Low-temperature hydraulic turbine

A hydraulic turbine and low-temperature technology, applied in stators, engine components, machines/engines, etc., can solve the problems of difficulty in positioning and installation of the whole machine structure, large loss of hydraulic turbine cooling capacity, and large flow loss at the exit of the impeller. Achieve the effects of improving energy utilization, reducing running cooling loss, and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

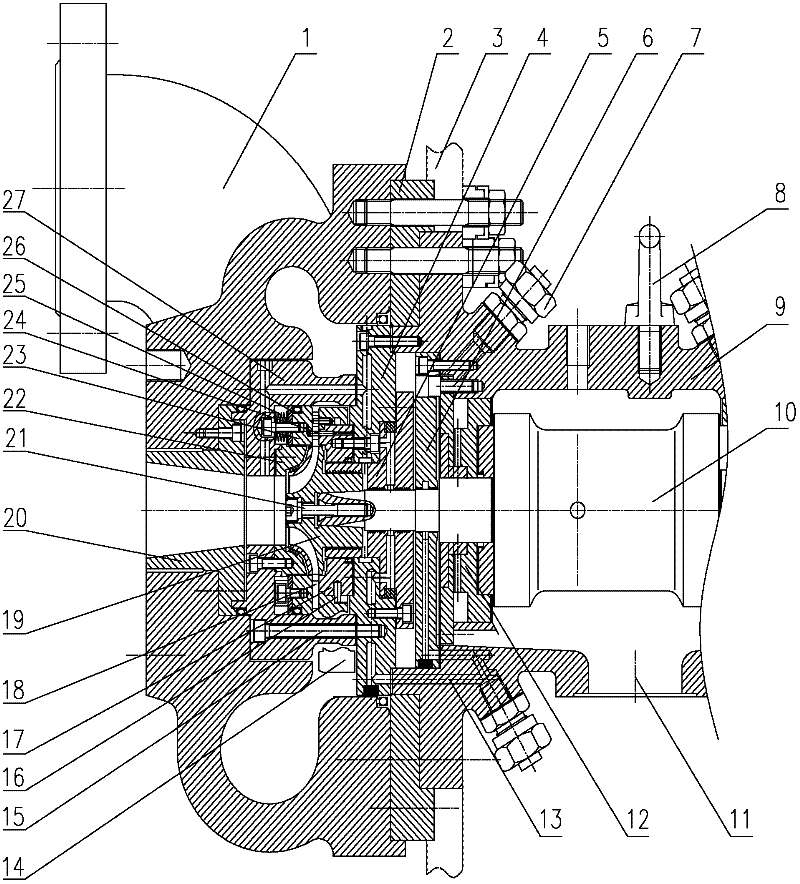

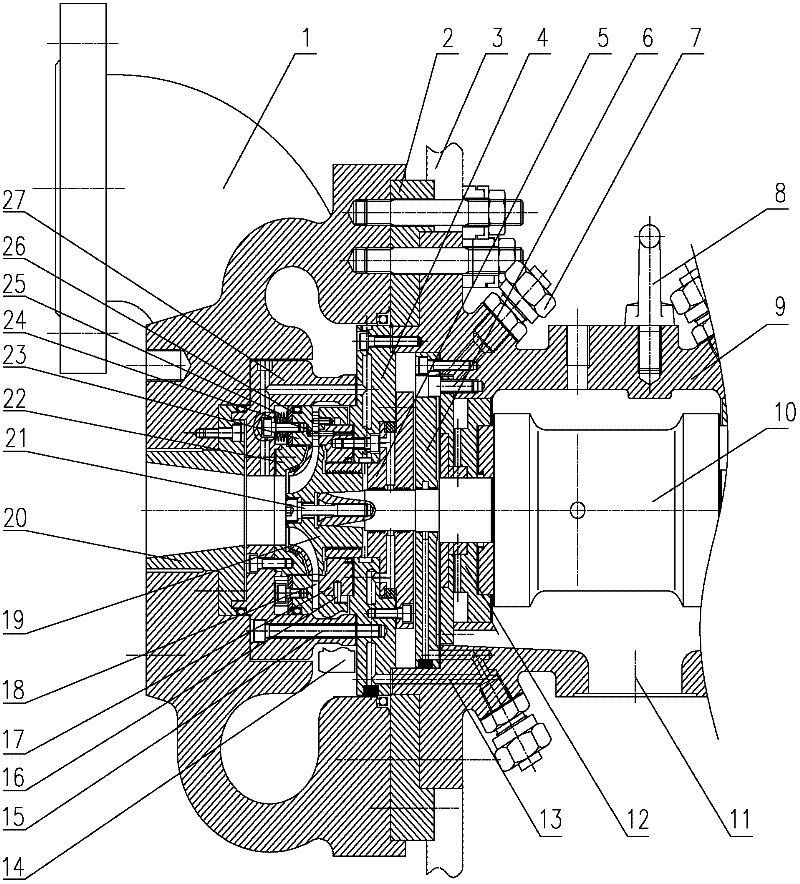

[0014] Such as figure 1 As shown, a low-temperature hydraulic turbine includes a casing 9; a thrust sliding bearing 12; a rotor; a nozzle group; a volute 1; a diffuser 20; The casing 9 includes eyebolt screws 8, oil discharge holes 11, bearing temperature measuring holes, bearing oil supply holes, air seal air supply holes, etc., on which joints 7 are connected with corresponding pipelines. The rotor includes a main shaft 10, an impeller 19, gear sleeves or couplings; the nozzle group includes a nozzle turntable 14, a nozzle chassis 17, a nozzle cover 23, a nozzle pressure plate 26, a nozzle compression flange 27, nozzle blades 18, and a nozzle adjustment mechanism. The seal includes a wheel cover side seal 22 , a shaft seal 5 , a gas seal 4 and an oil seal 6 .

[0015] The main shaft 10 is rotatably fixed in the housing 9 through two left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com