Patents

Literature

46results about How to "Increase electrode capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

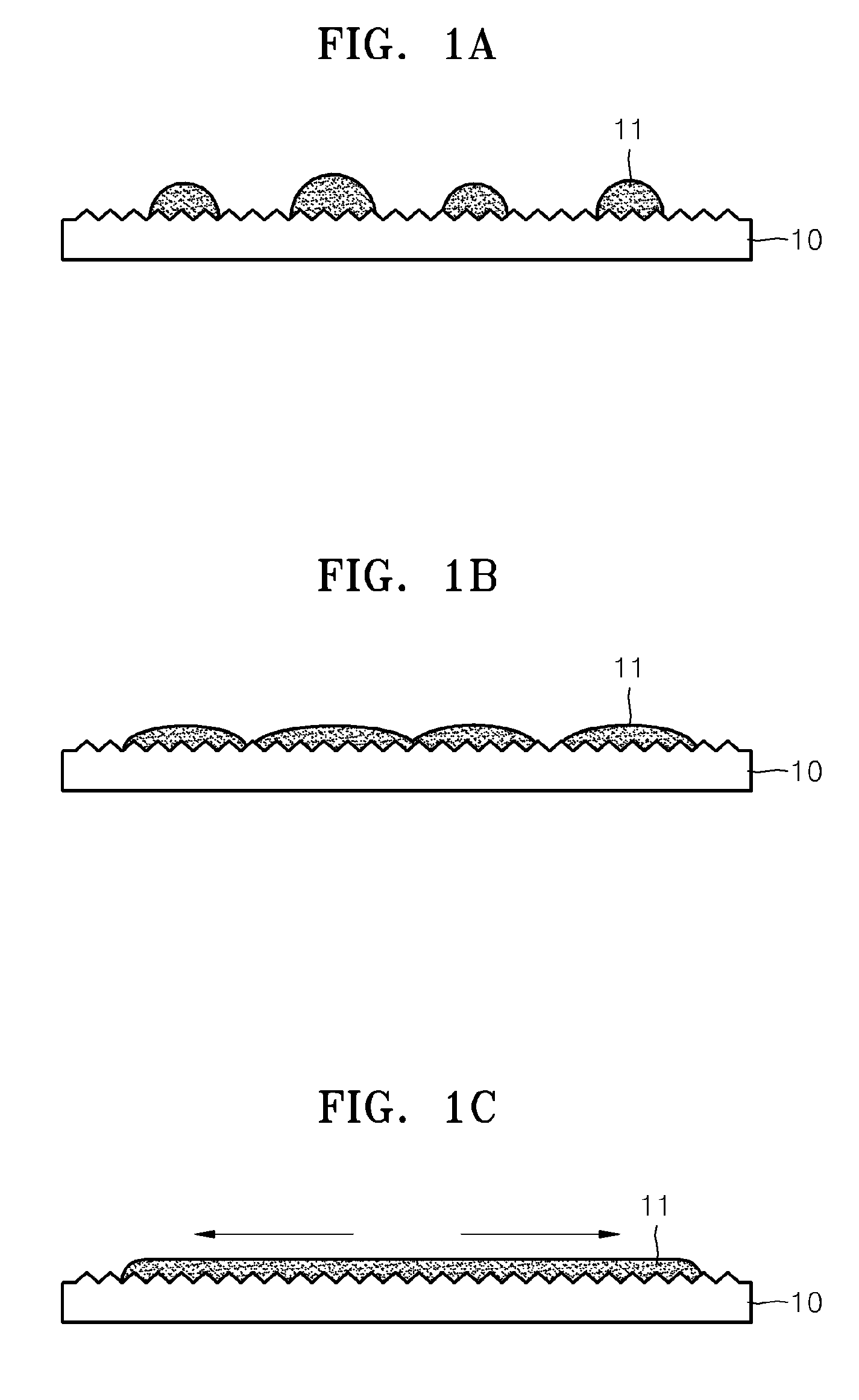

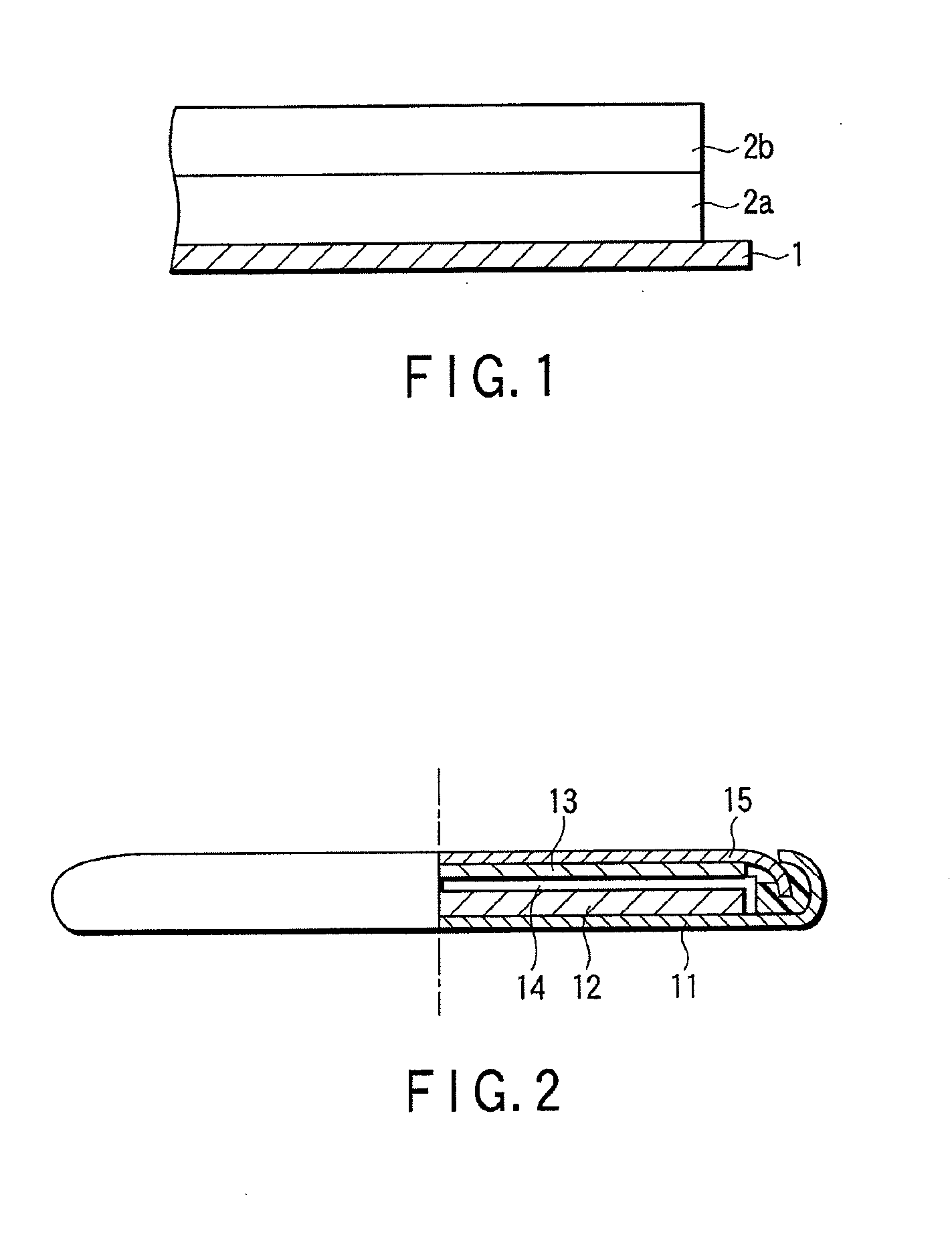

Electrode for secondary battery, manufacturing method thereof and secondary battery employing the same

InactiveUS20090098457A1Improve thickness uniformityIncrease electrode capacityCylinder pressesPlaten pressesElectrical batterySurface roughness

Provided are an electrode for a secondary battery employing an active material layer having improved thickness uniformity by printing low-viscosity ink on the active material layer, a manufacturing method of the electrode, and a secondary battery having improved electrode capacity due to the employing of the electrode. The electrode includes a current collector, and an active material layer formed by printing ink having a viscosity not exceeding 500 mPa·s on the current collector and drying the current collector, wherein the current collector has a surface roughness (Ra) in a range from about 0.025 to 1.0 μm.

Owner:SAMSUNG ELECTRONICS CO LTD

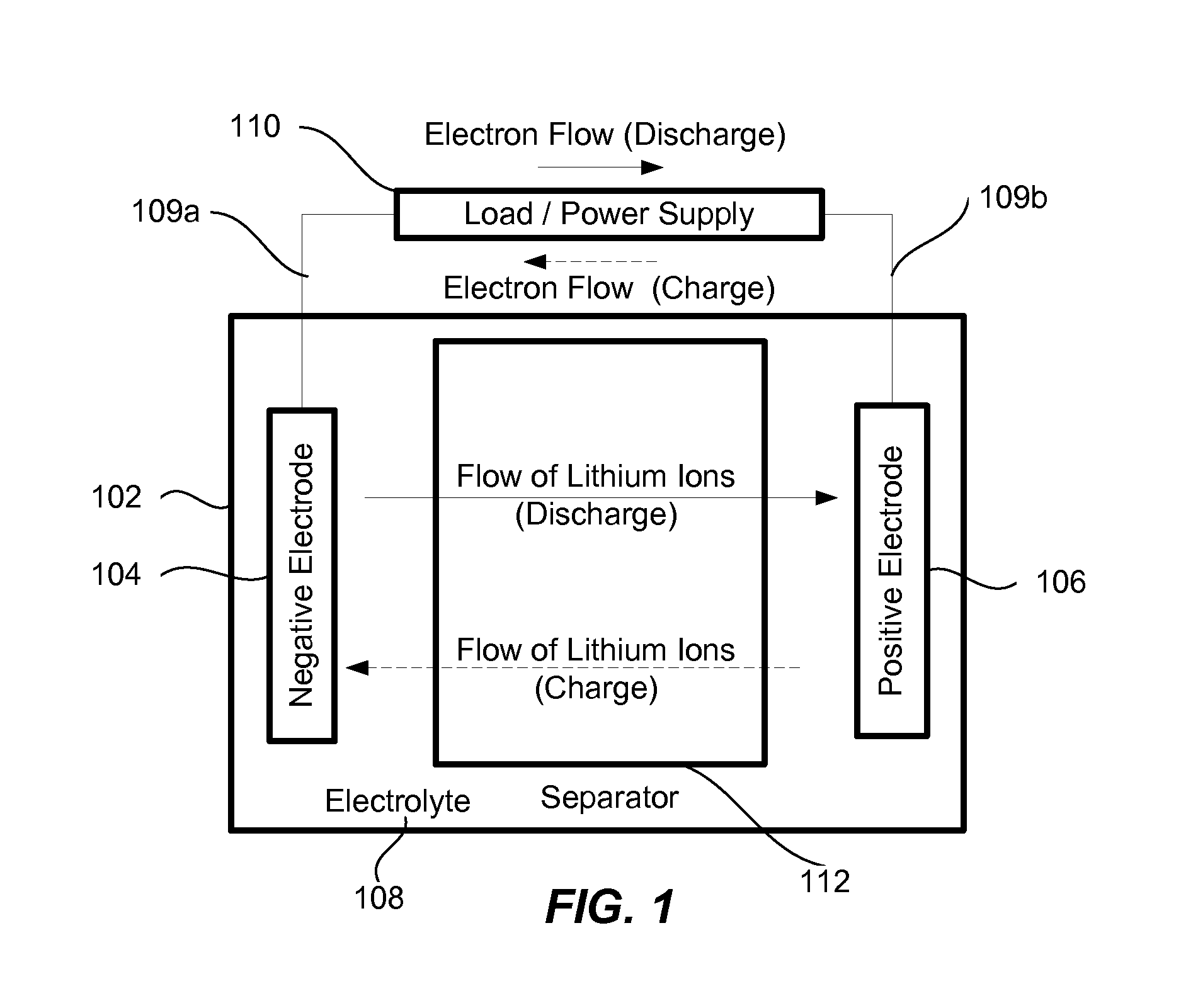

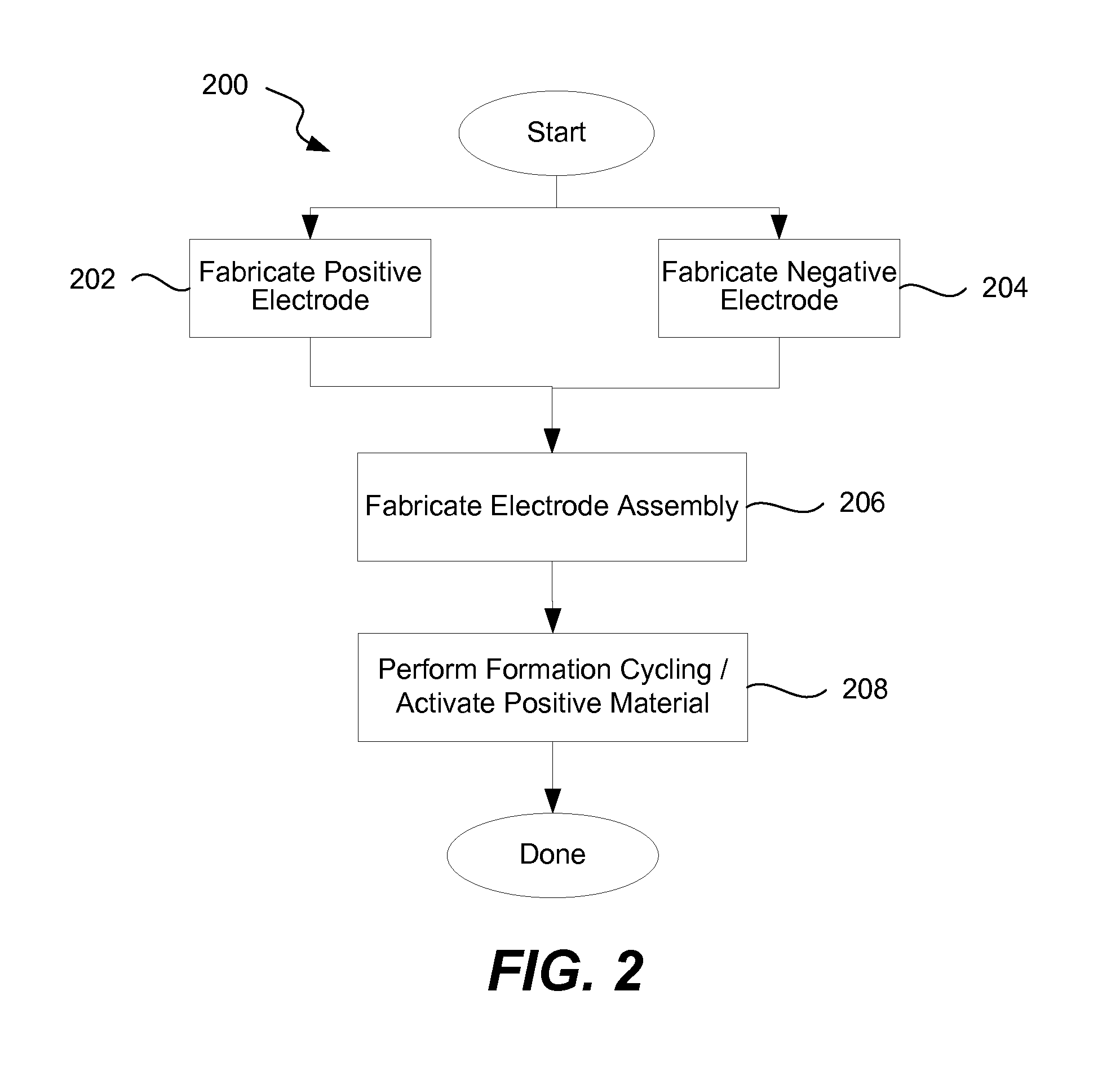

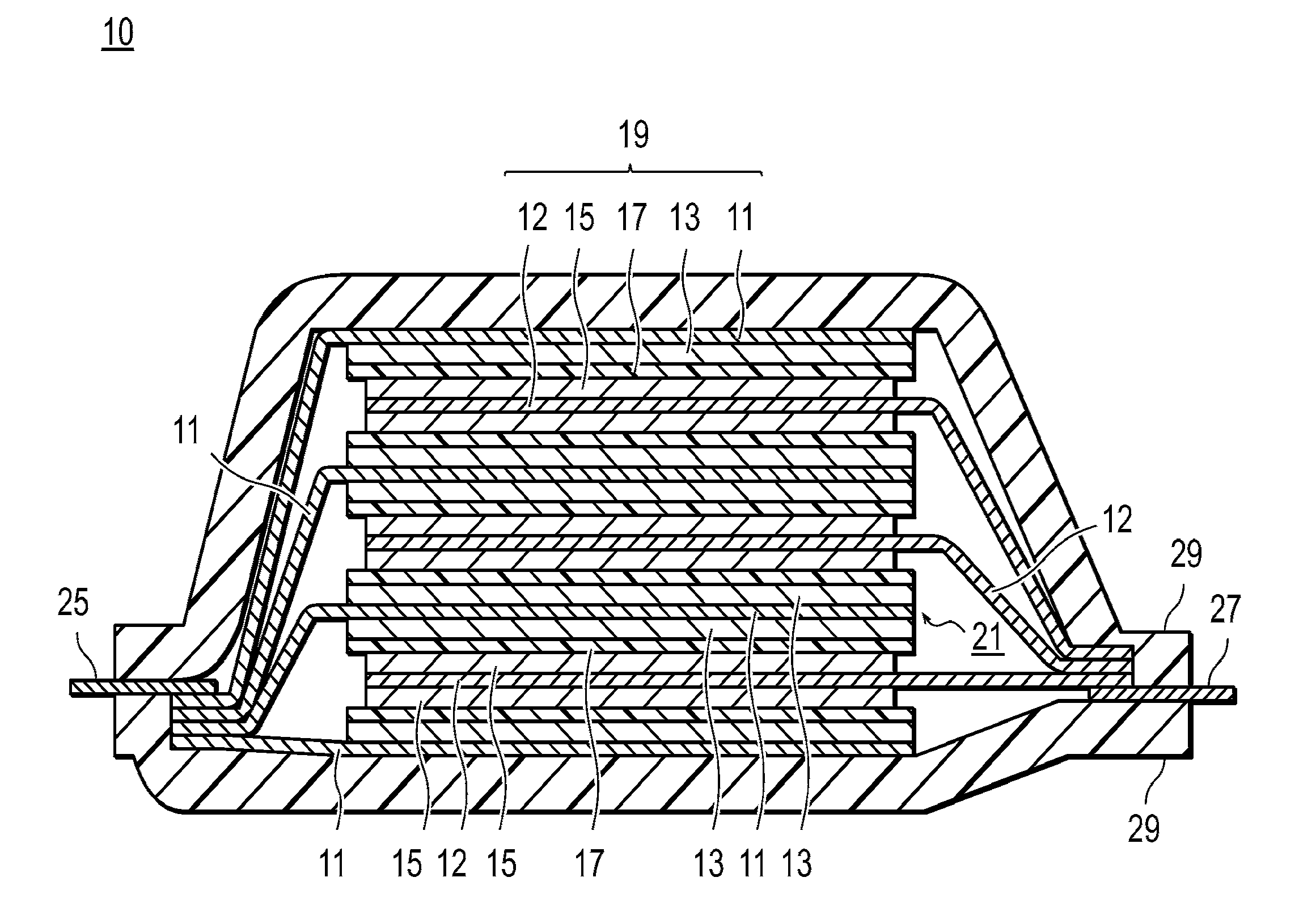

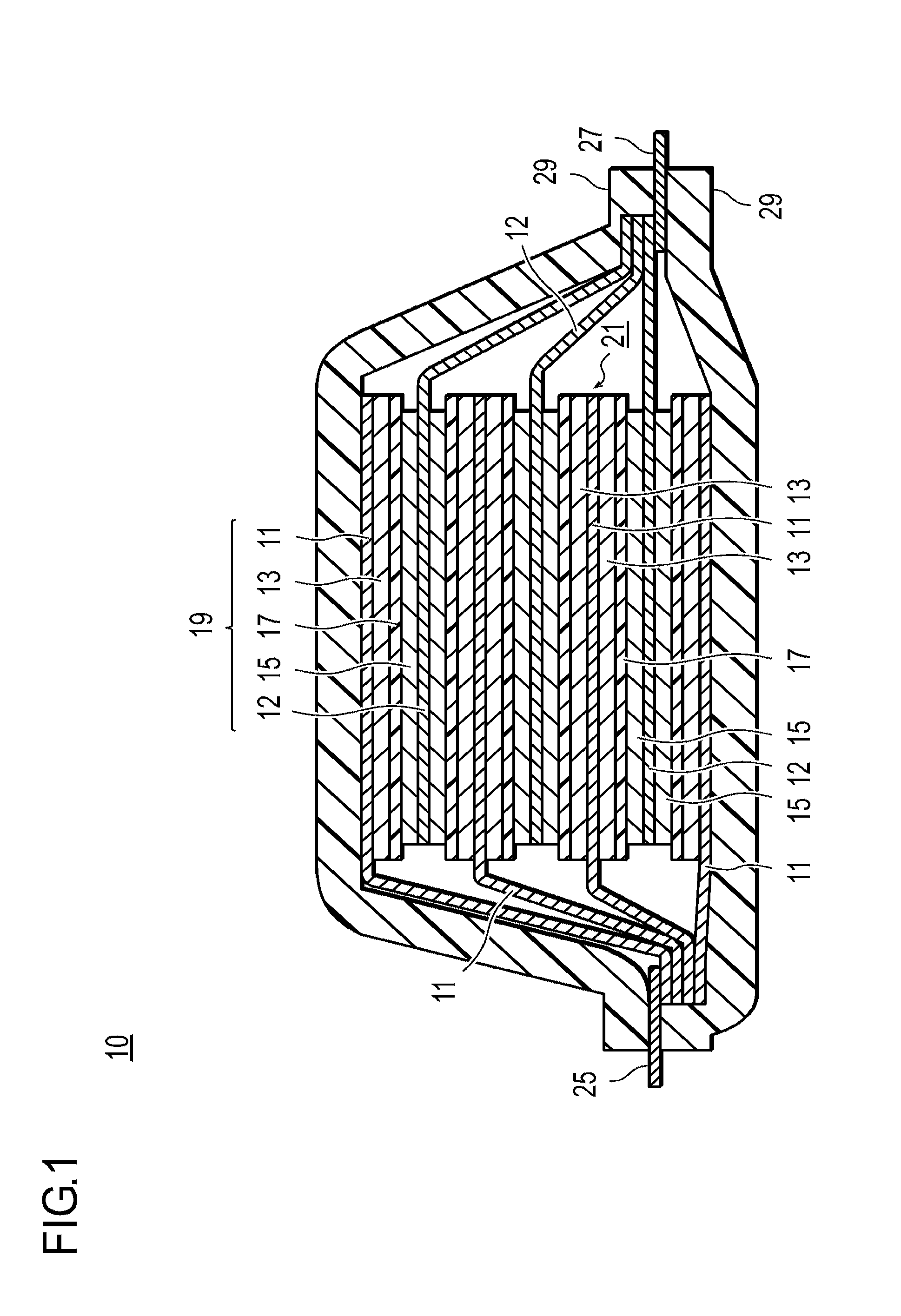

Variable capacity cell assembly

InactiveUS20110171502A1Increase electrode capacityLarge capacityBatteries circuit arrangementsAlkaline accumulatorsCapacity lossActive component

Electrochemical cells containing nanostructured negative active materials and composite positive active materials and methods of fabricating such electrochemical cells are provided. Positive active materials may have inactive components and active components. Inactive components may be activated and release additional lithium ions, which may offset some irreversible capacity losses in the electrochemical cells. In certain embodiments, the activation releases lithium ion having a columbic content of at least about 400 mAh / g based on the weight of the activated material.

Owner:AMPRIUS INC

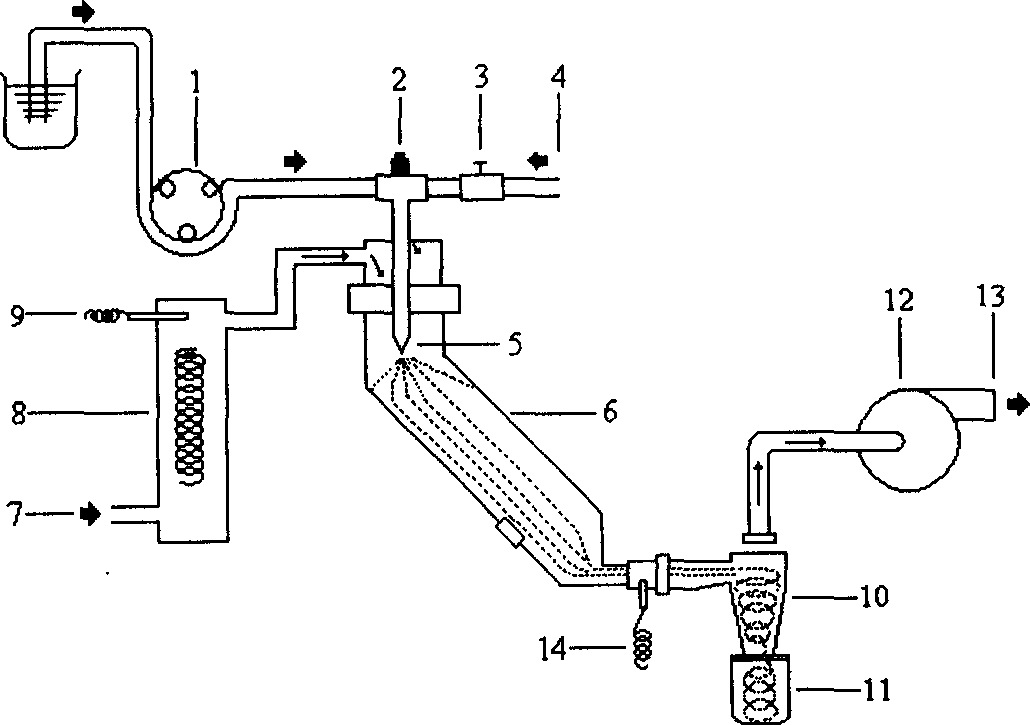

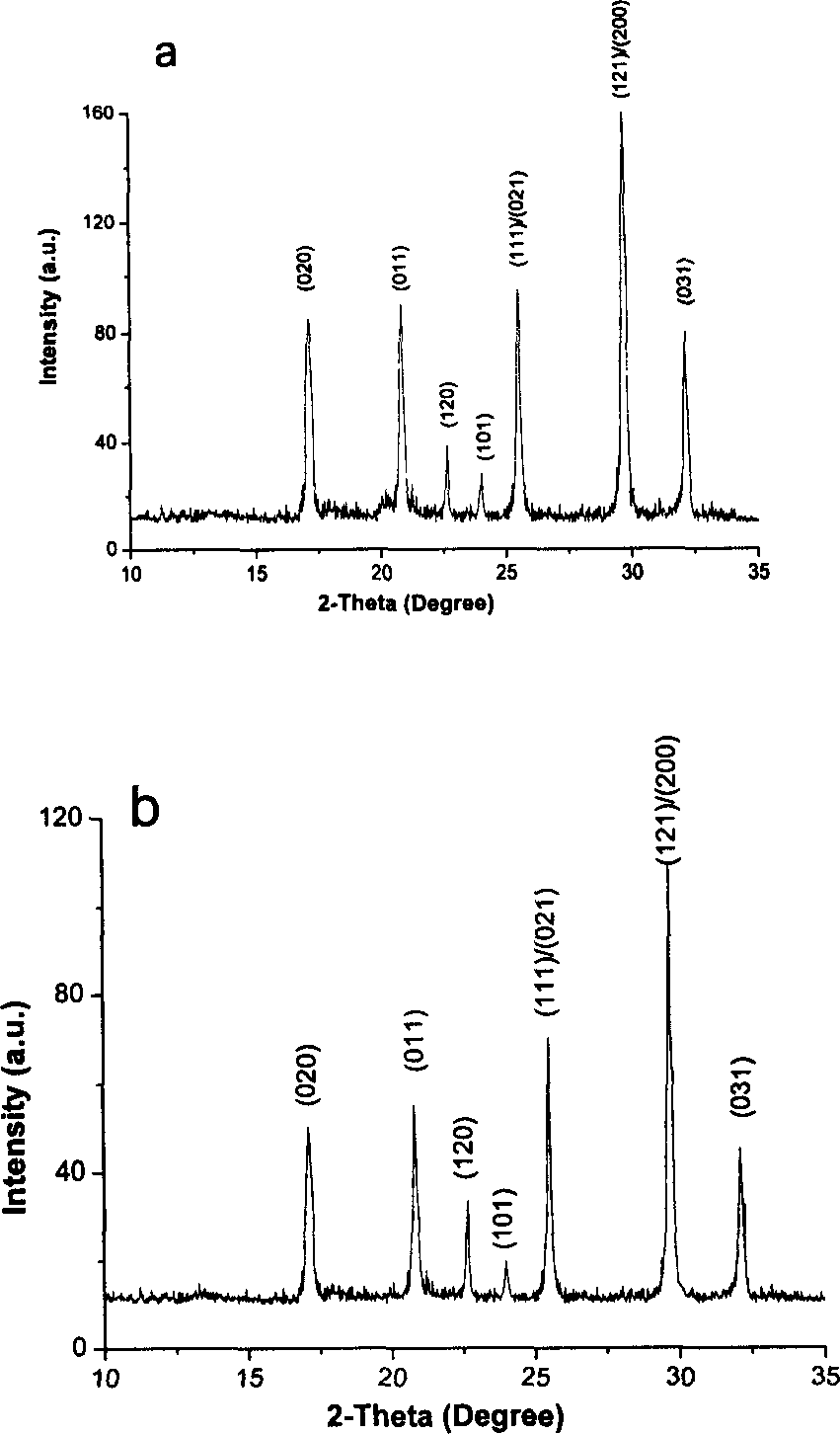

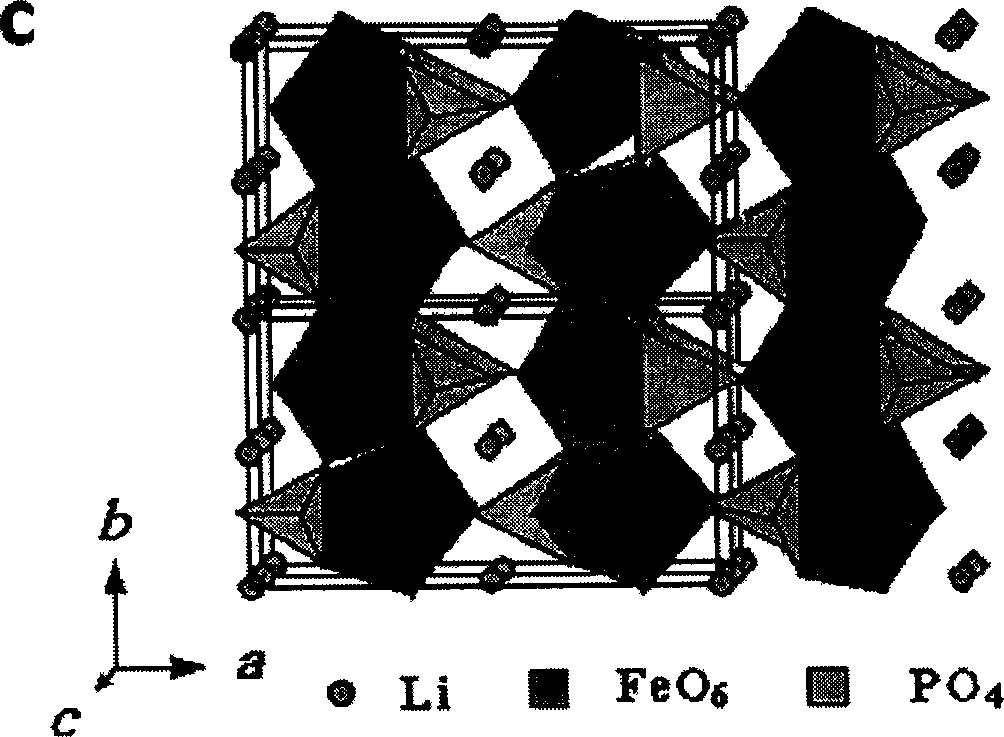

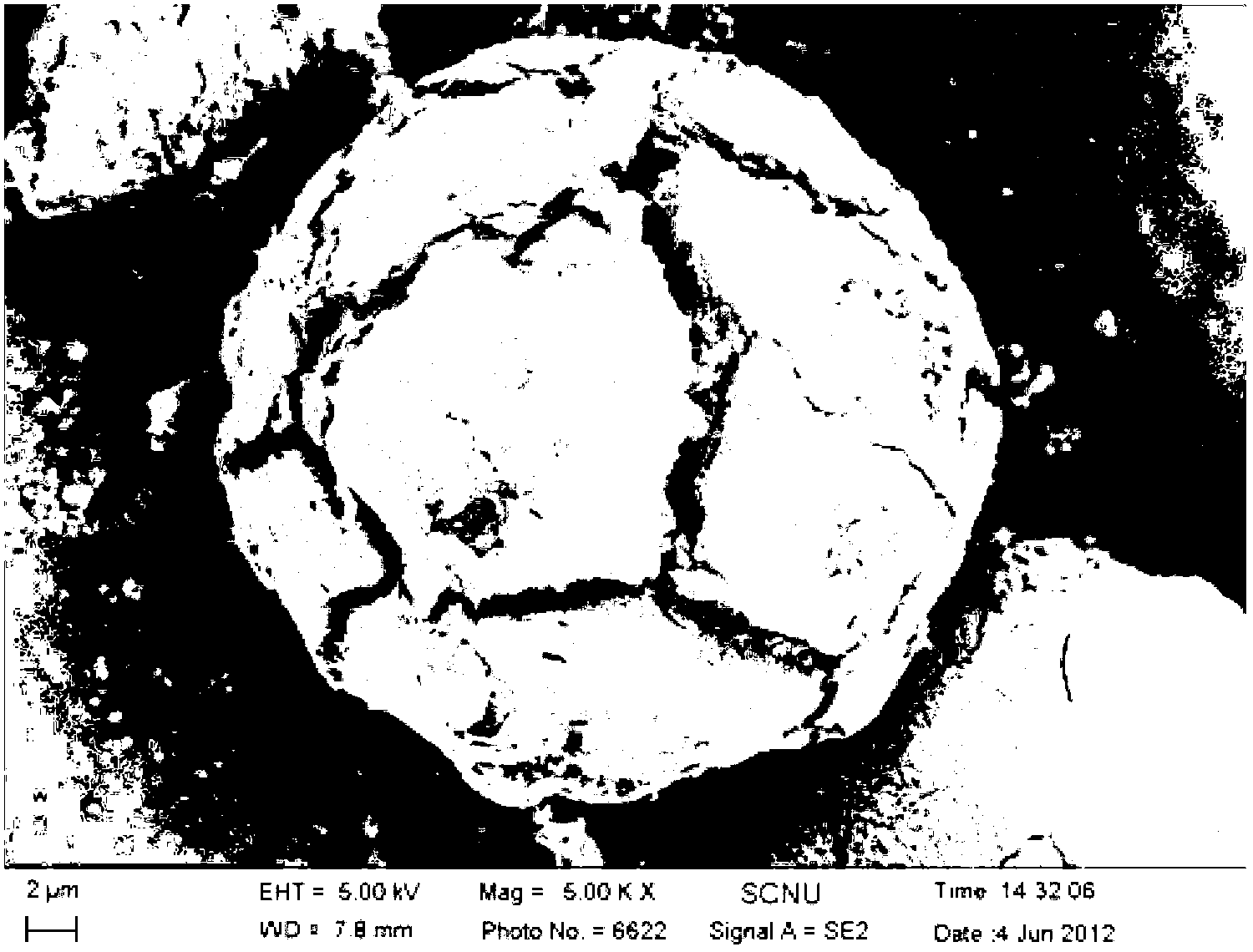

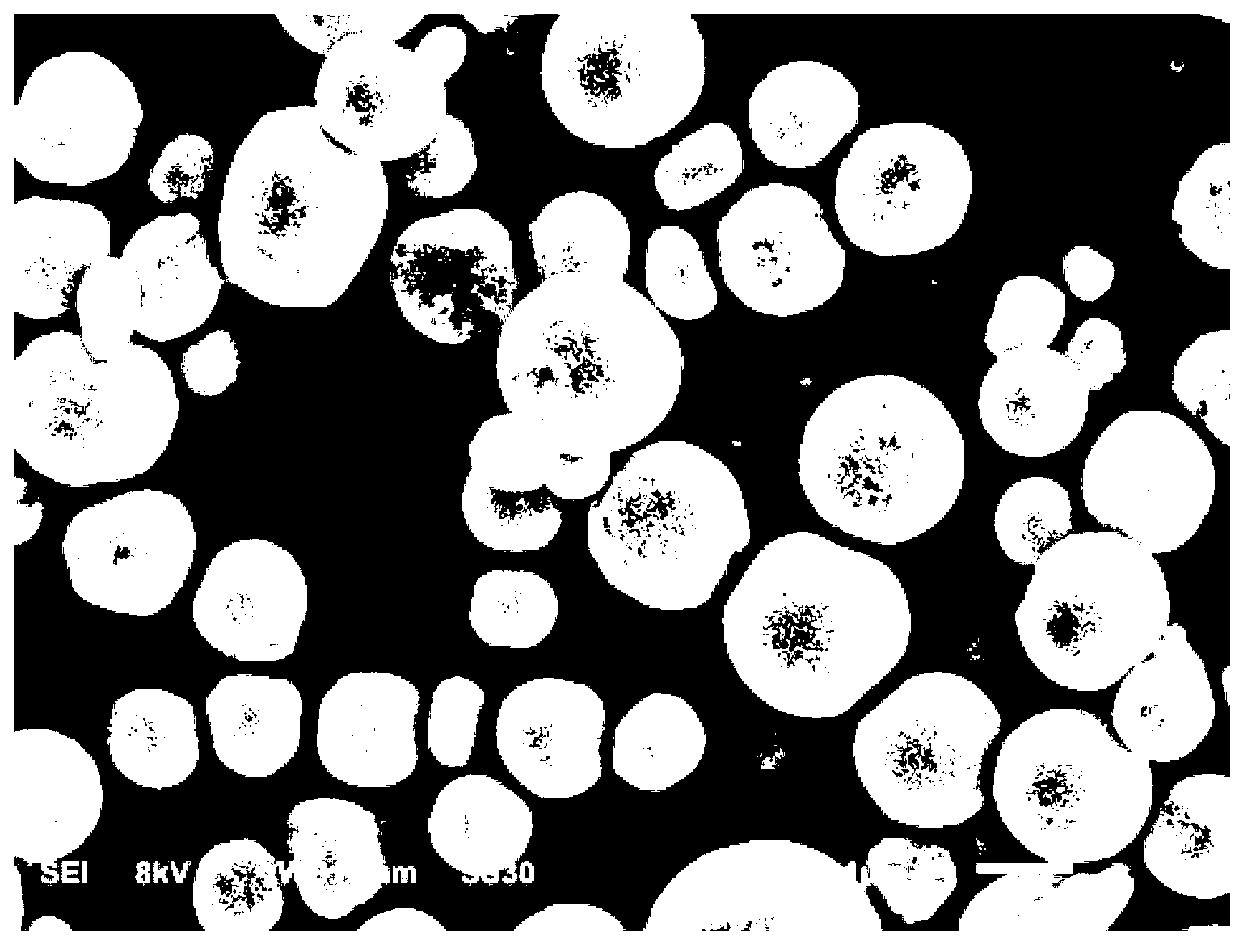

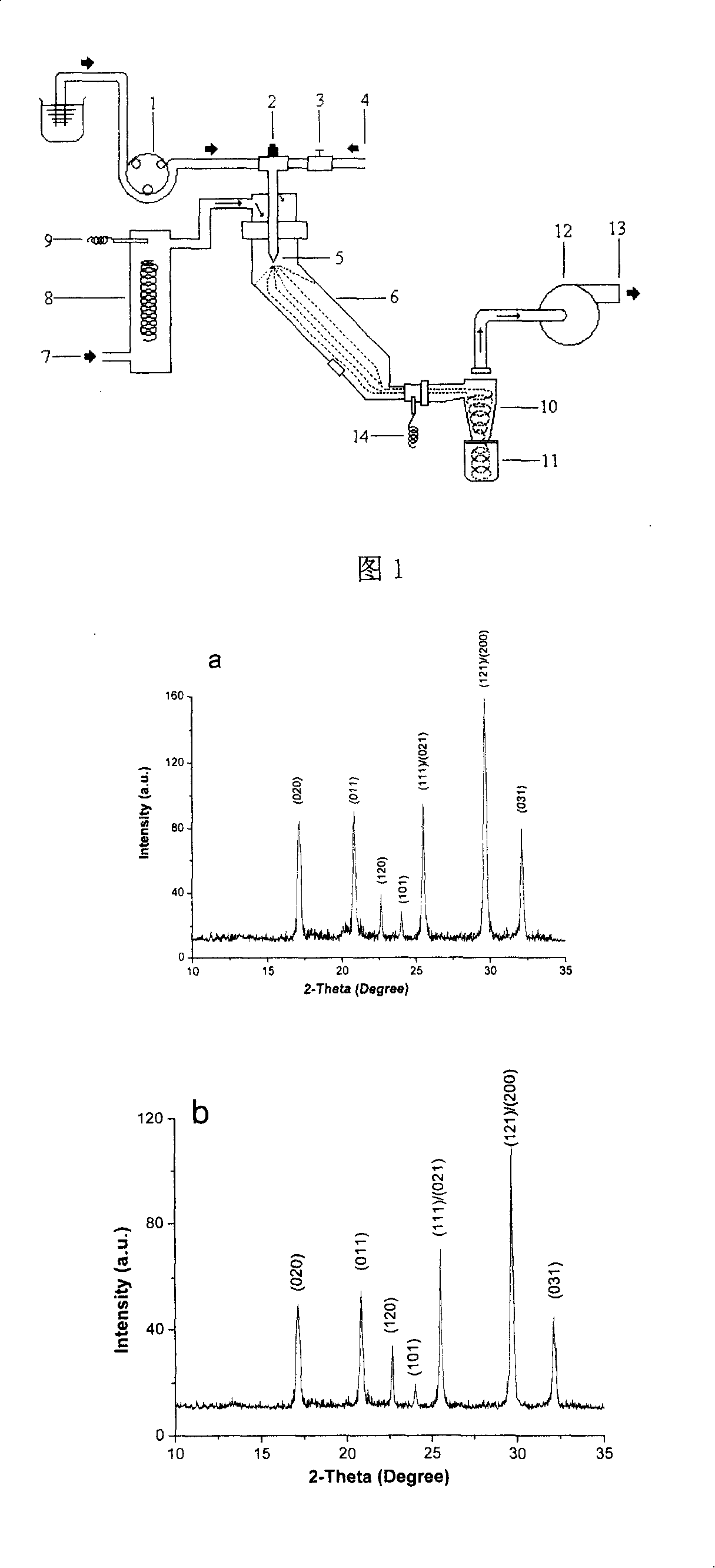

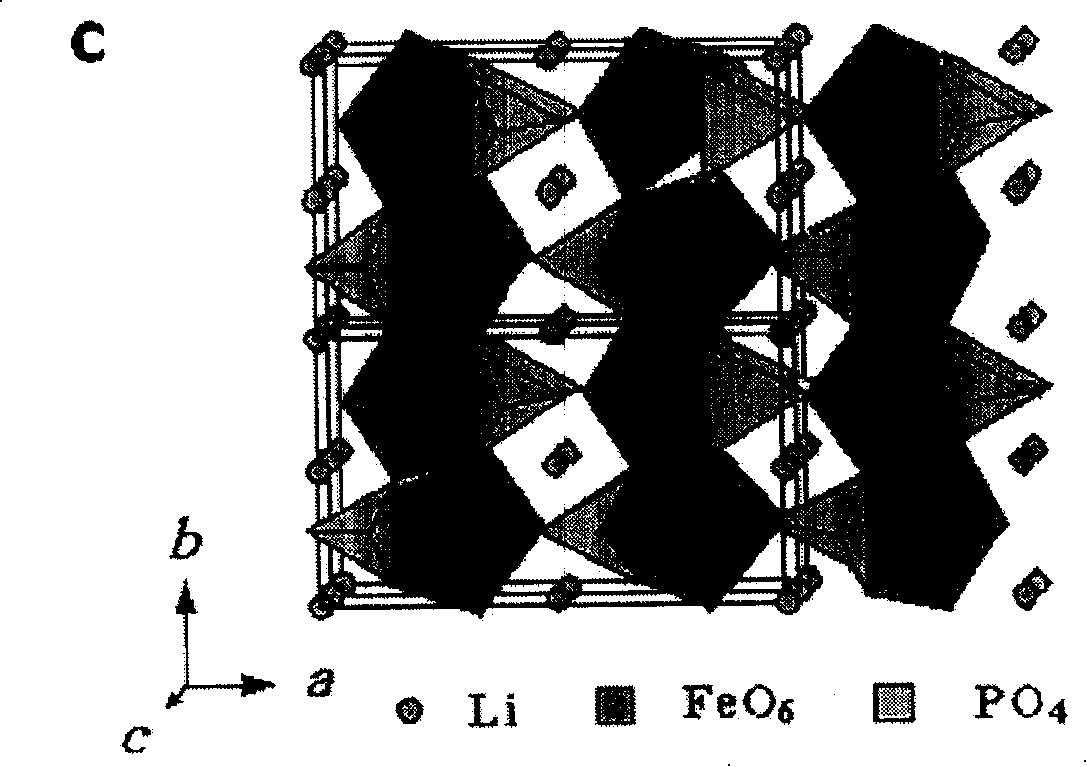

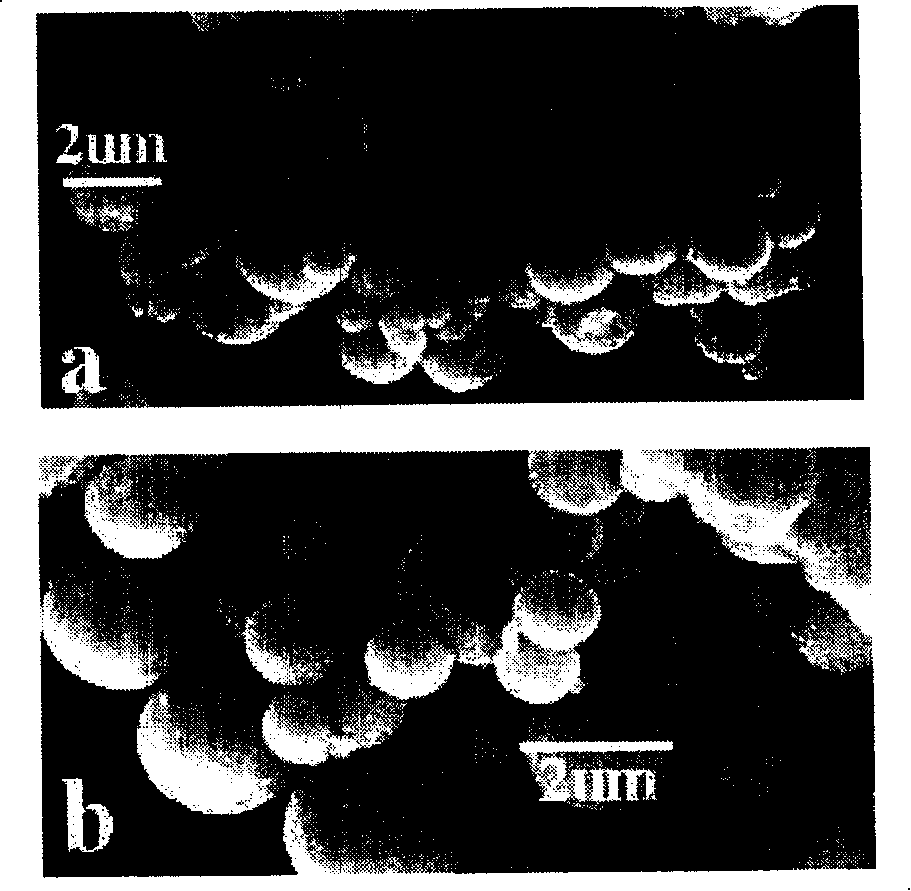

Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

InactiveCN1773754AProlong the fall timePromote growthCell electrodesPhosphorus compoundsLithium iron phosphateHigh density

An electrode material of Fe¿CLi phosphate and its composite metal phosphate is electrode material of LiFePO4 and LiFePO4 / MxP in high density spherical shape with diameter of 2micro m. The electrode material of LiFePO4 and LiFePO4 / MxP can be prepared by low ¿C temperature controllable one ¿C stage atomizing process in short flow.

Owner:NANKAI UNIV

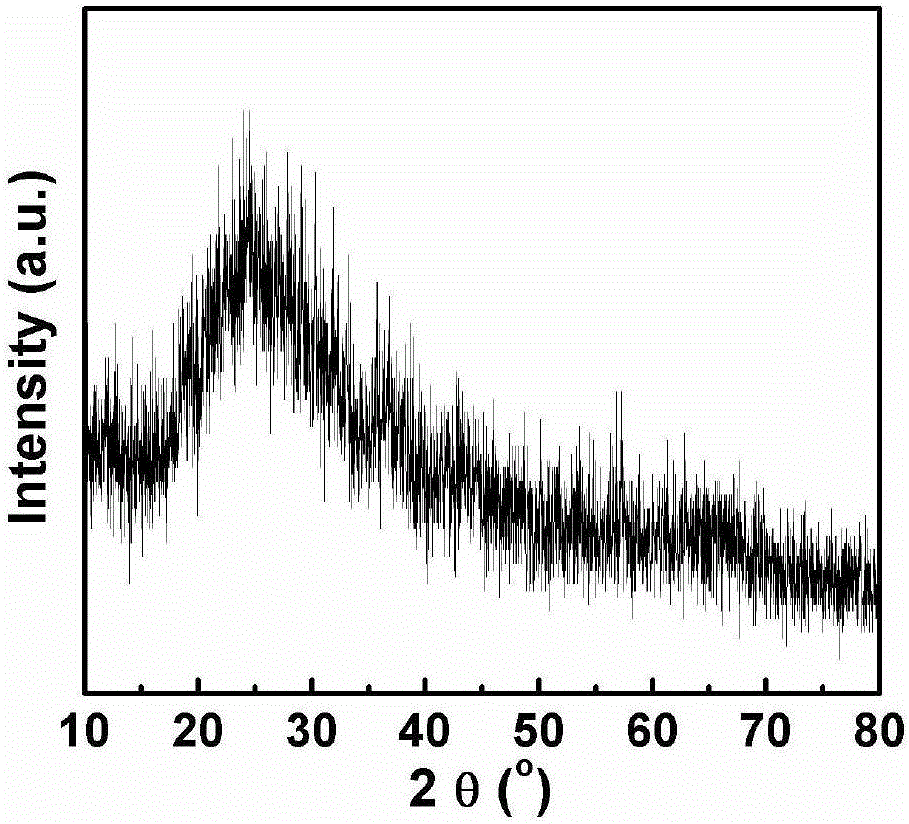

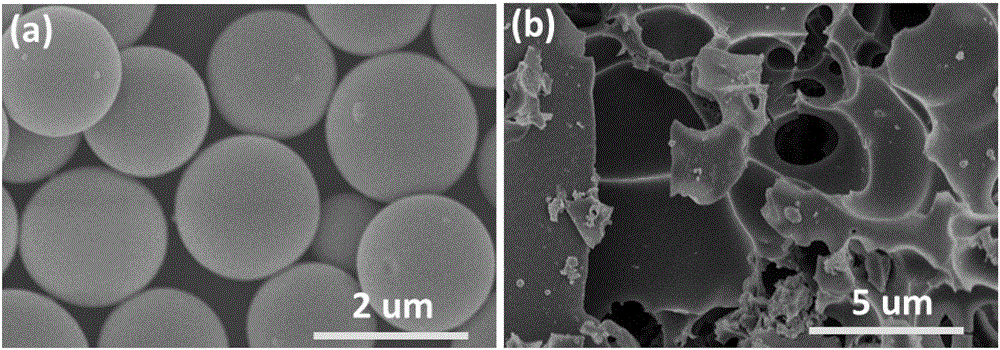

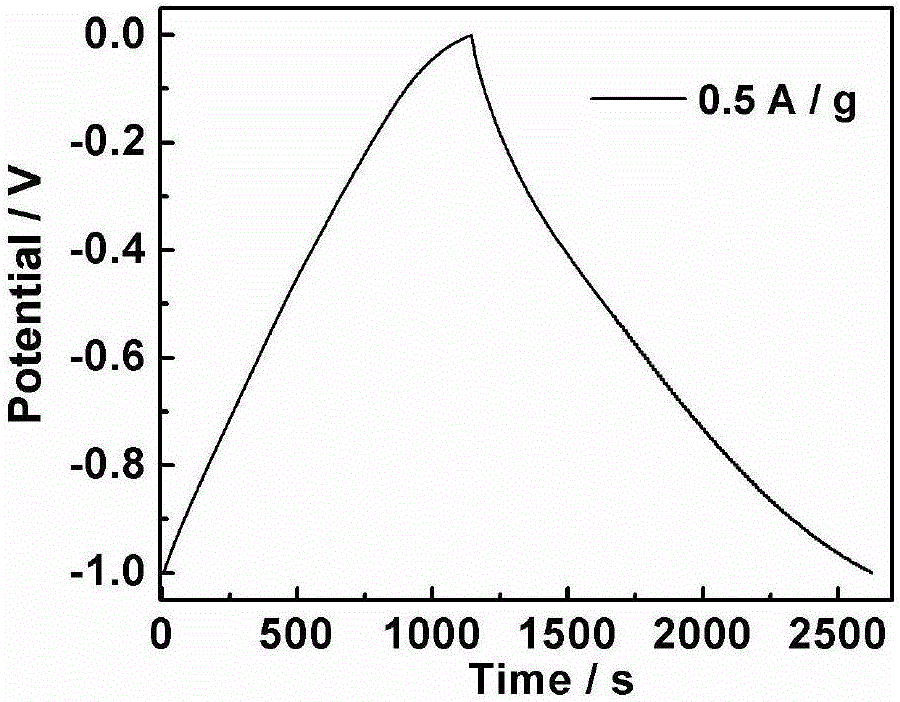

Preparation method with polysaccharide modified activated carbon as supercapacitor electrode material

InactiveCN105118678AEasy to operateStrong repeatabilityHybrid capacitor electrodesHybrid/EDL manufactureActivated carbonPotassium hydroxide

The invention provides a preparation method with polysaccharide modified activated carbon as a supercapacitor electrode material. Firstly, a polysaccharide thermal reaction is carried out to obtain a carbon ball, then the carbon ball and potassium hydroxide are mixed and soaked such that the potassium hydroxide is fully diffused into a carbon material, and finally the mixture is subjected to high-temperature calcinations such that the carbon ball is activated by the potassium hydroxide to obtain an activated carbon material. The polysaccharide modified activated carbon material prepared by using the method has the advantages of rich level pore structures and a large specific surface area, as a supercapacitor electrode material, the electrode capacity is high to 510F / g, and the method has the advantages of simple process operation, high reproducibility and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

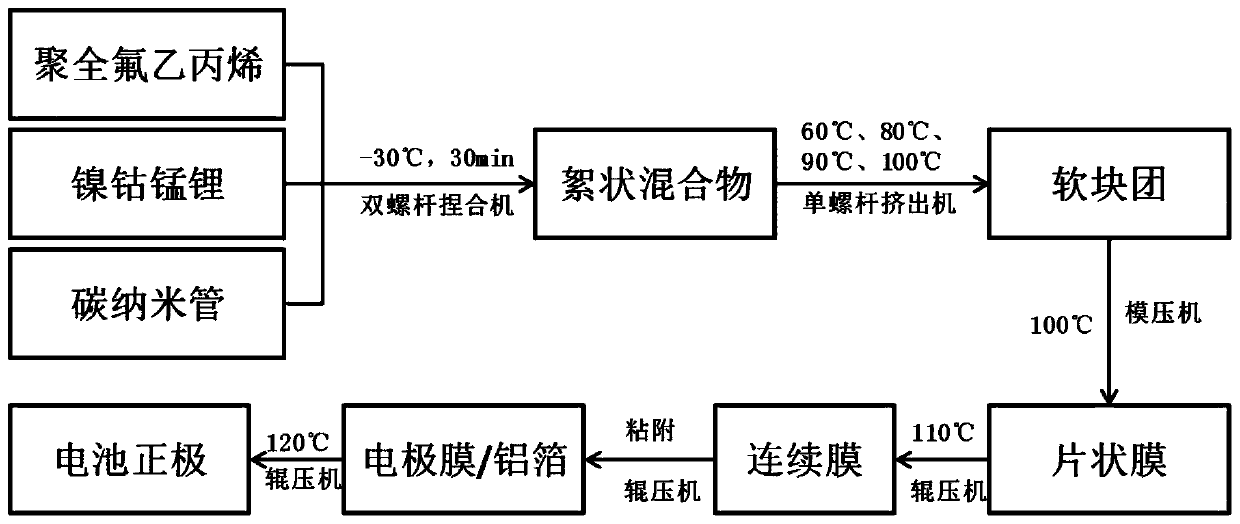

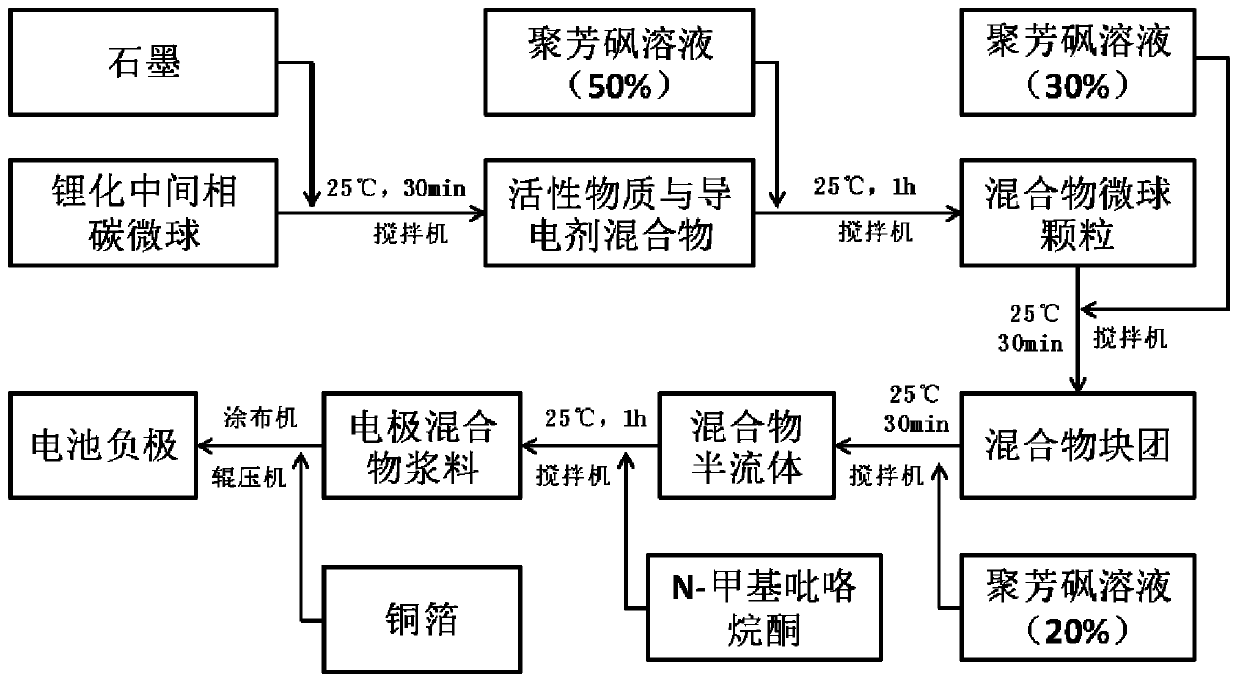

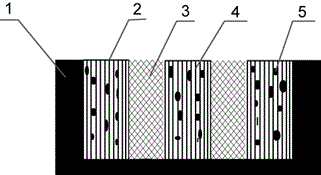

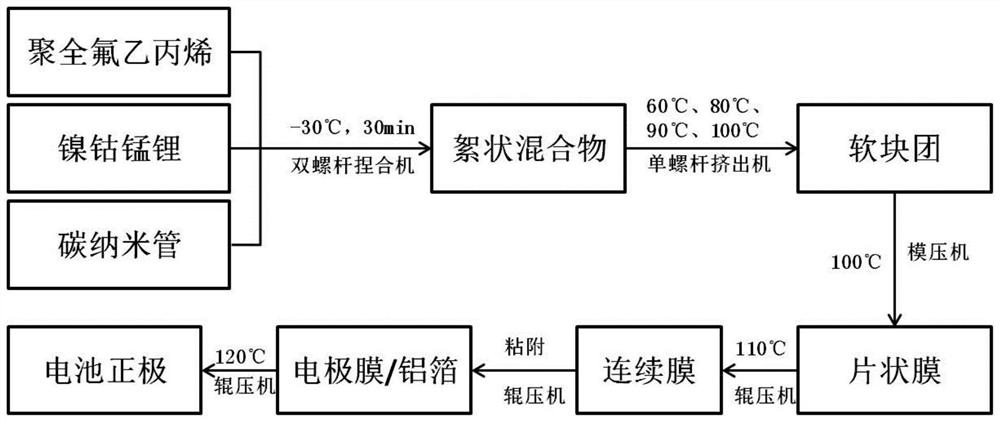

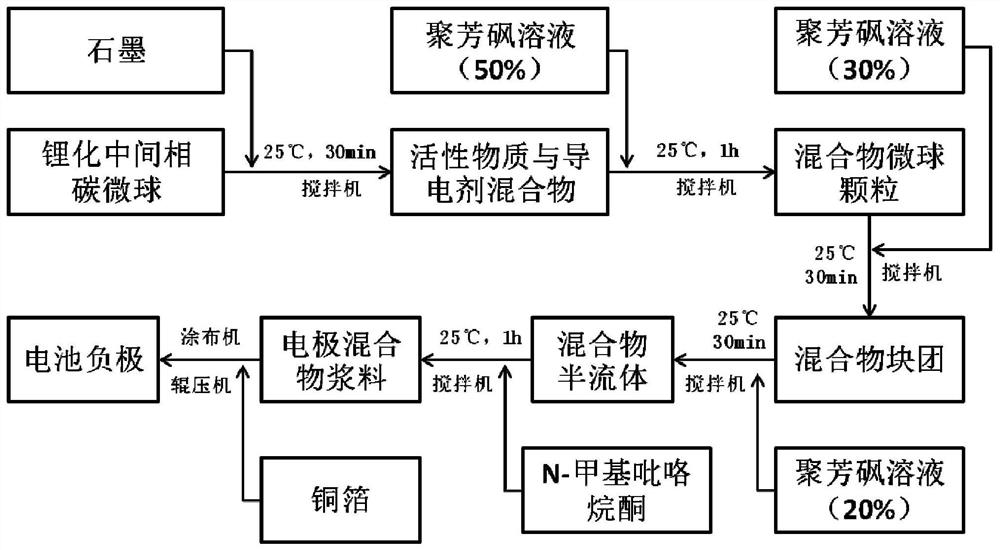

Electrode preparation method and battery

ActiveCN109841796AIncrease areal densityImprove structural stabilityElectrode manufacturing processesSecondary cellsLamellar crystalsInternal resistance

The invention discloses an electrode preparation method and a battery. The battery anode is prepared by pasting an electrode film prepared from an active substrate, a conductive agent and a binder toa current collector, the surface density of a pole piece is improved, the electrode capacity and the pole piece stability are improved, and the internal resistance is reduced. In the preparation process of the electrode film, lamellar crystals of the binder are stretched to paste the active substance and conductive agent, influence of expansion and contraction of the active substance caused by ionembedding and separating is reduced. The battery cathode is prepared by coating a slurry prepared from a pre-lithium active substance, a binder and a conductive agent on the current collector, the active substrate and conductive agent of the cathode are wetted rapidly, dispersed ultra-finely and homogeneous in a binder solution, the amount of the solvent for slurry dispersion is reduced, energy consumption for drying is reduced, the electrode process is shortened, and the load capacity of the cathode active substance is improved. The anode and cathode of the battery can be designed in an integrated way, and energy storage of the battery is improved. The electrode preparation method is simple, production and manufacture are realized by means of existing equipment, and the method is easy topopularize.

Owner:CHINA FIRST AUTOMOBILE

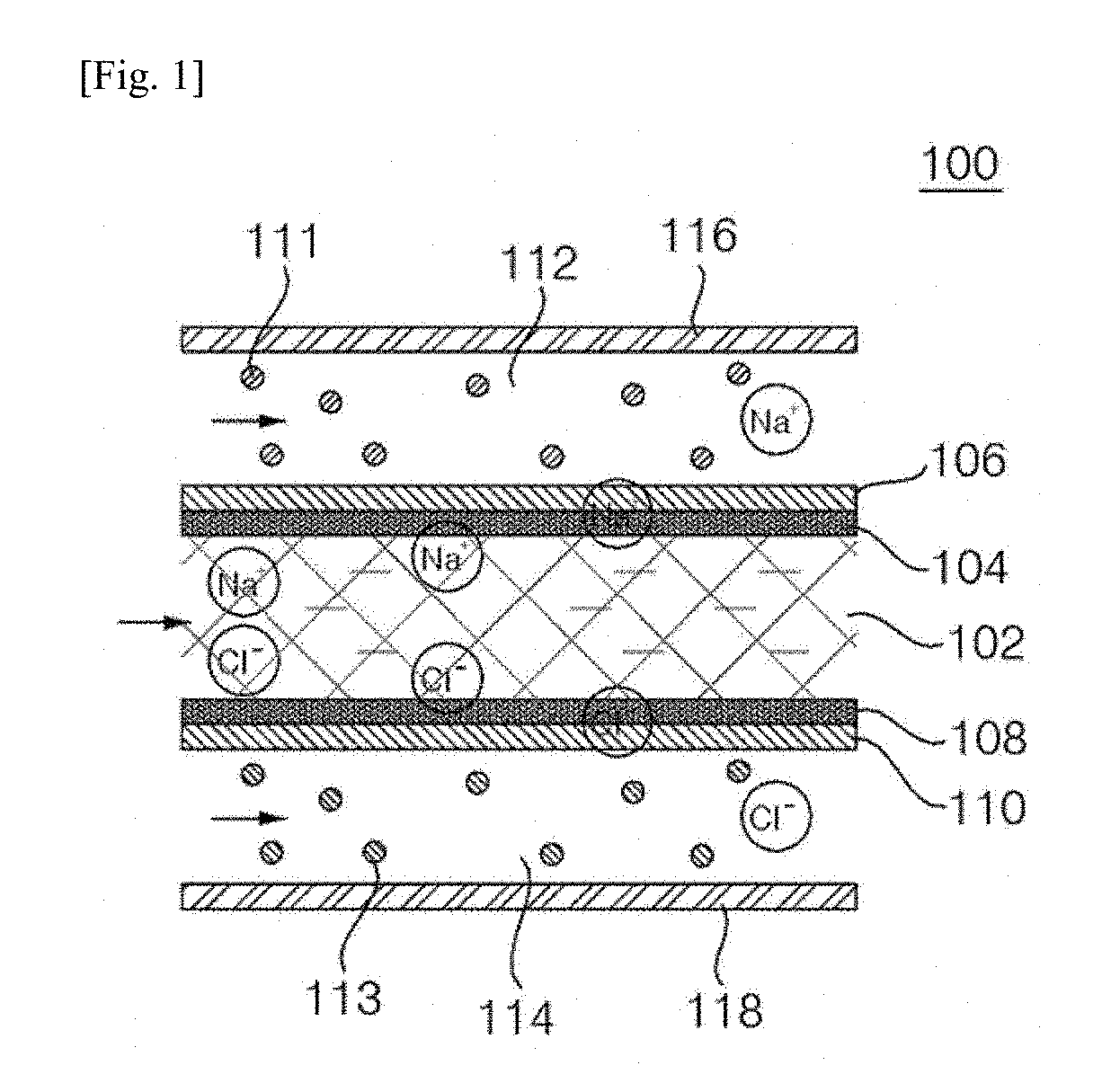

Water purification device

ActiveUS20100328841A1Increase capacityReduce contact resistanceStacked capacitorsConductive materialAqueous solutionCapacitor

Improved flow through capacitors (FTC) and methods for purifying aqueous solutions are disclosed. For example, FTC electrodes that are activated with a poly-electrolyte are disclosed.

Owner:VOLTEA

Si ALLOY NEGATIVE ELECTRODE ACTIVE MATERIAL FOR ELECTRIC DEVICE

ActiveUS20120175551A1Suppressing amorphous-crystal phase transitionImprove cycle lifeVapour deposition manufacturingSilicon alloyEngineering

[Problem]Provided is a negative electrode active material for an electric device which exhibits a well-balanced property of maintaining a high cycle property and attaining a high initial capacity.[Technical solution]The negative electrode active material for an electric device comprising an alloy having a composition formula SixZnyAlz (where each of x, y, and z represents amass percent value, satisfying (1) x+y+z=100, (2) 21≦x<100, (3) 0<y<79, and (4) 0<z<79).

Owner:NISSAN MOTOR CO LTD

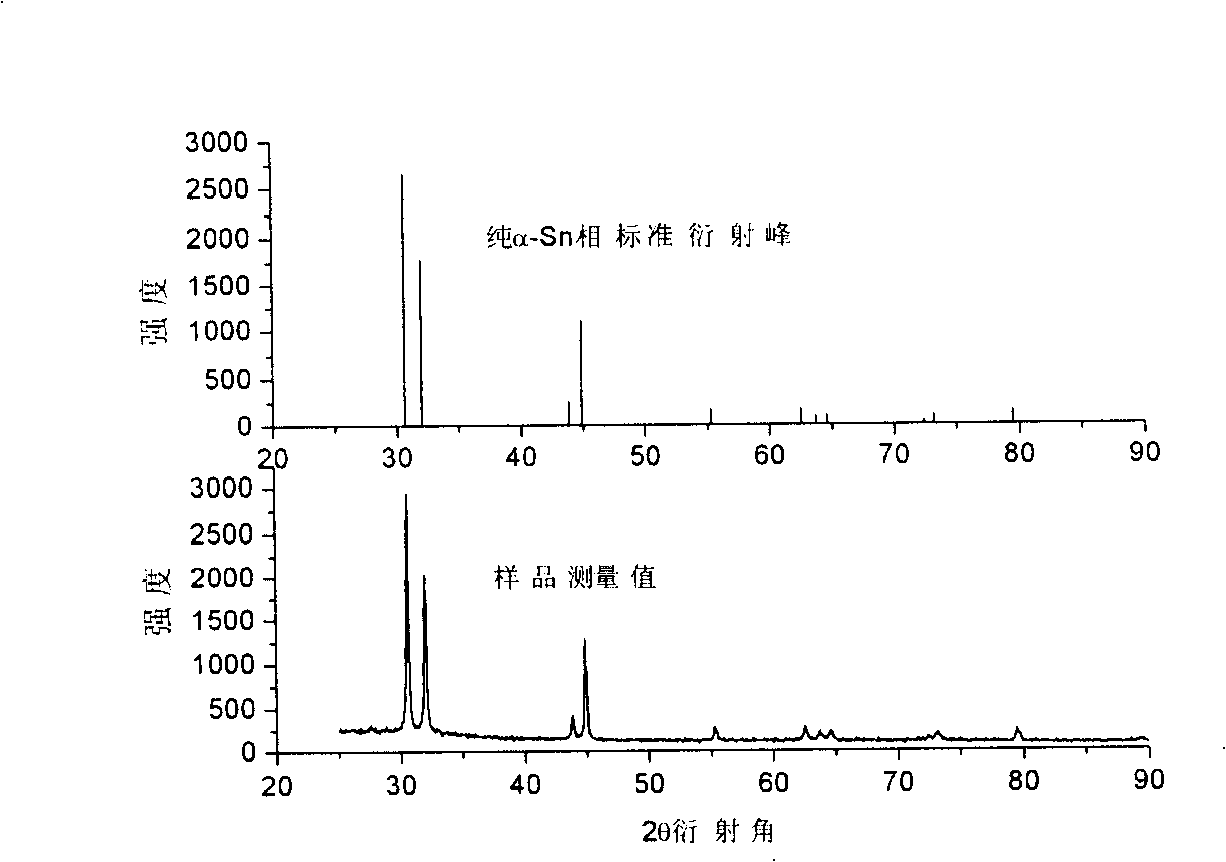

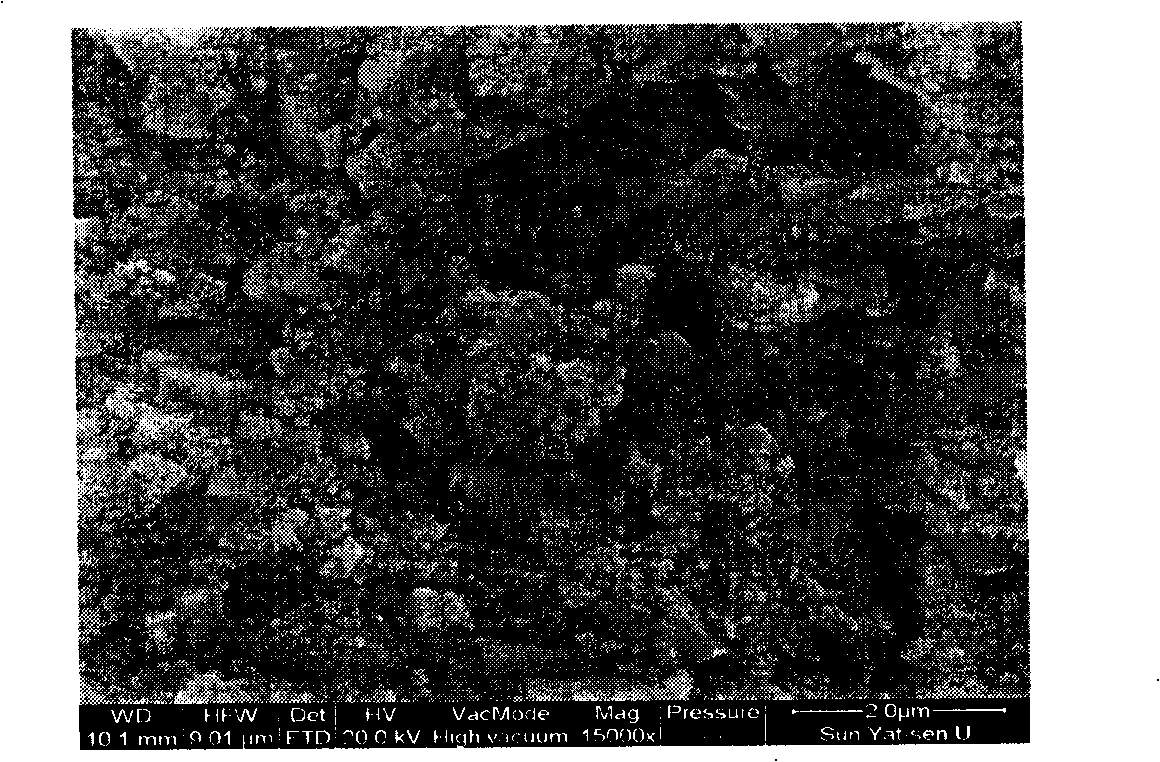

Aluminum-tin alloy film for lithium ionic cell negative electrode and method for preparing the same

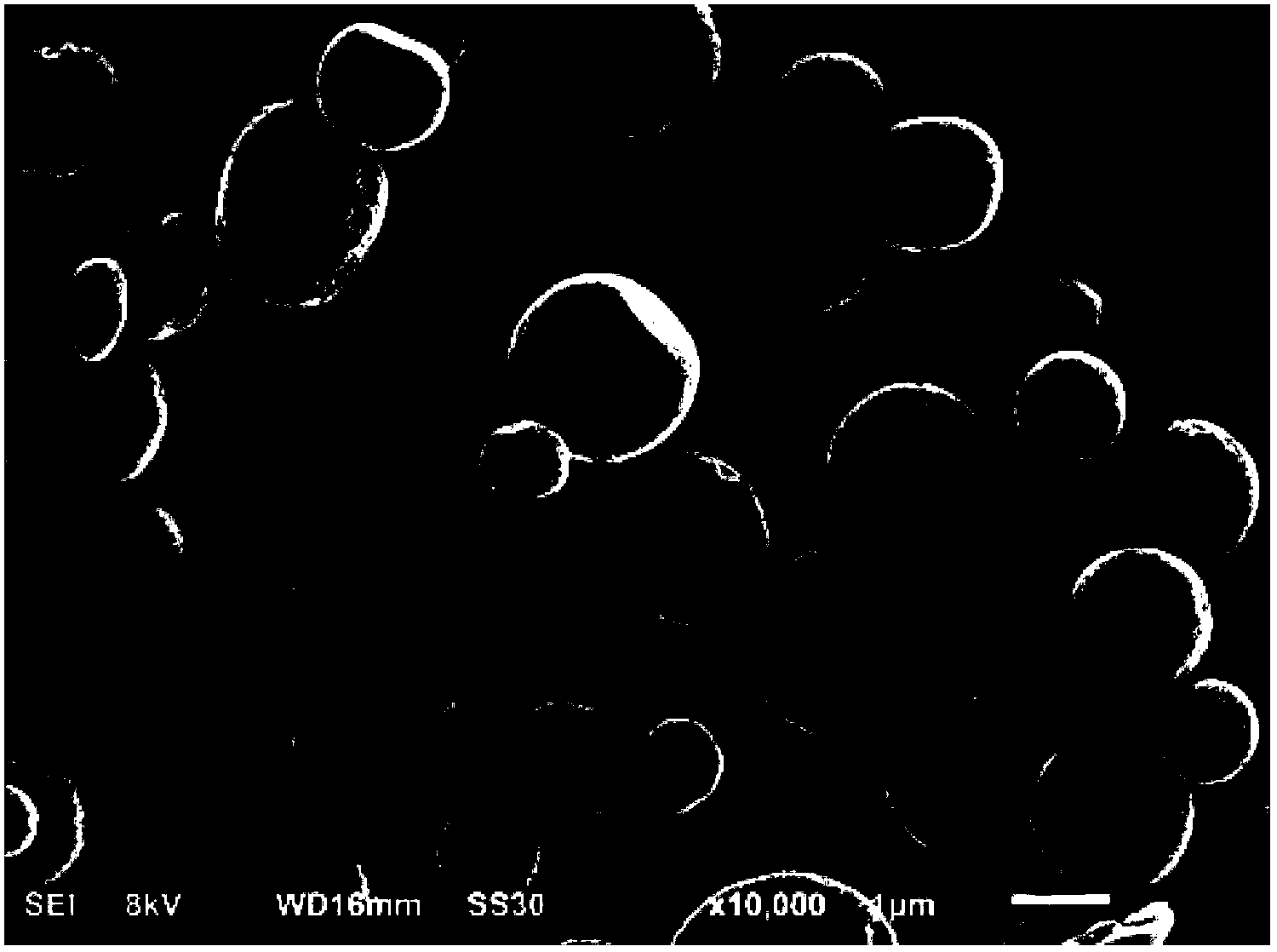

InactiveCN101339989AImprove cycle performanceIncrease electrode capacityElectrode manufacturing processesVacuum evaporation coatingMetal foilElectrical battery

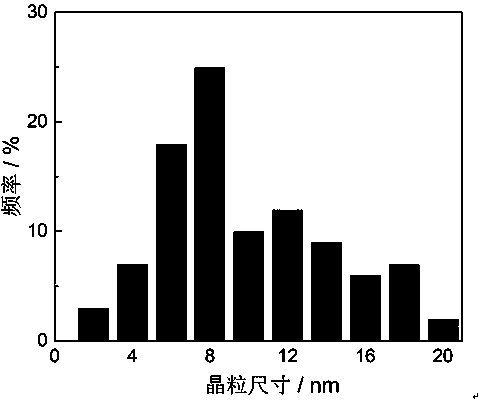

The invention provides a preparation method of a tin aluminum alloy membrane used in a lithium-ion battery cathode, which comprises the steps as follows: (1) a metal foil taken as a membrane electrode current collector is taken as a substrate for magnetron sputtering and the substrate is cleaned; (2) the air pressure of a sputtering chamber is adjusted to 1.0*10<-3>Pa or above, and then is adjusted within the range of 0.1-10Pa after inert gas is introduced; (3) the tin aluminum alloy membrane is prepared by magnetron sputtering, the sputtering power is needed to be adjusted within the range of 10W-5kW, the sputtering type belongs to DC magnetron sputtering or RF magnetron sputtering, and the sputtering deposition time is controlled within the range of 10-60 minutes. The tin aluminum alloy membrane used in the lithium-ion battery cathode prepared by using the method is composed of the tin aluminum alloy of solid solution alloy material; the tin aluminum alloy comprises 25-75% of tin and the rest is aluminum. The preparation method has the advantages of simple process, low cost, high efficiency and no by-product; the prepared membrane electrode material has uniform crystal grain, and good crystallinity and mechanical property.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation technology of nitrogen-doped mesoporous carbon composite metal oxide electrode material for supercapacitor

ActiveCN108878176AIncrease active pointLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureOxide compositeSugars carbohydrates

The invention discloses a preparation technology of a nitrogen-doped mesoporous carbon composite metal oxide electrode material for a supercapacitor, wherein the preparation method comprises the following steps of firstly, taking a mesoporous molecular sieve SBA-15 as a template agent, taking carbohydrate as a carbon source, and taking urea and hexamethylenetetramine as a nitrogen sources, performing calcining by inert gas, and removing the template agent to obtain nitrogen-doped mesoporous carbon; then, adding a metal salt solution, introducing inert gas for calcining to obtain a nitrogen-doped mesoporous carbon composite metal oxide composite material; and then mixing the material with polytetrafluoroethylene (PTFE) ) and the carbon black and then performing coating, pressing and dryingto obtain the nitrogen-doped mesoporous carbon composite metal oxide electrode material for the supercapacitor. The preparation method disclosed by the invention is low in cost and simple and convenient to operate. The nitrogen-doped mesoporous carbon prepared by the method disclosed by the invention is clear in pore passage and appropriate in pore size, the specific surface area is large, the distribution of the transition metal oxide nano particles is uniform, and the loading capacity is large. The electrochemical performance of the nitrogen-doped mesoporous carbon composite metal oxide electrode material is excellent, so that the electrode material has a wide market prospect in the field of energy storage materials such as supercapacitors and the like.

Owner:SHANDONG JIANZHU UNIV

Si ALLOY NEGATIVE ELECTRODE ACTIVE MATERIAL FOR ELECTRIC DEVICE

ActiveUS20120153220A1Suppressing amorphous-crystal phase transitionImprove cycle lifeCell electrodesSecondary cellsAlloyElectron

[Problem]Provided is a negative electrode active material for an electric device which exhibits a well-balanced property of maintaining a high cycle property and attaining a high initial capacity.[Technical solution]The negative electrode active material for an electric device comprising an alloy having a composition formula SixTiyZnz (where each of x, y, and z represents amass percent value, satisfying (1) x+y+z=100, (2) 38≦x<100, (3) 0<y<62, and (4) 0<z<62).

Owner:NISSAN MOTOR CO LTD

Tin dioxide/porous carbon composite lithium battery negative electrode material and preparation method

The invention discloses a tin dioxide / porous carbon composite lithium battery negative electrode material and a preparation method. The preparation method comprises the following steps: with fibroin and a high molecular polymer PAMAM as precursors, soaking a fibroin / PAMAM composite material after freeze drying treatment in a stannous sulfate aqueous solution for sufficient adsorption; performing high-temperature calcination to obtain the lithium battery negative electrode material. Sn<2+> and amino groups (mainly tertiary amino groups) in the PAMAM dendrimer can generate an effective complexing action so that the SnO2 nanoparticles are in-situ compounded on the surface of the fibroin / PAMAM; therefore, the yield of tin dioxide / porous carbon compound is higher, the uniform stability is better, and a lithium ion battery negative electrode material with high specific capacity and long cycle life is prepared finally.

Owner:赵兵

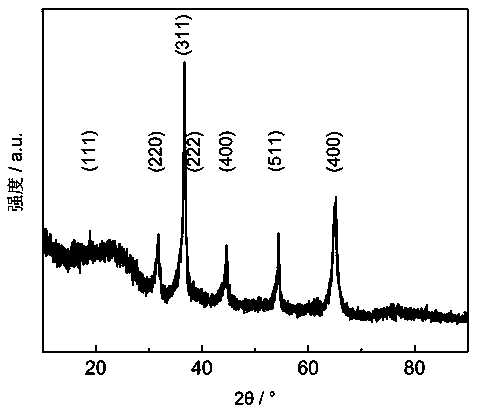

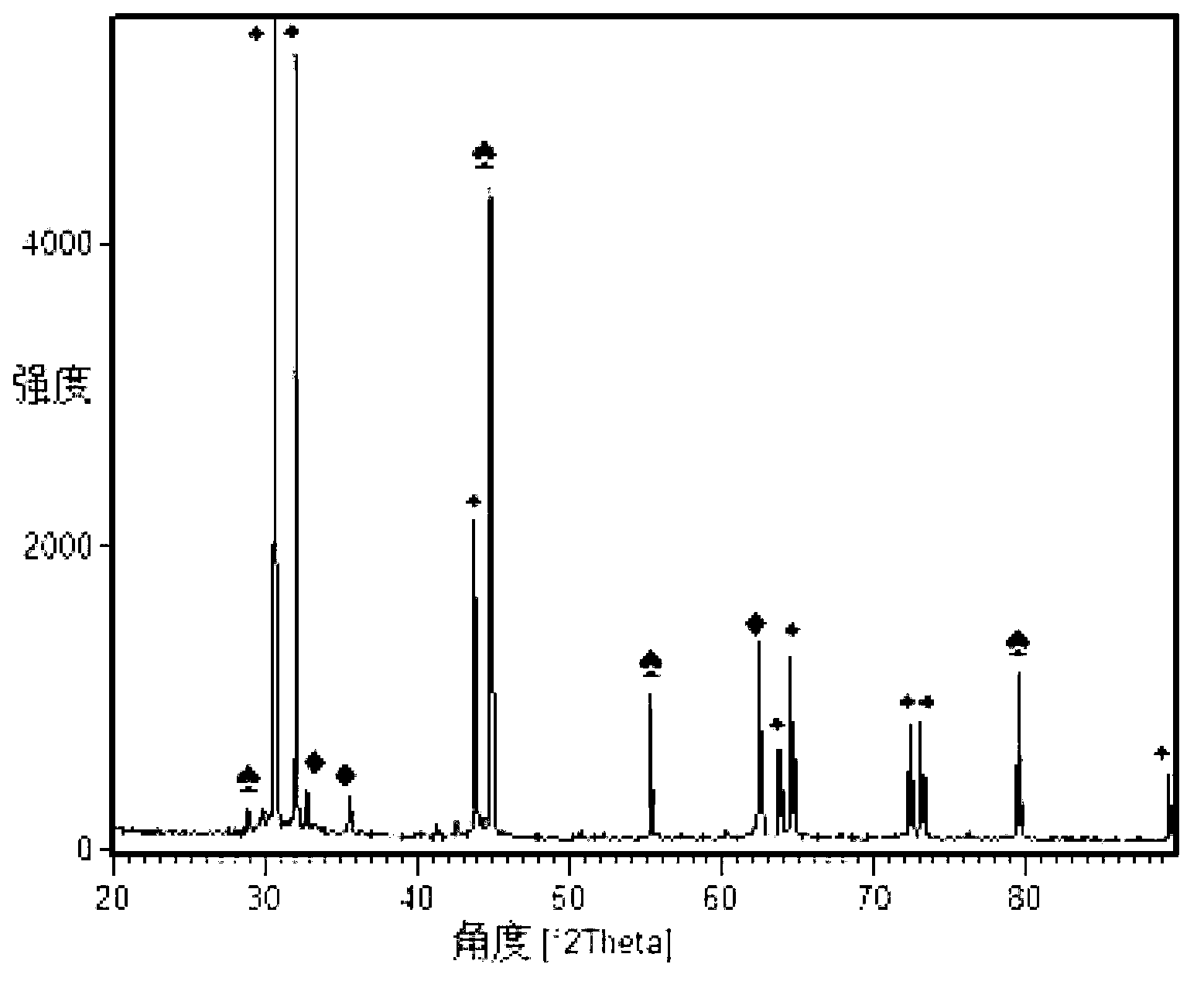

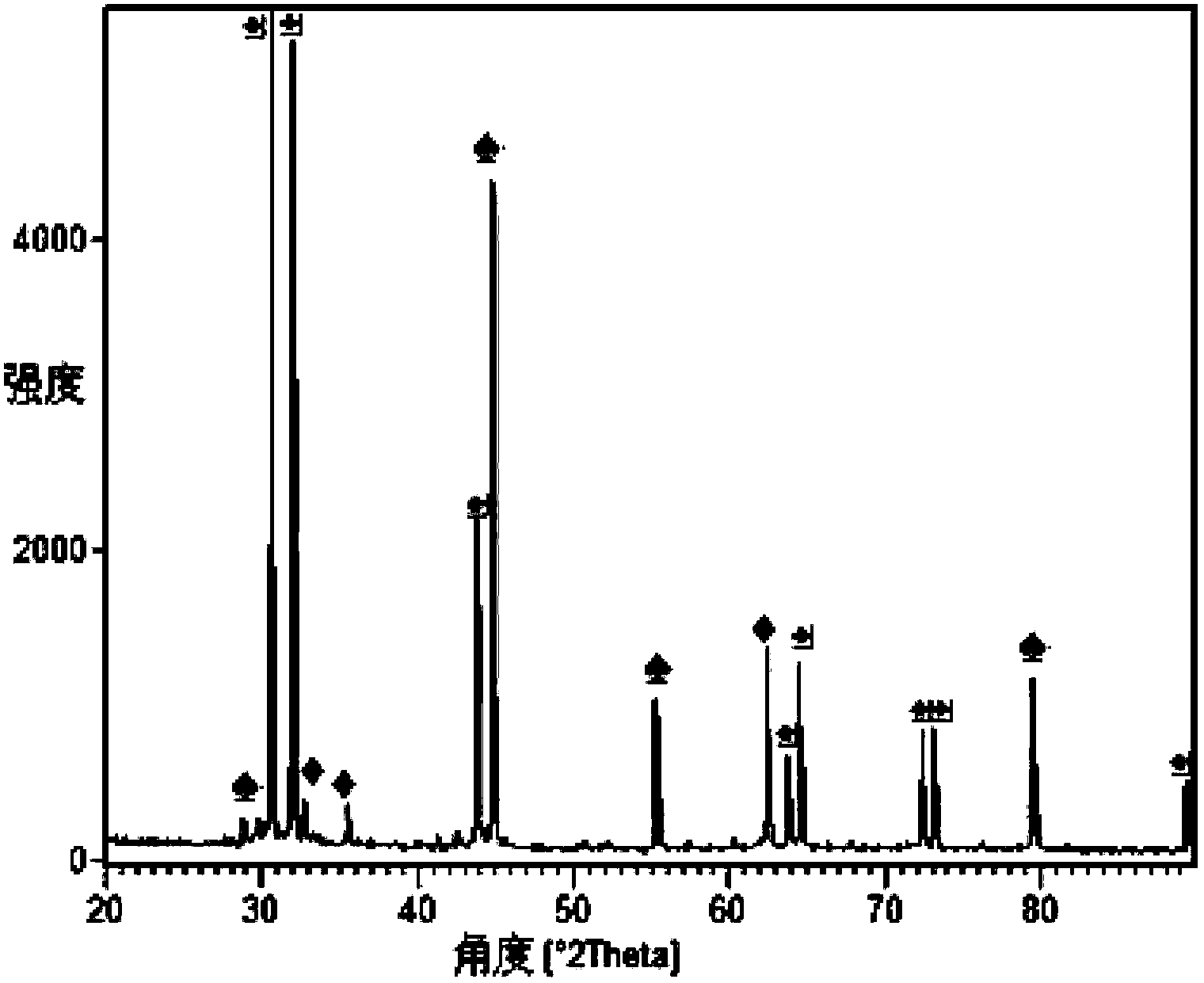

Sn-Co/C alloy cathode material of lithium ion battery and preparation method thereof

InactiveCN103000863ASmall particle sizeImprove cycle performanceCell electrodesAcid etchingCarbon coating

The invention discloses a Sn-Co / C alloy cathode material of a lithium ion battery and a preparation method thereof. The preparation method comprises the steps: uniformly mixing Sn powder and Co powder according to the mass ratio of (99:1) to (97:3), melting the mixture of the Sn powder and the Co powder, and carrying out spraying cooling to obtain a Sn-Co composite material; then adding an acid solution with the concentration being 1-3mol / L into a Sn-Co composite material for acid treatment to obtain a Sn-Co material subjected to the acid treatment; and mixing and sintering the Sn-Co material with an organic carbon source and asphalt in sequence to obtain an Sn-Co / C alloy cathode material. According to the invention, by adoption of acid etching, primary carbon coating based on the organic carbon source and secondary carbon coating based on the asphalt, the electrode is limited in expansion while being endowed with an expansion space, so that the material is prevented from being pulverized in a discharge / charge process. The prepared Sn-Co / C alloy cathode material is a solid solution alloy, has excellent mechanical strength, is free from the problem of electrode capacity reduction caused by the material itself, is improved in cyclic performance and electrode capacity at the same time, and has the advantages of high charge / discharge capacity and good cyclic performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

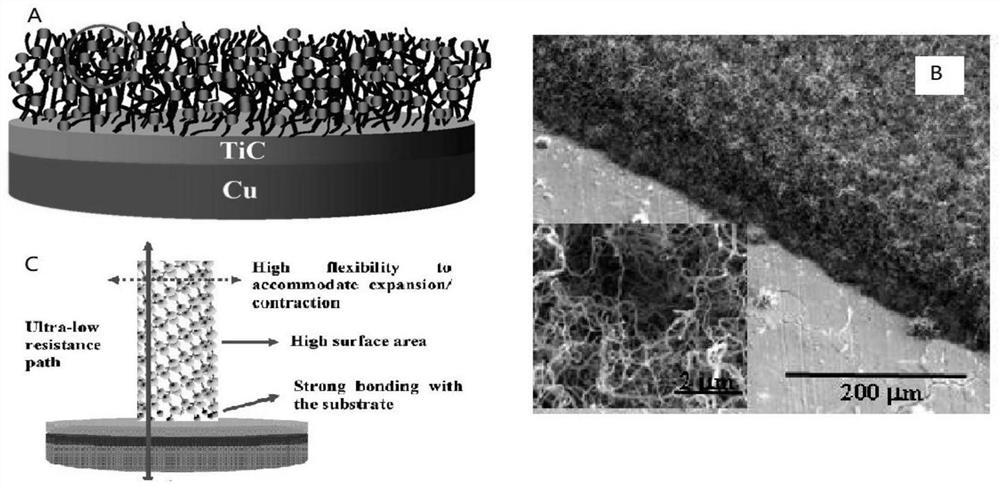

Carbon-based binderless composite material as well as preparation method and application thereof

PendingCN112499619AHigh bonding strengthGood electrical contactCell electrodesSecondary cellsCarbon filmAlkaline earth metal

The invention discloses a carbon-based binder-free composite material as well as a preparation method and application thereof, and belongs to the technical field of carbon material preparation. The carbon-based binderless composite material comprises a matrix, a carbon film and structural carbon. The carbon film is loaded on the surface of the matrix, and the structural carbon integrally formed with the carbon film grows on the carbon film. Alkali metal and alkaline earth metal catalysts are added in the preparation process, so that a carbon source is deposited on the surface of the matrix toform an integrally formed carbon film and structural carbon, the use of a binder is avoided, the effective specific surface area of the composite material is increased, the bonding strength and electrical contact performance of the carbon material and the matrix are improved, the electron, ion and atom transmission and chemical structure characteristics of the surface of the material are modified,and the composite material with excellent physical and chemical properties is prepared. The composite material prepared by the invention can be used for various battery electrodes, capacitor electrodes, various sensor electrodes, solar cell electrodes, water electrolysis hydrogen production electrodes, hydrogen storage materials, catalysts, catalyst carriers, composite material reinforcing materials and the like.

Owner:QINGDAO HENGNENGDA ENERGY TECH CO LTD

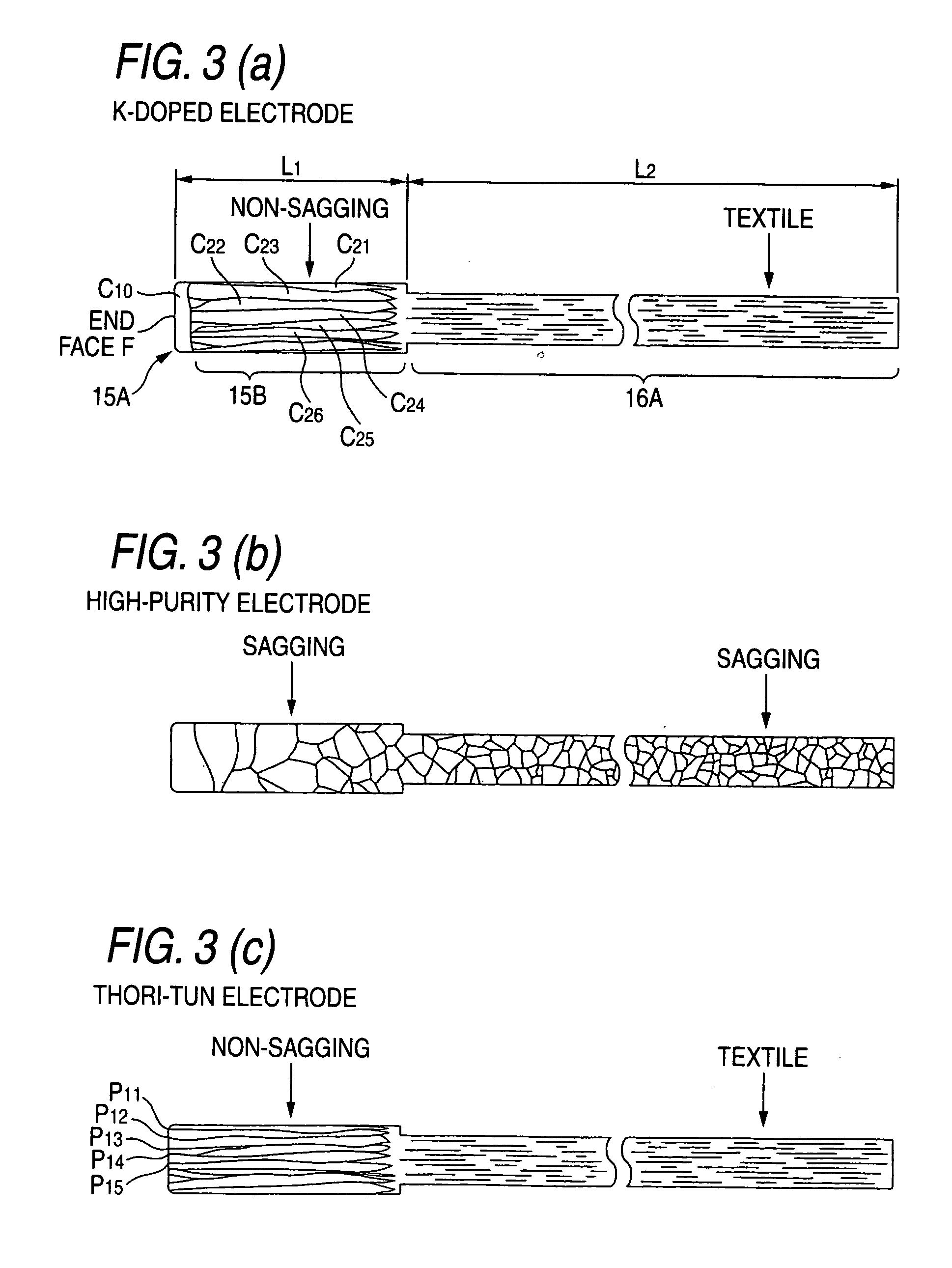

Arc tube for discharge lamp device

InactiveUS20070103082A1Containment leakSolution to short lifeDischarge tube luminescnet screensLamp detailsNoble gasSingle crystal

In a mercury free arc tube provided with a sealed glass chamber in which at least metallic halide for main light emission is sealed as well as rare gas by pinch-sealing both end openings of a glass tube and electrode bars are opposite to each other, the tip of a region projecting into the sealed glass chamber of each the electrode bars is formed of a single crystal. Owing to repetition of ON / OFF of the arc tube, the crystal at the tip of the electrode bar grows but the shape of the electrode end face formed of the single crystal remains unchanged. Further, even if the tip of the electrode bar is gradually consumed by thermal load acting on the tip of the electrode bar, the entire shape of the electrode end face is consumed nearly uniformly so that decline of the luminescent spot does not occur during discharging.

Owner:KOITO MFG CO LTD

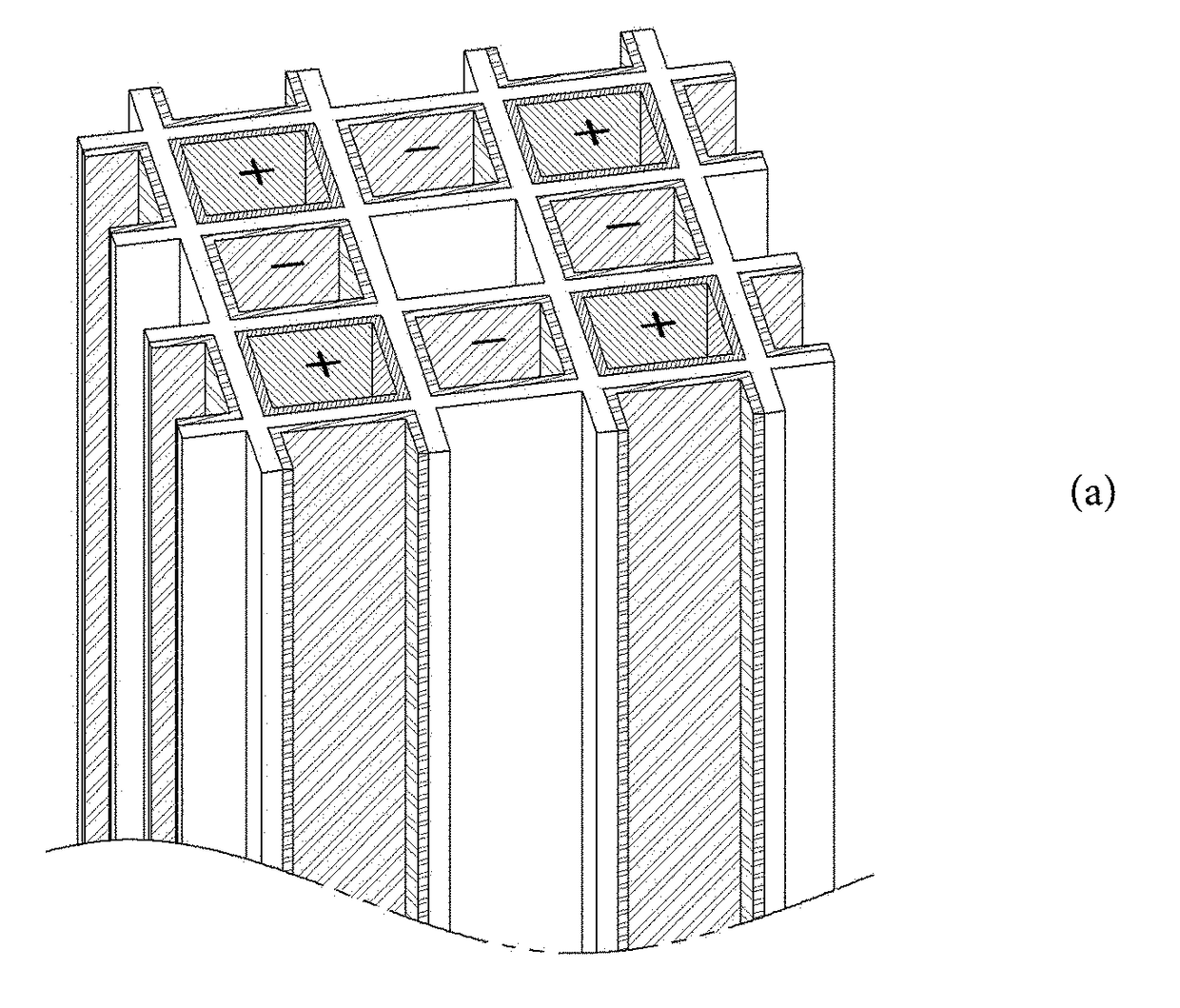

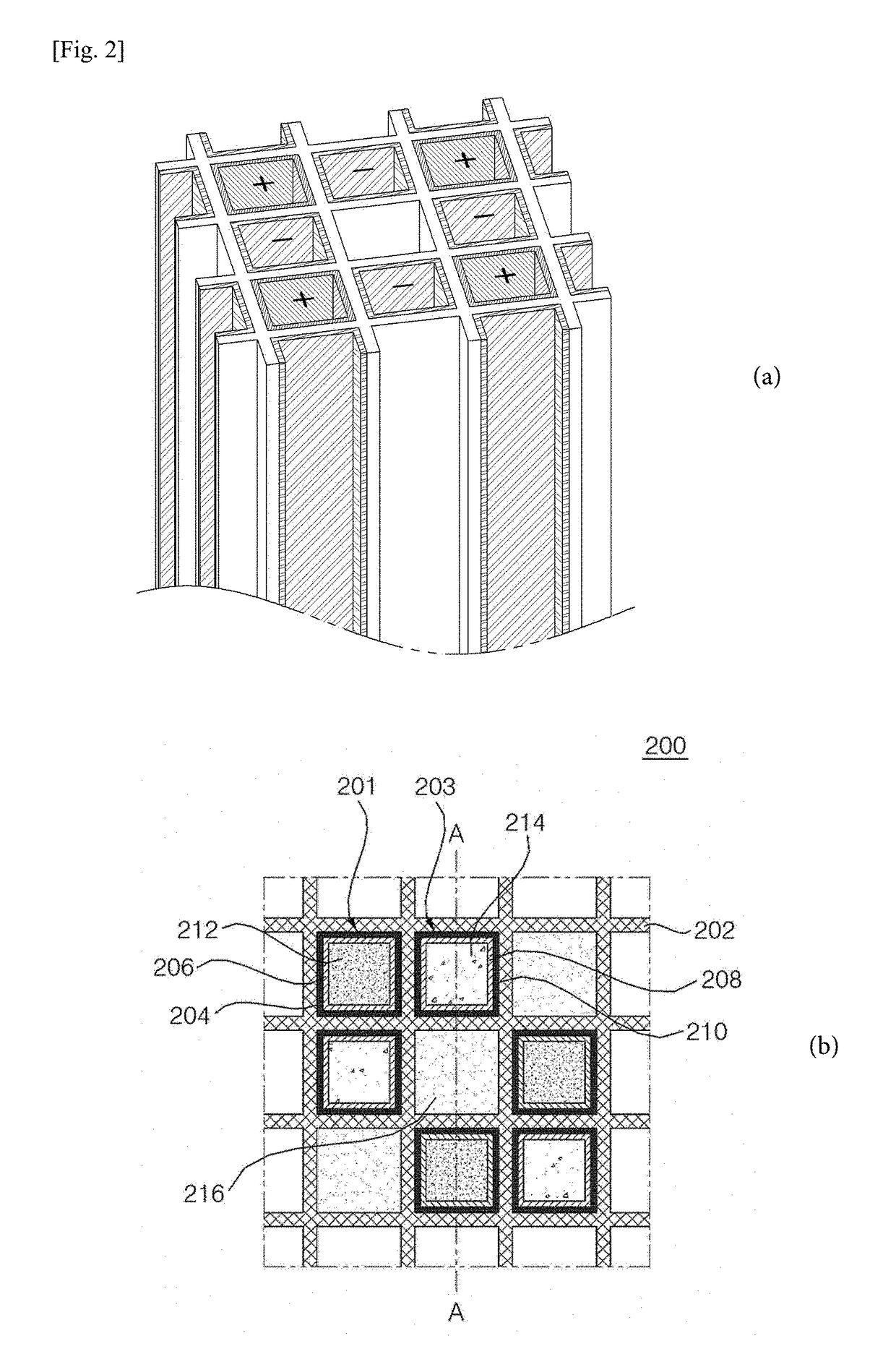

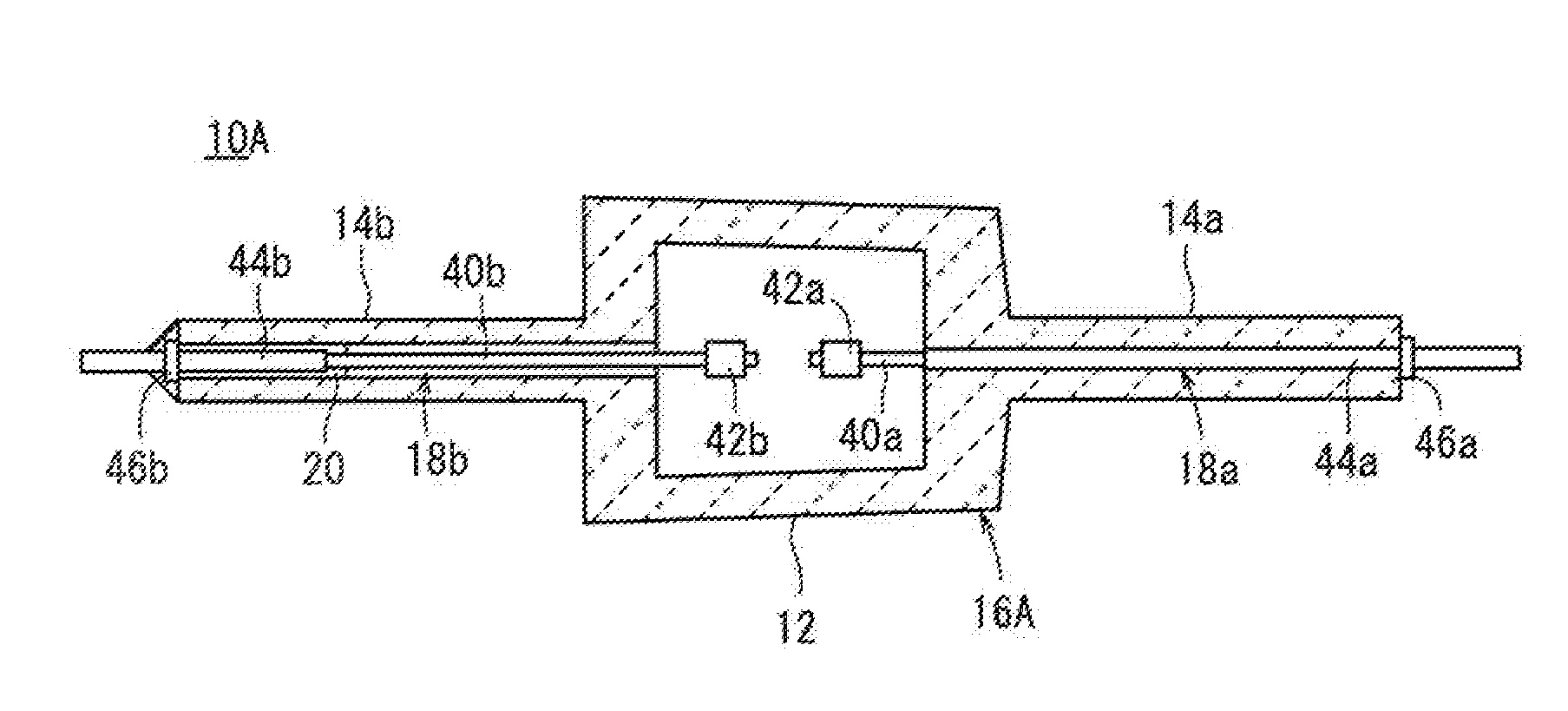

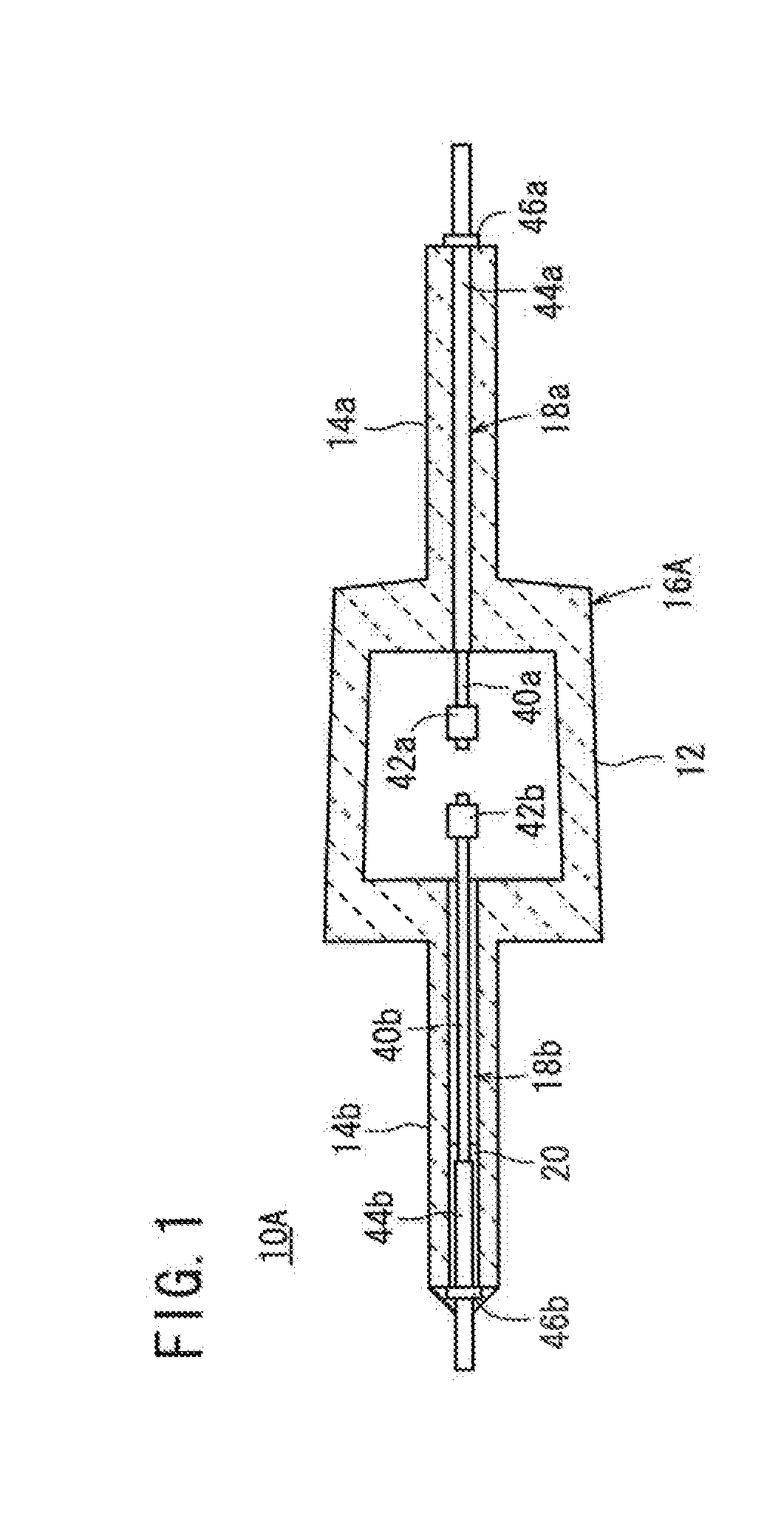

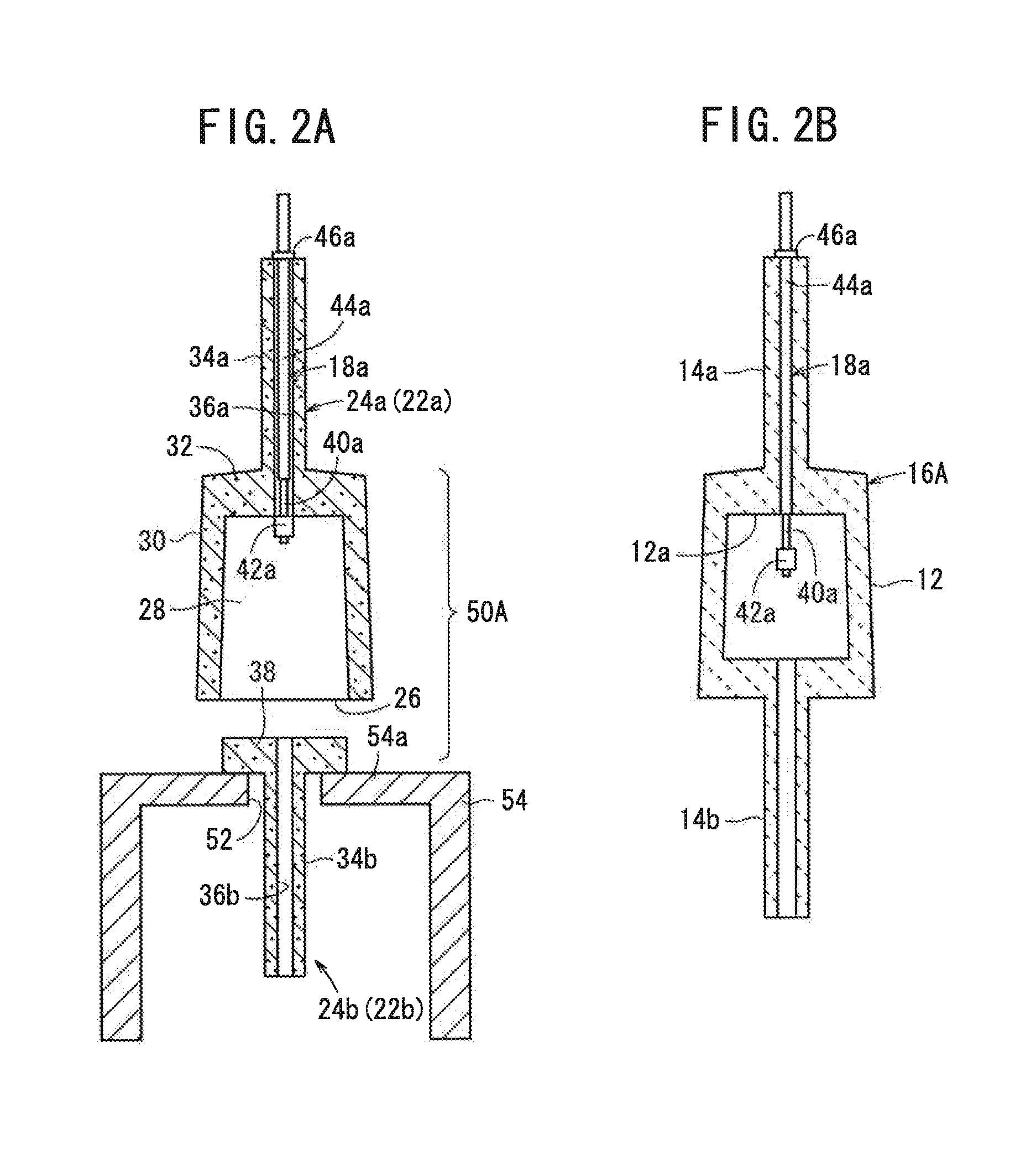

Electrochemical cell comprising channel-type flowable electrode units

ActiveUS20180123145A1Reduce manufacturing costReduce installation spacingGeneral water supply conservationWater/sewage treatment by electrochemical methodsManufacturing cost reductionElectrical battery

The present invention relates to an electrochemical cell having a channel-type flow-electrode unit.The channel-type flow-electrode structure according to the present invention, which has at least two channel-type flow-electrode units, can significantly reduce manufacturing costs and installation space by reducing the number of parts while extending the electrode capacity to be suitable for large-scale plants for electricity generation, energy storage, desalination, etc. In addition, the channel-type flow-electrode structure can be applied not only to a capacitive flow-electrode device and / or a redox flow battery device, but also to all of the devices for electricity generation, energy storage, and desalination while moving ions or protons.

Owner:KOREA INST OF ENERGY RES

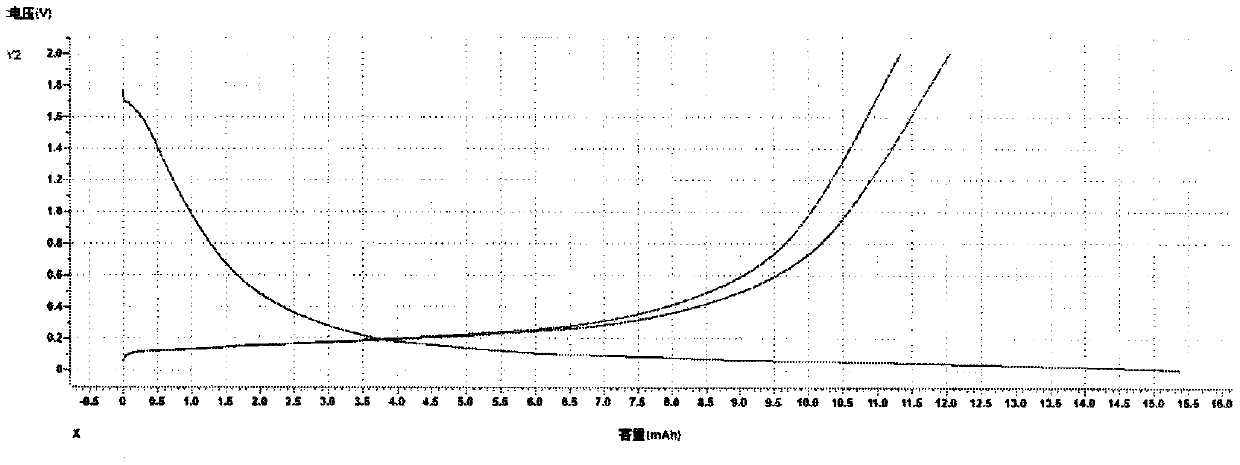

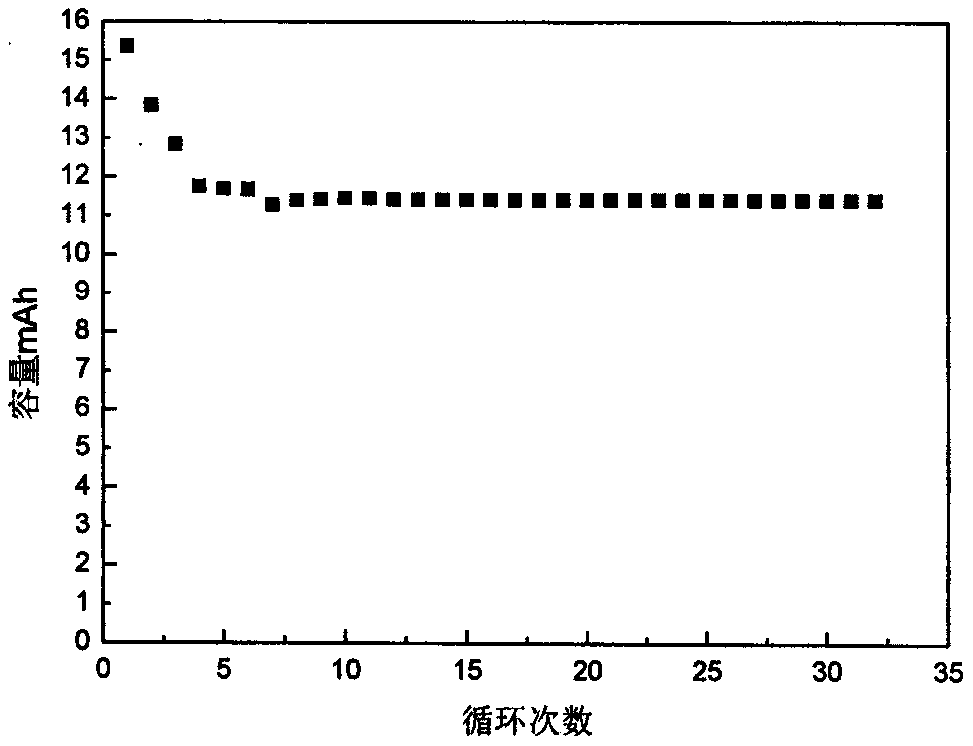

Method for improving electrode capacity through in-situ coated conductive macromolecule

ActiveCN108400308AIncrease electrode capacityPolymer improves electrode capacityCell electrodesSecondary cells servicing/maintenanceLithiumMixed materials

The invention relates to a preparation method of an electrode material, and specifically relates to a method for improving electrode capacity through in-situ coated conductive macromolecule, and belongs to the technical field of the electrochemistry. The method comprises the following steps: mechanically mixing and ball-milling the powdery battery material and the carbon at first, and then tableting the mixed material which is used as a positive electrode material to be assembled into the battery, charging the positive electrode material to 3-4.2V, and then taking out the charged electrode material and placing in the water solution containing the conductive macromolecule monomer and the surfactant to soak, taking out the soaked electrode to clean, and drying to obtain the electrode material with the in-situ coated conductive macromolecule. The electrode material can be applied to the lithium and sodium ion battery, and the battery capacity is greatly improved, and the preparation method is simple and easy to operate.

Owner:KUNMING UNIV OF SCI & TECH

Lithium secondary battery negative electrode active material and method for manufacturing same

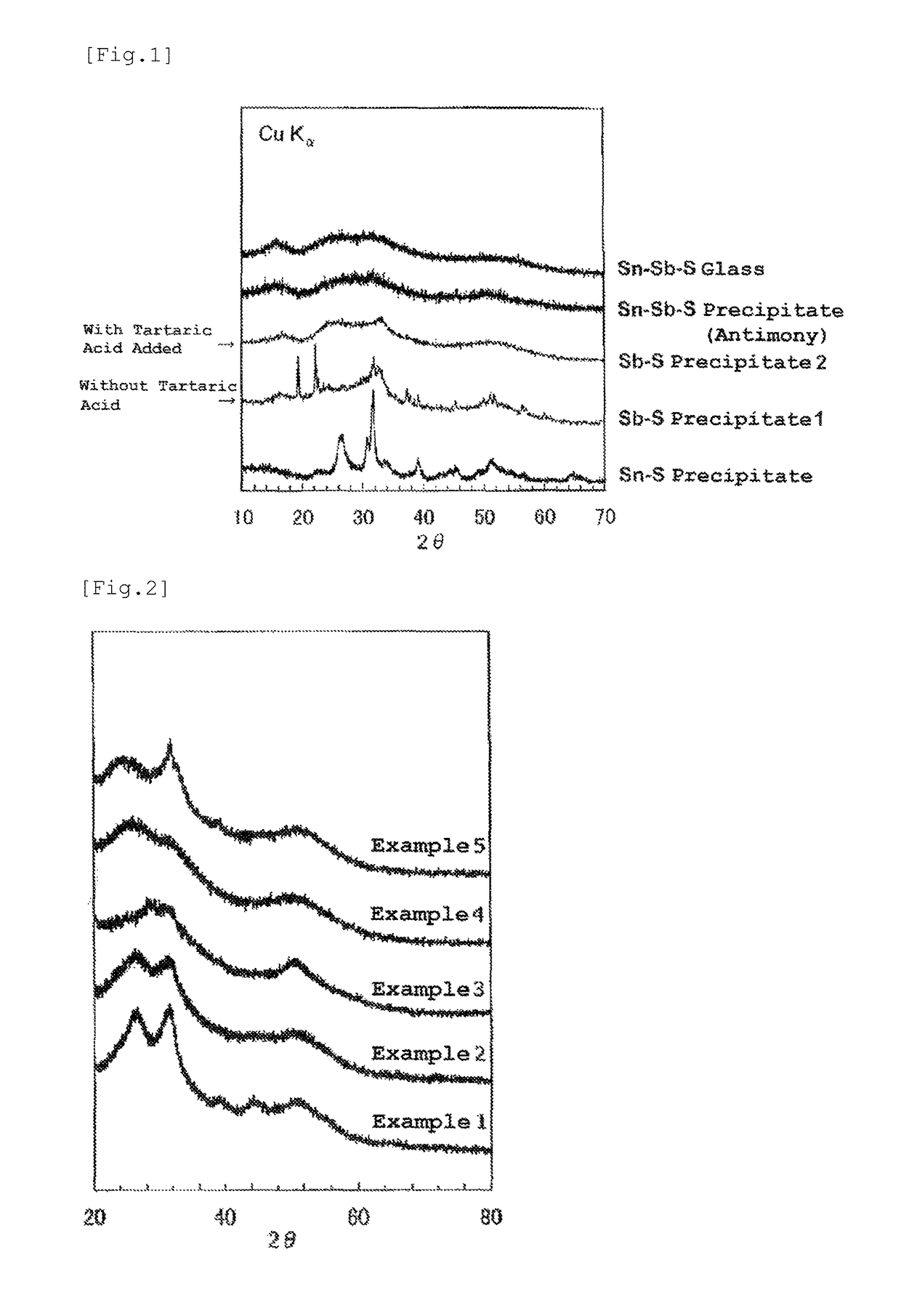

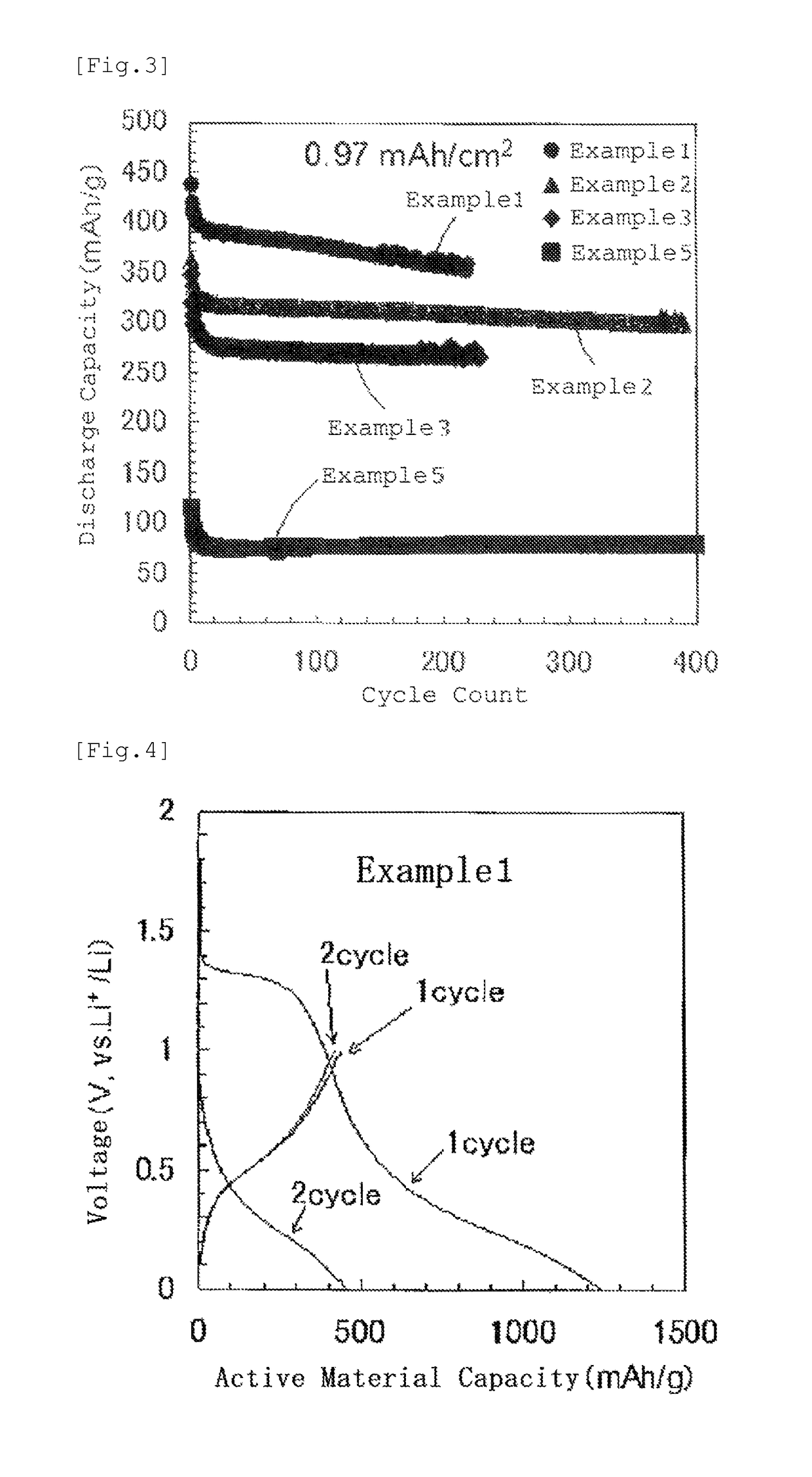

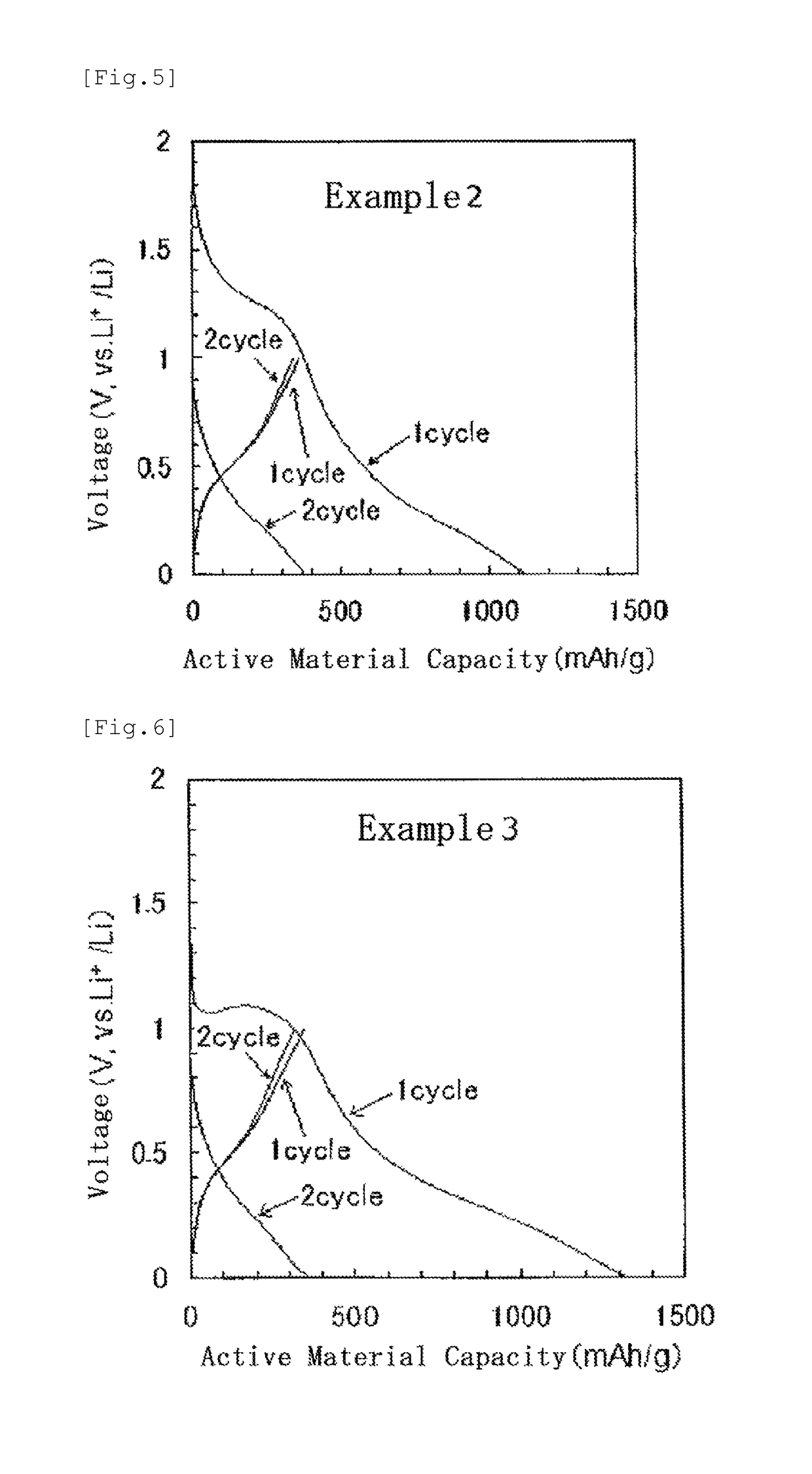

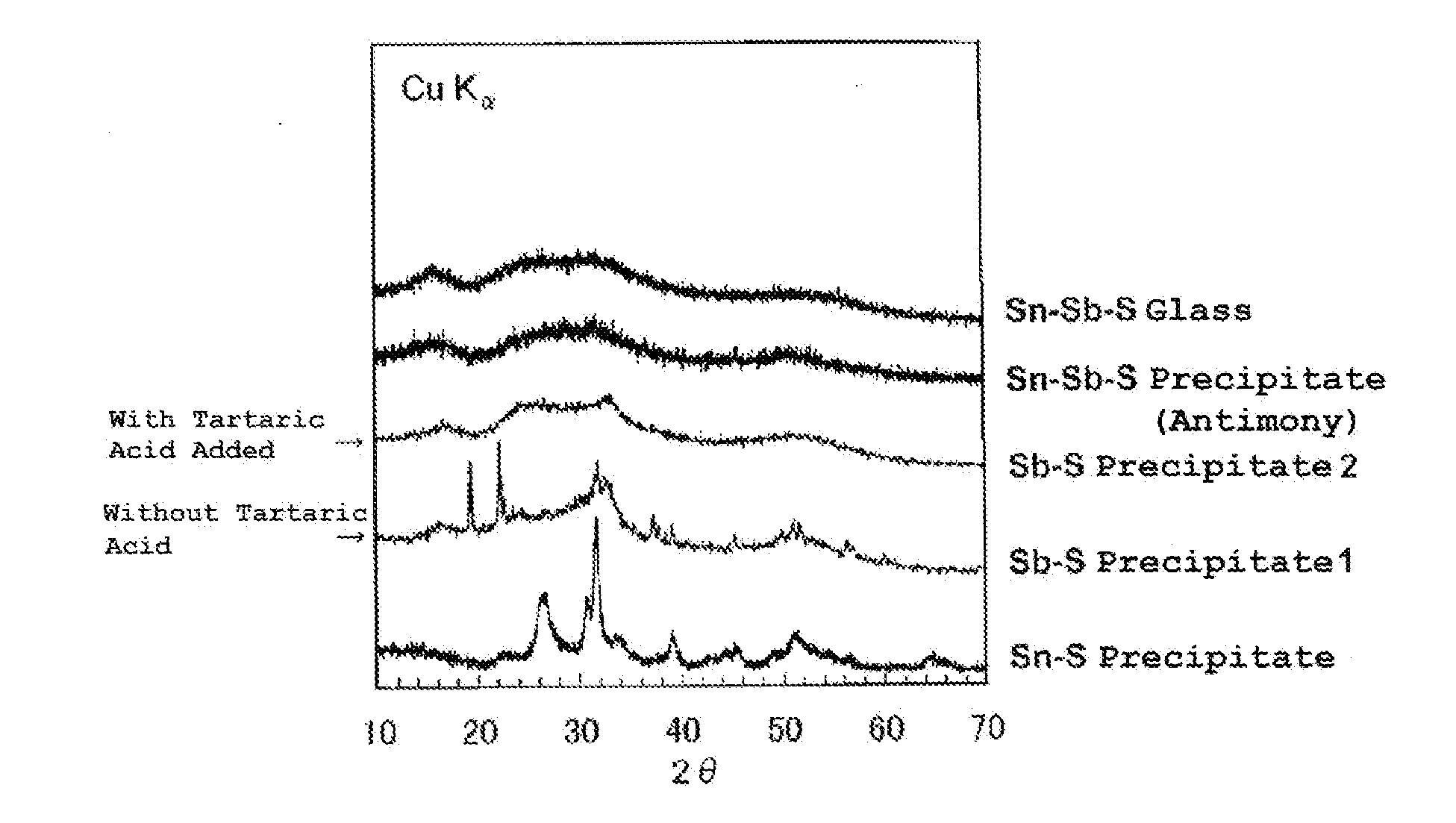

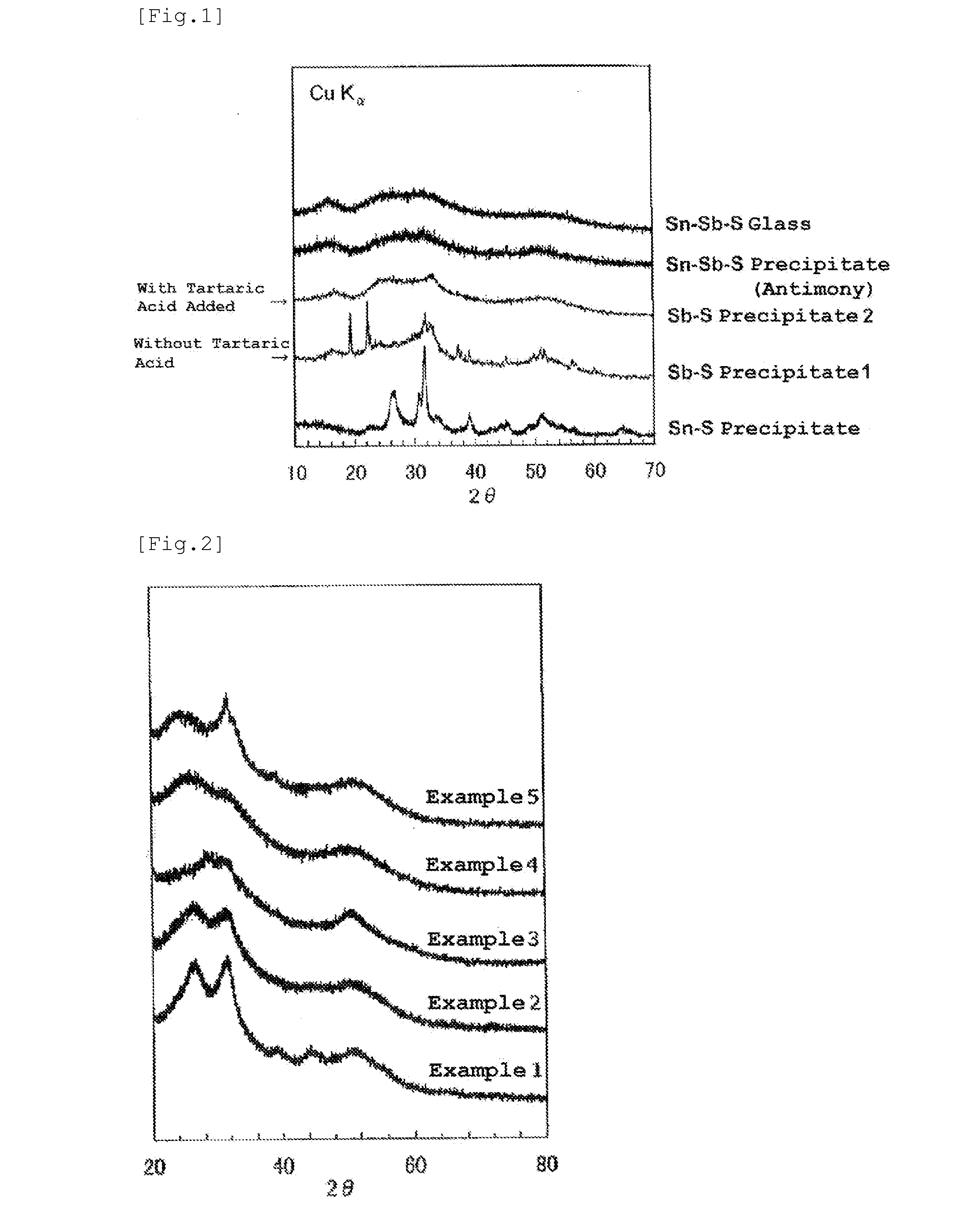

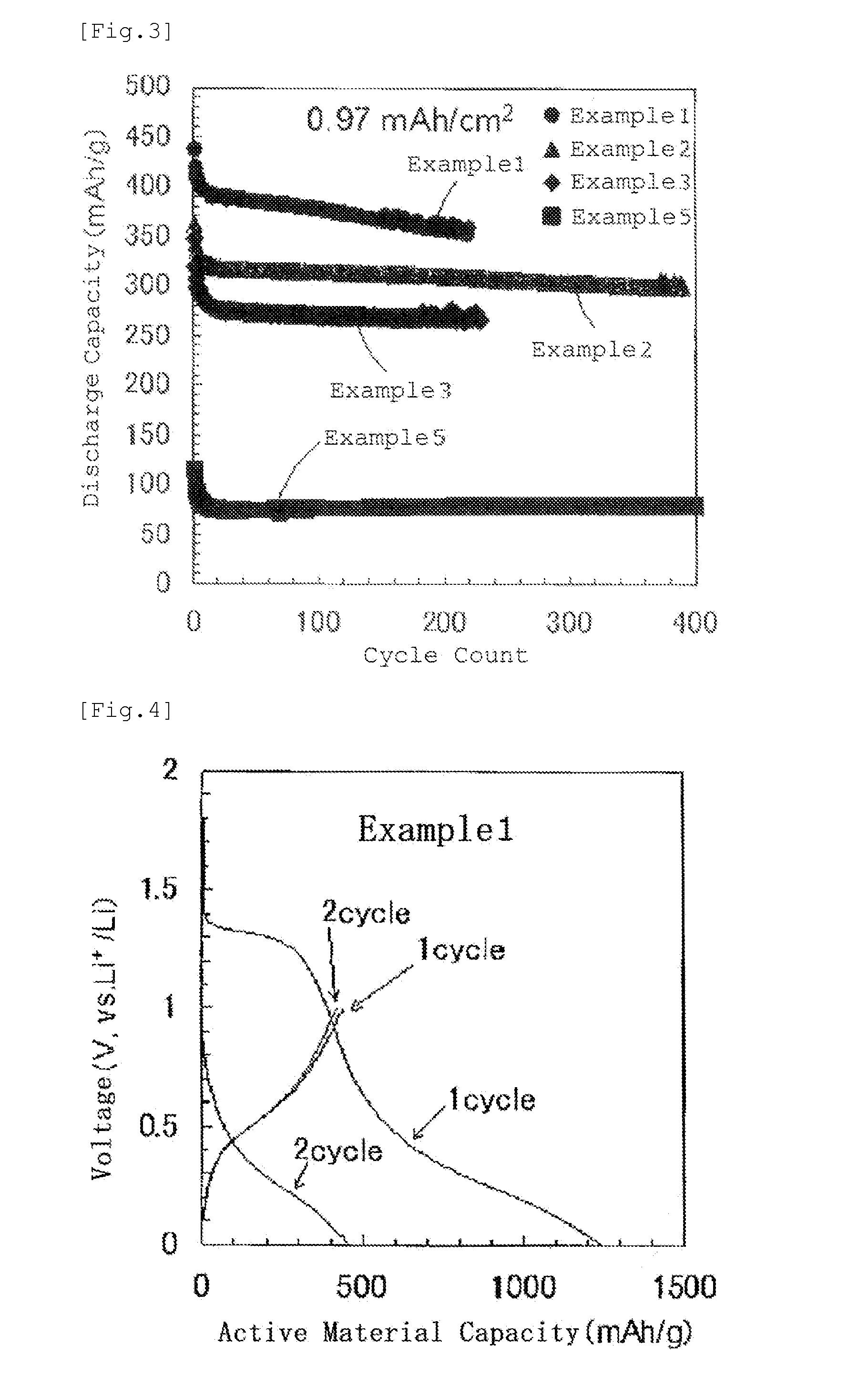

ActiveUS10141573B2Excellent output characteristic and cycle life characteristicEasily and inexpensively manufacture a negative electrode active materialTin compoundsNegative electrodesLithiumSulfide

The teachings herein are directed at a lithium secondary battery negative electrode active material consisting of a Sn Sb based sulfide that delivers a high electrode capacity density, excellent output characteristics, and excellent cycle life characteristics and also provide a method for manufacturing the lithium secondary battery negative electrode active material, said method being capable of easily manufacturing the high performance lithium secondary battery negative electrode active material at low cost without requiring a high-temperature processing step and special facilities as required in a glass melting method. The negative electrode active material preferably is prepared using a method that includes a step of obtaining a Sn Sb based sulfide precipitate by adding an alkali metal sulfide to a mixed solution of a tin halide and an antimony halide.

Owner:ISUZU GLASS +1

Lithium secondary battery negative electrode active material and method for manufacturing same

ActiveUS20160072127A1Easy and inexpensive to manufactureExcellent output characteristic and cycle life characteristicTin compoundsNegative electrodesGlass meltingSulfide

Problem: To provide a lithium secondary battery negative electrode active material consisting of a Sn—Sb based sulfide that delivers a high electrode capacity density, excellent output characteristics, and excellent cycle life characteristics and also provide a method for manufacturing the lithium secondary battery negative electrode active material, said method being capable of easily manufacturing the high performance lithium secondary battery negative electrode active material at low cost without requiring a high-temperature processing step and special facilities as required in a glass melting method.Solution: A method for manufacturing a lithium secondary battery negative electrode active material containing a Sn—Sb based sulfide comprises a step of obtaining a Sn—Sb based sulfide precipitate by adding an alkali metal sulfide to a mixed solution of a tin halide and an antimony halide.

Owner:ISUZU GLASS +1

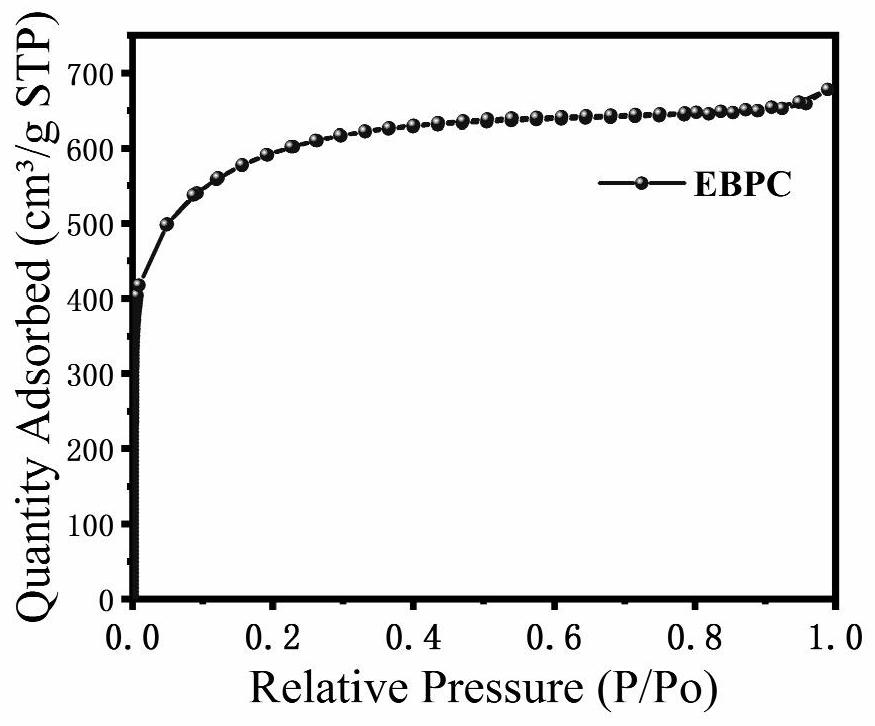

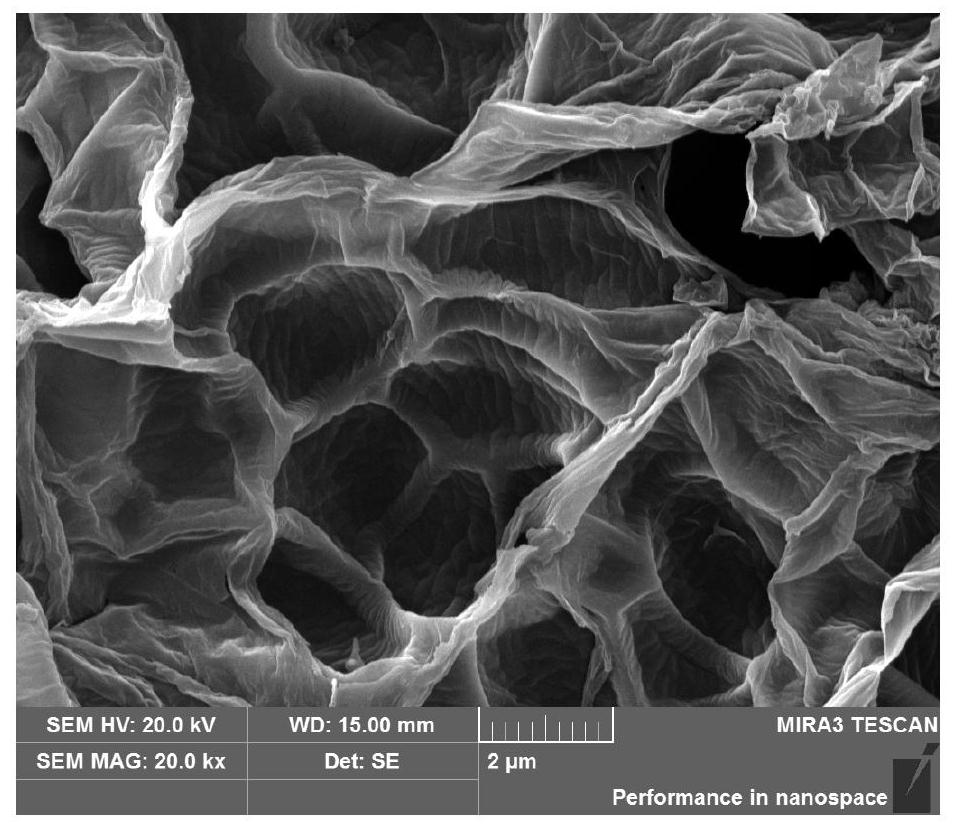

A kind of biomass porous activated carbon and its preparation method and application as electric double layer capacitor electrode material

ActiveCN109516459BWide variety of sourcesLow costCarbon compoundsHybrid capacitor electrodesFiberActivated carbon

The invention discloses biomass porous activated carbon and a preparation method thereof and application of the biomass porous activated carbon as an electrode material of a double electric layer capacitor. After a biomass raw material is pulverized by a high-energy pulverizer, the biomass raw material is placed in a furnace, protective gas is introduced into the furnace, the temperature is raisedto an activation temperature under a protective atmosphere, then activation gas is introduced into the furnace for activation treatment, protective gas is introduced into the furnace again, and the temperature is lowered to a normal temperature under a protective atmosphere to obtain the biomass porous activated carbon. The method maintains an original biological structure and ordered pore structure of wood fiber in the biomass material by high-energy pulverization combined with gas activation treatment, the prepared porous activated carbon has a large specific surface area and a high mass transfer rate and is applied as the electrode material of the electric double layer capacitor, and a capacitor with high energy density and good cycle performance can be obtained; and the porous activated carbon has a low preparation cost, simple operation and a short production cycle, and meets industrial production.

Owner:CENT SOUTH UNIV

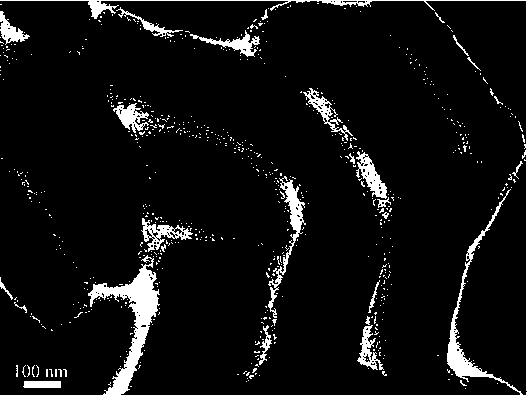

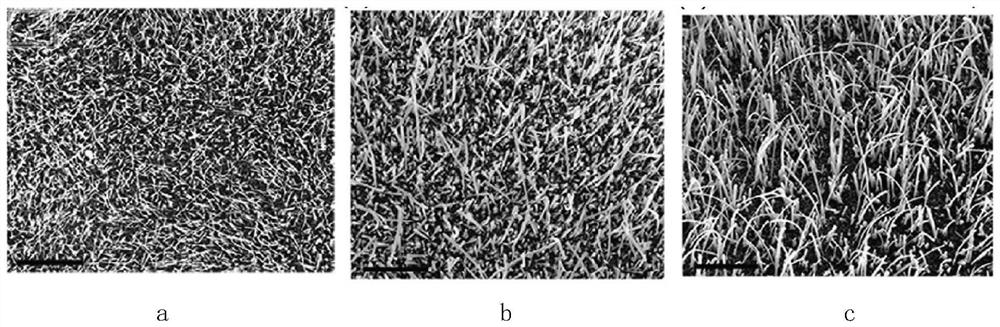

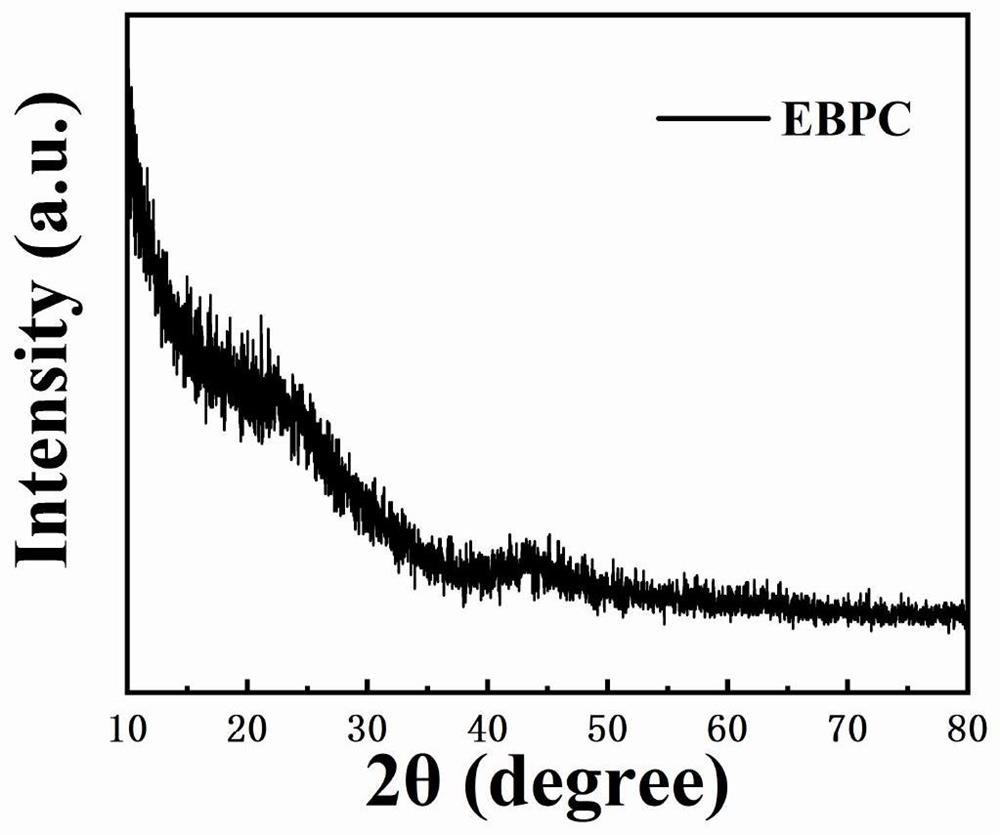

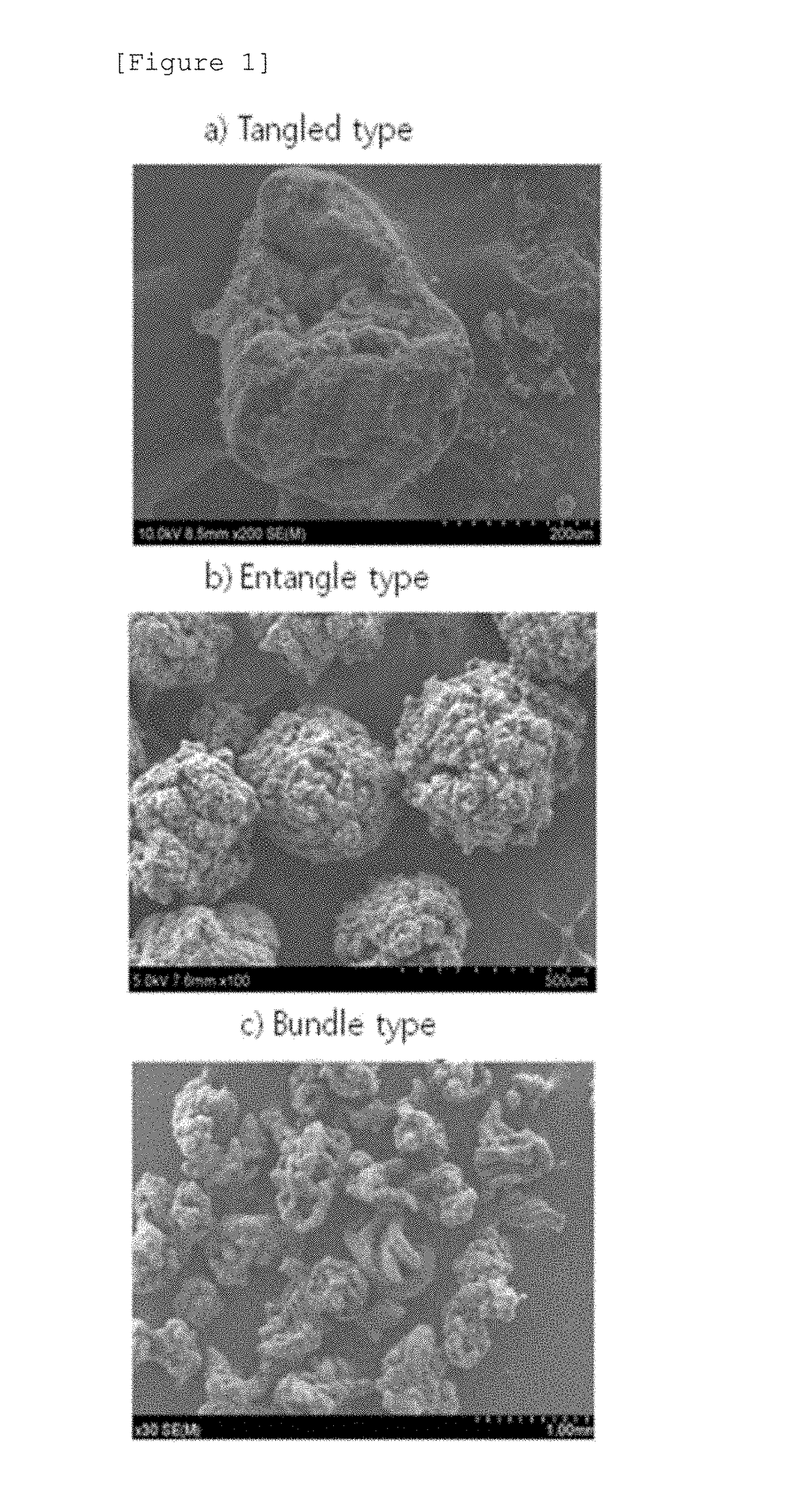

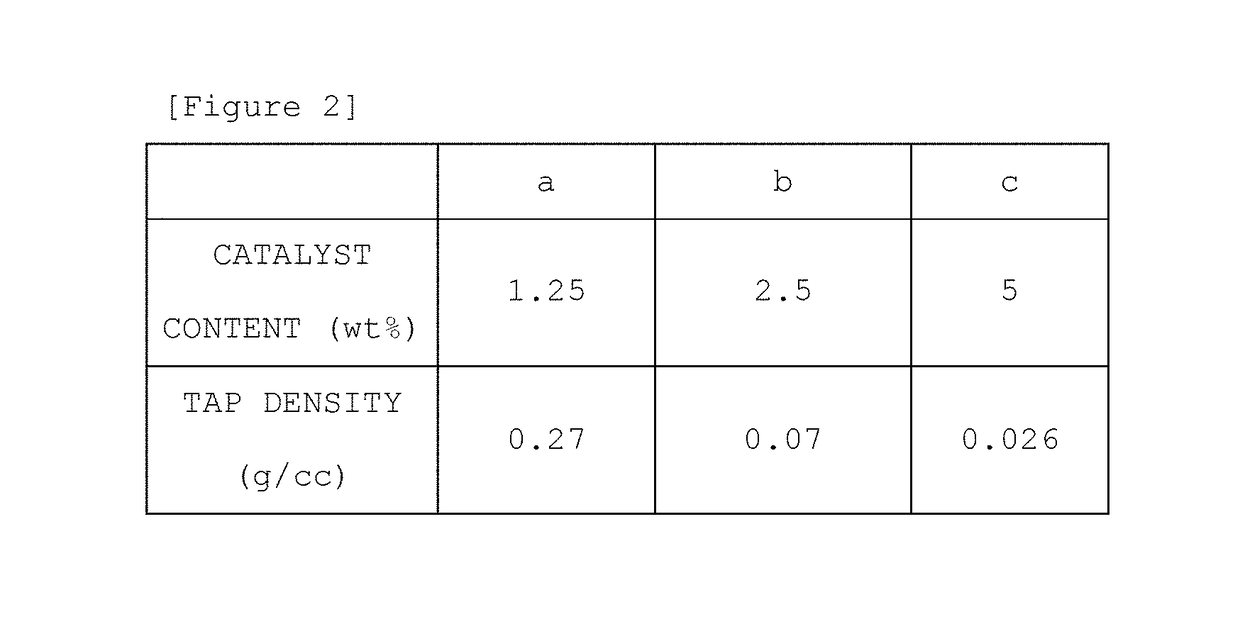

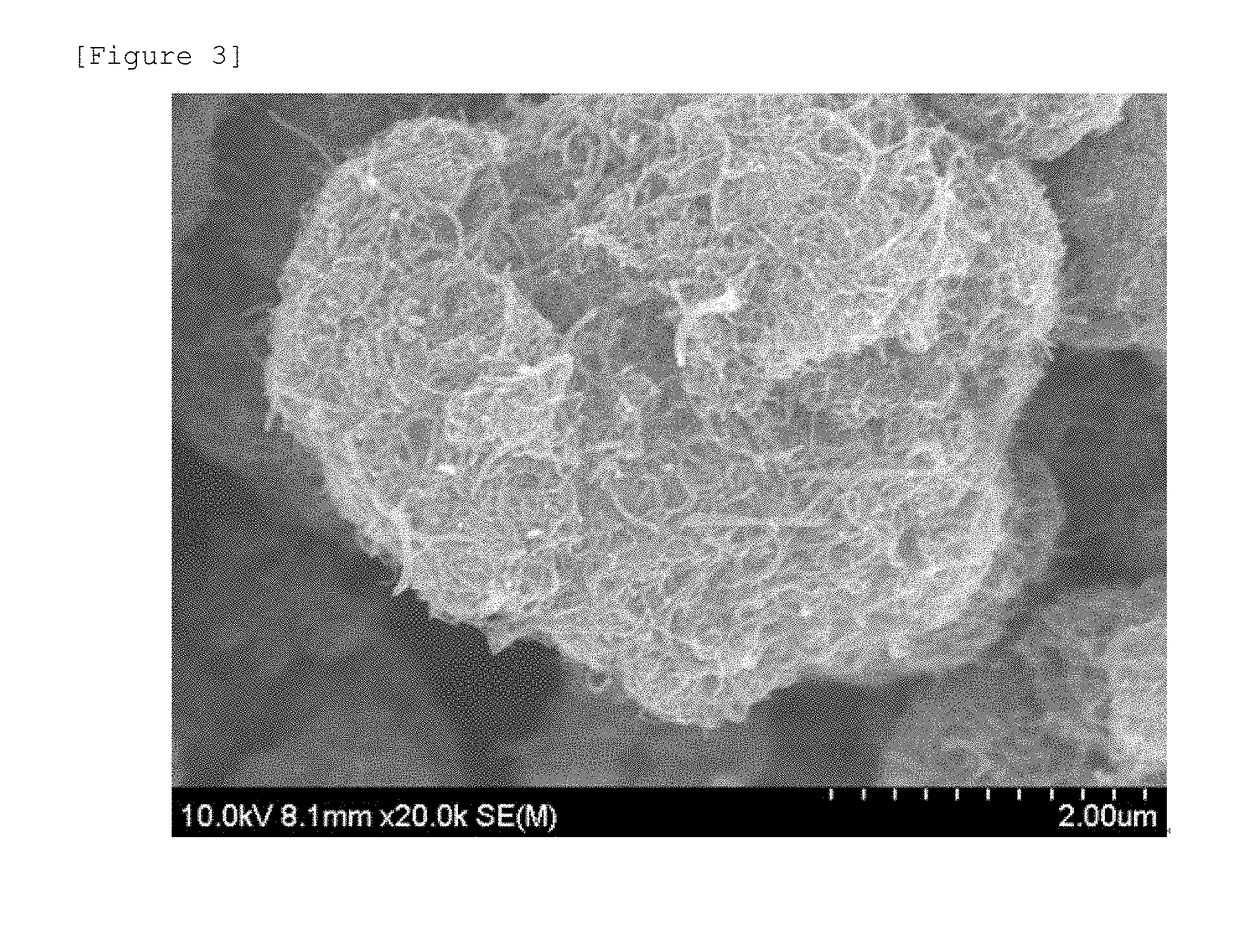

Carbon nanotube-sulfur composite comprising carbon nanotube aggregates, and method for preparing same

ActiveUS9911975B2Improve electronic conductivityIncrease electrode capacityFinal product manufactureNegative electrodesCarbon nanotubeOrganic chemistry

The present application relates to a carbon nanotube-sulfur composite including a carbon nanotube aggregate, and a method for preparing the same.

Owner:LG ENERGY SOLUTION LTD

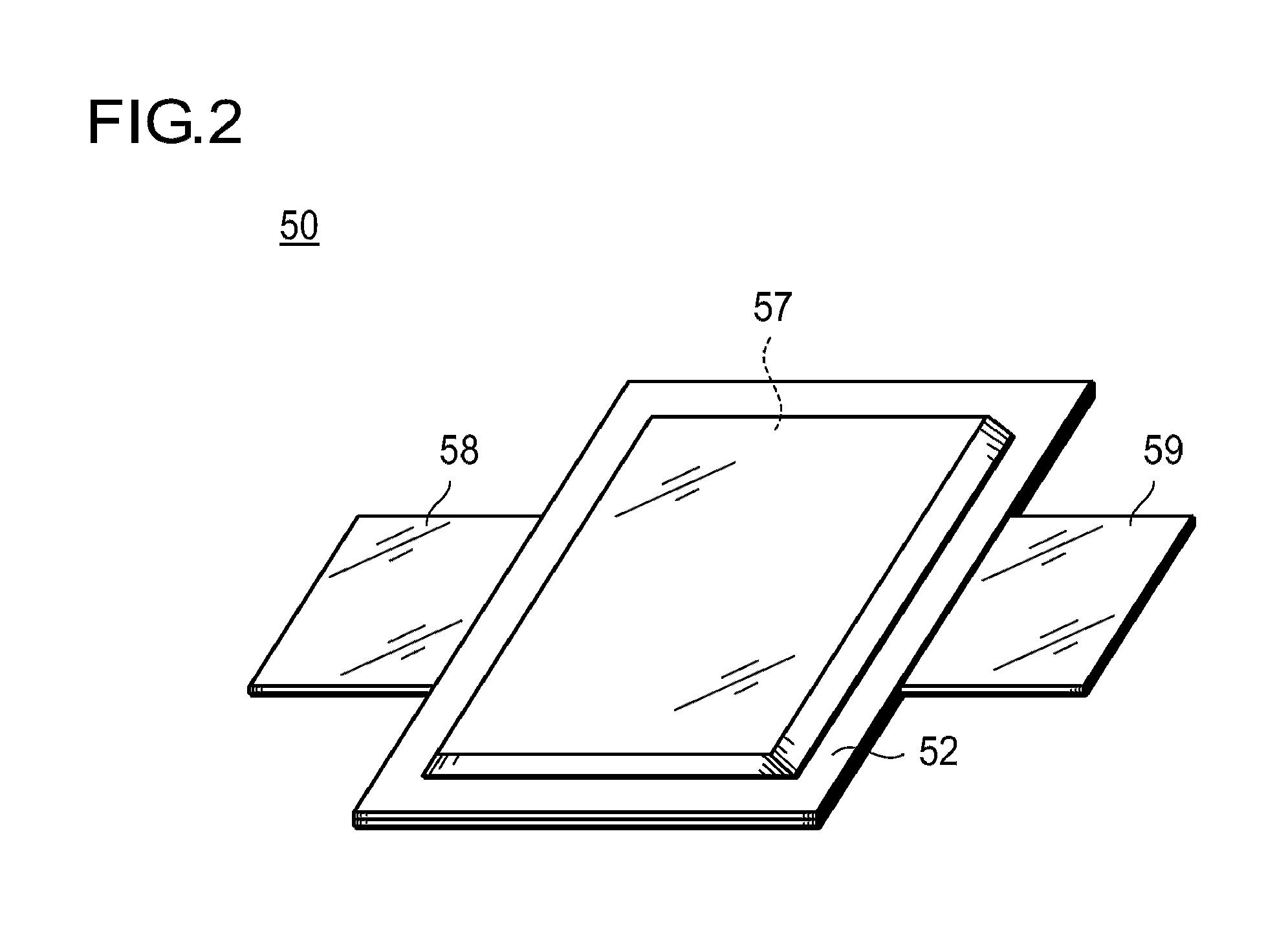

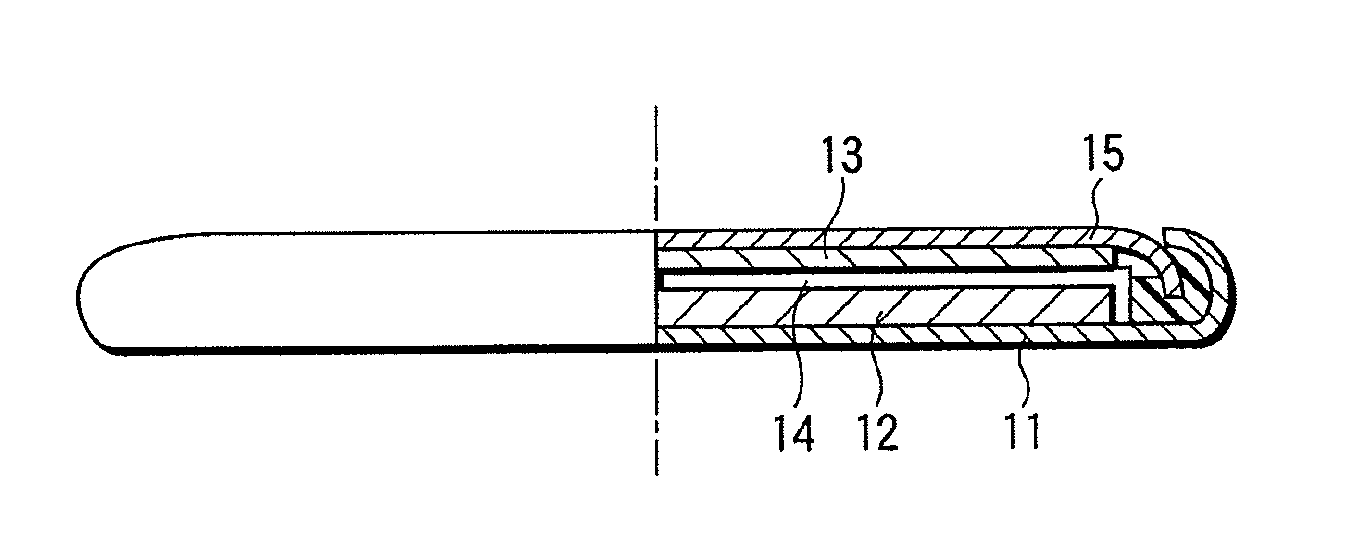

Cathode plate for secondary battery, manufacturing method thereof and secondary battery provided with the cathode plate

InactiveUS20130122366A1Increase electrode capacitySecure porosityActive material electrodesElectrode collector coatingLithium iron phosphateConductive materials

Disclosed is a cathode plate for a secondary battery, which includes a collector, and a cathode active material layer, wherein the cathode active material layer is formed of multiple layers of coating films formed on a surface of the collector and obtained by application and drying of an aqueous paste, which is obtained by kneading and dispersing an iron lithium phosphate material having an olivine structure as the cathode active material, an electroconductive material, a water-soluble thickner, a binder, and water as a dispersion medium.

Owner:ZEON CORP

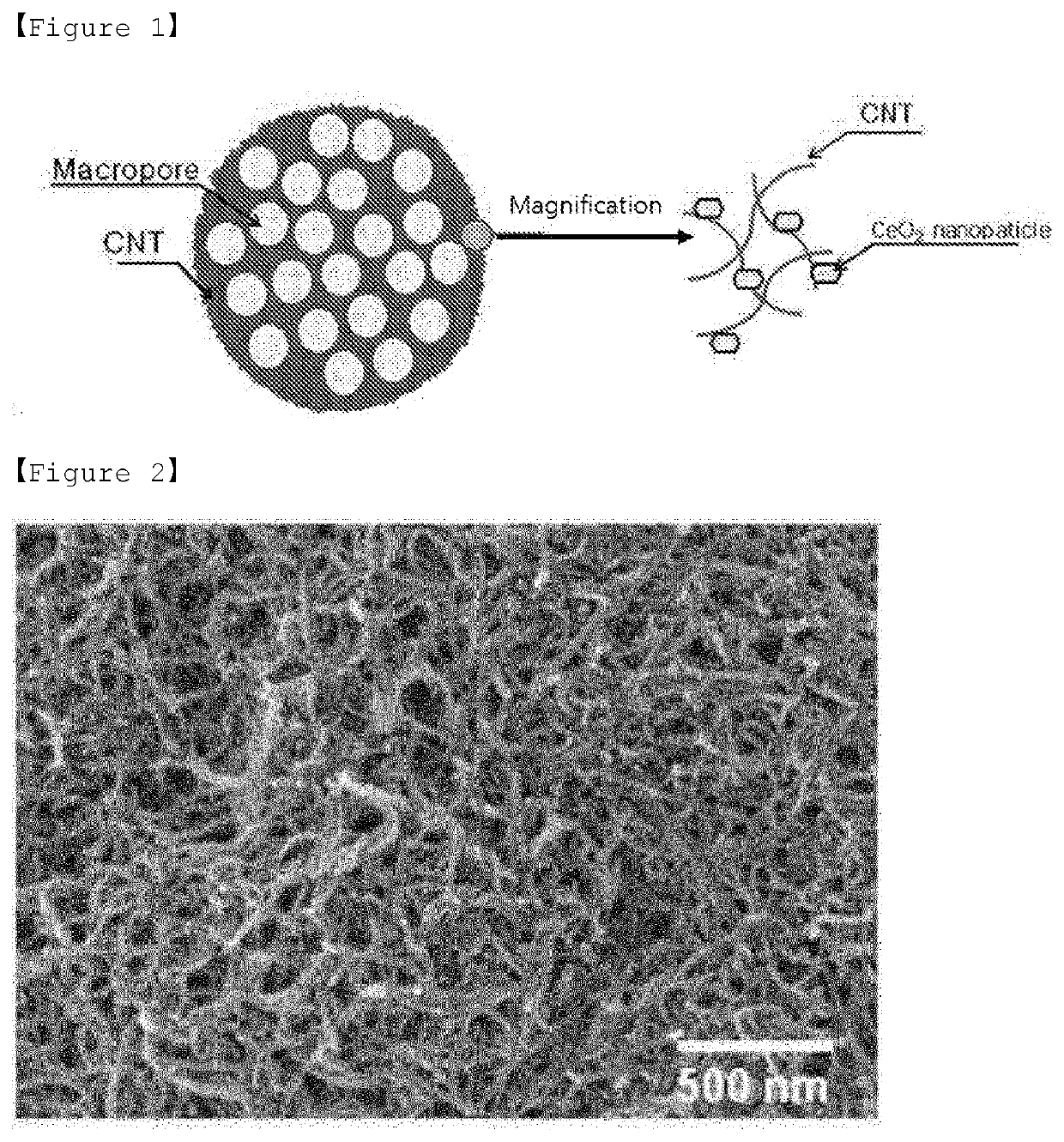

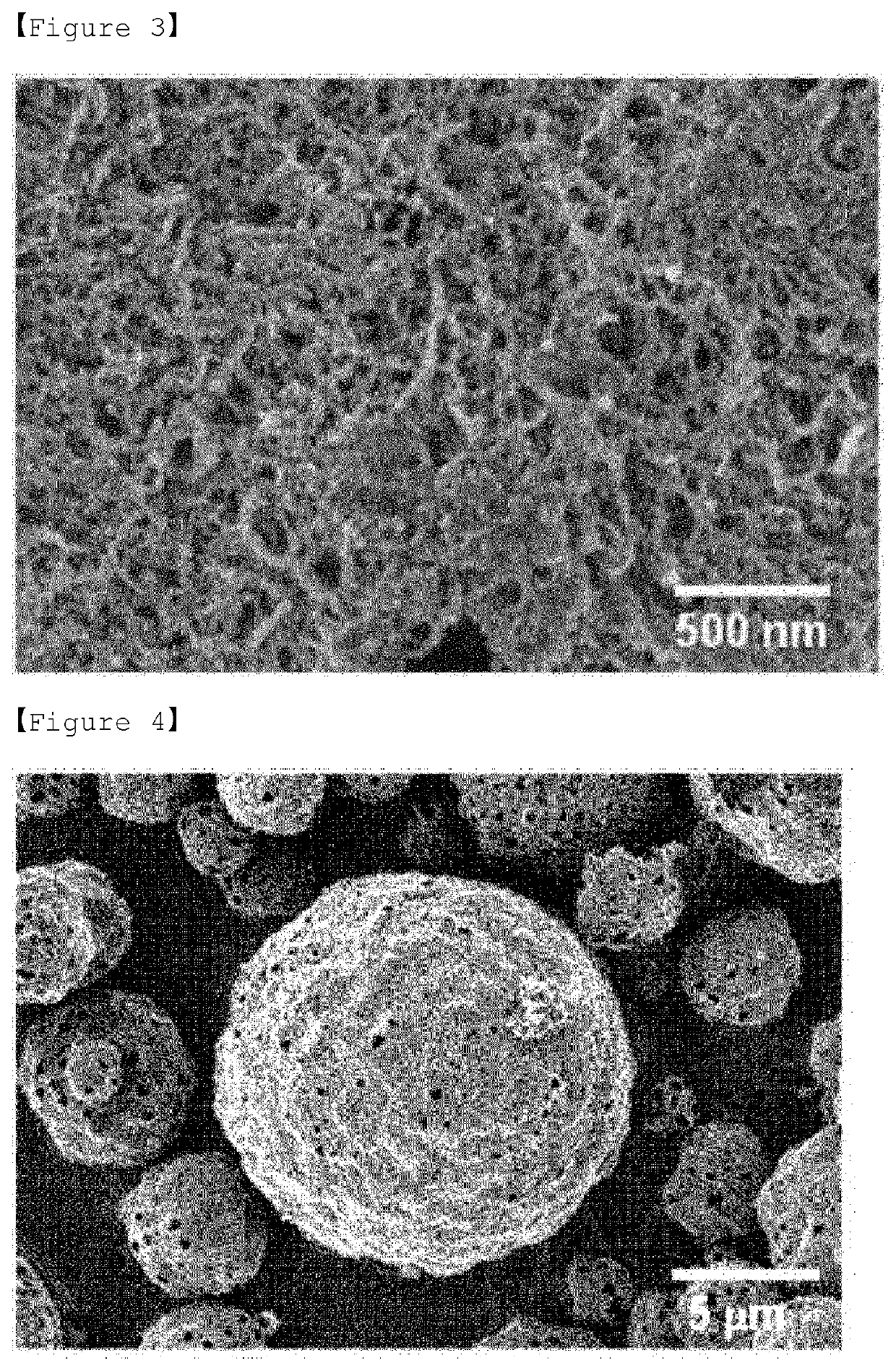

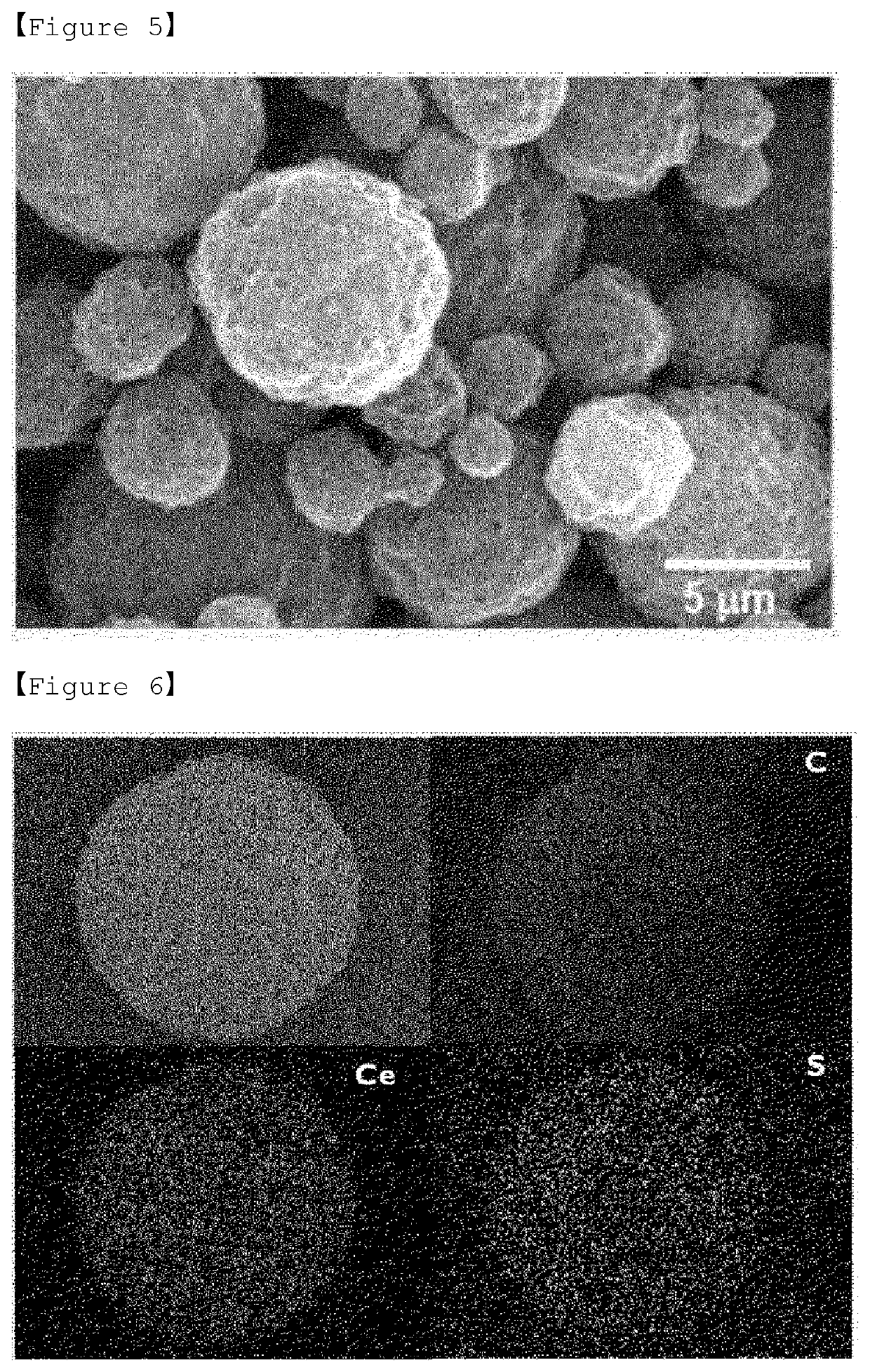

Ceria-carbon-sulfur composite, method for preparing same, and positive electrode and lithium-sulfur battery comprising same

PendingUS20200343535A1Excellent characteristicsImprove stabilityElectrode thermal treatmentSulfur preparation/purificationCarbon compositesLithium–sulfur battery

A ceria-carbon-sulfur (CeO2—C—S) composite including a ceria-carbon (CeO2—C) composite in which cylindrical carbon materials having ceria (CeO2) particles bonded to surfaces thereof are entangled and interconnected to each other in three dimensions; and sulfur introduced into at least a portion of an outer surface and an inside of the ceria-carbon composite, a method for preparing the same, and positive electrode for a lithium-sulfur battery and a lithium-sulfur battery including the same.

Owner:SOGANG UNIV RES FOUND +1

Arc tube and method of manufacturing same

InactiveUS20120133279A1Low efficiencyReduced service lifeLine/current collector detailsSolid cathode detailsShrink-fittingMaterials science

An arc tube includes a light emitting body for light therein and a ceramic tube having a first capillary and a second capillary integral with respective opposite sides of the light emitting body. A first electrode is inserted and sealed in the first capillary, and a second electrode is inserted and sealed in the second capillary. The first electrode is sealed in the first capillary by shrink fitting.

Owner:NGK INSULATORS LTD

Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

InactiveCN100389515CImprove controllabilityAchieve hybridElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateComposite electrode

An electrode material of Fe¿CLi phosphate and its composite metal phosphate is electrode material of LiFePO4 and LiFePO4 / MxP in high density spherical shape with diameter of 2micro m. The electrode material of LiFePO4 and LiFePO4 / MxP can be prepared by low ¿C temperature controllable one ¿C stage atomizing process in short flow.

Owner:NANKAI UNIV

Sn-Co/C alloy cathode material of lithium ion battery and preparation method thereof

InactiveCN103000863BSmall particle sizeImprove cycle performanceCell electrodesAcid etchingCarbon coating

The invention discloses a Sn-Co / C alloy cathode material of a lithium ion battery and a preparation method thereof. The preparation method comprises the steps: uniformly mixing Sn powder and Co powder according to the mass ratio of (99:1) to (97:3), melting the mixture of the Sn powder and the Co powder, and carrying out spraying cooling to obtain a Sn-Co composite material; then adding an acid solution with the concentration being 1-3mol / L into a Sn-Co composite material for acid treatment to obtain a Sn-Co material subjected to the acid treatment; and mixing and sintering the Sn-Co material with an organic carbon source and asphalt in sequence to obtain an Sn-Co / C alloy cathode material. According to the invention, by adoption of acid etching, primary carbon coating based on the organic carbon source and secondary carbon coating based on the asphalt, the electrode is limited in expansion while being endowed with an expansion space, so that the material is prevented from being pulverized in a discharge / charge process. The prepared Sn-Co / C alloy cathode material is a solid solution alloy, has excellent mechanical strength, is free from the problem of electrode capacity reduction caused by the material itself, is improved in cyclic performance and electrode capacity at the same time, and has the advantages of high charge / discharge capacity and good cyclic performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

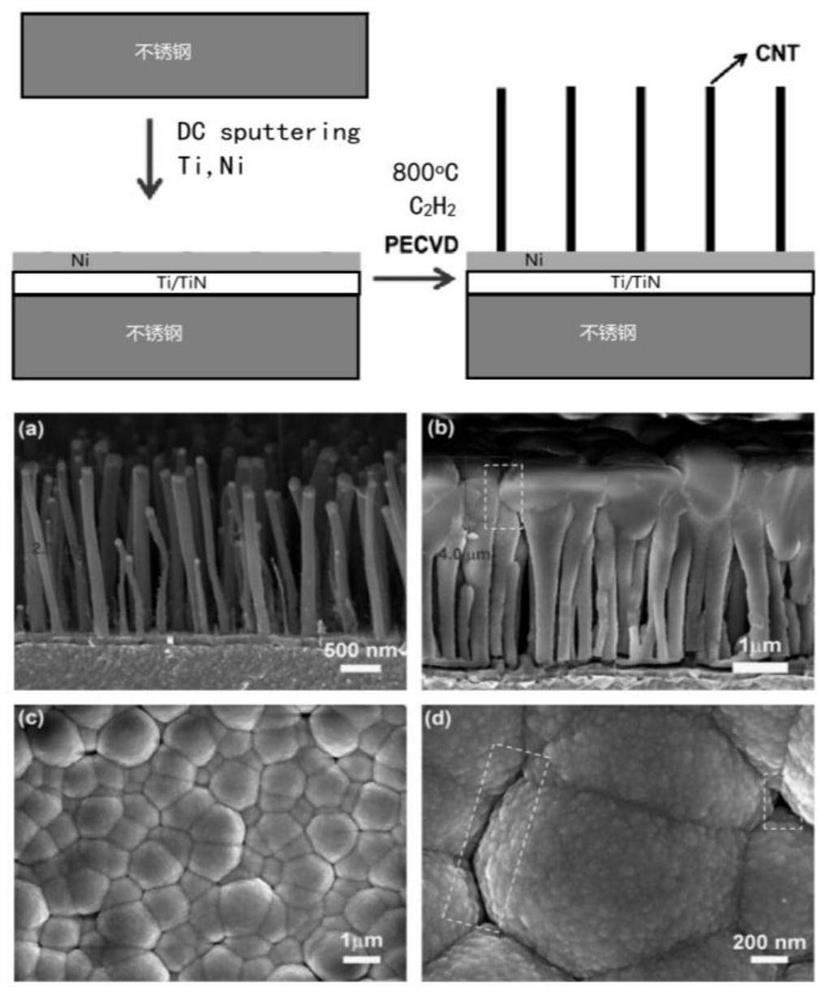

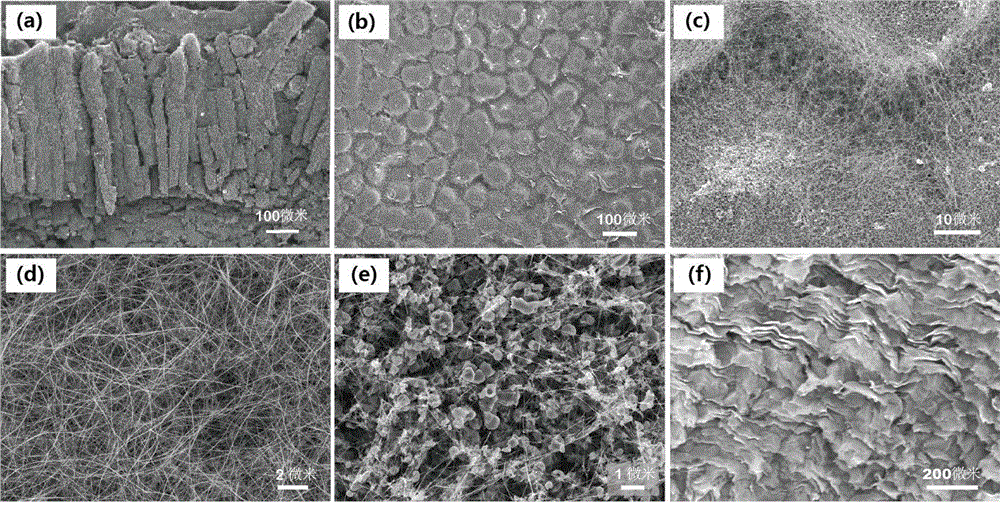

A kind of preparation method of binderless lithium ion battery negative electrode material

InactiveCN104134785BSimple processLarge poresCell electrodesSecondary cellsCarbon nanotubeCopper foil

Owner:NANJING UNIV OF POSTS & TELECOMM

Electrode preparation method and battery

ActiveCN109841796BIncrease areal densityImprove structural stabilityElectrode manufacturing processesSecondary cellsLamellar crystalsElectrical battery

The invention discloses an electrode preparation method and a battery. The battery anode is prepared by pasting an electrode film prepared from an active substrate, a conductive agent and a binder toa current collector, the surface density of a pole piece is improved, the electrode capacity and the pole piece stability are improved, and the internal resistance is reduced. In the preparation process of the electrode film, lamellar crystals of the binder are stretched to paste the active substance and conductive agent, influence of expansion and contraction of the active substance caused by ionembedding and separating is reduced. The battery cathode is prepared by coating a slurry prepared from a pre-lithium active substance, a binder and a conductive agent on the current collector, the active substrate and conductive agent of the cathode are wetted rapidly, dispersed ultra-finely and homogeneous in a binder solution, the amount of the solvent for slurry dispersion is reduced, energy consumption for drying is reduced, the electrode process is shortened, and the load capacity of the cathode active substance is improved. The anode and cathode of the battery can be designed in an integrated way, and energy storage of the battery is improved. The electrode preparation method is simple, production and manufacture are realized by means of existing equipment, and the method is easy topopularize.

Owner:CHINA FIRST AUTOMOBILE

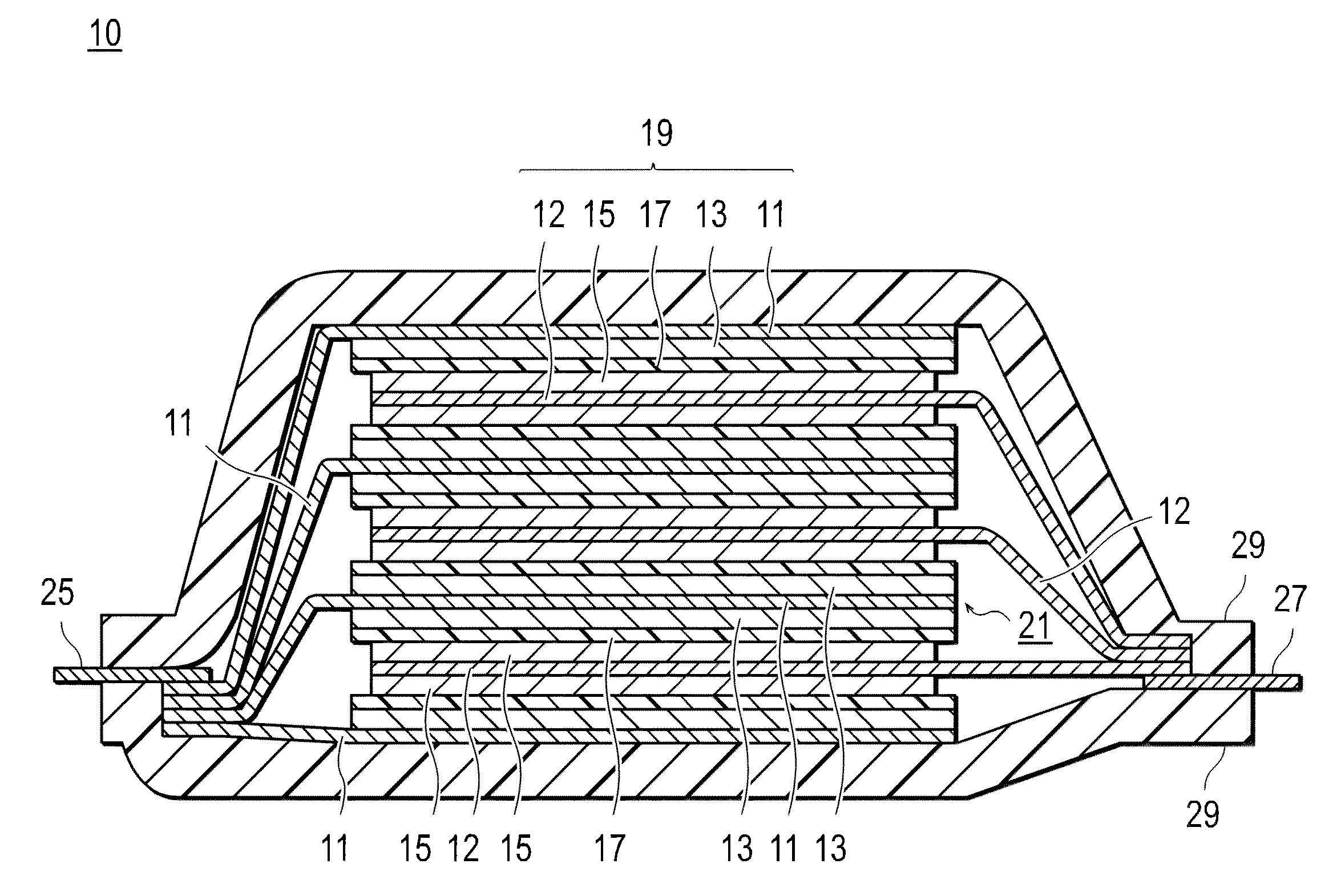

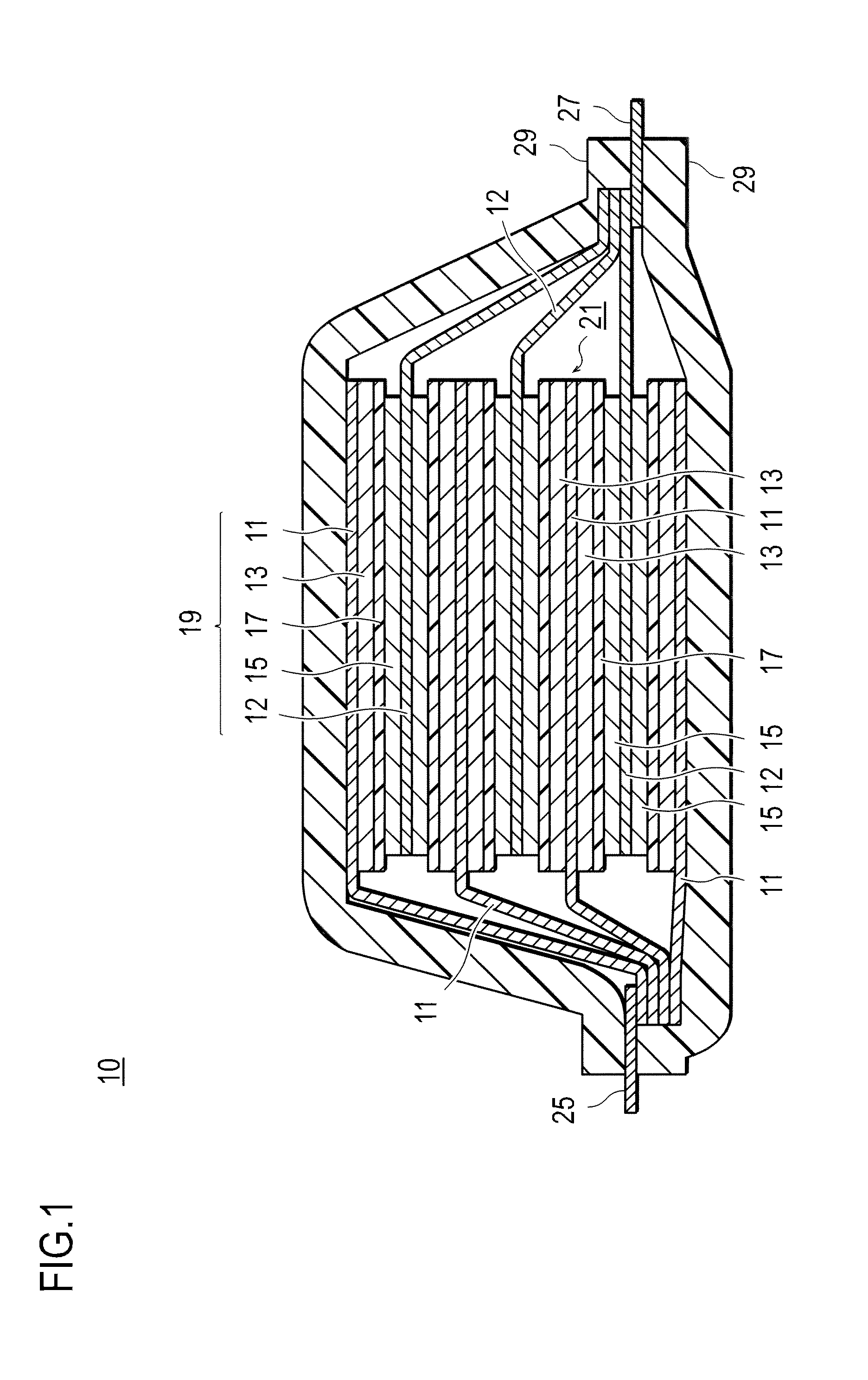

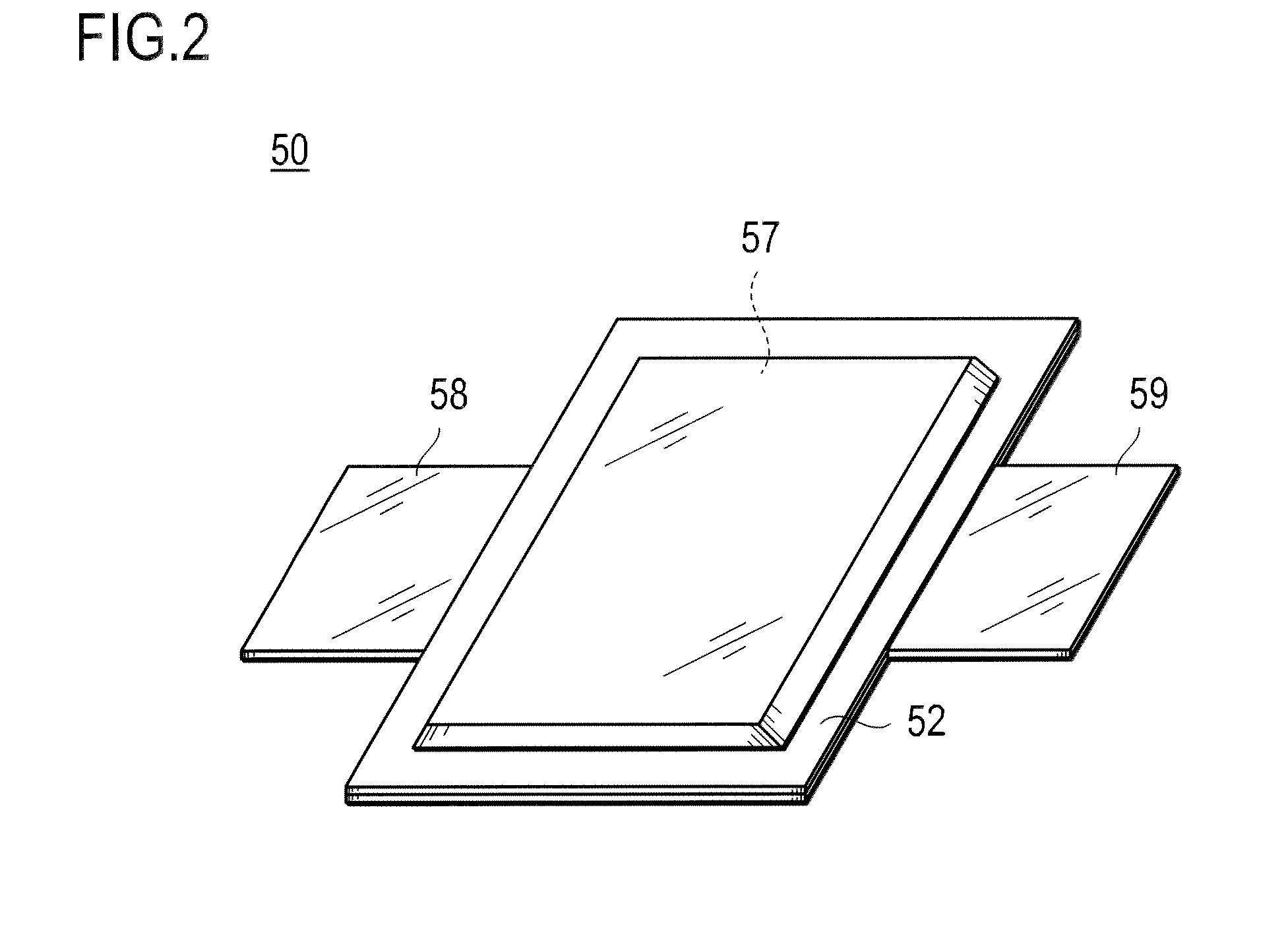

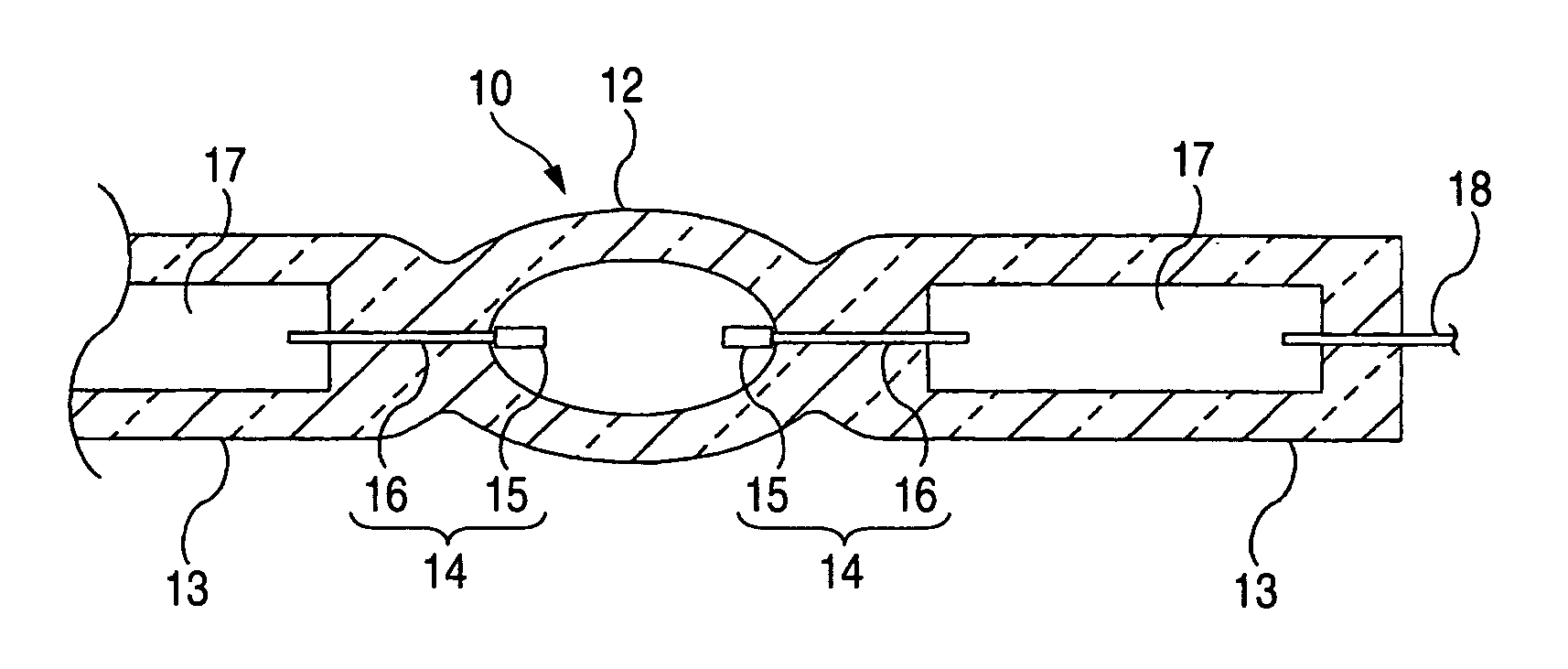

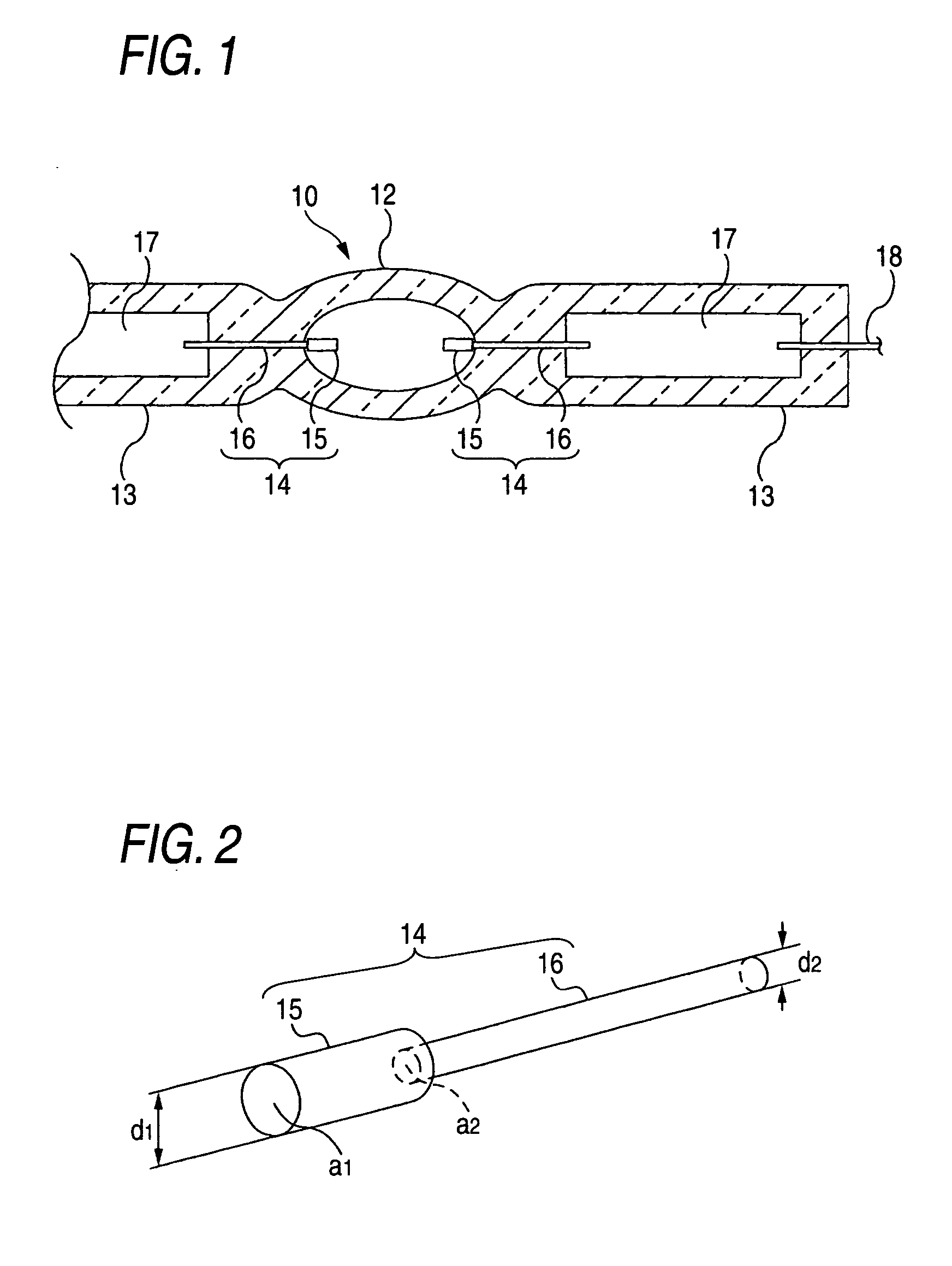

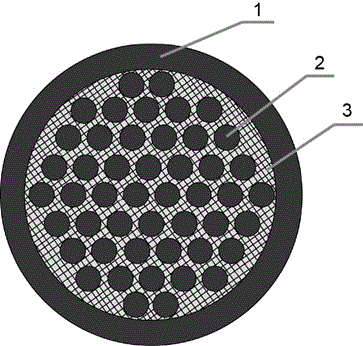

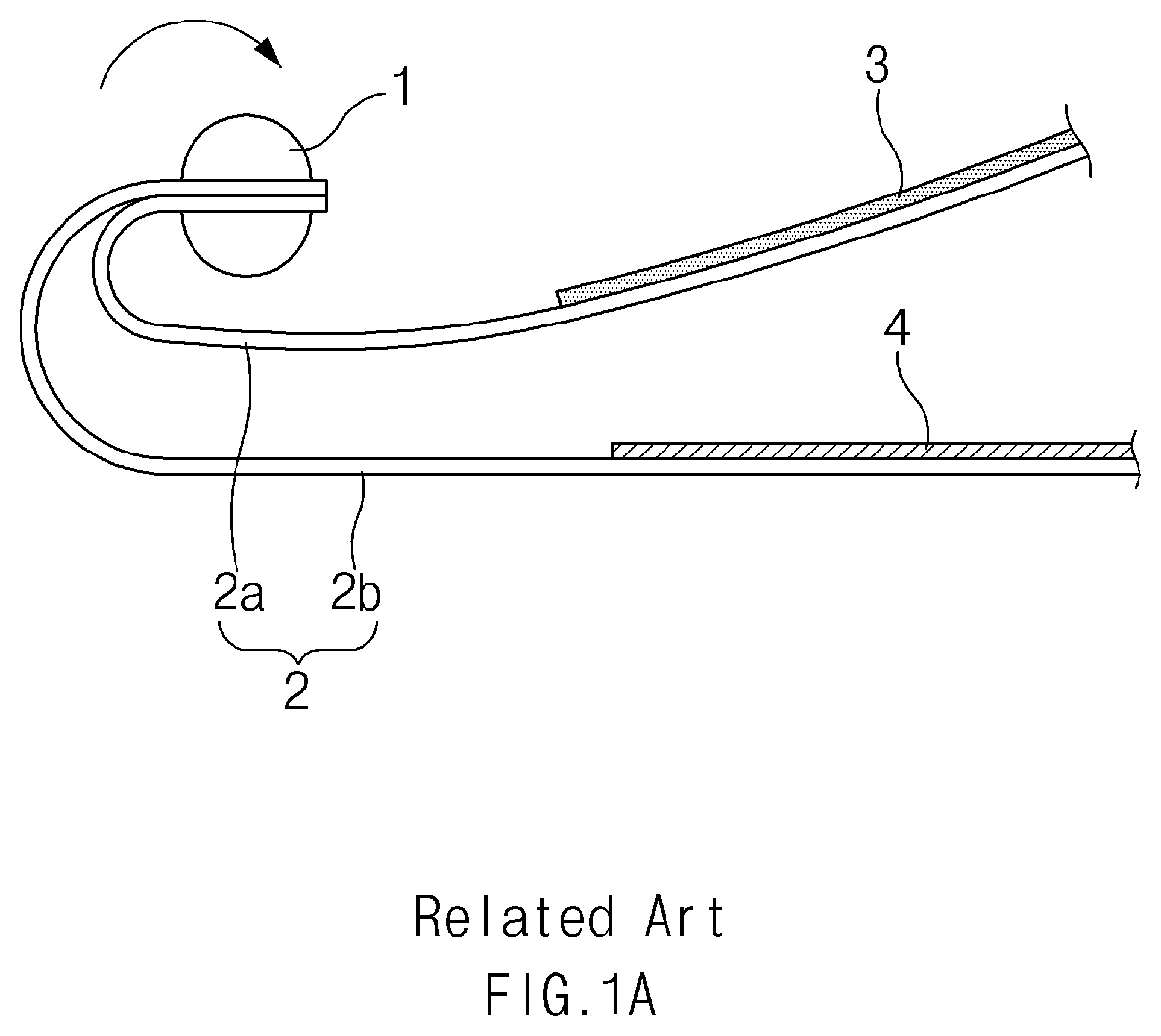

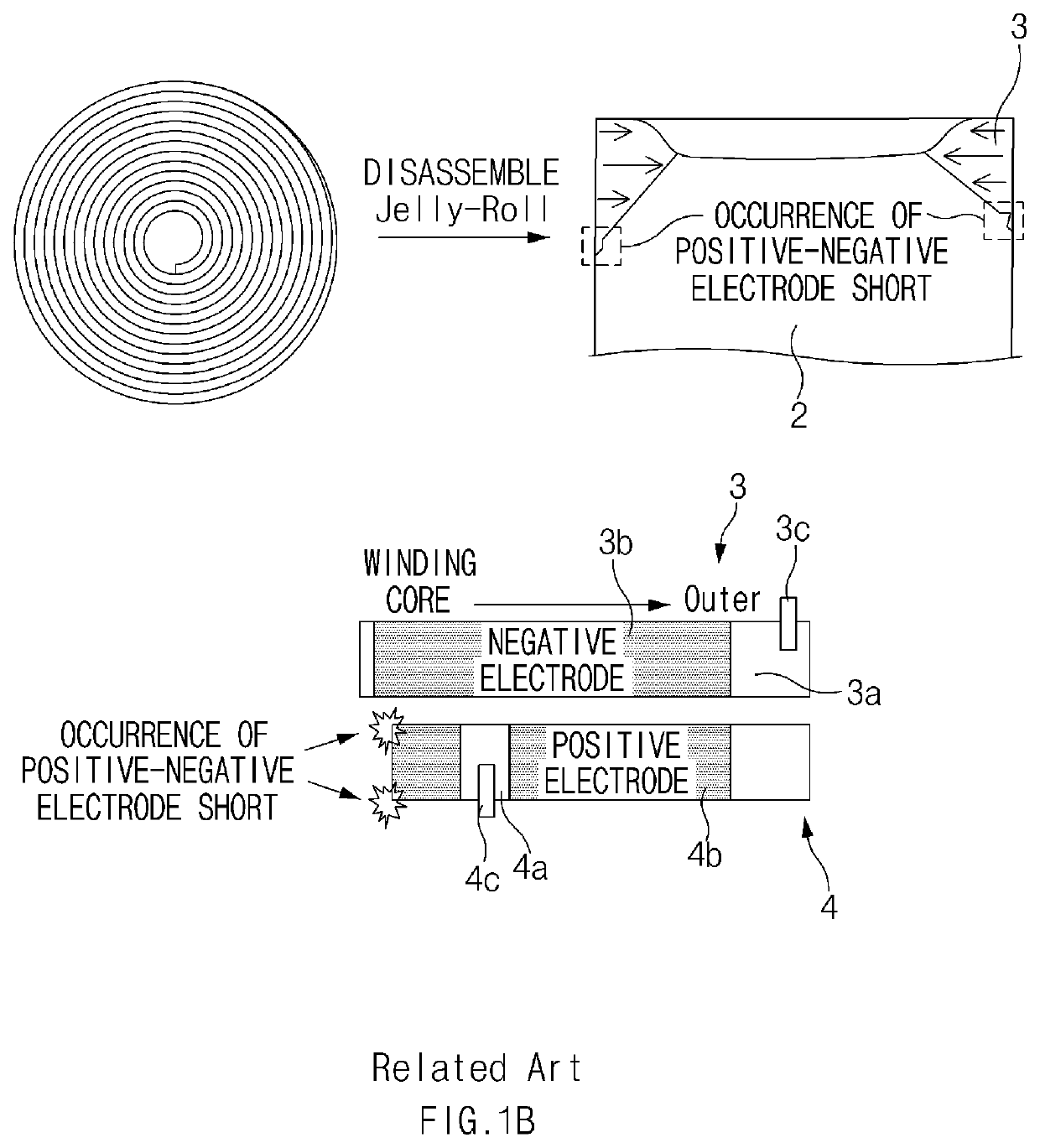

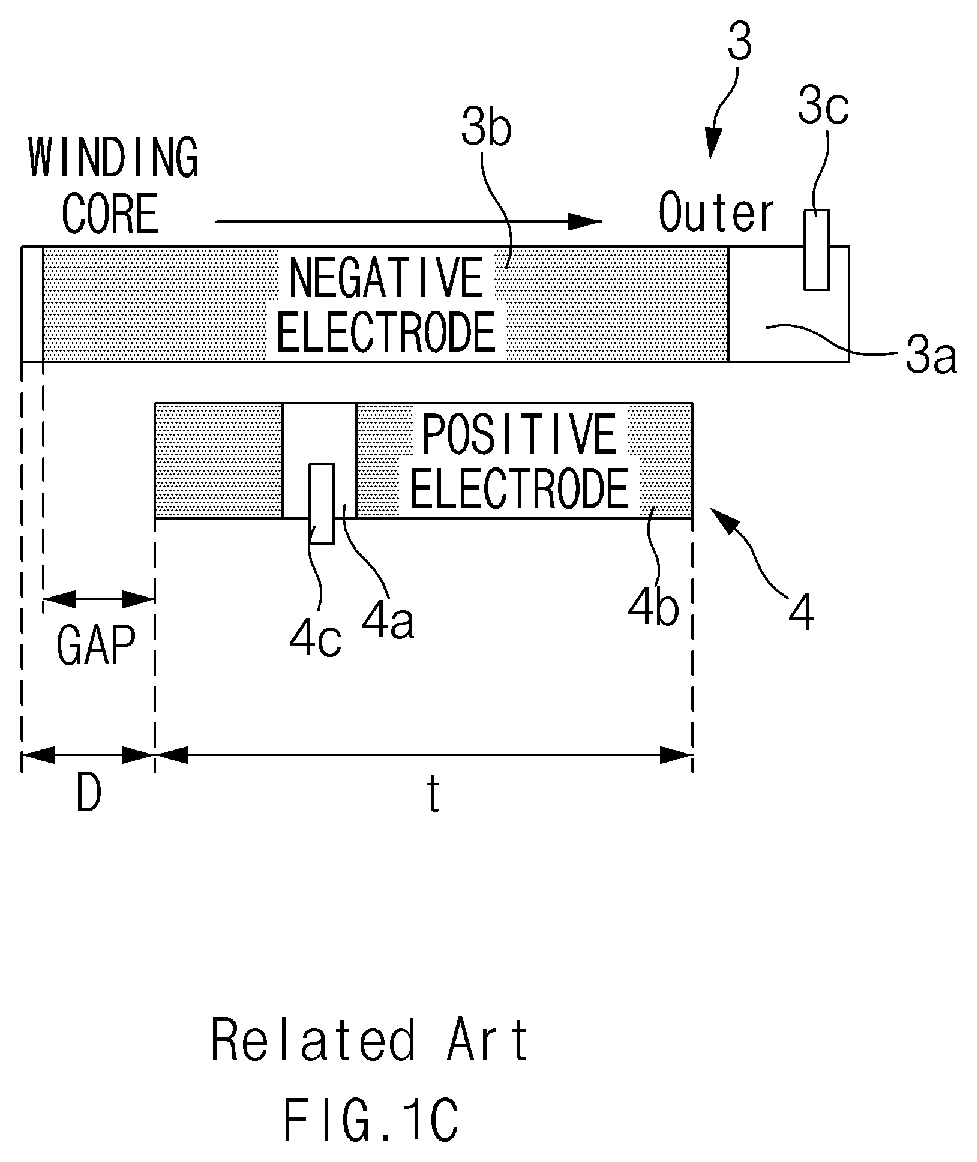

Electrode assembly and method for manufacturing same

PendingUS20220344697A1Shorten the lengthImprove the immunityFinal product manufactureWound/folded electrode electrodesEngineeringMaterials science

A jelly-roll type electrode assembly including a negative electrode, a first separator, a positive electrode, and a second separator that are wound together is provided. The negative electrode includes a negative electrode active material on a surface of a negative electrode collector and which has, on a first end thereof, a first negative electrode collector-exposed portion that is not coated with the negative electrode active material to expose the surface of the negative electrode collector. The negative electrode is wound together with the first separator such that the first negative electrode collector-exposed portion is disposed in a central region where the winding starts, and a negative electrode tab is coupled to the first negative electrode collector-exposed portion.

Owner:LG ENERGY SOLUTION LTD

A method of in-situ coating conductive polymers to improve electrode capacity

ActiveCN108400308BIncrease electrode capacityImprove conductivityCell electrodesSecondary cells servicing/maintenanceConductive polymerActive agent

The invention relates to a preparation method of an electrode material, in particular to a method for in-situ coating a conductive polymer to increase the capacity of an electrode, and belongs to the technical field of electrochemistry. In the present invention, firstly, the powdery battery material is mechanically mixed with acetylene black and ball-milled, then pressed into tablets, and assembled into a battery as a positive electrode material, charged to 3‑4.2V, and then the charged electrode material is taken out and placed in a conductive Soak in an aqueous solution of polymer monomers and surfactants, take out the soaked electrode material, wash it, and dry it to obtain the electrode material in-situ coated with a conductive polymer, which can be applied to Lithium and sodium ion batteries, and the battery capacity is greatly improved, and the preparation method is simple and easy to operate.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of binder-free lithium ion battery negative electrode material

ActiveCN111081992ASimple processLarge specific surface areaSecondary cellsElectrode moldingHydrofluoric acidSingle crystal

The invention belongs to the field of battery energy, and particularly relates to a preparation method of a binder-free lithium ion battery negative electrode material. The method comprises the following steps that: step 1, under the protection of argon, direct sintering and ball-milling are performed waste silicon powder generated by single crystal cutting; step 2, sodium silicate is added into an obtained product so as to be mixed with the product, ammonium chloride is added, and ball milling and drying are performed; 3, asphalt is added, and sintering is performed; 4, hydrofluoric acid soaking treatment is conducted, and washing is conducted until a product is neutral; 5, nano titanium dioxide particles are added, and carbon nanotubes are added, and ball milling is performed; and 6, tabletting is performed through a tabletting machine, so that the flaky silicon-based lithium ion battery negative electrode material can be obtained.

Owner:KAIFENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com