Improved compressor blade and achieving method thereof

A compressor and improved technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as the loss of compressor rotor blades and other problems, and achieve the effect of reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment realizes the improved compressor blade in the following ways:

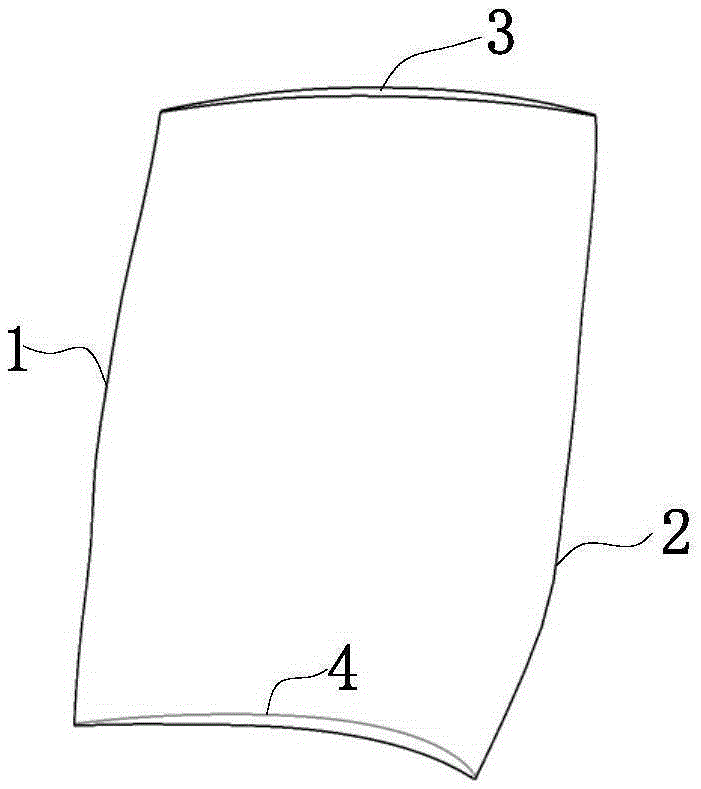

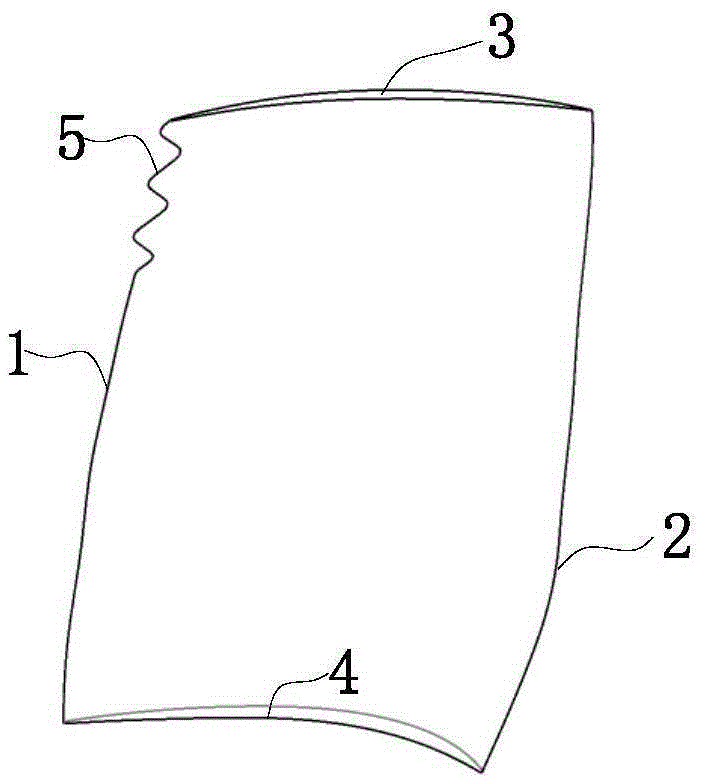

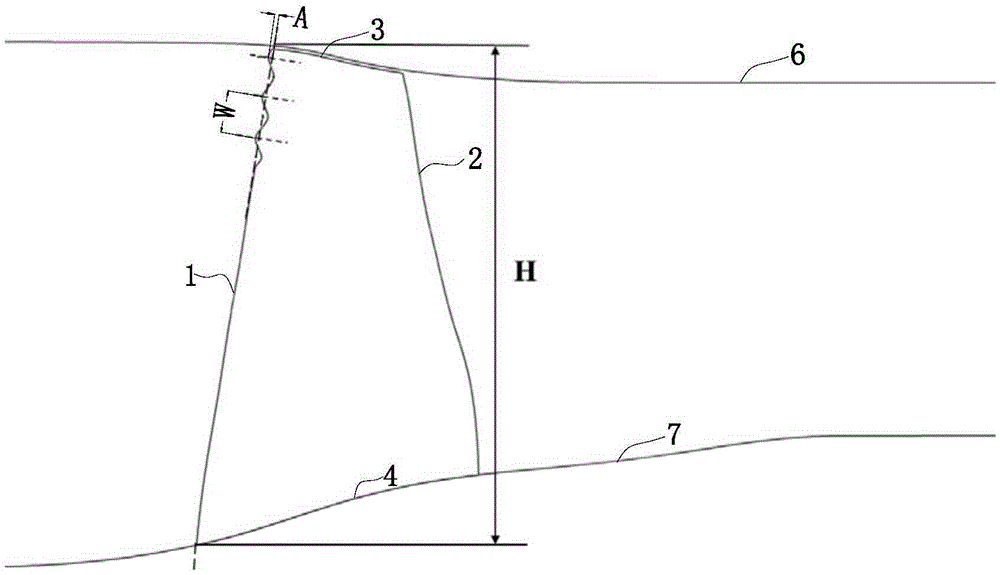

[0032] 1) For example figure 1 The prototype moving blade shown is parametrically modeled, and the prototype moving blade includes: leading edge 1, trailing edge 2, blade top 3 and blade root 4, and the radial stacking method of blades is determined as trailing edge stacking, that is, Ensure that the curve of the trailing edge 2 of the simulated moving blade remains unchanged from that of the prototype moving blade;

[0033] 2) According to the definition of the center arc: the locus of the center of the common tangent circle tangent to the pressure surface arc and the suction surface arc of the airfoil, the reference center arcs of the different blade height cross-section airfoils of the prototype moving blade are obtained, and the reference center The length of the arc is L, and the size of L changes with the change of the height H of the leading edge;

[0034] 3) Introduce the wave-shap...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The amplitude A is taken as 0.05L, and the wavelength W is taken as 0.1H.

[0048] Through numerical calculation, the improved compressor blade with this value reduces the relative total pressure loss coefficient by 3%, reduces the flow loss in the top area of the blade, and thus improves the performance of the compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com