Cavity supporting plate flame stabilizer with built-in oil rod

A flame stabilizer and concave cavity technology, applied in the combustion method, combustion chamber, combustion equipment and other directions, can solve the problems of limiting the performance of the concave cavity support plate flame stabilizer, achieve good atomization effect, simple structure, reduce infrared effect of radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

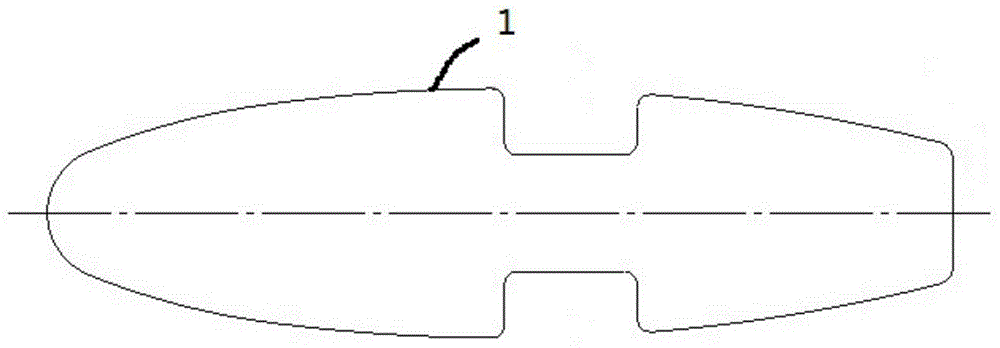

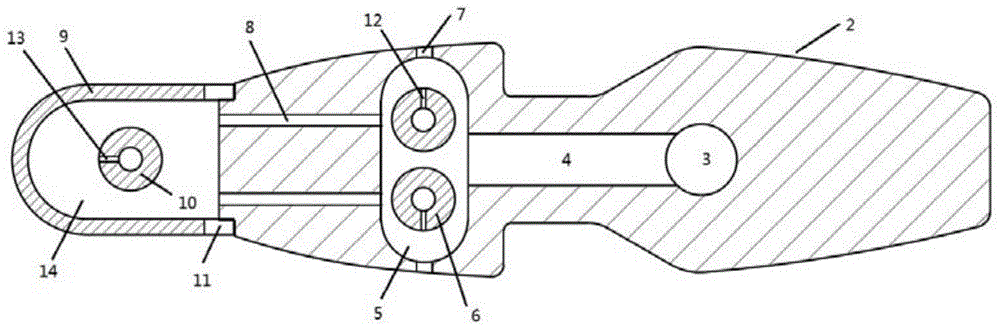

[0026] According to an embodiment of the present invention, for the concave cavity support plate flame stabilizer 1 proposed in the Chinese patent application No. 201010135627.X (see figure 1 ) was modified and designed, and the head structure of the original concave cavity support plate flame stabilizer was canceled and replaced by such figure 2 The shown scheme includes a semi-strip-shaped front baffle 9 , and the front baffle 9 is welded together with the cavity support plate 2 . Simultaneously, two cavities are designed inside the original solid concave cavity support plate, i.e. the rear cavity 3 and the front cavity 5, and there are two circular connecting passages 4 ( figure 2 Only one of them is shown in ) to connect.

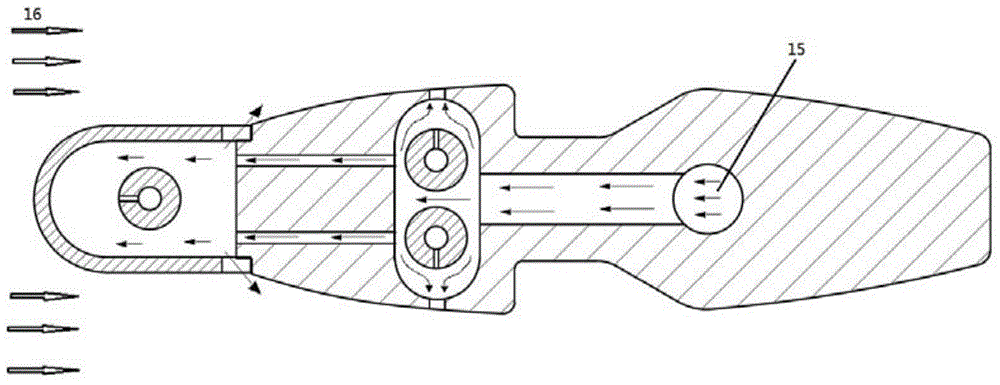

[0027] In the integrated design of the fuel injection system and the concave cavity support plate according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com