Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

A technology of lithium-ion batteries and conductive polymers, applied in battery electrodes, electrode manufacturing, lithium batteries, etc., can solve problems such as difficult mass production and troublesome process steps, and achieve high specific capacity, simple and clear steps, and long cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

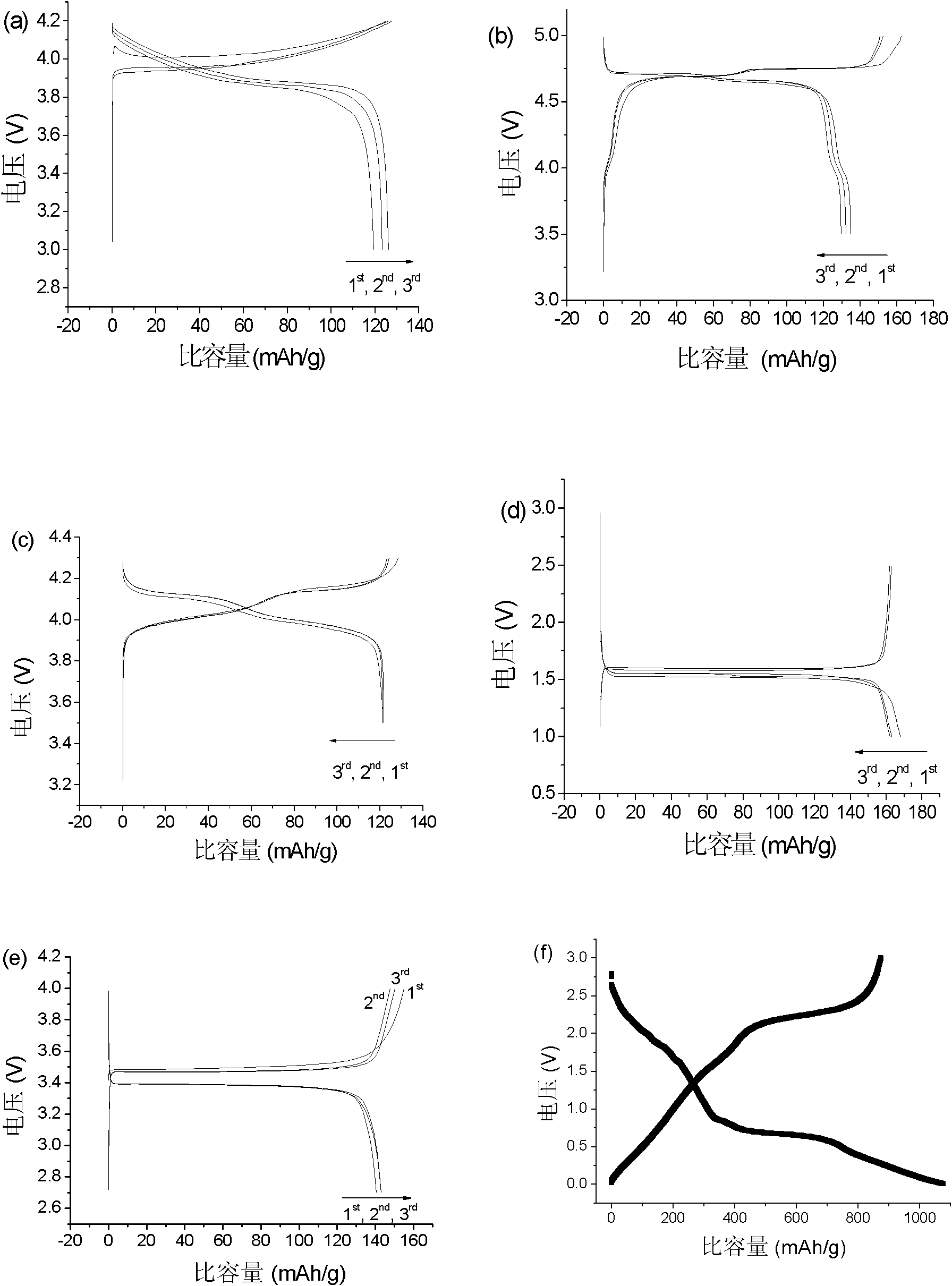

[0033] LiCoO 2 / PEDOT:PSS

[0034] Adjust the pH value of the PEDOT:PSS aqueous solution with ammonia water to be neutral (pH=6~9). 2g LiCoO 2 The powder was slowly added to an aqueous solution of PEDOT:PSS (10 mL), ultrasonically dispersed for 30 min, stirred for 2 hours, filtered, dried at 80°C for 3 hours, thoroughly ground, and then dried at 120°C for 2 hours. After fully grinding the prepared material, mix it with acetylene black and PVDF in a ratio of 80:10:10, and dry it at 80°C for 24 hours after coating to prepare LiCoO 2 electrode sheet. With lithium sheet as counter electrode, polyethylene film as diaphragm, 1MLiPF 6 / EC:DEC:DMC (v:v:v=1:1:1) conducts constant current charge and discharge tests for electrolyte assembled button cells (CR2025), with a voltage range of 3.0-4.2V.

Embodiment 2

[0036] LiNi 0.5 mn 1.5 o 4 / PEDOT:PSS

[0037] Adjust the pH value of the PEDOT:PSS aqueous solution with ammonia water to be neutral (pH=6~9). 0.5g LiNi 0.5 mn 1.5 o 4 Slowly add the powder into PEDOT:PSS aqueous solution (2mL), ultrasonically disperse for 30min, settle naturally, centrifuge, and then dry at 60℃~120℃ for 24 hours. After fully grinding the prepared material, mix it with acetylene black and PVDF in a ratio of 80:10:10, and dry it at 80°C for 24 hours after coating to prepare LiNi 0.5 mn 1.5 o 4 electrode. With a lithium sheet as the counter electrode, a polyethylene film as the separator, and 1M LiPF 6 / EC:DEC (v:v=1:1) conducts constant current charge and discharge tests for electrolyte assembled button cells (CR2025), and the voltage range is 3.5-5.0V.

Embodiment 3

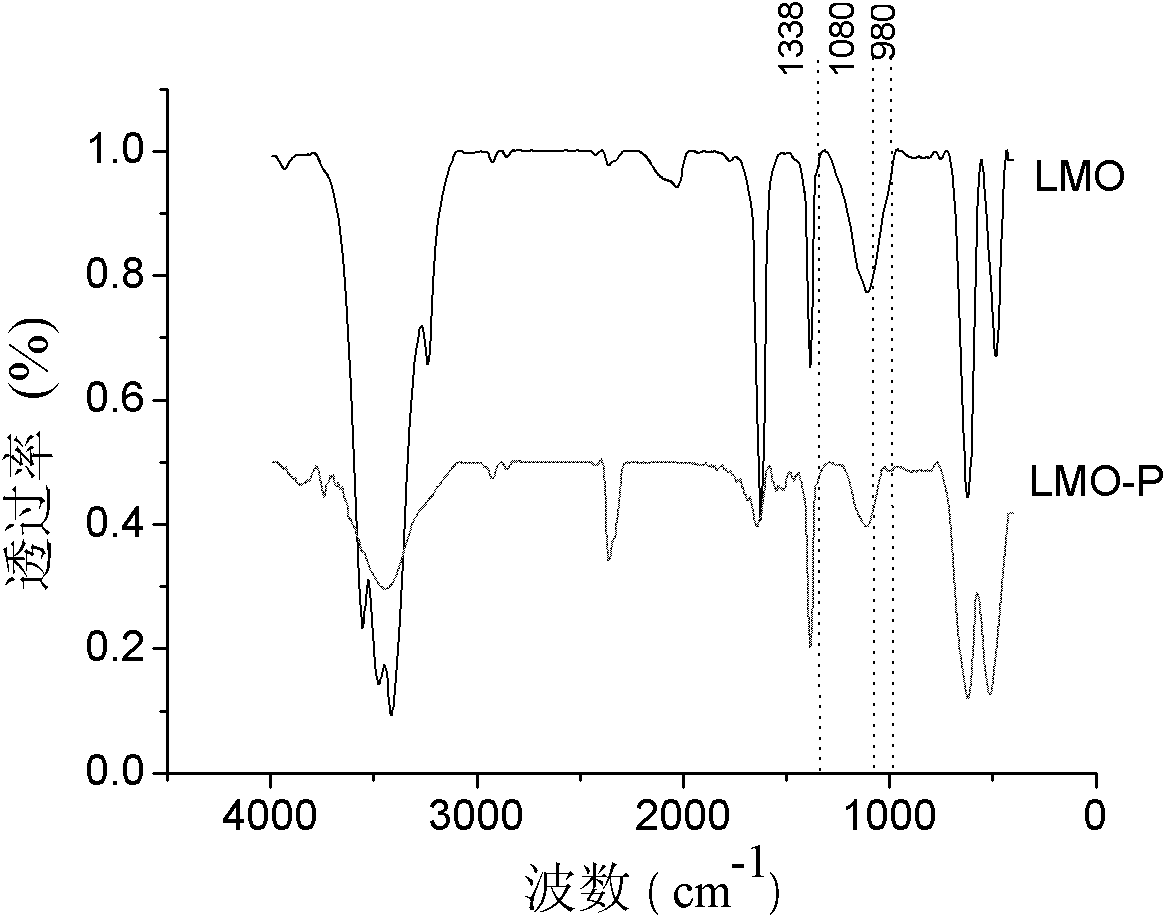

[0039] LiMn 2 o 4 / PEDOT:PSS

[0040] Adjust the pH value of the PEDOT:PSS aqueous solution with ammonia water to be neutral (pH=6~9). 0.5g LiMn 2 o 4 Slowly add the powder into PEDOT:PSS aqueous solution (2mL), ultrasonically disperse for 30min, settle naturally, centrifuge, and then dry at 60℃~120℃ for 24 hours. After fully grinding the prepared material, mix it with acetylene black and PVDF according to the ratio of 80:10:10, and dry it at 80°C for 24 hours after coating to prepare LiMn 2 o 4 electrode. With a lithium sheet as the counter electrode, a polyethylene film as the separator, and 1M LiPF 6 / EC:DEC (v:v=1:1) conducts constant current charge and discharge tests for electrolyte-assembled button batteries (CR2025), with a voltage range of 3.5-4.3V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com