Patents

Literature

241results about How to "Easy to corrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

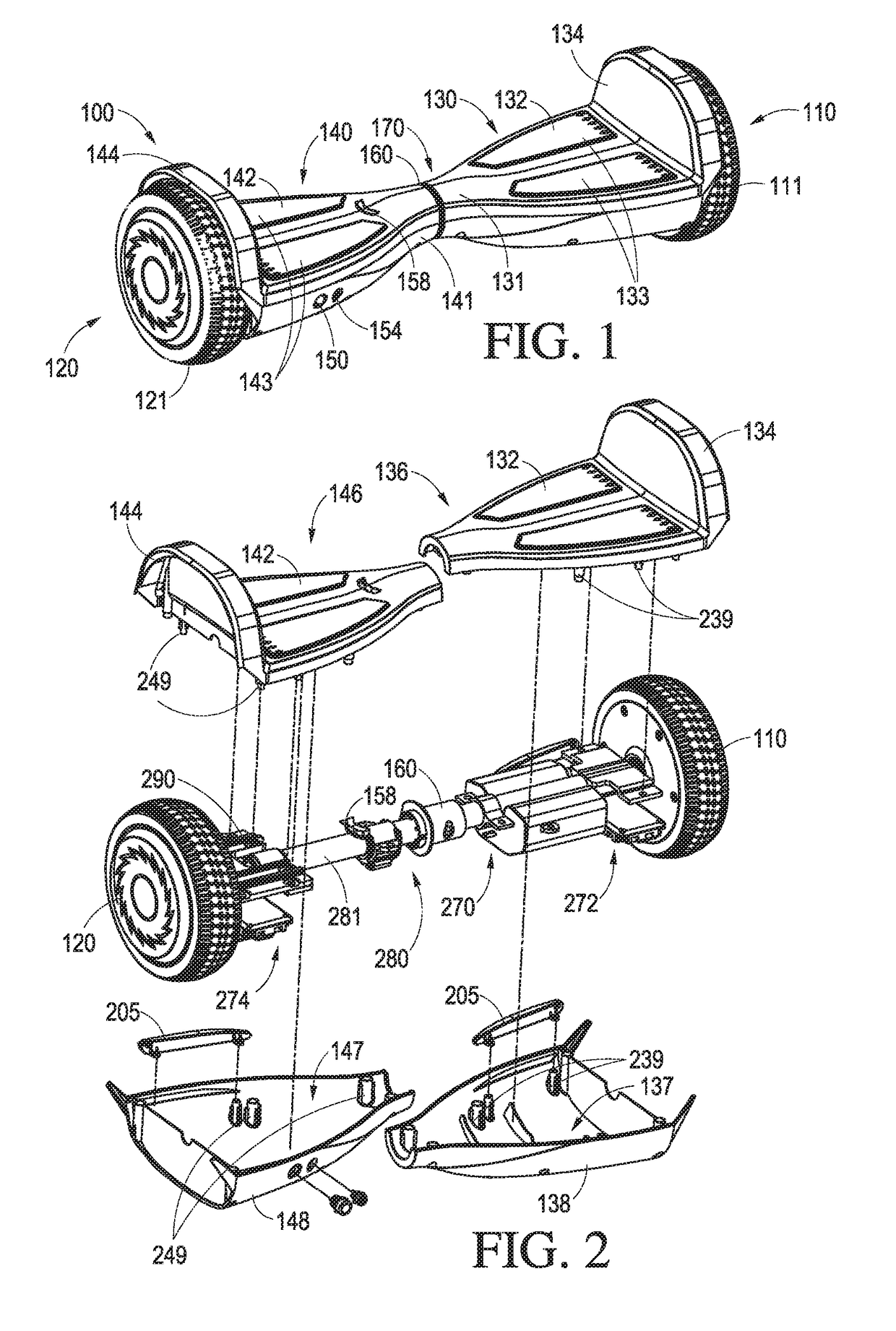

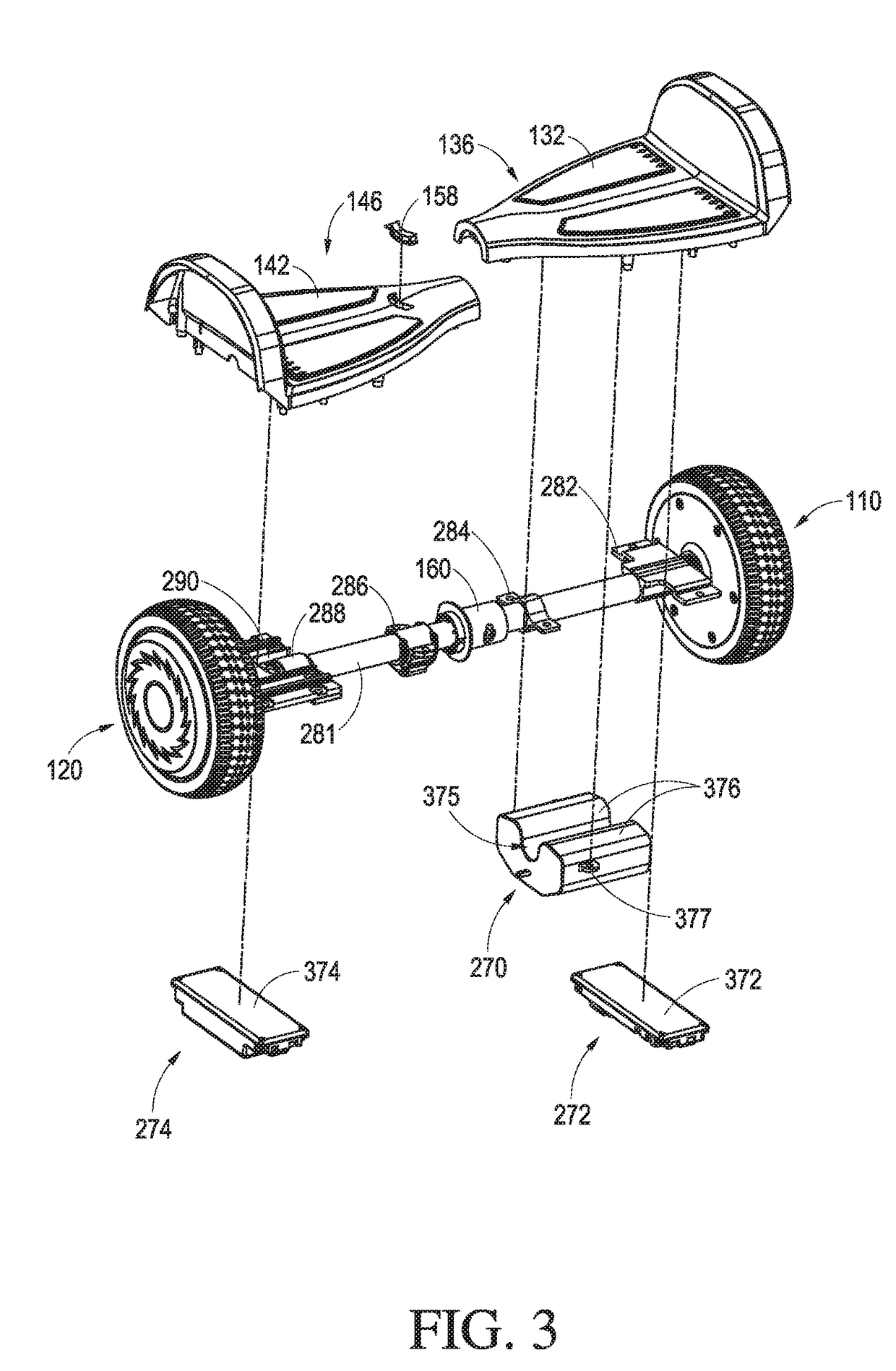

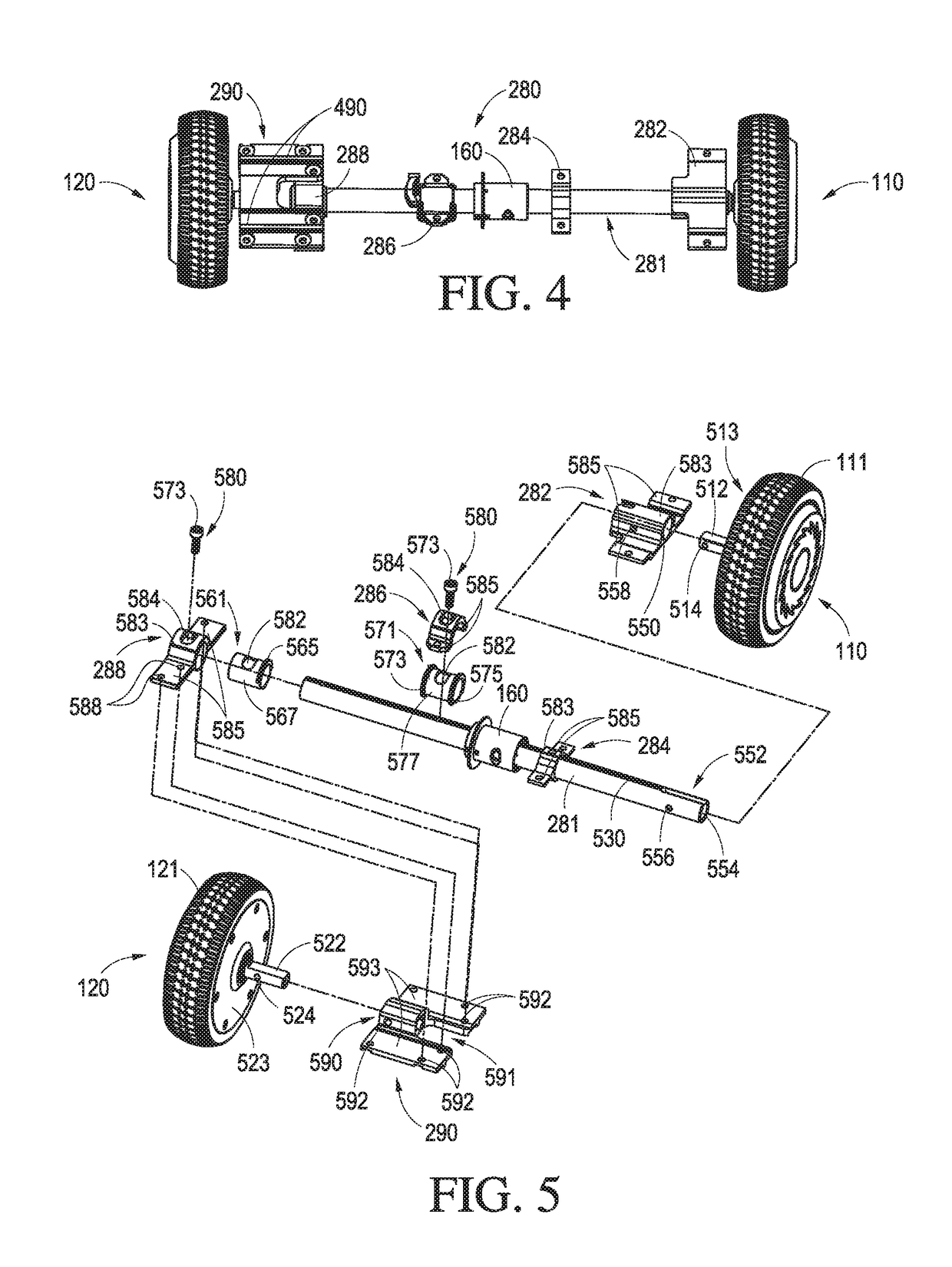

Electric balance vehicles

Owner:RAZOR USA

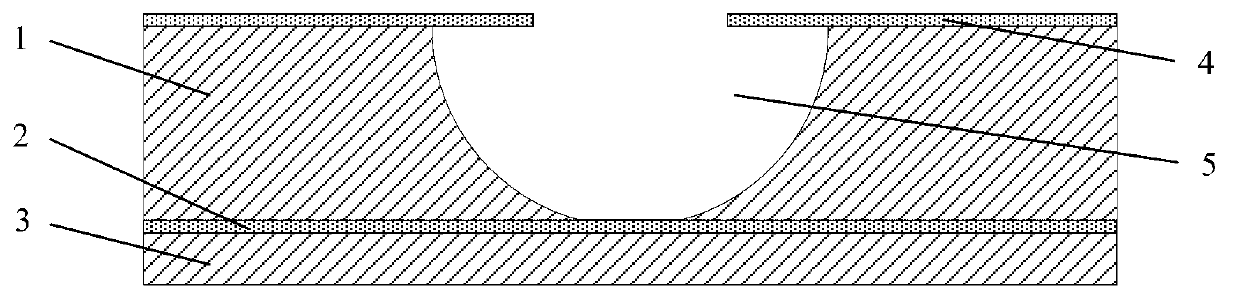

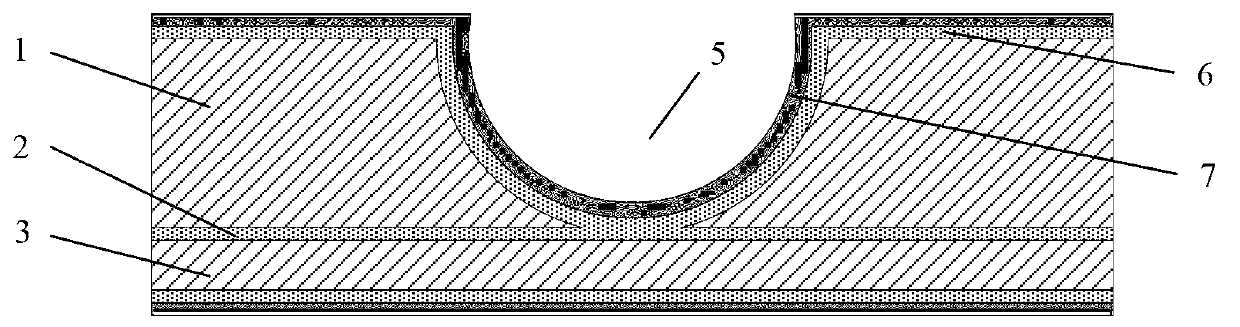

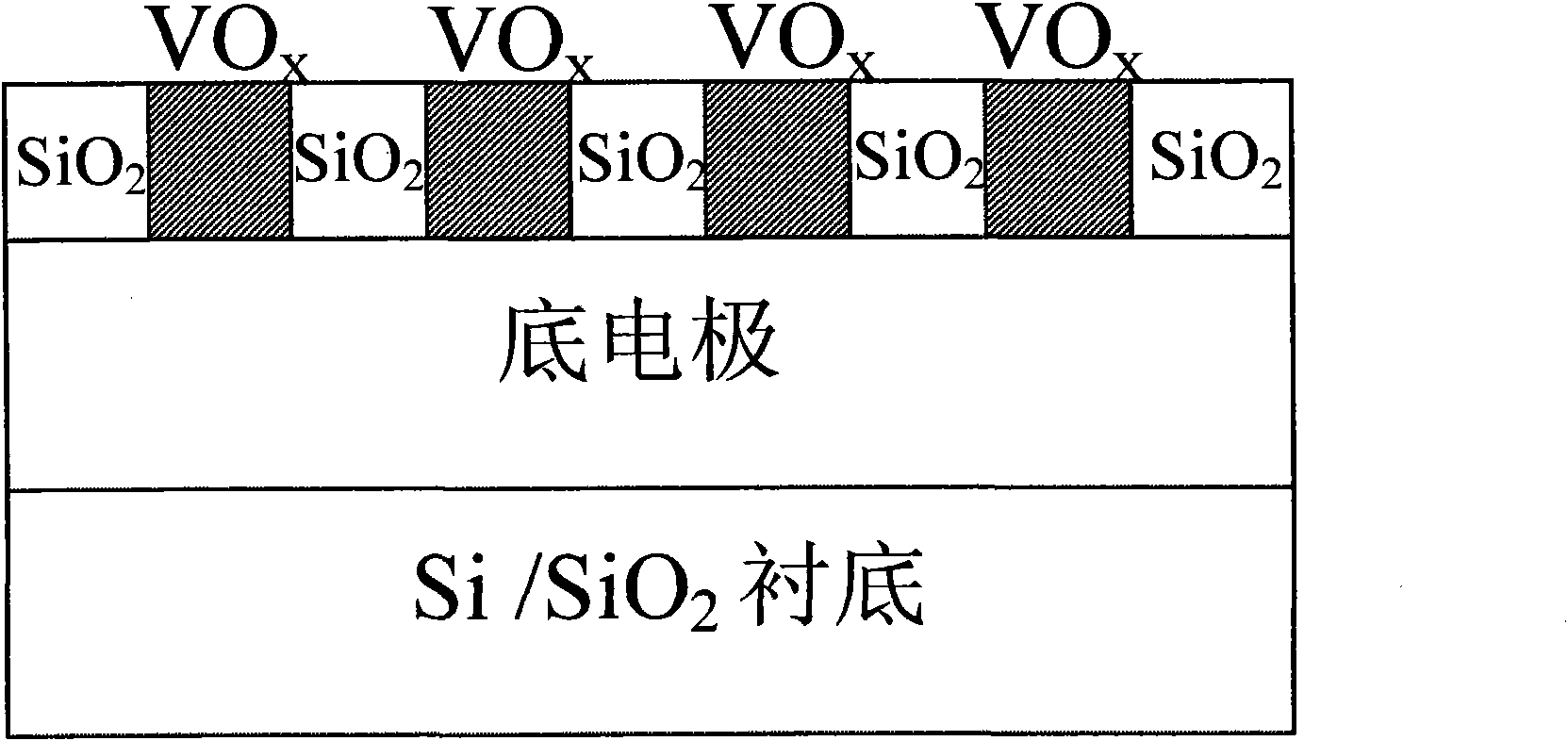

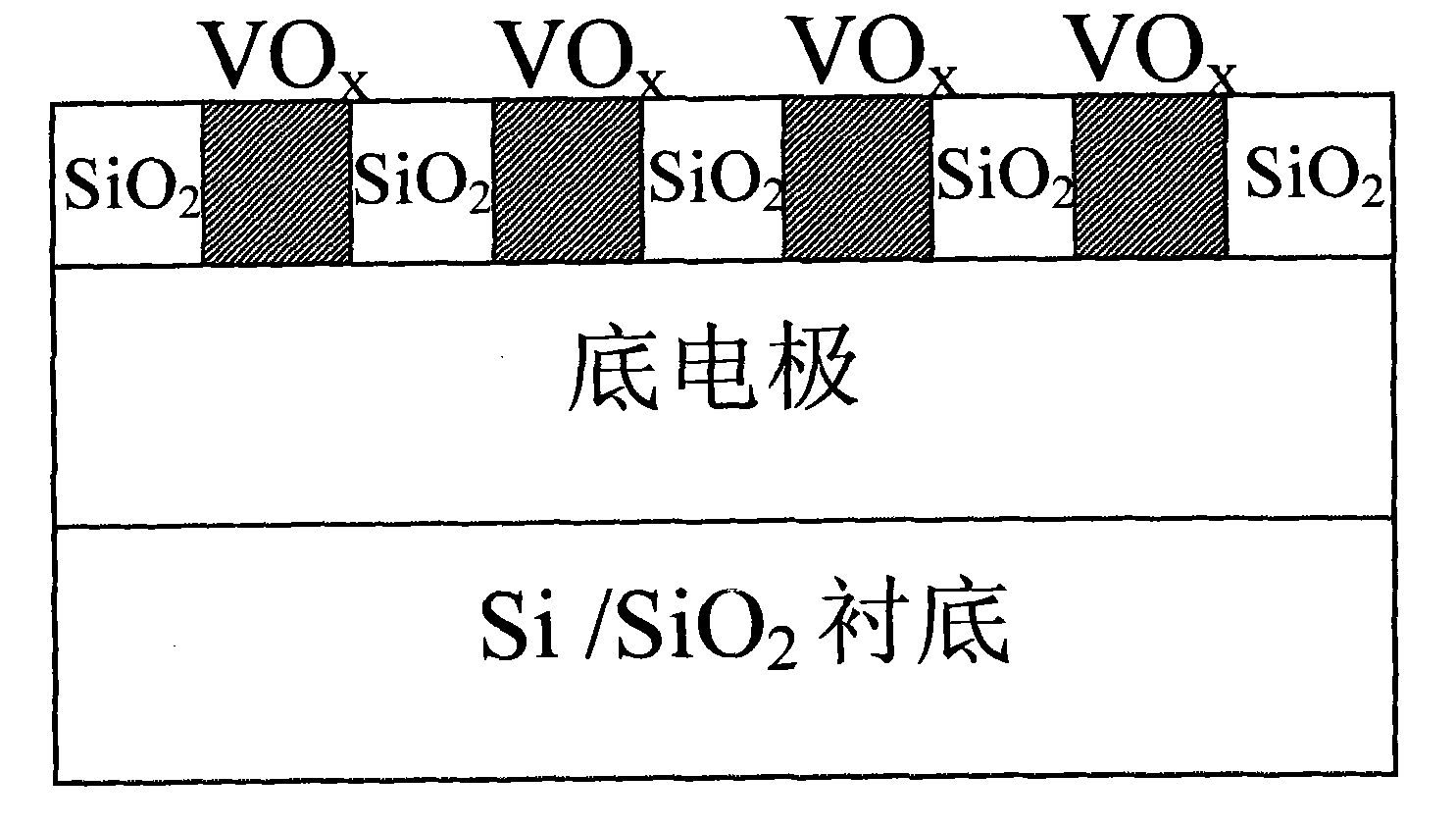

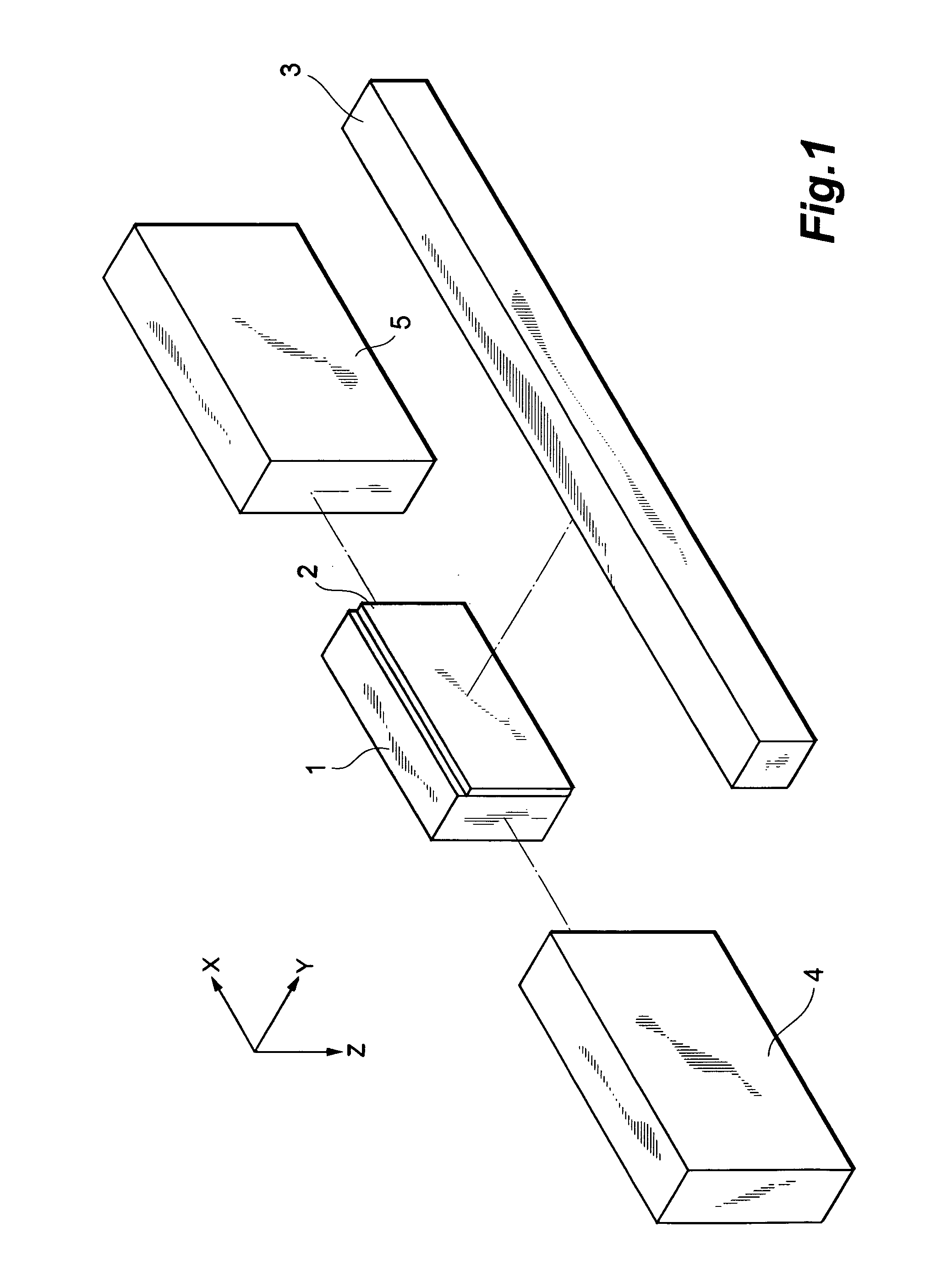

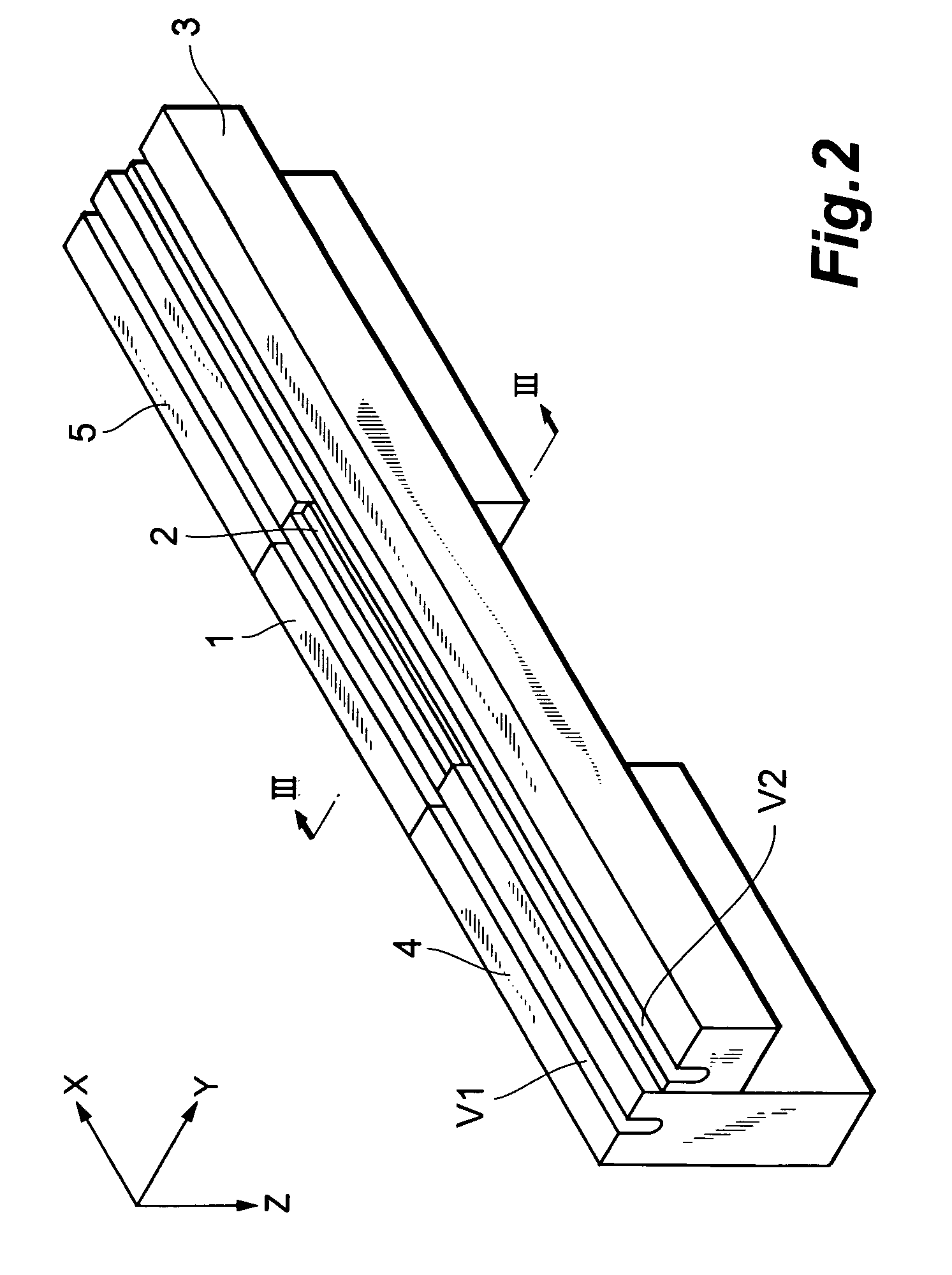

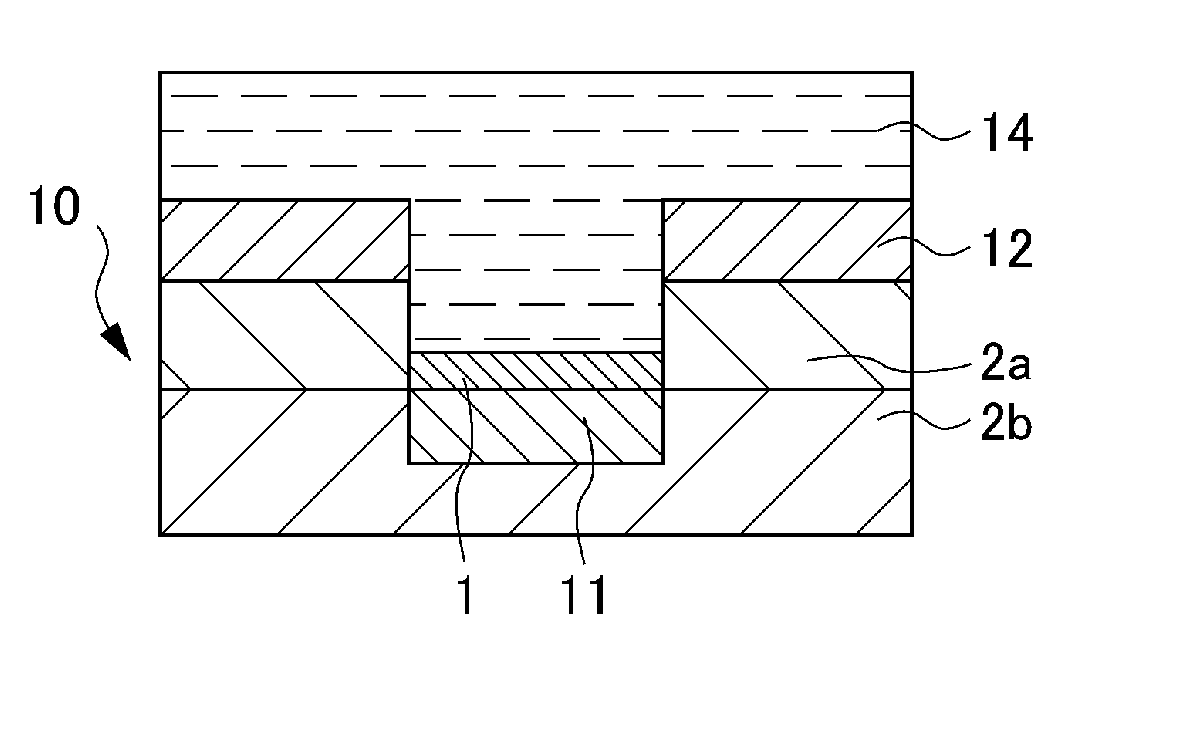

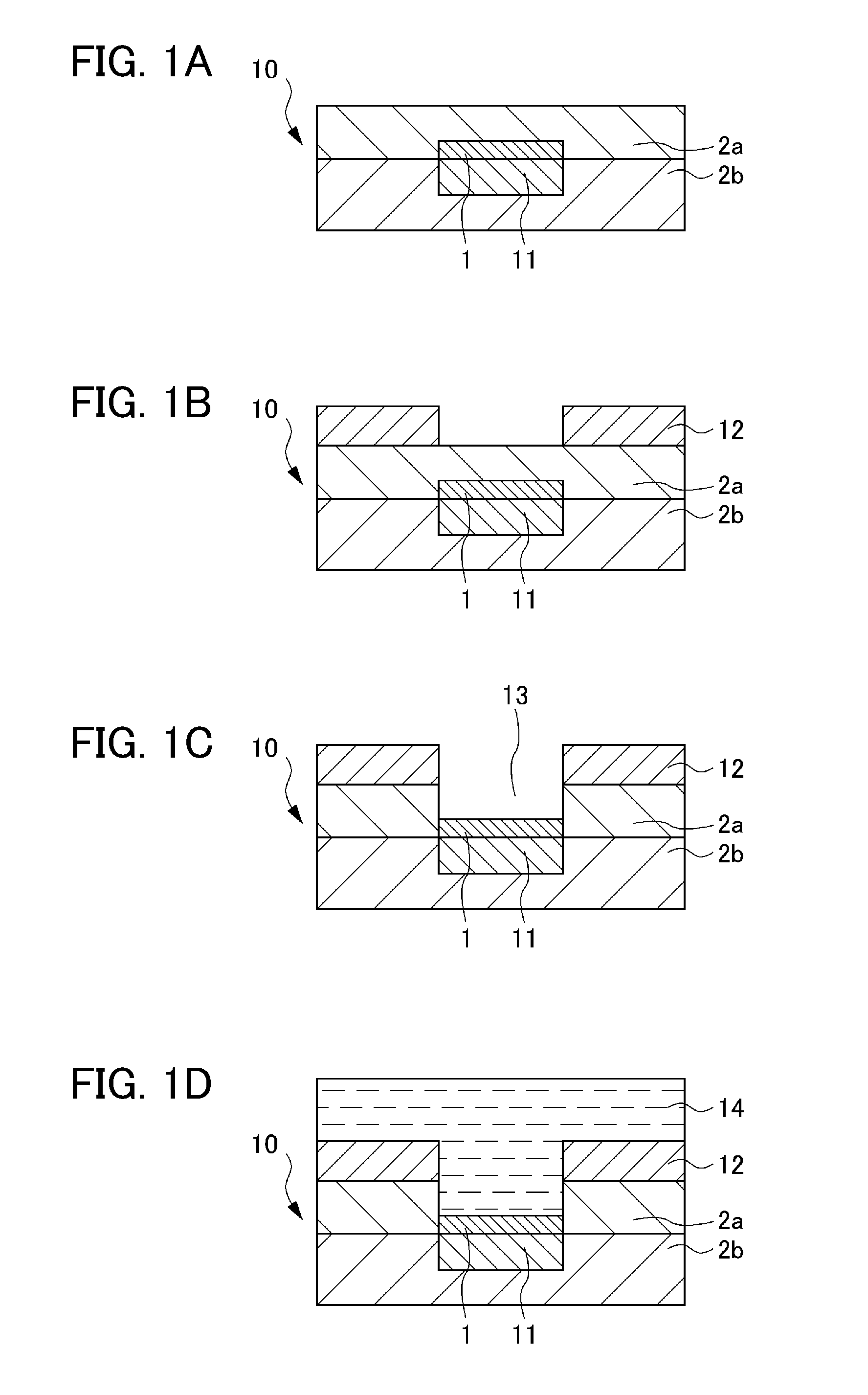

Miniature hemispherical resonant gyroscope based on SOI (Silicon on Insulator) silicon slice and manufacturing method of miniature hemispherical resonant gyroscope

InactiveCN103344229AEasy to driveEasy to detectDecorative surface effectsTurn-sensitive devicesCapacitanceGyroscope

The invention discloses a miniature hemispherical resonant gyroscope based on an SOI (silicon on insulator) silicon slice and a manufacturing method of the miniature hemispherical resonant gyroscope, belonging to the field of micro / nano processing and manufacturing. A driving electrode 16 and a sensitive electrode 17 of the gyroscope are composed of independent silicon blocks formed by dividing a structural silicon body 1 internally provided with a hemispherical hollow cavity through a plurality of radial structural silicon grooves 14, the area of the driving electrode 16 and the sensitive electrode 17 relative to a hemispherical harmonic oscillator 8 is increased, and the driving force and the detecting capacitance are increased to facilitate the driving and signal detection of the hemispherical harmonic oscillator 8; and meanwhile, the independent silicon blocks formed by the divided structural silicon body 1 enables a silicon dioxide sacrificial layer 6 to be corroded more easily. The gyroscope processing method disclosed by the invention is used for processing a supporting body hollow cavity 10 through ICP (inductively coupled plasma) etching and depositing conductive polysilicon to form a cylindrical supporting body 11, so that the size of the supporting surface of the supporting body is controllable to beneficially control the vibration mode distribution of the hemispherical harmonic oscillator 8; and meanwhile, when processing the driving electrode 16 and the sensitive electrode 17, the back surfaces of the driving electrode 16 and the sensitive electrode 17 are firstly processed to protect the hemispherical harmonic oscillator 8 from being corroded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sensor device

InactiveUS20140375321A1Properly detectEasy to corrodeElectric/magnetic detection for well-loggingMaterial impedancePhysicsCapacitance

Provided herein is a sensor device that may include a first electrode pair, a second electrode pair, and a detector. The first electrode pair may be covered with a protective film. The second electrode pair may have at least a portion thereof exposed to liquid. The detector may be configured to detect a property of the liquid by using a value concerning an electrical conductivity of the liquid as determined by using the second electrode pair and a value concerning a capacitance of the first electrode pair.

Owner:AISAN IND CO LTD

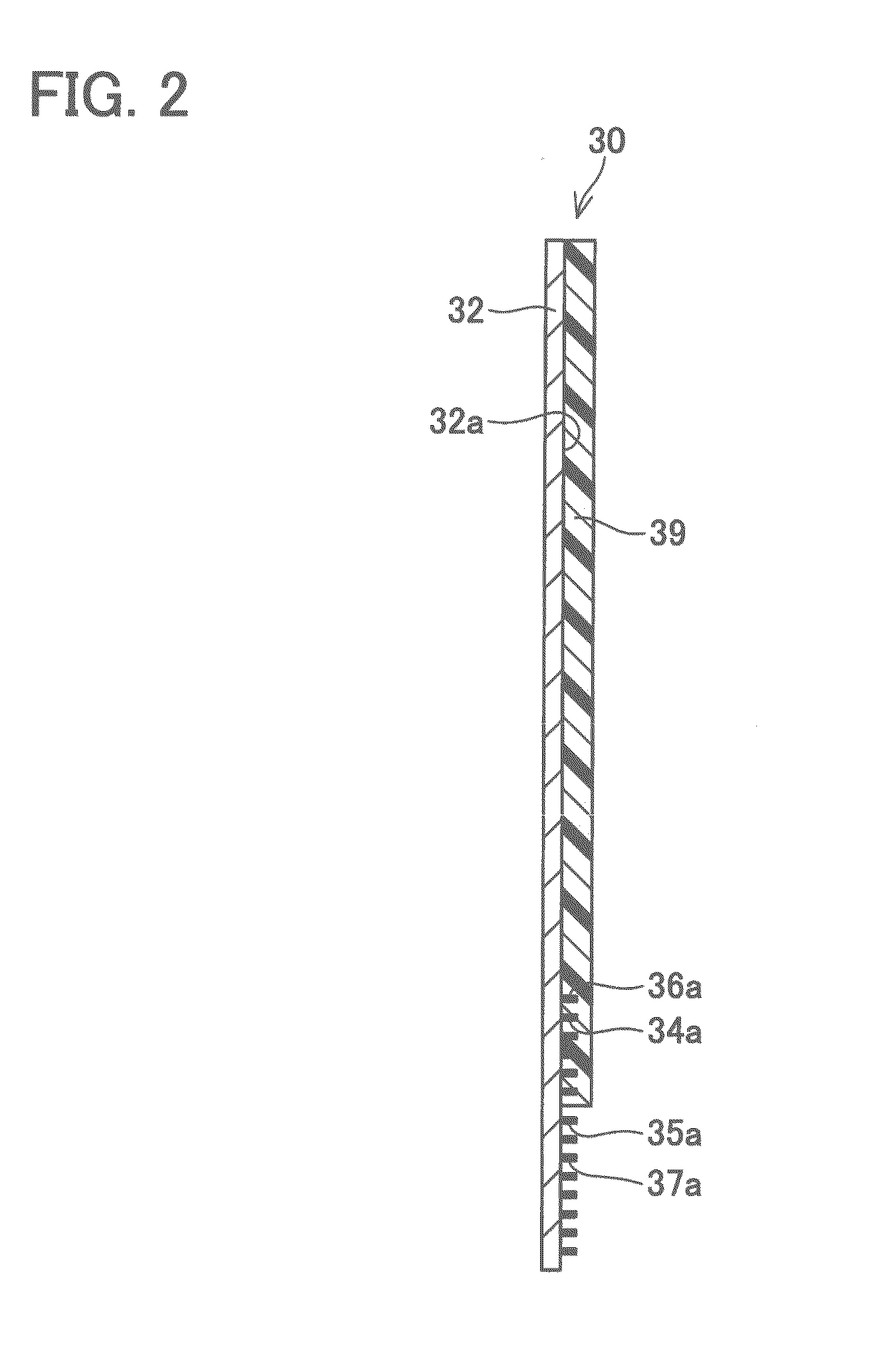

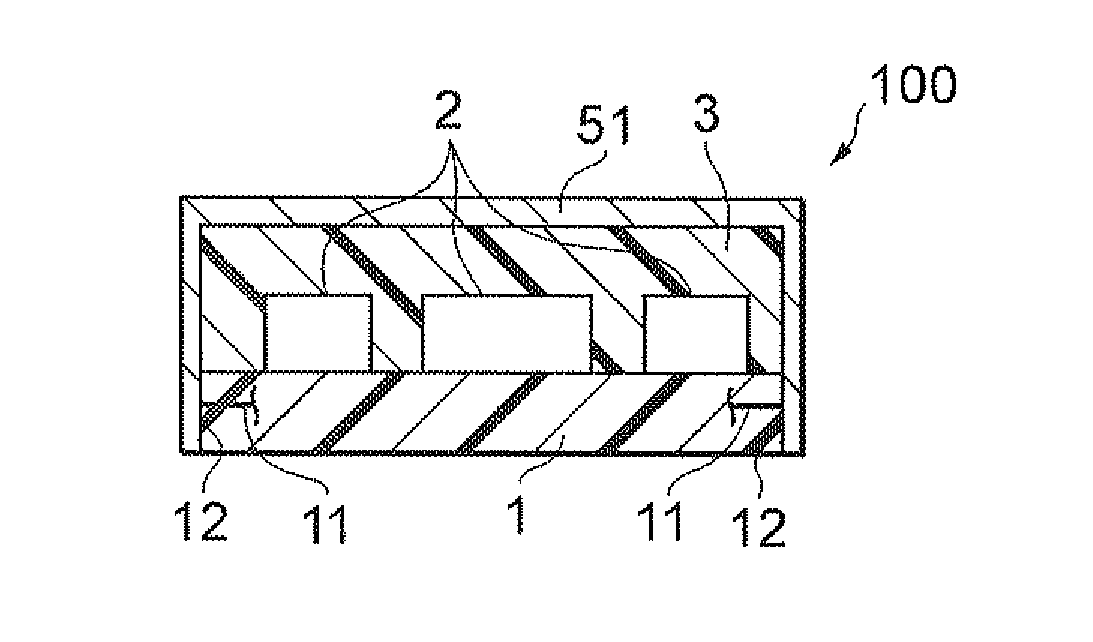

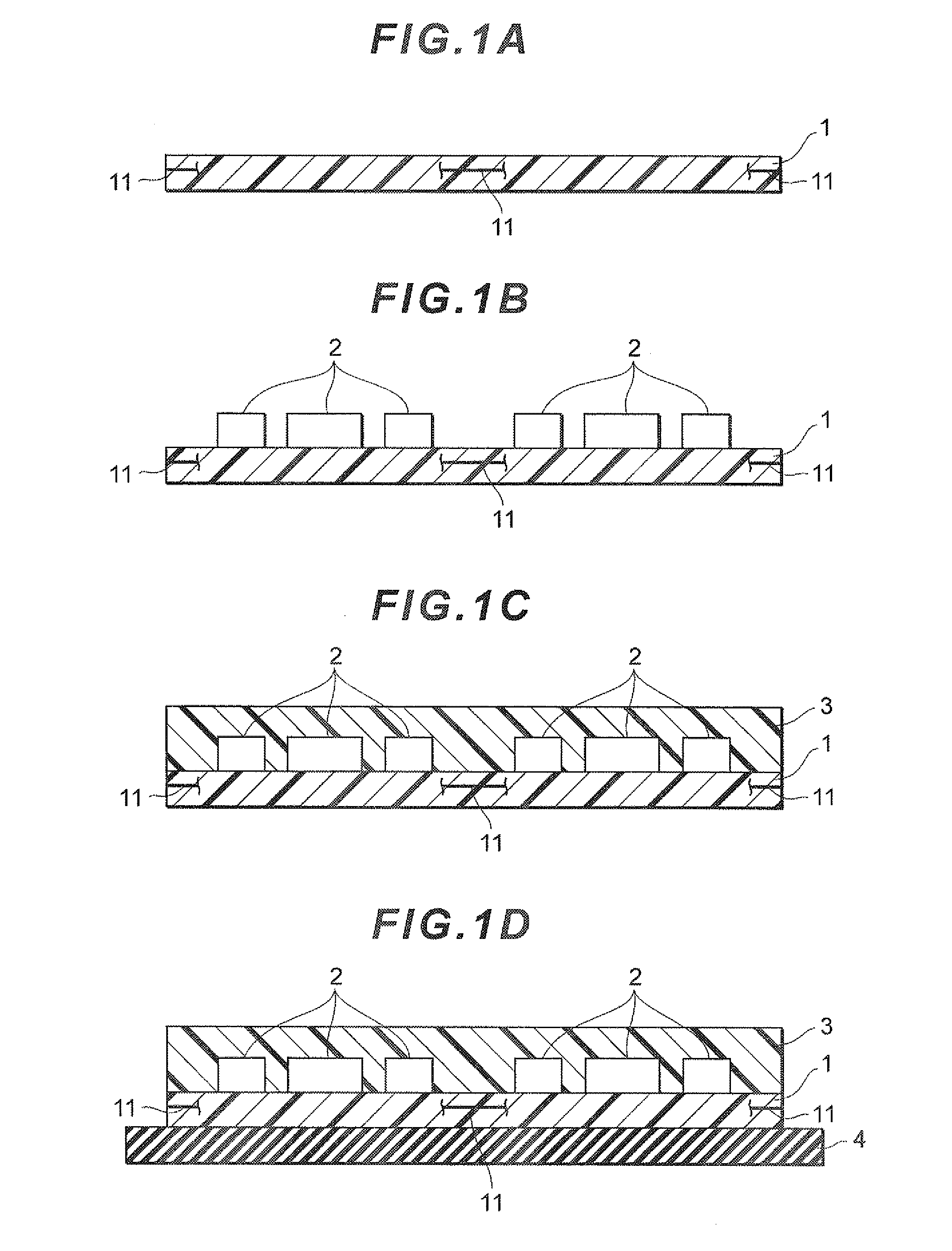

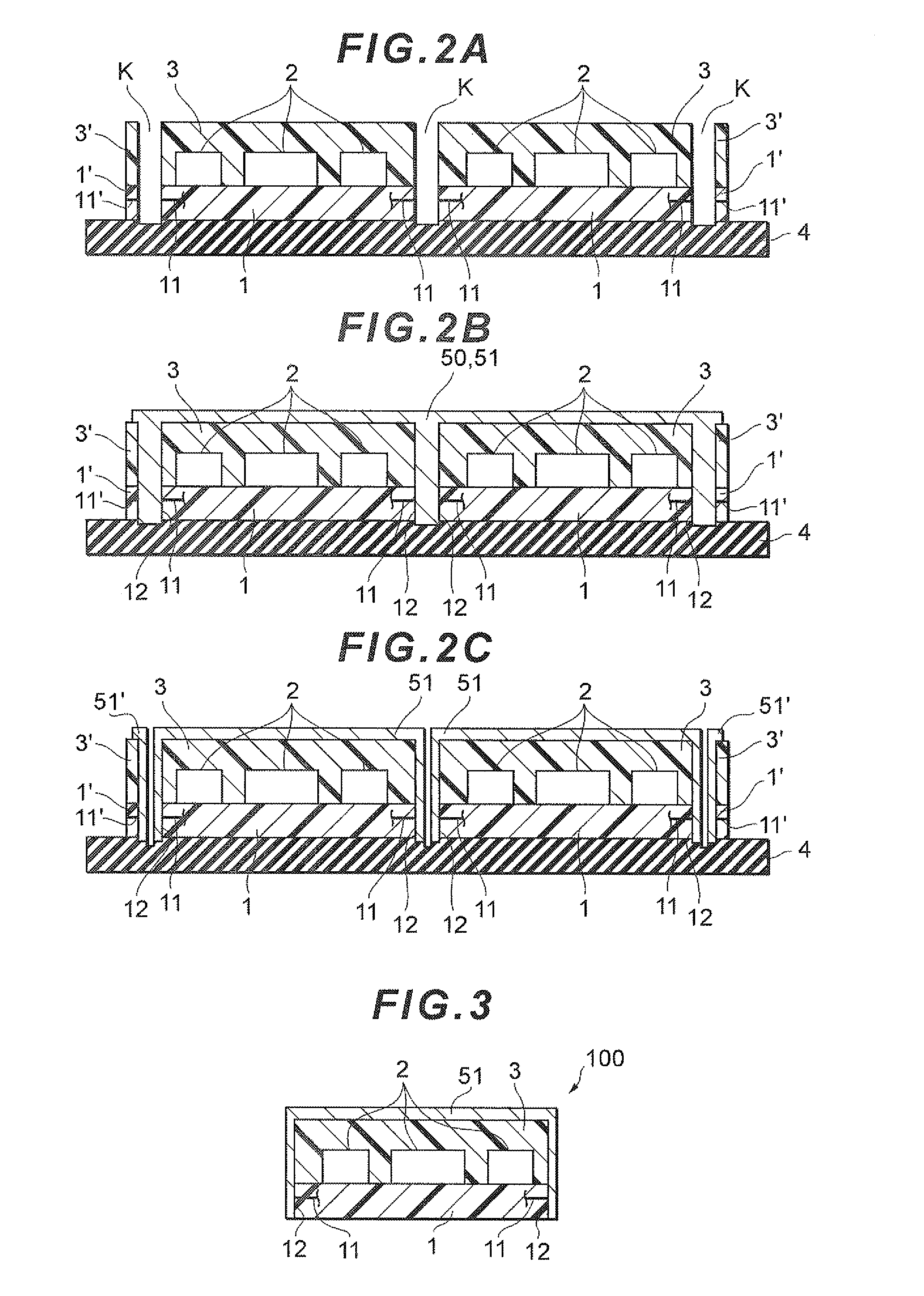

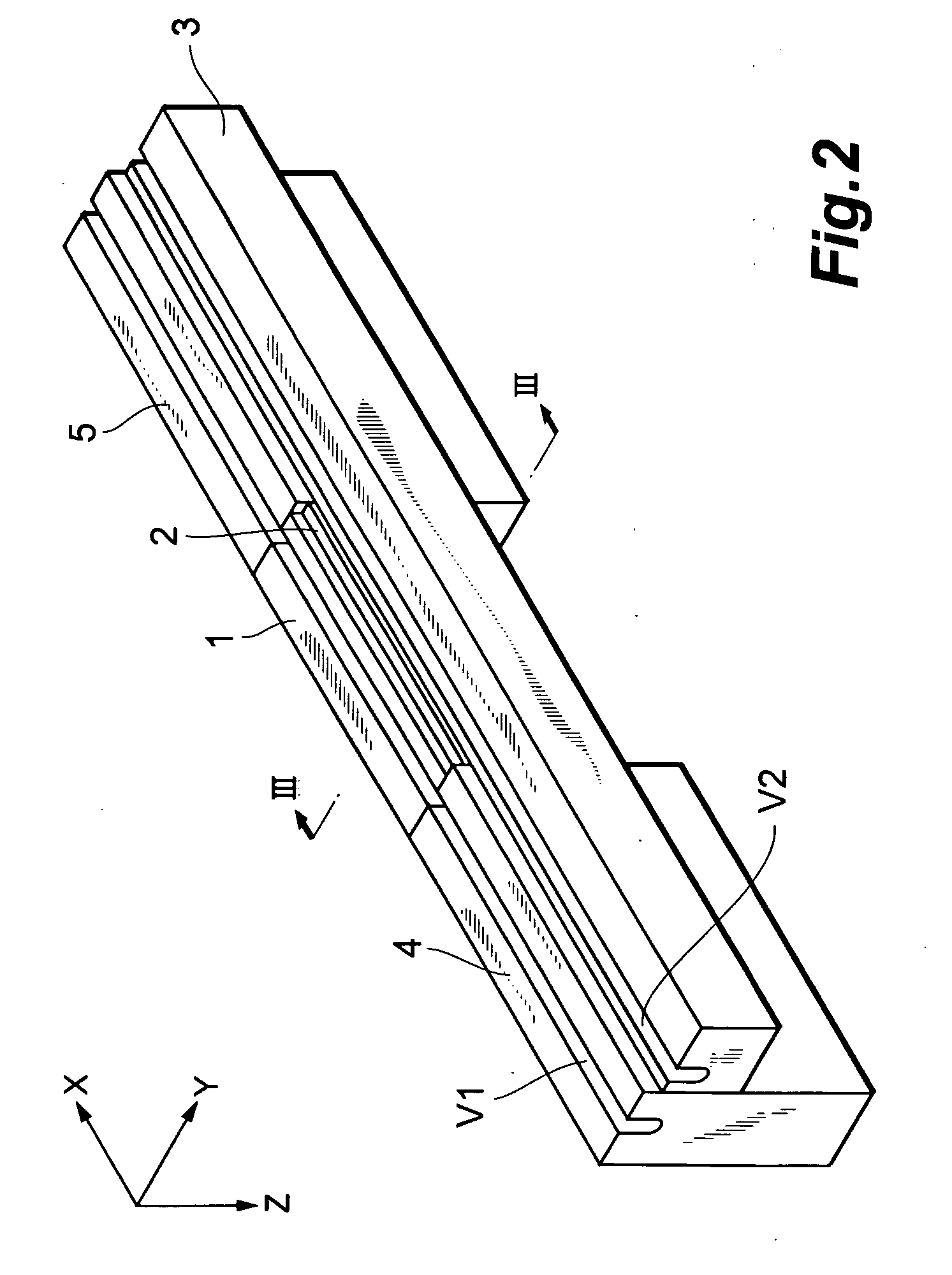

Electronic component module and method of manufacturing the same

InactiveUS20130256848A1Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCelsius DegreeEngineering

An electromagnetic component module includes: a molding resin provided so as to cover electronic components mounted on a substrate and a surface of the substrate; and a conductive shield formed so as to further cover the molding resin. The conductive shield includes a first filler and a second filler which are different from each other and the conductive shield is connected to ground wires exposed on lateral surfaces of the substrate. The average particle diameter of the first filler is ½ or less of the thickness of the ground wires and the second filler forms a metallic bond in the temperature range of 250 degrees Celsius or lower.

Owner:TDK CORPARATION

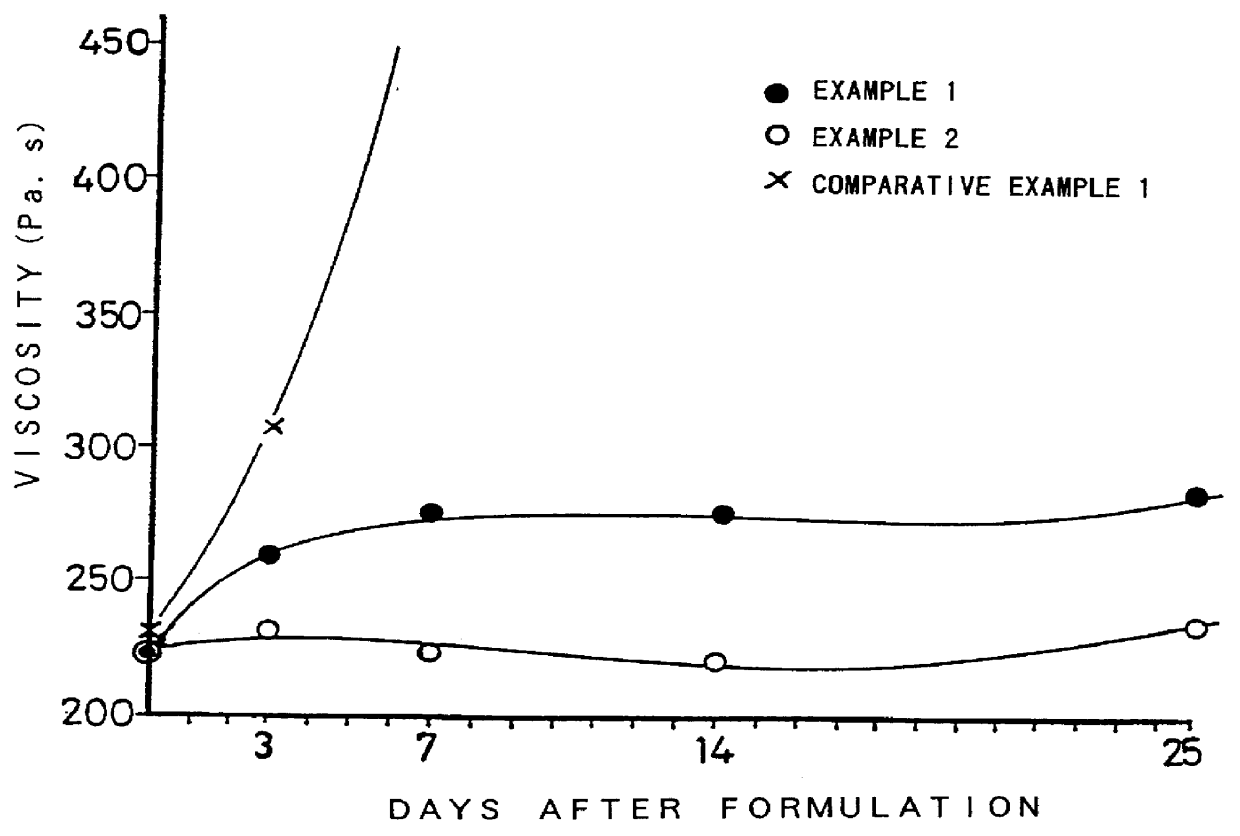

Solder paste

InactiveUS6159304AImprove solderabilityEasy to corrodeWelding/cutting media/materialsSoldering mediaEthylene oxideAlloy

In order to prevent aging of an Sn-Zn system alloy solder paste, 0.5-5% by weight of a compound obtained by adding an ethylene oxide to cyclohexylamine, preferably together with 0.5-5% by weight of a polyoxyethylene alkylamine is added to a flux of said solder paste.

Owner:PANASONIC CORP +1

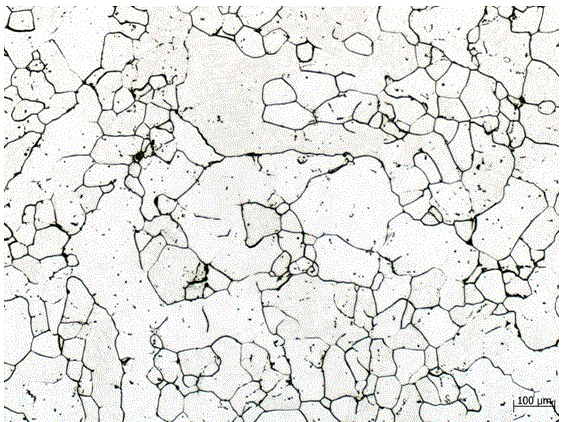

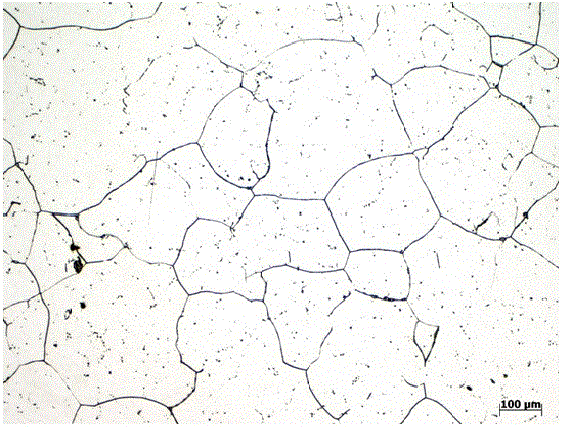

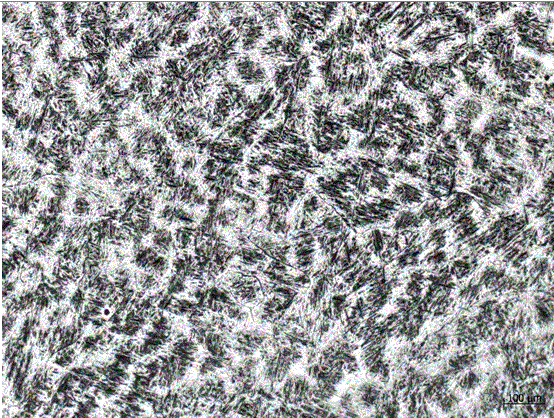

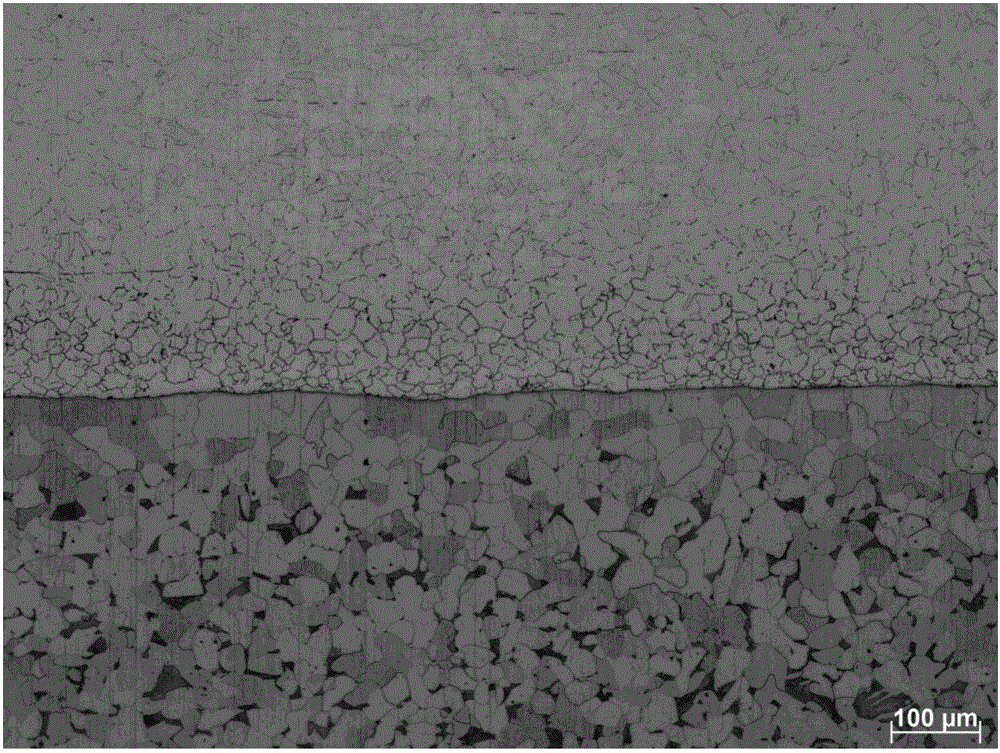

Ultra-supercritical martensite heat resisting cast steel original austenite grain size display method

ActiveCN105092437ASimple ingredientsEasy access to raw materialsPreparing sample for investigationParticle size analysisAlcoholNitric acid

The invention discloses an ultra-supercritical martensite heat resisting cast steel original austenite grain size display method, and belongs to the technical field of smelting metallographic structure sample analysis and inspection. The method comprises the steps that 1, austenitizing heat preservation is performed on a sample, wherein the temperature of a high-temperature furnace is increased to 1100 DEG C to 1150 DEG C, the sample is placed in the furnace for heat preservation, the temperature of the sample is quickly lowered to 800 DEG C in the furnace, heat preservation is performed, and then the temperature is lowered to the room temperature; 2, metallographic sample cutting is performed, wherein oxidation and decarbonization portions on the surface of a metallographic sample, with the specification of 15*15 mm, of the sample material processed through heat treatment are removed, and metallographic sample grinding and polishing are performed, wherein the surface of the sample is washed clean, and the sample is placed on a polishing machine to be polished; 3, a corrosive agent is prepared, wherein the volume ratio of nitric acid to alcohol is (6-10):(94-90), and chemical corrosion is performed, wherein the polished surface of the sample is upwards placed in a corrosive solution to enable the solution to cover the surface of the sample, and then the sample is taken out after being stood for 15-30 minutes on the room temperature condition; 4, grain size observation and statistics are performed, wherein a metallograph is taken for the sample.

Owner:CHINA FIRST HEAVY IND

Light high-strength ceramsite and preparation method thereof

ActiveCN106587931AReduce energy consumptionReduce processCeramic materials productionClaywaresRed mudExpanded clay aggregate

The invention provides light high-strength ceramsite comprising, by weight, 100 parts of solid raw materials and 1-15 parts of excitant. The solid raw materials include 100 parts of fly ash, 6-18 parts of high-aluminum fly ash, bauxite and red mud, 1-5 parts of micro-silica, 0.1-3 parts of surfactant and 6-24 parts of plasticizer. The excitant comprises 5-20 parts of alkali metal hydroxides and 80-95 parts of alkali metal silicates. The light high-strength ceramsite product is light and high in strength, the density level is 700-1100 kg / m<3>, the cylinder compressive strength can reach 10-20 MPa, and the ceramsite is not likely to be damaged. The ceramsite can be used for preparing lightweight aggregate high-performance concrete which serves as a load bearing structure and can be used for building wallboards, bridges, pipelines and the like, and has great application value.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Sepiolite-loaded nickel-based catalyst modified by two metals, as well as preparation method and application of sepiolite-loaded nickel-based catalyst

ActiveCN104923240ALow costEasy to makeCatalyst carriersCarboxylic acid nitrile preparationPotassiumReaction temperature

The invention relates to sepiolite-loaded nickel-based catalyst modified by two metals of potassium and lanthanum, as well as a preparation method and application of the sepiolite-loaded nickel-based catalyst to adiponitrile hydrogenation. The preparation method comprises the following steps: taking adiponitrile as a raw material and ethanol as a solvent, and taking sepiolite as a carrier of a catalyst to prepare a nickel-based sepiolite-loaded catalyst modified by potassium and lanthanum as additives. The preparation process of the catalyst comprises acid treatment on sepiolite, and steeping, drying, roasting and reducing of sepiolite after acid treatment. During the adiponitrile hydrogenation process, the reaction pressure is 1-2 MPa, and the reaction temperature is 100-120 DEG C. The catalyst has relatively high activity and 6-aminocapronitrile and hexamethylendiamine selectivity under relatively mild reaction conditions, the raw material of sepiolite is cheap and easy to obtain, and low in cost, and the catalyst is simple in preparation method, and has a good application prospect.

Owner:XIANGTAN UNIV

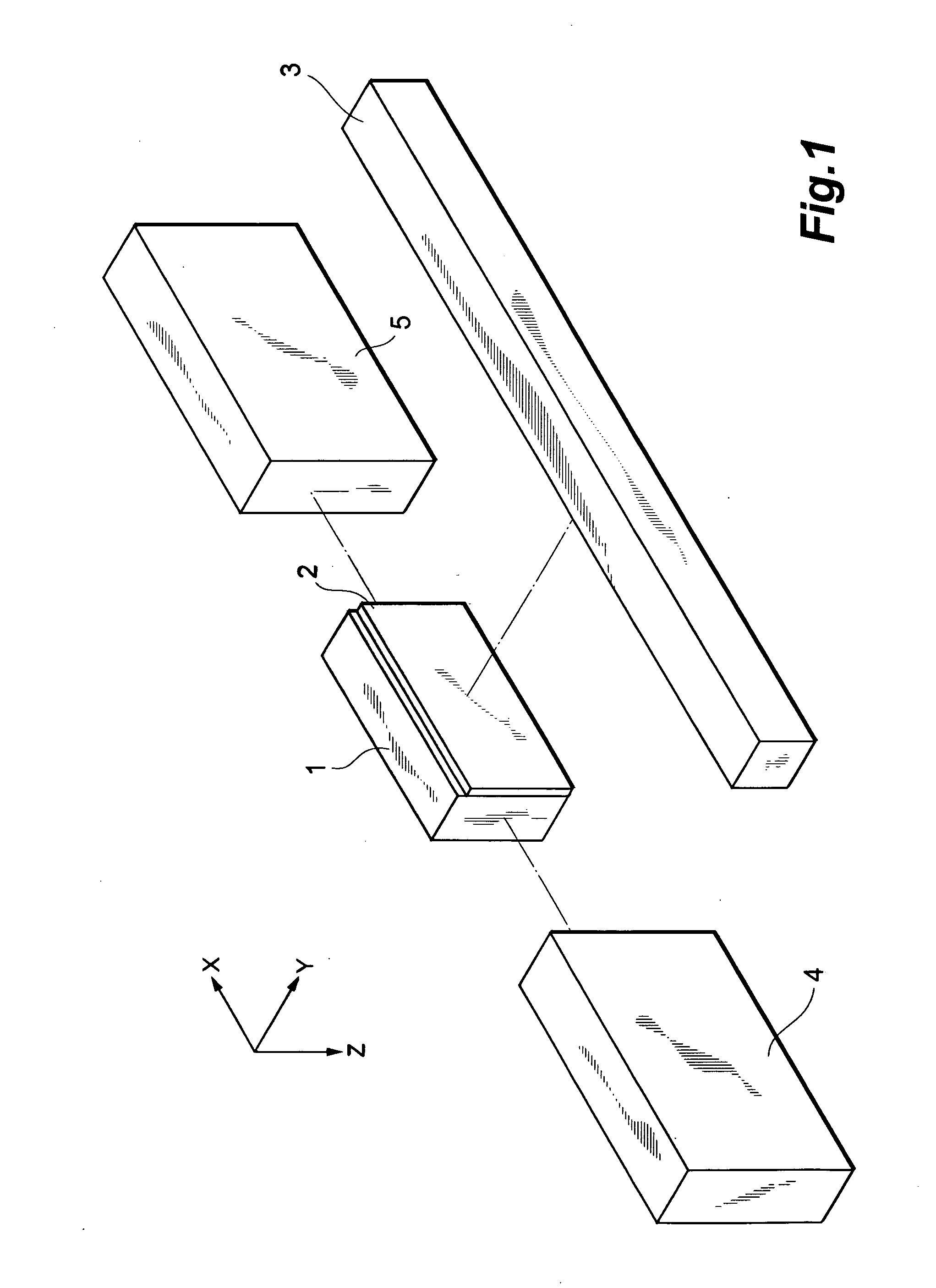

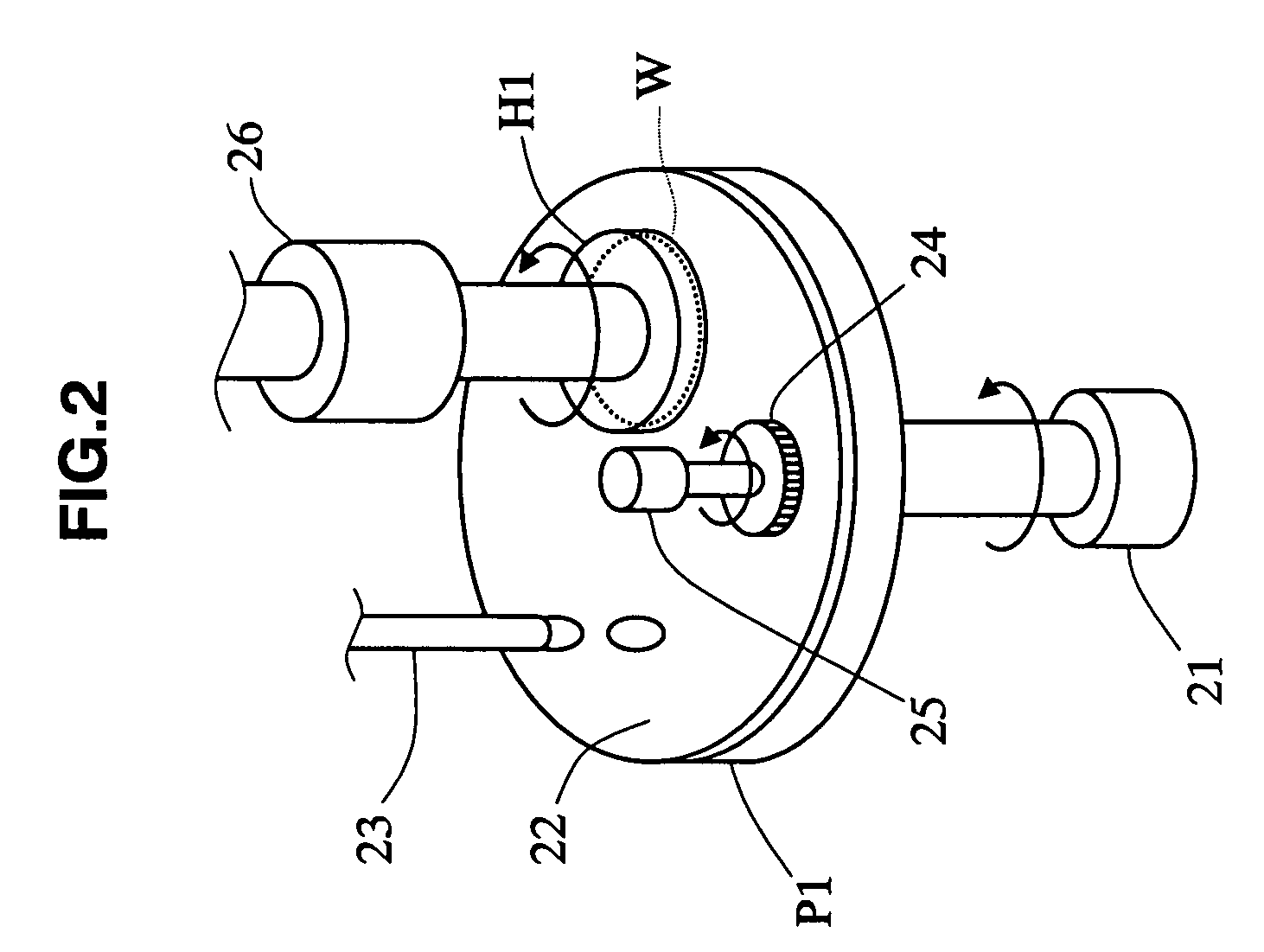

Magnetic tape head

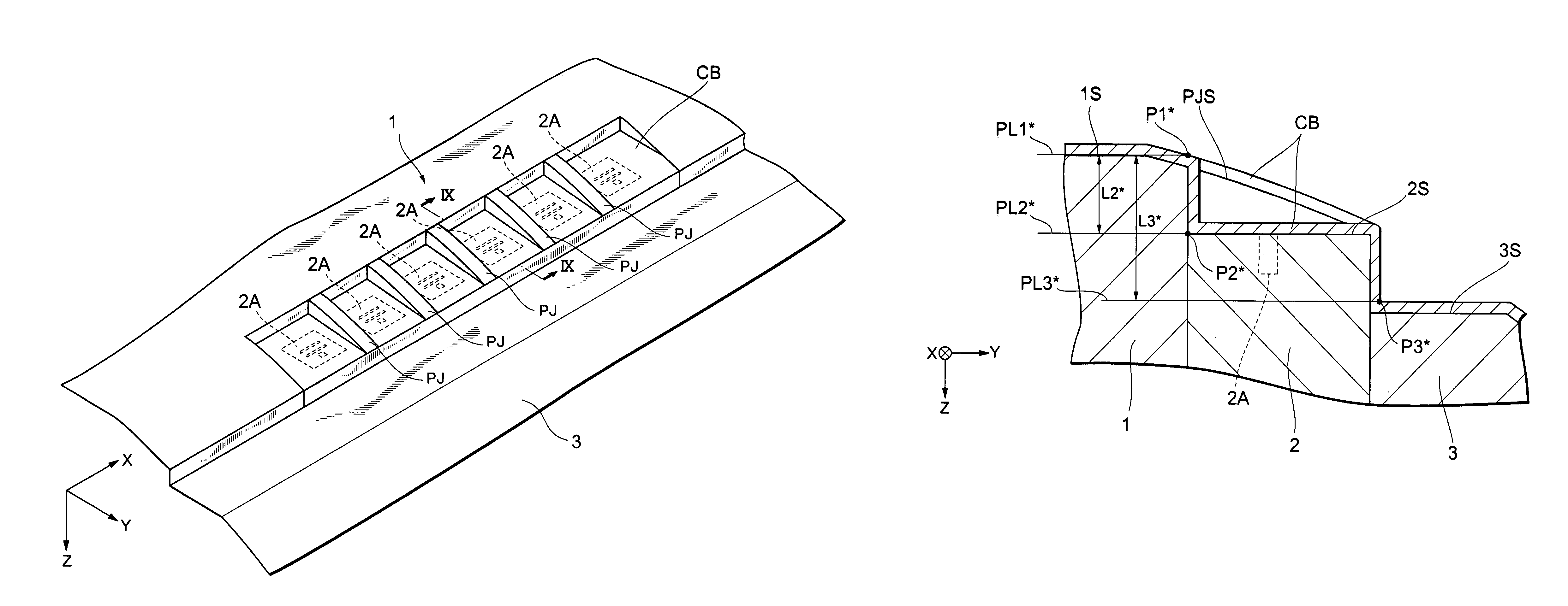

InactiveUS20090135520A1High precisionFlat surfaceManufacture head surfaceRecord information storageMagnetic tapeEngineering

A magnetic tape head has a base substrate, a magnetic head layer formed on the base substrate, and a closure piece formed on the magnetic head layer. The distance from a first plane comprising a point on the tape bearing surface of the base substrate to a third plane comprising a point on the tape bearing surface of the closure piece is equal to or greater than the distance from the first plane to a second plane comprising a point on the tape bearing surface of the magnetic head layer.

Owner:TDK CORPARATION

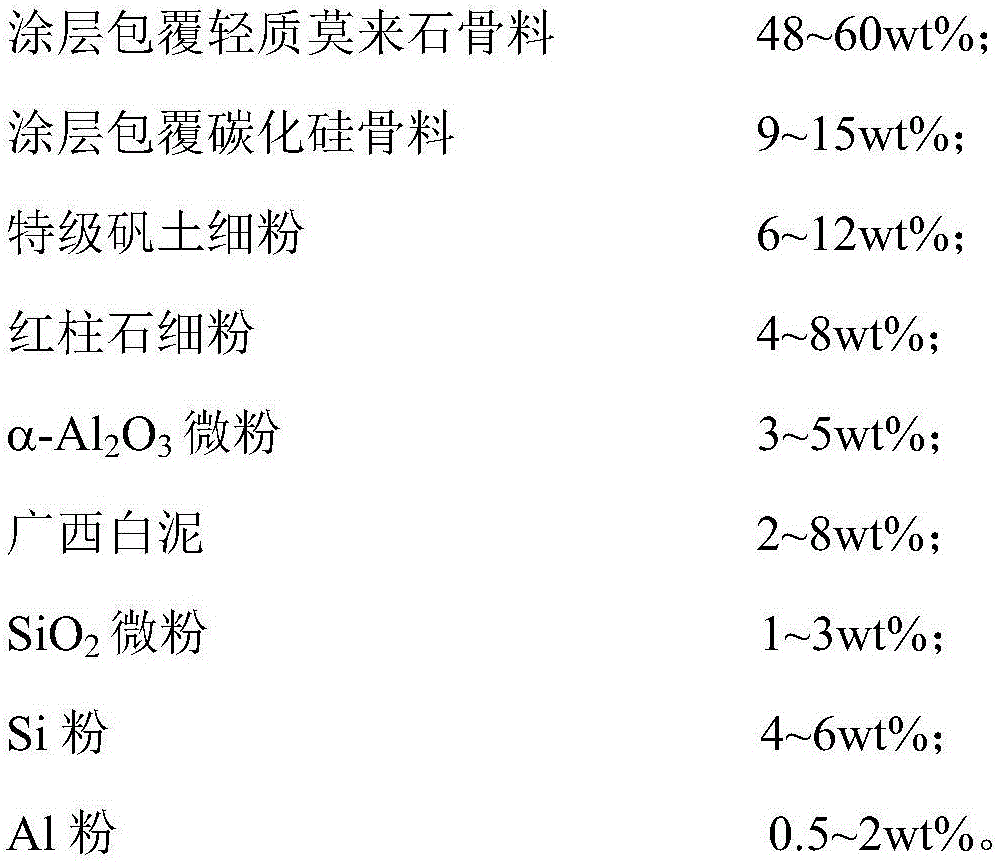

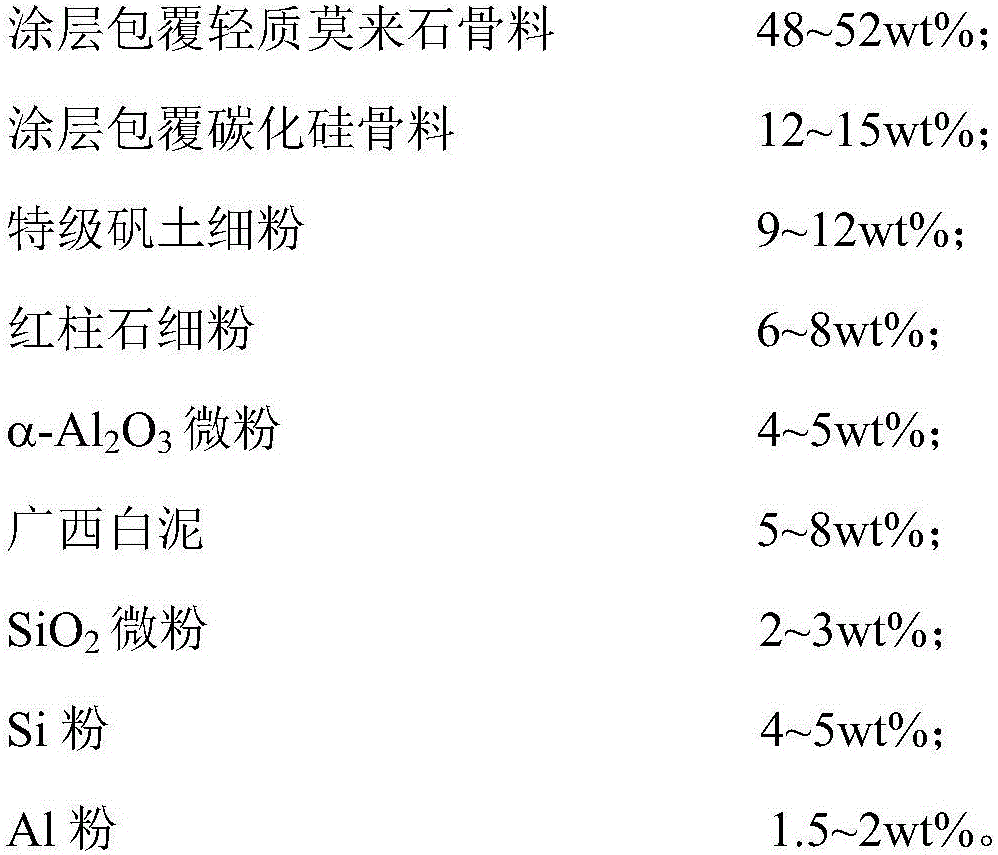

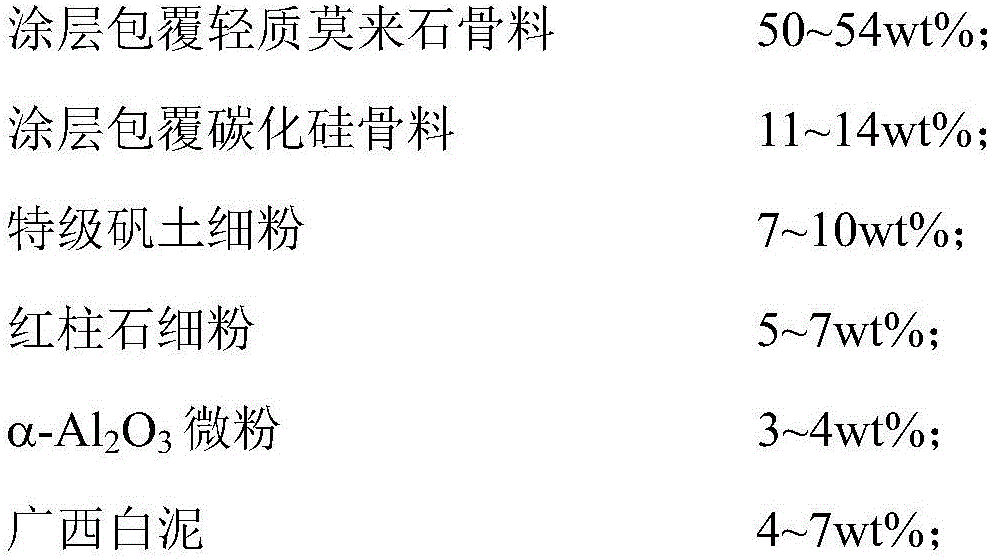

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

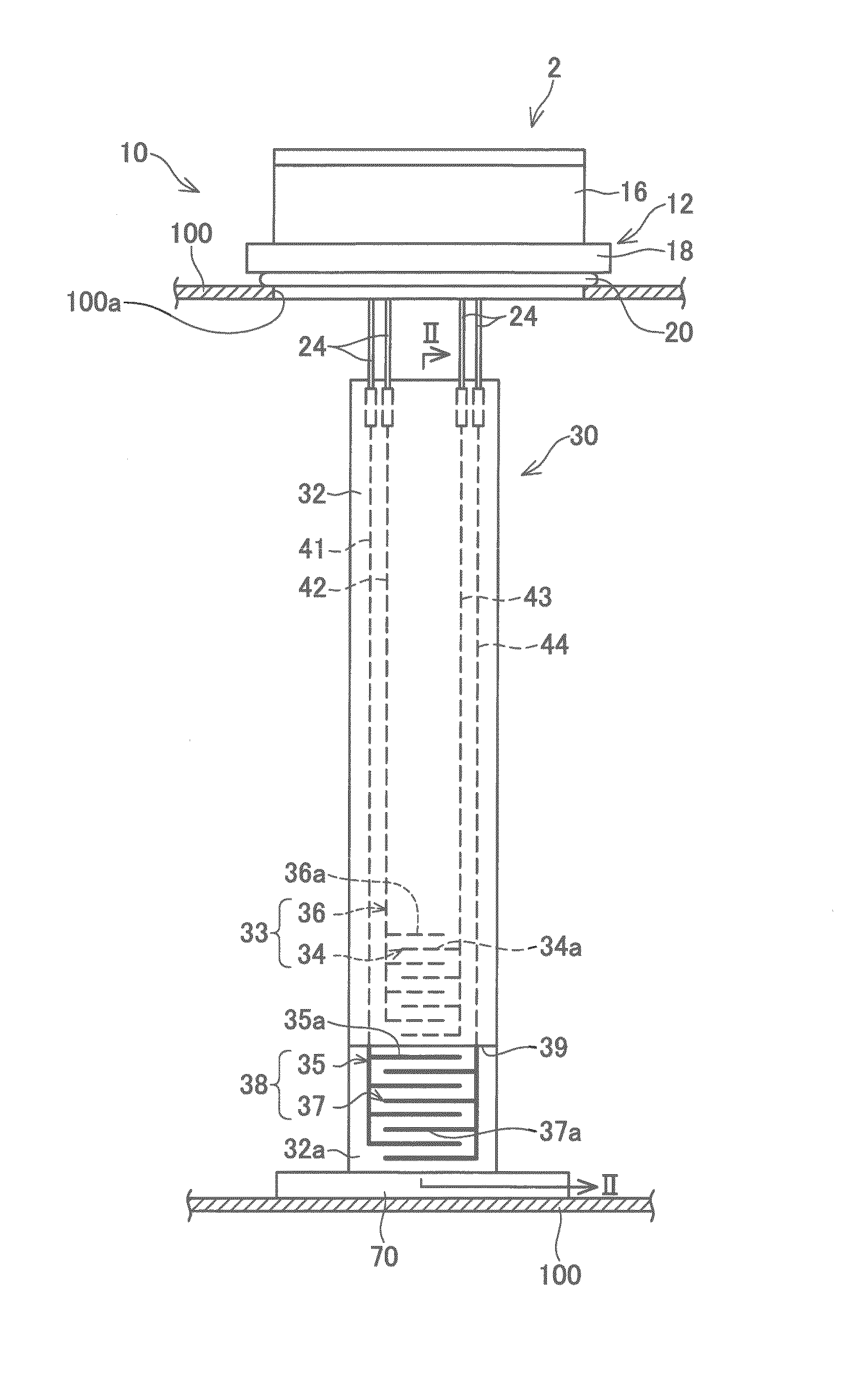

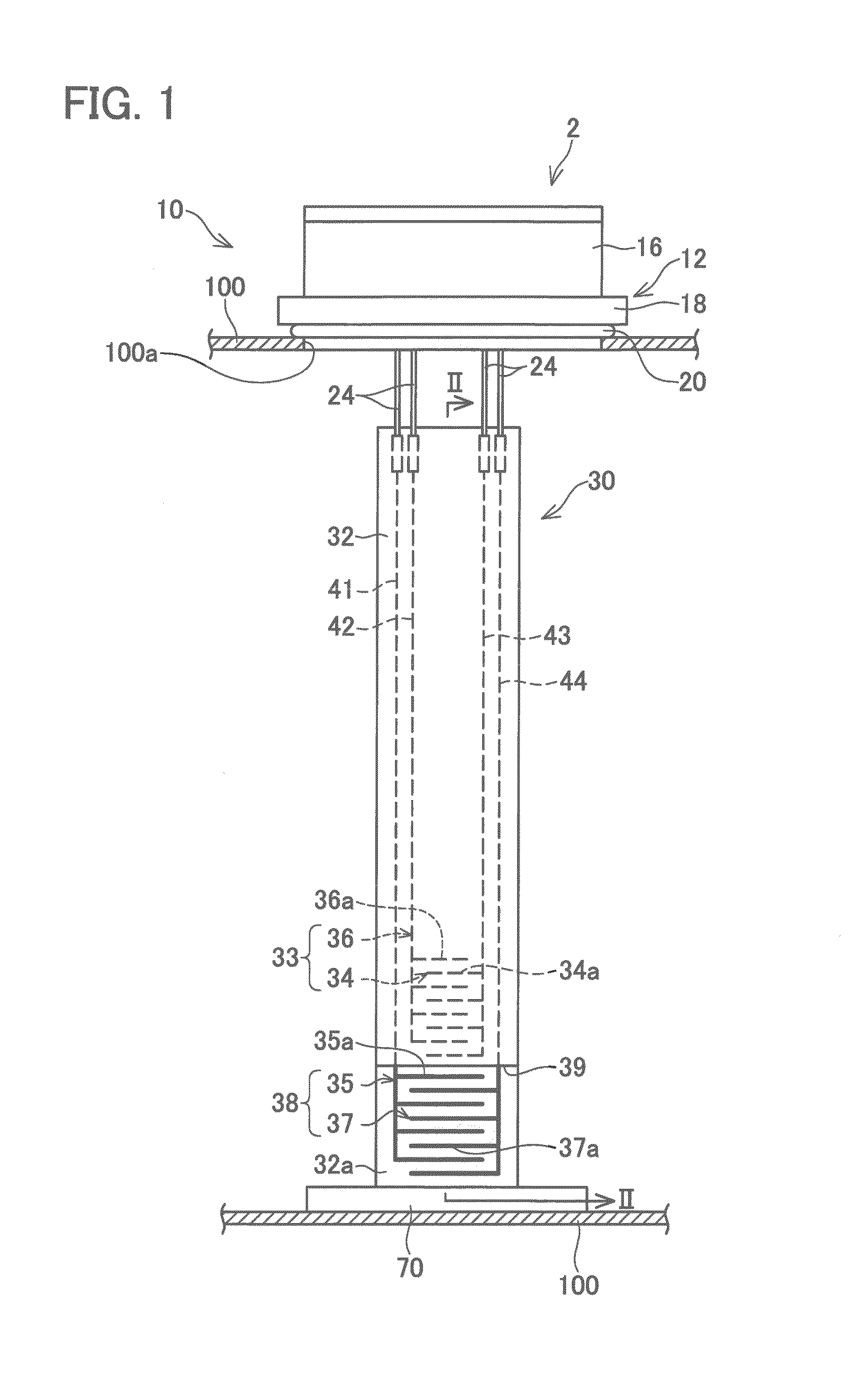

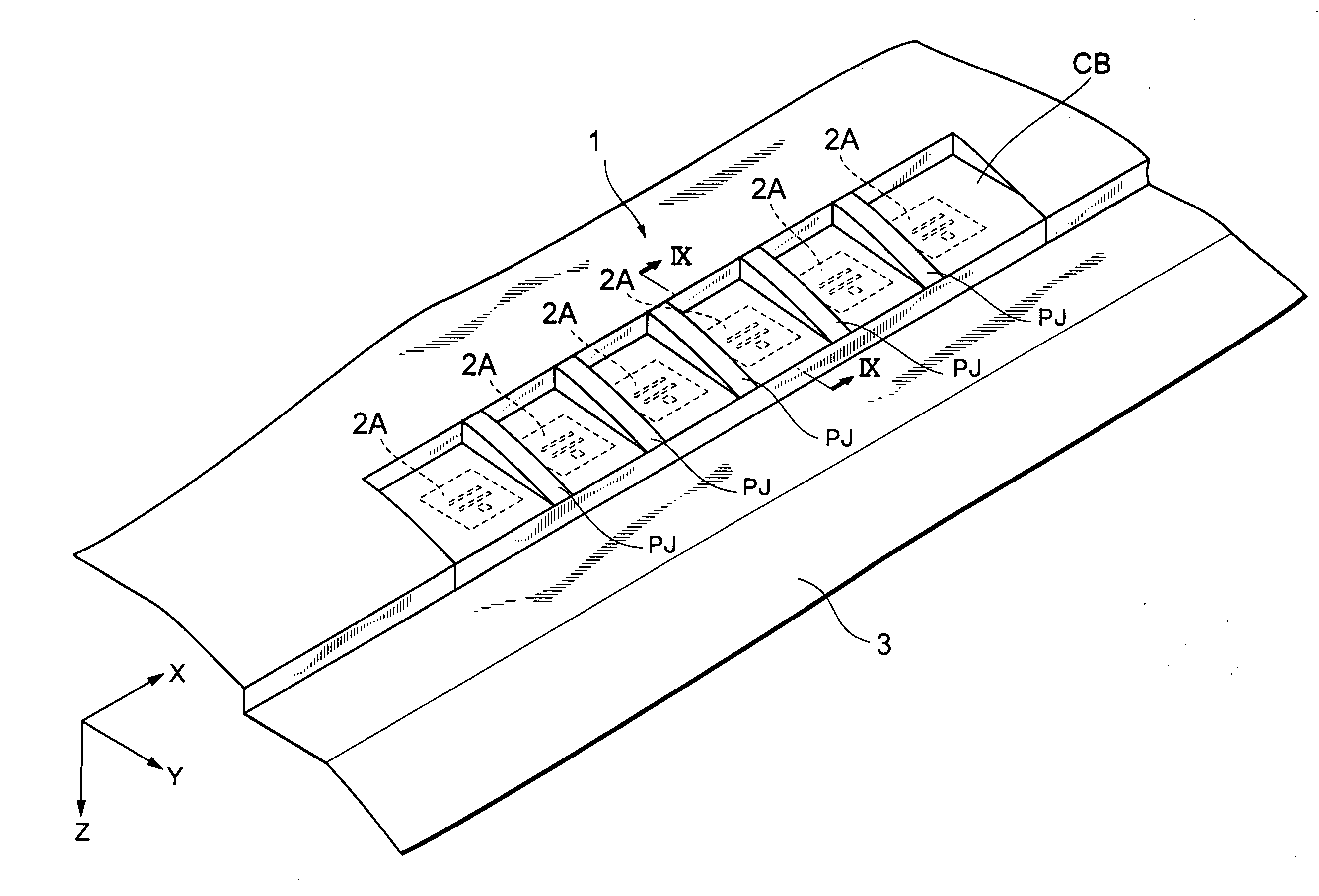

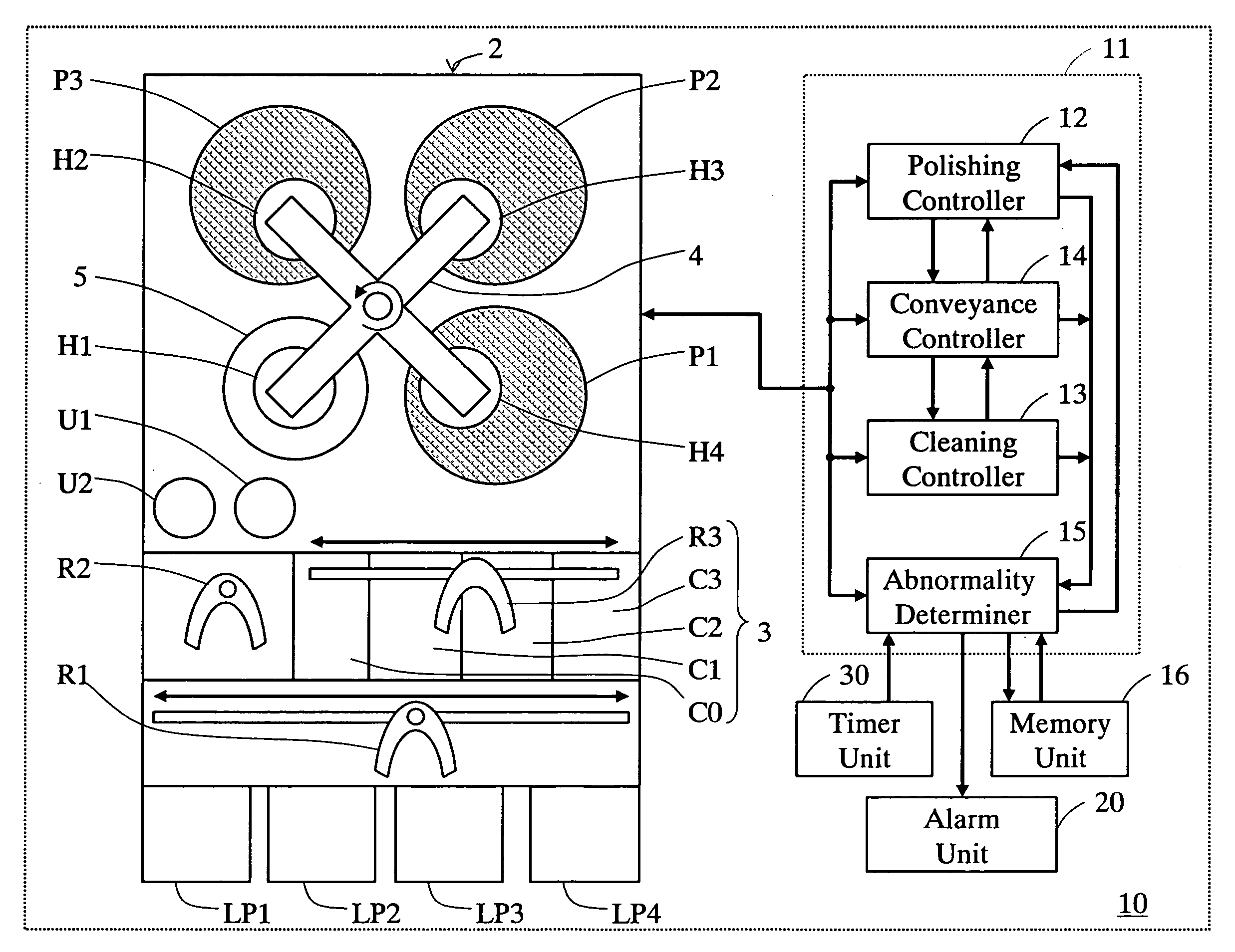

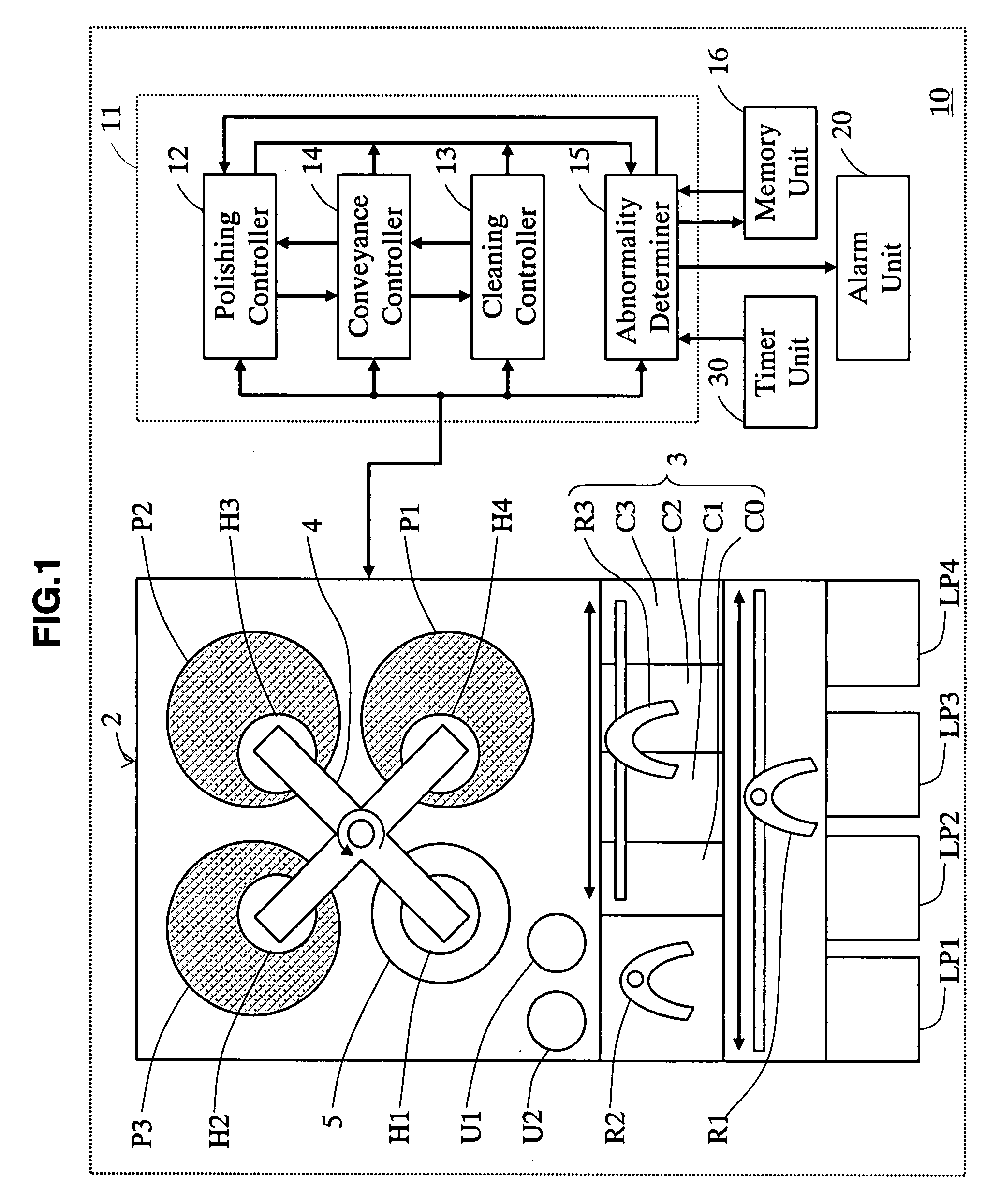

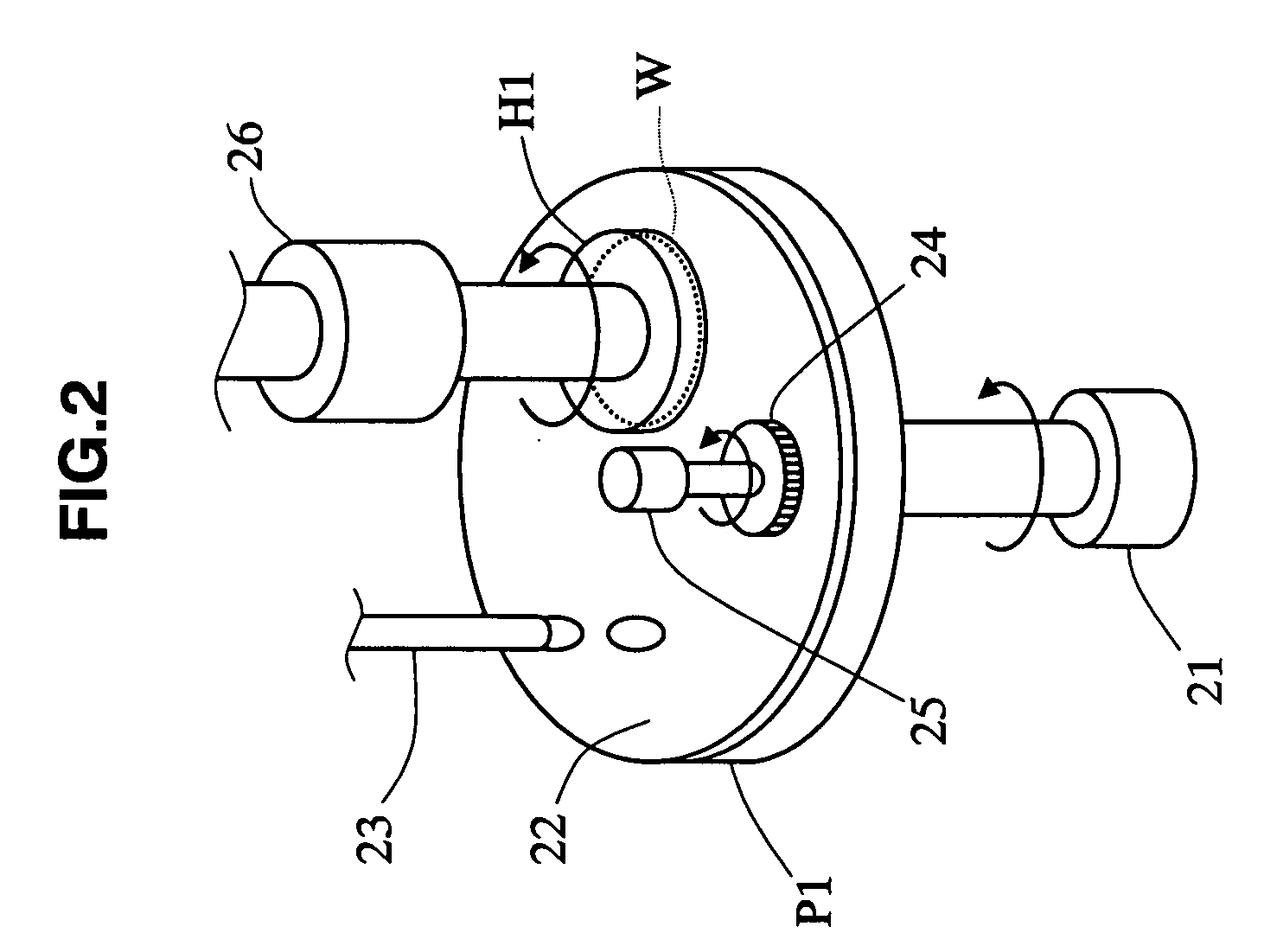

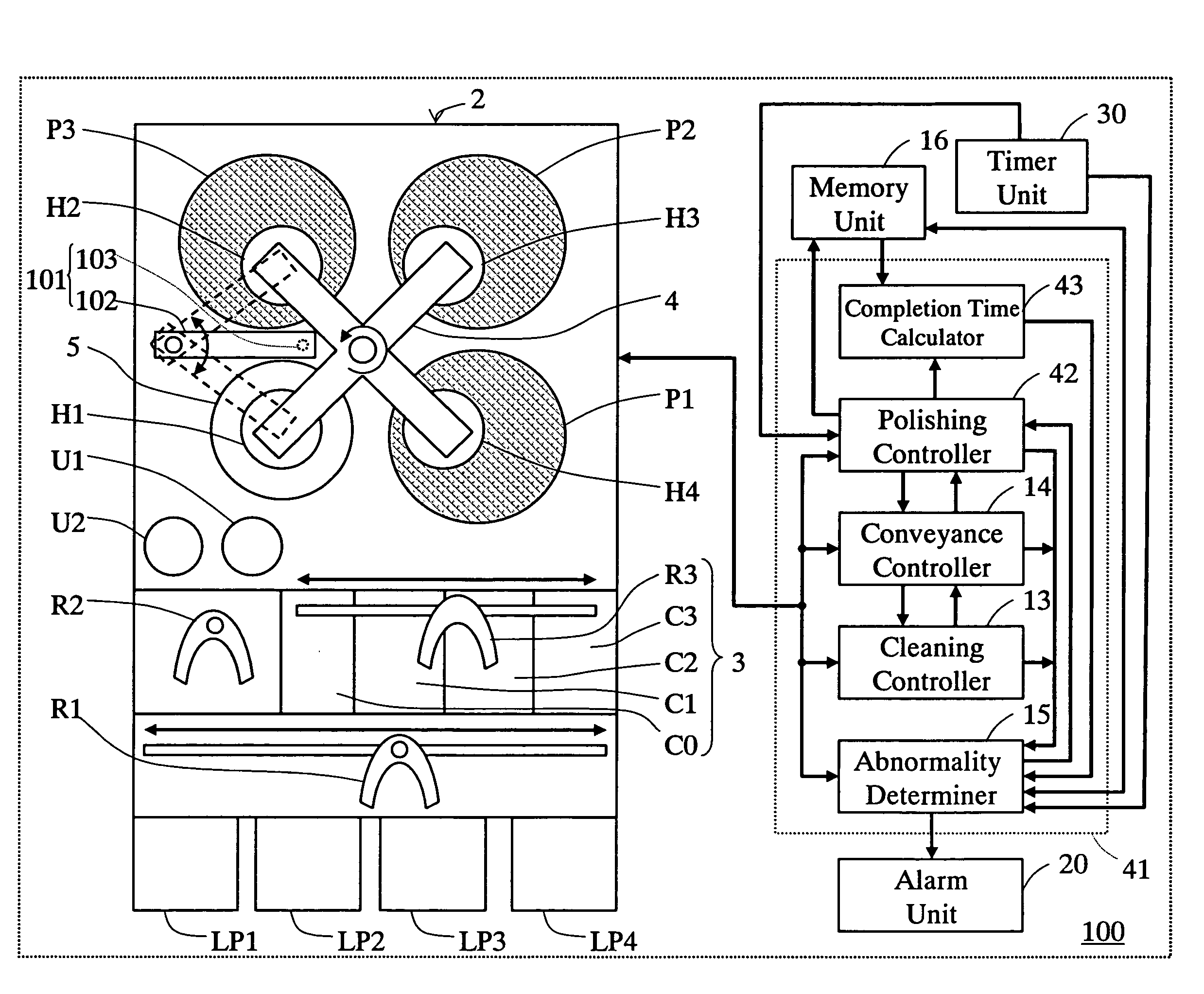

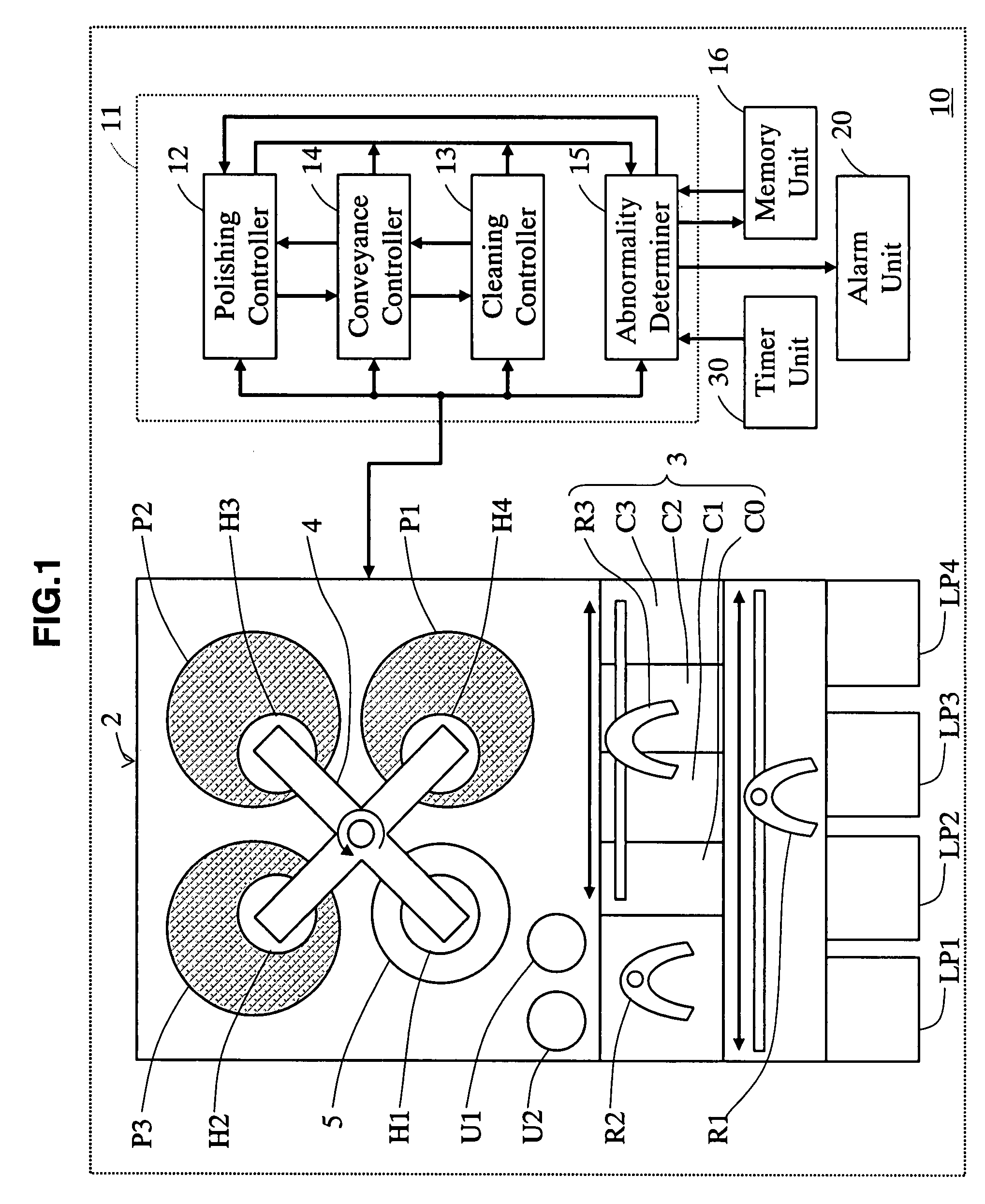

Substrate processing apparatus and substrate processing method

InactiveUS20080081540A1Easy to corrodeIncrease productionEdge grinding machinesSemiconductor/solid-state device manufacturingEngineeringCopper

The substrate processing apparatus relating to the present invention comprises a polishing section where wafers are sequentially arranged, and that has multiple polishing platens for polishing a metal film on the wafer surface in stages. The wafers are simultaneously conveyed between the polishing platens by a rotating head mechanism. Further, the wafers polished by the polishing platen for the final stage polishing are sequentially conveyed to a cleaning section and are cleaned. The wafers from the polishing section to the cleaning section are conveyed by a load-unload unit, a post-polishing wafer reversal unit and wet robots. Then, the operation of each part is controlled by an apparatus controller to start the cleaning processing of the polished wafers by the polishing platen for the final stage polishing within a predetermined time period from the completion of polishing by the polishing platen for the final stage polishing. With this control, corrosion to wiring containing corrodible metal, such as copper, can be assuredly prevented.

Owner:PANASONIC CORP

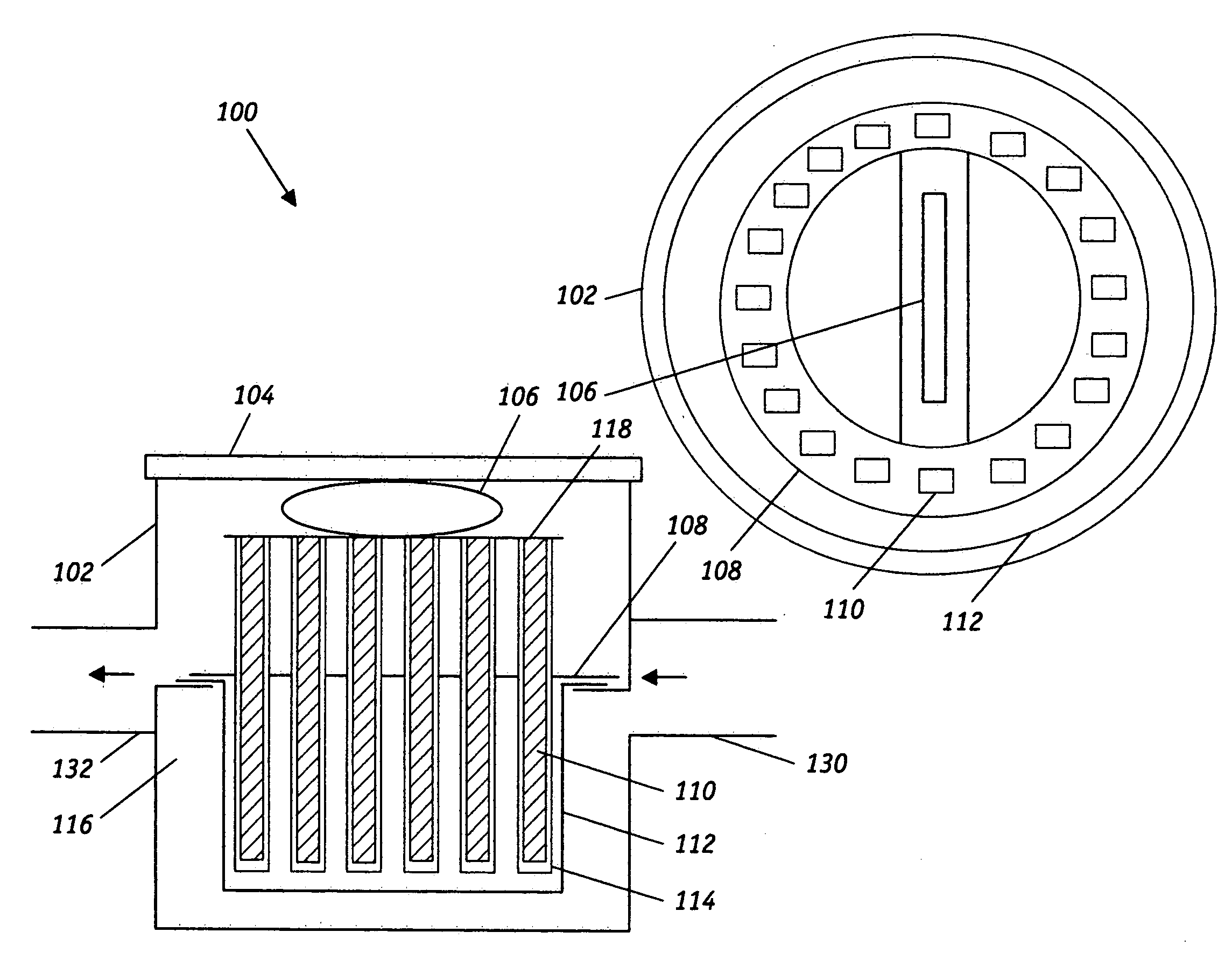

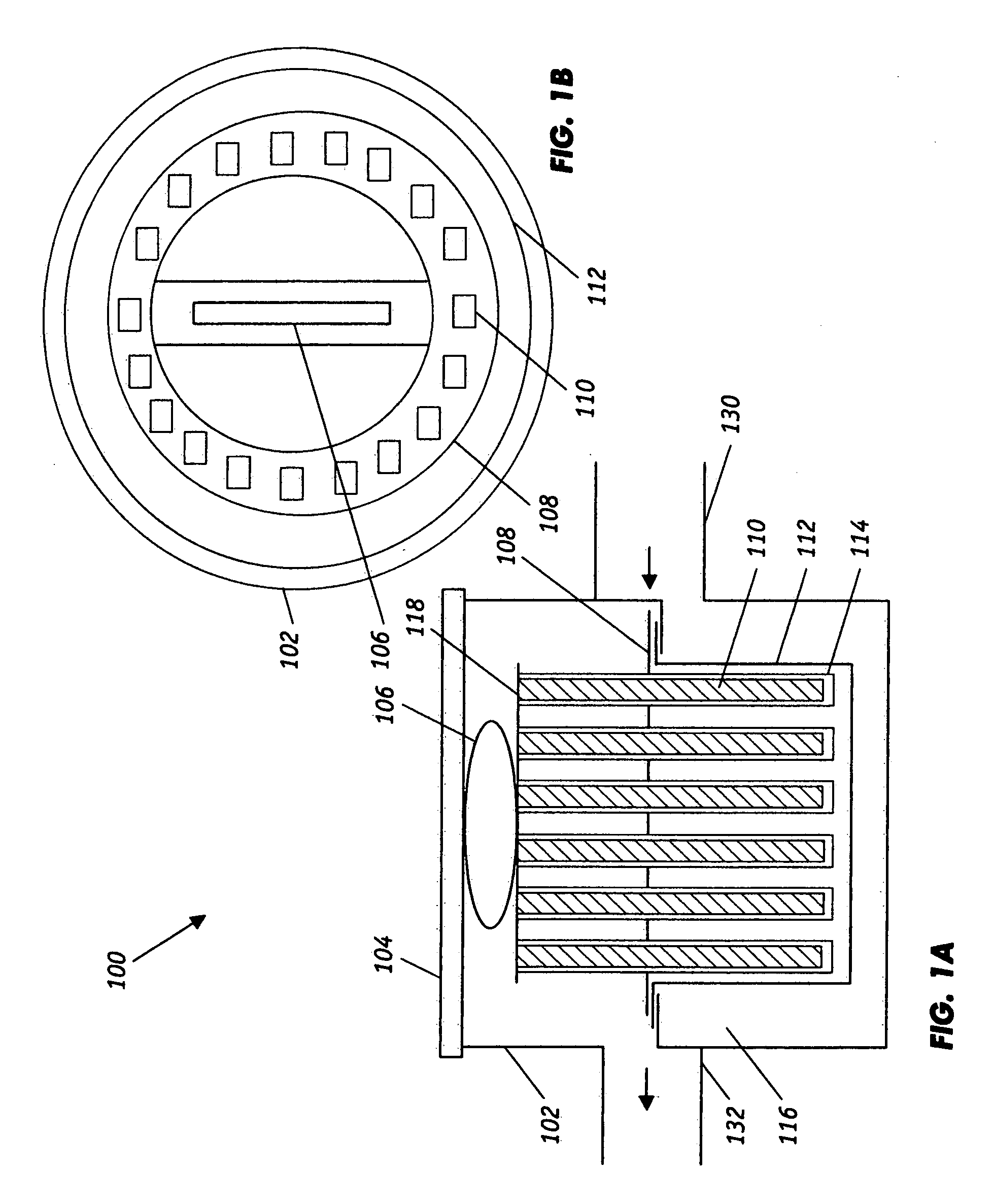

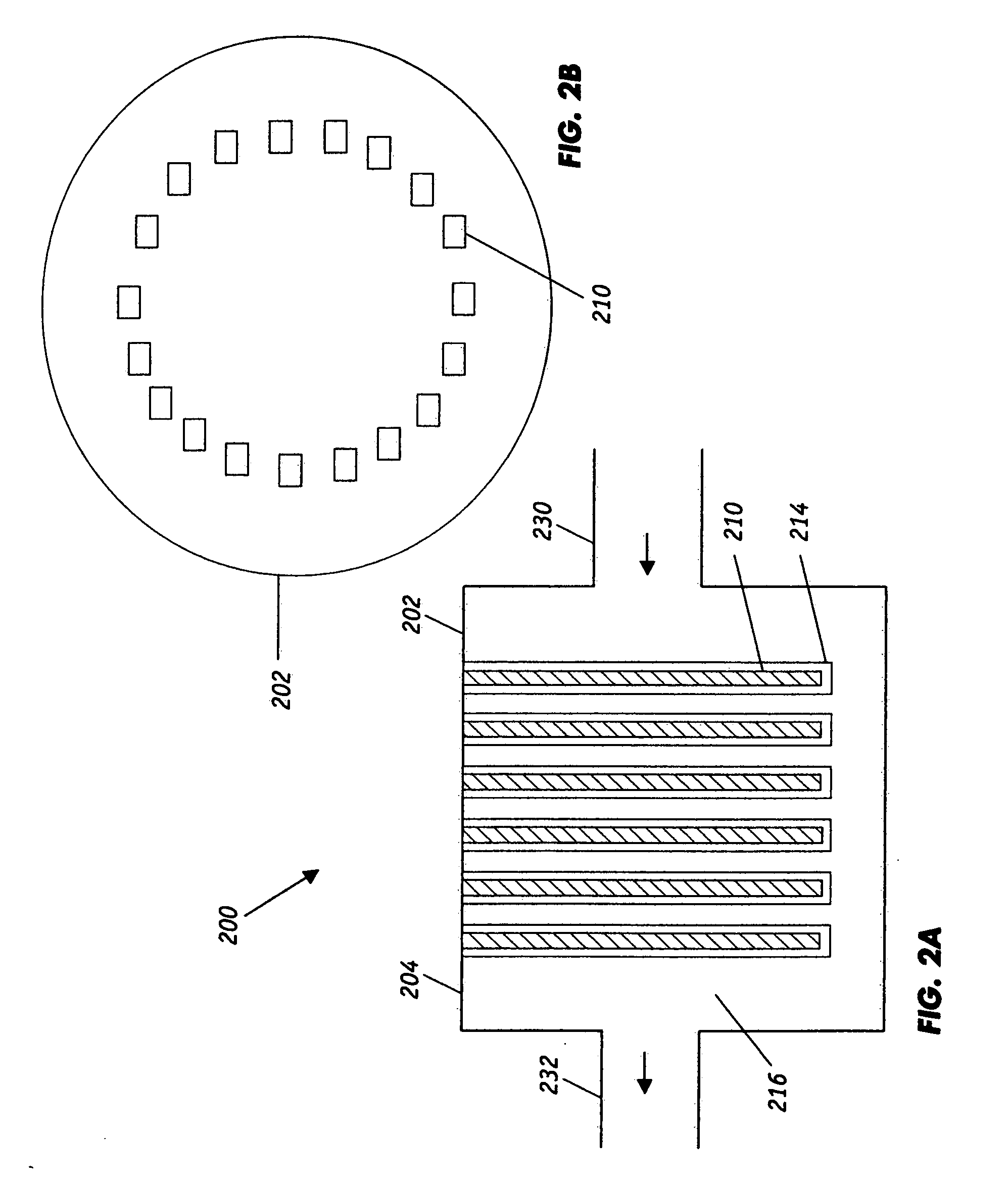

Novel filtration method for refining and chemical industries

InactiveUS20100065504A1Easy to corrodeEasy to disassembleElectrostatic separationWater/sewage treatment by magnetic/electric fieldsParticulatesChemical industry

A novel design of filters for removing iron rust particulates and other polymeric sludge from refinery and chemical process streams that are paramagnetic in nature is provided. The performance of these filters is greatly enhanced by the presence of the magnetic field induced by magnets. Basically, the filter comprises a high-pressure vessel with means to support the plurality of magnets in the form of bars or plates that are encased in stainless steel tubes or columns. Filters with various configurations are disclosed for accommodating the removal of contaminants from the process streams of different industries, with high efficiency for contaminants removal, simple construction, low operational and maintenance costs, and low hazardous operation.

Owner:CPC CORPORATION

Bolt structure for use with a magnesium alloy member for tightening magnesium alloy members with each other or with a heterogenenous material

InactiveUS6979161B2Avoid it happening againImprove corrosion resistanceLiquid surface applicatorsWashersZincMaterials science

The present invention provides for a bolt structure for use with a magnesium alloy member that can insulate between magnesium alloy members and steel or other bolts without lowering the bolt shaft power, and prevent occurrence of electrolytic corrosion with an electrolyte such as water. A cationic electrodeposition coating is also provided for the bolts structure, said coating having a film thickness of 15 μm or more is provided at least on the surface of the magnesium alloy member contacting with a bolt head, a powder coating having a film thickness of 40 to 150 μm is provided on the surface of the cationic electrodeposition coating, zinc-nickel plating and then cosmer treatment are carried out on the bolt, and an alumite-treated aluminum washer is interposed between the bolt head and the magnesium alloy member.

Owner:HONDA MOTOR CO LTD

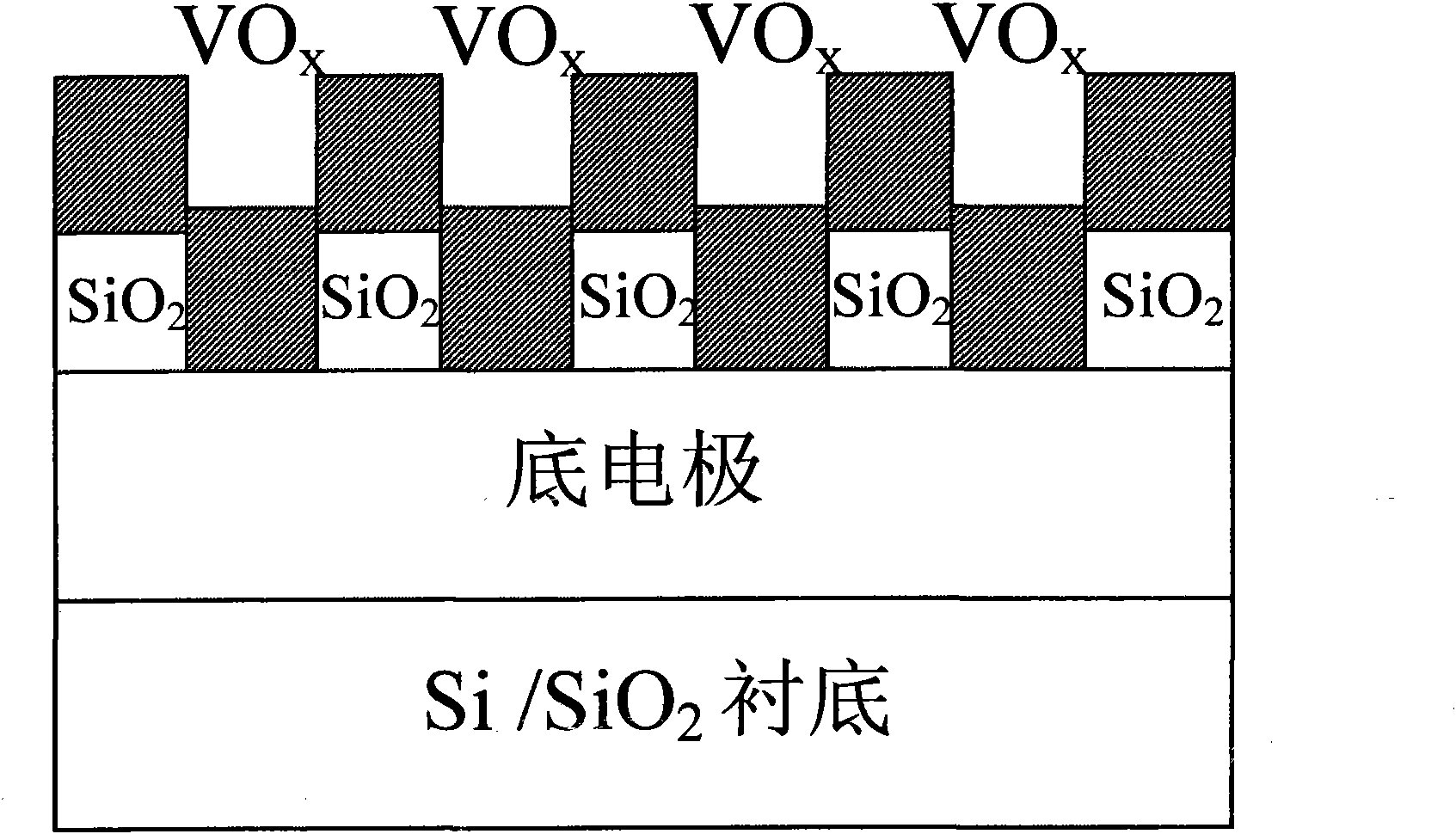

Nano polishing solution for chemically mechanical polishing of vanadium oxide and application thereof

ActiveCN102127372AEasy to corrodeEasy to polluteBiocideOther chemical processesOrganic basePolyethylene glycol

The invention relates to nano polishing solution for chemically mechanical polishing of vanadium oxide, which consists of a nano-abrasive, a pH regulator, a surfactant, a defoaming agent, a bactericide, a cleaning aid and a solvent, wherein the nano-abrasive is zirconium oxide, titanium oxide, plutonium oxide or silica; the pH regulator comprises inorganic base of KOH and organic base of tetramethylammonium, tetraethyl ammonium hydroxide or hydroxy amine; the surfactant is silicane polyethylene glycol ether, polyethylene glycol ether or 2-(2-dodecyloxyethoxy)ethanol; the defoaming agent is poly(dimethylsilane); the bactericide is isomerous thiazolidinone; the cleaning aid is isopropanol; and the solvent is deionized water. The invention has the advantages that: the polishing rate is stably controllable, the damage is low, the cleaning is simple, equipment is not corroded, the environment is not polluted, and the storage time is long; and a vanadium oxide film material is subjected to the chemically mechanical polishing by the nano polishing solution for preparing a resistive random access memory, and the method is simple and practicable, and is completely compatible with an integrated circuit process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Bolt tightening structure of magnesium alloy member

InactiveUS20020127083A1Avoid it happening againImprove corrosion resistanceLiquid surface applicatorsWashersZincPowder coating

The present invention provides a bolt tightening structure of a magnesium alloy member capable of insulating between magnesium alloy members and steel or other bolts without lowering the bolt shaft power, and preventing occurrence of electrolytic corrosion if contacting with electrolyte such as water. This is a bolt tightening structure of a magnesium alloy member for tightening magnesium alloy members with each other or a magnesium alloy member and a heterogeneous material by means of a bolt. Cationic electrodeposition coating having a film thickness of 15 .mu.m or more is provided at least on the surface of the magnesium alloy member contacting with a bolt head, a powder coating having a film thickness of 40 to 150 .mu.m is provided on surface of the cationic electrodeposition coating, zinc-nickel plating and then cosmer treatment are carried out on the bolts, and an alumite-treated aluminum washer is interposed between the bolt head and the magnesium alloy member.

Owner:HONDA MOTOR CO LTD

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

ActiveCN103895151AGood corrosion resistanceEasy to corrodeMetal layered productsPolymer chemistryResin composite

The invention relates to a preparation method of a stainless steel-resin composite and a stainless steel-resin composite prepared by the same. The preparation method comprises the following steps: S1. coating an ink on the surface of a pretreated stainless steel substrate in need of combining resin to obtain a stainless steel substrate of which part of surface is coated with an ink layer; S2. carrying out oxidization and passivation on the stainless steel substrate of which part of surface is coated with an ink layer, which is obtained in the step S1; S3. removing the ink layer coated on the surface of the stainless steel substrate obtained in the step S2; S4. putting the stainless steel substrate obtained in the step S3 into an acid and / or salt solution containing 2-30 wt% of A<-> to perform electrochemical corrosion, wherein A is halogen; and S5. carrying out injection molding on a resin composition onto the surface of the stainless steel substrate obtained in the step S4, and forming to obtain the stainless steel-resin composite. The prepared product has the advantages of strong binding force between stainless steel and resin, simple technique, no pollution and low cost, can easily implement large-scale production, and can not cause corrosion of the non-injection molding region of the stainless steel.

Owner:BYD CO LTD

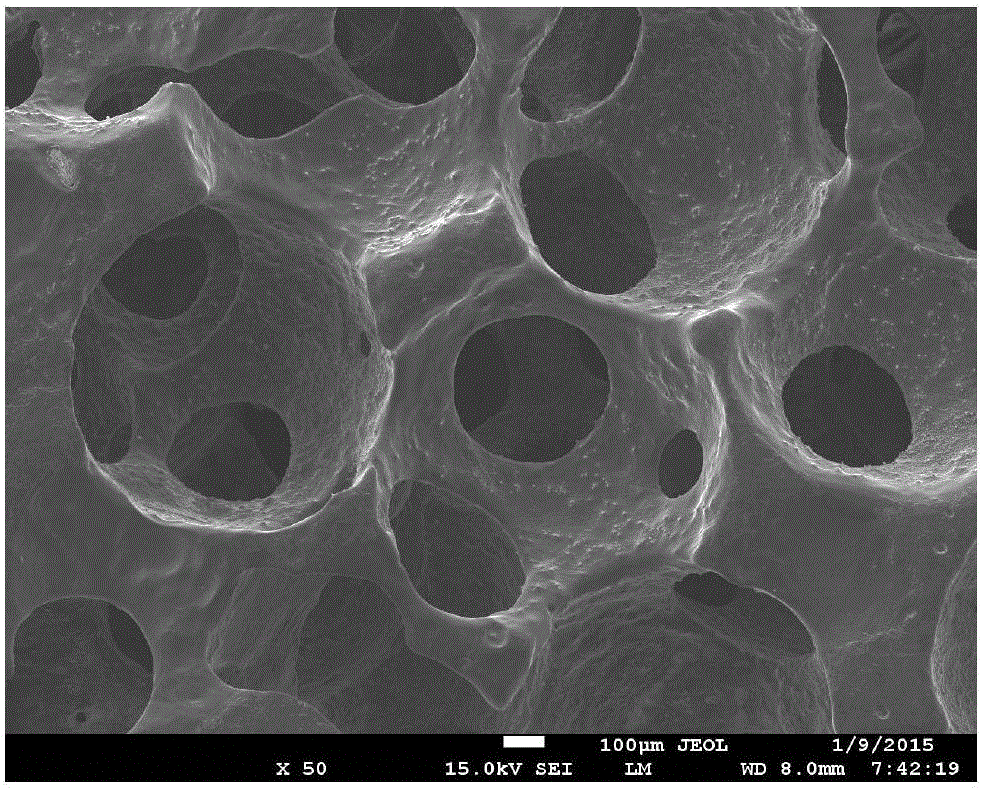

Preparation method and application of three-dimensional interpenetrating porous magnesium-based material

ActiveCN105039771ANo residueUniform distribution throughoutProsthesisHydrofluoric acidBone tissue engineering

The invention discloses a degradable three-dimensional porous magnesium-based biomaterial and a preparation method thereof. The porous magnesium and magnesium alloy materials are in a three-dimensional through complete opening structure; the hole pattern is a sphere with a controllable dimension; intercommunicating holes are uniform in distribution and controllable in dimension; and a magnesium fluoride film is uniformly generated on the surface of each hole wall. The holes of the material obtained by the method are uniform in overall distribution; the porosity and the mechanical property are controllable; titanium sphere or iron sphere particles are sintered in preparation, so as to obtain a porous preform with spherical openings; magnesium and magnesium alloy infiltrate into the preform and then are cooled to room temperature; and the preform is removed through hydrofluoric acid solution corrosion. The preparation method is simple in preparation technology and convenient to operate; an anti-corrosion anti-fouling membrane is formed on a magnesium and magnesium alloy matrix surface in the removal process of the preform; the magnesium-based biomaterial is good in connectivity, and relatively high in porosity and strength; the hole wall is free of corrosion or pore-forming agent residue phenomenon; a closed hole does not exist; and the magnesium-based biomaterial can be used as a new generation of degradable tissue engineering scaffold.

Owner:SHANGHAI JIAOTONG UNIV

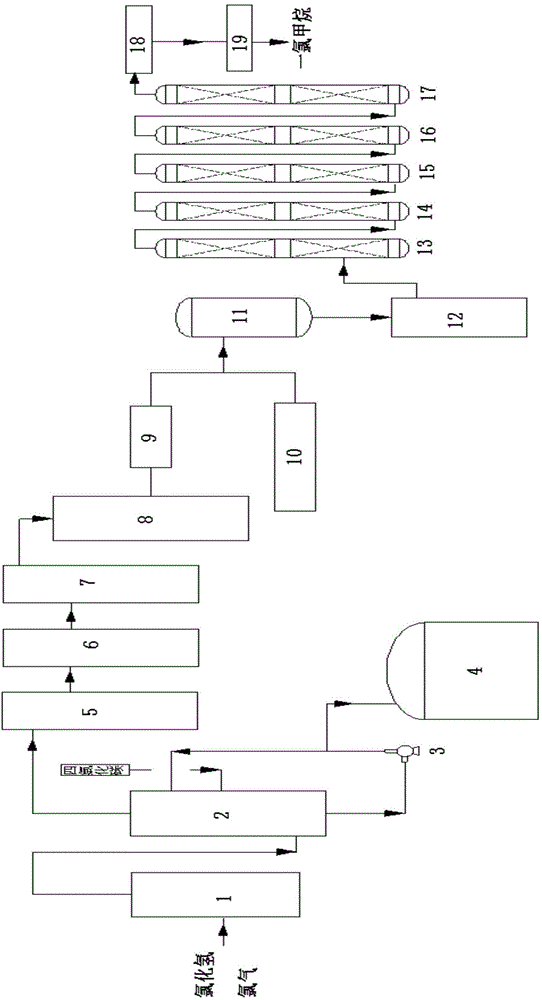

Method for producing methane chloride through byproduct hydrogen chloride in production process of tetrachloroethylene

ActiveCN104311383AResolve disposal issuesEasy to corrodeHalogenated hydrocarbon preparationGas phaseMixed gas

The invention relates to a method for producing methane chloride through a byproduct hydrogen chloride in production process of tetrachloroethylene. The method comprises the steps of (1) condensing the mixed gas of excess chlorine and the byproduct hydrogen chloride in production process of tetrachloroethylene, then absorbing the chlorine by carbon tetrachloride between -5DEG C and -21DEG C, condensing again, eliminating the foam, buffering, and compressing; (2) heating up the hydrogen chloride and methyl alcohol, then reacting for 2-5 seconds under the action of a catalyst aluminum oxide so as to obtain the mixed product of methane chloride, methane, chloroethane and dichloromethane, and (3) chilling and separating the mixed product, sequentially water washing, alkali washing, drying by sulfuric acid and compressing the gas phase at 0.6-0.95MPa, condensing at 25-40DEG C, so as to prepare the methane chloride. According to the method, the chlorine is adsorbed by carbon tetrachloride, so that the chlorine is prevented from entering into a reaction system of the hydrogen chloride and methyl alcohol to affect the purity and selectivity of the reaction product methane chloride.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

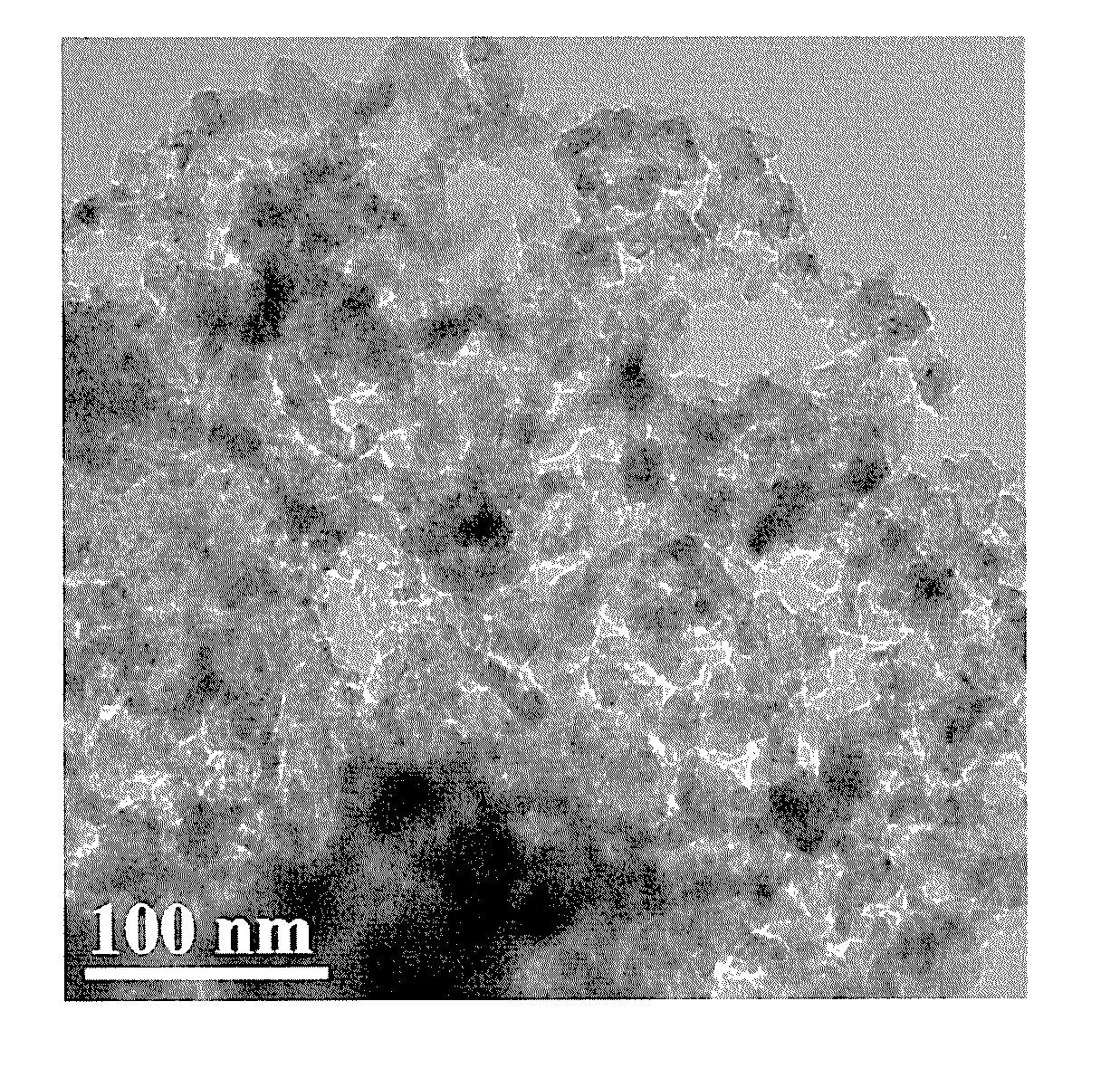

Low-platinum catalyst based on nitride nanoparticles and preparation method thereof

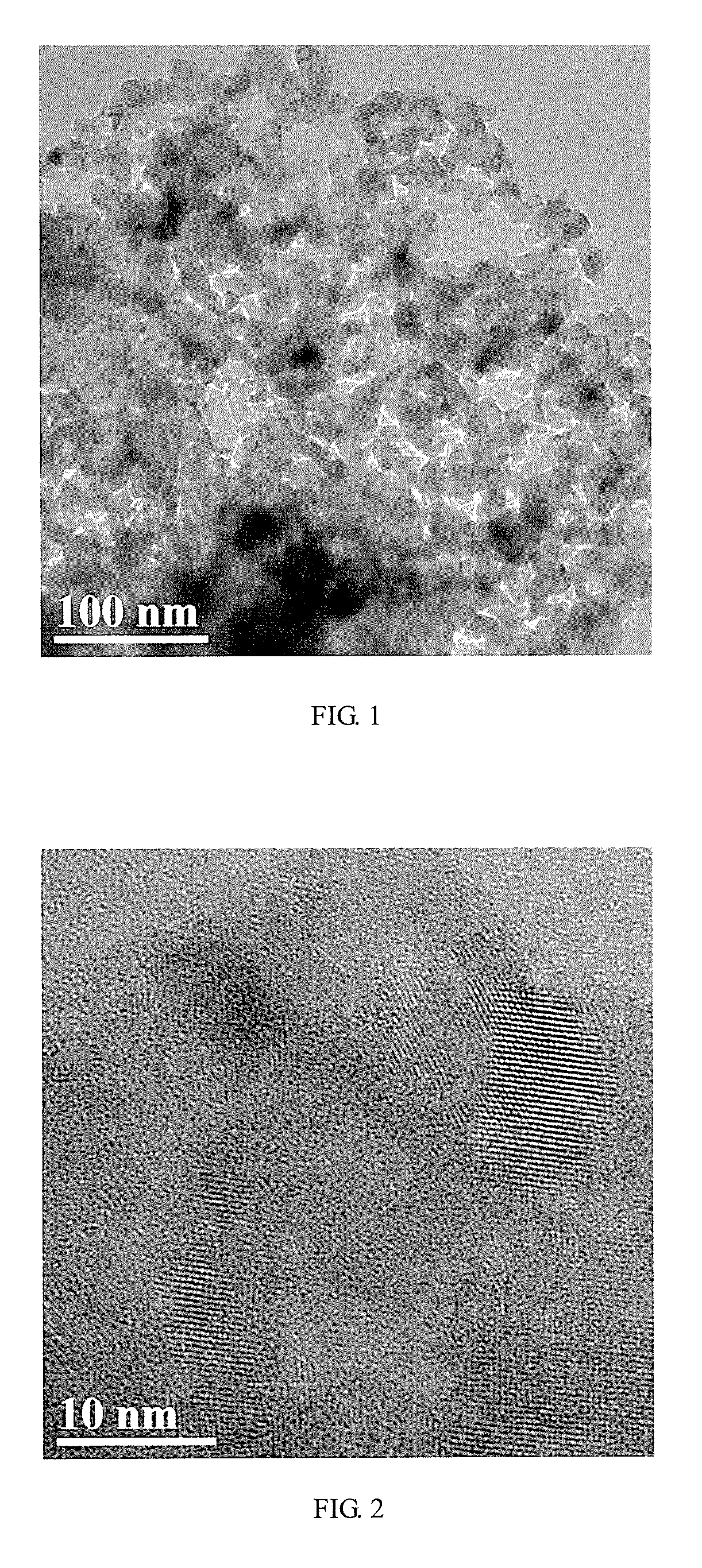

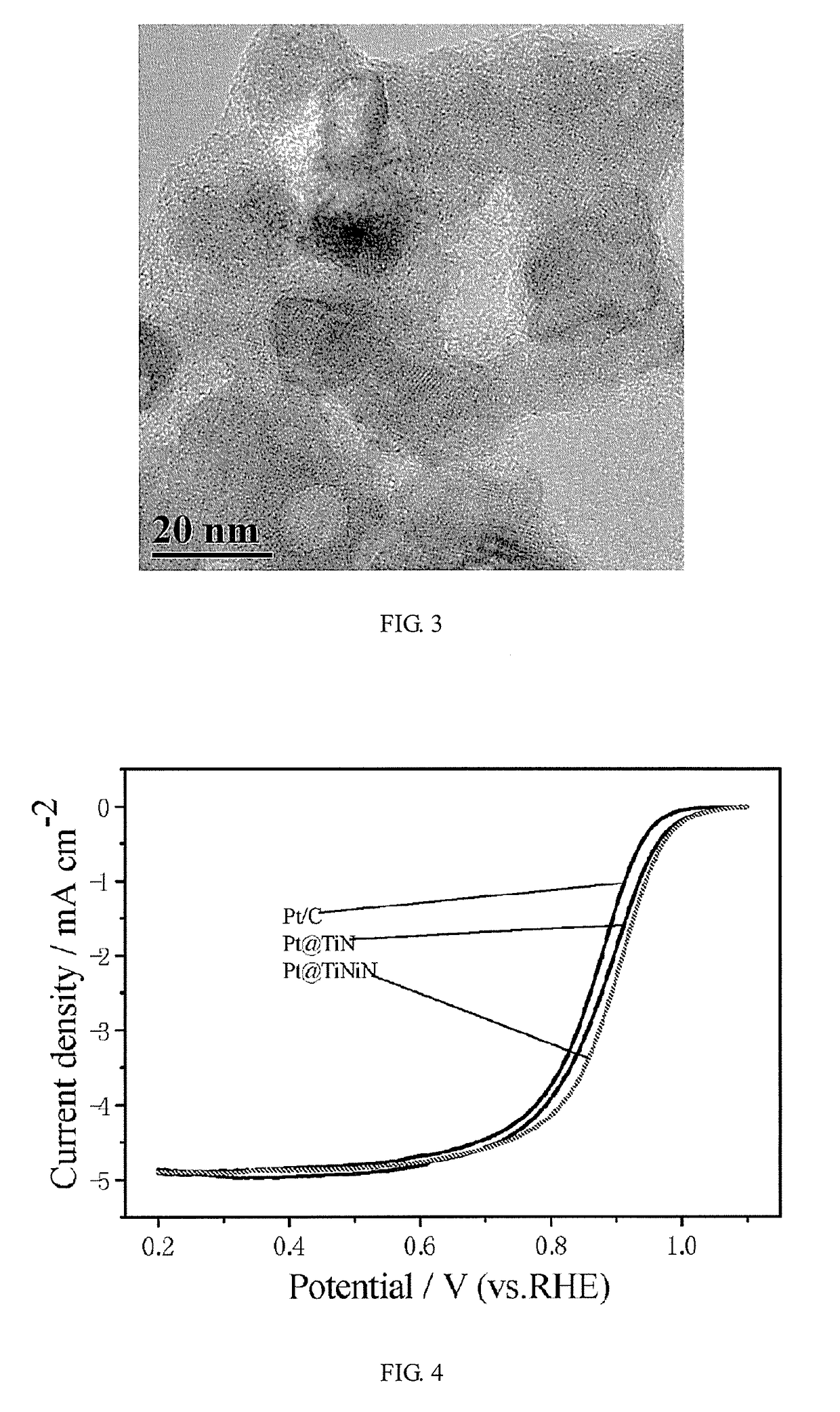

ActiveUS20180185825A1Improve performanceLower catalyst costsMaterial nanotechnologyCell electrodesPt elementPlatinum catalyst

A low-platinum catalyst based on nitride nanoparticles and a preparation method thereof. A component of an active metal of the catalyst directly clades on a surface of nitride particles or a surface of nitride particles loaded on a carbon support in an ultrathin atomic layer form. Preparation steps including: preparing a transition-metal ammonia complex first, nitriding the obtained ammonia complex solid under an atmosphere of ammonia gas to obtain nitride nanoparticles; loading the nitride nanoparticles on a surface of a working electrode, depositing an active component on a surface of the nitride nanoparticles by pulsed deposition, to obtain the low platinum loading catalyst using a nitride as a substrate. The catalyst may be used as an anode or a cathode catalyst of a low temperature fuel cell.

Owner:SOUTH CHINA UNIV OF TECH

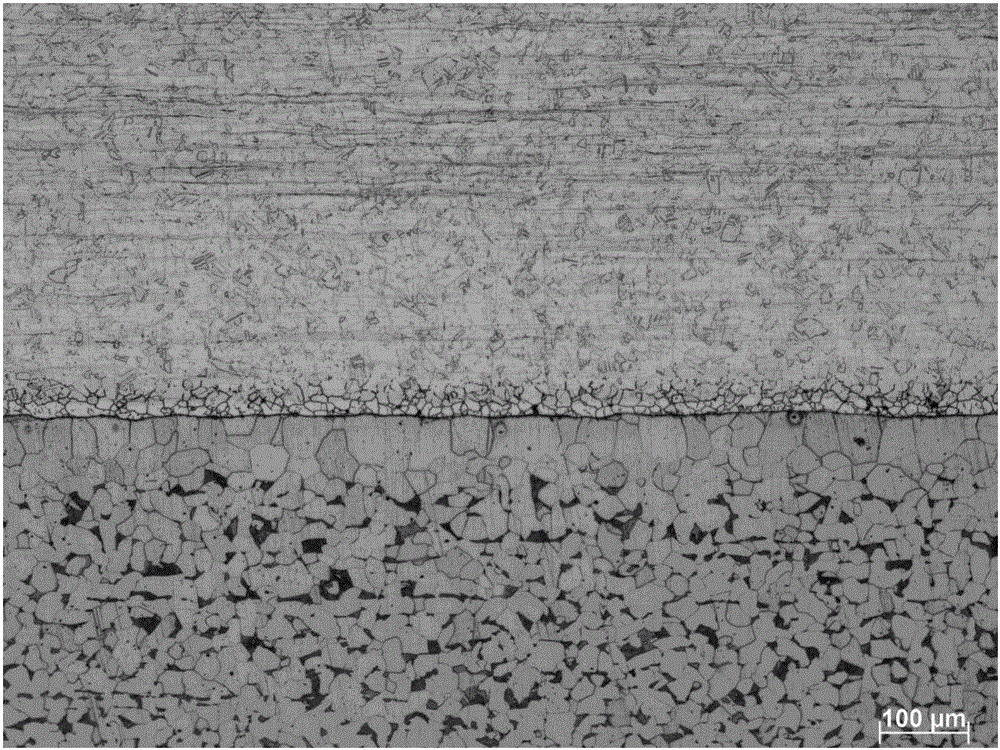

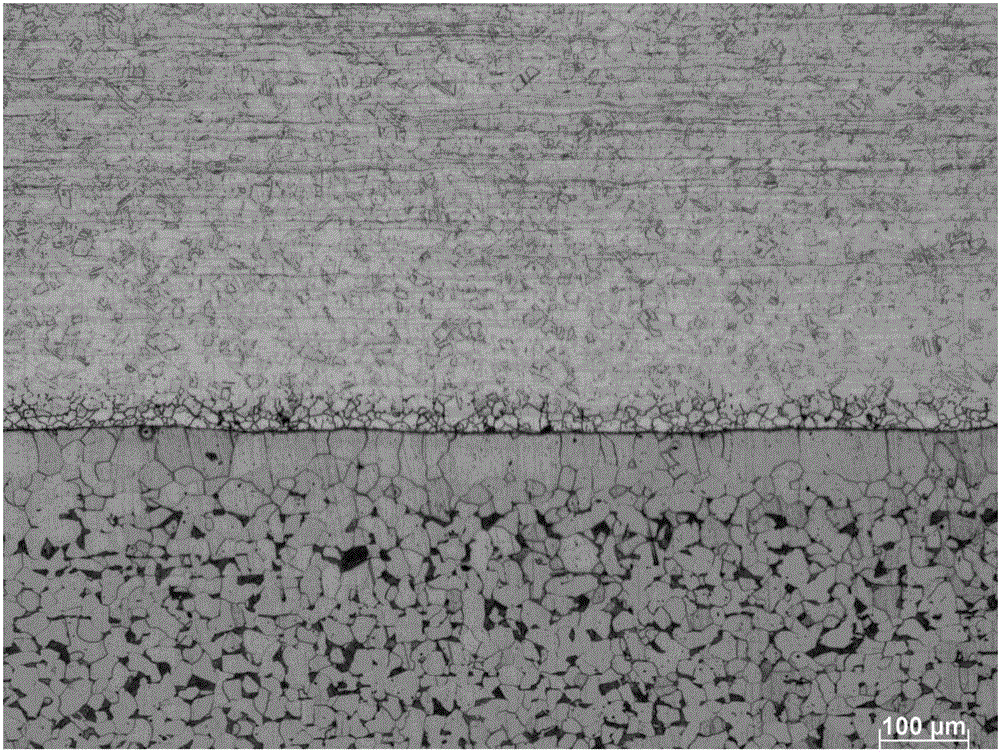

Electrolytic corrosion method of stainless steel/carbon steel composite plate metallographic structure

InactiveCN105908249AReduce corrosionStable in naturePreparing sample for investigationElectrolysisAlcohol

The invention discloses an electrolytic corrosion method of a stainless steel / carbon steel composite plate metallographic structure. According to the method, by means of the effects that an alcohol solution with the volume fraction of nitric acid being 2%-10% is used for corroding carbon steel and 5%-60% of a chromic acid solution is used for performing electrolytic corrosion on stainless steel, influences on the metallographic structure of the carbon steel are extremely small while electrolytic corrosion is performed on one side of the stainless steel. The method is good in corrosion effect, and the stainless steel / carbon steel composite plate metallographic structure can be displayed clearly.

Owner:HEBEI UNIV OF TECH

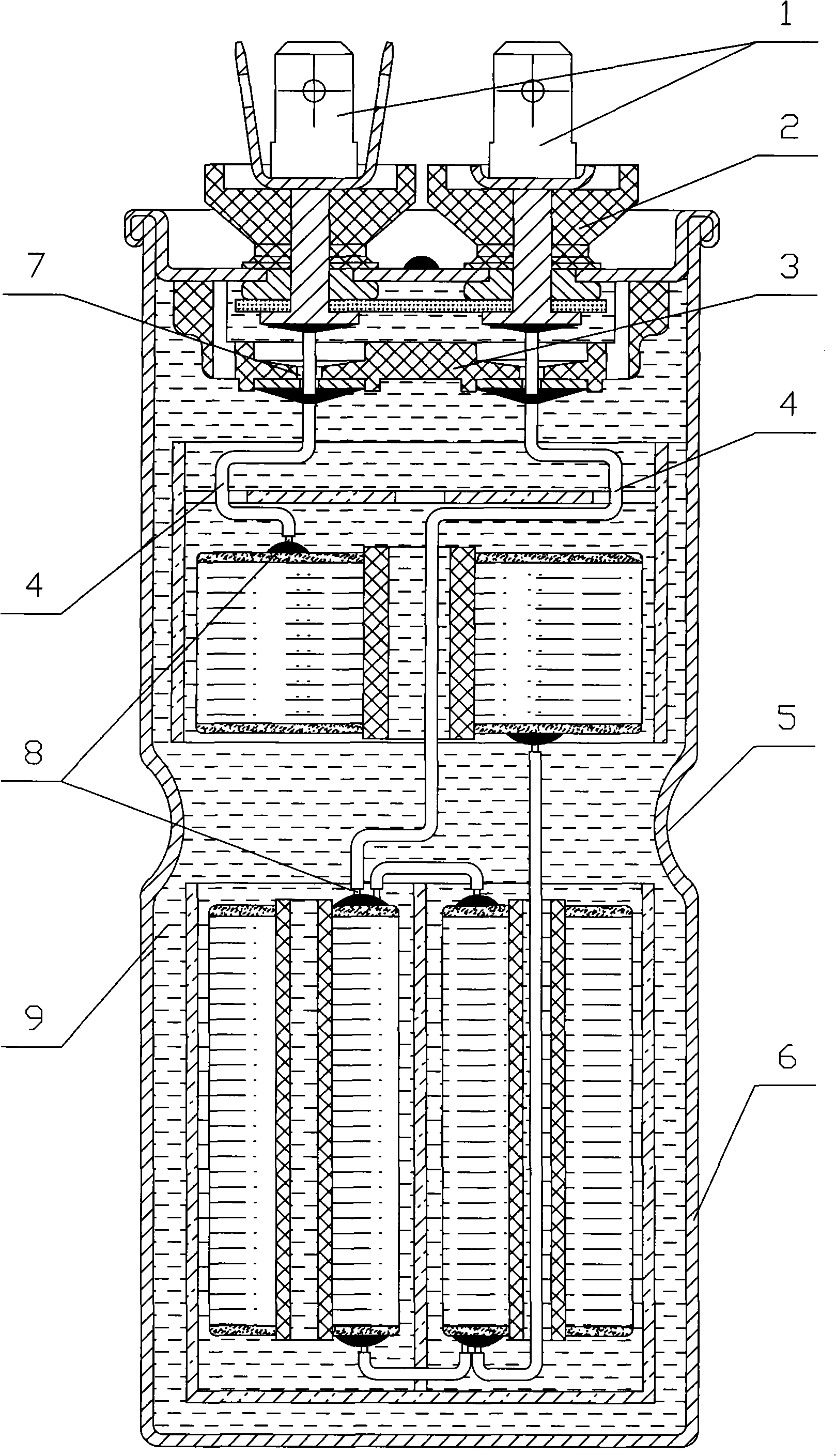

Firing and explosion prevention high voltage capacitor

InactiveCN101527200APrevent fallingWill not burn and explodeFixed capacitor housing/encapsulationHigh voltage capacitorsHigh pressure

The invention discloses a firing and explosion prevention high voltage capacitor, comprising a metal enclosed shell (6) and a shell cover component (2) with two exterior connection terminals (1); the shell (6) is internally provided with a set of capacitor cores connected in parallel and series; the two connection ends (8) of the capacitor core set are respectively connected with the two exterior connection terminals (1) by lead wires (4); the shell (6) is filled with steeping fluid (9) which is 330 methyl silicone oil; and the middle part of the shell (6) is provided with an annular groove (5) arranged in circumferential direction along the shell (6). With the above structure adopted, as the steeping fluid in the capacitor is 330 methyl silicone oil, the flaming-free property ensures that the capacitor can not fire or explode when the electric quantity is too large or the capacitor leaks; meanwhile the capacitor can be bound on other parts by the annular groove to avoid falling off during use.

Owner:NINGBO BICAI IND

Substrate processing apparatus and substrate processing method

InactiveUS7559823B2Easy to corrodeIncrease productionEdge grinding machinesSemiconductor/solid-state device manufacturingEngineeringCopper

The substrate processing apparatus relating to the present invention comprises a polishing section where wafers are sequentially arranged, and that has multiple polishing platens for polishing a metal film on the wafer surface in stages. The wafers are simultaneously conveyed between the polishing platens by a rotating head mechanism. Further, the wafers polished by the polishing platen for the final stage polishing are sequentially conveyed to a cleaning section and are cleaned. The wafers from the polishing section to the cleaning section are conveyed by a load-unload unit, a post-polishing wafer reversal unit and wet robots. Then, the operation of each part is controlled by an apparatus controller to start the cleaning processing of the polished wafers by the polishing platen for the final stage polishing within a predetermined time period from the completion of polishing by the polishing platen for the final stage polishing. With this control, corrosion to wiring containing corrodible metal, such as copper, can be assuredly prevented.

Owner:PANASONIC CORP

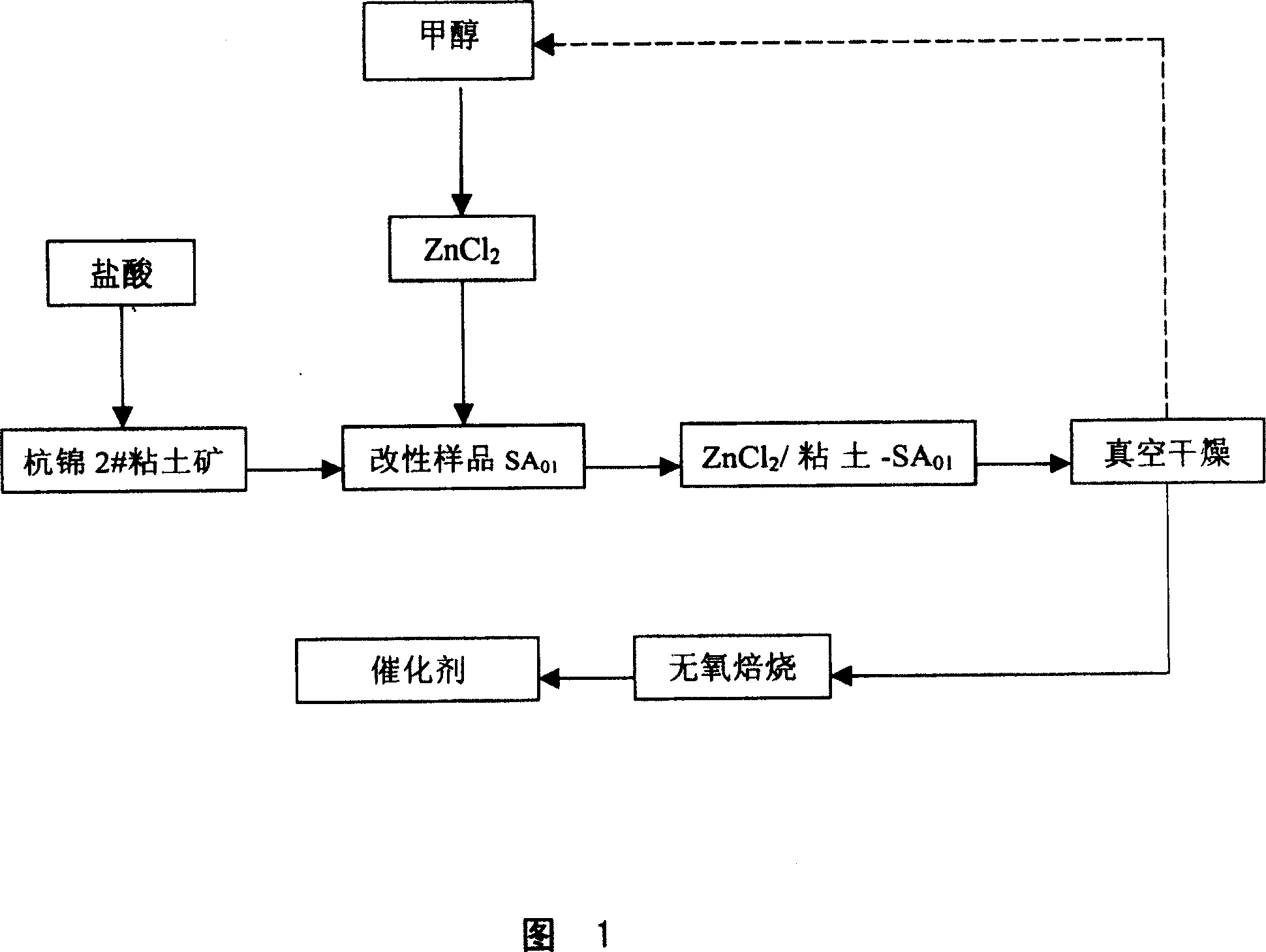

Method for preparing environment friendly catalyst

InactiveCN1322923CRich reservesLow costCatalyst carriersCatalyst activation/preparationRoom temperatureAgricultural engineering

The invention unfurls a way to produce a kind of catalyst of friendly environment. The way uses 2#soil--SA01 of feature changing as the carry ZnCl2, through dipping, evaporating to make ZnCl2 / soil--SA01 solid sample, at 70-80 degC, dry the sample in vacuum for 3--4h. In the protection of N2, fire at 250-300 degC for 3--4h cool the N2 to the room temperature, the ZnCl2 / soil--SA01 is made. The catalyst of the invention costs little, can be recovered. It achieves the material proper usage. The production of the catalyst belongs to the green production process.

Owner:INNER MONGOLIA NORMAL UNIVERSITY

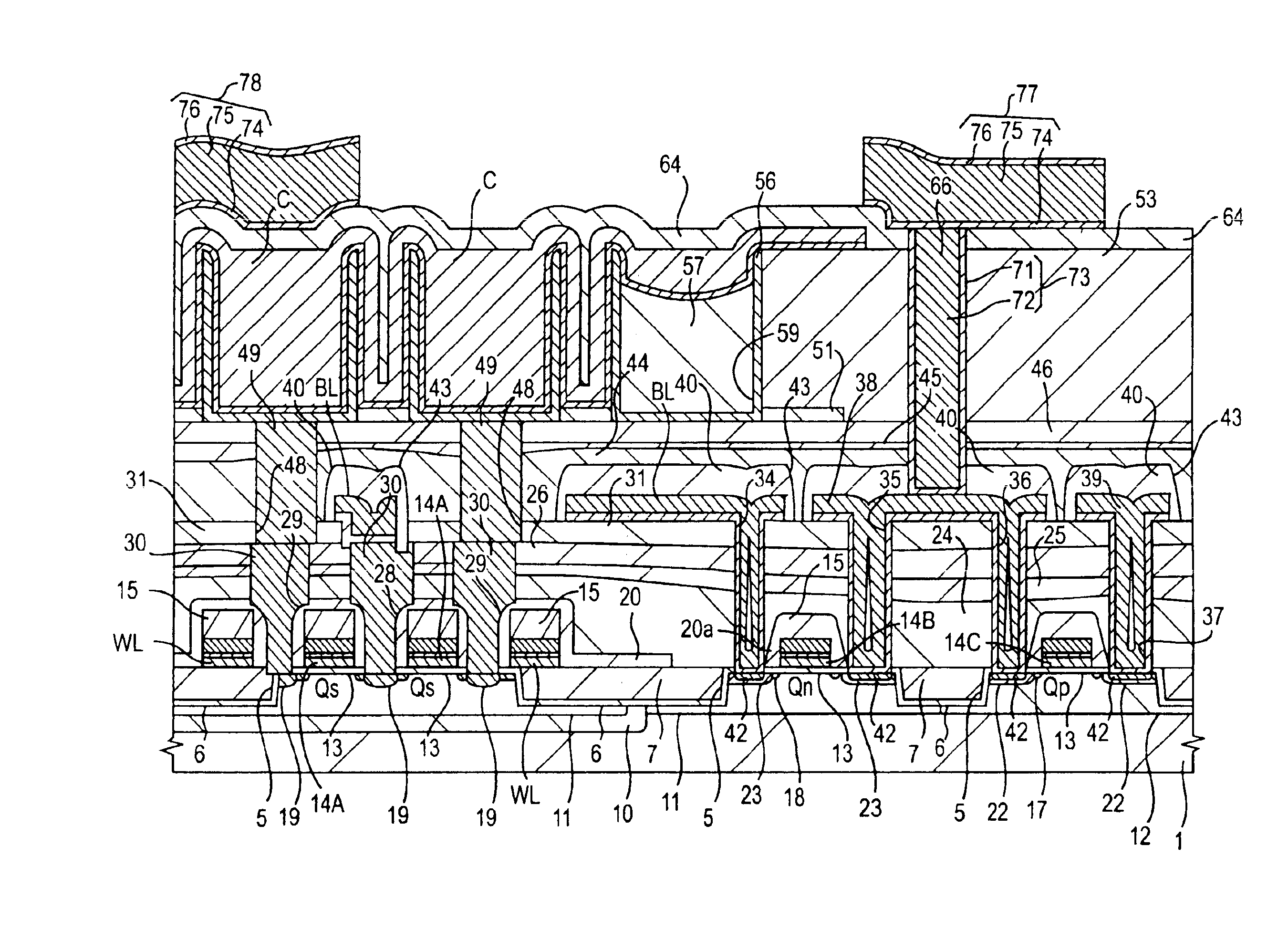

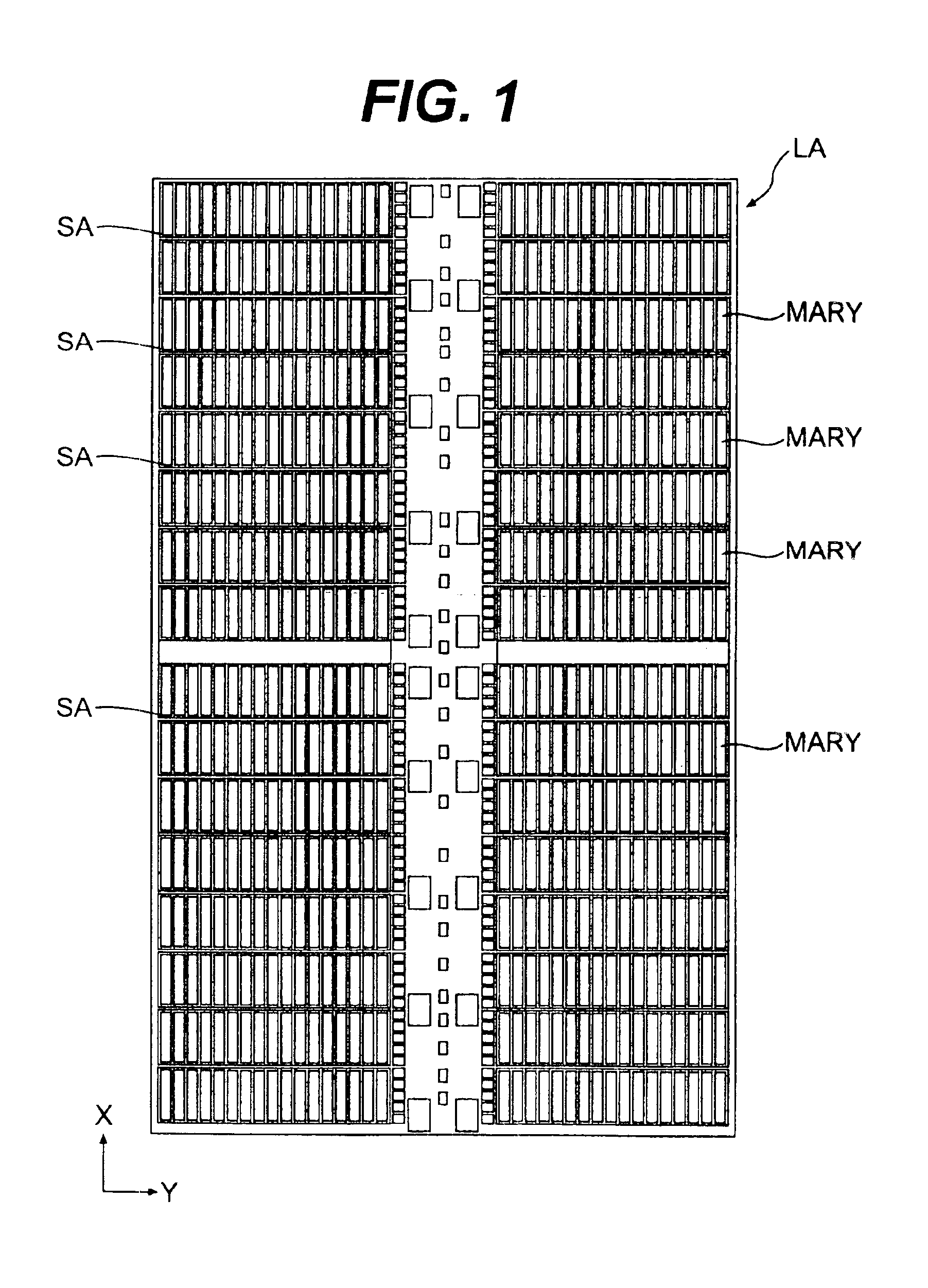

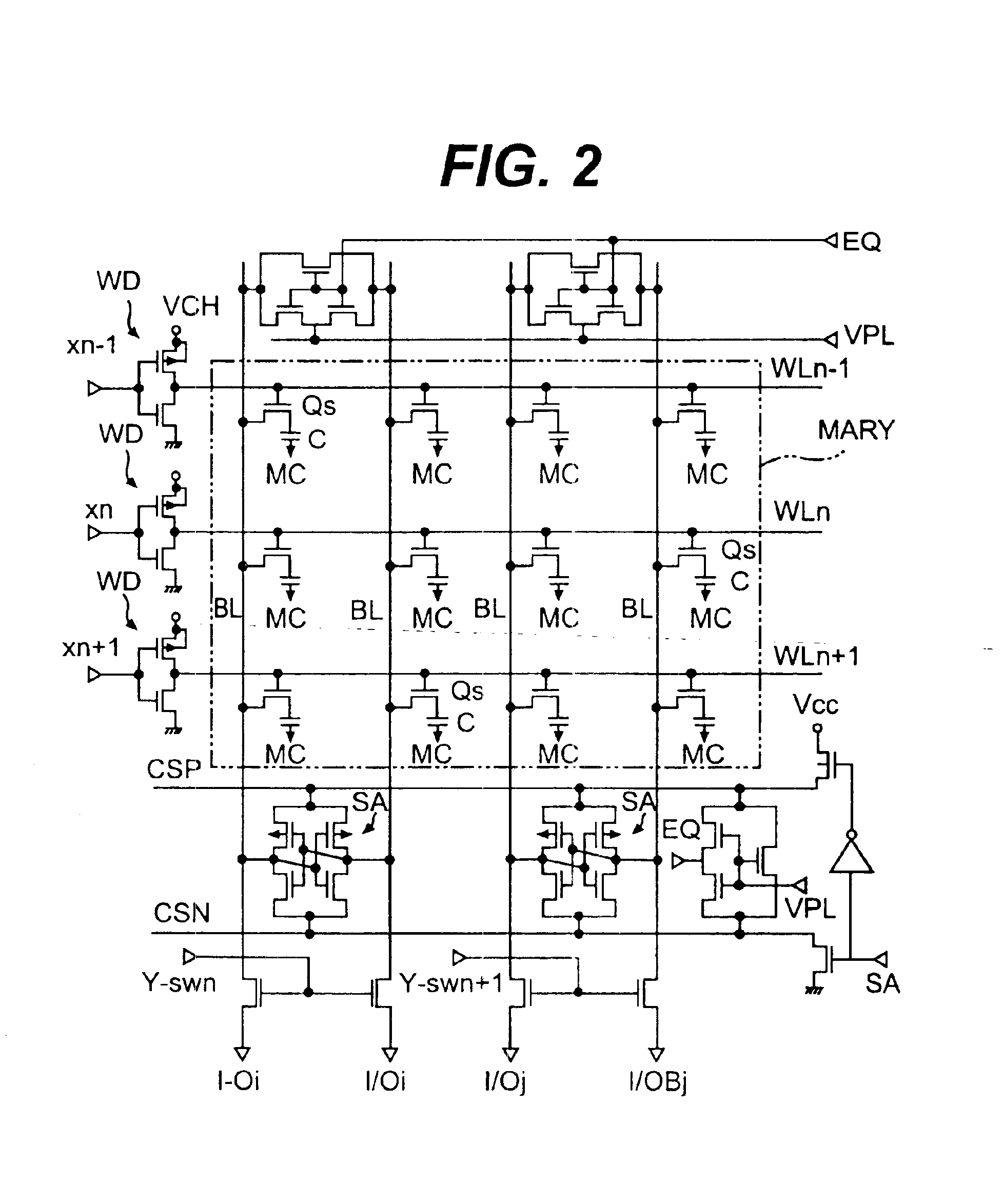

Method for fabricating semiconductor integrated circuit

InactiveUS6853081B2Easy to corrodeReduce corrosionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon oxide

The semiconductor device is formed according to the following steps. A TiN film 71 and a W film 72 are deposited on a silicon oxide film 64 including the inside of a via-hole 66 by the CVD method and thereafter, the W film 72 and TiN film 71 on the silicon oxide film 64 are etched back to leave only the inside of the via-hole 66 and form a plug 73. Then, a TiN film 74, Al-alloy film 75, and Ti film 76 are deposited on the silicon oxide film 64 including the surface of the plug 73 by the sputtering method and thereafter, the Ti film 76, Al-alloy film 75, and TiN film 74 are patterned to form second-layer wirings 77 and 78.

Owner:LONGITUDE SEMICON S A R L

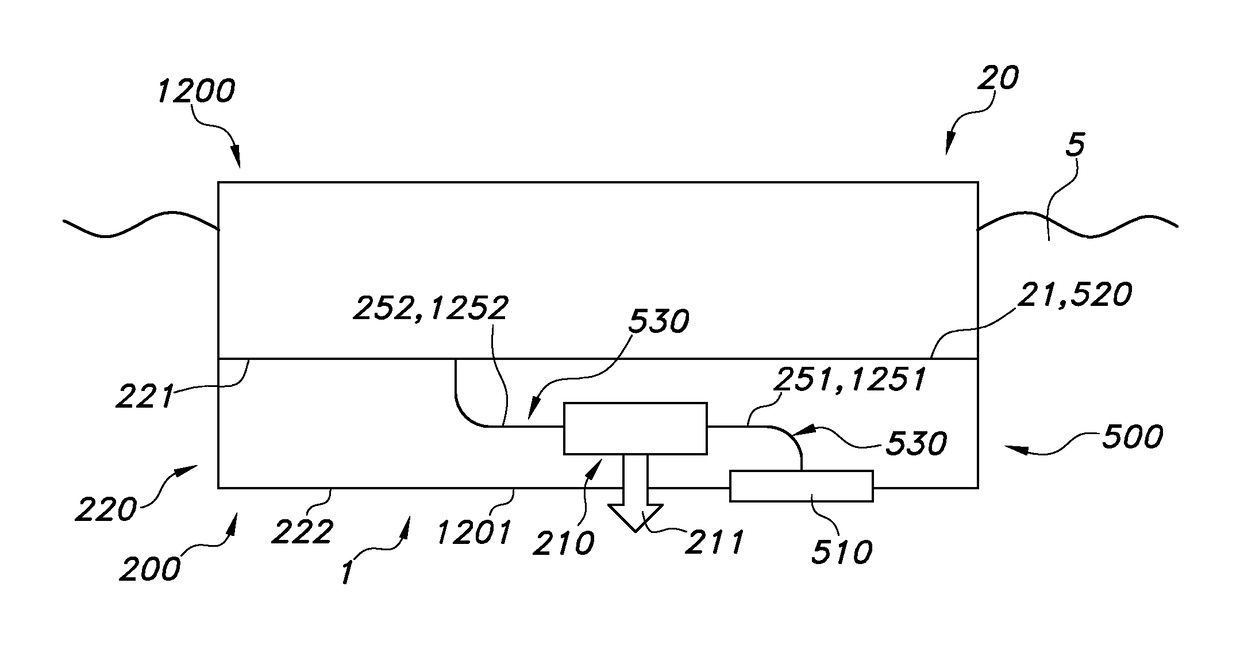

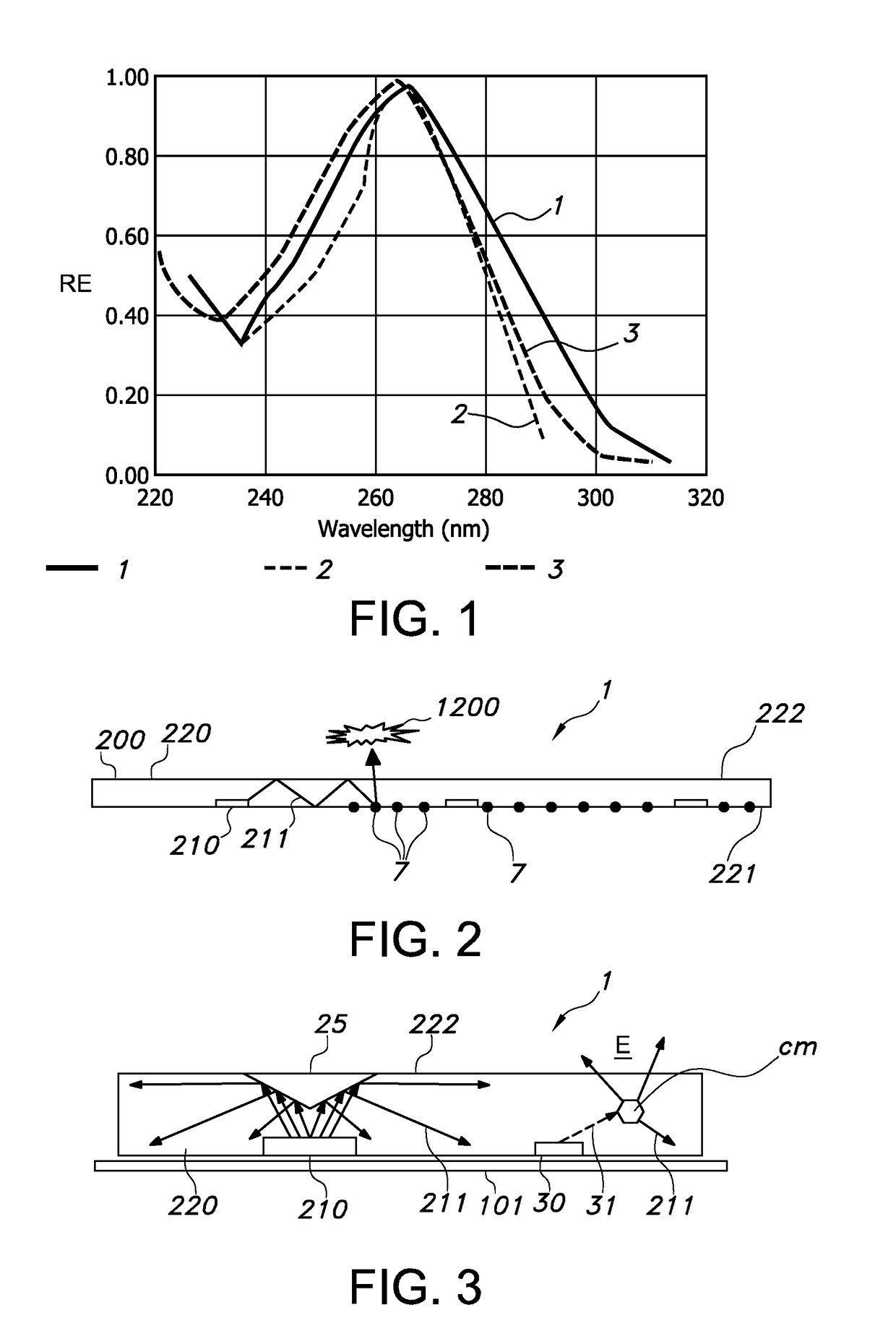

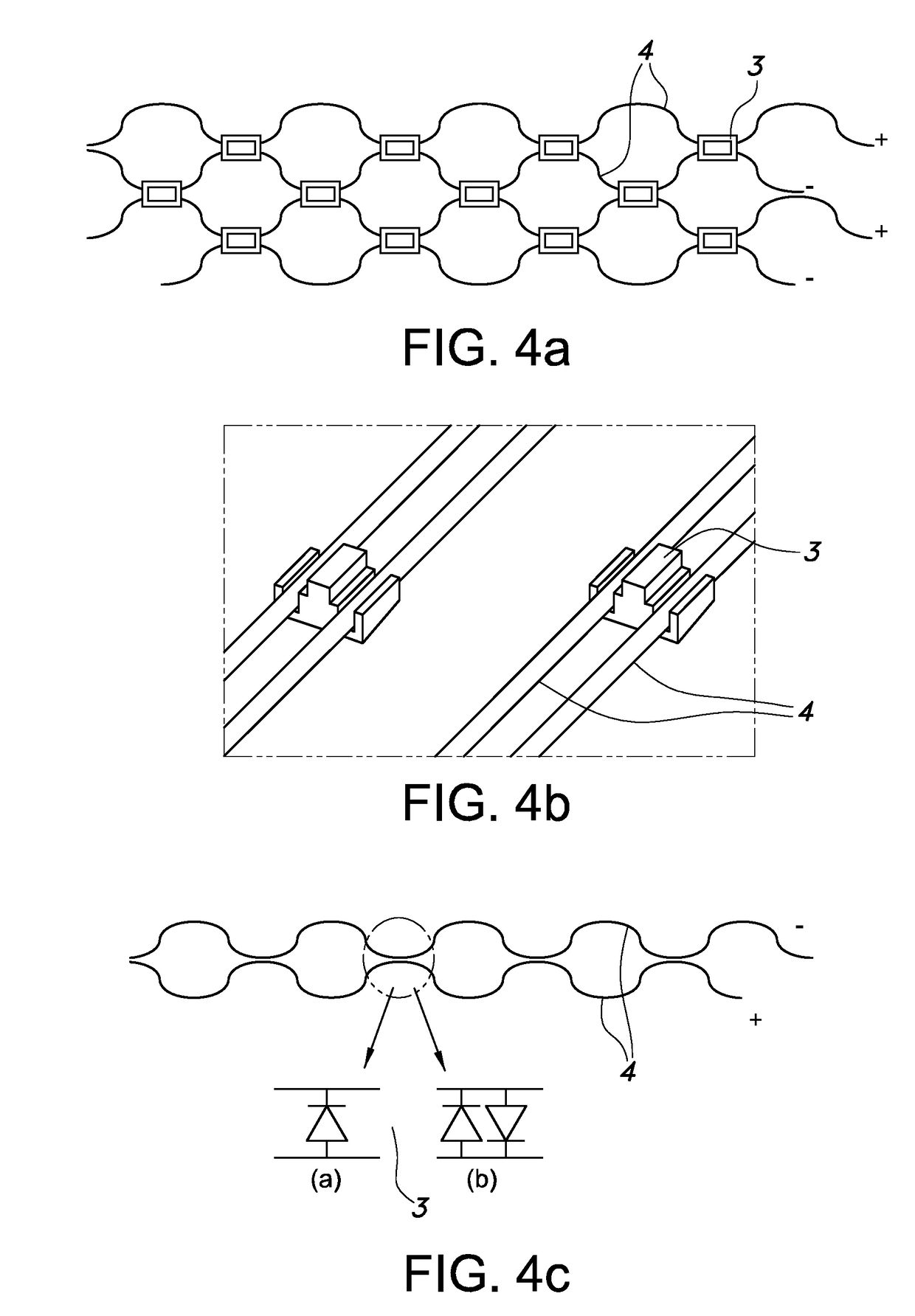

Anti-fouling system using energy harvested from salt water

InactiveUS20170190397A1Corrosion controlEasy to corrodeEnergy supplySeawater treatmentSaline waterSalt water

The invention provides an anti-fouling lighting system (1) configured for preventing or reducing biofouling on a fouling surface (1201) of an object (1200) that during use is at least temporarily exposed to a liquid, by providing an anti-fouling light (211) to said fouling surface (1201), the anti-fouling lighting system (1) comprising: —a lighting module (200) comprising a light source (210) configured to generate an anti-fouling light (211); and —an energy system (500) configured to locally harvest energy and configured to provide electrical power to said light lighting module (200), wherein the energy system (500) comprises (i) a sacrificial electrode (510), and (ii) a second energy system electrode (520), wherein the energy system (500) is configured to provide electrical power to the lighting module (200) when the sacrificial electrode (510) and the second energy system electrode (520) are in electrical contact with the liquid.

Owner:KONINKLJIJKE PHILIPS NV

Industrialized thick GEM (Gaseous Electron Multiplier) manufacturing method

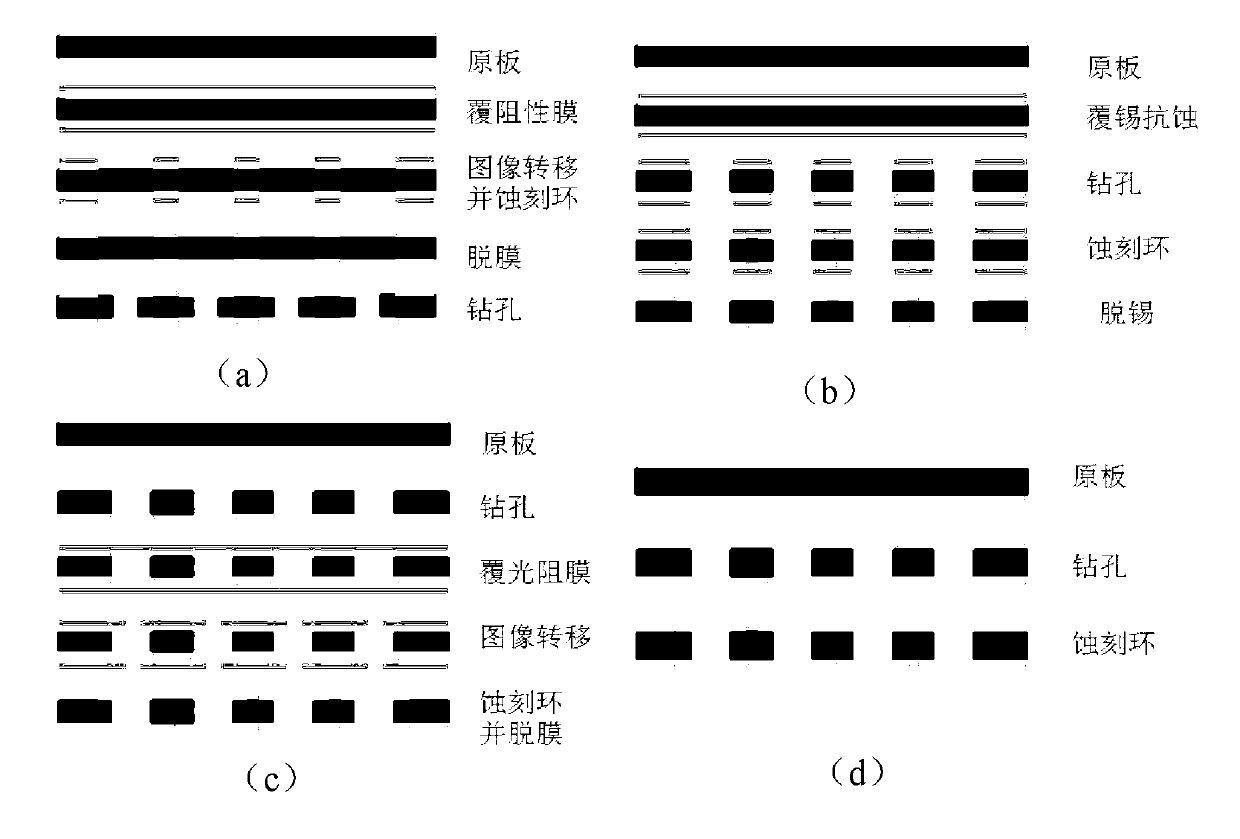

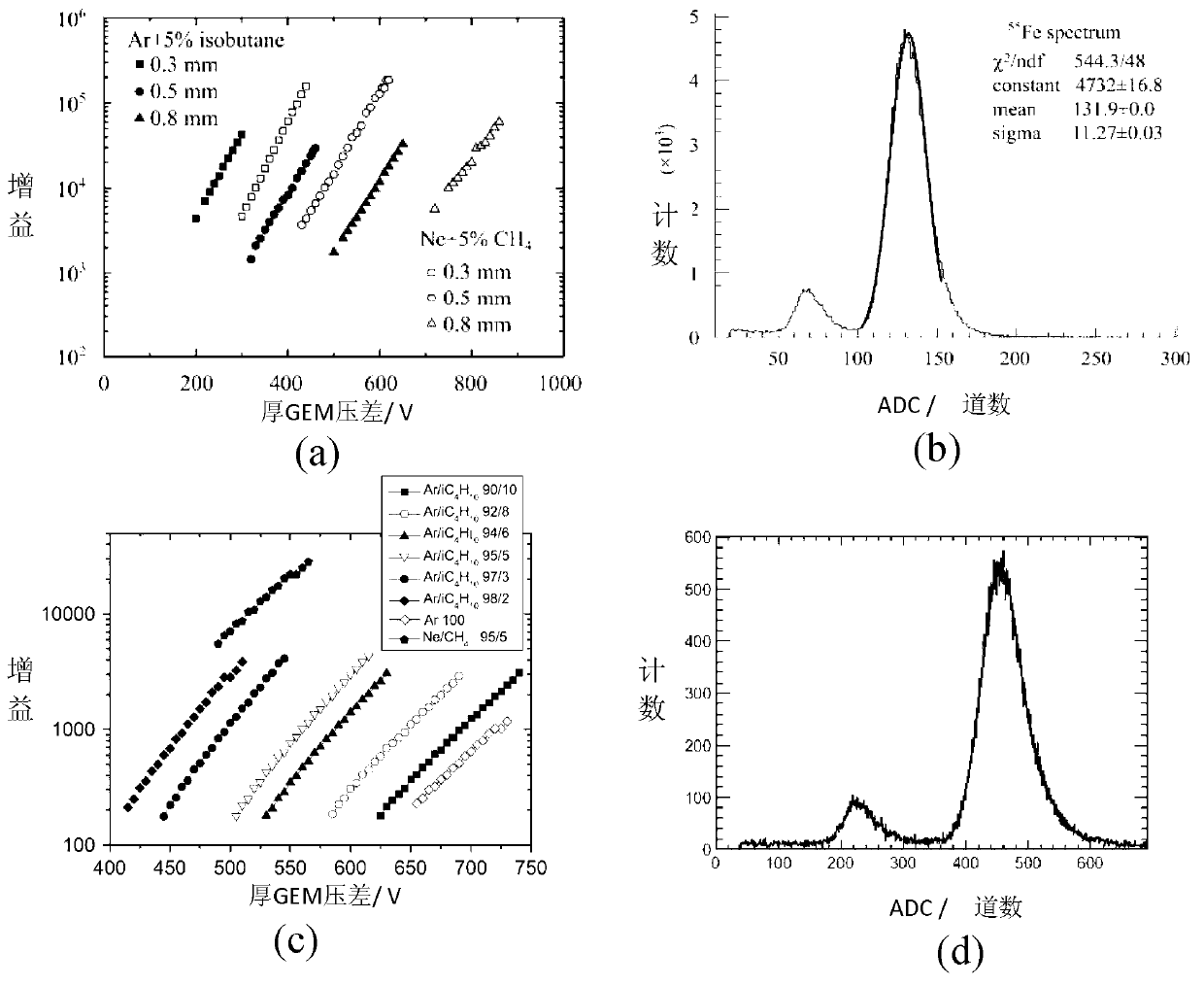

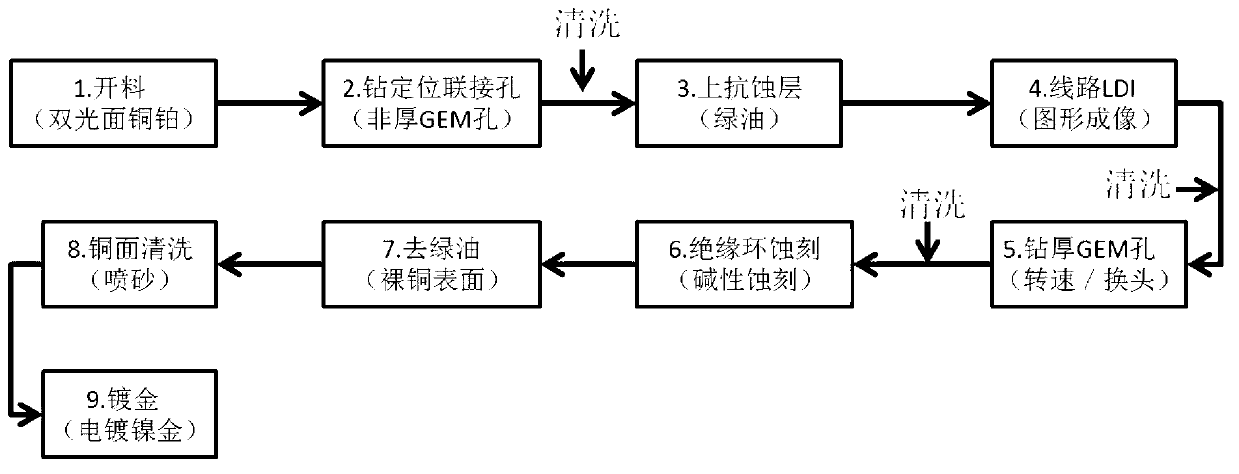

ActiveCN103280387AEasy to corrodeEase of mass productionCold cathode manufactureAssembly lineElectron multiplier

The invention discloses an industrialized thick GEM (Gaseous Electron Multiplier) manufacturing method, which comprises the following steps: (1) preparing positioning and connecting holes in a thick GEM original plate; (2) covering the thick GEM original plate treated by the step (1) with a corrosion resistant layer; (3) transferring the design image to the thick GEM original plate treated by the step (2); (4) preparing thick GEM holes in the thick GEM original plate treated by the step (3); (5) preparing insulating rings for all thick GEM holes; and (6) removing the corrosion resistant layer on the thick GEM original plate. The performance can be further improved by plating a gold layer on the thick GEM original plate treated by the step (6). According to the industrialized thick GEM manufacturing method, low-cost, short-period, large-area and high-yield industrialized whole assembly line batch production of the domestic thick GEM original plate is realized; the produced thick GEM has high gain and good gain stability and energy resolution, is ignition-resistant and can work in various argon-based and neon-based mixed gases.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

Magnetic tape head with magnetic head layer formed on base substrate

InactiveUS8009386B2High precisionEasy to moveManufacture head surfaceRecord information storageMagnetic tapeBearing surface

Owner:TDK CORPARATION

Cleaning liquid for lithography and method for cleaning substrate

ActiveUS20160122695A1Suppression problemGood removal effectOrganic detergent compounding agentsDecorative surface effectsLithographic artistHydroxylamine

A cleaning liquid for lithography that is capable of removing residual material which remains after an etching process, as well as suppressing corrosion of at least one of cobalt and alloys thereof, and a method for cleaning a substrate using the cleaning liquid. The cleaning liquid for lithography includes hydroxylamine, at least one basic compound selected from amine compounds other than hydroxylamine, and quaternary ammonium hydroxides, and water, and has a pH value of 8 or higher. The cleaning liquid is used in cleaning a substrate containing at least one of cobalt and alloys thereof.

Owner:TOKYO OHKA KOGYO CO LTD

Glass erosion liquid and preparation method thereof

The invention relates to a vitreous etching bath, which comprises 0.5%-8% microcosmic salt, 0.5%-8% pyrophosphate, 0.01%-0.5% inorganic alkaline, 5%-45% surface activator and 39%-93% water. The preparing method comprises the following steps: adding the microcosmic salt and the pyrophosphate in the water, heating in order to dissolve; adding inorganic alkaline and non-ionic surface activator and mixing. The invention can remove greasy dirt, fingerprint, particles and sio2 for buffed glass base plate, which can removes the impurity and Ceo2 on the glass, achieves the request of the environmental protection.

Owner:天津晶岭电子材料科技有限公司

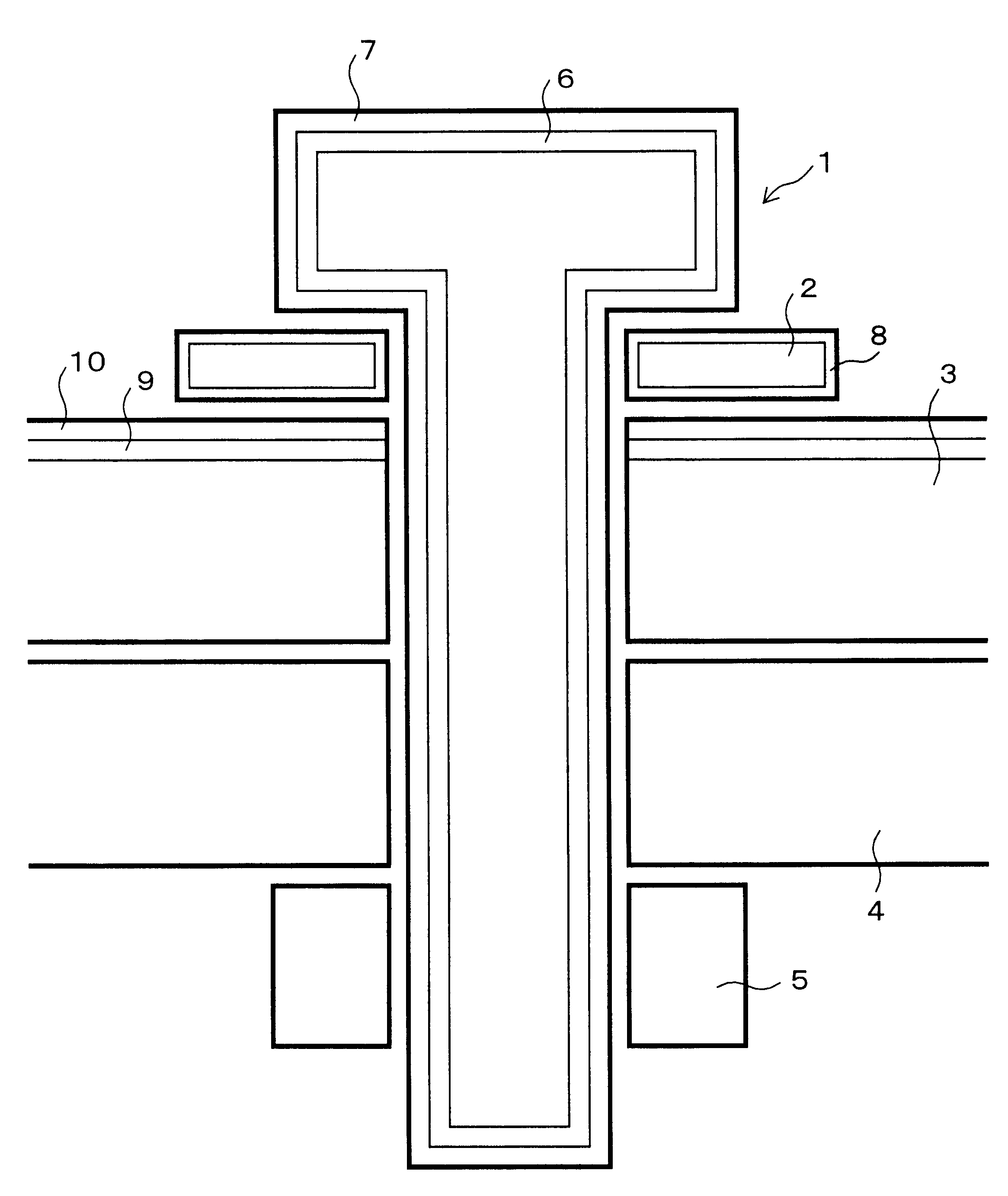

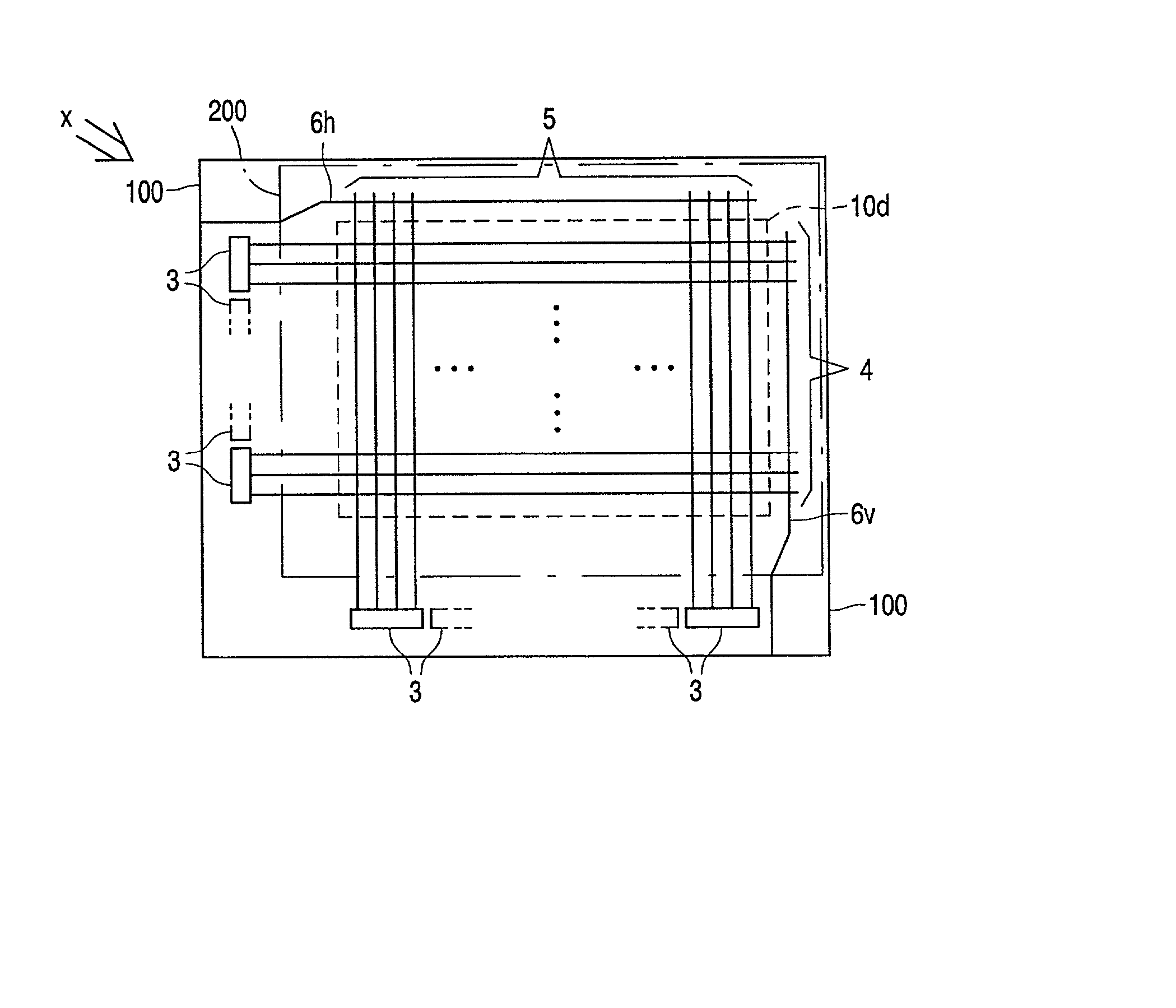

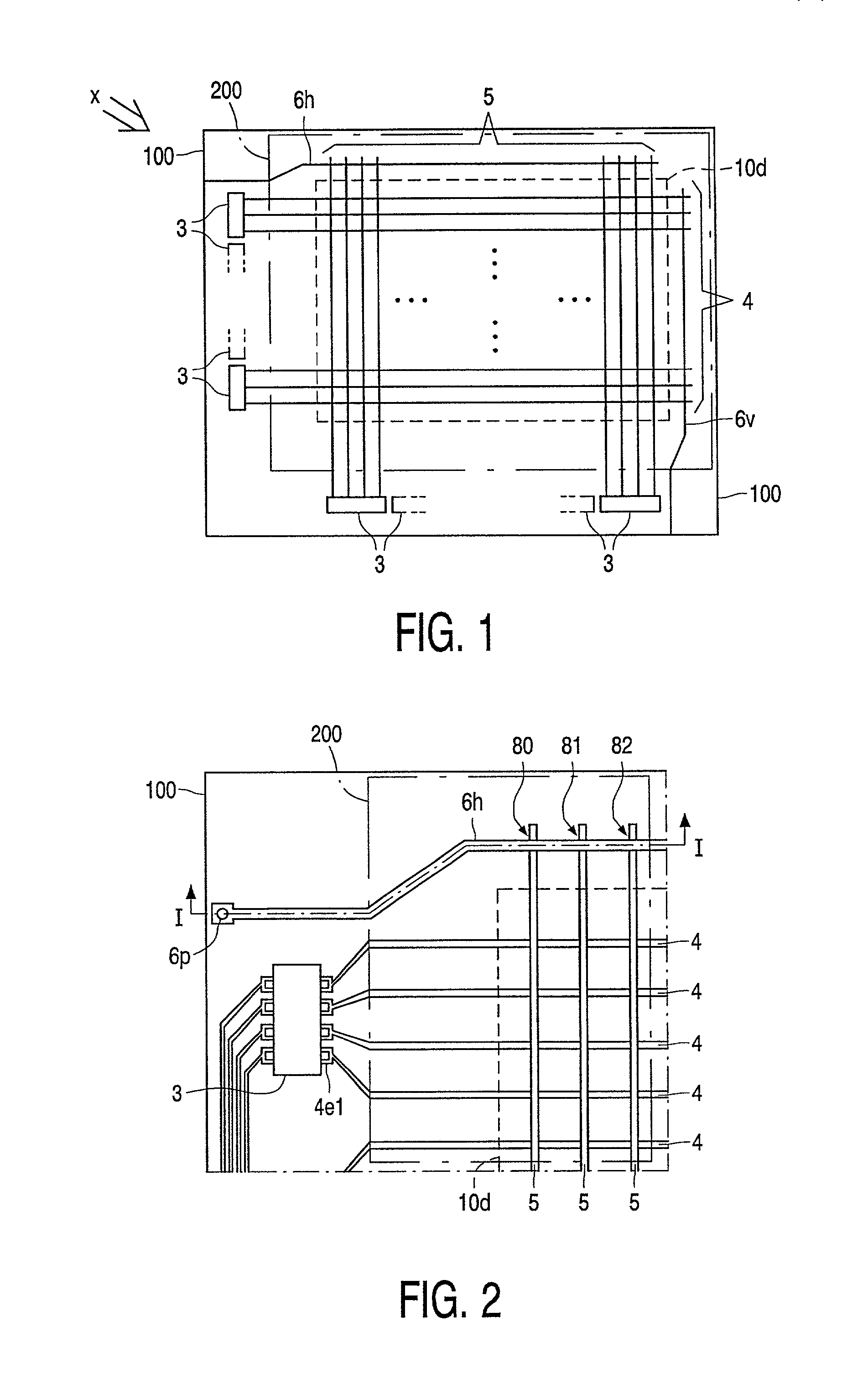

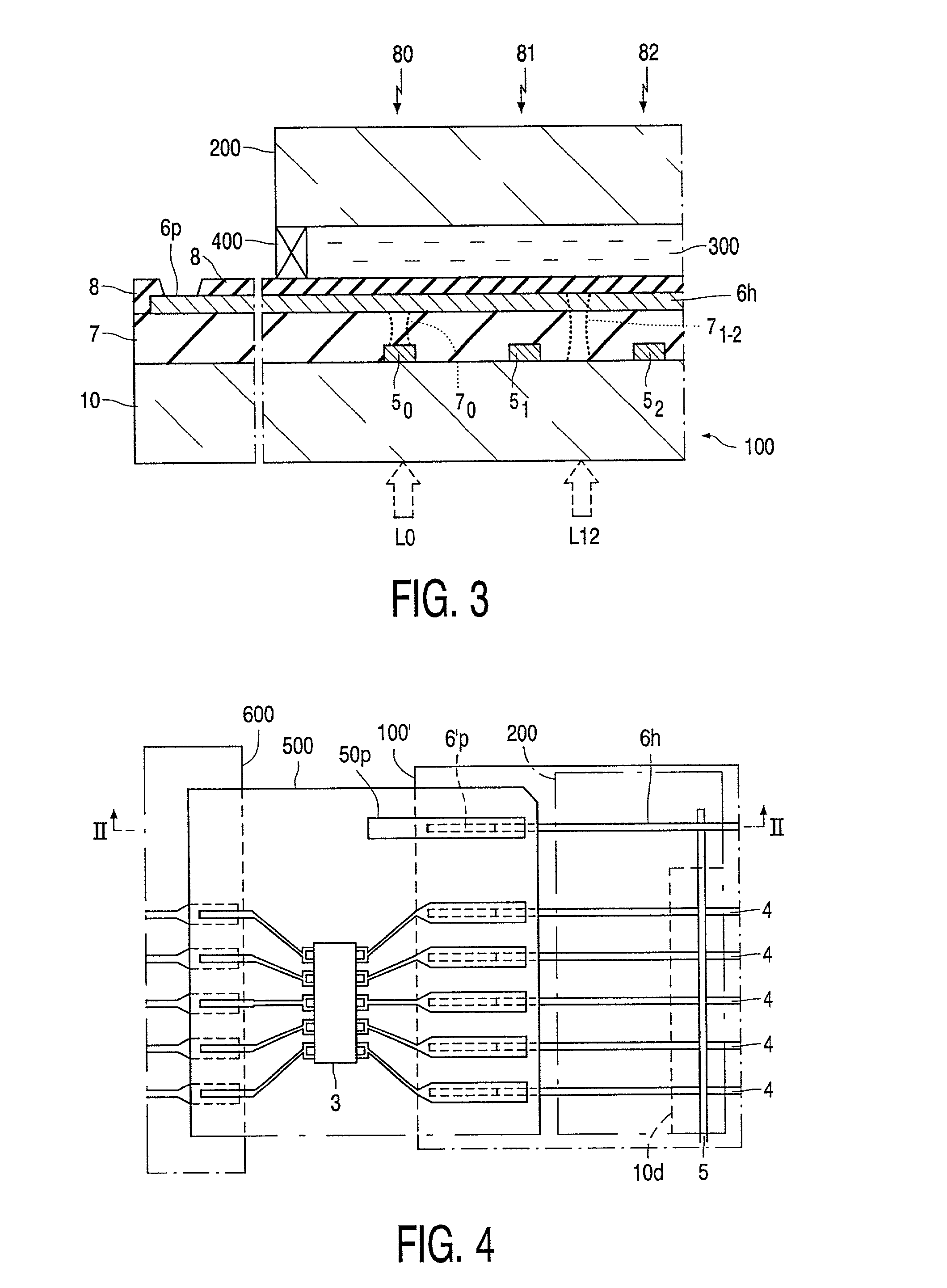

Liquid crystal display device having an auxiliary wiring

InactiveUS20030016326A1Avoid problemsEasy to corrodeSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayElectricity

To enable freely choose a bus-line to be monitored without such a problem that the bus-line is made corroded. A liquid crystal display device comprising: a substrate (10) in which a display area (10d) is delimited; and two series of bus-lines (4, 5) supported by the substrate, one ends of the bus-lines being located in proximity to one side of the display area, another ends of the bus-lines being located in proximity to another side of the display area which is opposite to the one side of the display area, the two series of bus-lines (4, 5) being arranged to extend over the display area in such a manner that the one series of bus-lines (4) is orthogonal to the other series of bus-lines (5). The display device further comprises: a conductive auxiliary wiring pattern (6h, 6v) which extends in such a manner that the pattern crosses another end(s) of the bus-line(s), which is / are all to be monitored, of the one series of bus-lines (4 or 5) via an electrically insulating layer (7), and which is led out to a predetermined location on a side of one ends of the bus-lines (5 or 4) of the other series to form a coupling portion (6p) capable of electrically connecting to the exterior.

Owner:INNOLUX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com