Patents

Literature

170 results about "Silvering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silvering is the chemical process of coating glass with a reflective substance. When glass mirrors first gained widespread usage in Europe during the 16th century, most were silvered with an amalgam of tin and mercury, but by the 19th century, mirrors were commonly made through a process by which silver was coated onto a glass surface. Today, sputtering aluminium or other compounds is more often used for this purpose, although the process may maintain the name "silvering".

Silver plating in electronics manufacture

Compositions and methods for silver plating onto metal surfaces such as PWBs in electronics manufacture to produce a silver plating which is greater than 80 atomic % silver, tarnish resistant, and has good solderability.

Owner:MACDERMID ENTHONE INC

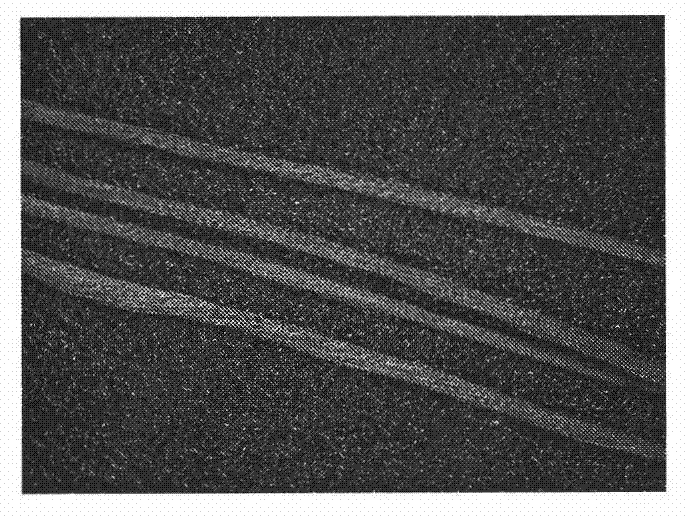

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

The invention relates to a preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers, which comprises the following concrete steps of: a. washing and oil removal; b. coarsening: increasing the surface roughness and the surface wettability of fibers; c. sensitizing: soaking the fibers by adopting an aqueous solution formed by stannous chloride and hydrochloric acid; d. activation: soaking the fibers by adopting an aqueous solution formed by palladium chloride and hydrochloric acid; e. chemical nickel plating; f. sensitizing; g. activation; h. chemical silver plating; and i. coating protection. The prepared high performance nickel-plated and silver-plated aromatic polyamide conductive fibers have good electric conductivity, characteristics of heat resistance, flame retardance, light weight and high strength and functions of eliminating static electricity, conducting electricity and transmitting electrical signals. Therefore, the prepared nickel-plated and silver-plated aromatic polyamide conductive fibers can be widely applied to special departments of aviation, space flight, war industry, communication and the like and can also satisfy the clothing and equipment requirements of staffs engaging radars, television relaying and the like.

Owner:SHANGHAI UNIV

Silver coated mirror

InactiveUS20010033935A1Convenient coatingIncreased durabilityMirrorsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsIndiumMaterials science

A process for forming a silver coating on a surface of a vitreous substrate is described. The process comprises an activating step in which said surface is contacted with an activating solution, a sensitising step in which said surface is contacted with a sensitising solution, and a subsequent silvering step in which said surface is contacted with a silvering solution comprising a source of silver to form the silver coating. The process is characterised in that said activating solution comprises ions of at least one of bismuth (III), chromium (II), gold (III), indium (III), nickel (II), palladium (II), platinum (II), rhodium (III), ruthenium (III), titanium (III), vanadium (III) and zinc (II).

Owner:GLAVERBEL SA

Silver layer formed by electrosilvering substrate material

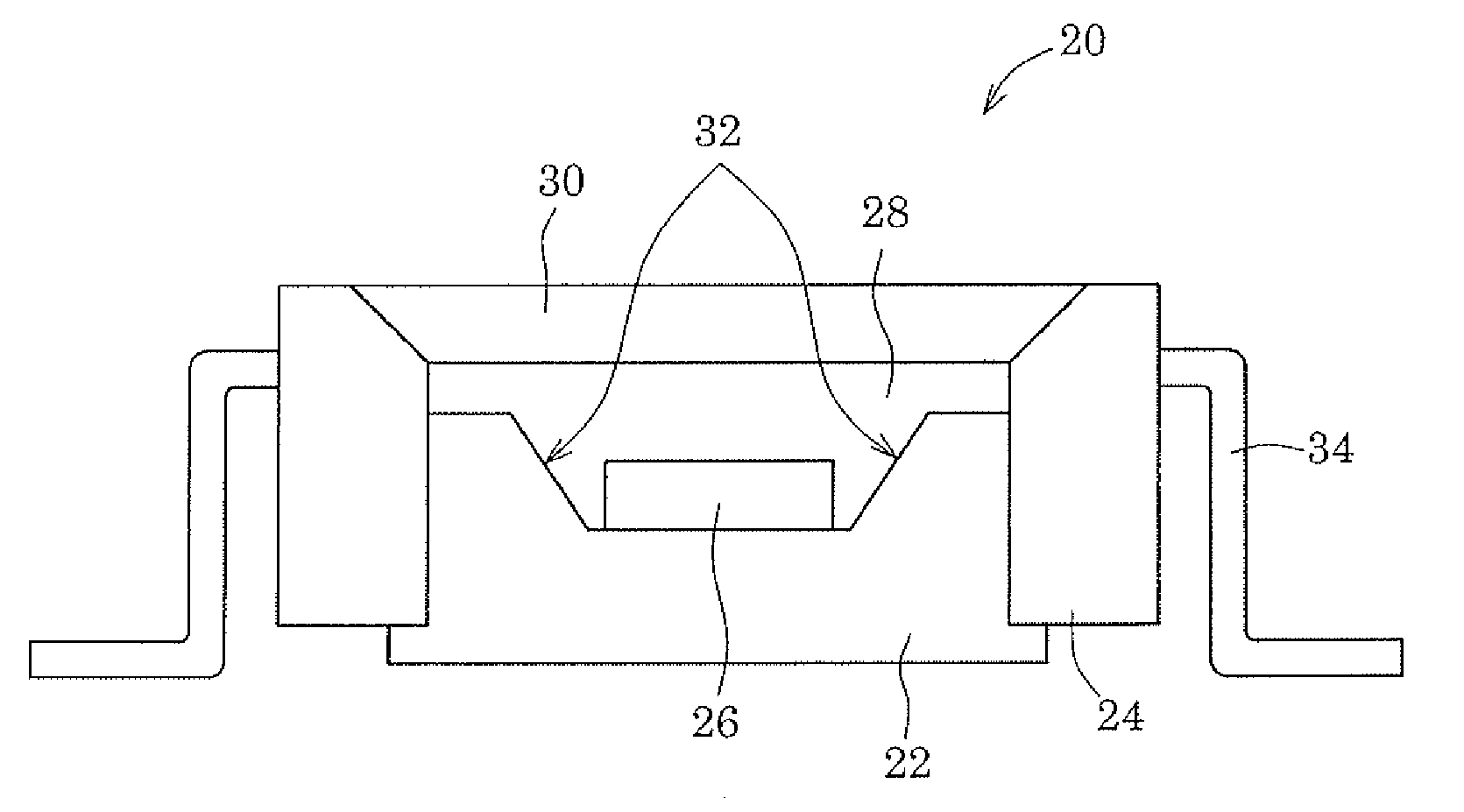

InactiveUS20080006911A1Effective reflectionInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesSilver plateSilver coating

Owner:MATSUSHITA ELECTRIC WORKS LTD

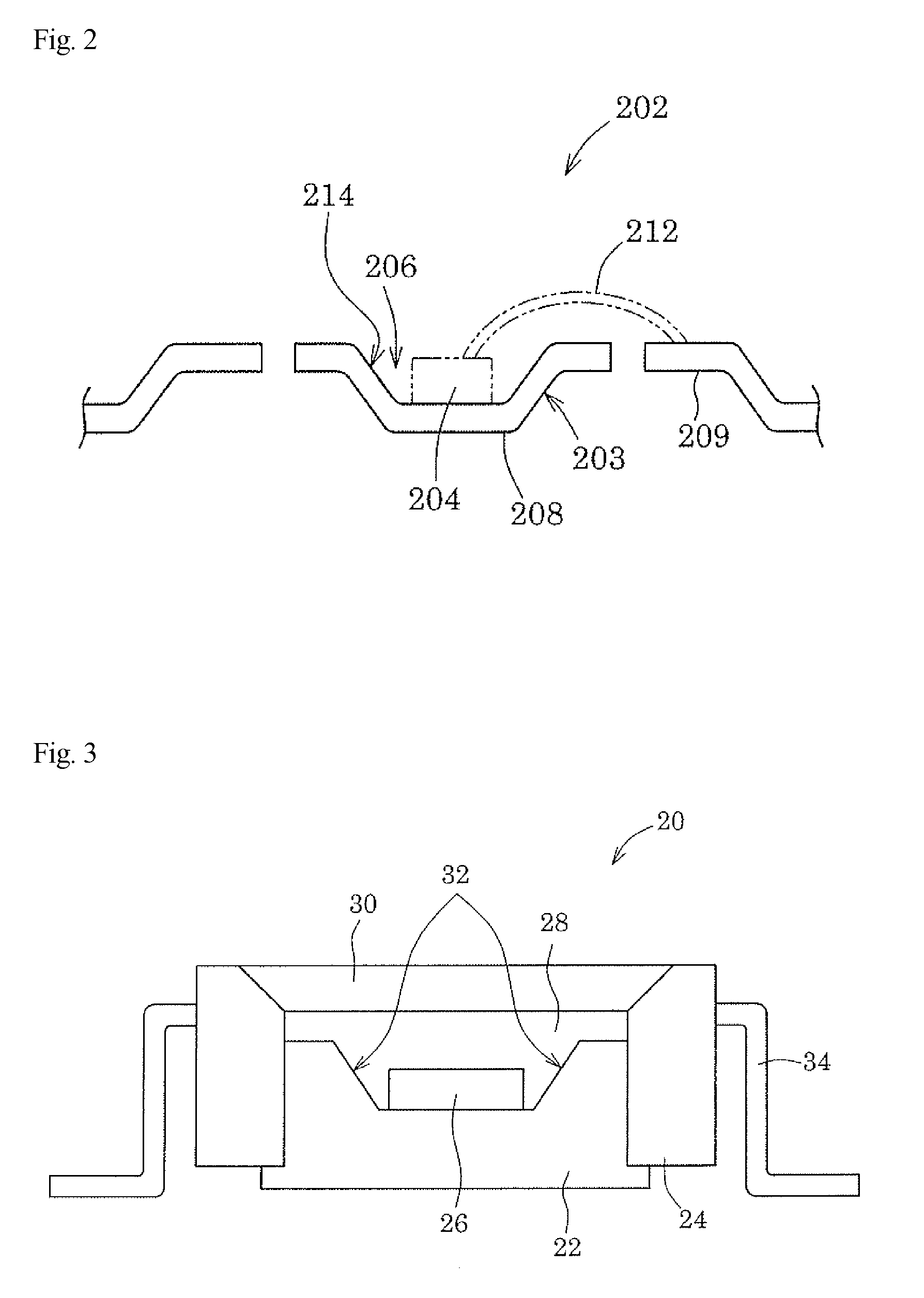

Plating structure and method for manufacturing electric material

InactiveUS20110012497A1Increase resistanceReduce contact resistanceIncadescent screens/filtersElectric discharge tubesTinningSilver plate

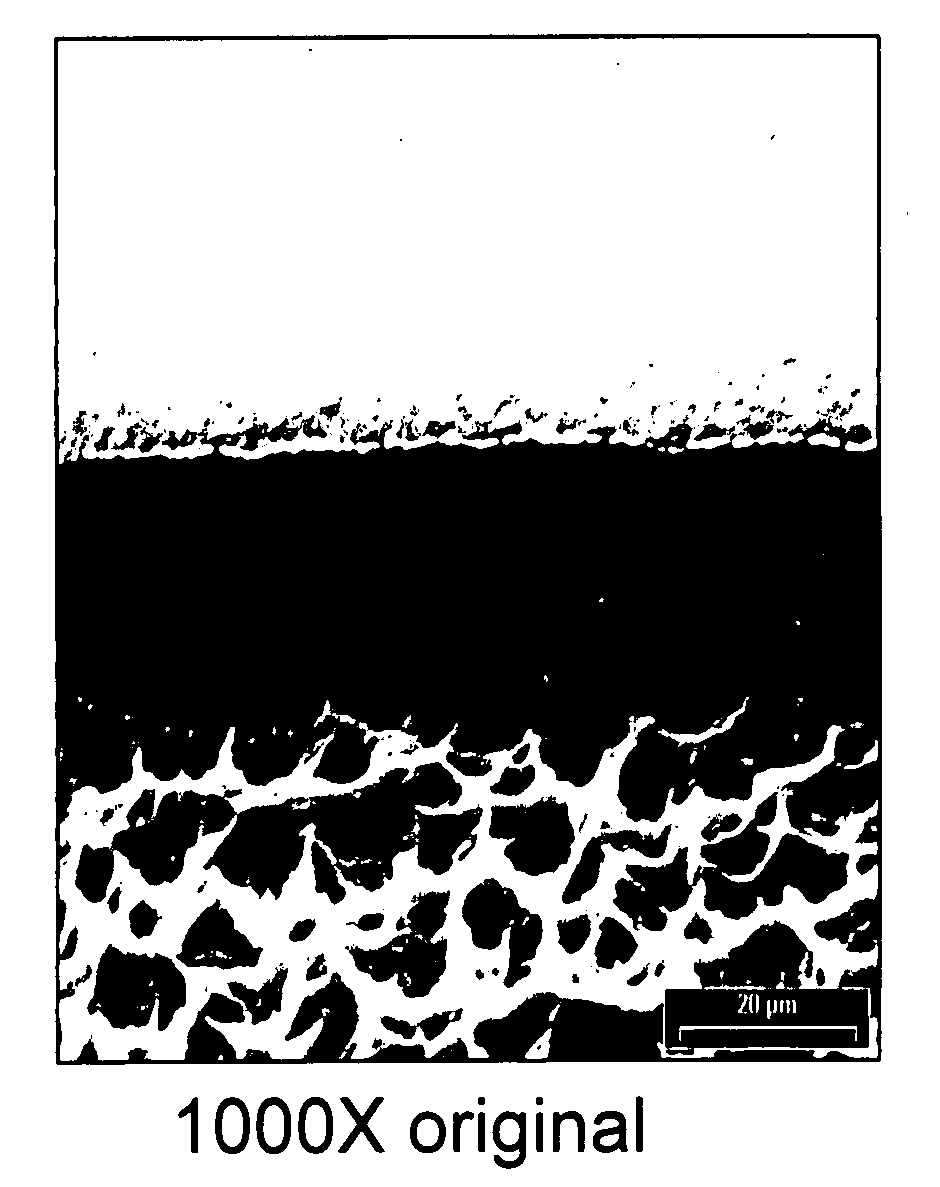

There is provided a plating structure obtained by heat-treating a silver-plated structure obtained by forming a tin-plated layer, an indium-plated layer, or a zinc-plated layer, having a thickness of 0.001 to 0.1 μm, on a surface of the silver-plated layer formed on a surface of a plating base. There is also provided a coating method for obtaining the plating structure which comprises the step of melting a particle deposit spottedly deposited at 2×10−6 to 8×10−6 g / cm2 such that the spot-deposited particles have gaps therebetween as viewed above and the particles each having an average diameter of 20 to 80 nm do not pile up in a direction perpendicular to the surface of the silver layer to obtain a film.

Owner:KYOWA ELECTRIC WIRE

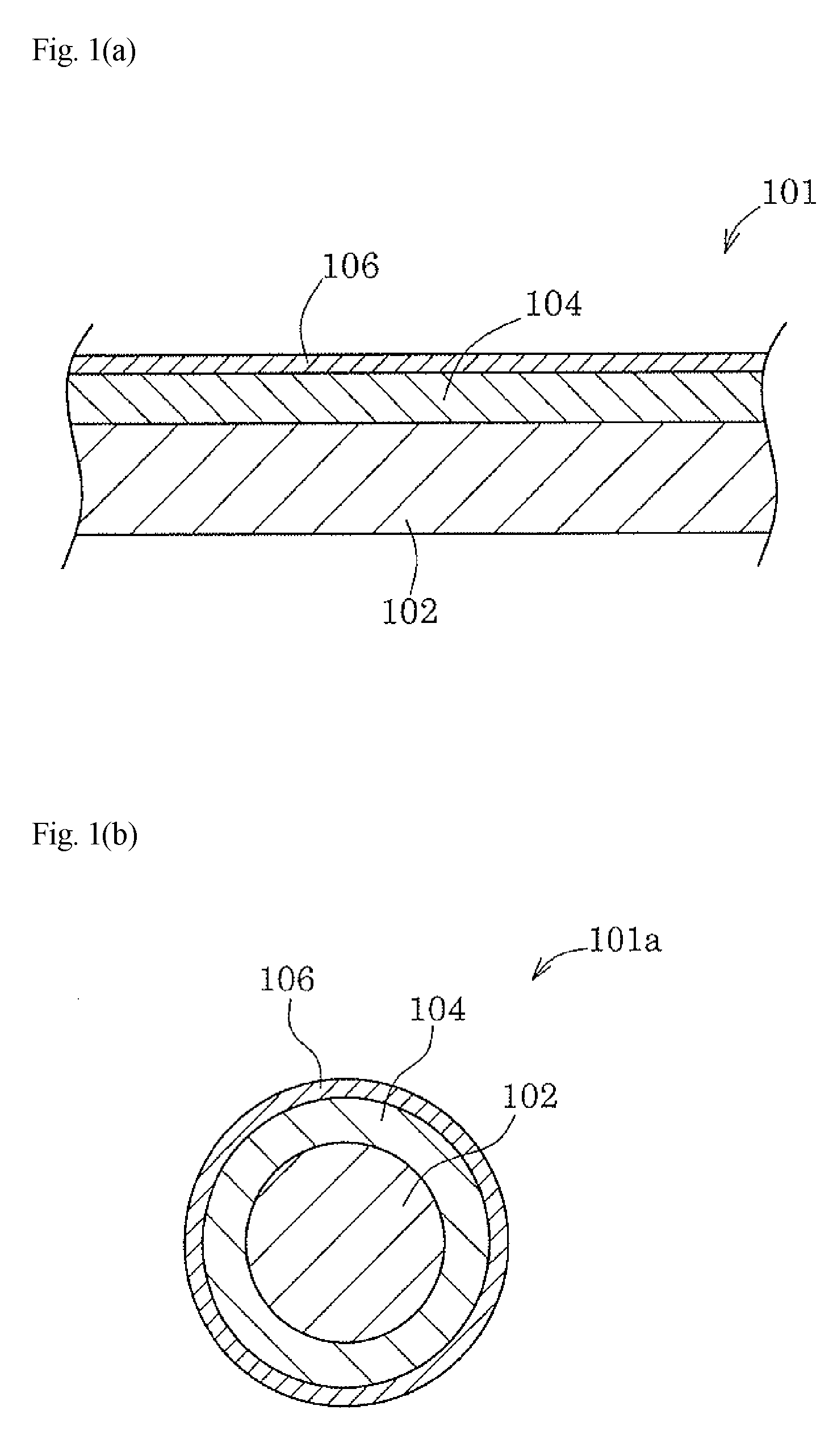

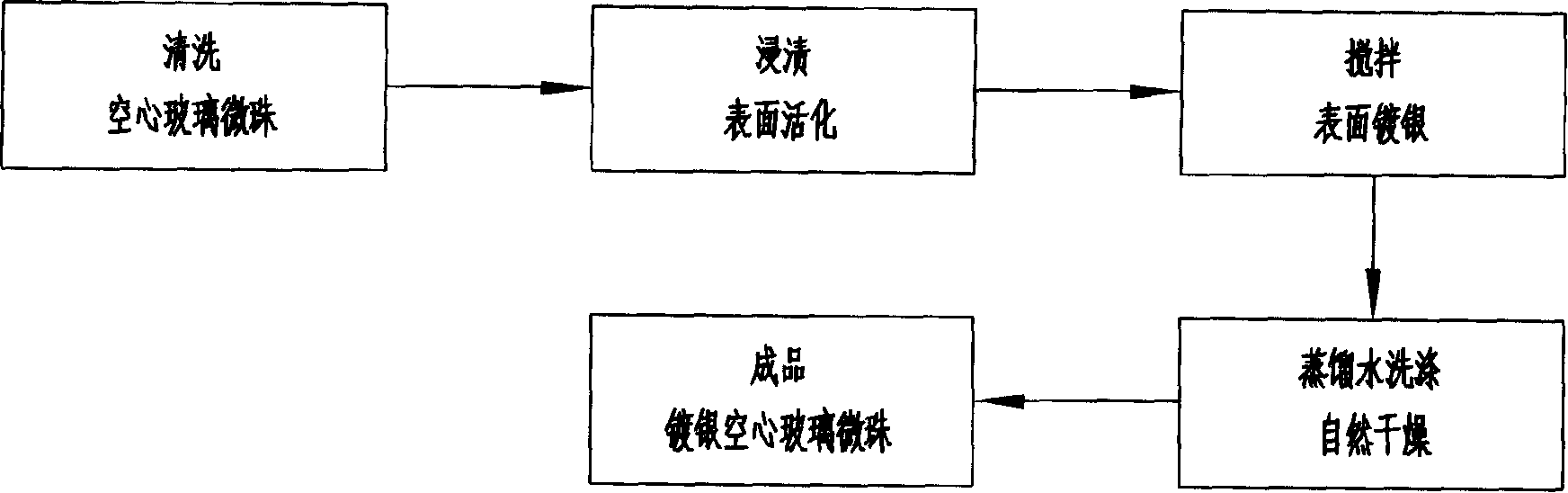

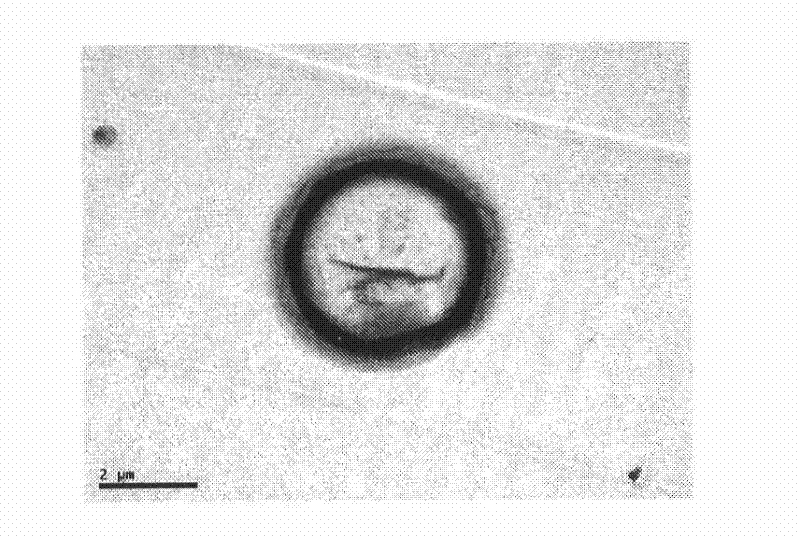

Process for coating silver on hollow glass micropearl surface and silver coated hollow glass micropearl thereof

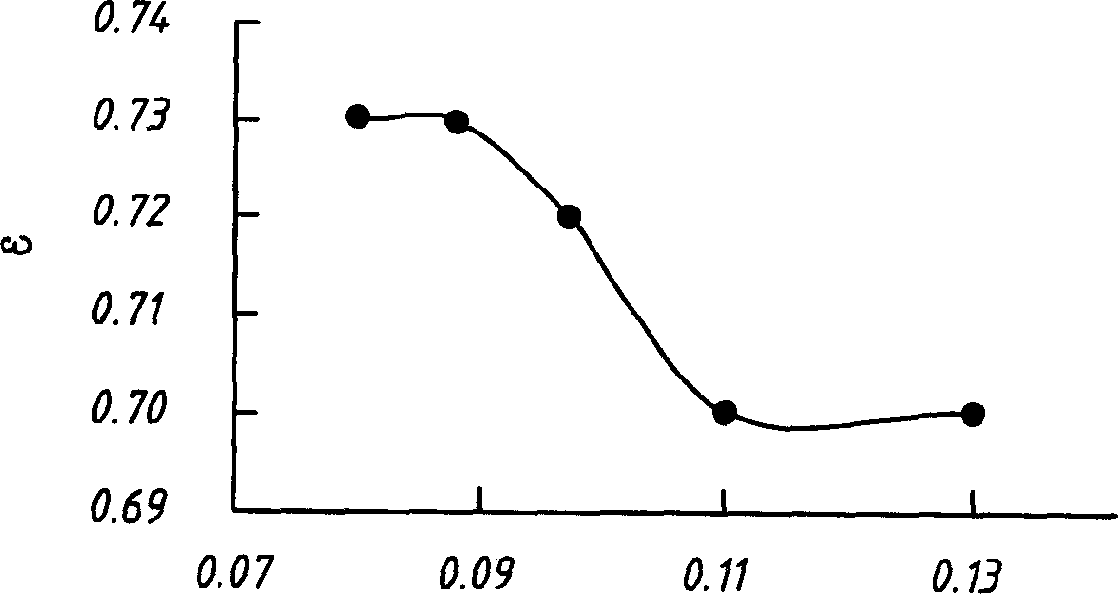

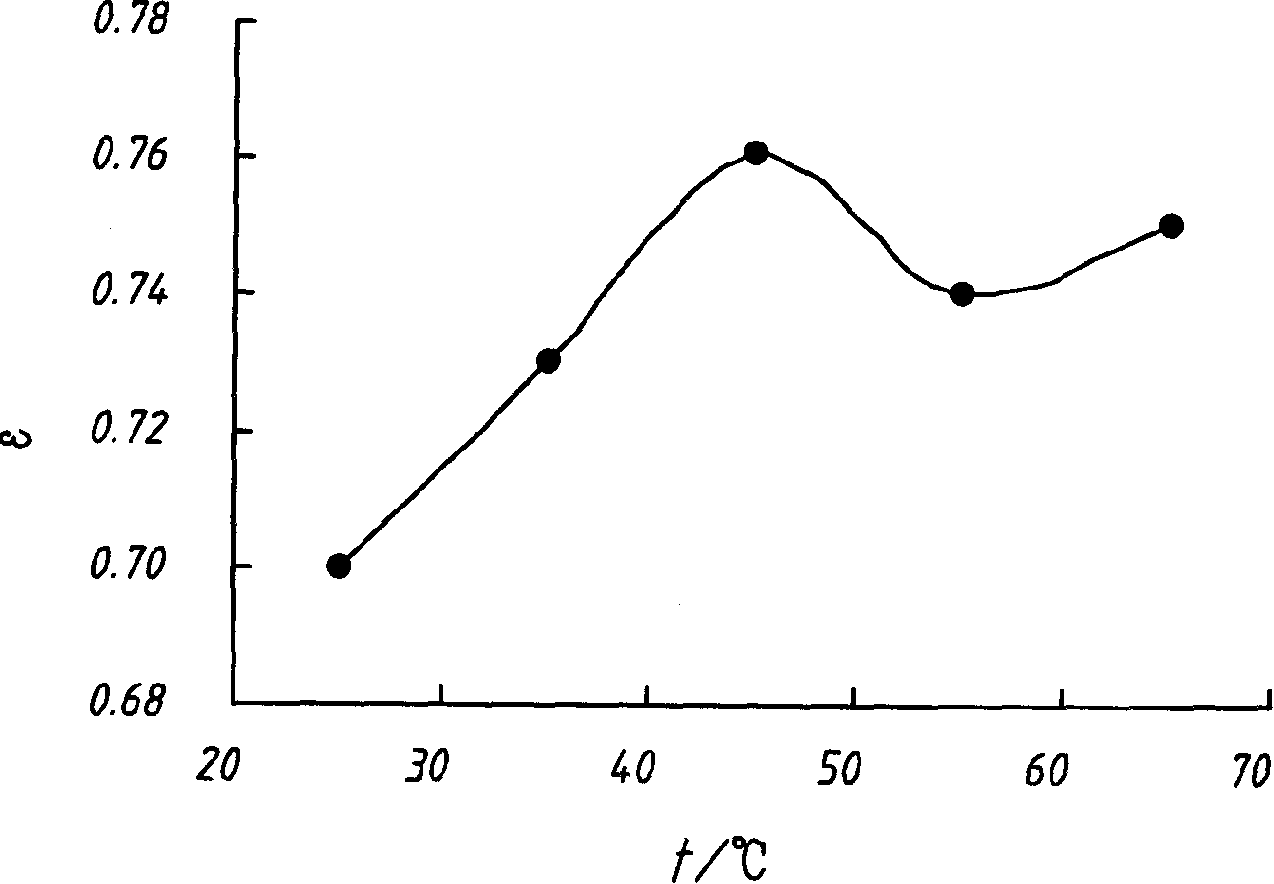

A process for chemically plating Ag on the surface of hollow glass micro-bead includes such steps as sensitizing and activating its surface and plating Ag by in-situ chemical deposition. Its product is composed of hollow glass micro-bead as core, activated layer and Ag layer has lower infrared emissivity and a certain radar wave absorpitivity.

Owner:CHONGQING UNIV

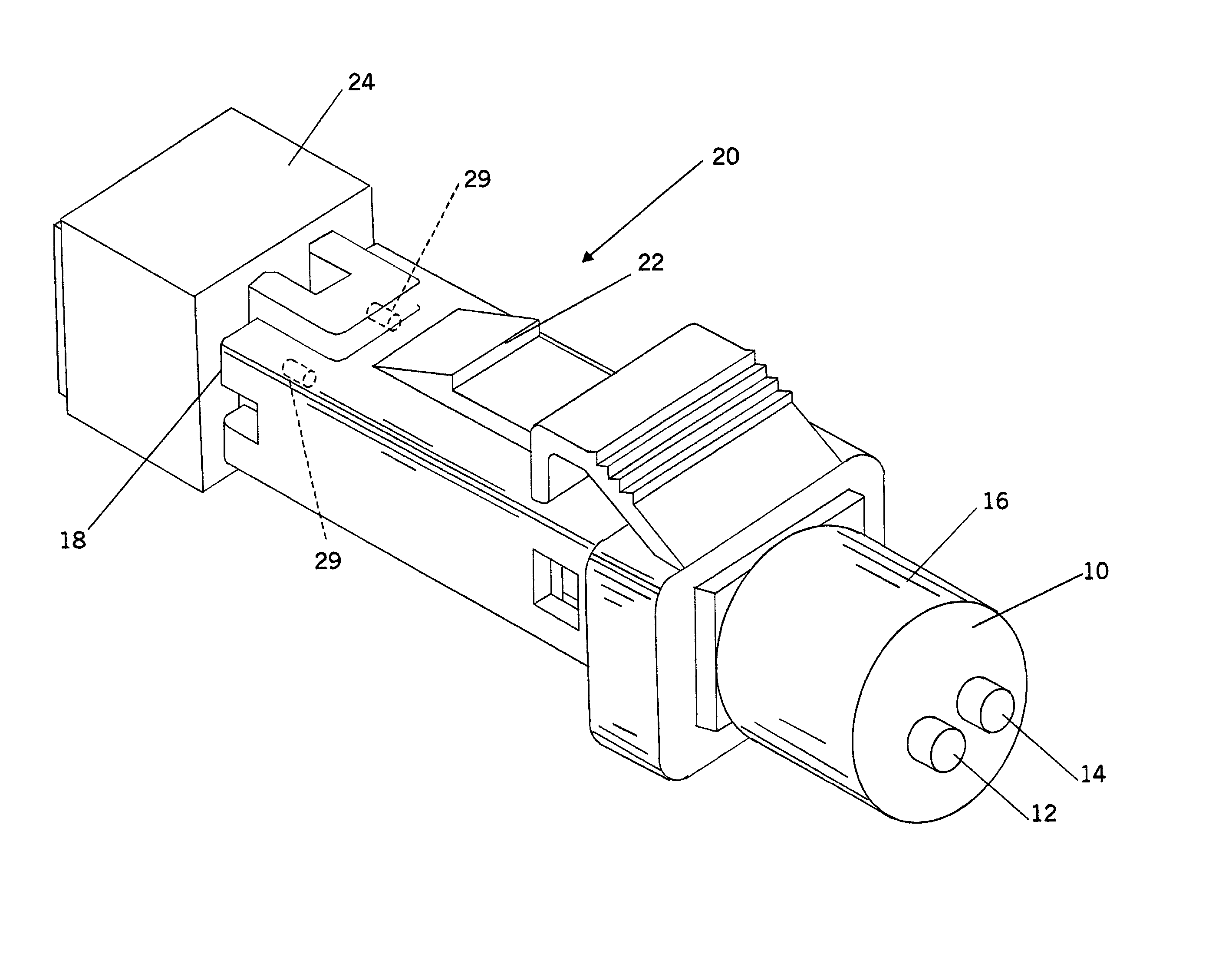

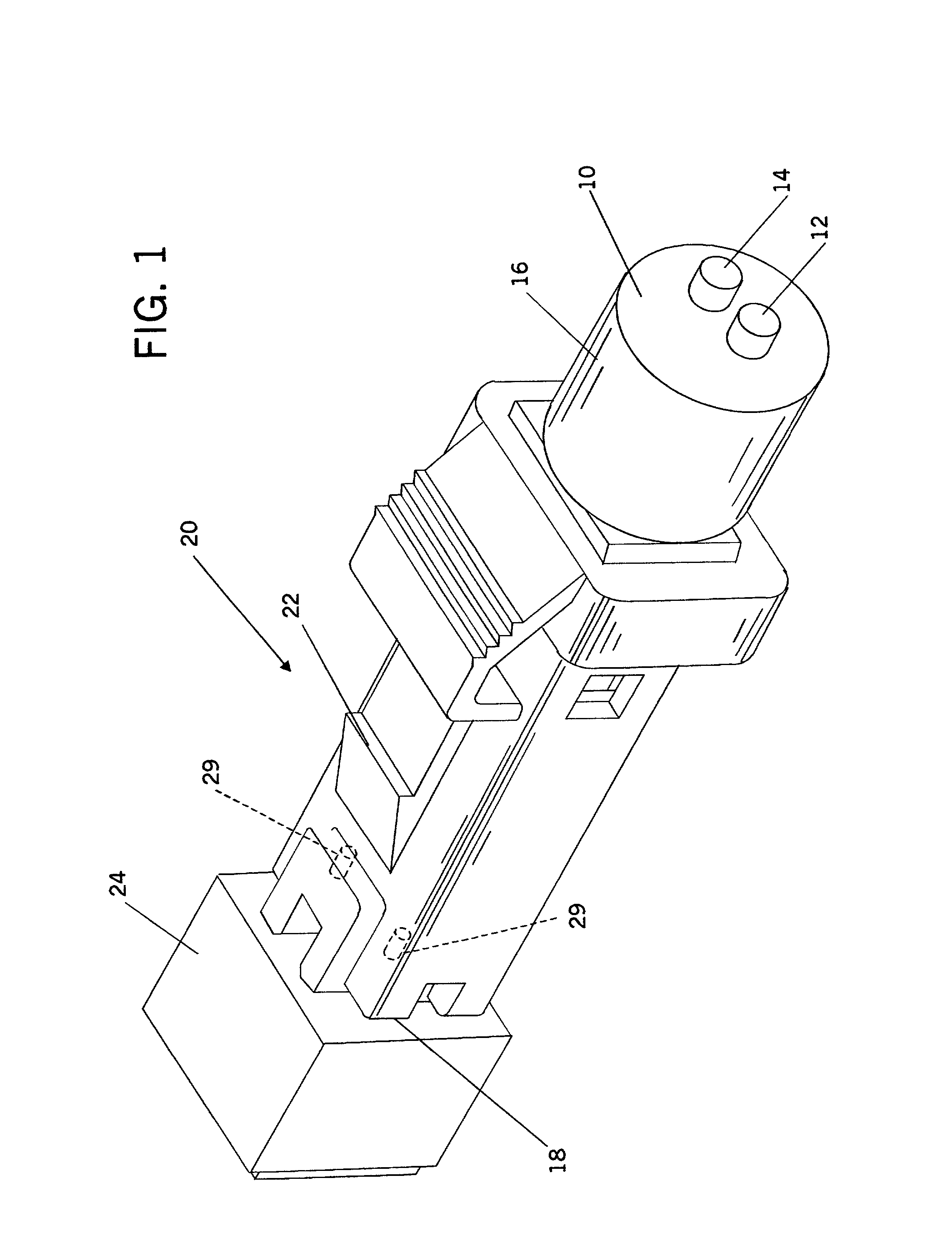

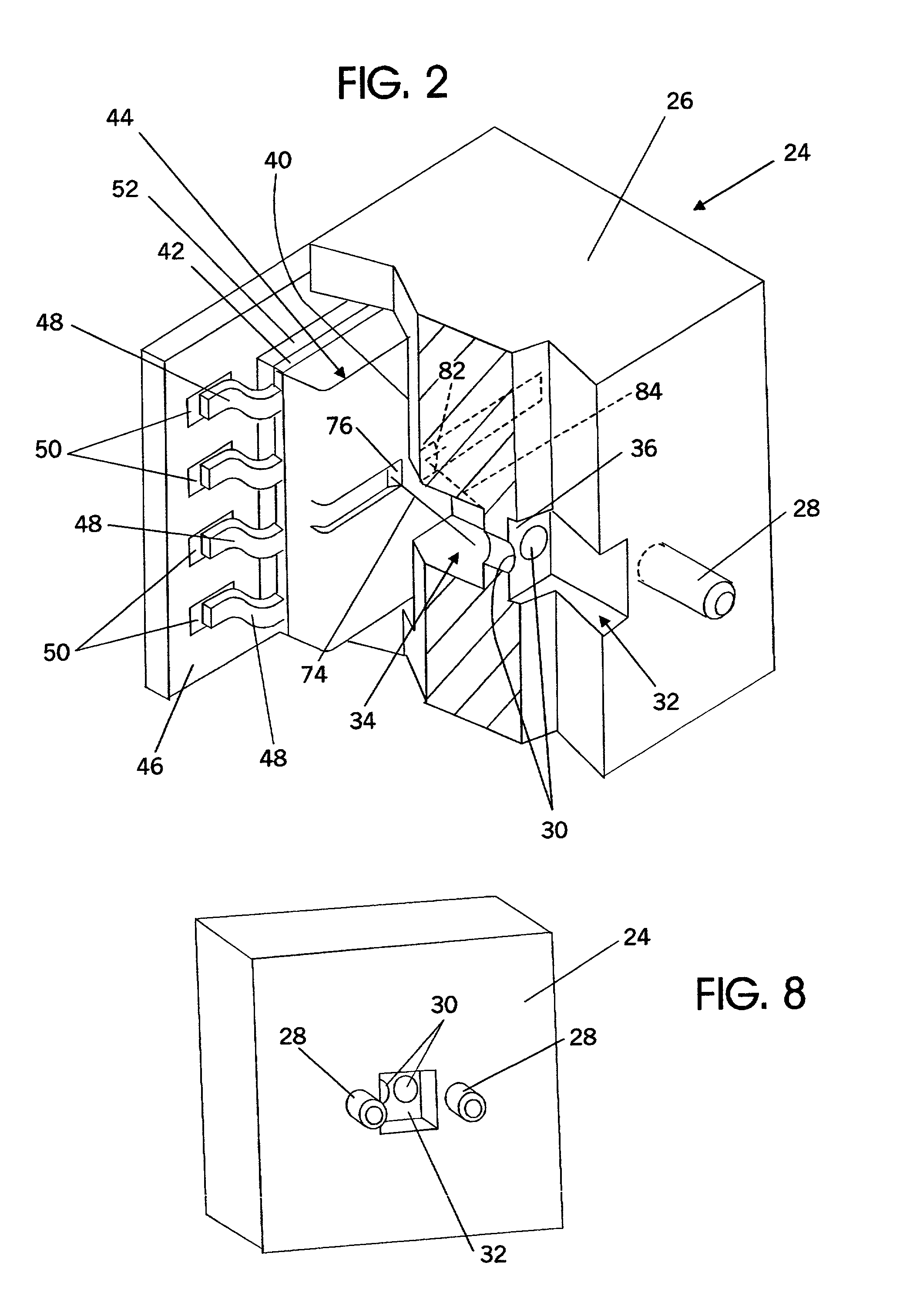

Optical subassembly for optical communications

InactiveUS20020196500A1Reduce back reflectionCoupling light guidesElectromagnetic transceiversData streamTransceiver

Owner:LUMENTUM OPERATIONS LLC

Preparation method of silver-plated copper powder

The invention provides a preparation method of silver-plated copper powder, which comprises the following steps: a, putting copper powder of which the granularity is 200-800 meshes into an alkali solution of which the weight concentration is 3-15% for washing with alkali, and then, washing with water, filtering and drying; b, putting the copper powder in the step a into an acid solution of which the weight concentration is 3-15% for washing with acid, washing with water to the neutrality, and then, filtering and drying; c, under the condition that the proportion by weight of copper powder to silver nitrate is 100:1-10, taking the silver nitrate, and dissolving the silver nitrate into water to form a silver nitrate water solution; d, under the condition that the proportion by weight of copper powder to ethylenediamine tetraacetic acid disodium salt is 100:1-10, taking the ethylenediamine tetraacetic acid disodium salt, dissolving the ethylenediamine tetraacetic acid disodium salt into water to form a water solution, putting the copper powder in the step b into the water solution for uniformly stirring, then adding the silver nitrate water solution in the step c and 0.05-5% copper powder weight of reducing agent for reacting for 0.5-4 hours, and cleaning, centrifuging and filtering to obtain the silver-plated copper powder; and e, adding the silver-plated copper powder after reaction into an organic acid ester mixed solution for soaking for 0.5-3 hours, and filtering and drying to obtain a product.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Silver plated hollow glass micro bead and its surface silver plating process

InactiveCN1974460AAchieve the purpose of coarseningAchieve hydroxylationSilver plateElectromagnetic shielding

The present invention discloses silver plated hollow glass bead and its surface sliver plating process. The technological process includes soaking hollow glass bead in alkaline solution to clean, roughen and surface hydroxylate; soaking the treated hollow glass bead in argentamine white stirring and heating to react for certain time, and adding reductant to activate and silver plate the hollow glass bead. Compared with traditional technology, the present invention has the advantages of simplified pre-treatment, shortened production period and low cost. The prepared silver plated hollow glass bead has excellent conducting performance and may be used as electromagnetic shielding material.

Owner:GUANGDONG UNIV OF TECH

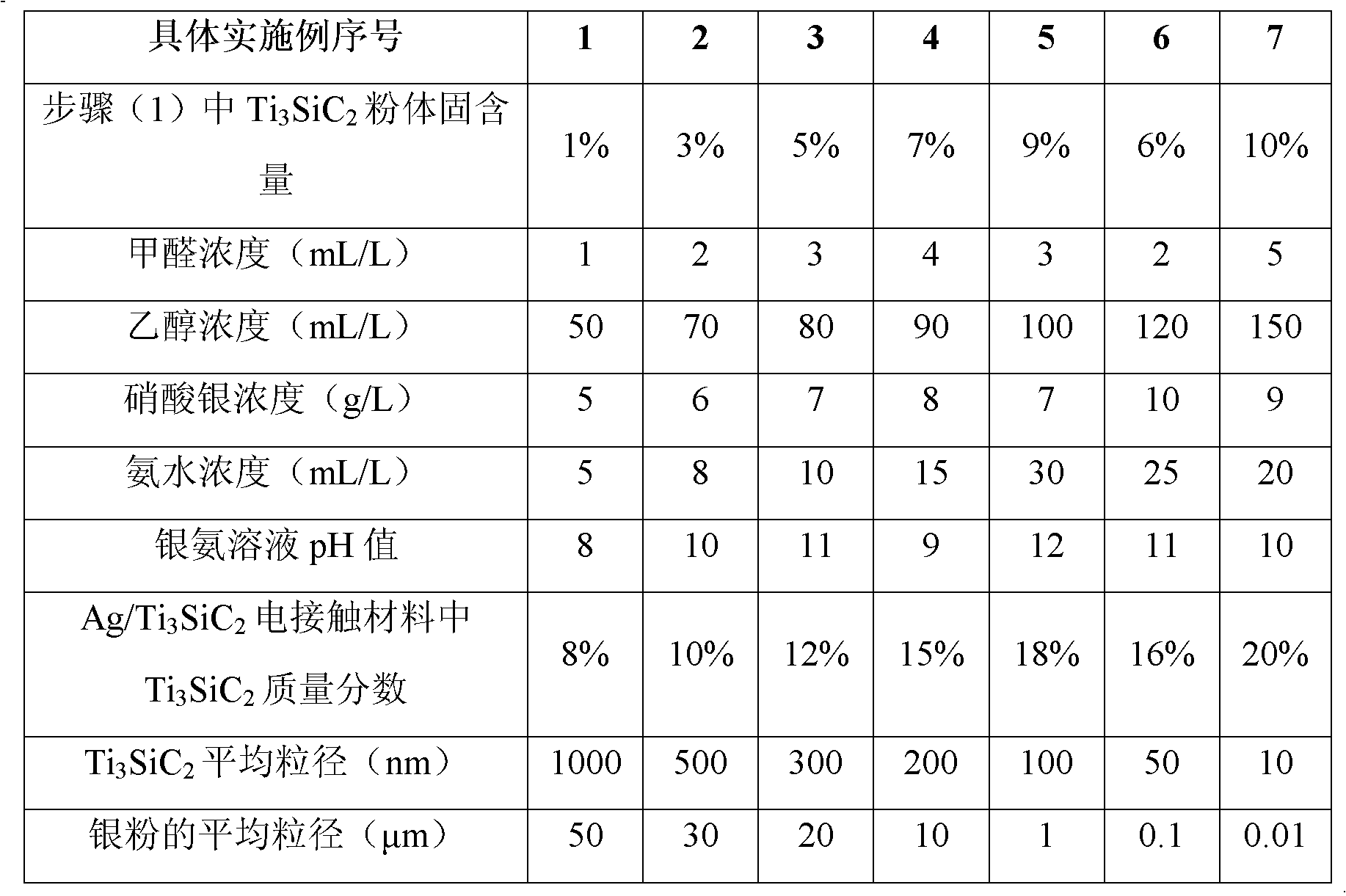

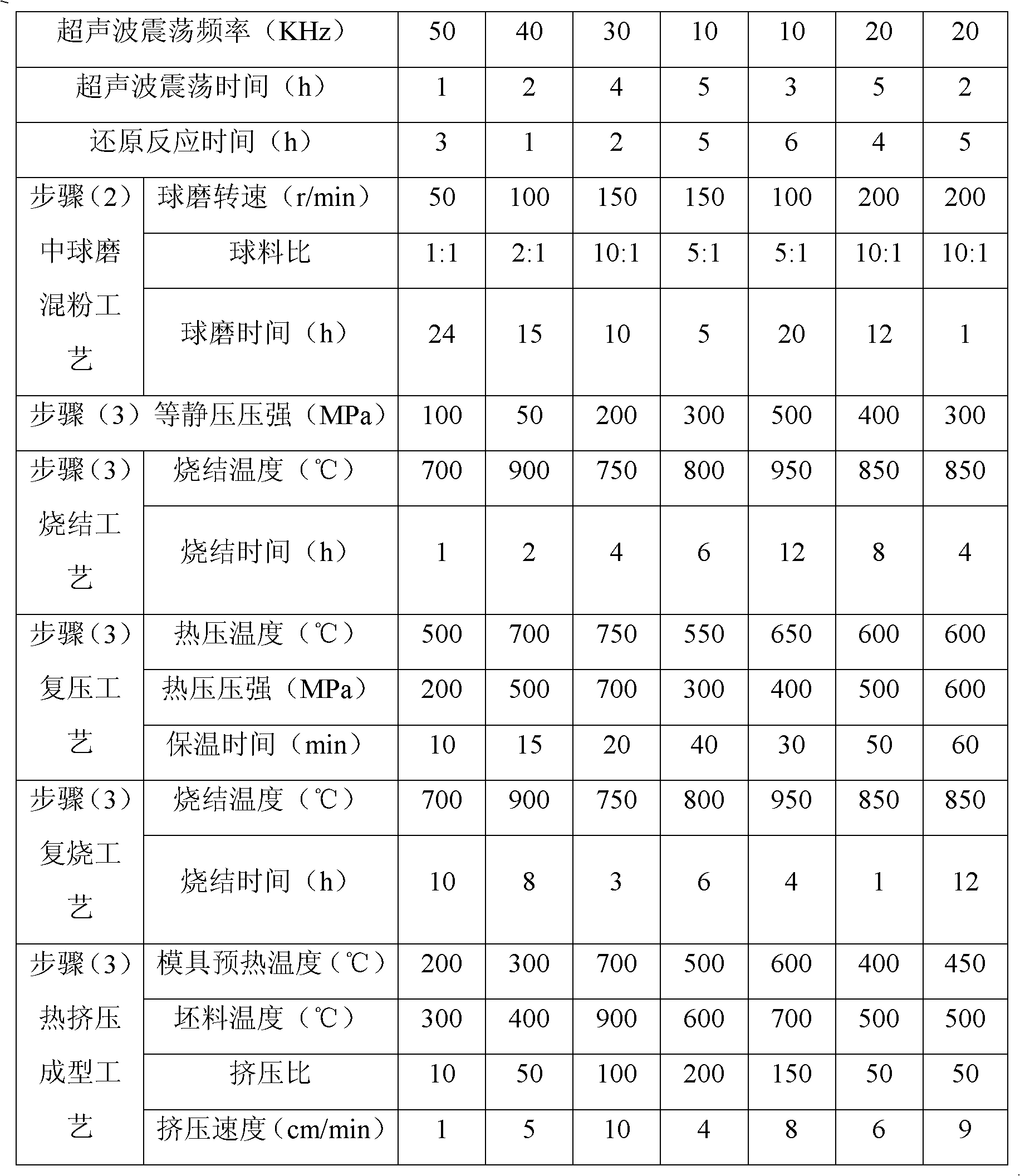

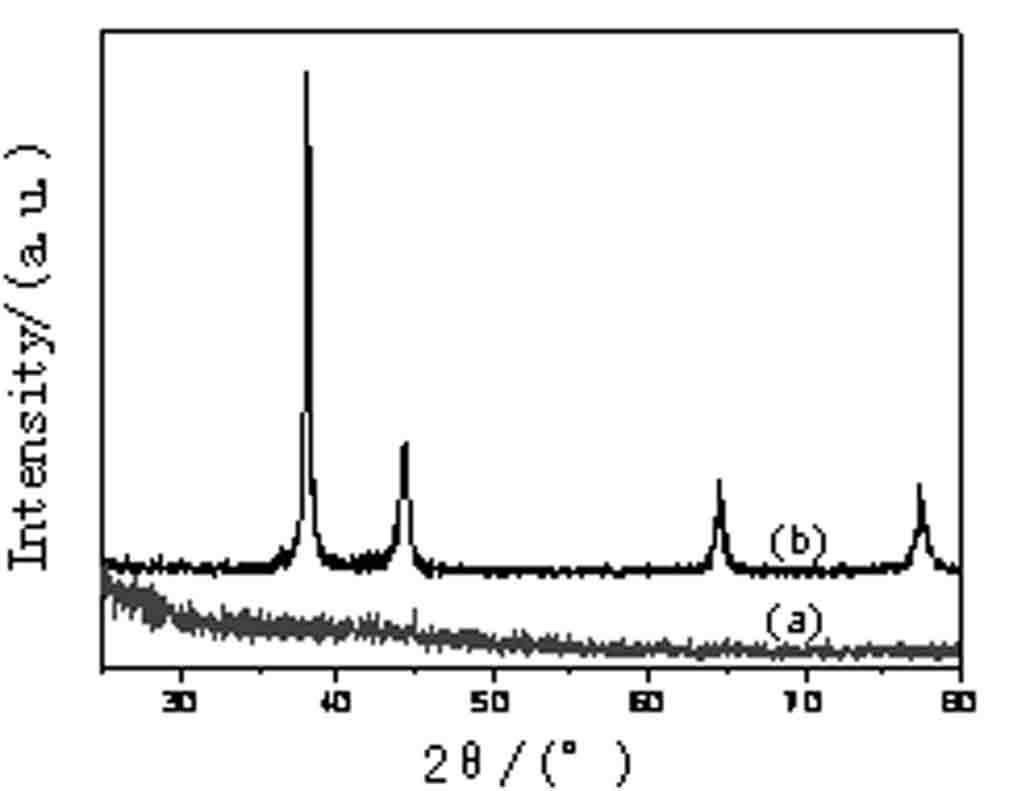

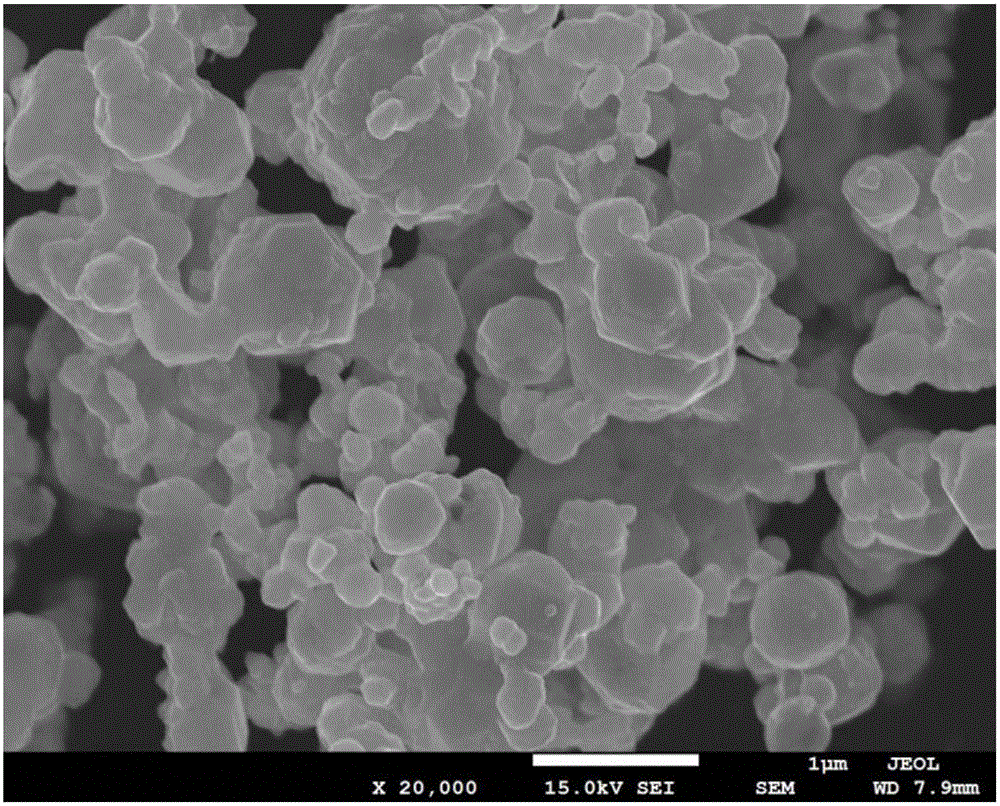

Preparation method of Ag / Ti3SiC2 electric contact composite material

InactiveCN102312150AImprove wettabilityHigh thermal conductivity at room temperatureContactsAlcoholDistilled water

The invention relates to a preparation method of a novel electric contact composite material, and provides a preparation method of an Ag / Ti3SiC2 electric contact composite material. The preparation method comprises the following steps of: preparing silver coated Ti3SiC2 powder by a Tollen reagent chemical silvering method, then cleaning the powder with distilled water to neutral, washing with alcohol and drying in vacuum; carrying out ball milling on dried powder and silver powder and mixing uniformly; compacting the uniformly mixed powder into a green body through isostatic pressing, then carrying out sintering, repressing and re-sintering, and finally moulding through hot extrusion to obtain a finished product. According to the invention, wetabilities of a reinforcing phase and a silver matrix are improved through a silver loaded surface technology; severe clustering will not occur on a surface of the material eroded by arc; and contact resistance keeps at a low and stable range; meanwhile, material surface temperature rise can be maintained at a low level. A mixing amount of the reinforcing phase in the composite material can be increased substantially, and silver can be saved by 5-10%, compared with an Ag / SnO2 material.

Owner:ZHEJIANG UNIV

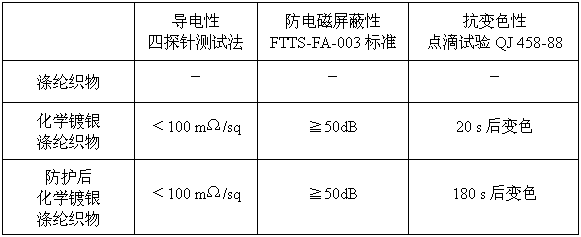

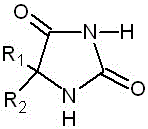

Silver plating solution for chemical silvering of polyester fabrics, silver plating method of silver plating solution and anti-tarnishing protection method of plating layer

The invention relates to a silver plating solution for chemical silvering of polyester fabrics, a silver plating method of the silver plating solution and an anti-tarnishing protection method of a plating layer. The silver plating solution is divided into a silver salt solution and a reducing agent solution, wherein constituents and concentrations of the silver salt solution are as follows: 5 to 10g / L of AgNO3, 55 to 65mL / L of ammonia water, 15 to 25mL / L of ethidene diamine, 5 to 10g / L of sodium thiosulfate and 5 to 10g / L of potassium hydroxide; and the constituents and the concentrations of the reducing agent solution are as follows: 5 to 10g / L of glucose, 1 to 5g / L of potassium sodium tartrate, 35 to 45mL / L of ethanol, and 70 to 80mg / L of polyethylene glycol 1000. The polyester fabrics with the plating layer prepared by the invention is durable in conductivity, excellent in anti-electromagnetic shielding capacity, and good in anti-tarnishing property, thereby being applied to preparation of conductive foam, conductive adhesive tapes, conductive hasps, shielding clothes and shielding caps and the like.

Owner:SHANGHAI UNIV

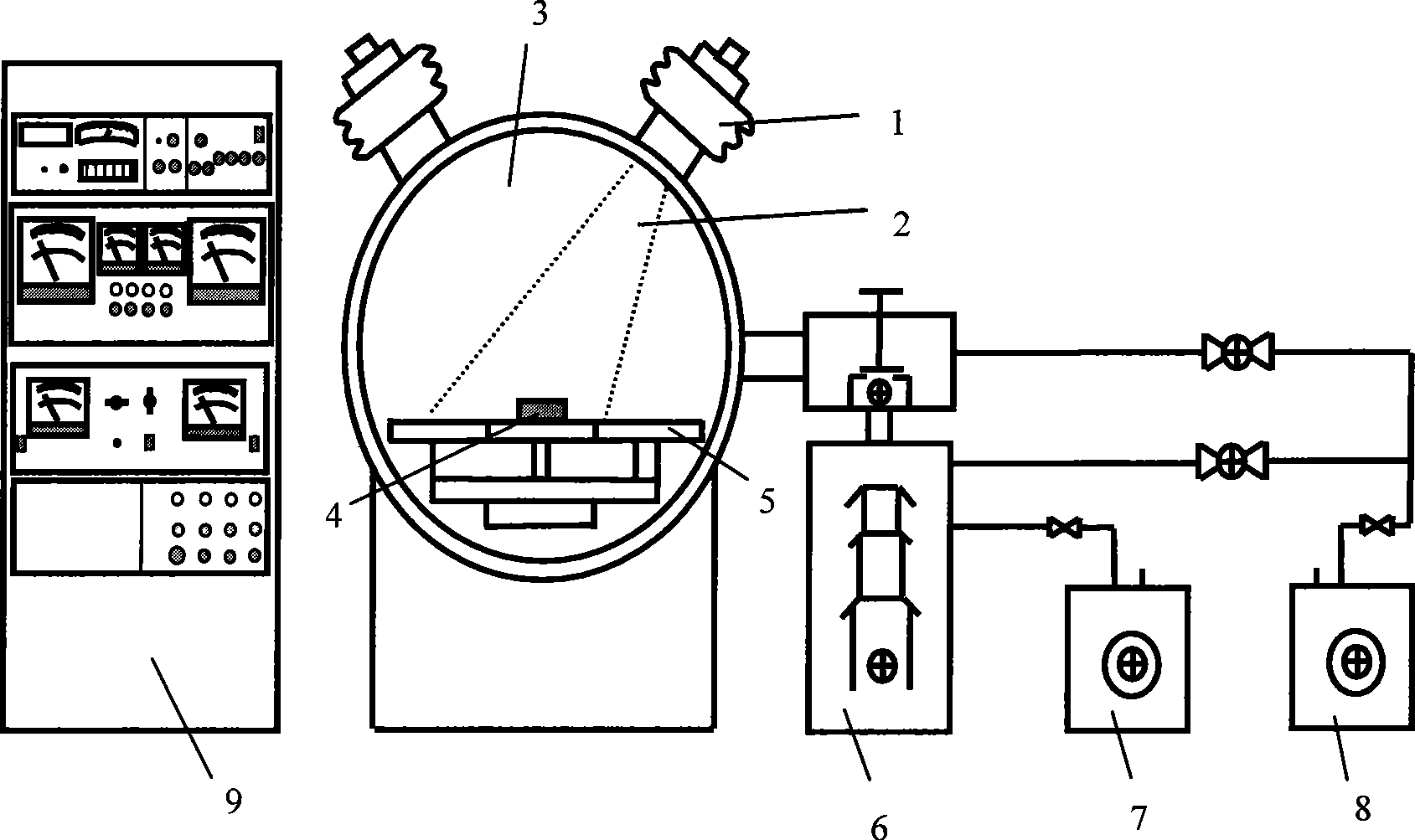

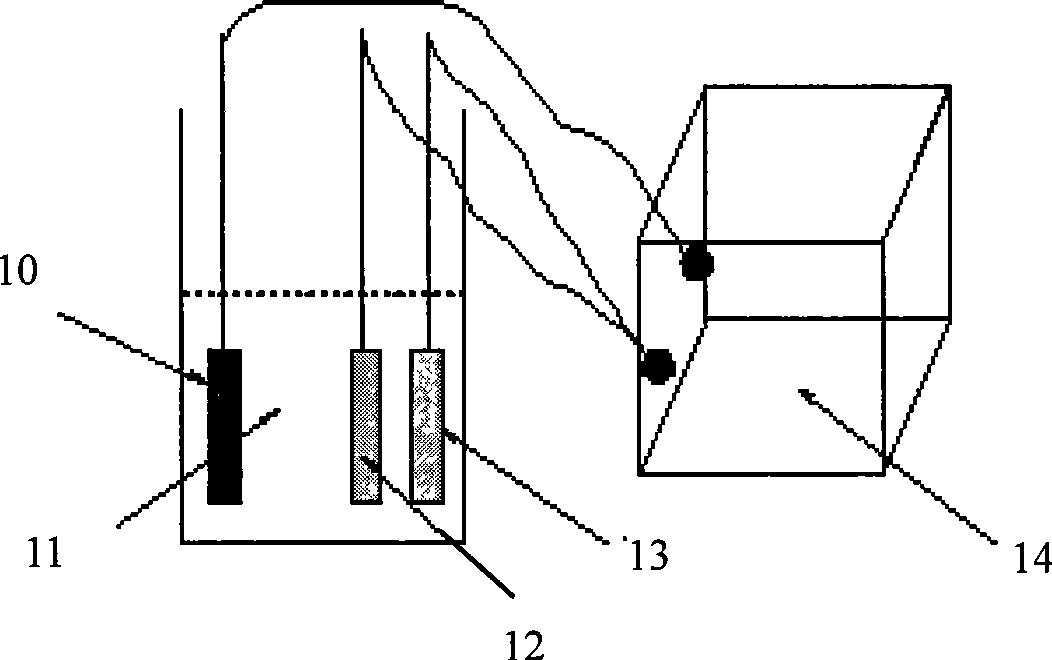

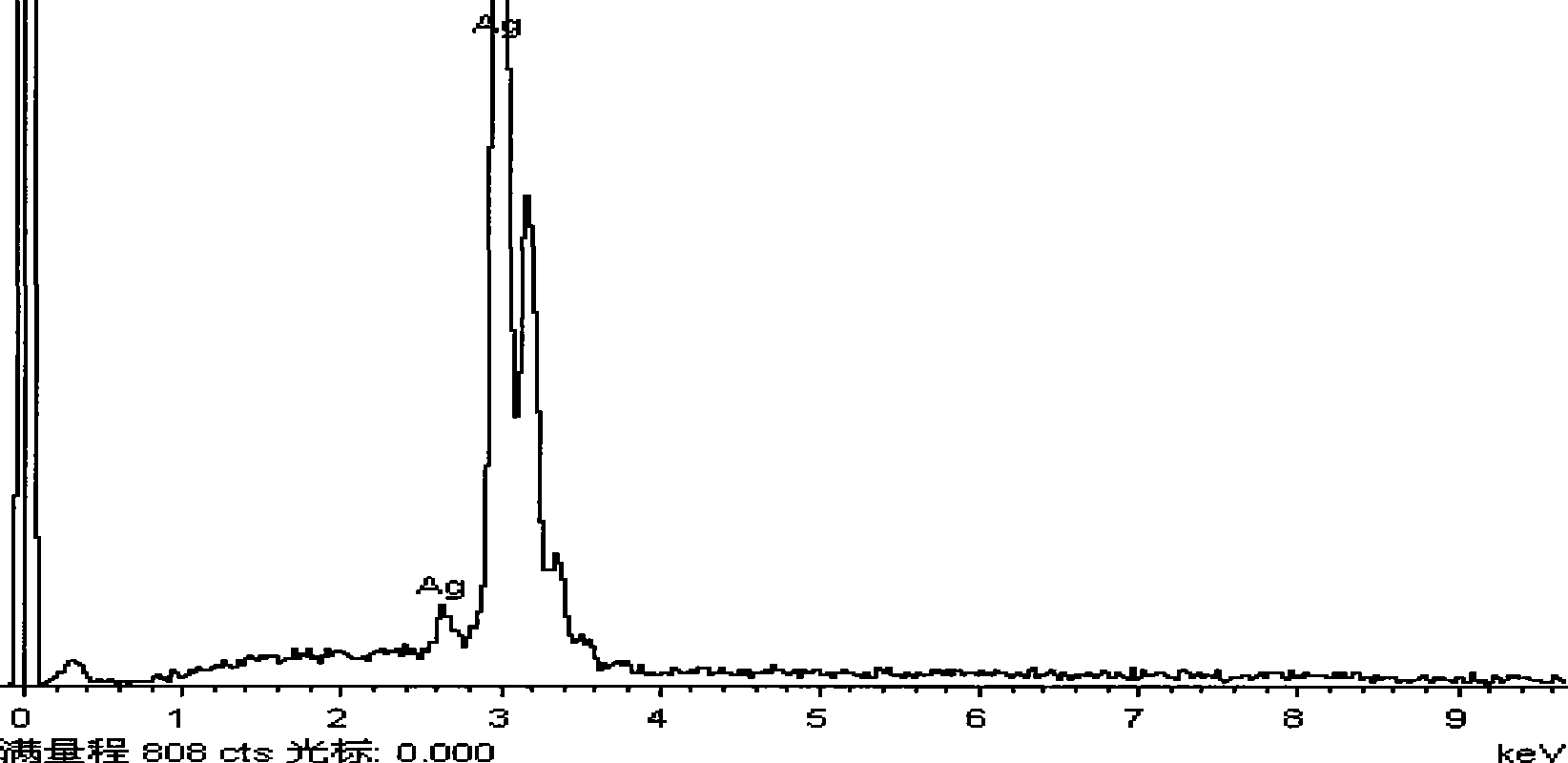

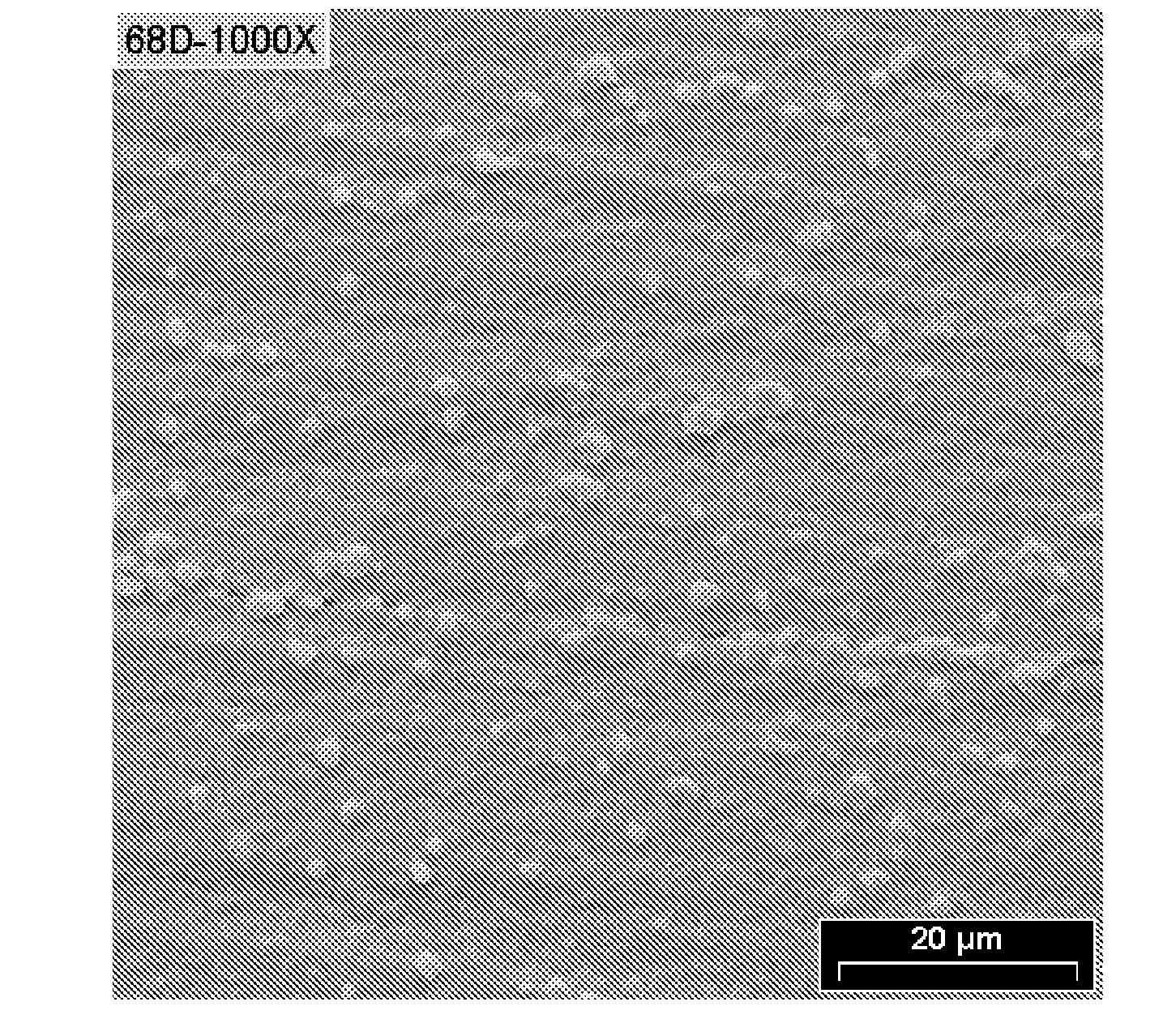

Process and device for coating silver on molybdenum foil used for solar cell paddle of aerospace aircraft

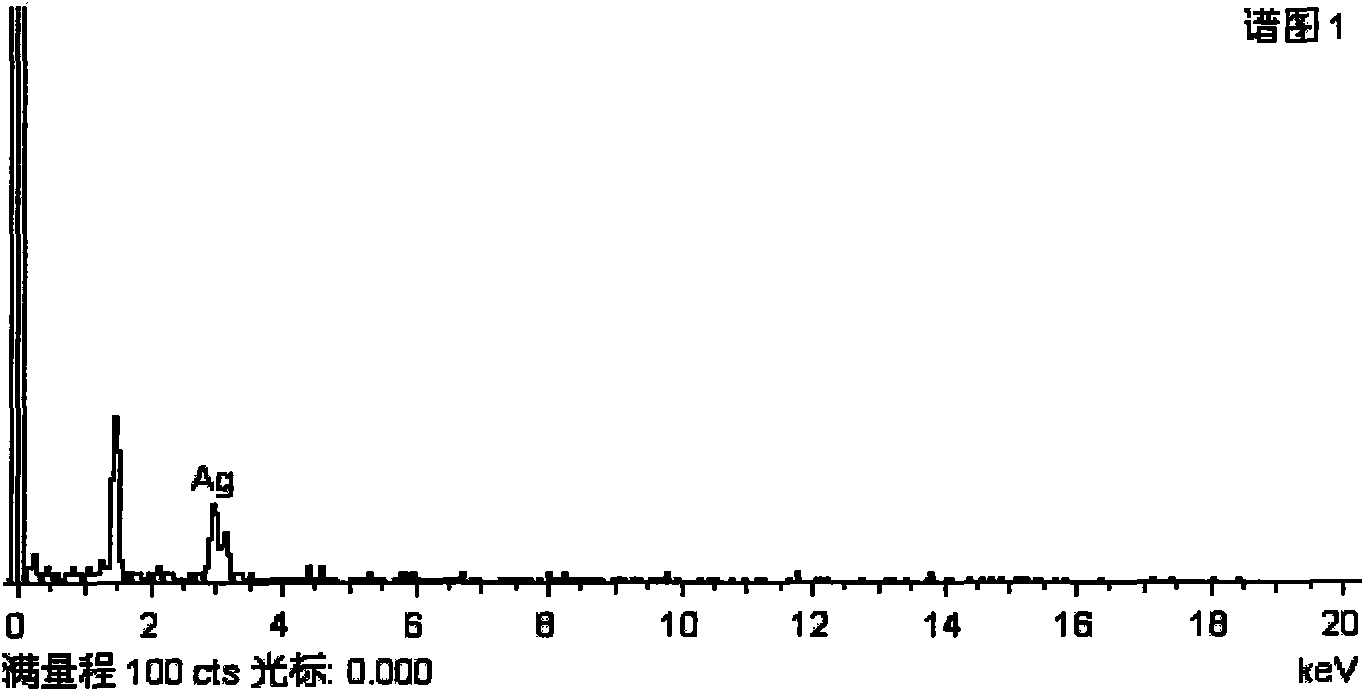

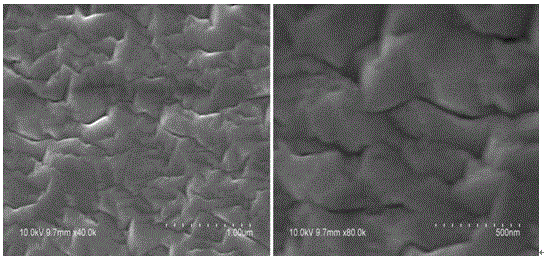

InactiveCN101393947AElectric discharge tubesFinal product manufactureSolar cellBiological activation

The invention relates to a silver electroplating technology for molybdenum foils used for panel substrate interconnecting flakes of solar cells of a space craft. The technology comprises the steps of molybdenum foils buffing and degreasing treatment, acid cleaning activation treatment, silver metal plasma injection, high temperature annealing treatment, silver leaching treatment, silver electroplating, EDS testing on the constituents of an electroplated layer, shape and morphology SEM observation, passivation for the electroplated molybdenum foils, and testing on the conductibility and the weldability of the electroplated molybdenum foils. The vacuum metal plasma injection technology provided by the invention comprises the following steps: injecting metallic elements as per certain energy and dosage into the molybdenum foil interconnecting flake material processed by buffing, degreasing treatment and acid cleaning activation treatment; carrying out silver leaching treatment after vacuum high temperature annealing; and carrying out non-cyanide silver electroplating so as to achieve a silver plating layer on the molybdenum foils, which is characterized by seamlessness, fine and round crystal grains and dense structure. The passivation treatment for the electroplated molybdenum foils gives the silver plating layer the ability to prevent the silver plating layer from being corroded by sulfide. Meanwhile, the conductibility and the weldability of electroplated aluminum foils are greatly improved without being affected by the passivation treatment.

Owner:TIANJIN UNIV

Nickel plating silvered glass bead and preparation method thereof

ActiveCN103130421AGood magnetic conductivityImprove conductivityChemical platingConductive materials

The invention belongs to the technical field of materials, relates to the functional material technology, in particular to electromagnetic shielding material technology, and relates to the preparation technology of the materials. According to a nickel plating silvered glass bead, the glass bead is adopted as a carrier, a nickel plating layer enables a powder body to be good in magnetic conductivity, a surface silvered layer enables the powder body to be good in electrical conductivity, and a nickel layer and a surface silver layer are respectively obtained through a chemical plating method. The glass bead is adopted as the carrier, the middle is the nickel layer, the surface is the silver layer, and the ratio between nickel and silver is between 1.5 and 4.0. A preparation method of the nickel plating silvered glass bead comprises the processes of preprocessing, chemical nickel-plating, chemical silvering and postprocessing. The power body has good magnetic conductivity and excellent electrical conductivity, electromagnetic shielding frequency range is wide, a good electromagnetic absorption effect is achieved in low frequency, and a good electromagnetic wave reflective effect is achieved in medium-high frequency. The nickel plating silvered glass bead is uniform in plating densification, good in intensity and impact resistance, small in density, suitable for the field of electromagnetic shielding, and particularly suitable for electromagnetic absorption, electromagnetic absorption and heat-conductive electricity-conductive materials.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

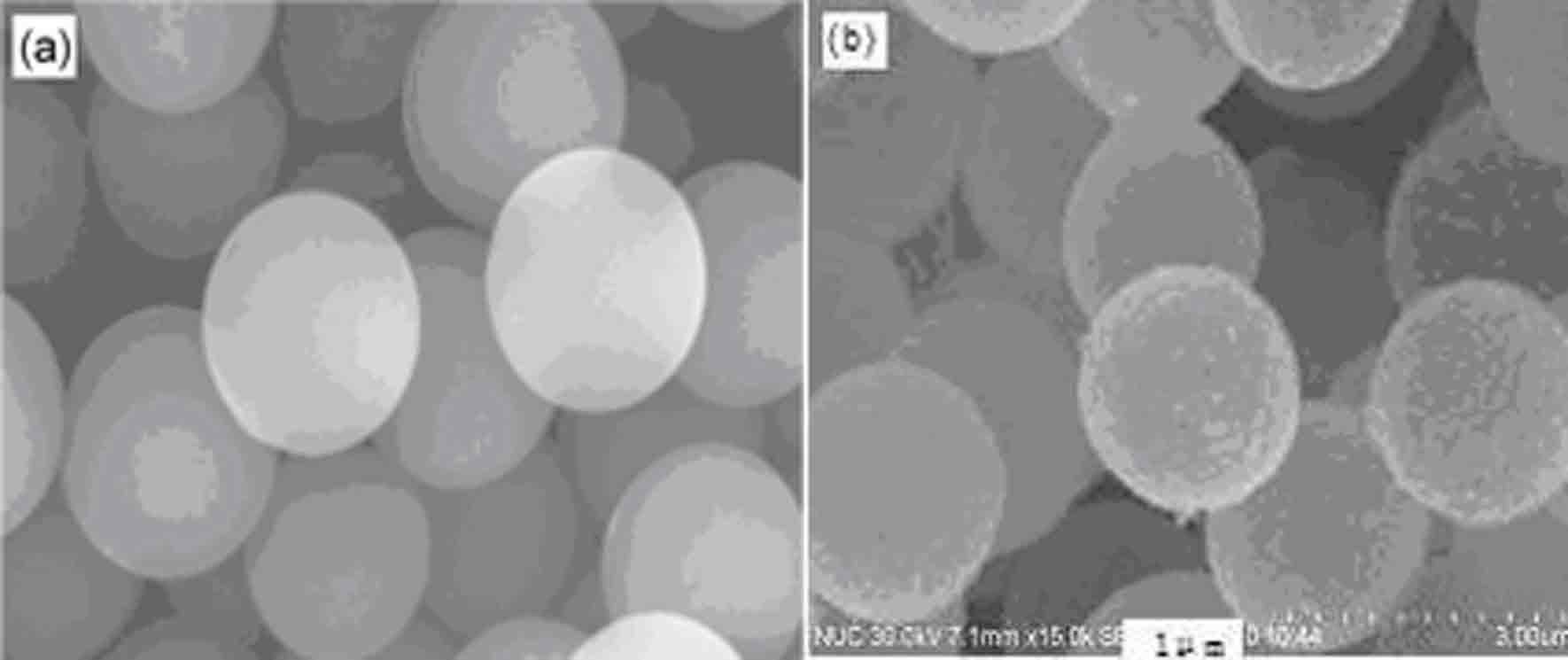

Chemical silvering method for PS (polystyrene) microspheres

ActiveCN102212801AIncrease profitLow densityLiquid/solution decomposition chemical coatingMicrospherePolystyrene

The invention provides a chemical silvering method for PS (polystyrene) microspheres, which comprises the following steps: coarsening the surfaces of PS microspheres; sensitizing and activating the coarsened PS microspheres; adding the treated PS microspheres into a silver-ammonia solution while stirring; adding a certain amount of reducer to finish the chemical surface silvering of the PS microspheres; and filtering, separating, washing, and drying in vacuum to obtain Ag / PS compound particles. The PS silvering method has a simple preparation process and simple composition of raw materials, and is easy to implement large-scale production; and the density of the prepared PS / Ag compound particles is less than 1.2*10<-3>kg.cm<-3>, and the resistivity is less than 4.2*10<-4>ohm.cm, thereby ensuring that the prepared PS / Ag compound particles have light weight and high conductivity.

Owner:ZHONGBEI UNIV

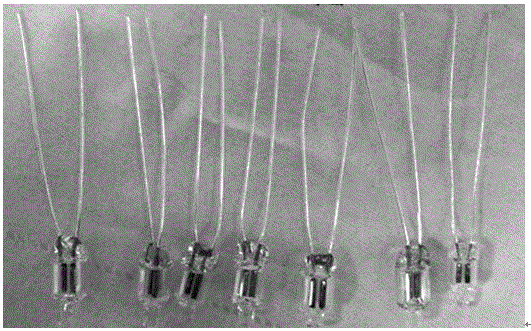

Gold or silver plated wire leads on christmas lights

InactiveUS20090128042A1Corrosion resistanceElectrical apparatusElectric light circuit arrangementSilver plateSilvering

Owner:JLJ

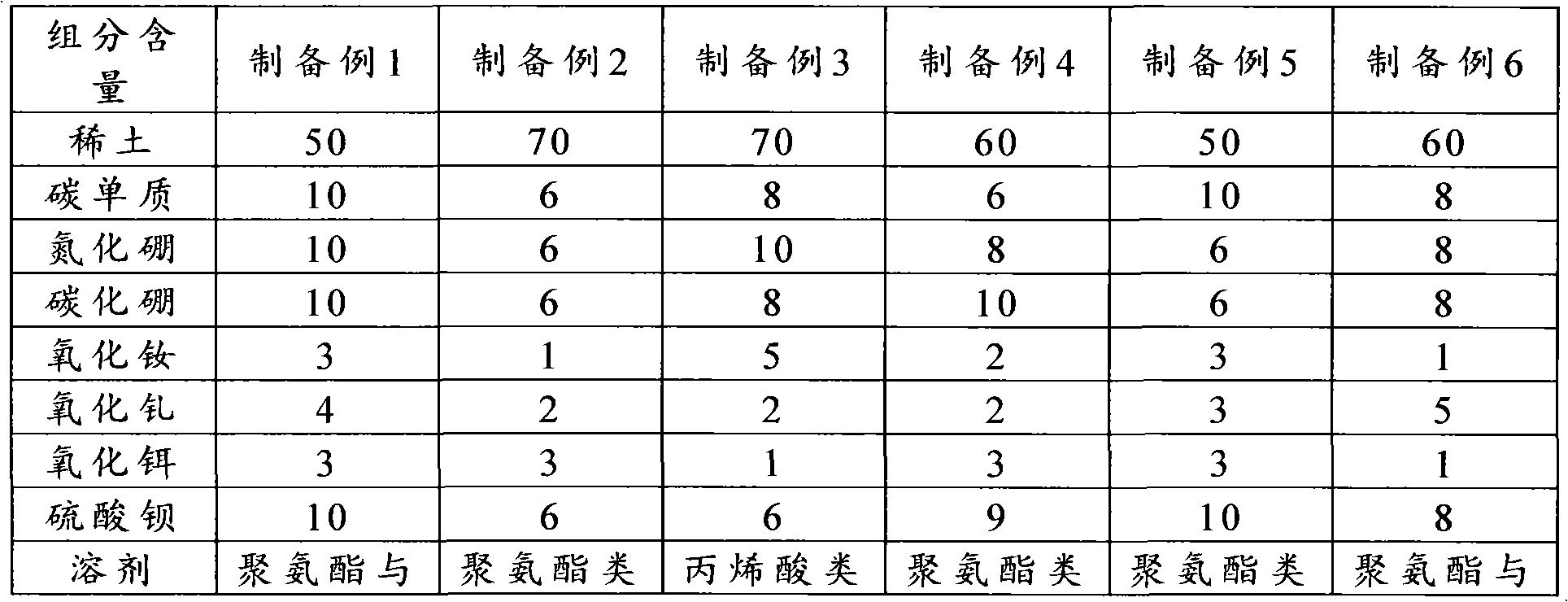

Silver-plated cloth with rare earth-shielding composite layer, preparation method thereof and clothes made of same

The invention relates to a piece of silver-plated cloth with a rare earth-shielding composite layer, comprising a piece of silver-plated cloth. The silver-plated cloth is characterized by comprising the rare earth-shielding composite layer, and the rare earth-shielding composite layer is formed by dissolving the following components in a solvent by mass percentage: 50-70 parts of rare earth and 30-50 parts of composite, wherein the composite comprises the following components by mass percentage: 6-10 parts of monoatomic carbon, 6-10 parts of boron nitride, 6-10 parts of boron carbide, 6-10 parts of neodymium oxide, gadolinium oxide and erbium oxide as well as 6-10 parts of barium sulfate. The silver-plated cloth with the rare earth-shielding composite layer can effectively shield various ionizing rays (x, alpha, beta or gamma) as well as electromagnetic radiation, and also has the function of shielding infrared rays; and the cloth achieves light weight and softness, and can be applied to the ray shielding of the fields of frocks, war industry, operations, electricians, and the like. The invention also relates to a method for preparing the silver-plated cloth with the rare earth-shielding composite layer and silver-plated clothes with the rare earth-shielding composite layer.

Owner:青岛天银纺织科技有限公司

Copper-free silver mirror and manufacturing method thereof

The invention provides a copper-free silver mirror which has sharp image and is not easy to fall off, which comprises a glass substrate; wherein, silver layers, mirror primer and mirror finish are arranged on the surface of the glass substrate in sequence; the thickness of the silver layer is 900-1000mg / m. The manufacturing method of the copper-free silver mirror comprises the following steps: 1) using polishing powder containing 70%-75% of CeO2 by weight to polish the surface of the glass substrate, carrying out deionized water rinsing on the surface, spraying active agent, standing for a period of time and carrying out deionized water rinsing again; 2) spraying catalyst solution which consists of the following components by weight percentage: 28-30% of PdC2, 5%-6% of Ru, 1%-1.2% of HC1 and the rest of deionized water; 3) coating silver layer with thickness of 900-1000 mg / m and passivant on the surface of the glass substrate; 4) carrying out deionized water rinsing and then drying; 5) curtaining the mirror primer and mirror finish. The mirror is sprayed with catalyst containing PdCl2 and the passivant containing Snf2 are sprayed rather than cooper layer, therefore, the image is sharper and not easy to fall off.

Owner:林嘉宏

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

Owner:SHANGHAI UNIV

Preparing method of antioxidant silvering copper powder

InactiveCN106086837AImprove stabilityImprove the problem of too fast releaseTransportation and packagingMetal-working apparatusSilver plateAmmonium hydroxide

The invention relates to a preparing method of antioxidant silvering copper powder. Sodium hypophosphite is adopted to serve as a reducing agent, deionized water is adopted to serve as a solvent, sodium hypophosphite reduction liquid is prepared, copper powder is adopted to serve as a base material to be added into the reduction liquid, PVP is added, ammonium hydroxide is added to adjust the pH value, and the pH value is stabilized to 11; silver nitrate serves as a silver source, the deionized water serve as a solvent to prepare oxidation liquid, an EDTA-2Na complexing agent is added, stability of plating liquid is improved, and the problem that in the silvering process, silver ions are released too fast is obviously solved; solutions are mixed, meanwhile, magnetic stirring is carried out, the adding temperature is kept to range from 30 DEG C to 80 DEG C, reaction is carried out for 20 min, centrifuging is carried out, and one-time-silvering copper powder is obtained; the one-time-silvering copper powder serves as the base material, the above steps are repeated twice, and third-time-silvering copper powder is obtained. High-temperature oxidation resistance of silver plated copper powder prepared through the method is excellent, and the method is suitable for replacing conductive phase silver powder of electronic paste.

Owner:JINLING INST OF TECH

Immersion tin silver plating in electronics manufacture

ActiveUS20110097597A1Liquid surface applicatorsLiquid/solution decomposition chemical coatingTinningSilver plate

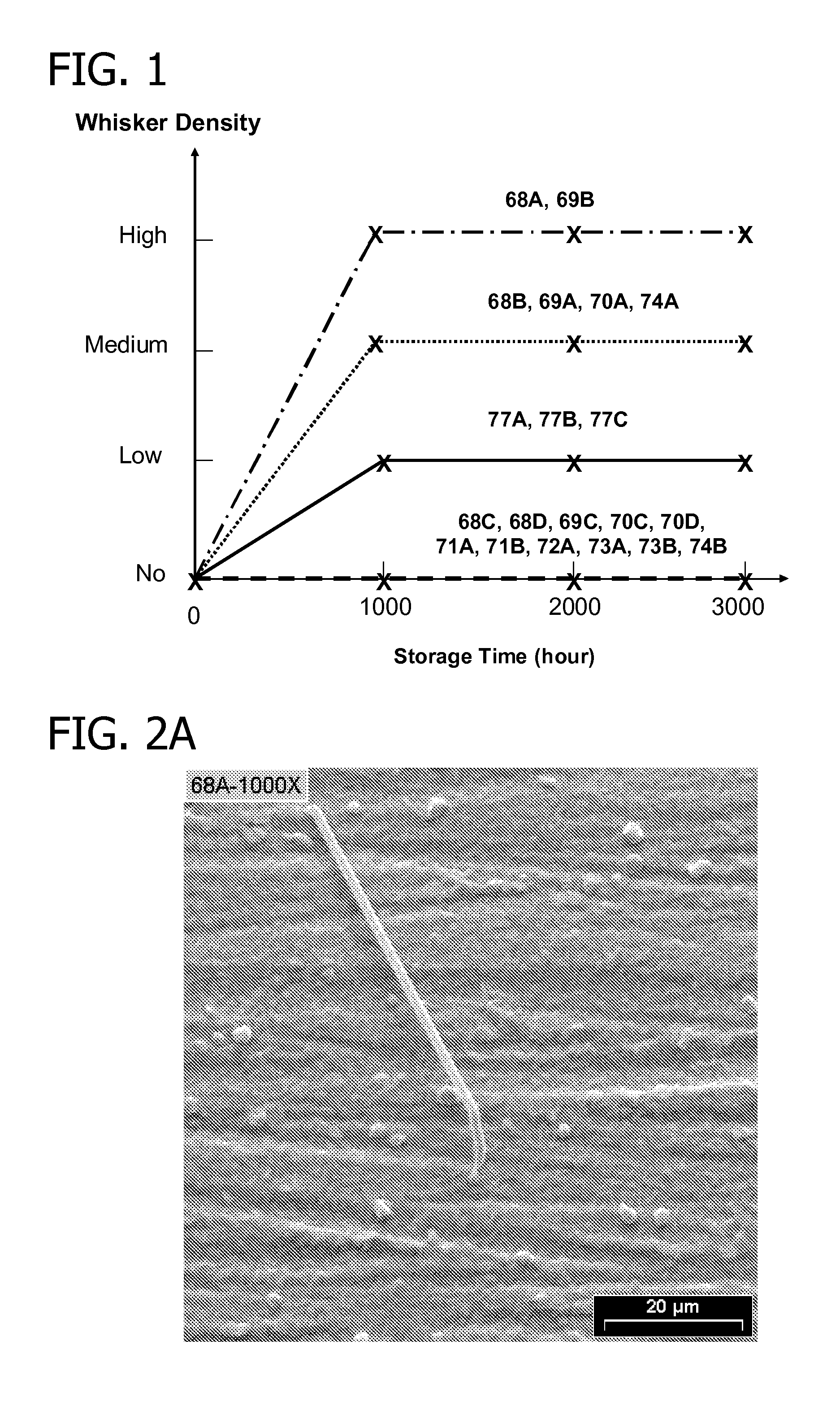

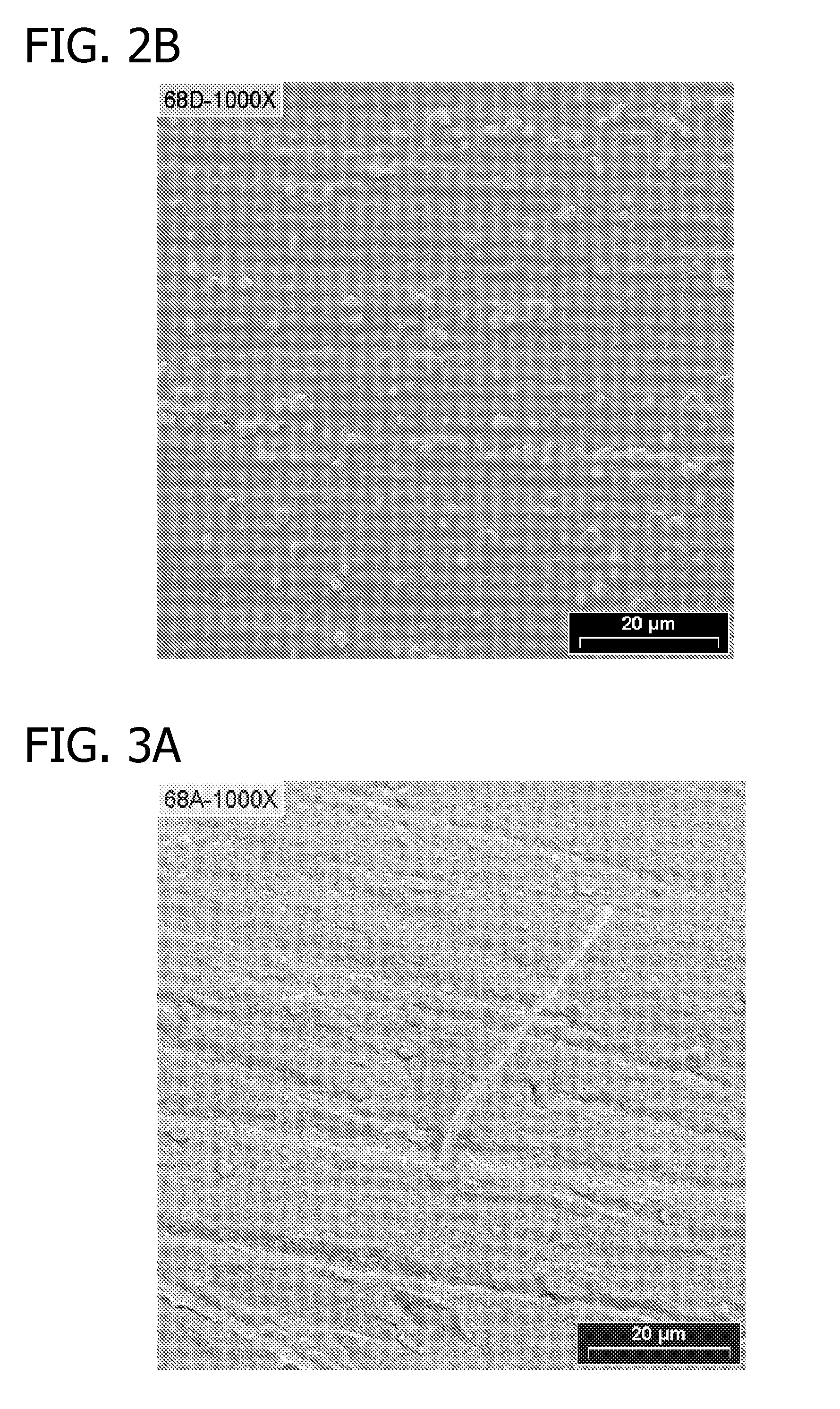

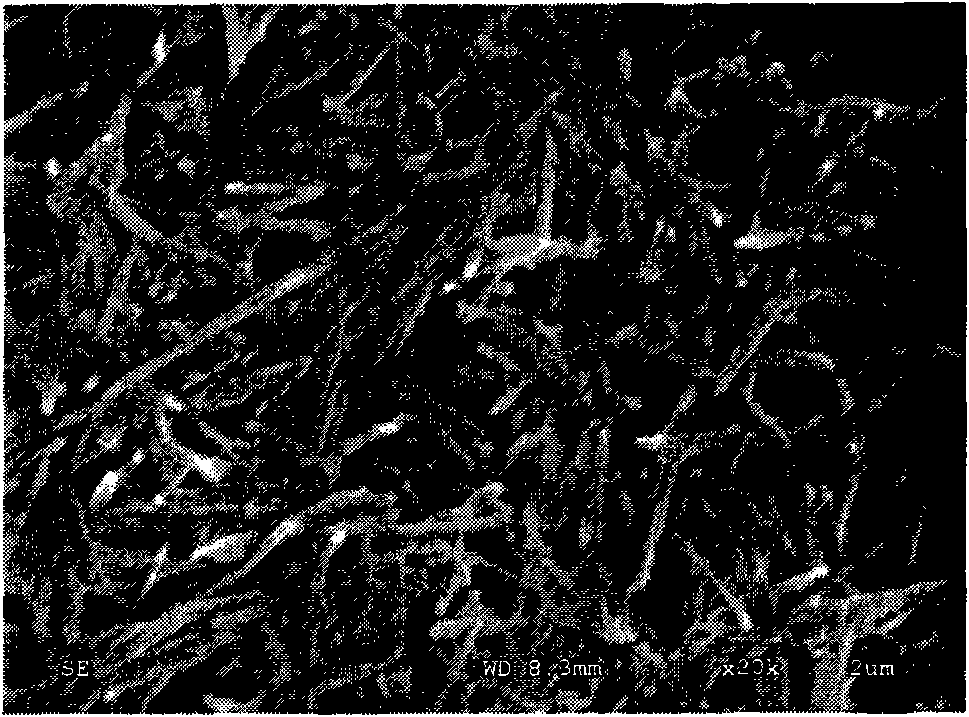

A method is provided for depositing a whisker resistant tin-based coating layer on a surface of a copper substrate. The method is useful for preparing an article comprising a copper substrate having a surface; and a tin-based coating layer on the surface of the substrate, wherein the tin-based coating layer has a thickness between 0.5 micrometers and 1.5 micrometers and has a resistance to formation of copper-tin intermetallics, wherein said resistance to formation of copper-tin intermetallics is characterized in that, upon exposure of the article to at least seven heating and cooling cycles in which each cycle comprises subjecting the article to a temperature of at least 217° C. followed by cooling to a temperature between about 20° C. and about 28° C., there remains a region of the tin coating layer that is free of copper that is at least 0.25 micrometers thick.

Owner:MACDERMID ENTHONE INC

Method for controlling additive distribution uniformity of silver-tin anhydride electride contact material

InactiveCN1641813AImprove distributionImprove mechanical propertiesContact materialsLiquid/solution decomposition chemical coatingCopper platingSilvering

The invention discloses a method to control the distributing homogeneity of silver- stannic oxide electric contact material additive. Before chemical silvering, taking chemical coppering to the SnO2 powder, takes oxide treatment; taking chemical silvering under ultrasonic joint together with additive. By using the invention, the distribution homogeneity of silver-stannic oxide material would be controlled, and the stannic oxide and silver basal body has good wetting property. The electric contact made following the inventioin has good sintering activity and machine shaping. It can be used to manufacture thread material and plural shapes of contacts.

Owner:LINGRI SURFACE ENG NINGBO

Method for preparing carbon nano tube silvered acrylic acid series electromagnetic shielding coating

ActiveCN101979708AImprove conductivityImprove shielding effectPigmenting treatmentLiquid/solution decomposition chemical coatingChemical platingAcrylic resin

The invention discloses a method for preparing a carbon nano tube silvered acrylic acid series electromagnetic shielding coating. The method comprises the following steps of: plating a layer of nickel on the surface of CNTs (carbon nano tubes) by adopting a chemical plating method, and then performing chemical silvering to obtain a silvered CNTs composite filler which takes the CNTs with high length-diameter ratio as cores and takes a uniform silvering layer as a shell; and mixing the prepared silvered CNTs, acrylic resin, ethyl acetate and n-butyl alcohol in a ratio, and dispersing the mixture uniformly to finally prepare the electromagnetic shielding coating with good electric conductivity and electromagnetic shielding effect. The layer of nickel is uniformly plated on the surface of the CNTs before the chemical silvering so that the bonding force between the silvering layer and the CNTs is improved and the silvered CNTs have better electric conductivity and dispersibility and are favorable for application in the electromagnetic shielding material field.

Owner:GUANGDONG UNIV OF TECH

Method for preparing rodlike ultrafine silver powder by carrying out chemical silvering on surfaces of attapulgite nanofibers

The invention discloses a method for preparing rodlike ultrafine silver powder by carrying out chemical silvering on surfaces of attapulgite nanofibers, and the method comprises the following steps: firstly, acidizing the natural soils of attapulgite by using a hydrochloric acid solution; then, carrying out oxidant-solution soaking and adsorption on the acidized attapulgite by using a silver nitrate solution; then, carrying out reduction activation treatment on the attapulgite subjected to adsorption; and finally, carrying out chemical silvering on the surface of the attapulgite subjected to reduction activation so as to obtain unidimensional rodlike ultrafine silver powder. The method provided by the invention has the advantages that a metal coating prepared by using the method is small in density, low in cost and complete in metal cladding, and has a rodlike nano structure, thereby creating a new field for the development and application of attapulgite, and improving the economic value added of attapulgite.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Nylon fiber surface chemical silver plating method

InactiveCN109161876AStrong interactionImprove conductivityLiquid/solution decomposition chemical coatingBiological activationSilvering

The invention belongs to the technical field of conductivity and discloses a nylon fiber surface chemical silver plating method which comprises the following steps: (1) removing oil, namely putting afixed amount of a fiber into a clean container, and putting an alkali oil remover for reducing surface tension of the fiber into the container; (2) carrying out sensitization treatment with a sensitization liquid A, namely completely soaking the fiber obtained in the step (1) into the sensitization liquid A prepared on site, and enabling the surface of the fiber to adsorb a layer of a metal with catalysis activity; (3) carrying out sensitization treatment on a sensitization liquid B, namely completely soaking the fiber obtained in the step (2) into the sensitization liquid B prepared on site,and forming hydrogen bonds by carbonyl functional groups on the surface of the fiber and carbonyl functional groups in the sensitization liquid B; (4) carrying out activation, namely completely soaking the fiber obtained in the step (3) into a silver amino solution prepared on site; (5) putting a fixed amount of glucose restore into the solution obtained in the step (4). By adopting the method, asilver plated layer with a solid plated layer can be made, and a conductive fiber with good conductivity can be manufactured.

Owner:陈明

Alkaline semi-bright non-cyanide immersion chemical silvering solution and preparation method thereof

InactiveCN106222633AStrong anti-pollutionImprove bindingLiquid/solution decomposition chemical coatingCyanideRoom temperature

The invention discloses an alkaline semi-bright non-cyanide immersion chemical silvering solution and a preparation method thereof. The silvering solution is stable and can be preserved for more than three years at the room temperature, the efficiency is high, the bonding force of a plating layer is good, and the surface of the plating layer is flat, semi-bright and good in anti-tarnish property. The silvering solution is easy to maintain, and only silver ions need to be supplemented during long-term operation; and in addition, the silvering solution is high in anti-pollution capacity and copper ion tolerance.

Owner:JIAXING UNIV

Chasing piece gilding and silvering process

InactiveCN1422758ASimple processLow priceDecorative surface effectsArtistic surface treatmentWaxLacquer

The gilding and silver-plating process of through-carved work includes the following steps: grinding the through-carved work and printing coat, bedding putty, spraying and brushing prime paint, using matched flow thick material to cover prime paint, after 5-10 hr., sticking pure golf foil or pure silver foil on the surface, pressurizing and planishing, spray-coating finish coat by using transparent lacquer, after 24 hr. applying polish wax and polishing. Said invention is simple in process, and its gilding and silver-plating effect is good, and its application is extensive.

Owner:曾剑

Chemical spray silvering method of fabric

ActiveCN102994990AAvoid self-decomposition reactionsFix instabilityLiquid/solution decomposition chemical coatingPolyesterInstability

The invention discloses a chemical spray silvering method of a fabric. The chemical spray silvering method comprises the following process steps: I, preprocessing the fabric so as to form a catalytic activity center on the surface of the fabric; and II, carrying out chemical spray silvering on the texture, and enabling the metallic silver to deposited onto the surface of a polyester fabric; the chemical spray silvering process is carried out by adopting a two-step spray-up way; and the reducing solution and the silver salt solution are respectively sprayed on the surface of the fabric during spraying up. According to the chemical spray silvering method, the reducing agent solution is not directly contacted with the silver salt solution in the implementation process of the method, so that the generation of self-decomposing reaction of the spray liquid can be avoided, and the problems of instability and environmental pollution caused by the spray liquid can be solved; and furthermore, the reducing agent solution and the silver salt solution can be recycled, and therefore, the consumption of the spray liquid can be reduced, and the cost can be lowered.

Owner:JIAXING HENENG TECH CO LTD

Method for production of silver-carring foam metal with disinfecting and sterilizing function

InactiveCN1481679AImprove the ability to kill germsIncrease surface areaBiocideAnimal repellantsPorosityChemical plating

The present invention relates to the field of air and water purifying technology, and is the preparation of silver-carrying foamed metal with sterilizing function. Foamed metal with certain pores or porosity suitable for filtered fluid is selected as carrier, and its surface is coated with silver or silver containing compound via electroplating, chemical plating or other physical or chemical process to produce the silver-carrying foamed metal with sterilizing function. The present invention has the features of great silver carrying surface area, high carrier strength and high bactericidal efficiency. For ever higher pathogenic bacteria killing capacity, hydroxyapatite and titanium dioxide with synergistic effect are also used. This kind of foamed metal has wide application foreground in purifying air and water.

Owner:SHANGHAI JIAO TONG UNIV

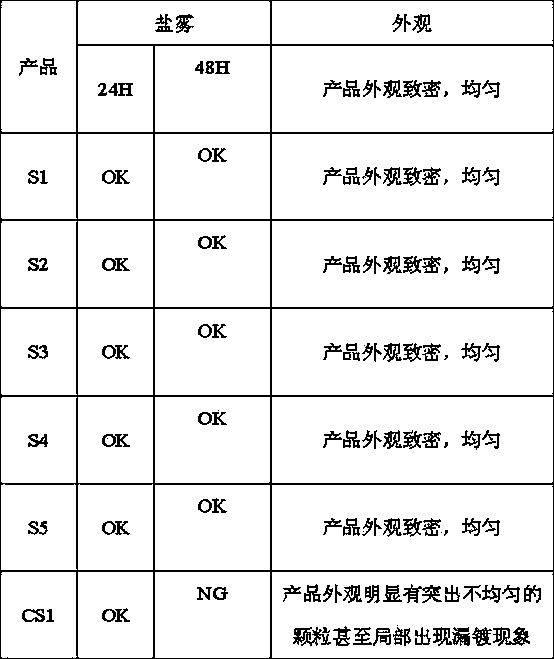

A chemical silvering solution and a silvering method

ActiveCN104342643AHigh glossPlay a stabilizing roleLiquid/solution decomposition chemical coatingBenzenePEG 400

A chemical silvering solution is provided. The chemical silvering solution comprises a silver salt, a complexing agent, a pH conditioner and additives. The additives comprise benzotriazole and polyethylene glycol. The weight ratio of the benzotriazole to the polyethylene glycol is 1:2.5-50. The polyethylene glycol is PEG-1000 or PEG-400. The pH of the chemical silvering solution is 8.2-10.2. A chemical silvering method using the chemical silvering solution is also provided by the invention. Products obtained by using the chemical silvering solution are compact and uniform in appearance, while products obtained by using silvering solutions of the same kind in the market have appearances with protruding and nonuniform particles and even have skip plating in local parts. The chemical silvering solution has a longer time for starting decomposition than the silvering solutions of the same kind in the market and is more stable.

Owner:BYD CO LTD

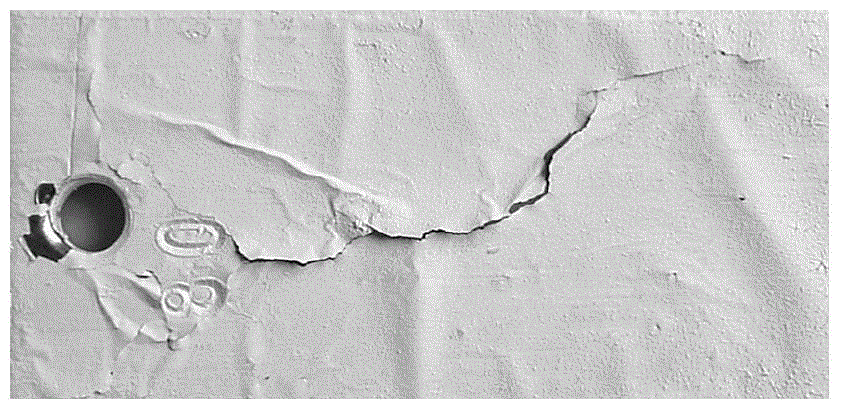

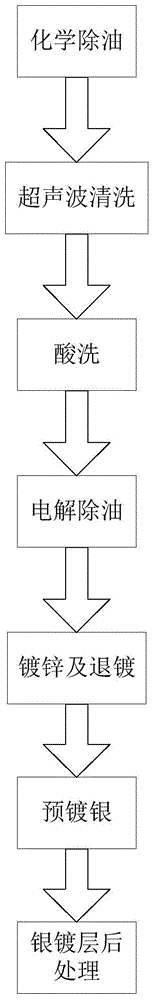

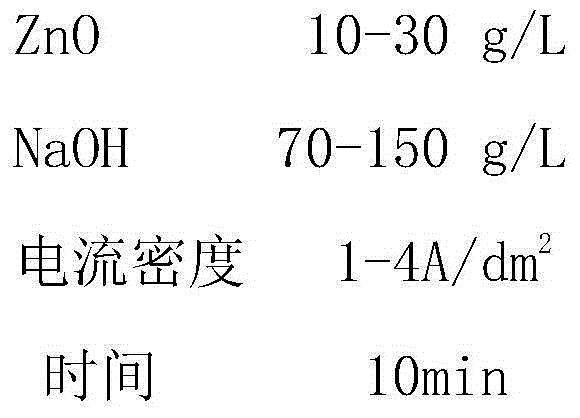

Lead brass silver plating process

The invention discloses a lead brass silver plating process which comprises the following steps: chemically deoiling; ultrasonically cleaning; pickling; electrolytically deoiling; galvanizing and stripping; pre-plating silver; and carrying out post-treatment process. In the galvanizing step, a zinc layer wraps and covers slag and dust on the surface of a part in a precipitation process. As zinc and copper have a relatively great potential difference, certain replacement reaction is bound to happen on zinc and copper to generate an intermediate layer mingled with copper and zinc. The intermediate layer enhances the bonding force of the two metals. In the pickling process, severe hydrogen evolution reaction plays a strong impact role on slag and dust, so that the slag and dust are separated from the surface of the part, therefore, a good deslagging and dedusting role is played. In the step of pre-plating silver, an alloy of copper and mercury covers the surface of the copper part through amalgamation first so as to improve bad replacement caused by a relatively great potential difference; and after amalgamation, silver is pre-plated on the surface of the copper part, and the appearance quality of the plate is improved well.

Owner:湖北三江航天红林探控有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com