Method for processing waste slurry

A treatment method and waste mud technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc., can solve the problem of high construction cost and treatment cost, natural environment, groundwater source Hidden dangers of ecological pollution, environmental pollution and other issues, to achieve the effect of eliminating environmental pollution risks, significant economic benefits, and saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with drawings and embodiments.

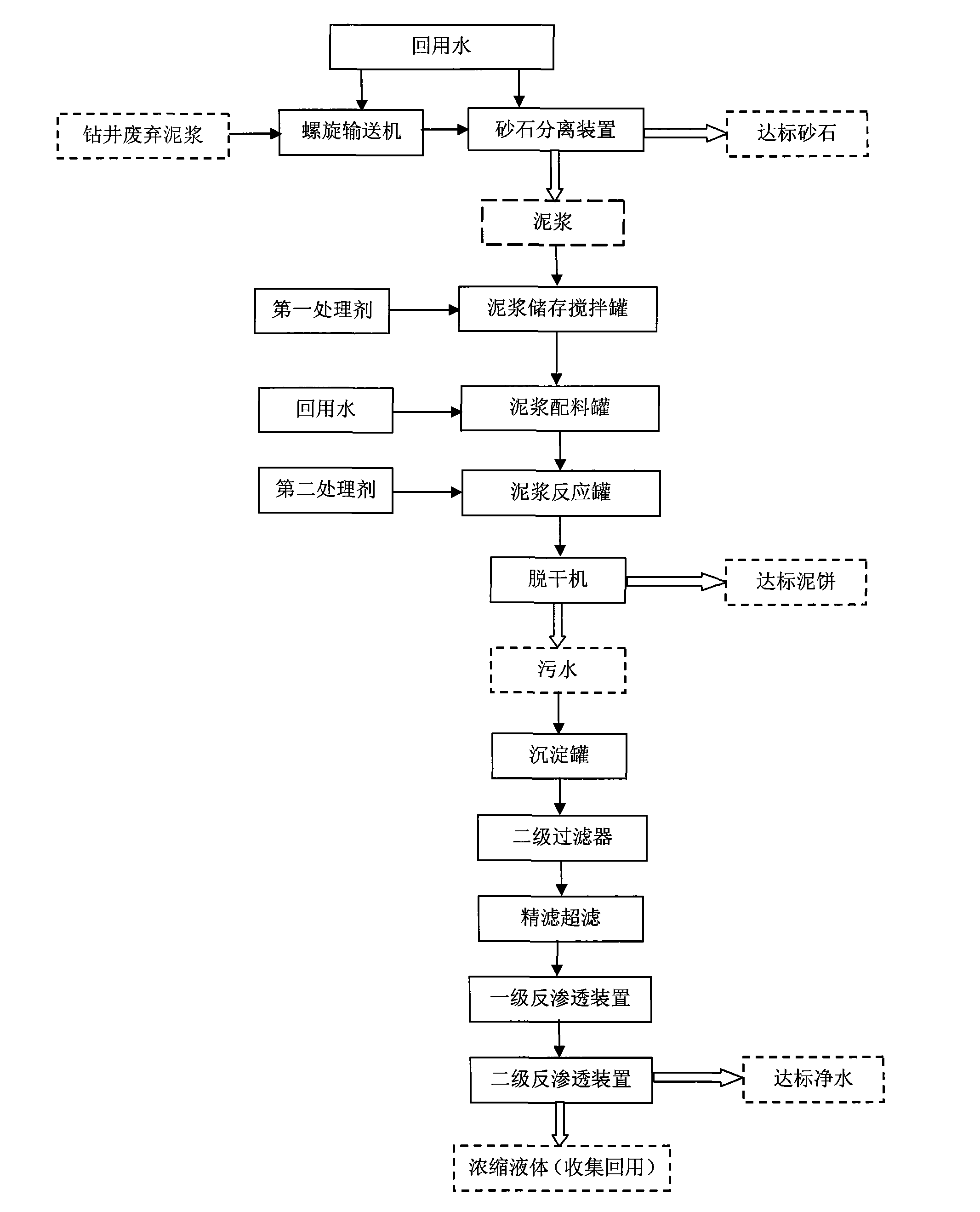

[0048] This embodiment adopts three processing units to realize the whole processing technology, and the processing flow is as follows: image 3 Shown:

[0049] 1. The first unit is mainly used to collect the hazardous drilling waste mud discharged from the drilling rig. First, it enters the screw conveyor, and then enters the sand and gravel separation device through the screw conveying and stirring. After stirring, washing and spiral separation, a large amount of mud contained in the mud is Inorganic particles and small rock pieces, cuttings, etc. are separated to alleviate and reduce the impact of such substances on subsequent processing.

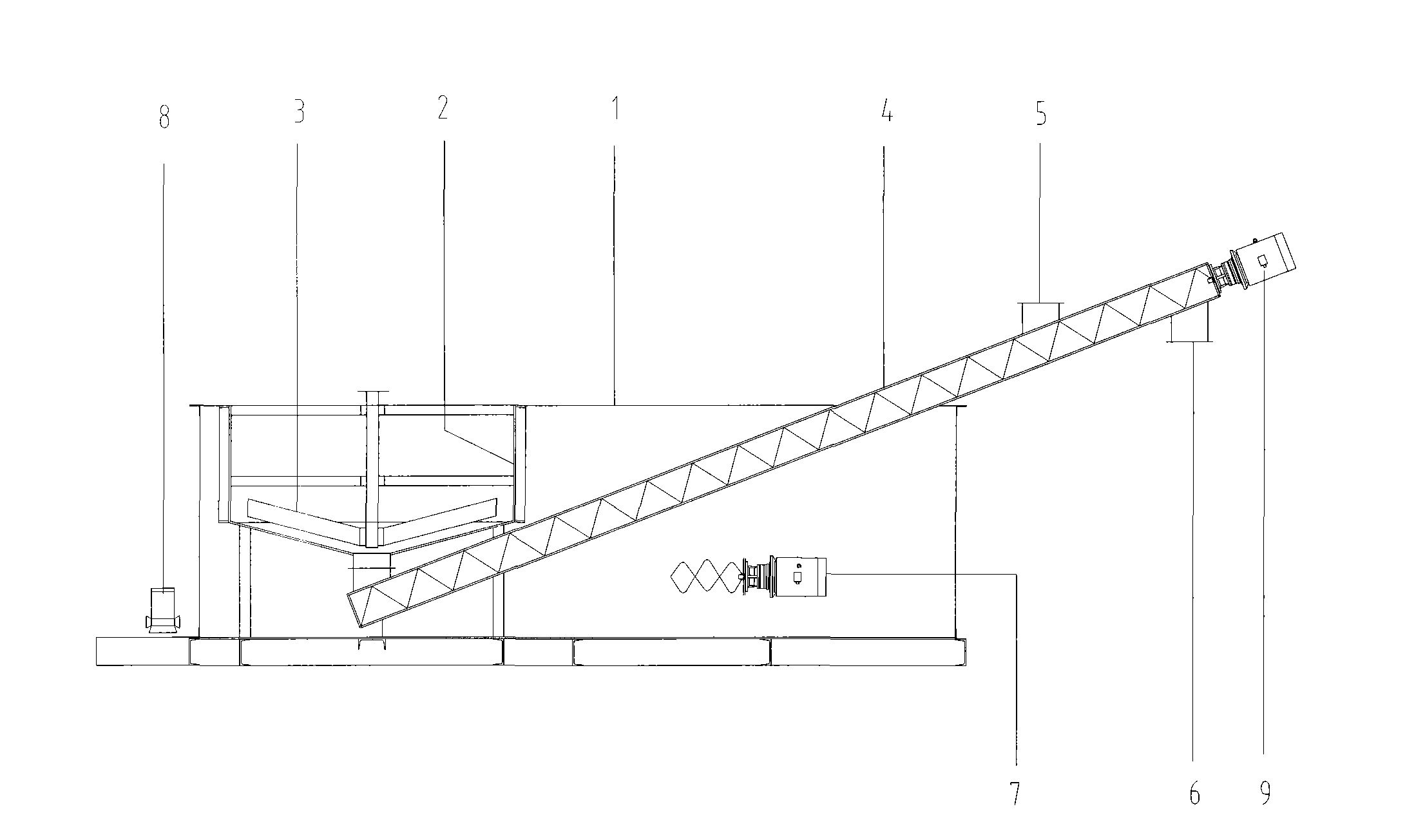

[0050] figure 1 It is a schematic diagram of a sand and gravel separation device in the form of a fixed sieve, including a box-shaped tank 1, and a cylindrical funnel-shaped fixed sieve 2 is arranged in the tank 1, and an anchor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com