Patents

Literature

2917 results about "Hazardous waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hazardous waste is waste that has substantial or potential threats to public health or the environment. Hazardous wastes may be found in different physical states such as gaseous, liquids, or solids. A hazardous waste is a special type of waste because it cannot be disposed of by common means like other by-products of our everyday lives. Depending on the physical state of the waste, treatment and solidification processes might be required.

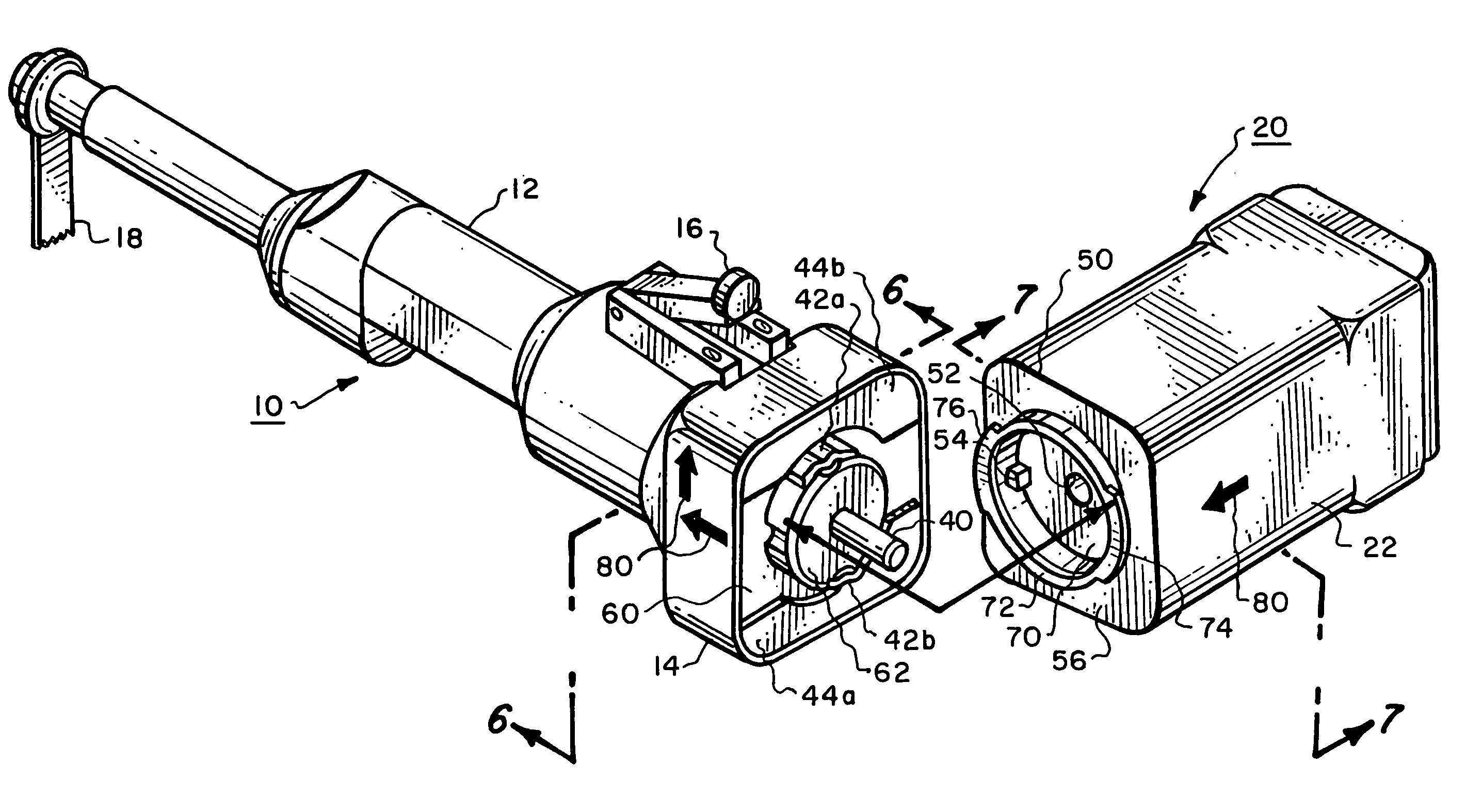

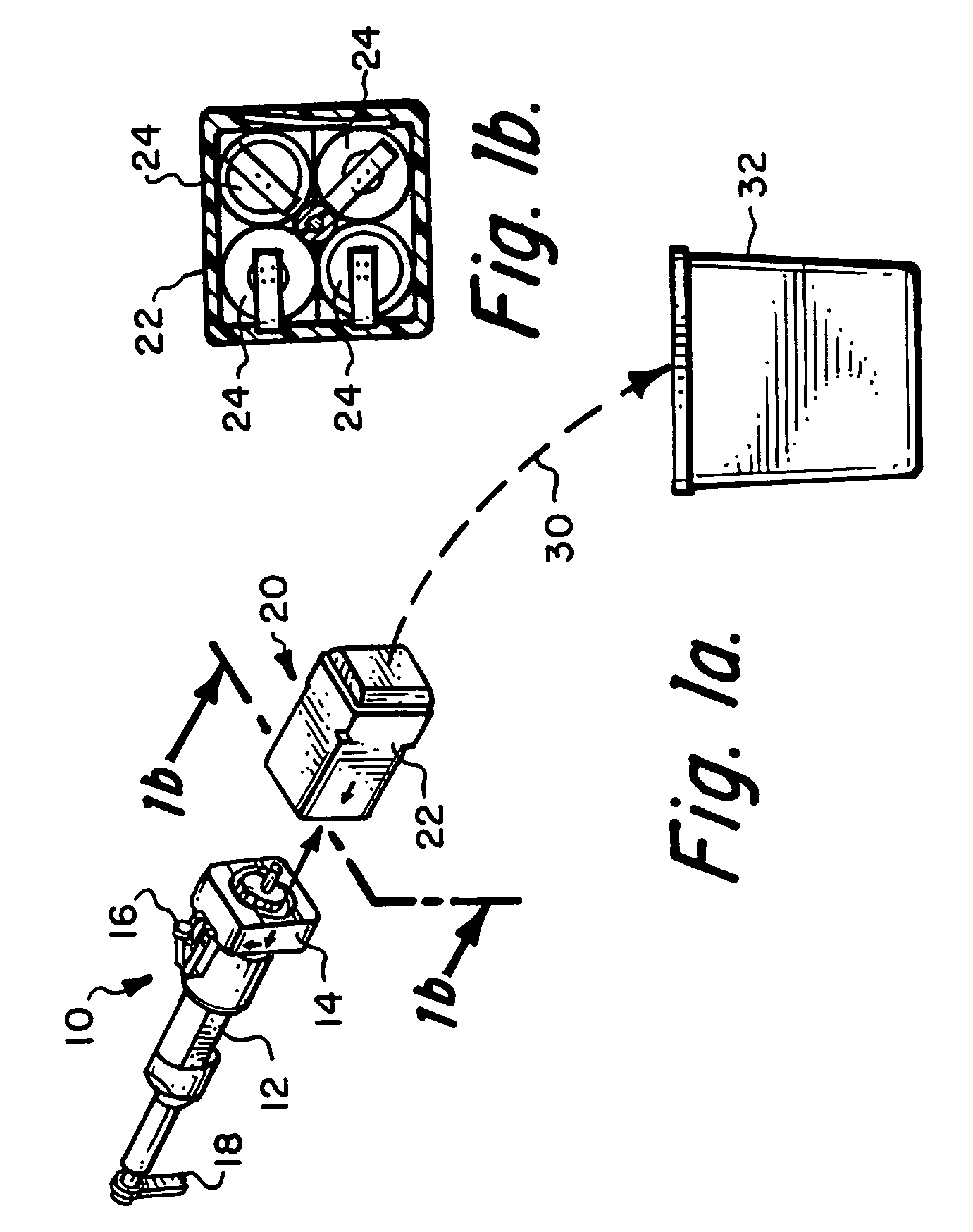

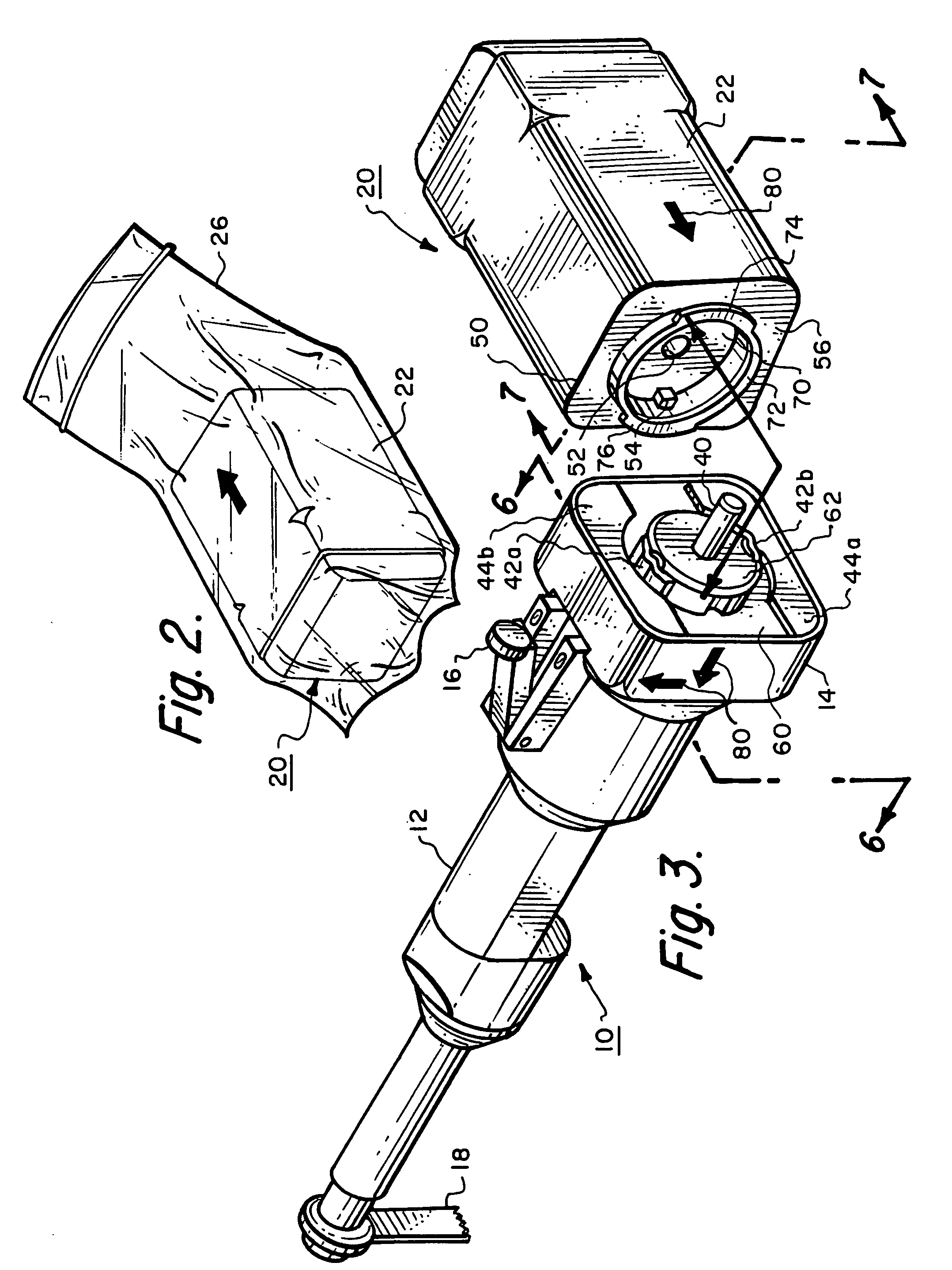

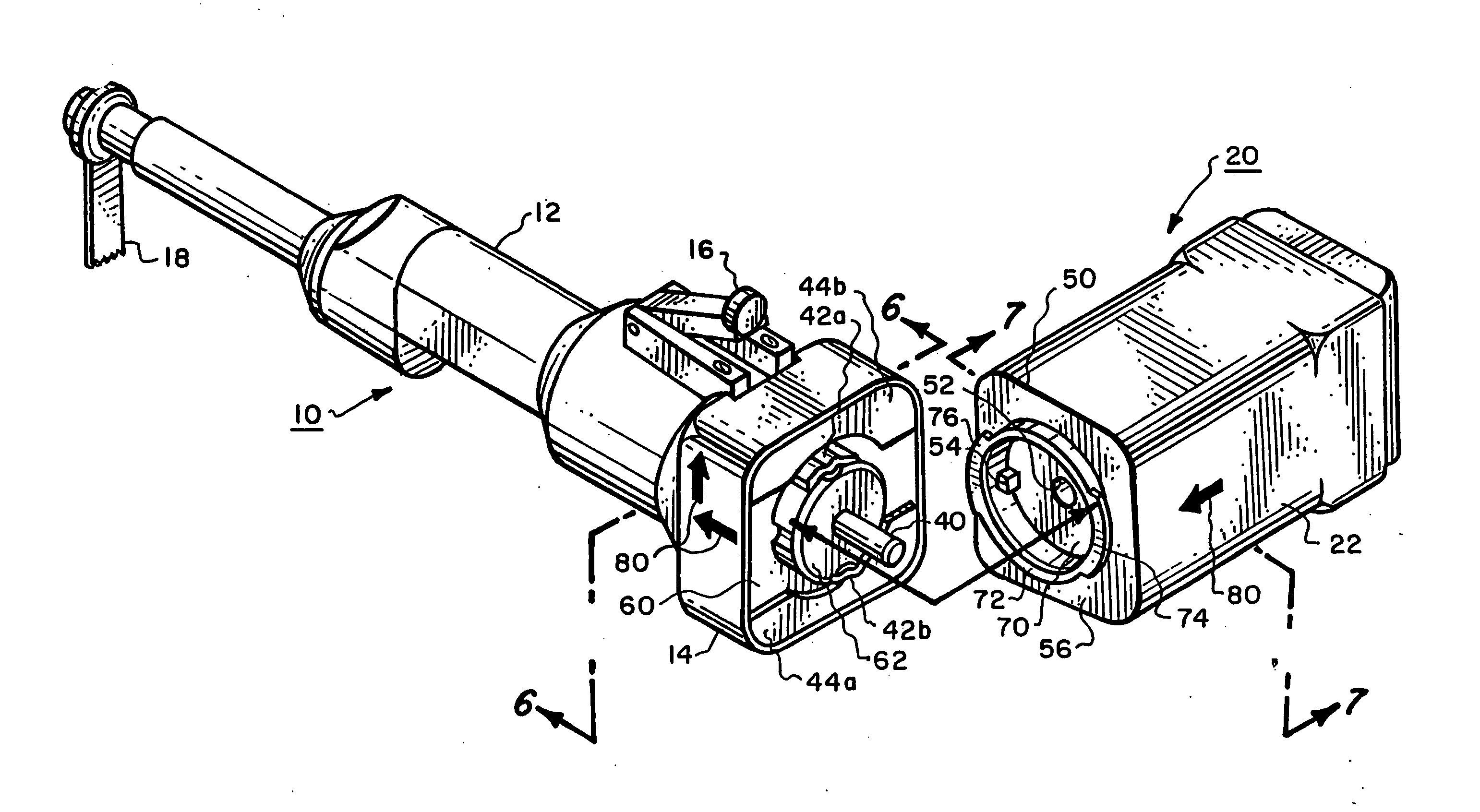

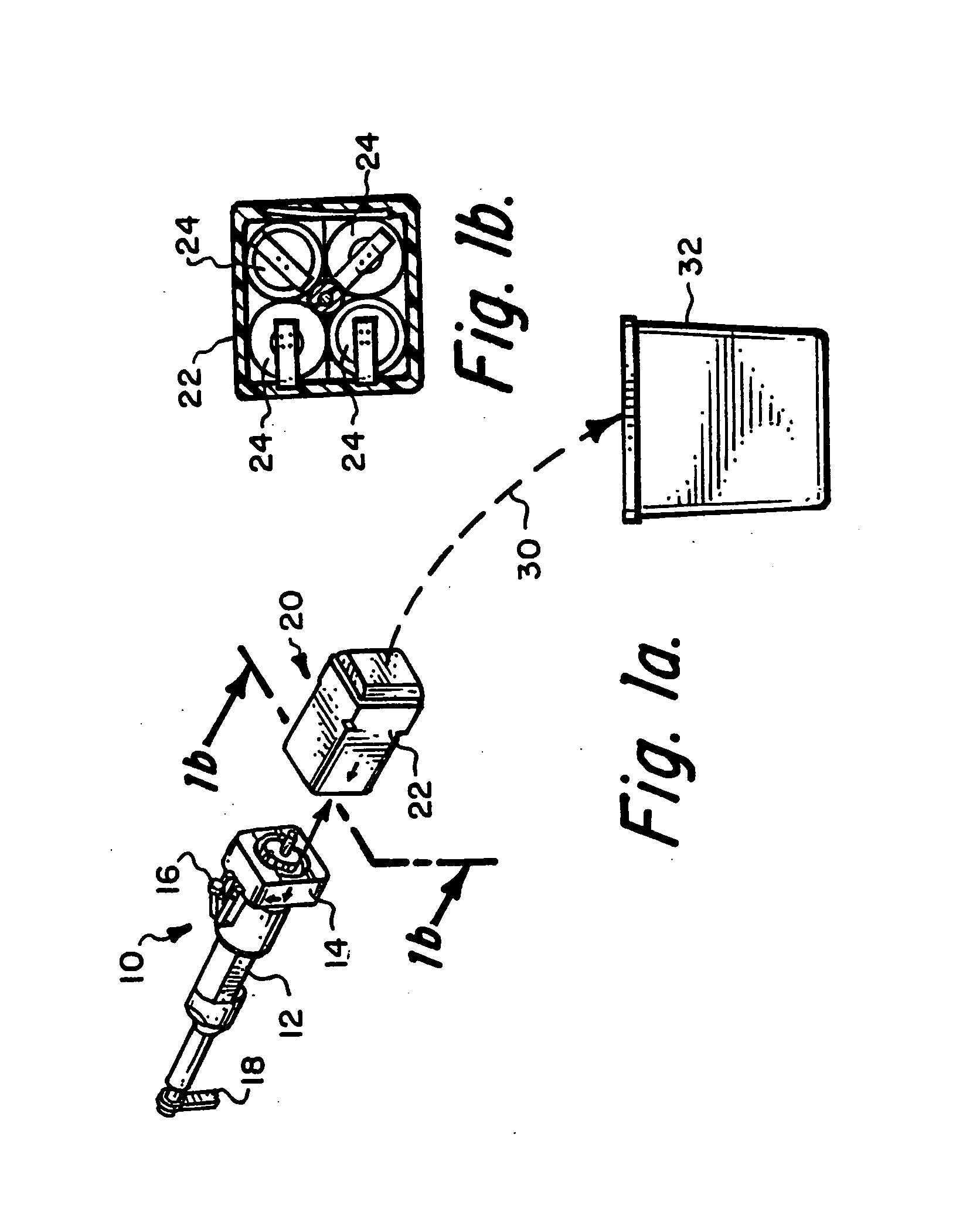

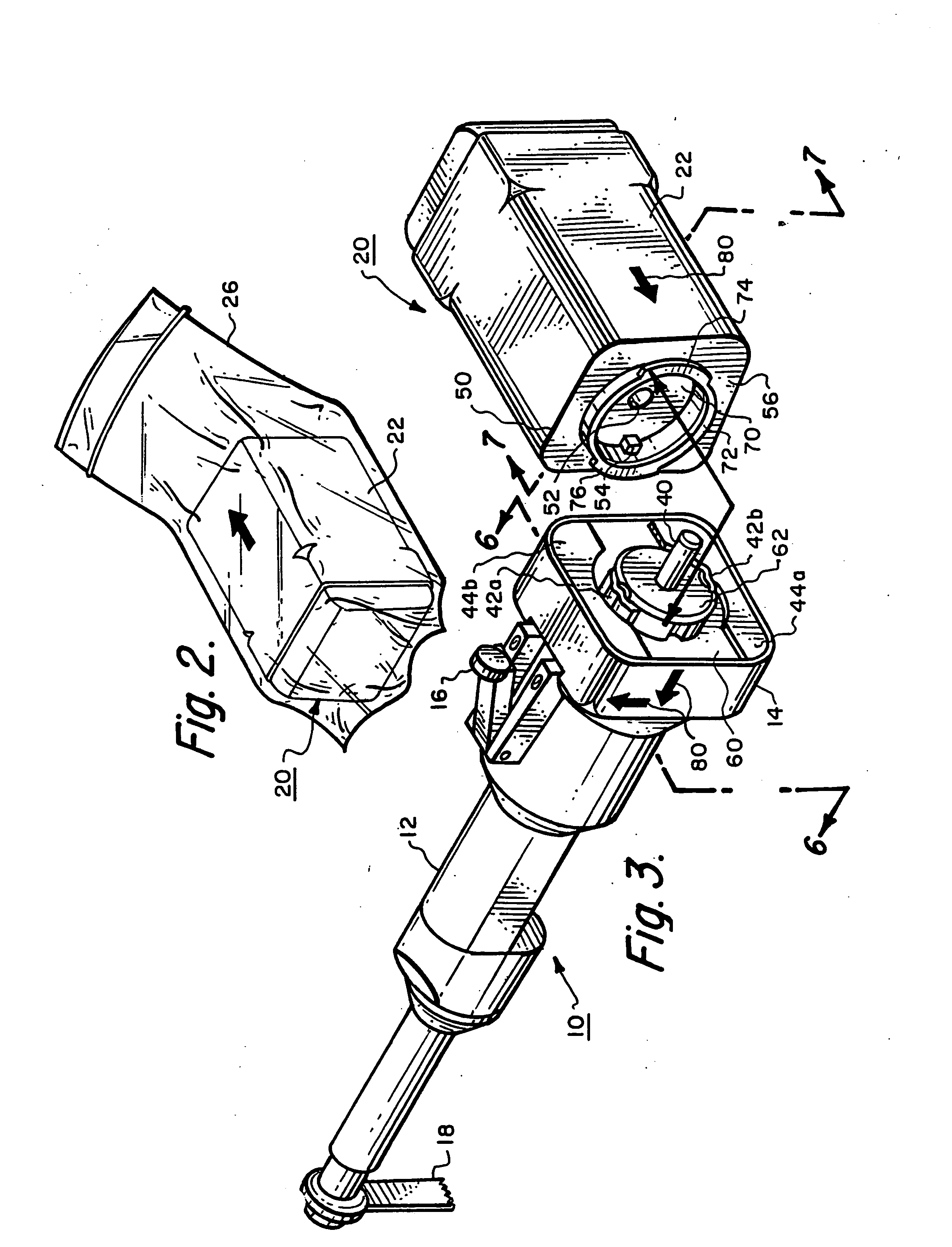

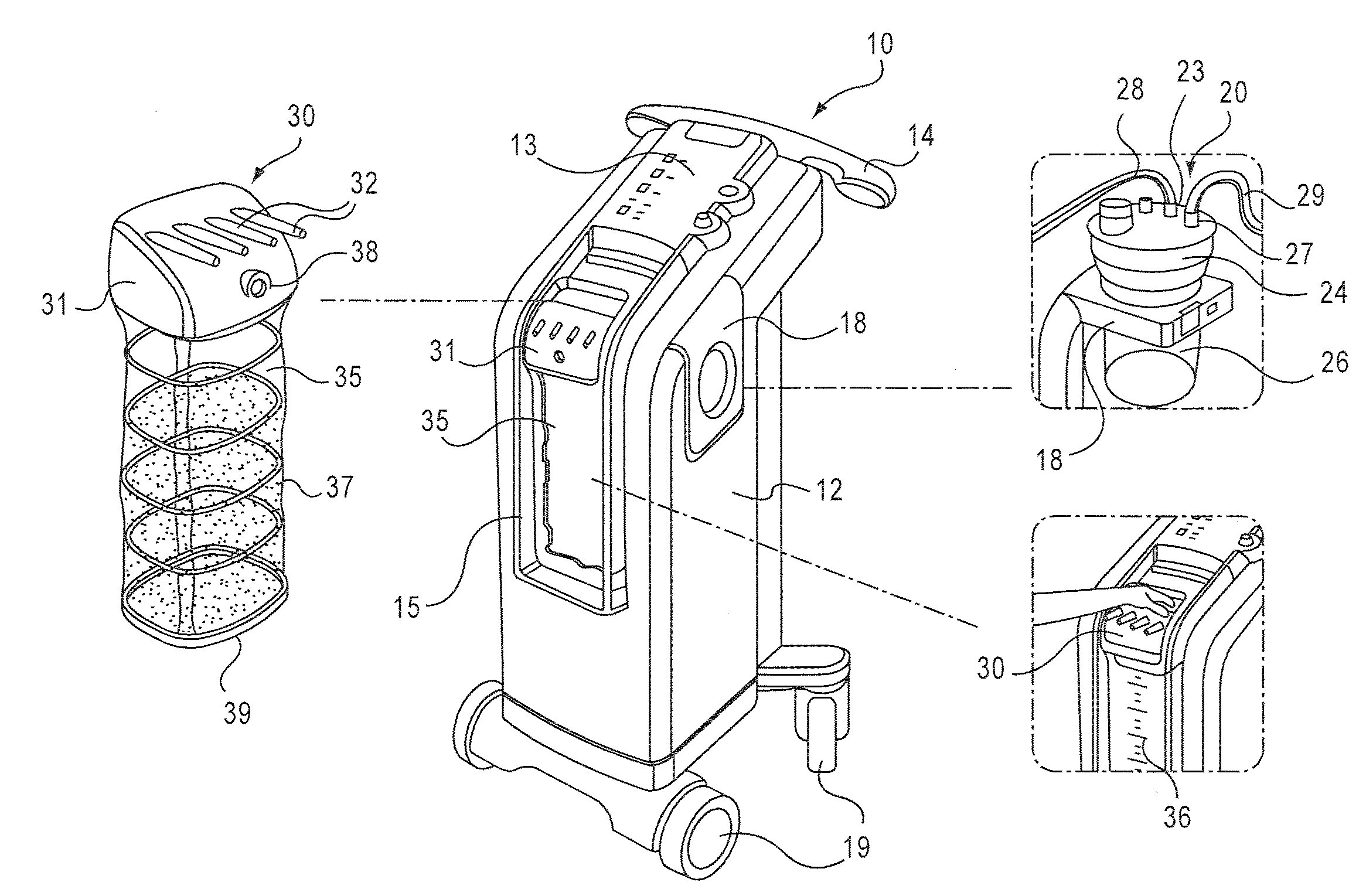

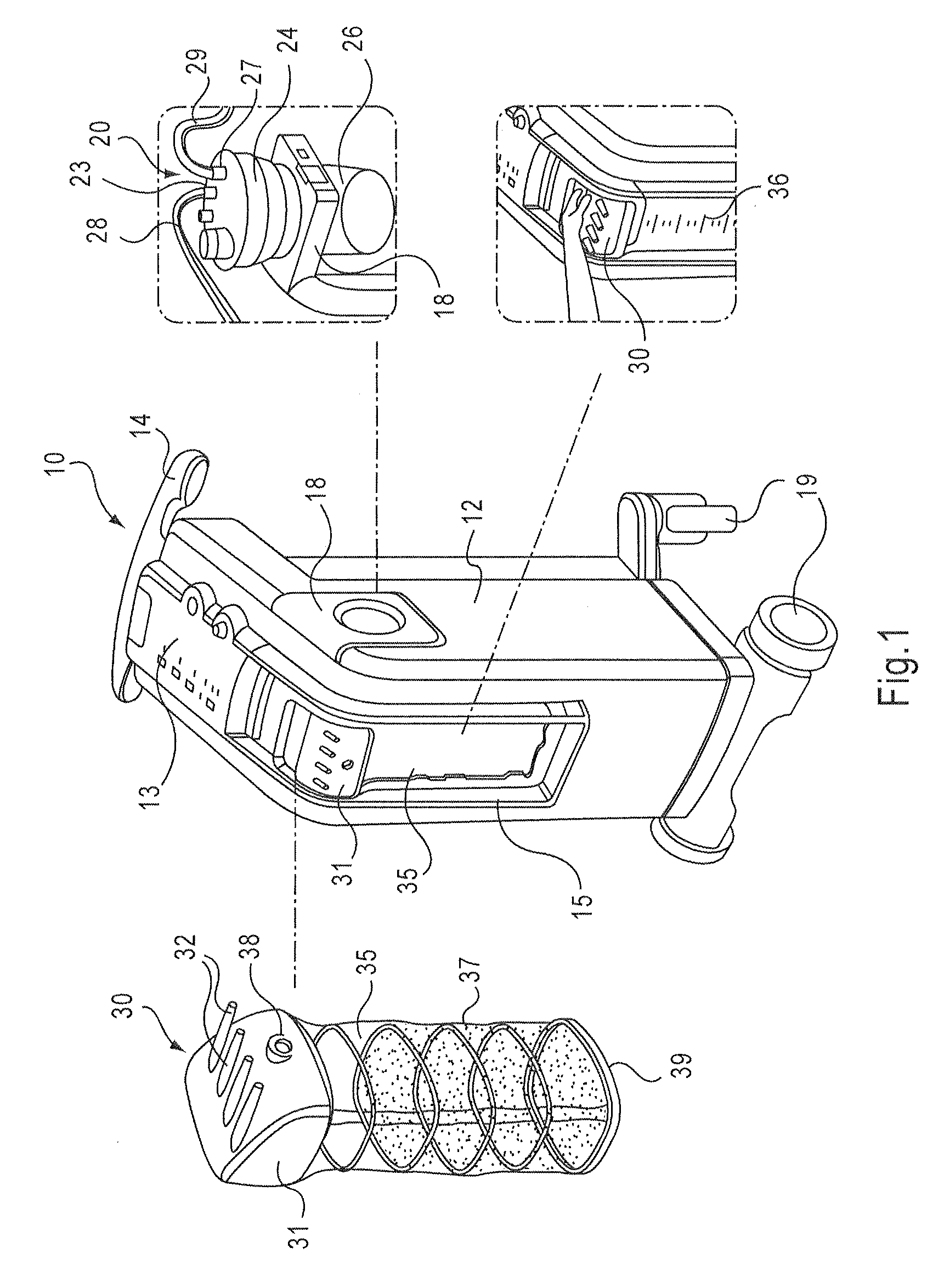

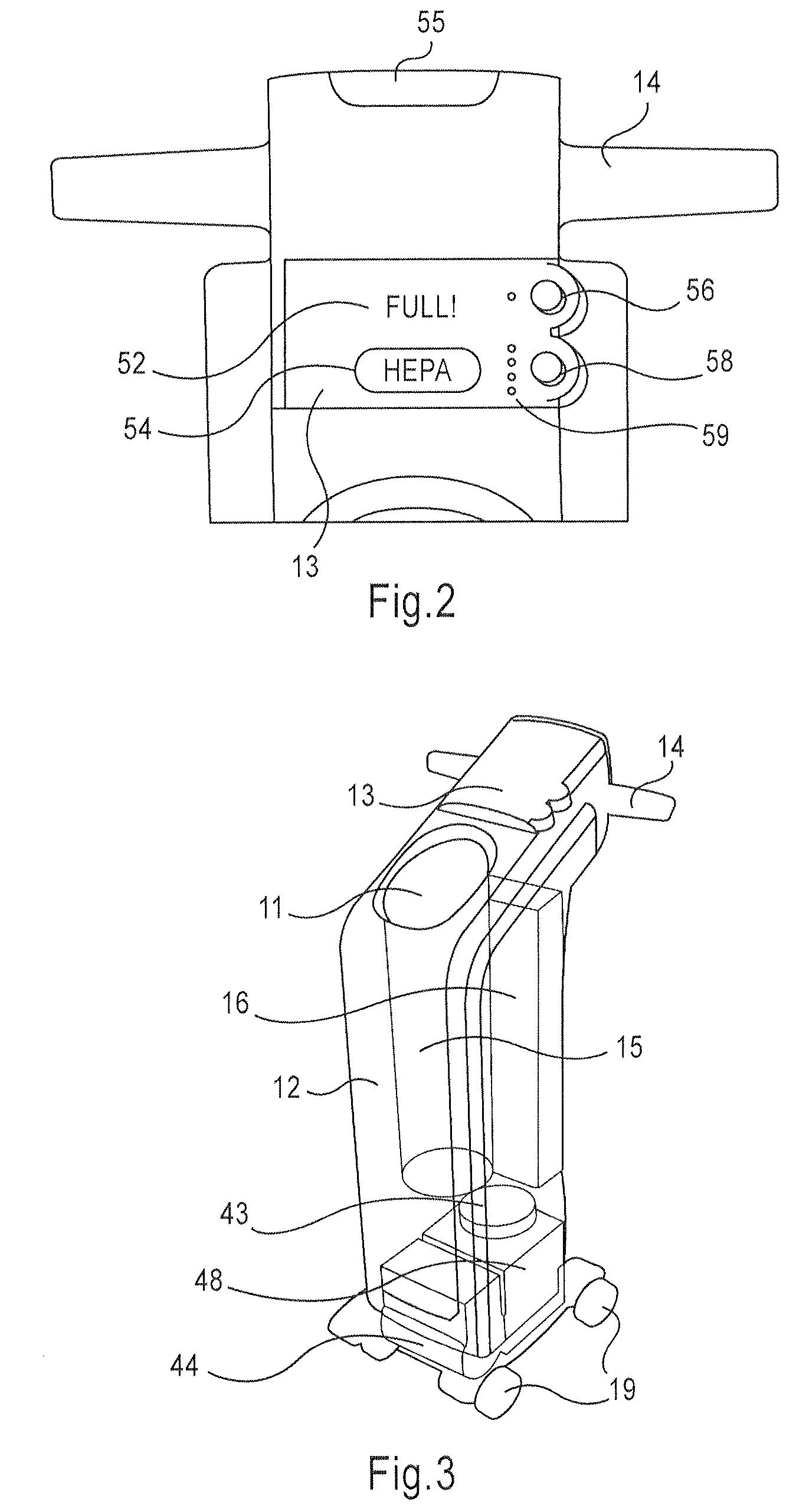

Cordless surgical handpiece with disposable battery; and method

A surgical procedure is disclosed utilizing a cordless surgical handpiece powered from a sterile battery pack that contains a battery in condition for immediate use without further charging or sterilization. The battery chemistry is based upon lithium / manganese dioxide, and the battery after a single use may be disposed of into non-hazardous waste. The compact surgical handpiece has a brushless DC motor and a manually operated external trigger for activating and controlling the motor operations. Interengaging sets of contacts on the handpiece and battery are adapted to become lockingly and conductively interengaged upon rotation of the battery pack relative to the handpiece, in a manner that rapidly achieves correct alignment of the parts and also ensures stable mechanical attachment and support during the surgical procedure.

Owner:MEDTRONIC INC

Electrical conductors formed from mixtures of metal powders and metallo-organic decomposition compounds

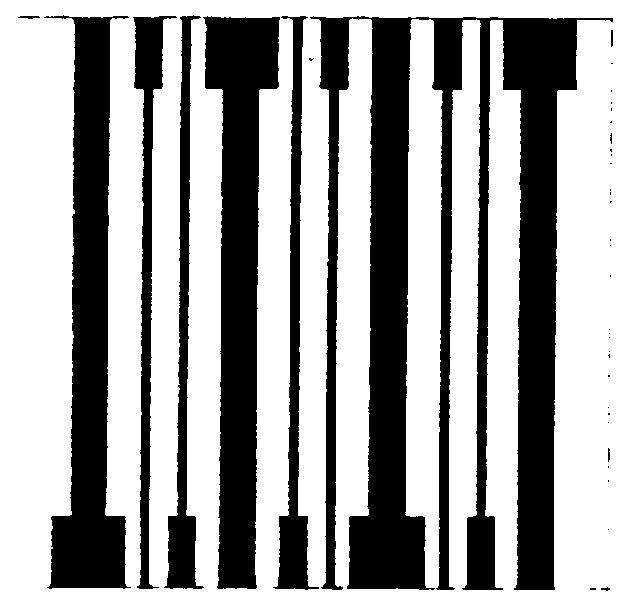

The present invention relates to a thick film formed of a mixture of metal powders and metallo-organic decomposition (MOD) compounds in an organic liquid vehicle and a process for advantageously applying them to a substrate by silk screening or other printing technology. The mixtures preferably contain metal flake with a ratio of the maximum dimension to the minimum dimension of between 5 and 50. The vehicle may include a colloidal metal powder with a diameter of about 10 to about 40 nanometers. The concentration of the colloidal metal in the suspension can range from about 10 to about 50% by weight. The MOD compound begins to decompose at a temperature of approximately about 200 DEG C. to promote consolidation of the metal constituents and bonding to the substrate which is complete at temperatures less than 450 DEG C. in a time less than six minutes. The mixtures can be applied by silk screening, stencilling, gravure or lithography to a polymer-based circuit board substrate for producing rigid and flexible printed wiring boards in a single operation with negligible generation of hazardous wastes. The same mixtures can be used in place of solder to assemble circuits by bonding electrical components to conductors as well as to make the conductors themselves.

Owner:PARELEC

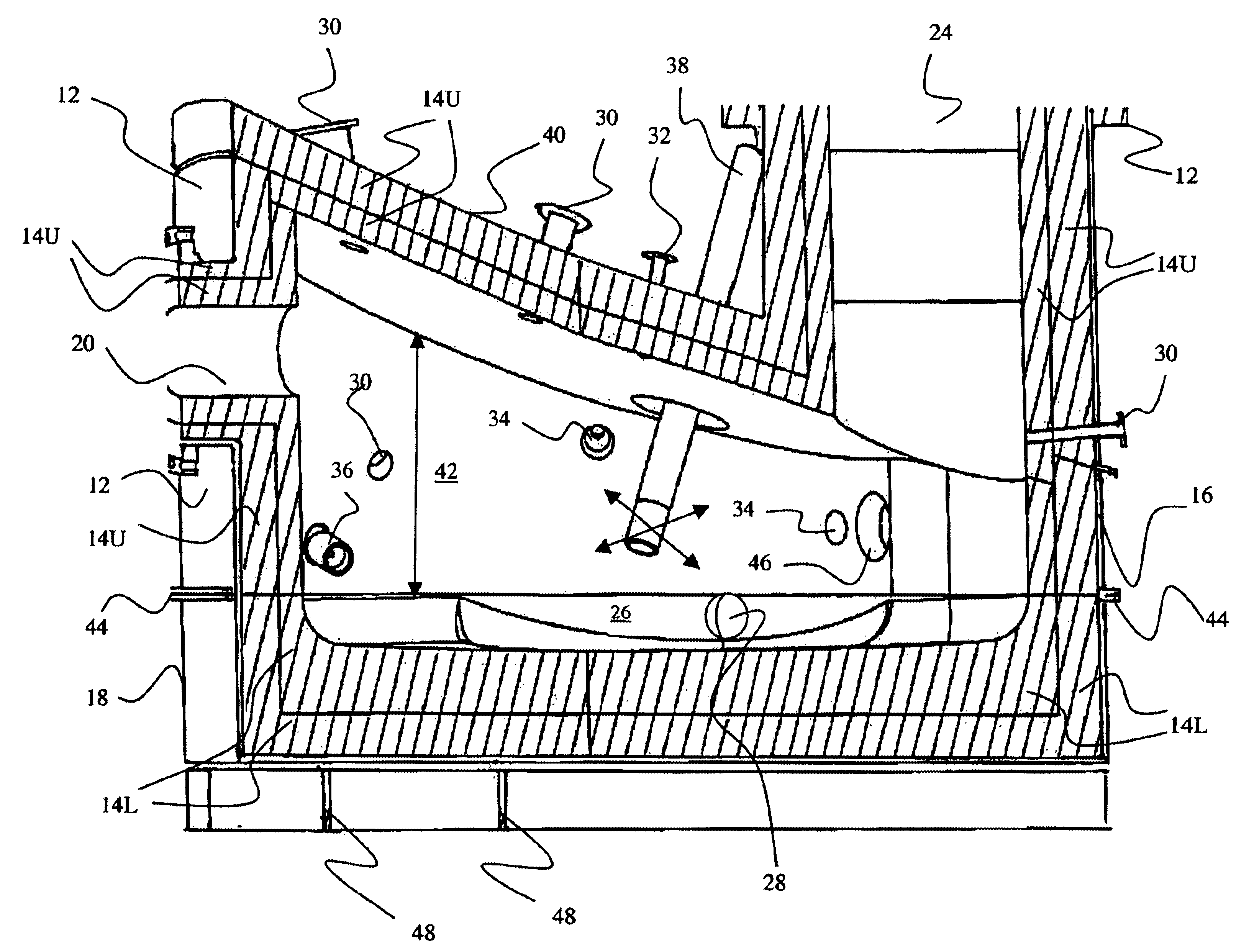

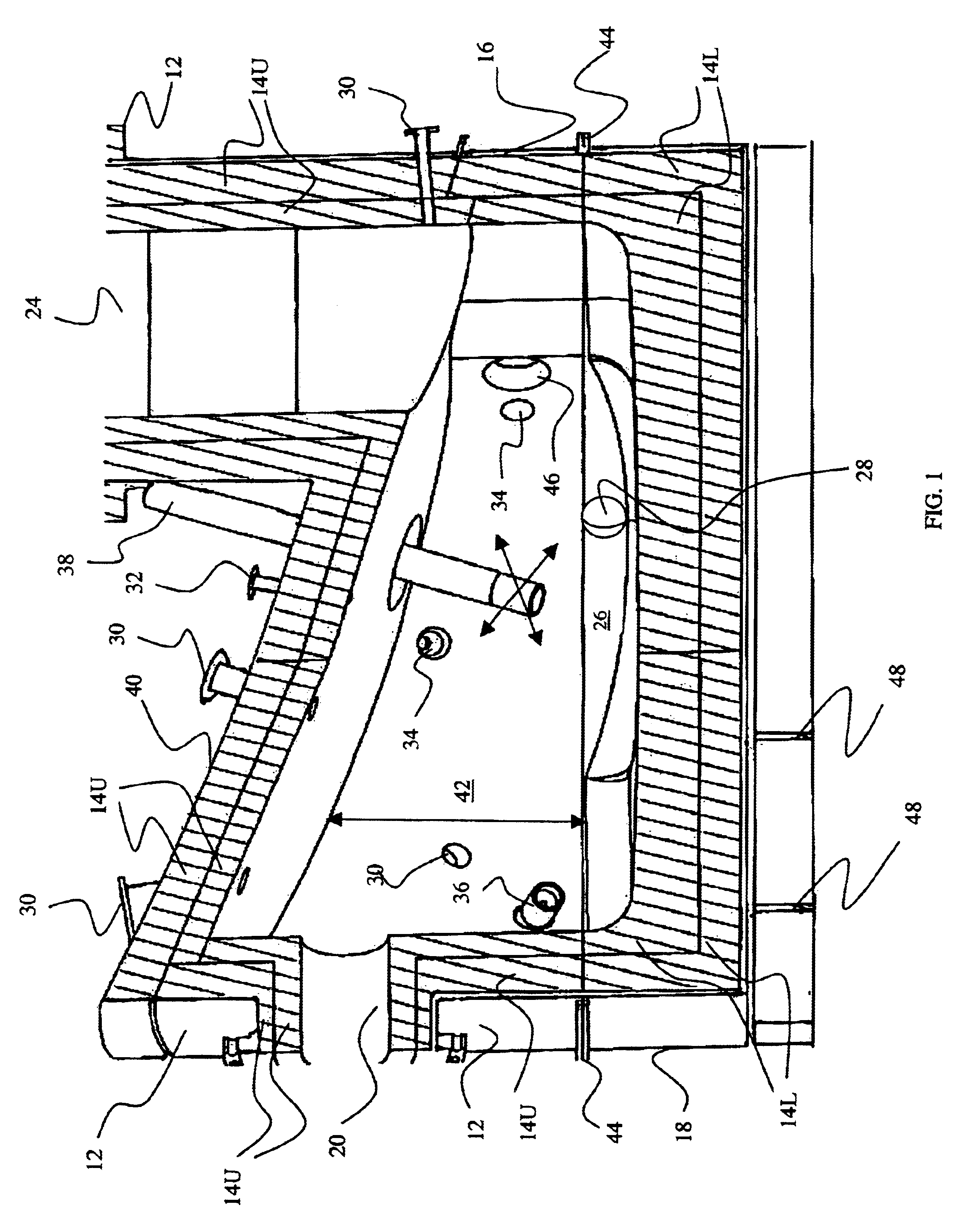

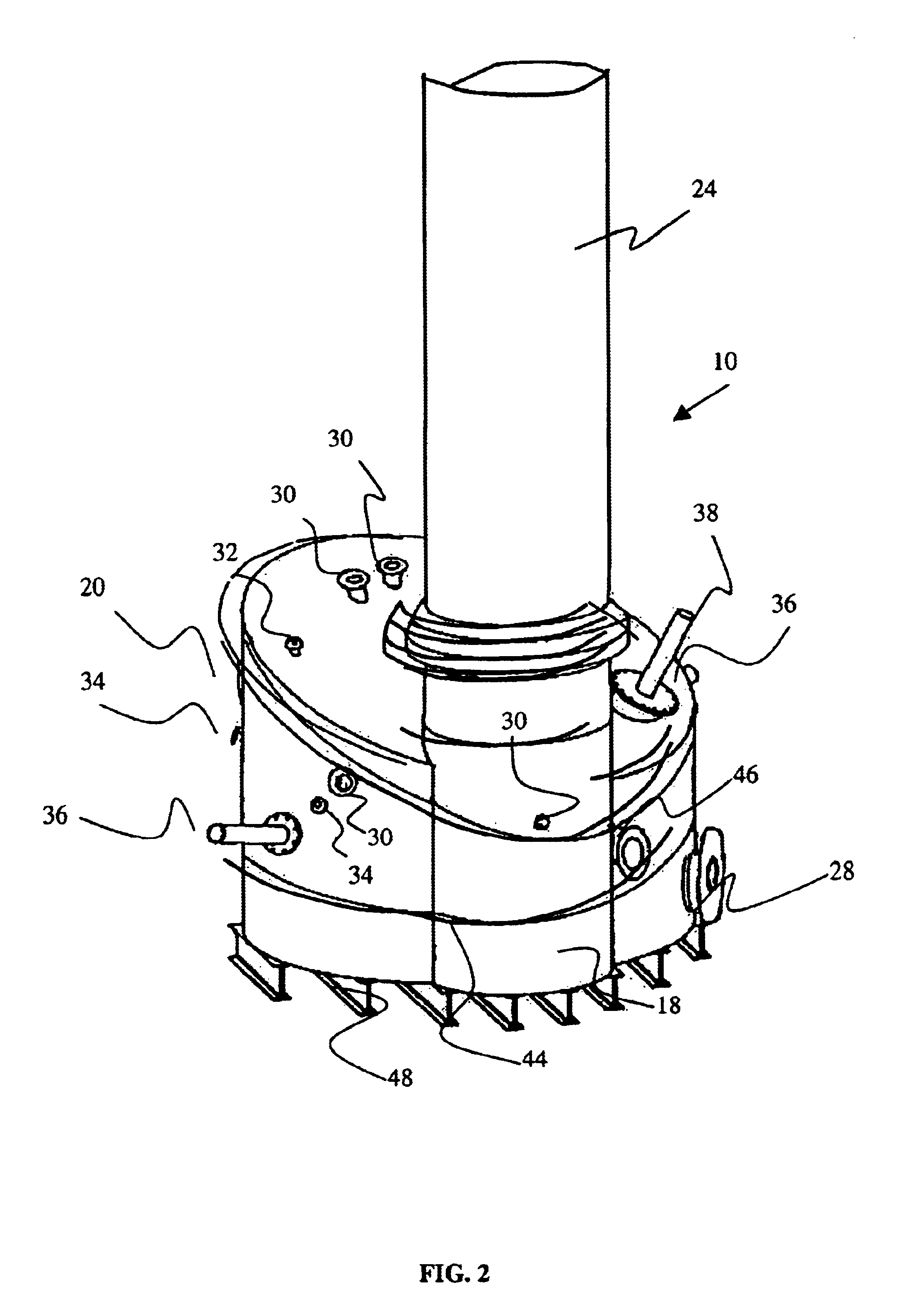

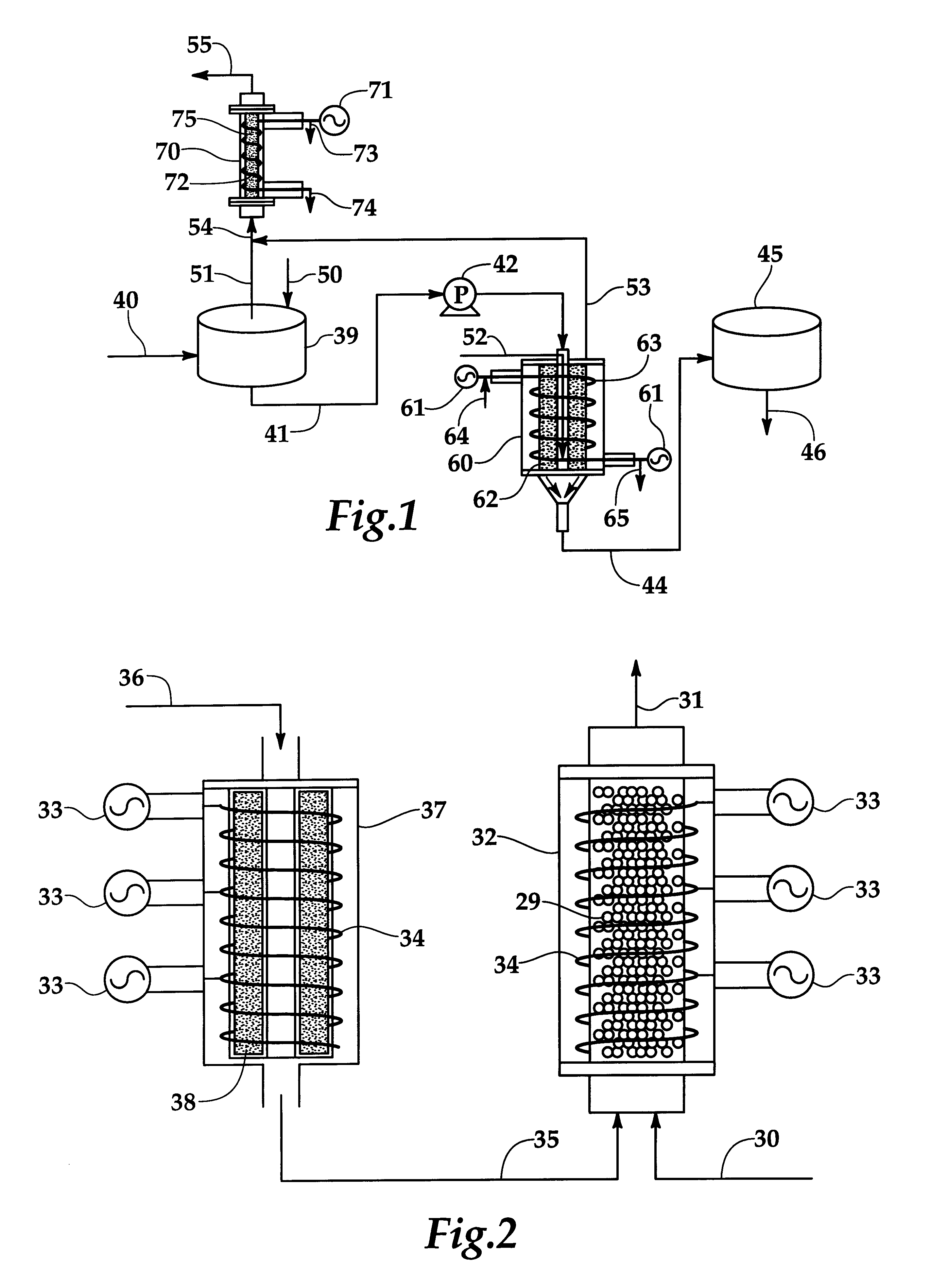

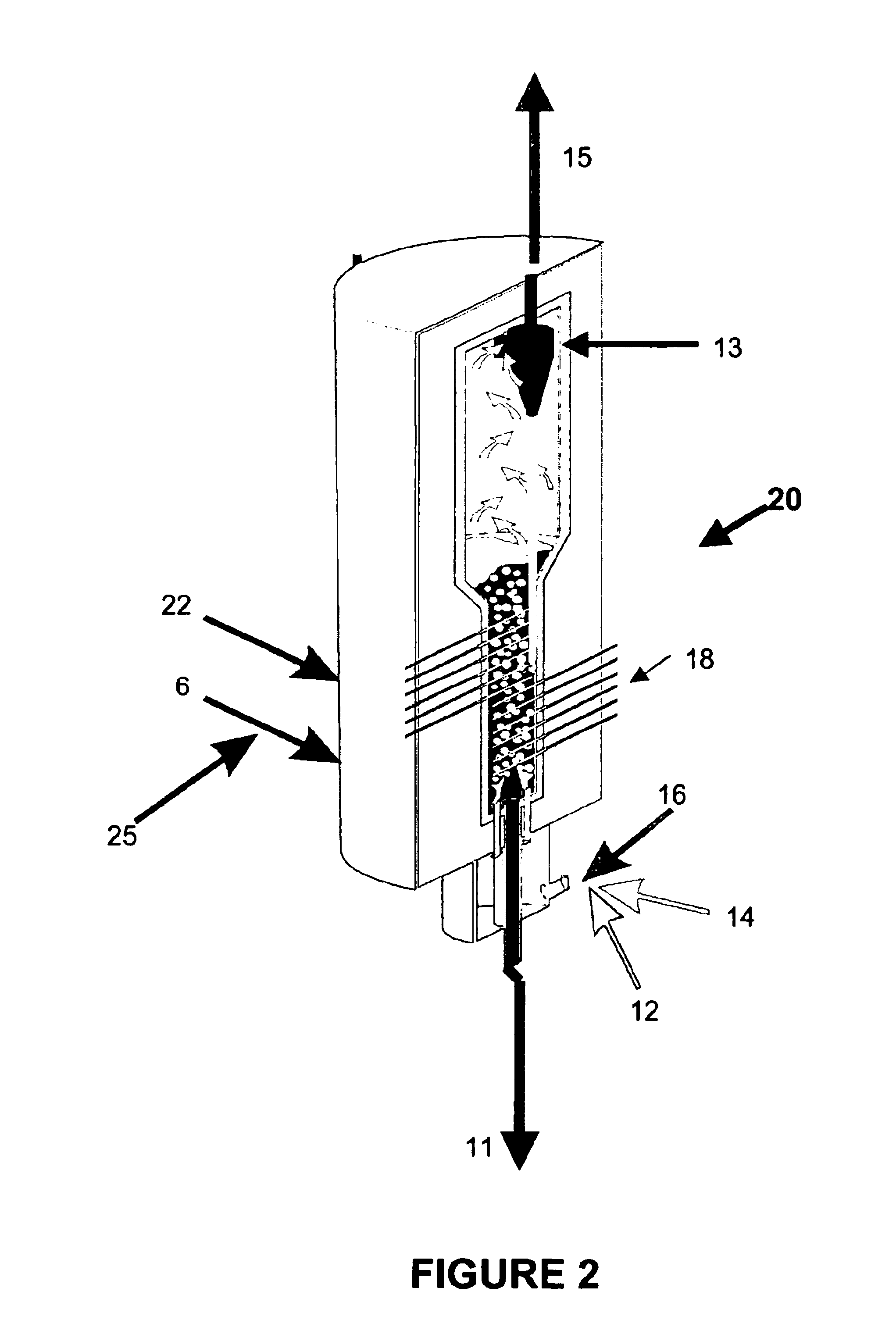

Multiple plasma generator hazardous waste processing system

A waste processing system is provided herein which entails the use of at least one fixed-position plasma arc generator for primary processing and at least one moveable plasma arc generator for secondary processing assistance and / or final conditioning of the slag prior to exit from the reactor vessel. This optimum processing environment is provided by control of reactor vessel configuration and real time control of processing characteristics to ensure maximum processing efficiency.

Owner:PLASCO ENERGY GROUP INC

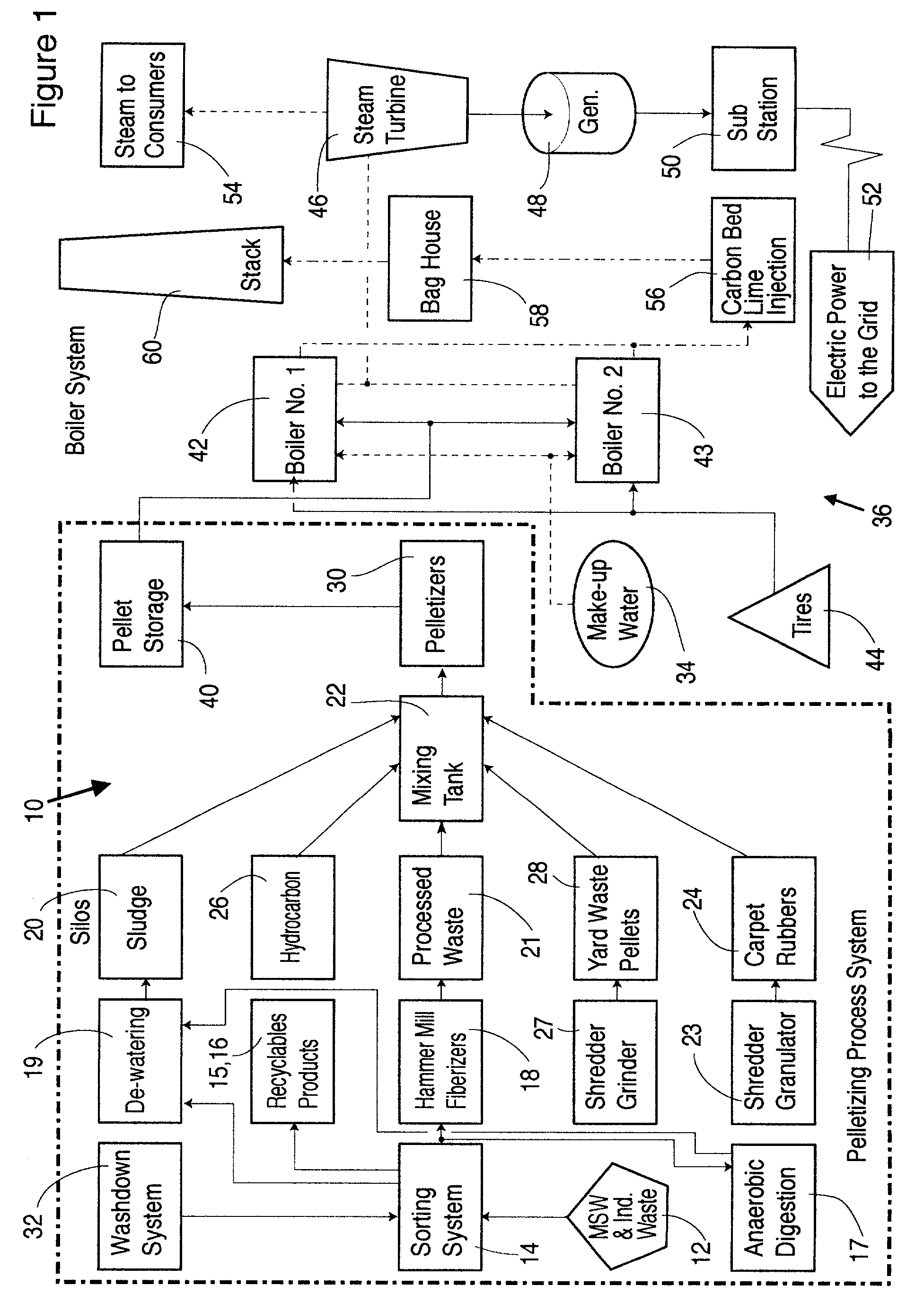

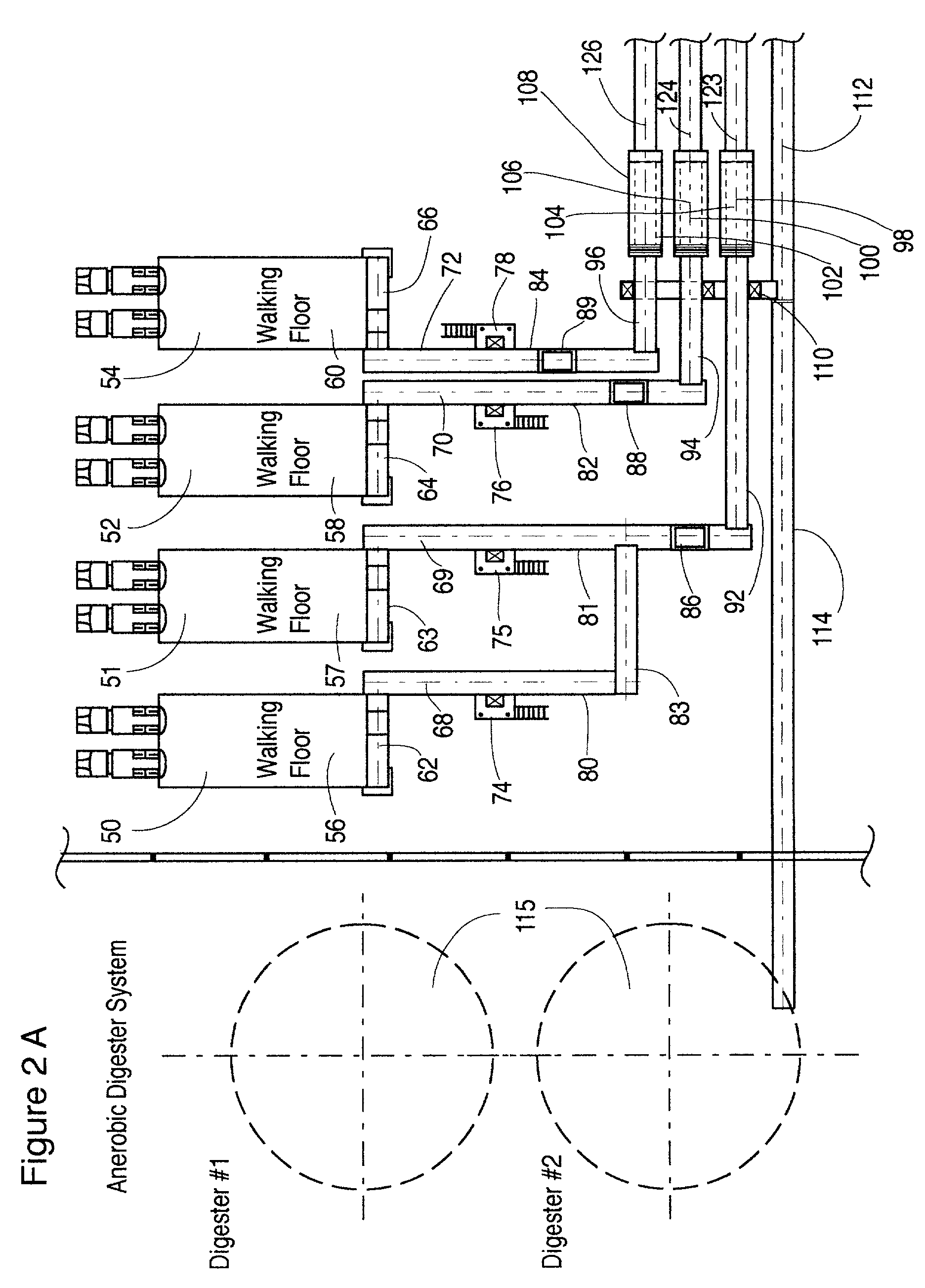

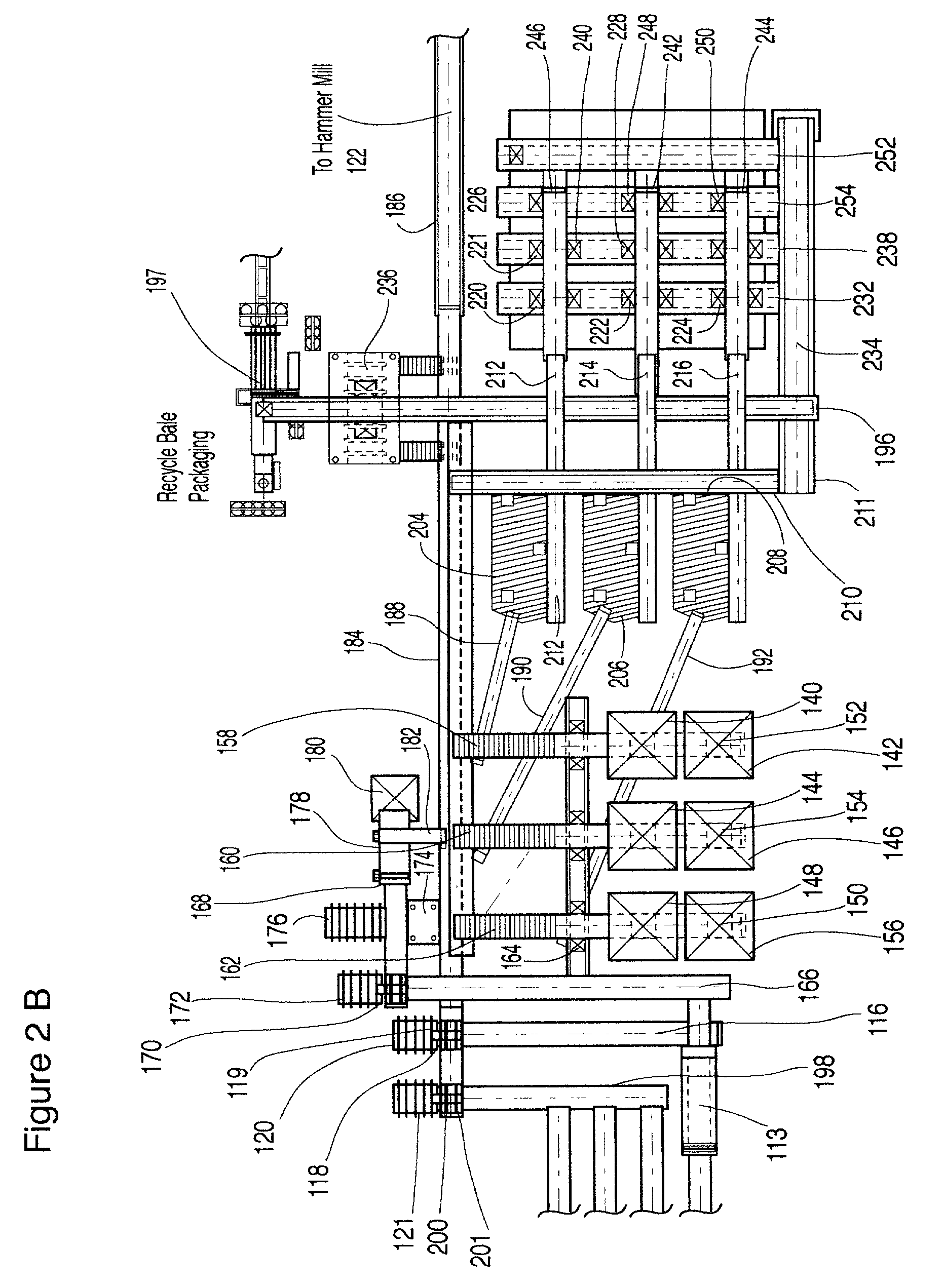

Conversion of municipal solid waste to high fuel value

InactiveUS7252691B2Increasing value of such fuelHigh fuel valueBiofuelsSolid fuelsEnvironmental engineeringUrban solid waste

A combustible pellet comprising municipal solid waste. The pellet has a water content of less than 10% by weight and a fuel value of at least 10,000 BTU. A process for the forming of a combustible pellet from municipal solid wastes, comprising the steps of removing solid hazardous waste from said municipal solid waste; subjecting the municipal solid waste so obtained to at least one step to separate recyclable products therefrom; and subjecting the resultant product to a shredding and a pulverizing step. A fluff with a water content of less than 10% by weight is obtained. The fluff is compacted to form a combustible pellet.

Owner:SENTINEL WASTE INT

Resource utilization process of organic hazardous waste

ActiveCN111185460AHarmlessAchieve reductionSolid waste disposalTransportation and packagingFluid phaseSlag

The invention discloses a resource utilization process of organic hazardous waste. The resource utilization process includes the steps that classified storage and treatment of solid-phase, solid-liquid mixing and liquid-phase organic hazardous waste are carried out; solid-phase crushing, grinding and screening treatment is carried out; solid-liquid mixing is carried out after solid-liquid separation, solid-phase grinding and liquid-phase sedimentation separation treatment is carried out; direct liquid-phase sedimentation is carried out; then after solid-liquid mixing, a fluxing agent is addedfor stirring, a stabilizer and a dispersing agent are added for slurrying, the slurry is fed into a gasifier, and the obtained gas is used as fuel gas after being subjected to cooling, dedusting, spraying and desulfuration; slag tapping and vitrification slag discharge are carried out; and waste water is recycled. The resource utilization process has the beneficial effects that solid phase, solid-liquid mixing and liquid-phase comprehensive treatment, harmless treatment and slag discharge are realized.

Owner:杰瑞邦达环保科技有限公司

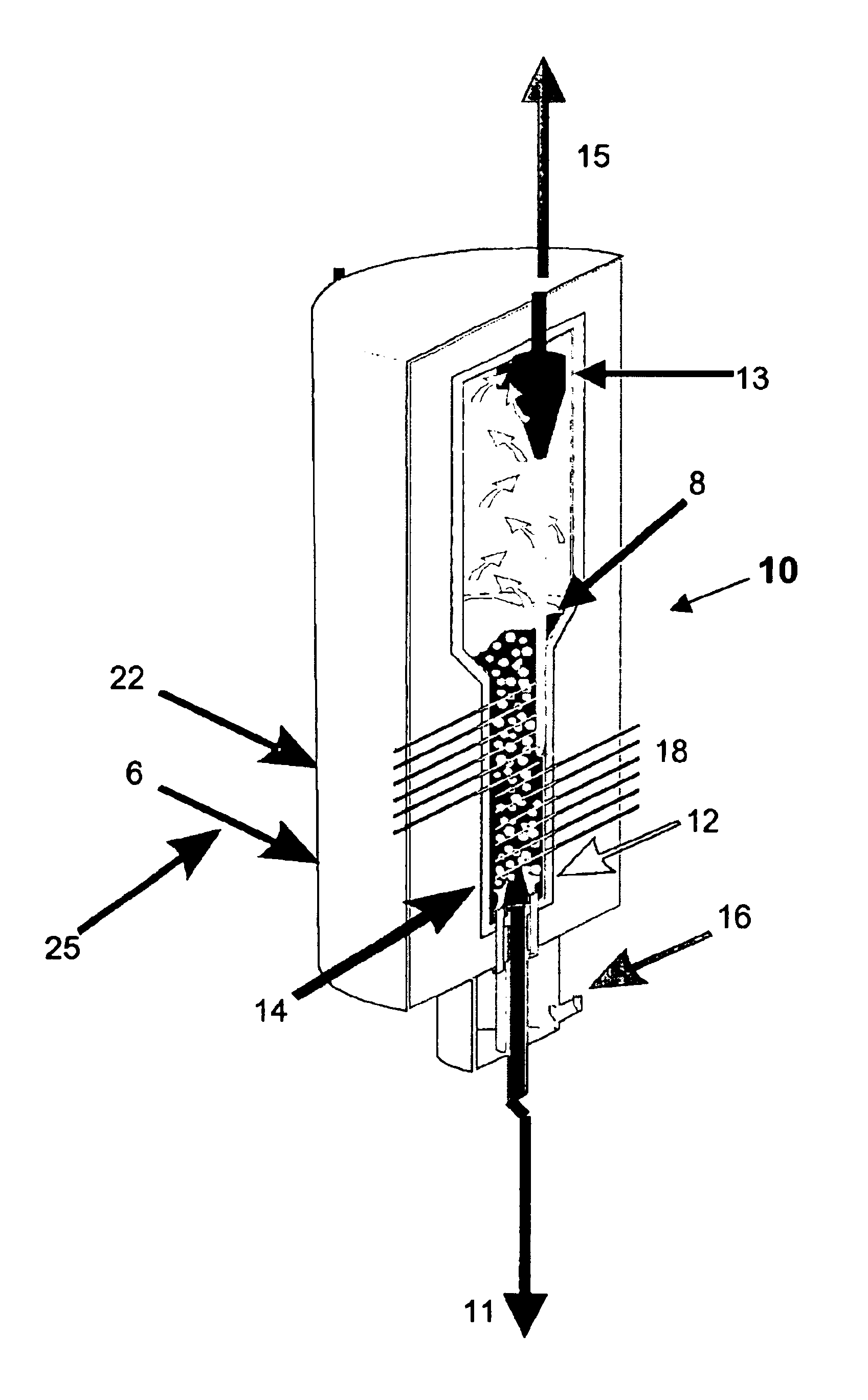

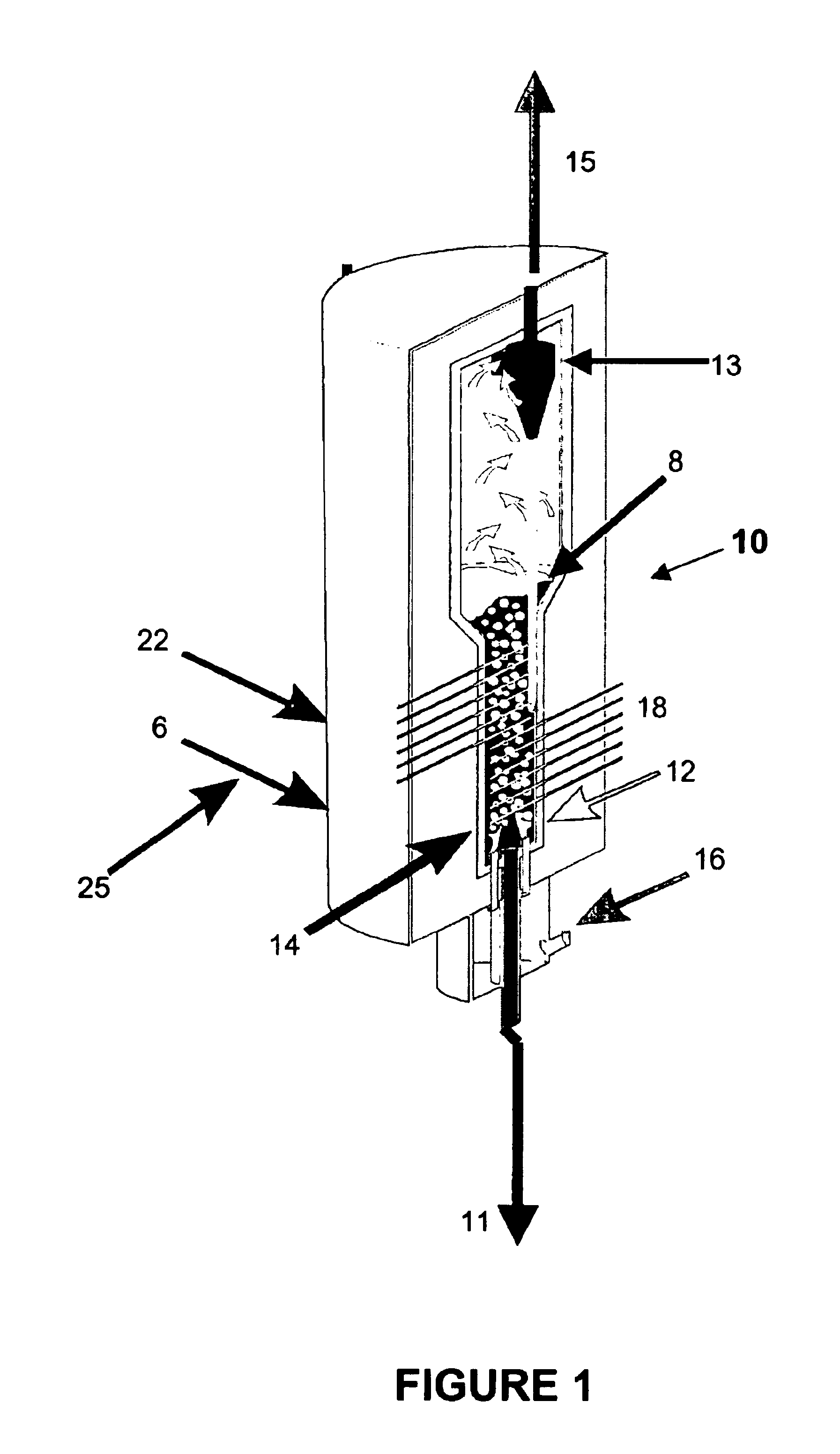

Disposable battery pack for a surgical drill; and method

A surgical procedure is disclosed utilizing a cordless surgical handpiece powered from a sterile battery pack that contains a battery in condition for immediate use without further charging or sterilization. The battery chemistry is based upon lithium / manganese dioxide, and the battery after a single use may be disposed of into non-hazardous waste. The compact surgical handpiece has a brushless DC motor and a manually operated external trigger for activating and controlling the motor operations. Interengaging sets of contacts on the handpiece and battery are adapted to become lockingly and conductively interengaged upon rotation of the battery pack relative to the handpiece, in a manner that rapidly achieves correct alignment of the parts and also ensures stable mechanical attachment and support during the surgical procedure.

Owner:MEDTRONIC INC

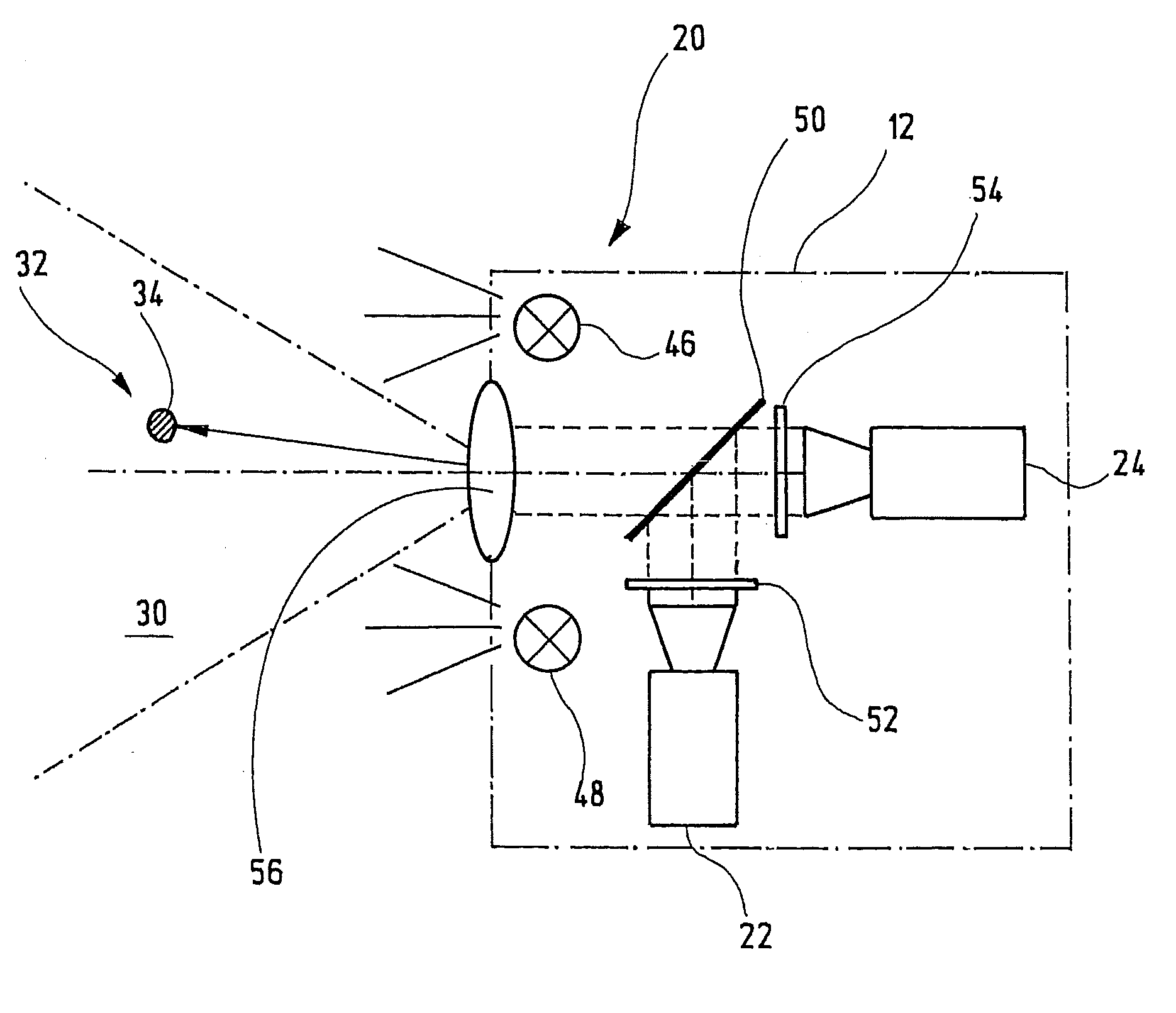

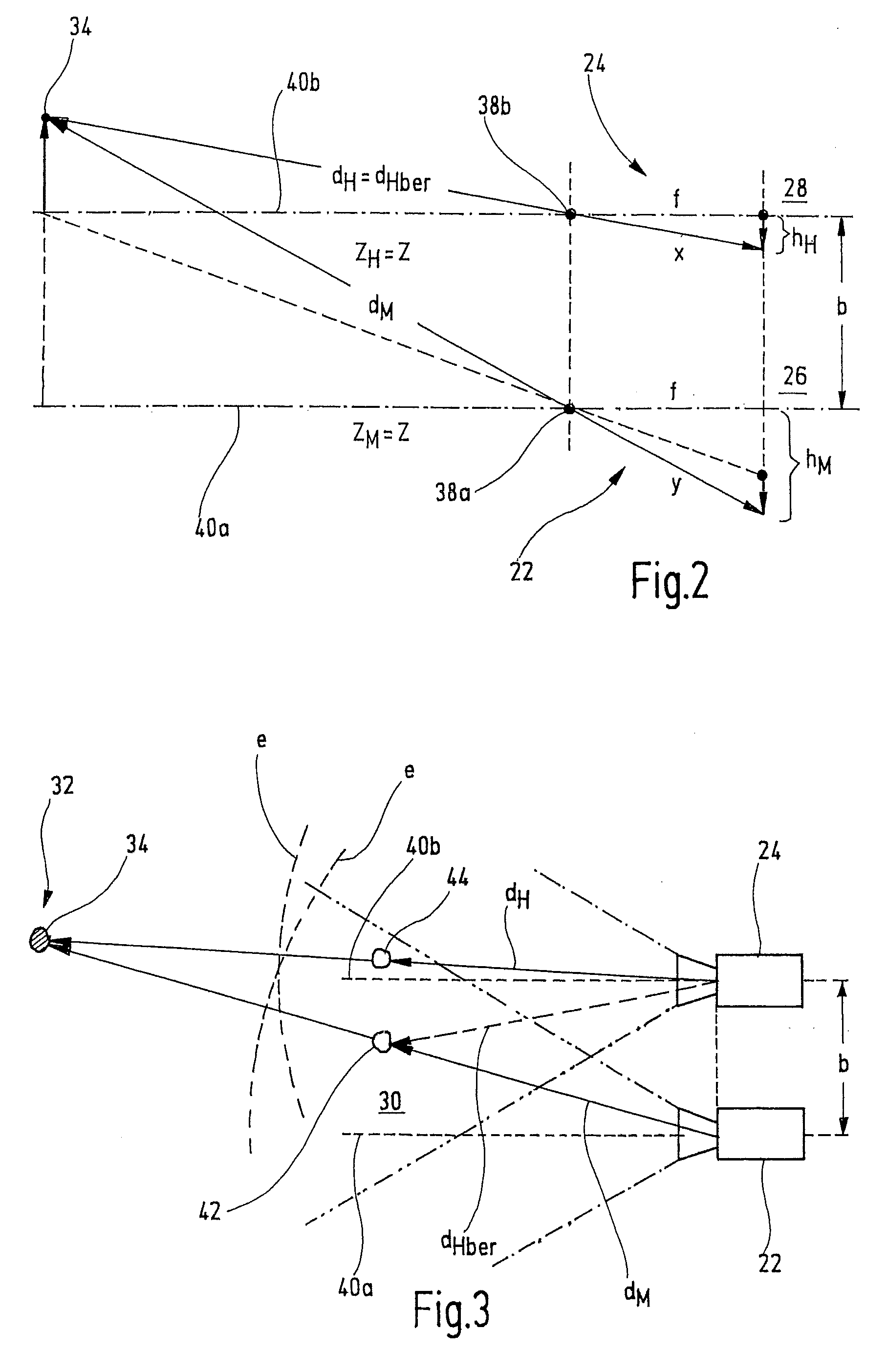

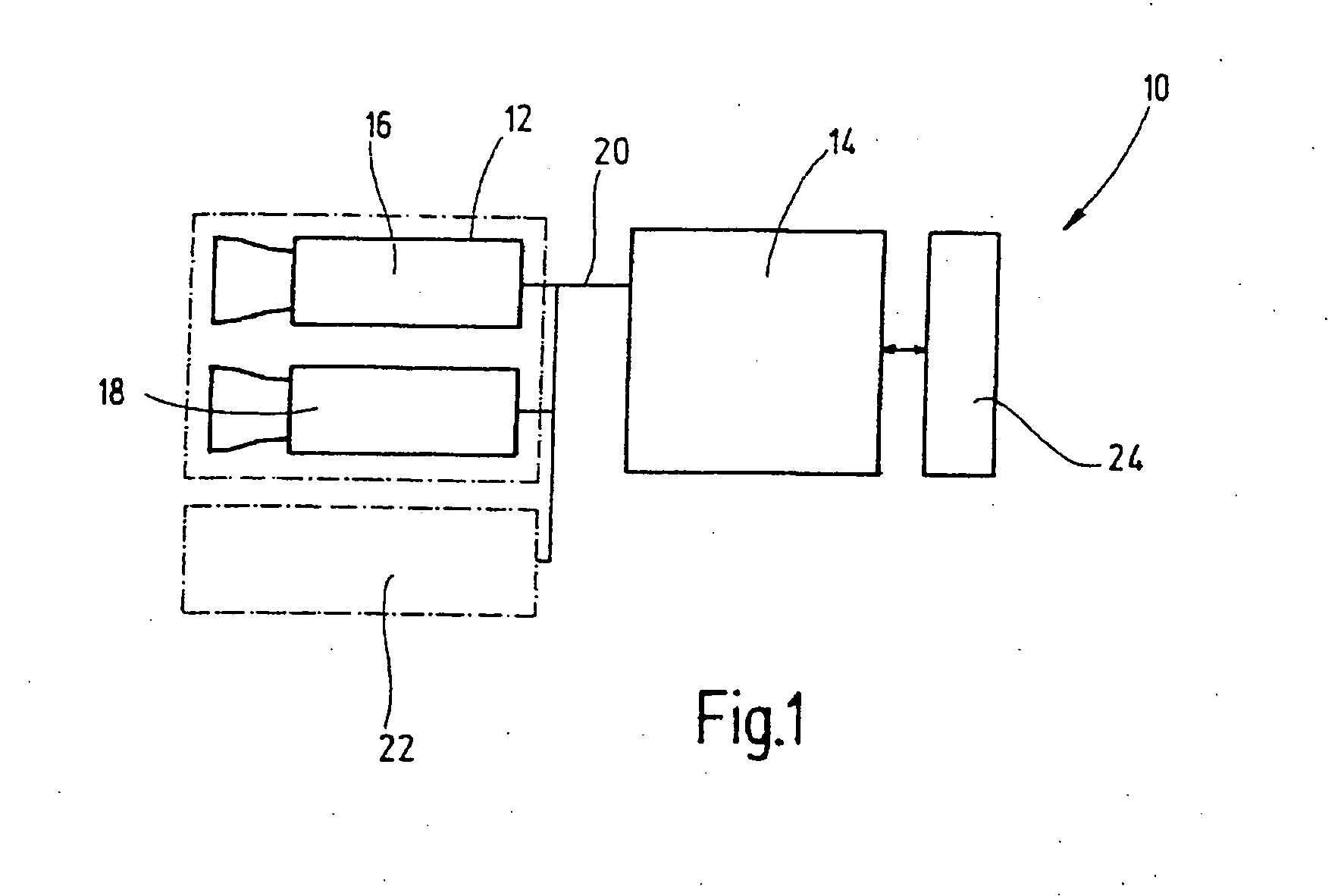

Apparatus and method for monitoring a spatial area, in particular for safeguarding a hazardous area of an automatically operated installation

ActiveUS20080273758A1Increased fail-safetySimple processOptical detectionEngineering safety devicesImage recordingLight signal

An apparatus for monitoring a spatial area, in particular for safeguarding a hazardous area of an automatically operated installation, comprises an illumination device which at least temporarily emits light signals into the spatial area. A first image recording unit records a first image of the spatial area. The first image recording unit comprises an image sensor having a plurality of pixels. An evaluation unit determines a distance value for at least one spatial area point, which is located in the spatial area and is imaged on at least one pixel, by means of a propagation type measurement. The propagation type measurement suffers from a limited unambiguity range. Therefore, a test device is designed to check the distance value by means of a reference distance value determined from a second image of said spatial area.

Owner:PILZ (COMPANY)

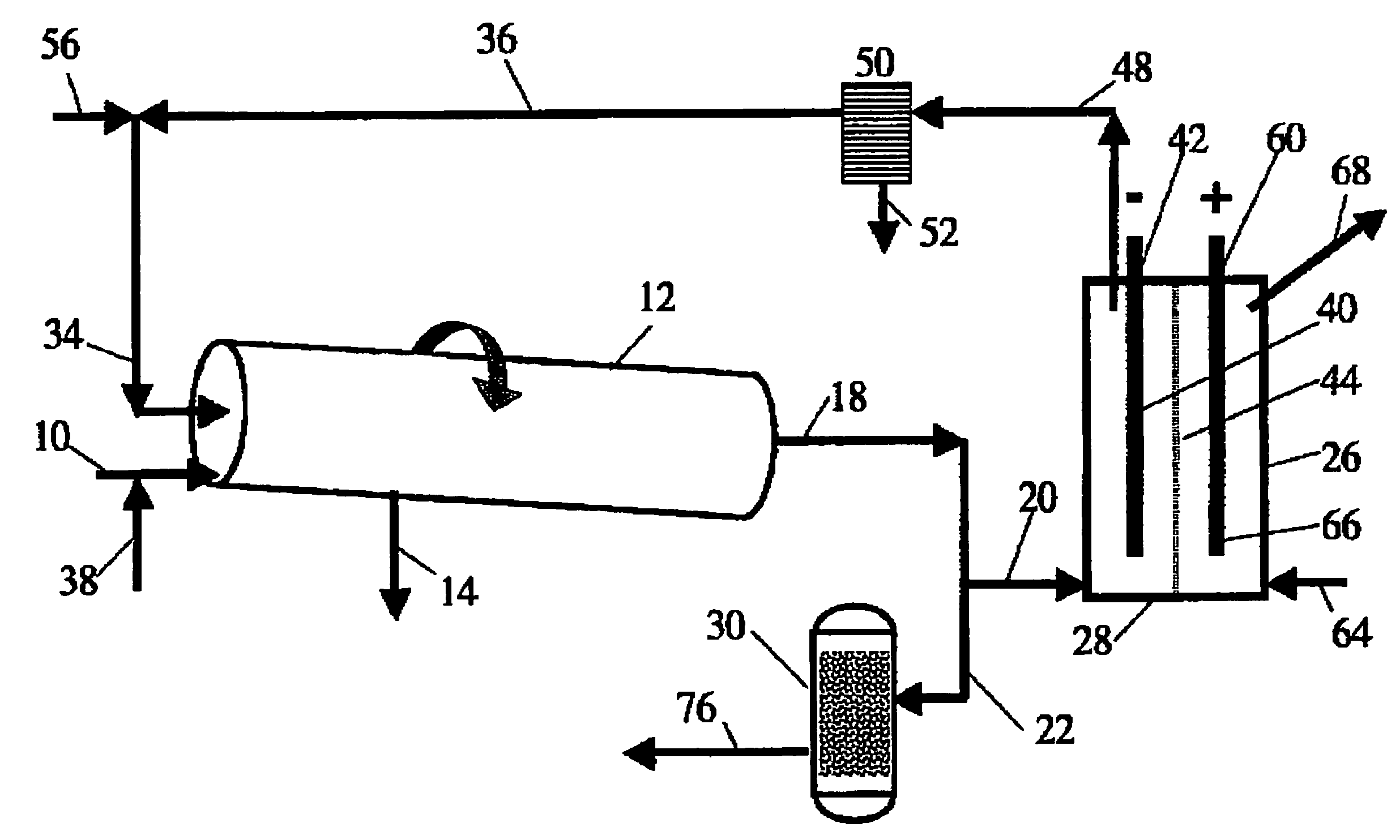

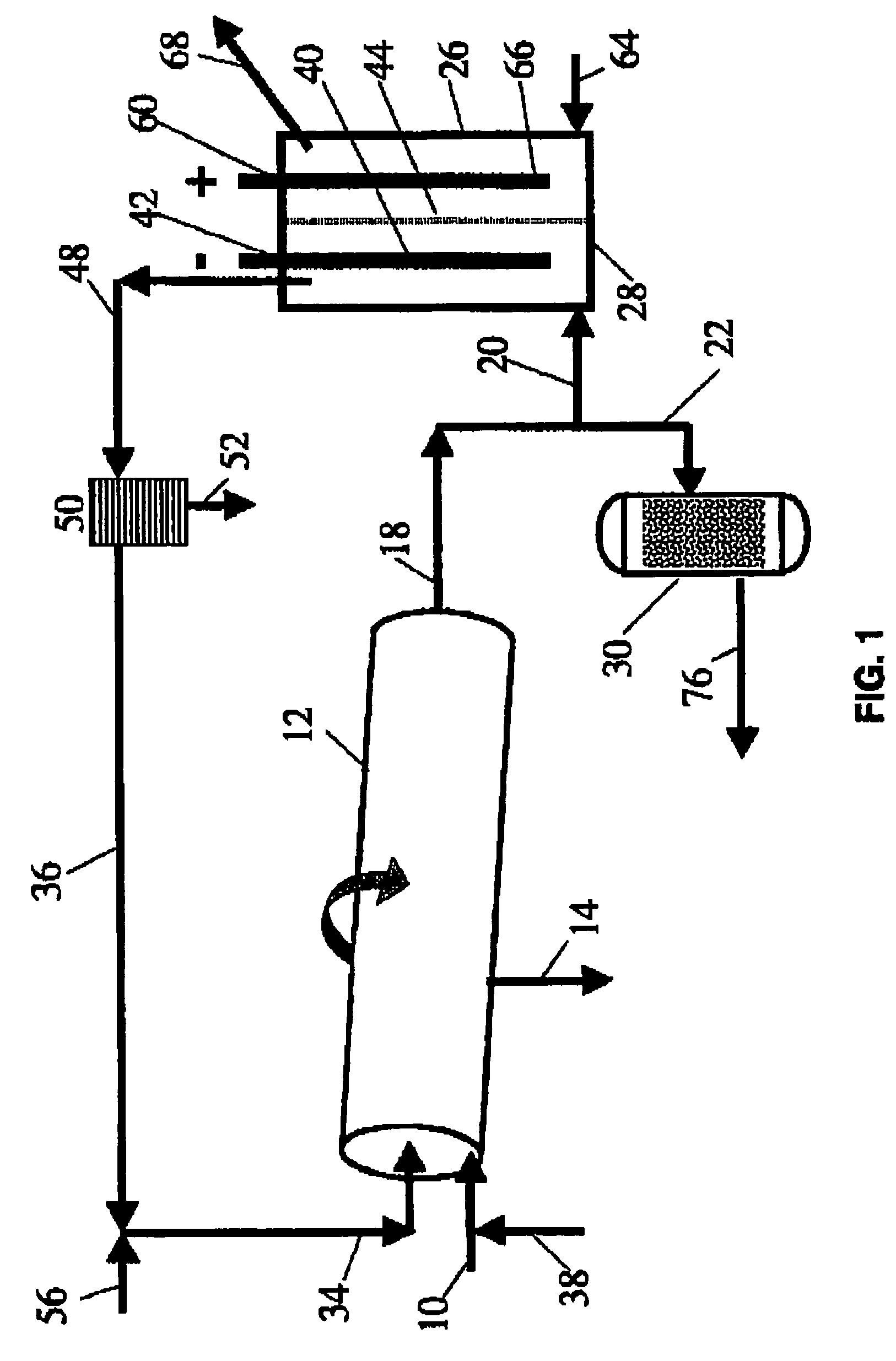

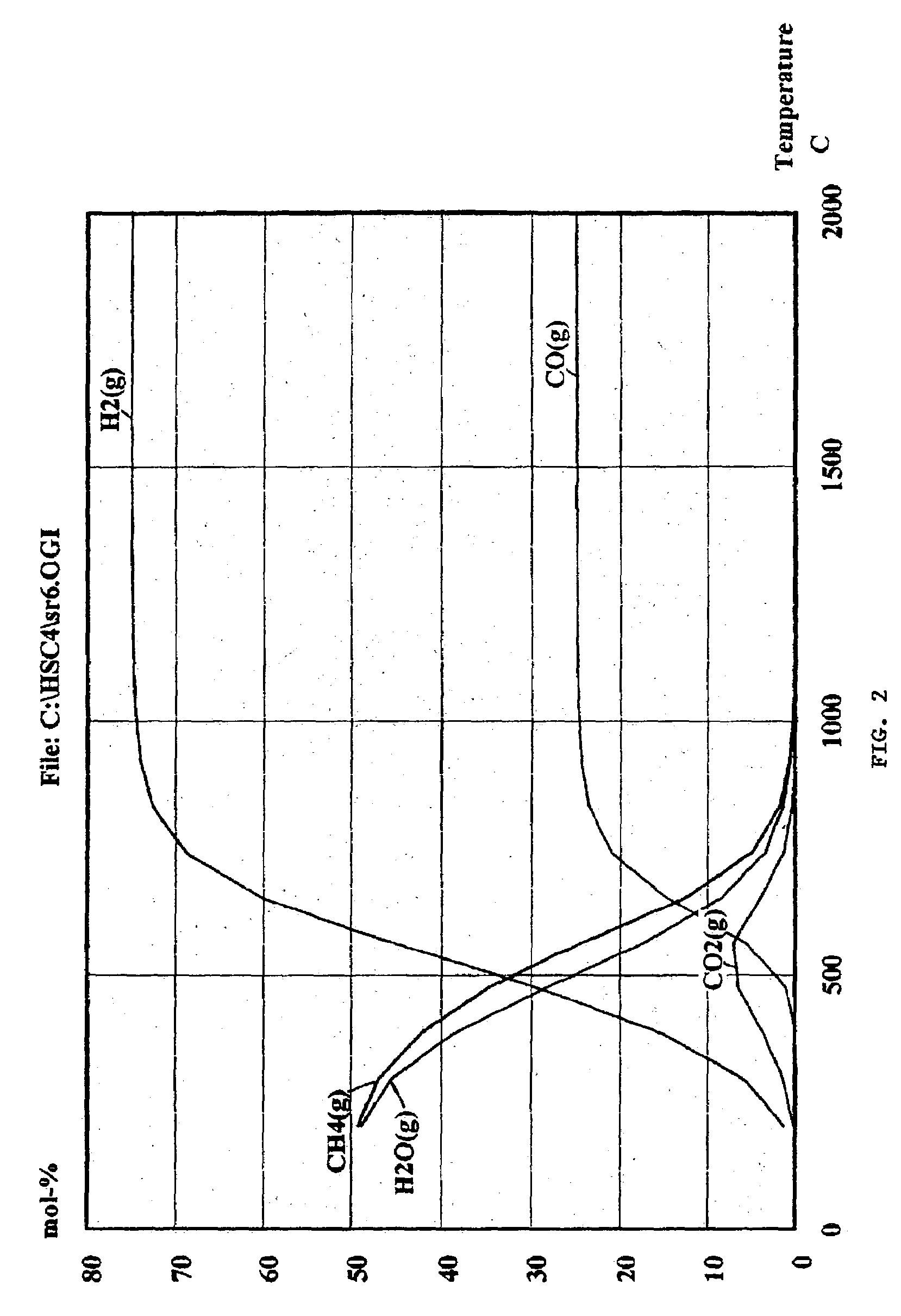

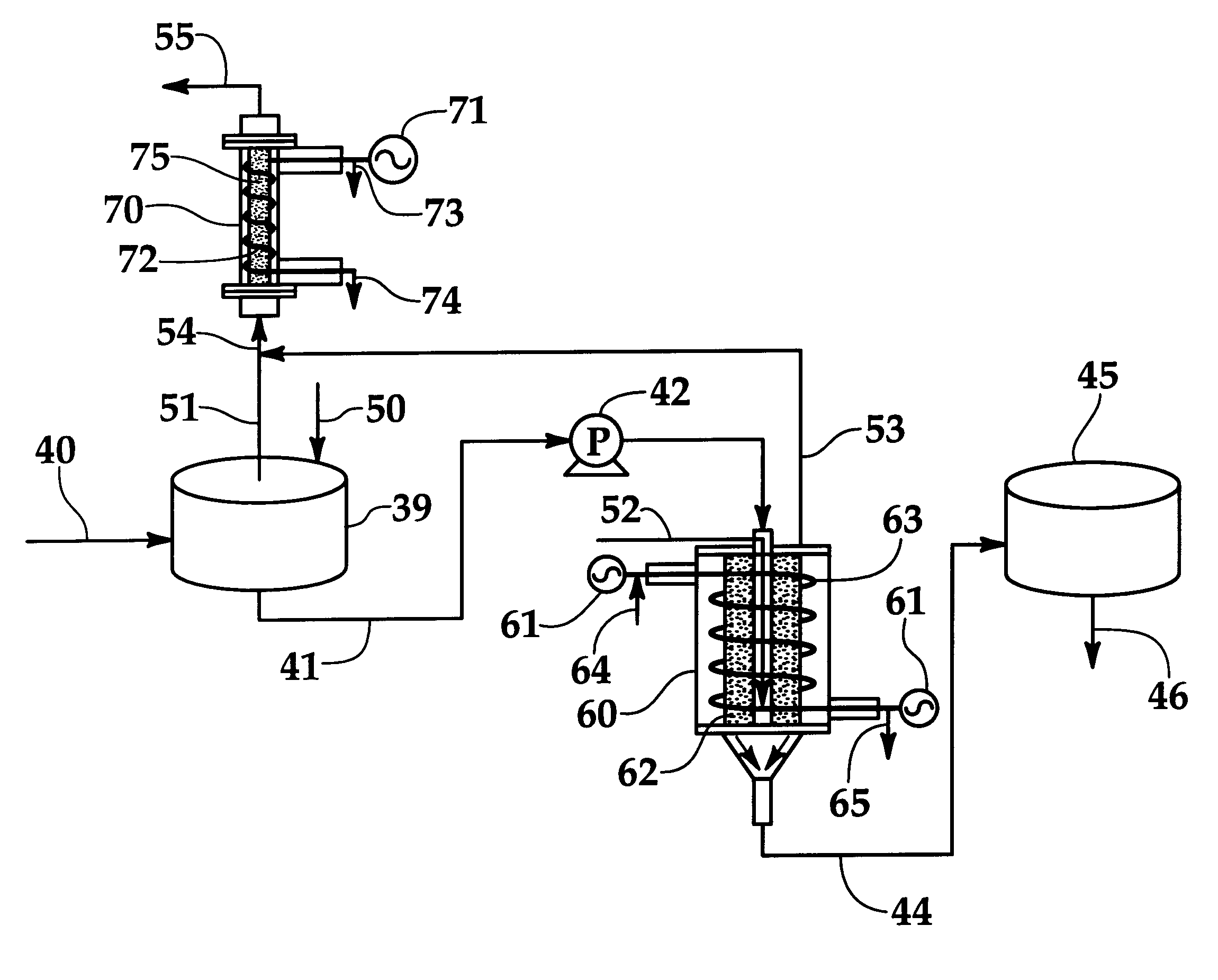

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

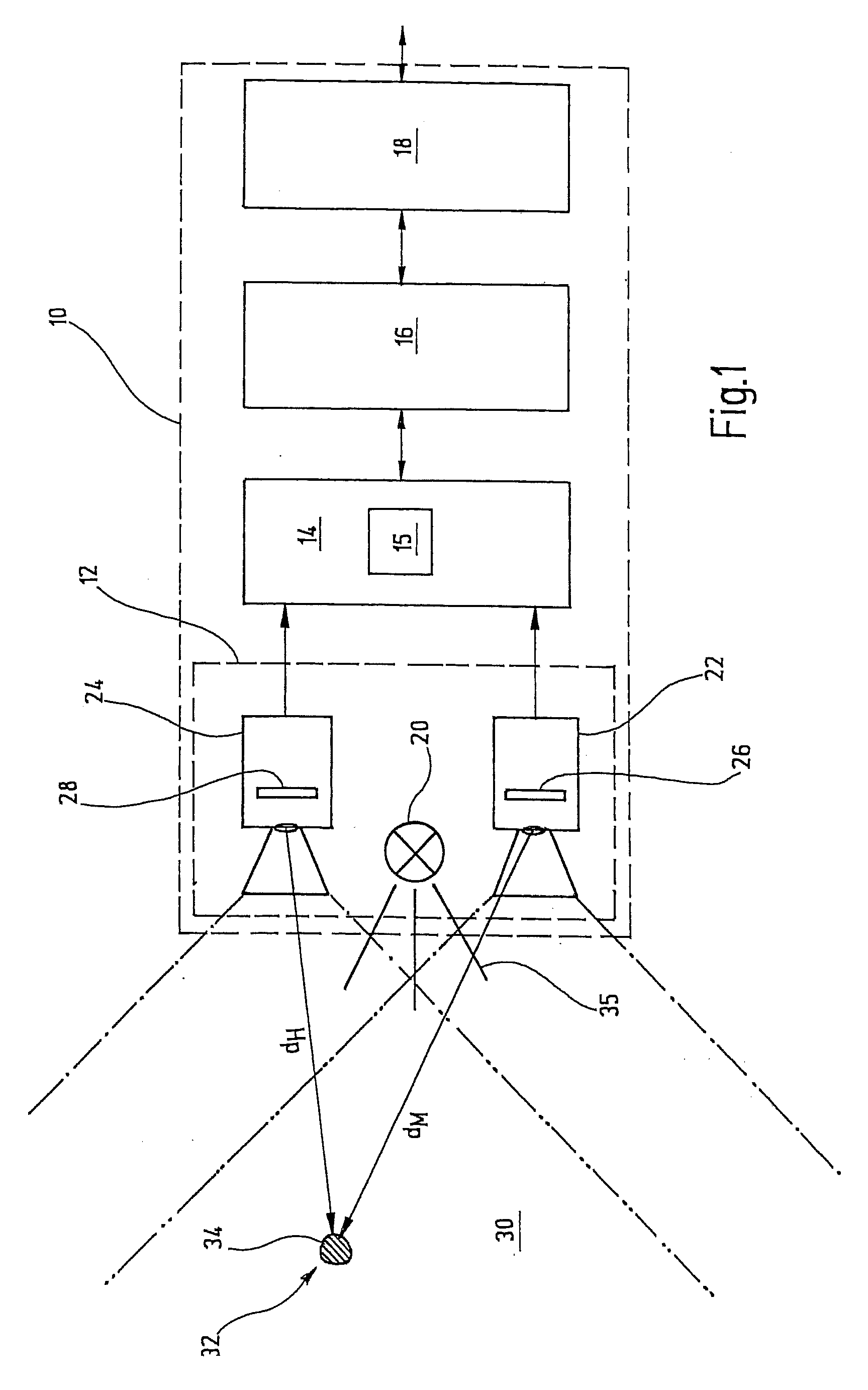

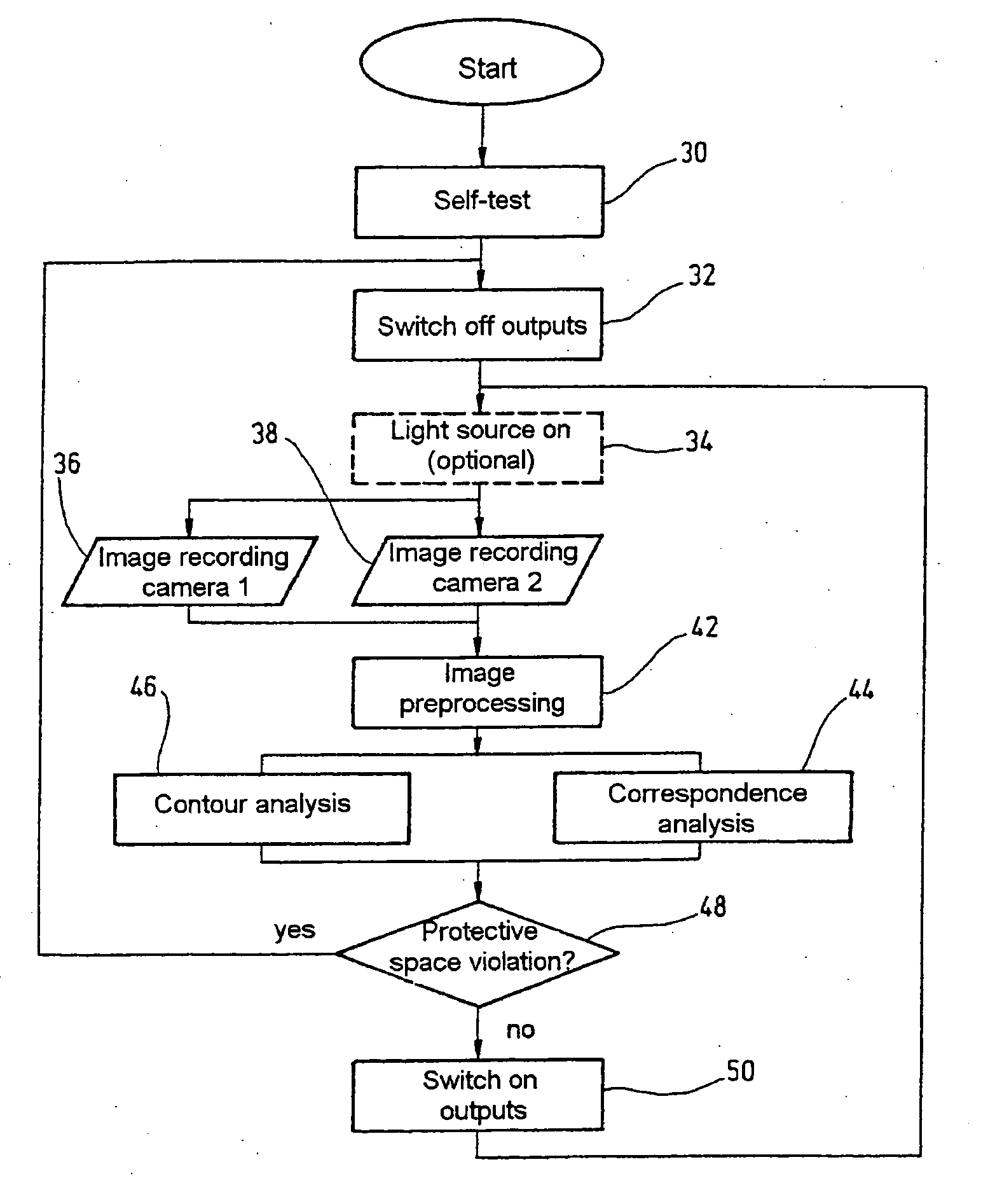

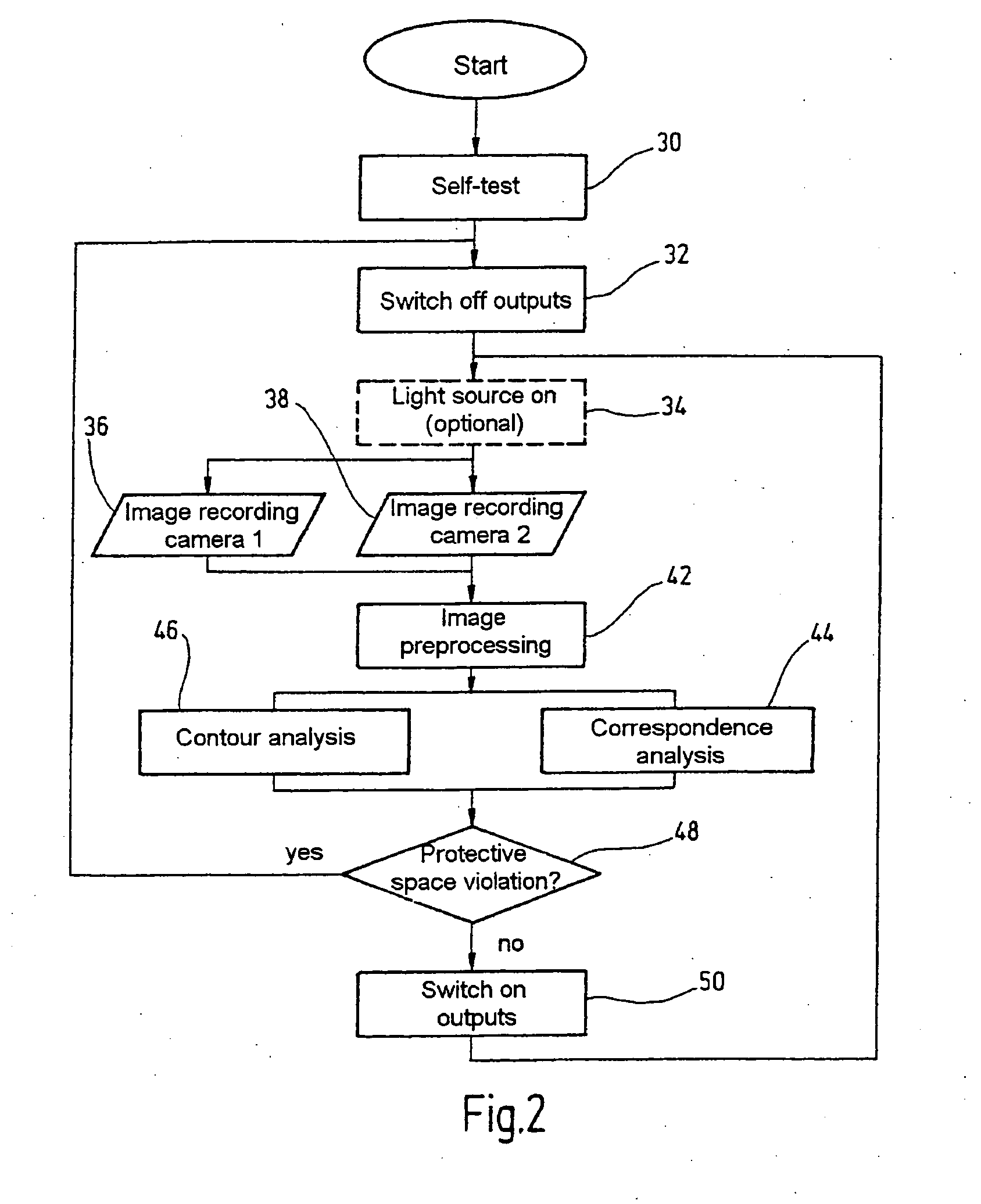

Method and device for safeguarding a hazardous area

InactiveUS20050207618A1Solve the lack of reliabilityImage enhancementProgramme-controlled manipulatorForeign matterImage recording

In order to safeguard a hazardous area, in particular the hazardous area of an automatically operating machine, images of the hazardous area are recorded with at least a first and a second image recording unit that are arranged offset from one another. The images of the scene are subjected to three-dimensional scene analyses using different three-dimensional scene analysis methods, and the hazardous area is safeguarded when at least one of the scene analysis methods detects a foreign object.

Owner:PILZ (COMPANY)

Process for microwave decomposition of hazardous matter

InactiveUS6187988B1Promote oxidationNitrogen compoundsLiquid separation by electricityActivated carbonHydrazine compound

This process occurs in the presence of activated carbon or its equivalent by decomposing adsorbed hazardous materials, such as hydrazine and microorganisms, on the carbon surface by radiofrequency energy in the microwave range at near ambient conditions of temperature and pressure. Further microwave oxidation to nonhazardous gases occurs in the presence of a microwaves enhanced oxidation catalyst.

Owner:CHA CHANG YUL

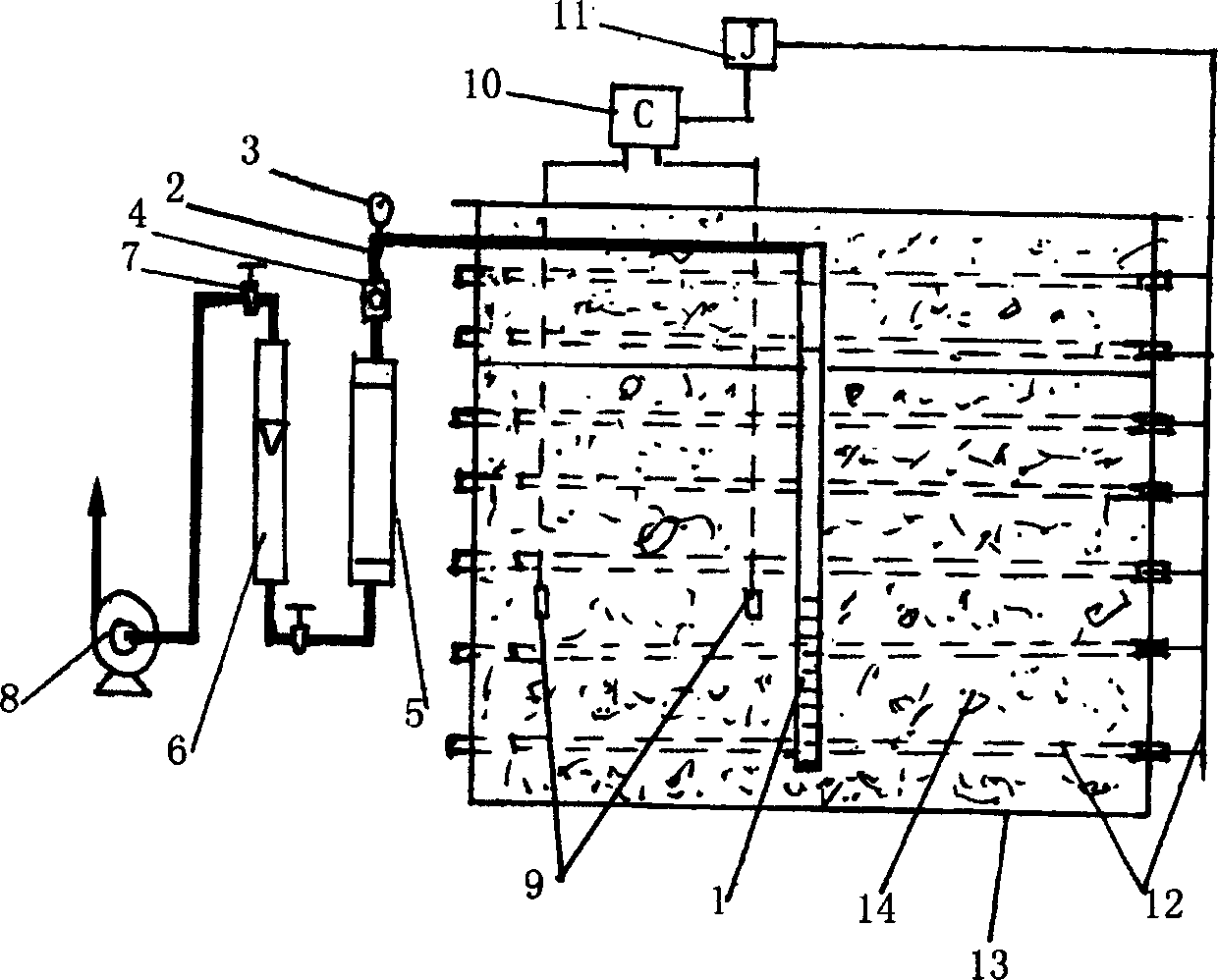

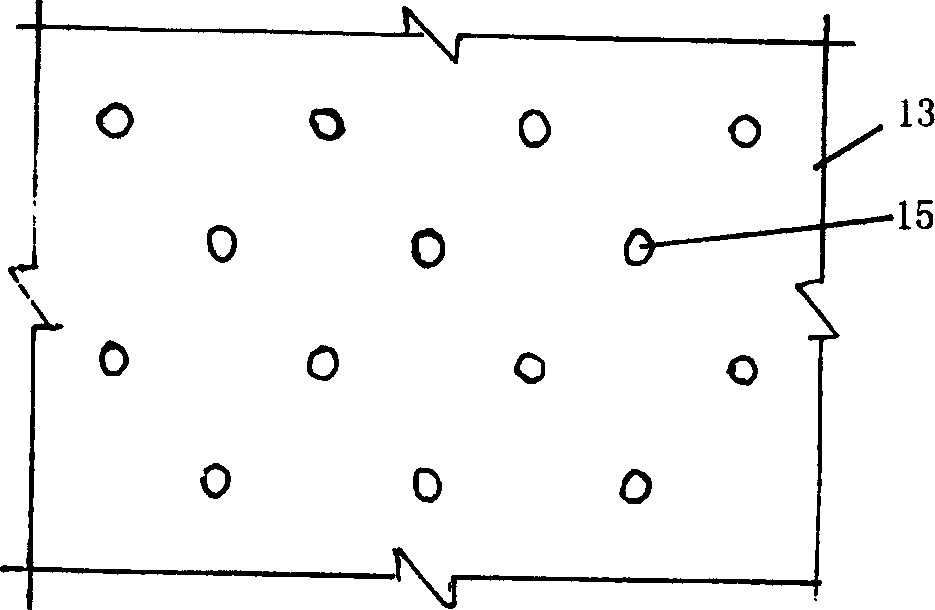

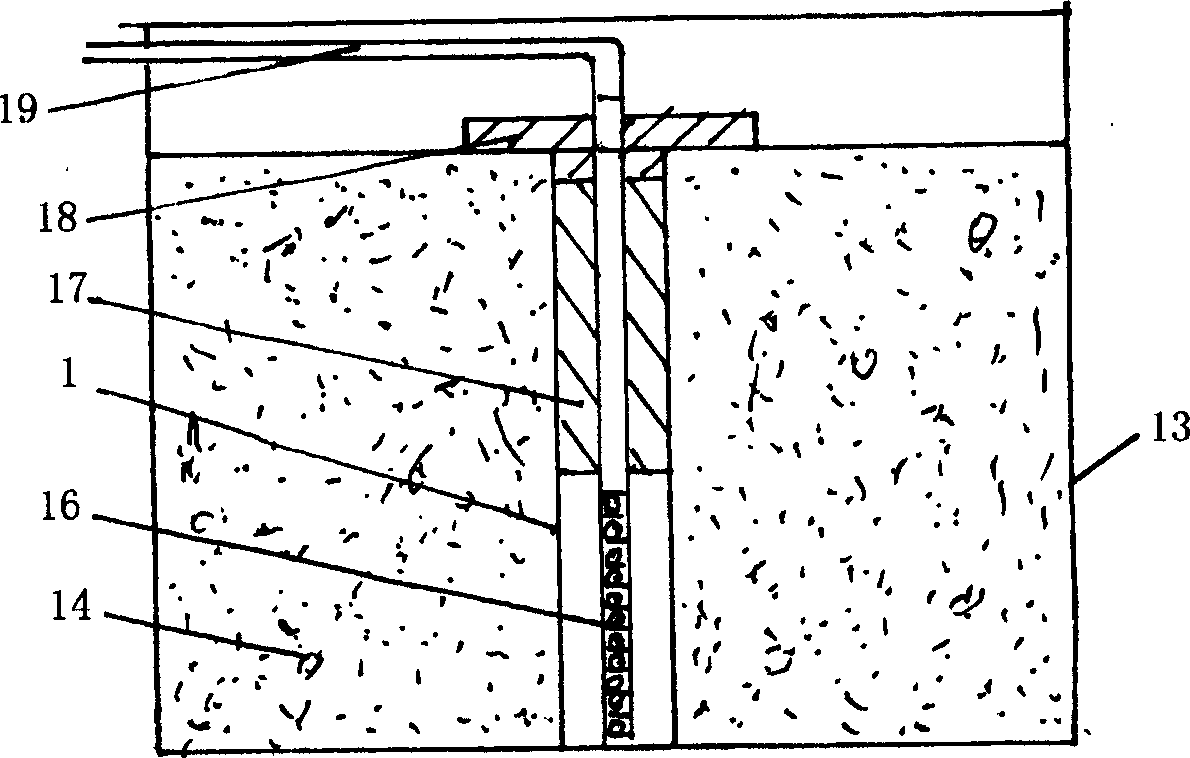

Kerb treating process and device for volatile and semi-volatile organic substance polluted soil

InactiveCN1586747AIncrease relative volatilityConvenient and fast off-site managementContaminated soil reclamationPollution soilFresh air

The outside treating process of polluted soil includes the following steps: excavating the polluted soil, filling the soil inside the treating apparatus, pumping with vacuum pump to form certain vacuum degree in the pumping well while intruding fresh air into soil to promote the volatilization of pollutant and taking out the volatile. The soil may be also heated to speed the volatilization. The treating apparatus consists of exhaust well with exhaust pipeline, temperature controlling sensor and heater embedded into soil pipe. The treated soil may be re-filled or used in other site.

Owner:TSINGHUA UNIV

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

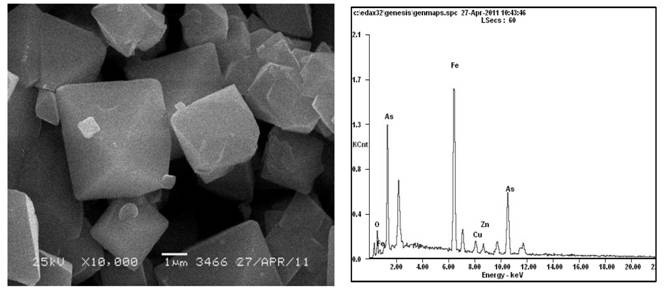

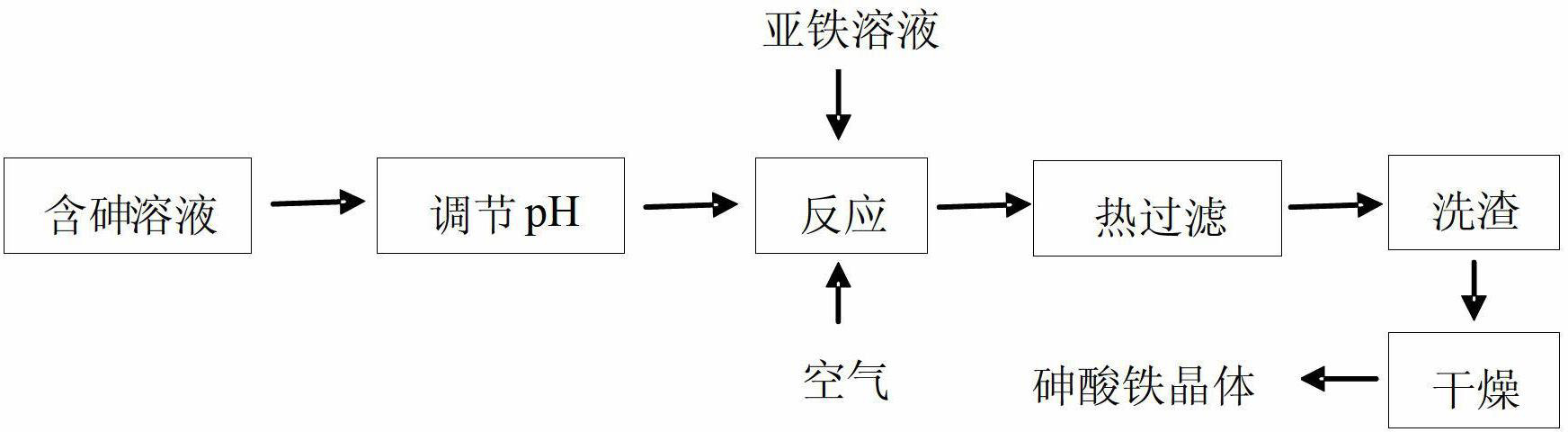

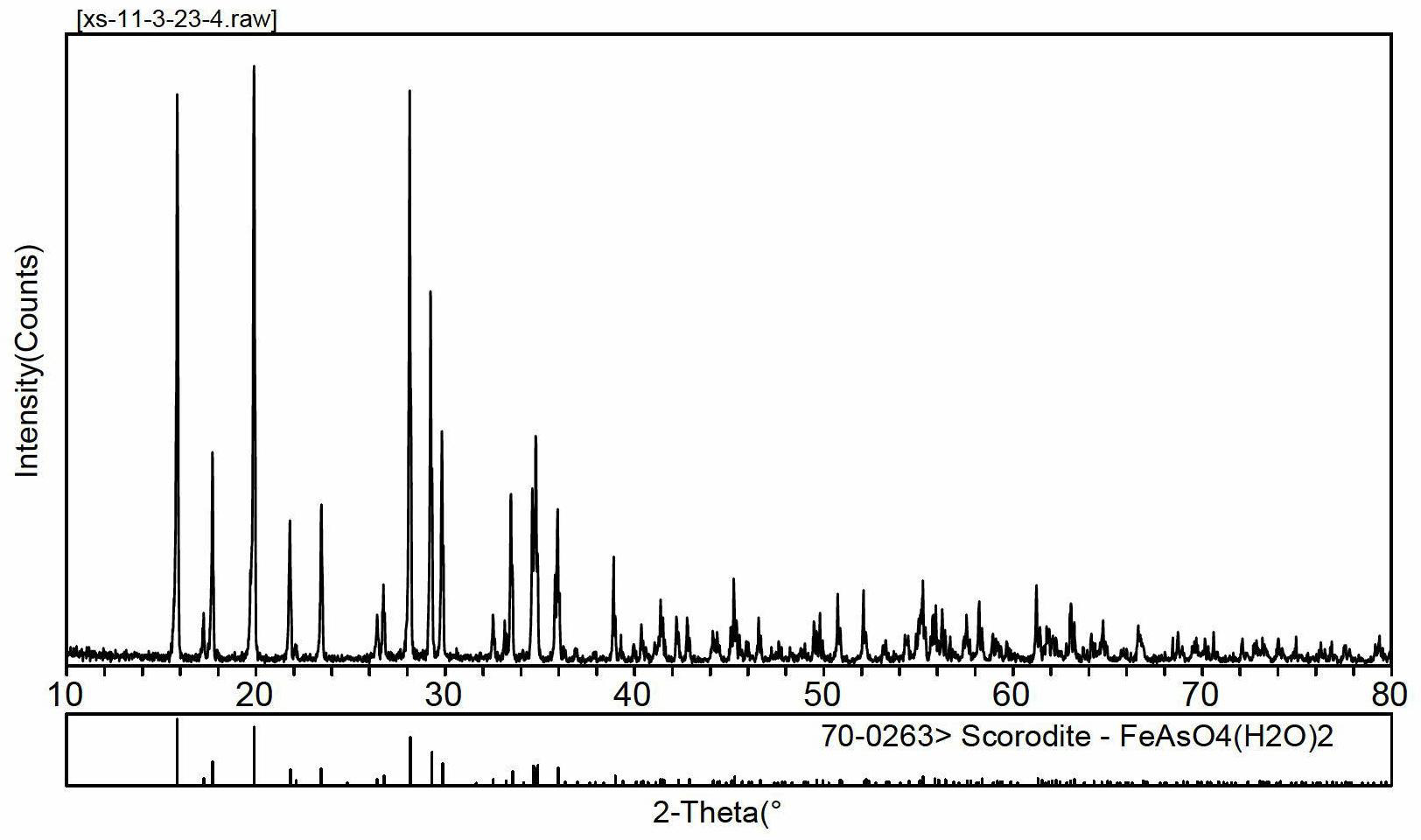

Method for precipitating and stabilizing As from As-containing solution

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

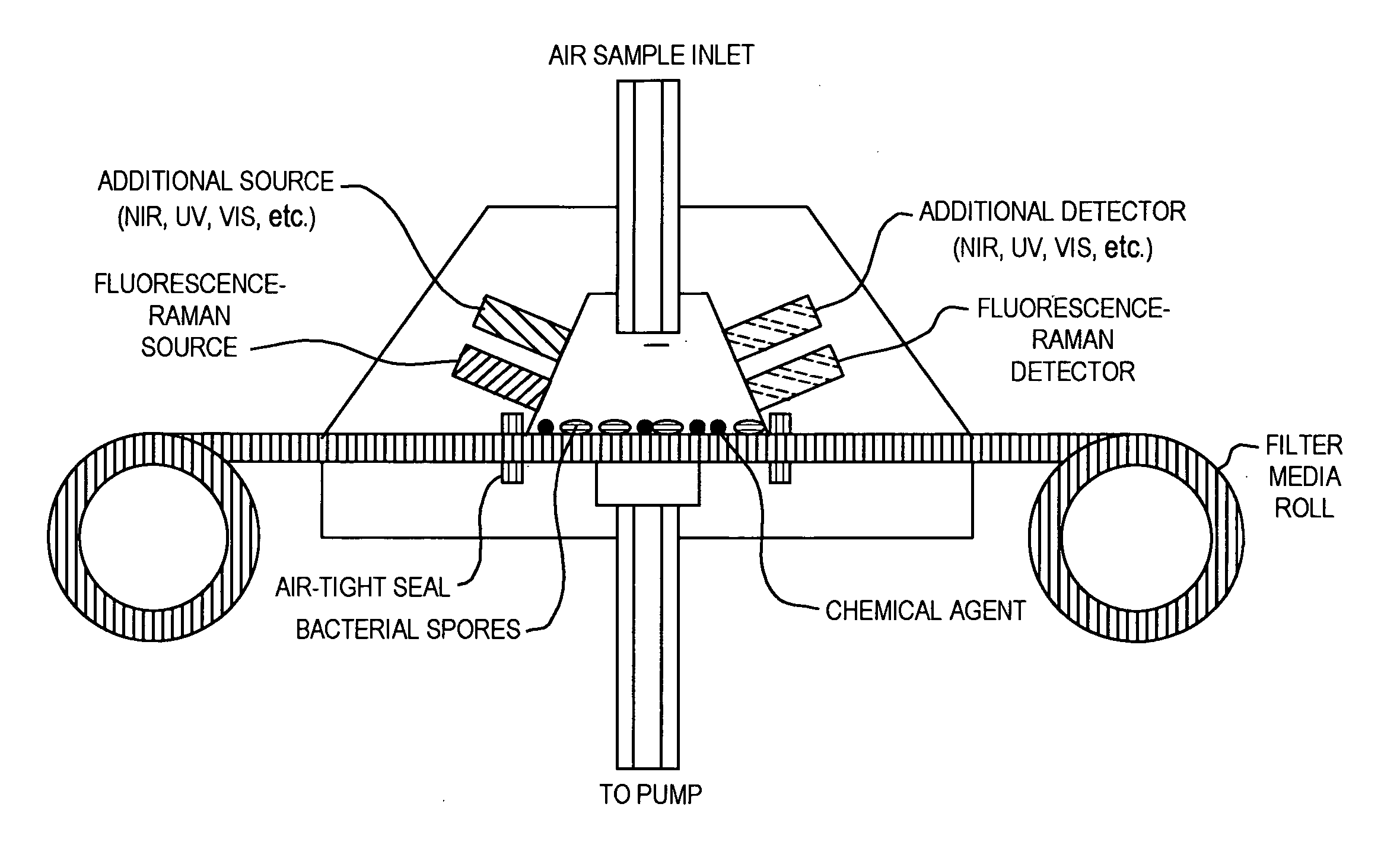

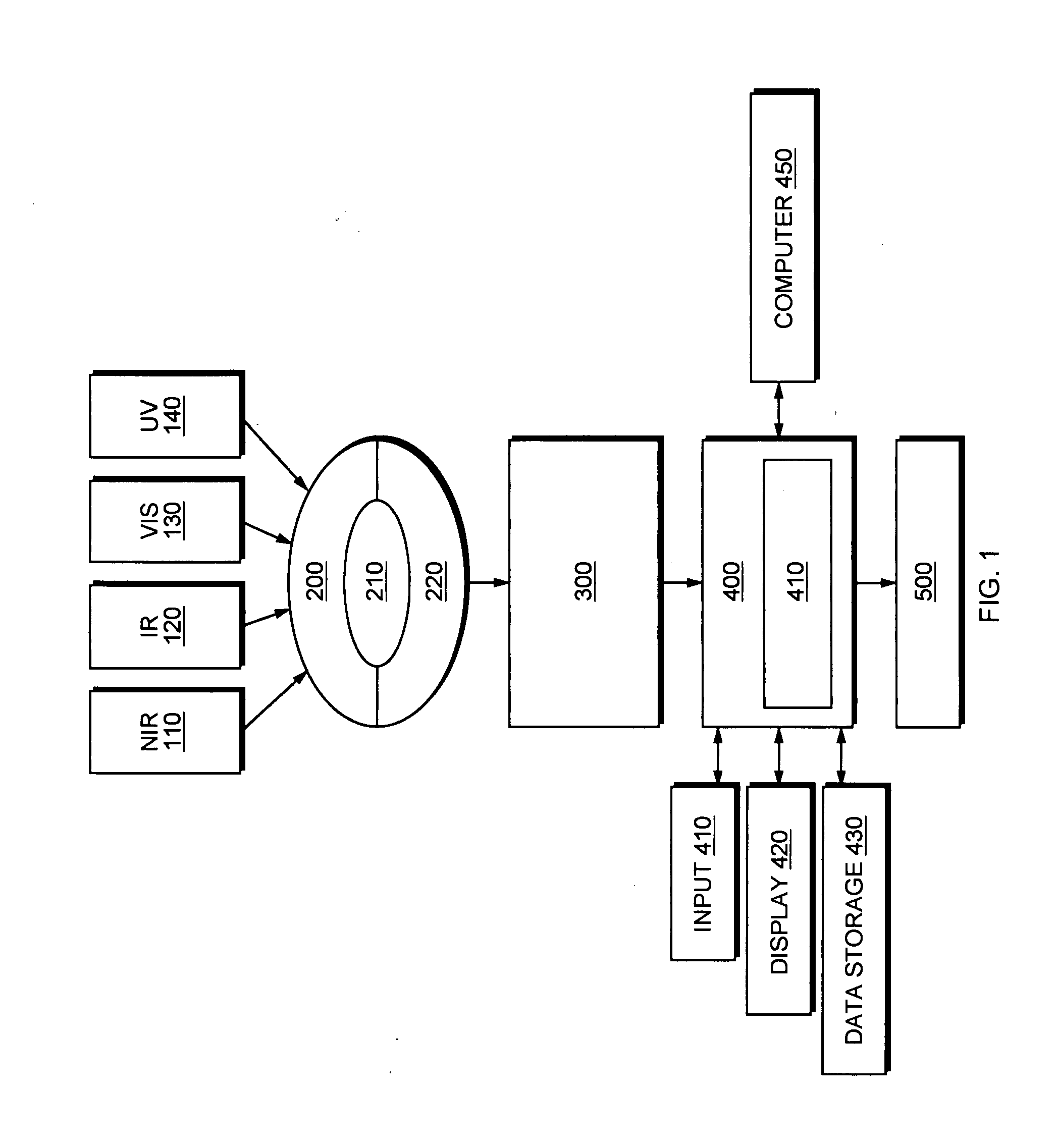

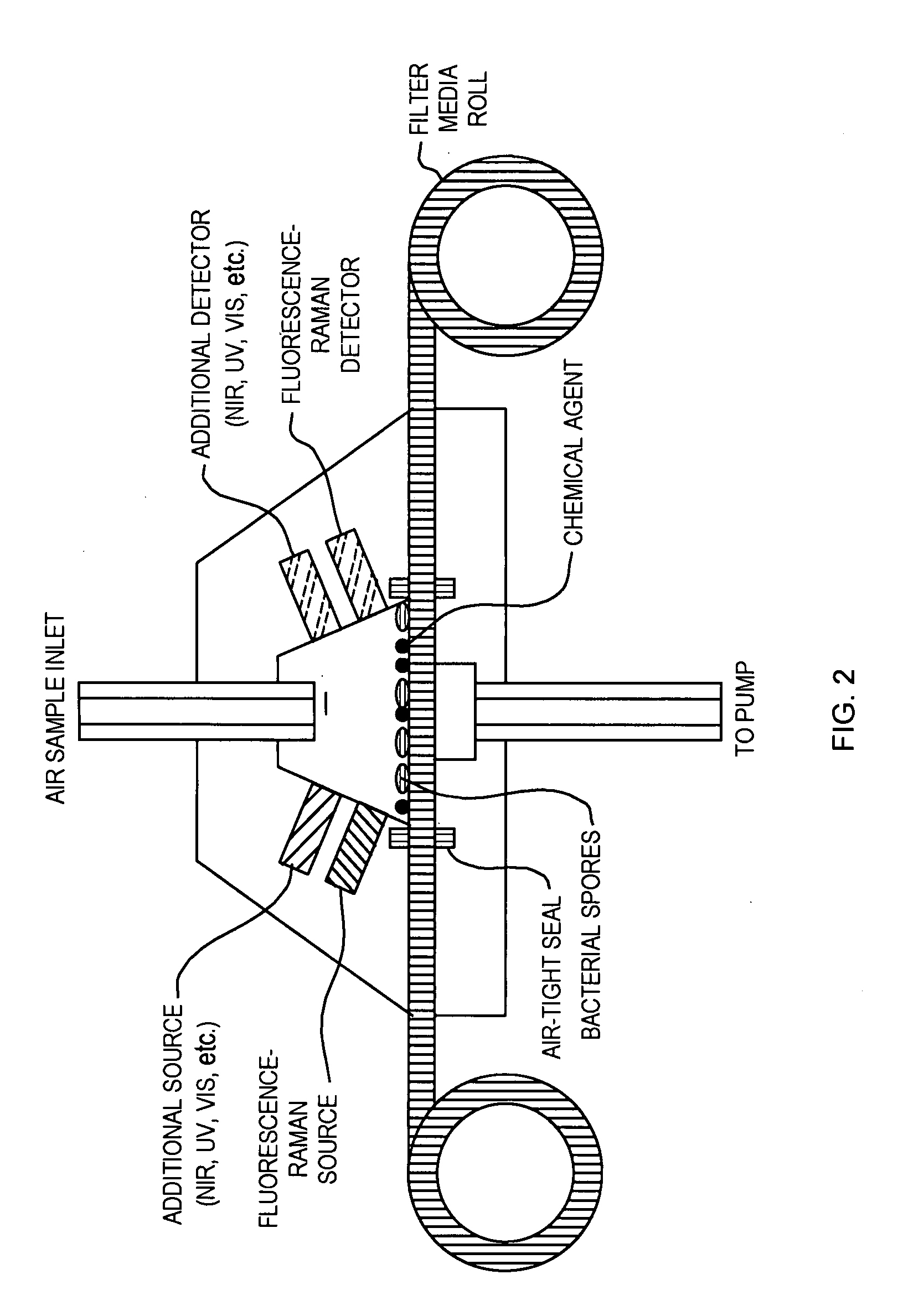

Multimodal method for identifying hazardous agents

ActiveUS20080192246A1Shorten the timeRadiation pyrometryRaman/scattering spectroscopyOptical propertySpectral analysis

The invention relates to apparatus and methods for assessing occurrence of a hazardous agent in a sample by performing multimodal spectral analysis of the sample. Methods of employing Raman spectroscopy for entities in a sample which exhibit one or more optical properties characteristic of a hazardous agent are disclosed. Devices and systems suitable for performing such methods are also disclosed.

Owner:CHEMIMAGE CORP

Fluid collection and disposal system having interchangeable collection and other features and methods relating thereto

InactiveUS20090005747A1Lower the volumeImprove convenienceHollow article cleaningMedical devicesBlood collectionCollection system

Various implementations of a fluid collection system having a flexible liner are disclosed. In one exemplary variation, the fluid collection system may include a flexible liner configured to collapse, a plurality of containers, back storage, specimen collection containers, and / or automatic connection to a suction source to reduce the volume of medical wastes, reduce the frequency of disposal cycles, reduce risk of exposure to potentially hazardous waste.

Owner:ALLEGIANCE CORP

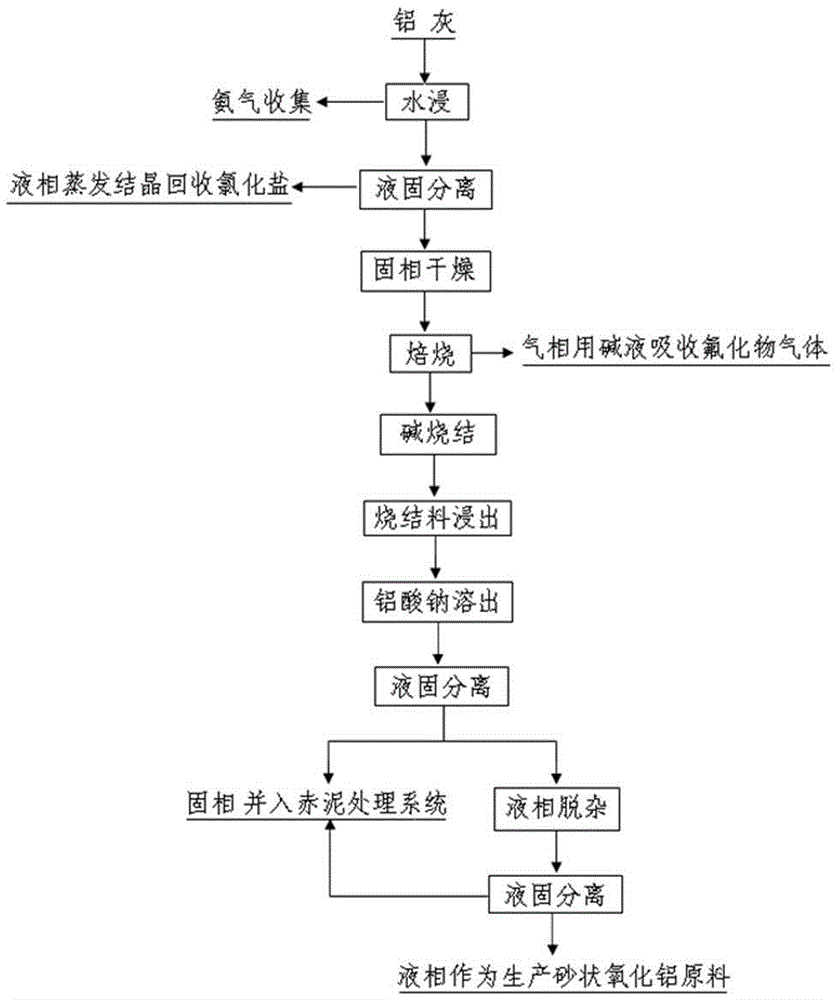

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

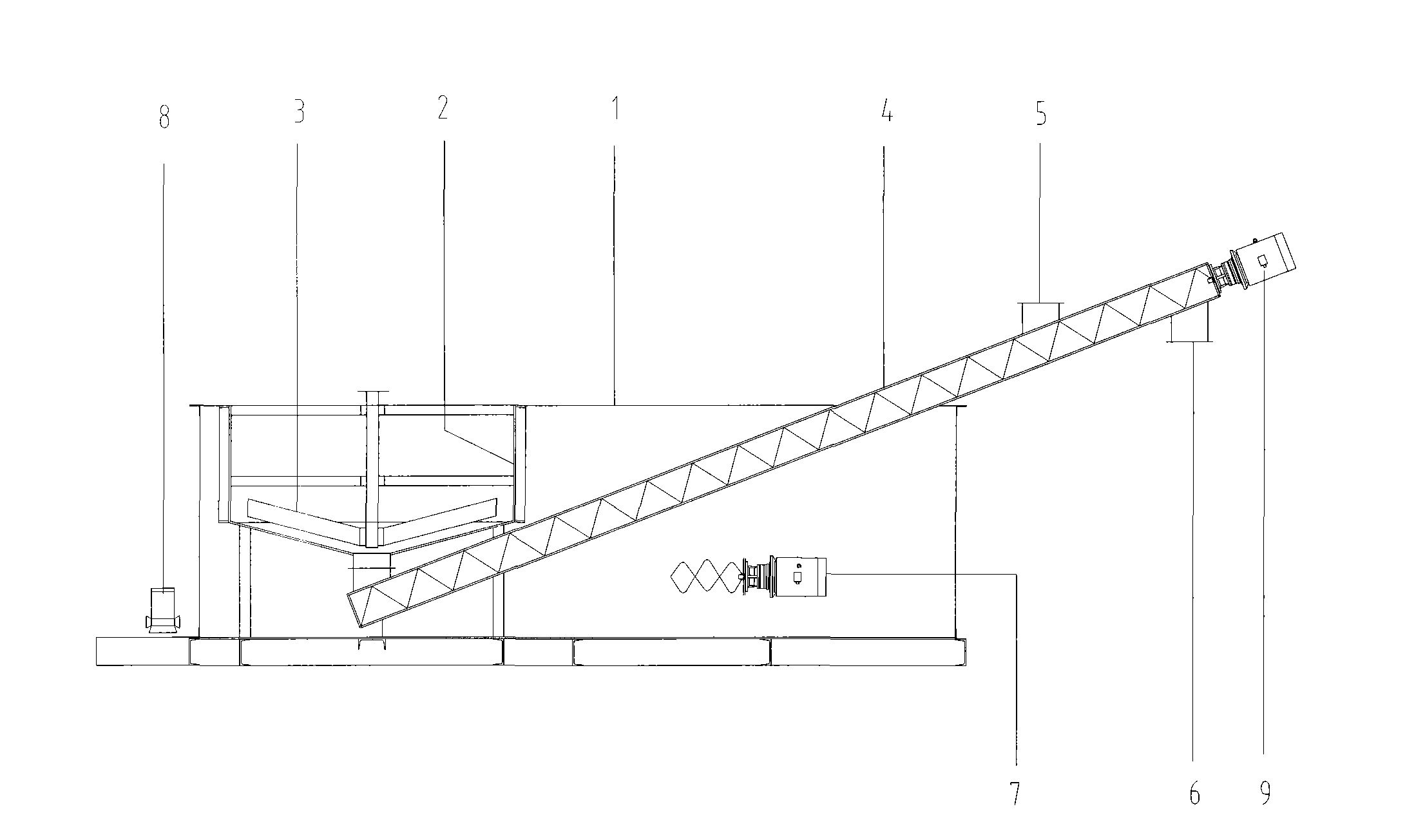

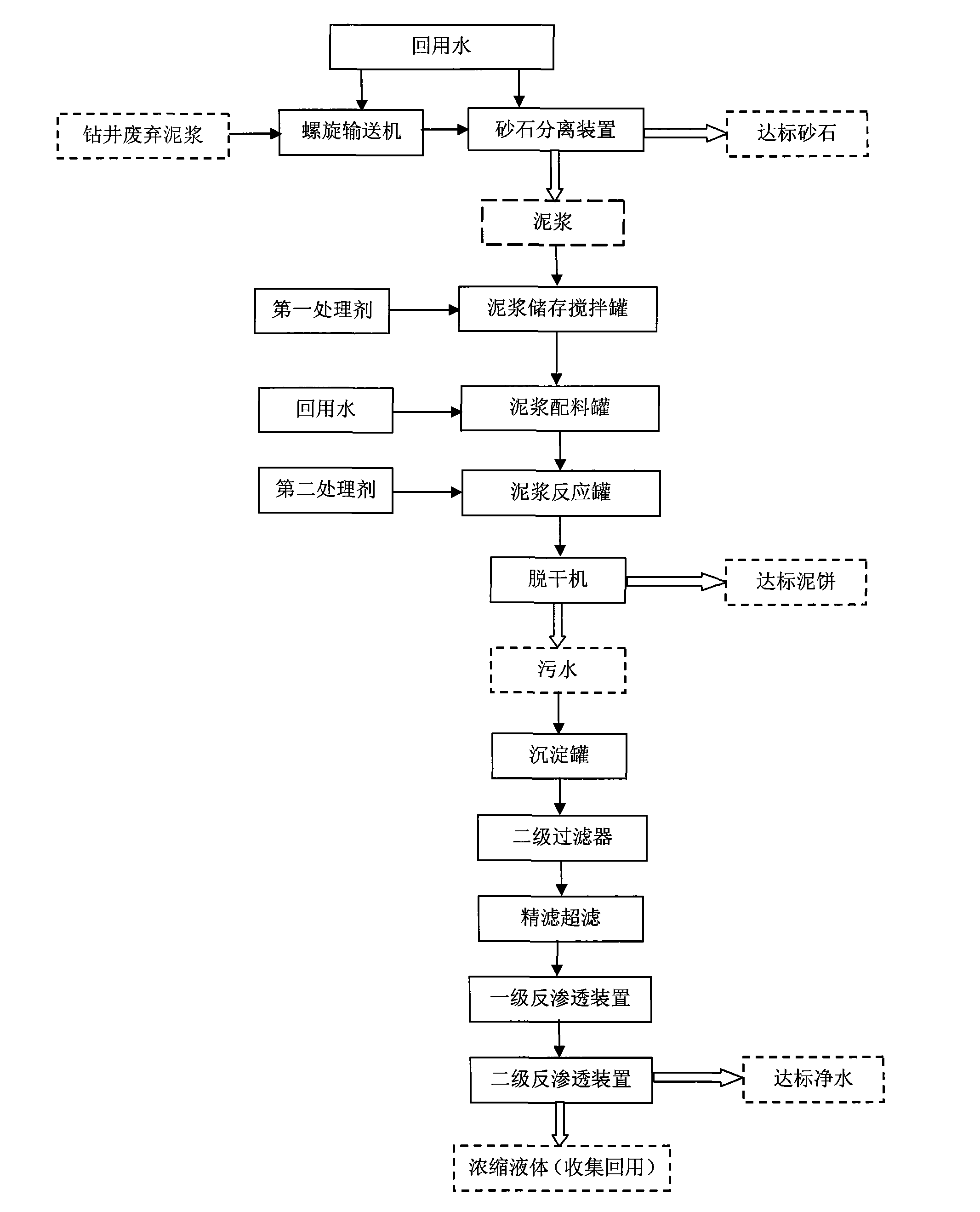

Method for processing waste slurry

ActiveCN101538096ASave land resourcesObvious technical advantagesWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningFiltrationWell drilling

The invention discloses a method for processing waste slurry, comprising the following steps: firstly, a sand-stone segregation apparatus separates, washes and discharges the drill cuttings sand and stone in the slurry; the pH value of the remaining slurry is adjusted and the COD value thereof is reduced; the solid and the liquid are separated from each other in a way of composite flocculating; water solution is separated out from the solid in a way of mechanical drying; the dried solid isolate meets the relative standard so as to be processed in a way of stacking or land filling; finally the separated water solution is processed in a way of filtration and reverse osmosis so as to obtain fresh water which is recycled or discharged on the spot. The method can be carried out by matching with an unit device and make continuously impending treatment of the well drilling waste slurry during drilling synchronously with normal well drilling production so as to continuously process the efflux hazardous waste to meet the discharge standard with out loading in the well drilling of oil-gas field, change the prior traditional whole efflux curingprocess mode, and fills the gap of an environmentally friendly governing field of oil drilling in the domestic.

Owner:北京华盛坤泰环境科技股份有限公司

Method for chemiophysical stabilization of waste

InactiveUS20050049449A1Solid waste managementSolid waste disposalEngineeringEnvironmental engineering

This invention provides a method for stabilization of combined heavy metal bearing materials and wastes subject to acid and water leaching tests or leach conditions by addition of stabilizing agents such that the leaching potential is inhibited to desired levels and the material or waste is free flowing. The resultant material or waste after stabilization is deemed suitable for on-site reuse, off-site reuse or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH EDWARD

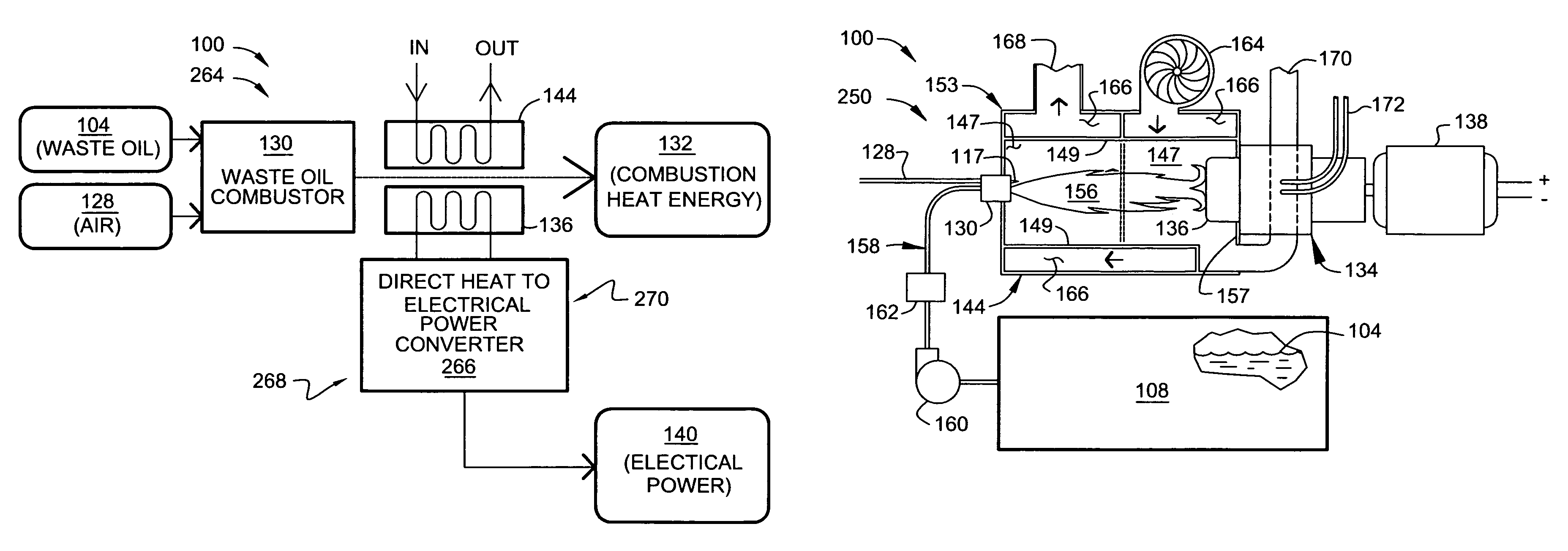

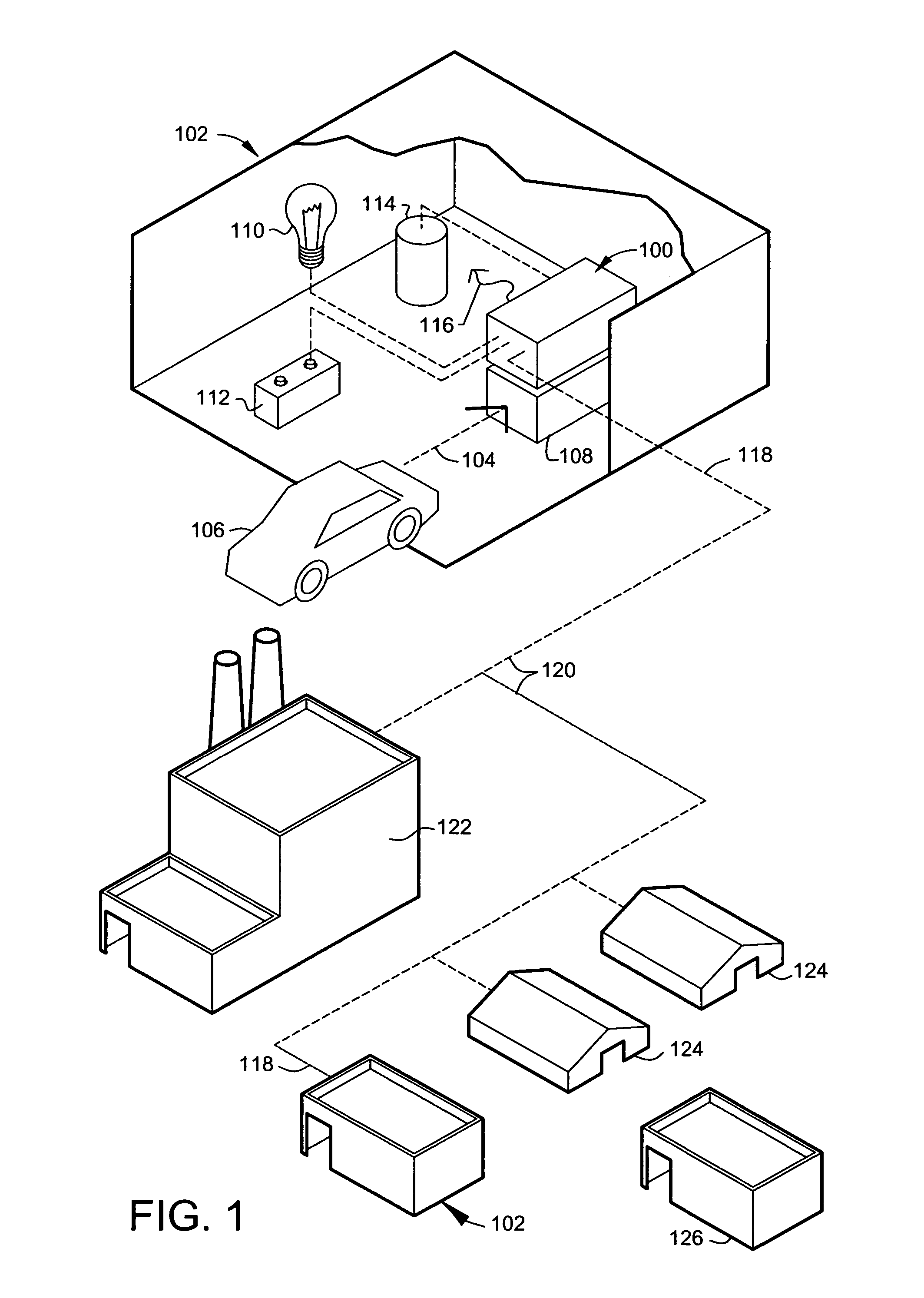

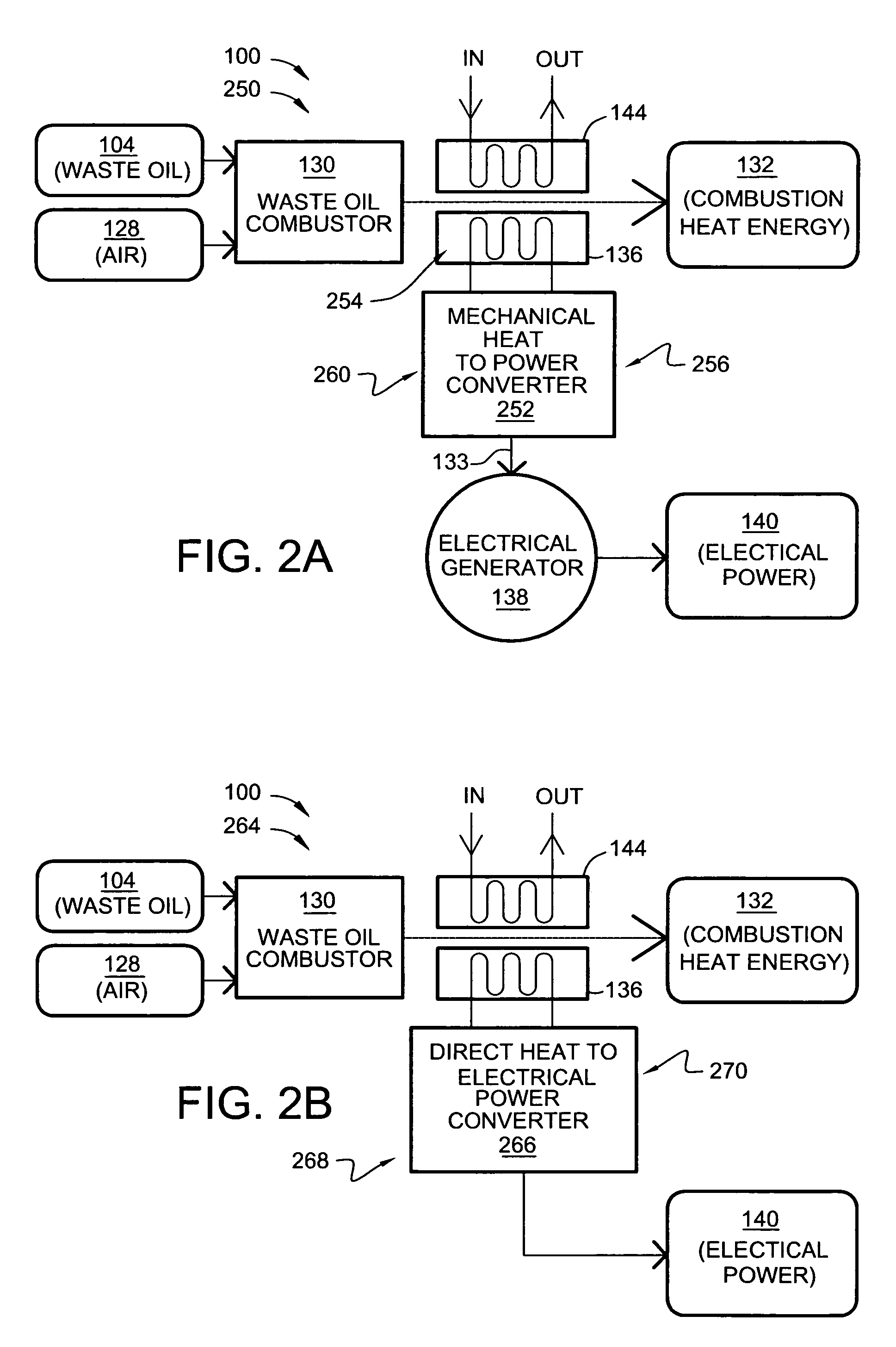

Waste oil electrical generation systems

Owner:BASSETT TERRY E

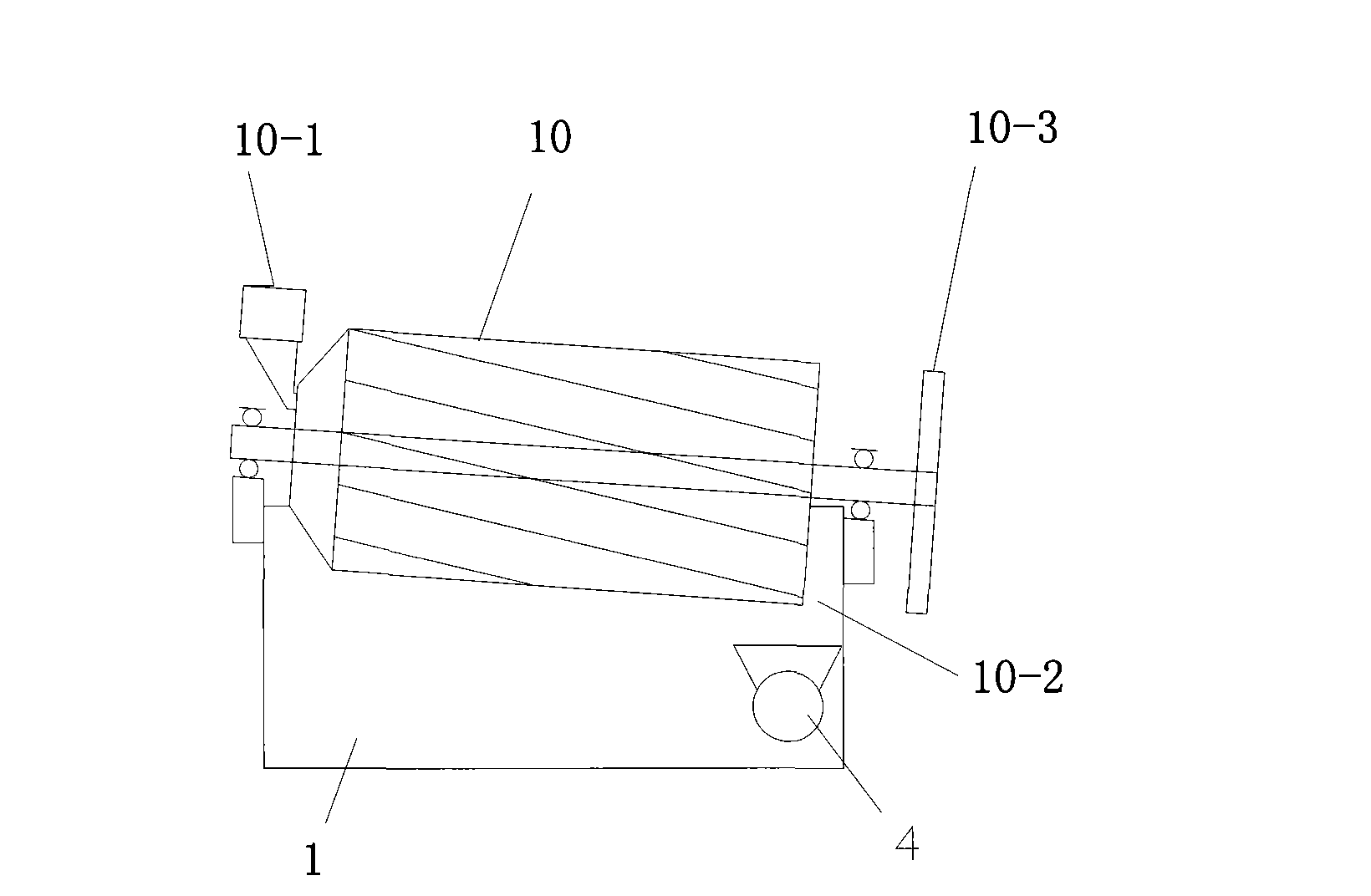

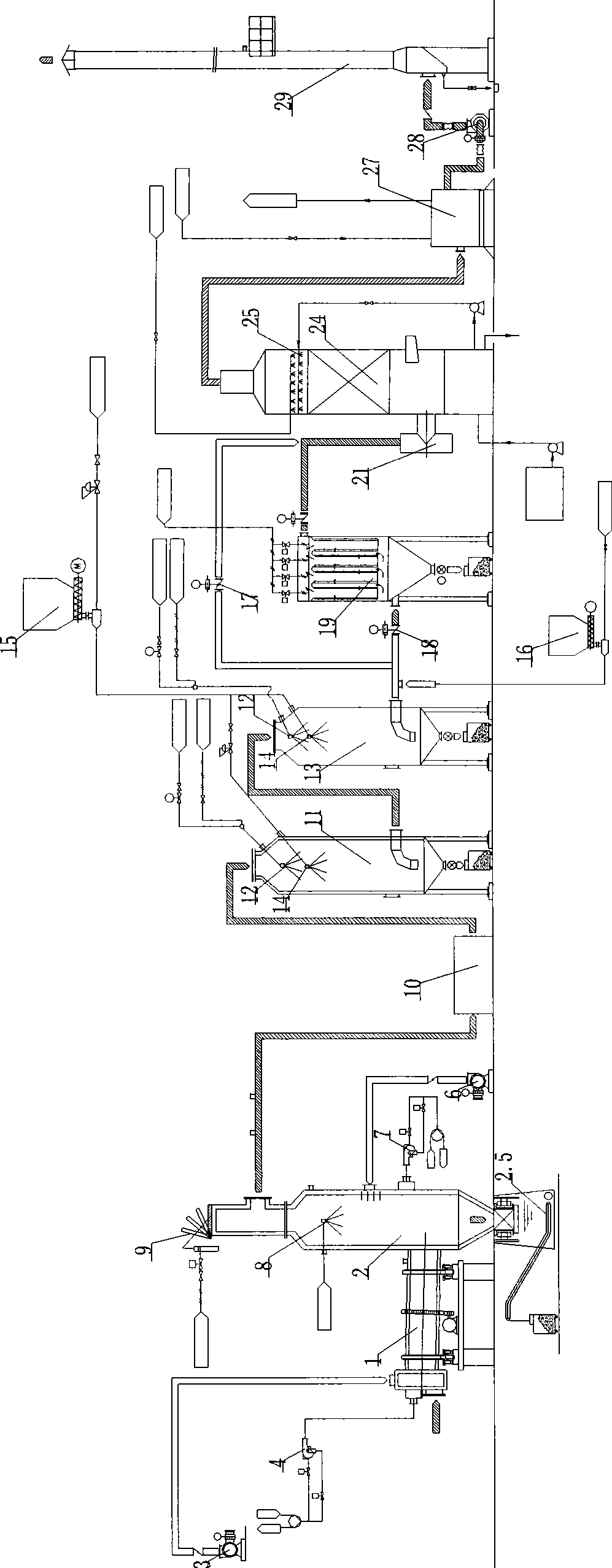

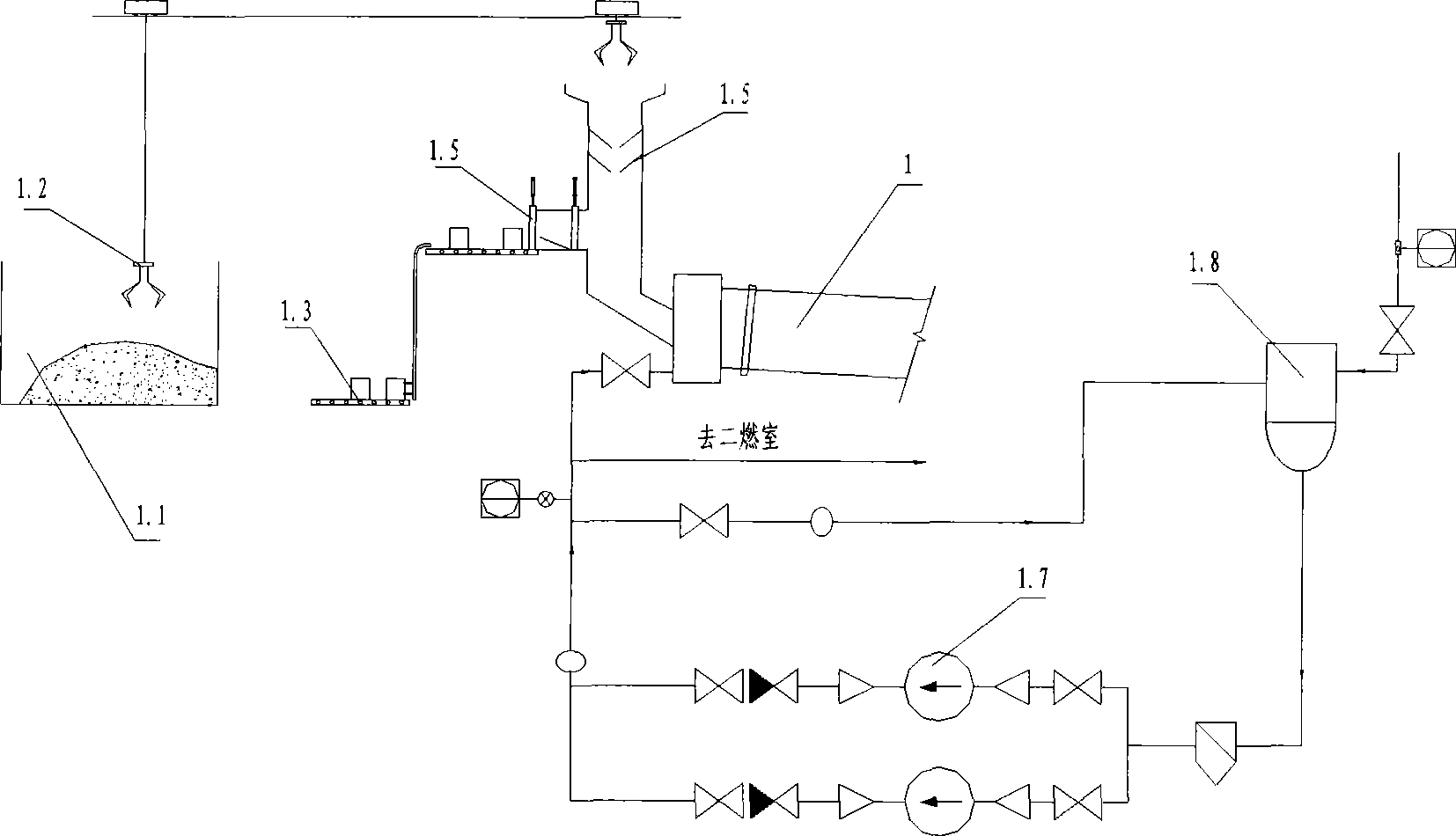

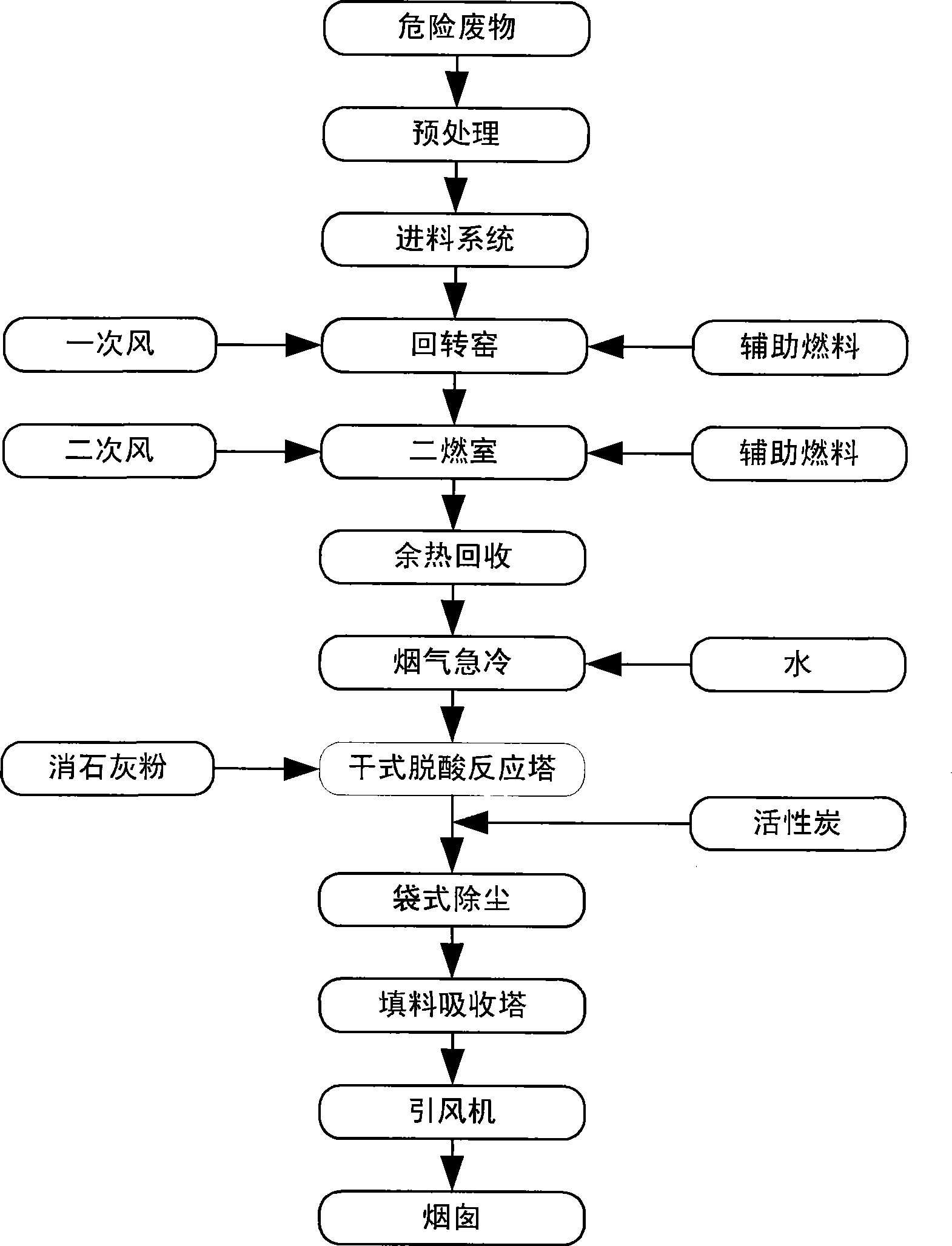

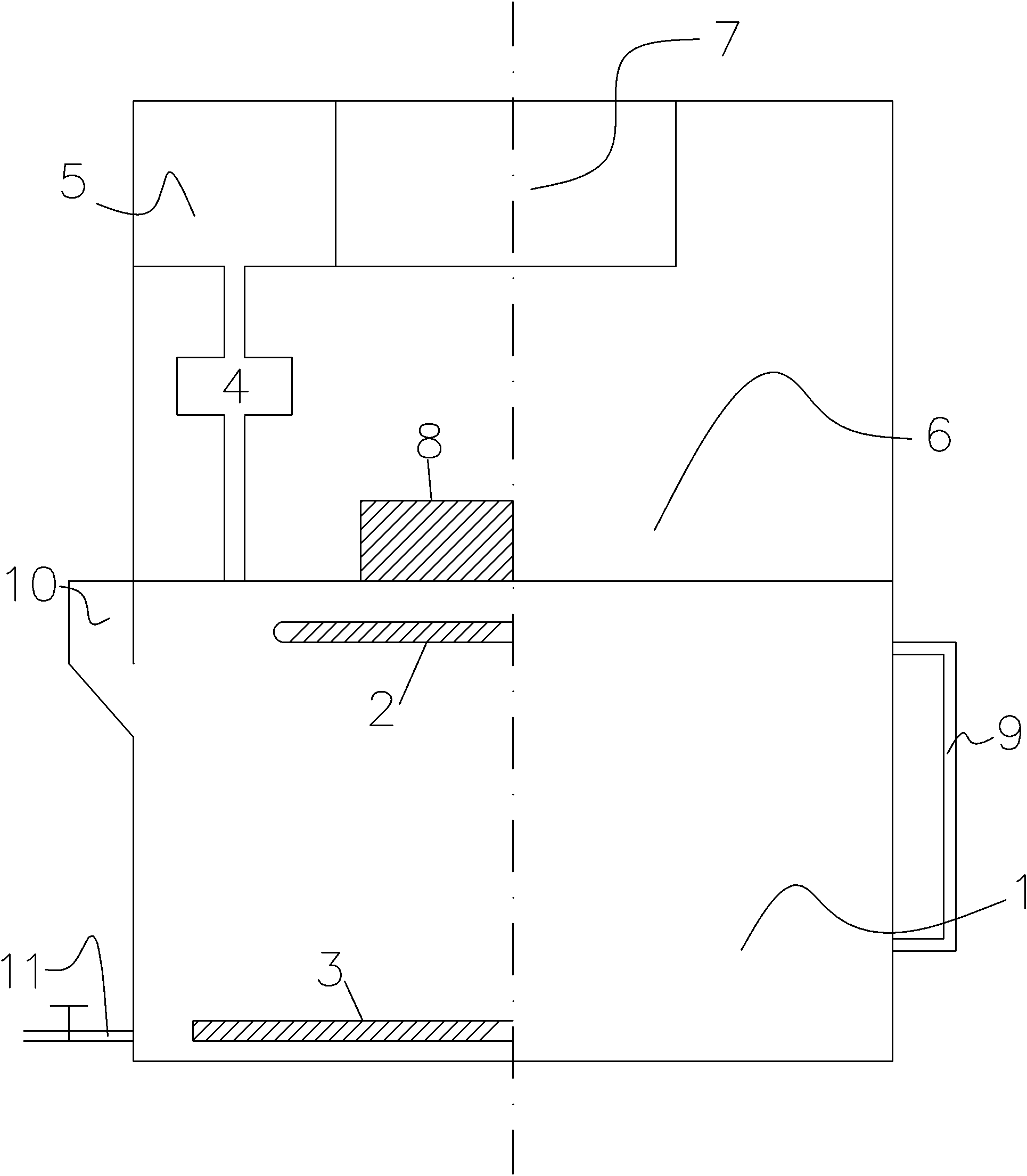

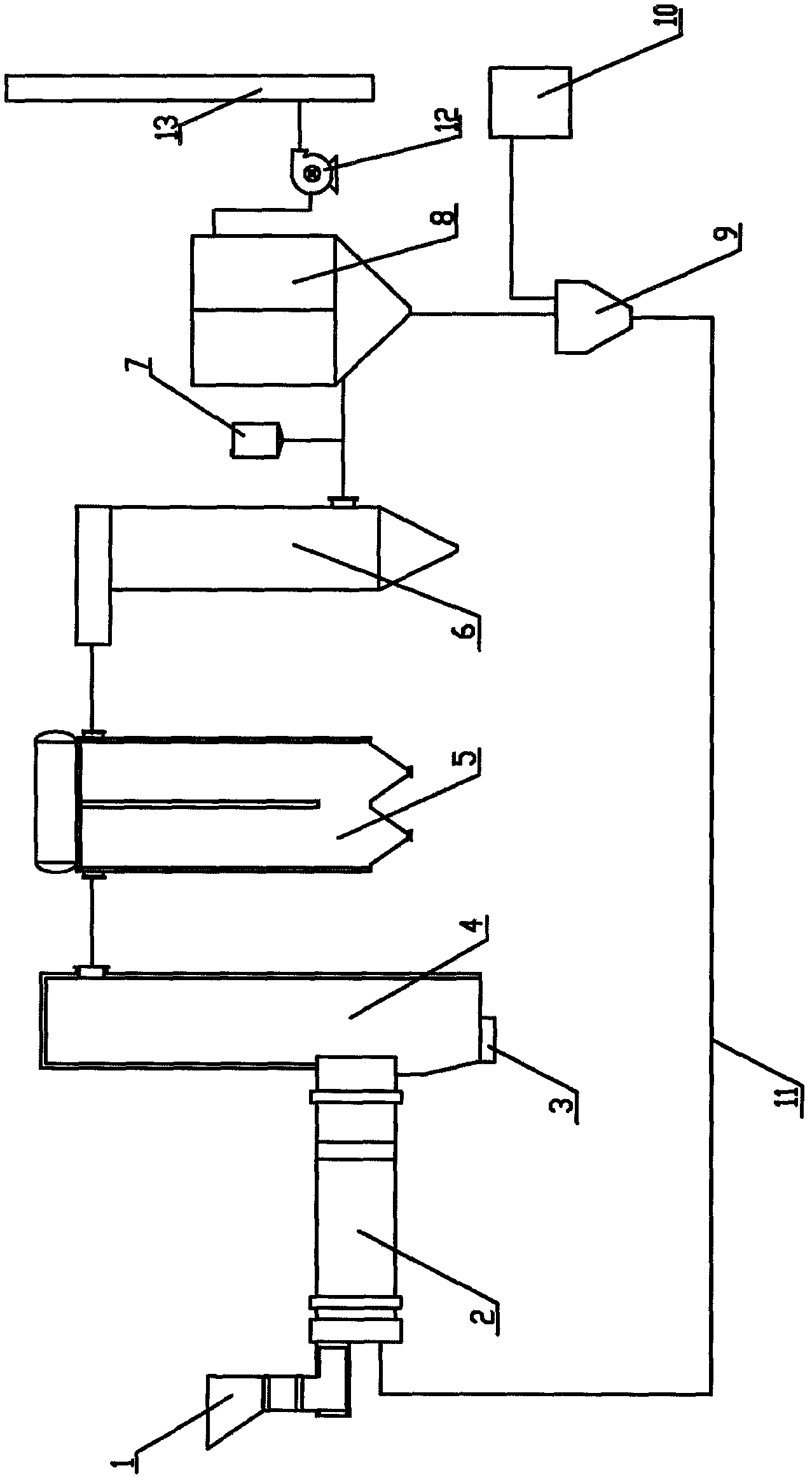

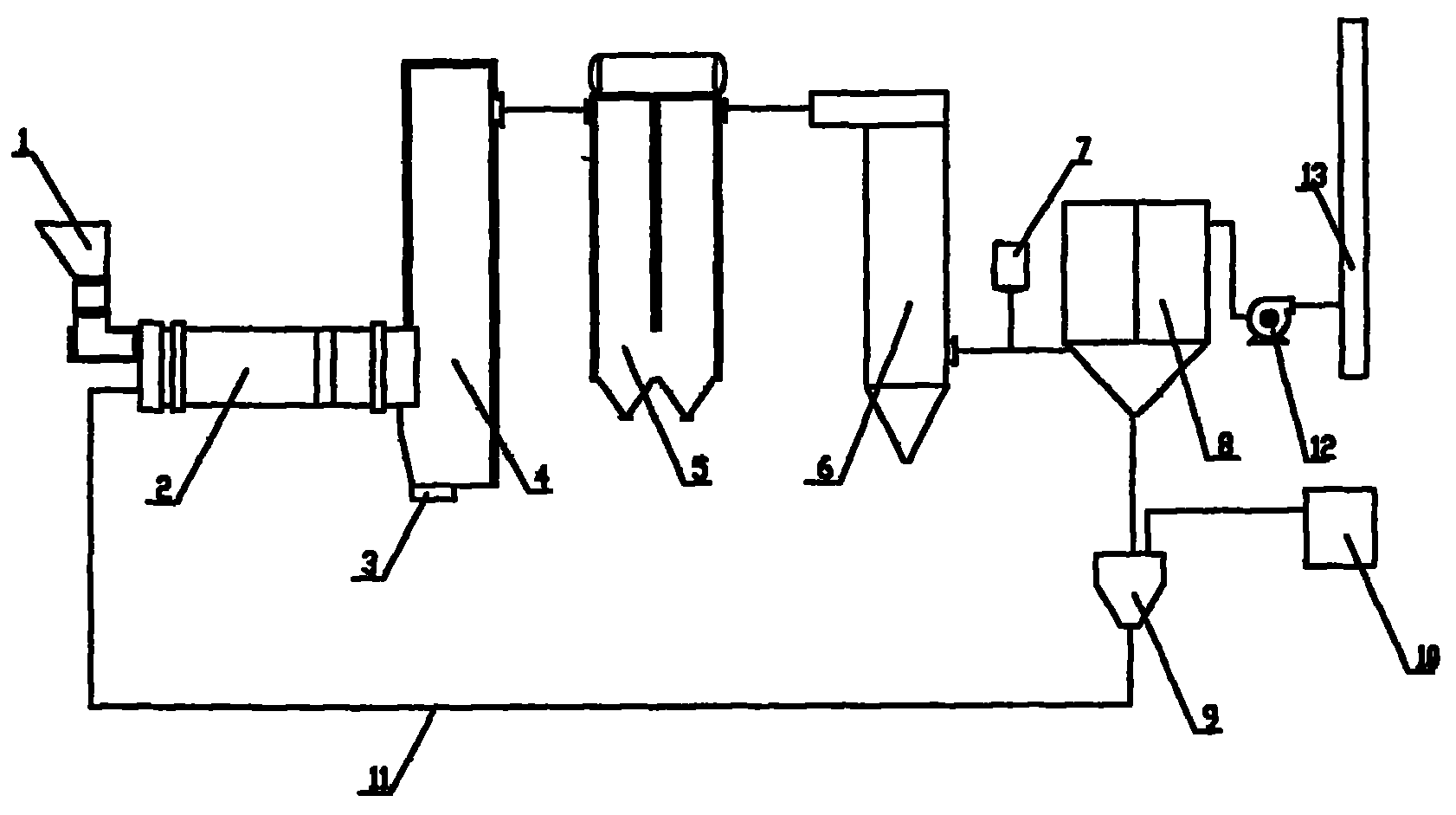

Industrial dangerous waste incineration processing system for realizing multiple physical states

A system for implementing multiple-physical state industry dangerous waste incineration and disposal relates to the garbage disposal technology of the environment protection technical field. Two seal doors are arranged at a bulk waste material feed port or a barreled waste material feed port on a rotary kiln feed hopper. The rotary kiln and a second combustion chamber frame all adopt carbon steel materials, refractory materials a working layer of the rotary kiln select chromium fused alumina abrasion-proof plastic materials, refractory materials of the second combustion chamber select abrasion-proof pouring materials. The rotary kiln is provided with a primary fan and a combustion-supporting combustor 1 which are connected with the rotary kiln, the second combustion chamber is provided with a second fan and a combustion-supporting combustor 2 which are connected with the second combustion chamber, a stuffing absorbing tower and a flue gas heater are connected in turn between the bag-type dust remover and a draught fan. Compared to the prior art, the invention can effectively destroy large quantities of toxic and noxious high molecule organic matters, can effectively avoid phenomenon of the collapse fall of the rotary kiln incineration furnace wall and the burning ring of the steel body, and can avoid high-temperature corrosion and low-temperature corrosion, the invention has advantages of good operation economical performance, fluent slag system and low pollution discharge index.

Owner:TONGFANG ENVIRONMENT

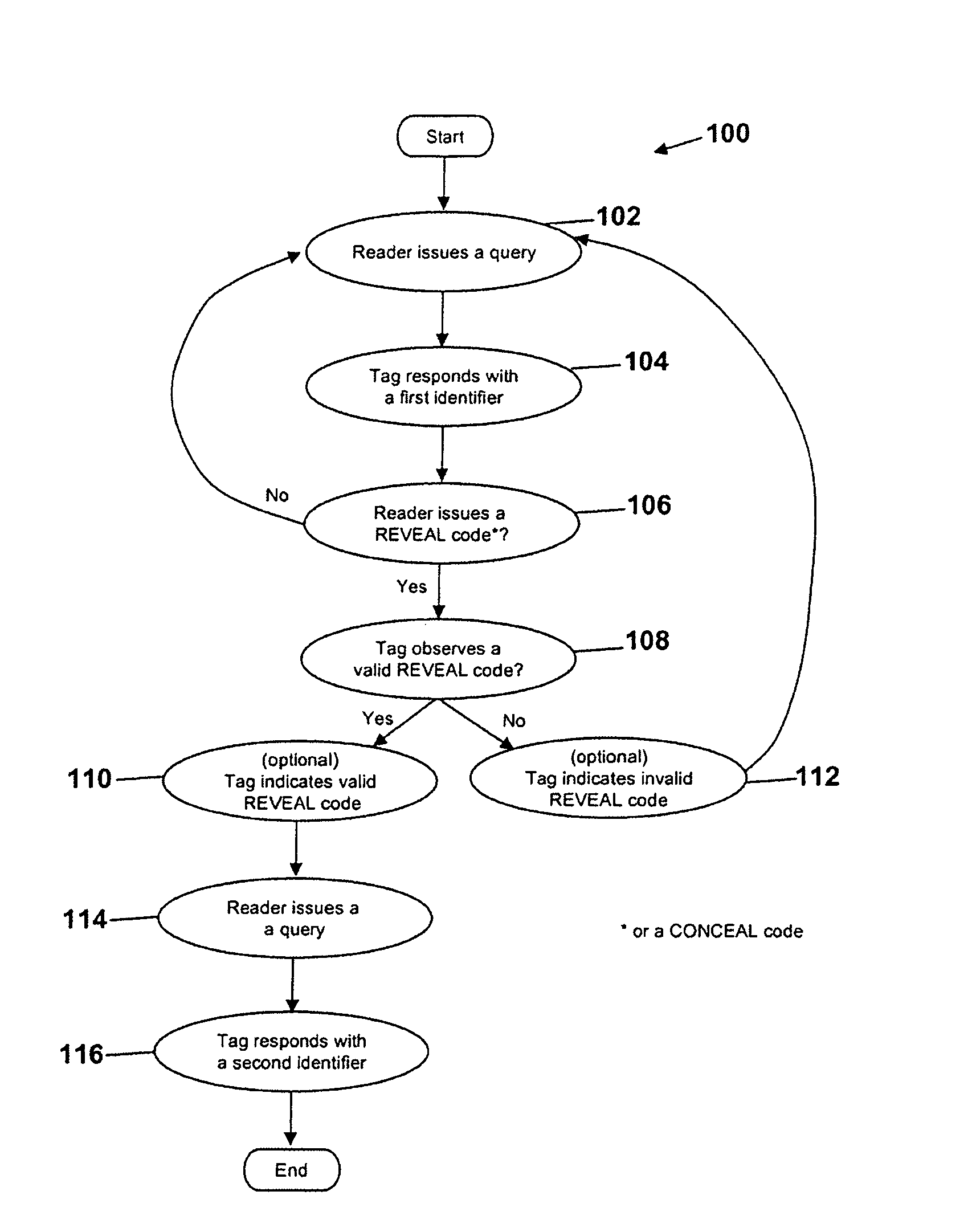

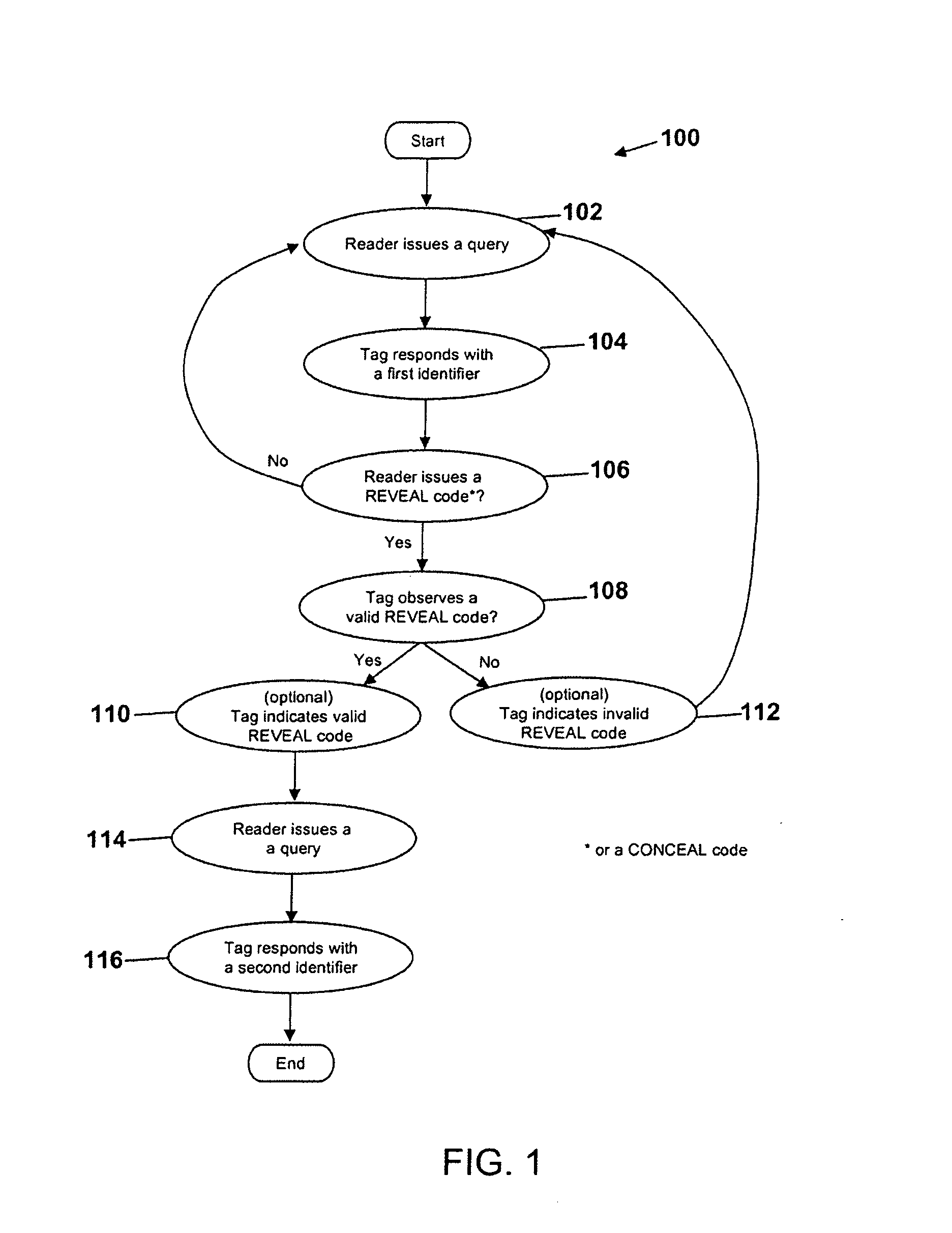

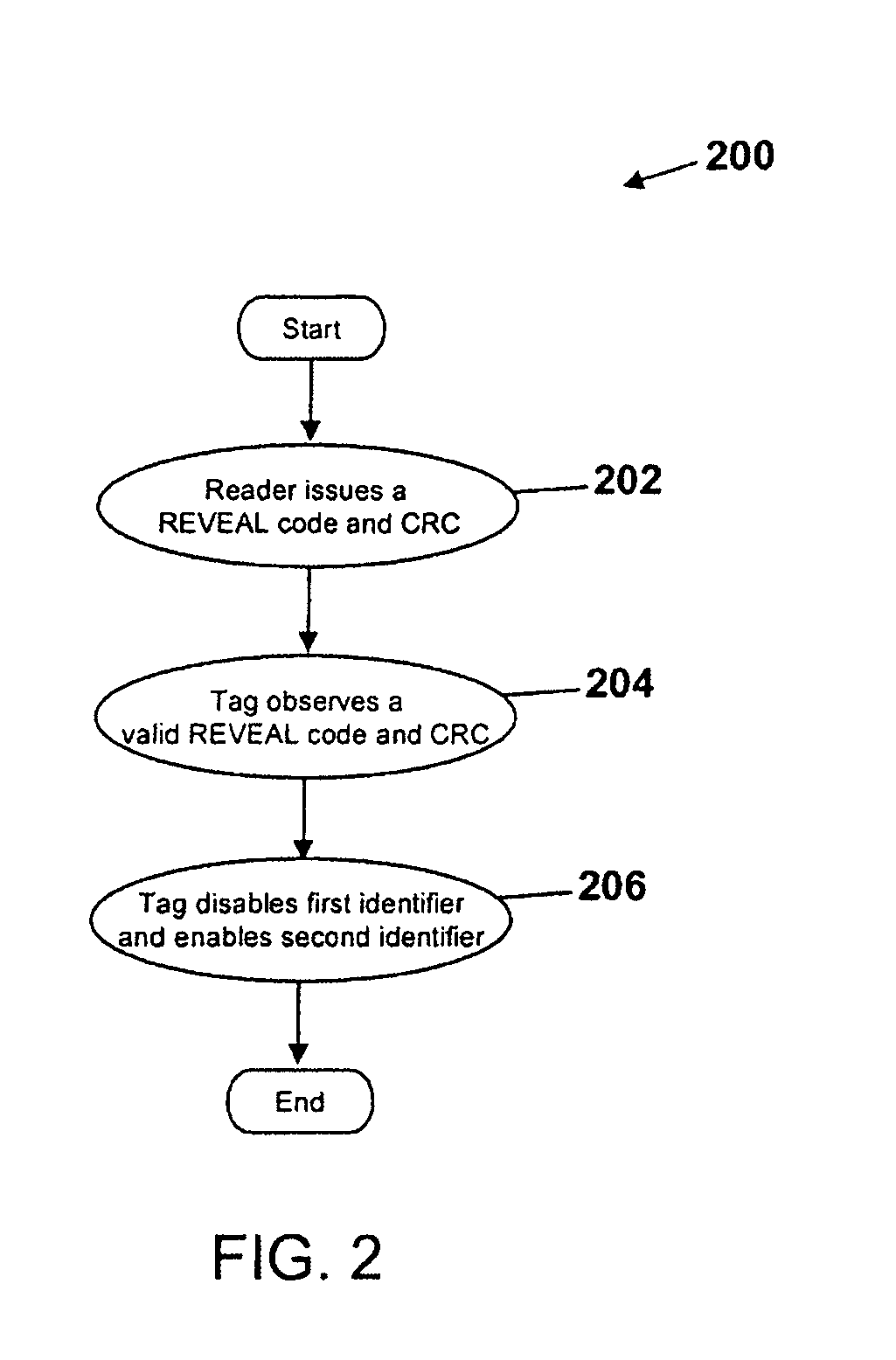

Tiered radio frequency identification

ActiveUS20080211637A1Avoid inconsistent power usageImprove securityAcutation objectsCash registersUser identifierRadio frequency

Methods and apparatuses for tiered RFID communication are provided, inter alia, for privacy and security in at least certain embodiments. An RFID tag includes first and second memory locations respectively storing first and second identifiers. The tag is configured to respond to an identification query with the first identifier until receipt of a command code. After receipt of the command code, the tag is configured to respond to the identification query with the second identifier. The first identifier can be permanently disabled for privacy. In a one embodiment, the first identifier is an electronic product code, and the second identifier is a recycling identifier, hazardous waste information, or regulatory disposal requirement. In another embodiment, the first and second identifiers can identify the tag's associated item with differing levels of specificity for improved security.

Owner:RUIZHANG TECH LTD CO

Process for the treatment of waste streams

The present invention is directed to a process for treating, reducing, and / or stabilizing various wastes or flue gases. In one embodiment, the process is directed to treatment of alkali bearing wastes that include nitrate and / or nitrite-rich wastes. Optionally, the disclosed method can be utilized for treatment of hazardous wastes, including radioactive hazardous waste compounds. In general, the present invention includes processing a waste or gaseous stream with the addition of suitable carbon-containing additives to treat and reduce nitrogen-containing compounds in the waste. Additives may be gaseous, liquid or solid reduction-promoting agents, catalysts, and the like. The reaction products obtained from the process of the invention include mainly alkali carbonate, nitrogen, hydrogen, carbon monoxide and carbon dioxide.

Owner:MFG & TECH CONVERSION INT

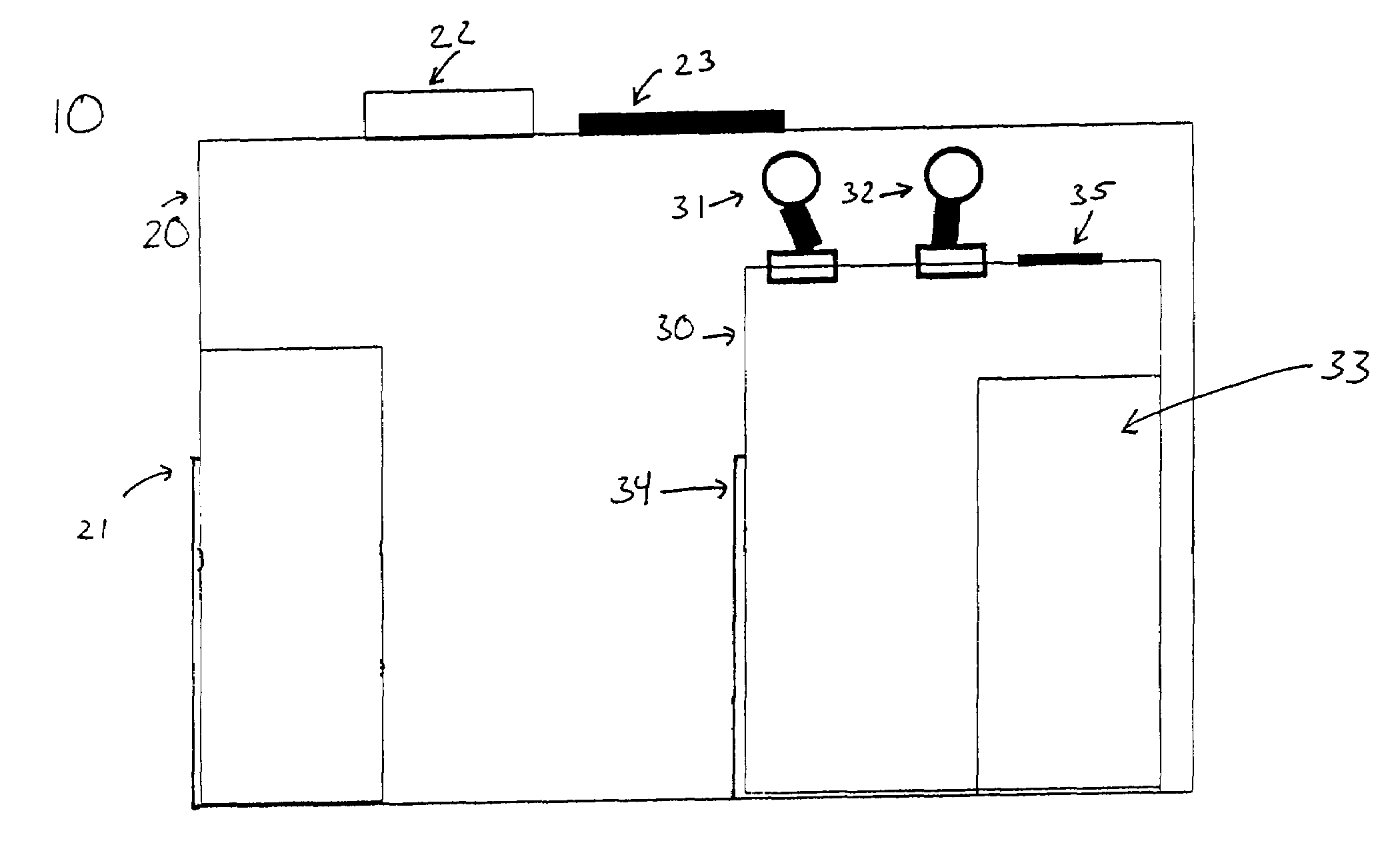

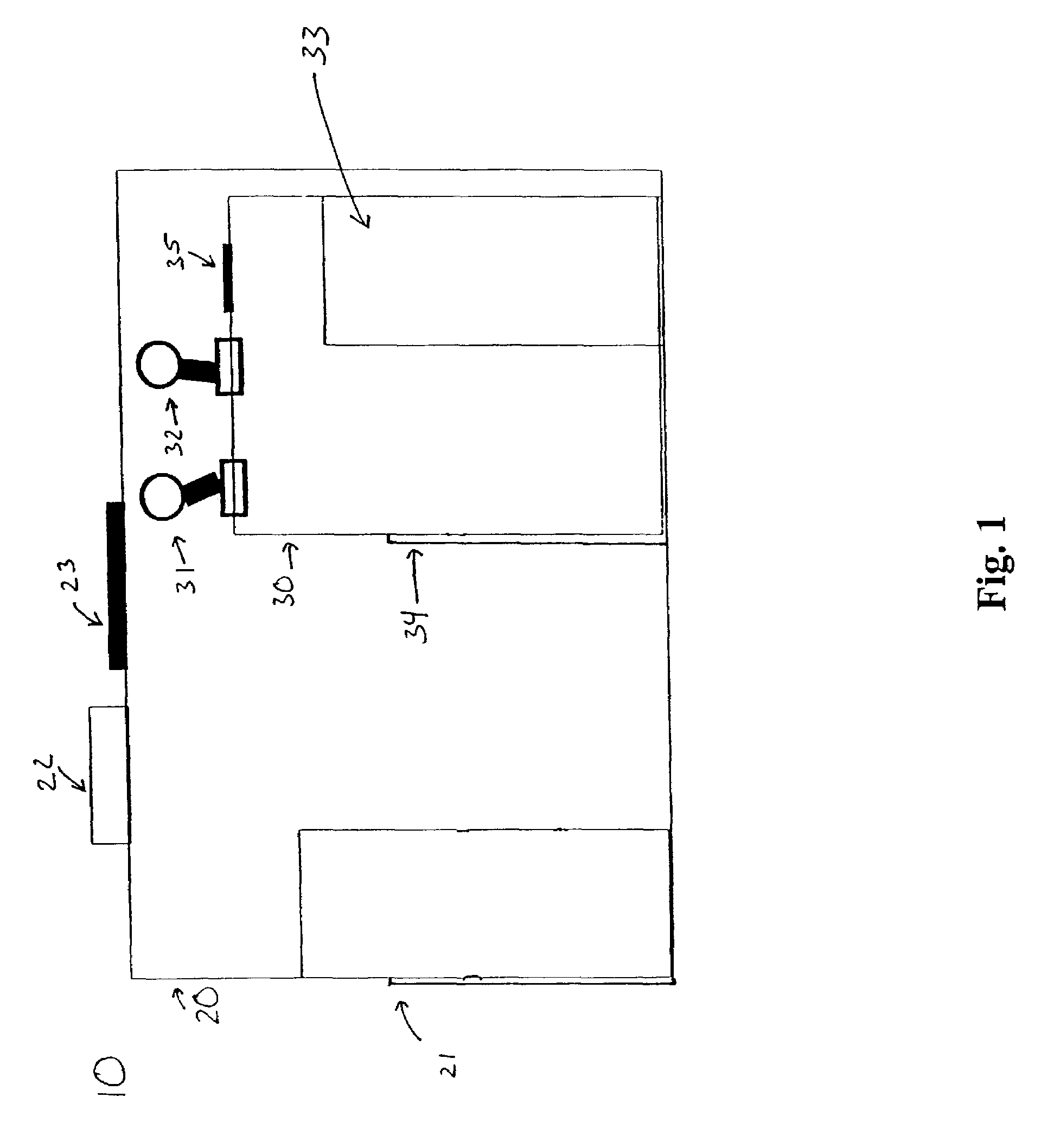

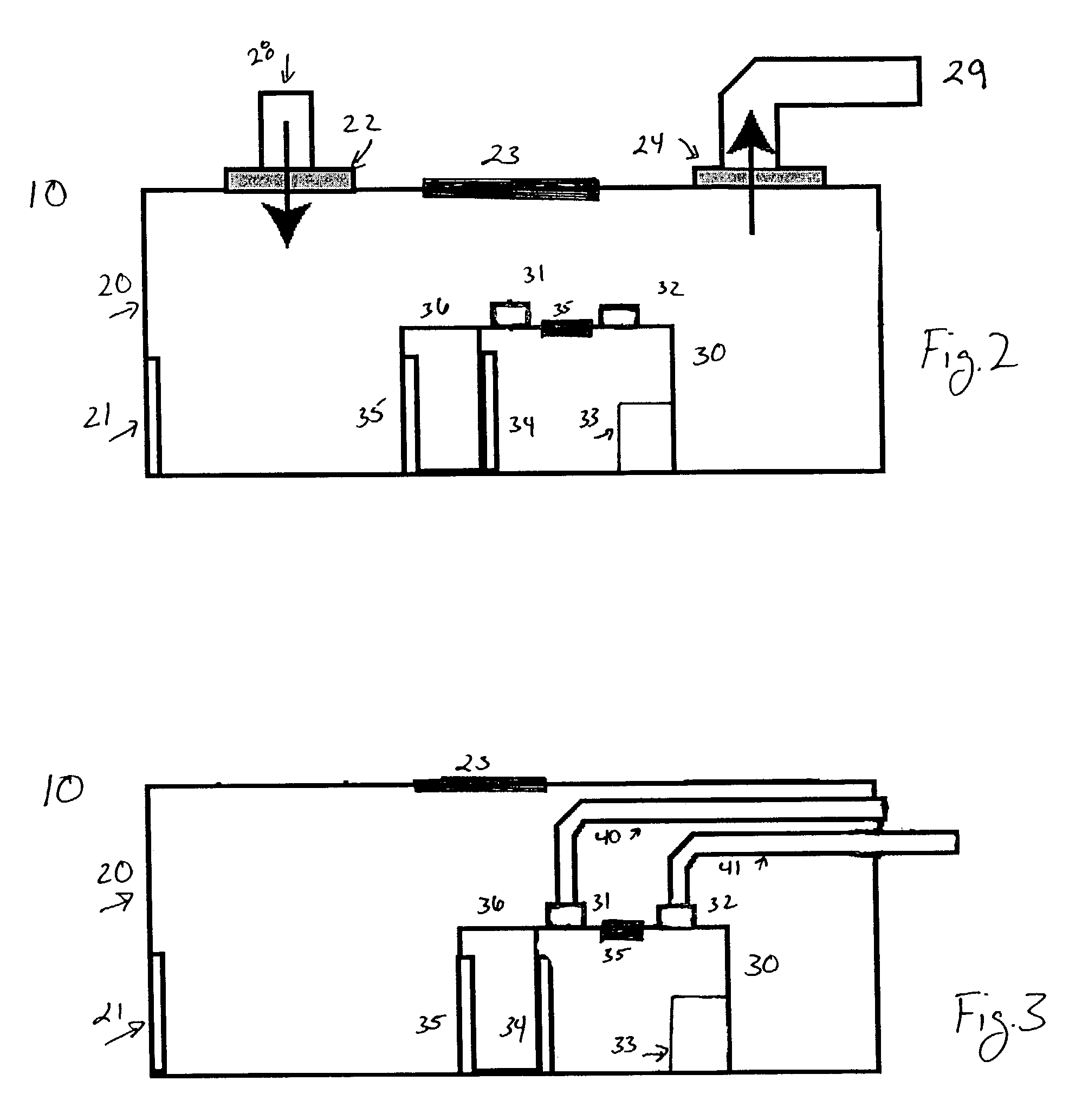

Modular biosafety containment apparatus and system

InactiveUS7335243B2Rapid deploymentNegative pressurizationCombination devicesDispersed particle filtrationModularityEngineering

Owner:HOMAN JANE +1

Method for stabilizing heavy metal bearing waste in a waste generation stream

InactiveUS6050929AReduce solubilityReduce LeachabilitySolid waste disposalRadioactive decontaminationWaste treatmentHazardous waste

Heavy metal bearing products during production, processing and / or handling, and / or in landfills, storage or retention areas are stabilized prior to the generation or management as a waste by applying heavy metal stabilizing agents into the product stream thus avoiding complex and costly processing and treatment of waste under hazardous waste regulations.

Owner:FORRESTER KEITH EDWARD

Method and device for degrading pollutants through ultraviolet catalytic wet oxidation

InactiveCN101863526AWide variety of sourcesEasy to separateWater/sewage treatment by irradiationWater/sewage treatment by oxidationHigh concentrationChemical oxygen demand

The invention discloses a method for rapidly and efficiently degrading pollutants through ultraviolet catalytic wet oxidation at the normal temperature and normal pressure and designs a typical device for implementing the method. In the method, ultraviolet light, an oxidant and a catalyst are introduced into a reaction system; and a wet oxidation reaction can be performed under the mild conditions of normal temperature and normal pressure by utilizing the synergistic catalytic oxidation of the ultraviolet light, the oxidant and the catalyst. Compared with the traditional catalytic wet oxidation method which needs to be implemented under the reaction conditions of high temperature and high pressure, the method can be implemented under the conditions of a temperature of between 25 and 80 DEG C and normal pressure, wherein organic pollutants in high-concentration toxic and hazardous waste water can be decomposed to be harmless components such as carbon dioxide (CO2), water and the like through the high oxidizing property; and the removal rate of chemical oxygen demand (COD) chromium (Cr) after the treatment of a plurality of representative high-concentration organic waste water can reach over 95 percent, and the biochemical property can be improved obviously. The method has the advantages of mild reaction, high treating efficiency, complete degradation, clean and environmental-friendly process, energy conservation and wide application prospect.

Owner:李朝林

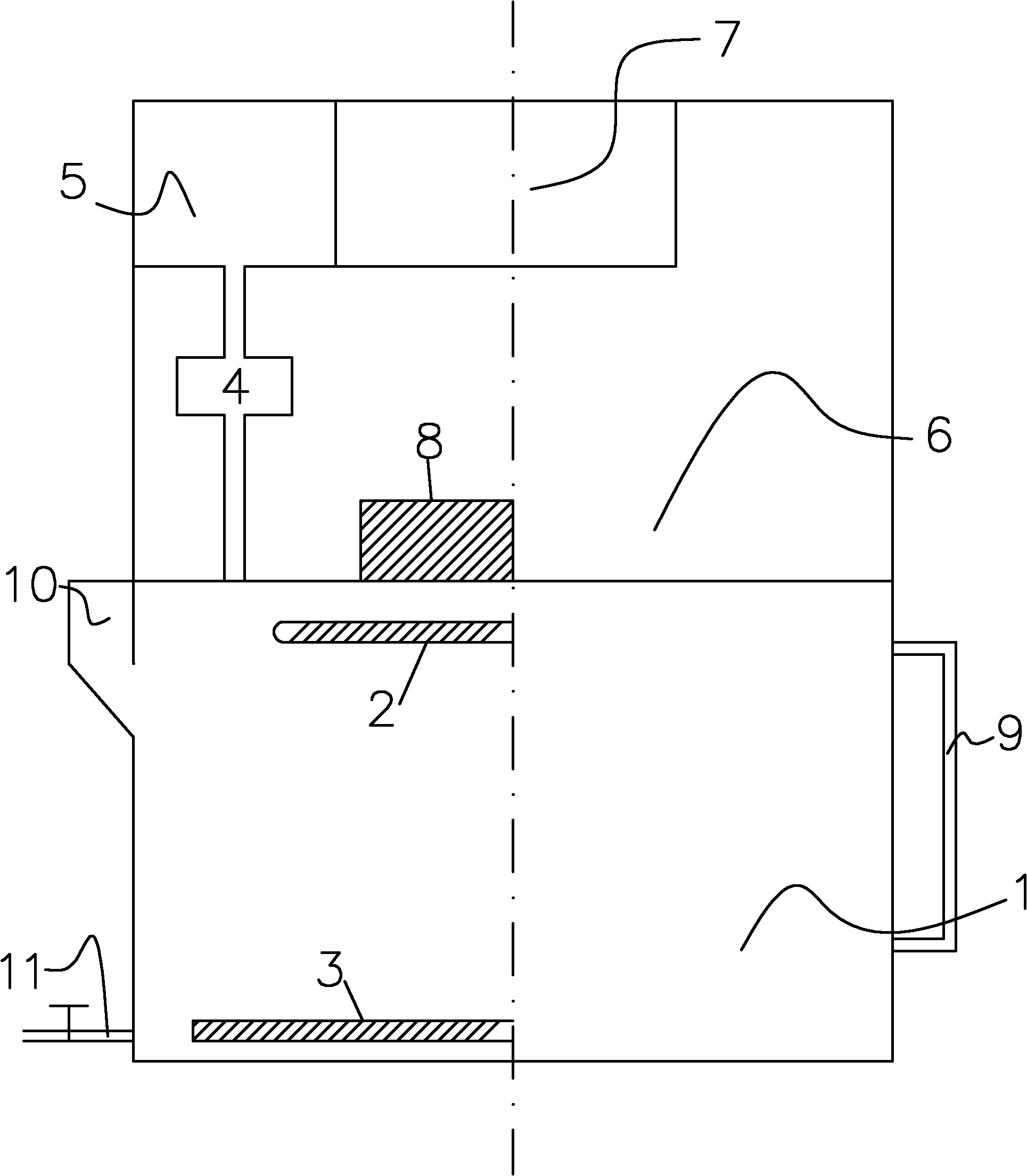

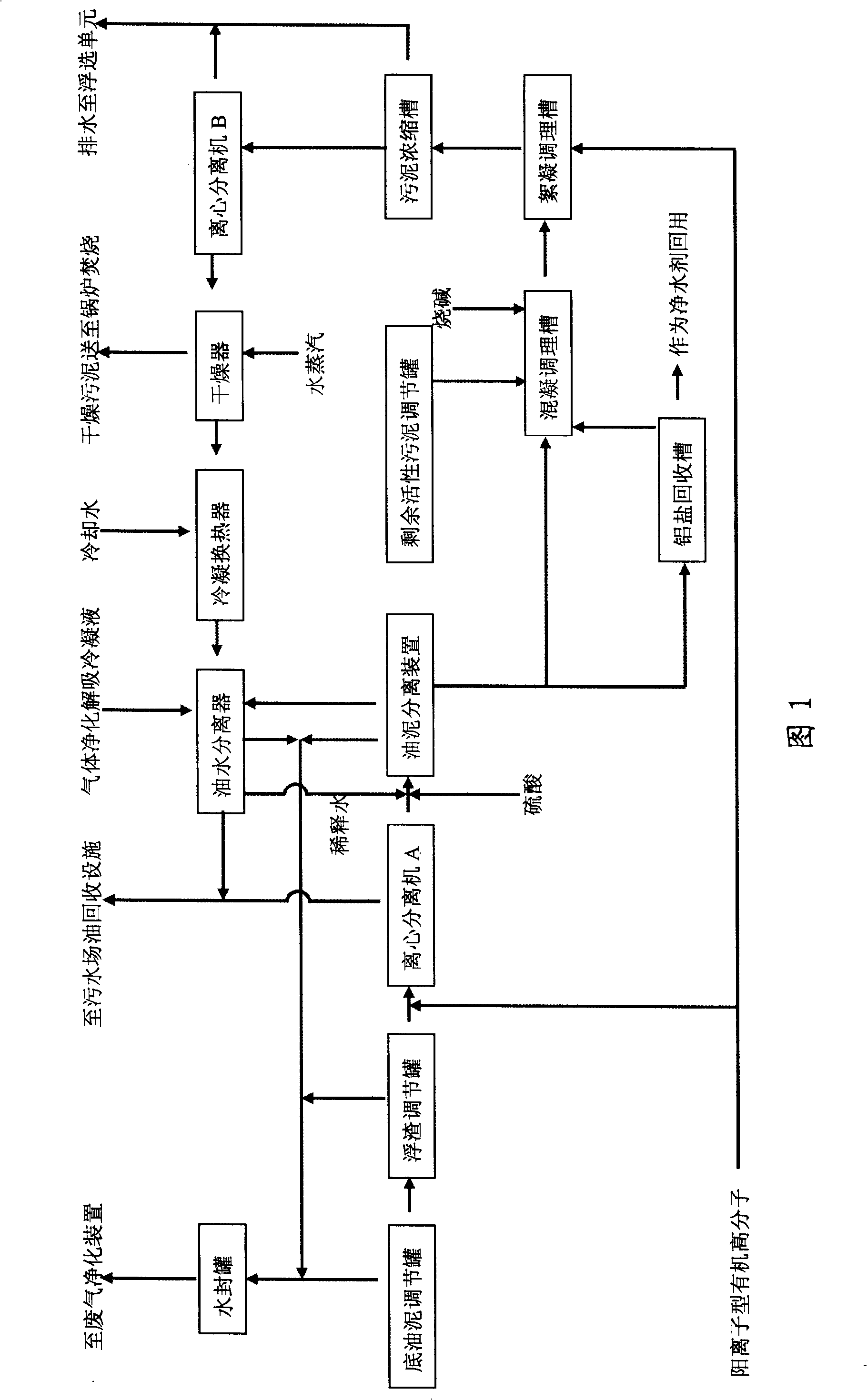

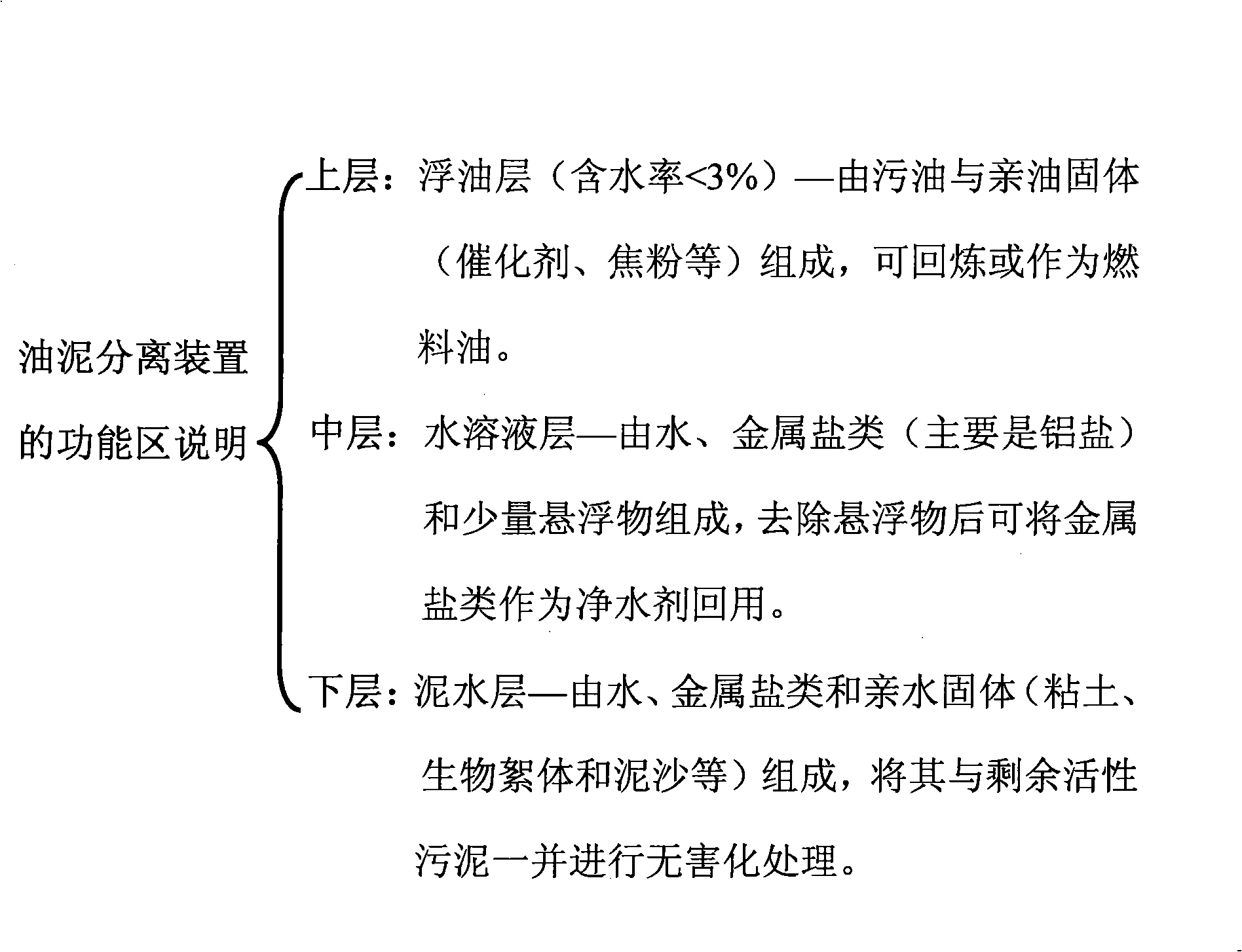

Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

InactiveCN101343137ASave resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningIncinerator apparatusChemical industryActivated sludge

The invention discloses a method of harmless treatment to residual activated sludge produced by bottom sludge, scum and biochemical treatment units in the petrochemical industry, which comprises: emulsion breaking to the bottom sludge and scum; separation of oil, water and mud of products after emulsion breaking; and recovery of dirty oil at the upper part and sedimentation of mud-water mixture at the lower part, recovery of clear liquor at the upper part, and treatment of coagulation conditioning, flocculation conditioning, sludge concentration, sludge dewatering, sludge drying and sludge incineration to mud-water mixture at the bottom part and the residual activated sludge sequentially. The method can effectively recycle useful oil substances and aluminum-containing compounds in the bottom sludge and scum, purify possibly released malodorous gases in mud produced in the process of storage and disposal, and carry out the treatment such as sludge conditioning, dewatering and drying sequentially to the residual mass hazardous wastes after the recycling treatment, then utilize the current boilers in enterprises to implement the direct incineration treatment. The method has advantages of simple operation and running, safety and reliability, complete resource recovery, controllable water removal, and maximally reducing the environmental pollution.

Owner:罗德春

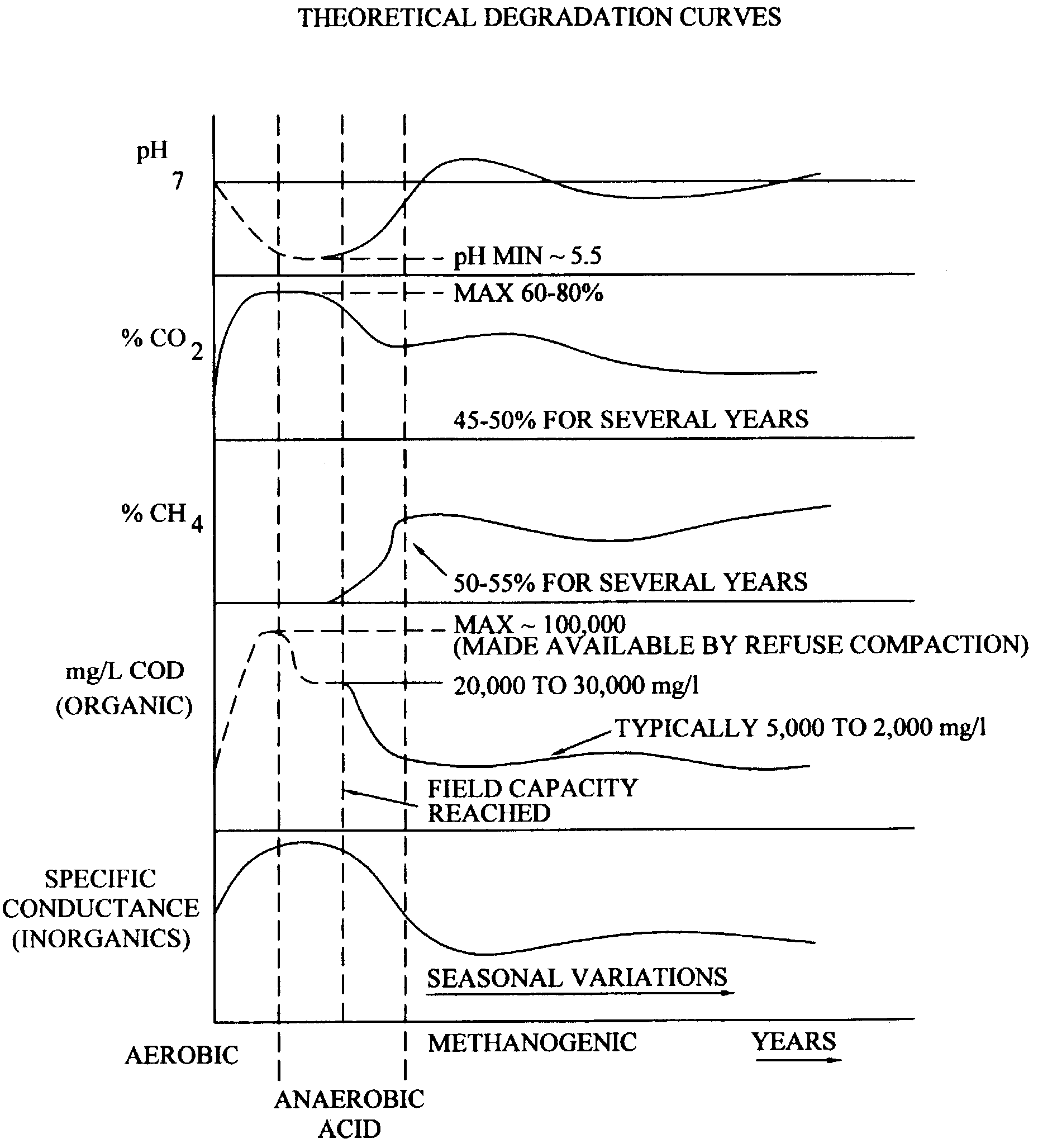

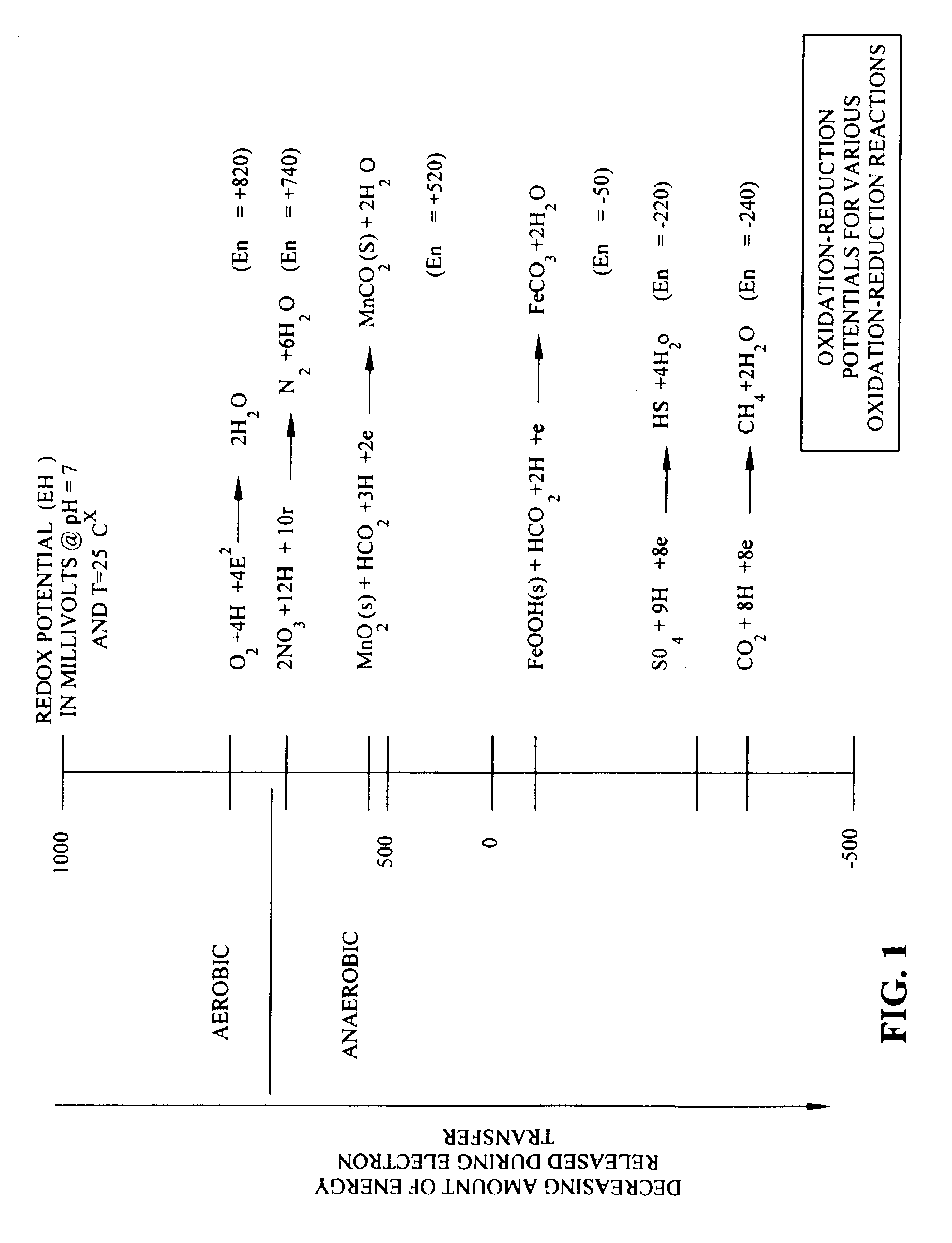

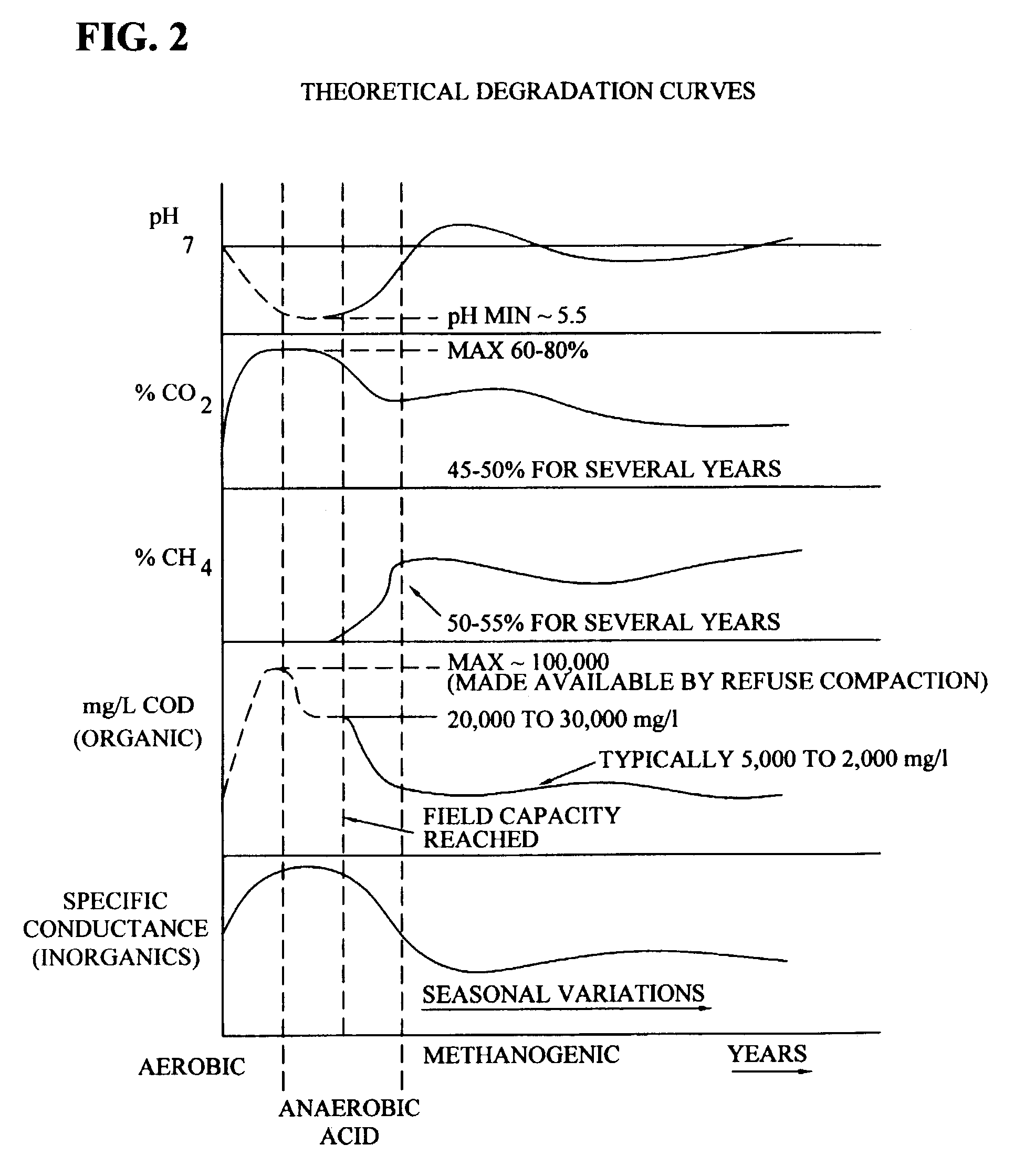

Hazardous waste stabilization methods, products and testing procedures

InactiveUS6991593B2Protect environmentFacilitate methodSludge treatmentSolid waste disposalElectric arc furnaceEnvironmental engineering

A process for the stabilization of metal bearing waste is provided that is based upon the discovery that landfills have anaerobic environments. This process includes adjusting the pH of the waste and adding a sulfide containing reducing agent to the waste to achieve a reducing environment. In one embodiment, electric arc furnace dust is stabilized for landfill disposal. Also provided is a method for a determination of landfilled waste leachability. This method is performed under conditions that simulate the chemical characteristics of landfills. In one embodiment, stabilized metal bearing waste is deoxygenated and a simulated leachate is prepared under anaerobic conditions.

Owner:HERITAGE ENVIRONMENTAL SERVICES

Melting solidification integrated method and system for incineration of hazardous wastes and incinerated fly ash

The invention discloses a melting solidification integrated method and a melting solidification integrated system for the incineration of hazardous wastes and incinerated fly ash. The method comprises the following steps of: incinerating and melting the hazardous wastes by using a multi-section incinerator which consists of a slag rotary kiln and a secondary combustion chamber; recovering the heat of smoke generated during incineration by using an afterheat boiler; conveying fly ash collected by a bag-type dust collector to the slag rotary kiln by using a silo pump and a fly ash return pipeline; performing compatibility on the fly ash and medical wastes, so that the fly ash is melted at a high temperature in the slag rotary kiln; and performing water quenching to form vitreous slag, and wrapping heavy metal by using the slag to realize the stable solidification of the metal. In the method, heat energy generated by combusting the hazardous wastes is utilized fully to provide energy for the melting solidification of the fly ash, the problem of high cost of stabilization treatment of the fly ash is solved while the innocent treatment of the hazardous wastes is realized, running cost is reduced, and the important effects of energy conservation, emission reduction and waste control by the wastes are achieved; and due to the adoption of an integrated design, the integrated system is reasonably and compactly connected and has a mature equipment structure and higher economy.

Owner:ZHEJIANG UNIV

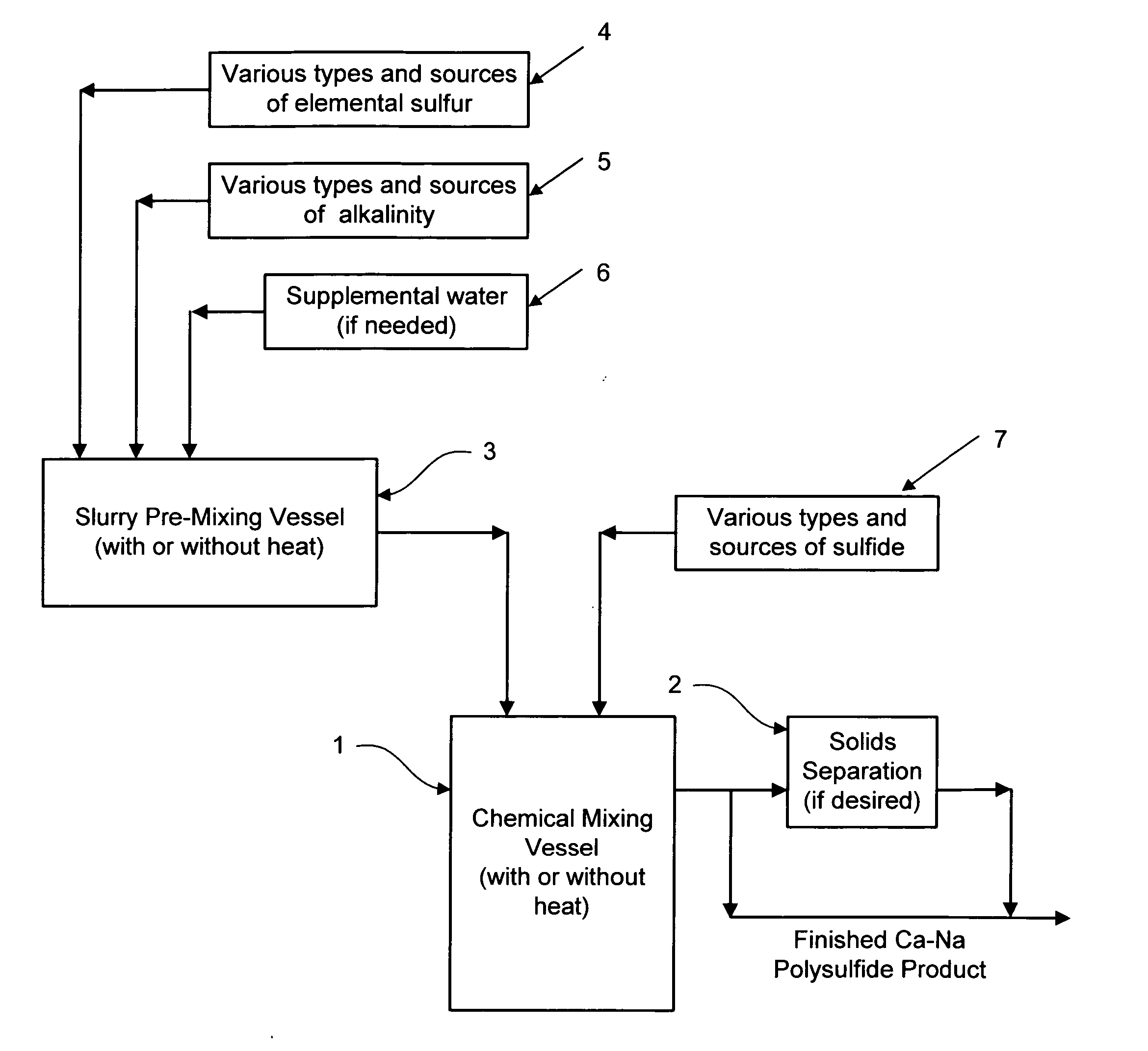

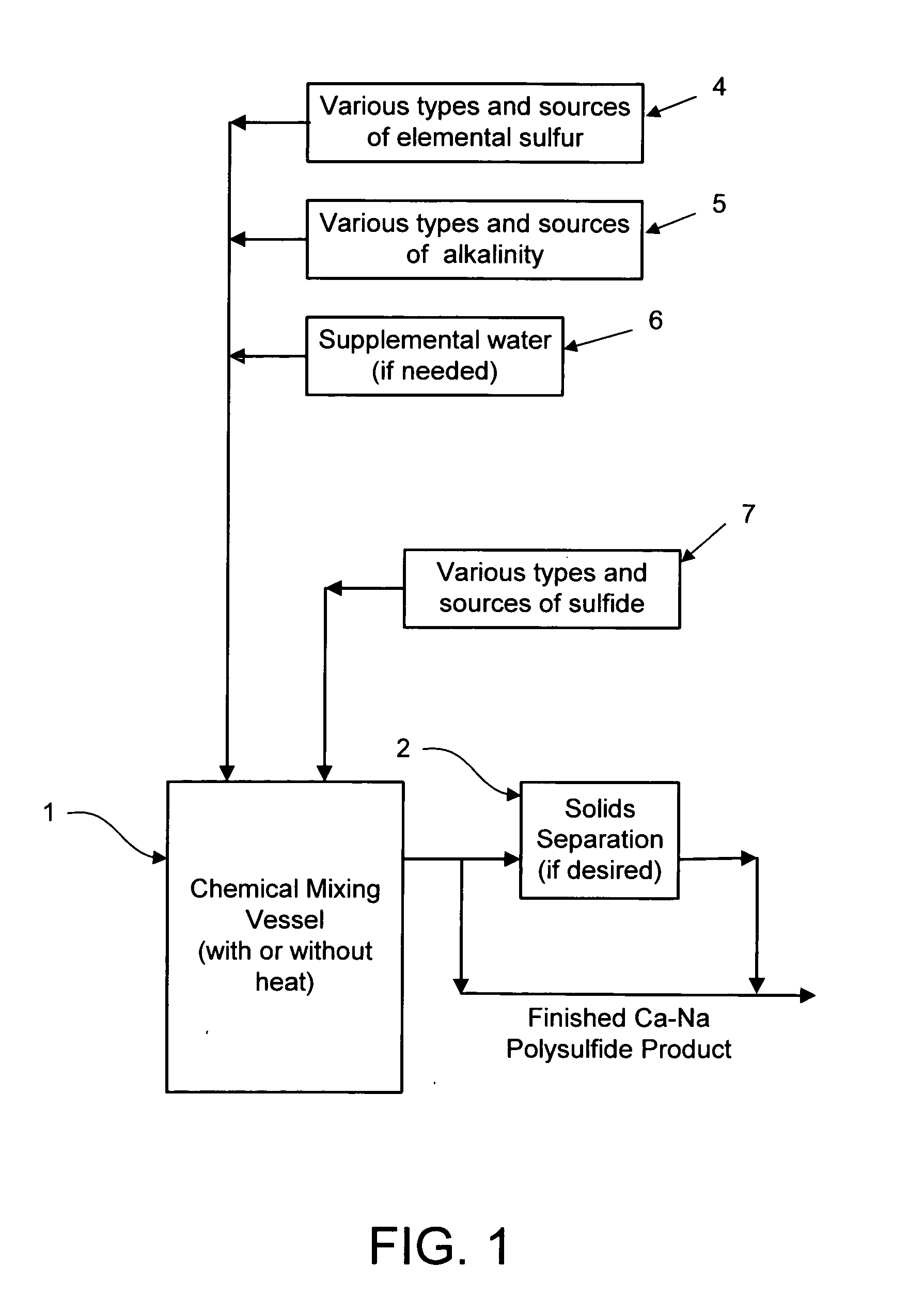

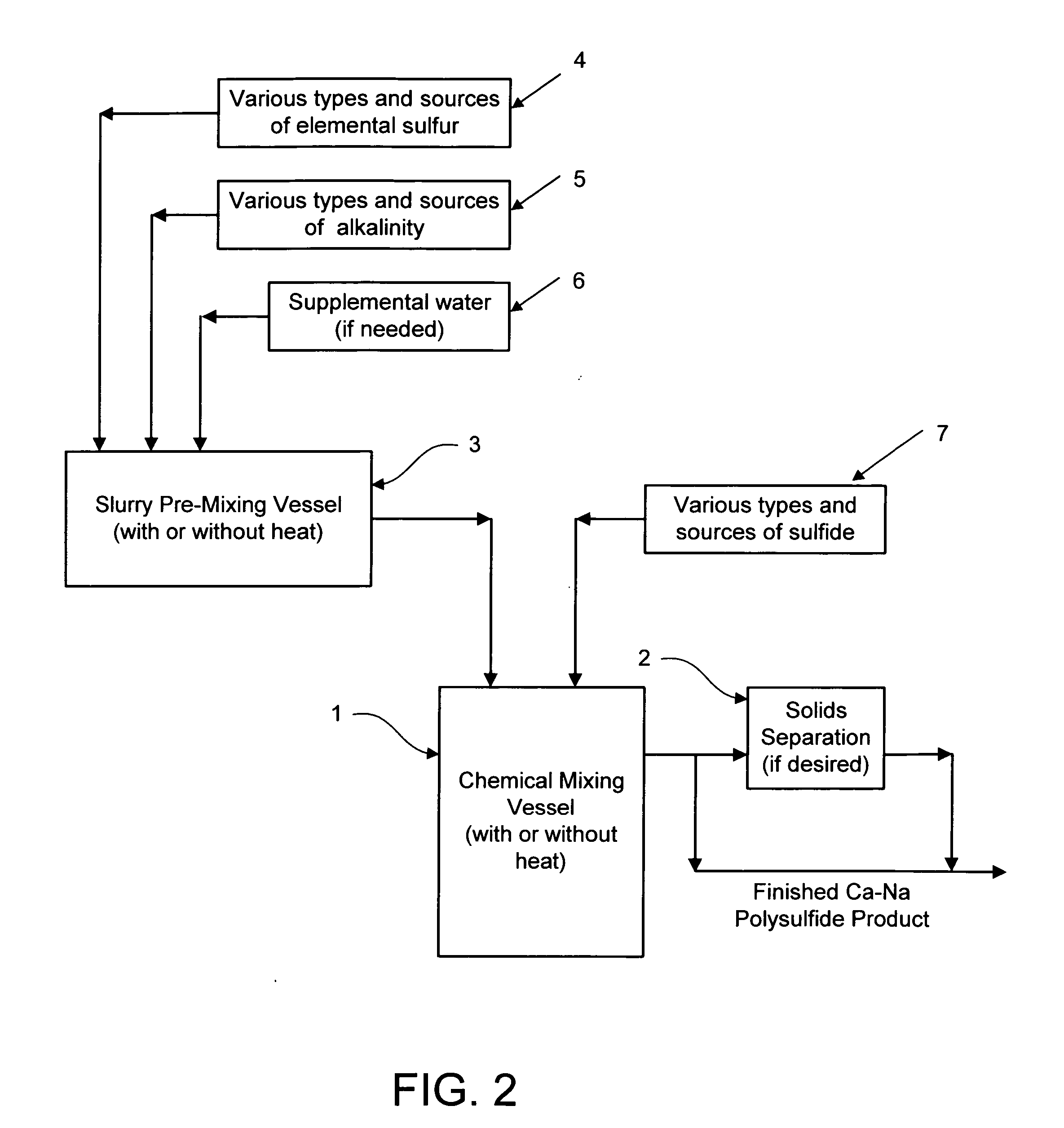

Calcium-sodium polysulfide chemical reagent and production methods

Owner:REDOX TECH GRP

Method for preparing ceramsite by utilizing dried sludge and burnt fly ash

InactiveCN102060426AAchieving simultaneous reductionAchieving processing powerSludge treatment by de-watering/drying/thickeningSodium BentoniteExpanded clay aggregate

The invention discloses a method for preparing ceramsite by utilizing dried sludge and burnt fly ash, belonging to the technology of reduction, harmless treatment and disposal and recycling of dangerous solid waste. The method comprises the following steps of: drying dewatered sludge with moisture content of 75-85% to obtain dry sludge; crushing the dry sludge, and then screening; mixing the screened dry sludge, burnt fly ash and bentonite uniformly according to a certain proportion to obtain a mixture; injecting the mixture into a powder pressing machine for extruding and forming to obtain a blank; preheating the blank at certain time; roasting the blank at high temperature at certain time; and naturally cooling to room temperature to obtain a ceramsite product. Simultaneous reduction, harmless treatment and disposal and recycling of two dangerous wastes of the burnt fly ash and municipal sludge are realized with the method, and the produced ceramsite product conforms to the standard of toxic leaching and meets the requirement of lightweight aggregate of buildings. The method has the advantages of simplicity in process, less investment, low operating cost, large required quantity of the produced ceramsite products and the like.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com