Module type multifunctional pulse conversion turbocharging system

A technology of turbocharging system and pulse conversion, which is applied in the direction of gas turbine devices, machines/engines, internal combustion piston engines, etc. It can solve the problems of diesel engines not reaching power, scavenging interference, and affecting reliability, so as to reduce maintenance time and The effect of low cost, low gas flow loss, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

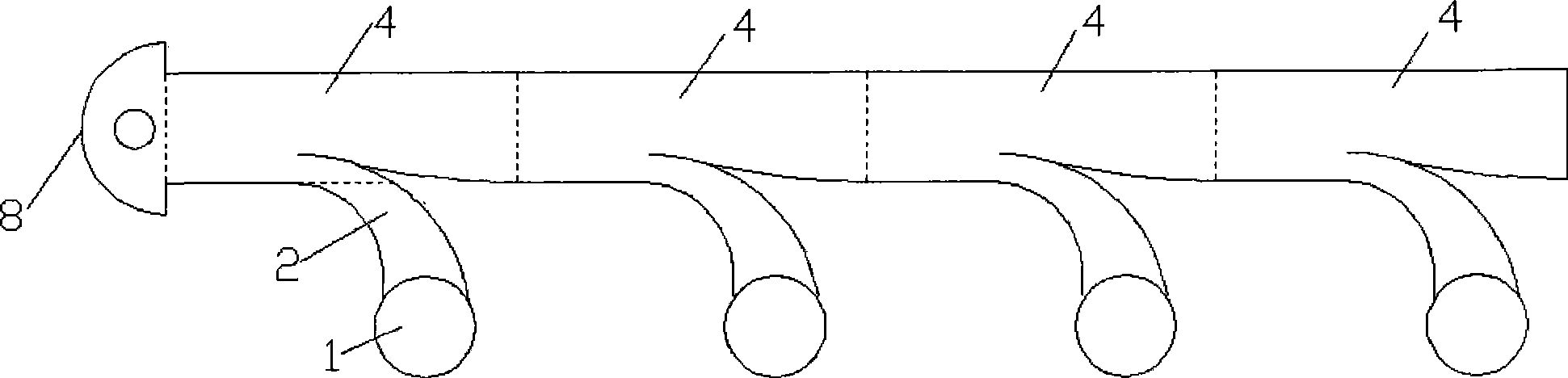

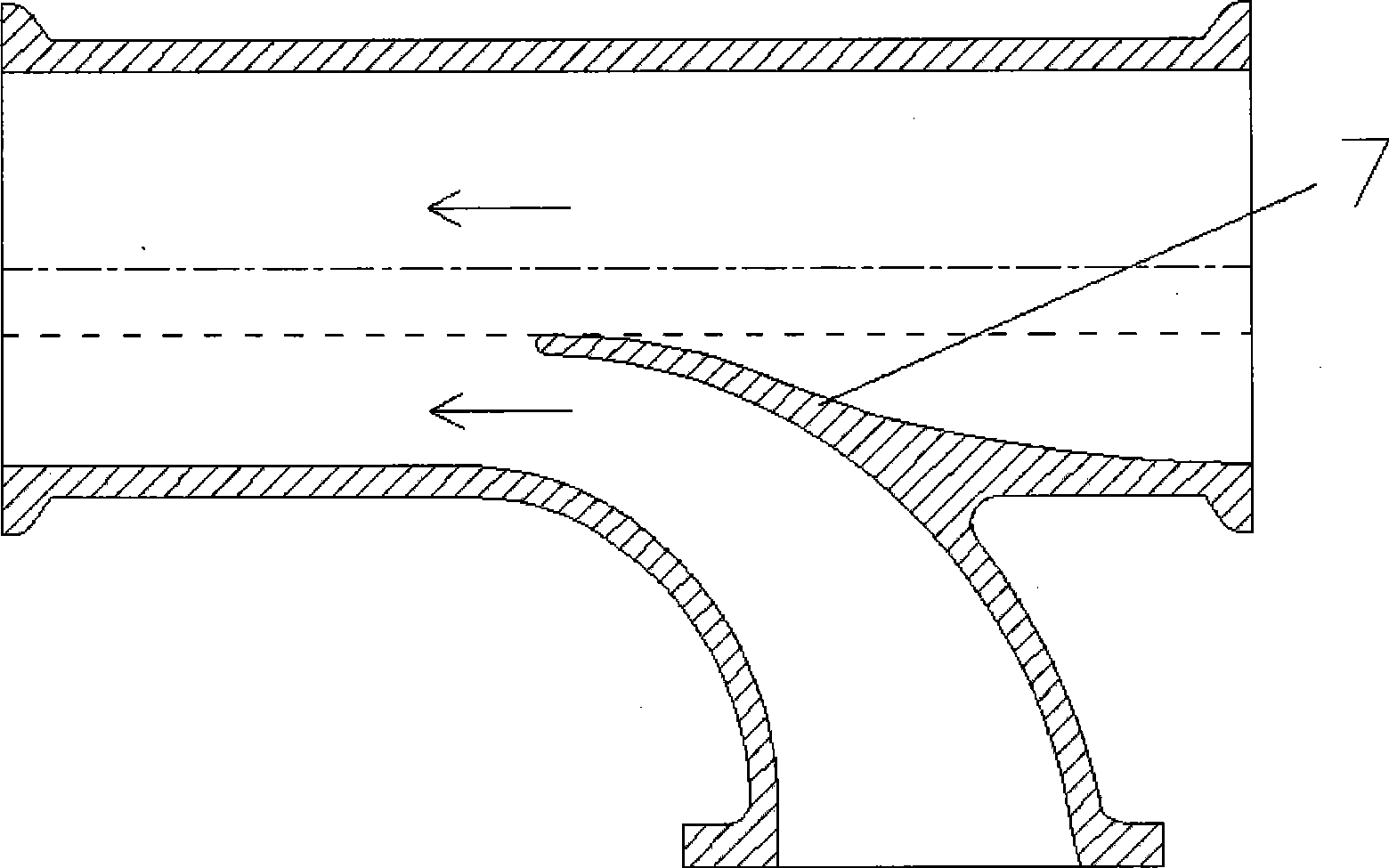

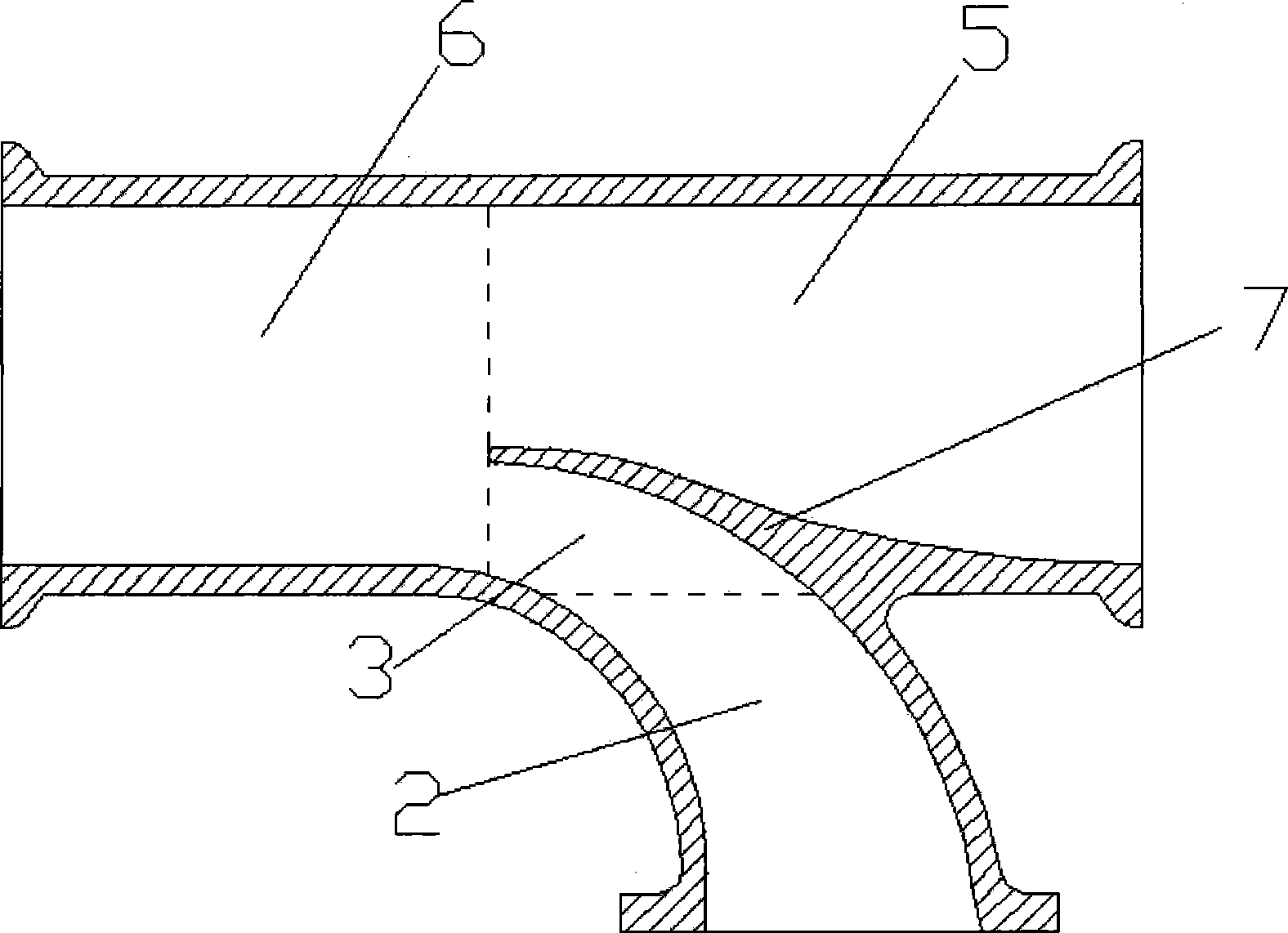

[0012] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a cylinder 1, an exhaust branch pipe 2, an exhaust pipe section 4, a turbine 8 and a baffle 7, each exhaust pipe section 4 is connected to form an exhaust manifold, and the outlet of the exhaust manifold is opposite to the inlet of the turbine 8. Connected, the deflector 7 is inserted into the exhaust pipe section 4 at the junction of the exhaust branch pipe 2 and the exhaust pipe section 4, and gradually extends along the exhaust gas flow direction to be parallel to the axis of the exhaust pipe section 4; the deflector 7 is an arch The baffle 7 is smoothly connected to the inner wall of the exhaust pipe section 4 at the insertion position, and both edges of the baffle 7 are smoothly connected with the inner wall of the exhaust pipe section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com