Patents

Literature

13136results about "Shock proofing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

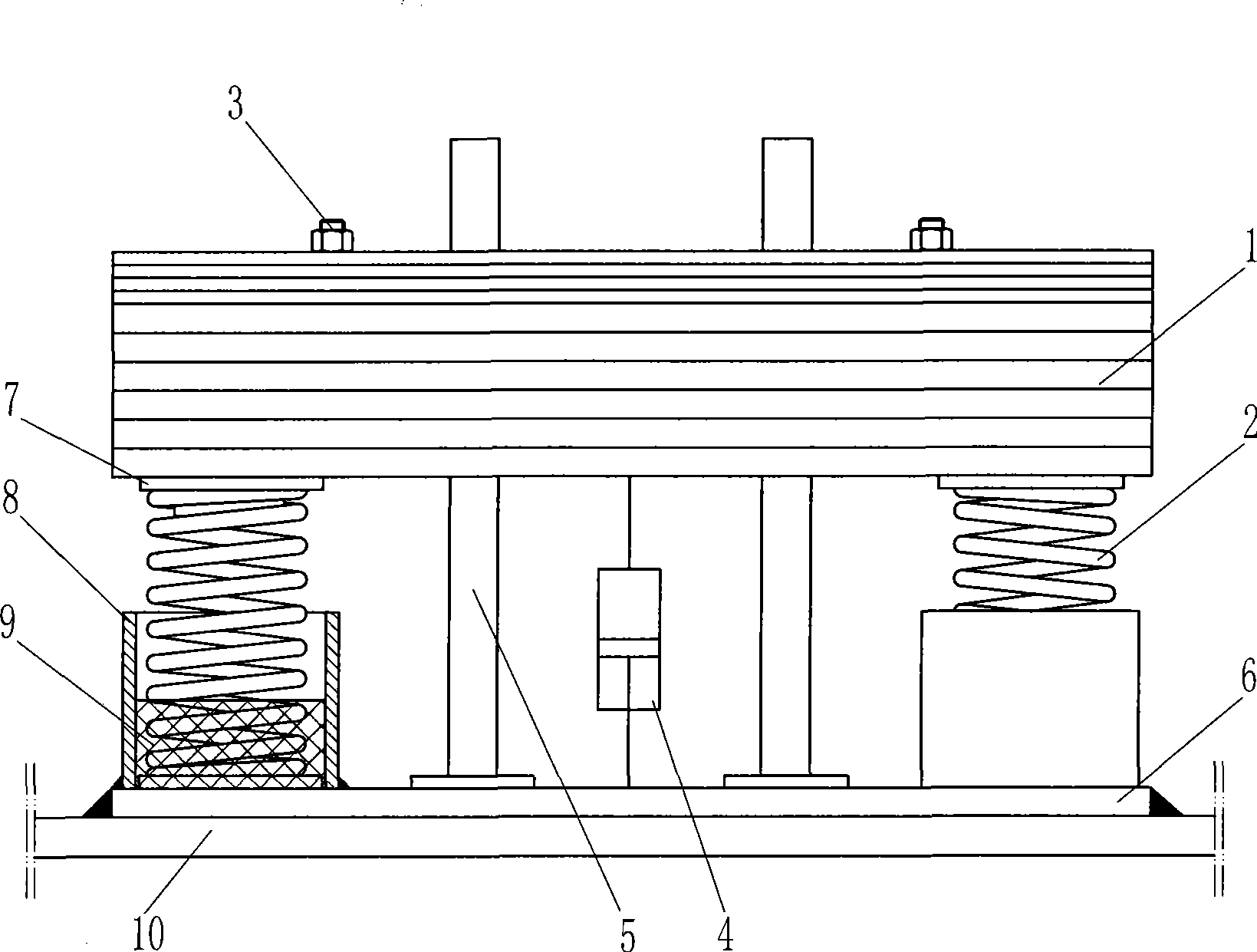

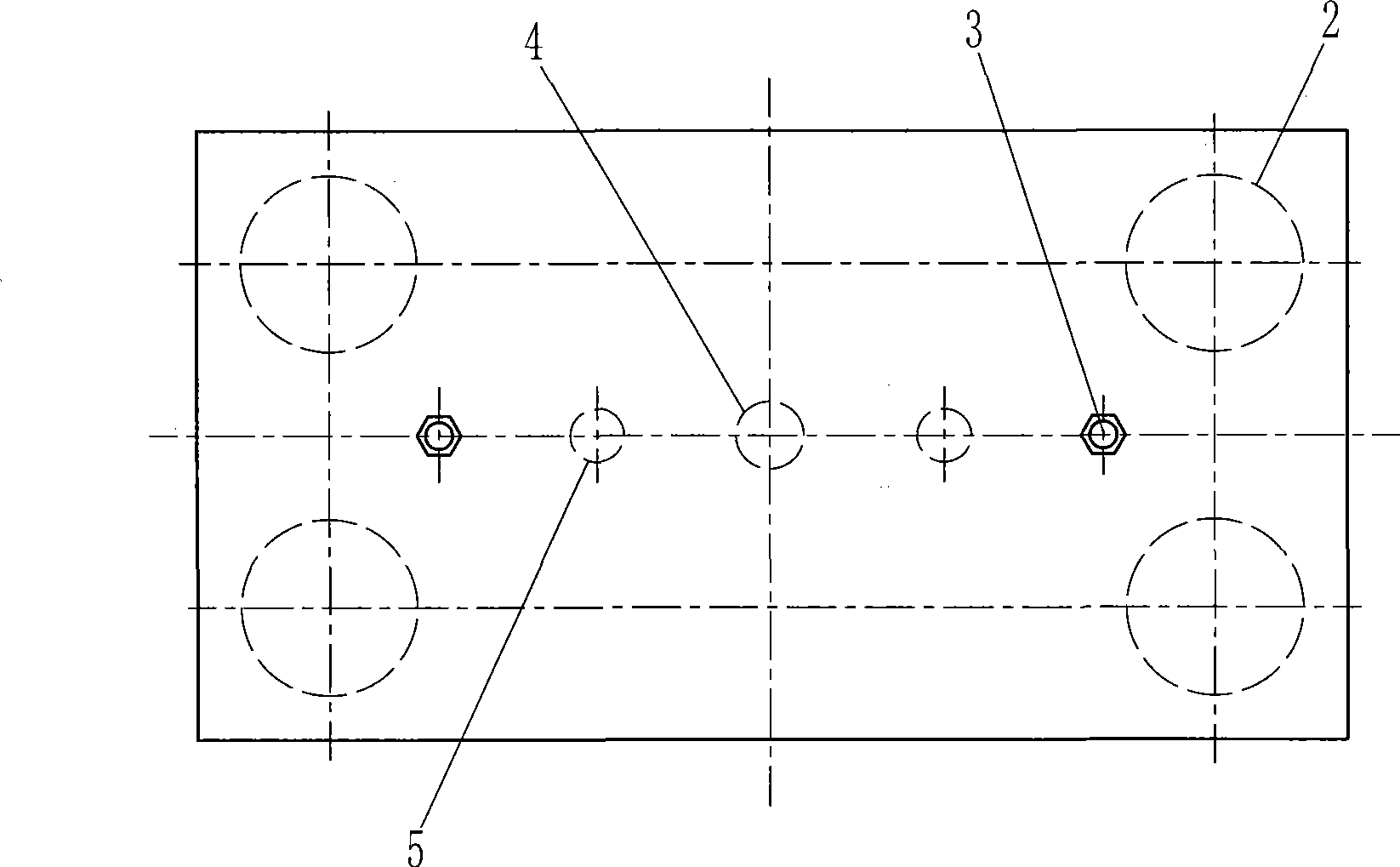

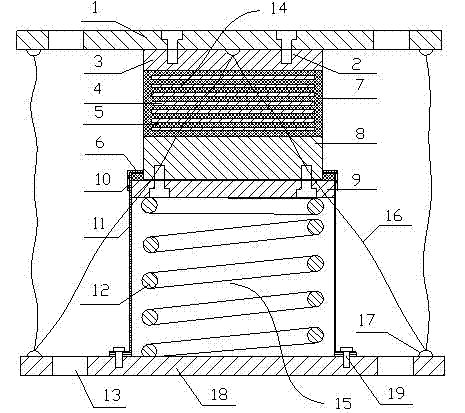

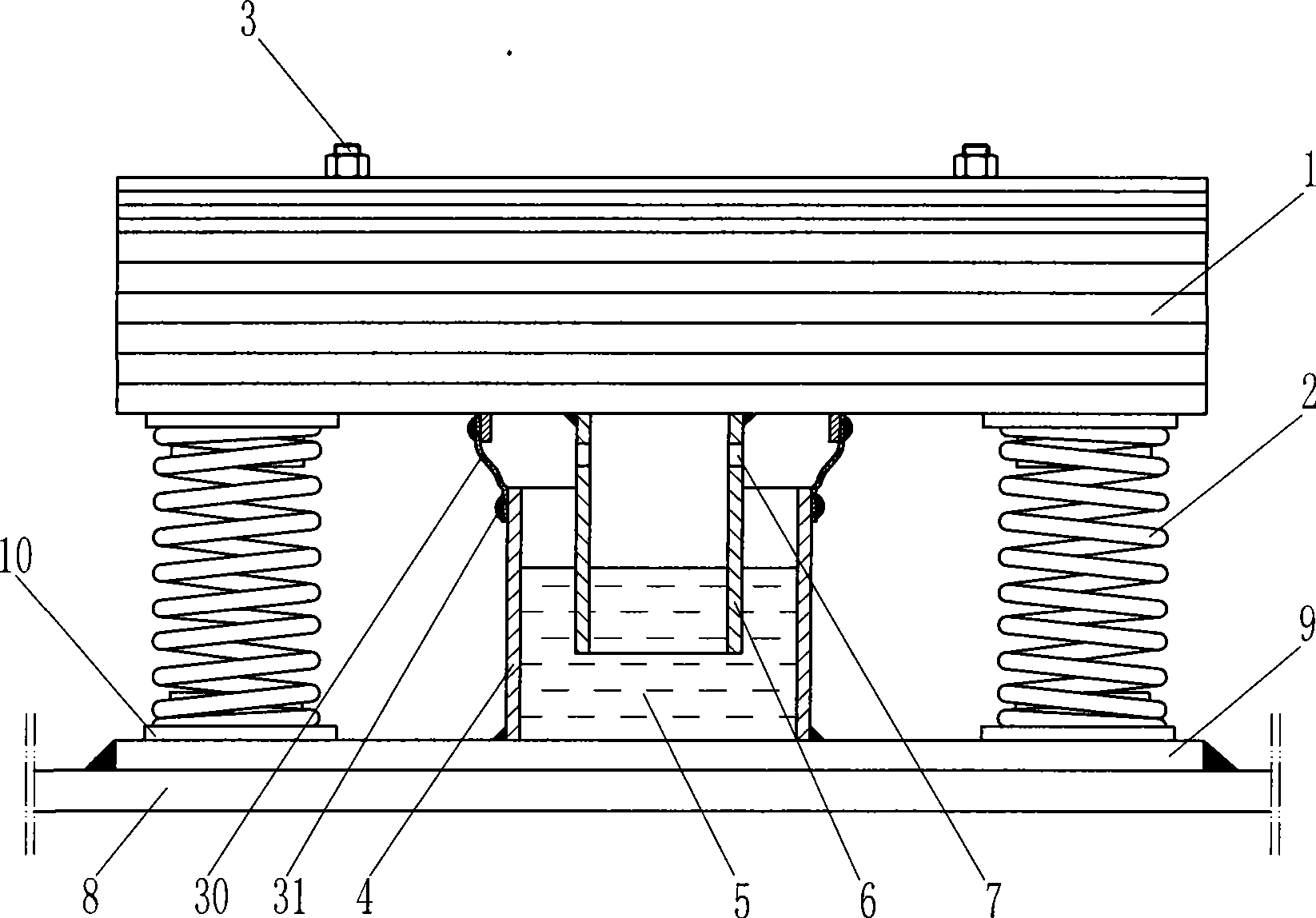

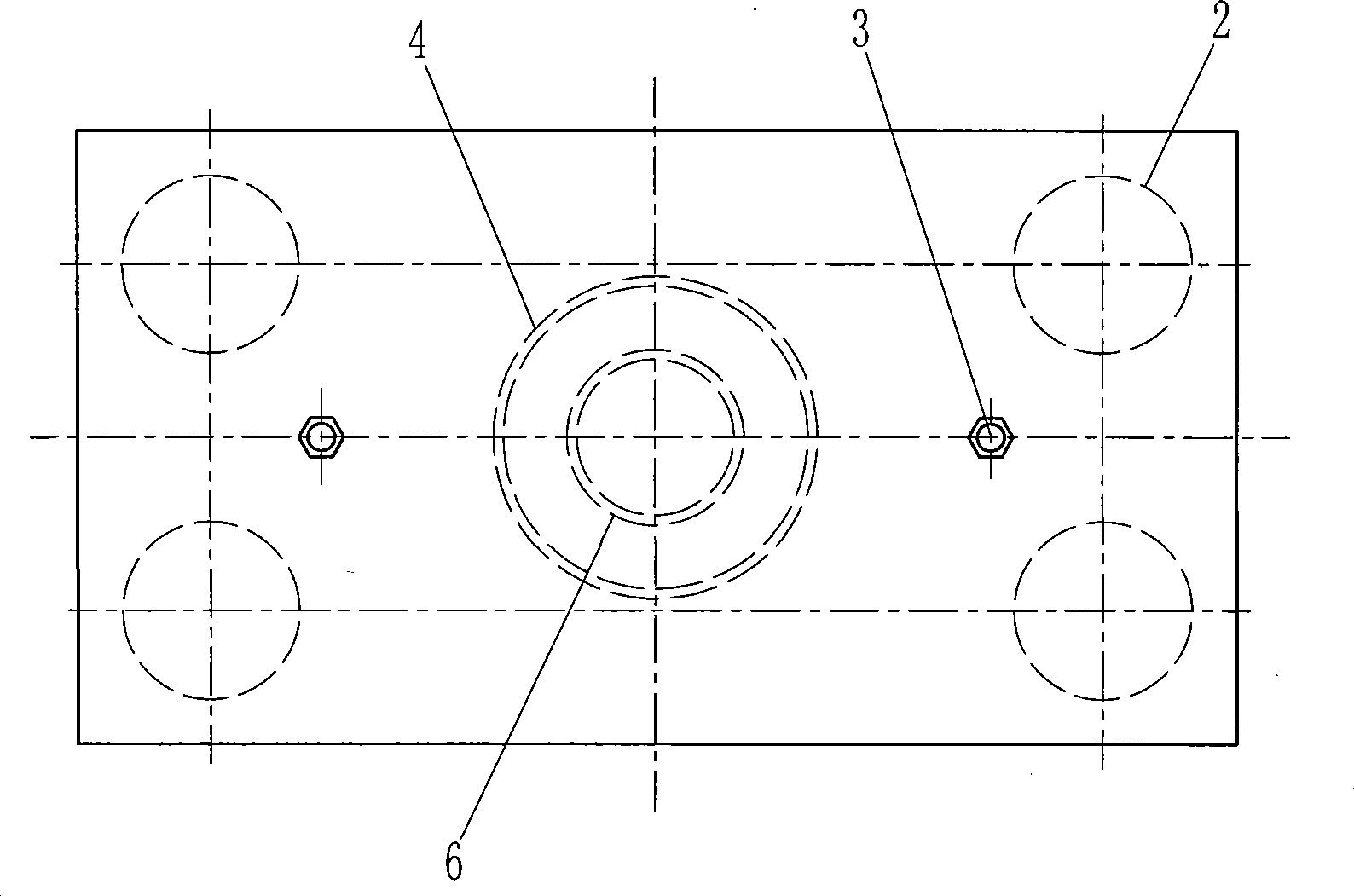

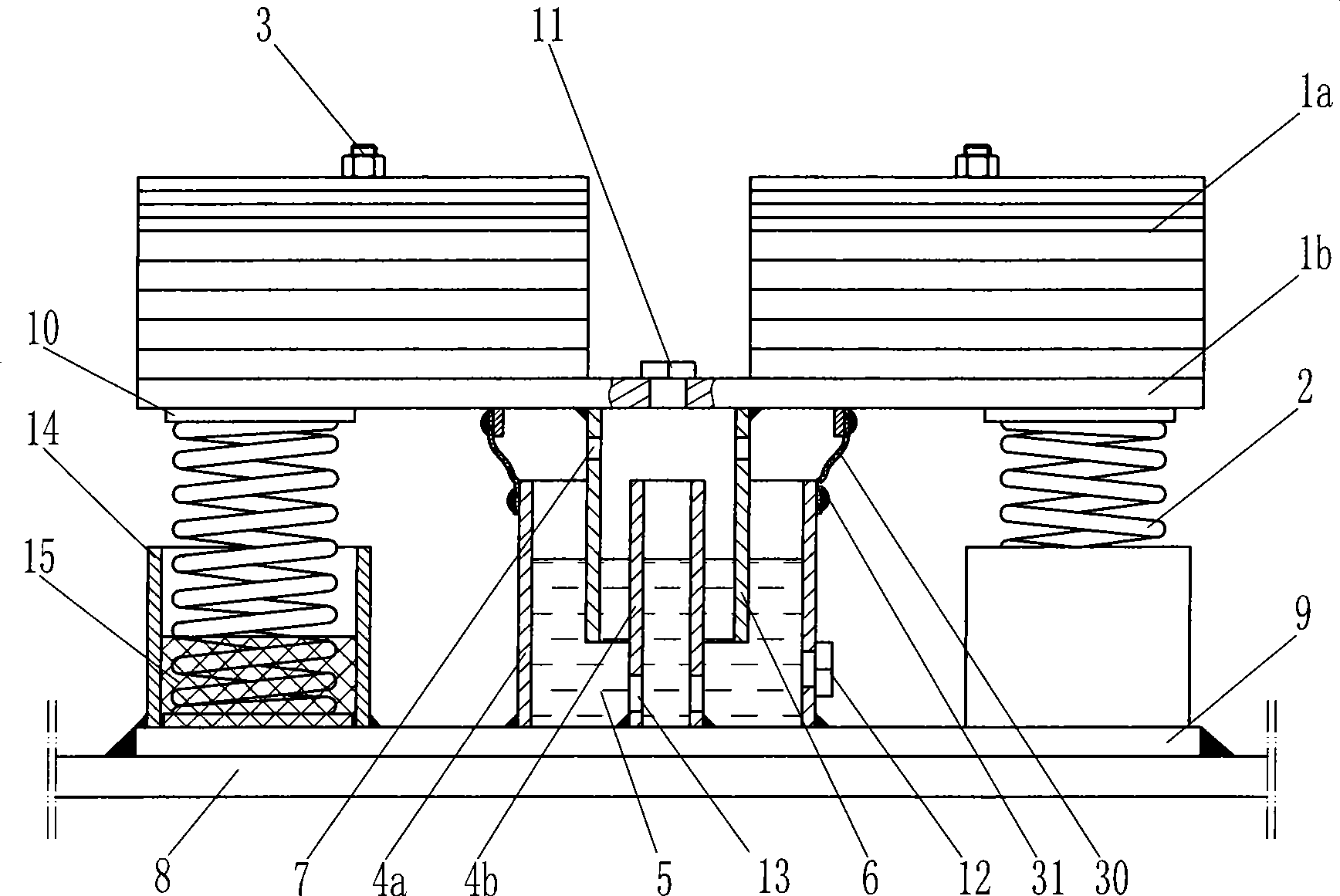

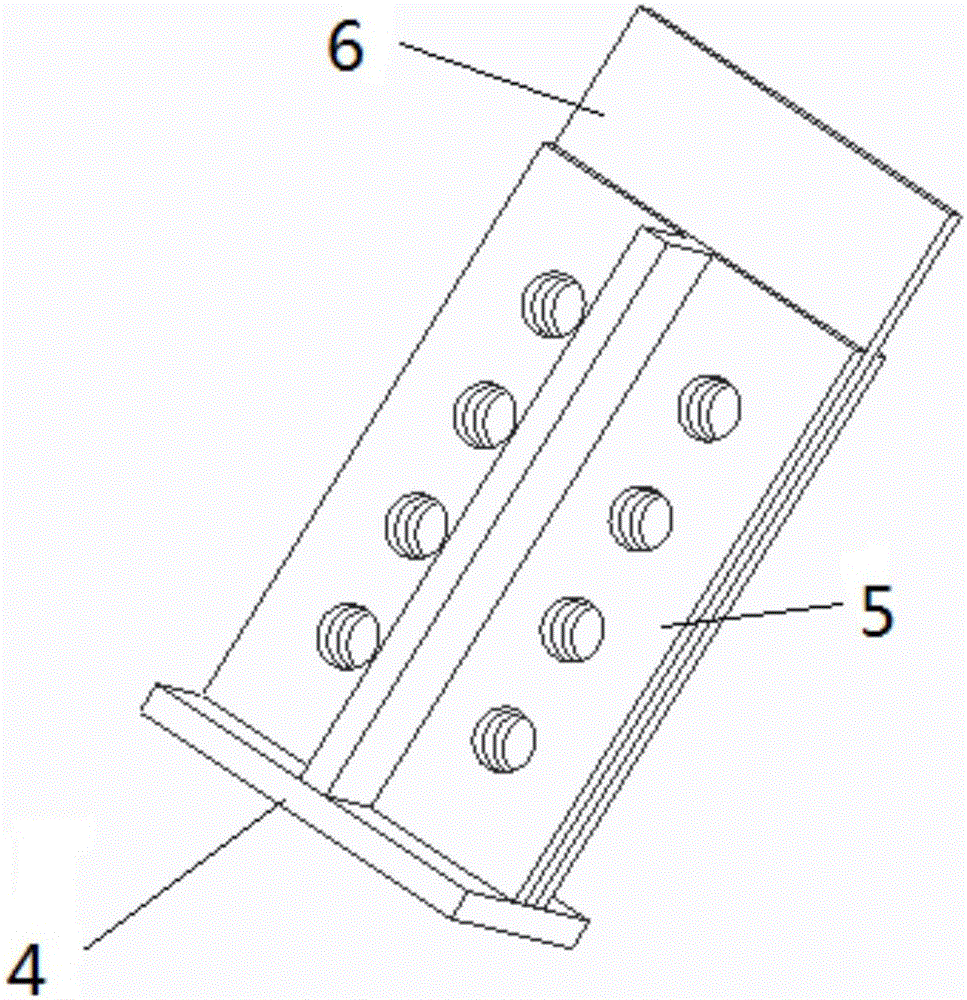

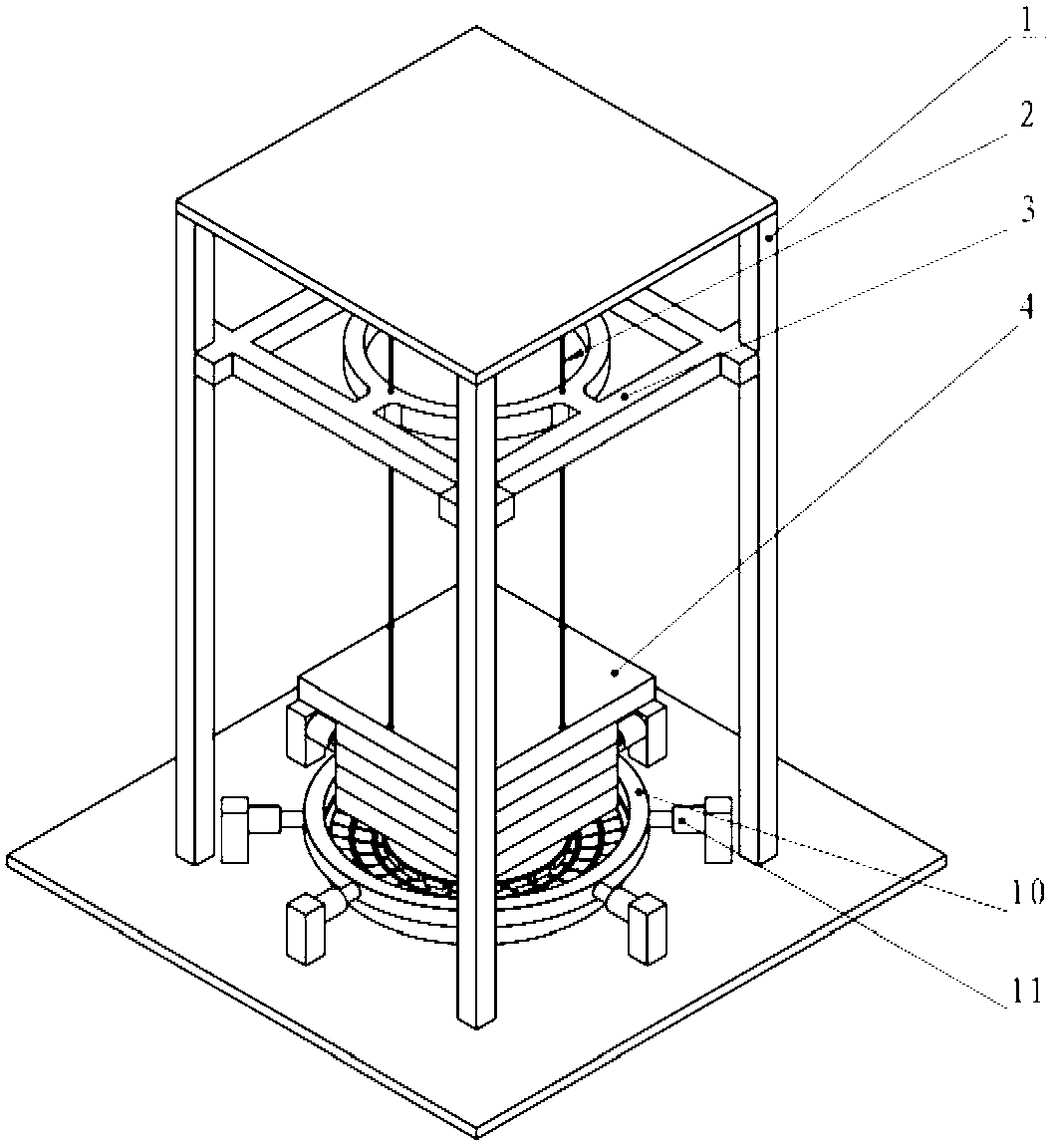

Spring stiffness adjustable tuning quality damper

ActiveCN101457553ASmooth movementSolution to short lifeSpringsSolid based dampersSocial benefitsCoil spring

The invention specifically relates to a mass tuned vibration reducer used for controlling the vibration of an aerobridge in the airport, a large-span pedestrian bridge, a port trestle, high-rise buildings and the related structures. The mass tuned vibration reducer comprises a mass block, a spring, a damper and a base; wherein, the spring can be a spiral spring, a disc spring or a plate spring, and the end part of the spring is provided with a rigidity regulating device. The mass tuned vibration reducer can successfully realize the regulation on the natural frequency of a TMD system under the condition of needing not to assemble and disassemble the TMD since the end part of the spring is provided with the rigidity regulating device, so as to simplify the difficulty of regulation work, avoid the waste of manpower and materials and greatly reduce the construction cost. Meanwhile, the natural frequency and the damping of the system can be regulated in an optimized way under the condition of needing not to assemble and disassemble the TMD, thereby better exerting the vibration absorption performance of the mass tuned vibration reducer, ensuring safety and stableness of the pedestrians and vehicles on the large-span bridge and the thin and high building, contributing to prolonging the service lives of the thin and high building and the bridge, and having remarkable economic and social benefits.

Owner:尹学军 +1

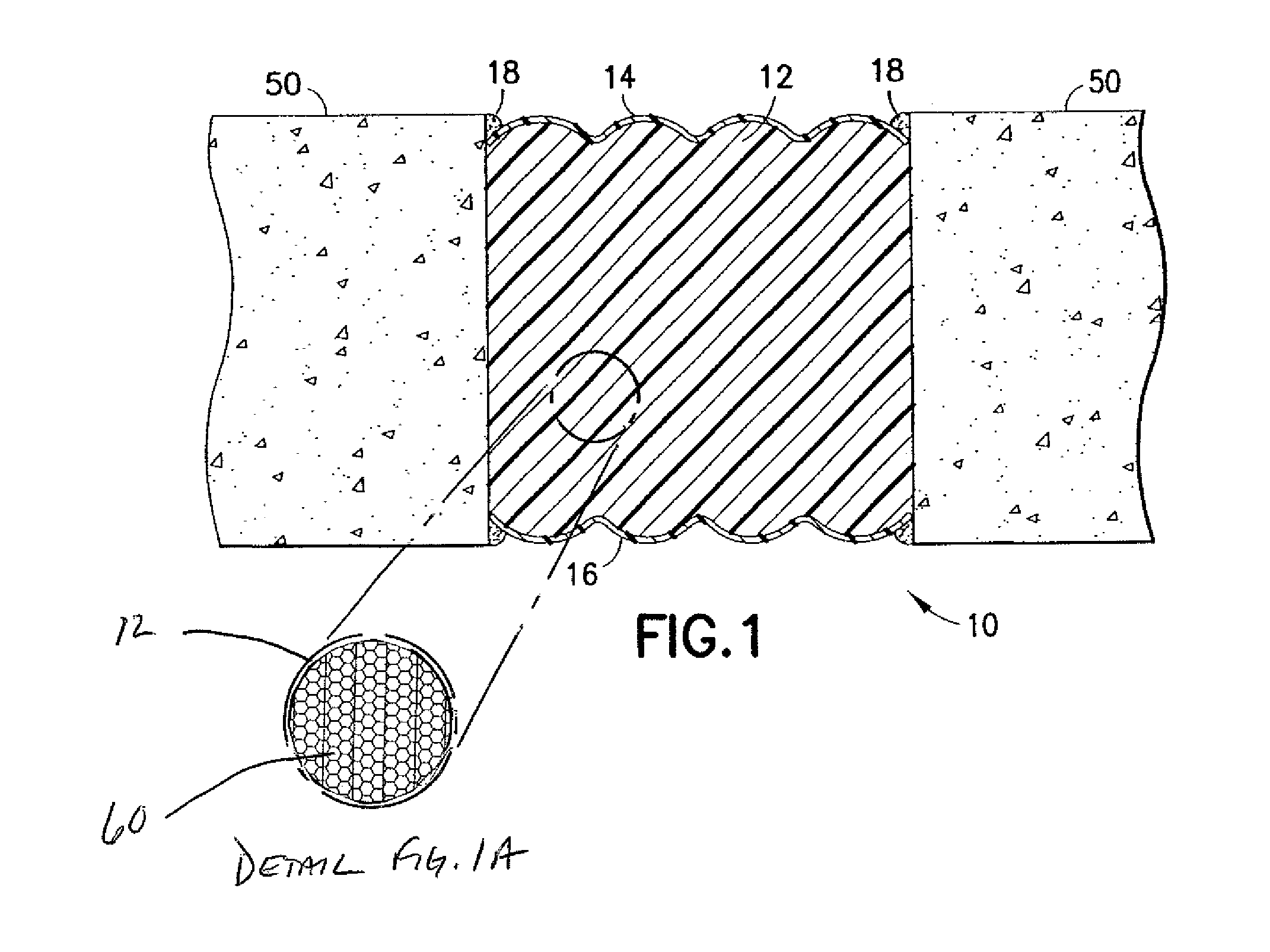

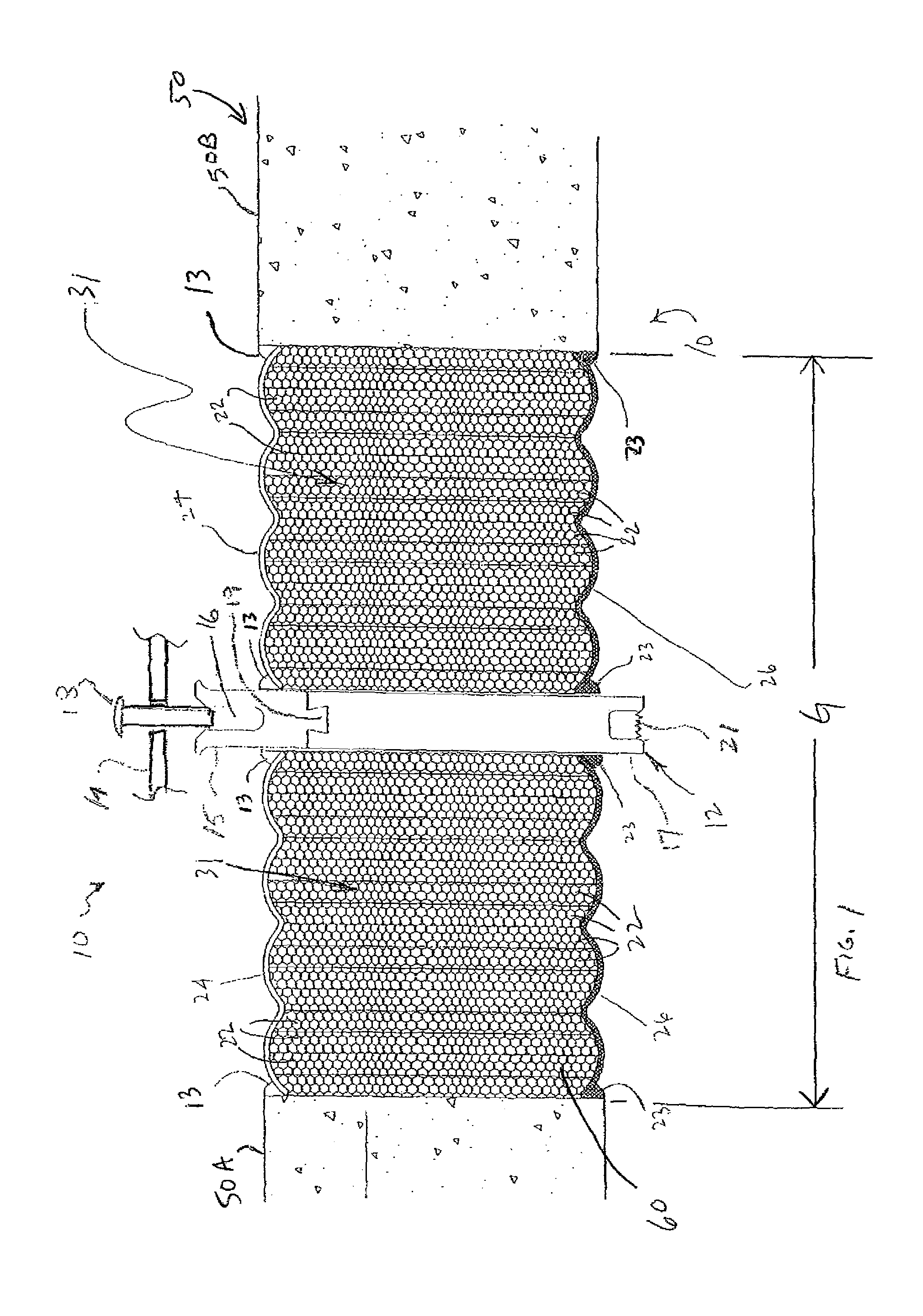

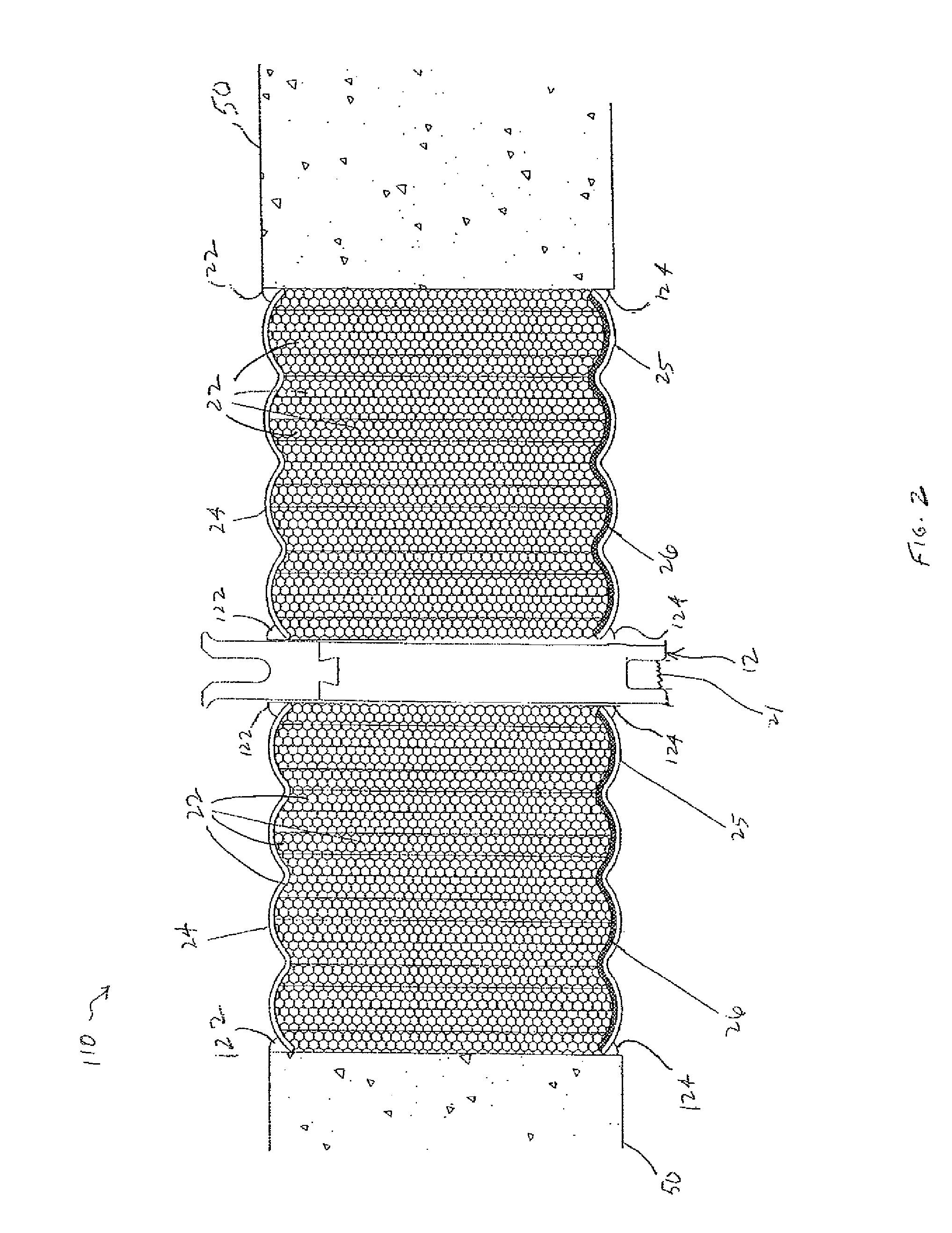

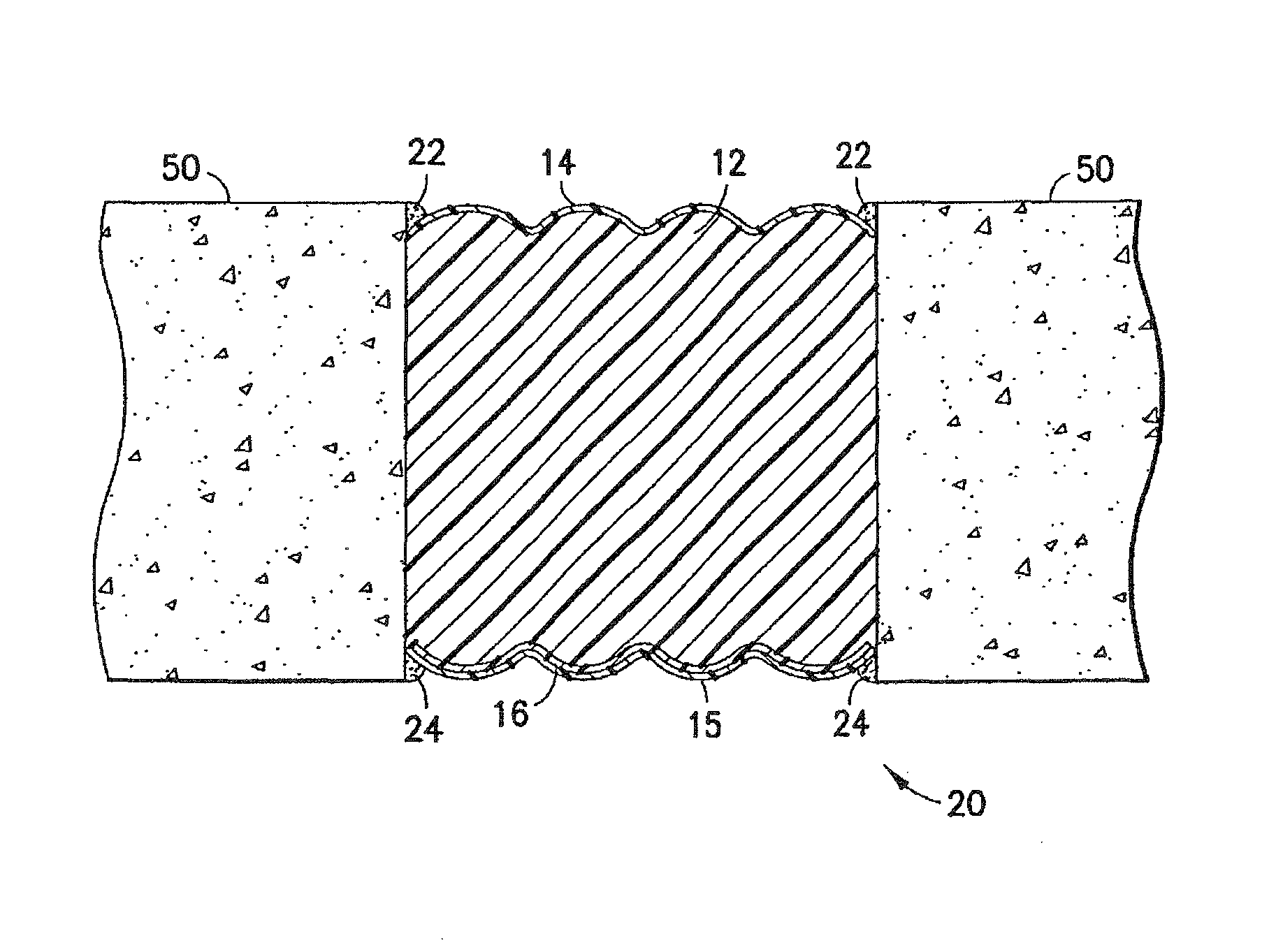

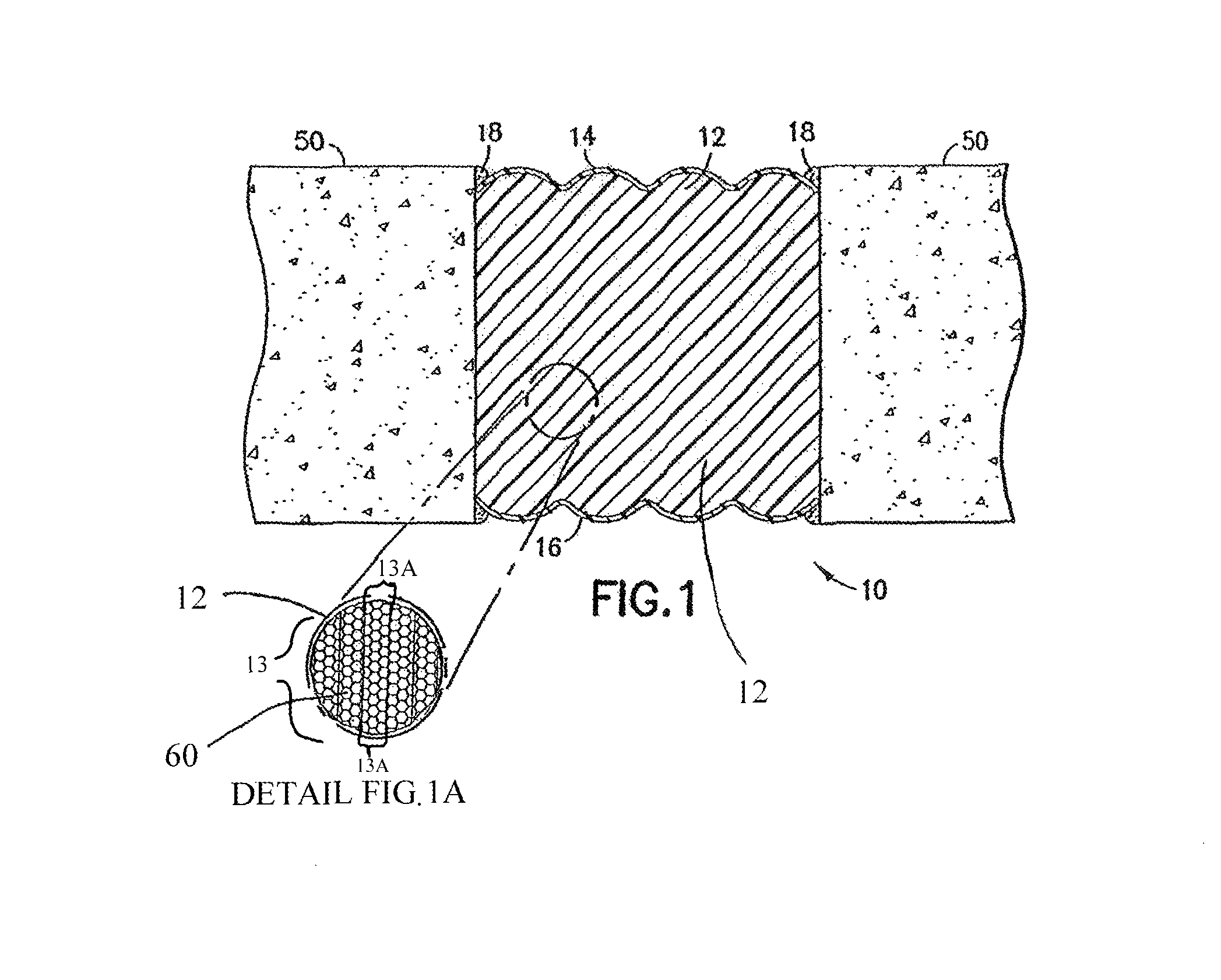

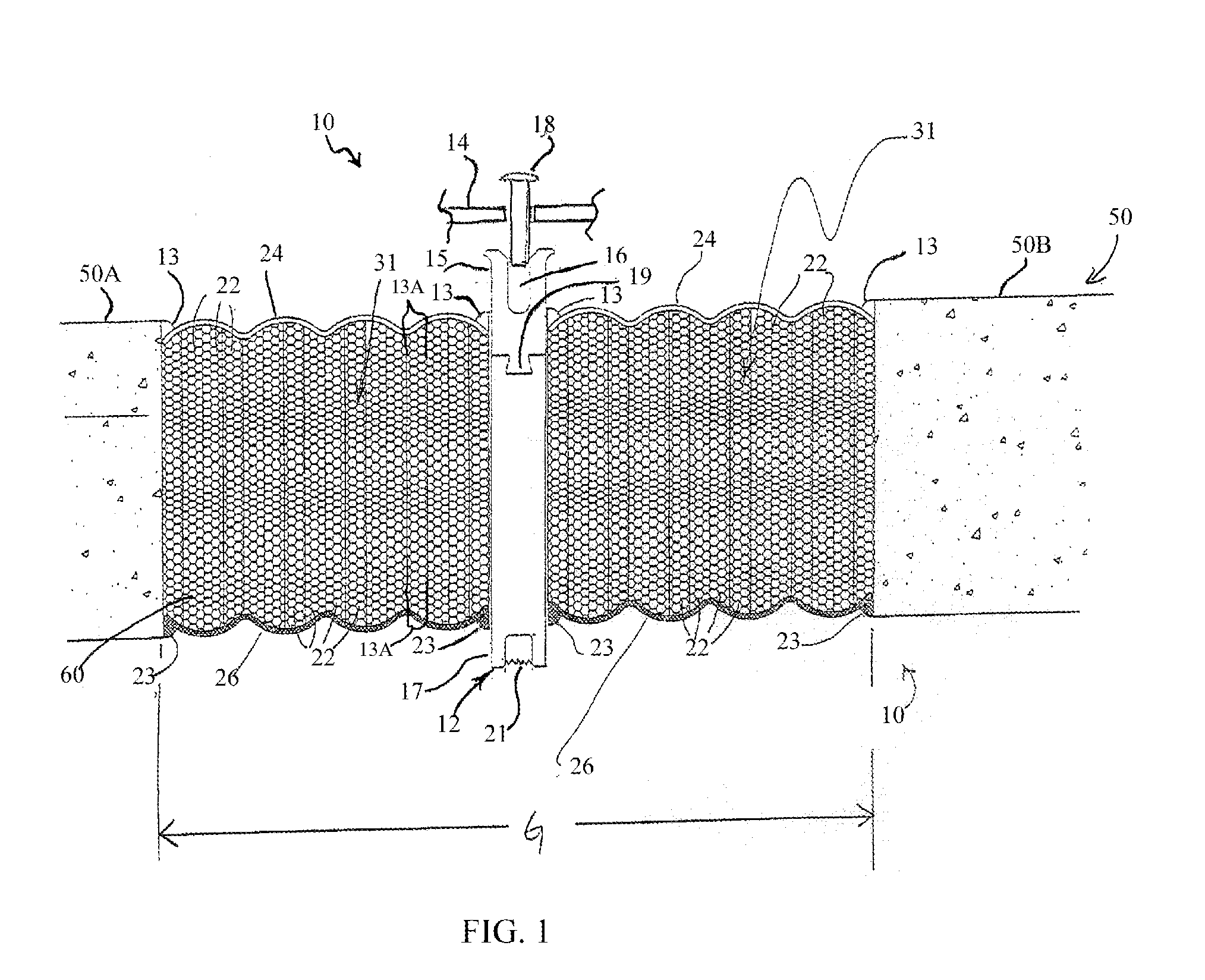

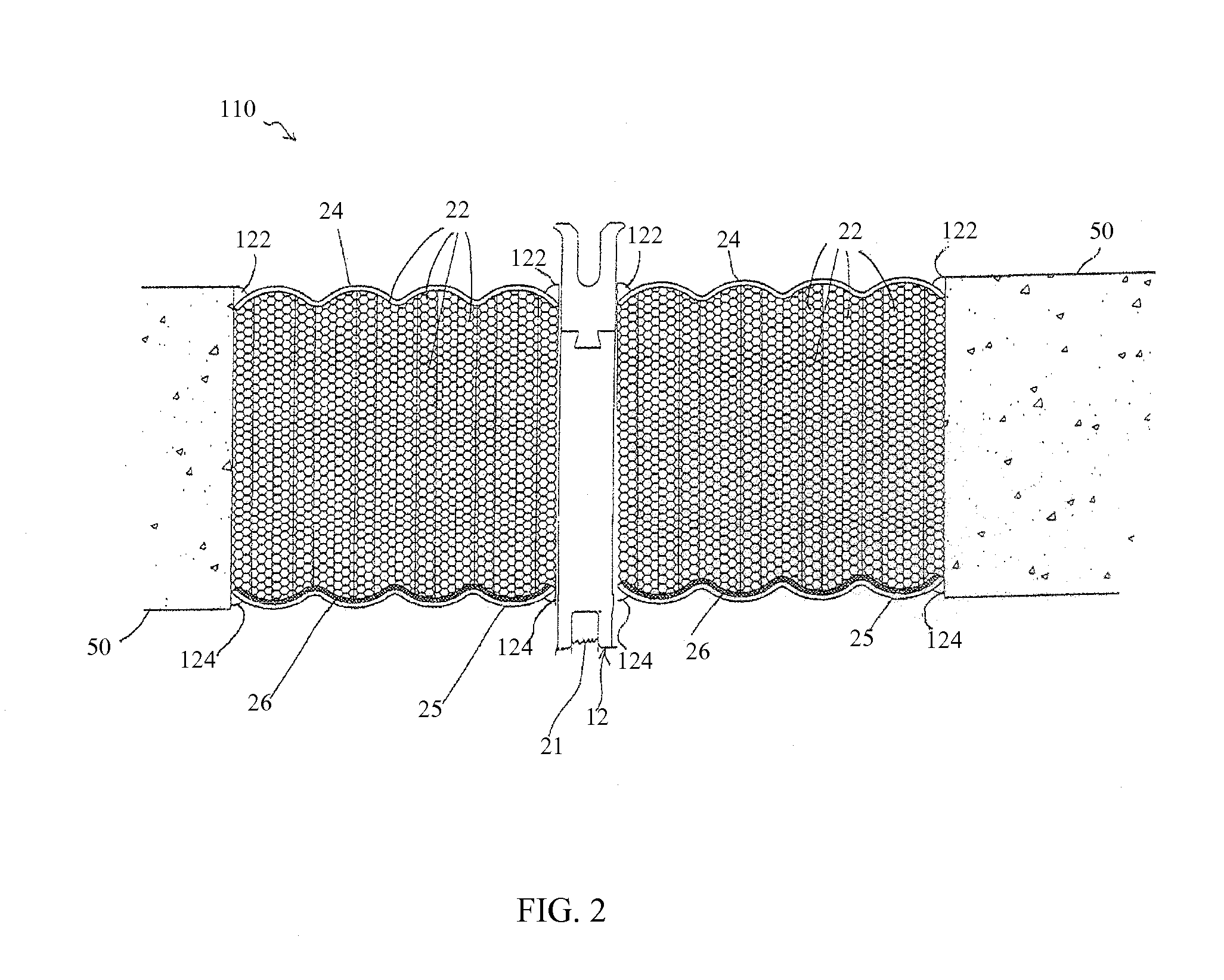

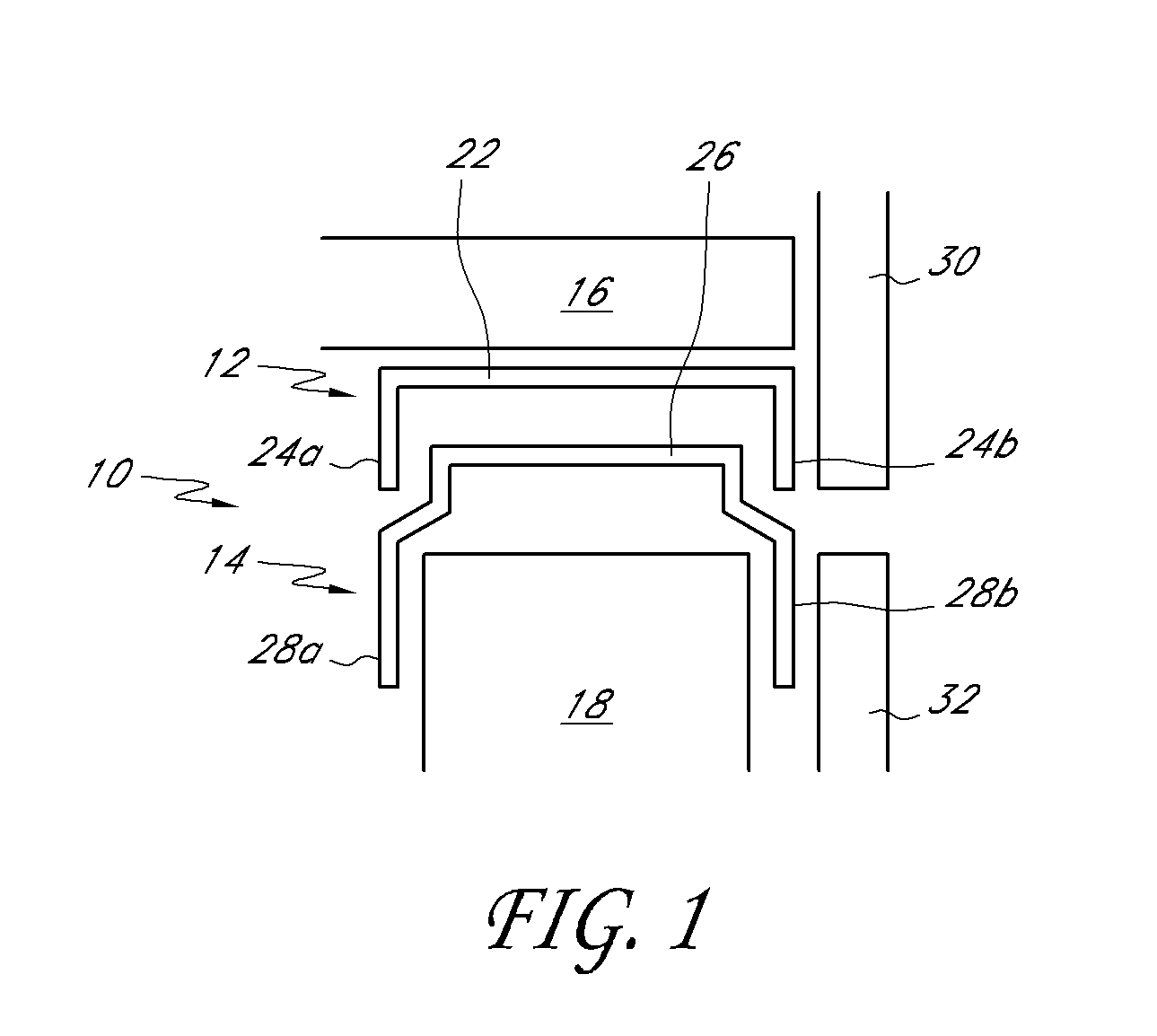

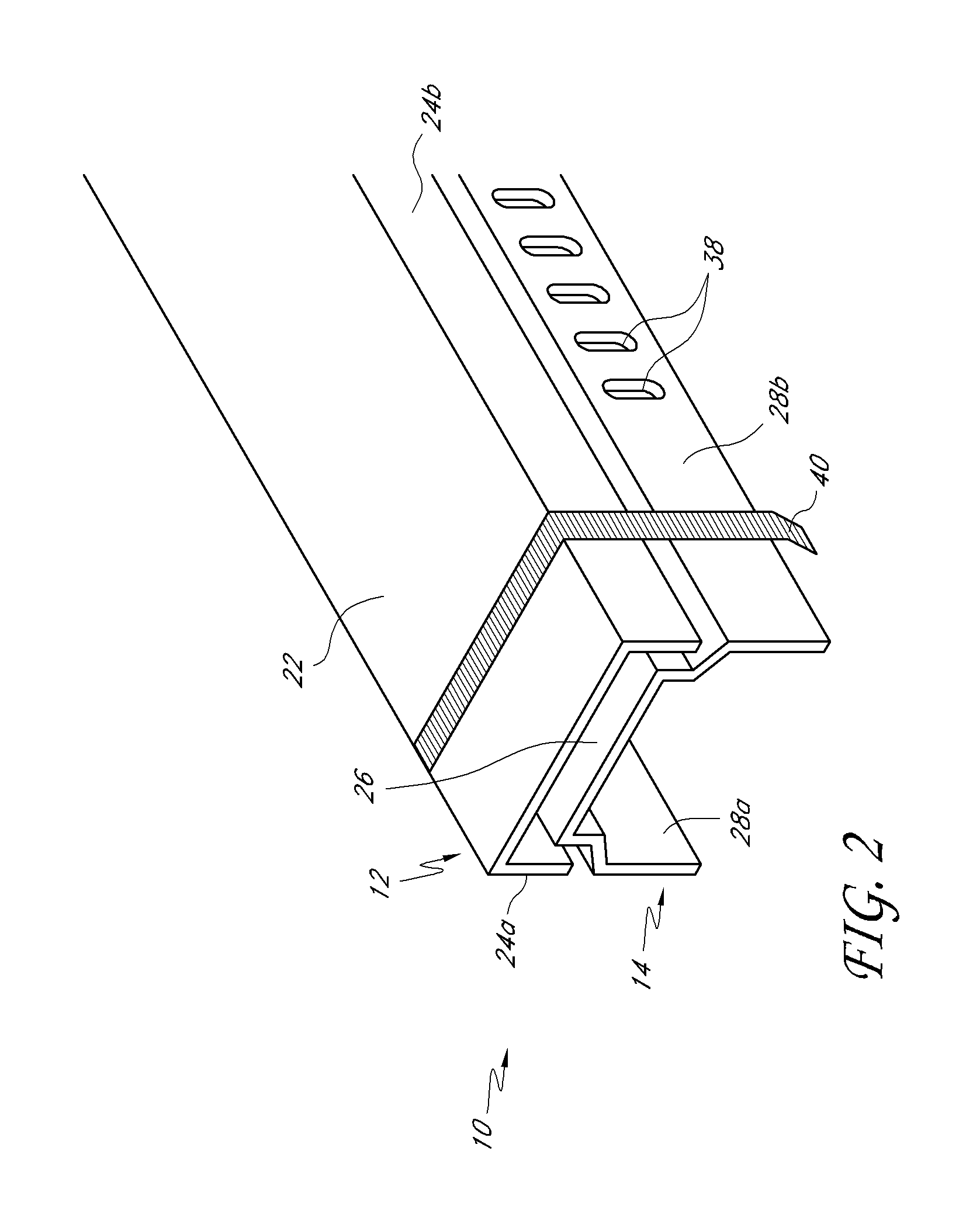

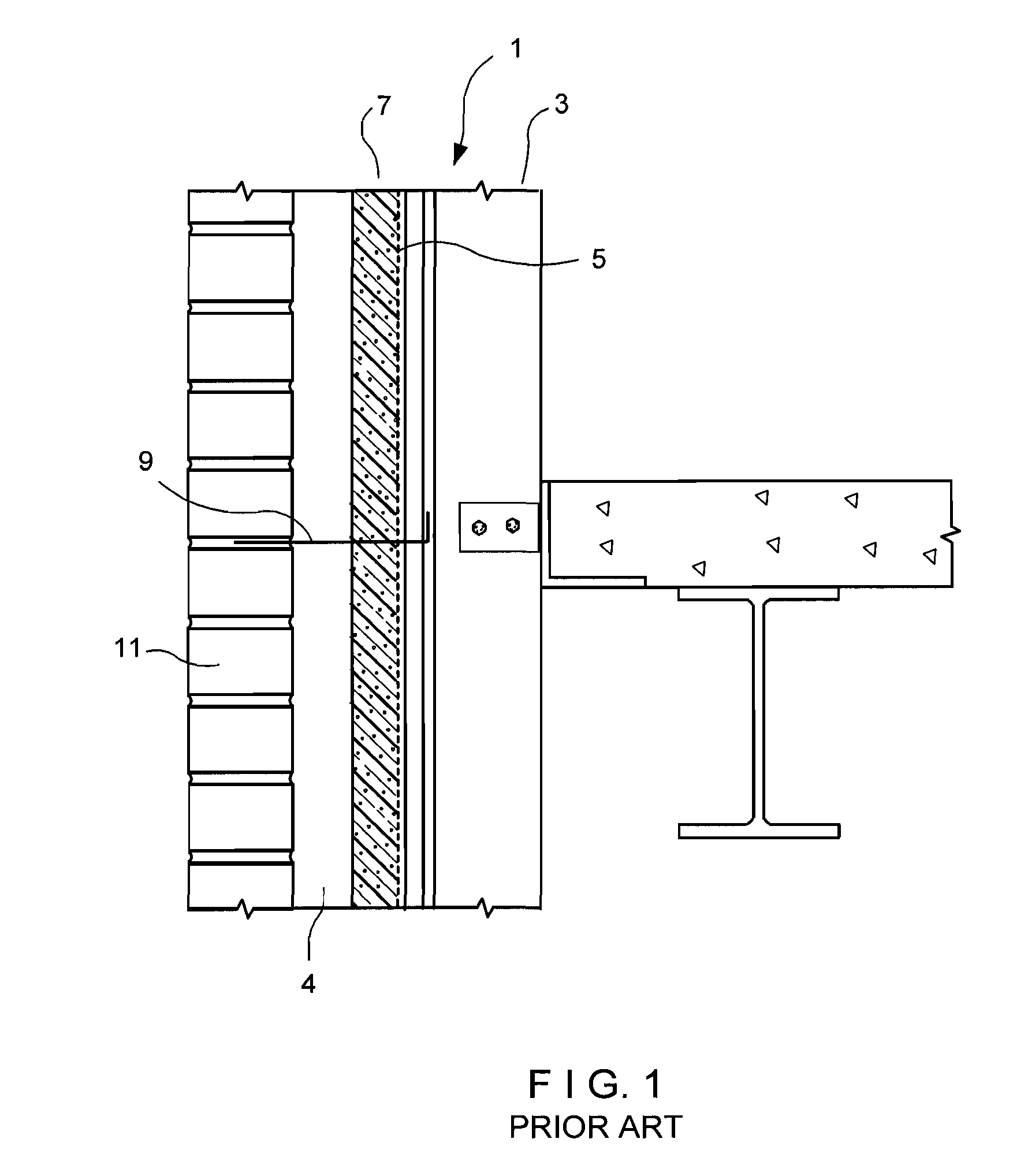

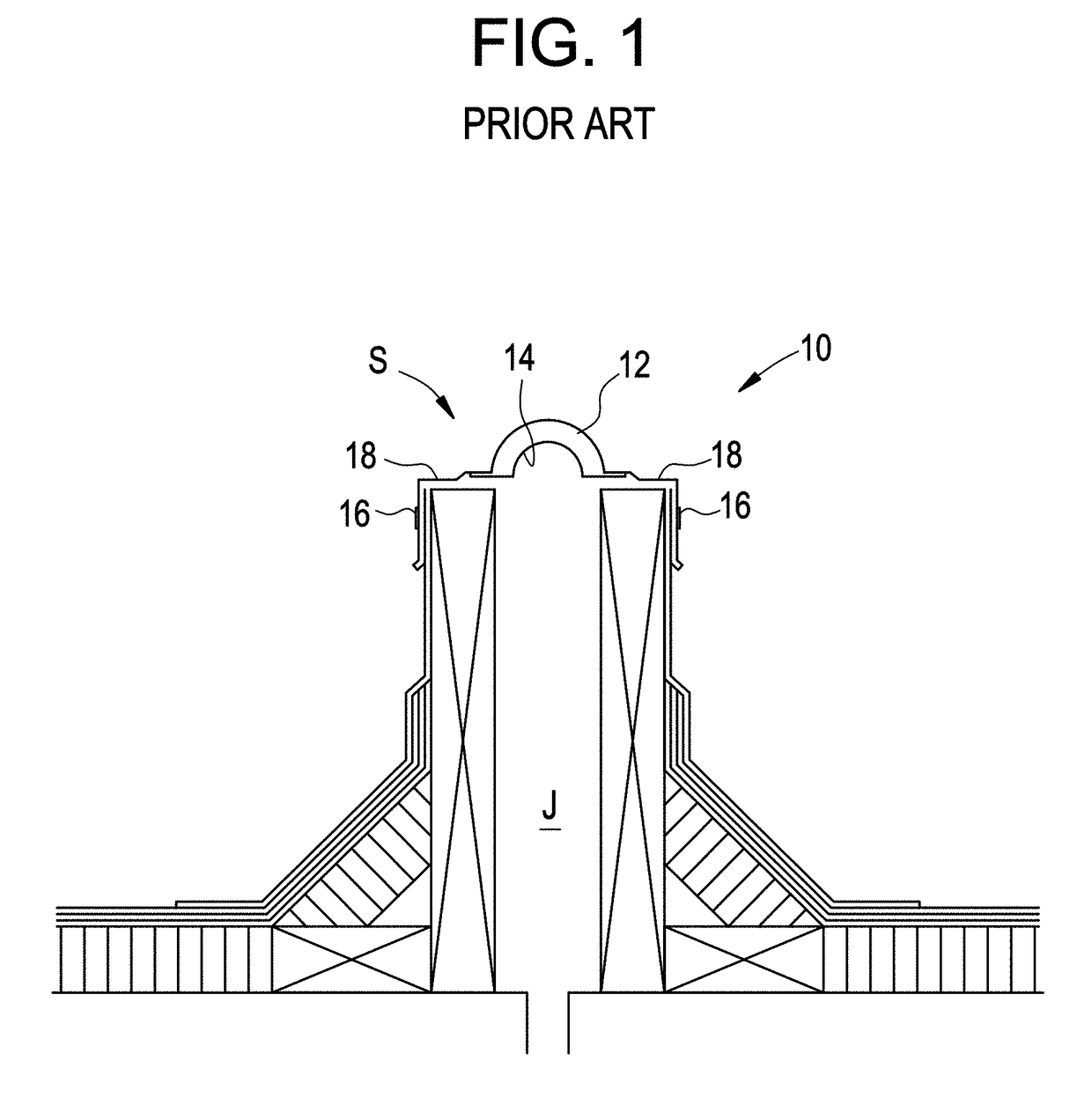

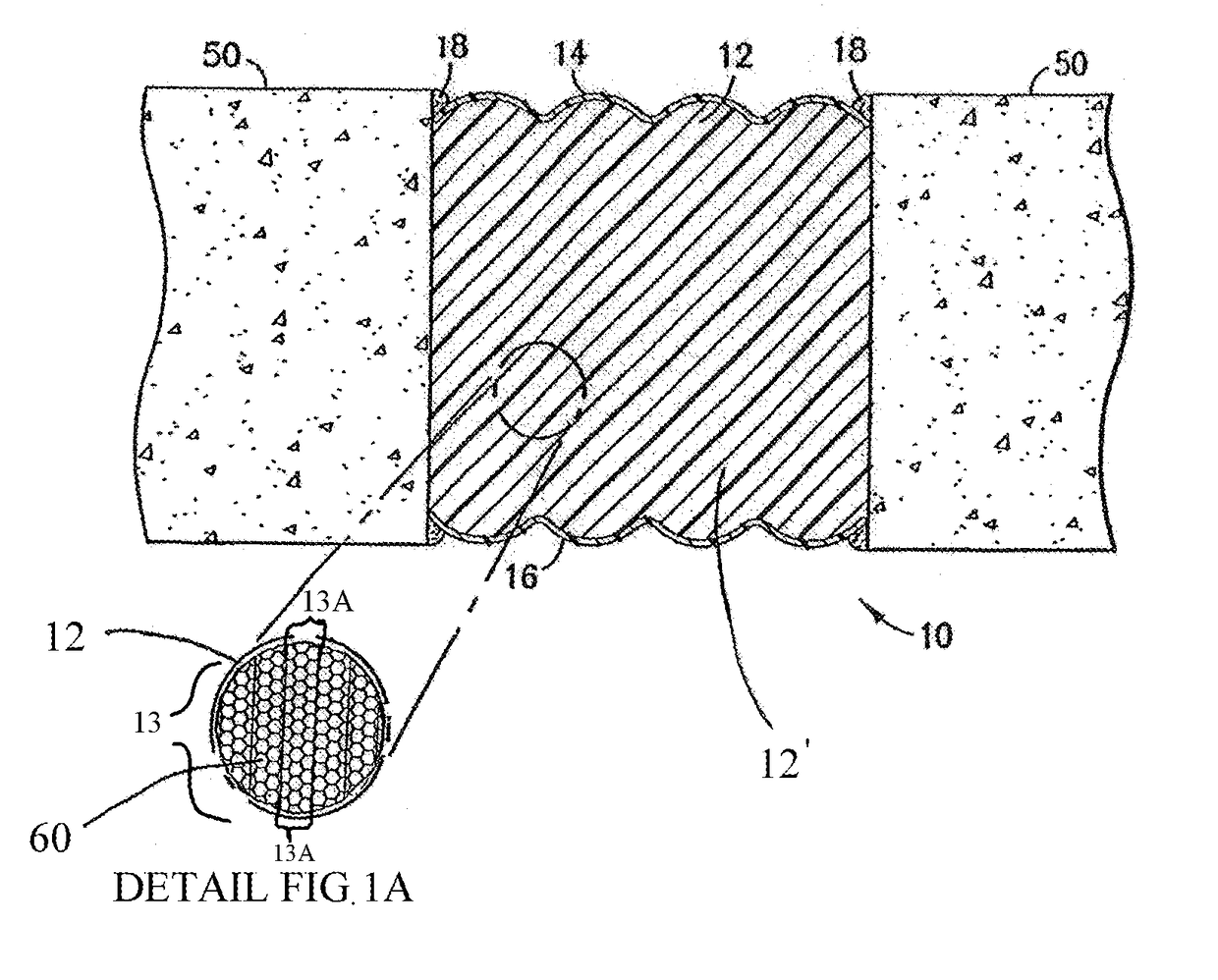

Fire and water resistant expansion joint system

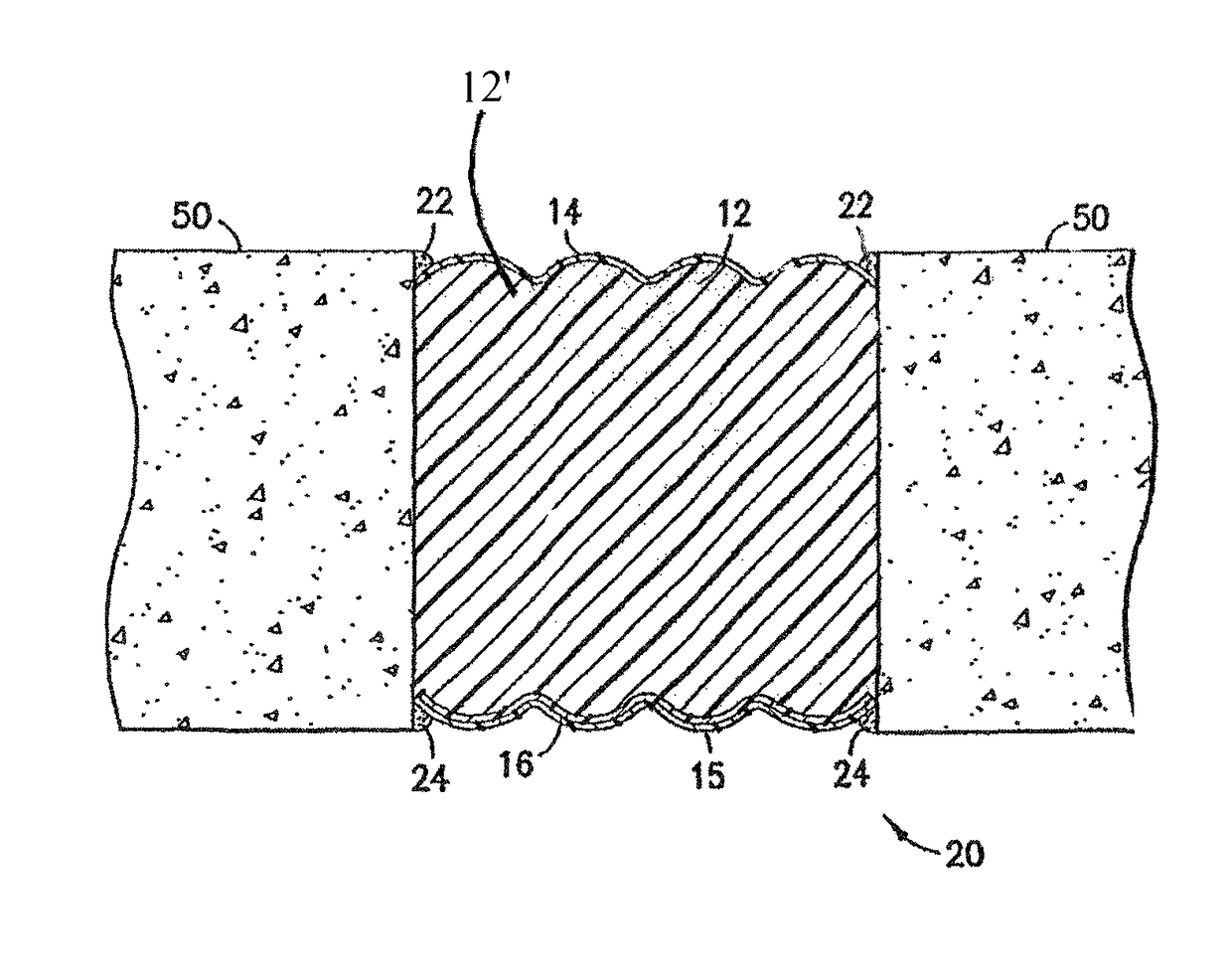

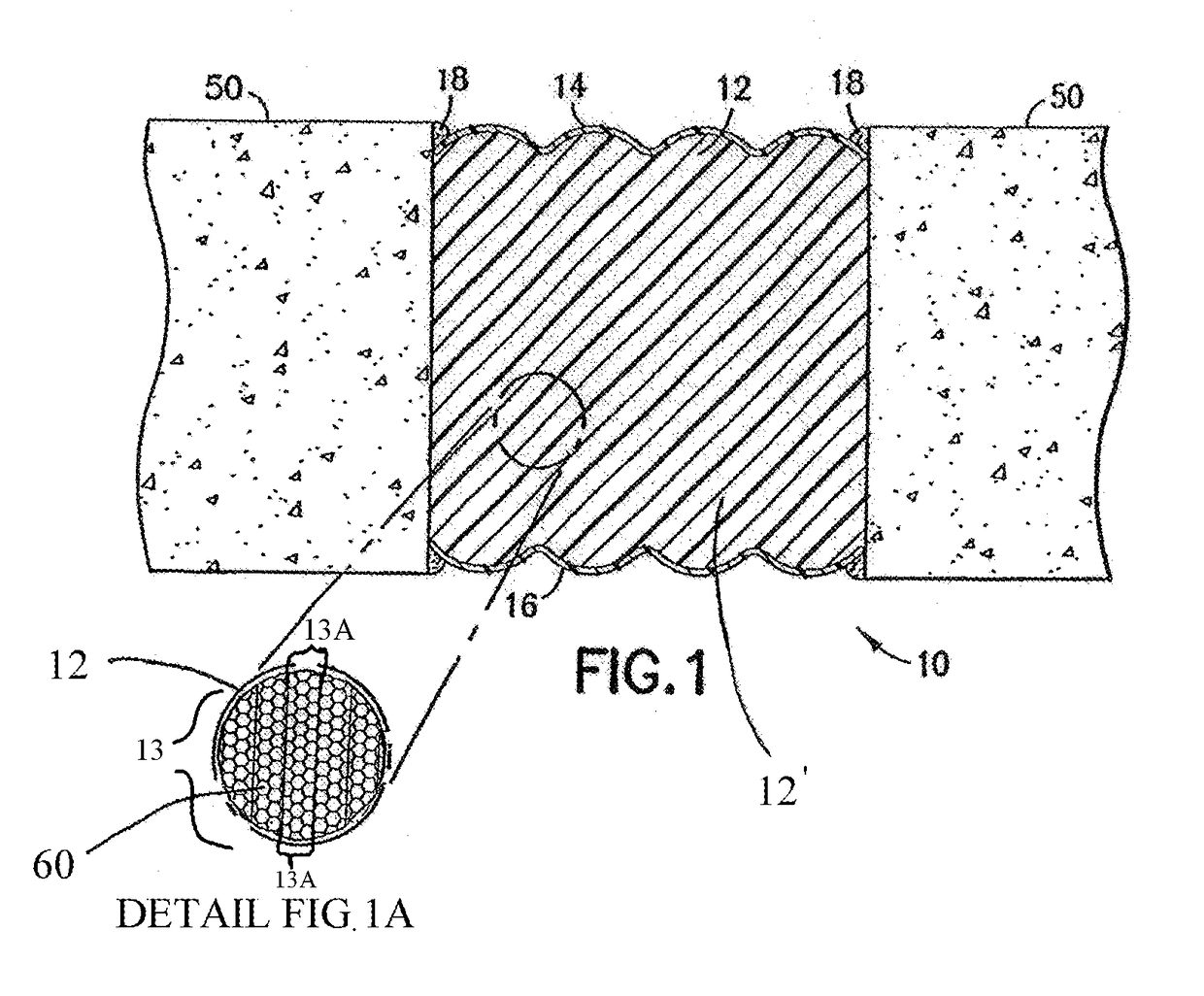

A fire resistant and water resistant expansion joint system comprises a compressed lamination of fire retardant infused open celled foam, one coat of an elastomeric waterproofing or water resistant material on the lamination, and another coat of an intumescent material on an opposing surface of the lamination, thereby providing fire resistance in one direction and water resistance in the opposite direction. The intumescent material may be further coated with a similar elastomeric material, thereby providing fire resistance in one direction and water resistance in both directions. In the alternative, the compressed lamination may comprise first and second opposing layers of intumescent material thereon each having a respective layer of elastomeric material to provide both water resistance and fire resistance in both directions.

Owner:EMSEAL JOINT SYST

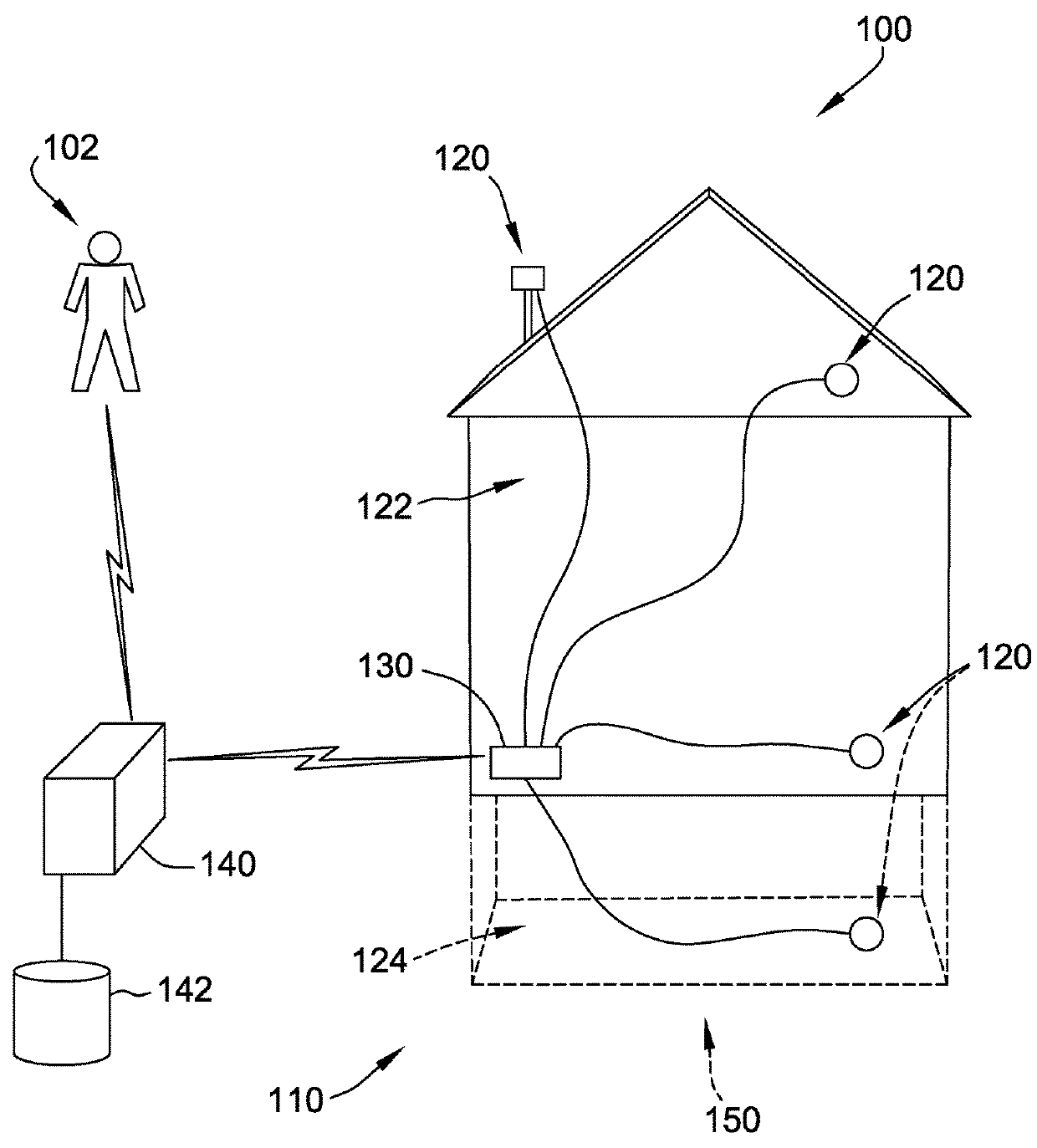

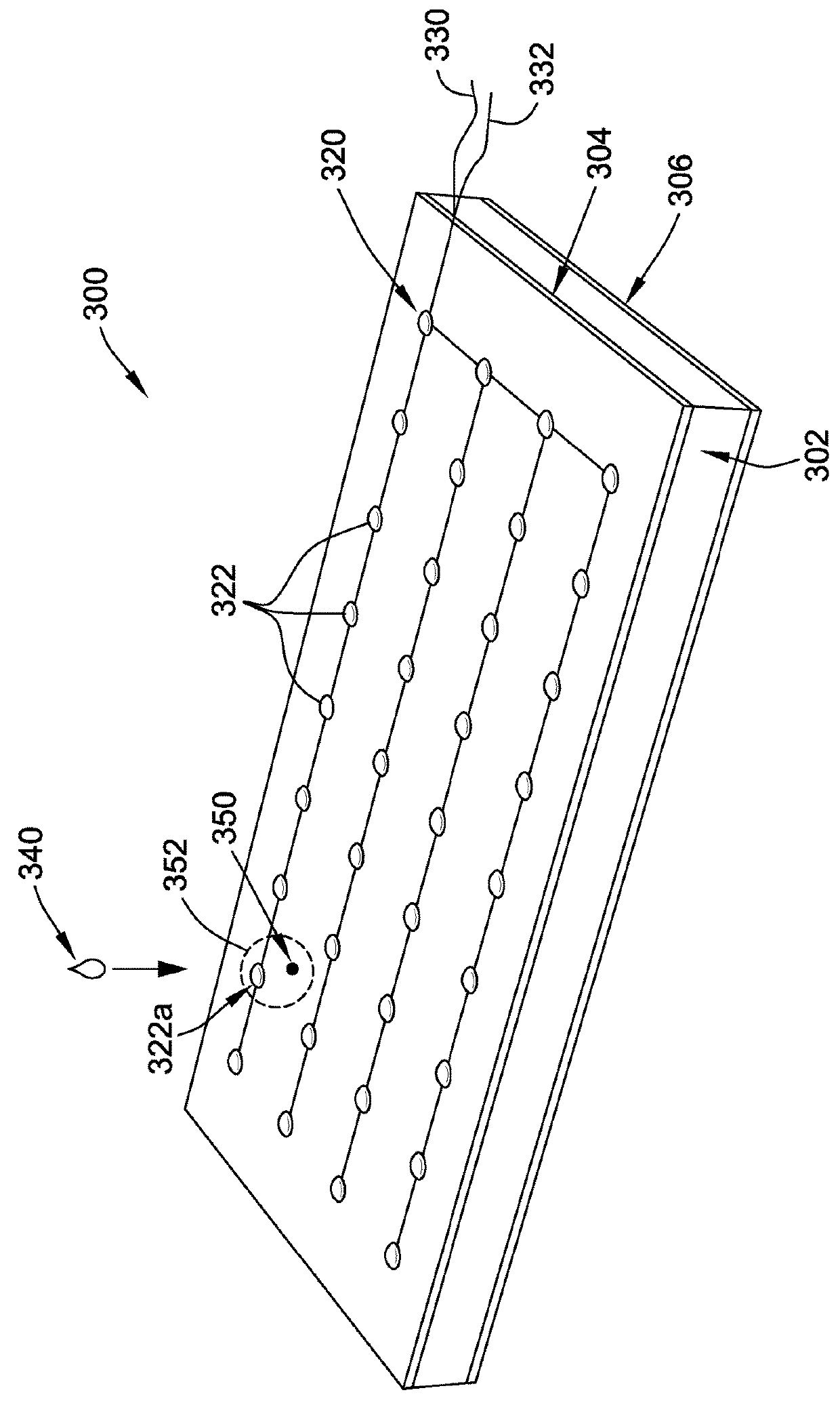

Systems and methods for monitoring building health

ActiveUS10042341B1Early detectionDetection of fluid at leakage pointWallsArchitectural engineeringRemedial action

A building monitoring computer system for monitoring building integrity may be provided. Various types of sensors may be embedded throughout or within certain portions of different types of building or construction material making up the building, such as within roofing, foundation, or structural materials. The sensors may be in wireless communication with a home controller. The sensors may be water, moisture, temperature, vibration, or other types of sensors, and may detect unexpected or abnormal conditions within the home. The sensors and / or home controller may transmit alerts to a mobile device of the home owner associated with the unexpected condition, and / or that remedial actions may be required to repair the home or mitigate further damage to the home. The sensor data may also be communicated to an insurance provider remote server to facilitate the insurance provider communicating insurance-related recommendations, updating insurance policies, or preparing insurance claims for review for home owners.

Owner:STATE FARM MUTUAL AUTOMOBILE INSURANCE

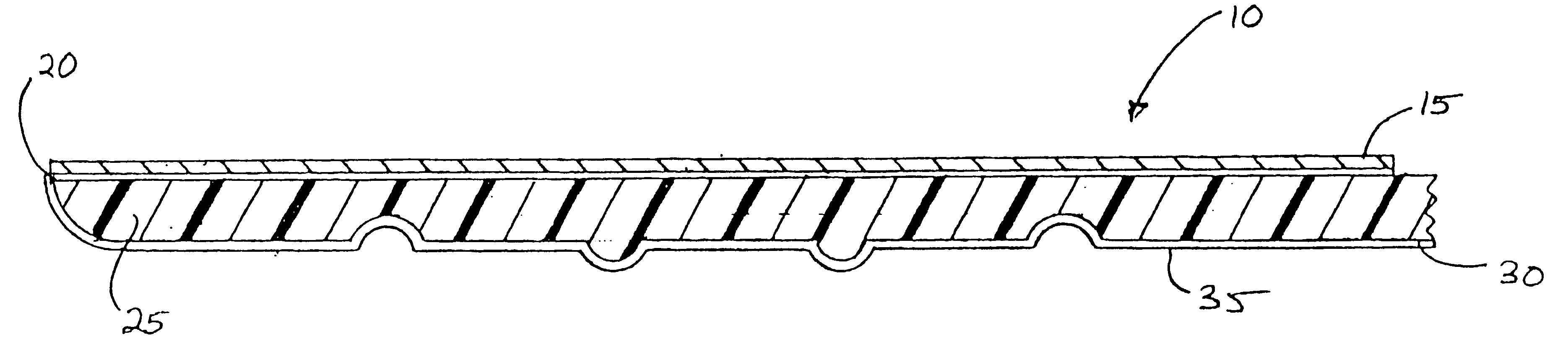

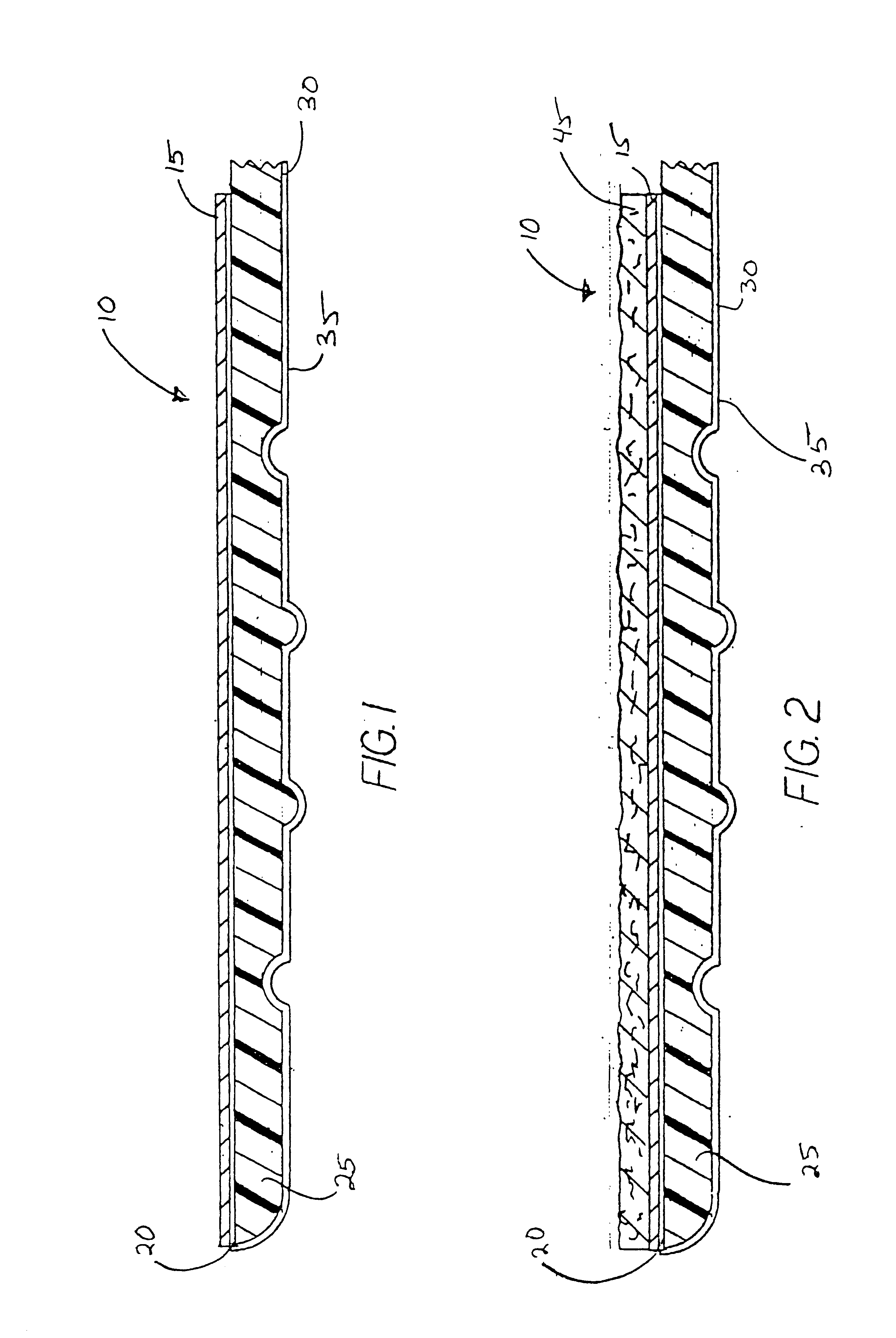

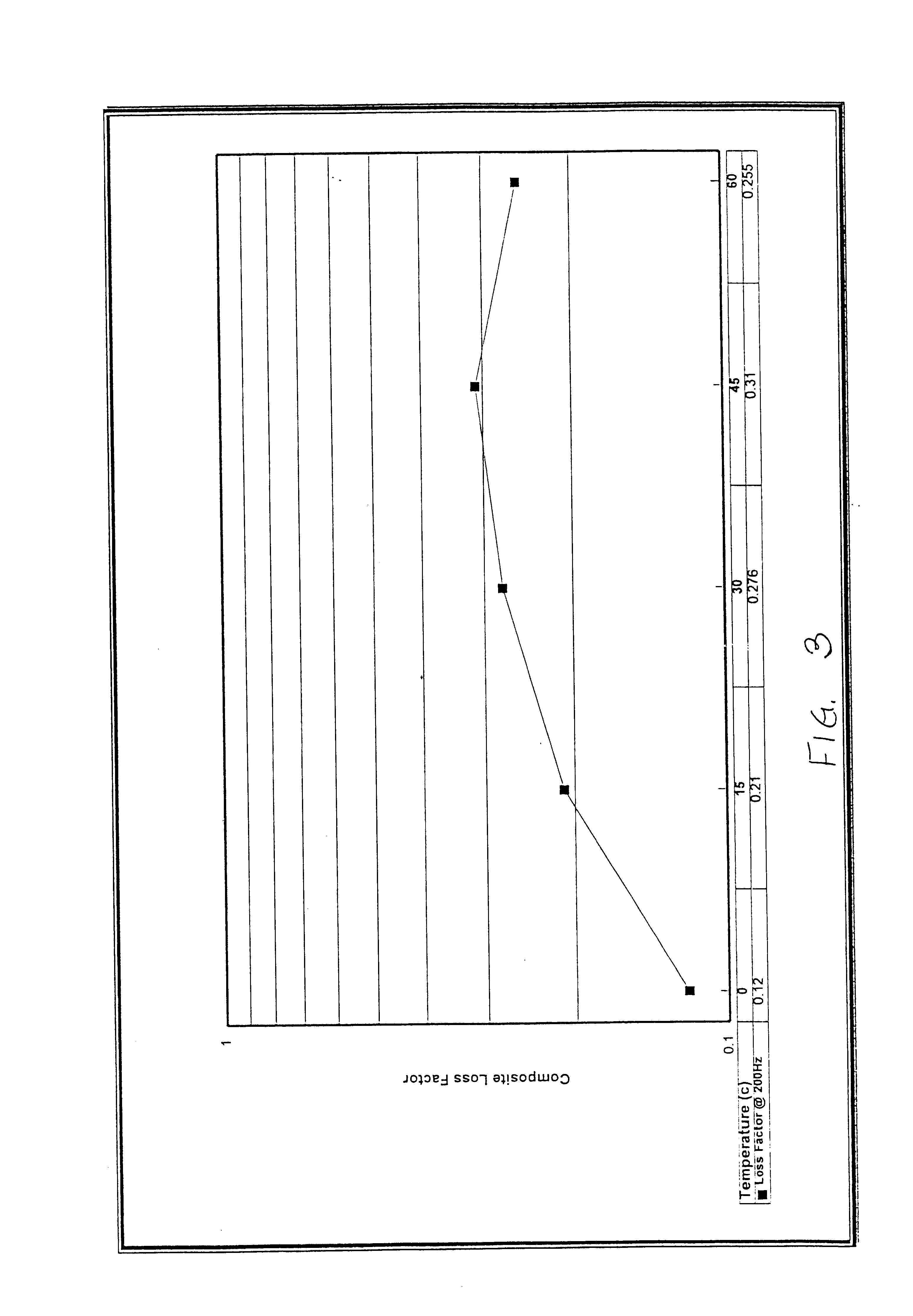

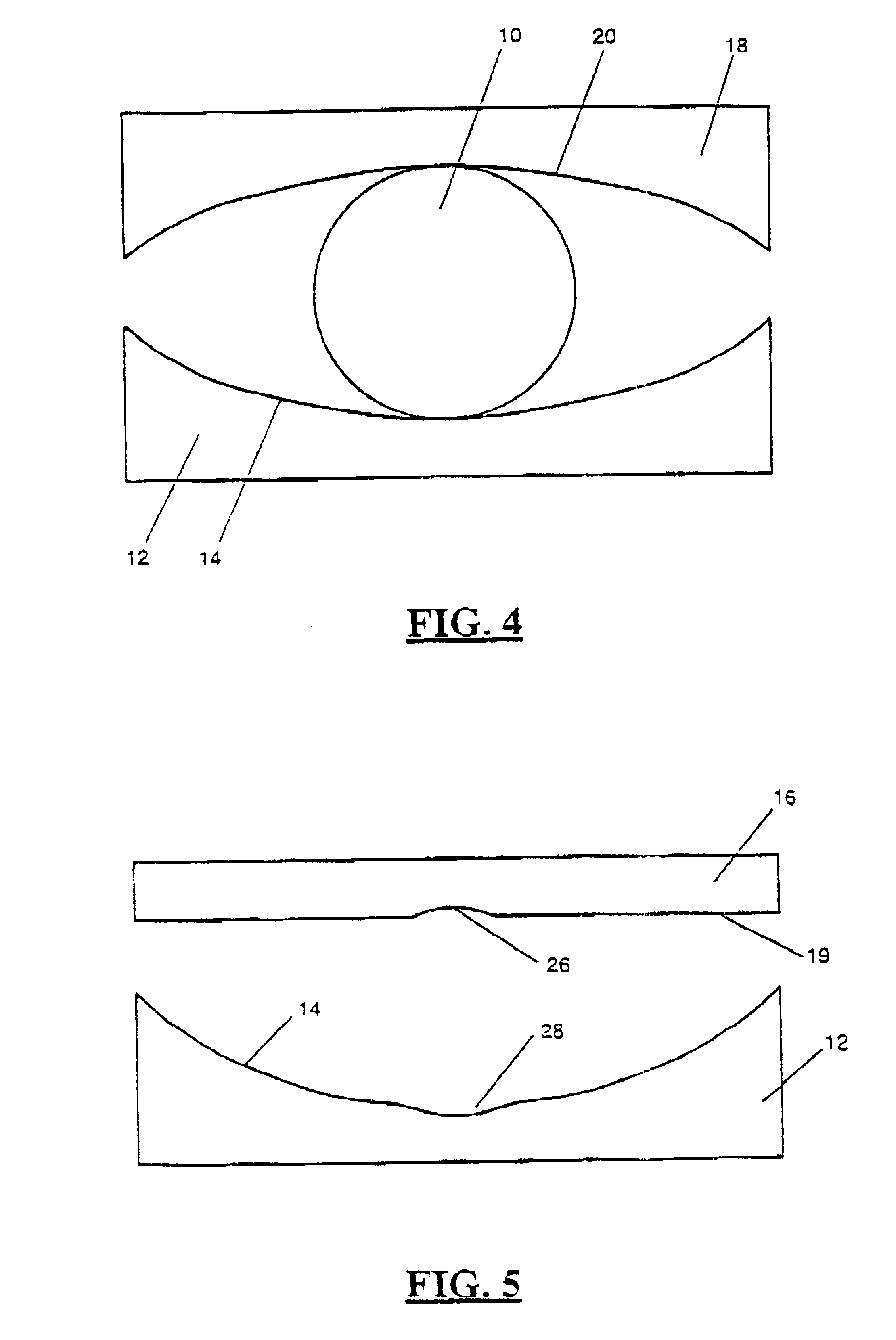

Vibration dampening laminate

The present invention provides a vibration dampening laminate that is lightweight and has superior sound insulation and vibration dampening properties. The vibration dampening laminate comprises a constraining layer, a viscoelastic adhesive layer, a foam spacing layer and a pressure sensitive adhesive layer including a release layer. The pressure sensitive adhesive layer and release layer are contoured to fit a profile of the article being soundproofed and vibration dampened.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

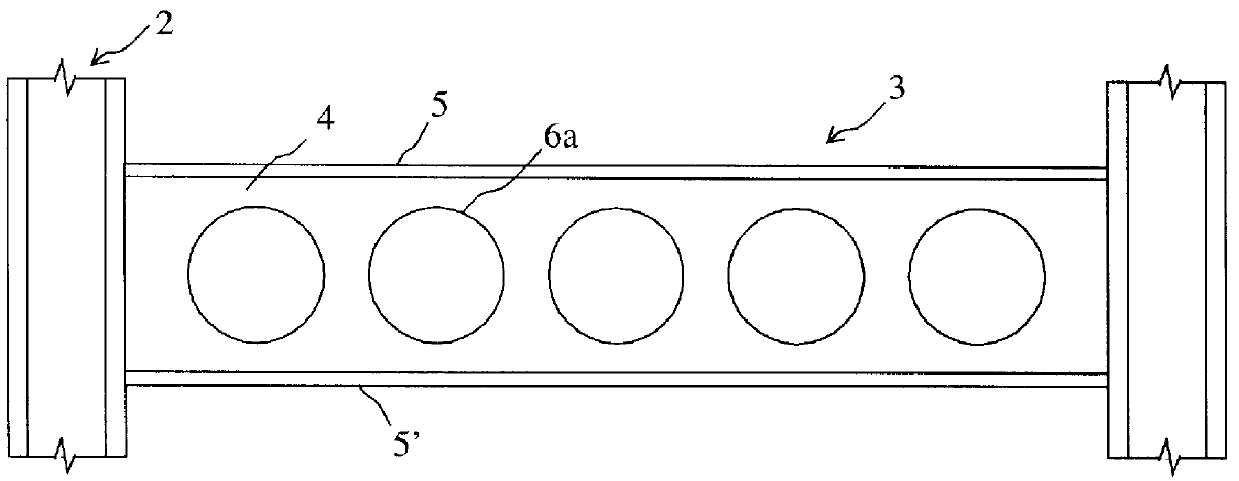

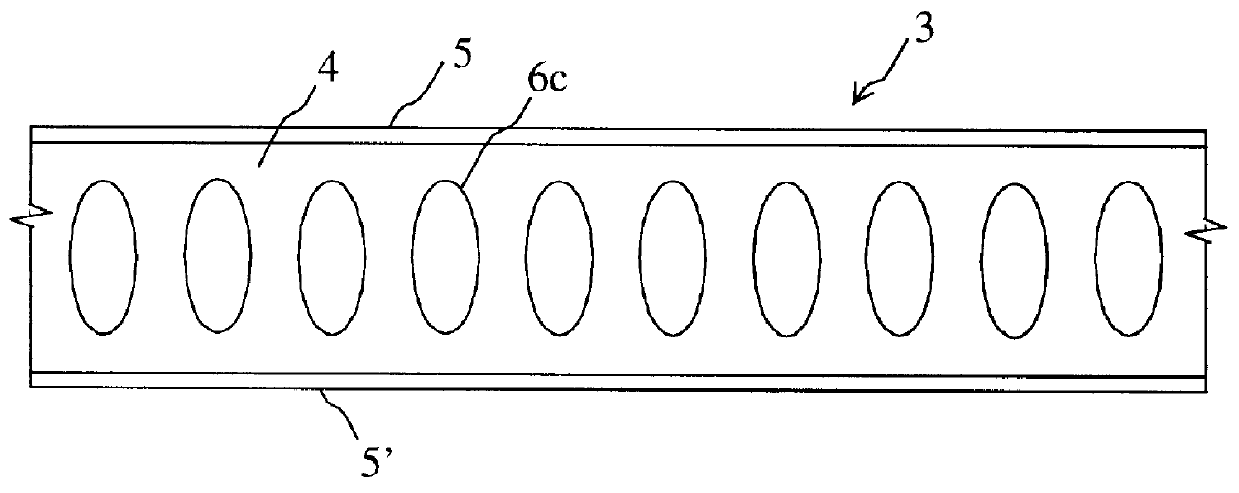

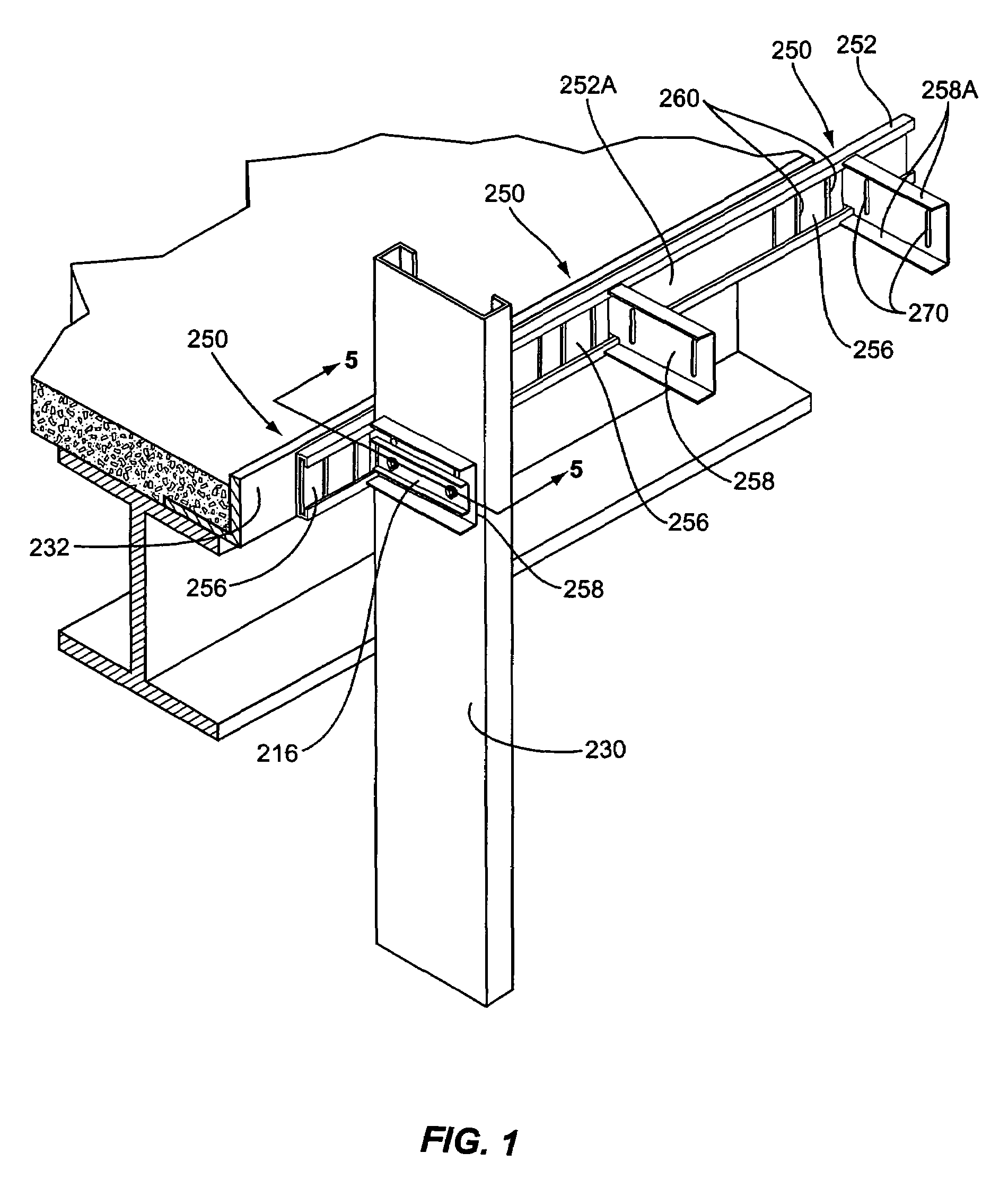

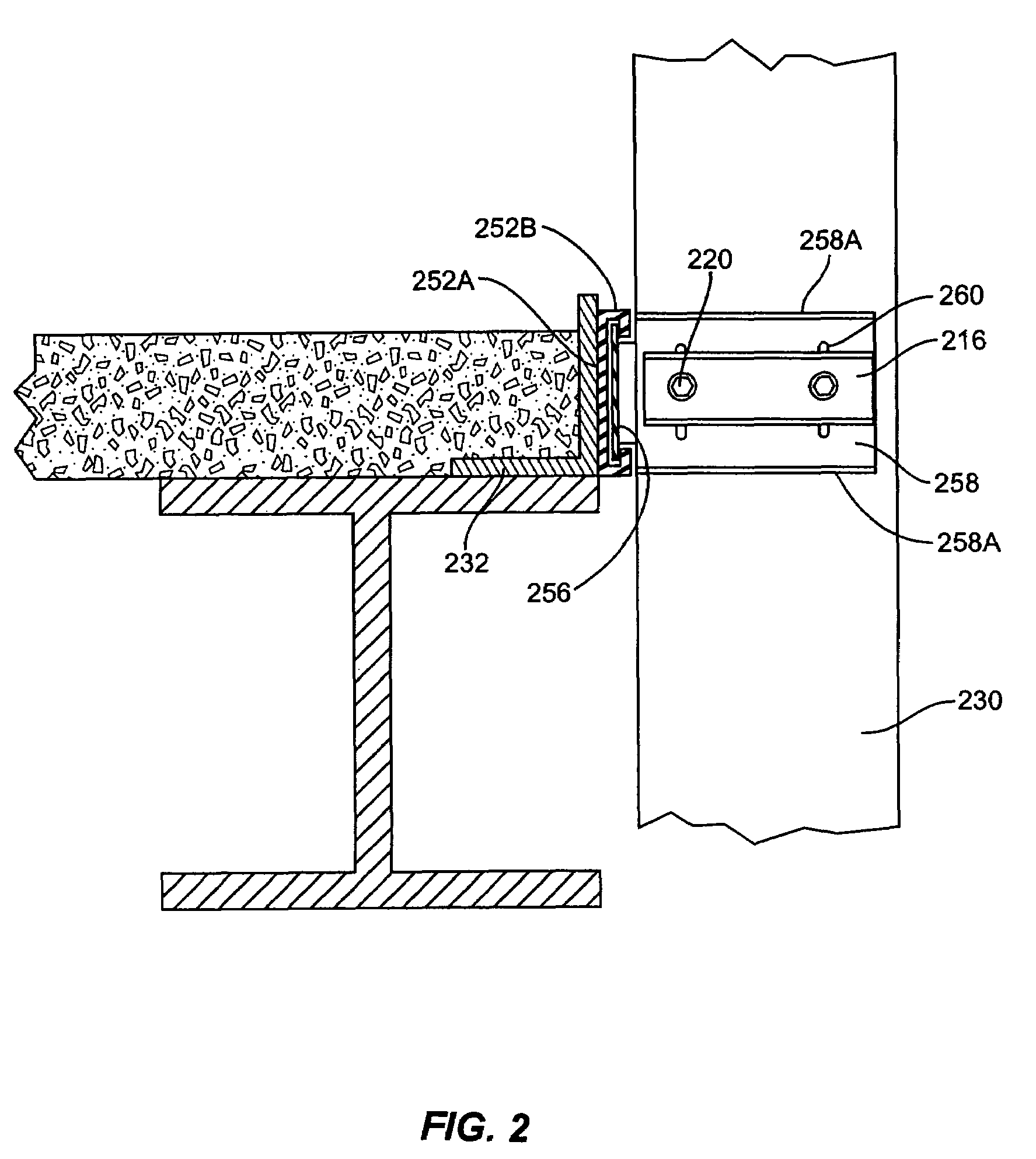

Moment-resistant structure, sustainer and method of resisting episodic loads

The present invention relates to a moment-resistant structure, sustainer, and method of construction for deformably resisting episodic loads, particularly those of high intensity. The episodic loads may be due to earthquake, impact, or other intense episodic sources. The structure and sustainer may be in buildings, bridges, or other civil works, land vehicles, watercraft, aircraft, spacecraft, machinery, or other structural systems or apparati. Deformation capacity is enhanced by the use of multiple dissipative zones. Dissipative zones that function in a manner similar to plastic hinges are determined by one or more voids that are located in the web of a sustainer. The one or more voids are of a size, shape, and configuration to assure that the dissipative zones deform inelastically when a critical stress, i.e., a maximum allowable demand, is reached, thereby developing the action of a structural fuse, preventing the occurrence of stress and strain demands sufficient to cause fracture of the connection welds or adjacent heat-affected zones, i.e., preventing the stress and strain demands from exceeding the strength capacity of the connection welds or adjacent heat-affected zones. The sustainers may be removably connected to the remainder of the structure, facilitating their replacement after inelastic deformation. The structure, sustainer, and method of construction may be utilized in new construction and in the rehabilitation of existing construction. Mechanical equipment and utilities may pass through the voids.

Owner:ASCHHEIM MARK AMOS

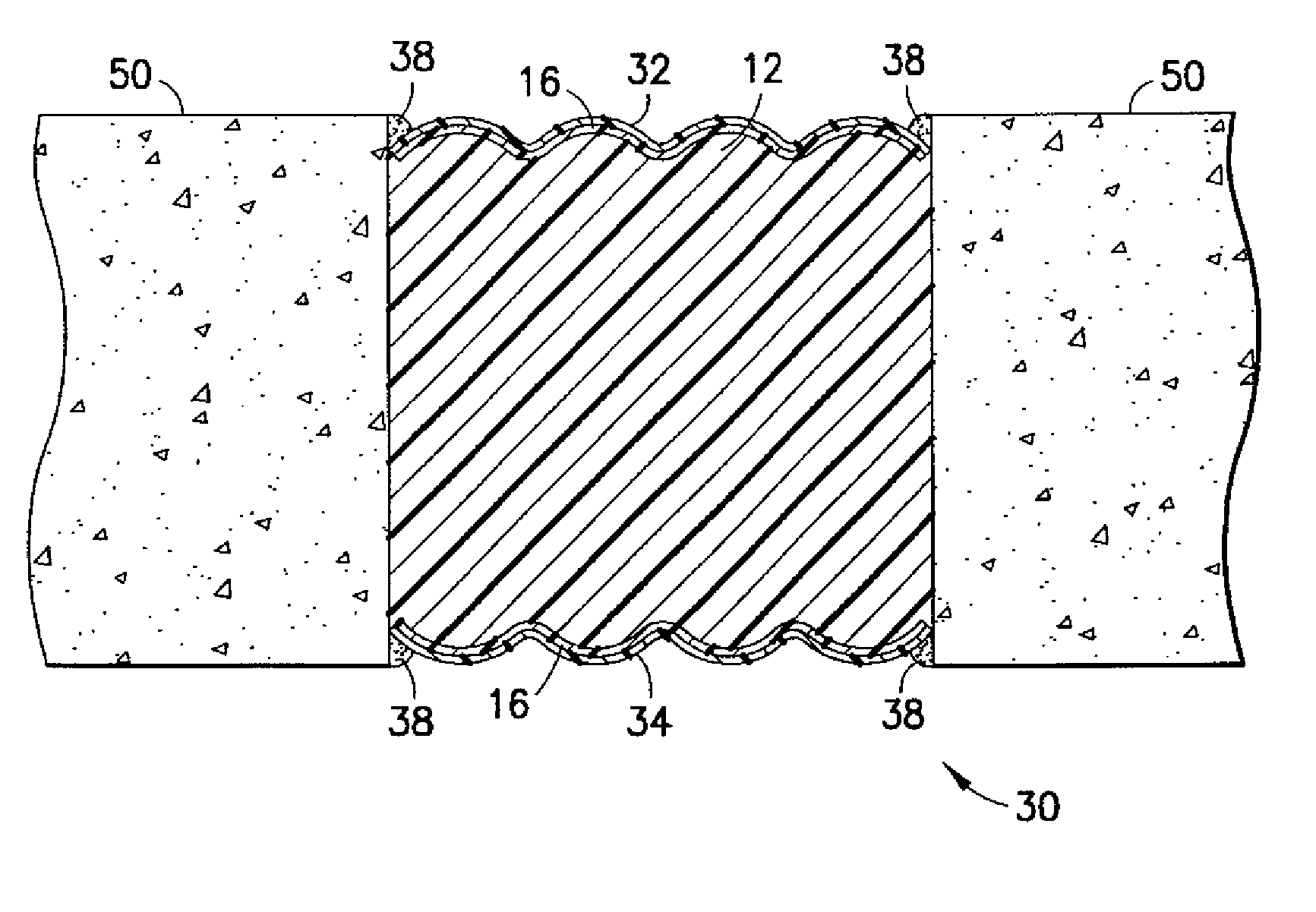

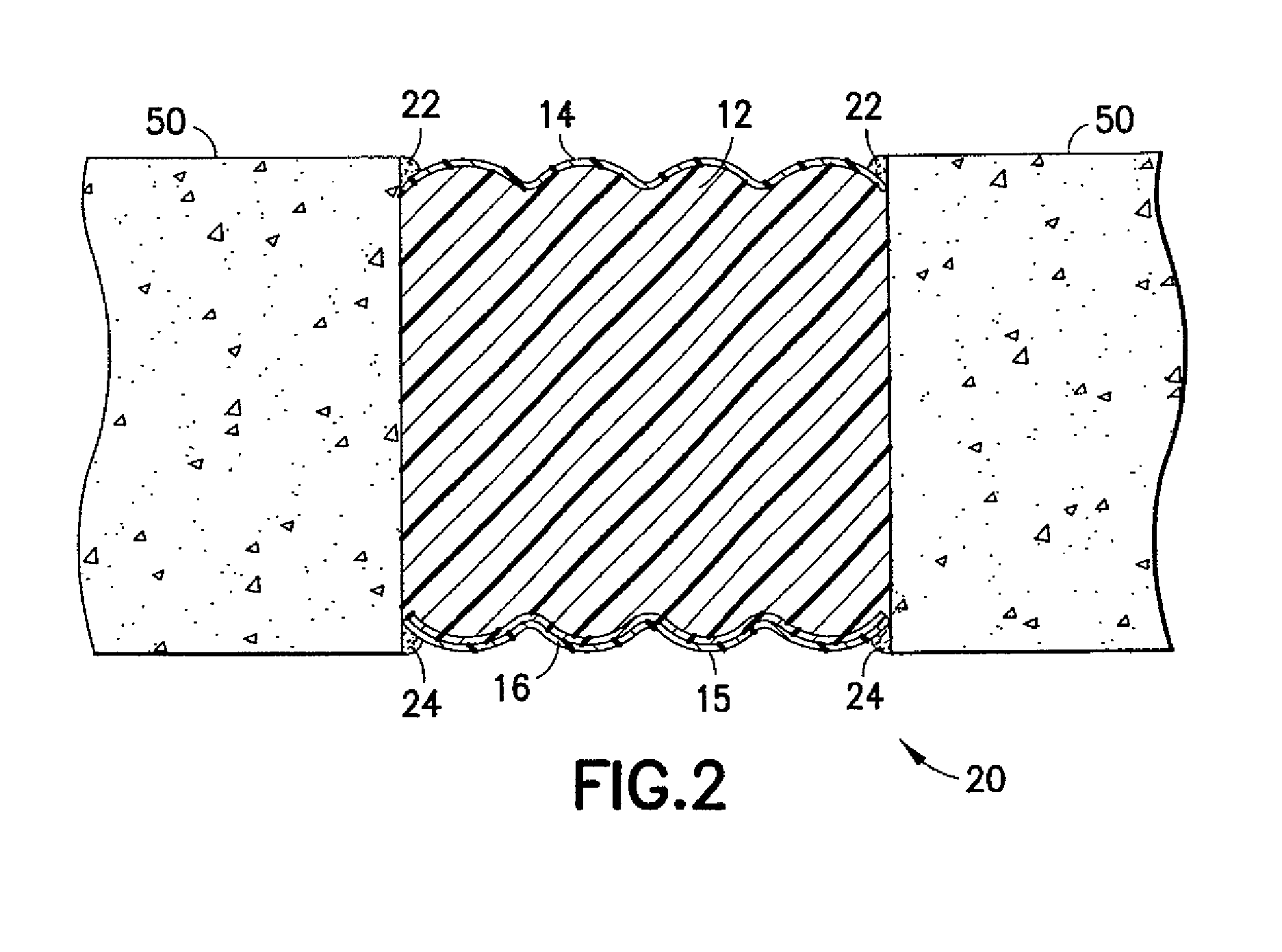

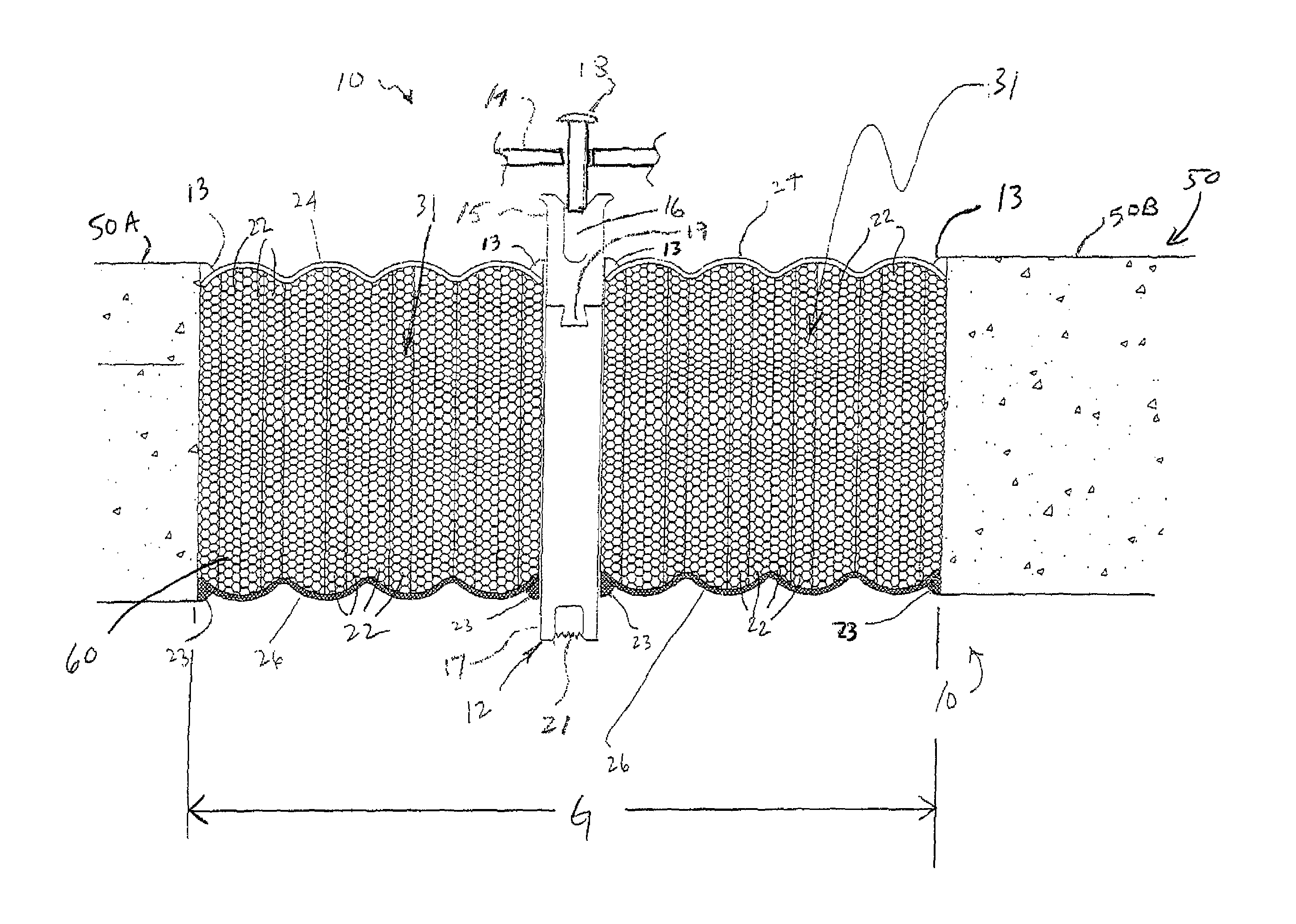

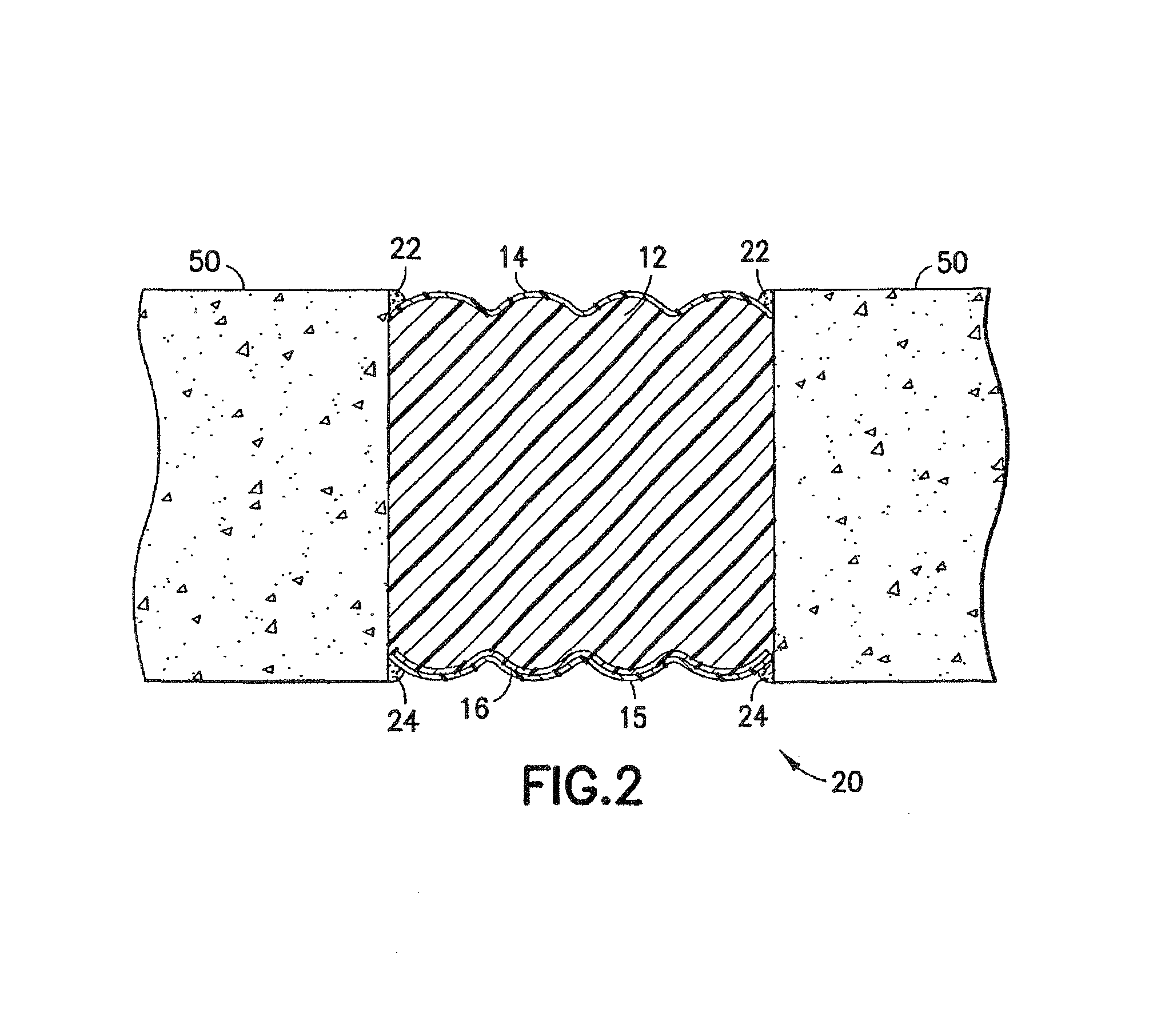

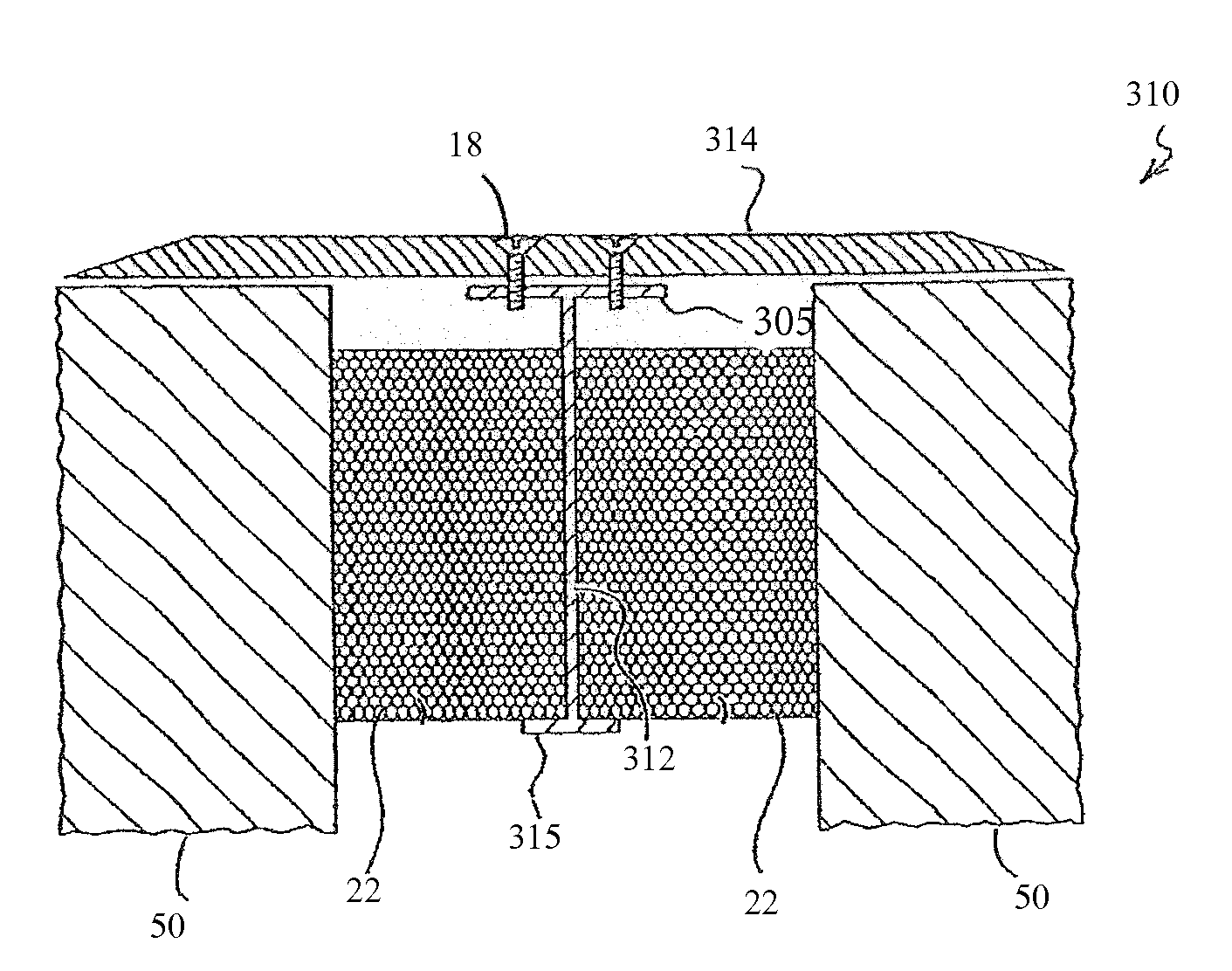

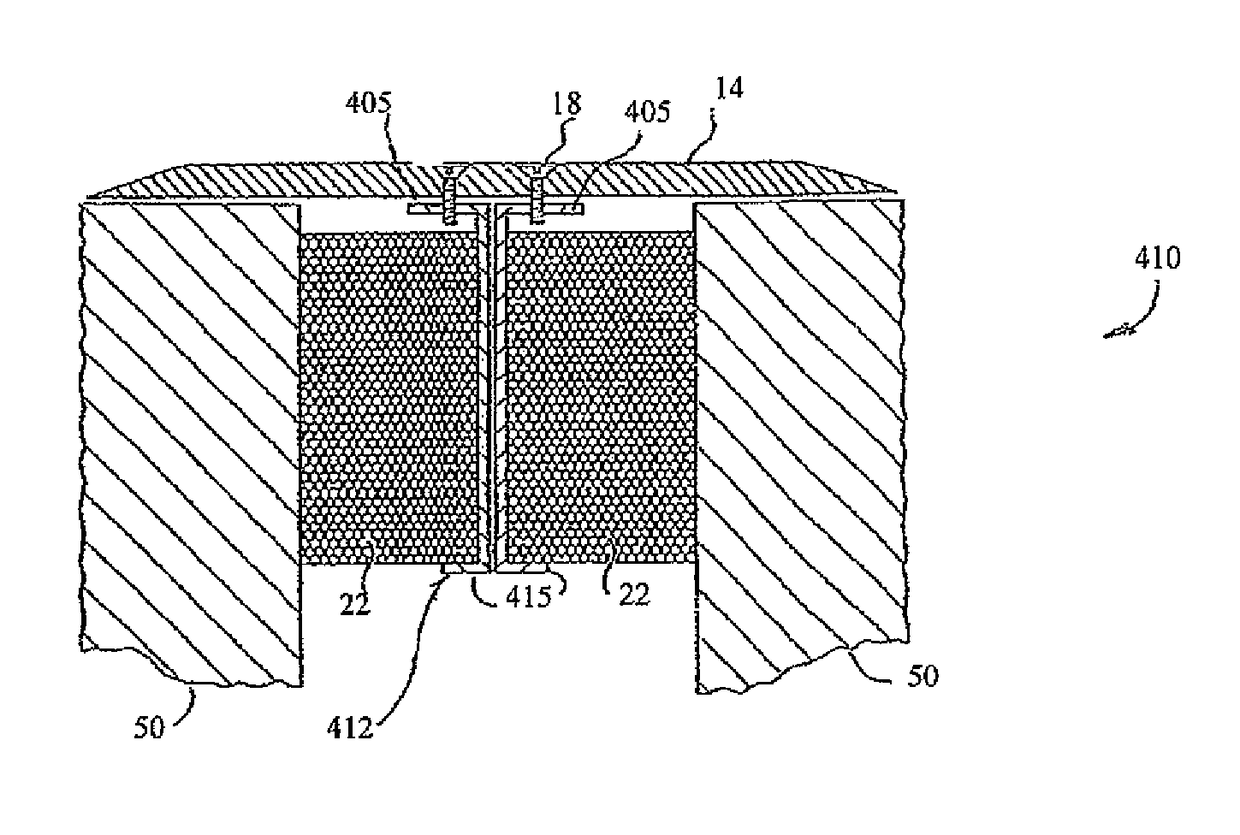

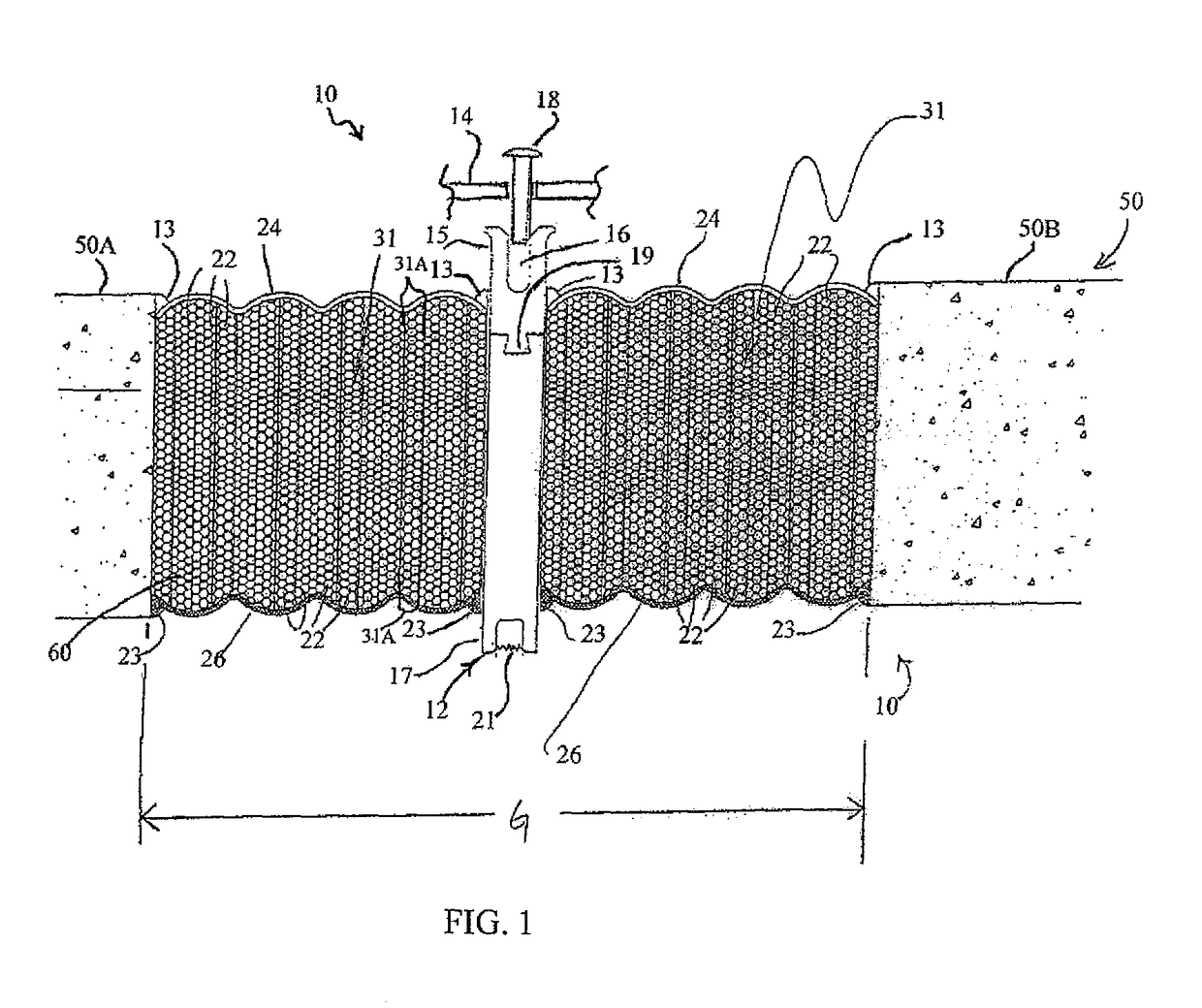

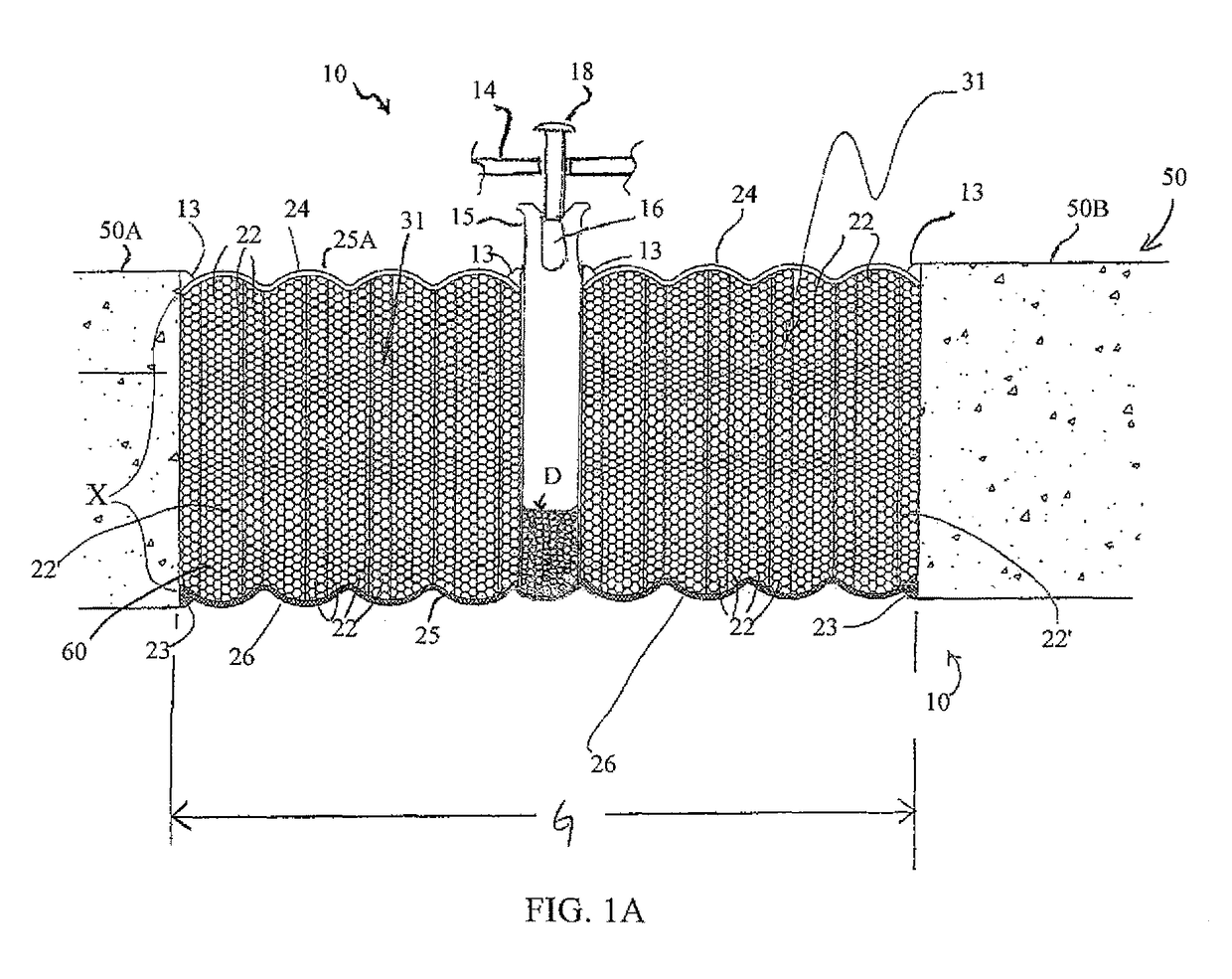

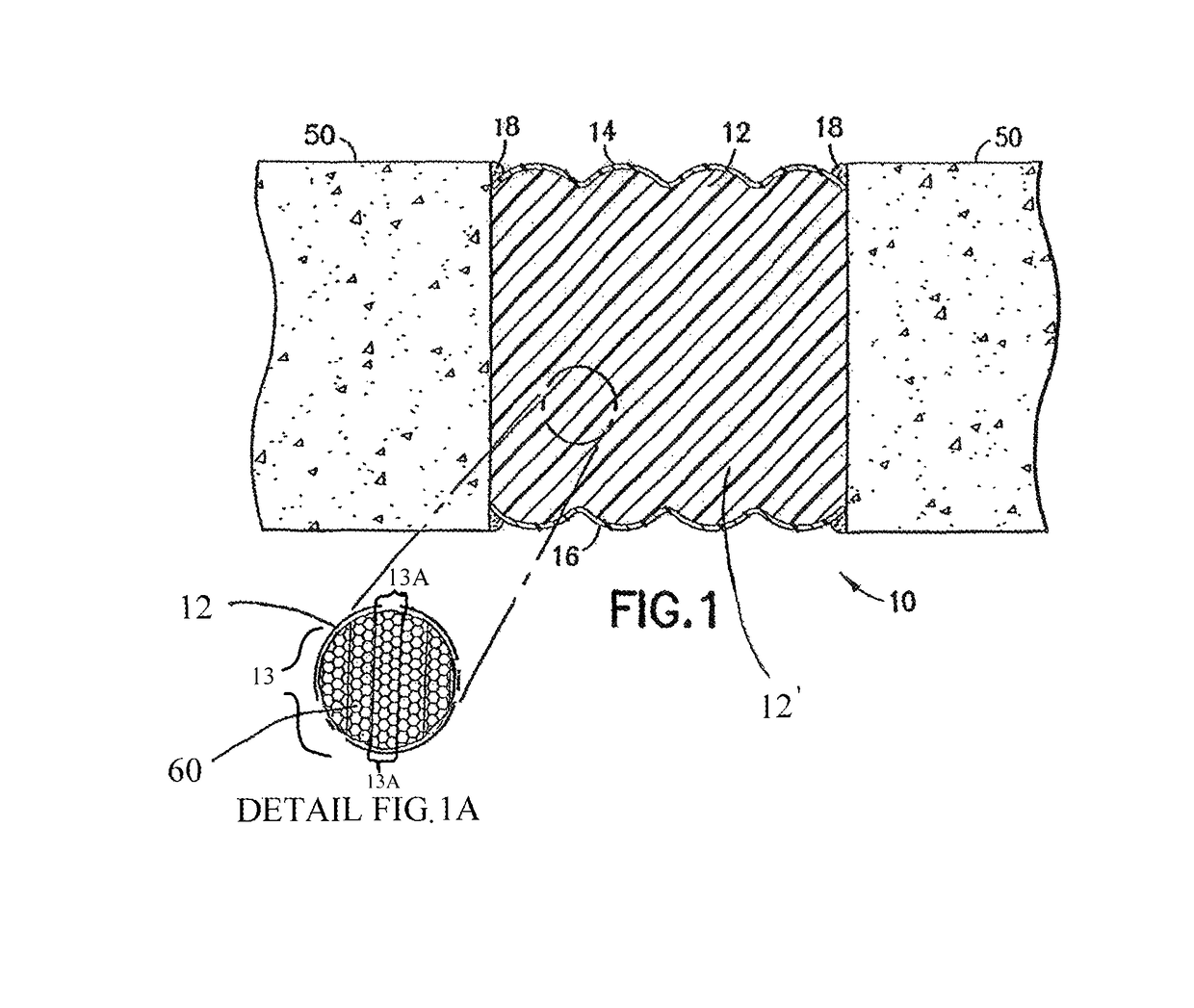

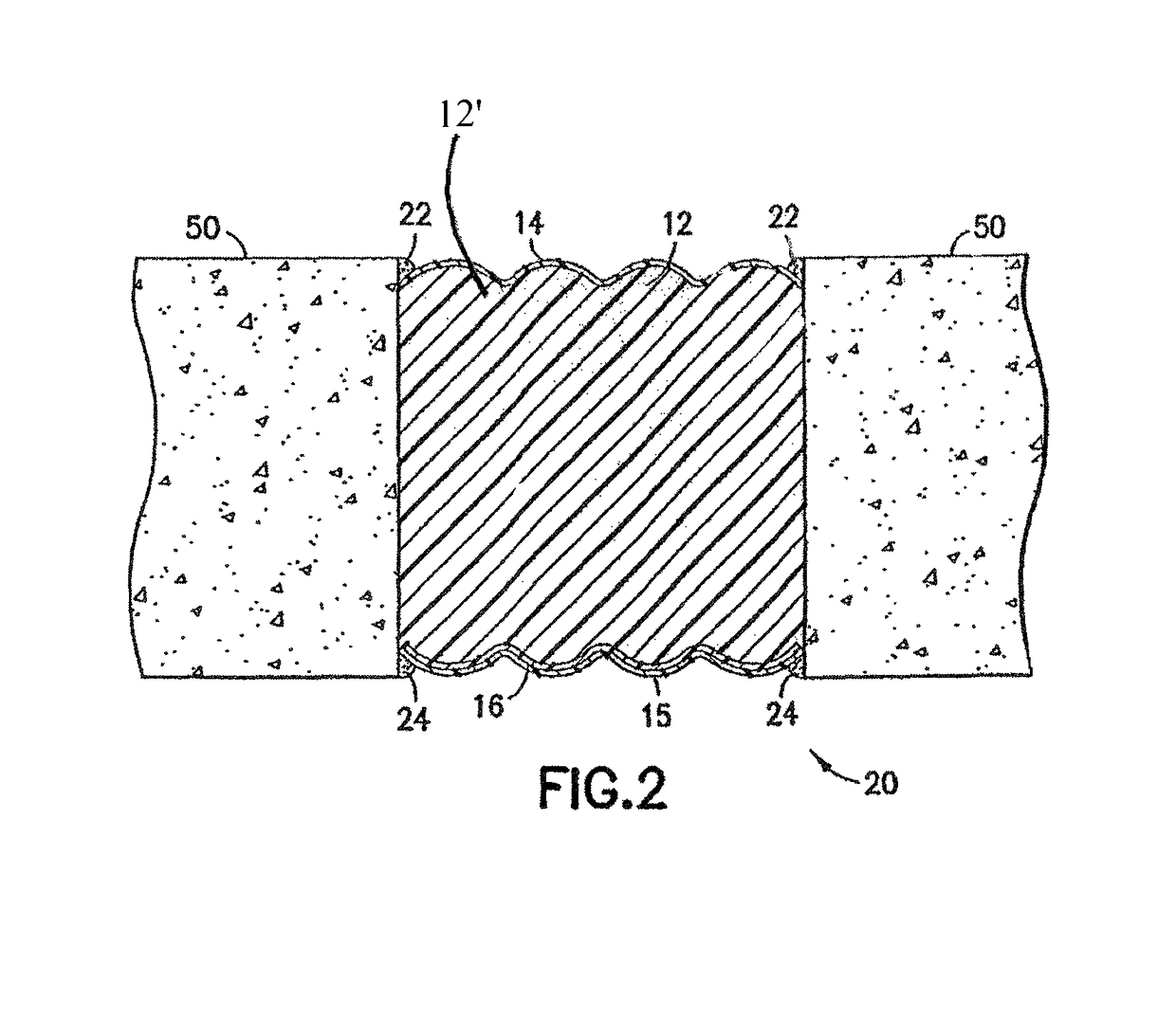

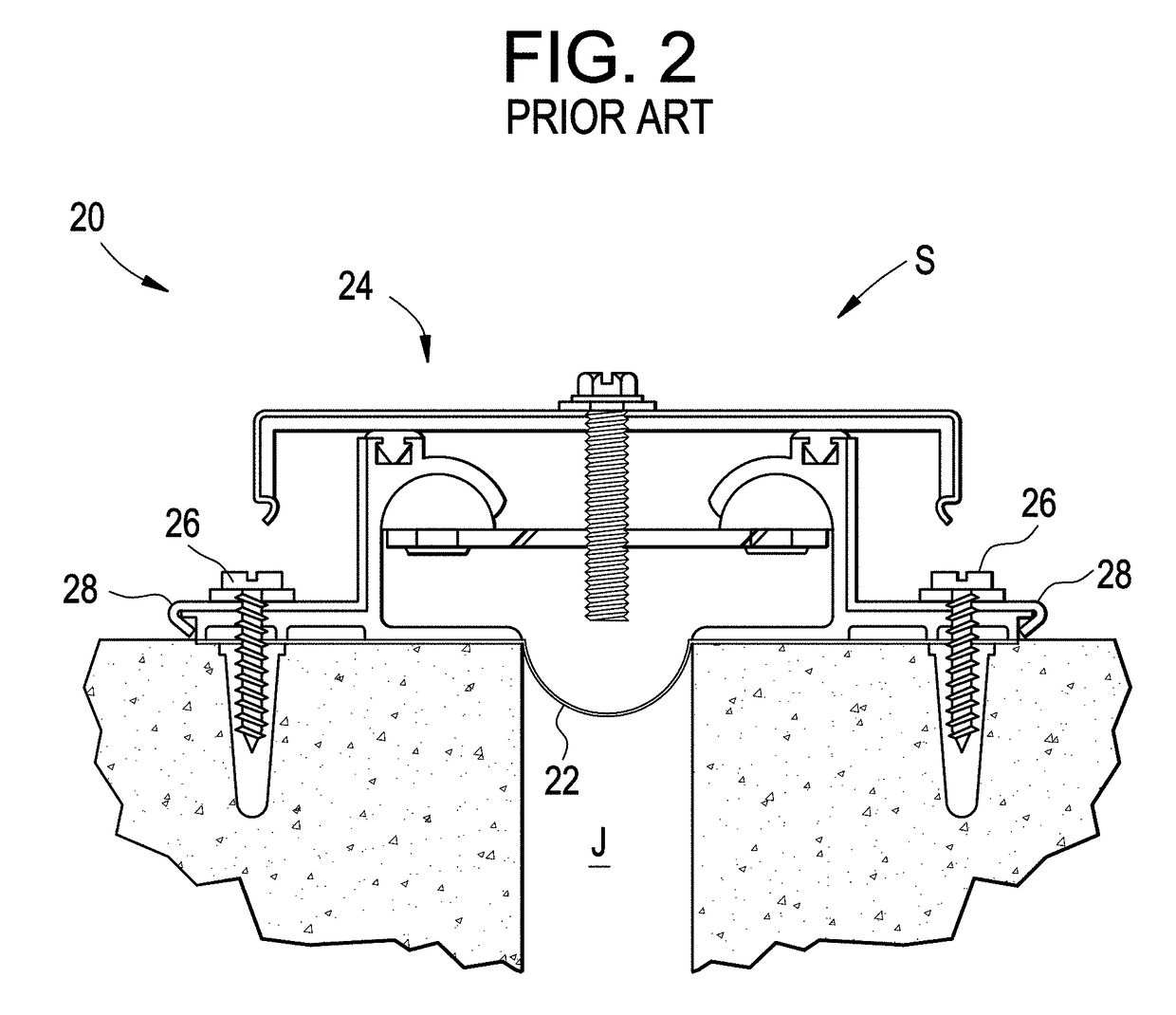

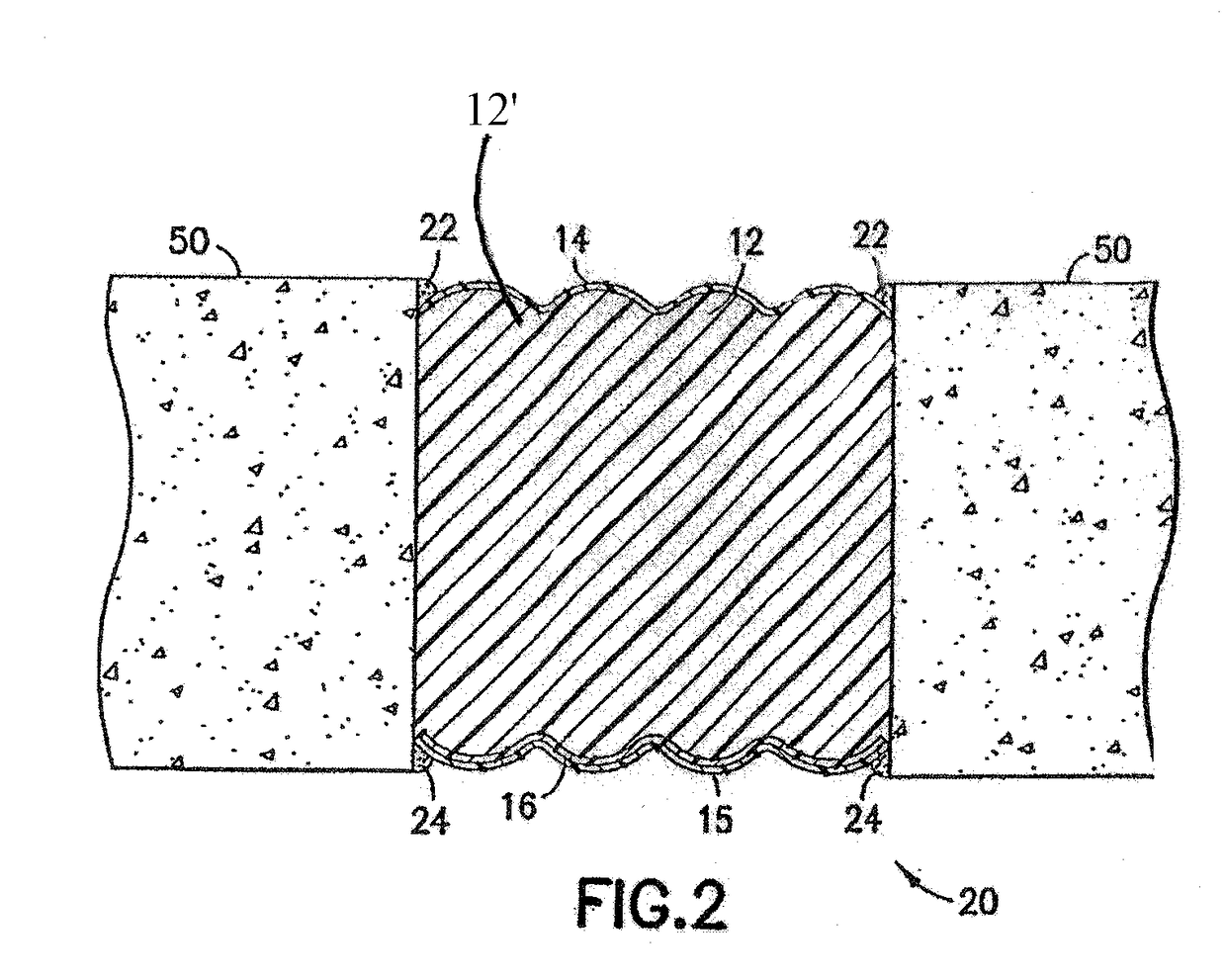

Fire and water resistant expansion and seismic joint system

An expansion joint system has a cover plate; a spline attached to the cover plate along a first edge of the spline; and two portions of open celled foam, each portion being located on an opposing face of the spline. The open celled foam has a fire-retardant material infused therein and layers of waterproof elastomer disposed thereon. The spline depends from the cover plate and is positioned in a gap between substantially coplanar substrates such that the cover plate overlies the gap. Each portion of the open celled foam is compressed between a respective face of the spline and a face of one of the coplanar substrates. An intumescent material may be incorporated into the spline.

Owner:SIKA TECH AG

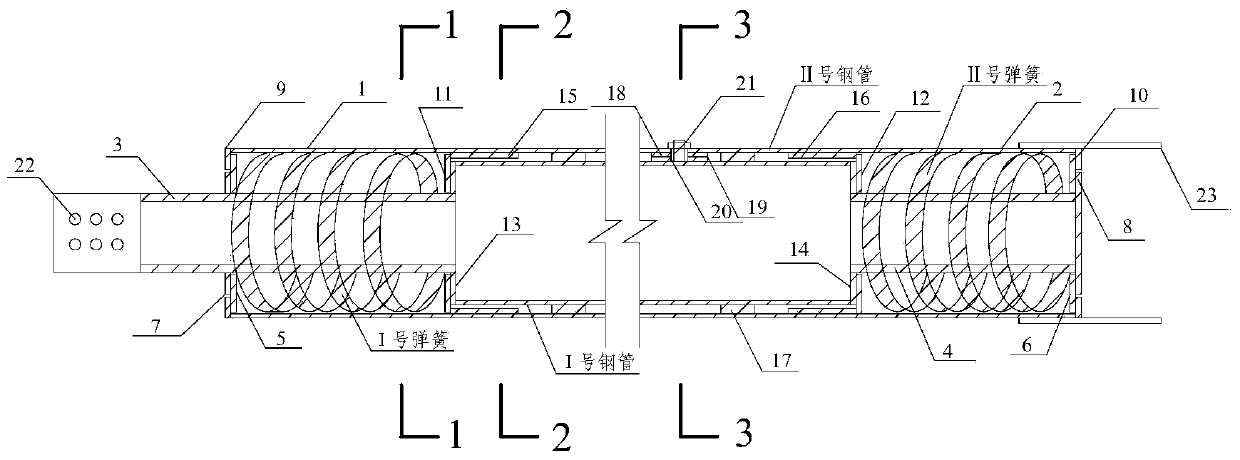

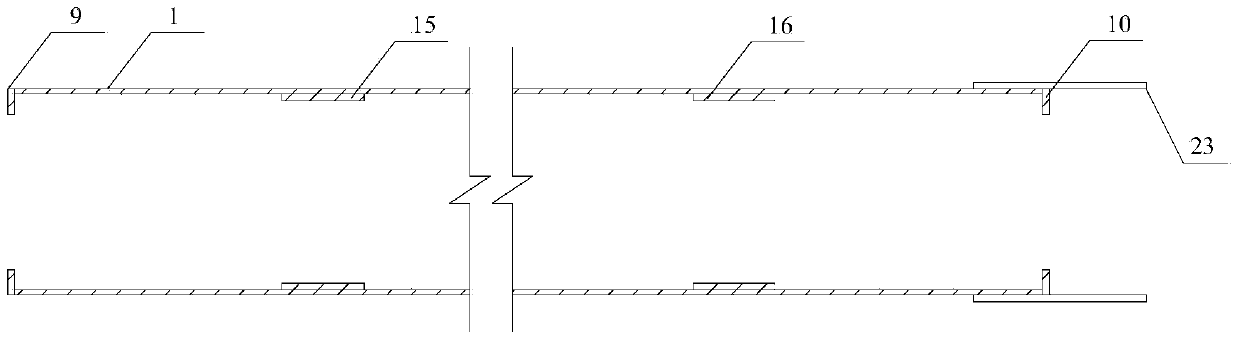

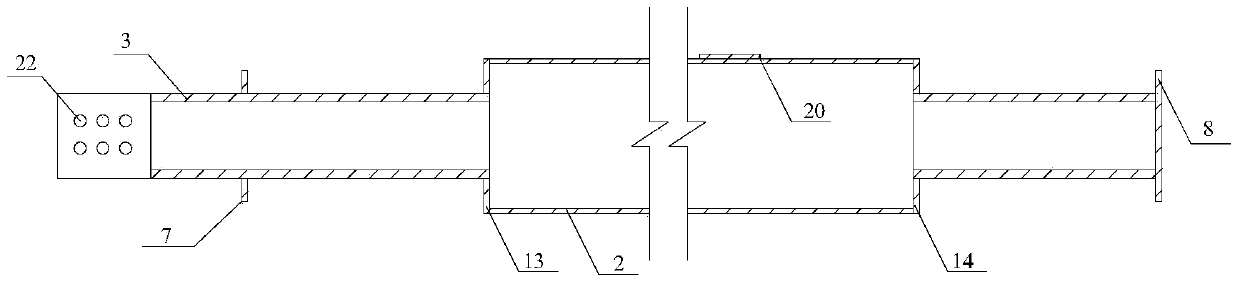

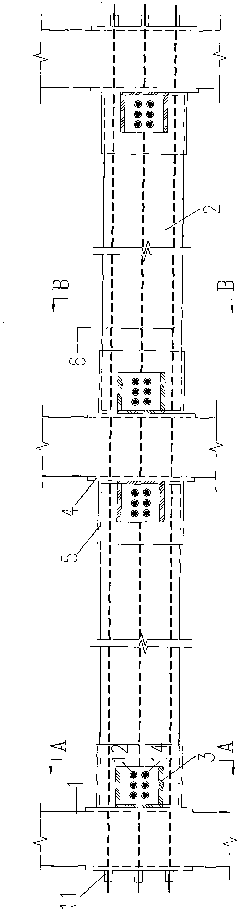

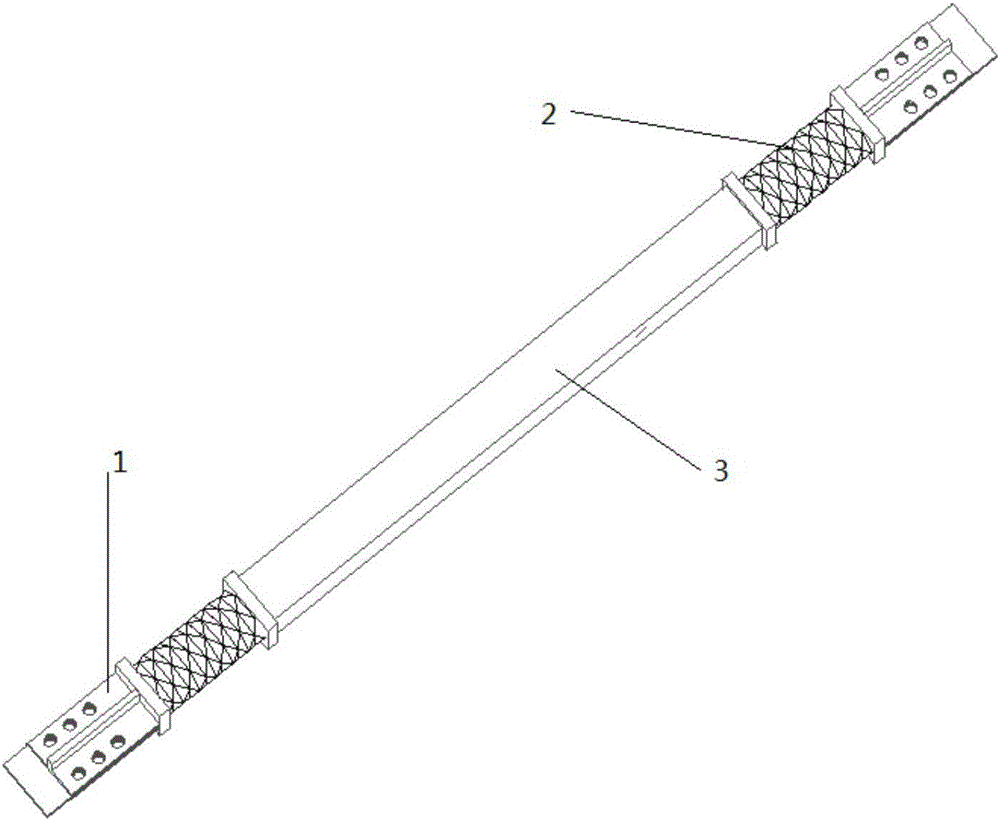

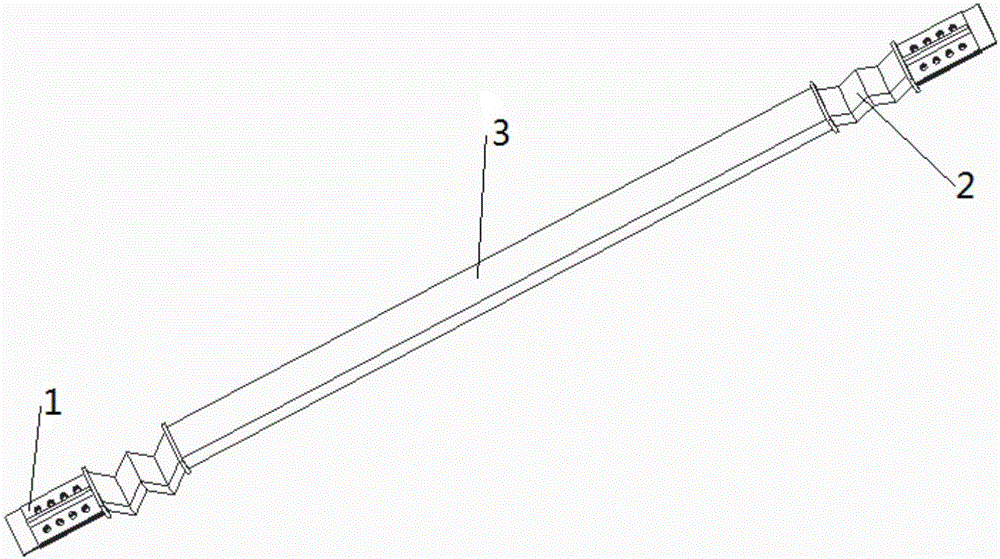

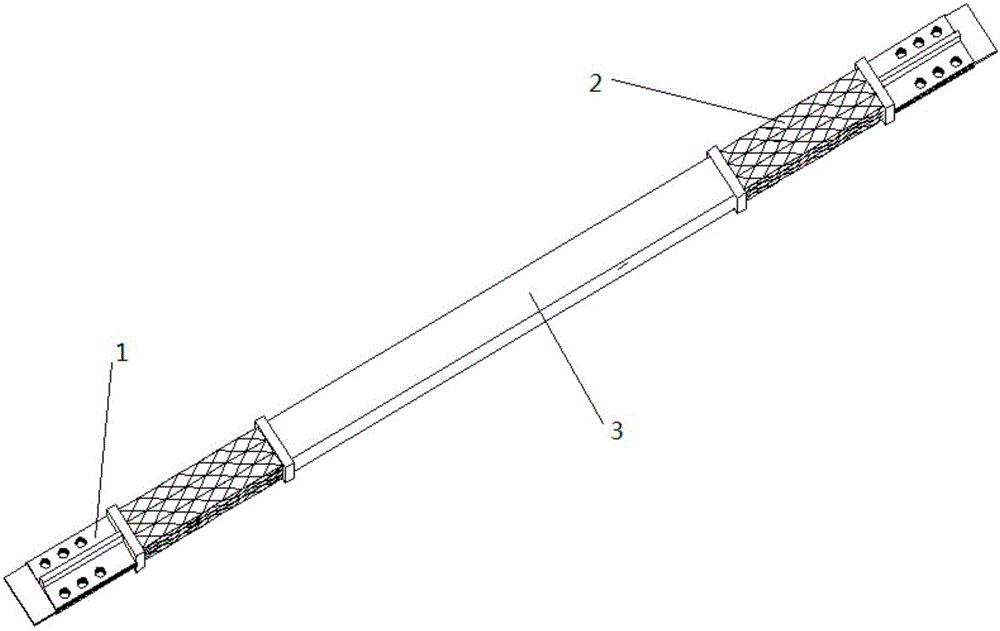

Setup spring self-recovery energy dissipation brace

ActiveCN103469921AReduce residual deformationEasy constructionShock proofingResidual deformationPipe

The invention discloses a setup spring self-recovery energy dissipation brace in the technical field of self-recovery energy dissipation braces. The brace comprises an inner pipe, an outer pipe, a spring, a spring baffle and a guide block; the inner pipe comprises a left inner pipe, a right inner pipe, a first steel pipe, a first steel pipe left baffle, a first steel pipe right baffle, an inner pipe left stopper, an inner pipe right stopper, an inner pipe outer friction plate, a high-strength bolt and an inner pipe connecting plate; the outer pipe comprises a left outer pipe, a right outer pipe, a second steel pipe, an outer pipe left baffle, an outer pipe right baffle, an outer pipe internal left stopper, an outer pipe internal right stopper, an outer pipe inner friction plate and an outer pipe connecting plate; the spring comprises a first spring and a second spring, wherein the first spring is sleeved outside the left inner pipe, and the second spring is sleeved outside the right inner pipe; two ends of the spring are connected with the spring baffle. The brace has the advantages that residual deformation of a structure is decreased, the brace is convenient to construct and easy to maintain and replace after earthquake action, and normal usage state affecting time is shortened.

Owner:BEIJING JIAOTONG UNIV

Fire and water resistant expansion joint system

A fire resistant and water resistant expansion joint system comprises a compressed lamination of fire retardant infused open celled foam, one coat of an elastomeric waterproofing or water resistant material on the lamination, and another coat of an intumescent material on an opposing surface of the lamination, thereby providing fire resistance in one direction and water resistance in the opposite direction. The intumescent material may be further coated with a similar elastomeric material, thereby providing fire resistance in one direction and water resistance in both directions. In the alternative, the compressed lamination may comprise first and second opposing layers of intumescent material thereon each having a respective layer of elastomeric material to provide both water resistance and fire resistance in both directions.

Owner:EMSEAL JOINT SYST

Fire and water resistant expansion and seismic joint system

A fire and water resistant expansion joint system has a cover plate; a spline attached to the cover plate along a first edge of the spline; and two portions of foam, each portion being located on an opposing face of the spline. The foam has a fire-retardant material infused therein. The spline depends from the cover plate and is positioned in a gap between substantially coplanar substrates such that the cover plate overlies the gap. Each portion of the foam is compressed between a respective face of the spline and a face of one of the coplanar substrates.

Owner:EMSEAL JOINT SYST

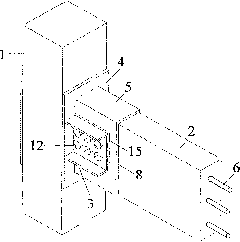

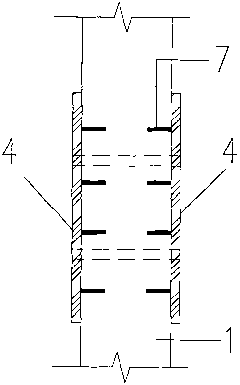

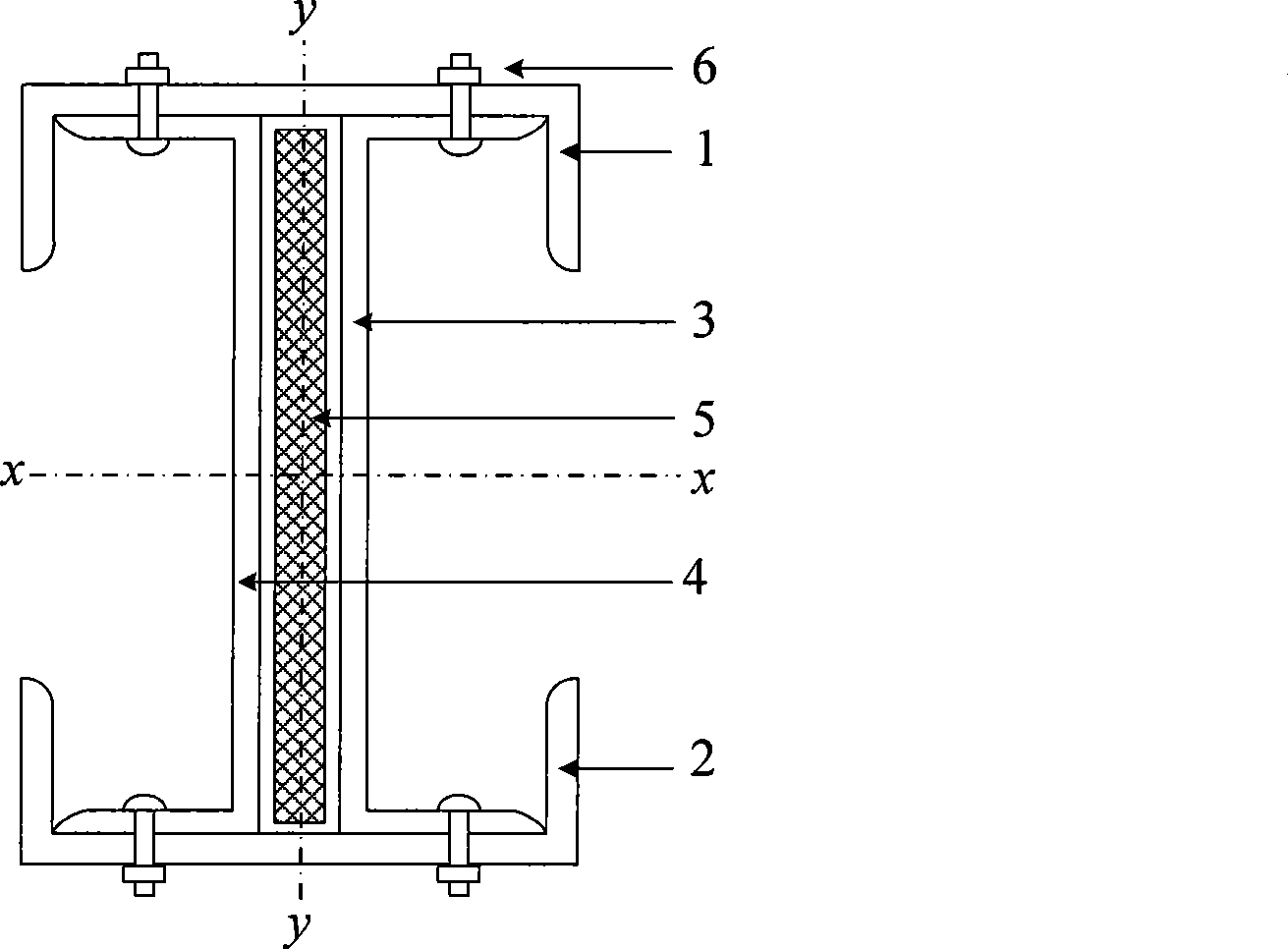

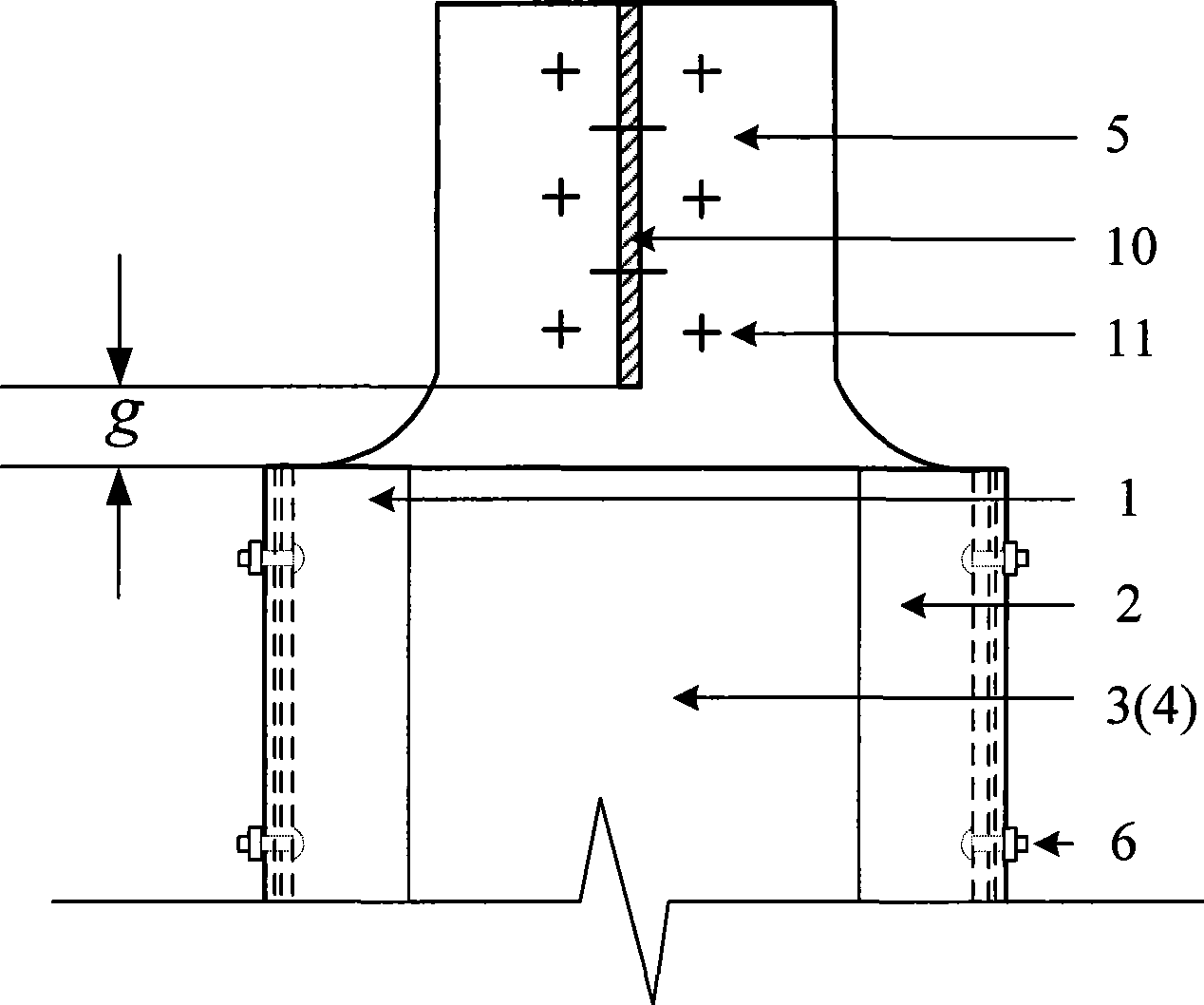

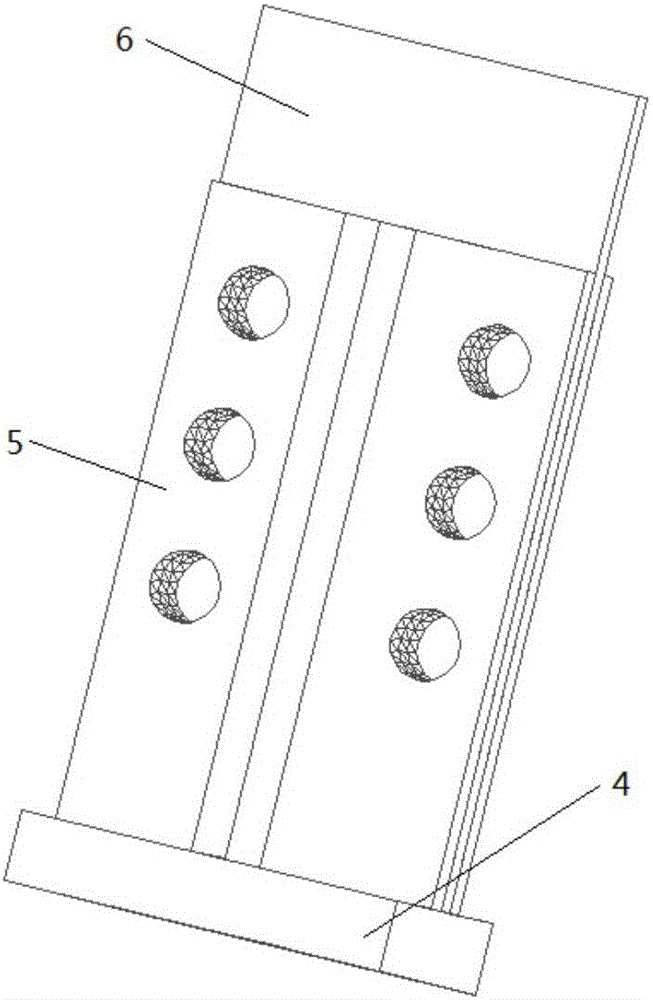

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

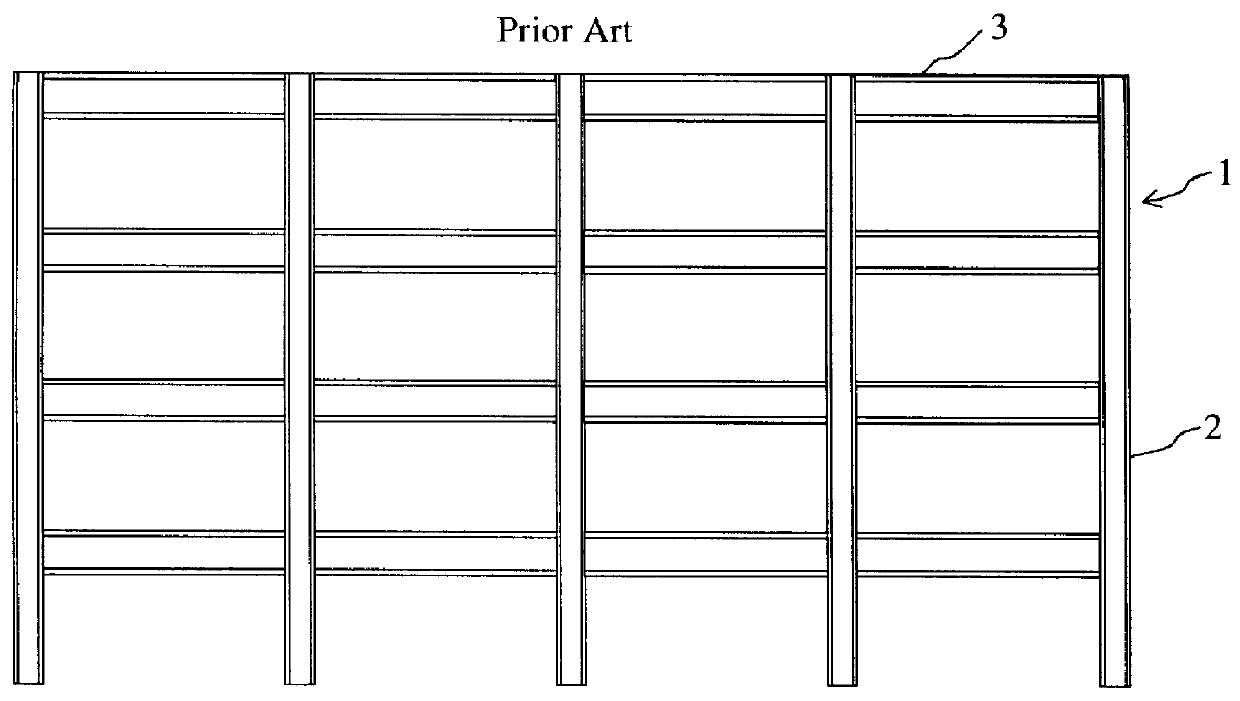

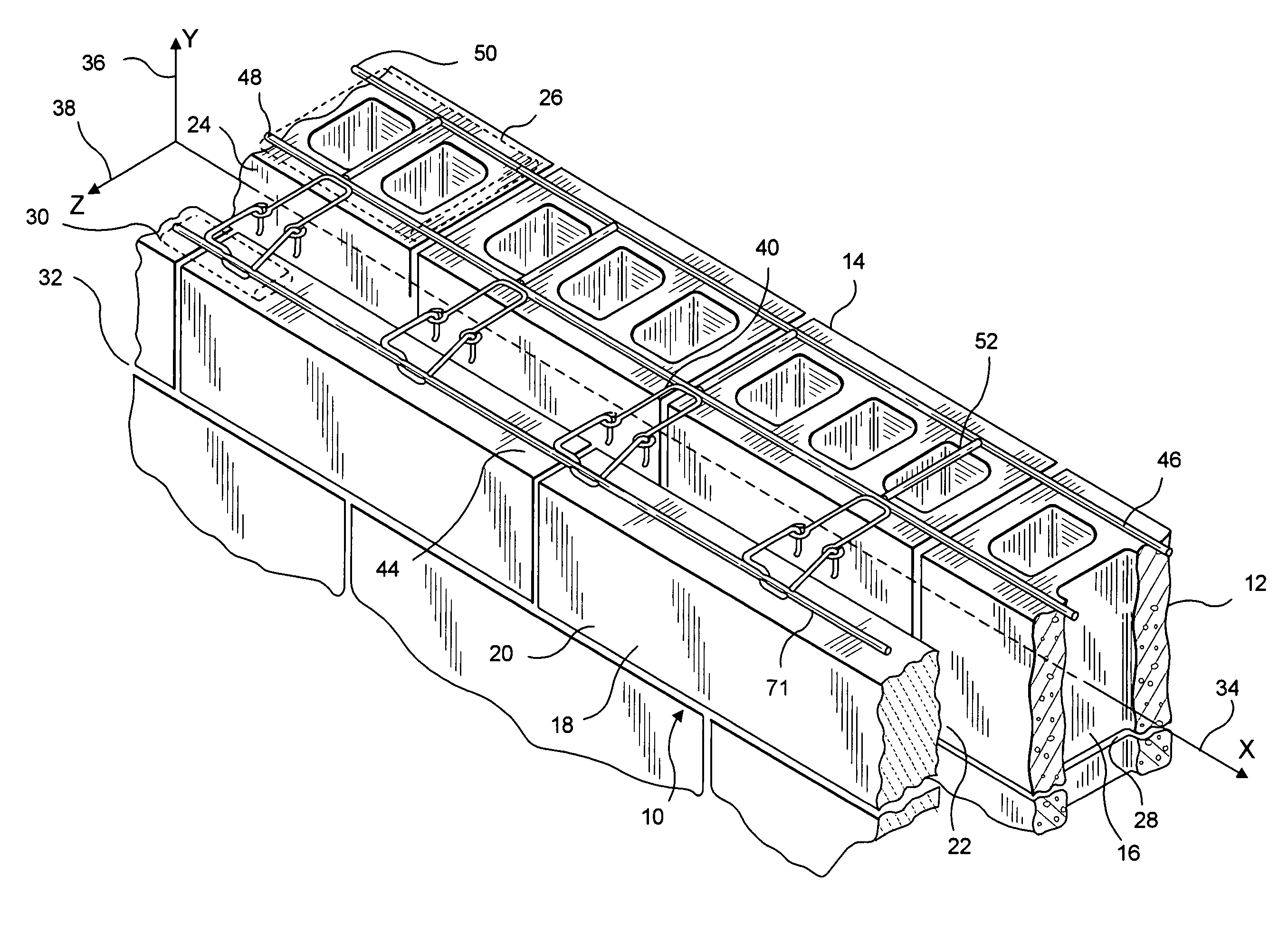

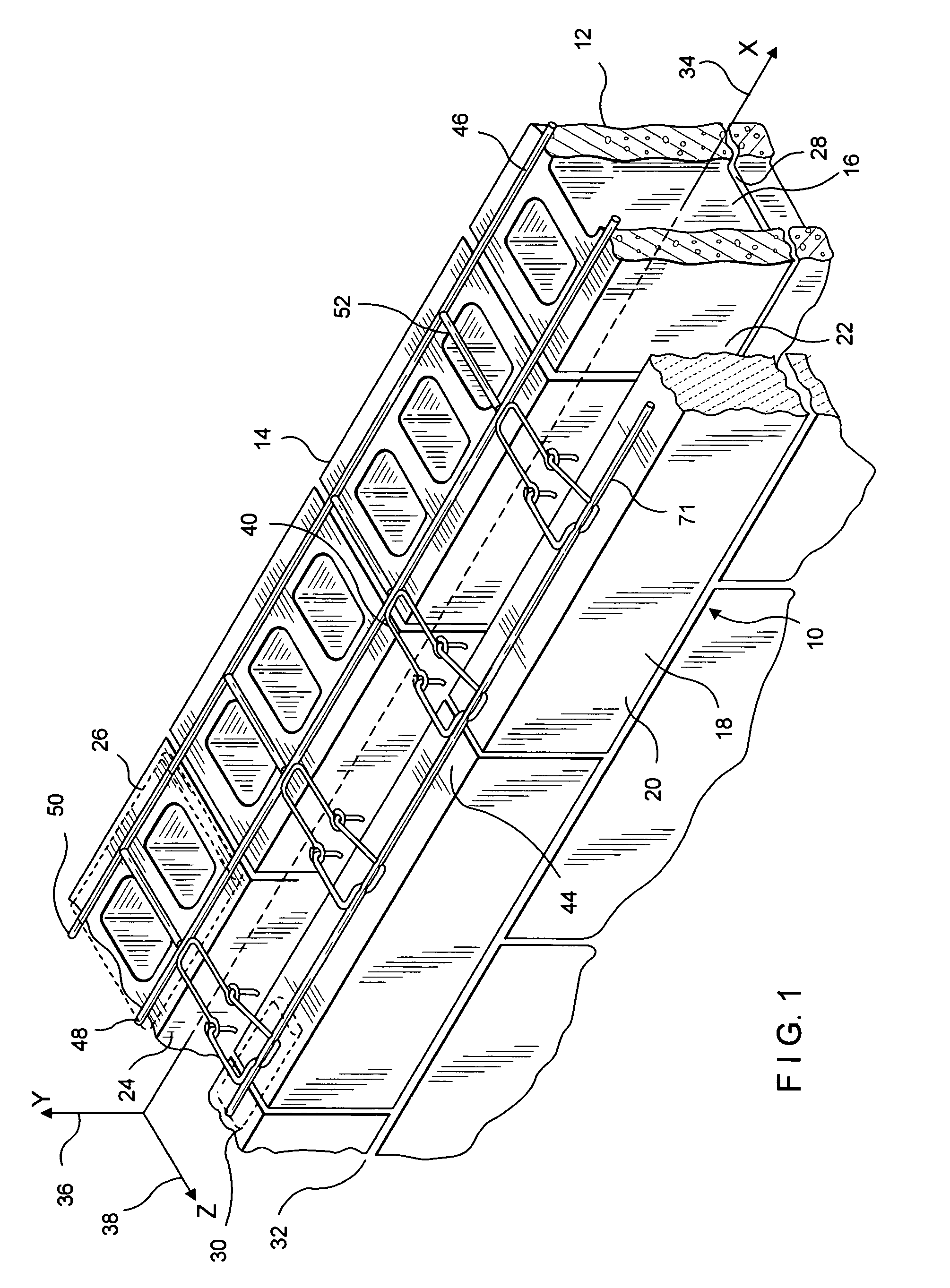

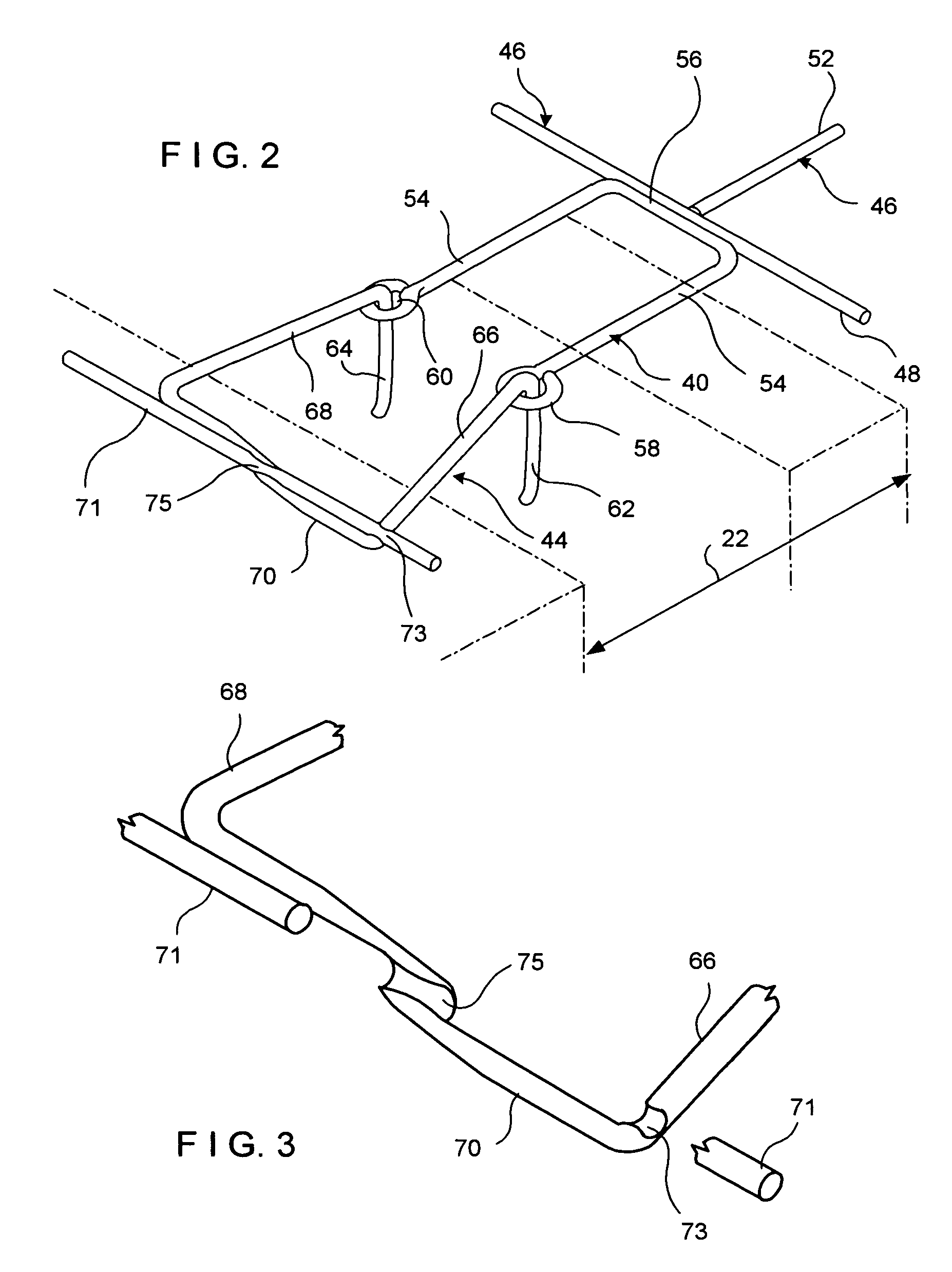

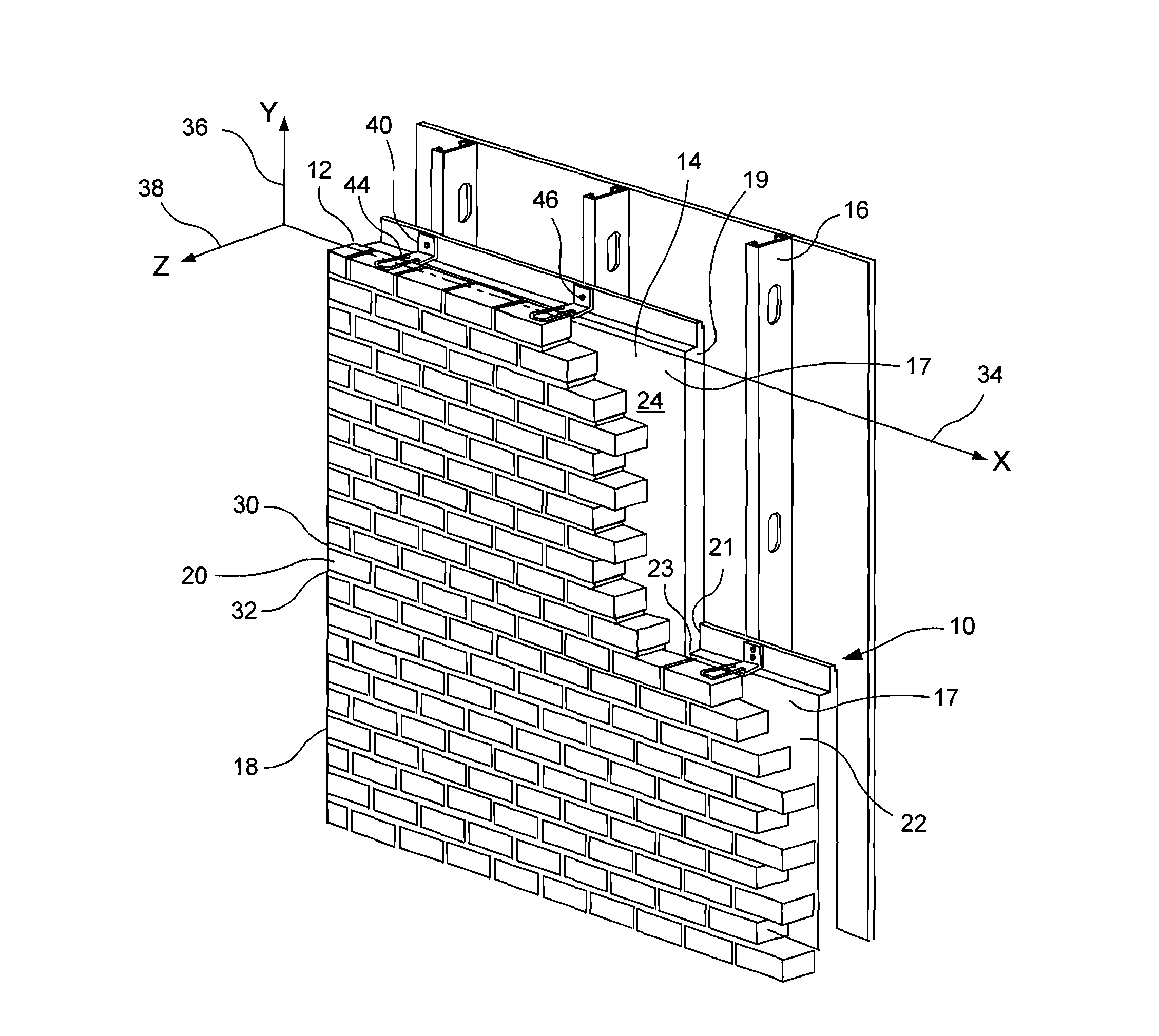

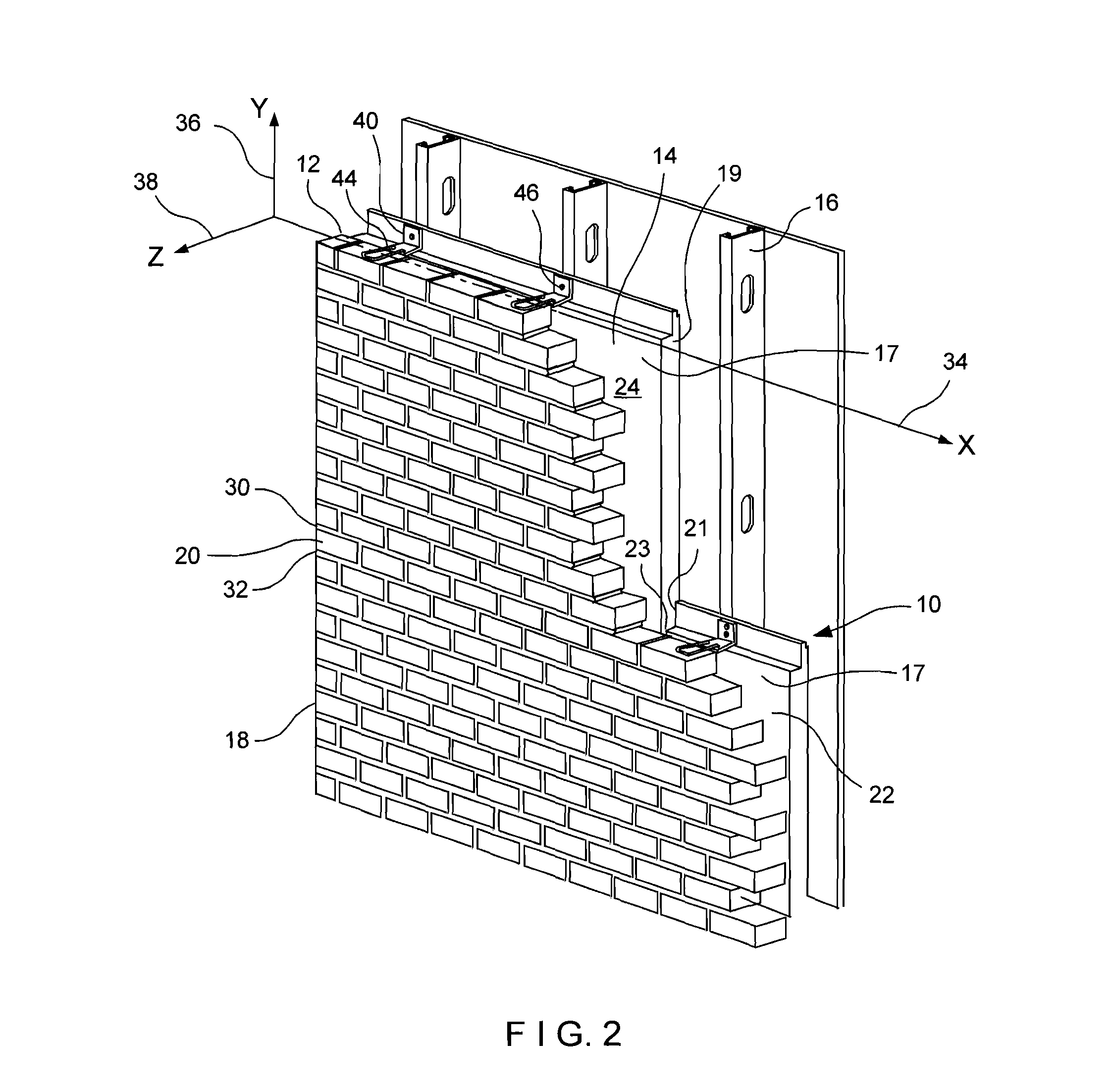

Snap-in wire tie

ActiveUS7325366B1Reduce manufacturing costLower unit costConstruction materialFloorsEngineeringCavity wall

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder- or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder- or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

Perimeter clip for seismic ceilings

Owner:3DXLP LLC +1

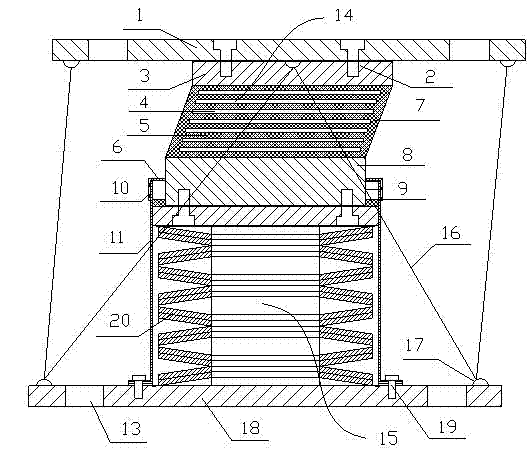

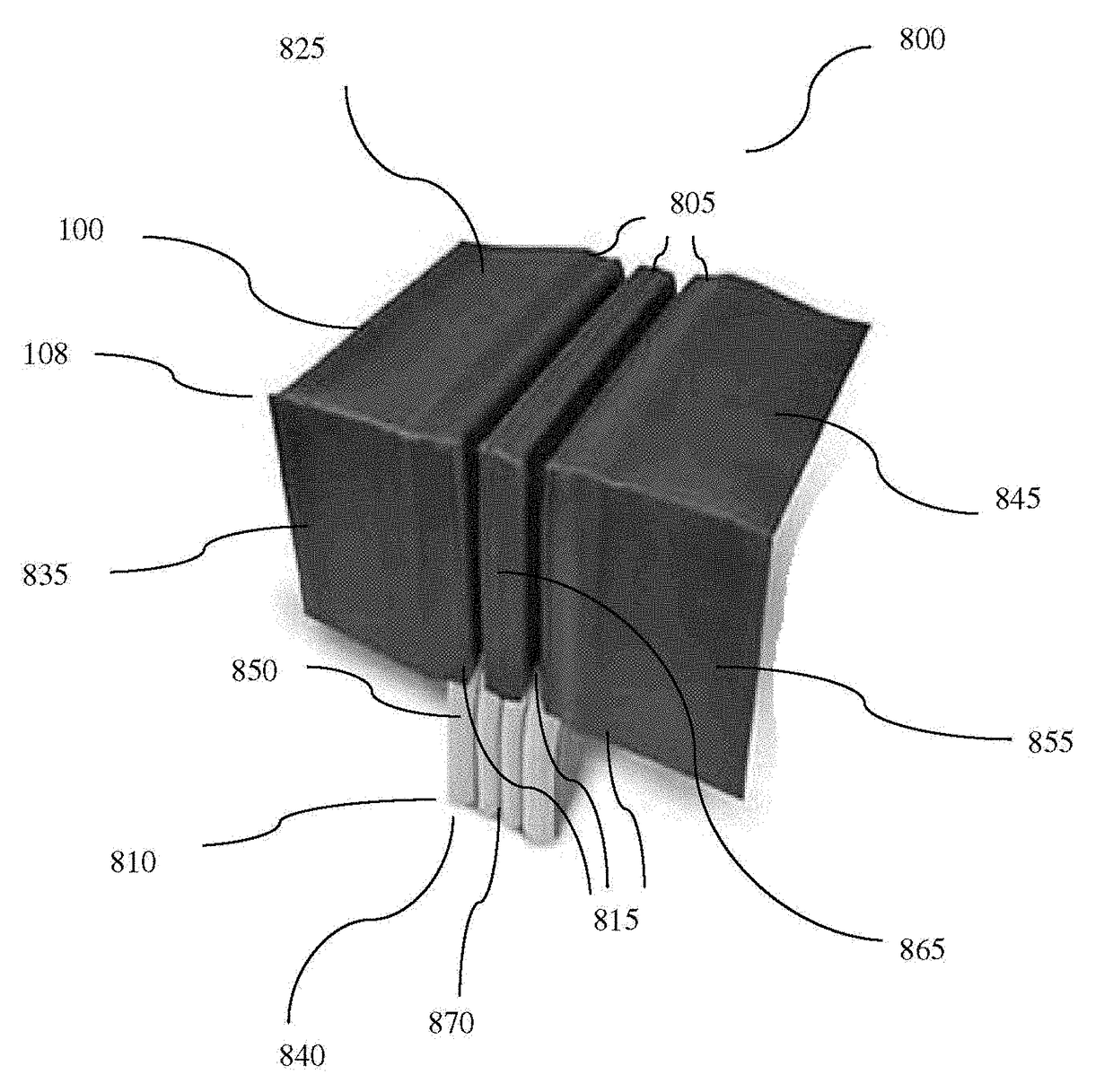

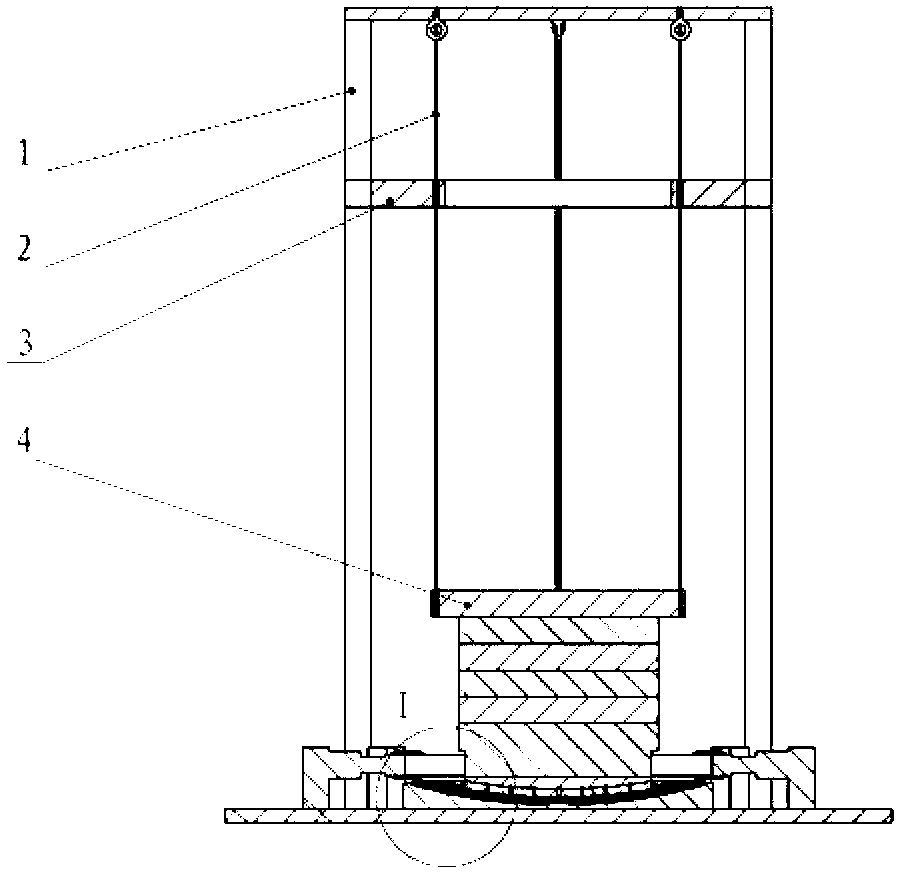

Structural three-dimensional shock isolation and anti-overturning device

The invention relates to a structural three-dimensional shock isolation and anti-overturning device. The main body mechanism of the device is formed by connecting a laminated rubber shock isolation support and a spring shock isolation support in series, and an upper connecting plate and a lower connecting plate are respectively arranged on the upper and lower sides of the main body mechanism. The device is characterized in that: a tensile steel wire rope uniformly distributed on four sides of the main body mechanism is arranged between the upper connecting plate and the lower connecting plate, and the limit deformation of the tensile steel wire rope in the horizontal direction is greater than the horizontal shearing elastic deformation of the main body mechanism. Through the device, the tensile strength of a common three-dimensional shock isolation device is improved, and swing of a high-rise building in an earthquake and even huge tension generated by overturning are resisted; meanwhile, because external tensile steel wire ropes are adopted, the device is convenient to mount and replace and has lower replacing expense.

Owner:FUZHOU UNIV

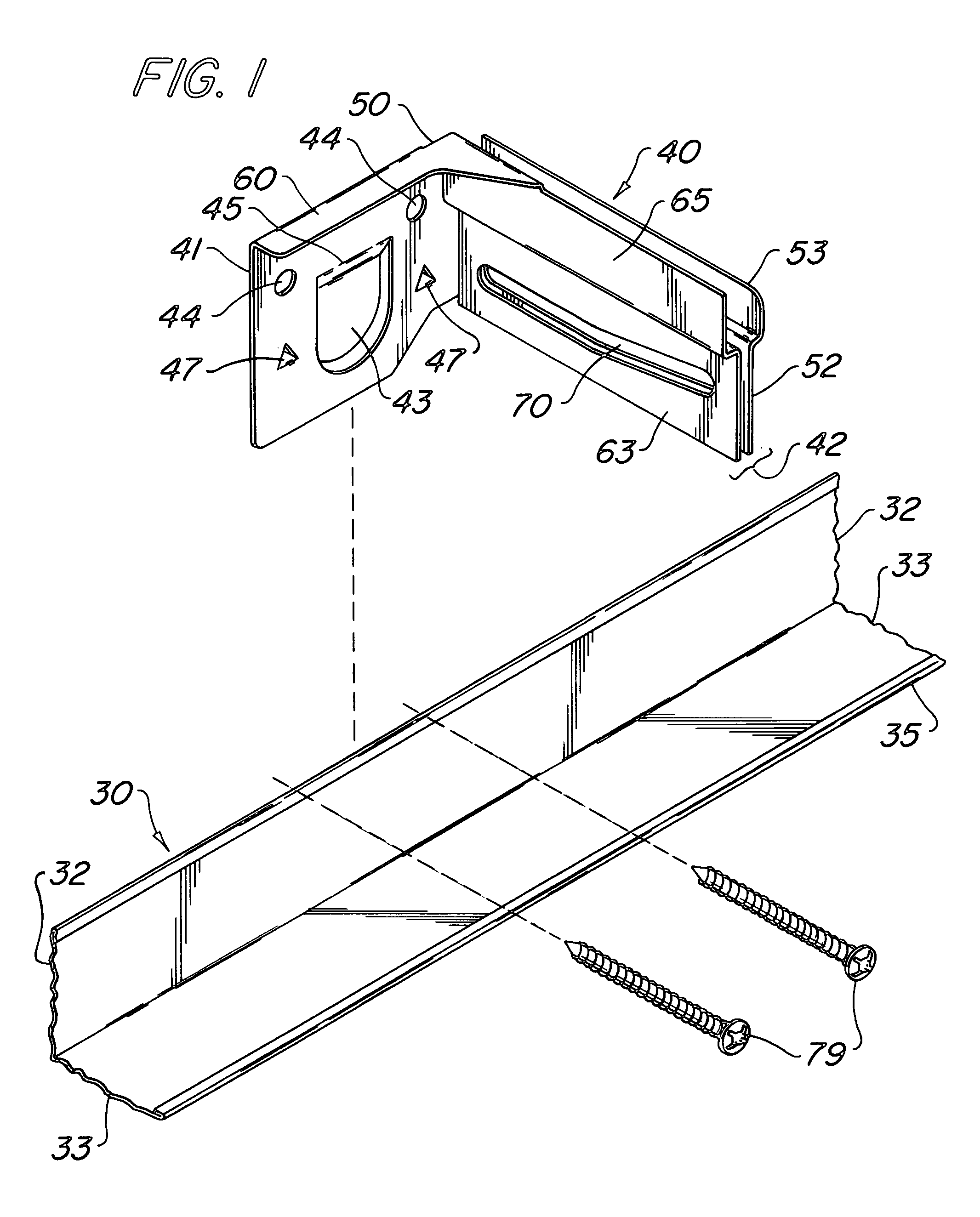

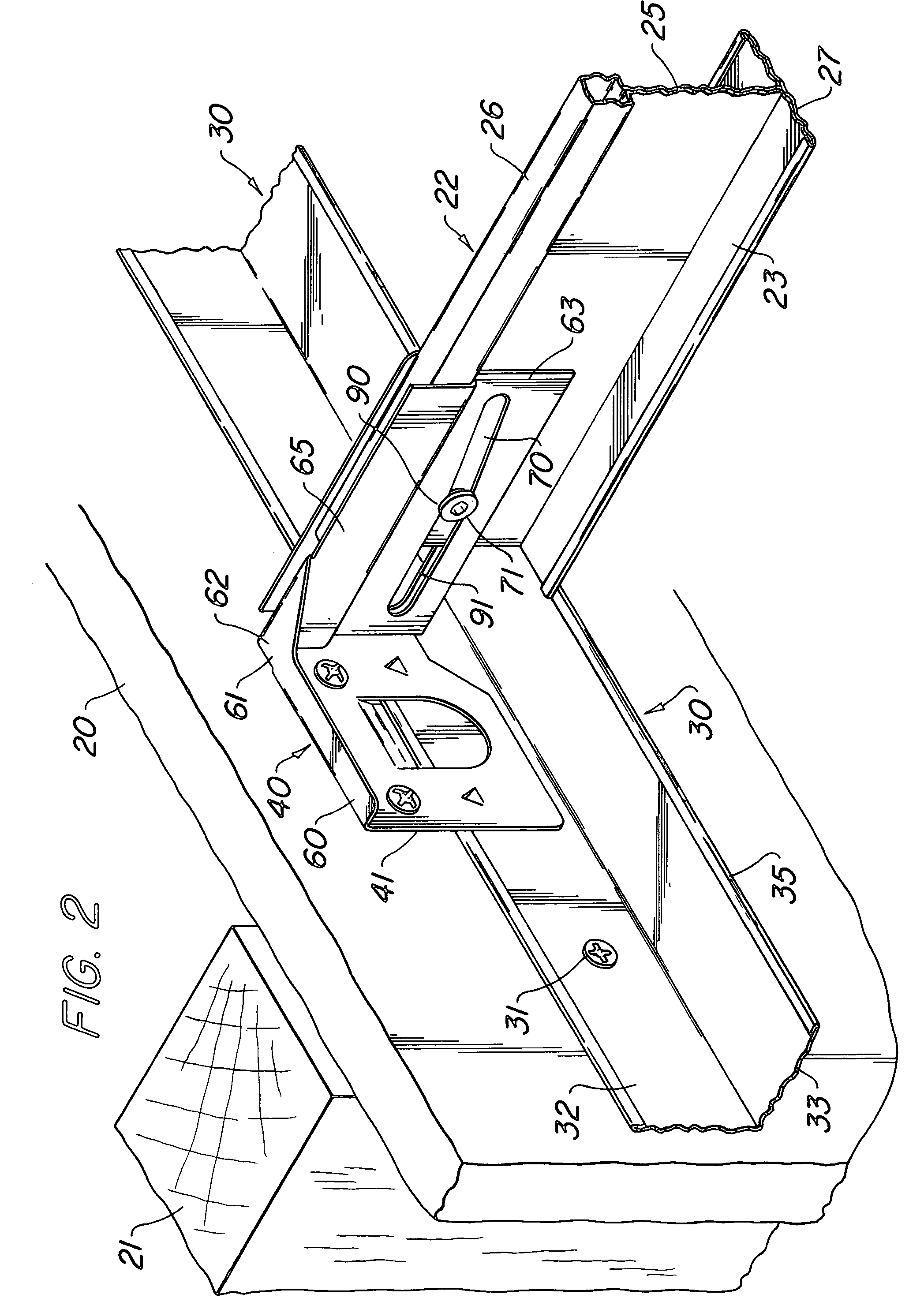

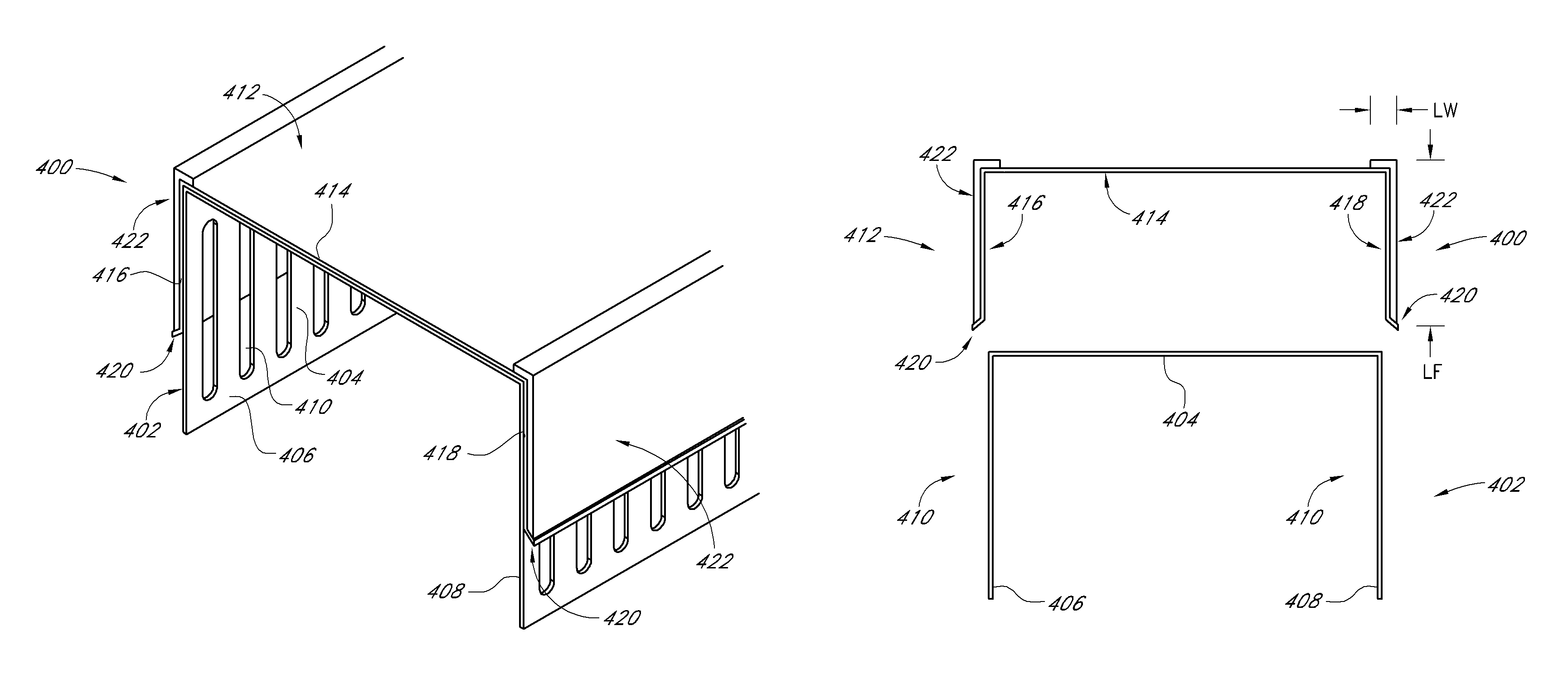

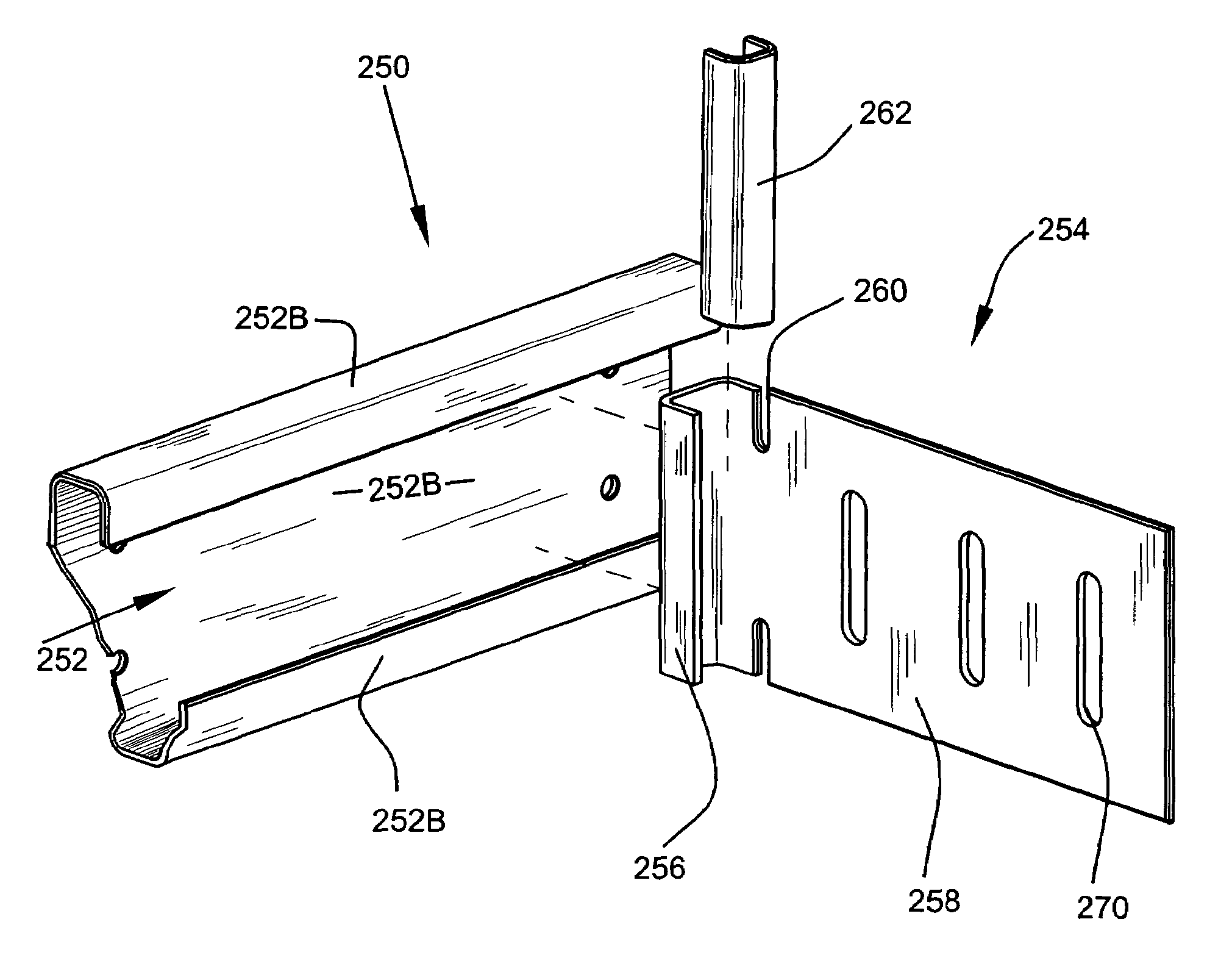

Two-piece track system

ActiveUS8555566B2Enhances and maximizes deflection lengthEasy to createWallsPublic buildingsSill plateMechanical engineering

A fire-rated receiver channel includes at least one intumescent or other fire-resistant material strip. The receiver channel can nest with a framing member, such as metal tracks, headers, header tracks, sill plates, bottom tracks, metal studs, wood studs or wall partitions, and placed at a perimeter of a wall assembly to create a fire block arrangement. In other arrangements, a track assembly includes two nested tracks, an inner track and outer track. The assembly is designed so that the outside width of the outer track is equal to or less than the outside width of the inner track to present a substantially flush external surface for attachment of exterior sheathing elements when the assembly is used in an external wall.

Owner:CEMCO LLC

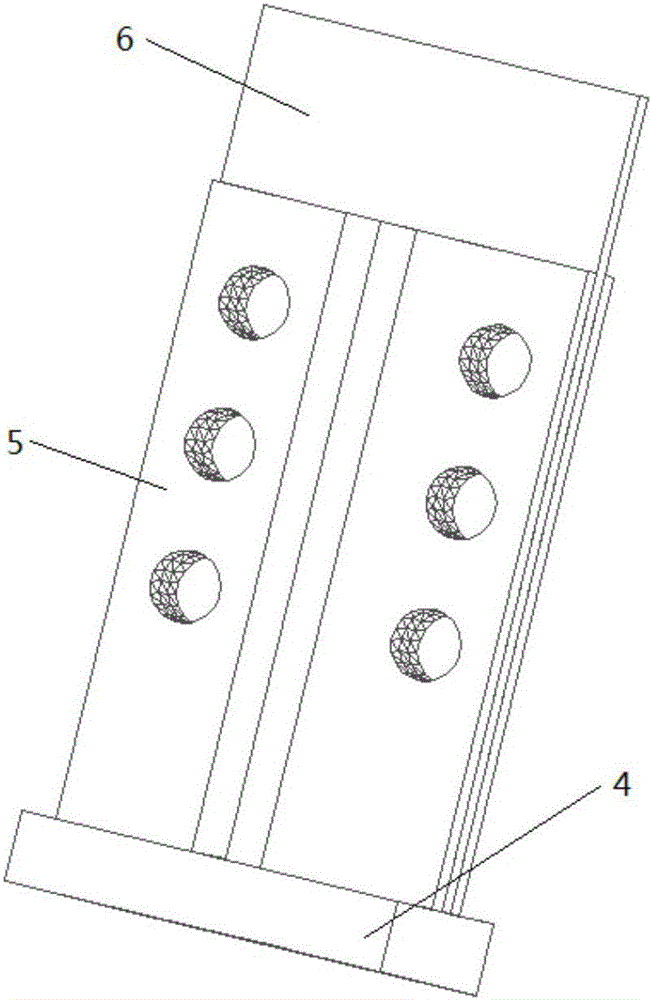

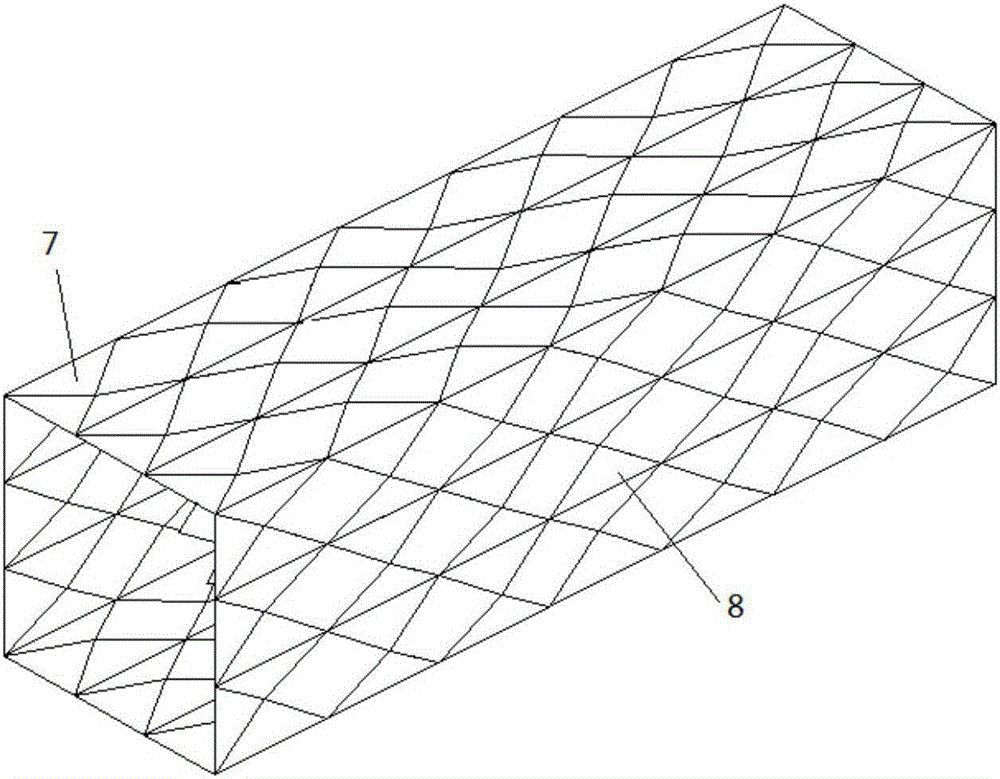

Buckling control support with diamond type energy dissipation units at ends

ActiveCN105888348AImprove protectionQuality assuranceProtective buildings/sheltersShock proofingManufacturing technologyBuckling-restrained brace

The invention discloses a buckling control support with diamond type energy dissipation units at the ends. The buckling control support is characterized by being composed of end restraint sections, energy dissipation sections and a straight supporting section, wherein the two ends of the buckling control support are connected with beam and column members or joints into a whole through high-strength bolts to achieve the purpose of improving the lateral stiffness of the members. The buckling control support with the diamond type energy dissipation units at the ends maintains resilience under the action of a small earthquake and enters a yield stage under the action of a medium earthquake or a major earthquake, and the effect of a damper can be achieved due to the good hystersis energy dissipation performance of the buckling control support. Compared with a traditional buckling control support, the procedures of adding a sleeve outside a core energy dissipation member, performing grouting and the like in the traditional manufacturing process are omitted in the manufacturing technology, and manufacturing is convenient; the support can be prefabricated in a factory, the member quality is guaranteed, the workload of site construction operation is reduced, and energy conservation and environment protection are achieved.

Owner:SOUTHEAST UNIV

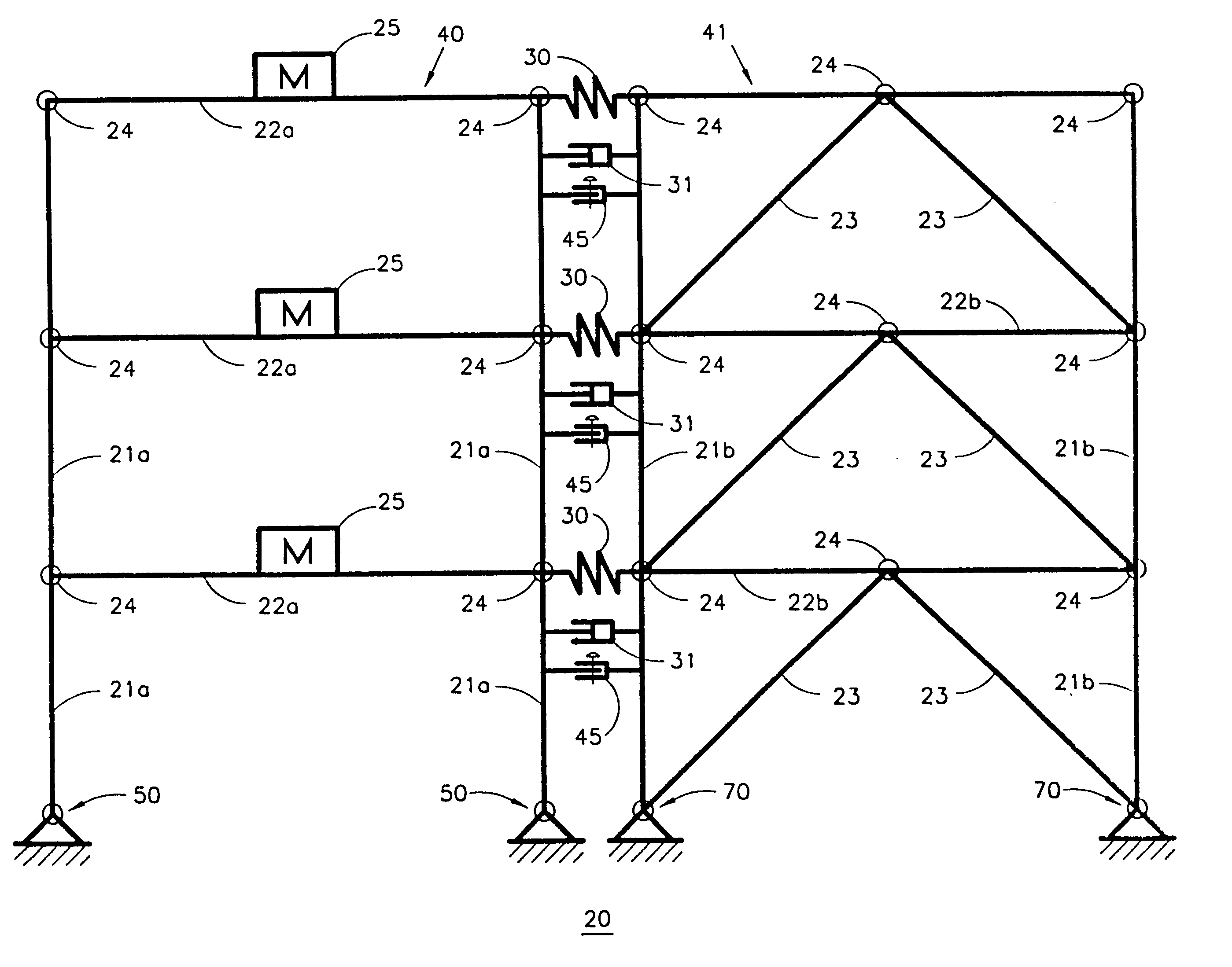

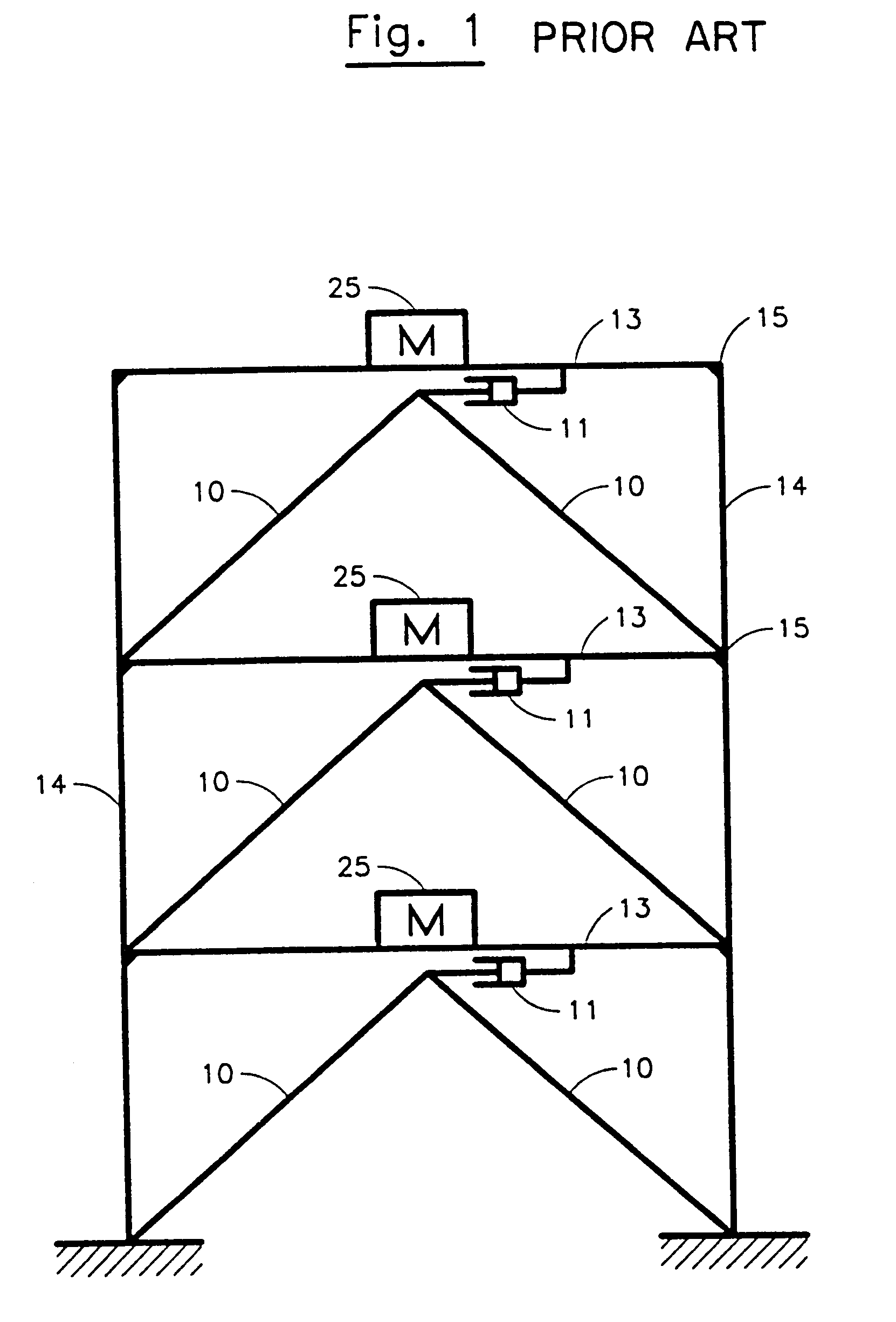

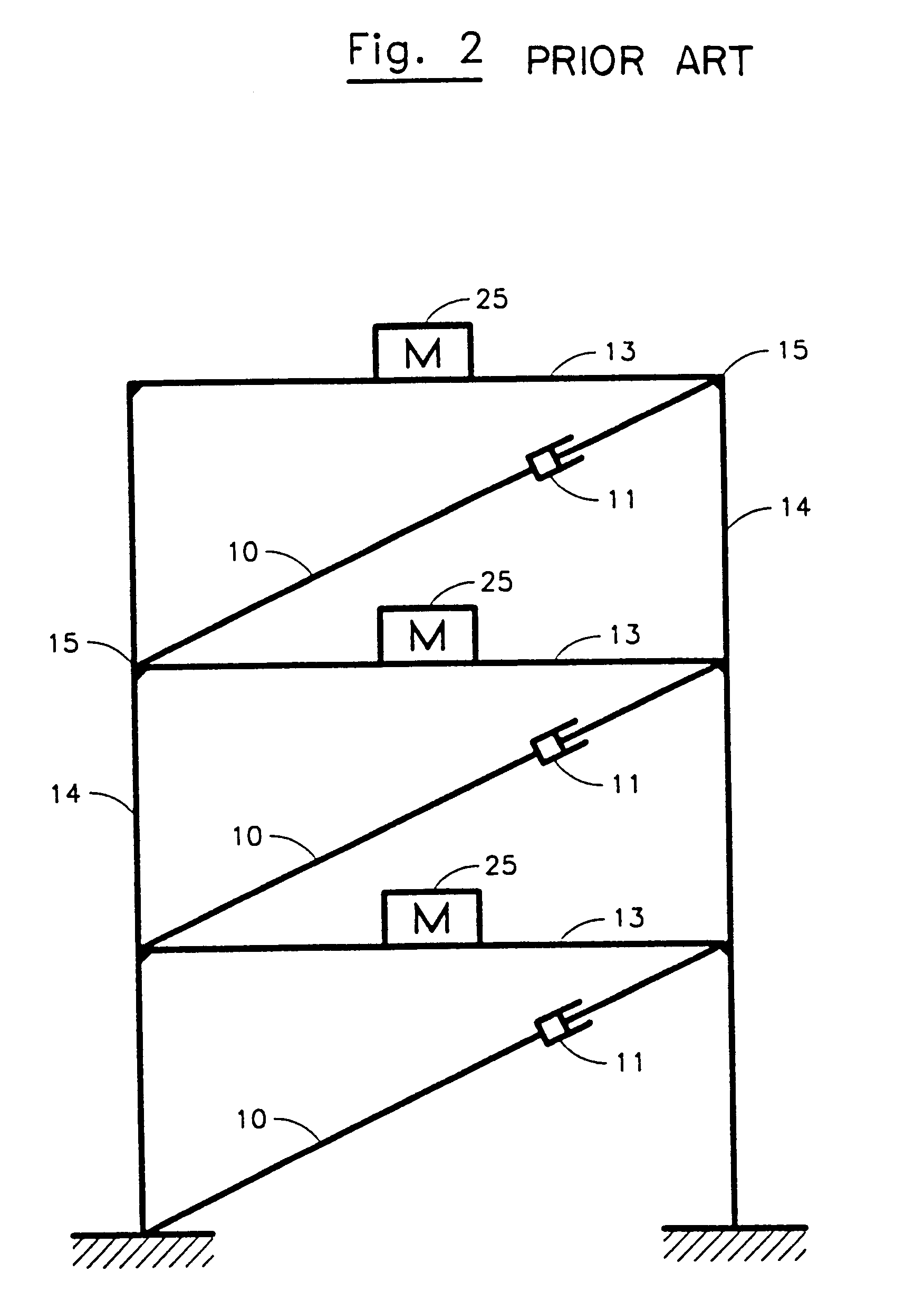

Method and apparatus to control seismic forces, accelerations, and displacements of structures

A seismic energy dissipation system for use with structures such as buildings, bridges and the like. The system includes a gravity frame, at least one reaction frame, and connection apparatus for connecting the gravity frame and the reaction frame. The connection apparatus includes springs for setting a period of response and energy dissipation units for dissipating energy within the structure, thus controlling the response of a structure with respect to internal forces, accelerations and deformations due to external excitations such as wind or earthquake.

Owner:TIPPING STEVEN B +1

Fire and water resistant expansion and seismic joint system

A fire and water resistant expansion and seismic joint system has a cover plate; a spline attached to the cover plate along a first edge of the spline; and a core comprising a first core portion and a second core portion, each portion being located on an opposing face of the spline. The first core portion and the second core portion have a fire-retardant material infused therein. The spline depends from the cover plate in a one piece construction and extends into the core to a depth within the core, and is positioned in a gap between substantially coplanar substrates such that the cover plate overlies the gap. Each portion of the core is compressed between a respective face of the spline and a face of one of the coplanar substrates.

Owner:EMSEAL JOINT SYST

Anchor System for Composite Panel

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

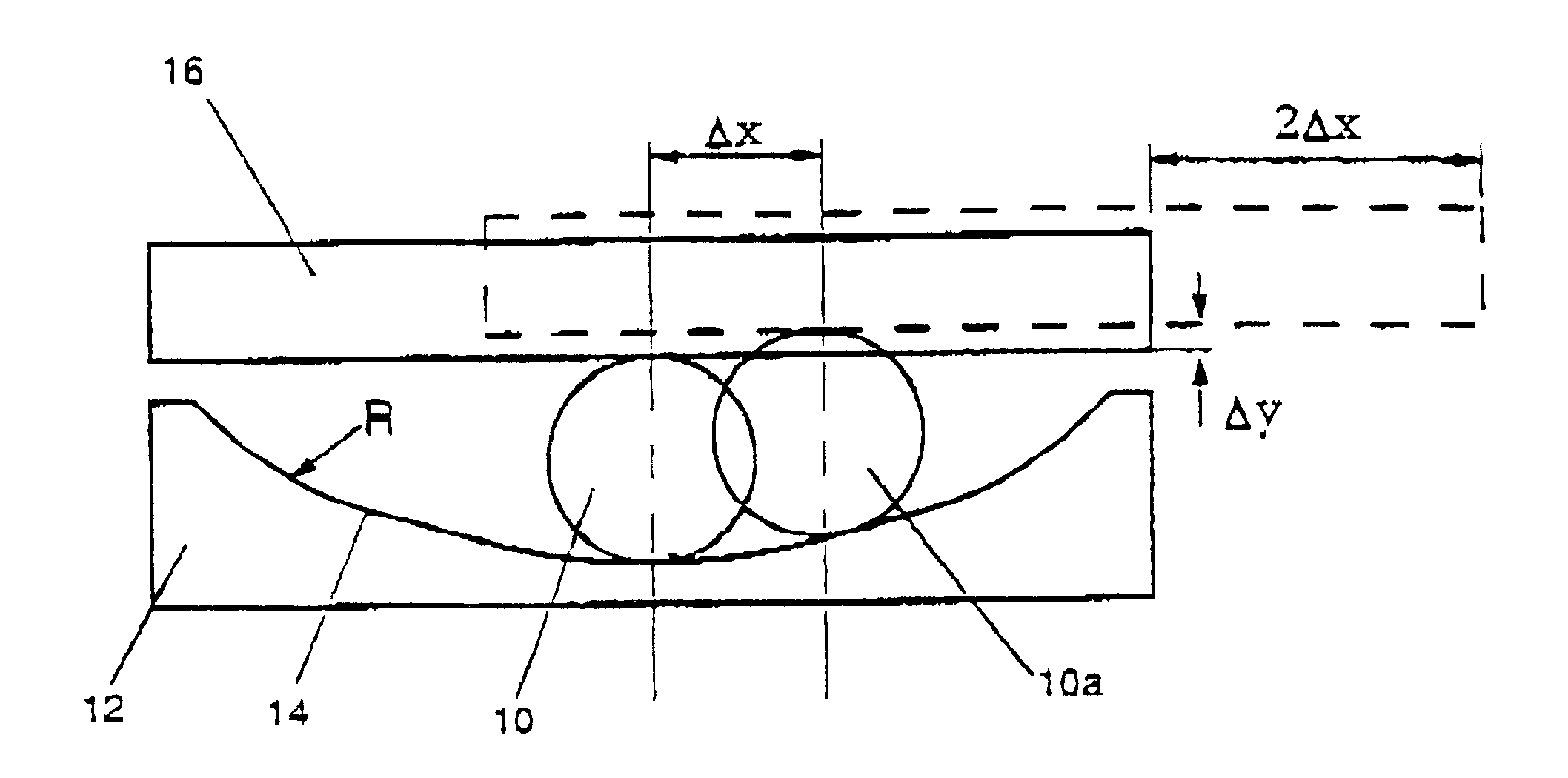

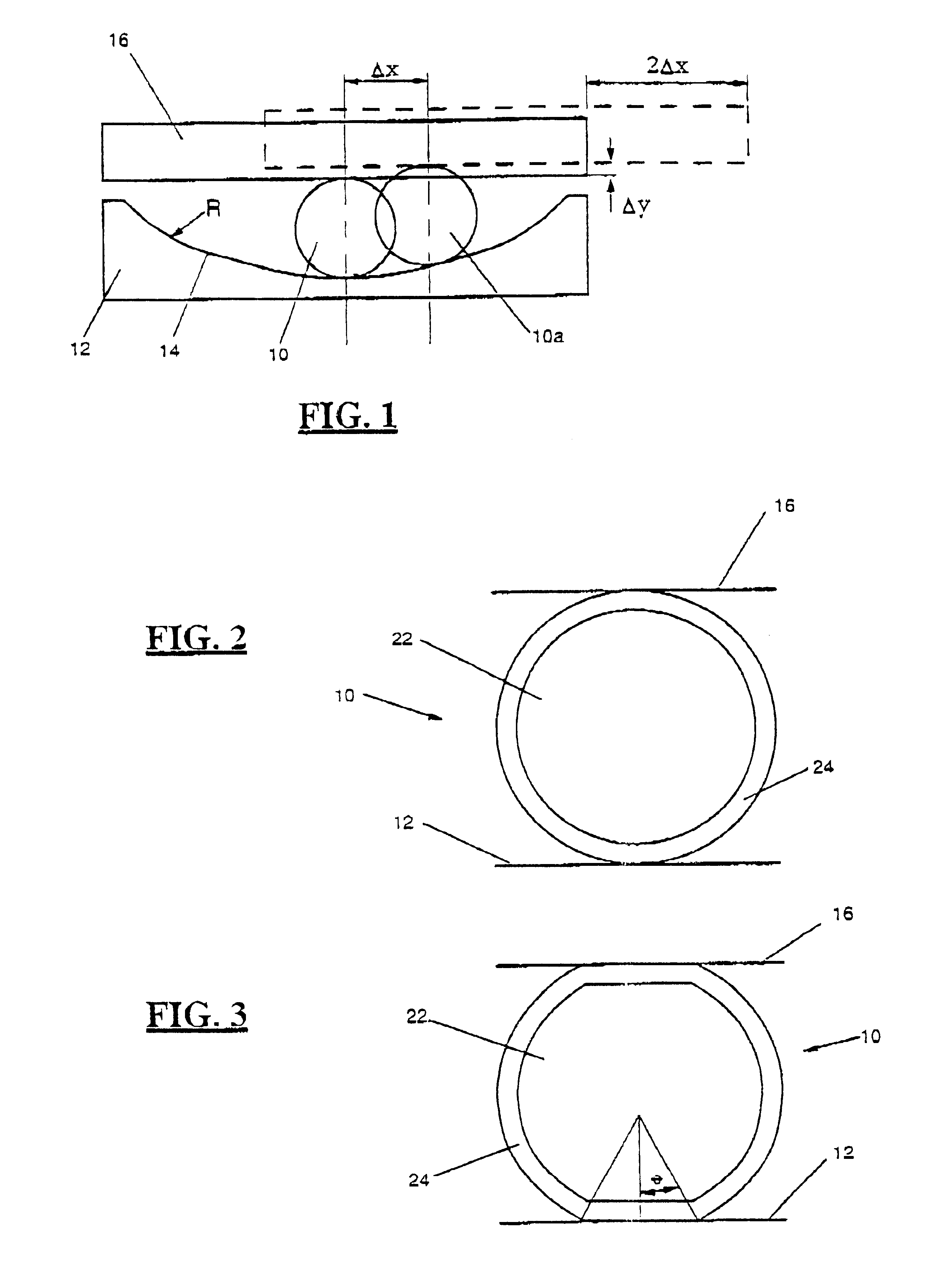

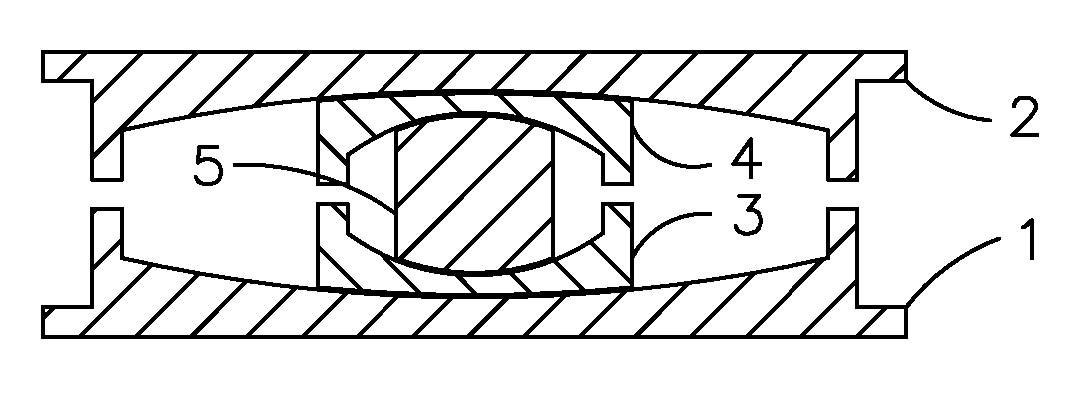

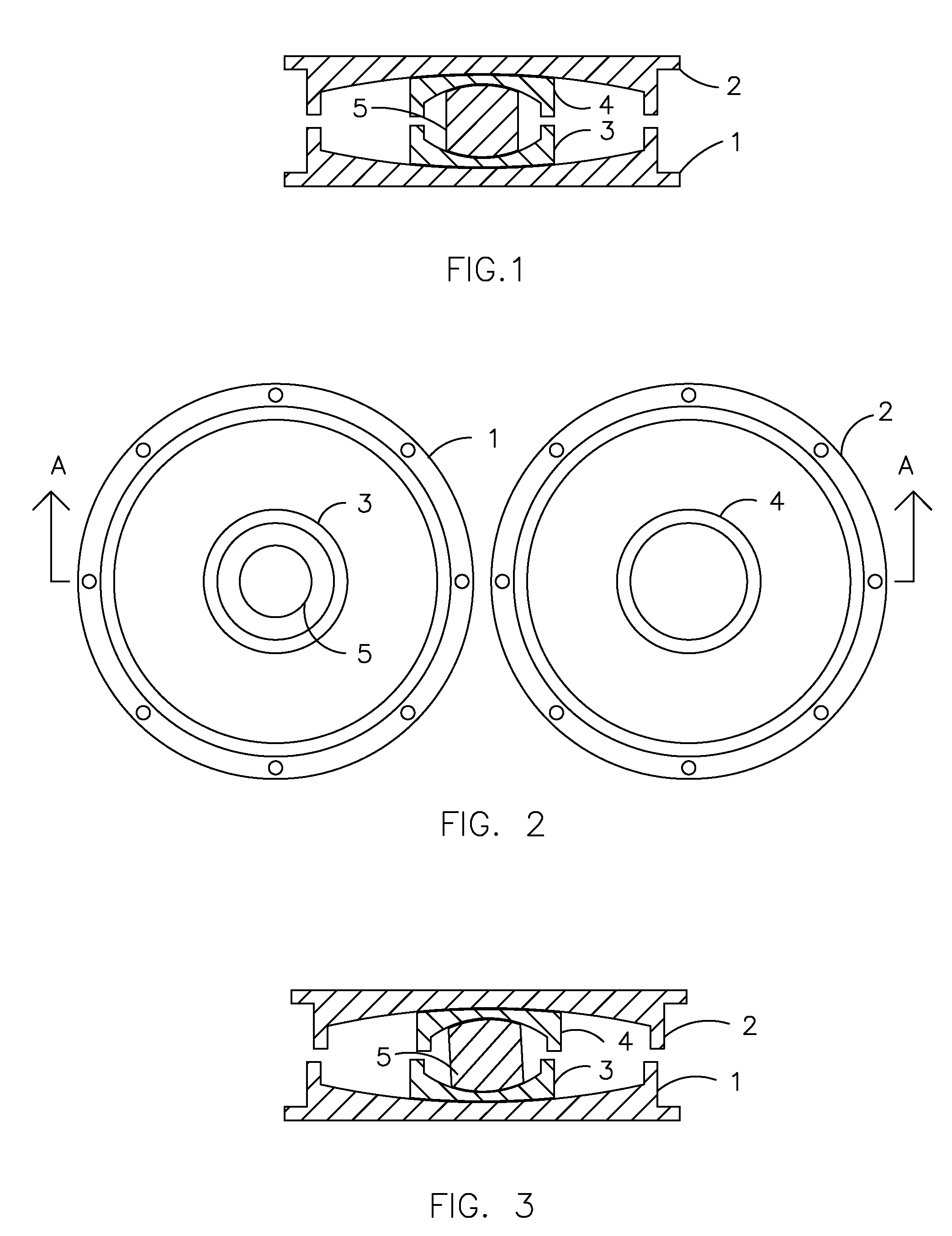

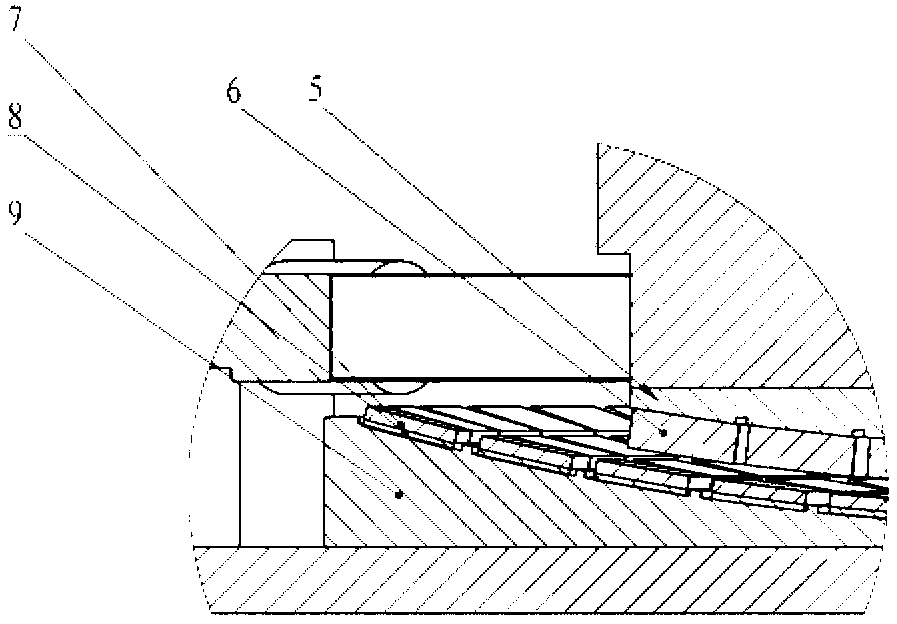

Energy absorber

InactiveUS6321492B1Increase coefficient of frictionNon-rotating vibration suppressionProtective foundationRelative motionEngineering

The invention described is a system for seismic isolation or vibration of structures which is simple, relatively inexpensive and readily used for smaller structures. It involves use of bearings comprising a ball (10) and ball seats (12, 18) interposed between the structure and its foundation. Either the ball itself (24) or the seat surface (15) on which it rolls is compressible, the resistance to that compression providing a frictional braking force resisting rolling of the ball. This serves to dampen relative movement between the structure and its foundation. There are described several alternative constructions of the friction ball which is the preferred central element in the bearing device. There may be a plurality of balls (44, 47) in each combination of balls and seats.

Owner:ROBINSON SEISMIC

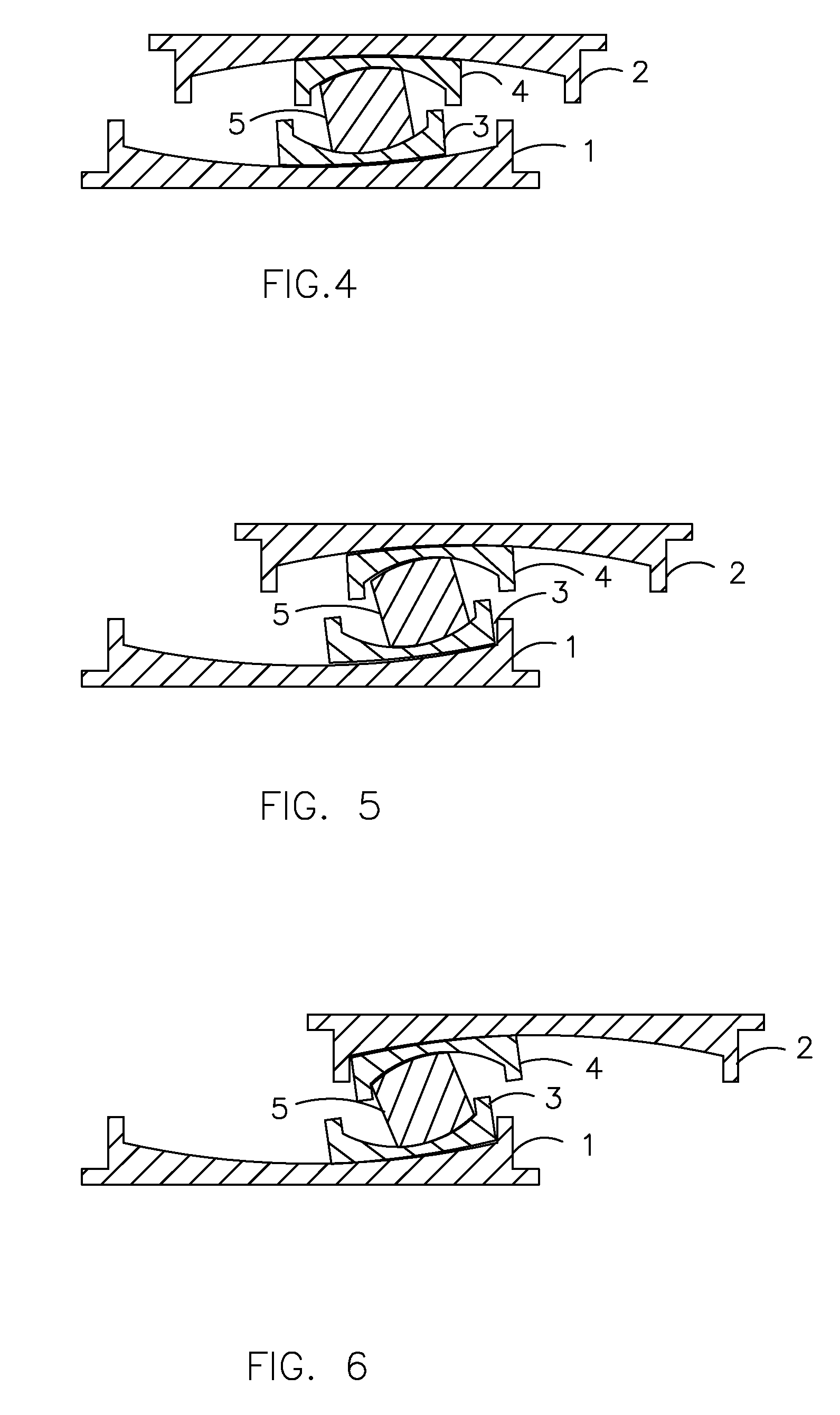

Sliding Pendulum Seismic Isolation System

ActiveUS20060174555A1Increase effective frictionReduce earthquake forceStands/trestlesKitchen equipmentCost effectivenessSeismic gap

An inventive method is presented for a sliding pendulum seismic isolation system that reduces seismic forces on the supported structure and reduces the costs of the isolation bearings, seismic gaps, and supported structural frame. The inventive method is to configure the isolation system to achieve increased effective friction with increased displacement amplitudes, and to employ specific bearing configurations that suit the different types and magnitudes of loads present at particular structure support locations. Three bearing configurations are presented which are comprised of multiple sliders that slide along different concave spherical surfaces, each constituting an independent sliding pendulum mechanism having a specified pendulum length and friction. Two bearing configurations are presented which are comprised of multiple sliders that slide along different concave or convex cylindrical surfaces, one configured to carry both compression and tension loads, and one configured to be cost-effective for carrying light compression loads and accommodating large displacements.

Owner:EARTHQUAKE PROTECTION SYST

Fire and water resistant expansion joint system

A fire resistant and water resistant expansion joint system comprises a core; and a fire retardant infused into the core. The core infused with the fire retardant is configured to define a profile to facilitate compression of the fire and water resistant expansion joint when installed between substantially coplanar substrates.

Owner:EMSEAL JOINT SYST

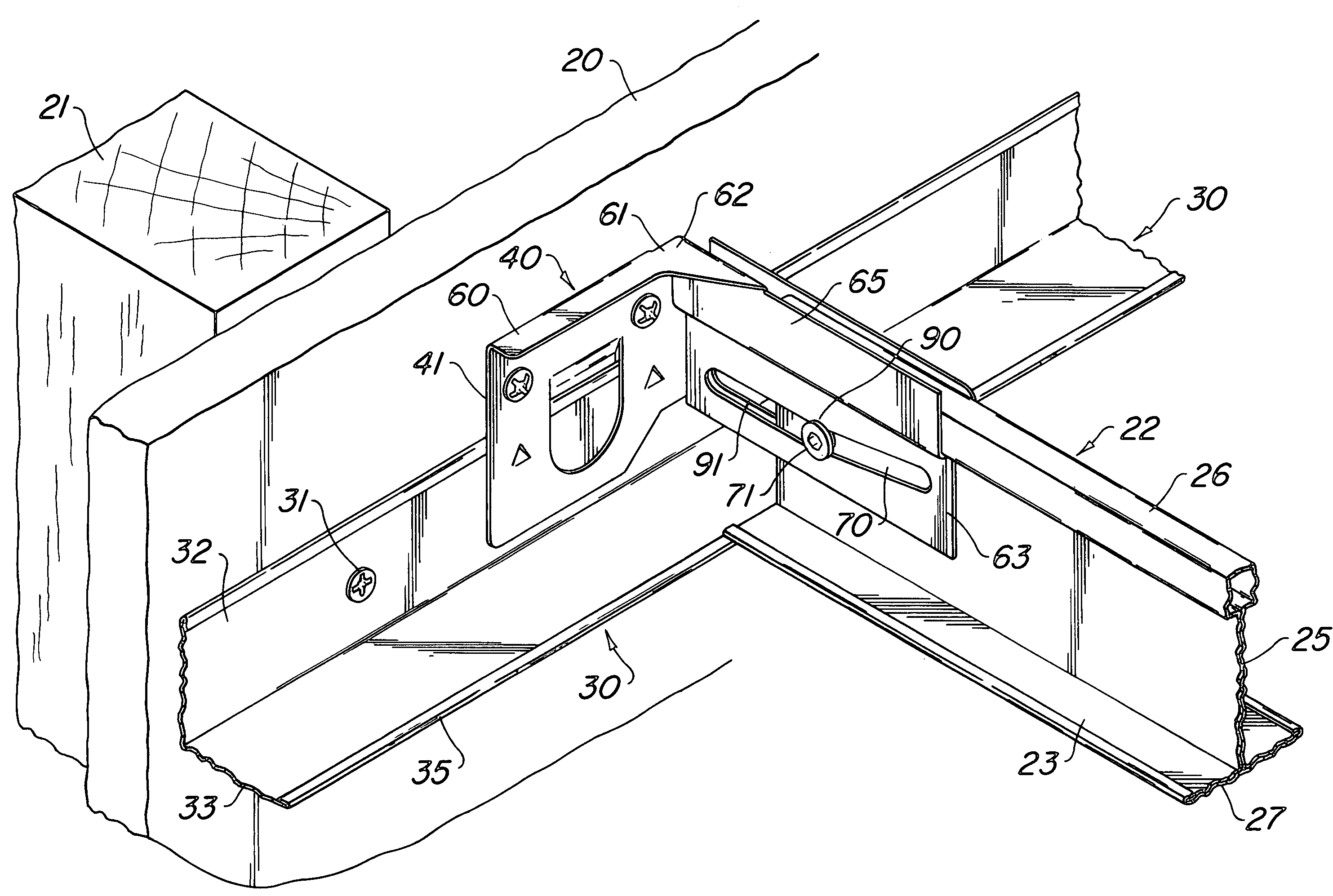

Connector assembly for allowing relative movement between two building members

A connector assembly for a building structure is provided. The connector assembly includes an elongated track that is mounted to a first member of a building frame structure. A connecting member is connected to the elongated track and retained within a pair of opposed channels that form a part of the track. Connected to the connecting member is a second member of the building frame structure. Formed in the connecting member is at least one elongated slot that permits the connecting member to be connected to the second member and for there to be relative movement between the connecting member and the second member. Further, the connecting member is slidable back and forth within the elongated track. Thus, it is appreciated that bidirectional movement between the first and second members can be accommodated by the connecting member sliding back and forth along the track on one hand and by there being relative movement about the connection between the connecting member and the second member.

Owner:THE STEEL NETWORK

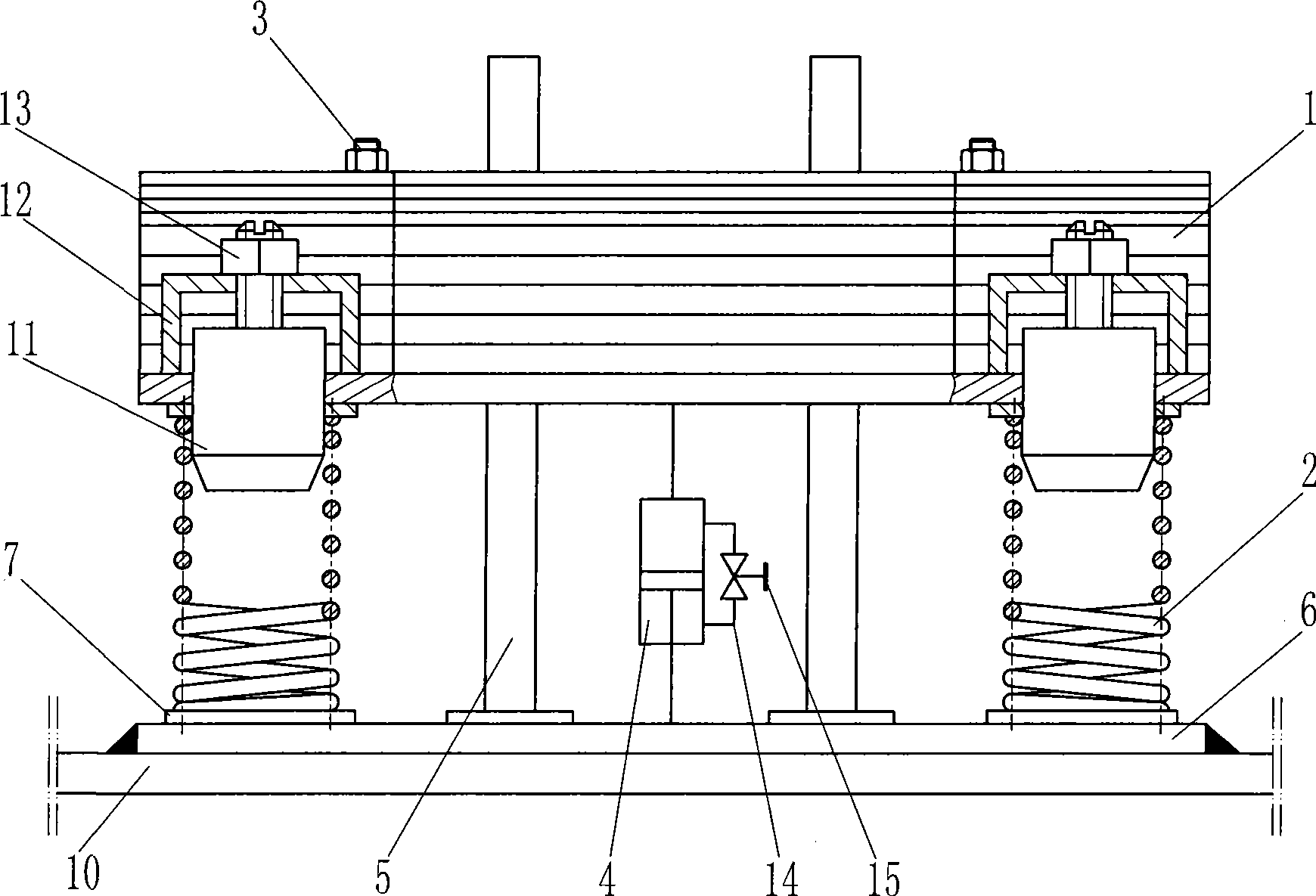

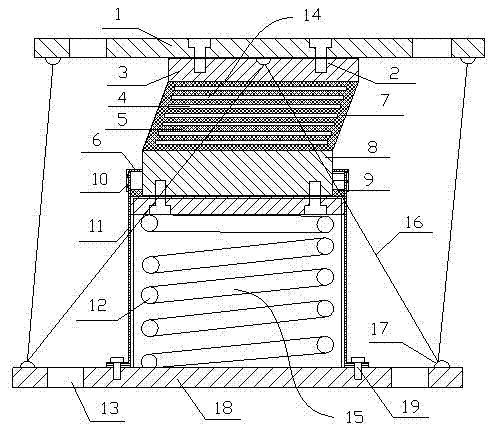

Damping ratio adjustable tuning quality damper

ActiveCN101457554AChange the damping ratioDamping Ratio OptimizationSpringsSolid based dampersDamping ratioEngineering

The invention specifically relates to a mass tuned vibration reducer used for regulating the subsidence ratio of the vibration of the related structures. The mass tuned vibration reducer comprises a mass block, a spring, a damper and a base, and is characterized in that the damper is an adhesion-type damper formed by a damping cylinder, adhesive damping fluid and a piston, wherein, the piston and the adhesive damping fluid are arranged in the damping cylinder, and at least part of the piston is immerged into the adhesive damping fluid. The mass tuned vibration reducer adopts the adhesion-type damper formed by the adhesive damping fluid and the piston and can provide three dimensional damping, so as to effectively prevent side tumbling and ensure the vibration reducer realizes smooth actions; vibration mass is not needed to be provided with a special guide device, so that the mass tuned vibration reducer has reliable work and higher cost performance, and basically needs no maintenance. Meanwhile, the mass tuned vibration reducer realizes the aim of regulating the natural frequency and the subsidence ratio at any time, thus better exerting the vibration absorption performance of the mass tuned vibration reducer, ensuring stableness and safety of the pedestrians and vehicles on the large-span bridge and the thin and high building, contributing to prolonging the service lives of the thin and high building and the bridge, and having remarkable economic and social benefits.

Owner:尹学军 +1

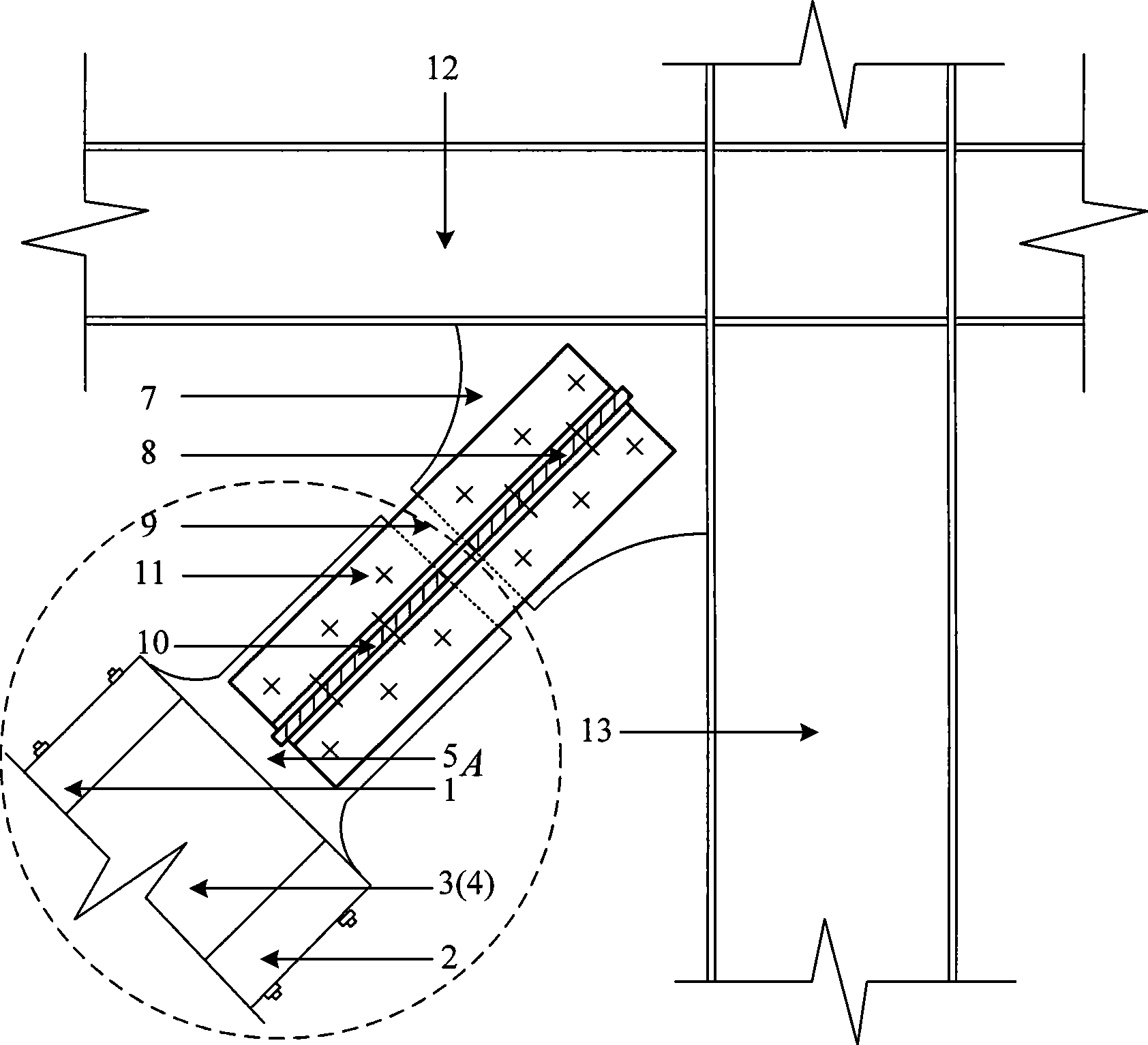

All-steel buckling-preventing energy-consuming brace

The invention relates to an all-steel buckling-preventing energy-consuming brace, which belongs to the technical field of structural engineering. The brace is characterized in that the buckling-preventing energy-consuming brace consists of four hot-rolled groove-shape section steels and a kernel linear steel plate; the four hot-rolled groove-shape section steels are connected through high-strength bolts to form a peripheral constraint component capable of forming a constraint mechanism to the kernel linear steel plate; and a certain gap is reserved between the kernel steel plate and the peripheral constraint component and is coated with unbonded material so as to guarantee the smooth slippage between the two and play a role in anticorrosive protection. The all-steel buckling-preventing energy-consuming brace provided by the invention can provide good effect of resisting lateral force for a plurality of high-rise steel structures, and can achieve total cross-section yielding under the action of large earthquakes so as to effectively consume energy. In addition, as the buckling-preventing energy-consuming brace is an all-assembled component, the brace has the advantages that the brace is easy to machine and install, capable of effectively reducing structural construction cost and excellent in performance.

Owner:TSINGHUA UNIV

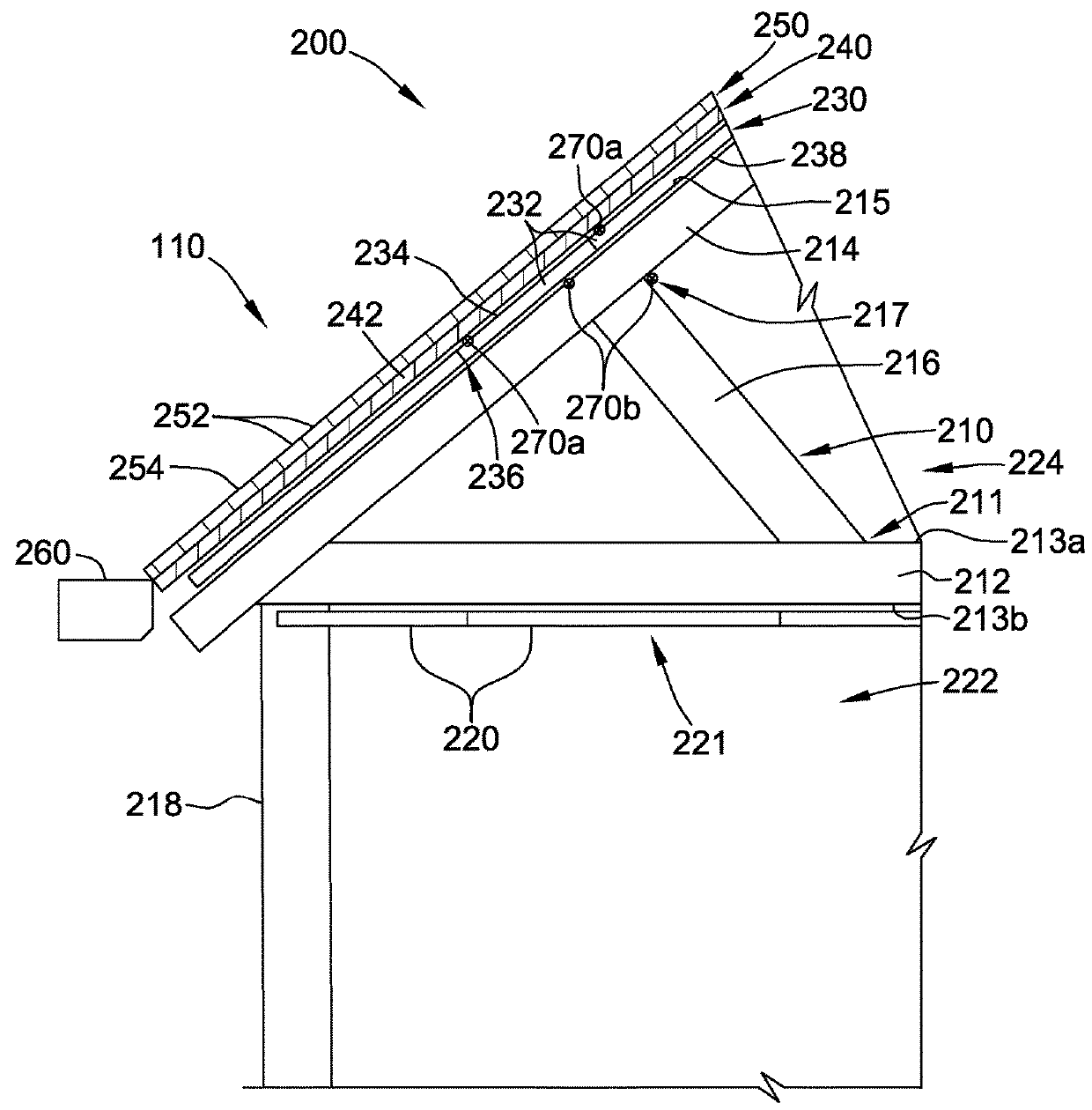

Fire and water resistant, integrated wall and roof expansion joint seal system

ActiveUS20170342708A1Facilitate interlayingImprove sealingRoof coveringConstruction materialEngineeringExpansion joint

A fire and water resistant, integrated wall and roof expansion joint seal system includes an expansion joint seal for a structure. The seal includes a central portion having an underside and at least one central chamber disposed around a centerline, a first flange portion extending outwardly from the centerline and a second flange portion extending outwardly from the centerline in a direction opposite the first flange portion. The system further includes a joint closure. The joint closure includes a core and a layer of a water resistant material disposed on the core. The joint closure further includes an end portion configured to match and integrate with the underside of the central portion to form the watertight, integrated wall and roof expansion joint seal system. A fire retardant material is included in the core in an amount effective to pass testing mandated by UL 2079, and the core with the fire retardant material therein is configured to facilitate compression of the core when installed between the first substrate and the second substrate by repeatedly expanding and contracting to accommodate movement of the first substrate and the second substrate; and the core with the fire retardant material included therein is configured to pass the testing mandated by UL 2079. Movement of one or both of the first substrate and the second substrate causes a response in the central portion to maintain the seal.

Owner:EMSEAL JOINT SYST

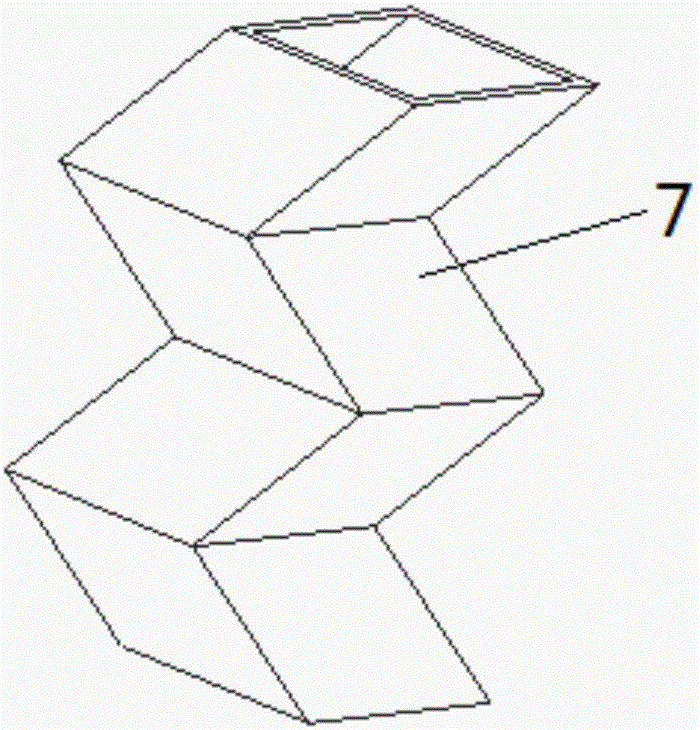

Energy dissipation type buckling constraint support with symmetrical initial imperfection unit at end

ActiveCN105971356AOptimize layoutFlexible layoutProtective buildings/sheltersShock proofingManufacturing technologyBuckling-restrained brace

The invention discloses an energy dissipation type buckling constraint support with a symmetrical initial imperfection unit at the end. The energy dissipation type buckling constraint support is characterized in that the support is composed of an end constraint segment, an energy dissipation segment and a support straight segment; and the two ends are connected with beams or column components or nodes to form a whole through bolt connection so as to achieve the purpose of improving of the resistant-lateral rigidity of components. The energy dissipation type buckling constraint support with the symmetrical initial imperfection unit at the end is adopted, and thus under the action of a small earthquake, the buckling constraint support keeps elasticity; and under the action of a medium earthquake or a severe earthquake, the buckling constraint support enters a yield stage, and the effect of a damper can further be achieved through the good hysteretic energy dissipation performance of the buckling constraint support. Compared with traditional buckling constraint supports, according to a manufacturing technology of the energy dissipation type buckling constraint support, the processes of adding a sleeve outside a core energy dissipation component, grouting and the like in the traditional manufacturing process are avoided in the manufacturing technology, so that manufacturing is convenient. The energy dissipation type buckling constraint support can be prefabricated and formed in a factory, the quality of the components is ensured, the workload of site operation is reduced, and energy conservation and environment protection are achieved.

Owner:SOUTHEAST UNIV

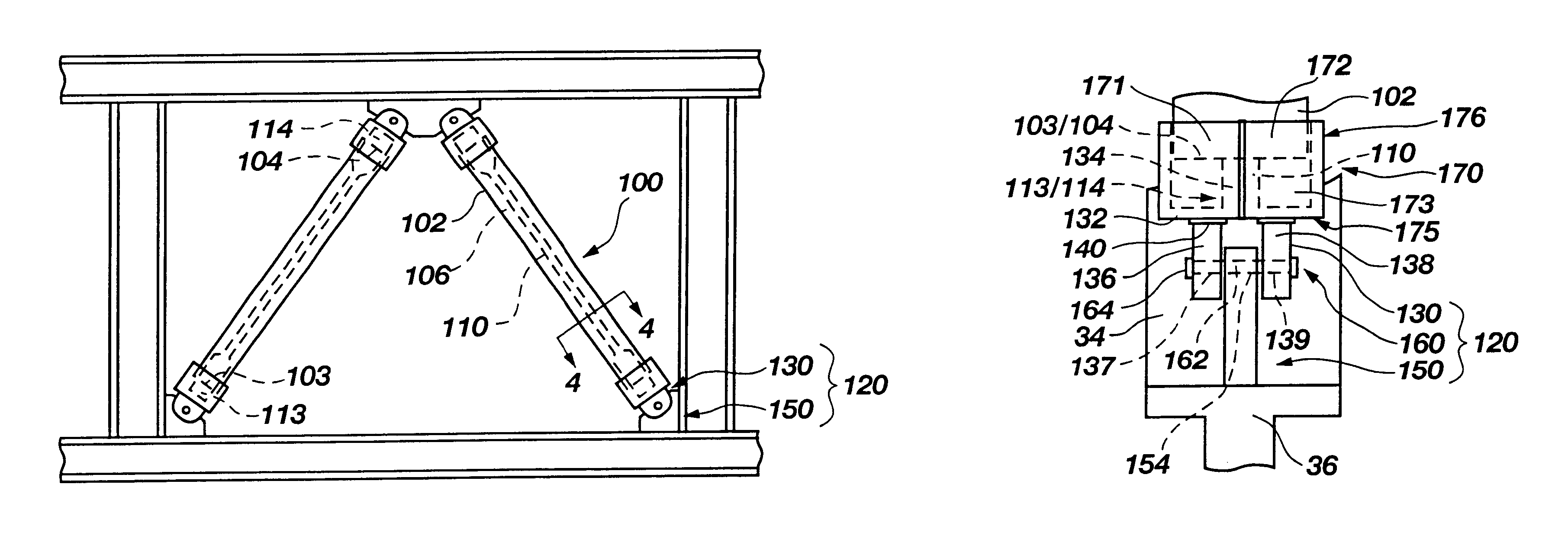

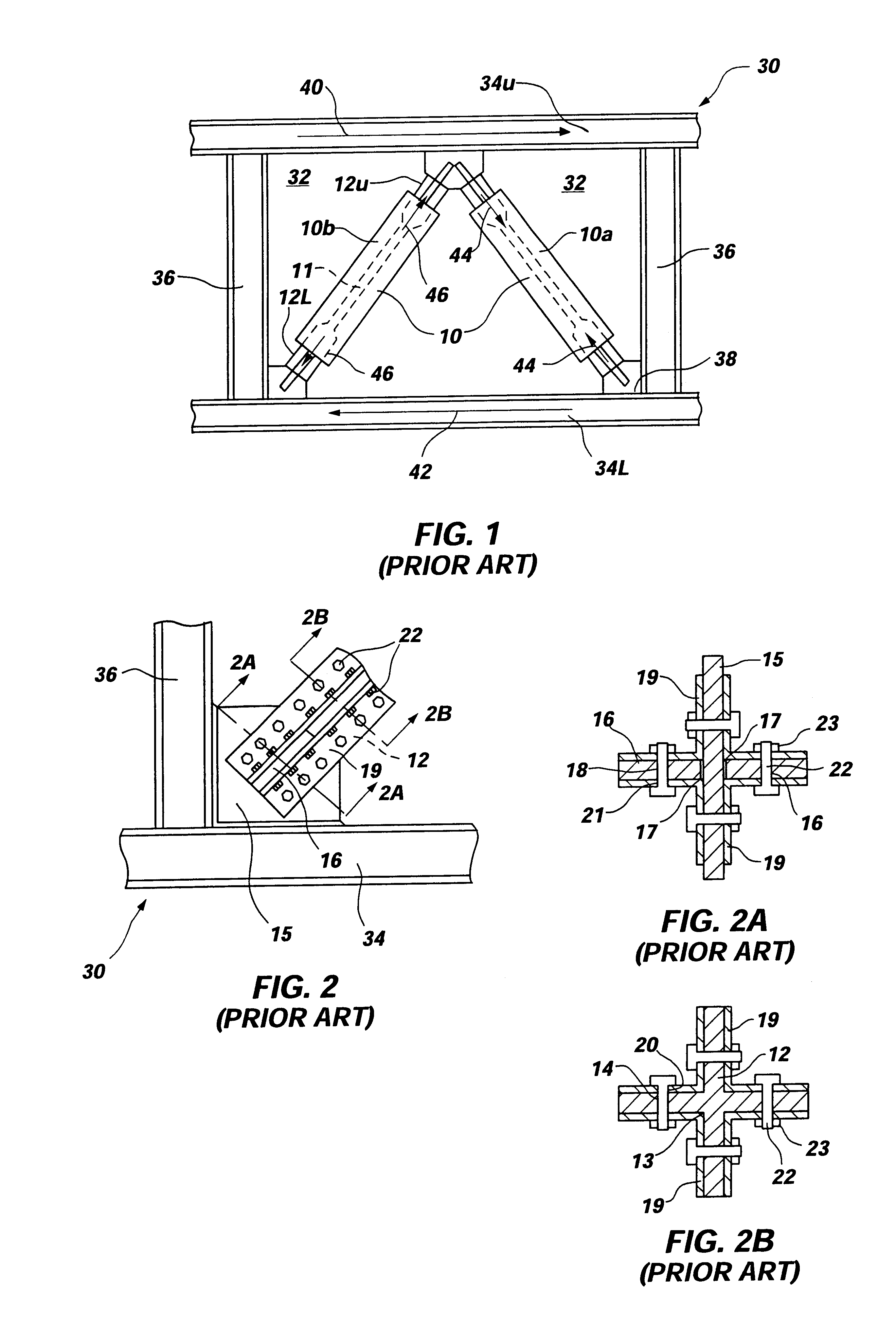

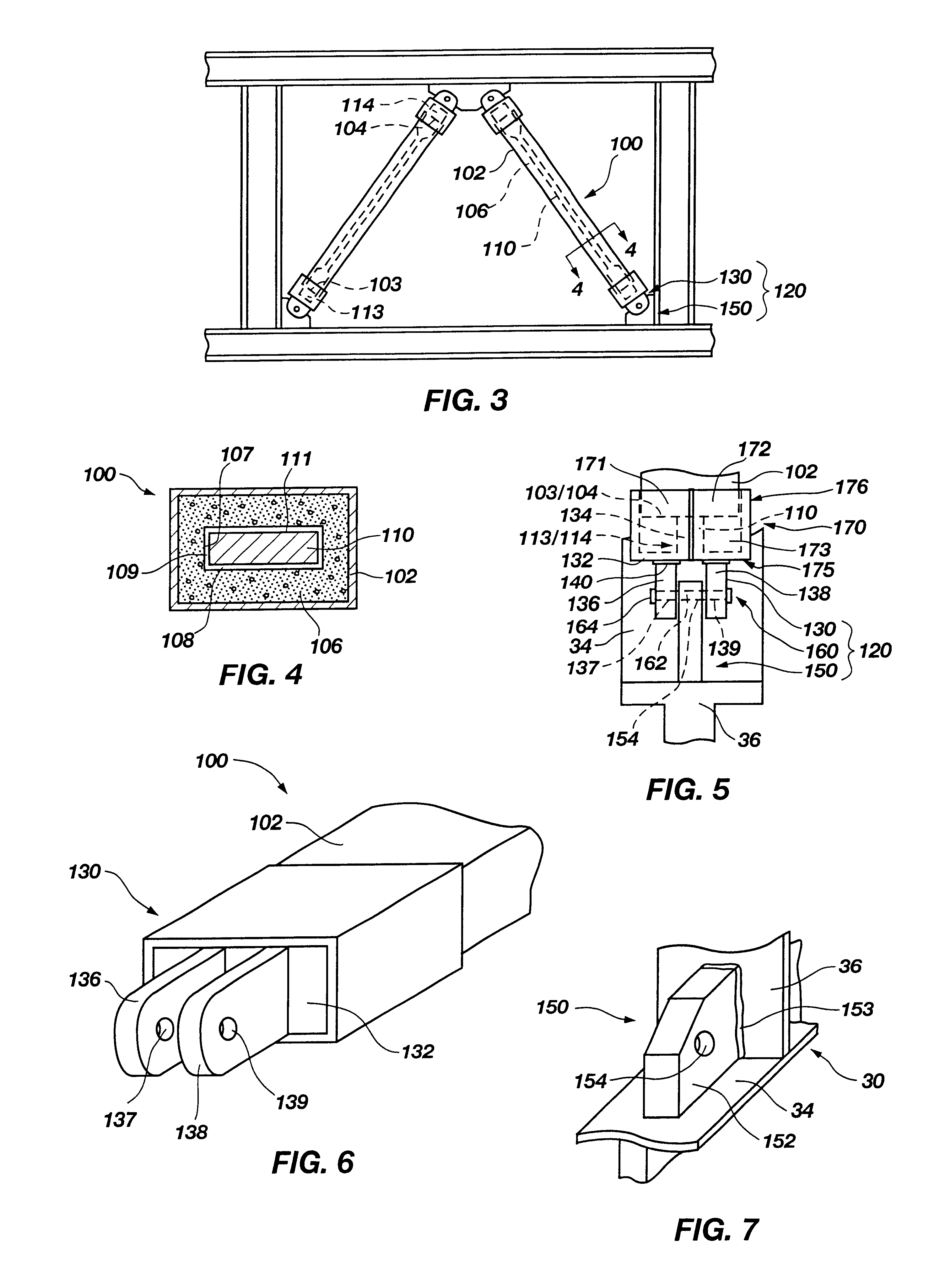

Pin and collar connection apparatus for use with seismic braces, seismic braces including the pin and collar connection, and methods

InactiveUS6837010B2Easy ArticulationThe process is simple and fastYielding couplingRopes and cables for vehicles/pulleyCouplingEngineering

A nonrigid connection apparatus includes a frame-side member securable to a steel structural frame, a brace-side member securable to a seismic brace, and a coupling element that nonrigidly secures the frame-side and brace-side members to each other. By way of example, the nonrigid connection element may provide a hinge-type connection, which substantially isolates a seismic brace from nonaxial loads. As another example, the nonrigid connection element may be a ball-and-socket type connection, which substantially isolates a seismic brace from nonaxial loads and absorbs any shear and moment applied thereto when the seismic brace drifts out of an intended plane of the steel structural frame. The nonrigid connection element may also include a collar to stabilize the brace-side member and prevent shears and moments from causing the same to buckle in an unintended direction. Methods of installing and using the nonrigid connection apparatus are also disclosed.

Owner:COREBRACE LLC

Pendulum eddy current tuning mass damper device

The invention relates to a pendulum eddy current tuning mass damper device which comprises a support, a steel cable, a cable-length adjusting device, a mass block, a permanent magnet adjustment frame, a permanent magnet, a copper plate, a magnetic iron plate, a copper plate and magnetic iron plate adjusting frame, a limiting stopper and a limiting damper. The mass block is formed by connecting of a steel plate through bolts and is hung on the support through the steel cable, the length of the steel cable is adjusted by the cable-length adjusting device, the permanent magnet adjusting frame is installed on the bottom of the mass block, the magnetic iron plate is overlapped on the bottom of the copper plate, and the copper plate and the magnetic iron plate are connected on the copper plate and magnetic iron plate adjusting frame through the bolts. The copper plate and magnetic iron plate adjusting frame is installed on the structural base, the limiting stopper is placed on the periphery of the bottom of the mass block, one end of the limiting damper is connected on the limiting stopper, and the other end of the limiting damper is connected on the structural base which is placed below the limiting damper. The pendulum eddy current tuning mass damper device is long in service life, high in reliability, maintenance-free and high in sensibility and the like, damping adjustment is accurate, convenient and wide in adjustment range, and the friction of the whole TMD structure is nearly zero.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

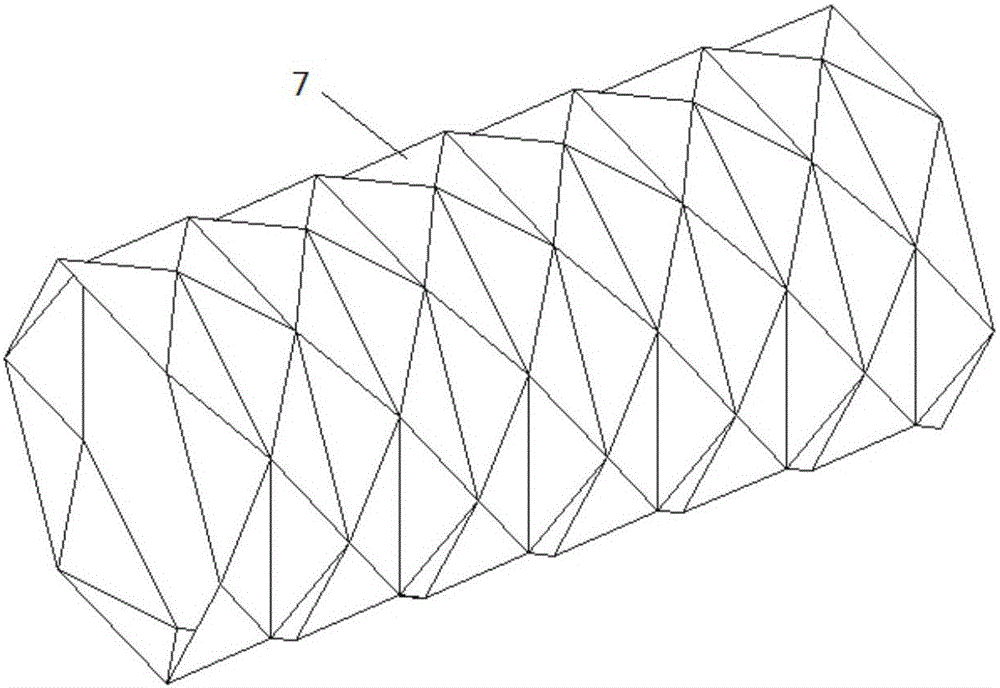

Buckling control support with bidirectional pyramid-shaped energy dissipation units at ends

ActiveCN106049952AImprove protectionPrevent bucklingProtective buildings/sheltersShock proofingNODALBuckling-restrained brace

The invention discloses a buckling control support with bidirectional pyramid-shaped energy dissipation units at the ends. The buckling control support with the bidirectional pyramid-shaped energy dissipation units at the ends is characterized in that the buckling control support is composed of end restraint sections, energy dissipation sections and a straight supporting section, and the two ends are connected with beam or column components or joints into a whole through bolts, so that the purpose of increasing the resistant-lateral rigidity of a component is achieved. By the adoption of the buckling control support with the bidirectional pyramid-shaped energy dissipation units at the ends, under the small shock action, the buckling control support is kept elastic; and under the medium or great shock action, the buckling control support is switched to a buckling stage, and a damper effect can be achieved through the good hysteretic energy dissipation performance of the buckling control support. Compared with a traditional buckling restraint support, the steps of additional arrangement of a sleeve outside a core energy dissipation component, grouting and the like in a traditional manufacturing process are omitted on the aspect of the manufacturing technique, and manufacturing is convenient; and the support can be prefabricated in a factory, the quality of the component is guaranteed, the filed construction workload is reduced, energy is saved, and environmental friendliness is achieved.

Owner:SOUTHEAST UNIV

Fire and/or water resistant expansion joint system

An expansion joint system comprises a core; and a fire retardant included in the core in an amount effective to pass testing mandated by UL 2079. The core with the fire retardant is configured to facilitate compression of the expansion joint system when installed between substrates by repeatedly expanding and contracting to accommodate movement of the substrates; and the core with the fire retardant included therein is configured to pass the testing mandated by UL 2079.

Owner:SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com