Patents

Literature

790results about How to "Reduce flow loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

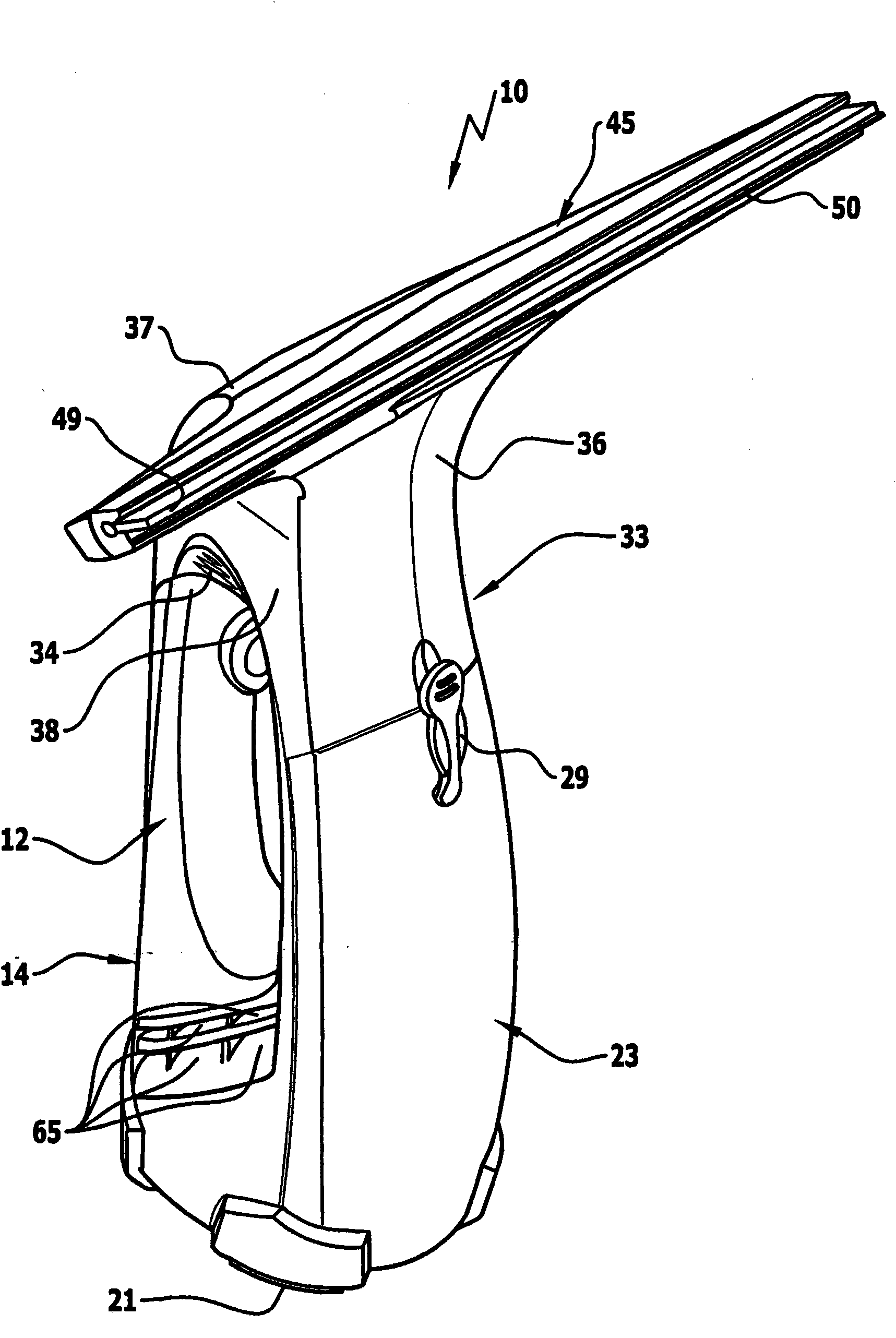

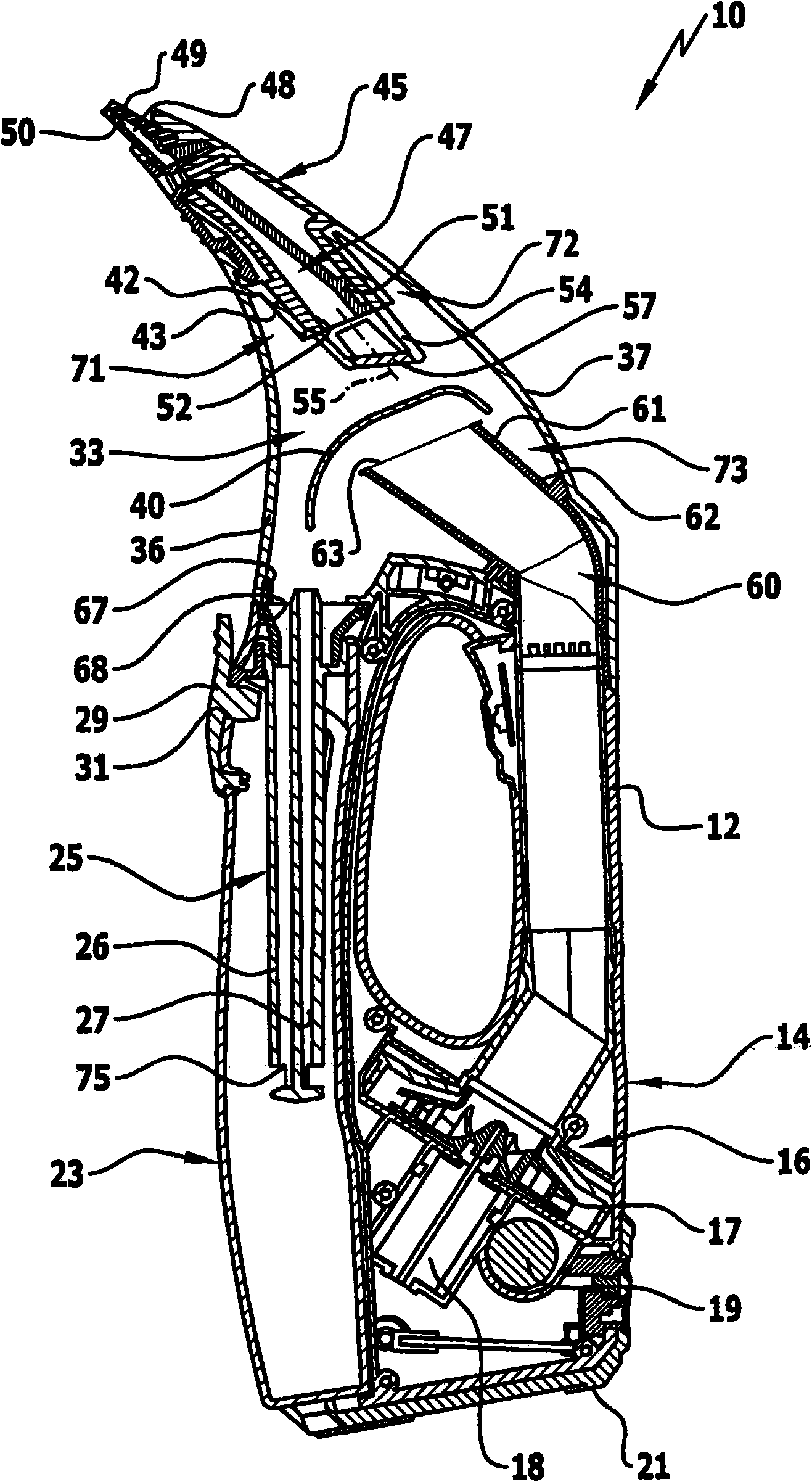

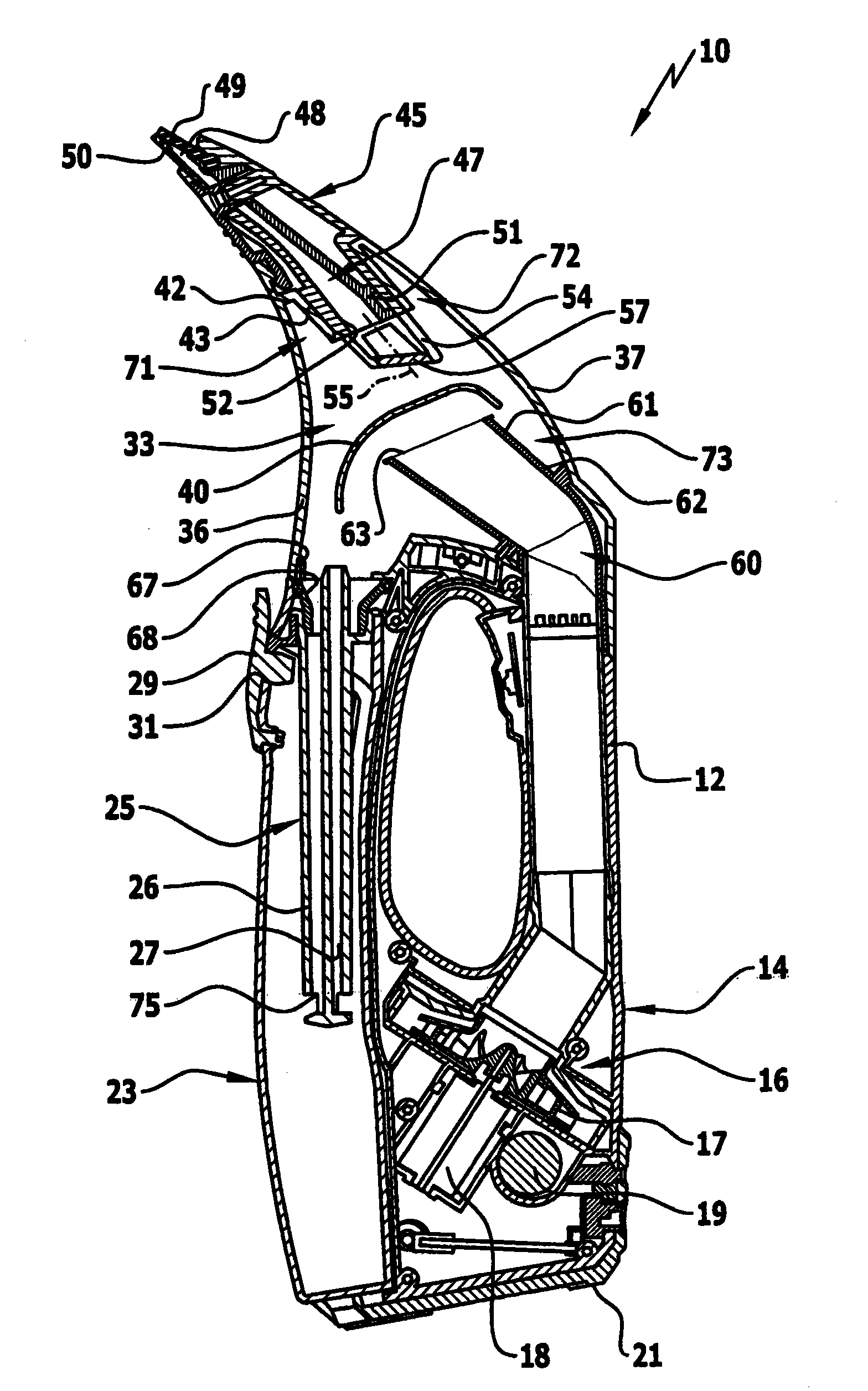

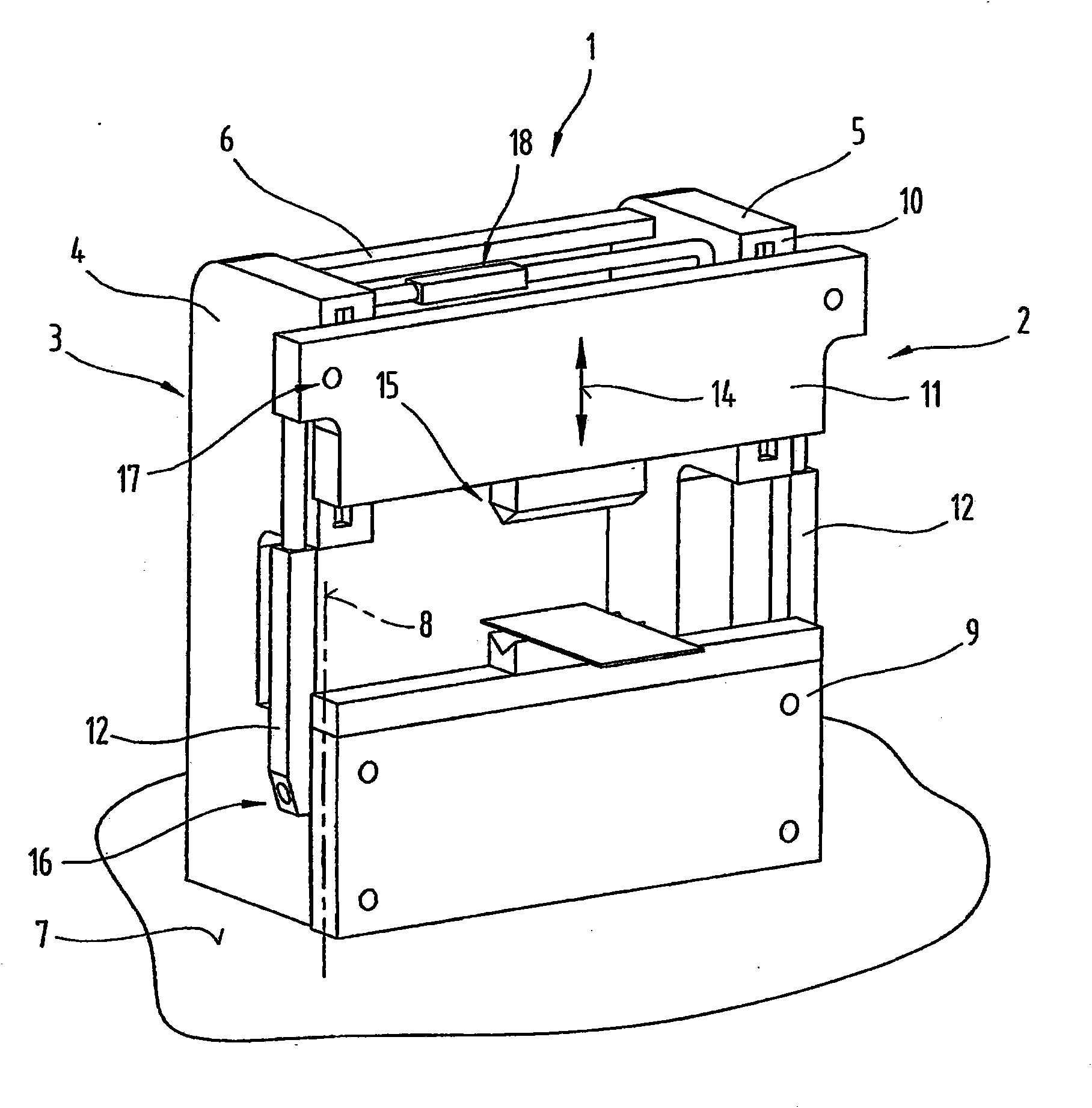

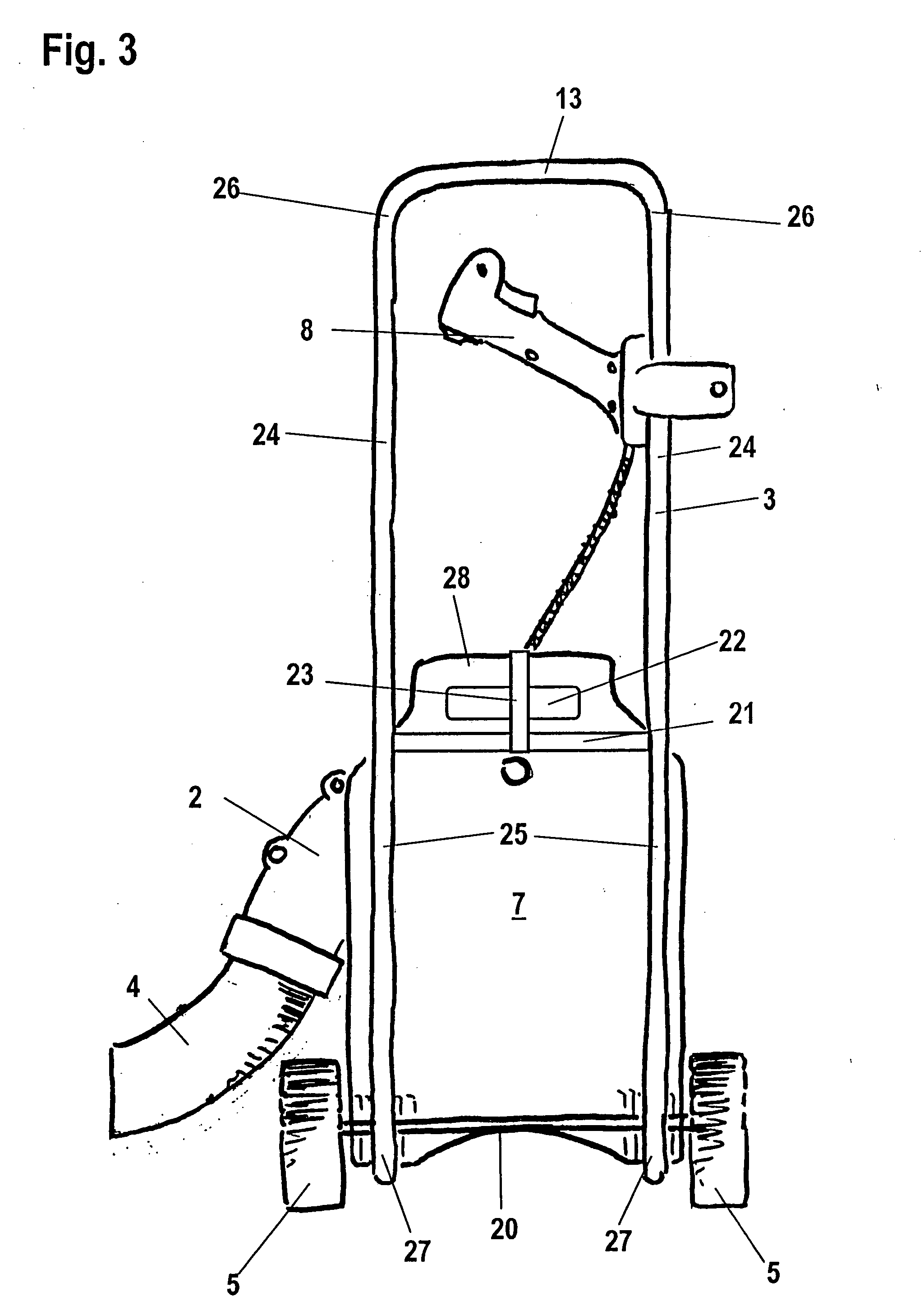

Portable hard surface vacuum

InactiveCN101909499AEasy to separateReduce flow lossCarpet cleanersFloor cleanersLiquid tankLow stress

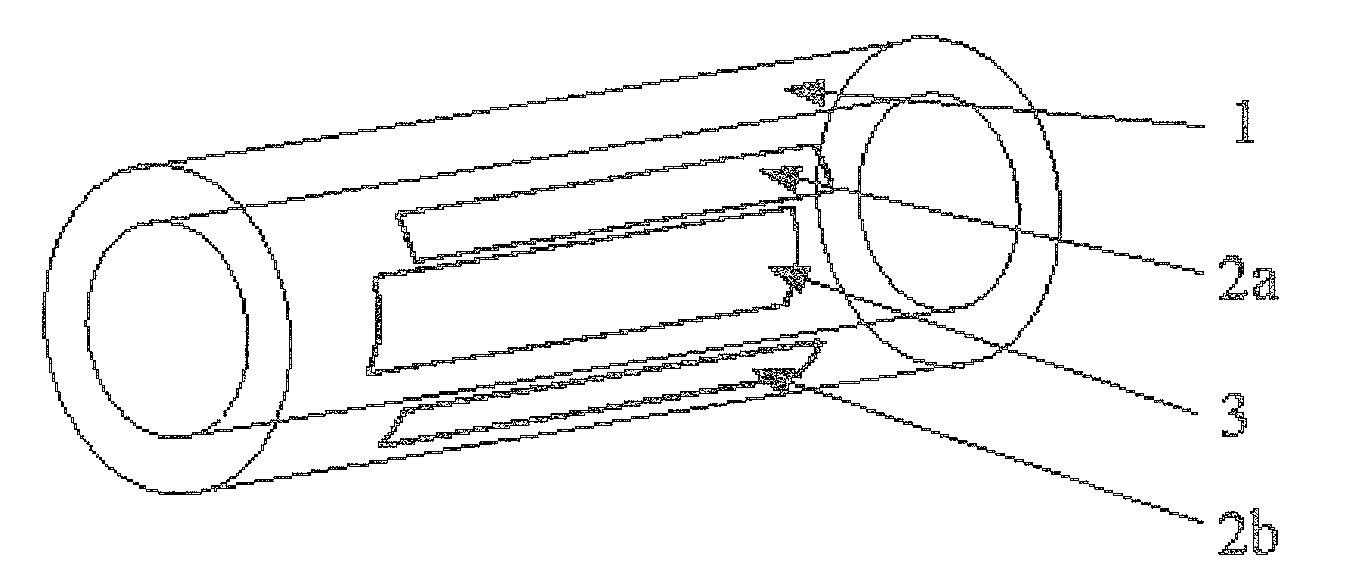

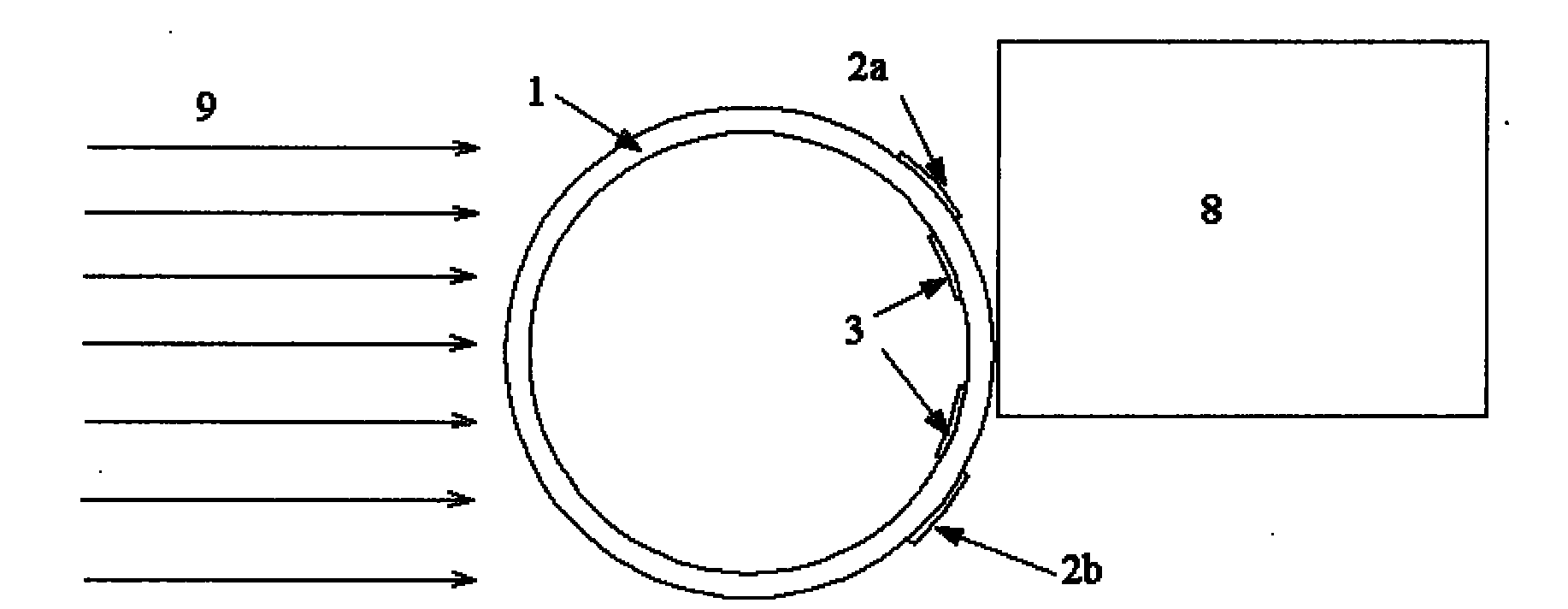

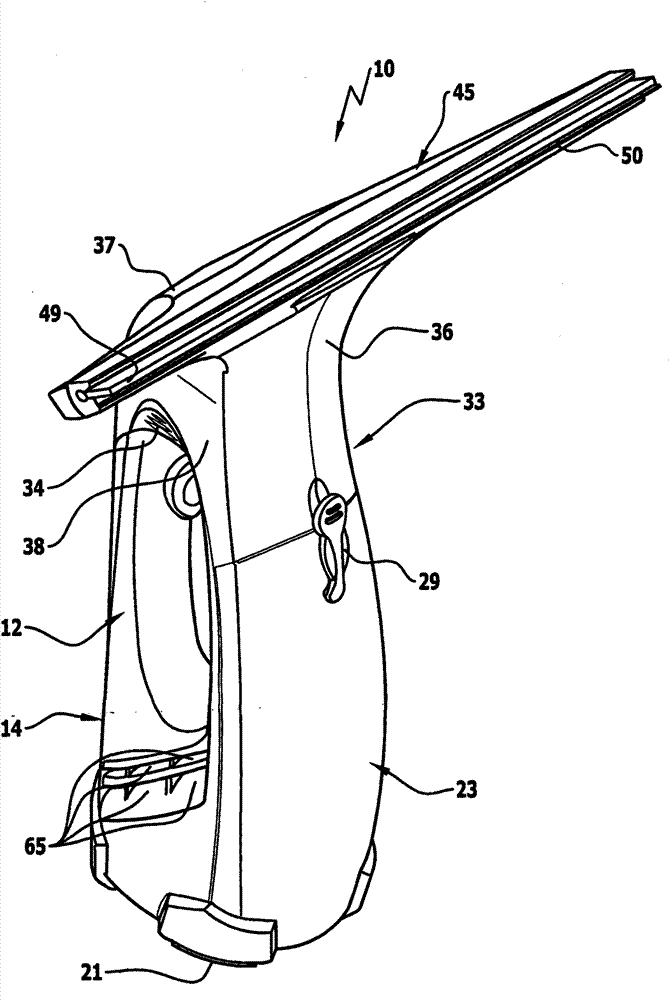

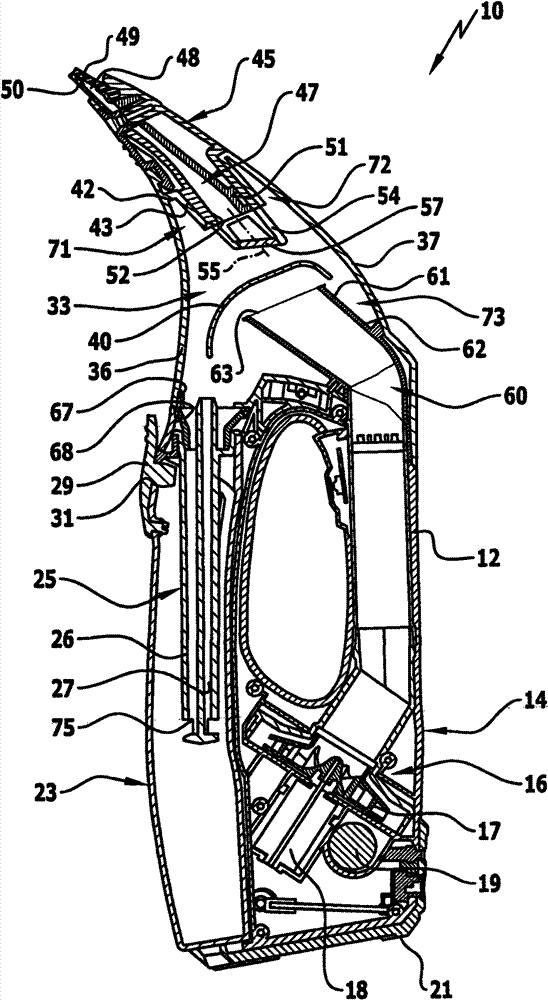

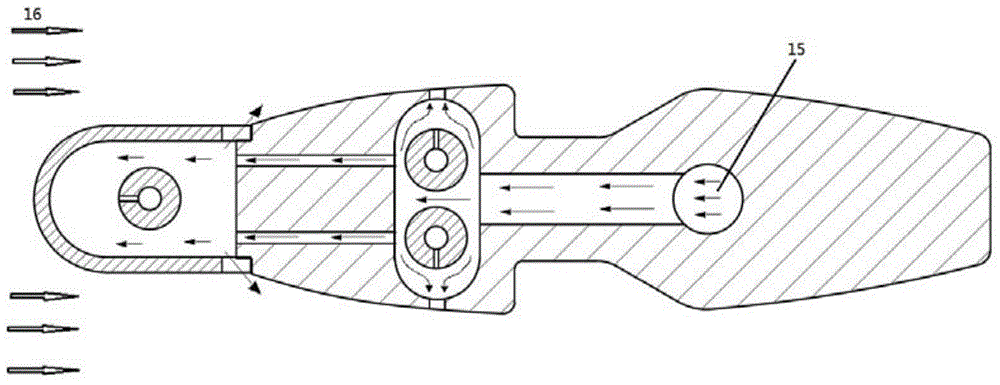

The invention relates to a portable hard surface vacuum (10) comprising a suction nozzle (45) and a suction unit (16), which is in fluid connection with the suction nozzle, for vacuuming a liquid-air mixture from a hard surface, and comprising a separating device (40, 57) for separating liquid from the liquid-air mixture and comprising a waste liquid tank (23) for receiving the separated liquid. In order to refine the hard surface vacuum in such a way that a constant suction flow is provided, regardless of the fill level of the waste liquid tank, and such that operation in an arbitrary orientation in relation to the vertical position can be carried out, a separating chamber (33) is arranged between the suction nozzle and the suction unit, said chamber housing the separating unit and being in fluid connection via a suction line (47) to the suction port (48) of the suction nozzle and in fluid connection to the suction unit via a suction line (60), and said chamber being connected via an outlet opening (67) to the waste liquid tank, wherein the port regions (51, 61) of the suction (47) and vacuum line within the separating chamber are surrounded at least partially by intermediate storage regions (71, 72, 73) for separated liquid in the circumferential direction.

Owner:ALFRED KARCHER GMBH & CO KG

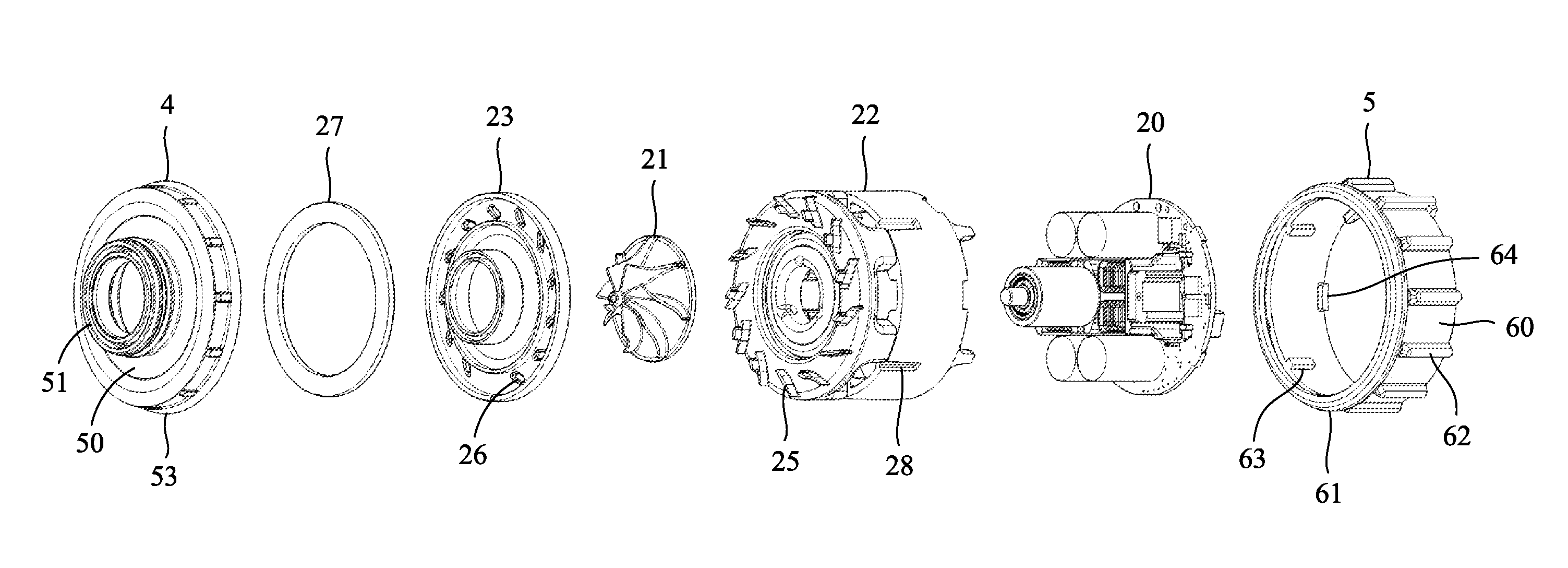

Compressor flow path

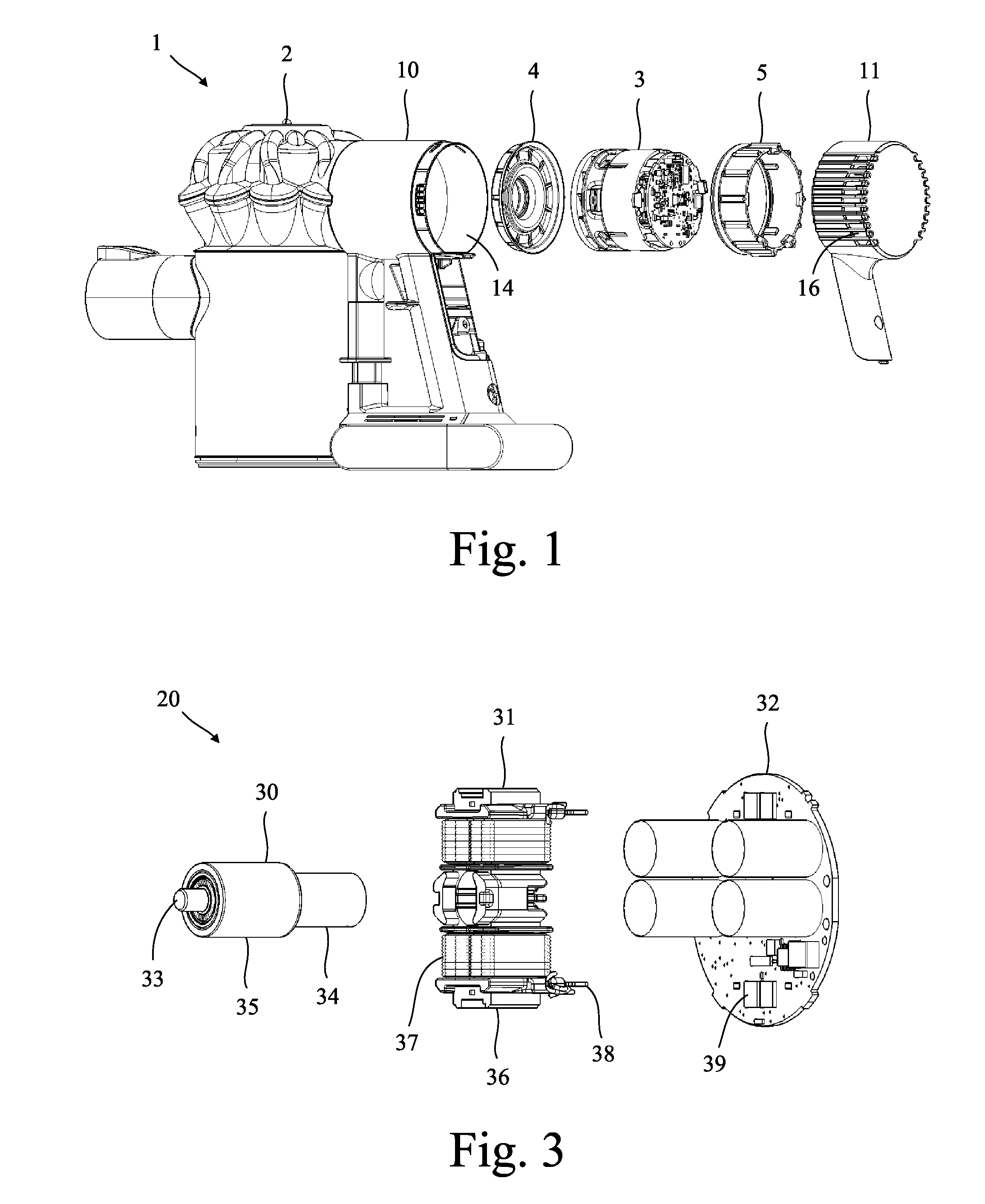

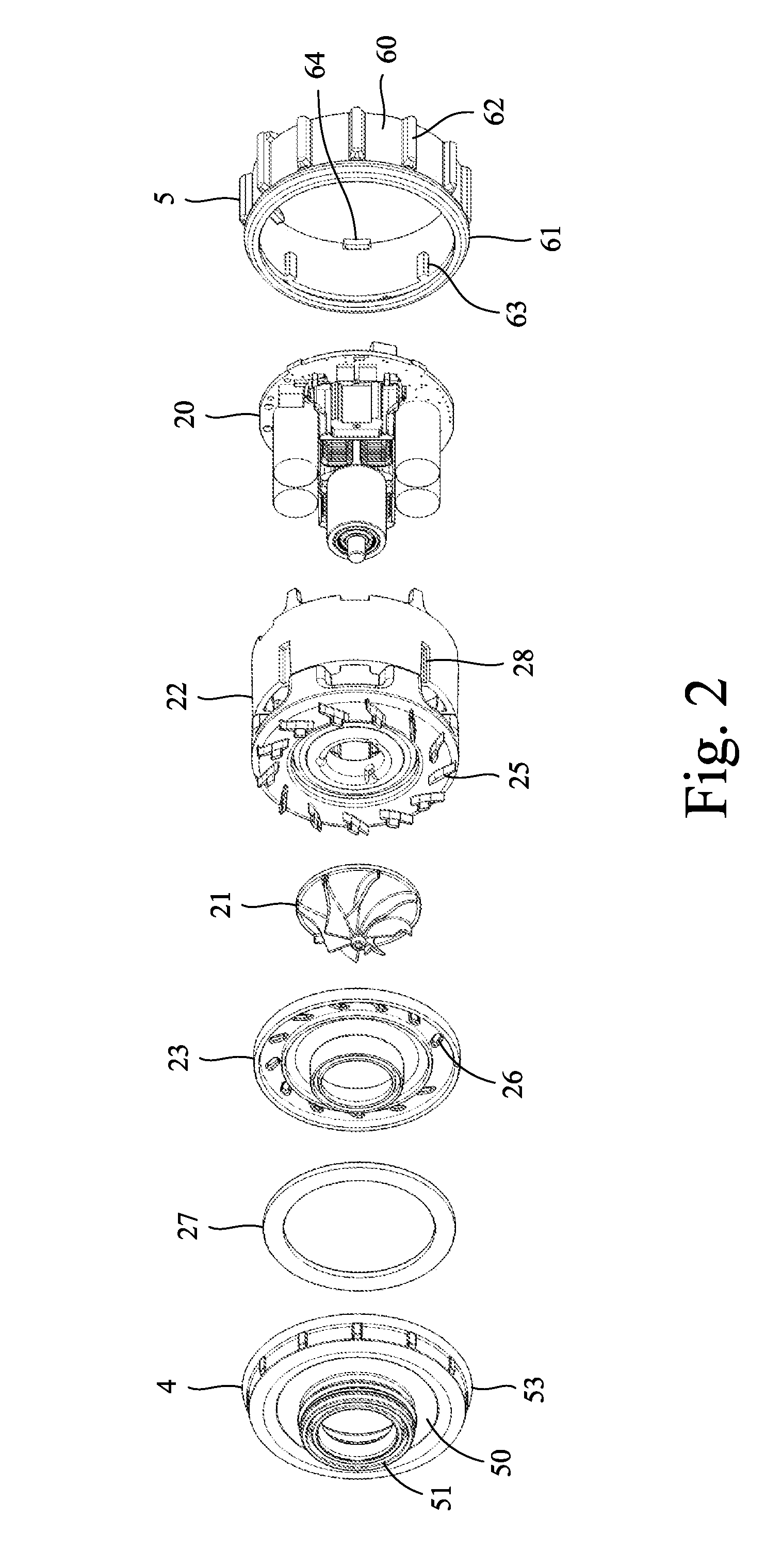

ActiveUS20140325789A1Simplify assemblyReduce flow lossMagnetic circuitCooling/ventillation arrangementImpellerEngineering

A product that includes a compressor, a housing and a vibration isolation mount located between the compressor and the housing. The compressor includes an impeller, a first inlet located upstream of the impeller, a first outlet located downstream of the impeller, a second inlet located downstream of the first outlet, and a second outlet located downstream of the second inlet. During operation, fluid enters the compressor via the first inlet and exits the compressor via the first outlet. The mount creates a restriction between the compressor and the housing that causes fluid exiting the first outlet to re-enter the compressor via the second inlet.

Owner:DYSON TECH LTD

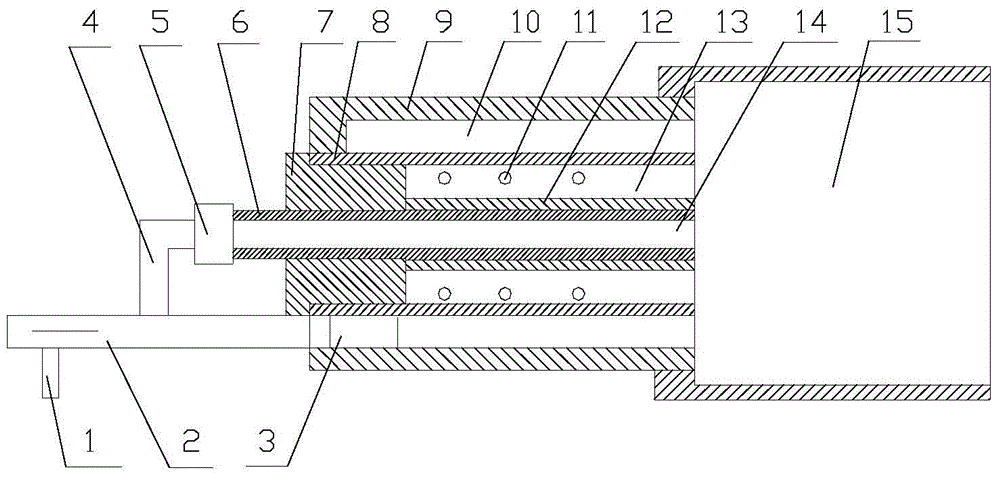

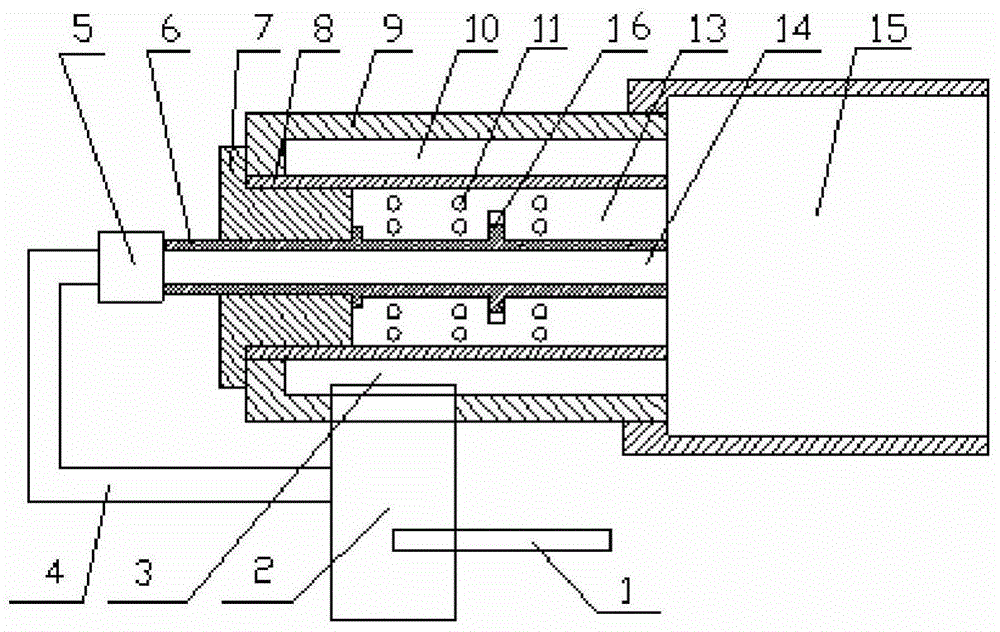

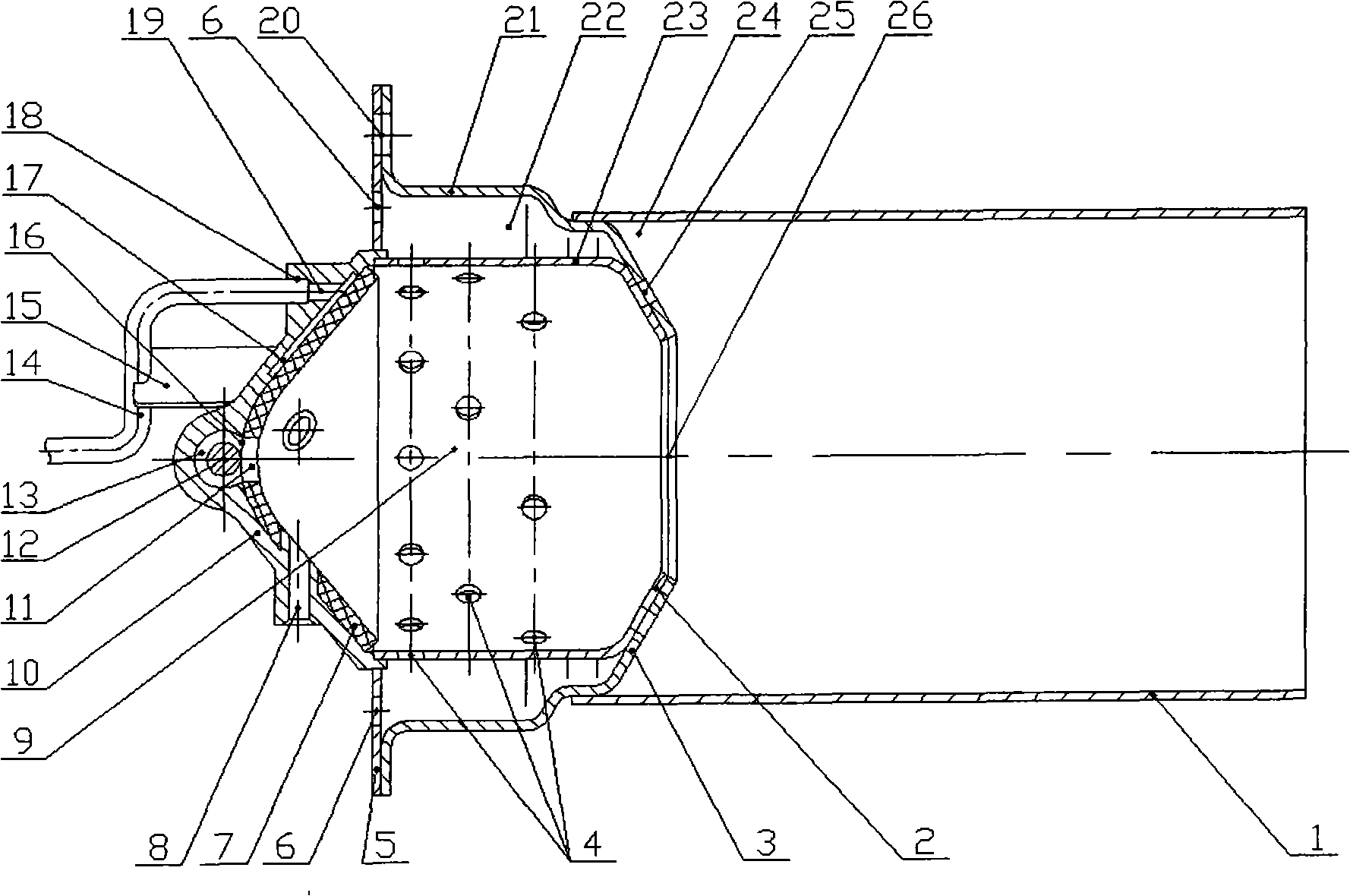

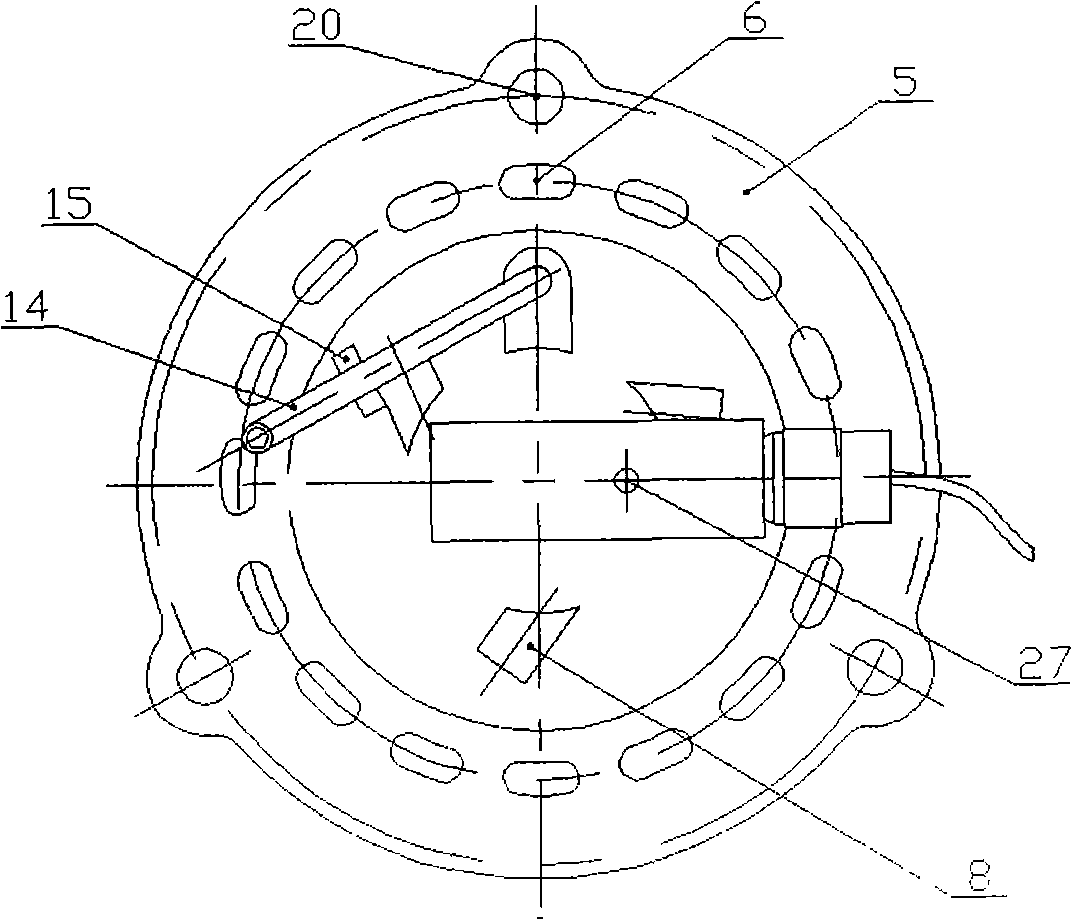

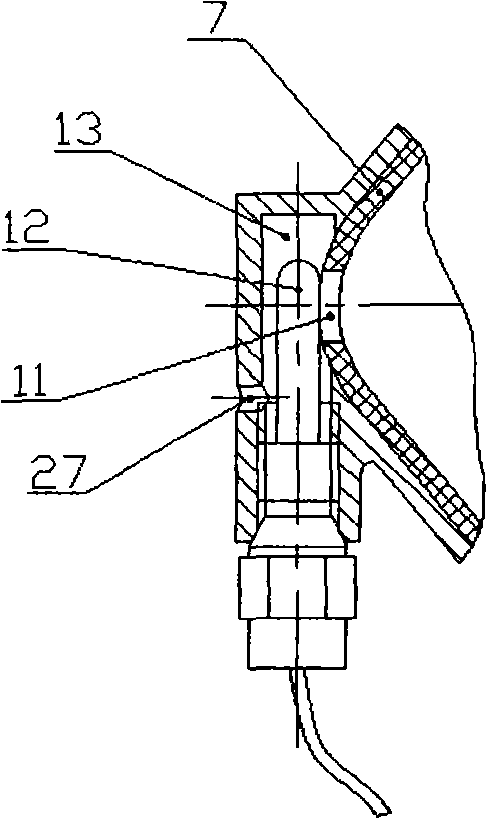

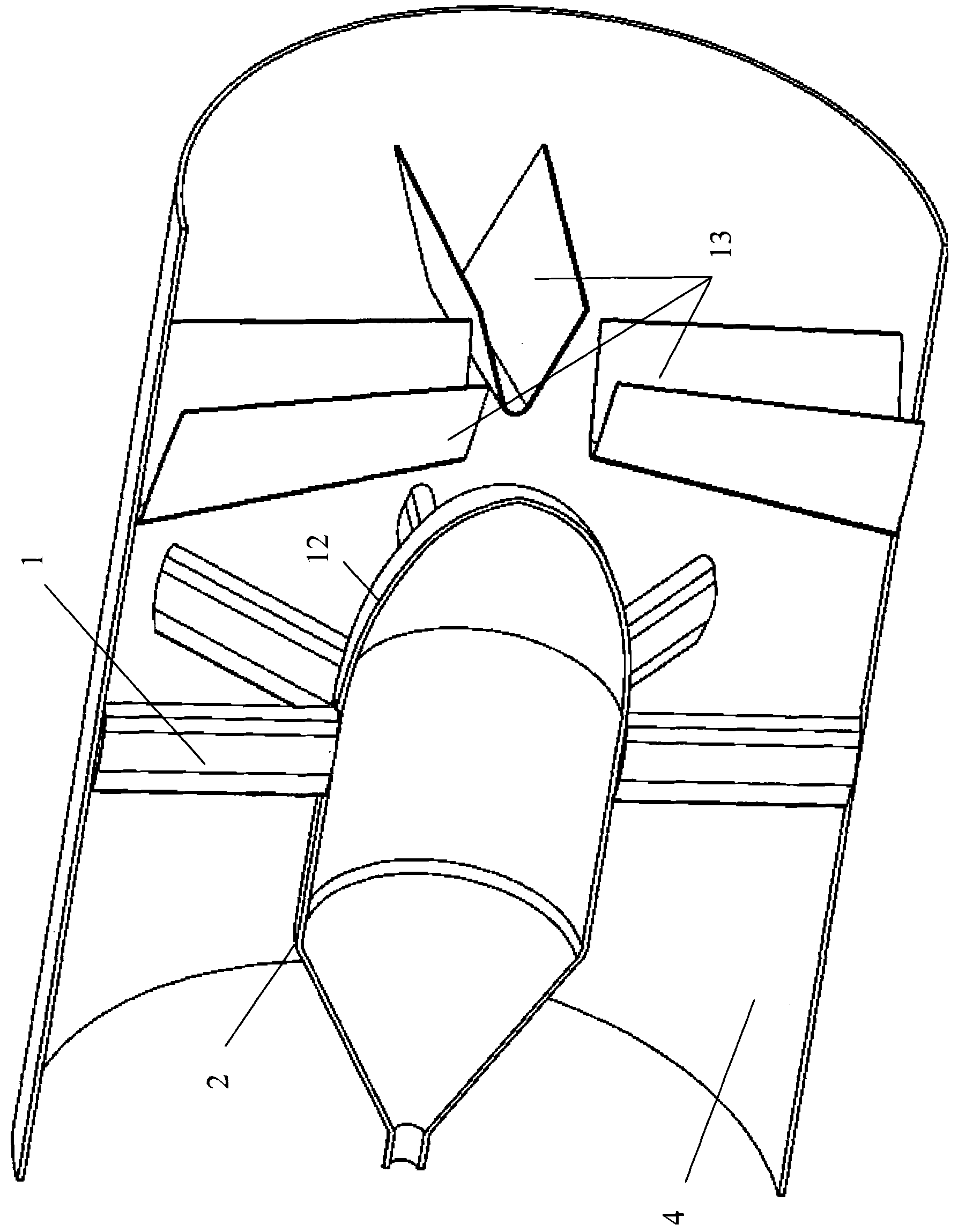

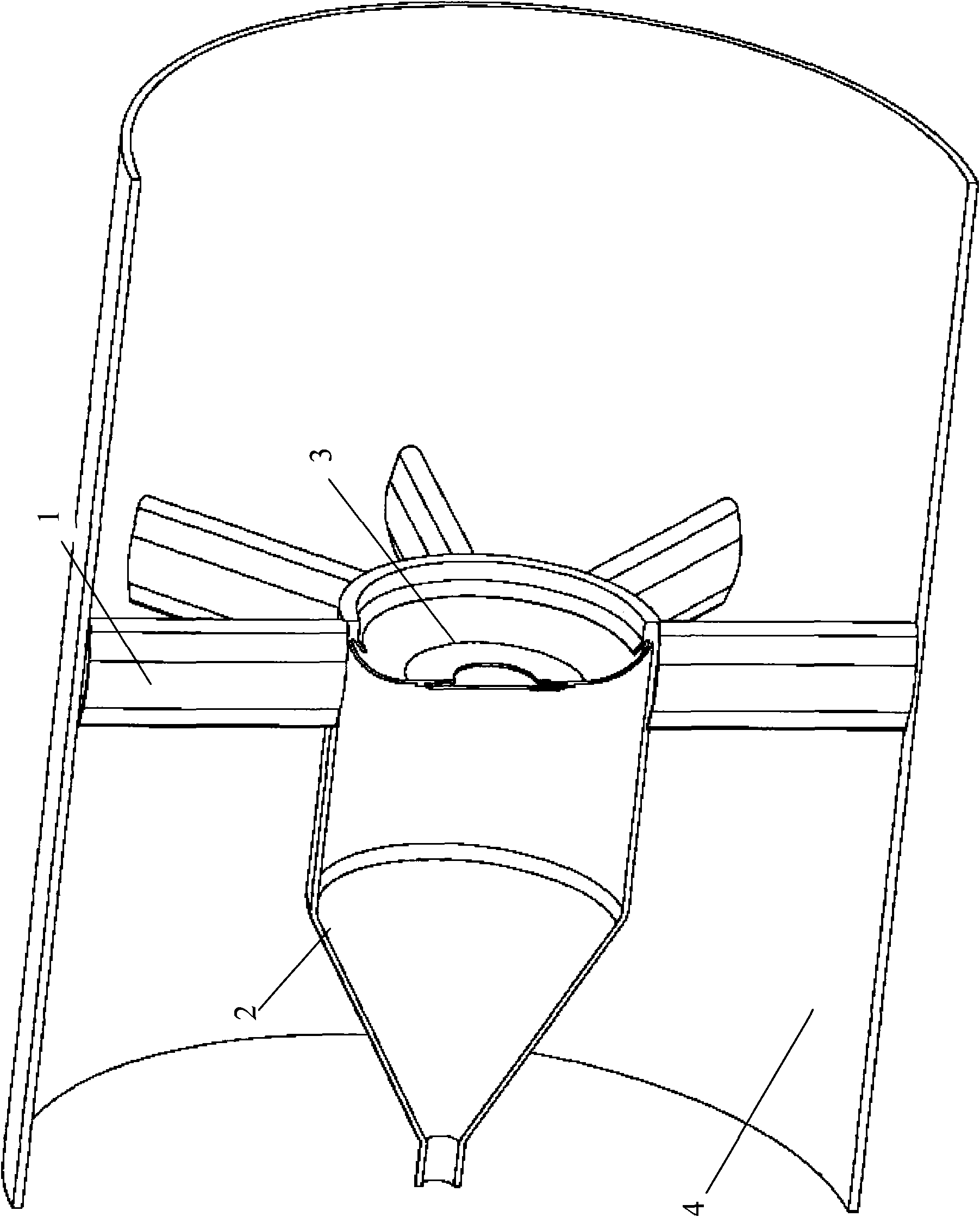

Multichannel plasma area igniting burner

ActiveCN104879780AAct as ignition sourceFlame stabilityGas turbine plantsCombustion ignitionCombustion chamberLow speed

The invention discloses a multichannel plasma area igniting burner. The igniting burner comprises a plasma power supply, a nozzle, an air inlet fish nozzle, a tangential air hole, an air pipe, a hollow insulator, a high-voltage electrode, an insulation piece, a low-voltage electrode, a housing, a swirl chamber, air vents, barrier mediums, a low-speed area, center jet flow and a flame stabilization chamber. Fuel oil is atomized by the use of a splash plate disposed inside the air inlet pipe, mixed gas composed of high-speed rotation air-flow and direct current jet flow is disposed inside the igniting burner, and the two flows cool the igniting burner. The space between the high-voltage electrode and the low-voltage electrode is filled with the inflammable mixed gas flowing at a low speed, so that multi-point discharge and ignition can be carried out in a low-speed mixed gas area inside the igniting burner; and an on-duty high-temperature combustion thermonuclear area and the flame stabilization chamber have ignition source and flame stabilization functions and form a miniature high-speed combustion chamber, so that the combustion chamber can efficiently and reliably ignite and keep flames stable under poor conditions such as high-speed, low-temperature, low-pressure, coal firing and the like.

Owner:PEKING UNIV

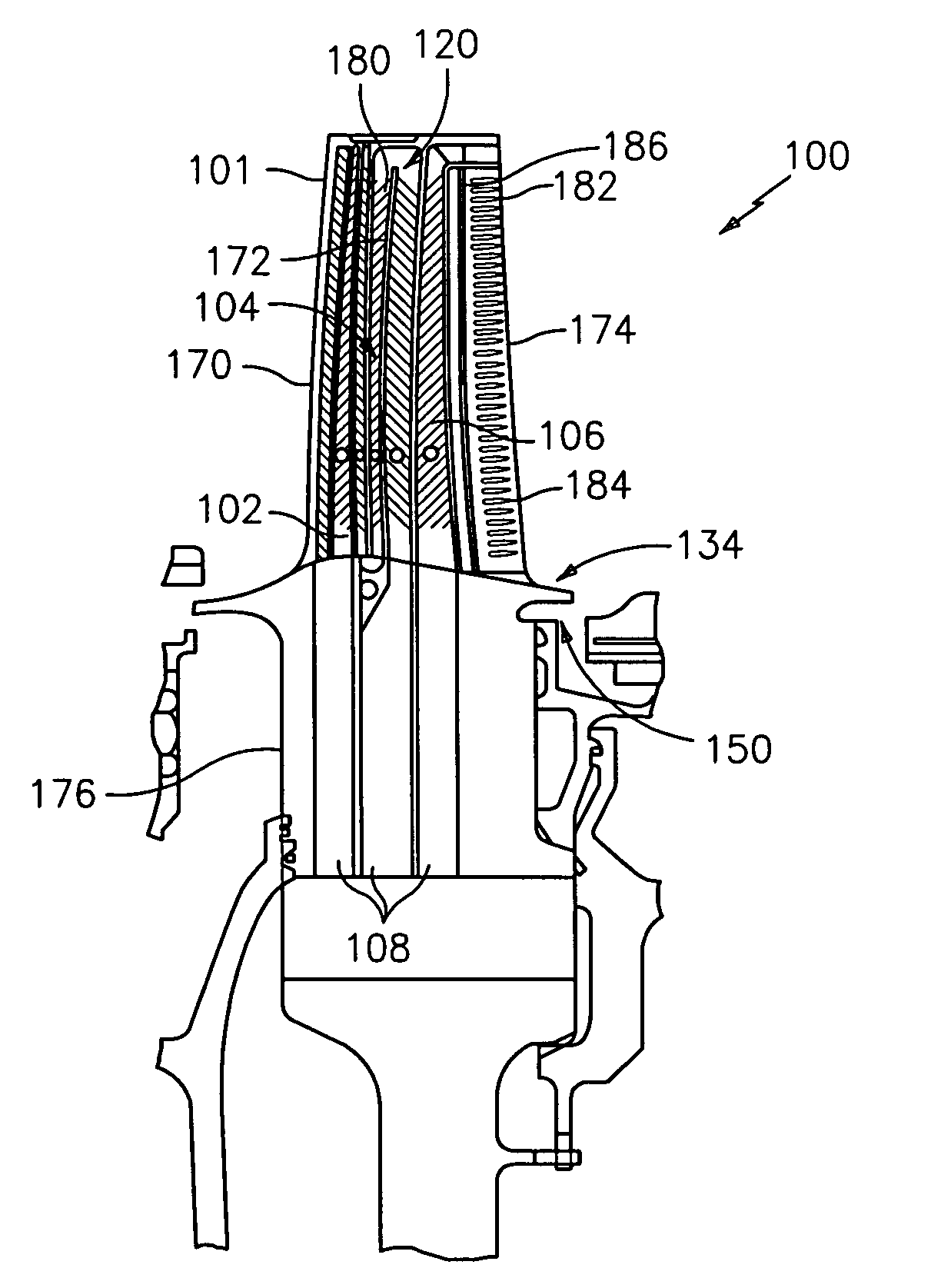

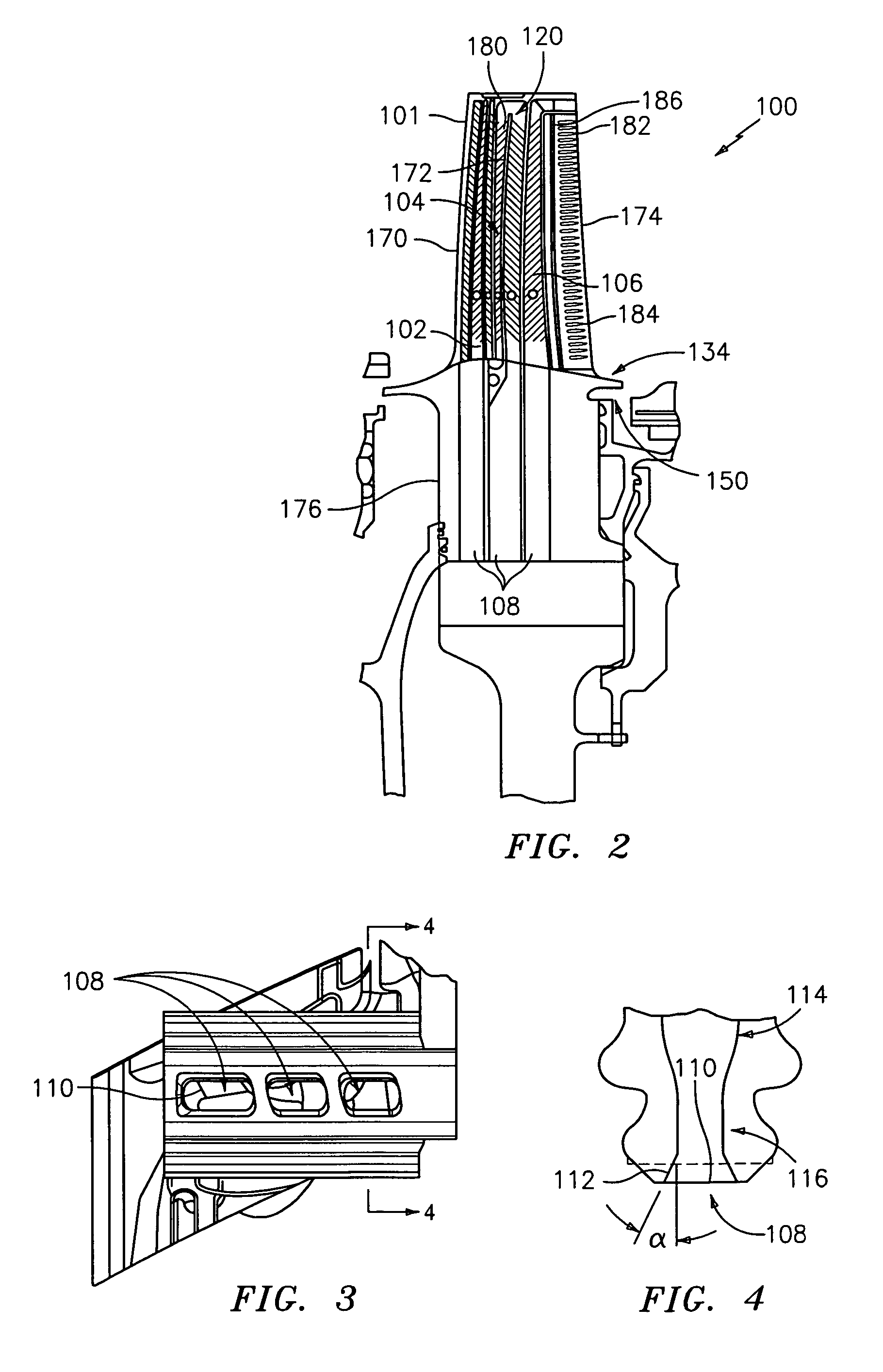

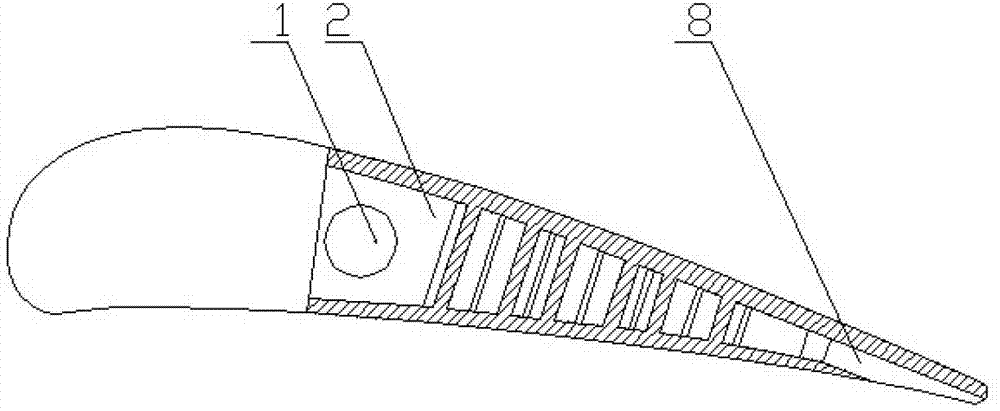

Cooled turbine blade

ActiveUS20070140848A1Reduce flow lossReduce traffic lossPropellersEngine manufactureTrailing edgeCooling channel

A turbine engine component, such as a turbine blade, has an airfoil portion, a plurality of cooling passages within the airfoil portion with each of the cooling passages having an inlet for a cooling fluid. Each inlet has a flared bellmouth inlet portion. The turbine engine component may further have a dirt funnel at the tip of the airfoil portion, a platform with at least one beveled edge, and an undercut trailing edge slot.

Owner:RAYTHEON TECH CORP

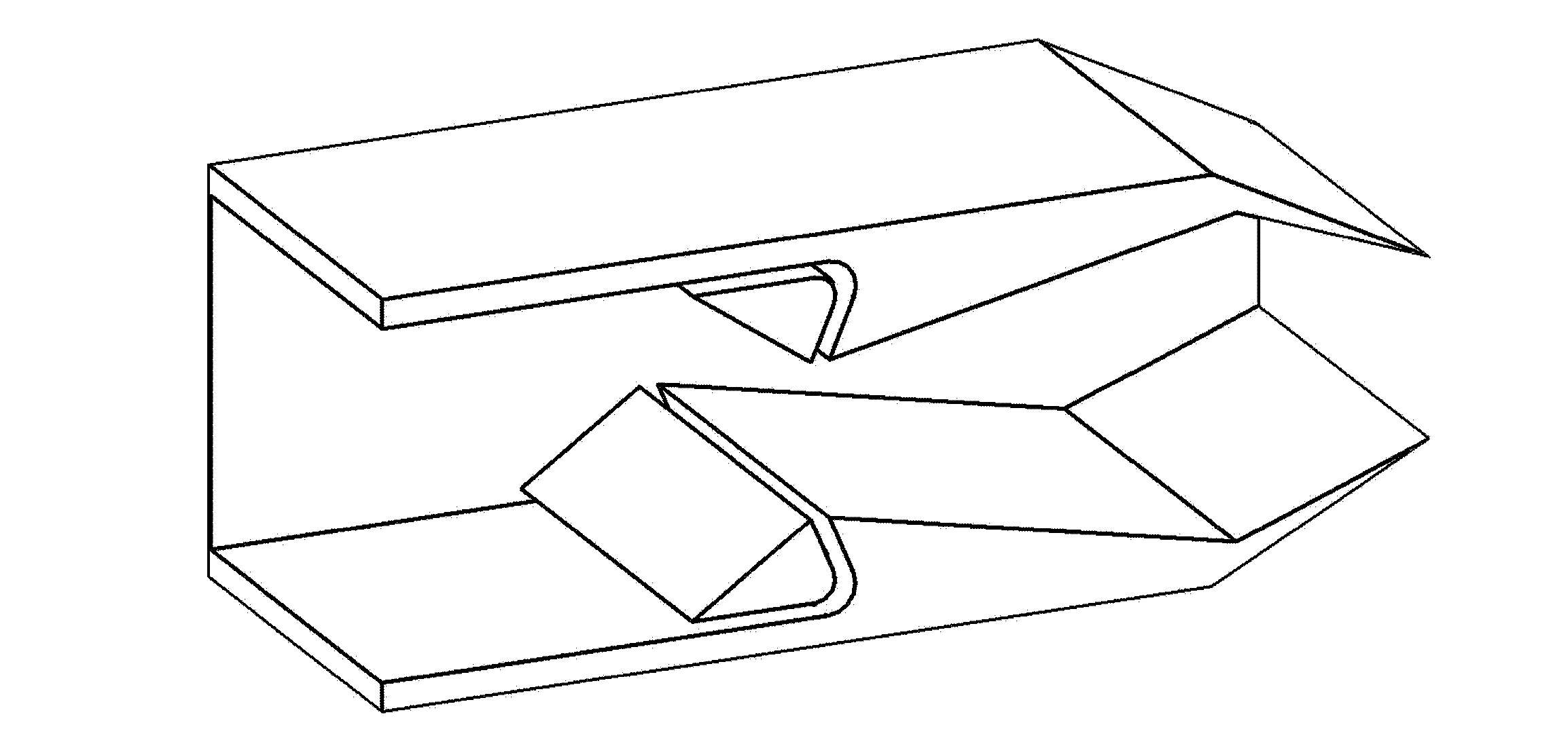

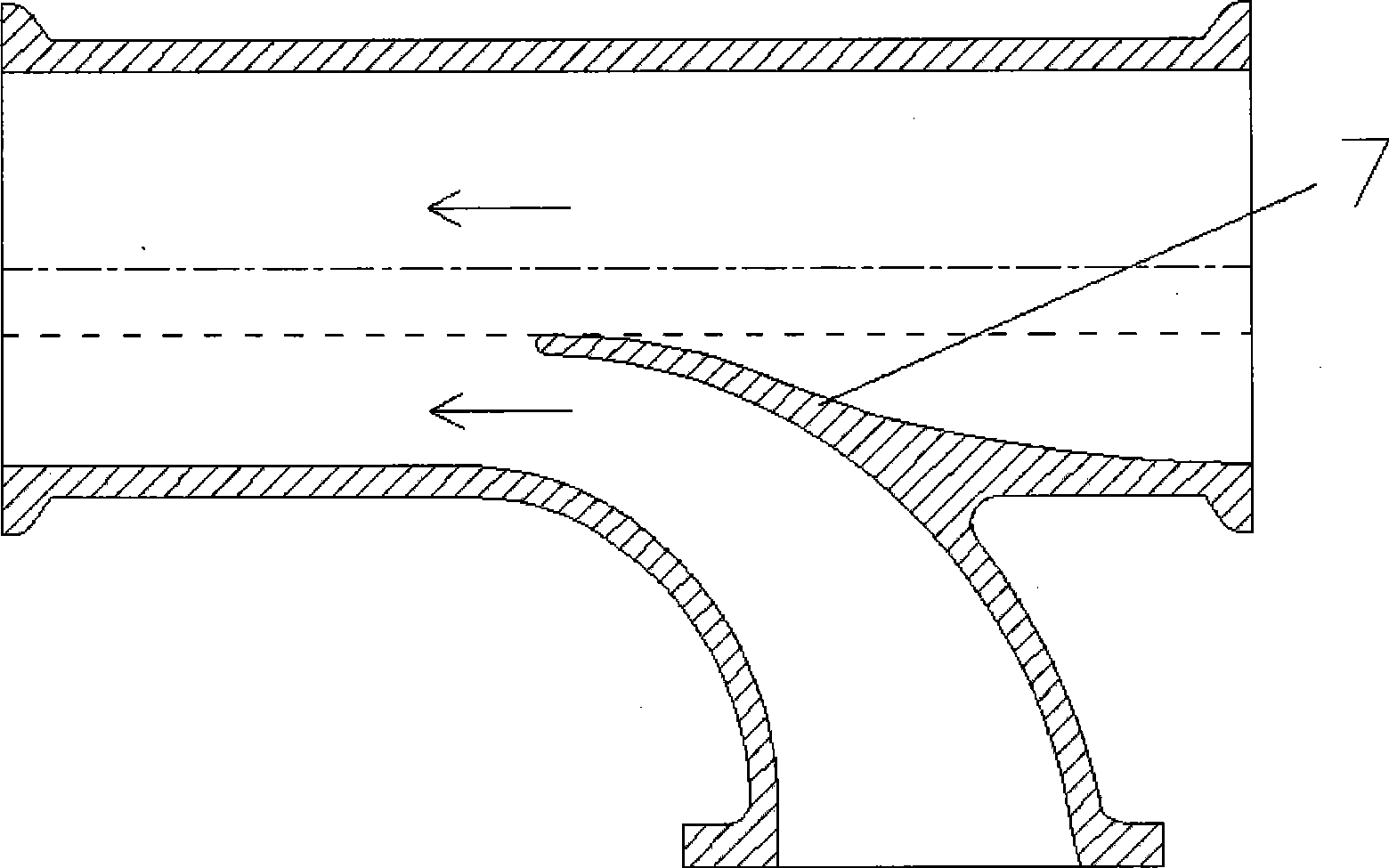

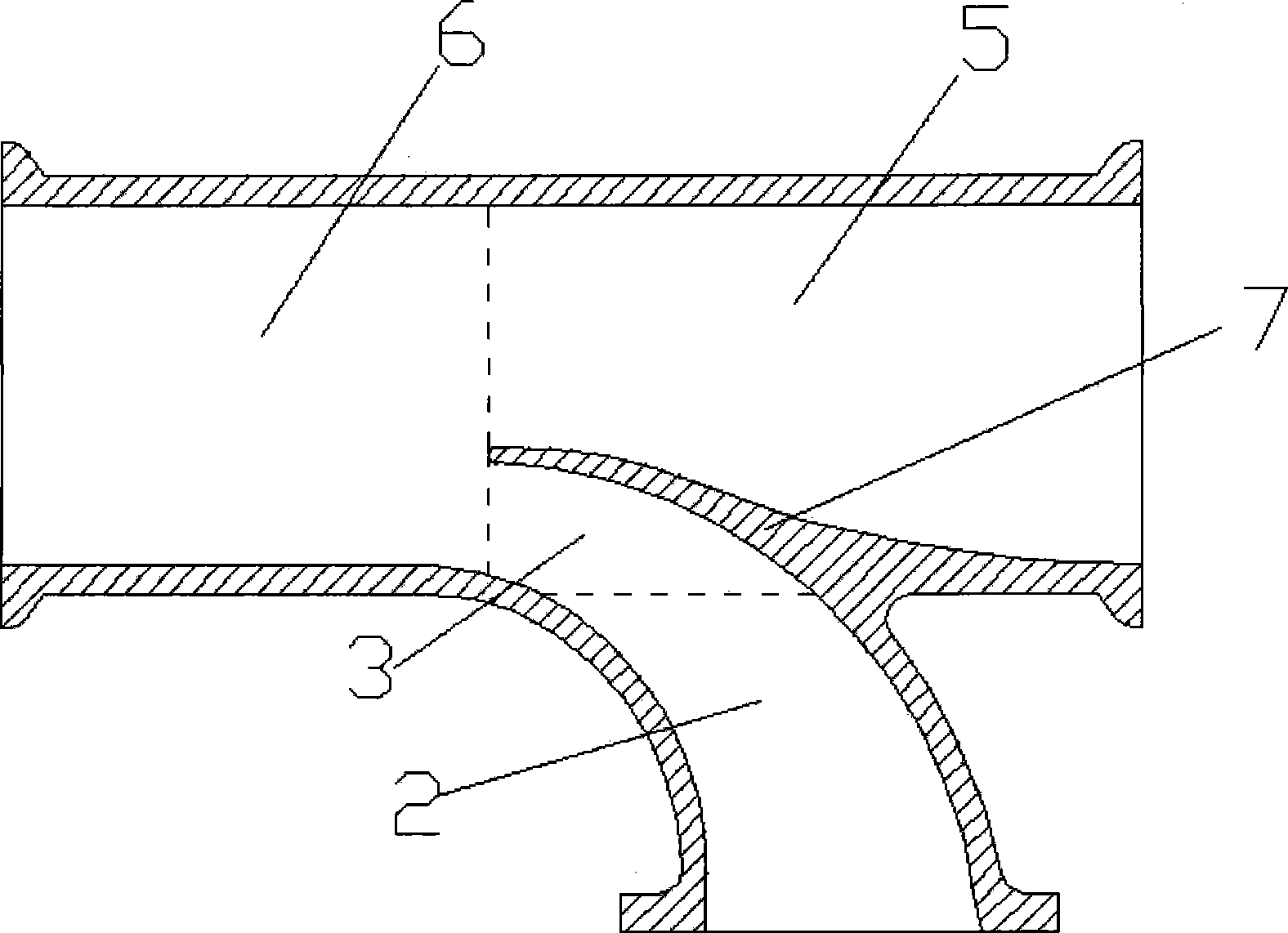

Bypass type double-throat passive vectoring sprayer nozzle

The invention discloses a bypass type double-throat passive vectoring sprayer nozzle, comprising a sprayer nozzle main body, wherein the inner flow channel of the sprayer nozzle main body comprises front contraction sections of the throats, a bypass convex block, a first throat, a second throat front part expanded contraction section, throat reentrant cavities and a second throat; the front contraction sections of the throats are provided with bypass channels close to the first throat, wherein the inlets of the bypass channels are arranged facing the fluid entrance of the inner flow channel of the nozzle main body while the outlets of the bypass channels are arranged on the first throat. Therefore, the bypass channels are arranged in the double-throat nozzle to change the flow structure in the double-throat nozzle to further make the outflow of the nozzle achieve deviation, that is, producing and maintaining vector deflection. In addition, when the bypass type double-throat passive vectoring sprayer nozzle produces a thrust vector, a little flow loss is caused. The bypass type double-throat passive vectoring sprayer nozzle also has a simple structure, and does not influence performances of the nozzle when the nozzle works normally without vector deflections.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

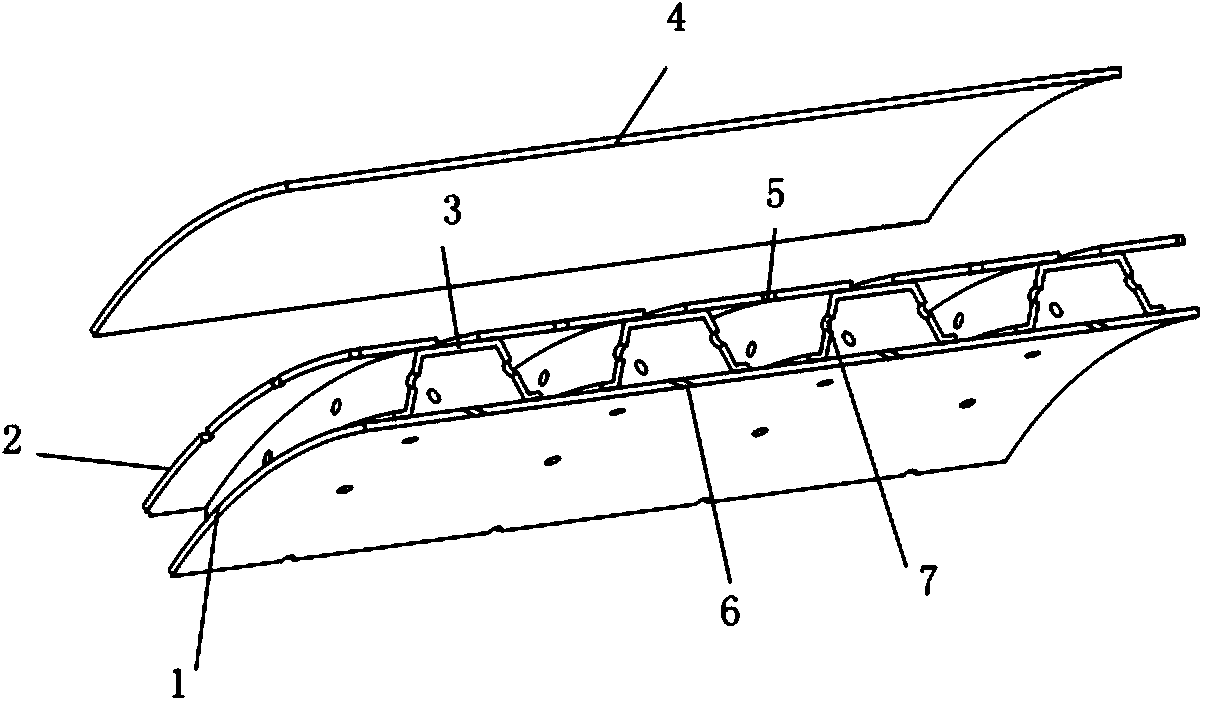

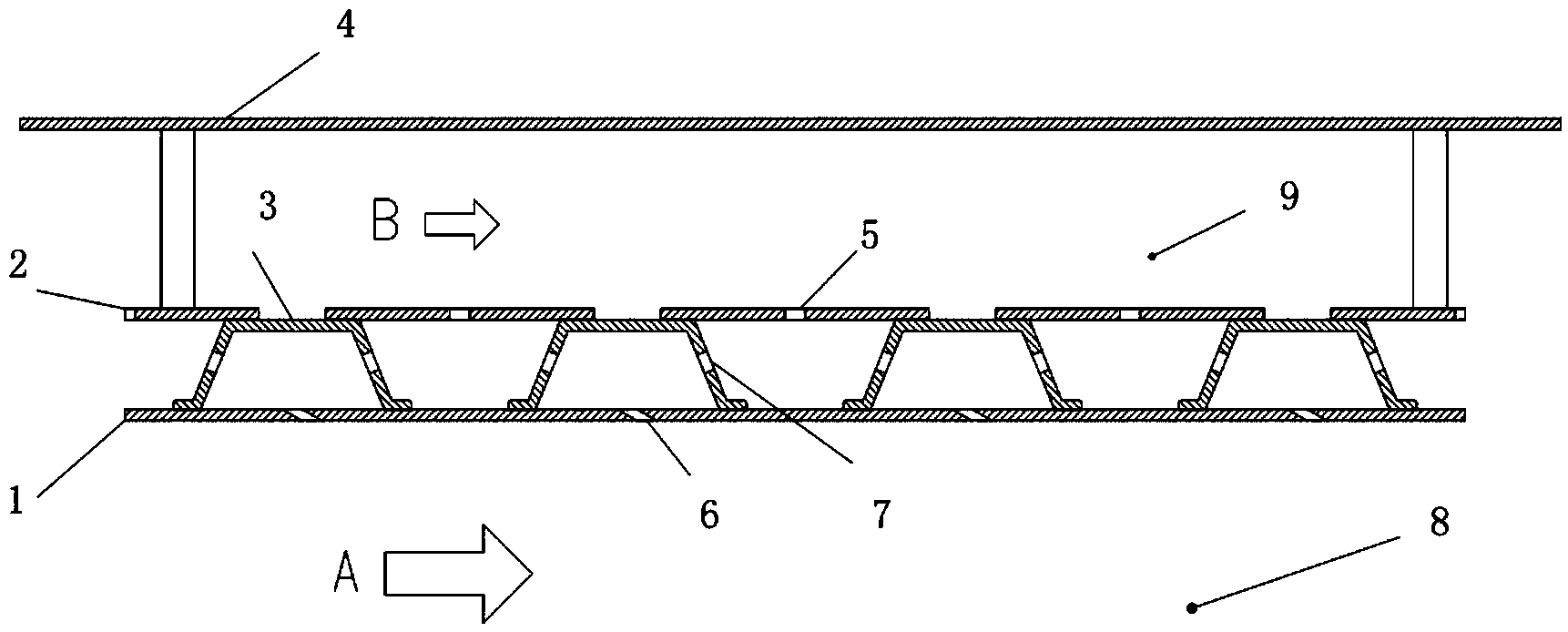

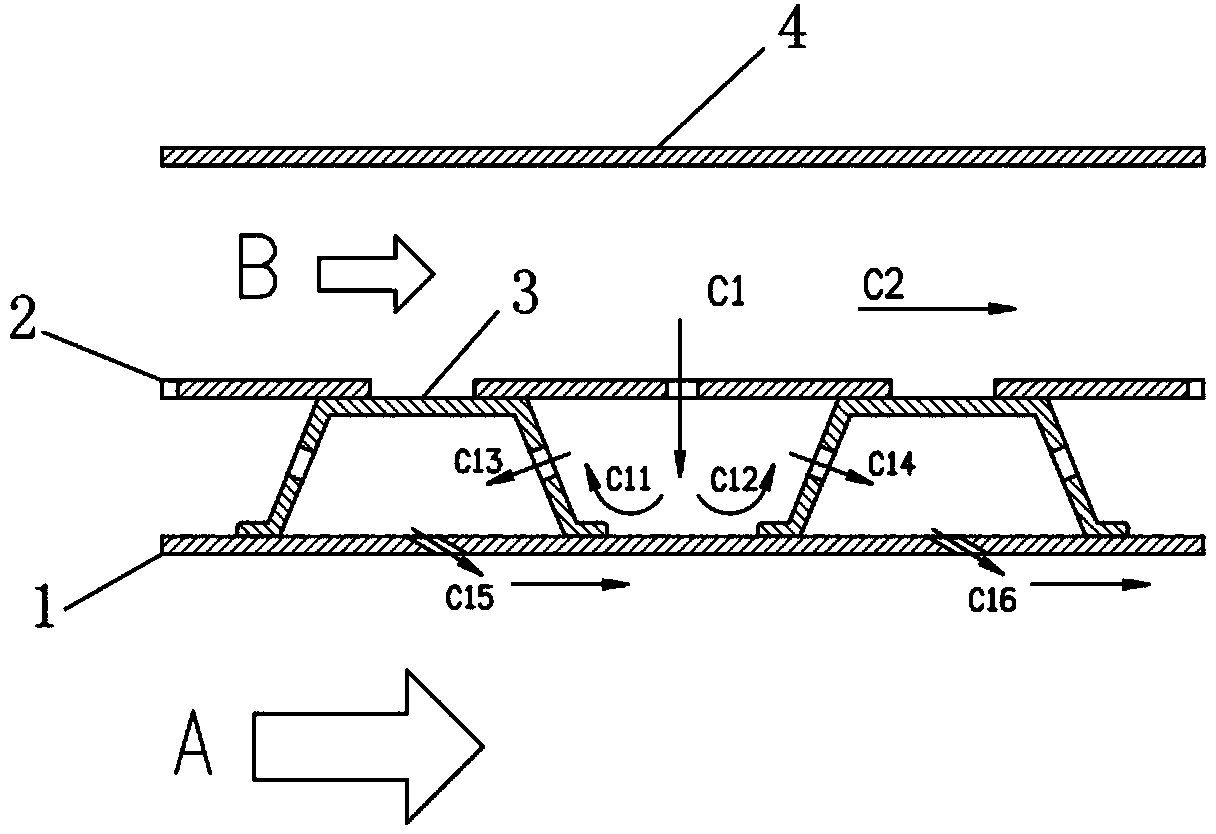

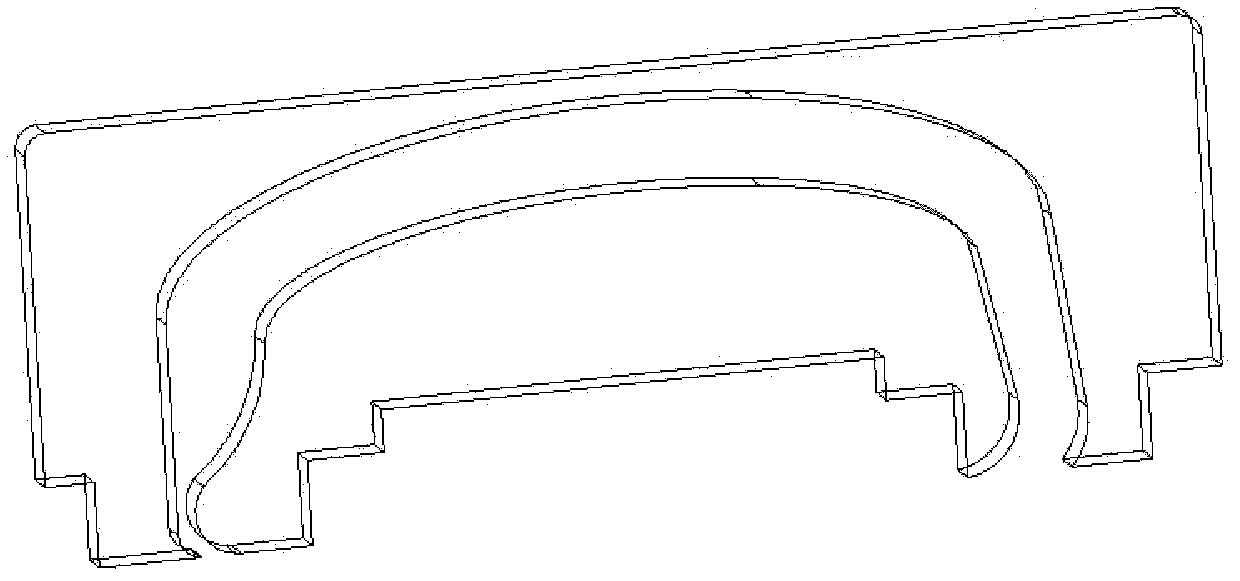

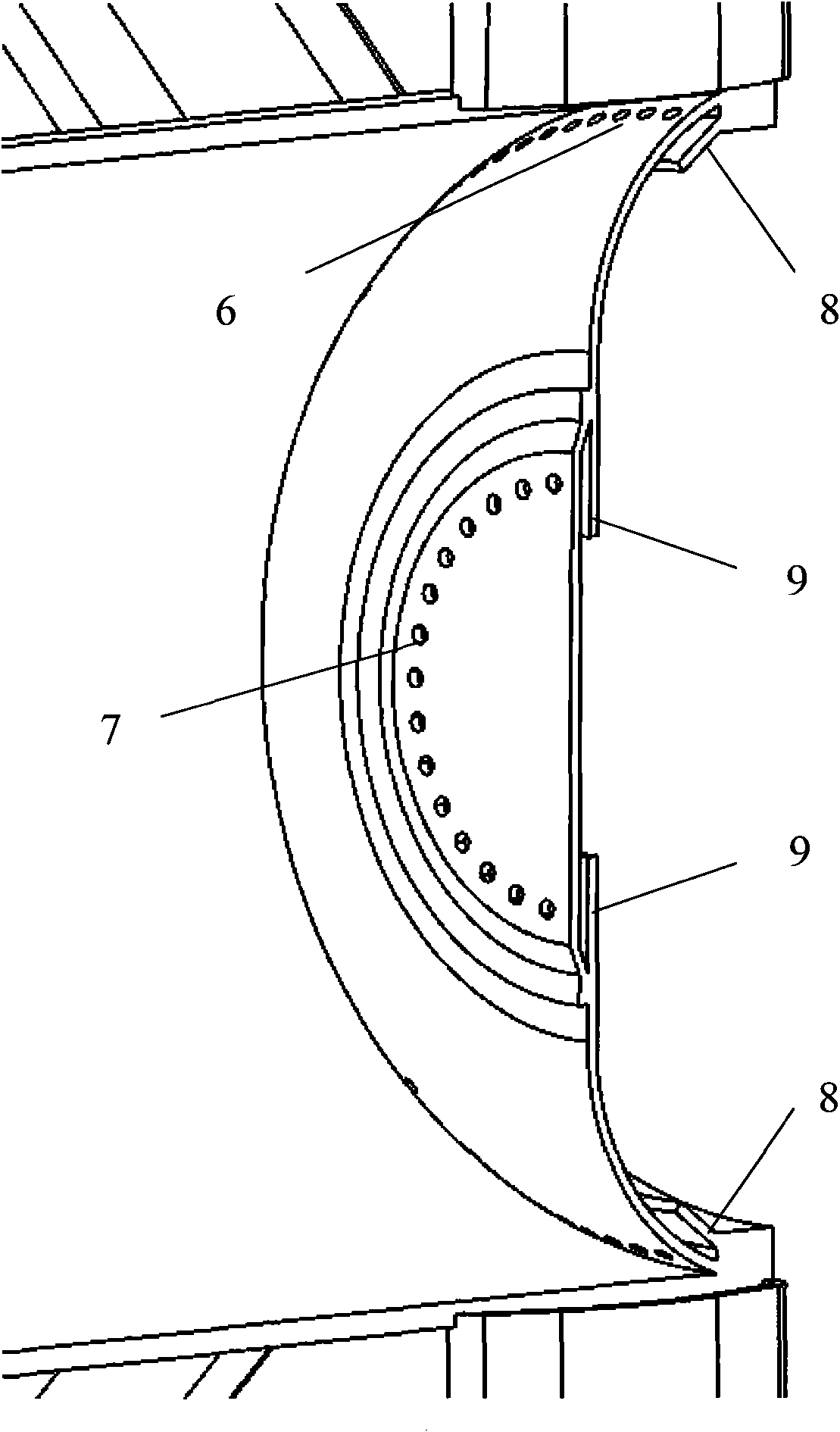

Double-layer-wall heat insulation screen used for afterburner

InactiveCN103968418AReduce heat load and gas flow lossReduce wall temperatureContinuous combustion chamberCombustion chamberEngineering

The invention discloses a double-layer-wall heat insulation screen used for an afterburner. Cooling protection is formed for the wall surface of the afterburner by using an inner convection cooling mode and a gas side air film cooling mode. The double-layer-wall heat insulation screen comprises a gas side gas film hole plate, a cool air side impacting plate and a trapezoidal reinforcing frame. The gas side air film hole plate serves as the inner wall of a cylinder body of the afterburner, the inner side of the gas side air film hole plate is provided with a main gas duct of the afterburner, the cool air side impacting plate and an outer wall surface form a cool air duct, and the trapezoidal reinforcing frame is arranged between the impacting plate and the air film hole plate. The double-layer-wall heat insulation screen is formed by the impacting plate, the air film hole plate and the trapezoidal reinforcing frame. Cooling air is made to form an air film on the gas side inner wall of the heat insulation screen, and heat load and gas flow losses are reduced. In addition, composite cooling is formed through inner convection cooling and outer air film cooling of a double-layer wall, incoming heat is brought away through convection heat exchange, and the cool air utilization rate is increased. Reduction is achieved after reflection, the effect of vibration prevention is achieved, the service life of the afterburner is prolonged, and the reliability of the afterburner is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

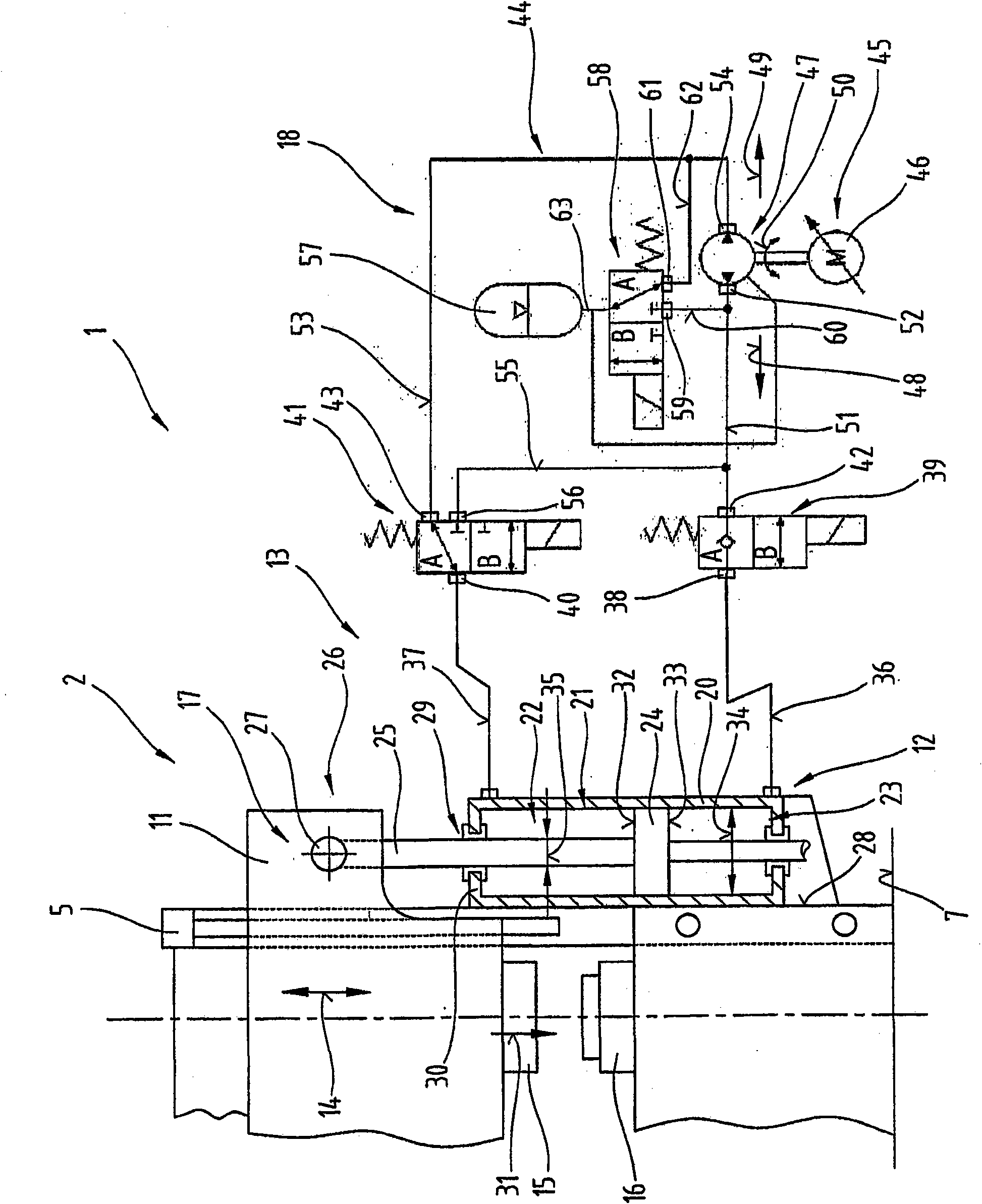

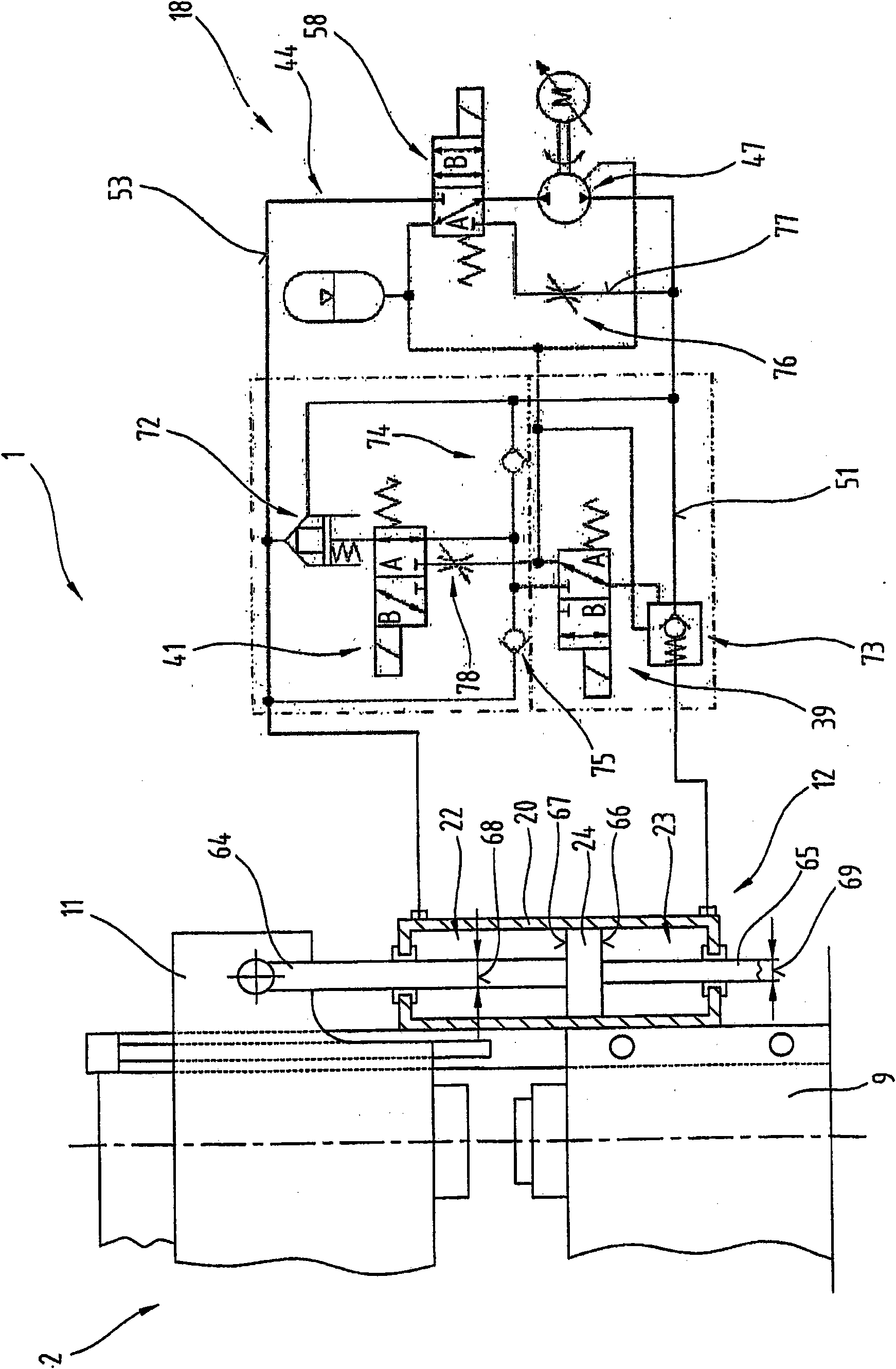

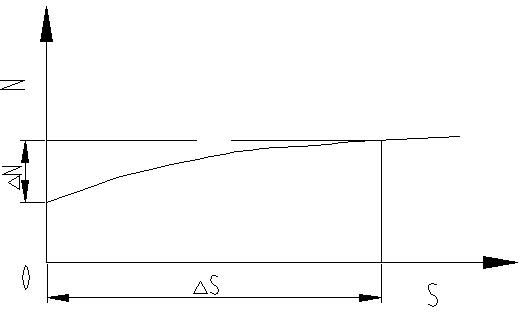

Drive device for a bending press

ActiveCN101835601AHigh and fast stroke speedSmooth control transitionServomotorsTelemotorsHydraulic pumpDrive motor

The invention relates to a drive device (1) for a bending press, especially a folding press (2), comprising a press frame (3), a press table (9) and a press bar (11) that can be adjusted relative to the press table (9) via a hydraulic system (18) comprising a hydraulic pump (47), controlled drive motor (45), switch and control means and pressure lines and at least one pressure cylinder (12) whichcan be supplied with at least one pressure medium. The hydraulic system (18) forms a closed system together with a ring line (44) comprising the hydraulic pump (47), control valves (39, 41, 58, 84, 86, 87, 88, 89) and an accumulator (57). The ring line comprises a first line section (51) between a pressure chamber (23) of the pressure cylinder (12) and the hydraulic pump (47) and a second line section (53) between a second pressure chamber (22) of the pressure cylinder (12) and the hydraulic pump (47). The accumulator (57) can optionally be in fluid connection with the first line section (51)or the second line section (53) to take up or release a storage volume of the pressure medium.

Owner:TRUMPF MASCHEN AUSTRIA

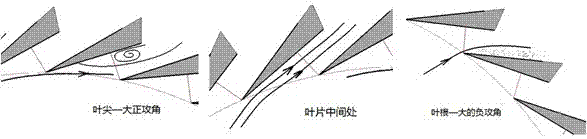

Sweeping and twisting type three-dimensional blade diffuser and design method thereof

The invention relates to a sweeping and twisting type three-dimensional blade diffuser. According to the structure, the front edges of blades are designed into a sweeping shape, the sweeping angle ranges from -45 degrees to 45 degrees, and the blades are suitable for incoming flow and are twisted to be expanded into different air flow angles. The main blade is designed into a three-dimensional integral structure from an inlet to an outlet in the axial direction. The flow-dividing blades are arranged on the rear section in a main blade channel. The sweeping and twisting type three-dimensional blade diffuser has the advantages that interaction of shock waves and a boundary layer is relieved, so that flow in the diffuser is modified; blade surface air flow separation and load loss which are caused by a relative large positive / negative attack angle in part of the blades in the high portion are eliminated, flow loss is reduced, and therefore a stator part diffuser of a centrifugal / oblique flow gas compressor can reach the higher efficiency and the larger pressure ratio. The strength of the shock waves is changed and the shock waves are even eliminated and influence caused by interaction of the shock waves and the boundary layer is relieved; flow loss caused by the overlarge positive attack angle or the overlarge negative attack angle is avoided, the expansion capacity and the operation range of the diffuser are improved, and therefore the improvement in the performance of the whole-level gas compressor is assisted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

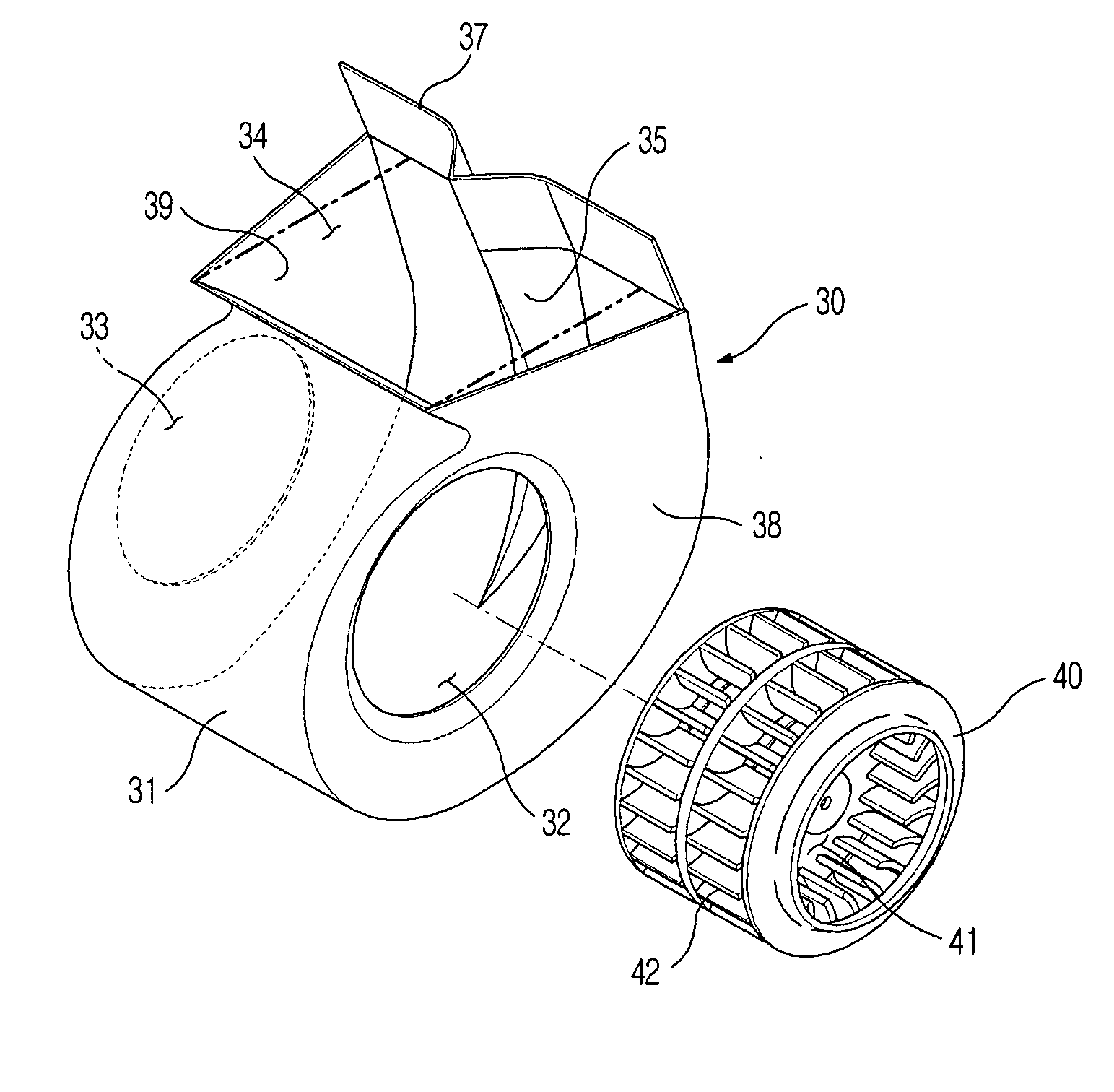

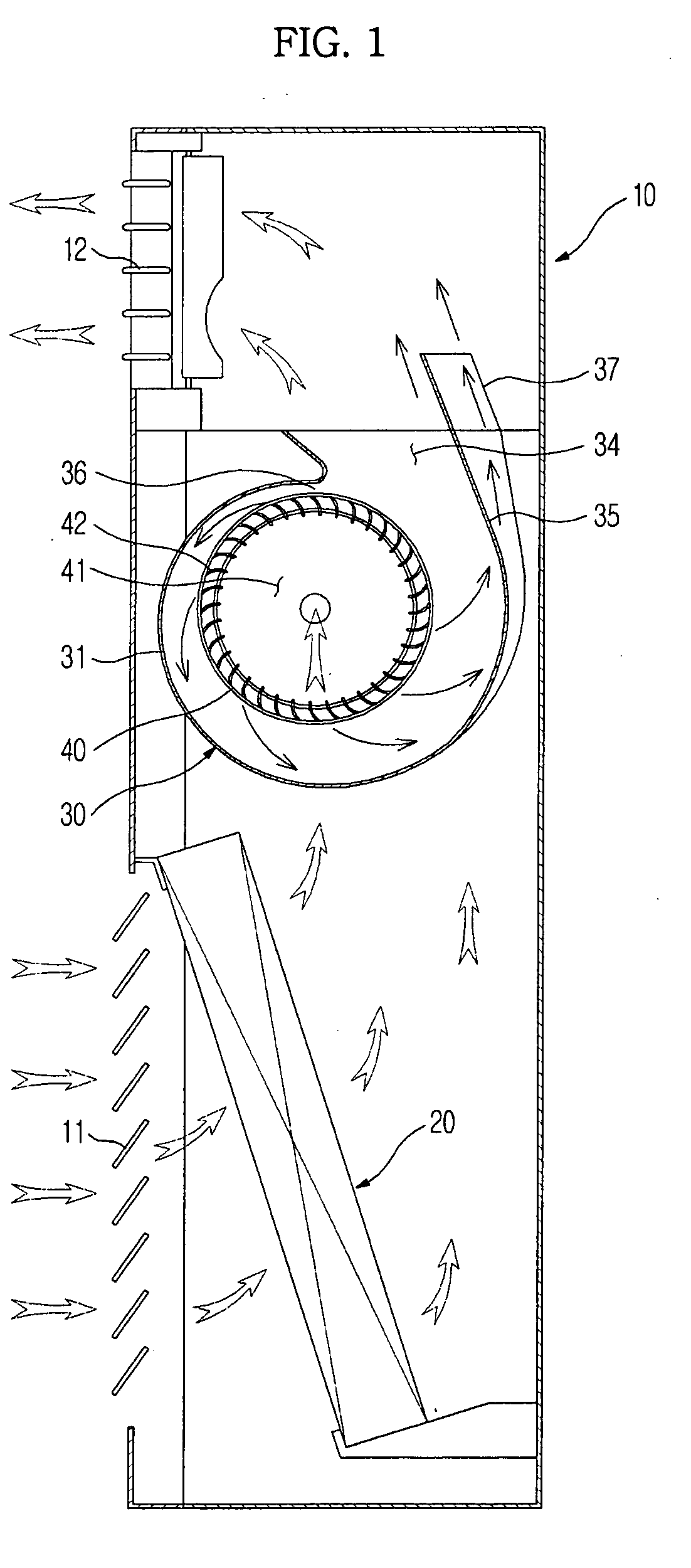

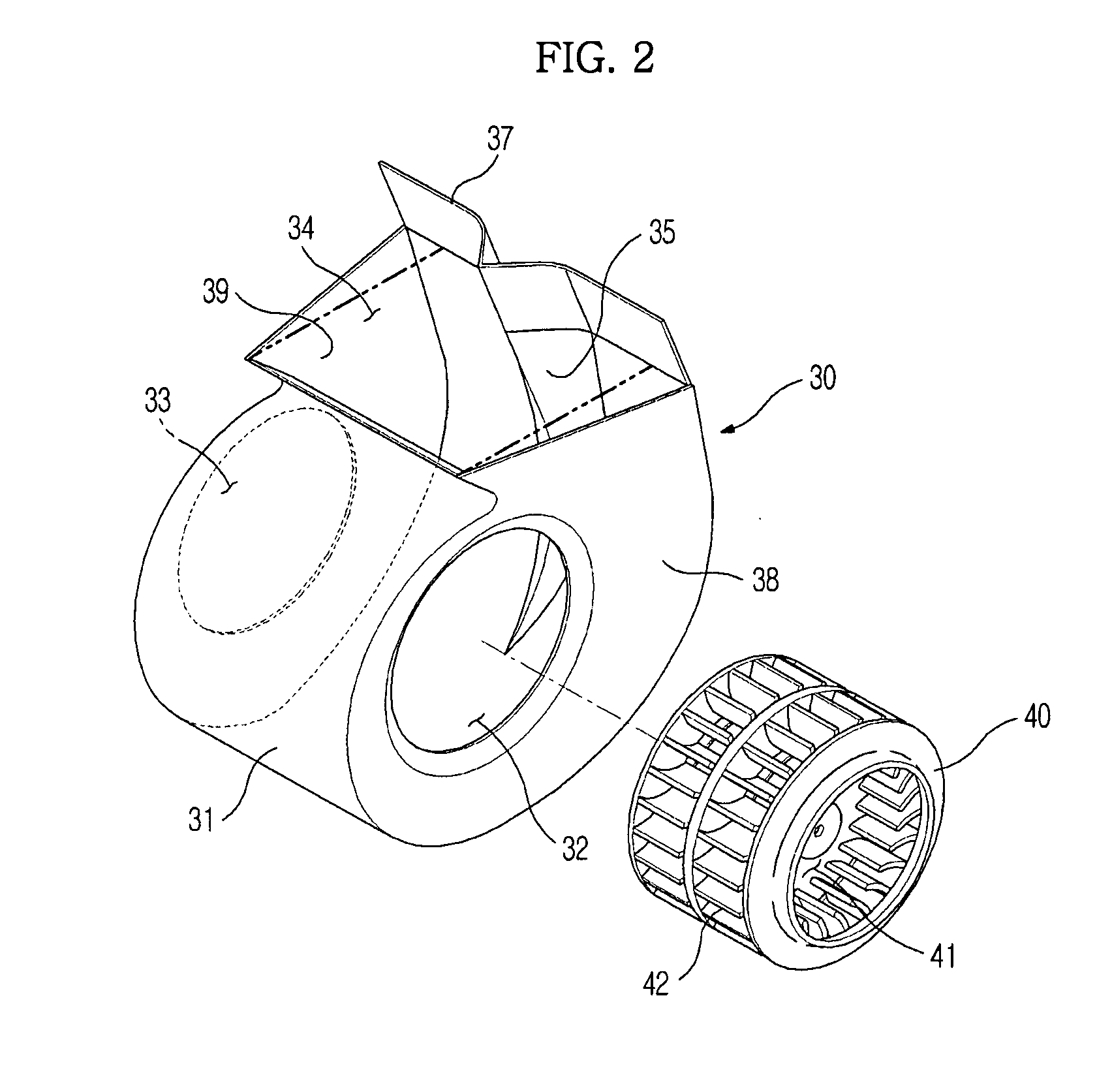

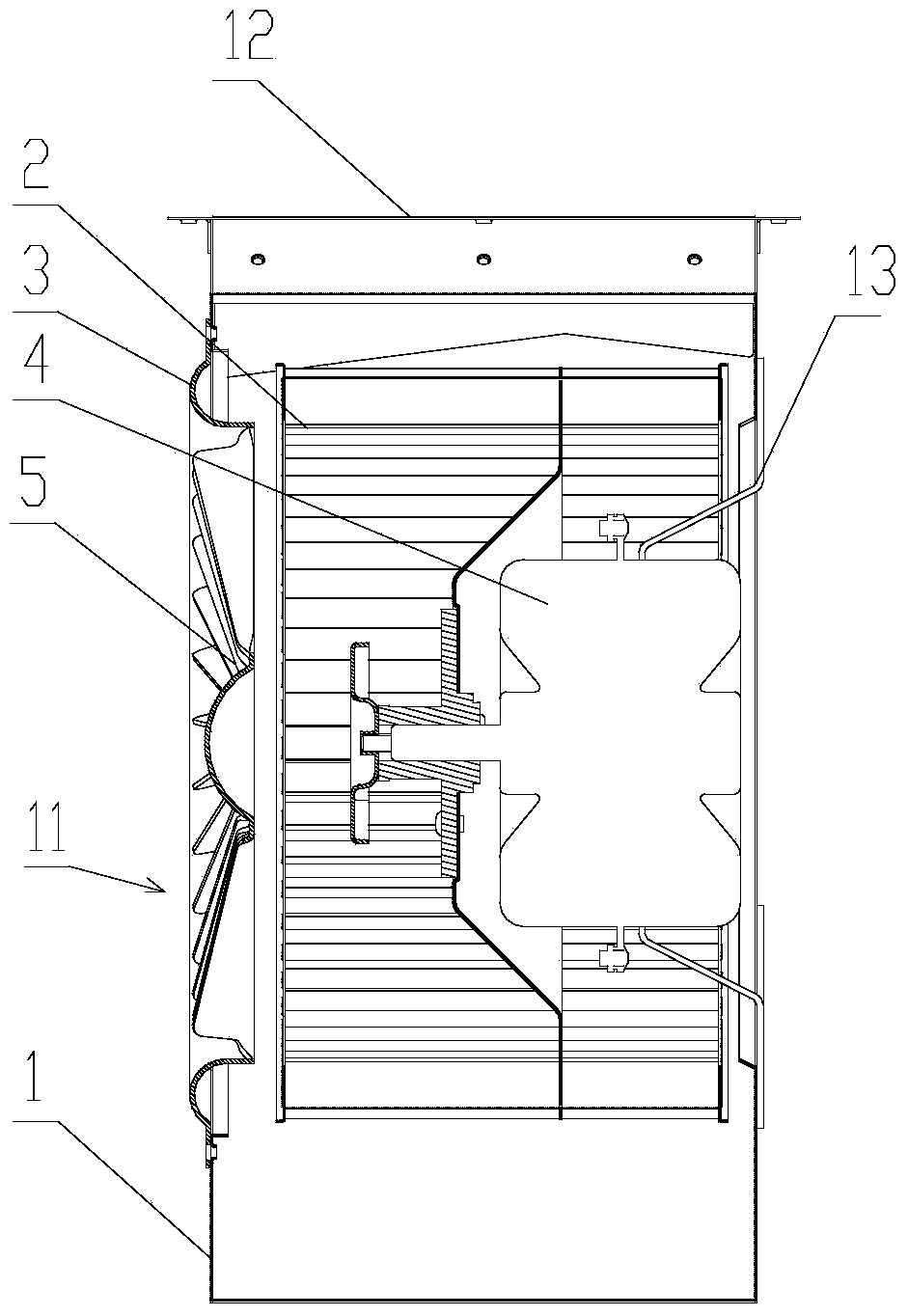

Blower and air conditioner having the same

InactiveUS20090145583A1Reducing discharge noiseReduce flow lossPump componentsSemiconductor/solid-state device detailsEngineeringAir blower

A blower having a divergence guide portion to reduce flow loss and discharge noise and an air conditioner having the same are provided. The blower includes a scroll casing, suction holes provided at opposite positions of the scroll casing, a discharge hole provided at a top position of the scroll casing, a centrifugal fan received in the scroll casing, and a divergence guide portion gently diverging air to the discharge hole after passing through the centrifugal fan to diffuse the air to both sides of the discharge hole.

Owner:SAMSUNG ELECTRONICS CO LTD

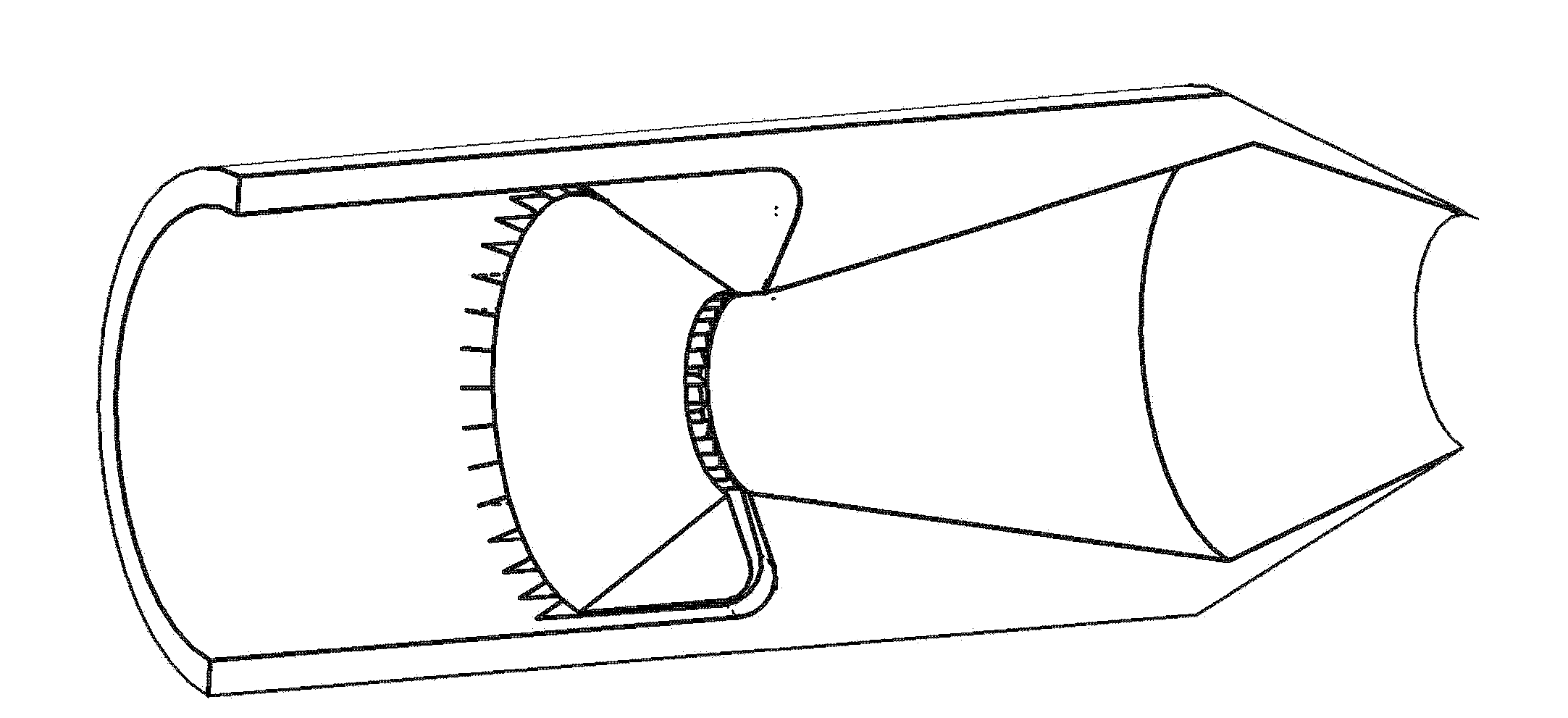

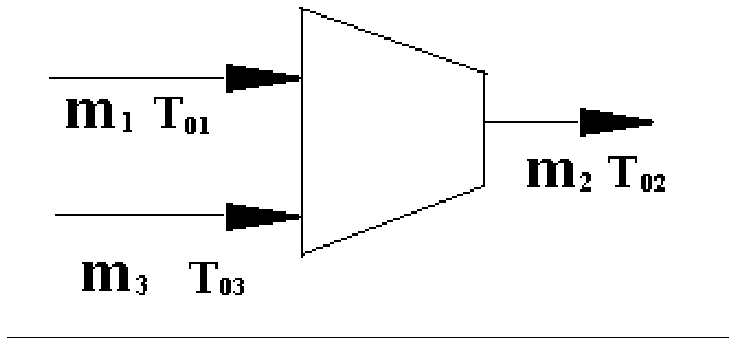

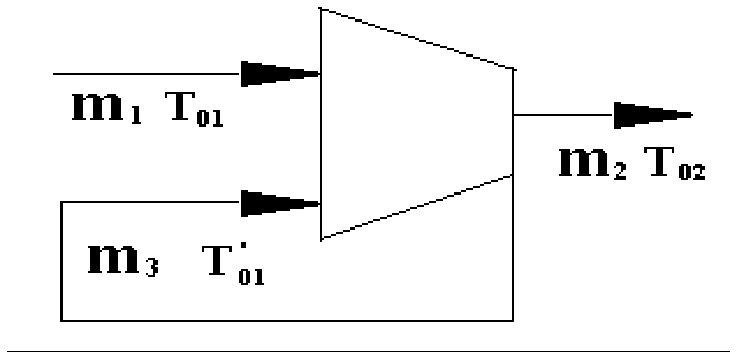

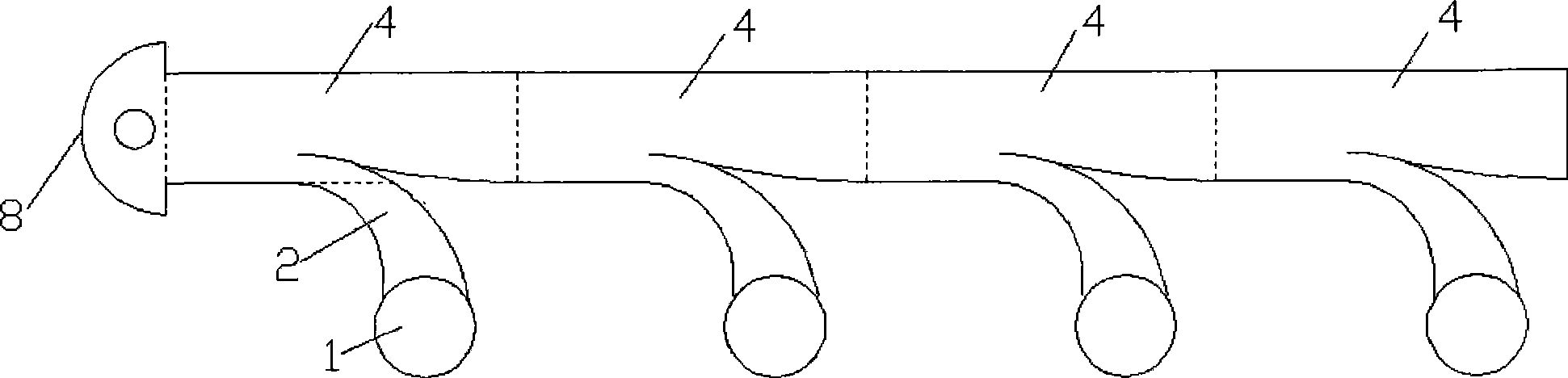

Self-air-entraining jet mechanism for axial fan/compressor

The invention discloses a self-air-entraining jet mechanism for an axial fan / compressor, and relates to the technology of combustion turbines. According to the self-air-entraining jet mechanism for the axial fan / compressor, diffusion deceleration is achieved by adopting an increasing pipe as an outlet at the rear stage of the axial fan / compressor, and the flow loss is reduced; and the air inlet nozzle end adopts a Laval nozzle to achieve the purposes of acceleration and decompression, so that the momentum of the outlet of the air inlet nozzle is maximized and the purpose of improving the stability margin is achieved to the largest extent. When the self-air-entraining jet mechanism for the axial fan / compressor is in operation, gas at the rear stage is guided into the top area of a movable vane at the front stage to be jetted, so that the purposes of improving the stall speed and increasing the stability margin are achieved, and therefore the axial fan / compressor can run under the working conditions of higher pressure ratio and wide stall margin.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

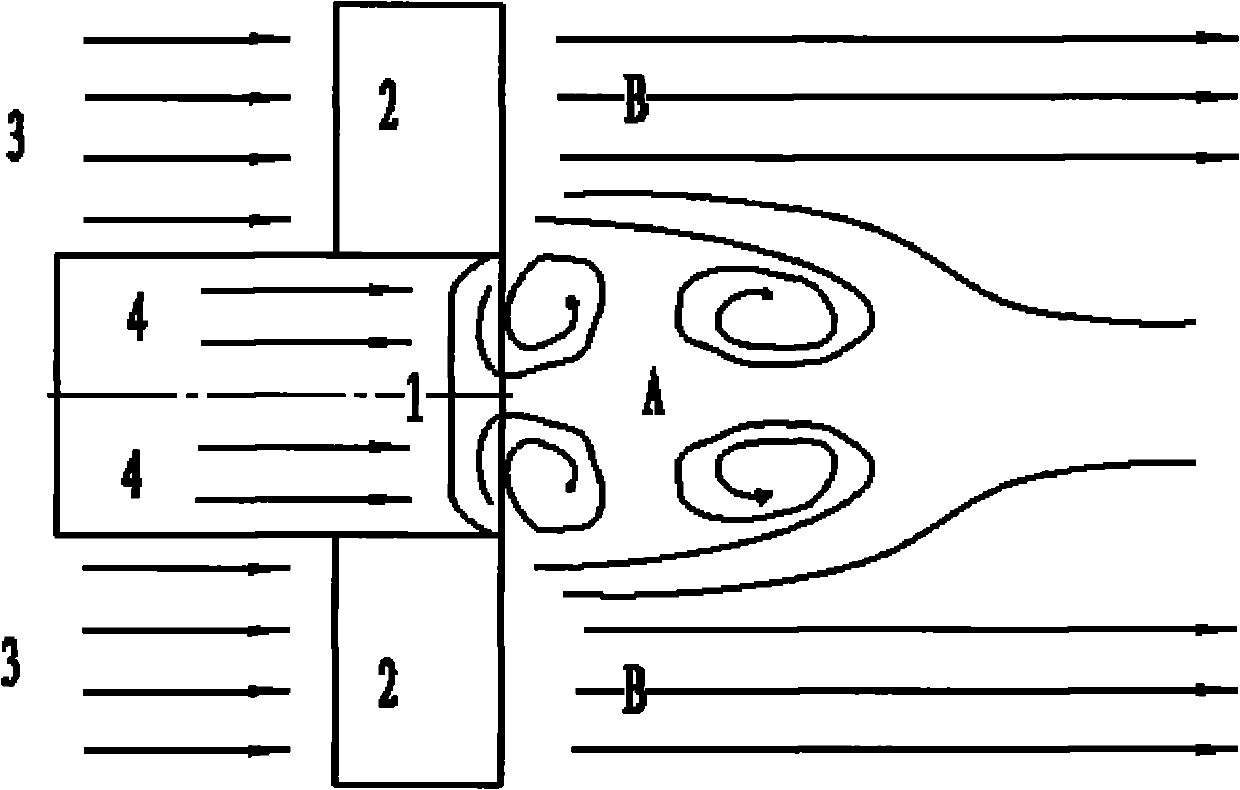

Flame stabilizer with jet injection

InactiveCN101776283AReduce weightGood Burn ProgramContinuous combustion chamberCombustion chamberJet injection

The invention provides a flame stabilizer for an after-combustion chamber of a gas turbine engine. In the device, which is characterized in that turbine rear frames are integrated, a radial flame stabilizer and a center cone in the prior art are omitted, and the an upstream concave structure and the a jet injection gas flow are used for forming a vortex system to form a necessary backflow region for flame stabilization, thereby reducing the amount of parts, shortening the total length of the combustion chamber, lightening the structural weight, reducing the resistance loss, and enabling the thrust-weight ratio of the engine to have great expansion lifting space.

Owner:BEIHANG UNIV

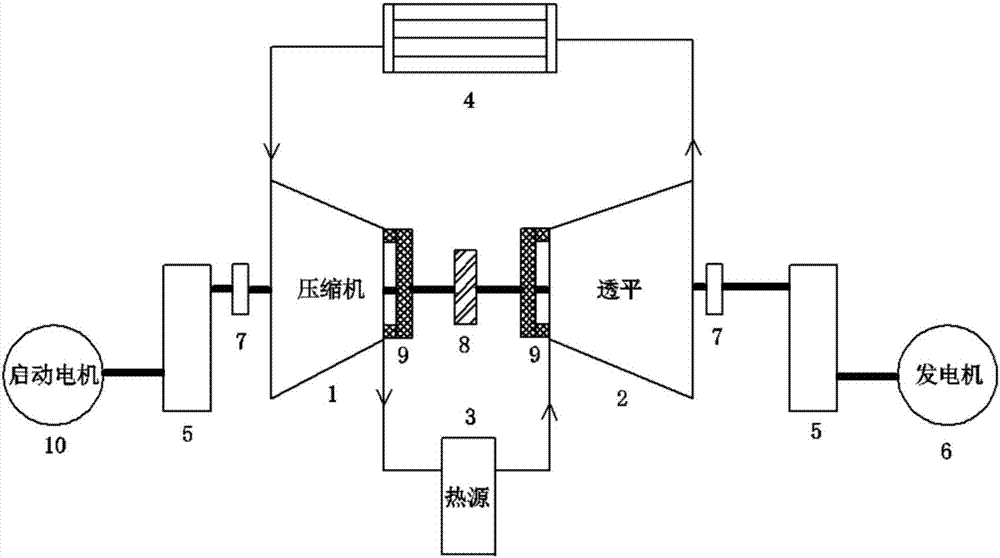

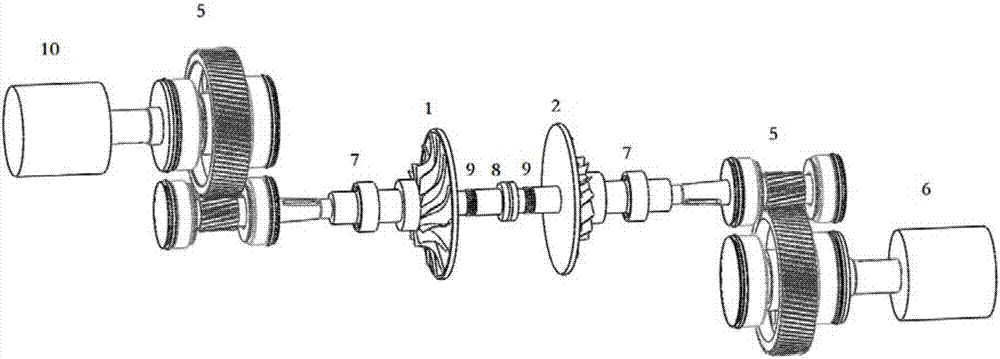

Supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure

InactiveCN107461227AViscosity of working mediumSmall working fluid viscositySteam engine plantsMotor driveElectric machine

The invention discloses a supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure. A supercritical carbon dioxide working medium sequentially flows through a centrifugal compressor to improve pressure and a heat source to improve temperature, and finally after output work in a radial-inward-flow turbine, the supercritical carbon dioxide working medium enters a cooler to be cooled and circulates to enter the centrifugal compressor again. A start motor drives the coaxial structure to start working through one gearbox, the coaxial structure is formed by the radial-inward-flow turbine and the centrifugal compressor through a rotor shaft, the centrifugal compressor is driven by one part of output work of the radial-inward-flow turbine, and the other part of output work of the radial-inward-flow turbine is output into a generator through the other gearbox. Radial bearings are arranged at the shaft ends of the two sides of the coaxial structure, a thrust bearing is arranged in the middle of the coaxial structure, and the type adapting to the corresponding rotary shaft rotating speed can be selected. Furthermore, the form of supercritical carbon dioxide dry gas seals is adopted in sealing parts. The supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure has the prominent beneficial effects of being simple and compact in structure, high in pneumatic efficiency, low in manufacturing cost and the like and has wide market prospects.

Owner:XI AN JIAOTONG UNIV

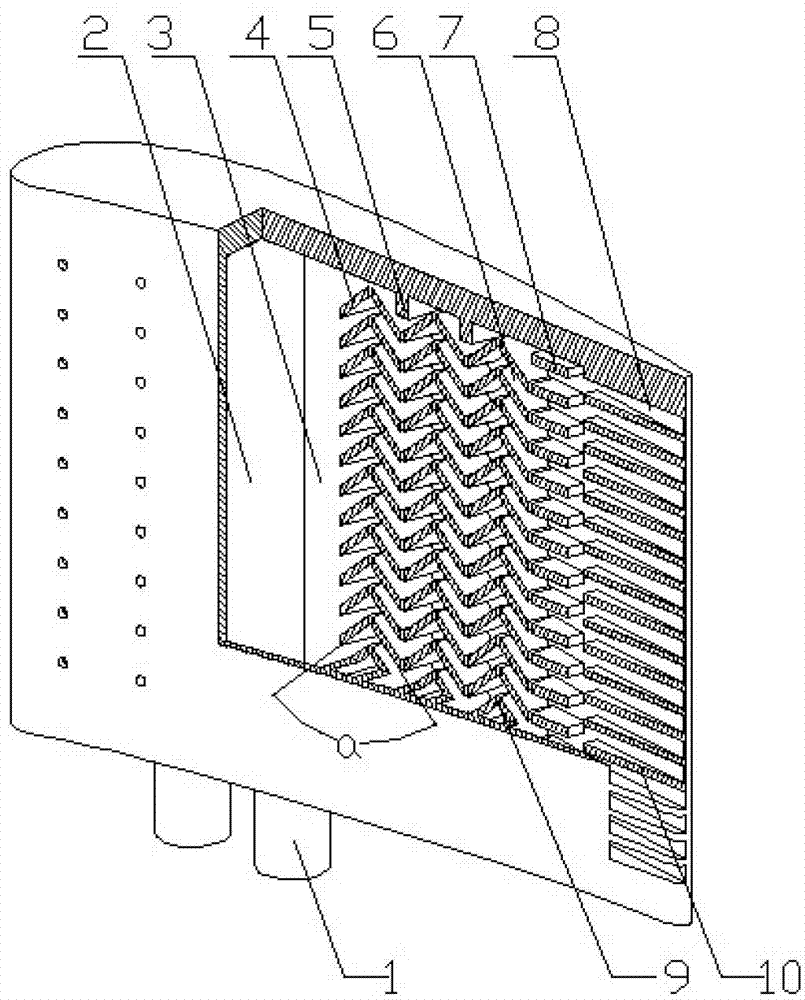

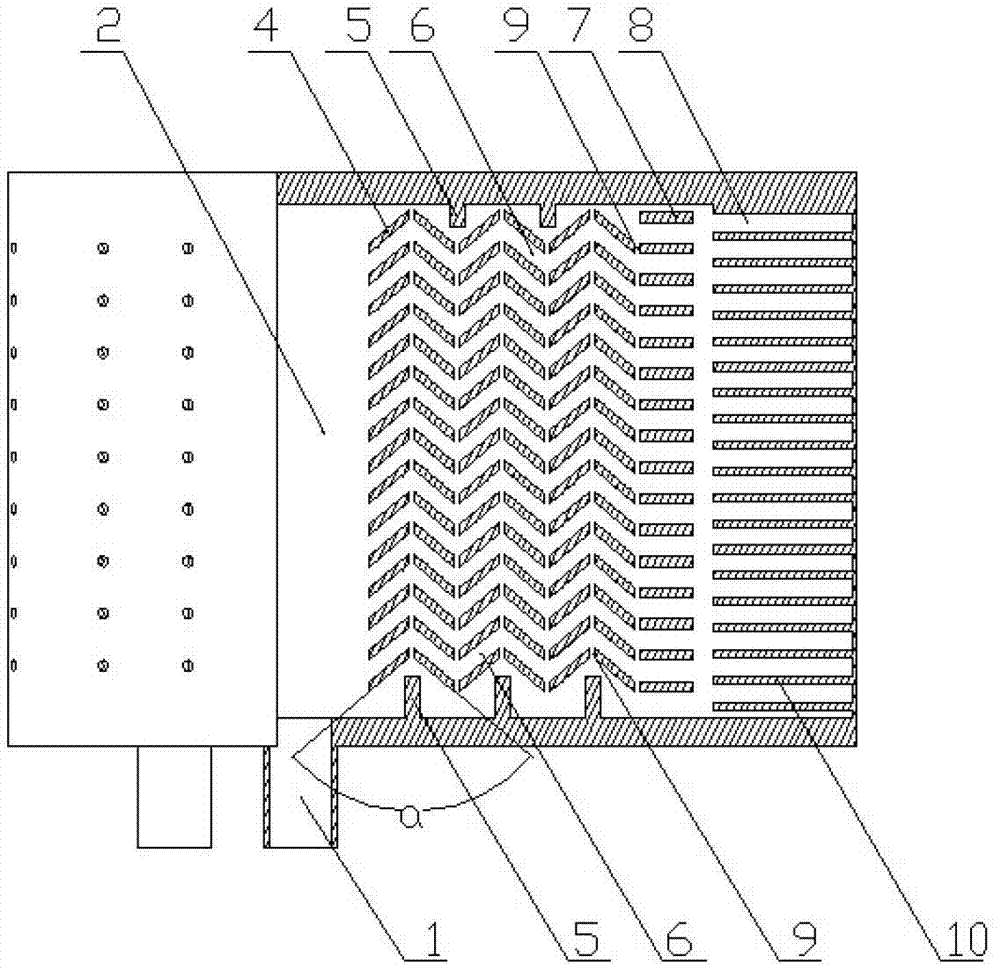

W-shaped rib channel cooling structure suitable for turbine blade backside cooling cavity

InactiveCN103089335AIncrease contact areaReasonable designBlade accessoriesMachines/enginesImpellerTurbine blade

The invention discloses a W-shaped rib channel cooling structure suitable for a turbine blade backside cooling cavity and belongs to the field of turbomachinery design. The structure comprises a blade backside cooling cavity, inclined diversion fins, linear diversion fins and flow blocking fins; a plurality of rows of inclined diversion fins on the inner wall of the blade backside cooling cavity are distributed in a W-shaped manner; the linear diversion fins are arranged in a space between the last row of inclined diversion fins and blade tailing edge split seam; and a W-shaped cooling channel is formed by a space defined by the inclined diversion fins, linear diversion fins and the inner wall of the blade backside cooling cavity. According to the W-shaped rib channel cooling structure, the W-shaped rib channel cooling structure is arranged in the blade backside cooling cavity, the rib channel has diversion and acceleration effects on an inner fluid, and simultaneously the blades are reinforced with the arrangement of W-shaped fins. Besides, the structure is simple and reasonable in design, and is suitable for the internal cooling system of turbine blades of a gas turbine.

Owner:SHANGHAI JIAO TONG UNIV

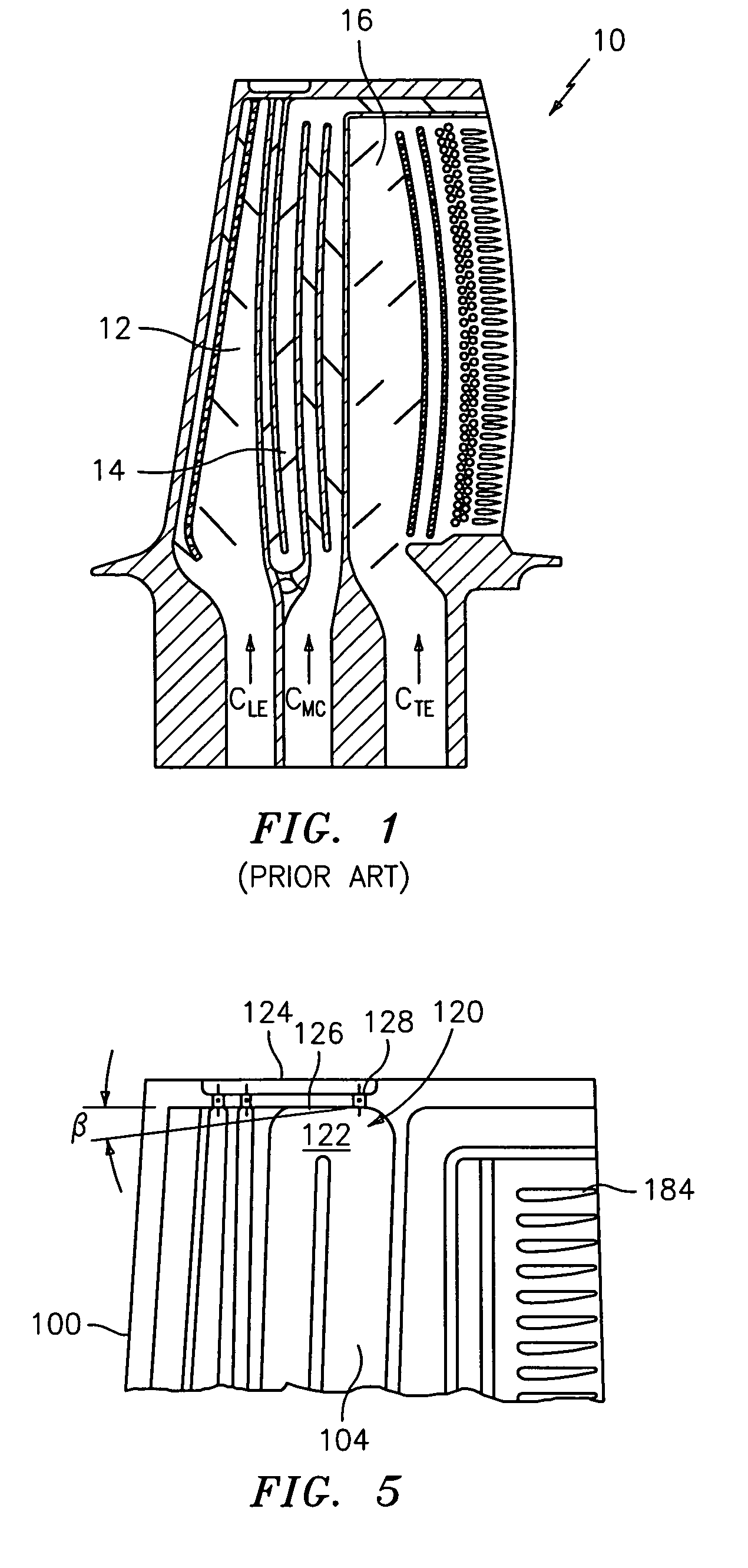

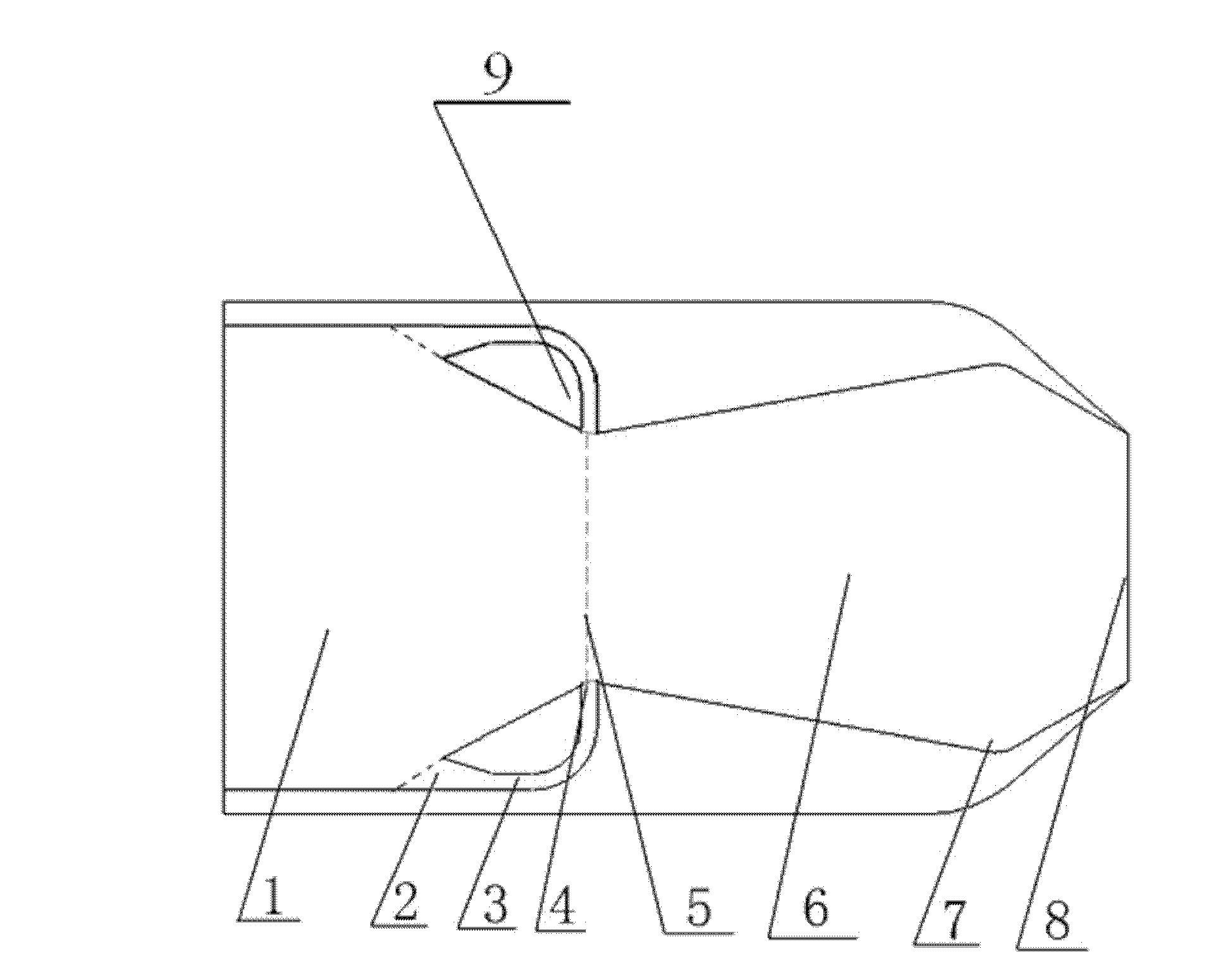

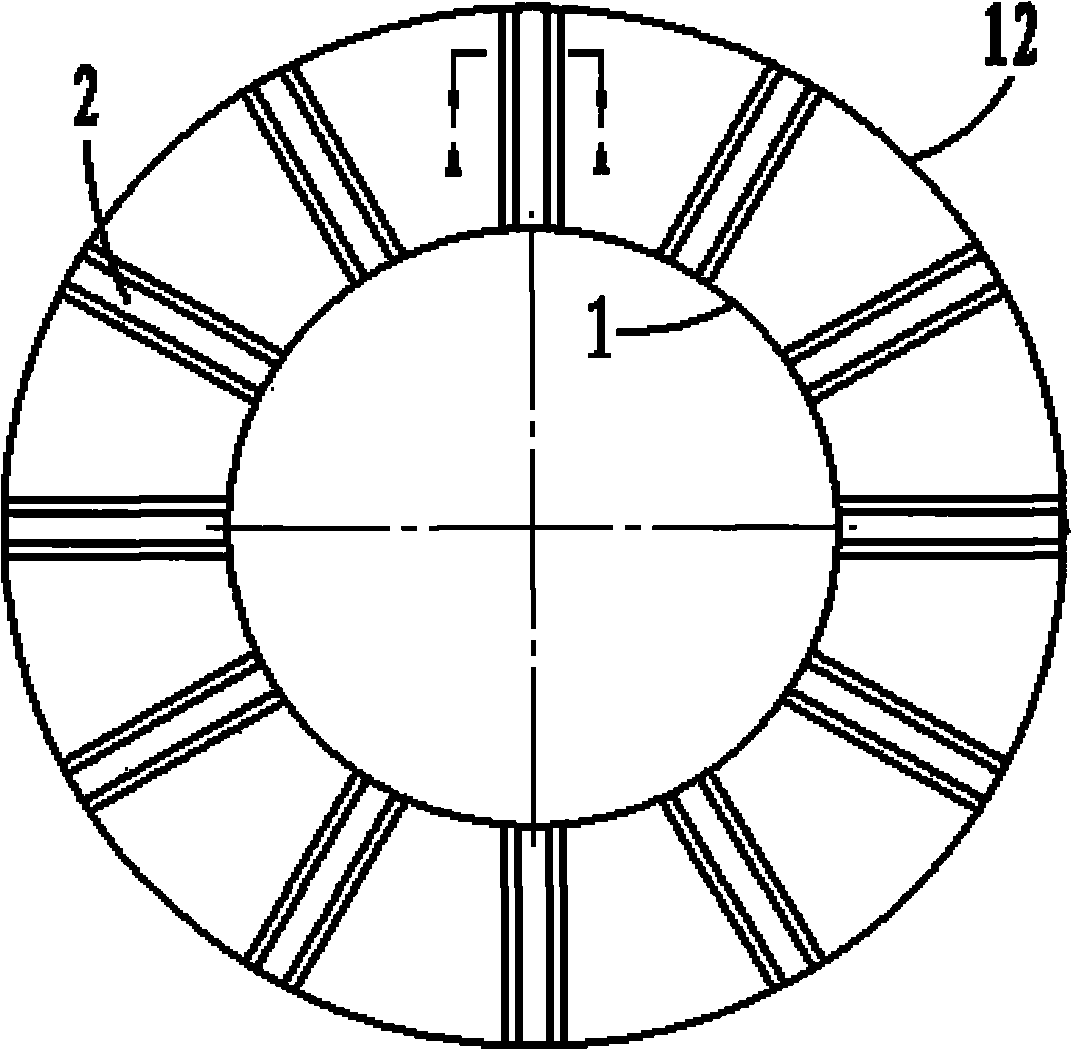

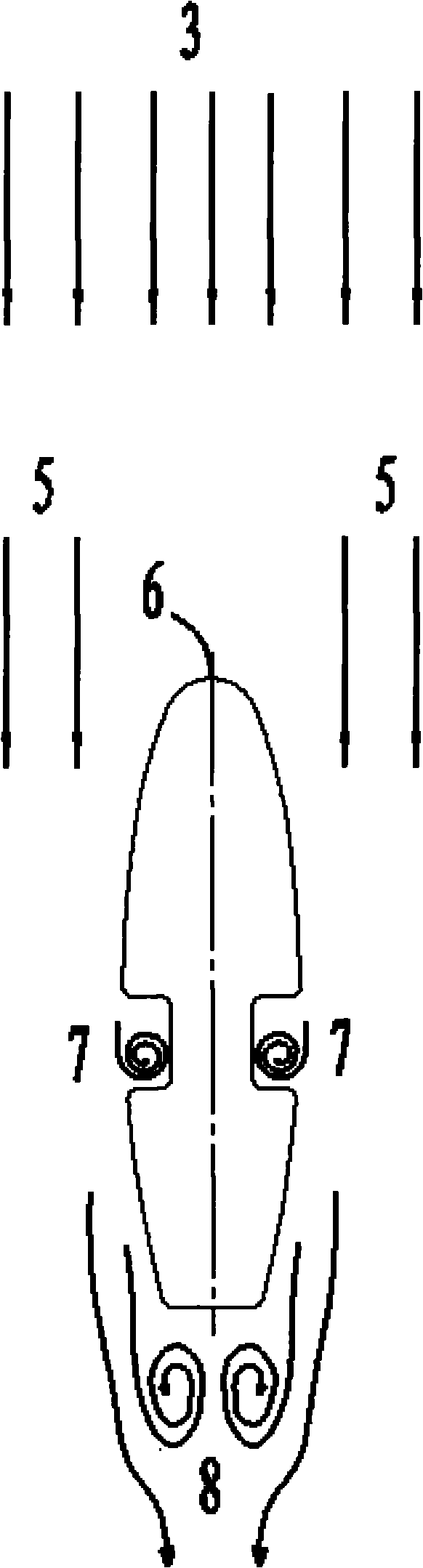

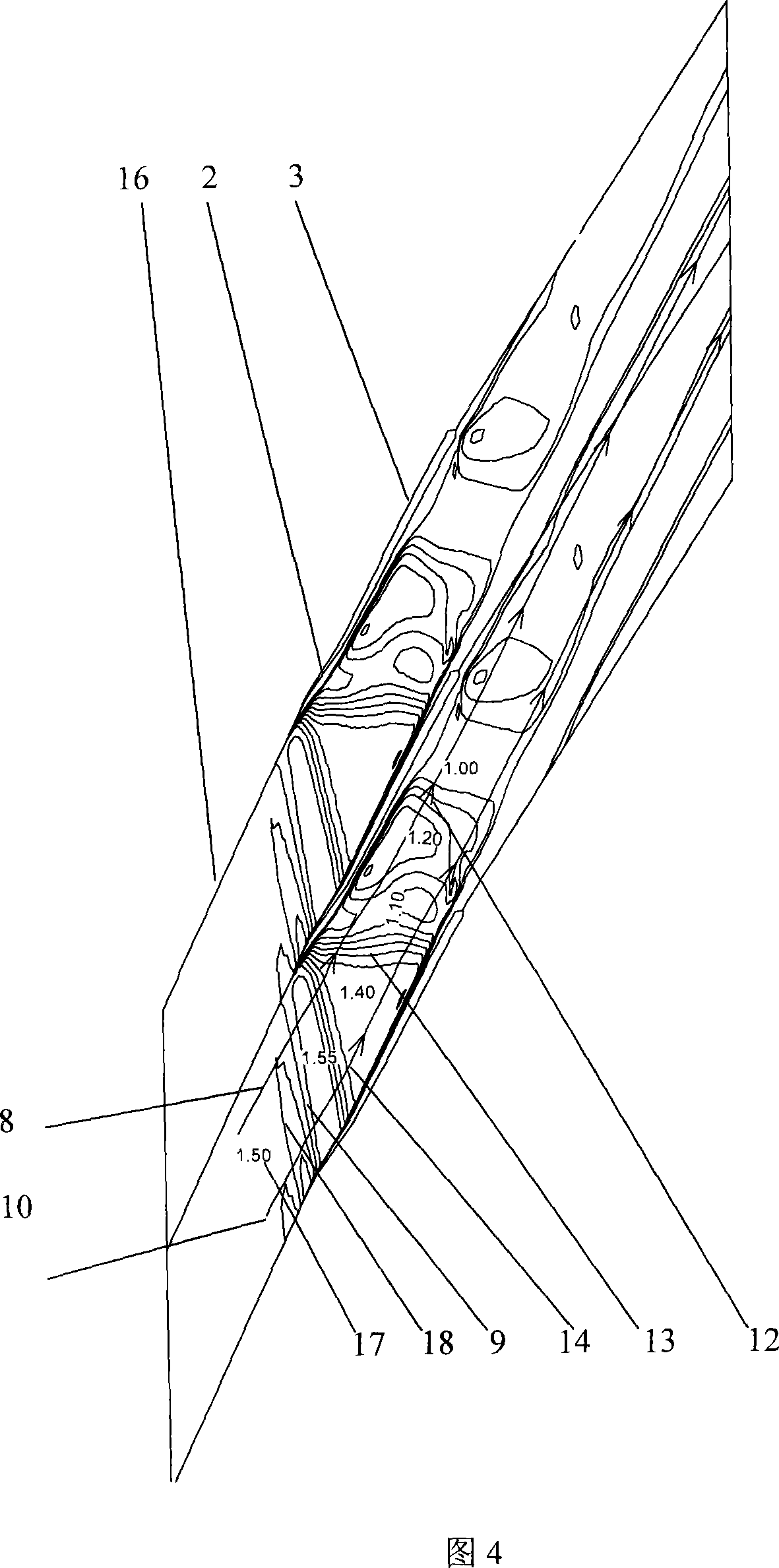

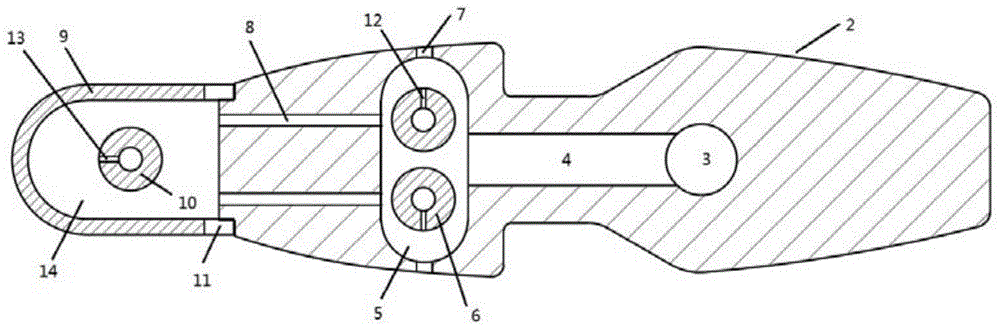

Flame stabilizing device and method for supporting plate with cavities

InactiveCN102200292AIncrease swirl areaExtended Radial Coverage AreaContinuous combustion chamberCombustion chamberLow speed

The invention provides a flame stabilizing device and method of an afterburner for a gas turbine engine. In the device, the original turbine rear frame supporting plate is replaced with the supporting plate with the cavities; and the device is characterized in that: the section of the supporting plate is in the shape of a wing with a suddenly expanded trailing edge and is provided with the cavities. The aim of stabilizing flame is fulfilled through a low-speed backflow region formed by flowing gas flow through the cavities of the supporting plate and the suddenly expanded part of the trailing edge. The invention provides the turbine rear frame supporting plate (2) of the afterburner for the gas turbine engine; the afterburner comprises a case (12), a turbine rear frame inner wall (1) and a plurality of turbine rear frame supporting plates (2), wherein the turbine rear frame supporting plates (2) are connected with the case (12) and the turbine rear frame inner wall (1); and the turbine rear frame supporting plate (2) is characterized by being provided with the cavities (9).

Owner:BEIHANG UNIV

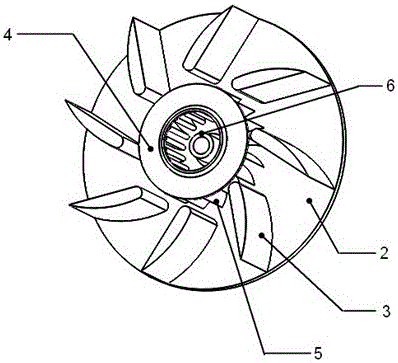

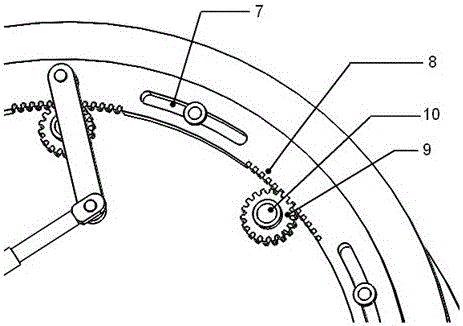

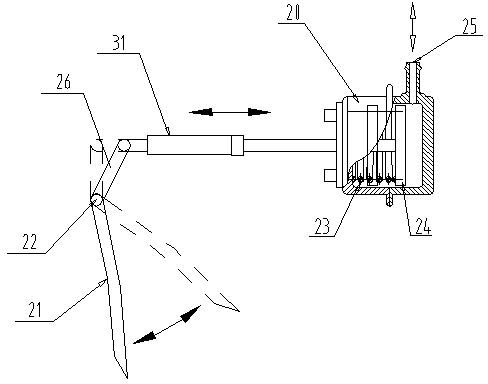

Centrifugal fan device remotely controlled with Bluetooth and with blades adjustable

ActiveCN105756987ARealize the effect of one machine with multiple functionsGood value for moneyPump componentsEngine controlImpellerAir volume

The invention discloses a centrifugal fan device remotely controlled with the Bluetooth and with blades adjustable. The centrifugal fan device comprises an outer impeller, an inner impeller, an impeller cover, impeller discs, a film type parameter sensor, a blade adjusting device, an electric push rod and a Bluetooth intelligent terminal; the outer impeller comprises an outer impeller disc and outer blades, and the inner impeller comprises the impeller cover, an inner impeller disc and inner blades; the inner impeller disc of the inner impeller is fixed to a shaft disc; the blades of the outer impeller and the inner impeller are in wing shapes respectively, through cooperation of the inner impeller and the outer impeller, the proper angle of auxiliary impeller blades can be adjusted according to the air volume under different working conditions, the effect of multiple purposes of a centrifugal fan is achieved, the purpose that the centrifugal fan device can still work stably and efficiently under the off-rating condition is achieved, remote control and automated adjustment are achieved through the Bluetooth intelligent terminal, advancement of modern technology will be undoubtedly integrated into production and life of people, and the problem of inconvenience brought by arrangement positions and space is solved through remote control with high controllability and stability.

Owner:嘉兴芸诗娇电子商务有限公司

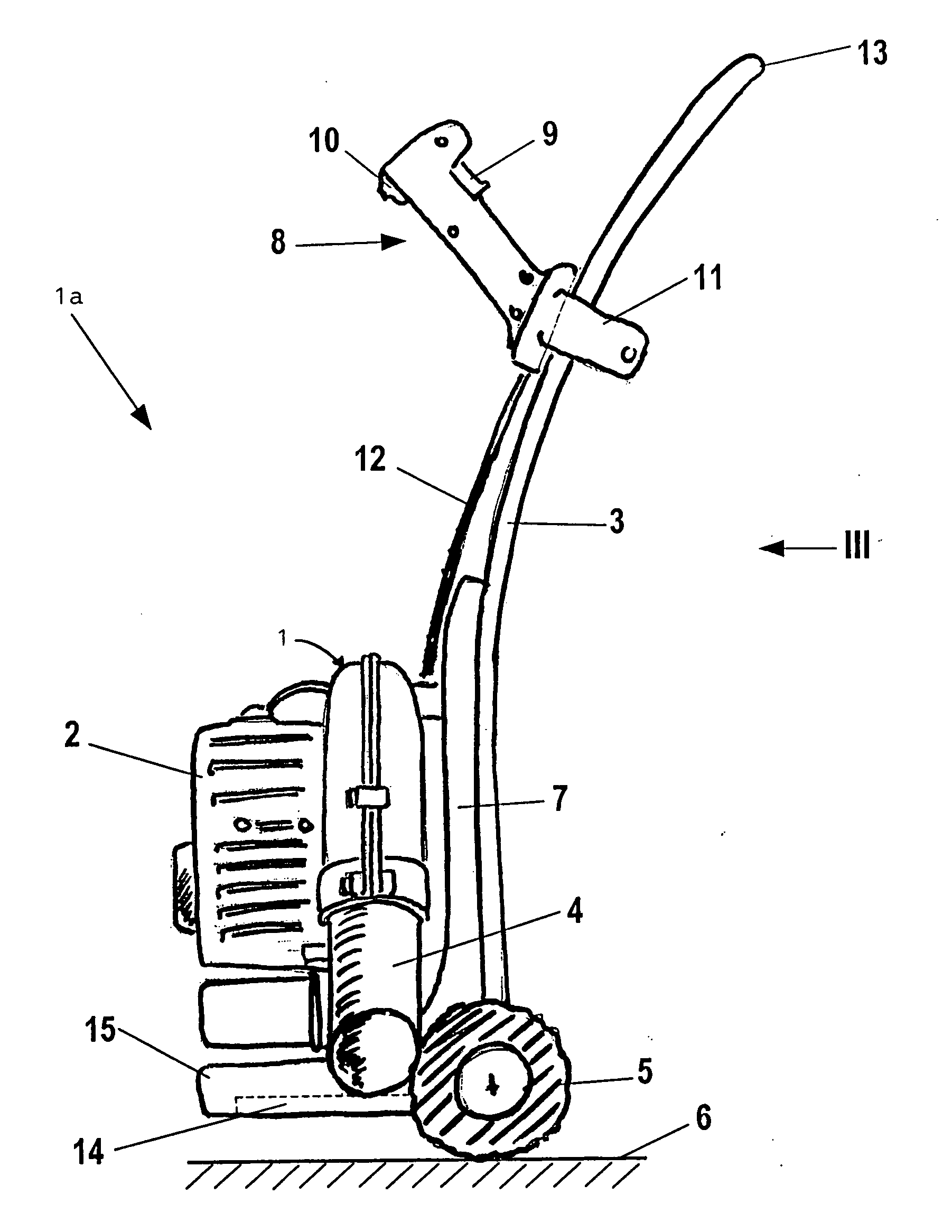

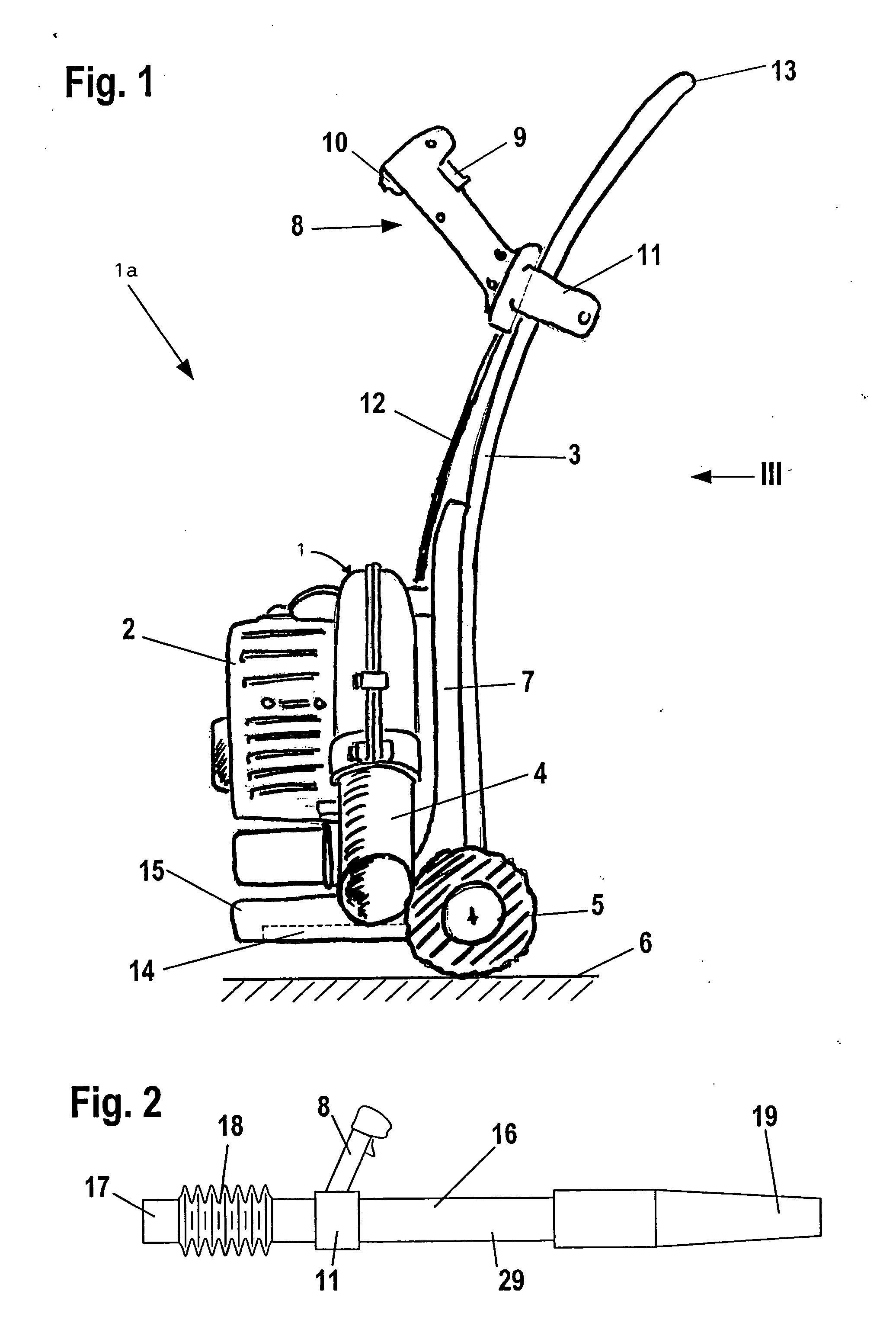

Portable blower

Owner:ANDREAS STIHL AG & CO KG

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

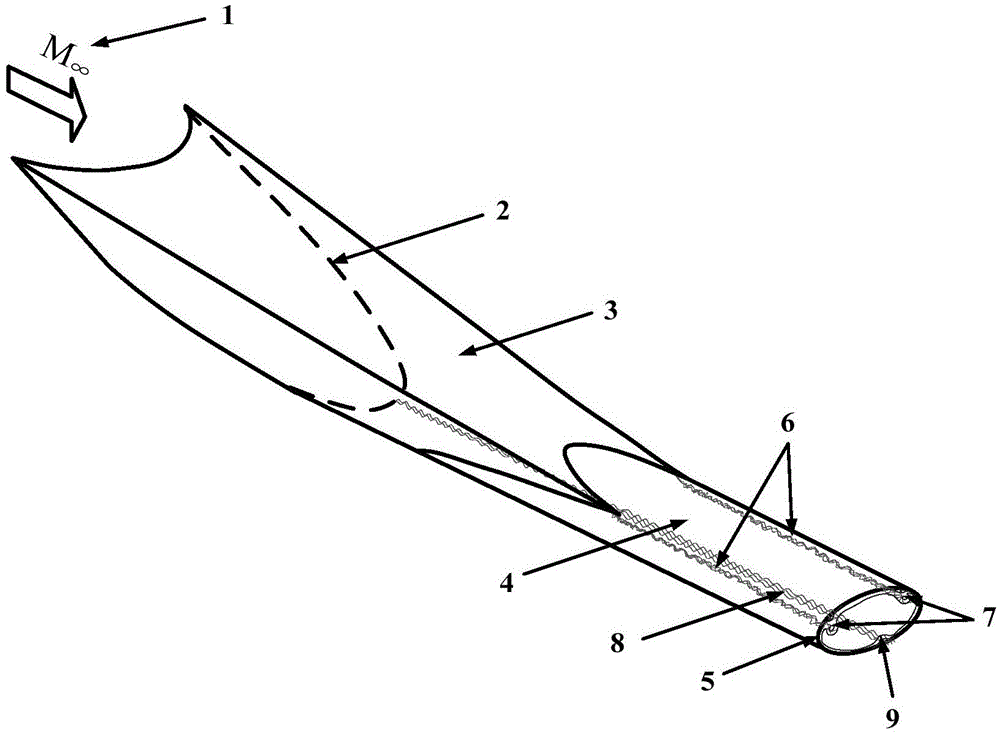

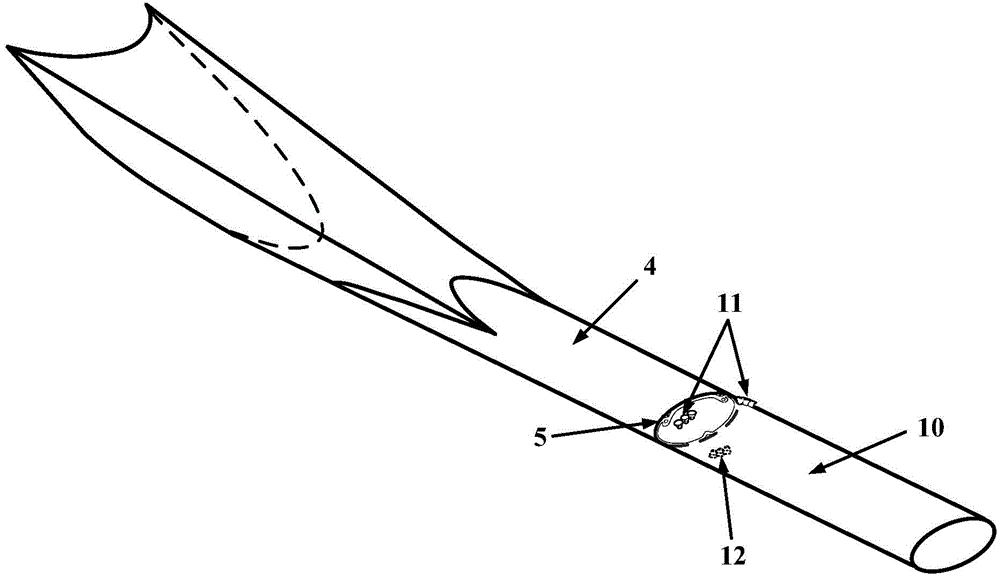

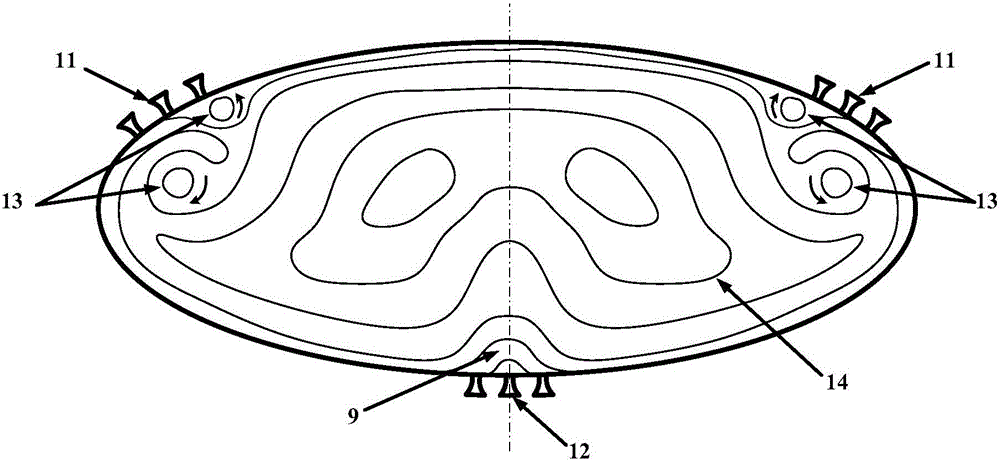

Design method of fuel injection system for scramjet engine

ActiveCN103605876ASuppress non-uniformitySmooth connectionSustainable transportationSpecial data processing applicationsCombustion chamberInlet channel

The invention discloses a design method of a fuel injection system for a scramjet engine and relates to a near space vehicle. Nozzles can be distributed in the following three ways: according to flowing characteristics, the nozzles are distributed on a near vortex wall surface circumferentially, or distributed along the flowing direction, or distributed in a 'triangle' shape on the near vortex wall surface. In the component design of the existing scramjet engine, the defect that the outlet uniformity needs to be controlled as much as possible in the design of a gas inlet channel, while a non-uniform vortex structure needs to be artificially introduced in the design of a combustion chamber, is solved. By virtue of a low-energy / low-velocity zone and a corner vortex structure of the outlet of a three-dimensional internal-retraction gas inlet channel, the nozzles of a combustion chamber are reasonably arranged, the relation of flowing characteristics between the gas inlet channel and a supersonic combustion chamber is strengthened, and the fuel injection and mixing effects can be enhanced, so that the combustion efficiency is raised indirectly, and the overall performance of the scramjet engine is improved.

Owner:XIAMEN UNIV

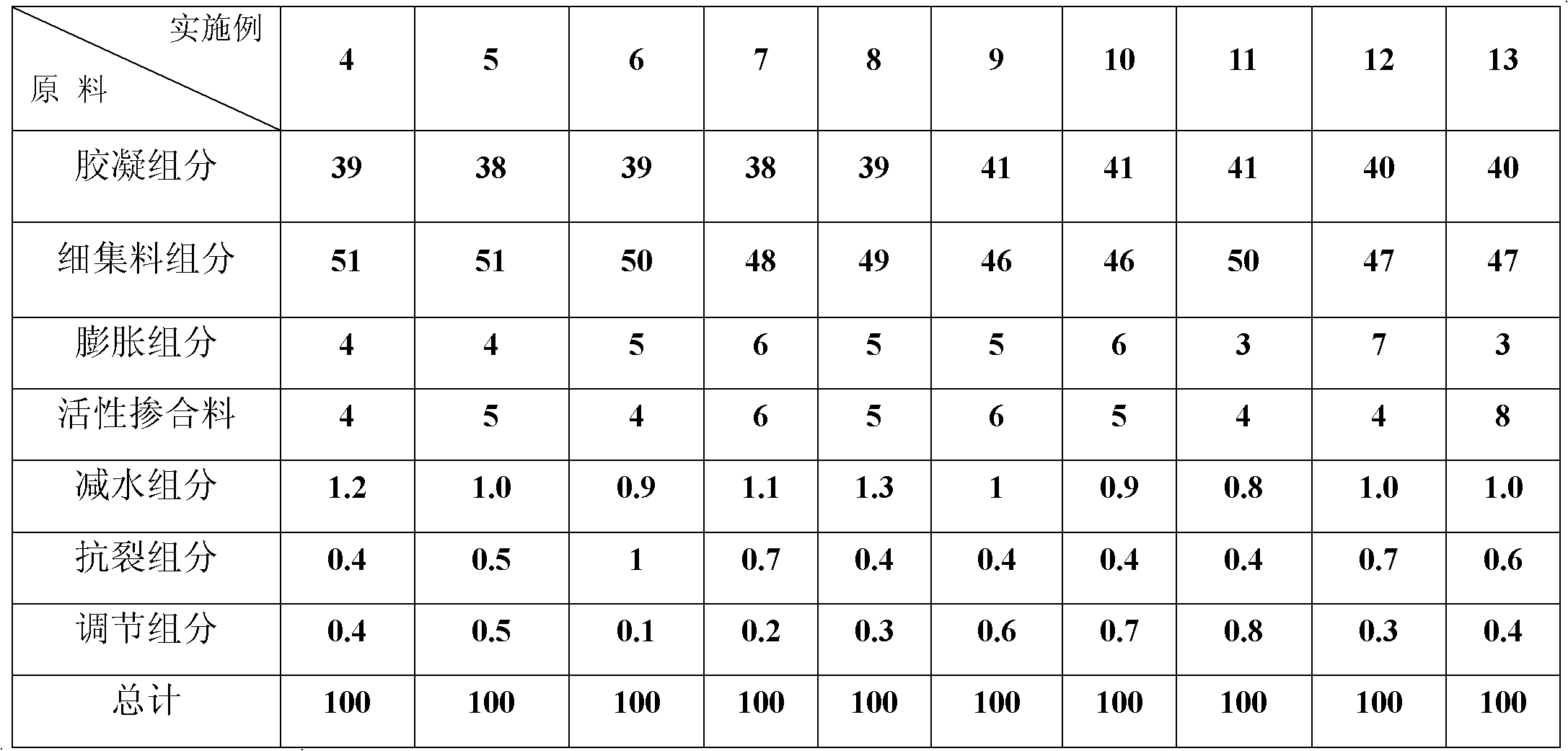

High-strength micro-expansion prestress anchoring grouting material and preparation method thereof

InactiveCN102180628AImprove rheologyGuaranteed StrengthSolid waste managementMass ratioQuality by Design

The invention discloses a high-strength micro-expansion prestress anchoring grouting material and a preparation method thereof. The material is prepared from a gelatinization component, a fine aggregate component, an expansion component, an active doped material, a water reducing component, a crack resistant component and a regulation component in a certain weight proportion. The preparation method specifically comprises the following steps: A, adding the gelatinization component, the expansion component, the active doped material, the crack resistant component and the water reducing component in a ball-mill in a designed mass ratio for commonly mixing and grinding, so as to obtain a even powder material; B, at room temperature and normal pressure, grinding until the Blaine specific surface of the material is not less than 350m<2> / kg; and C, evenly mixing and stirring the obtained in the step B with quartz sand prepared in a proportion at the room temperature and the normal pressure so as to obtain the grouting material. The method is practicable and is convenient for operation; the grouting material has high early strength and micro-expansion, thereby effectively compensating the hydration shrinkage of a cement-based material, obviously improving the adhesive strength of an anchor rod and a periphery base, effectively protecting the anchor rod from being corroded and prolonging the service of the anchor rod.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

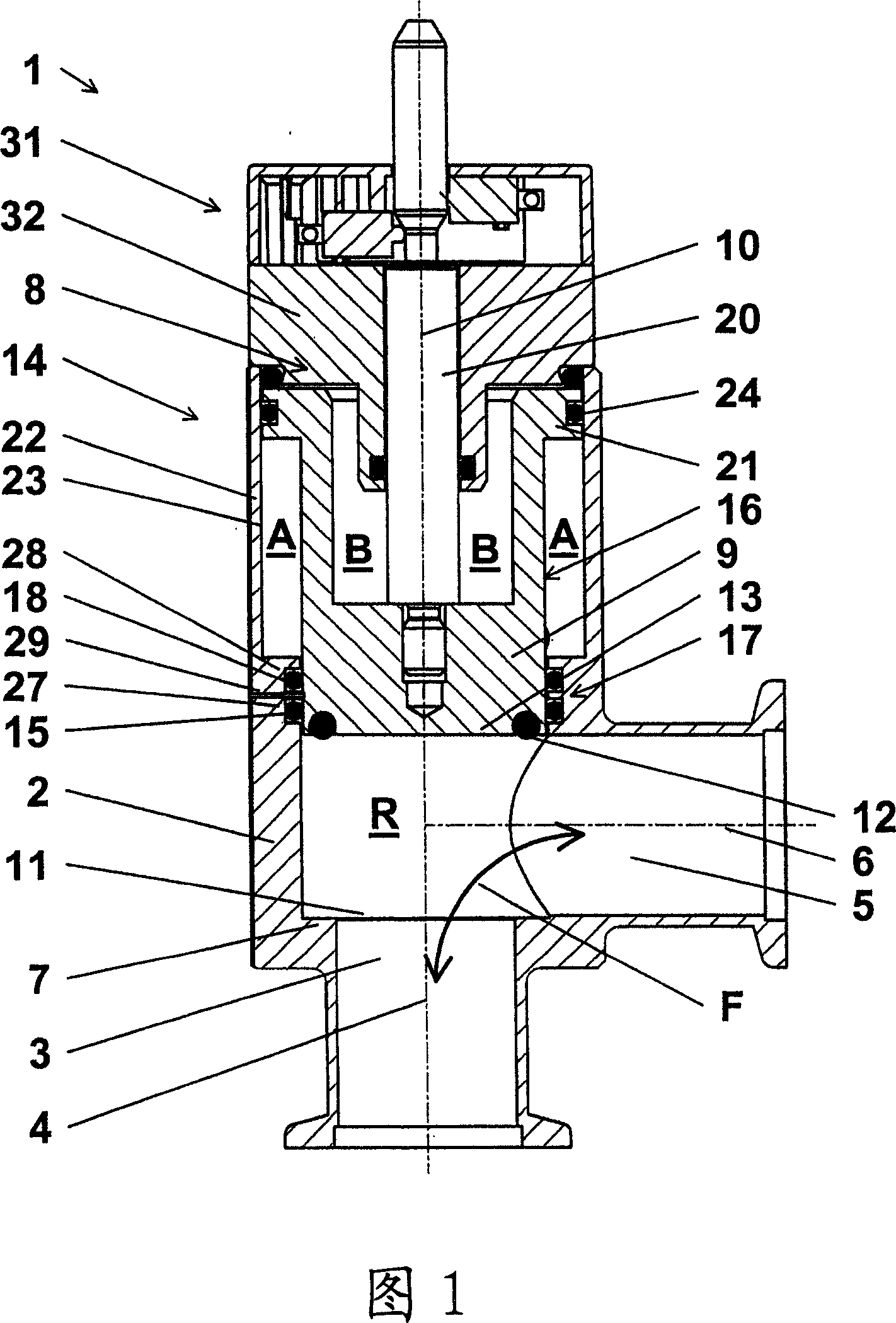

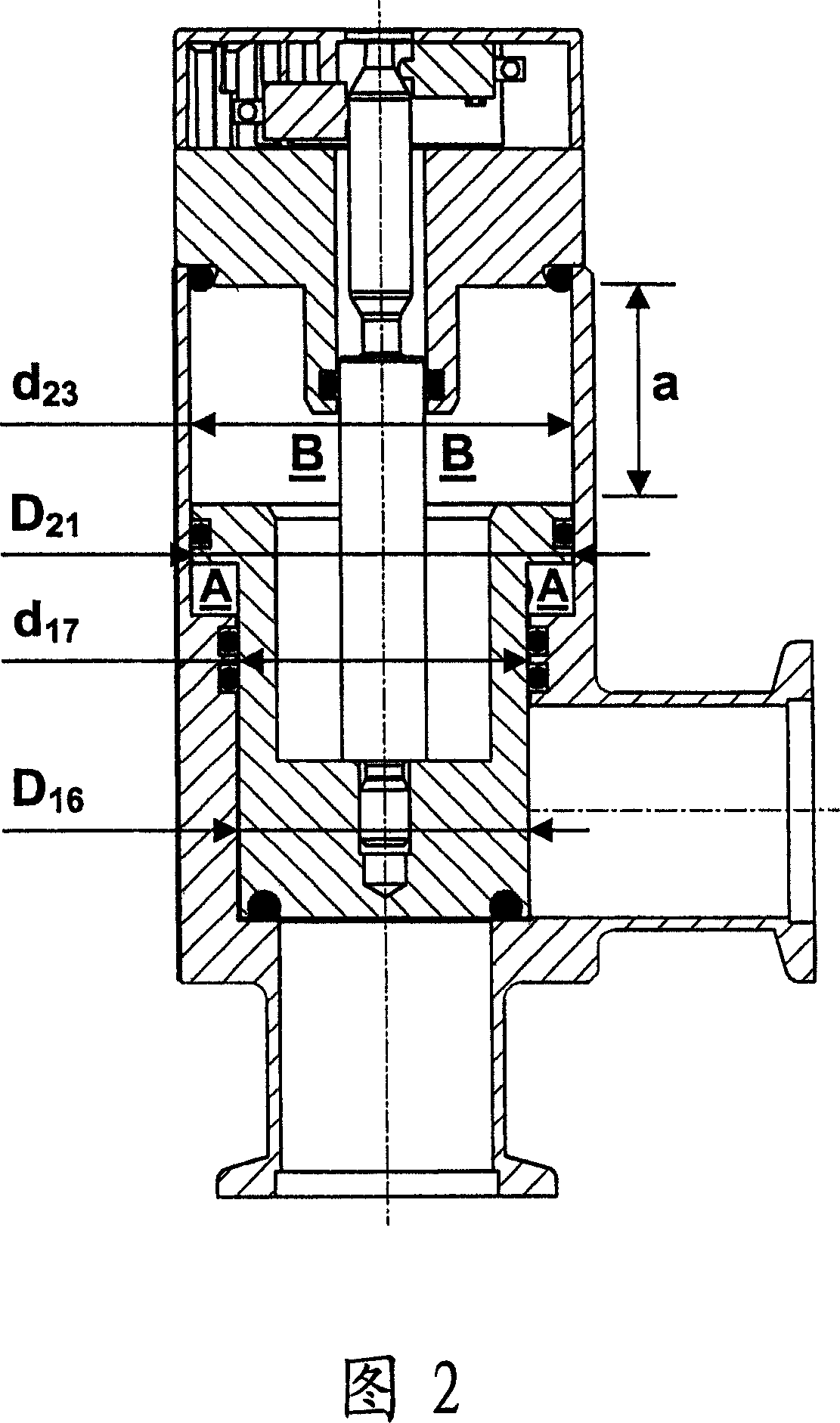

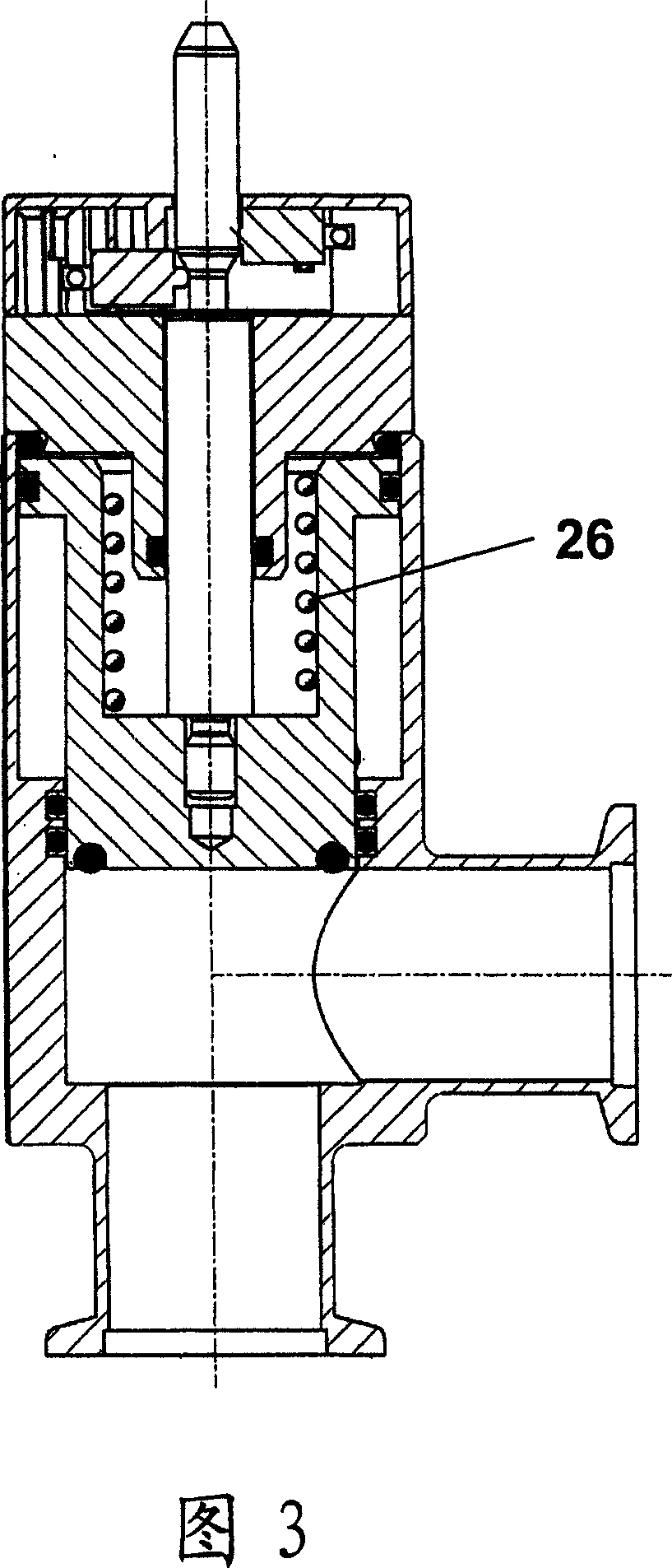

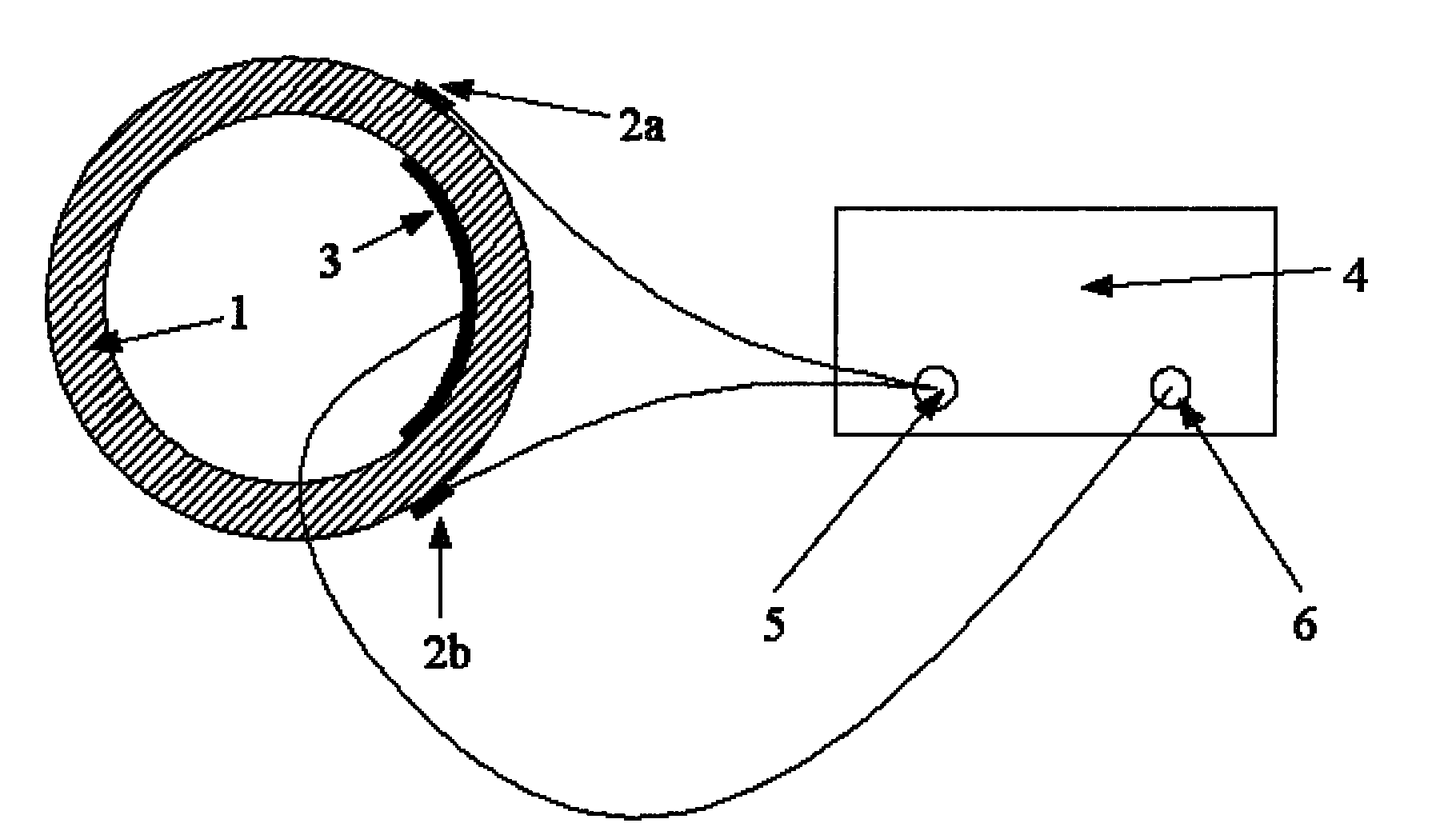

Valve for essentially gastight closing a flow path

InactiveCN1928402AWon't get dirtyReduced risk of unwanted reactionsOperating means/releasing devices for valvesSlide valvePistonVALVE PORT

Maintenance-friendly, compact valve having a simple design for essentially gastight closing of a flow path between two ports arranged at an angle. A valve part which is arranged in a valve housing so as to be displaceable along an axis and whose closing surface can be brought into contact with a valve seat of the first port for closing the flow path and can be brought out of contact for opening the flow path is in the form of a cylindrical piston having an end face forming the closing surface and a piston outer surface. The valve housing has a cylindrical passage which extends opposite the valve seat along the axis and through which the piston is passed and can be displaced and inside which a sealing or guide element is arranged. The piston and the passage are dimensioned so that the piston outer surface is closely enclosed along the adjustment distance by the sealing or guide element of the passage. It is thus possible for essentially only a single adjustable component of the valve, namely the easily cleanable piston consisting in particular of a single material, to be guided in the flow space so that the maintenance of the valve is substantially simplified and few different materials bound the flow space. In a further development, the drive mechanism of the piston is formed at least partly by an outer piston space between a piston step and the passage, so that the piston forms a component of the drive mechanism, permitting a compact design of the valve.

Owner:VAT HLDG AG

Dielectric barrier discharge (DBD) plasma trailing edge jetting device and method

InactiveCN102595758AImprove the flow fieldReduce flow lossAlighting gearPlasma techniqueJet flowAircraft landing

The invention discloses a dielectric barrier discharge (DBD) plasma trailing edge jetting device and method, relating to a flow control technology. The device comprises a plurality of groups of plasma exciters, insulating media and a high-voltage power supply and is used for improving the flowing at a wake area for the flow around a cylinder, wherein the plasma excitation of certain strength is applied to a proper position at a leeward of the cylinder, the movement of low-velocity flowing bodies in a boundary layer is accelerated to form jet flows on a wake space at the trailing edge of the cylinder, so that a wake low-velocity area can be flattened to further achieve the effects of improving a flow field at the wake area and reducing wake losses pneumatic noises, and the device can be applied to resistance reduction and noise reduction for an aircraft landing gear. The DBD plasma trailing edge jetting device disclosed by the invention has the advantages of simple and compact structure, high reaction speed, low energy consumption and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Portable hard surface vacuum

InactiveCN101909499BEasy to separateReduce flow lossCarpet cleanersFloor cleanersLiquid tankWaste management

The invention relates to a portable hard surface vacuum (10) comprising a suction nozzle (45) and a suction unit (16), which is in fluid connection with the suction nozzle, for vacuuming a liquid-air mixture from a hard surface, and comprising a separating device (40, 57) for separating liquid from the liquid-air mixture and comprising a waste liquid tank (23) for receiving the separated liquid. In order to refine the hard surface vacuum in such a way that a constant suction flow is provided, regardless of the fill level of the waste liquid tank, and such that operation in an arbitrary orientation in relation to the vertical position can be carried out, a separating chamber (33) is arranged between the suction nozzle and the suction unit, said chamber housing the separating unit and beingin fluid connection via a suction line (47) to the suction port (48) of the suction nozzle and in fluid connection to the suction unit via a suction line (60), and said chamber being connected via anoutlet opening (67) to the waste liquid tank, wherein the port regions (51, 61) of the suction (47) and vacuum line within the separating chamber are surrounded at least partially by intermediate storage regions (71, 72, 73) for separated liquid in the circumferential direction.

Owner:ALFRED KARCHER GMBH & CO KG

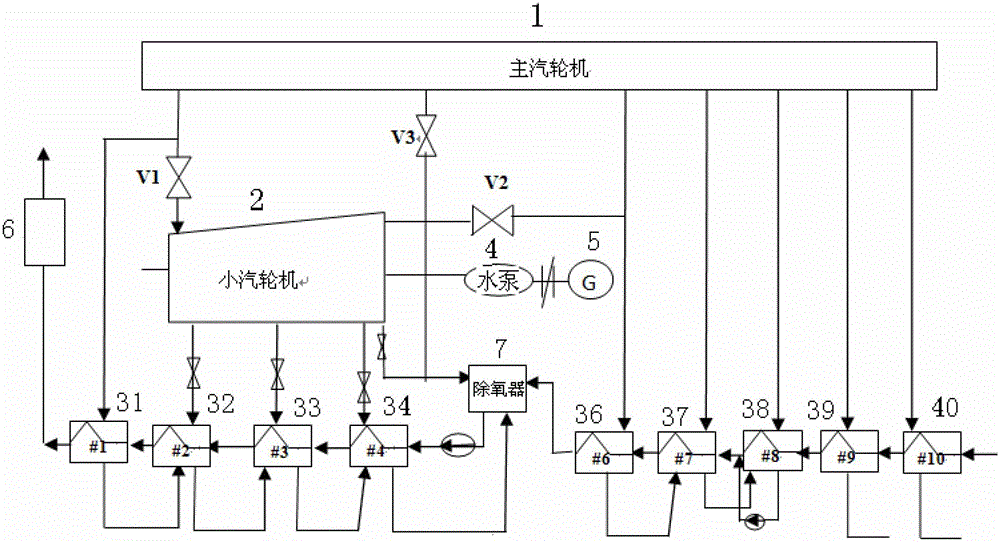

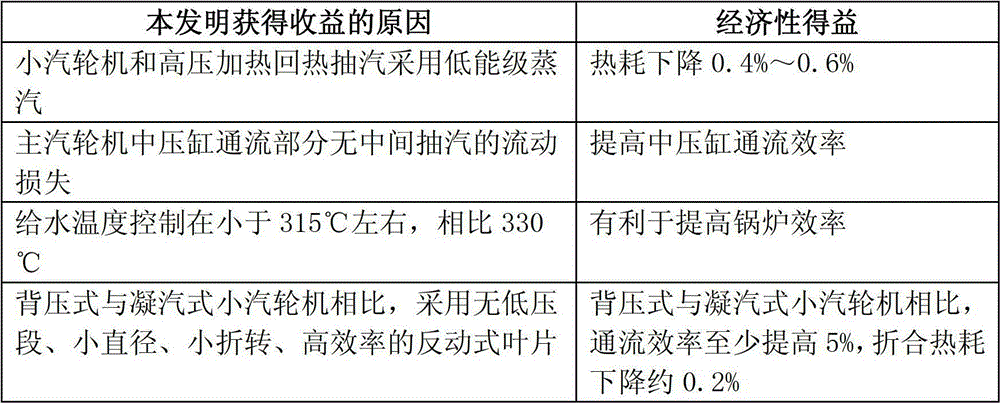

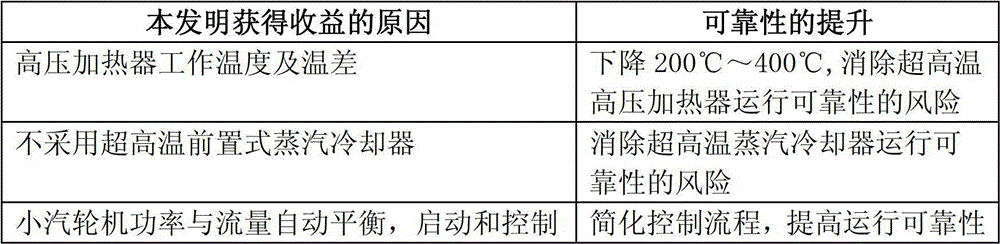

Dual-machine regenerative steam extraction steam thermodynamic system

ActiveCN102720550AReduce the temperatureImprove efficiencySteam useEnergy industryEngineeringIntermediate stage

The invention provides a dual-machine regenerative steam extraction steam thermodynamic system. In the system, the intermediate stage of a high pressure cylinder of a main steam turbine is provided with a high pressure steam extraction opening, the high pressure steam extraction opening is respectively connected with a steam inlet of a small steam turbine and one high pressure heater with the highest steam inlet parameter in a plurality of high pressure heaters through high pressure steam extraction pipelines, the intermediate stage of the small steam turbine is provided with a plurality of regenerative steam extraction openings which are connected with the rest high pressure heaters except the high pressure heater with the highest steam inlet parameter through regenerative steam extraction pipelines, and a steam exhaust port of the small steam turbine is connected with a deaerator through a steam exhaust pipeline of the small steam turbine. According to the system disclosed by the invention, a high-temperature preposed steam cooler can be omitted, and the feed-water temperature of a boiler is reduced, which helps to improve the efficiency of the boiler and reduce the heat consumption of a machine set; and flow loss can be effectively reduced, the circulation efficiency is improved, and the cost of equipment is reduced.

Owner:SHANGHAI TURBINE

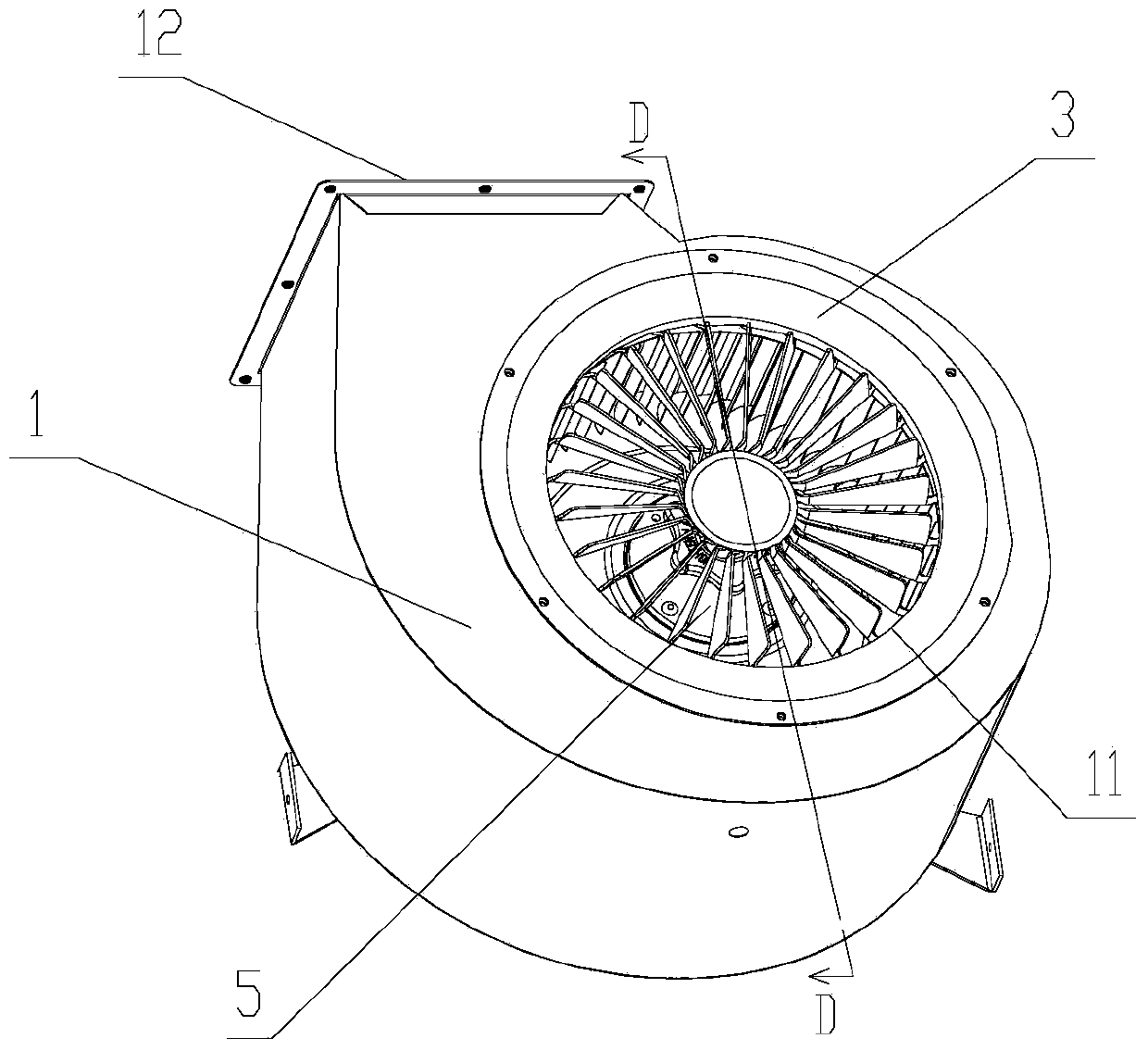

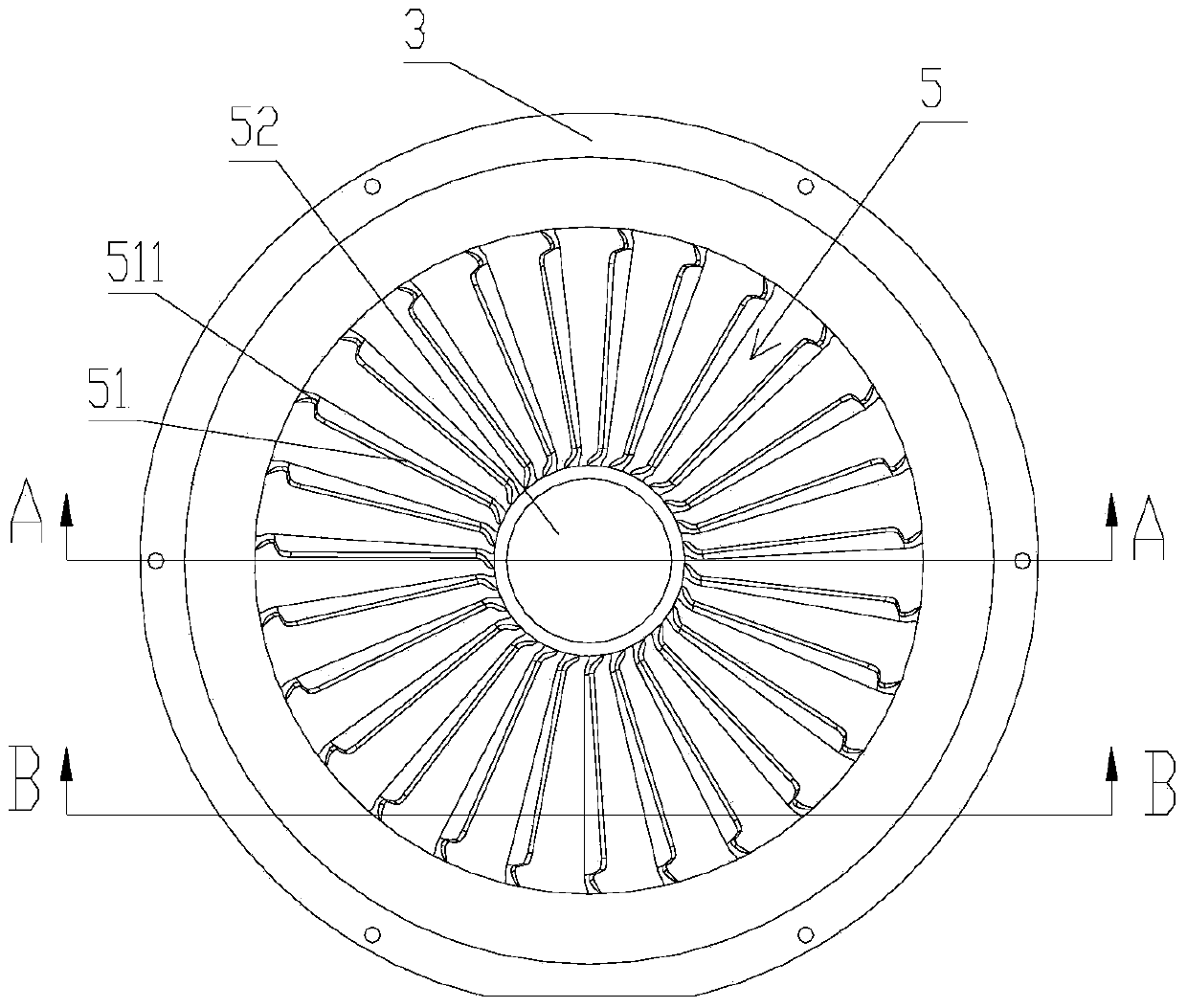

Multi-wing centrifugal fan

InactiveCN104179728AReduced intake angle of attackReduce flow lossPump componentsPumpsImpellerAir volume

The invention provides a multi-wing centrifugal fan. The multi-wing centrifugal fan comprises a spiral case, an impeller and a motor, wherein the motor is fixed on the spiral case; the impeller is arranged on a rotating shaft of the motor and is placed in the spiral case; the spiral case is provided with an air inlet channel and an air outlet channel; a blade guiding device is arranged in the air inlet channel of the spiral case and comprises guiding blades and a hub; the guiding blades are annularly distributed on the periphery of the hub and are inclined; and the inclined direction of the guiding blades is the same with the rotation direction of the impeller. Because the blade guider is arranged in the air inlet channel of the spiral case, before air flow flows through the guiding blades of the blade guider from the air inlet channel and enters a cavity of the impeller, the guiding blades rotate in advance, the rotation direction of the guiding blades is the same with that of the impeller, the air inlet attract angle of an inlet of the impeller can be reduced, so that the flowing loss of the inlet of the impeller is reduced, and the air volume of the fan is increased.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

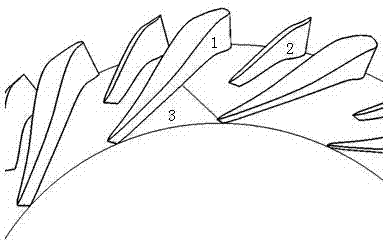

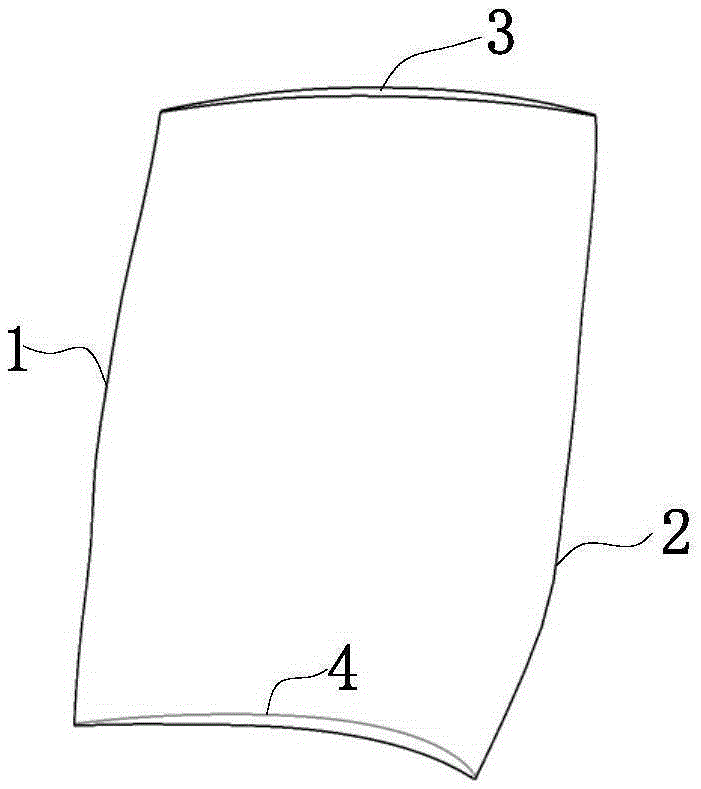

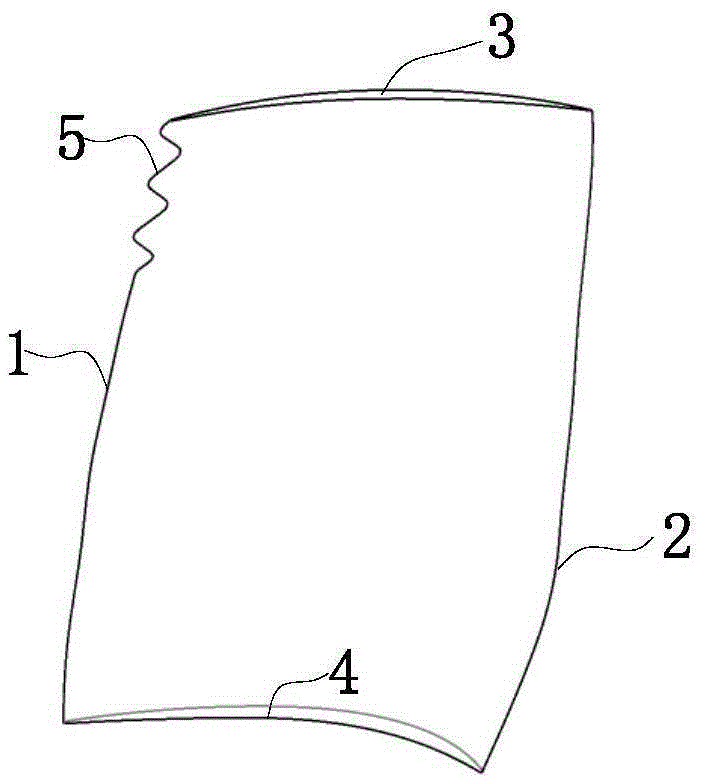

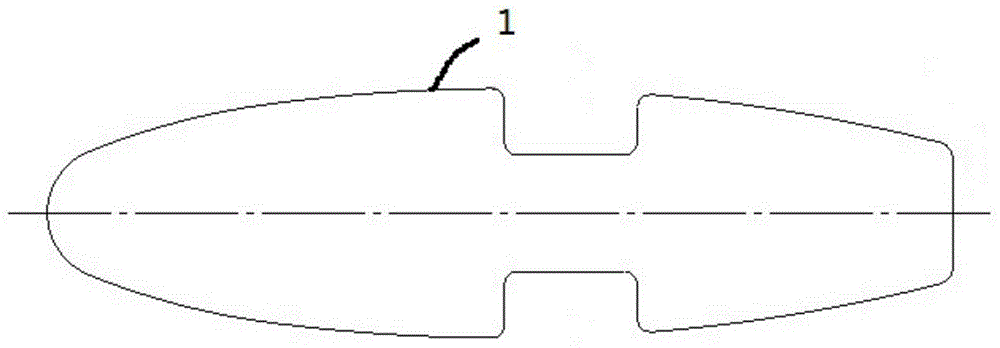

Improved compressor blade and achieving method thereof

The invention discloses an improved compressor blade and an achieving method thereof. A movable blade body comprises a front edge and a tail edge. The leaf height of the front edge is H, and a corrugated knotted protrusion structure is arranged on the top of the front edge. The curve form of the corrugated knotted protrusion structure is a cubic spline curve, and amplitudes of crests and troughs of the corrugated knotted protrusion structure are different. The corrugated knotted protrusion structure is arranged on the top of the front edge within the range of 0.76 H-H. The wave amplitude of points on the curve is A, and the length of a benchmark mean camber line corresponding to the points is L, wherein A is larger than 0 and smaller than or equal to 0.05 L, the wavelength is W, and the W is larger than 0 and smaller than or equal to 0.1 H. According to the structural characteristic of front edge knotted protrusions of the flipper of the humpback, corrugated knotted protrusions with a certain wave amplitude and wavelength are arranged on the top area of the front edge of the movable blade body, the low resistance characteristic of the corrugated knotted protrusions is utilized, the flow loss on the top area of the blade is reduced, and the performance of a compressor is improved.

Owner:SHANGHAI JIAO TONG UNIV

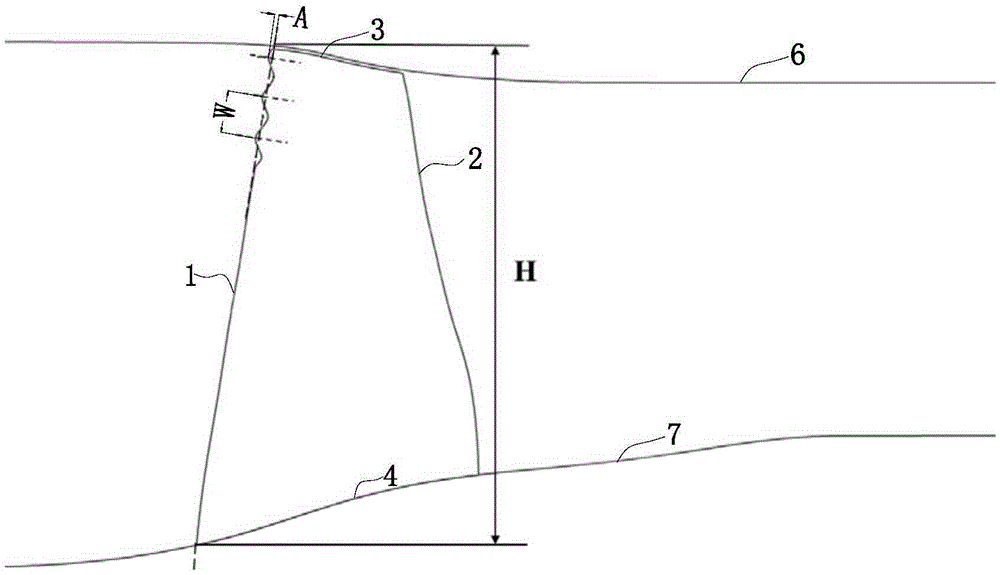

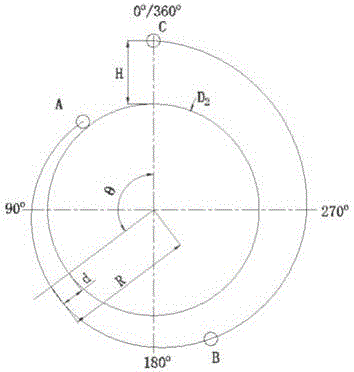

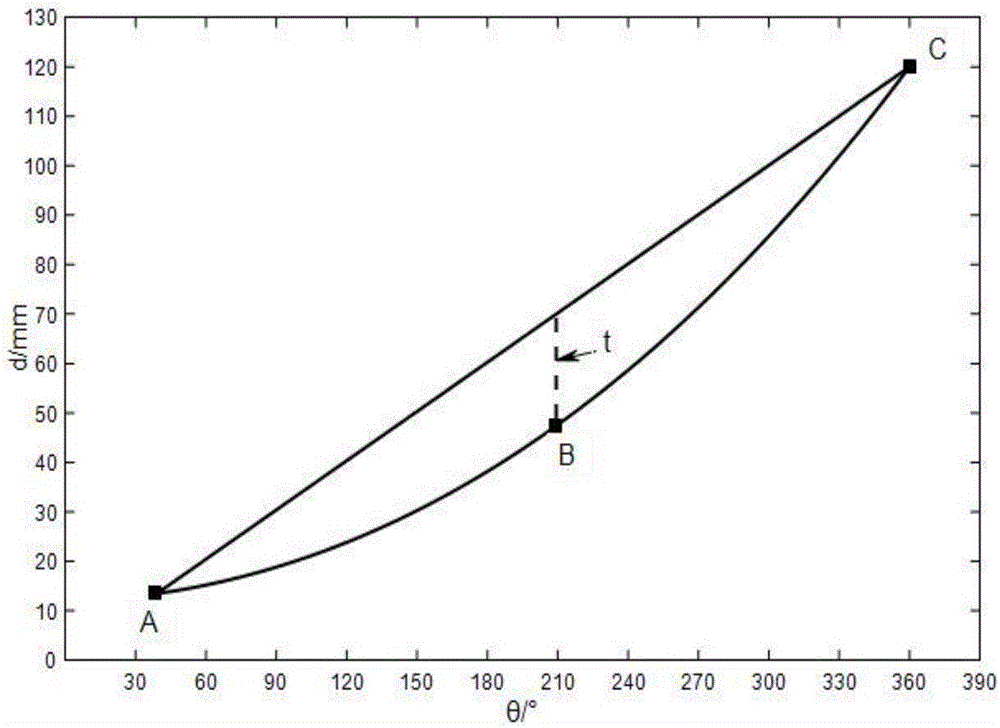

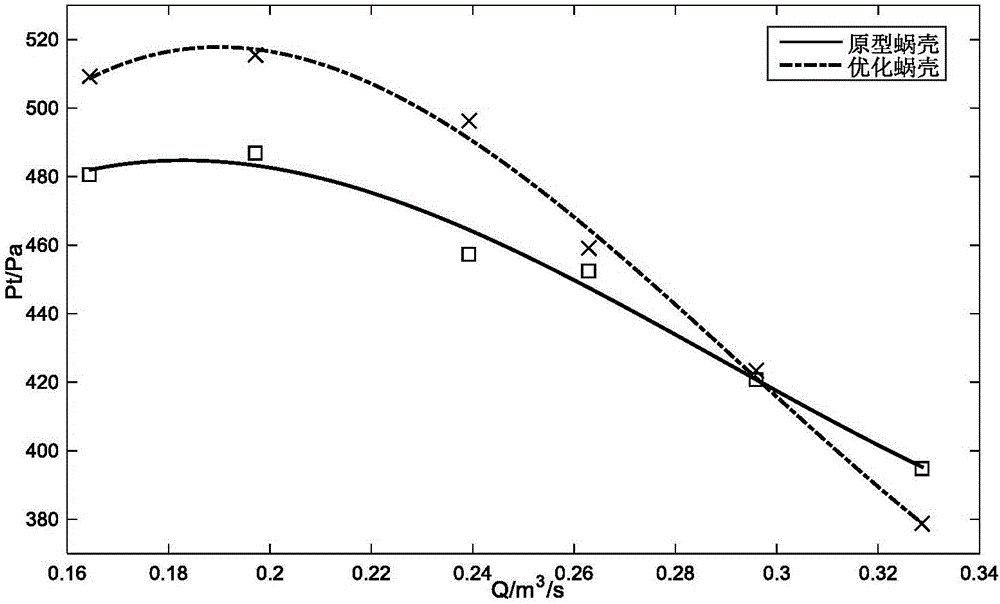

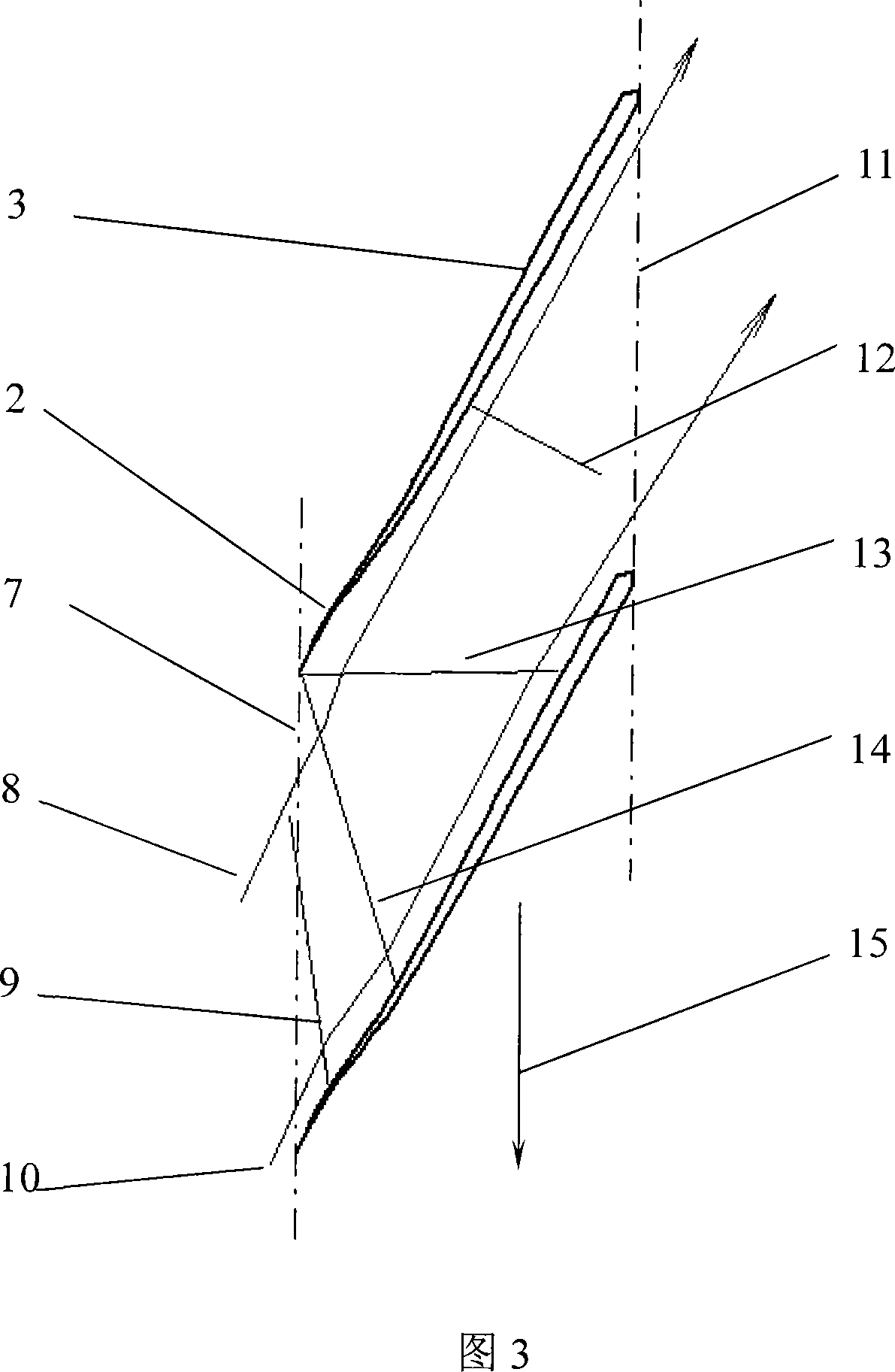

Centrifugal fan volute profile design method

InactiveCN106802974AImprove the diffusion capacityImprove machine efficiencyGeometric CADDesign optimisation/simulationEngineeringCentrifugal fan

The invention relates to a centrifugal fan volute profile design method. The method comprises the steps that three control points of A, B, and C are determined; coordinates on a theta angle distance d coordinate system of the three control points of A, B, and C are calculated and determined, three control points is drawn on the theta angle distance d coordinate system, and the three control points are fitted to a continuous curve; the coordinates of the three points of A, B, and C on the theta angle distance d coordinate system is converted into coordinates on a polar coordinate system; a volute profile is drawn. The centrifugal fan volute profile design method is simple, the volute profile drawn according to the method is capable of controlling volute sectional area distribution, and the volute sectional area increasing according to a designated law can be ensured; at the same time, by controlling the coordinate of A, centrifugal fan volute tongue position and volute tongue gap size can be controlled; the diffusion effect of the centrifugal fan volute can be effectively improved, fan outlet total pressure is increased in a certain range, the flow loss in the volute is reduced, and the fan overall efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

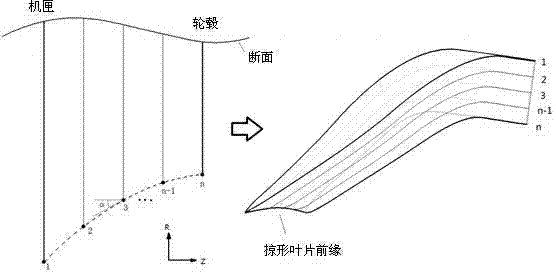

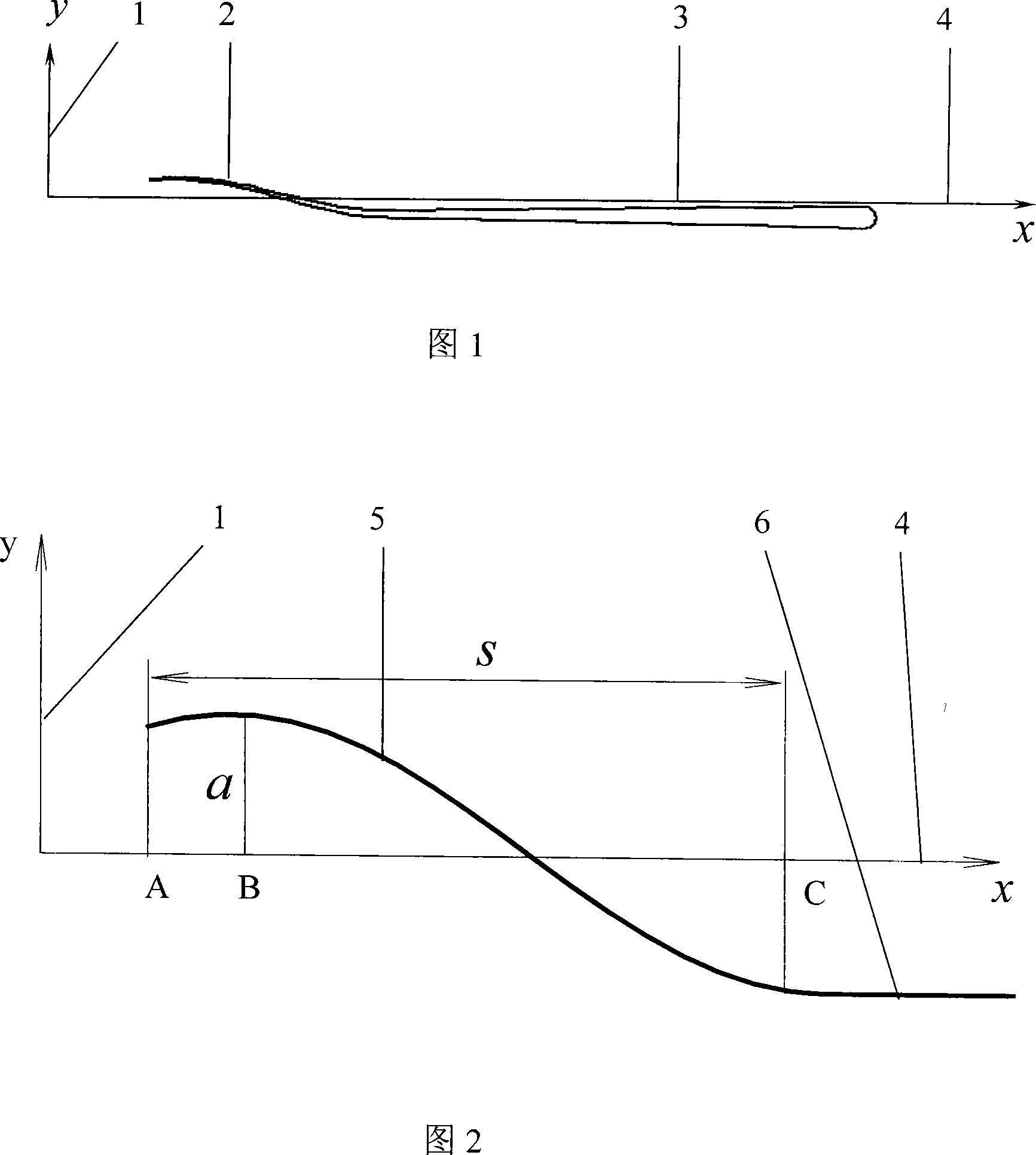

Ultrasound profile applied to aerial engine fan/compressor rotor and design method thereof

InactiveCN101182784AGood off-design performanceIncrease pressureBlade accessoriesMachines/enginesImpellerSuction stress

The present invention relates to an ultrasonic blade and a design method applied to aeroengine fans or aerocompressor rotors, pertaining to the art of impeller mechanical technology. The blade is characterized in that the small part of the blade on the front edge is S-shape and the large rear at the rear is flat and the thickness of the blade gradually increased from front to back; the ultrasonic air current flows into a grid formed by the blade, produces an expansion wave in the entrance of the grid, consequently forms an oblique shock wave in the transition from the S-shaped suction surface of the blade to the flat section intersected with the front edge of the adjacent blade, then produces a reflection shock wave and reproduces a local shock wave near the exit of the grid. The design method of the blade includes the following process: the front part is confirmed to be S-shaped and the rear part is divided by a straight medial camber line; the thickness distribution of the blade, which gradually increases from front to back, is confirmed; the surface mold of the blade is confirmed according to the medial camber line and the thickness distribution of the blade. The blade provided by the present invention can effectively reduce the flowing loss, increase the rim power of the rotor and improve the overall pressure ratio.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

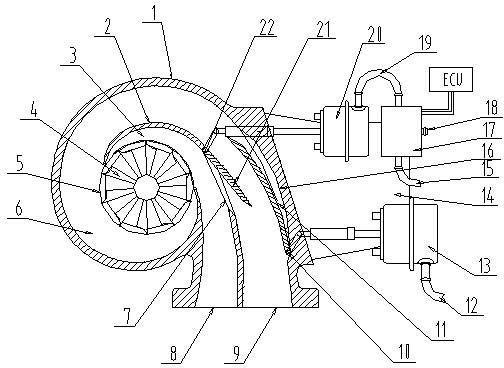

Module type multifunctional pulse conversion turbocharging system

InactiveCN101413423AReduce flow lossScavenging is good forInternal combustion piston enginesGas turbine plantsExternal combustion engineEngineering

The invention relates to a module type multifunctional pulse conversion turbocharging system and belongs to the technical field of internal combustion engine. The module type multifunctional pulse conversion turbocharging system comprises a cylinder, an exhaust branch pipe, an exhaust pipe section, a turbine and a guide plate. The guide plate is inserted into the exhaust pipe section from a connecting part between the exhaust branch pipe and the exhaust pipe section, and gradually extends along the flowing direction of exhaust air till the guide plate is parallel to the axial line of the exhaust pipe section; the exhaust pipe section is divided into an upstream section of the exhaust pipe section, a lower downstream section of the exhaust pipe section and an extending section of the exhaust branch pipe; and the sectional area of the upstream section of the exhaust pipe section is gradually reduced. High-speed air current can be formed in an outlet of the upstream section of the exhaust pipe section; and a low-pressure region is formed in an outlet of the extending section of the exhaust branch pipe in order that scavenging is favored instead of being interfered. The air current of the outlet of the extending section of the exhaust branch pipe is basically parallel to the axial line of the exhaust pipe section, thereby producing no interference of air current. The module type multifunctional pulse conversion turbocharging system has the advantages that the module type multifunctional pulse conversion turbocharging system has simple structure, less occupation and convenient disassembly and assembly, reduces maintenance time and expense and is suitable for large-power four-stroke diesel engines with 4 to 20 cylinders and diversified supercharging degrees..

Owner:SHANGHAI JIAO TONG UNIV

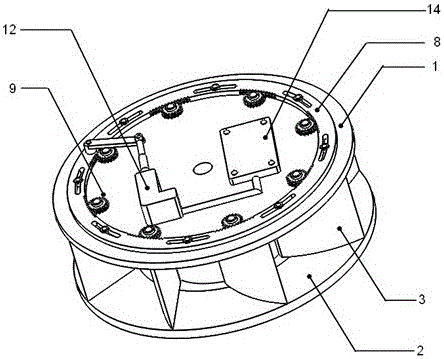

Cavity supporting plate flame stabilizer with built-in oil rod

InactiveCN104373964AReduce wall temperatureImprove stealth performanceContinuous combustion chamberIntegrated designPetroleum engineering

The invention provides an integrated design scheme of an oil injection system and a cavity supporting plate flame stabilization device, and discloses a cavity supporting plate flame stabilizer with a built-in oil rod. An oil injection rod is arranged in an inner cavity of a cavity supporting plate in a built-in mode, in this way, the number of components of an afterburner can be decreased, flow losses caused by the components are lowered, and the overall performance of the afterburner is improved. Meanwhile, the built-in oil injection rod can be subjected to pneumatic nebulization through cooling airflow which flows past the inside of the cavity supporting plate. Compared with a traditional direct-injection type oil injection mode, the atomization effect is better, and the organization burning capacity of the flame stabilizer and the combustion efficiency of the afterburner are further improved.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com