Patents

Literature

1194results about How to "Easy to locate and install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

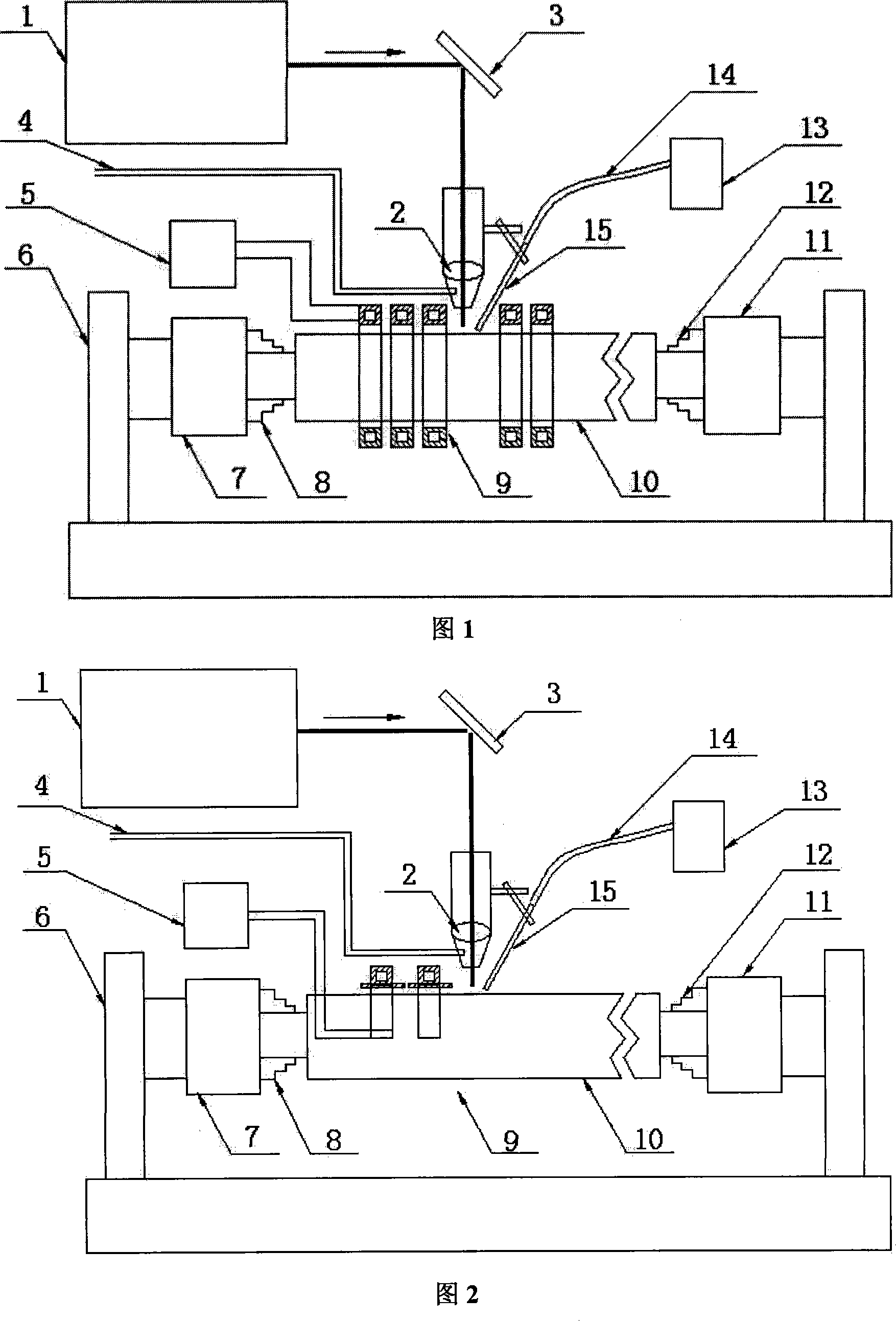

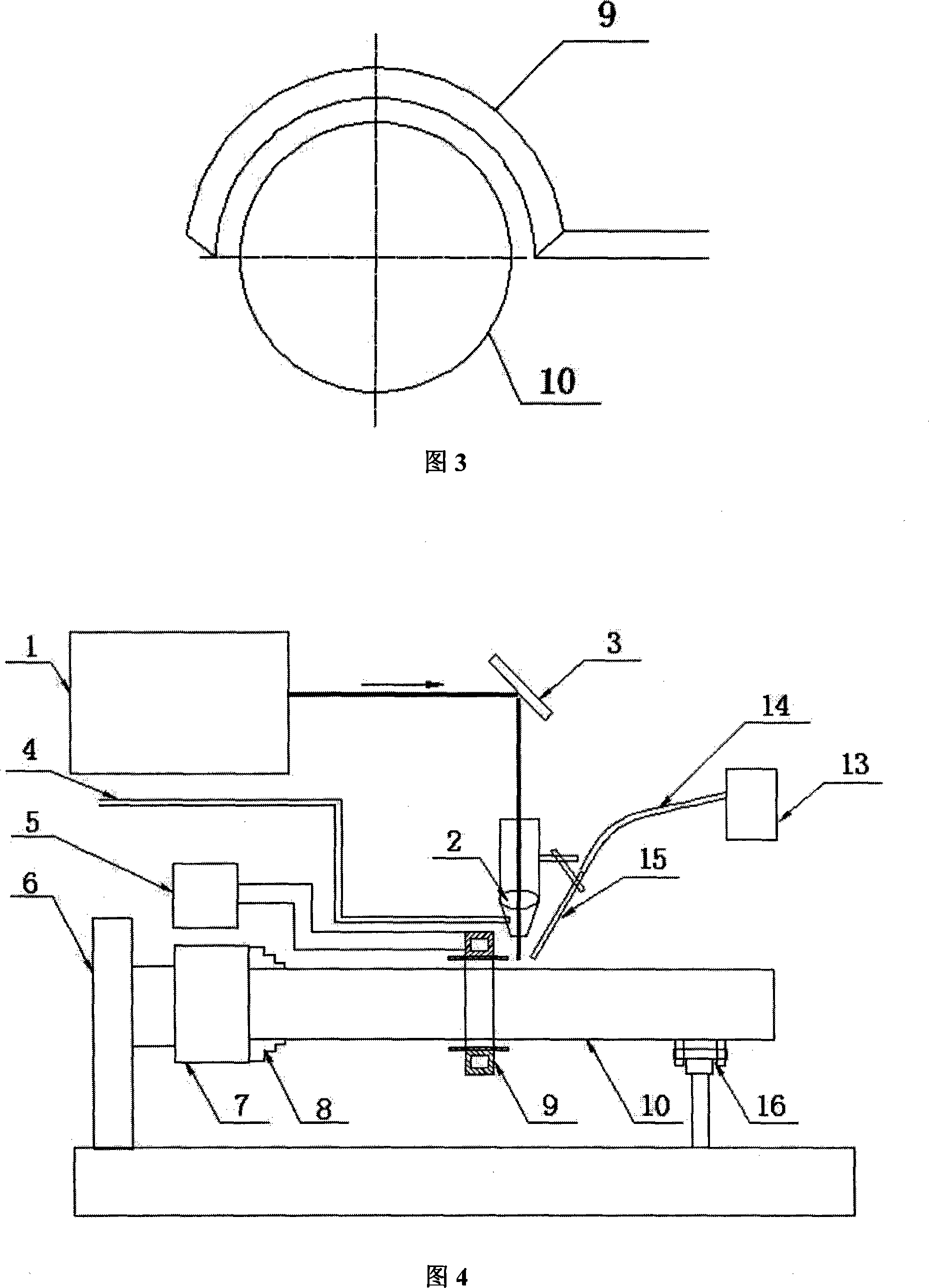

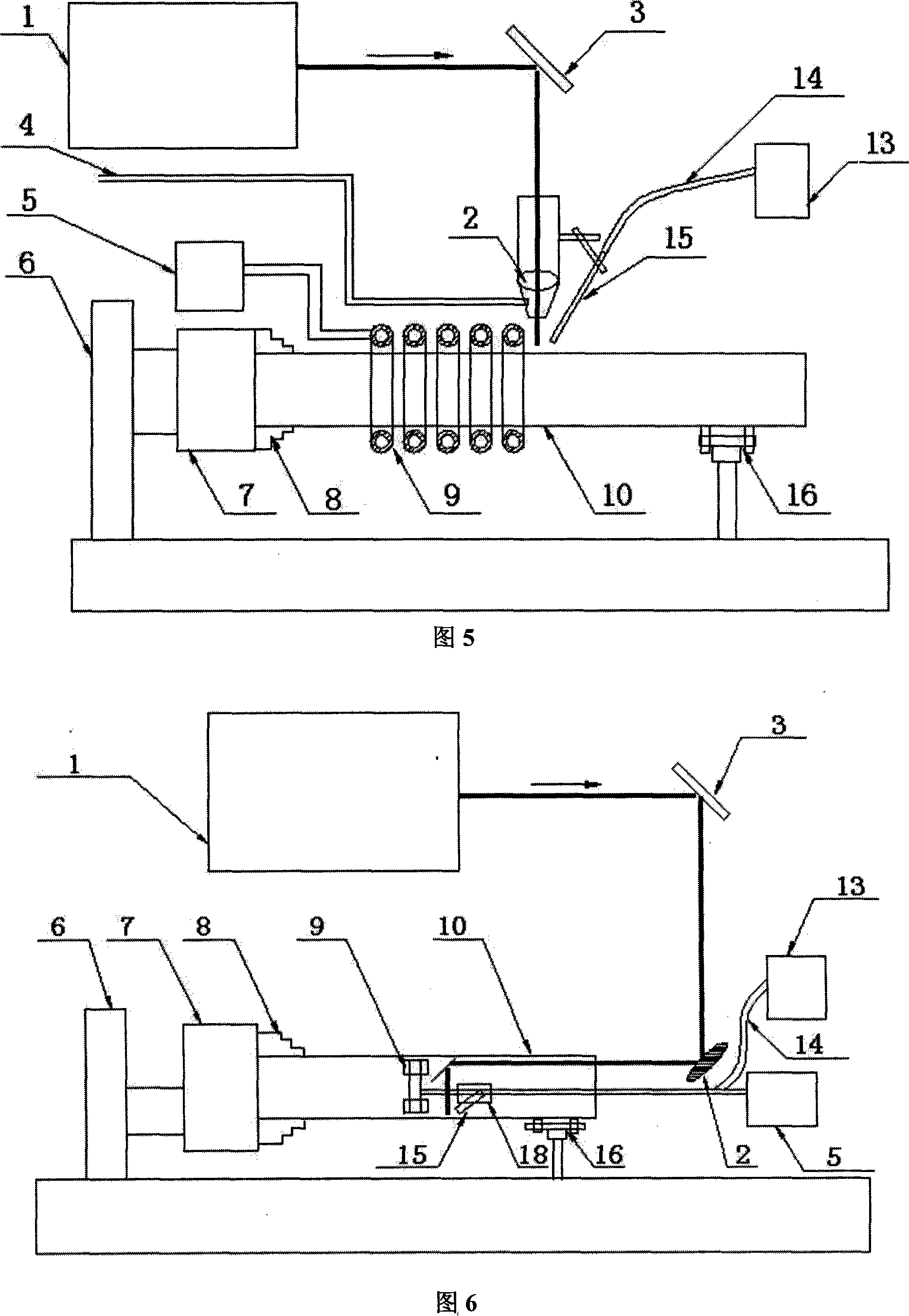

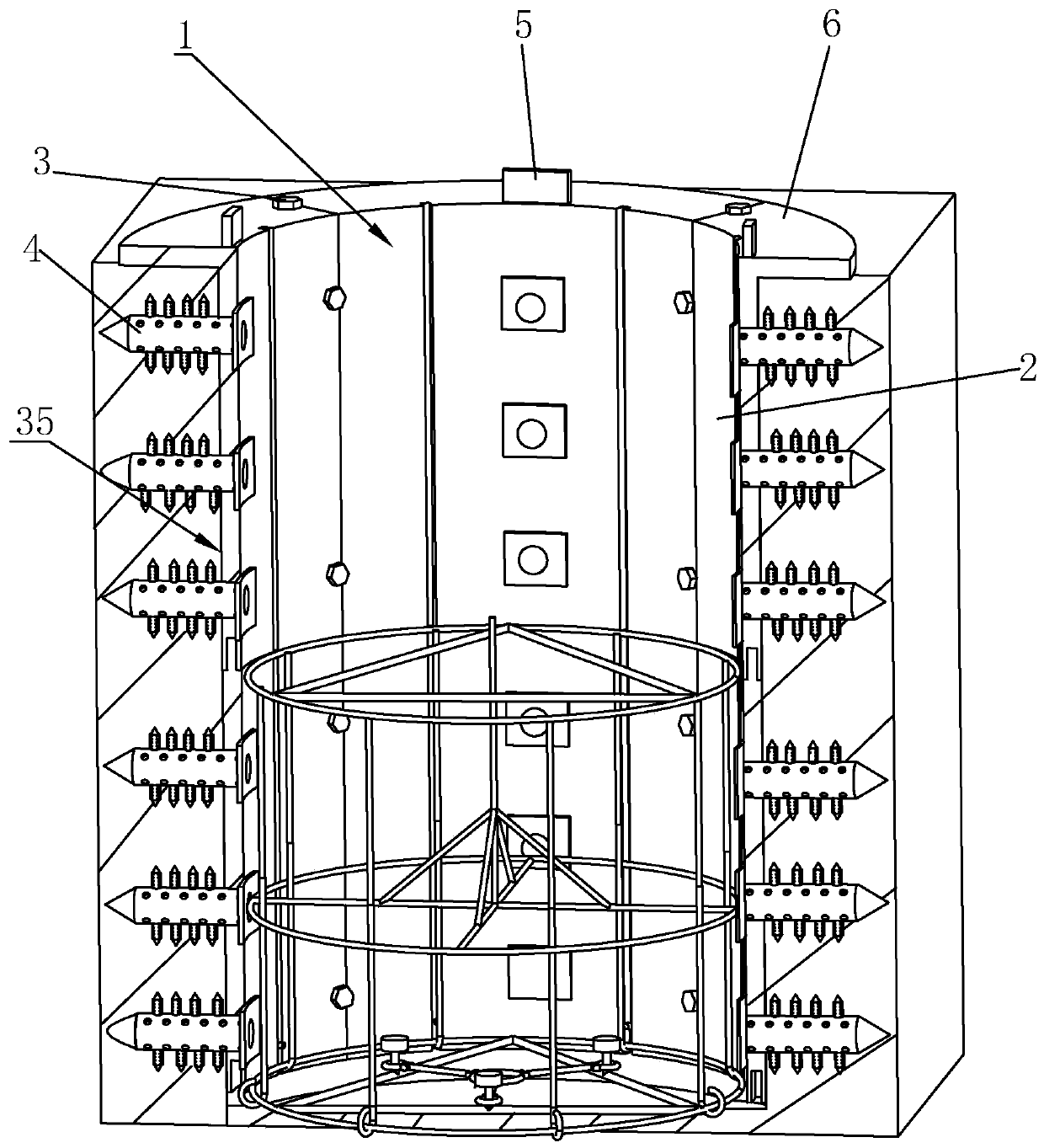

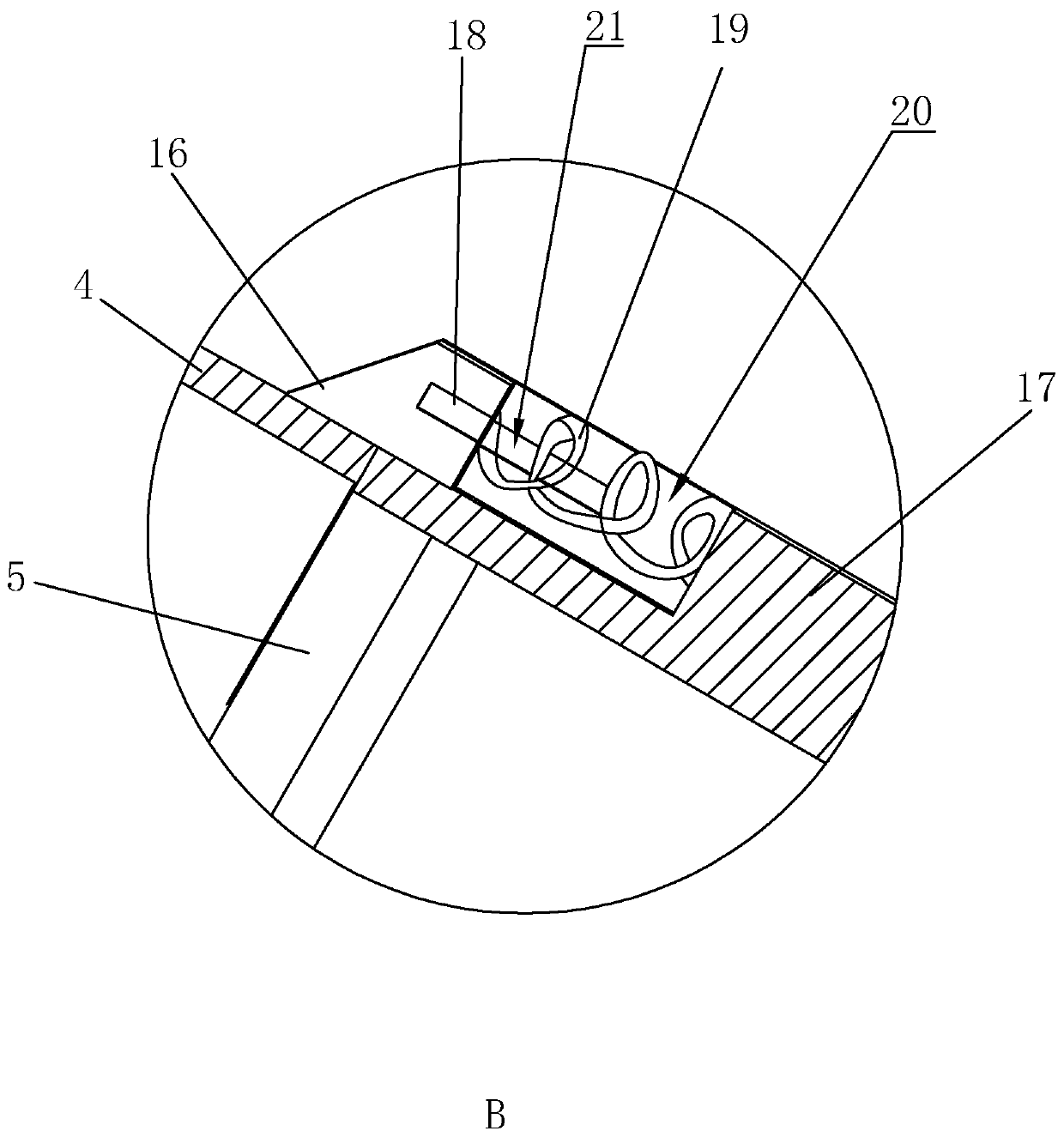

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

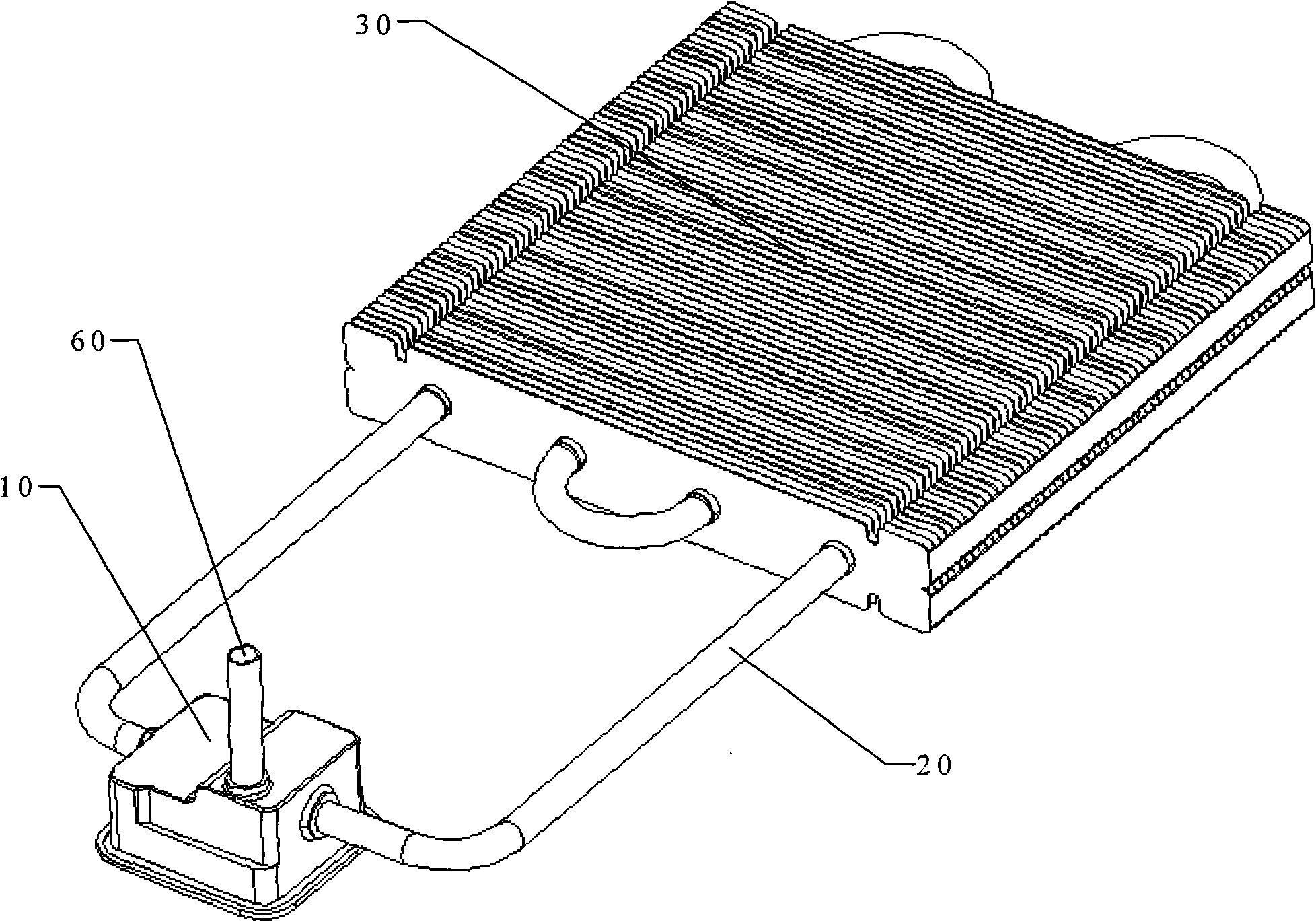

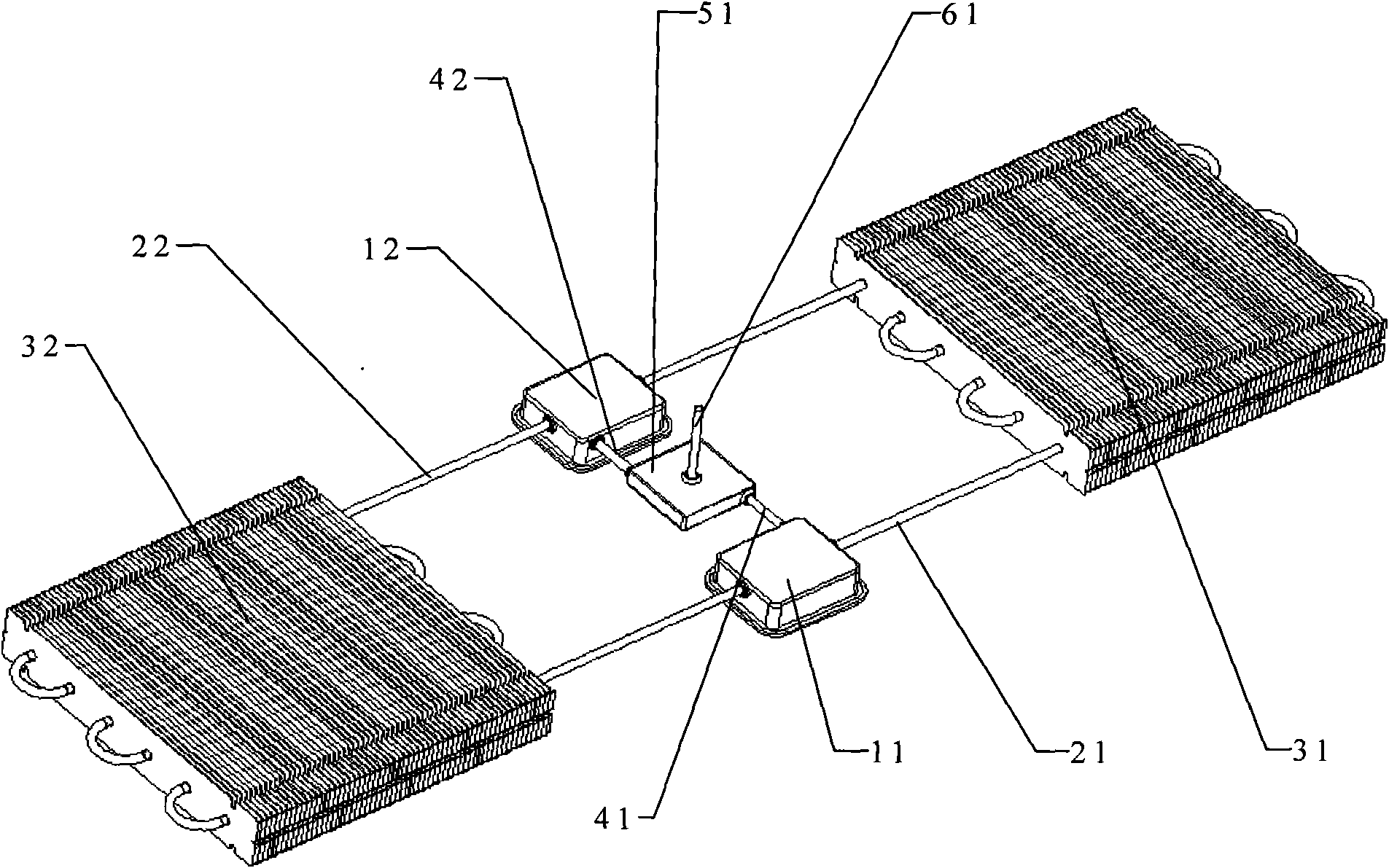

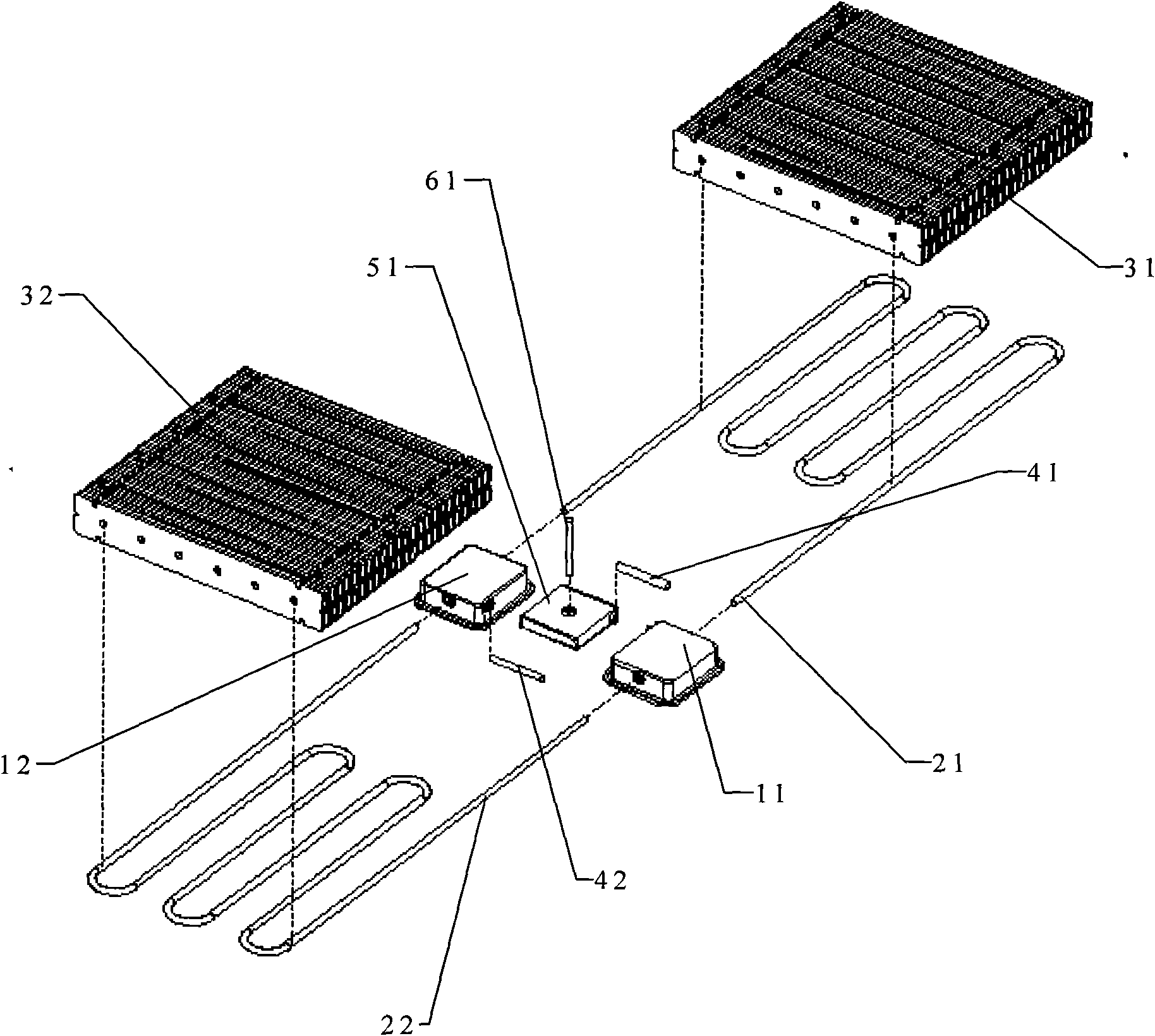

Serial-parallel type multi-evaporator loop heat pipe

InactiveCN101566442AMeet simultaneous heat dissipation requirementsAvoid disadvantagesSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHigh energy

A serial-parallel type multi-evaporator loop heat pipe comprises at least two groups of evaporators, at least two gas-liquid pipelines, at least two groups of condensers and at least one group of working fluid compensation chamber. The arrangement of a plurality of evaporators adopts a sequential serial-parallel type, namely the gas-liquid pipelines are used for connecting a back evaporator liquid inlet with a front steam outlet and connecting the steam outlet of the final evaporator with the first liquid inlet of the first evaporator; the gas-liquid pipeline is provided with the condenser; and the multi-group of the evaporators commonly use at least one group of working fluid compensation chambers that are connected with each other by the liquid compensation pipelines. The loop heat pipe can meet the simultaneous heat dissipation requirement of a plurality of heat sources, is mainly applicable to the heat dissipation of computer chips, and can be also used for the cooling of light-emitting diode lighting equipment, chips in communication industries and internal high-energy heating parts of military, medical and aerospace equipment.

Owner:BEIJING AVC TECH RES CENT

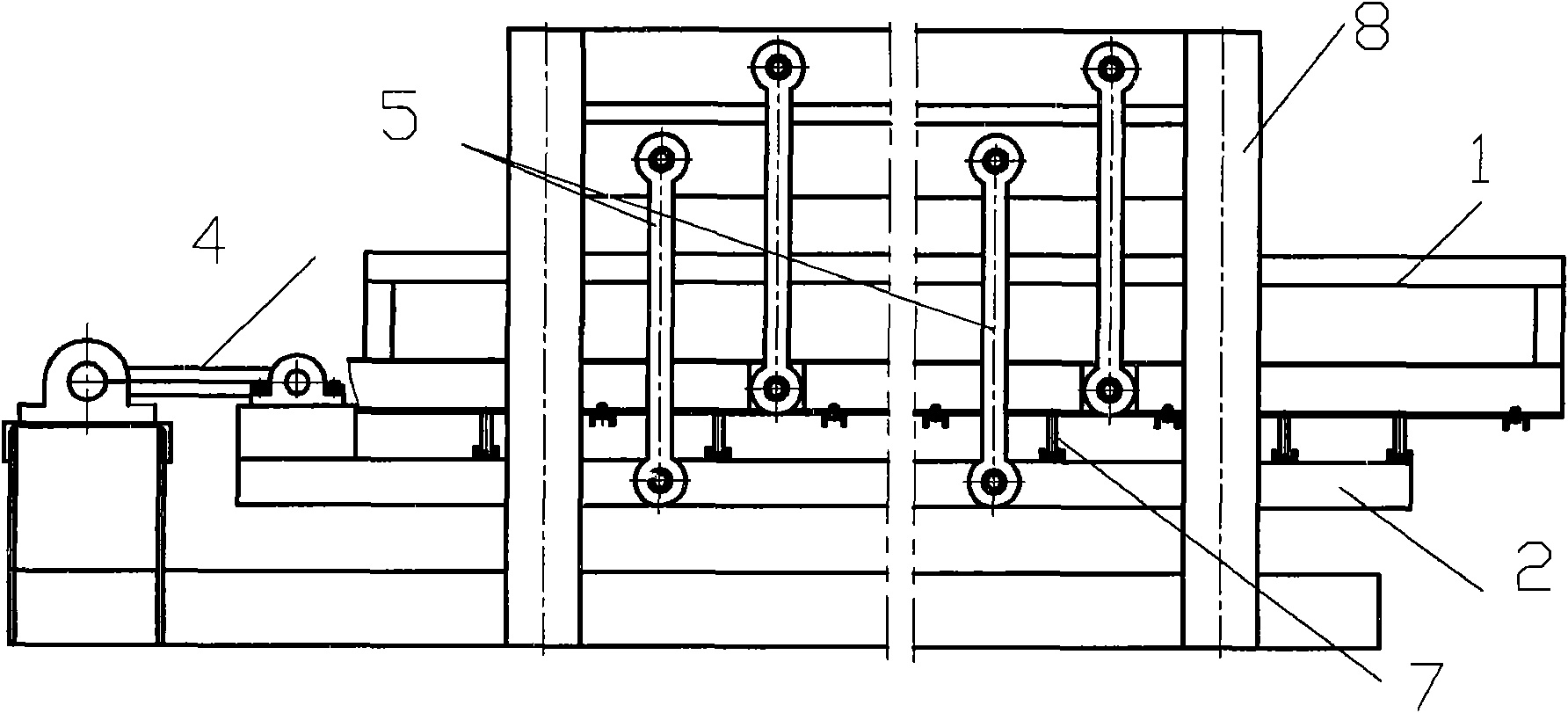

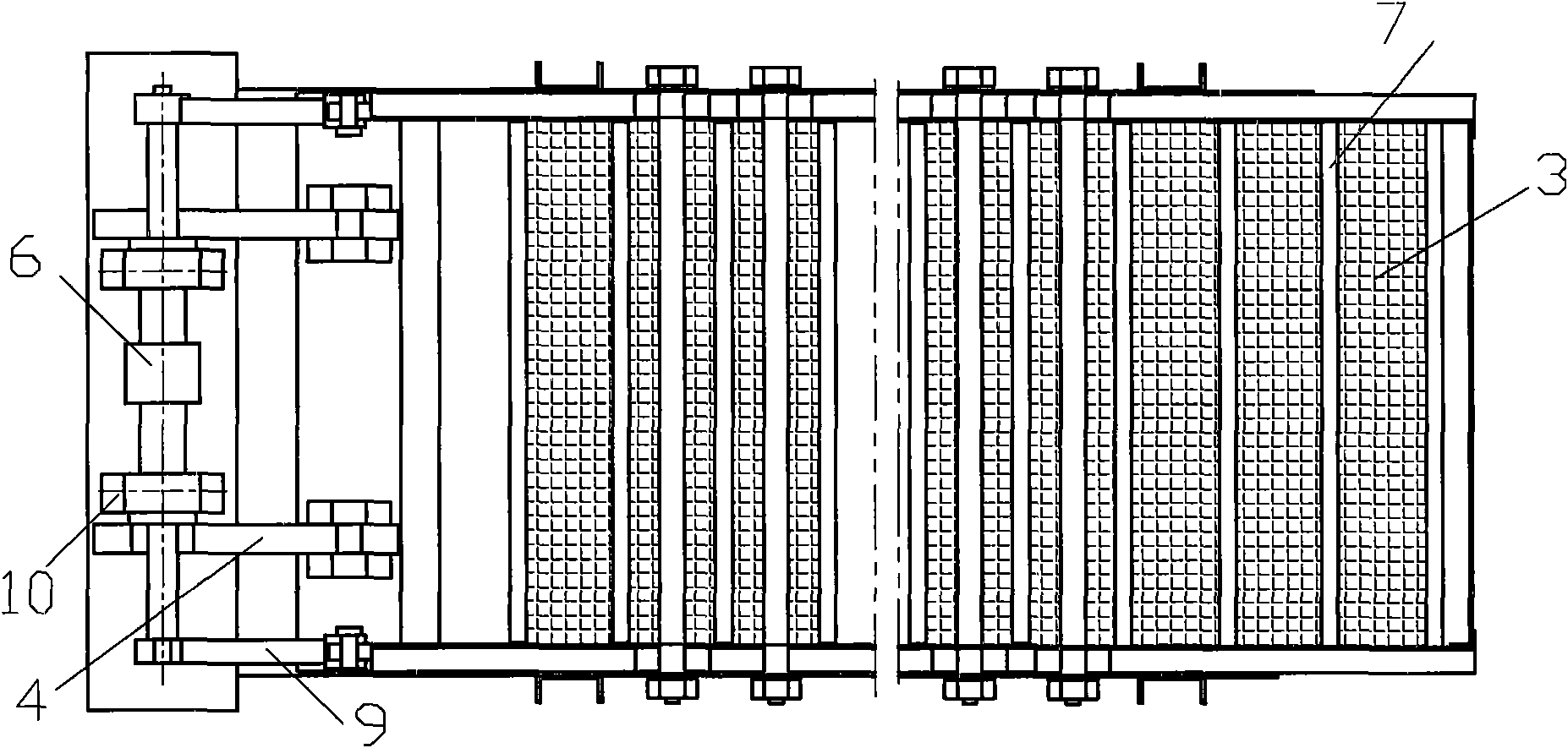

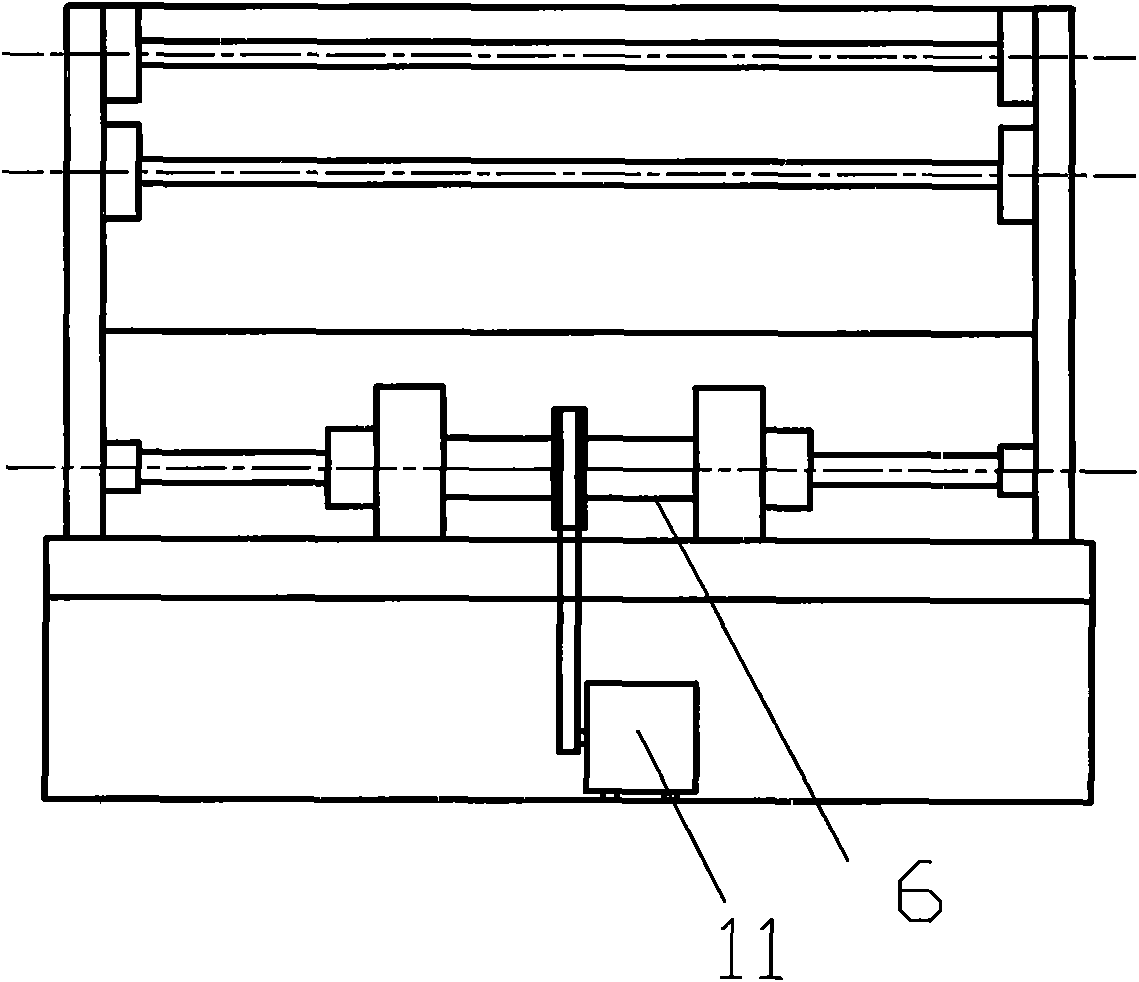

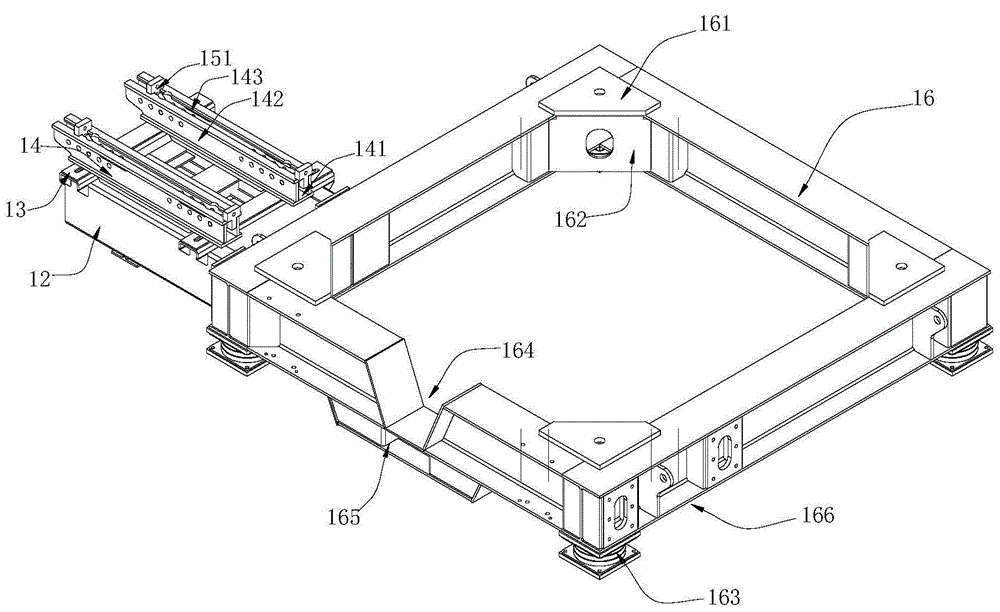

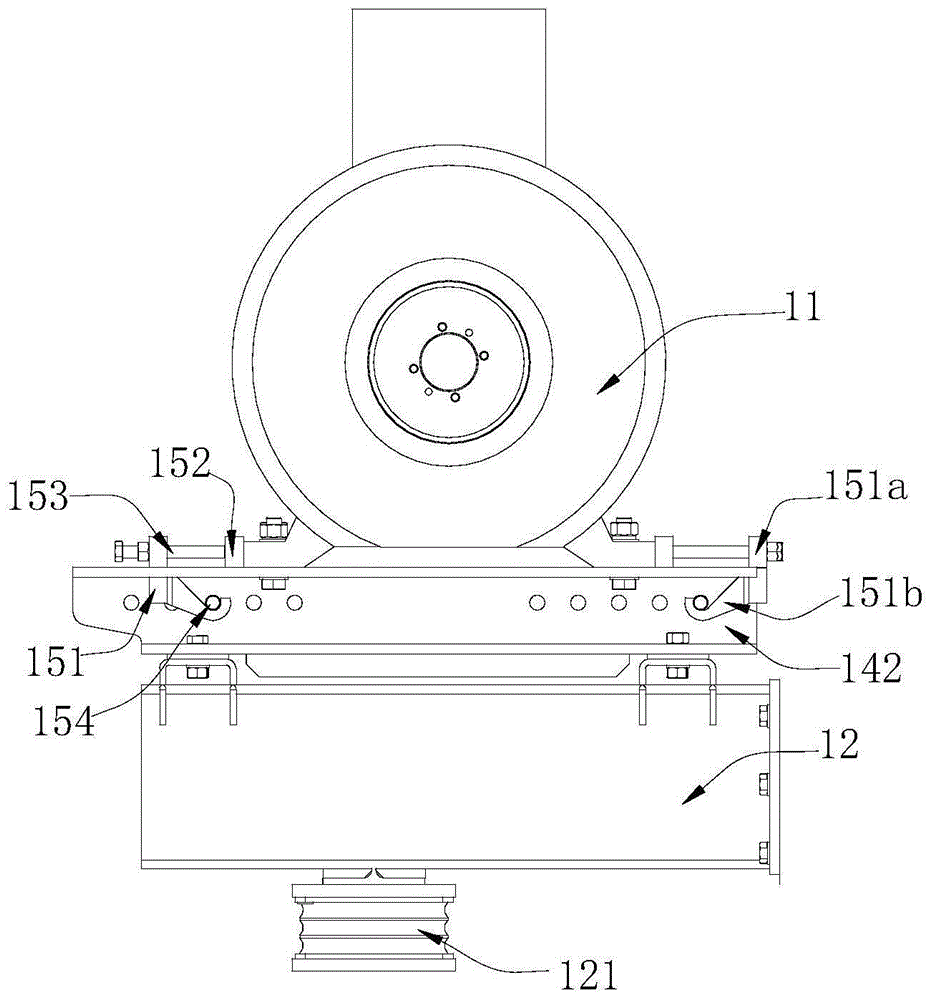

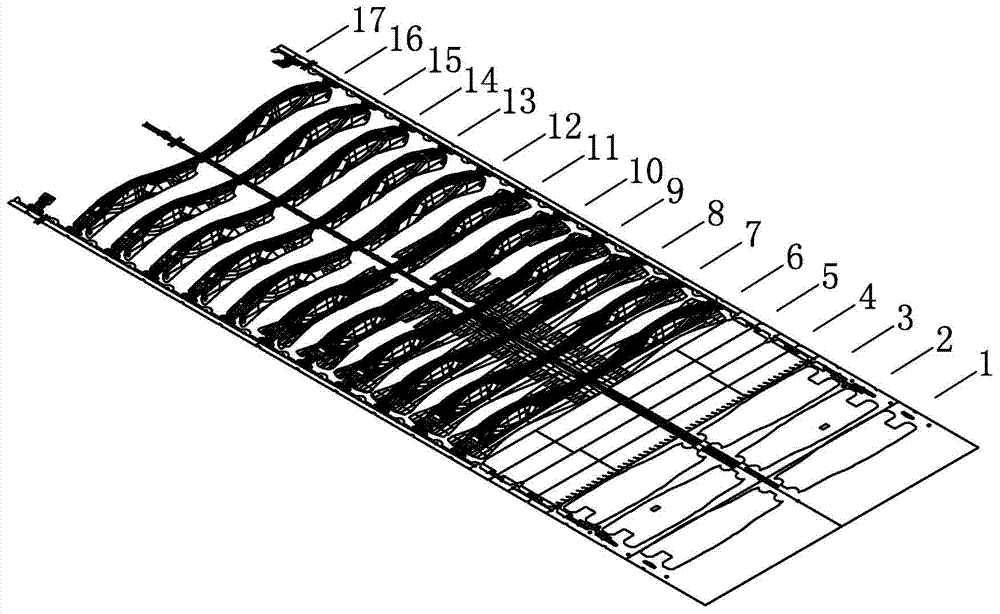

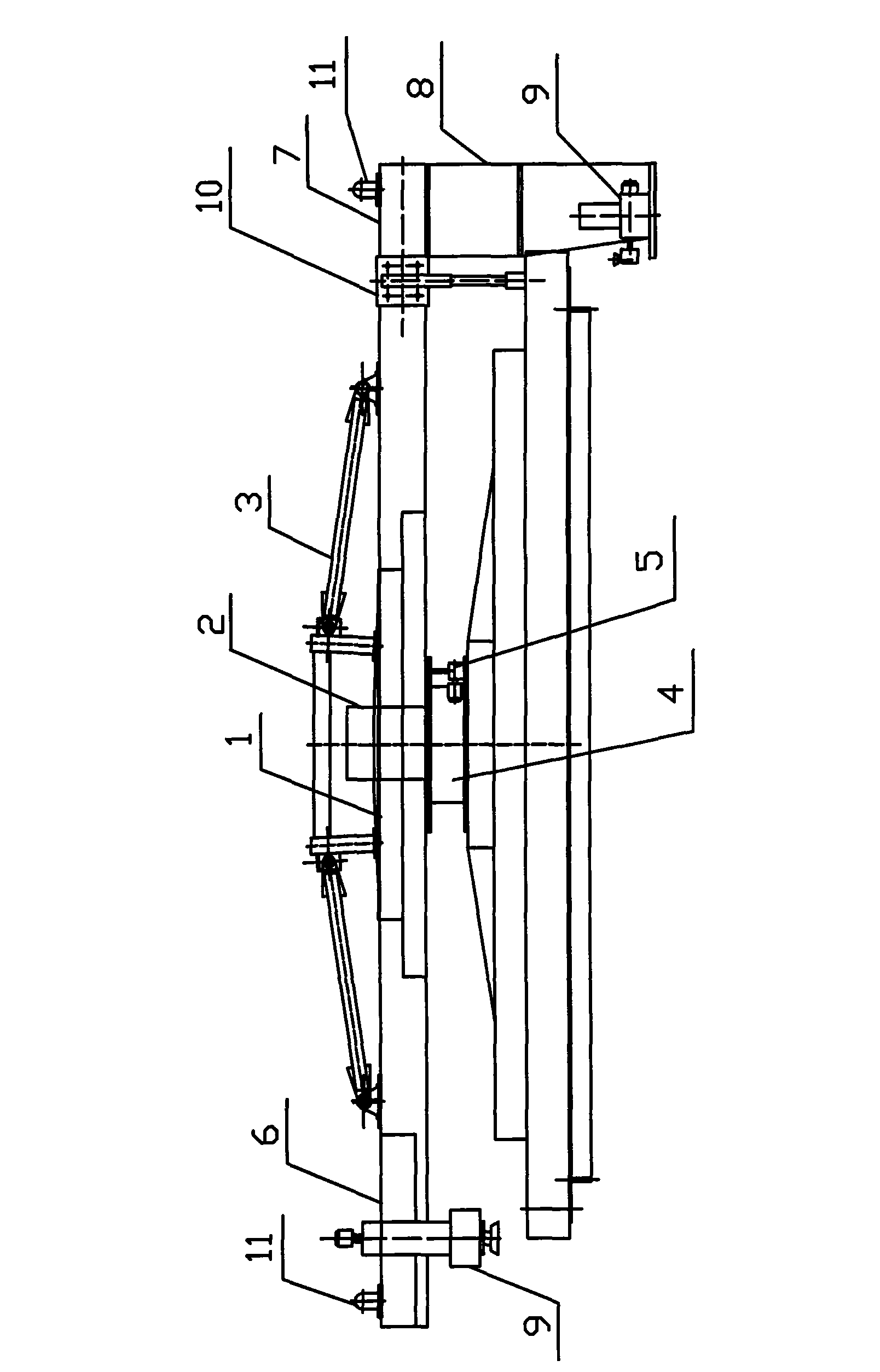

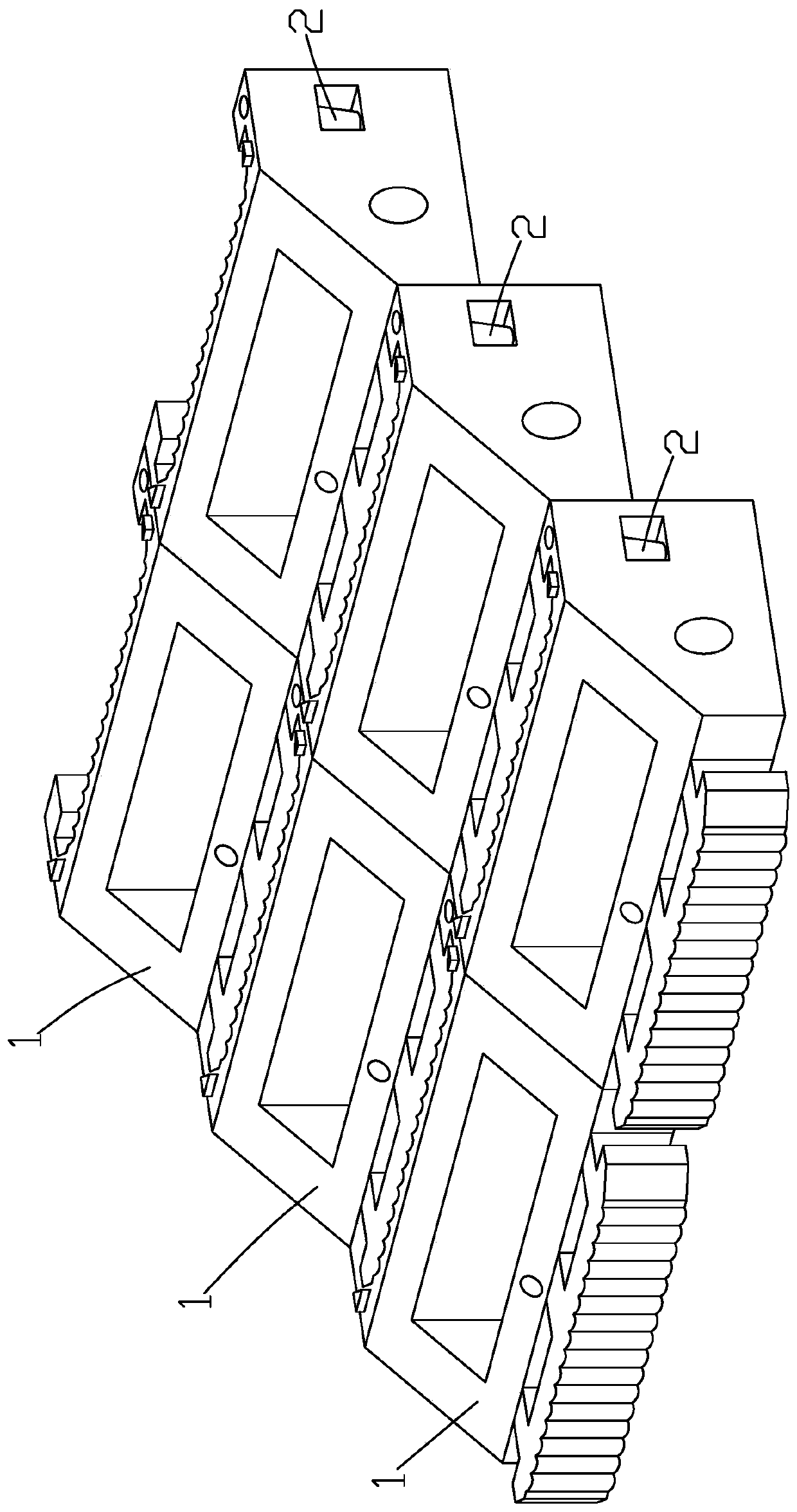

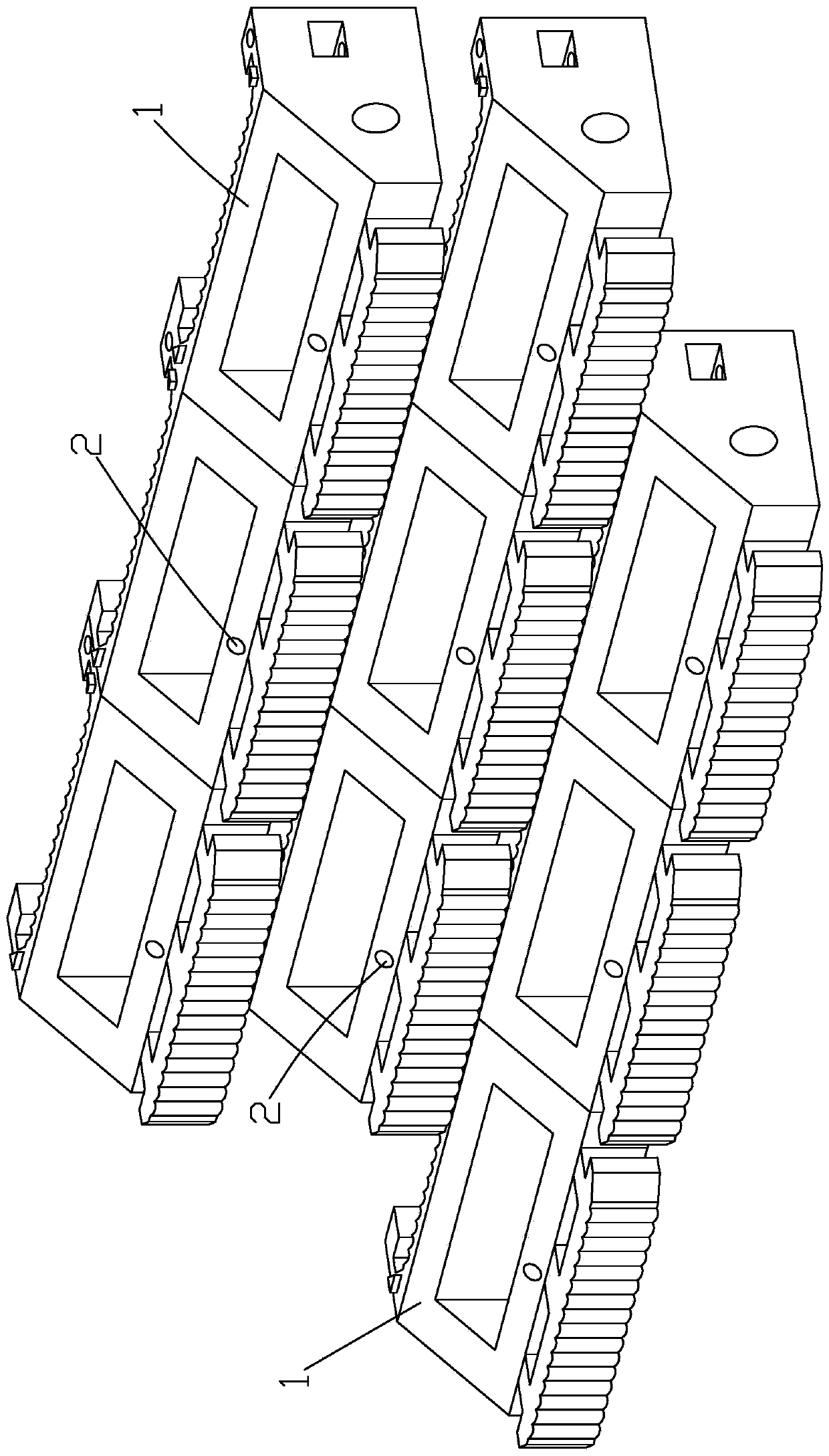

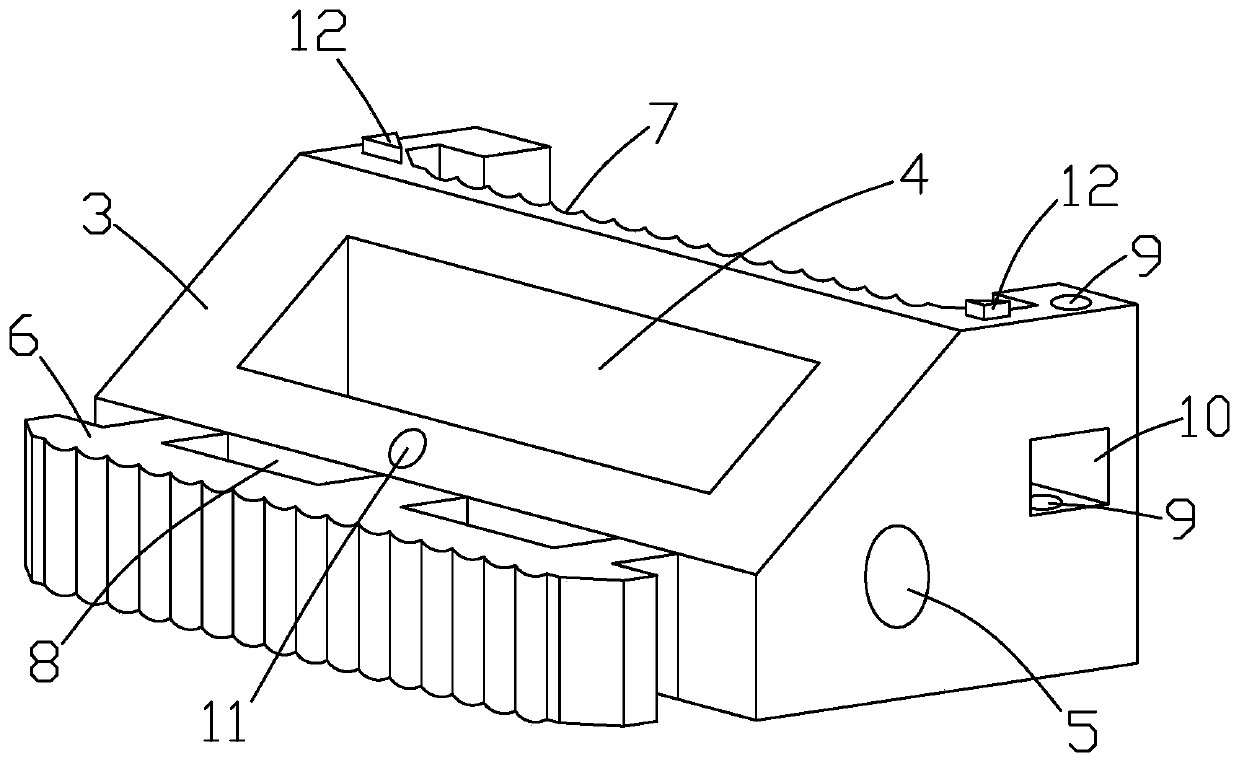

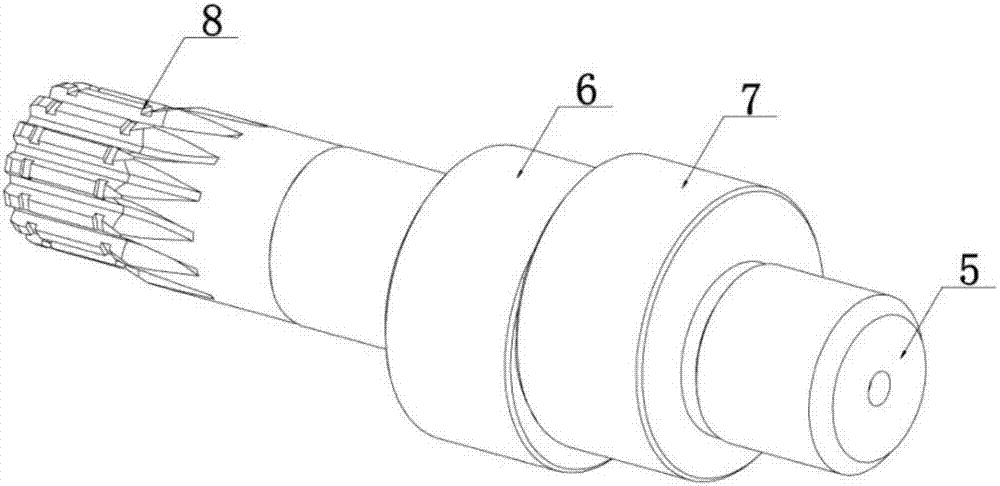

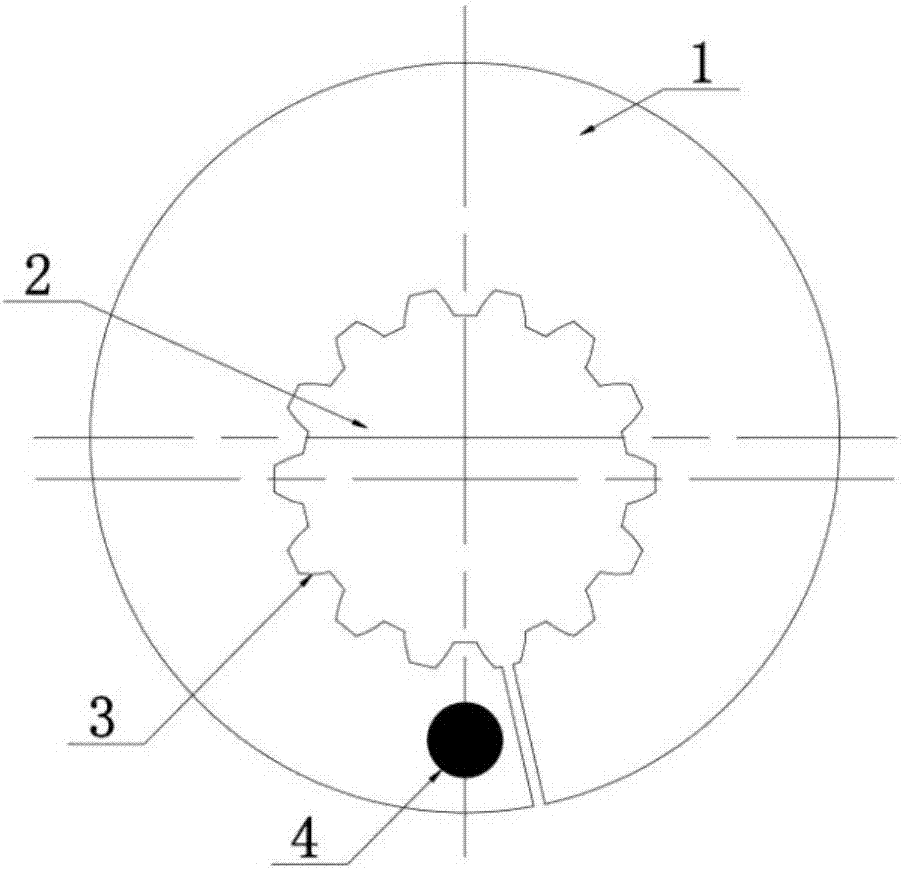

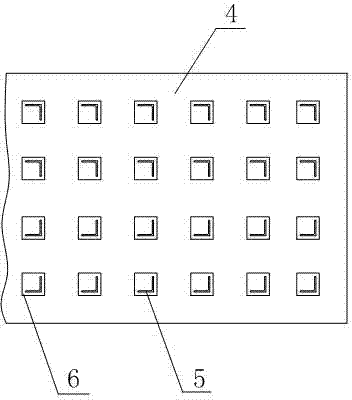

Centralized driving flip-flow screen

ActiveCN101664738AImprove reliabilityExtended service lifeSievingScreeningDrive shaftRelative motion

The invention discloses a centralized driving flip-flow screen, which mainly comprises an upper screen box, a lower screen box, an elastic screen stencil formed by connecting a plurality of rectangular screen plates, a driving shaft for connecting the upper and lower screen boxes, a supporting frame, a driving shaft and a belt wheel driving mechanism, wherein the belt wheel driving mechanism is arranged at the middle lower part of the driving shaft, the middle part of the driving shaft is provided with a belt wheel connected with the belt wheel driving mechanism, and the axes at the left and the right of the belt wheel are symmetric and are machined with two eccentric axis sections respectively to form the coaxial four-section eccentric driving shaft; an upper cross beam of the supportingframe is a semi-columnar upper cross beam; the relative motion of the two screen boxes fulfills the deflection motion of the screen stencil so as to realize material screening; and the centralized driving flip-flow screen adopts the structure that the number of the screen hole of the screen surface at the front end is less, the number of the screen hole of the screen surface at the middle sectionis medium and the number of the screen hole of the screen surface of the tail section is more in the aspect of the screen hole arrangement so as to ensure the effects that the screen surface at the front end is not easy to break when conveying the materials and the integral screen surface screens uniformly; and the centralized driving flip-flow screen has the advantages of simple structure, stableoperation, energy consumption conservation, long service life and wide practicability.

Owner:CHINA UNIV OF MINING & TECH

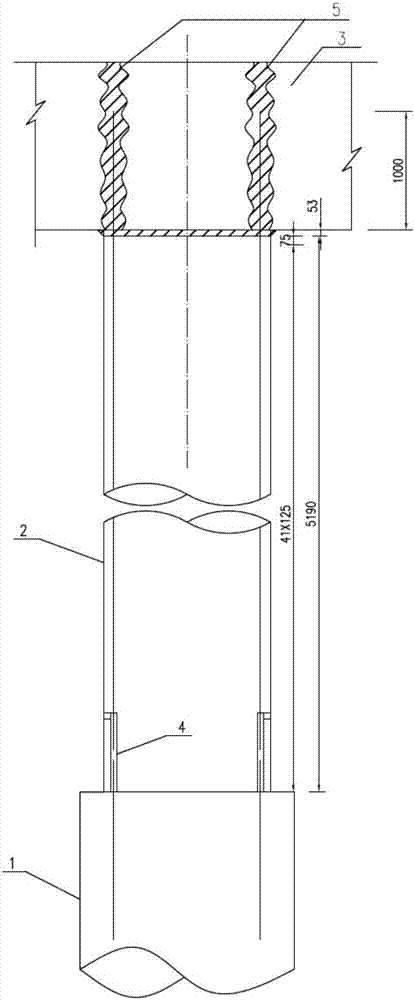

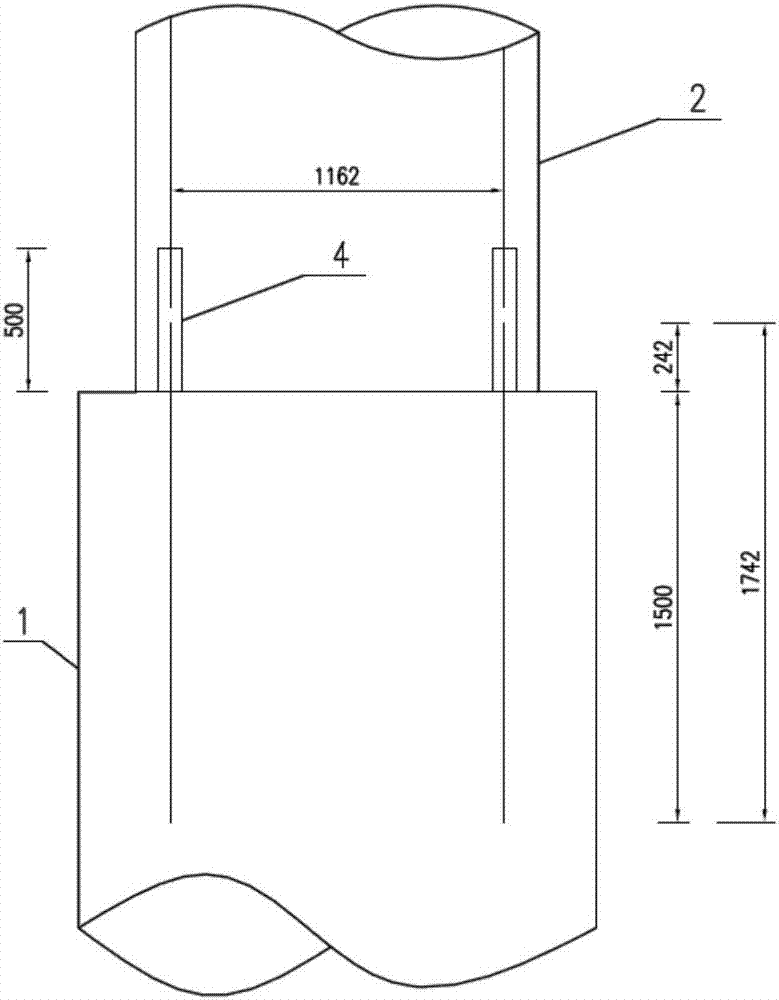

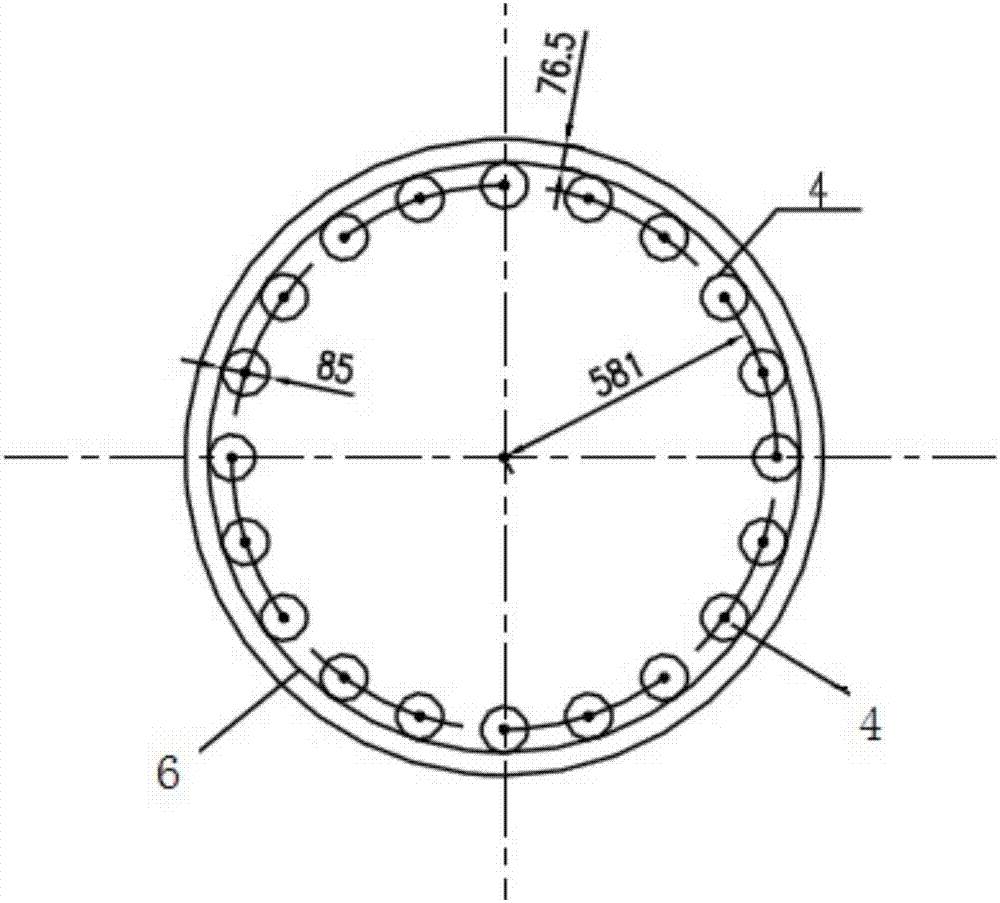

Assembled bridge pier and construction method thereof

InactiveCN107447647AFast constructionReliable connection forceBridge structural detailsBridge erection/assemblyRebarBuilding construction

The invention discloses an assembled bridge pier. The assembled bridge pier comprises a pile foundation, a prefabricated pier column and a prefabricated cover beam, wherein a reinforcement is reserved at the top end of the pile foundation; a grouting sleeve is reserved at the bottom end of the prefabricated pier column; the reinforcement of the pile foundation is accommodated in the grouting sleeve, and a grouting material is poured in the grouting sleeve; a reinforcement is reserved at the top end of the prefabricated pier column; a corrugated pipe is arranged on the prefabricated cover beam; the reinforcement of the prefabricated pier column is accommodated in the corrugated pipe; and concrete is cast in the corrugated pipe. The assembled bridge pier is excellent in stress performance, high in construction speed, short in period and simple in process.

Owner:WUHAN UNIV OF TECH

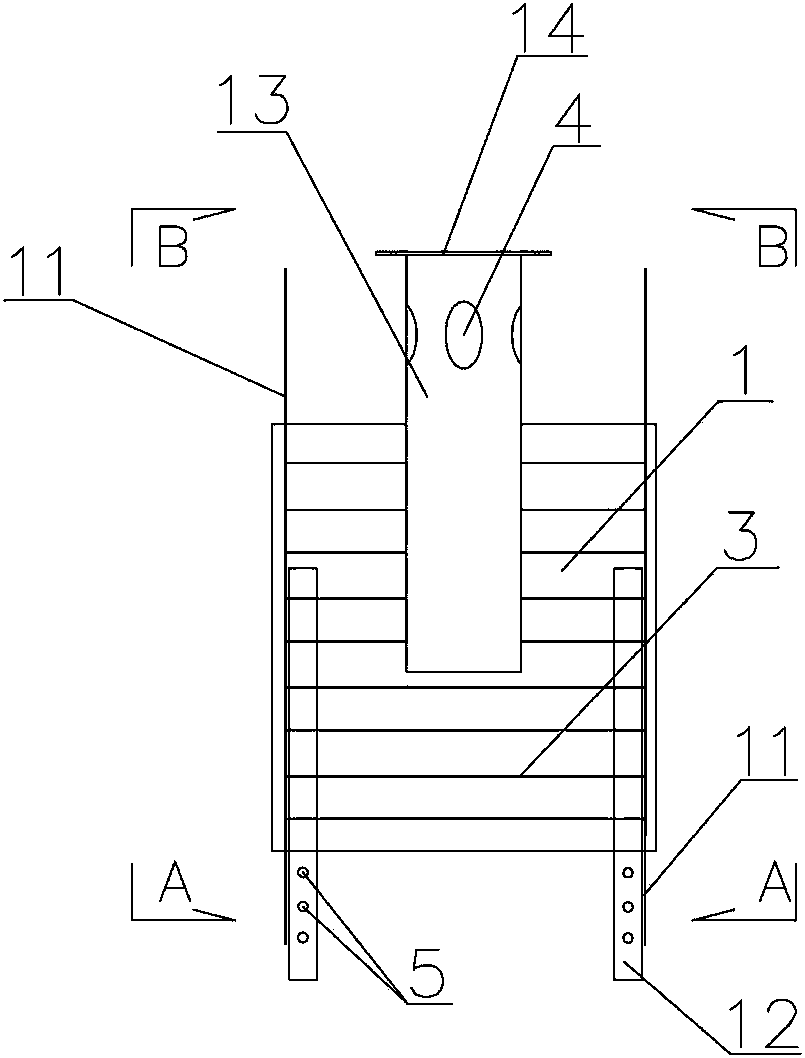

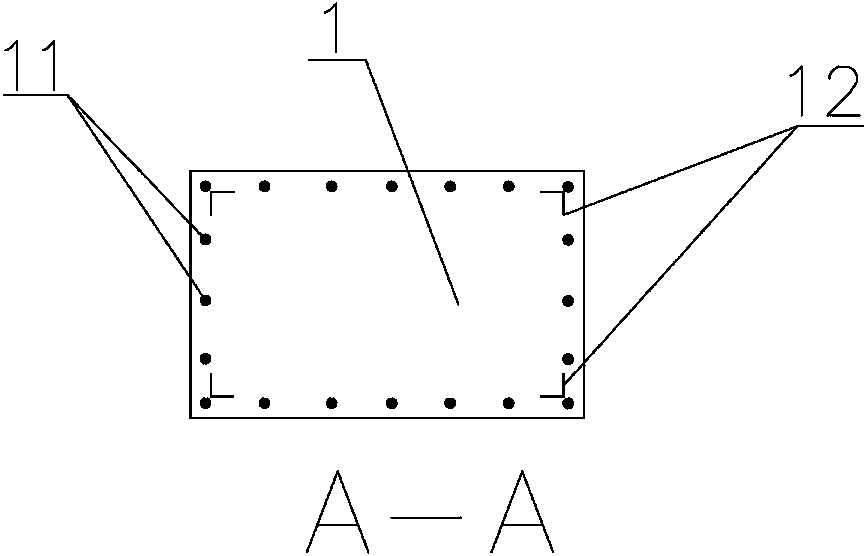

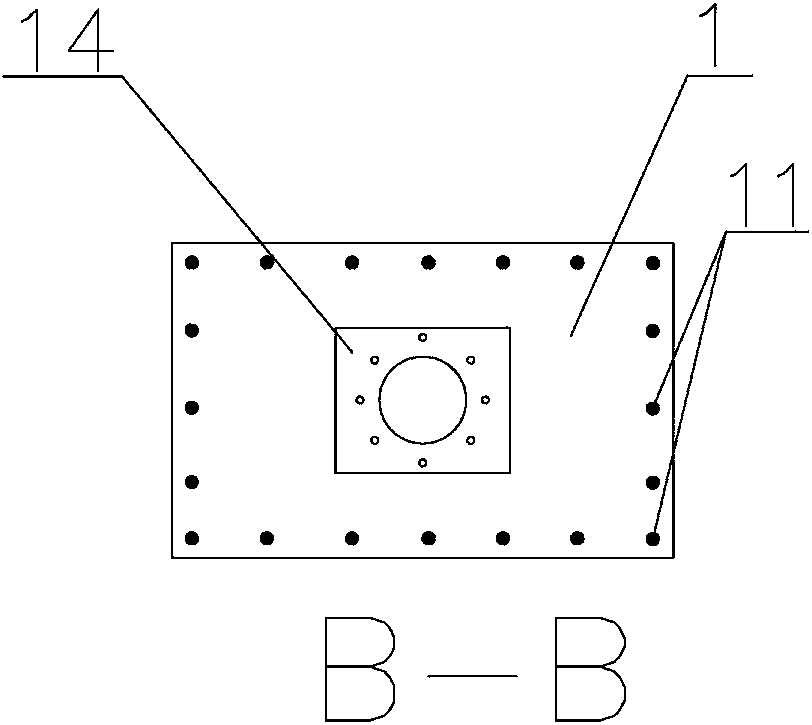

Prefabricated column and precast construction method thereof

ActiveCN104088397AFirmly connectedNo technical quality requirementsStrutsBuilding material handlingArchitectural engineeringRebar

The invention relates to a prefabricated column and a precast construction method. The prefabricated column comprises a lower prefabricated column and an upper prefabricated column matching the lower prefabricated column, a first vertical steel bar extending out of the upper and lower ends of the lower prefabricated column is arranged in the lower prefabricated column, the lower end of the lower prefabricated column is provided with a first connection member, the upper end of the lower prefabricated column is provided with a first steel pipe and a first flange plate welded to the top surface of the first steel pipe, a second vertical steel bar extending out of the upper and lower ends of the upper prefabricated column is arranged in the upper prefabricated column, the upper end of the upper prefabricated column is provided with a second connection member, the lower end of the upper prefabricated column is provided with a second steel pipe and a second flange plate welded to the top surface of the second steel pipe, the top of a second pre-embedded steel pipe is in a butt connection relationship with two auxiliary steel pipes, the first flange plate and the second flange plate are in a butt connection relationship by bolts, the first connection member is connected to the second connection member by threads, and the first vertical steel bar and the second vertical steel bar are bound by stirrups. The prefabricated column can be constructed simply, has a low price, and is suitable for buildings having high floor height and large column sectional area.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

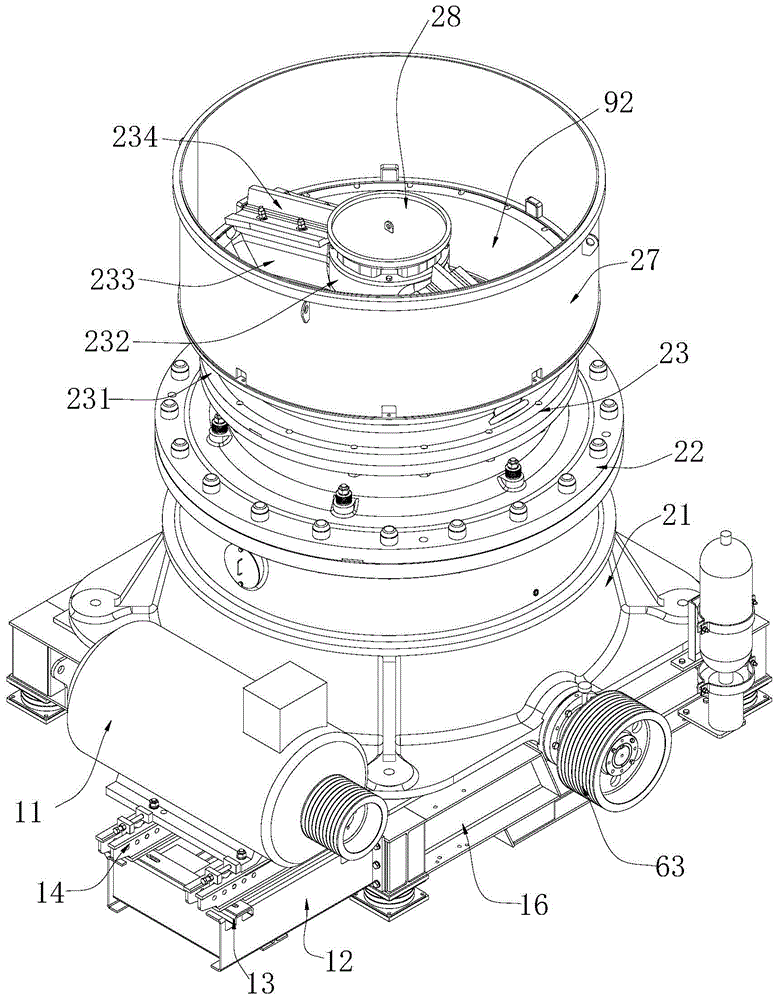

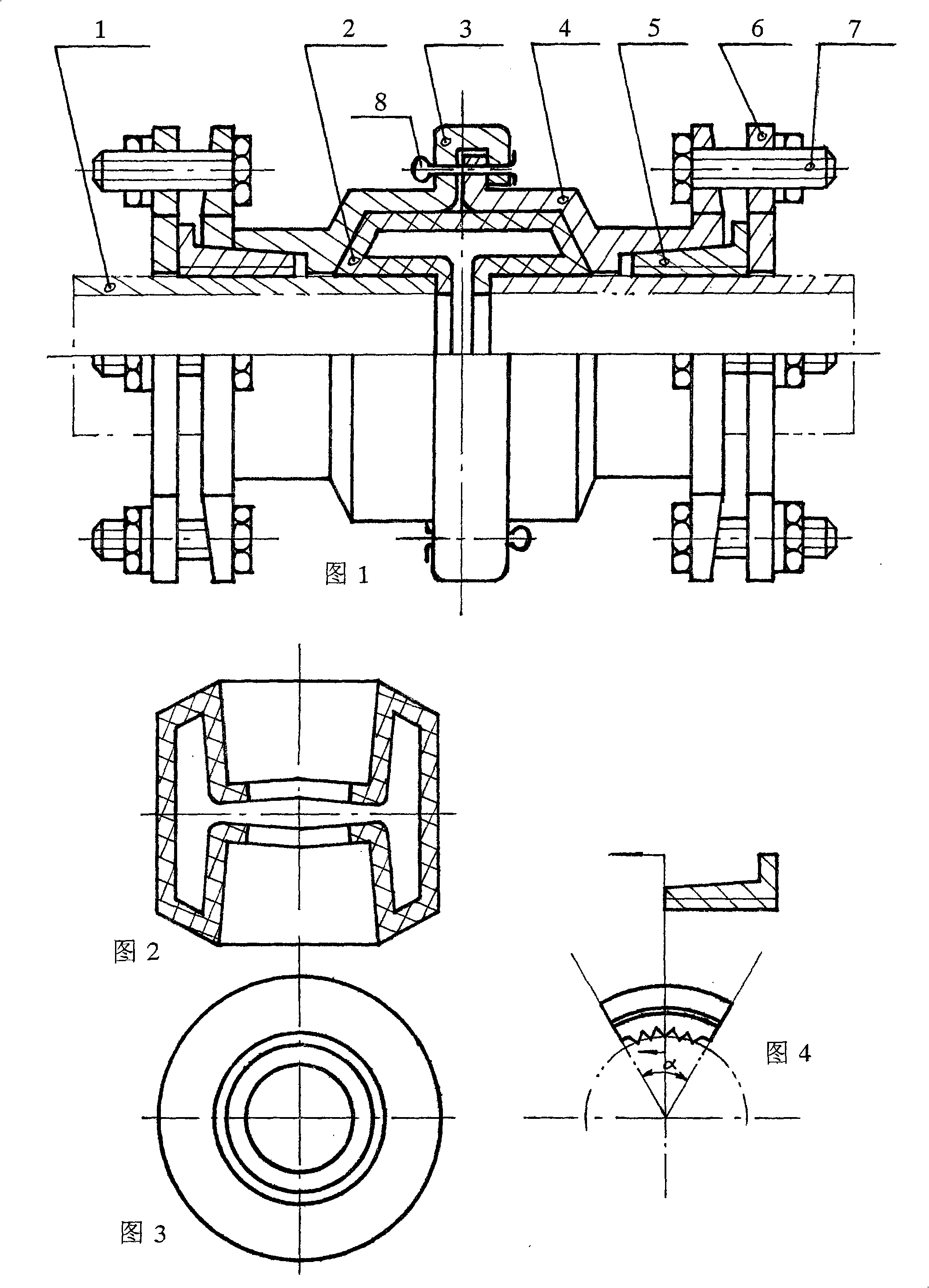

Hydraulic type cone crusher

ActiveCN104437725AIncrease stone flowImprove crushing efficiencyGrain treatmentsElectric machineryStructural engineering

The invention relates to the field of mining equipment, in particular to a hydraulic type cone crusher. The hydraulic type cone crusher comprises a machine base, a driving motor, a machine frame, a transmission mechanism, an eccentric mechanism, a hydraulic lifting mechanism, a moving cone spindle set and a bearing assembly, wherein the driving motor and the machine frame are arranged on the machine base, and the transmission mechanism, the eccentric mechanism, the hydraulic lifting mechanism, the moving cone spindle set and the bearing assembly are arranged in the machine frame. The driving motor drives the eccentric mechanism through the transmission mechanism, and the lower end of the moving cone spindle set is positioned and installed in the eccentric mechanism. The hydraulic lifting mechanism is located below the moving cone spindle set. The hydraulic lifting mechanism and the moving cone spindle set are connected through the bearing assembly. The hydraulic type cone crusher is high in strength, good in stability and convenient to install.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

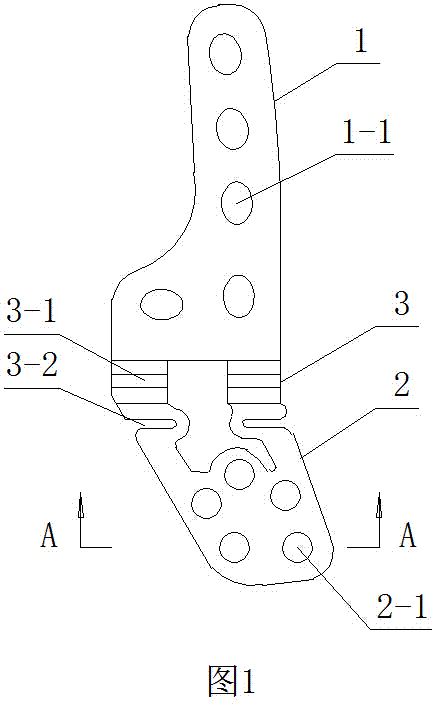

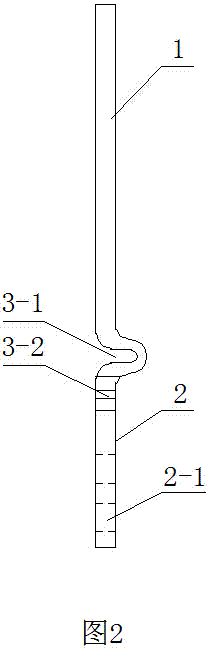

Flexible fixing plate for acromioclavicular joint

ActiveCN104116553AFixed firmlyEasy installation and positioningBone platesSteel platesSacroiliac joint

The invention relates to a flexible fixing plate for the acromioclavicular joint and belongs to the technical field of implantation materials in human bodies. The flexible fixing plate for the acromioclavicular joint is composed of an arc-shaped upper main board, an arc-shaped lower main board and an elastic deformation structure. The arc-shaped upper main board and the arc-shaped lower main board are connected and fixed through the two ends of the elastic deformation structure, and an upper main board fixing hole and a lower main board fixing hole are manufactured in the arc-shaped upper main board and the arc-shaped lower main board. Through the elastic deformation structure and the two arc-shaped main boards, the acromioclavicular joint can be elastically fixed, the original anatomical correspondence of the acromioclavicular joint can be restored to the maximum extent, the flexible fixing plate is firm and reliable in fixation, easy, convenient and accurate to install and position and good in treatment and healing effect, and postoperative restoration loss can be avoided. The flexible fixing plate for the acromioclavicular joint solves the problems that because the compressive stress of an existing hook steel plate structure on the acromion and the clavicle is too large, pain, the pressure swelling feeling, hook disengagement and fear of movement can be caused to a patient easily; the common problems that surgical restoration is not ideal, subacromial tissue is injured, and the treatment effect is seriously affected because an elastic micro movement fixing plate for the acromioclavicular joint is not high enough in elasticity are solved.

Owner:BIODA DIAGNOSTICS WUHAN

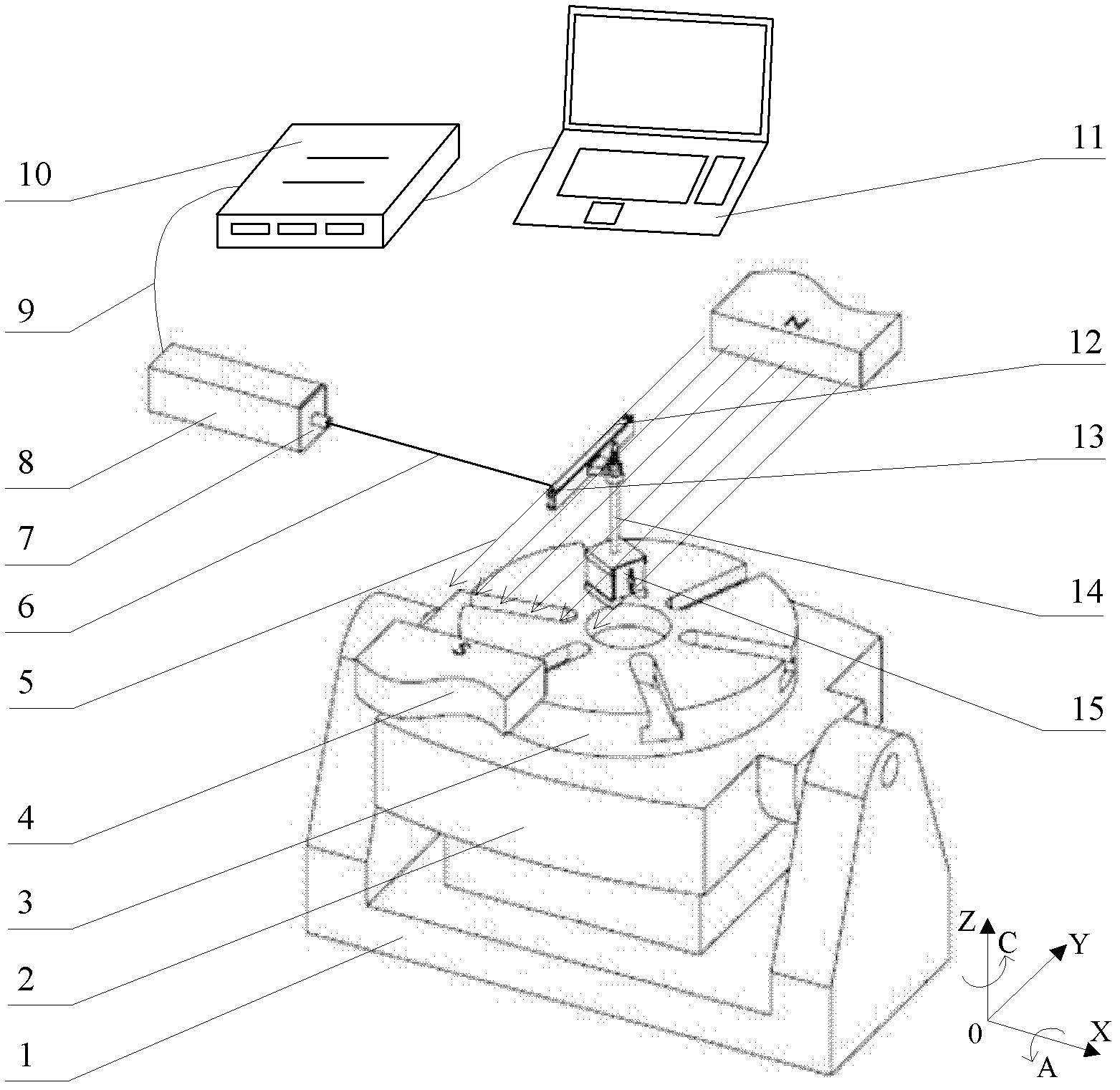

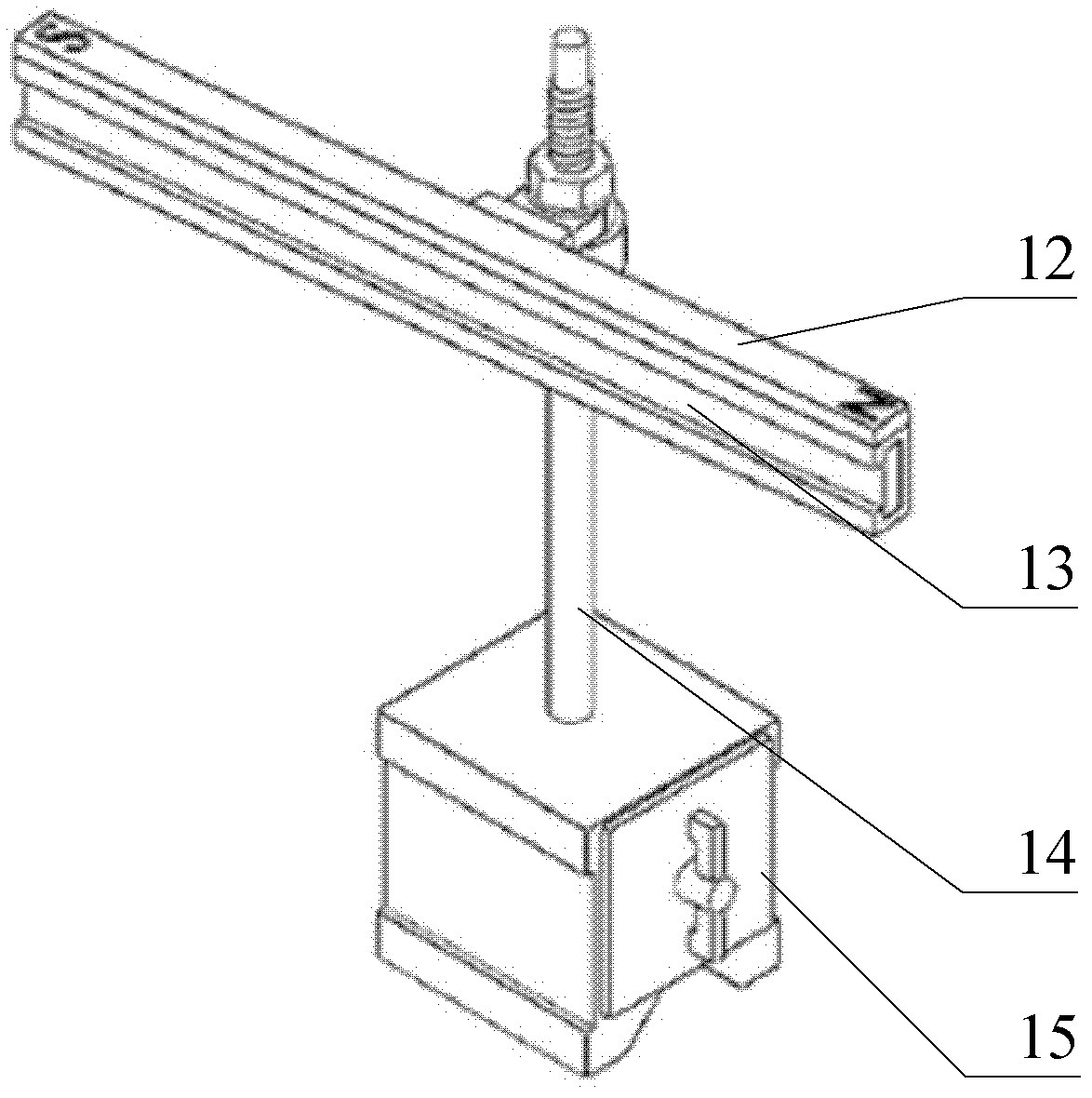

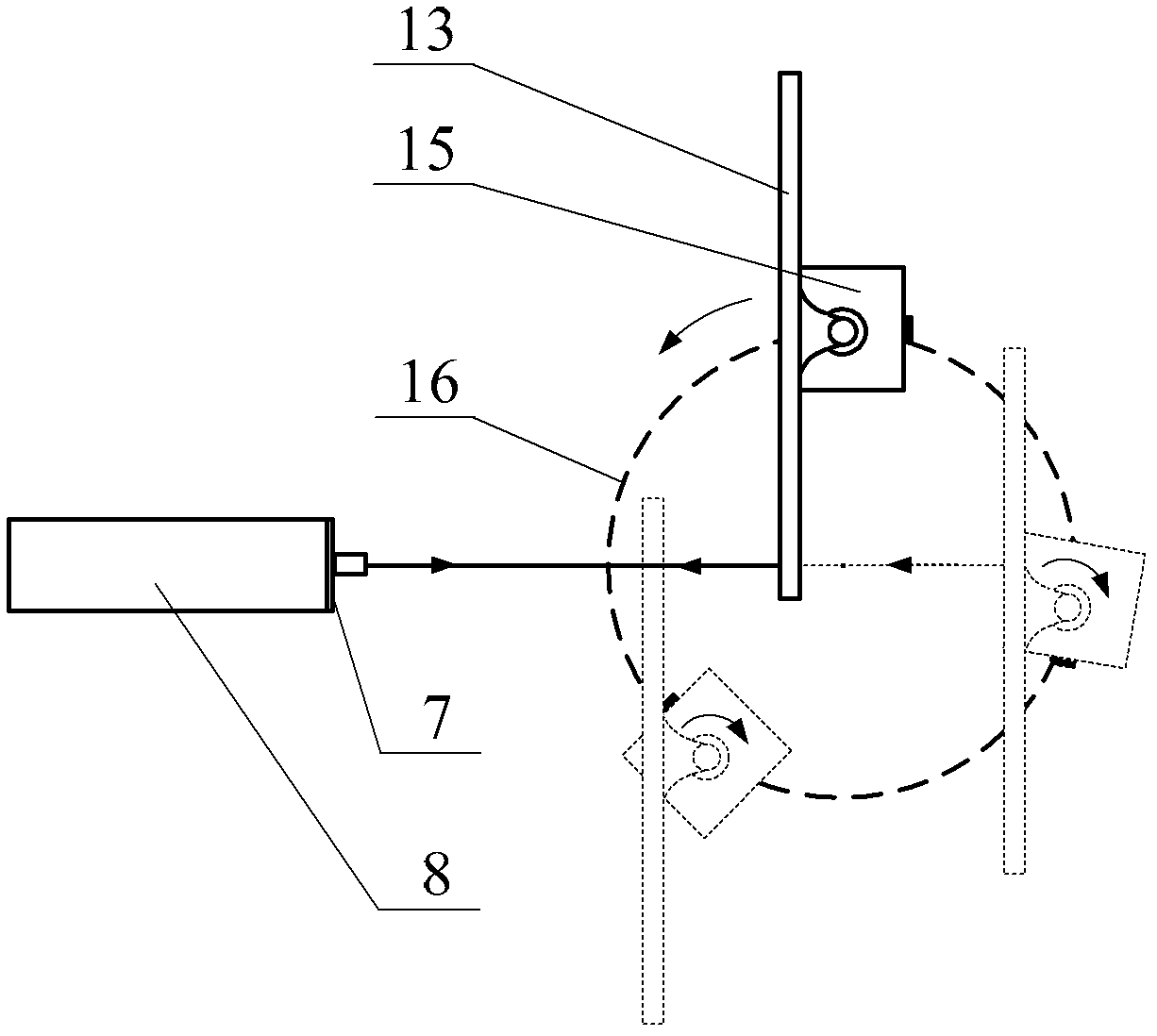

Device and method for measuring rotation angle error of rotary table of machine tool

InactiveCN102554710AGuarantee directionEasy to measureMeasurement/indication equipmentsLaser rangingMeasurement device

The invention discloses a device for measuring rotation angle error of a rotary table of a machine tool. The device comprises a support fixed on the rotary table; a reflecting mirror keeping running fit with the support; a magnetic field generator for generating a magnetic field; a magnetic field sensing member fixedly mounted on the reflecting mirror for keeping the direction of the reflecting mirror under the action of the magnetic field; and a laser ranging device for transmitting / receiving a laser beam to / from the reflecting mirror, and transforming the distance change of the reflecting mirror to the actual rotation angle of the rotary table. The device is simple in structure, convenient in measurement and easy to implementation, and can guide the direction of the reflecting mirror without contacting the reflecting mirror through the magnetic field and the magnetic field sensing member so as to facilitate distance measurement by the laser ranging device. The invention also discloses a method for measuring the rotation angle error of the rotary table of the machine tool. The method is convenient and accurate in measurement, and can calculate the error according to the actual rotation angle and a preset angle so as to provide the basis for error compensation of the machine tool.

Owner:ZHEJIANG UNIV

Progressive-die forming die for automobile suspension control arm lower piece

ActiveCN103920808AReduce frictionFast feedingShaping toolsPerforating toolsEngineeringDying processes

The invention belongs to the technical field of progressive dies and relates to a progressive-die forming die for an automobile suspension control arm lower piece. The progressive-die forming die comprises an upper die, a lower die, an inclined punching tool and a drawing tool, the inclined punching tool and the drawing tool are arranged between the upper die and the lower die, a plurality of feeding guide components are fixed on two lateral sides of a material belt moving track on the upper surface of the lower die at intervals along the material belt moving direction respectively, and stable and quick conveying of a material belt is realized; a nitrogen cylinder is arranged on each of an upper die seat and a lower die seat, so that buffering effect during drawing is enabled to be better; a wedge driving block is arranged on the lower die and matched with a sliding block with a punching head, so that side punching of a side hole punching process is realized. The progressive-die forming die is suitable for a progressive die processed by completing a series of different punching processes in a stroke of a punching machine each time.

Owner:TAIZHOU HUANGYAN DEDAO MOLD

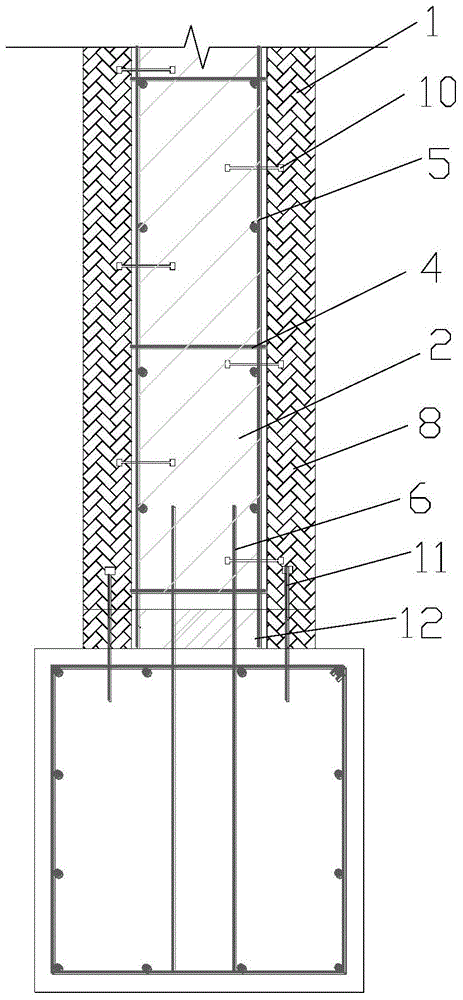

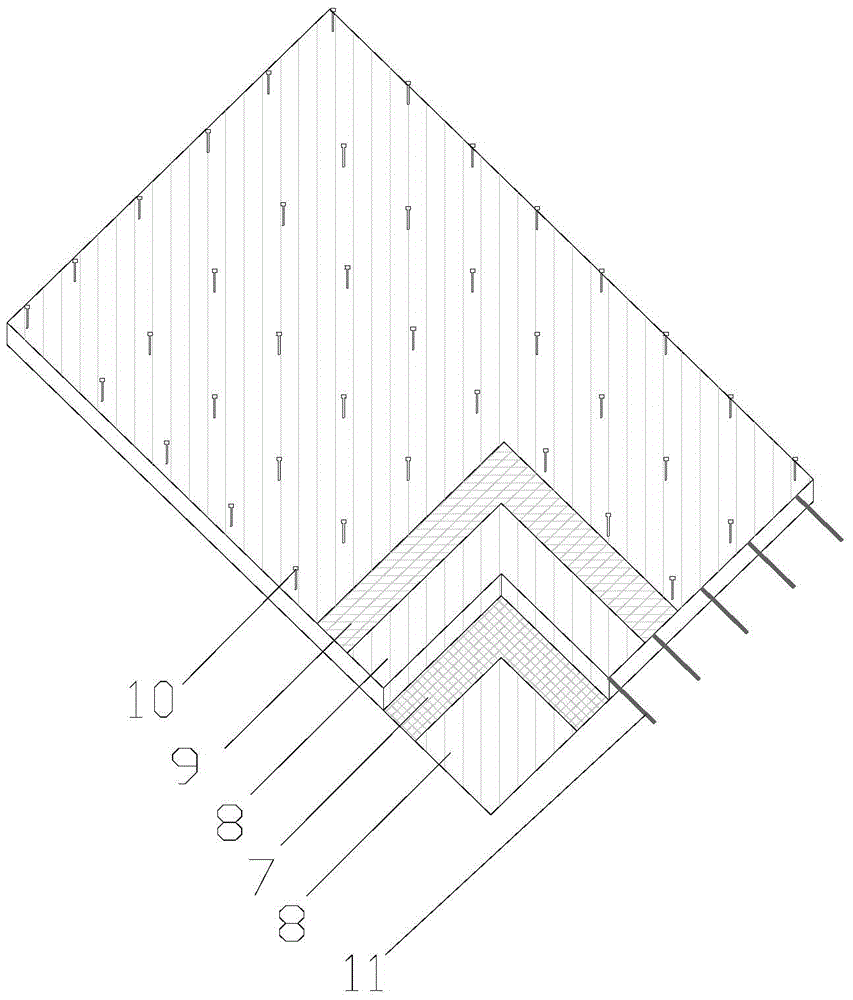

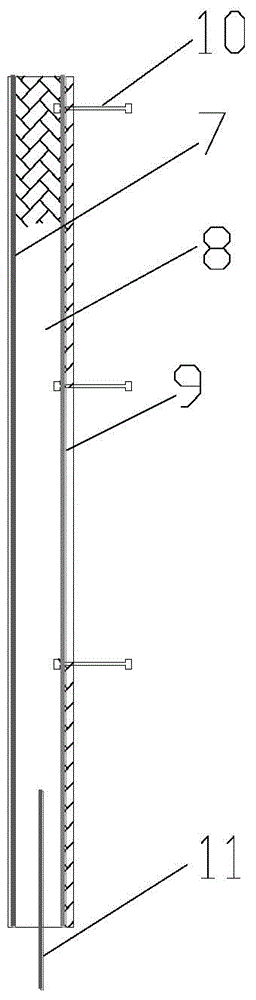

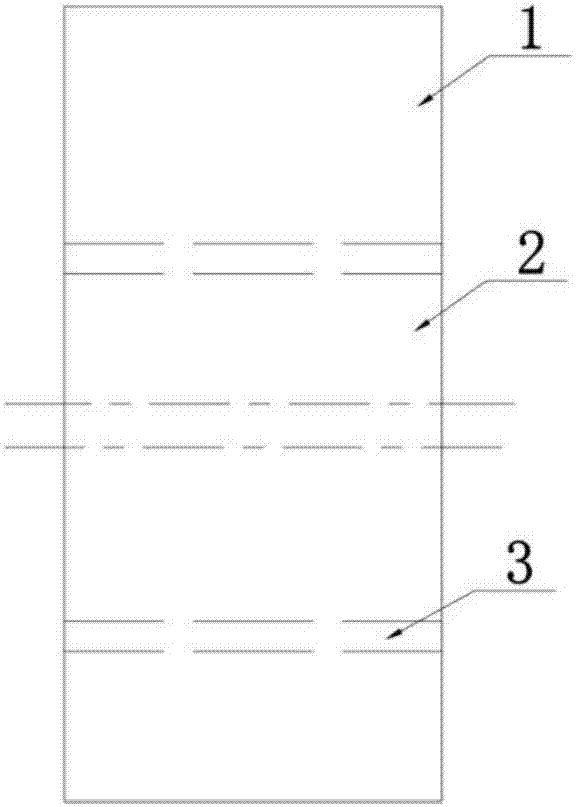

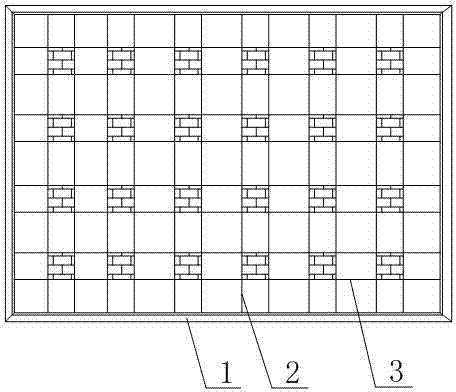

Self heat insulation laminated shear wall structure and construction process

InactiveCN104674987AHigh strengthMeet building energy-saving requirementsWallsBuilding material handlingInsulation layerReinforced concrete

The invention discloses a self heat insulation laminated shear wall structure and a construction process. The self heat insulation laminated shear wall structure comprises a light-weight self heat insulation concrete template, a cast-in-plate reinforced concrete structure layer and a foundation, wherein the cast-in-plate reinforced concrete structure layer is arranged between the light-weight self heat insulation concrete temperature at the outer side and the light-weight self heat insulation concrete template at the inner side, the foundation is positioned under the shear wall, and the light-weight self heat insulation concrete template comprises a fabric net, regeneration light-weight aggregate heat insulation concrete, a steel wire net piece, a shear connecting element and a bottom screw bolt steel bar. The light-weight self heat insulation permanent template is a heat insulation layer, also achieves the template effect, and is also a part of the structure for participating in the integral deformation work, the deformation slide moving between prefabricated and cast-in-plate parts is also borne through the introduction of the shear connecting element, meanwhile, the lifting effect between the permanent template and the cast-in-plate concrete is also resisted, and the problems of connection firmness and durability between the heat insulation layer and the structure layer are thoroughly solved.

Owner:NANJING UNIV OF TECH

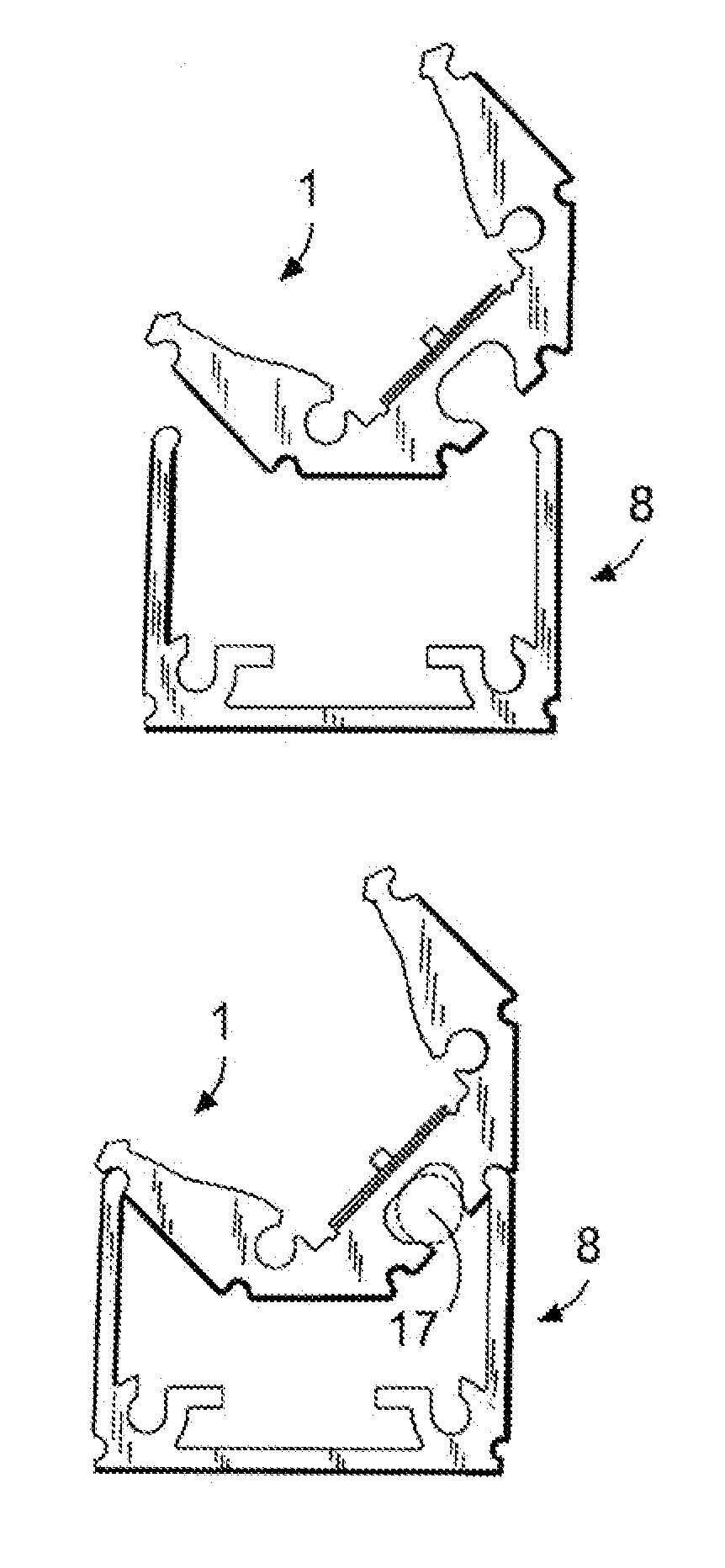

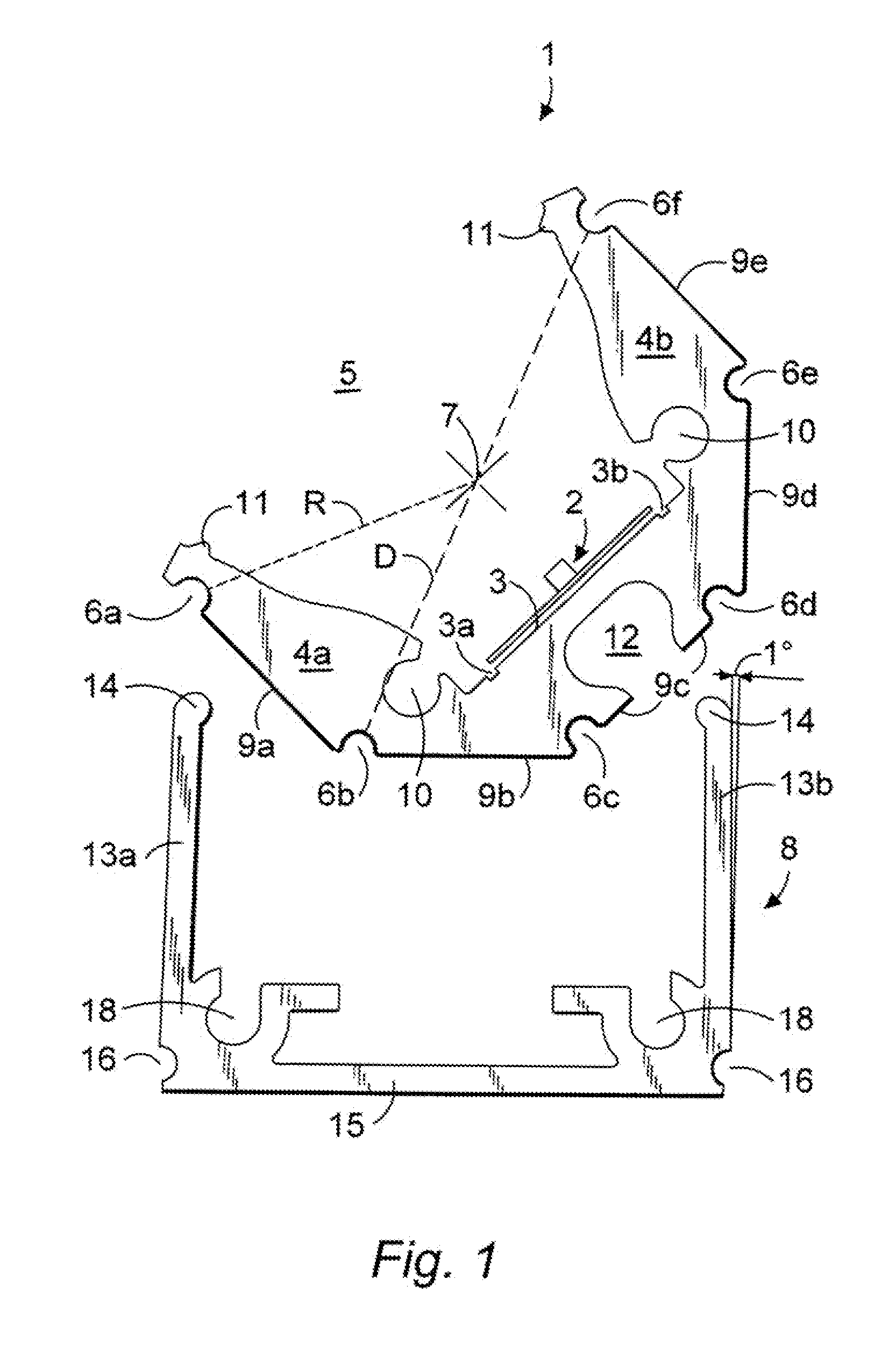

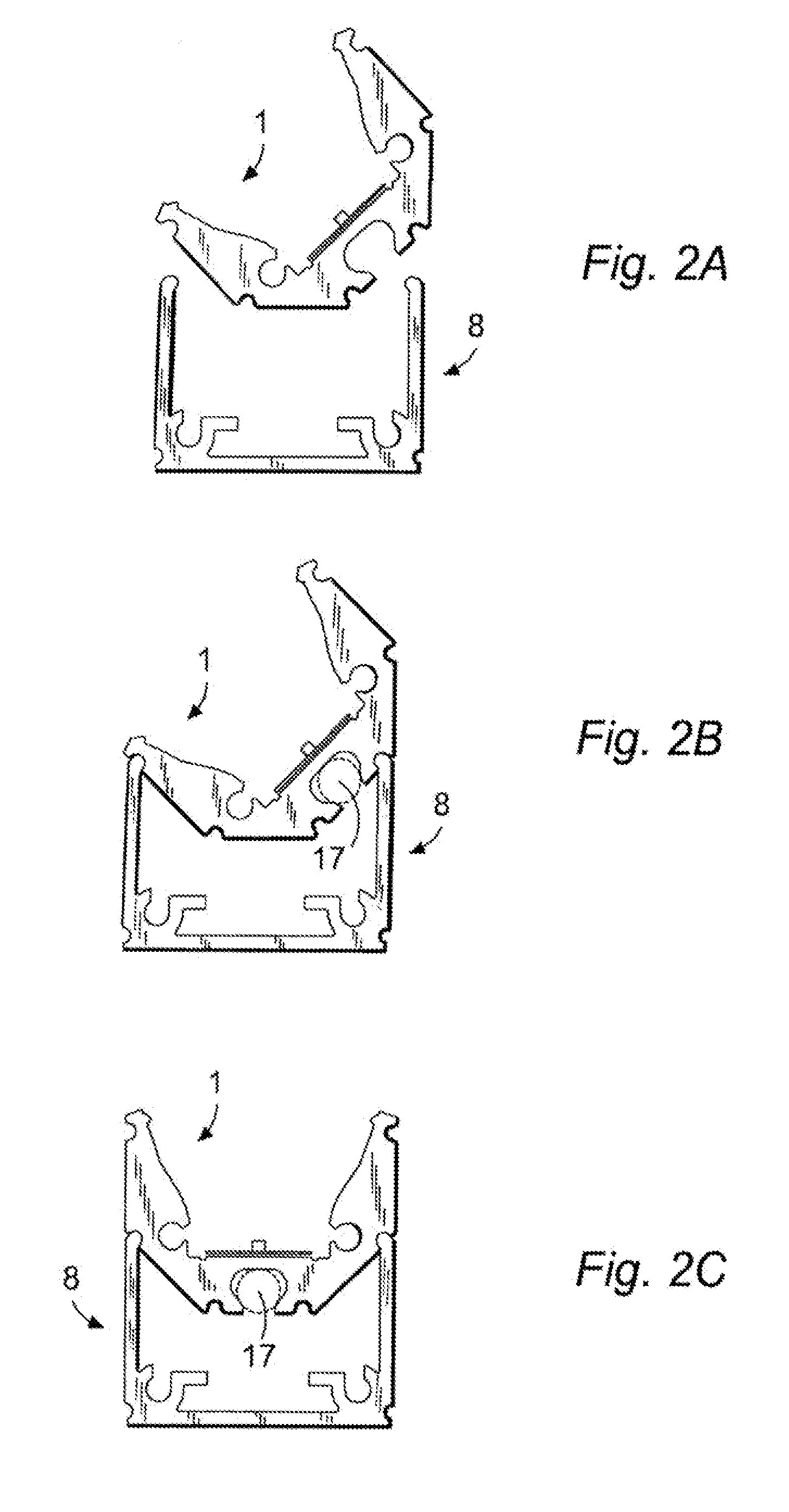

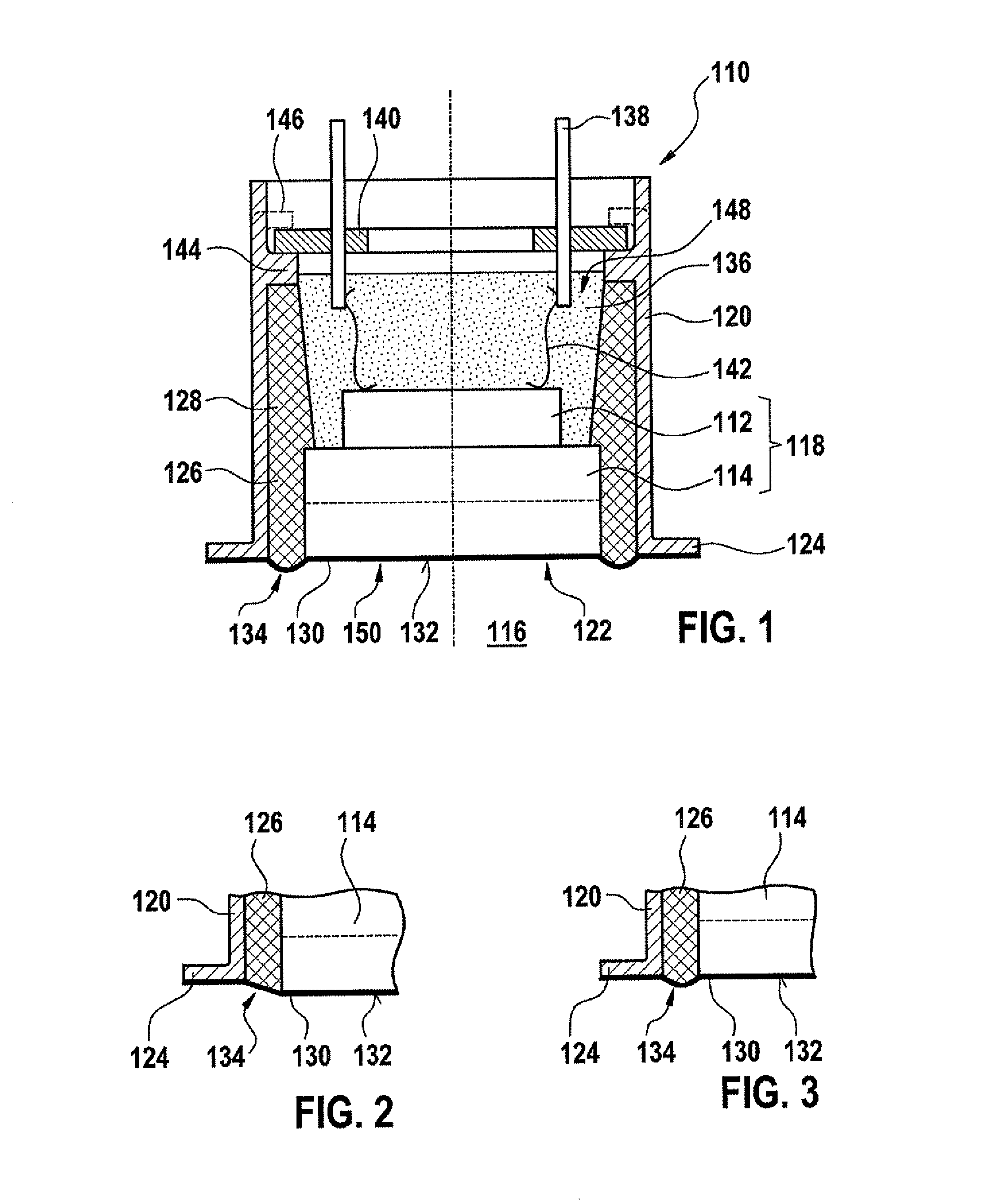

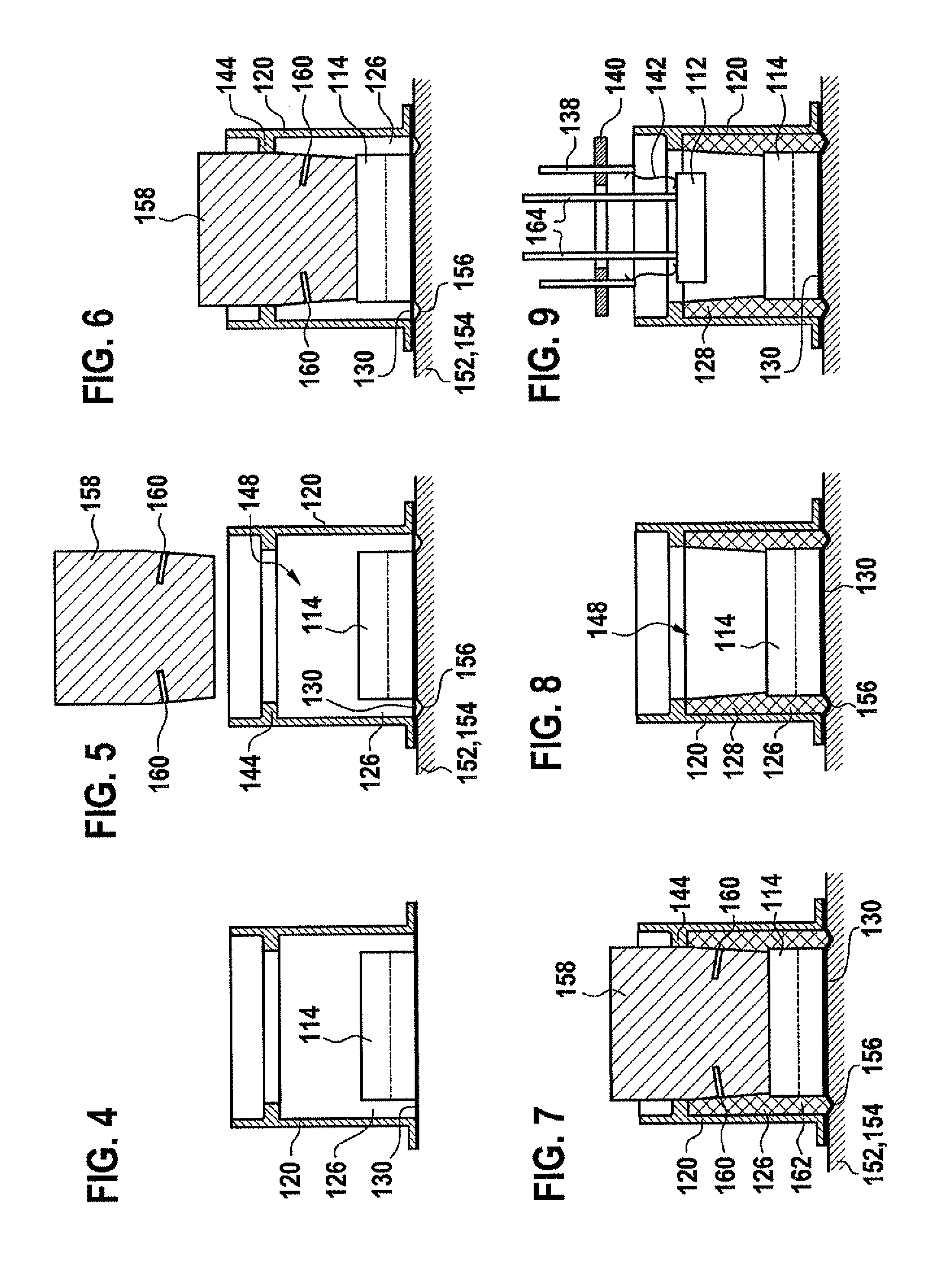

Mounting rail for a lamp

ActiveUS20130039052A1Facilitate positioning and fixationEasy to locate and installCoupling device connectionsLighting support devicesMechanical engineeringOpen cavity

A generally U-section adapter profile extending along a longitudinal axis forms a longitudinally extending and transversely open cavity and has an outer surface formed with an array of at least three longitudinally extending and radially outwardly directed outer mounting formations radially spaced from the longitudinal axis and angularly spaced around the longitudinal axis. An elongated light emitter is provided in the cavity. A generally U-section mounting rail extending parallel to the axis opens radially toward the axis and has two side walls formed with inwardly directed and longitudinally extending inner mounting formations generally complementary to the outer formations and spaced so that the profile can be fitted to the rail in at least two different positions in each of which the two inner formations of the rail engage in two of the outer formations of the profile.

Owner:LED LINEAR

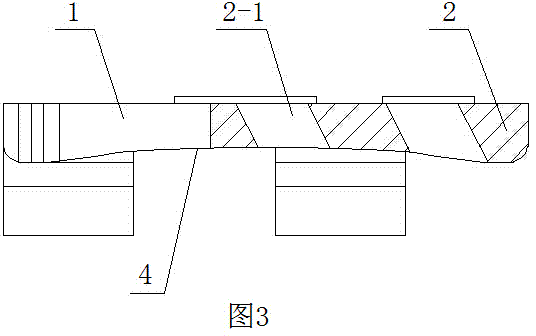

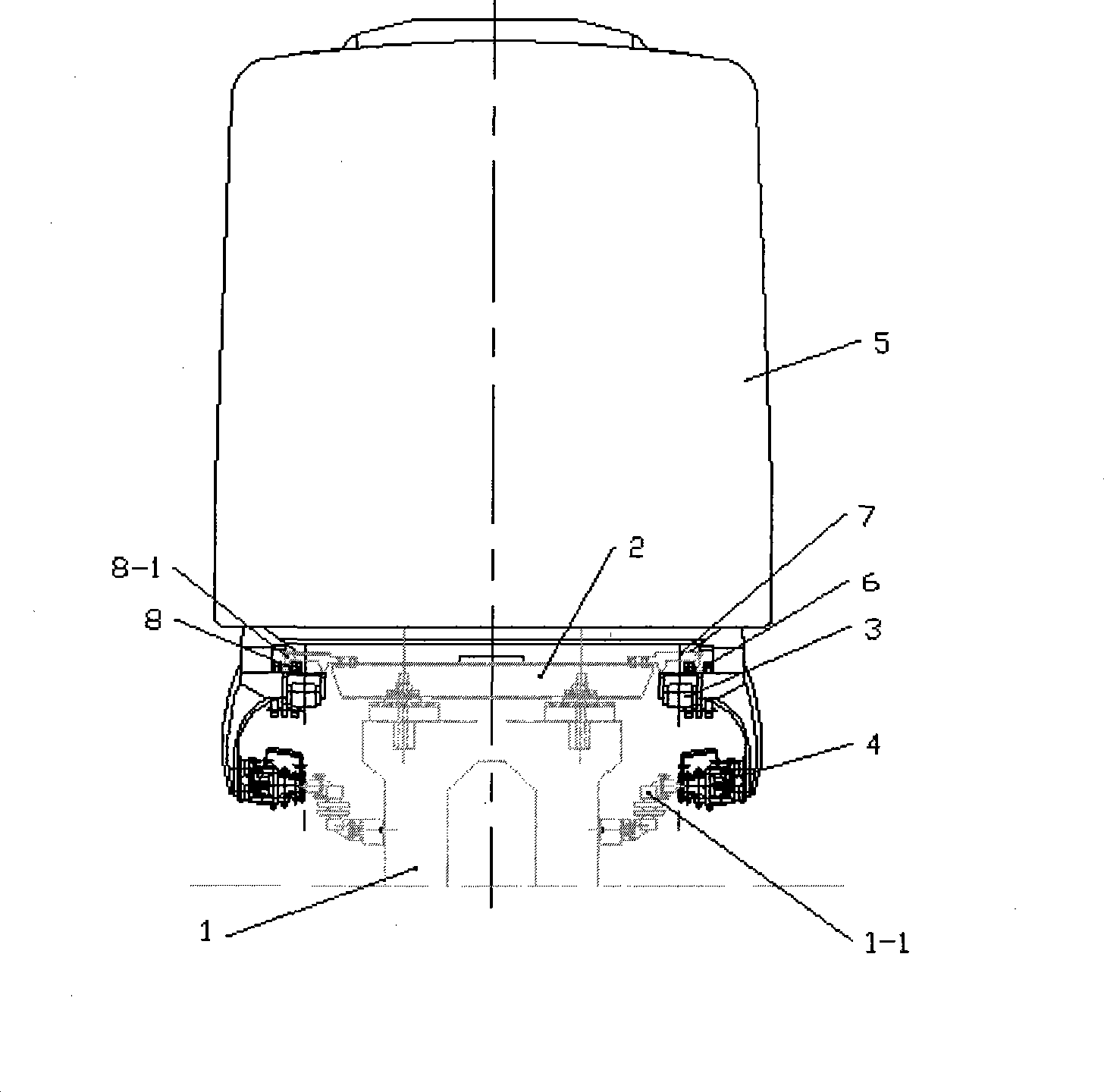

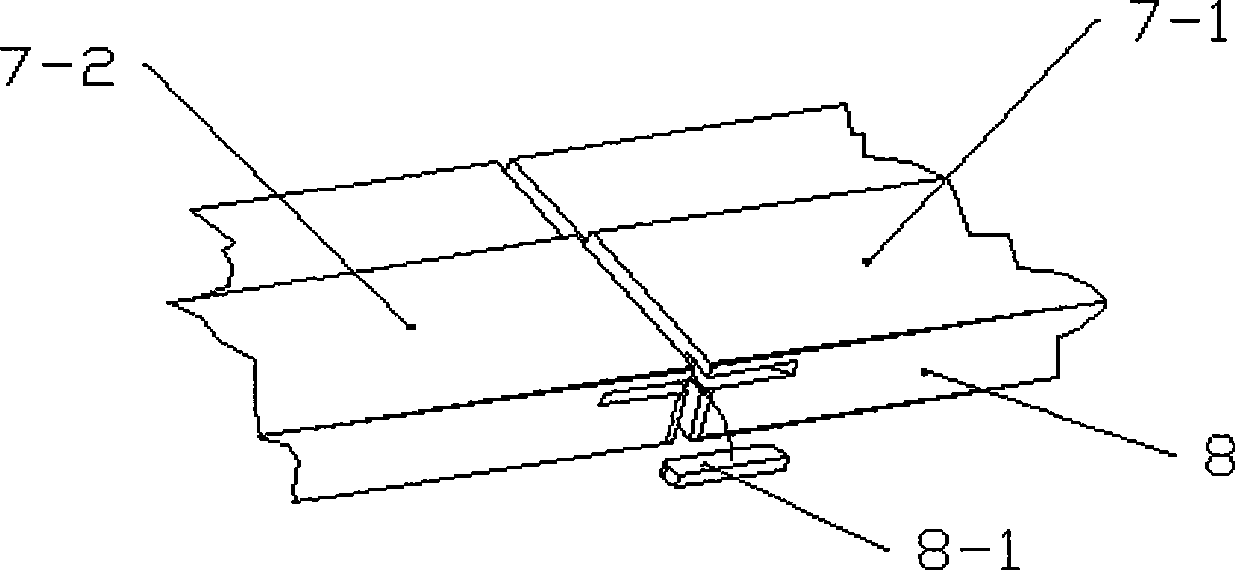

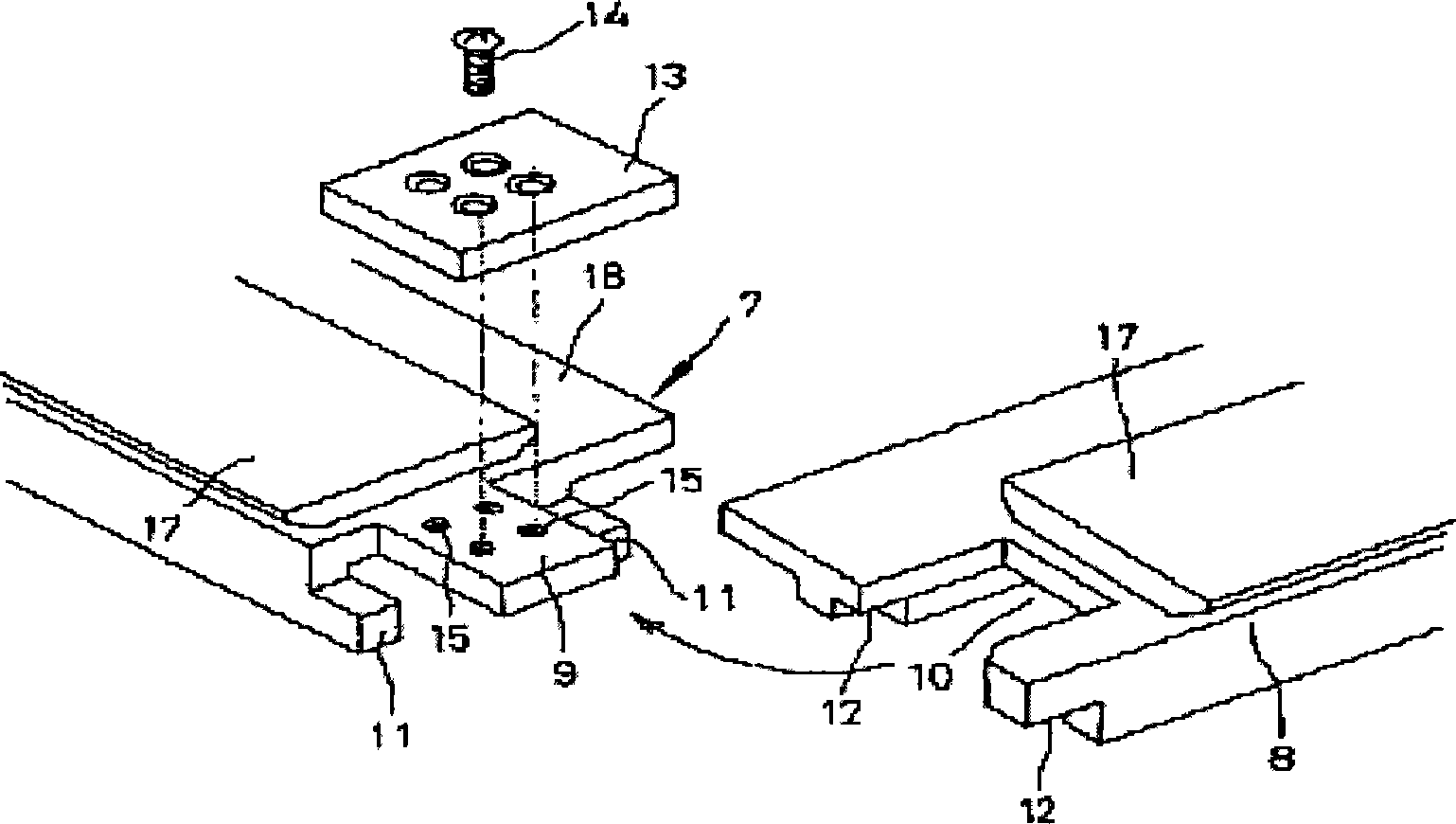

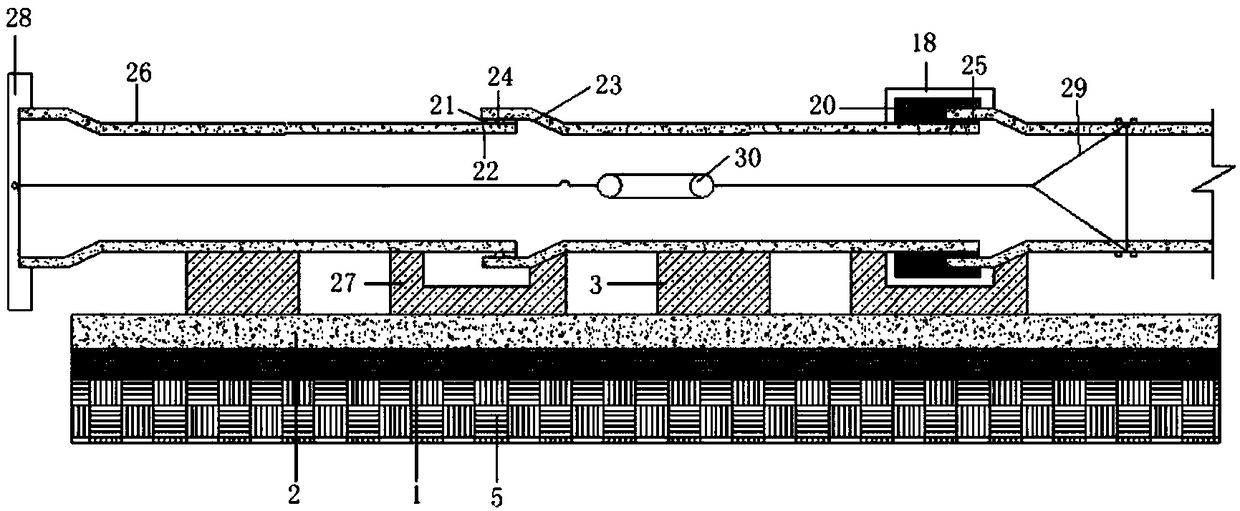

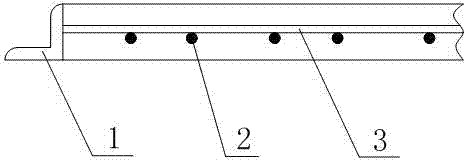

Low speed magnetic floating system F rail seaming structure and processing method thereof

InactiveCN101377070AEasy to locate and installSimple structureRailway tracksLow speedTemperature difference

The present invention discloses an F rail seam structure, which is designed by adopting the normal conducting electromagnetic levitation technology and provided by a low-speed magnetic levitation system for the levitation and guiding of vehicles. The F rail seam structure has the following characteristics: the end of a F rail is milled into an embedding surface, so that a convex splicing part is formed; the end of the convex splicing part is shaped like a circular arc (or planar); circular arc-shaped (or planar) end surfaces are formed on the convex splicing part and a step formed on the upper and the lower ends of the body of the F rail; and a concave part and a circular arc-shaped (or planar) end surface which match the circular arc-shaped (or planar) end surfaces on the convex splicing part and the step are formed on the end surface of the other end of the F rail. While still ensuring rail seam expansion adjustment, vertical and lateral positioning and the rail expansion adjustment of a turnout, the F rail seam structure is simplified and can be easily centered in the process of machining and installation. The F rail seam structure not only can ensure the centering adjustment of rails but also can adjust the temperature-difference expansion of the rails and realize the stretching adjustment of the turning of the turnout. The F rail seam structure is generally used in a passive guiding type low-speed magnetic levitation system.

Owner:TONGJI UNIV

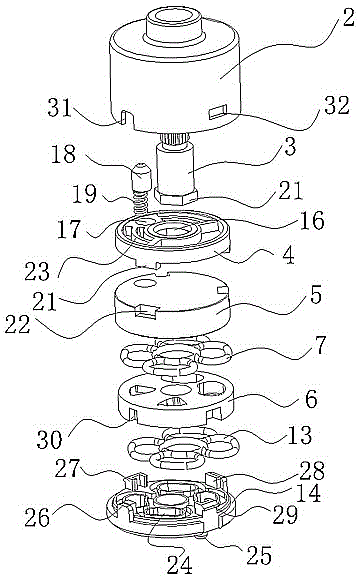

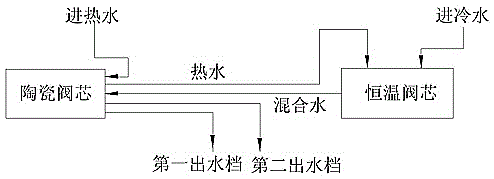

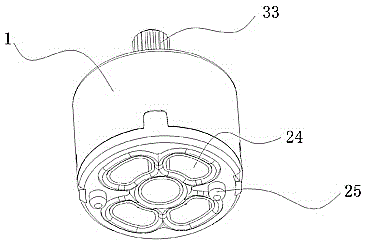

Ceramic valve element achieving double-path water output

InactiveCN105156714AReduced side sealReduce the number of sealsOperating means/releasing devices for valvesMultiple way valvesEngineeringThermal water

The embodiment of the invention discloses a ceramic valve element achieving double-path water output. The ceramic valve element comprises a valve element shell, an adjusting handle, a drive plate, a moving sheet, a static sheet, a sealing piece and a base from top to bottom. The static sheet is provided with a hot water inlet, a hot water outlet, a mixed water inlet, a first gear water outlet and a second gear water outlet which are connected with pipelines. Three flow guide channels are arranged on the moving sheet, and the flow guide channels of the moving sheet are driven by rotating the adjusting handle of the ceramic valve element to match the static sheet to form a water output closing state or a first gear water output state or a second gear water output state. A spring hole is formed along the end face of the drive plate, and a gear collision bead and a spring are arranged in the spring hole. A gear pit is arranged on the top wall of the valve element shell, and the gear collision bead is located in the gear pit in a pluggable manner along with rotation of the drive plate. According to the ceramic valve element achieving double-path water output, the wear resistance and ageing resistance are improved, the service life is prolonged, locating and mounting are convenient, and processing is easy.

Owner:TAIZHOU GUOREN TEMPERATURE CONTROL SANITARY WARE TECH CO LTD

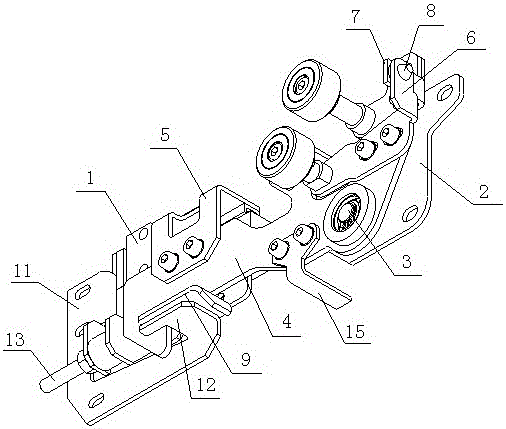

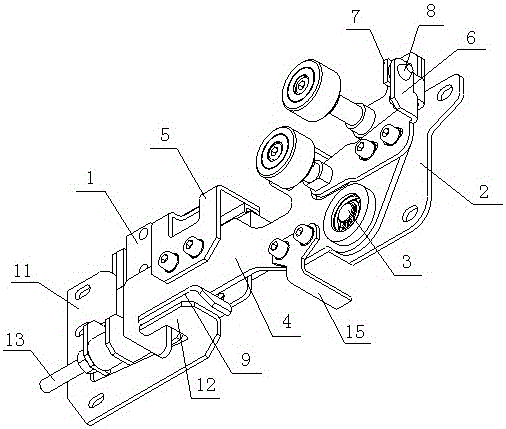

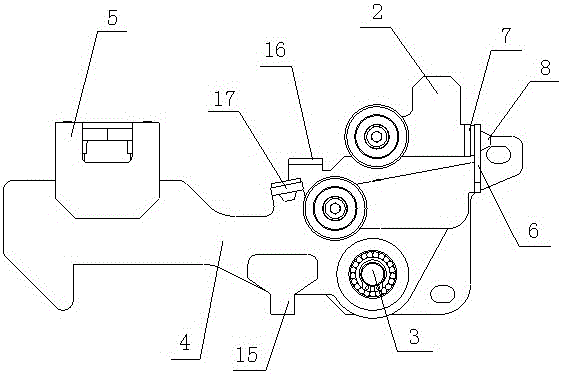

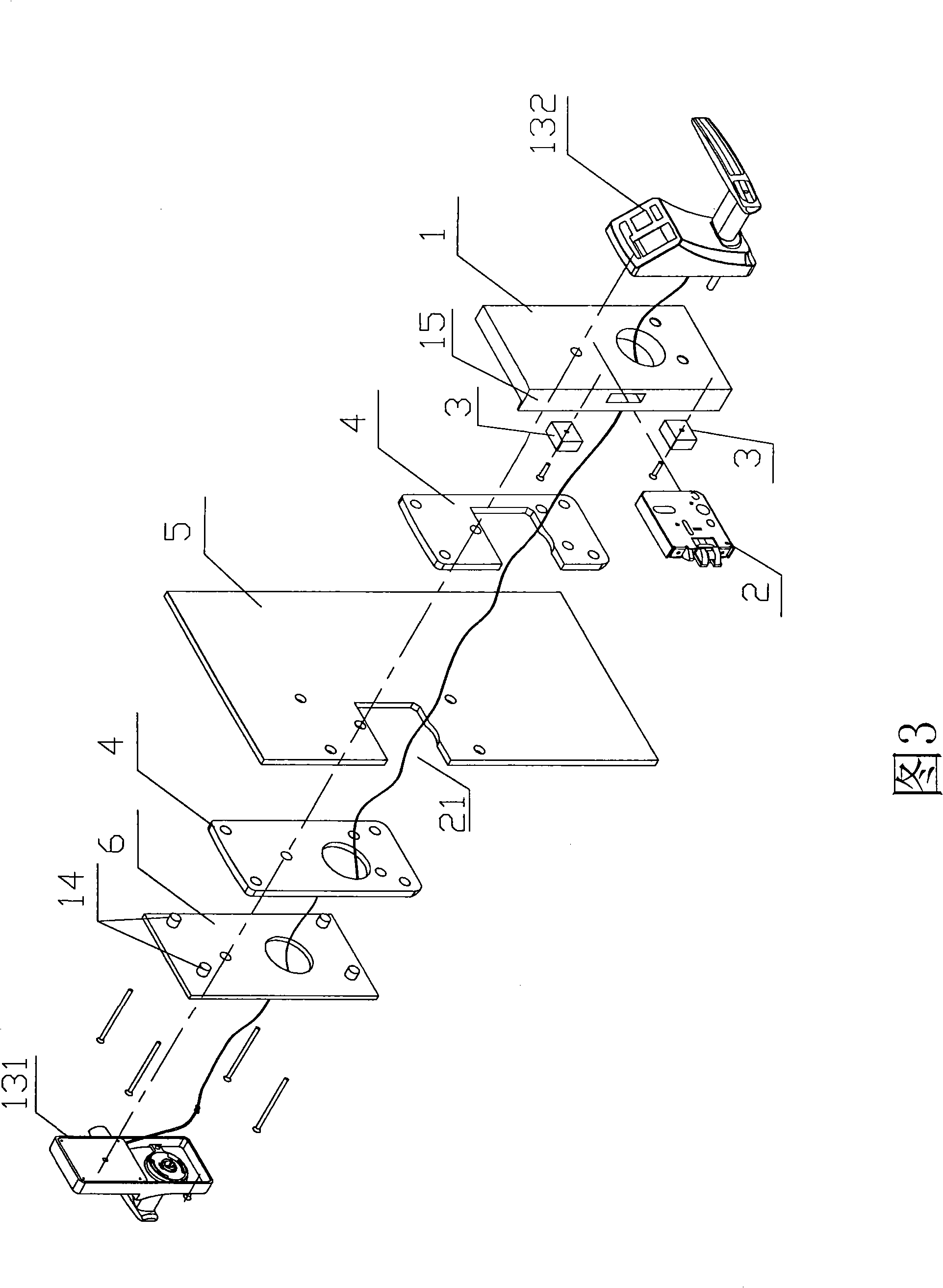

Door lock structure for external elevator floor door

InactiveCN106395582AQuick positioning installationEasy to installBuilding liftsMechanical engineeringFloor level

The invention relates to a door lock structure for an external elevator floor door. The door lock structure is mounted above an elevator door, and comprises a left hanging plate and a door lock fixing plate which are mounted on a door head, wherein a lock hook assembly is arranged on the door lock fixing plate, and comprises a rotating shaft which is rotationally connected with the door lock fixing plate; a lock hook is arranged on the rotating shaft; a connecting plate is arranged at the front end of the lock hook; a first movable limiting plate is arranged at the rear end of the lock hook; a first fixed limiting plate is arranged on the door lock fixing plate; the first movable limiting plate is arranged on the outer side of the first fixed limiting plate; a positioning bulge is arranged on the first movable limiting plate; a first lock groove plate used for being matched with the lock hook is arranged on the left hanging plate and provided with a slope; and the slope is matched with the inclined surface at the front end of the lock hook. Through the matching between the first fixed limiting plate and the first movable limiting plate as well as through arrangement of the positioning bulge, the lock hook can be rapidly mounted and positioned. Accordingly, the mounting is convenient and rapid, a lot of time is saved, the mounting efficiency is improved, and the safety performance is guaranteed.

Owner:SUZHOU HEYANG METAL PROD

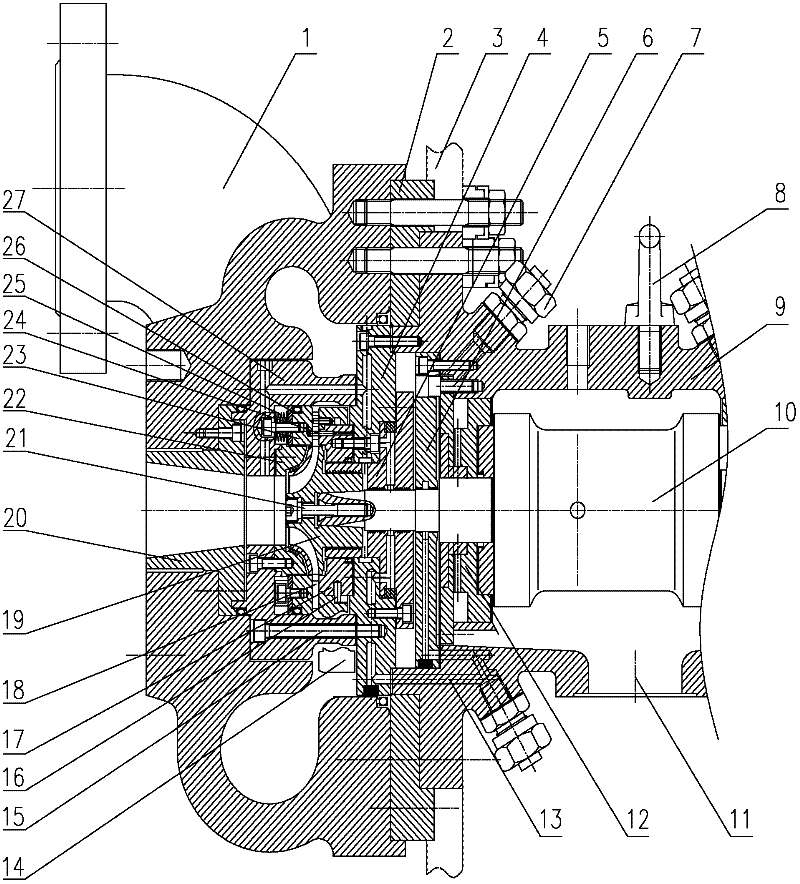

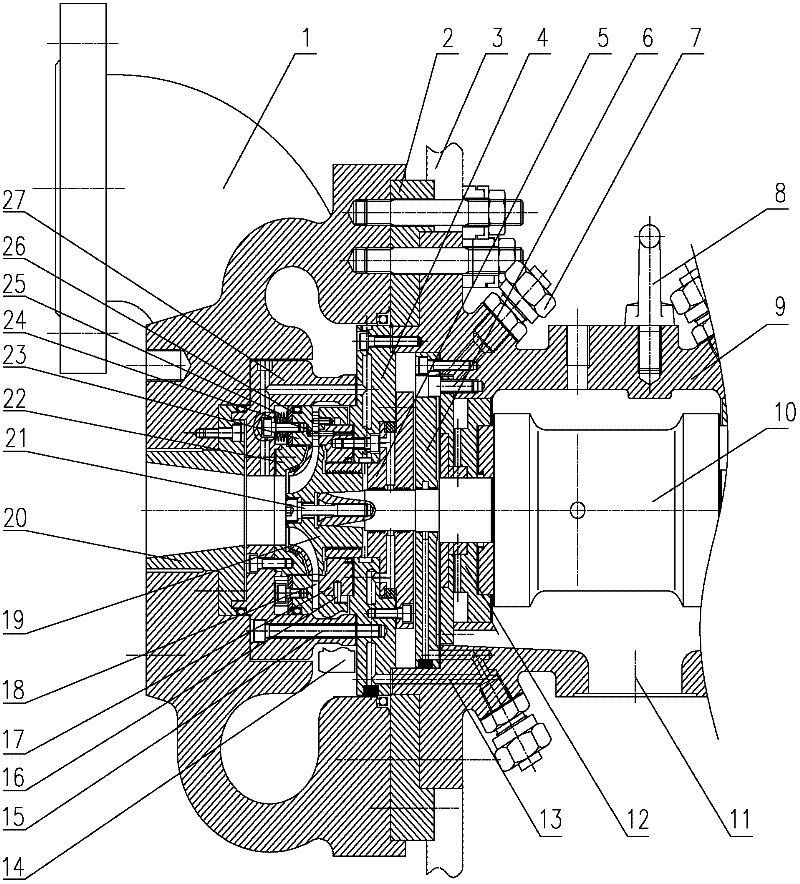

Low-temperature hydraulic turbine

ActiveCN102562170AReduce running cold lossReduce energy consumptionStatorsNon-positive displacement enginesImpellerHydraulic turbines

The invention discloses a low-temperature hydraulic turbine. A rotor impeller end and a nozzle set are completely arranged in a cavity in a volute; a volute main body is placed into a perlite sand cold-keeping box; a heat-insulating cushion for insulating is arranged between the volute and a shell, so that a cold screen is effectively realized; an oil seal with an oil slinger structure is not used in a rotor, so that the use of a rotating part is reduced and the running reliability is increased; the nozzle set is completely connected with the shell through a nozzle clamping flange; the compressing degree of a nozzle compressing plate to a nozzle blade is adjusted by a disc spring; a nozzle turntable is axially and rotatably connected with a nozzle chassis and a nozzle adjusting mechanism passing through the volute is used for adjusting an angle; an outlet of the impeller is connected with a pressure expanding pipe, so as to reduce the flow rate at the outlet of the impeller and reduce the flowing loss; a lateral sealing and a shaft sealing of a wheel cover are respectively fixed in the axial direction on the nozzle clamping flange and a sealing gas piece; and the sealing gas piece and the oil seal are both fixed in the axial direction on the shell through bolts, so that the axial part of the whole turbine is conveniently positioned and mounted.

Owner:开山(西安)透平机械有限公司

Novel rotating miller

InactiveCN101648287AEasy to locate and installLow costLarge fixed membersMilling equipment detailsEngineeringOrbit plane

The invention discloses a novel rotating miller which comprises a main beam that is connected with an electric appliance cabinet; a drag link mechanism is arranged above the main beam, a workbench isarranged below the main beam, a rotating mechanism is arranged at the lower end of the workbench, and a left beam and a right beam are arranged at the left end and the right end of the main beam, wherein the right beam is connected with a longitudinal beam, the left beam and the right beam are connected to a power cutting head, a support structure is arranged at the side of the connection part ofthe main beam and the right beam, and alarm lamps are arranged at two ends of the main beam. The invention has good security, small volume, convenient installation and gas milling speed and can achieve the advantages that two annular orbit planes are processed simultaneously after once positioning, and the parallelism degree is high after being processed.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

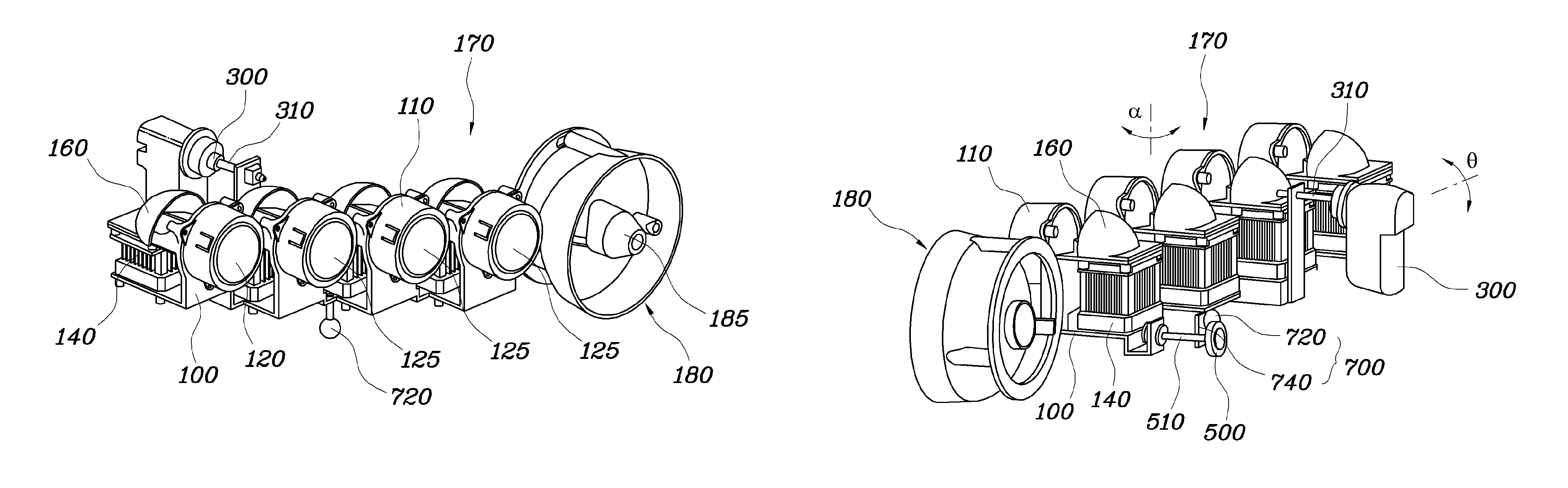

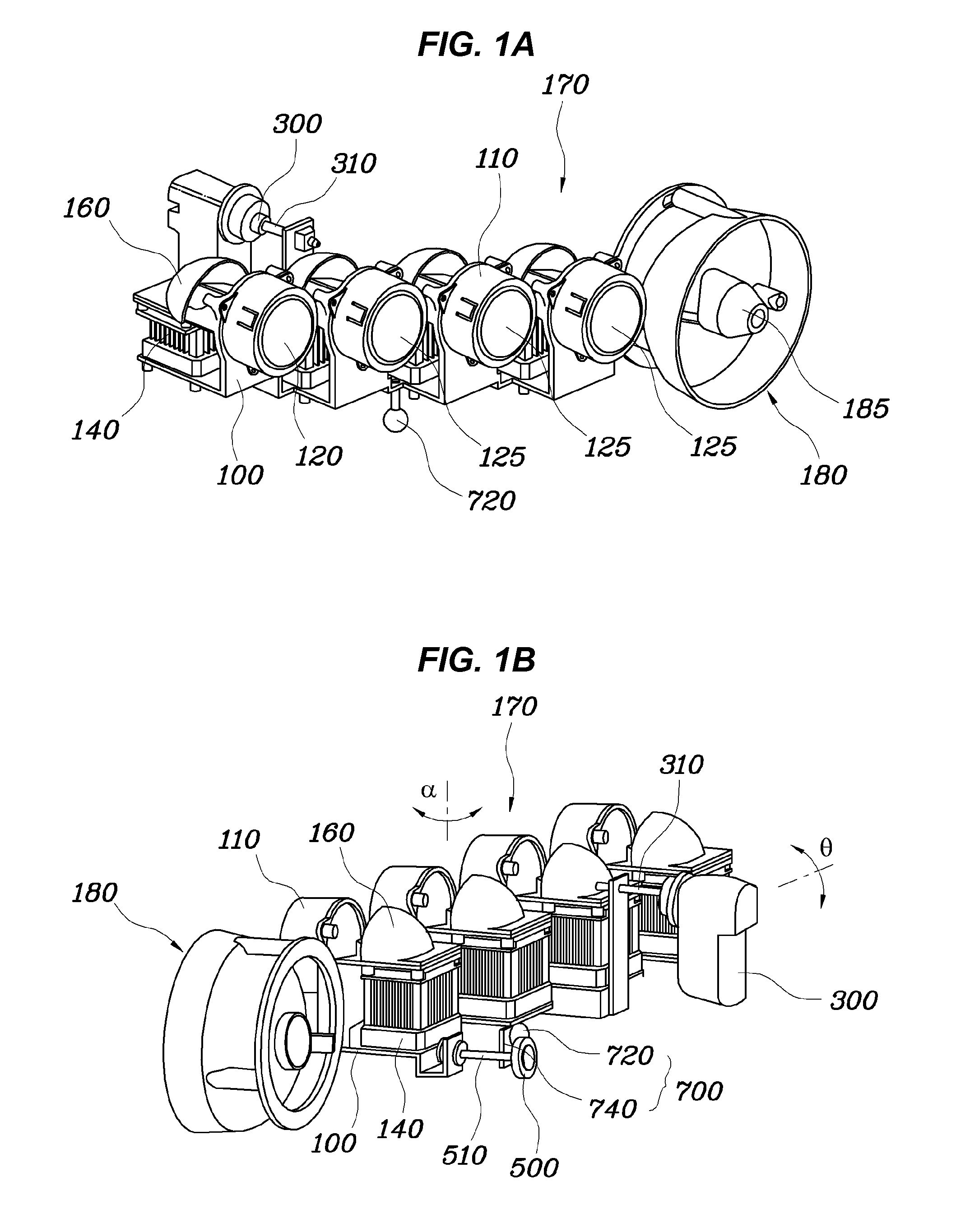

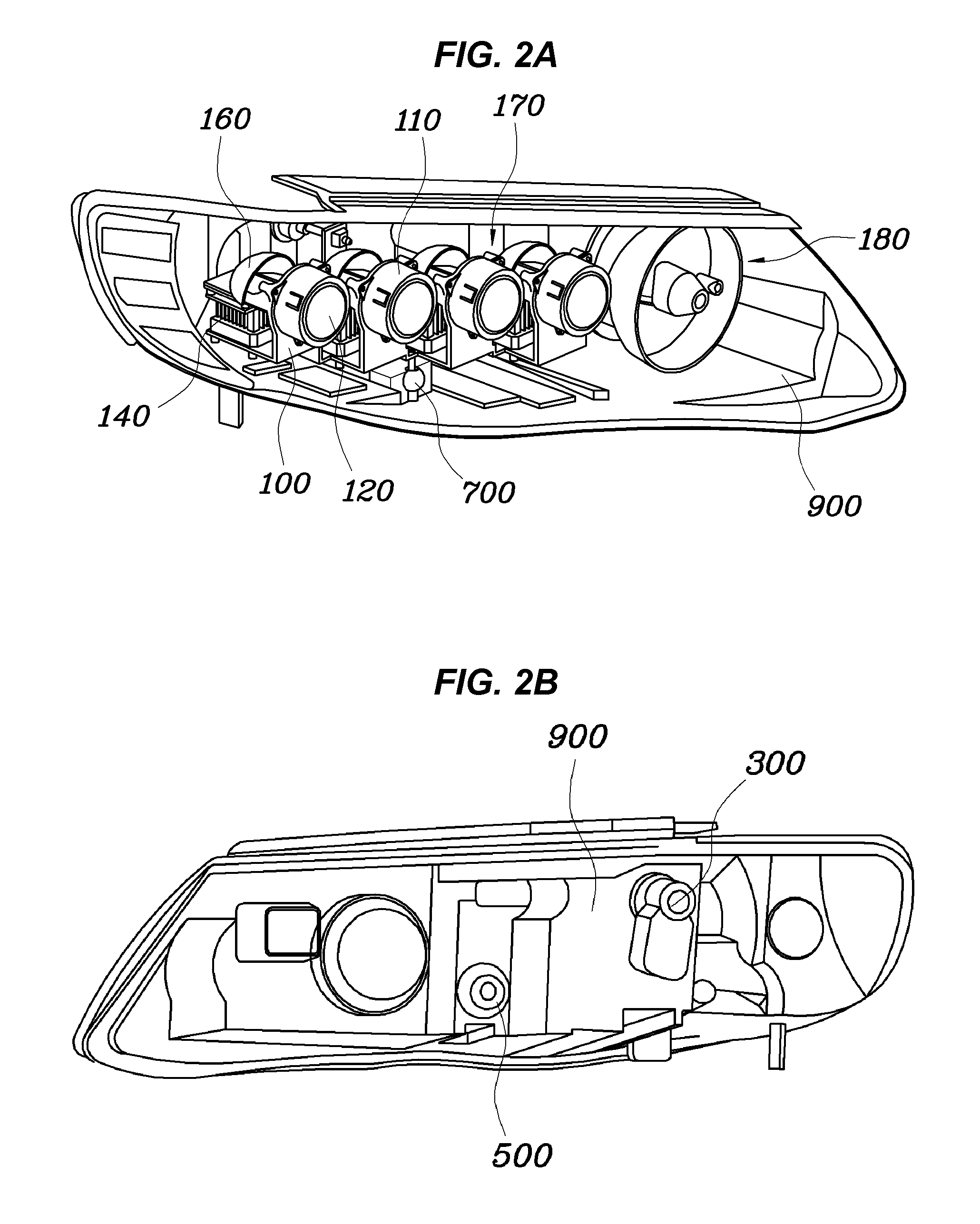

Apparatus for aiming LED headlamp

ActiveUS7784955B2Easy to locate and installImprove abilitiesVehicle headlampsVehicle interior lightingComputer moduleEngineering

Owner:HYUNDAI MOTOR CO LTD +1

Novel riverway ecological slope protection structure and slope protection method thereof

InactiveCN110725278AImprove connection strengthImprove connection stabilityCoastlines protectionRiver routingSurface cleaning

The invention discloses a novel riverway ecological slope protection structure and a slope protection method thereof. The novel riverway ecological slope protection structure includes ecological blocks and anchor nails, and the two ecological blocks adjacent to each other in an up-down or left-right mode are fixedly connected by the anchor nails. The slope protection method includes the steps of riverway slope protection surface cleaning, foundation construction, ecological block machining, ecological block construction, water retaining mechanism removal, and slope protection maintenance. According to the novel riverway ecological slope protection structure, connection strength and stability between the two adjacent ecological blocks adjacent to each other in the up-down or left-right modeare greatly improved through the anchor nails, thus the stability of the entire ecological slope protection structure is improved, the protection effect of the slope protection structure is improvedto prevent water and soil loss on the riverway slope protection surface, the slope protection method is simple in steps and high in practicability, slope protection construction of different riverwayslope protection surfaces can be met, the construction efficiency is high, the construction period is shortened, and the effect of preventing soil and water loss is significant.

Owner:浙江永安工程咨询集团有限公司

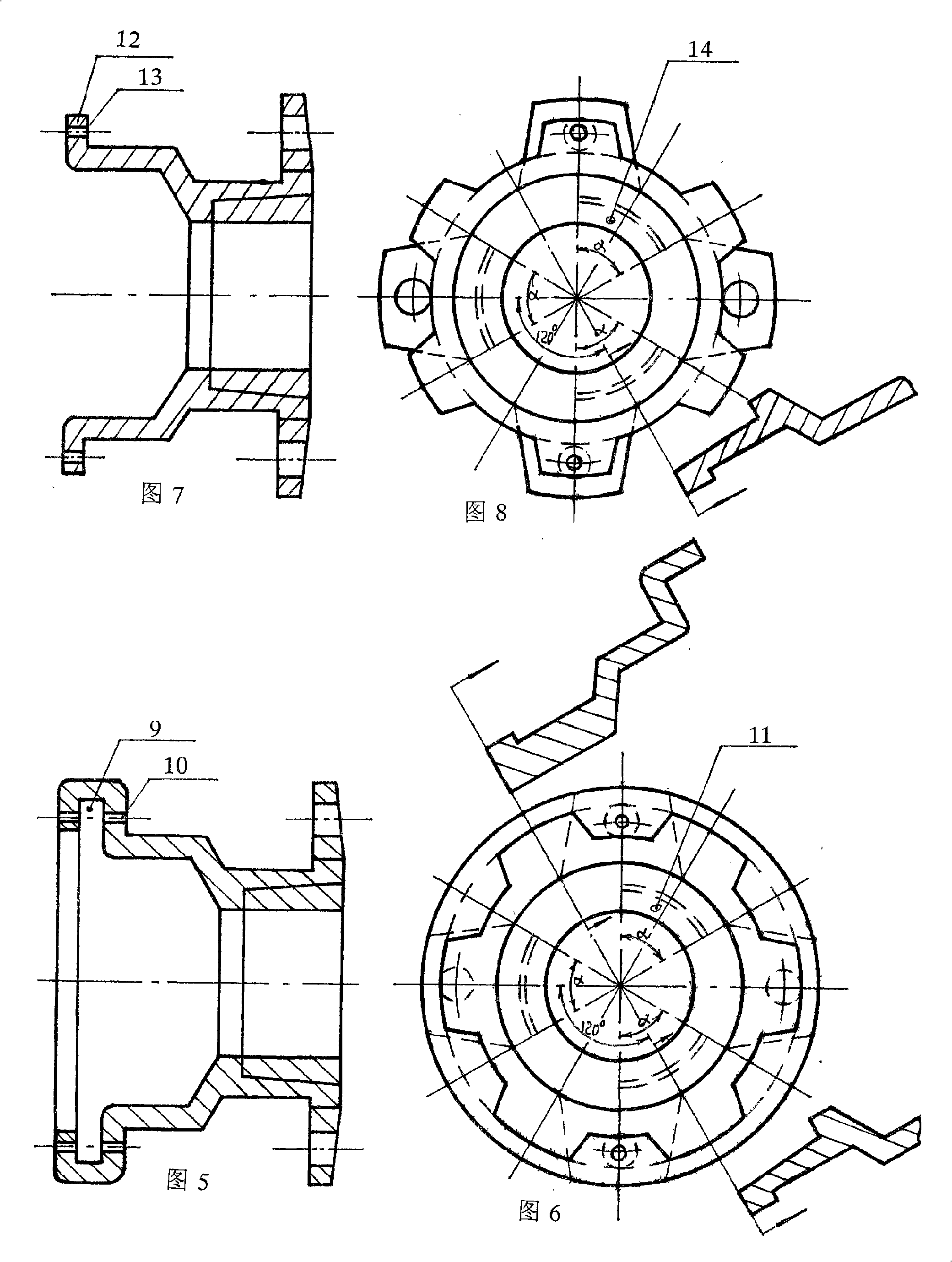

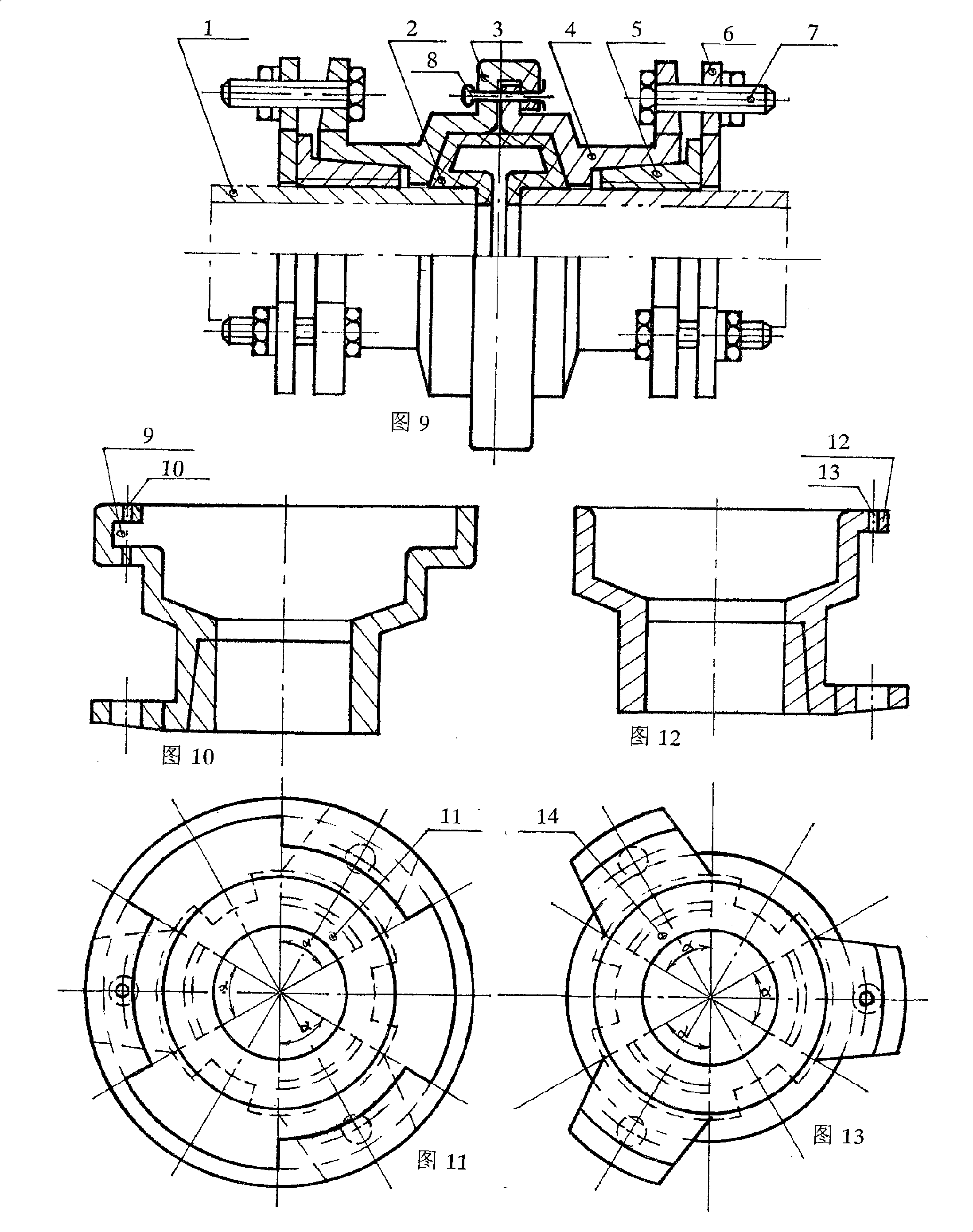

Double-eccentric fixture and machining method for double-eccentric shaft

ActiveCN107030495ASimple structureEasy to adjustWork clamping meansPositioning apparatusEngineeringMachining

The invention discloses a double-eccentric fixture and a machining method for a double-eccentric shaft. The double-eccentric fixture comprises a fixture body. The fixture body is of a cylinder structure and is provided with an eccentric inner spline through hole. The eccentric distance between the center line of the eccentric inner spline through hole and the axis of the fixture body is equal to the distance between the center line of the eccentric circle of the to-be-machined workpiece shaft and the axis of the to-be-machined workpiece shaft. The machining method for the double-eccentric shaft comprises the following steps that the fixture is installed, and the workpiece shaft is matched with a fixture spline; the first eccentric circle body is machined through a turning mechanism, and the straight line where R0 is located and the straight line where R1 is located after turning are located in the same plane and are corresponding in eccentric direction; and the double-eccentric fixture is rotated, the second eccentric circle body is machined through the turning mechanism, and the straight line where R0 is located and the straight line where R2 is located after turning are located in the same plane and are corresponding in eccentric direction. The double-eccentric fixture is simple in structure and convenient to operate, can be matched with an ordinary lathe to conduct machining on an eccentric part of the double-eccentric shaft without other auxiliary components, and reduces the machining cost of the double-eccentric shaft.

Owner:YANTAI AIDI PRECISION MASCH CO LTD

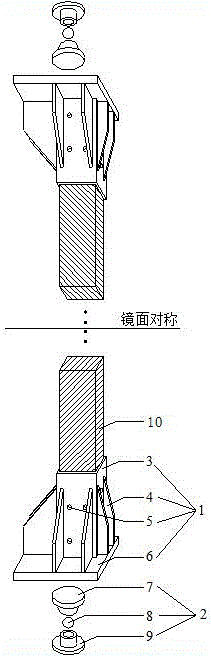

Bidirectional eccentric loading device for bamboo bending members, and installation method

InactiveCN106124179ASimple structureGuaranteed frictionMachine part testingStructural engineeringEccentric loading

The invention relates to a bidirectional eccentric loading device for bamboo bending members, and an installation method. The device comprises two steel cylinder sleeves which are in vertical mirror symmetry, two ball hinged seats, and the bamboo bending members. The steel cylinder sleeves are disposed on the ball hinged seats, and the bamboo bending members are inserted into hollow steel cylinders in the steel cylinder sleeves. The device is advantageous in that 1), the structure is simple and is easy to install, the main body of the loading device only comprises the steel cylinder sleeves and the ball hinged seats, and the installation step is easy; 2), the device is clear in force transmission and is good in integrity, the steel cylinder sleeves can serve as attached corbels fixed at two ends of the member so as to enlarge the force bearing range of an end face, and the ball hinged seats achieve the hinging of the members; 3), the eccentric position is flexible and controllable, ball hinges and the steel cylinder sleeves are connected through holding-on teeth, and the movable ball hinges change the relative position of the steel cylinder sleeves and the ball hinges, thereby achieving the design of different eccentric distances easily; 4), the device is high in popularity, a bamboo member in any rectangular shape can be connected with the device through a steel filling piece and a reserved bolt hole, and the device can be used for carrying out the bidirectional eccentric bearing test of many types of bamboo materials.

Owner:NANJING FORESTRY UNIV

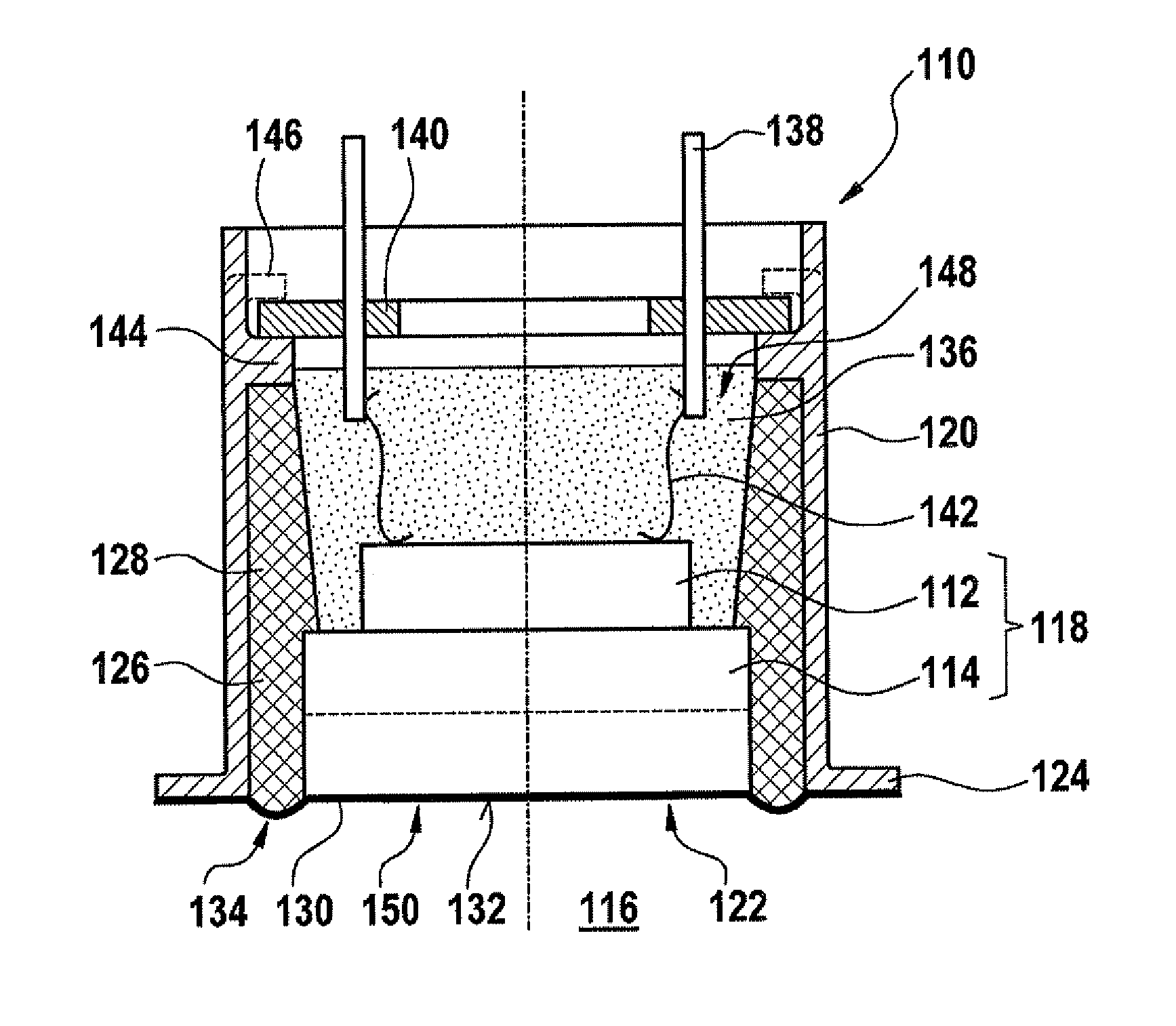

Ultrasonic transducer for use in a fluid medium

InactiveUS20120260742A1Sealing is not affectedDecoupling of structure-borne noisePiezoelectric/electrostrictive device manufacture/assemblyWave based measurement systemsElectricityTransducer

An ultrasonic transducer for use in a fluid medium is proposed. The ultrasonic transducer includes at least one transducer core which has at least one acoustic / electric transducer element, in particular a piezoelectric transducer element. The ultrasonic transducer furthermore includes at least one housing, at least one housing opening being at least partially sealed against the fluid medium with the aid of a sealing film which is connected to the transducer core. The sealing film has at least one expansion deformation which is configured to permit a relative movement between the transducer core and the housing.

Owner:ROBERT BOSCH GMBH

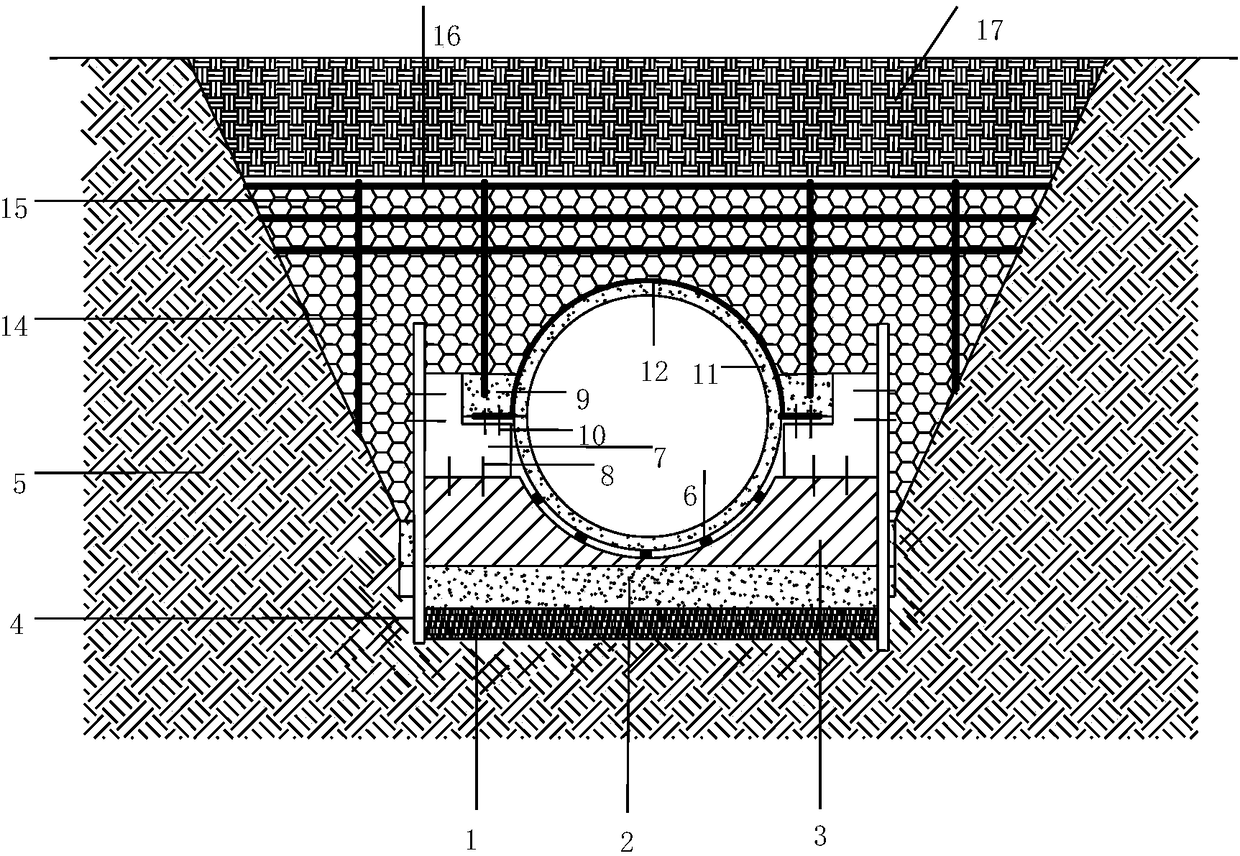

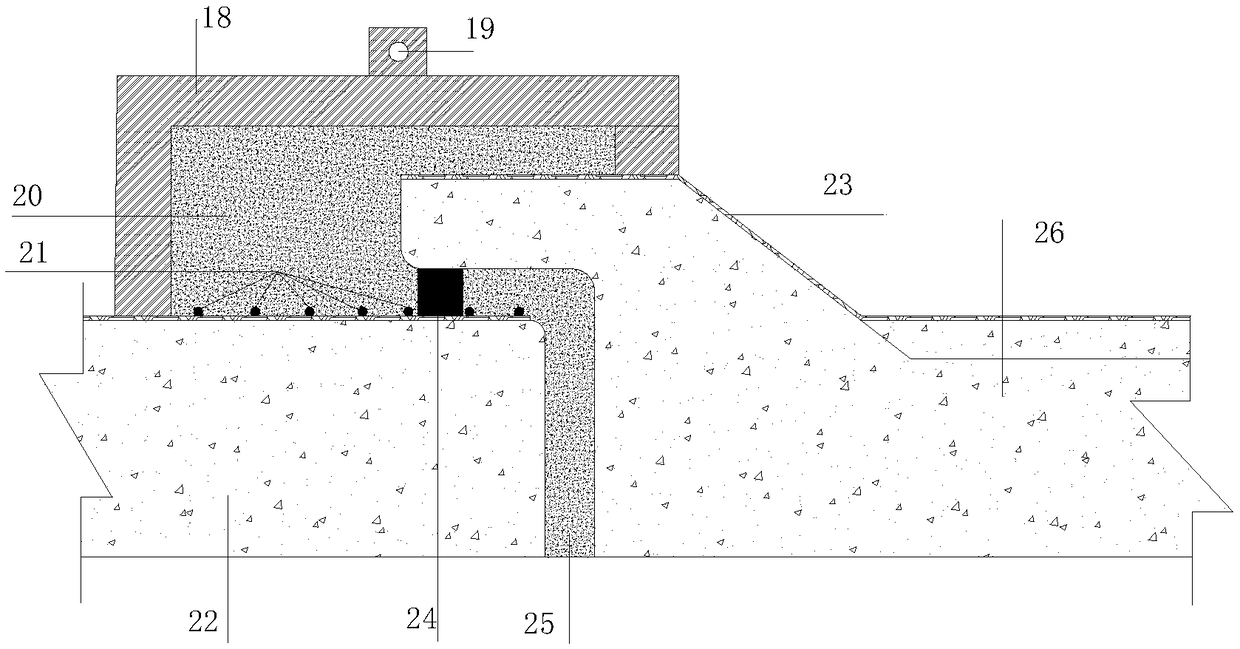

Large-diameter composite butt and strap joint rainwater pipe system and construction method

InactiveCN108457355AEasy to installEasy to locate and installSewer pipelinesButt jointArchitectural engineering

The invention discloses a large-diameter composite butt and strap joint rainwater pipe system and a construction method. The rainwater pipe system comprises rainwater pipes, wherein the bottoms of therainwater pipes are located and fixed by two bases; a plain concrete cushion layer and a flexible cushion layer are sequentially paved on the lower surfaces of the bases; the upper surfaces of the rainwater pipes are pressed and locked by an arc-shaped lock; the upper surfaces of the rainwater pipes are covered by cellular concrete and the upper sides are back-filled with plain soil; and the construction method comprises the following construction steps: construction preparation, construction layout, pipe trough excavating, cushion layer construction, batten fixed tightening latch pre-buring,pipe base installation, rainwater pipe installation, separated butt and strap mold installation, applying cement mortar to the butt and strap, butt and strap maintenance, calking groove treatment, installing vertical supporting ribs and the like. The structure (the rainwater pipe system) provided by the invention is convenient to mount and dismount; the rainwater pipes can be located with high precision; the rainwater pipes, which are free from disturbance in a butt-joint process, are good in stability; and the butt and strap are good in waterproofing effect and can adapt to rainwater and sewage pipelines that foundation soil is relatively poor, foundation hardness is uneven or located in earthquake areas; therefore, relatively good economic and technical benefits are achieved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Self-compensating fastening type large-diameter fast joint

InactiveCN101344206AShorten the installation periodQuick connectionFluid pressure sealed jointsPipeline expansion-compensationPipe fittingOmni directional

The invention relates to a self-compensating fastening large-caliber fast adaptor which is used for butt jointing of two pipes and solves the defects of high cost and poor practicability in the prior art. The invention is characterized in that: the outer circumference of pipe fittings is encircled by a rubber sealing boot 2, a convex ring of which is arranged among the pipe fittings. Left and right sleeves 3 and 4 are respectively sheathed on the pipe fittings, and pressed on the outer surface of the rubber sealing boot 2. A trough 9 of the left sleeve 3 is meshed with a projection 12 of the right sleeve 4. A cotter pin 8 fixedly locks the left and right sleeves 3 and 4. A claw 5 is provided with a pointed teeth on the concave surface, arranged in dovetail inner cone troughs 11 and 14 in the left and right sleeves 3 and 4, pasted on the outer wall of the pipe fittings, can slide along the axial direction of the pipe fittings and concentrically contract to occlude and tighten the pipe fittings. The fast adaptor is high, middle and low pressure resistant. The self-compensating fastening omni-directional secure seal with firm soft syncretic is provided without welding or flange type, not being opened with trench type, and not being provided with a compensator additionally, thereby saving labor and time, especially under the condition of severe environment, the fast adaptor of the invention has the advantages of being convenient and fast, low cost, energy saving and environmental protection. The fast adaptor of the invention is used for connecting two pipes through which the fluid is to be conveyed.

Owner:王甲南

Unmanned high-precision locating system and locating method used for mounting deep sea jacket

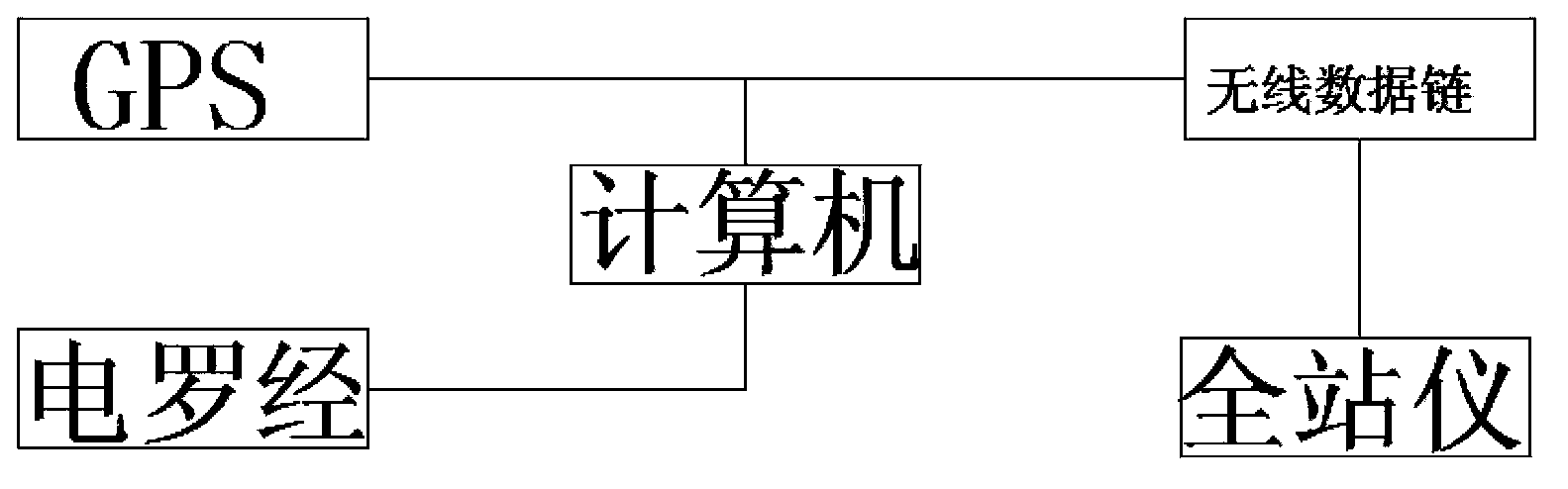

InactiveCN103901457AEasy to install and locateHigh precisionSatellite radio beaconingTotal stationEngineering

The invention provides an unmanned high-precision locating system used for mounting a deep sea jacket. The unmanned high-precision locating system is characterized in that the locating system comprises a GPS, a gyrocompass, a computer, a displayer and a total station, the GPS is connected with the computer, the gyrocompass is connected with the computer, the displayer is connected with the computer, and the total station is connected with the computer. The unmanned high-precision locating system has the advantages that according to the technical scheme, inconvenience caused by the mounting characteristic of the deep sea jacket is removed, the jacket is mounted and located more conveniently, and meanwhile the mounting and locating precision of the jacket is improved.

Owner:TIANJIN HARBOR MARINE ENG

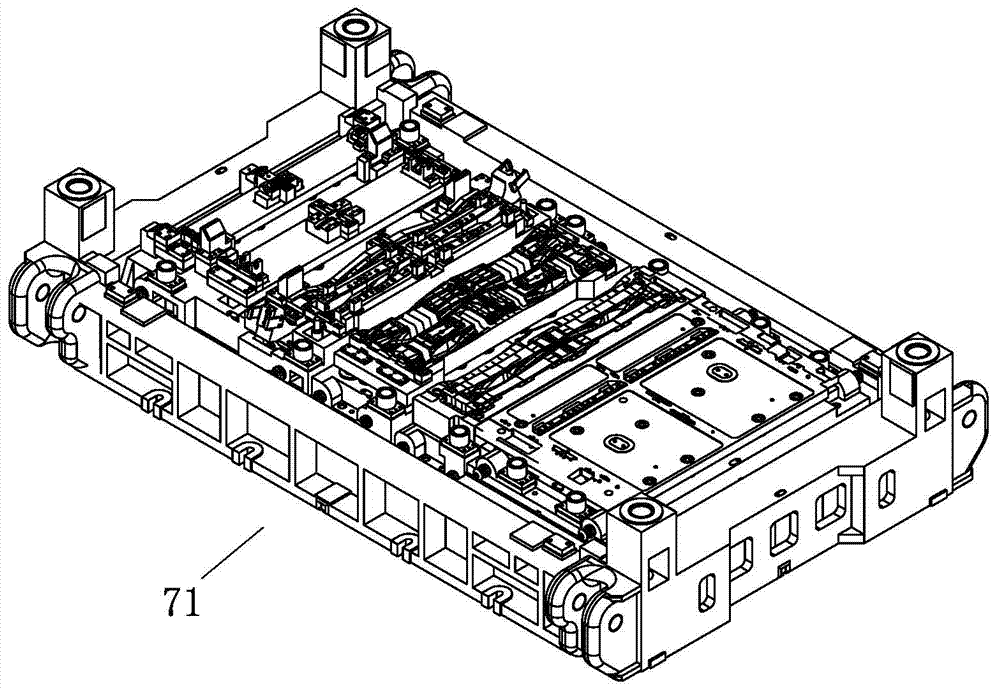

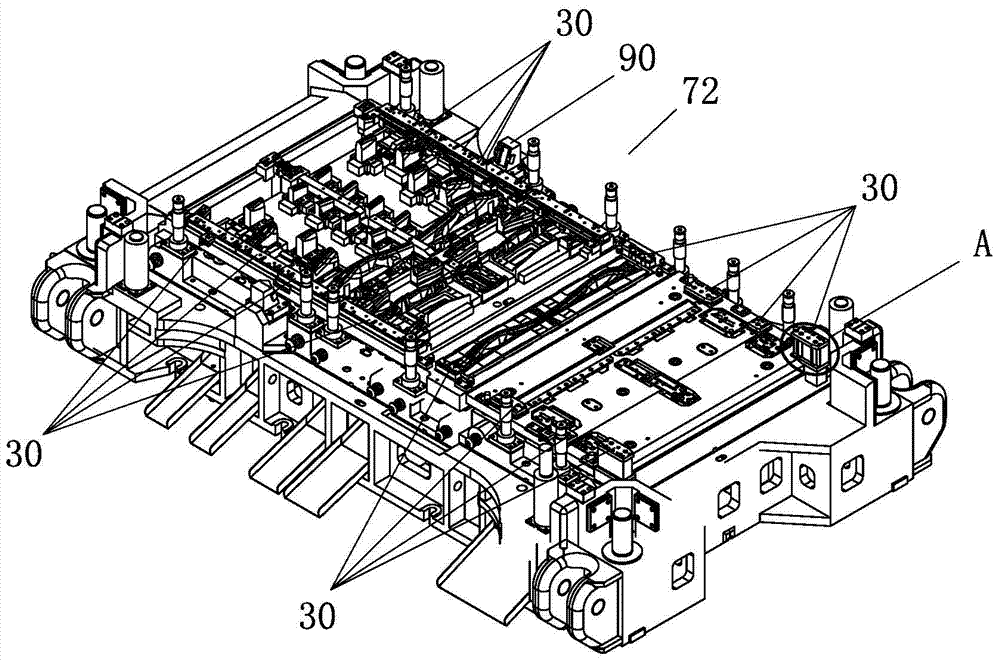

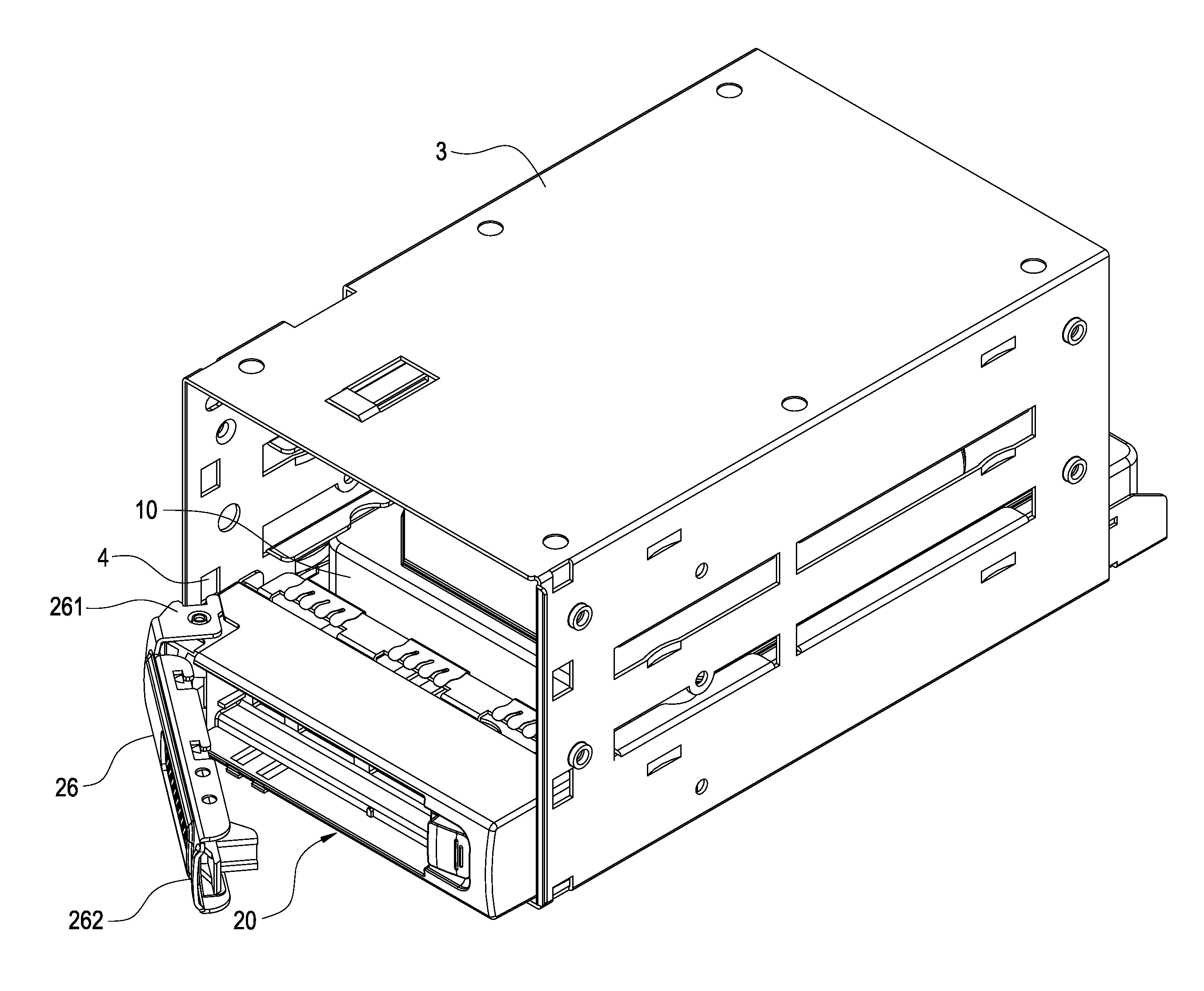

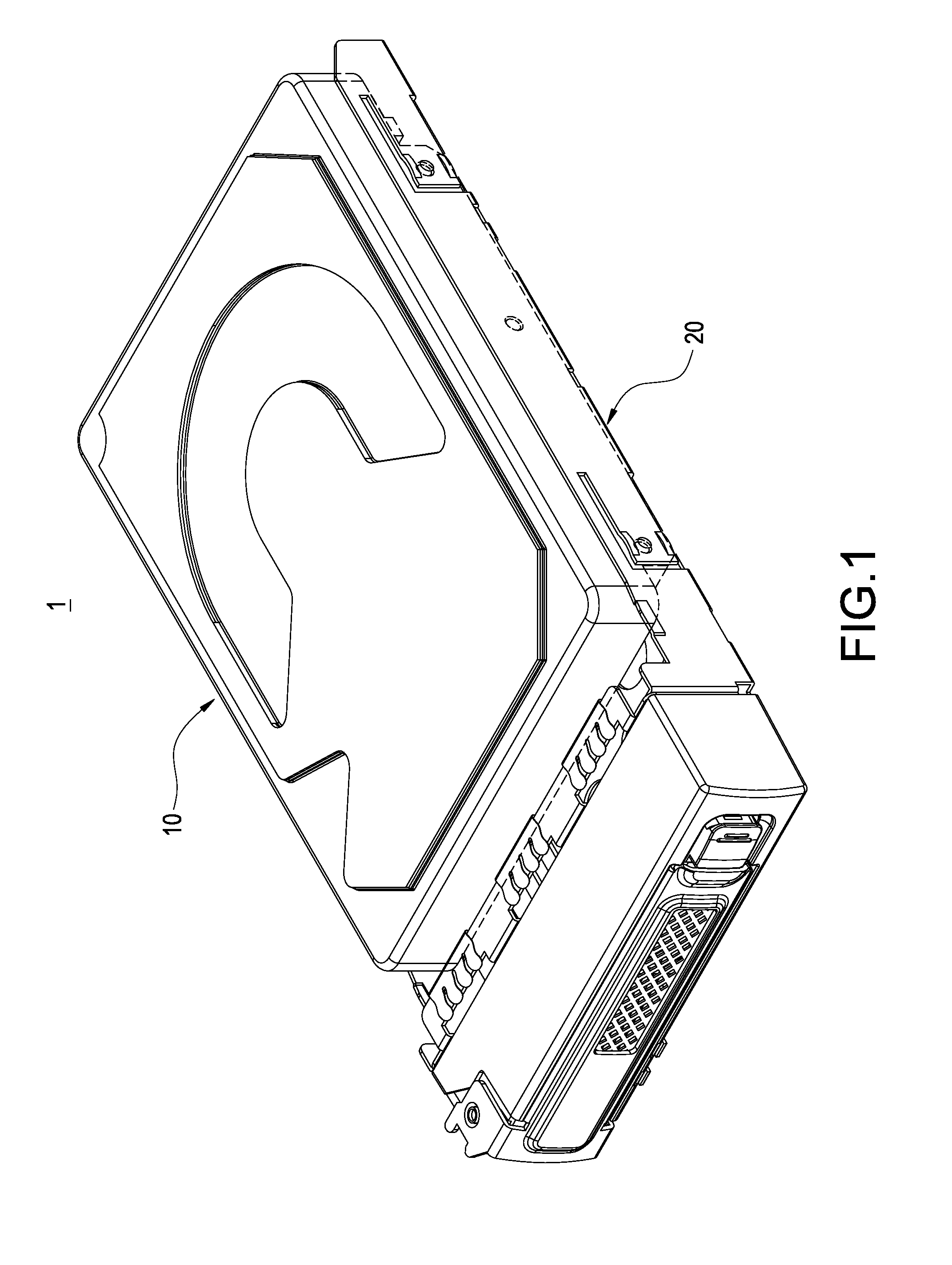

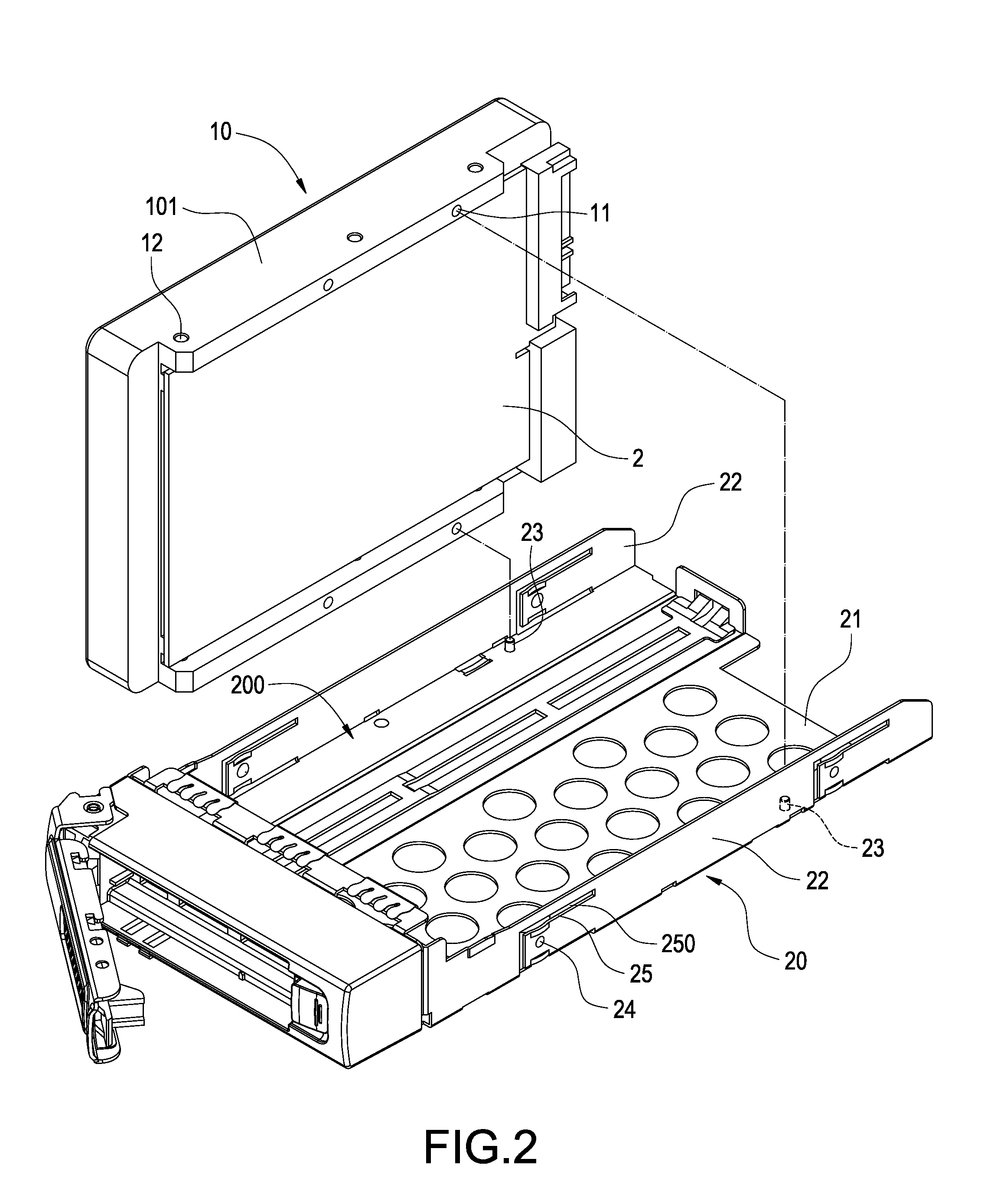

Positioning structure for removable hard drive

ActiveUS20130313955A1Easy to locate and installAvoid lostClosed casingsCasings with display/control unitsHard disc driveEngineering

A positioning structure for a removable hard drive includes an enclosure and a tray. The enclosure is used for being mounted by the hard drive, and disposed with a plurality of positioning holes. The tray includes a bottom and two side walls vertically extending therefrom. A space being is formed by the bottom and the side walls. The bottom is formed with a plurality of positioning pillars corresponding to the positioning holes. The enclosure is received in the space, and the positioning holes are correspondingly inserted by the positioning pillars.

Owner:AIC INC

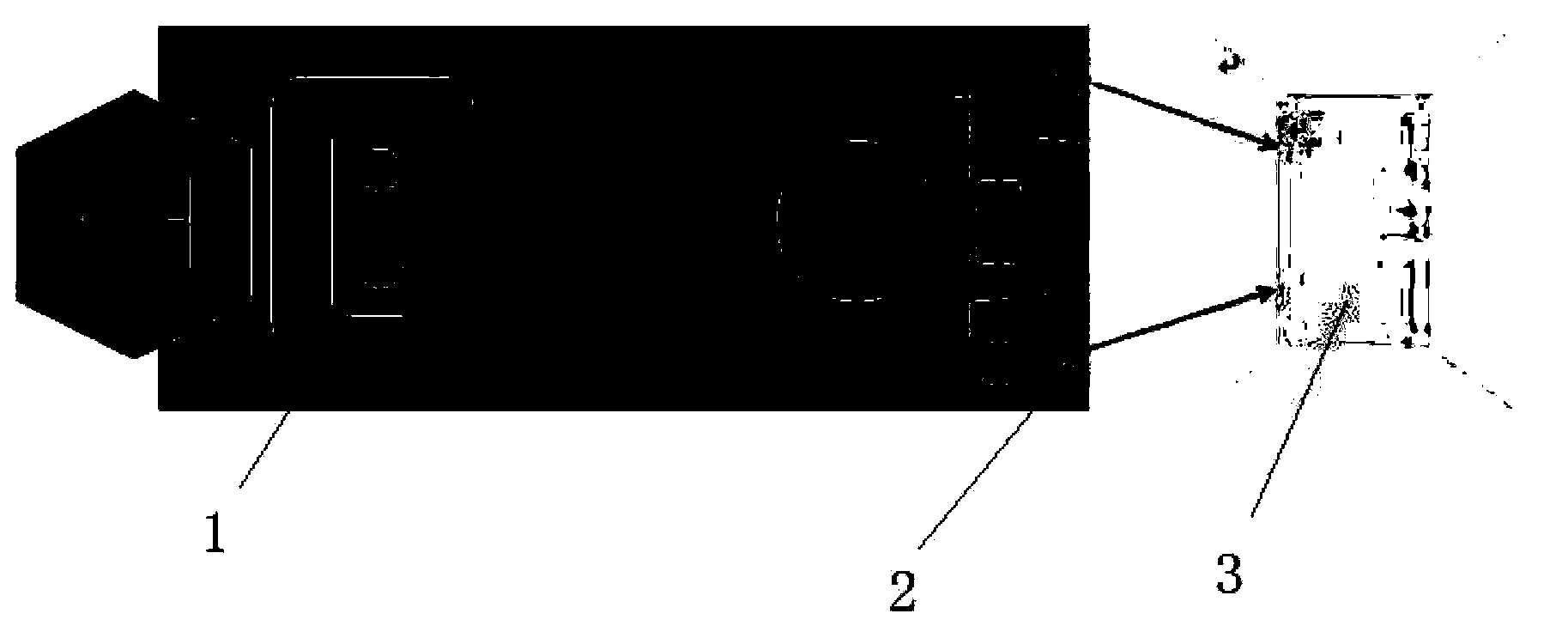

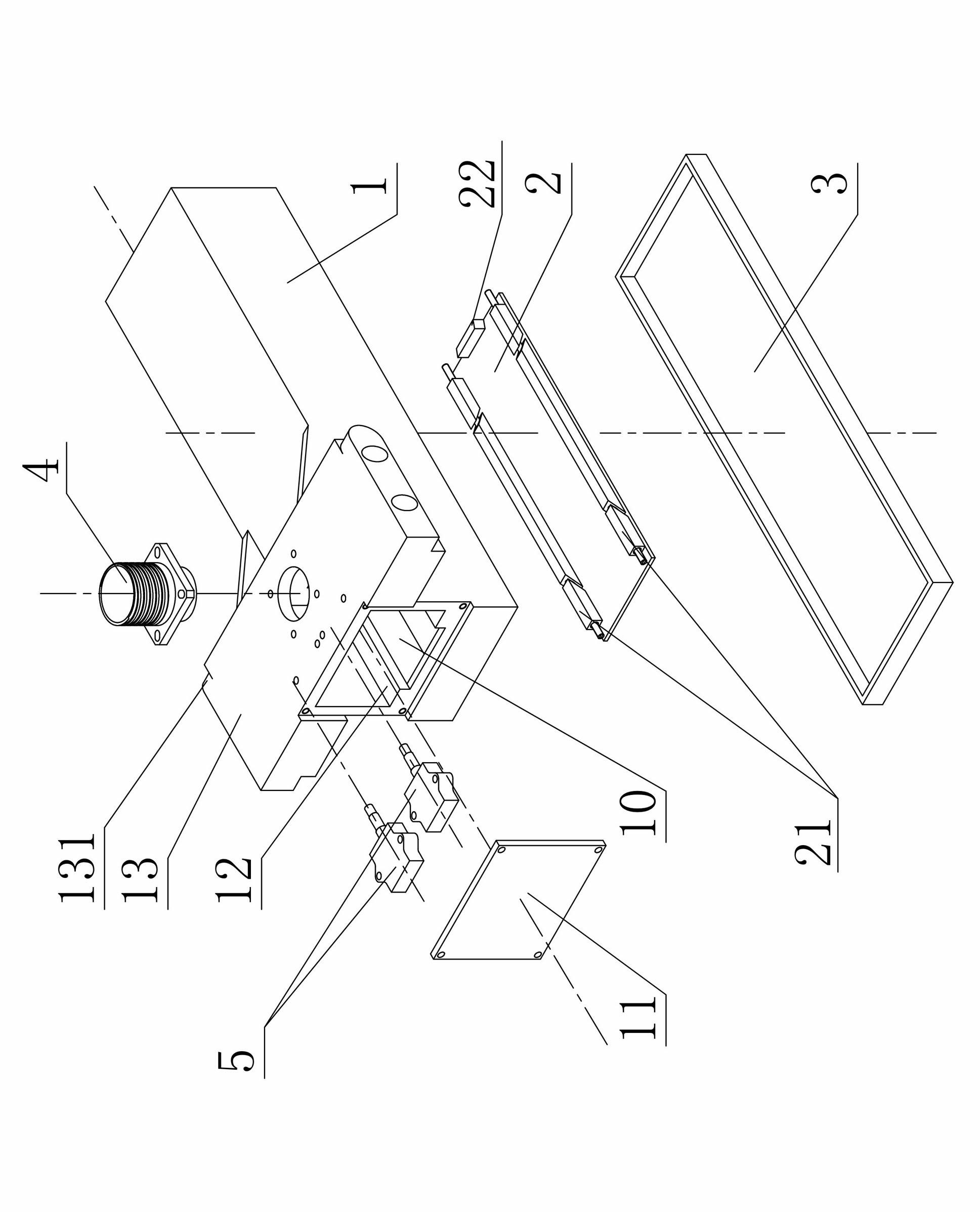

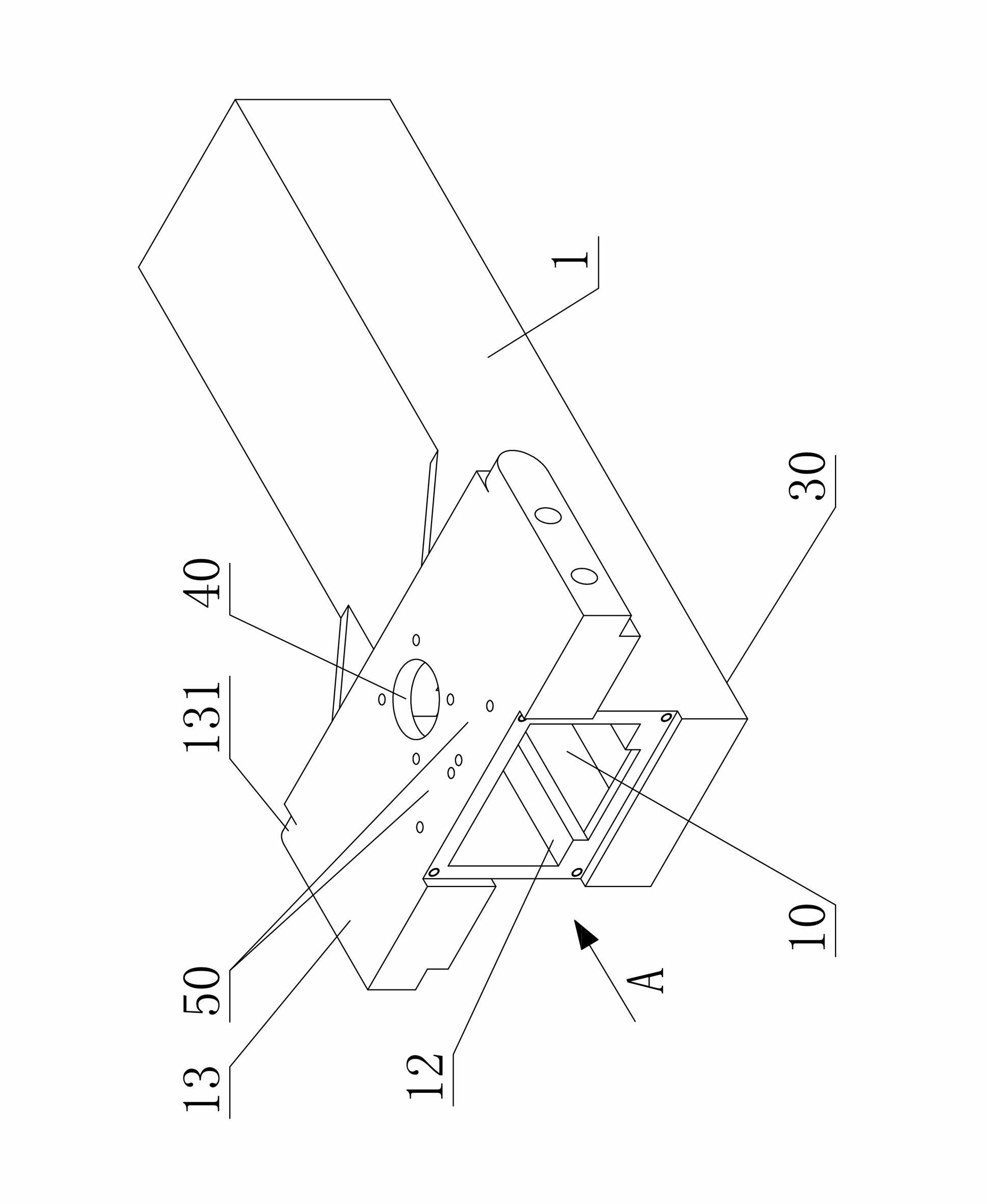

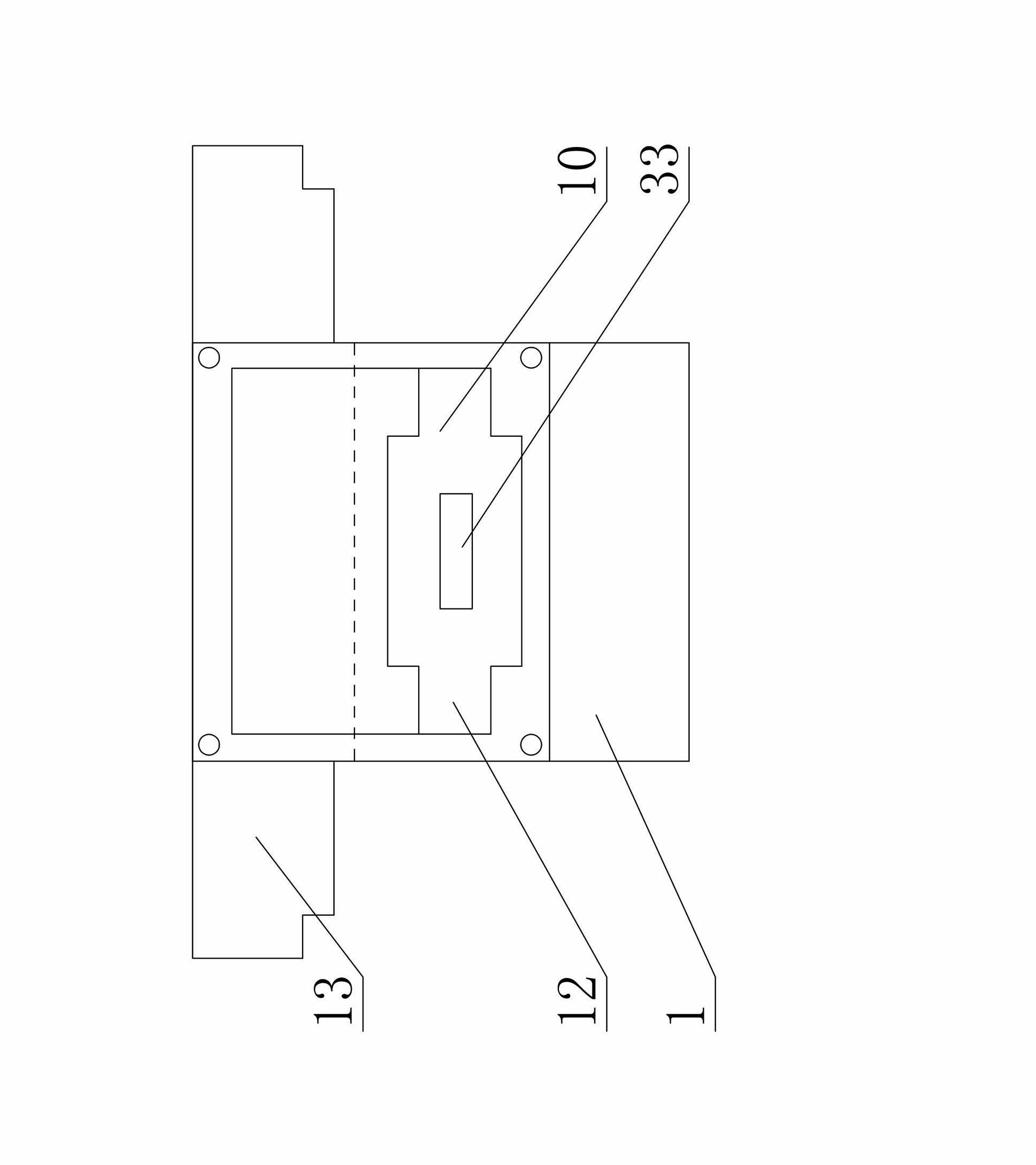

Suspension gap sensor for medium-low-speed maglev train

ActiveCN102102975AImprove anti-interference abilityImprove commissioning and maintenance efficiencyUsing electrical meansMeasurement apparatus housingsAutomotive engineeringPrinted circuit board

The invention discloses a suspension gap sensor for a medium-low-speed maglev train. The suspension gap sensor comprises a shell (1), a control circuit board (2) and a resonant circuit (32), wherein the shell (1) is provided with a coil circuit board (3) which is equipped with a printed circuit board coil (31), and the coil circuit board (3) is connected with the control circuit board (2). The suspension gap sensor has the advantages of good interference resistance, firmness, reliability, compact structure, high integration, excellent waterproof and dustproof capabilities, and rapidness and convenience for maintenance.

Owner:NAT UNIV OF DEFENSE TECH +1

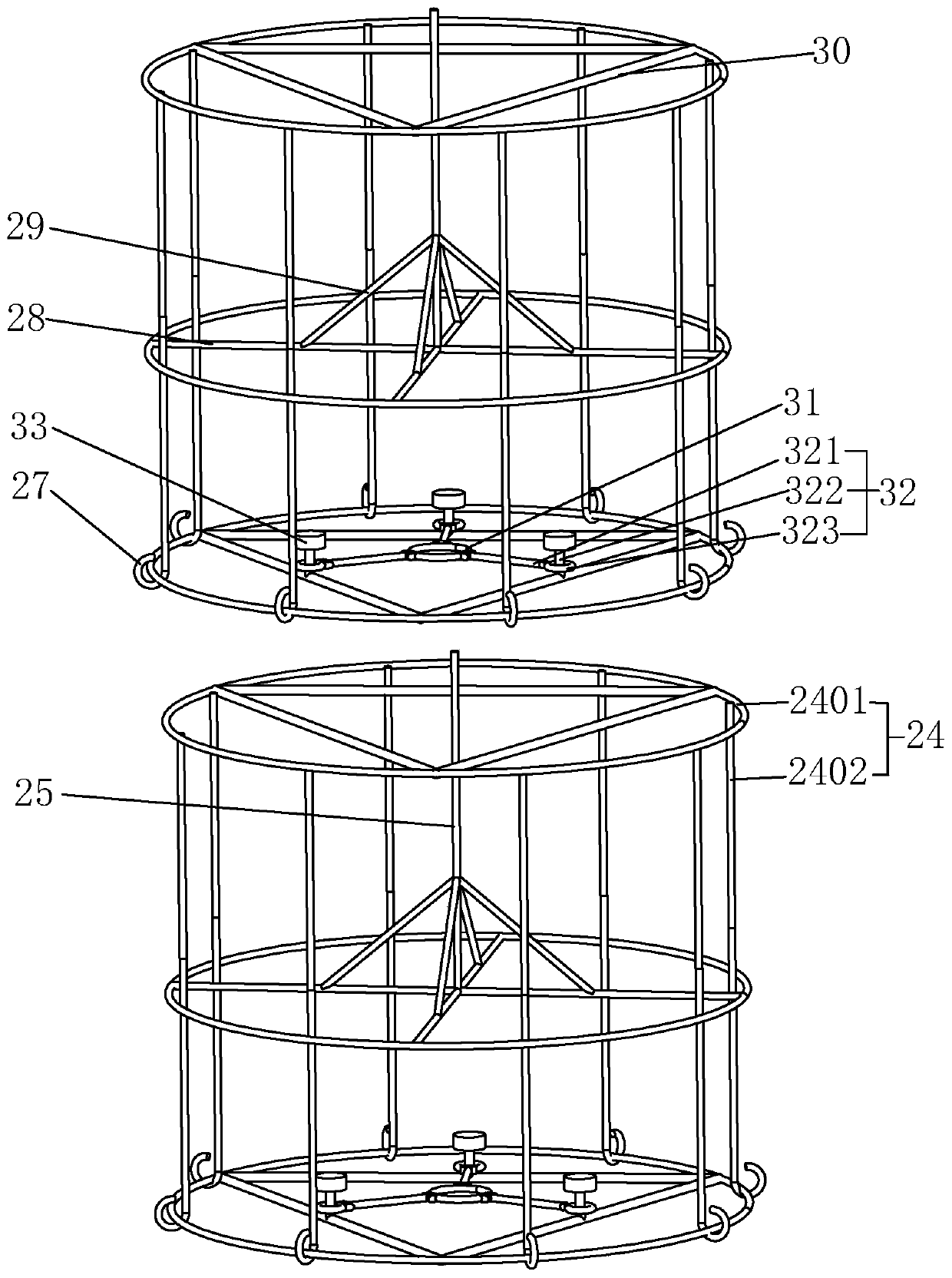

Manual hole digging pile and construction method of manual hole digging pile

ActiveCN111535303AGood flexibilityReduce rotation or offset movementBulkheads/pilesSteel platesRebar

The invention relates to the technical field of engineering construction, in particular to a manual hole digging pile and a construction method of the manual hole digging pile. The manual hole diggingpile comprises a protecting wall and a reinforcement cage. The protecting wall is arranged in a pile hole and is composed of a plurality of arc-shaped steel plates in a circumferential direction of apore wall of the pile hole to encircle a grouting channel, the grouting channel is used for placing the reinforcement cage, a supporting part for fixing the arc-shaped steel plate is arranged betweeneach arc-shaped steel plate and the pore wall of the pile hole, the reinforcement cage is formed by stacking a plurality of unit cages in the grouting channel successively, a guide ring is arranged at the bottom of each unit cage, a plurality of connecting assemblies are connected between the unit cages and the guide rings, each unit cage is internally provided with a vertically arranged guide bar, the guide bar stretches outside one end of the unit cage, and when two adjacent unit cages are stacked together, the guide ring is arranged on the guide bar in a sleeving manner. The reinforcementcage can be suitable for depth of different hole digging piles, so that the manual hole digging pile is relatively high in flexibility and the invention provides the construction method for construction.

Owner:广东裕基建筑工程有限公司

Construction control method for large direct-buried steel anchor fluke embedded part

ActiveCN103485539AControl precisionAchieve precise positioningBuilding material handlingRebarSteel plates

The invention discloses a construction control method for a large direct-buried steel anchor fluke embedded part. The construction control method comprises the steps of pouring concrete under a corbel steel bar cage or a frame beam, burying the bottom ends of supporting angle steel in the concrete, enabling the top ends of the supporting angle steel to be higher than the upper surface of the corbel steel bar cage or the frame beam, using a leveling instrument to mark the height of the bottom face of an embedded part steel plate on each angle steel and then cutting off redundant portions; placing a positioning frame on the corbel steel bar cage, enabling four corners to be welded and fixed with the corbel steel bar cage through electric welding, placing a piece of square steel slightly larger than an anchor plate into one hole after the hole is adjusted, sequentially adjusting steel bars at the anchor fluke positions, hoisting the embedded part to the position right above the installing position and slowly placing the embedded part on the supporting angle steel, wherein the bottom of the embedded part is in direct contact with the top ends of the supporting angle steel. By adopting the construction control method, the installing time can be shortened, and the installing accuracy can be improved.

Owner:CHINA MCC5 GROUP CORP

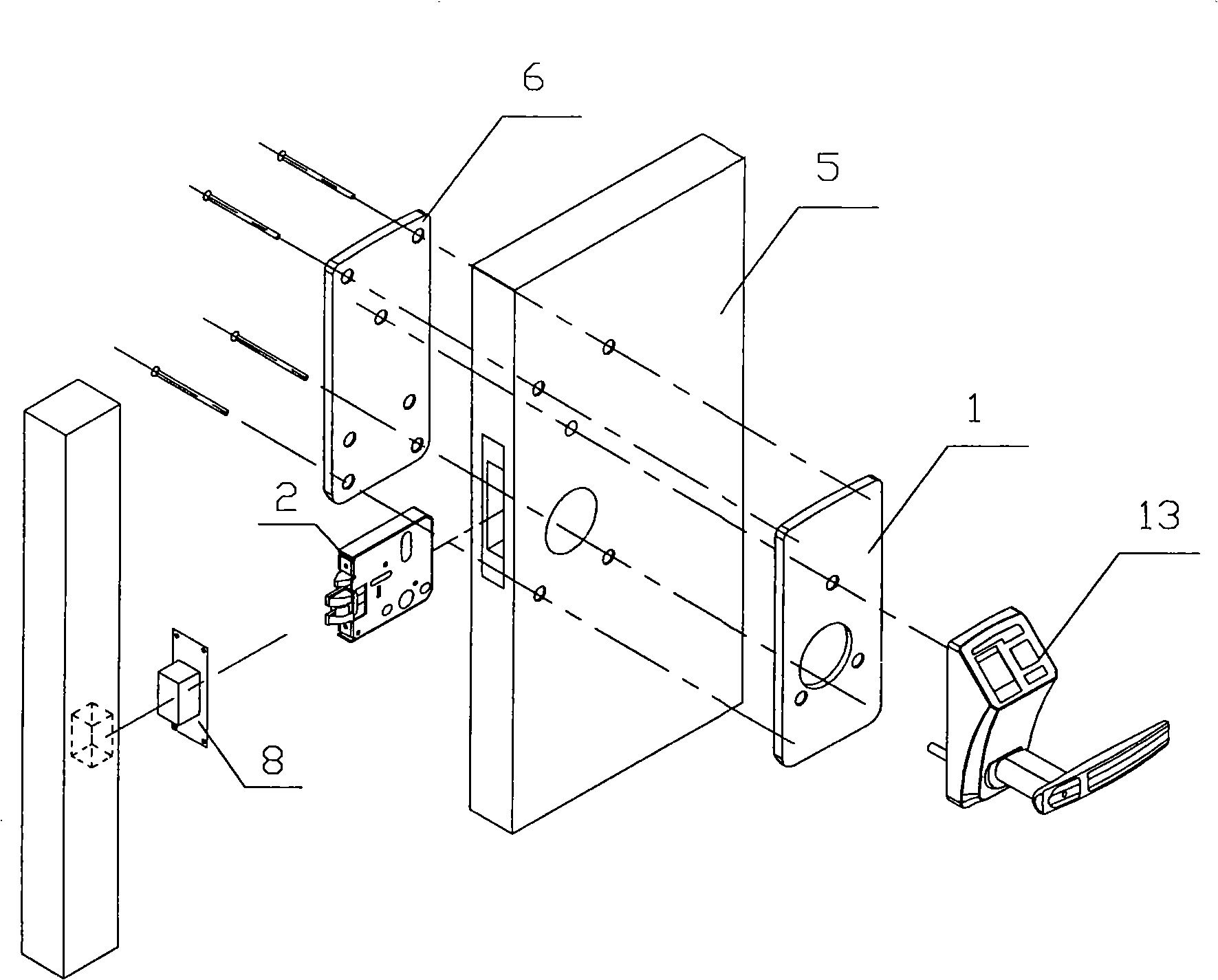

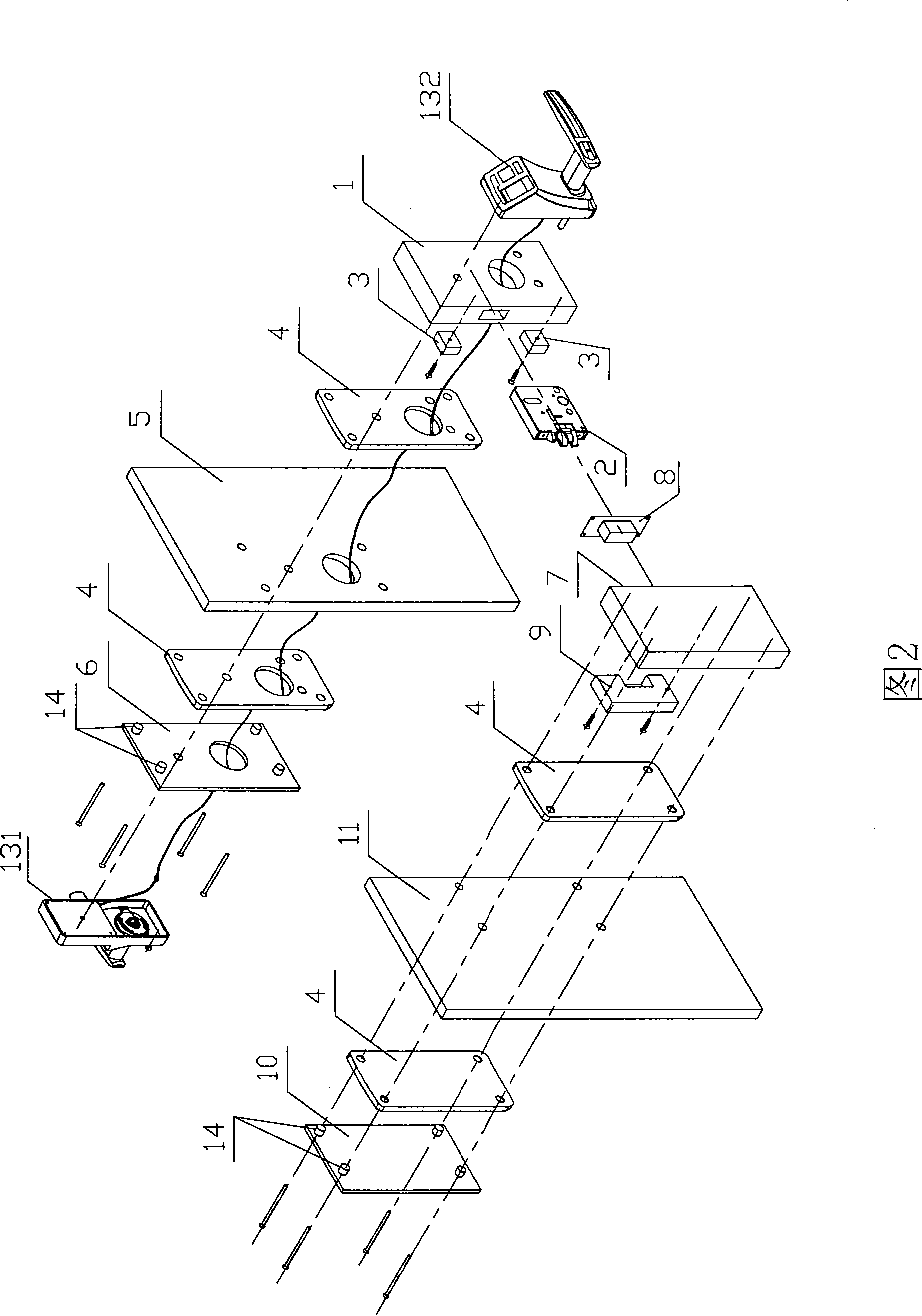

Installation structure of electronic lock

InactiveCN101255777ANeat appearanceReduce complexityElectric permutation locksSoftware engineeringFastener

The present invention discloses an installation structure of an electronic lock which comprises an electronic control unit box. The invention is characterized in that the structure also comprises two separated inner fixing plate and external fixing plate. The inner fixing plate and the external fixing plate can traverse the door leaf through the fastener and are oppositely installed and fixed on two sides of the door leaf. The electronic control unit box is detachably fixed on the external surface of the external fixing plate or the inner fixing plate. The invention has the characteristics of simple structure, convenient and reliable installation, wider installation range of the electronic lock and the like. The invention is widely applied on the installation of the electronic lock in various kinds of door, the installation of traditional core inserting door lock and the improvement and change of the old lock.

Owner:曹湛斌

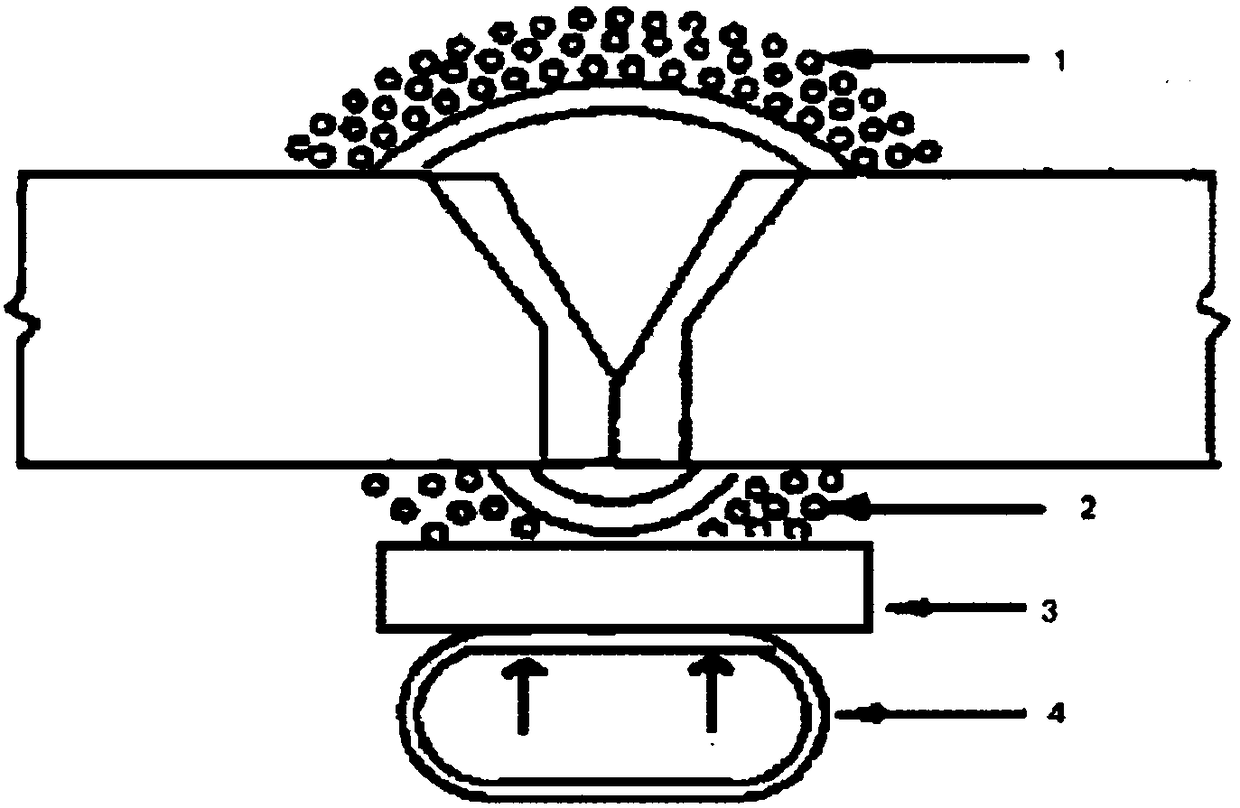

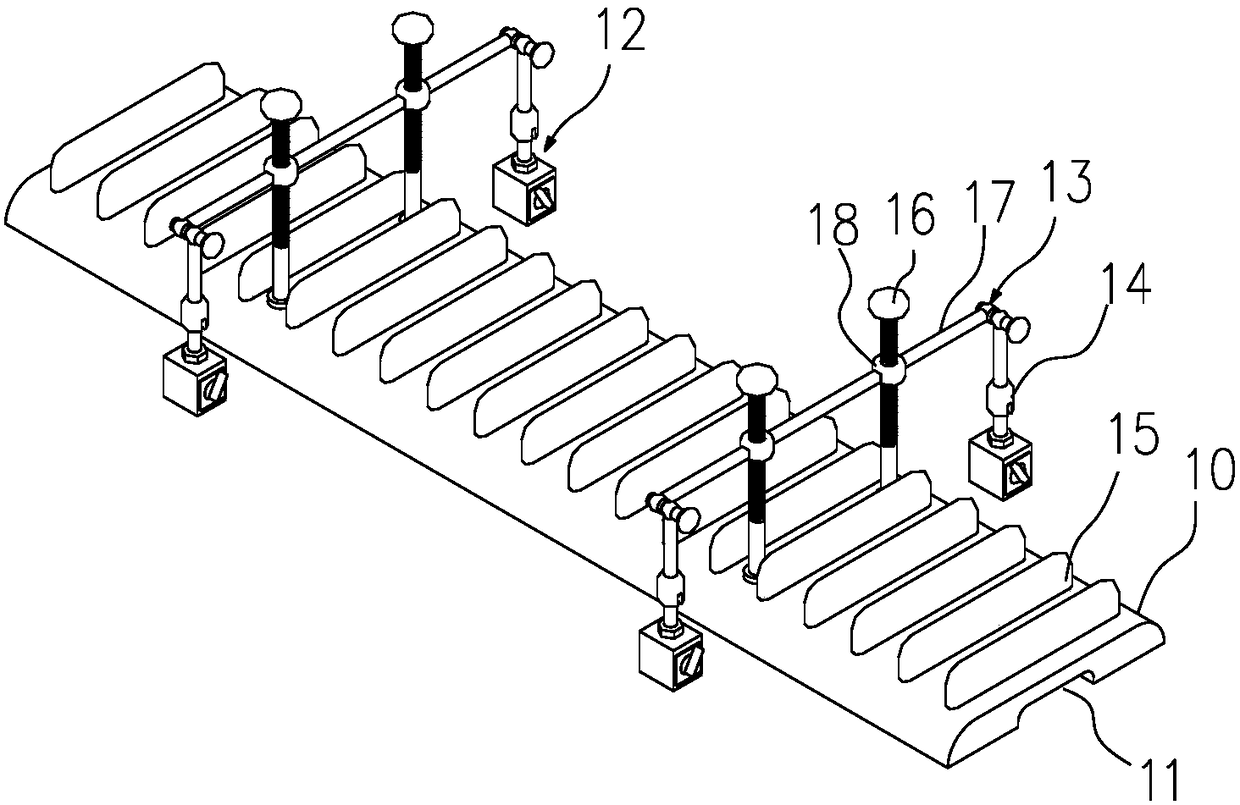

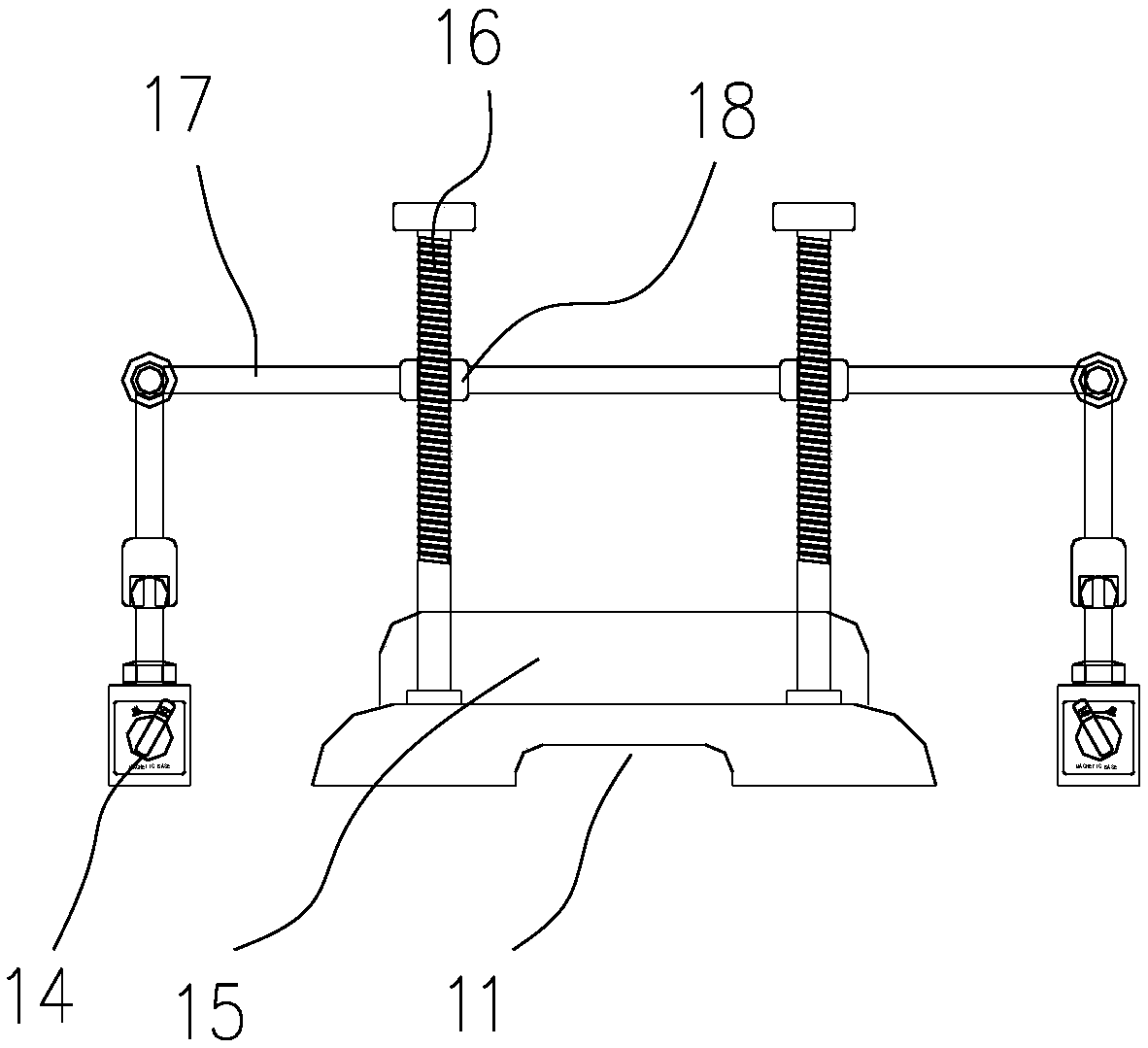

Detachable liner plate device for FCB method welding and application method of detachable liner plate device

The invention discloses a detachable liner plate device for FCB method welding and an application method of the detachable liner plate device, and relates to the technical field of welding equipment.The detachable liner plate device comprises a liner plate provided with a groove-shaped bearing face and a fixing device. The fixing device comprises a support arranged on the other side, opposite tothe bearing face, of the liner plate, and a plurality of magnetic meter bases arranged on the support. The liner device is placed on a to-be-welded steel plate, and the bearing table face of the linerplate bears and is attached to the back face of a welding line of the to-be-welded steel plate, the positions of the magnetic meter bases relative to the to-be-welded steel plate are adjusted, the magnetic meter bases are opened, the to-be-welded steel plate and the liner plate are attached and fixed, and welding operation is conducted; and after welding is finished, the magnetic meter bases areclosed, the positions of the magnetic meter bases relative to the to-be-welded steel plate are adjusted again, and the liner device is integrally taken down. By usage of the detachable liner plate device, limitation from the construction site is avoided, the welding stations are conveniently converted, and the beneficial effects that the welding efficiency is high, and flexibility and convenienceare achieved are achieved.

Owner:QINGDAO WUCHUAN HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com