Patents

Literature

19682results about "Gearing details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

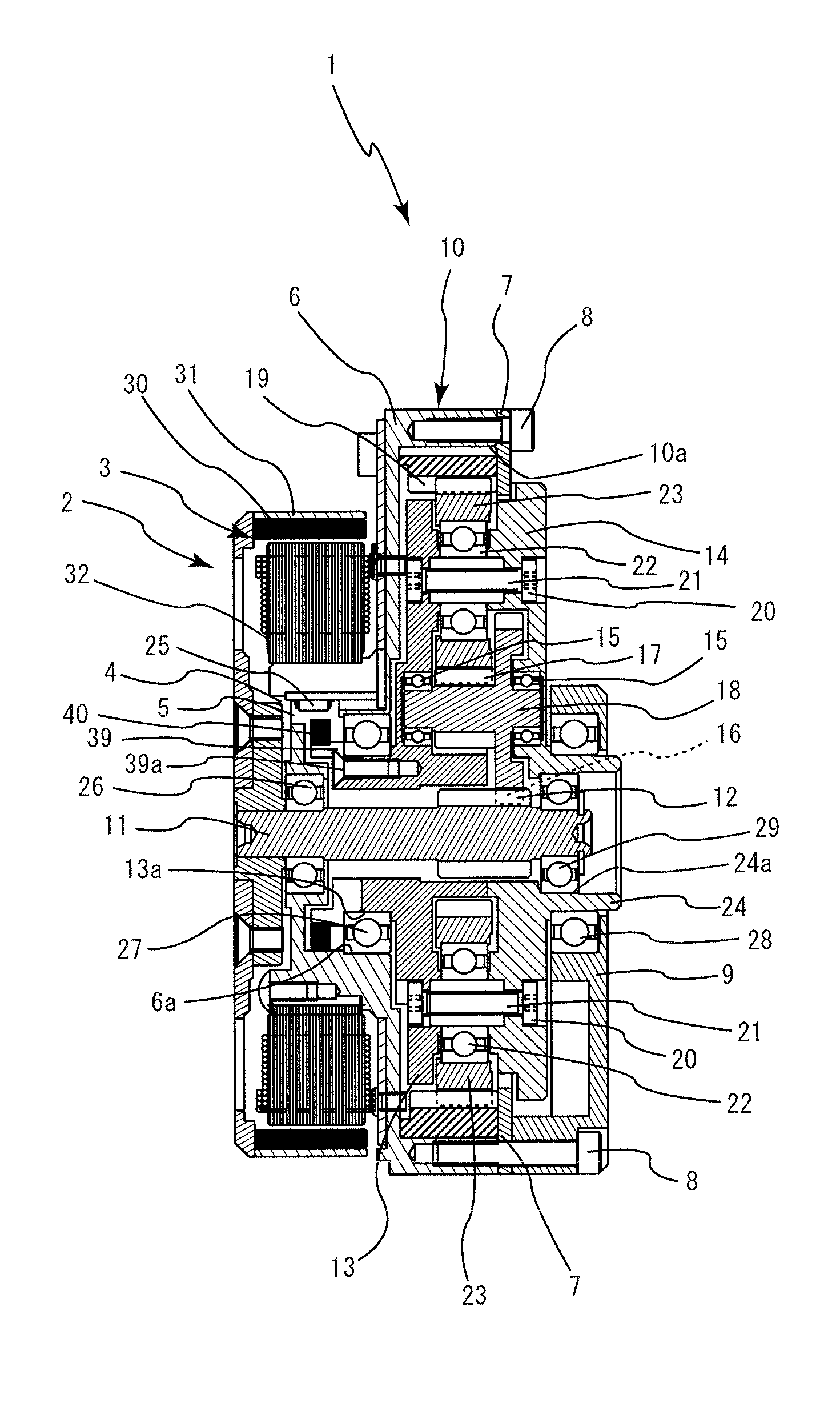

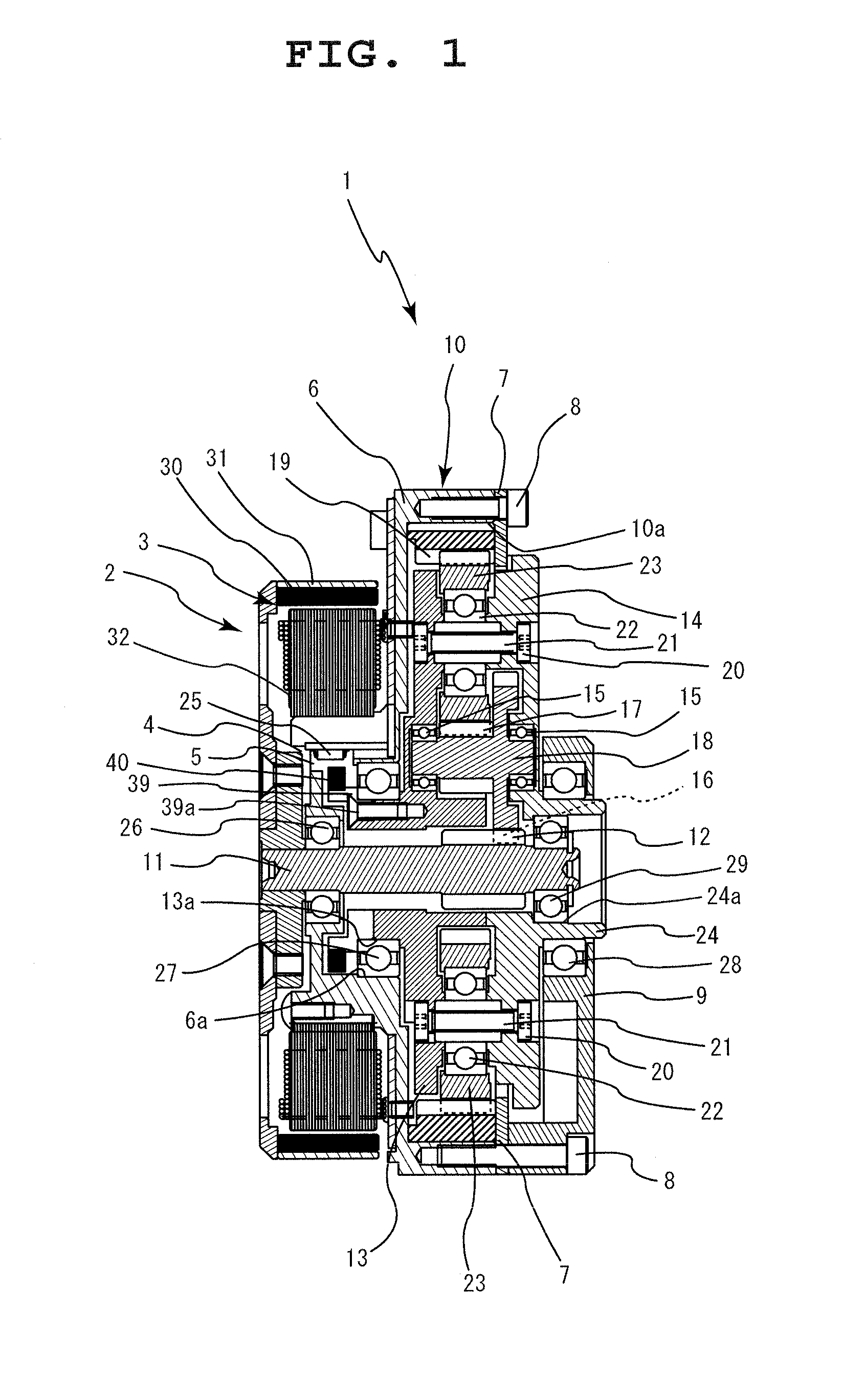

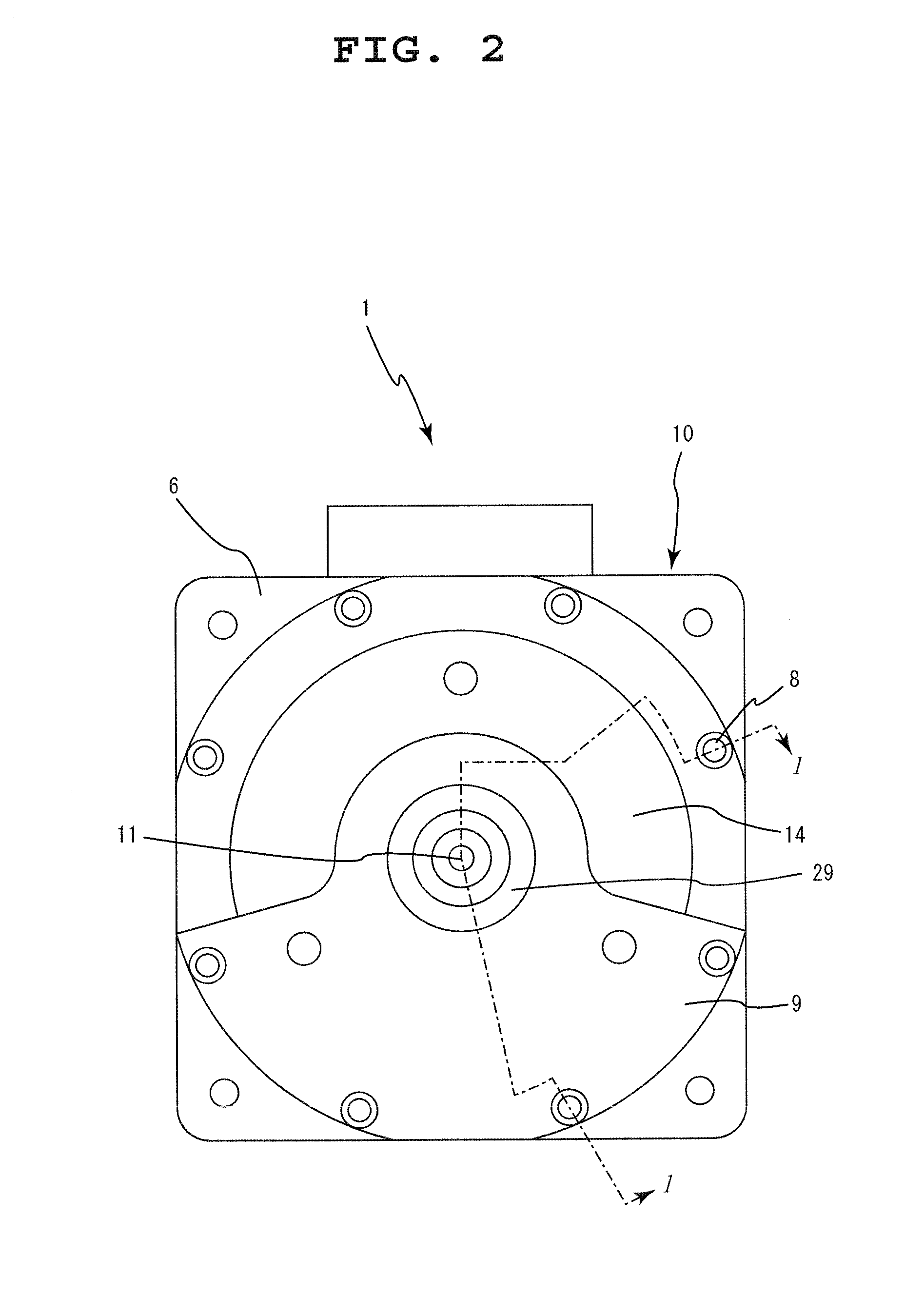

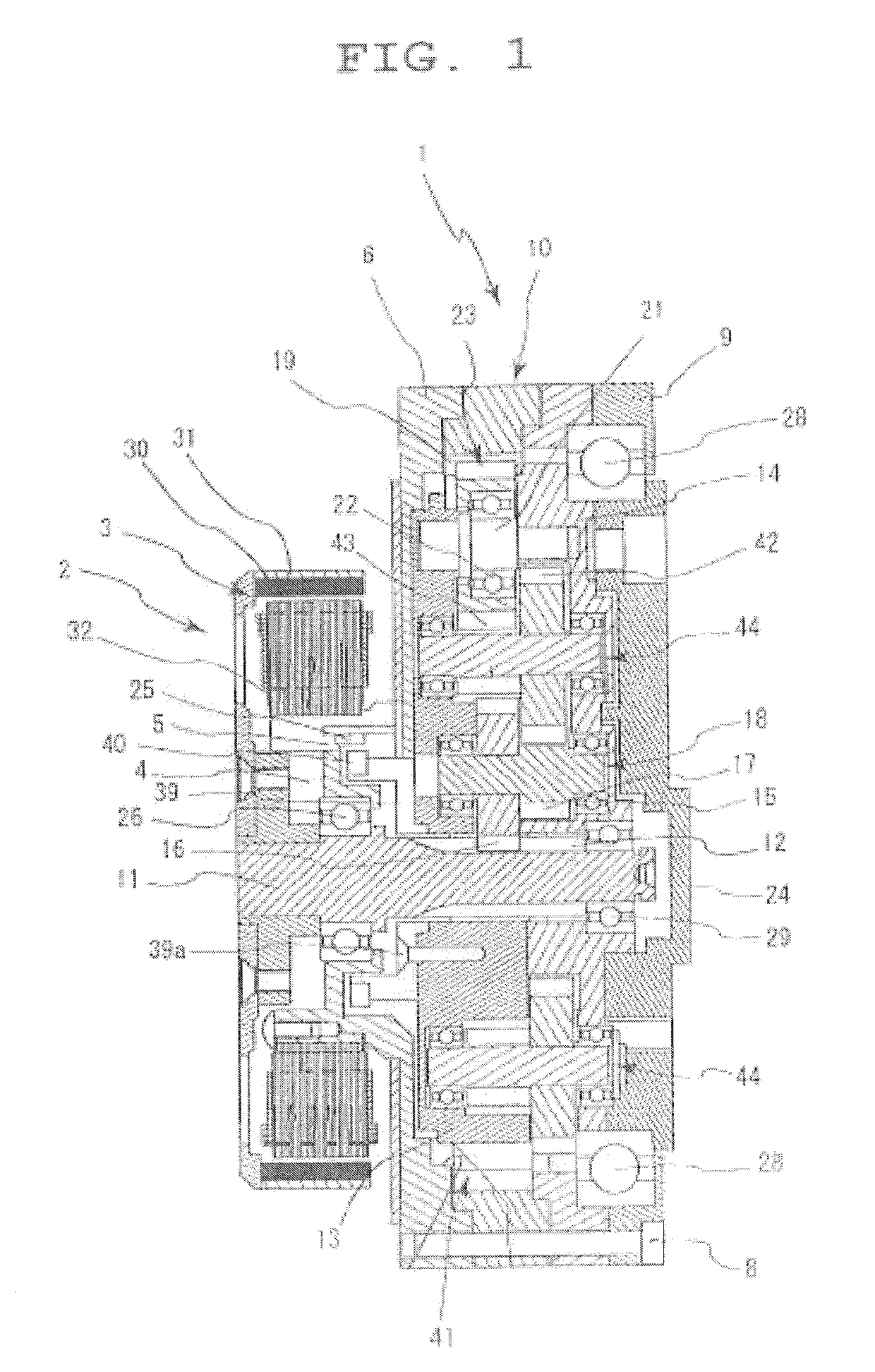

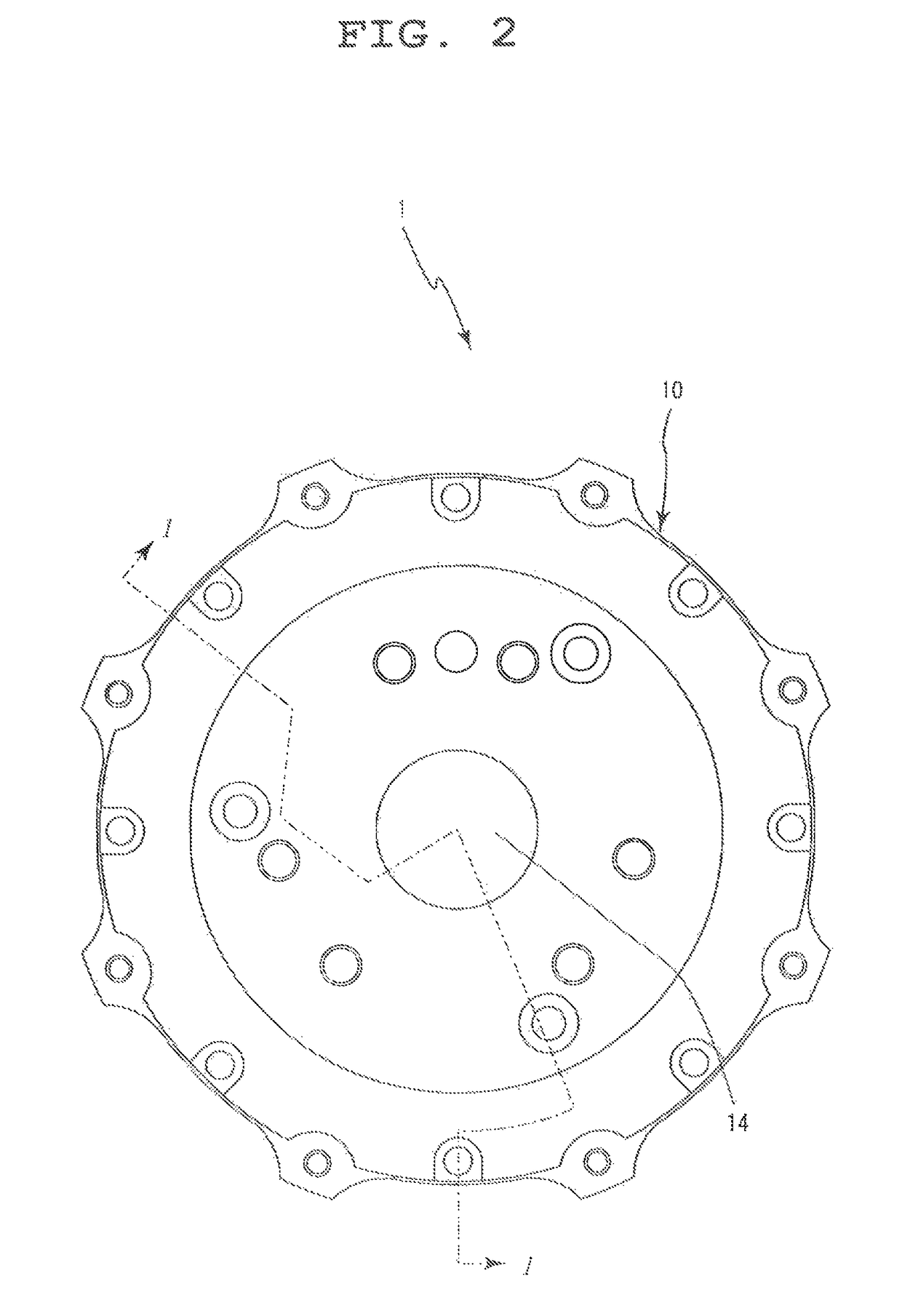

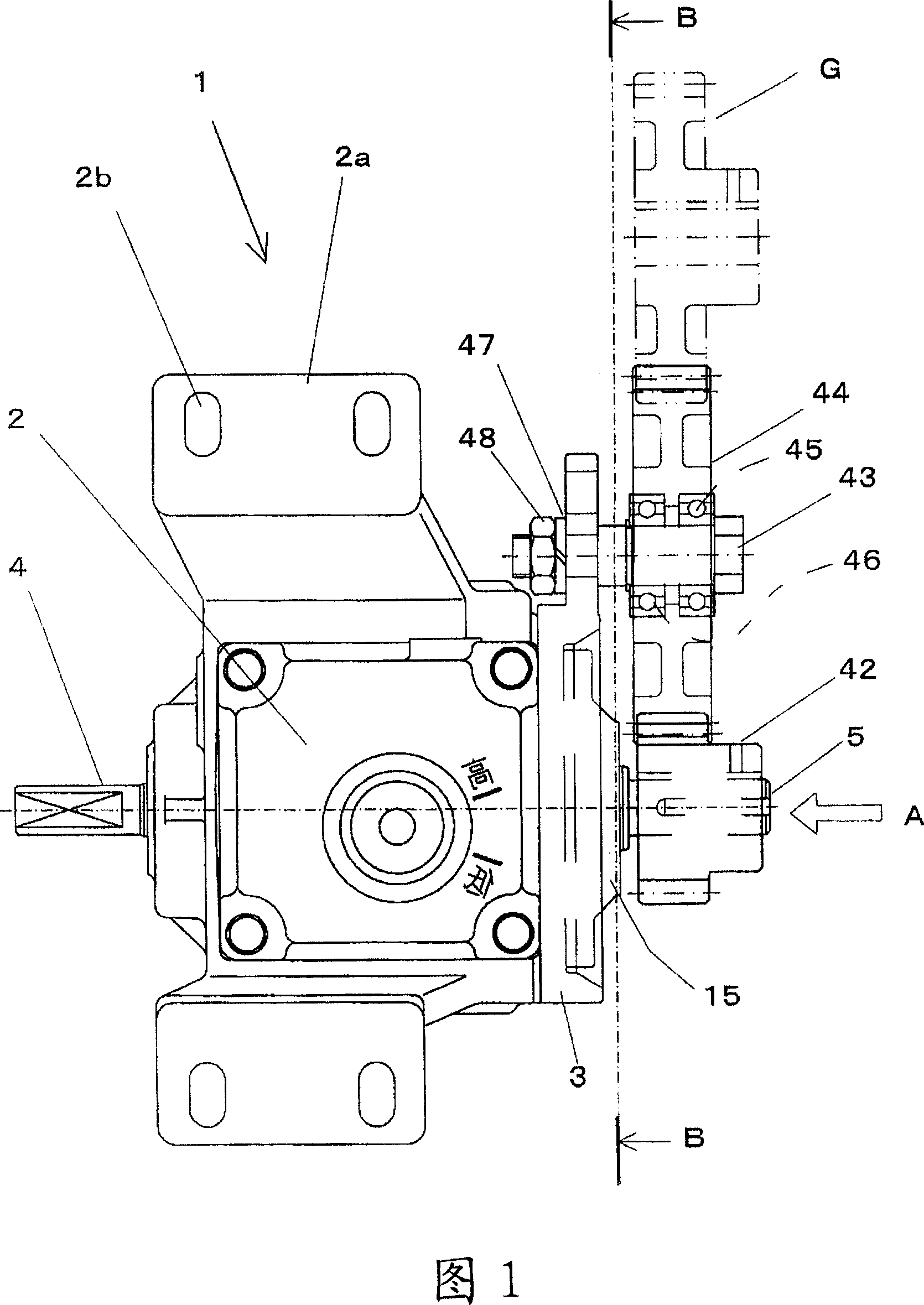

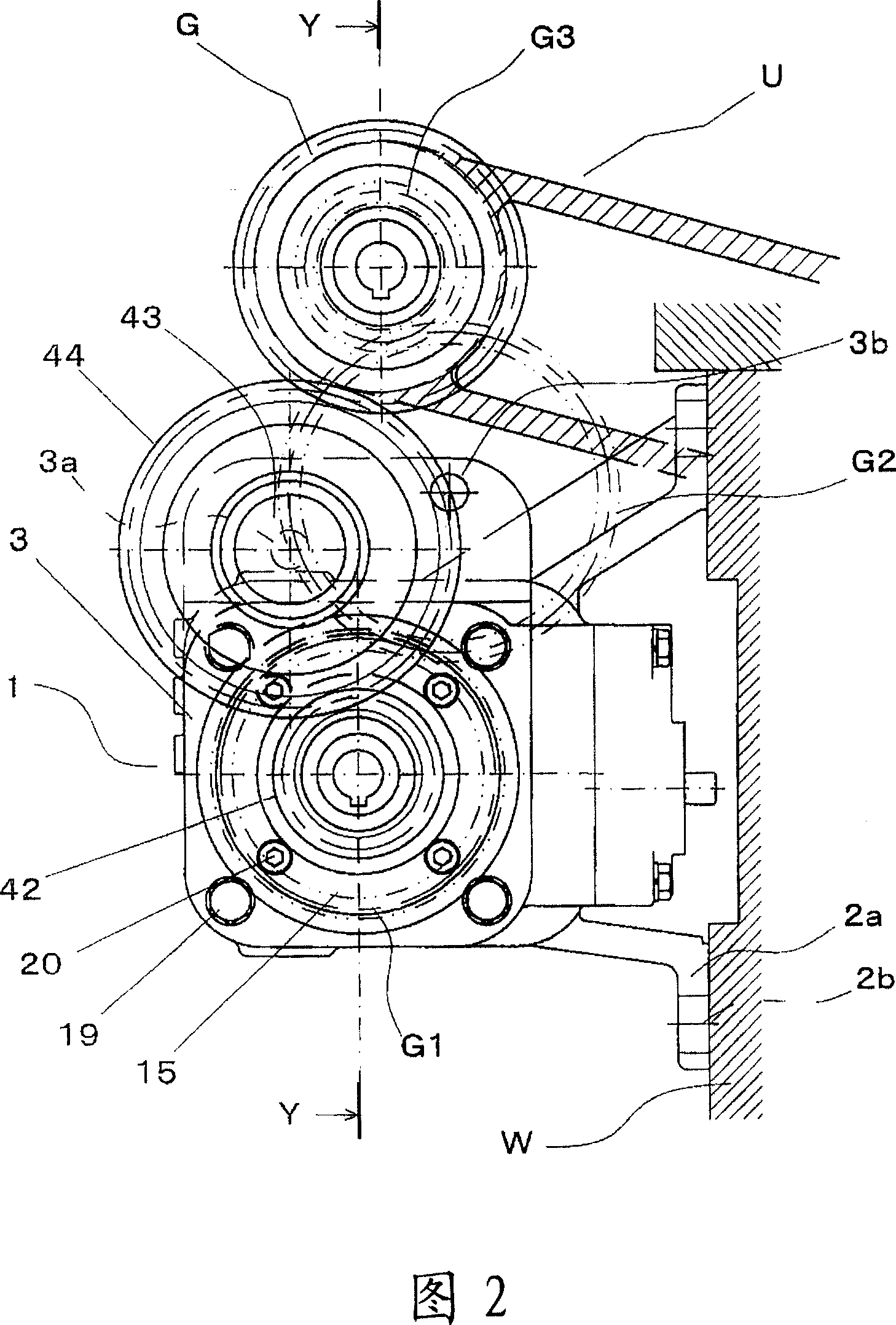

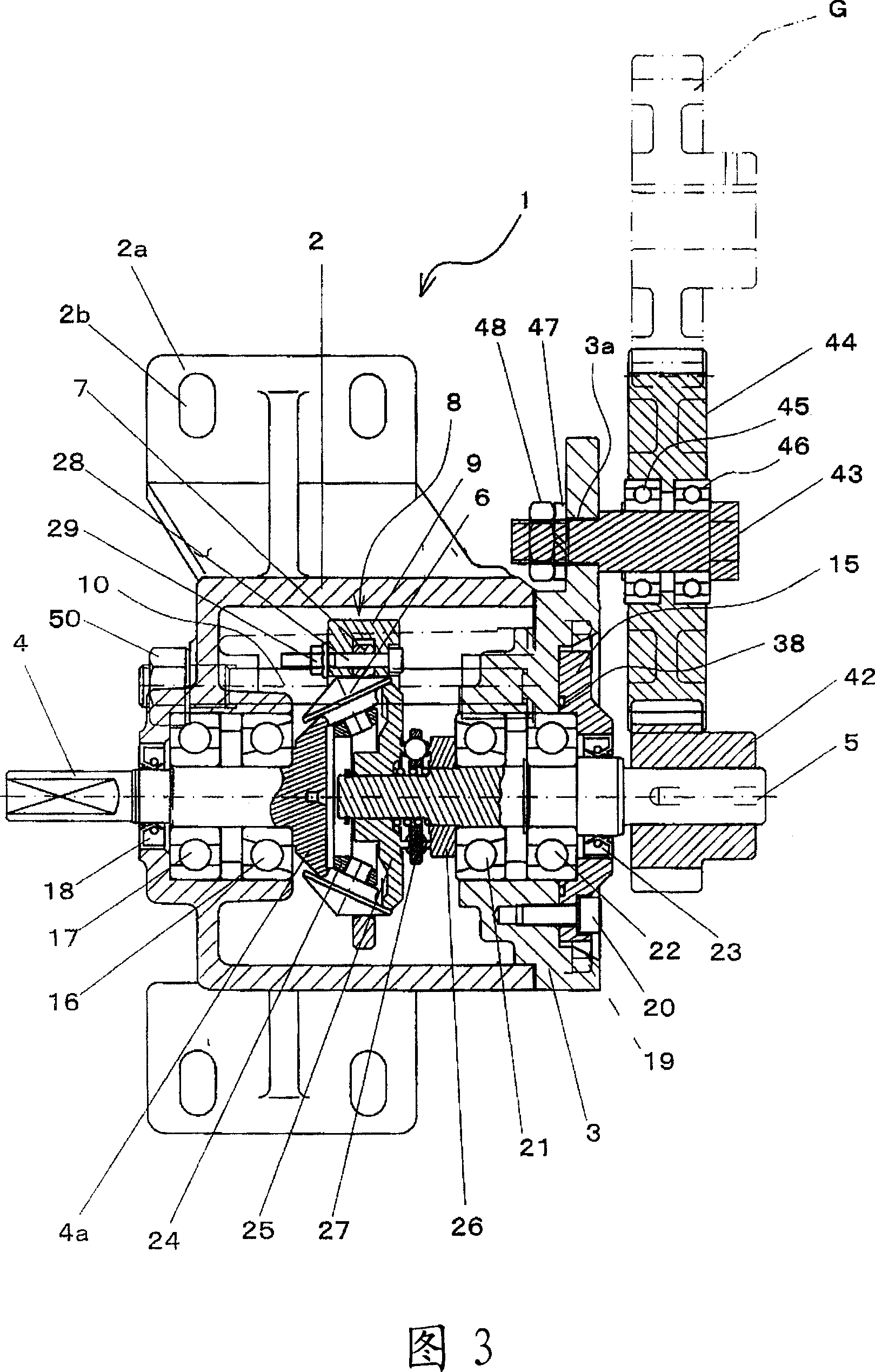

Thin-type gear motor and muscle force assisting device using thin-type gear motor

InactiveUS20160069449A1Small sizeReduce weightToothed gearingsSignalling system detailsMuscle forceGear wheel

In a thin-type gear motor and a muscle force assisting device that uses the thin-type gear motor in which high torque output is achieved, thinness and size and weight reduction are achieved, and further size reduction is achieved by an absolute sensor that is capable of detecting a rotation angle of an output shaft after speed reduction and is situated in a space that is conventionally not used.

Owner:COPAL ELECTRON CO LTD

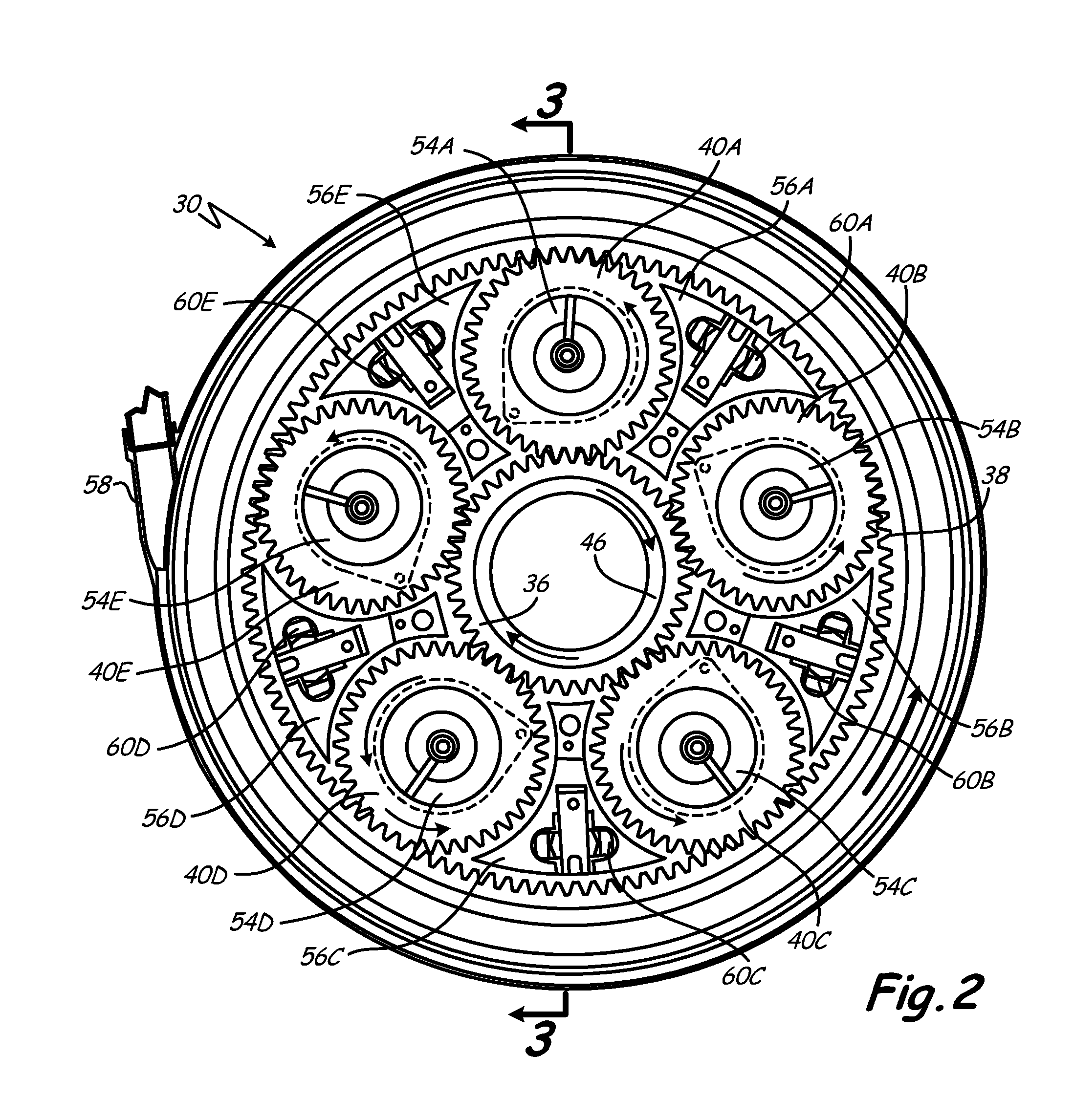

Gear motor including reduction mechanism

ActiveUS9689466B2Thinness and size and weight reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can he achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

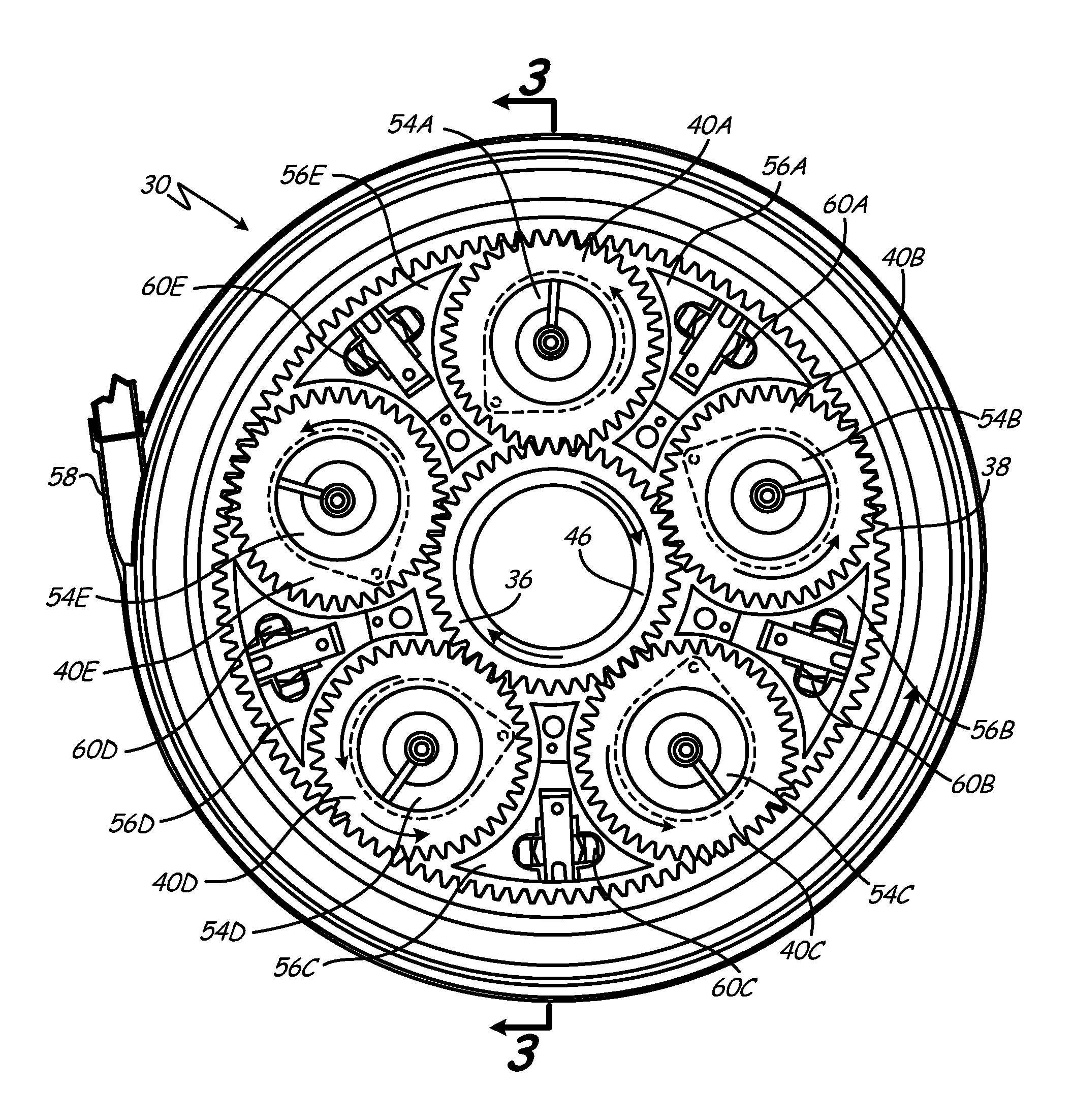

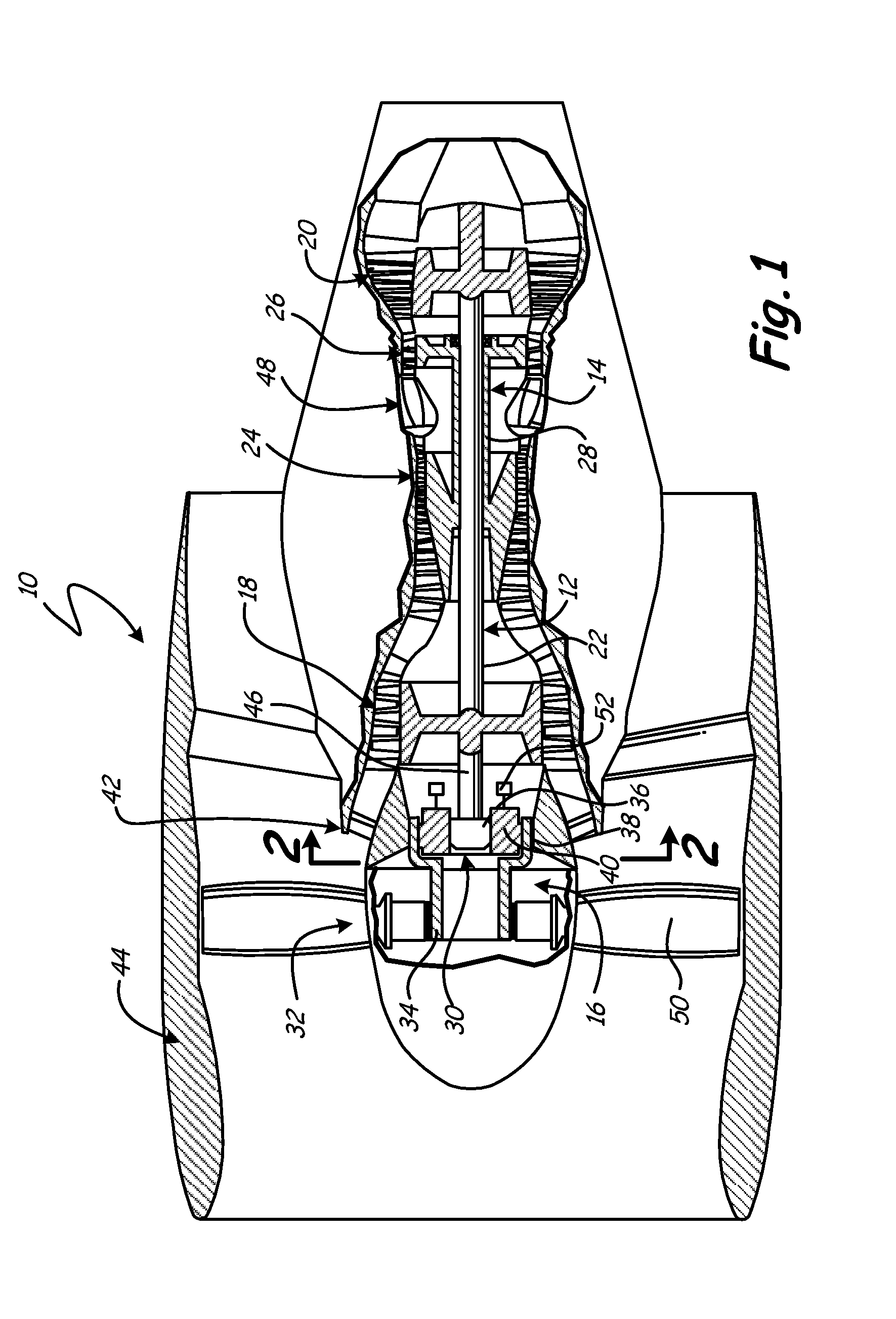

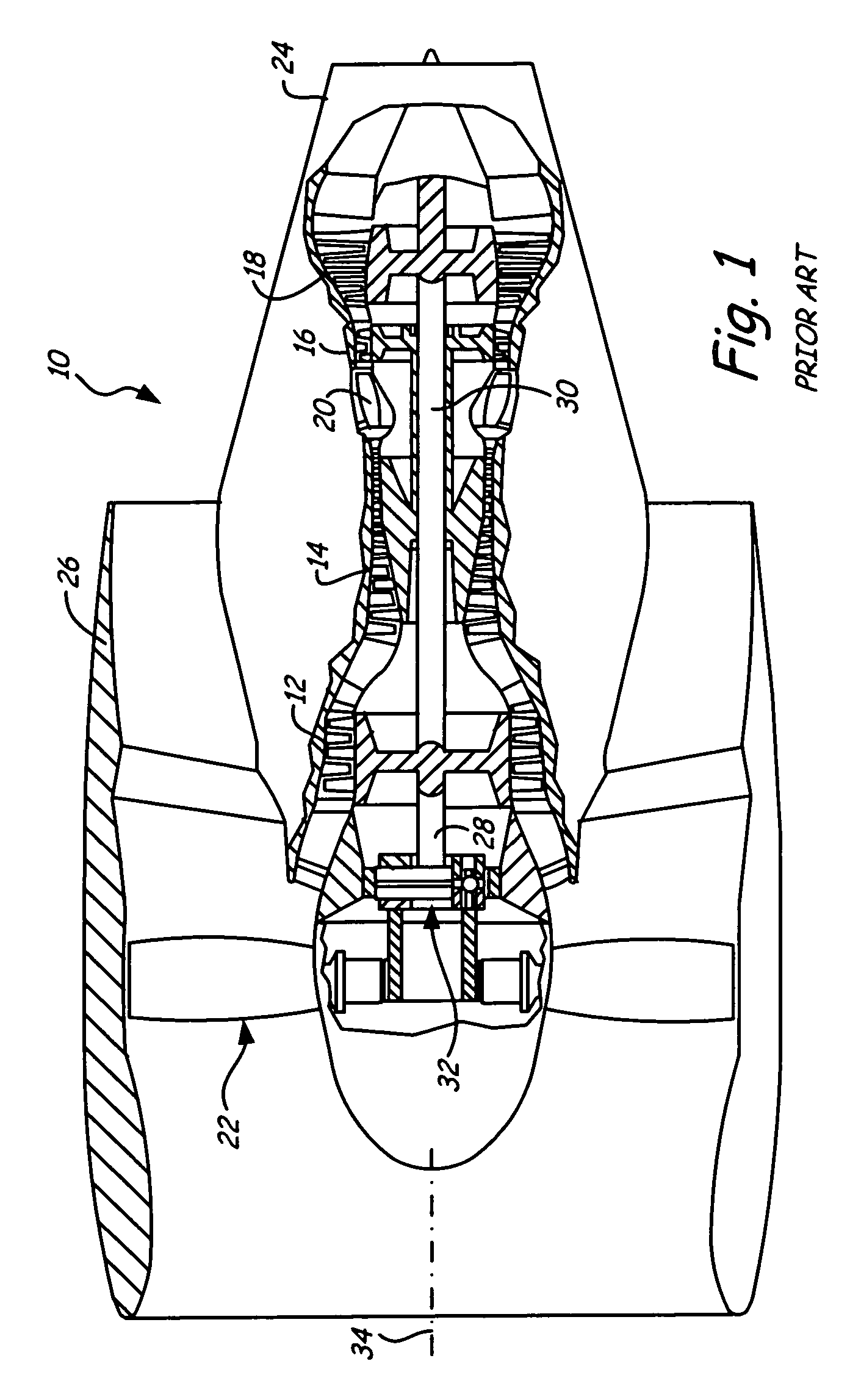

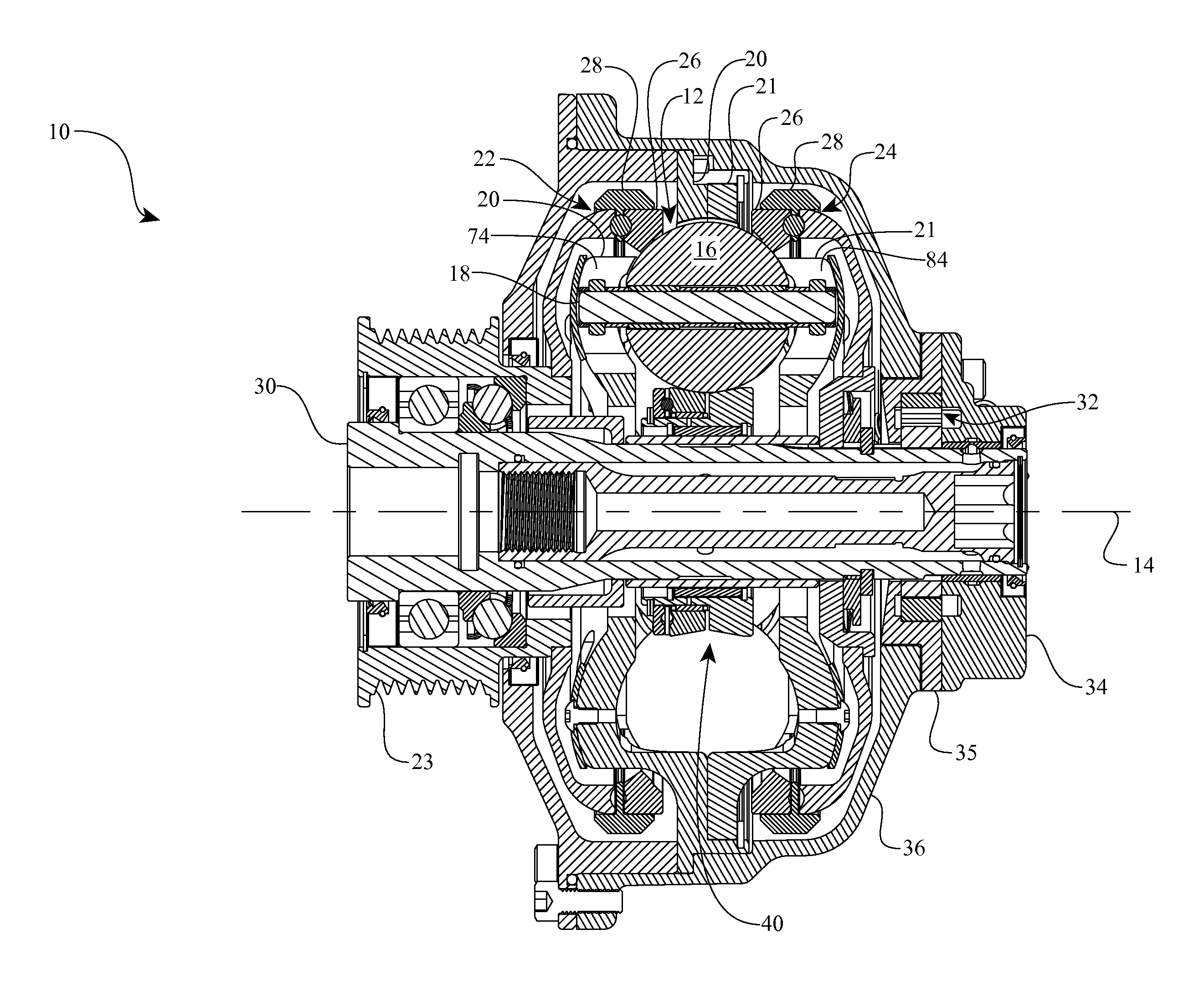

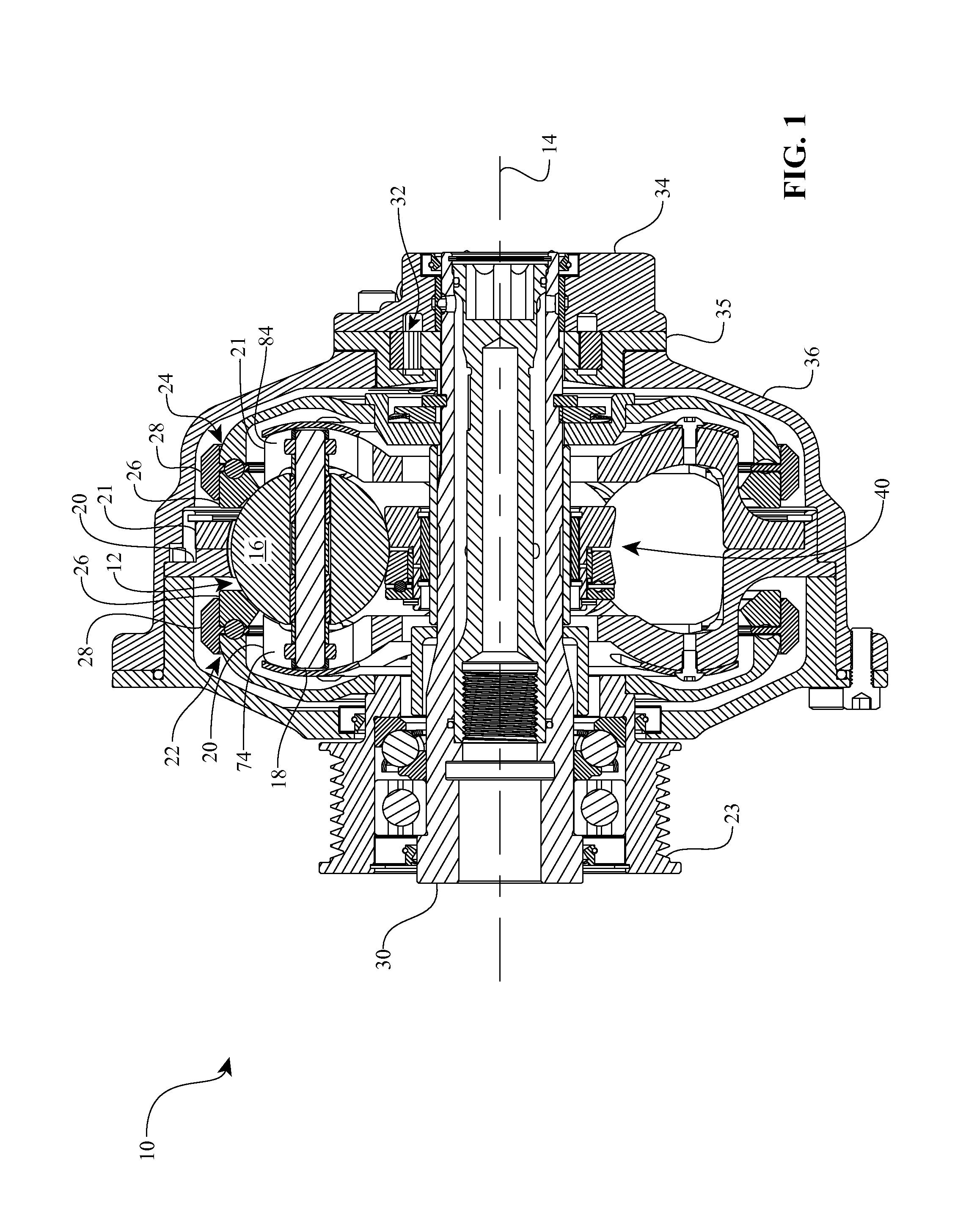

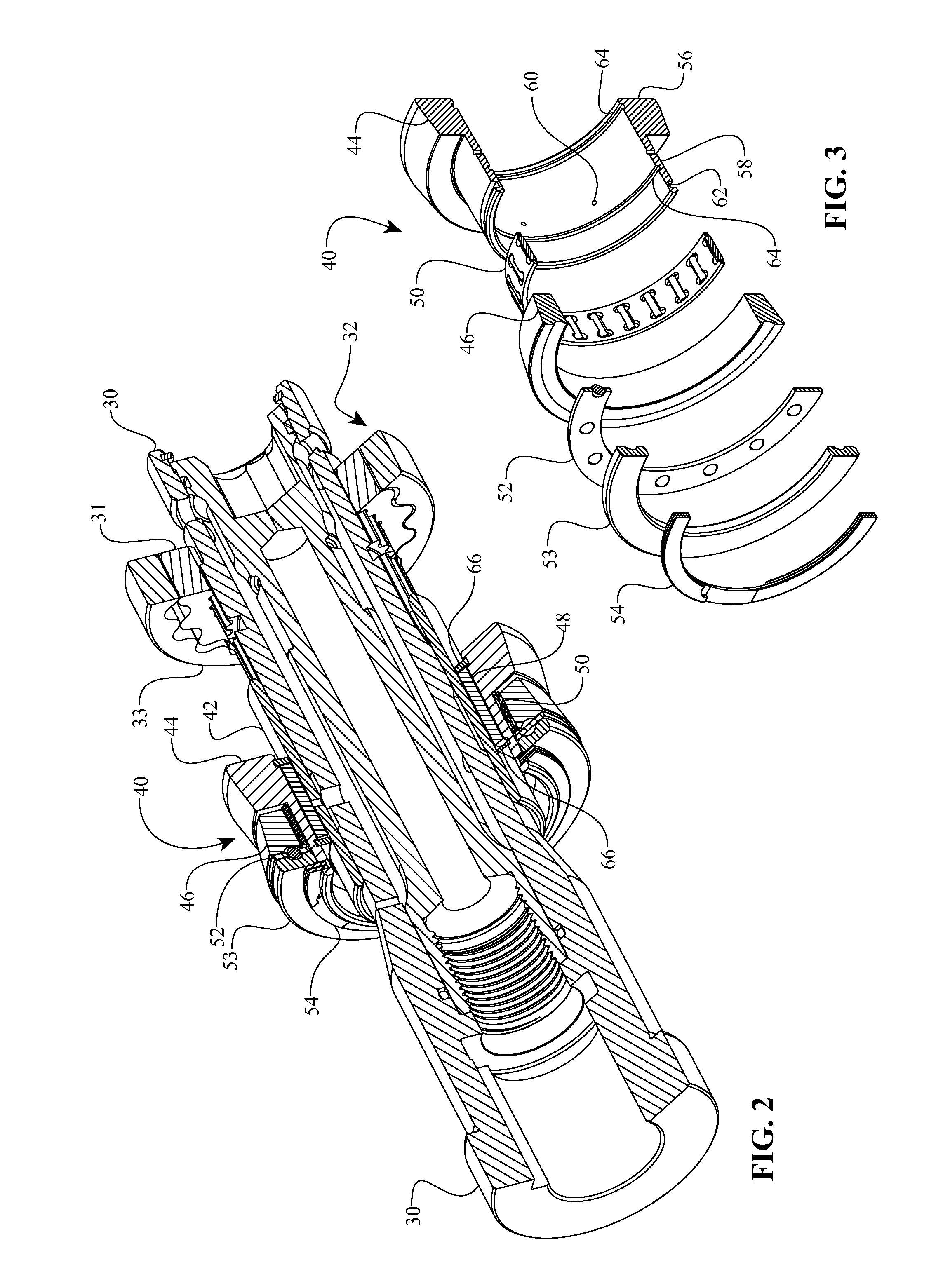

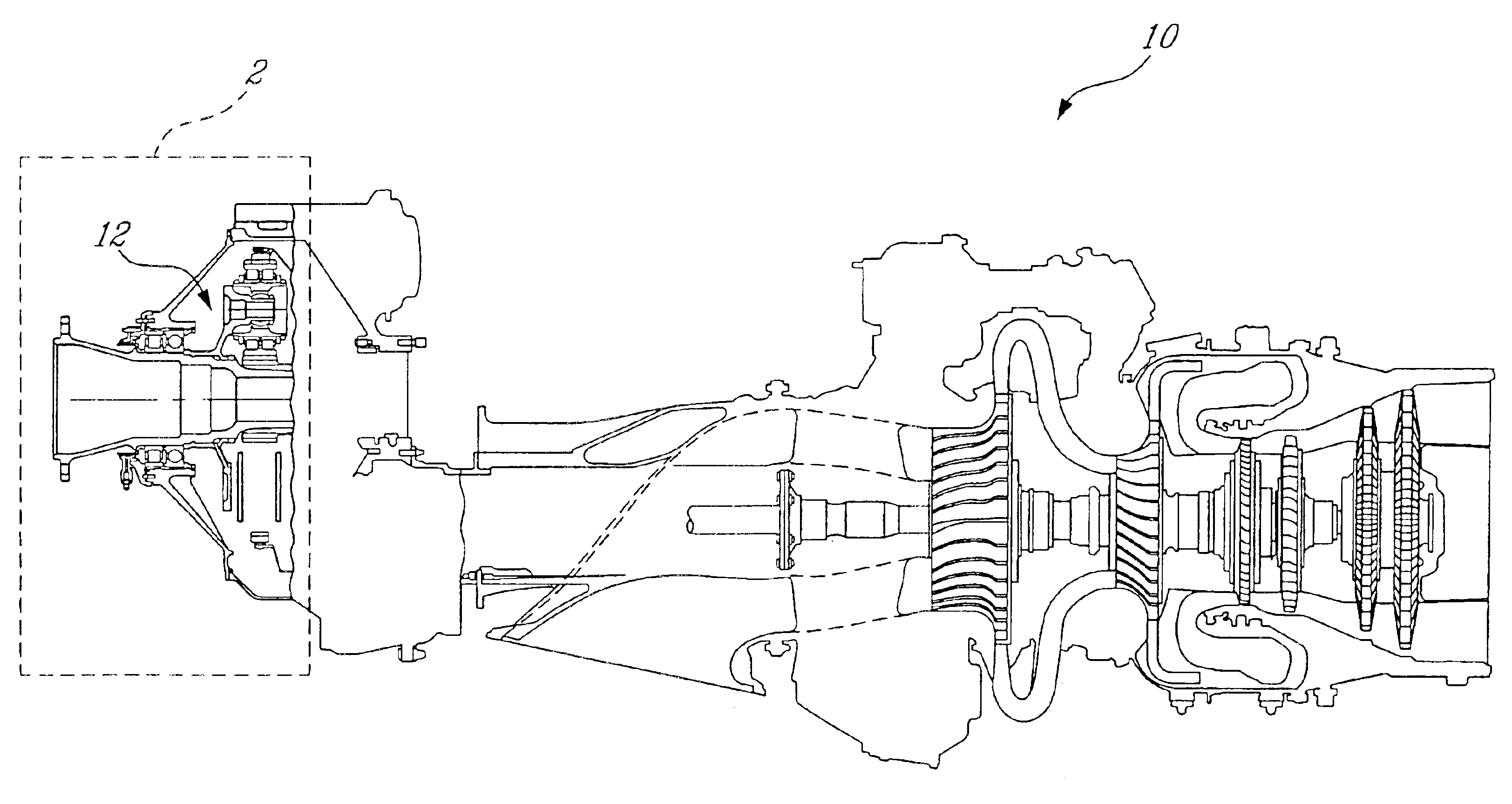

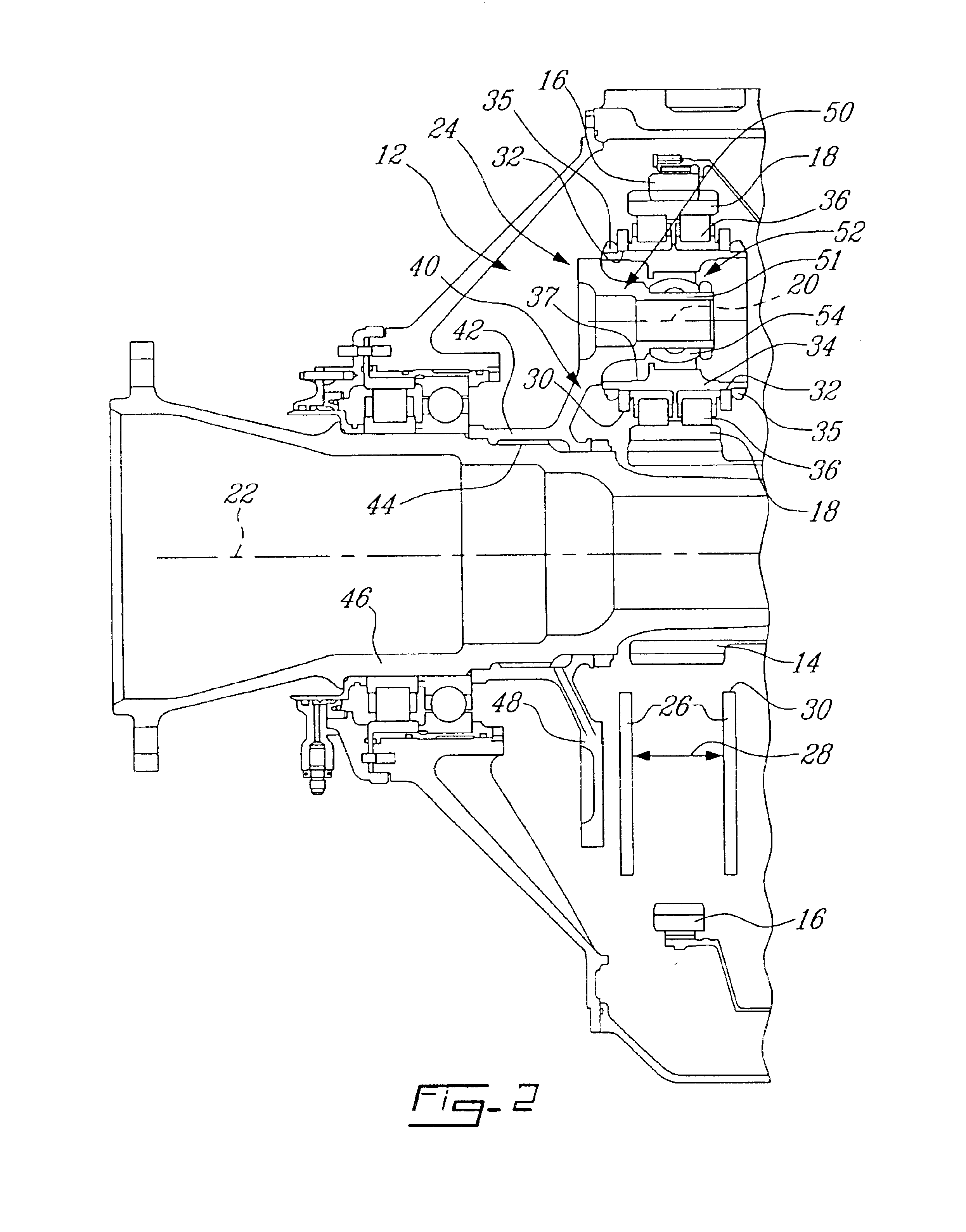

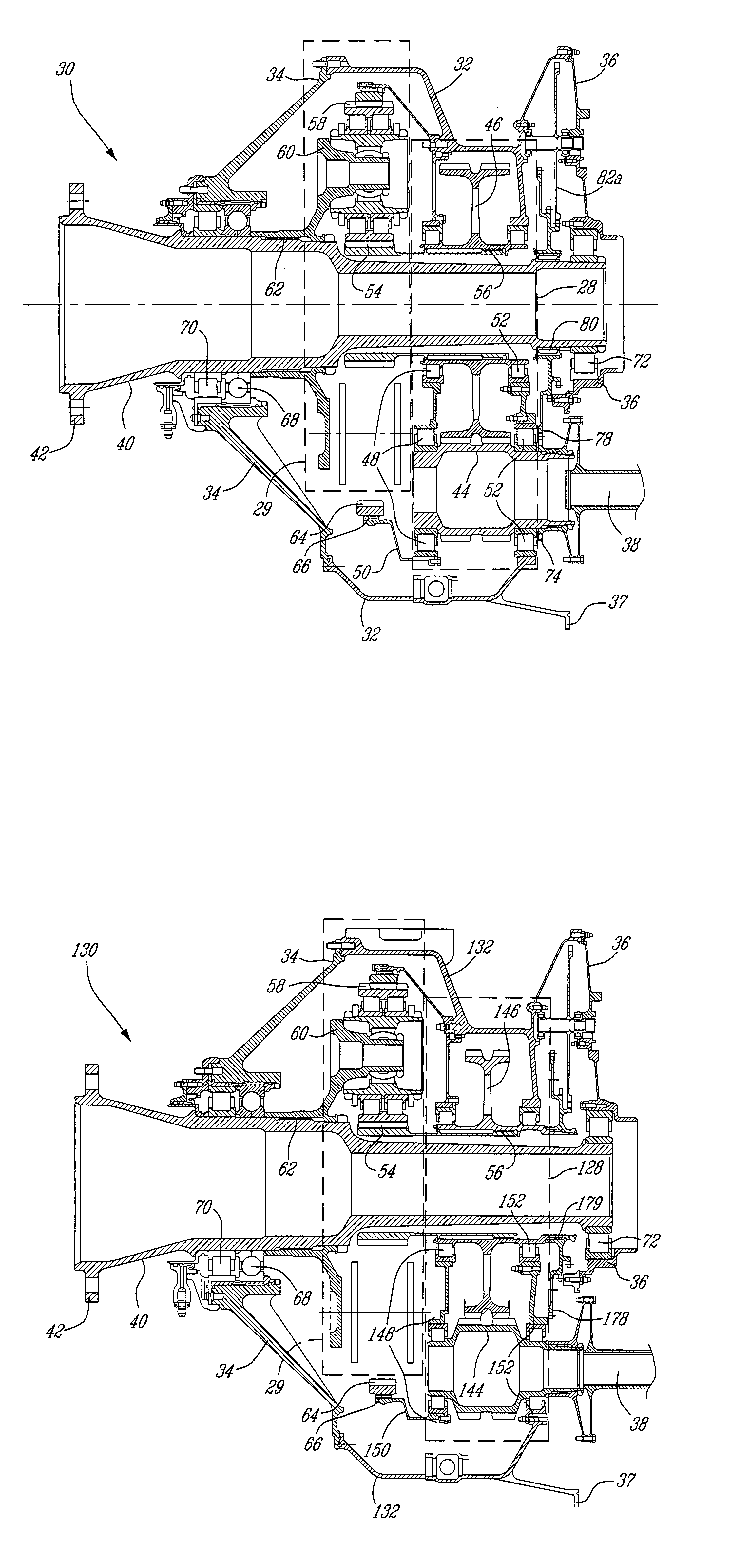

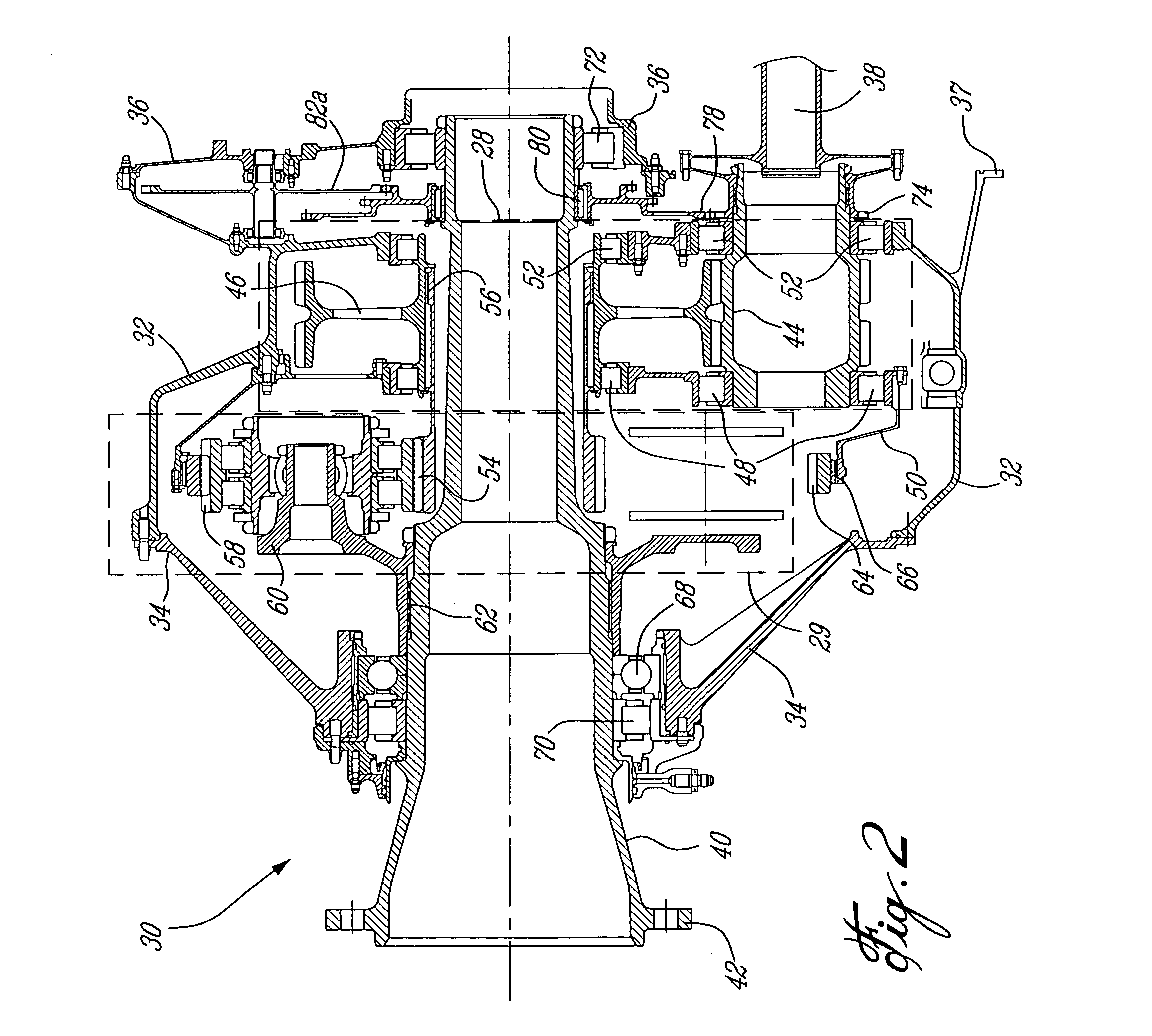

Coupling system for a star gear train in a gas turbine engine

A star gear train for use in a gas turbine engine includes a sun gear, a ring gear, a plurality of star gears and a coupling system. The sun gear is rotatable by a shaft. The ring gear is secured to a ring gear shaft. Each of the plurality of star gears is rotatably mounted in a star carrier and meshes with the sun gear and the ring gear. The coupling system comprises a sun gear flexible coupling, a carrier flexible coupling and a deflection limiter. The sun gear flexible coupling connects the sun gear to the shaft. The carrier flexible coupling connects the carrier to a non-rotating mechanical ground. The deflection limiter is connected to the star carrier to limit excessive radial and circumferential displacement of the star gear train.

Owner:RTX CORP

Epicyclic gear train integral sun gear coupling design

A coupling system for connecting a sun gear to a shaft within a planetary gear train, includes a sun gear coupling connecting the sun gear to the shaft. The sun gear coupling has at least one undulant flexible section joined to an inflexible spindle for accommodating misalignment between the sun gear and the shaft. The flexible section comprises a cylindrical ring having a diameter greater than the diameter of the spindle, and joined to the spindle by two longitudinally spaced apart diaphragms. The juncture between the diaphragms, the ring, and the spindle is curved in cross section on an outer side to improve flexibility and minimize stress concentrations, and the inner sides of the diaphragms are straight edges which result in a non-symmetric contour of the diaphragm walls.

Owner:RTX CORP

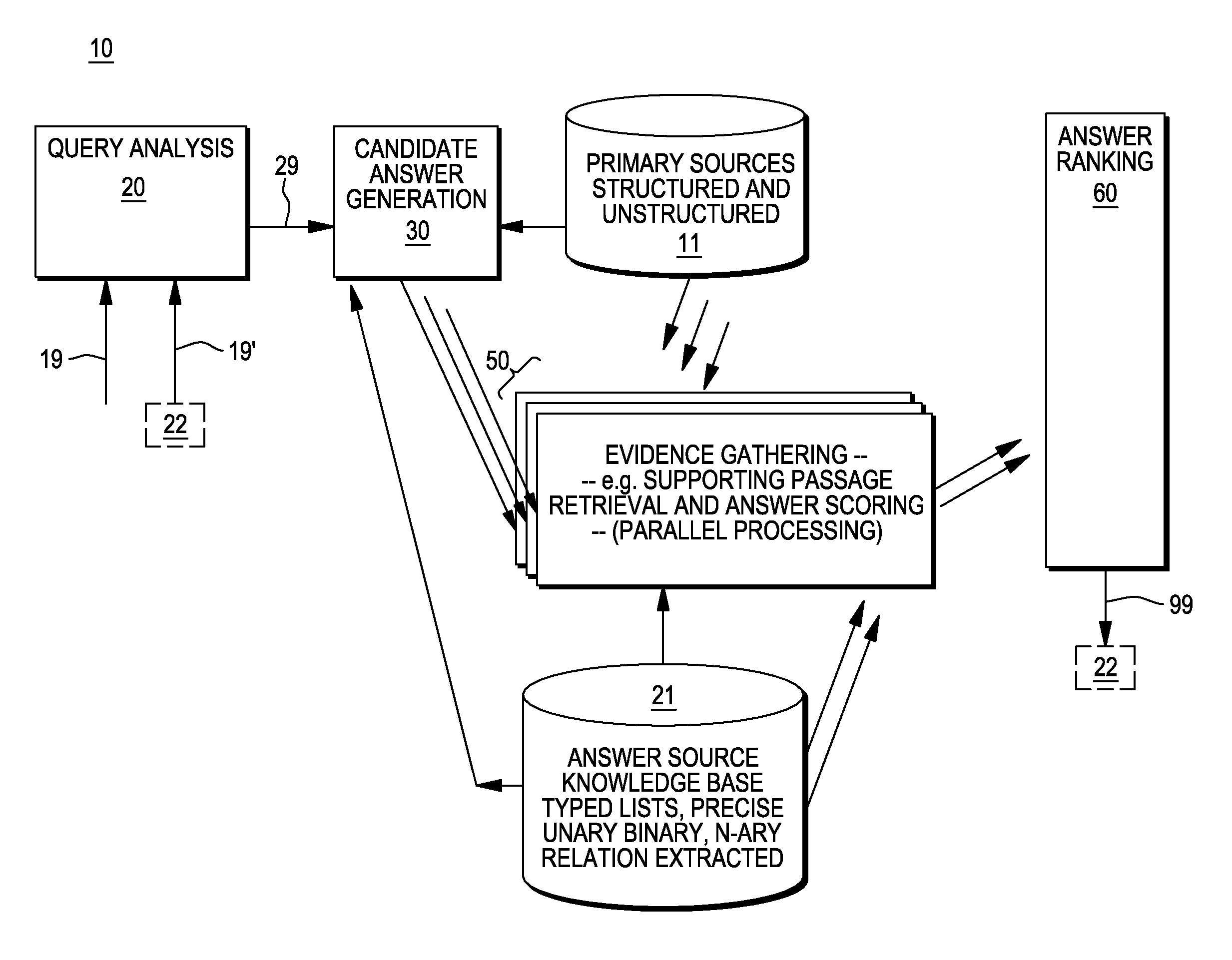

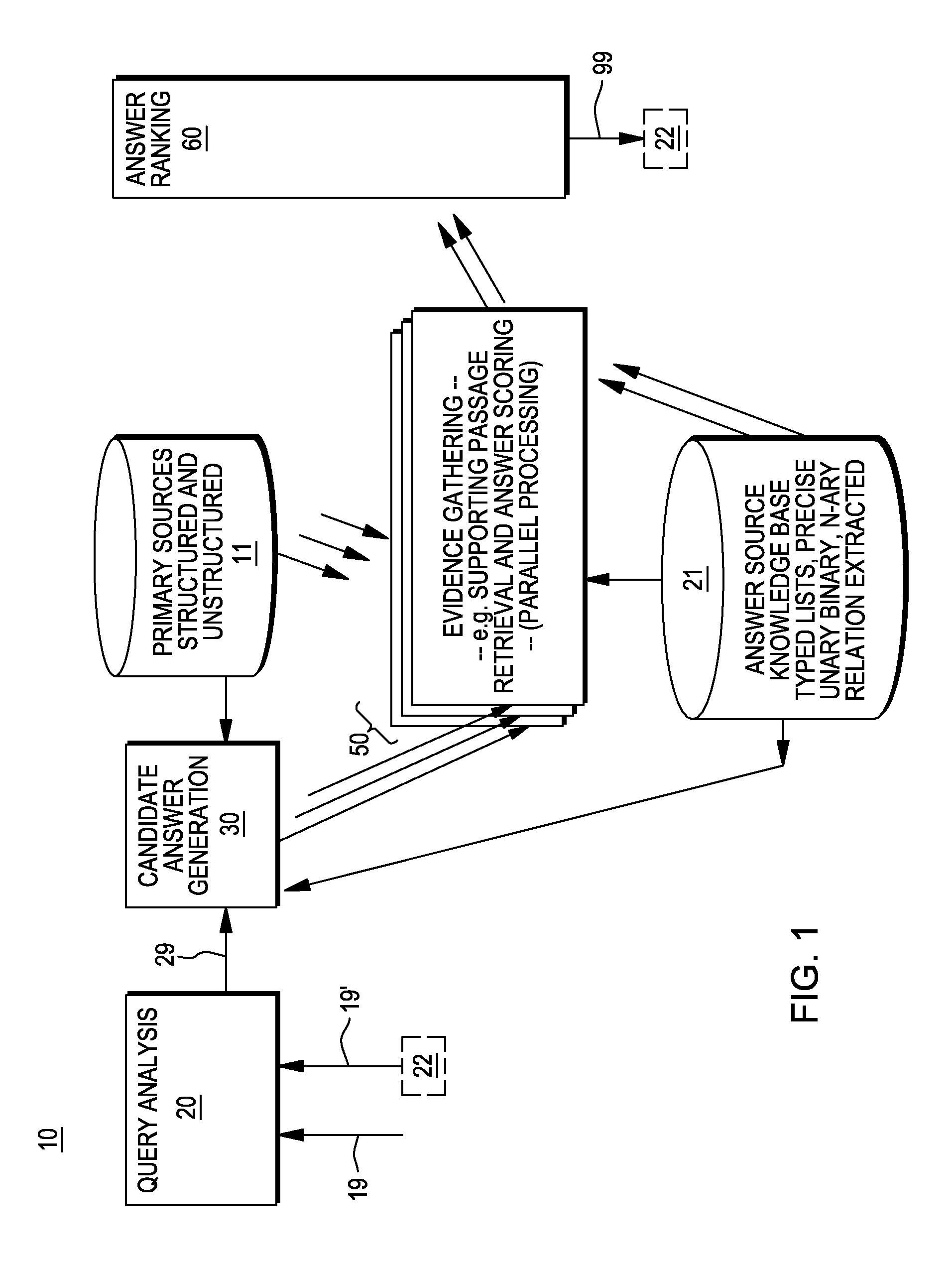

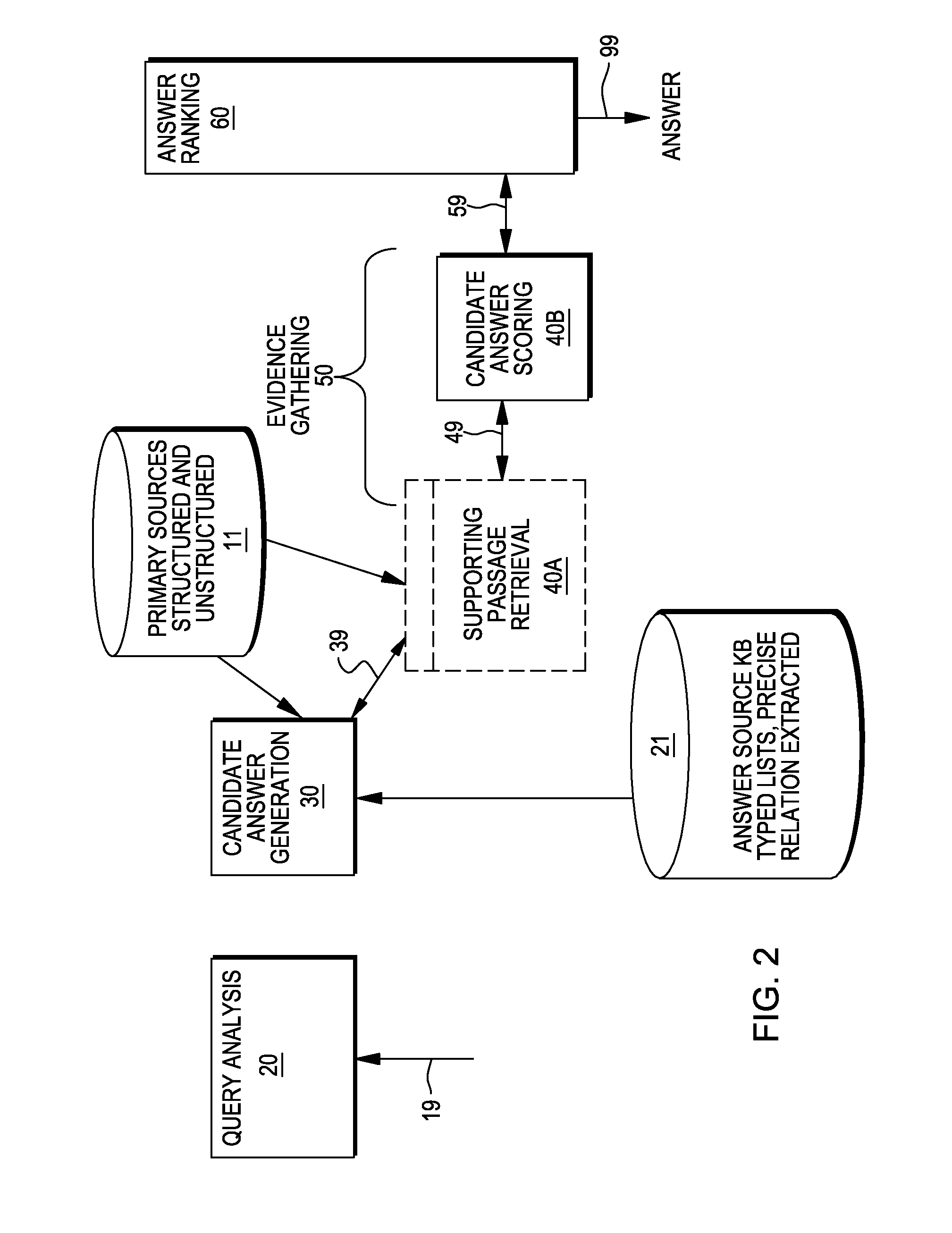

Providing answers to questions using multiple models to score candidate answers

ActiveUS20130007055A1Digital data information retrievalDigital data processing detailsRankingMultiple Models

A method, system and computer program product for generating answers to questions. In one embodiment, the method comprises receiving an input query; conducting a search to identify candidate answers to the input query, and producing a plurality of scores for each of the candidate answers. For each of the candidate answers, one, of a plurality of candidate ranking functions, is selected. This selected ranking function is applied to the each of the candidate answers to determine a ranking for the candidate answer based on the scores for that candidate answer. One or more of the candidate answers is selected, based on the rankings for the candidate answers, as one or more answers to the input query. In an embodiment, the ranking function selection is performed using information about the question. In an embodiment, the ranking function selection is performed using information about each answer.

Owner:INT BUSINESS MASCH CORP

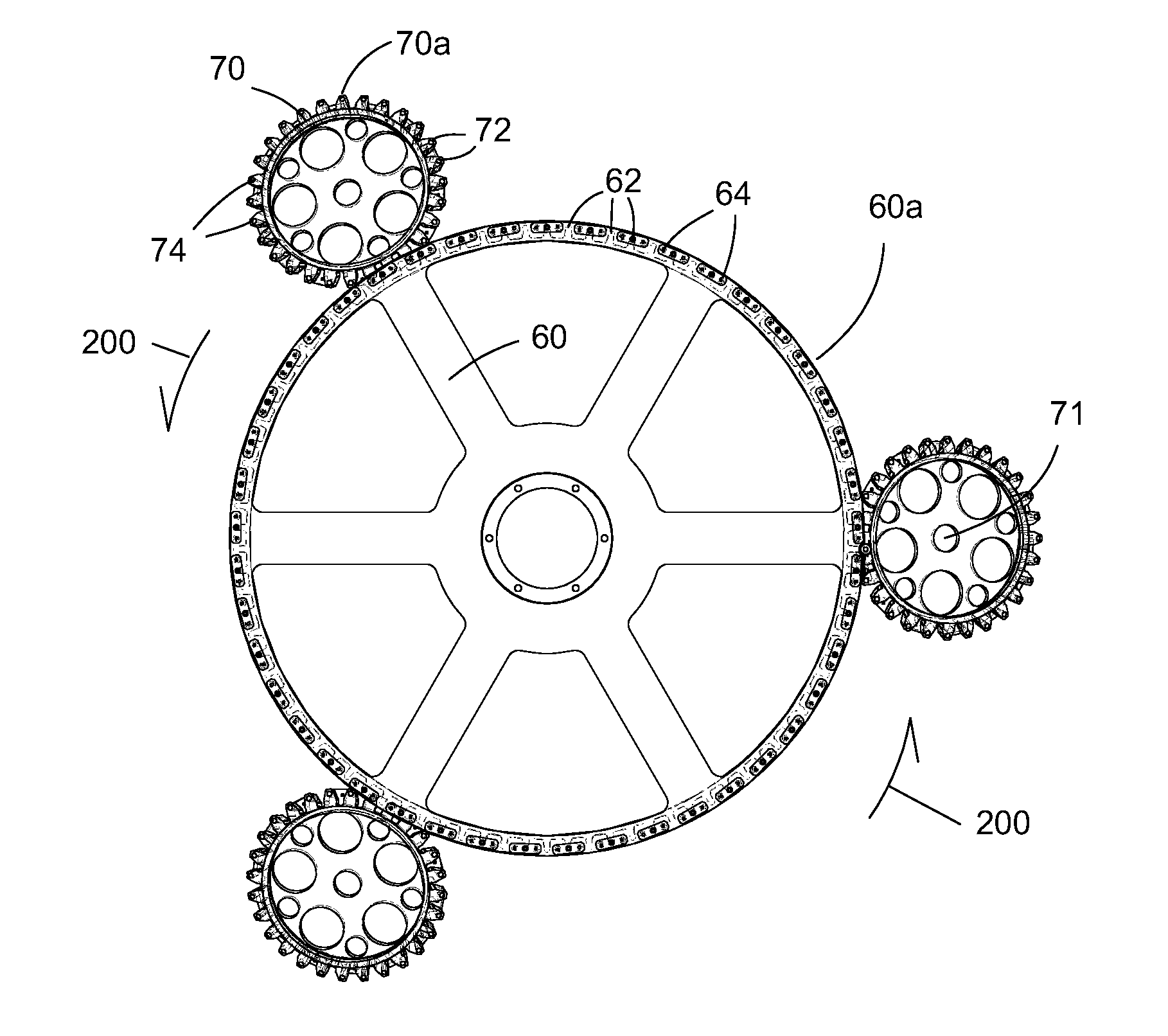

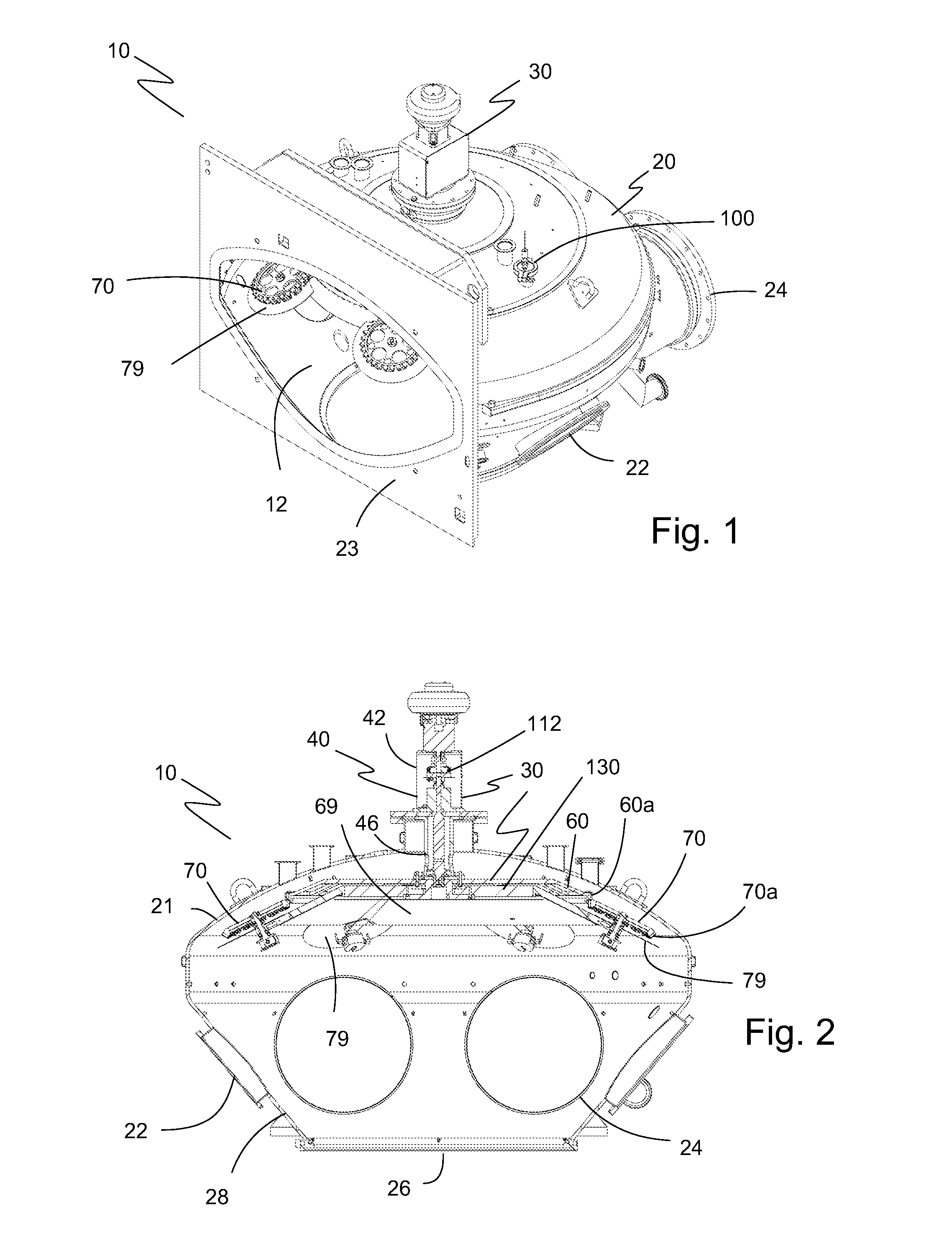

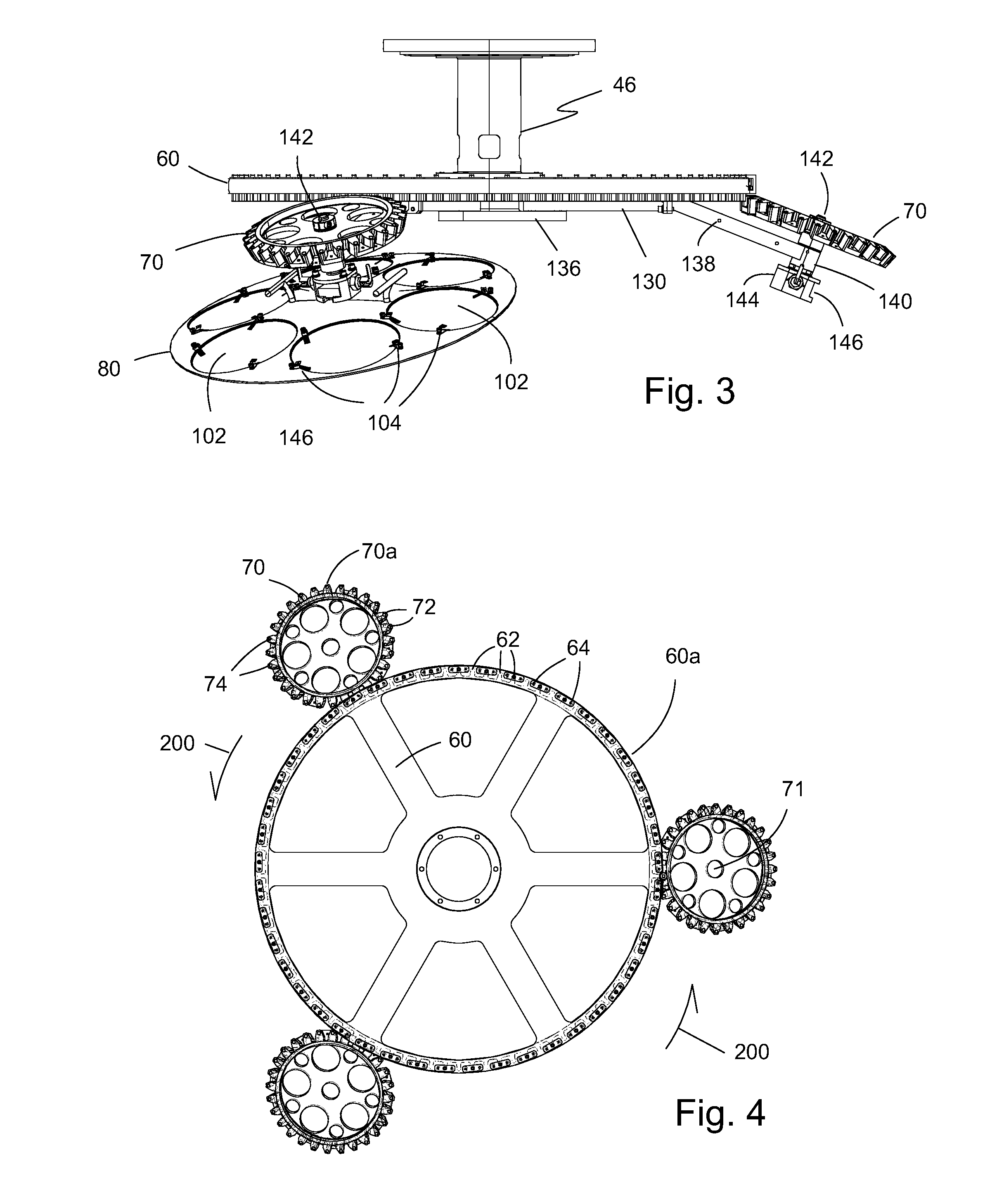

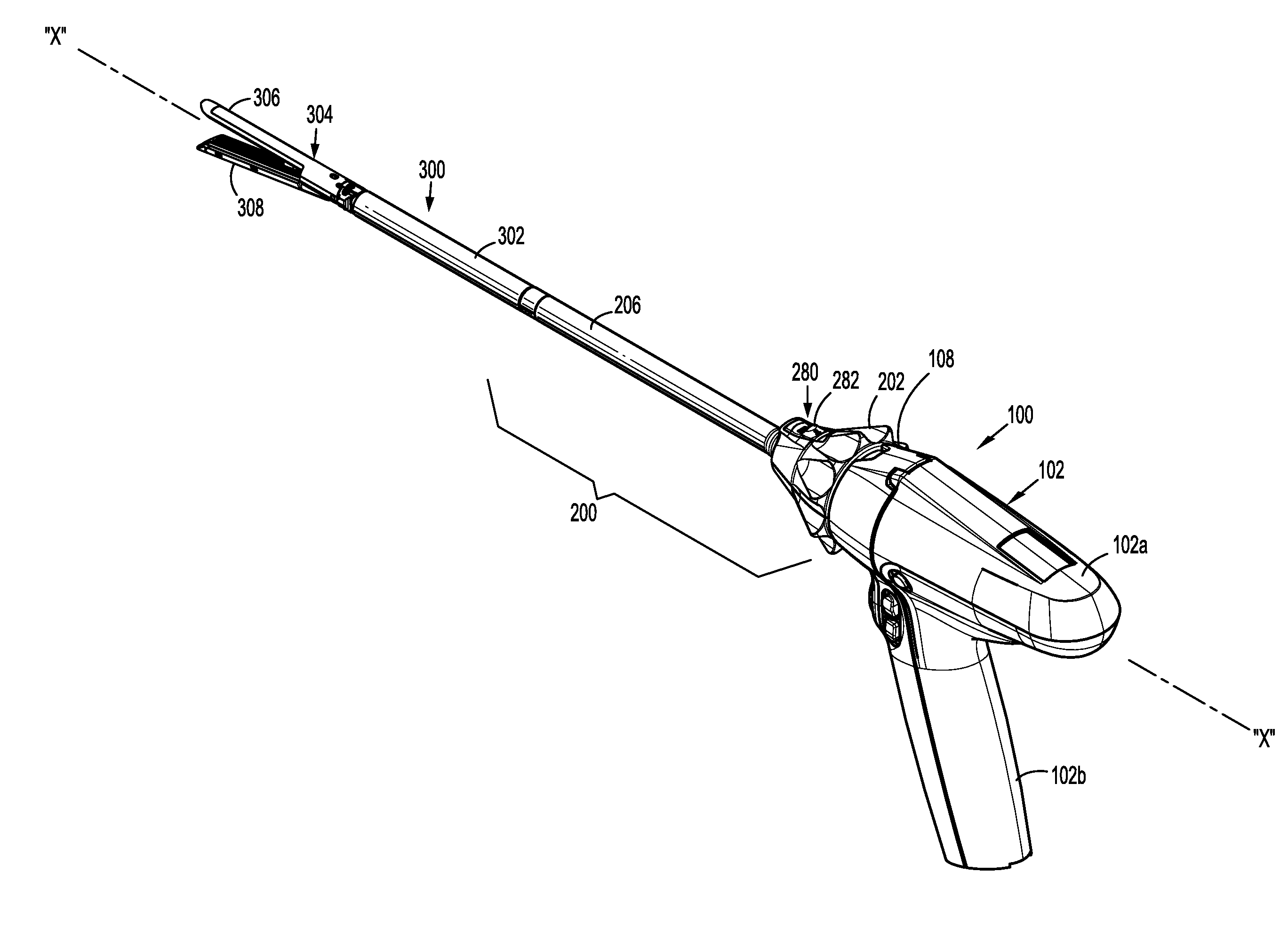

Non-contact magnetic drive assembly with mechanical stop elements

ActiveUS20130095973A1Improve throughputMinimizing particulate contaminationVacuum evaporation coatingSemiconductor/solid-state device manufacturingMechanical driveVacuum deposition

A non-contact magnetic drive assembly with mechanical stop elements for a vacuum deposition system employing a lift-off process having a HULA configuration featuring a plurality of magnets coupled in an annular orientation to a central ring and an orbital ring, each magnet of the orbital ring becomes superposed with a magnet of the central ring as the orbital ring rotates, and a central drive component driving either the central ring, the orbital ring around the central ring or both simultaneously, the central drive component provides a rotational speed allowing non-contact, magnetic drive rotation of the orbital ring around the central ring until a difference between a magnetic drive torque of the superposed magnets and the rotational speed of the central drive component causes the superposed magnets to decouple enabling mechanical drive rotation by interactive contact between a plurality of central ring teeth and a plurality of orbital ring.

Owner:FERROTEC USA CORP

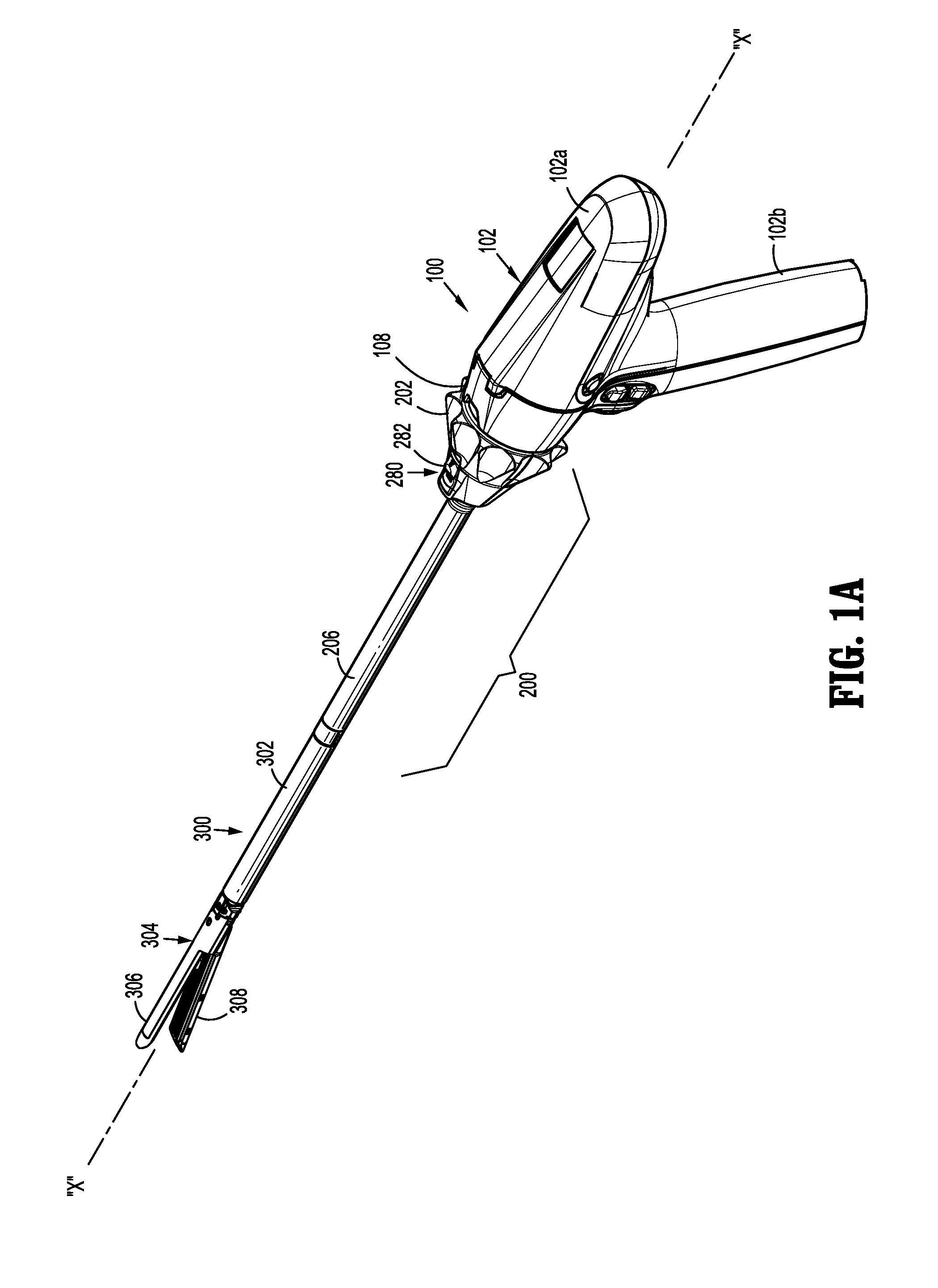

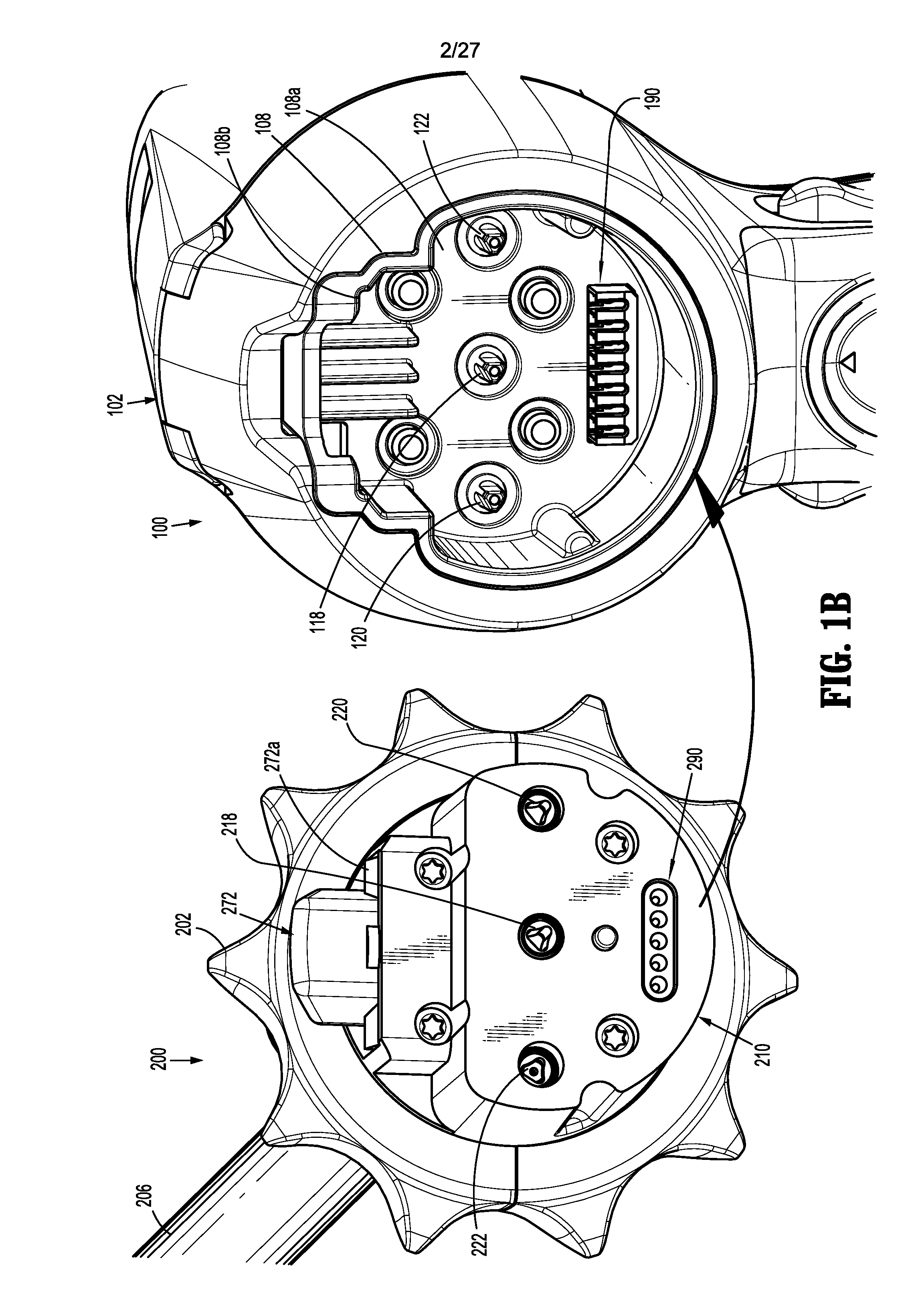

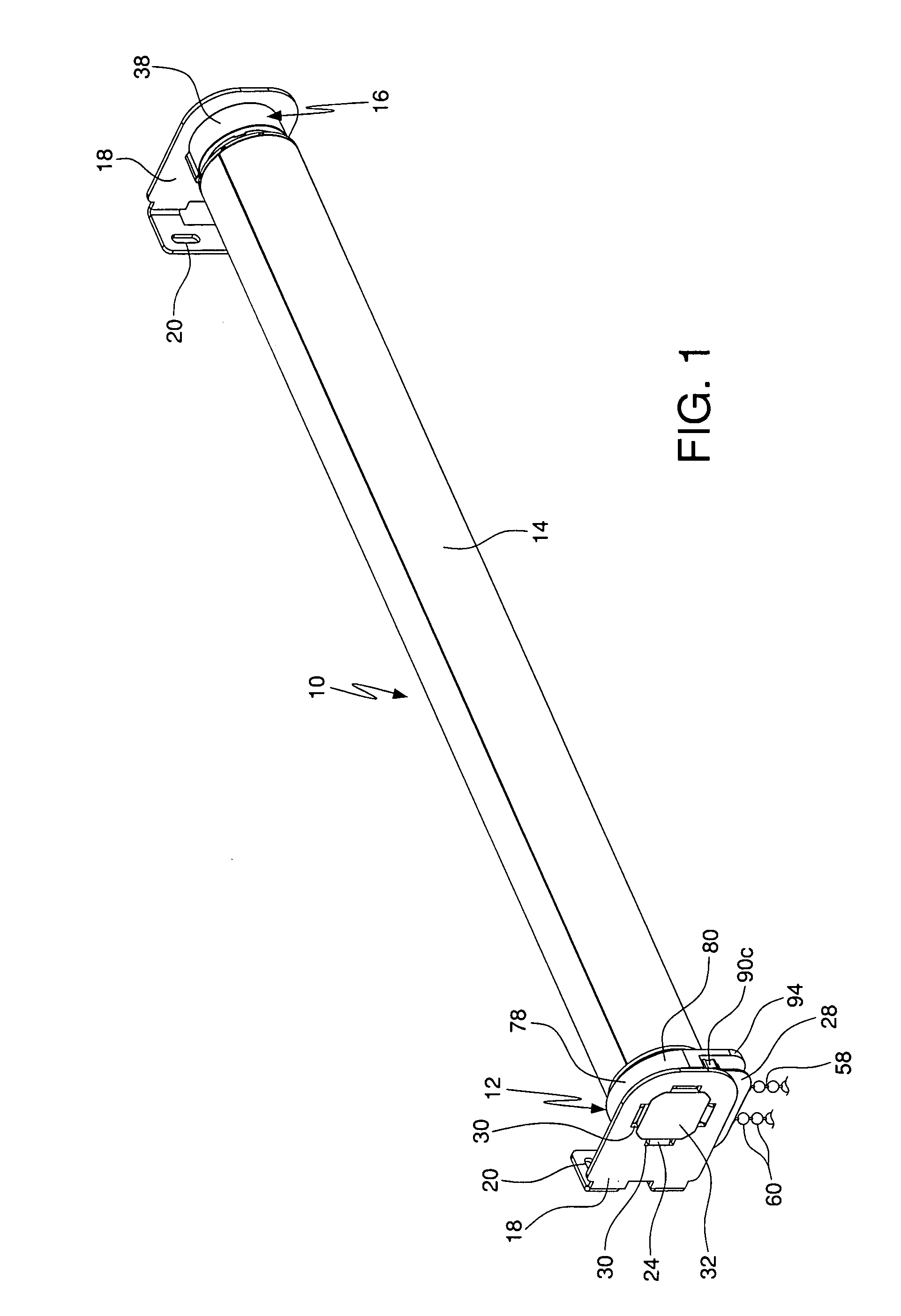

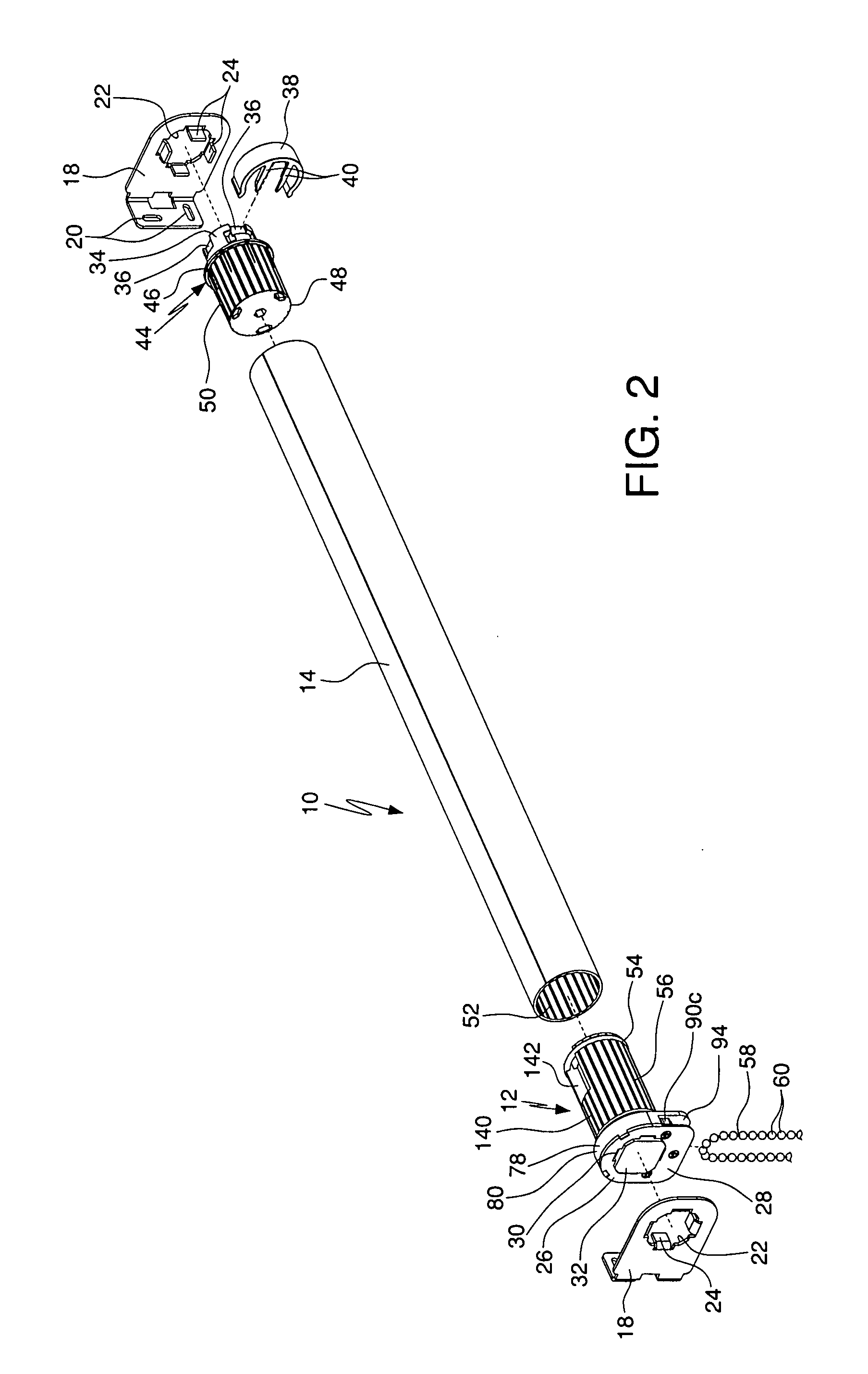

Adapter assembly for interconnecting electromechanical surgical devices and surgical loading units, and surgical systems thereof

The present disclosure relates to adapter assemblies for use with and to electrically and mechanically interconnect electromechanical surgical devices and surgical loading units, and to surgical systems including hand held electromechanical surgical devices and adapter assemblies for connecting surgical loading units to the hand held electromechanical surgical devices.

Owner:TYCO HEALTHCARE GRP LP

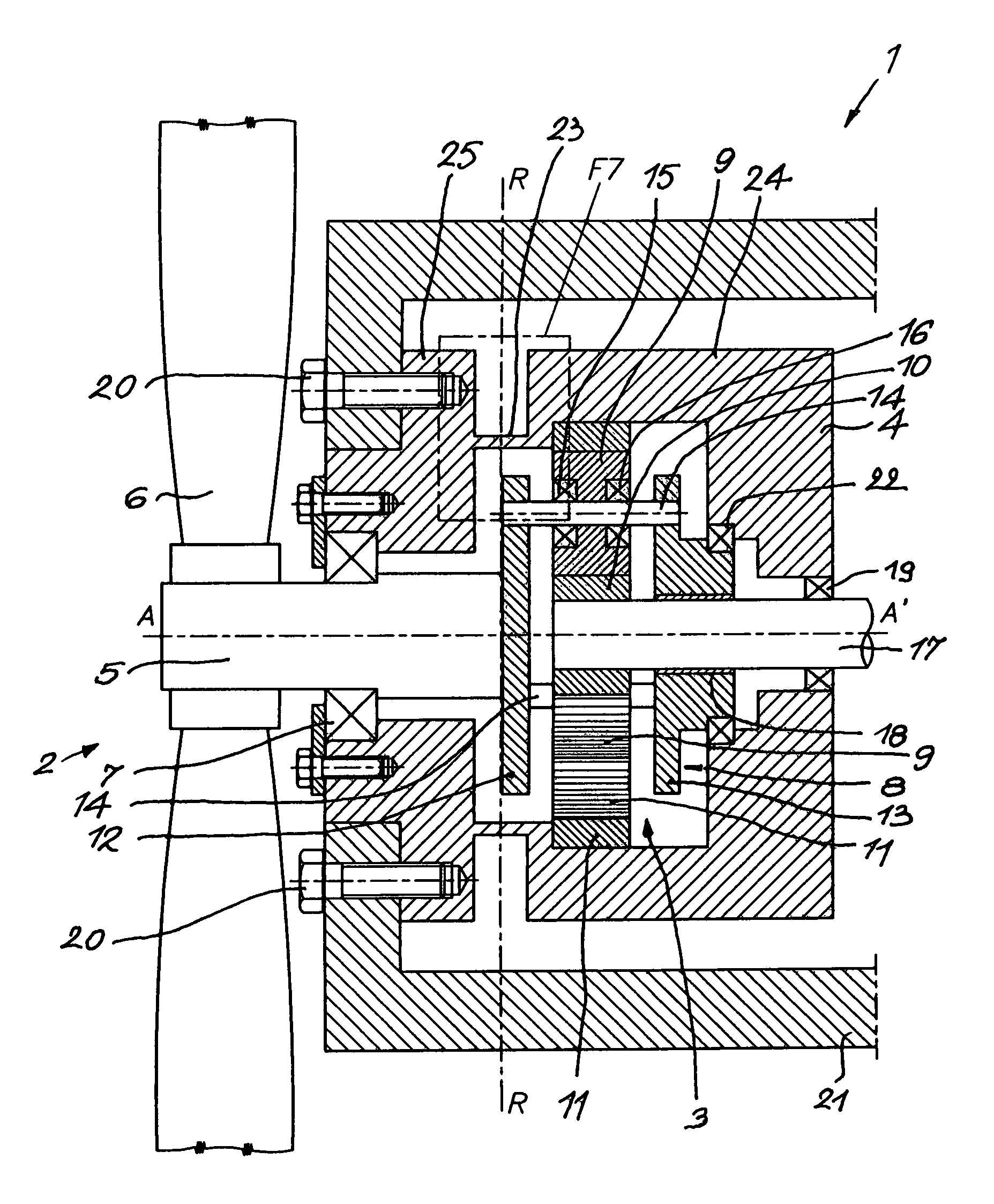

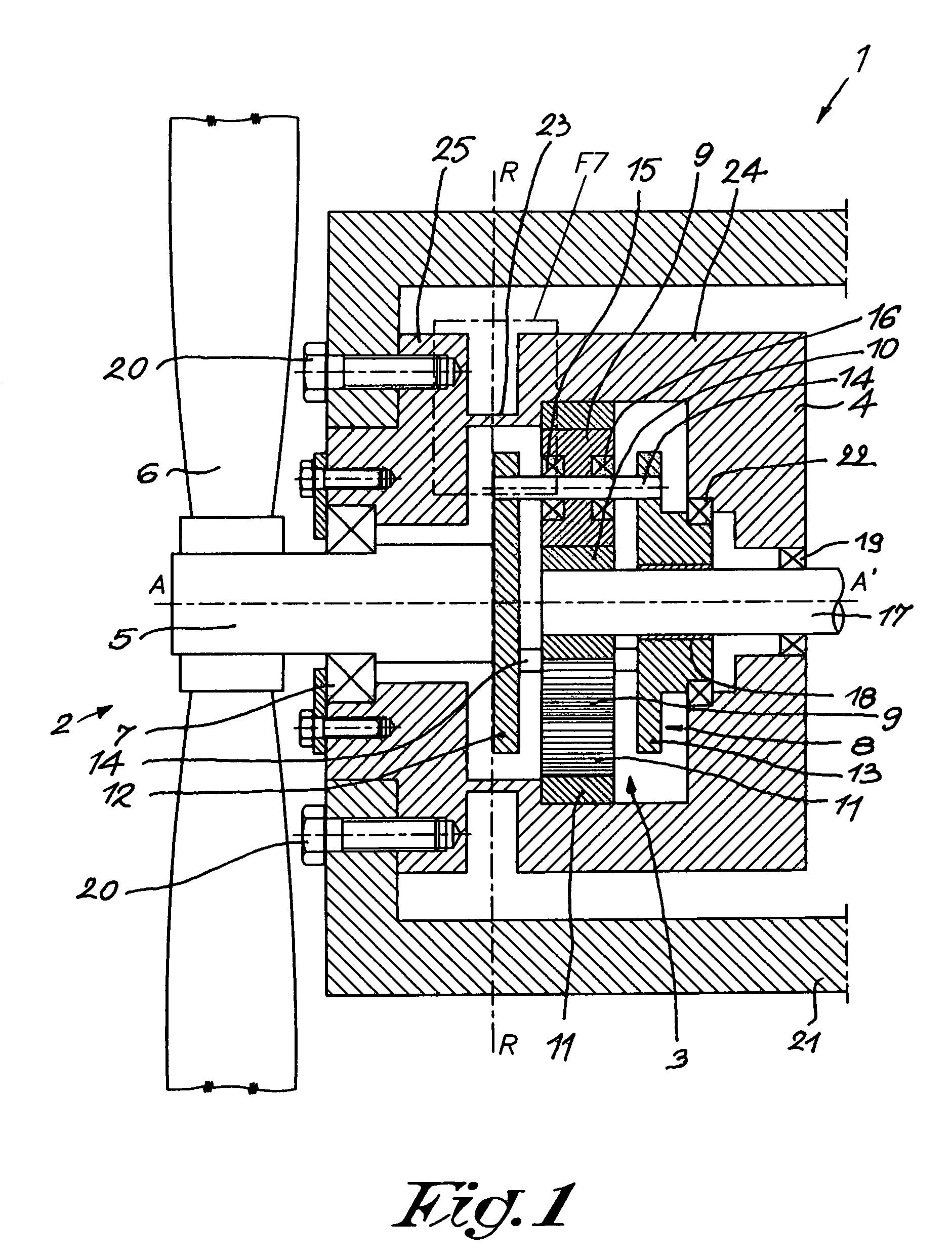

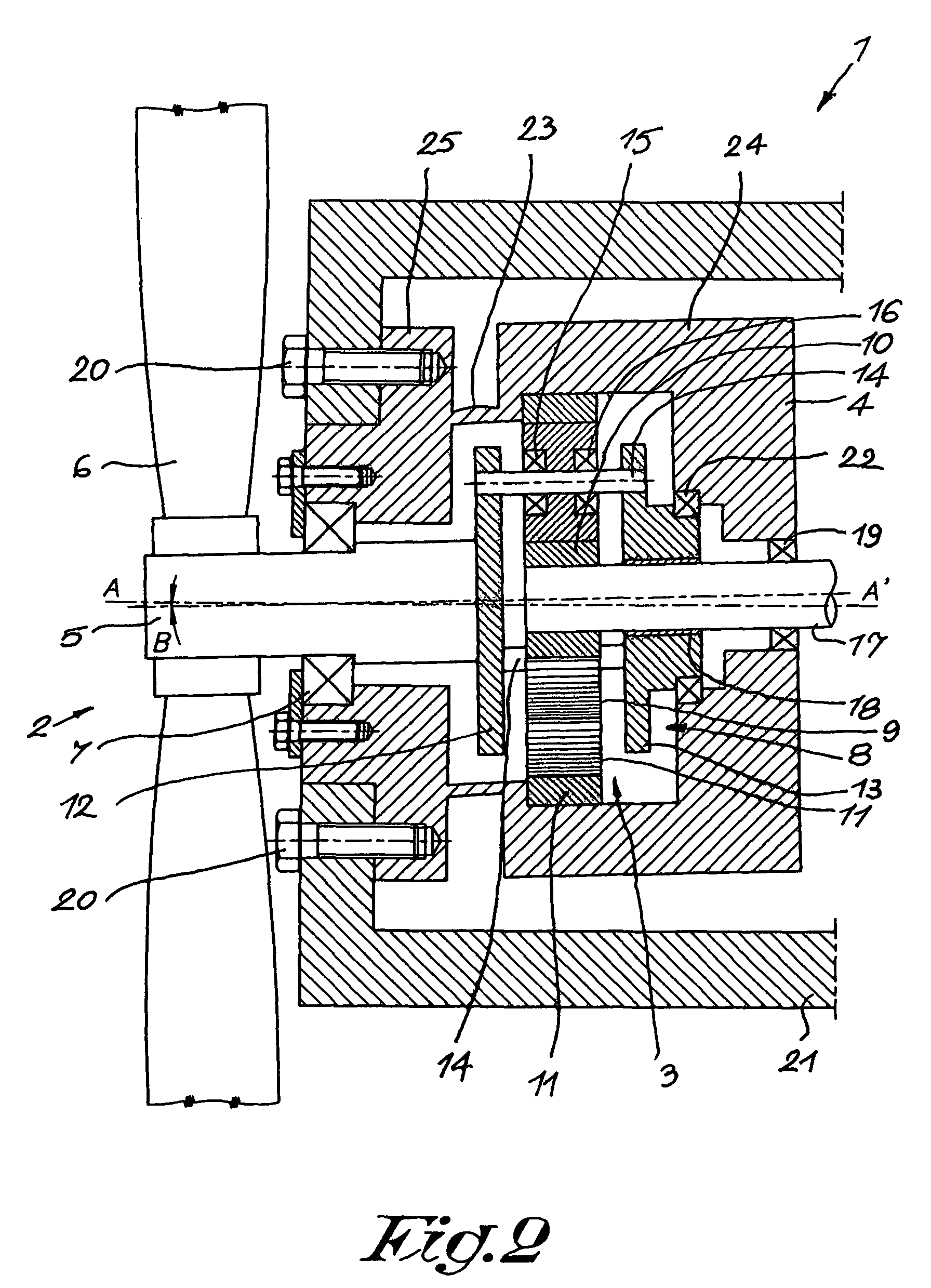

Gearbox for a wind turbine

A gearbox for a wind turbine includes a ring wheel unit provided in a housing; a driving shaft designed to be coupled to the rotor of the wind turbine and a single main bearing or a pair of main bearings which rotatably support the driving shaft in the housing. The ring wheel unit is formed of a sun wheel, a planet wheel, ring wheel which is fixed to the housing in a non-rotating manner and a planet carrier which is rigidly connected to the driving shaft. An additional bearing rotatably supports the planet carrier or the driving shaft relative to the housing. Between the part of the housing having the main bearing or the main bearings and the part of the housing with the additional bearing and the ring wheel, an elastic part is provided with relative torsional stiffness, yet relatively flexible to loads in the axial and / or radial direction.

Owner:HANSEN TRANSMISSIONS INT NV

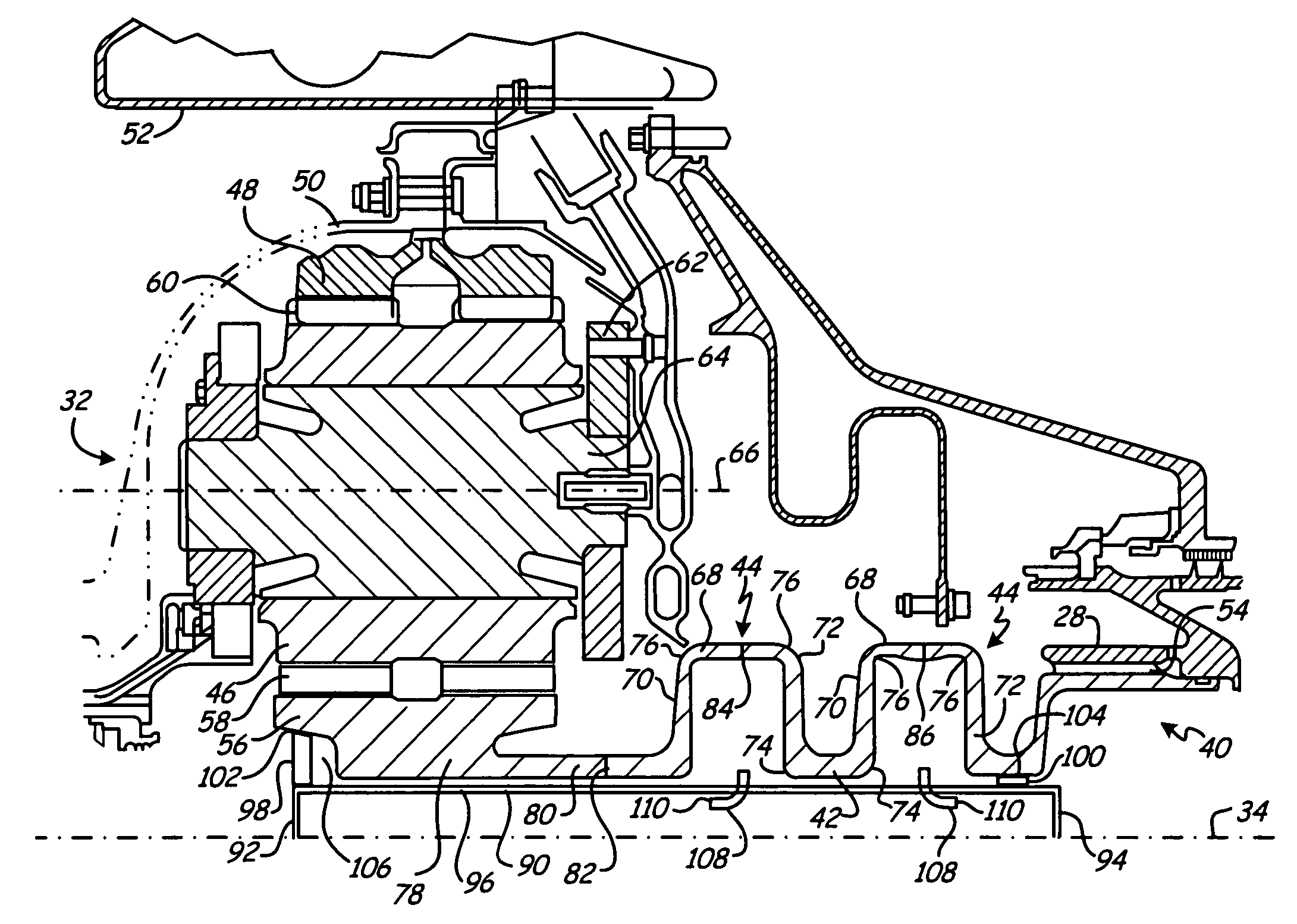

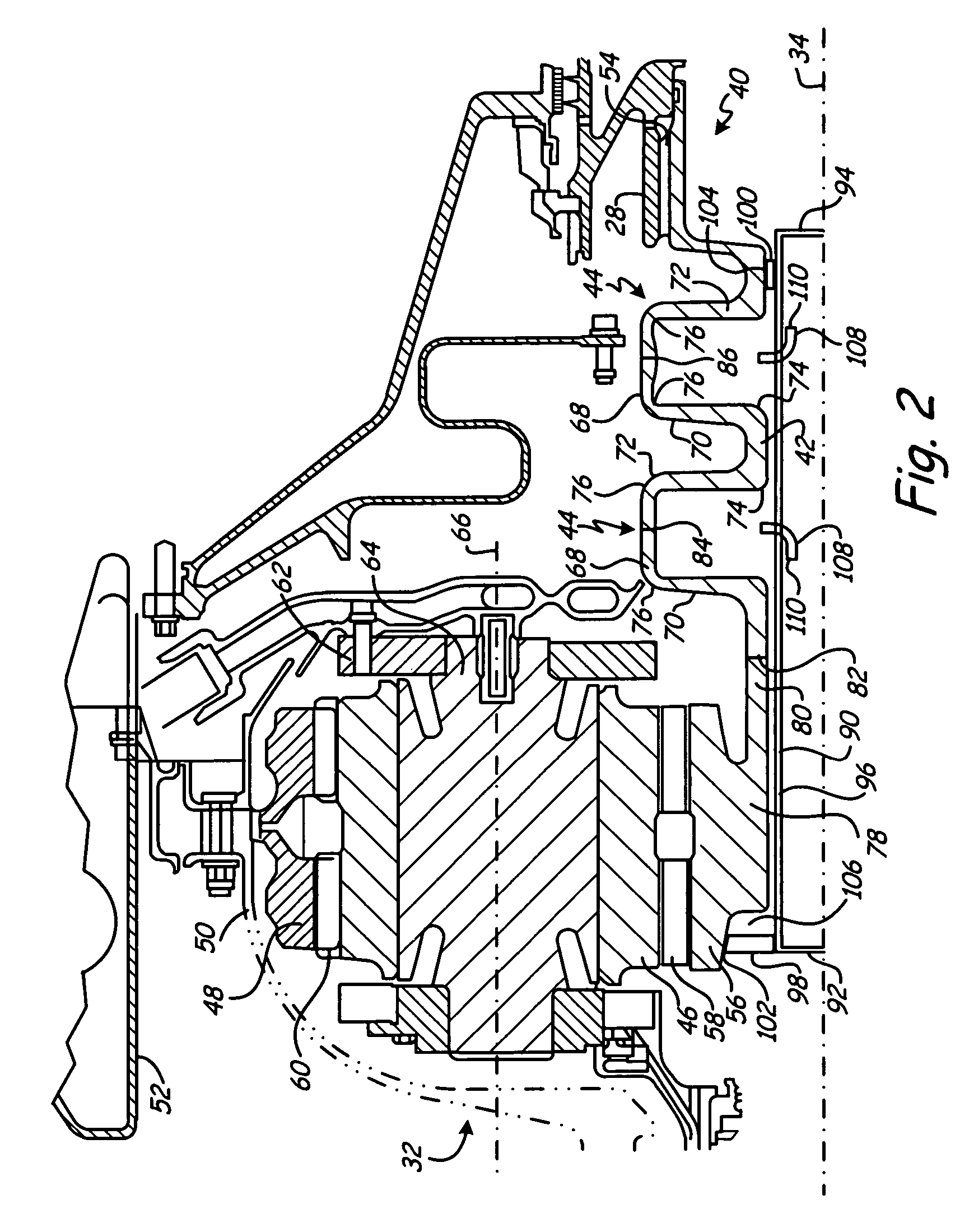

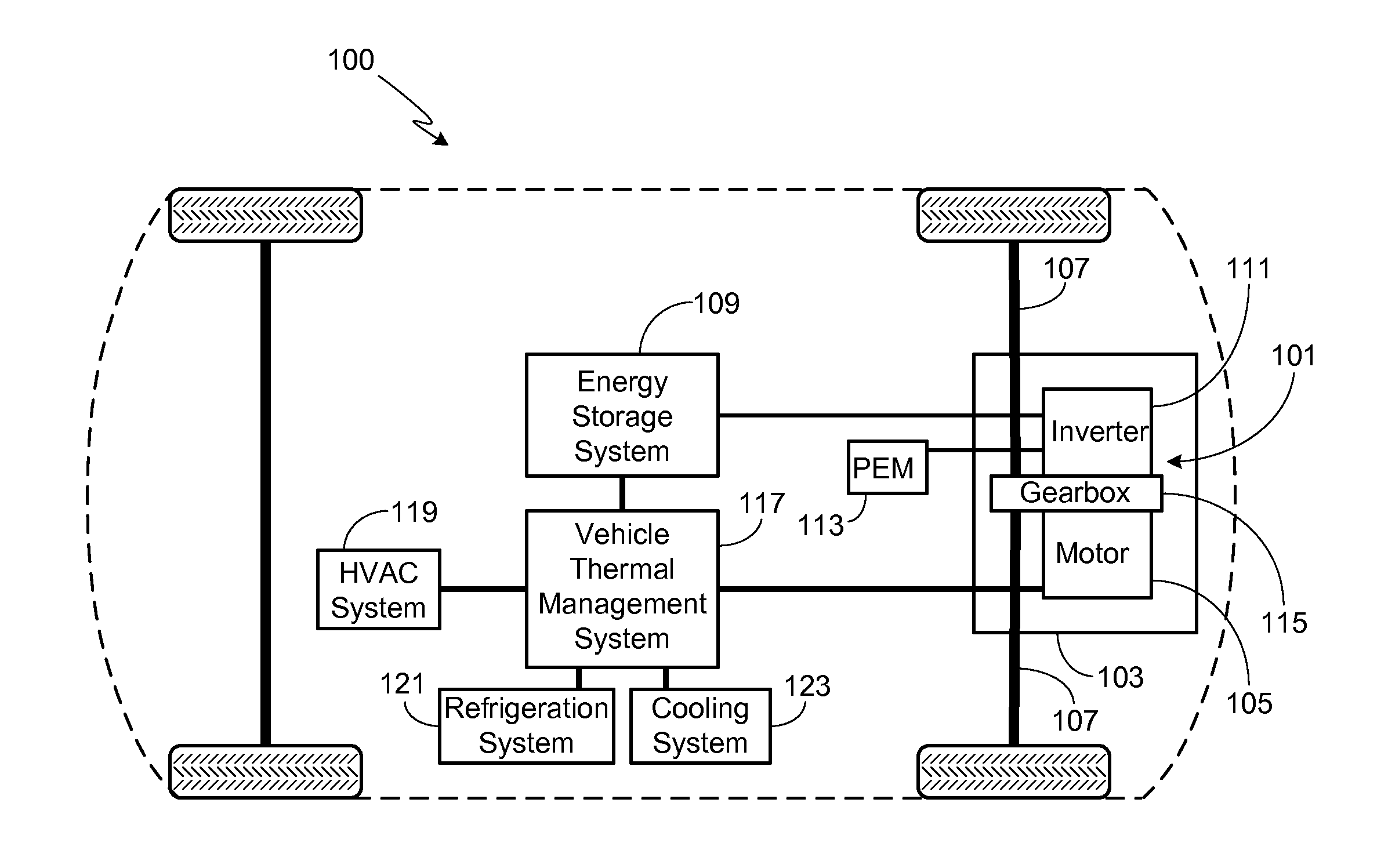

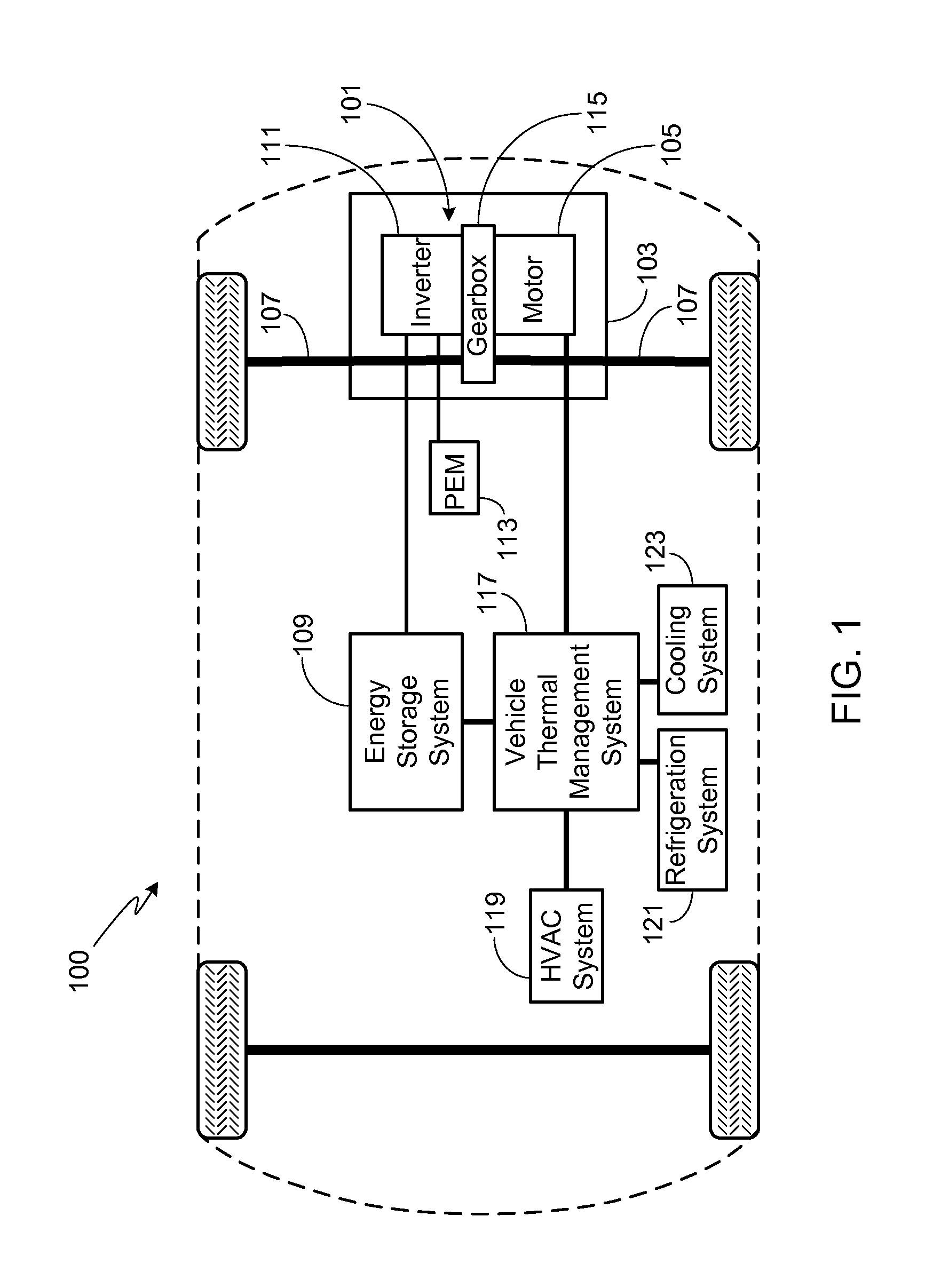

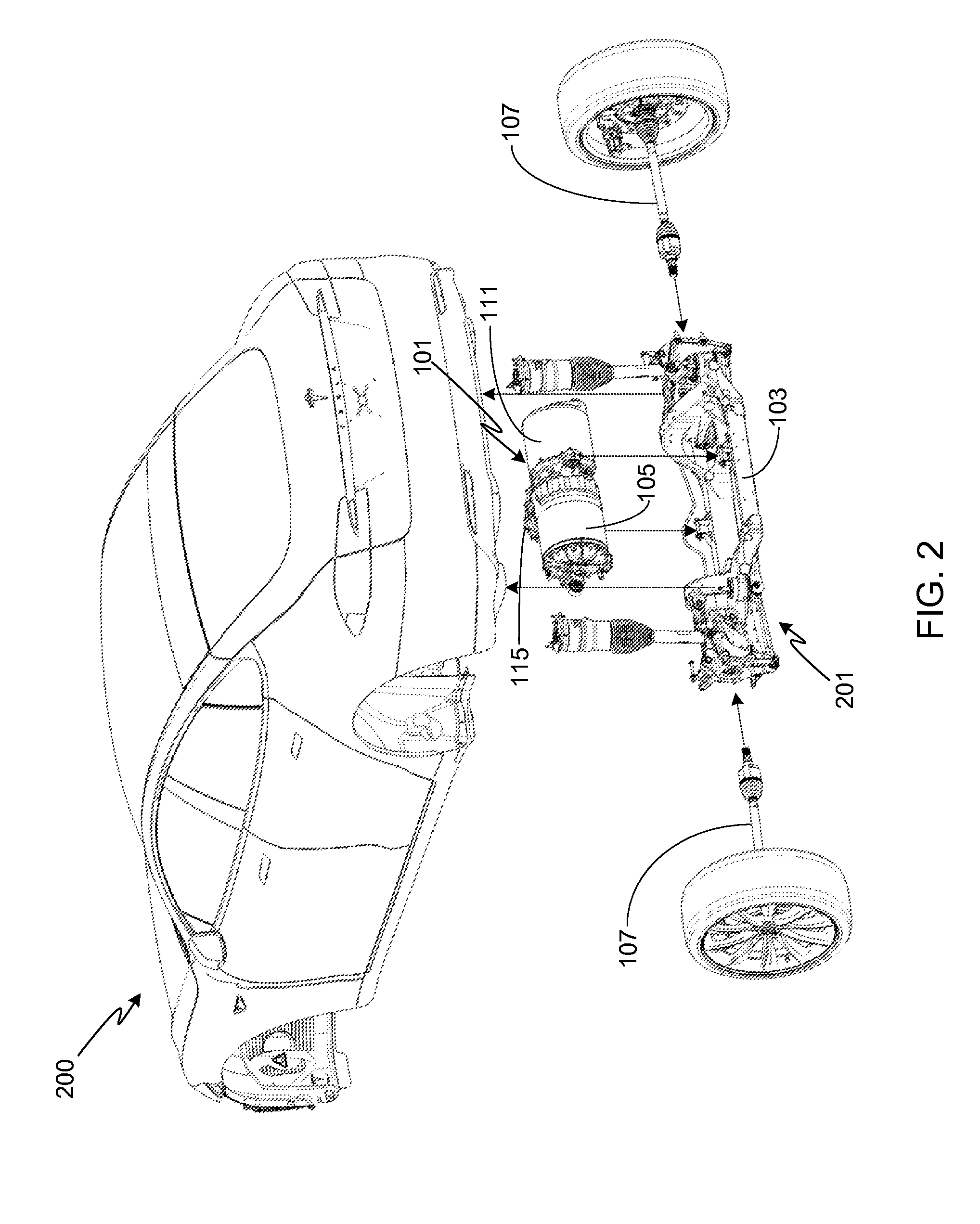

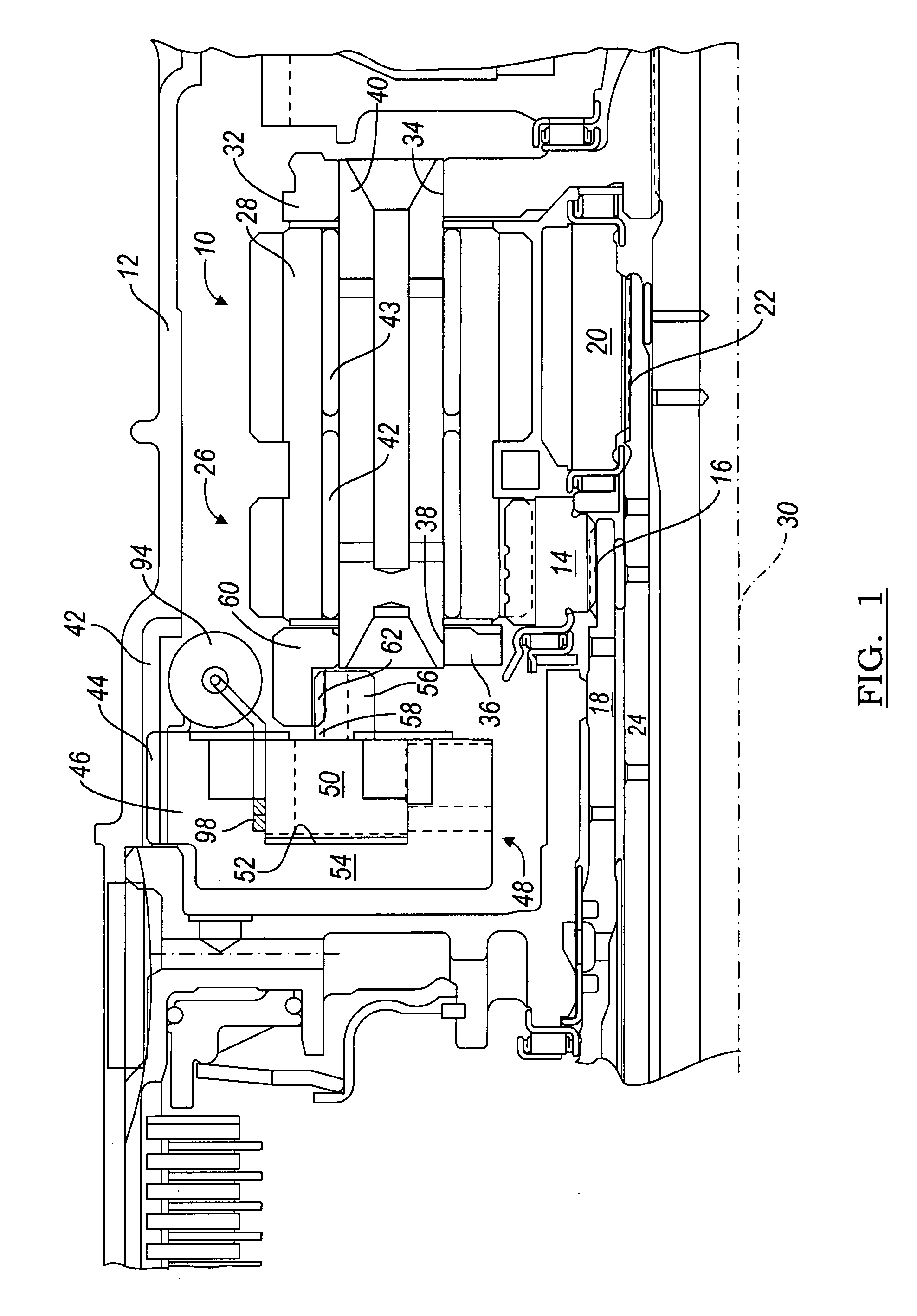

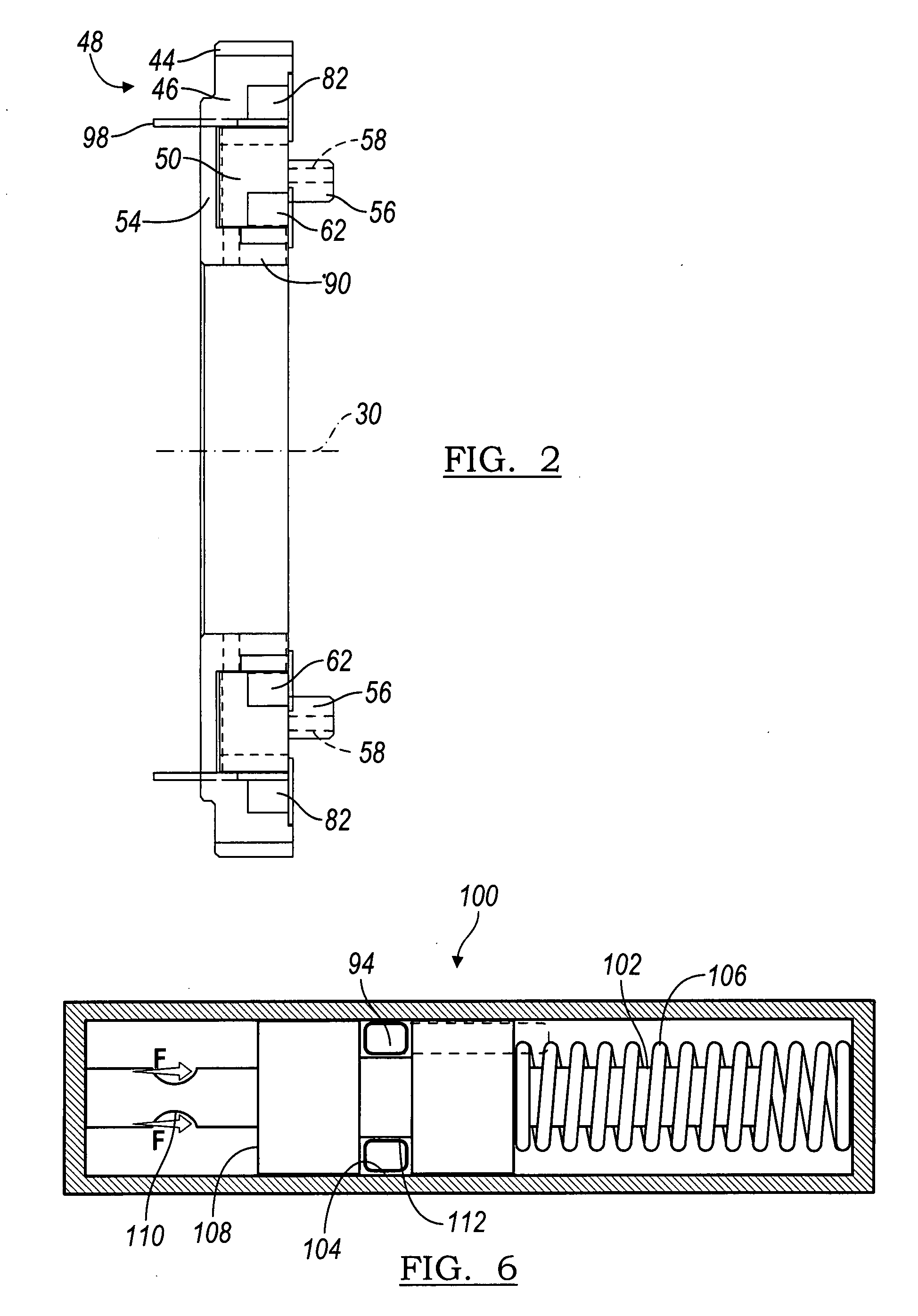

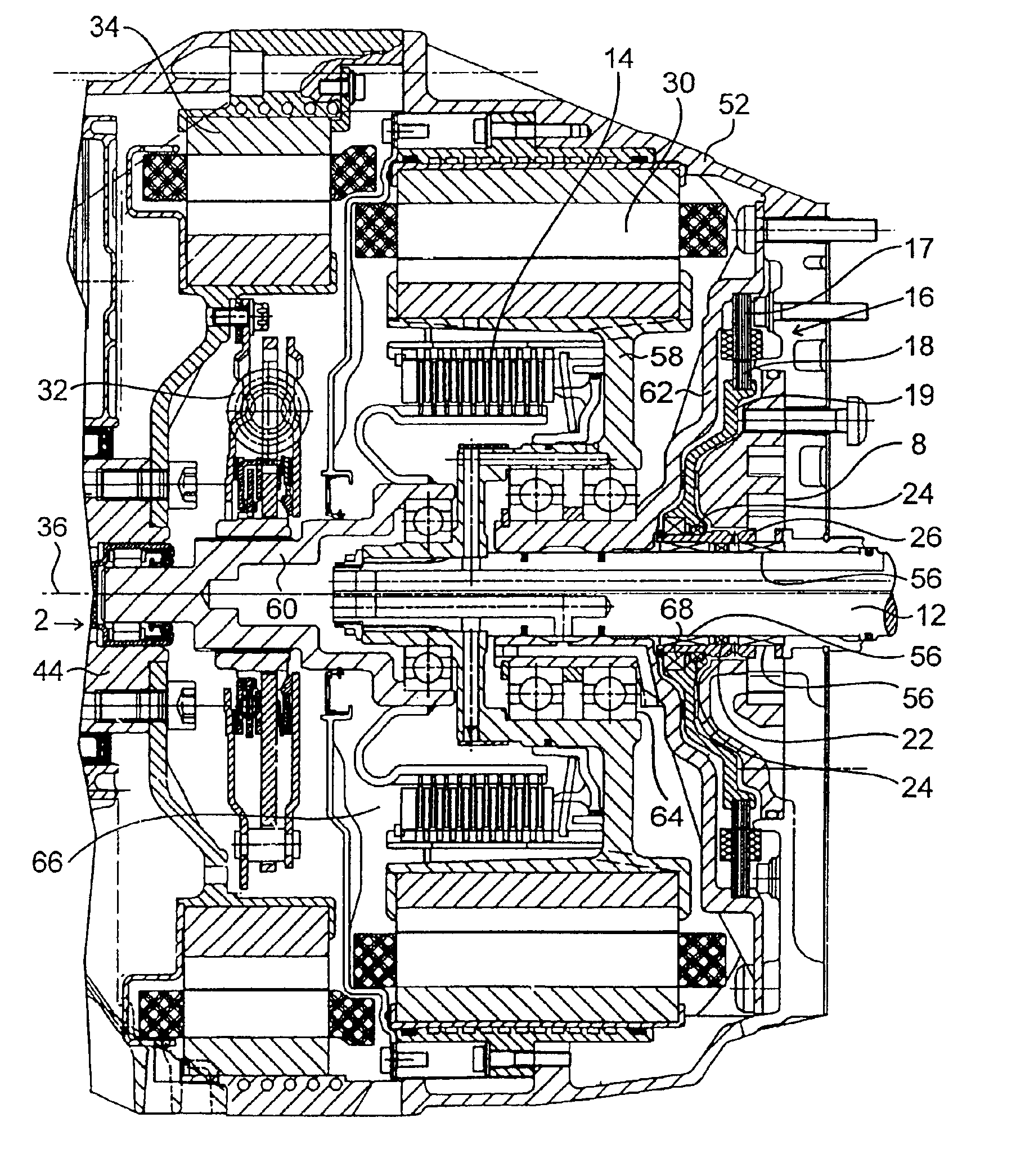

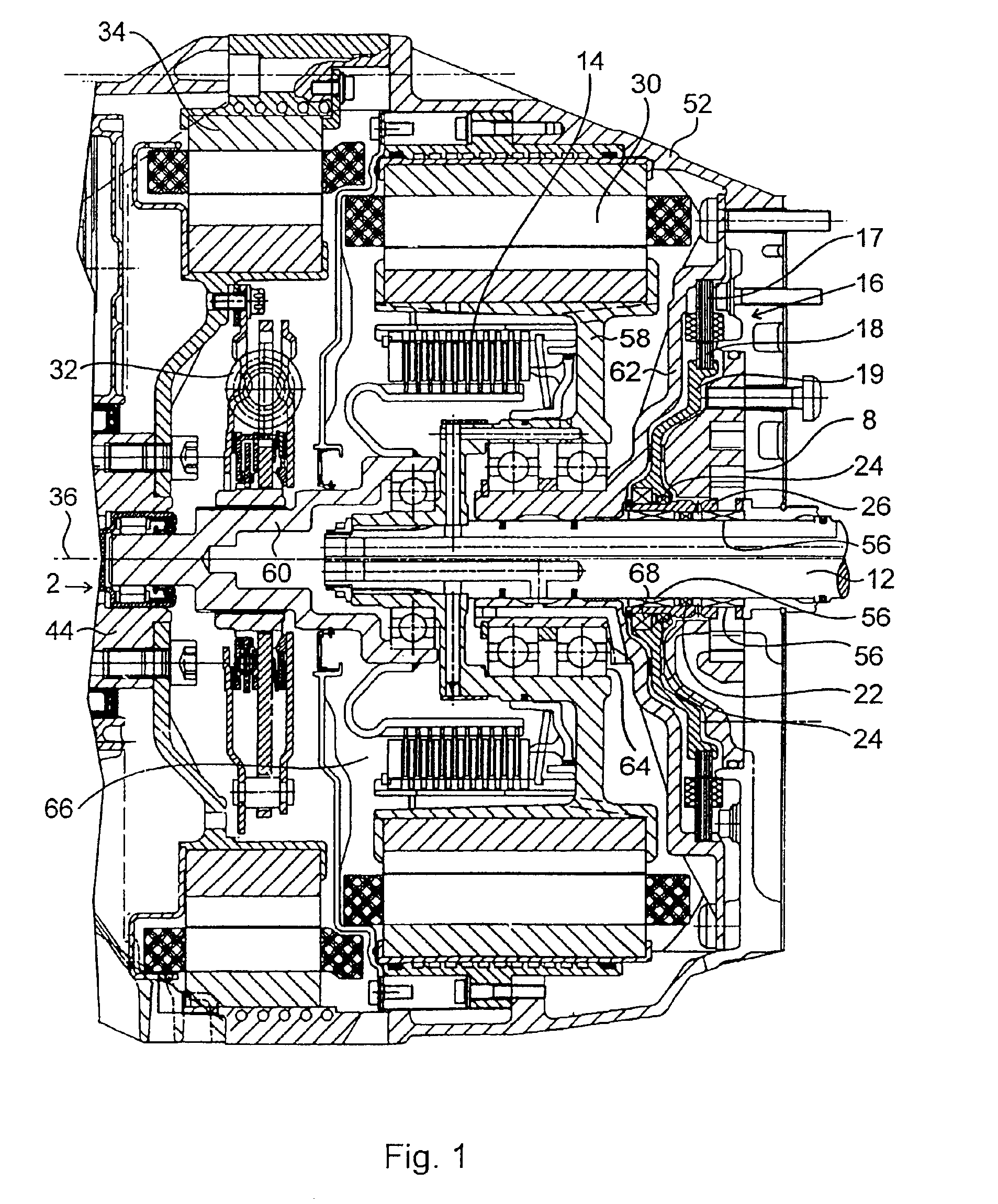

Thermal Management System for Use with an Integrated Motor Assembly

ActiveUS20120153718A1Reduce weightEasy to assembleHybrid vehiclesGearboxesManufacturing cost reductionPower inverter

An integrated drive system assembly is provided that combines an electric motor, a power inverter assembly and a gearbox into a single, multi-piece enclosure. Combining these components into a single enclosure reduces weight, reduces drive system complexity, reduces system volume, simplifies assembly integration into an electric vehicle, reduces manufacturing cost, allows the flexible and lengthy electrical cables between the power inverter and the electric motor to be replaced with short, low loss, rigid bus bars, and simplifies component cooling by allowing the use of a common thermal management system. The common thermal management system includes a liquid coolant loop that is thermally coupled to the electric motor, the power inverter assembly and the gearbox.

Owner:TESLA INC

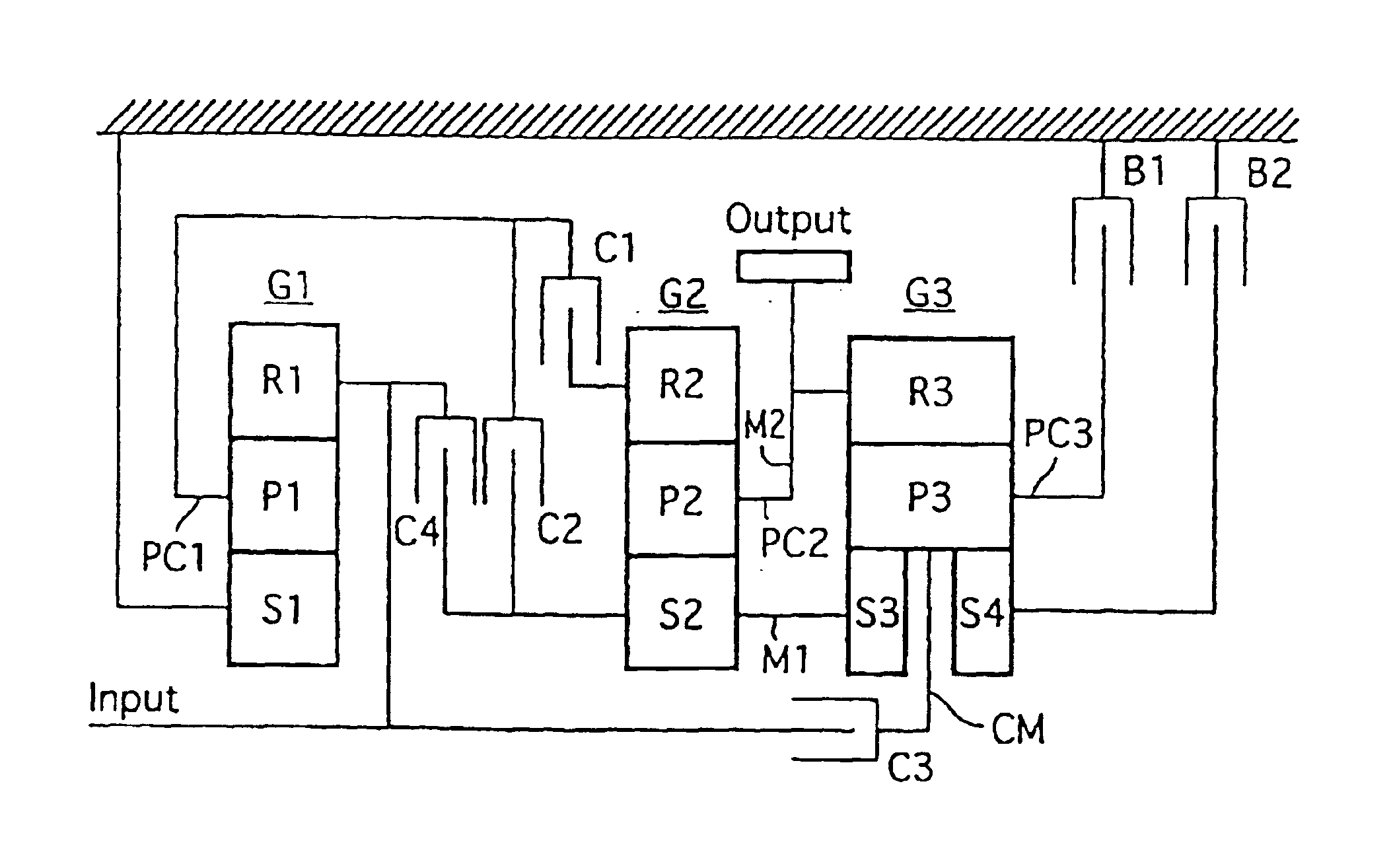

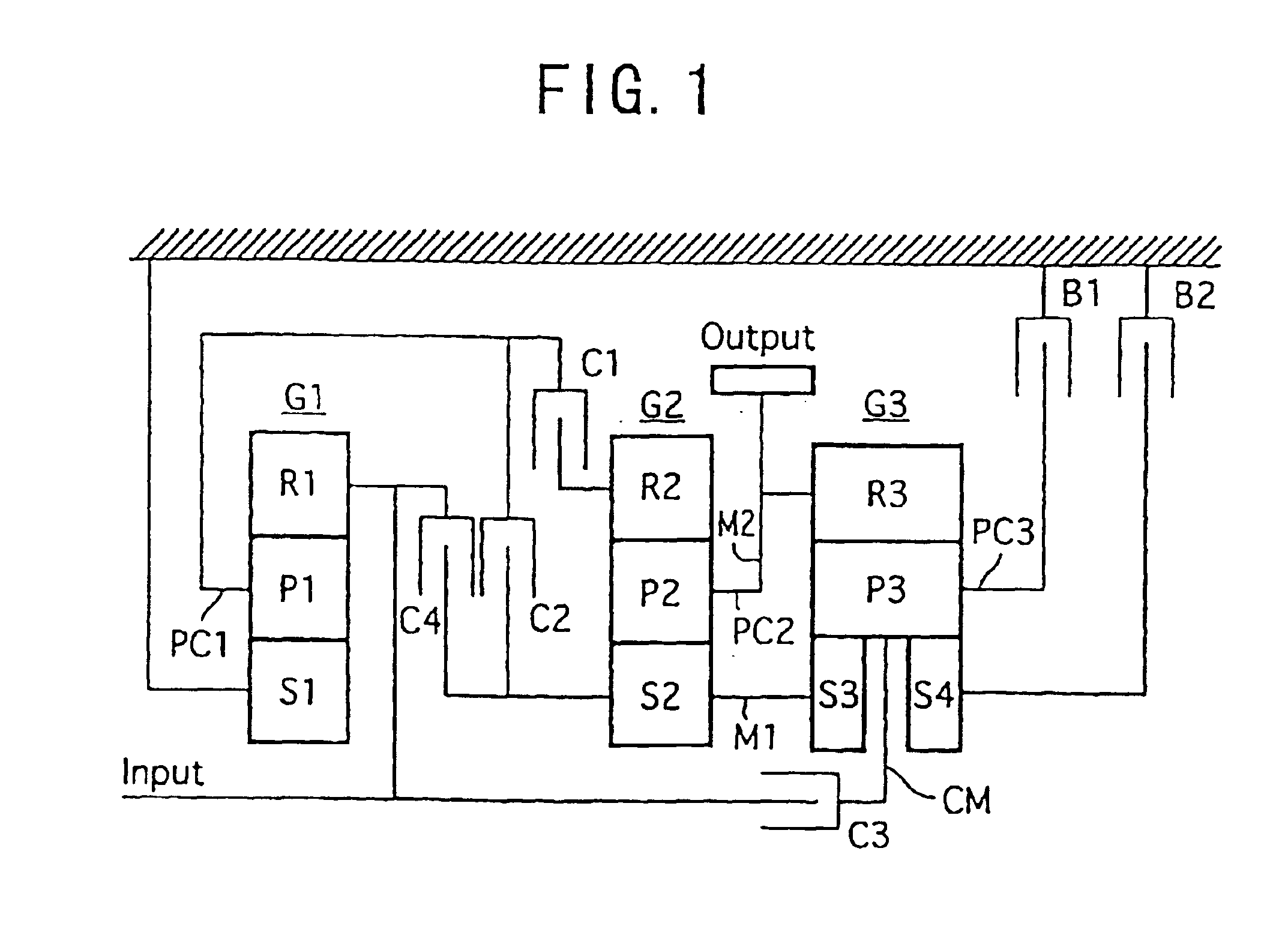

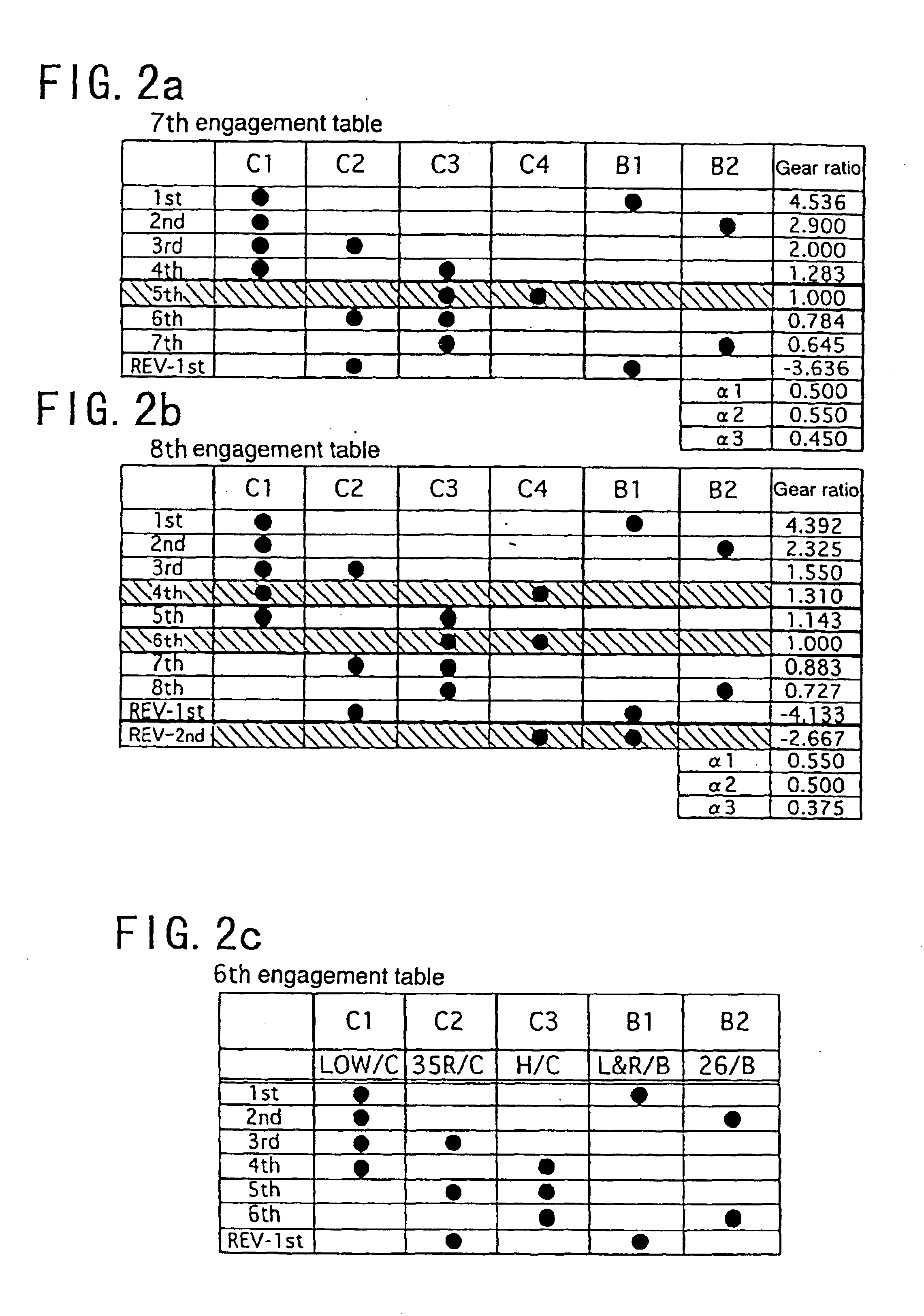

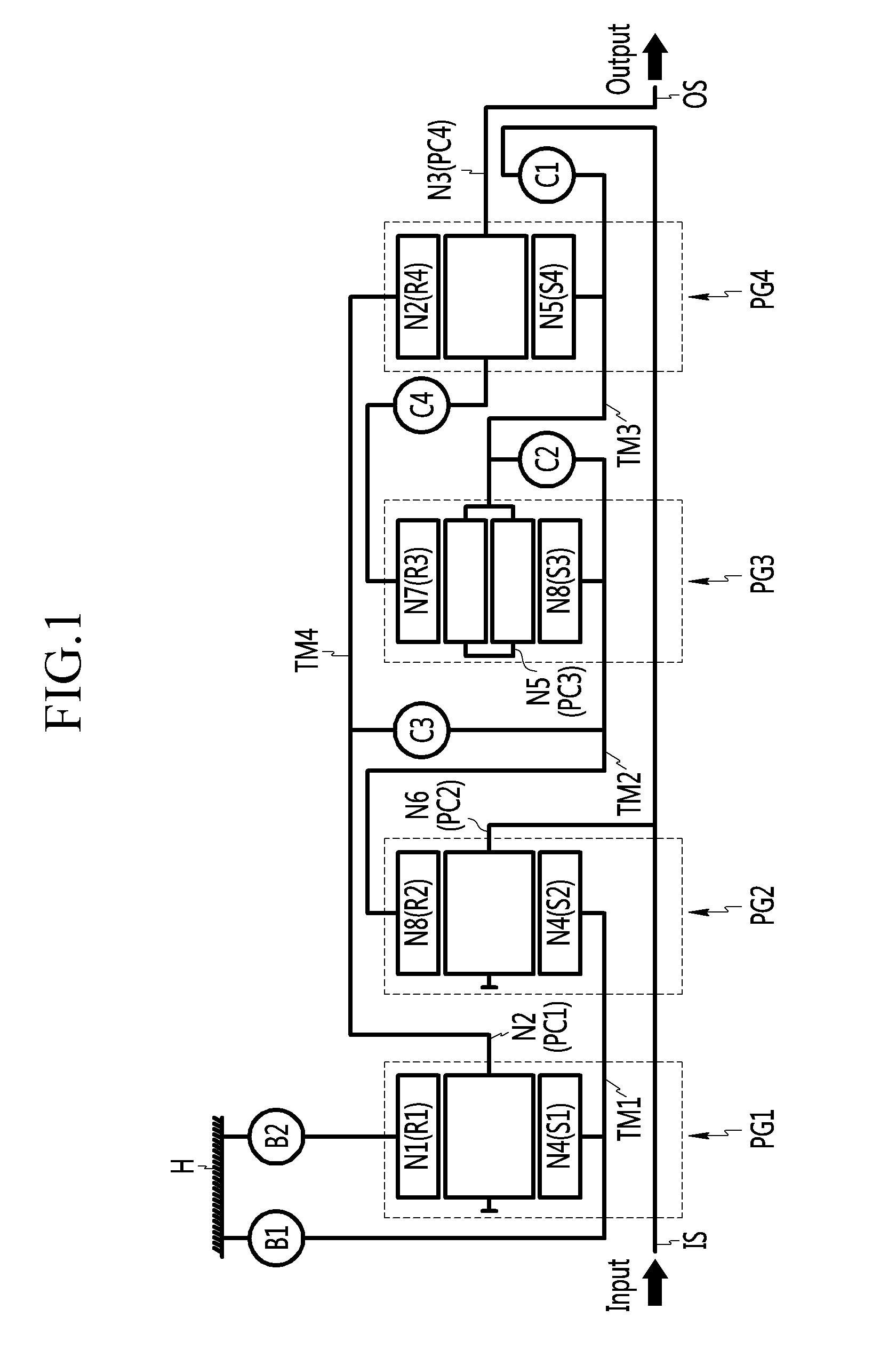

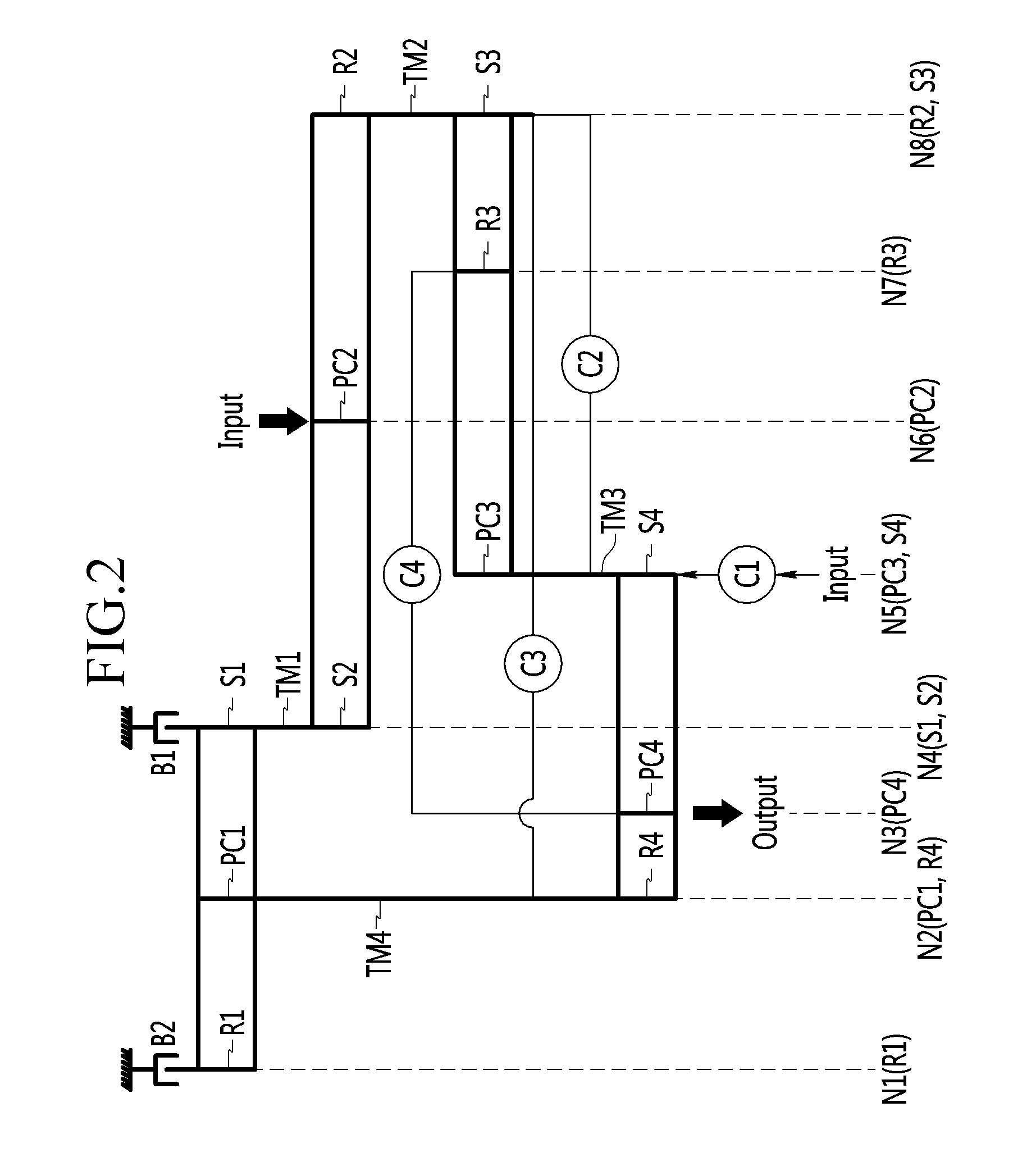

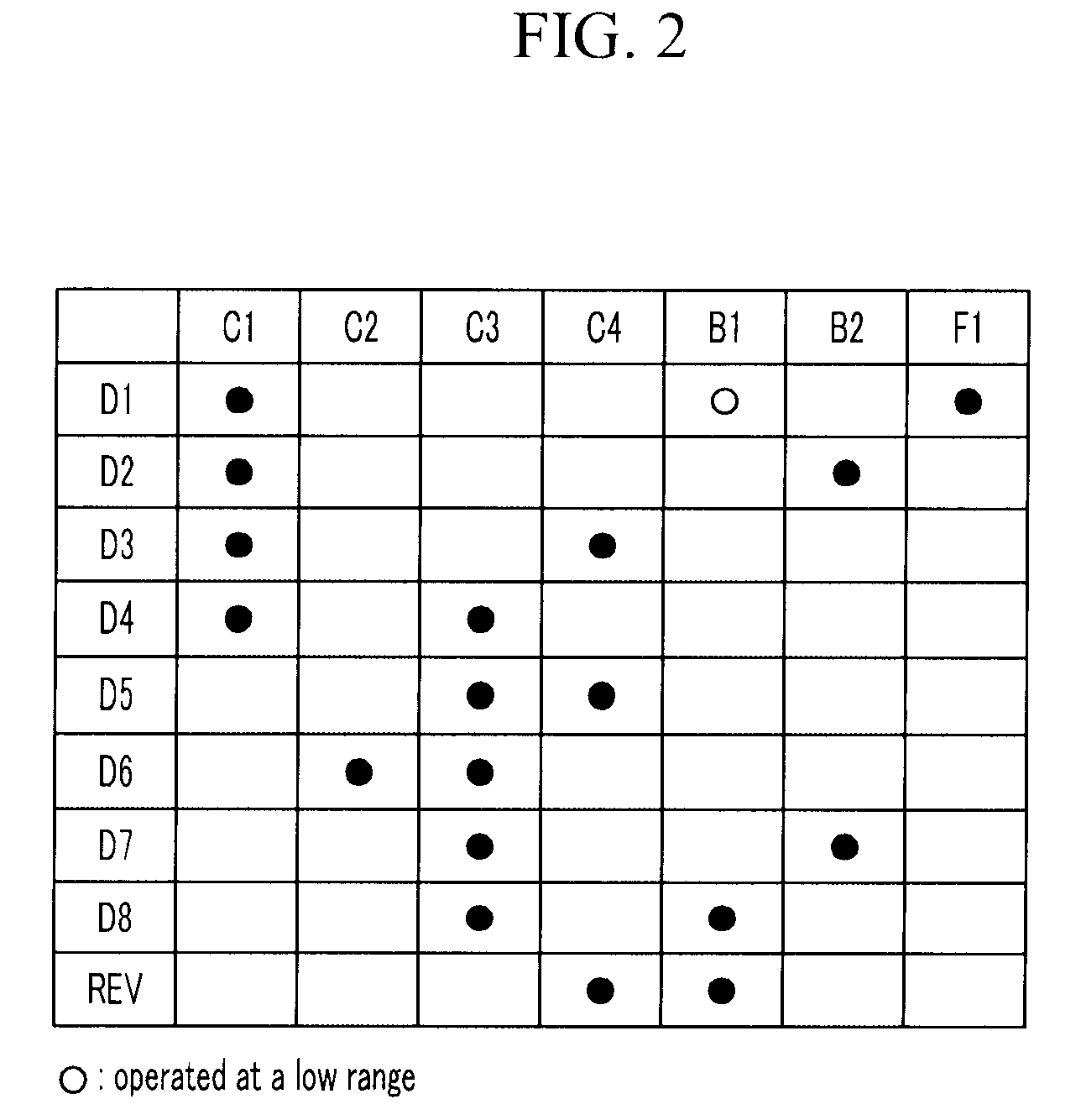

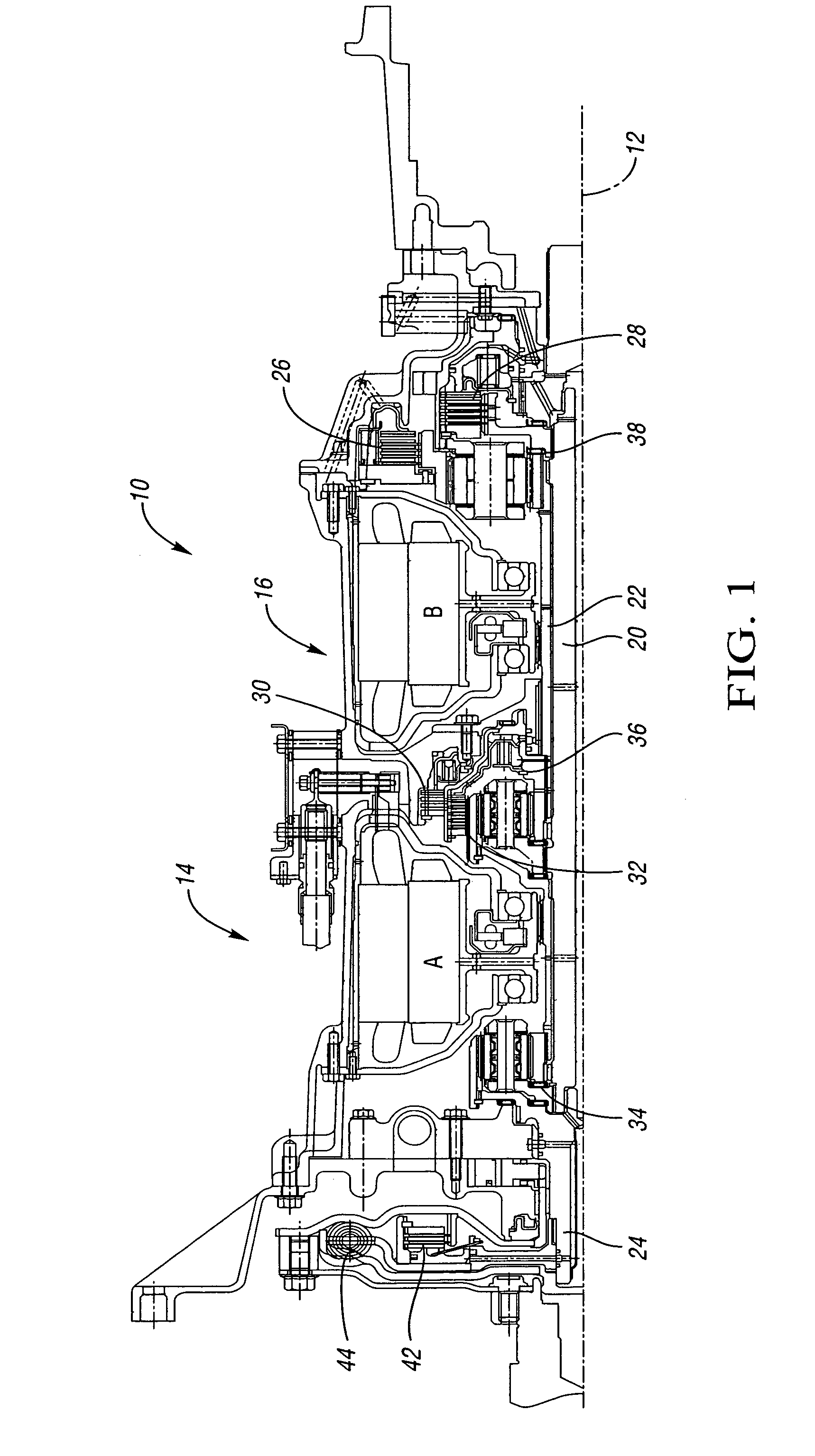

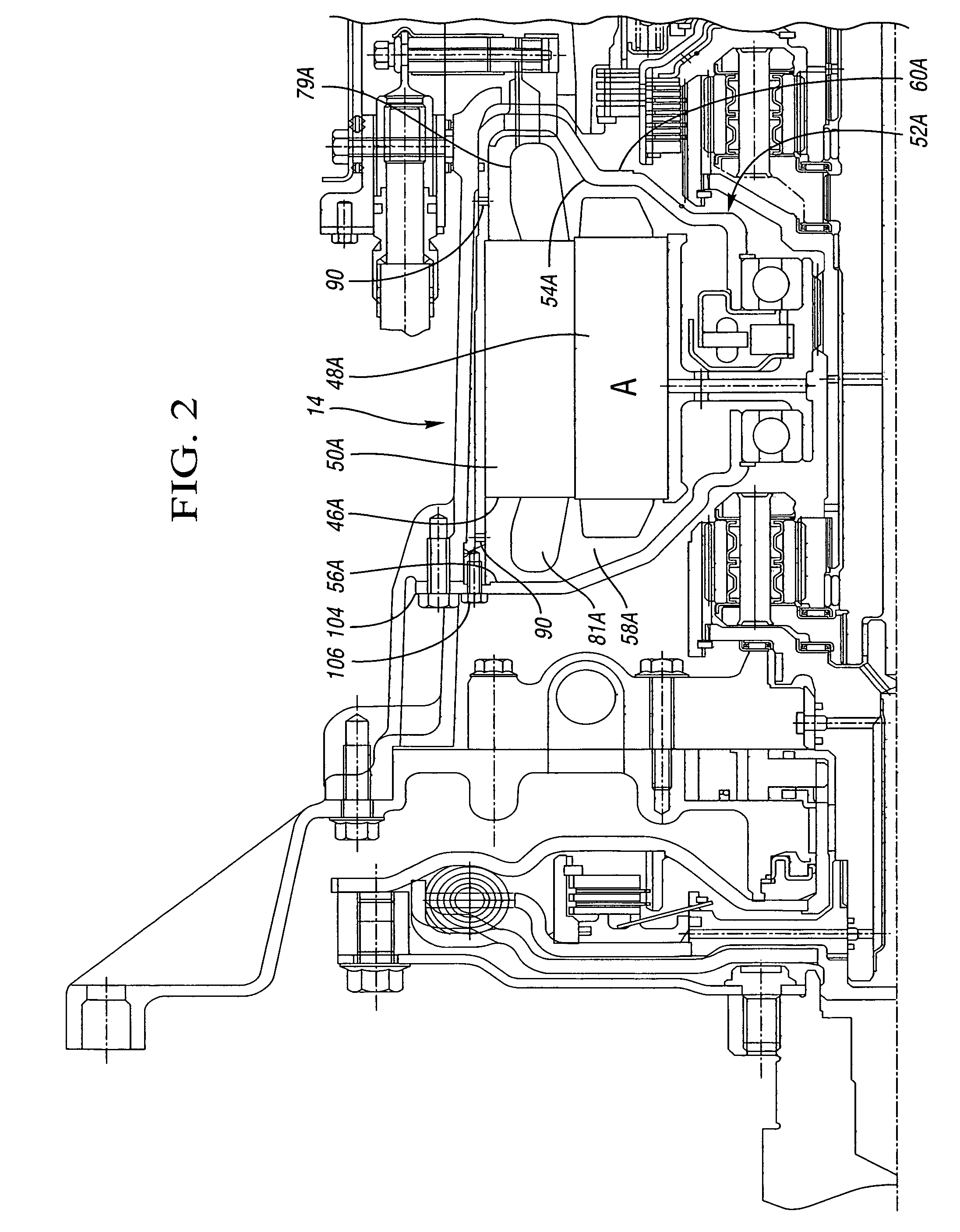

Gear-operated speed change apparatus for automatic transmission

InactiveUS6910985B2Strength advantage of gearToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A gear-operated speed change apparatus for an automatic transmission, which can make the degree of freedom for selecting a gear ratio higher than that of the case using the Ravigneaux type composite planetary gear train, while achieving a strength advantage of the gear train, an improvement in the fuel economy, coaxial positioning of the input port and output portions and size reduction of the automatic transmission altogether. The apparatus can achieve at least seven forward speeds and one reverse speed by engaging / releasing four clutches and two brakes. One of the three planetary gear sets can reduce the speed of an input rotation always or increase the input rotation always. One of the remaining two planetary gear sets is a double sun gear type planetary gear set including a third carrier having a center member positioned between two sun gears for inputting or outputting a rotation.

Owner:JATCO LTD

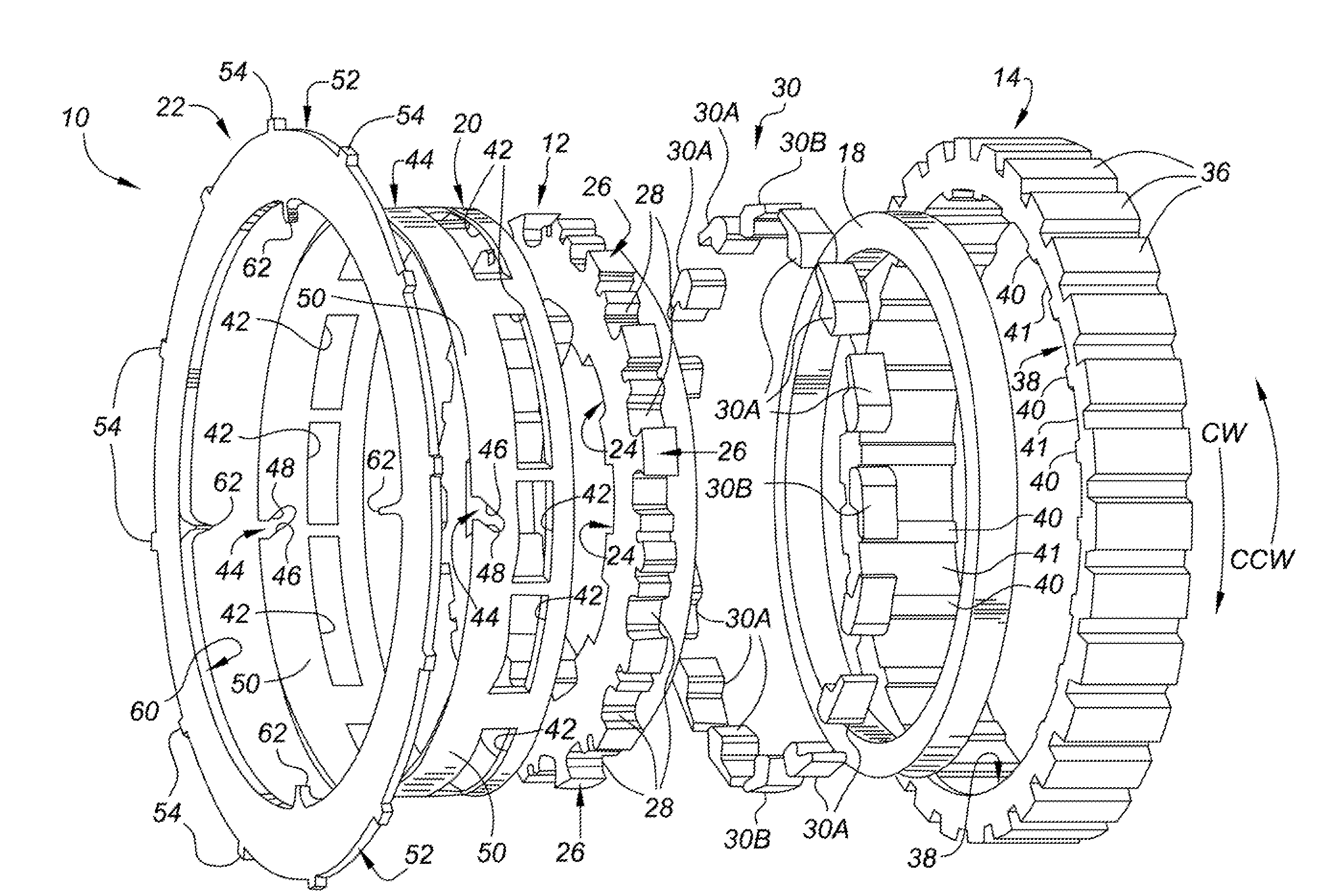

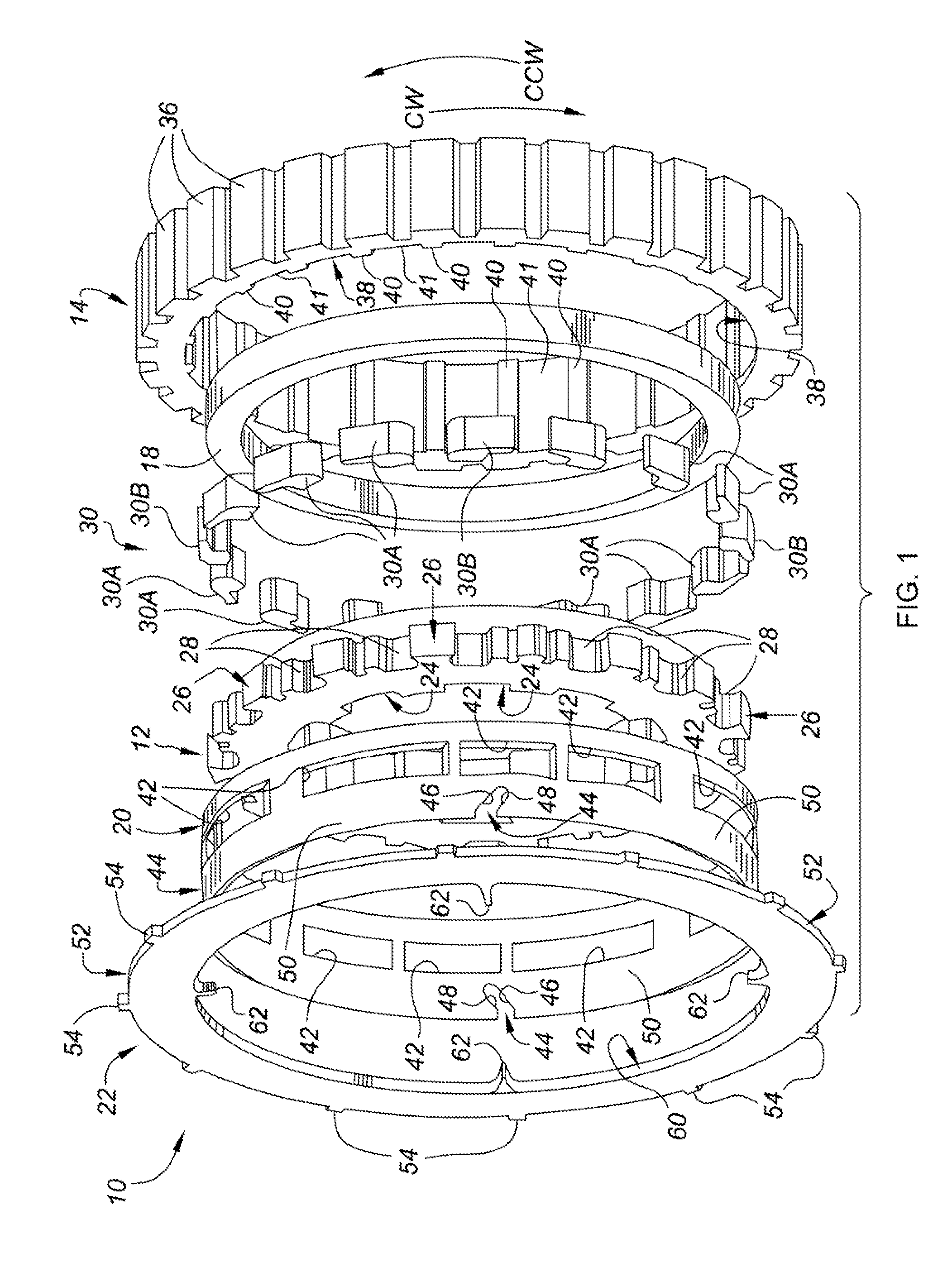

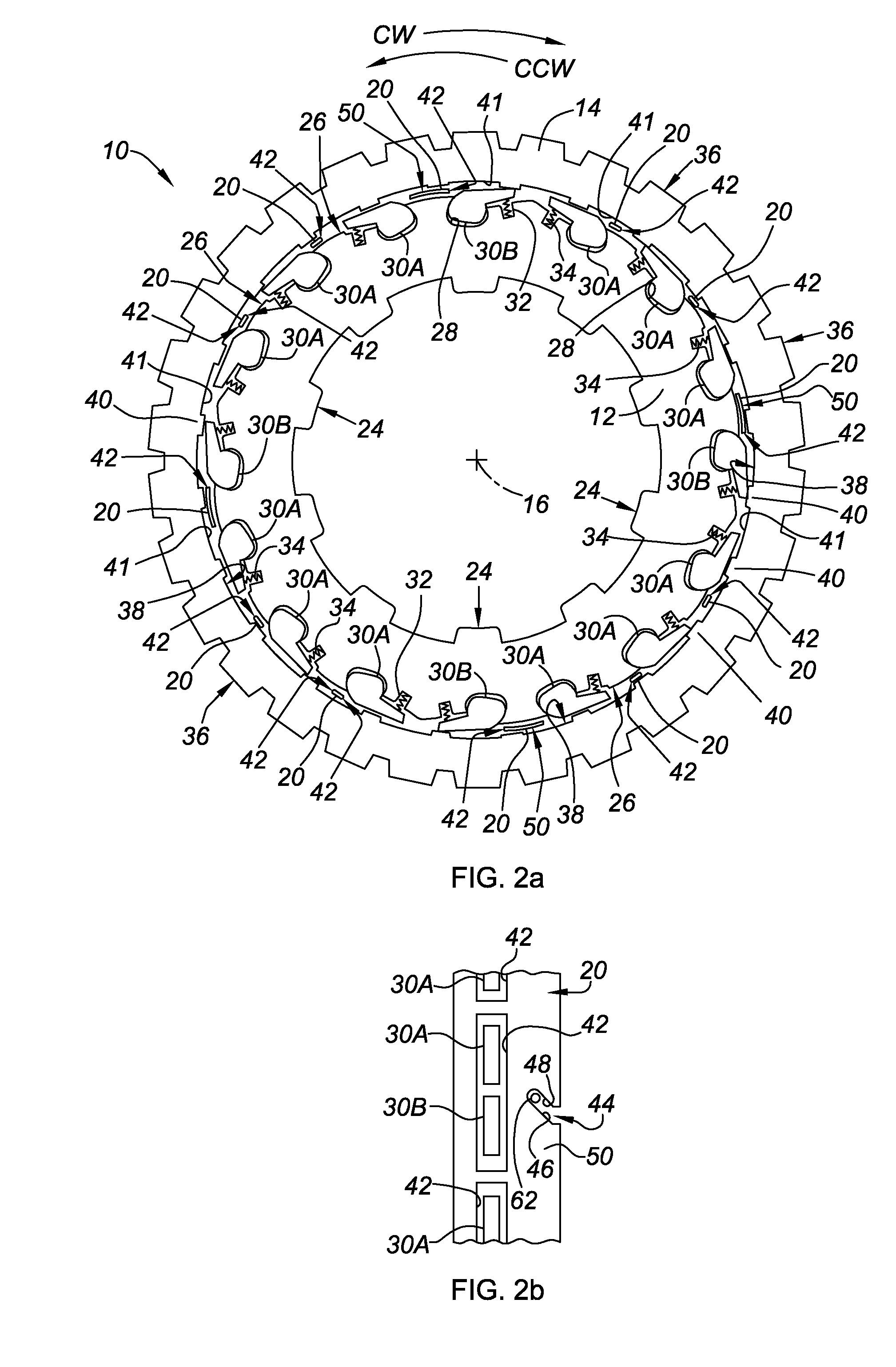

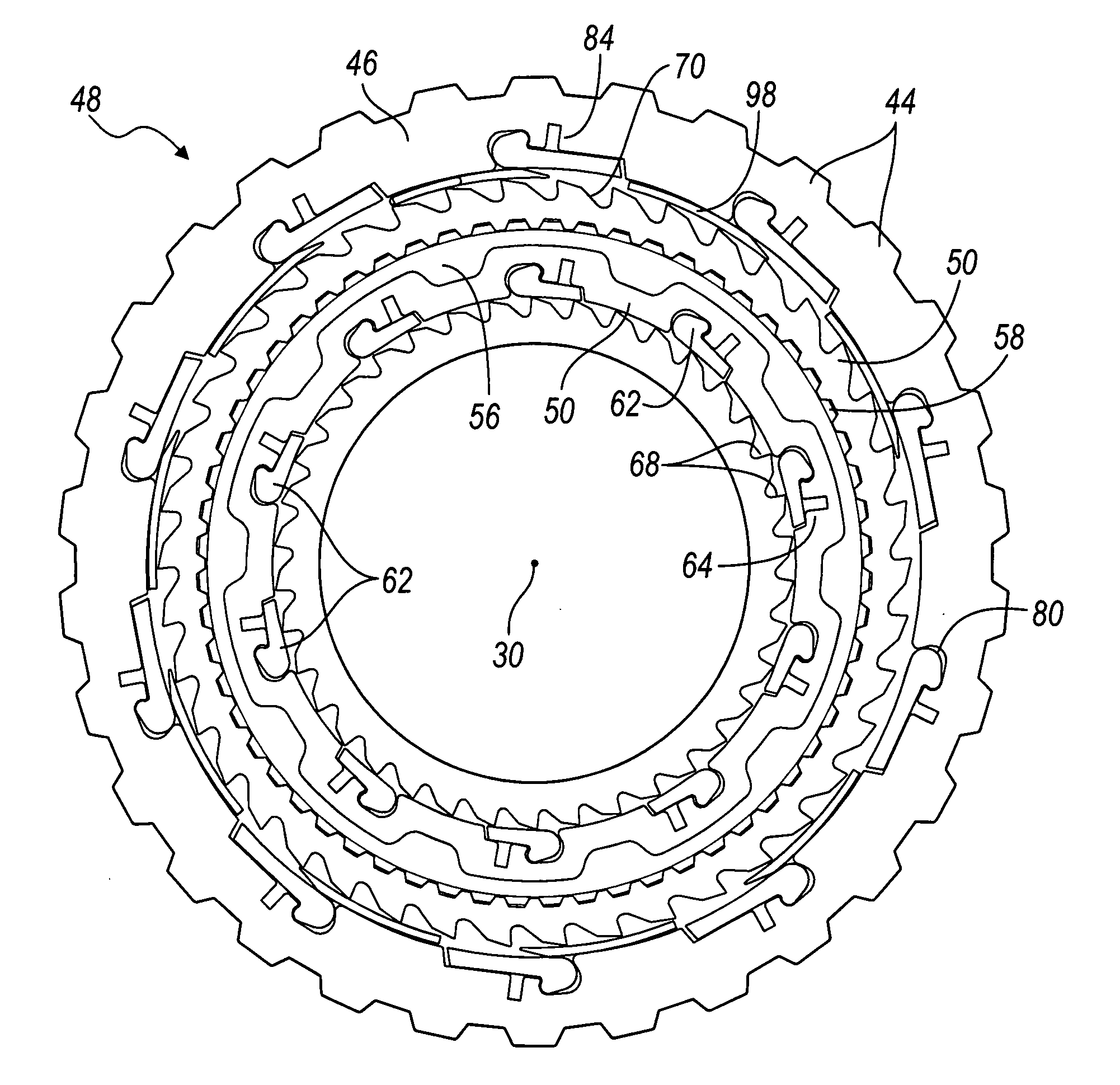

Selectable One-Way Rocker Clutch

The present invention provides a selectable one-way rocker clutch assembly having an inner race disposed radially within an outer race, first and second plurality of rockers, a selector ring and an apply plate. The inner race defines a plurality of pockets configured to operatively retain the first and second plurality of rockers. The first plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a first direction. The second plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a second direction. The selector ring is disposed radially between the inner race and outer race. The apply plate is configured to engage with the selector ring and, in so doing, rotate the selector ring to thereby selectively retract the first and / or second plurality of rockers and thus control the state of the rocker clutch assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

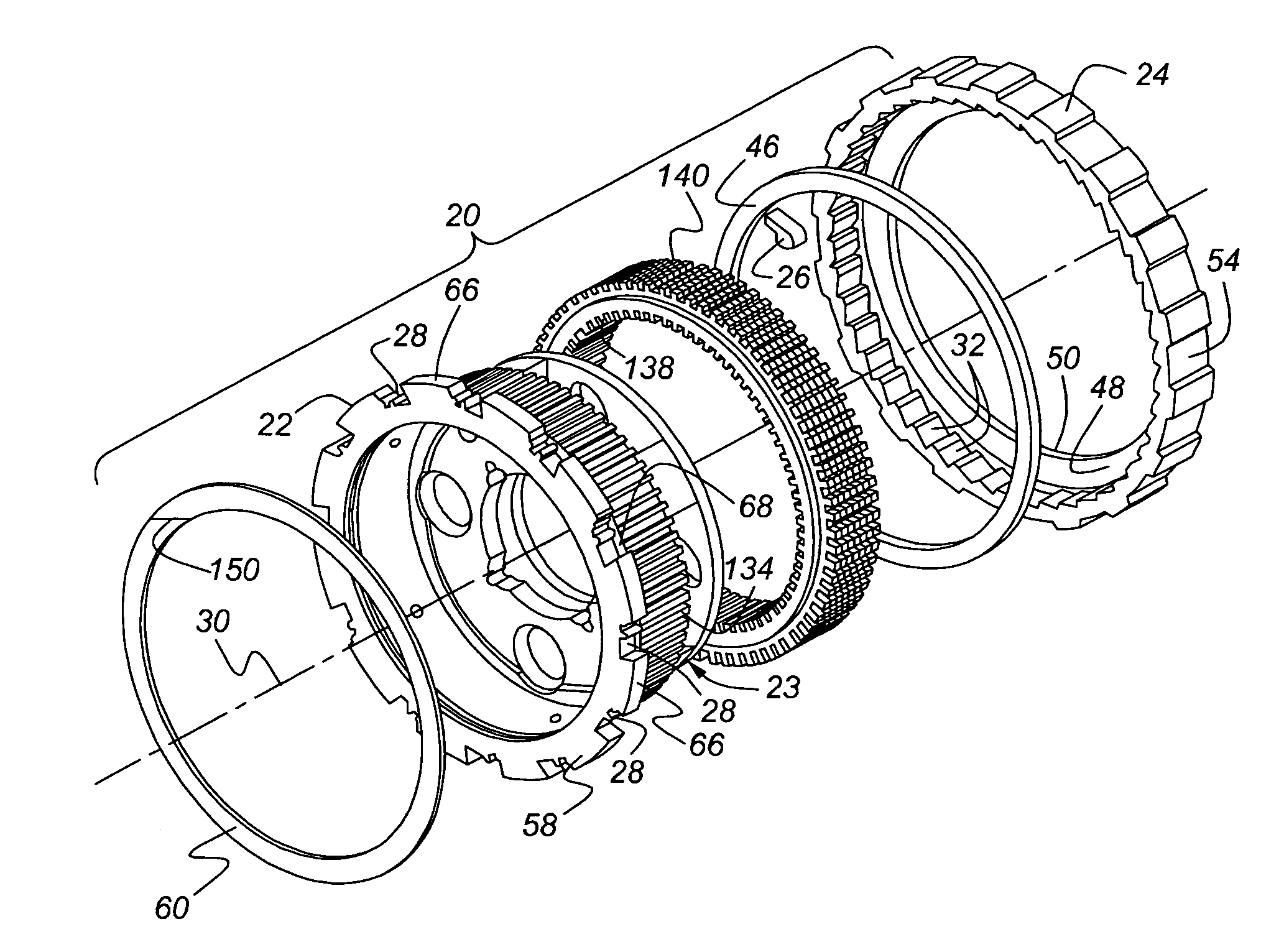

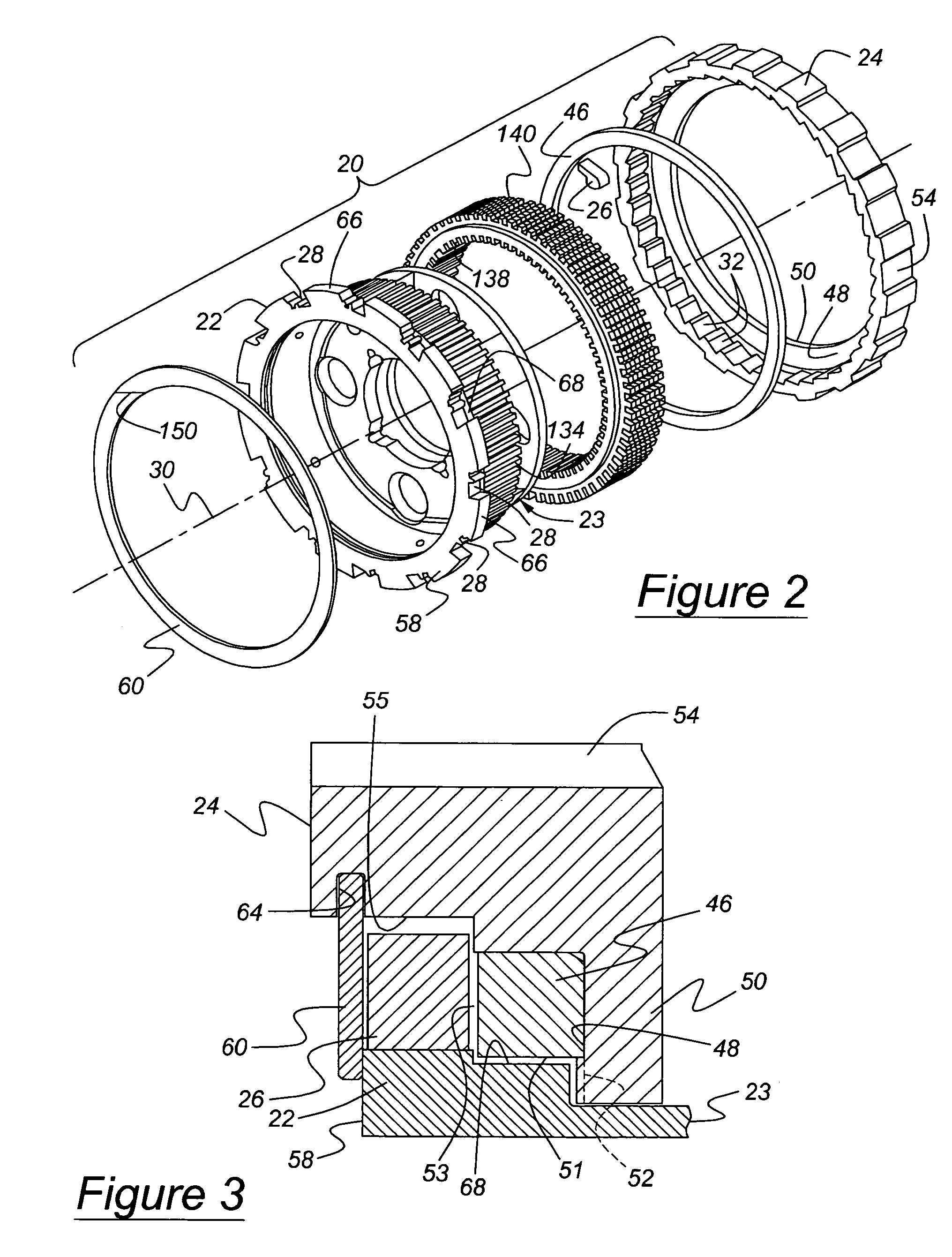

Automatic transmission carrier assembly including an overrunning brake

ActiveUS7223198B2Well formedEliminate needToothed gearingsGearing detailsAutomatic transmissionEngineering

A carrier assembly for a planetary gearset of a transmission includes a pinion carrier, a one-way brake having a rocker ring integral with the carrier and having multiple pockets mutually spaced about an axis and located on an outer radial surface of the carrier. A cam ring includes multiple notches angularly spaced about the axis and facing the rocker ring. A rocker, located in each pocket, pivots about a pivot center to engage the cam ring, and a spring urges each rocker to pivot toward engagement with the cam ring. A hydraulically actuated friction brake secured to the carrier alternately holds the carrier against rotation relative to a housing and permits the carrier to rotate.

Owner:FORD GLOBAL TECH LLC

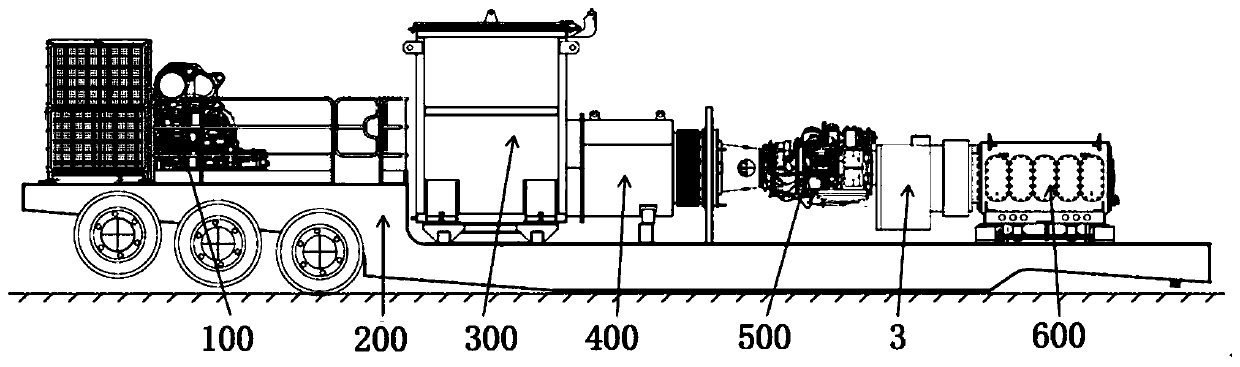

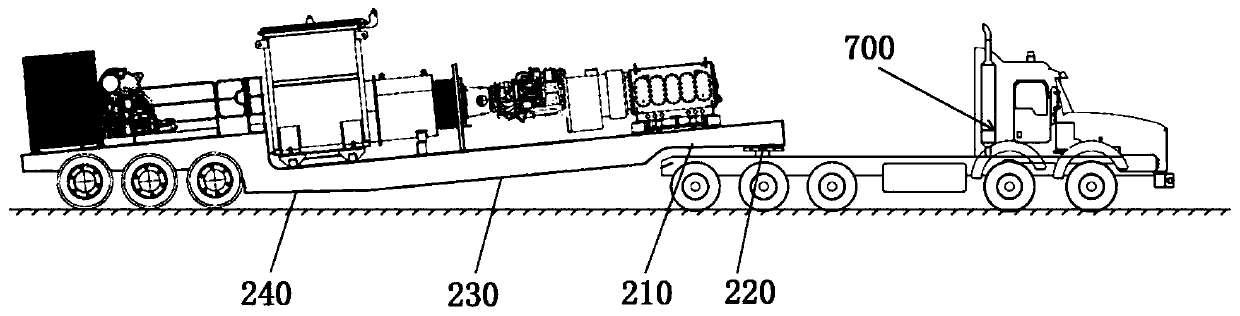

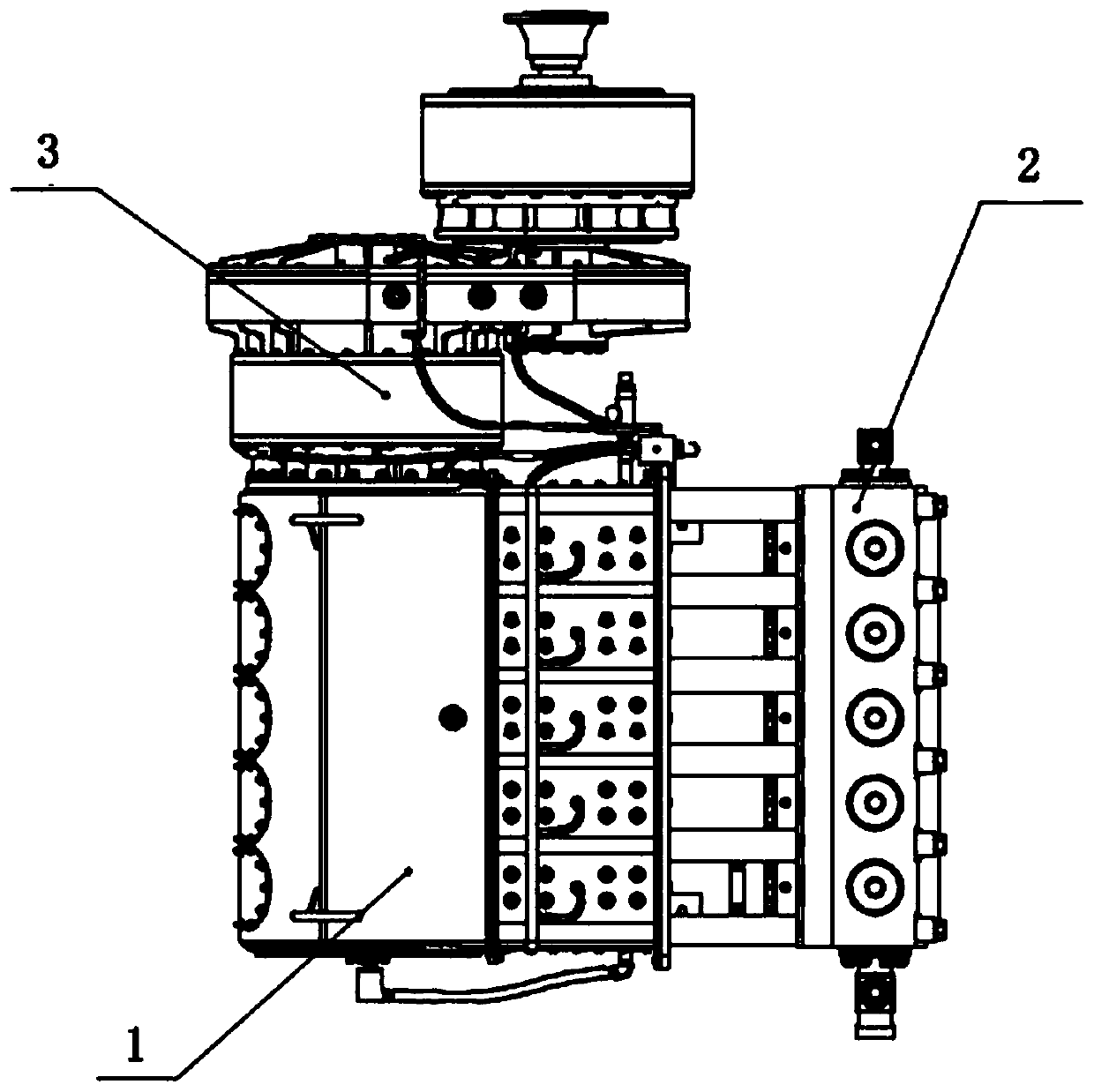

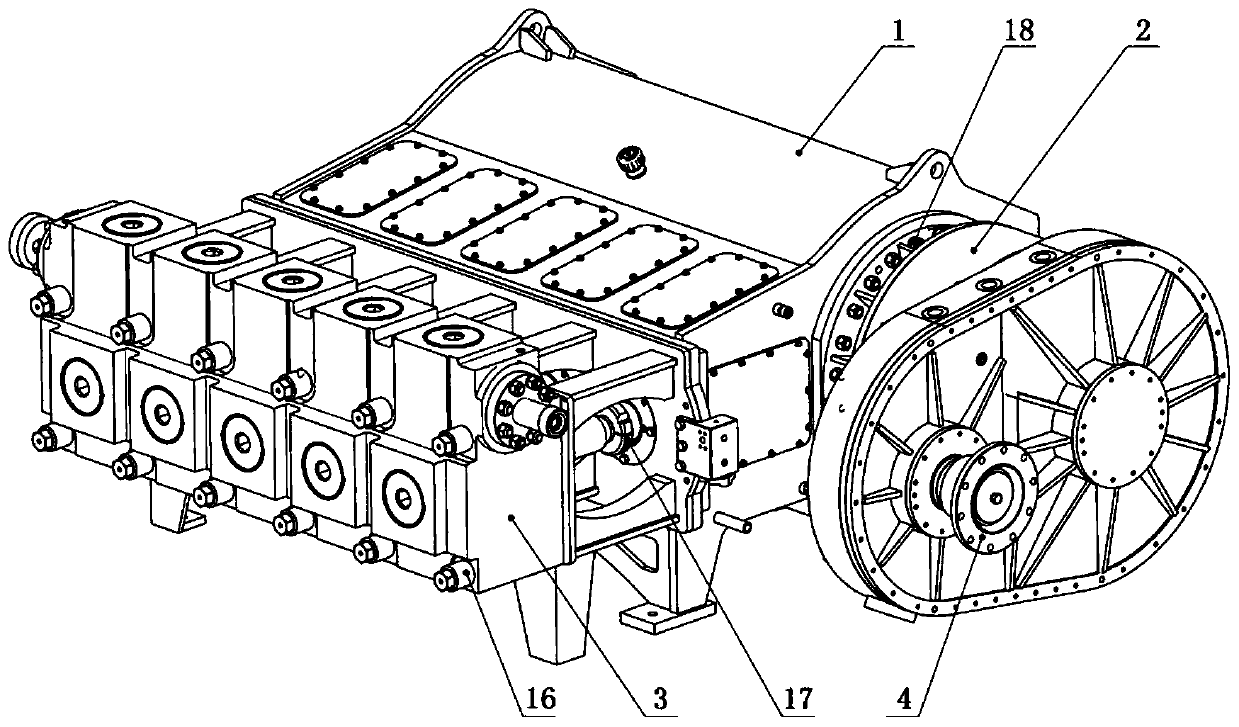

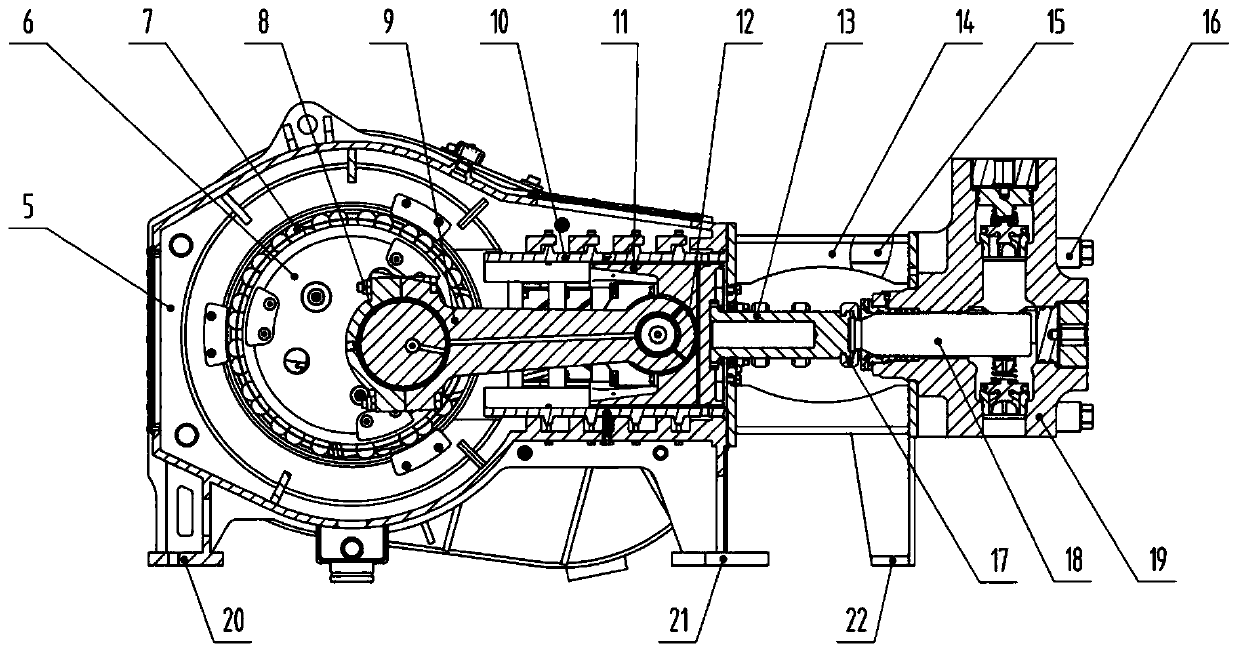

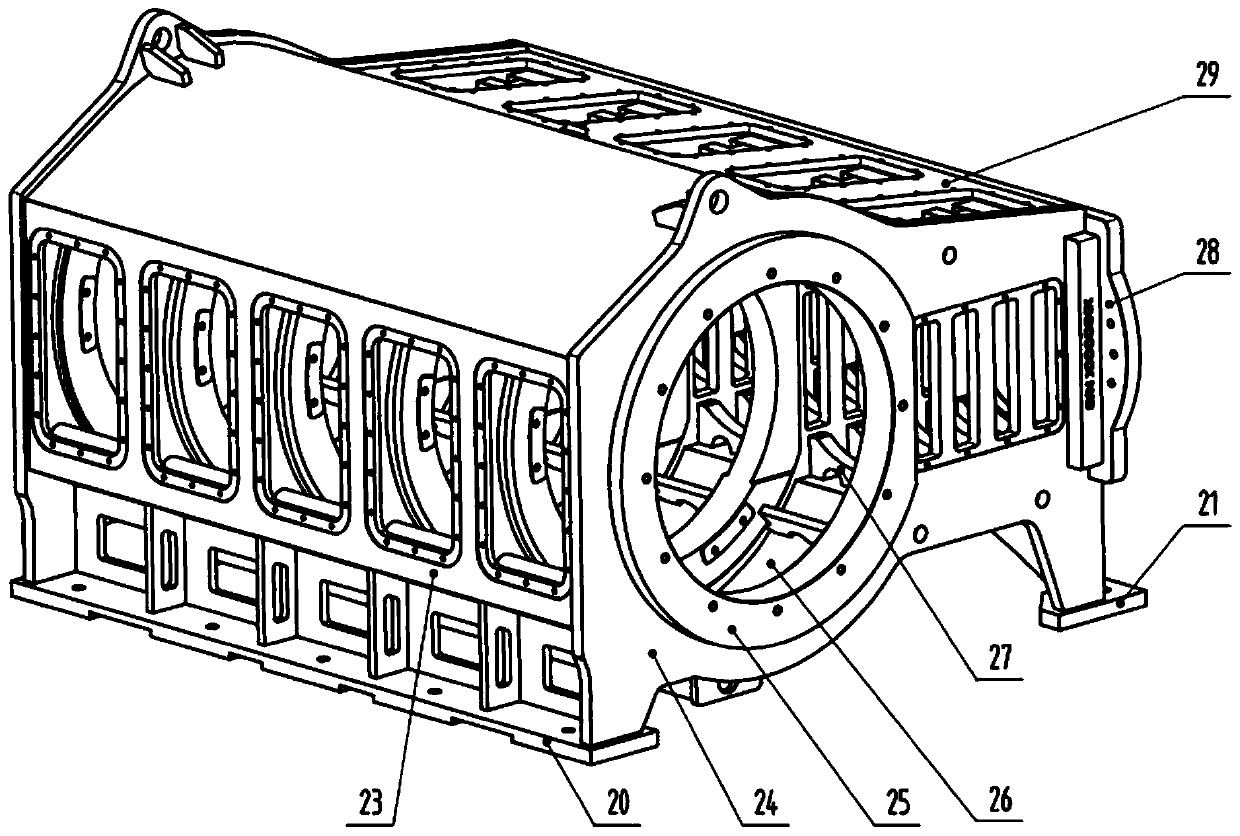

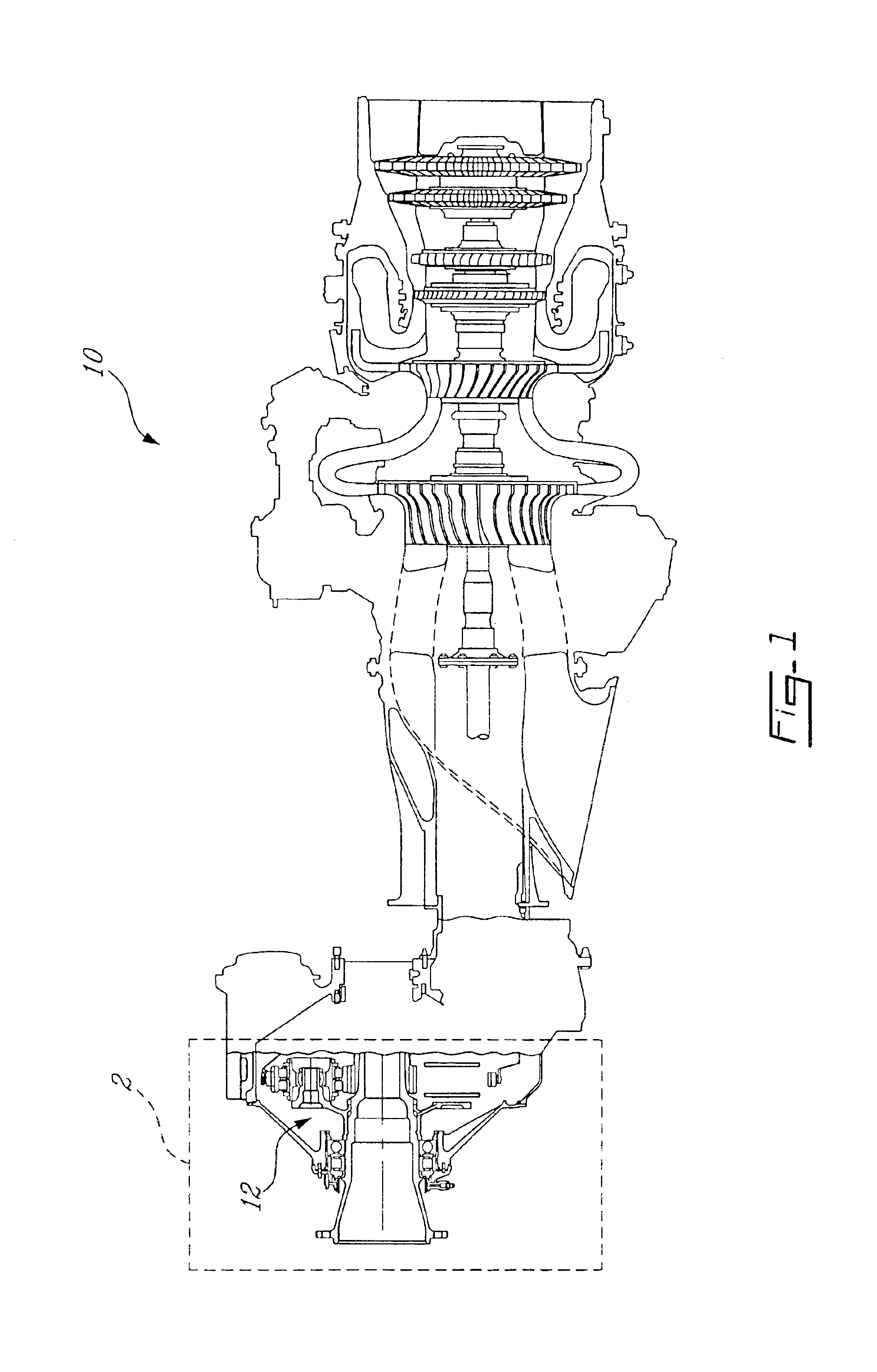

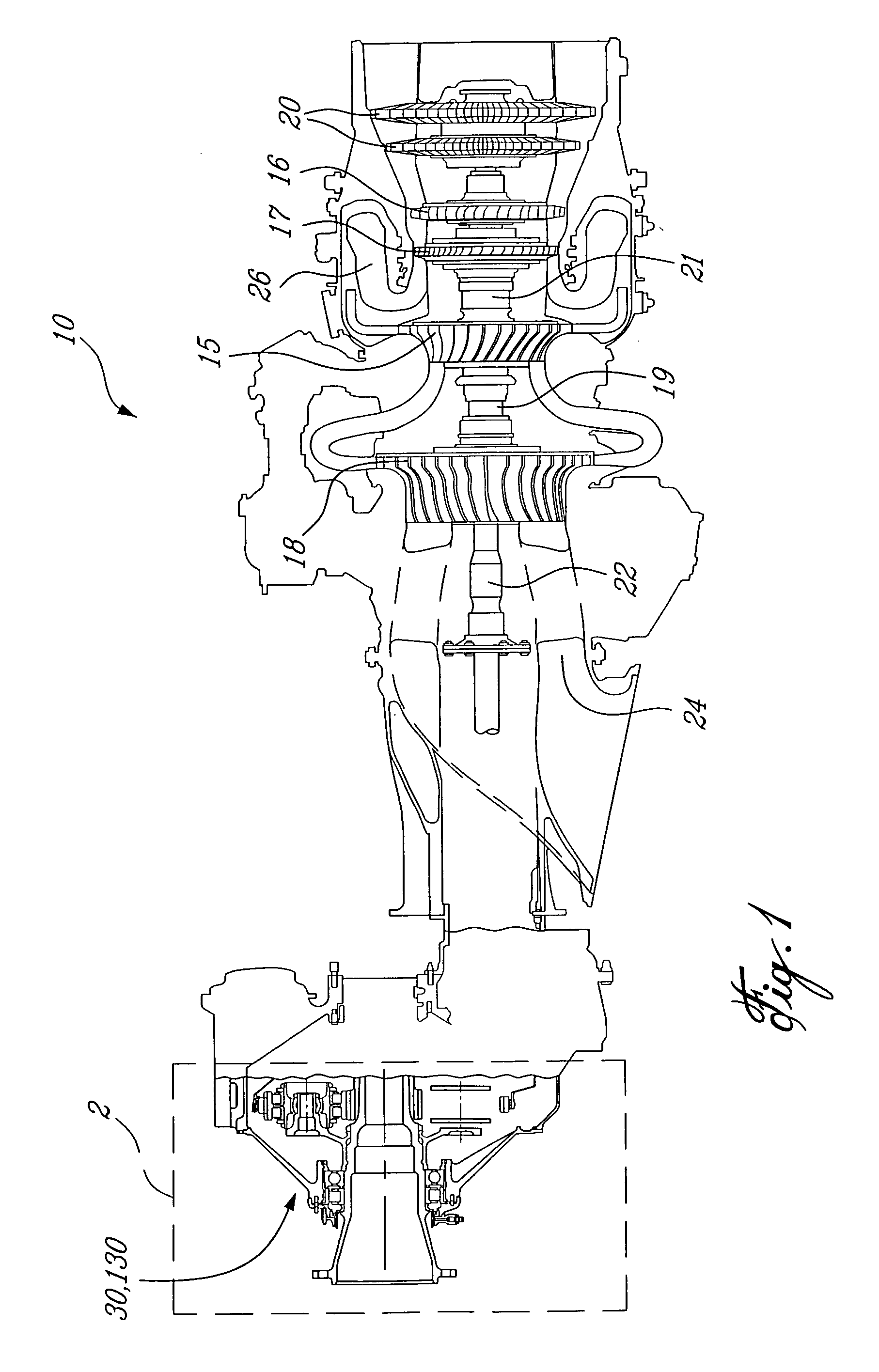

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

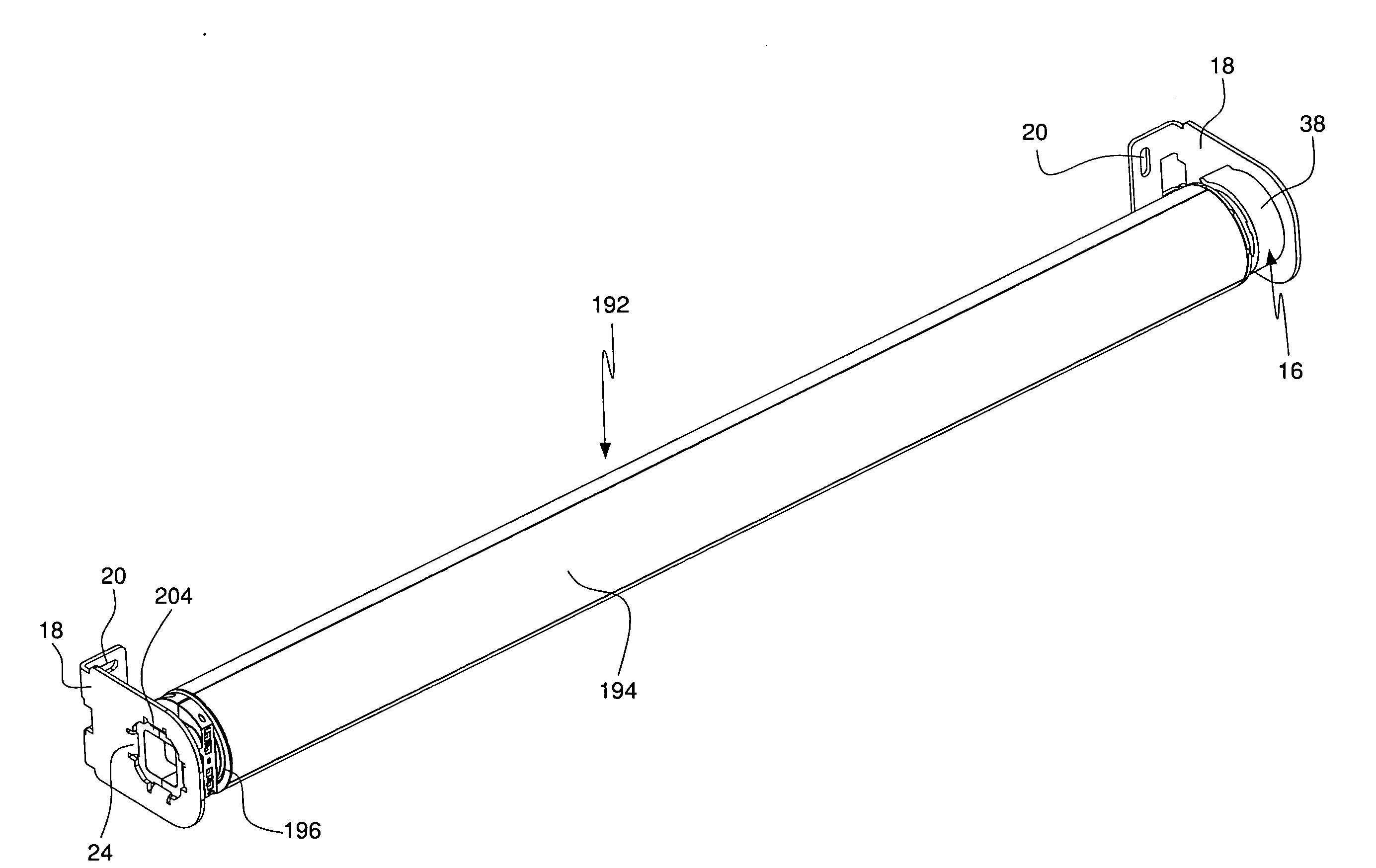

Manual roller shade having clutch mechanism, chain guide and universal mounting

A manual roller shade includes a clutch mechanism having a gear train transferring rotation of an input sprocket to rotation of an output member engaging a roller tube. The gear train includes a sun gear, planet gears supported by a carrier and engaging the sun gear, and a ring gear engaging the planet gears. According to one embodiment, the carrier does not rotate. The ratio between the diameters of the input sprocket and the roller tube is selected to offset mechanical advantage of the gear train to provide an effective gear train ratio of approximately 2:1. A drive chain guide system includes spaced guide wheels controlling where a drive chain is suspended from the manual shade. A roller shade mounting system includes a bracket receiving either an input assembly of the manual roller shade or a motor of a motorized roller shade to facilitate conversion.

Owner:LUTRON TECH CO LLC

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Continuously variable transmission

Owner:FALLBROOK INTPROP COMPANY

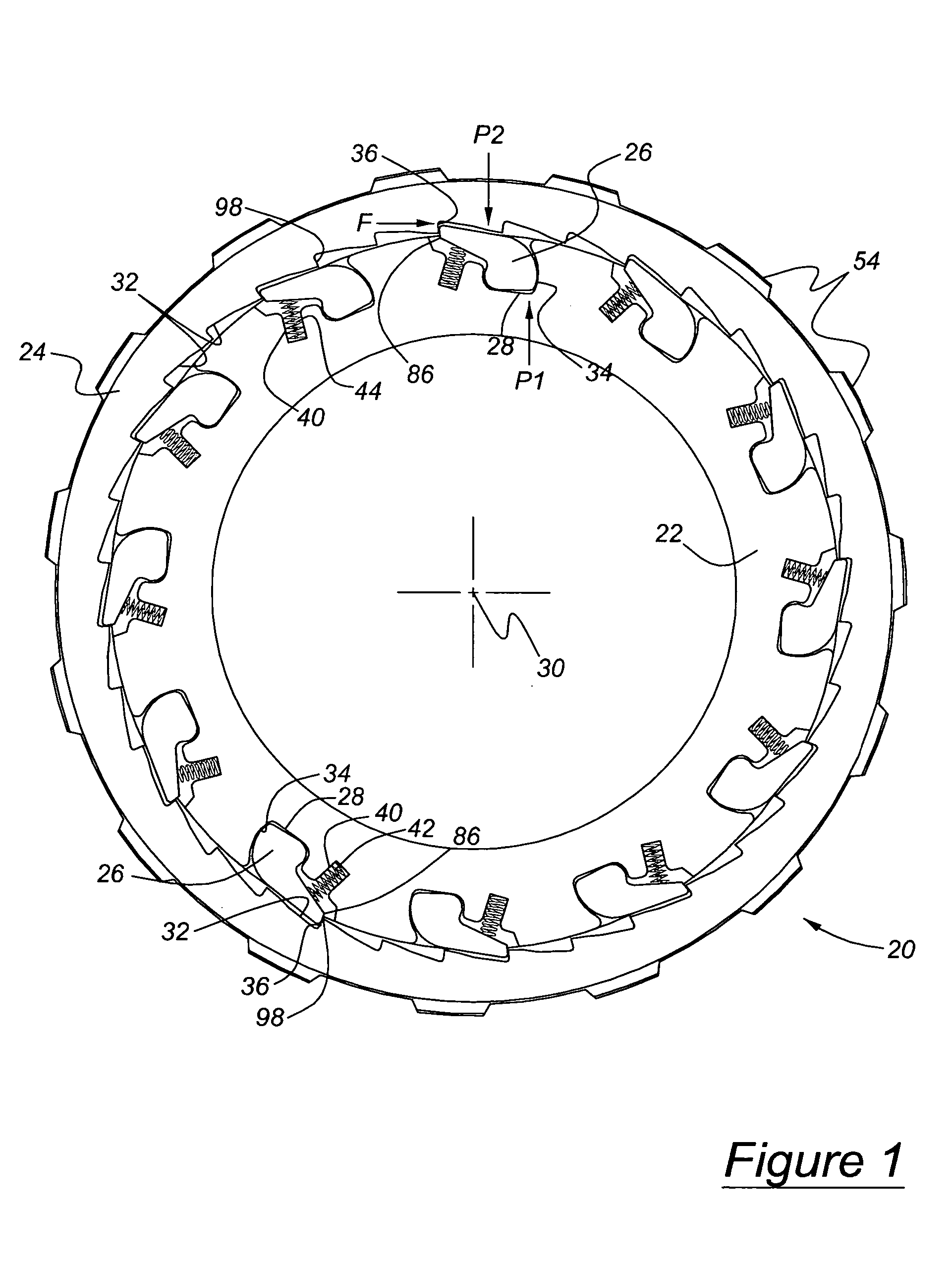

Selectively controlled rocker one-way clutch

ActiveUS20080185253A1Easy to assembleSignificantly reducing backlashToothed gearingsFriction clutchesEngineeringClutch

An overrunning clutch assembly includes a first ring having pockets spaced mutually about an axis, rockers each located in a pocket, springs each urging a rocker to pivot in a respective pocket, and first notches arranged around the axis. A second ring includes second pockets spaced mutually about the axis, second rockers each located in a second pocket such that at least one second rocker is engageable with a notch, second springs each urging a second rocker toward engagement with a notch, and second notches around the axis, at least one rocker being engageable with at least one second notch. A control member moves about the axis alternately to prevent the first rockers from engaging the second notches and to permit the first rockers to engage the second notches.

Owner:FORD GLOBAL TECH LLC

Compact epicyclic gear carrier

ActiveUS7104918B2Closely arrangedReduced torque induced twistEngine fuctionsToothed gearingsGear wheelEngineering

An epicyclic gear carrier assembly for use in an epicyclic gear train of a gas turbine engine, the epicyclic gear train having a central axis and a plurality of epicyclic gears rotatable about individual gear axes. The epicyclic gear carrier assembly comprises at least a carrier plate defining a plurality of circumferentially spaced axle bores which are disposed radially outward from the central axis and are co-axial with the individual gear axes. A plurality of corresponding gear axles are disposed within the axle bores, and the plurality of epicyclic gears are rotatably mounted to the gear axles via bearing elements. An epicyclic carrier member comprises a plurality of axle engaging elements that are co-axial with the gear axles and are engaged thereto by load transmission members such that load is transferred from the gear axles to the epicyclic carrier member.

Owner:PRATT & WHITNEY CANADA CORP

Motor vehicle drive arrangement

A motor vehicle drive arrangement has a locomotive drive train and at least one liquid pump capable of being driven by the latter. During a standstill in rotation or during very slow rotation of the locomotive drive train, the pump is capable of being driven by an electric motor instead of by the locomotive drive train. Beyond a defined minimum rotational speed of the locomotive drive train, the liquid pump is capable of being driven by the latter instead of by the electric motor. At least one free-wheel is provided for this purpose.

Owner:DAIMLER AG

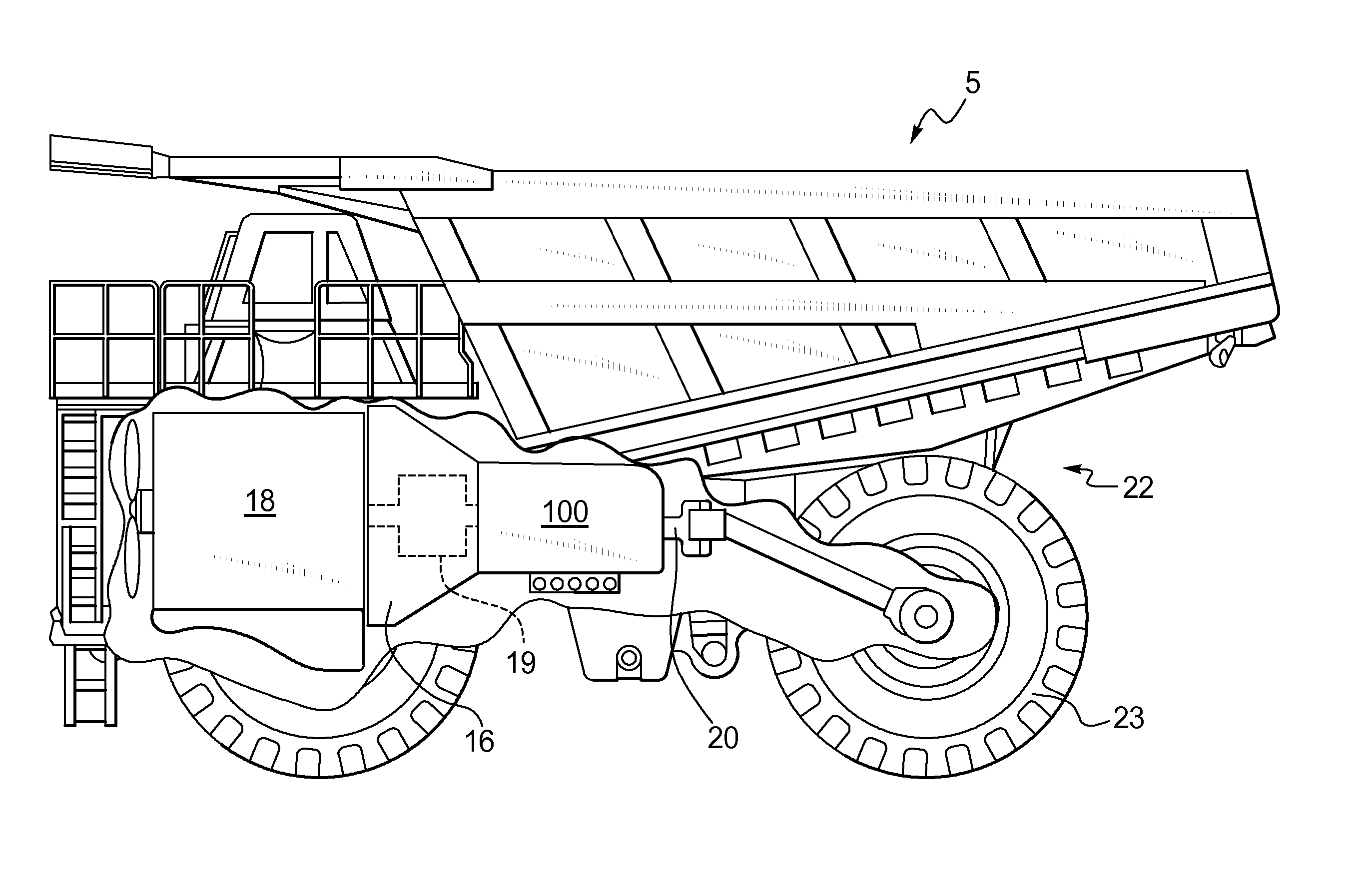

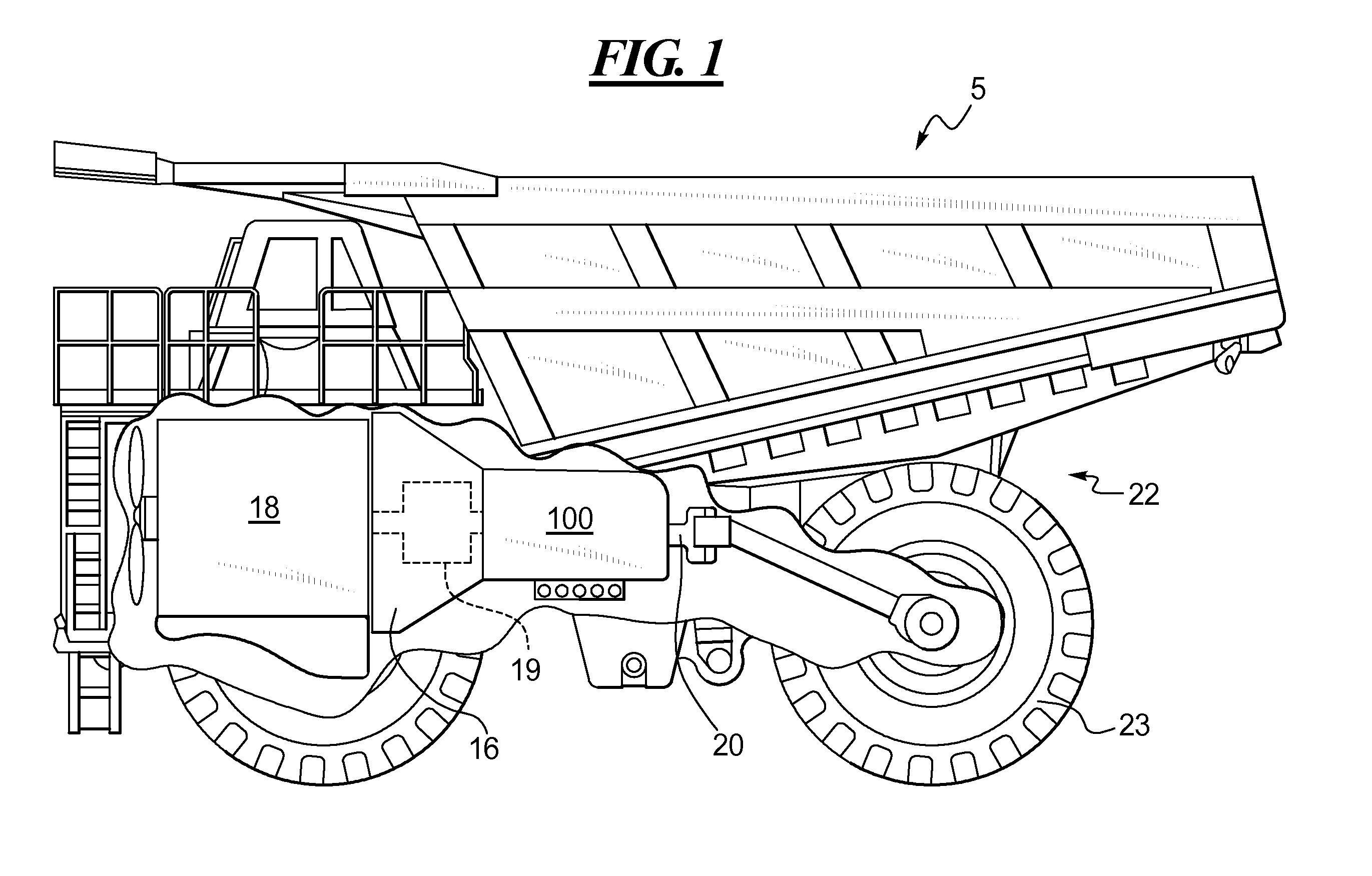

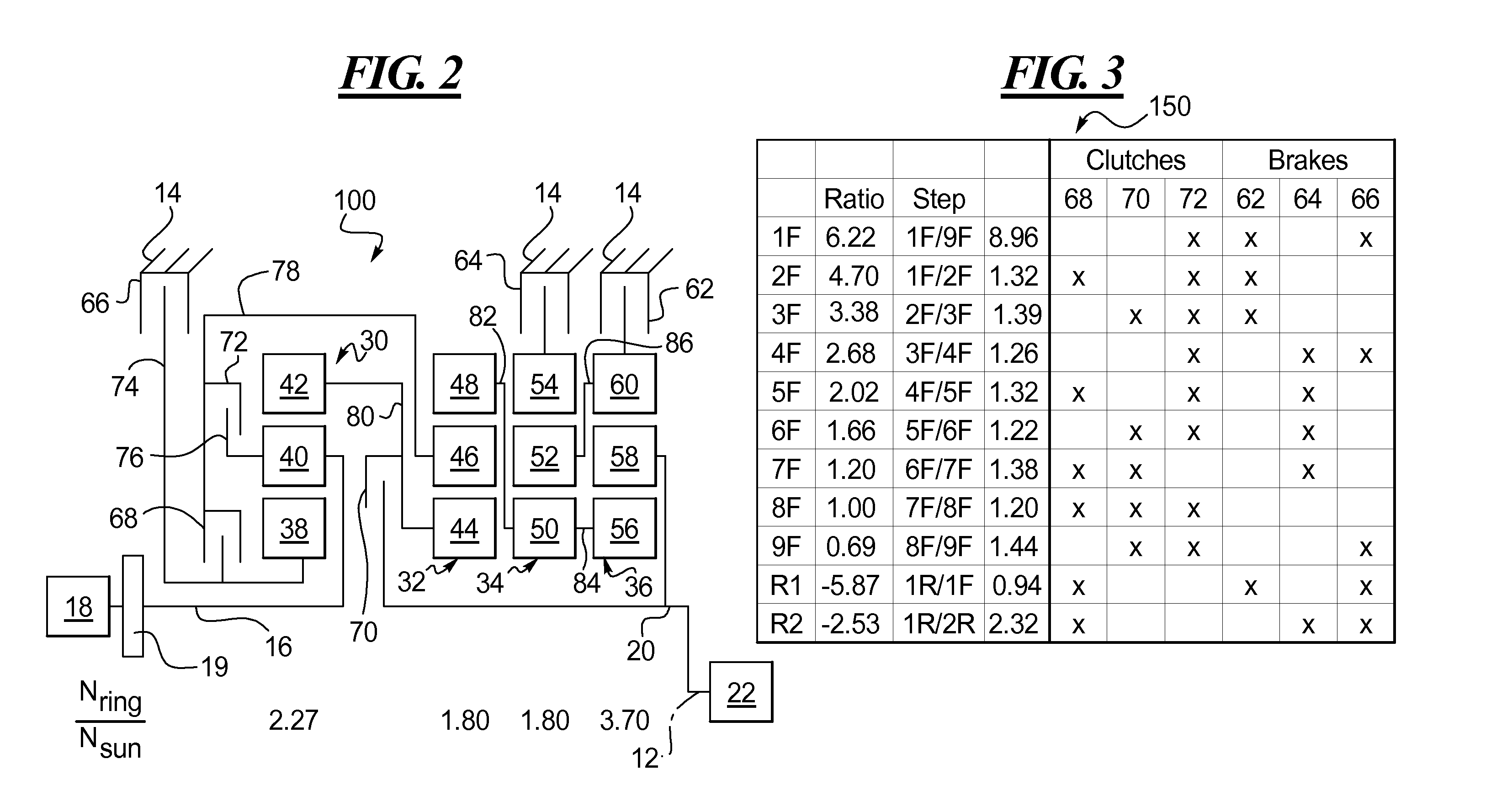

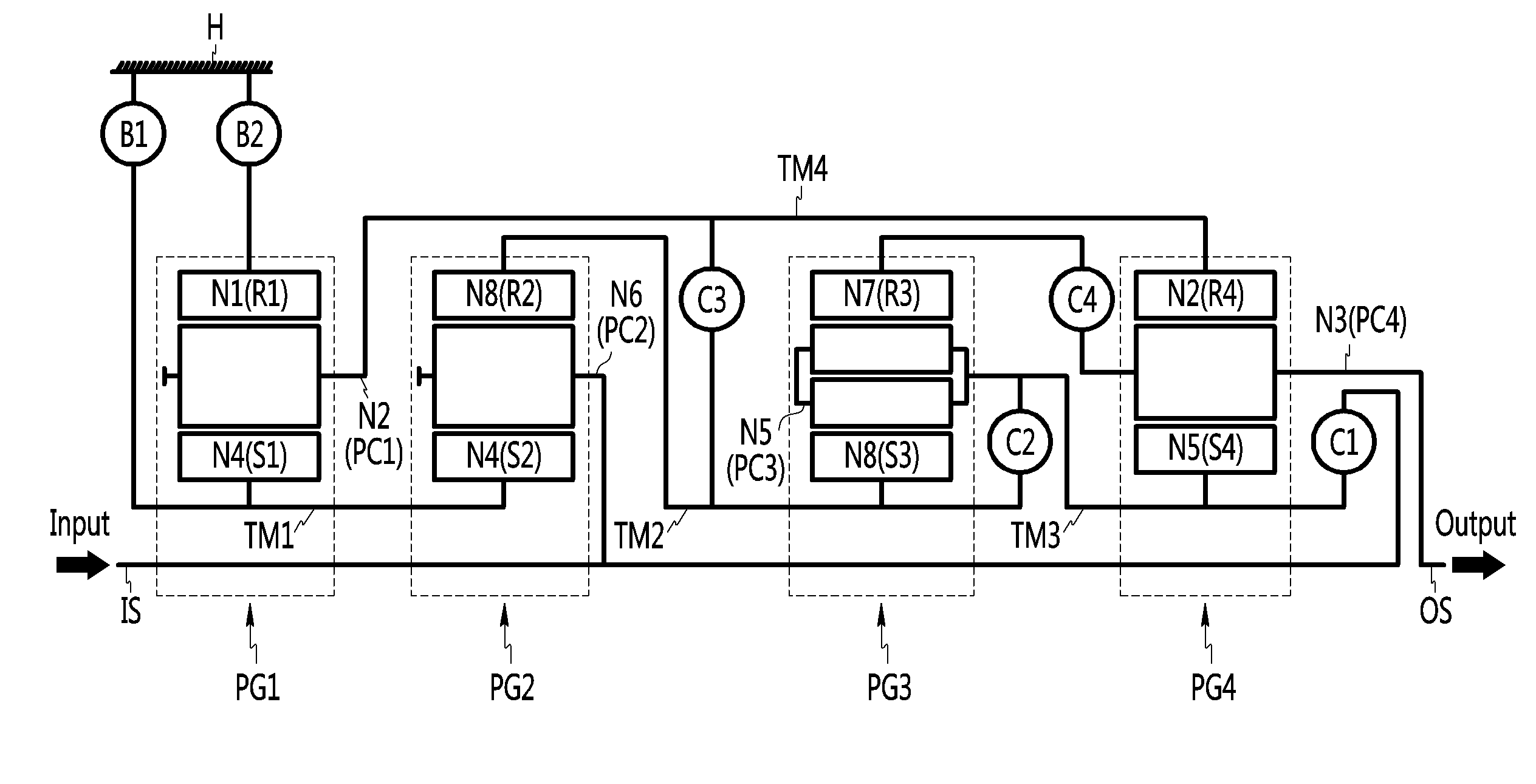

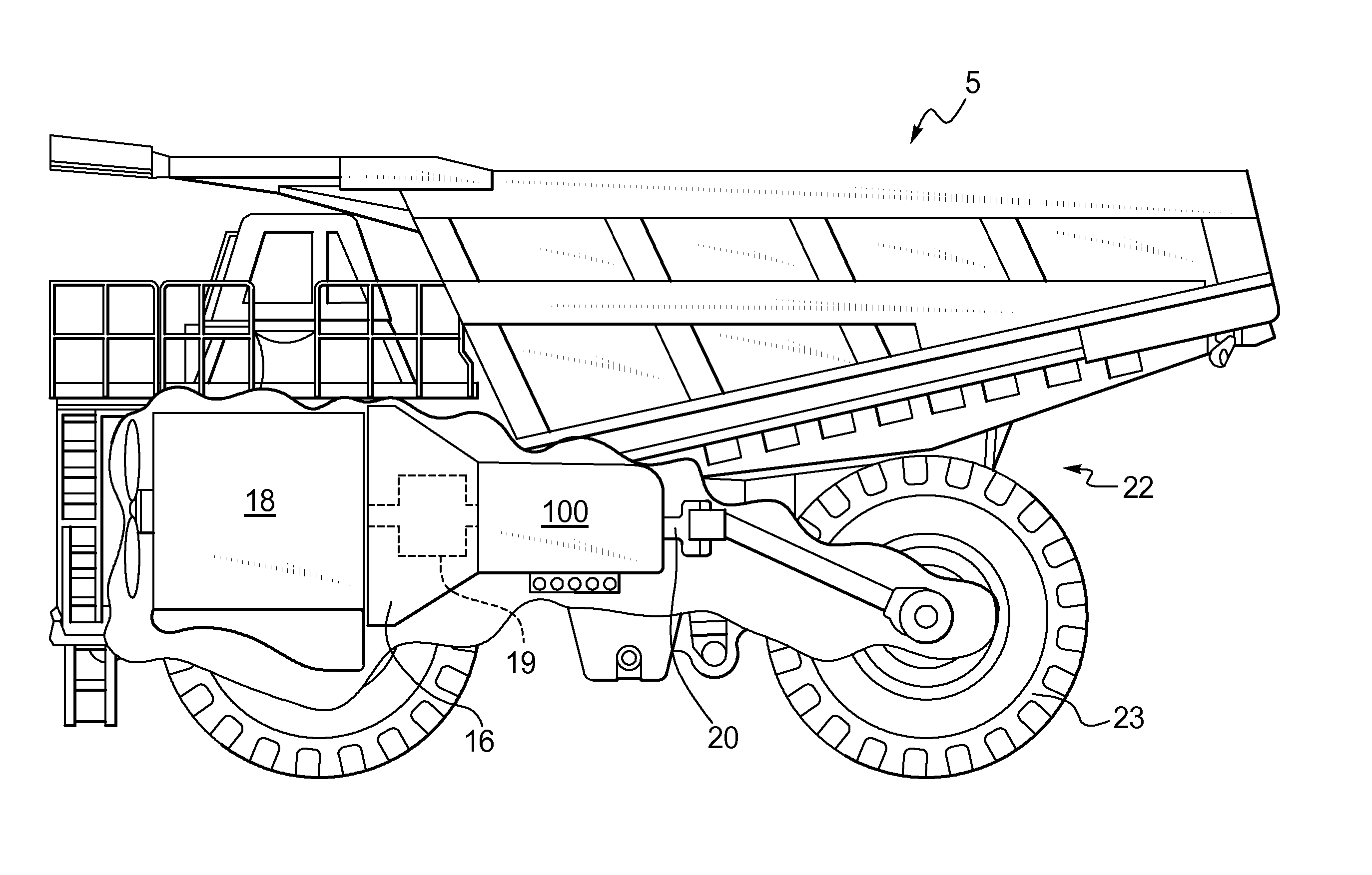

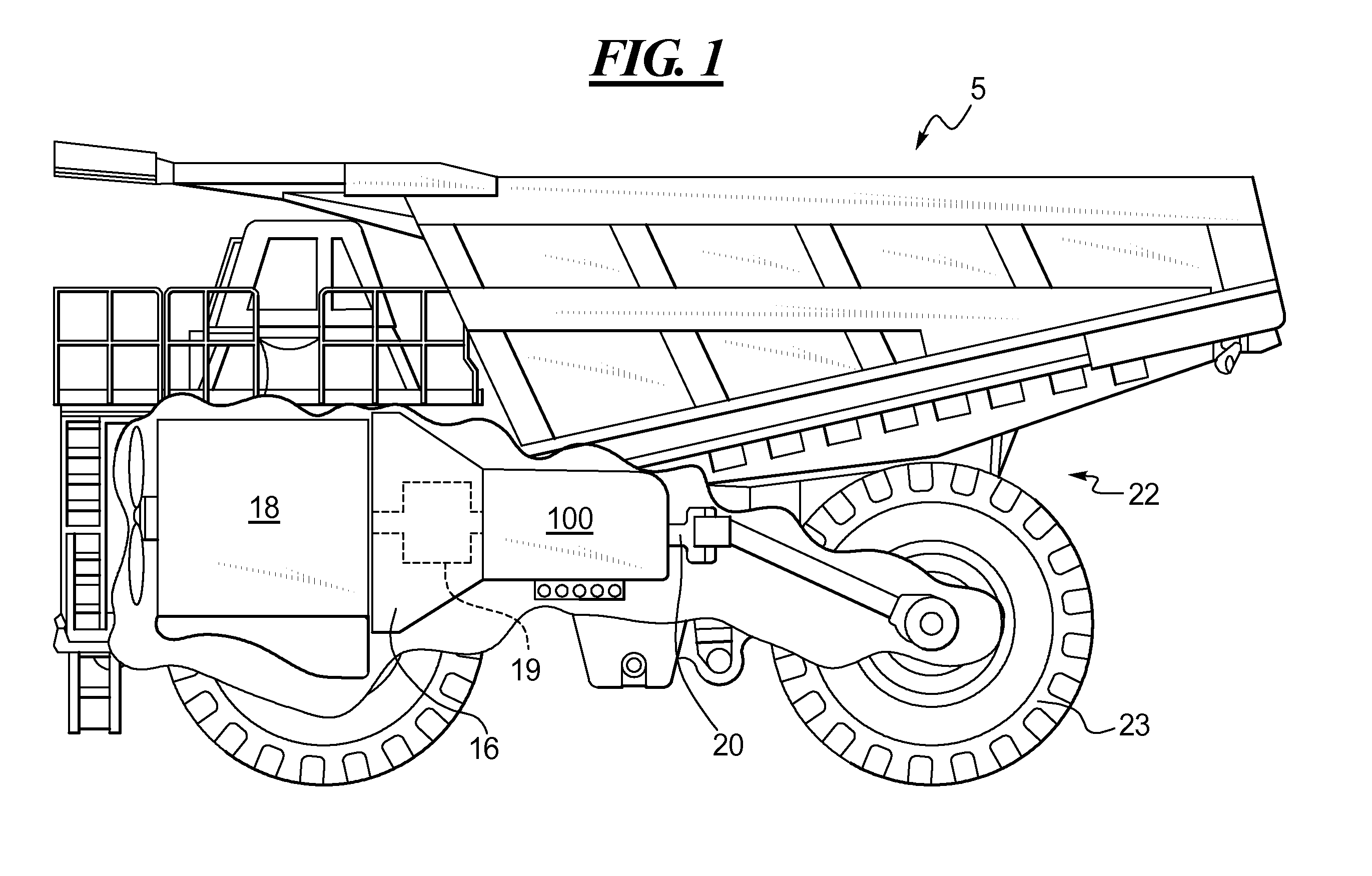

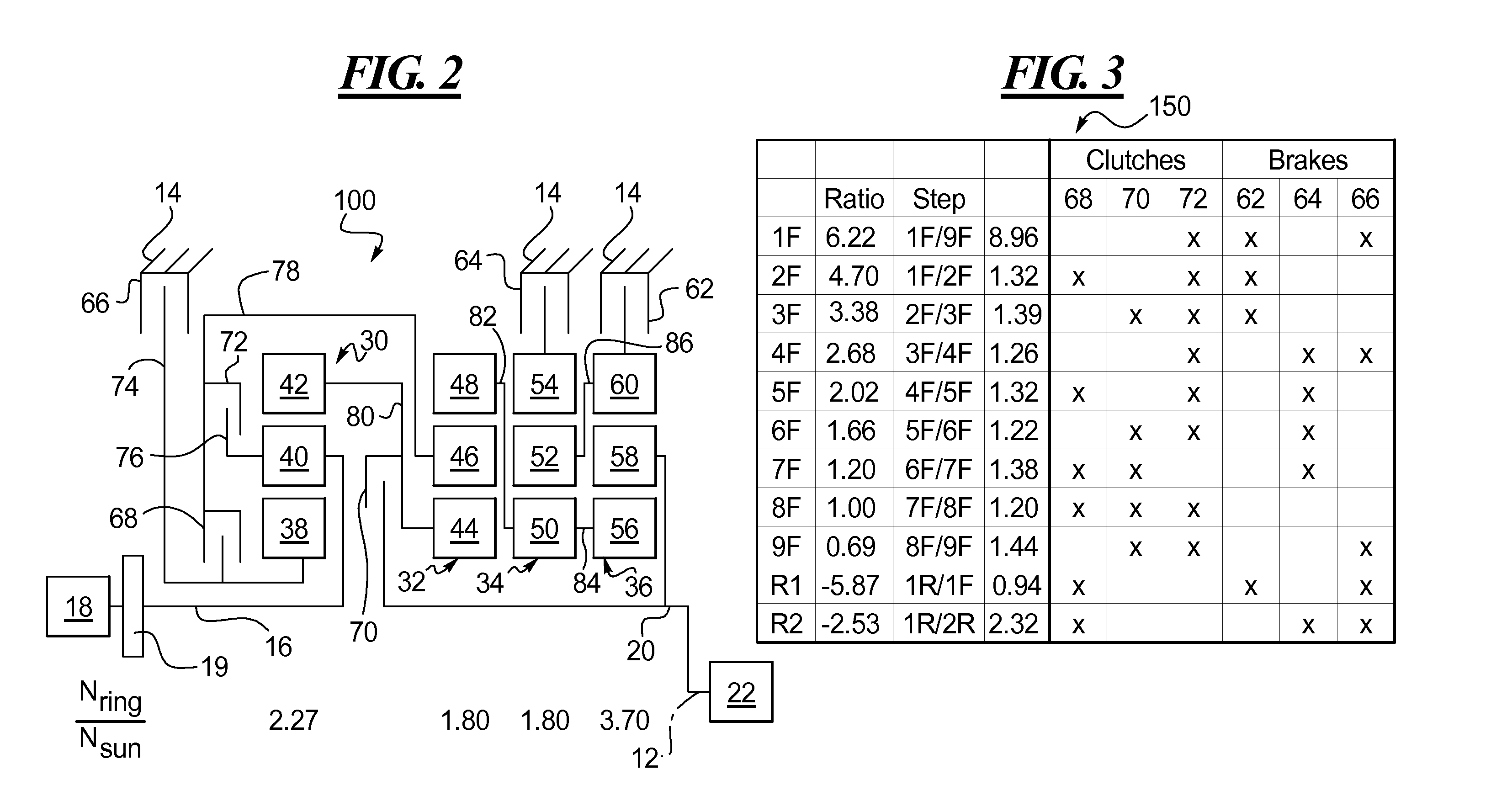

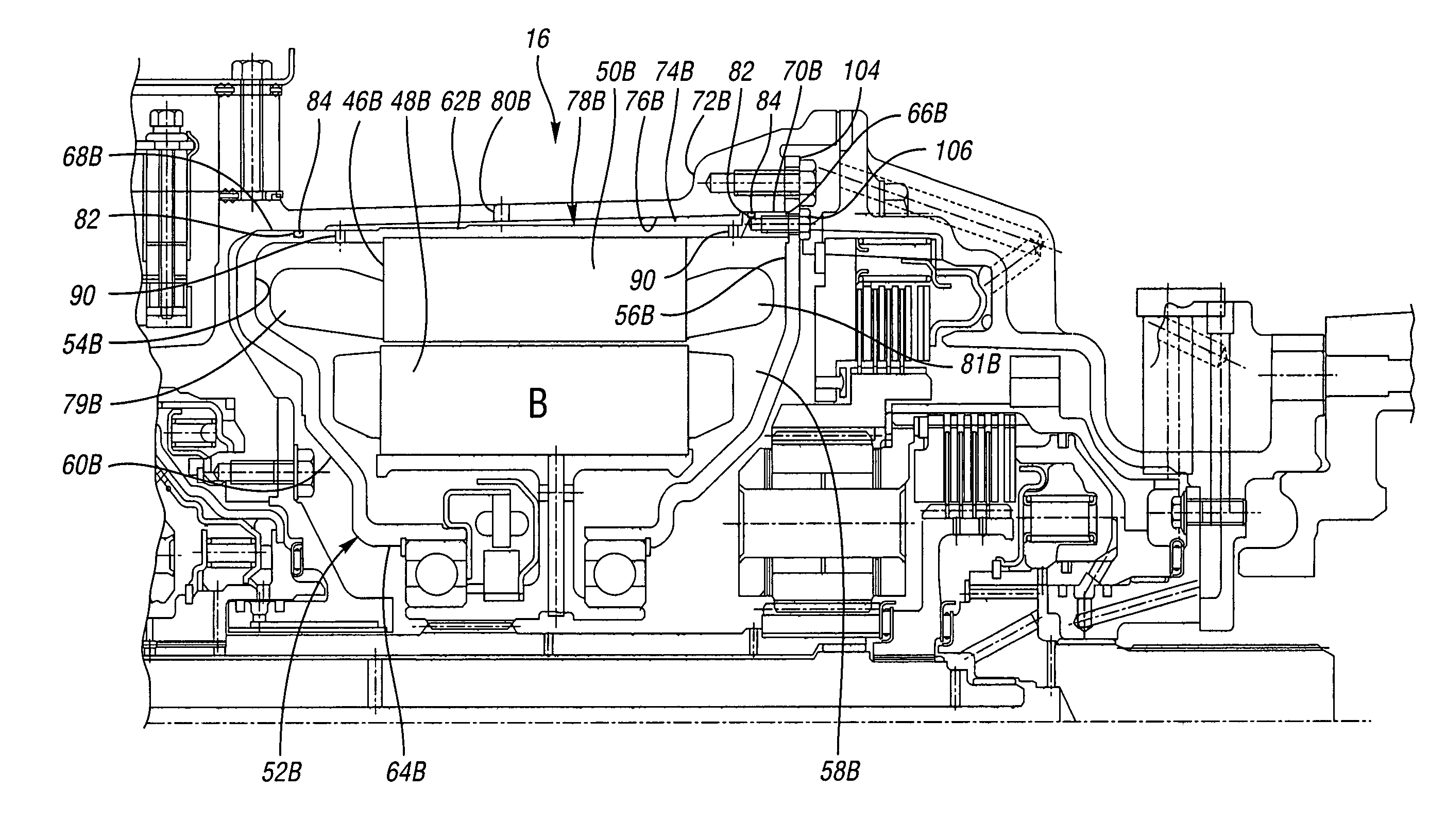

Multi-Speed Transmission

A multi-speed transmission may include an input member and an output member disposed in a housing. A first planetary gear set, a second planetary gear set, a third planetary gear set, and a fourth planetary gear set may also be disposed in the housing, each planetary gear set including a sun gear, a planet carrier, and a ring gear. Six control elements may be operably coupled to the planetary gear sets and selectively engageable to create a set of different gear ratios between the input member and the output member, the set of different gear ratios including at least nine forward gear ratios and at least two reverse gear ratios.

Owner:CATERPILLAR INC

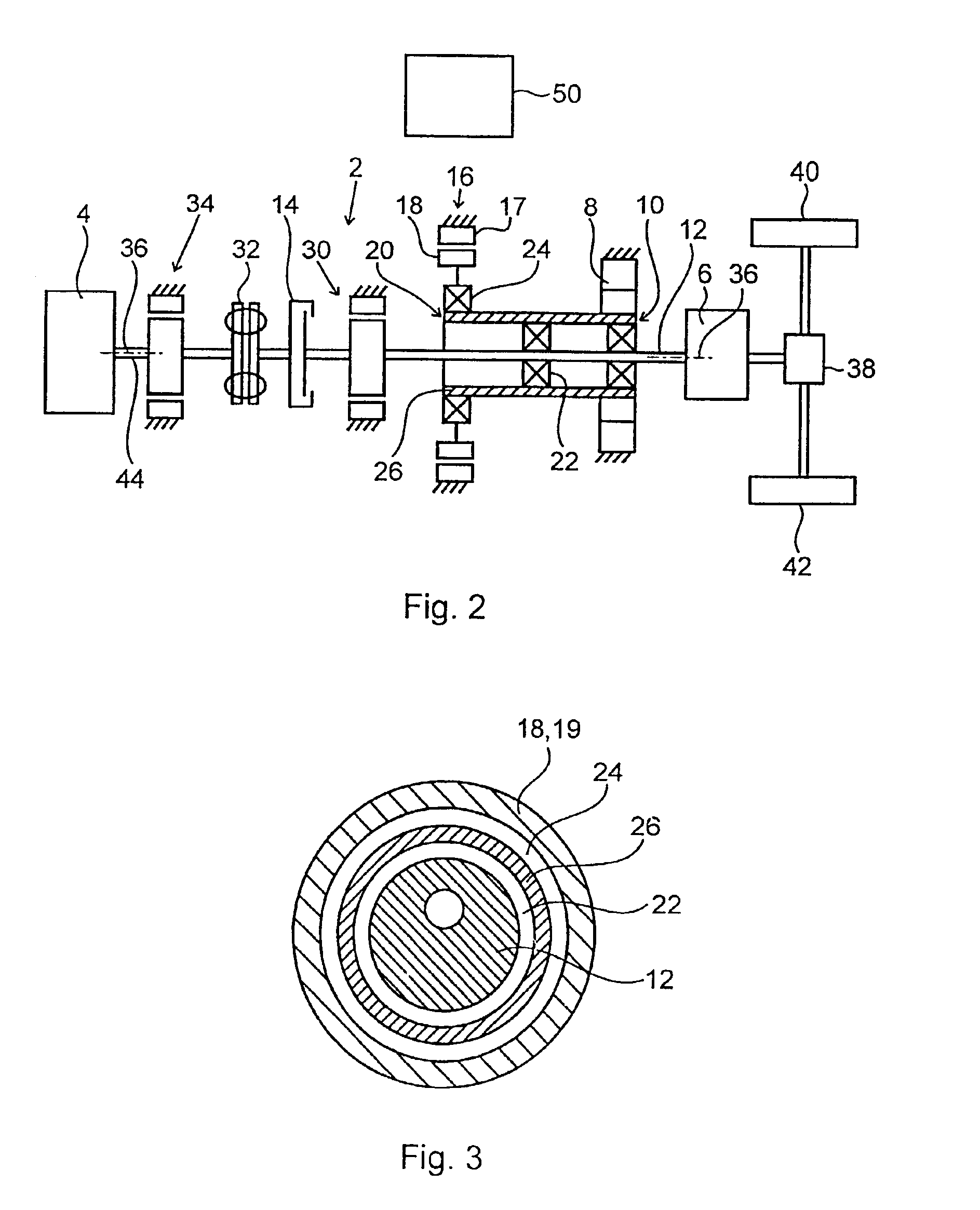

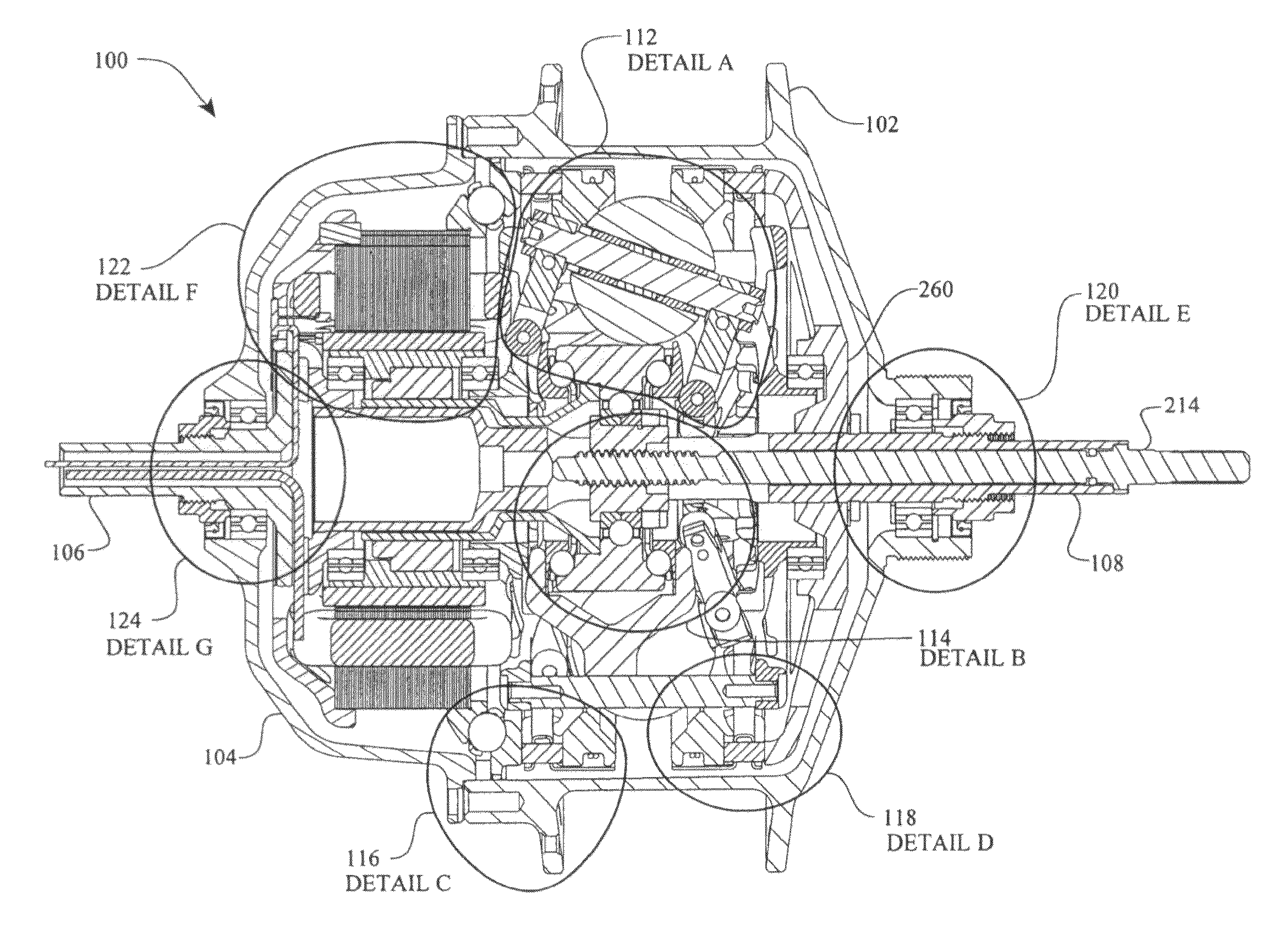

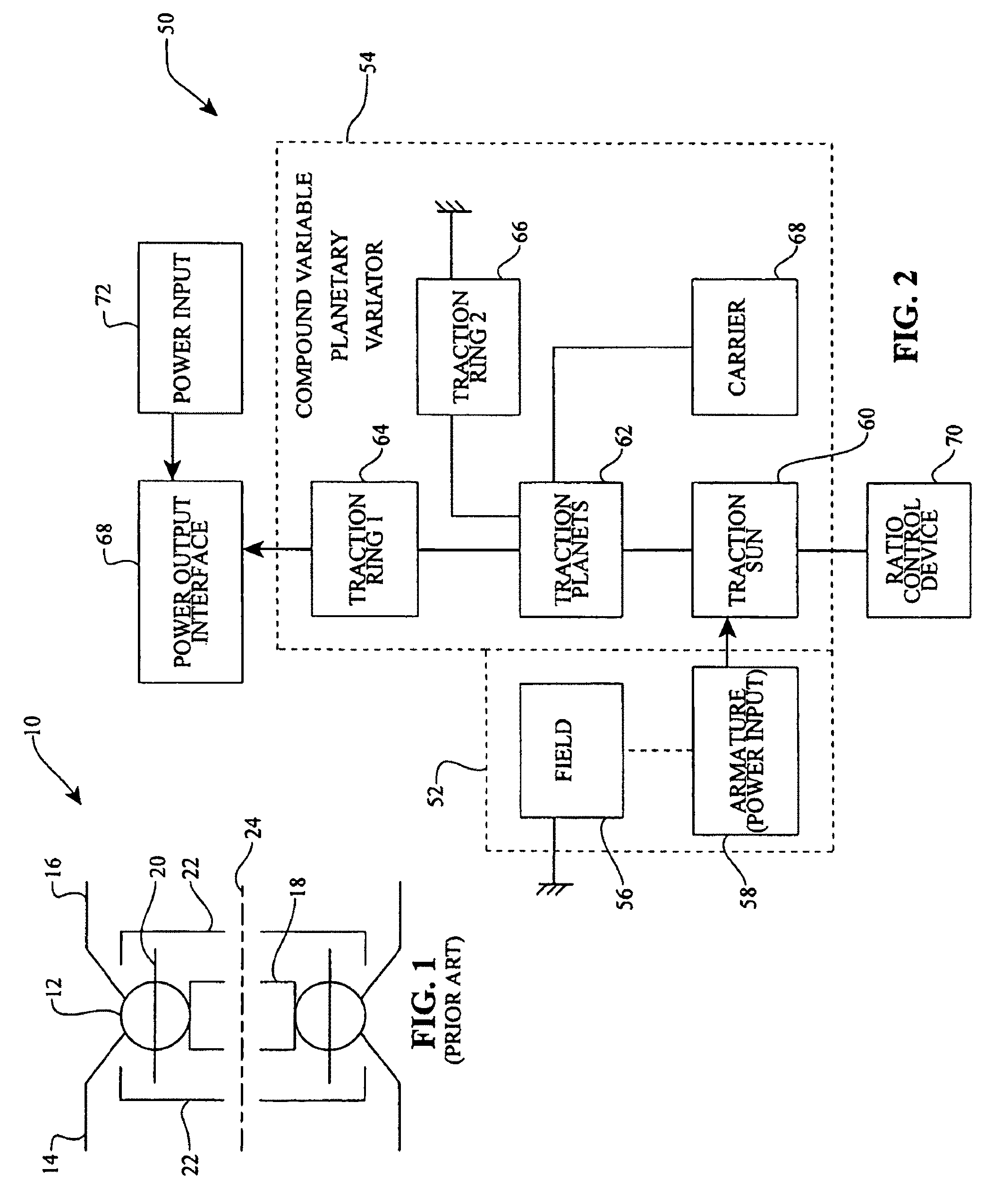

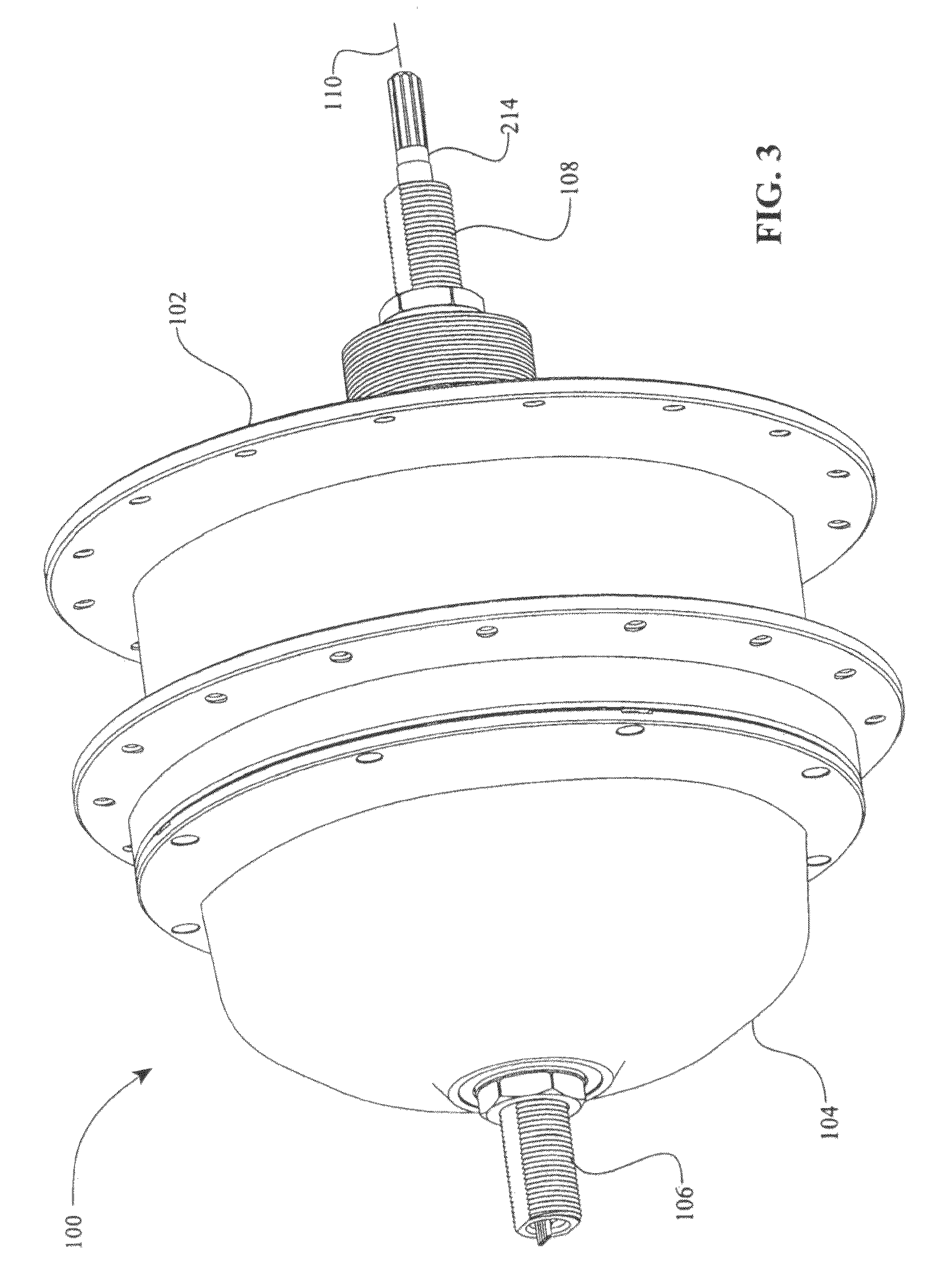

Electric traction drives

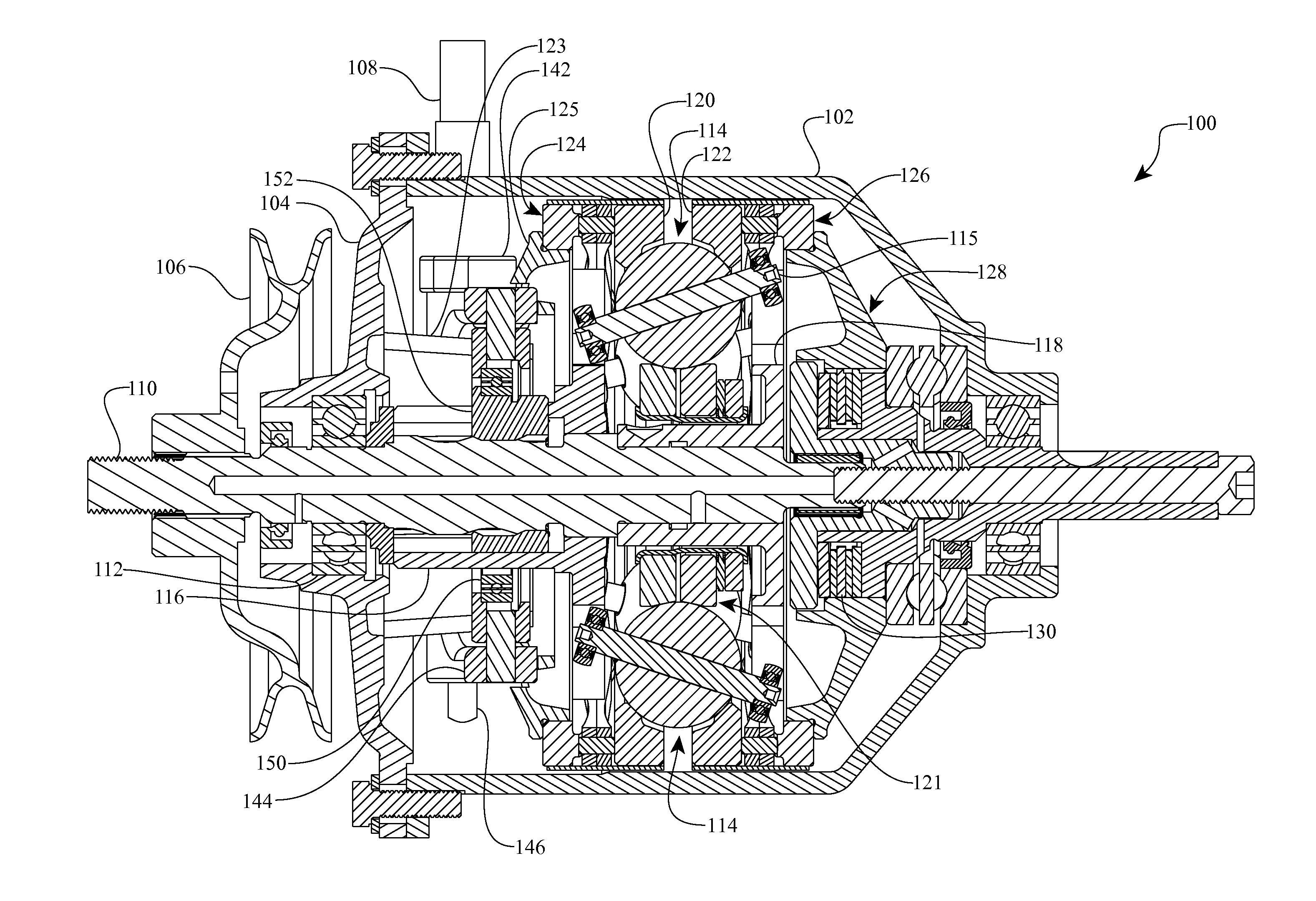

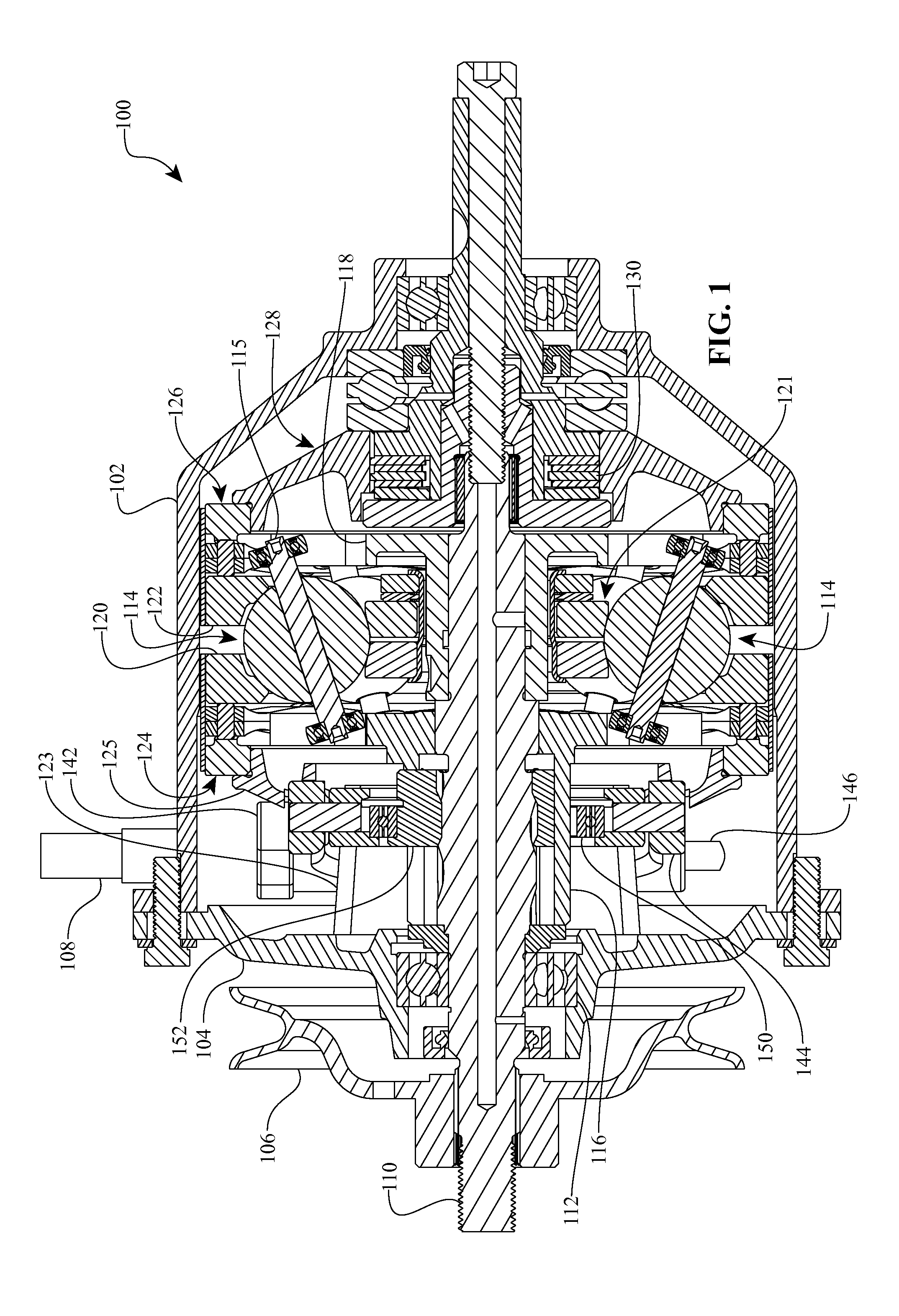

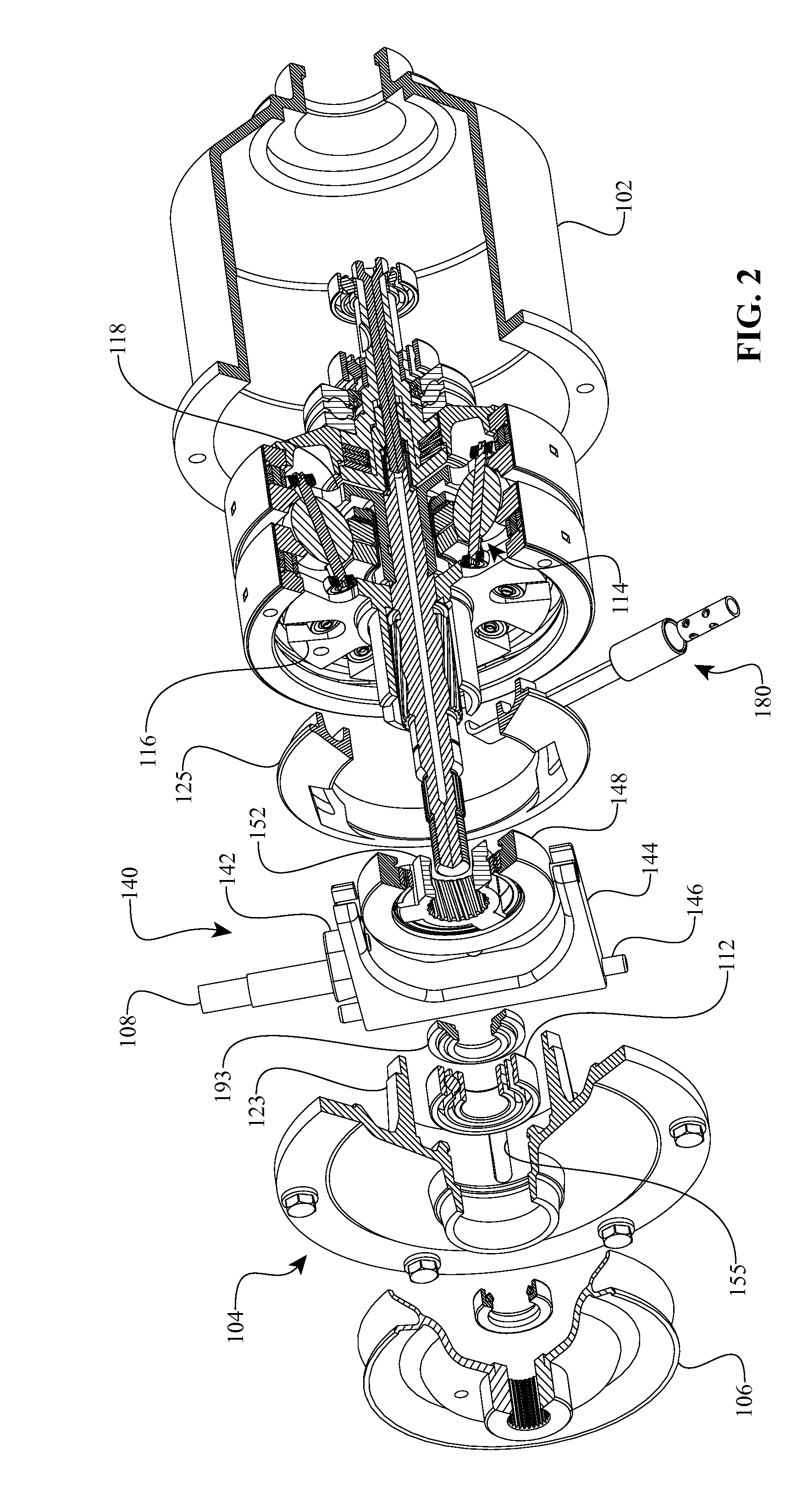

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for electric traction drives employing a continuously variable transmission (CVT) having a variator provided with a plurality of tilting traction planets and opposing traction rings. In one embodiment, an electric traction drive is provided with an electromotive device configured to transfer power to or from a traction sun of a CVT, In other embodiments, an electric traction drive is provided with an electromotive device that couples to certain components of a CVT such as a traction ring, a carrier assembly, and a main axle. Various inventive shifting assemblies having shift cams and shift cam cages can be used to facilitate adjusting the transmission speed ratio of a CVT. Various related devices include embodiments of, for example, a power input apparatus, a speed ratio shifter, a shift cam actuator, a shift nut, and a carrier assembly configured to support the tilting traction planets.

Owner:FALLBROOK INTPROP COMPANY

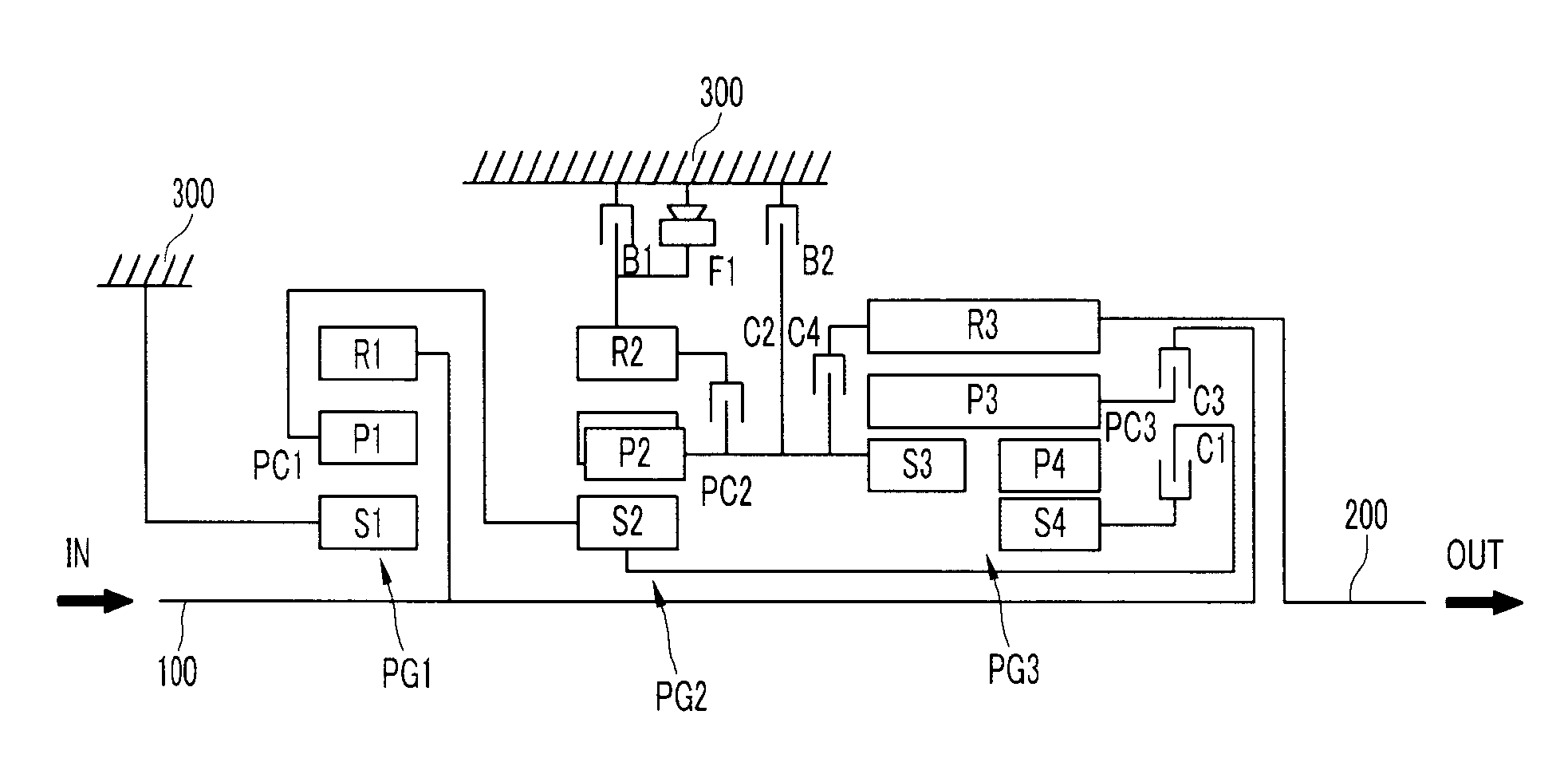

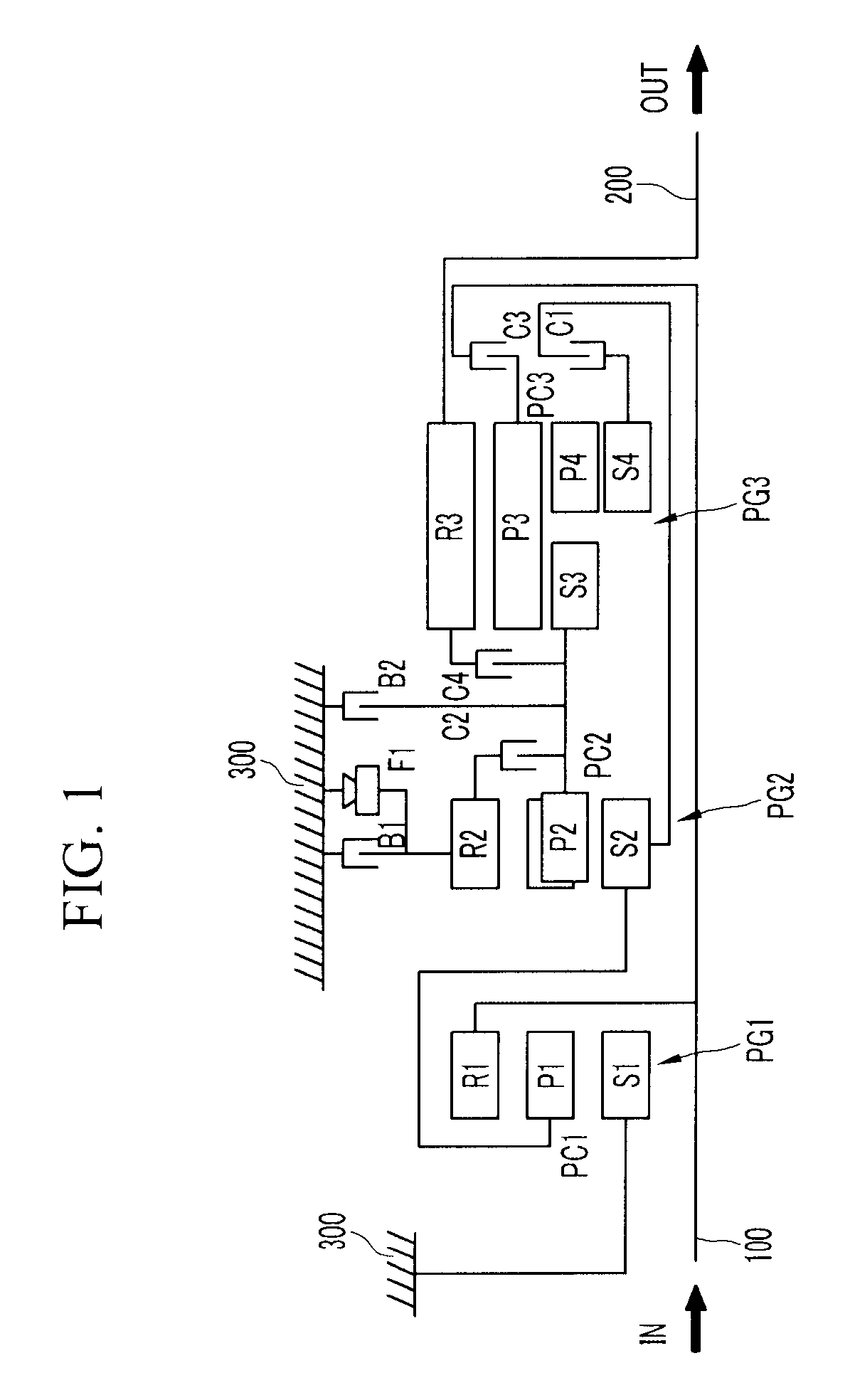

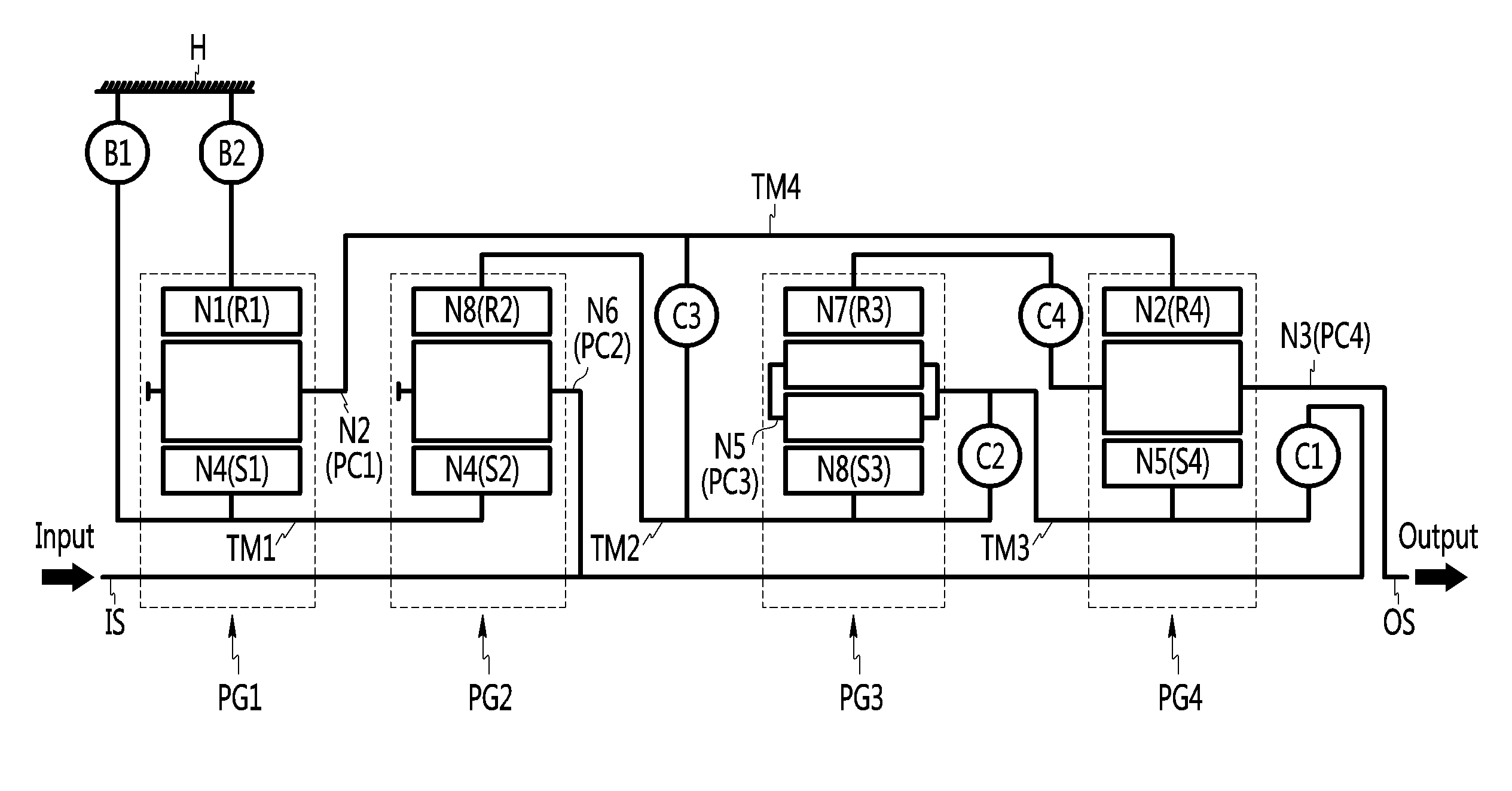

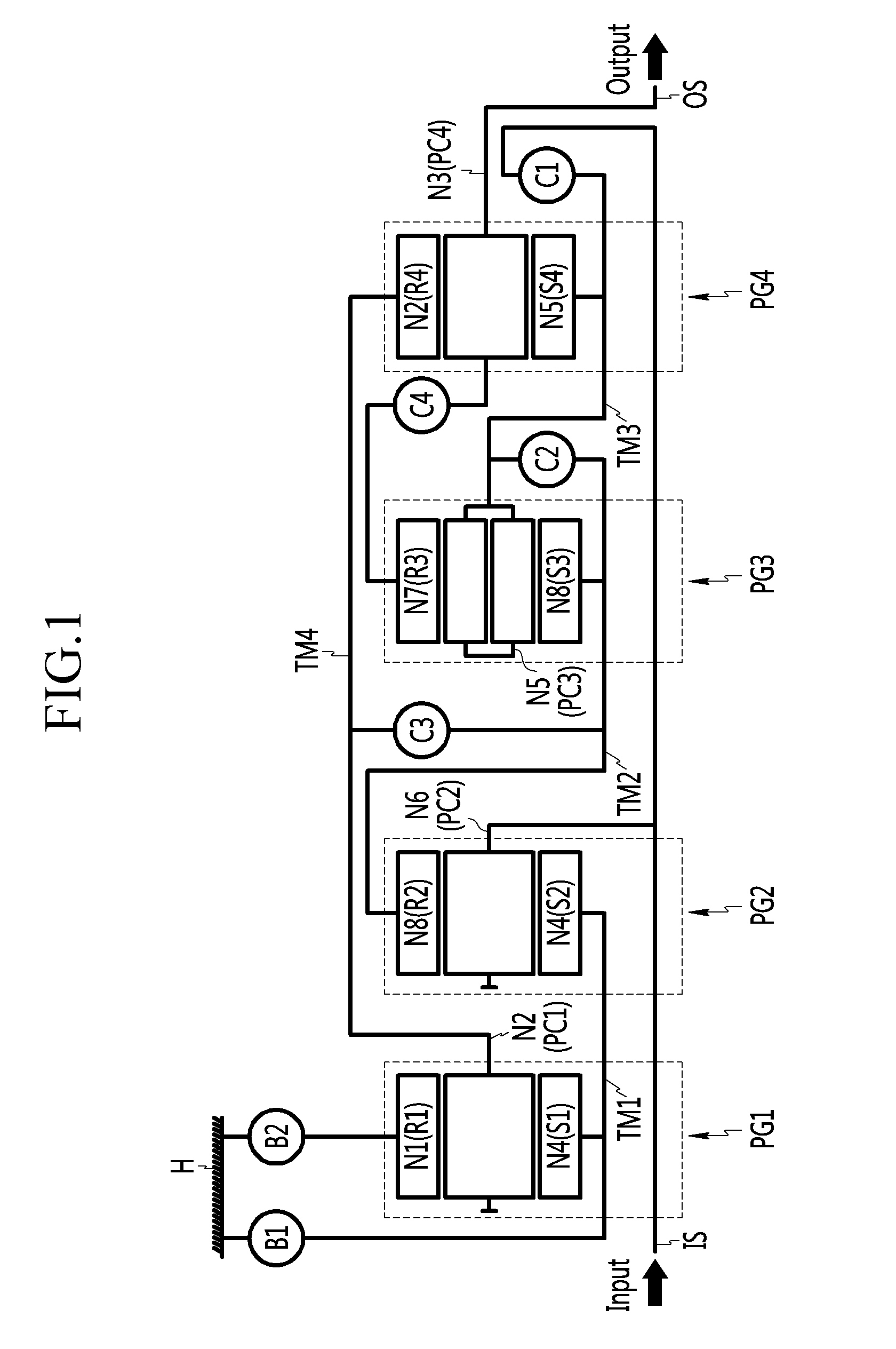

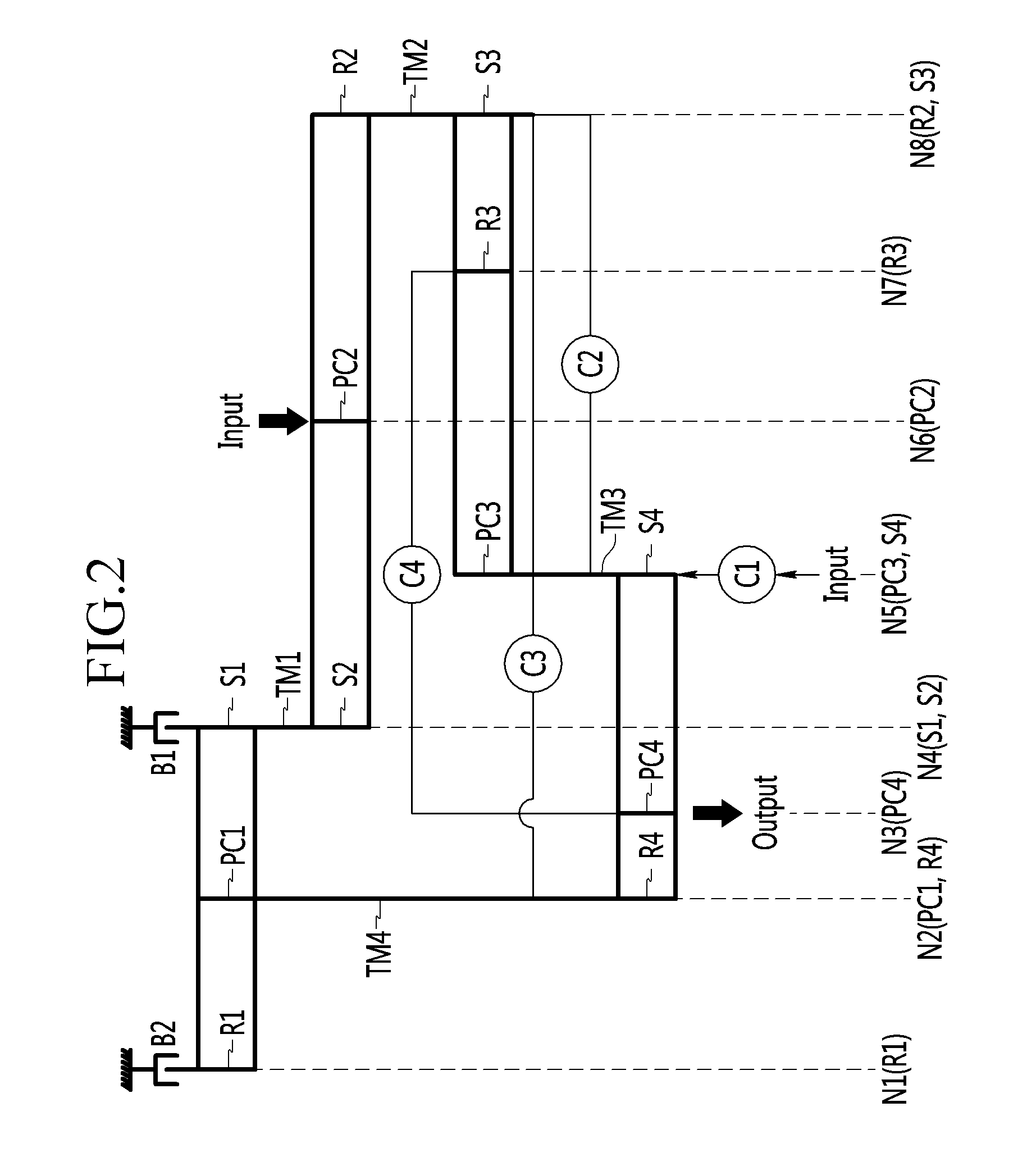

Gear train of automatic transmission for vehicles

InactiveUS20110245013A1Simple structureImprove fuel economyToothed gearingsTransmission elementsDelivery PerformanceAutomatic transmission

A gear train of an automatic transmission realizes at least ten forward speeds and one reverse speed by combining four simple planetary gear sets with four clutches and two brakes. In addition, three friction elements are operated at each shift-speed. Therefore, the gear train has advantages of simplifying structures of the automatic transmission and improving power delivery performance and fuel economy.

Owner:HYUNDAI MOTOR CO LTD

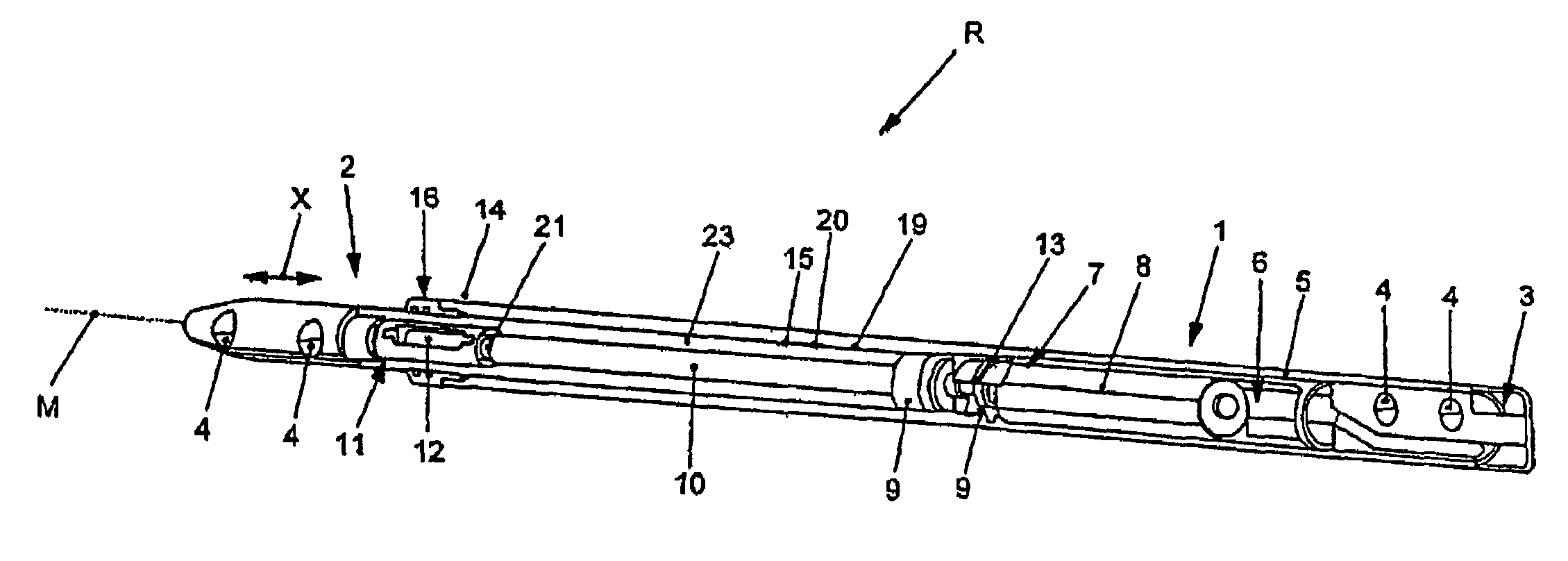

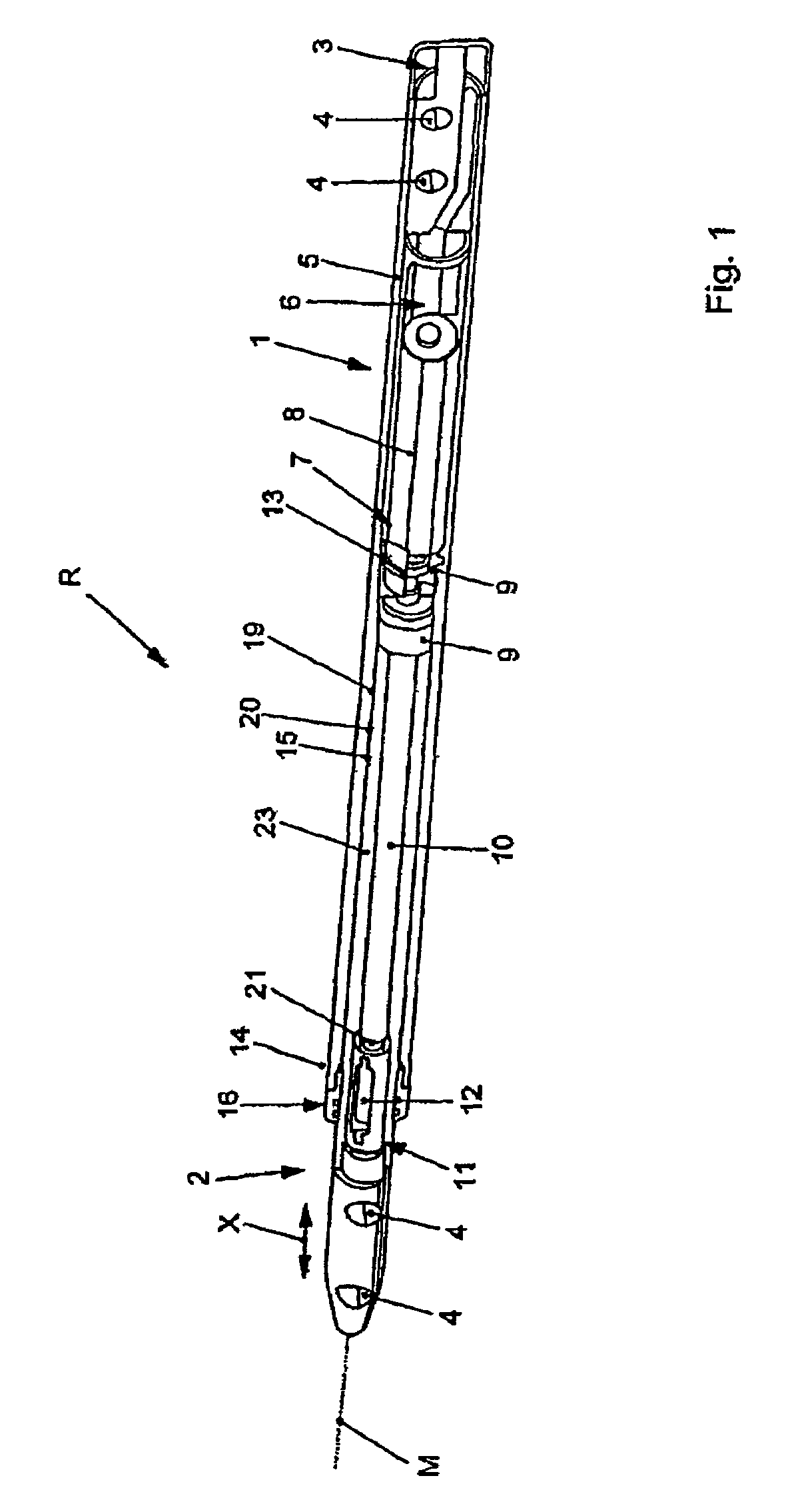

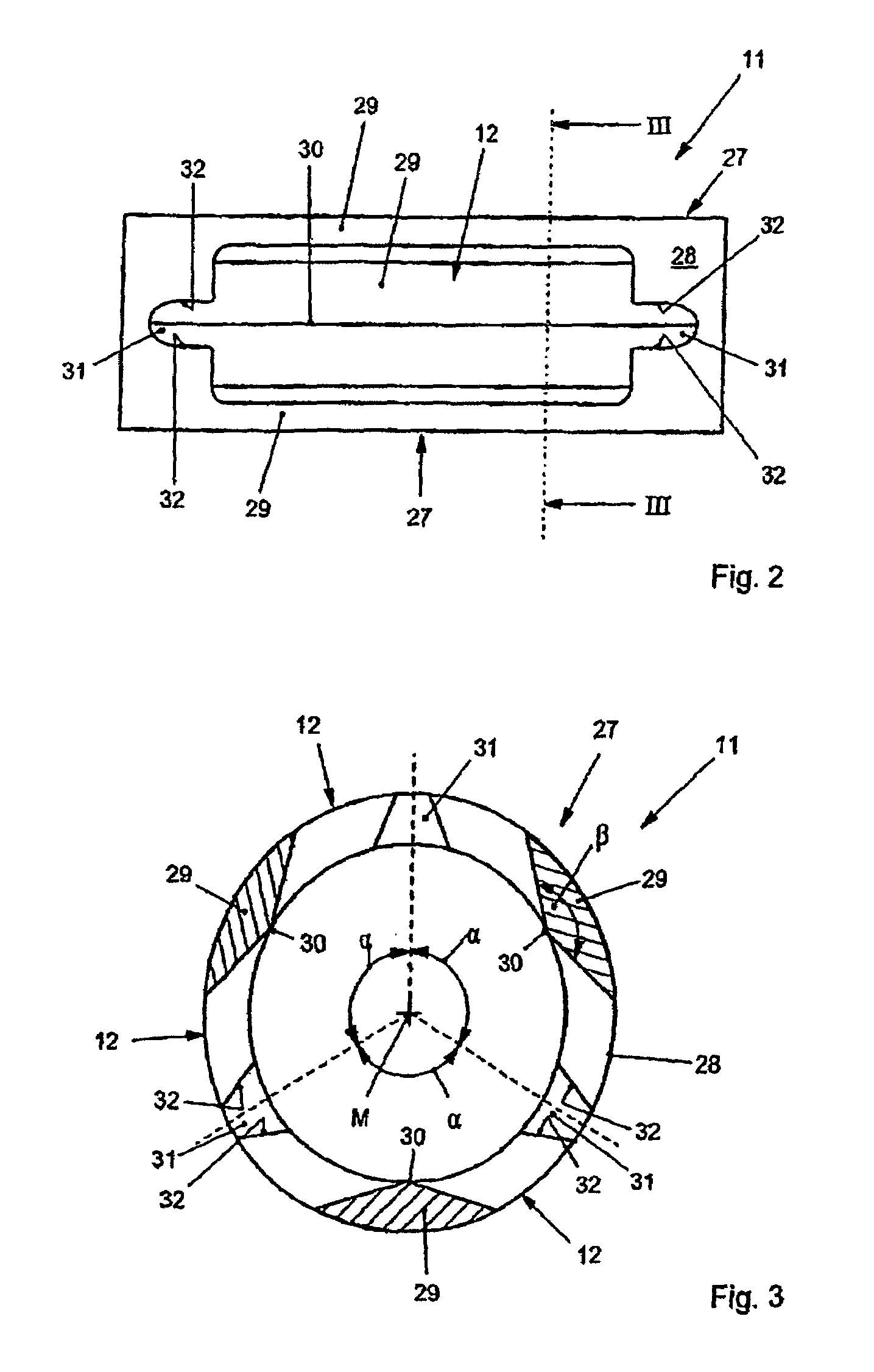

Planetary roll system, in particular for a device for extending bones

InactiveUS7666184B2Reduce the overall diameterEasy to assembleInternal osteosythesisDiagnosticsThumb oppositionEngineering

Owner:WITTENSTEIN GROUP

Multi-speed transmission

Owner:CATERPILLAR INC

Infinitely variable transmissions, continuously variable transmissions, methods, assemblies, subassemblies, and components therefor

ActiveUS20110218072A1Toothed gearingsGearing controlControl systemContinuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for infinitely variable transmissions (IVT). In one embodiment, a control system is adapted to facilitate a change in the ratio of an IVT. In another embodiment, a control system includes a carrier member configured to have a number of radially offset slots. Various inventive carrier members and carrier drivers can be used to facilitate shifting the ratio of an IVT. In some embodiments, the traction planet assemblies include planet axles configured to cooperate with the carrier members. In one embodiment, the carrier member is configured to rotate and apply a skew condition to each of the planet axles. In some embodiments, a carrier member is operably coupled to a carrier driver. In some embodiments, the carrier member is configured to couple to a source of rotational power. Among other things, shift control interfaces for an IVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

Power train of automatic transmission

Owner:HYUNDAI MOTOR CO LTD

Stepless speed changer

InactiveCN1940348AReduce defectsQuality improvementGearing detailsFriction gearingsRotational axisControl theory

The present invention provides a gearless drive mechanism, facilitating the connection between an output shaft of a continuously variable transmission and a rotating shaft of a driven body, and transmitting the rotating speed of the output shaft to the rotating shaft of the driven body with good accuracy. The gearless drive mechanism includes: an input shaft 4 rotating on receiving the driving force; an output shaft 5, one end of which is connected to the input shaft through a variable speed mechanism, the other end being projected from a casing; a first gear 42 disposed outside the casing 3 to be spline-coupled to the projecting part of the output shaft 5 and rotated in a body with the output shaft 5; and a second gear 44 rotatablely supported on the casing 3 through a support shaft 43 to mesh with the first gear 42.

Owner:NIDEC SHIMPO CORP

Gear train of automatic transmission for vehicles

InactiveUS8333676B2Simple structureImprove economyToothed gearingsTransmission elementsDelivery PerformanceAutomatic transmission

A gear train of an automatic transmission realizes at least ten forward speeds and one reverse speed by combining four simple planetary gear sets with four clutches and two brakes. In addition, three friction elements are operated at each shift-speed. Therefore, the gear train has advantages of simplifying structures of the automatic transmission and improving power delivery performance and fuel economy.

Owner:HYUNDAI MOTOR CO LTD

Method and apparatus for cooling a hybrid transmission electric motor

ActiveUS7002267B2Avoid excessive accumulationHybrid vehiclesAsynchronous induction motorsEngineeringCoolant

Owner:GM GLOBAL TECH OPERATIONS LLC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com