Patents

Literature

48 results about "Tarnish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tarnish is a thin layer of corrosion that forms over copper, brass, silver, aluminum, magnesium, neodymium and other similar metals as their outermost layer undergoes a chemical reaction. Tarnish does not always result from the sole effects of oxygen in the air. For example, silver needs hydrogen sulfide to tarnish, although it may tarnish with oxygen over time. It often appears as a dull, gray or black film or coating over metal. Tarnish is a surface phenomenon that is self-limiting, unlike rust. Only the top few layers of the metal react, and the layer of tarnish seals and protects the underlying layers from reacting.

Silver plating anti-color changing protecting agent composition

InactiveCN101503798APrevent discolorationDoes not affect conductivityMetallic material coating processesBenzoxazoleSilver plate

The invention relates to a silver plating anti-tarnish protectant compound. The protectant compound comprises the following components in percentage by weight: 13 to 15 percent of aliphatic alcohol polyoxyethylene ether, 8 to 10 percent of 1-phenyl-pentasulfhydyl tetrazole, 4 to 5 percent of 2-sulfhydryl benzoxazole, 3 to 5 percent of t-dodecyl mercaptan, 3 to 5 percent of 2-sulfhydryl benzimidazole, 8 to 10 percent of anhydrous ethanol, 8 to 10 percent of ethylene glycol, and the balance of deionized water. The silver plating anti-tarnish protectant compound forms a protective complex film on a silver surface, has a higher corrosion inhibition rate, and obviously improves the sulfidation resistance and abrasion resistance of the silver surface. The silver plating anti-tarnish protectant compound is mainly used for the tarnish prevention of silvered electronic parts and components, and is also applied to the sulfidation and tarnish prevention of silver or silvered jewellery, jewelry, ornaments, artwork, tableware, and the like. The silver plating anti-tarnish protectant compound can effectively protect silvered articles against sulfidation and tarnish in a certain period, keep the original metal luster and has no influence on the conductivity and weldability of the parts.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Material for Dissipating Heat From and/or Reducing Heat Signature of Electronic Devices and Clothing

ActiveUS20170229692A1Reducing heat signatureHeat dissipationGlovesBattery isolationElectromagnetic interferenceEngineering

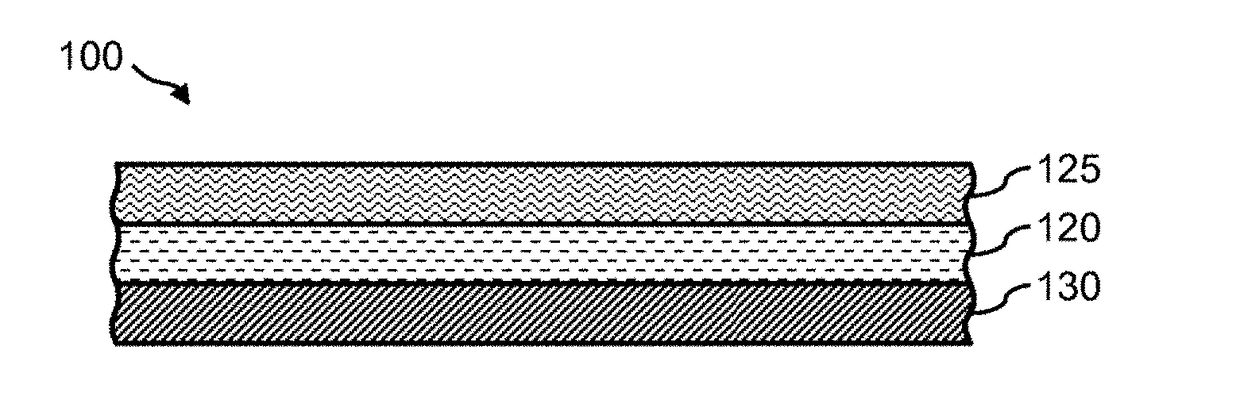

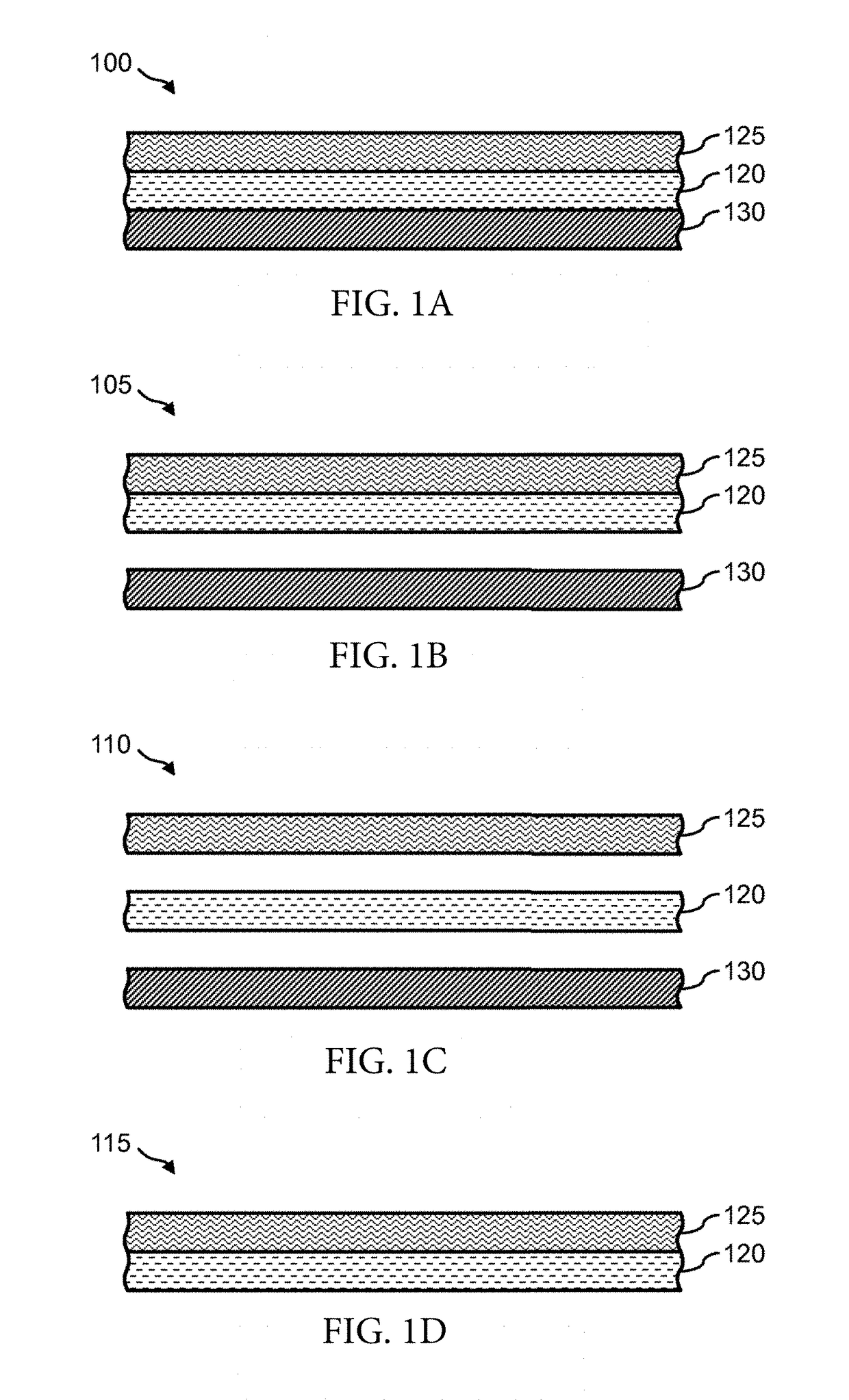

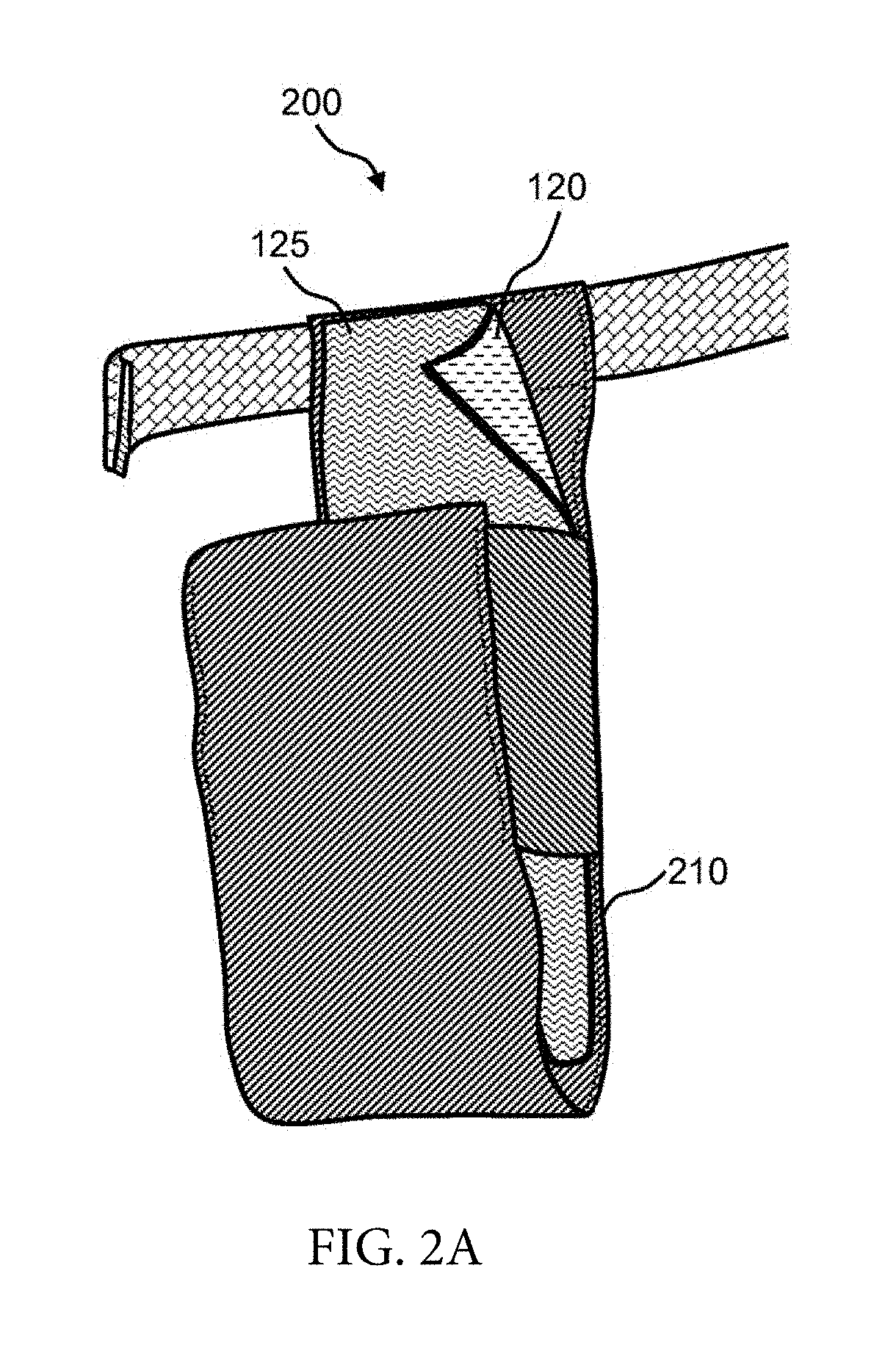

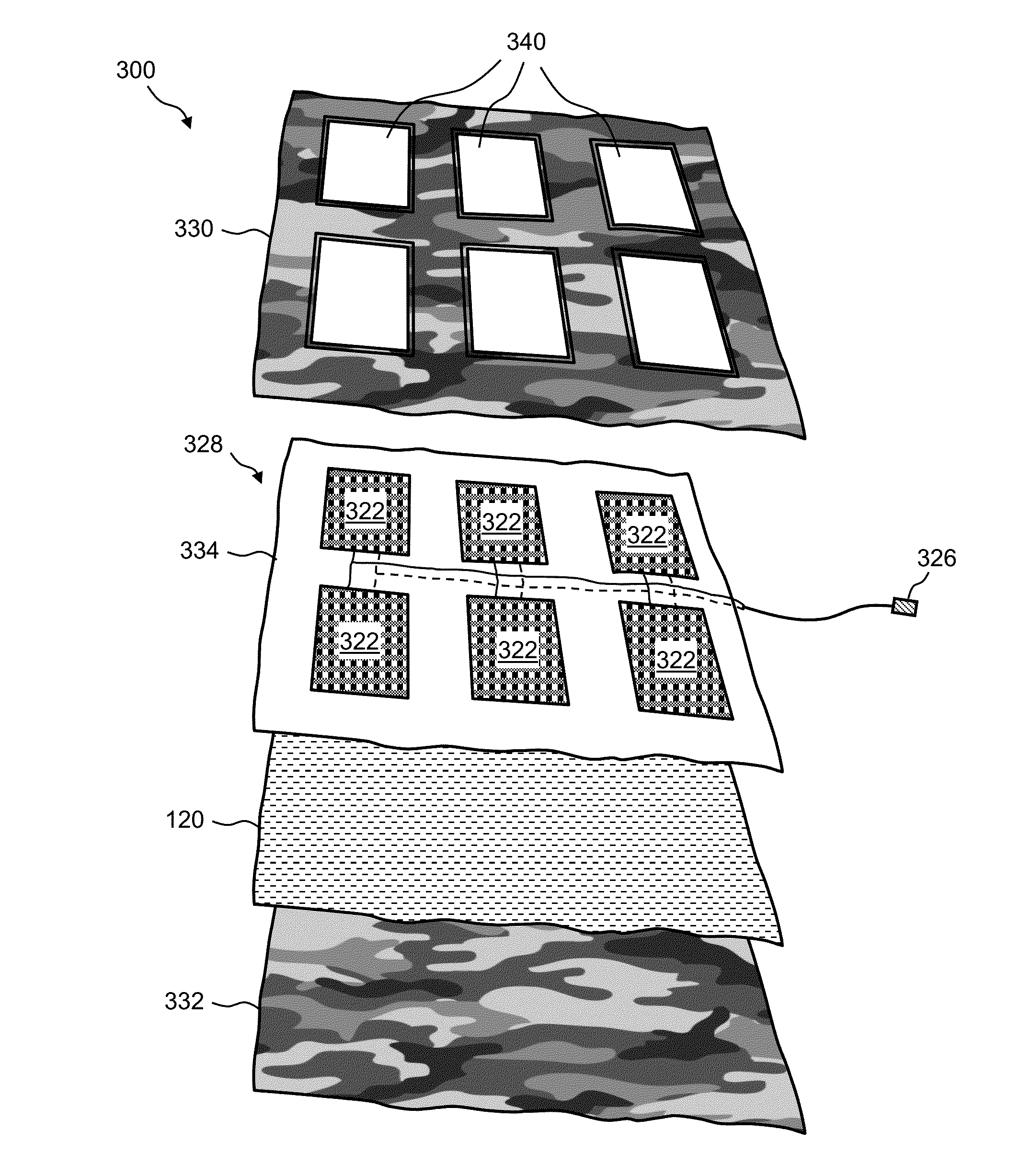

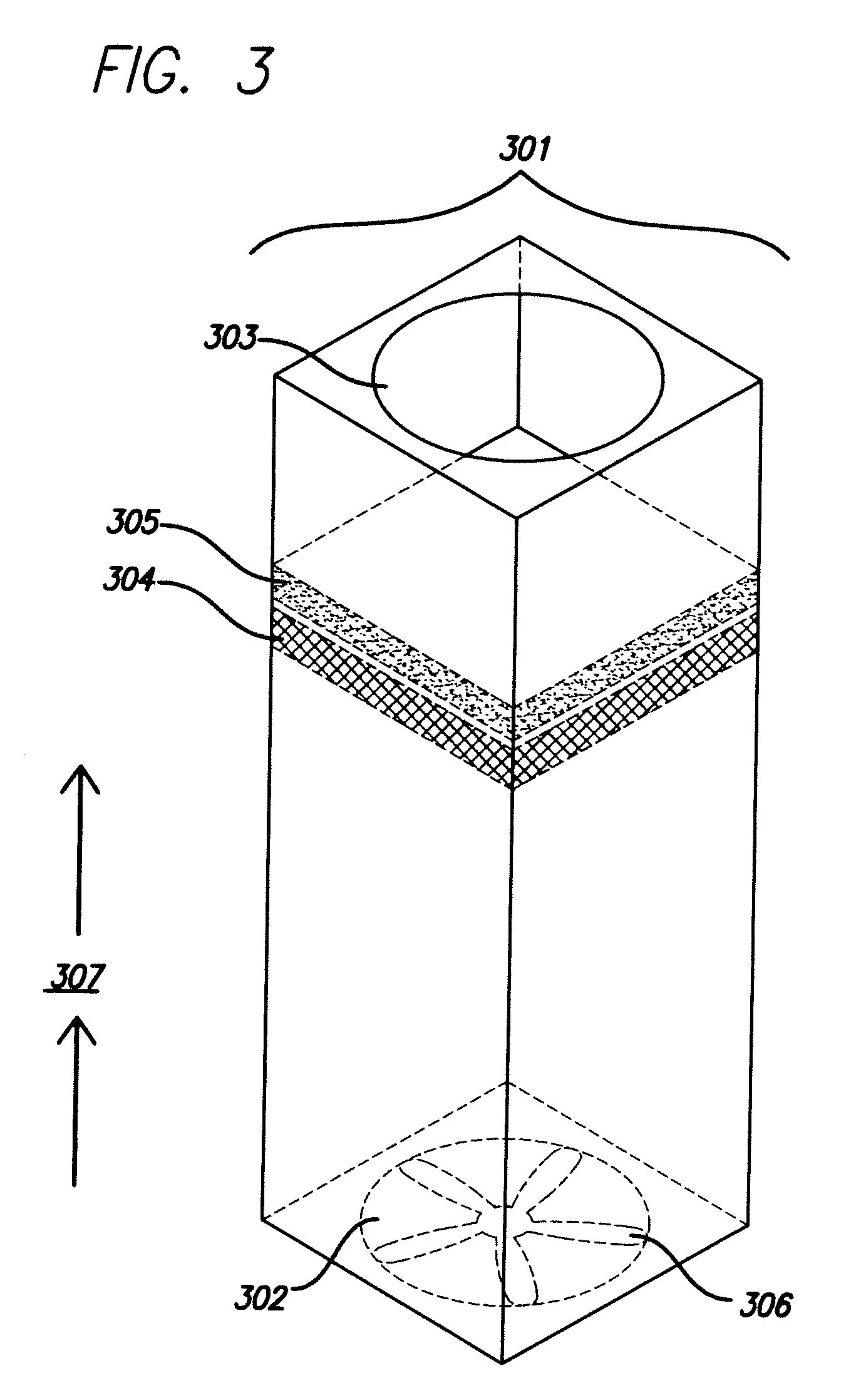

Systems, methods and articles having a heat-shielding or blocking, heat-dissipating and / or heat signature-reducing material layer or coating are disclosed. In one example, the heat-shielding or blocking, heat-dissipating and / or heat signature-reducing material completely covers the interior of a housing having a plurality of battery cells removably disposed therein. Other examples include a heat-shielding or blocking, heat-dissipating and / or heat signature-reducing material layer having anti-static, anti-radio frequency (RF), anti-electromagnetic interference (EMI), anti-tarnish, and / or anti-corrosion materials and properties that effectively protect battery-operated devices and / or the batteries that power them from damage or diminished operation.

Owner:LAT ENTERPRISES

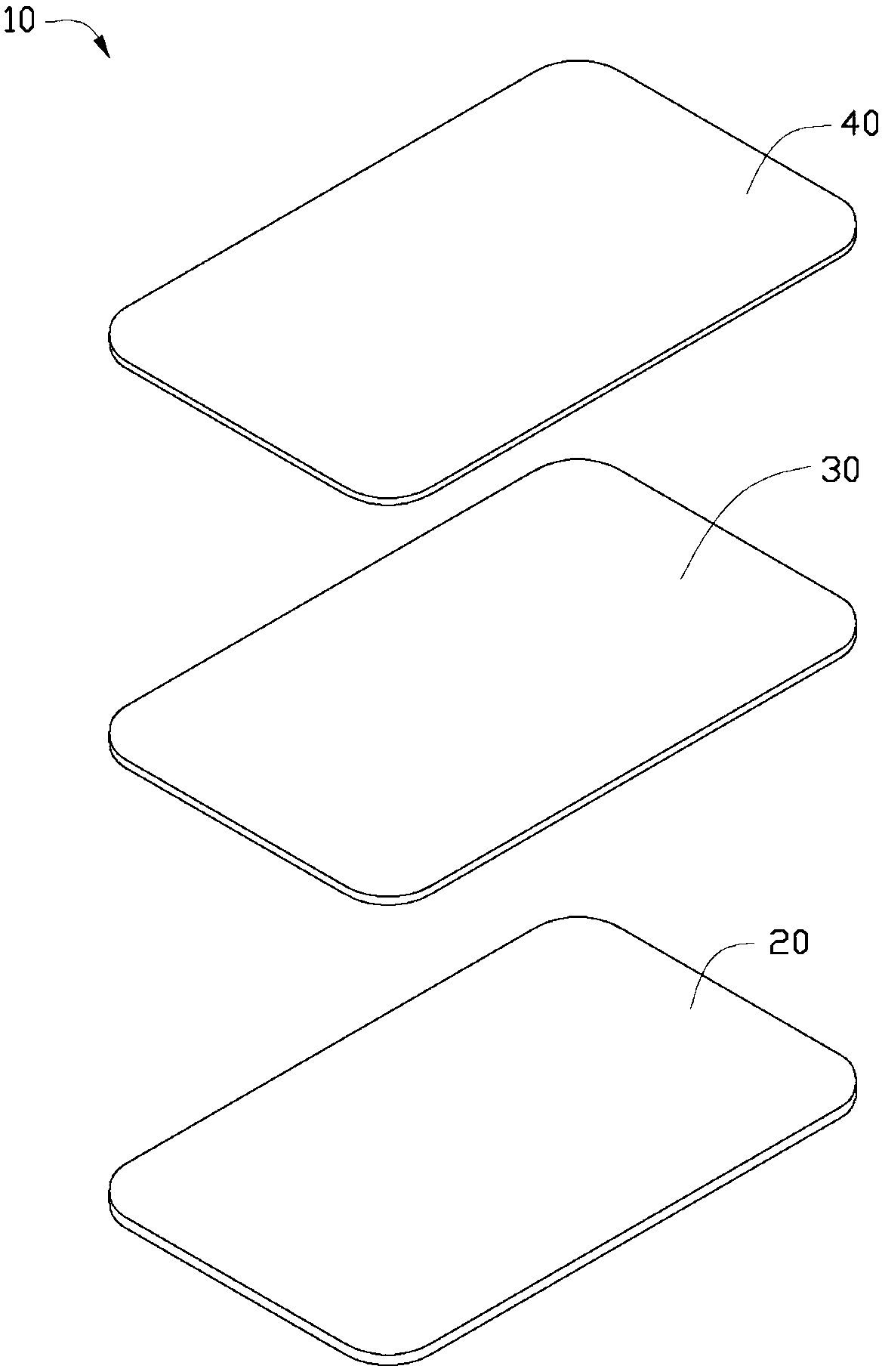

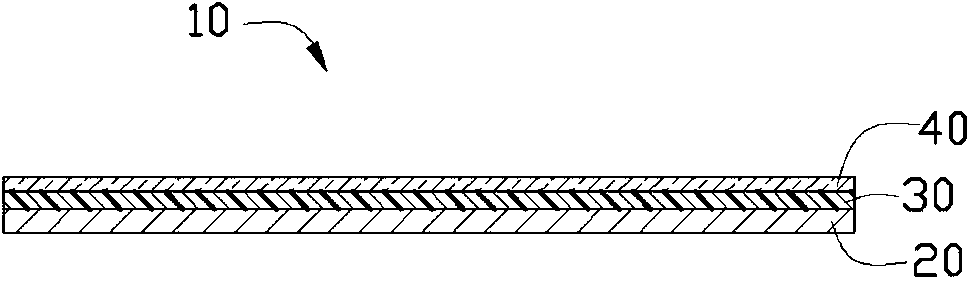

Material for Dissipating Heat From and/or Reducing Heat Signature of Electronic Devices and Clothing

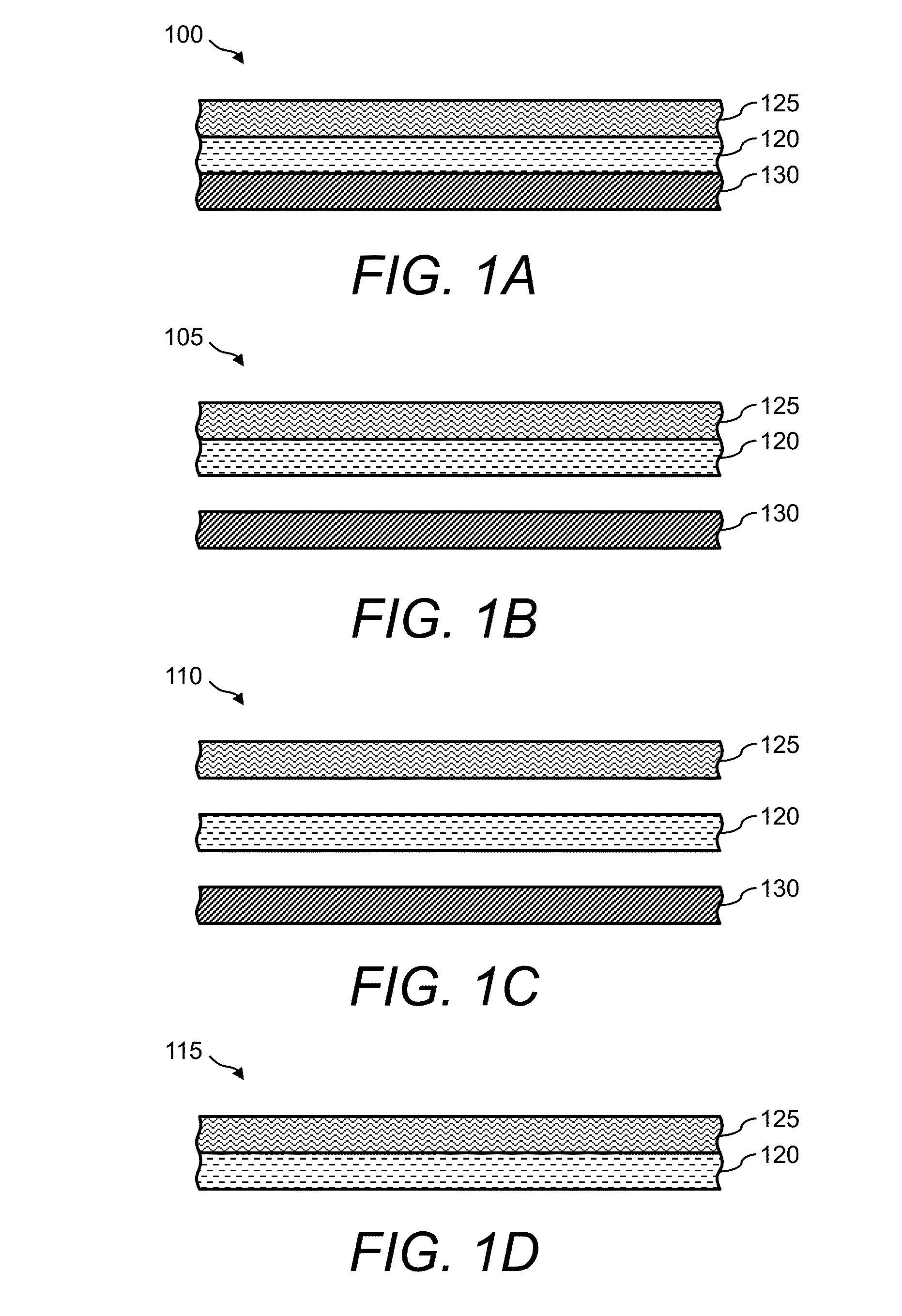

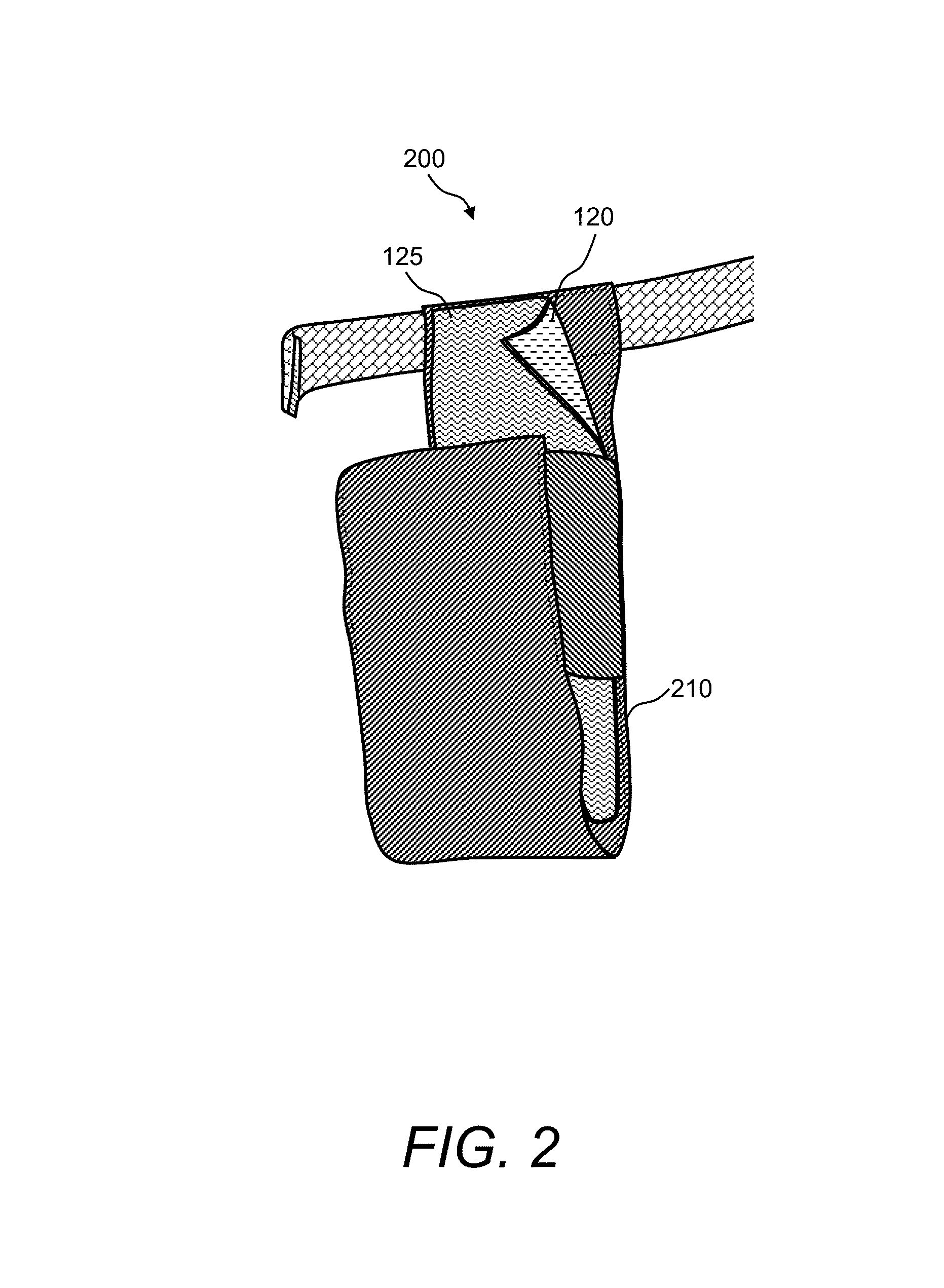

A material for dissipating heat from and / or reducing the heat signature of electronic devices and clothing is disclosed. In one example, a heat-dissipating and / or heat signature-reducing layer is sandwiched between two substrates, wherein the substrates may be flexible, rigid, or a combination of both flexible and rigid. Further, examples of the heat-dissipating and / or heat signature-reducing layer include anti-static, anti-radio frequency (RF), anti-electromagnetic interference (EMI), anti-tarnish, and / or anti-corrosion materials.

Owner:LAT ENTERPRISES

PVD (Physical Vapor Deposition) film on electronic product metal surface and preparation method thereof

ActiveCN103305802ARich in colorVacuum evaporation coatingSputtering coatingPre treatmentChemical vapor deposition

The invention discloses a PVD (Physical Vapor Deposition) film on an electronic product metal surface and a preparation method of the PVD film. The PVD film comprises a metal base material, wherein a plurality layers of metal or metal compound films are deposited on the surface of the metal base material; the thickness of the film is 0.1-3mu m; the preparation method comprises the following steps of: selecting a product to be machined as the base material; carrying out pretreatment; coating the film on the base material which is subjected to pretreatment by using a magnetron sputtering machine, namely, firstly, baking the base material at 120-200 DEG C, secondly, carrying out ion cleaning on the base material in the vacuum state greater than 7*10<-3>Pa, wherein the cleaning time is set as 5-10 minutes, and the vacuum degree in ion cleaning is reduced to be about 7*10<-1>Pa; after the ion cleaning is accomplished, and coating the film on the base material in the vacuum state of 6.4*10<-3>Pa, wherein the vacuum degree in coating the film is reduced to be about 2.3*10<-1>Pa. Colors can be coated on the metal surface, such as a golden yellow series, a dark series, silver, coffee, tarnish, a blue series, a purple series and the like; the film layers are solid; the color is variable; in-batch production can be conducted.

Owner:DONGMING XINGYE SCI TECH CO LTD

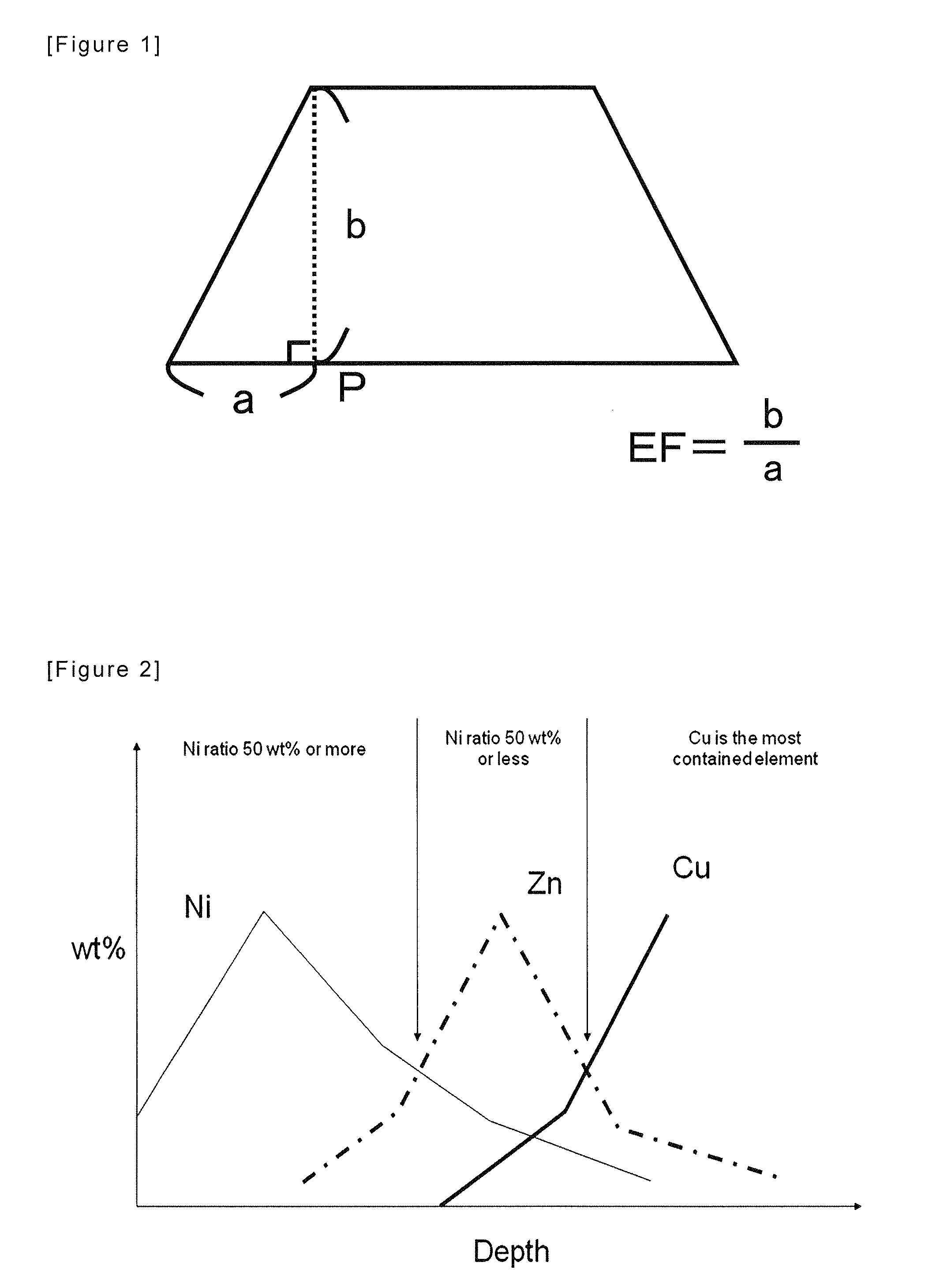

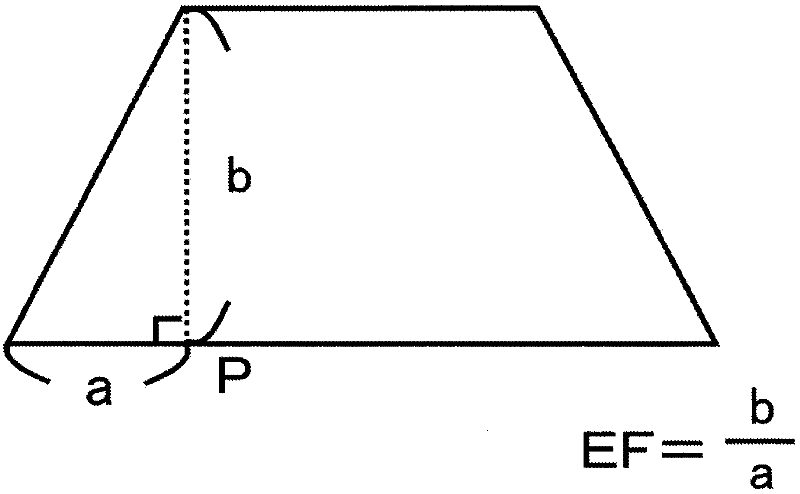

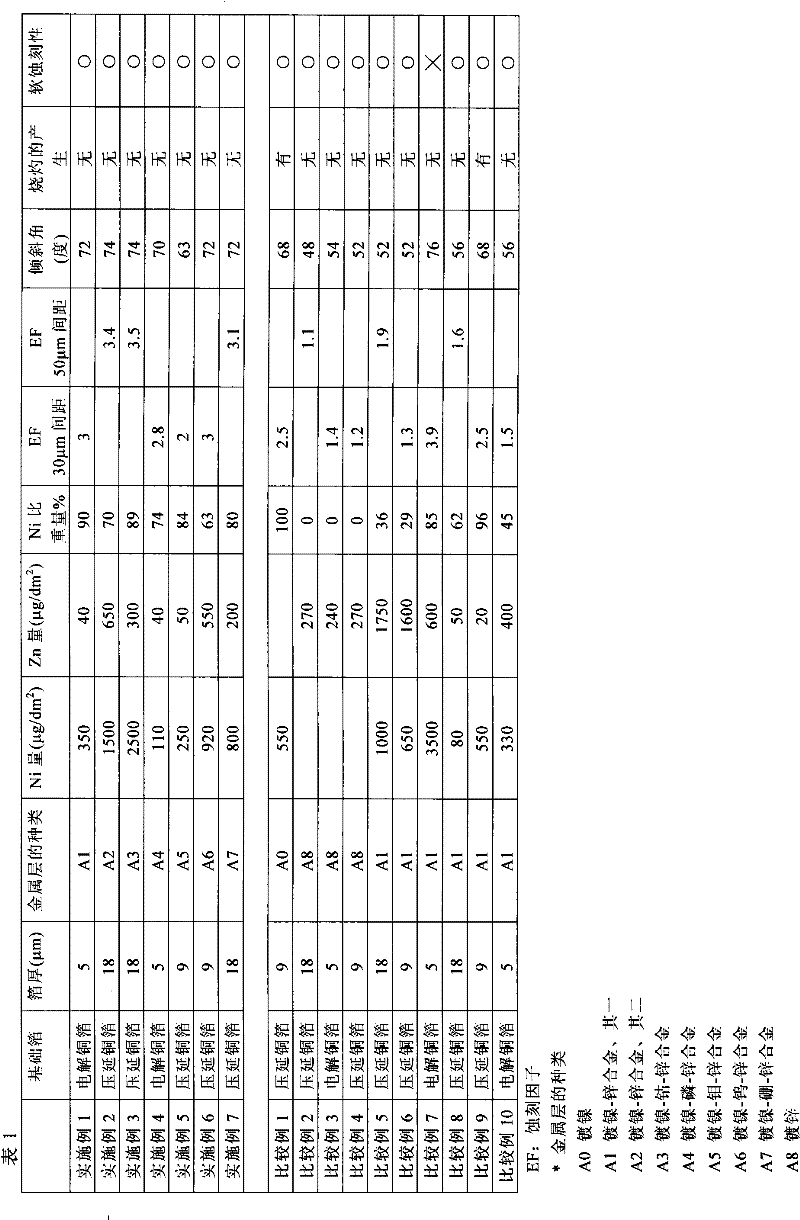

Rolled Copper Foil or Electrolytic Copper Foil for Electronic Circuit, and Method of Forming Electronic Circuit Using Same

InactiveUS20110259848A1Prevent saggingShorten molding timeSemiconductor/solid-state device detailsPrinted circuit aspectsNickel alloyCopper foil

Provided is a rolled copper foil or electrolytic copper foil for an electronic circuit to be used for forming a circuit by etching, wherein the rolled copper foil or the electrolytic copper foil comprises a nickel alloy layer with lower etching rate than copper, which is formed on an etching side of the copper foil, and the nickel alloy layer contains zinc. This invention aims to prevent sagging caused by the etching, to form a uniform circuit having the intended circuit width, and to shorten the time of forming a circuit by etching as much as possible, when forming a circuit by etching a copper foil of the copper-clad laminate; and also aims to make the thickness of the nickel alloy layer as thin as possible, to inhibit oxidation when exposed to heat, to prevent tarnish (discoloration) known as “YAKE”, to improve the etching properties in pattern etching, and to prevent the occurrence of short circuits and defects in the circuit width.

Owner:JX NIPPON MINING& METALS CORP

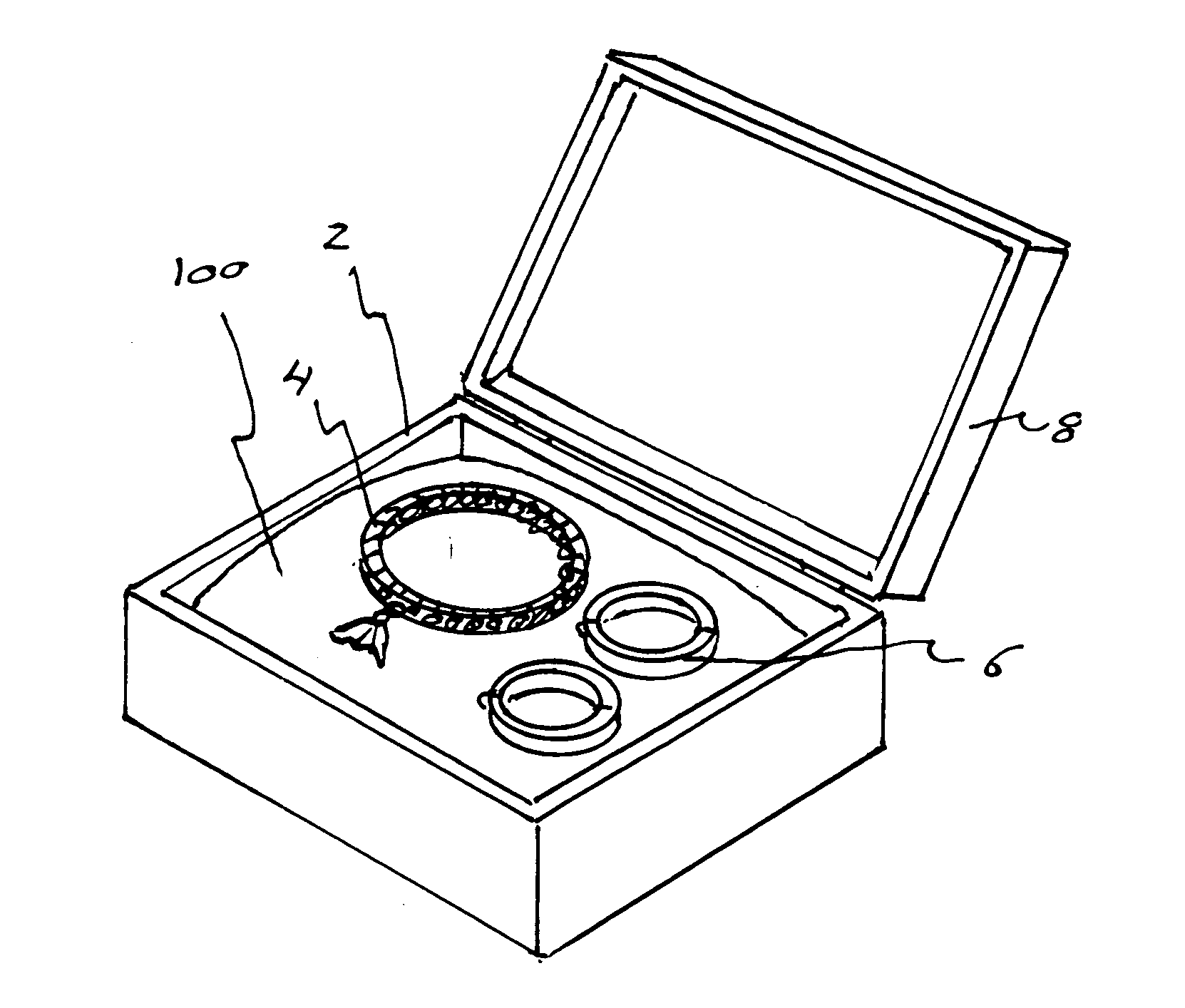

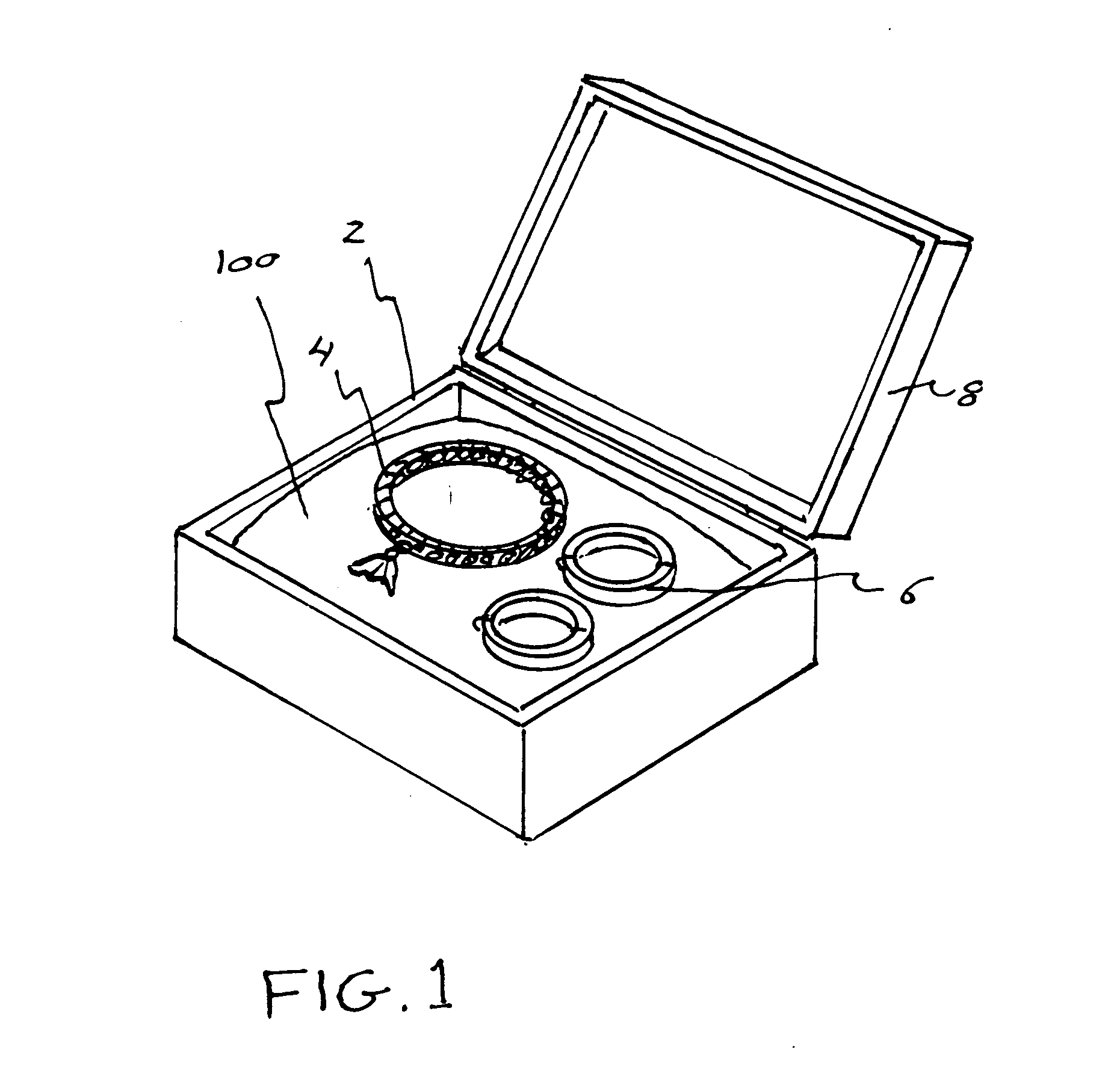

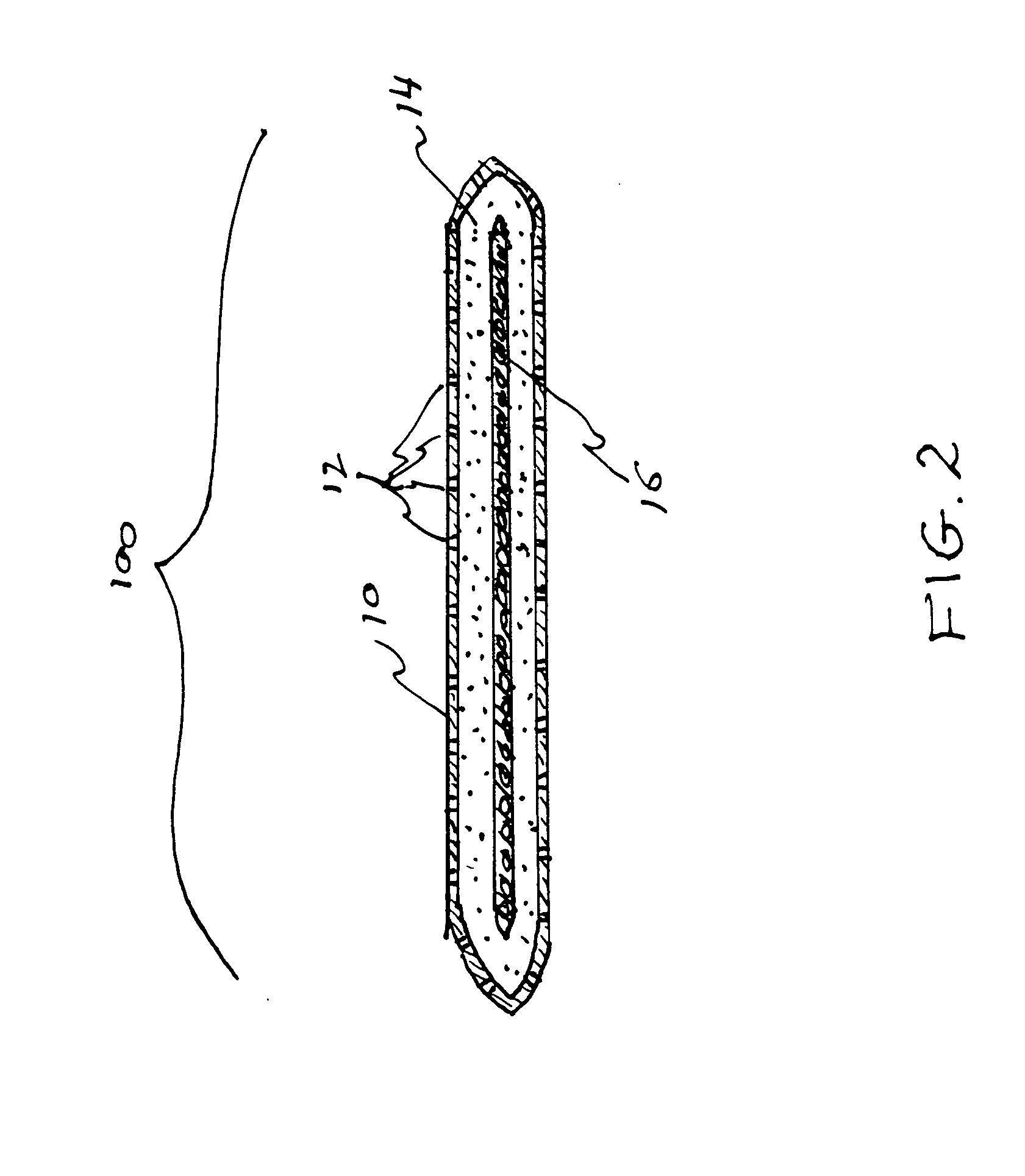

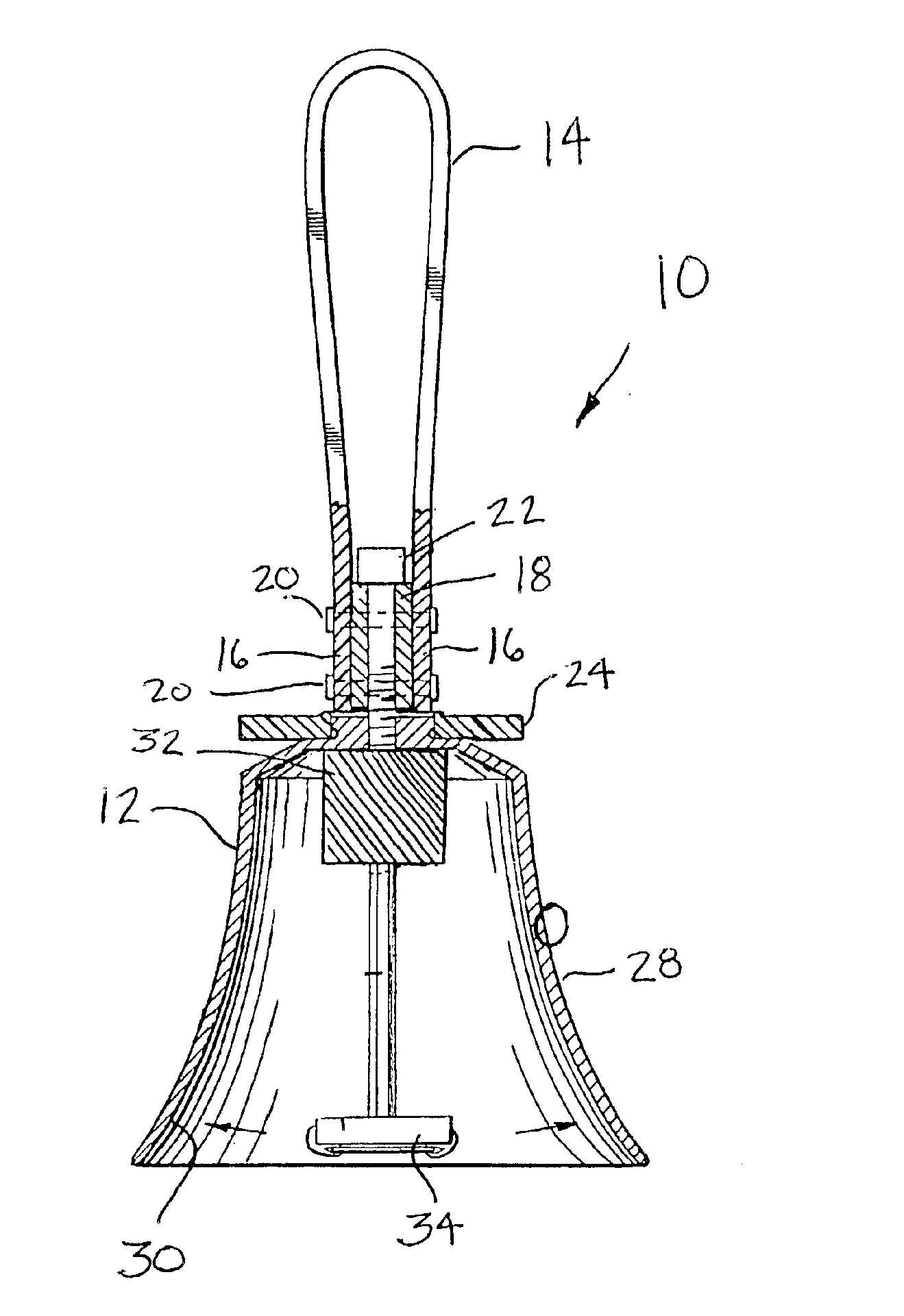

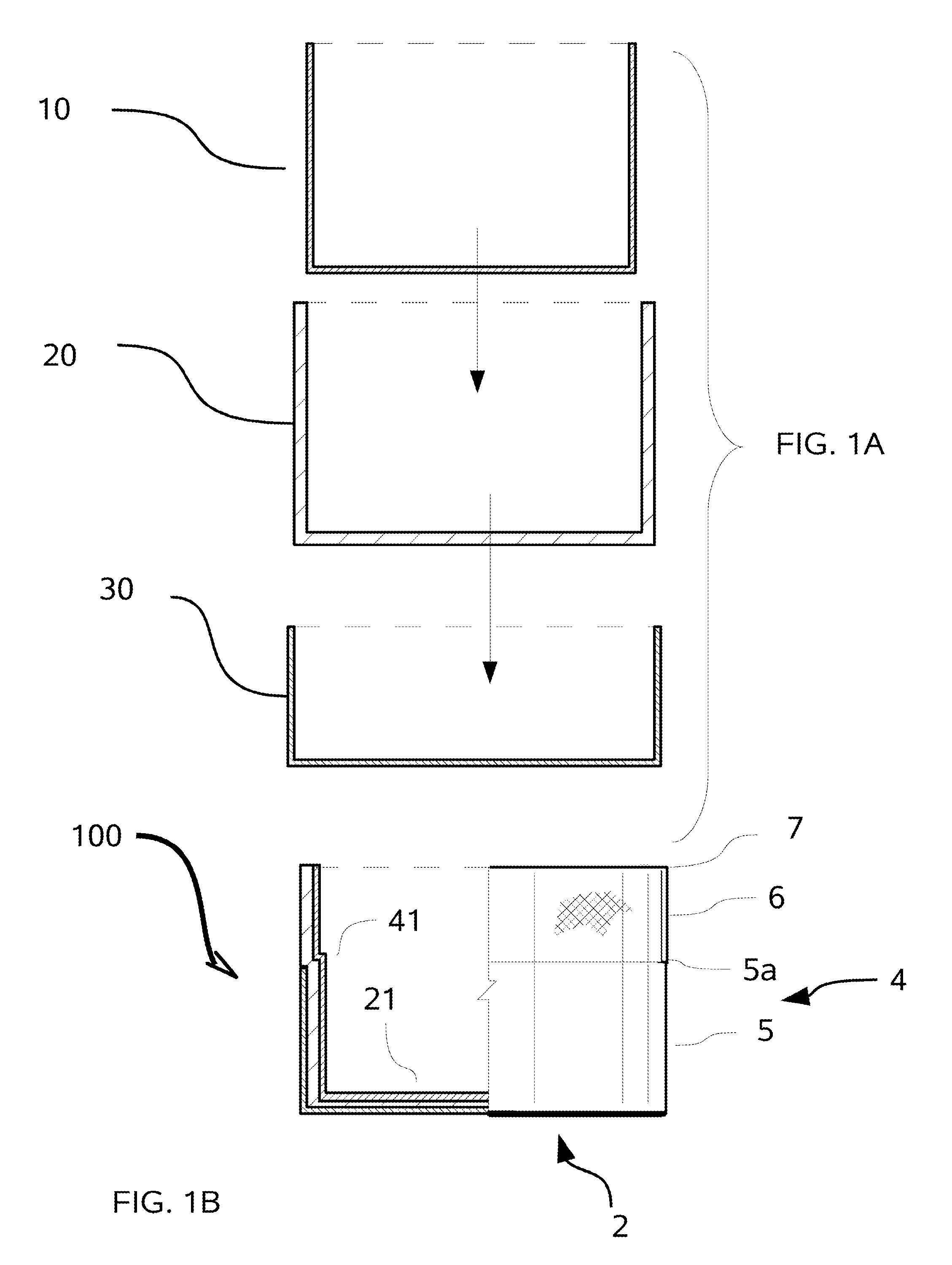

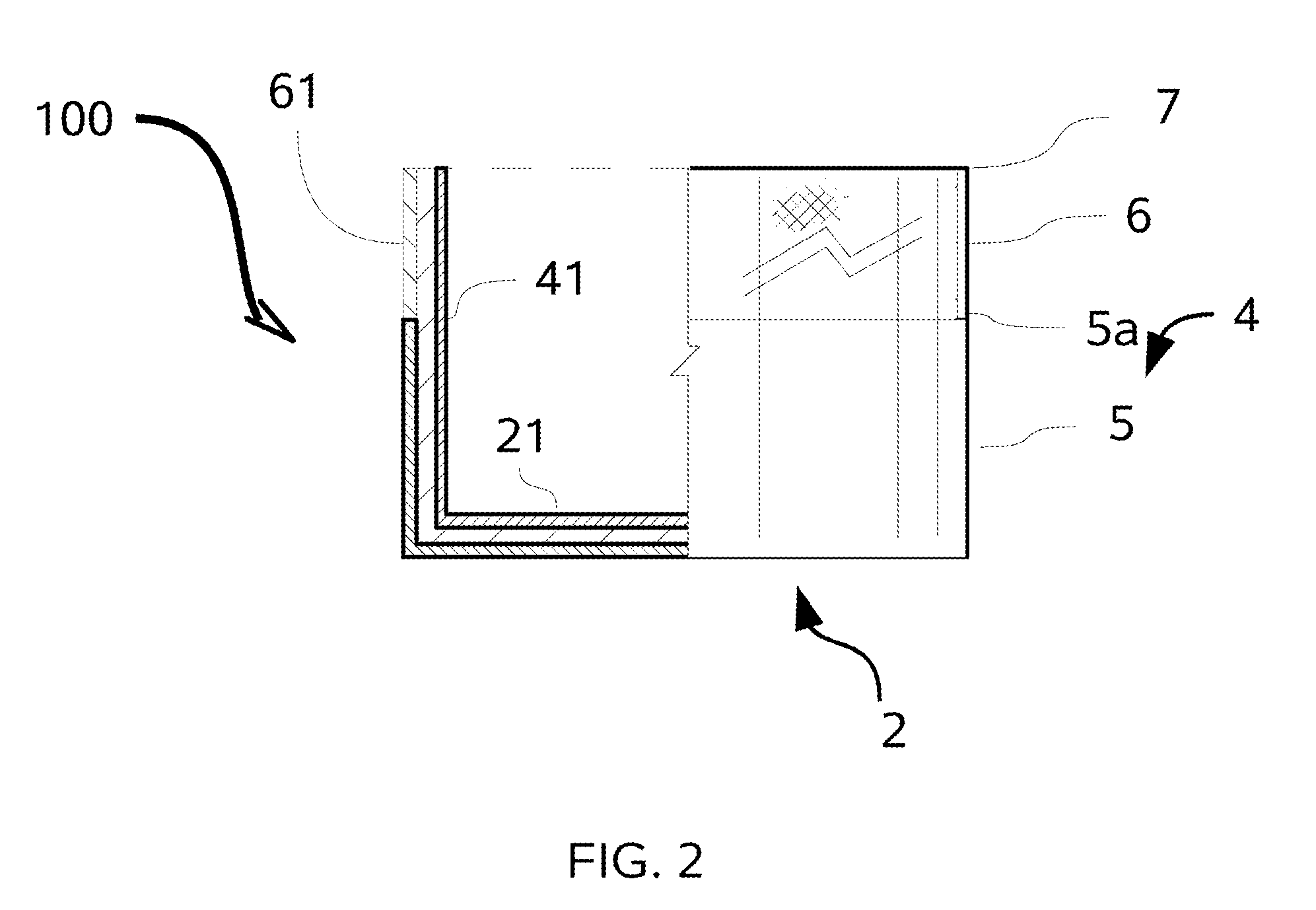

Anti tarnish jewelry box insert

InactiveUS20110266163A1Keep metal jewelry from becoming tarnishedLuggageOther accessoriesActivated carbonPetroleum engineering

An anti tarnish jewelry box insert with an outer flexible housing, an inner open celled foam layer and an inner activated carbon retaining layer. The outer flexible cover is made from breathable material. The activated carbon retaining layer resides within the center of the flexible housing. The open celled foam layer resides just above the activated carbon retaining layer. The flexible housing is made of breathable material and fully covers the activated carbon retaining layer and the foam layer. A preferred embodiment includes the insert is sized to form a floor of a standard jewelry box.

Owner:MOSTOWY RICHARD

Tarnish inhibiting composition and article containing it

InactiveUS7261839B2Protect the surfaceCombat tarnishing of a lustrous silver objectOther chemical processesContainers preventing decayScavengerAdjuvant

An effective tarnish inhibiting (“TI”) polymer composition including a scavenger for hydrogen sulfide optionally in the presence of an acid gas such as sulfur dioxide, provides excellent protection against tarnishing of the lustrous surfaces of a silver object. When the composition is thermoformed into a box-like container or extruded as film which contains uniformly dispersed solid micron-sized particles of the scavenger chosen from zinc oxide and a silicate of an alkali metal in an amount no greater than 5% by weight of the polymer, it is transparent so that the condition of the stored silver may be assessed. A solid inert adjuvant may be added. All solid particles in the material have a primary particle size smaller than 53 μm which makes it possible to obtain the uniform dispersion. A silver object may be wrapped in the film, or stored in a sealed box so that the solid particles in the polymer are not coated on the surfaces of the silver object.

Owner:NORTHERN TECH INT CORP

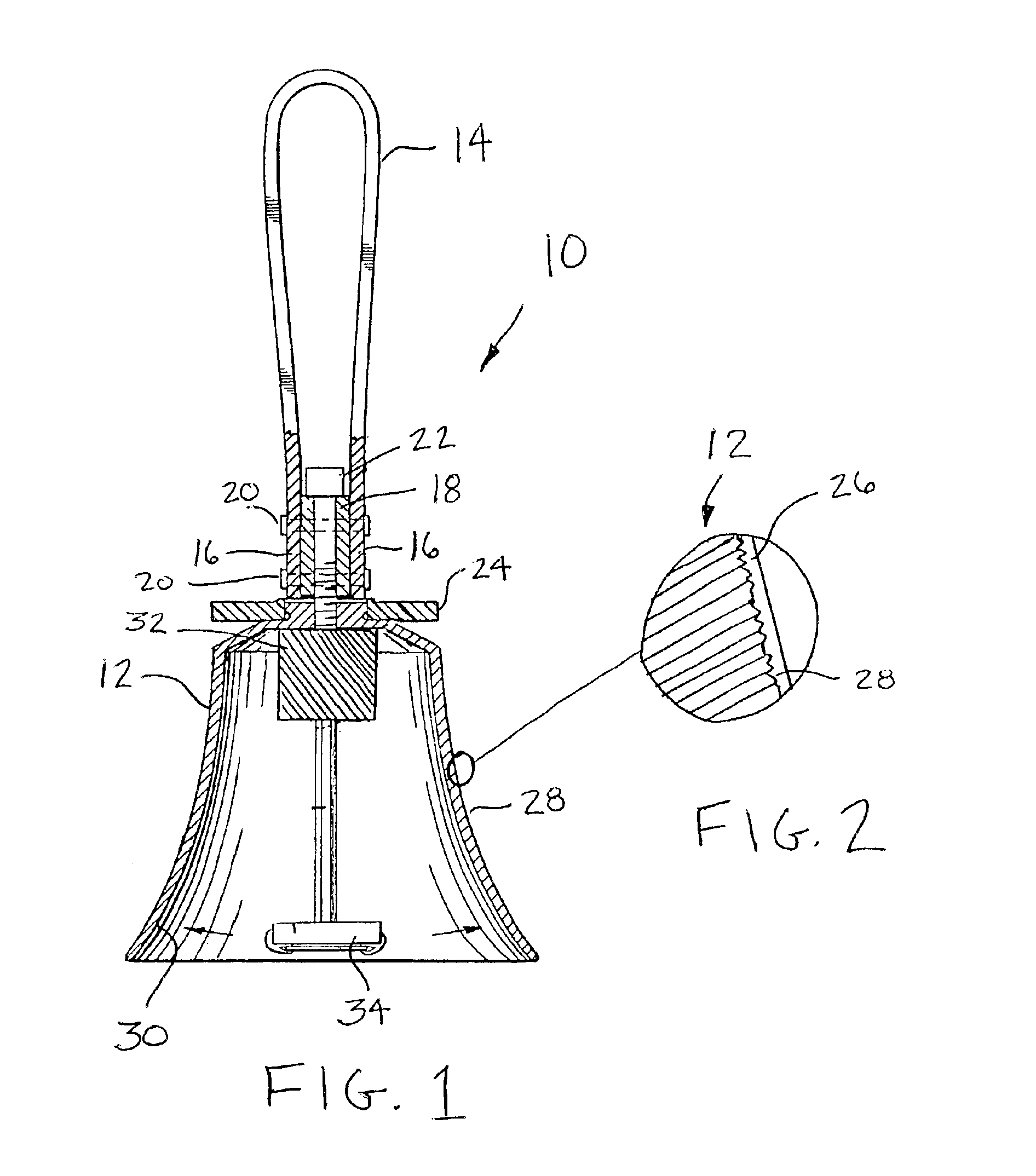

Tarnish-resistant handbell and its method of manufacture

A handbell has a bell body with an inner surface engageable by a clapper to produce a sound corresponding to a note of the musical scale and an outer surface with a vapor deposited nitride layer that resists tarnish. Preferably, the vapor deposited nitrate layer has a thickness of less than about 5 microns and does not adversely affect the sound produced when the handbell is rung. In addition, preferably the vapor deposited nitrate layer is zirconium nitride or titanium nitride and has a Vickers hardness (HV) of at least 2300. A method of making and / or refurbishing a handbell is also disclosed.

Owner:SCHULMERICH CARILLONS

Rolled Copper Foil or Electrolytic Copper Foil for Electronic Circuit, and Method of Forming Electronic Circuit using same

InactiveUS20110297641A1Prevent saggingShorten the timePrinted circuit aspectsConductive material chemical/electrolytical removalElectrolysisHeat resistance

Provided is a rolled copper foil or electrolytic copper foil for an electronic circuit to be used for forming a circuit by etching, wherein the copper foil comprises a nickel or nickel alloy layer with a lower etching rate than copper formed on an etching side of the rolled copper foil or electrolytic copper foil, and a heat resistance layer composed of zinc or zinc alloy or its oxide formed on the nickel or nickel alloy layer. This invention aims to prevent sagging caused by the etching, to form a uniform circuit having the intended circuit width, and to shorten the time of forming a circuit by etching as much as possible, when forming a circuit by etching a copper foil of the copper-clad laminate; and also aims to make the thickness of the nickel or nickel alloy layer as thin as possible, to inhibit oxidation when exposed to heat, to prevent tarnish (discoloration) known as “YAKS”, to improve the etching properties in pattern etching, and to prevent the occurrence of short circuits and defects in the circuit width.

Owner:JX NIPPON MINING& METALS CORP

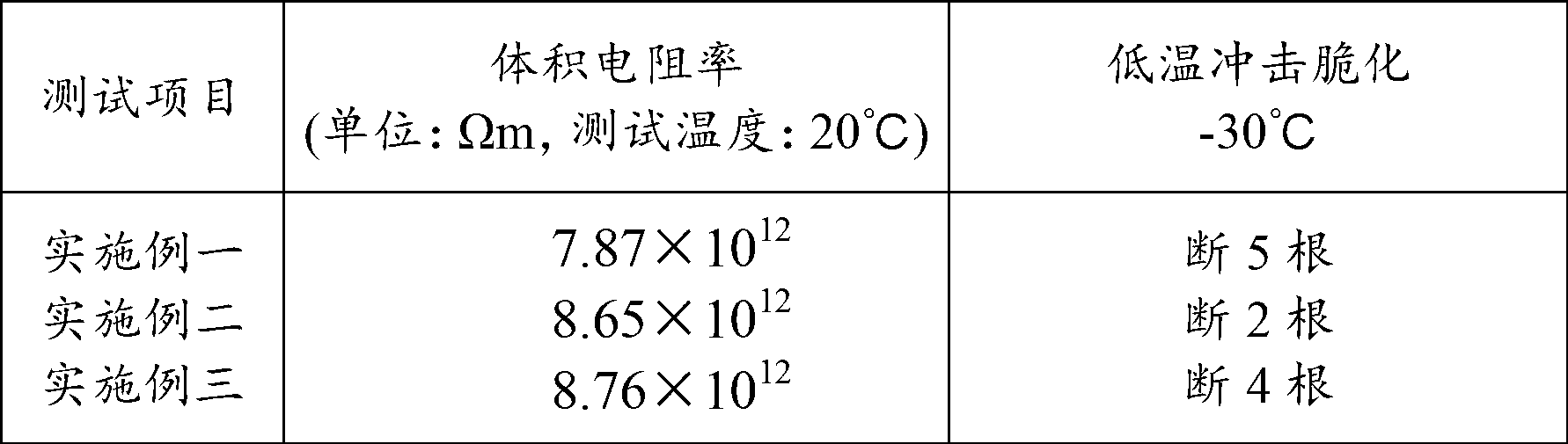

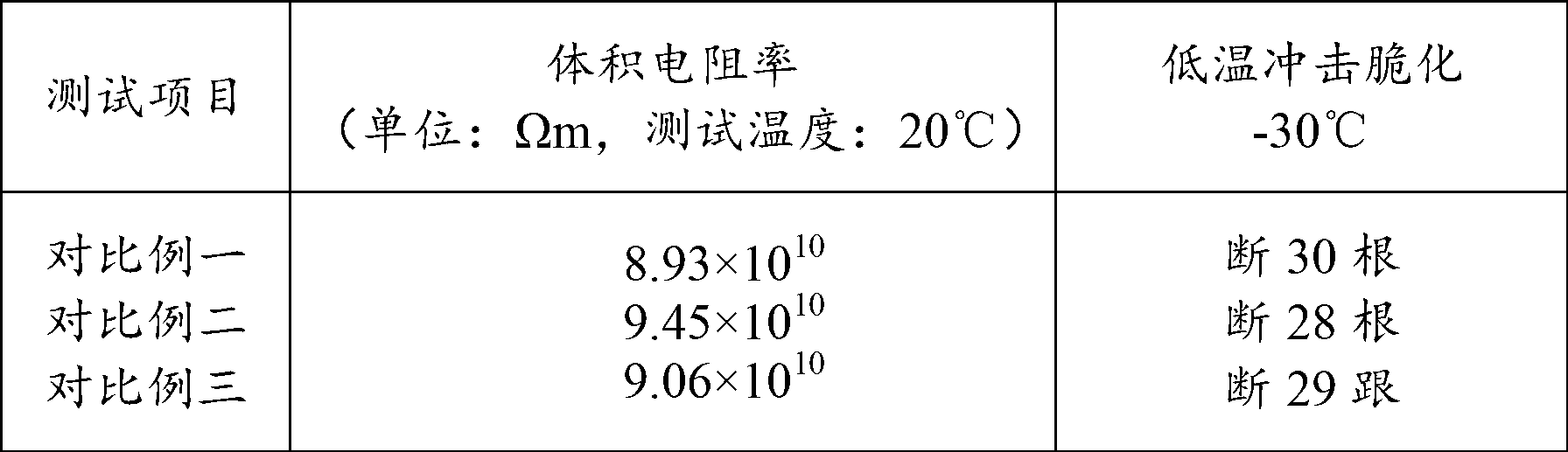

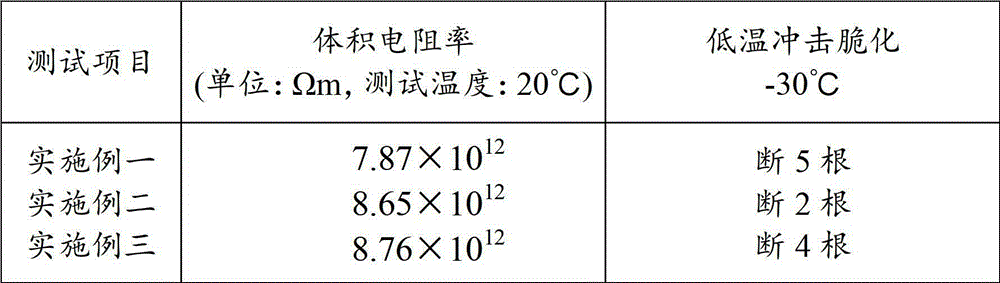

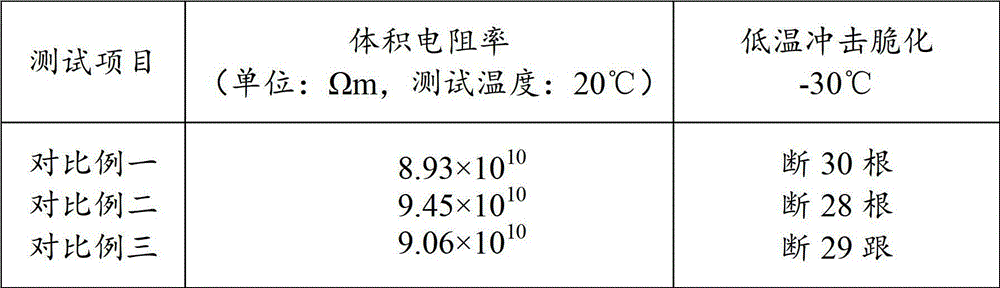

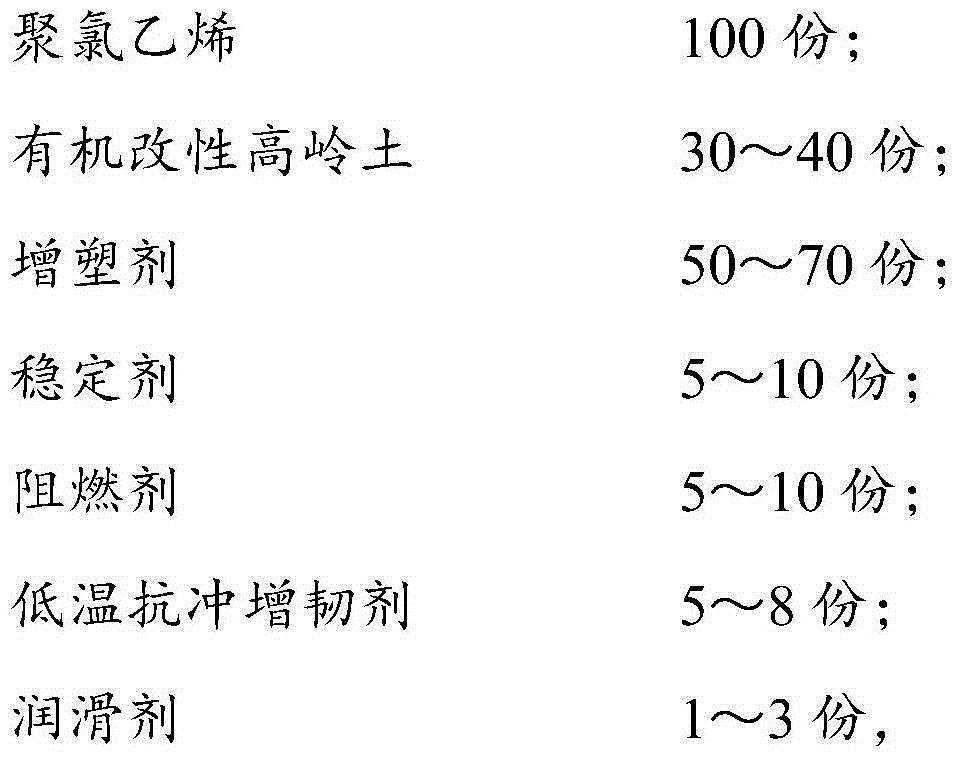

Environment-friendly nontoxic high-insulation low temperature-resistant polyvinyl chloride cable material and preparation process thereof

ActiveCN103059471ASimple preparation processGood effectPlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention provides an environment-friendly nontoxic high-insulation low temperature-resistant polyvinyl chloride cable material which comprises, by weight, 100 parts of polyvinyl chloride, 30 to 40 parts of organic modified kaolin, 50 to 70 parts of a plasticizer, 5 to 10 parts of a stabilizing agent, 5 to 10 parts of a fire retardant, 5 to 8 parts of a low temperature antishock toughening agent and 1 to 3 parts of a lubricant. The invention further provides a preparation process for the anti-tarnish crosslinked polyvinyl chloride material. The environment-friendly nontoxic high-insulation low temperature-resistant polyvinyl chloride cable material provided by the invention has the advantages of low cost for raw materials, environment-friendliness, excellent insulating properties and low temperature resistance and wide application prospects.

Owner:深圳市帝源新材料科技股份有限公司

Method of surface treatment and surface treated article provied by the same

InactiveUS20110236654A1Improve uniformityPrevent oxidation/tarnish occurringCeramic layered productsGlass/slag layered productsOptoelectronicsAtomic layer deposition

A method of surface treatment and surface treated article provided by the same are disclosed. The method of surface treatment of the present invention comprises: providing a substrate; and forming a ceramic layer on a surface of the substrate by atomic layer deposition (ALD), wherein the ceramic layer has a thickness of 1 nm to 1000 nm. The method of surface treatment of the present invention utilizes an atomic layer deposition (ALD) method to form a ceramic layer on a surface of the substrate, in which the formed ceramic layer has excellent uniformity and is randomly and entirely coated on the surface of the substrate. Therefore, the substrate surface treated by the method of the present invention is able to have a color the same as or different to that of the surface of the substrate and simultaneously prevent oxidation / tarnish occurring.

Owner:NATIONAL TSING HUA UNIVERSITY

Anti-tarnish aqueous treatment

InactiveUS6896739B1Inorganic/elemental detergent compounding agentsSurface-active detergent compositionsThioureaCopper

An aqueous solution that has the capacity for removing tarnish and other soil from copper, silver, gold and other noble metals and alloys thereof comprises an acid, thiourea and a transition metal salt. The aqueous material can be used to treat the surfaces of such articles for the purpose of removing tarnish. Such tarnish is removed by the composition and the composition treats the metal surface to retard the re-appearance of tarnish contaminants.

Owner:FOR YOUR EASE ONLY

Anti-tarnish aqueous treatment

InactiveUS20050121052A1Inorganic/elemental detergent compounding agentsSurface-active detergent compositionsSoil scienceThiourea

An aqueous solution that has the capacity for removing tarnish and other soil from copper, silver, gold and other noble metals and alloys thereof comprises an acid, thiourea and a transition metal salt. The aqueous material can be used to treat the surfaces of such articles for the purpose of removing tarnish. Such tarnish is removed by the composition and the composition treats the metal surface to retard the re-appearance of tarnish contaminants.

Owner:FOR YOUR EASE ONLY

Coatings For Metal Surfaces

InactiveUS20140134398A1Easy to corrodeEasy to oxidizePretreated surfacesRecord information storageLiquid layerPhosphate

An iron-containing metal surface, such as a brushed stainless steel, comprises a heat-set layer of a metal phosphate reaction product formed between a surface metal and phosphate precursor wherein the reaction product layer h an average thickness less than 2 micrometers. A metal surface, that resists retention of environmental stains or marks as well as resisting tarnish at elevated temperatures, is formed by forming a reaction product with the metal surface by heat setting a surface liquid layer containing a phosphate precursor such as a phosphate ester-containing solution or phosphoric acid solution, and optionally containing a phospho alumina precursor, onto the metal surface. An article coated in accordance with this invention is similar in appearance to a similar article without such a coating for maintaining original aesthetic properties.

Owner:APPL THIN FILMS INC

Preparation method of red wine hyaluronic acid face mask

InactiveCN102100648ADelay agingIncrease roughnessCosmetic preparationsToilet preparationsAdditive ingredientSkin color

The invention discloses a red wine hyaluronic acid face mask and a preparation method thereof, and the face mask contains the following components: a red wine, a hyaluronic acid stock solution, a thickening agent and an antimicrobial in a weight ratio of 100:100:5:1. The preparation process of the red wine hyaluronic acid face mask comprises the following steps: (1) selecting a red wine; (2) processing the red wine by hydroxyethylcellulose; (3) mixing the processed red wine and hydroxyethylcellulose together to prepare a mixed solution with a thick and jellied texture; (4) adding a prepared hyaluronic acid stock solution and phenoxyethanol into the mixture obtained in step (3); (5) adding a prepared antimicrobial and a plant essential oil into the mixture obtained in step (4), and shaking the mixture uniformly to obtain the product. After smeared on the face, the mask of the invention can be absorbed by the skin easily, so the mask can increase skin moisture retention, allow the skin to be smooth, tender, and fine, allow the skin color to be red and healthy, slow down the ageing of the skin, and improve the coarseness and the tarnish of the skin caused by ageing; the mask of the invention has the advantages of simple preparation process, antioxidation effect, skin blood circulation promotion, and convenient use.

Owner:上海子夏投资管理有限公司

Tarnish-resisting master batch and preparation method thereof

The invention discloses tarnish-resisting master batch. When color cable materials are secondarily processed, the tarnish-resisting master batch and the color cable materials are collectively added into a high blending machine to be uniformly mixed, then the mixture is extruded and granulated, a color PVC (polyvinyl chloride) product is consistent with the original color after being secondarily processed, an original product can be formed through the processing, and the cost is reduced. The tarnish-resisting master batch comprises PVC resin and plasticizer, and is characterized by also comprising titanium dioxide and purple pigment, wherein the weight ratio of each ingredient of the master batch is as follows: 100 parts of PVC resin, 30 to 70 parts of plasticizer, 10 to 100 parts of titanium dioxide, and 0.5 to 5 parts of purple pigment. All ingredients are uniformly mixed and extruded through an extruder to be granulated to obtain the tarnish-resisting master batch.

Owner:SUZHOU HENGLI COMM MATERIAL +1

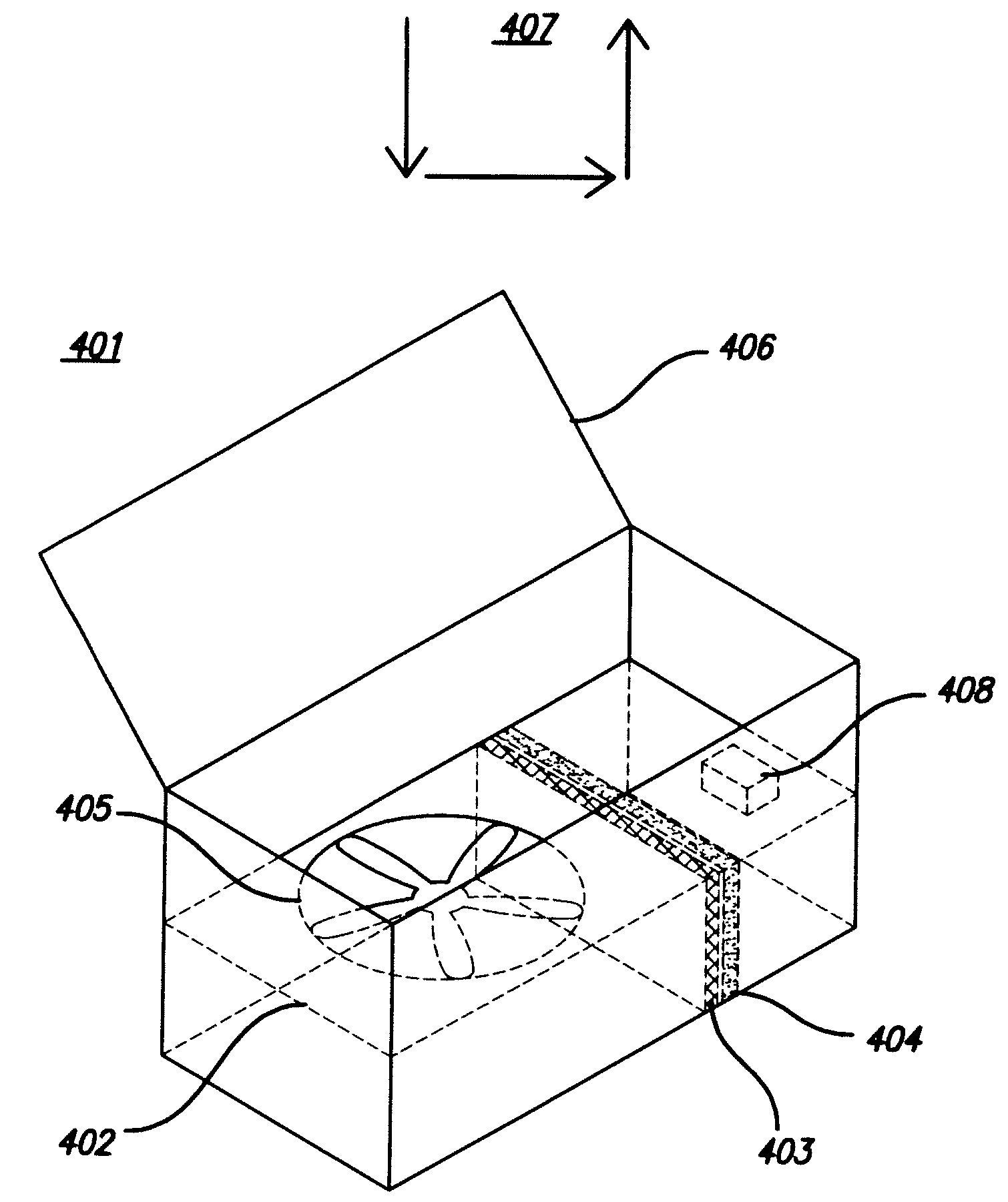

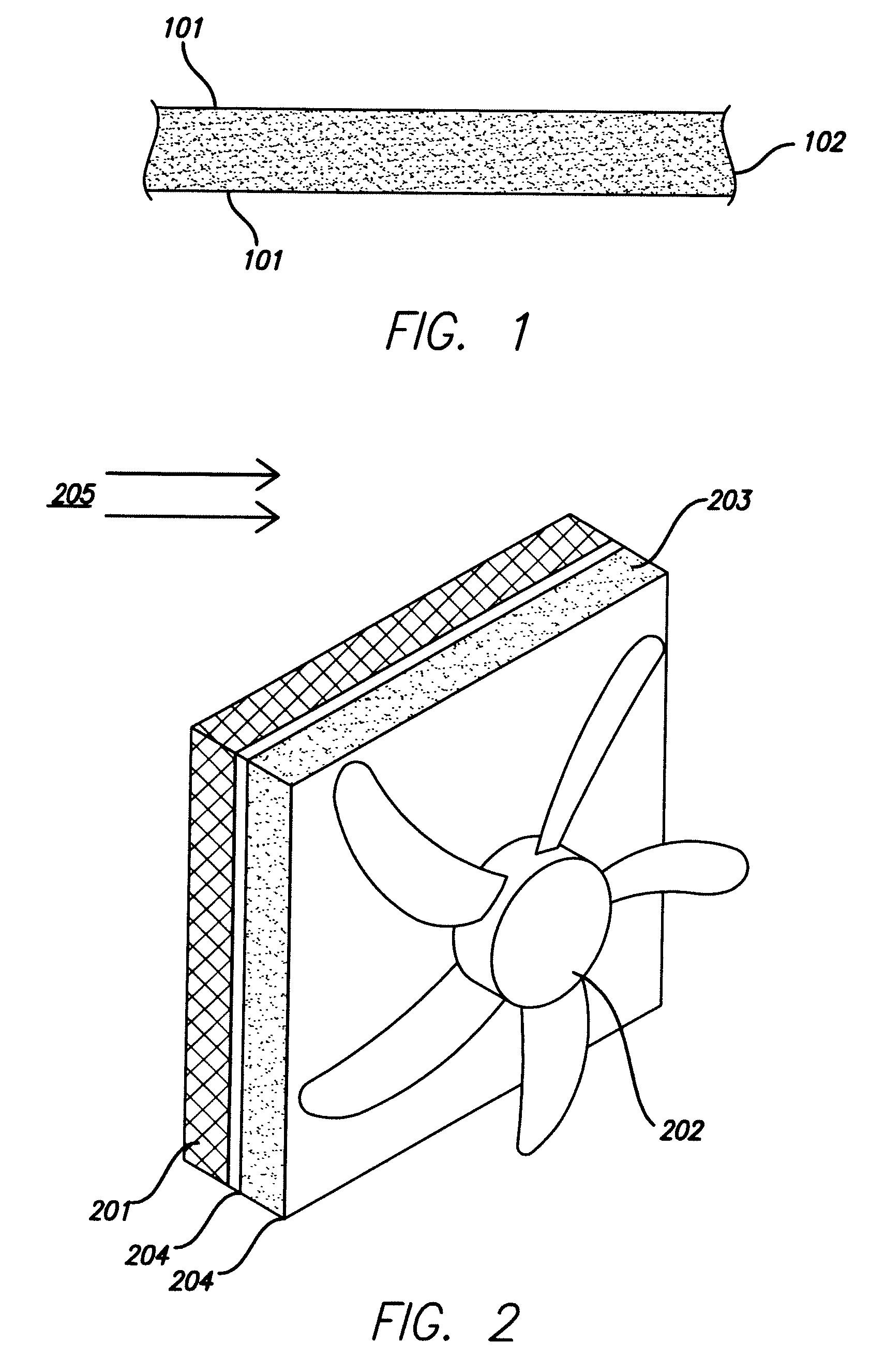

Apparatus for the prevention of metal tarnish

A filter, an apparatus and a method for preventing and / or reducing the formation of tarnish on objects that contain a metal are provided; for example, objects containing silver, copper and / or brass. The apparatus comprises a device that circulates the air in an enclosed space through particulate and adsorbent filters to reduce the amount of tarnishing agents present in said enclosure.

Owner:STORBO SCOTT +1

Rolled copper foil or electrolytic copper foil for electronic circuits and method of forming electronic circuits using them

InactiveCN102264951AUniform widthReduce thicknessPrinted circuit aspectsMetallic material coating processesCopper foilNickel alloy

Owner:JX NIPPON MINING & METALS CORP

Tarnish Inhibiting Composition for Metal Leadframes

InactiveUS20130045391A1Avoid tarnishingReduce diffuseAnti-corrosive paintsThin material handlingSilver plateCarboxylic acid

An aqueous tarnish inhibiting solution comprising a mercapto carboxylic acid and a corrosion inhibitor to produce an anti-tarnish layer on metal surfaces, such as silver plated copper leadframes and a method of using the same is provided. The composition provides an improved anti-tarnish layer that does not affect wirebondability or the adhesion of a mold compound to a leadframe.

Owner:MACDERMID ACUMEN INC

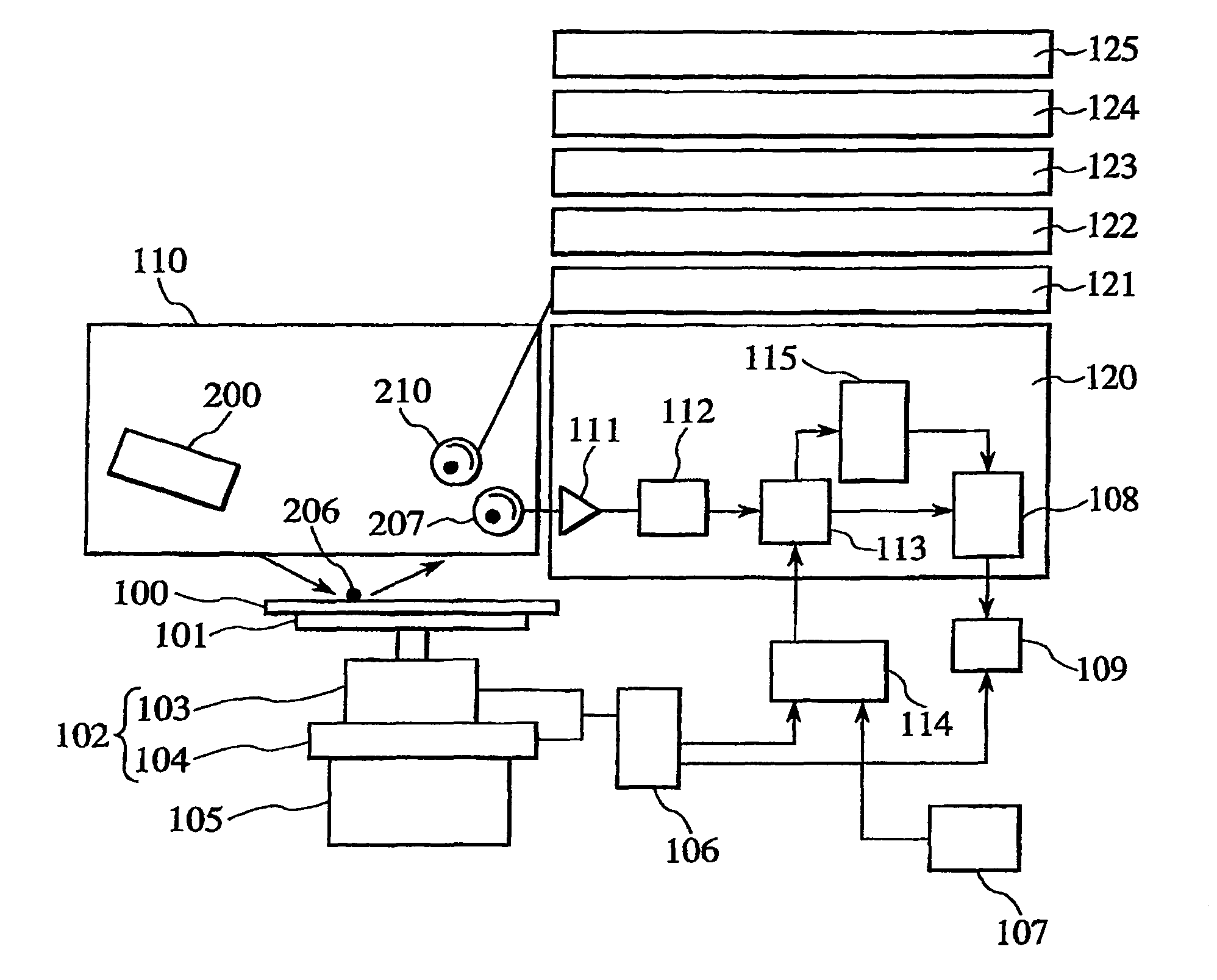

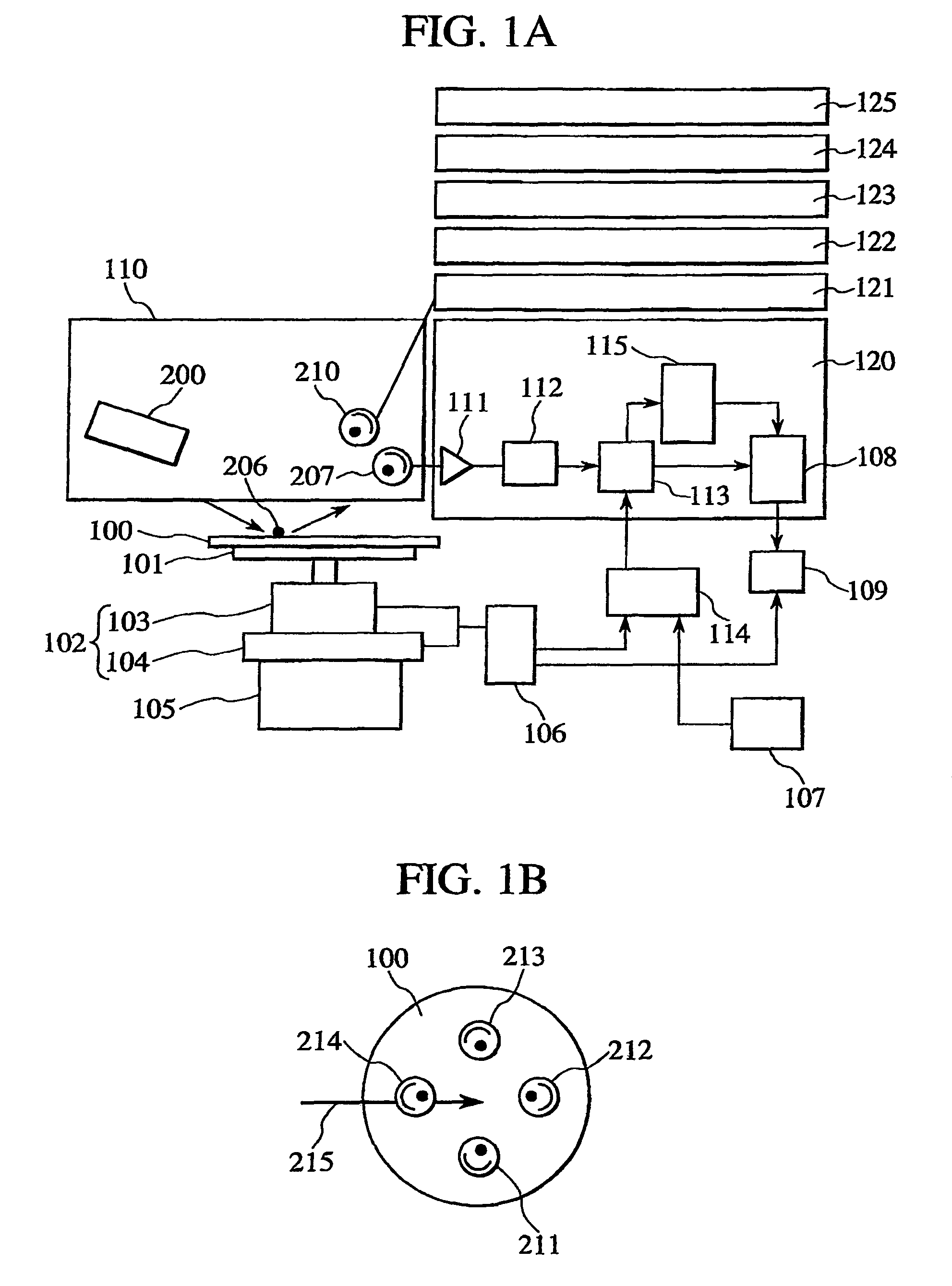

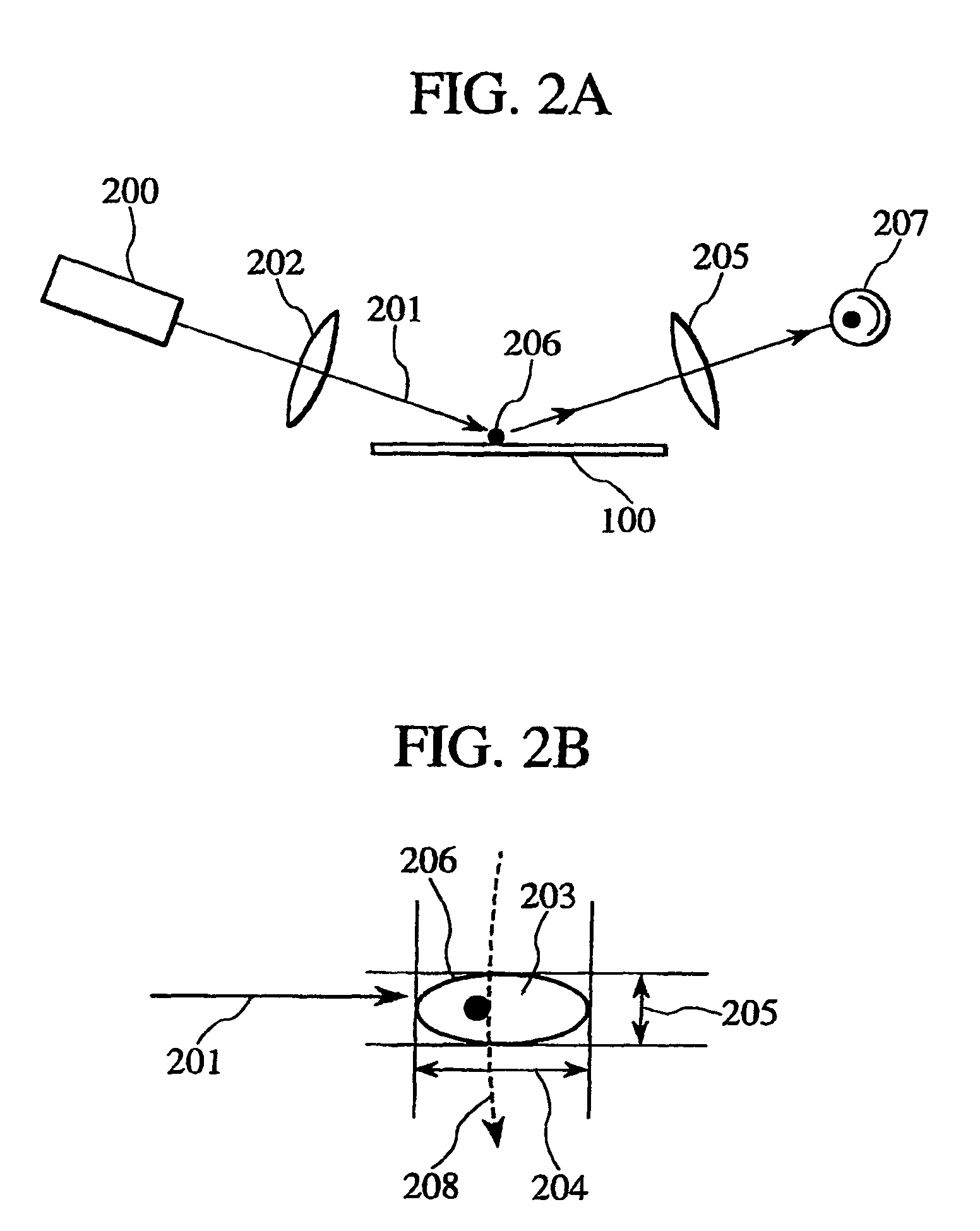

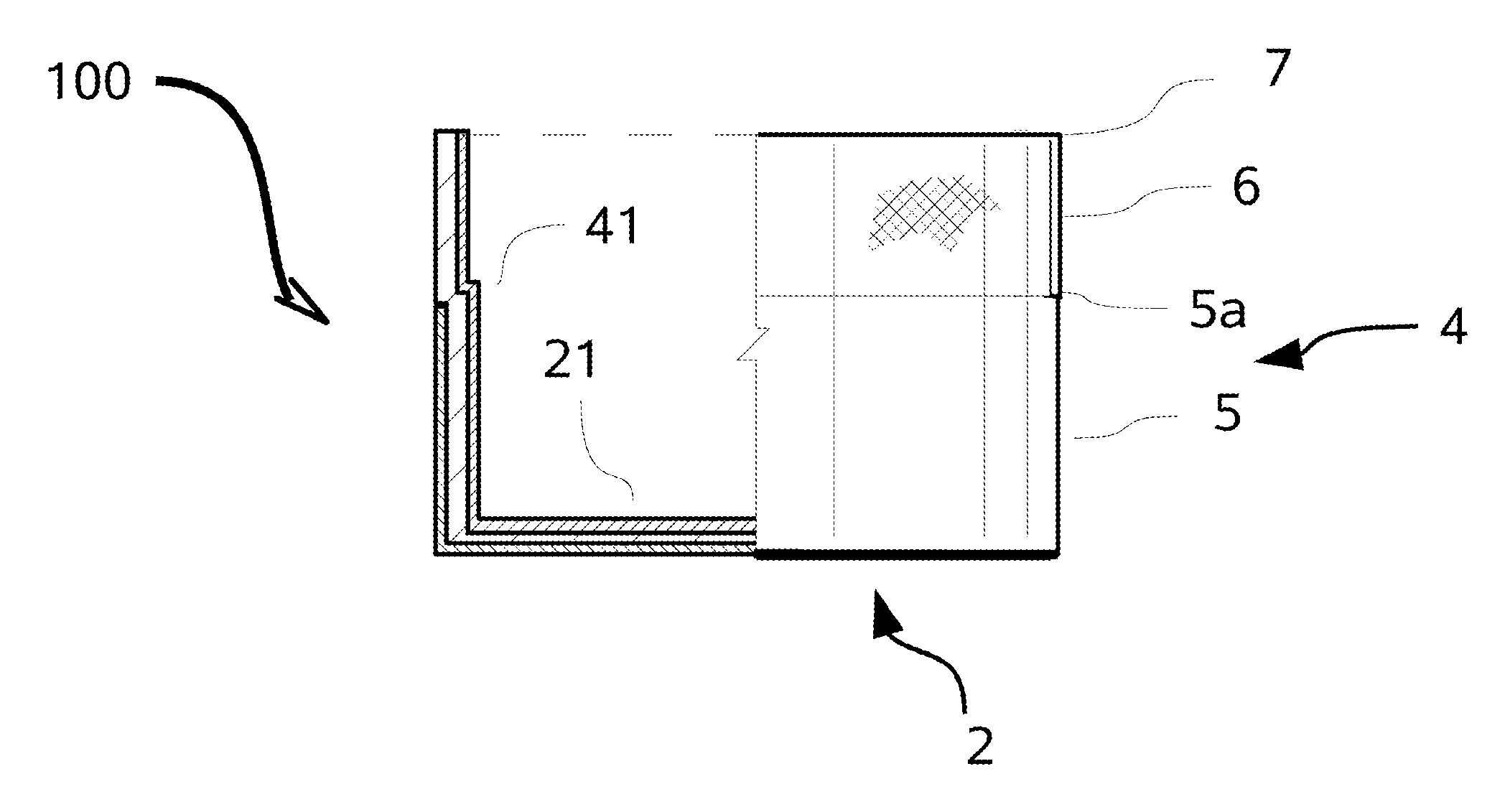

Inspection apparatus and inspection method

ActiveUS8101935B2Accurate detectionAccurately determineInvestigating moving sheetsCounting objects on conveyorsDigital dataForeign matter

Owner:HITACHI HIGH-TECH CORP

Silver Anti-Tarnishing Agent, Silver Anti-Tarnishing Resin Composition, Silver Anti-Tarnishing Method, And Light-Emitting Diode Using Same

InactiveUS20130032853A1No reduction in illuminanceIncreased durabilityOther chemical processesCoatingsSilver platePhosphate

The present invention relates to a silver anti-tarnish agent having, as an effective component, a zinc salt and / or a zinc complex, preferably at least one kind selected from the group consisting of a carboxylic acid zinc salt having a carbon atom number of 3 to 20, a phosphoric acid zinc salt, a phosphate ester zinc salt and a carbonyl compound zinc complex; a silver anti-tarnish method for preventing tarnish of a silver part by applying said silver anti-tarnish agent to the silver part. According to the present invention, tarnish of a silver part such as a silver-plated part due to a sulfur-based gas can be prevented. The present invention is useful particularly as a silver anti-tarnish agent for a light-emitting diode and allows preventing tarnish of a silver part of a light-emitting diode and reduction in illuminance by applying the silver anti-tarnish agent of the present invention to a silver part such as a silver-plated part of a light-emitting diode for covering the silver part.

Owner:NIPPON KAYAKU CO LTD

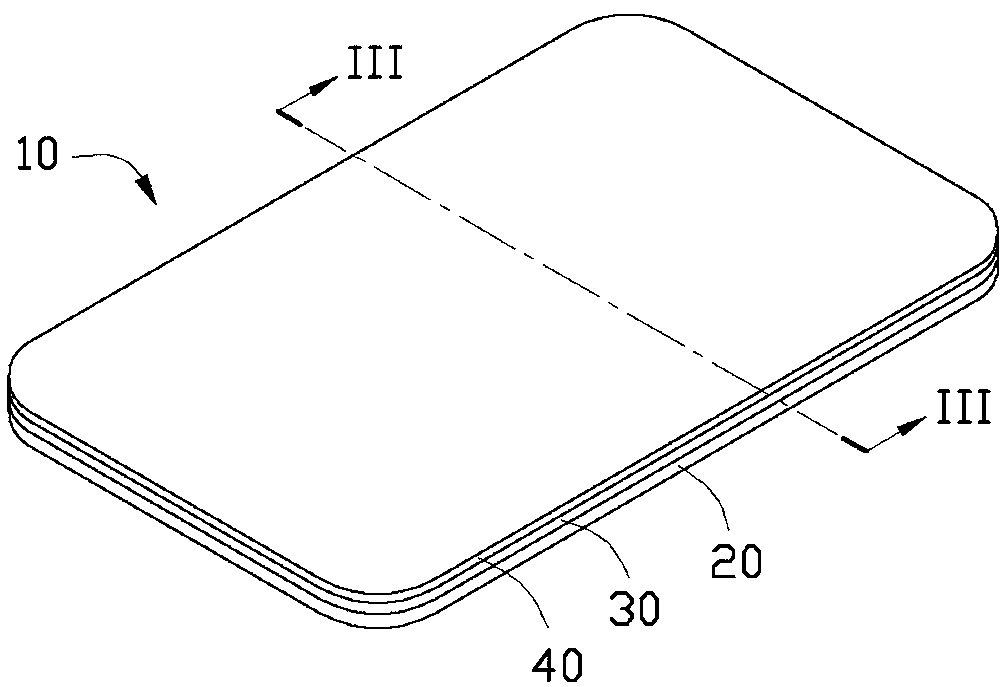

An electronic device casing and a manufacture method thereof

InactiveCN102724824AImprove aestheticsIncreased durabilityLamination ancillary operationsLaminationEndurabilityEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

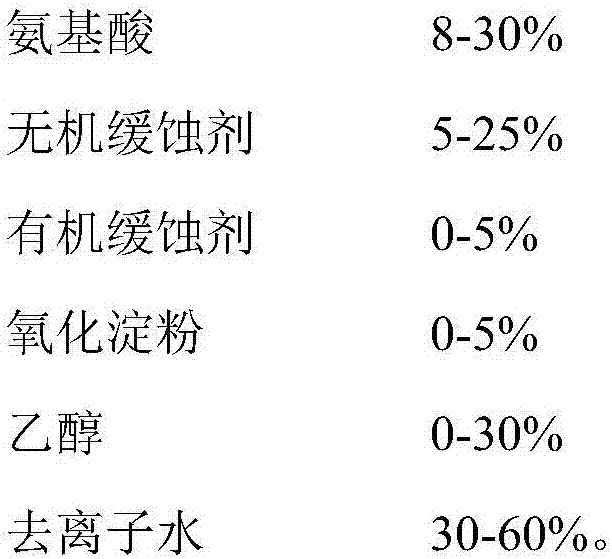

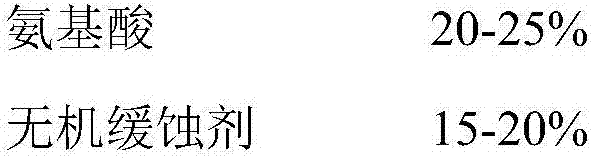

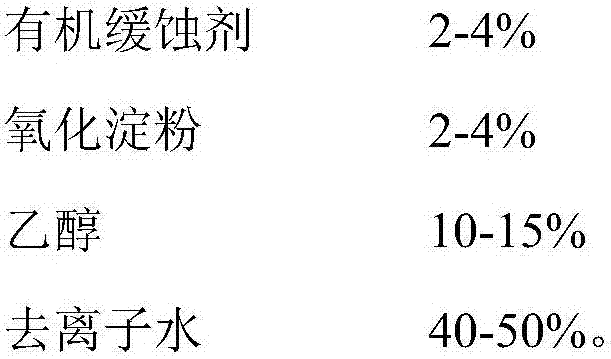

Green and environment-friendly copper tarnish prevention agent and preparation method thereof

InactiveCN106917092AHigh corrosion inhibition efficiencyEfficient anti-tarnish effectTungstateCopper

The invention relates to a green and environment-friendly copper tarnish prevention agent and a preparation method thereof, and belongs to the technical field of metal tarnish prevention. The green and environment-friendly copper tarnish prevention agent is prepared from, by mass, 8%-30% of amino acid, 5%-25% of an inorganic corrosion inhibitor, 0%-5% of an organic corrosion inhibitor, 0%-5% of oxidized starch, 0%-30% of ethanol and 30%-60% of deionized water; amino acid is an environment-friendly chemical with the good biodegradability and can inhibit corrosion of metals such as copper by serving as a nontoxic and environment-friendly corrosion inhibitor, and tungstate has a protection effect on copper, is low in toxicity and environmental pollution and is an inorganic corrosion inhibitor having a great developing prospect. Accordingly, by compounding multiple corrosion inhibitors, the corrosion inhibition efficiency is improved through the synergistic effect among molecules of the corrosion inhibitors; the adopted raw materials are all environment-friendly chemicals, and therefore the prepared finished product is green and environmentally friendly; the product has an efficient tarnish prevention effect on the surface of a copper product.

Owner:江门市盈盛焊接材料科技有限公司

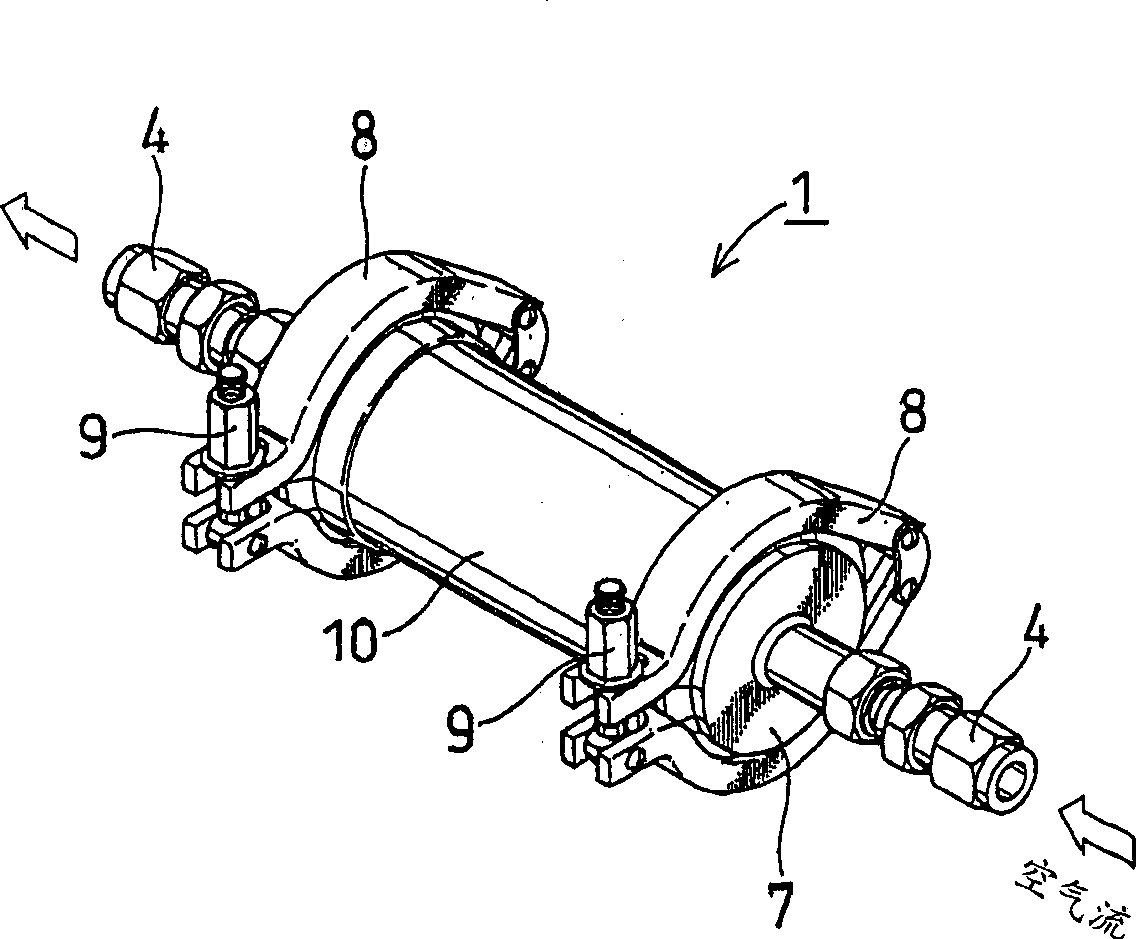

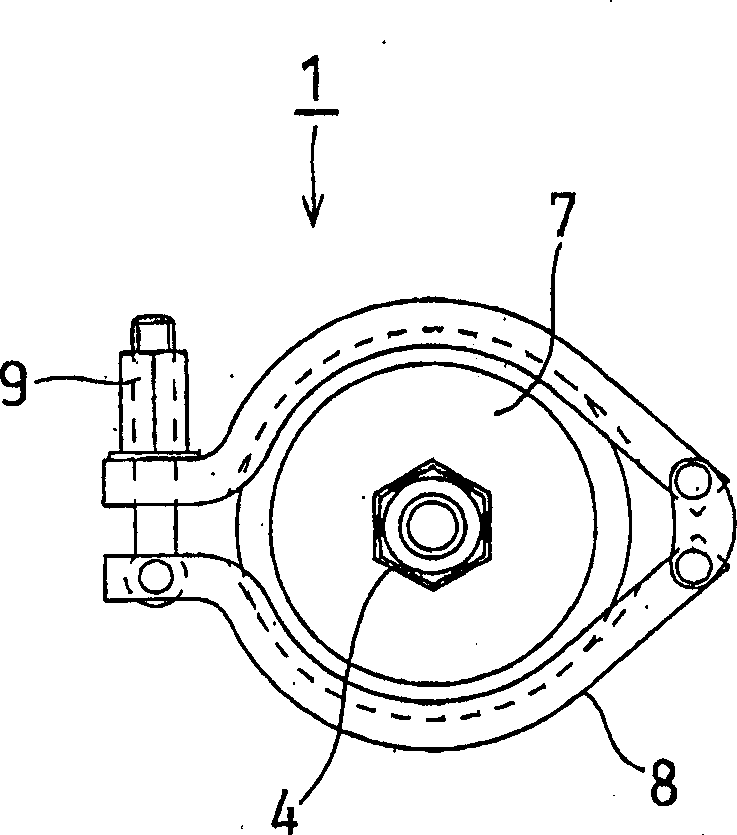

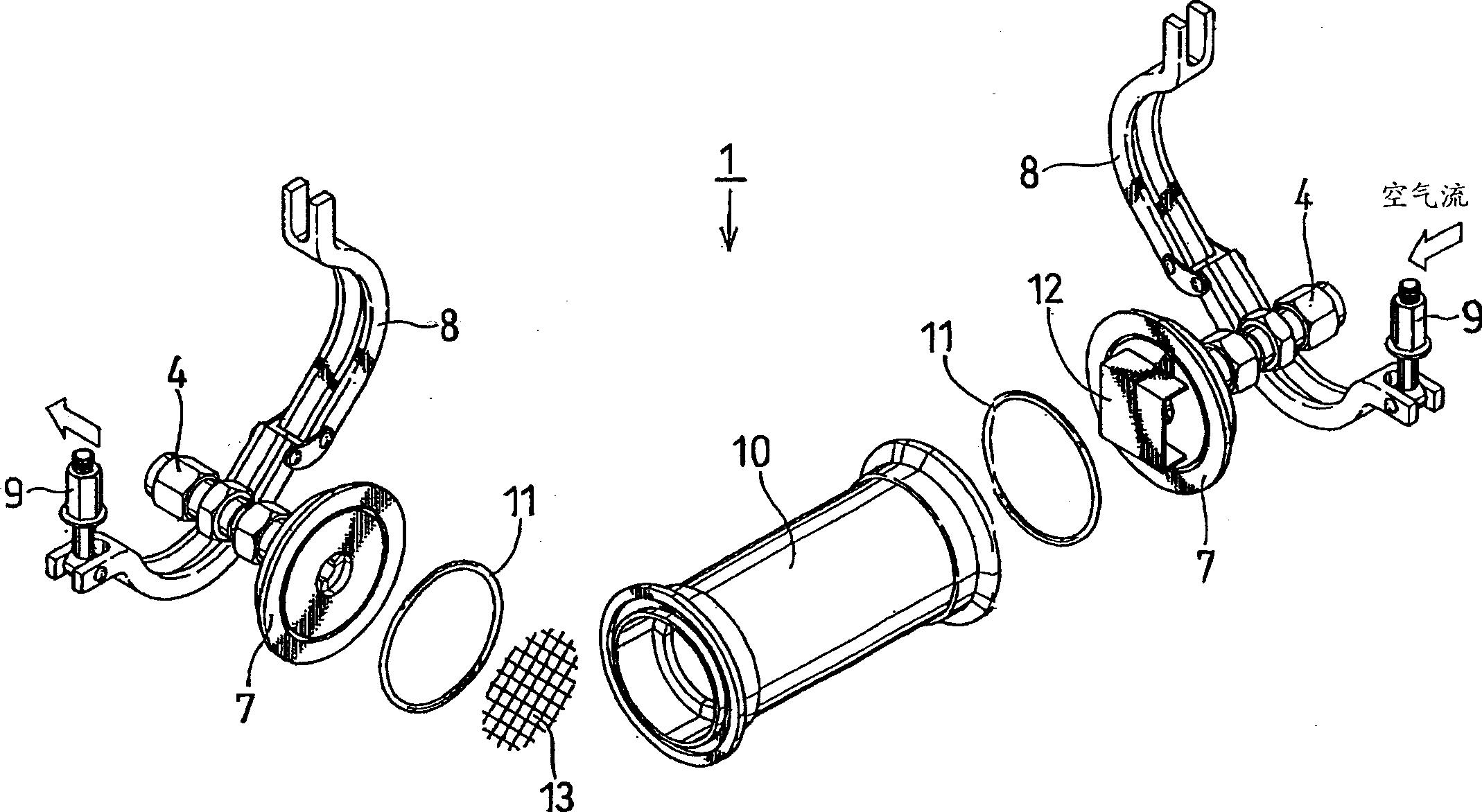

Chemical filter

InactiveCN1357403AGuaranteed purityReduce problems encounteredGas treatmentFinal product manufactureBoiling pointSorbent

A chemical filter includes a unit body and an adsorbent housed in the unit body. The adsorbent is for adsorbing a gas. The chemical filter provides a purified gas in which the concentration of ammonia and the concentration of organic gases having a boiling point of about 150° C. or higher, respectively are about 1 ppb(v) or less. This purified gas is applicable for a semiconductor manufacturing system without causing troubles of tarnish and the like.

Owner:NITTA CORP

Coatings for Metal Surfaces

InactiveUS20160340787A1Metallic material coating processesThin material handlingLiquid layerPhosphate

An iron-containing metal surface, such as a brushed stainless steel, comprises a heat-set layer of a metal phosphate reaction product formed between a surface metal and phosphate precursor wherein the reaction product layer has an average thickness less than 2 micrometers. A metal surface, that resists retention of environmental stains or marks as well as resisting tarnish at elevated temperatures, is formed by forming a reaction product with the metal surface by heat setting a surface liquid layer containing a phosphate precursor such as a phosphate ester-containing solution or phosphoric acid solution, and optionally containing a phospho alumina precursor, onto the metal surface. An article coated in accordance with this invention is similar in appearance to a similar article without such a coating for maintaining original aesthetic properties.

Owner:APPL THIN FILMS INC

Preparation method of pearl covered with metal coated film on surface

InactiveCN102061447AImprove anti-aging propertiesImprove qualityVacuum evaporation coatingSputtering coatingIon bombardmentPhysical chemistry

The invention discloses a preparation method of a pearl with a metal coated film on the surface. Tiny particles in the environment can be extremely easily adsorbed and deposited on the surface of a natural pearl which can be easily subjected to the influence or corrosion of air, light, sweat, cosmetics and the like and becomes yellow and tarnishes. The technical scheme adopted by the invention comprises the following steps: 1) removing oil and dirt on the surface of the natural pearl; 2) vacuumizing a vacuum multi-arc ion coating machine with a vacuum unit; 3) heating the natural pearl, introducing inert gas into the vacuum multi-arc ion coating machine, and performing ion bombardment on the natural pearl; and 4) continuing heating the natural pearl and plating at least one layer of metal coated film on the surface. Through the invention, a stable protection film layer with a dense structure is formed on the surface of the natural pearl, the anti-aging ability of the natural pearl is improved, and the pearl can not easily fade, become yellow or tarnish in the long-time storage and use process; and moreover, the flatness of the pearl surface is improved, and the quality and value of the pearl are effectively upgraded.

Owner:天威英利 +3

An environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material and its preparation process

ActiveCN103059471BSimple preparation processGood effectPlastic/resin/waxes insulatorsEnvironmental resistancePlasticizer

Owner:深圳市帝源新材料科技股份有限公司

Cookware with Tarnish Protected Copper Exterior

InactiveUS20080099466A1Simpler and costMaintaining the beauty of copper cookwareCooking-vessel materialsBaking vesselsChange colorFingerprint

An article of cookware in the form of a cooking vessel exposes only a portion of a copper inner layer on the upper portion of the exterior sidewall. The layer does not change color or tarnish as it sufficiently distal from the bottom of the cooking vessel that it is not subject to direct heat and oxidation during normal use. The unique bright color of the native copper is further protected from tarnish caused by fingerprint by a protective coating that can withstand moderate heating.

Owner:MEYER INTPROP

Staining-resisting artificial quartz stone sheet material

The invention discloses a staining-resisting artificial quartz stone sheet material. The staining-resisting artificial quartz stone sheet material is prepared from the following raw materials in partsby weight: 15 to 20 parts of 800-mesh quartz powder, 10 to 12 parts of 400-mesh quartz powder, 12 to 15 parts of 80-mesh quartz sand, 18 to 25 parts of 60-mesh quartz sand, 2 to 6 parts of epoxy resin, 1 to 5 parts of polyvinyl chloride resin, 3 to 5 parts of phenol-formaldehyde resin, 0.5 to 2 parts of a pigment, 1 to 2 parts of a curing agent, 0.2 to 3 parts of a coupling agent, 2 to 3 parts ofa first staining-resisting agent and 3 to 5 parts of a second staining-resisting agent. The artificial quartz stone sheet material disclosed by the invention has great staining-resisting performance.The artificial quartz stone sheet material disclosed by the invention is not easy to deform, crack, foam, fade, tarnish and the like, and has the characteristics of low production cost, good decoration effect and no deformation.

Owner:佛山市欧泊石业有限公司

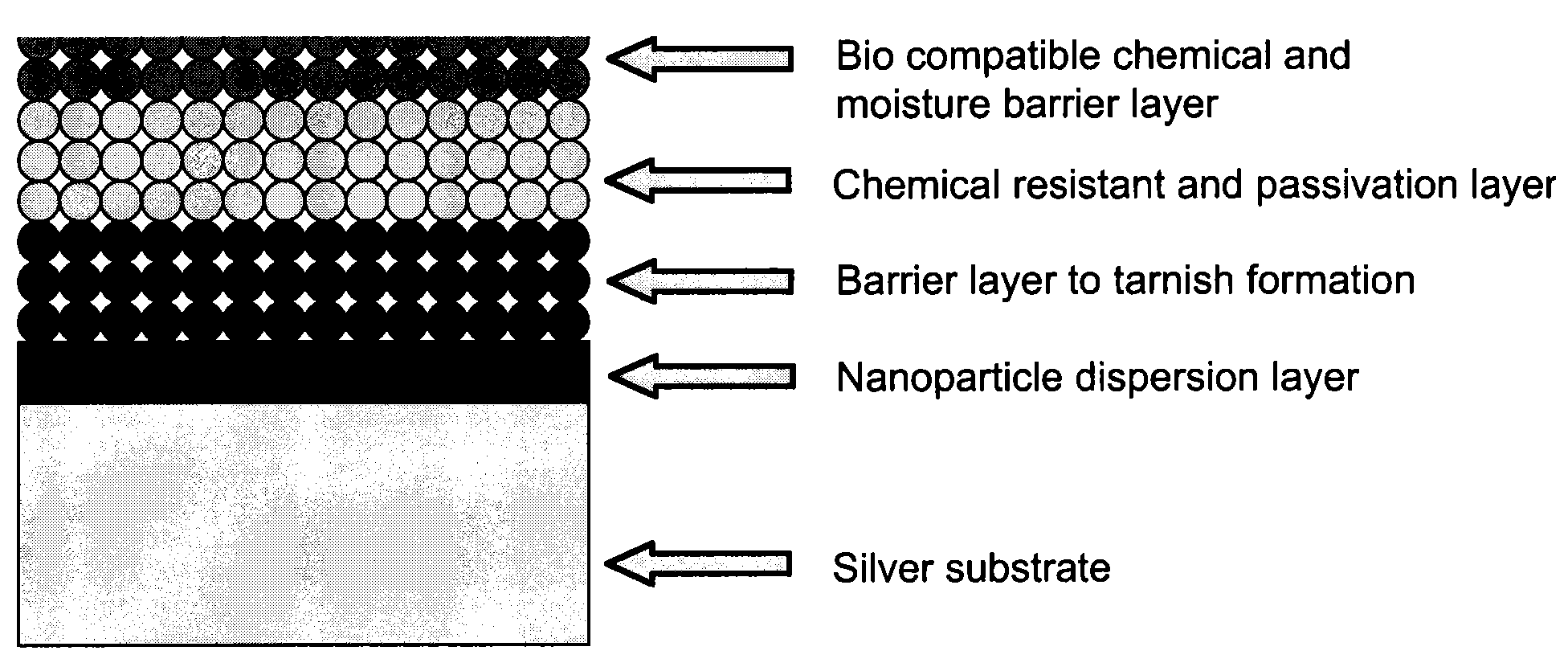

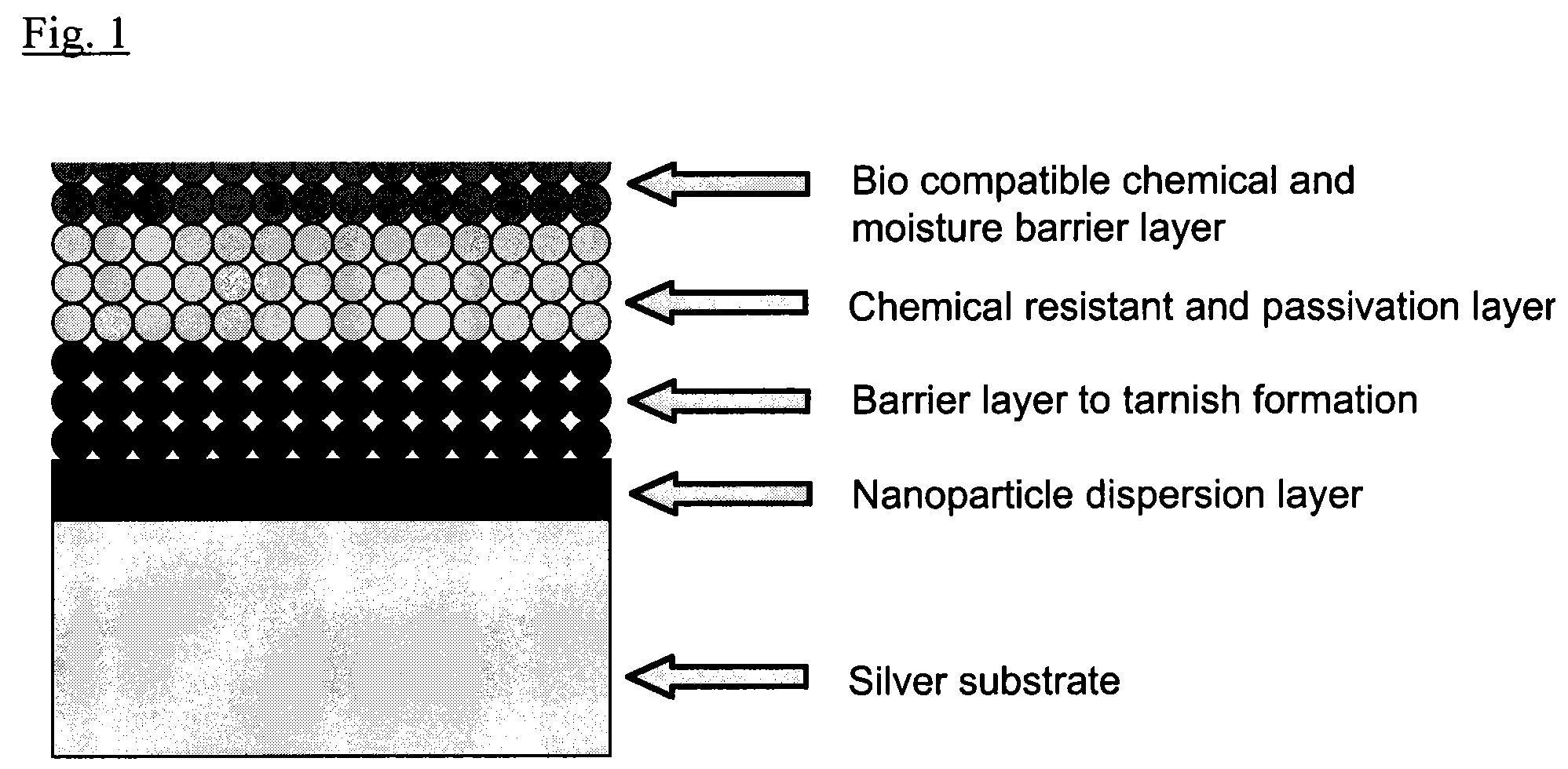

Method for imparting tarnish protection or tarnish protection with color appearance to silver, silver alloys, silver films, silver products and other non precious metals

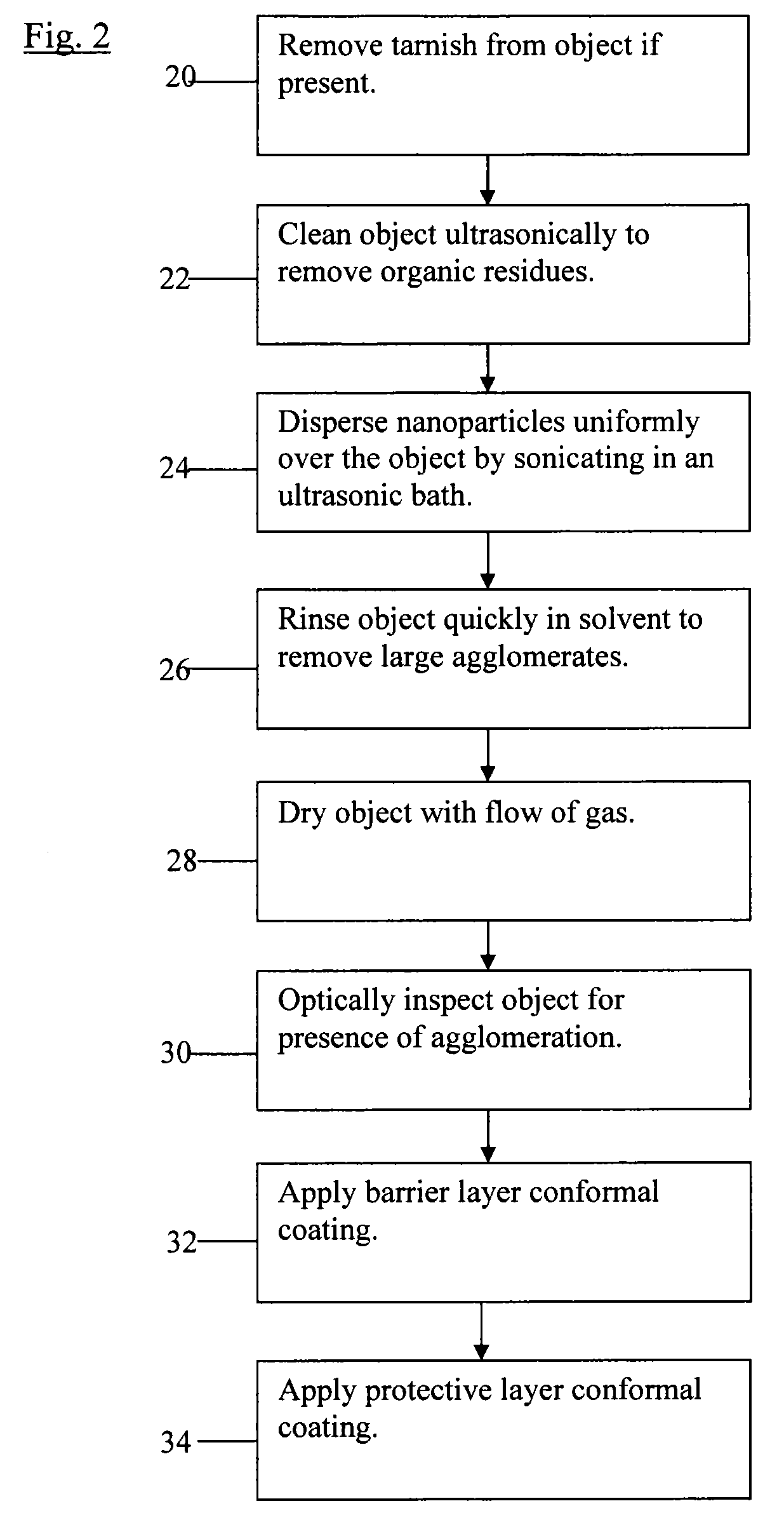

ActiveUS8802202B2Paper/cardboard layered productsMechanical vibrations separationSolventNon precious metal

A method of surface coating a metallic object, including removing substantially all of the existing silver sulfide tarnish if present, ultrasonically cleaning the object with immersion in a solvent, uniformly dispersing selected nanoparticles over the surface of the object by sonicating the object in an ultrasonic bath containing the selected nanoparticles. The invention further includes quickly rinsing the object with solvent upon removal from the ultrasonic bath to inhibit formation of large agglomerates, drying the object with a flow of gas, optically inspecting the object for the presence of agglomeration and applying a barrier layer conformal coating and a protective layer conformal coating.

Owner:SERENITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com