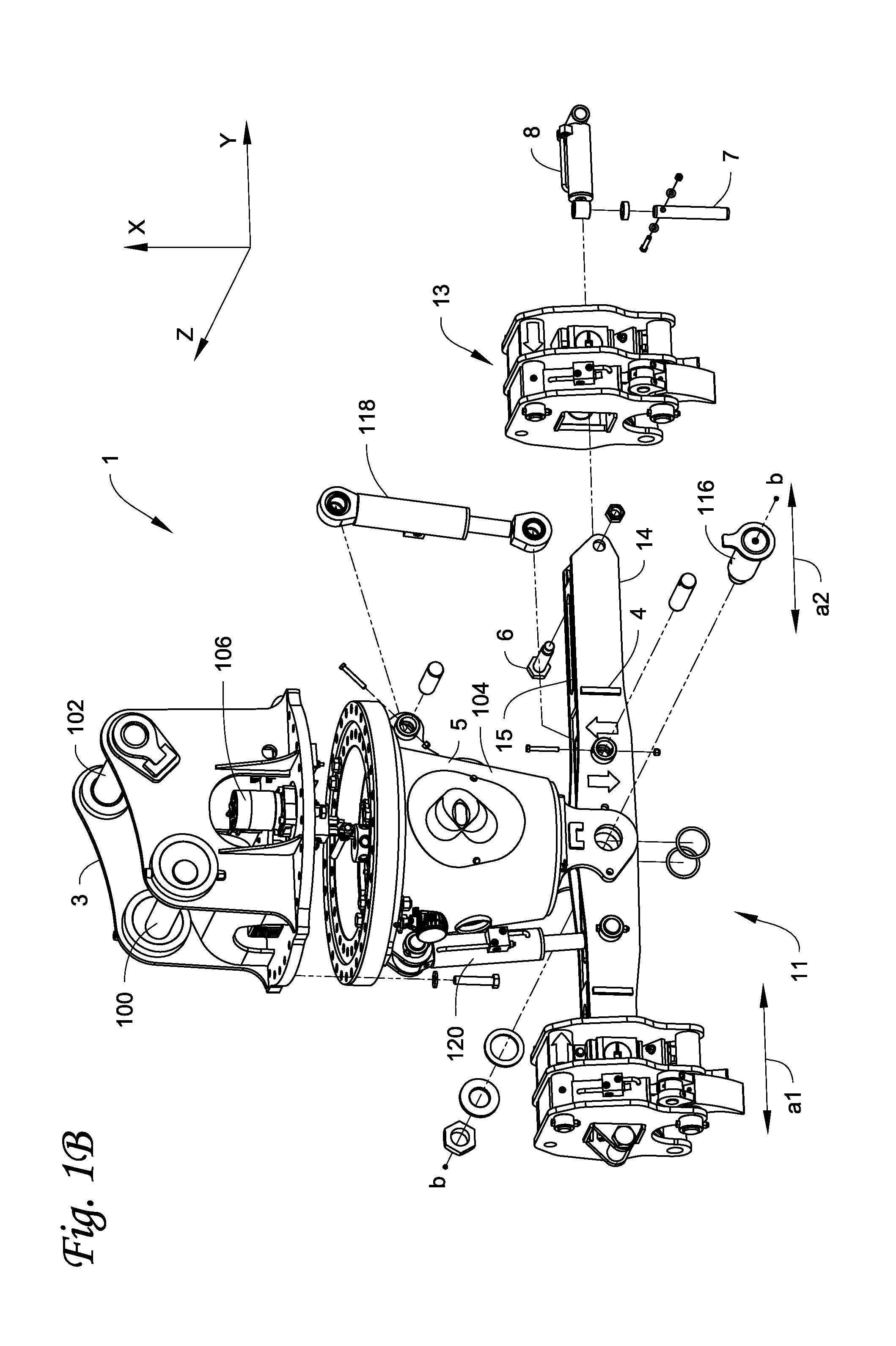

Gripping assembly and gripping members for a grapple attachment

ActiveUS20100308609A1Easy loading and unloadingReduce manpowerDrilling rodsGripping headsPositive controlEngineering

A gripping assembly with gripping members, as part of a grapple attachment, used to grasp and manipulate elongated objects, for example pipe, is described. Due to the gripping action of the gripping members and tilt control capabilities of the grapple attachment, total positive control of the pipe is maintained, even if the gripping assembly picks up pipe off center. The grapple attachment is able to be used on all pipe surface types, including pipe surfaces that are dirty, snow or ice covered. The gripping members are configured to prevent damage to the pipe and to adjacent pipes, and will not crush the pipe.

Owner:LAVALLEY IND

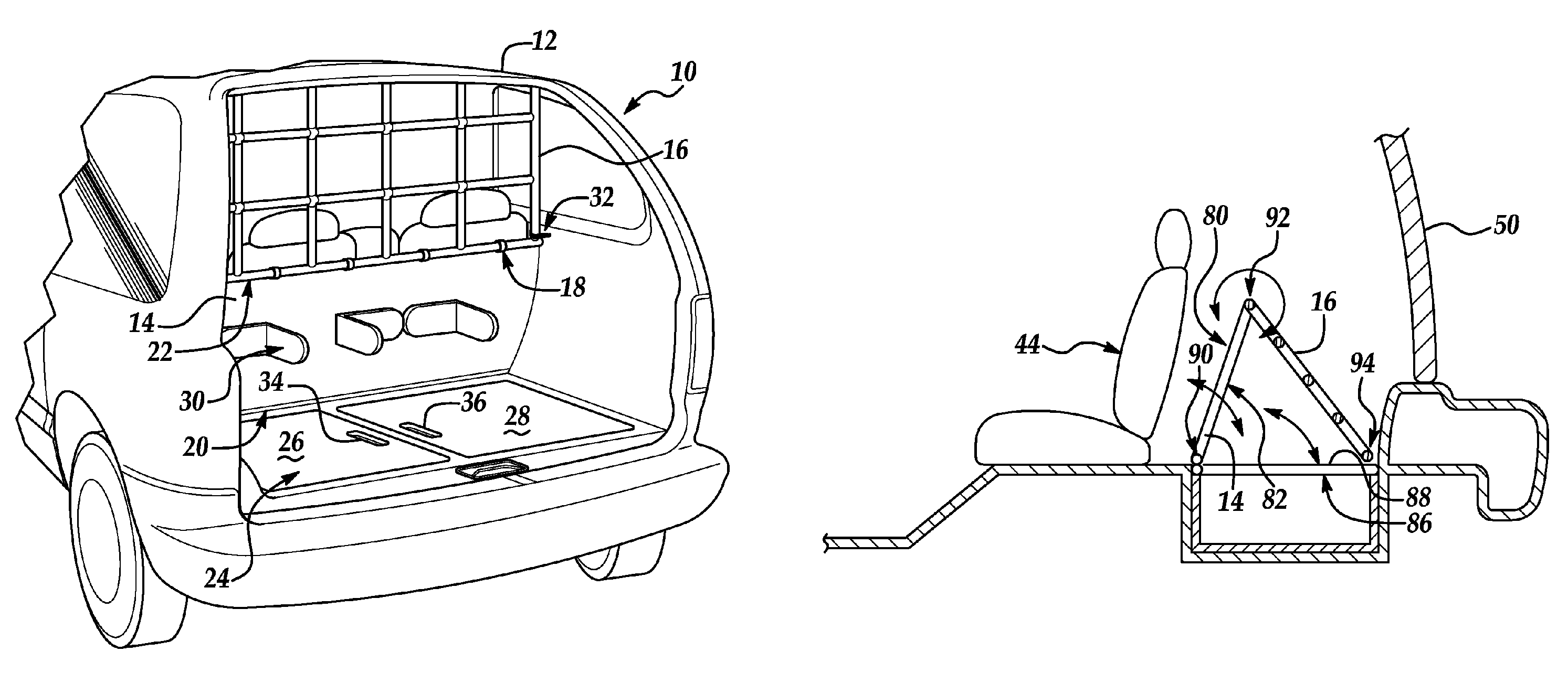

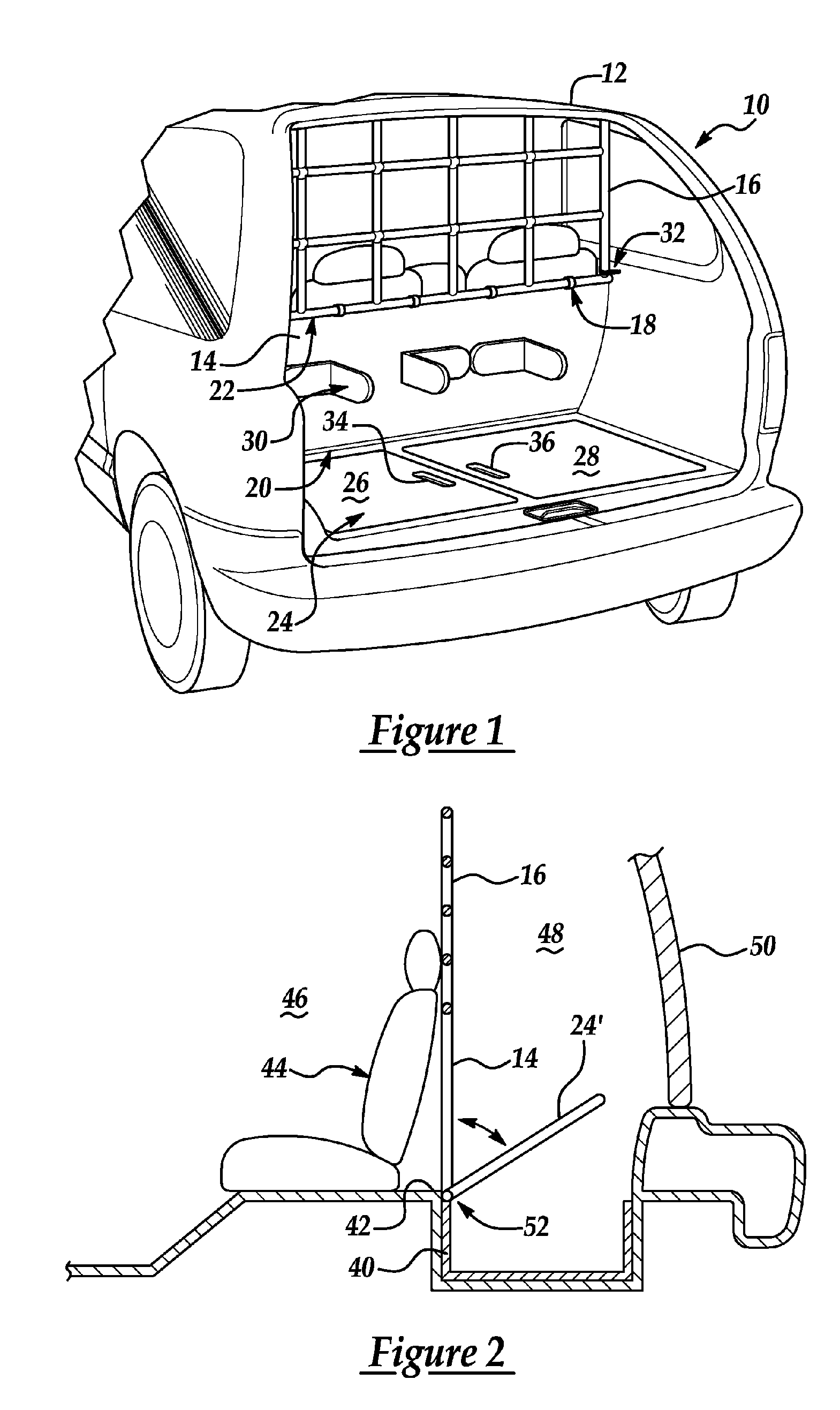

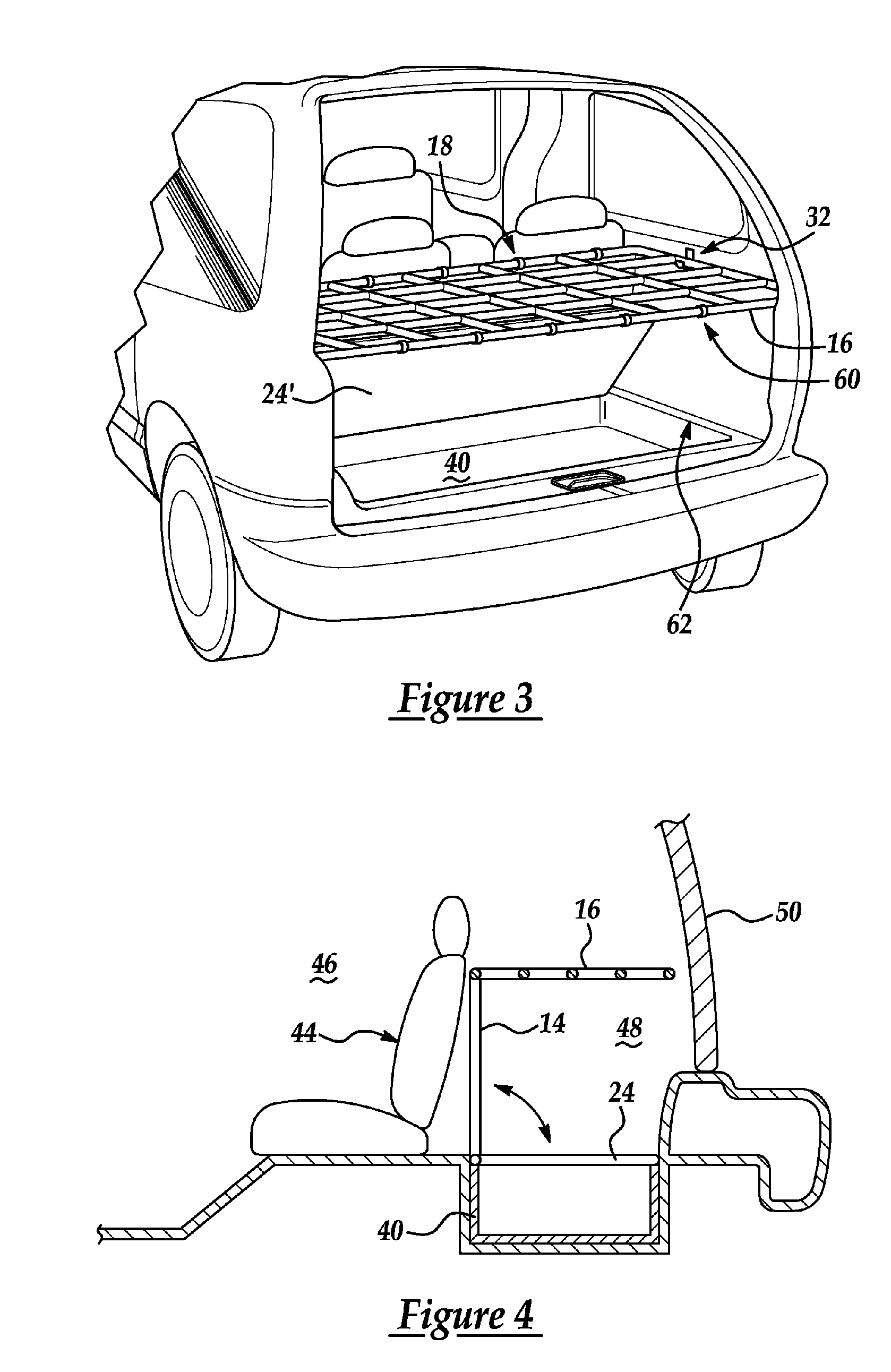

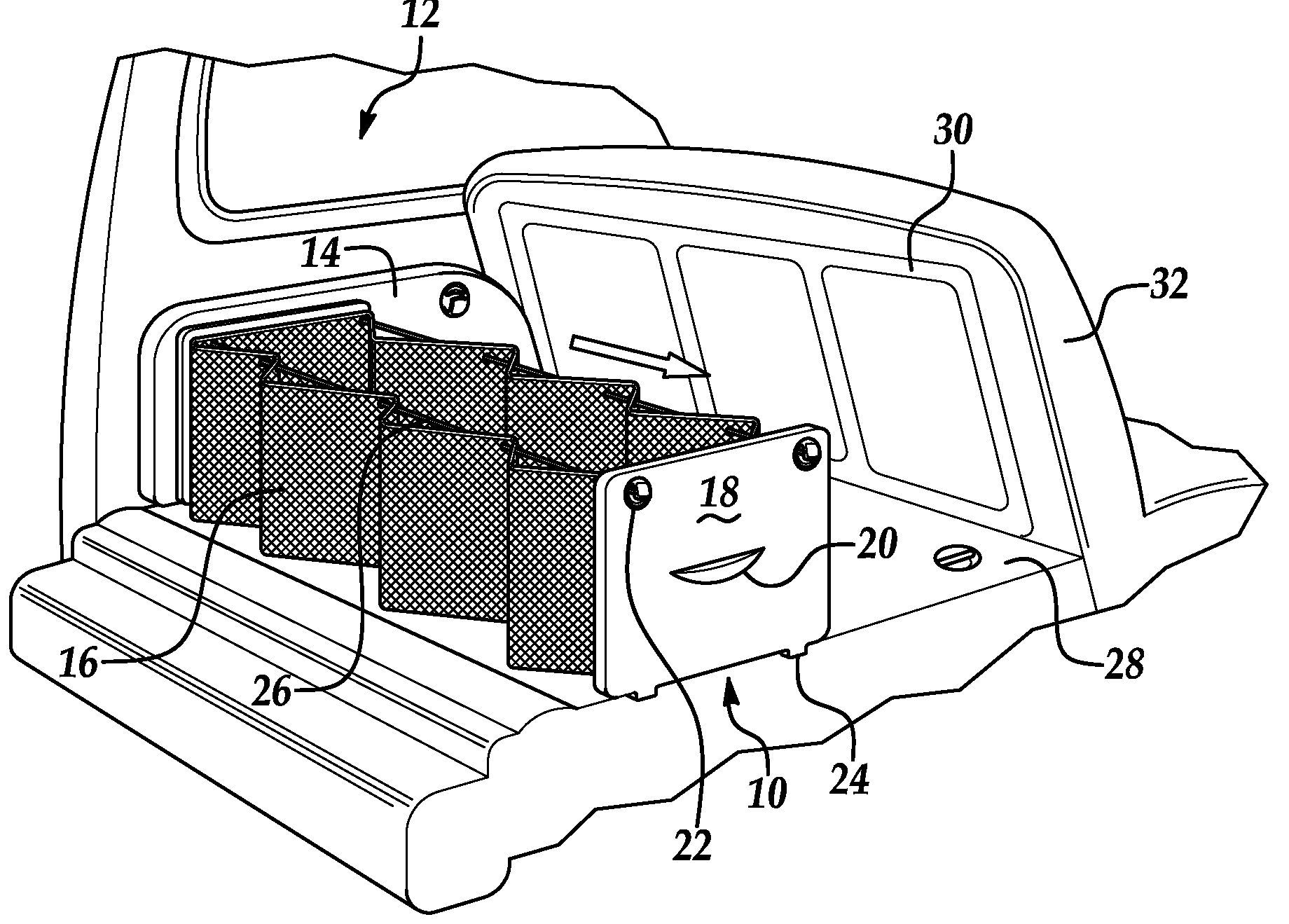

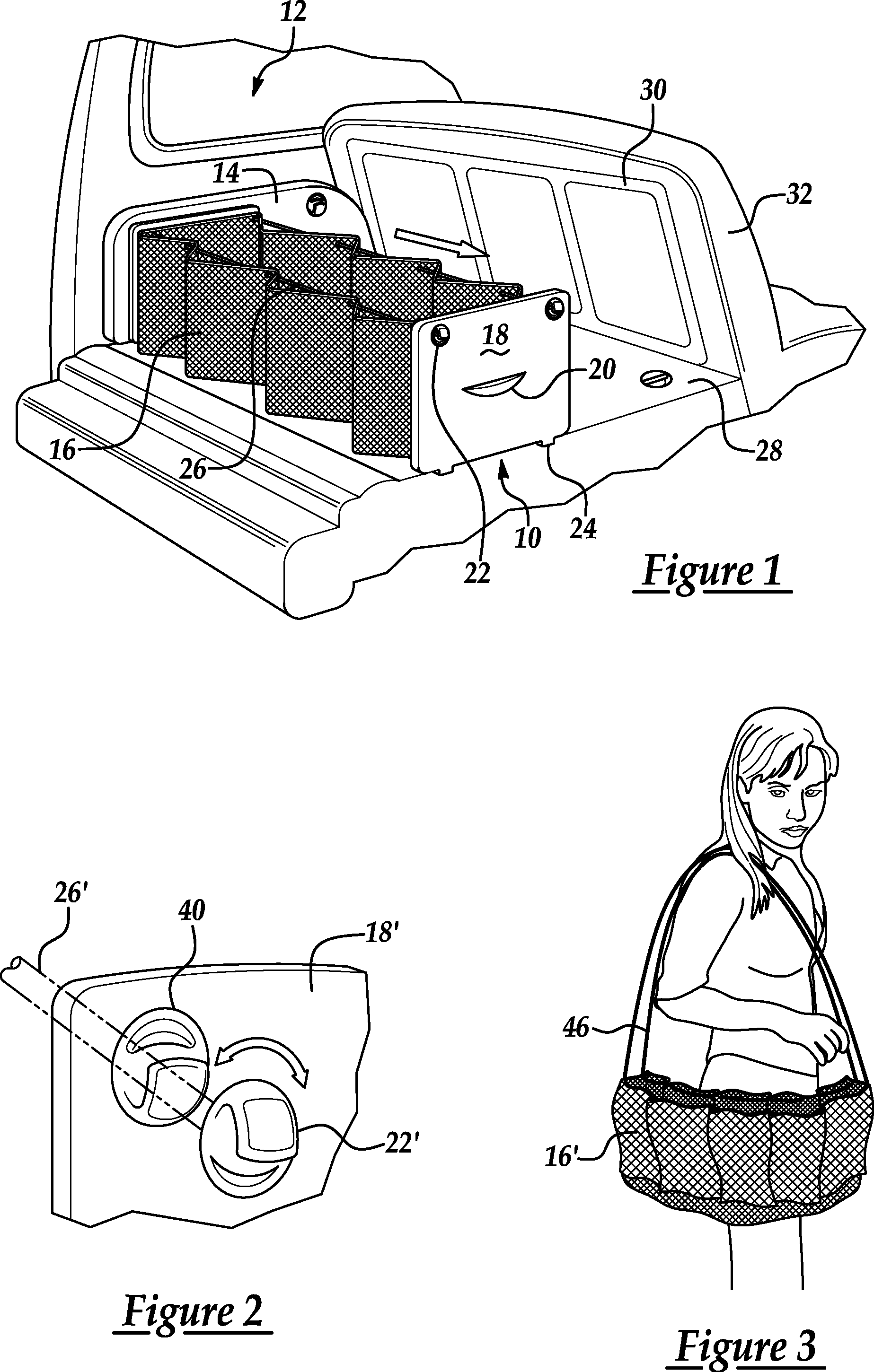

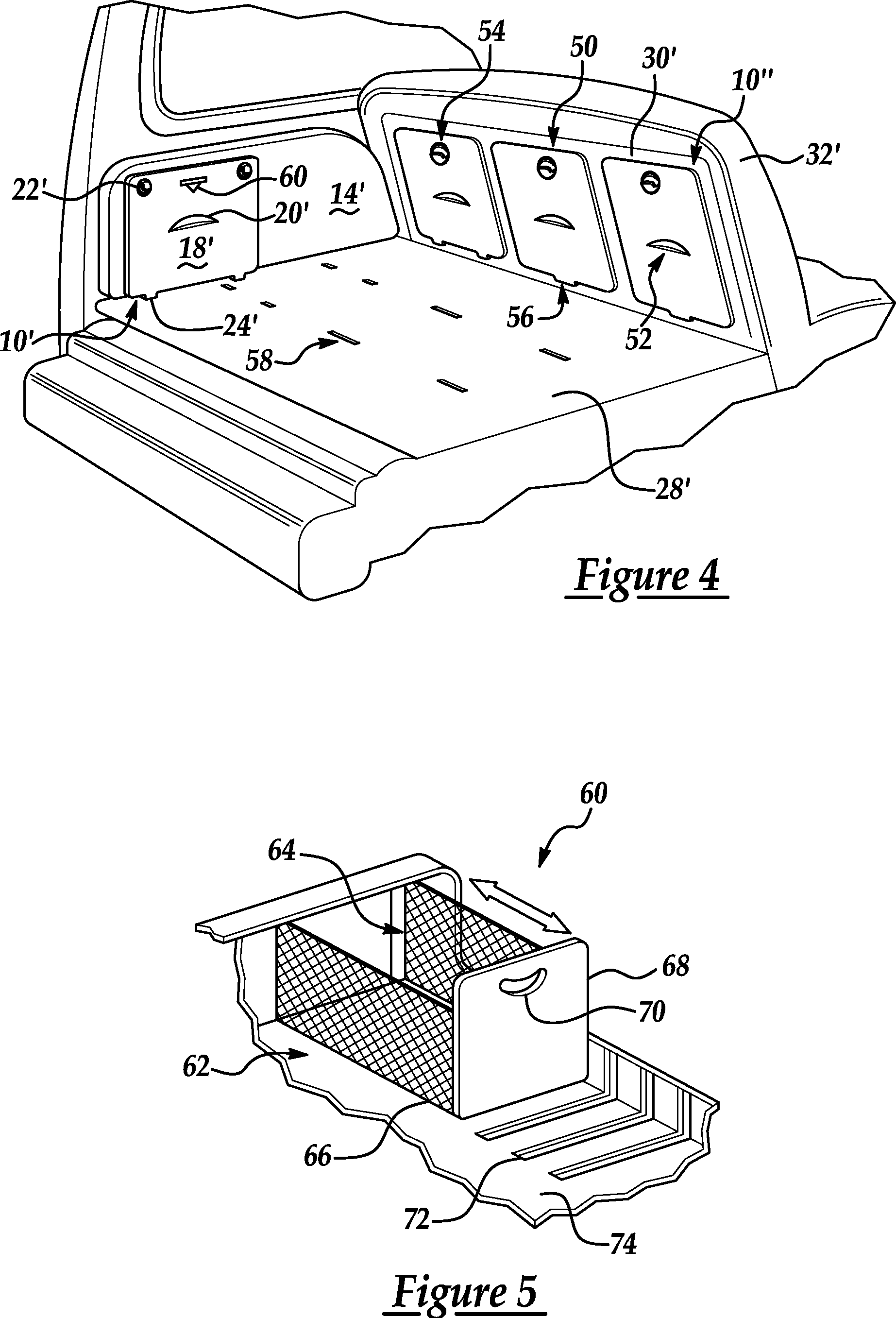

Cargo management system having vehicle load floor with cargo cage

InactiveUS7059646B1Solve the lack of spaceHigh strengthVehicle arrangementsPassenger spaceFace sheetManagement system

A cargo management system for a vehicle includes a substantially rigid load floor panel pivotally connected along a first edge to a base to provide a load floor substantially flush with a vehicle floor when stowed, and pivotally connected along an opposite edge to a rigid grid that may be deployed in a first position above and generally parallel to the base, and a second position generally transverse to the base to extend above any vehicle seats and generally separate a cargo area from a passenger area. The cargo management system may also include a secondary door, panel, or other device to cover a storage well or compartment of the base and to support additional cargo when the load floor panel is deployed.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

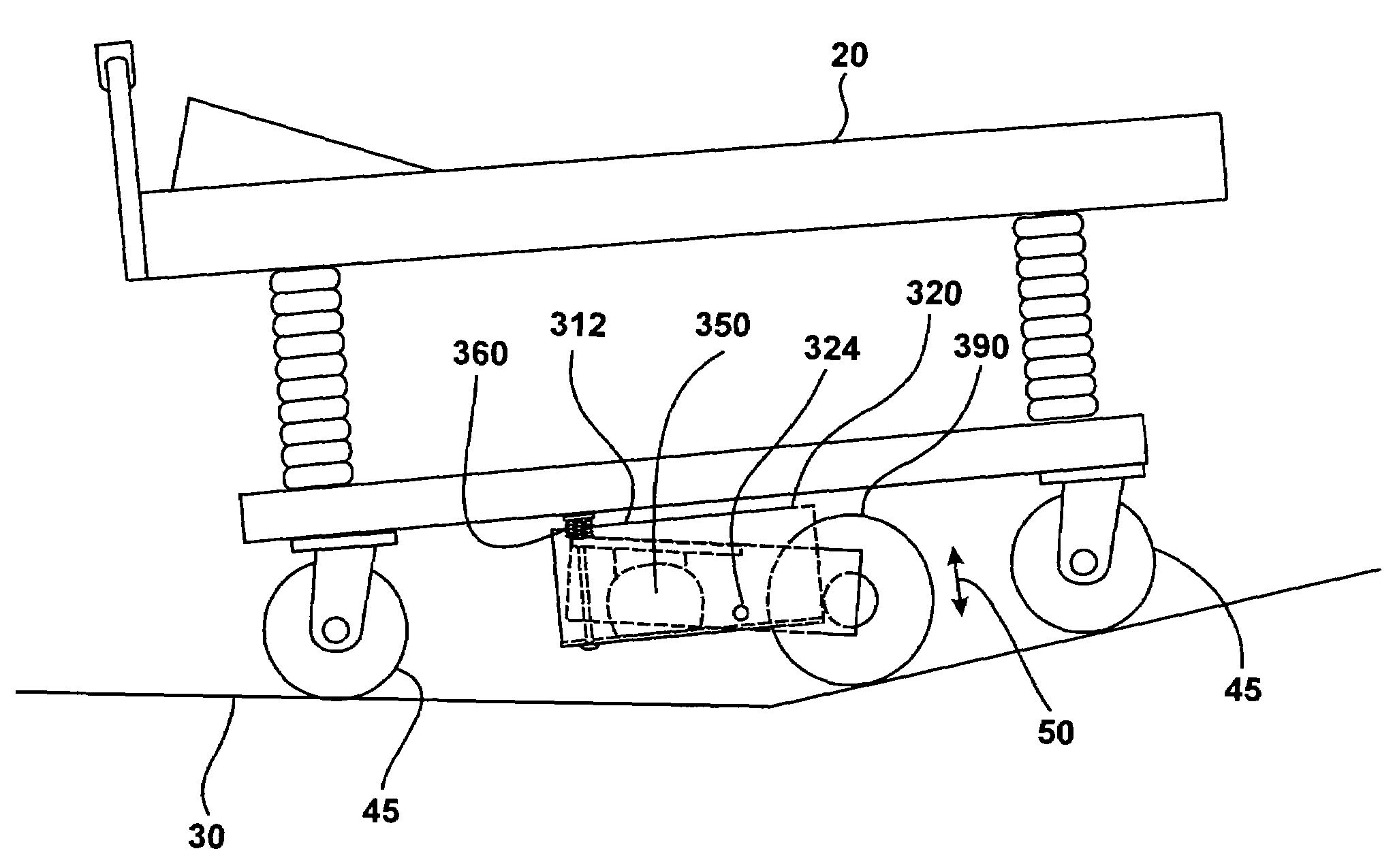

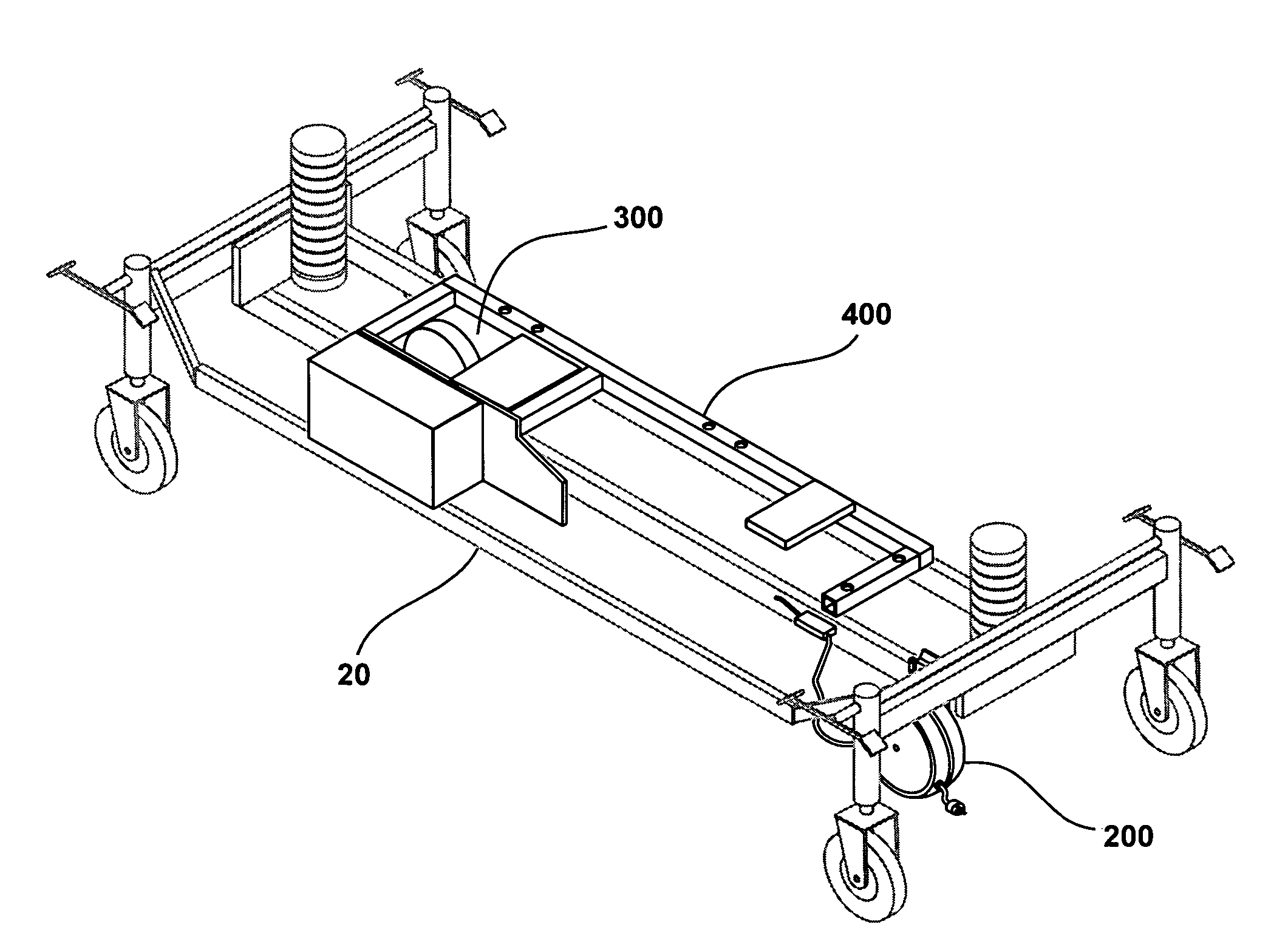

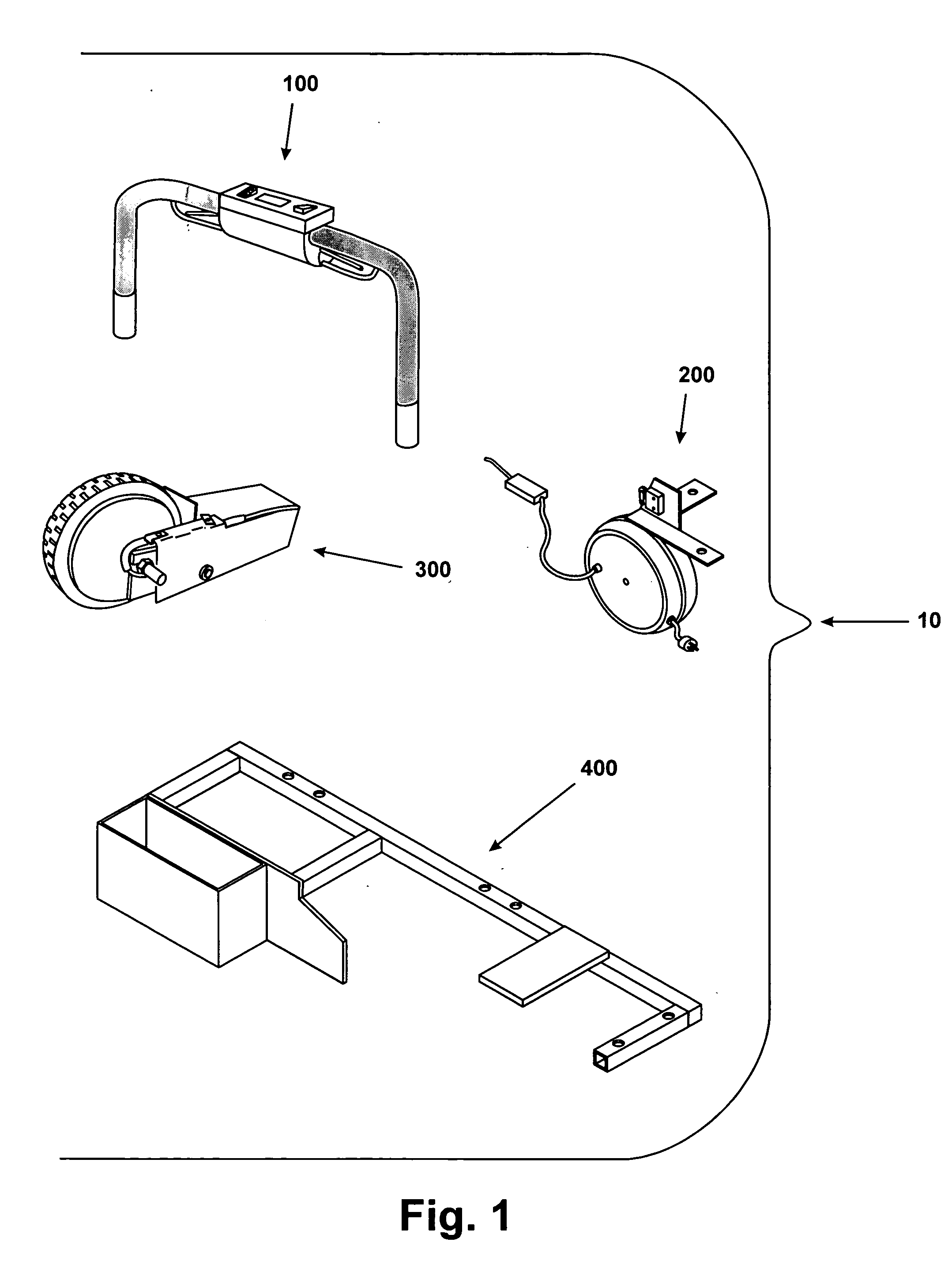

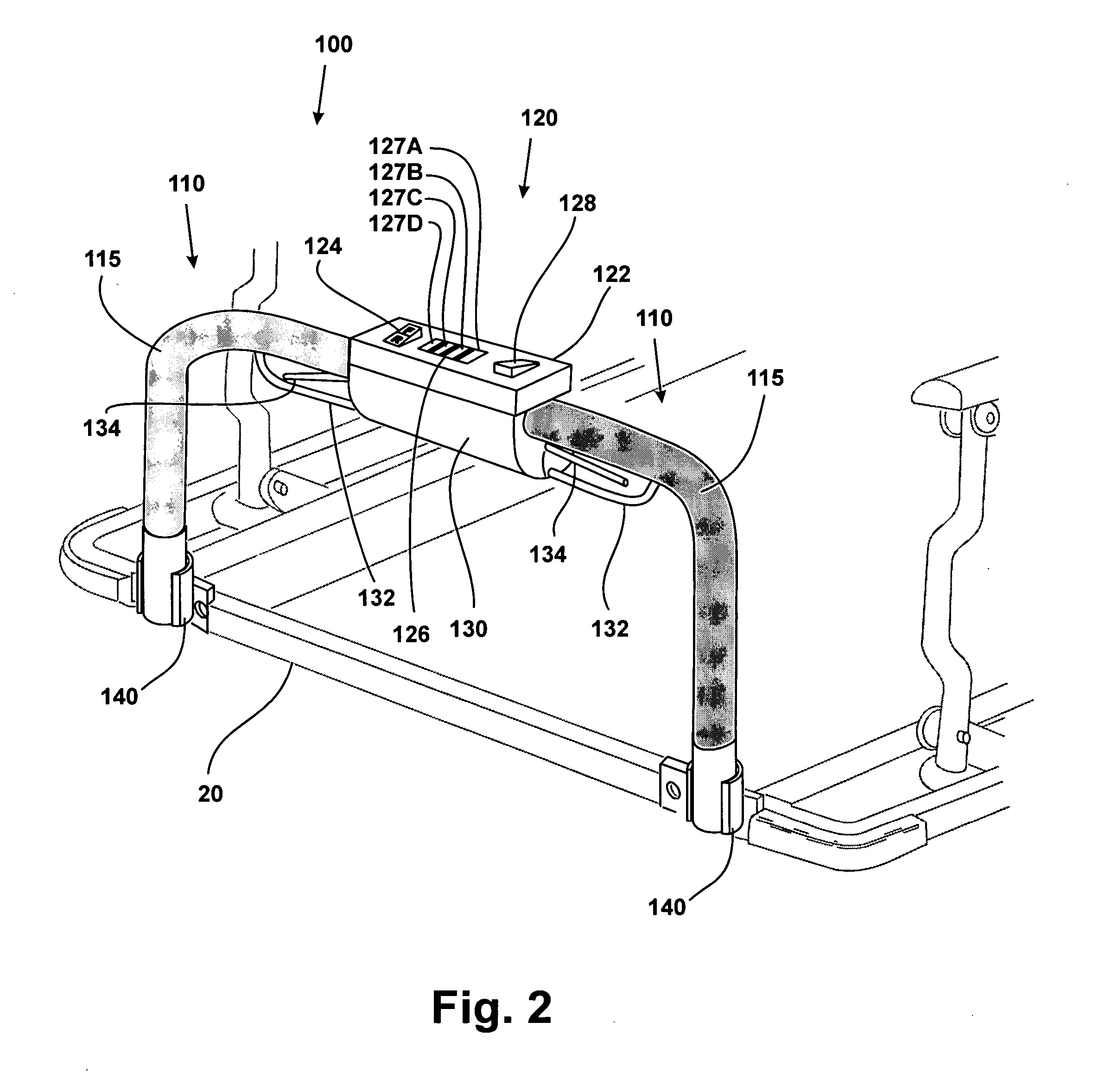

Self propelled gurney and related structure confidential and proprietary document

ActiveUS7191854B2Easily and quickly mountEasy loading and unloadingElectric propulsion mountingStretcherBattery state of chargeBattery charge

A modular drive unit for a gurney including a control / handle module, a cord reel / charger module, a drive module, and a chassis assembly, plus all needed electrical wiring harnesses and pneumatic tubing to connect them. The modules mount to any existing gurney and to each other without making permanent modifications to the gurney. The gurney is controlled by a handle assembly containing all necessary controls and indicators to allow the operator to select forward or reverse direction, increase or reduce speed of travel, observe the state of battery charge, and energize or deenergize power from the various modules. In addition, the handle may be swung down through 180 degrees to facilitate loading and unloading the gurney.

Owner:GEROPHARM

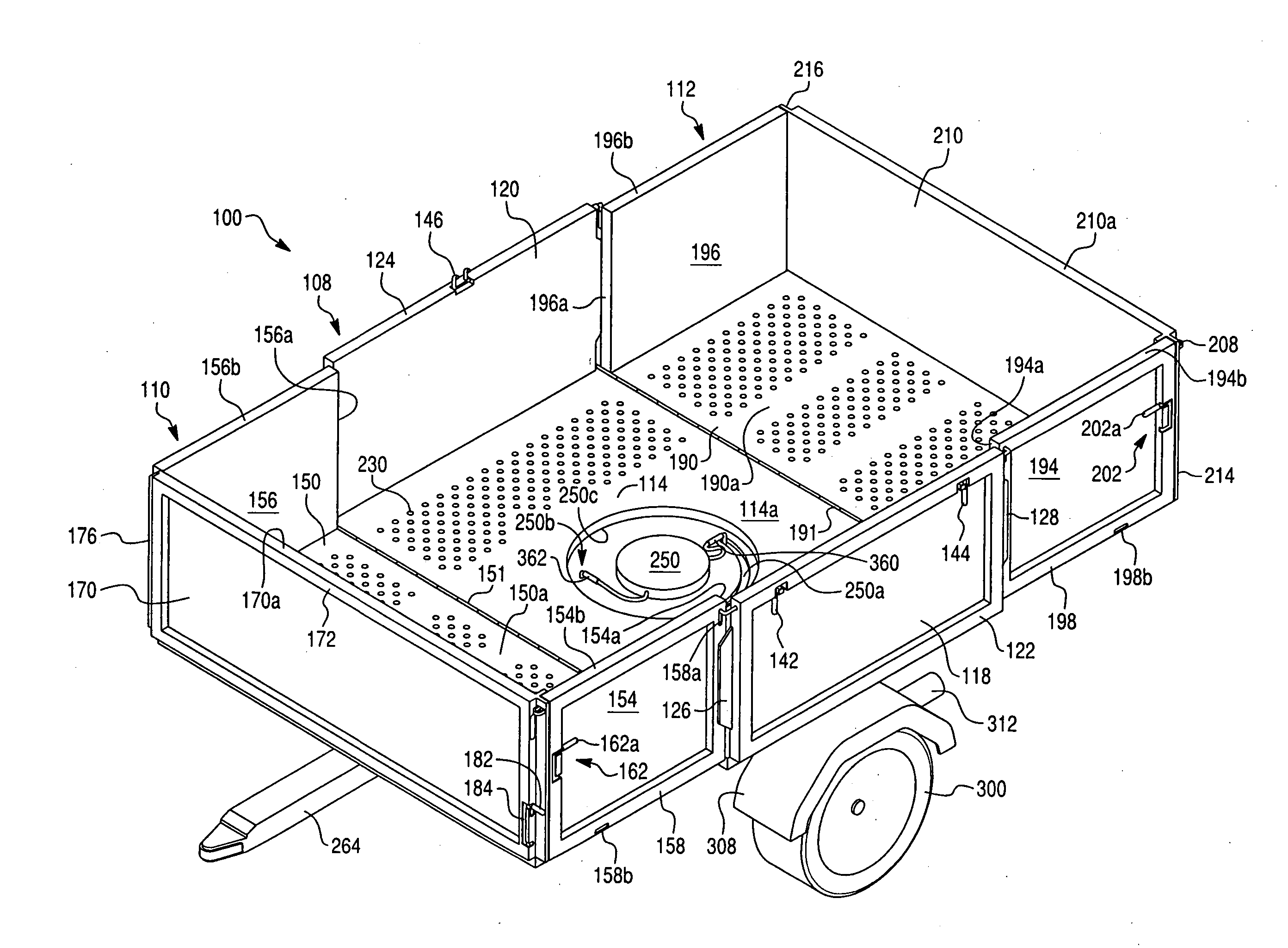

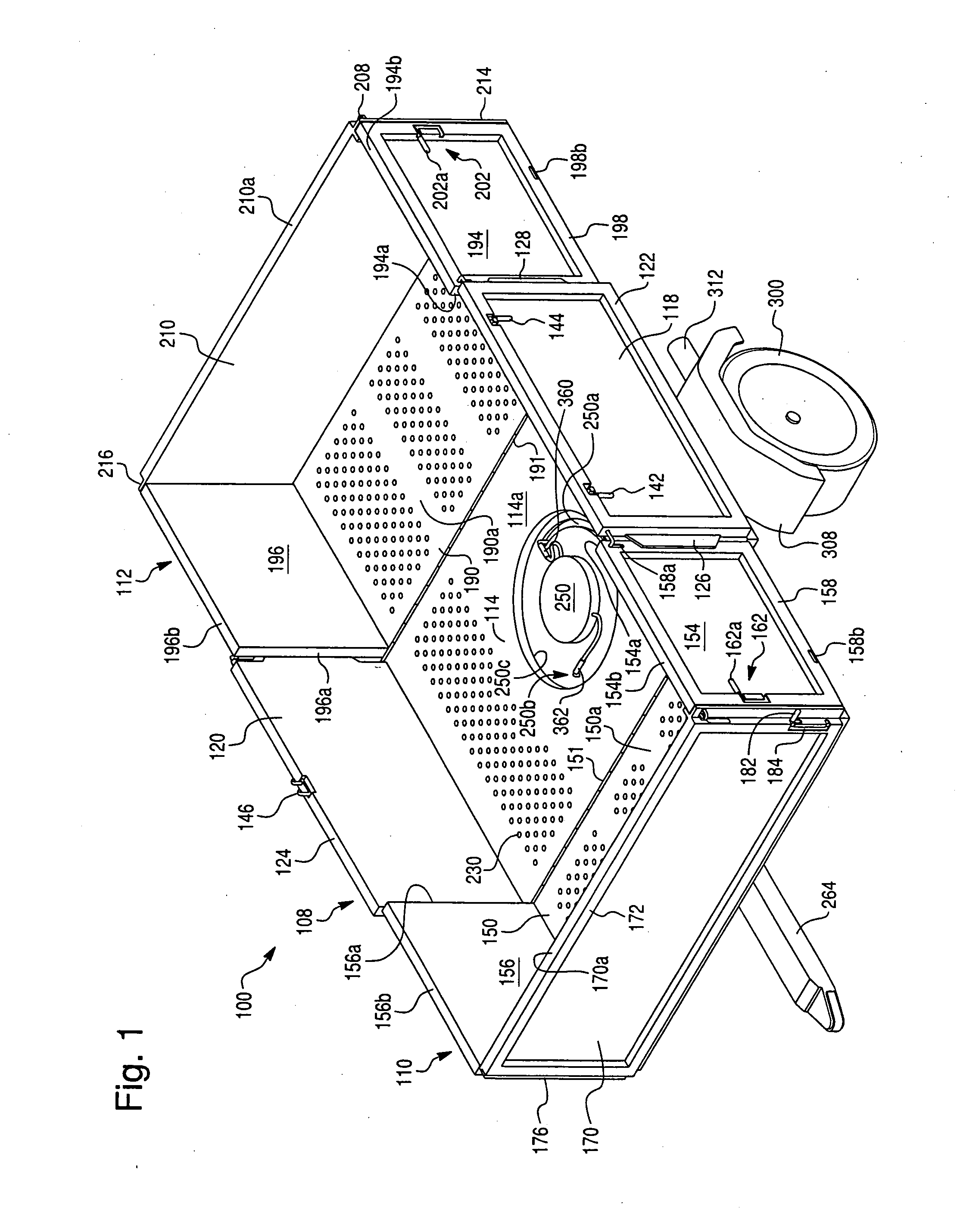

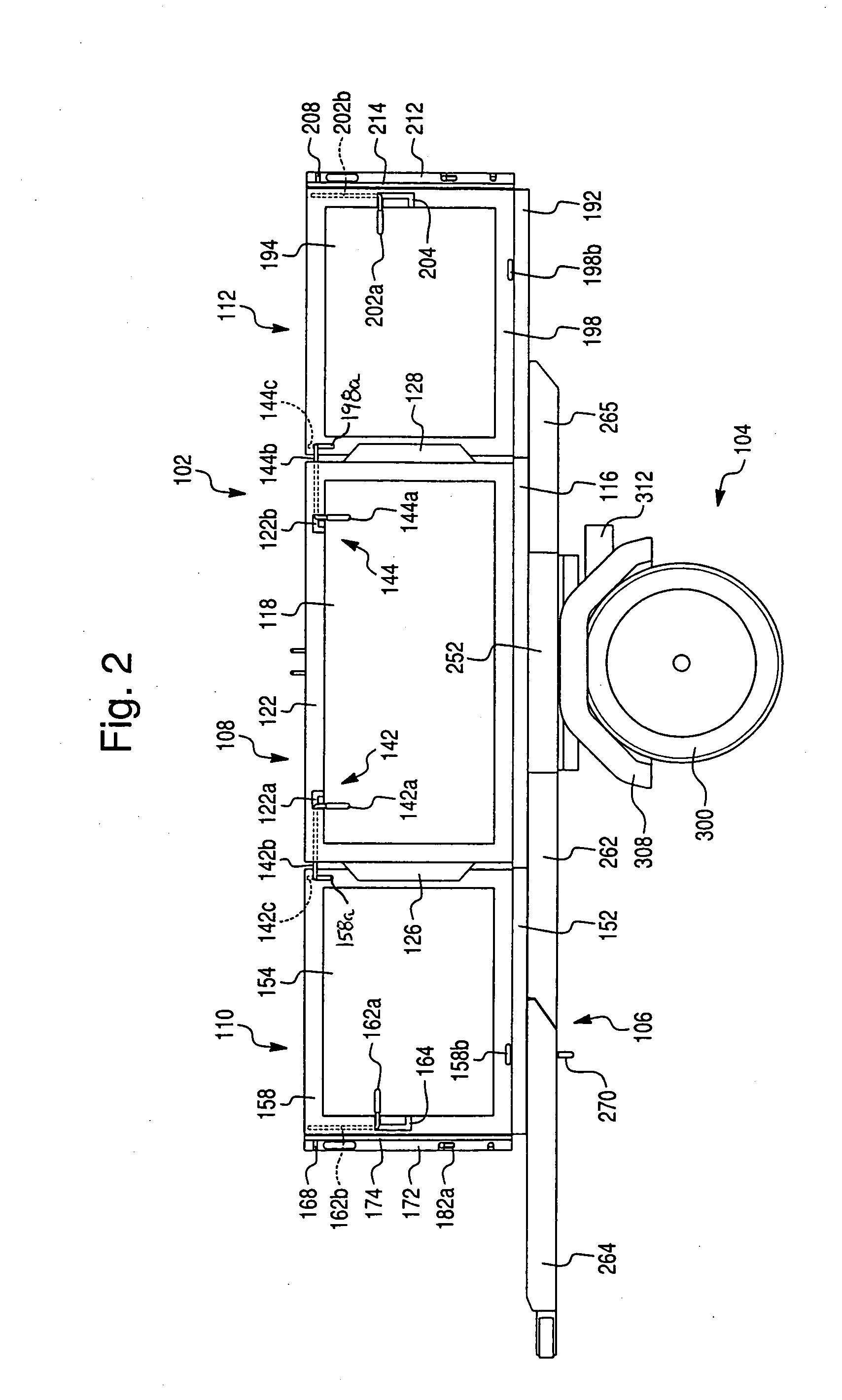

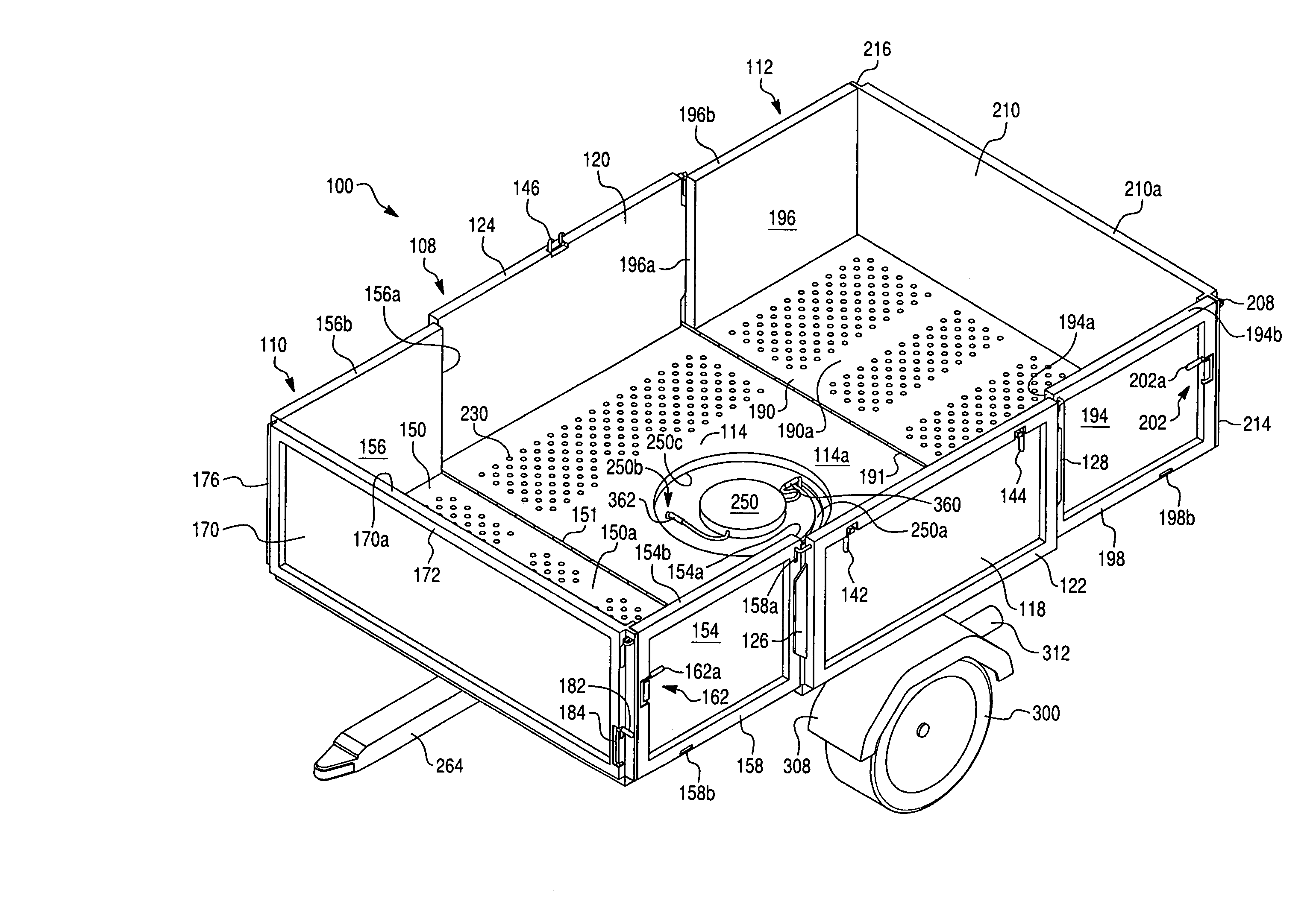

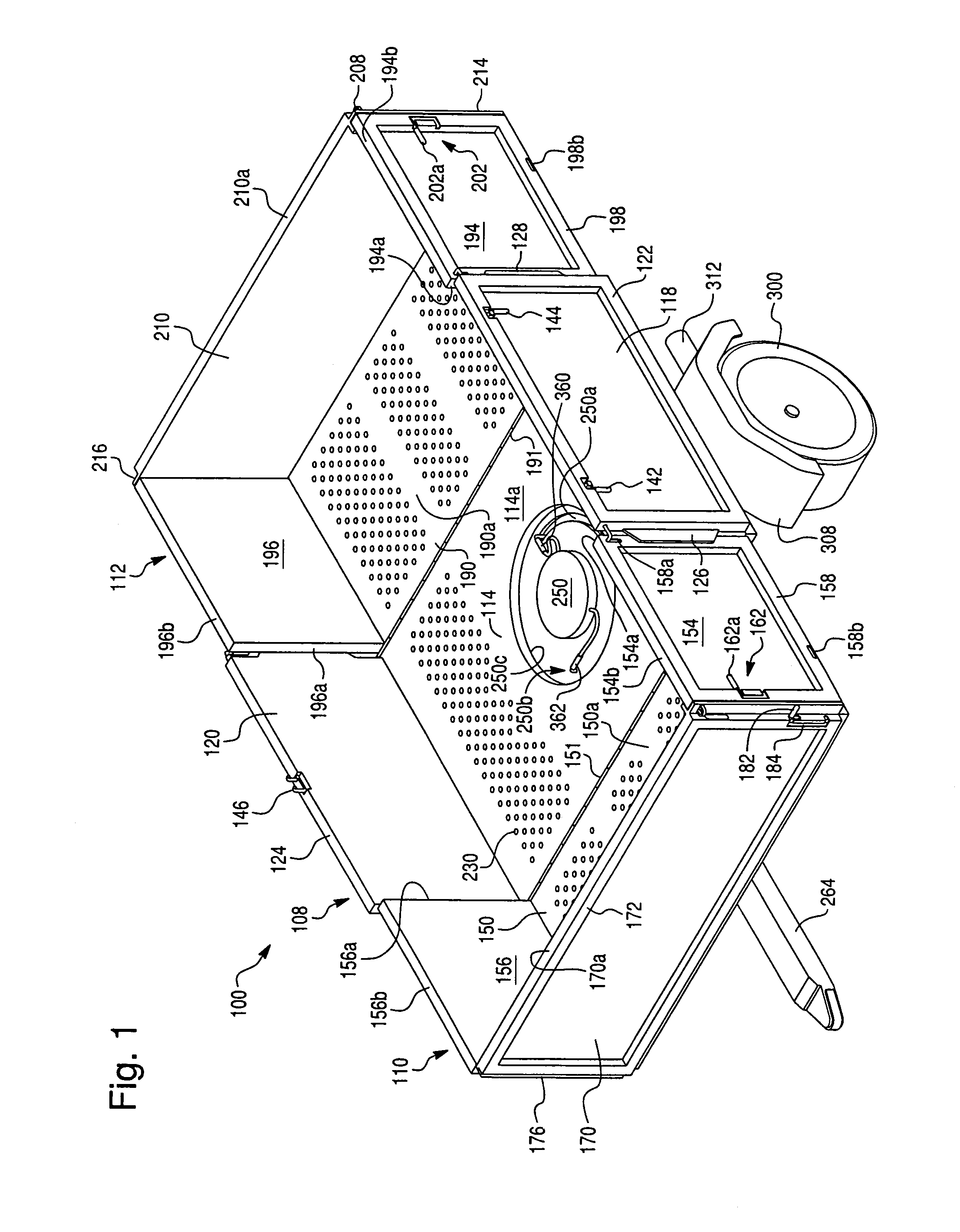

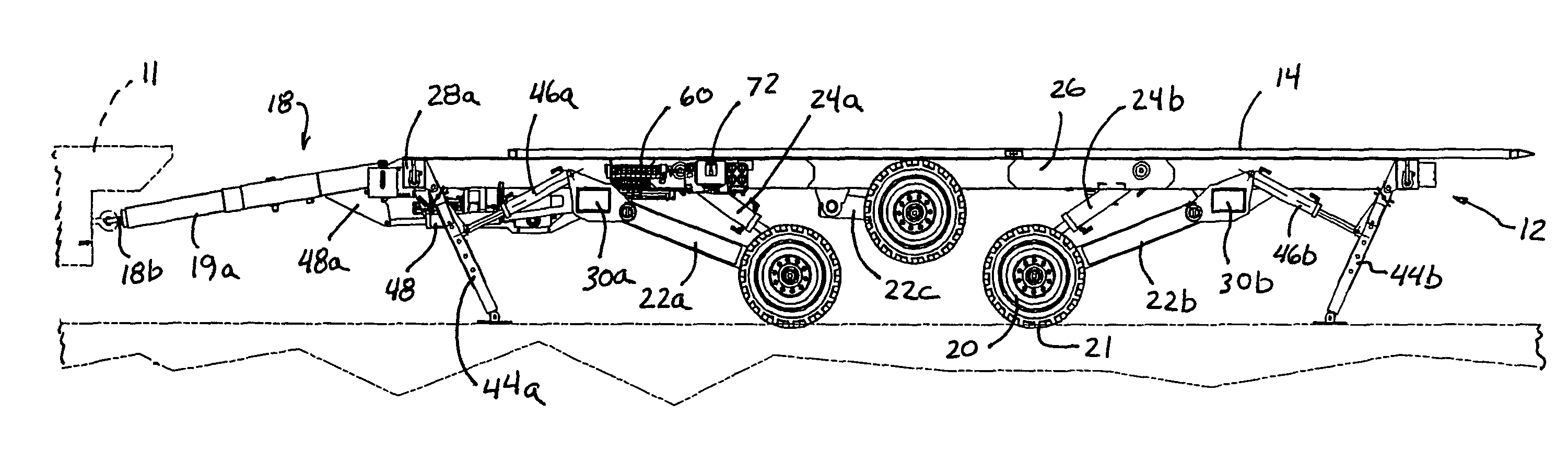

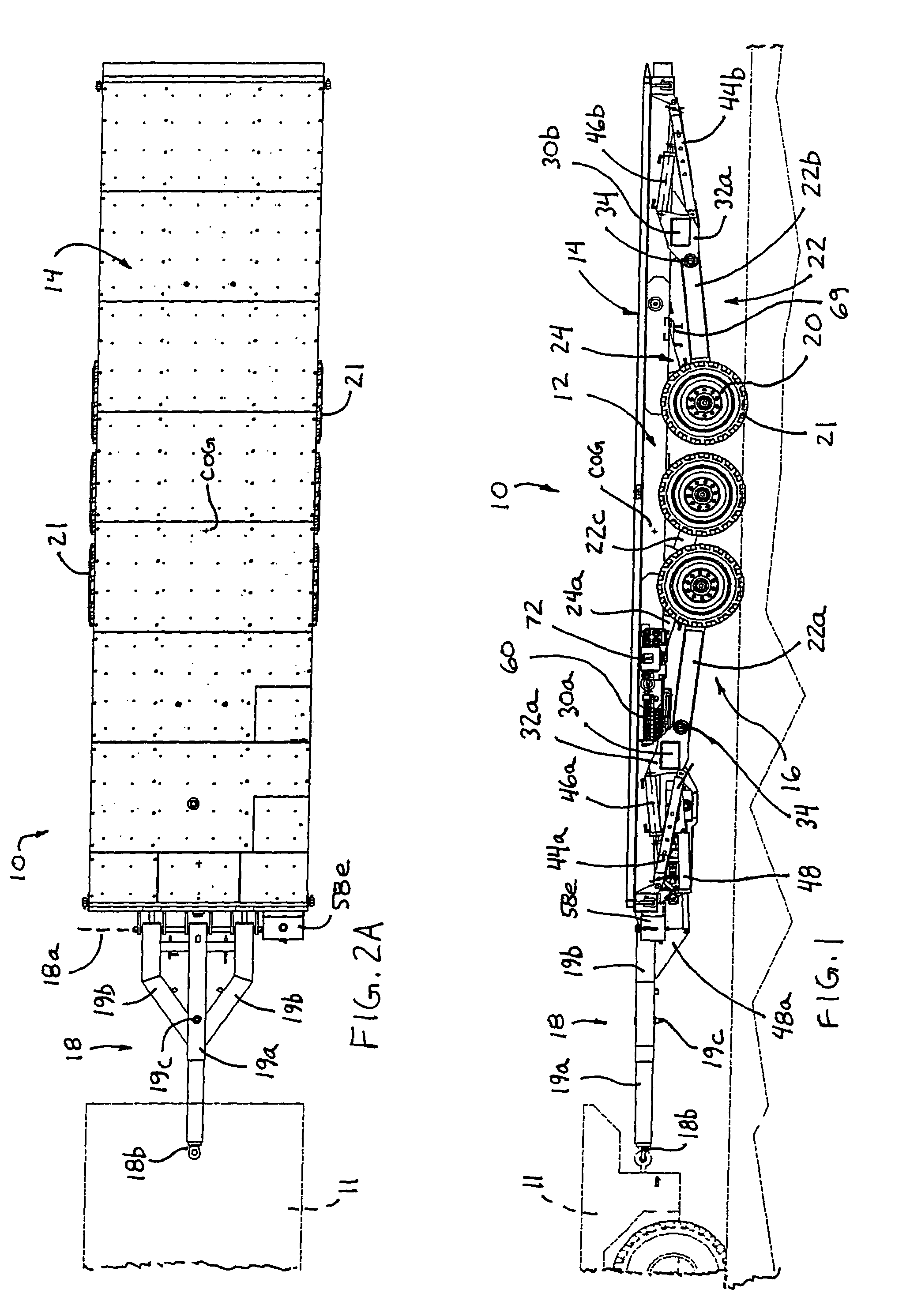

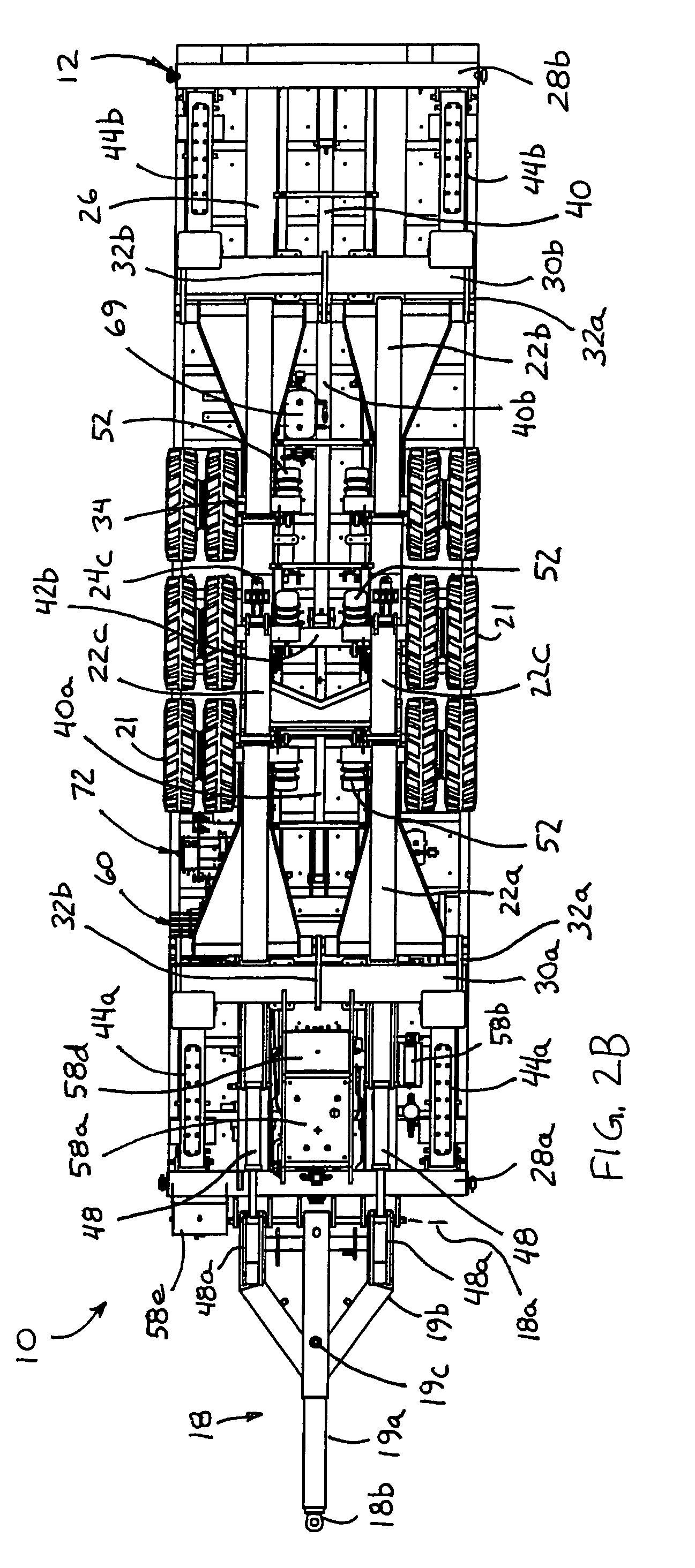

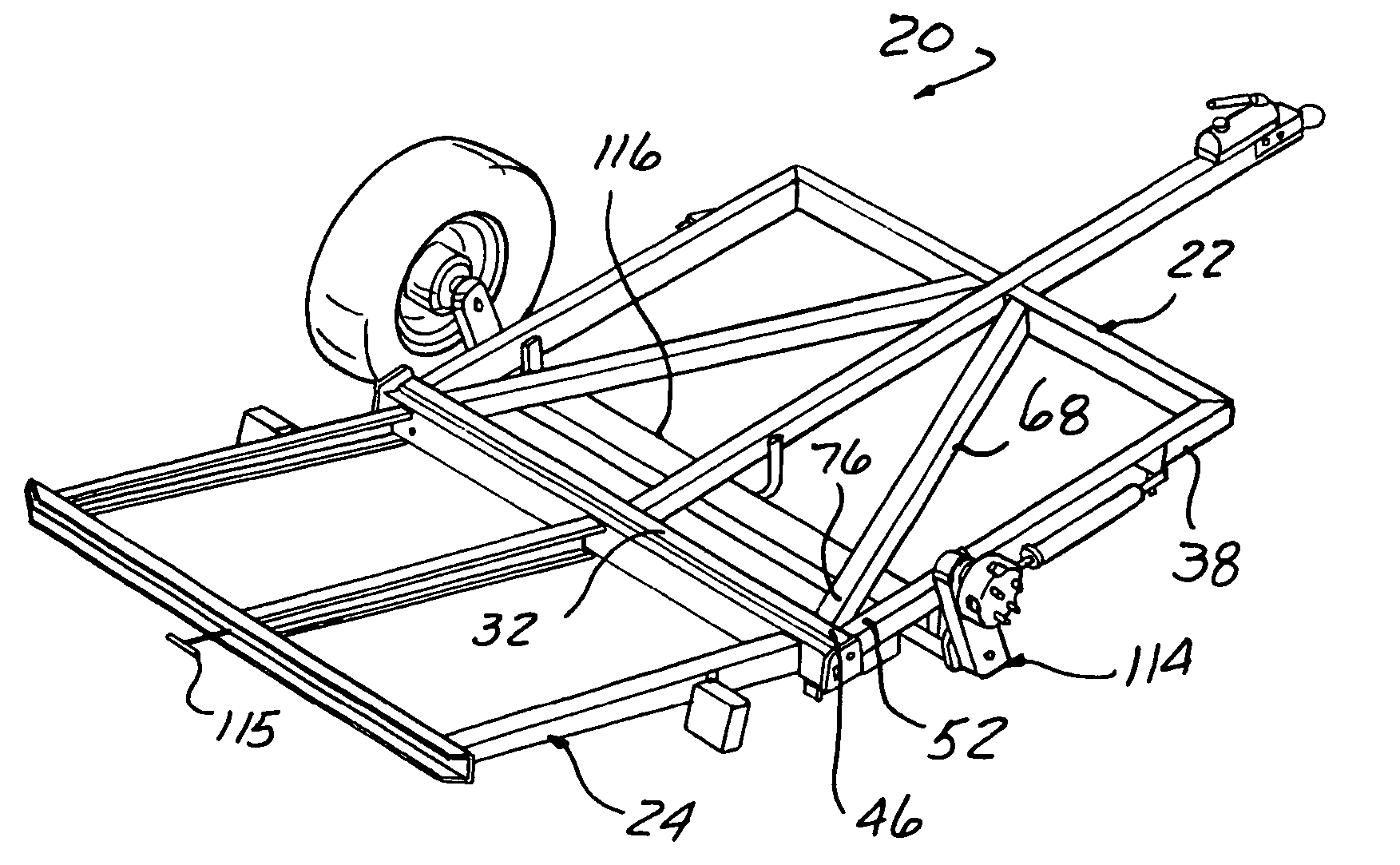

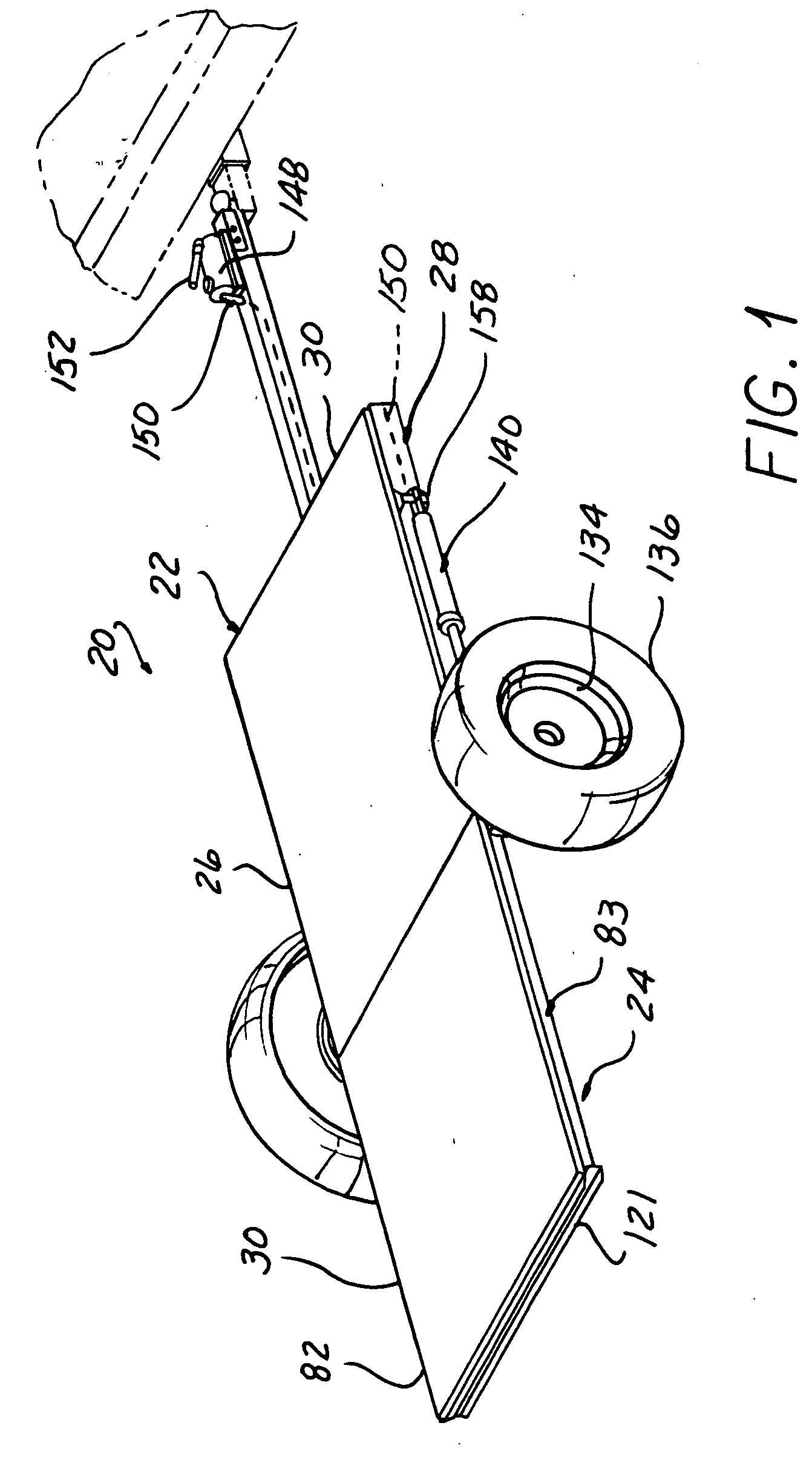

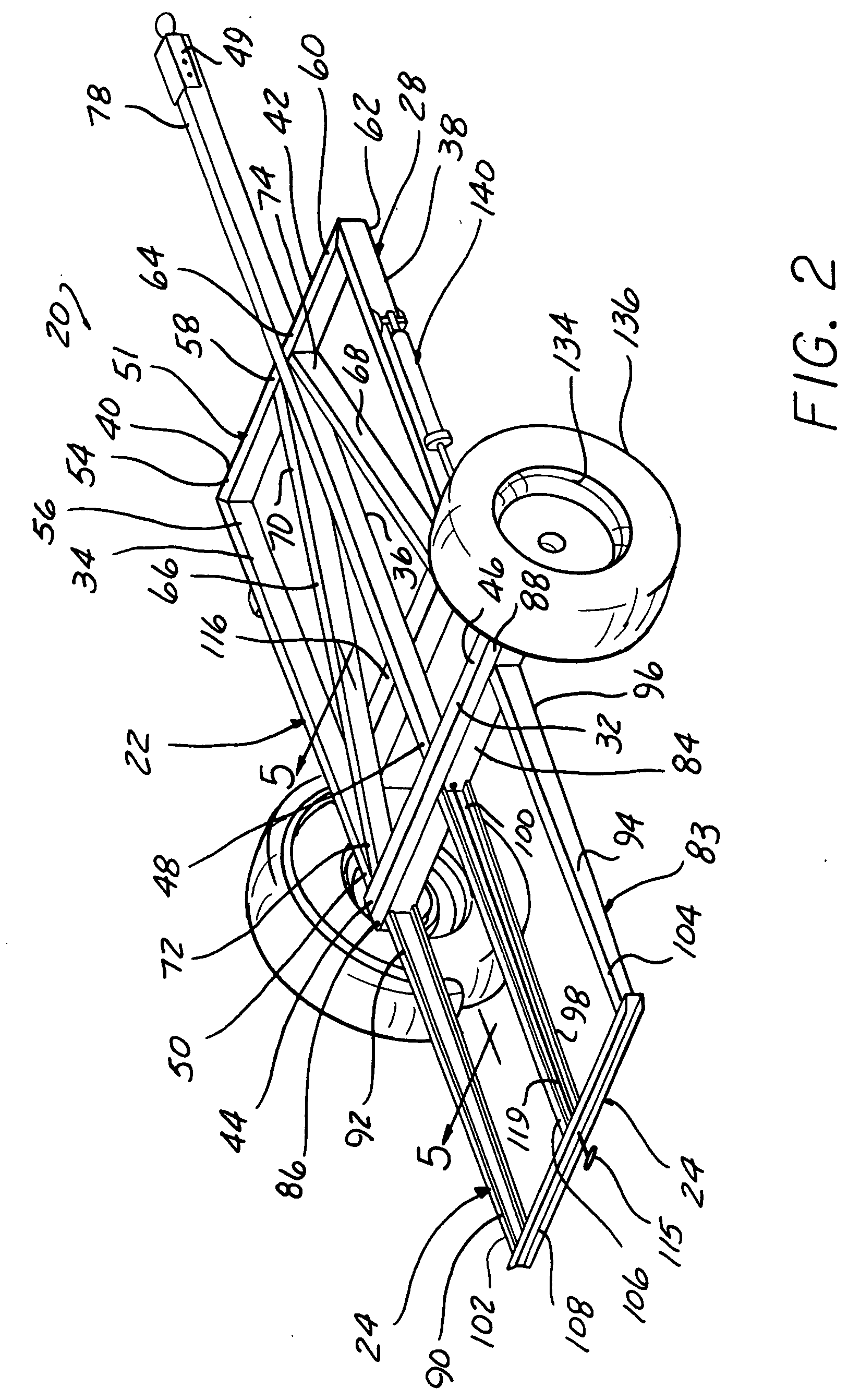

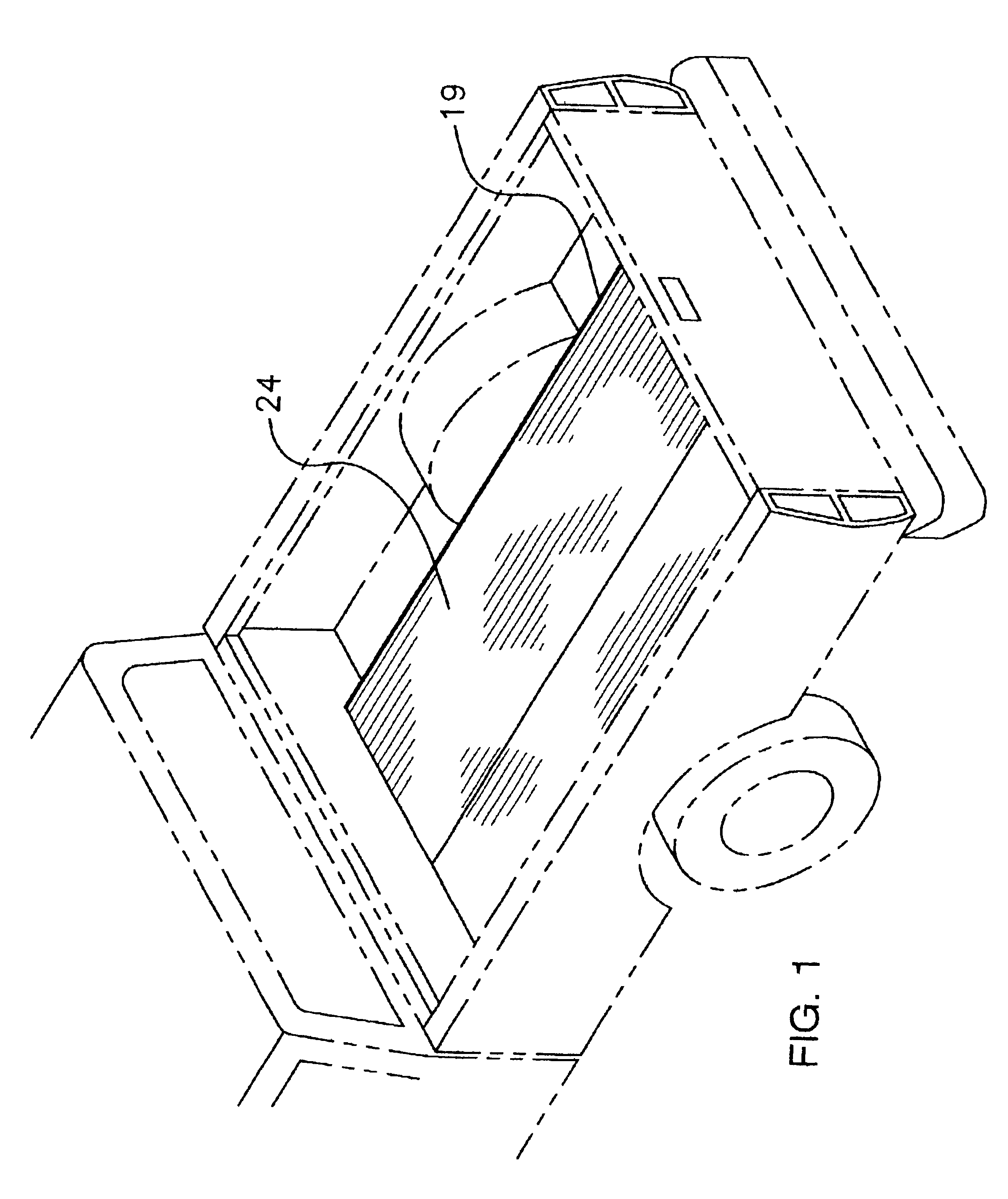

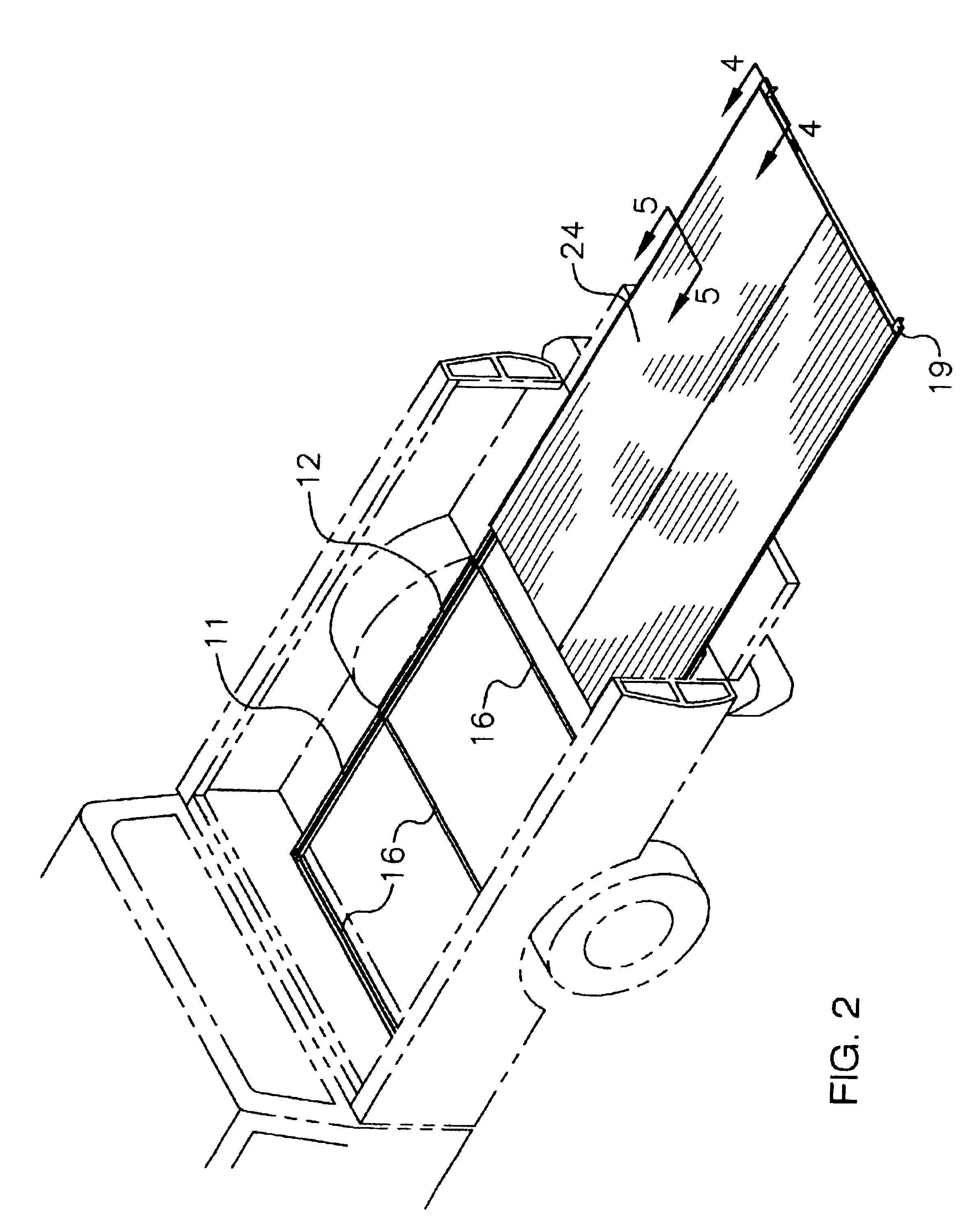

Trailer assembly

InactiveUS20050093273A1To overcome the lack of versatilityEasy loading and unloadingCarriage/perambulator accessoriesHand carts with one axisClassical mechanicsStructural engineering

A trailer assembly is provided that includes a bed subassembly having a plurality of sections movably coupled to one another for permitting movement between an extended configuration and a folded configuration. In an embodiment, in the folded configuration the plurality of sections collectively form a bottom surface, an upper surface, and surrounding side walls of an enclosable compartment, at least one of the sections having an access member movable between an open position for permitting access to the compartment and a closed position for enclosing the compartment as the sections are maintained in the folded configuration. The trailer assembly optionally may include a wheel subassembly and drawbar, which may be freely and independently rotatable relative to one another and the bed subassembly.

Owner:MCDONELL LINDSAY

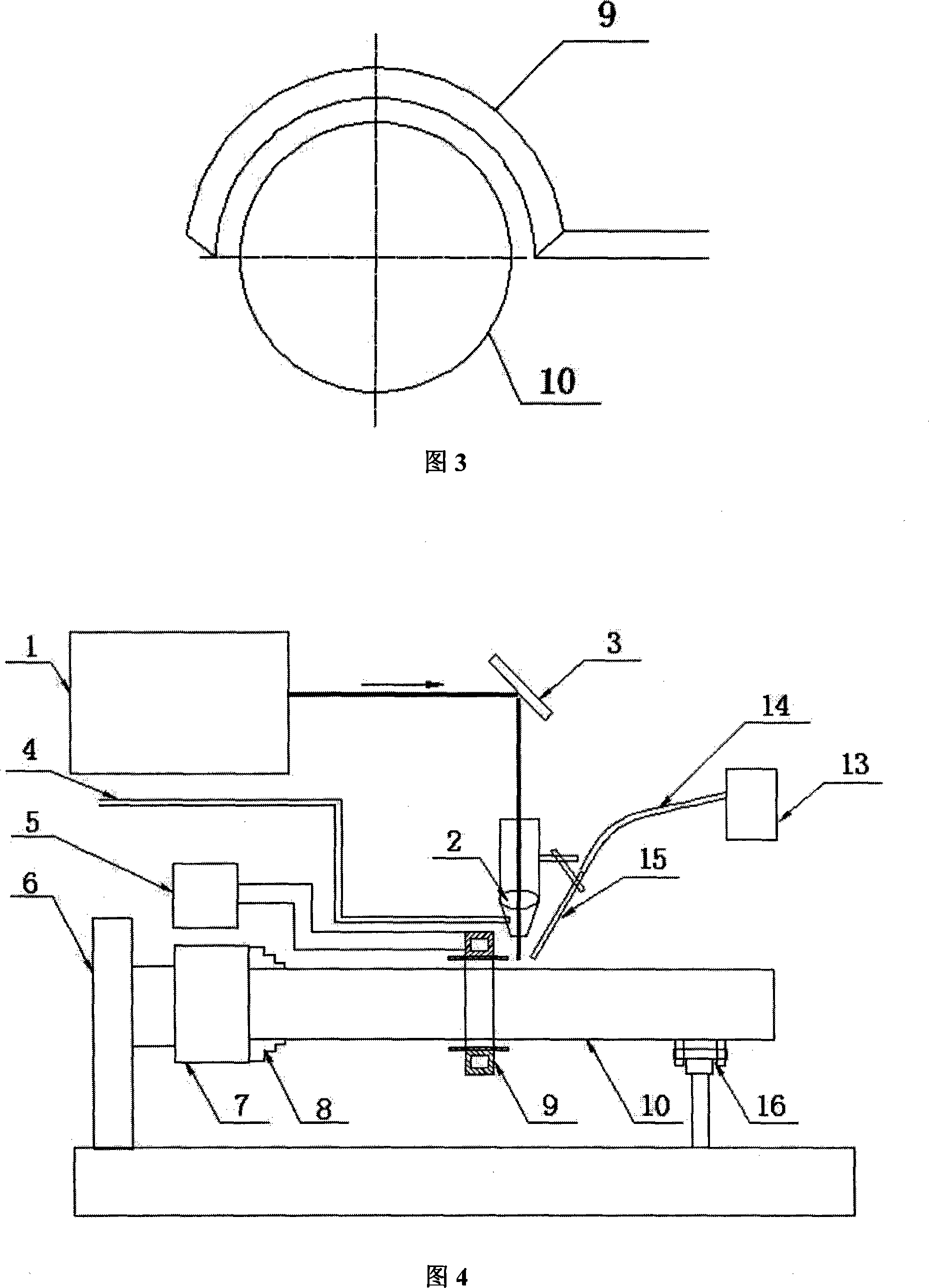

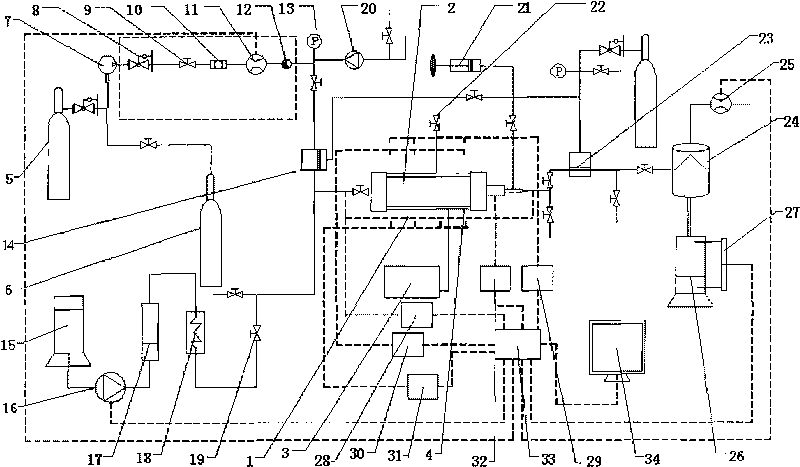

Simulation method and experimental device for carbon dioxide replacement exploitation of gas hydrate

The invention discloses an experimental device and a method for carbon dioxide replacement exploitation of gas hydrate. The experimental device comprises a one-dimensional model, a gas supply unit, a working solution supply unit, an axial compression control unit, a back pressure control unit and an environment control unit. Each unit is respectively provided with a sensor connected to a data processing unit. The one-dimensional model is arranged in the environment control unit. The inside of the one-dimensional model is a sealed simulation cavity. The upper part of the one-dimensional model is provided with a gas and solution inlet, a gas and solution outlet and an axial compression solution inlet. A gas output pipeline of the gas supply unit is communicated with the gas and solution inlet after being connected with a working solution output pipeline of the working solution supply unit. A back pressure acquisition pipeline is communicated with the gas and solution outlet. The axial compression control unit is connected with the axial compression solution inlet. The one-dimensional model is also provided with a vacuum-pumping interface. The invention can really simulate the external environment to carry out simulation exploitation of carbon dioxide replacement of the gas hydrate, and can provide guidance for the carbon dioxide replacement exploitation of the gas hydrate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

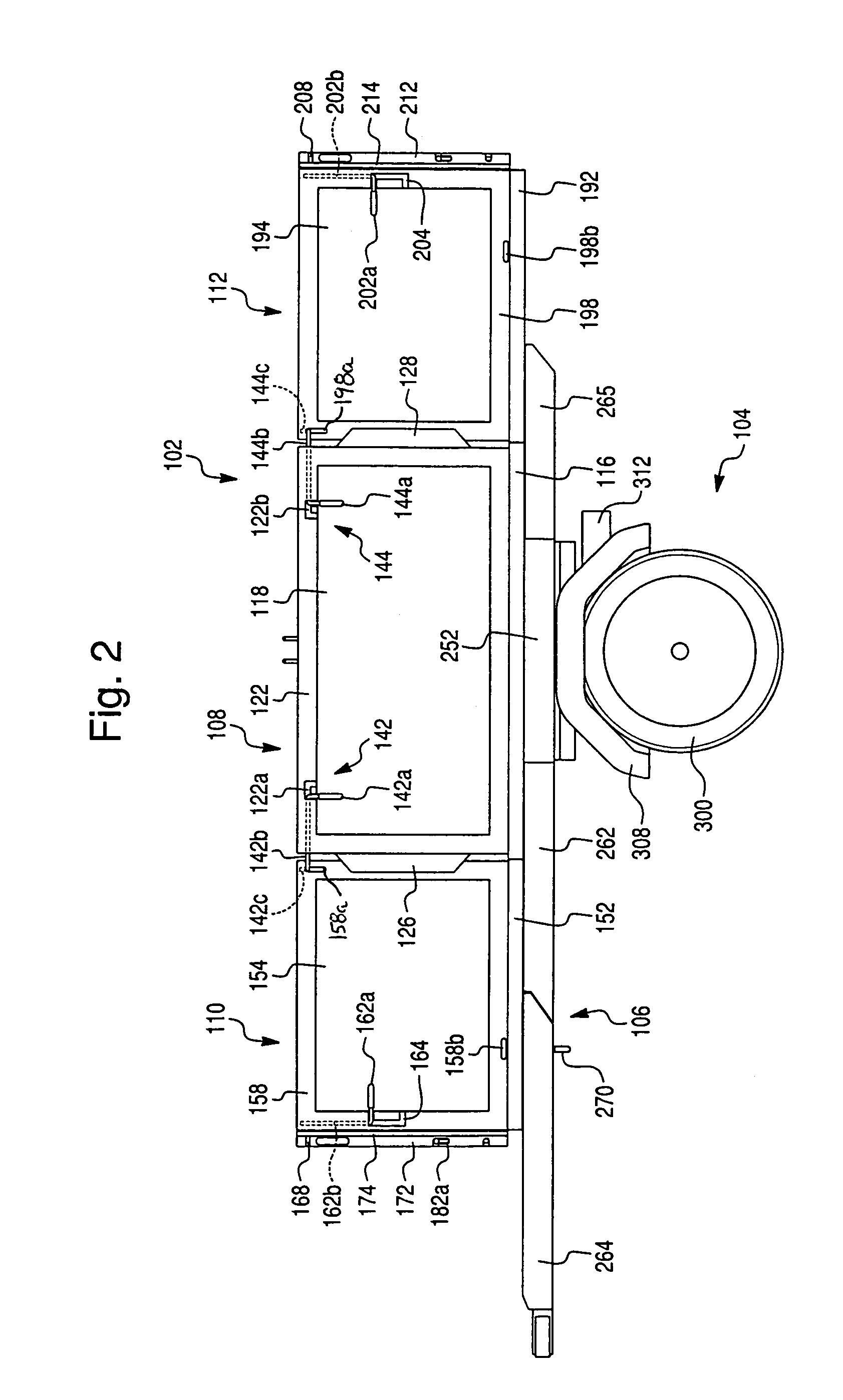

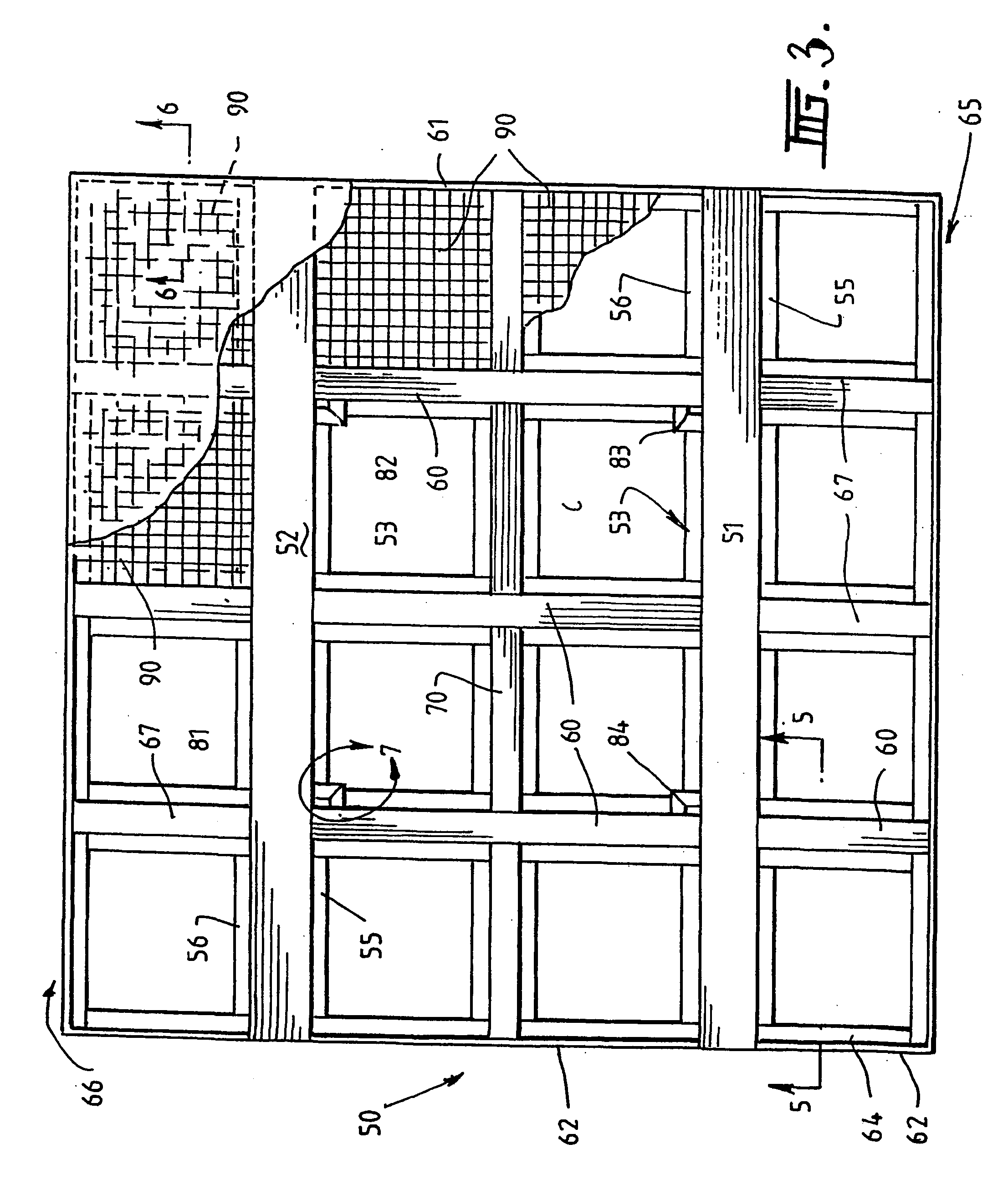

Integrated expandable cargo system for vehicles

InactiveUS7121601B2Easy loading and unloadingLuggage compartmentVehicle arrangementsTruckMechanical engineering

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Trailer assembly

InactiveUS7052033B2To overcome the lack of versatilityEasy loading and unloadingCarriage/perambulator accessoriesHand carts with one axisBiomedical engineering

A trailer assembly is provided that includes a bed subassembly having a plurality of sections movably coupled to one another for permitting movement between an extended configuration and a folded configuration. In an embodiment, in the folded configuration the plurality of sections collectively form a bottom surface, an upper surface, and surrounding side walls of an enclosable compartment, at least one of the sections having an access member movable between an open position for permitting access to the compartment and a closed position for enclosing the compartment as the sections are maintained in the folded configuration. The trailer assembly optionally may include a wheel subassembly and drawbar, which may be freely and independently rotatable relative to one another and the bed subassembly.

Owner:MCDONELL LINDSAY

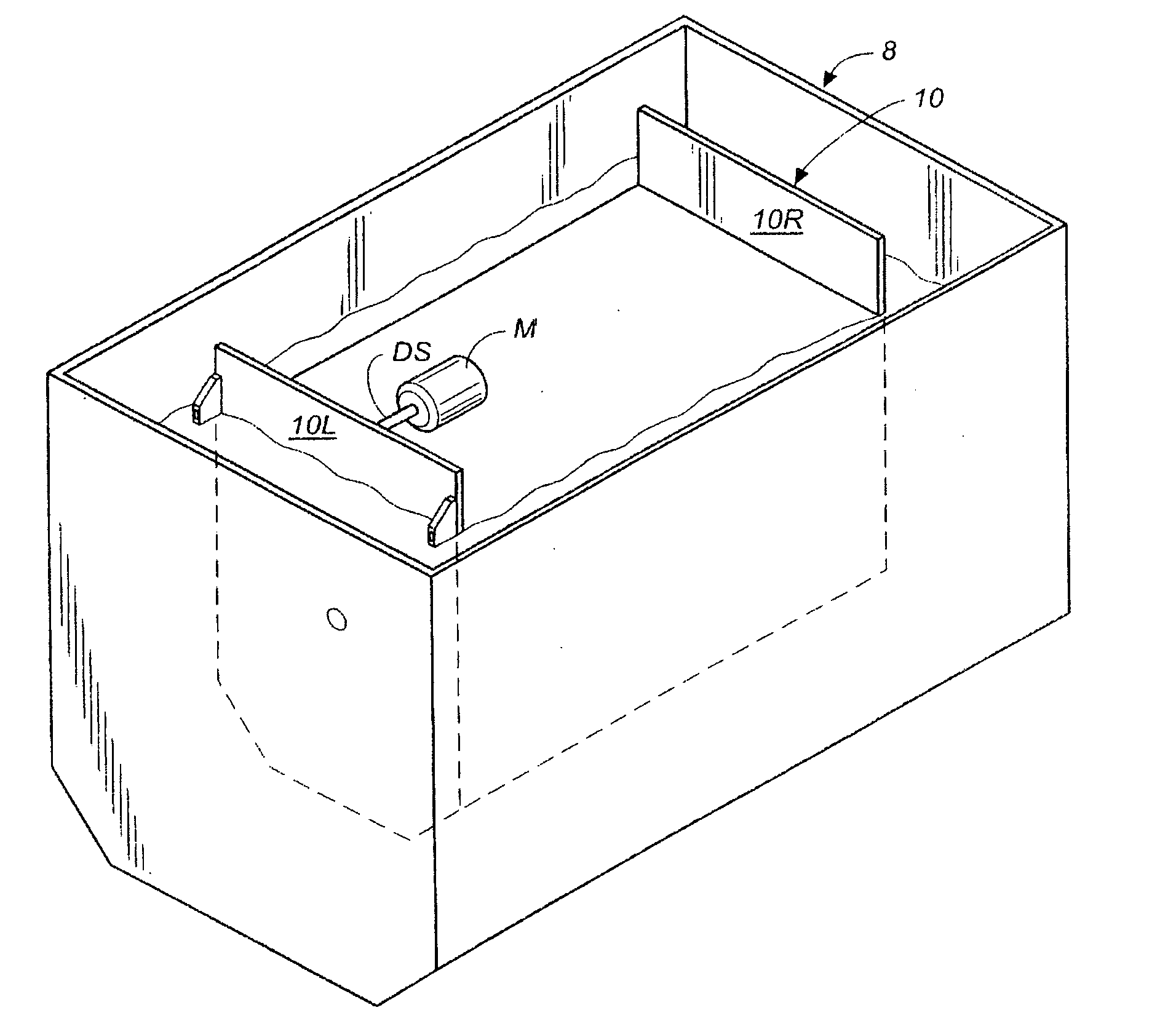

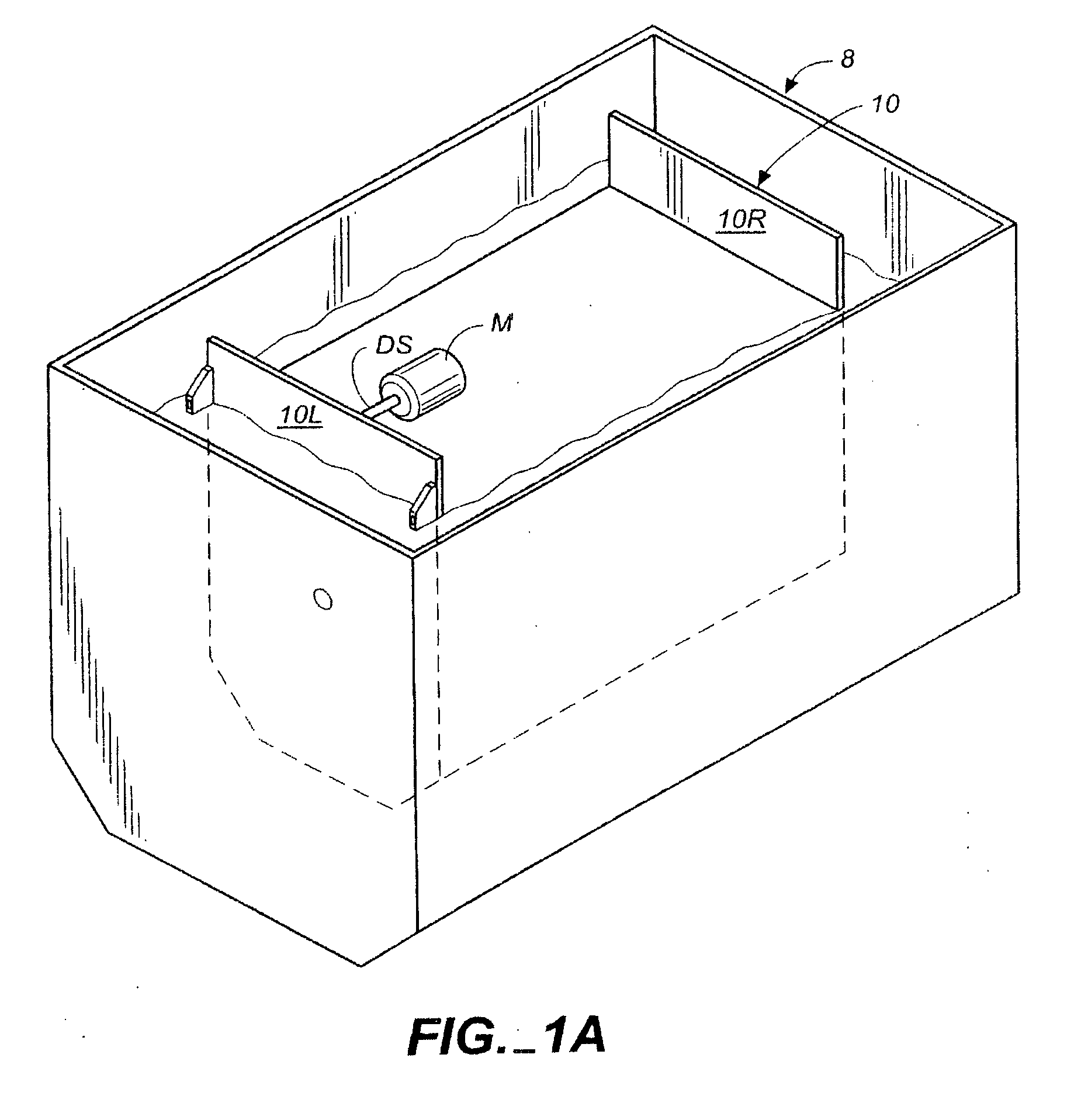

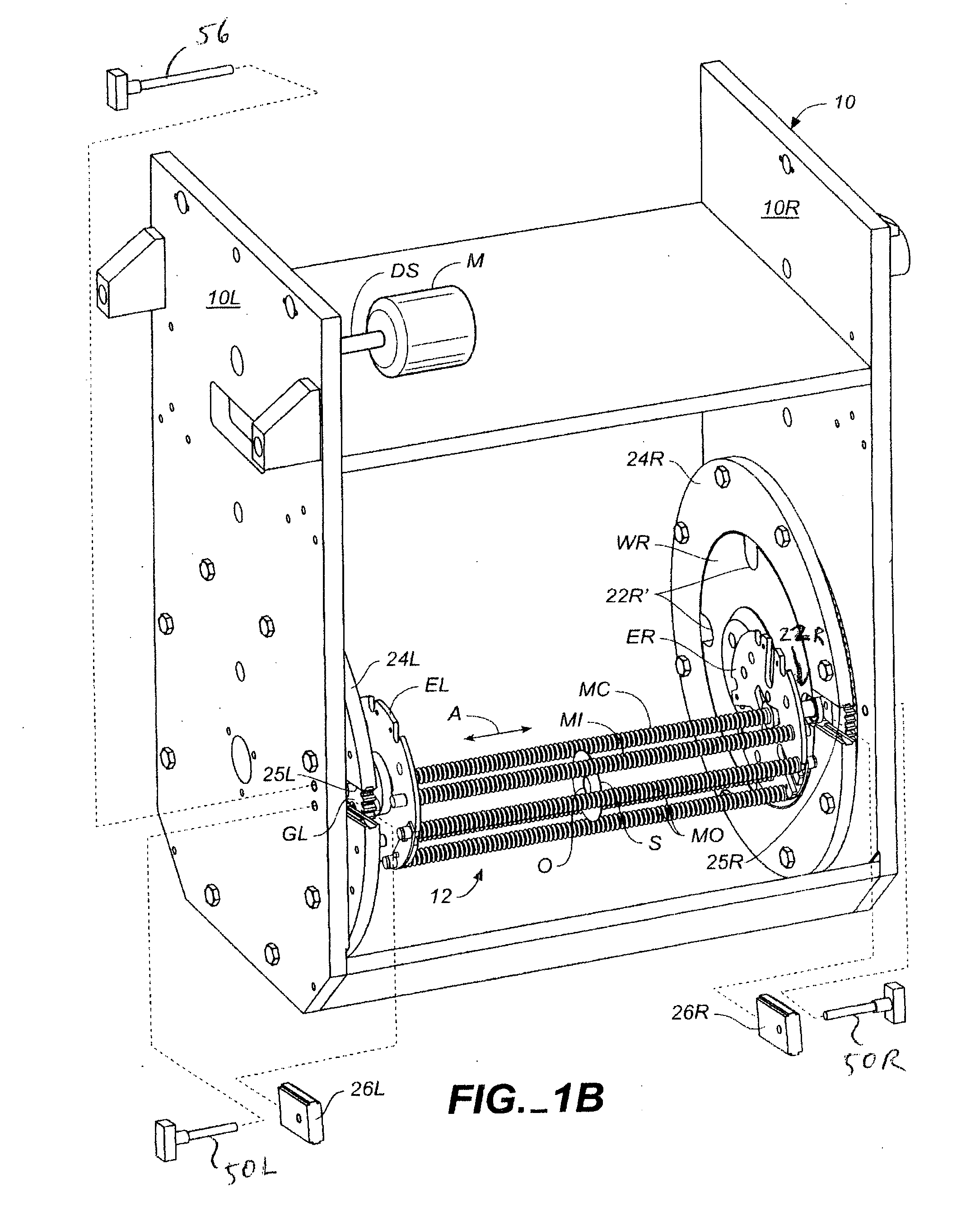

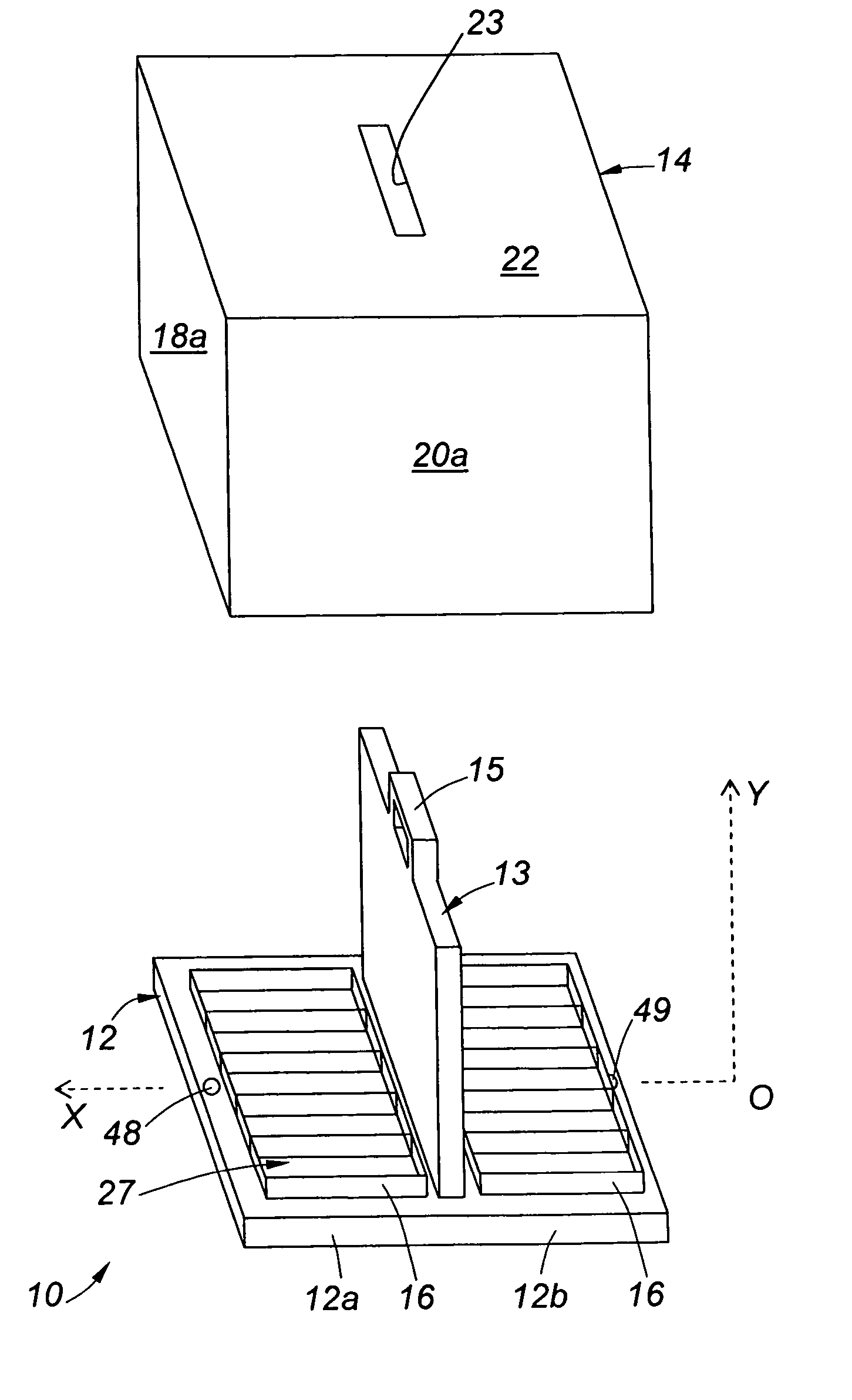

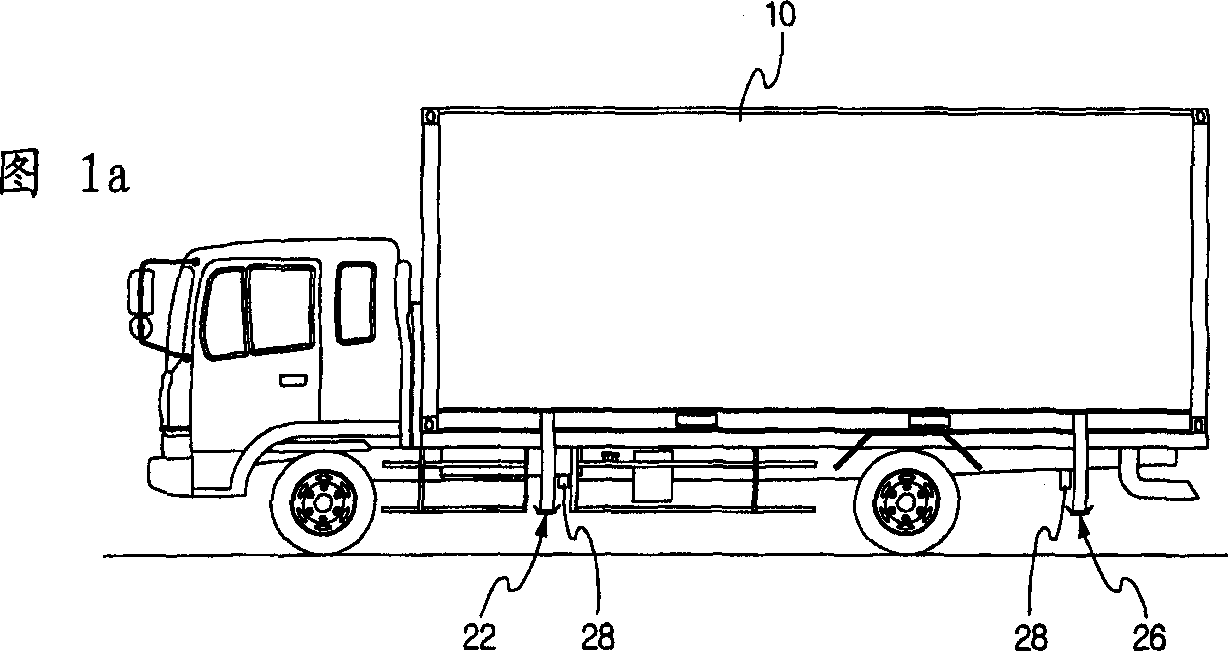

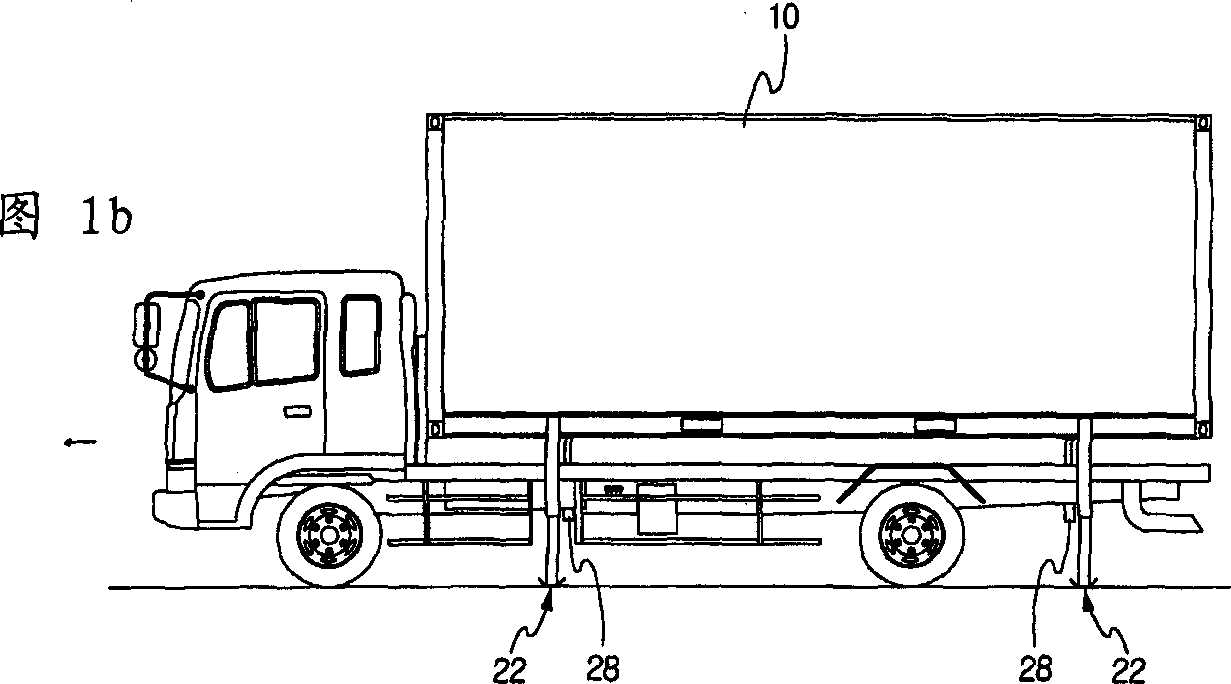

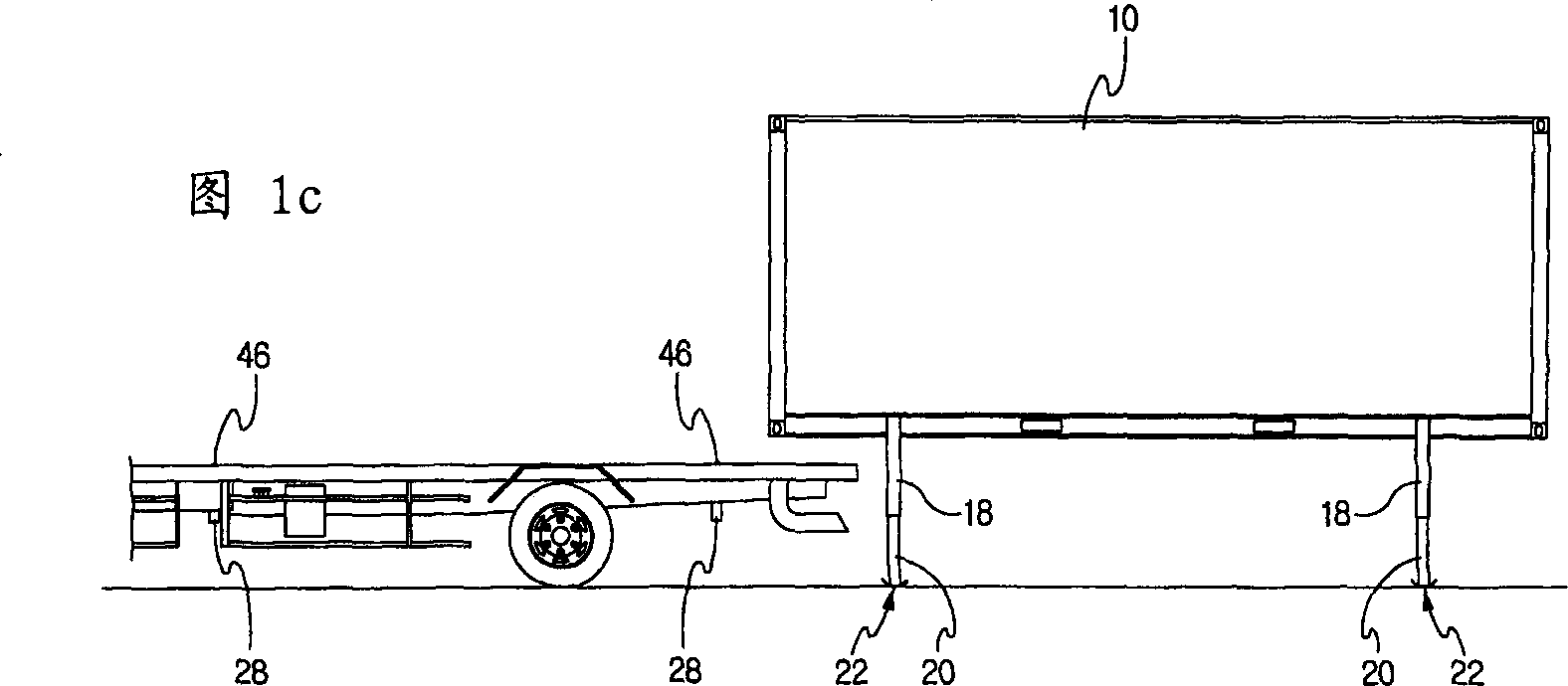

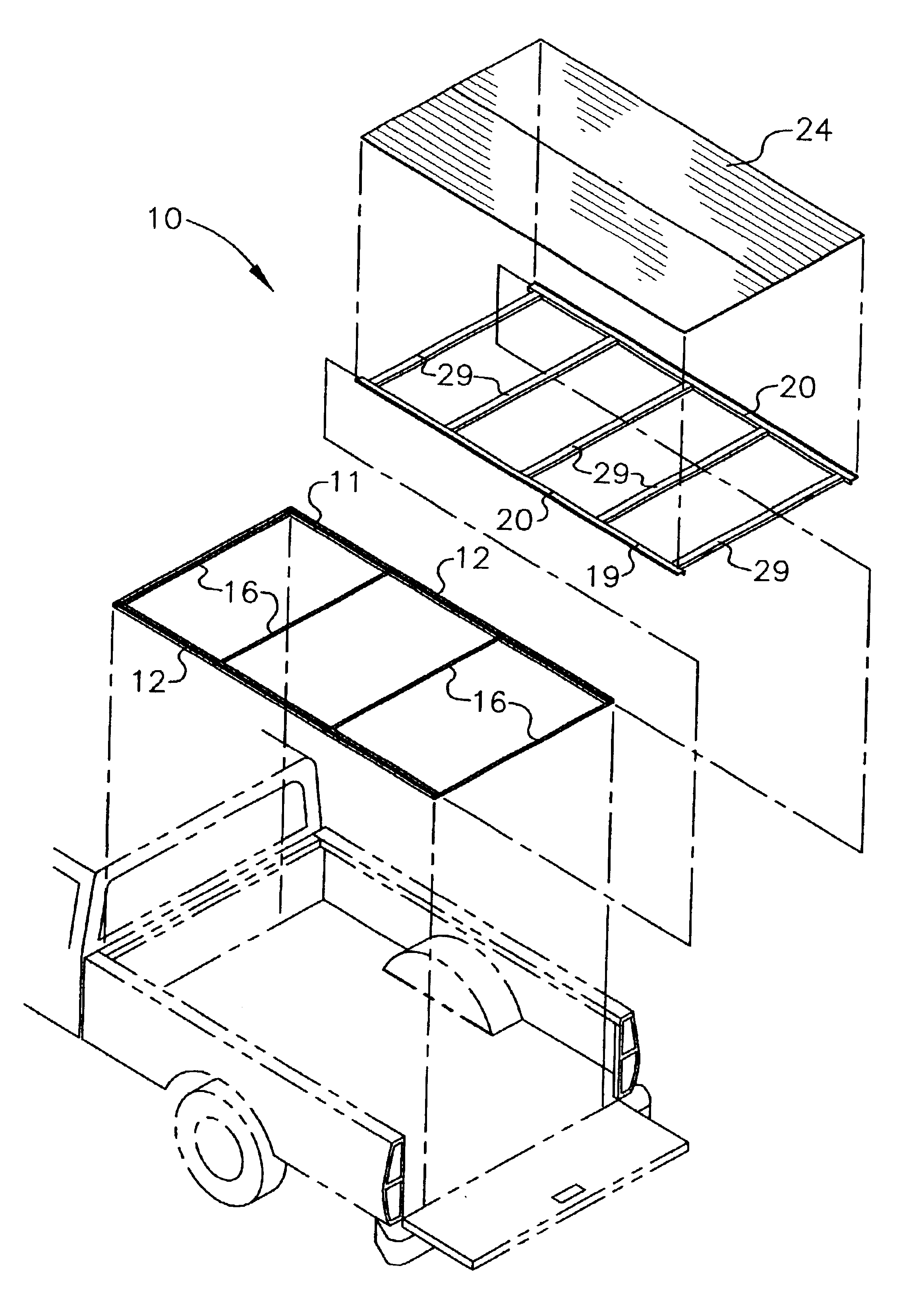

Loading/unloading equipment for container

InactiveCN1333174AEasy loading and unloadingLarge containersVehicle with removable loadingEngineeringRigid body

Disclosed is a container loading and unloading apparatus, which overcomes a problem of a conventional container in that a special equipment such as a forklift truck, a crane or the like is necessarily mobilized whenever the loading or unloading work is performed because the container is simply a cuboidal rigid body. The present invention makes it possible to perform the loading and unloading works of the container main body at the time of its storage and transportation without a separate loading and unloading equipment by providing a container supporter to secure a space for loading the container main body on a chassis of a freight car, thereby reducing equipments and labor as well as facilitating the loading and unloading works.

Owner:KOSMAN

Cargo carrier

InactiveUS7950675B1Ease unloadingEasy to adjustVehicle cleaning apparatusConvertible cyclesClassical mechanicsSupport surface

A cargo carrier for movably supporting cargo includes a frame configured to support cargo at the cargo carrier and at least two wheels at each side of the frame. Each of the wheels is rotatably mounted to a respective support arm. The support arms are pivotally mounted to respective sides of the frame and are pivotable relative to the frame to adjust at least one of a height and tilt of the frame relative to a support surface. The cargo carrier is readily adapted to position the frame at a lower position for road applications and a raised position for uneven terrain applications. The cargo carrier may include a deck that is movably mounted to the frame and is longitudinally movable along the frame.

Owner:ABSOLUTE ELECTRONICS SOLUTIONS

Folding trailer with kneeling device

InactiveUS20050184485A1Easy to unloadEasy loading and unloadingCarriage/perambulator accessoriesUnderstructuresControl armEngineering

A preferred embodiment of a folding trailer with kneeling device is disclosed. The trailer includes a kneeling mechanism that is moveable between a traveling position and a kneeling position. The kneeling mechanism includes a pair of control arms that are cantilevered from the ends of a tubular control shaft. The control shaft is hingeably connected to a frame of the trailer. At least one hydraulically actuated cylinder is used to control the positioning of the kneeling mechanism with respect to the frame of the trailer. Placing the kneeling mechanism place in the kneeling position causes the trailer edge of the trailer to be positioned proximate to the ground to facilitate loading and unloading of the trailer.

Owner:ALTAIR ENGINEERING

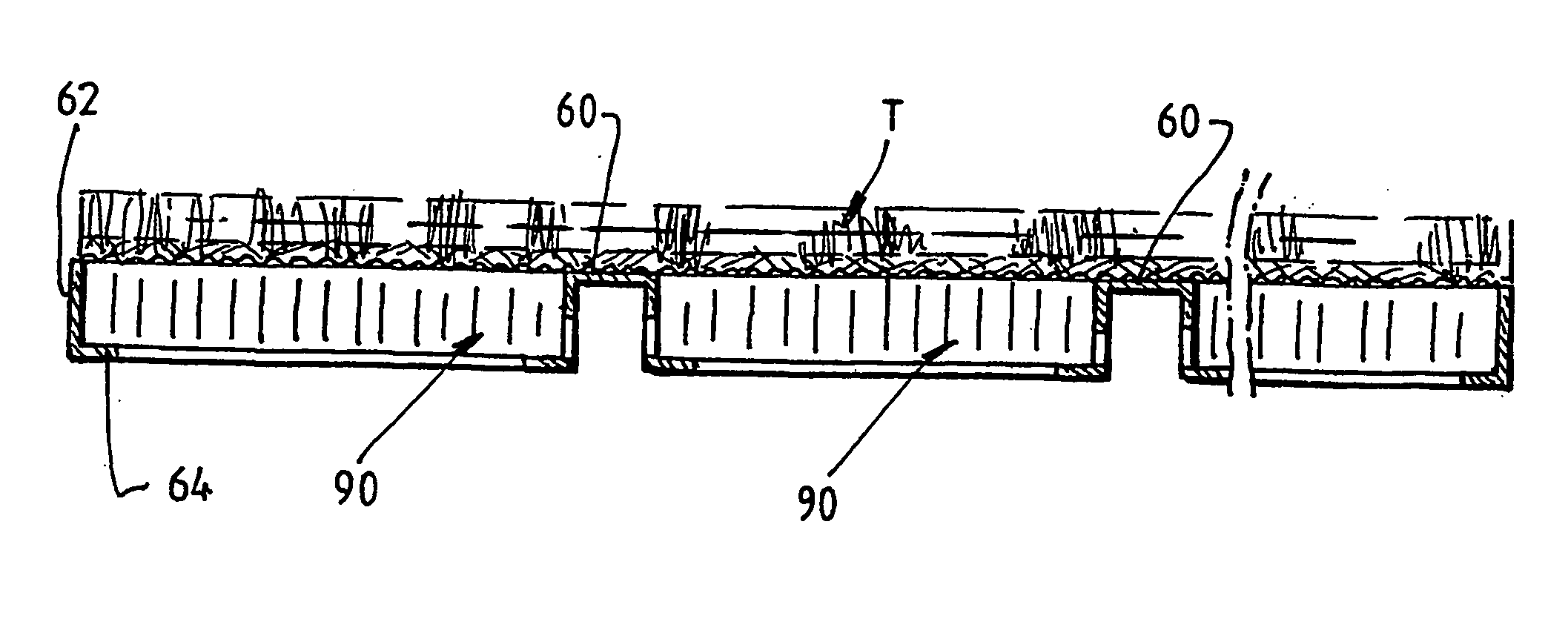

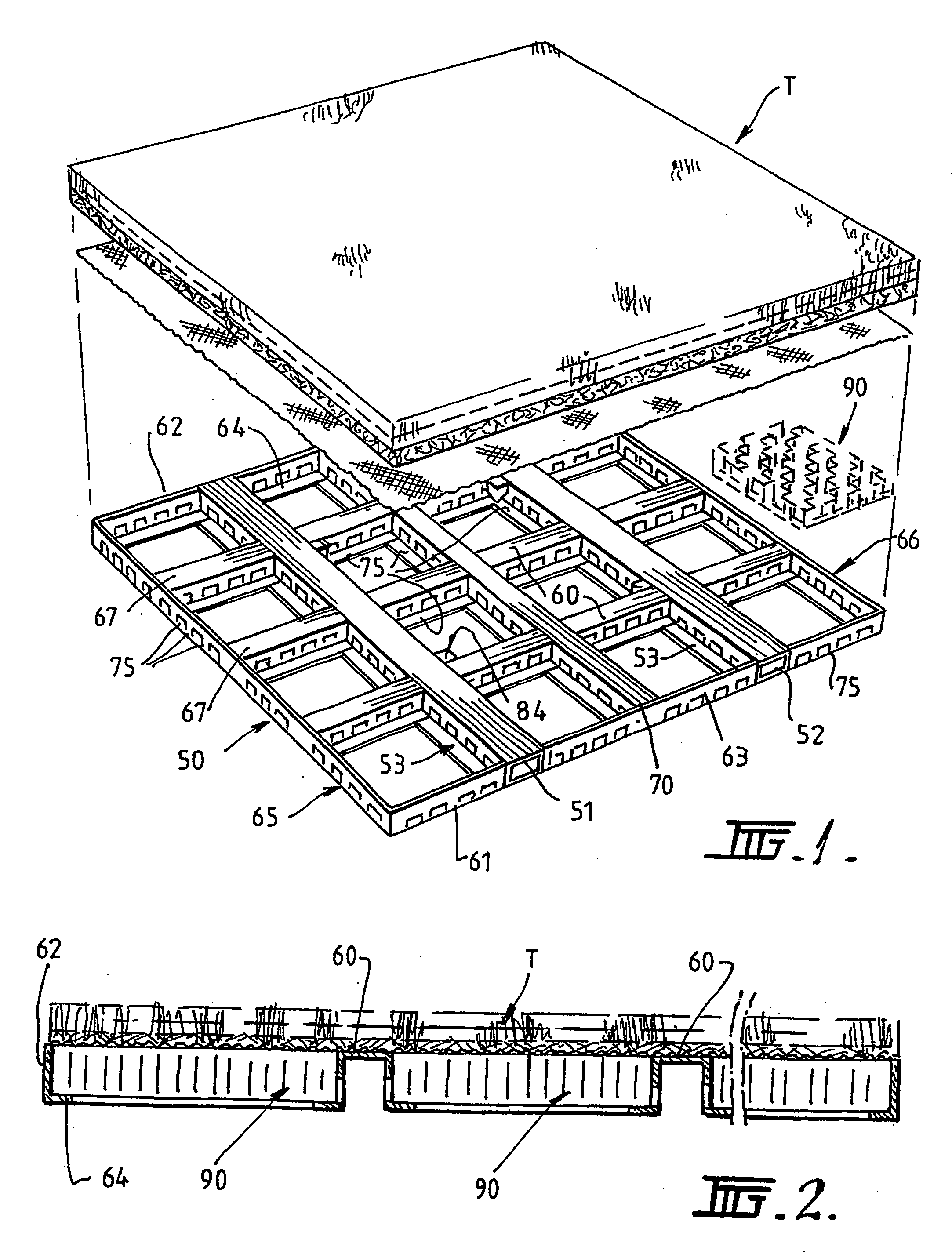

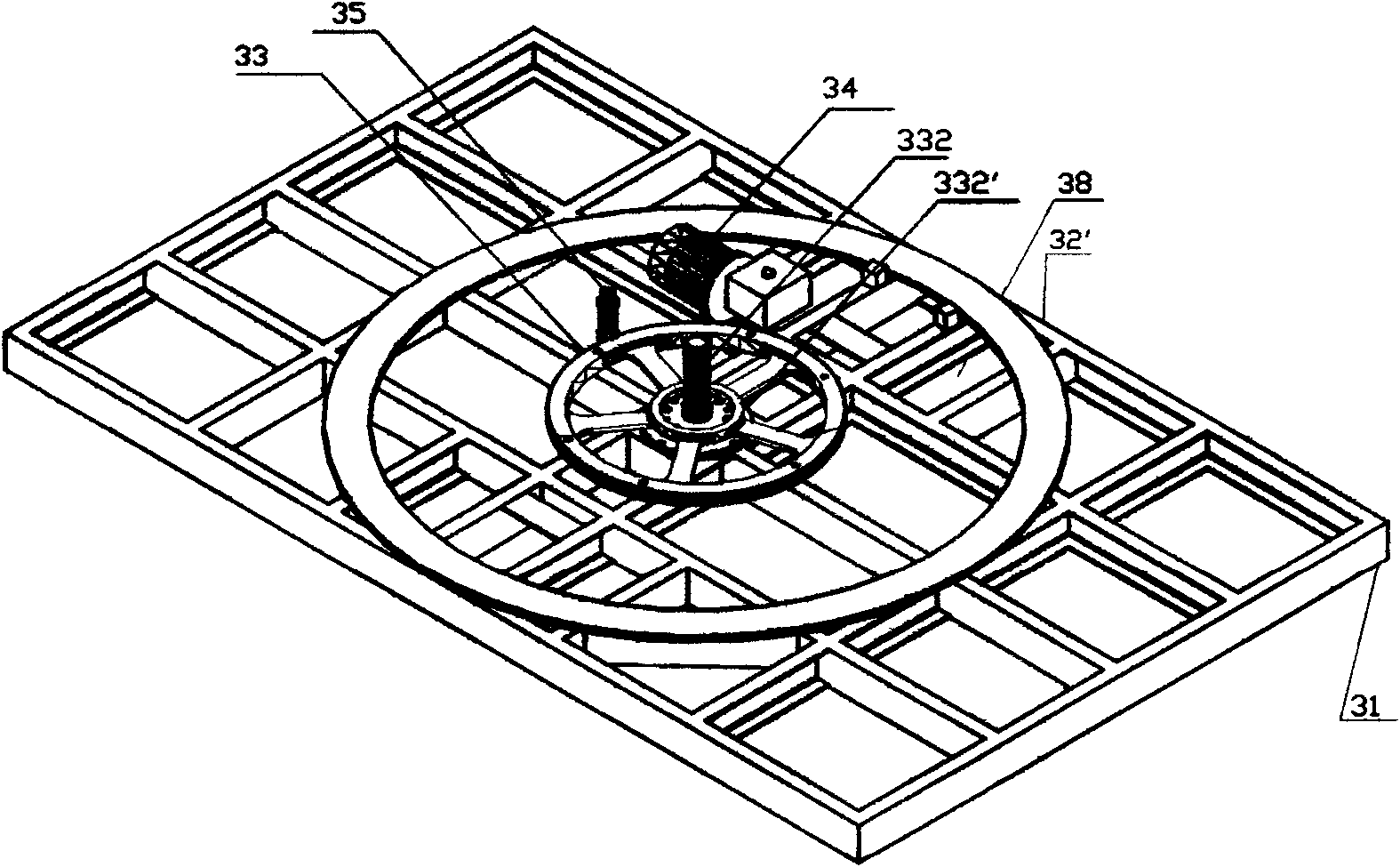

Liftable turfing systems

InactiveUS20060242901A1Precise positioningEasy loading and unloadingSki bindingsTurf growingArtificial turfEngineering

A liftable support structure for a turf system, the support structure comprising a skeletal framework having an open based structure with upstanding sides and at least two parallel spaced cross beams, the framework defining open subsections, each subsection having a base defining a ledge structure, each subsection supporting a latticework panel that sits on the ledge structure, the framework having a plurality of spaced lifting points and the cross beams defining access to forklift tines. A pallet for natural or artificial turf comprising a structure moulded in foamed plastics to have a closed planar top surface supported by a lattice work of mutually perpendicular walls defining a flexible open base, the structure defining a pair of elongate spaced parallel channels extending across each side to facilitate forklift tine entry.

Owner:STRATHAYR

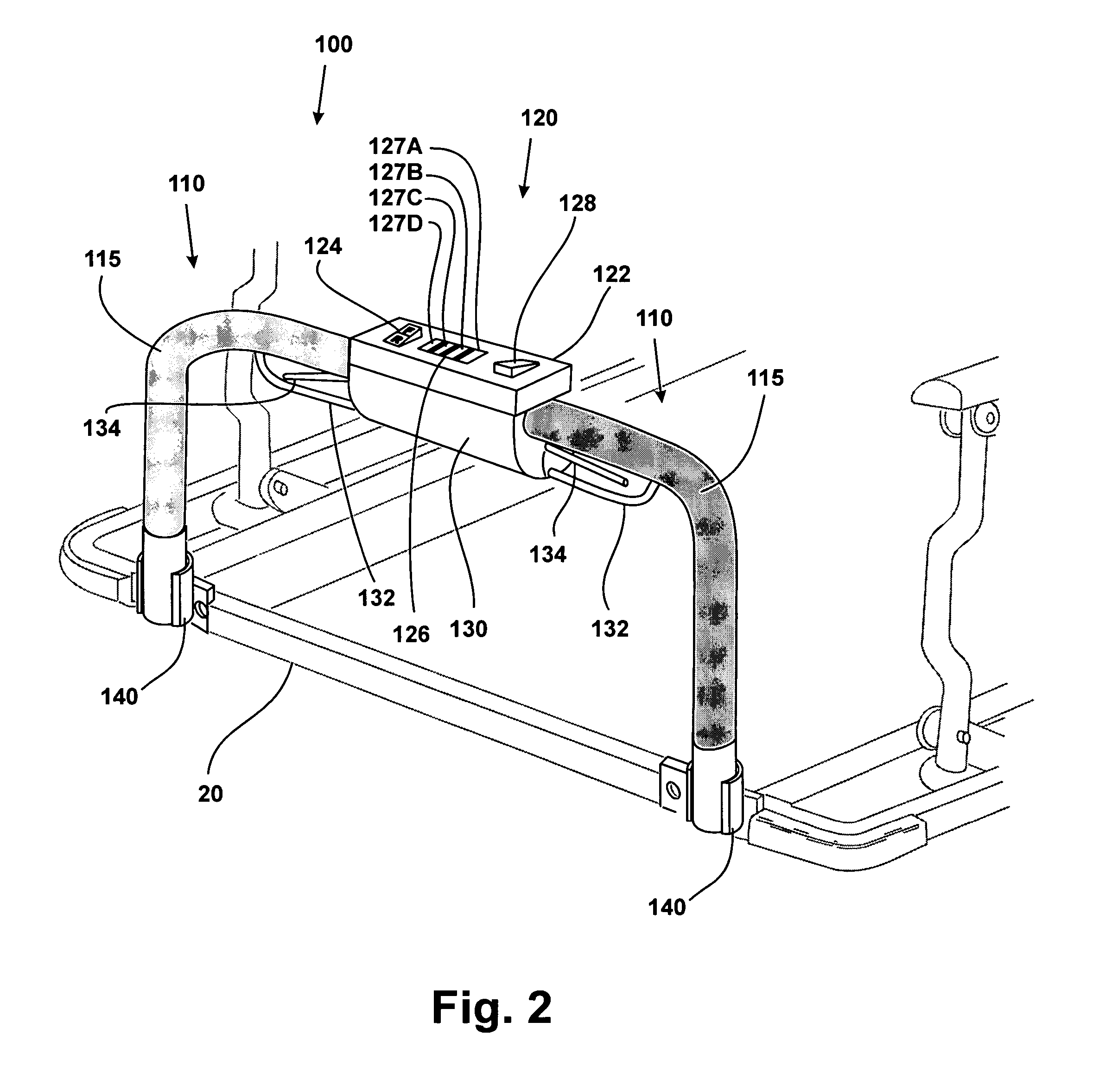

Self propelled gurney and related structure confidential and proprietary document

ActiveUS20050126835A1Easily and quickly mountMinimal effortStretcherElectric propulsion mountingBattery state of chargeBattery charge

The present invention comprises a series of modules, including a control / handle module, a cord reel / charger module, a drive module, and a chassis assembly, plus all needed electrical wiring harnesses and pneumatic tubing to connect them. Also included are means to mount the modules to any existing gurney and to each other without making permanent modifications to the gurney. The gurney is controlled by a handle assembly containing all necessary controls and indicators to allow the operator to select forward or reverse direction, increase or reduce speed of travel, observe the state of battery charge, and energize or deenergize power from the various modules. In addition, the handle may be swung down through 180 degrees to facilitate loading and unloading the gurney.

Owner:GEROPHARM

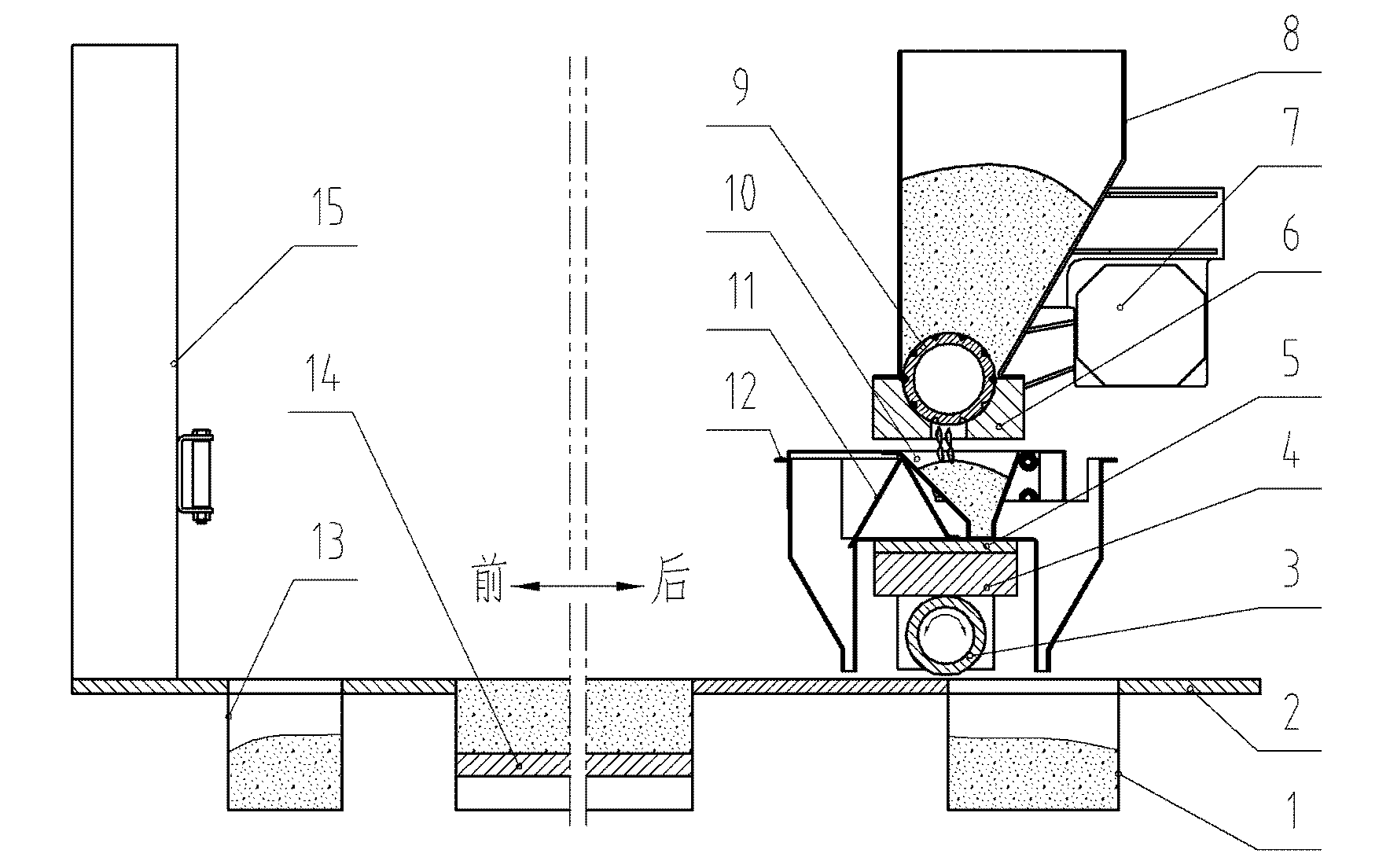

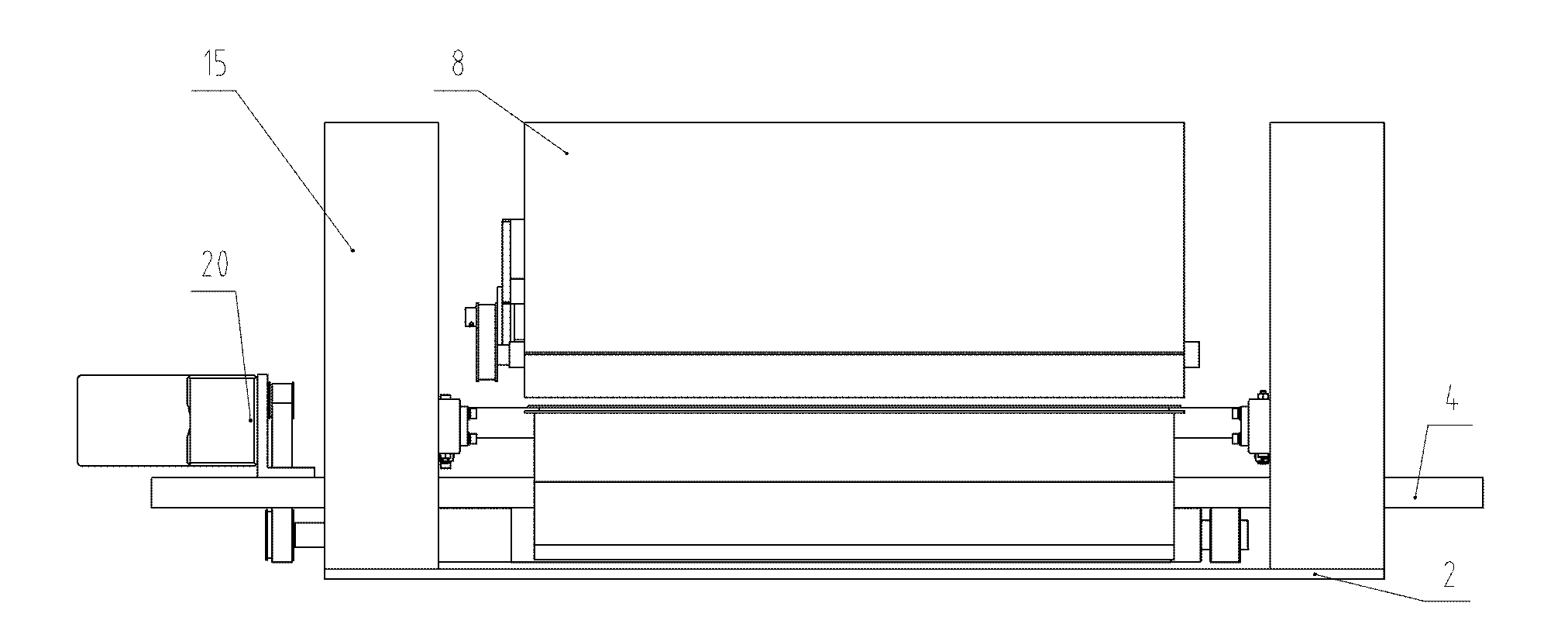

Rapid shaping automatic powder feeding and spreading device

ActiveCN101885062AImprove wear resistanceReduce frictionConveyor partsRapid prototypingMaterials science

The invention relates to a rapid shaping automatic powder feeding and spreading device, comprising a workbench, a working plane, a quantitative powder feeding device and a powder spreading device, wherein, the working plane is arranged on the workbench, the powder spreading device is arranged above the workbench, and the quantitative powder feeding device is fixed on the upper part of the powder spreading device. The rapid shaping automatic powder feeding and spreading device is characterized in that the powder spreading device comprises a powder pressing roller, a connecting plate, a powder spreading bucket and a return powder feeding device, wherein, the powder pressing roller is arranged under the connecting plate; the powder spreading bucket comprises a front bucket and a rear bucket, and the front bucket and the rear bucket are respectively arranged at two sides of the powder pressing roller after penetrating the connecting plate; and the return powder feeding device is arranged above the powder spreading bucket and on the connecting plate. The automatic power feeding and spreading device can realize round-trip powder spreading via the powder spreading device with only one powder feeding device, thus greatly simplifying the structure; and the device has the characteristics of high powder spreading efficiency, reliable operation, saved space, saved cost, higher operating efficiency and the like.

Owner:WUHAN BINHU MECHANICAL & ELECTRICAL

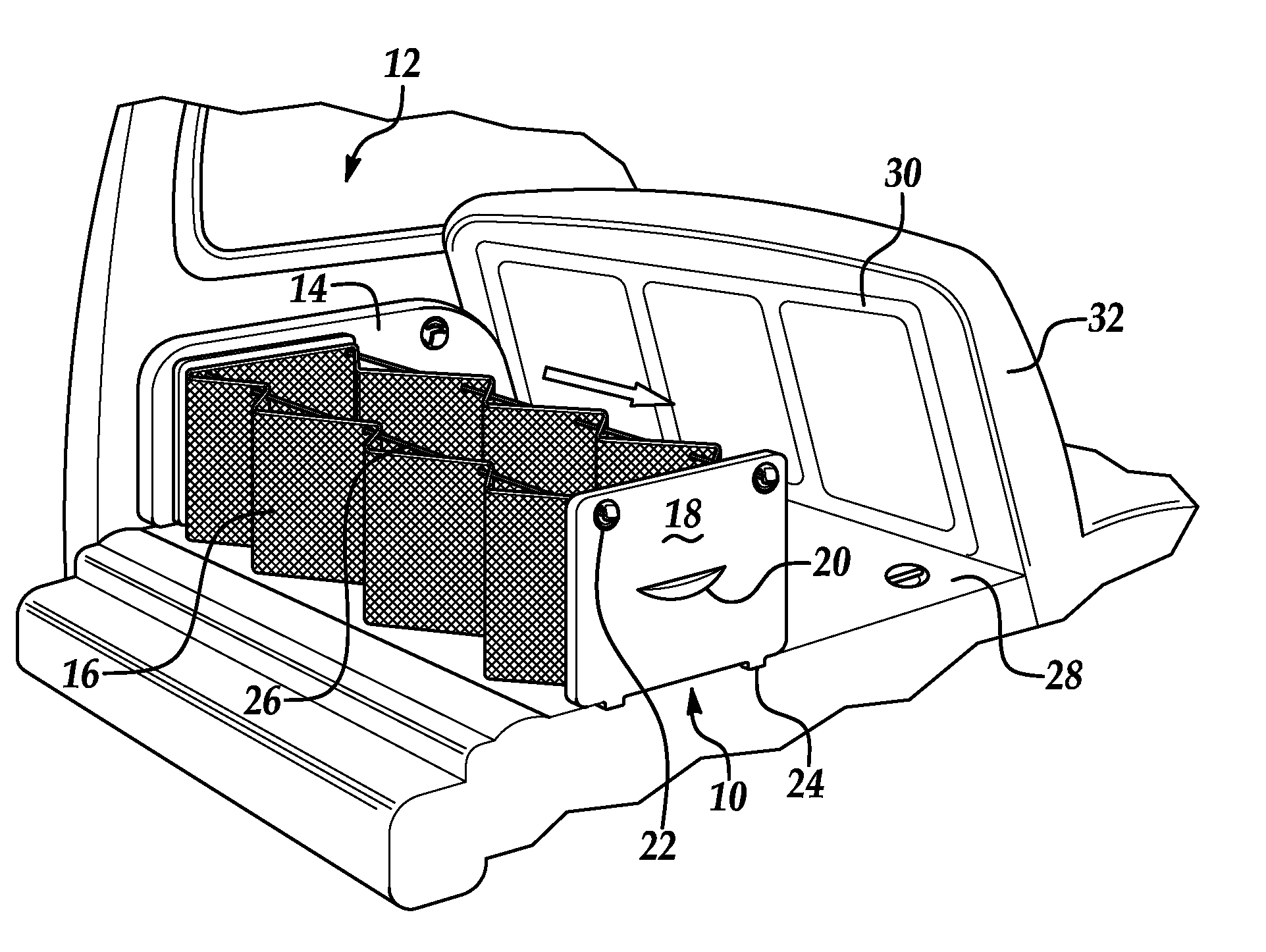

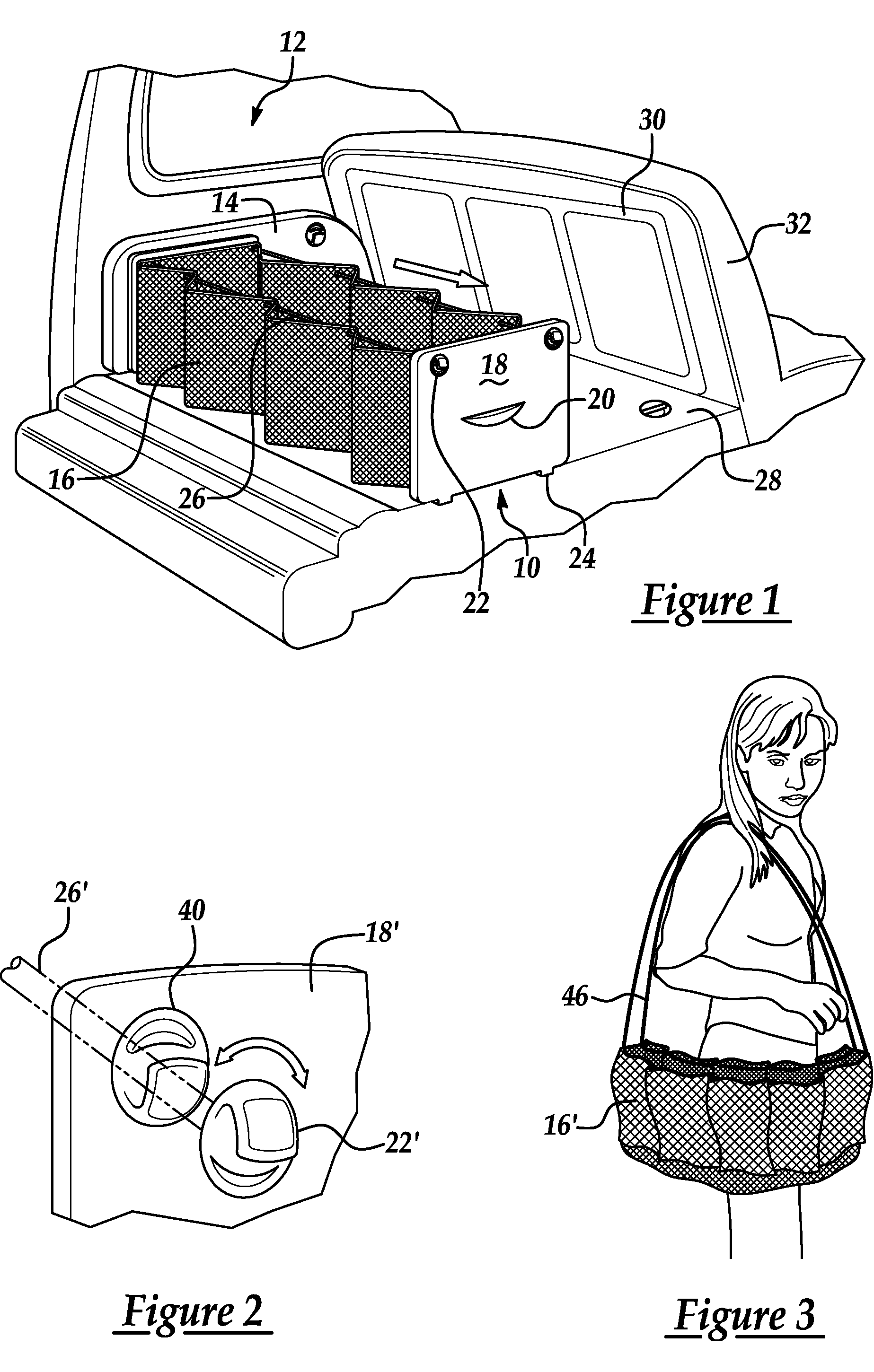

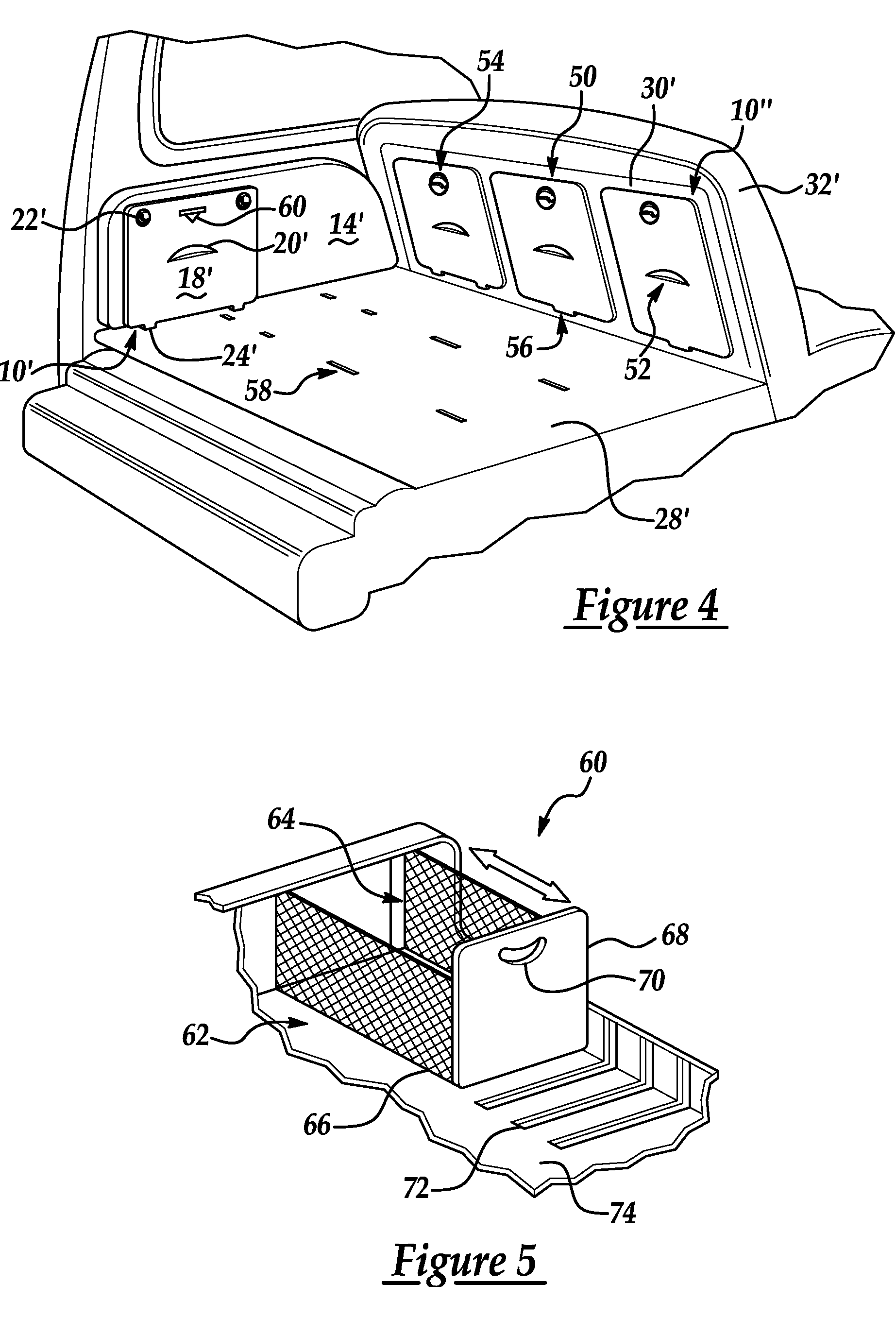

Integrated expandable cargo system for vehicles

InactiveUS20060022479A1Easy to unloadAesthetically pleasingLuggage compartmentVehicle arrangementsEngineeringTruck

An integrated storage system for vehicles includes an expandable container secured to and extendable from a vertical panel of the vehicle to at least one predetermined position to accommodate cargo. The container is collapsible so that it is substantially flush with the vertical panel when not in use and may be made of fabric or netting, for example. A semi-rigid end panel with a handle may be secured to the container to facilitate deploying and stowing the container. Depending on the application, the container may be removable from the vehicle to transport cargo. The storage system may be integrated into various locations including a cargo area, behind a seat or seats, in a truck bed, or in the trunk of a vehicle, for example.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

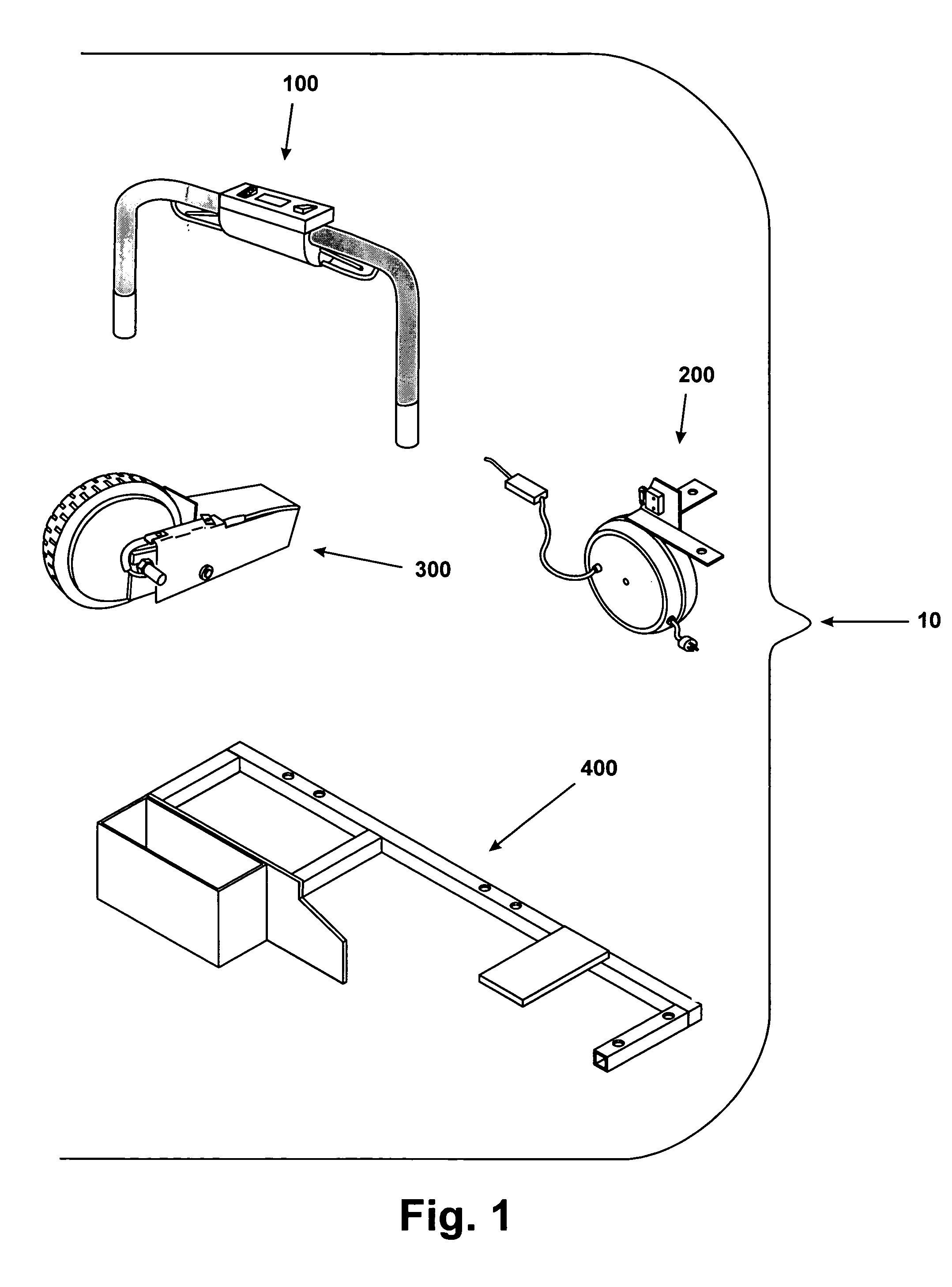

Slidable truck bed-supported cargo carrier assembly

InactiveUS6860536B1Easy to unloadEasy to useVehicle with living accommodationVehicle with loading gatesBraced frameEngineering

A slidable truck bed-supported cargo carrier assembly for facilitating the loading and unloading of items and objects from truck boxes. The slidable truck bed-supported cargo carrier assembly includes a base support assembly including a base support frame being adapted to rest upon a floor of a truck box, and also including roller assemblies being attached to base support frame; and also includes a deck support frame being slidably disposed upon the base support assembly; and further includes a deck being mounted upon the deck support frame; and also includes a locking assembly for securing the deck support frame to the base support frame.

Owner:SCHIMUNEK KERRY W

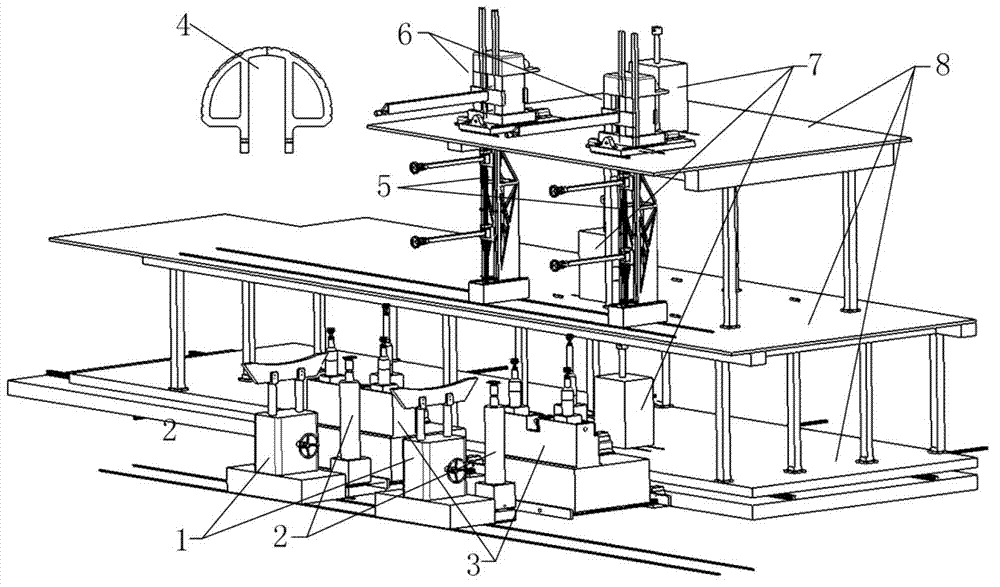

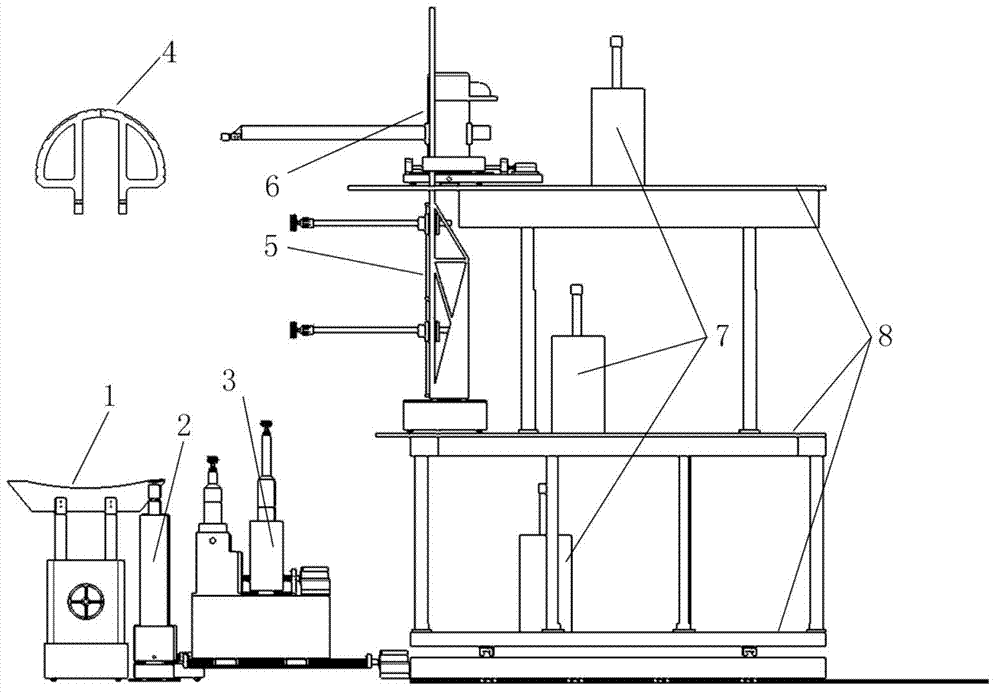

Method and device for folding and flexibly positioning body wallboard

ActiveCN102765489AAchieve six degrees of freedomRealize multi-posture adjustmentAircraft assemblyLaser trackerFuselage

The invention provides a method and a device for folding and flexibly positioning a body wallboard. Due to the method and the tool for folding and flexibly positioning the body wallboard, lots of special clamping boards are not needed and good flexibility is achieved; a positioner clamping mechanism can be adsorbed on a positioning support surface of the wallboard, so that six-freedom-degree and multi-pose regulation of the body wallboard can be achieved; laser trackers distributed on a first layer of working table, a second layer of working table and a third layer of working table can feed back assembling information at real time, thus drastically improving assembly accuracy; the body wallboard is fixed by the adsorption positioning mechanism, thus being simple in assembly and disassembly, reducing manual operation and improving assembly efficiency; and in addition, the method and the device have good generality, so that the method and the device can be suitable for folding process of body wallboard structures with different sizes and satisfy folding requirement of various body wallboards.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

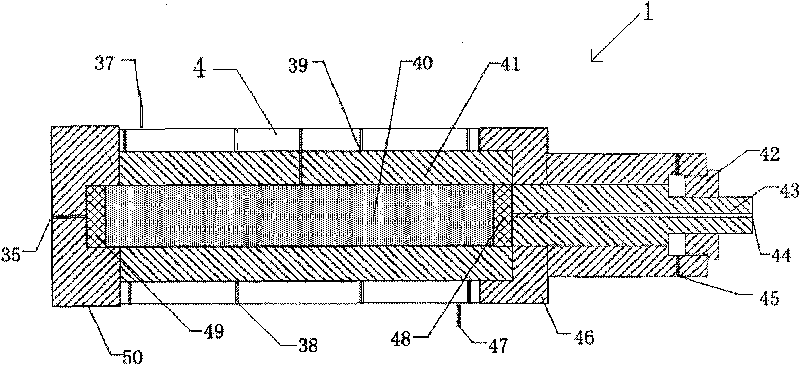

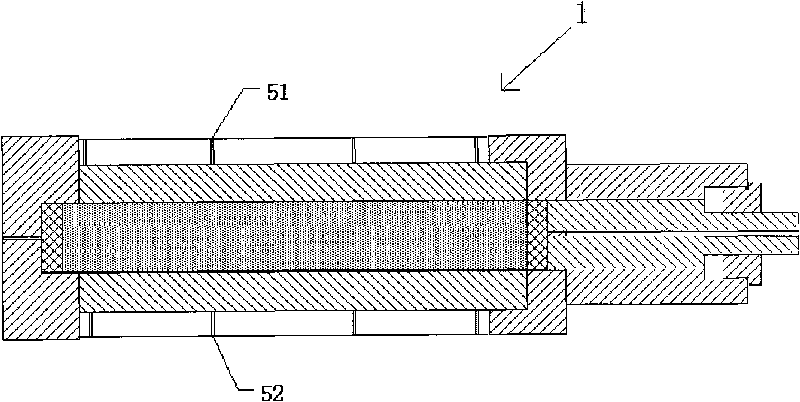

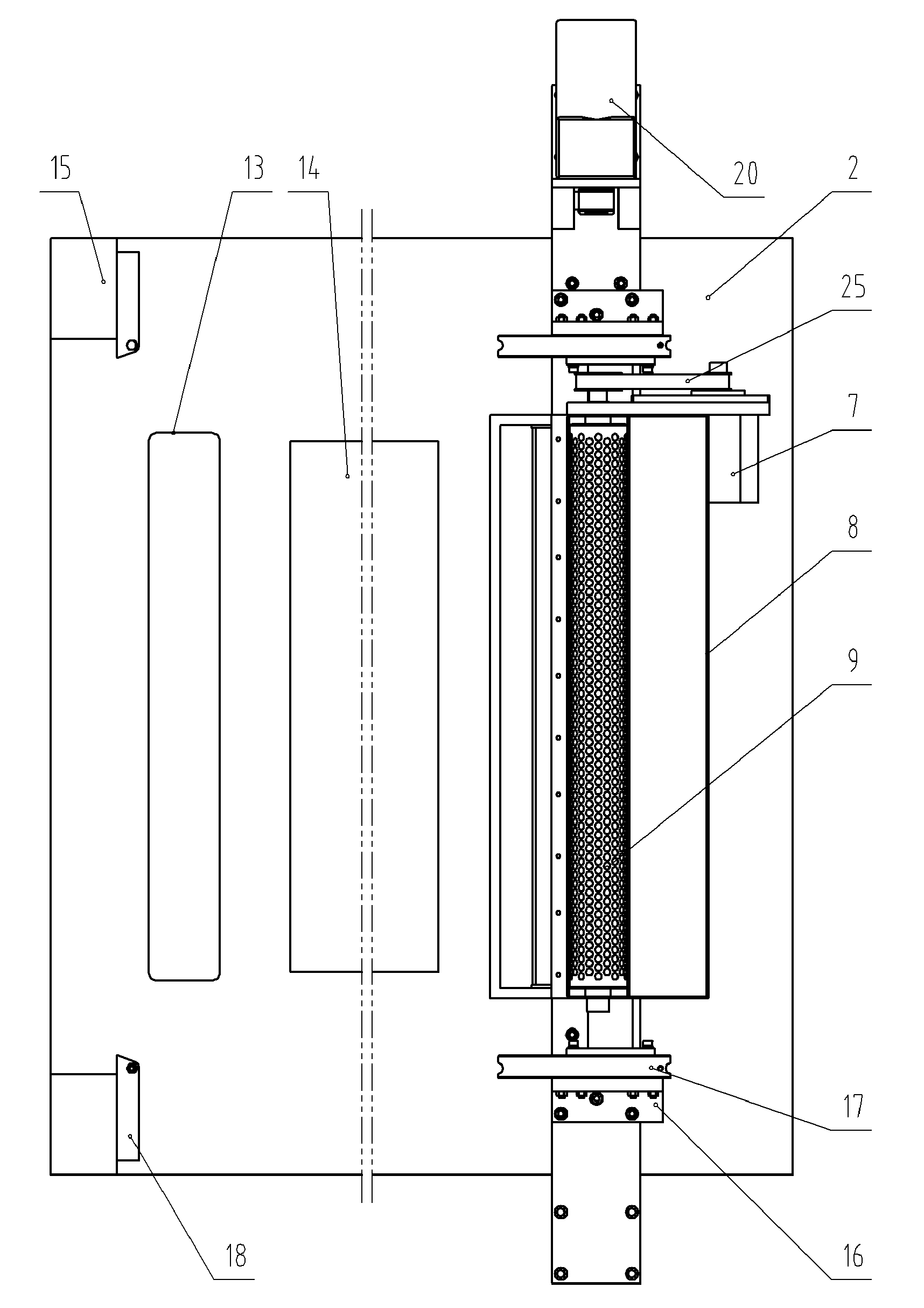

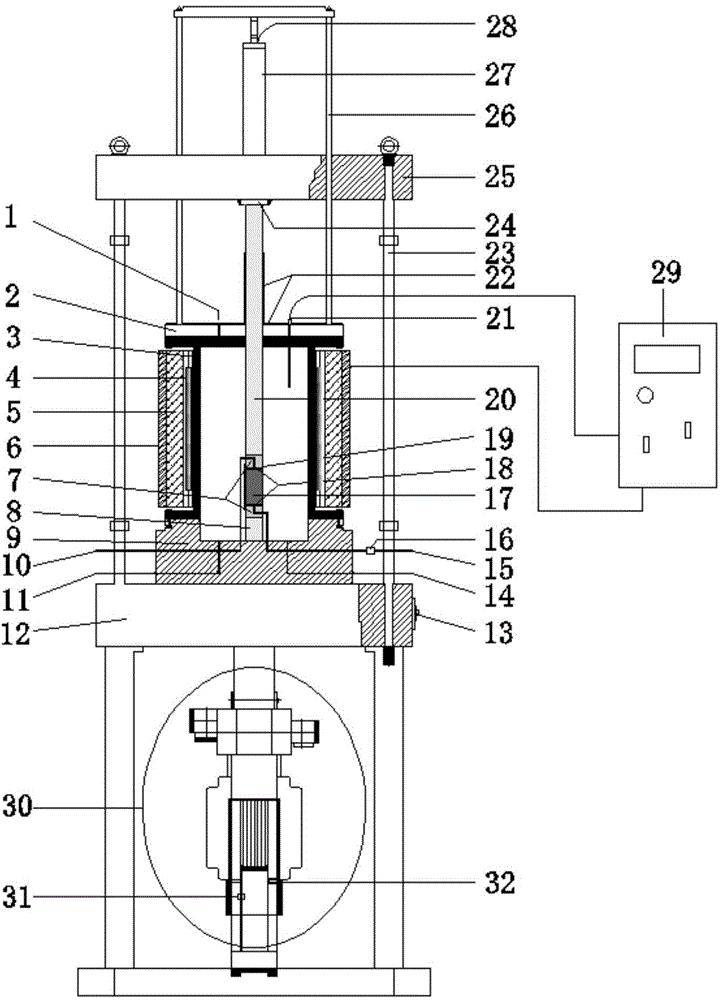

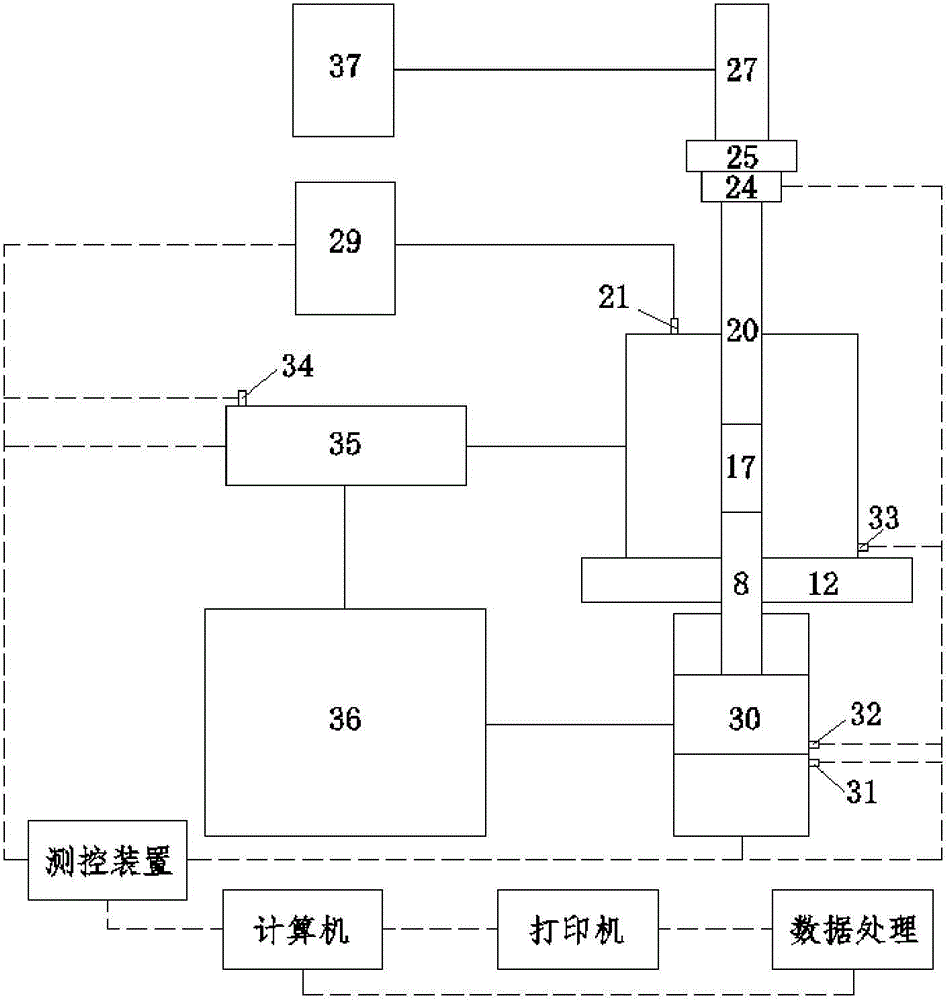

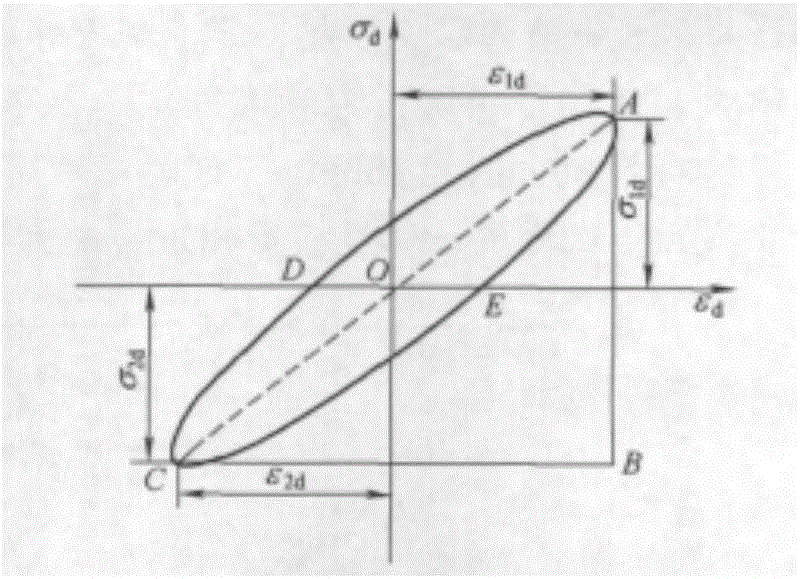

Rock-soil body temperature-control dynamic characteristic test system and test method

ActiveCN104596852AEasy loading and unloadingImprove suitabilityMaterial strength using tensile/compressive forcesStatic stressHeating temperature

The invention discloses a rock-soil body temperature-control dynamic characteristic test system and method, is characterized in that the system includes a dynamic triaxial pressure chamber and a temperature control device; the dynamic triaxial pressure chamber comprises a pressure chamber cylinder body, a piston rod and an upper dowel bar; a sample is arranged between the lower end of the upper dowel bar and the upper end of the piston rod; the dynamic triaxial pressure chamber also includes a pressure sensor, an axial displacement sensor, a deformation sensor, a confining pressure sensor, a lateral displacement sensor and a pore pressure sensor; the temperature control device includes a temperature sensor, a temperature controller and an arc plate type heater symmetrically coating the outer wall of the pressure chamber cylinder body. The temperature-control dynamic characteristic test method mainly includes installing the sample, setting the temperature control device, carrying out drainage consolidation of the sample, applying dynamic / static stress, and completing a temperature-control dynamic / static triaxial test, to determine the cumulative plastic strain, dynamic damping ratio, dynamic elastic modulus and other indexes of a rock-soil body under different temperatures. The system and the method have the advantages of uniform heating temperature, short heating time and low cost, and can accurately control the temperature in the pressure chamber.

Owner:NINGBO UNIV

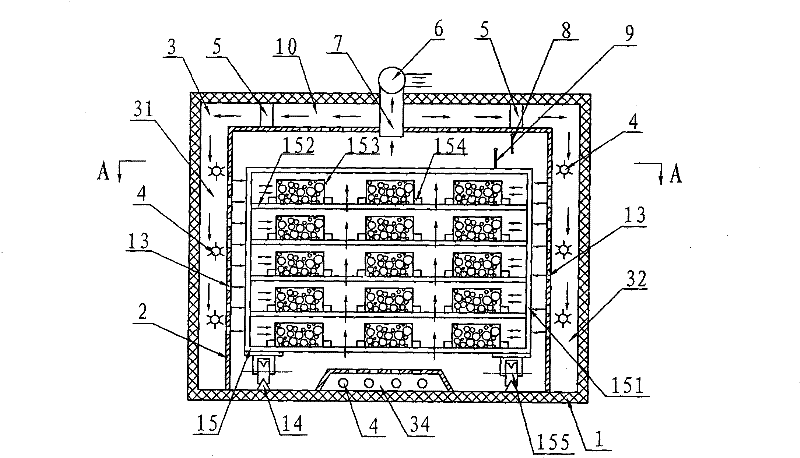

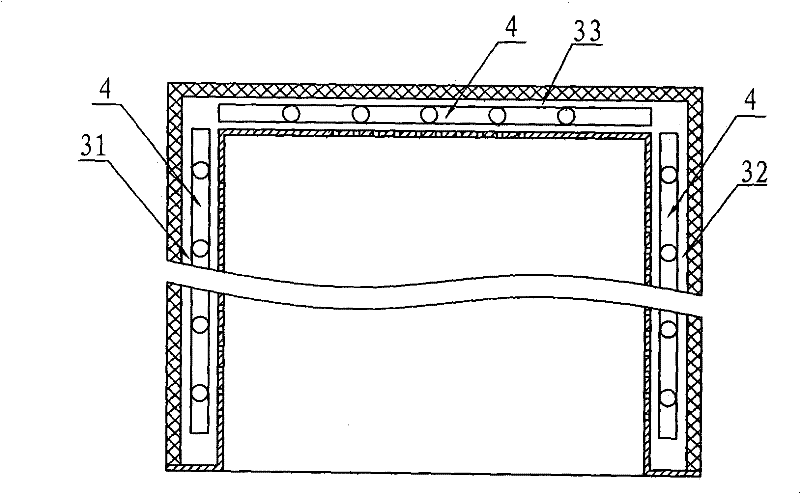

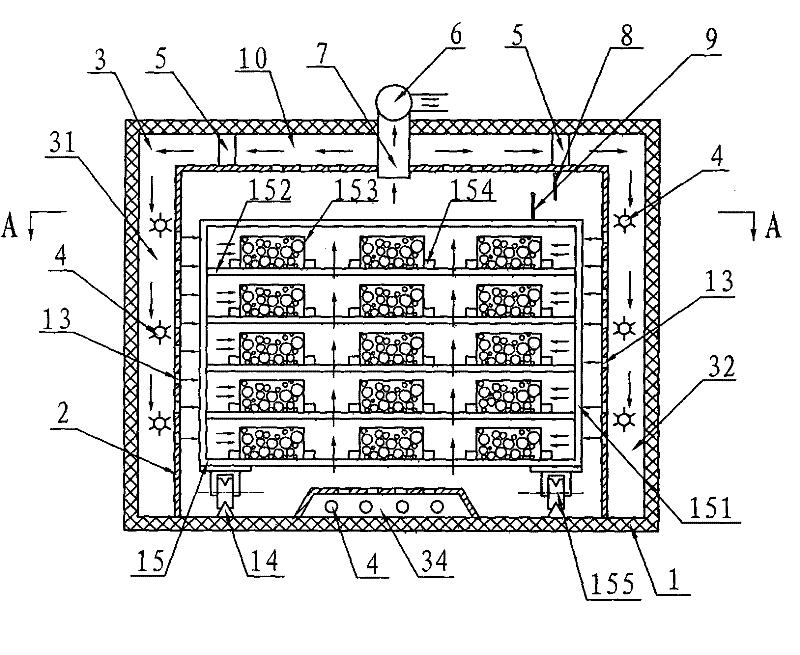

Special baking oven and special movable material rack thereof for silicon material

InactiveCN101749928AEasy loading and unloadingFully contactedDrying solid materials with heatDrying gas arrangementsThermal insulationProcess engineering

The invention relates to a special baking oven and a special material rack thereof for silicon material. The baking oven comprises a thermal insulation shell, an inner container, a high temperature air cavity, a hot air duct, a heater, a circulating fan, a dehumidifier, a dehumidification pipe, a humidity sensor, a temperature sensor, a frame body, idler wheels and a silicon material box, wherein the high temperature air cavity is arranged on top of the inner container, the hot air duct is arranged around the inner container, the heater is arranged in the baking oven, the circulating fan is arranged between the high temperature air cavity and the hot air duct, the dehumidifier is communicated with the inner chamber of the inner container, and the humidity sensor and the temperature sensor are arranged to realize automation control of the baking oven. The movable baking shelf thereof can facilitate loading / unloading and in / out of silicon material, save baking preparation time, and has the advantages of high baking efficiency and low energy consumption. The whole silicon material box can be directly moved in the baking oven for baking, thereby greatly shortening technology preparation time and reducing labor strength of operators.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

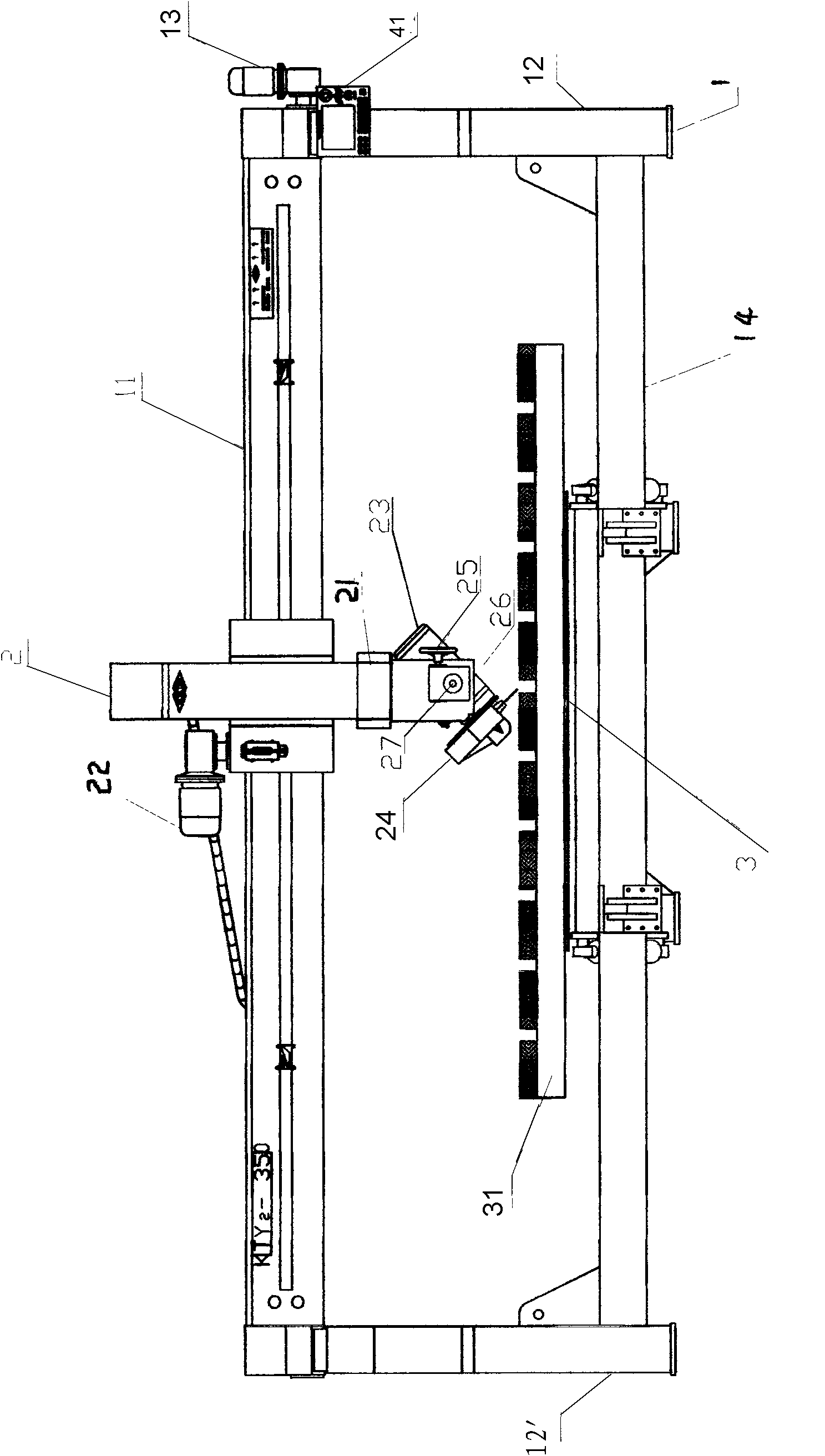

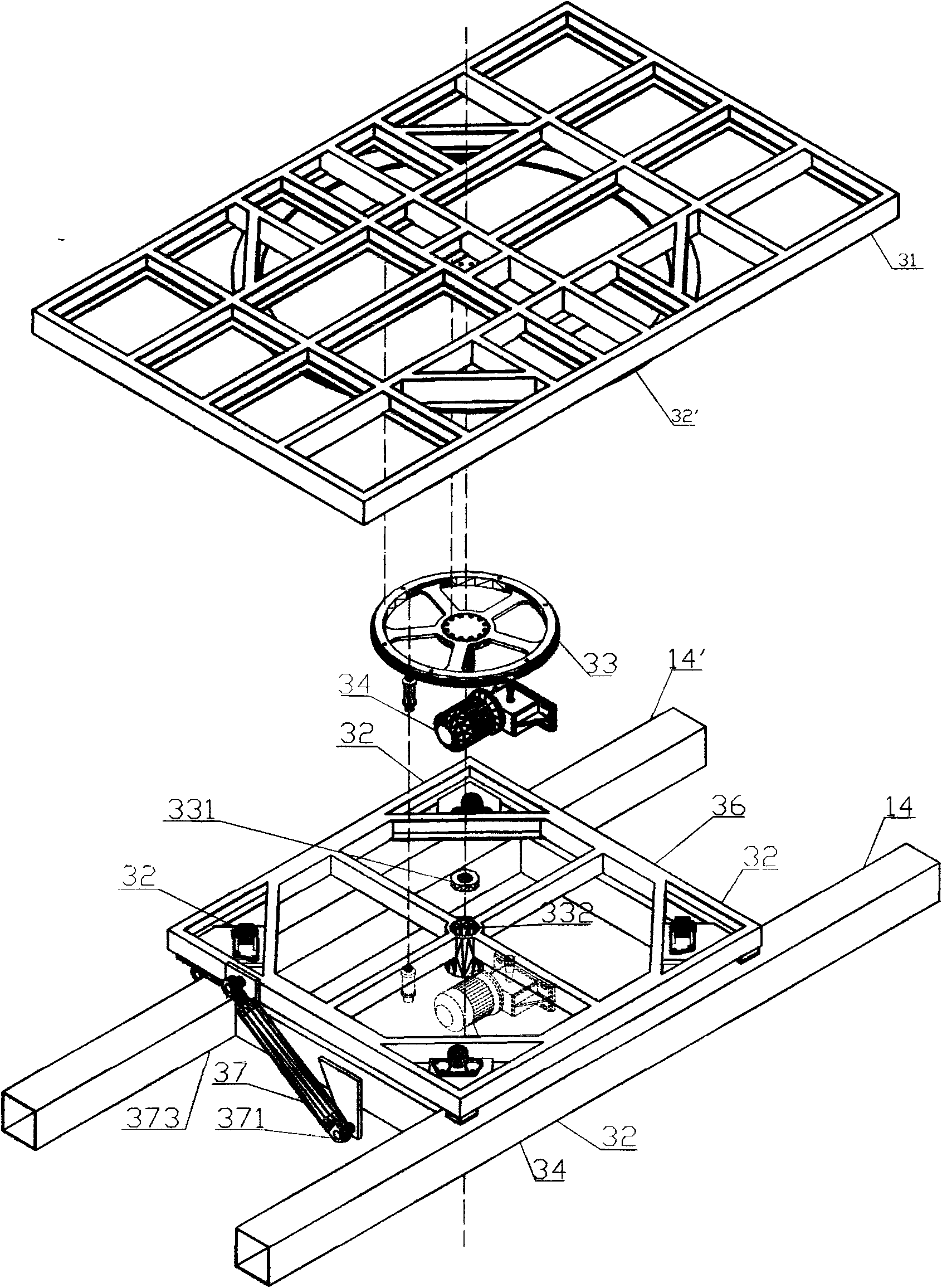

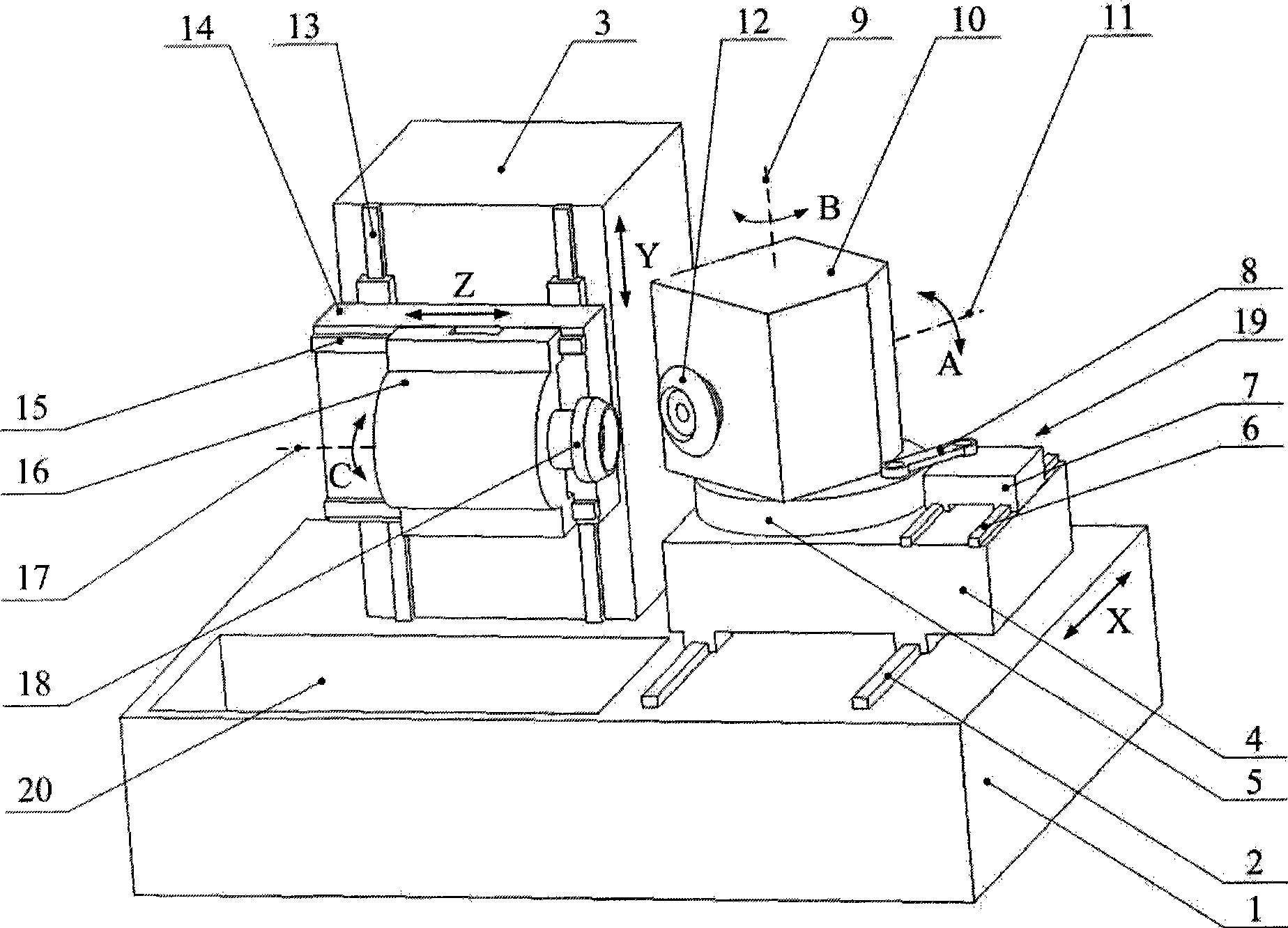

Angle-free stone automatic cutting machine

InactiveCN101670622AEasy to processEasy loading and unloadingStone-like material working toolsGear driveBridge type

The invention relates to an angle-free stone automatic cutting machine, comprising a bridge type machine rack 1 which comprises a beam, a guide rail support and a bottom beam, a cutting machine head 2which comprises a water-cooling motor and a tool, and a working table 3 which comprises a tabletop board, a large gear and a turning cushion plate; the cutting machine head 2 moves along the longitudinal and horizontal direction when being arranged on the beam, and comprises a machine head assembly 21 which rotates under the driving of a worm gear and can swing around a central shaft; the tabletop board of the working table 3 is driven by the large gear driven by a speed reducer, is supported by four supporting wheels, rotates on the turning cushion plate and is detected by a coder; the turning cushion plate and the tabletop board can turn over 85 degrees under the driving of an oil cylinder. The water-cooling motor is provided with a cooling water coil pipe between a stator sleeve and amotor shell, the coil pipe is soaked in cooling oil. The working table can move arbitrarily with 360 degrees on the plane, the processing precision is high, the equipment is simple and the machine issuitable for processing stones with various shapes.

Owner:陈思扬

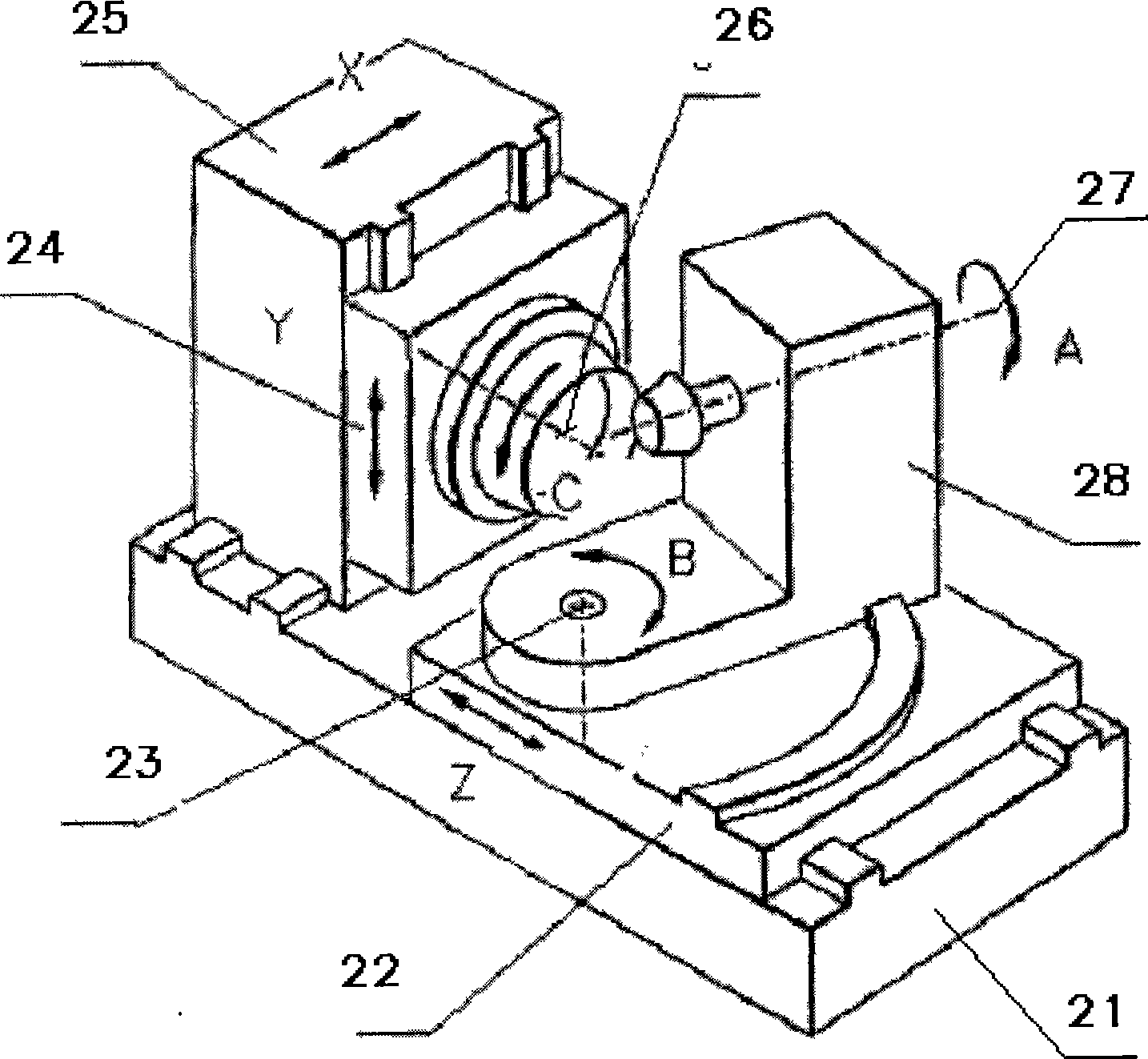

Six-axis five-linkage spiral taper gear cutting machine tool

InactiveCN101508039AEasy loading and unloadingEasy to realize automatic loading and unloadingLarge fixed membersMetal working apparatusGear cuttingEngineering

The invention relates to a six-axis five-linkage spiral bevel gear cutting machine. A lathe bed is provided with a fixed upright post and an X-direction linear guiderail with an X-axis slipway which is driven by a driving mechanism to move along the guiderail; the X-axis slipway is provided with a rotary table and a rotary table driving mechanism; the rotary table is provided with a workpiece box with a workpiece main shaft which is driven by the driving mechanism to rotate; one lateral surface of the upright post is provided with a Y-direction linear guiderail perpendicular to the X-direction linear guiderail; the Y-direction linear guiderail is provided with a Y-axis slipway which is driven by the driving mechanism to move along the guiderail; the Y-axis slipway is provided with a Z-direction linear guiderail perpendicular to the Y-direction linear guiderail; the Z-direction linear guiderail is provided with a tool box which is driven by the driving mechanism to move along the guiderail; and the tool box is provided with a rotatable tool spindle. The six-axis five-linkage spiral bevel gear cutting machine has the advantages of simple and stable structure, good reliability, good rigidity, few parts, small occupied area, easy protection and chip removal, and convenient assembly and disassembly of workpieces and tools.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

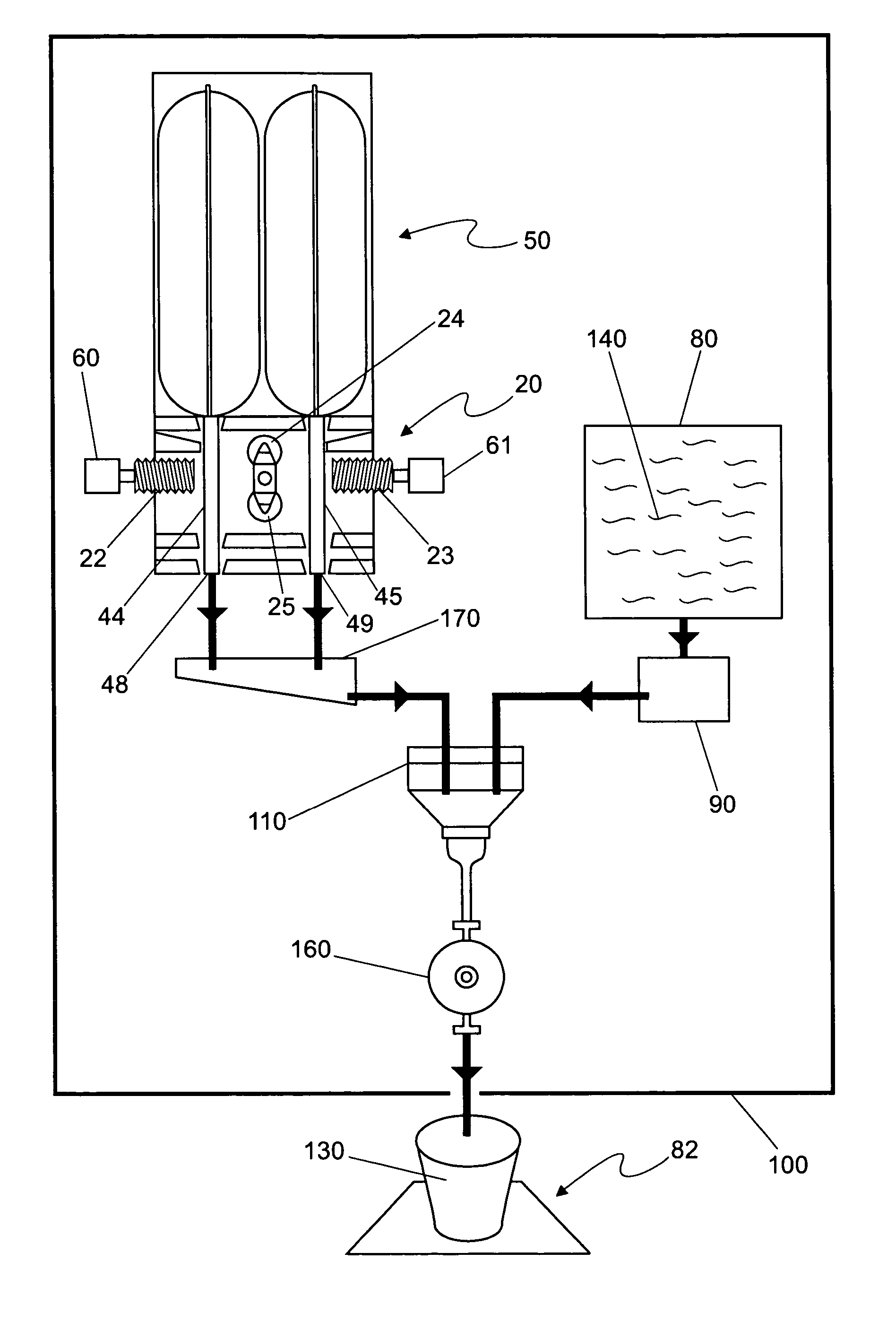

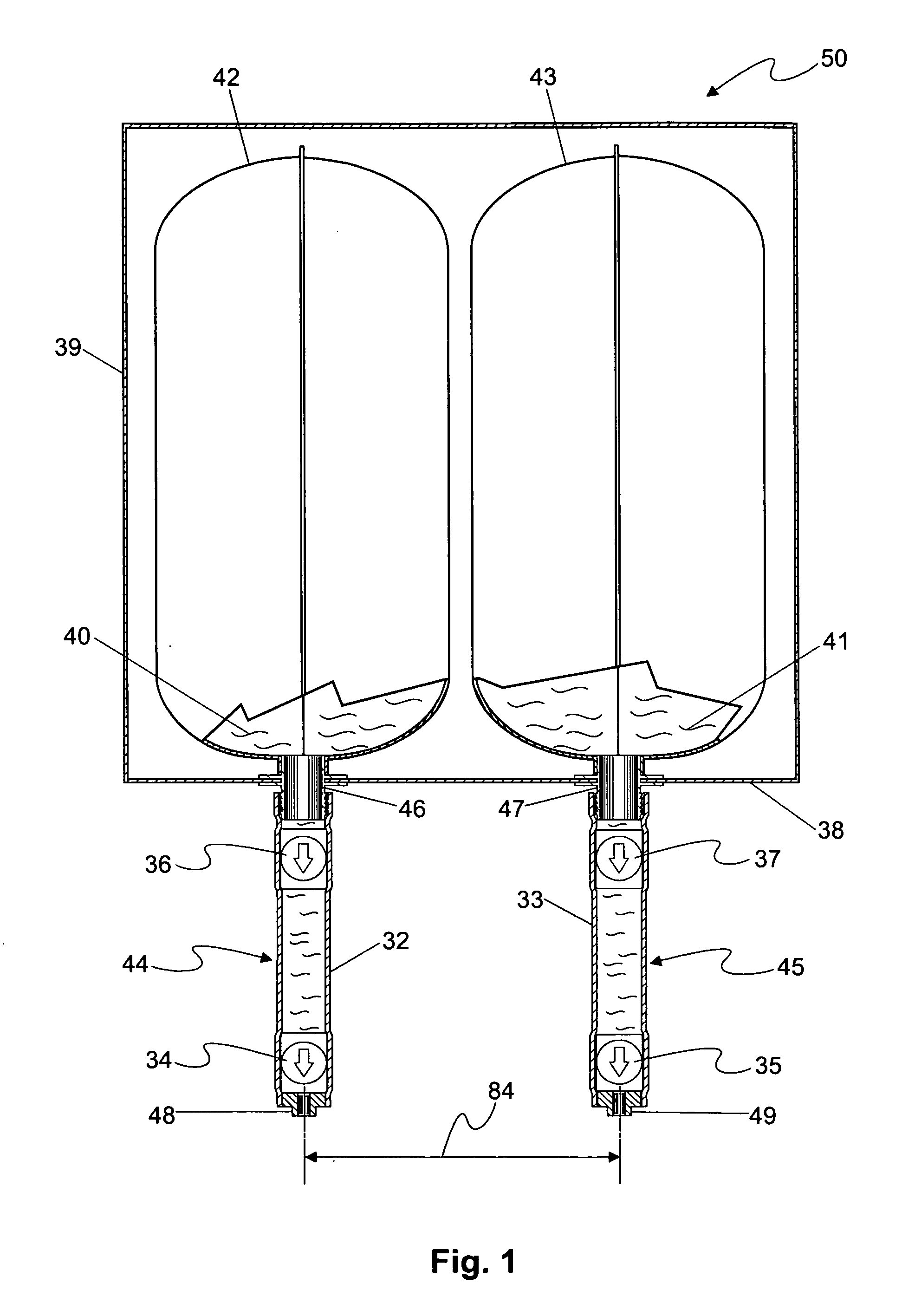

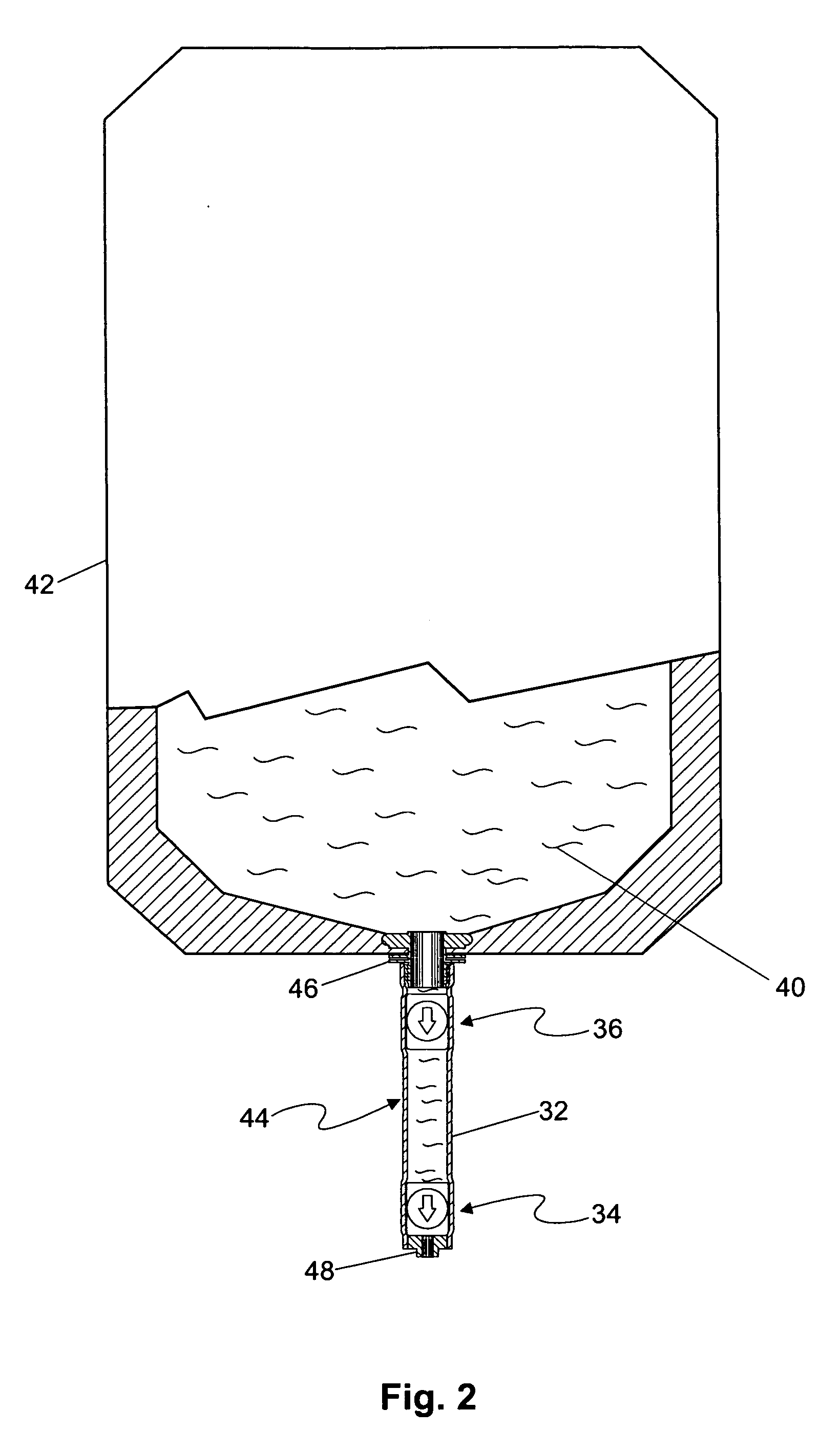

Food dispenser with pump for easy loading of containers therein

InactiveUS20070068966A1Easily load and unloadEasy loadingLiquid transferring devicesLiquid dispensingPeristaltic pumpEngineering

The present invention relates generally to dispensing system configured for dispensing a food product. The invention also relates to a peristaltic pump that has a pumping member configured to move along a path through a pumping position and a loading position. The pump also includes a motor in drivable association with the pumping member to move the pumping member along the path and a backing member having a surface configured to cooperate with the pumping member to pinch a conduit therebetween when the pumping member engages the conduit to establish peristaltic association in the pumping position to peristaltically pump a fluid therethrough. When the pumping member is in the loading position, the pumping member is disposed to allow the conduit to be received in and removed from a pumping space. The present invention also relates to a method for dispensing a food product using a peristaltic pump.

Owner:NESTEC SA

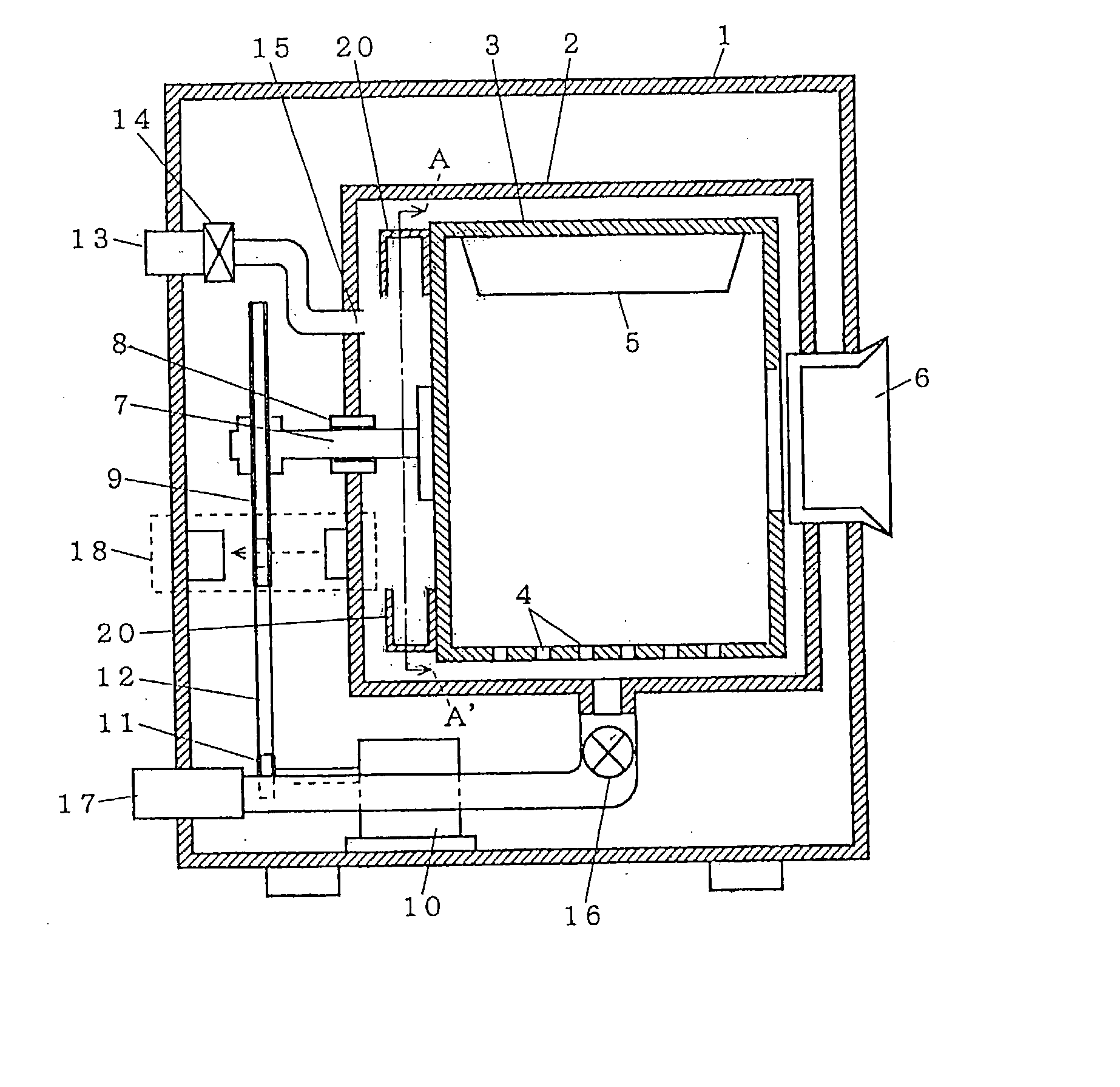

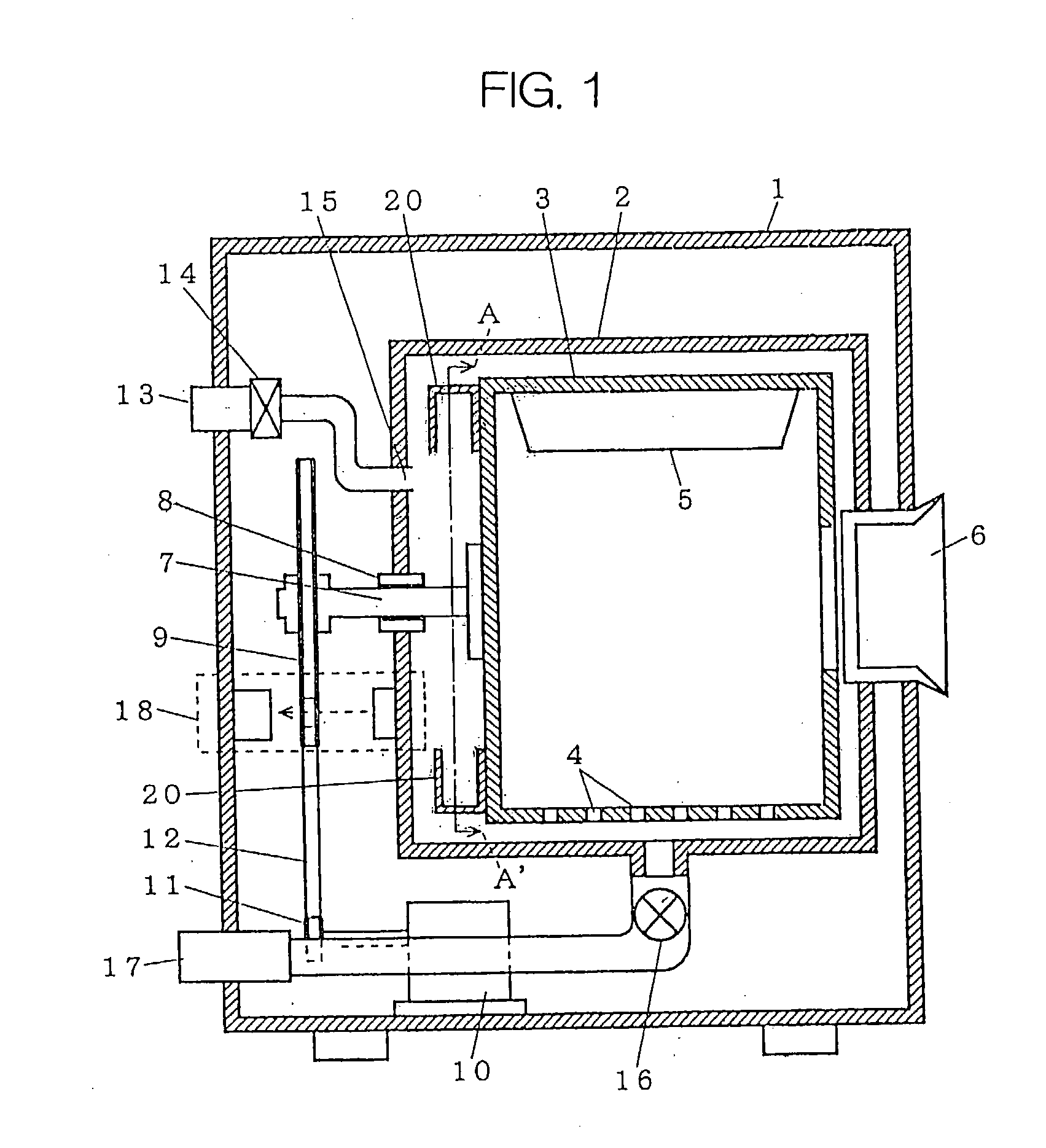

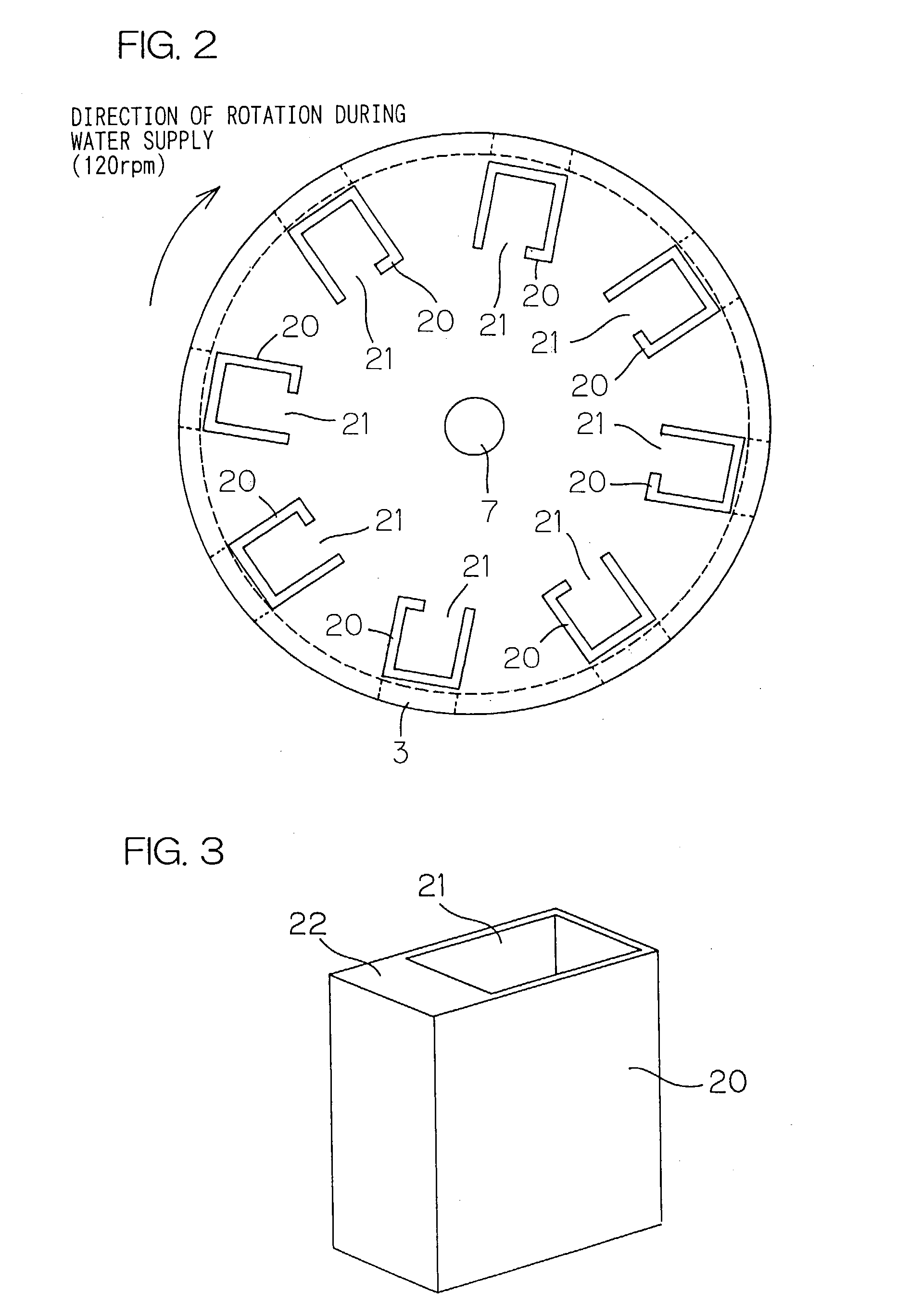

Drum type washing machine and its control method

InactiveUS20030140427A1Preventing vibration and noiseEasy loading and unloadingOther washing machinesControl devices for washing apparatusCentrifugal forceDehydration

The present invention provides a drum-type washing machine which features suppression of vibrations and noises during dehydration. To this end, an unbalanced load occurring around a rotation axis of the drum due to uneven distribution of laundry is canceled. More specifically, a plurality of water tanks (20) each having an opening on the inner periphery thereof are provided around the rotation axis on the back side of the drum (3). Where an eccentric load occurring due to the uneven distribution of the laundry is greater than an allowable level, a water supply valve (14) is opened to introduce water into the respective water tanks (20) with the drum 3 kept rotated, and the water is kept retained in the water tanks by a centrifugal force. Thereafter, the rotation speed of the drum (3) is temporarily reduced at a time point according to the position of the eccentric load to cause the water to fall only from water tanks (20) located at the same position as the position of the eccentric load or adjacent the position of the eccentric load for reduction of the weight of the water retained therein. The eccentric load occurring due to the uneven distribution of the laundry is canceled by an eccentric load generated by the water tanks not fully filled with the water and the other water tanks fully filled with the water, whereby the unbalanced load exerted on the entire drum (3) can be eliminated.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com