Patents

Literature

967results about "Tin compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

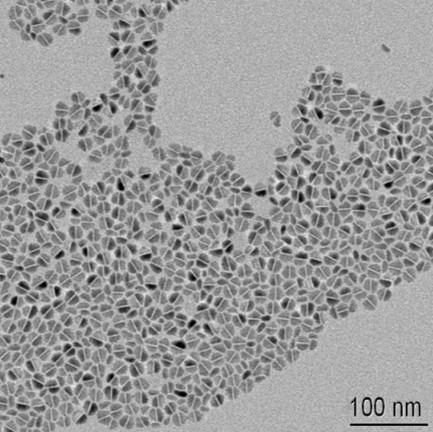

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

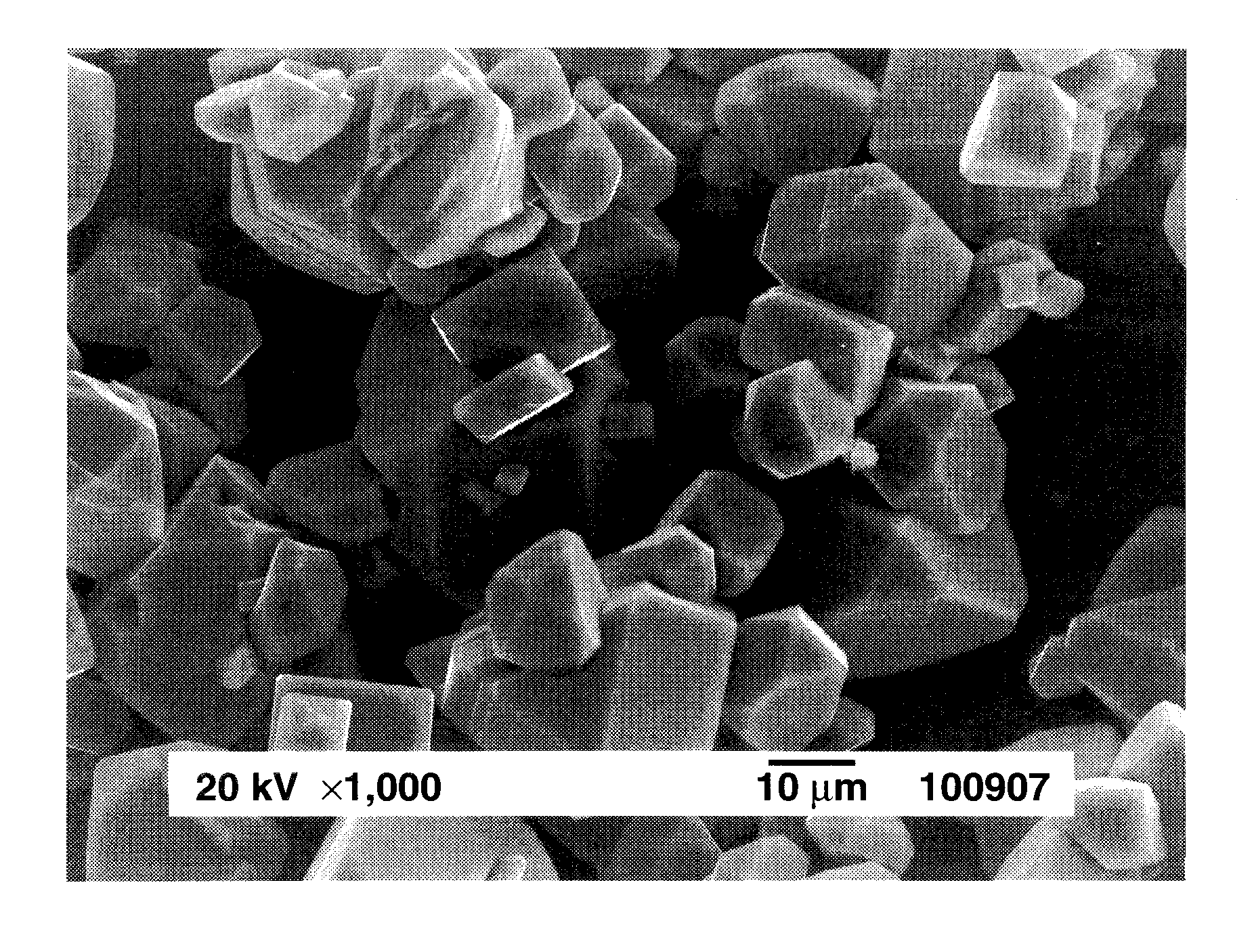

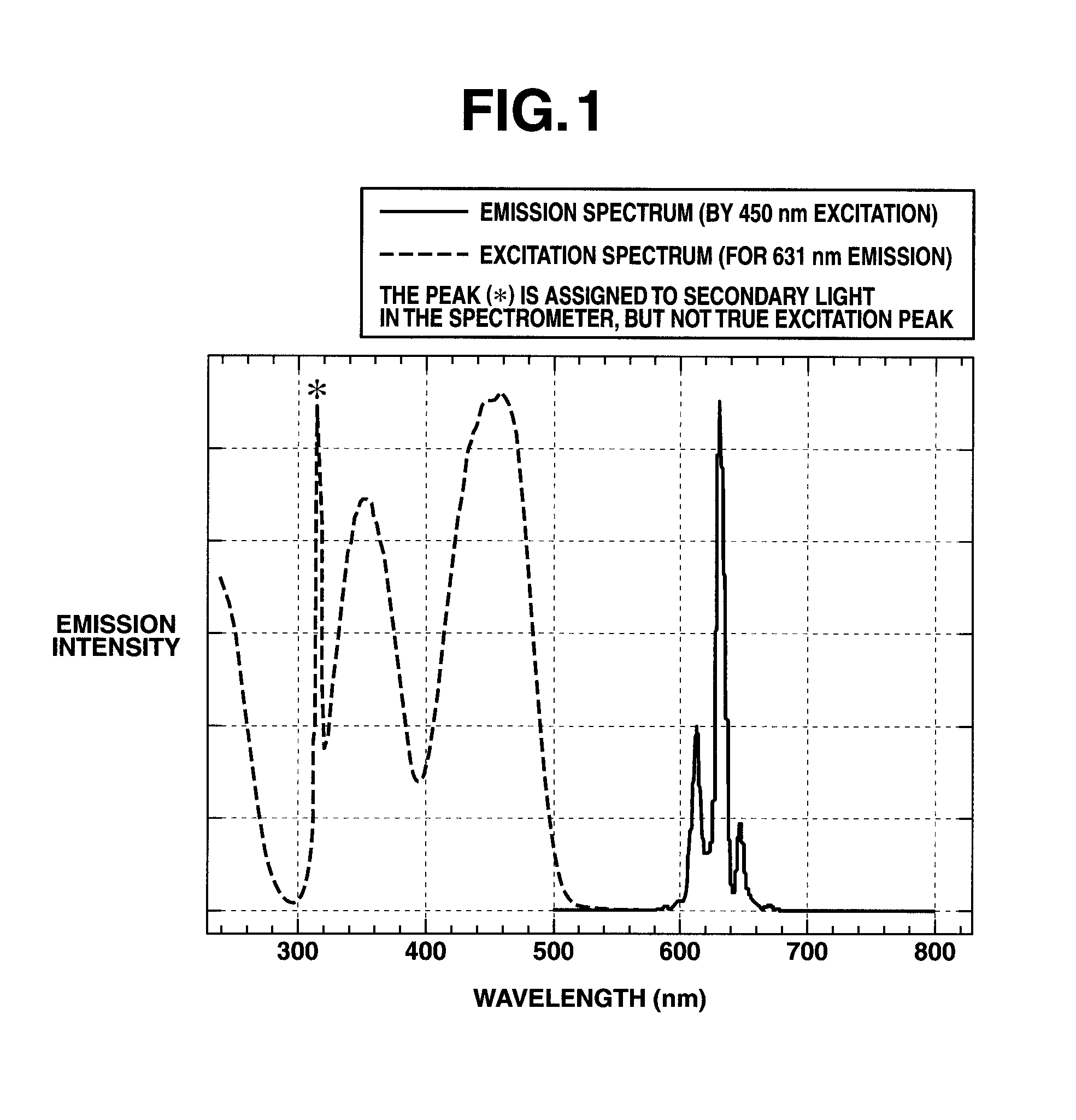

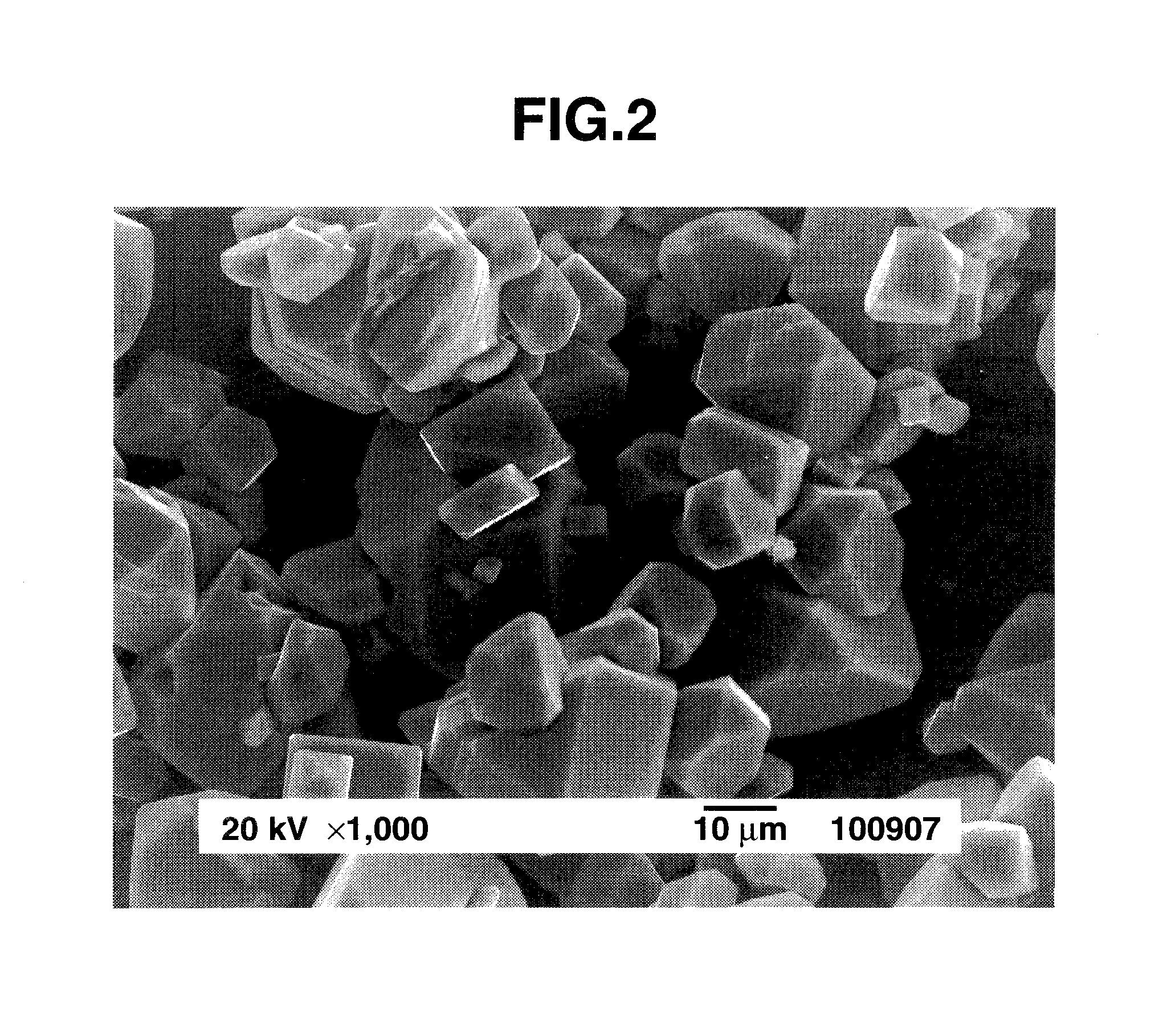

Preparation of complex fluoride and complex fluoride phosphor

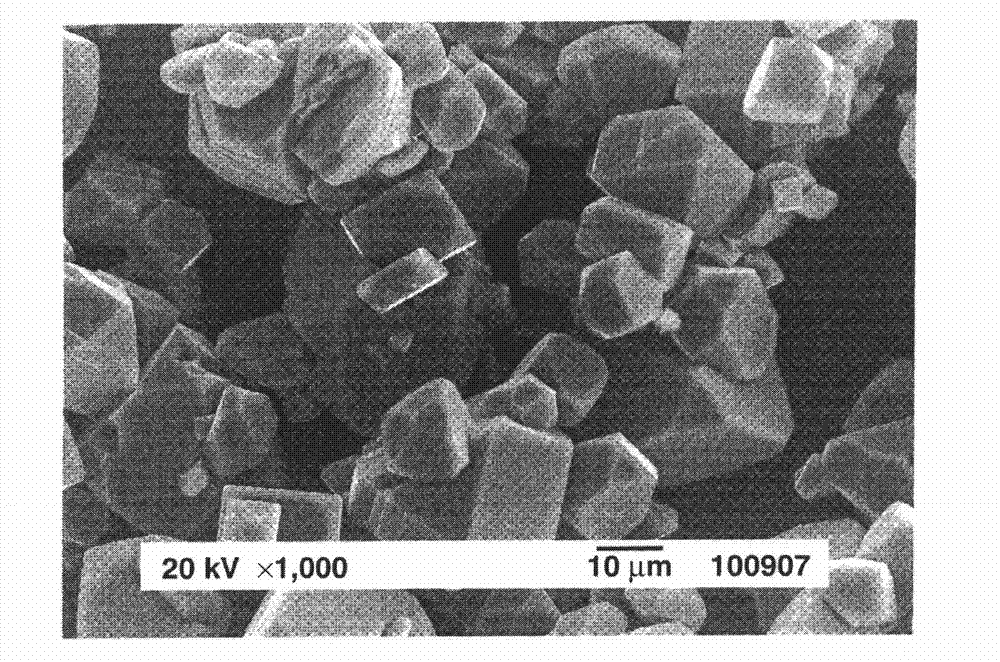

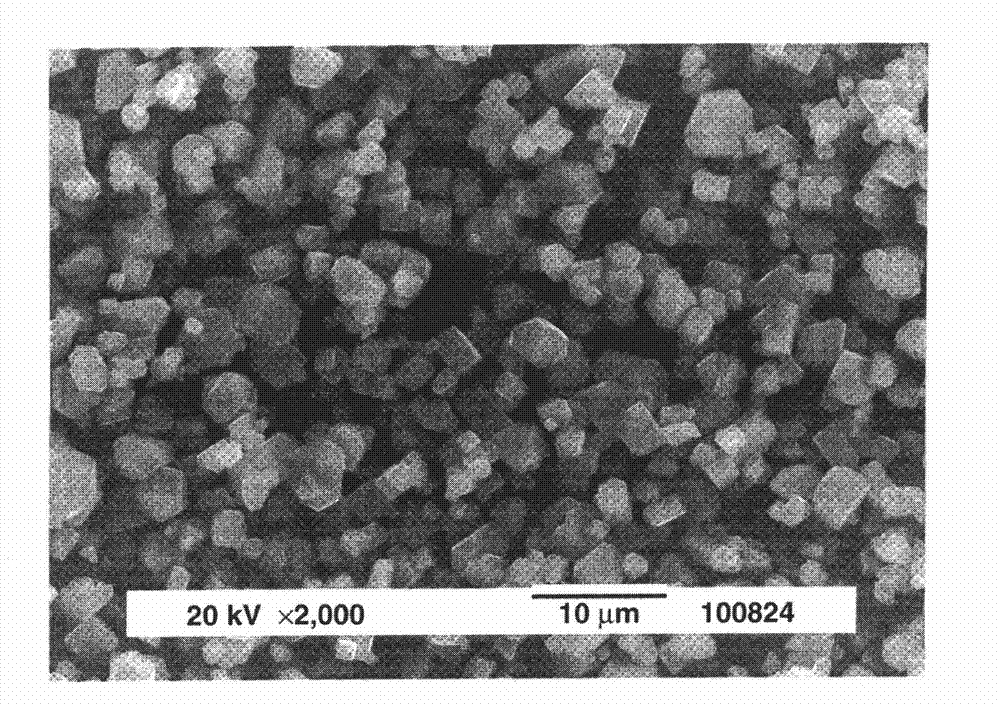

ActiveUS20120256125A1Uniform sizeSatisfactory emissive propertyTin compoundsSilicon halogen compoundsPhysical chemistryFluoride

A complex fluoride A2MF6 wherein M is a tetravalent element Si, Ti, Zr, Hf, Ge or Sn, A is an alkali metal Li, Na, K, Rb or Cs is prepared by providing a first solution containing a fluoride of M, providing a second solution containing a compound of A and / or the compound of A in solid form, mixing the first solution with the second solution and / or the solid for reacting the fluoride of M with the compound of A, and recovering the resulting solid product via solid-liquid separation.

Owner:SHIN ETSU CHEM IND CO LTD

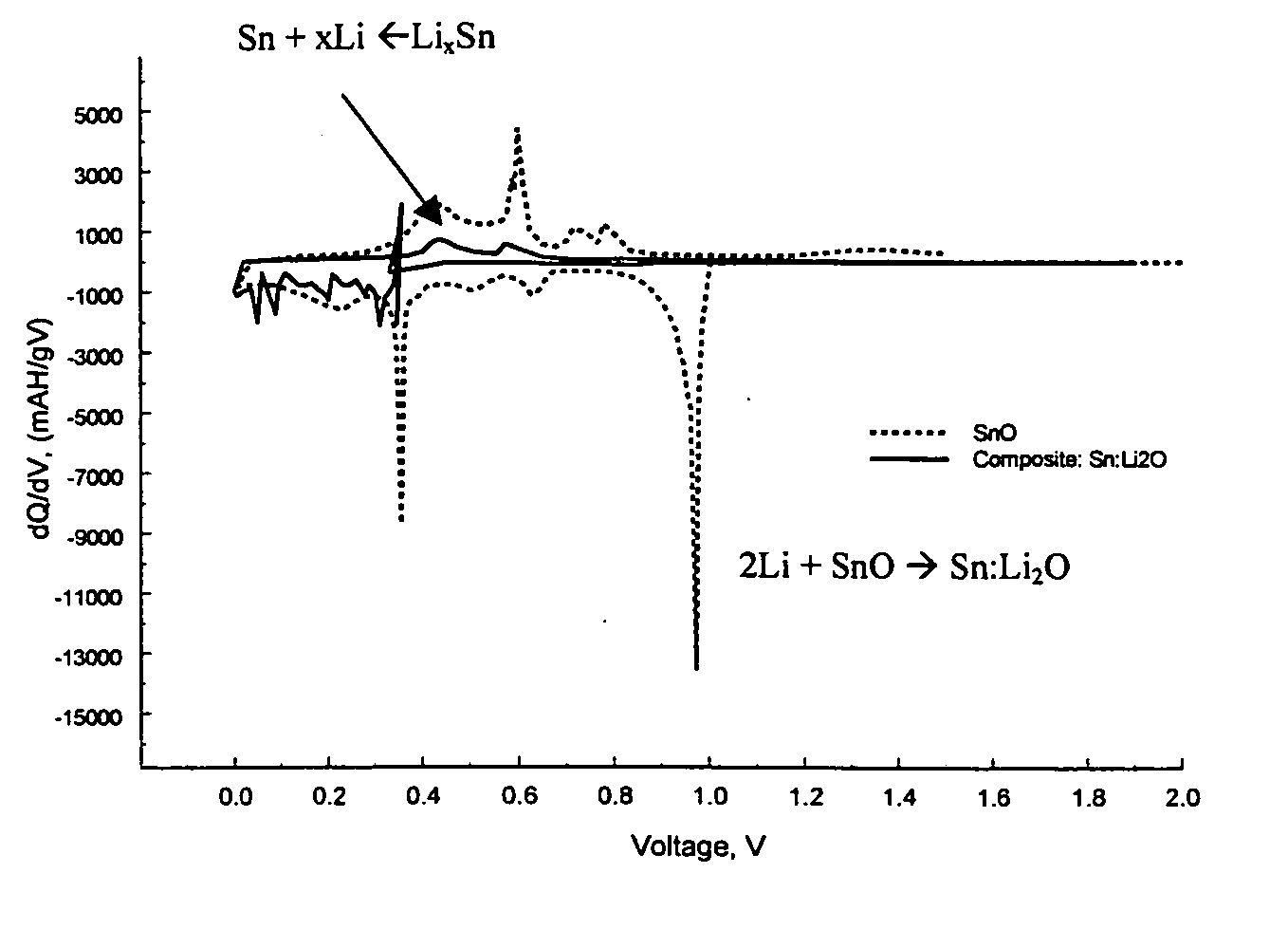

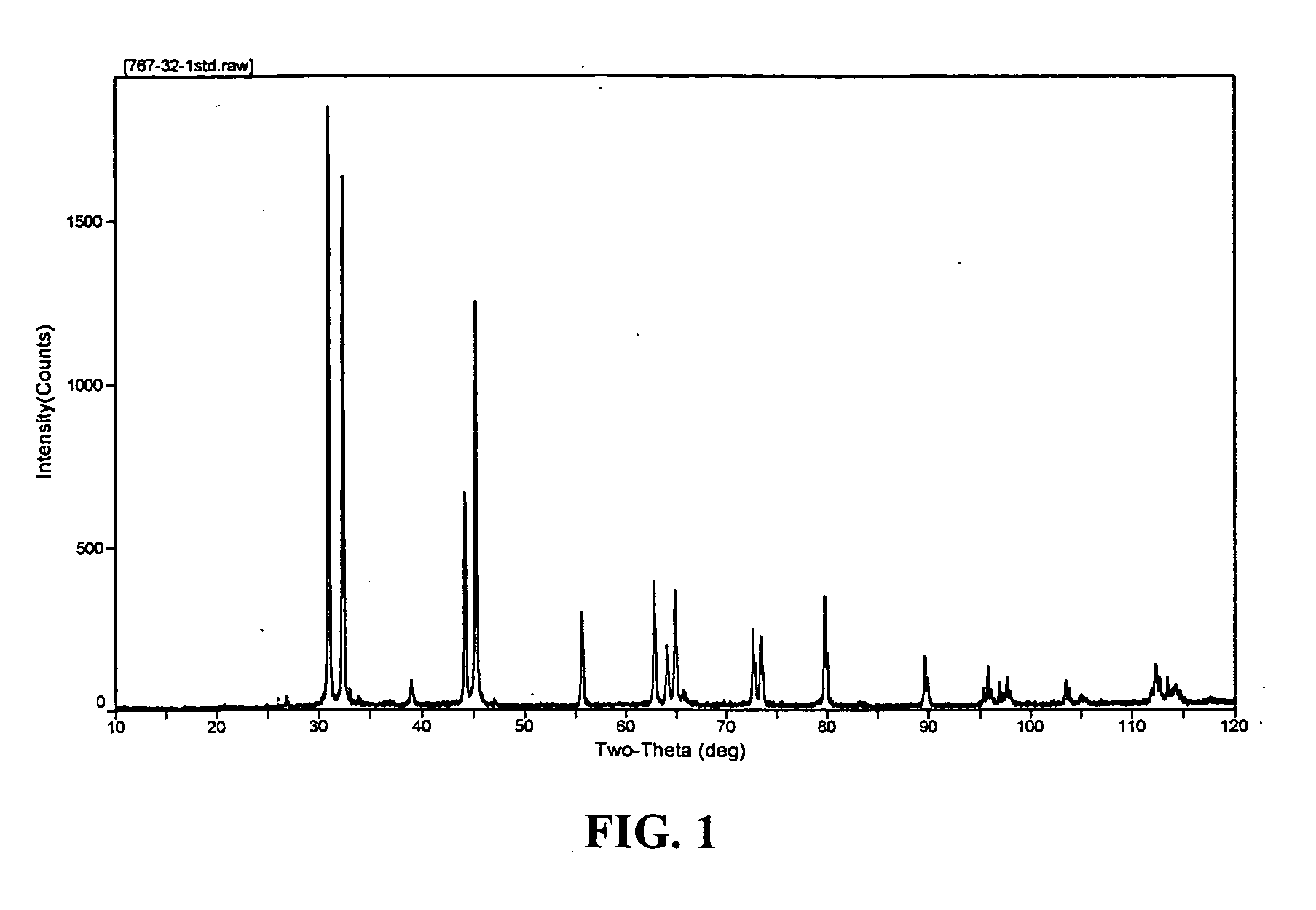

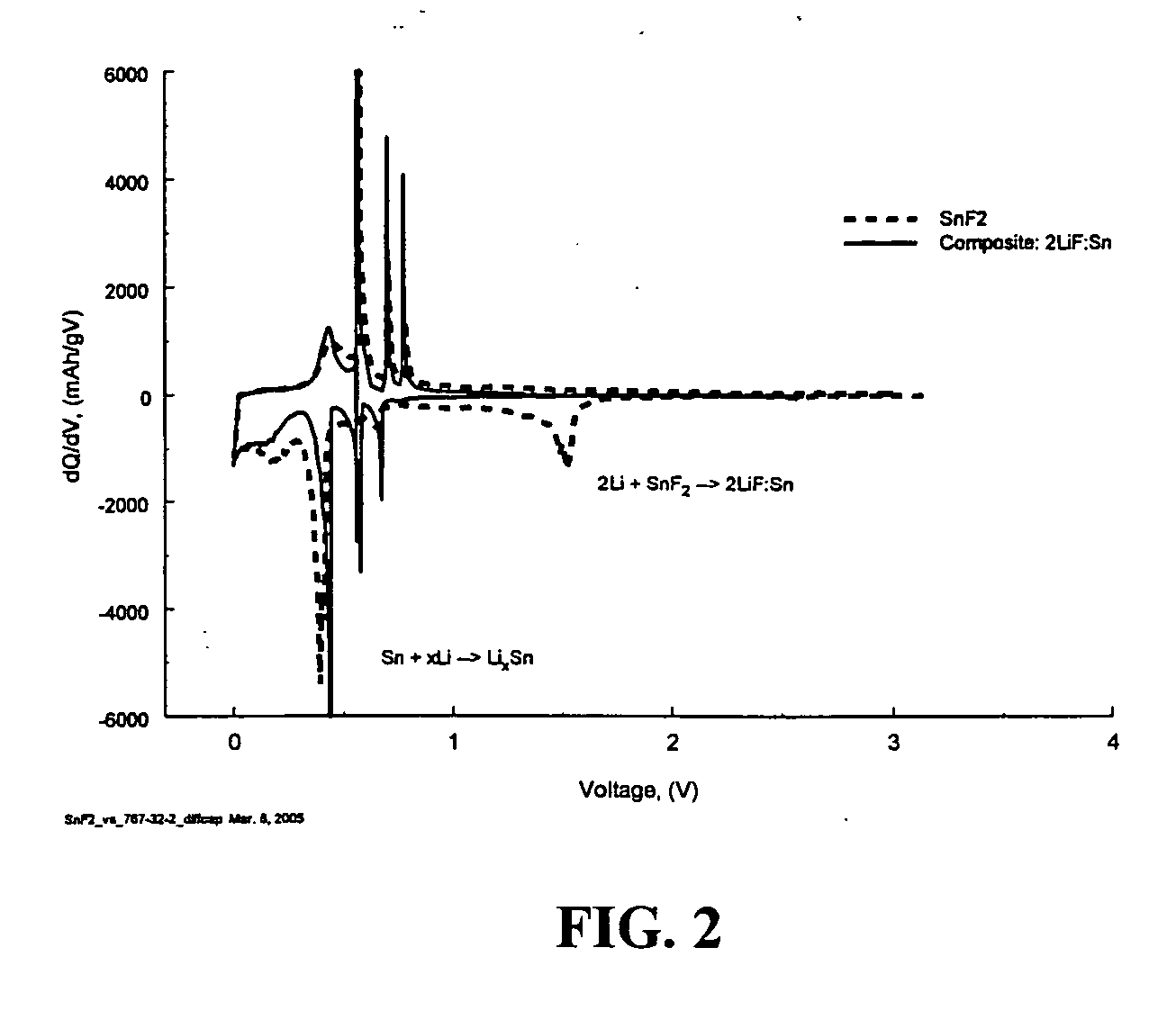

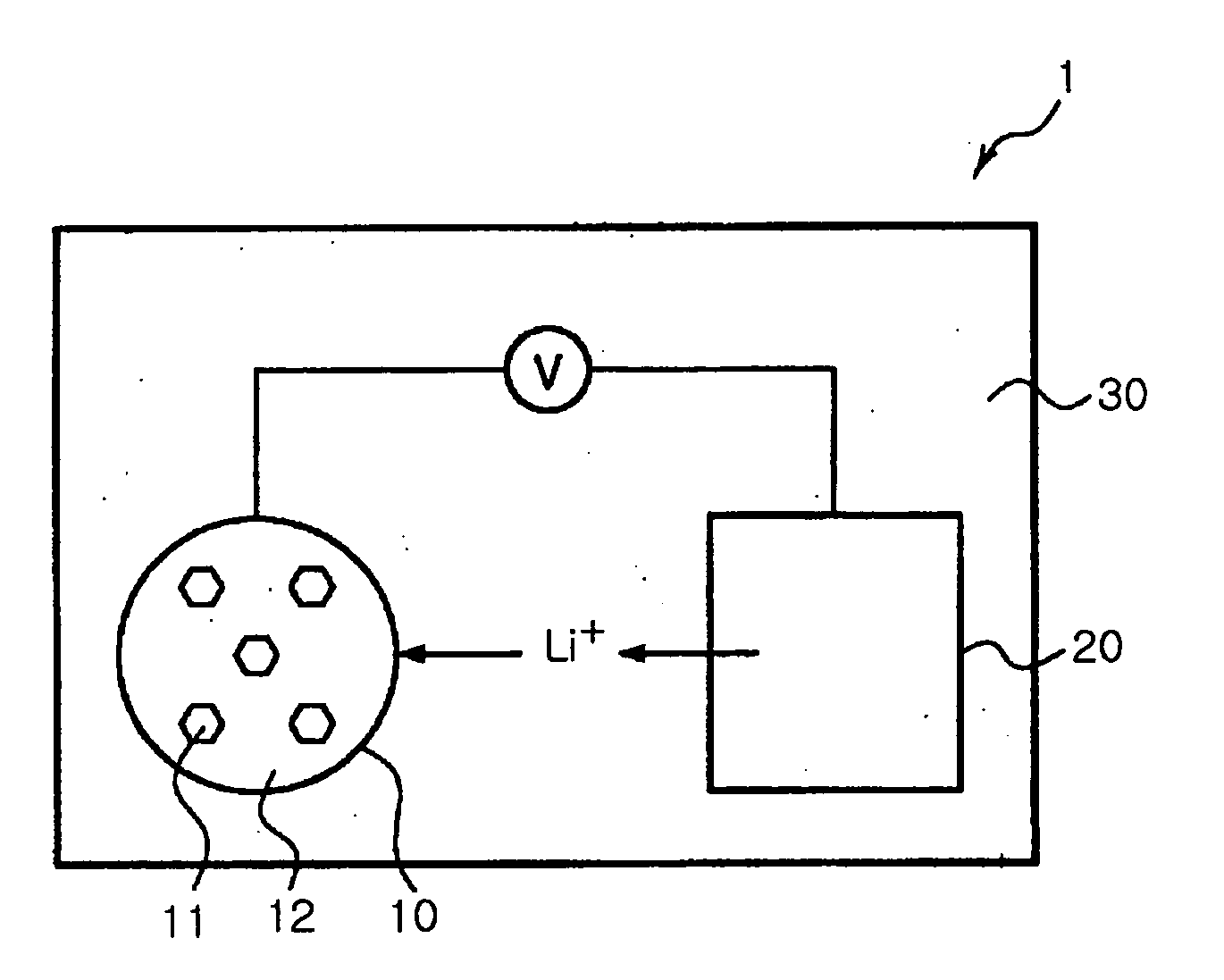

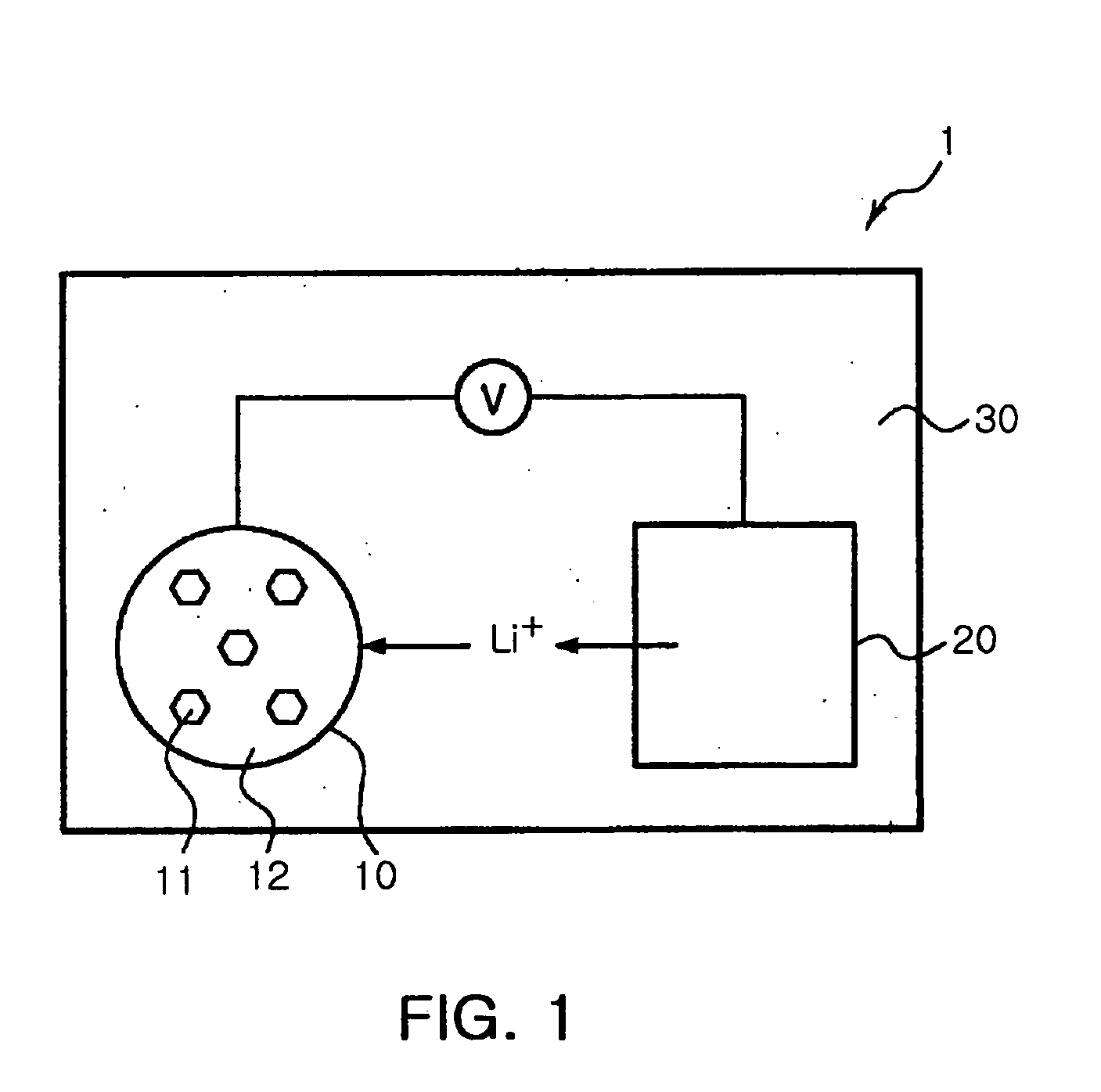

Composite materials of nano-dispersed silicon and tin and methods of making the same

Composite compounds of tin and lithium, silicon and lithium, or tin, silicon, and lithium having tin and silicon nano-dispersed in a lithium-containing matrix may be used as electrode materials and particularly anode materials for use with rechargeable batteries. Methods of making the composite compounds include the oxidation of alloys, the reaction of stabilized lithium metal powder with tin and silicon oxides, and the reaction of inorganic salts of lithium with tin and silicon containing compounds.

Owner:LIVENT USA CORP

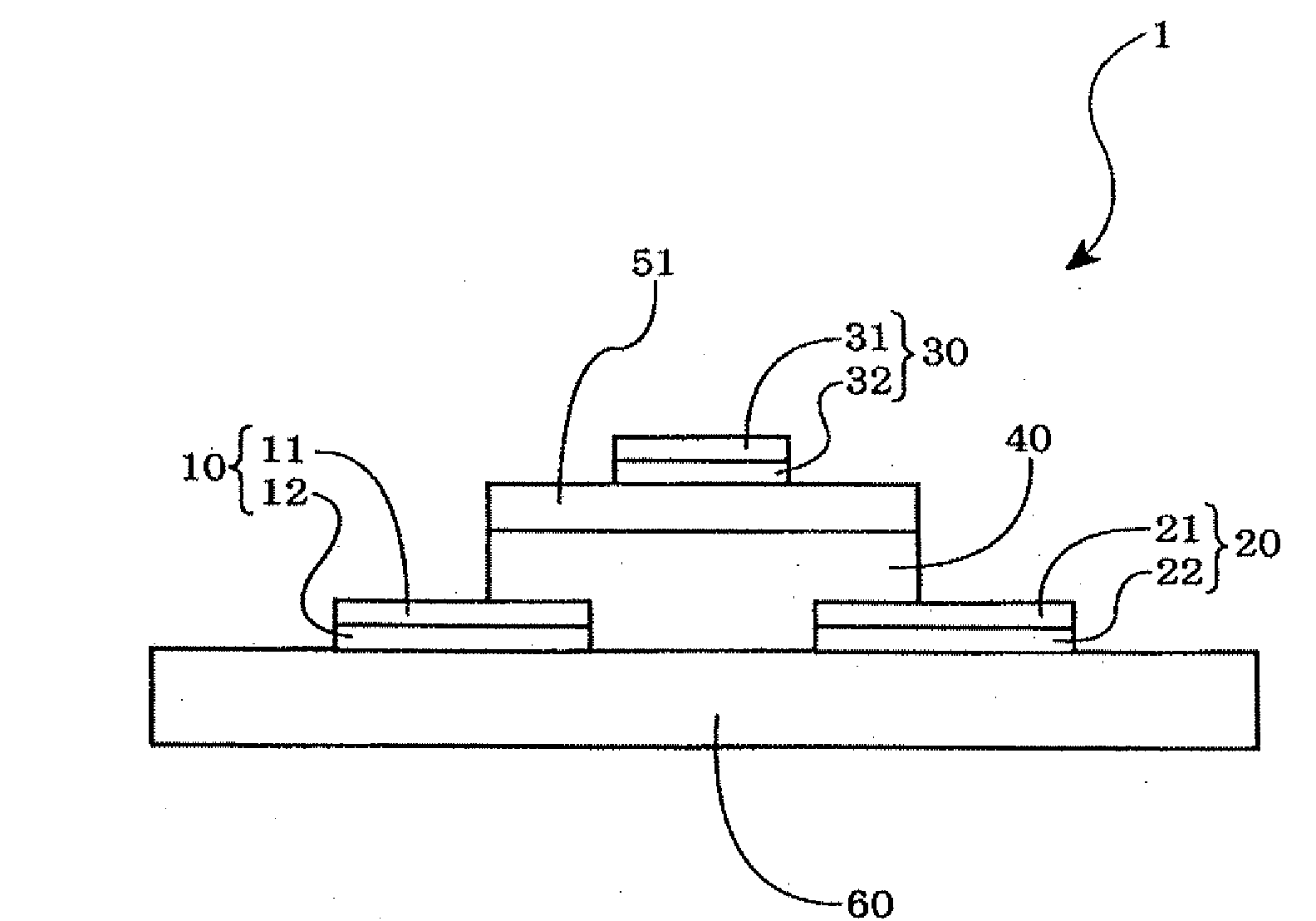

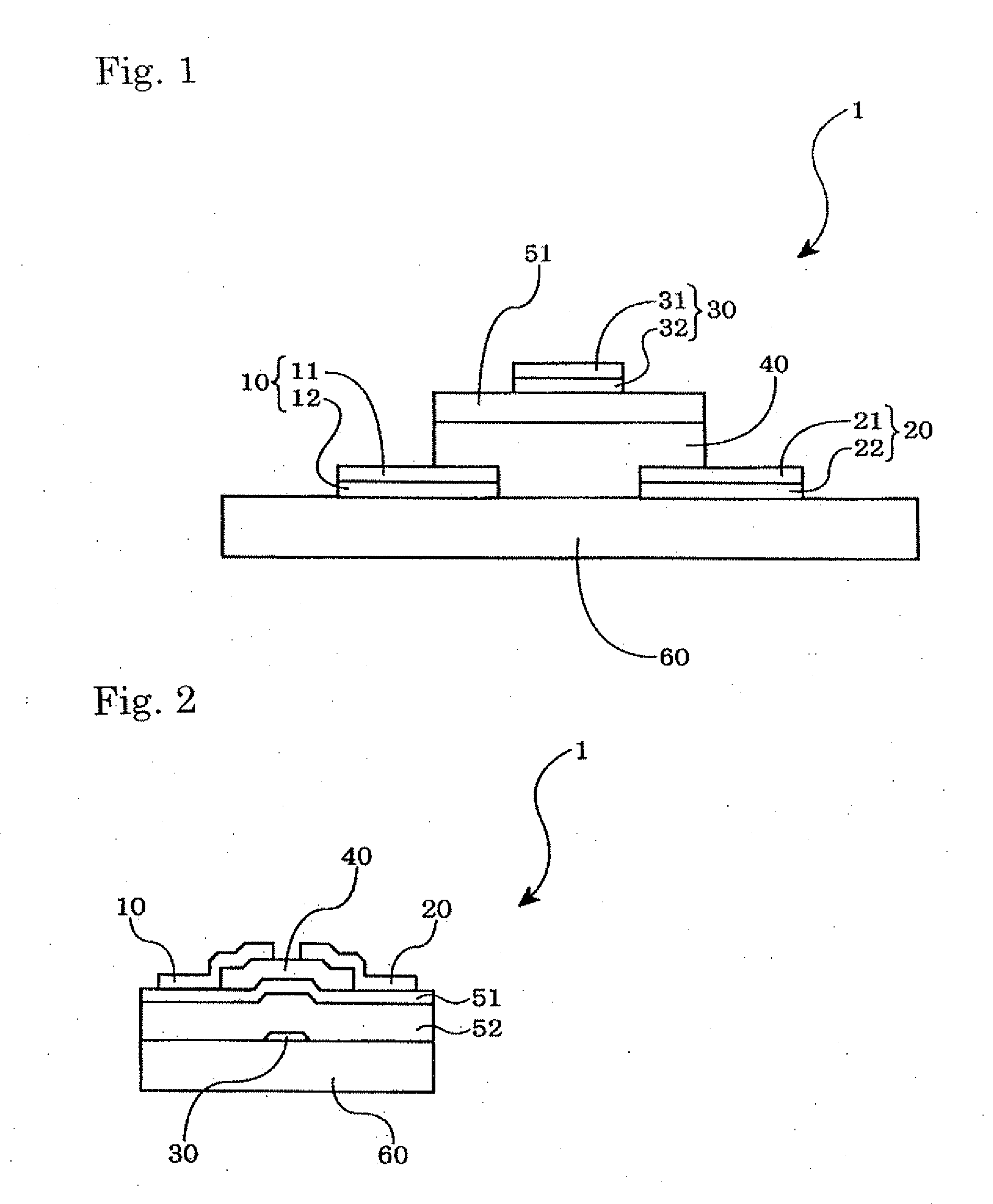

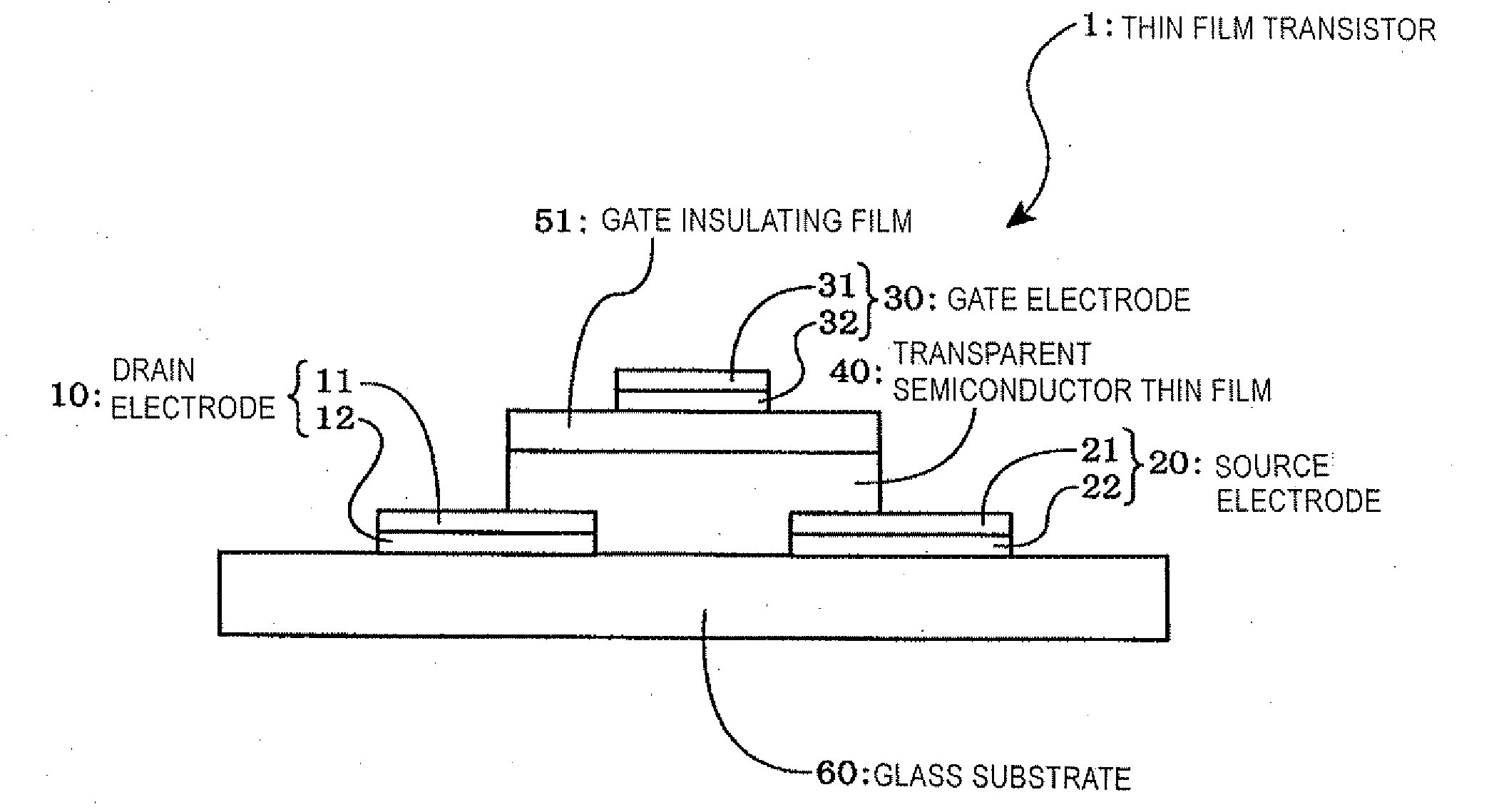

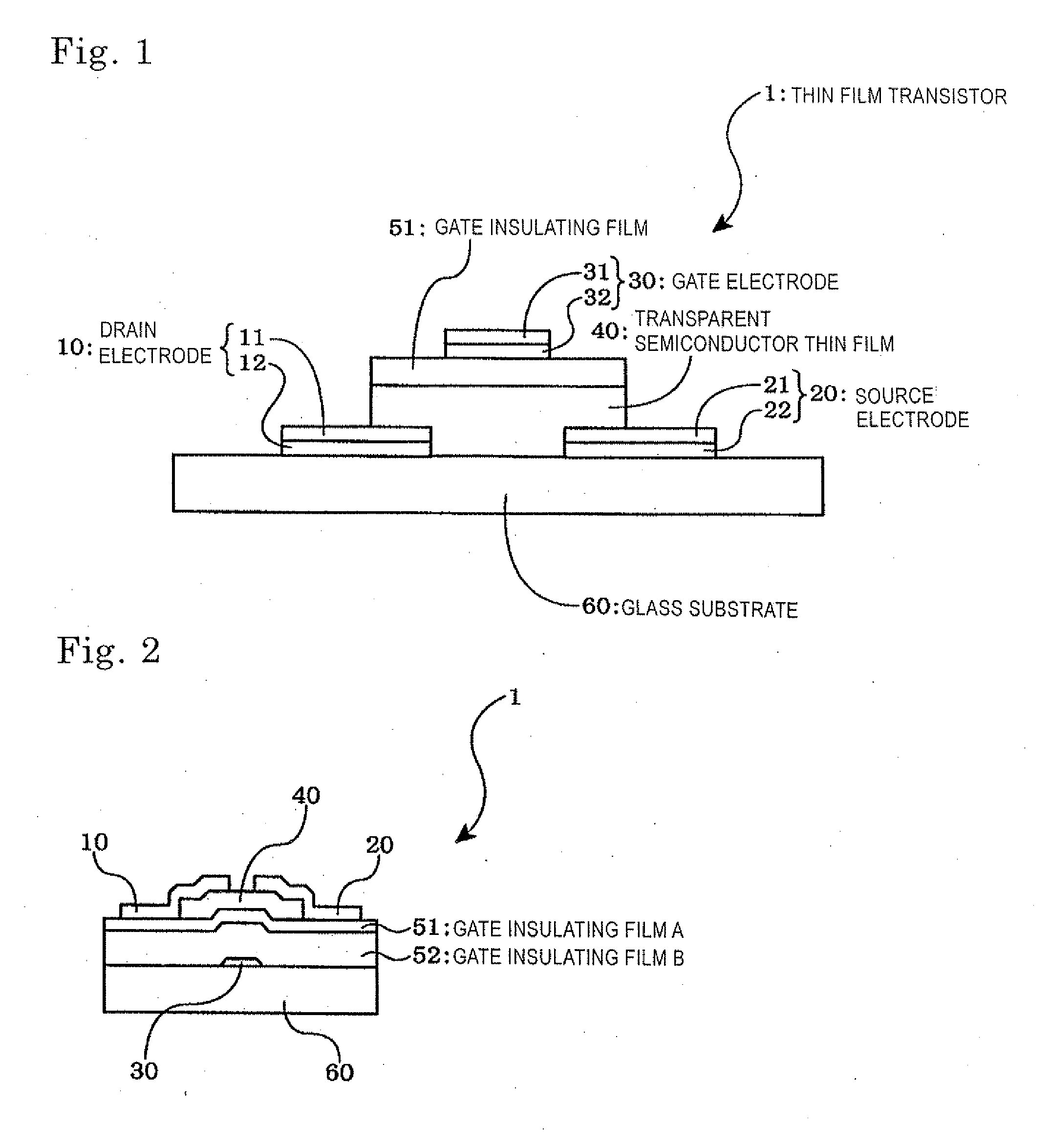

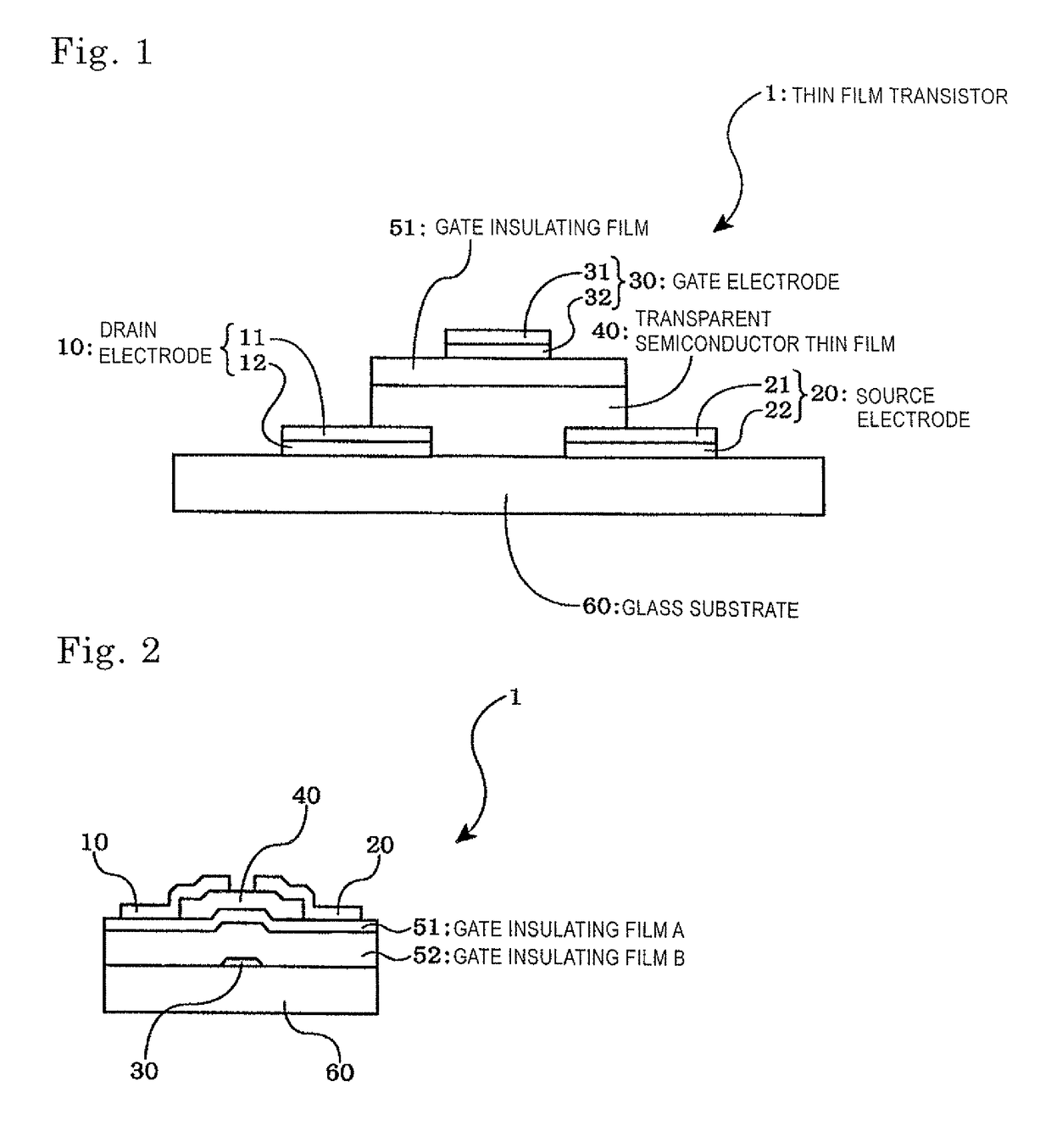

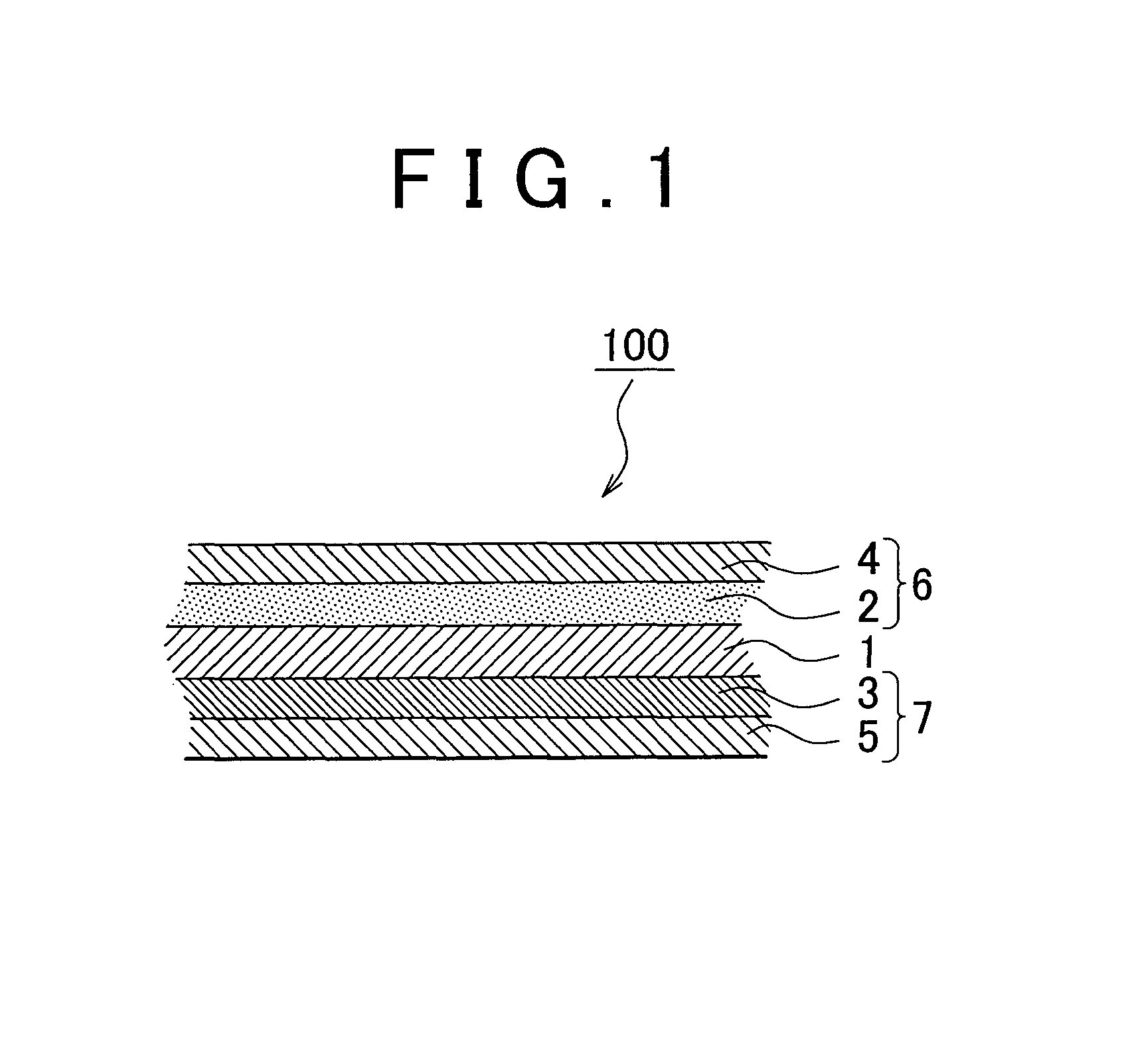

Semiconductor thin film, method for producing the same, and thin film transistor

InactiveUS20090090914A1Improve mobilityReduce carrier concentrationTransistorCellsIndiumSemiconductor

Owner:IDEMITSU KOSAN CO LTD

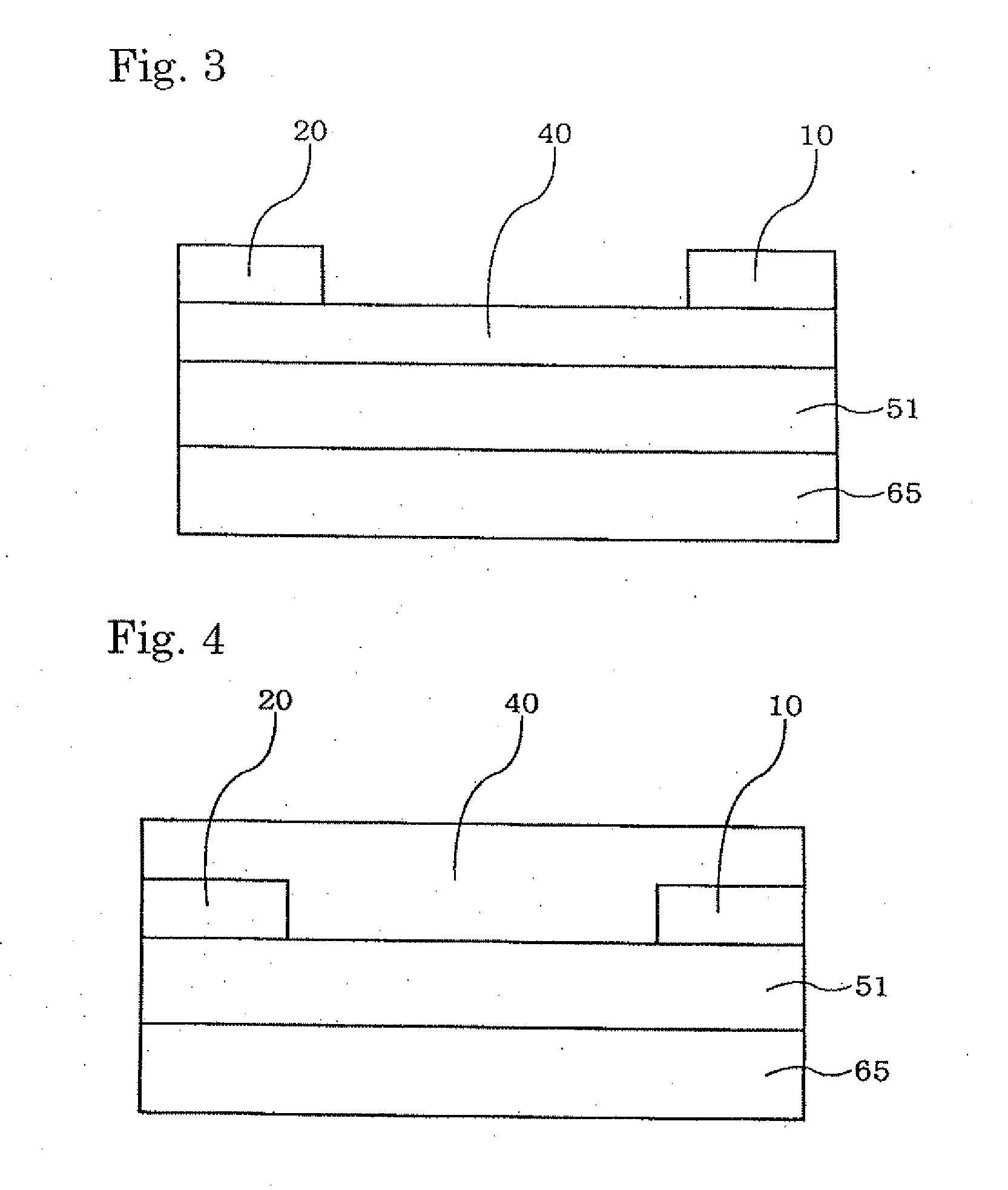

Semiconductor thin film and method for manufacturing same, and thin film transistor

ActiveUS20090267064A1Hardly erroneously operatesSmall currentTransistorTin compoundsCharge carrierZinc

The present invention provides a semiconductor thin film which can be manufactured at a relatively low temperature even on a flexible resin substrate. As a semiconductor thin film having a low carrier concentration, a high Hall mobility and a large energy band gap, an amorphous film containing zinc oxide and tin oxide is formed to obtain a carrier density of 10+17 cm−3 or less, a Hall mobility of 2 cm2 / V·sec or higher, and an energy band gap of 2.4 eV or more. Then, the amorphous film is oxidized to form a transparent semiconductor thin film 40.

Owner:IDEMITSU KOSAN CO LTD

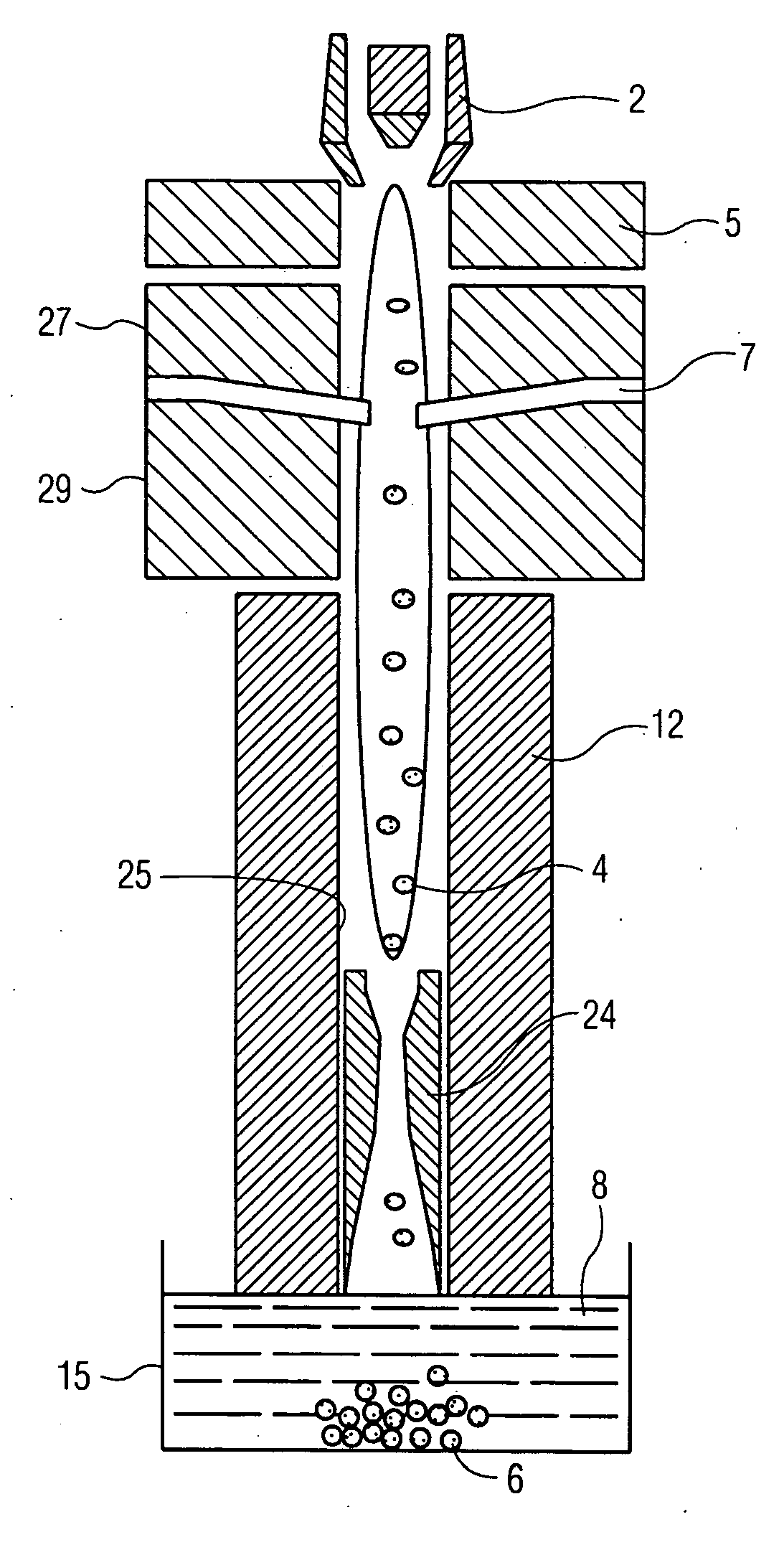

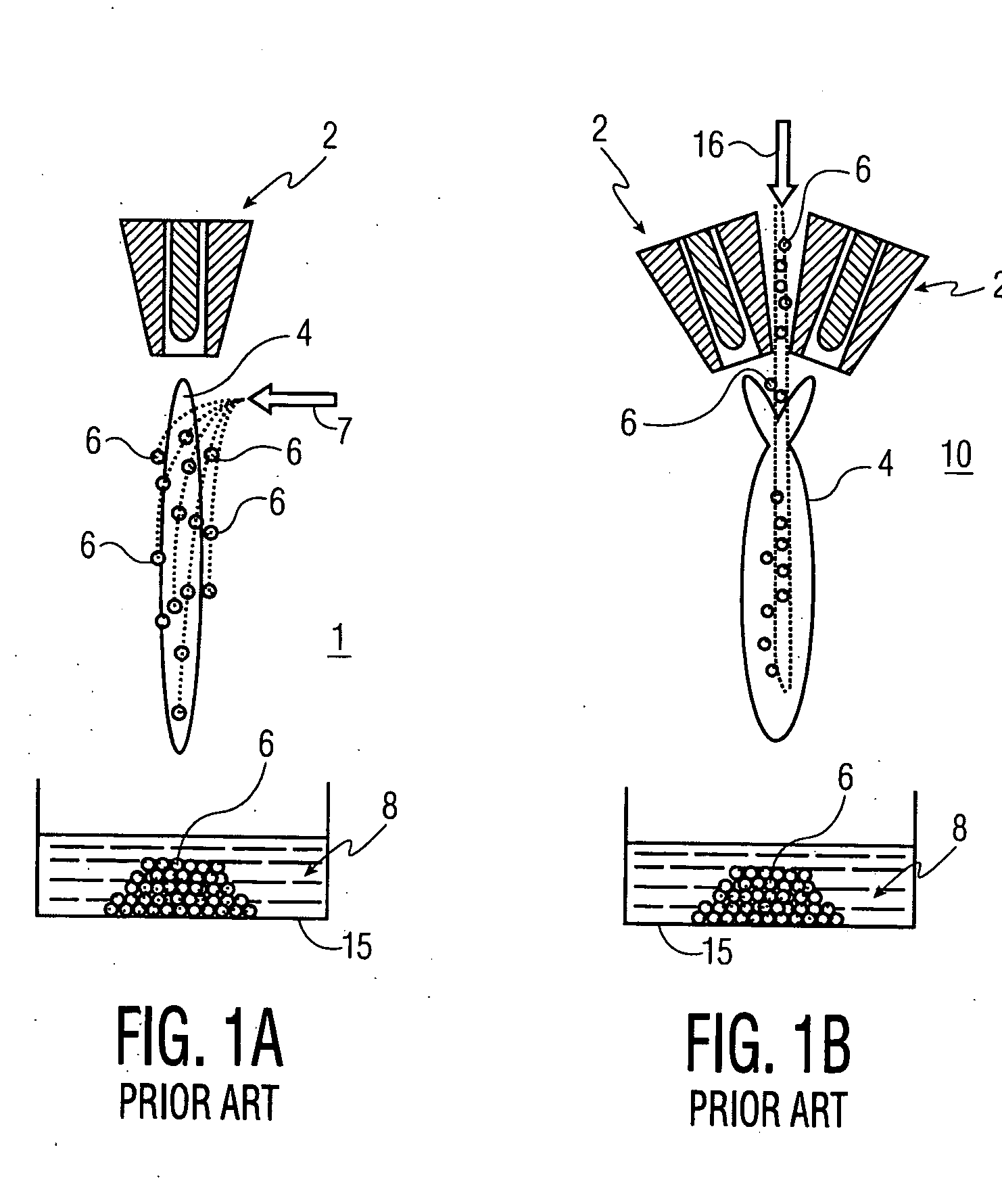

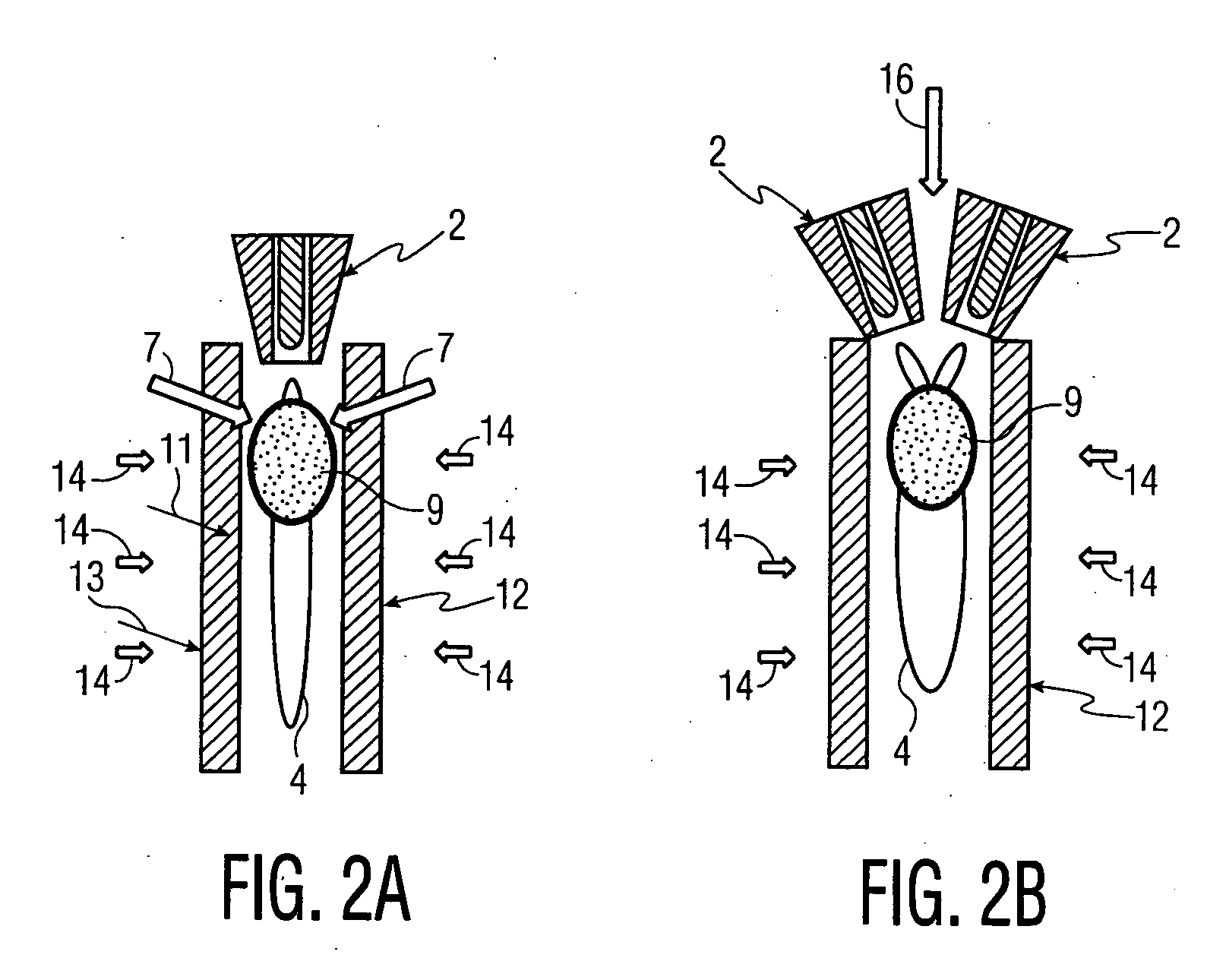

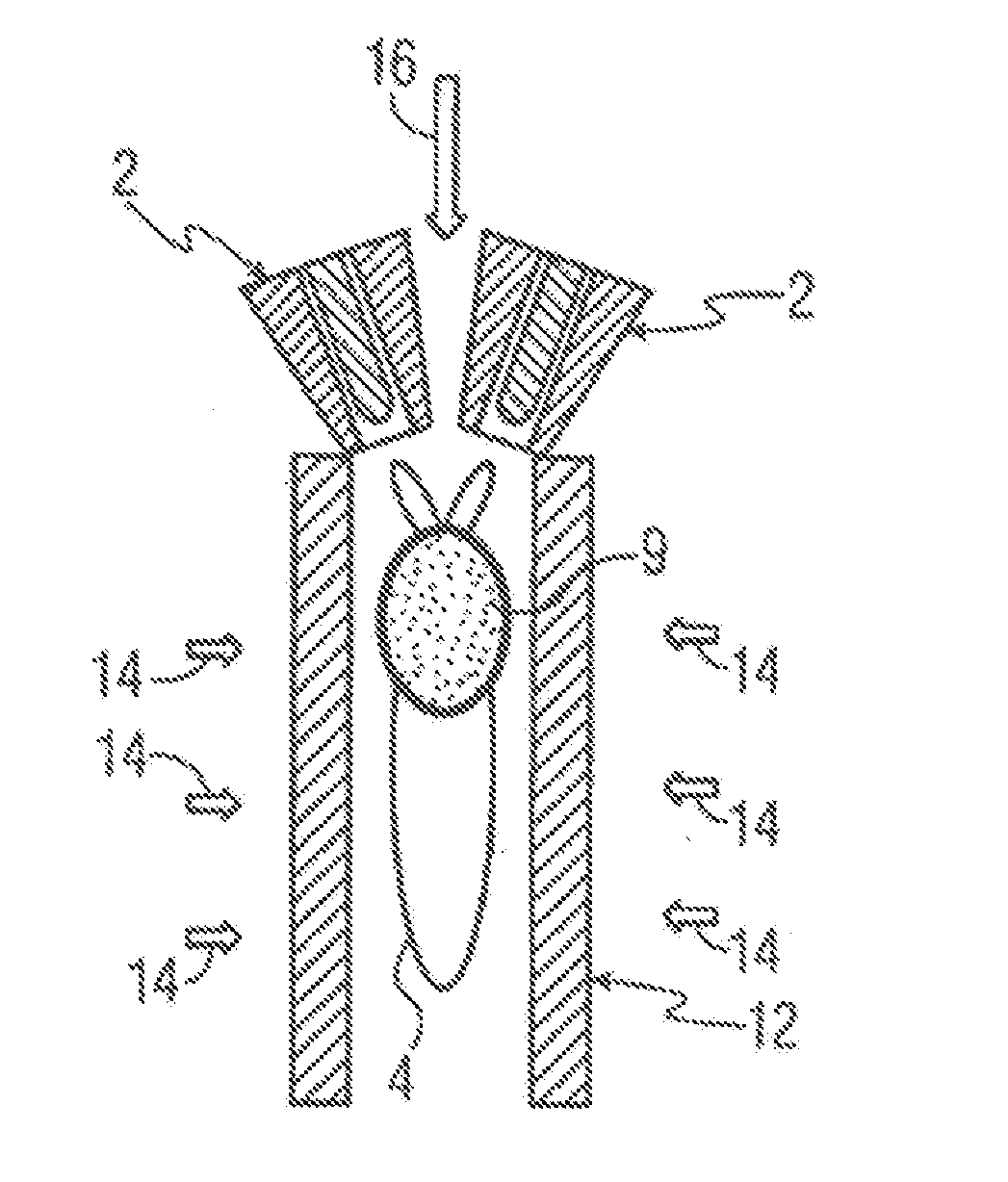

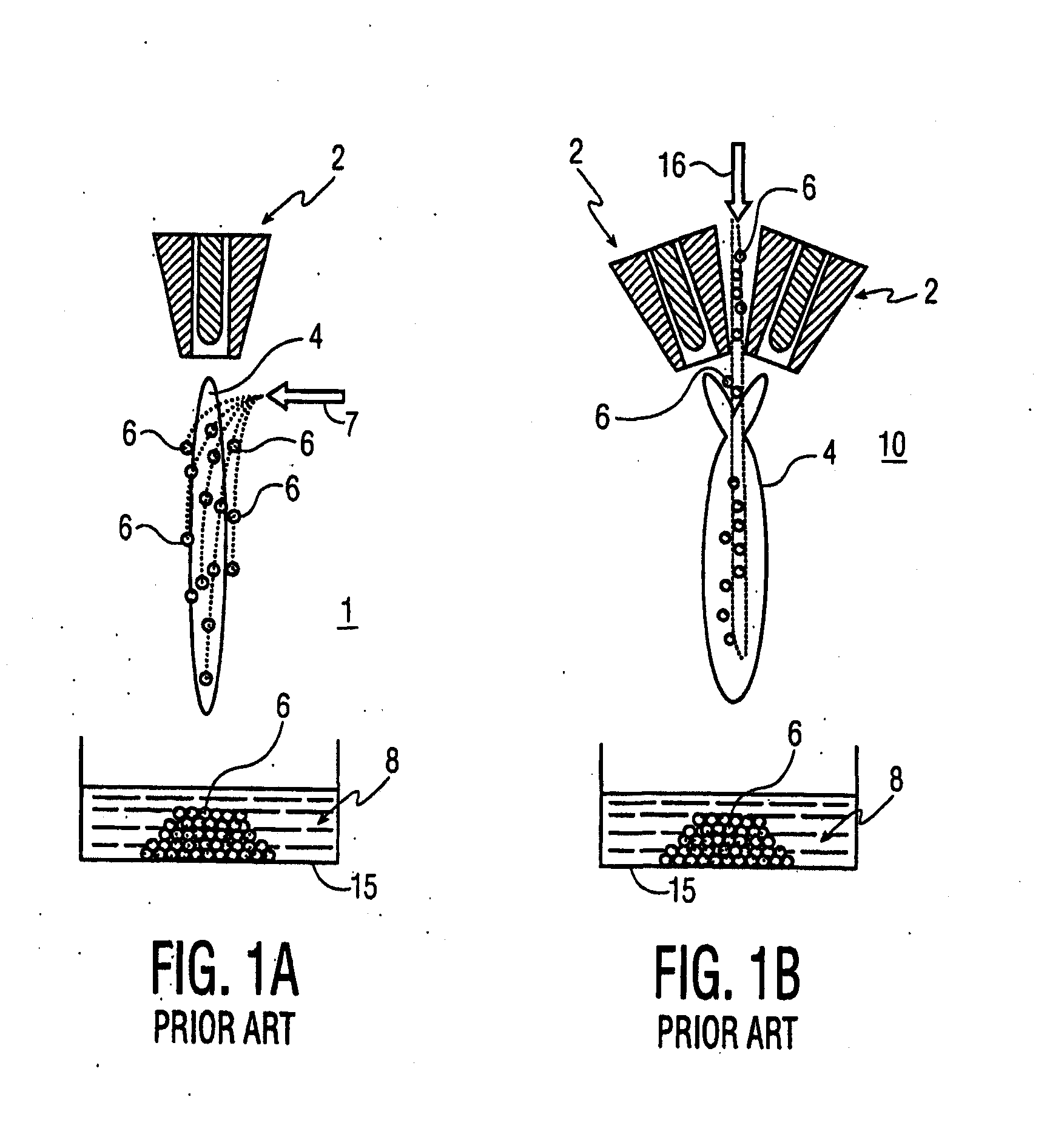

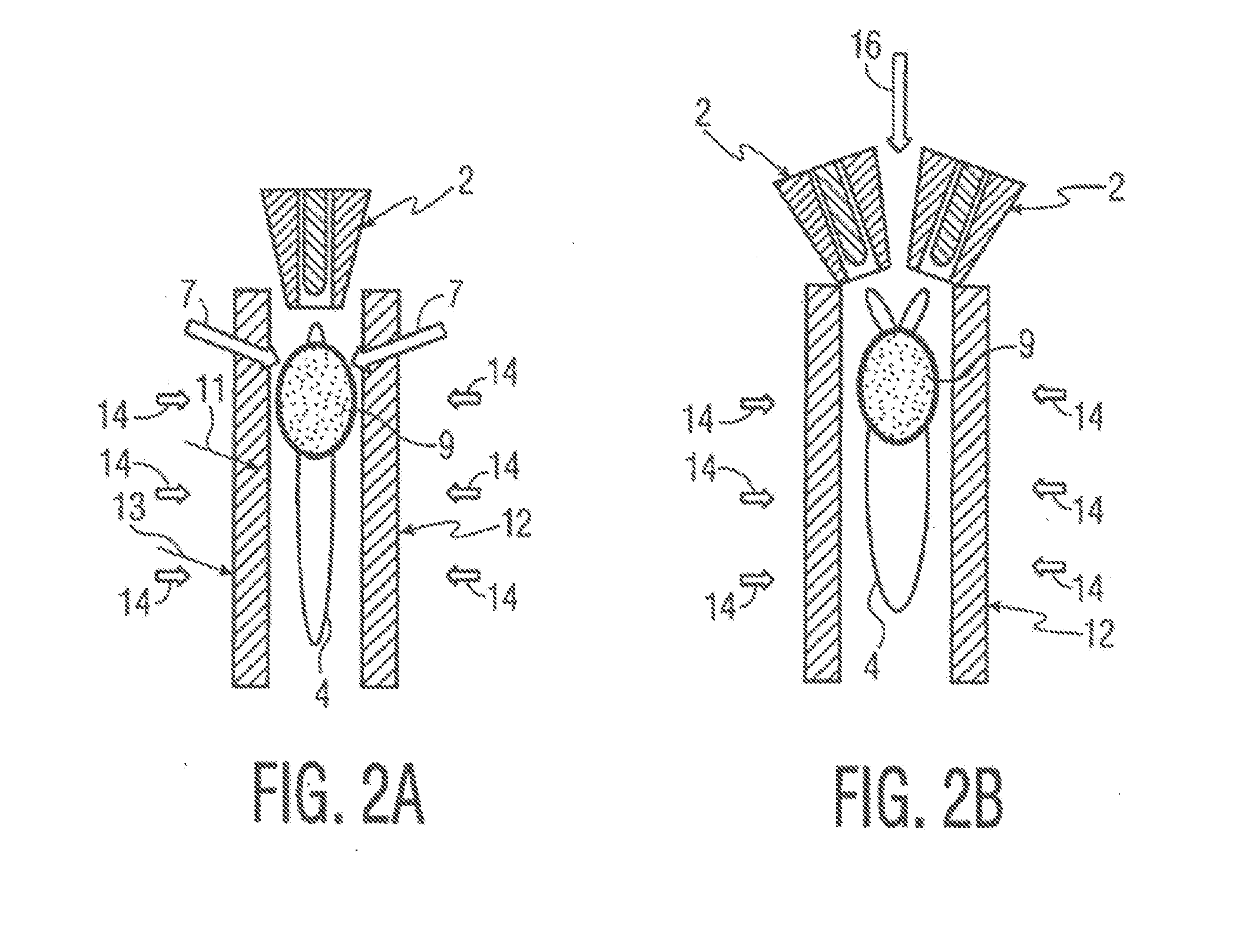

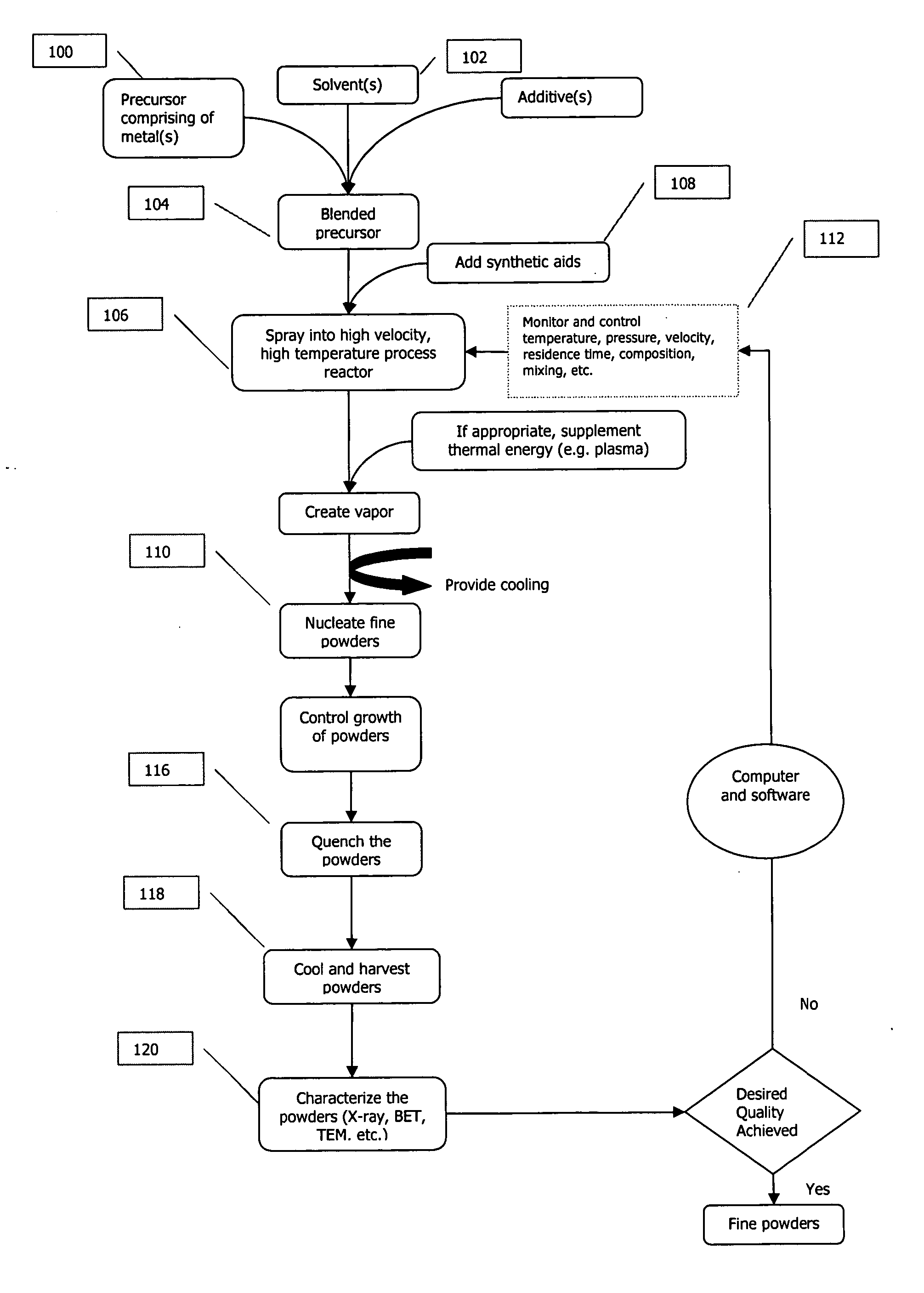

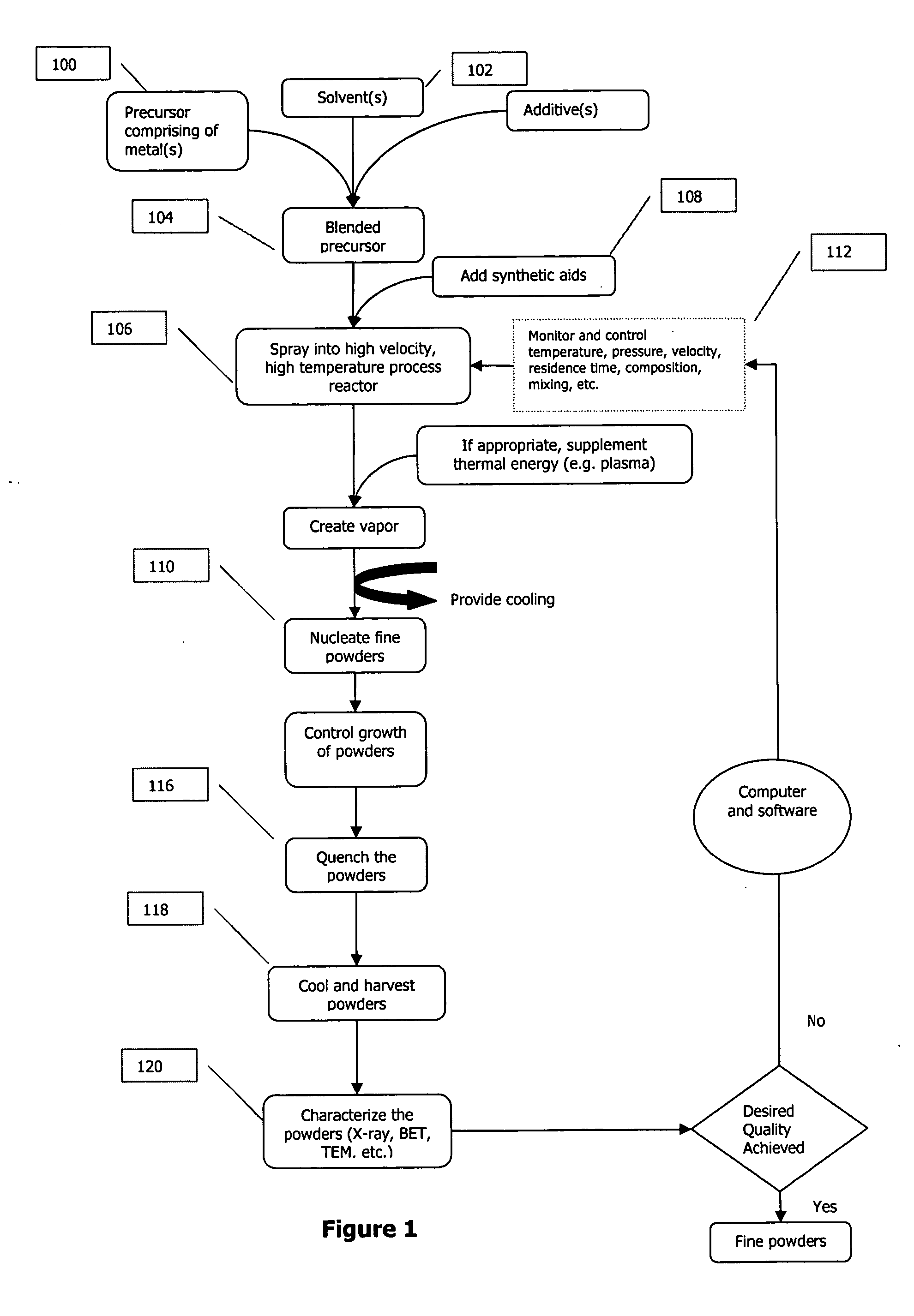

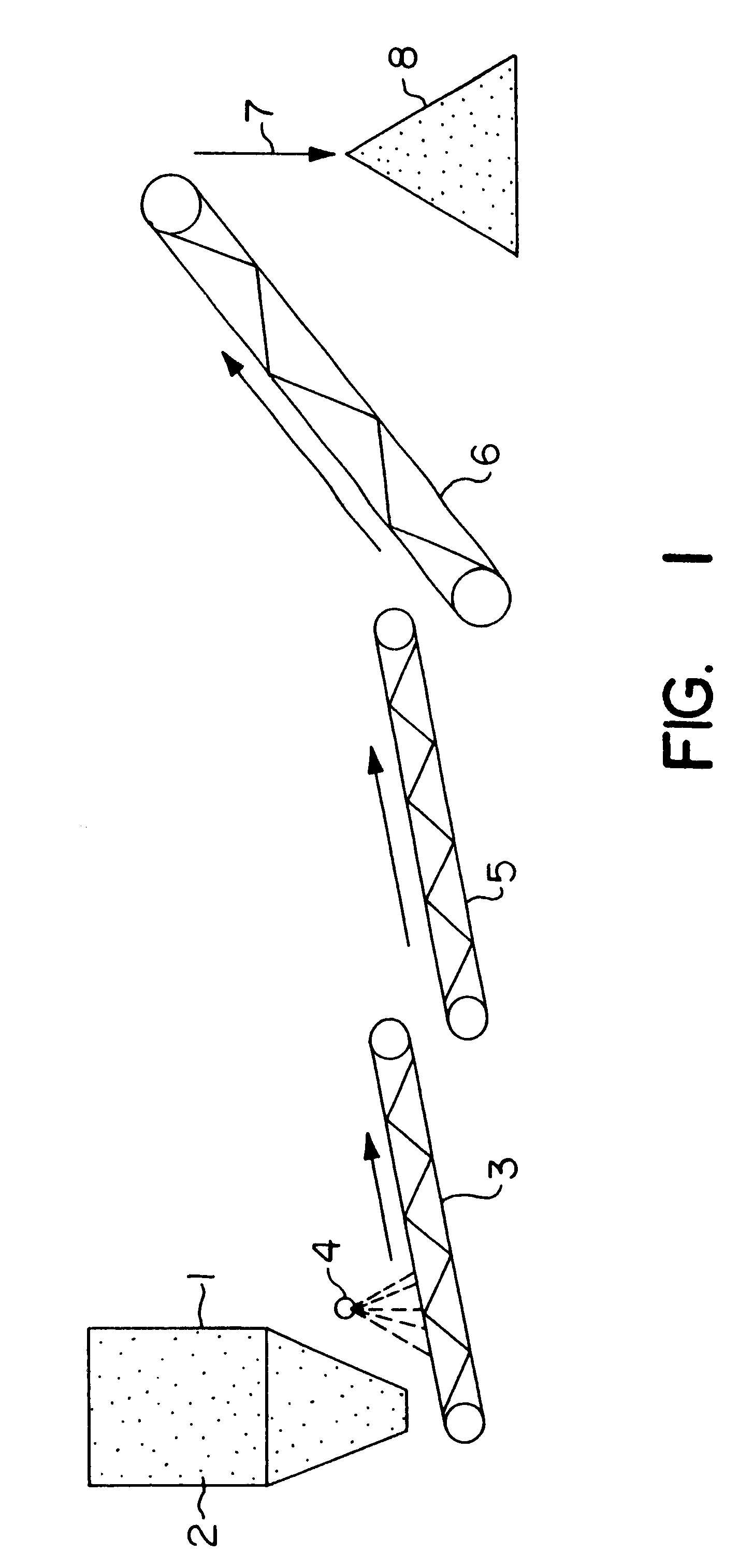

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

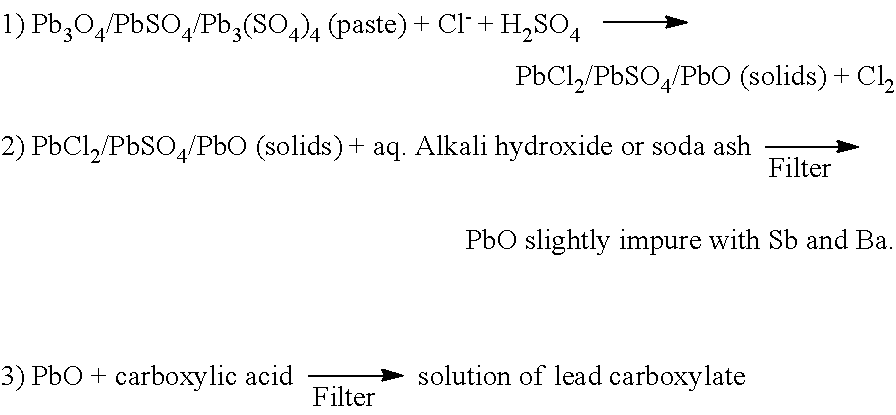

Process for recovering lead oxides from exhausted batteries

ActiveUS7507496B1Speed up the processObtained inexpensivelySolvent extractionPrimary cell maintainance/servicingLead dioxideLead oxide

A process for recovering lead oxides from the spent paste of exhausted lead acid batteries. The process provides heating the spent paste with an alkali hydroxide solution at elevated temperatures prior to calcinations. Calcination is at various temperatures so that either lead mono-oxide, lead dioxide or red lead is obtained as the principal product. There is also provided the use of the lead oxide to prepare the paste for positive and negative electrodes or other lead compounds.

Owner:RETRIEV TECH +1

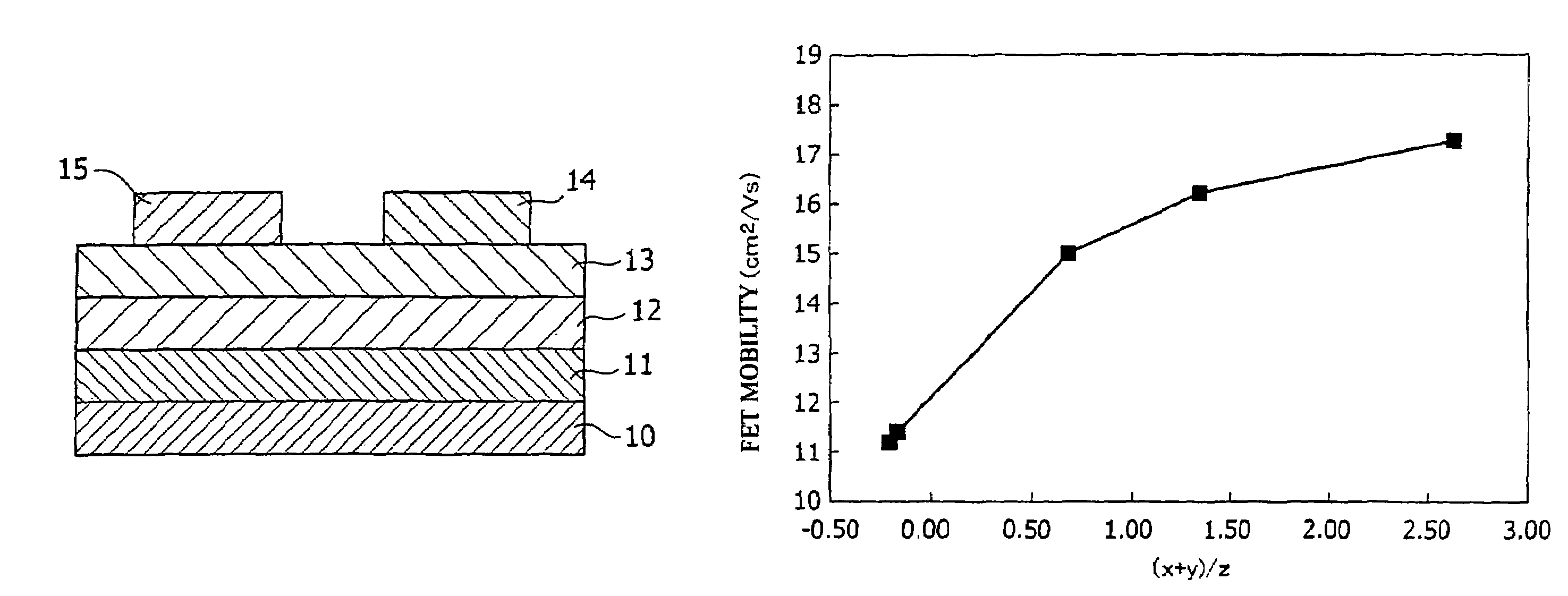

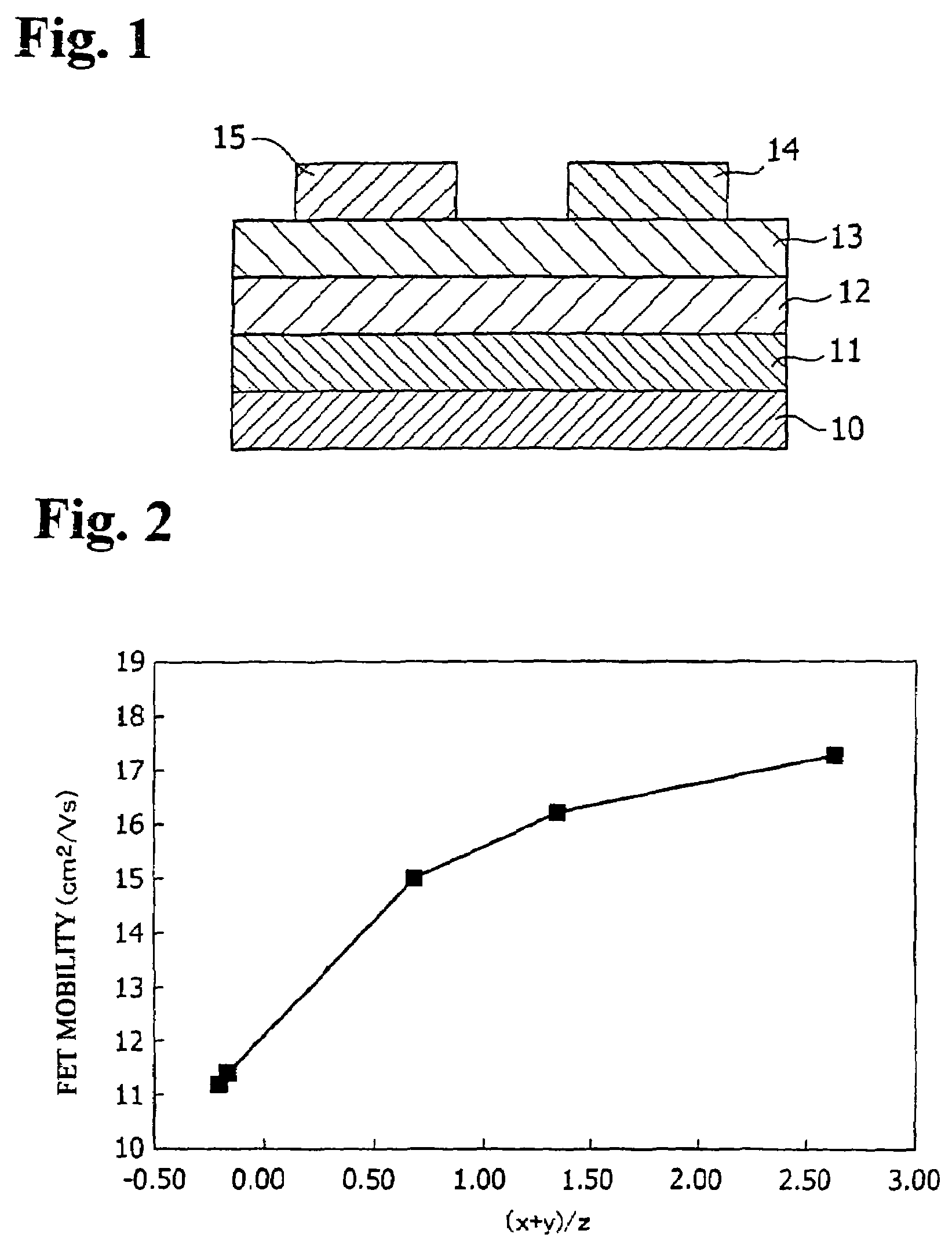

Oxide semiconductor, thin-film transistor and method for producing the same

InactiveUS7807515B2Total current dropMaintain mobilityTin compoundsSemiconductor/solid-state device manufacturingSemiconductorHeat treated

Disclosed is an oxide semiconductor having an amorphous structure, wherein higher mobility and reduced carrier concentration are achieved. Also disclosed are a thin film transistor, a method for producing the oxide semiconductor, and a method for producing the thin film transistor. Specifically disclosed is an oxide semiconductor which is characterized by being composed of an amorphous oxide represented by the following a general formula: Inx+1MZny+1SnzO(4+1.5x+y+2z) (wherein M is Ga or Al, 0≦x≦1, −0.2≦y≦1.2, z≧0.4 and 0.5≦(x+y) / z≦3). This oxide semiconductor is preferably subjected to a heat treatment in an oxidizing gas atmosphere after film formation. Also specifically disclosed is a thin film transistor which is characterized by comprising the oxide semiconductor.

Owner:FUJI ELECTRIC CO LTD

Low visibility laser marking additive

InactiveUS7187396B2Retains laser markabilityReduce total powerRecording apparatusNanotechVisibilityParticulates

Owner:ENGELHARD CORP

Semiconductor thin film and method for manufacturing same, and thin film transistor

ActiveUS7906777B2Hardly erroneously operatesSmall currentTin compoundsSemiconductor/solid-state device manufacturingCharge carrierZinc

Owner:IDEMITSU KOSAN CO LTD

Stabilization method for lead projectile impact area

Owner:FORRESTER KEITH E

Shrouded-Plasma Process and Apparatus for the Production of Metastable Nanostructured Materials

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:KEAR BERNARD H +2

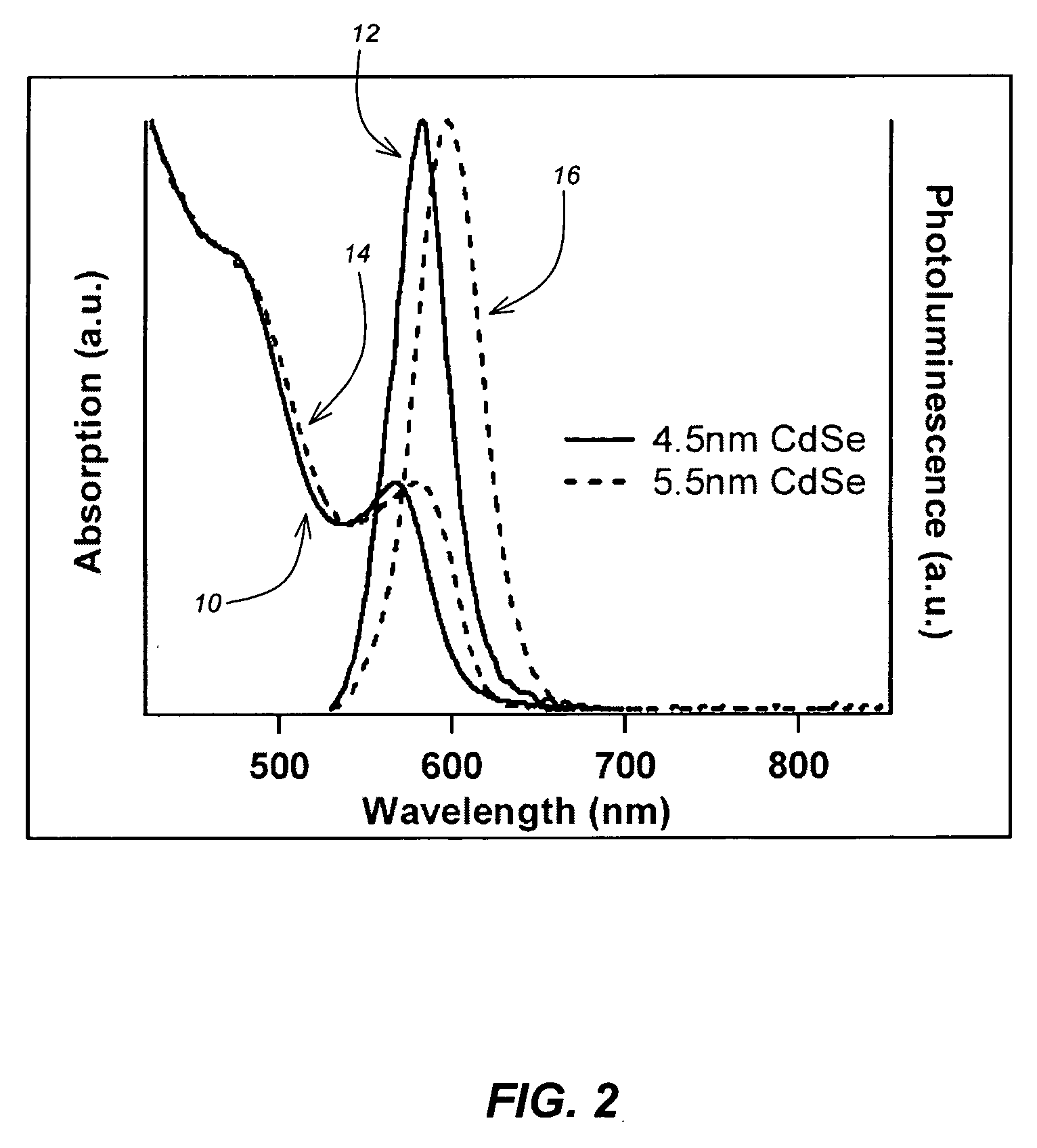

Quantum dots, rods, wires, sheets, and ribbons, and uses thereof

ActiveUS20140252316A1Improve stand-alone performanceImprove mobilityMaterial nanotechnologyNanoinformaticsQuantum dotNanocrystal

Described are ZnxCd1-xSySe1-y / ZnSzSe1-z core / shell nanocrystals, CdTe / CdS / ZnS core / shell / shell nanocrystals, optionally ally doped Zn(S,Se,Te) nano- and quantum wires, and SnS quantum sheets or ribbons, methods for making the same, and their use in biomedical and photonic applications, such as sensors for analytes in cells and preparation of field effect transistors.

Owner:ARIZONA STATE UNIVERSITY

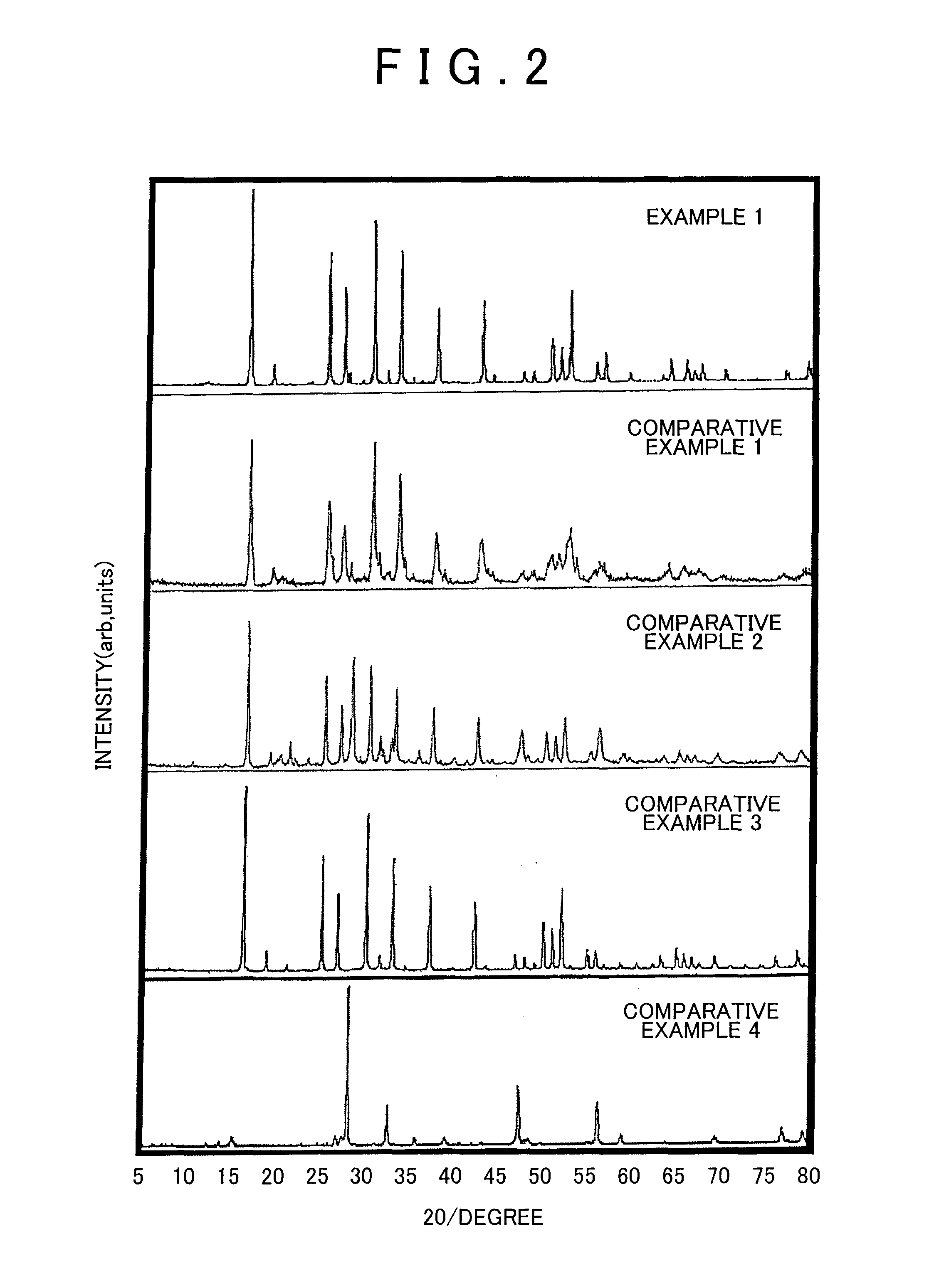

Preparation of complex fluoride and complex fluoride phosphor

ActiveCN102732249AHigh yieldSatisfied with launch performanceTin compoundsFluoride preparationPhosphorFluoride

A complex fluoride A 2 MF 6 wherein M is a tetravalent element Si, Ti, Zr, Hf, Ge or Sn, A is an alkali metal Li, Na, K, Rb or Cs is prepared by providing a first solution containing a fluoride of M, providing a second solution containing a compound of A and / or the compound of A in solid form, mixing the first solution with the second solution and / or the solid for reacting the fluoride of M with the compound of A, and recovering the resulting solid product via solid-liquid separation.

Owner:SHIN ETSU CHEM CO LTD

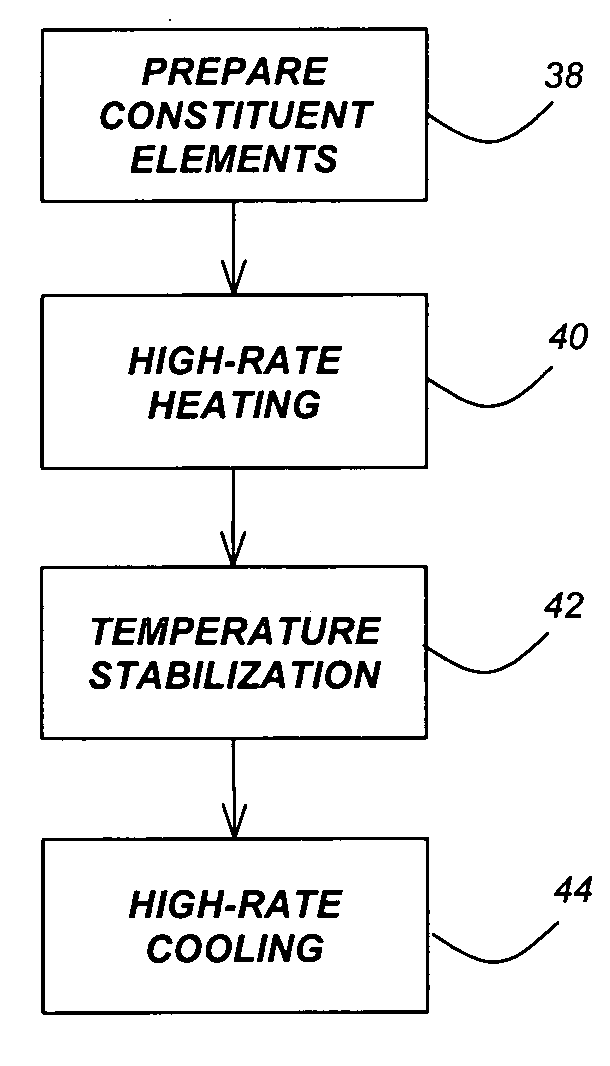

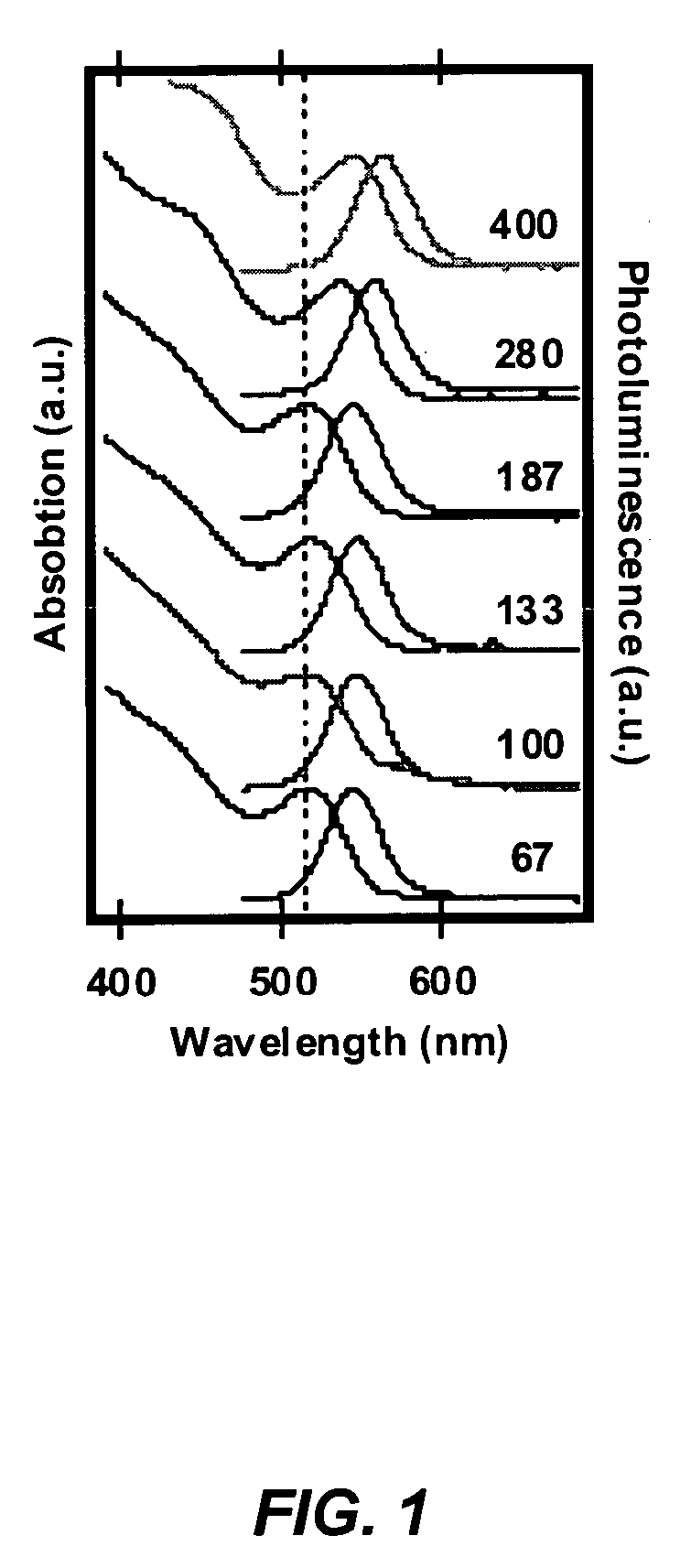

Method for synthesis of colloidal nanoparticles

InactiveUS20060060998A1Large-scale, safe, convenient, reproducible, and energy-efficient productionHigh crystallinityDielectric heatingNanoinformaticsColloidal nanoparticlesContinuous flow

A method for synthesis of high quality colloidal nanoparticles using comprises a high heating rate process. Irradiation of single mode, high power, microwave is a particularly well suited technique to realize high quality semiconductor nanoparticles. The use of microwave radiation effectively automates the synthesis, and more importantly, permits the use of a continuous flow microwave reactor for commercial preparation of the high quality colloidal nanoparticles.

Owner:RGT UNIV OF CALIFORNIA

Garnet-type solid electrolyte, secondary battery containing garnet-type solid electrolyte, and method of producing garnet-type solid electrolyte

ActiveUS9034526B2Few crystal defectHigh crystallinityTin compoundsTantalum compoundsLithiumLanthanum

Owner:TOYOTA JIDOSHA KK +1

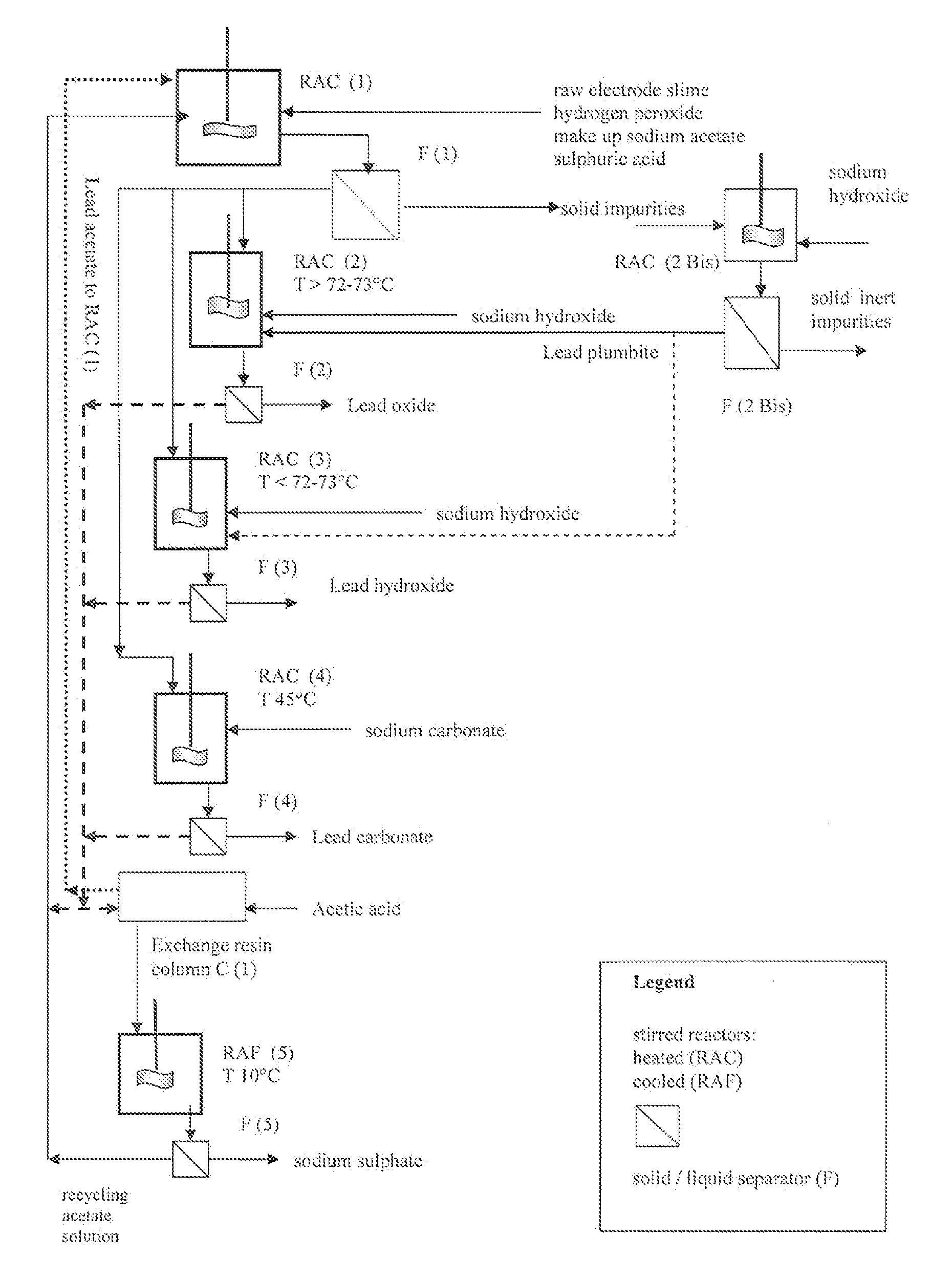

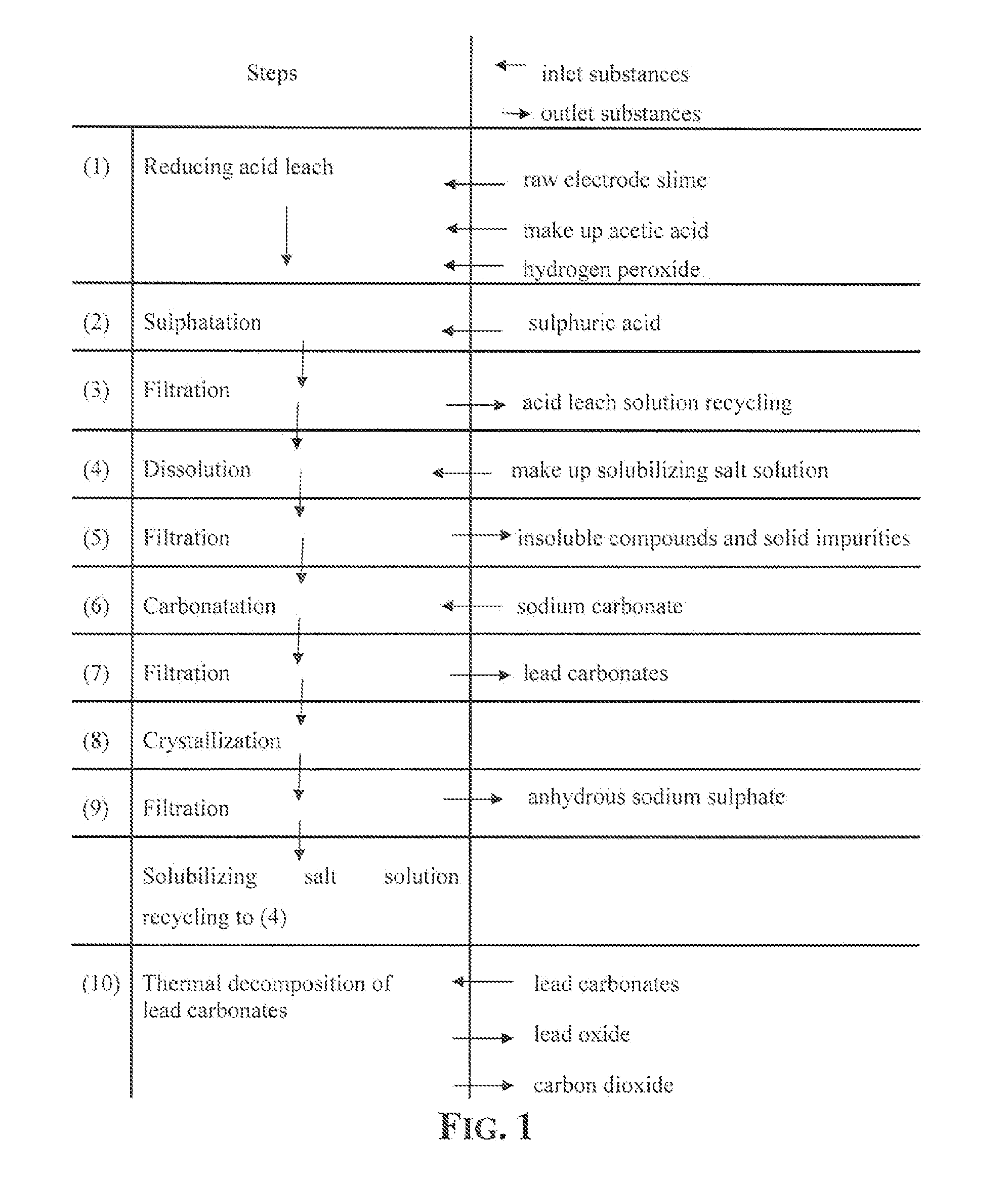

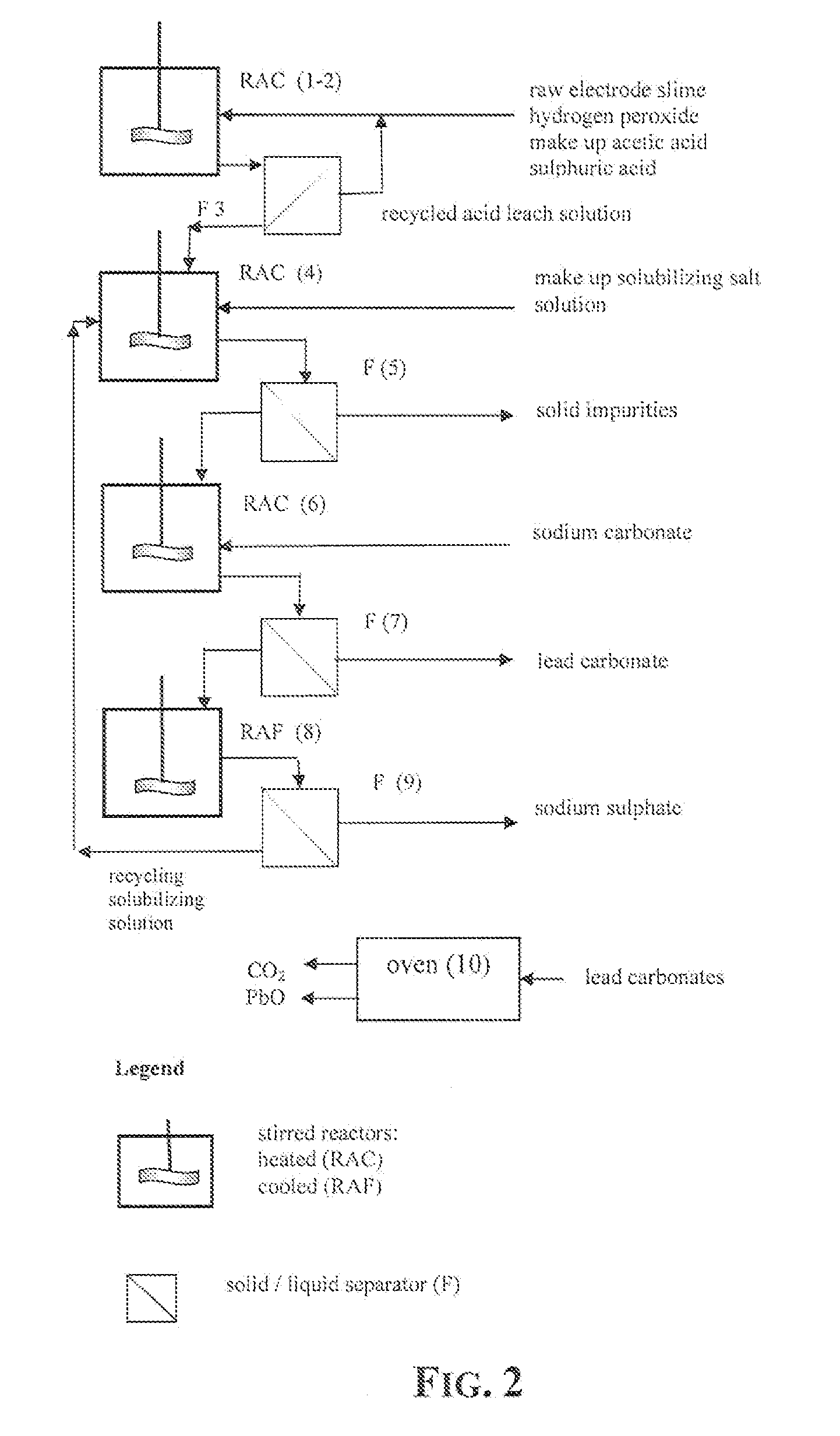

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

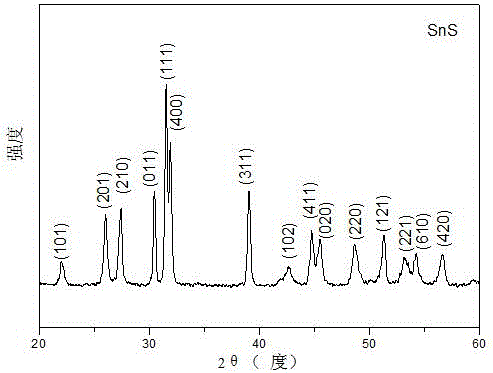

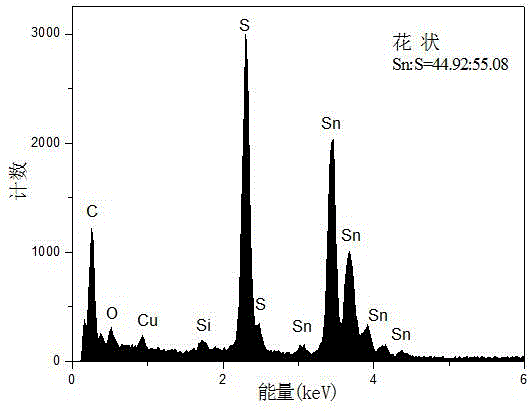

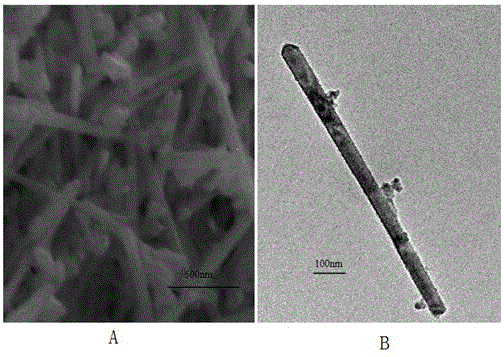

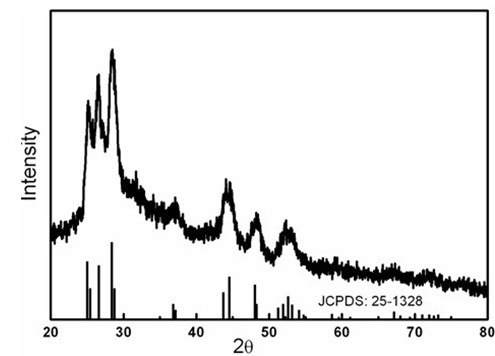

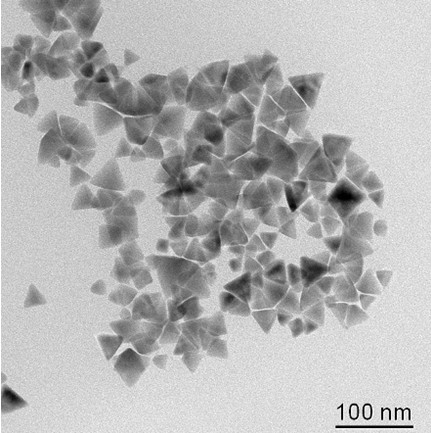

Preparation method and application of tin sulfide material

ActiveCN105800674ASimple methodMild reaction conditionsMaterial nanotechnologyPhysical/chemical process catalystsActive agentReaction temperature

The invention discloses a preparation method of a tin sulfide material. A solvothermal method is adopted, dehydrate-stannous chloride is used as a tin source, the morphology and particle size of the synthetic material are controlled by controlling a sulfur source, the reaction temperature, reaction time, the solvent variety and the surfactant variety, and the SnS photocatalytic material with controllable morphology and high quality is prepared. The method is simple in preparation and easy to carry out, the yield is high, consumed time is short, cost is low, reaction conditions are mild, good development prospects are achieved, industrial production is easy to achieve, and the prepared material has high photocatalytic activity and has good industrial application prospects when serving as the photocatalytic material.

Owner:KUNMING UNIV OF SCI & TECH

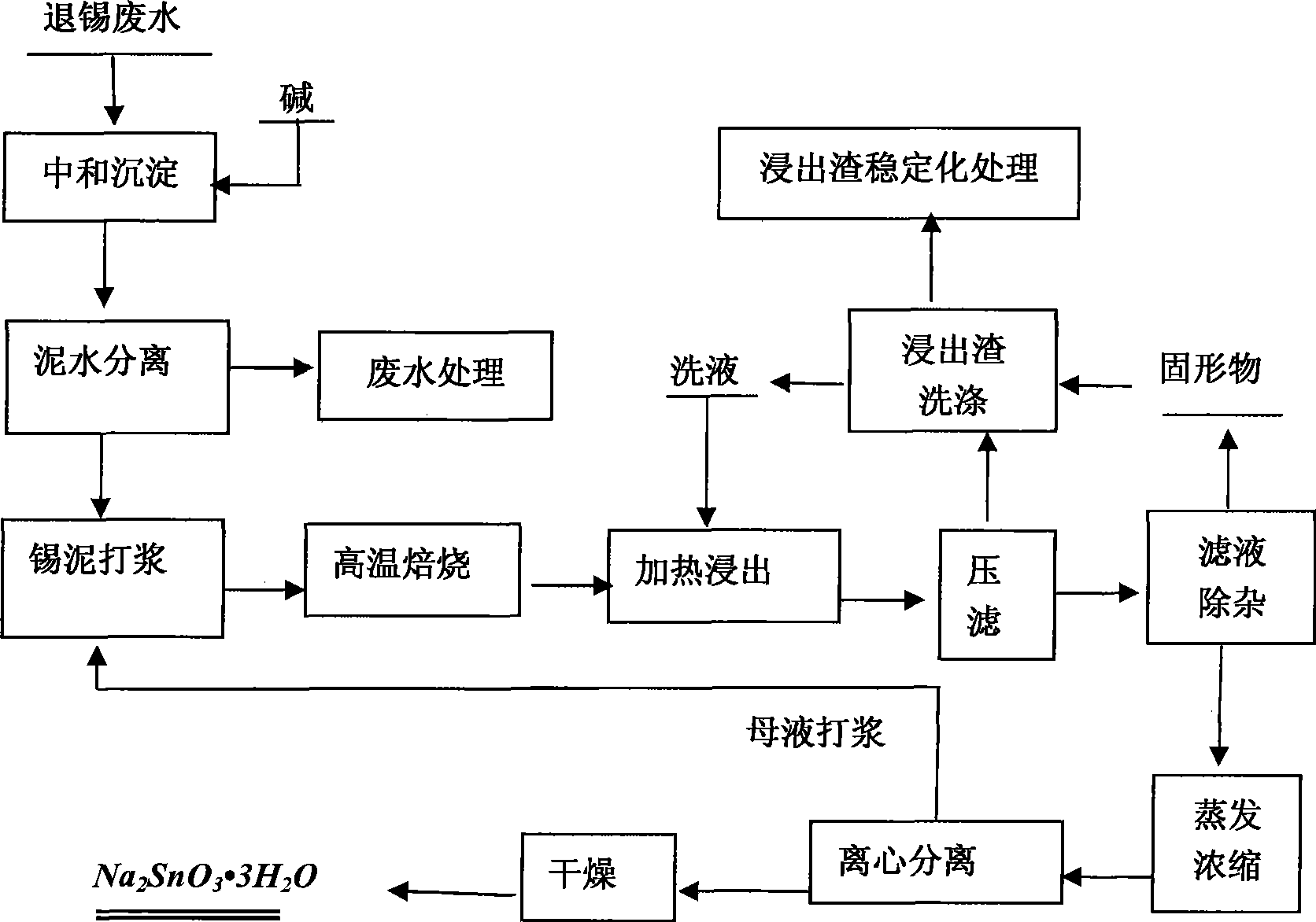

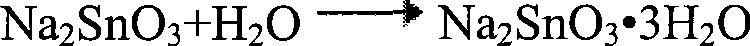

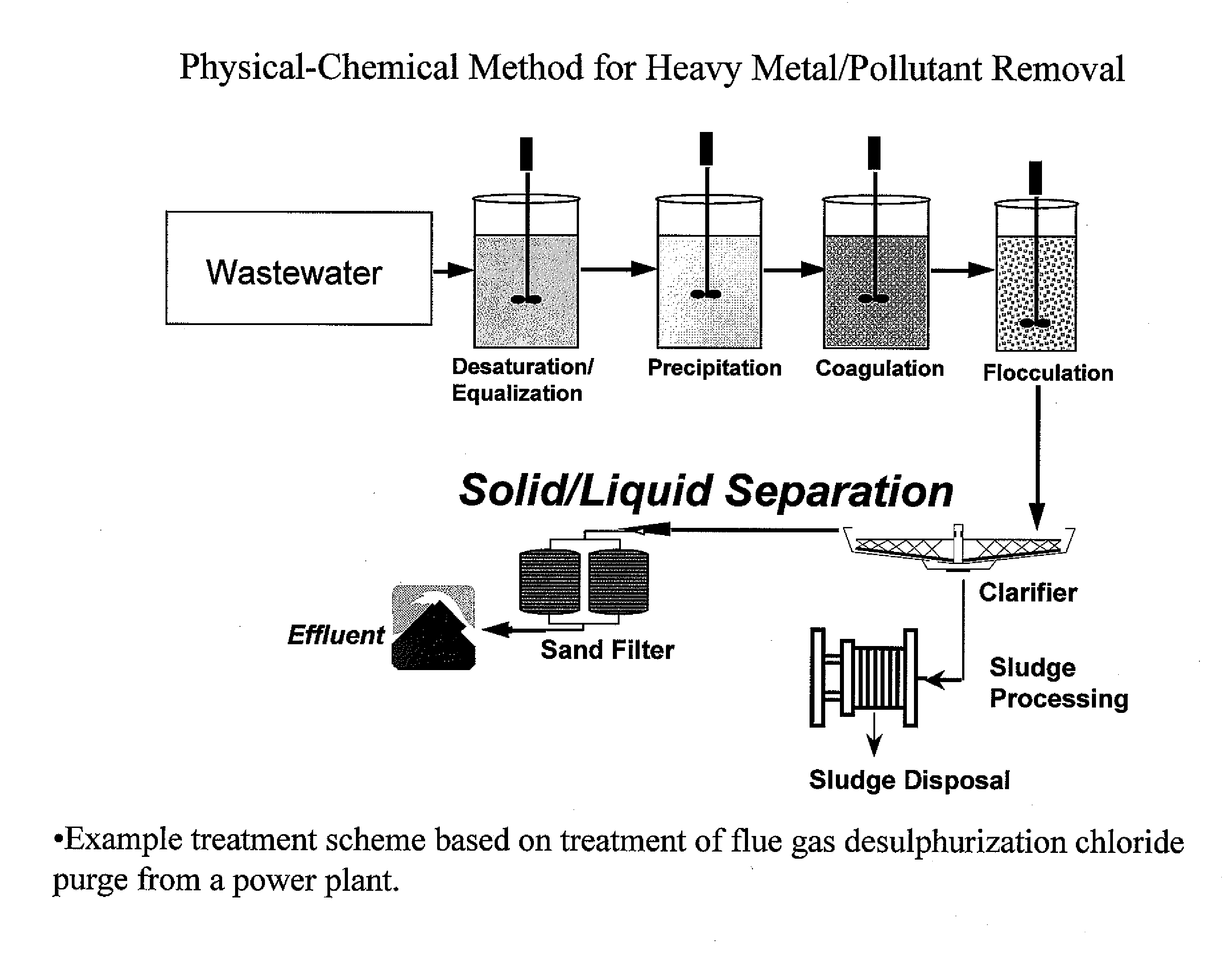

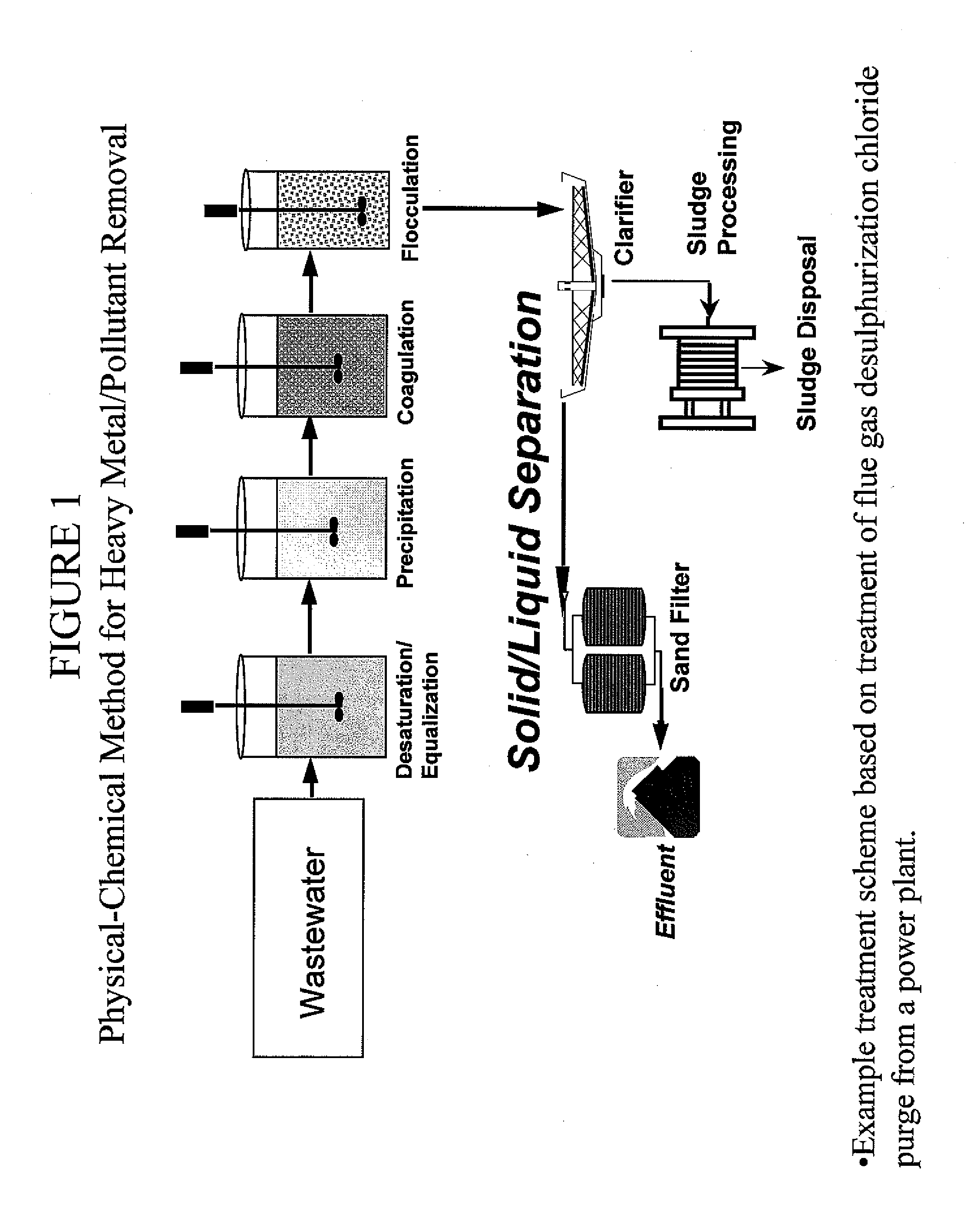

Method for preparing sodium stannate using circuit board tin-stripping wastewater

ActiveCN101497458AReduce manufacturing costRaise the gradeTin compoundsMultistage water/sewage treatmentResource utilizationSludge

The invention relates to a method for preparing sodium stannate by utilizing tin-stripping wastewater of a circuit board. Collected tin-stripping wastewater is neutralized and precipitated by adding alkali to obtain tin sludge with higher tin content; the tin sludge is beat by adding the alkali, and is subjected to high-temperature roasting and countercurrent leaching; then a leachate is subjected to filter pressing; a filtrate is subjected to evaporation, concentration and centrifugal separation after impurity removal; and 10 to 15 percent sodium hydroxide solution is used to wash the obtained product, and thus a crude sodium stannate product can be obtained and then is vacuum dried at a temperature of between 100 and 110 DEG C for 2 to 3.0 hours to obtain a sodium stannate product. The method ensures that the separation rate of tin in the tin-stripping wastewater can reach more than 99 percent, finds a novel treatment way for the tin-stripping wastewater which is produced by printed circuit board industry and is extremely difficult to treat, gives a reasonable fate for all pollutants in the tin-stripping wastewater, and realizes the resource utilization of useful components of the tin-stripping wastewater to the utmost extent when realizing the innoxious treatment of the tin-stripping wastewater.

Owner:江西东江环保技术有限公司

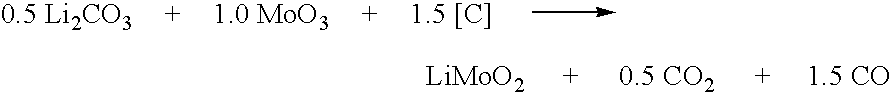

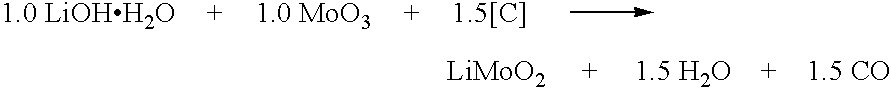

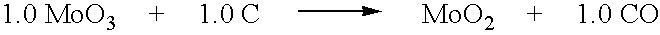

Synthesis of Metal Compounds Under Carbothermal Conditions

InactiveUS20050255026A1Economical and convenient processLower capability requirementsPhosphatesLithium compoundsOxidation stateGraphite

Active materials of the invention contain at least one alkali metal and at least one other metal capable of being oxidized to a higher oxidation state. Preferred other metals are accordingly selected from the group consisting of transition metals (defined as Groups 4-11 of the periodic table), as well as certain other non-transition metals such as tin, bismuth, and lead. The active materials may be synthesized in single step reactions or in multi-step reactions. In at least one of the steps of the synthesis reaction, reducing carbon is used as a starting material. In one aspect, the reducing carbon is provided by elemental carbon, preferably in particulate form such as graphites, amorphous carbon, carbon blacks and the like. In another aspect, reducing carbon may also be provided by an organic precursor material, or by a mixture of elemental carbon and organic precursor material.

Owner:LITHIUM WERKS TECH BV +1

Recovery of high purity lead oxide from lead acid battery paste

There is provided a process for recovering high purity litharge PbO from spent lead acid battery paste at low temperatures and the further preparation of highly pure lead oxides and Pb(OH)2.

Owner:RETRIEV TECH

Manufacturing methods for nanomaterial dispersions and products thereof

InactiveUS20060016371A1Increase volumeLow cost productionMaterial nanotechnologyAlkaline earth titanatesManufactured nanomaterialsApplications of nanotechnology

Methods for manufacturing nanomaterial dispersions, such as nanomaterial concentrates, and related nanotechnology are provided. The nanomaterial concentrates provided can be more cheaply stored and transported compared to non-concentrate nanomaterial forms.

Owner:PPG IND OHIO INC

Preparation method of general-purpose multi-metal sulfide nano-material

InactiveCN102633297AHigh yieldAdjustable phaseTin compoundsGallium/indium/thallium compoundsPhenanthrolineDiethyldithiocarbamic Acid

The invention discloses a preparation method of a general-purpose multi-metal sulfide nano-material. The preparation method comprises the following steps of: taking two or more different metal diethyldithiocarbamates, or two or more different metal phenanthroline diethyldithiocarbamates, or the combination of the metal diethyldithiocarbamates and the metal phenanthroline diethyldithiocarbamates as reaction predecessors, performing co-thermal decomposition in a mixed solution of surfactants with different coordination properties, and performing nucleation and growth so as to prepare a high-quality multi-metal sulfide nano-material by one step. The multi-metal sulfide prepared by the preparation method disclosed by the invention has the advantages of pure phase state, adjustable composition, uniform and controllable appearance and size, high yield, low toxicity or no toxicity, better dispersivity in a non-polar organic solvent, easiness in control of reaction conditions, mild preparation conditions, simple operation, good repeatability and capability of realizing large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Metal scavenging polymers and uses thereof

ActiveUS20110243819A1Dispersed particle filtrationSelenium/tellurium compundsWastewater systemsMonomer

Uses for a composition comprising a polymer derived from at least two monomers: acrylic-x and an alkylamine, wherein said polymer is modified to contain a functional group capable of scavenging one or more compositions containing one or more metals are disclosed. These polymers have many uses in various mediums, including wastewater systems.

Owner:ECOLAB USA INC

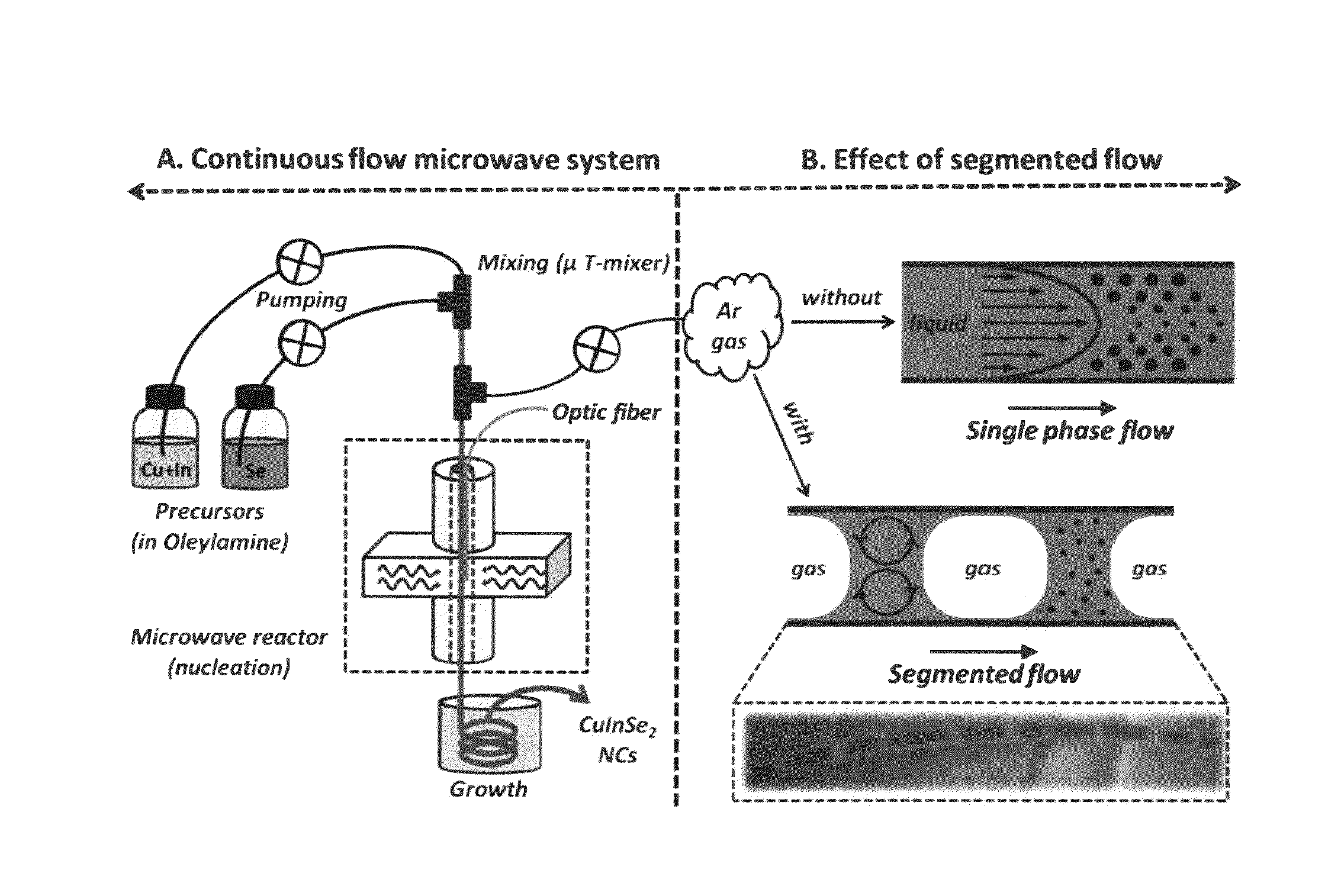

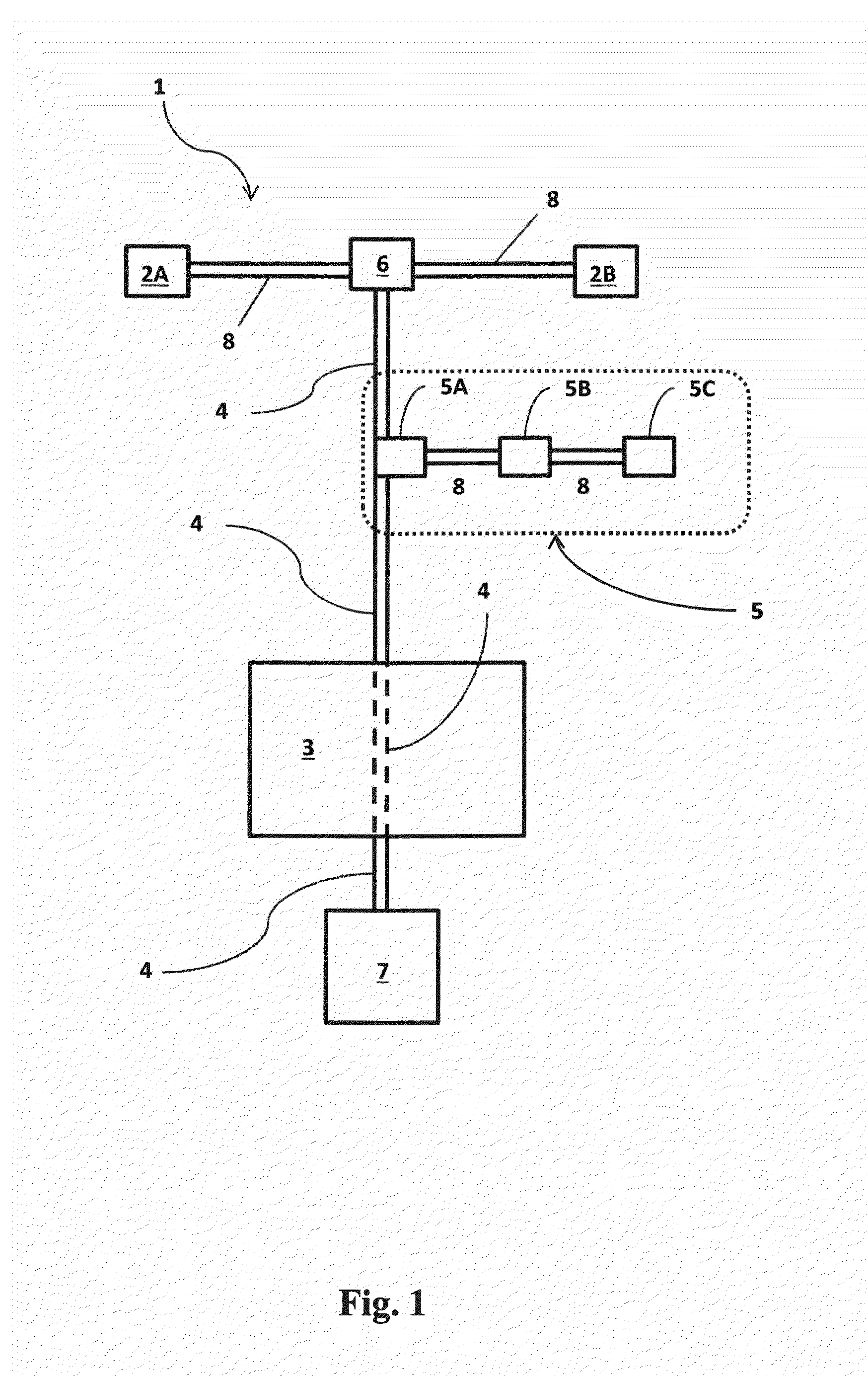

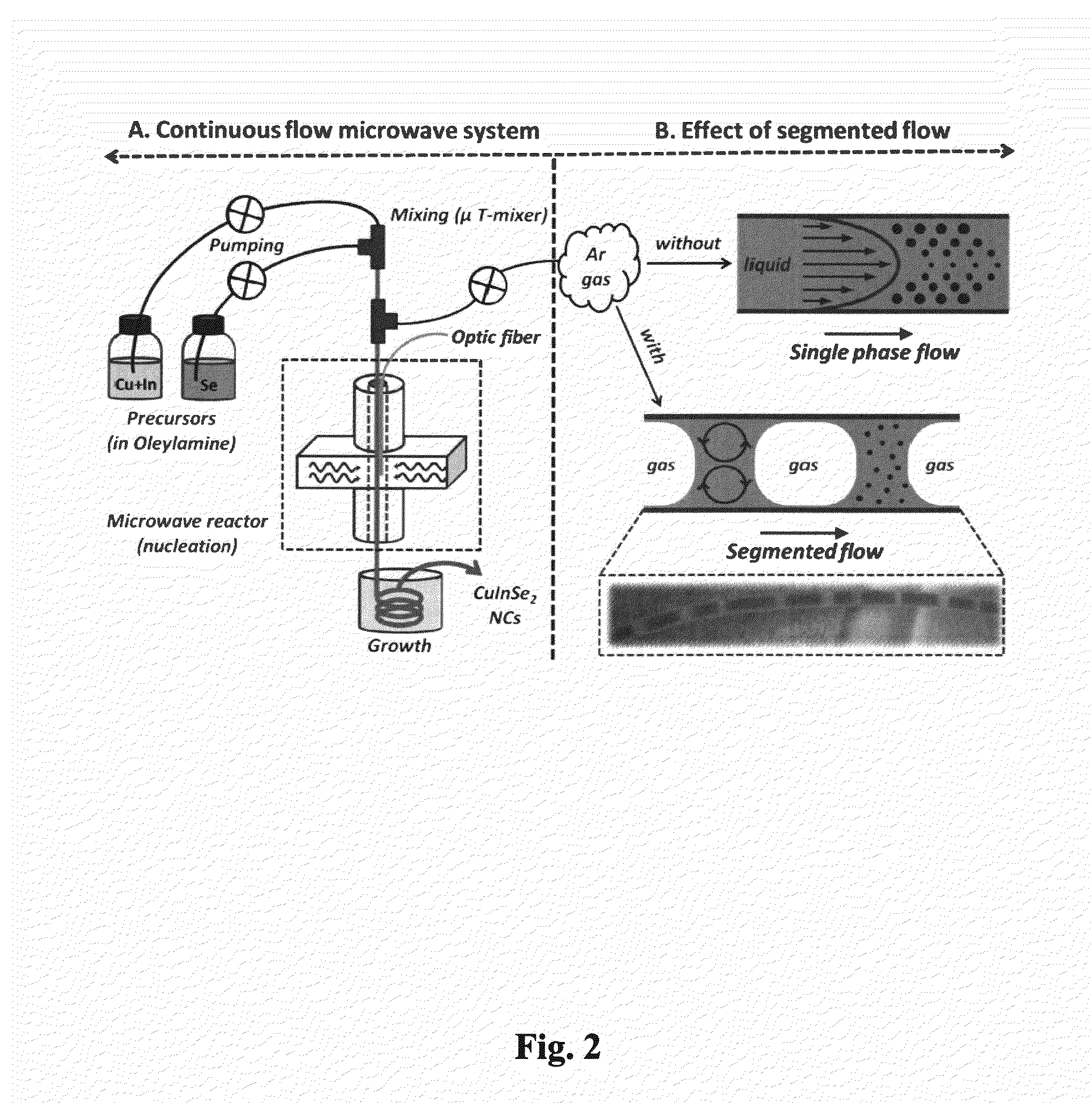

Continuous microwave-assisted segmented flow reactor for high-quality nanocrystal synthesis

ActiveUS20150182936A1Quality improvementTin compoundsPhosphorus sulfur/selenium/tellurium compoundsProcess engineeringContinuous flow

Systems and methods for synthesizing high-quality nanocrystals via segmented, continuous flow microwave-assisted reactor were developed.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Synthesis of metal compounds under carbothermal conditions

InactiveUS7060206B2Economical and convenient processLower capability requirementsCell electrodesSulfur compoundsOxidation stateGraphite

Active materials of the invention contain at least one alkali metal and at least one other metal capable of being oxidized to a higher oxidation state. Preferred other metals are accordingly selected from the group consisting of transition metals (defined as Groups 4–11 of the periodic table), as well as certain other non-transition metals such as tin, bismuth, and lead. The active materials may be synthesized in single step reactions or in multi-step reactions. In at least one of the steps of the synthesis reaction, reducing carbon is used as a starting material. In one aspect, the reducing carbon is provided by elemental carbon, preferably in particulate form such as graphites, amorphous carbon, carbon blacks and the like. In another aspect, reducing carbon may also be provided by an organic precursor material, or by a mixture of elemental carbon and organic precursor material.

Owner:LITHIUM WERKS TECH BV

Method of preparing nano hydroxyl zinc stannate and nano zinc stannate

The invention provides a preparation method for nanometer zinc hydroxystannate and nanometer zinc stannate. Said method uses tin compounds as raw materials to prepare zinc hydroxystannate with particle size of 2-100 nm. Nanometer zinc stannate can be obtained by sintering the zinc hydroxystannate at high temperature. Zinc hydroxystannate (xZnO*ySnO*zH2O) has a molar ratio of x : y : z at 1 : 0.8-1.4 : 1-5. They can be used alone or mixed for polymer materials, and has a good effect on flame retardancy and smoke suppression. Nanometer zinc hydroxystannate can merely be used in the material operating less than 180DEG C, while nanometer zinc stannate can be used for various polymer materials. In addition, both can be also used for gas-sensitive materials and lubricant additives.

Owner:HENAN UNIVERSITY

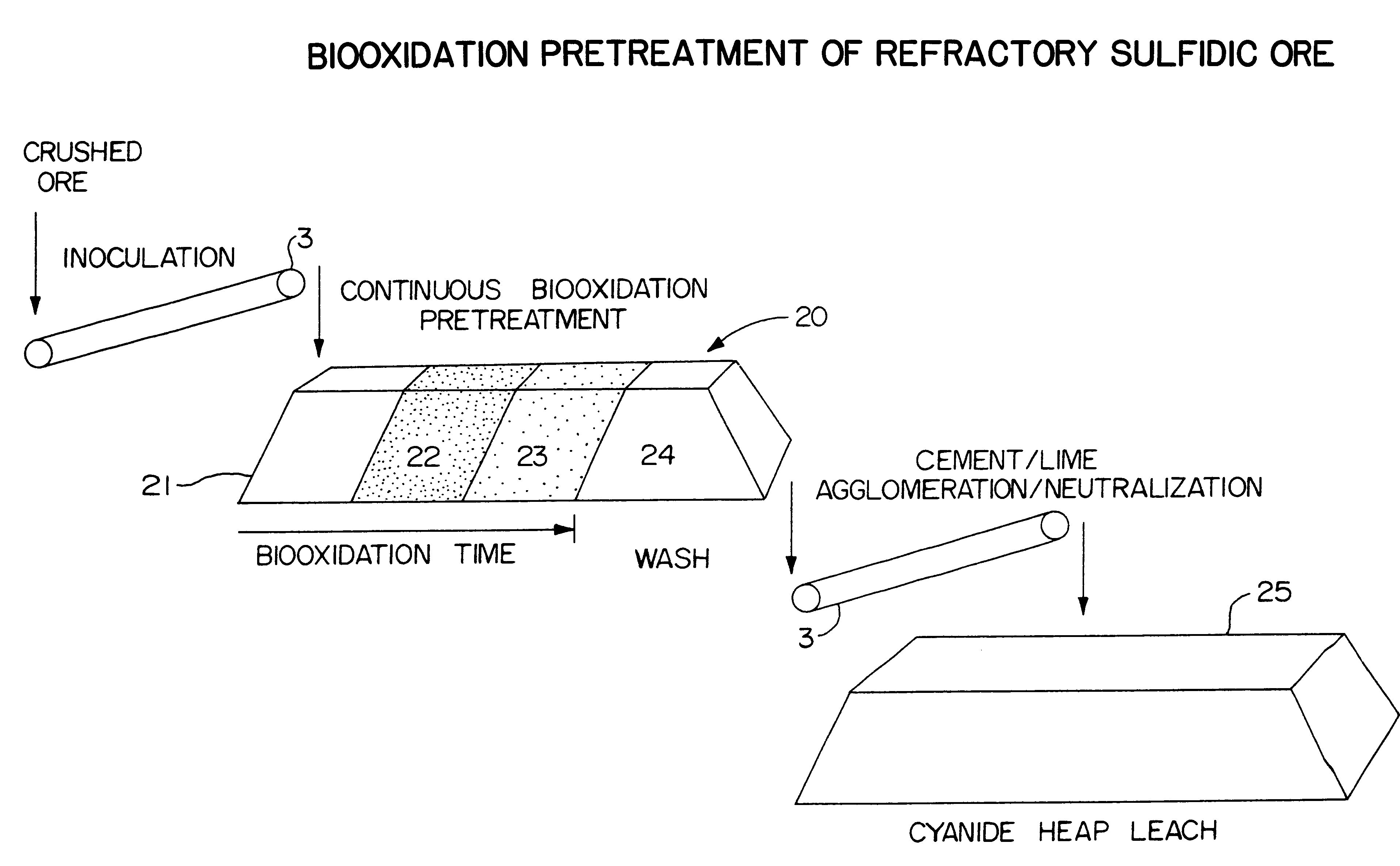

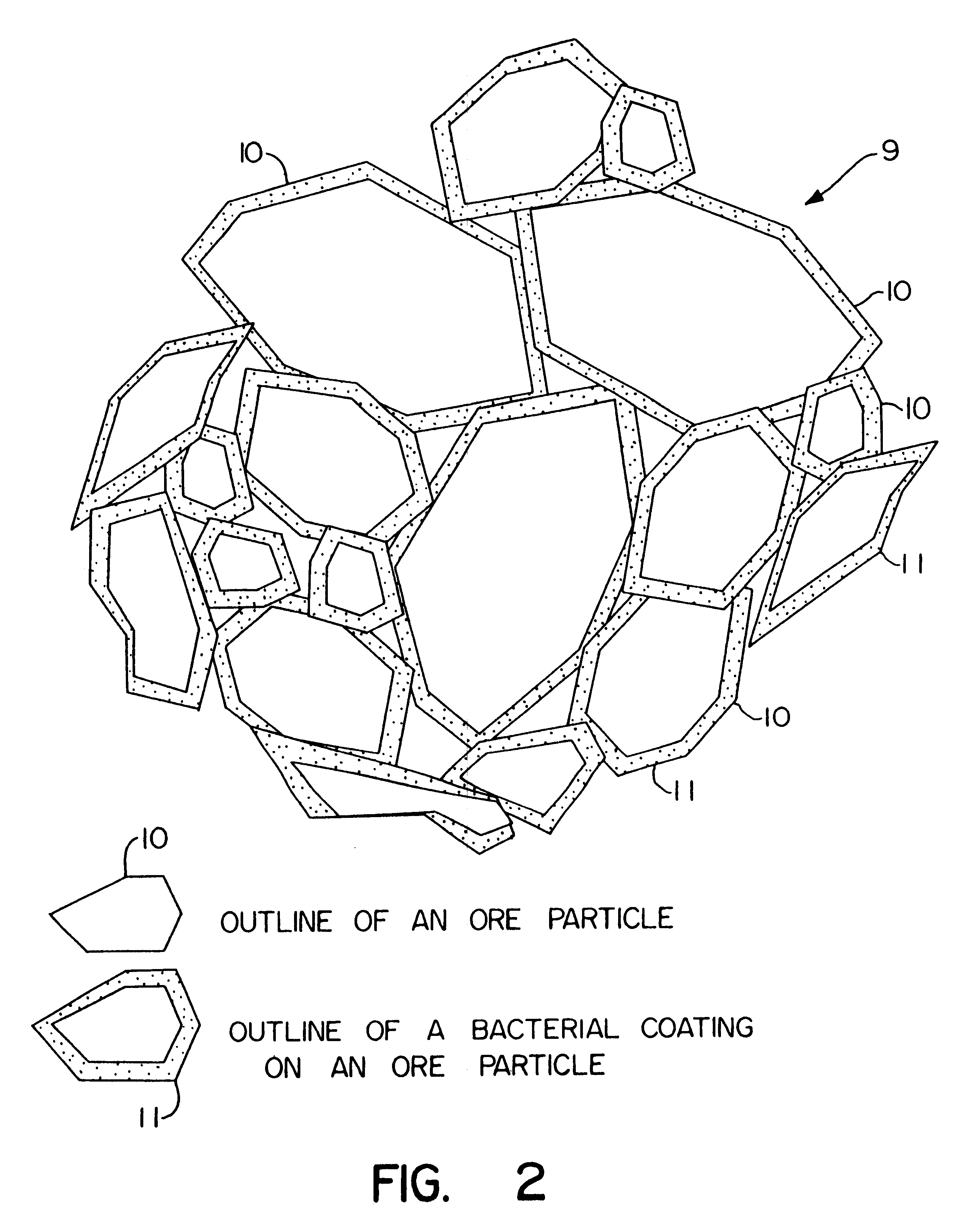

Biooxidation process for recovery of metal values from sulfur-containing ore materials

InactiveUS6383458B1Increase ratingsIncrease attractivenessTransuranic element compoundsSolvent extractionParticulatesPartial oxidation

A process for the recovery of one or more metal values from a metal ore material comprising those of one or more values and a matrix material having a sulfur content wherein the sulfur is present in an oxidation-reduction state of zero or less comprisinga. forming particulates from particles of said ore and an inoculate comprising bacteria capable of at least partially oxidizing the sulfur content;b. forming a heap of said particulates;c. biooxidizing the sulfur content andd. recovering those one or more metal values.

Owner:NEWMONT USA LTD

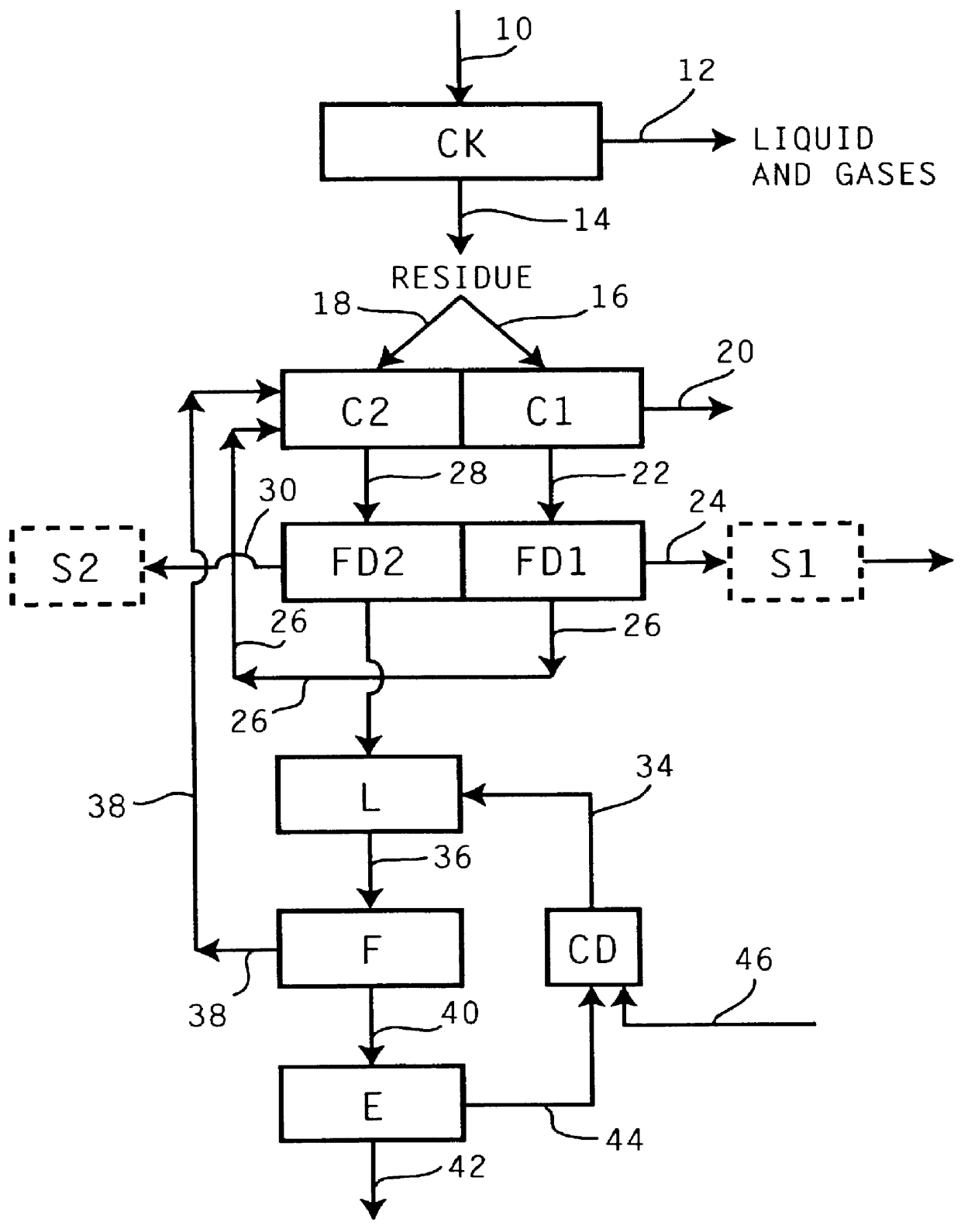

Recovery of the transition metal component of catalyst used in heavy feed hydroconversion

The invention relates to a process for recovering the transition metal component of catalysts used in the hydroconversion of heavy hydrocarbonaceous materials. In accordance with the invention, a slurry of a transition metal catalyst and hydrocarbon is catalytically desulfurized resulting in a desulfurized product and a solid residue containing the transition metal. The transition metal may be recovered by coking the residue and then dividing the coker residue into two portions are combusted with the flue dust from the first combustion zone being conducted to the second combustion zone. The flue dust from the second combustion zone is treated with ammonia and ammonium carbonate in order to obtain ammonium molybdate.

Owner:EXXON RES & ENG CO

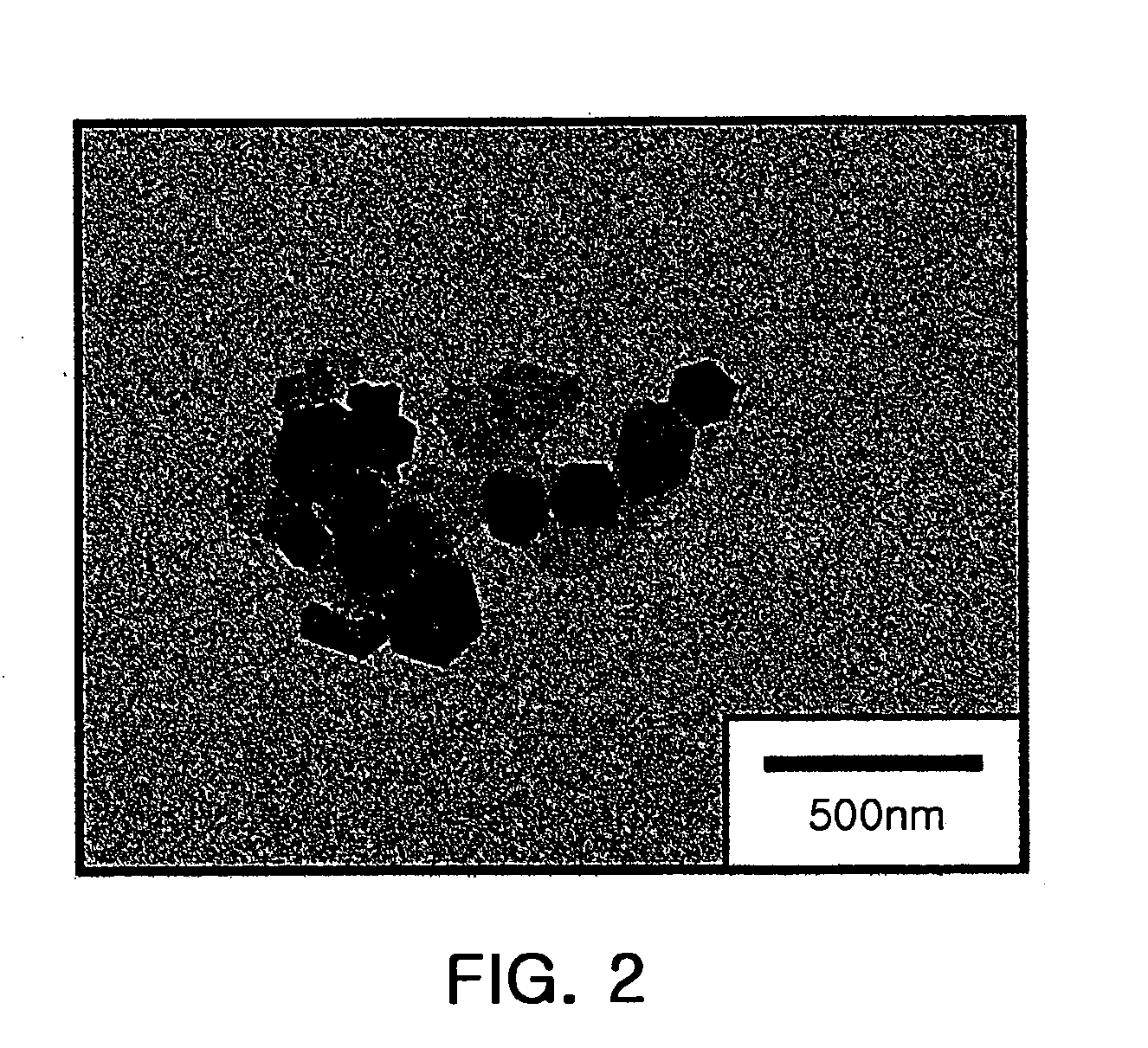

Preparing method of tin sulfide nanoparticles and manufacturing method of lithium ion battery using the same

InactiveUS20090029258A1Small sizeEasily controlled in size and morphologyMaterial nanotechnologyTin compoundsNanoparticleSodium-ion battery

There is provided a method of preparing tin sulfide nanoparticles, in which tin sulfide particles are prepared selectively, easily controlled in size and morphology and can be massively produced more easily through a simpler process. The method includes: mixing a tin sulfide precursor with at least one surfactant into a mixture; and heating the mixture.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com