Patents

Literature

907 results about "Mechanical wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

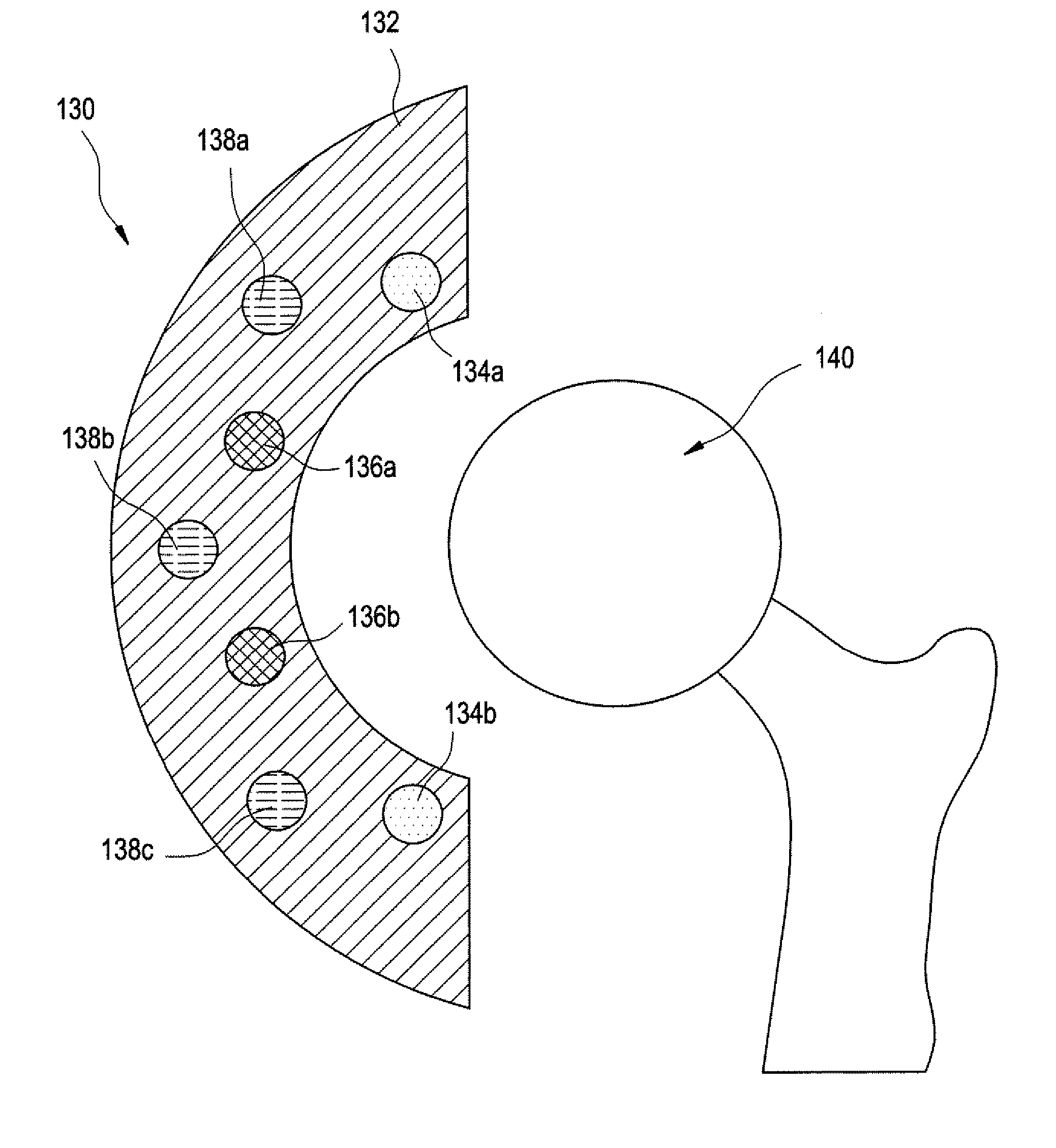

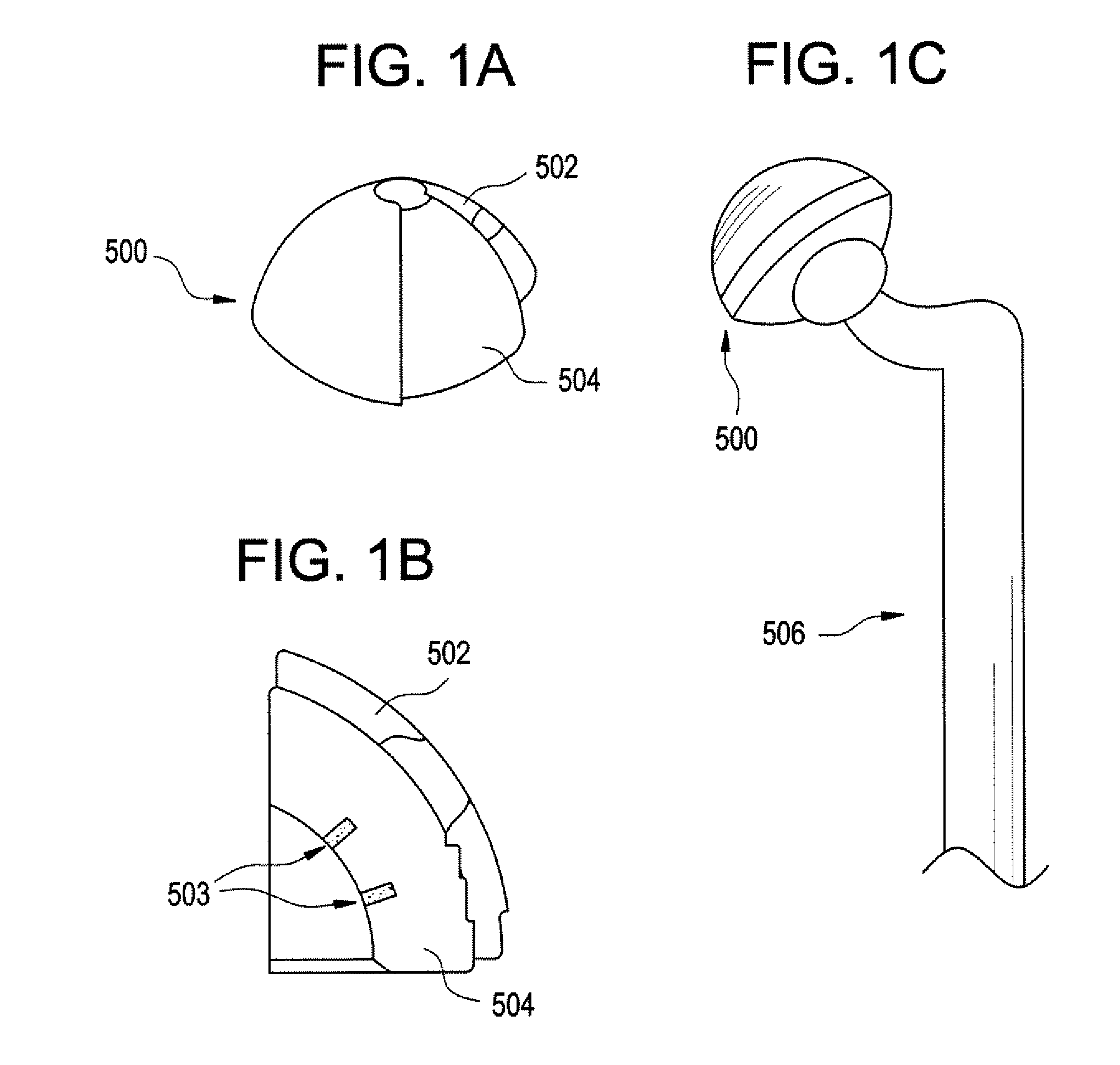

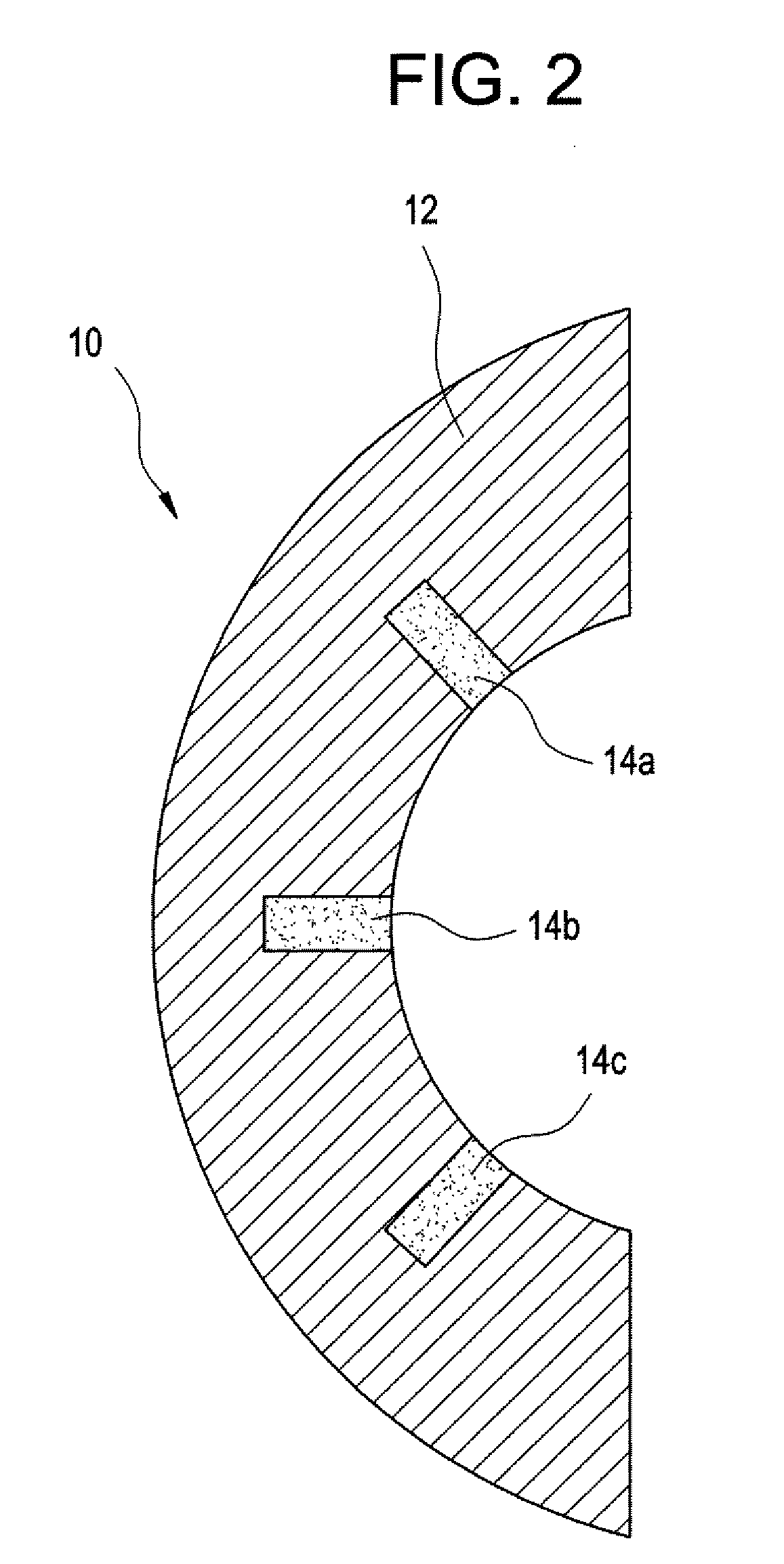

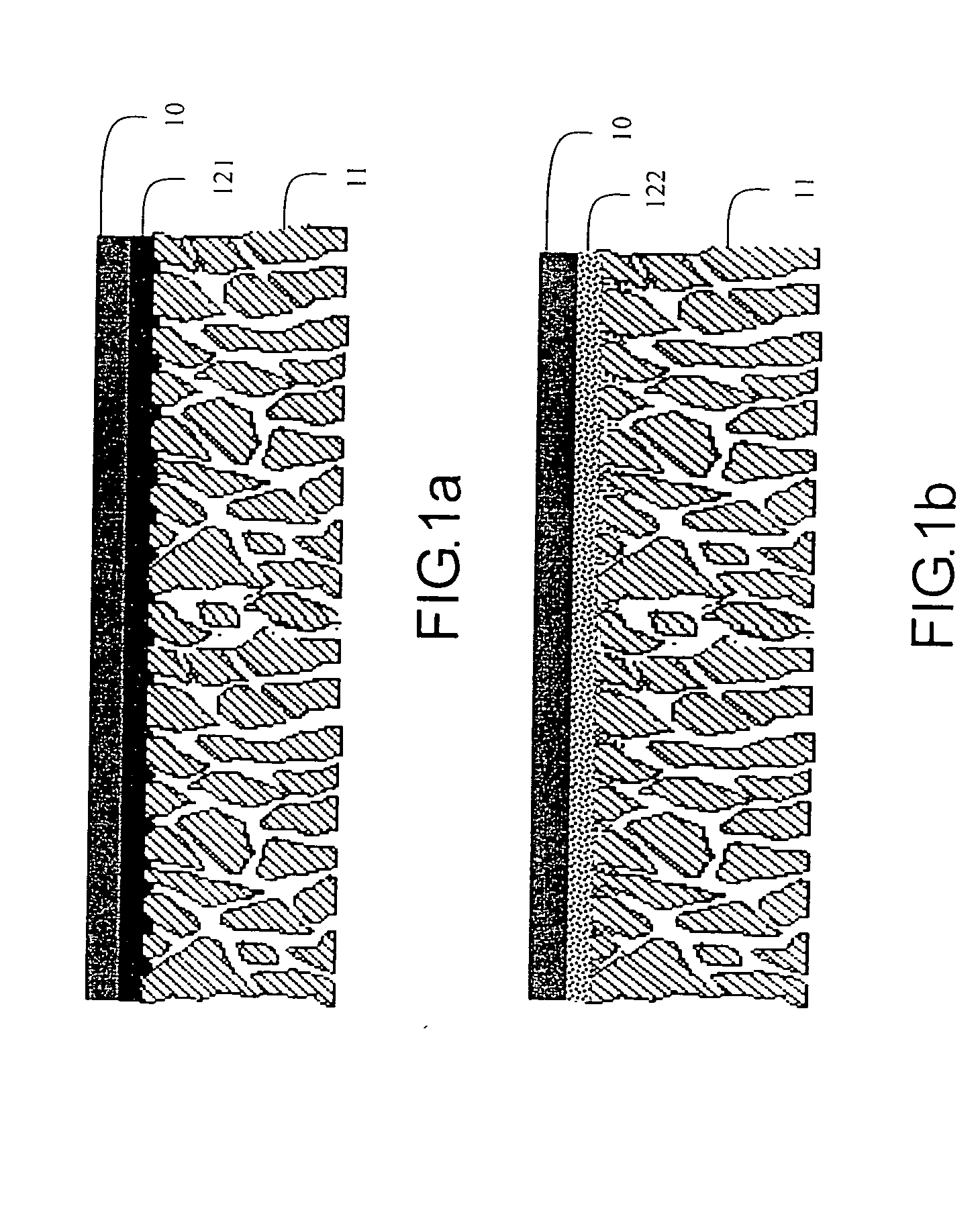

Passive wear-indicating sensor for implantable prosthetic device

InactiveUS20070088442A1Easy to detectUltrasonic/sonic/infrasonic diagnosticsJoint implantsDevice implantMechanical wear

A method is provided for non-invasively detecting mechanical wear of a prosthetic device implanted in a patient, the method comprises using a non-invasive imaging technique to image the prosthetic device that includes a wear indicating composition; and detecting whether the wear indicating composition has been released from the prosthetic device, and, if so, the location, type, and / or amount thereof. The implant device includes a prosthetic device body having at least one outer surface area; at least one reservoir (e.g., a plurality of discretely spaced micro-reservoirs) in the device body; a wear indicator composition disposed in said at least one reservoir, wherein mechanical wear of the at least one outer surface area of the device body in vivo causes release of at least part of the wear indicator composition. The prosthetic device body may be one for replacement of a hip, a knee, a shoulder, an elbow, or a vertebra.

Owner:MICROCHIPS INC

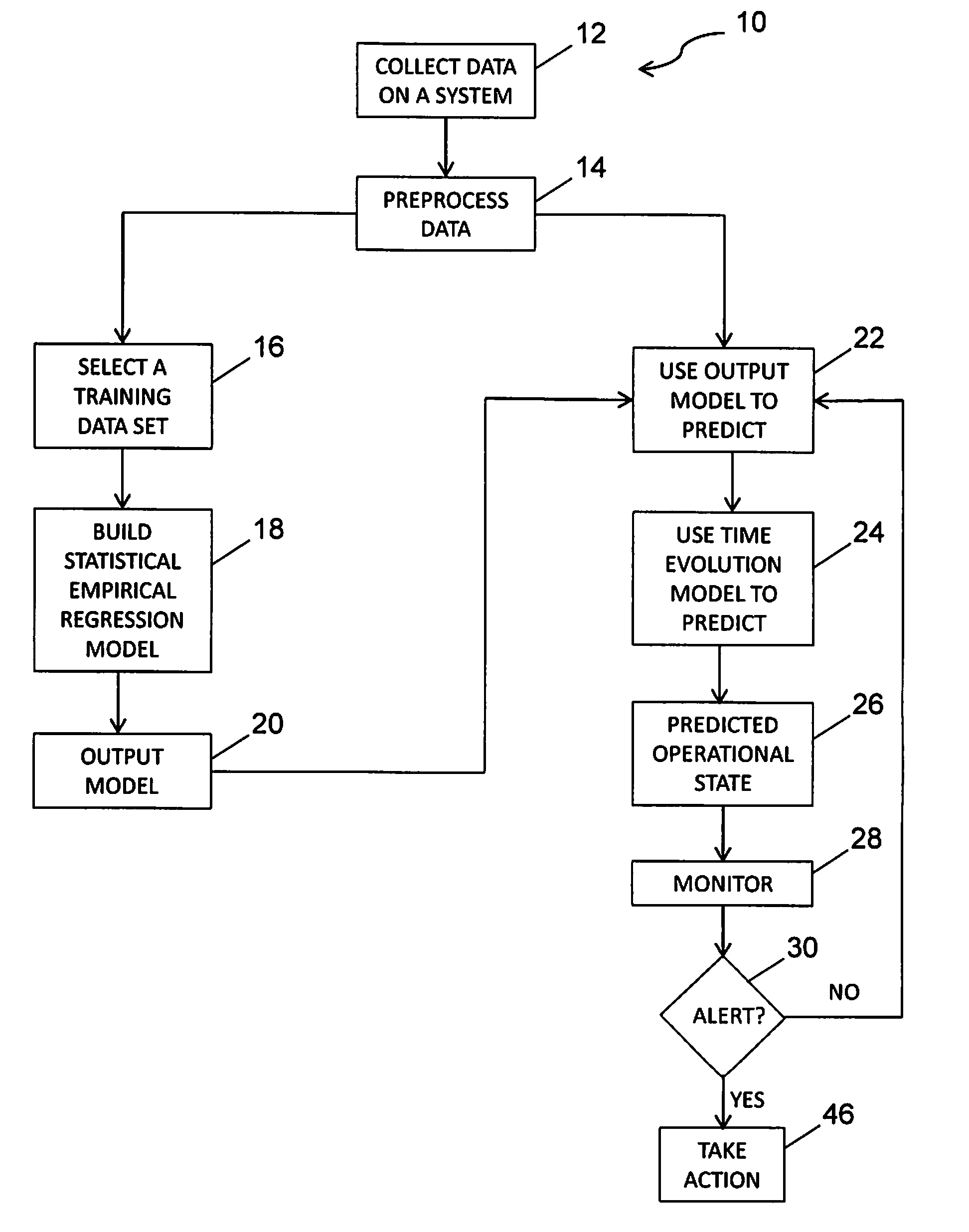

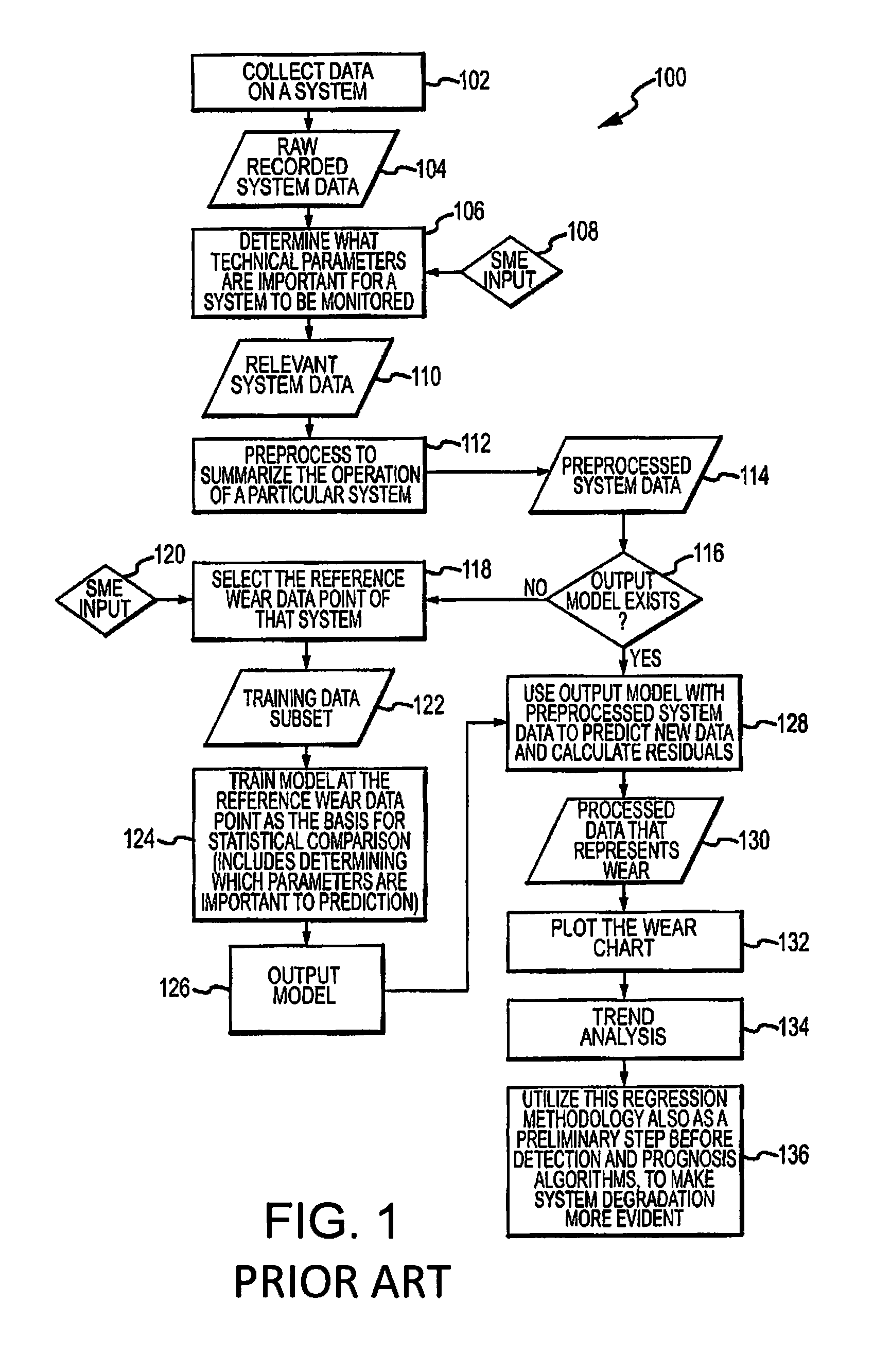

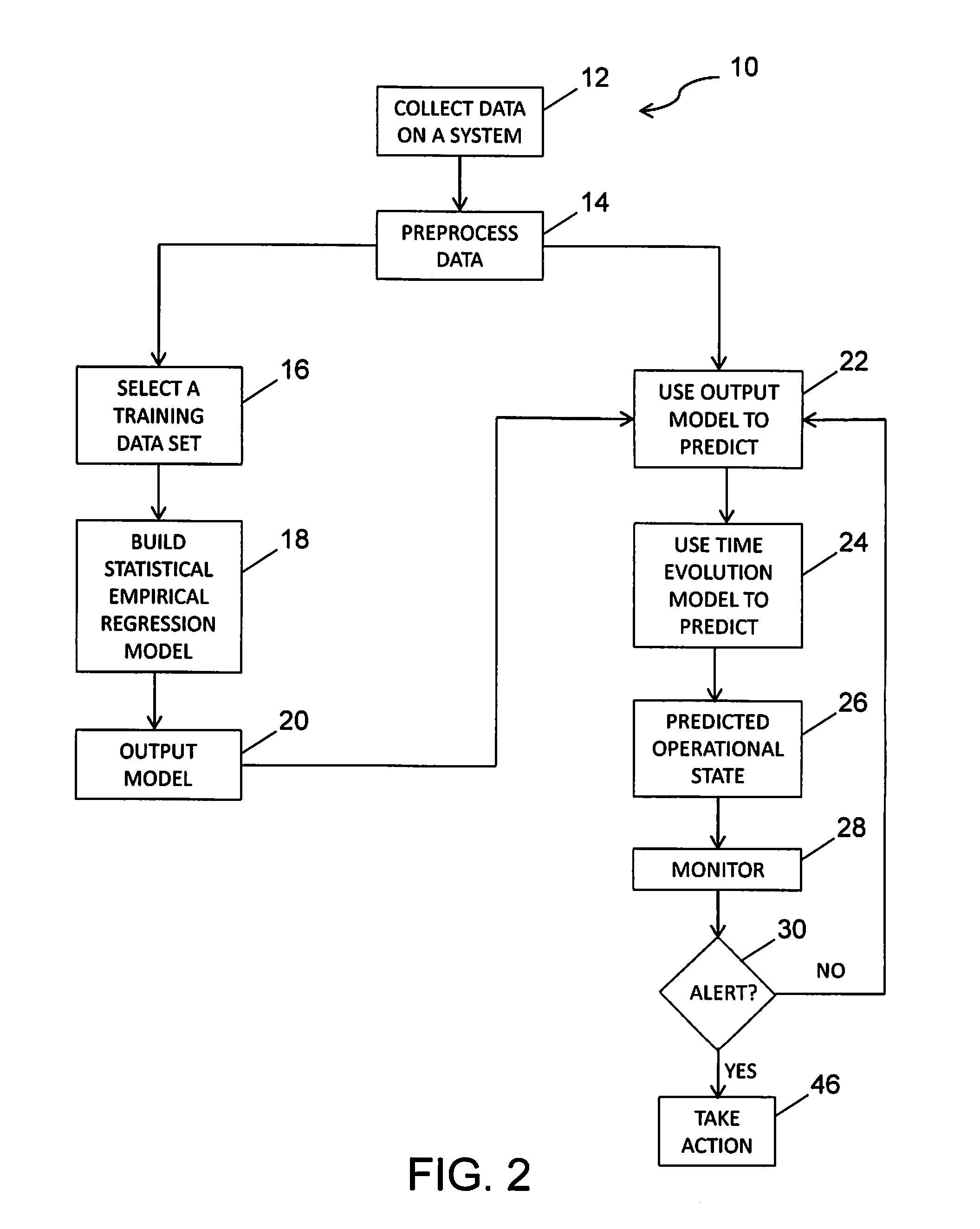

Coupling time evolution model with empirical regression model to estimate mechanical wear

ActiveUS8600917B1Low variabilityEasy to operateDigital computer detailsMachine learningMechanical wearStatistical learning

Mechanical systems wear or change over time. Data collected over a system's life can be input to statistical learning models to predict this wear / change. Previous work by the inventors trained a flexible empirical regression model at a fixed point of wear, and then applied it independently at time points over the life of an engine to predict wear. The embodiment disclosed herein relates those wear predictions over time using a time evolution model. The time evolution model is sequentially updated with new data, and effectively tunes the empirical model for each engine. The combined model predicts wear with dramatically reduced variability. The benefit of reduced variability is that engine wear is more evident, and it is possible to detect operational anomalies more quickly. In addition to tracking wear, the model is also used as the basis for a Bayesian approach to monitor for sudden changes and reject outliers, and adapt the model after these events.

Owner:THE BOEING CO

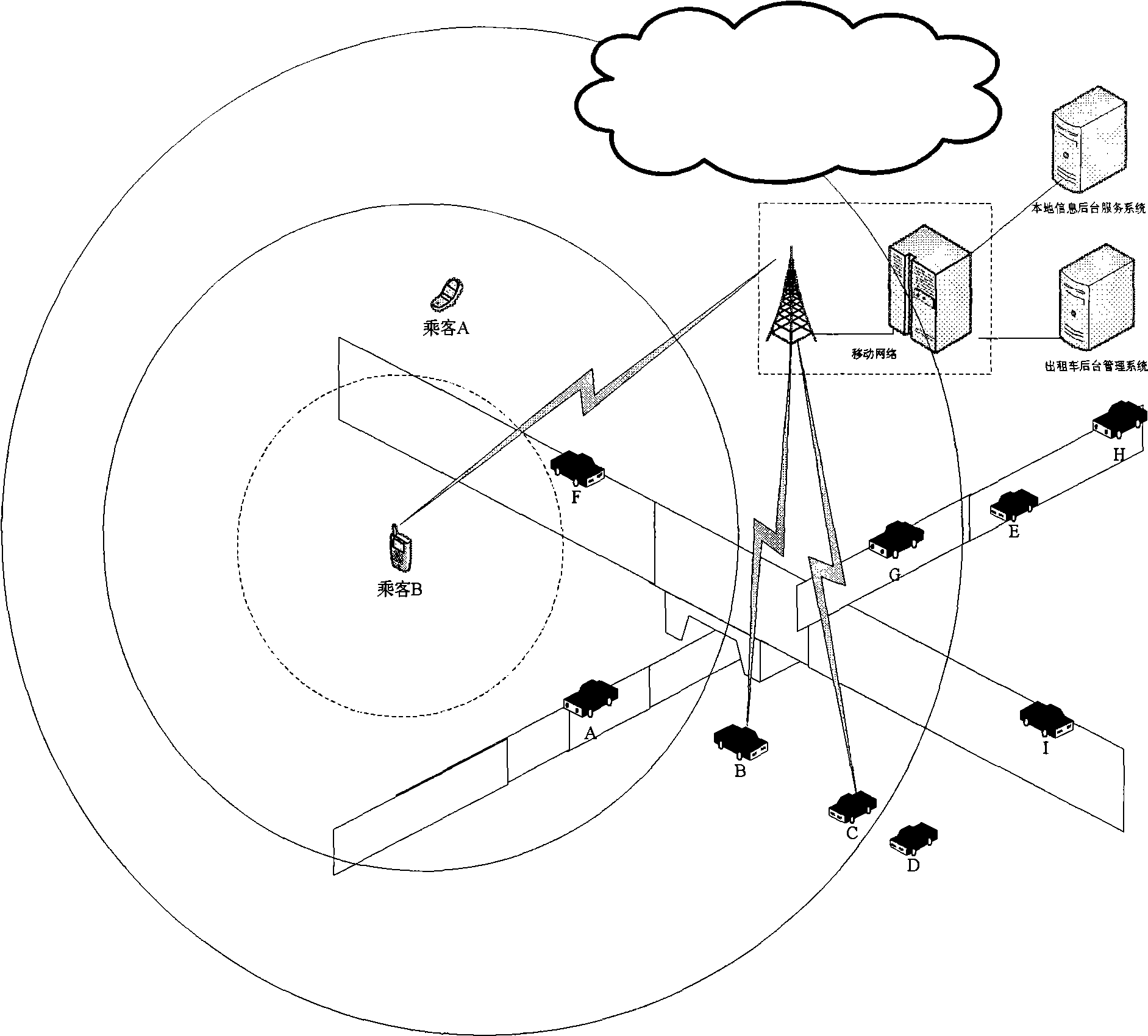

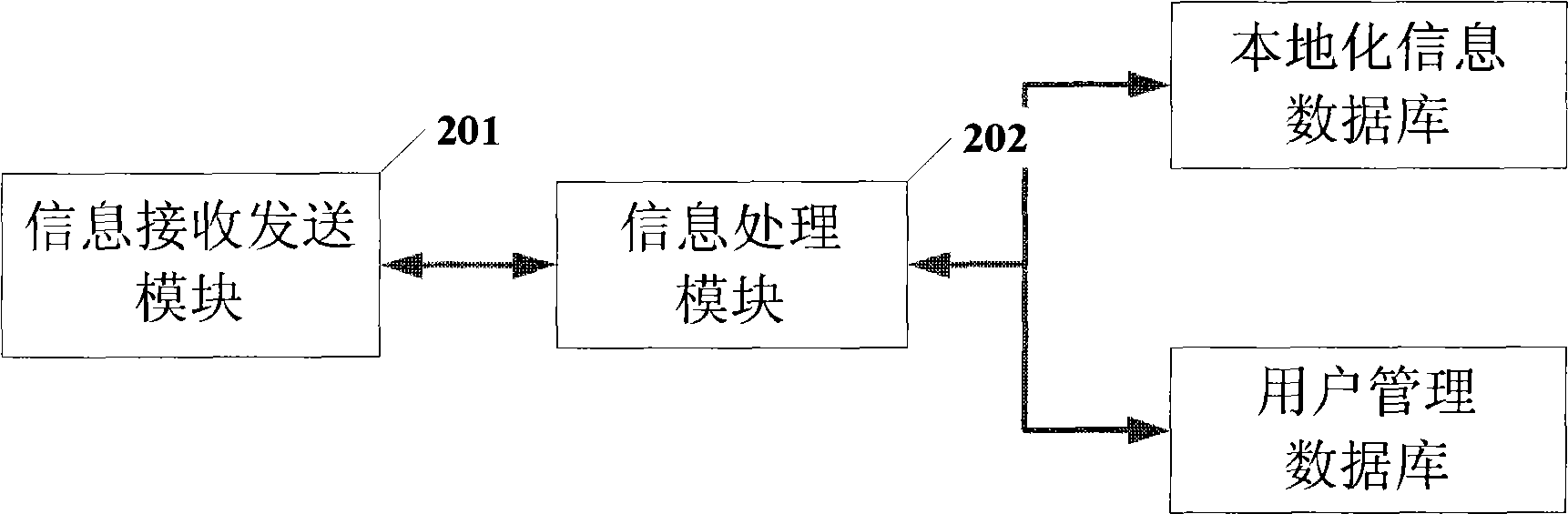

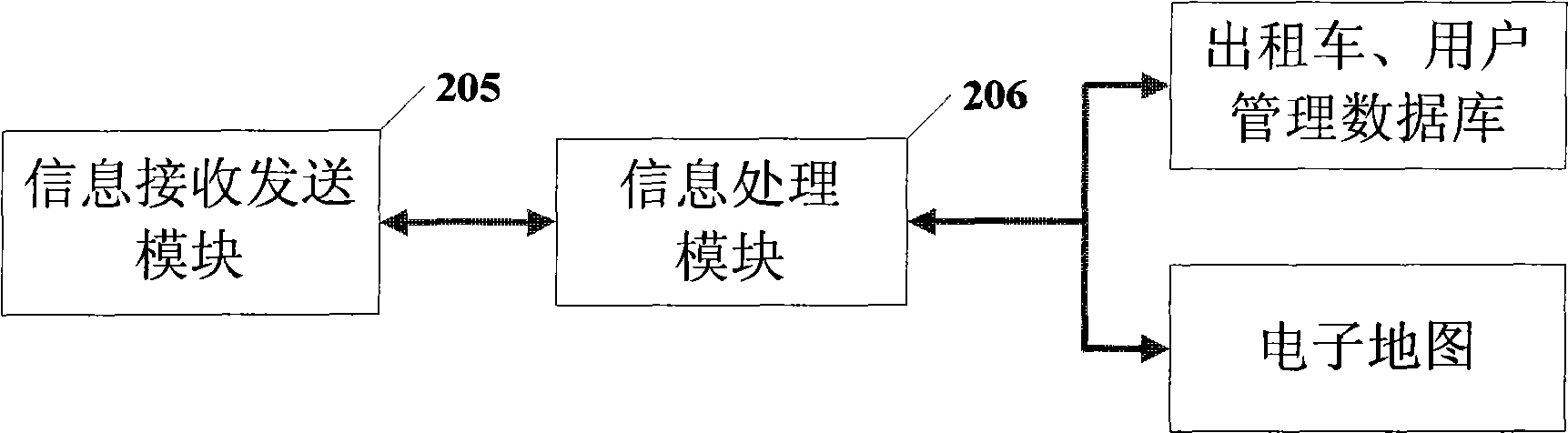

Immediate taxi calling assignment managing system and calling assignment managing method

InactiveCN101520950AReduce fuel consumptionReduced mechanical propertiesRoad vehicles traffic controlPosition fixationMechanical wearCar sharing

The invention relates to a wireless car rental system and a car rental method for using between passengers and a car renting company, comprising a mobile phone, a local information background service system, a taxi background management system, a built-in taxi GPS calling device and a mobile communication network platform; the mobile phone forms bidirectional wireless communication with the signal receiving and transmitting ends of the local information background service system and the taxi background management system by the mobile communication network platform, and the signal receiving and transmitting ends of the taxi background management system form bidirectional wireless communication with the GPS calling devices in n taxis. The invention has the following advantages: 1. aimless running of the taxi on the road is avoided; 2. fuel consumption and mechanical wear of the taxi are reduced, and traffic jam is relieved; 3. a user can call a taxi only by dialing the button calling the taxi in local service wherever the user is and regardless of difference of the taxi number all around the country; and 4. the invention provides effective passenger-picking up route for traffic balance, thus realizing effective car-sharing service.

Owner:上海掌穆通信科技有限公司

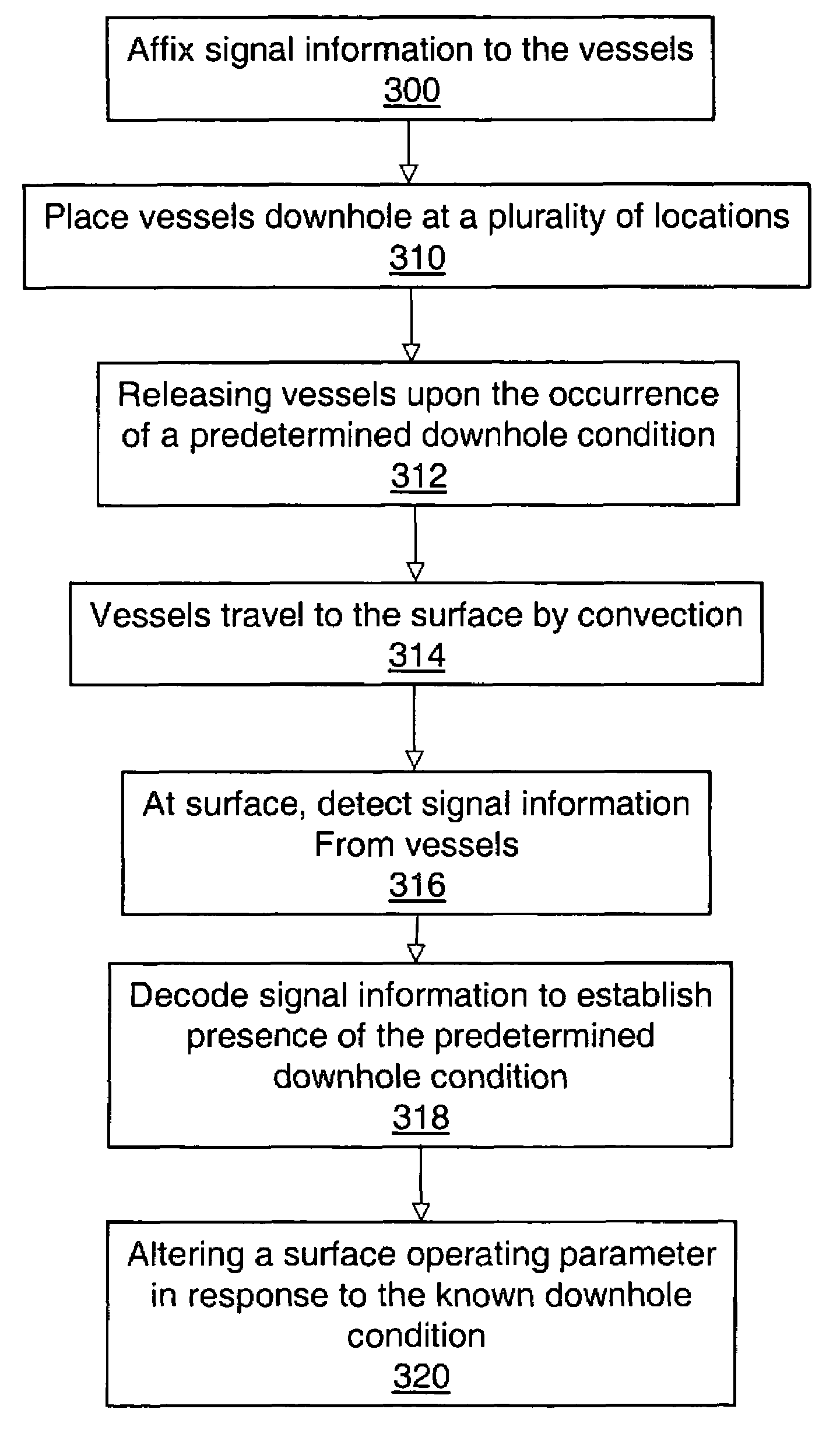

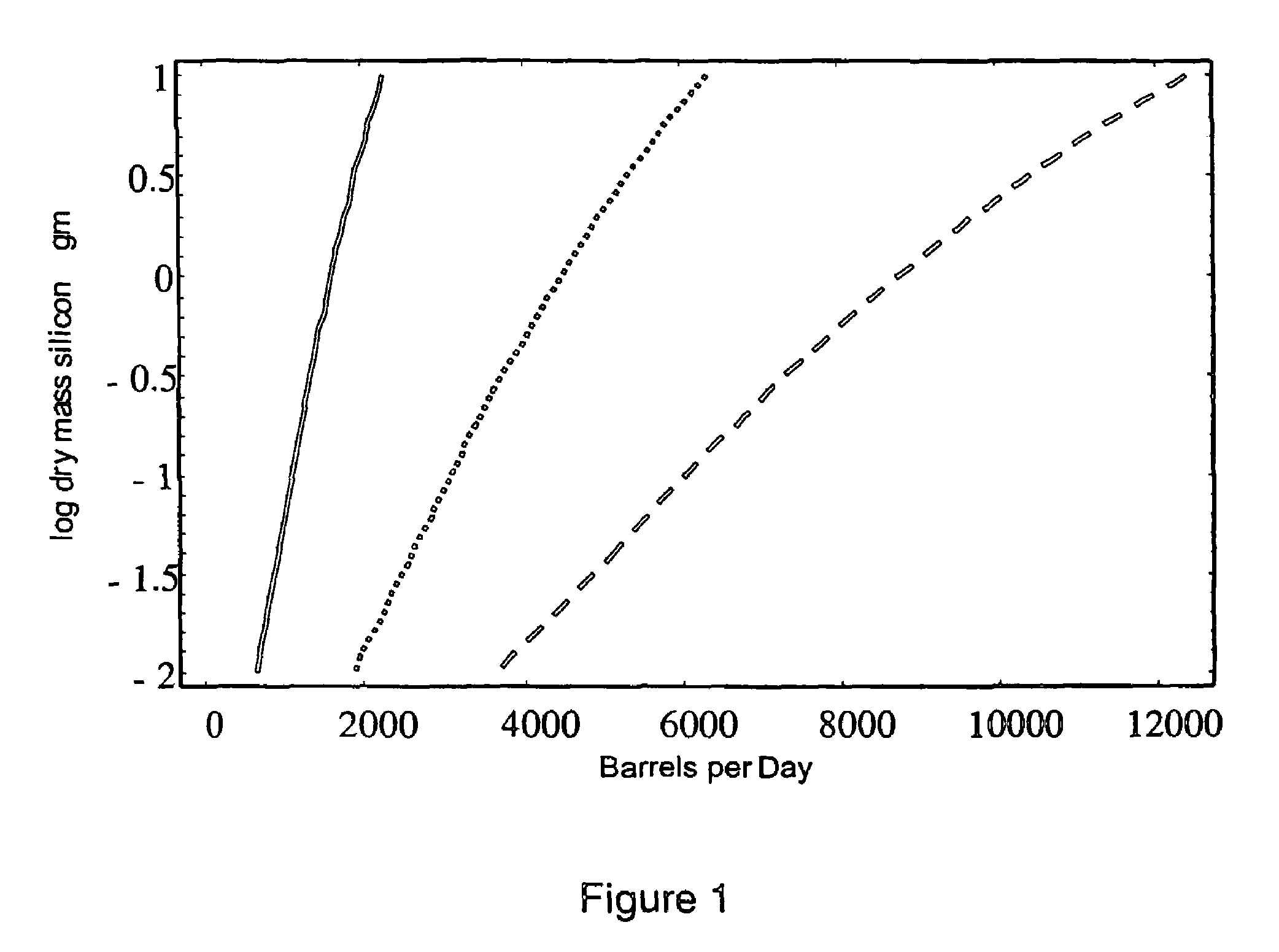

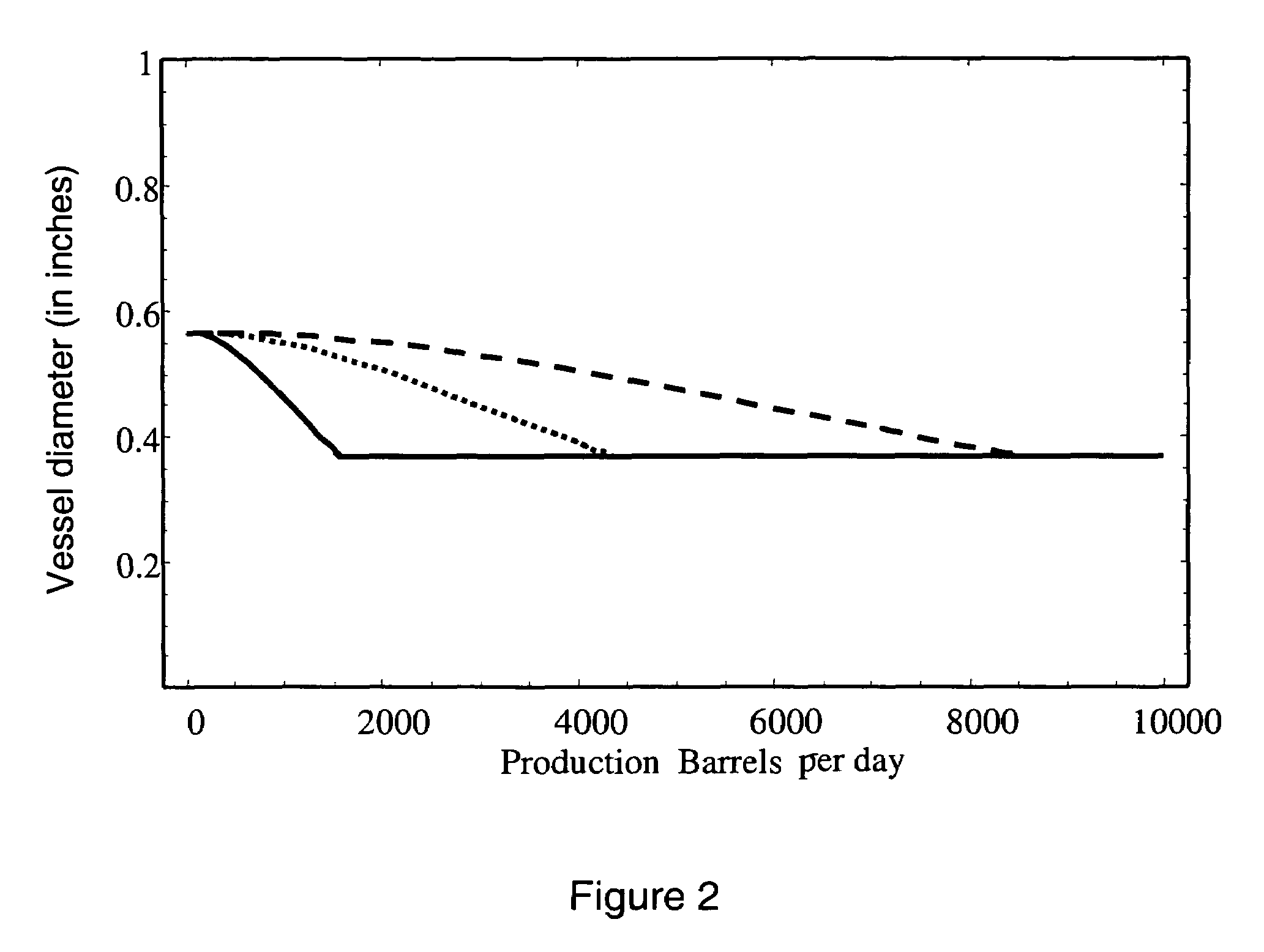

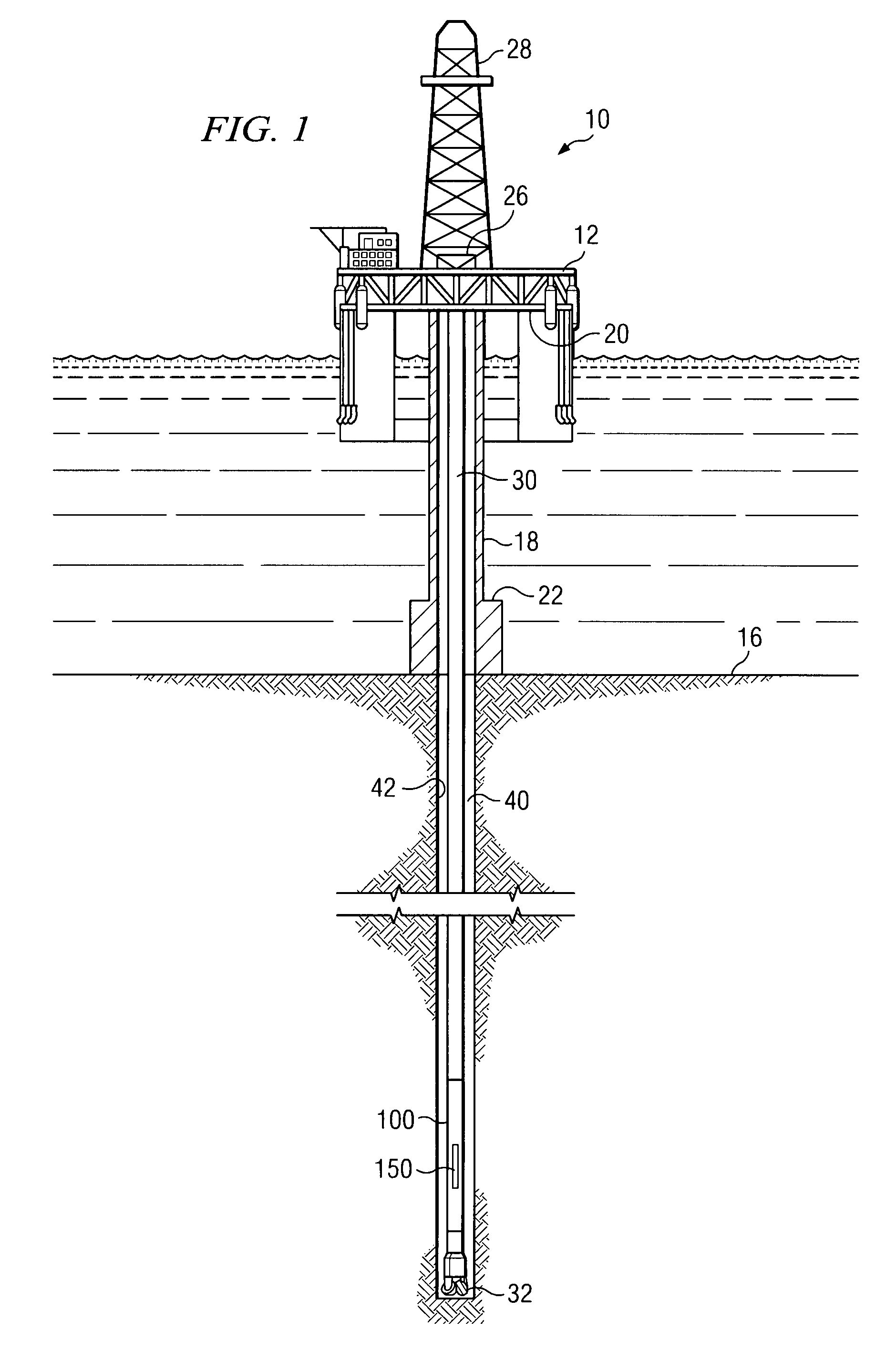

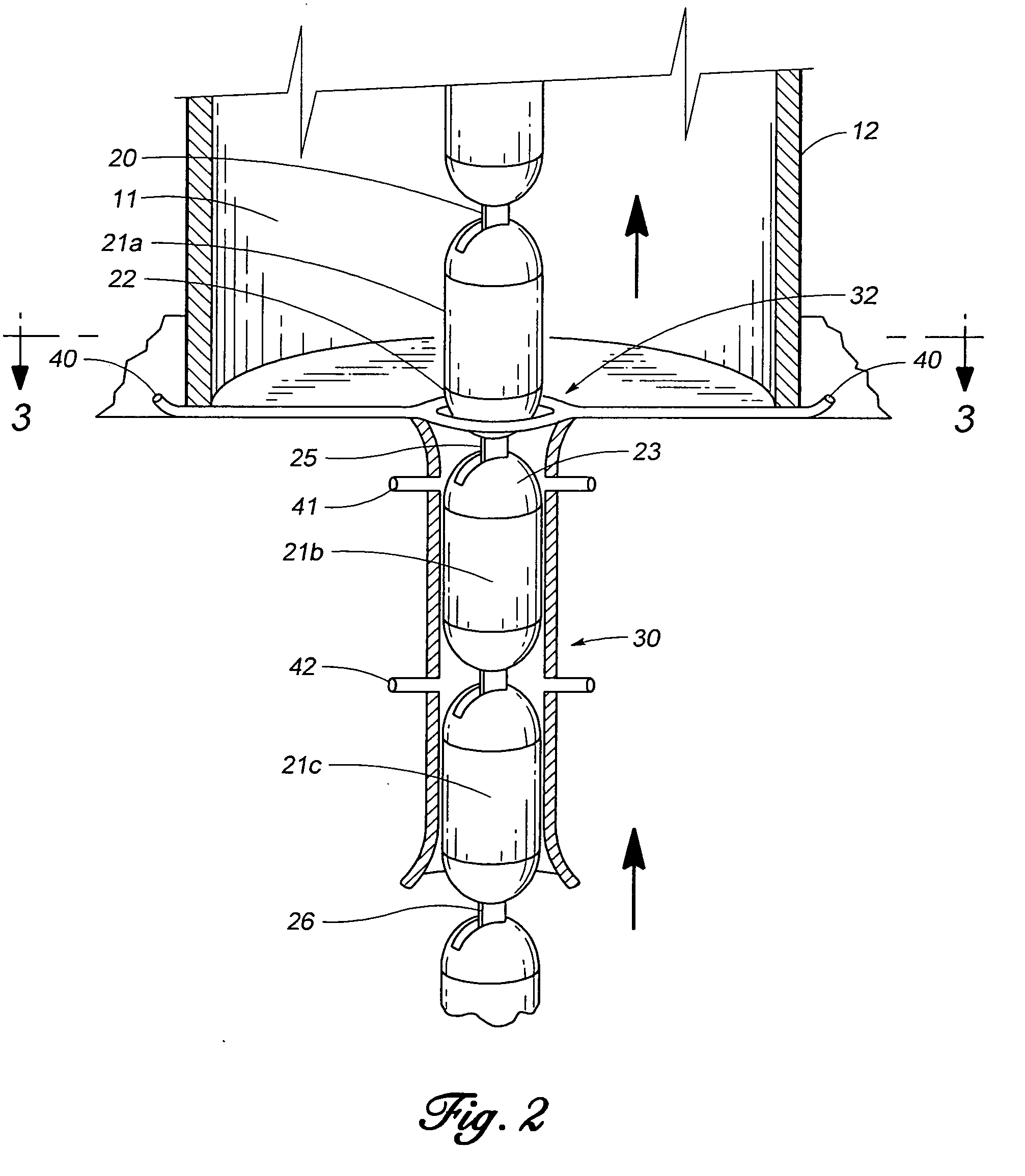

System and method for wellbore communication

InactiveUS6993432B2Simple and robustElectric/magnetic detection for well-loggingSurveyMarine engineeringMechanical wear

A method and system is disclosed for communicating information from a downhole location to the surface including a plurality of releasable vessels containing predetermined signal information affixed to the vessels prior to placement of the vessels downhole and indicative of the presence of at least one of three or more predetermined downhole conditions and a sensing and releasing system that senses the occurrence of the downhole condition, such as a simple threshold, and release the vessels in response to the sensing. The predetermined downhole condition can be characteristic of the fluid being produced in the borehole, such as water fraction, a certain level of mechanical wear or damage to downhole equipment such as bit wear, or the firing a one or more charges on a wireline deployed perforation tool.

Owner:SCHLUMBERGER TECH CORP

Wellbore evaluation system and method

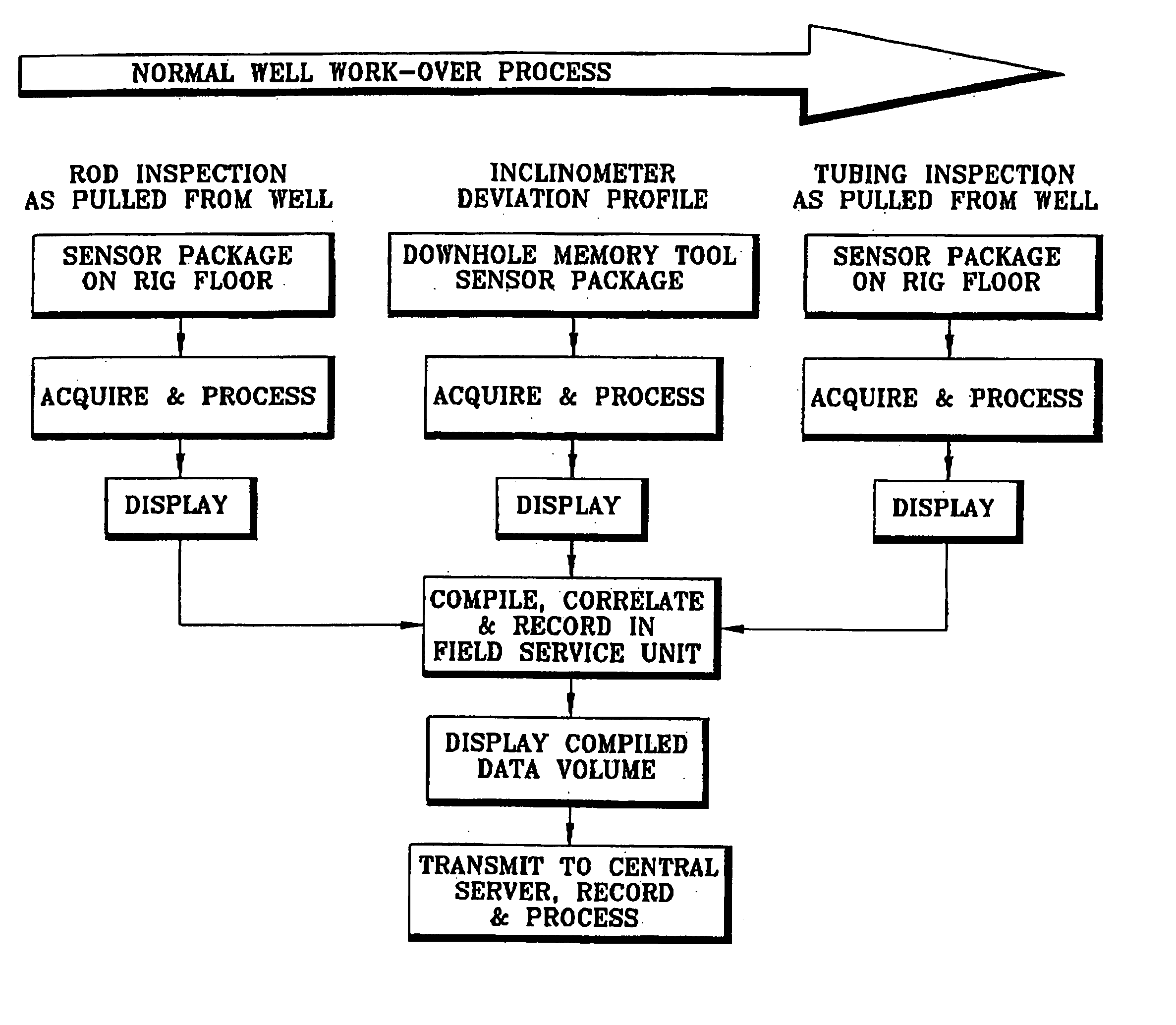

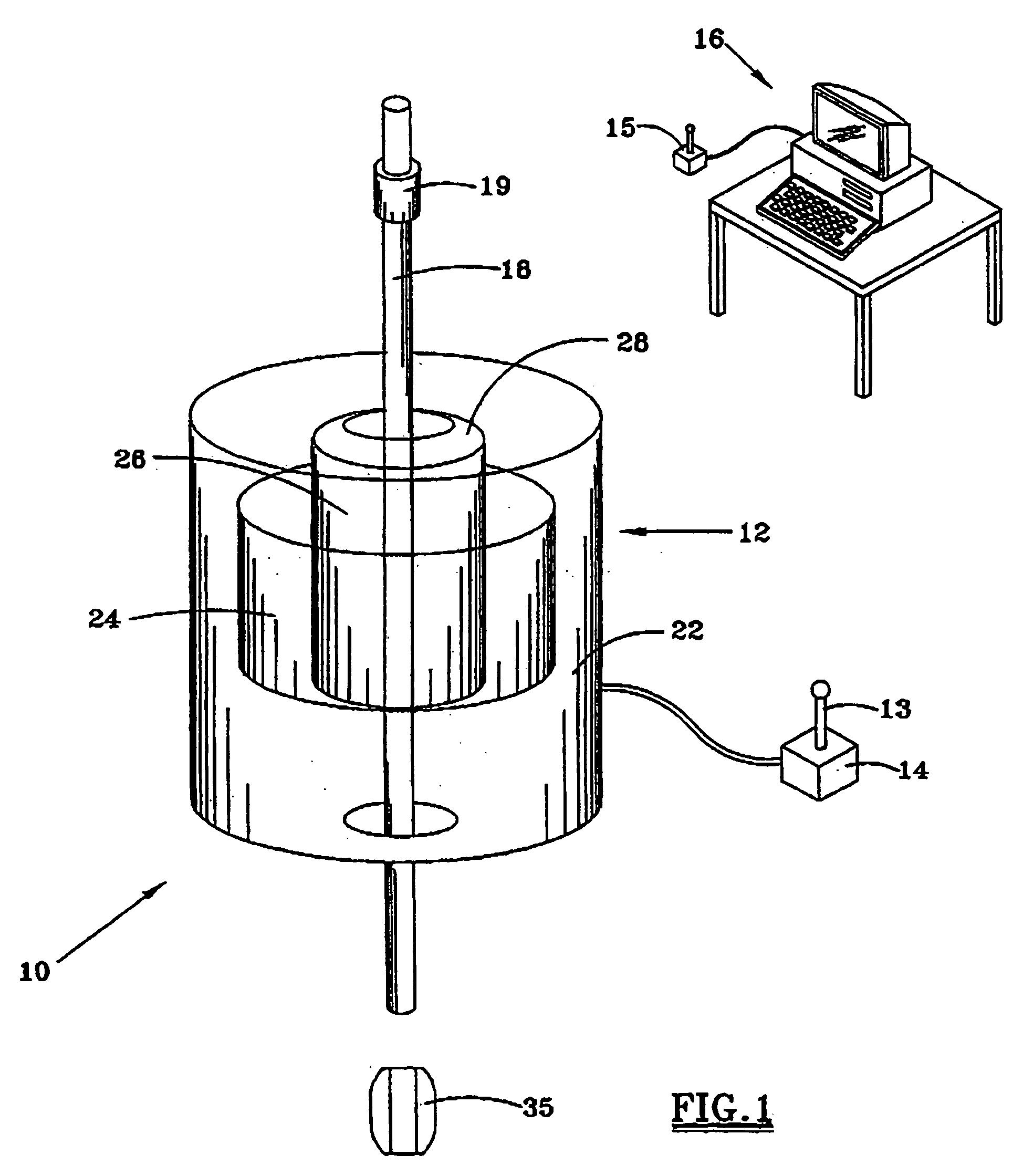

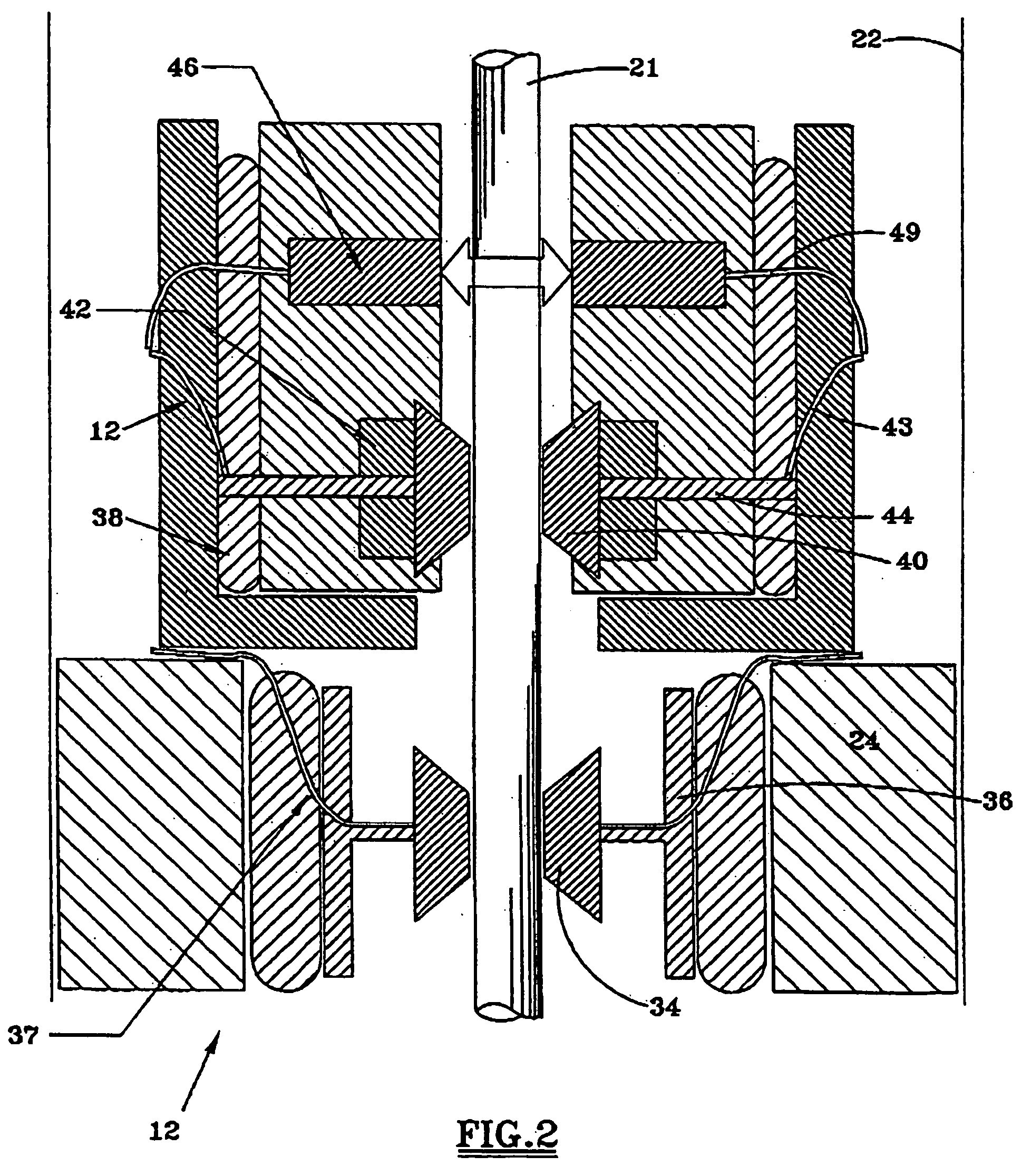

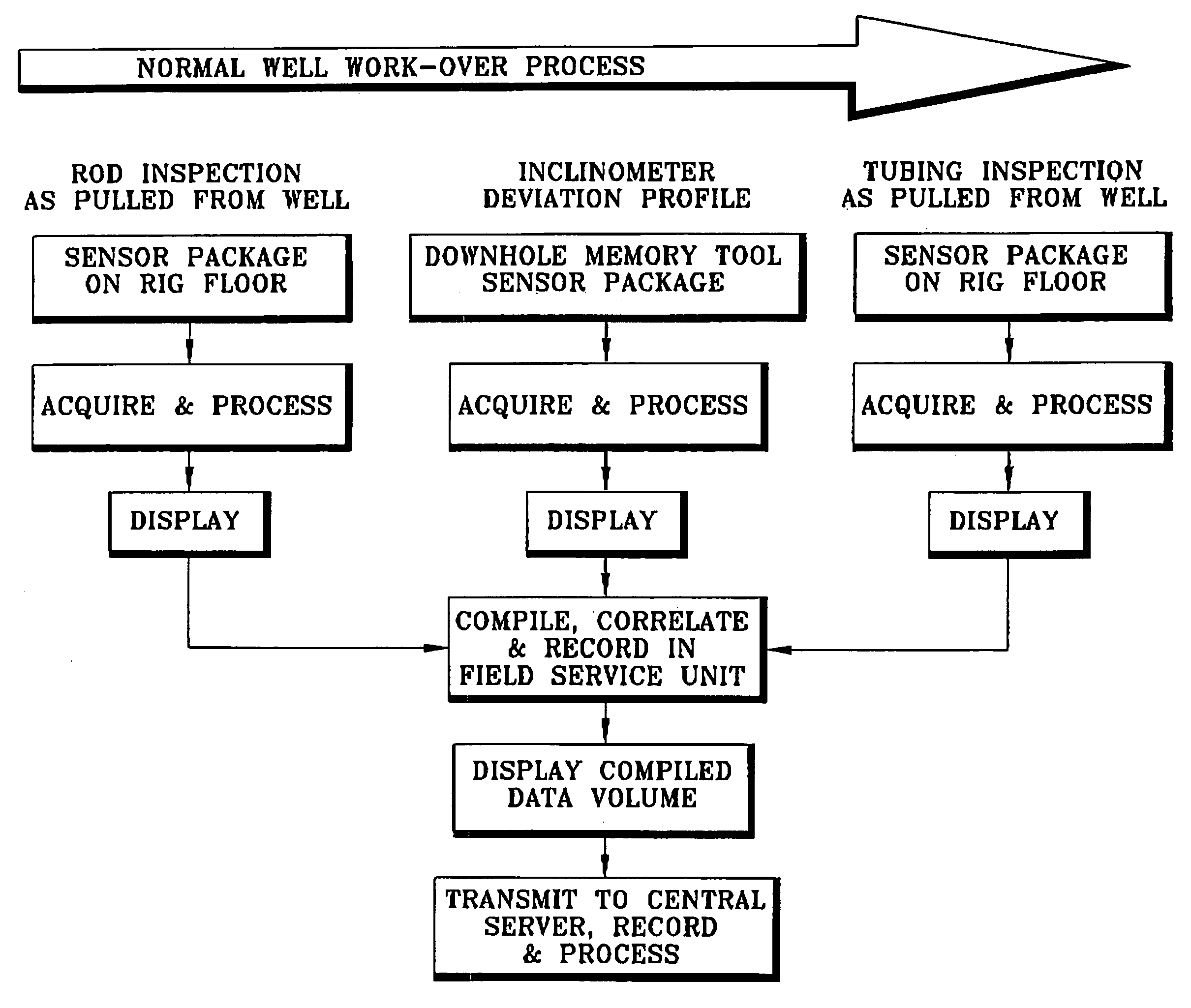

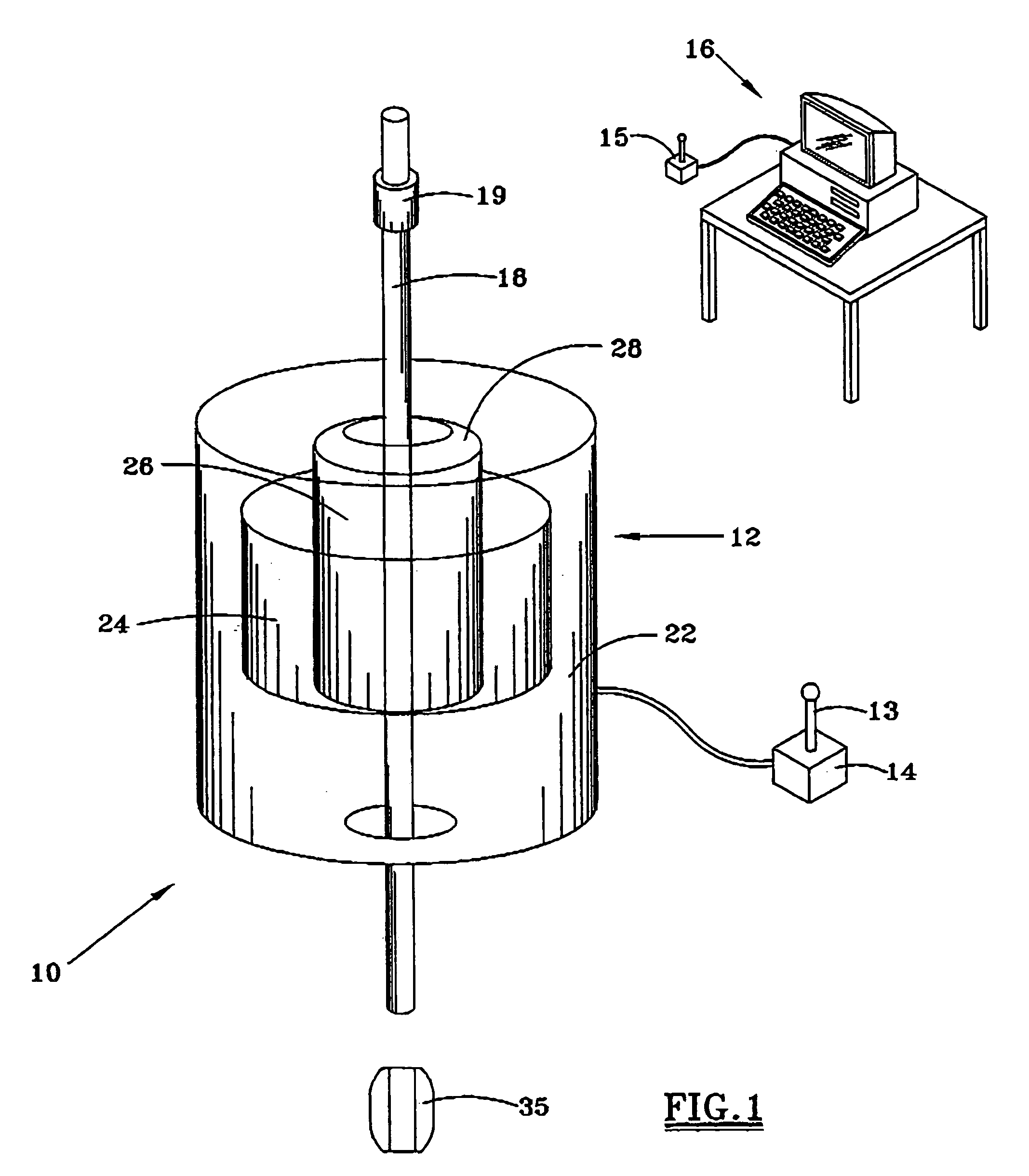

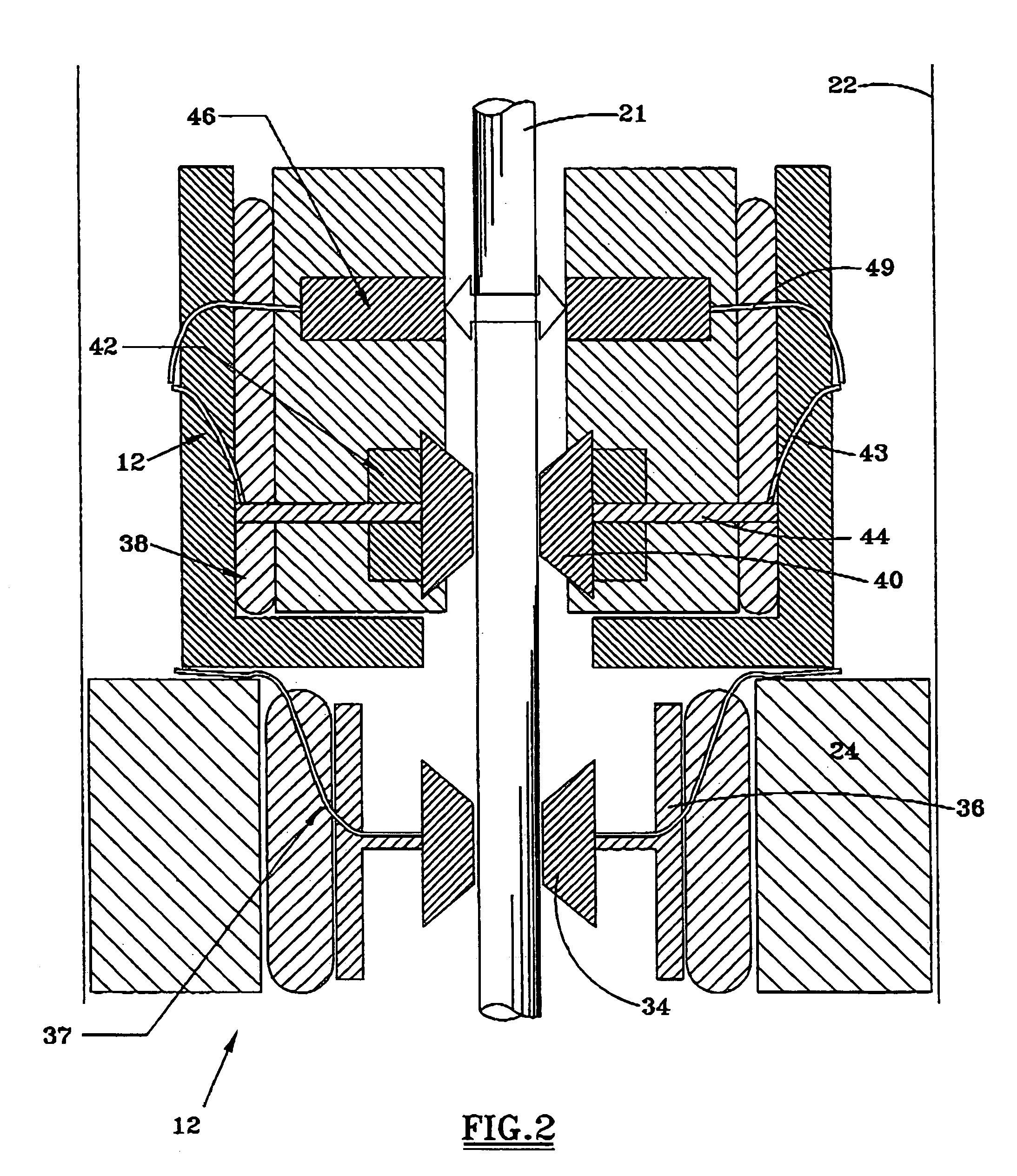

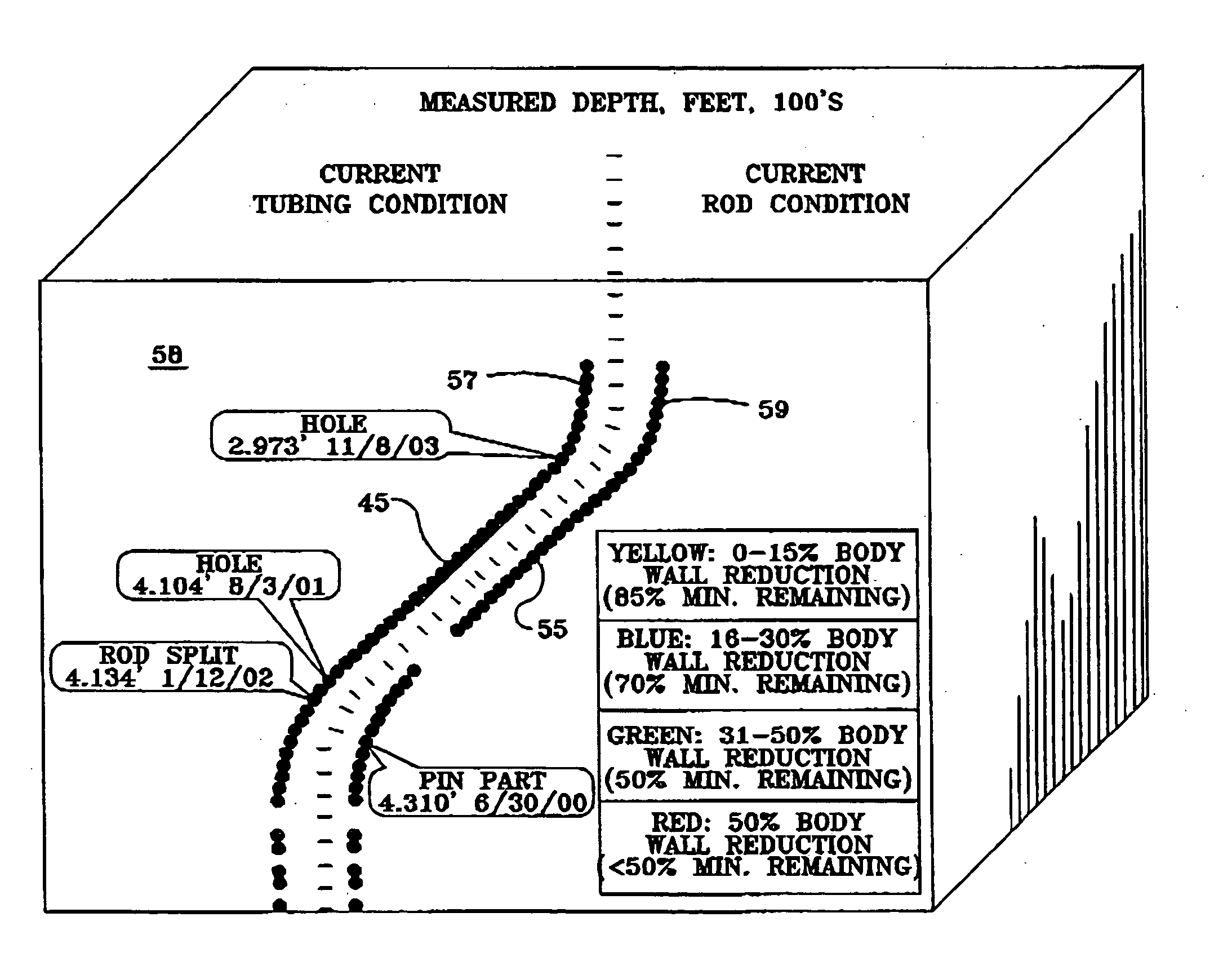

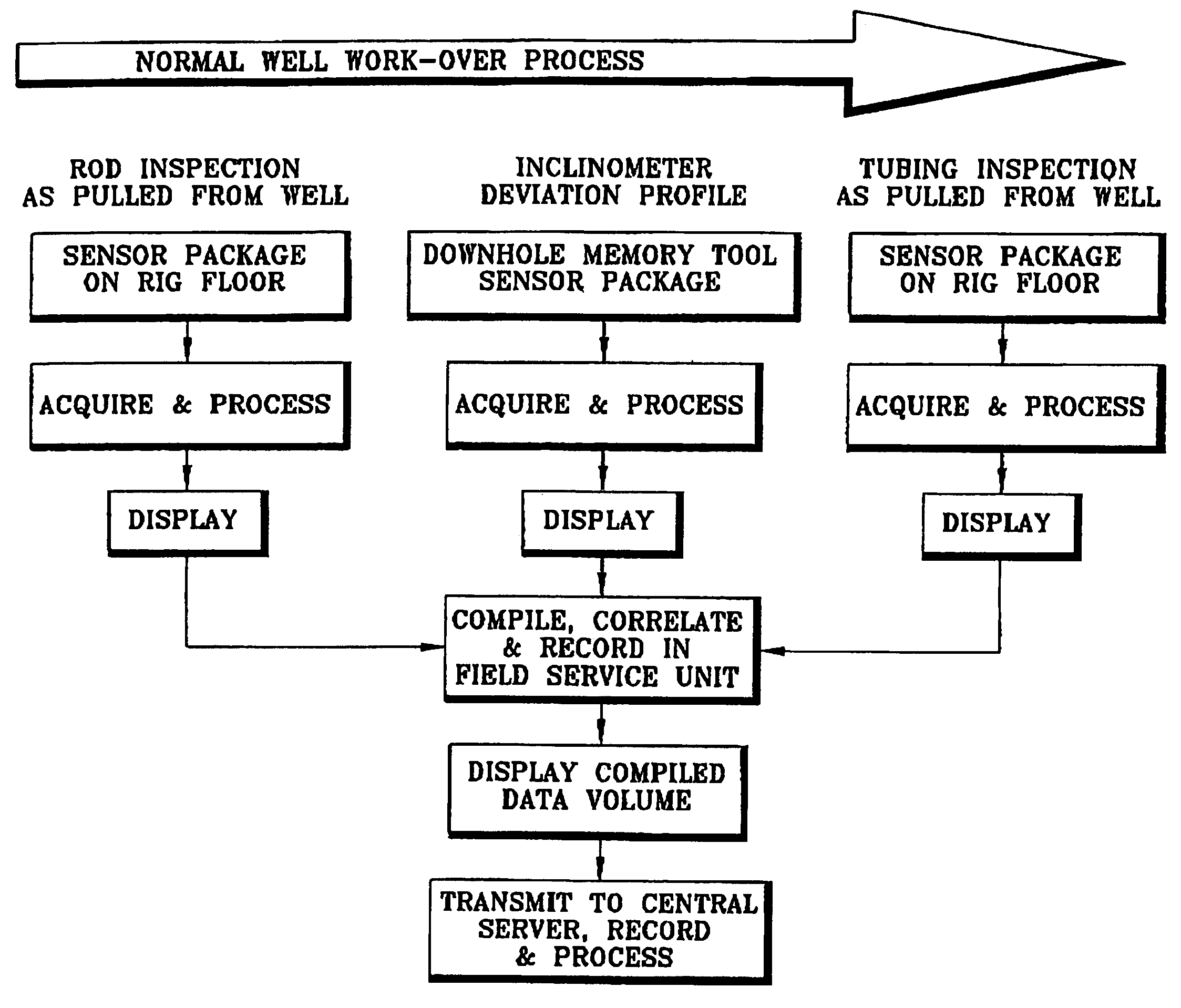

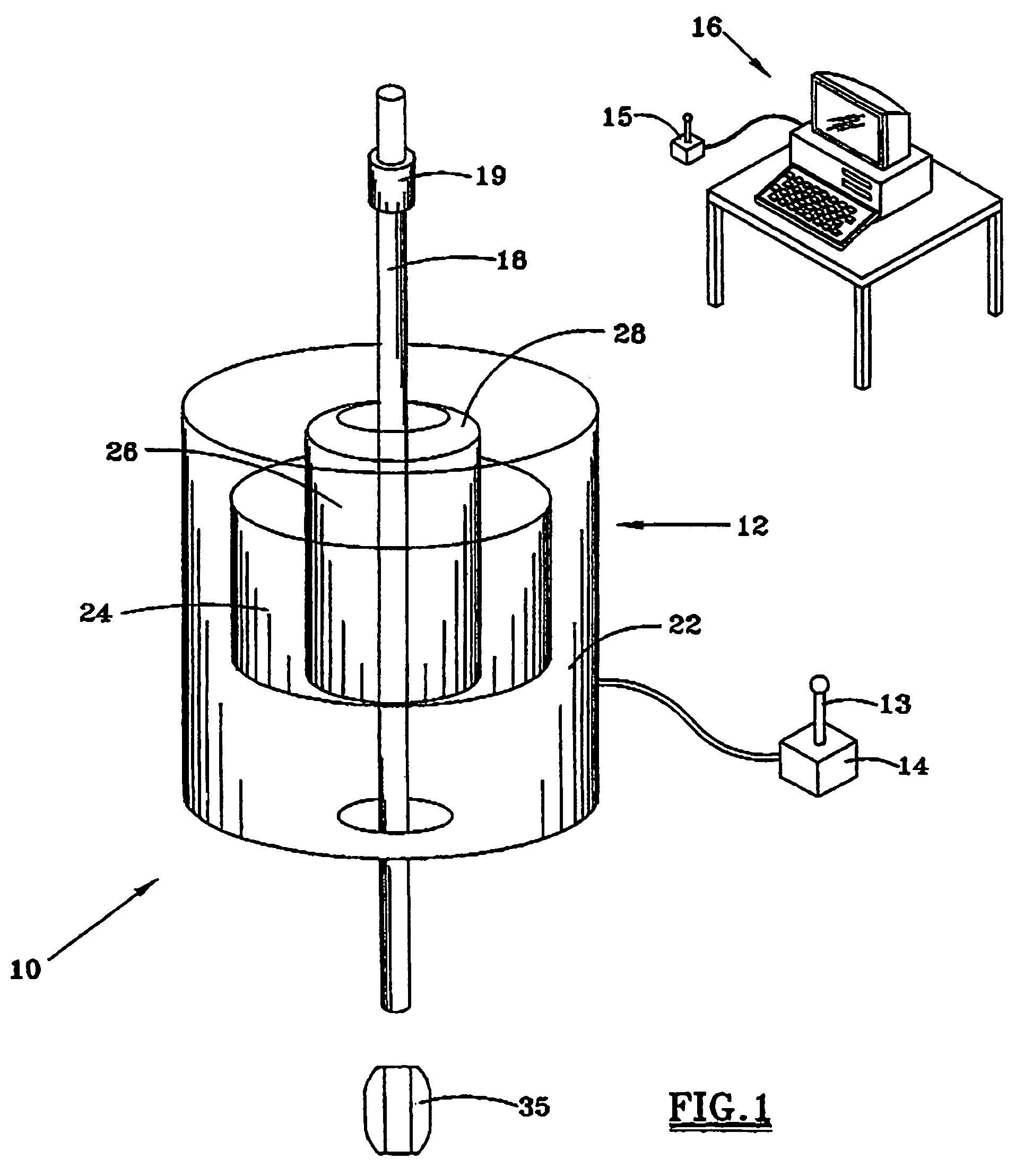

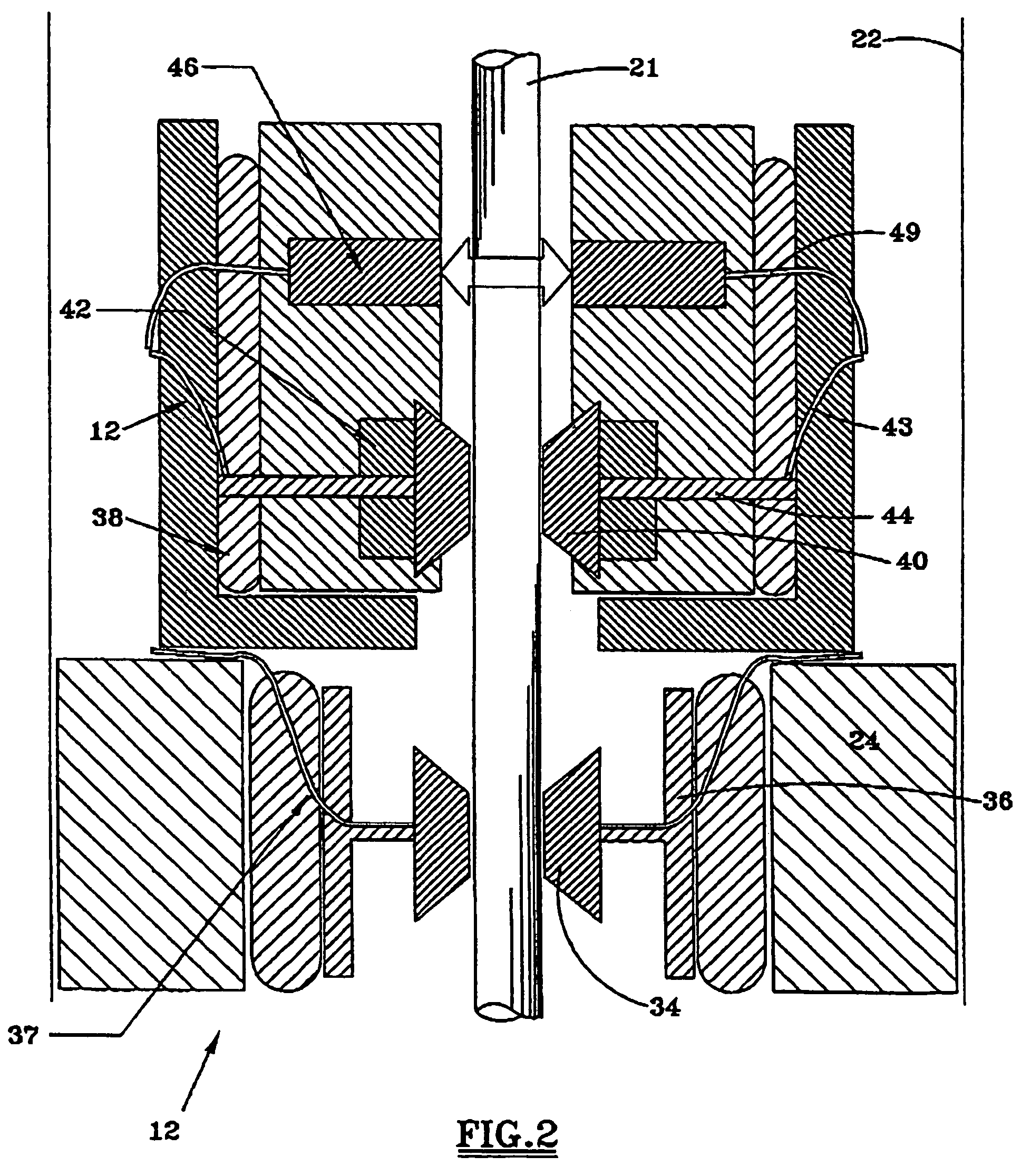

ActiveUS20060271299A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

Wellbore evaluation system and method

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the well, a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile, and a tubing sensor senses and measures wear and corrosion to the production tubing string as it is removed from the well to determine a tubing profile. A data acquisition computer is in communication with the sensors for computing and comparing two or more of the respective deviation profile, rod profile, and tubing profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

Wellbore evaluation system and method

ActiveUS20050267686A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the well, a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile, and a tubing sensor senses and measures wear and corrosion to the production tubing string as it is removed from the well to determine a tubing profile. A data acquisition computer is in communication with the sensors for computing and comparing two or more of the respective deviation profile, rod profile, and tubing profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

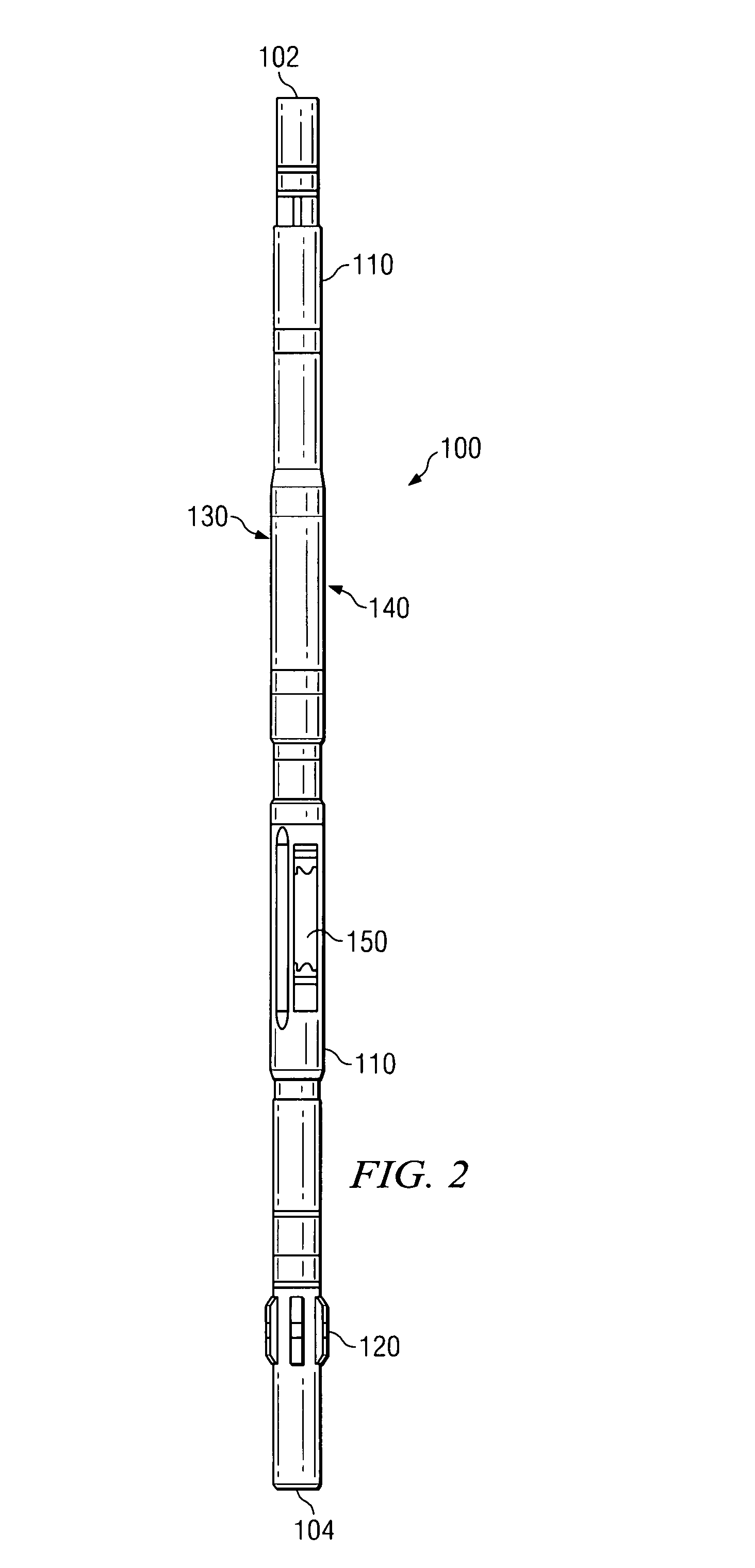

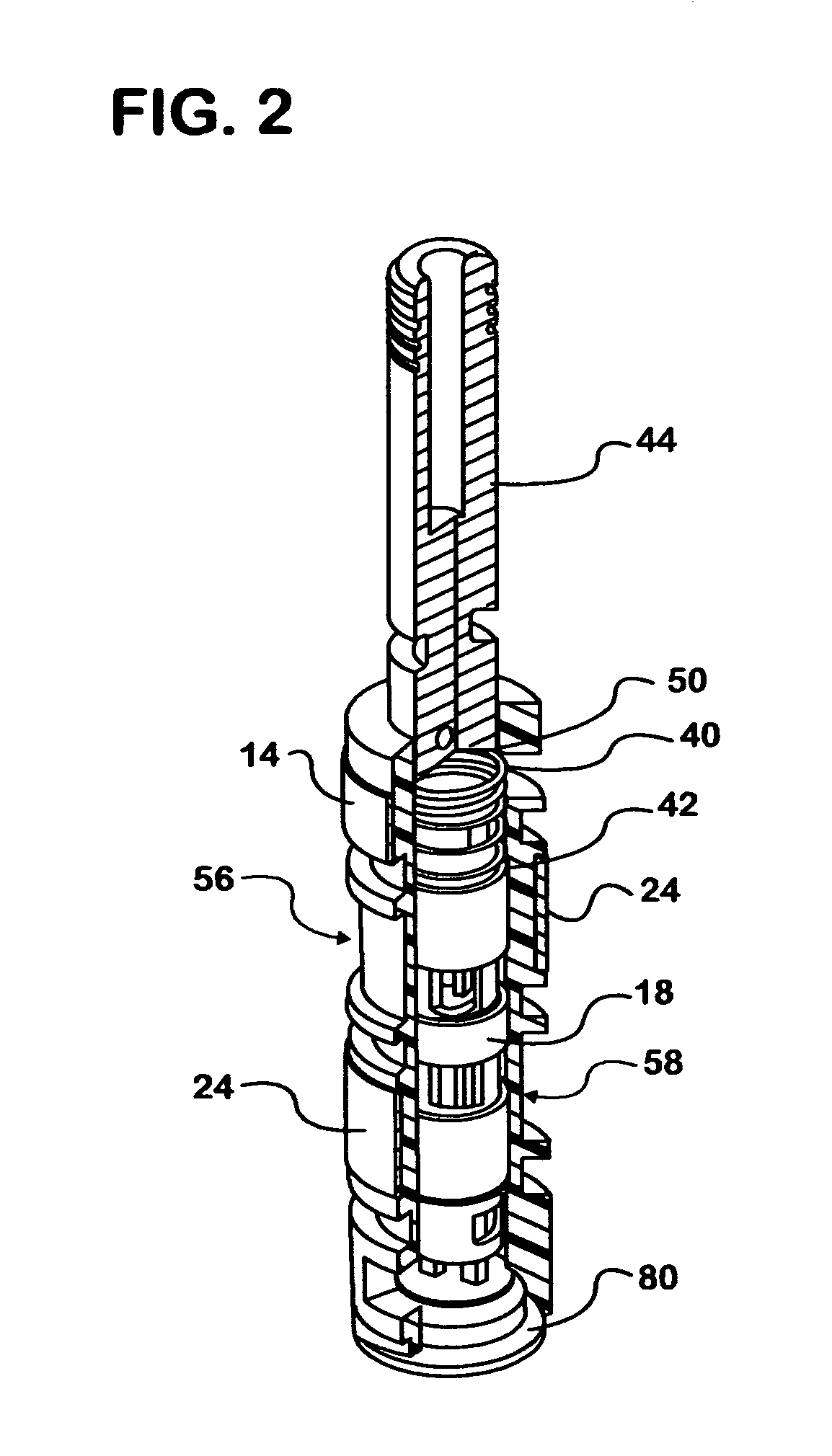

Linear position sensor for downhole tools and method of use

InactiveUS7377333B1Accurate and reliable measurementSmall driftDrilling rodsDerricks/mastsMechanical wearEngineering

Aspects of this invention include a downhole tool having first and second members disposed to translate substantially linearly with respect to one another. A magnet is deployed on the first member and a plurality of magnetic field sensors is deployed on the second member. The magnetic field sensors are spaced in a direction substantially parallel with a direction of translation between the first and second members. The tool typically further includes a controller disposed to determine a linear position of the first and second members with respect to one another from magnetic flux measurements made at the magnetic field sensors. Exemplary position sensor embodiments of the present invention are non-contact and therefore are not typically subject to mechanical wear. Embodiments of the invention therefore tend to advantageously provide for accurate and reliable linear position measurements.

Owner:SCHLUMBERGER TECH CORP

Oil/gas separation membrane, its use in gas sensor and process for producing the same

InactiveUS20050086998A1Losing mechanical propertyLosing permeation efficiencyPreparing sample for investigationFuel testingAdhesiveHexafluoropropylene

An oil gas separation membrane combines a gas permeable yet oil and temperature resistant bulk polymer membrane such as poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-hexafluoropropylene); a porous metal support such as sintered metal frit disk made with stainless steel, bronze or nickel; and an highly gas permeable adhesive that bonds firmly the bulk polymer membrane and the metal frit surface together. The adhesive is either a homogenous polymer that has desirable gas permeability, or a coalescent porous polymer particulates network. A gas sensor employing the oil gas separation membrane for detecting and monitoring fault gases of oil filled electrical equipment requires no mechanical wearing or moving part such as pump and valve and the gas sensor is operated normally under various temperature and pressure conditions.

Owner:ASENSOR TECH

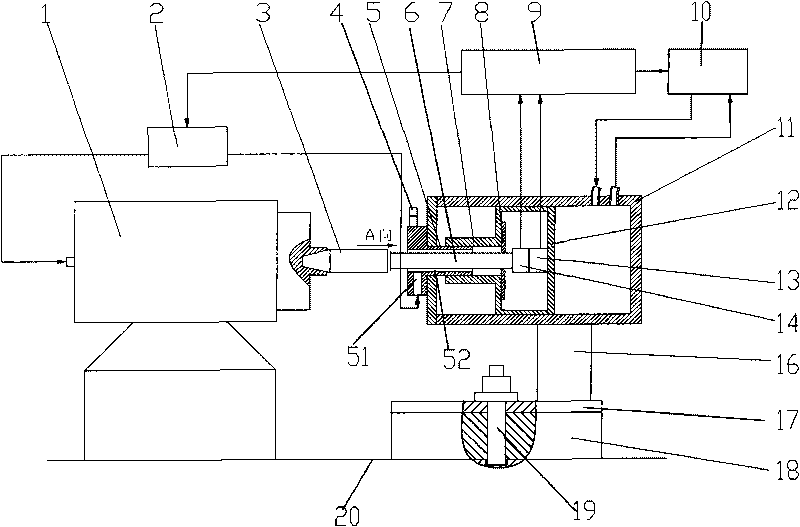

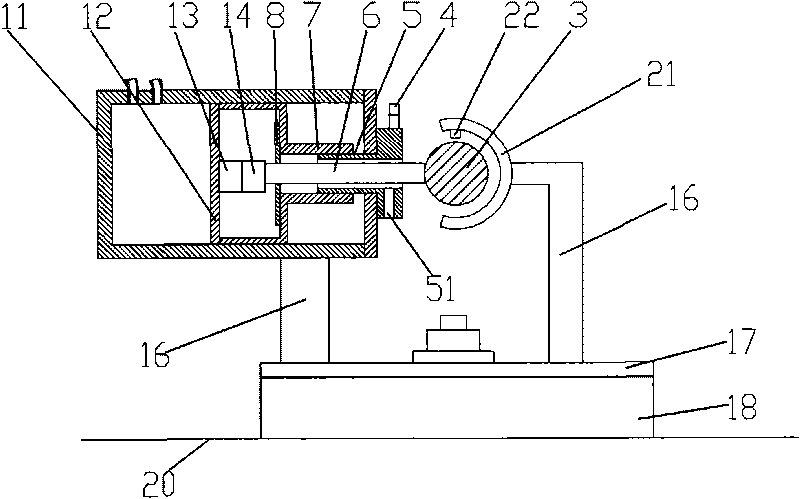

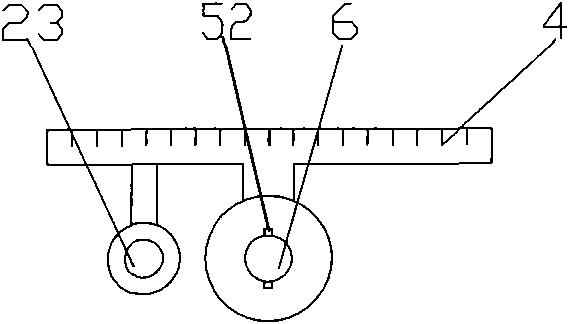

Device for testing dynamic stiffness and constant pressure of high-speed electric spindle

InactiveCN101718658AContinuous dynamic loadingContinuous measurement in real timeMachine part testingMaterial strength using tensile/compressive forcesAutomatic controlMechanical wear

The invention discloses a device for testing dynamic stiffness and constant pressure of a high-speed electric spindle, comprising a base, a loading system, a lubricating and cooling system and an automatic control unit, wherein the loading system comprises a hydraulic cylinder component, a hydraulic cylinder oil way system and a loading rod. In the invention, a loading value and a deformation value are collected through a pressure sensor and a displacement sensor by adopting a hydraulic cylinder and combining the automatic control unit; and the control unit controls the loading pressure of the hydraulic cylinder according to the variation of the loading value and the deformation value and can detect the high-speed electric spindle under the condition of dead load so as to avoid frictional heating generated by mechanical contact in a high-speed running state of the high-speed electric spindle and influence of mechanical wear to test precision and realize continuous and stable dynamic loading and real-time measurement of the high-speed electric spindle, therefore, the invention has high measurement precision and can conveniently finish various functions including data collection, display, storage, analysis, calculation, control, trigger and the like. The whole device has the advantages of compact structure, convenient use and low cost.

Owner:CHONGQING UNIV

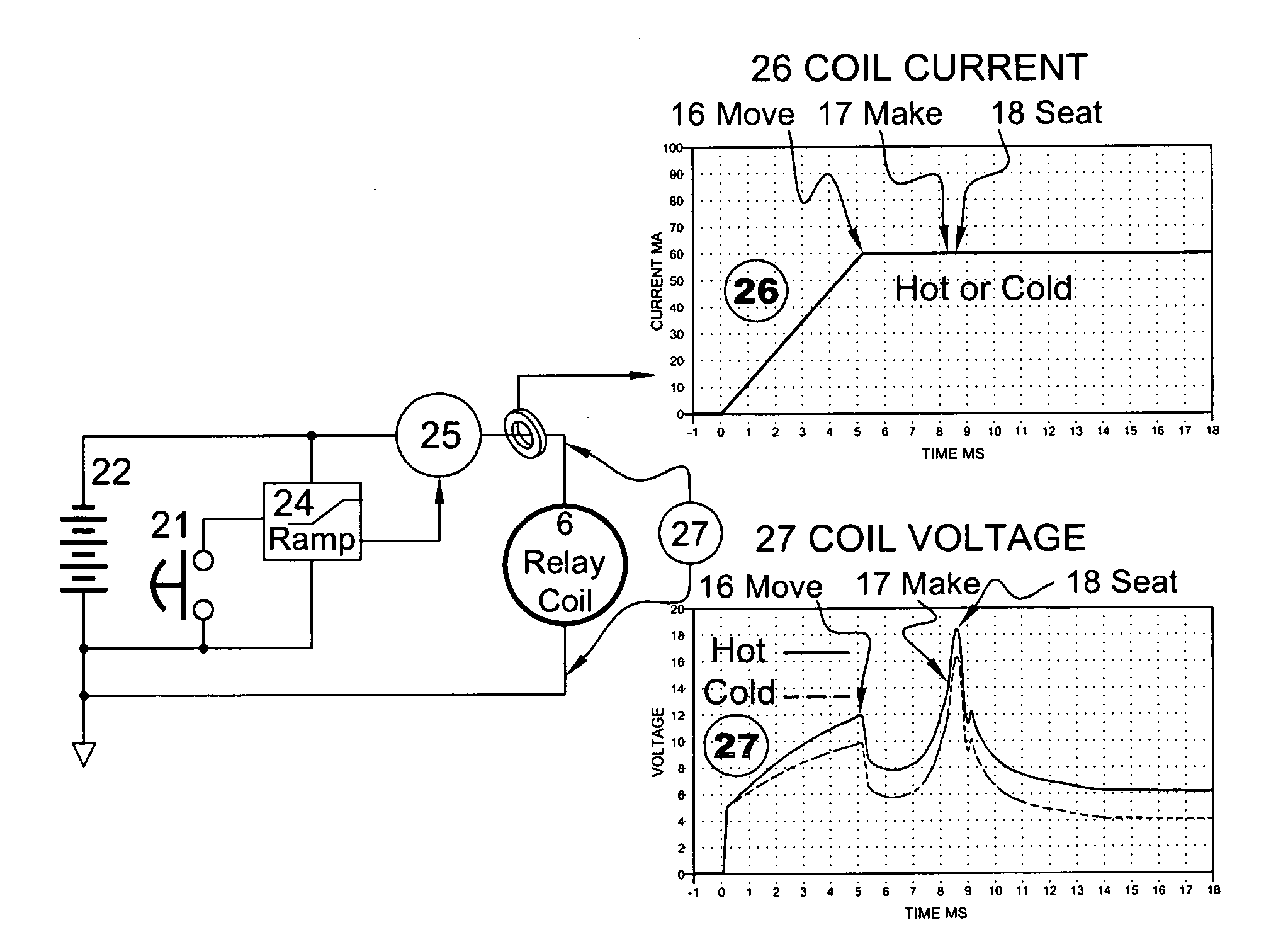

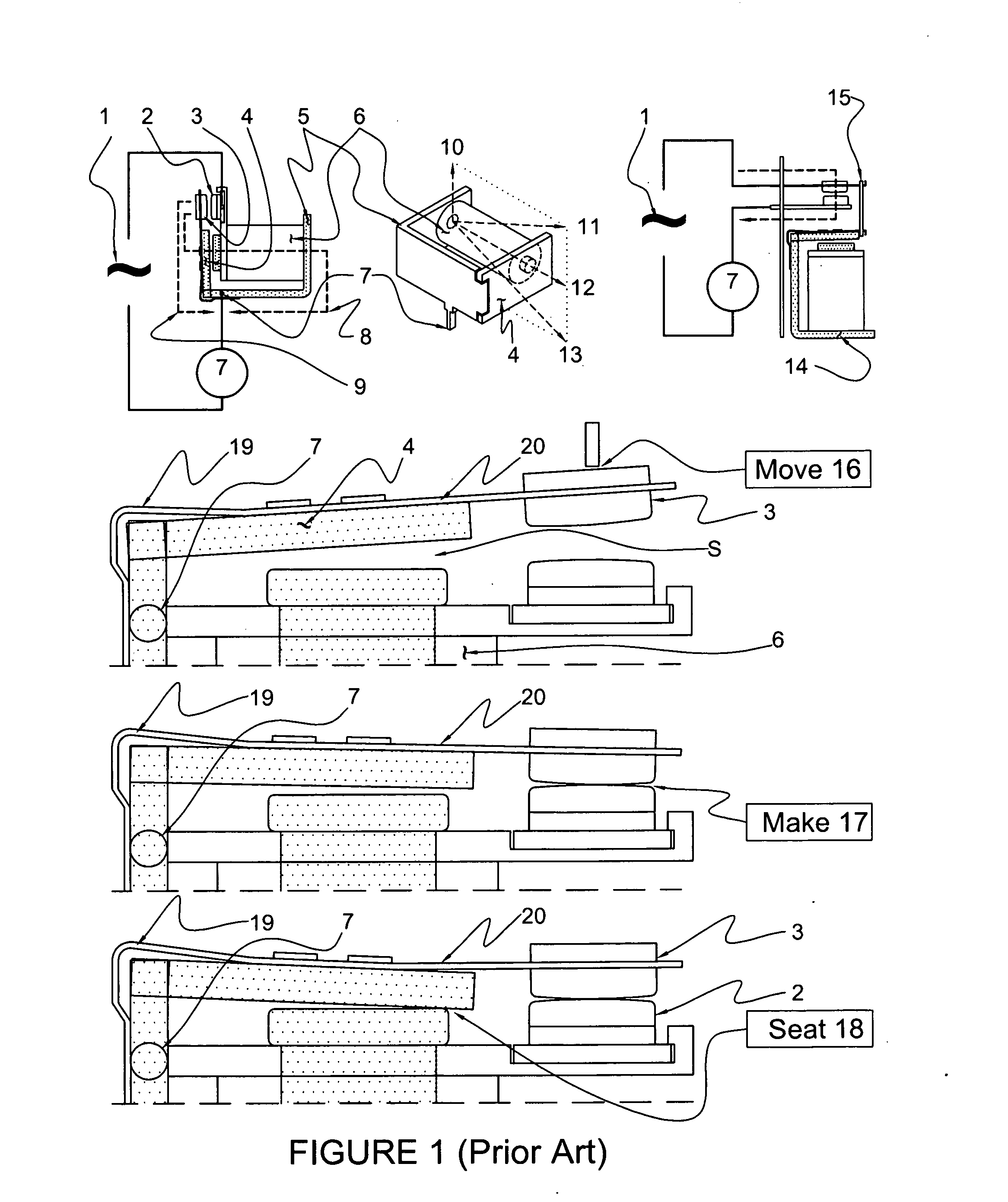

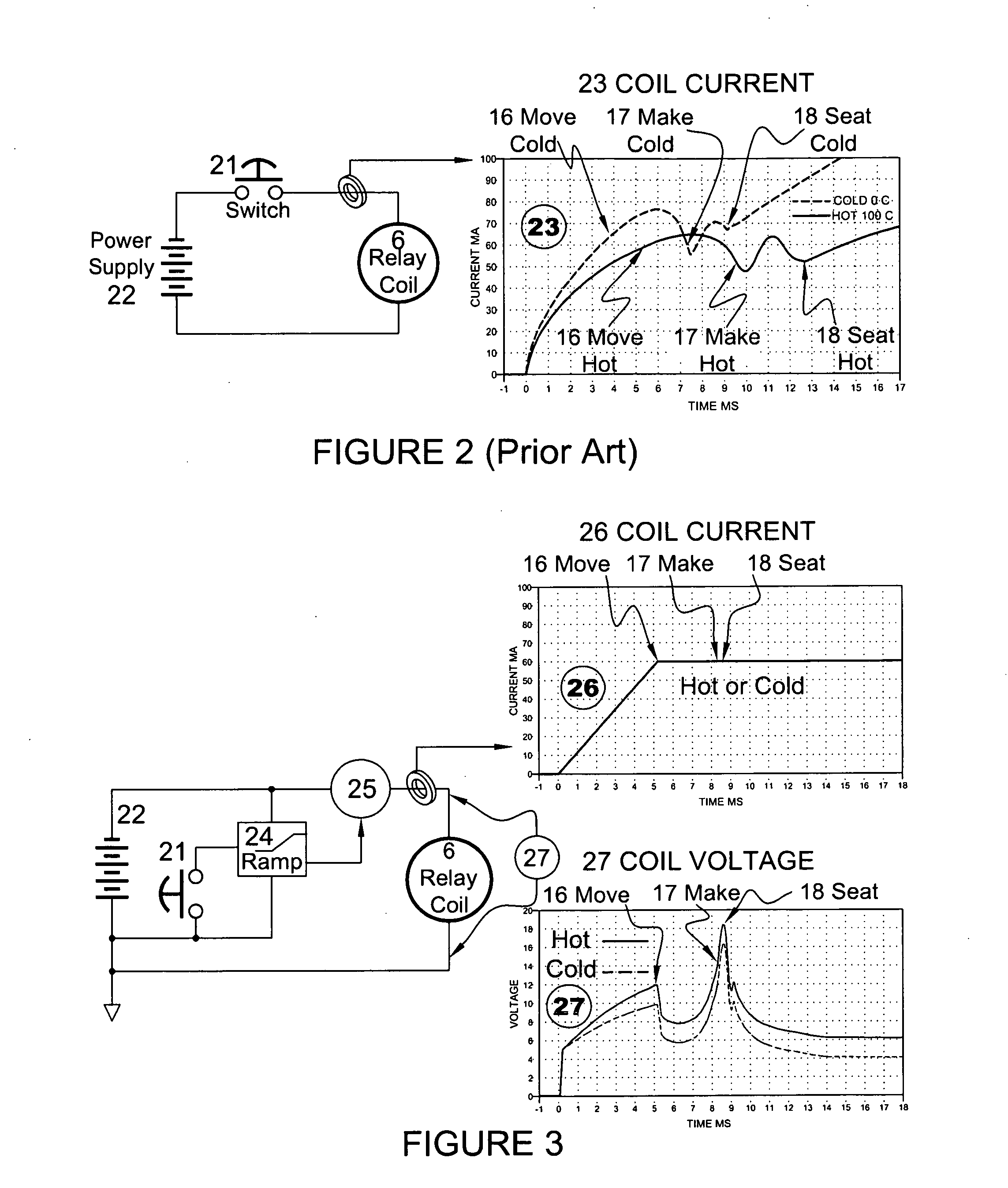

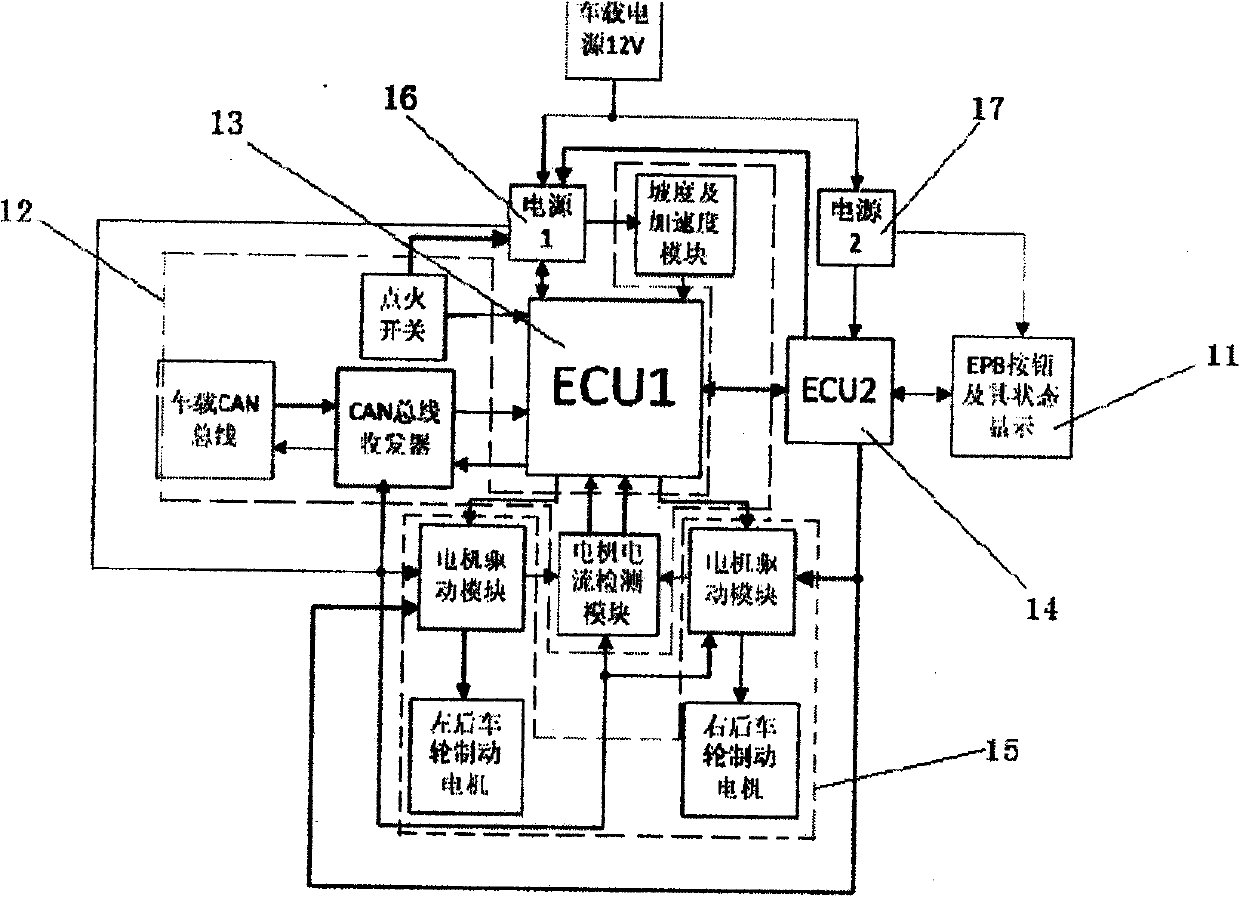

Relay Coil Drive Circuit

InactiveUS20100265629A1Reduces prolonged low pressureMaintaining contact pressureElectric switchesPolarised relaysMagnetic tension forceContact pressure

Relay contacts operate with a snap action when disclosed electronic waveforms, profile its coil current. Snap action reduces the prolonged low pressure that damages relay contacts. This means of driving the relay coil also reverses the properties of its voltage and current. Coil voltage now varies with movement of its armature, frame current, coil resistance, back-EMF, and temperature. Coil current follows a profile that is stable and independent of these changing electrical, mechanical, and environmental factors. Since coil voltage has no direct magnetic or mechanical effect its changes do not affect relay operation. However the relays new stable current profile has a dramatic affect. It moves, makes, breaks and seats predictably, regardless of its temperature, residual magnetism, or mechanical wear. Power-line synchronization means takes advantage of this new stability, concentrating on the position and pressure of the contact. The contact starts to move closed after the peak power-line voltage and makes at zero voltage. Full contact pressure is maintained until load-current is near zero and contact break occurs before zero current. Several types of coil current profiles are disclosed along with analog and software controlled embodiments. New relay friendly electronic reset logic is disclosed to maintain contact pressure during power losses caused by load-surge and load-shorts. Zero crossing and power-line voltage are combined with logic that does not disable but delays relay operation. Relay contact to coil noise problems are disclosed along with suppression techniques to stop electronic circuitry induced contact chatter. Diagnostic techniques and production methods are disclosed for relays that are sealed inside an enclosure. Automatic and manual timing adjustment means are also disclosed.

Owner:MECHANICAL INGENUITY CORP

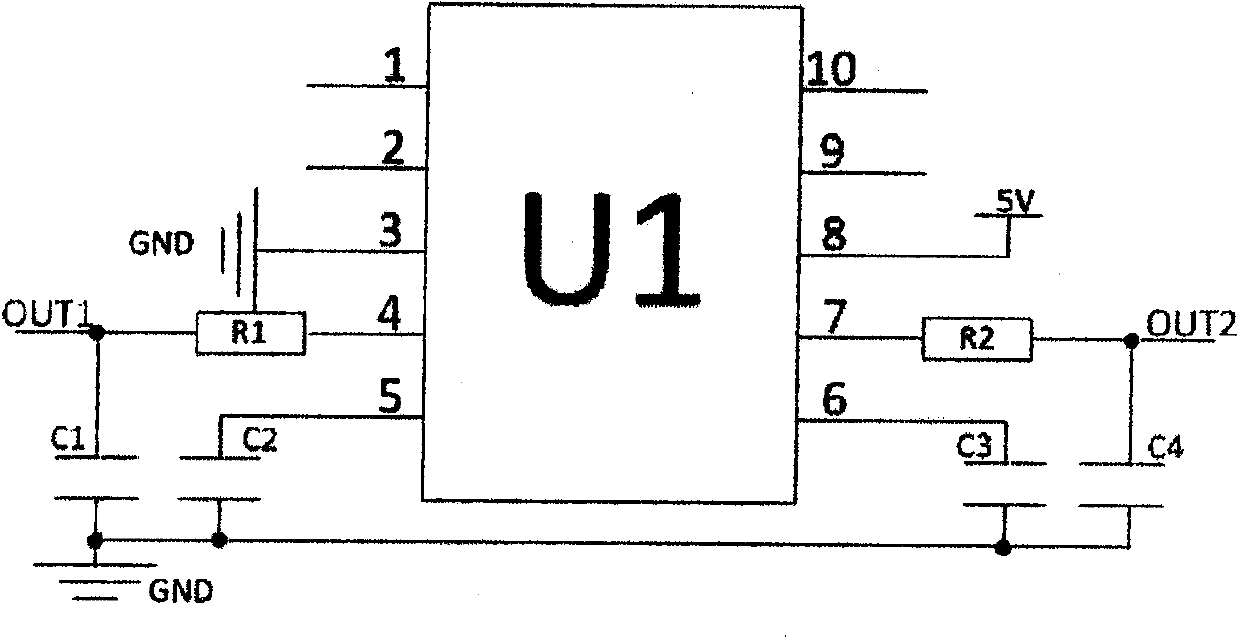

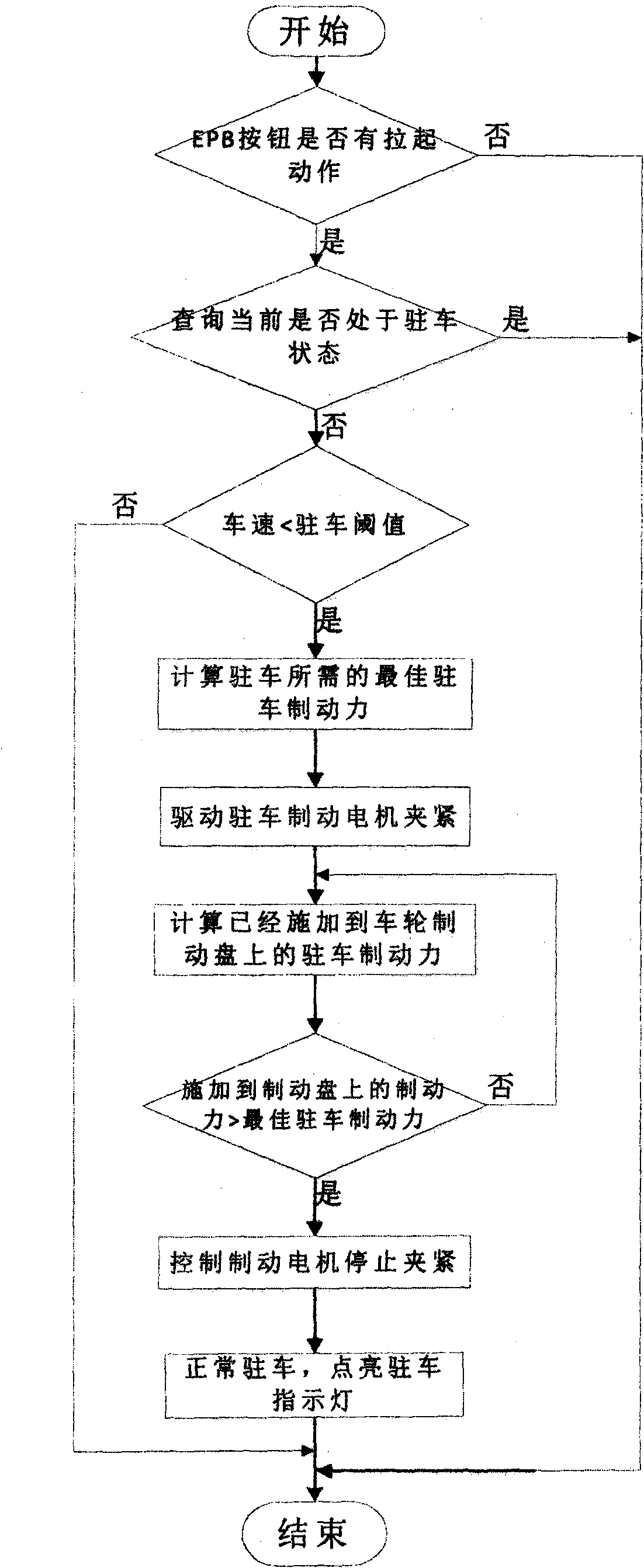

Vehicle parking braking system and control method for same

InactiveCN103863293ASave spaceCompact designBraking action transmissionHand actuated initiationsExecution unitCalipers

The invention discloses a vehicle parking braking system, which comprises a signal acquisition unit for acquiring a vehicle state signal and a signal input unit for inputting a driver operation instruction, wherein the signal acquisition unit and the signal input unit output signals to a control unit; the control unit analyzes and processes the signals, and controls an execution unit to enable a vehicle brake caliper to clamp or release a brake disc. According to the system, required optimal braking force can be provided for parking, and the mechanical abrasion of the brake caliper is effectively reduced; in addition, the system can function in emergency braking after a travel braking system fails, so that a vehicle can be safety parked, and the safety of the vehicle is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

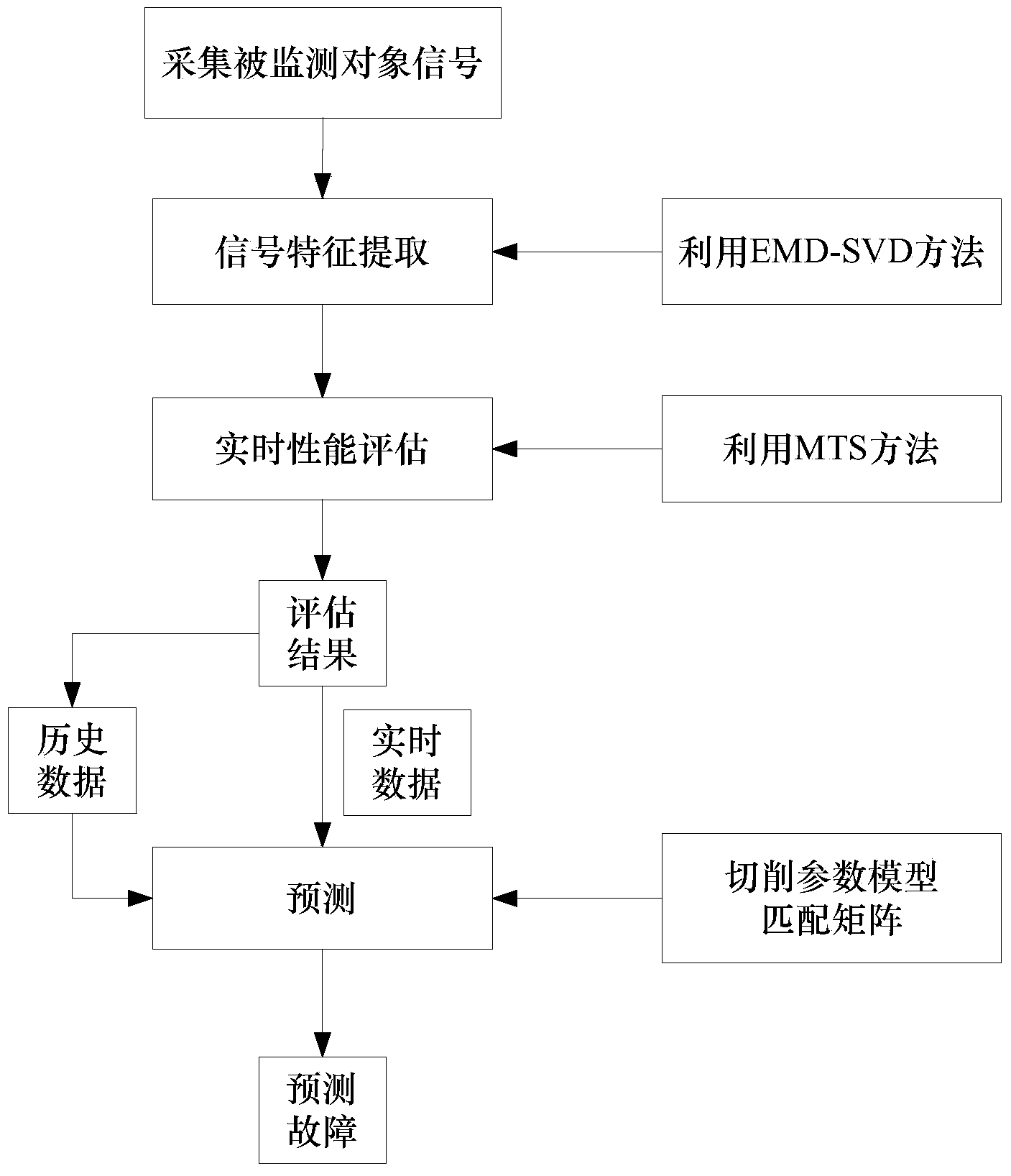

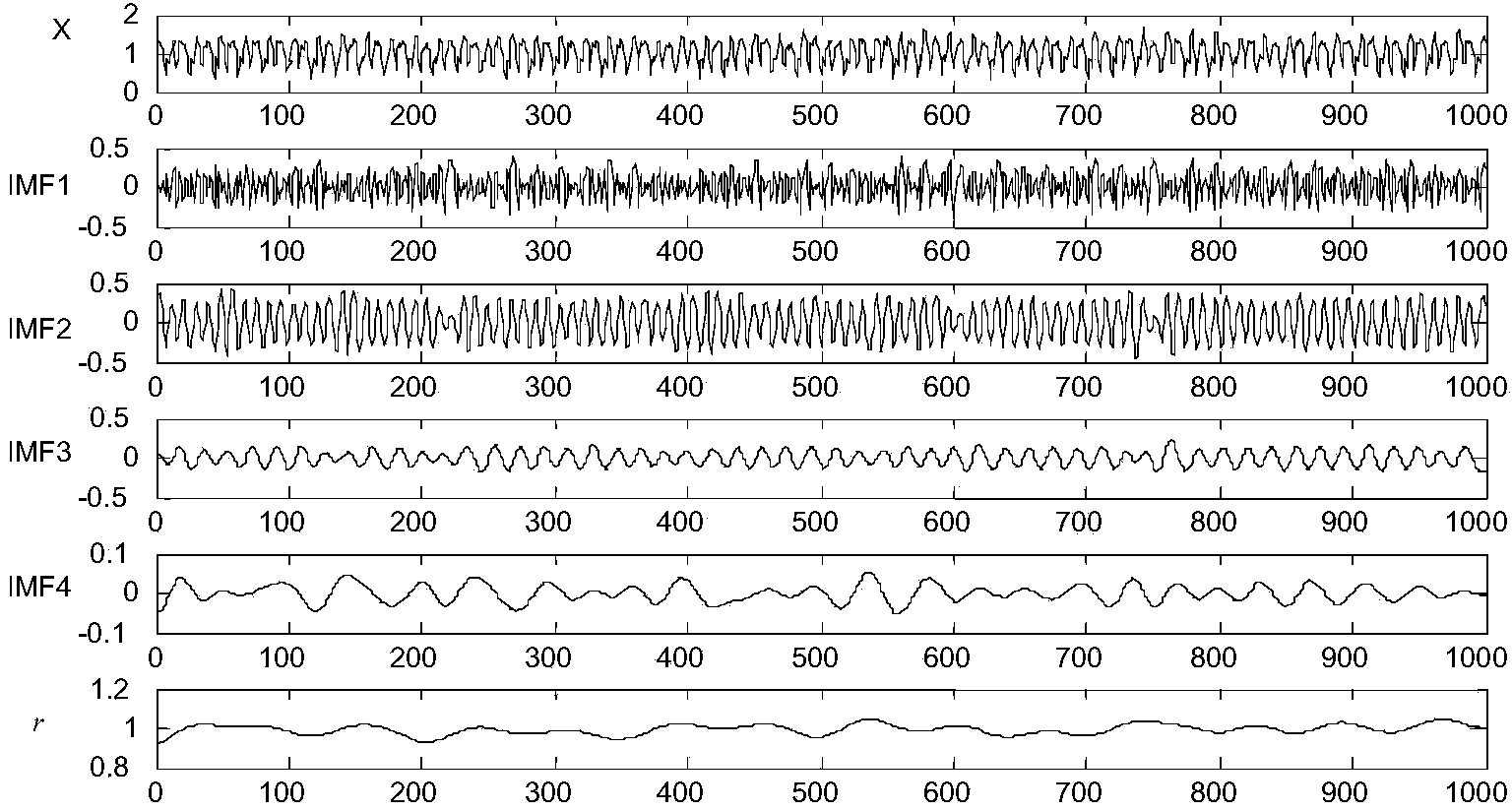

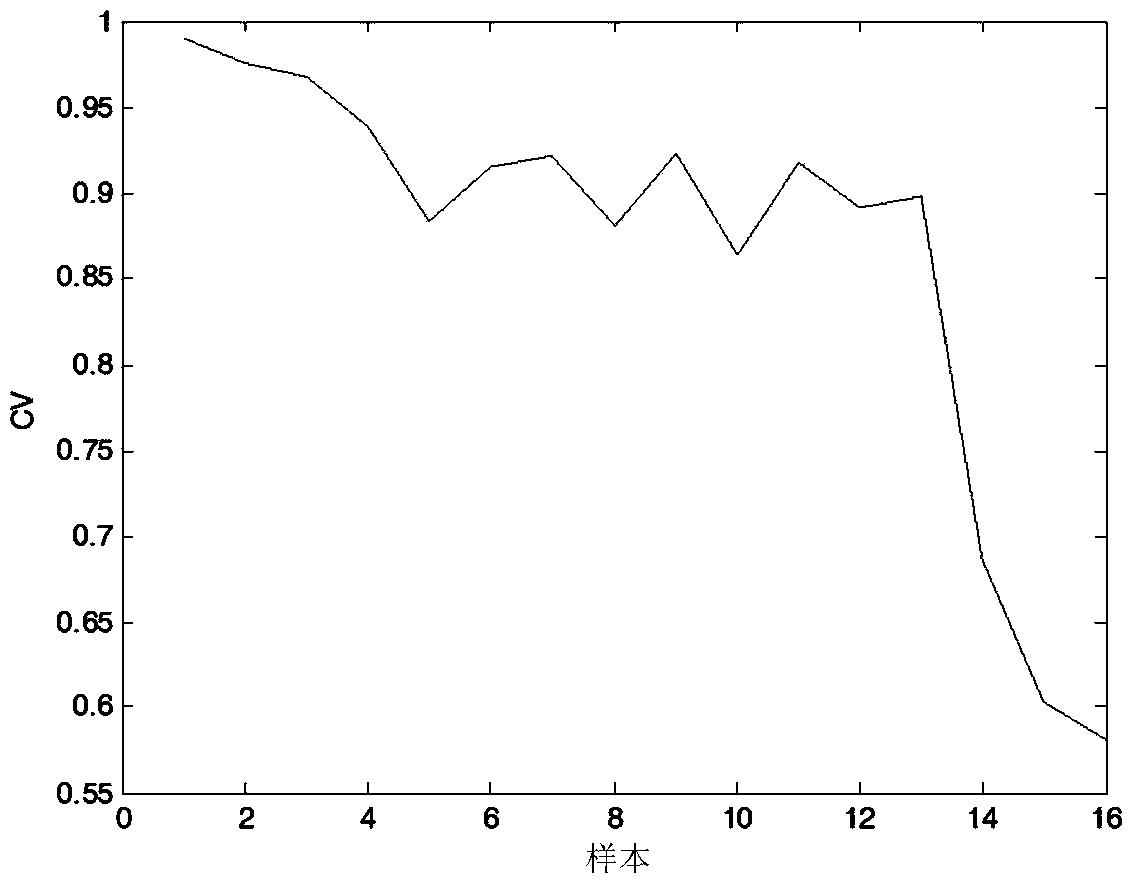

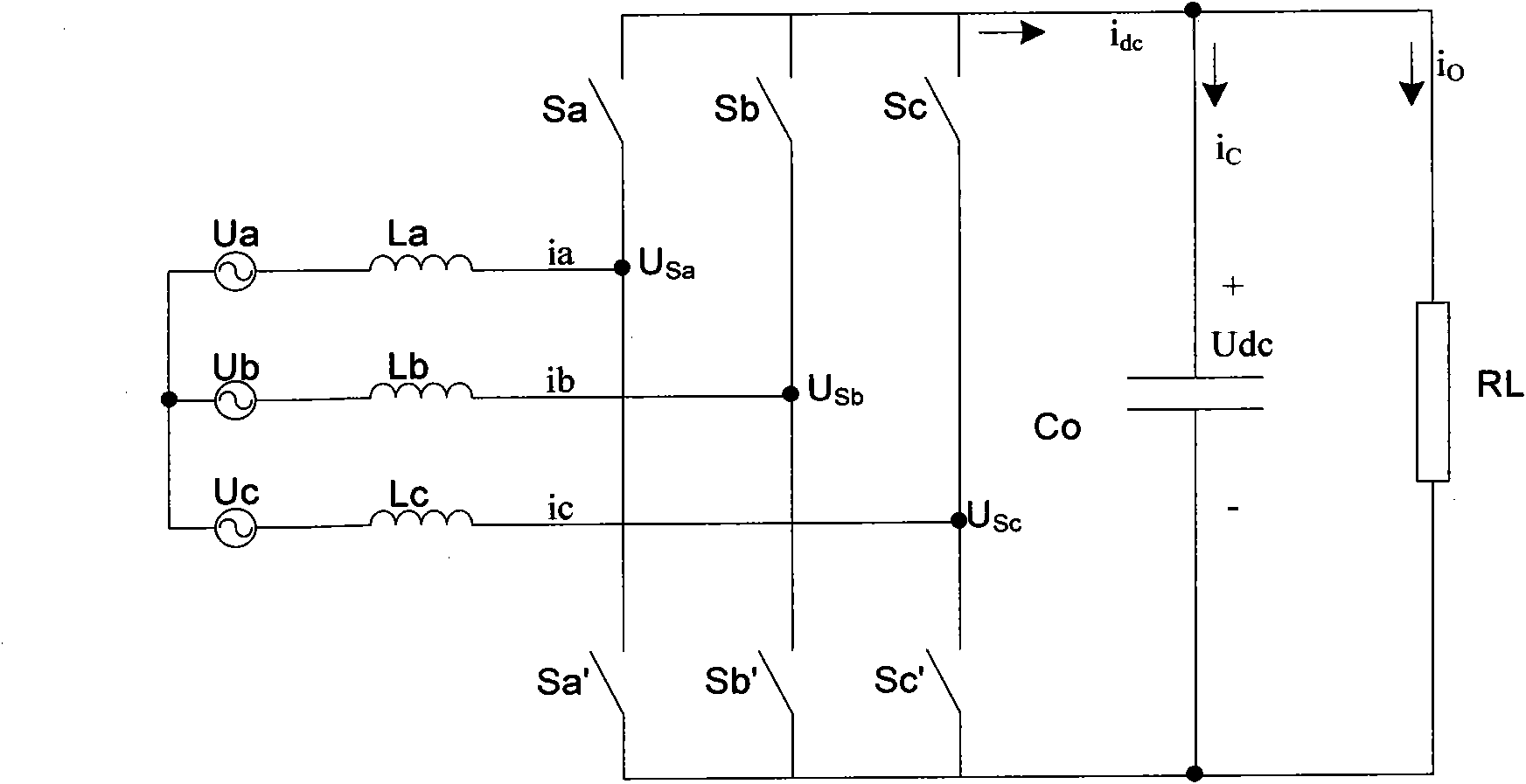

Mechanical wearing part performance assessment and prediction method based on EMD (empirical mode decomposition)-SVD (singular value decomposition) and MTS (Mahalanobis-Taguchi system)

InactiveCN103674511AAvoid error-prone problemsSave math featuresMachine part testingSingular value decompositionFeature vector

The invention provides a mechanical wearing part performance assessment and prediction method based on based on EMD (empirical mode decomposition)-SVD (singular value decomposition) and an MTS (Mahalanobis-Taguchi system), and belongs to the technical field of mechanical wearing part fault diagnosis. The method comprises: first of all, performing noise reduction processing on acquired signals of a monitored object, then performing EMD on the signals, selecting effective IMF (intrinsic mode function) components and residual functions to form an initial matrix, performing SVD on the initial matrix, and performing normalization processing on obtained characteristic values to obtain characteristic vectors; then using an MTS method to calculate an MD (Mahalanobis Distance), and using a Taguchi method to perform optimization and reduction on the characteristic vectors; and converting the MD into a confidence value, performing assessment on the performance of mechanical wearing parts through tracking the trend of the confidence value, and performing prediction on a fault through a correlation module or a matching matrix between the confidence value and conditions of the monitored object. The method provided by the invention avoids the problem of easily occurring errors when a conventional method is used for processing non-linear non-stationary signals, and reduces fault generation probability, thereby being suitable for industrial real-time monitoring.

Owner:BEIHANG UNIV

Energy-saving control system for permanent magnet synchronous escalator

InactiveCN101863413ASave energyReduce wearEscalatorsMechanical wearPermanent magnet synchronous motor

The invention discloses an energy-saving control system for a permanent magnet synchronous escalator. The main loop is that: each phase of a three-phase power supply is connected with two groups of pulse width modulation controllers in star connection through an inductor and a resistor in sequence, wherein the central points of each group of pulse width modulation controllers are a positive electrode output end and a negative electrode output end respectively; and a capacitor is in bridge connection with the positive electrode output end and the negative electrode output end; the control circuit is that: a voltage signal and a current signal of each phase are sampled from each phase of the three-phase power supply and connected with a microprocessor through a shaping and isolating circuit; the voltage output from the positive electrode output end and the negative electrode output end is connected with the microprocessor through an isolating circuit; the three-phase pulse width modulation output of the microprocessor is connected with each pulse width modulation controller through a driver and an isolator respectively; and the microprocessor is connected with a failure protection circuit, a keyboard and a display and communication interface circuit. The energy-saving control system has the most important characteristic of energy conservation, so the average energy conservation of the escalator reaches over 40 percent, the average energy consumption is 50 percent of that during single-speed operation, the mechanical wearing is reduced, and the service life of the parts and the entire machine is prolonged.

Owner:TIANJIN URBAN CONSTR COLLEGE

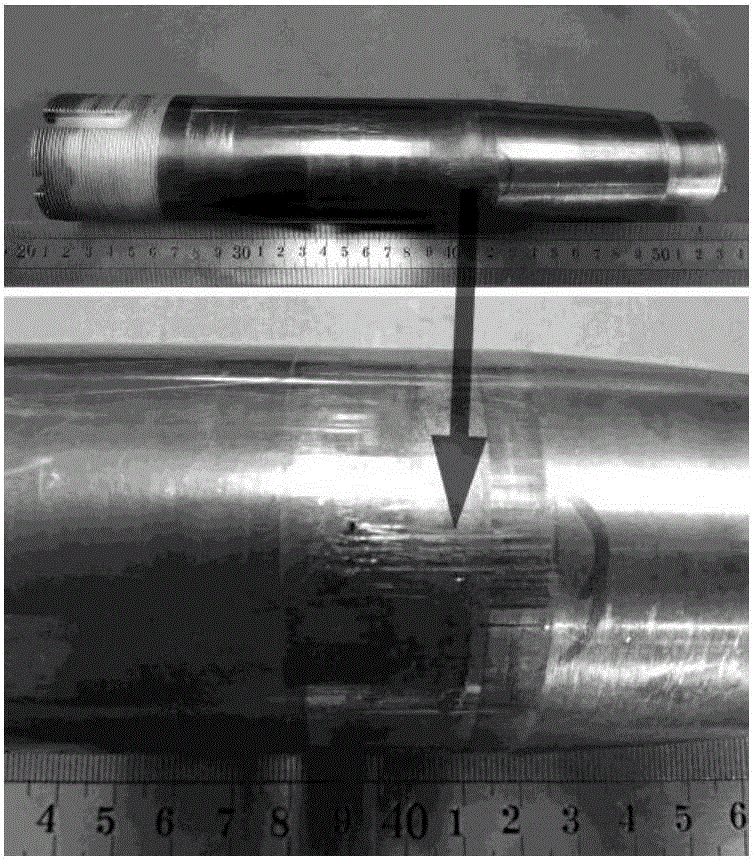

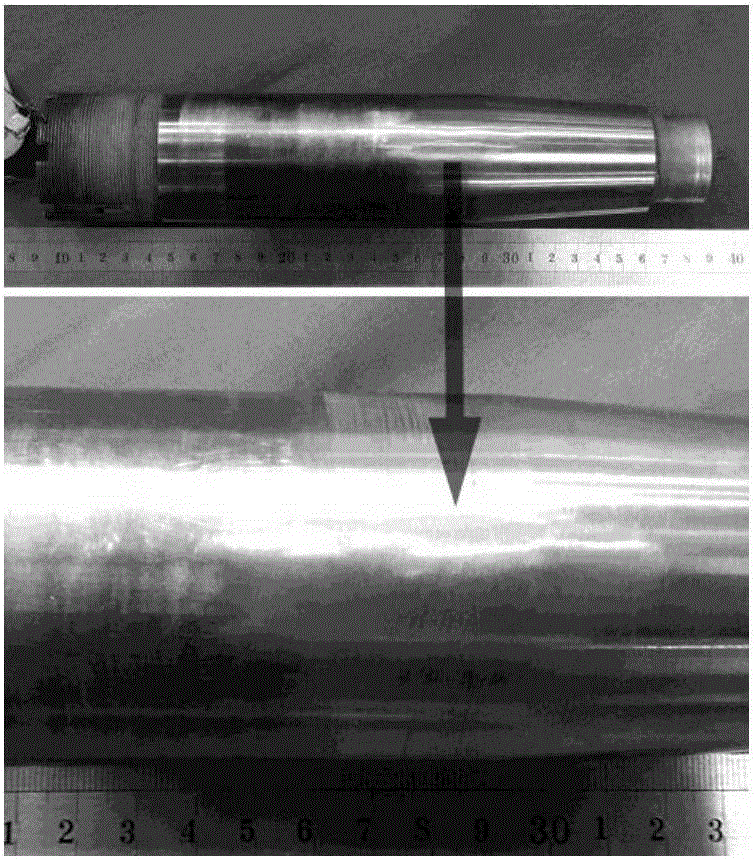

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Wellbore evaluation system and method

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

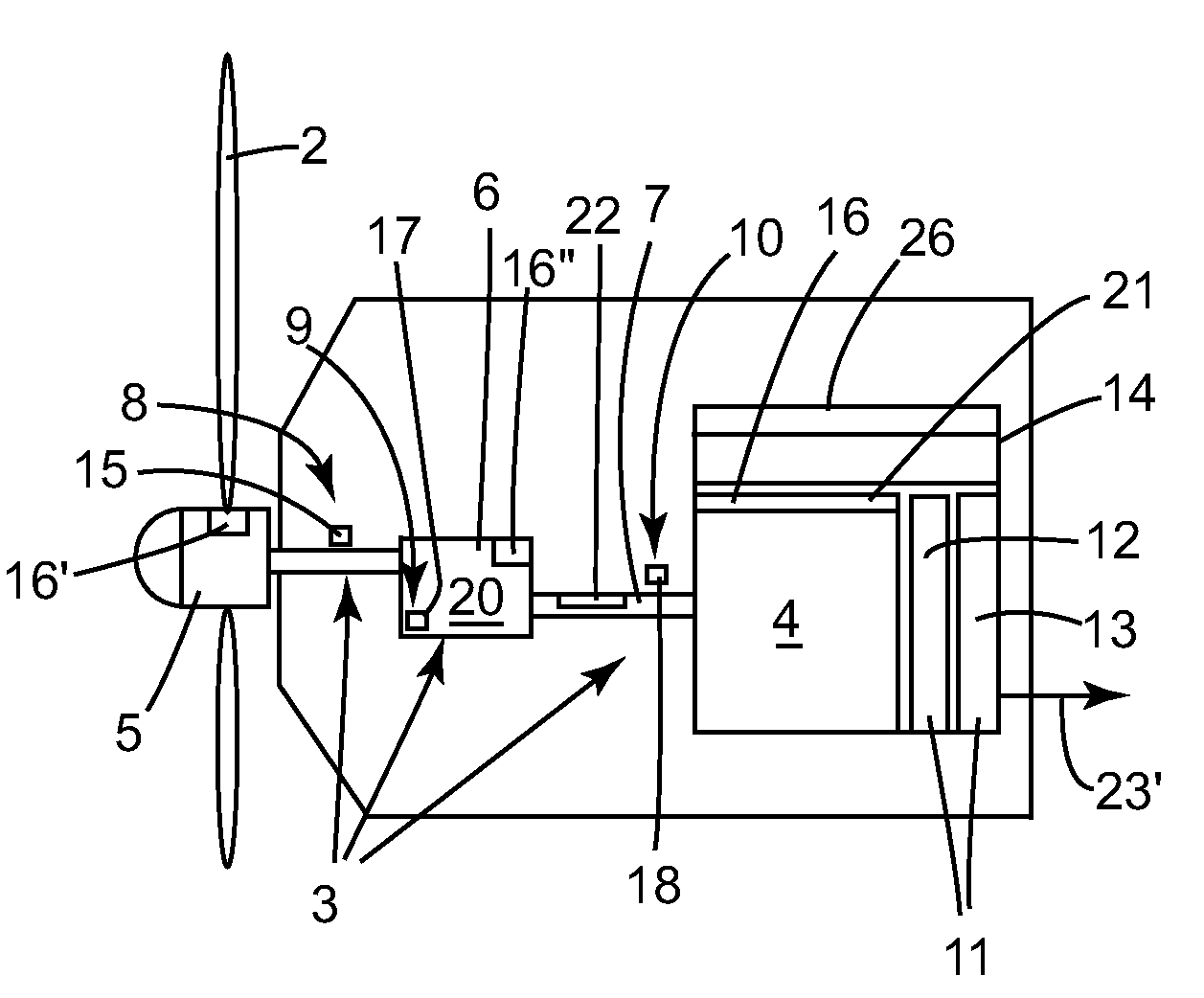

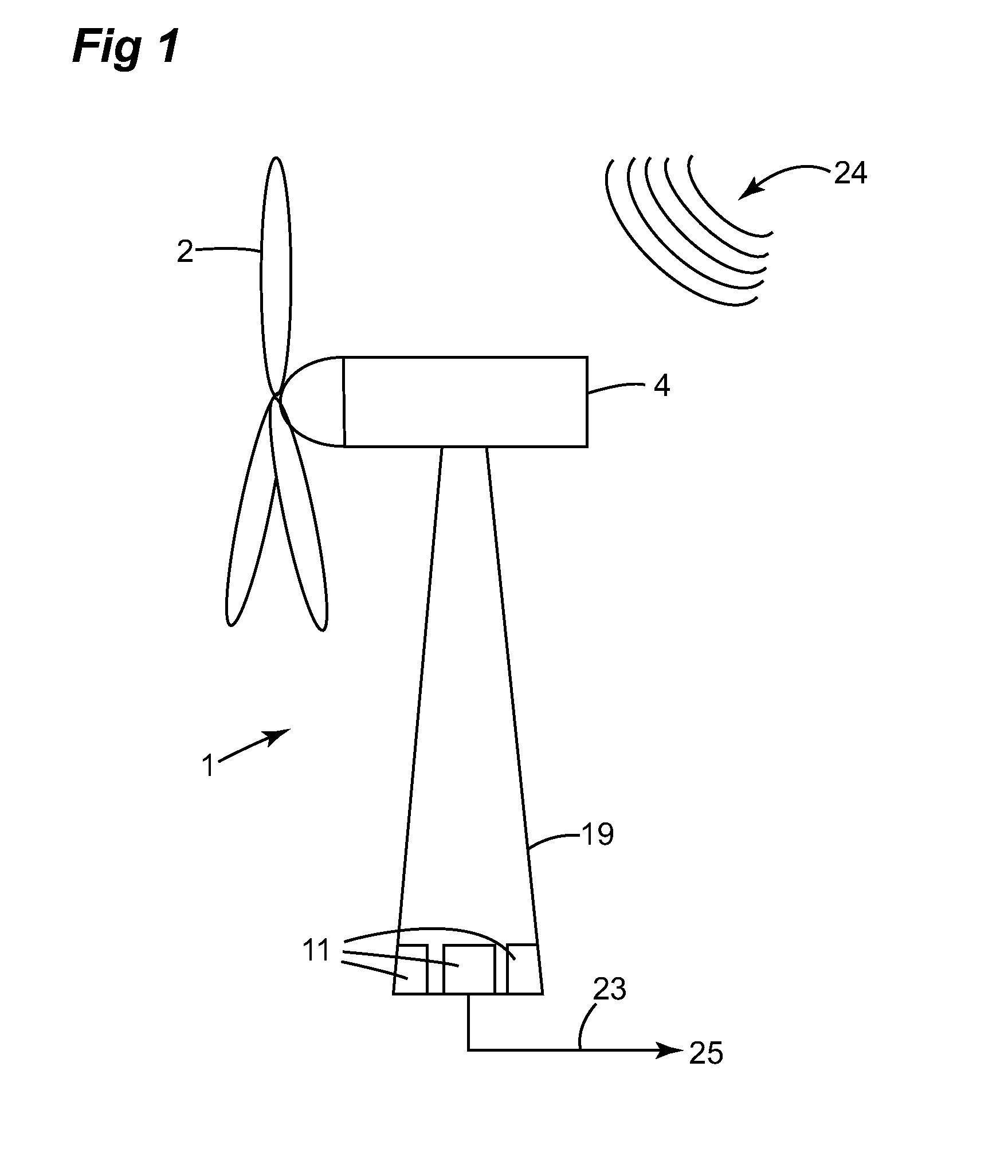

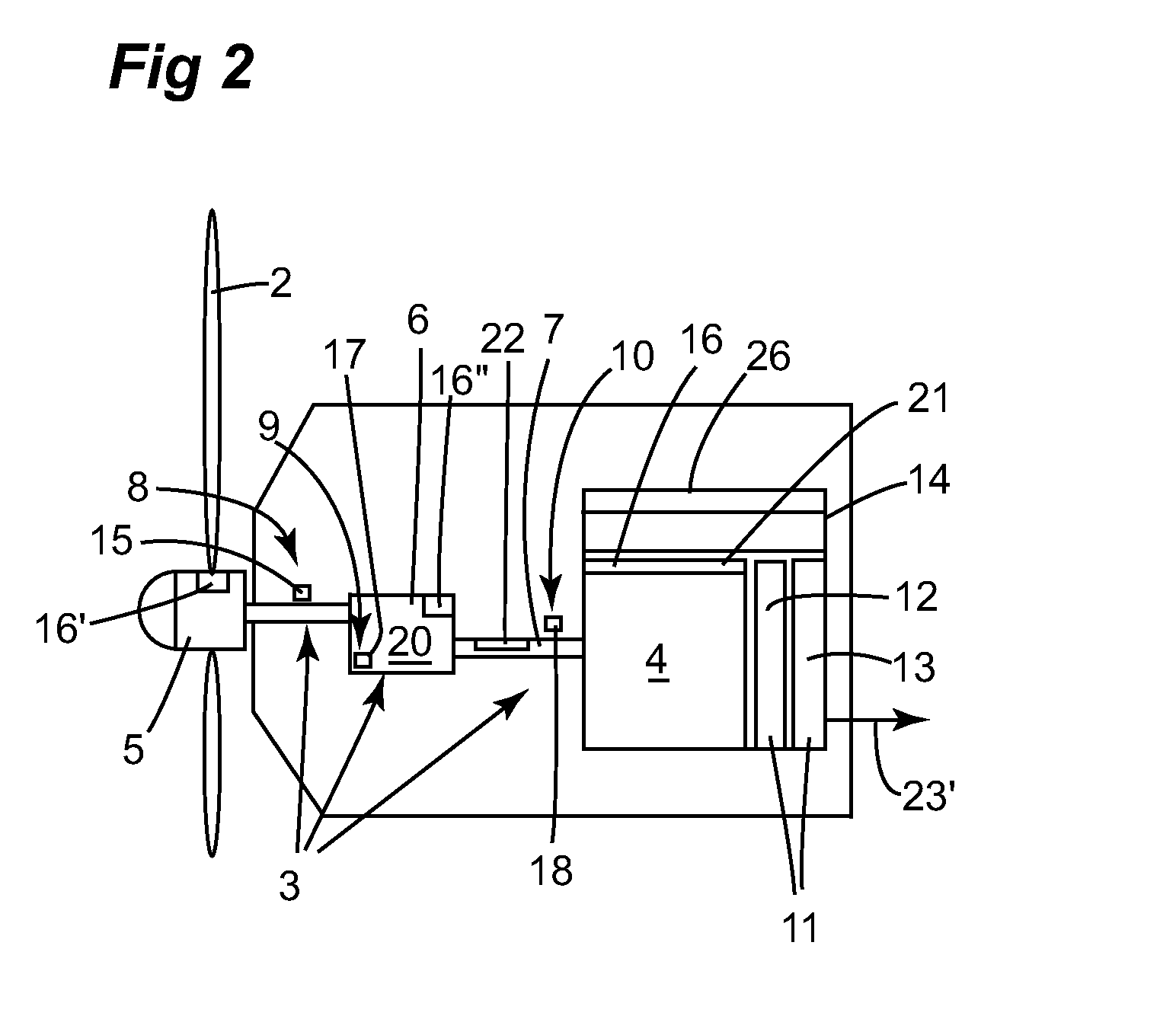

Model based wind turbine drive train vibration damper

ActiveUS20090230681A1Reduce mechanical vibrationReduced wear and tear on partsPropellersPump componentsPower stationResonance

The invention concerns a method for reducing mechanical oscillation in a wind power plant which comprises a plurality of rotor blades, a wind turbine drive train and a generator, wherein the rotor blades are rotatably connected to the generator by the wind turbine drive train. The method comprises the steps: mathematically modeling the dynamical response and / or transfer function of a group of rotatable parts of the wind power plant, the group of rotatable parts comprising at least the wind turbine drive train, and determining dynamical response and / or transfer function of the group; in operation of the wind power plant, determining a first parameter characteristic of the mechanical oscillation at a first location, controlling the operation of at least one rotatable part in response to the dynamical response and / or transfer function of the group and at least the first parameter. In effect, resonance induced mechanical wear is reduced which leads to an increased life time of the wind power plant.

Owner:GENERAL ELECTRIC CO

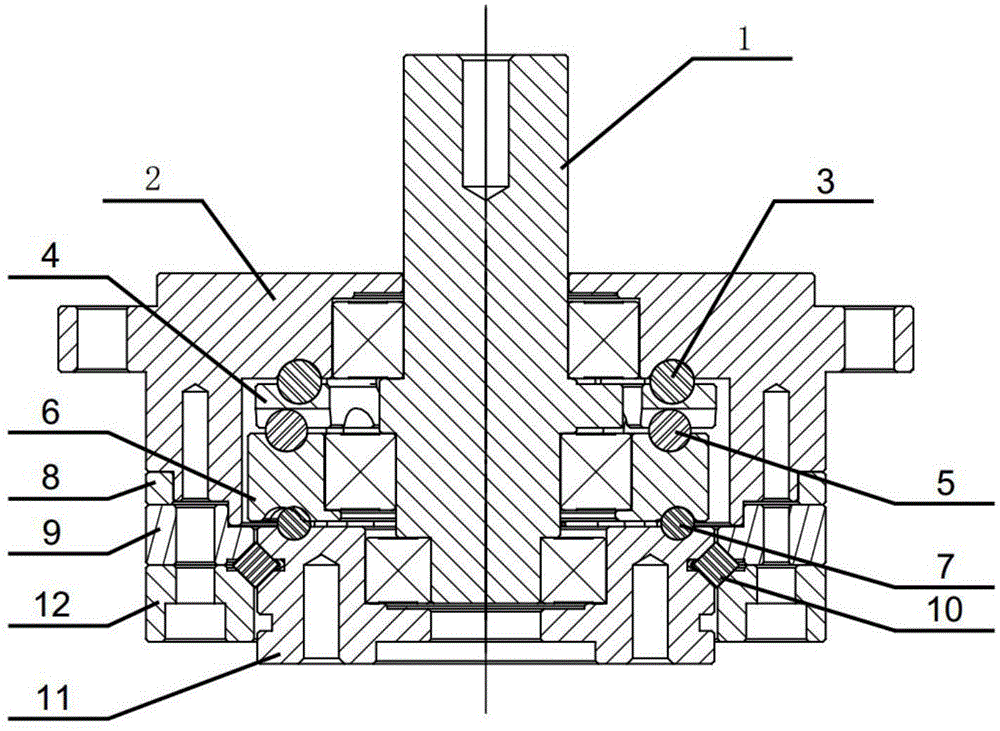

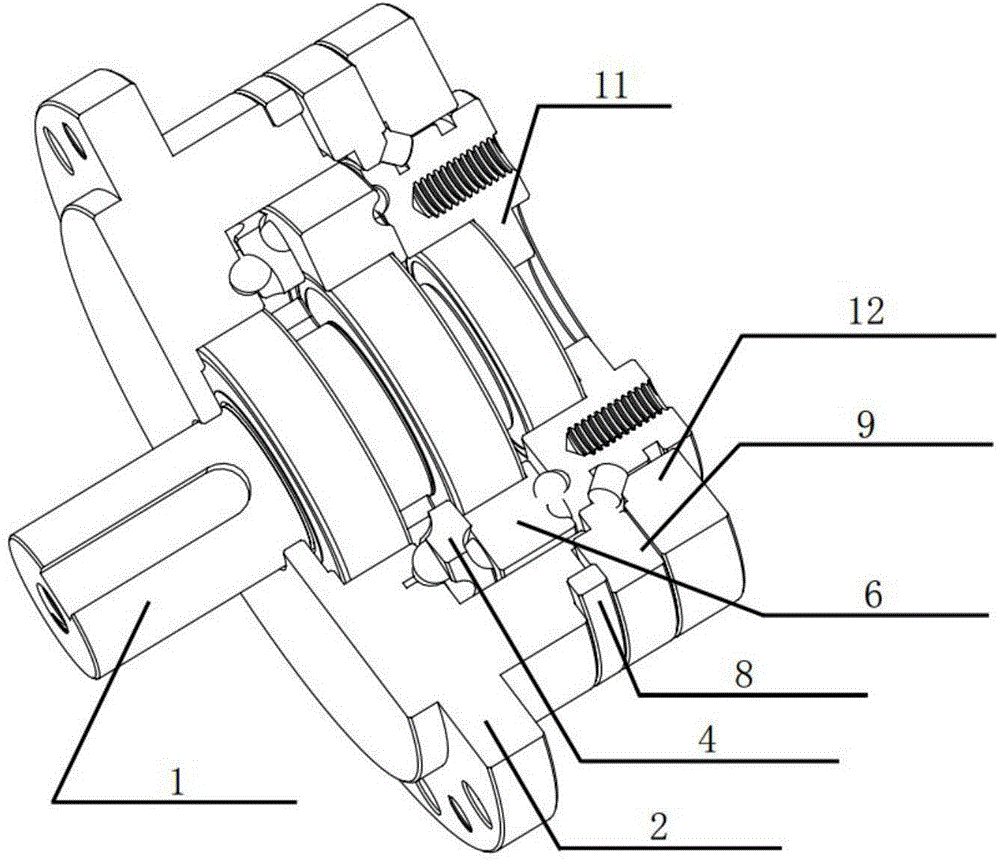

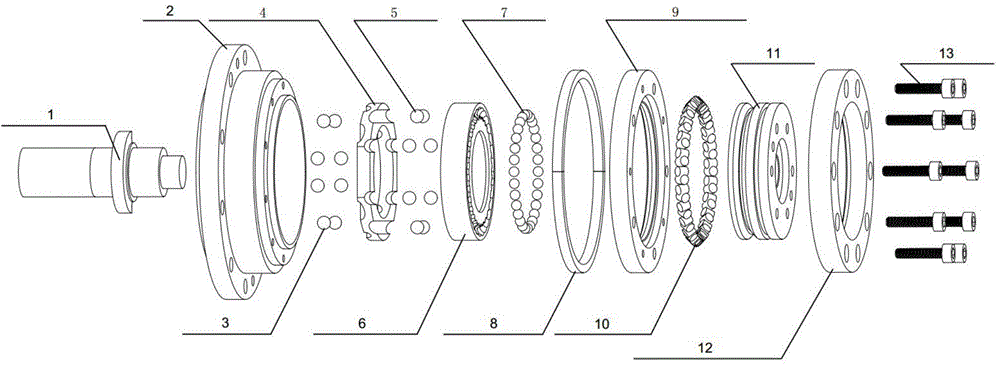

Crosshead shoes driving reducer for multi-joint robot

ActiveCN104964011ACompact structureReduce noiseGearing detailsFriction gearingsMechanical wearReducer

The invention relates to a crosshead shoes driving reducer for a multi-joint robot. The crosshead shoe driving reducer for the multi-joint robot comprises input shafts, output shafts, reducer bodies, crosshead shoes, transmission balls, track controllers and drive balls. The input shafts, the crosshead shoes, the track controllers and the output shaft are installed in the reducer bodies. Transmission tracks used for the installation of the transmission balls are arranged in the crosshead shoes. The transmission balls move in the transmission tracks to convey the movement of the input shafts to the track controllers. Moving track used for the installation of the drive balls are arranged on the lower surfaces of the track controllers. The track controllers adjust the output of the output shafts through the drive balls. According to the crosshead shoe driving reducer for the multi-joint robot, automatic adjustment for complete consistency of movement and eccentric magnitude of an eccentric shaft is achieved, the tracks of the transmission balls and the tracks of the track controllers of the reducer are completely consistent, the output of the reducer is stable, and the mechanical wear rate is low.

Owner:中正数据技术有限公司

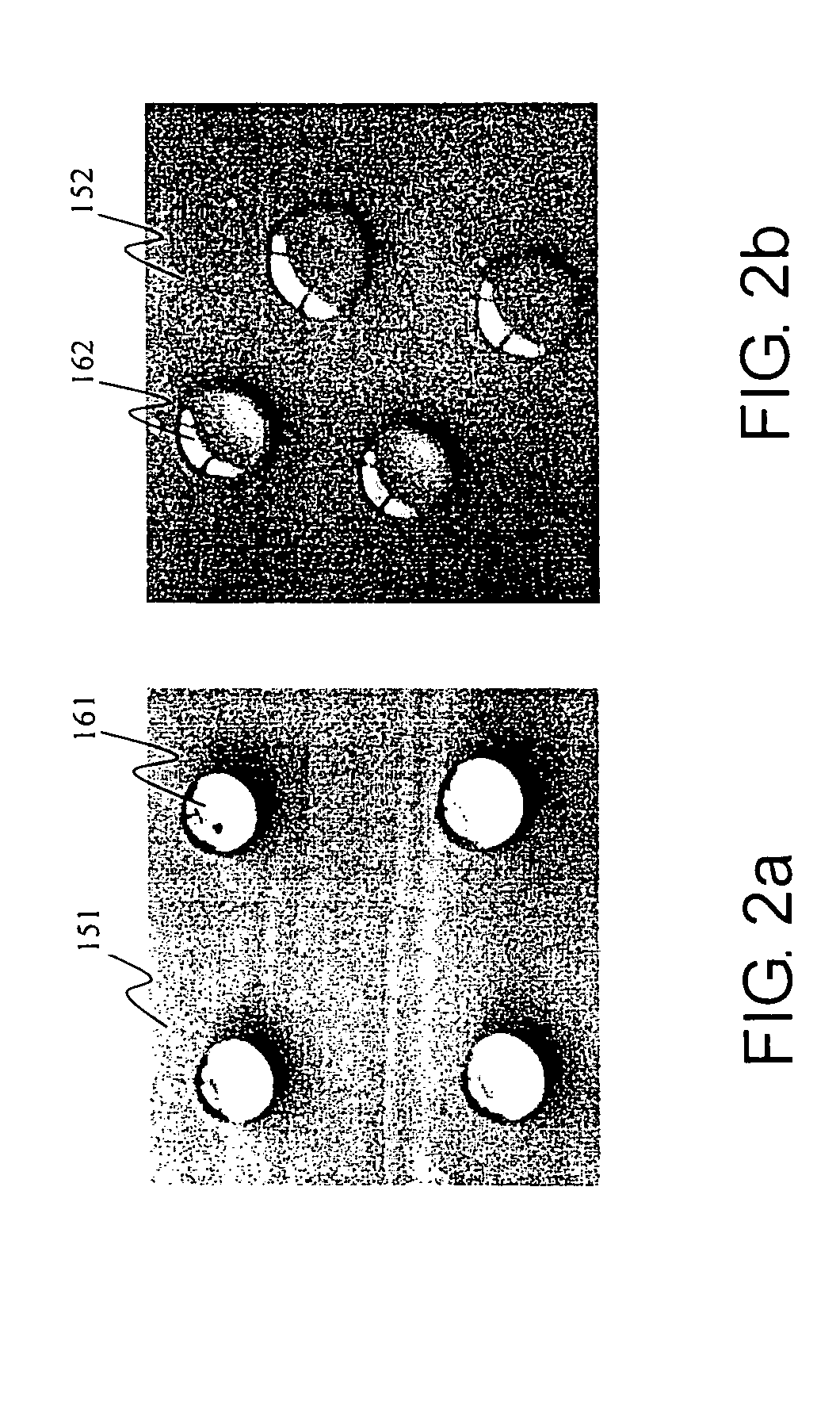

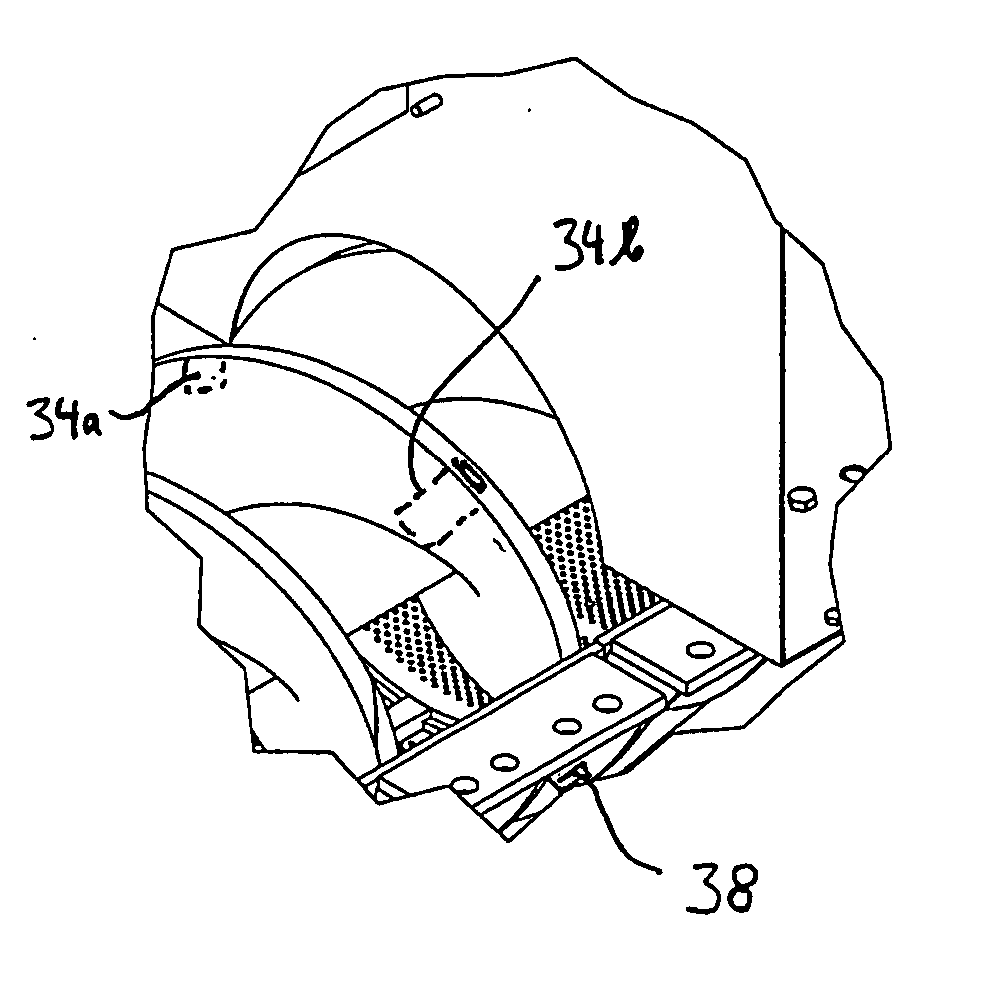

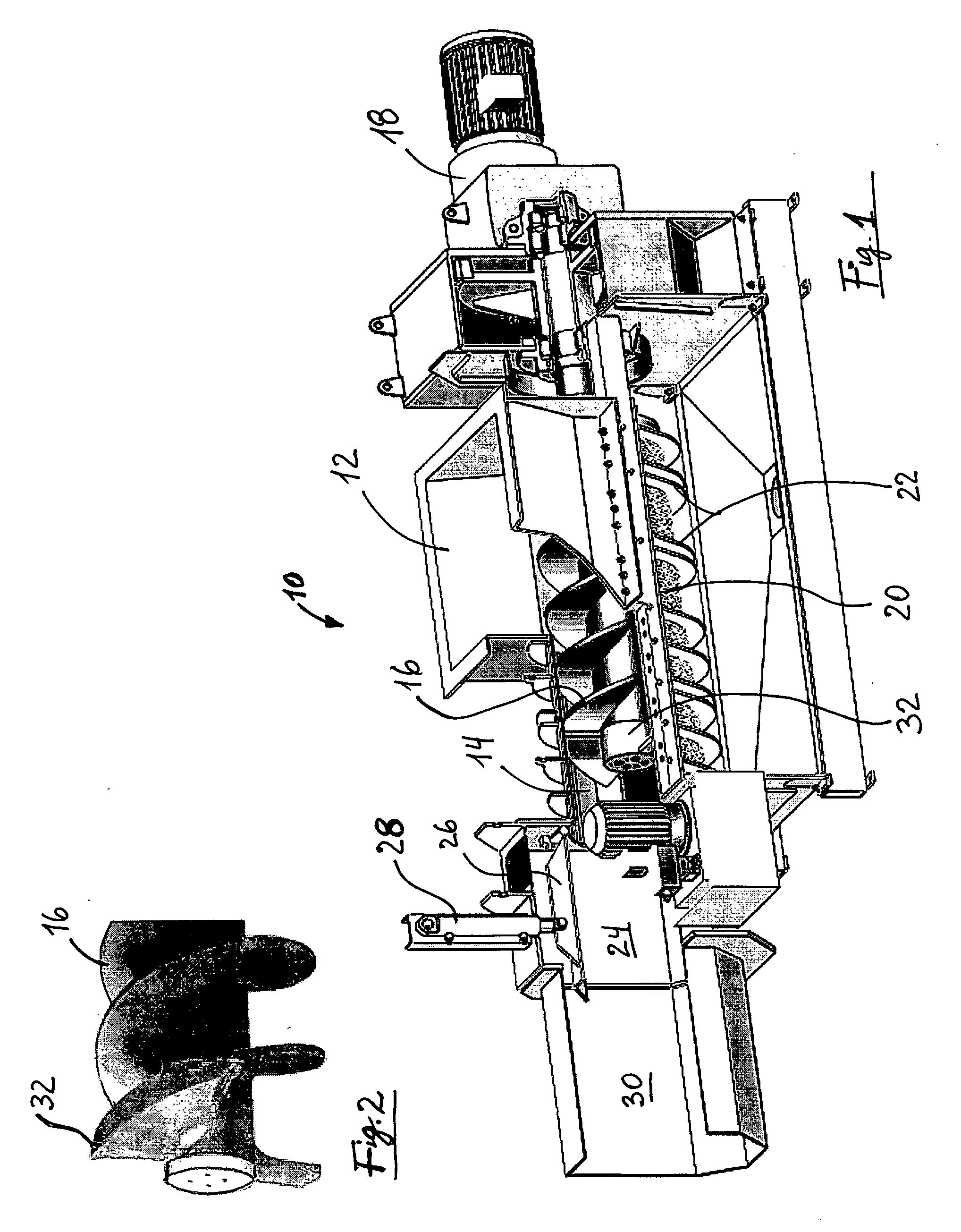

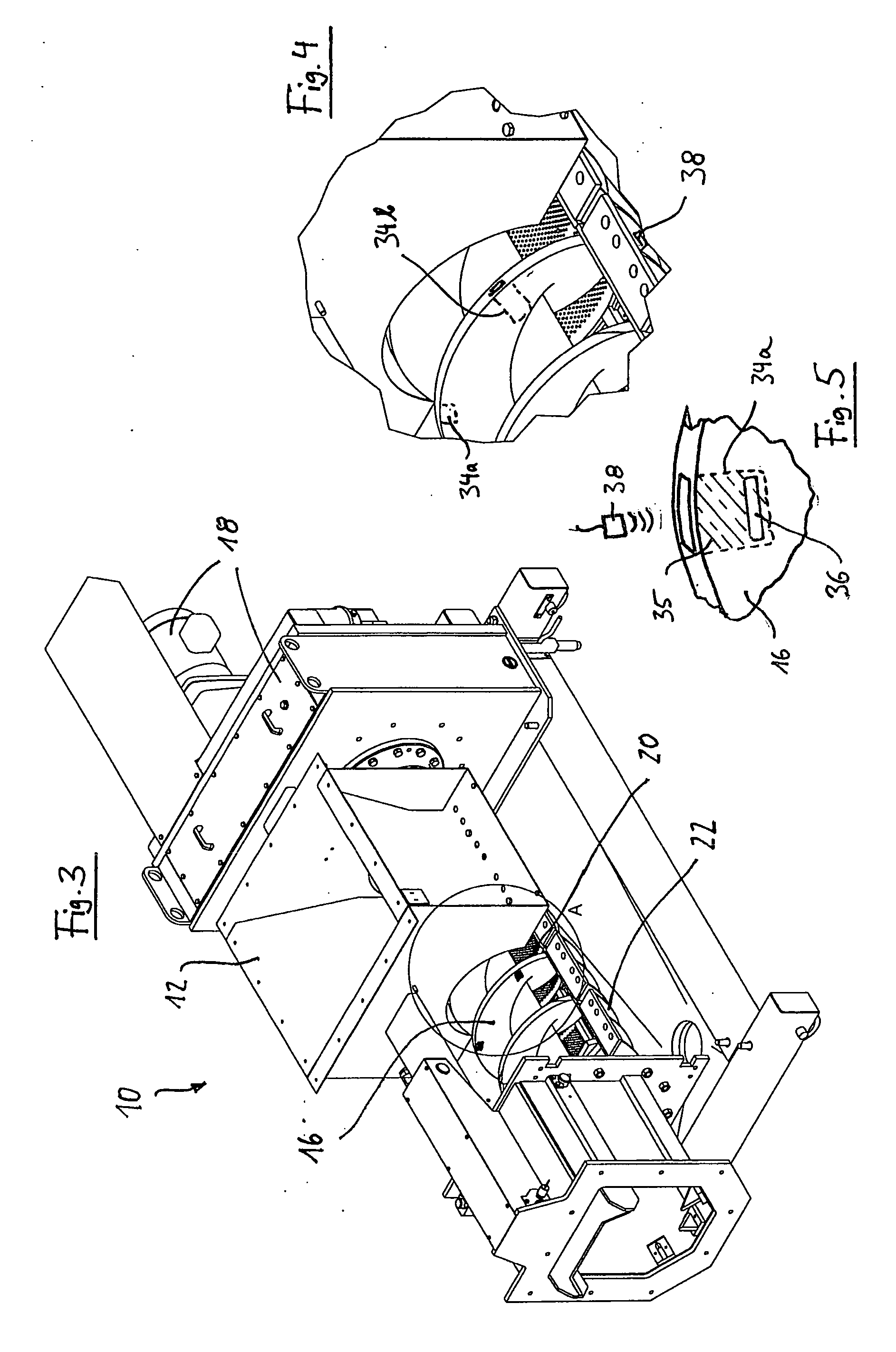

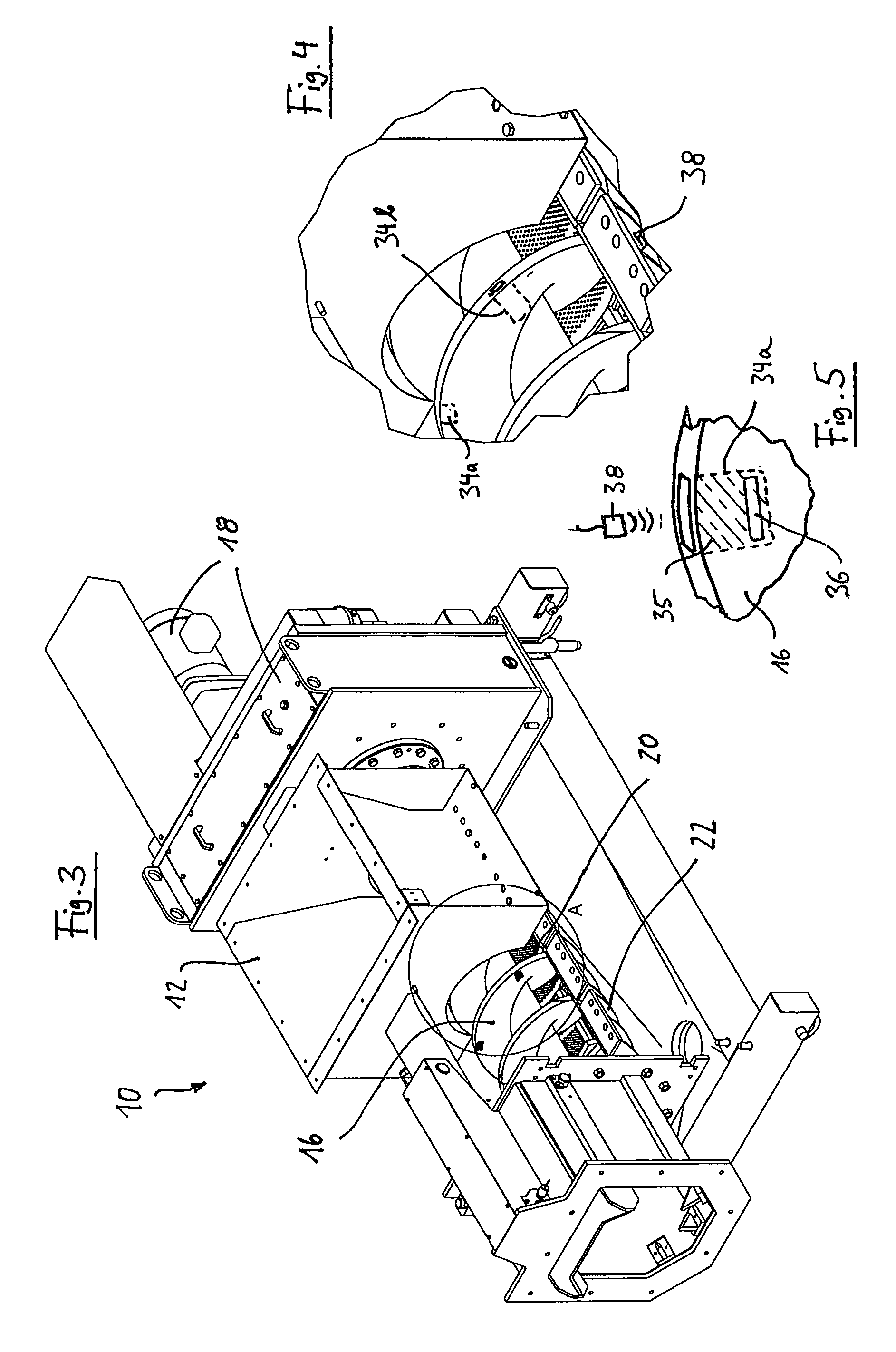

Wear detection by transponder destruction

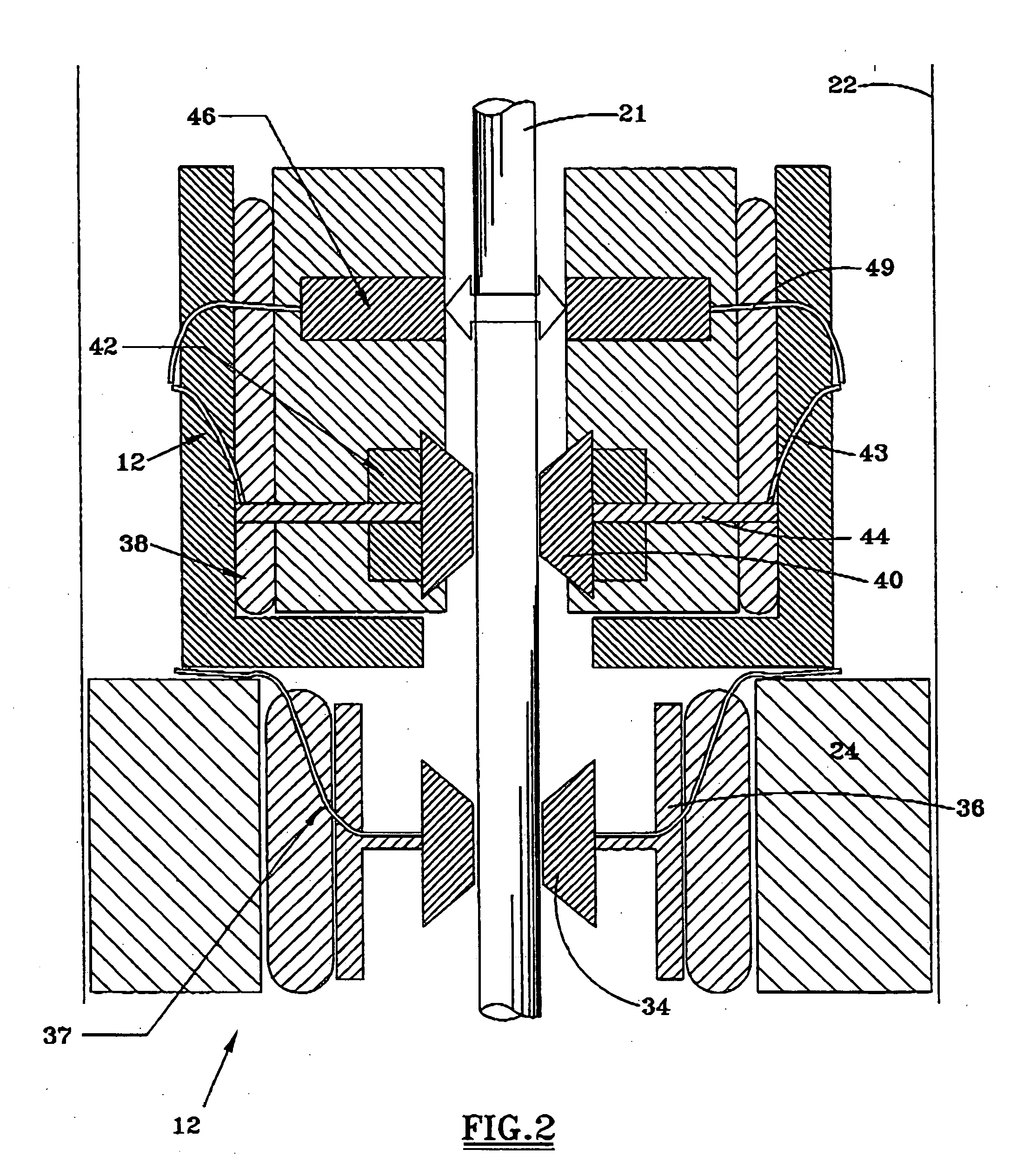

InactiveUS20060226984A1Improve wear resistanceParticular wear-resistance or hardnessMeasurement devicesControl devices for conveyorsMachine partsMechanical wear

The invention relates to a system and a method for the detection of the wear state of machine parts which are subject to mechanical wear, by means of an electronic transmitting / receiving device (38) and at least one transponder device (36), which is embedded in the machine part (16) and sends back an acknowledgement signal in response to a transmitted signal which is transmitted by the transmitting / receiving device (38), in which case the reaching of a predetermined wear value can be indicated by the destruction of the transponder device (36) and by the lack of the acknowledgement signal associated with this. The invention is based on the discovery that the arrangement of a transponder device at a specific position which is a measure of a predetermined wear state means that the operational readiness of the transponder device, on the one hand, is indicated in advance by its signal return, and the reaching of the predetermined wear value is indicated by its destruction.

Owner:MERI ENTSORGUNGSTECHN FUR DIE PAPIERIND

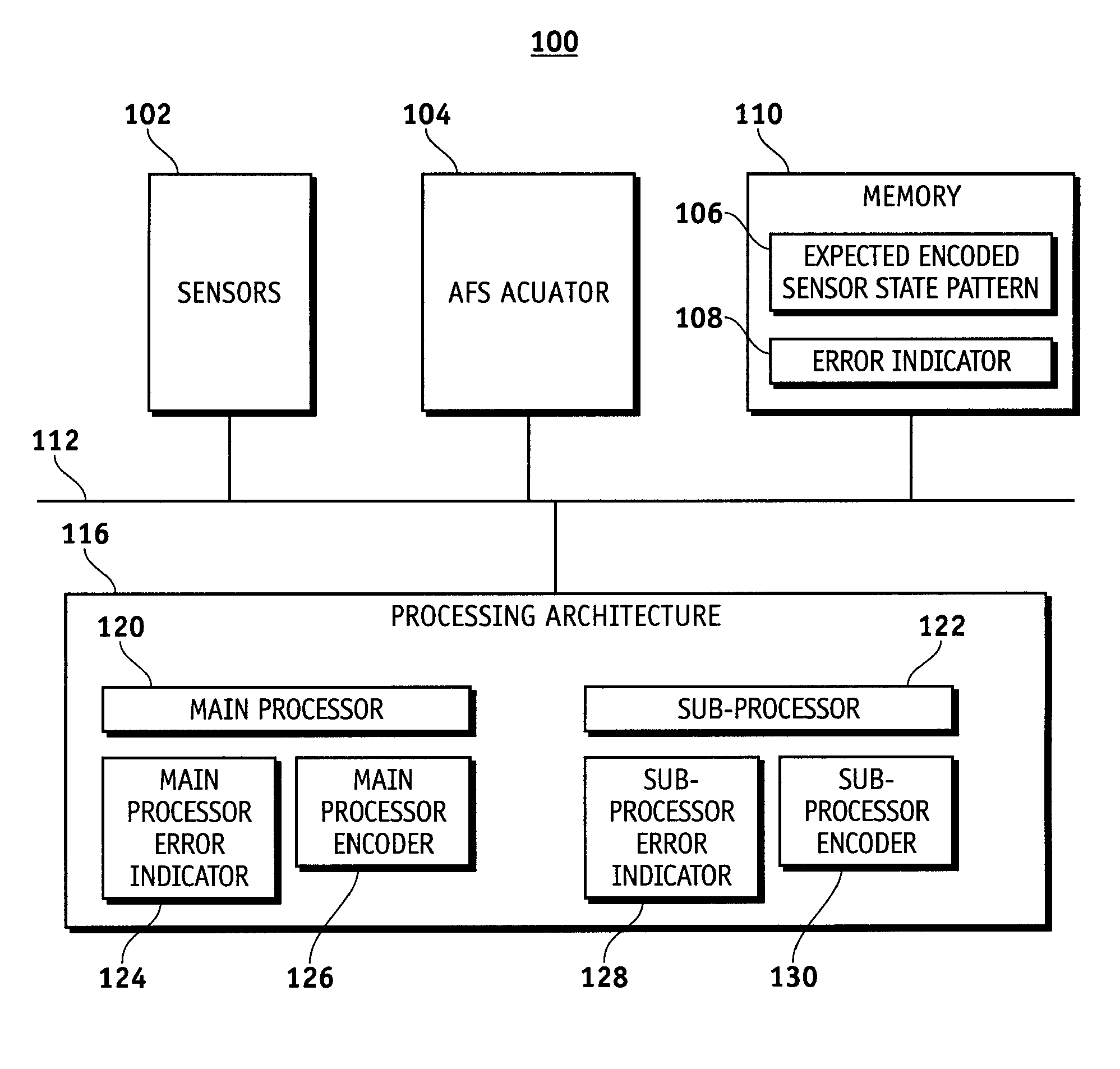

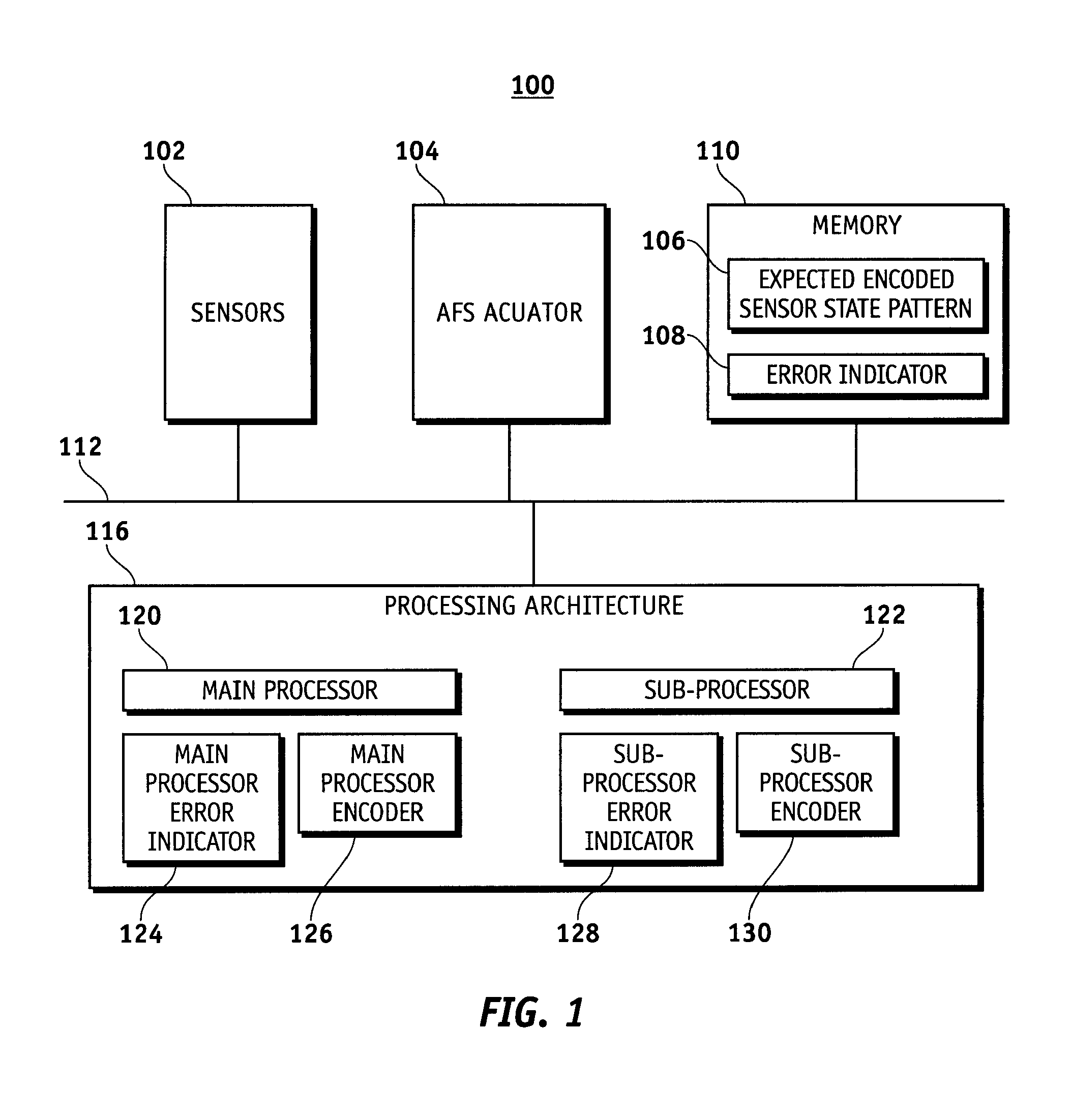

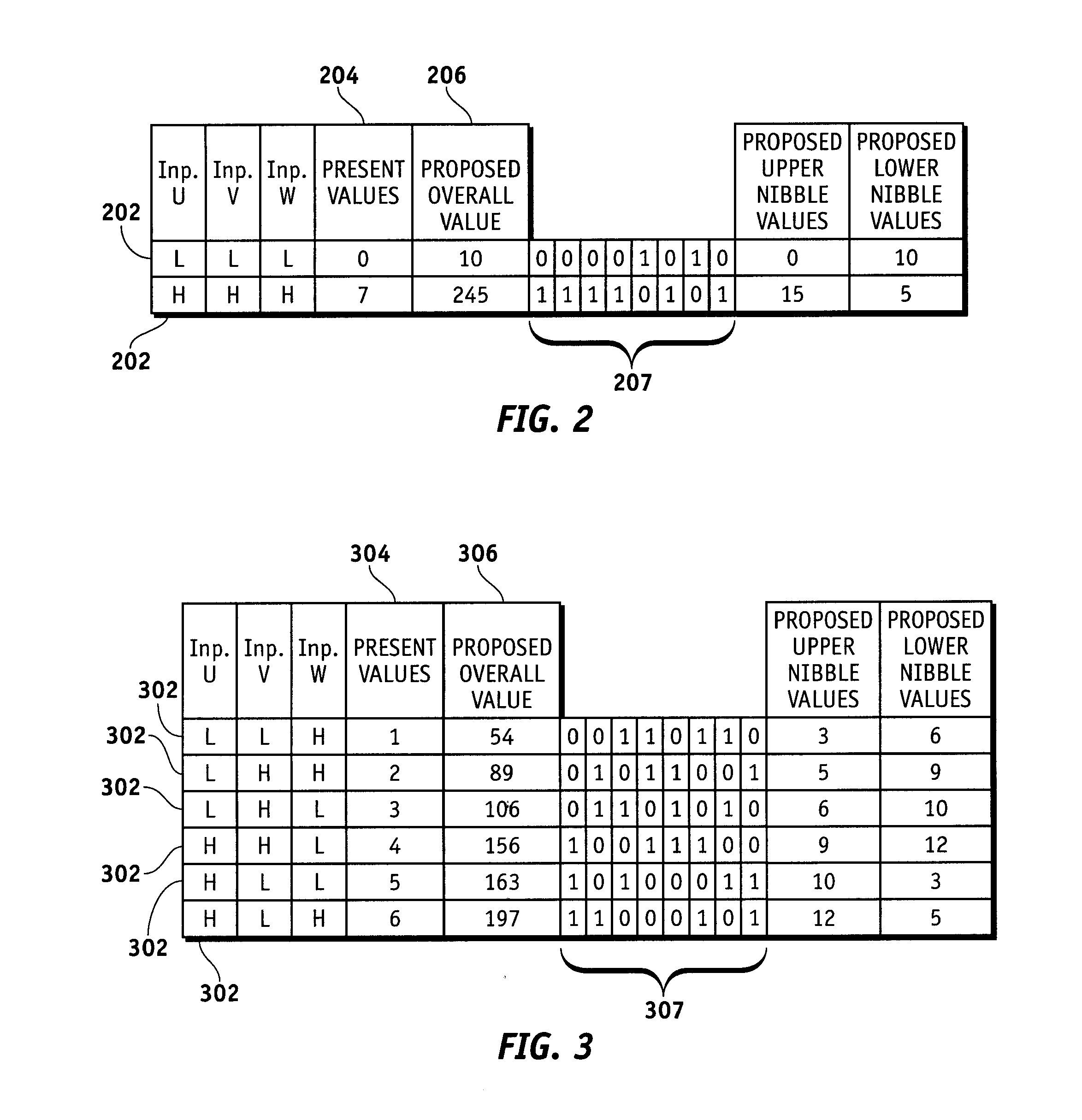

Mechanical and electrical locking coordination security strategy for an active front steer system

InactiveUS20080065294A1Reduce errorsDigital data processing detailsSteering initiationsElectricityControl system

A system as described herein relates generally to automotive active front steering control systems having a main processor and a redundant sub-processor. The system provides a way of controlling the electrical and mechanical locking of an actuator motor in a variable gear ratio active front steering system. The method enables the sub-processor to electrically lock the active front steer actuator motor via the main processor to reduce mechanical wear or damage to the variable gear ratio system if the main processor is unable to electrically lock the actuator motor before it mechanically locks the actuator motor. The system also provides an error detecting technique that is robust to false failures and allows the active front steering system to safely transition into a fail safe mode if an error occurs.

Owner:GM GLOBAL TECH OPERATIONS LLC

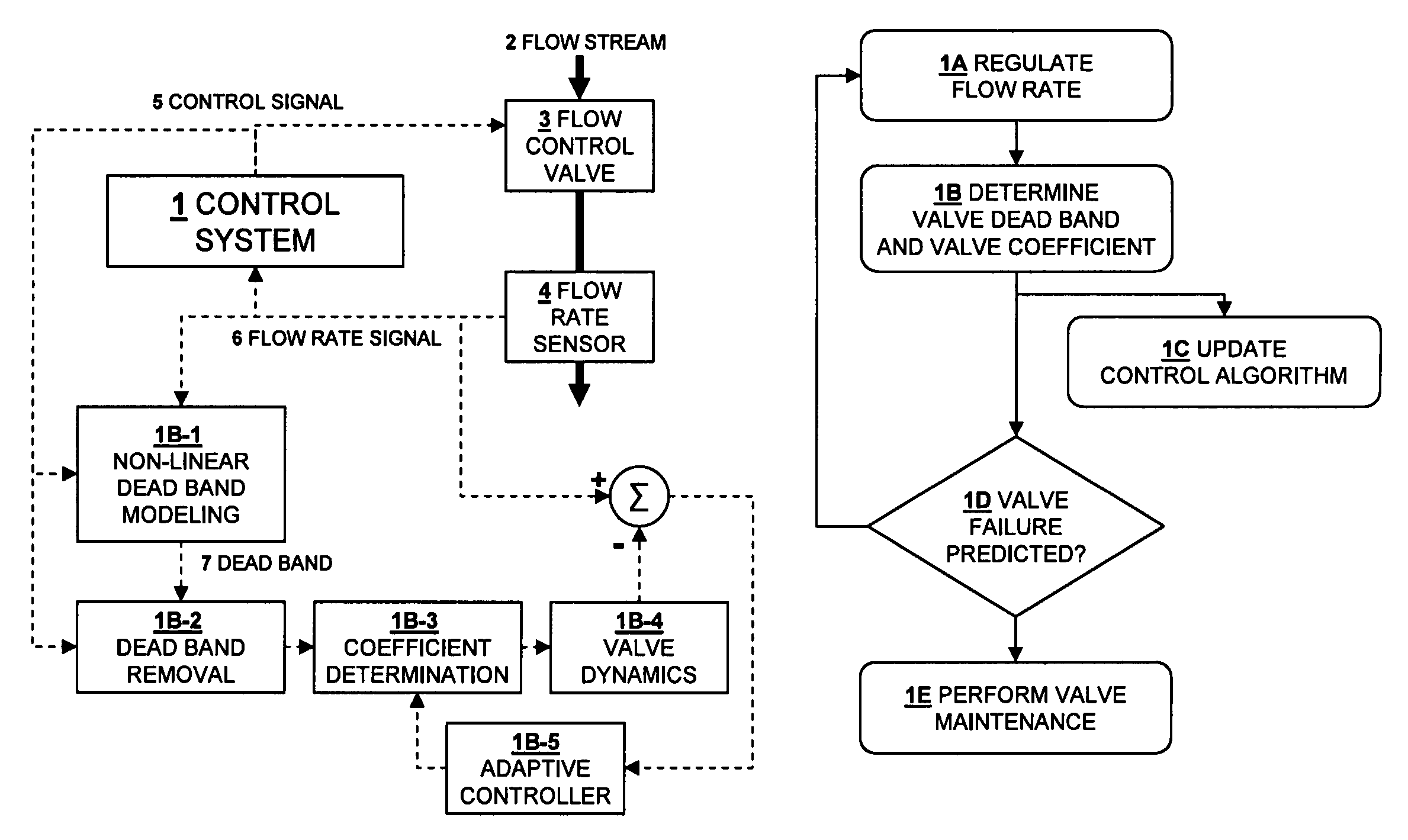

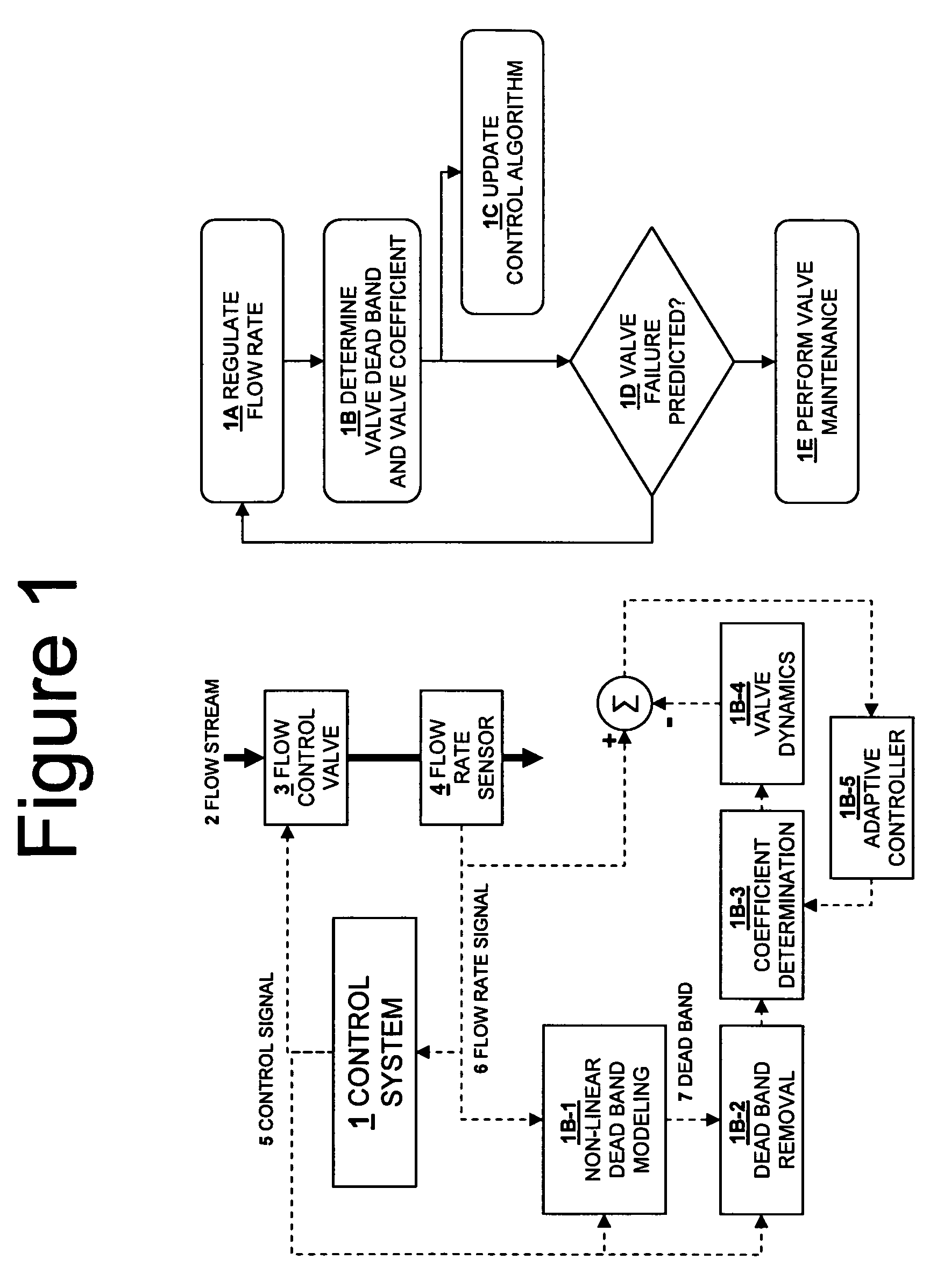

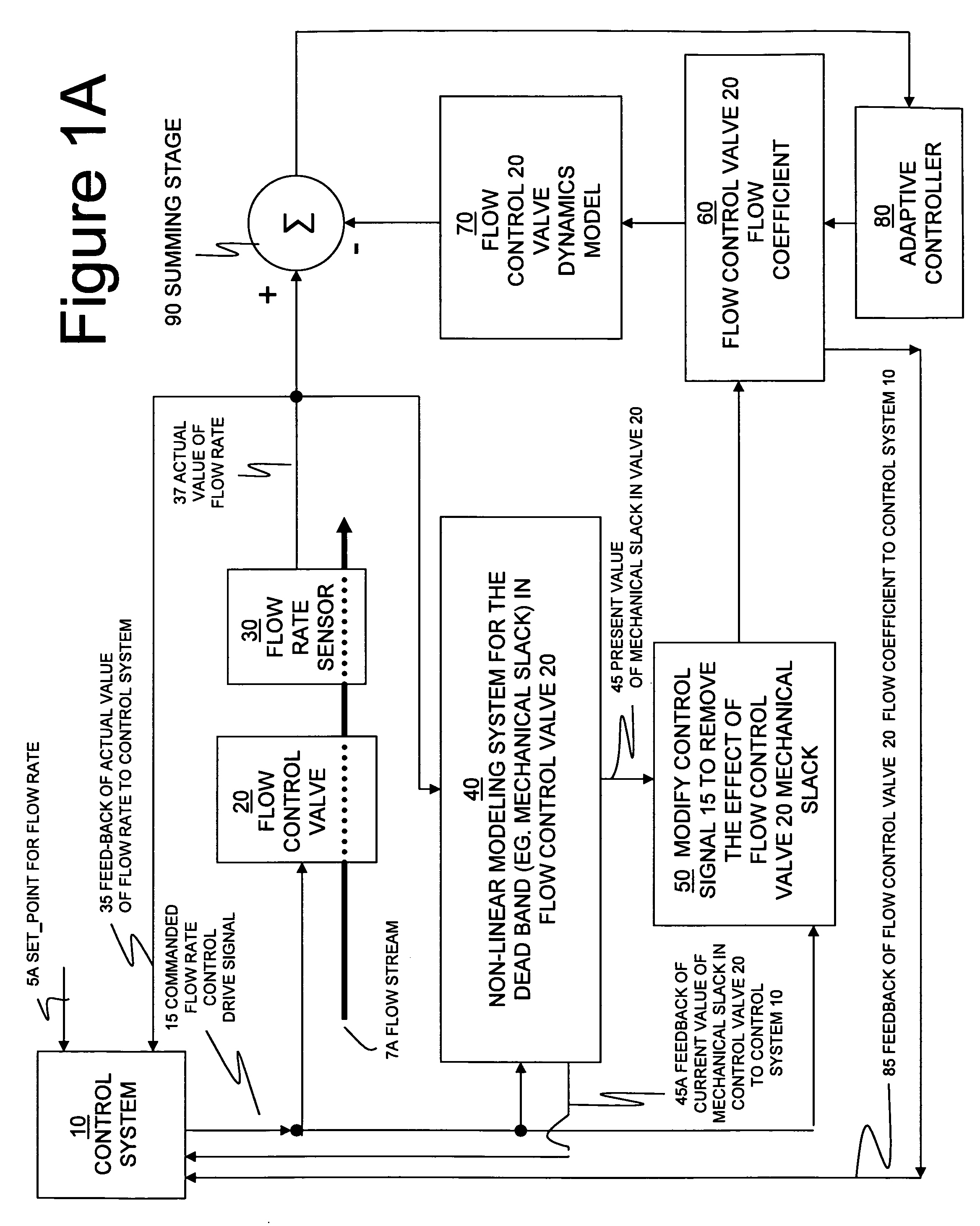

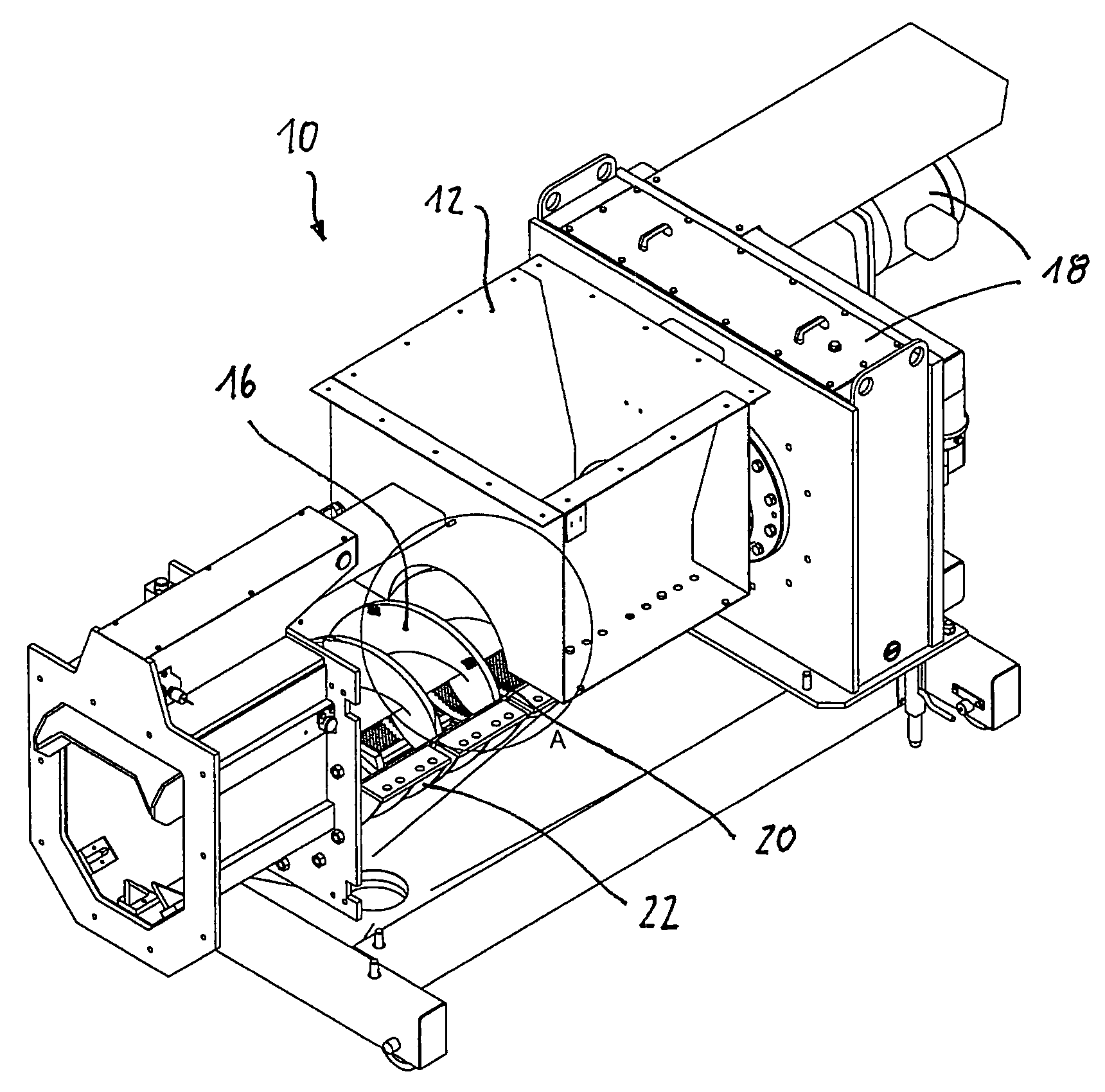

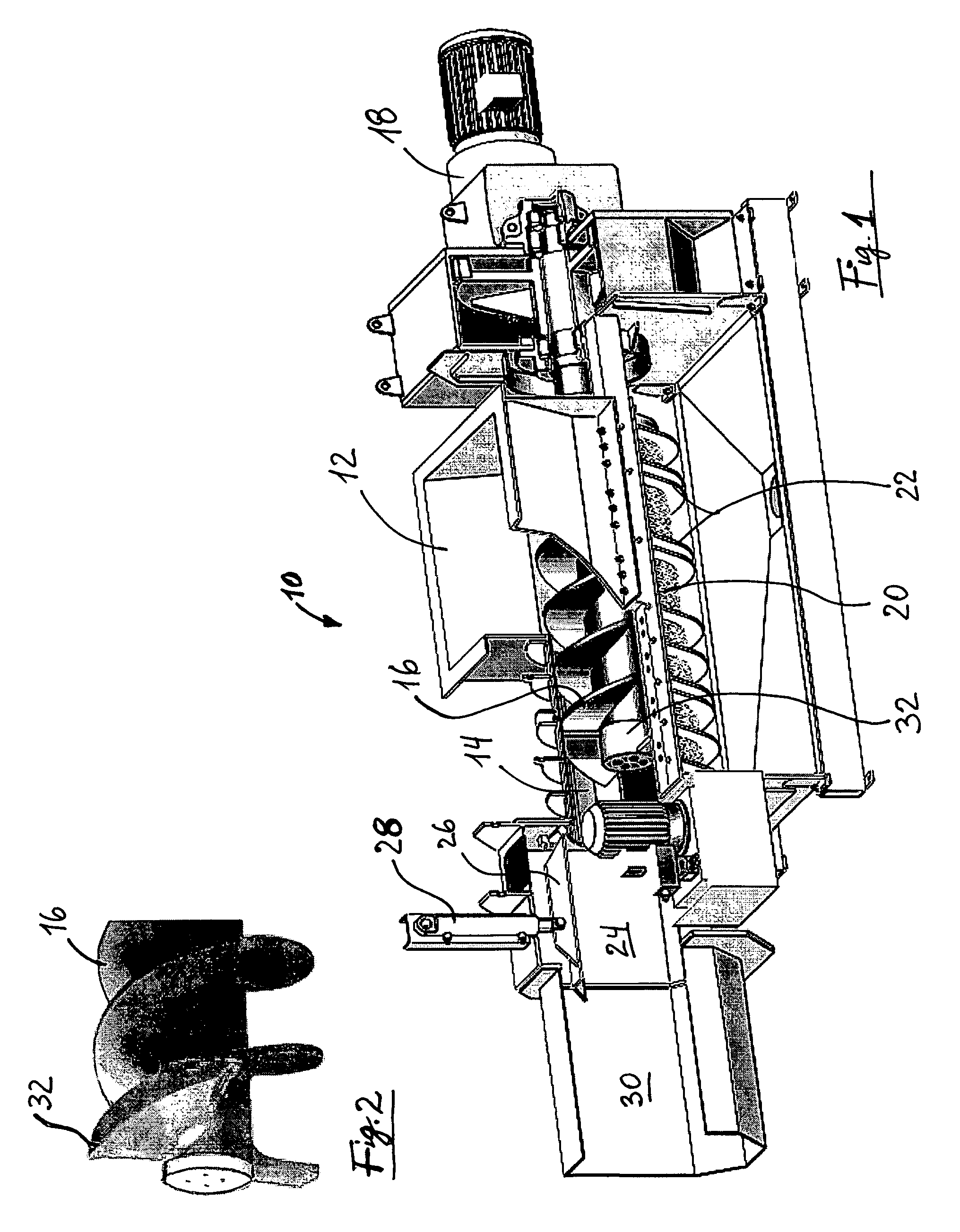

Methods for managing flow control valves in process systems

InactiveUS20080183336A1Amount of signal is lostLose amountTesting/monitoring control systemsRatio controlProcess systemsNon linear dynamic

Methods for managing the operational condition of flow control valves in process systems. As a control valve experiences mechanical wear during operation, the physical changes to the valve can alter its dead band and flow coefficient. A non-linear dynamic model determines the present dead band by modeling the relationship between the actual flow through the valve and the commanded drive signal to the valve. The present valve flow coefficient can be determined by removing the dead band from the drive signal and using that modified signal in a flow rate model for the valve to adaptively find the flow coefficient value which matches the predicted flow from the flow rate model to the present measured flow from a flow rate sensor. The present dead band and flow coefficient can be used to update valve control algorithms and to make valve maintenance decisions.

Owner:HALLIBURTON ENERGY SERVICES INC

Wear detection by transponder destruction

InactiveUS7248154B2Improve wear resistanceParticular wear-resistance or hardnessMeasurement devicesControl devices for conveyorsMachine partsMechanical wear

The invention relates to a system and a method for the detection of the wear state of machine parts which are subject to mechanical wear, by means of an electronic transmitting / receiving device (38) and at least one transponder device (36), which is embedded in the machine part (16) and sends back an acknowledgement signal in response to a transmitted signal which is transmitted by the transmitting / receiving device (38), in which case the reaching of a predetermined wear value can be indicated by the destruction of the transponder device (36) and by the lack of the acknowledgement signal associated with this. The invention is based on the discovery that the arrangement of a transponder device at a specific position which is a measure of a predetermined wear state means that the operational readiness of the transponder device, on the one hand, is indicated in advance by its signal return, and the reaching of the predetermined wear value is indicated by its destruction.

Owner:MERI ENTSORGUNGSTECHN FUR DIE PAPIERIND

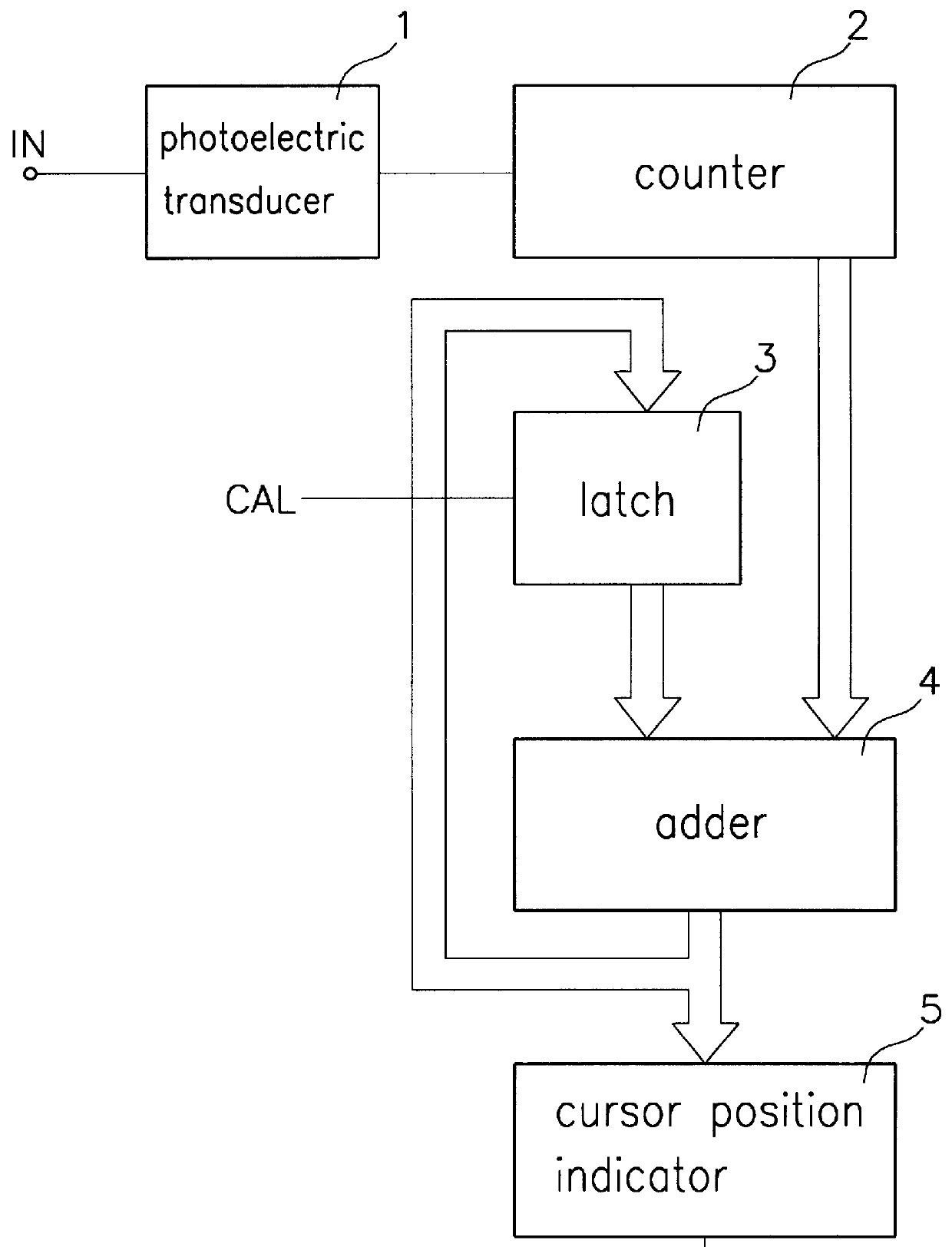

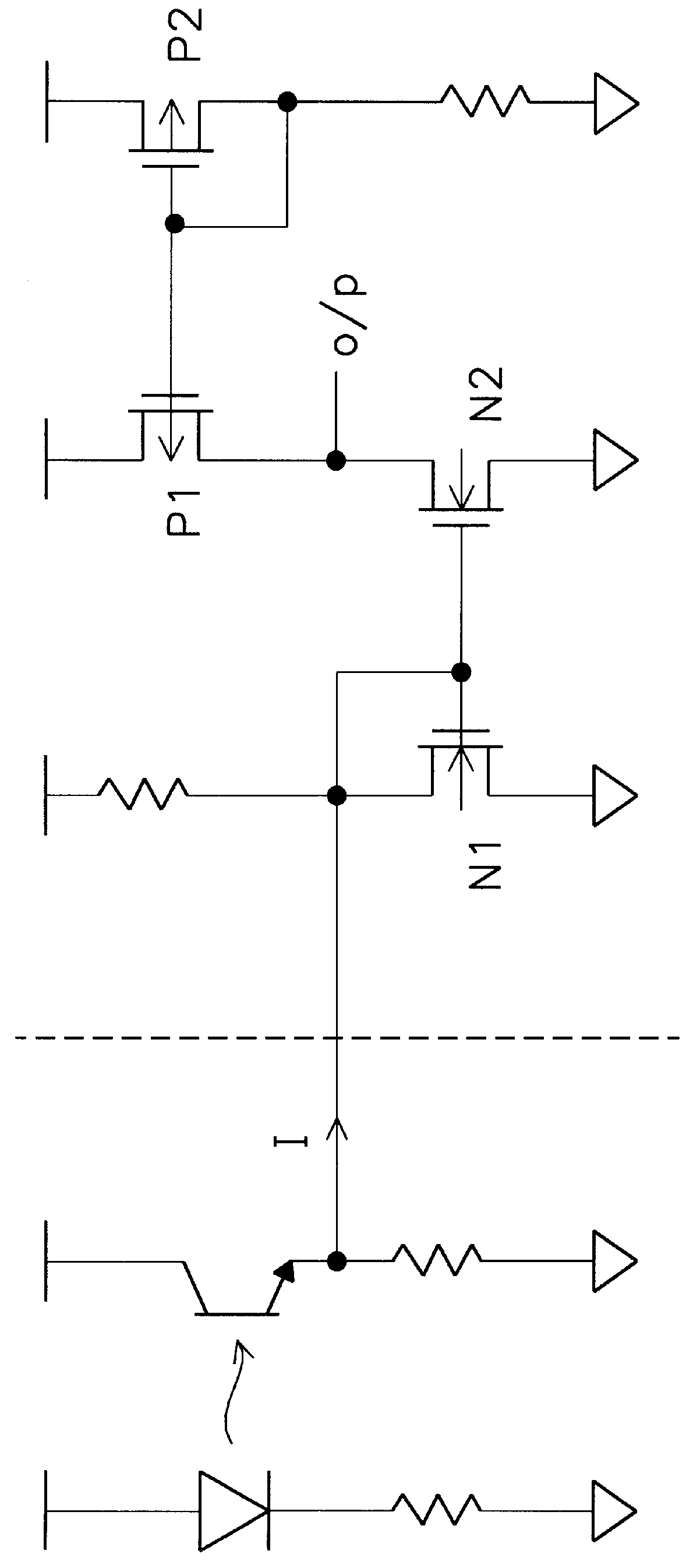

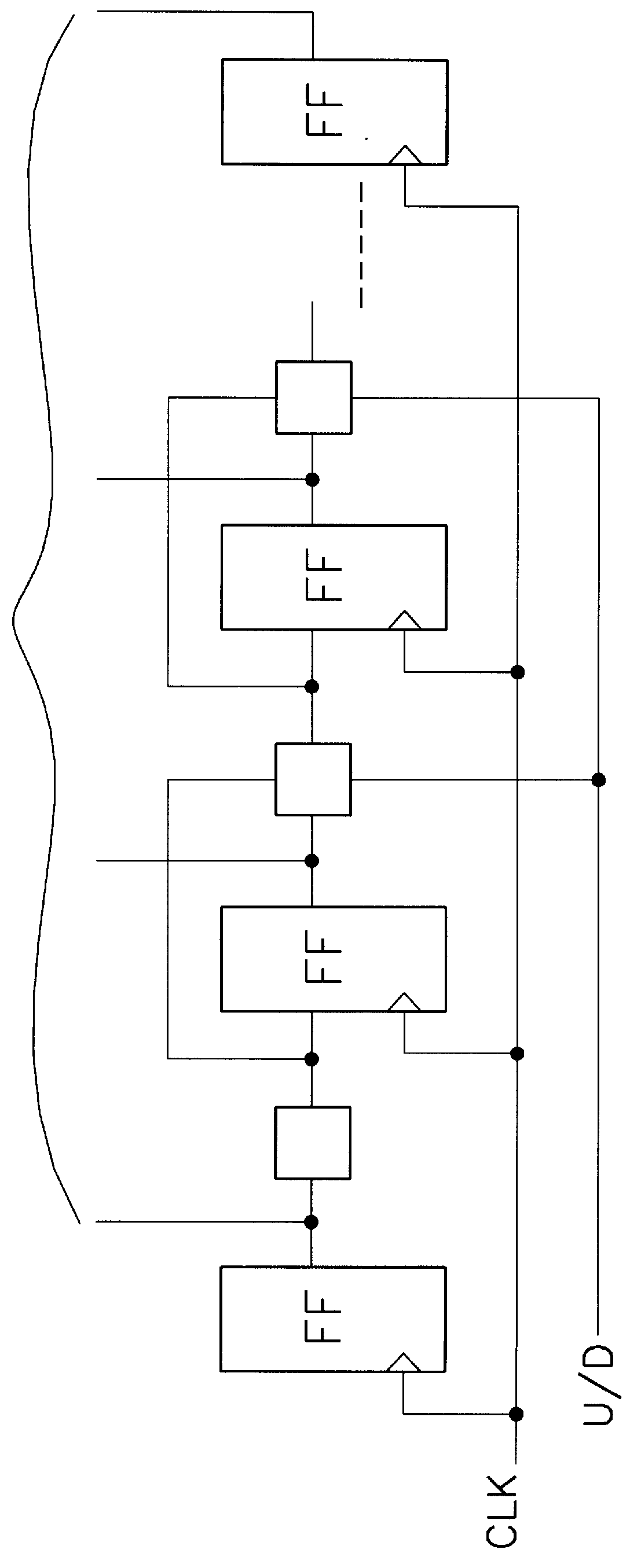

Joystick control device having cursor correcting function

InactiveUS6034669AEliminate bad effectsEasy to correctManual control with multiple controlled membersCathode-ray tube indicatorsJoystickMechanical wear

A joystick control device having cursor correcting function, in which the conventional adjustable resistor is replaced by a photoelectric element for detecting the movement of the joystick, thereby eliminates the ill effects caused by mechanical attrition of resistor. Additionally, the parameter drifts caused by IC manufacturing processes are corrected using shift correction of joystick; therefore, every individual mass-produced IC shows similar good behavior.

Owner:REALTEK SEMICON CORP

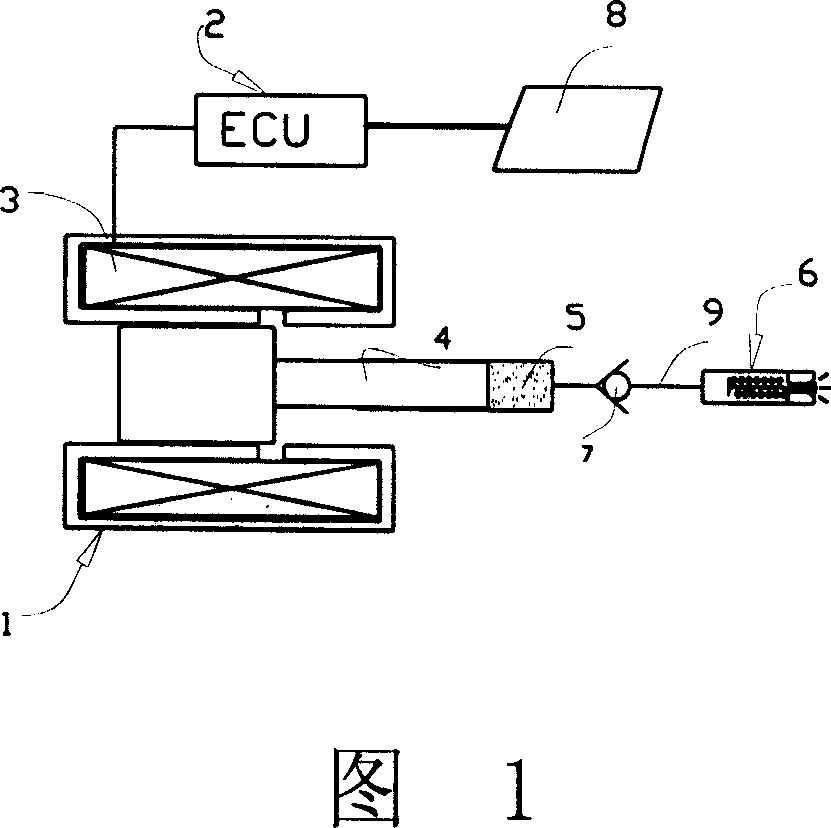

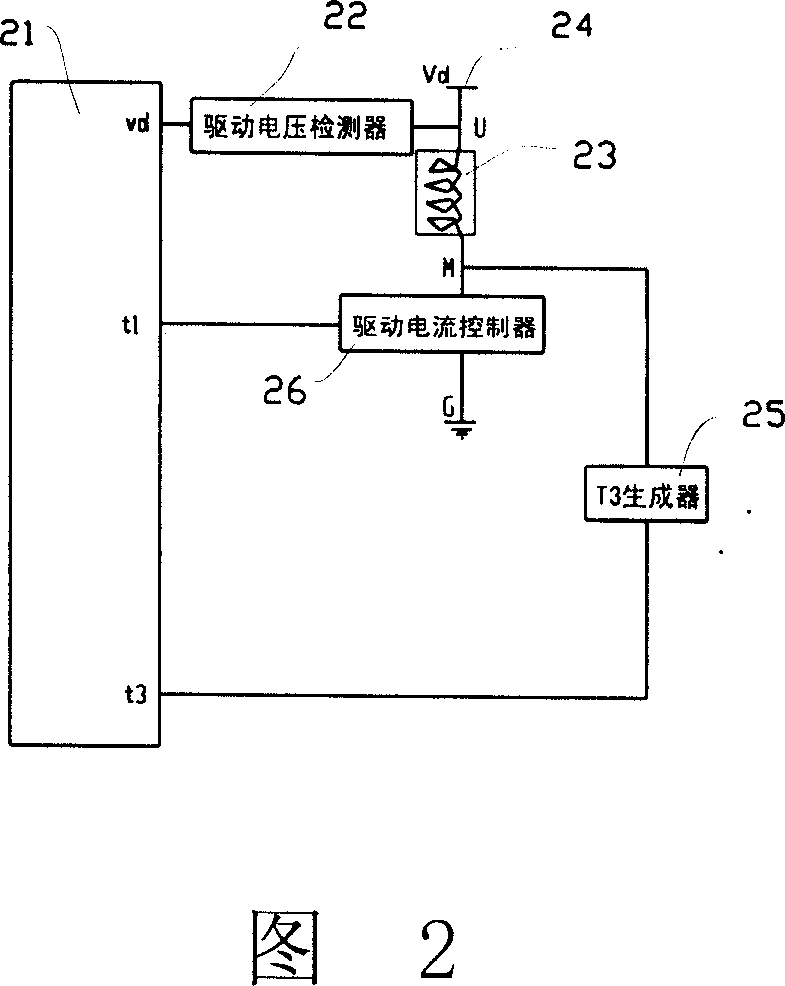

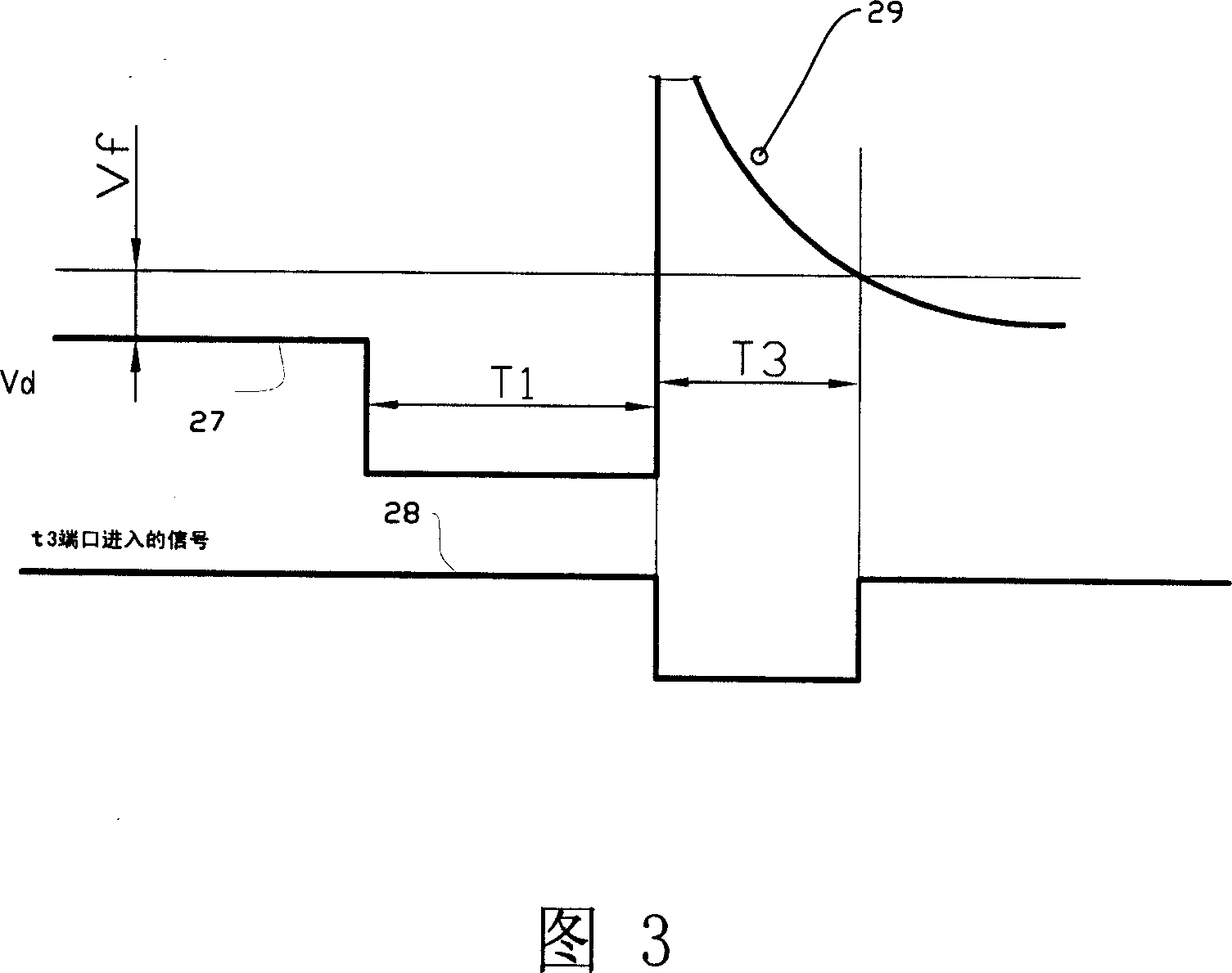

Electromagnetic fuel pump nozzle drive control method and its device

A drive control method and drive control device for an electromagnetism fuel pump spray nozzle, an aiming feedback signal is obtained by a plunger displacement signal, especially characteristic parameters of the residual voltage curve, based on the aiming feedback signal a driving pulse width is predicted, the aiming oil quantity reached by each oil injection is controlled by the predicted driving pulse width, thereby realizing close loop control for the electromagnetism fuel oil pump nozzle device to improve precision supplied for the engine fuel, and avoid and reduce change of jet flow caused by factors such as mechanical wear, change of backspring force, change of nozzle opening pressure, change of fuel channel resistance, change of nozzle flow coefficient, change of friction force brought by the change of liquid viscidity and fuel impurity, change of driving voltage, in the meanwhile, the invention can realize real time monitoring for the working of the electromagnetism fuel injection pump nozzle by the ECU unit, and perform abnormal condition and fault diagnosis.

Owner:塞尔福(厦门)工业有限公司

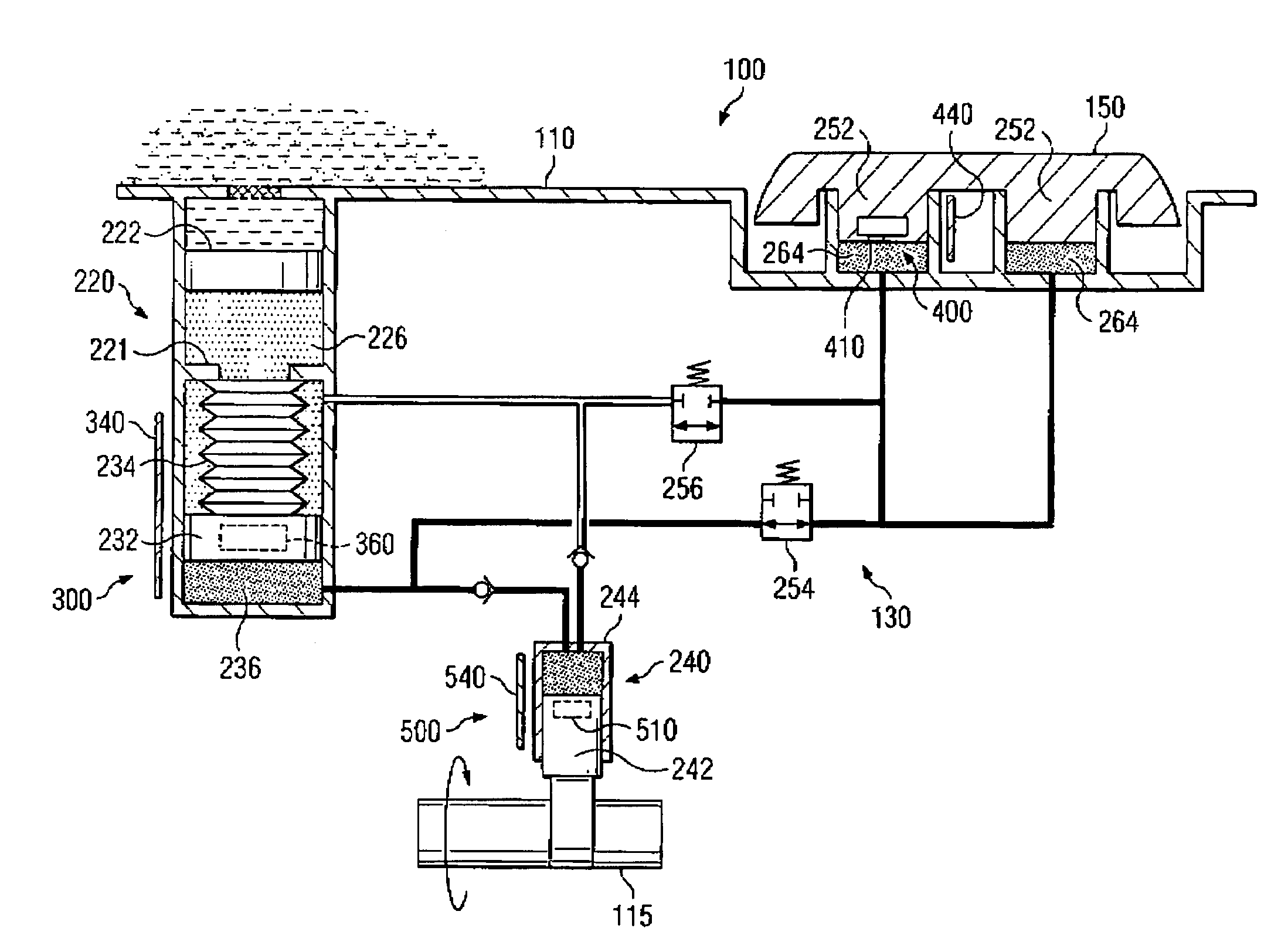

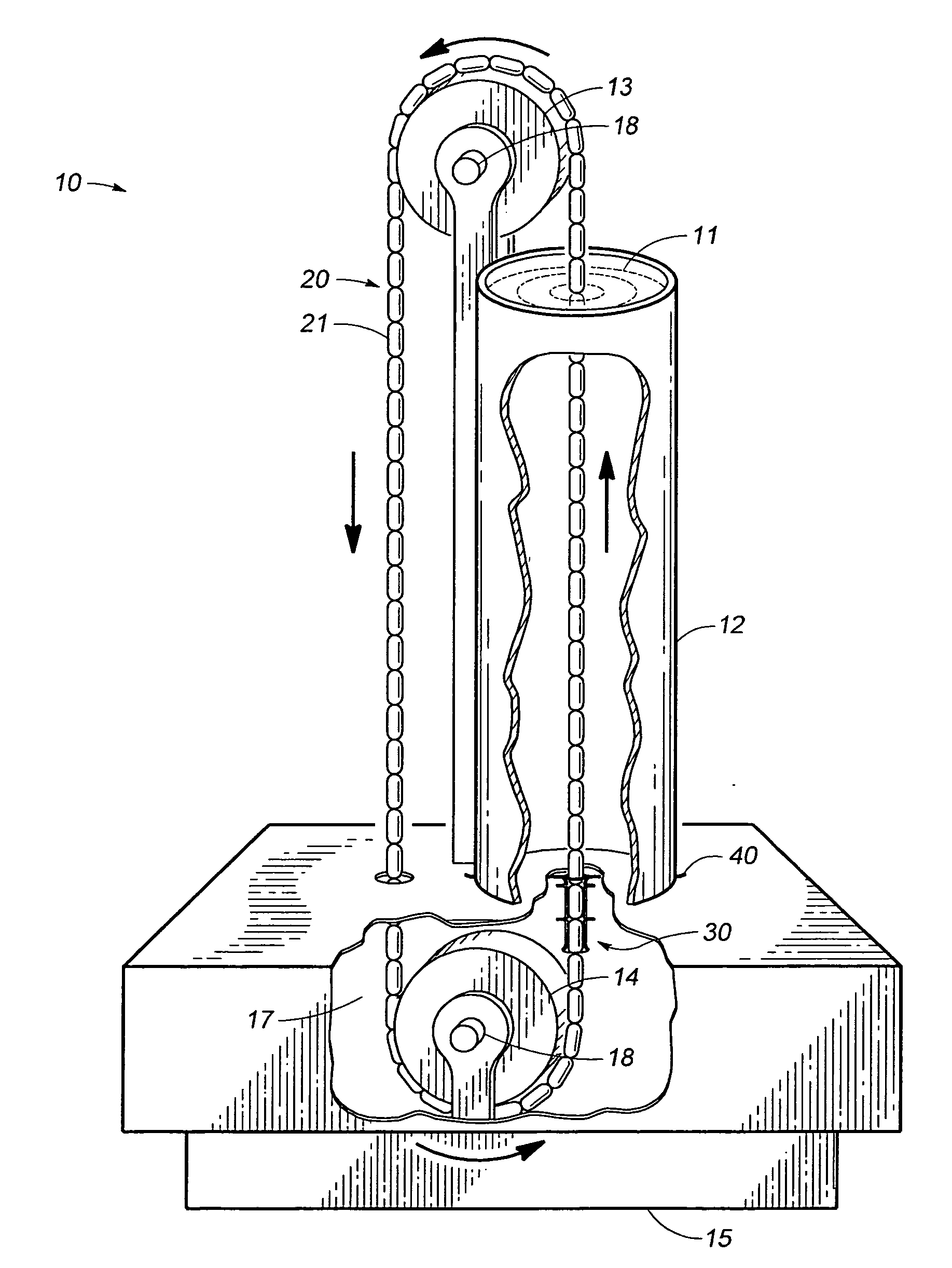

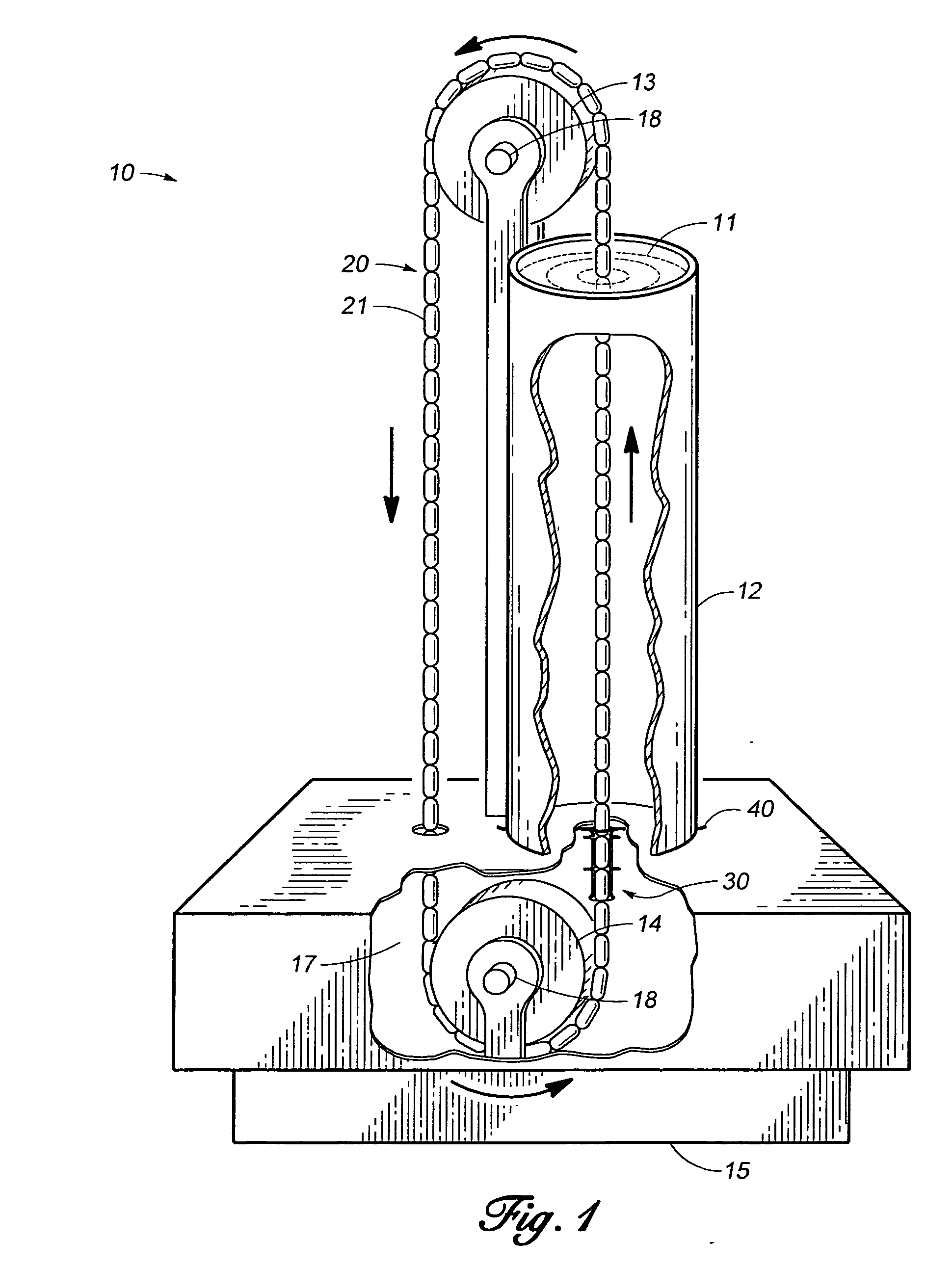

"Closed Loop" Economy of Motion Machine

InactiveUS20100223922A1Preventing working fluid lossIncrease power generationHydro energy generationMachines/enginesDifferential pressureMechanical wear

A means and apparatus for fluid containment providing for closed loop operation of an apparatus within a column of liquid. The apparatus extracts power from a buoyant source within the contained column of liquid and is comprised of an endless chain of movable buoyant objects, a means to convert the movement of the chain into useful work and a tank filled with a constant volume column of liquid. The buoyant objects comprising the chain sequentially enter the bottom of the liquid column through an airlock seal of the current invention, move up through the column and emerge at the surface. The emerging buoyant objects leave the tank and are directed to the tank bottom where each buoyant object repeats the cycle. As the chain of buoyant objects cycles through the displaced column of liquid, the volume of liquid remains constant, with one buoyant object of the chain entering the bottom of the liquid column as one is exiting at the top surface. The invention provides for closed loop operation of the apparatus and increased control fluid flow rates within the apparatus to addresses liquid leakage due to mechanical wear at seals and to provide a controlled method for removal of friction generated heat within the apparatus. Chambered sections within the apparatus create fluid flow restriction zones where differential pressure can be controlled to further reduce the force requirement for injecting each buoyant object (a.k.a. displacing element) into the bottom of the contained column of liquid.

Owner:MCGAHEE VINCENT DEPAUL

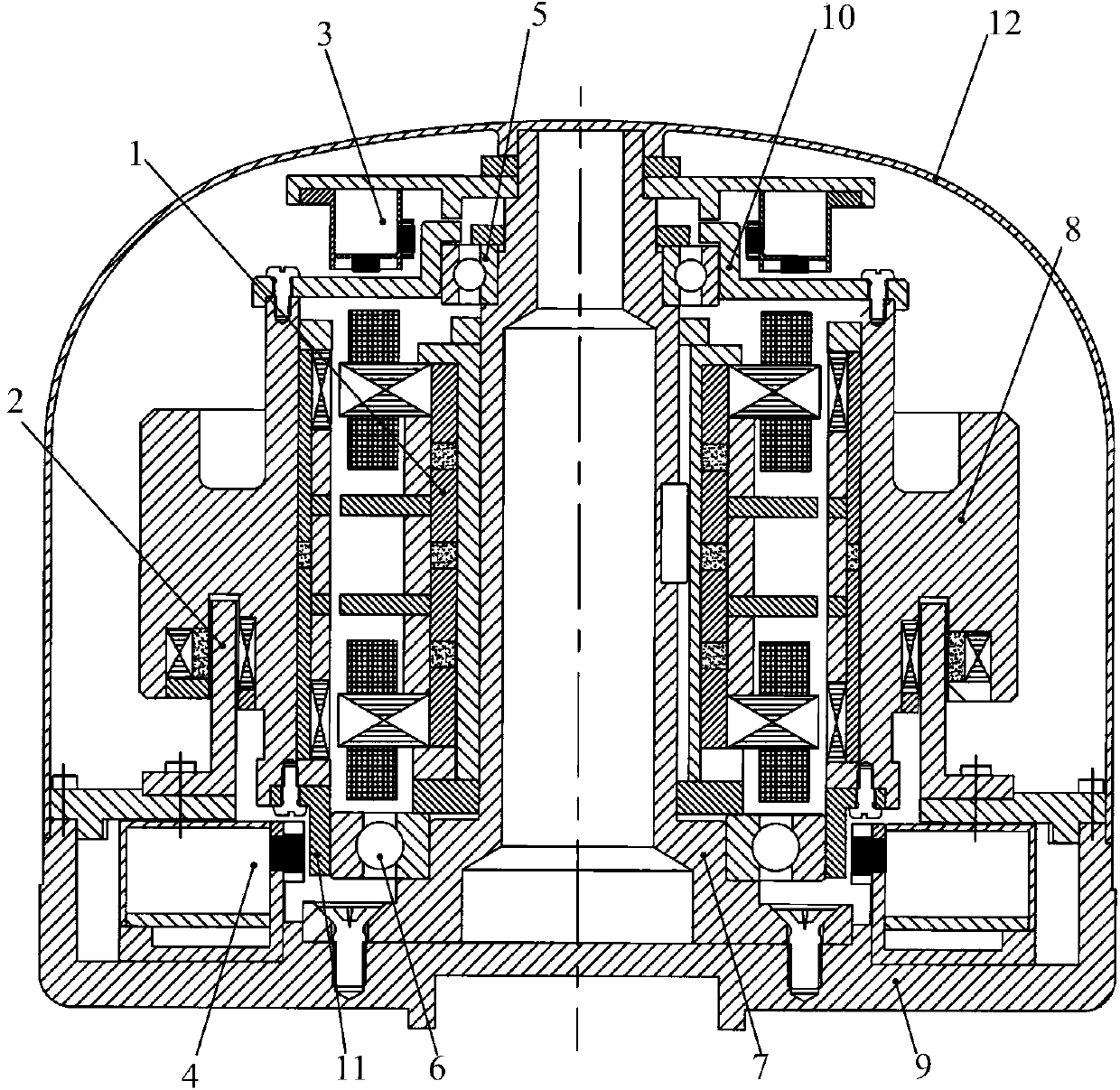

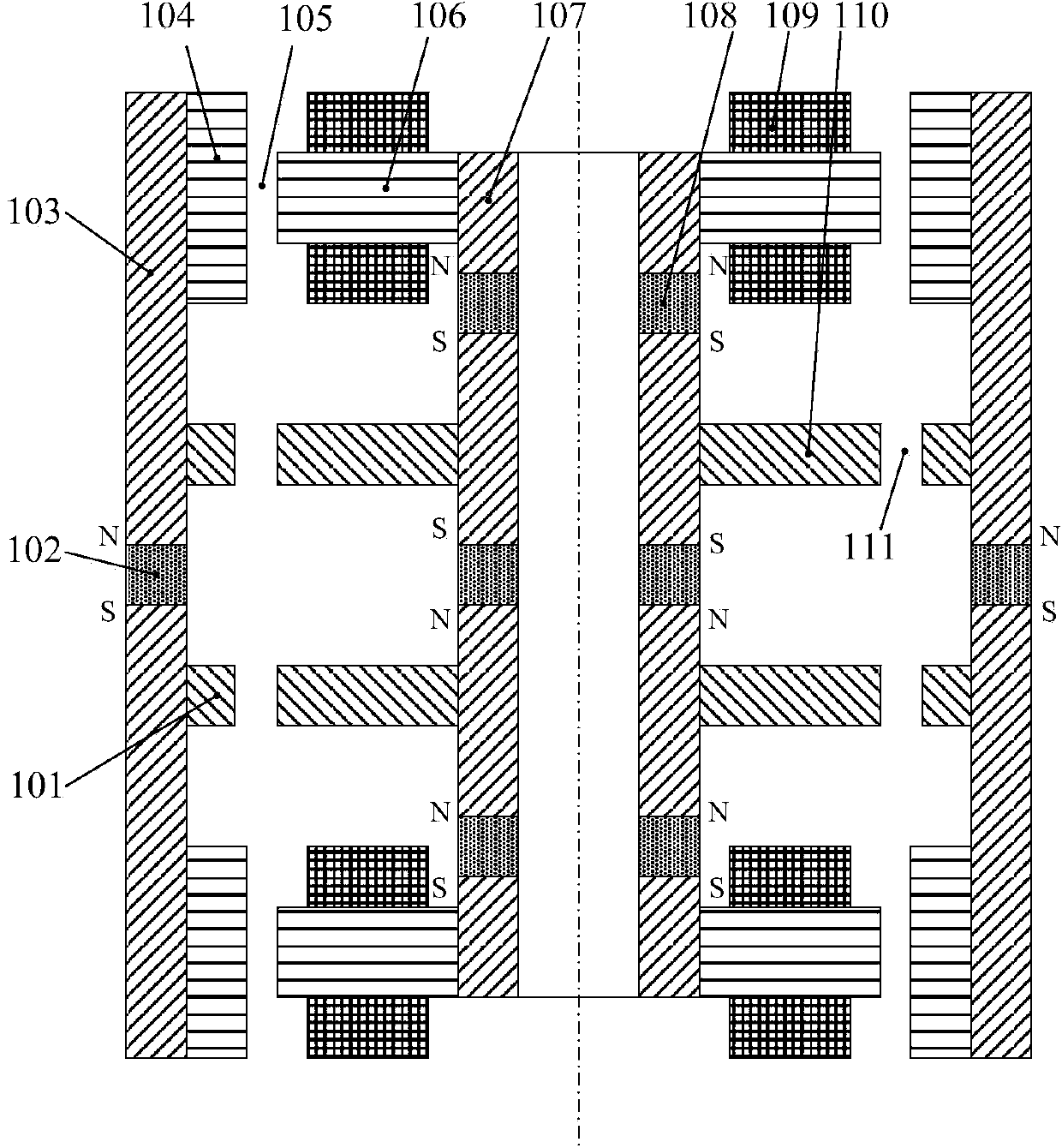

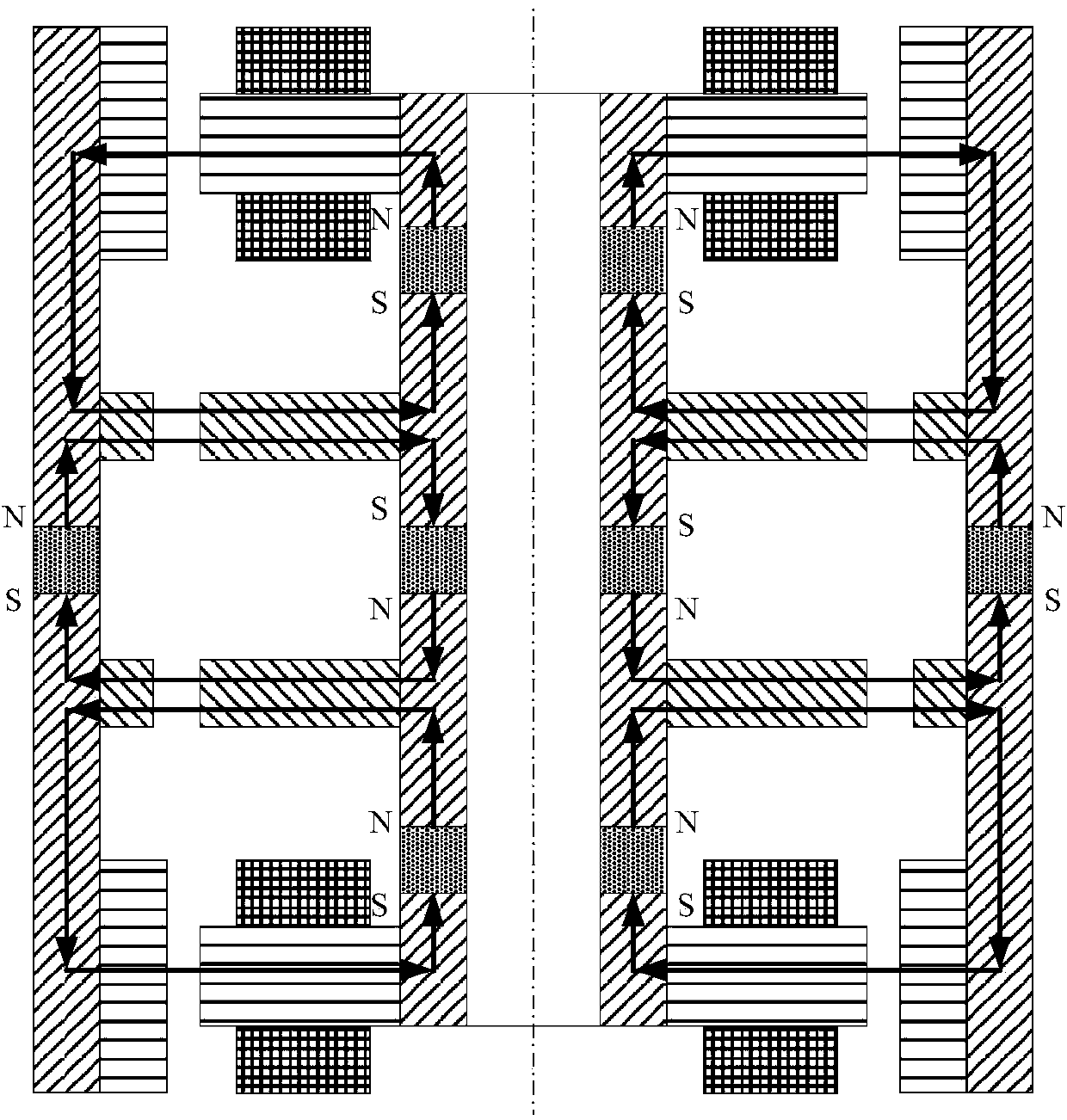

Four-degrees-of-freedom magnetic suspension flywheel

ActiveCN104201935AOvercome the defect of large axial lengthEasy to disassembleMagnetic holding devicesBearingsEarth observationMagnetic bearing

The invention discloses a four-degrees-of-freedom magnetic suspension flywheel. The four-degrees-of-freedom magnetic suspension flywheel is capable of being used as an attitude control execution mechanism for spacecrafts of a satellite, an earth observation platform, a space telescope and the like, and is composed of a four-degrees-of-freedom magnetic bearing, a high-speed motor, a radial-axial integrated sensor, a radial sensor, an upper protection bearing, a lower protection bearing, a mandrel, a wheel body, a base, an upper sensor detection ring, a lower sensor detection ring and a shell, wherein the active portion of the four-degrees-of-freedom magnetic bearing controls the radial translation and deflection of the rotor of the flywheel, and the axial translation of the rotor of the flywheel is realized through the passive portion of the four-degrees-of-freedom magnetic bearing. Each component of the four-degrees-of-freedom magnetic suspension flywheel disclosed by the invention is compact in layout, thus reducing the volume and weight, eliminating the rotational speed zero-passage friction force and mechanical wear of the flywheel of the mechanical bearing, improving the control accuracy of the flywheel and prolonging the service life of the flywheel.

Owner:BEIHANG UNIV

Cell-less composite type artificial skin and preparation thereof

The invention relates to a cell-free compound artificial skin and a preparation method thereof. The compound skin of the invention is provided with a double layer structure of a dermis layer and an epidermis layer; the dermis layer is a loose porous structure made of extracellular matrix; gel-shaped epidermis-like materials are coated on the upper surface of the dermis layer to solidify, thus forming the epidermis layer, and the epidermis layer is inserted into a void structure of the surface of the dermis layer; compared with the existing skin substitutes, the skin of the invention has the functions of promoting the regeneration of wound skin, enhancing the elasticity, flexibility and mechanical wear resistance of the skin after the wound is healed, reducing the scar proliferation, controlling the contracture, improving the success rate of skin implantation and improving the healing quality; the skin of the invention has a sustained release function and can make individual-based treatment for different diseases by releasing different drugs and being directly applied to the treatment of skin defects caused by inflammations, ulcers, burn wounds and iatrogenic causes; the epidermis layer and the dermis layer are embedded together organically with a tight structure; the shapes, sizes and the thicknesses of the skin can be prepared according to specific requirements. The skin of the invention has wide sources of preparation materials, simple production process, short production period, long period of product storage and convenient transportation.

Owner:西安组织工程工程技术研究中心

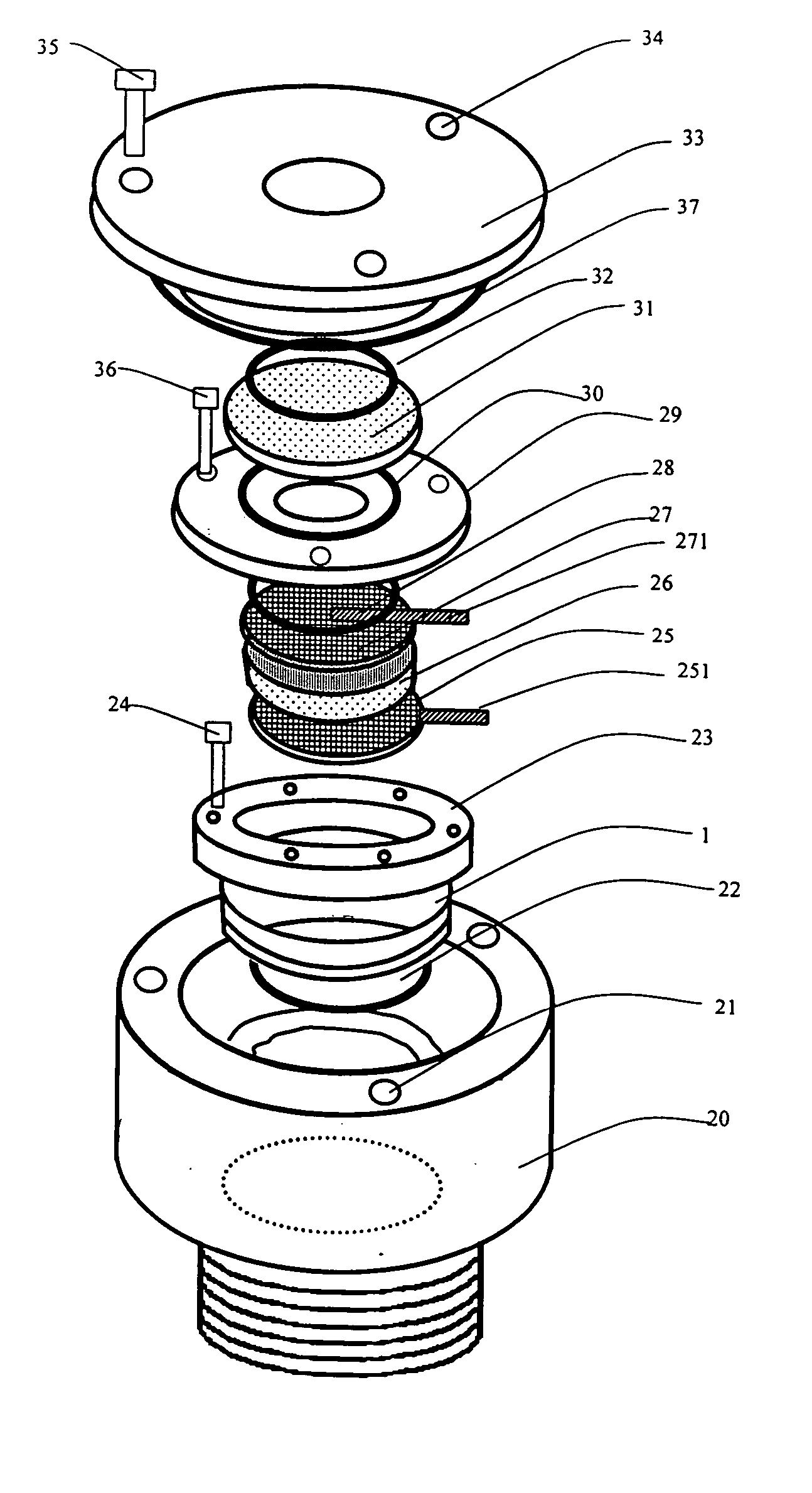

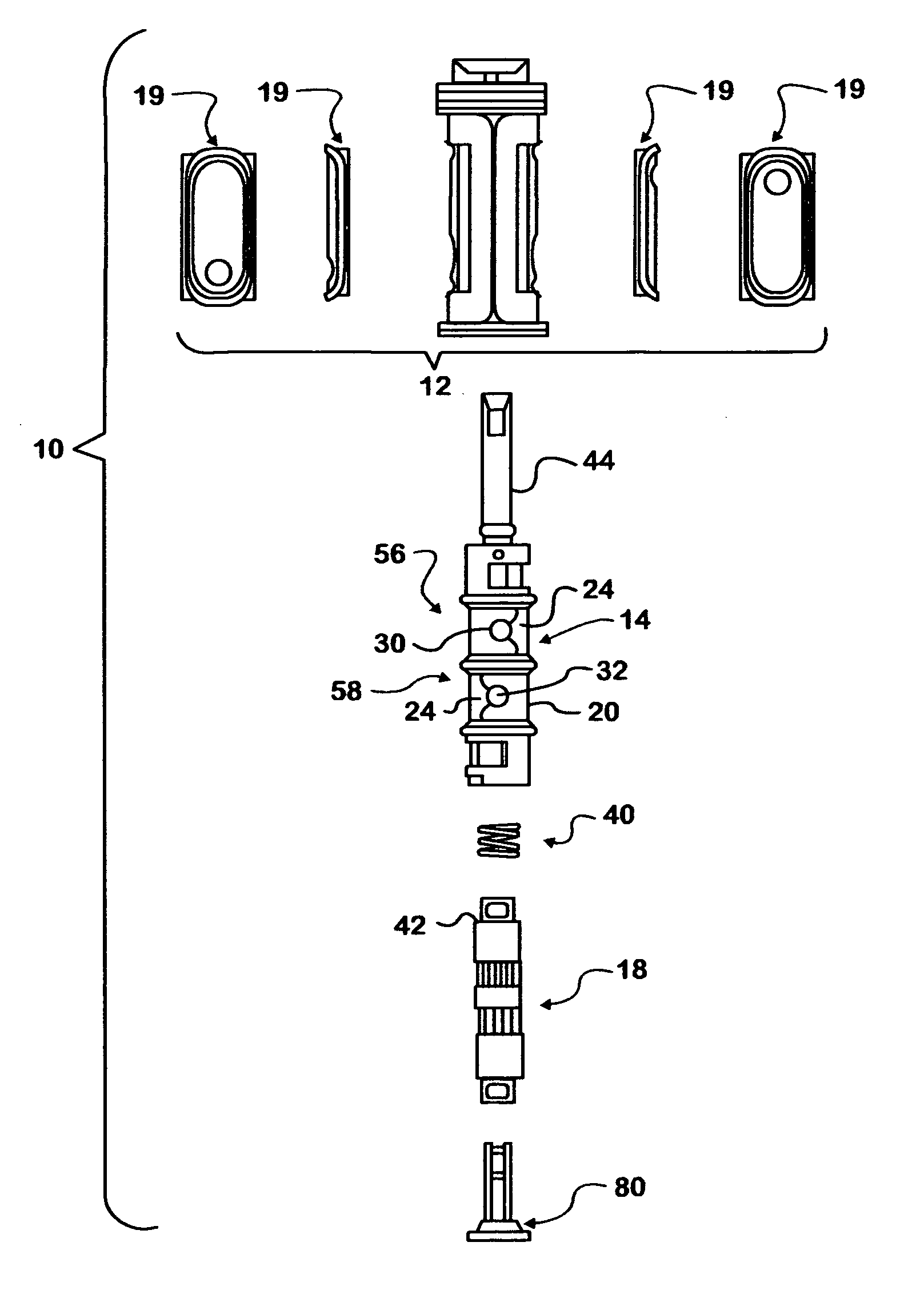

Pressure balancing cartridge for mixing valve

InactiveUS7165570B1Expensive to manufactureExtended service lifeMultiple way valvesThin material handlingMechanical wearPressure balance

A pressure balancing cartridge for mixing hot and cold water includes a casing having a sleeve therein which further includes a reciprocating balancing spool therein. There are seal members positioned to form a seal between the sleeve and the casing. Further, a spring is incorporated to protect a balancing spool of the valve from “water hammer” shock and to mechanically shear and digest any deposited matter in the area of the spring. Still further, by using material other than stainless steel, failure of the balancing spool is eliminated in “bad” water environments.Finally, the seal members comprise stainless steel clips or inserts. To address issues of mechanical wear, all improvements defined above increase useful longevity of the cartridge.

Owner:LORDAHL VAR

Fabrication method of covered-type flexible-rigid board by laser depth control

InactiveCN108617114AProtection from potion bitesProtect mechanical propertiesPrinted circuit assemblingPrinted circuits structural associationsMechanical wearLaser cutting

The invention discloses a fabrication method of a covered-type flexible-rigid board by laser depth control. The fabrication method comprises the following steps of respectively fabricating inner-layercircuits of a flexible core board and a rigid core board, wherein the flexible core board comprises a flexible board region and a flexible-rigid region; attaching a coverage film onto the flexible board region on the flexible core board in an alignment way; laminating the flexible core plate and the rigid core board by non-flowing glue PP to form a generation plate, and forming a window in a position, corresponding to the flexible board region, on the non-flowing glue PP; sequentially fabricating an outer-layer circuit and a welding-resistant layer on the production plate, and performing surface processing; and performing depth-control cutting on a position, corresponding to the circumference of the flexible board region, on the production plate by employing a laser cutting mode, and removing a part, corresponding to the flexible board region, on the rigid core board after uncovering to fabricate the flexible-rigid board. With the adoption of the method, the flexible board region is effectively prevented from being bitten by a medium, and mechanical wear and scrap are effectively prevented.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

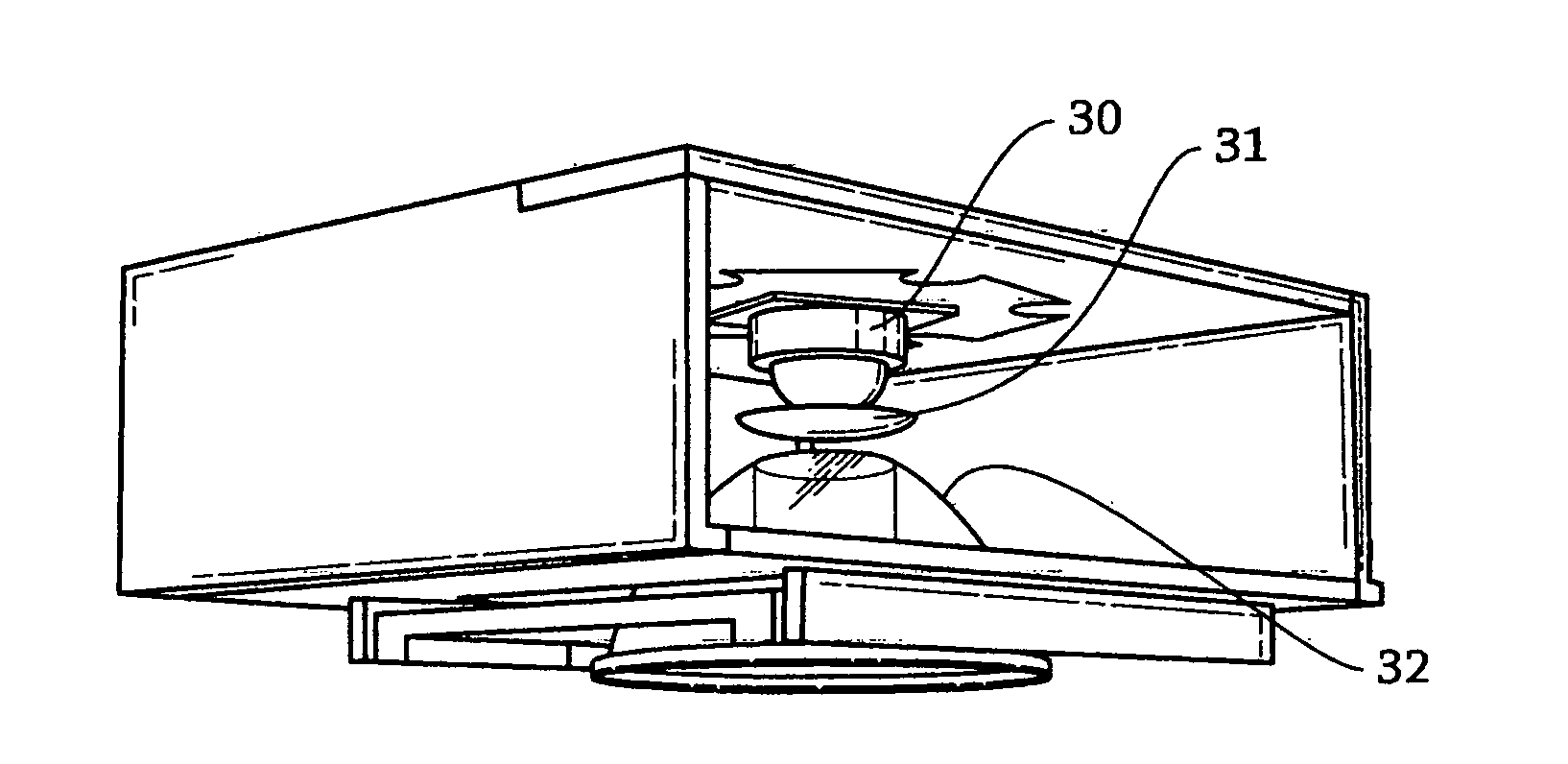

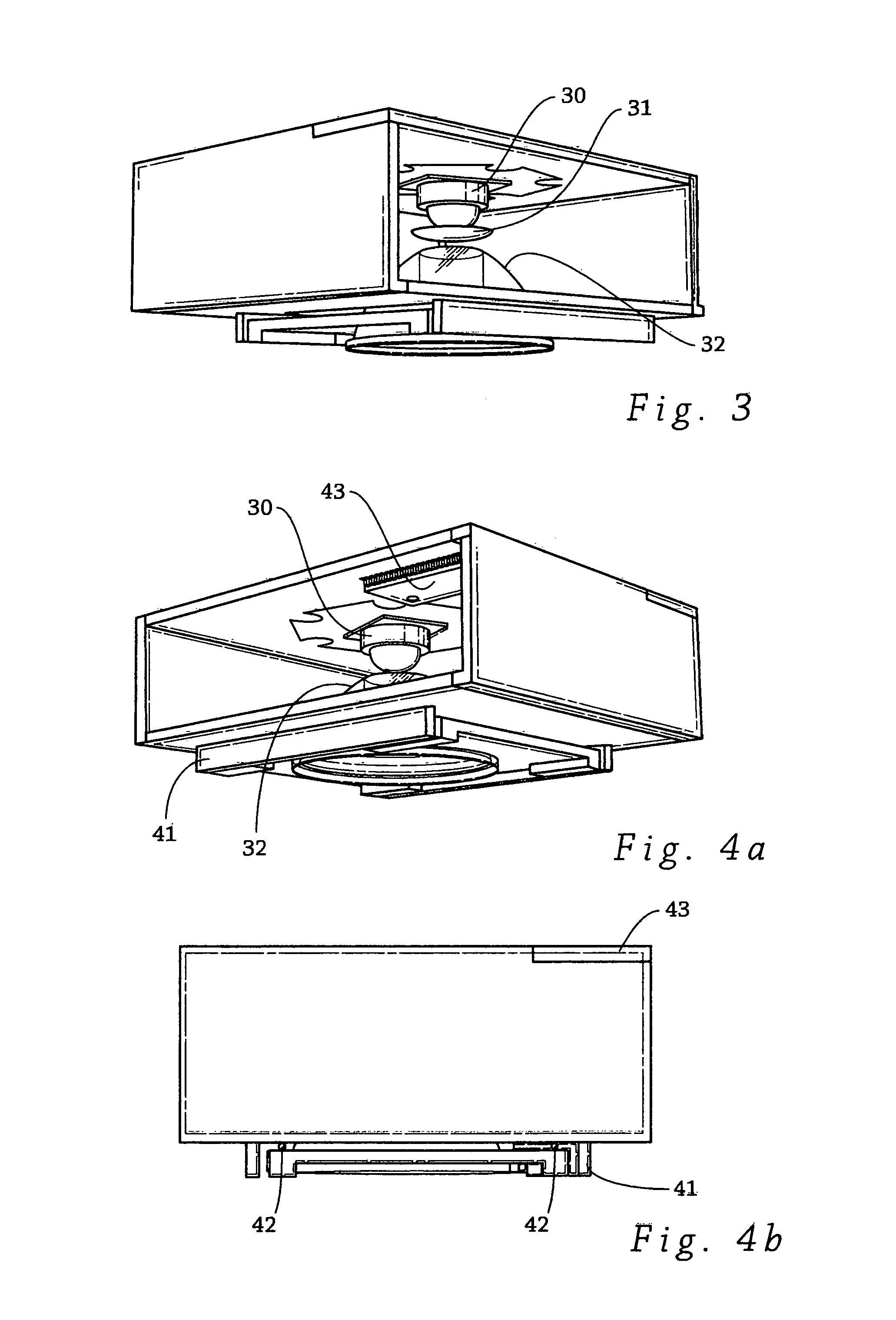

Dynamic lighting system

InactiveUS20110222301A1Extend your lifeMinimal mechanical wearOptical signallingSpectral modifiersElectric power transmissionEffect light

Methods and systems for dynamic lighting systems are disclosed. The dynamic lighting system invented has minimal mechanical wear and is reacting quickly to fast changes by using magnetic power transmission moving optical elements between light sources, preferably types of LEDs or OLEDS, and objects to be illuminated. Movements of the optical elements can be either linear in up to three dimensions, tilted or on spherical tracks. Positions of the optical elements can be progressively taken and appointed.

Owner:DIGITAL IMAGING SYST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com