Patents

Literature

1408 results about "Silver plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver plate is a coating of pure silver on a base metal such as copper or nickel silver (an alloy of nickel, copper, and zinc) and was developed later than sterling or coin, but various forms date to the 18th century.

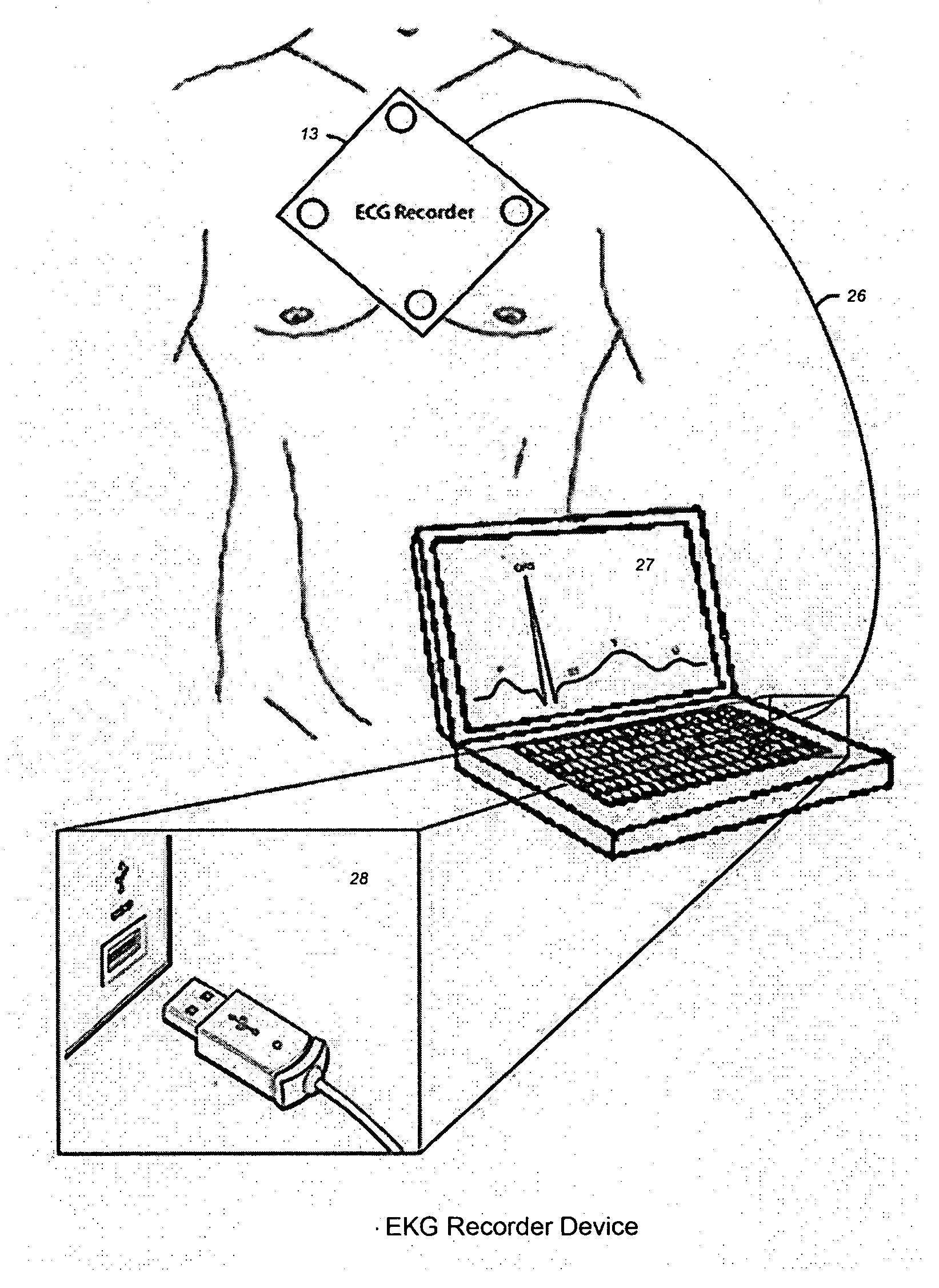

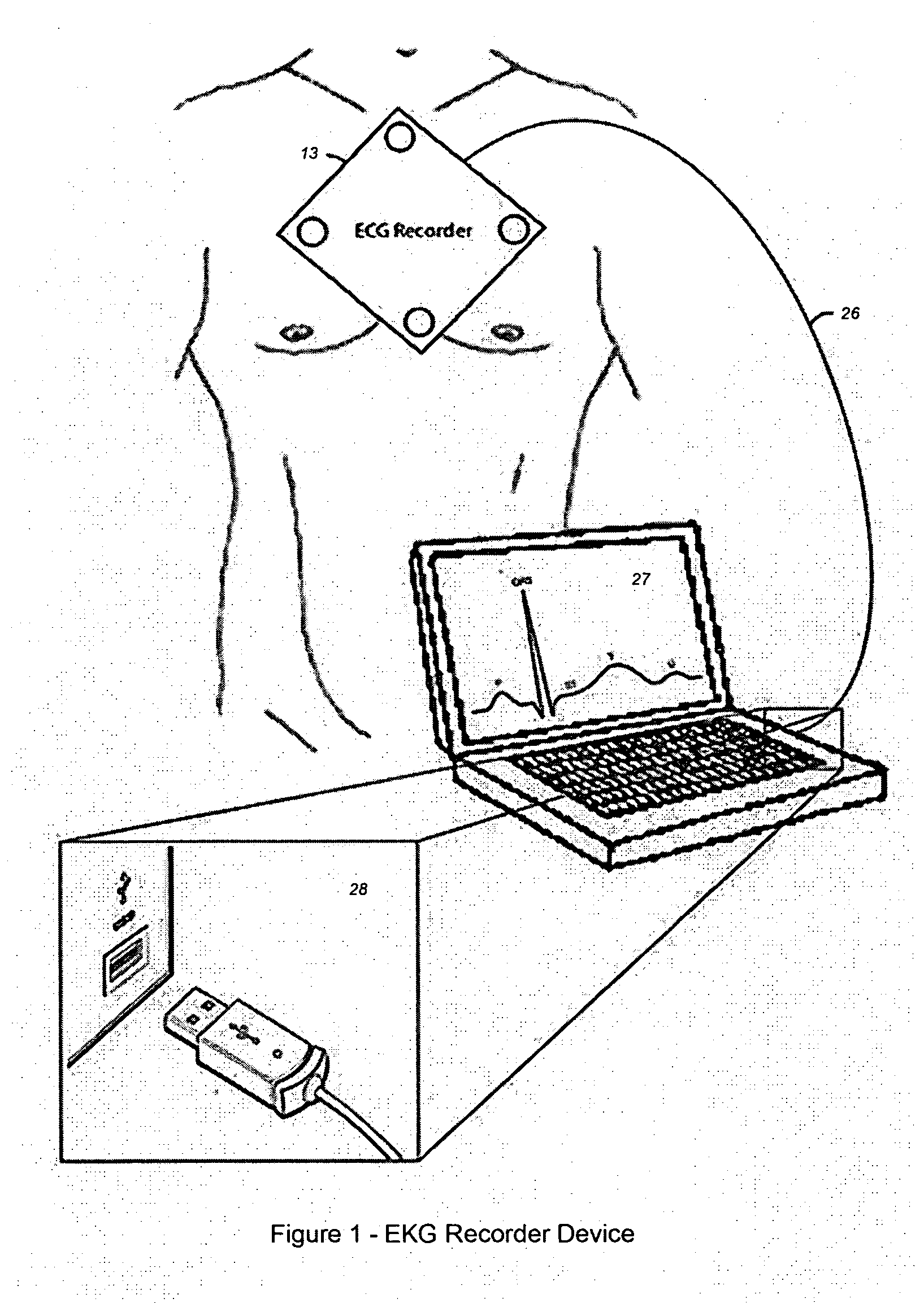

Personal heart rhythm recording device

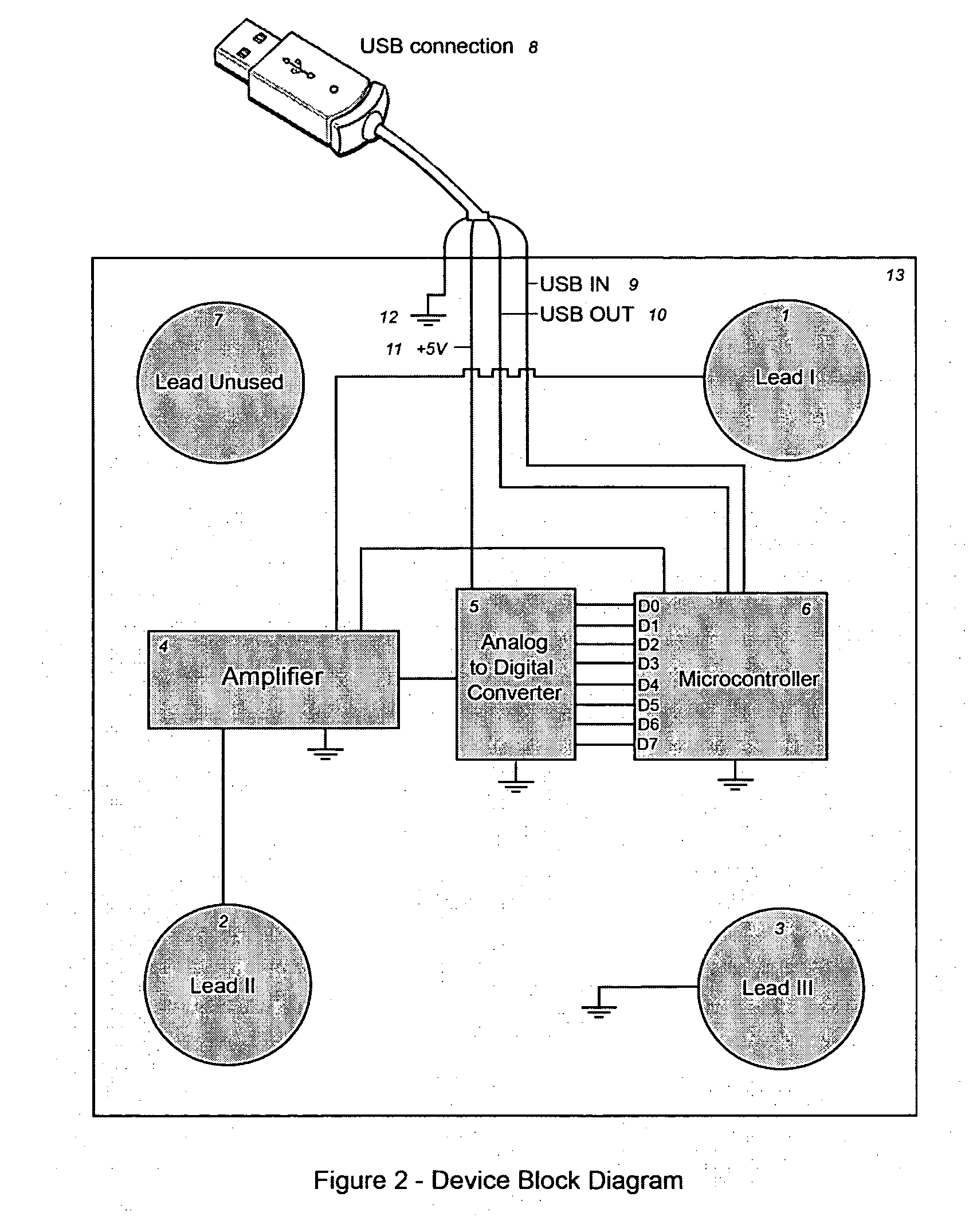

An electrocardiographic device for recording the rhythm of the human heart using a home personal computer and printer. This device consists of three silver-plated leads, a 1000× amplifier, an analog to digital computer, an oscillating timing clock, a microcontroller unit, a USB input bus, a data output bus, and computer software for displaying the rhythm graphically. The advantages of this device include convenience, low cost, and repeatability. A patient can record their cardiac rhythm themselves at any time whenever a sudden cardiac arrhythmia occurs without traveling to the doctor's office or emergency room. Based on the low cost of this inexpensive device a patient can own his own rhythm recording device instead of paying for expensive Holter monitors or event recorders from a doctor's office. Lastly, this device can be used repeatedly without the expense of disposable electrodes or limitations of monitoring device memory restricting the number of electrocardiographic recordings.

Owner:NICHOLS ALLEN BRYANT JR +1

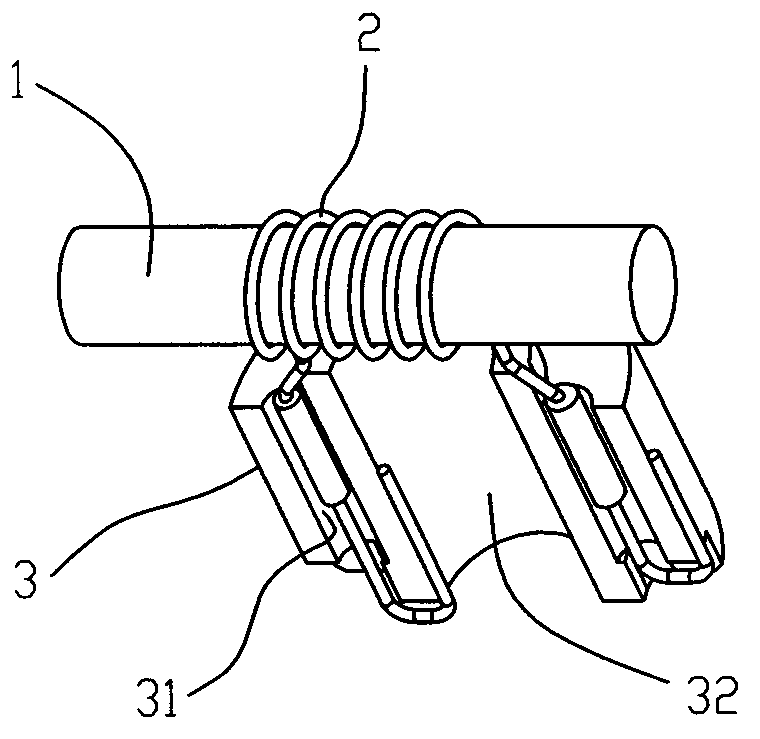

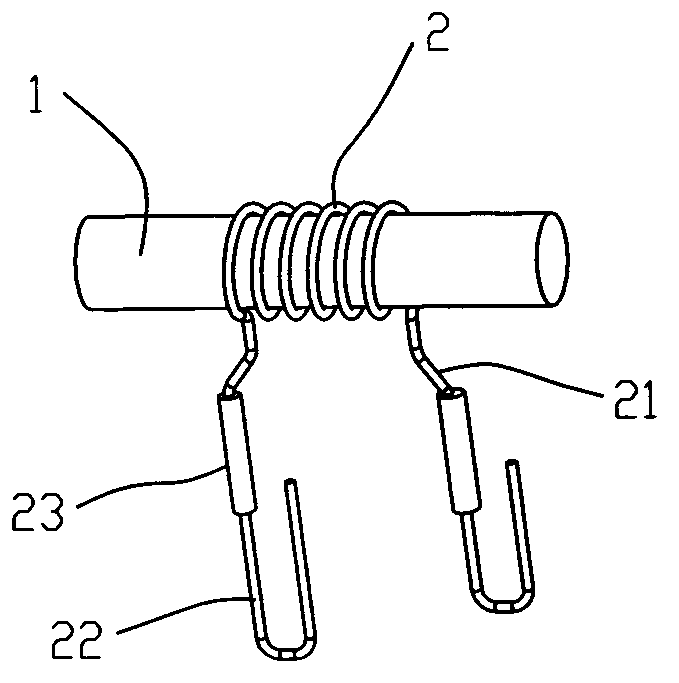

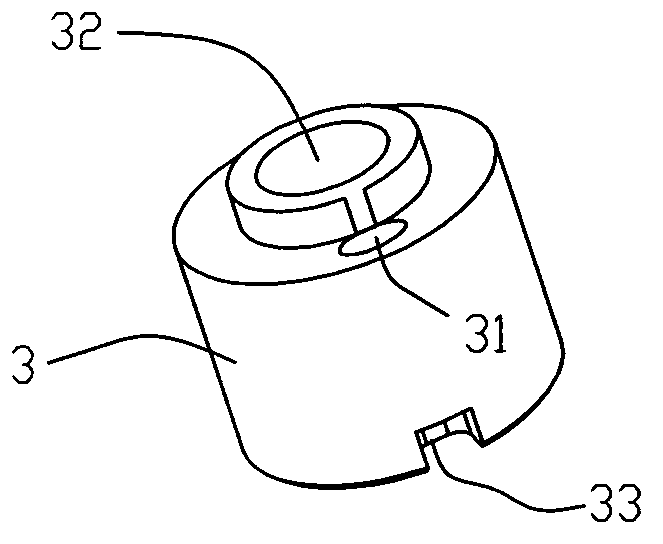

Atomization device for electronic cigarette as well as atomizer and electronic cigarette

The invention discloses an atomization device for electronic cigarette and particularly provide an atomization device for electronic cigarette, which can effectively control a heating range of a heating filament, does not change taste of the electronic cigarette, and can reduce contact resistance at a joint of the heating filament and an electrode. According to the implementation scheme, the atomization device for the electronic cigarette comprises a thread bushing and an electrode ring, wherein the electrode ring is fixedly arranged in the thread bushing; a glass fiber core, the heating filament wound on the glass fiber core, and a heating filament bracket are further arranged in the thread bushing; silver-plated electronic bare wires are respectively and fixedly connected to two pins of the heating filament, and a through hole and an inner hole for guiding the two electronic bare wires are formed in the heating filament bracket; and after respectively penetrating through the through hole, the electronic bare wires are in contacted with the thread bushing and the electrode ring. The invention further discloses an atomizer and an electronic cigarette which contain the atomization device.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method of preparing electric conductive adhesive by chemical plating silver on graphite powder surface

InactiveCN1919933AEase of mass productionLow resistivityInorganic pigment treatmentSemiconductor/solid-state device manufacturingChemical platingSilver plate

The invention discloses a chemical silver plating preparing conducting resin method on the graphite powder surface in the chemical silver plating and micro-electronics connection material technique domain, which comprises the following steps: oxidizing the graphite powder in the air at 600-650DEG C; putting the dispersant, reducer and stabilizing agent in de-ionized water for reduced liquid; adding in graphite powder to stir; putting the silver nitrate in the de-ionized water; adding in ammonia and sodium hydroxide to get argentamine; putting the reduced liquid in the argentamine liquid to finish chemical silver plating on the graphite powder surface; filtering; separating and washing; drying in vacuum to get silver coated graphite powder.

Owner:TSINGHUA UNIV

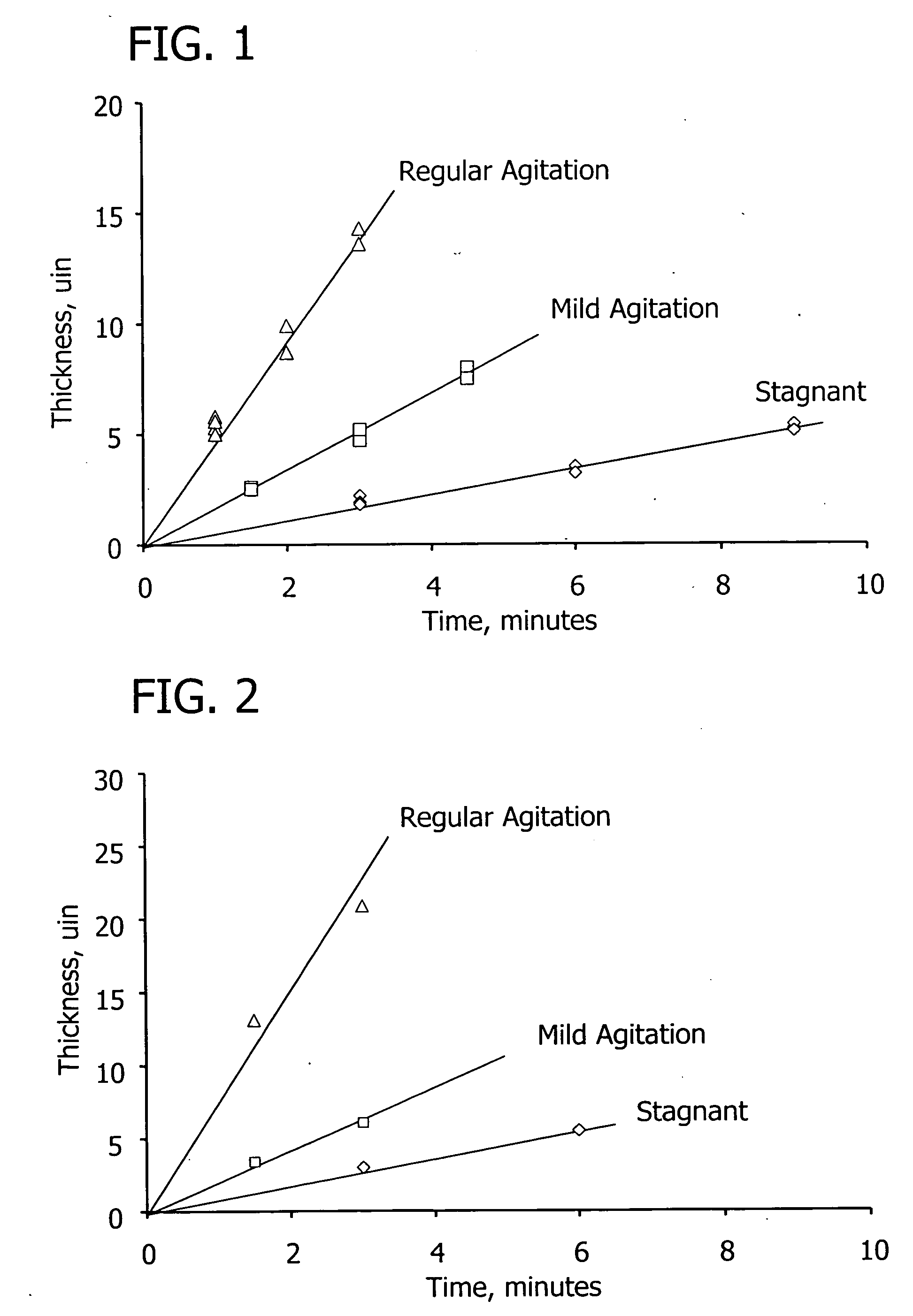

Silver plating in electronics manufacture

Compositions and methods for silver plating onto metal surfaces such as PWBs in electronics manufacture to produce a silver plating which is greater than 80 atomic % silver, tarnish resistant, and has good solderability.

Owner:MACDERMID ENTHONE INC

Fabric capable of preventing electromagnetic radiation

InactiveCN101942729AElastic fit and comfortableHarm reductionWeft knittingWarp knittingYarnSilver plate

The invention relates to a fabric capable of preventing electromagnetic radiation, which is knitted or weaved. The warp and the abb of the fabric comprise covering yarn. The covering yarn takes one of silver plating fiber, carbon fiber and carbon black organic fiber as core yarn and takes comfortable fiber as skin yarn; the silver plating fiber is formed by carrying out silver plating on synthetic fiber; the weight ratio of the corn yarn to the skin yarn is 10-70:30-90; and the comfortable fiber is one of cotton, wool, silk, hemp, viscose, bamboo fiber, bamboo carbon fiber, soybean fiber, PLA fiber, alginate fibre, milk fiber and pearl fiber. The invention can shield electromagnetic wave, and the shield effect is above 99%. The skin yarn in the covering yarn adopts natural fiber, and the natural fiber on the outer layer has the characteristics of moisture absorption, ventilation and comfort.

Owner:汕头市奥山服饰有限公司

Chemical method for silver coating on copper powder surface

The invention relates to a method for copper powder surface chemical plating silver, belonging to field of chemical silver plating. Said method comprises following steps: putting copper powder into diluted acid of 5-10% to remove oxide on surface of copper powder; adding disperser of 1-30% of copper powder by weight, stabilizer of 10-60% of copper powder by weight into deionized water to form reducing liquid, adding copper powder and stirring; adding silver nitrate into deionized water, adding ammonia, stirring and adding sodium-hydroxide and getting silver amine solvent; adding silver amine solvent into reducing liquid under stirring, finishing chemical silver plating of copper surface 10-50 minutes later; filtering, separating and washing, vacuum drying and getting silver-coated copper powder. The process is characterized by simple preparation and raw material, reduced silver-plated layer on container wall by adding silver amine solvent into reducing liquid, high silver converting rate. The electrical resistance of got copper powder is smaller than 2*10-4 omegacm.

Owner:TSINGHUA UNIV

Non-cyanide silver plating bath composition

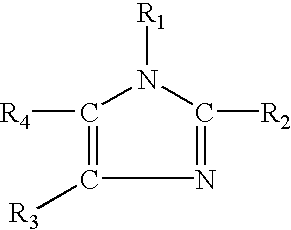

InactiveUS20050183961A1Chemically stableIncrease brightnessChemical vapor deposition coatingCyanideSilver plate

Disclosed is an electroplating solution for the deposition of silver; said solution containing silver in the form of a complex of silver with hydantoin or a substituted hydantoin compound; said solution also containing an excess of the hydantoin or substituted hydantoin compound employed, together with an effective quantity of a nonprecipitating electrolyte salt, and also an effective quantity of 2,2′ dipyridyl for the purpose of obtaining a mirror-bright to brilliant deposit.

Owner:TECHNIC INC

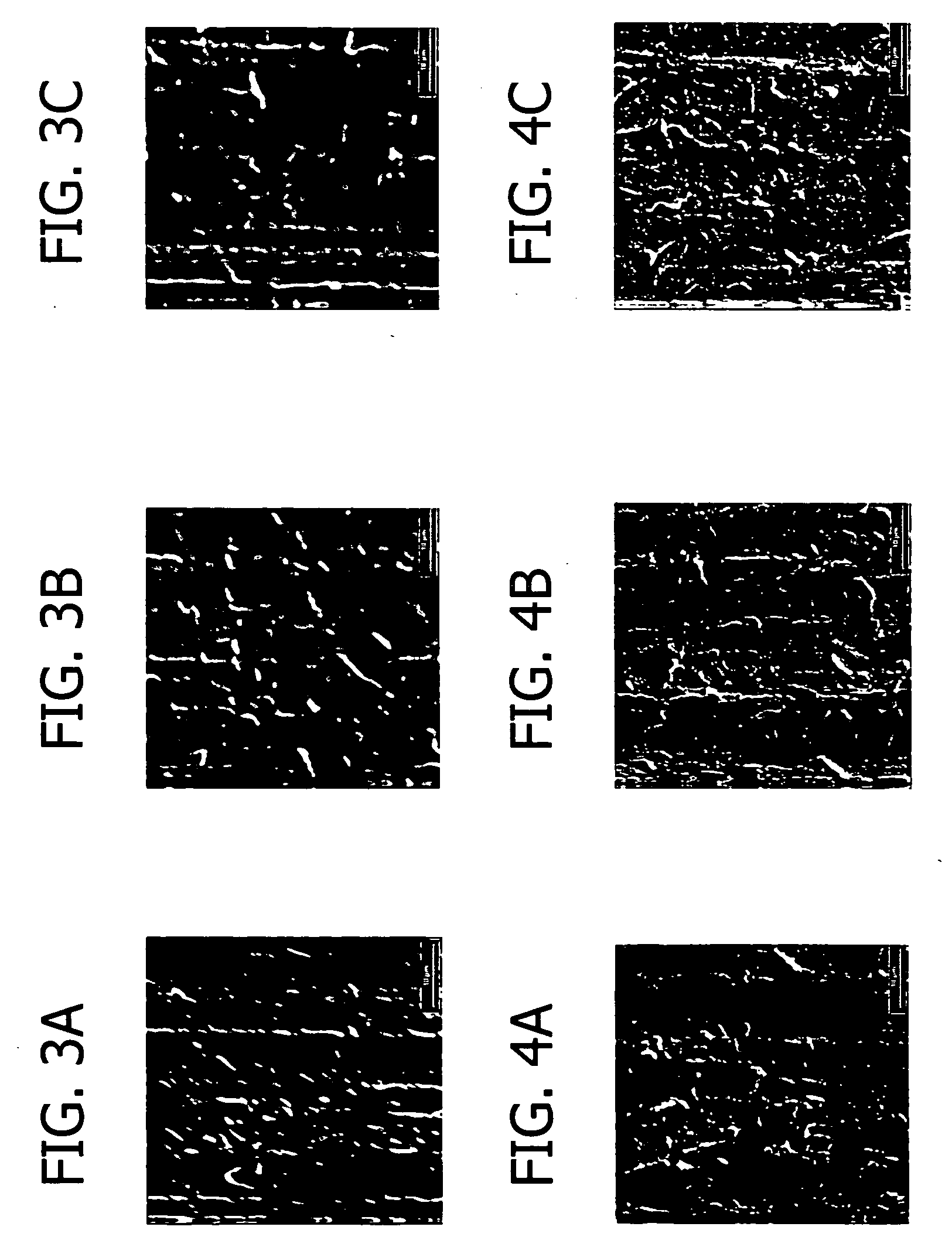

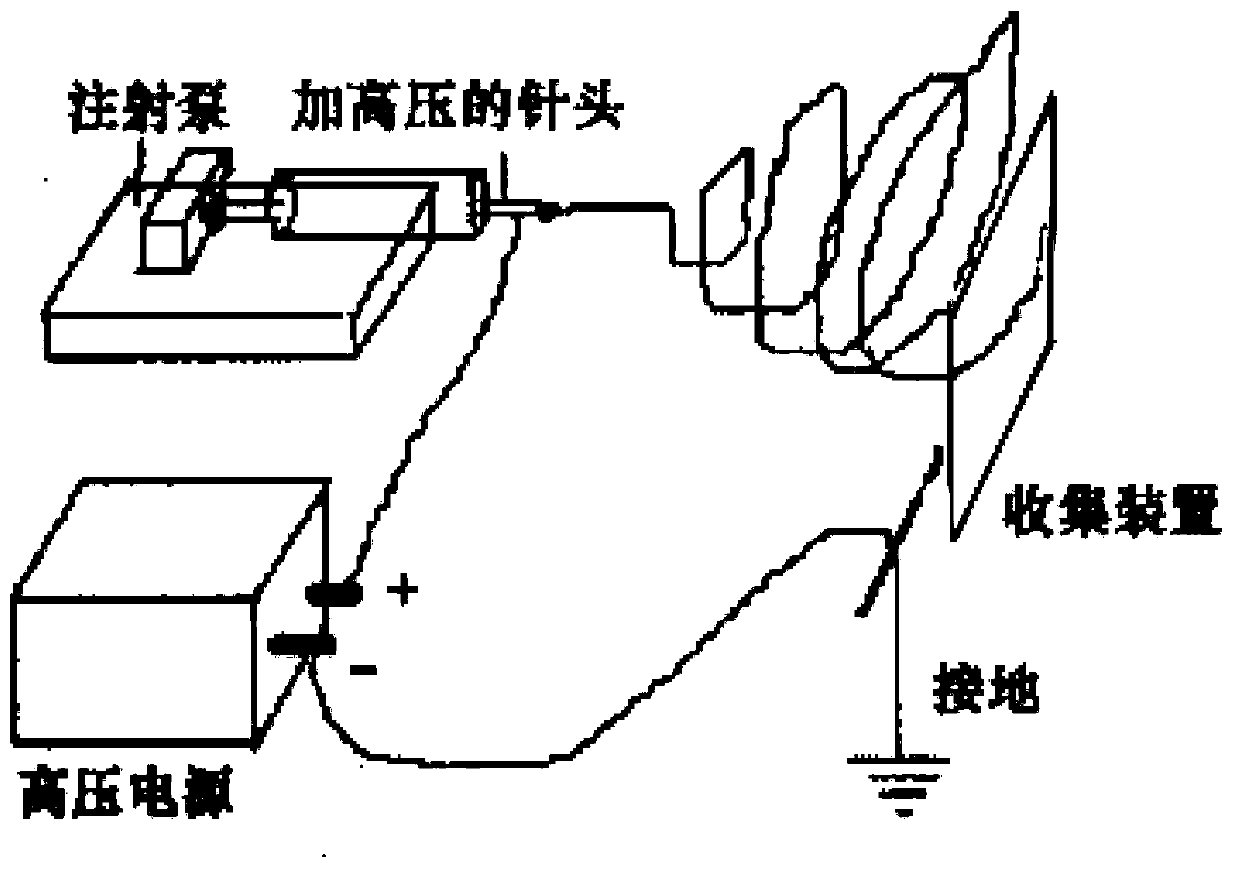

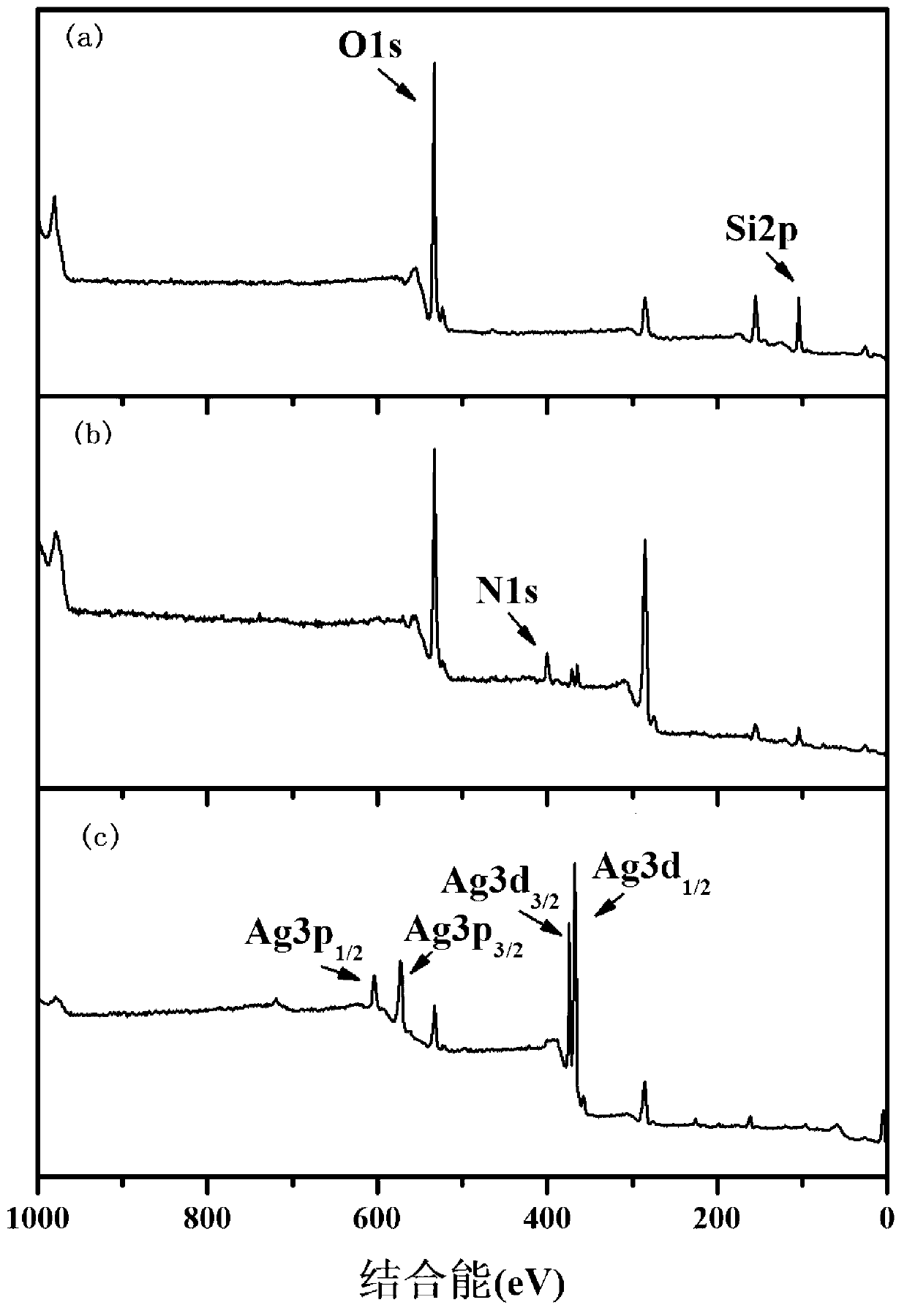

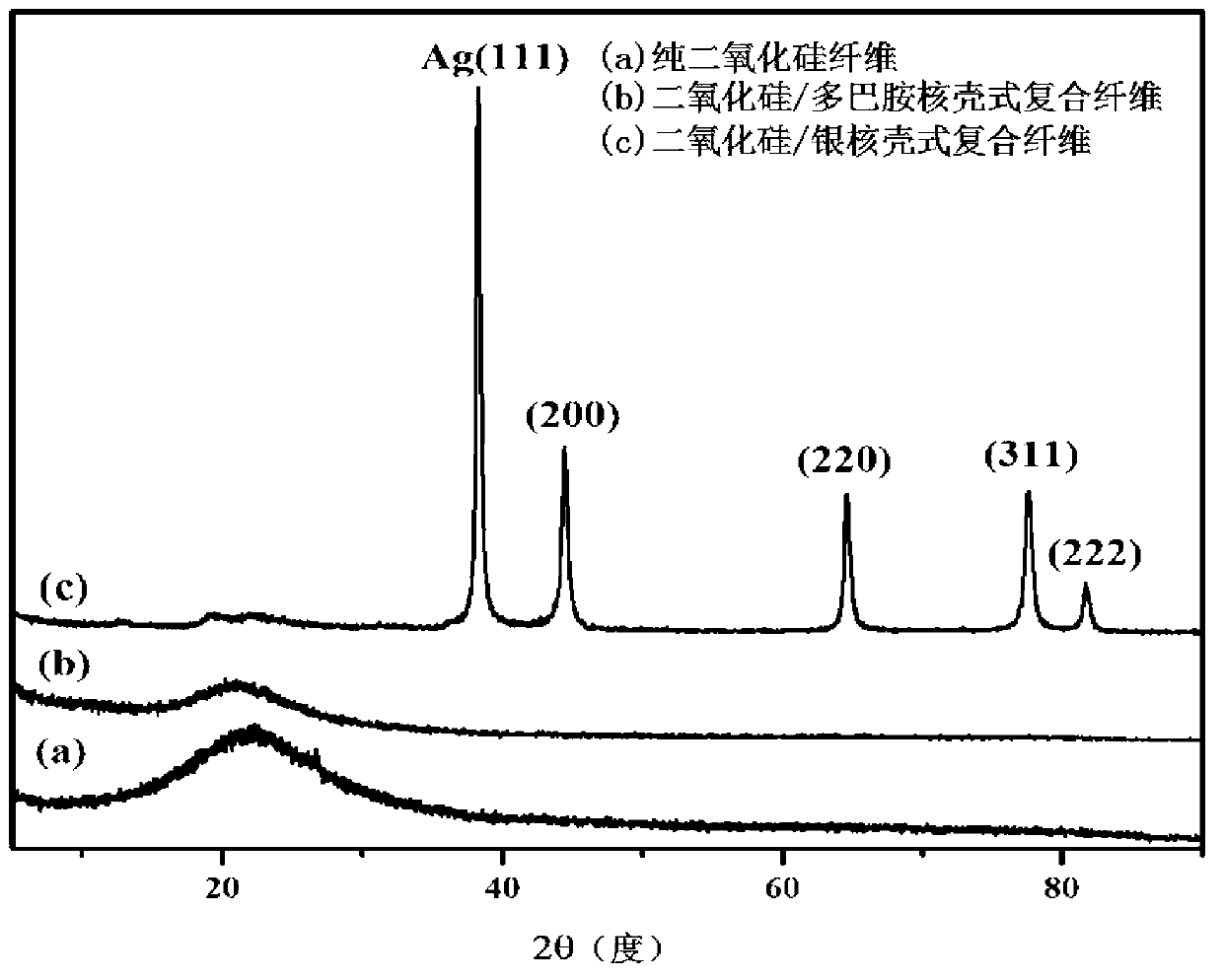

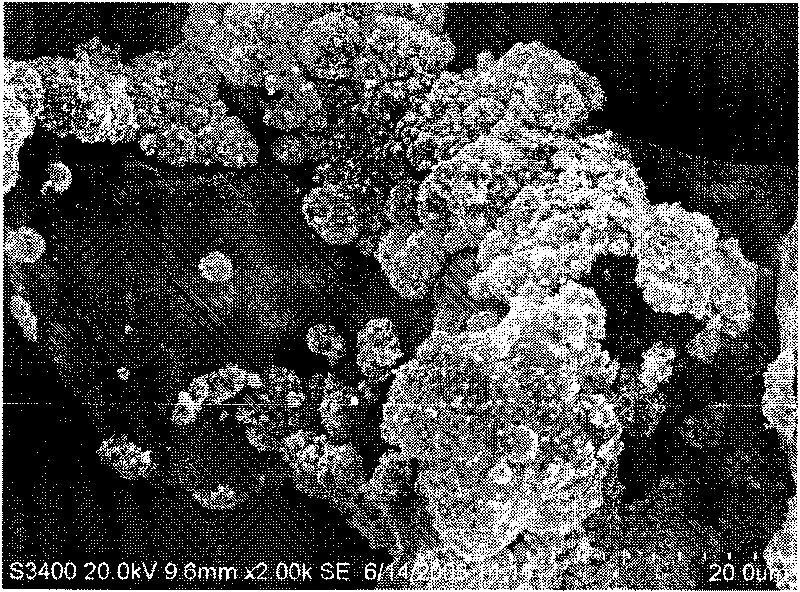

Method for preparing surface silver-plated electric-spinning fiber by using dopamine

ActiveCN103276379ASimple and fast operationShort timeLiquid/solution decomposition chemical coatingTextile decorationFiberSilver plate

The invention discloses a method for preparing a surface silver-plated electric-spinning fiber by using dopamine. The method comprises the following steps of: preparing a matrix fiber by using a static electric-spinning method, depositing the dopamine on the surface of the matrix under alkali condition, subsequently putting the matrix which is subjected to surface functionalization by using poly-dopamine into a silver plating liquid, adding a reducing agent glucose solution and preparing the surface silver-plated composite fiber which is good in coating property and conductivity. The method disclosed by the invention is simple to operate and short in time; and the composite material prepared by using the method is good in coating property and conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

The invention relates to a preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers, which comprises the following concrete steps of: a. washing and oil removal; b. coarsening: increasing the surface roughness and the surface wettability of fibers; c. sensitizing: soaking the fibers by adopting an aqueous solution formed by stannous chloride and hydrochloric acid; d. activation: soaking the fibers by adopting an aqueous solution formed by palladium chloride and hydrochloric acid; e. chemical nickel plating; f. sensitizing; g. activation; h. chemical silver plating; and i. coating protection. The prepared high performance nickel-plated and silver-plated aromatic polyamide conductive fibers have good electric conductivity, characteristics of heat resistance, flame retardance, light weight and high strength and functions of eliminating static electricity, conducting electricity and transmitting electrical signals. Therefore, the prepared nickel-plated and silver-plated aromatic polyamide conductive fibers can be widely applied to special departments of aviation, space flight, war industry, communication and the like and can also satisfy the clothing and equipment requirements of staffs engaging radars, television relaying and the like.

Owner:SHANGHAI UNIV

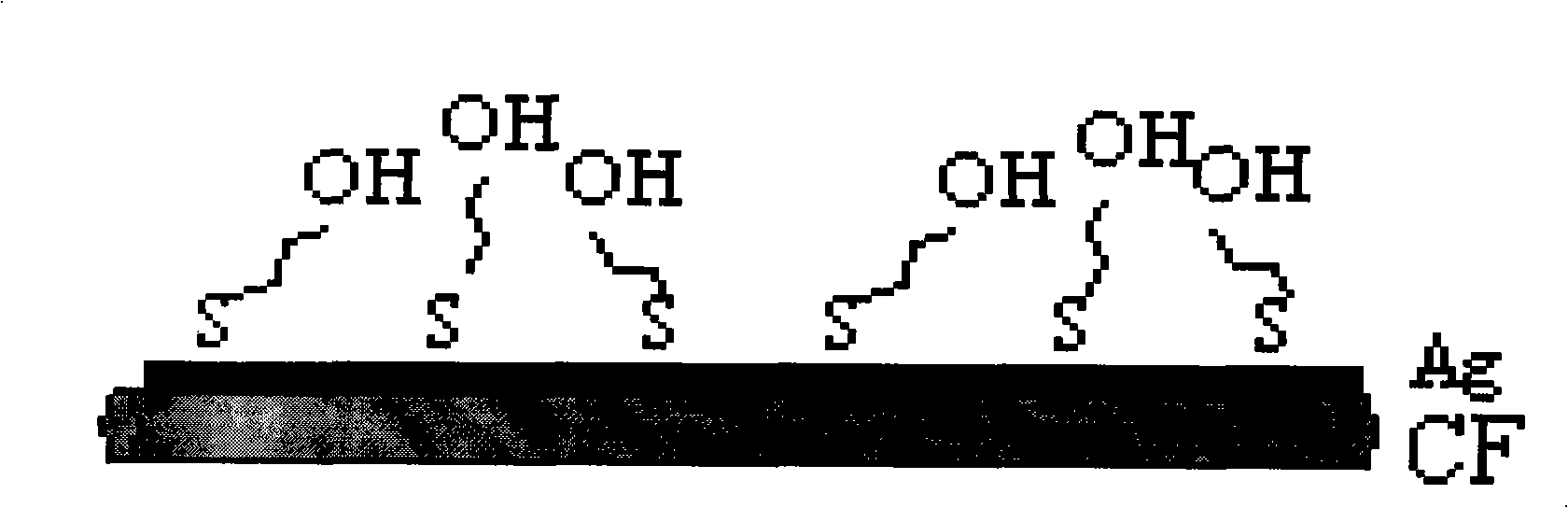

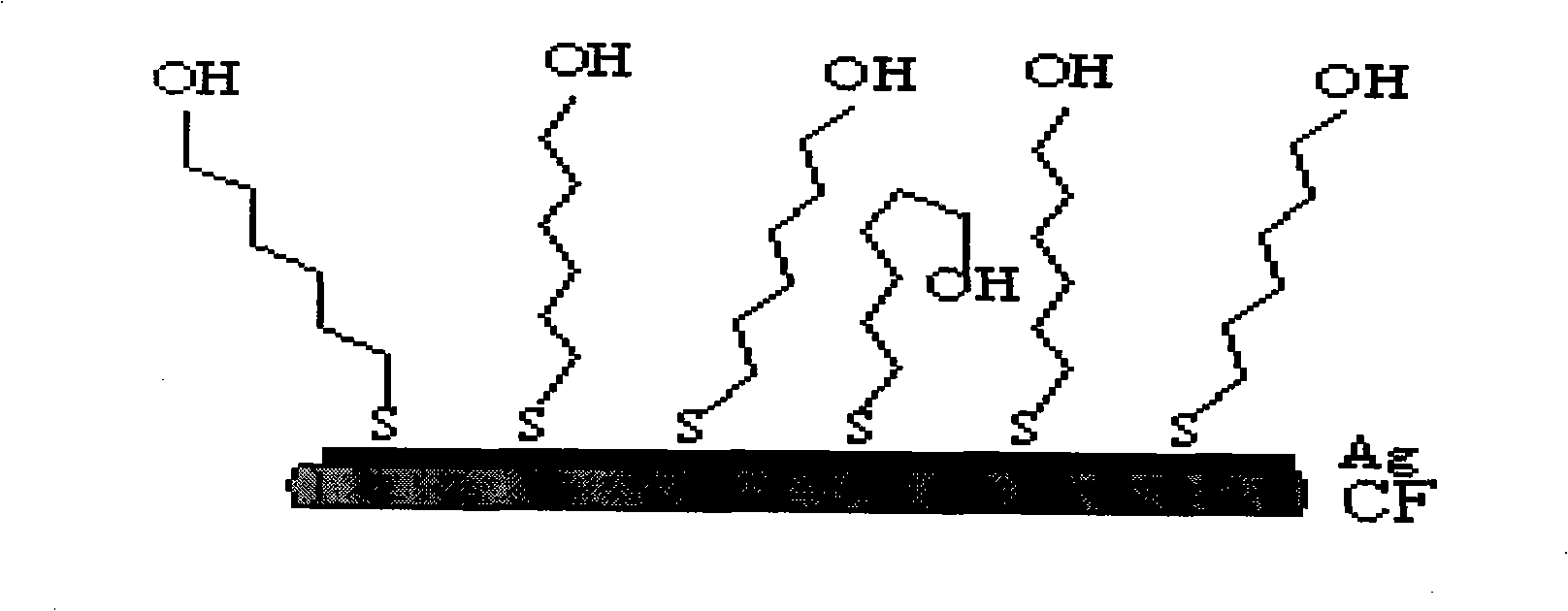

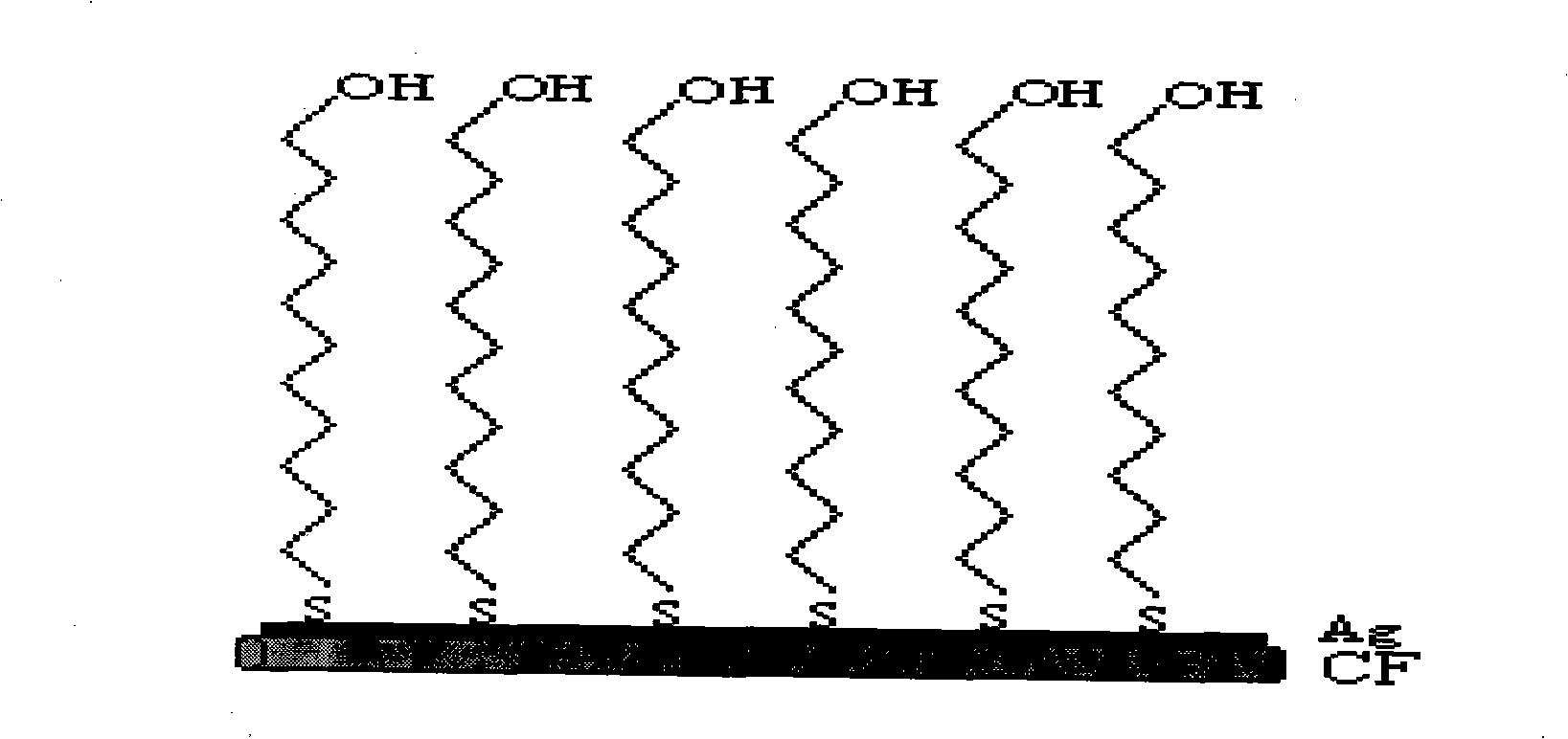

Carbon fiber surface modification method

The invention discloses a carbon fiber surface modification method, and relates to a carbon fiber modification method. The invention solves the problem of the uncontrollability of the distribution and arrangement of a carbon fiber surface functional group, which is not propitious to the study of the mechanism of a carbon fiber interface. The carbon fiber is plated with silver after surface pre-processing, then the carbon fiber with the silver-plated surface is infused in the dilute solution of thiol molecule containing sulfur element; depending on the coactions of the bonding reaction of sulfur atoms and metb and the force among self-assembly molecules, the thiol molecule has chemical absorption on the fiber surface and forms a closely arranged and ordered two-dimensional self-assembly single molecule membrane; two procedures are as follows: 1. the chemical plating of silver on the carbon fiber surface; and 2. the self assembly of molecules of organic sulfide on the silver-plating carbon fiber. The carbon fiber surface modification method has the advantages of realizing controllable, directional and ordered arrangement on the carbon fiber surface functional group from the molecule level, thus being beneficial to the study of the mechanism of the carbon fiber composite material interface.

Owner:HARBIN INST OF TECH

Cyanide-free silver plating solution containing auxiliary complexing agent

InactiveCN102277601AGood binding and brightPlating solution is stableSupporting electrolyteContinuous use

The invention discloses cyanogen-free silver-plating electroplating liquid containing an auxiliary complexing agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent is composed of a silver ion source material, a complexing agent, the auxiliary complexing agent, a supporting electrolyte, an electroplating additive, a pH adjusting agent and the like;the components of the electroplating liquid and the contents are as follows: 30-60 g / L of silver ion source material, 140-200 g / L of complexing agent, 10-50 g / L of auxiliary complexing agent, 10-30 g / L of supporting electrolyte, 100-800 mg / L of electroplating additive and 10-30 g / L of pH adjusting agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent provided by the invention has the advantages that: the electroplating liquid is stable and has low toxicity, the anodic passivation in the electroplating process can be better inhibited, the anodeis normally dissolved, the electroplating liquid can be continuously utilized for long time, the electroplating layer has a good bonding force and is bright, and the electroplating liquid can be applied to multiple fields including decorative electroplating, functional electroplating and the like.

Owner:NANJING UNIV

Non-cyanide silver plating bath composition

Owner:TECHNIC INC

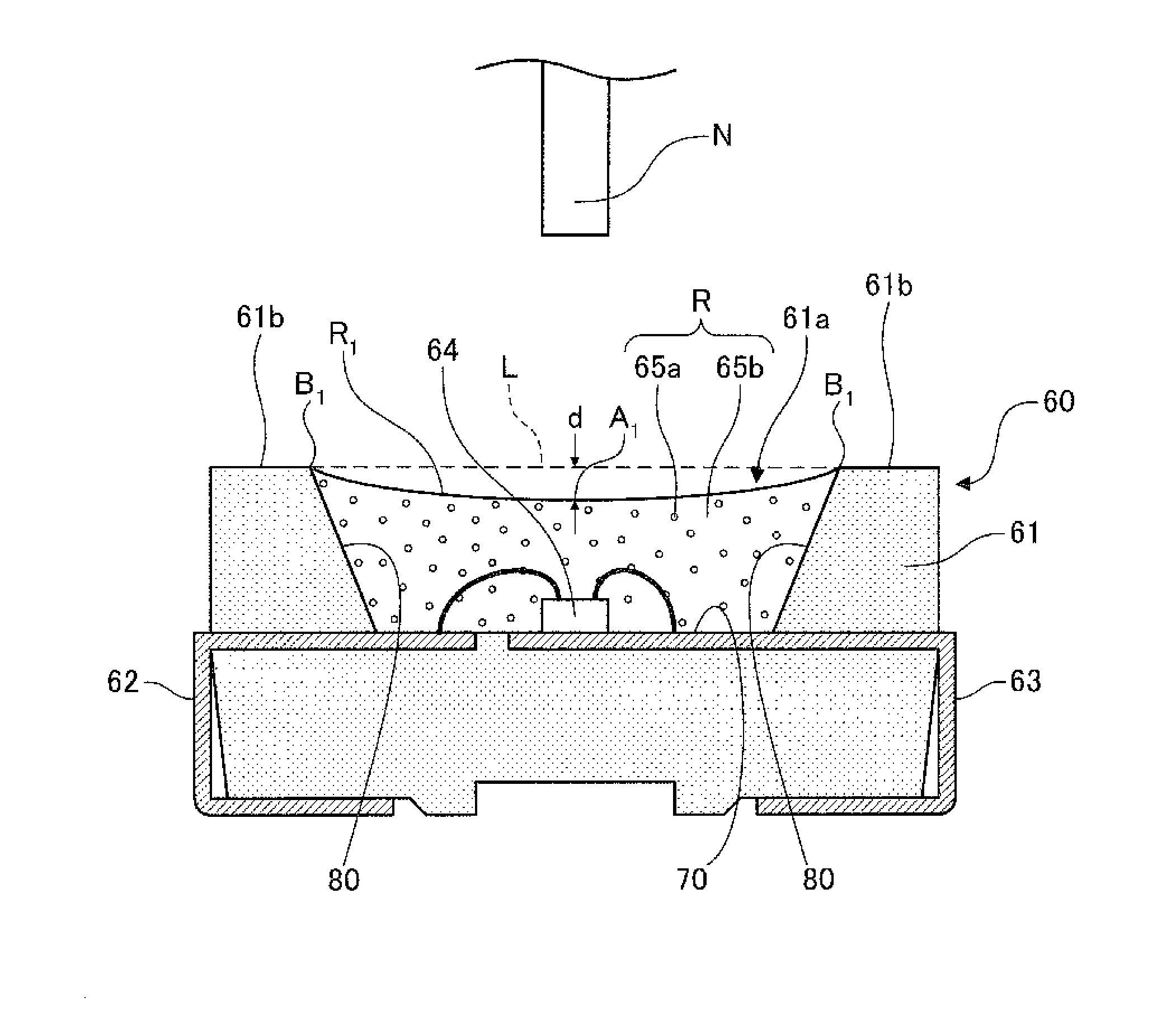

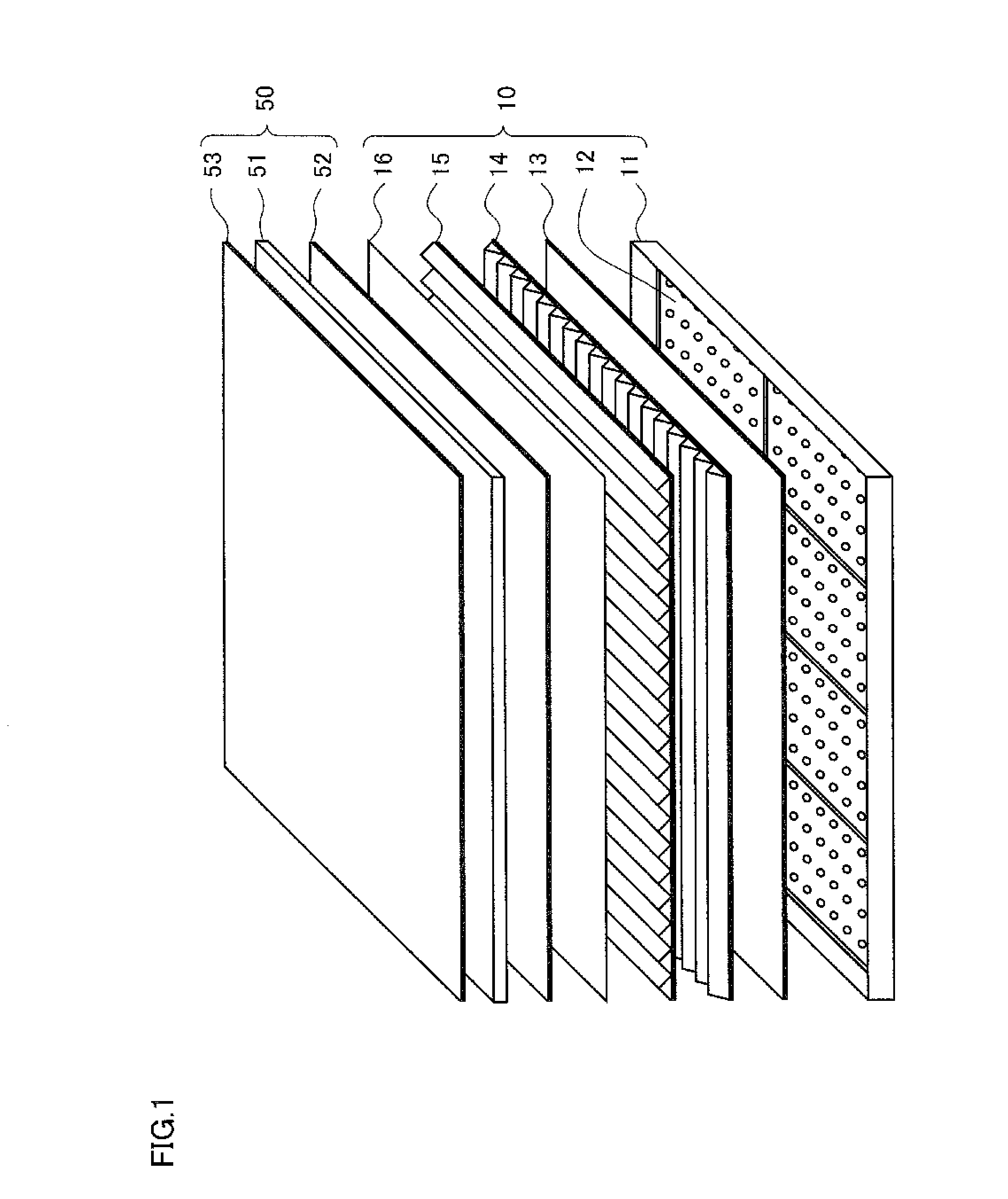

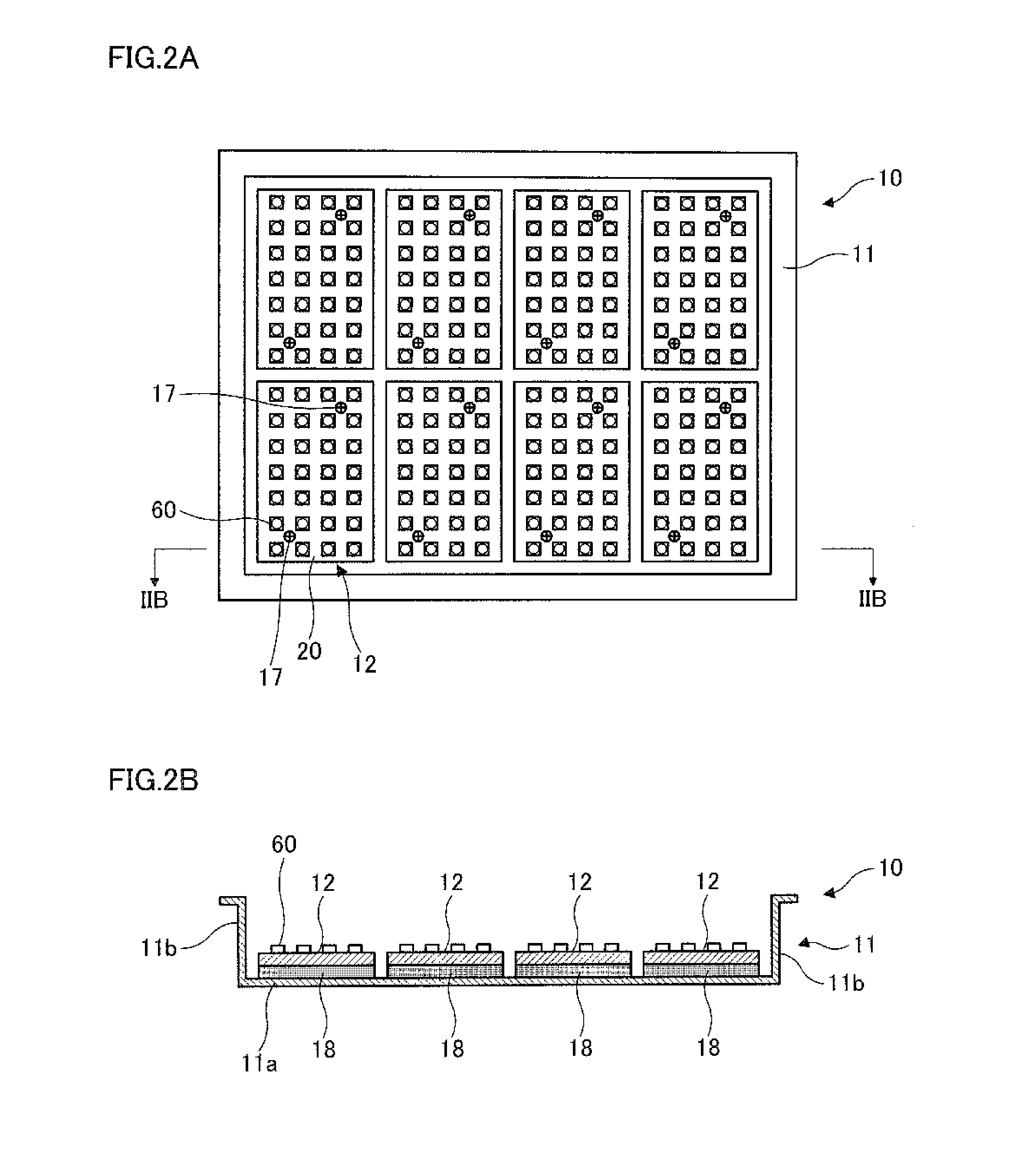

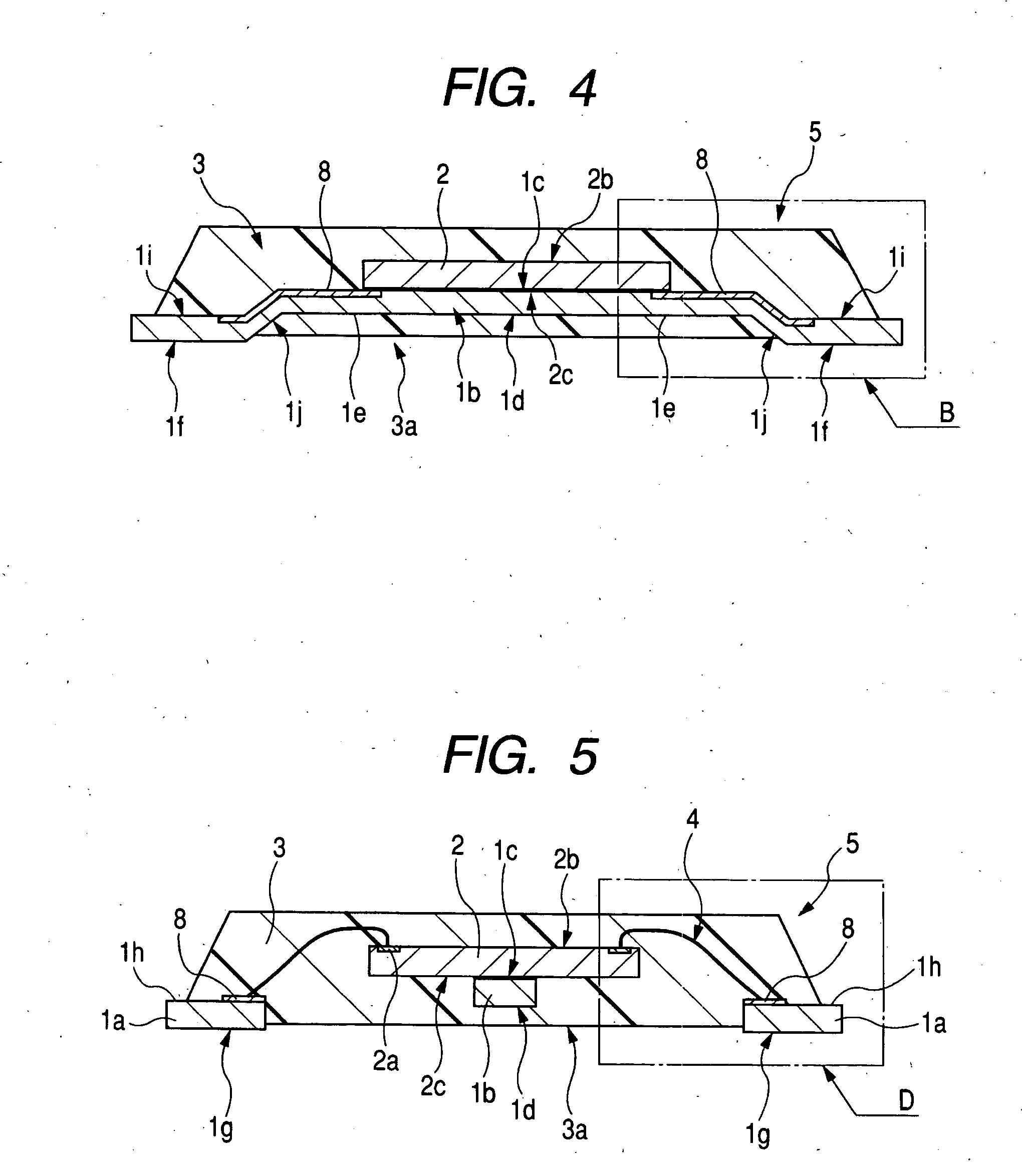

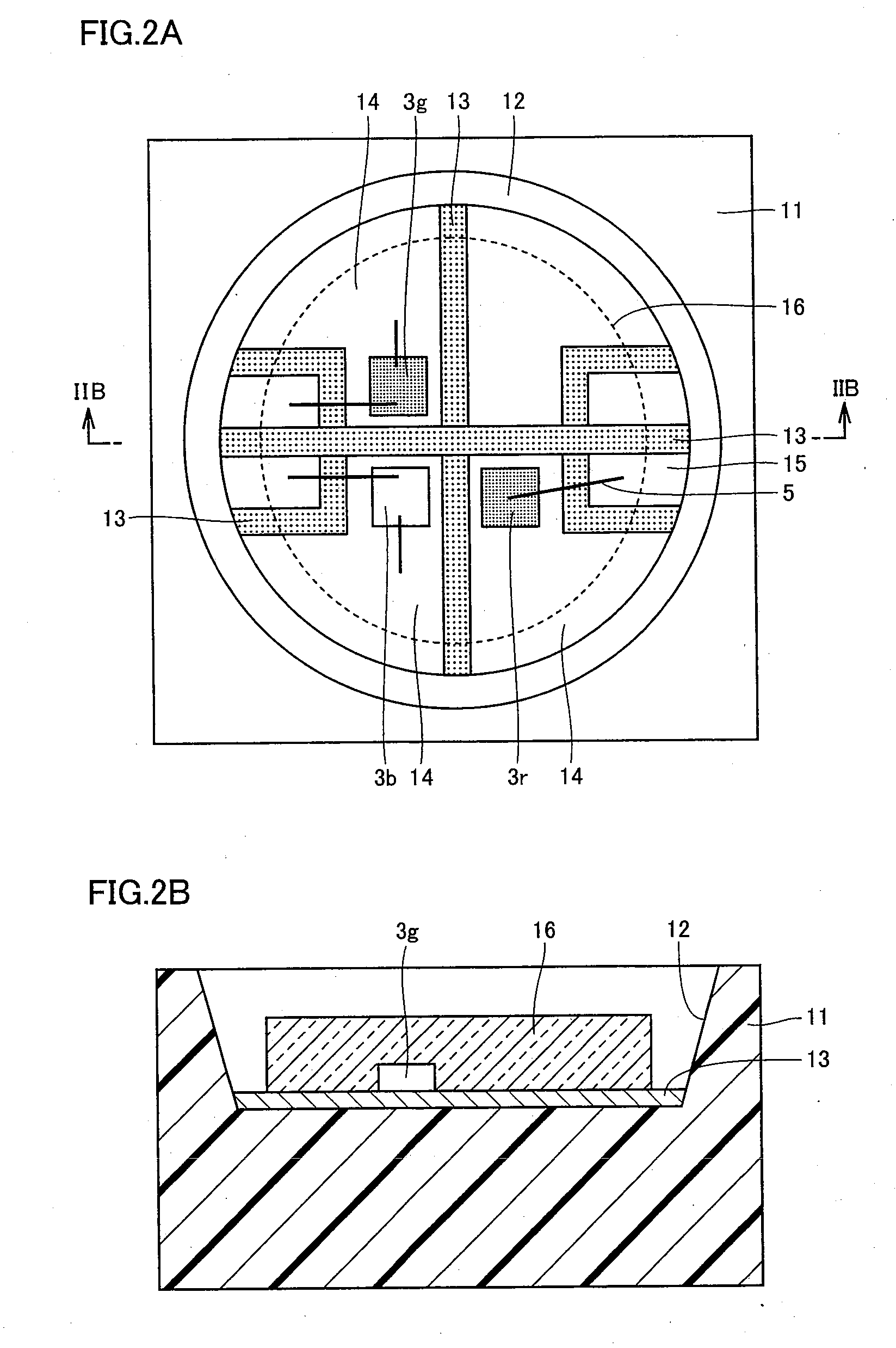

Light emitting unit, light emitting module, and display device

InactiveUS20120044667A1Improve extraction efficiencyPoint-like light sourcePortable electric lightingSilver plateDisplay device

A light emitting unit (60) is provided with a resin container (61) in which a recessed portion (61a) is formed, an anode lead portion (62) and a cathode lead portion (63) which are provided so as to be exposed on the bottom surface of the recessed portion (61a), a semiconductor light emitting element (64) attached to the cathode lead portion (63) on the bottom surface (70) of the recessed portion (61a), and a sealing resin (65) provided so as to cover the recessed portion (61a). The resin container (61) is produced from a white resin containing titania as a coloring agent. The anode lead portion (62) and the cathode lead portion (63) are each configured by forming a silver-plated layer with the gloss level set in the range of 0.3-1.0 inclusive on a metal plate based on a copper alloy or the like. Thus, the efficiency of extraction of light outputted from the light emitting unit is improved.

Owner:SHOWA DENKO KK

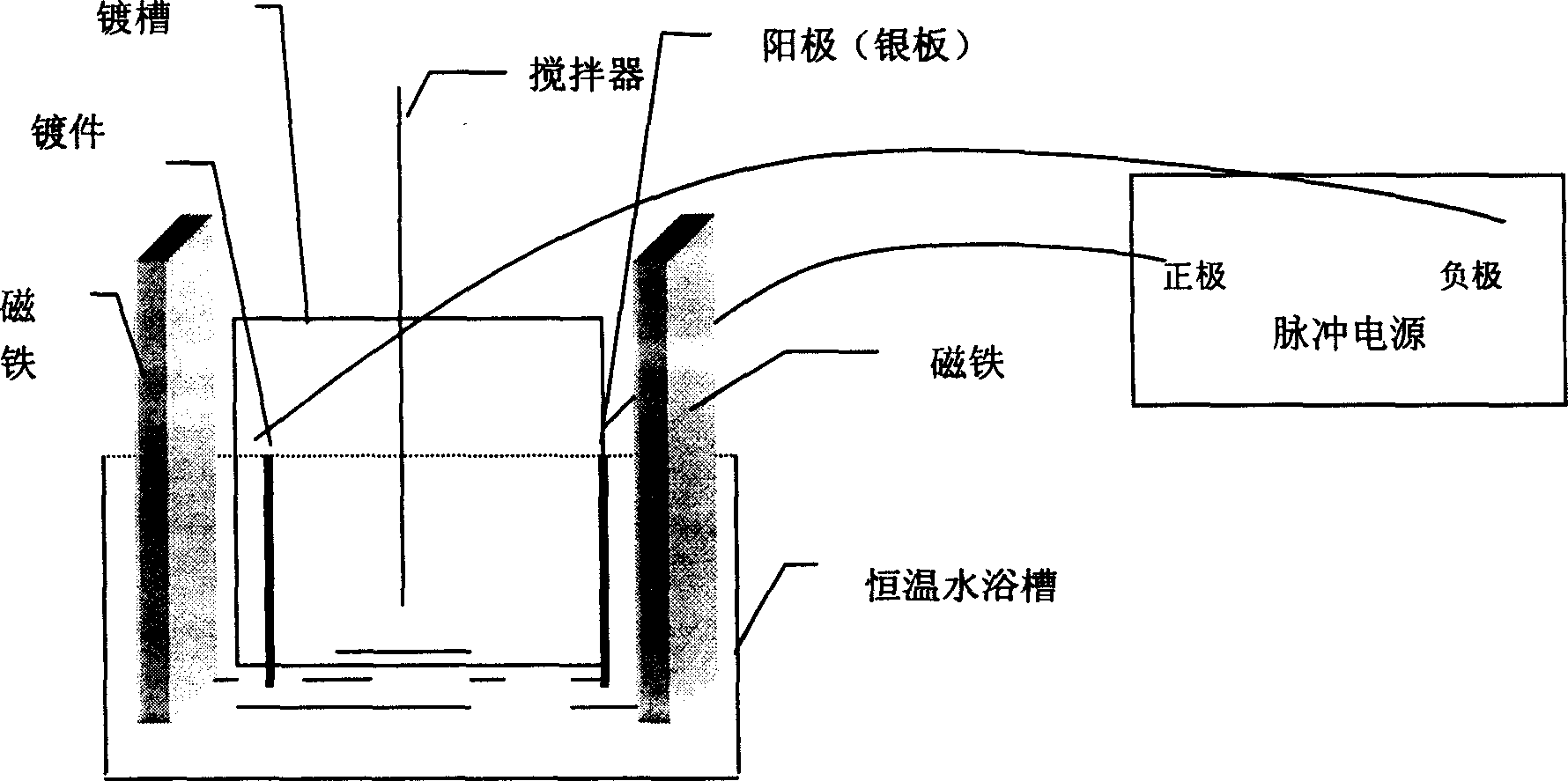

Technology of non-cyanide silver coating

A process of silver coating with no cyanogens at the action of magnetic field and impulse current. The main process is impulsive silver coating. Ingredients of the solution are as follow. AgNO3,50-60g / L; sodium thiosulfate, 250-350g / L; potassium, 90-110g / L; K2SO4,20-30g / L; boracic acid, 25-35g / L; brightener,5m / L. Stir at 20-40deg.C for 10min. pH of silvering solution is 4.2-4.8. Mean impulse current density is 0.5-1ms. Duty ratio is 5-15%. Orientation of magnetic field is parallel with that of impulse current. Square ratio of positive and negative pole is bigger than 2.

Owner:SHANGHAI UNIV

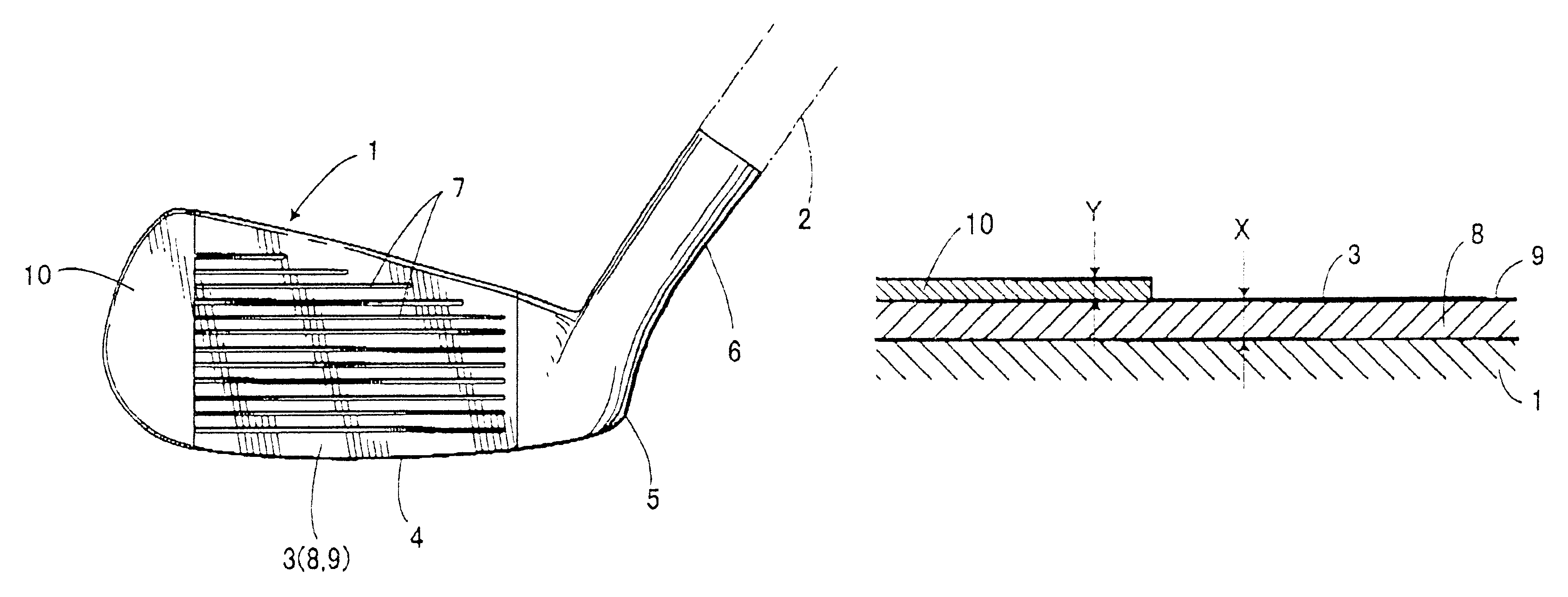

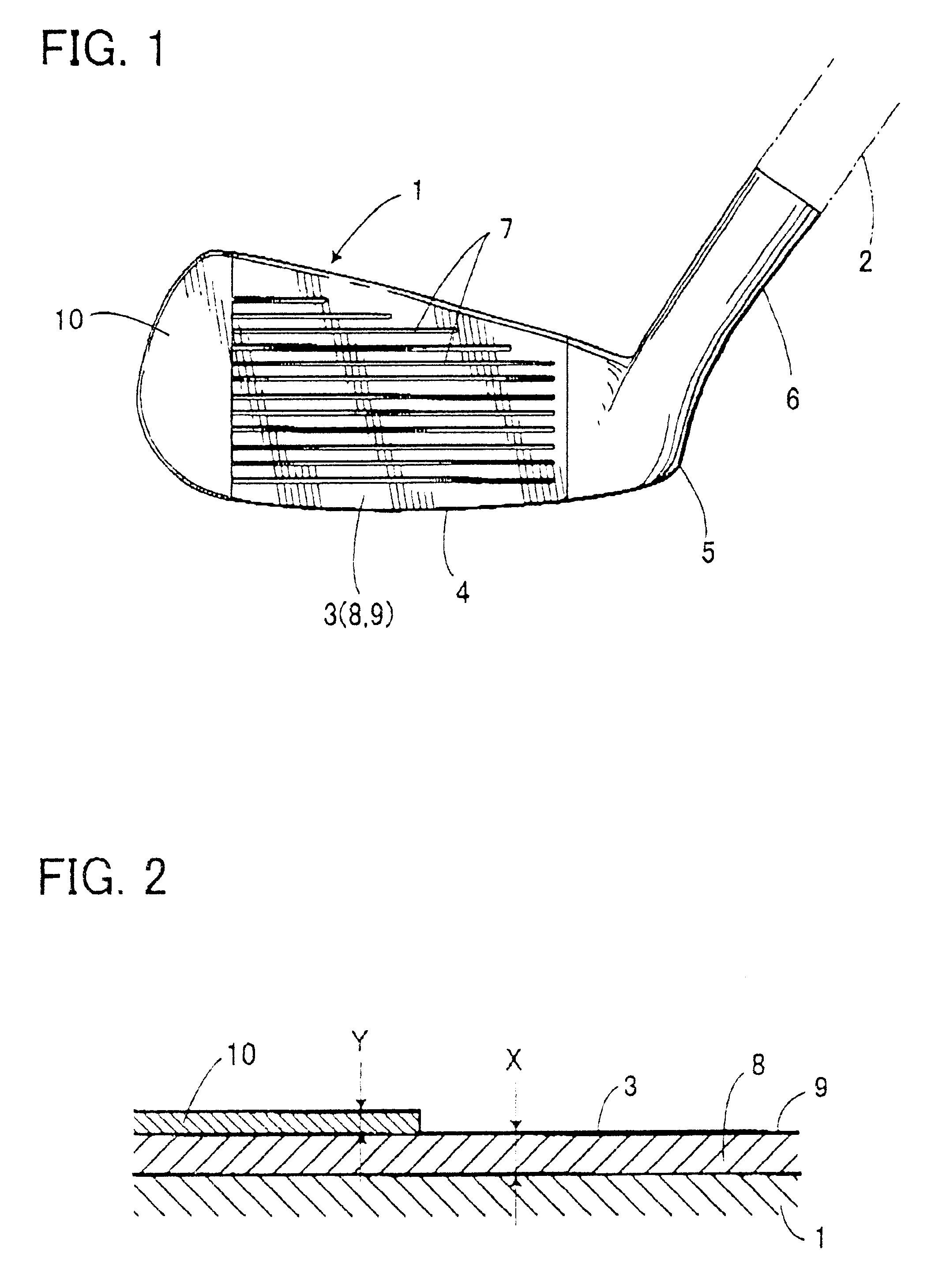

Golf club

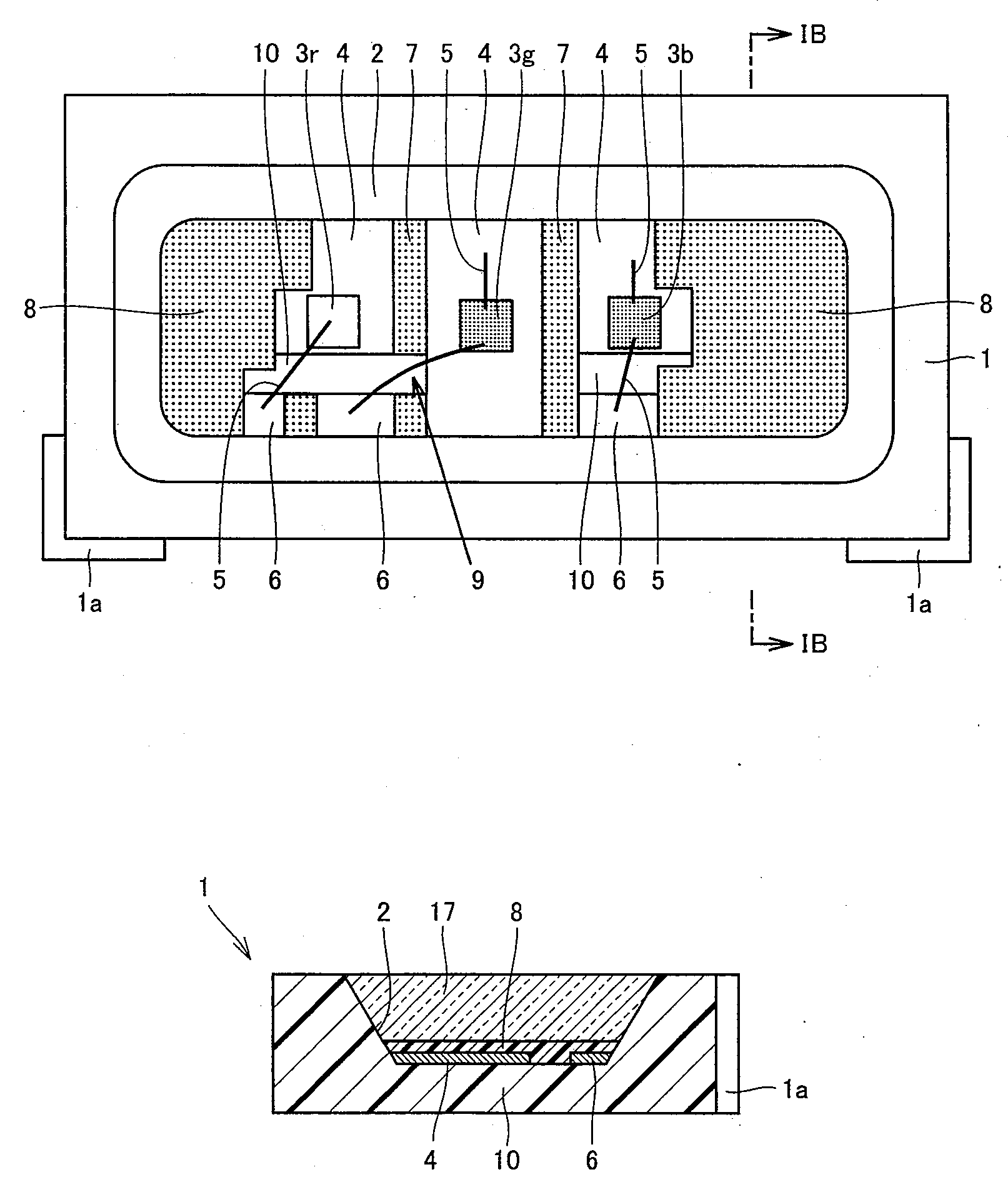

A golf club which can give a golf player a soft feel of striking. A metallic head 1 has a face 3 whose surface is formed with a silver plating layer 8 of Hv 200 or below. Thus, the surface of the face 3 is protected from rust, and a softer feel of striking can be obtained when he strikes a ball, unlike conventional golf clubs with hard plating layer. As the surface for striking balls is comparatively soft, a period of time that a ball is contact with the face 3 is prolonged, thus making it easier for a player to give a spin to the ball. A black layer 9 is formed on the silver plated surface of the face 3, and thus less reflection of light is resulted at the time of addressing a ball, so that balls can be addressed easily.

Owner:ENDO MFG COMPANY

Silver-plated copper powder and its prepn process

InactiveCN1403233AImprove conductivityStrong anti-migration abilityLiquid/solution decomposition chemical coatingSilver plateAdhesive

The present invention discloses one high performance silver-plated copper powder and its preparation process. Copper powder after being acid pickled is dispersed in dispersant solution, silver nitrate solution complexed with organic amine compound is added under stirring and at certain temperature for reaction, and through further water washing, filtering to separate, vacuum drying, silver-plated copper powder with silver content of 4.5-30 wt% is produced. Compared with available technology, the present invention has the features of stable and high conductivity, and the silver-plated copper powder may be used widely in conducting adhesive, conducting paint and other fields needing conducting and electrostatic conducting material.

Owner:WUHAN UNIV

Silver plating anti-color changing protecting agent composition

InactiveCN101503798APrevent discolorationDoes not affect conductivityMetallic material coating processesBenzoxazoleSilver plate

The invention relates to a silver plating anti-tarnish protectant compound. The protectant compound comprises the following components in percentage by weight: 13 to 15 percent of aliphatic alcohol polyoxyethylene ether, 8 to 10 percent of 1-phenyl-pentasulfhydyl tetrazole, 4 to 5 percent of 2-sulfhydryl benzoxazole, 3 to 5 percent of t-dodecyl mercaptan, 3 to 5 percent of 2-sulfhydryl benzimidazole, 8 to 10 percent of anhydrous ethanol, 8 to 10 percent of ethylene glycol, and the balance of deionized water. The silver plating anti-tarnish protectant compound forms a protective complex film on a silver surface, has a higher corrosion inhibition rate, and obviously improves the sulfidation resistance and abrasion resistance of the silver surface. The silver plating anti-tarnish protectant compound is mainly used for the tarnish prevention of silvered electronic parts and components, and is also applied to the sulfidation and tarnish prevention of silver or silvered jewellery, jewelry, ornaments, artwork, tableware, and the like. The silver plating anti-tarnish protectant compound can effectively protect silvered articles against sulfidation and tarnish in a certain period, keep the original metal luster and has no influence on the conductivity and weldability of the parts.

Owner:JIANGXI SCI & TECH NORMAL UNIV

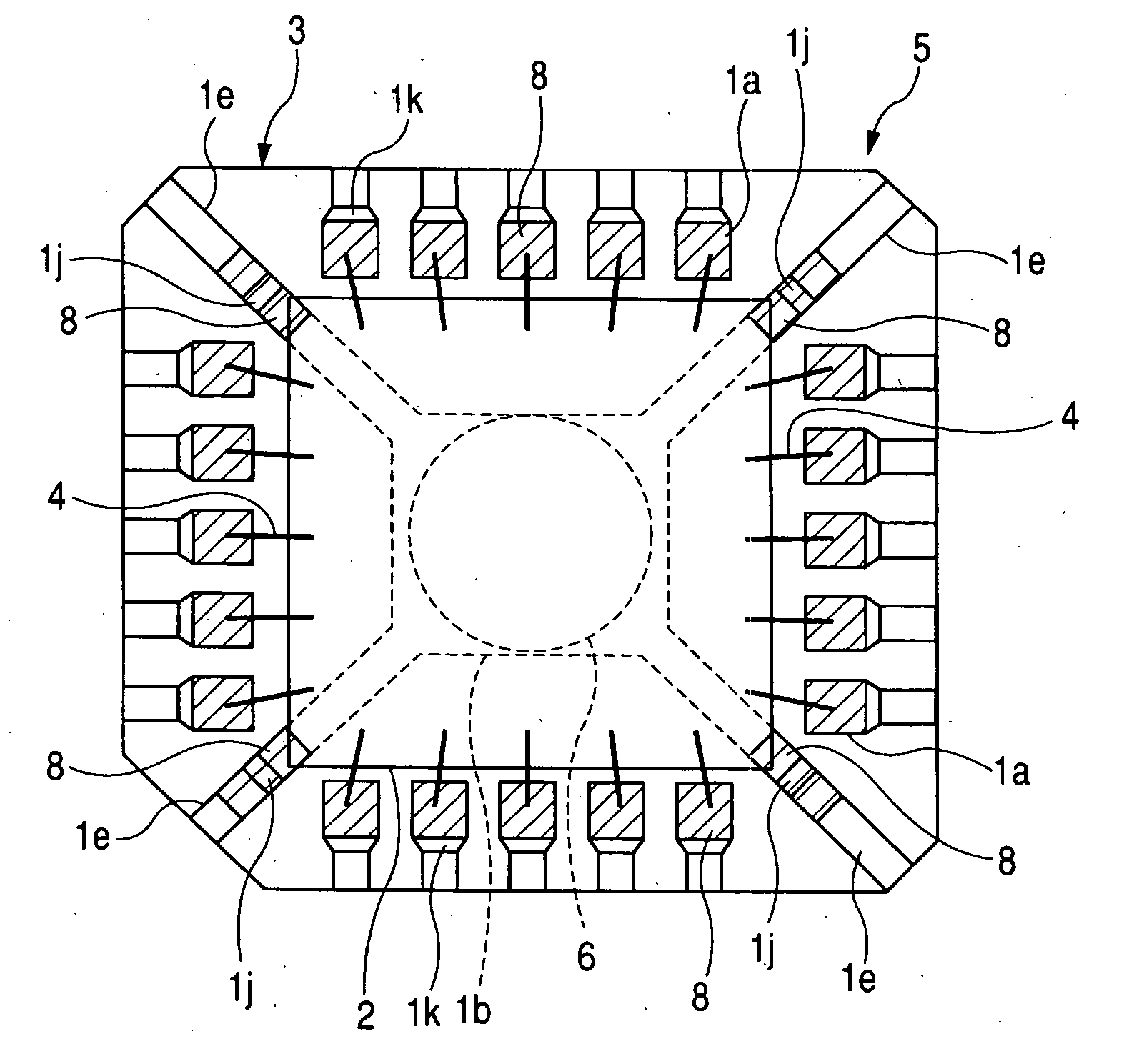

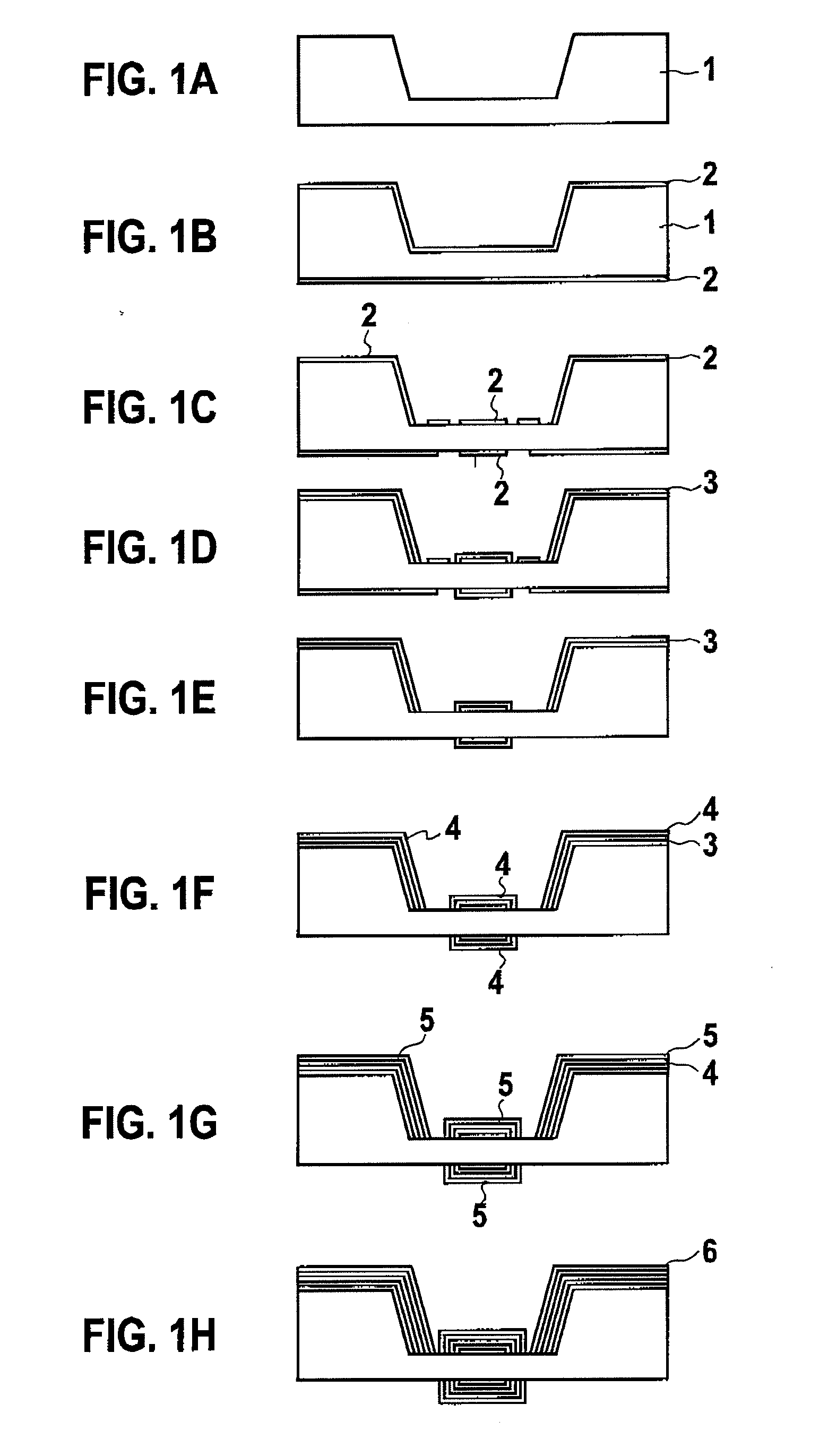

Method of manufacturing a semiconductor device

InactiveUS20060240599A1Prevent cracking and chippingReduce harmSemiconductor/solid-state device detailsSolid-state devicesSilver plateDevice material

According to the method of manufacturing a semiconductor device, a lead frame is provided wherein the thickness of a tab-side end portion of a silver plating for wire connection formed on each suspending lead 1e is smaller than that of a silver plating formed on each lead. Thereafter, a semiconductor chip is mounted onto a tab. In this case, since the entire surface of the silver plating on the suspending lead 1e is in a crushed state, it is possible to prevent contact of the semiconductor chip with the silver plating when mounting the chip onto the tab. Consequently, in a die bonding process, the semiconductor chip can slide on the tab without contacting the silver plating and thereby making it possible to diminish damage to the semiconductor chip when mounted onto the tab and hence to possibly prevent cracking or chipping of the chip when assembling the semiconductor device.

Owner:RENESAS ELECTRONICS CORP

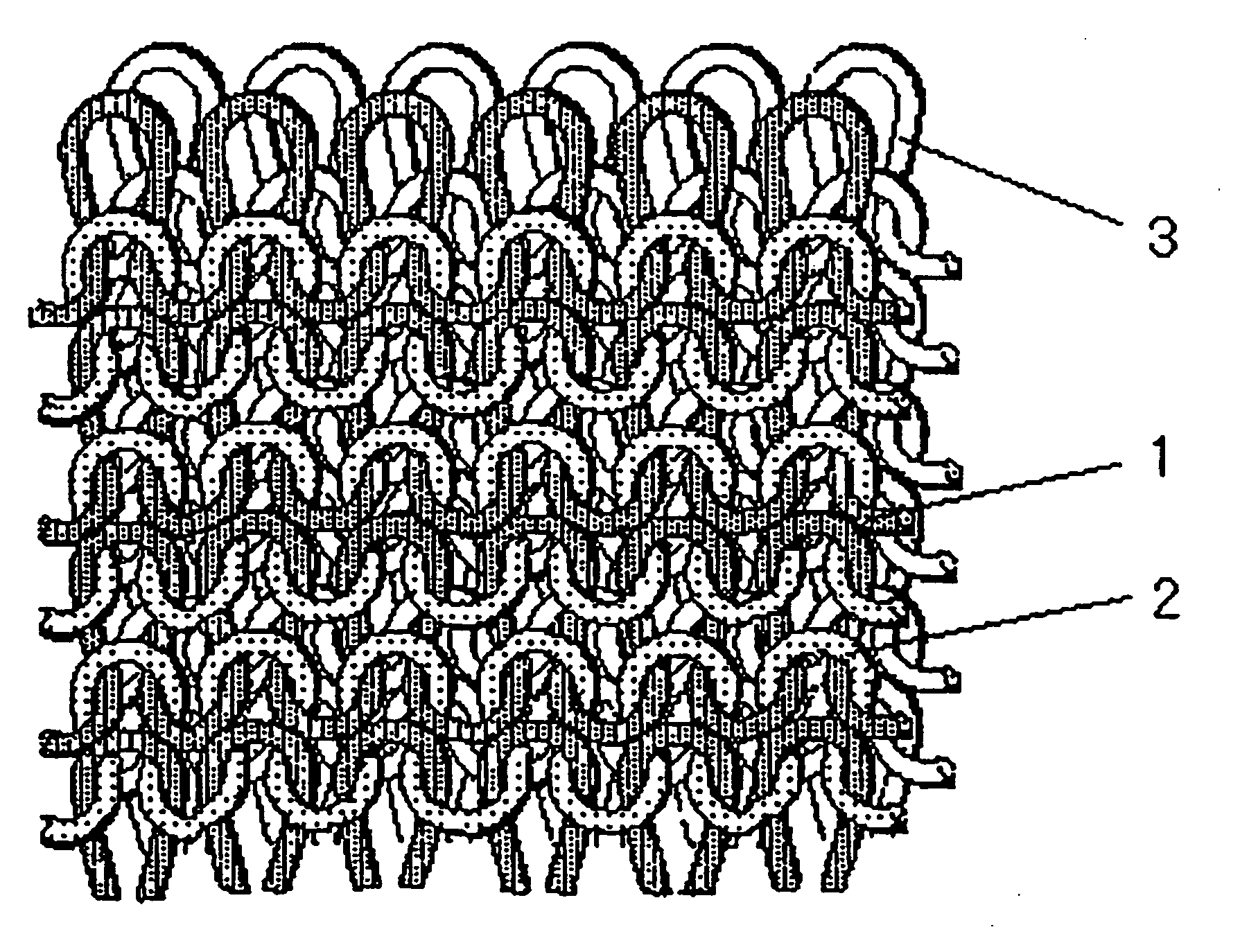

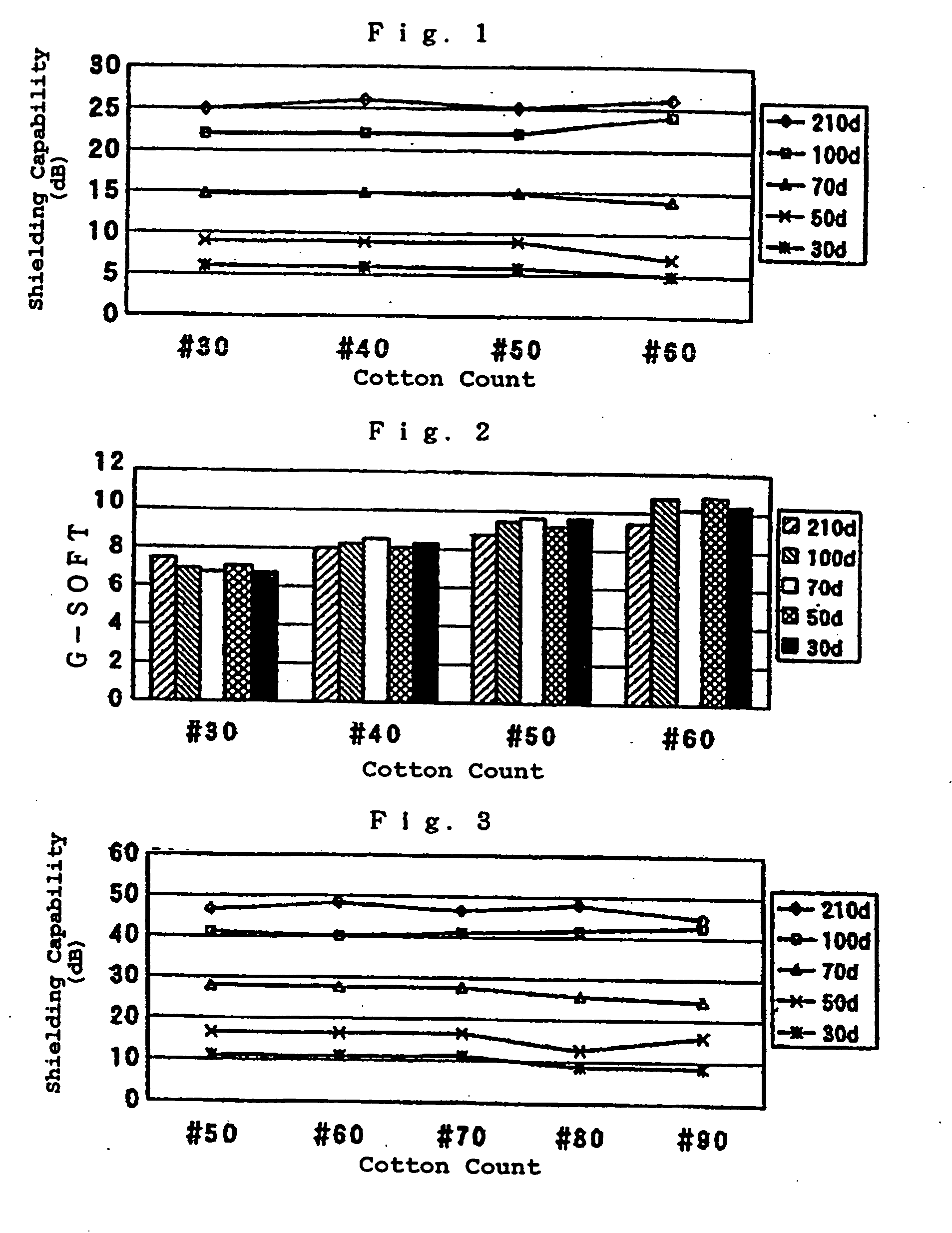

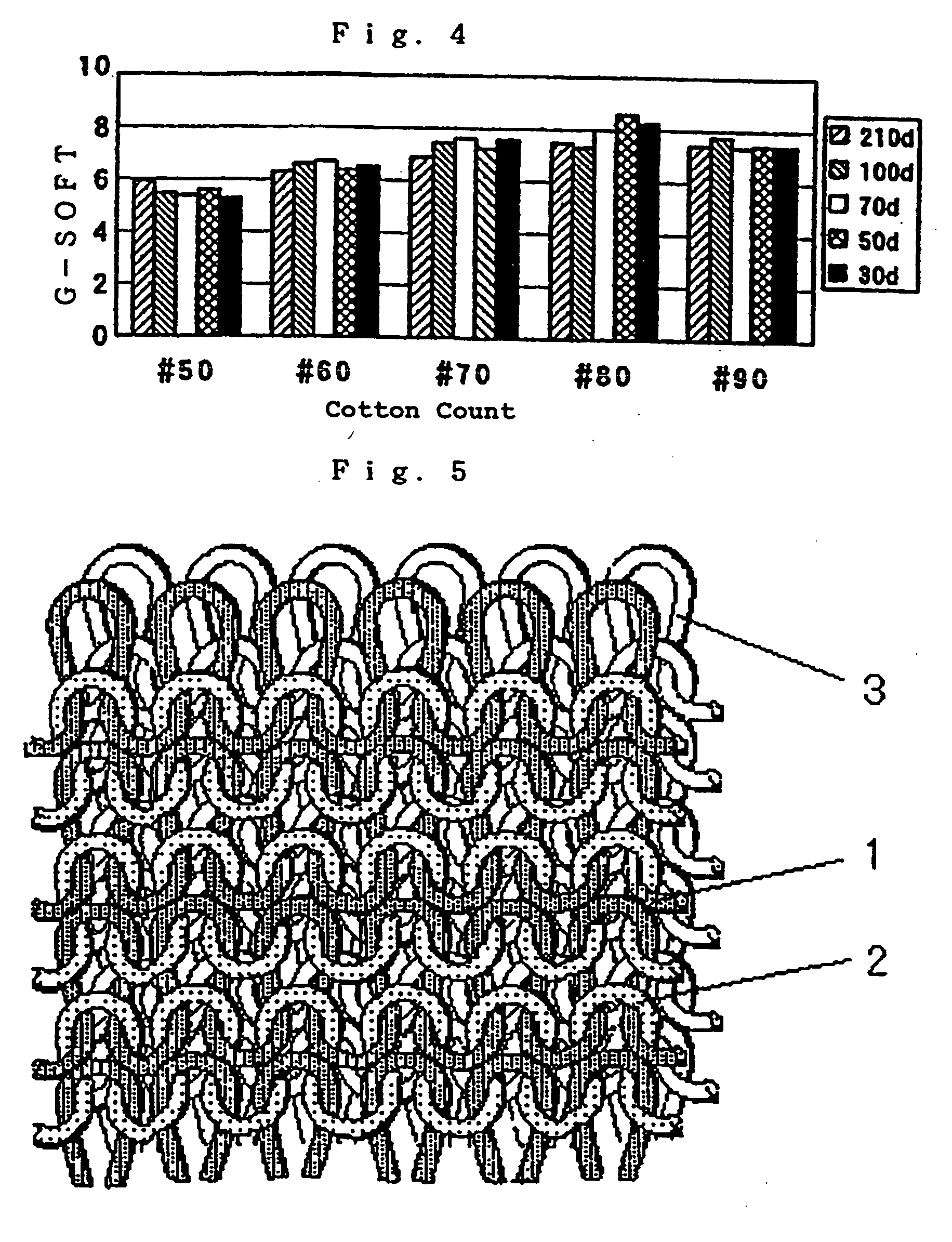

Electromagnetic wave shielding knitted material and electromagnetic wave shielding garment

InactiveUS20060264137A1Malfunction can be causedLess amountShielding materialsOrnamental textile articlesYarnSilver plate

A garment made of a reversible electromagnetic wave shielding knitted material comprising a conductive fiber yarn and an elastic fiber yarn interknitted with each other as a surface side and a natural fiber yarn as a back side, wherein the proportion of the elastic fiber yarn is greater than 0 but not greater than 2 / 3 of the total amount of the conductive fiber yarn and the elastic fiber yarn interknitted with each other, the conductive fiber yarn is a silver-plated nylon yarn having a denier (d) of about 70 to about 210, the natural fiber yarn is a cotton yarn having a count of 30 to 150, and the material has a KES hand value (G-soft) of at least 6 and an electromagnetic wave shielding capability of at least 20 dB.

Owner:ISHIHARA KEN +7

Method for displacement chemical silver plating on copper powder

InactiveCN101709461AIncrease profitHigh activityLiquid/solution decomposition chemical coatingAcid etchingSilver plate

The invention discloses a method for displacement chemical silver plating on copper powder. The method comprises the following steps of: cleaning and oil removal, water washing, acid etching, water washing, catalytic liquid treating, chemical silver plating and the like. In the method, a catalytic liquid capable of preplanting catalytic mass points is developed; the surface of the copper powder is preplanted with discretely distributed palladium mass points after the copper powder is treated by the catalytic liquid at a room temperature by controlling components, pH value and treatment time of the catalytic liquid; and the preplanted palladium mass points can catalyze and promote the silver ion reduction to improve precipitation speed and to retard copper-ammonia complex ions to be absorbed on the copper surface so as to obtain a sliver plating layer with good cladding performance in the chemical silver-plating process for the copper powder. Compared with the conventional method of displacement chemical silver plating, the method realizes surface activation of the copper powder by pretreating the catalytic liquid, a silver content of the silver plating copper powder is greatly improved, the problems of poor cladding performance of replacement type chemical silver plating and the like are solved, and the method is simple in process and convenient to operate and has good application prospect.

Owner:GUANGDONG UNIV OF TECH

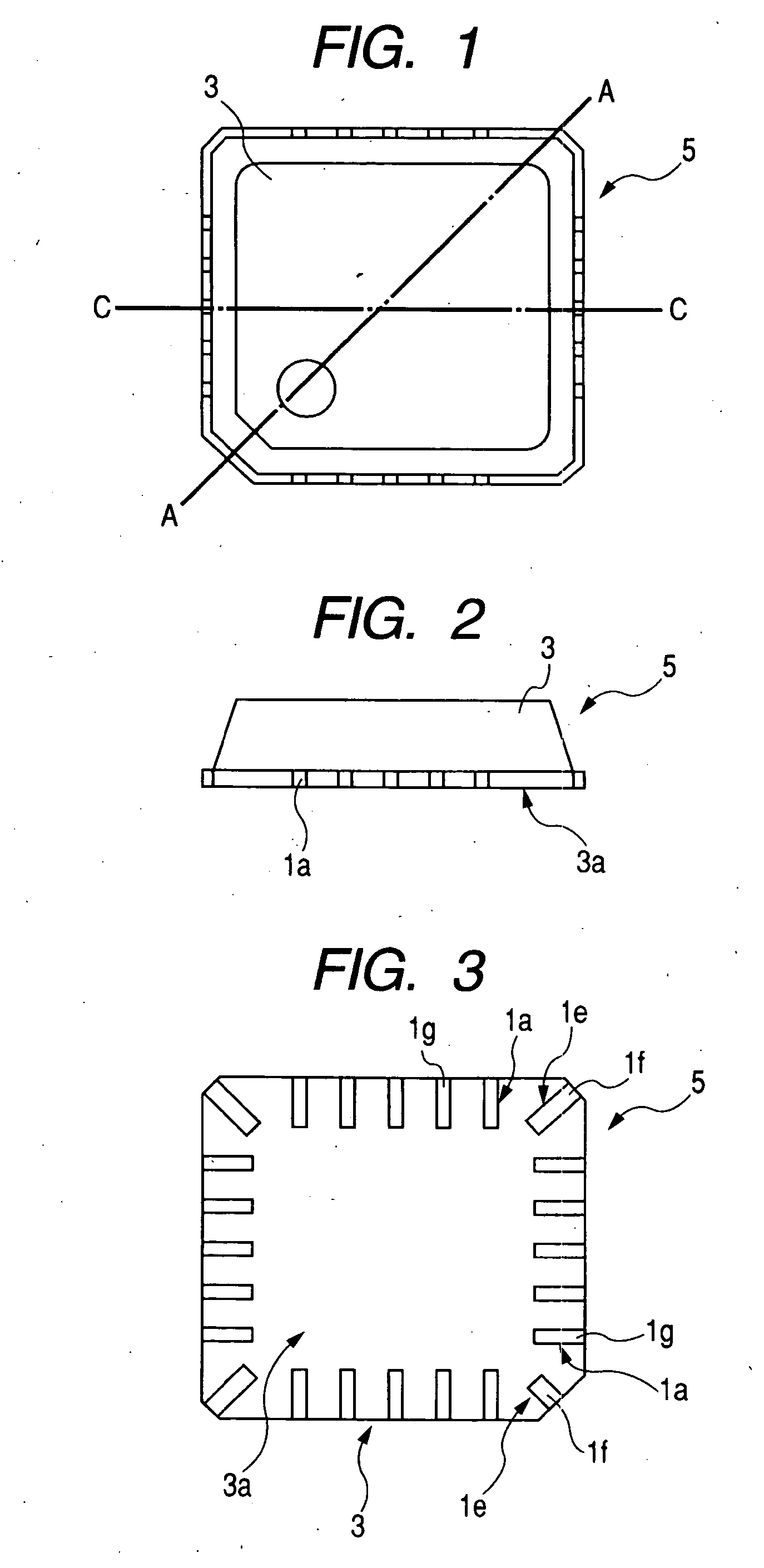

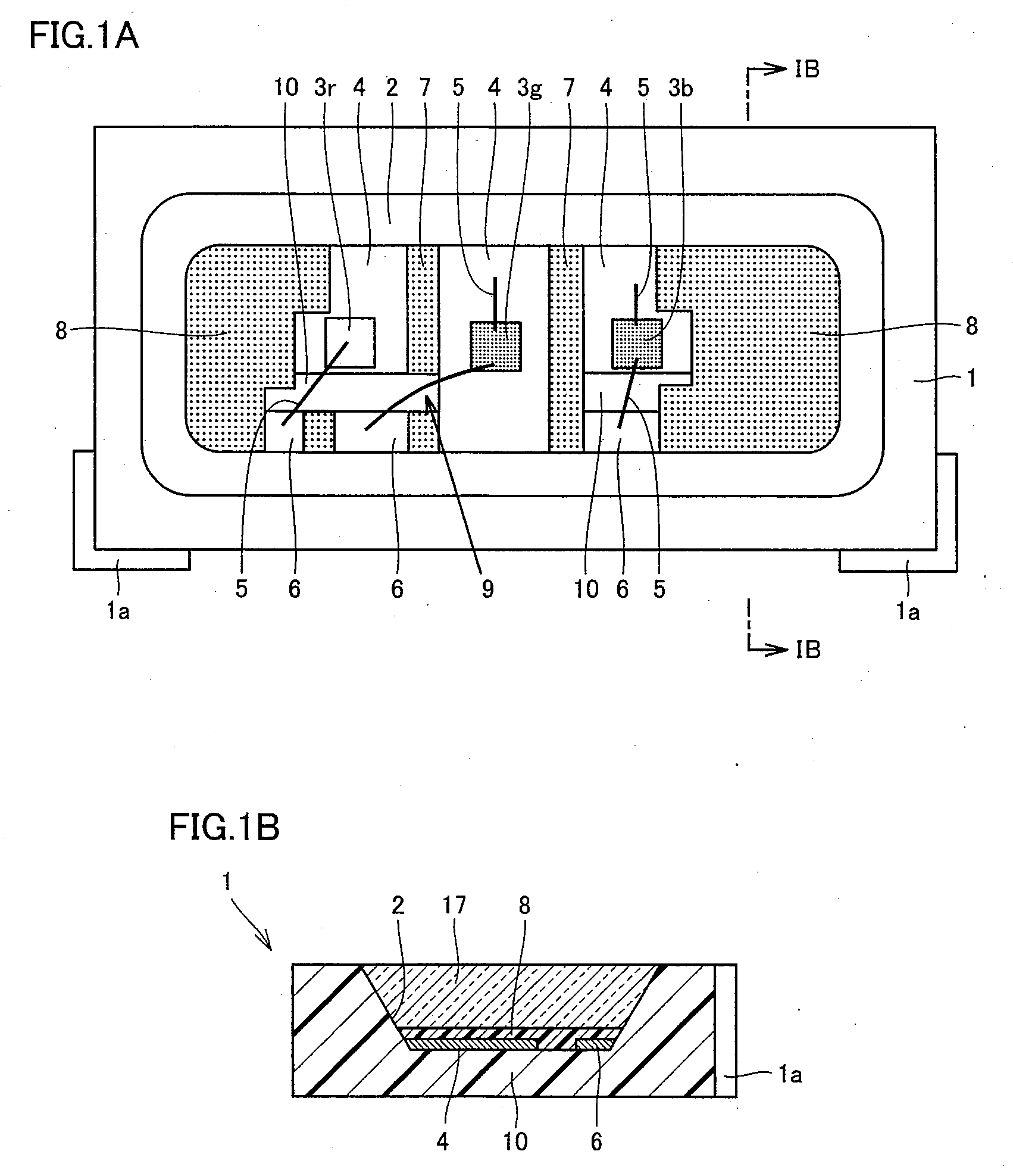

Semiconductor light emitting device

InactiveUS20090194782A1Solve the lack of reliabilityReduce contact areaSolid-state devicesSemiconductor devicesSilver plateEngineering

A silver-plated metal member region on which a light emitting element is disposed, an extraction electrode having a copper plate pattern, and a convex resin portion separating the metal member region into a plurality of sections are provided on the bottom surface of a concave portion in a package of a semiconductor light emitting device. A covering resin is partially formed on the metal member region and a sealing resin is placed to cover the metal member region, the covering resin and the convex resin portion. According to this configuration, the area of contact is decreased between the sealing resin and the metal member region having the light emitting element placed thereon, to thereby prevent the light emitting element from falling off and being displaced from the metal member region, with the result that a semiconductor light emitting device of high reliability can be provided.

Owner:HEAVY DUTY LIGHTING LLC

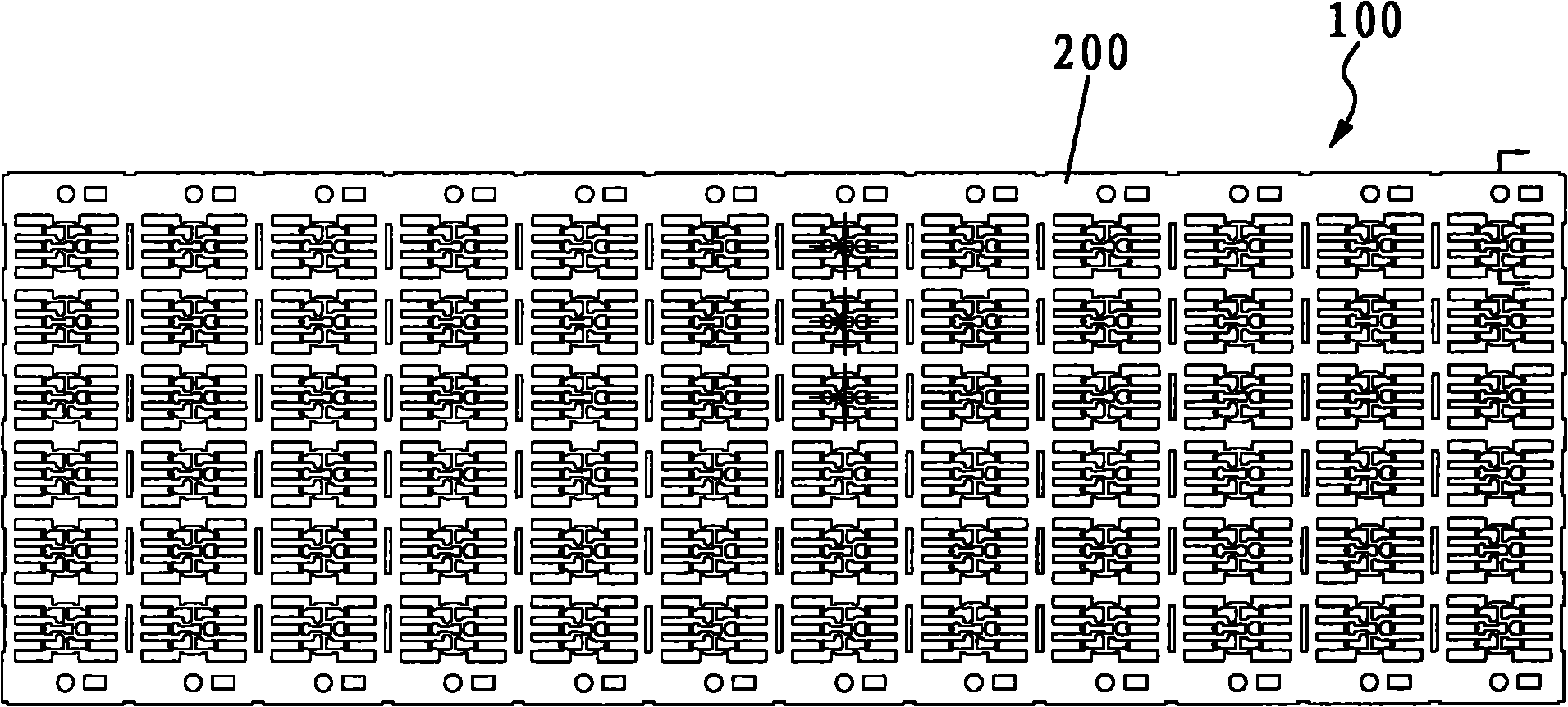

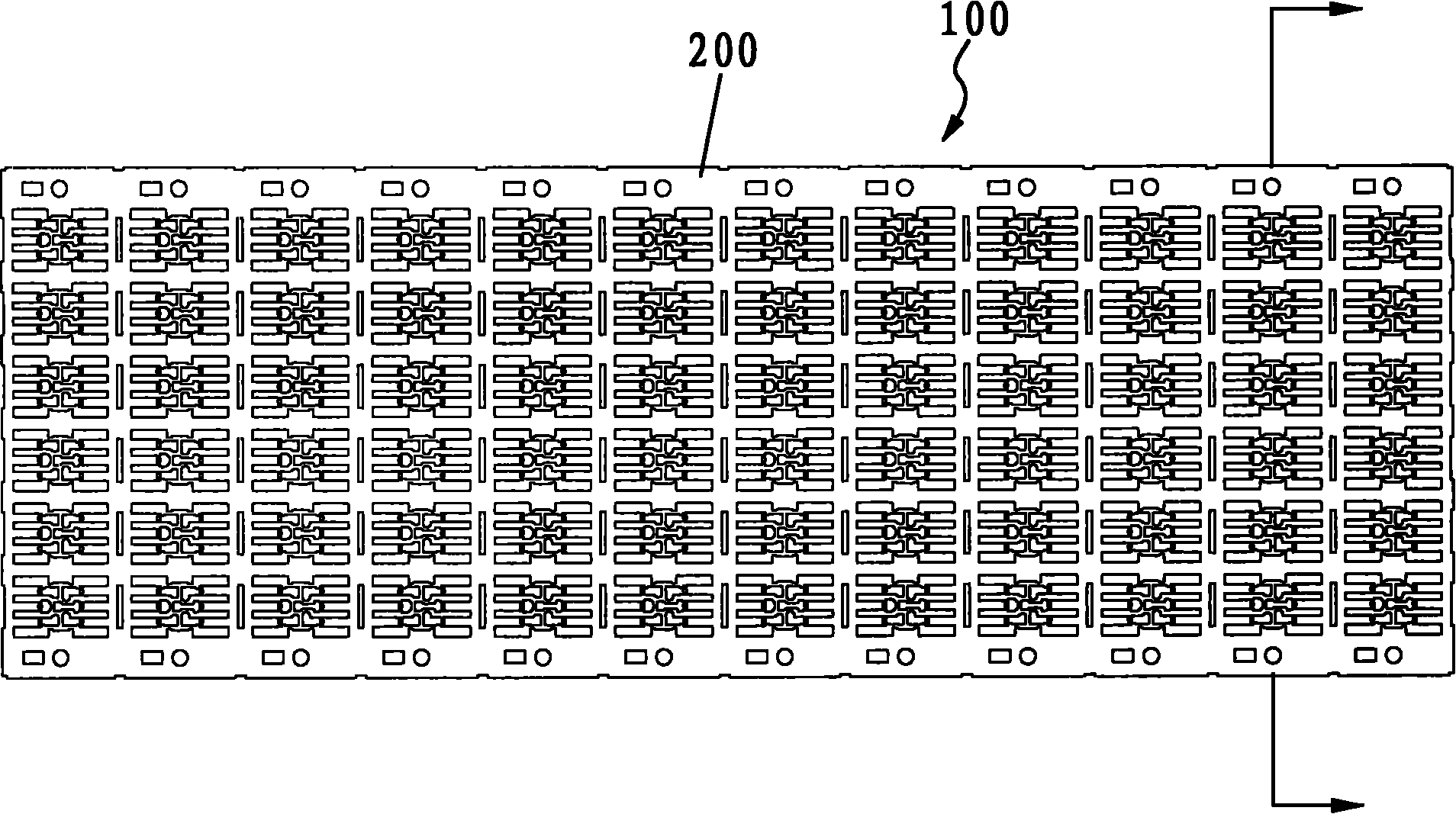

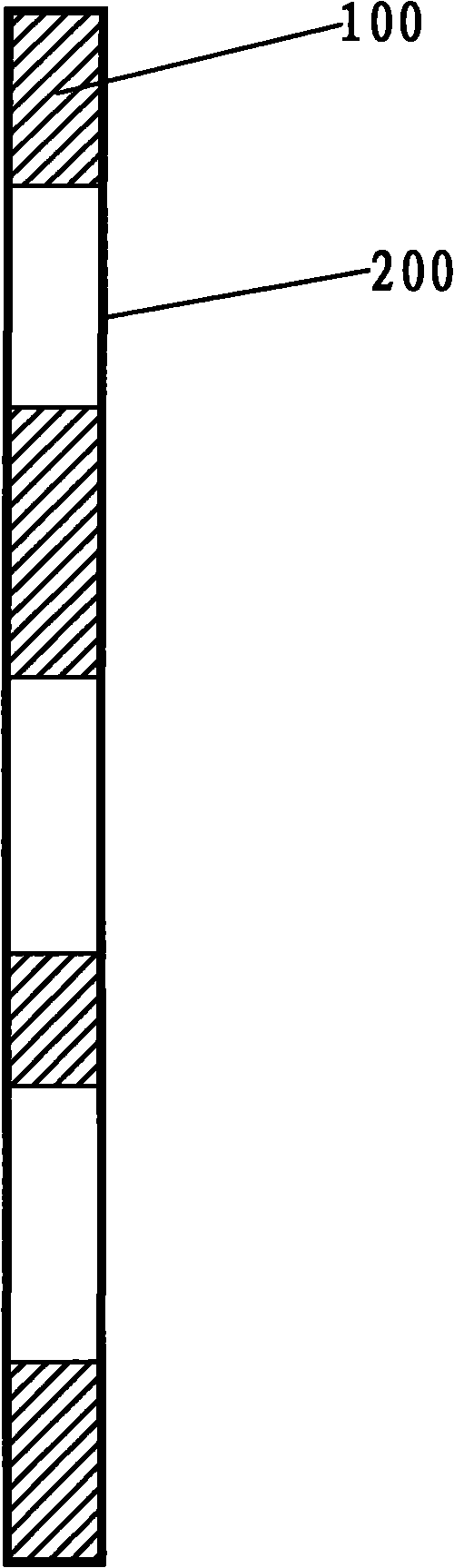

LED lead frame and electroplating method and electroplating equipment thereof

InactiveCN101867009AReduce manufacturing costIncrease production costSemiconductor devicesCopper platingSilver plate

The invention discloses an LED lead frame which is divided into three parts, i.e. a side frame, a functional area and a chip placing area; an anti-replacement protective film is formed on the whole lead frame; a primary silver plated layer is formed on the whole functional area by selecting electroplating silver, and a secondary silver plated layer is formed on the chip placing area by local silver electroplating, so that the silver plated layer of the chip placing area is thicker than the silver plated layer of the functional area around; and an anti-copper oxidation organic protective film is formed on the side frame. The electroplating method comprises the following steps: chemical deoiling->electrolytic deoiling->water washing->acid washing->water washing->copper plating->water washing->anti-replacement treatment->water washing->electroplating silver selection for functional areas on the back side and on the front side->local silver electroplating of chip placing area->silver recovery->water washing->deplating->water washing->neutralization->water washing->anti-copper oxidization treatment->water washing->hot water washing->drying. The invention also discloses electroplating equipment. The invention can effectively use metal silver, reduces the cost, improves the bonding force between plastics and the lead frame, and achieves the purpose of anti-layering.

Owner:XIAMEN YONGHONG TECH

Silver-plated conductive polyester fiber and preparation method thereof

The invention discloses a silver-plated conductive polyester fiber and a preparation method thereof, belonging to the field of conductive fibers. The silver-plated conductive polyester fiber comprises a polyester fiber, a silver layer coating the surface of the polyester fiber, and an ITO (Indium Tin Oxide) layer between the polyester fiber and the silver layer. The preparation method comprises the following steps in sequence: washing away an oil agent from the fiber, roughening the surface of the fiber, coating the roughened surface with an ITO sol layer, sensitizing, and plating with silver. By virtue of the introduced ITO sol layer between the silver layer and the fiber, on the one hand, the affinity of a metallic simple substance and a fiber polymer can be achieved, so that the combination strength of the silver layer and the fiber is enhanced; on the other hand, an ITO-Ag composite structure is built on the surface of the fiber; and by virtue of the composite structure, the conductivity of the silver-plated conductive fiber can be enhanced remarkably, and simultaneously the thickness of the plating layer can be reduced. The technology is simple, the conditions are moderate and the requirement on large-scale production is satisfied.

Owner:DALIAN POLYTECHNIC UNIVERSITY

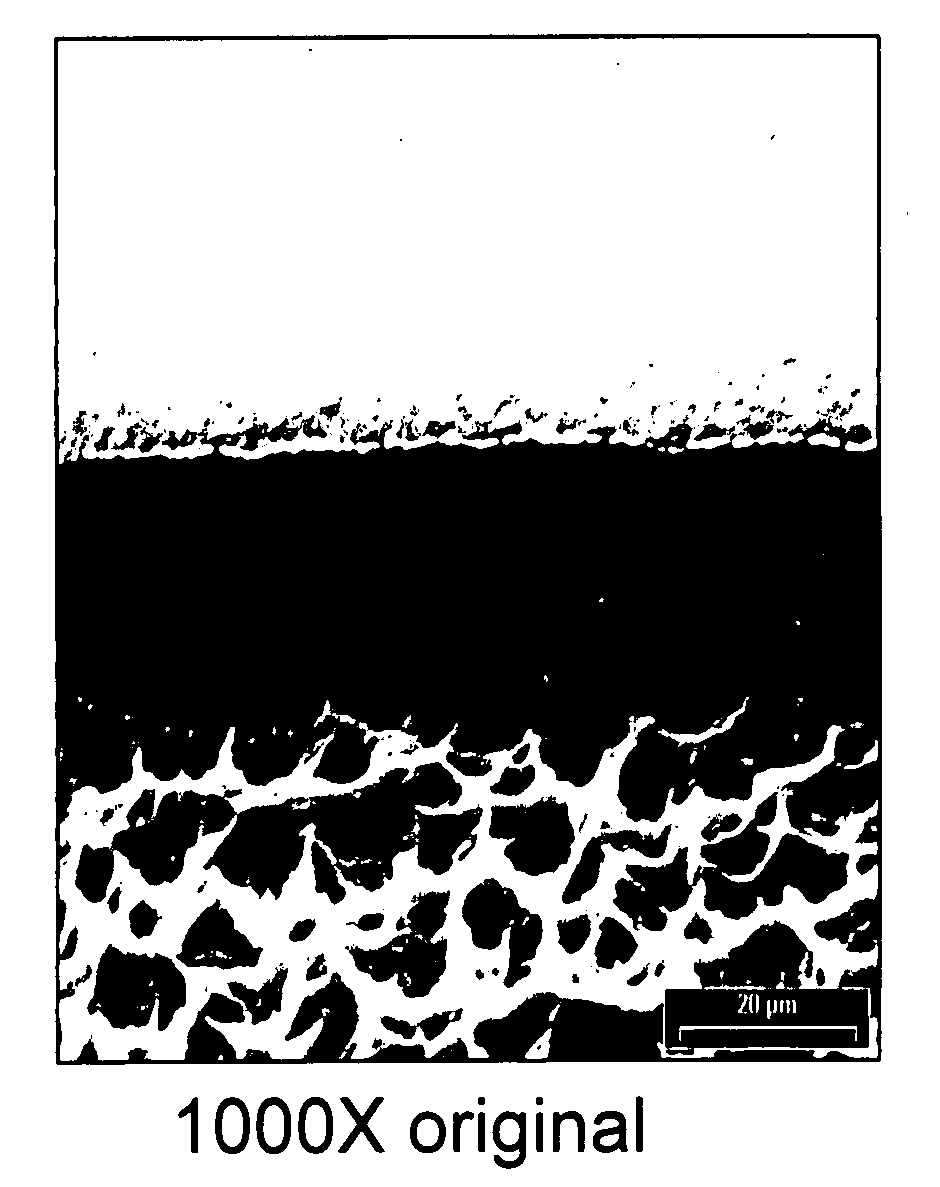

Silver layer formed by electrosilvering substrate material

InactiveUS20080006911A1Effective reflectionInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesSilver plateSilver coating

Owner:MATSUSHITA ELECTRIC WORKS LTD

Medical anti-microbial silver-plated dressing and preparation method thereof

InactiveCN102492925AHigh antibacterial efficiencyIncrease profitVacuum evaporation coatingSputtering coatingSputteringSilver plate

The invention discloses a medical anti-microbial silver-plated dressing and a preparation method thereof. The preparation method of the medical anti-microbial silver-plated dressing includes steps of mixing calcium alginate fibers and cellulose fibers to prepare a dressing substrate and preparing a silver-particle plated layer on the surface of the dressing substrate by means of vacuum sputtering. The medical anti-microbial silver-plated dressing has broad-spectrum anti-microbial performance, is simple and easy in preparation method and low in cost.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

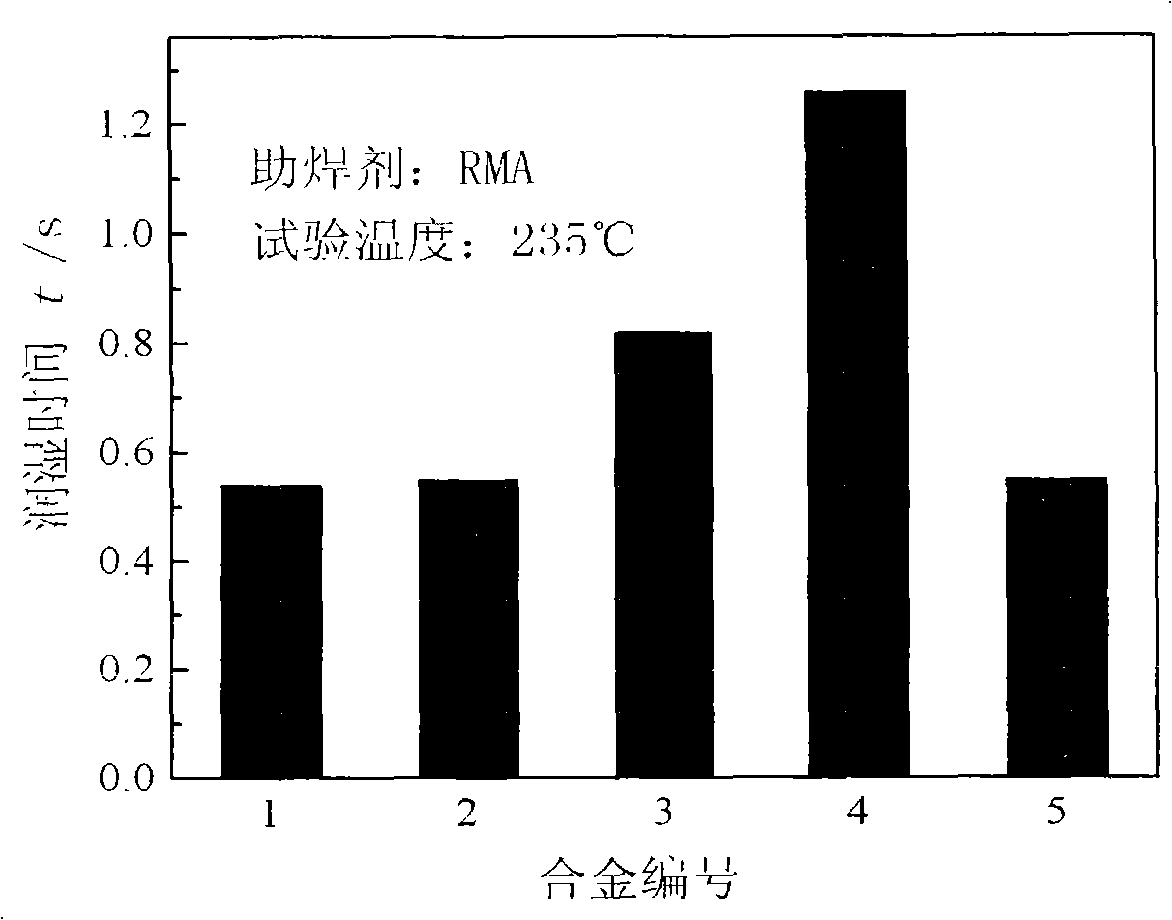

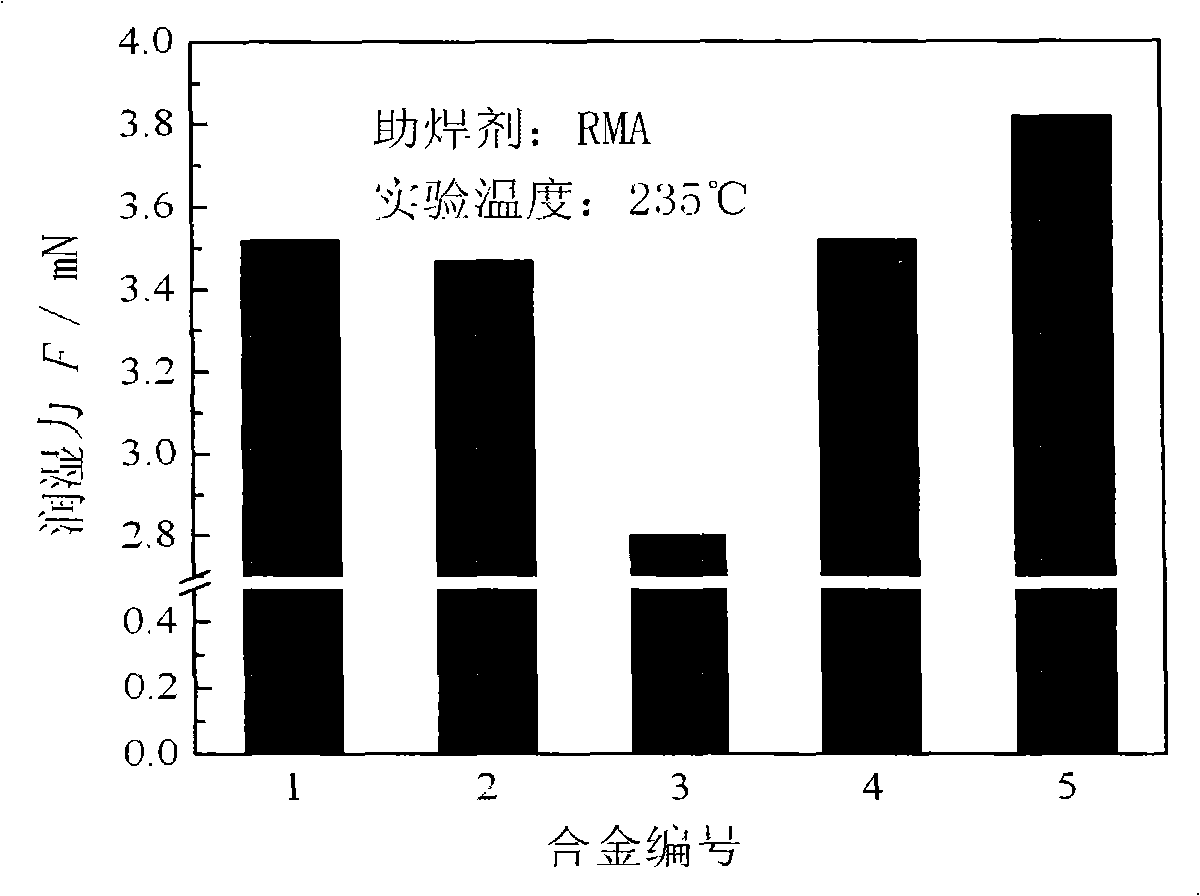

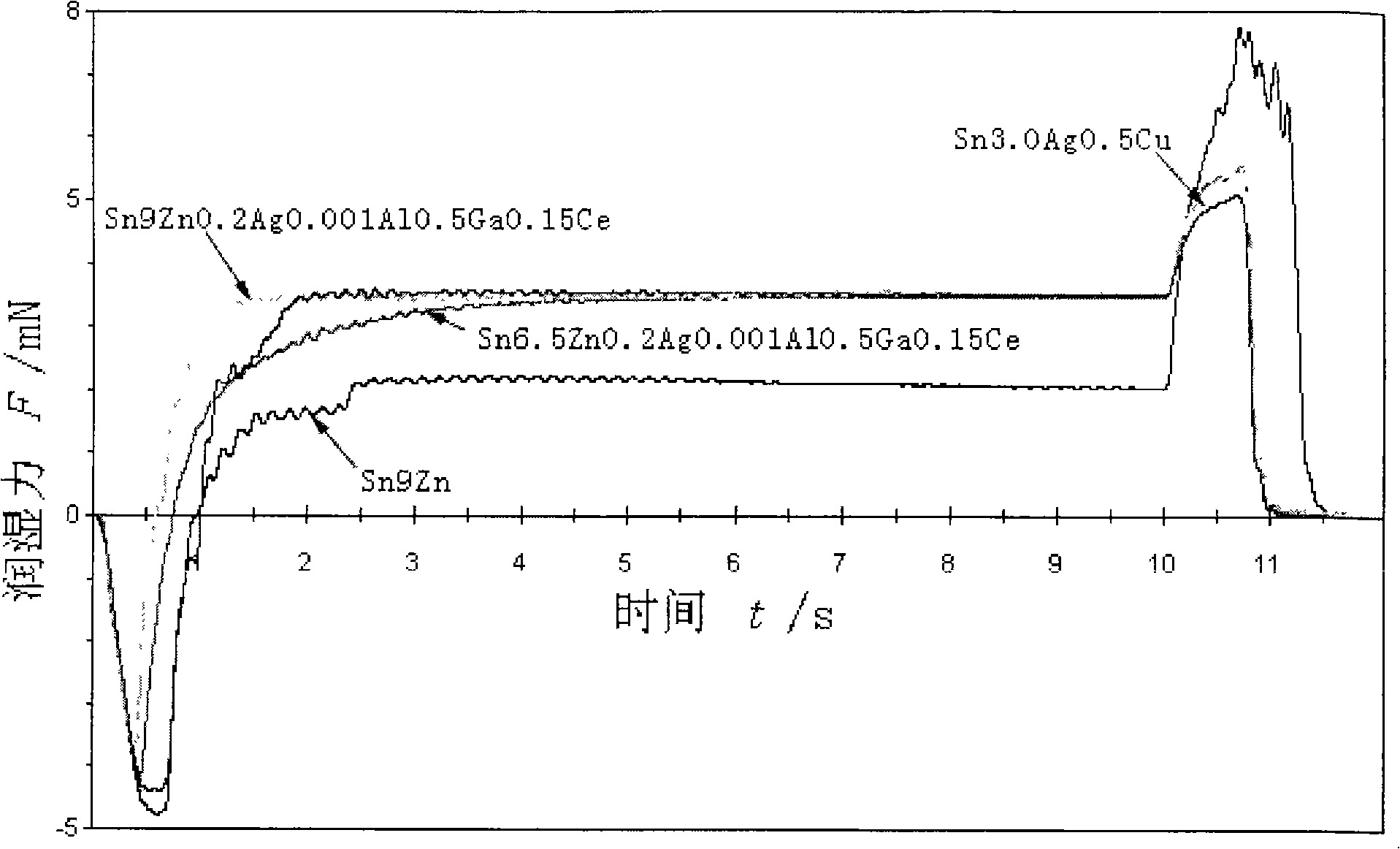

Sn-Zn-Ga-Ce leadless brazing filler metal

InactiveCN101269446AReduce oxidationImprove wettabilityWelding/cutting media/materialsSoldering mediaSilver plateCerium

The invention relates to Sn-Zn-Ga-Ce lead-free brazing filler metal, which belongs to a metal material and a braze welding material of the metallurgic field. The chemical constitution according to a mass percentage is as follows: 5 to 10 percent of zinc, 0.05 to 3 percent of gallium, 0.001 to 0.5 percent of cerium, 0.01 to 3 percent of silver, 0.001 to 0.5 percent of aluminum, and rest percent of tin. Market sold tin ingot, zinc ingot metal, gallium, silver ingot (or silver plate), aluminum ingot and metal cerium are in a mixture ratio according to requirements; when smelting, optimization screened and determined covering agentia is added or inactive gas protection is adopted for smelting and casting, so as to get a bar. Through extruding and drawing, the brazing filler metal silk material is gained (scaling powder can also be added so as to make flux-cored brace welding wire). With the adoption of a powder manufacturing apparatus, new brazing filler metal can be made to a graininess (the graininess size is between 0.106 mm (140 mu) to 0.0380 mm (400 mu)) so as to be used for BGA packaging or made to the soldering paste for use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for enhancing the solderability of a surface

InactiveUS6905587B2Improve solderabilityResistant to electromigrationPretreated surfacesLiquid/solution decomposition chemical coatingSilver plateSolderability

A method for enhancing the solderability of a metallic surface is disclosed where the metallic surface is plated with an immersion silver plate prior to soldering, which immersion silver plate is treated with an additive selected from the group consisting of fatty amines, fatty amides, quaternary salts, amphateric salts, resinous amines, resinous amides, fatty acids, resinous acids, ethoxylated derivatives of any of the foregoing, and mixtures of any of the foregoing. The immersion silver deposits created are resistant to electromigration.

Owner:MACDERMID INC

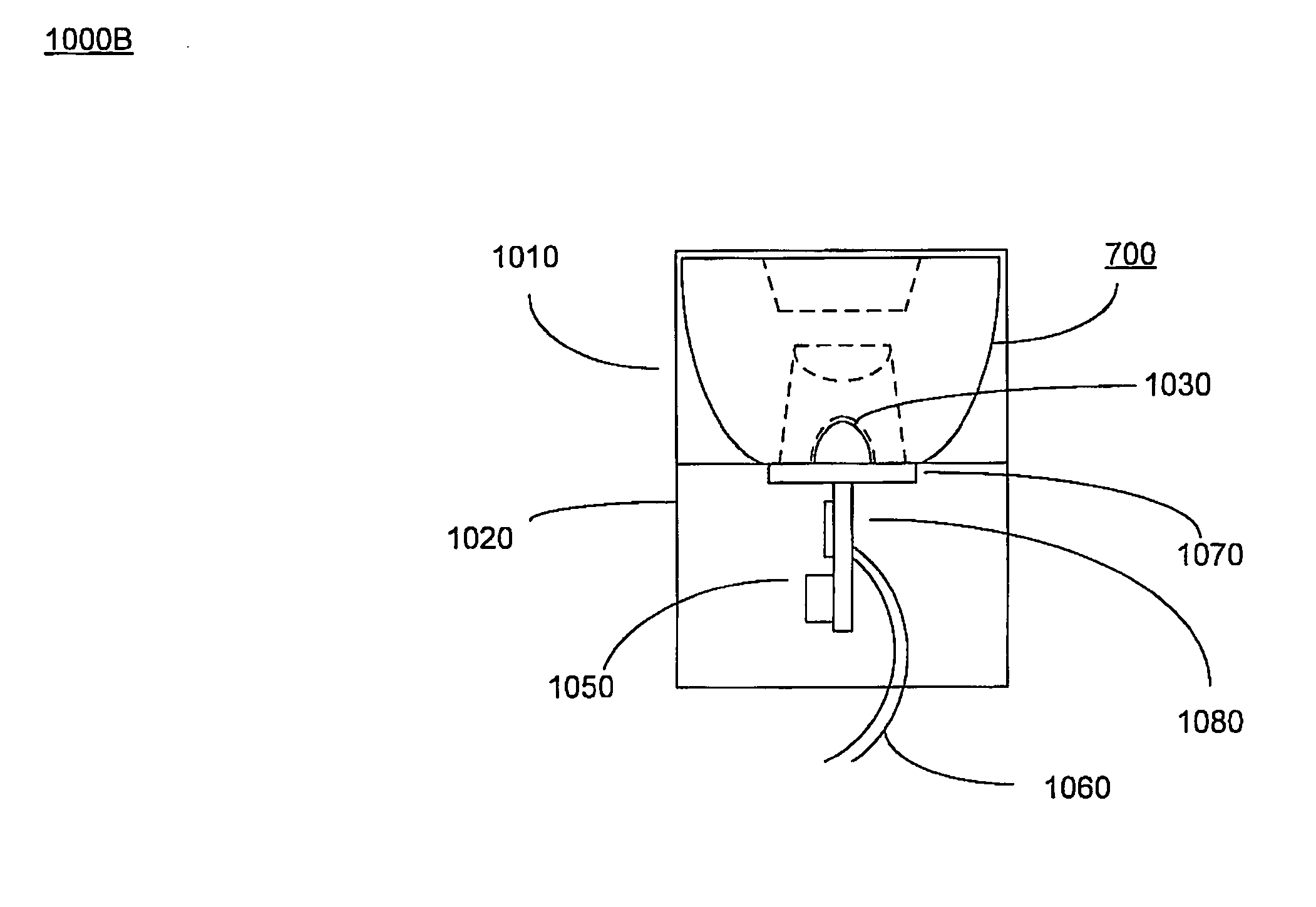

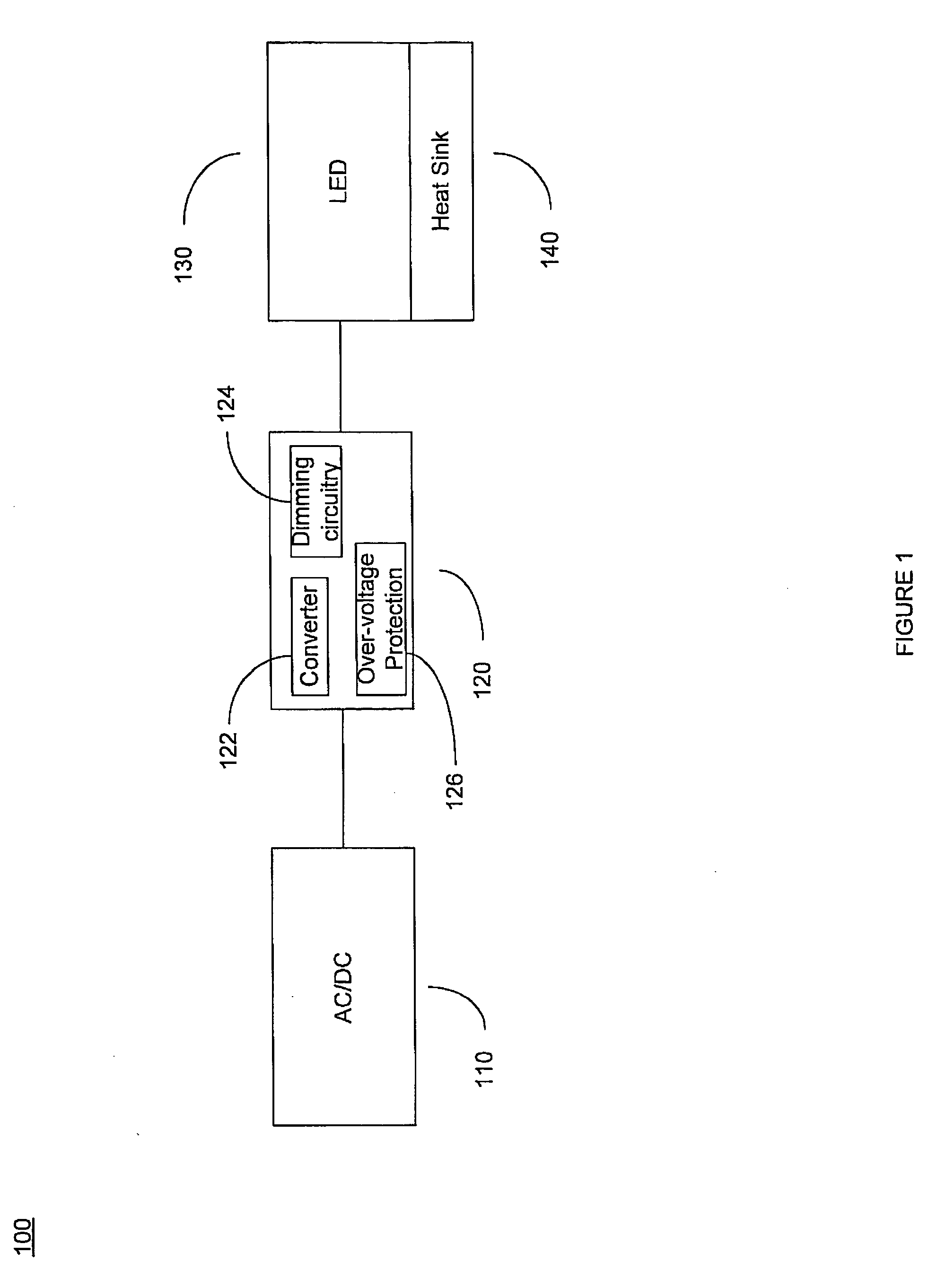

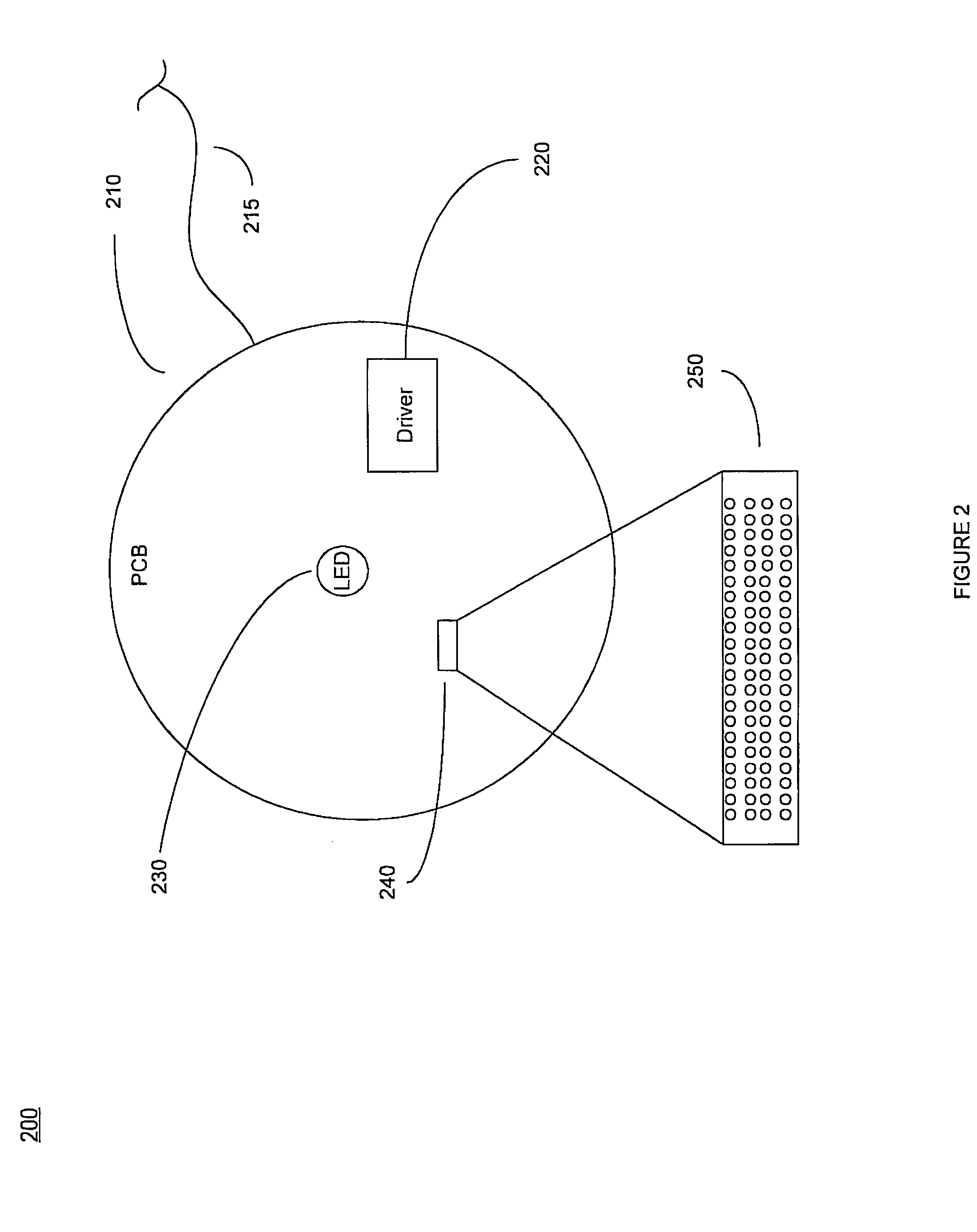

Light device having LED illumination and an electronic circuit board

InactiveUS20080122364A1Avoid potential damageIncrease flexibilityMechanical apparatusElectric circuit arrangementsSilver plateEngineering

A light device having an electronic circuit board light emitting diode (LED) illumination. In one embodiment an LED is disposed on a single board which is operable with a power supply and equipped with a heat sink for dissipating heat. In one embodiment, the heat sink is formed by at least one layer of nickel and silver plate distributed over the single board. The heat sink may also be formed by a plurality of vias for allowing air flow to dissipate heat. The single board further contains a converter for accepting multiple input voltages and providing conversion to a voltage operable for the LED. The device further includes an over voltage protection component for preventing damage to the electronic components if an input voltage outside of their operating range is applied. A dimming component is used and is operable with an external dimming component belonging to other electronic devices.

Owner:LED GREEN POWER

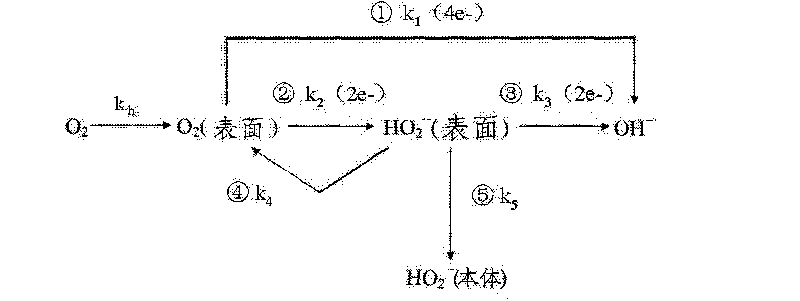

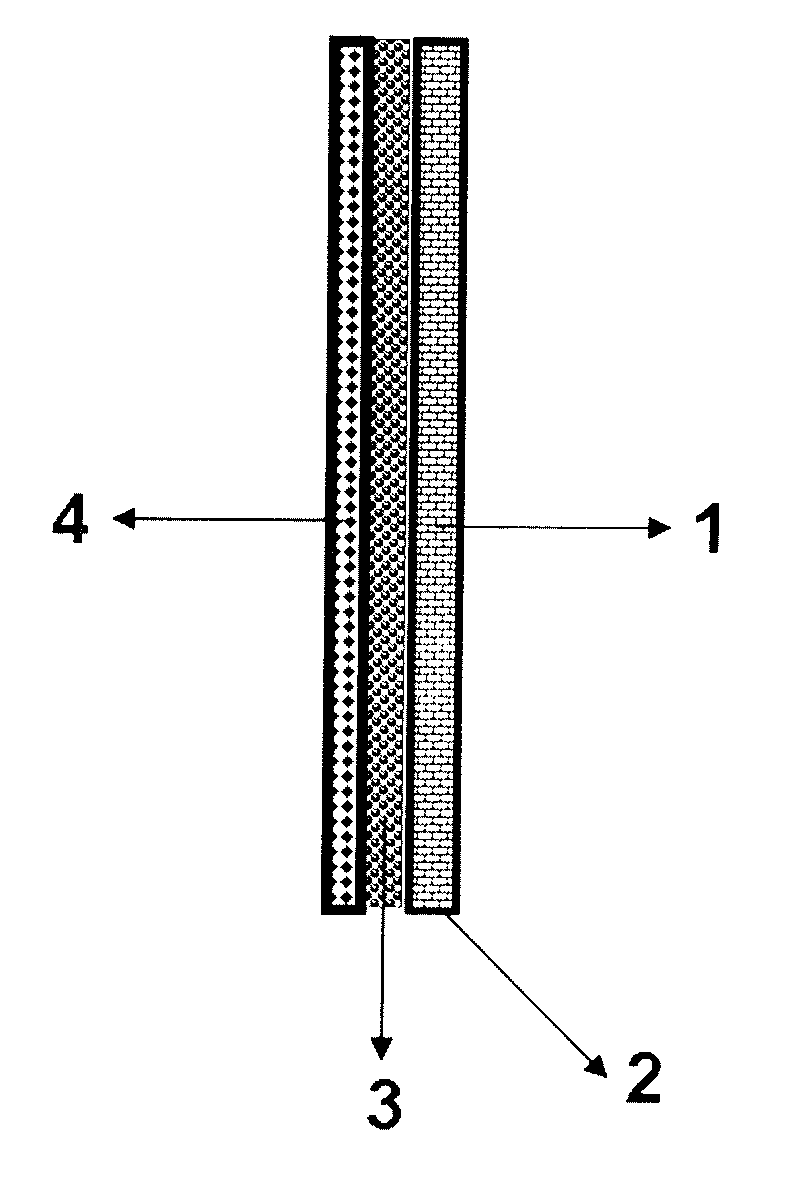

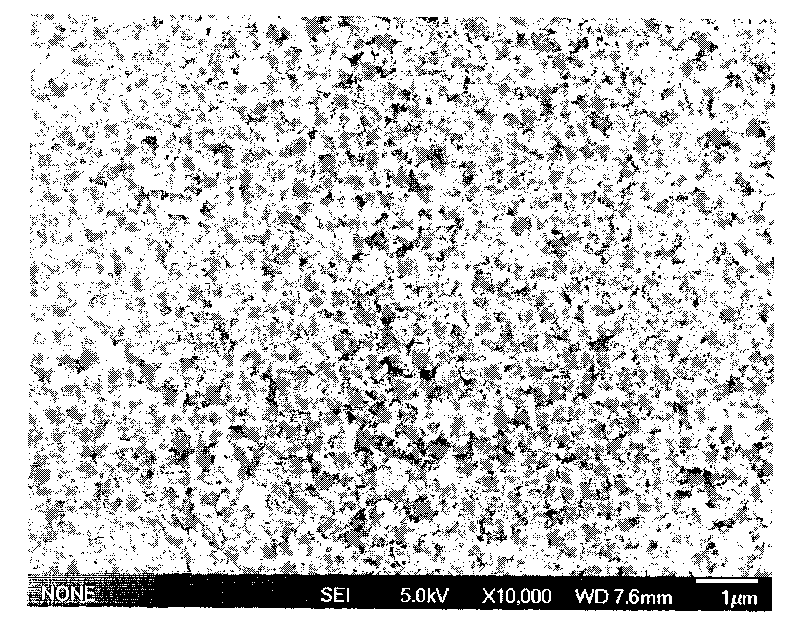

Gas diffusion electrode and preparation method thereof

ActiveCN101736360AImprove corrosion resistanceImprove conductivityElectrode shape/formsElectrolysisSilver plate

The invention provides a gas diffusion electrode and a preparation method thereof. The gas diffusion electrode in the invention is prepared by the following steps: (1) homogenating graphon, isopropanol and polytetrafluoroethylene emulsion, smearing on silver-plated foamed nickel, and cold moulding to obtain the diffusion layer and the current collector; (2) covering the support body silver-plated nickel net on the current collector and cold moulding; and (3) homogenating the silver-carbon catalyst, acidulated graphon, isopropanol and polytetrafluoroethylene emulsion, smearing on the support body and heat forming. The gas diffusion electrode provided by the invention has good corrosion resistance and electrical conductivity in alkali liquor, and long service life, and is suitable for electrolysis reaction in chlorine alkali industry.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com