Ultra-supercritical martensite heat resisting cast steel original austenite grain size display method

A technology of austenitic grain and heat-resistant cast steel, which is applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc. It can solve the problems of complex operation, high operator requirements, and difficulty in mastering, and achieve simple corrosion conditions , easy to master, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

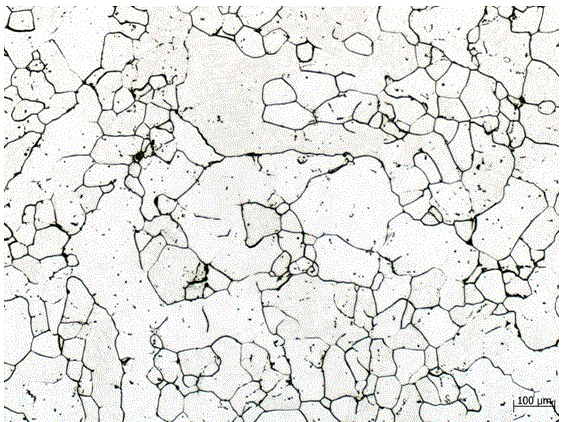

Embodiment 1

[0037]To perform grain display on ZG13Cr9Mo2Co1NiVNbNB cast steel material, the following steps are adopted:

[0038] first step:

[0039] Heat treatment for displaying original austenite grains: raise the temperature of the high-temperature furnace to 1100°C, and after the temperature stabilizes, put the sample in the furnace for 30 minutes, then quickly drop the temperature in the furnace to 800°C, and continue to hold the sample for 100 hours, then cooled to room temperature;

[0040] Step two:

[0041] Grinding and polishing of metallographic samples:

[0042] a. Cutting of metallographic samples: Cut a 15×15mm metallographic sample from the heat-treated sample showing the original austenite grains, remove the oxidized and decarburized part of the surface, and cut off about 5mm±1mm;

[0043] b. Grinding and polishing of metallographic samples: first remove the cutting marks on the surface of the sample with a grinding wheel, and then grind with water-resistant sandpaper...

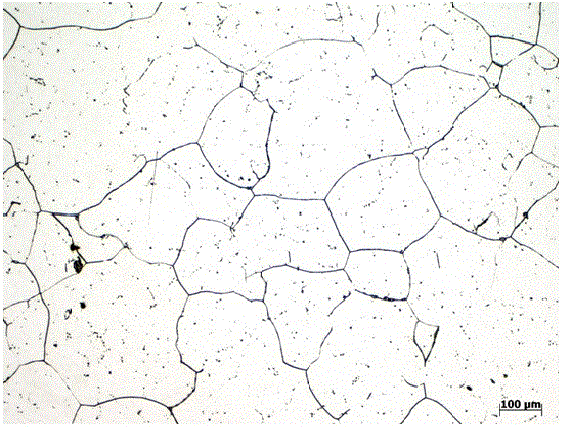

Embodiment 2

[0051] To perform grain display on ZG13Cr9Mo2Co1NiVNbNB cast steel material, the following steps are adopted:

[0052] The first step: heat treatment for displaying the original austenite grains: raise the temperature of the high-temperature furnace to 1150°C, and after the temperature is stable, put the sample in the furnace for 16 hours, and then quickly drop the temperature in the furnace to 800°C, test The sample was kept warm for 100 hours, and then cooled to room temperature;

[0053] The second step: Grinding and polishing of the metallographic sample:

[0054] a. Cutting of metallographic samples: Cut a 15×15mm metallographic sample from the heat-treated sample showing the original austenite grains, remove the oxidized and decarburized part of the surface, and cut off about 5mm±1mm;

[0055] b. Grinding and polishing of metallographic samples: first remove the cutting marks on the surface of the sample with a grinding wheel, and then grind with water-resistant sandpap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com