Drum type washing machine and its control method

a washing machine and drum technology, applied in the direction of washing machines with receptacles, other washing machines, textiles and paper, etc., can solve the problems of insufficient suppression of vibrations occurring during dehydration and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0043] [First Embodiment]

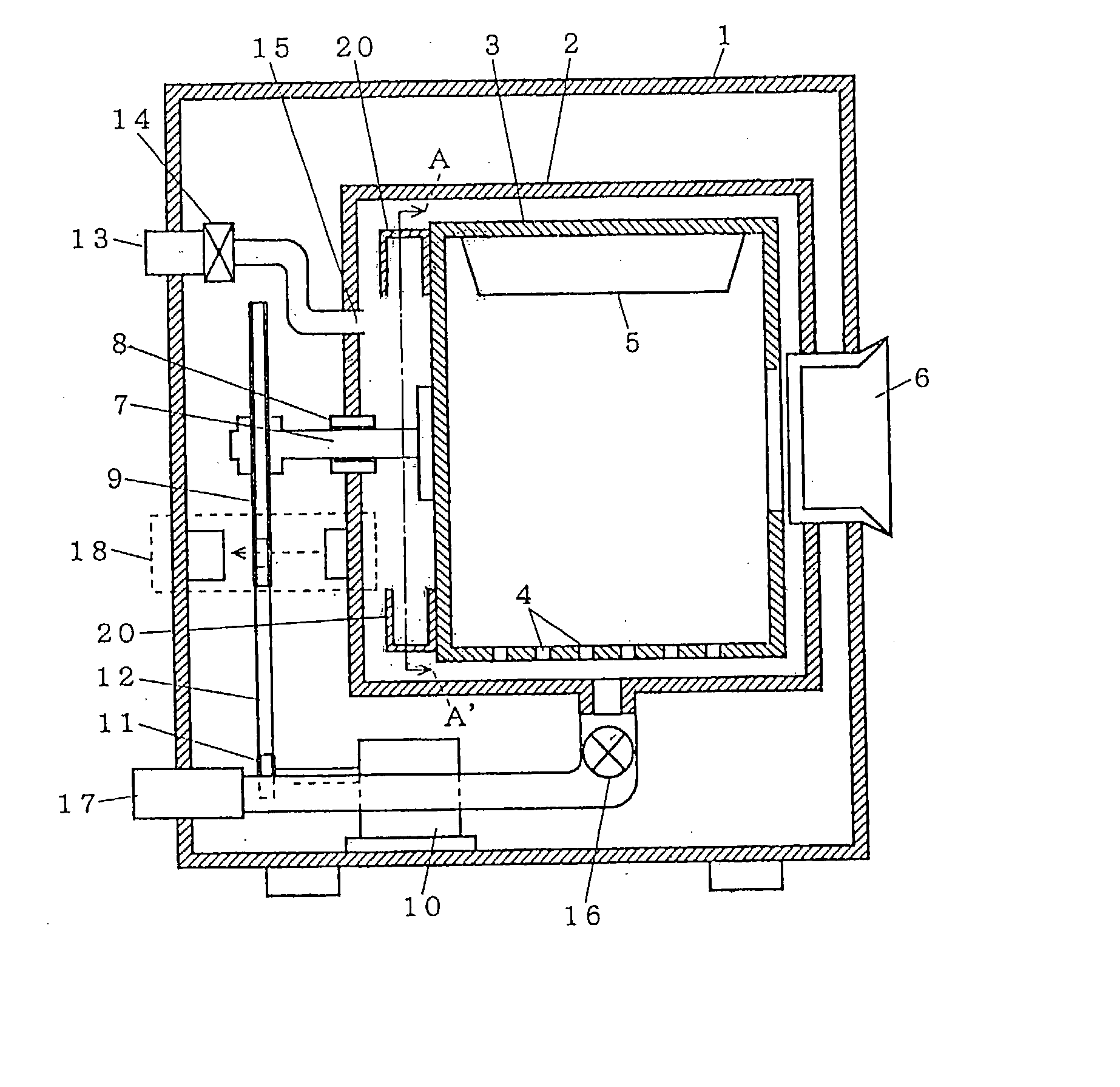

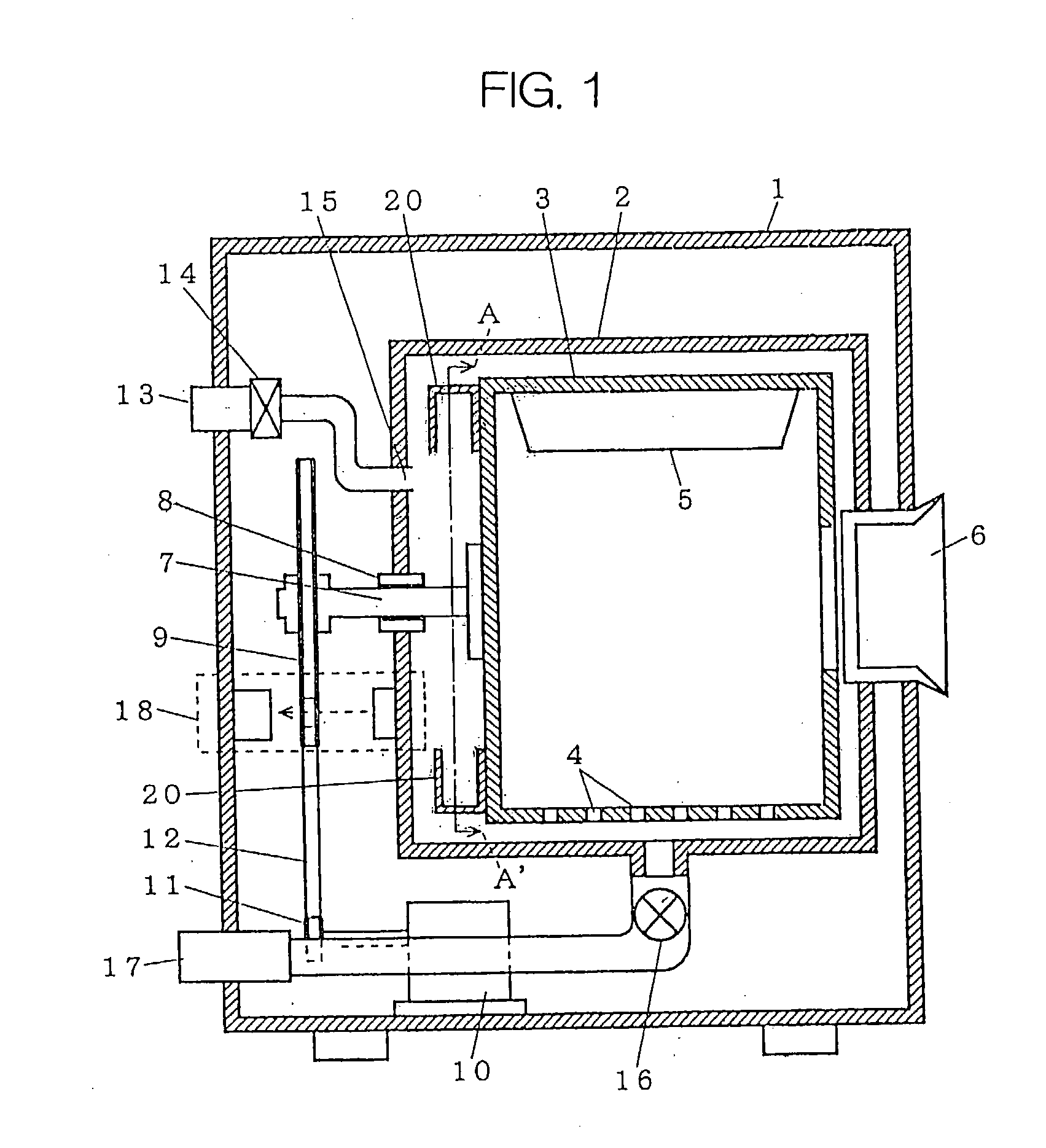

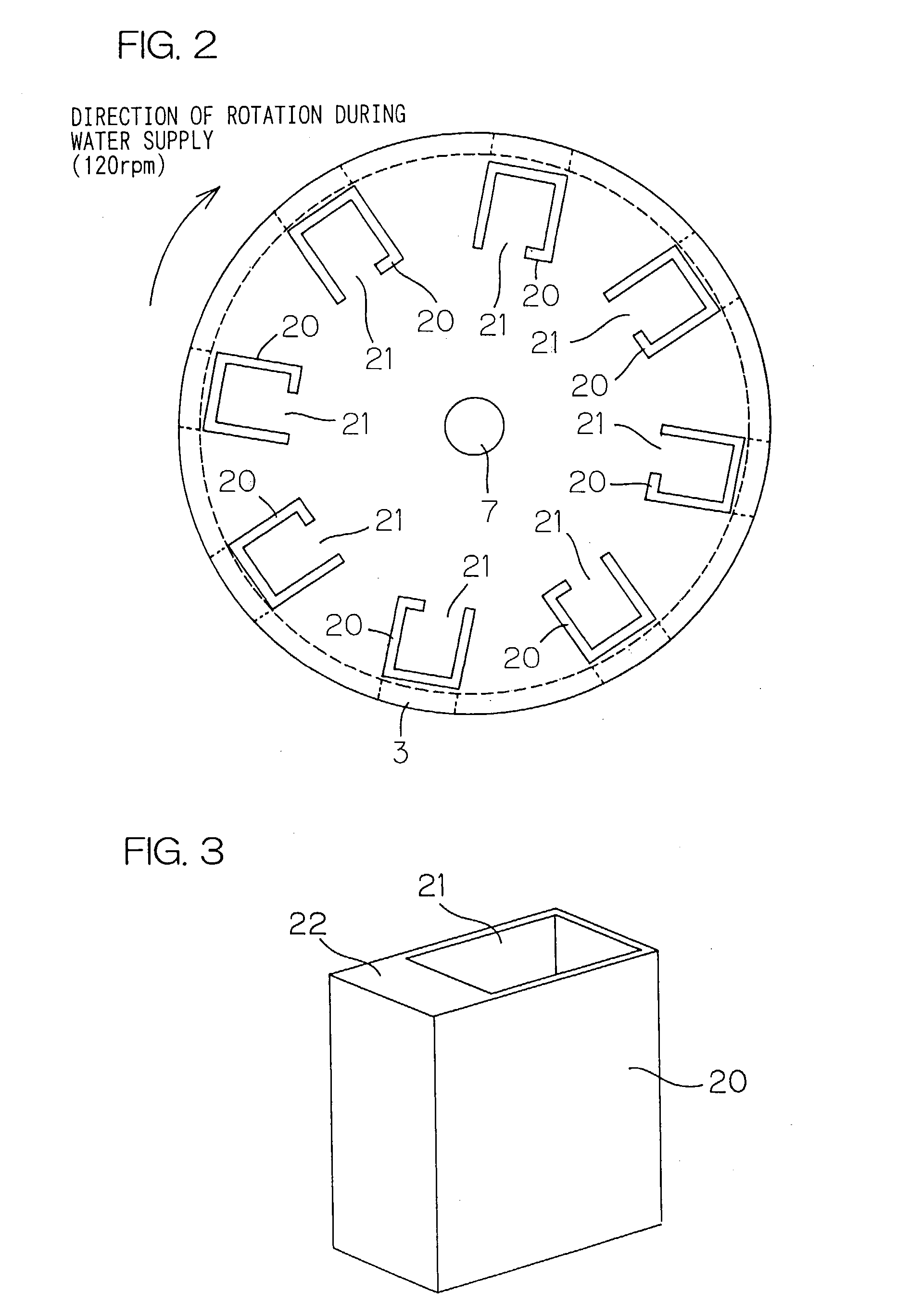

[0044] A drum-type washing machine according to a first embodiment of the present invention will hereinafter be described with reference to FIGS. 1 to 9.

[0045] FIG. 1 is a vertical sectional view illustrating the overall construction of the drum-type washing machine. A cylindrical outer tub 2 is provided in a housing 1, and a cylindrical drum 3 for retaining laundry is supported by a rotation shaft 7 within the outer tub 2. A door 6 through which laundry is loaded in the drum is openably provided on a front opening of the drum 3. Baffles 5 for stirring up the laundry are provided at proper positions on an inner circumferential surface of the drum 3. A multiplicity of water communication perforations 4 are formed in a circumferential wall of the drum 3. In a washing process and a rinsing process, water supplied into the outer tub 2 flows into the drum 3 through the water communication perforations 4. In a centrifugal dehydration process, water extracted from ...

second embodiment

[0080] [Second Embodiment]

[0081] A drum-type washing machine according to a second embodiment of the present invention will next be described with reference to FIGS. 10 to 12.

[0082] FIG. 10 is a vertical sectional view illustrating the overall construction of the drum-type washing machine according to the second embodiment. Components having the same construction as those of the washing machine of the first embodiment are denoted by the same reference numerals, and no explanation will be given thereto. In the washing machine, a balancer 23 which is a hollow annular component containing a predetermined amount of water (or any other liquid, such as a saline solution or a potassium chloride solution, preferably having a higher density) is provided on the back side of the drum 3. FIG. 11 is a sectional view taken along a line B-B' in FIG. 10. In the balancer 23, L-shaped partition walls 24 are provided at predetermined angular intervals as radially projecting from the circumference of t...

third embodiment

[0092] [Third Embodiment]

[0093] A drum-type washing machine according to a third embodiment of the present invention will be described with reference to FIGS. 13 to 18.

[0094] FIG. 13 is a vertical sectional view illustrating the overall construction of the drum-type washing machine according to the third embodiment. Components having the same construction as those of the washing machines of the first and second embodiments are denoted by the same reference characters, and no explanation will be given thereto.

[0095] This washing machine obviates the rotation sensor 18 provided in the washing machines of the first and second embodiments. Instead, an acceleration sensor 29 is provided on a front upper portion of the outer tub 2. The acceleration sensor 29 mainly serves to detect a vertical acceleration of the outer tub 2. The magnitude and position of an eccentric load exerted on the drum 3 are determined on the basis of the result of the detection by the acceleration sensor 29.

[0096] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com