Method for preparing sodium stannate using circuit board tin-stripping wastewater

A technology of tin stripping wastewater and sodium stannate, applied in chemical instruments and methods, tin compounds, water/sewage multi-stage treatment, etc., can solve the problems of low recycling rate of valuable metals, difficult treatment, environmental hazards, etc. Achieve resource utilization, reduce production costs, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

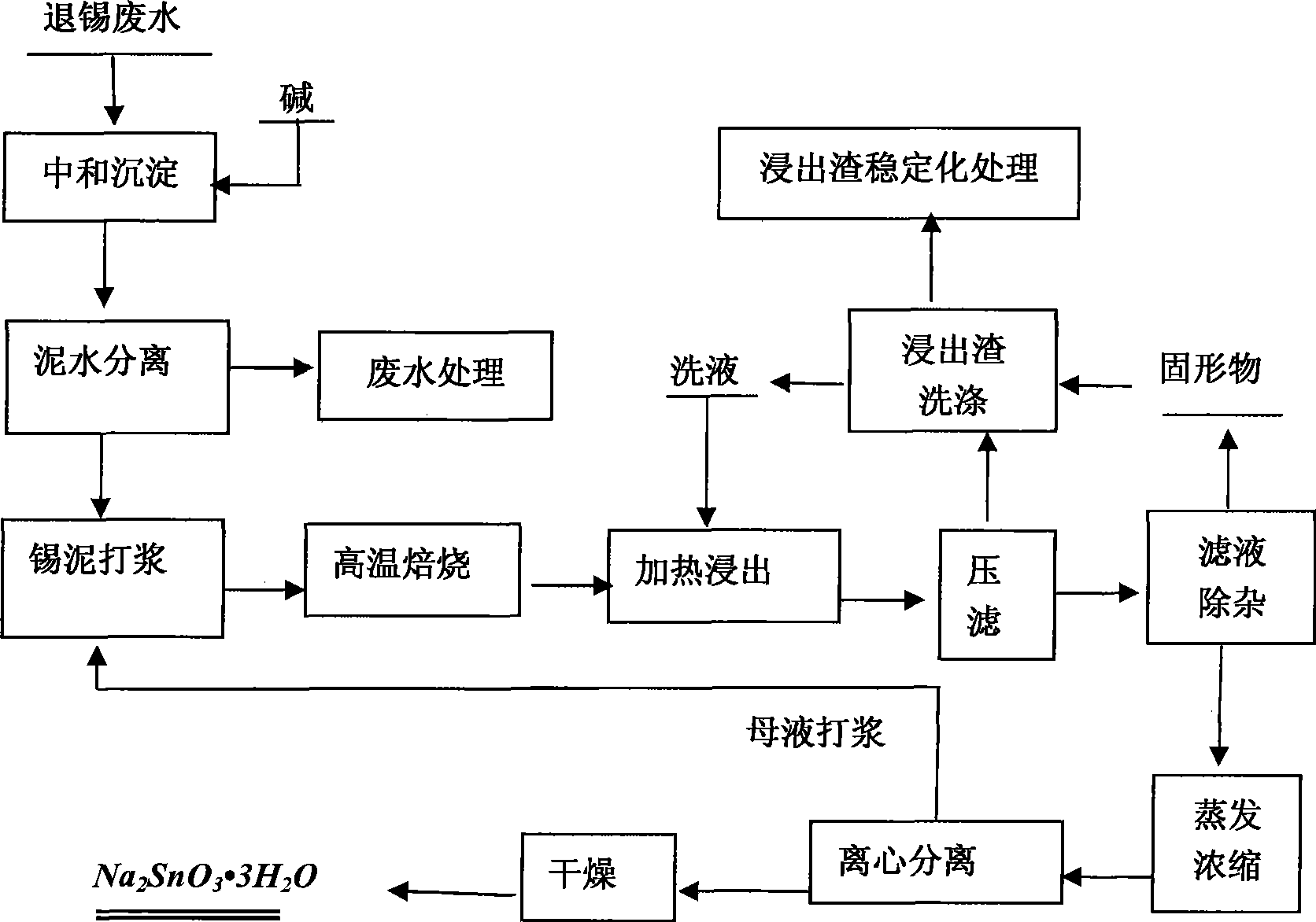

Method used

Image

Examples

example 1-3

[0050] The tin stripping wastewater from three manufacturers of circuit board factory A, B, and C is the second type of tin stripping wastewater introduced in the technical background of the present invention, and its composition analysis is shown in Table-3.

[0051] Table-3 Main components of tin stripping wastewater

[0052] Composition and content

(g / L) sn

Cu

Pb

Fe

Example 1 (A) 107.00 45.75 40.50 27.55 Example 2 (B) 80.50 30.80 40.20 15.00 Example 3 (C) 120.60 48.60 50.30 35.20

[0053] Add ammonium carbonate to the three kinds of tin stripping wastewater A, B, and C respectively for neutralization and precipitation, the pH value is controlled between 7.0 and 8.5, and the above neutralized waste liquid is subjected to pressure filtration to obtain a filter cake (i.e., tin sludge ); the filtrate enters the wastewater treatment system for further treatment and then discharges up to standard.

[0054] After testing...

example 4

[0063] Originated from the circuit board factory D, belongs to the first kind of tin stripping wastewater introduced in the technical background of the present invention and the third kind of tin stripping wastewater derived from the circuit board factory E and the second one from the circuit board factory A described in Example 1 The tin stripping wastewater is mixed and the water quality is balanced.

[0064] Add 18% industrial ammonia water to this kind of tin stripping wastewater for neutralization and precipitation, the pH value is controlled between 7.5 and 8.5, and the above-mentioned neutralized waste liquid is subjected to pressure filtration to obtain a filter cake (i.e. tin sludge); filtrate After entering the wastewater treatment system for further treatment, it will be discharged up to standard.

[0065] Add sodium hydroxide solution to the filter cake, beat it, roast it at 950°C for 4.5 hours, take the roasted dry material, and carry out two-stage countercurrent ...

example 5

[0071] The applicant of the present invention is an environmental protection enterprise specializing in the treatment and disposal of hazardous waste including circuit board waste. Using the technology provided by the present invention, it has built a production line for treating 5,000 tons of tin stripping wastewater per year.

[0072] The treatment process is as follows: add ammonium bicarbonate to the collected tin stripping wastewater (mainly the second type, and occasionally collect the first or third type and then merge them into the second tin stripping wastewater). and precipitation to obtain tin mud, with an annual output of about 1,500 tons, and the average tin content in the tin mud is 16%.

[0073] Add sodium hydroxide solution to the obtained tin mud, beat it, and roast it at 900°C for 4 hours, take the roasted dry material, and perform three-stage countercurrent leaching on it with water, the ratio of solid to liquid is 1:3, the leaching temperature is 92°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com