Pendulum eddy current tuning mass damper device

A technology of tuning mass damping and eddy current, which is applied to building components, shockproof, etc., can solve the problems of high cost, difficult maintenance, and low service life of seals, and achieve the effects of accurate damping adjustment, large adjustment range, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

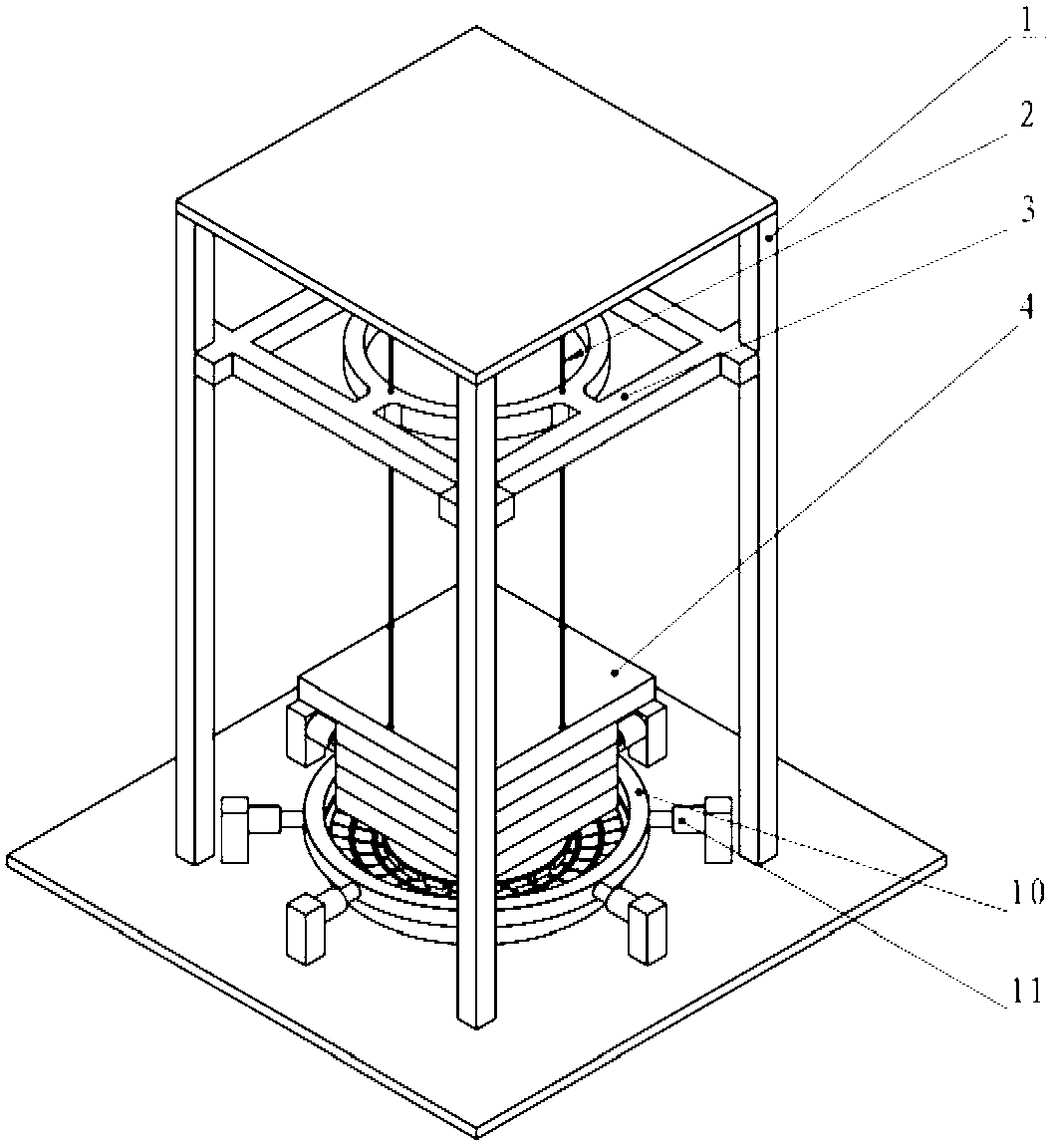

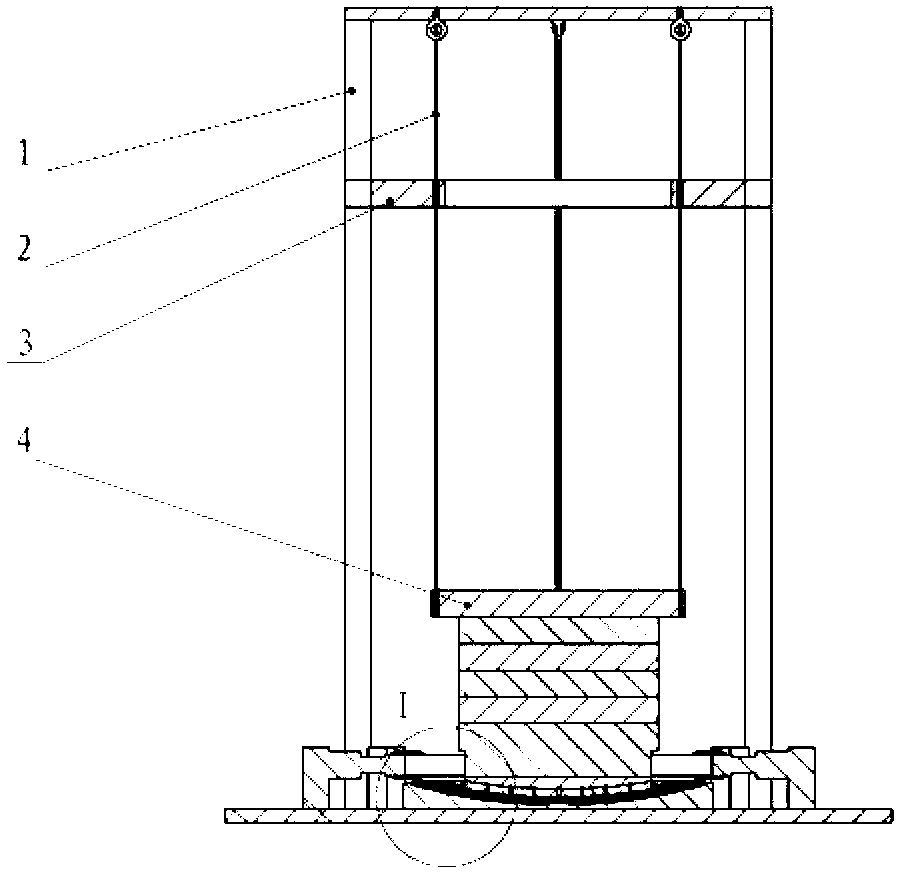

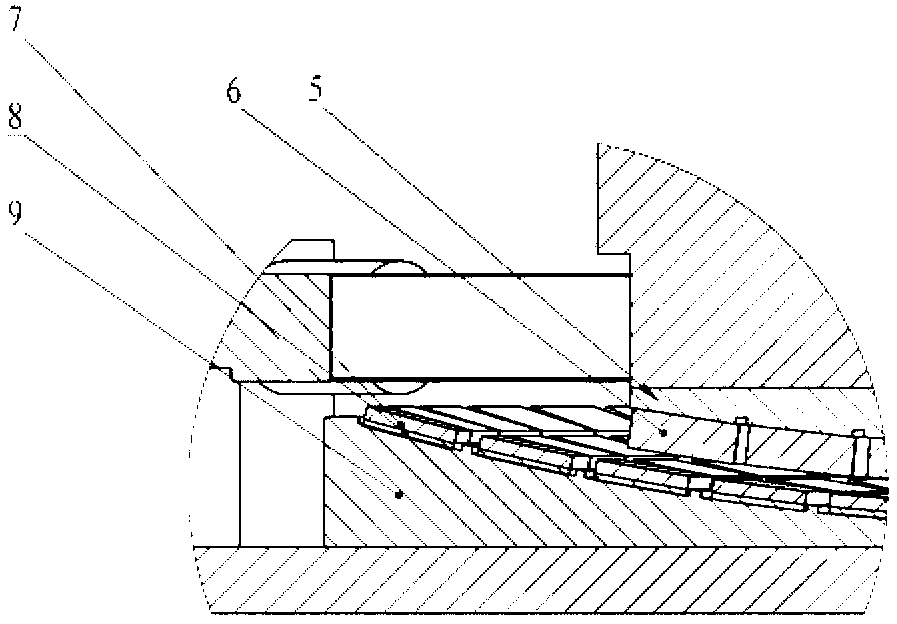

[0037] The structure of the pendulum eddy current tuned mass damper device is as follows: Figure 1-3 As shown, it is installed on the structural foundation, including bracket 1, steel cable 2, cable length adjuster 3, mass block 4, permanent magnet adjustment frame 5, permanent magnet 6, copper plate 7, magnet guide plate 8, copper plate and magnet guide plate Adjustment frame 9, limiter 10 and limit damper 11. Wherein, the bracket 1 can also be a structural body, and the mass block 4 is made of steel plates connected by bolts, and the number of steel plates can be increased or decreased as required. The mass block 4 is suspended on the support 1 through the steel cable 2, and the cable length adjuster 3 is installed on the support 1, and the length of the steel cable 2 is adjusted through its up and down movement, thereby adjusting the swing radius of the mass block 4. The permanent magnet 6 is installed on the permanent magnet adjusting frame 5 by screws, and the permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com