Patents

Literature

3203 results about "Battery electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanostructured Materials for Battery Applications

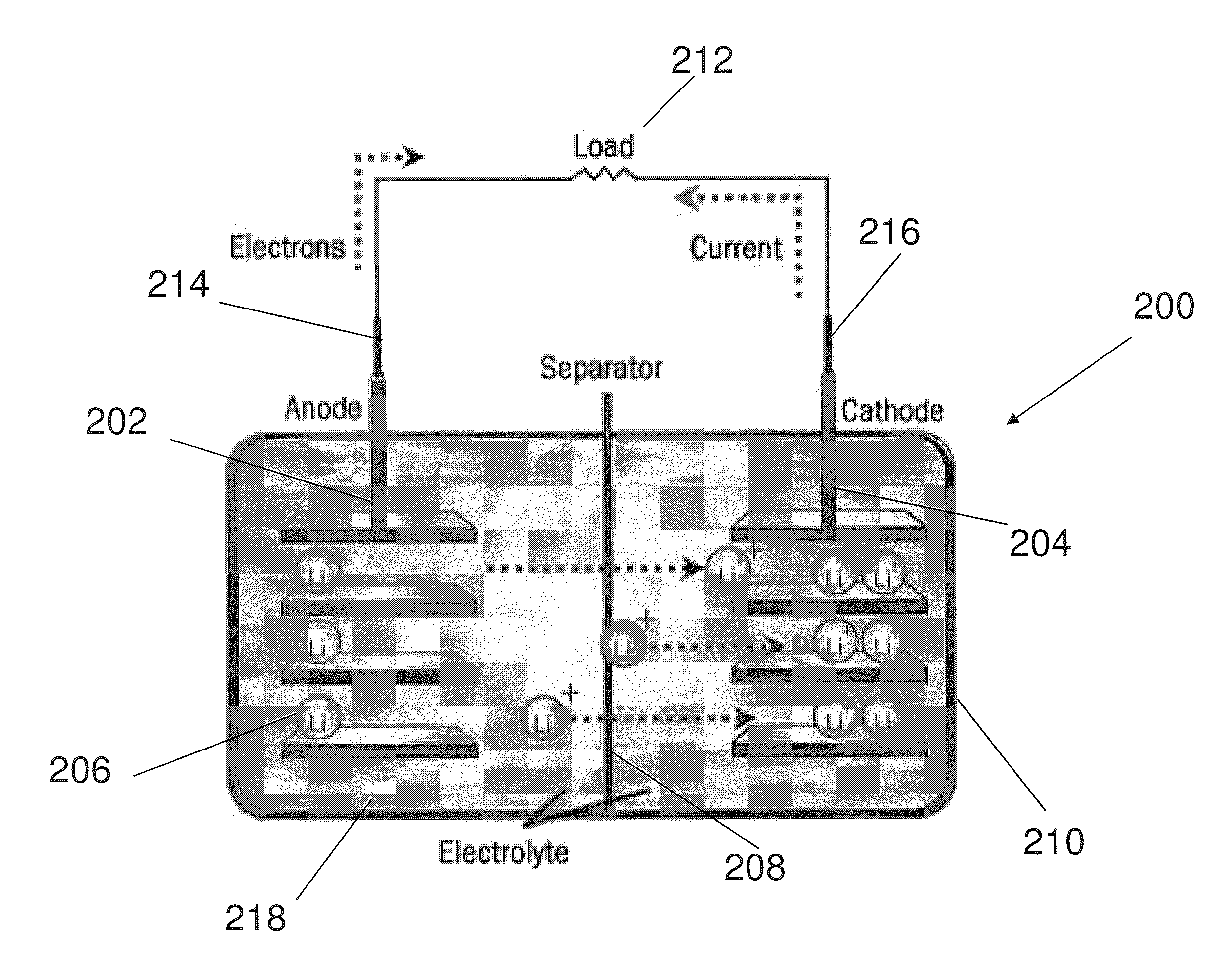

The present invention relates to nanostructured materials (including nanowires) for use in batteries. Exemplary materials include carbon-comprising, Si-based nanostructures, nanostructured materials disposed on carbon-based substrates, and nanostructures comprising nanoscale scaffolds. The present invention also provides methods of preparing battery electrodes, and batteries, using the nanostructured materials.

Owner:ONED MATERIAL INC

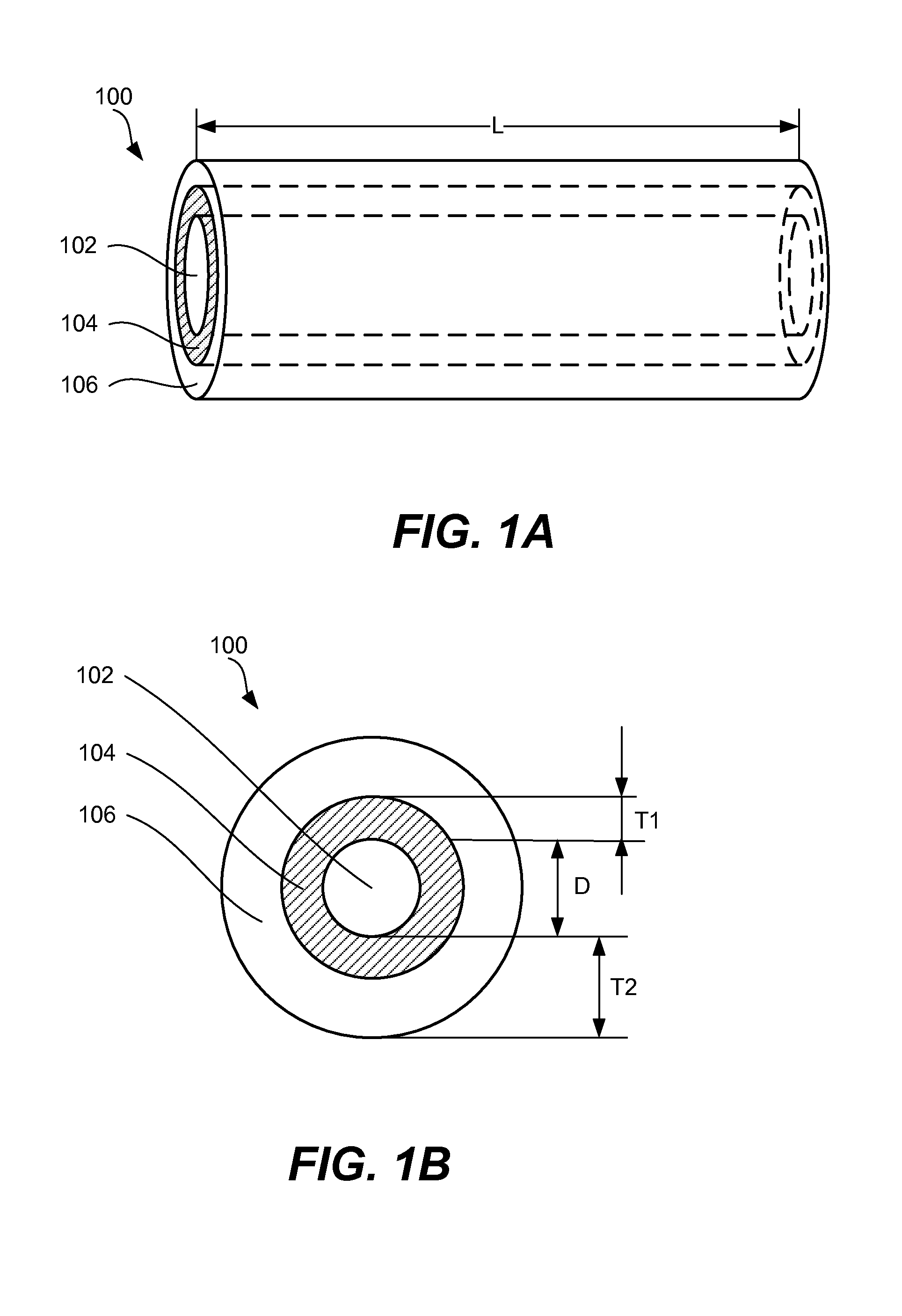

Core-shell high capacity nanowires for battery electrodes

InactiveUS20100330421A1Large capacityInhibition formationMaterial nanotechnologyNanostructure manufactureNanowireElectrochemistry

Provided are nanostructures containing electrochemically active materials, battery electrodes containing these nanostructures for use in electrochemical batteries, such as lithium ion batteries, and methods of forming the nanostructures and battery electrodes. The nanostructures include conductive cores, inner shells containing active materials, and outer shells partially coating the inner shells. The high capacity active materials having a stable capacity of at least about 1000 mAh / g can be used. Some examples include silicon, tin, and / or germanium. The outer shells may be configured to substantially prevent formation of Solid Electrolyte lnterphase (SEI) layers directly on the inner shells. The conductive cores and / or outer shells may include carbon containing materials. The nanostructures are used to form battery electrodes, in which the nanostructures that are in electronic communication with conductive substrates of the electrodes.

Owner:AMPRIUS INC

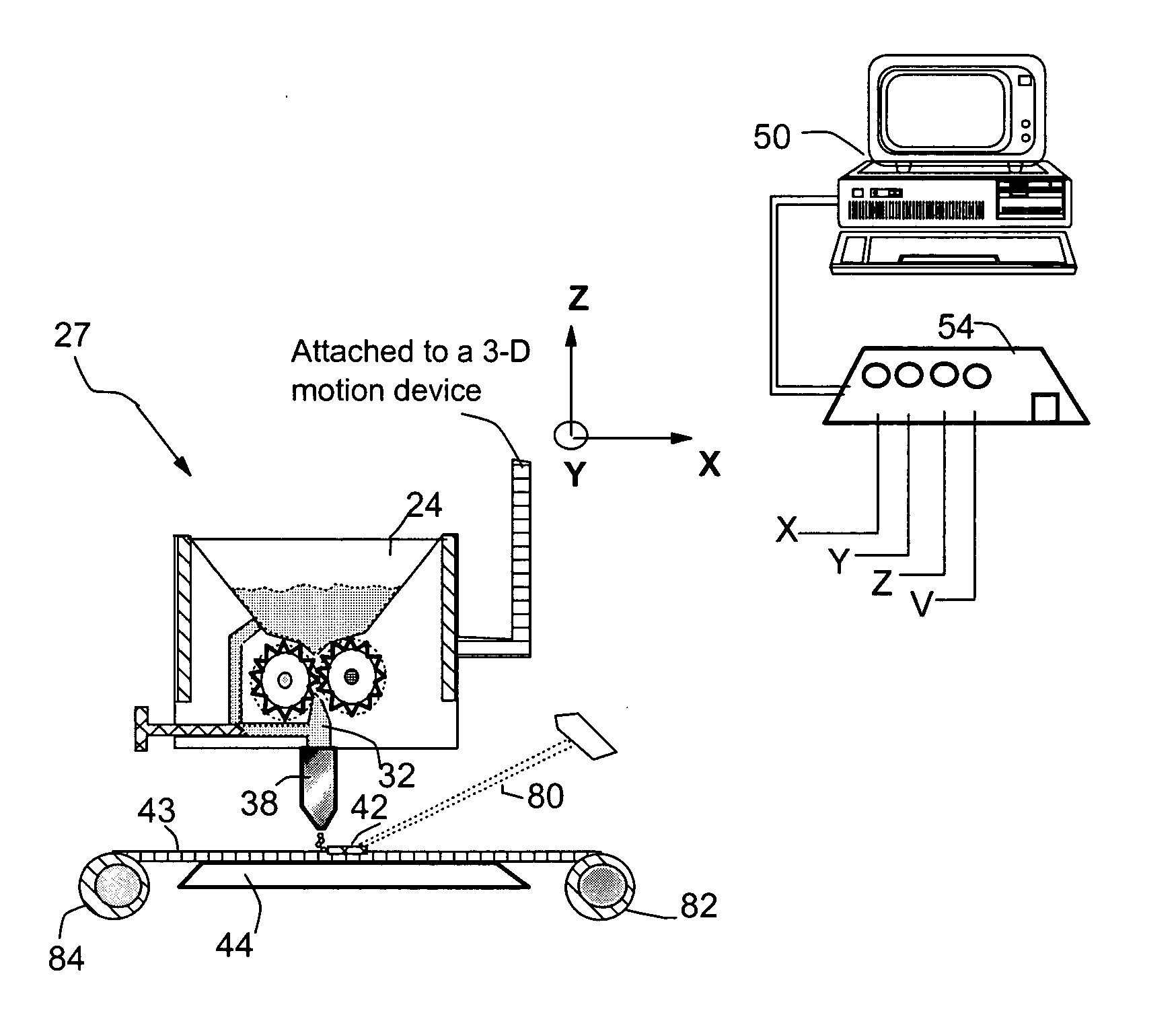

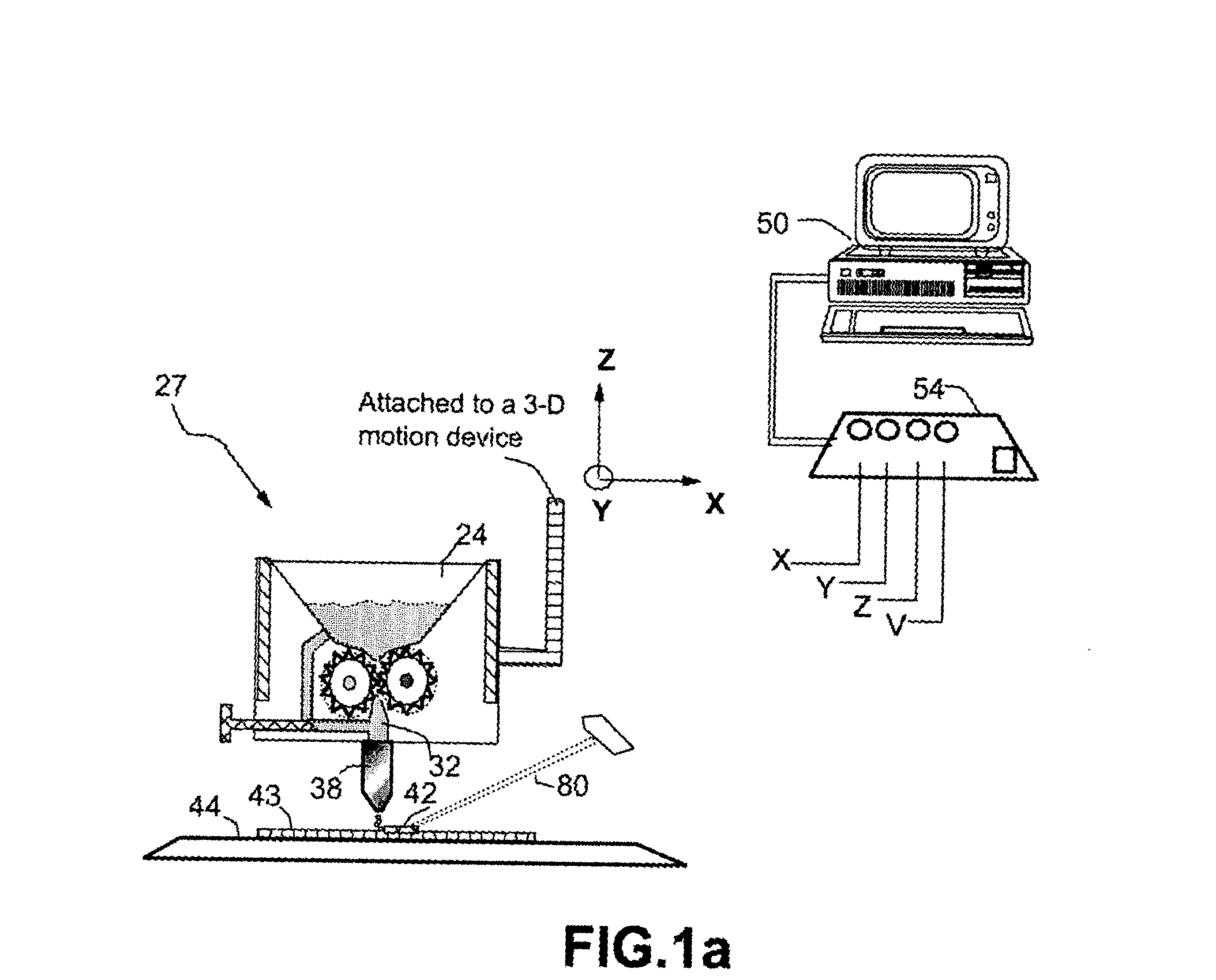

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

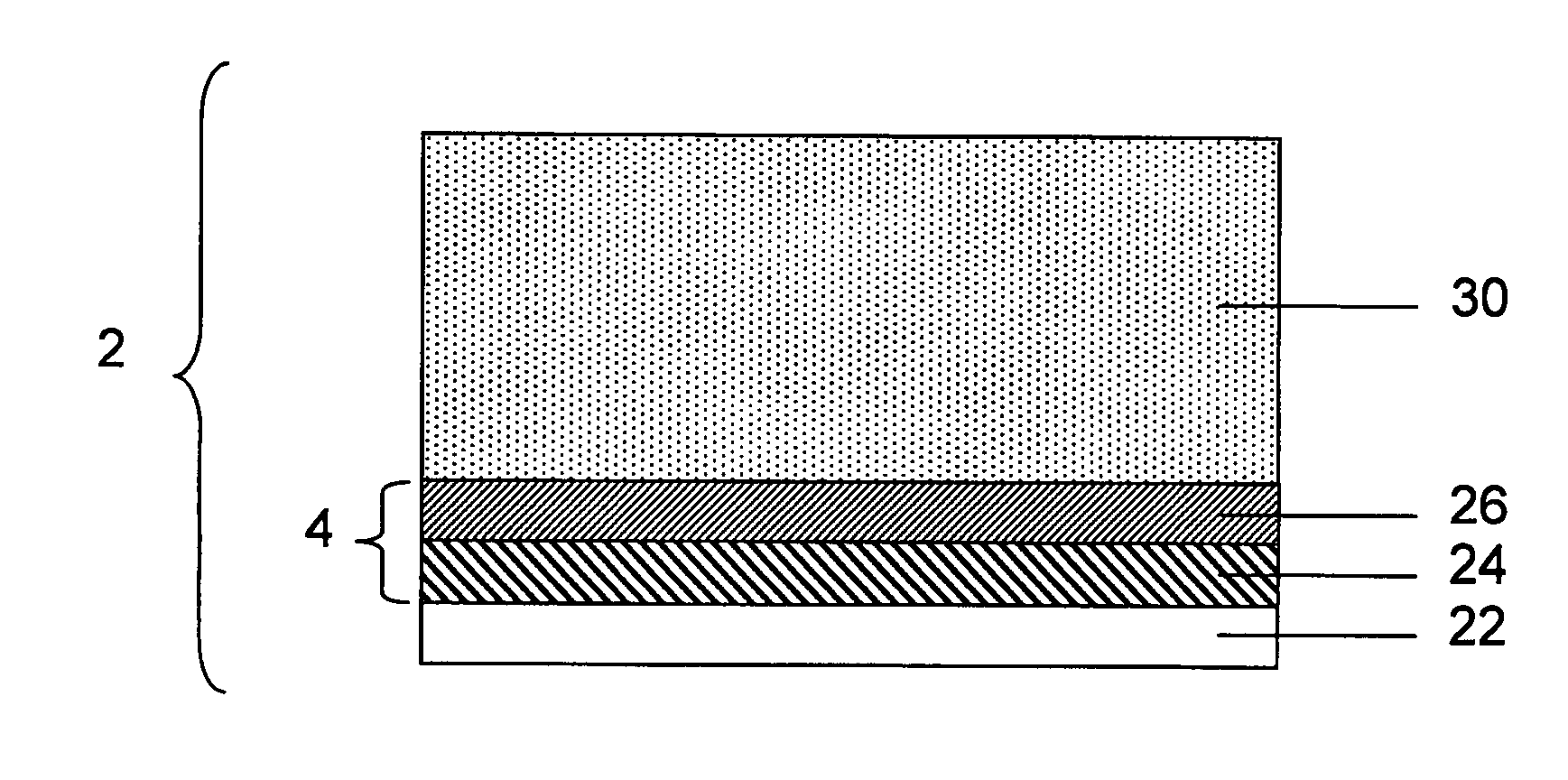

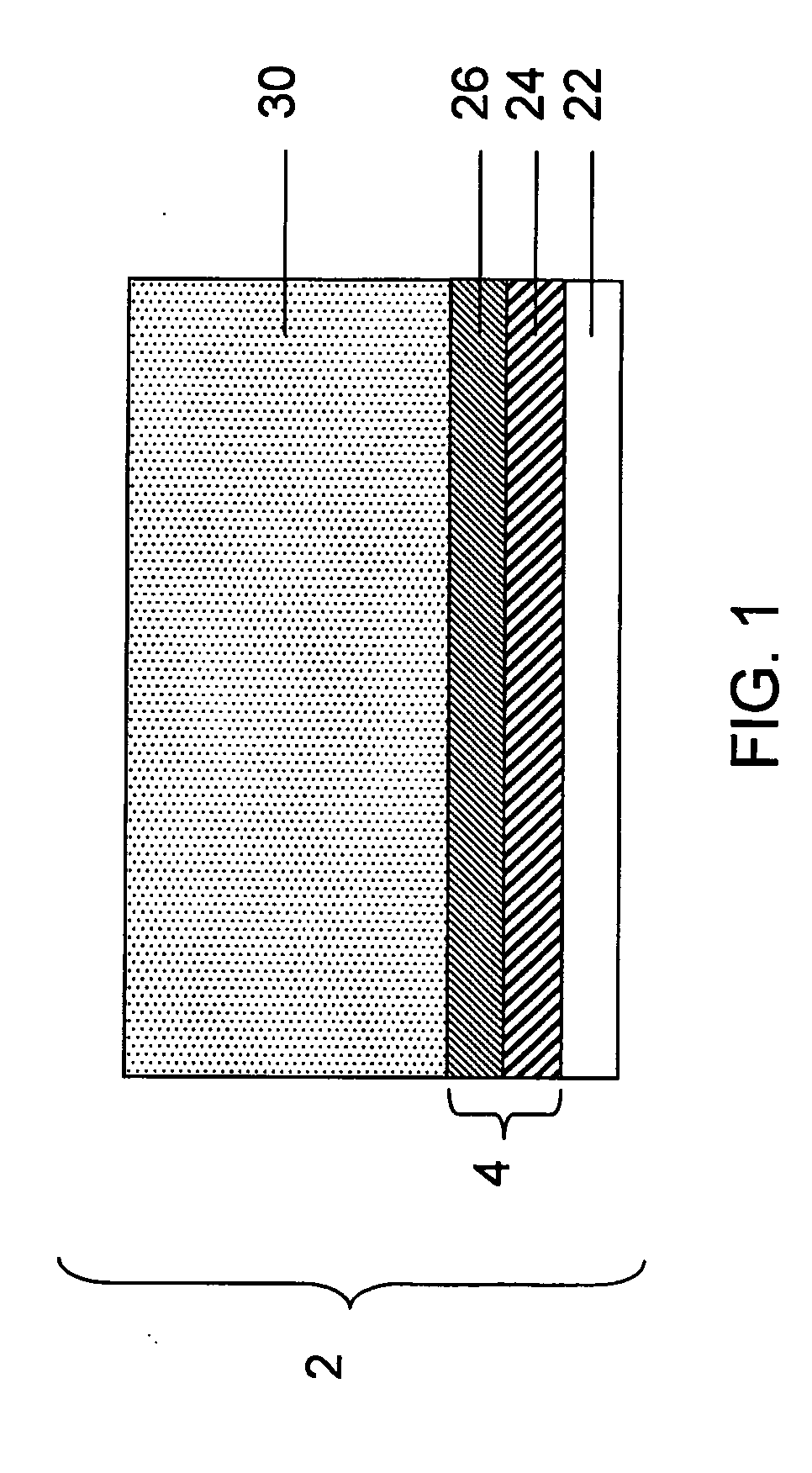

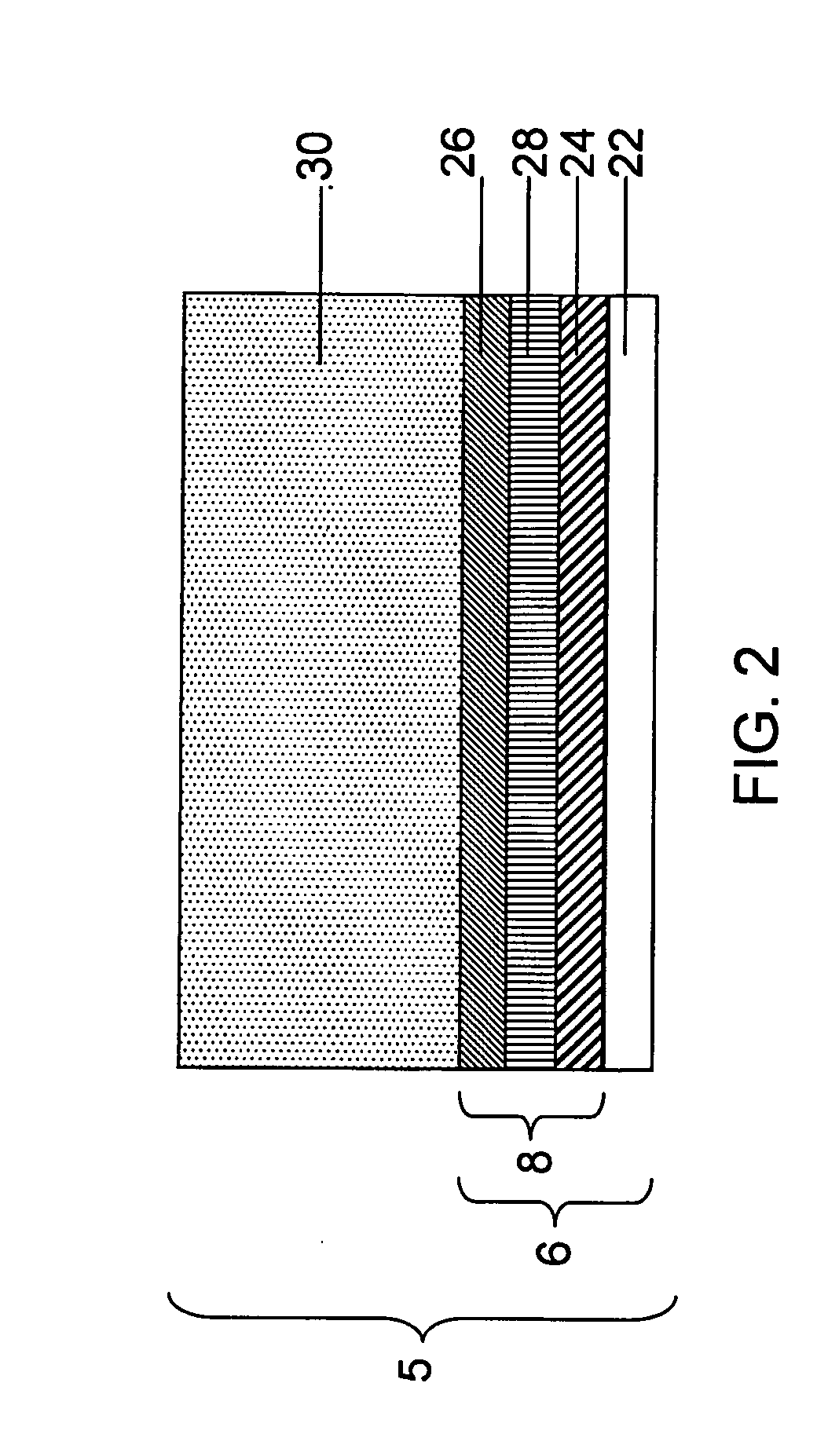

Primer for battery electrode

ActiveUS20100291442A1Electrode carriers/collectorsActive material electrodesPolyvinyl alcoholCrosslinked polymers

Primer arrangements that facilitate electrical conduction and adhesive connection between an electroactive material and a current collector are presented. In some embodiments, primer arrangements described herein include first and second primer layers. The first primer layer may be designed to provide good adhesion to a conductive support. In one particular embodiment, the first primer layer comprises a substantially uncrosslinked polymer having hydroxyl functional groups, e.g., polyvinyl alcohol. The materials used to form the second primer layer may be chosen such that the second primer layer adheres well to both the first primer layer and an electroactive layer. In certain embodiments including combinations of first and second primer layers, one or both of the first and second primer layers comprises less than 30% by weight of a crosslinked polymeric material. A primer including only a single layer of polymeric material is also provided.

Owner:SION POWER CORP

Energy storage device

ActiveUS20100203362A1Reduce heatImprove conductivityLead-acid accumulatorsCapacitor and primary/secondary cellsTin dioxideConductive materials

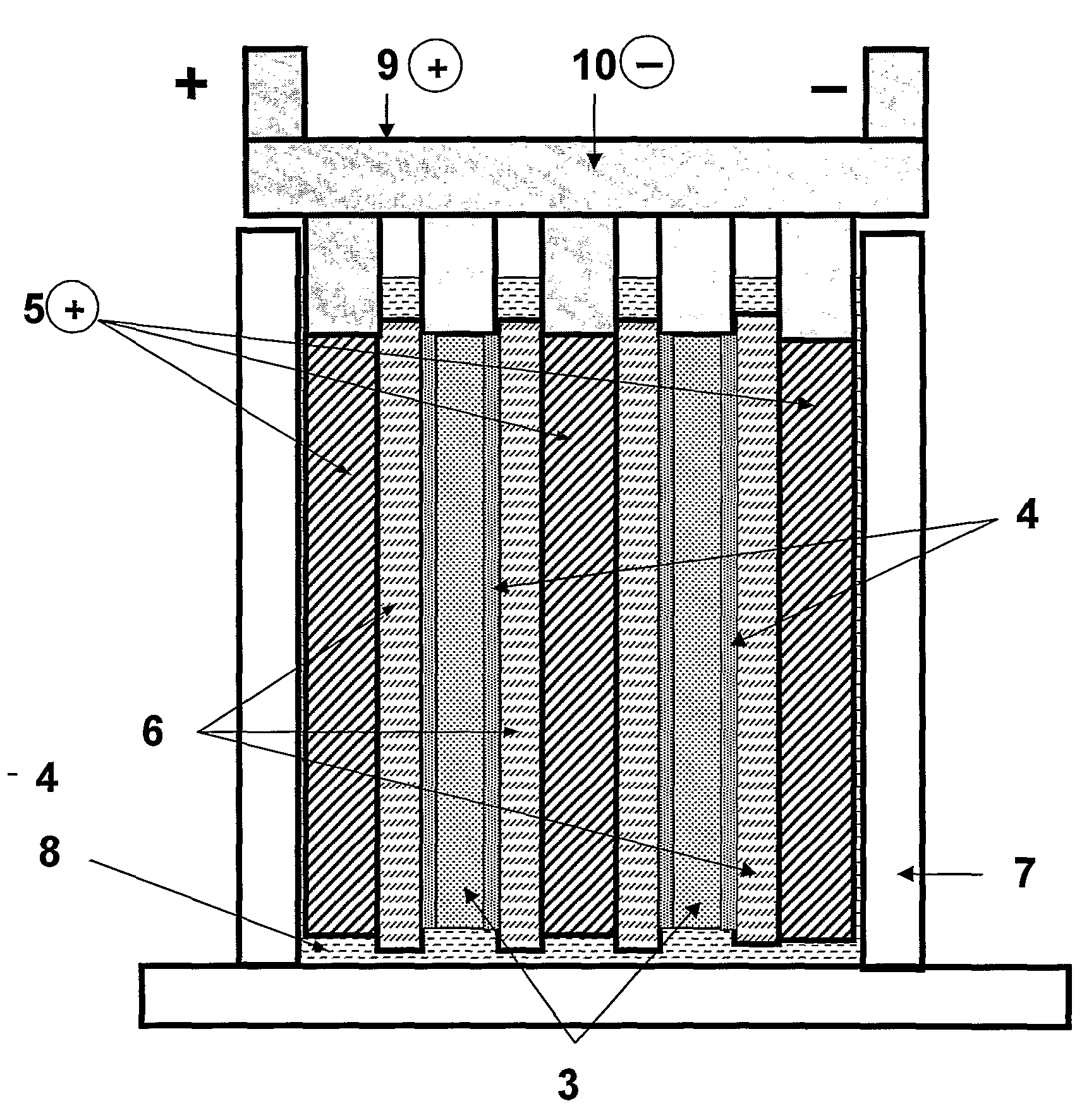

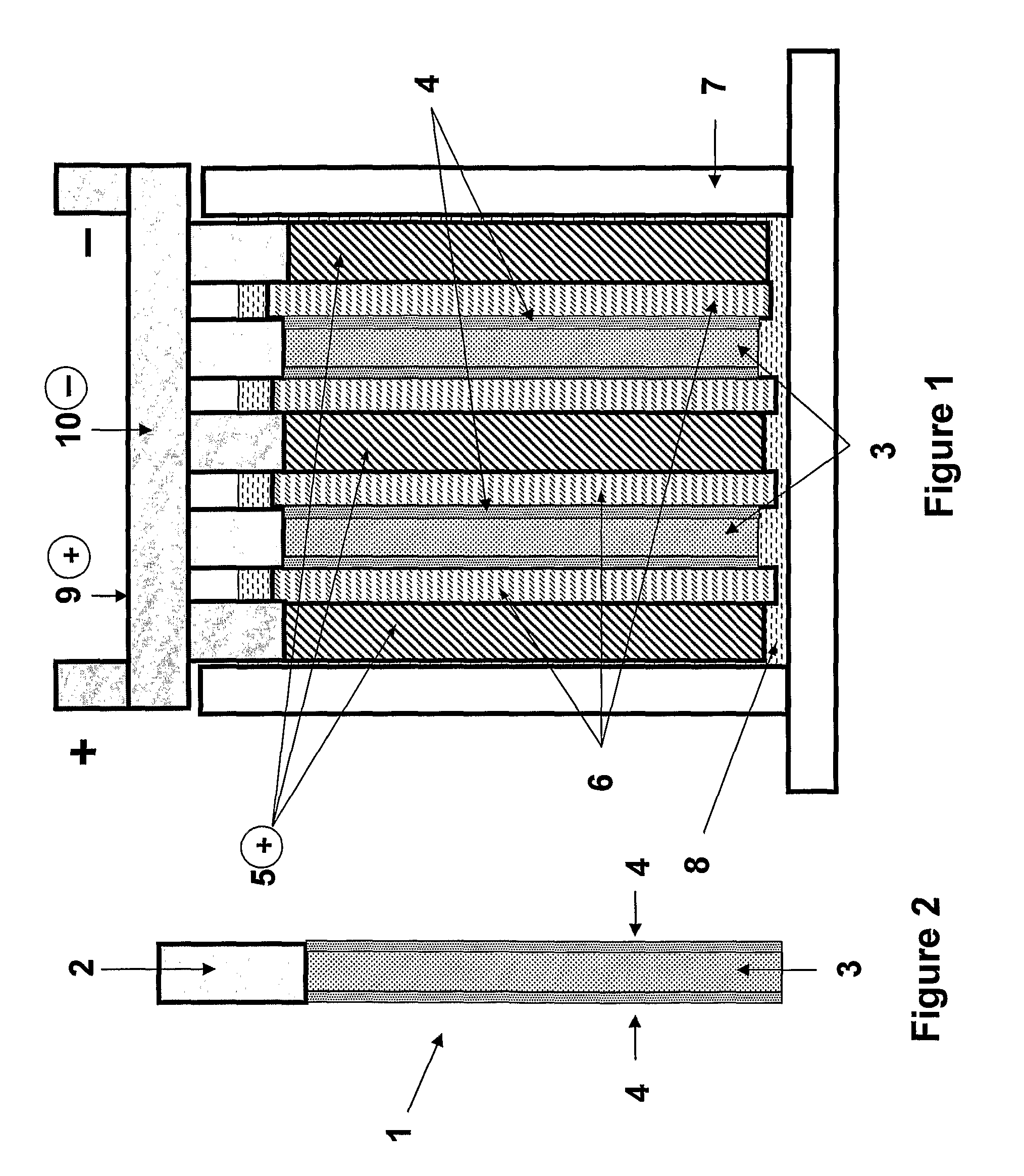

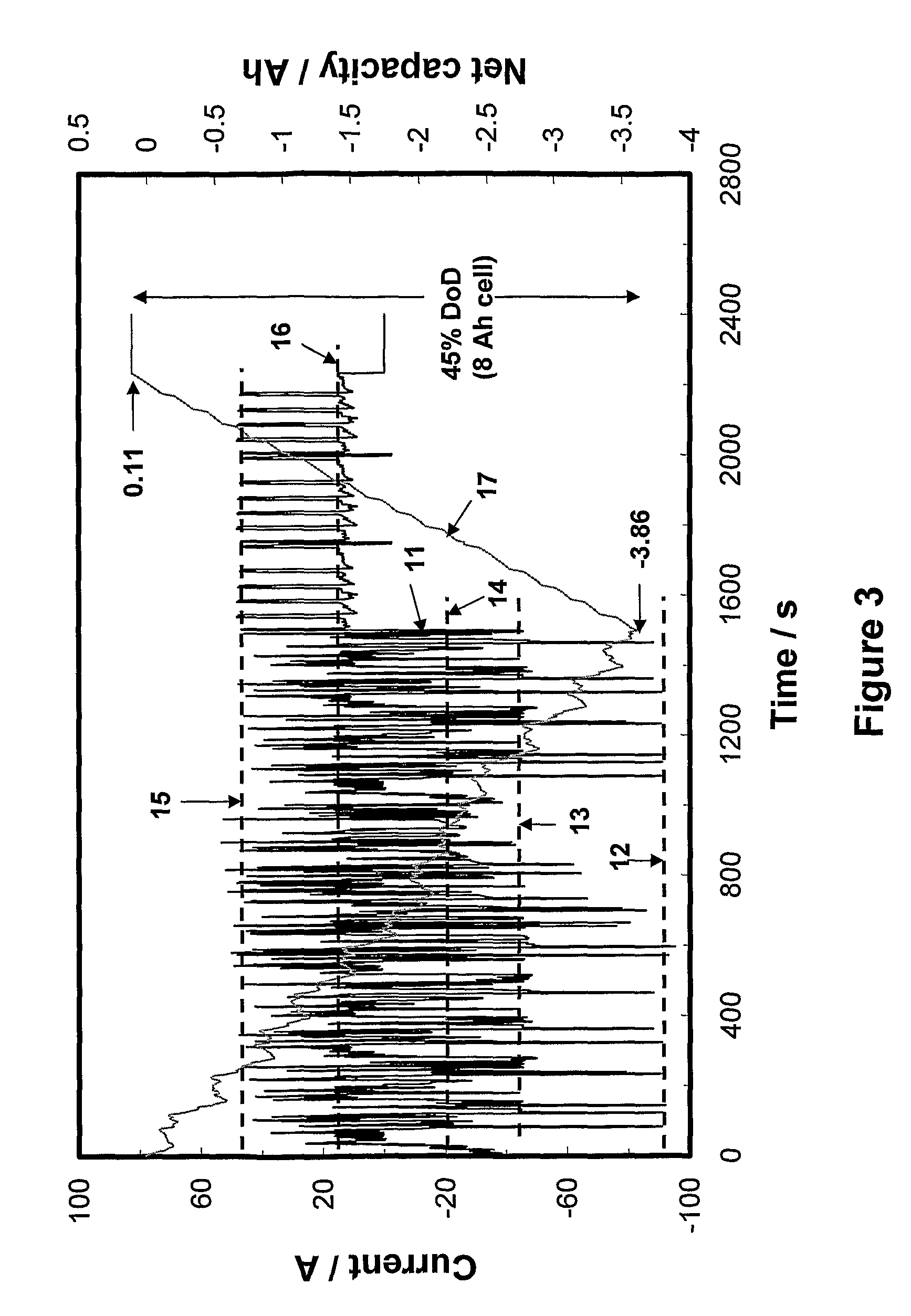

An energy storage device comprising at least one negative electrode, wherein each negative electrode is individually selected from (i) an electrode comprising negative battery electrode material; (ii) an electrode comprising capacitor electrode material; (iii) a mixed electrode comprising either—a mixture of battery and capacitor electrode material or—a region of battery electrode material and a region of capacitor electrode material, or—a combination thereof, and wherein the energy storage device either comprises at least one electrode of type (iii), or comprises at least one electrode of each of types (i) and (ii),—at least one positive electrode, wherein the positive electrode comprises positive battery electrode material and a charging ability-increasing additive, such as one or a mixture of: (a) carbon nanomaterial, vapour grown carbon fibre, fullerene, or a mixture thereof, and (b) tin dioxide conductive materials.

Owner:COMMONWEALTH SCI & IND RES ORG +1

Electrode composite, battery electrode formed from said composite, and lithium battery comprising such an electrode

InactiveUS20110163274A1Improve cycle stabilityGood dispersionMaterial nanotechnologyNon-metal conductorsElectrical batteryCarbon nanofiber

An electrode composite and to its manufacturing process. The composite includes an active element, i.e. one exhibiting electrochemical activity, a conductive additive and a binder. The conductive additive is a mixture of conductive additives containing at least carbon nanofibres (CNFs) and at least carbon nanotubes (CNTs). Also, the negative electrodes for electrochemical devices of the lithium battery type including said composite and to the secondary (Li-ion) batteries provided with such a negative electrode.

Owner:ARKEMA FRANCE SA +1

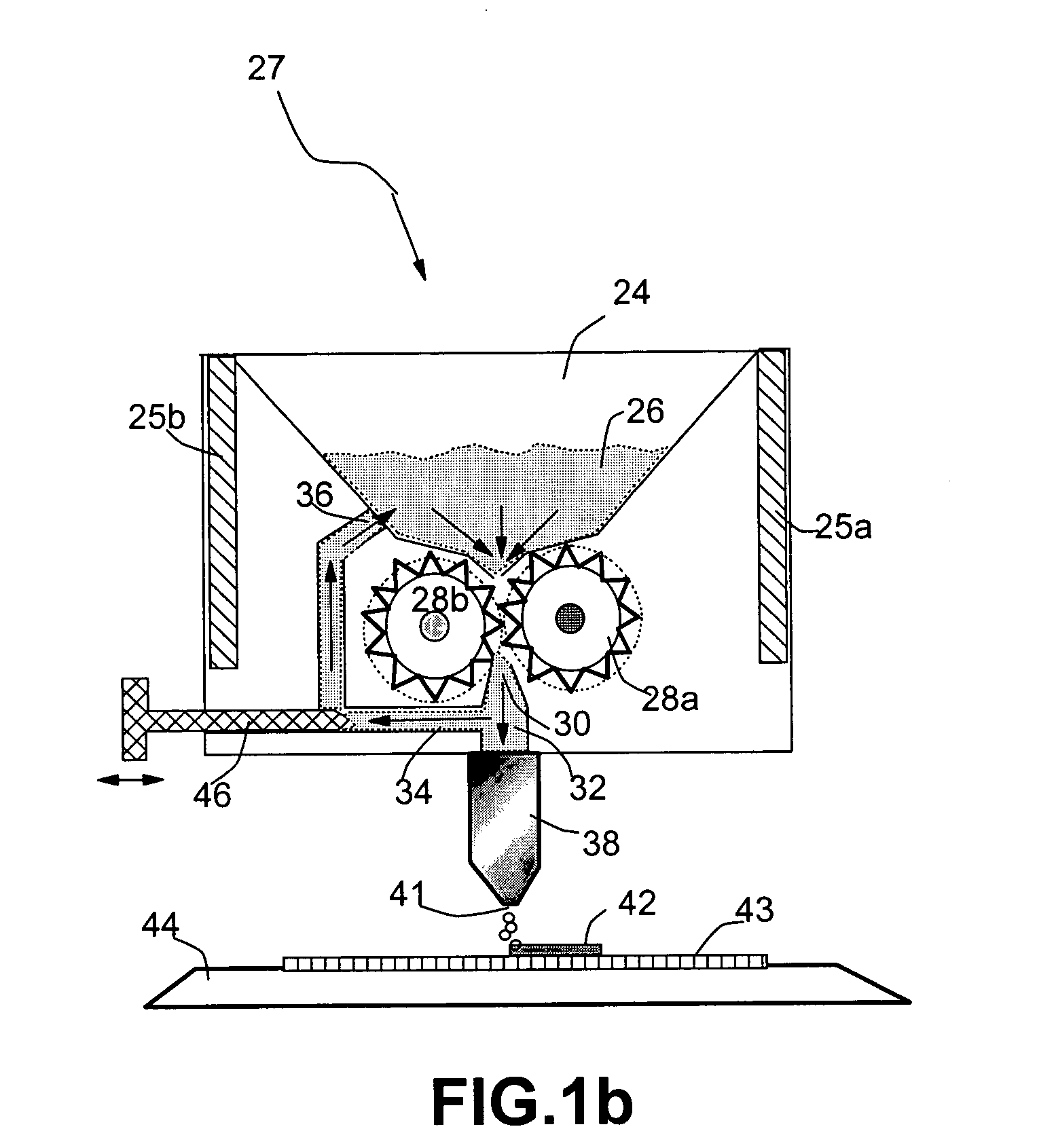

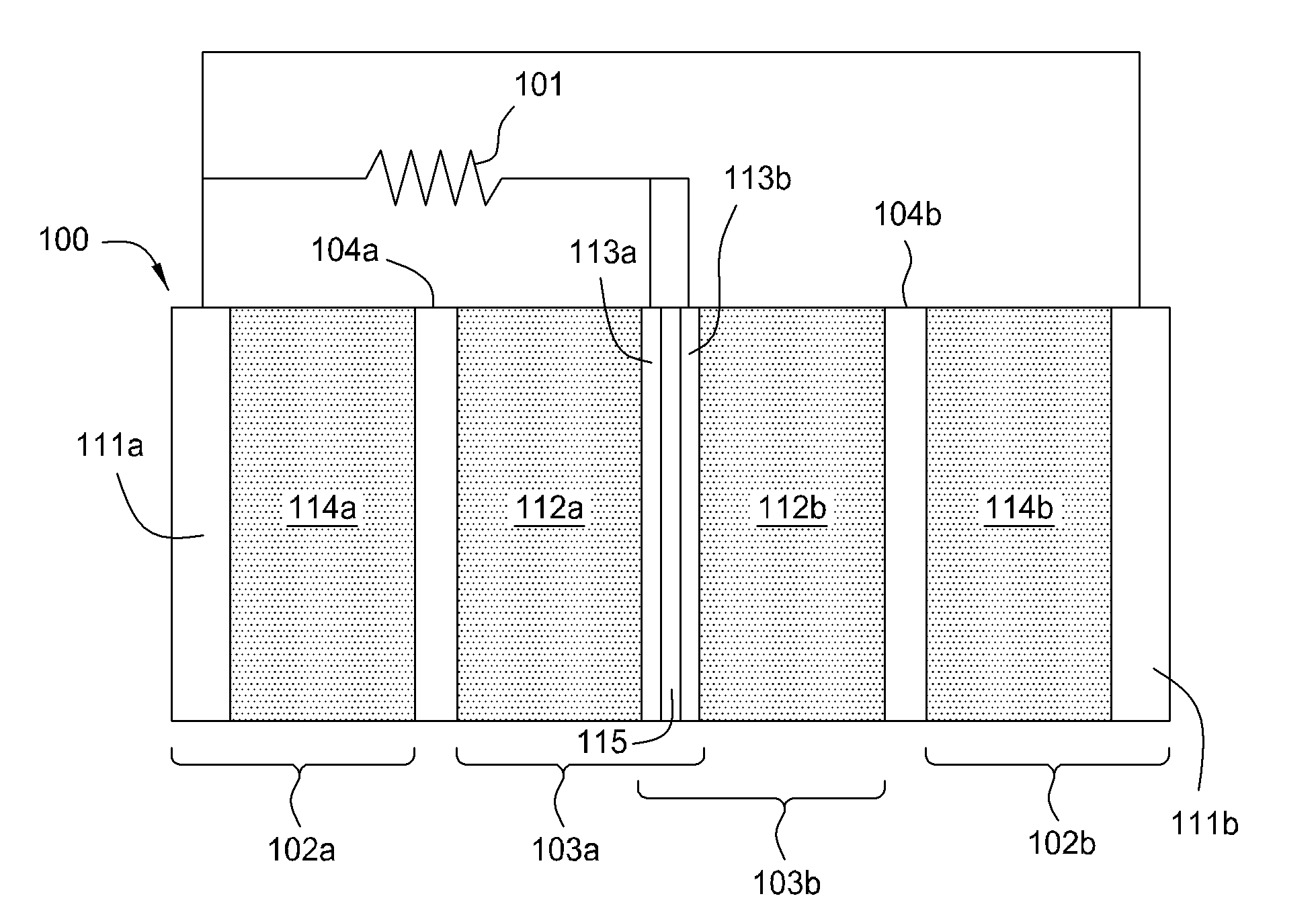

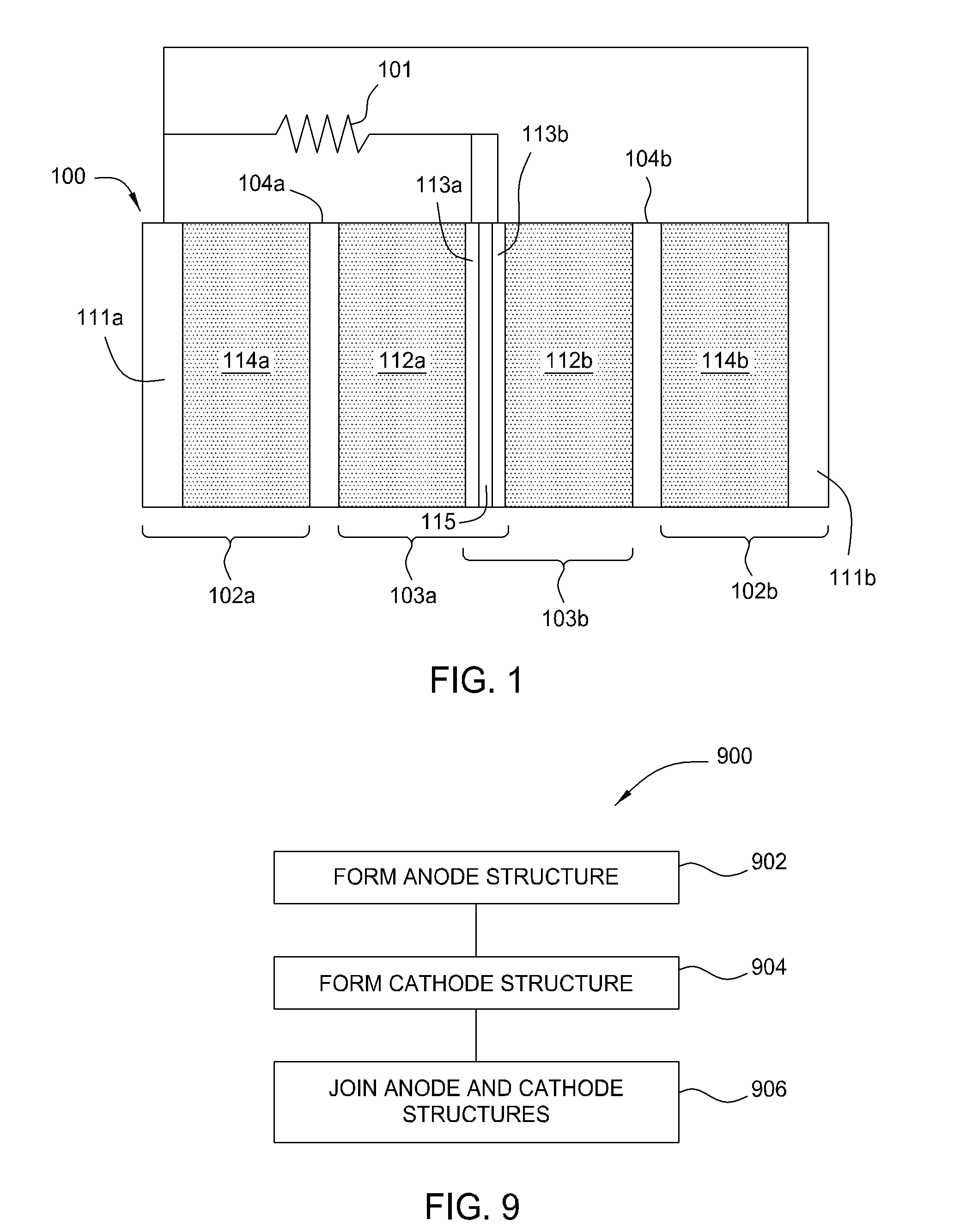

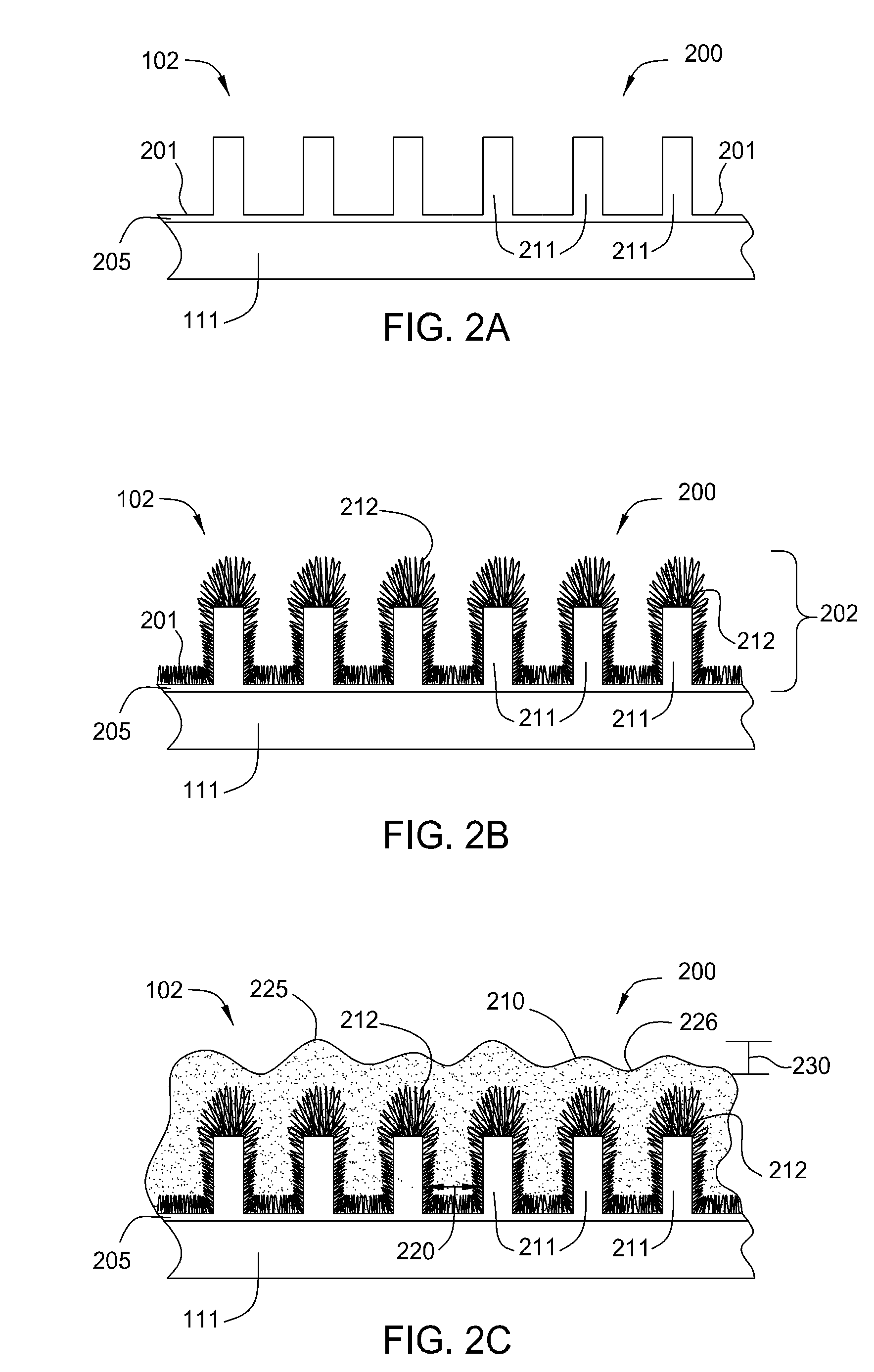

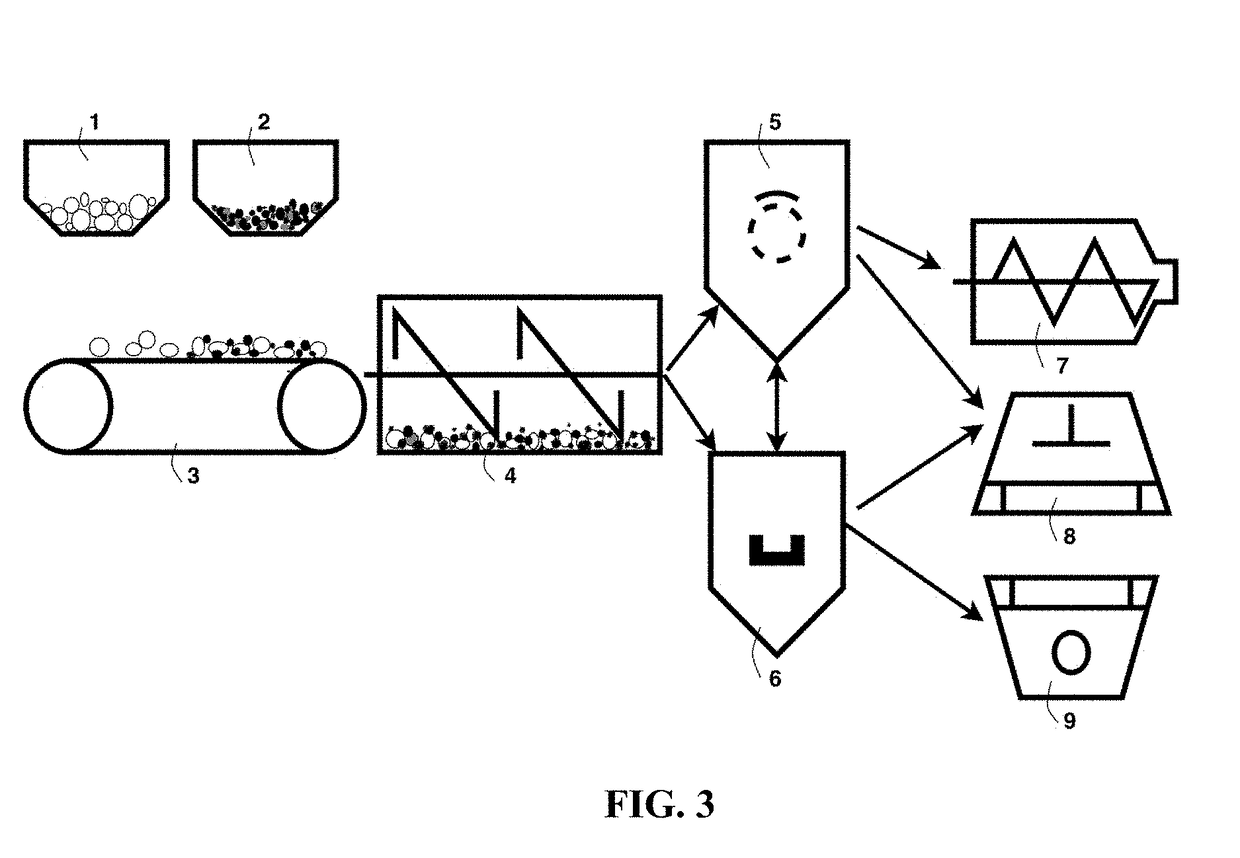

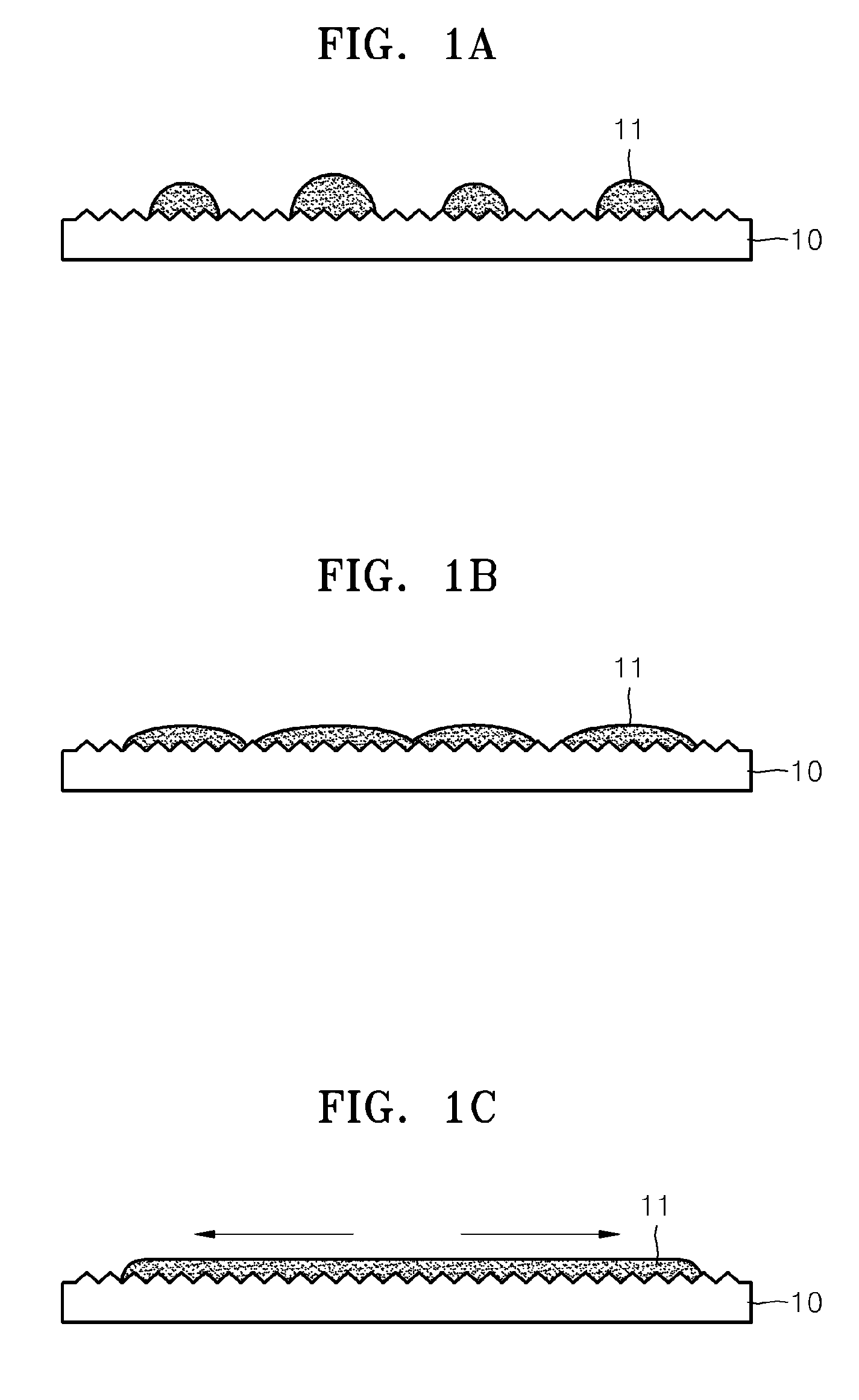

Compressed powder 3D battery electrode manufacturing

Embodiments of the invention contemplate forming an electrochemical device and device components, such as a battery cell or supercapacitor, using thin-film or layer deposition processes and other related methods for forming the same. In one embodiment, a battery bi-layer cell is provided. The battery bi-layer cell comprises an anode structure comprising a conductive collector substrate, a plurality of pockets formed on the conductive collector substrate by conductive microstructures comprising a plurality of columnar projections, and an anodically active powder deposited in and over the plurality of pockets, an insulative separator layer formed over the plurality of pockets, and a cathode structure joined over the insulative separator.

Owner:APPLIED MATERIALS INC

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

Battery electrode structure and method for manufacture thereof

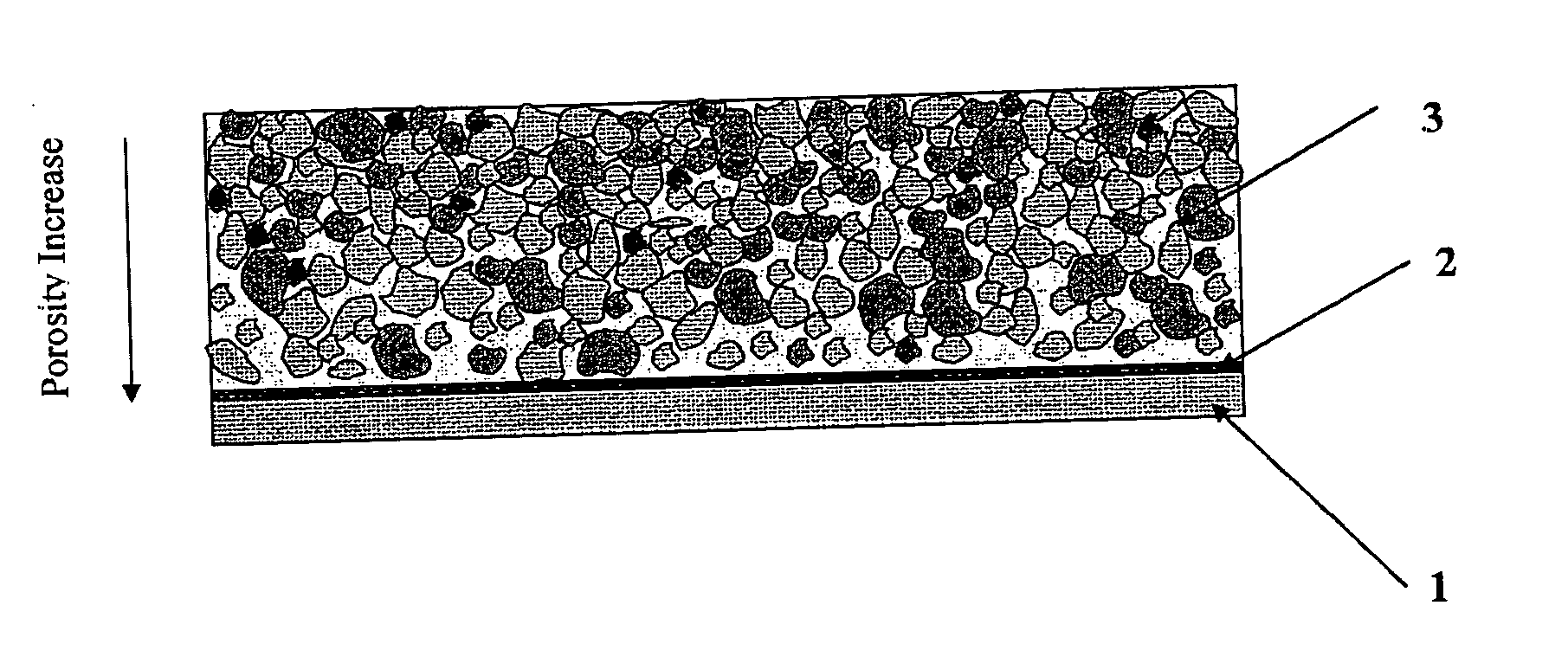

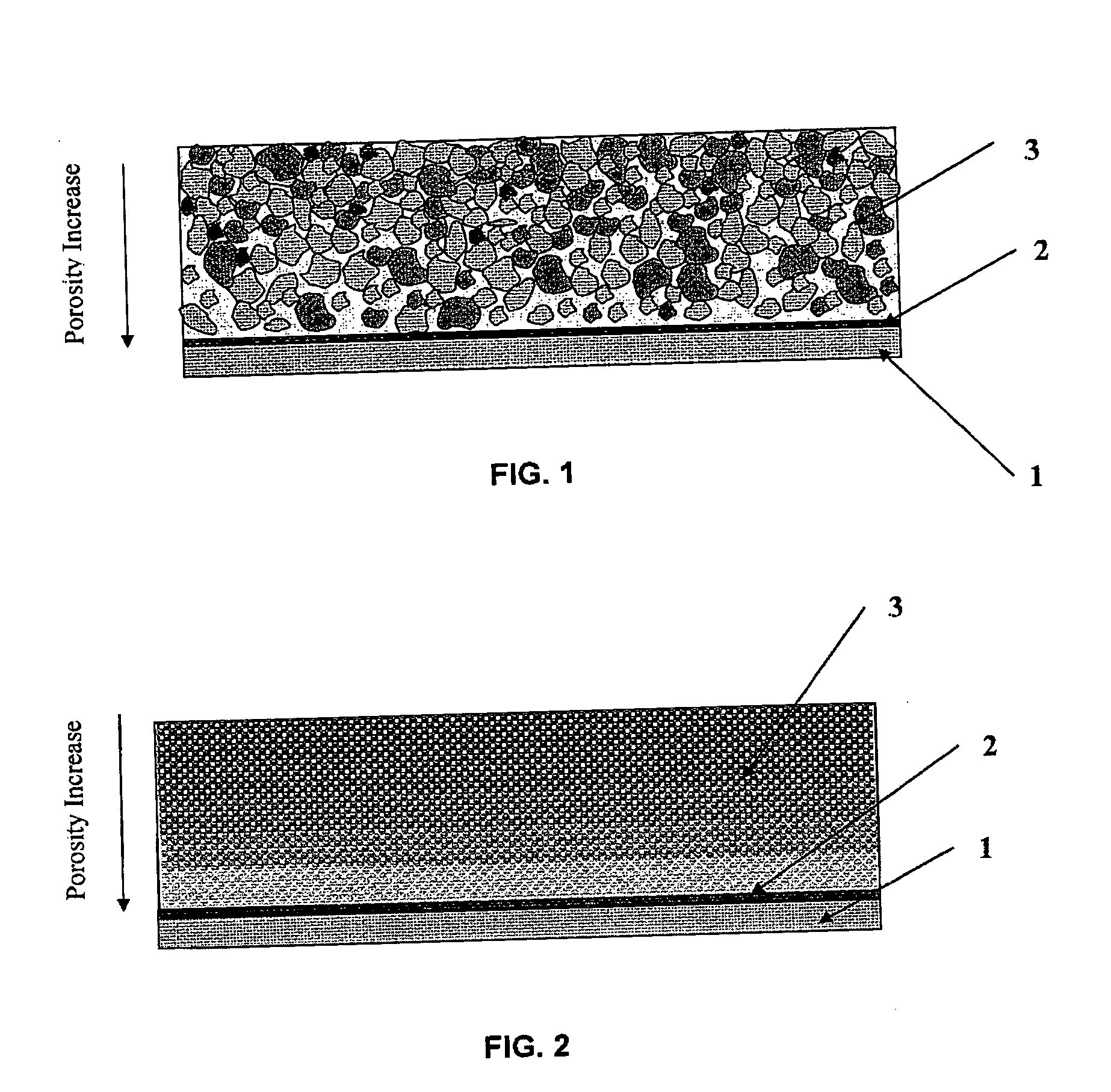

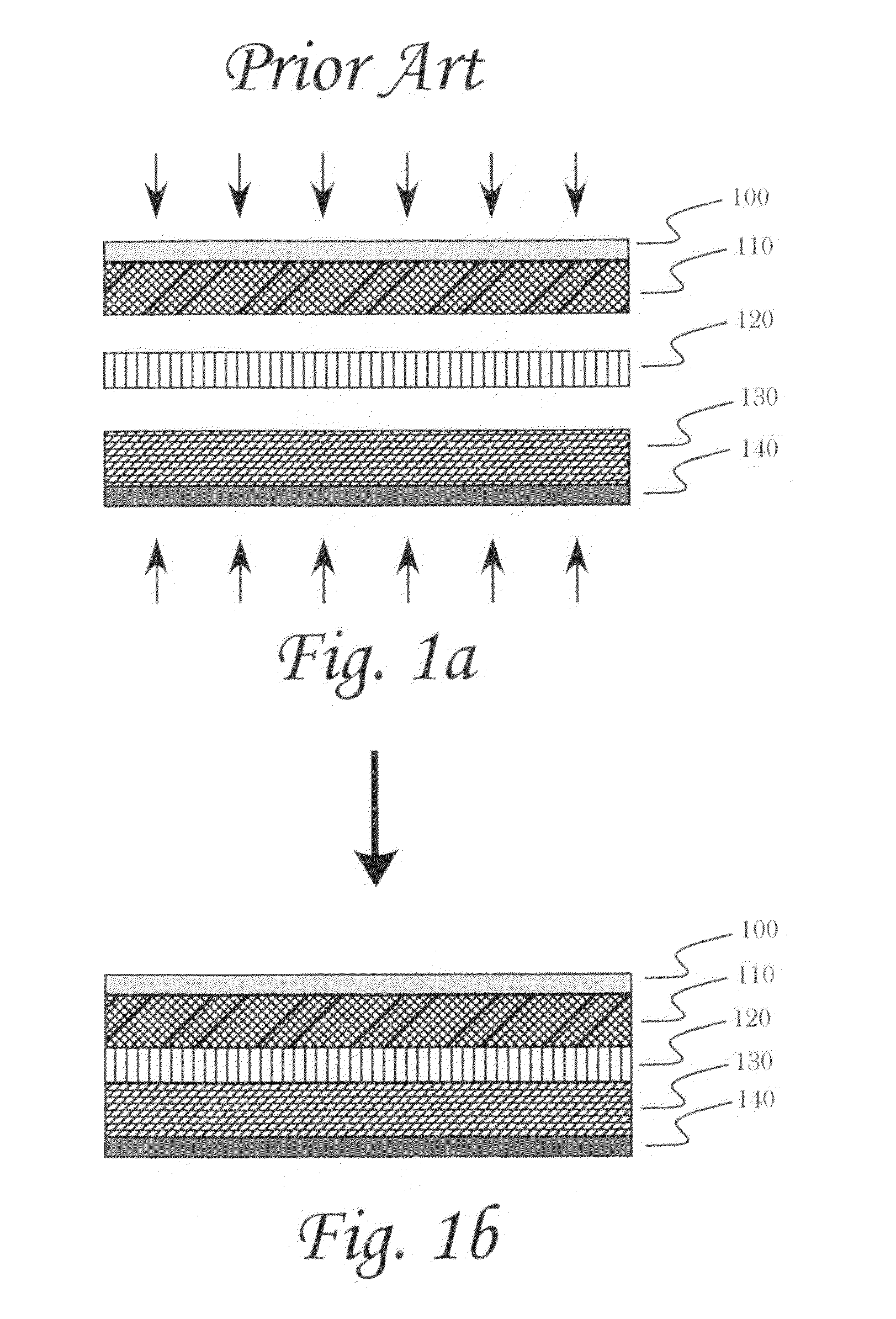

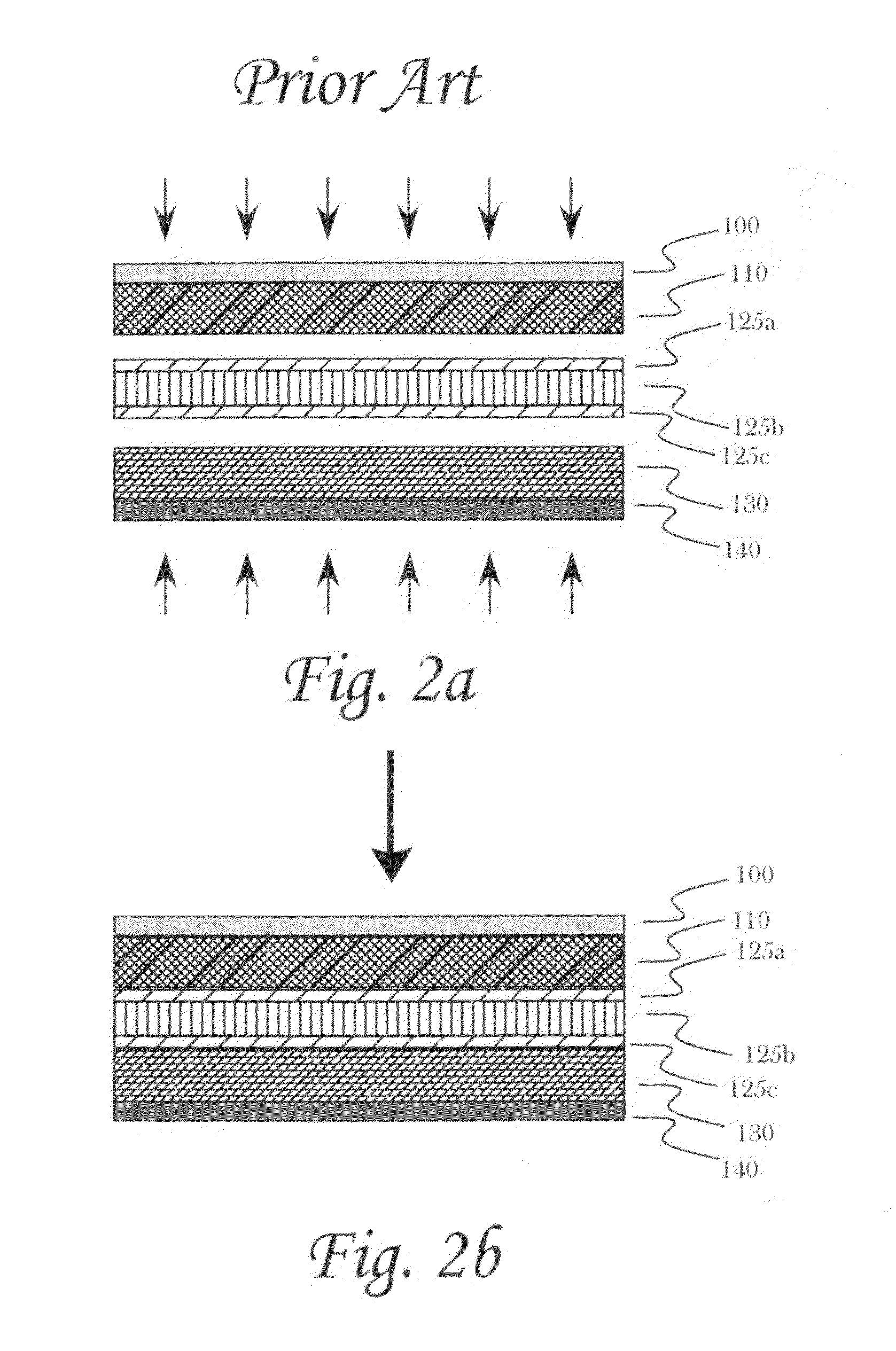

InactiveUS20060024579A1Increase energy densityReduce porositySecondary cellsActive material electrodesPorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional election conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure may be characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in for example chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:OXIS ENERGY

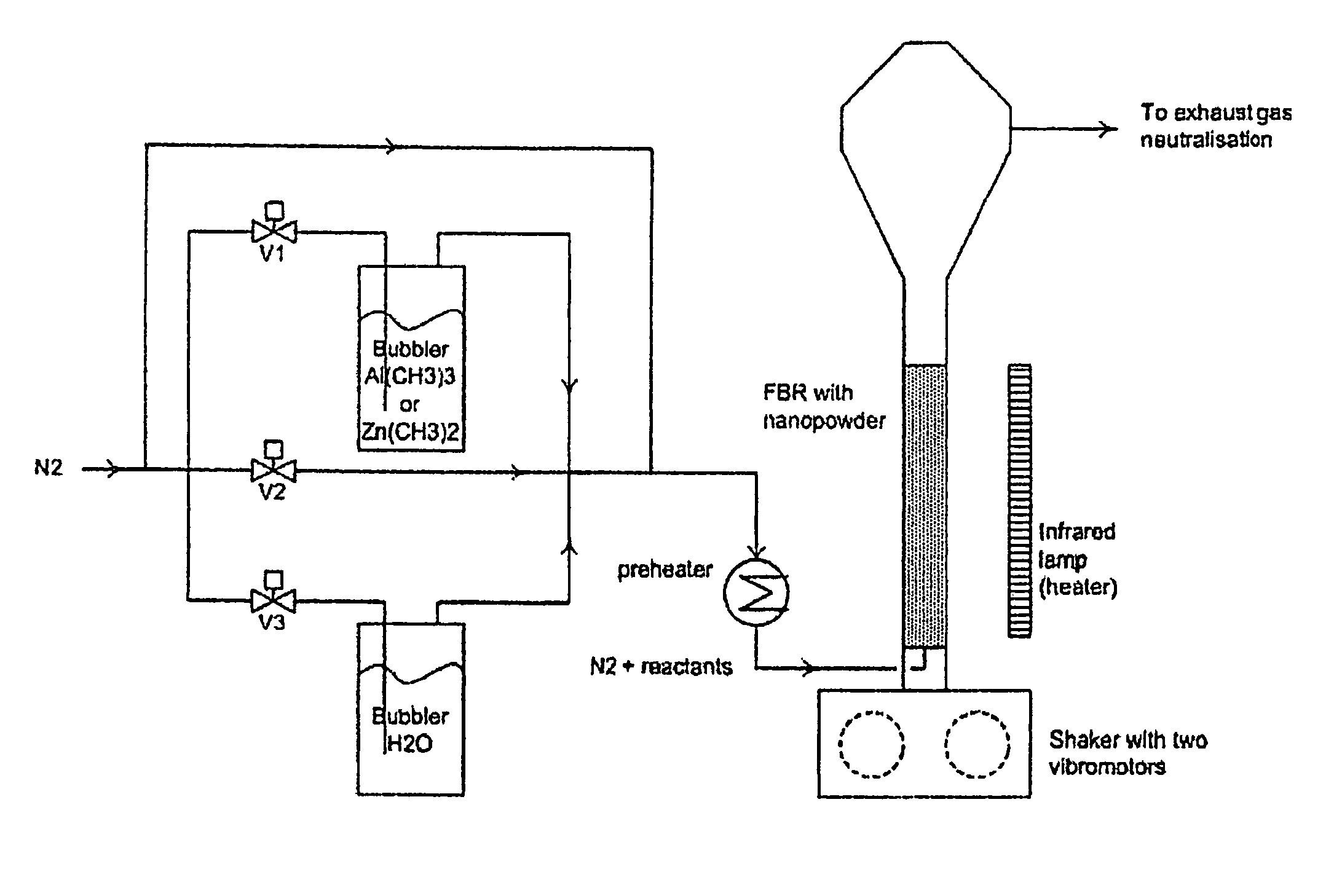

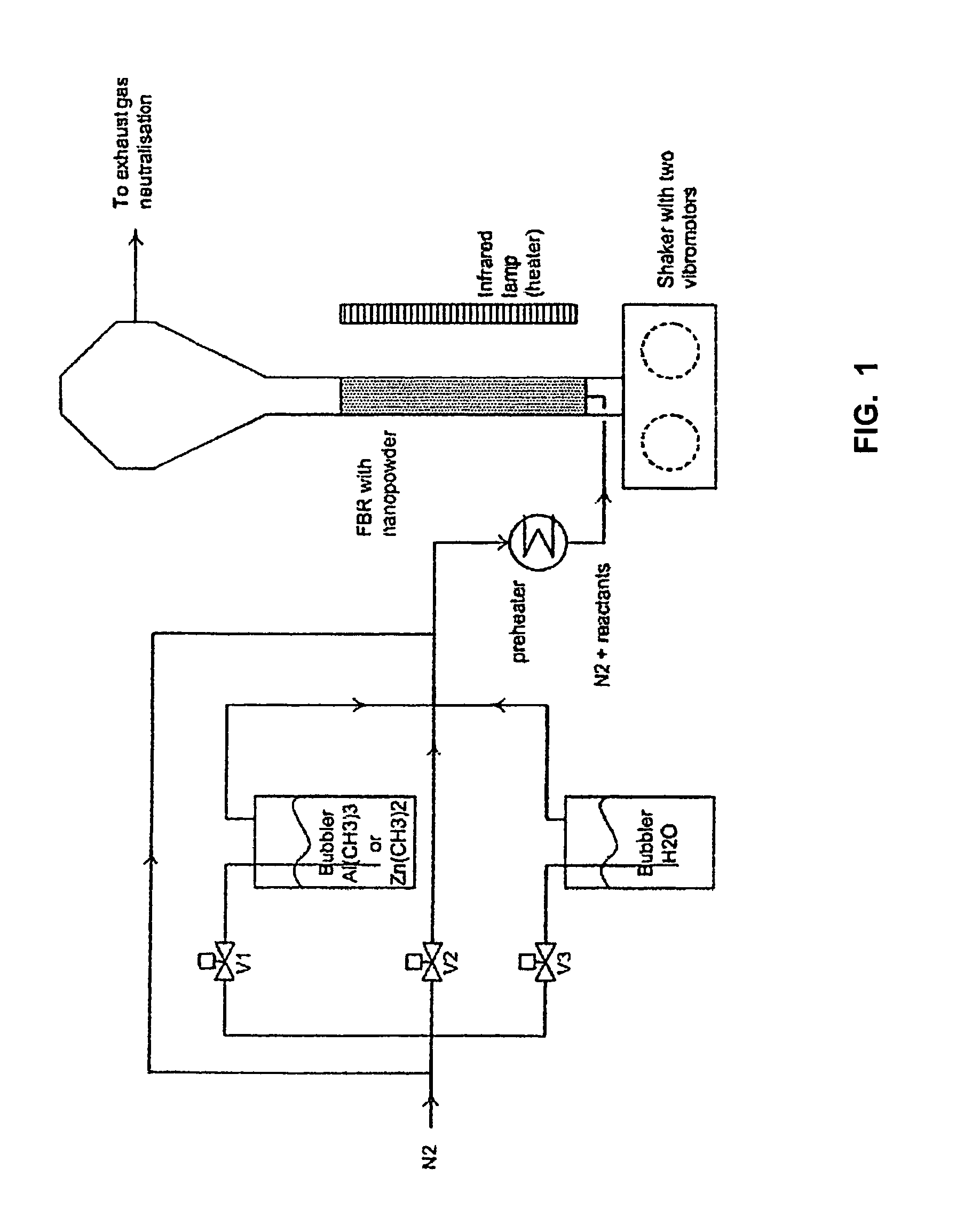

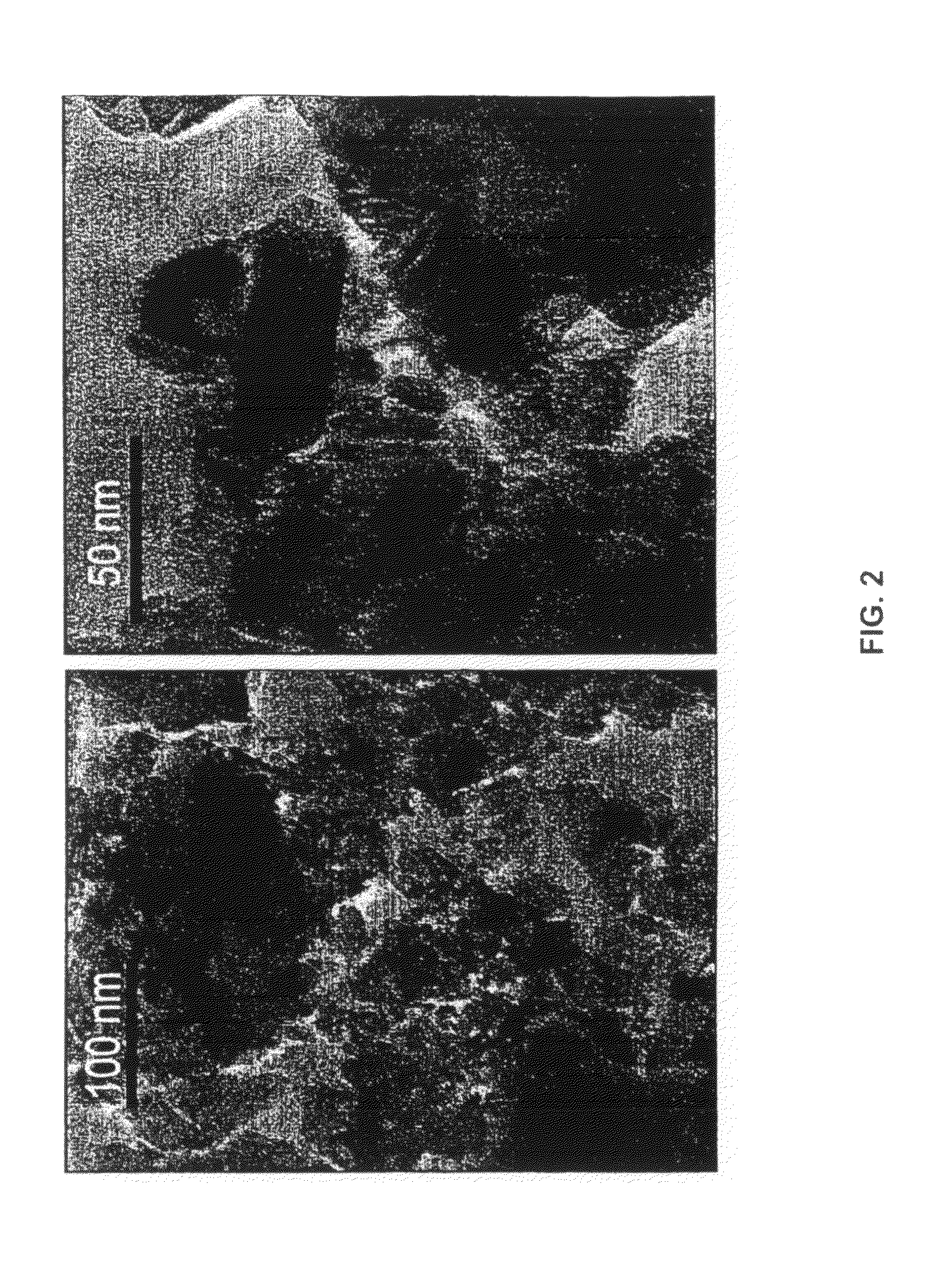

Method for covering particles, especially a battery electrode material particles, and particles obtained with such method and a battery comprising such particle

A method for covering particles having a diameter of maximally 60 μm by means of atomic layer deposition, whereby said method comprises the step of fluidizing said particles in a fluidized bed reactor using a first reactant gas comprising a first reactant for substantially completely covering said particles with a monolayer of said first reactant.

Owner:PNEUMATICOAT TECH LLC

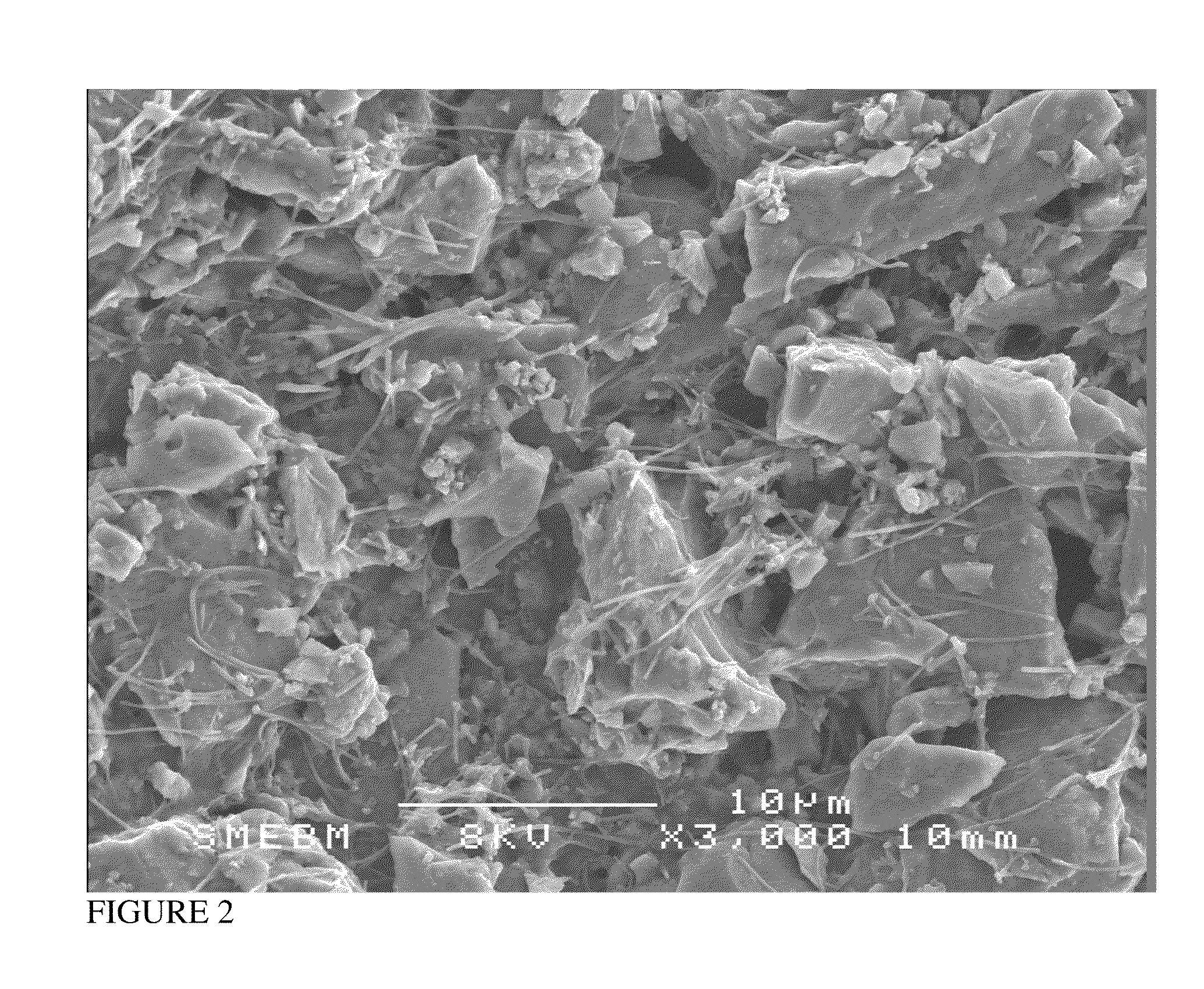

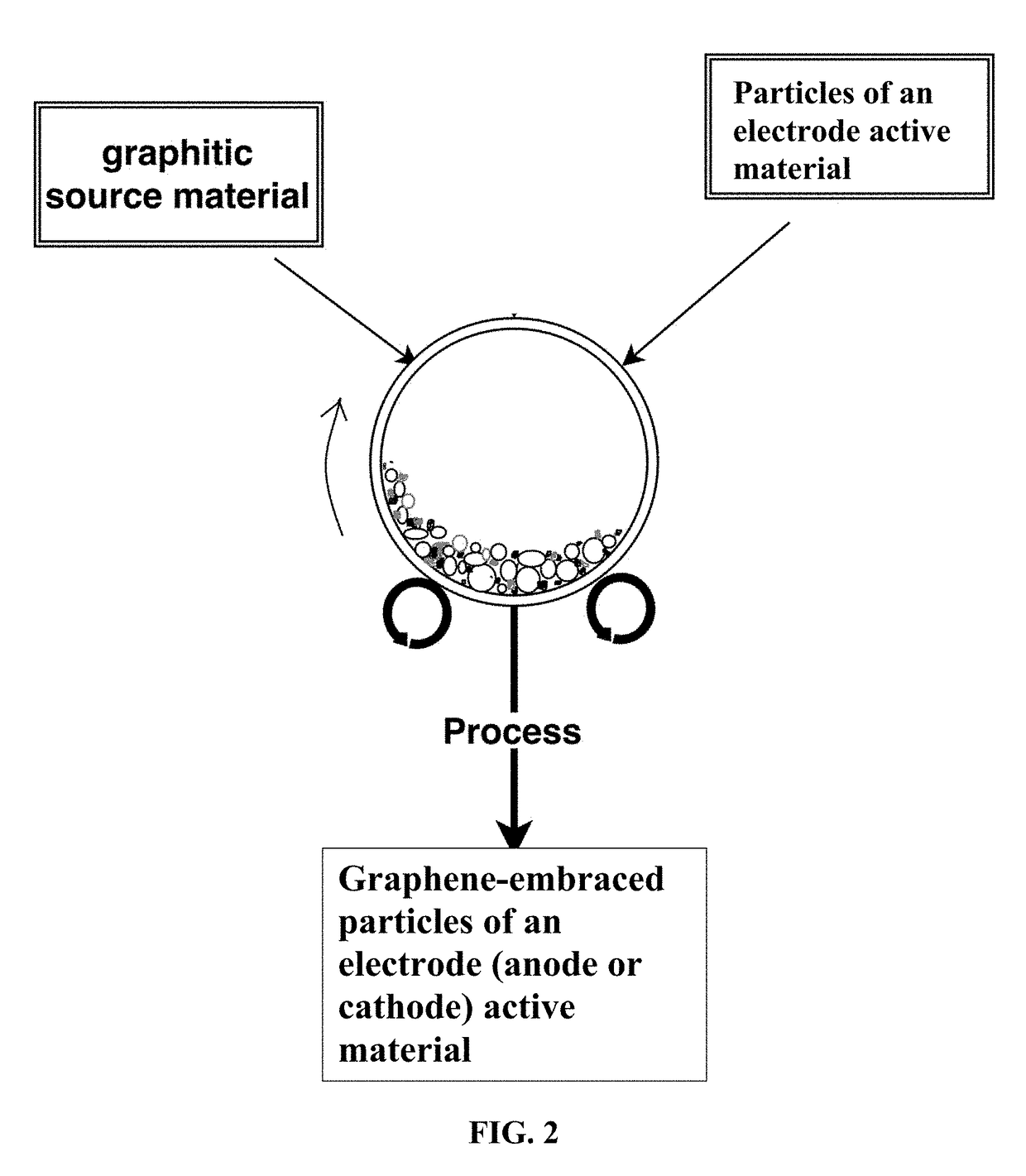

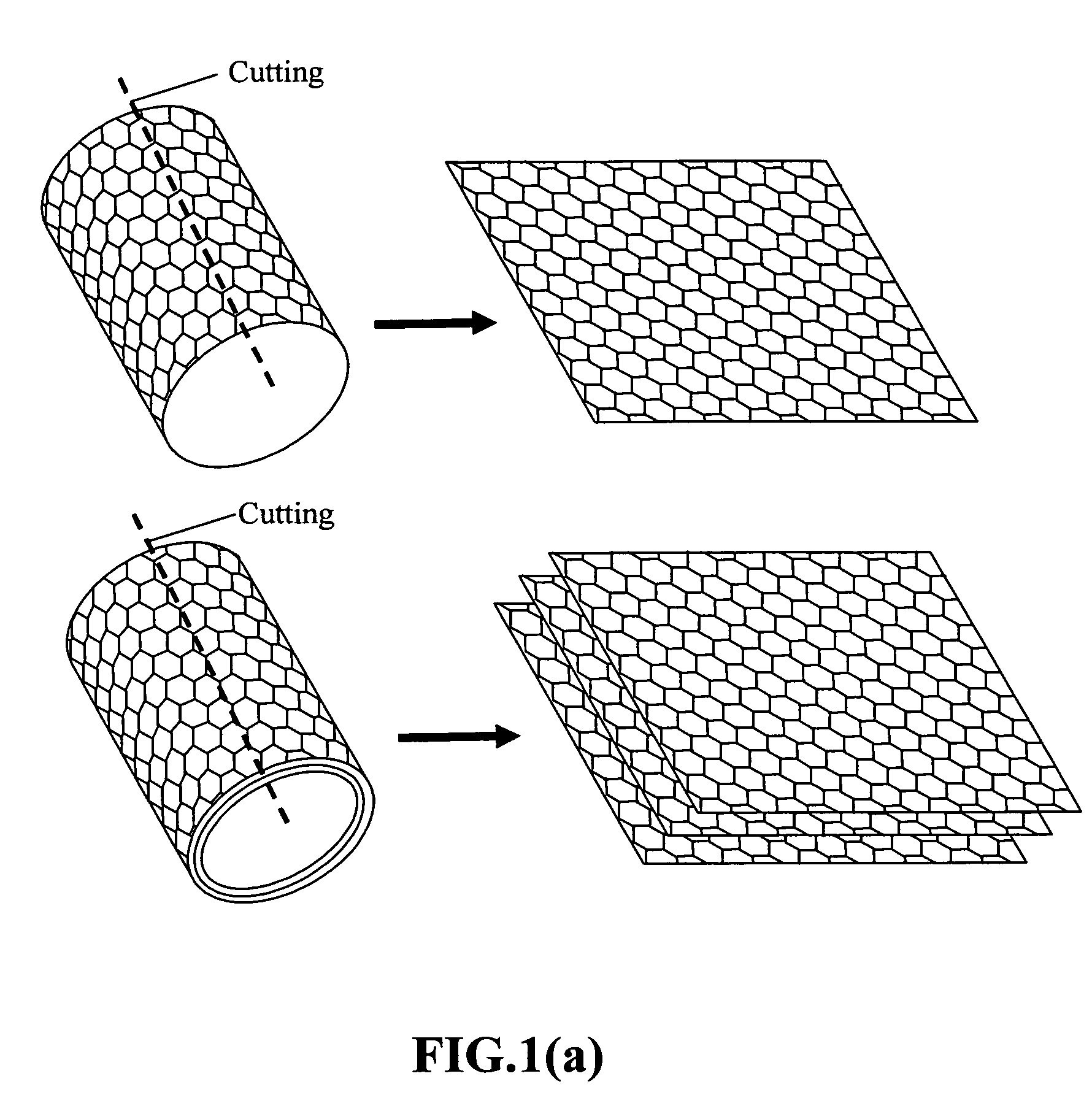

Chemical-Free Production of Graphene-Encapsulated Electrode Active Material Particles for Battery Applications

ActiveUS20170338472A1Improve mechanical propertiesImprove thermal conductivityGrapheneNegative electrodesEnergy impactGraphite

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles and multiple particles of a solid electrode active material to form a mixture in an impacting chamber of an energy impacting apparatus, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets and no ball-milling media; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for transferring graphene sheets from the graphitic material to surfaces of electrode active material particles to produce graphene-embraced electrode active material particles; and c) recovering the particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:GLOBAL GRAPHENE GRP INC

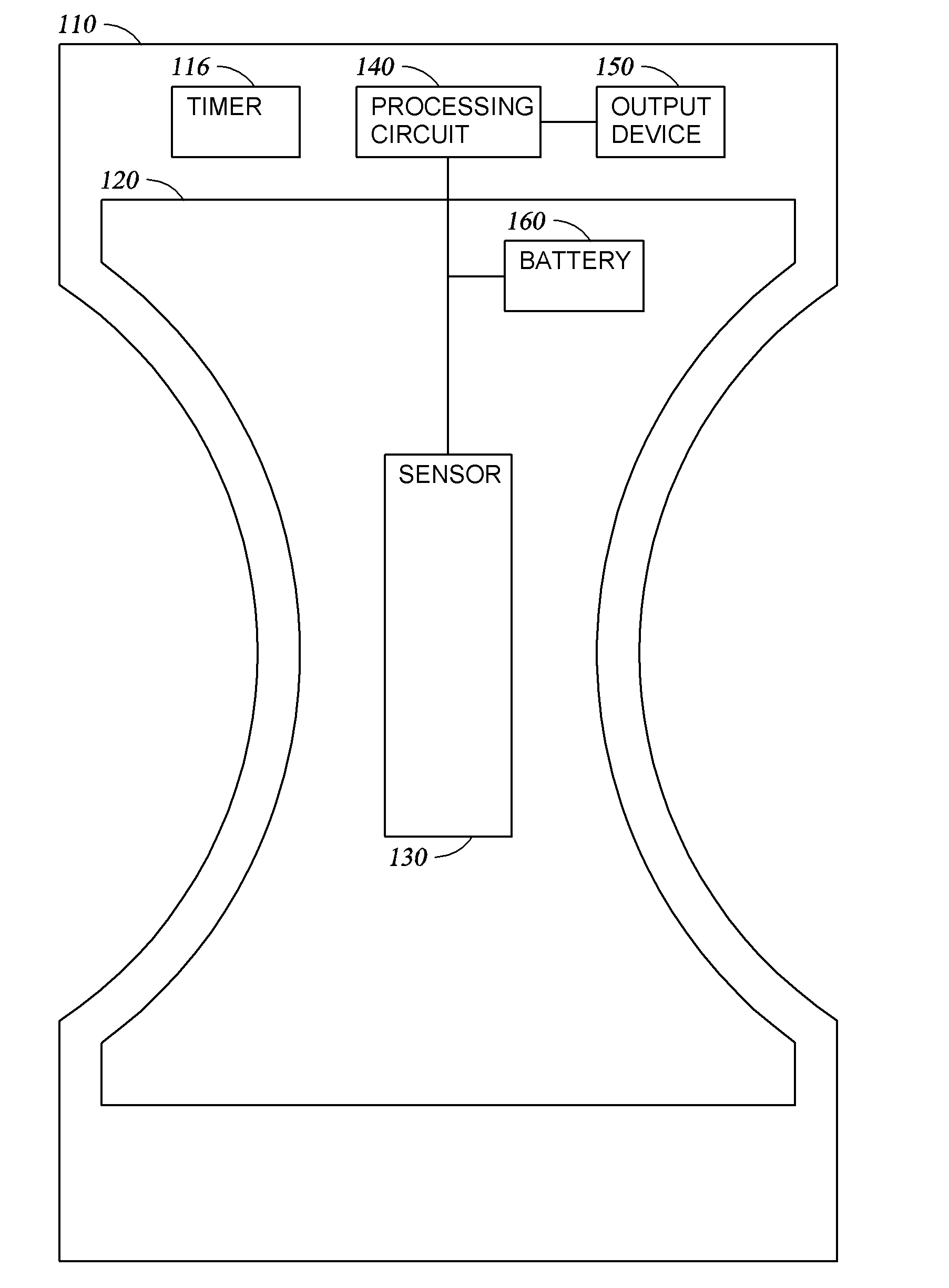

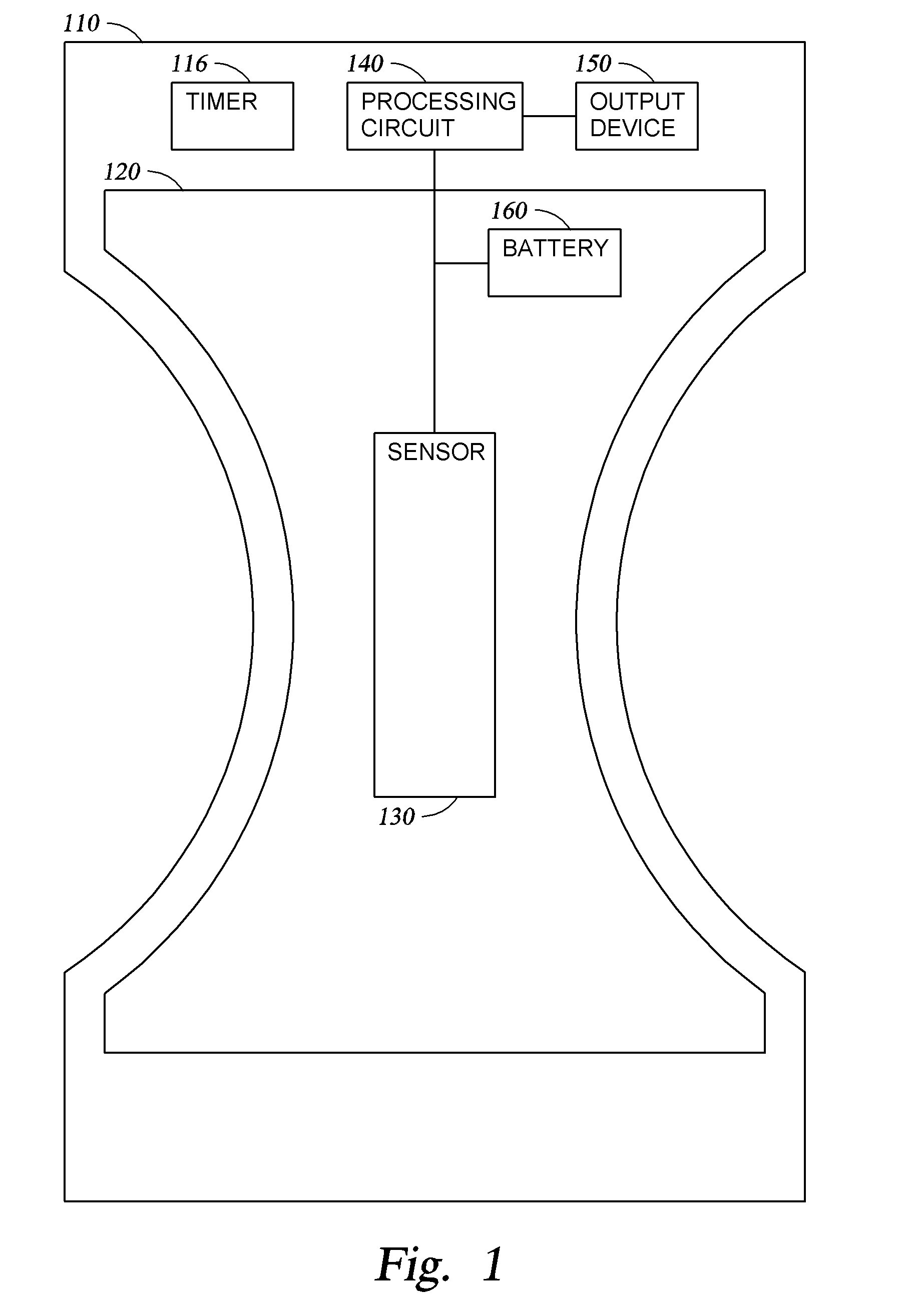

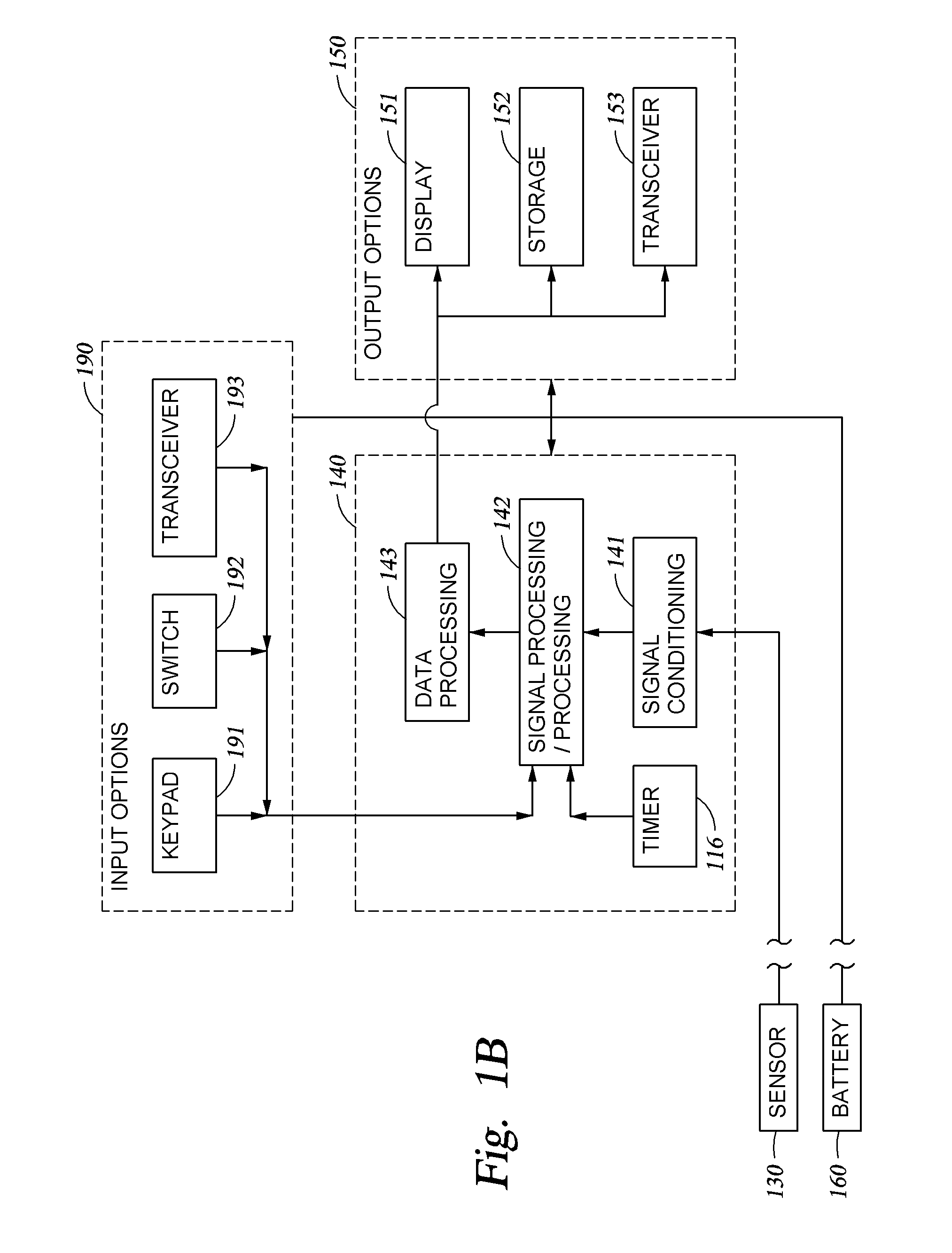

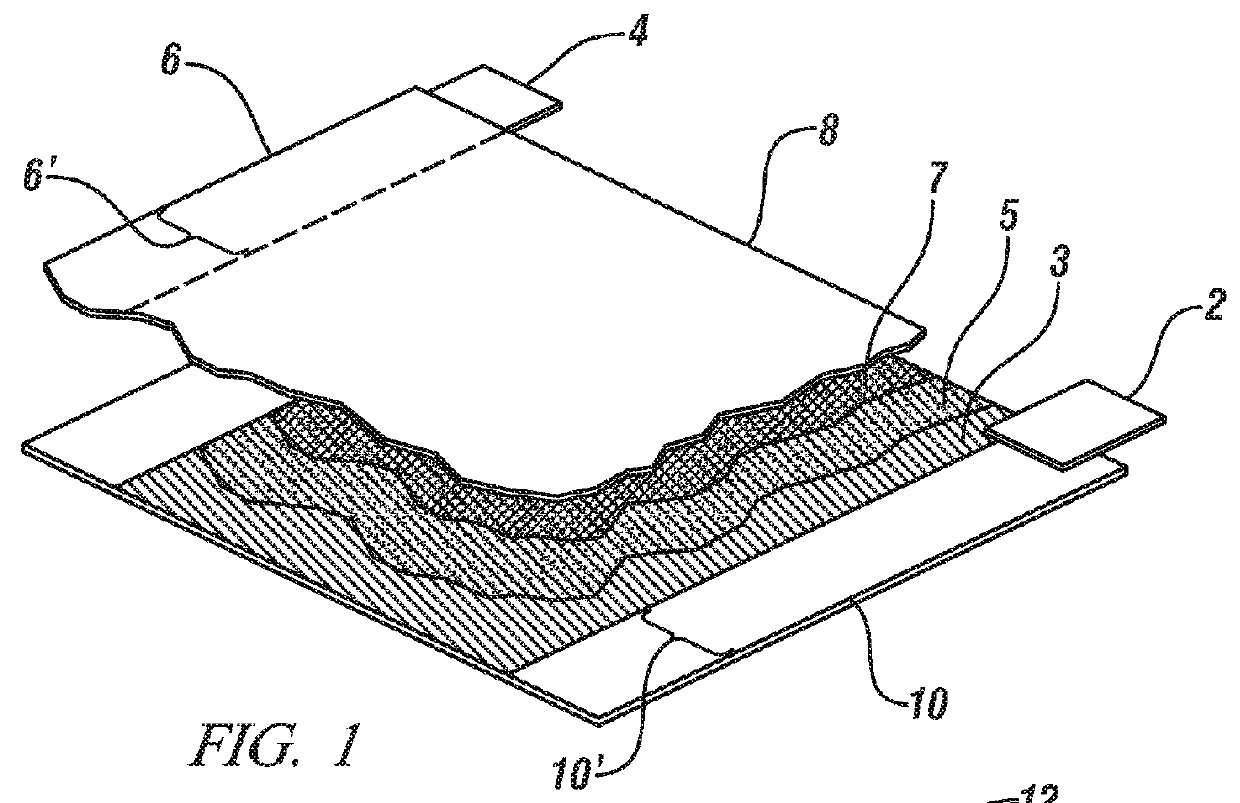

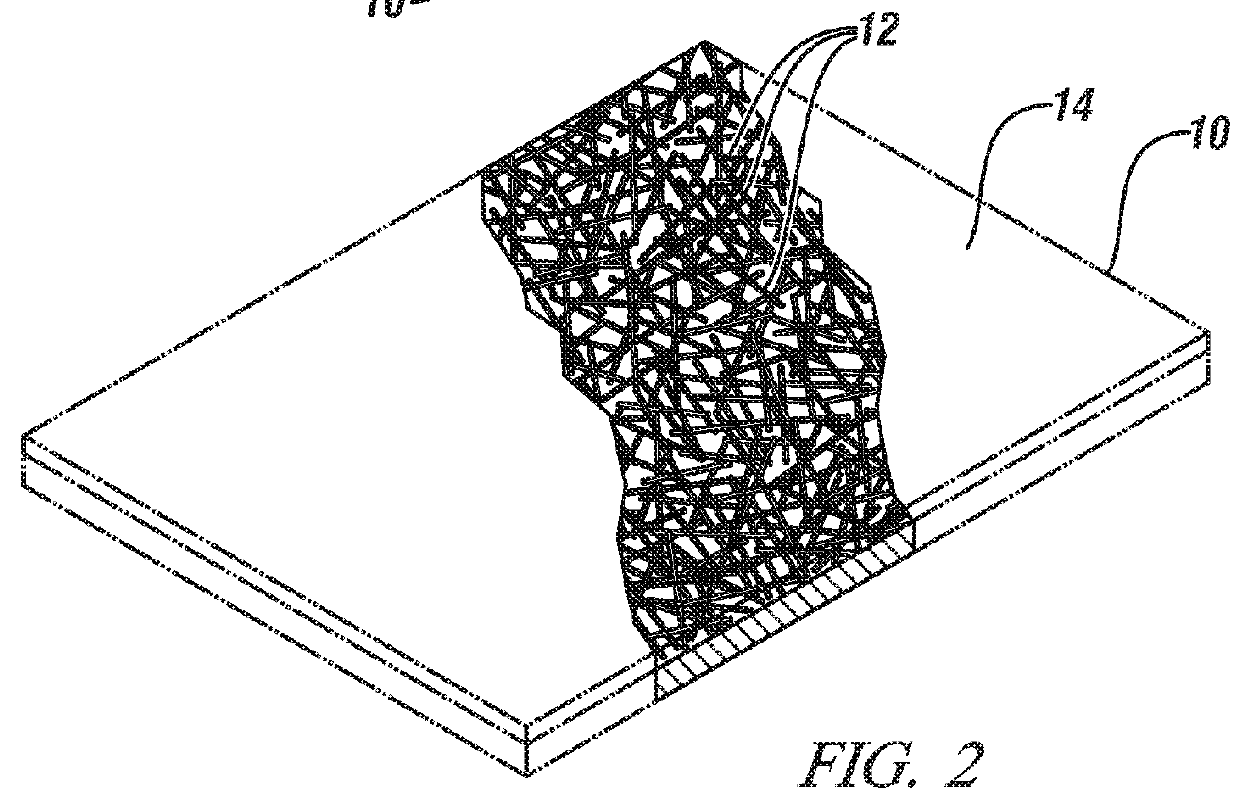

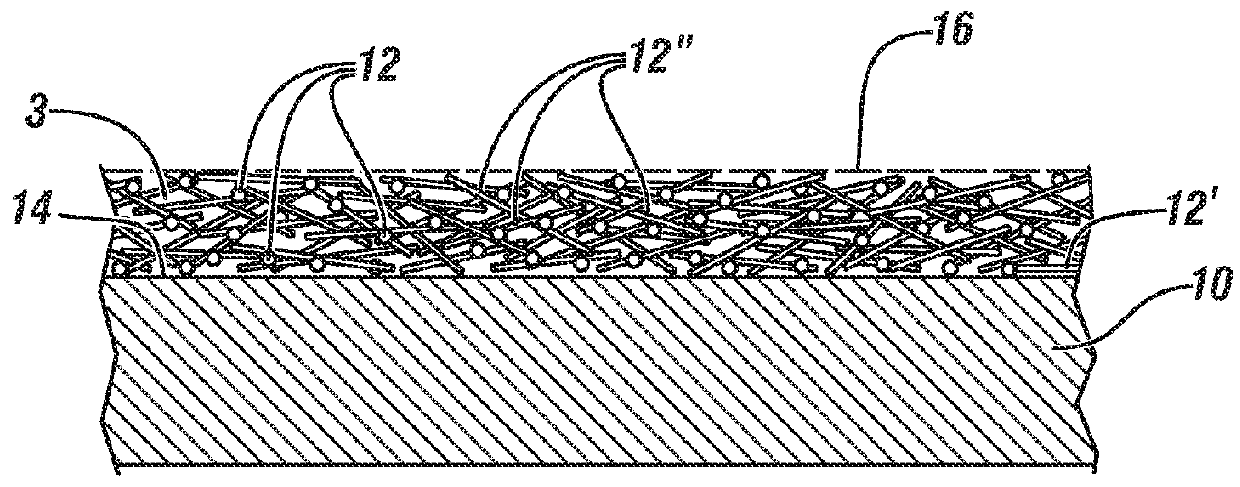

Sensors and disposable articles that contain the sensors

Embodiments of the invention provide a sensor for detecting the presence of fluid in an absorbent article. The sensor may include a fluid activated battery. Fluid received in the absorbent article may connect electrodes of the fluid activated battery and cause a voltage to be generated between battery electrodes. The voltage generated between the electrodes may provide power to the sensor circuit. In one embodiment, the fluid activated battery may be configured to detect the presence of fluid in the absorbent article and the presence and / or amount of particular substances in the received fluid.

Owner:KIMBERLY-CLARK WORLDWIDE INC

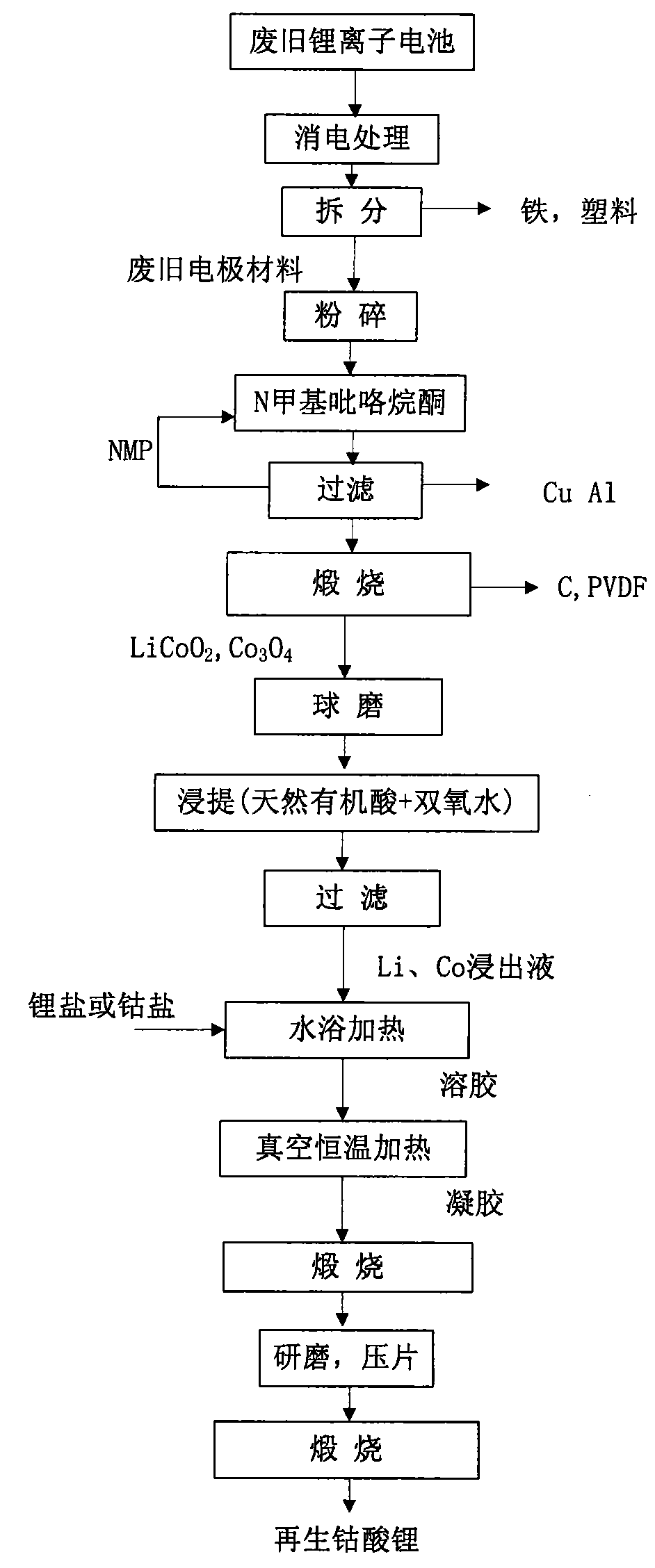

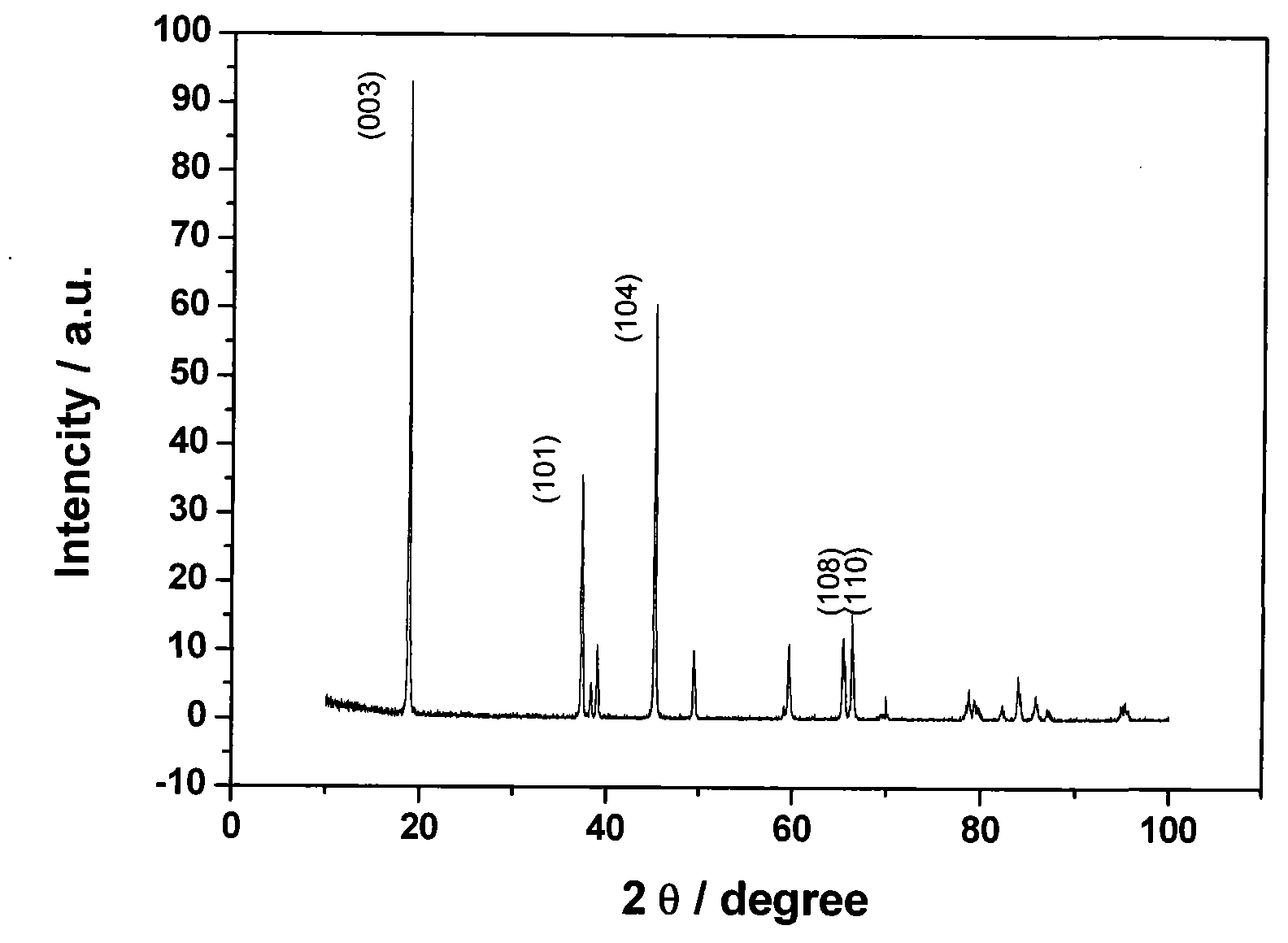

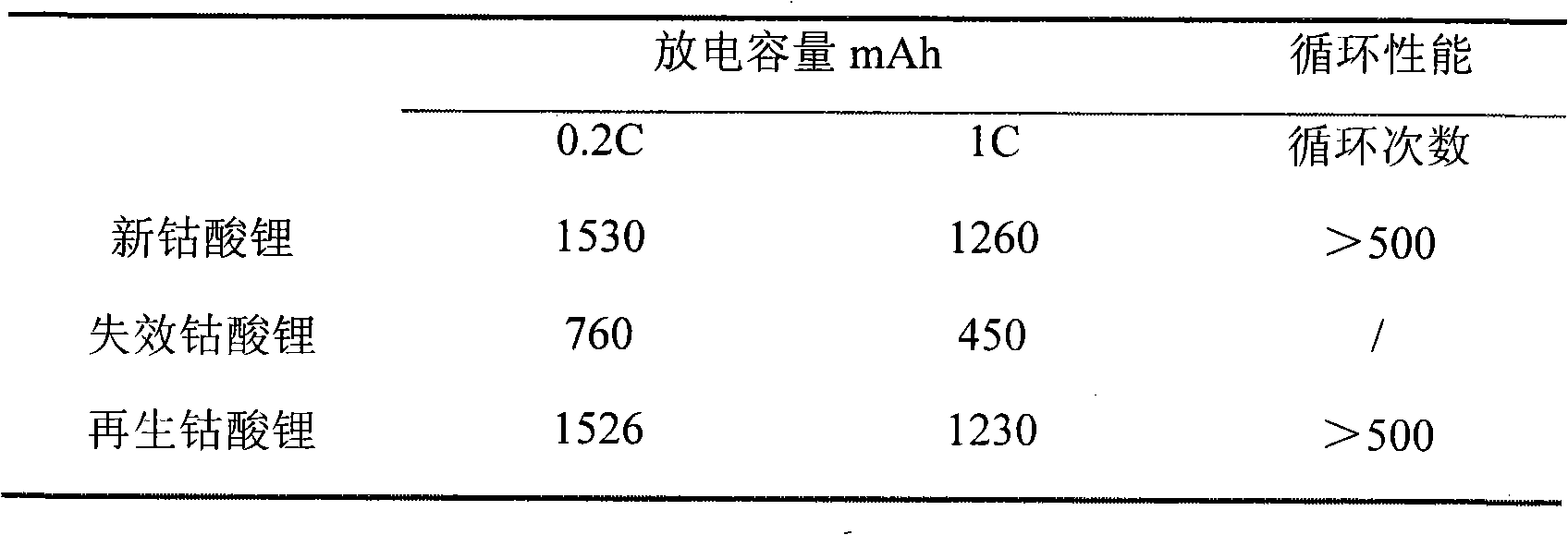

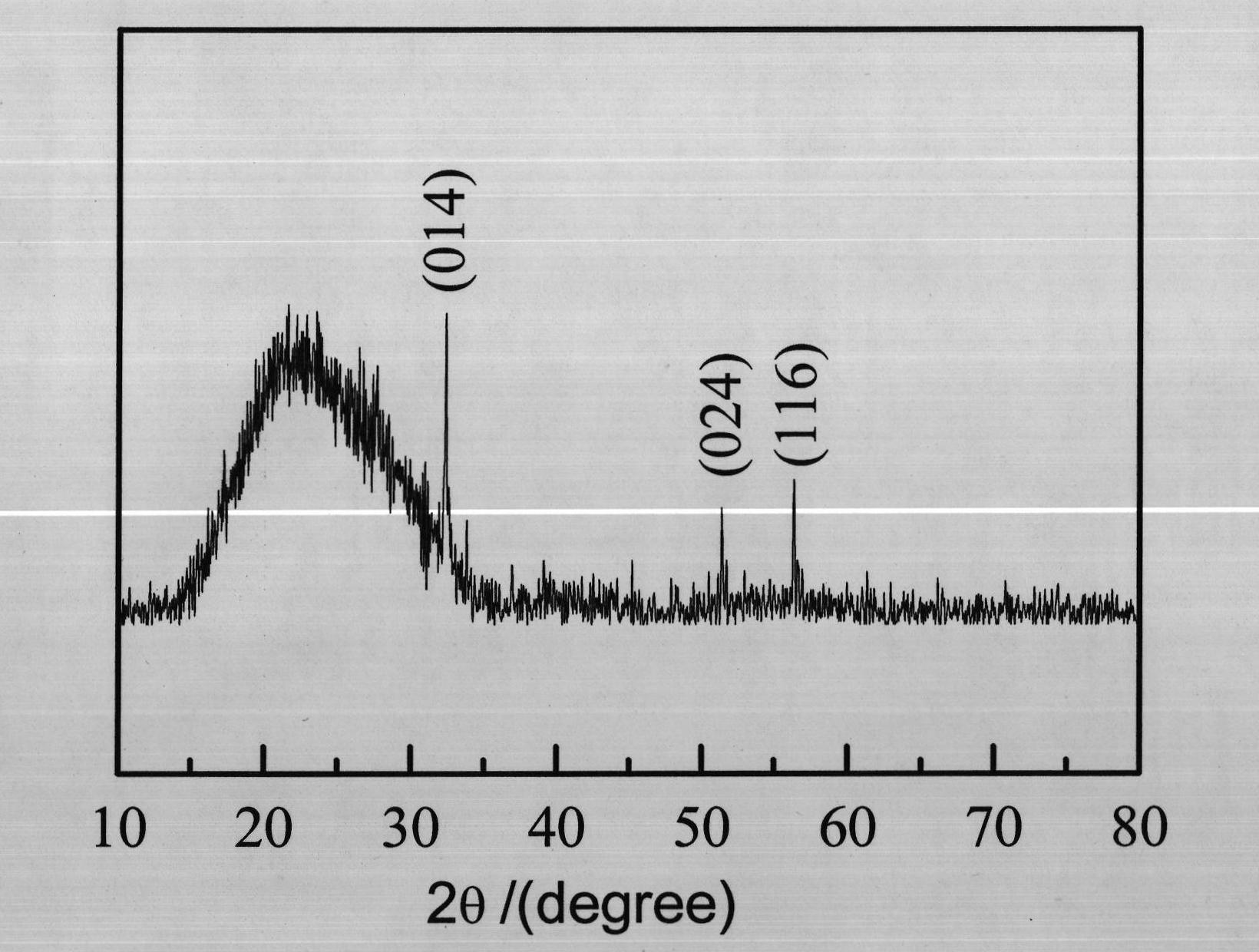

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

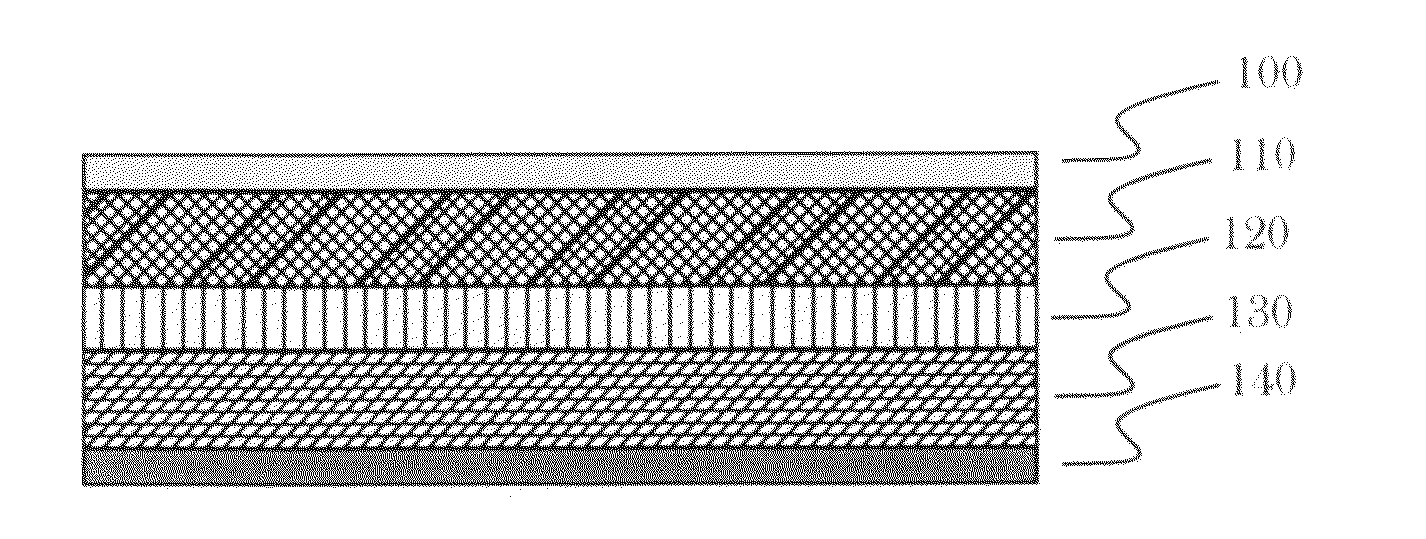

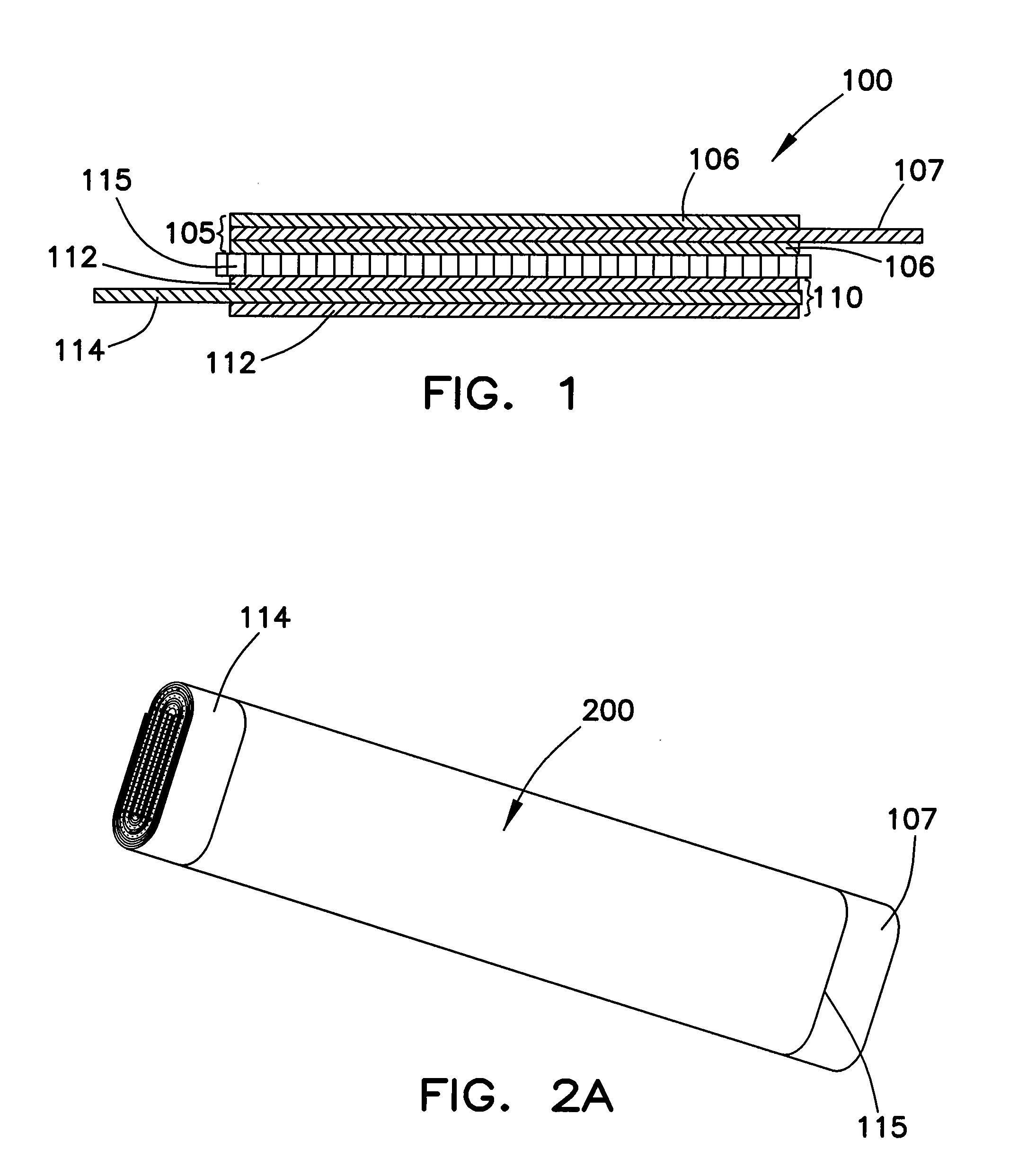

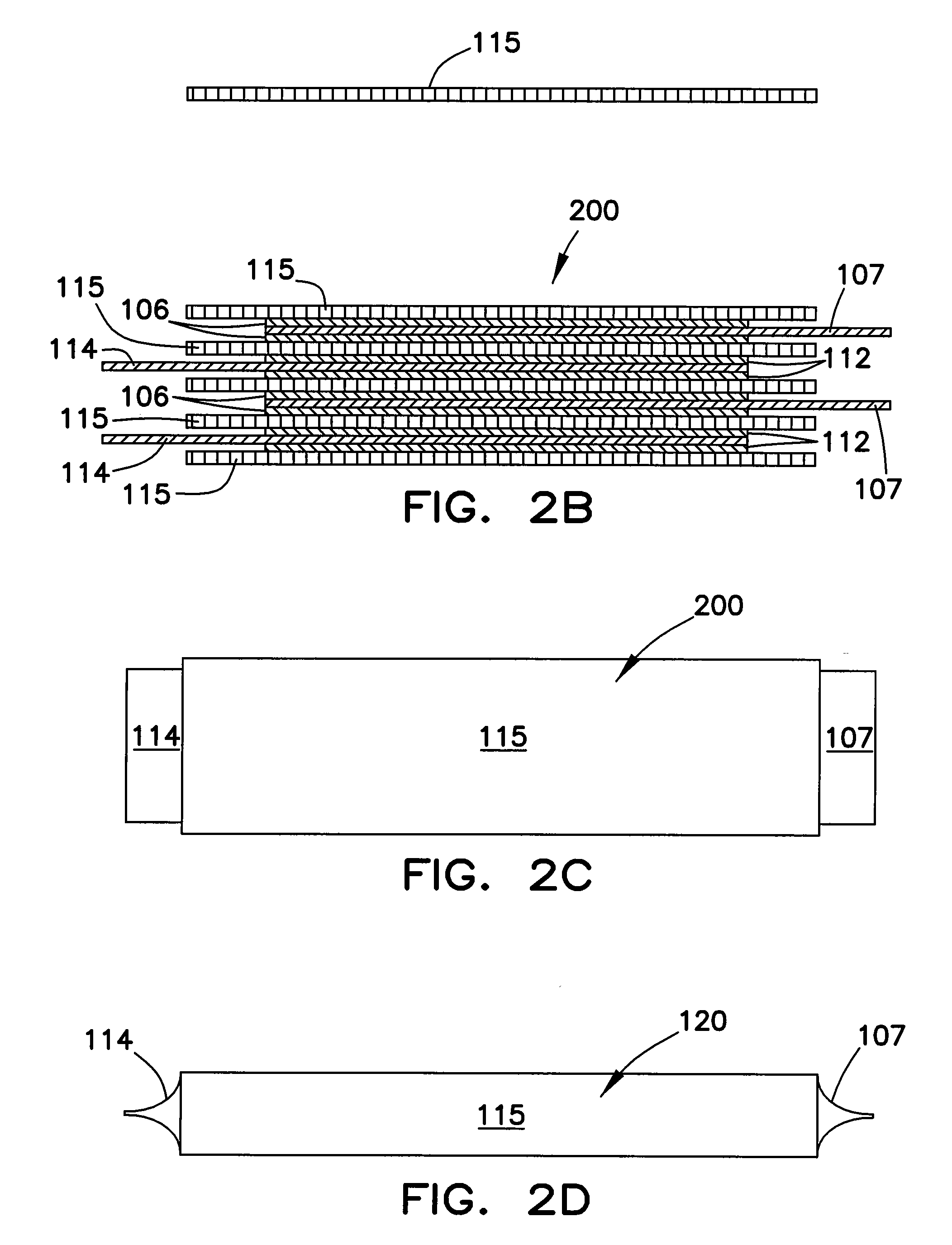

Polymer supported electrodes

InactiveUS20110183203A1Prevent thermal runawayInhibit growthMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSpray coatingPolymer supported

Methods and devices arising from the practice thereof for making and using battery electrodes formed onto ion permeable, electrically non-conductive substrates, preferably battery separators are disclosed herein. Electrodes are formed onto substrates using a variety of methods including, but not limited to, spray coating and electrophoretic deposition. Electrically conductive layers may be applied to the electrode coating layer side opposite or adjacent to the substrate to act as current collectors for the battery. Multilayer devices having alternating layers of conductive layers, electrode layers and substrates, wherein the conductive layers may be in electrical communication with other conductive layers to form a battery.

Owner:MOLECULAR NANOSYST

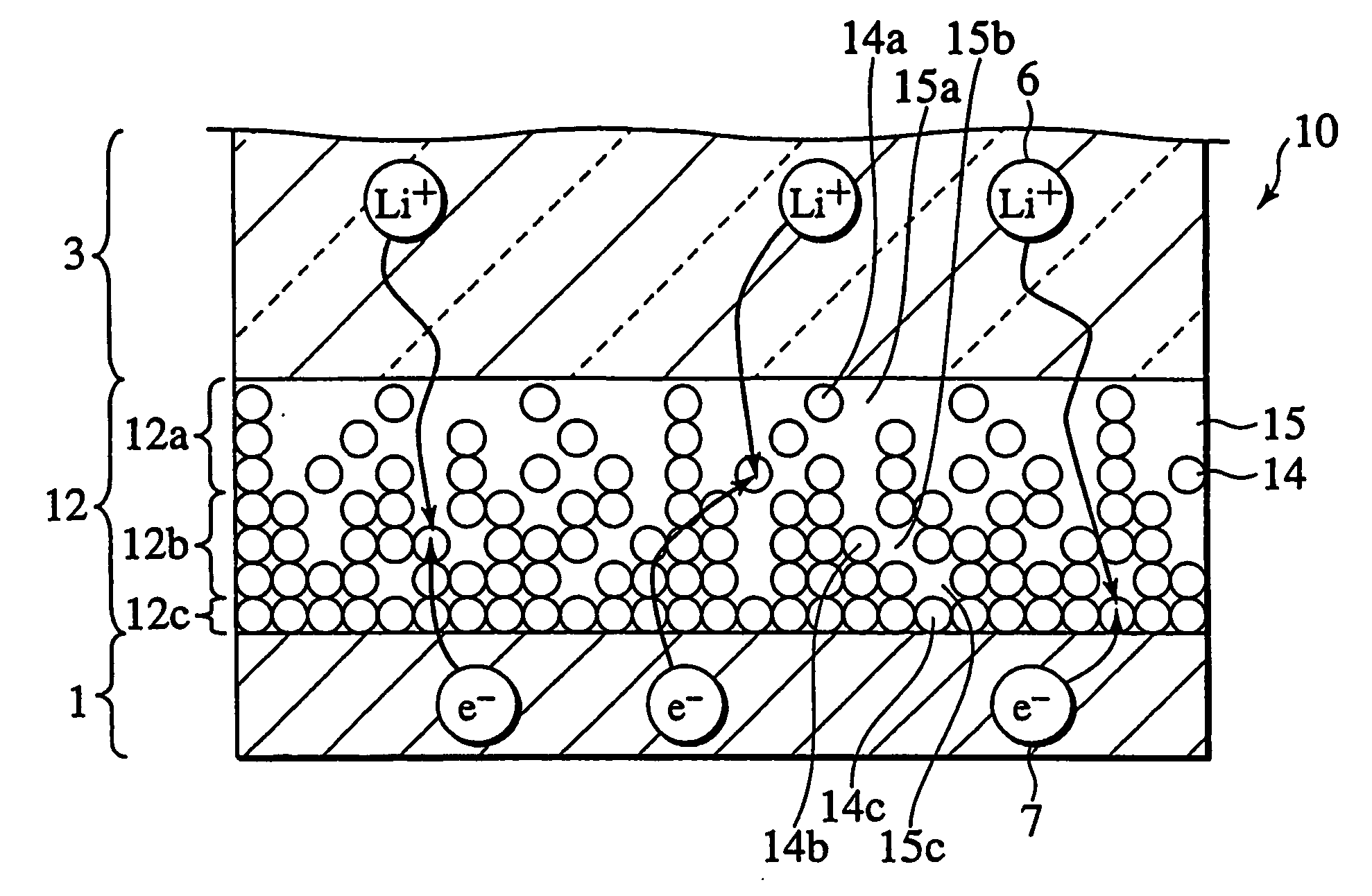

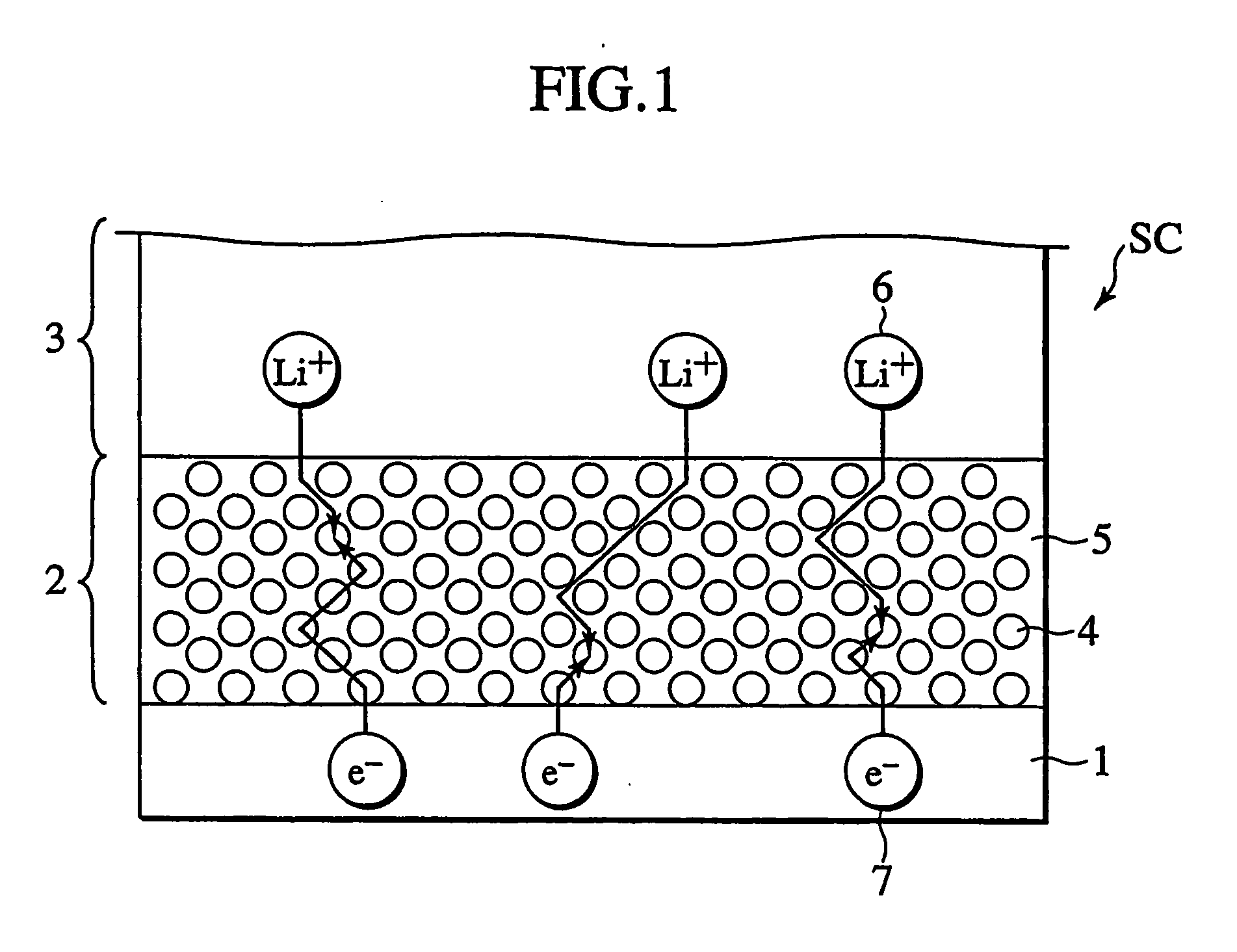

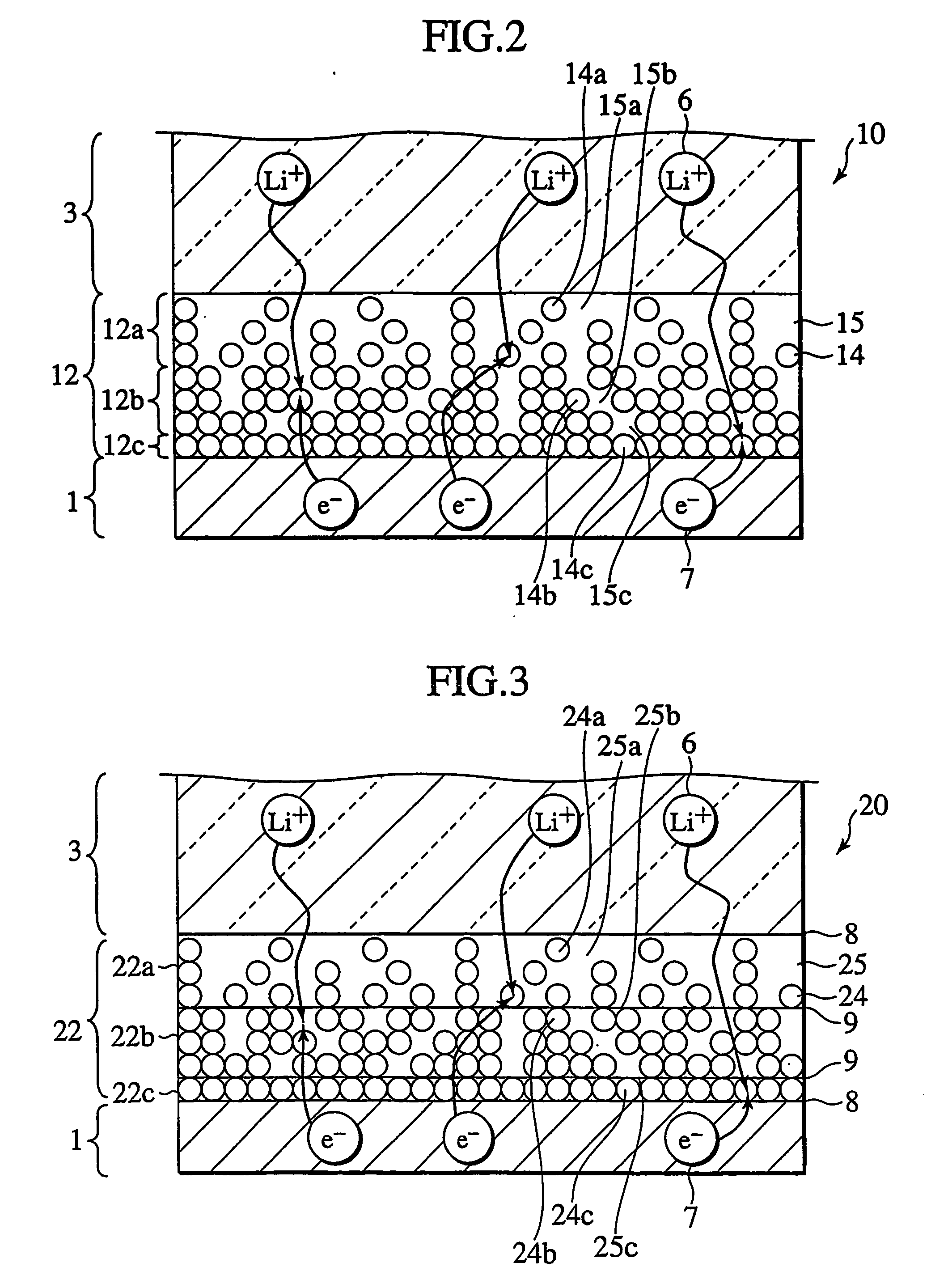

Secondary cell electrode and fabrication method, and secondary cell, complex cell, and vehicle

InactiveUS20060251965A1Solid electrolyte cellsActive material electrodesElectrolyteMaterials science

In a nonaqueous electrolyte cell-oriented electrode (10), an electrode active material layer (12) formed on a collector (1) has a density gradient developed with a gradient of a varied concentration of a solid along a thickness from a surface of the electrode active material layer (12) toward the collector (1), and in a gel electrolyte cell-oriented electrode (30), an electrode active material layer (32) formed on a collector (1) has a density gradient developed with (a) gradient(s) of (a) varied concentration(s) of one or both of an electrolyte salt and a film forming material along a thickness from a surface of the electrode active material layer (32) toward the collector (1).

Owner:NISSAN MOTOR CO LTD

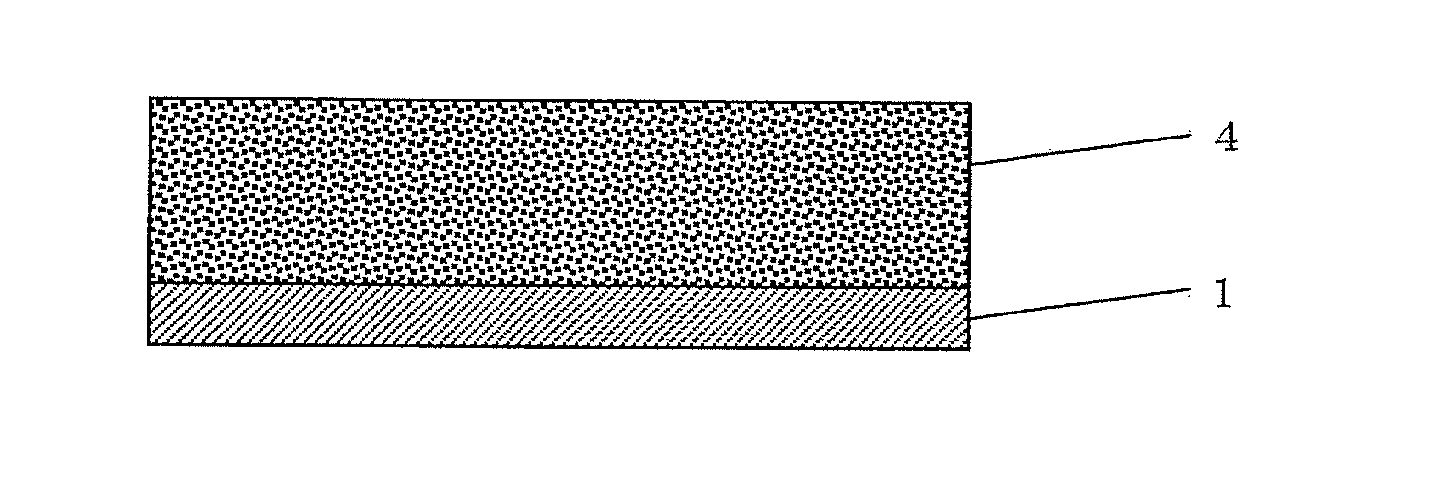

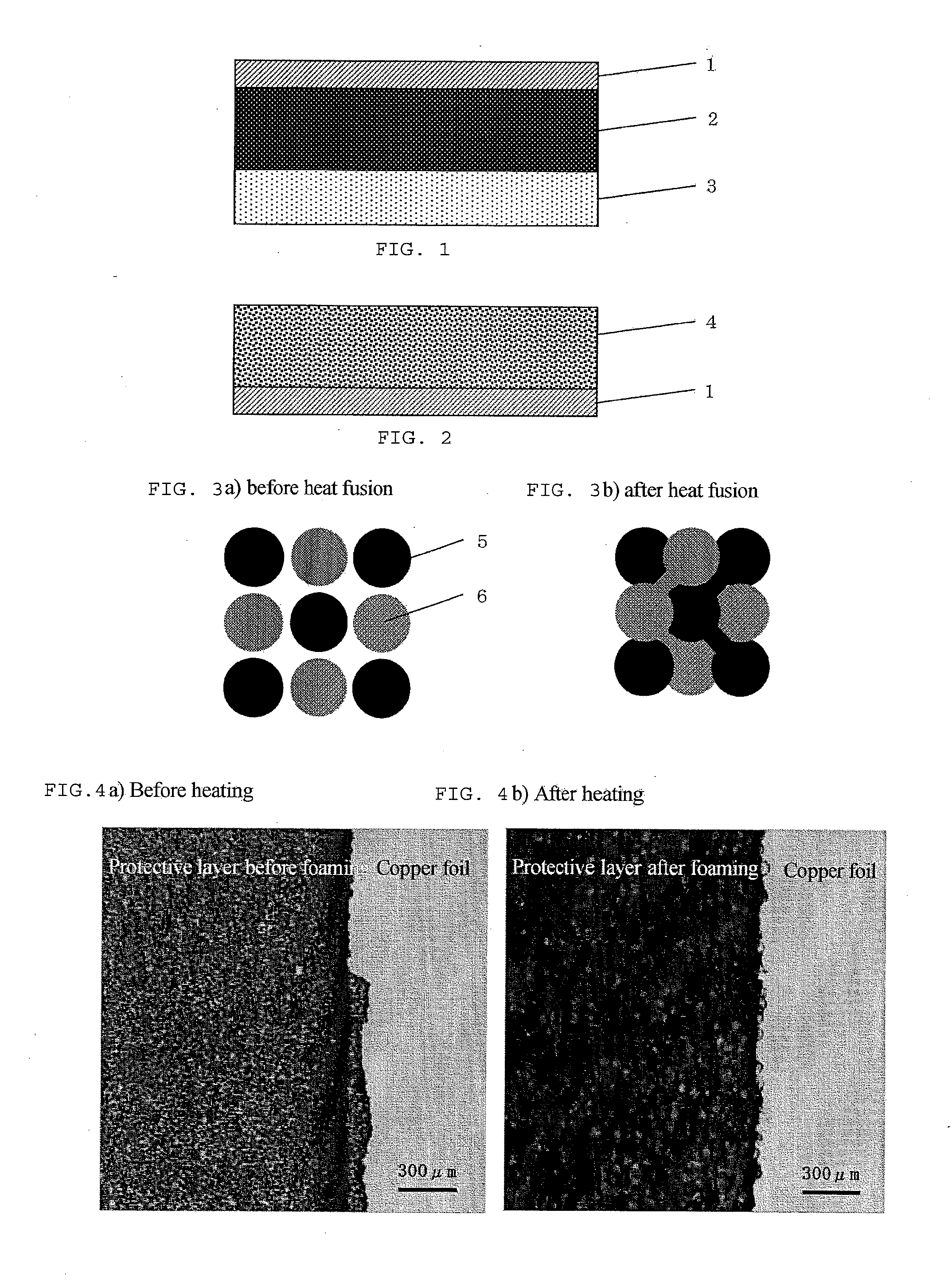

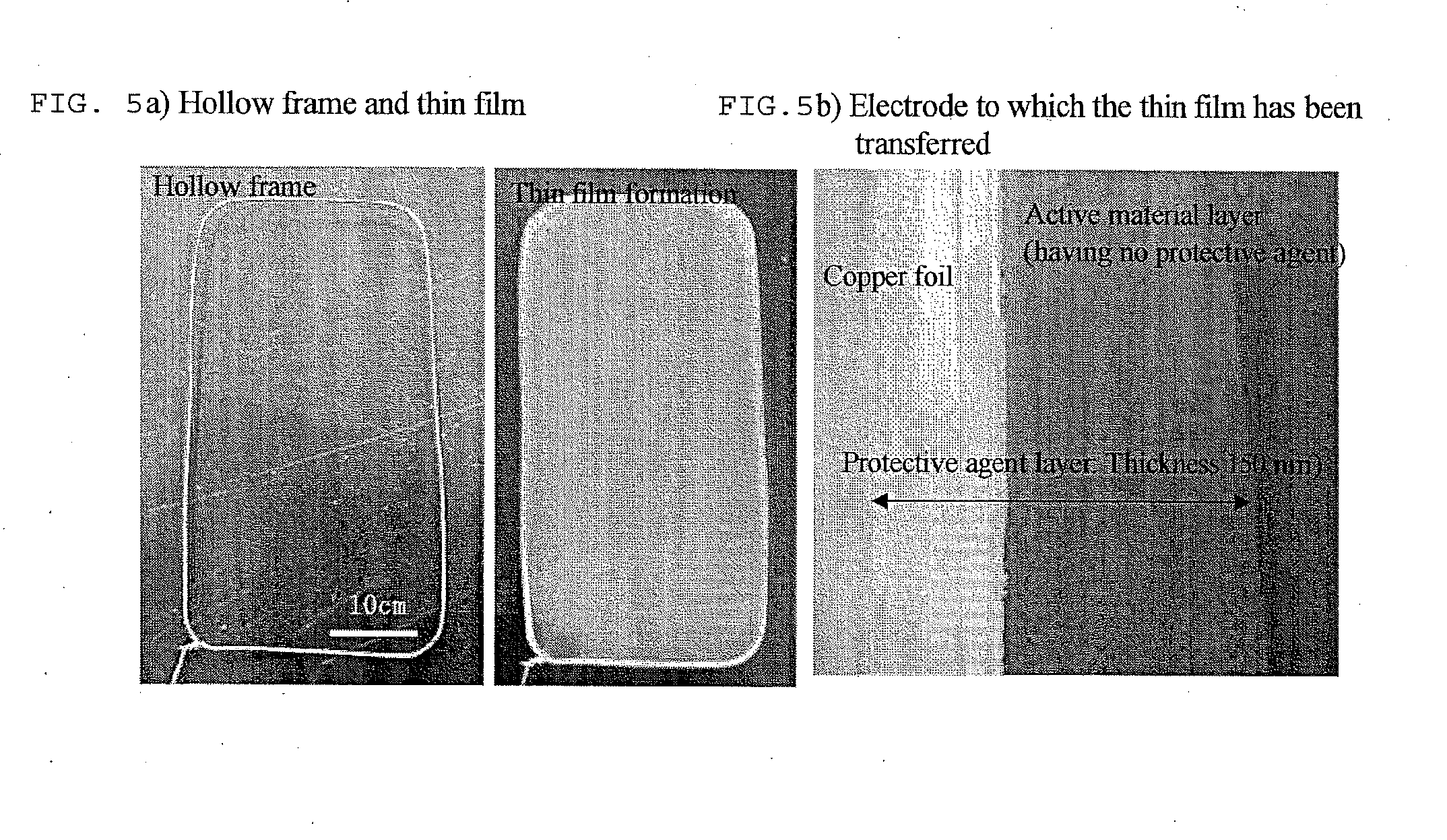

Battery electrode or separator surface protective agent composition, battery electrode or separator protected by the composition, and battery having the battery electrode or separator

ActiveUS20130260207A1Excellent electrolytic solution impregnation propertyImprove heat resistanceCosmetic preparationsNon-fibrous pulp additionHot meltEngineering

A battery electrode or separator surface protective agent composition having fluidity and being capable of being solidified by hot melt, and comprising at least two types of organic particles comprising organic materials, wherein the organic particles of types different from each other are substantially incompatible with each other, wherein when the composition is solidified by hot melt, the organic particles of the same type thermally fuse with one another to form a continuous phase.

Owner:KYORITSU KAGAKU SANGYO KK

Electrode for secondary battery, manufacturing method thereof and secondary battery employing the same

InactiveUS20090098457A1Improve thickness uniformityIncrease electrode capacityCylinder pressesPlaten pressesElectrical batterySurface roughness

Provided are an electrode for a secondary battery employing an active material layer having improved thickness uniformity by printing low-viscosity ink on the active material layer, a manufacturing method of the electrode, and a secondary battery having improved electrode capacity due to the employing of the electrode. The electrode includes a current collector, and an active material layer formed by printing ink having a viscosity not exceeding 500 mPa·s on the current collector and drying the current collector, wherein the current collector has a surface roughness (Ra) in a range from about 0.025 to 1.0 μm.

Owner:SAMSUNG ELECTRONICS CO LTD

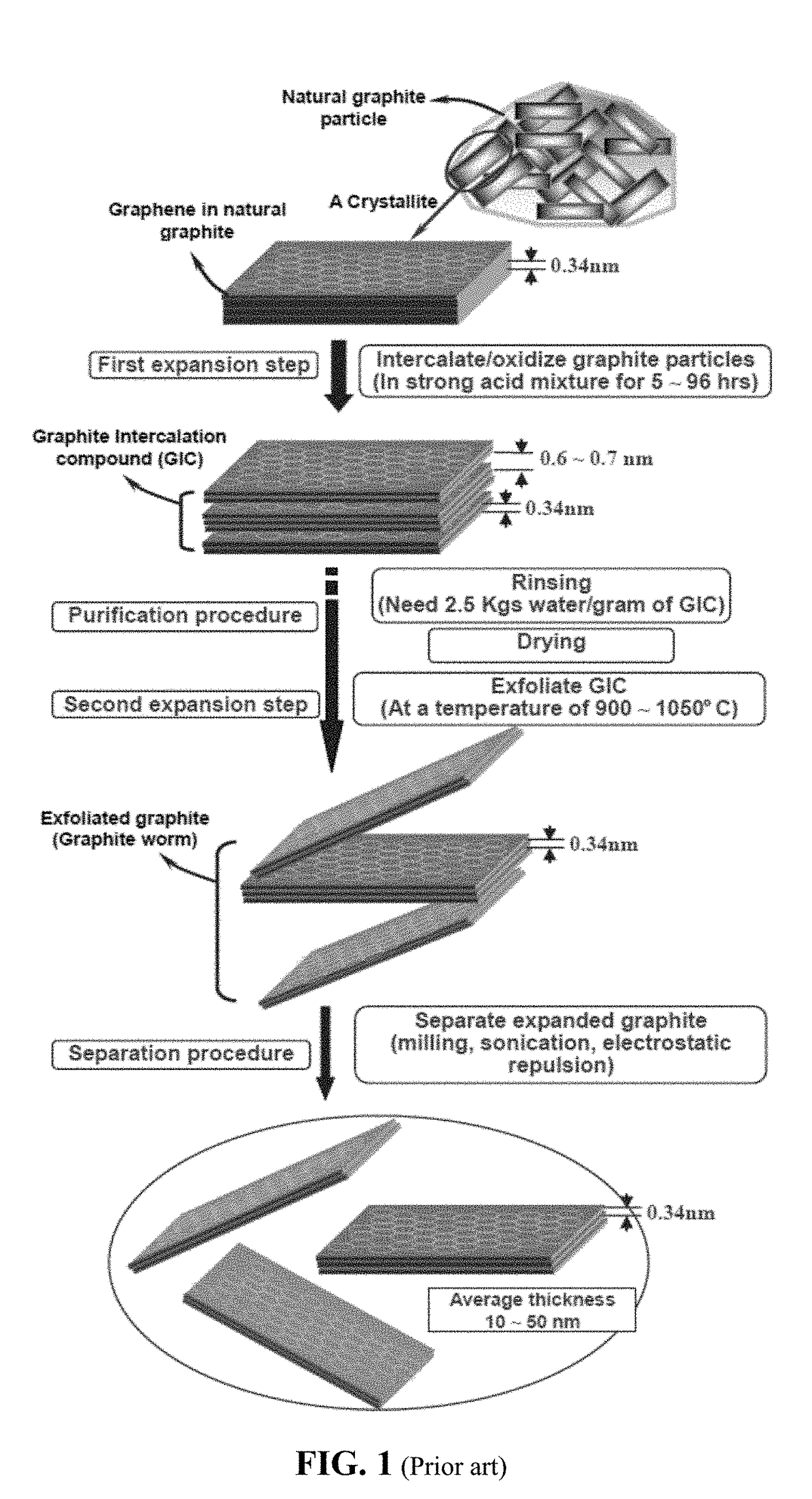

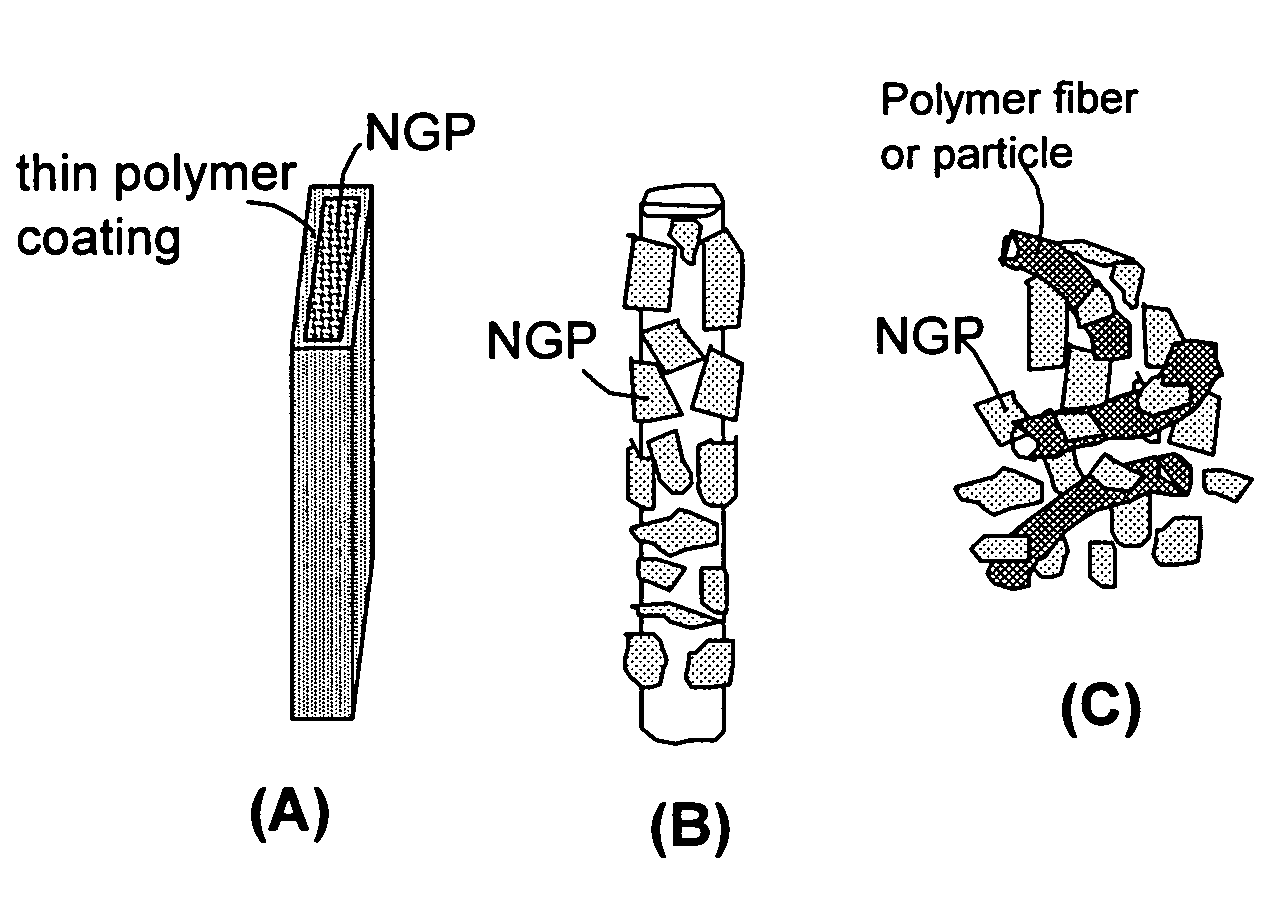

Highly conductive nano-scaled graphene plate nanocomposites

Disclosed is a nano-composite material comprising fully separated nano-scaled graphene platelets (NGPs) dispersed in a matrix material, wherein each of the platelets comprises a sheet of graphite plane or multiple sheets of graphite plane and has a thickness no greater than 100 nm and the platelets have an average length, width, or diameter no greater than 500 nm. The graphene plates are present in an amount no less than 15% by weight based on the total weight of the platelets and the matrix material combined. Typically, the nanocomposite is electrically conductive with a bulk conductivity no less than 10 S / cm and more typically no less than 100 S / cm. Highly conductive NGP nanocomposites are particularly useful for fuel cell flow field plate (bipolar plate) and battery electrode applications. Nanocomposites with high NGP proportions can be used in automotive friction plates and aircraft brake components.

Owner:GLOBAL GRAPHENE GRP INC

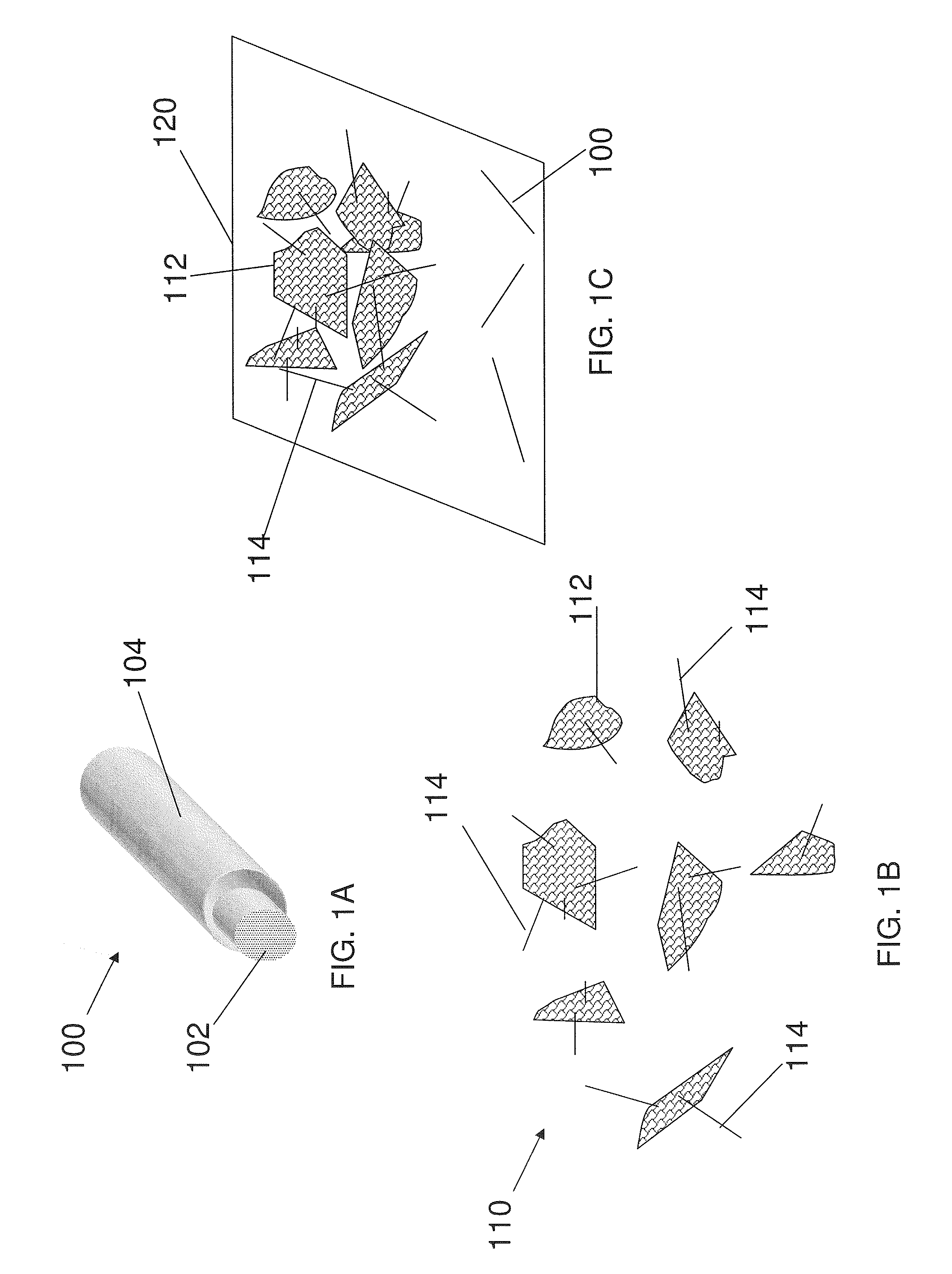

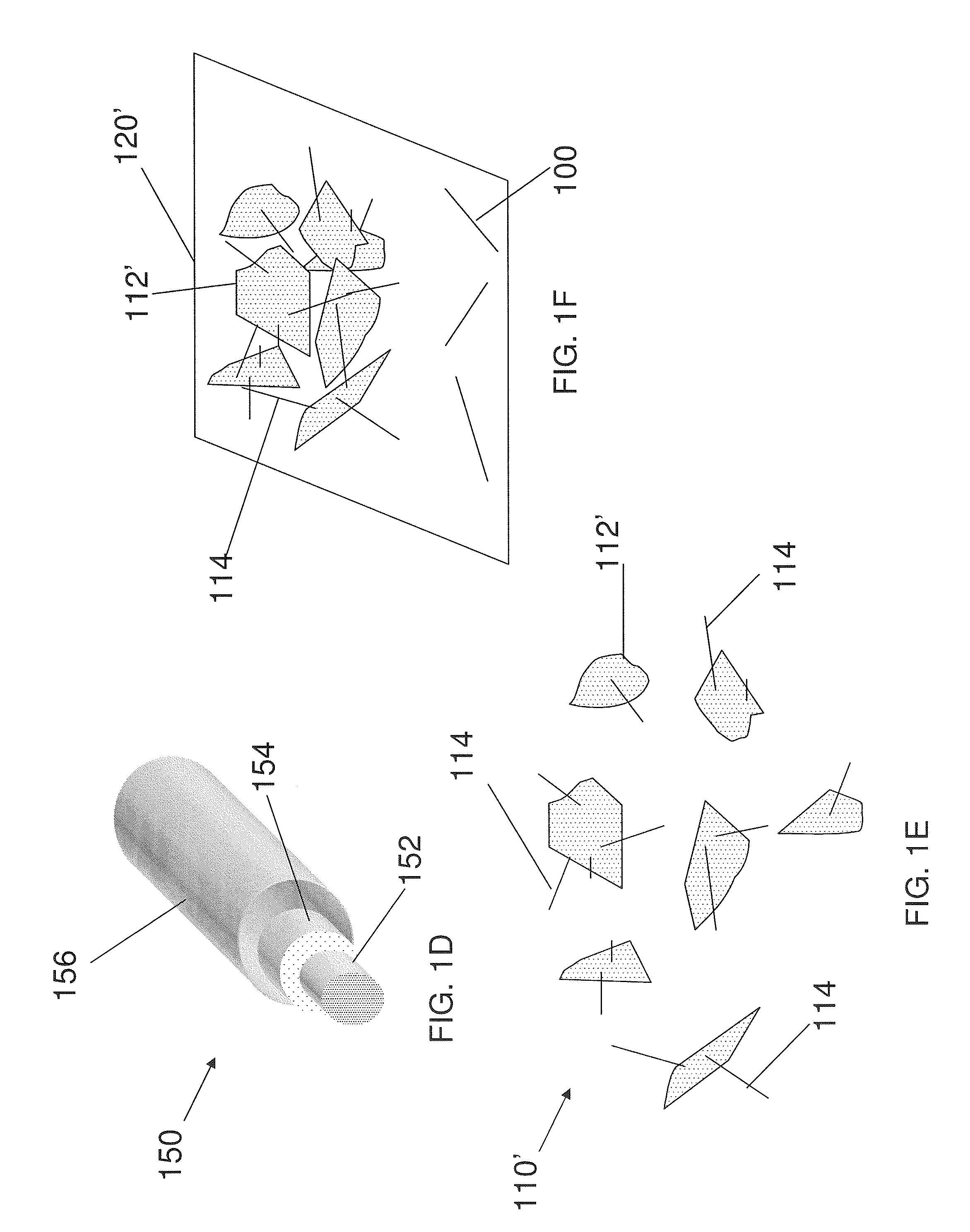

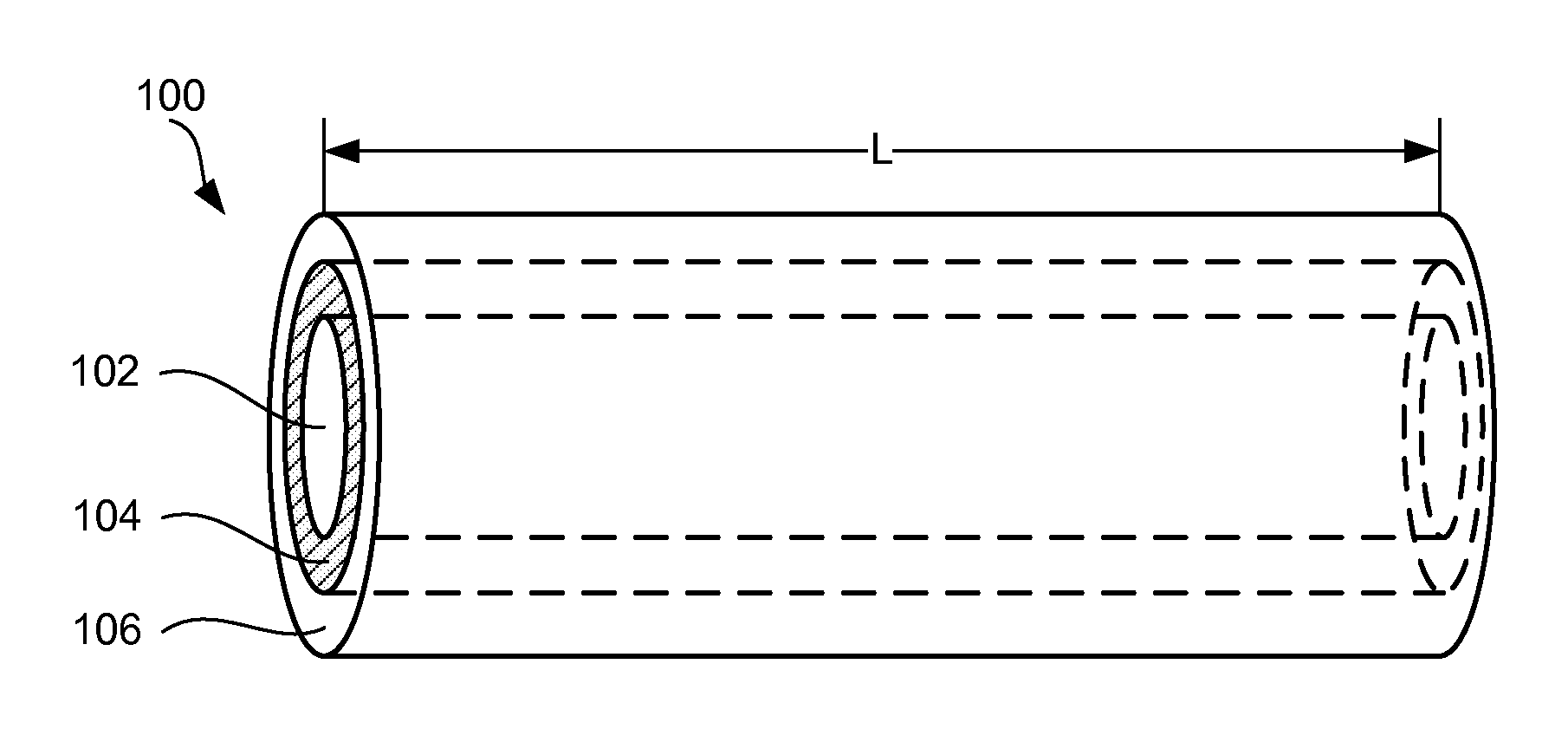

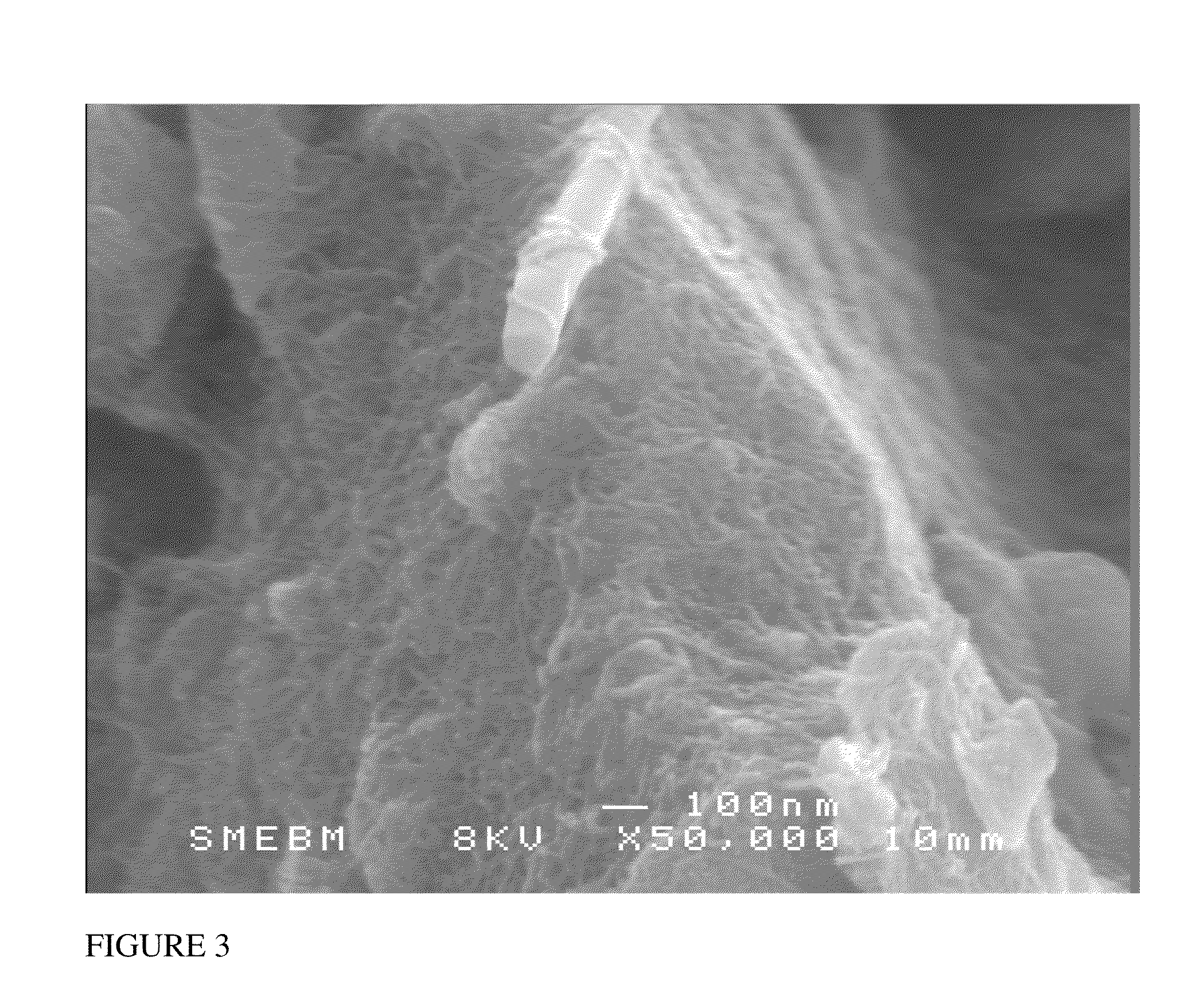

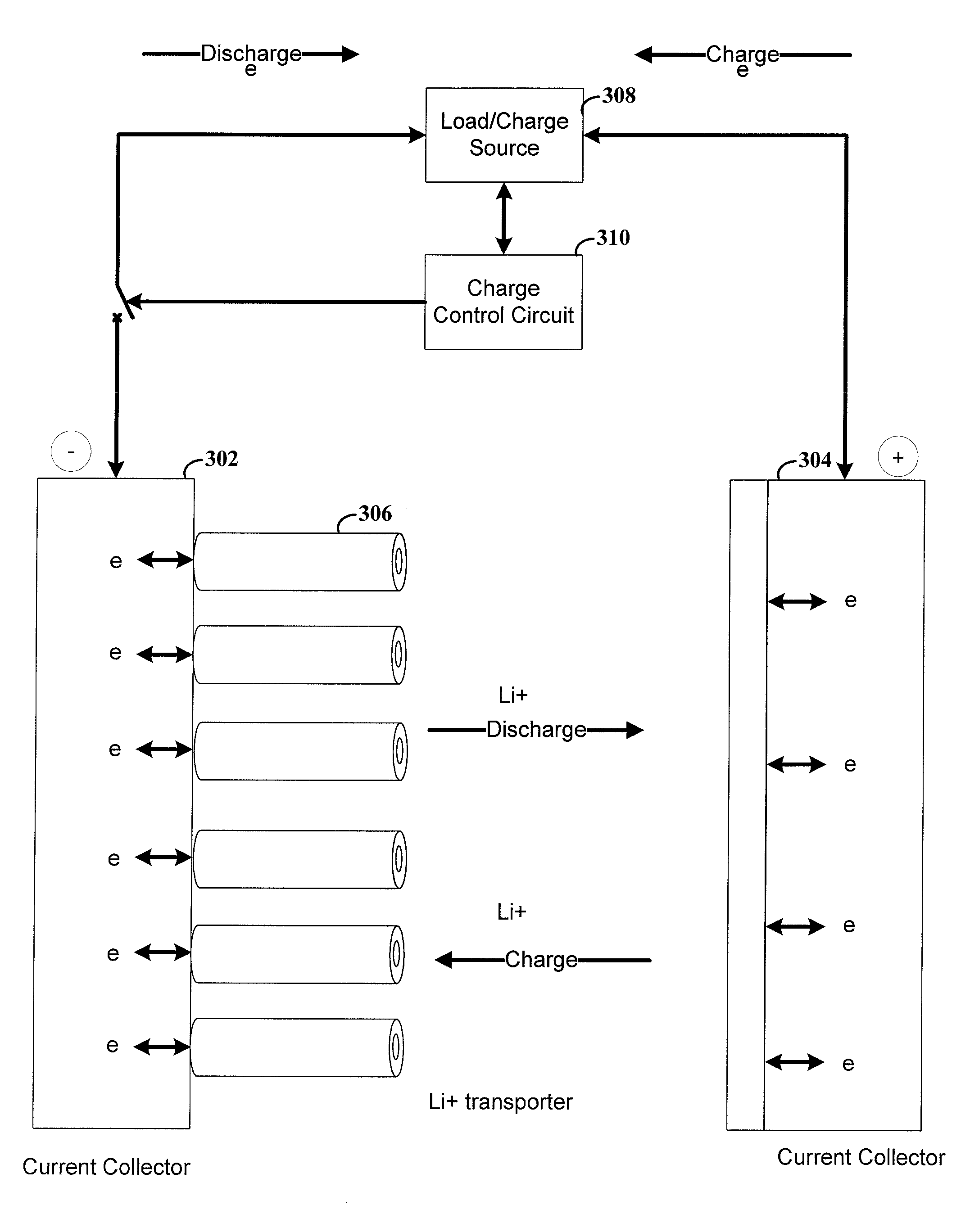

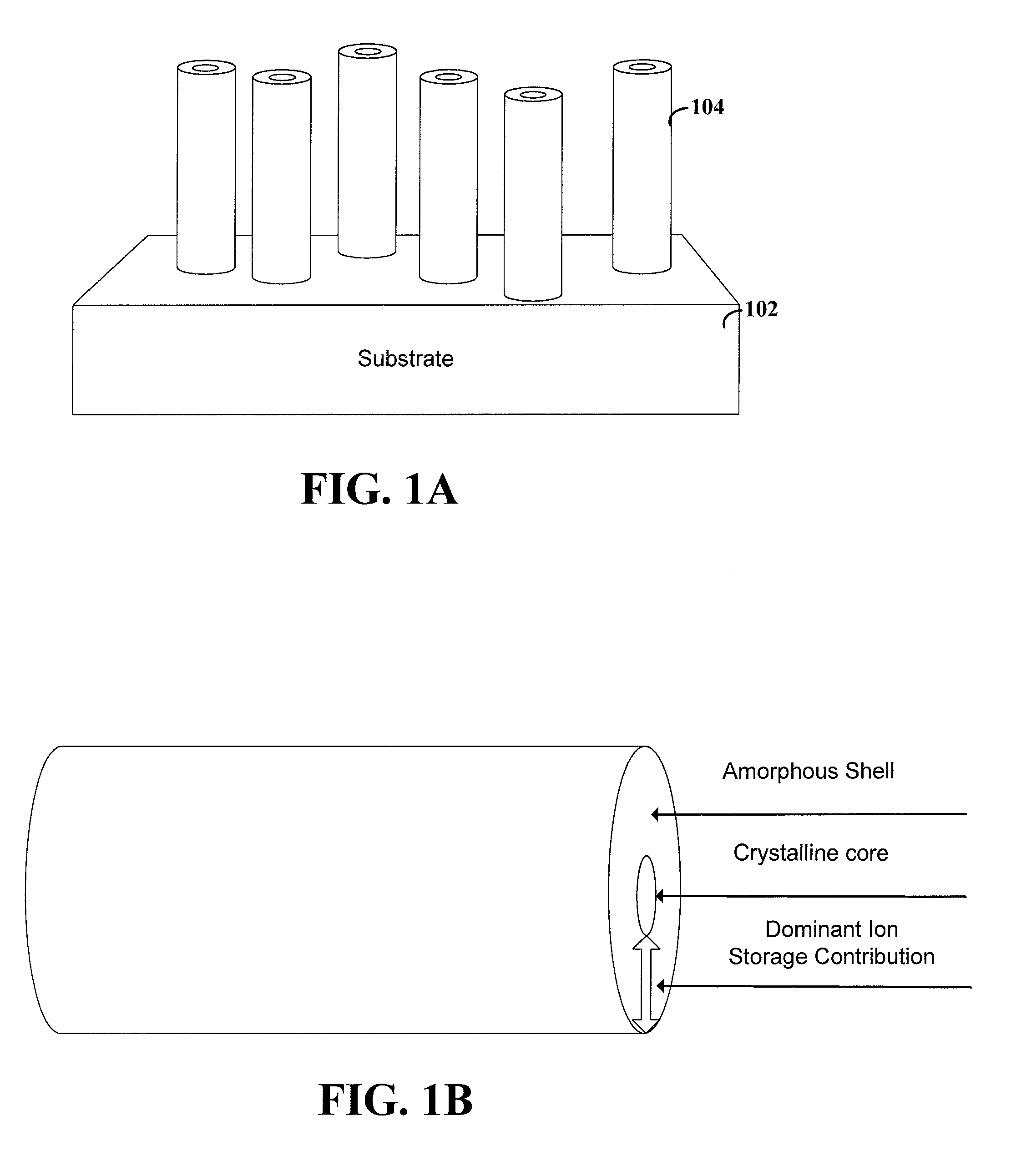

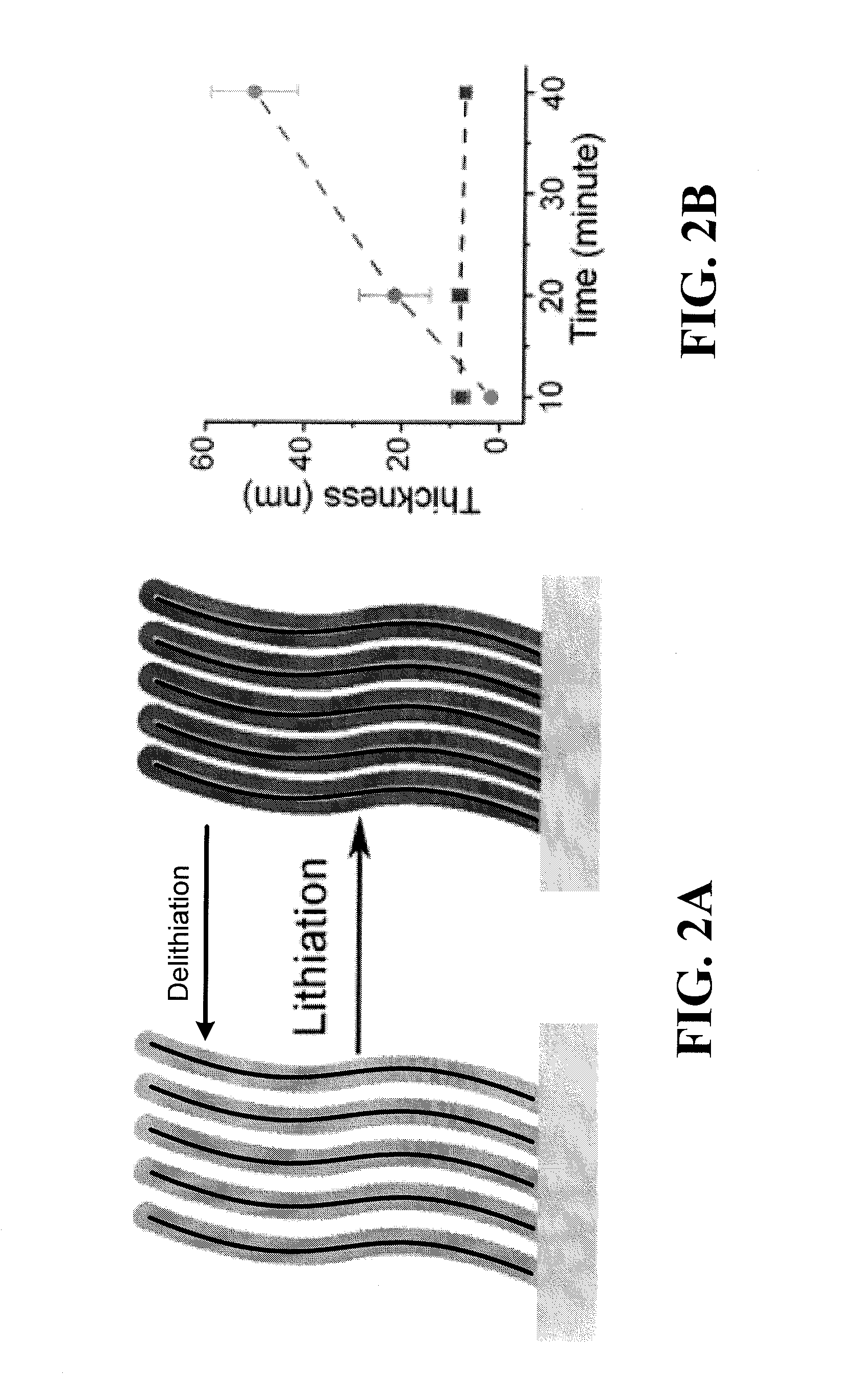

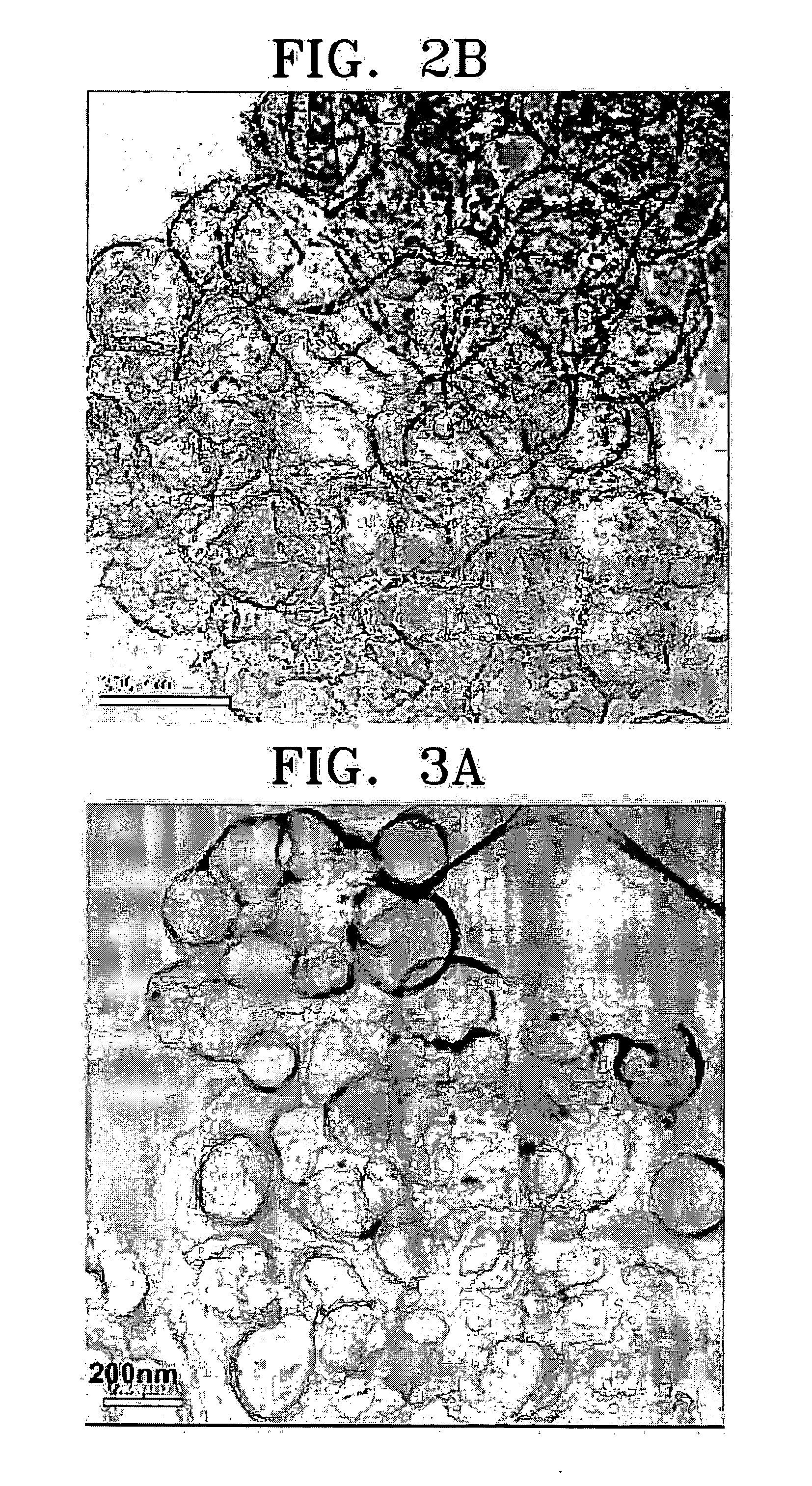

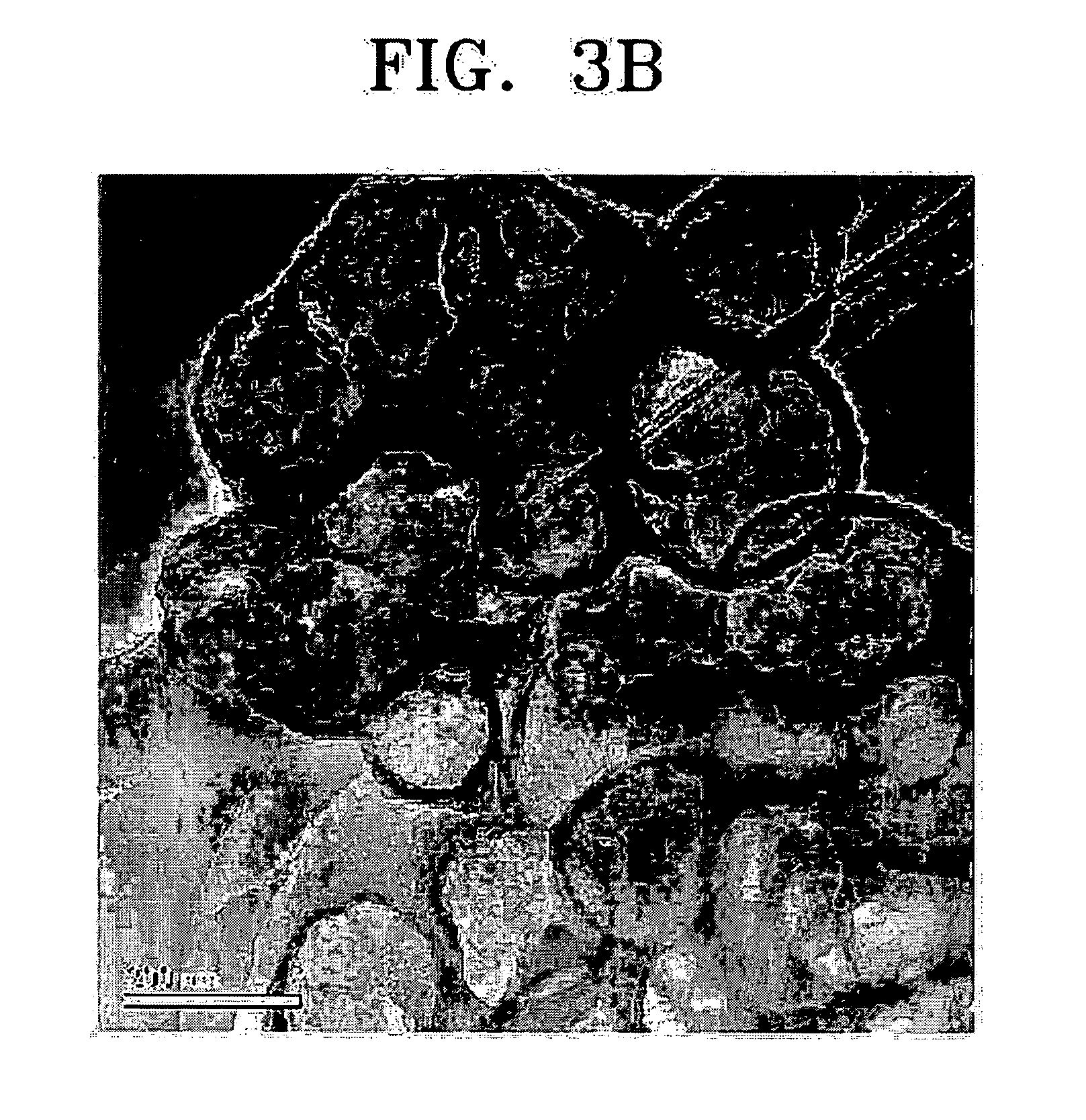

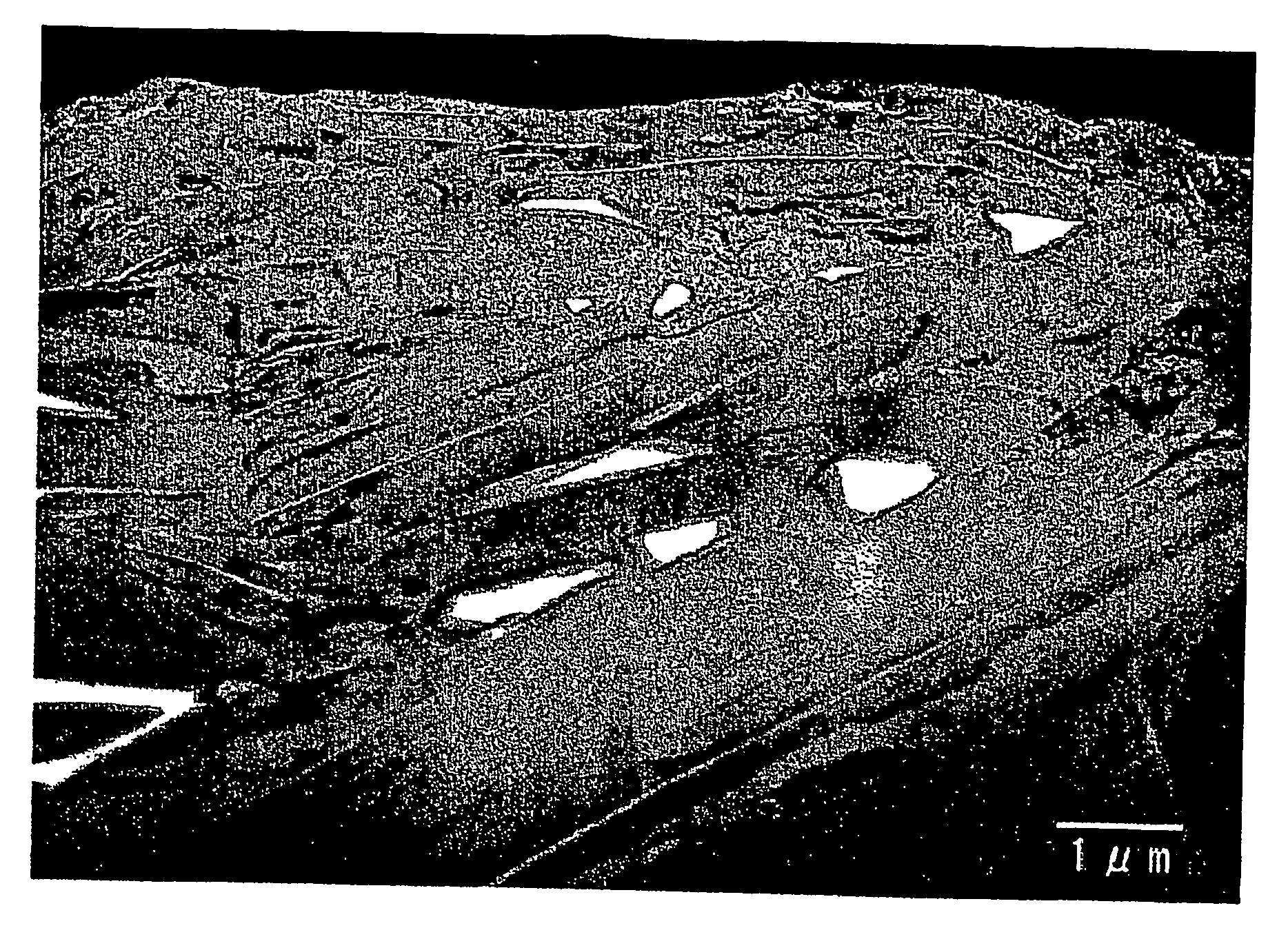

Crystalline-amorphous nanowires for battery electrodes

ActiveUS20110151290A1Material nanotechnologyElectrode manufacturing processesNanowireCrystallization

Electrodes, batteries, methods for use and manufacturing are implemented to provide ion-based electrical power sources and related devices. Consistent with one such method, a battery electrode is produced having nanowires of a first material. The electrode is produced using a single growth condition to promote growth of crystalline nanowires on a conductive substrate and of the first material, and promote, by maintaining the growth condition, growth of an amorphous portion that surrounds the crystalline nanowires.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

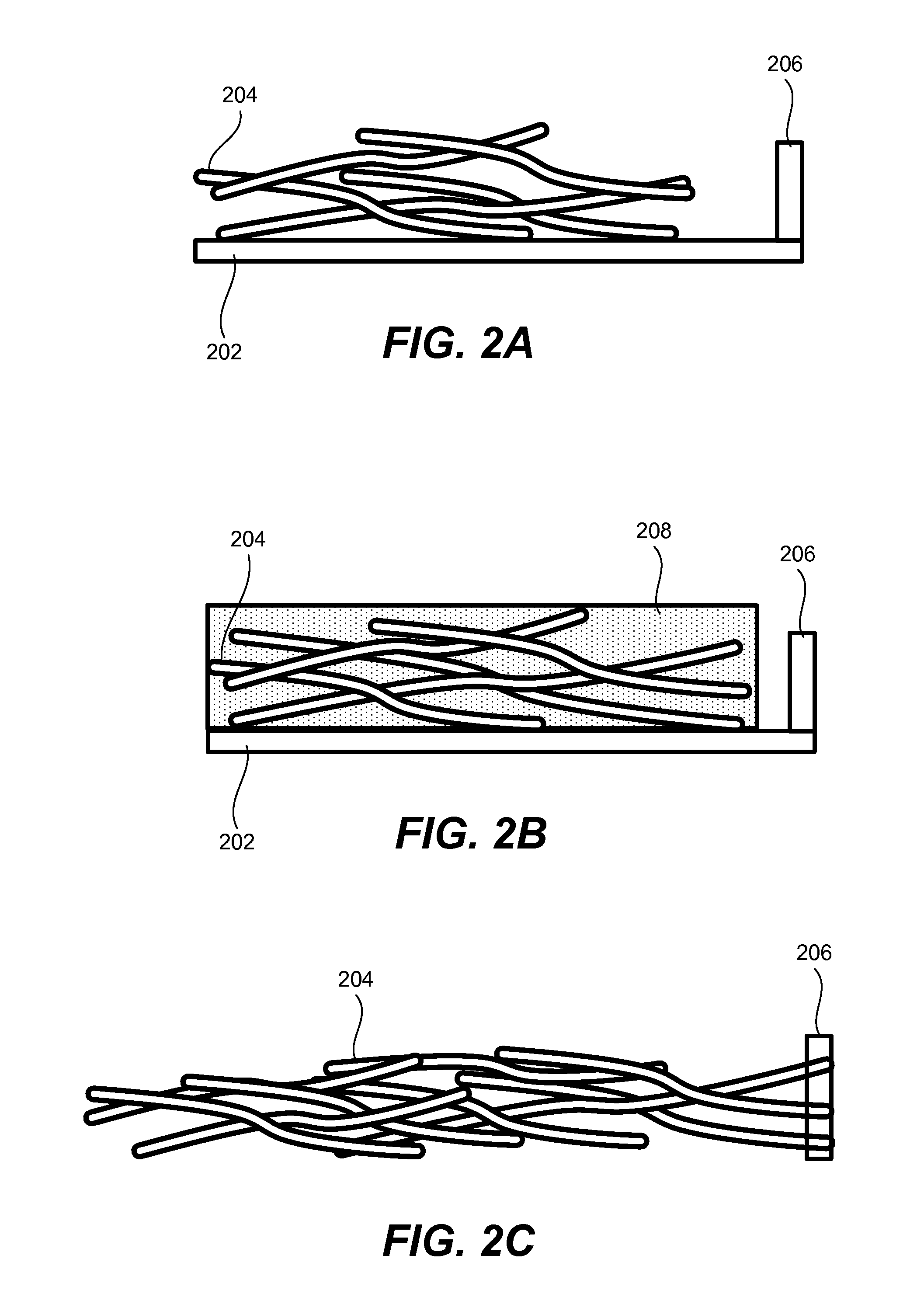

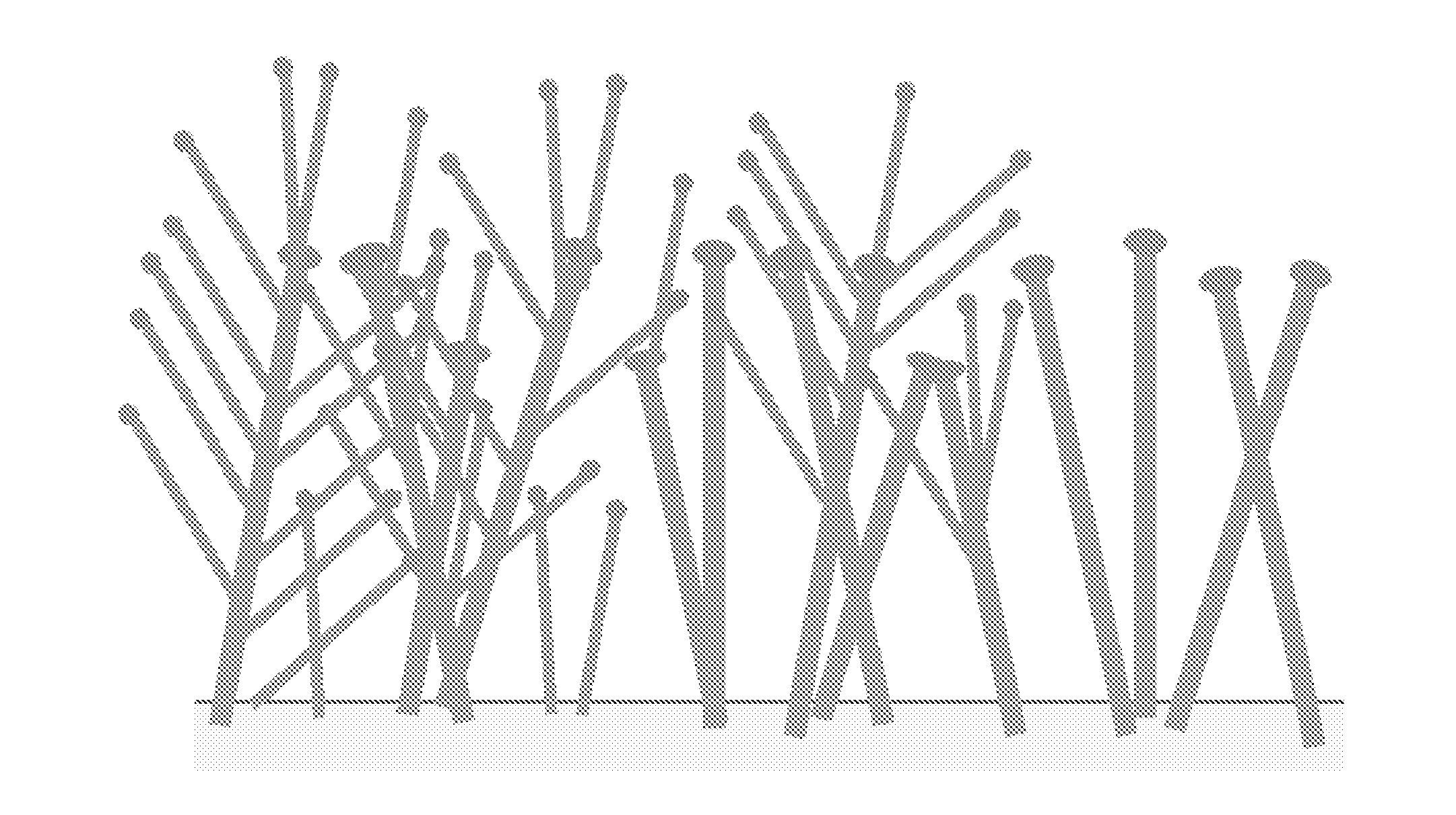

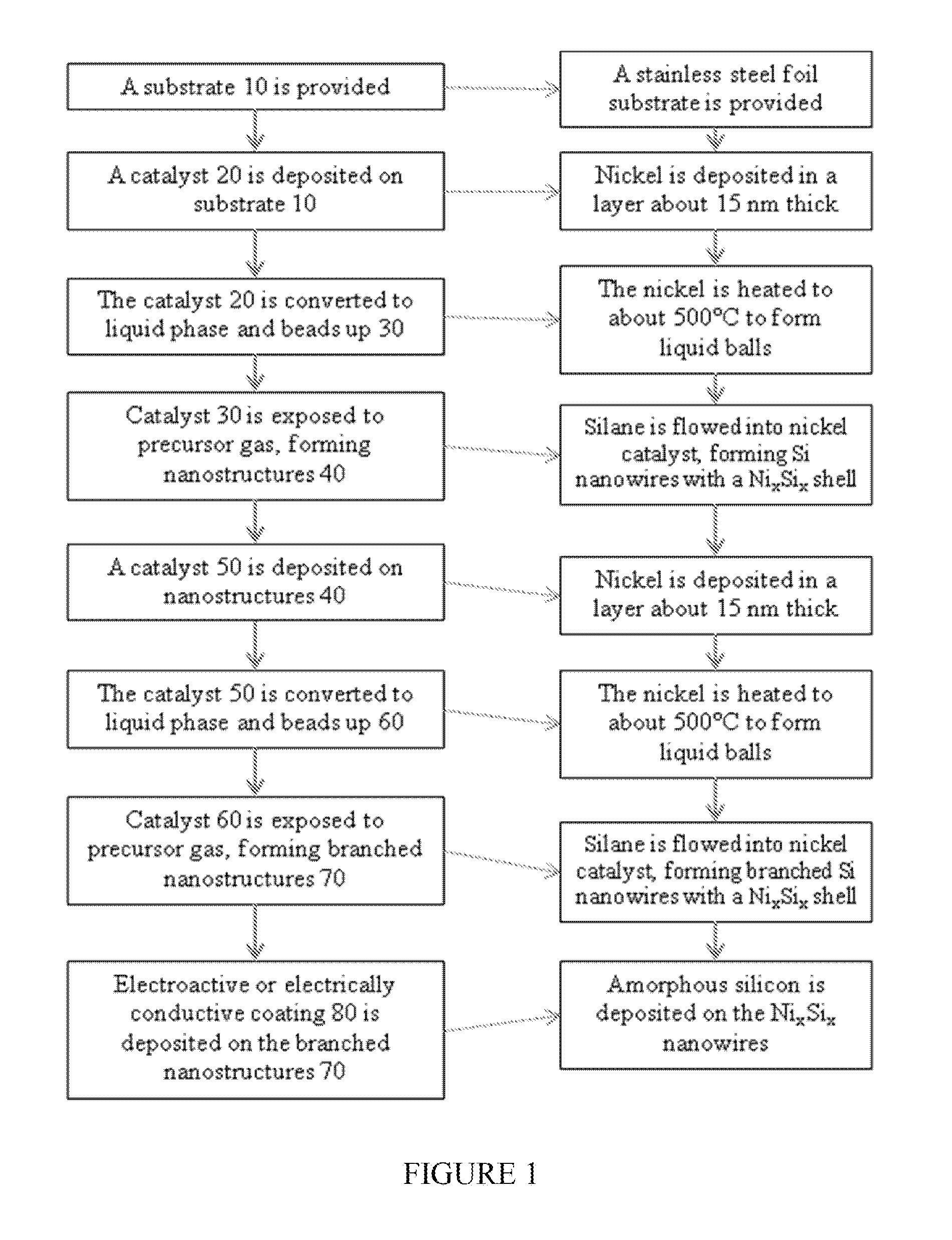

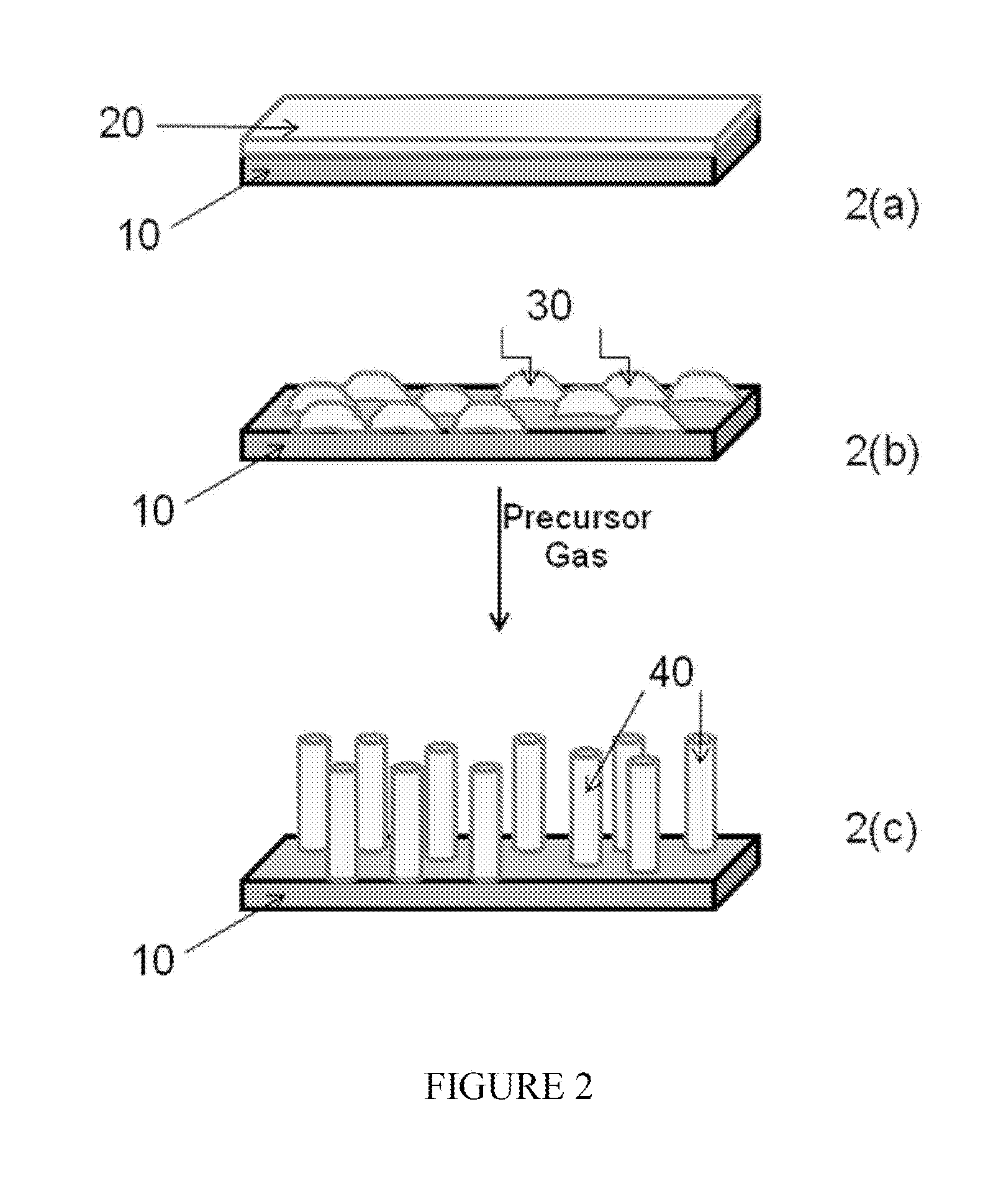

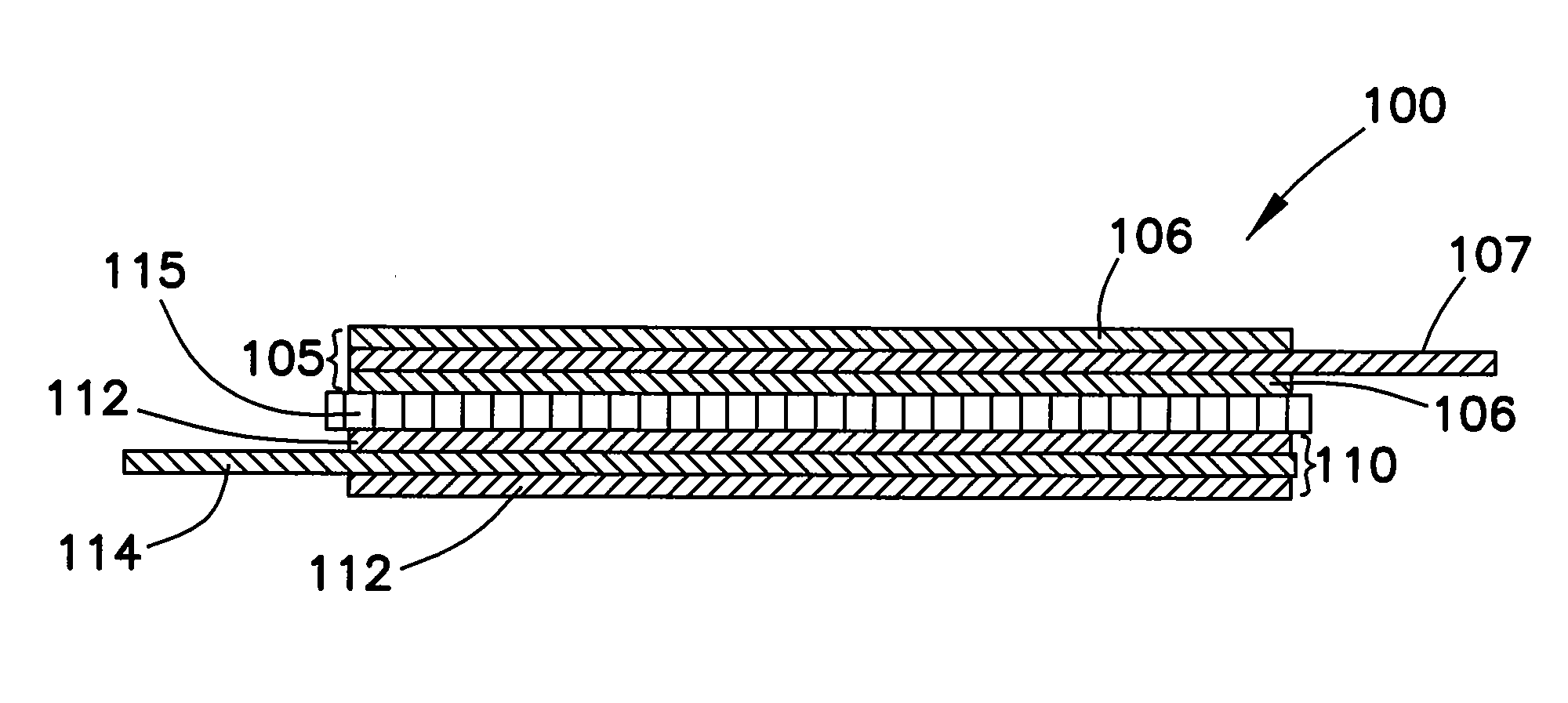

Branched nanostructures for battery electrodes

ActiveUS20130143124A1Relieve pressureStress problemElectrode manufacturing processesElectrode carriers/collectorsNanostructureElectrochemical electrode

The invention relates to electrochemical electrodes containing branched nanostructures having increased surface area and flexibility. These branched nanostructures allow for higher anode density, resulting in the creation of smaller, longer-lasting, more efficient batteries which require less area for the same charging capacity. Also disclosed are methods for creating said branched nanostructures and electrodes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

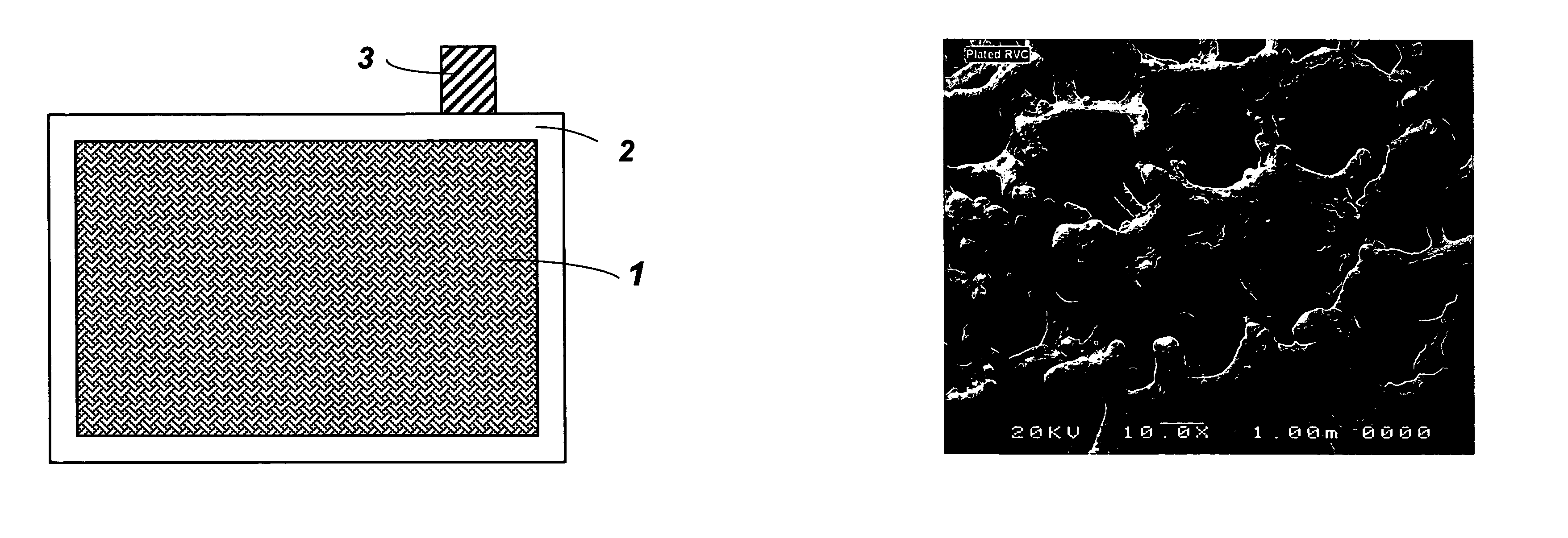

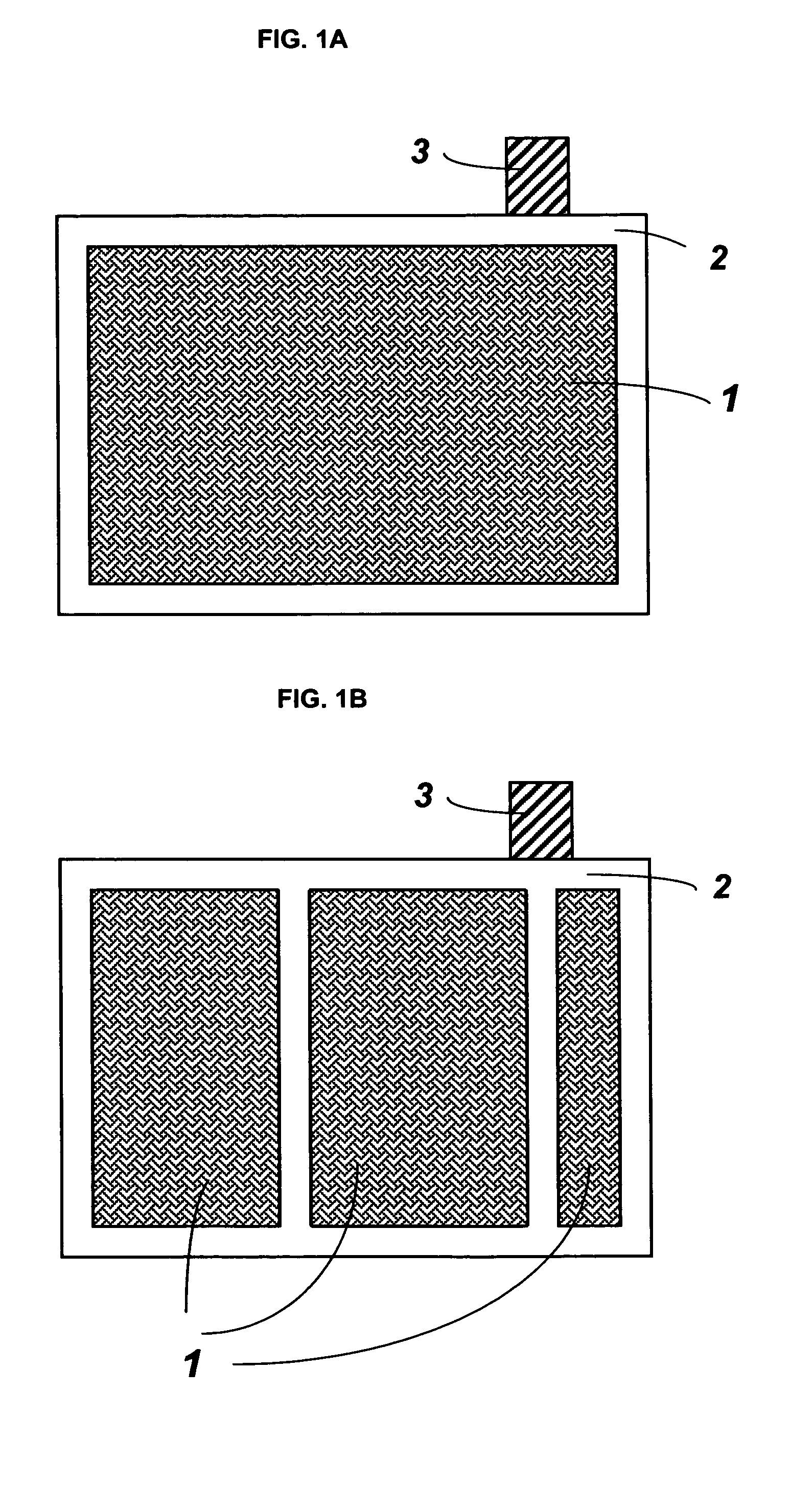

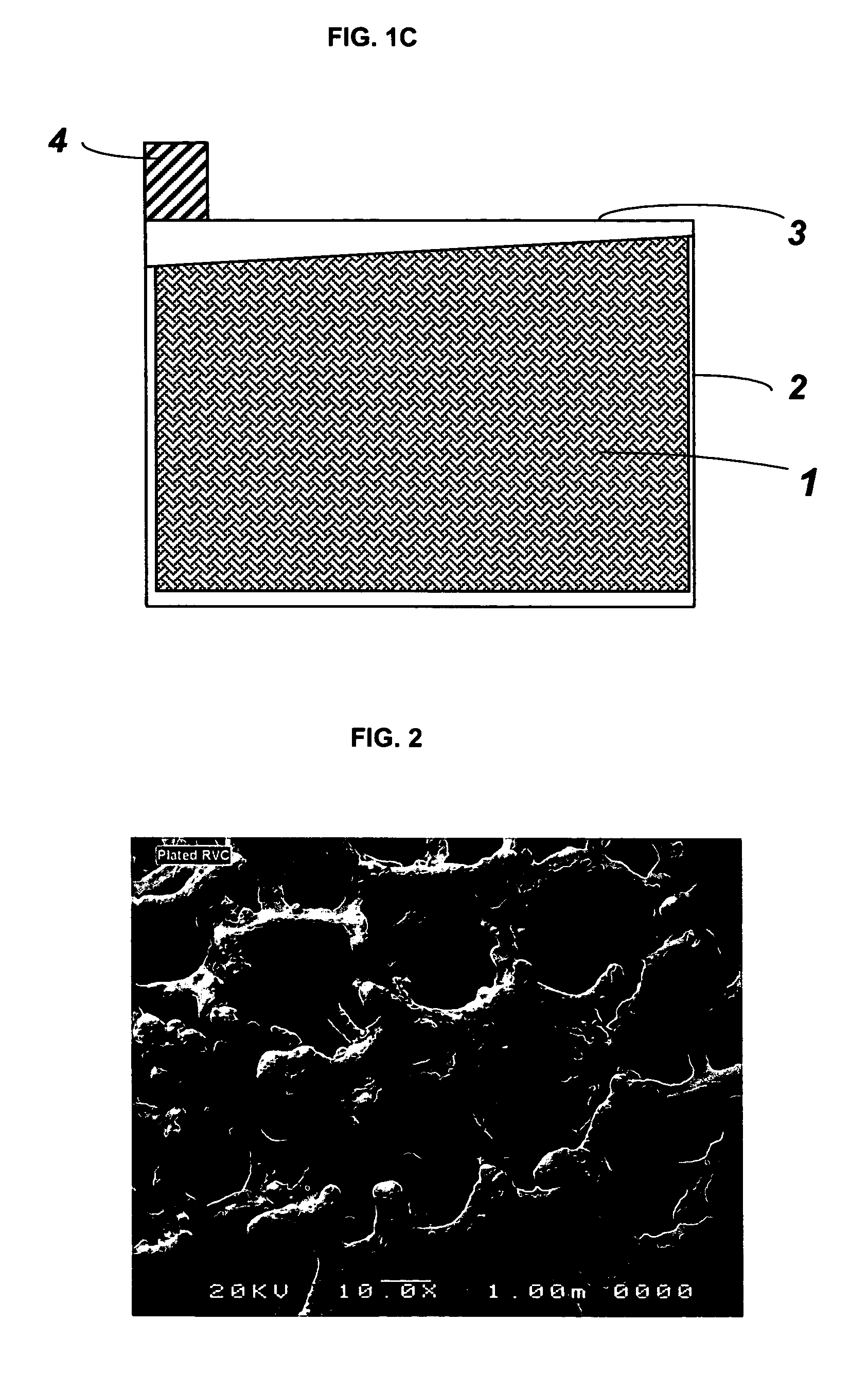

Current collector structure and methods to improve the performance of a lead-acid battery

InactiveUS7060391B2Improve performanceAchieve recyclabilityElectrode carriers/collectorsLead-acid accumulator electrodesAlloyTin

A battery, a battery electrode structure, and methods to make the same. The product and method comprise applying a layer of lead-tin containing alloy to substrates for anodes or cathodes for lead-acid batteries, in which the substrates are porous or reticulated.

Owner:POWER TECH INC

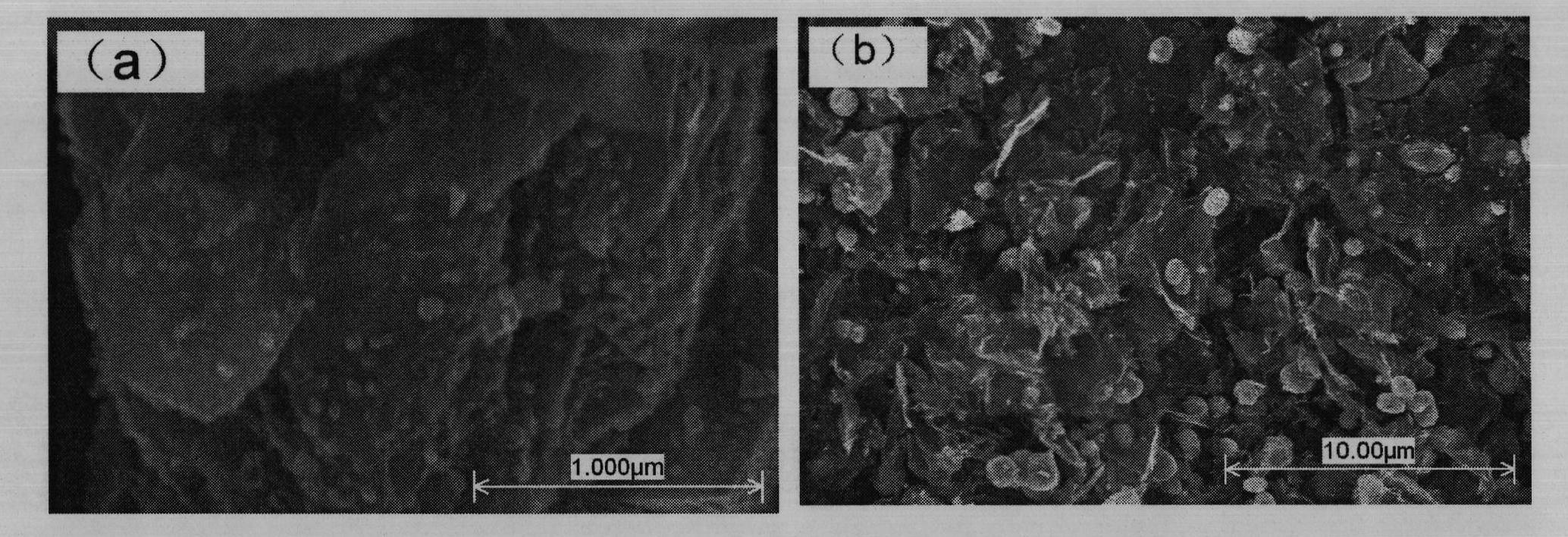

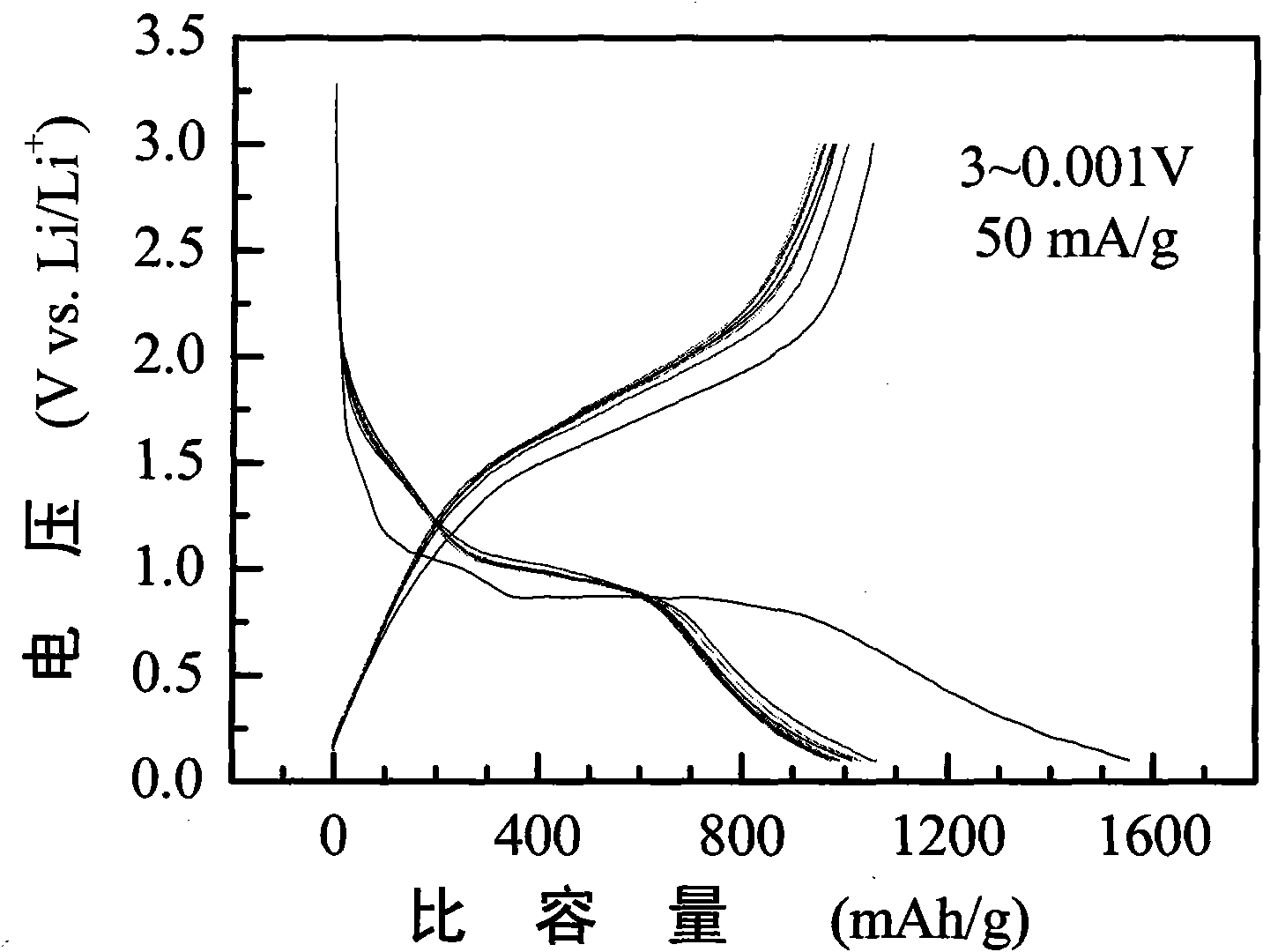

Graphene-based nano iron oxide composite material and preparation method thereof

InactiveCN102130334AAvoid reunionPrevent heavy stackingMaterial nanotechnologyCell electrodesNano compositesFreeze-drying

The invention discloses a graphene-based nano iron oxide composite material and a preparation method thereof. By the method, iron oxide nano granules with uniform diameter and controllable shape and components can be loaded on graphene. The method comprises the following steps of: uniformly dispersing graphite oxide into deionized water by adopting an ultrasonic method to obtain graphene oxide solution; adding an iron salt precursor into the obtained solution and mixing the precursor and the solution uniformly, adjusting the pH of the solution, and hydrolyzing the iron salt; putting the mixed solution into a reaction kettle and performing hydrothermal reaction; and finally, cleaning and freeze-drying the obtained product to obtain the graphene-based nano iron oxide composite material. The raw materials are common and easily obtained, the cost is low, and the preparation process is simple, safe and environmentally-friendly; the prepared graphene-based nano iron oxide composite material has good structural stability and monodispersity; when the composite material is used as a lithium iron battery electrode material, the charge / discharge capacity can reach over 1,000mAh / g; and the composite material has good multiplying power performance and cycle life.

Owner:CHINA UNIV OF MINING & TECH

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

High capacity electrode and methods for its fabrication and use

InactiveUS20070099084A1Improve cycle lifeMinimised mechanical strainElectrode manufacturing processesSecondary cellsAlloyBuffering agent

A battery electrode comprises an electrically conductive substrate having an electrochemically active electrode composition supported thereupon. The composition includes an active material capable of reversibly alloying with lithium, which material shows a volume change upon such reversible alloying. The composition includes a buffering agent which accommodates the volume change in the active material and minimizes mechanical strain in the composition. The active composition may further include materials such as carbon. The active material may comprise silicon, aluminum, antimony, antimony oxides, bismuth, bismuth oxides, tin, tin oxides, chromium, chromium oxides, tungsten, and tungsten oxides or lithium alloys of the foregoing. The buffering agent may comprise a metal or a metal oxide or lithium alloys of the foregoing. Also disclosed are batteries which incorporate these electrodes, methods for the fabrication of the electrodes and methods for the fabrication and operation of the batteries.

Owner:A123 SYSTEMS LLC

Battery electrode

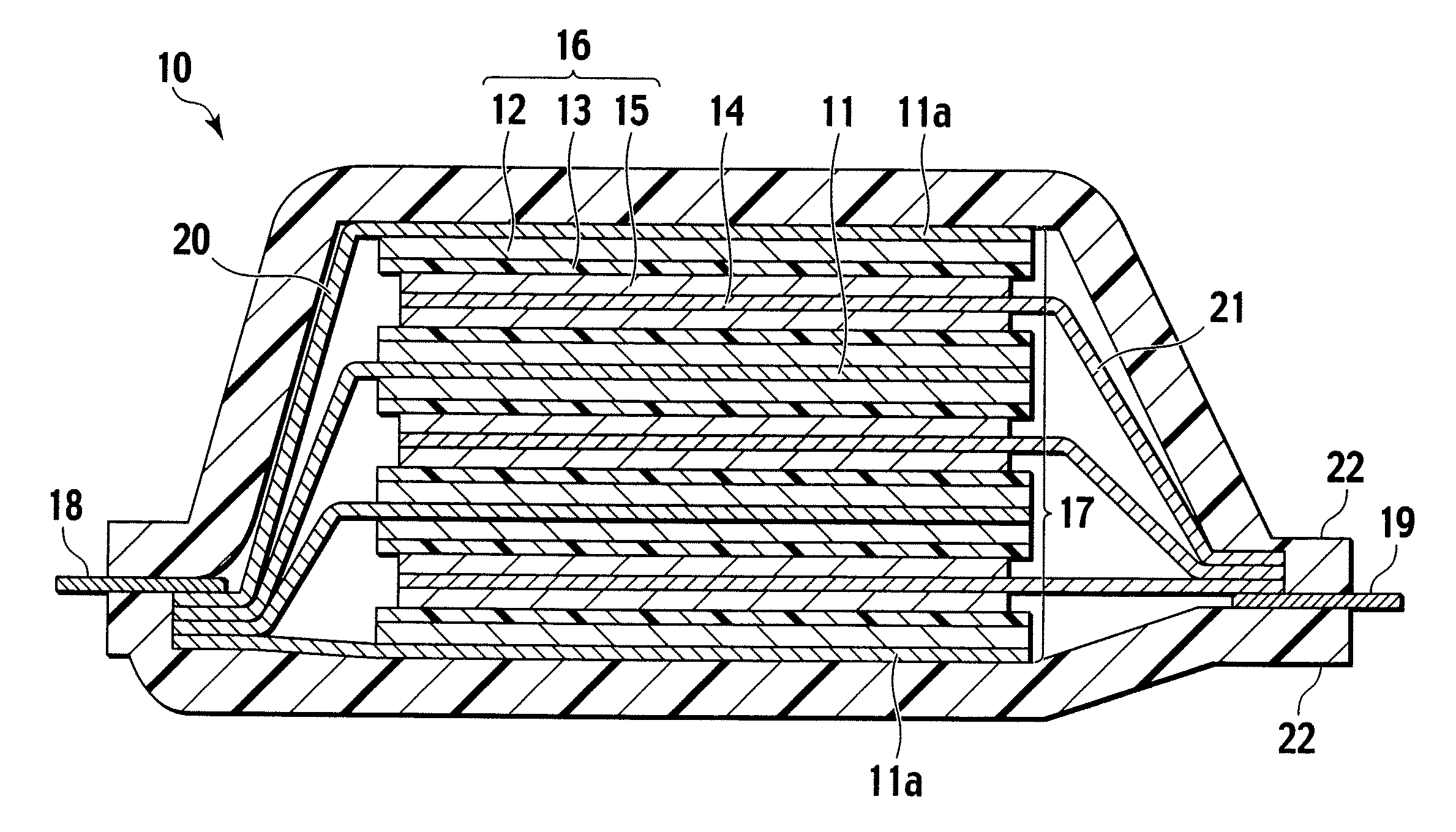

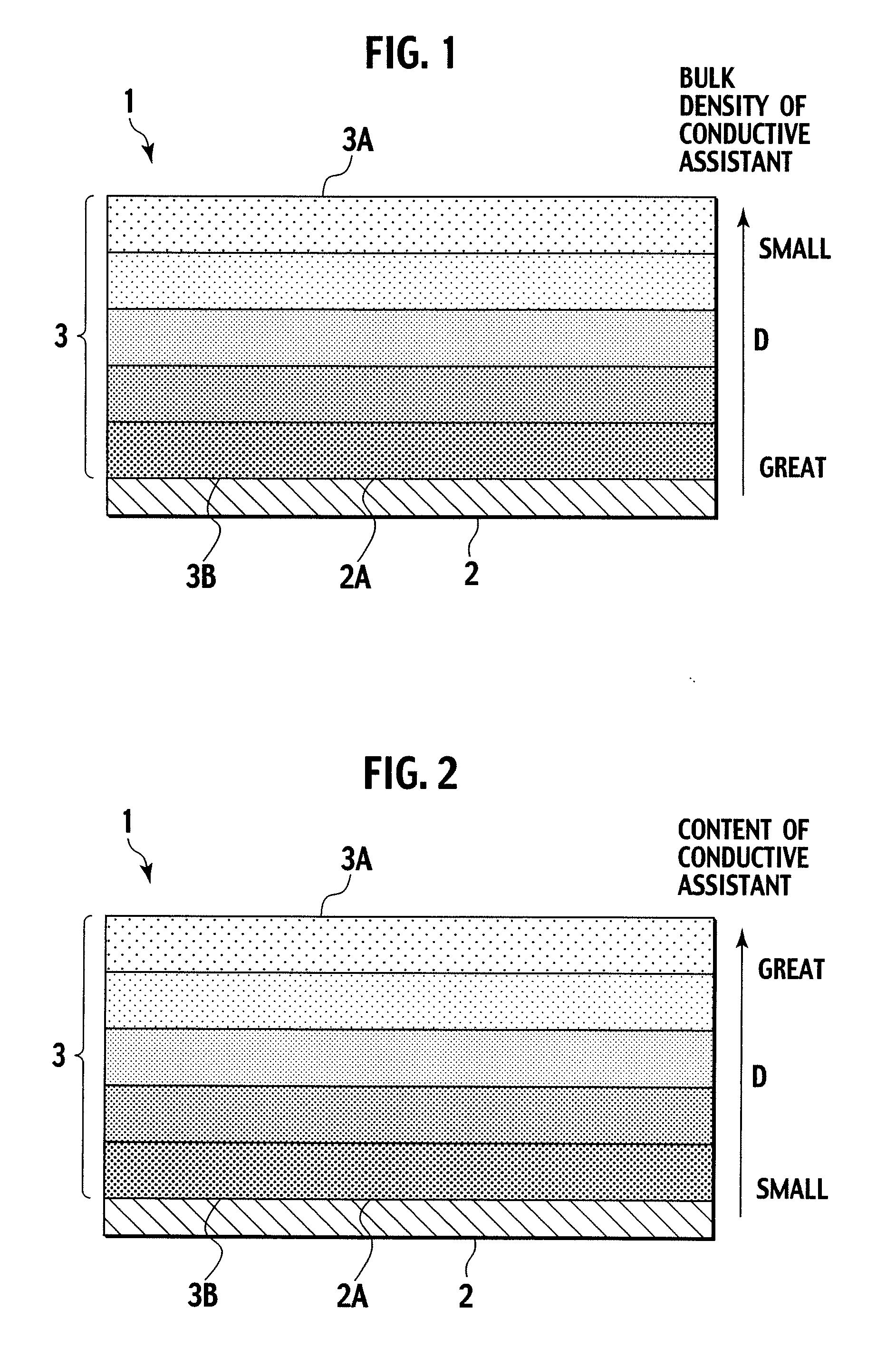

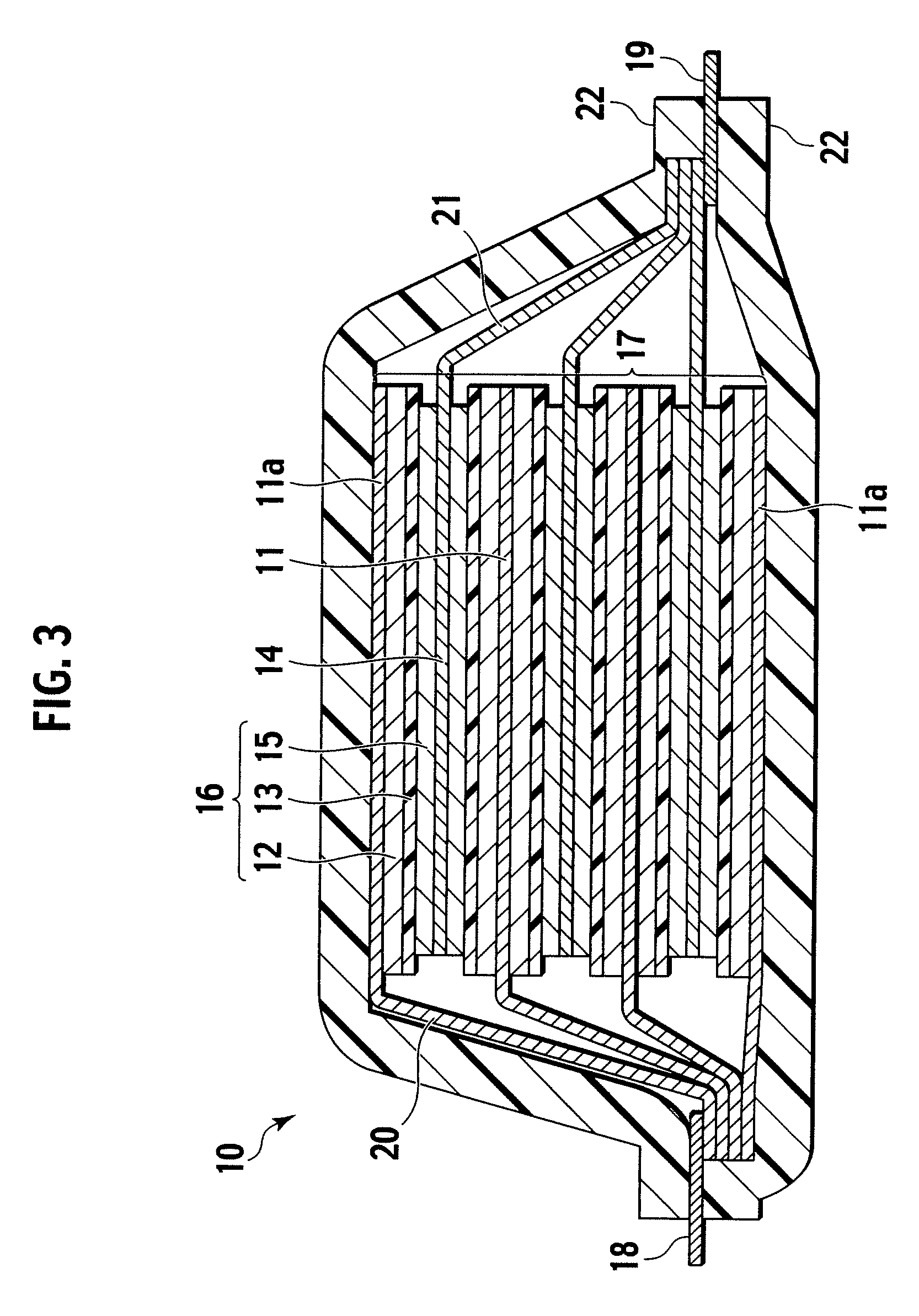

InactiveUS20080318133A1Increase productionEnergy densityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsEngineeringBattery cell

A battery electrode, includes: a collector; and an active material layer formed on a surface of the collector and including: an active material, and a conductive additive having a bulk density which is gradually decreased in a direction from a collector side of the active material layer to a surface side of the active material layer.

Owner:NISSAN MOTOR CO LTD

Carbon nanosphere with at least one opening, method for preparing the same, carbon nanosphere-impregnated catalyst using the carbon nanosphere, and fuel cell using the catalyst

InactiveUS20060239890A1Improve area utilizationReduce mass transfer resistanceMaterial nanotechnologySpecific nanostructure formationHigh current densityFuel cells

A carbon nanosphere has at least one opening. The carbon nanosphere is obtained by preparing a carbon nanosphere and treating it with an acid to form the opening. The carbon nanosphere with at least one opening has higher utilization of a surface area and electrical conductivity and lower mass transfer resistance than a conventional carbon nanotube, thus allowing for higher current density and cell voltage with a smaller amount of metal catalyst per unit area of a fuel cell electrode.

Owner:SAMSUNG SDI CO LTD

Battery electrode sheet

ActiveUS20090311607A1Reduce thicknessCell temperature controlActive material electrodesEngineeringElectrode material

A battery electrode sheet comprises a conductive substrate and an electrode material coated on at least a portion of the conductive substrate. The coated portion of the conductive substrate comprises a first region, a second region, and a transition region between the first and second regions. The electrode material on the first region has a first thickness; and the electrode material on the second region has a second thickness, which is smaller than the first thickness. The electrode material on the transition region has a thickness that decreases between the first and second regions.

Owner:BYD CO LTD

Binder for electrode for lithium ion secondary battery, and utilization thereof

InactiveUS6881517B1Improve featuresEasy to repeatElectrode carriers/collectorsElectrode collector coatingLithiumPhysical chemistry

A binder for a lithium ion secondary battery characterized by comprising a polymer containing structural units derived from 1,3-butadiene, said polymer having a 1,2-vinyl structure content in the range of 2% to 25% by mole. A lithium ion secondary battery provided with an electrode made using this binder exhibits improved characteristics at repetition of charge-discharge cycle and improved storage stability.

Owner:ZEON CORP

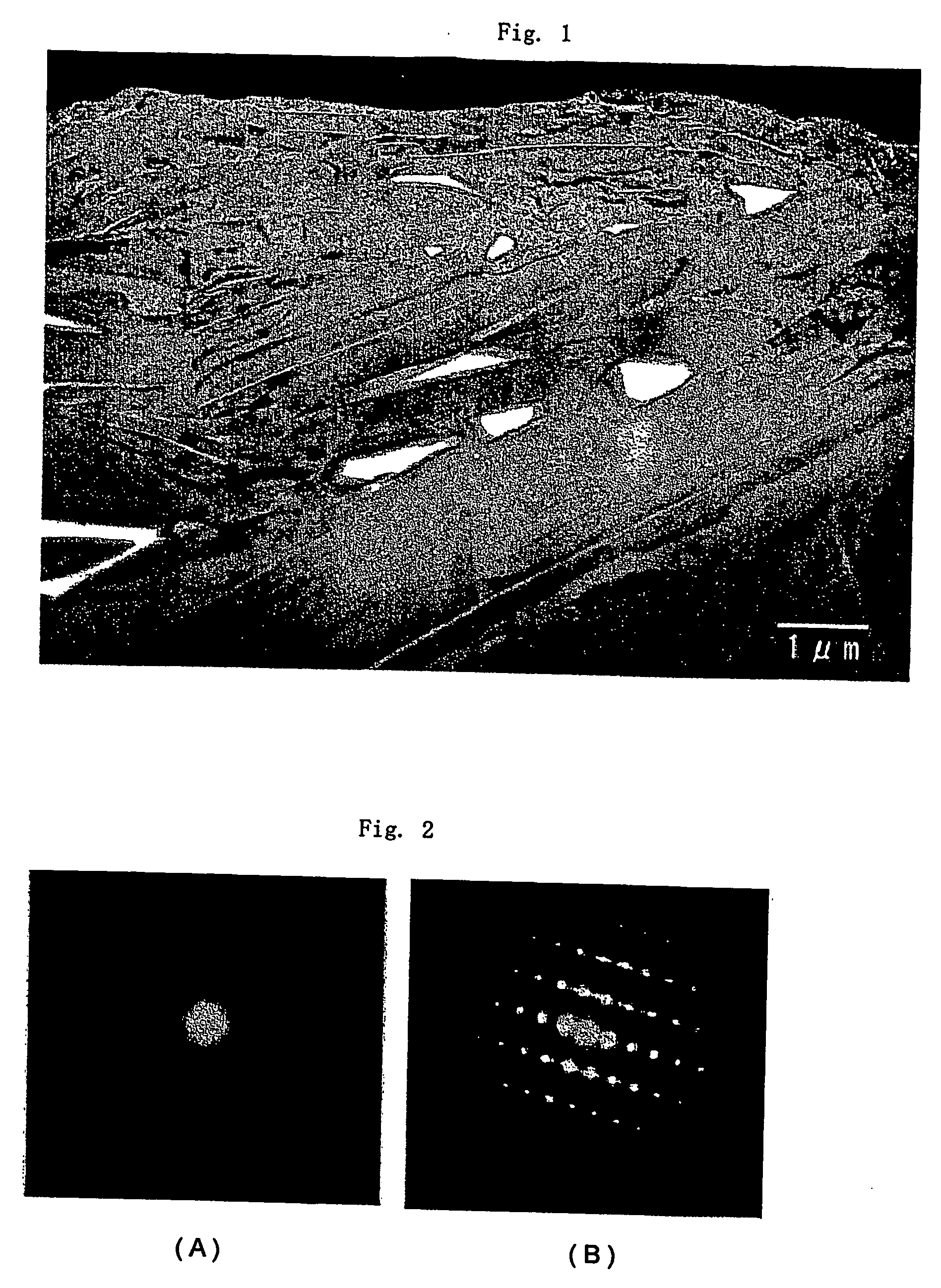

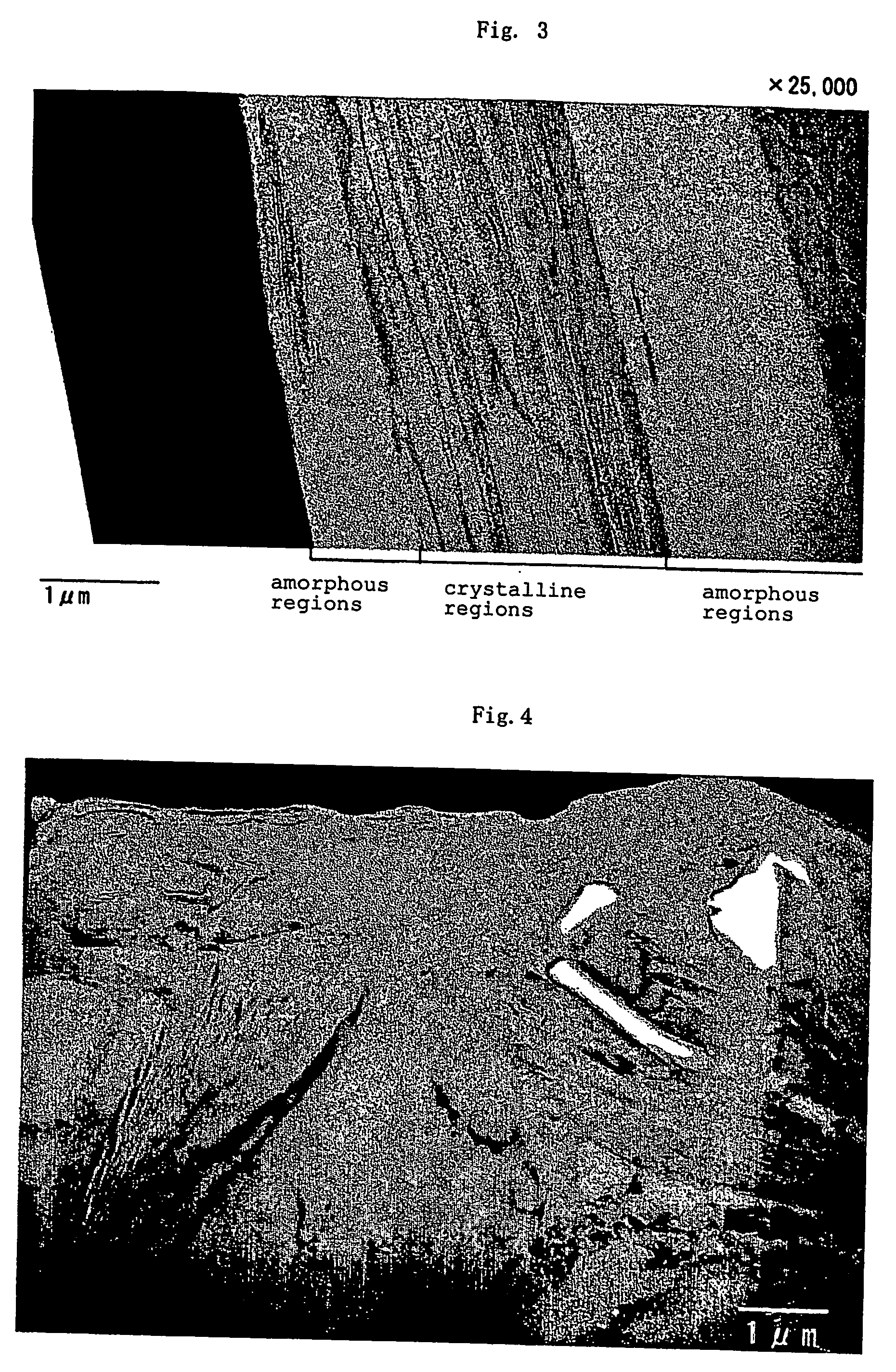

Carbon material for battery electrode and production method and use thereof

InactiveUS20060133980A1Improve discharge capacityReduce irreversible capacityElectrode manufacturing processesActive material electrodesFiberCarbon fibers

The invention relates to a carbon material for forming a battery electrode, comprising carbon powder having a homogeneous structure which is produced by causing an organic compound, serving as a ra.w material of a polymer, to deposit onto and / or permeate into carbonaceous particles, and subsequently polymerizing the organic compound, followed by thermal treatment at a temperature of 1,800 to 3,300° C., which comprises a structure which is substantially uniform throughout the entirety of the particle from the surface to the central core where a graphite crystal structure region and an amorphous structure region are distributed. By using the material, a battery having high discharging capacity and low irreversible capacity, with excellent coulombic efficiency and excellent cycle characteristics can be fabricated. The carbon material of the invention may contain carbon fiber filaments. Average roundness, BET specific surface area, true density, laser Roman R value, and average particle size were investigated.

Owner:SHOWA DENKO KK

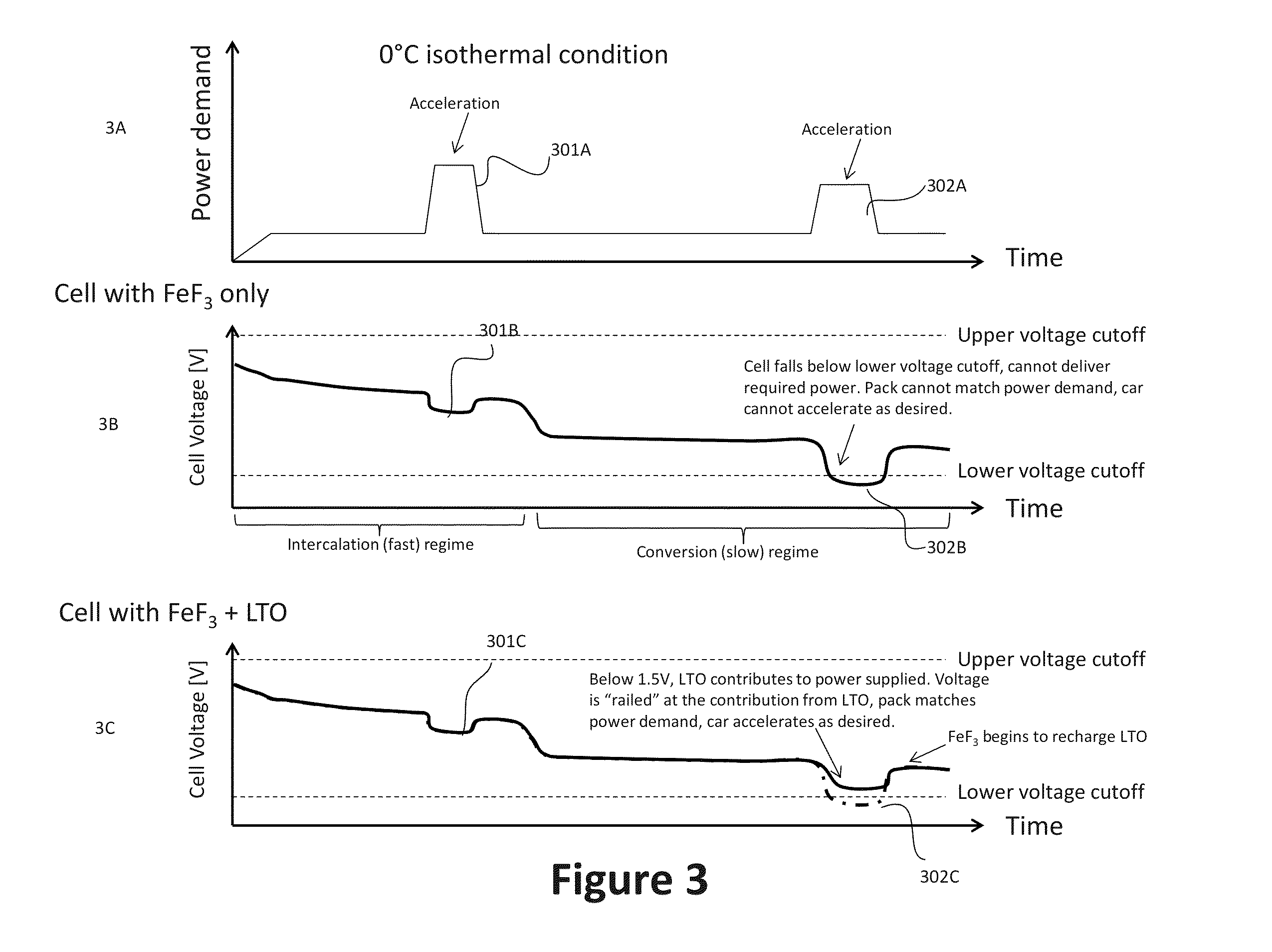

Hybrid electrodes with both intercalation and conversion materials

InactiveUS20150243974A1Reduce voltageElectrode carriers/collectorsSolid electrolyte cellsEngineeringBattery electrode

The disclosure set forth herein is directed to battery devices and methods therefor. More specifically, embodiments of the instant disclosure provide a battery electrode that comprises both intercalation chemistry material and conversion chemistry material, which can be used in automotive applications. There are other embodiments as well.

Owner:QUANTUMSCAPE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com