Patents

Literature

149 results about "Slow rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

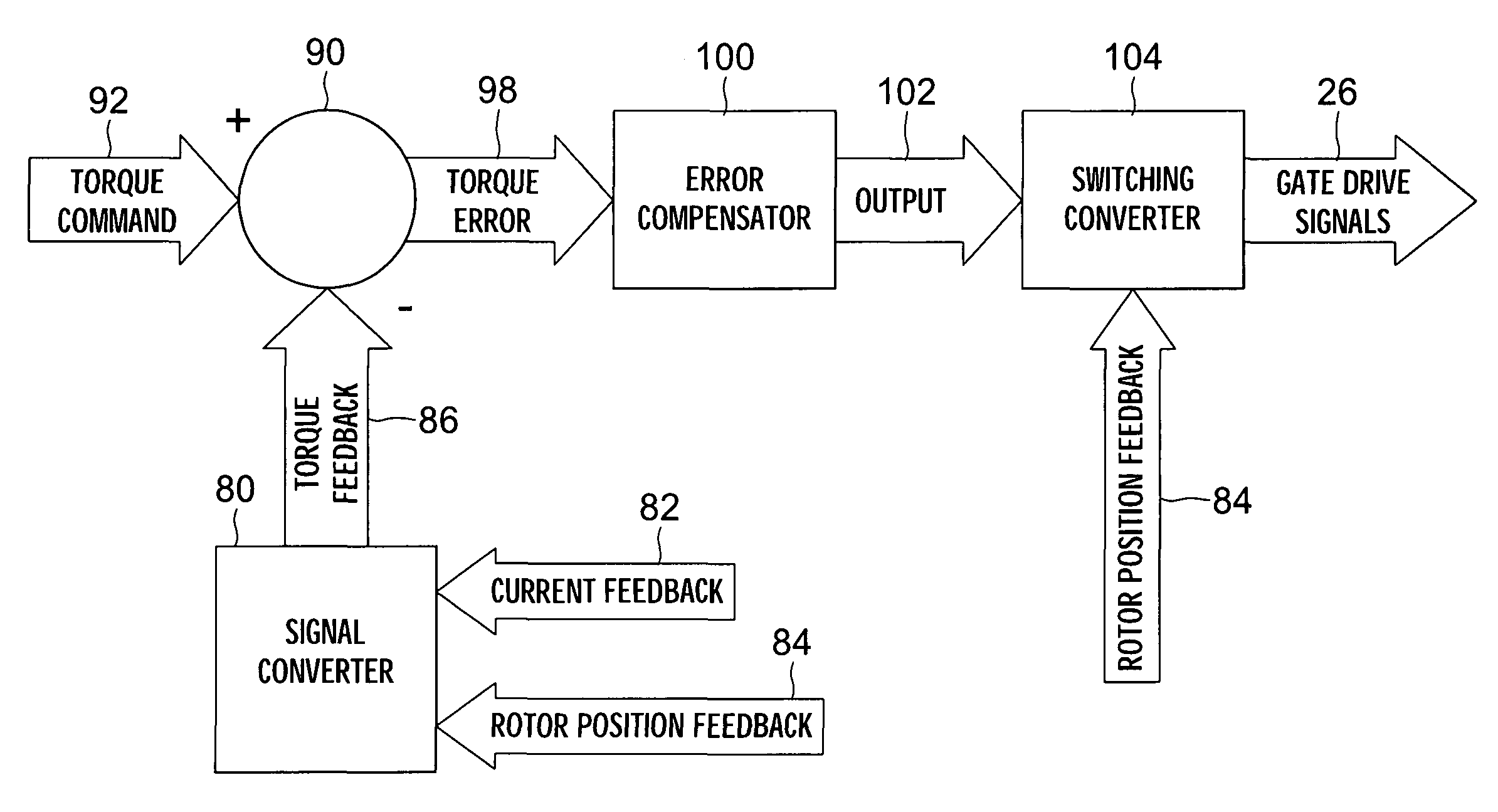

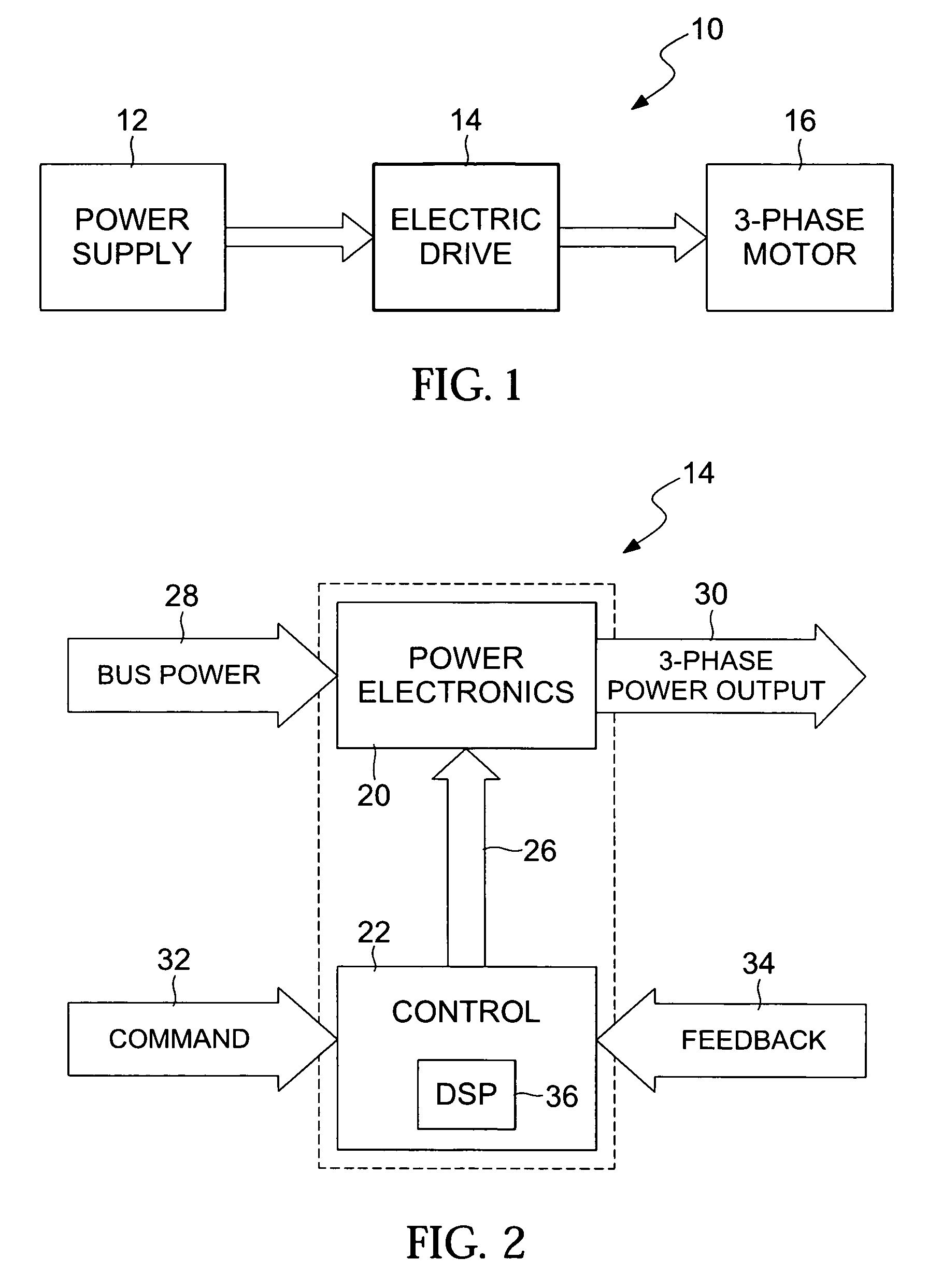

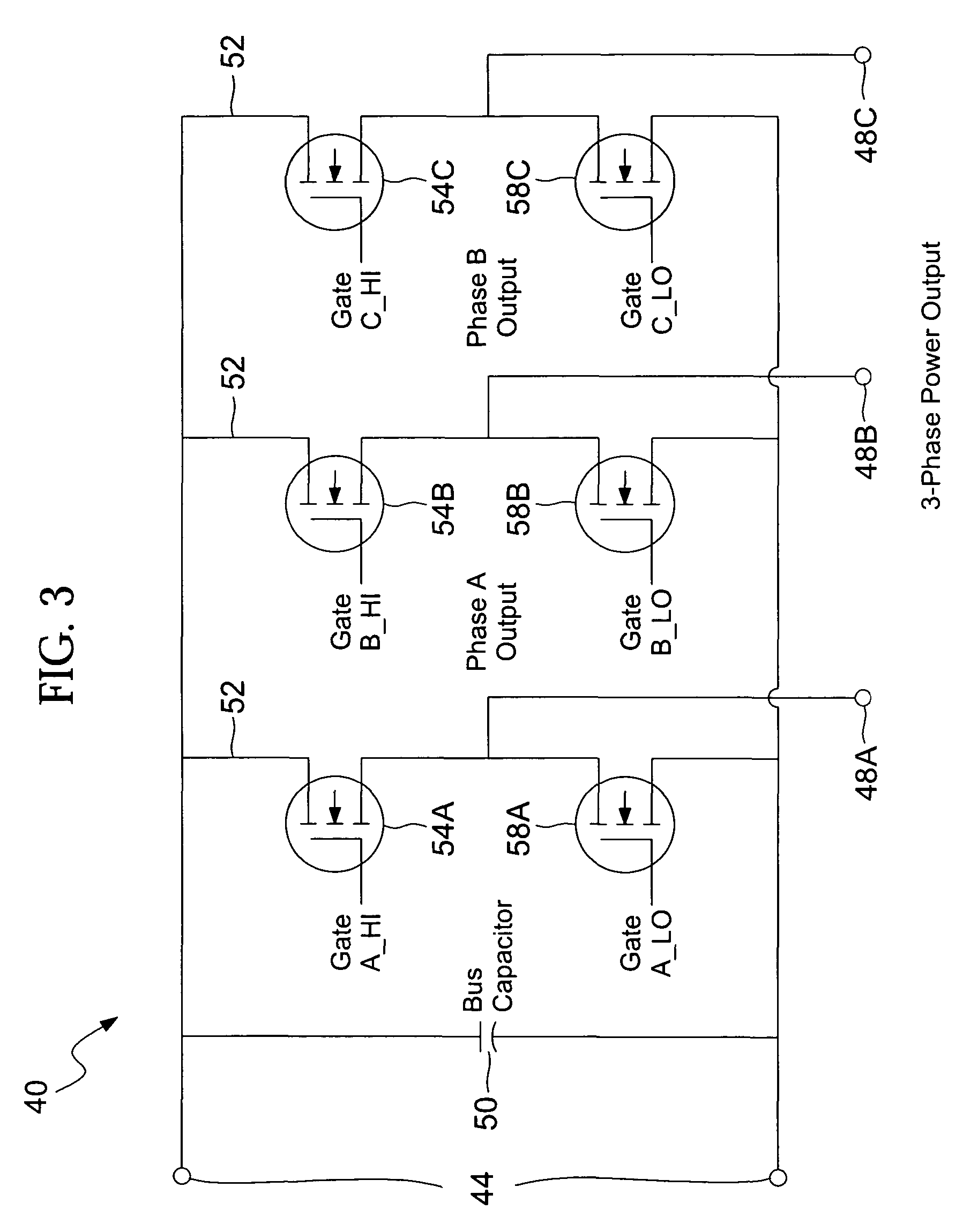

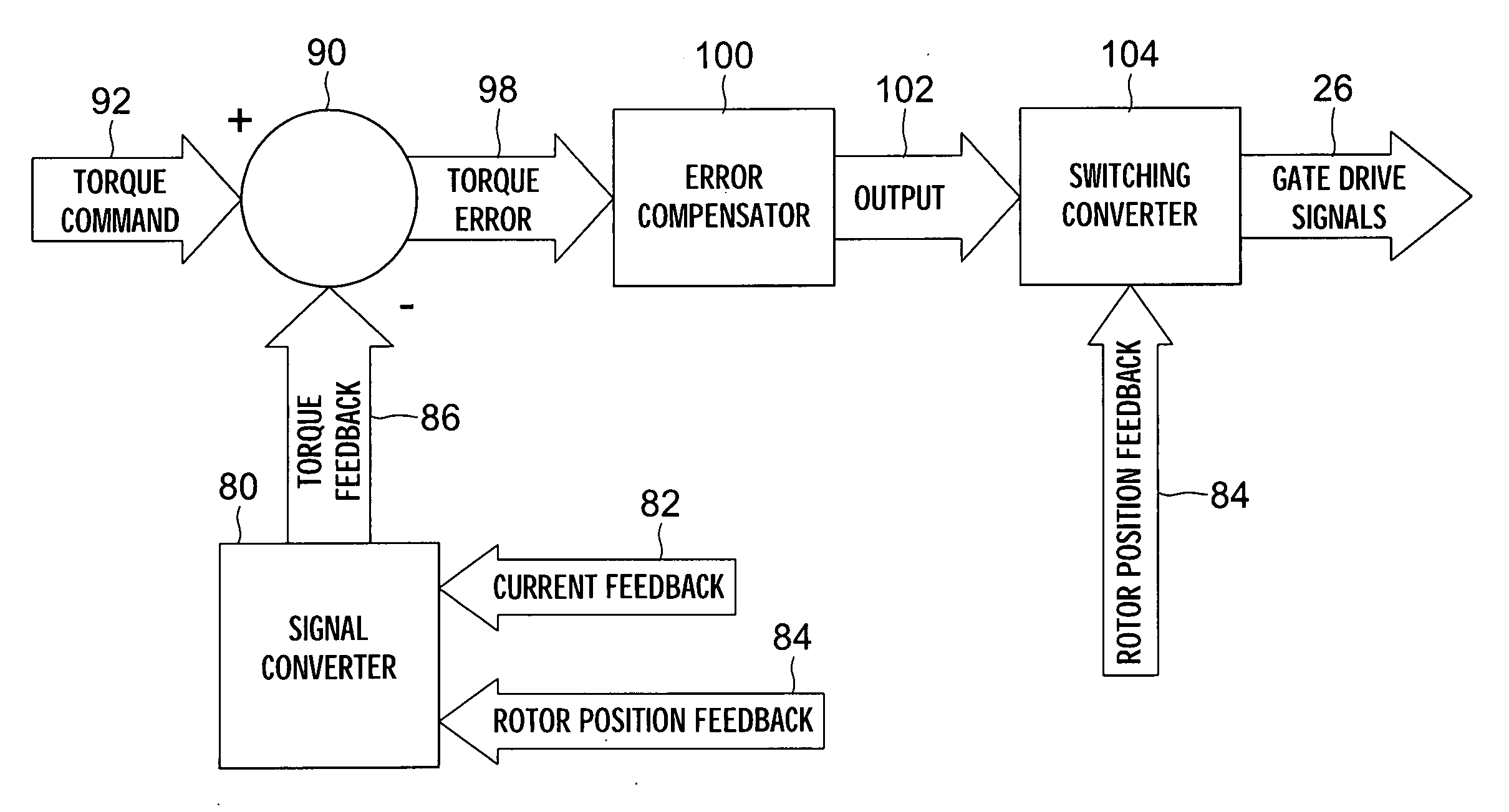

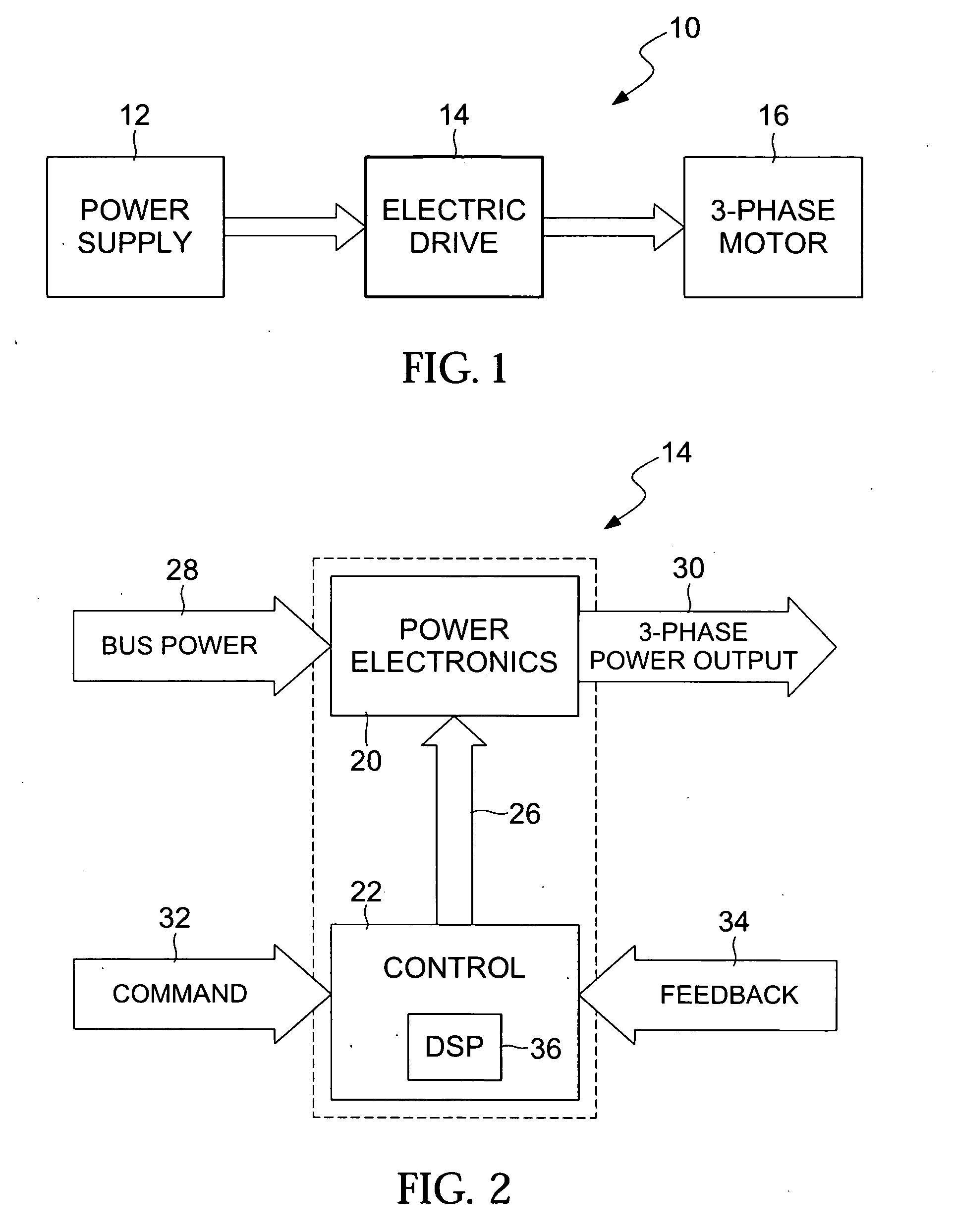

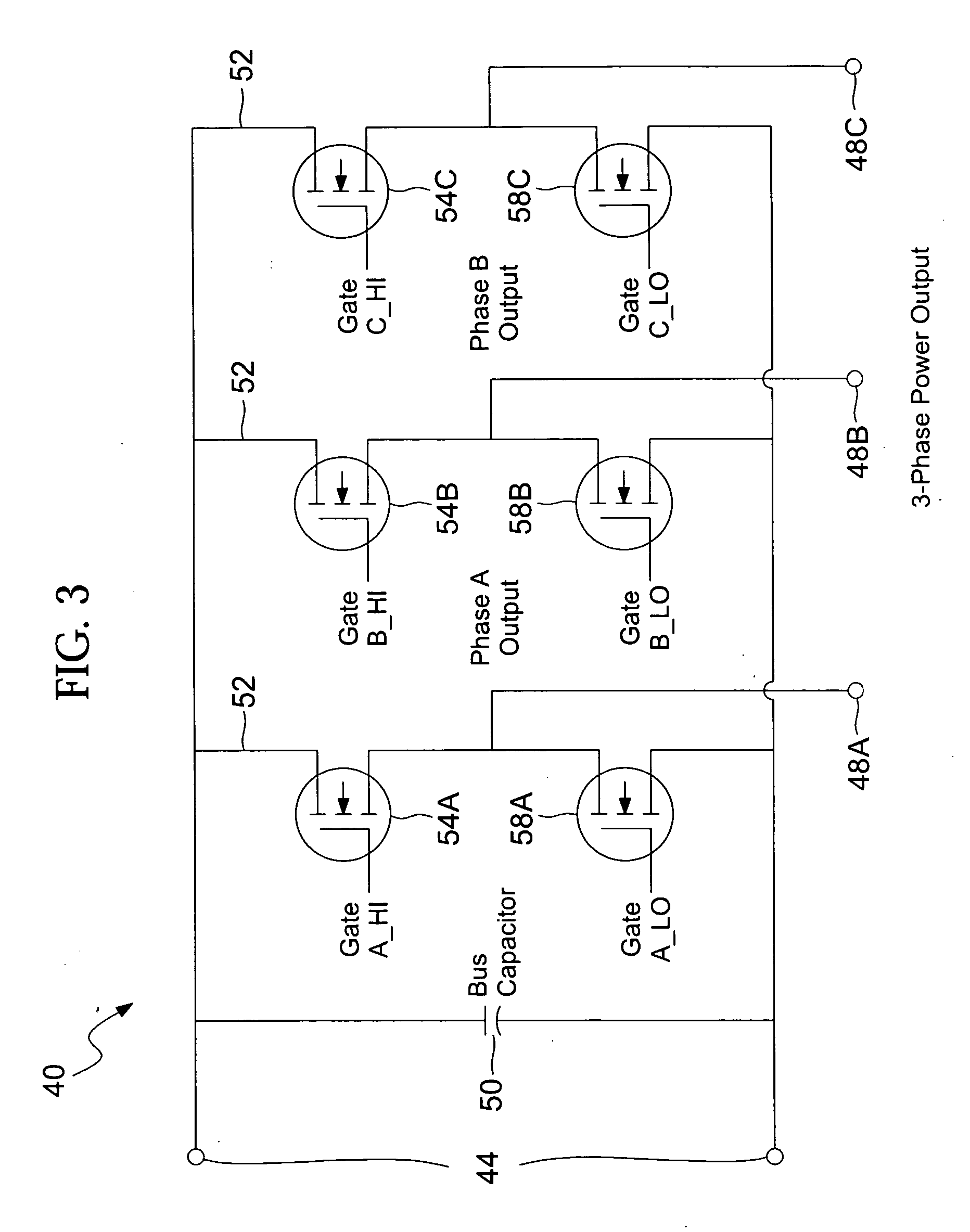

Torque controller in an electric motor

ActiveUS7898198B2Motor control for very low speedsDC motor speed/torque controlMaximum torqueSlow rotation

The torque of a motor operated by an inverter circuit is controlled to allow maximum torque in the motor when the motor is stalled or at low rotation speeds. Control is accomplished by providing a switching frequency to the motor at a first switching frequency, detecting a rotation speed of the motor, and switching the current to the motor to a second switching frequency when the rotation speed of the motor drops to a predetermined slow rotation speed. The second switching frequency is less than the first switching frequency.

Owner:DRS NETWORK & IMAGING SYST

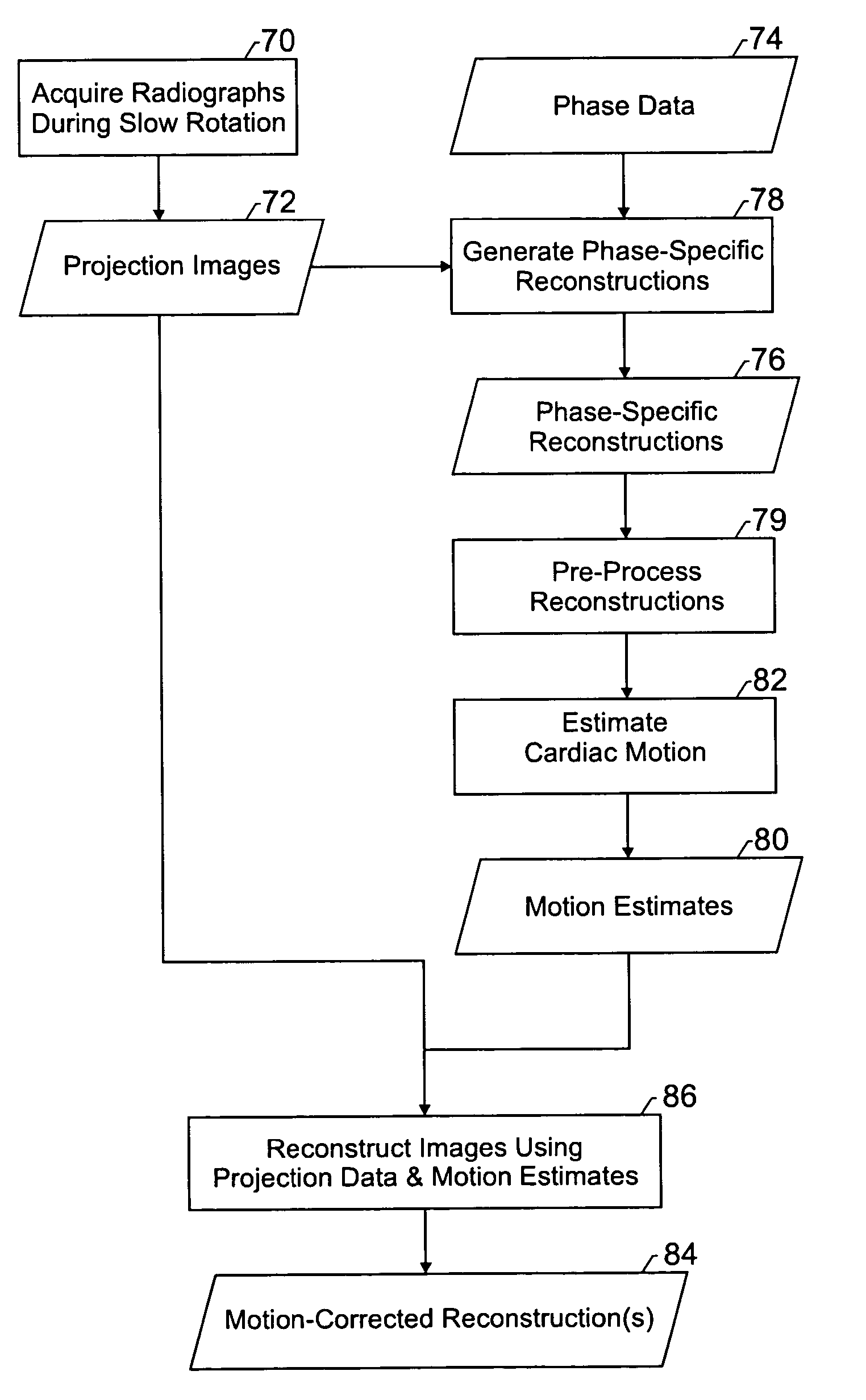

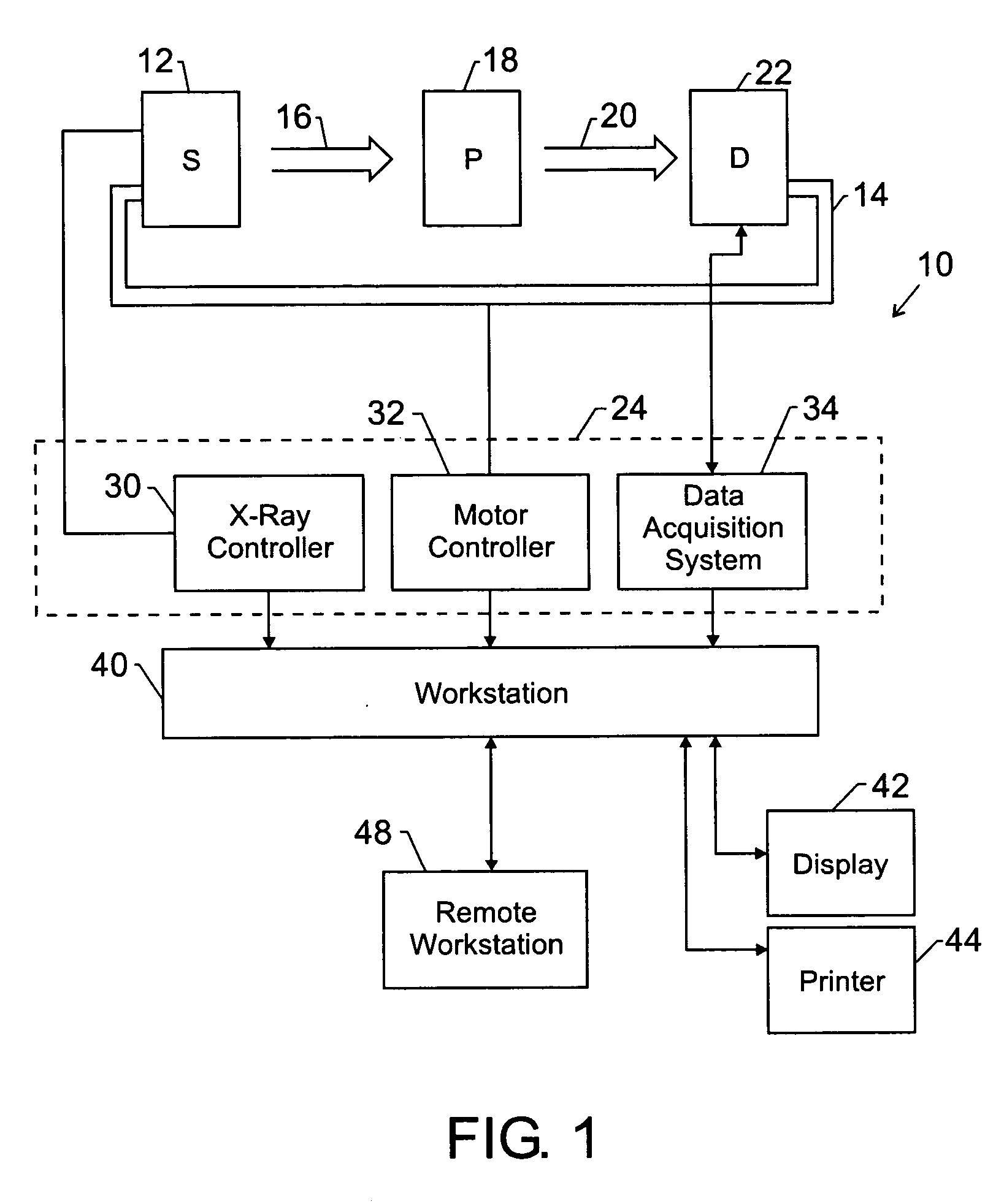

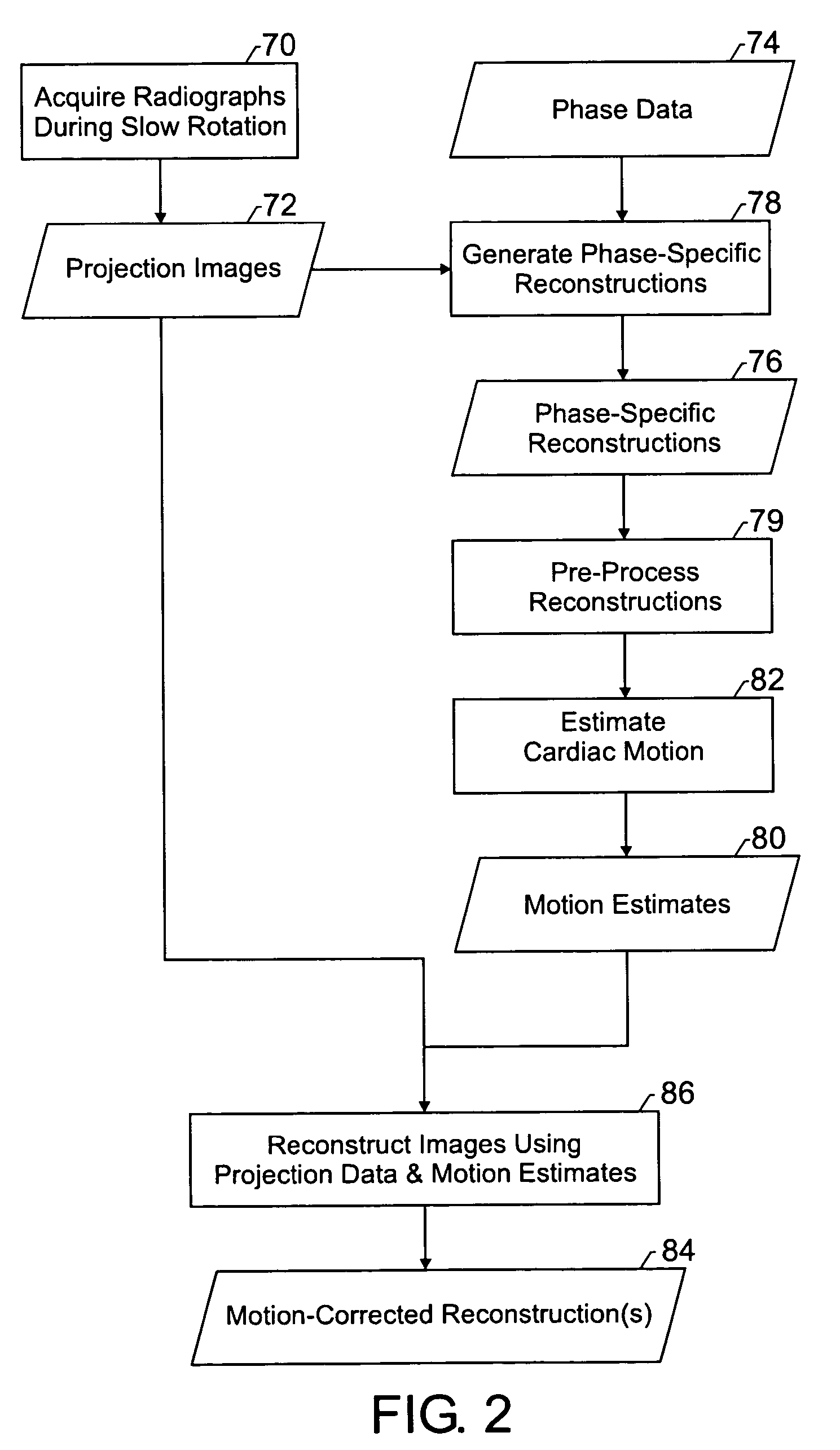

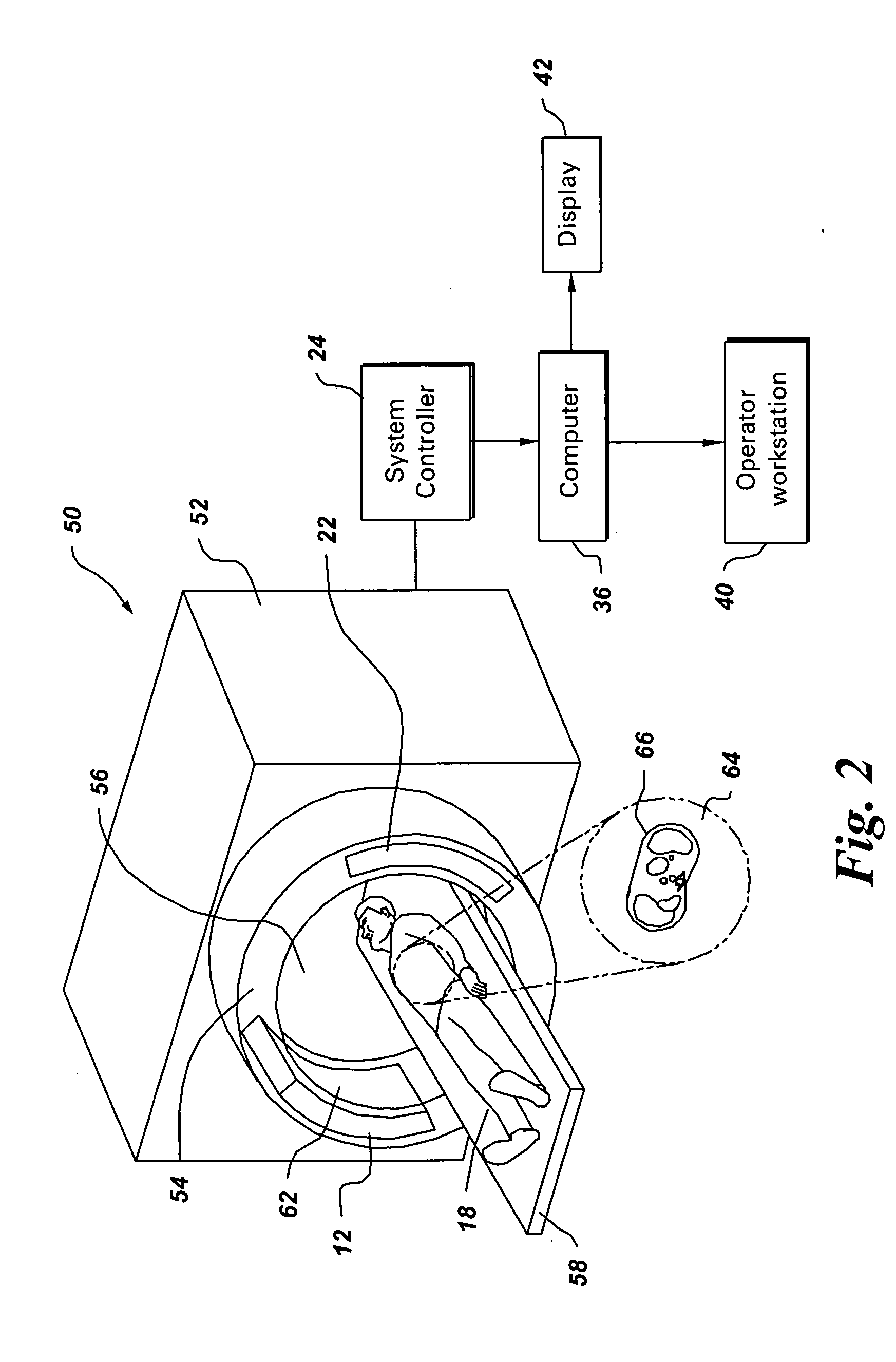

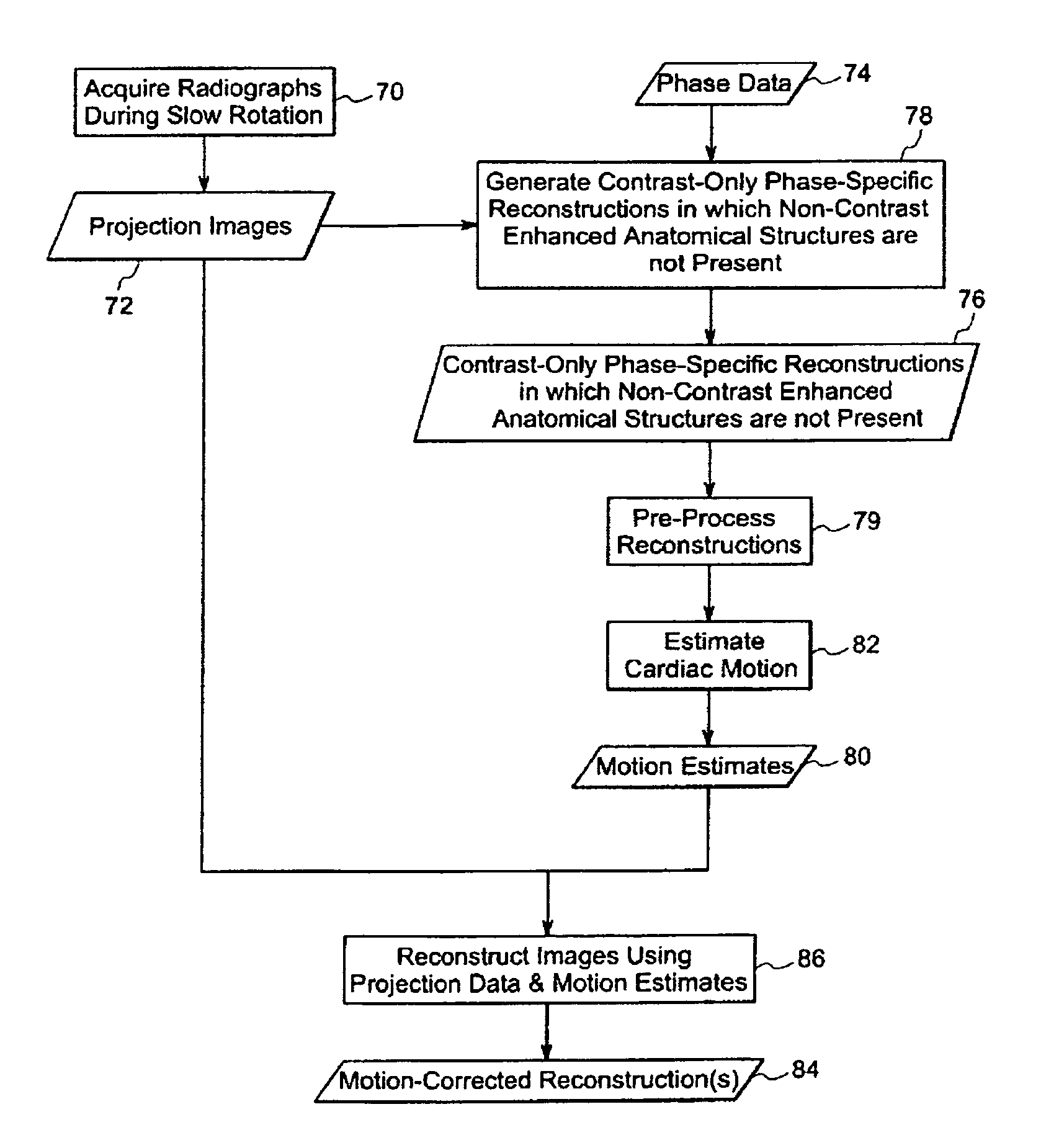

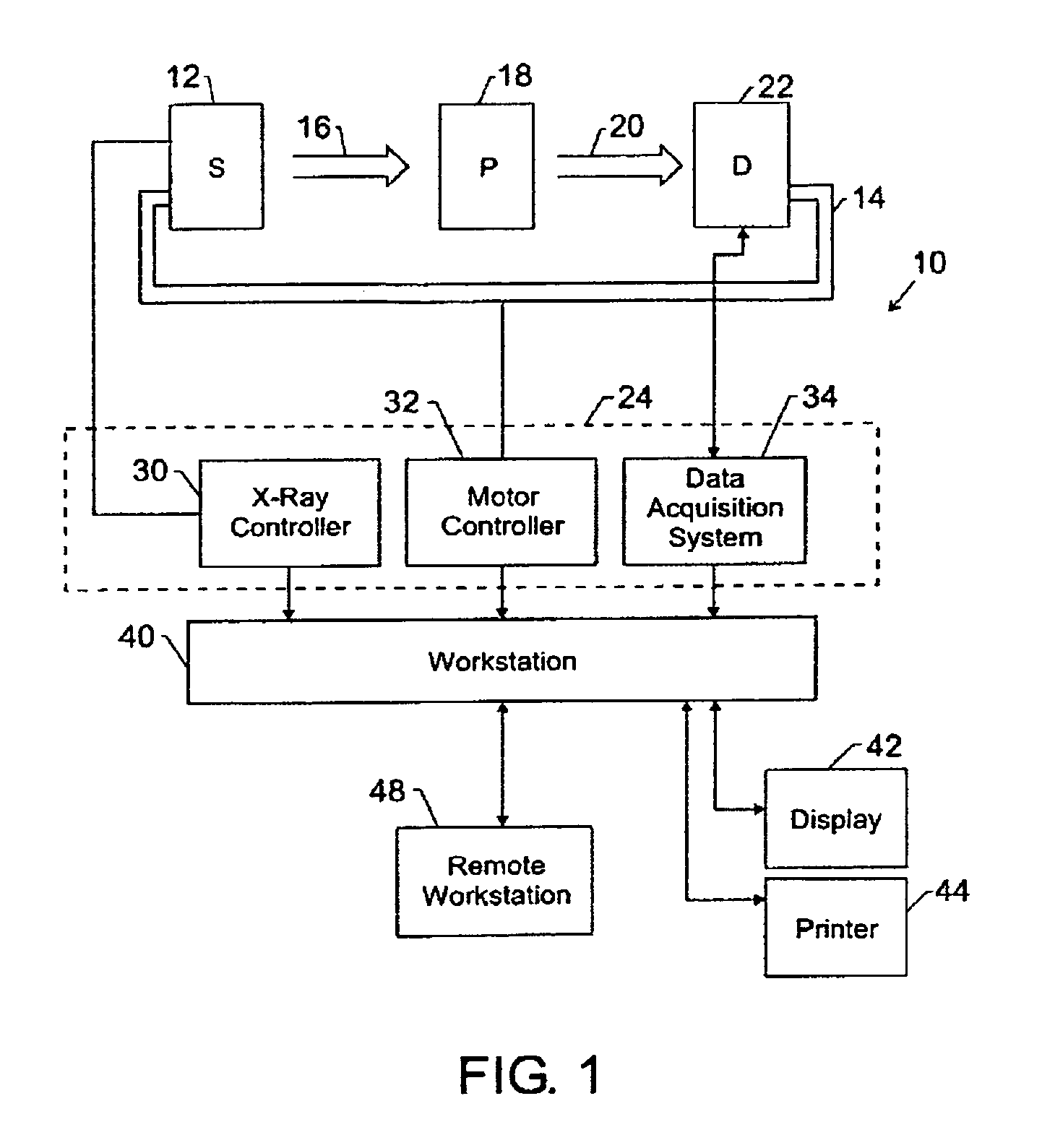

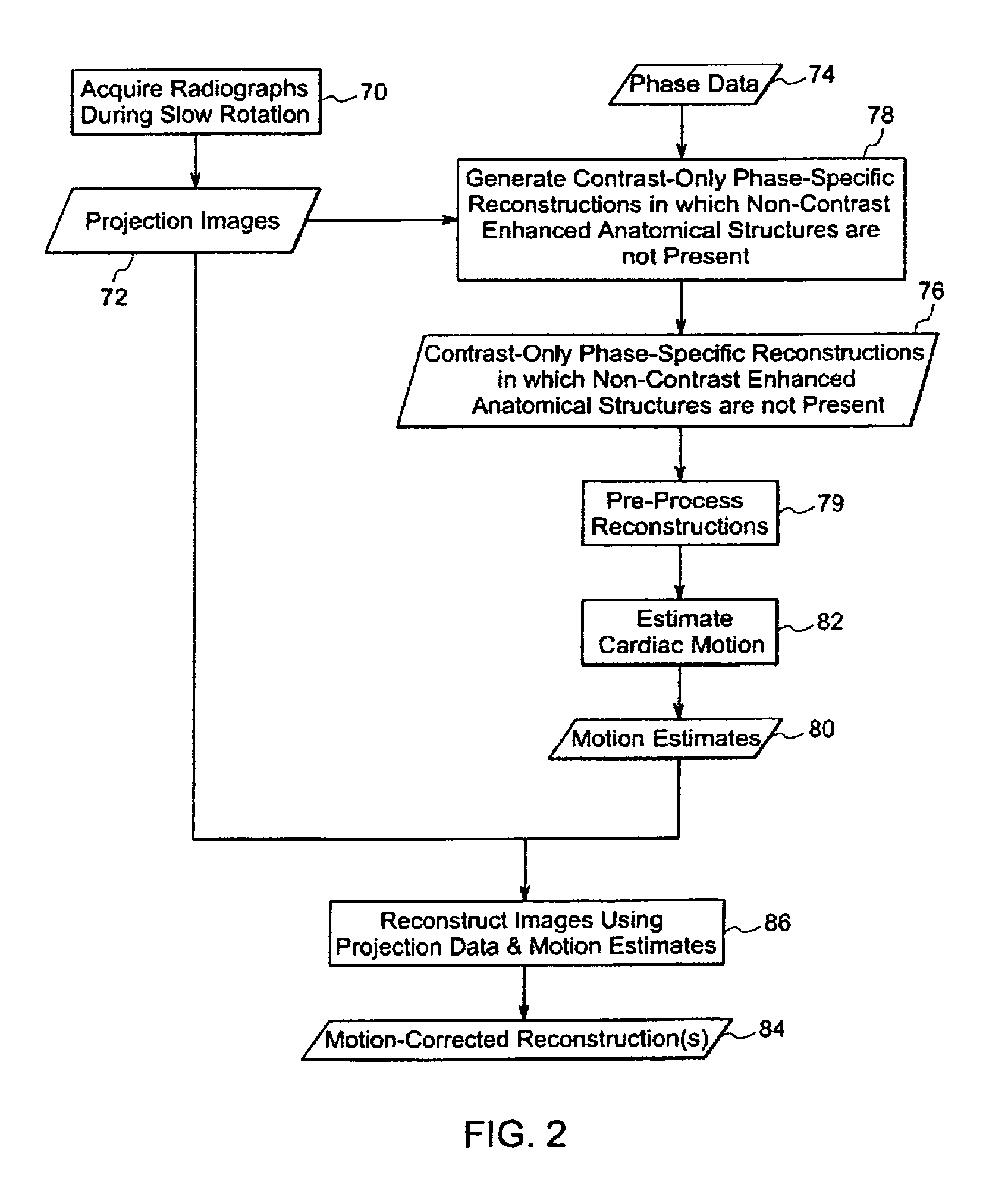

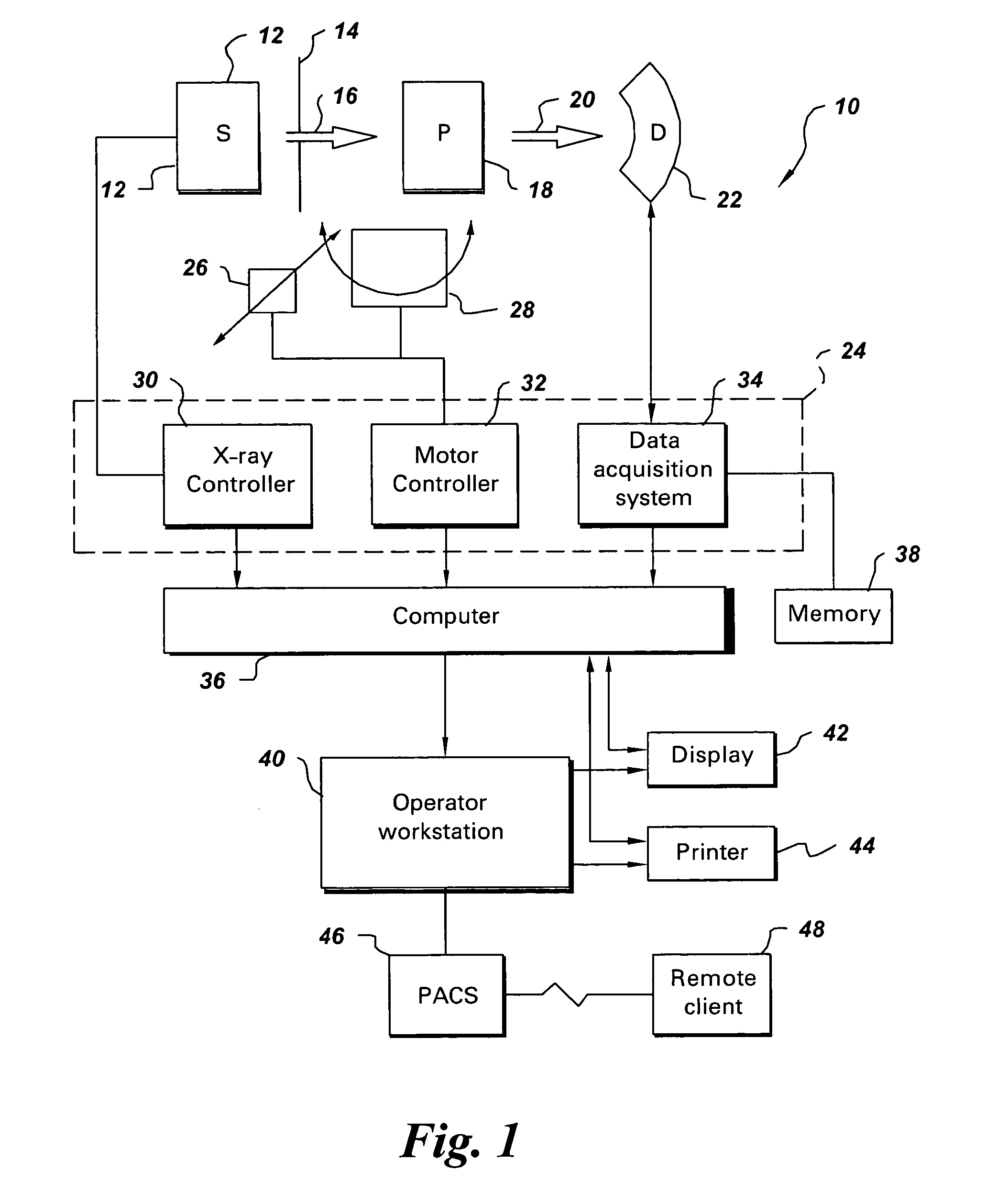

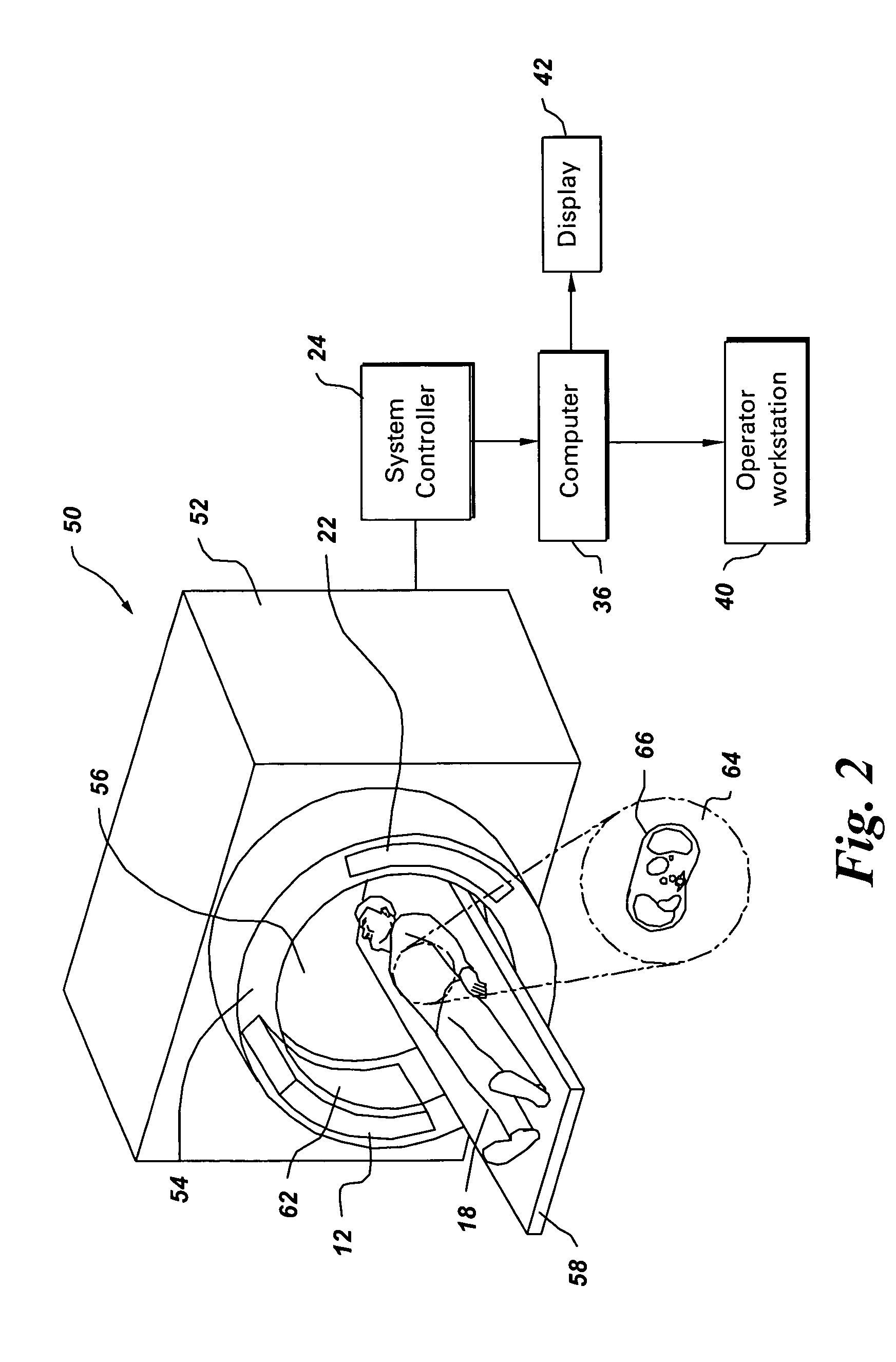

Method and apparatus for correcting motion in image reconstruction

A plurality of projection images are acquired over an angular range during the slow rotation of a C-arm gantry having a source and detector. Phase-specific reconstructions are generated from the plurality of projections, wherein each phase-specific reconstruction is generated generally from projections acquired at or near the respective phase. In one embodiment, a plurality of motion estimates are generated based upon the phase-specific reconstructions. One or more motion-corrected reconstructions may be generated using the respective motion estimates and projections. The motion-corrected reconstructions may be associated to form motion-corrected volume renderings.

Owner:GENERAL ELECTRIC CO

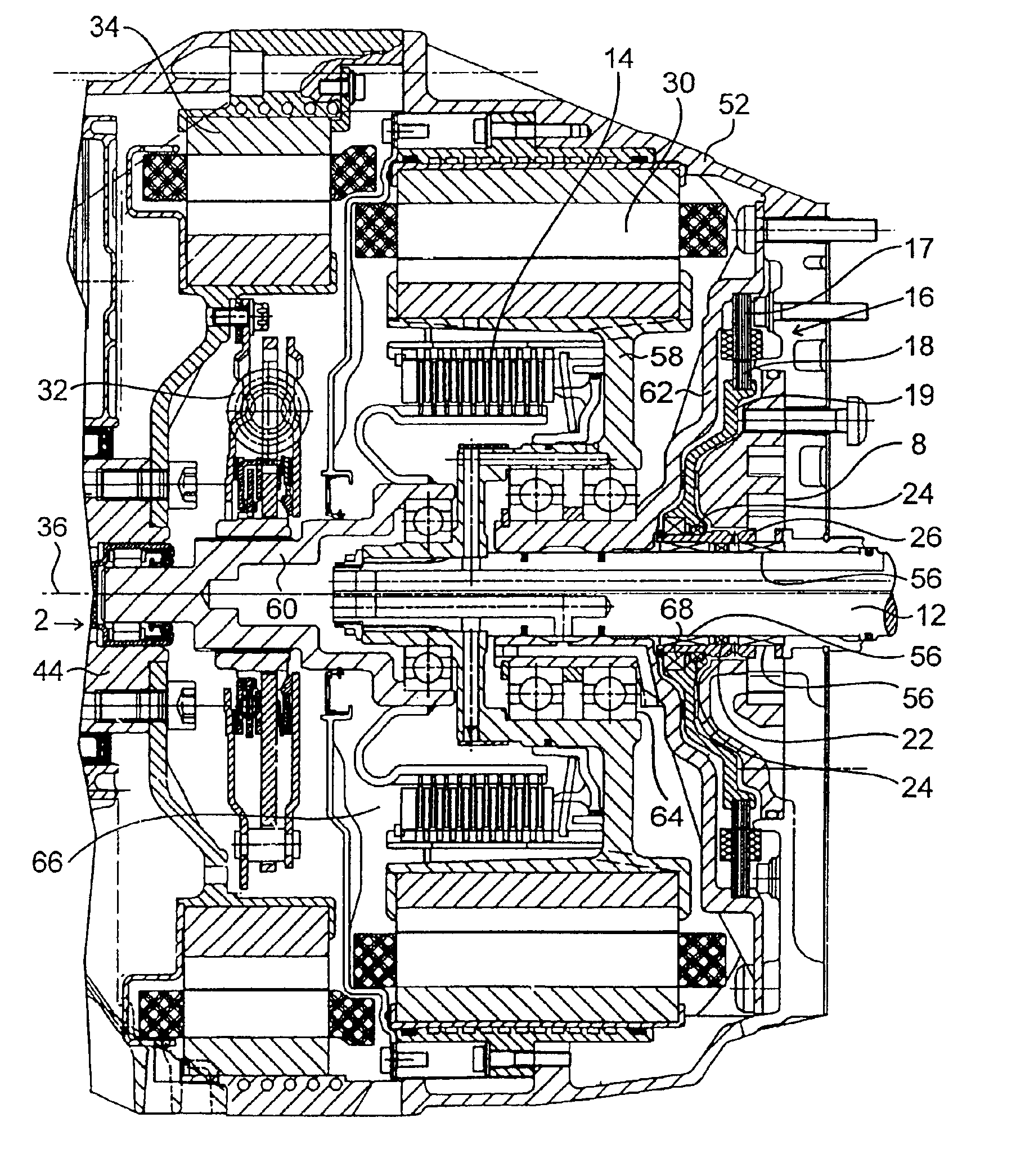

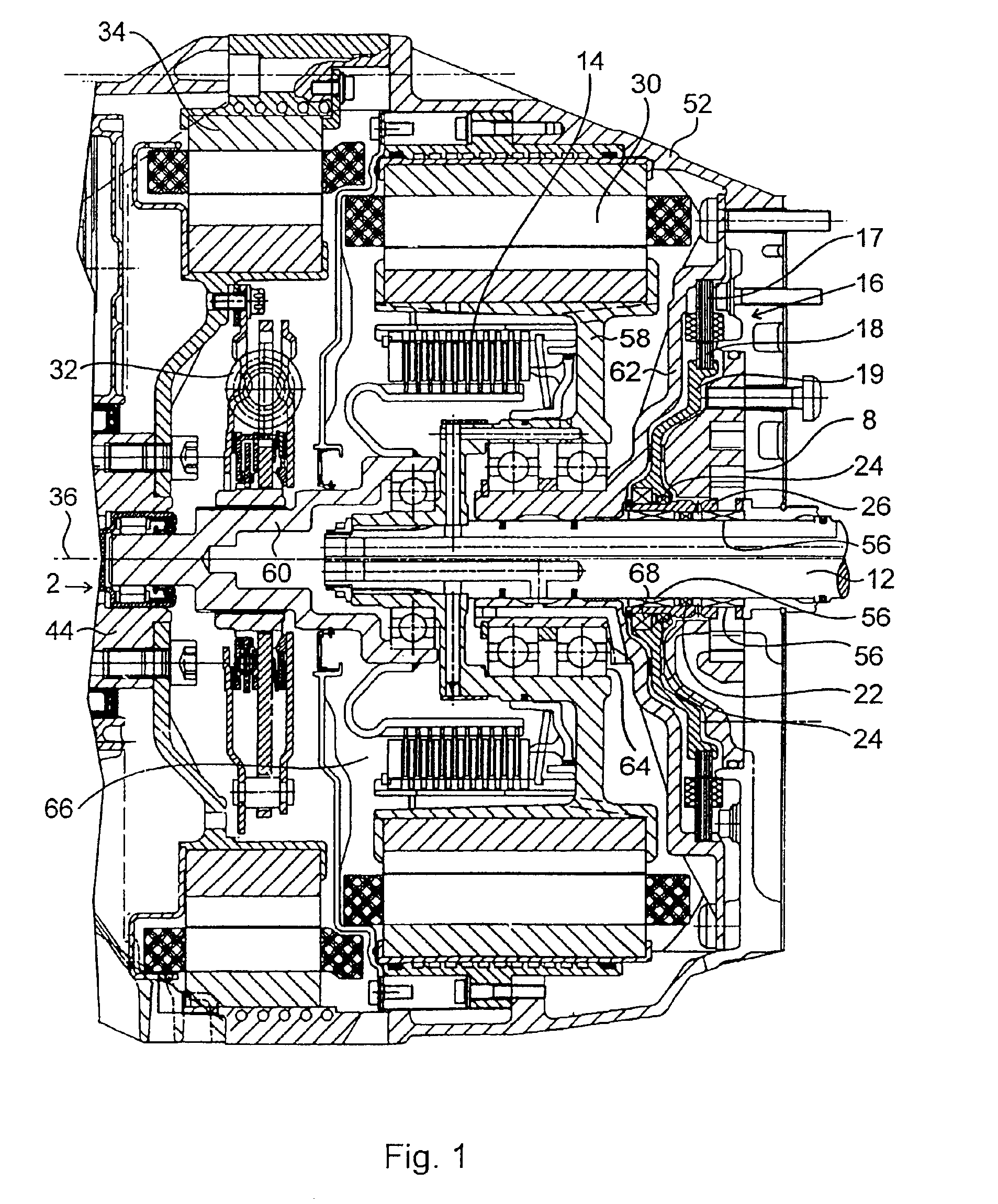

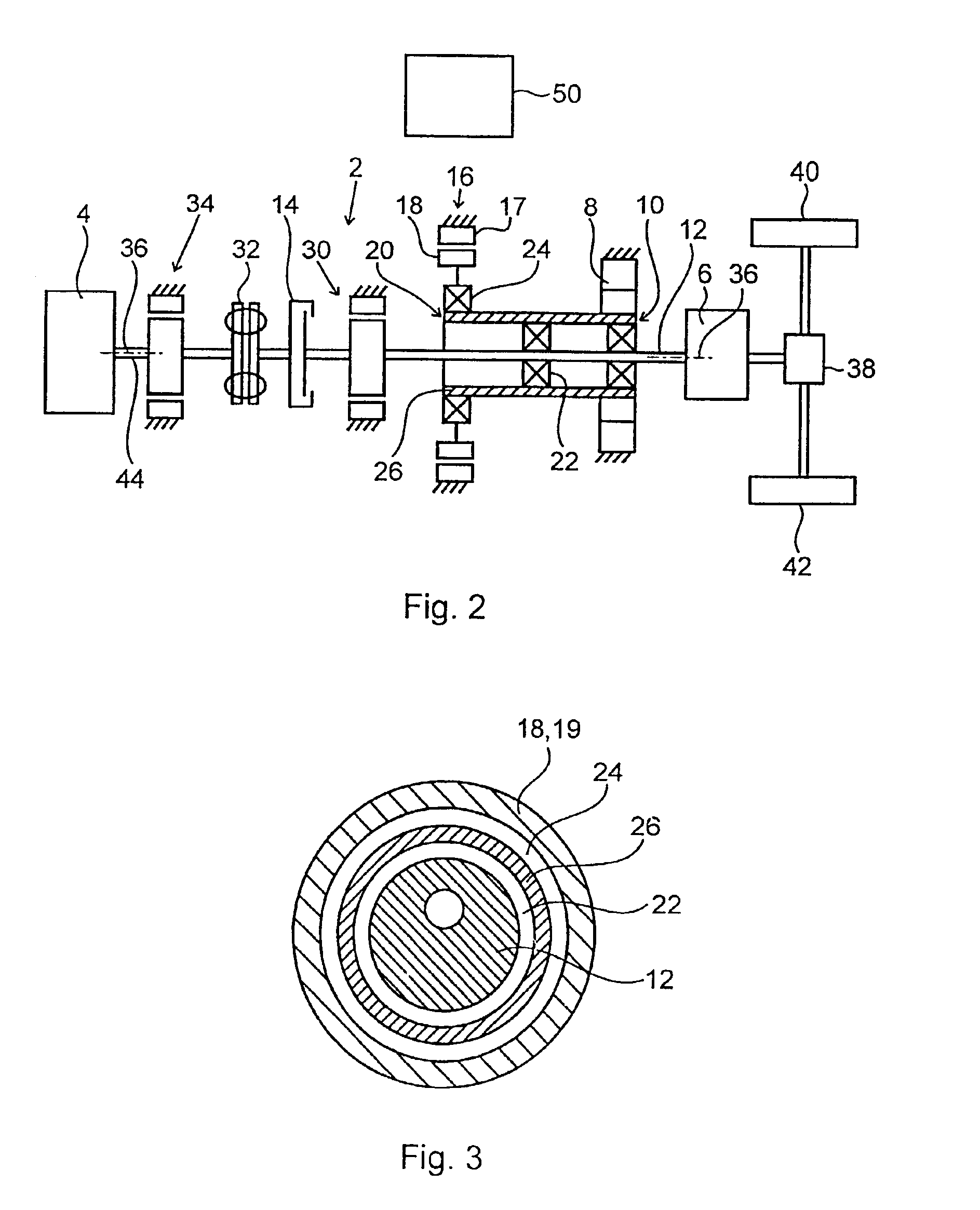

Motor vehicle drive arrangement

A motor vehicle drive arrangement has a locomotive drive train and at least one liquid pump capable of being driven by the latter. During a standstill in rotation or during very slow rotation of the locomotive drive train, the pump is capable of being driven by an electric motor instead of by the locomotive drive train. Beyond a defined minimum rotational speed of the locomotive drive train, the liquid pump is capable of being driven by the latter instead of by the electric motor. At least one free-wheel is provided for this purpose.

Owner:DAIMLER AG

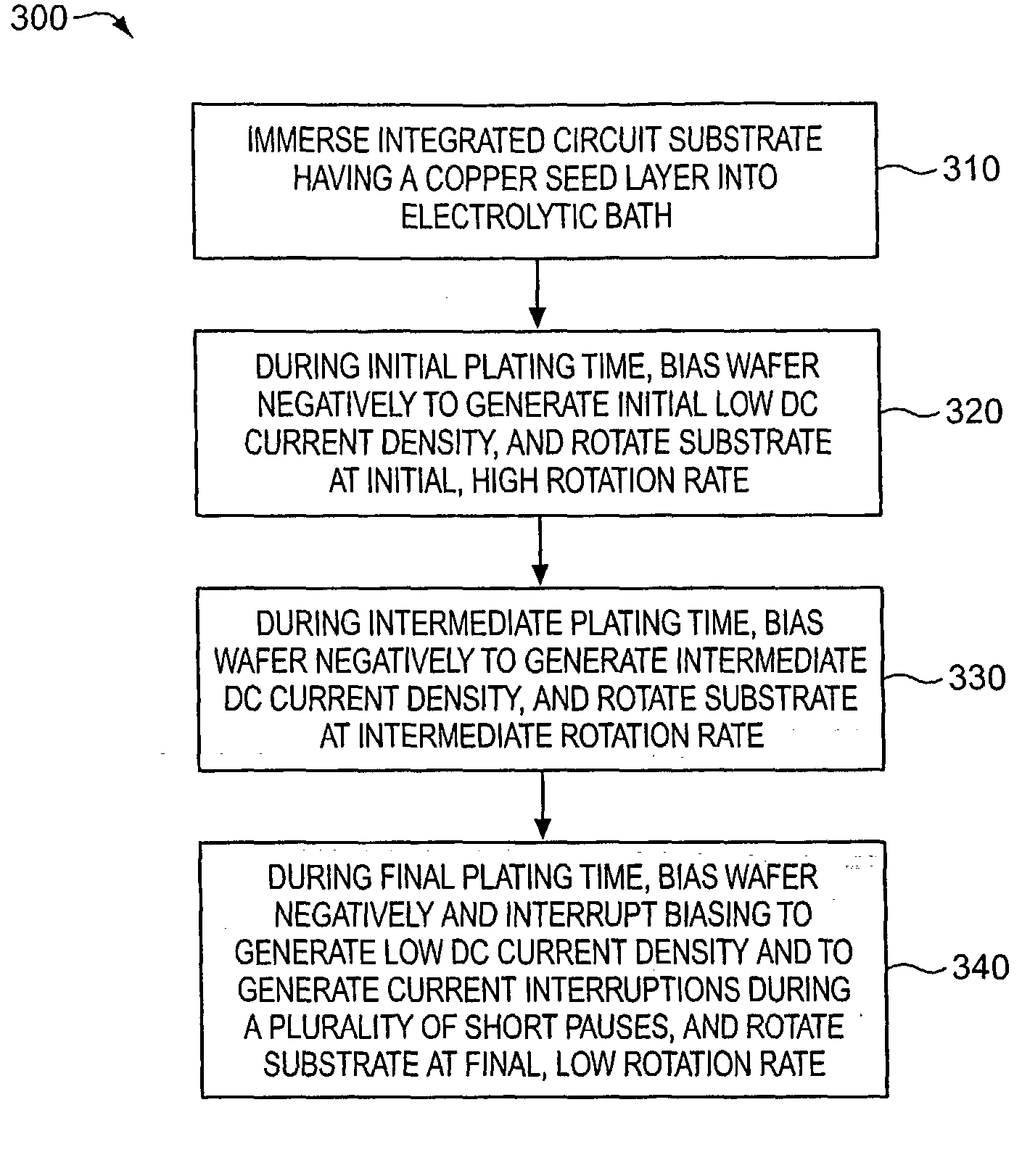

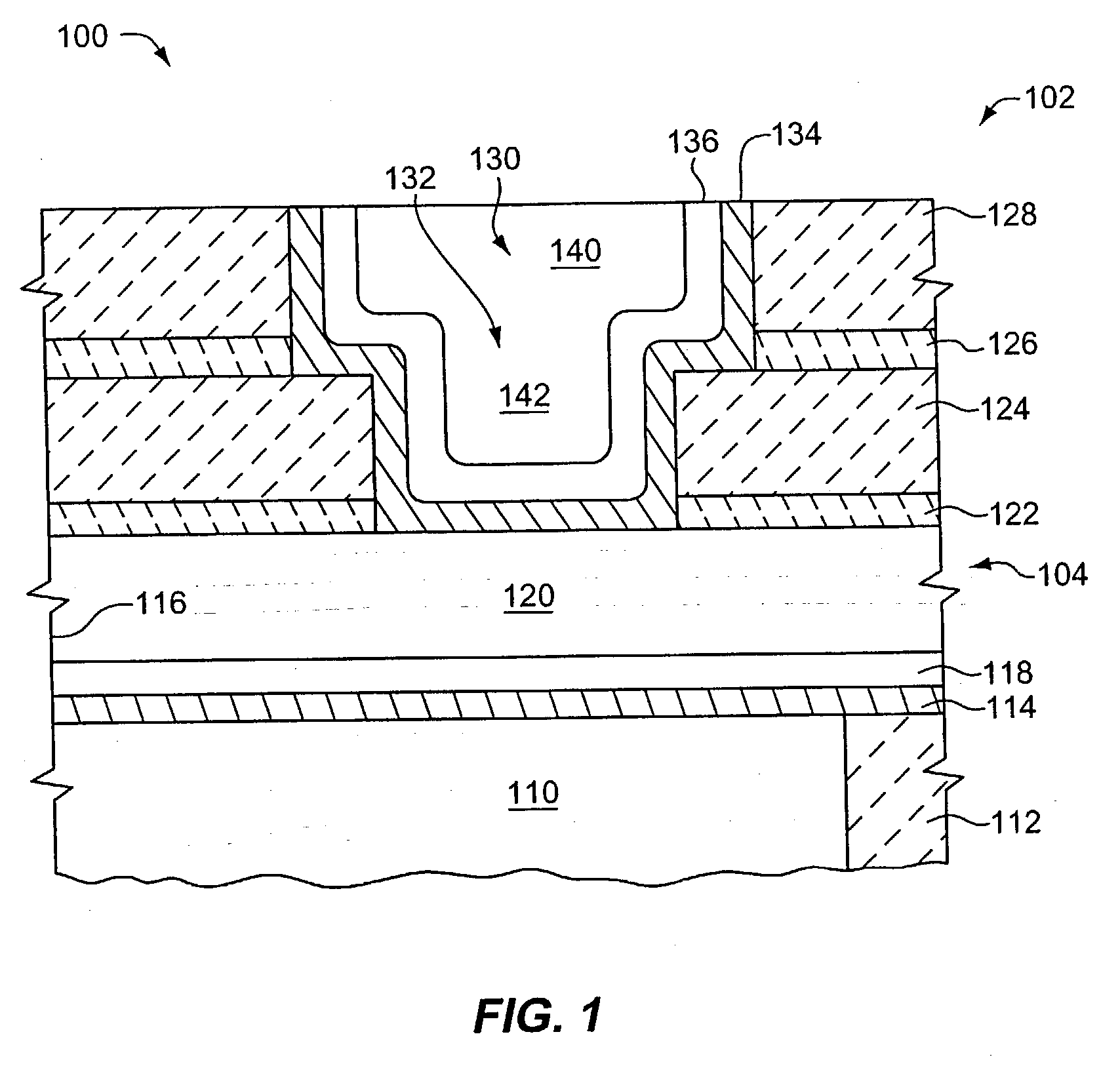

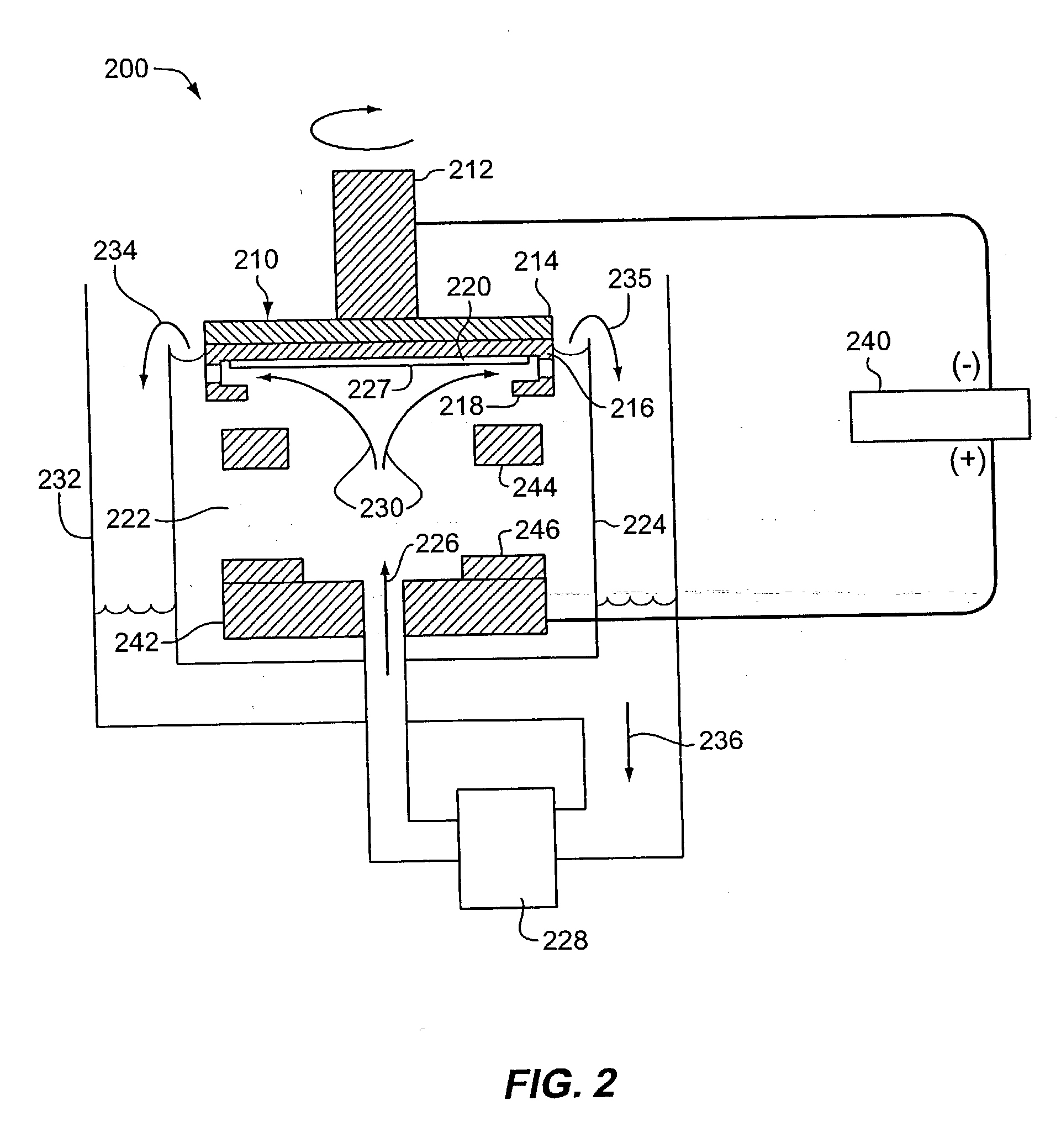

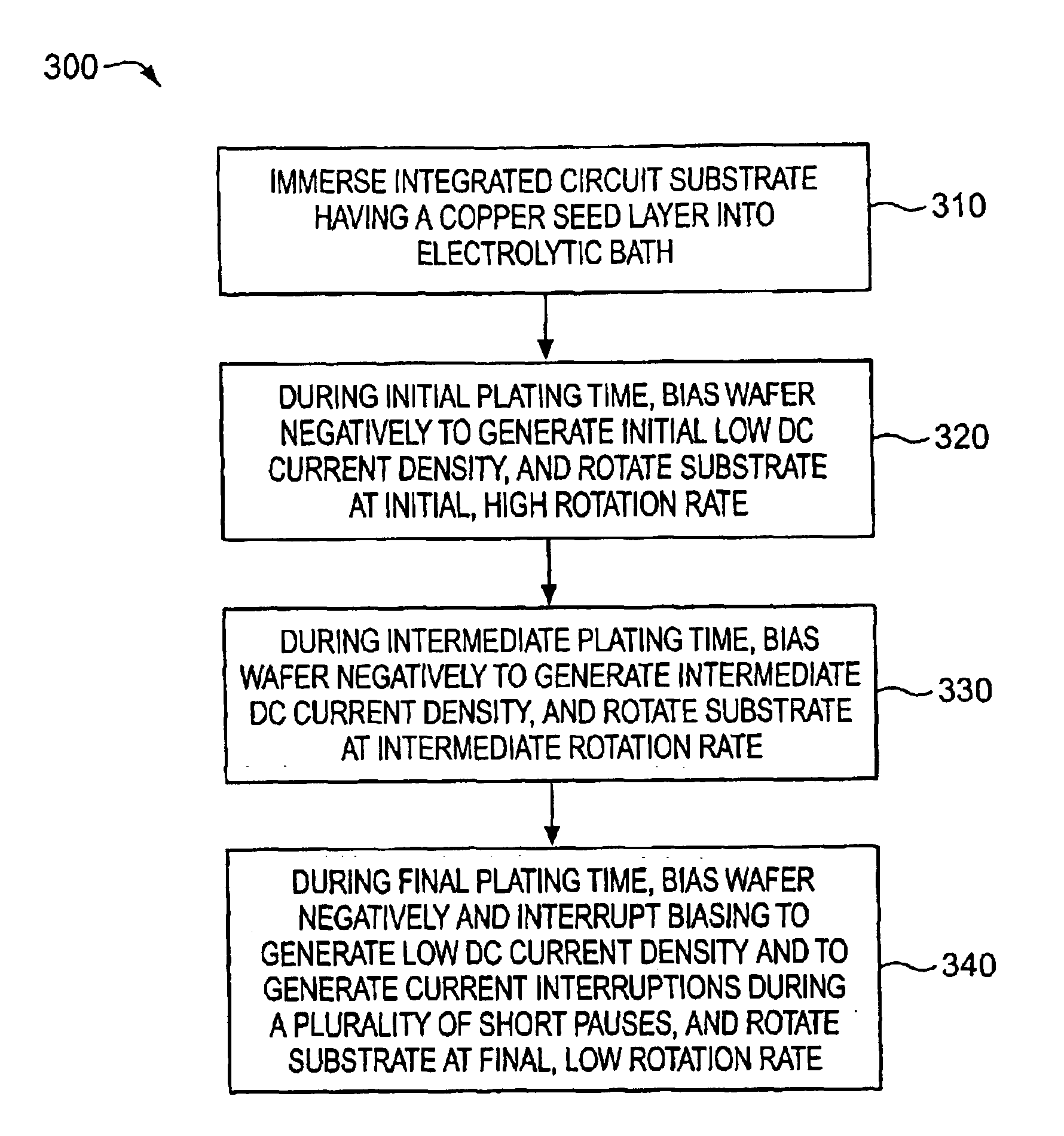

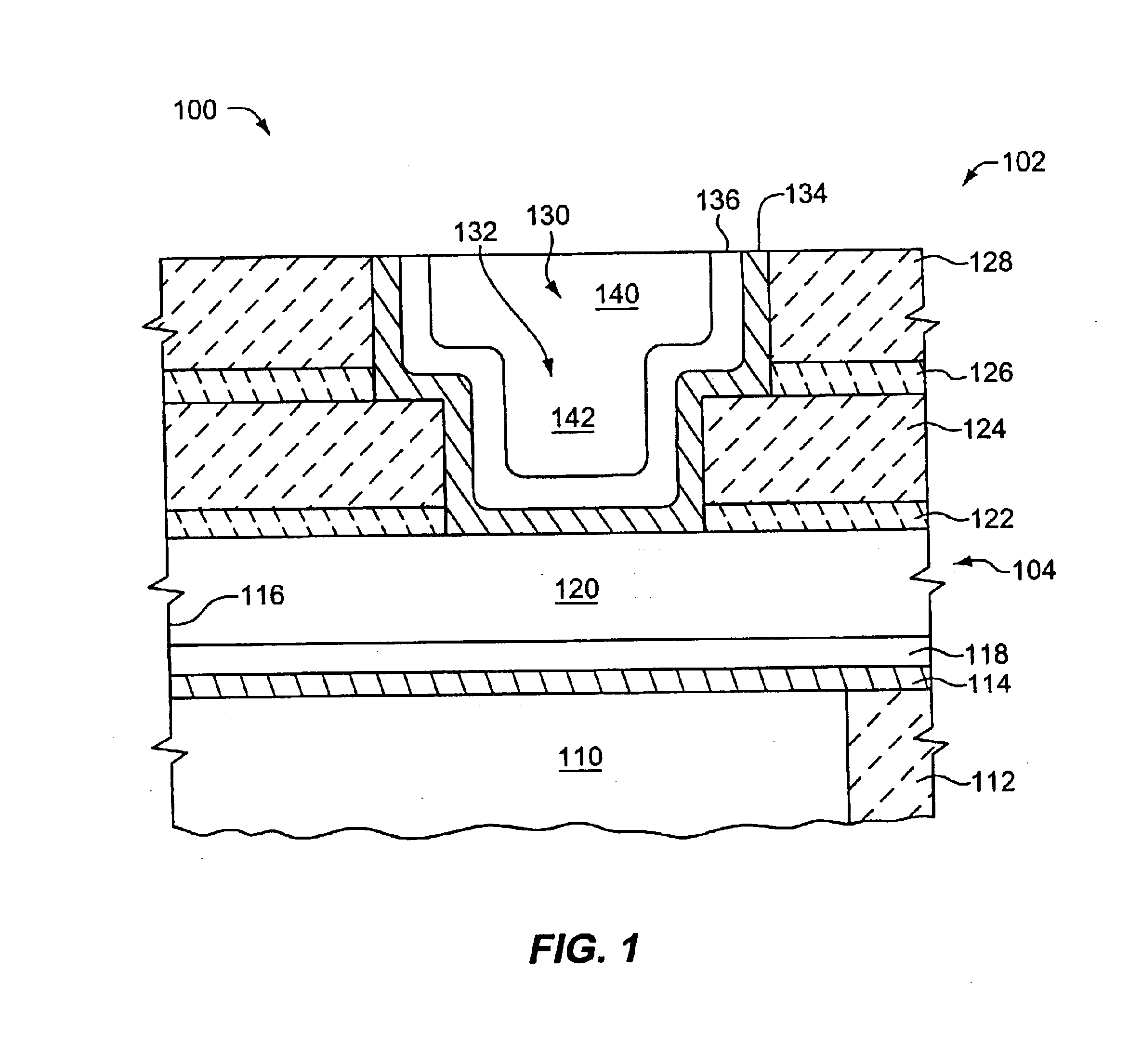

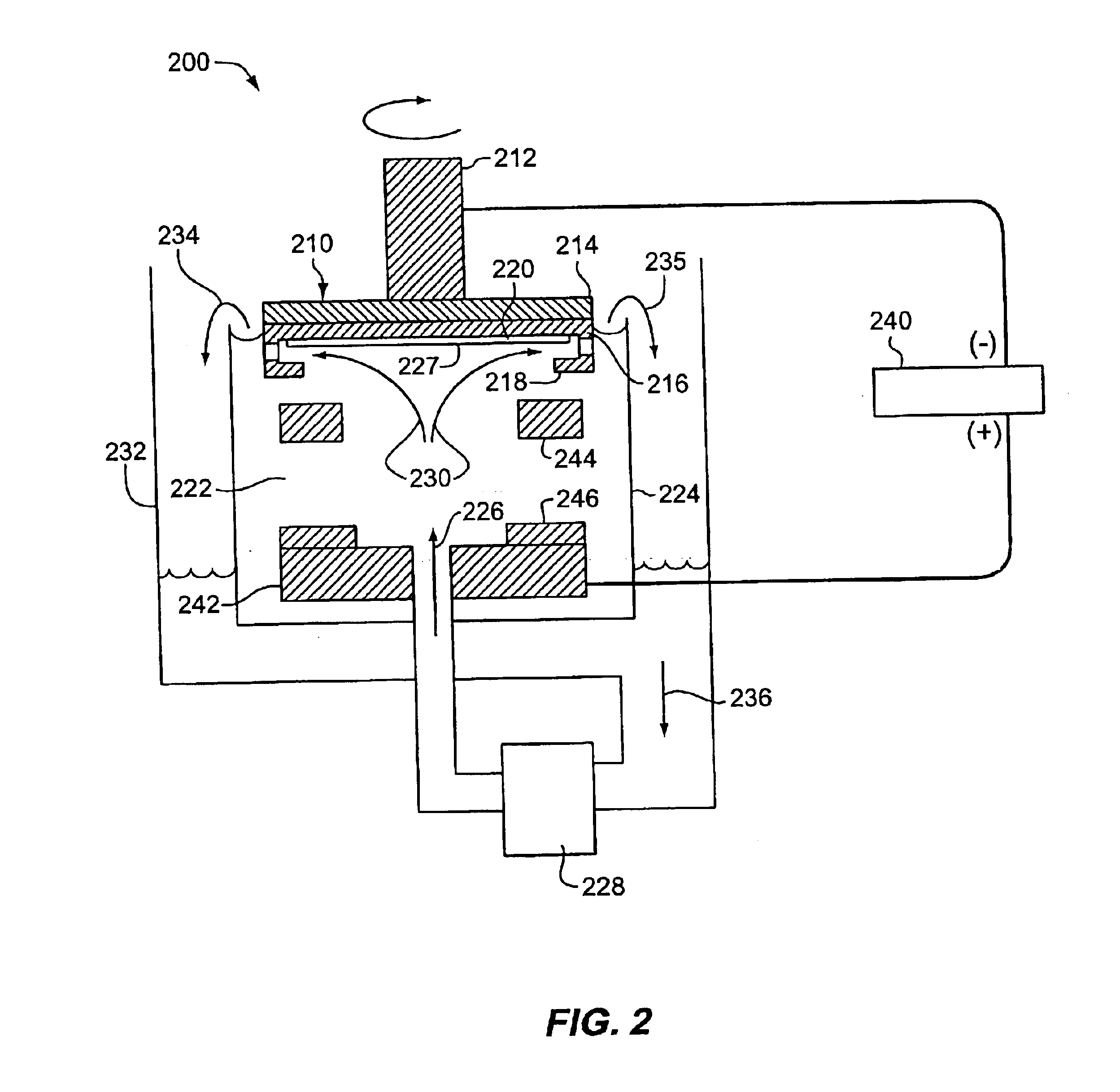

Electroplating using DC current interruption and variable rotation rate

A negative bias is applied to an integrated circuit wafer immersed in an electrolytic plating solution to generate a DC current. After about ten percent to sixty percent of the final layer thickness has formed in a first plating time, biasing is interrupted during short pauses during a second plating time to generate substantially zero DC current. The pauses are from about 2 milliseconds to 5 seconds long, and typically about 10 milliseconds to 500 milliseconds. Generally, about 2 pauses to 100 pauses are used, and typically about 3 pauses to 15 pauses. Generally, the DC current density during the second plating time is greater than the DC current density during the initial plating time. Typically, the integrated circuit wafer is rotated during electroplating. Preferably, the wafer is rotated at a slower rotation rate during the second plating time than during the first plating time.

Owner:NOVELLUS SYSTEMS

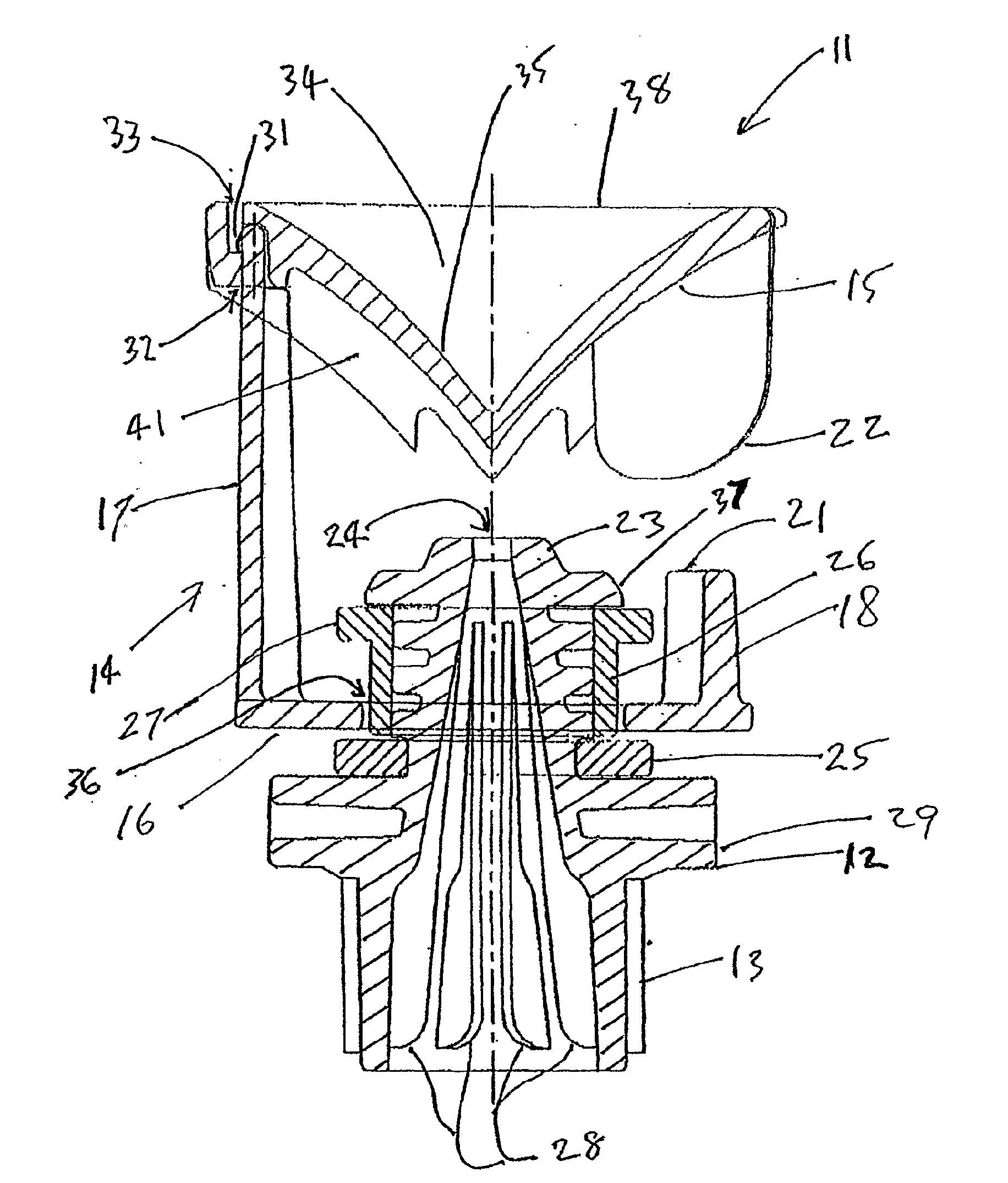

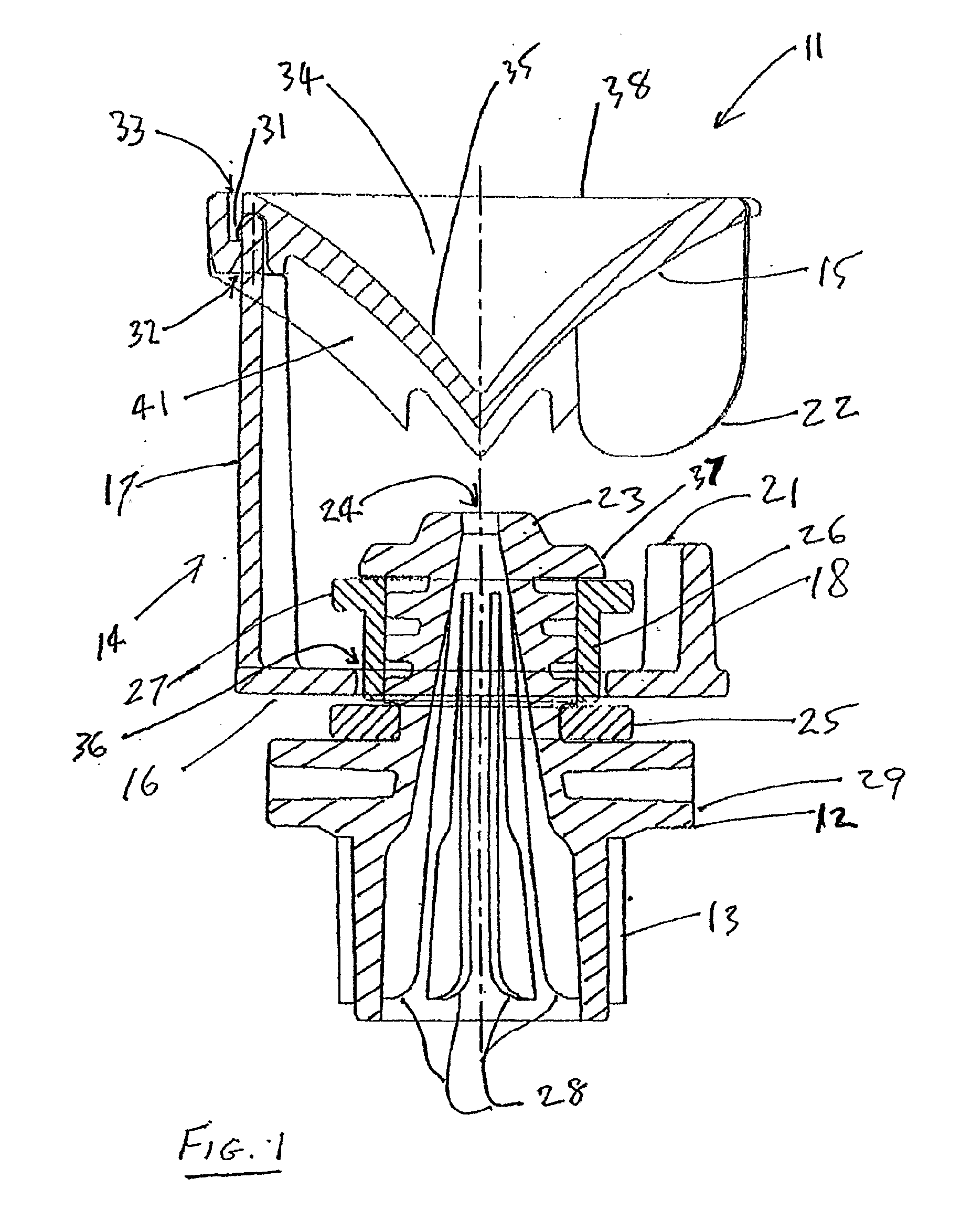

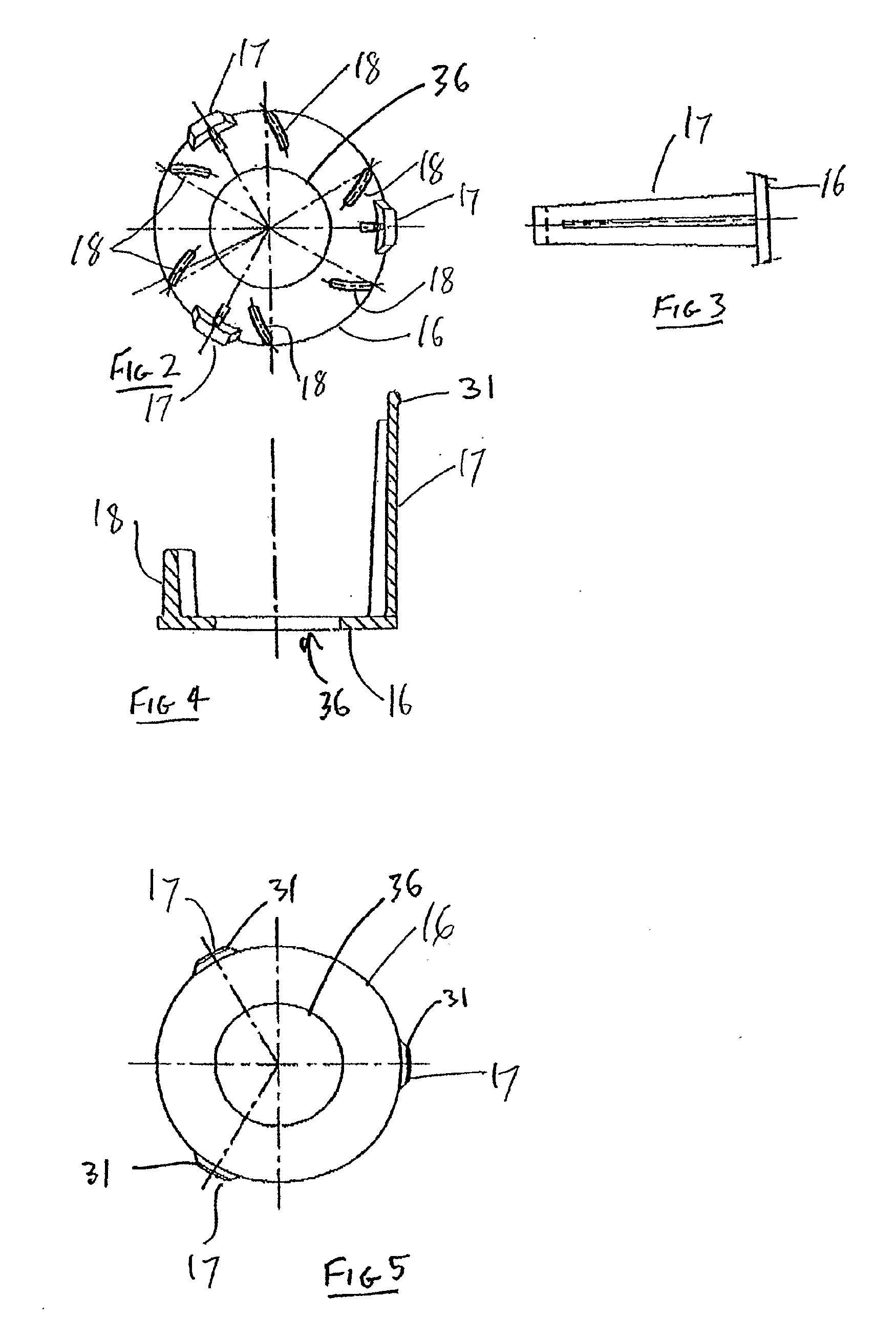

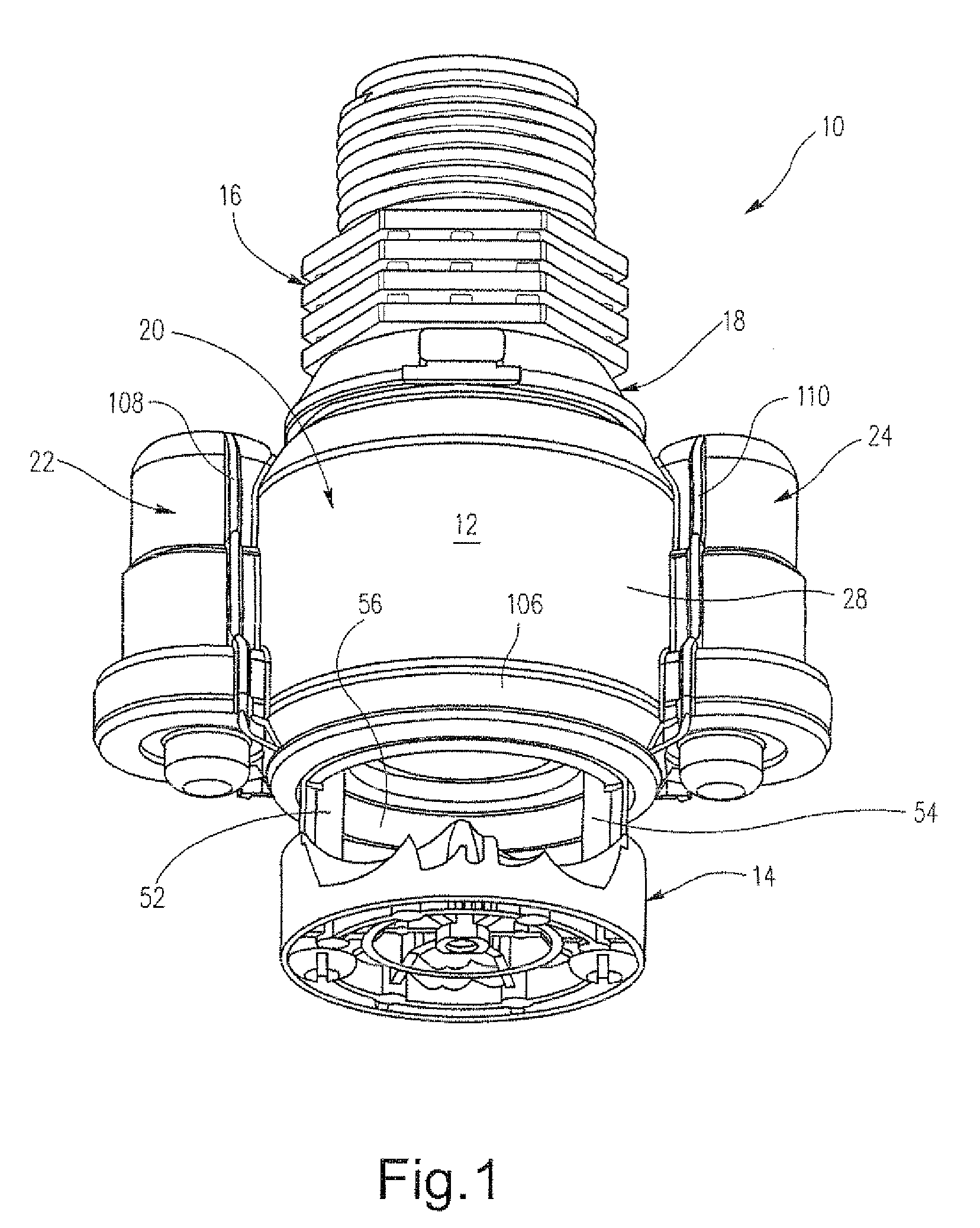

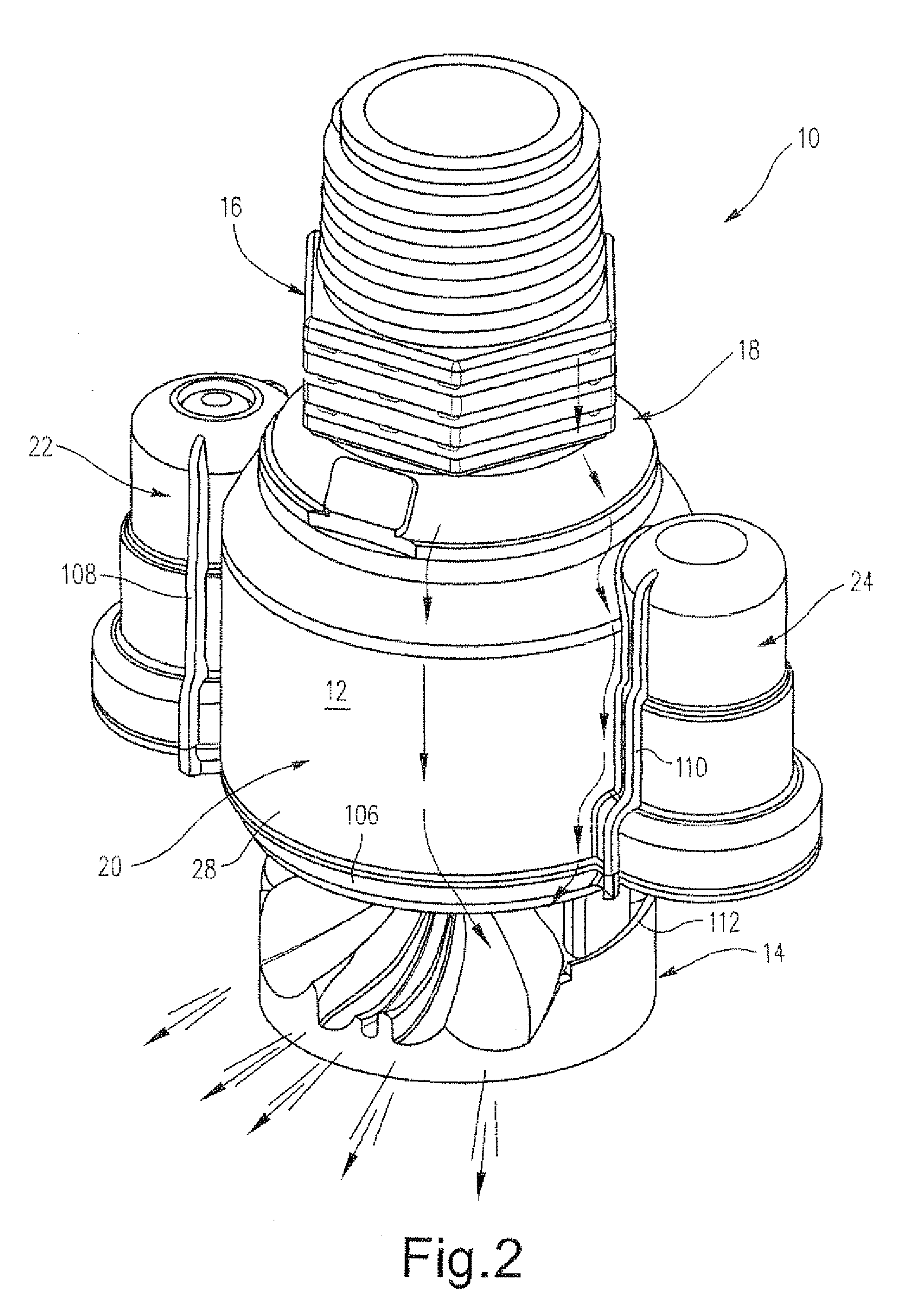

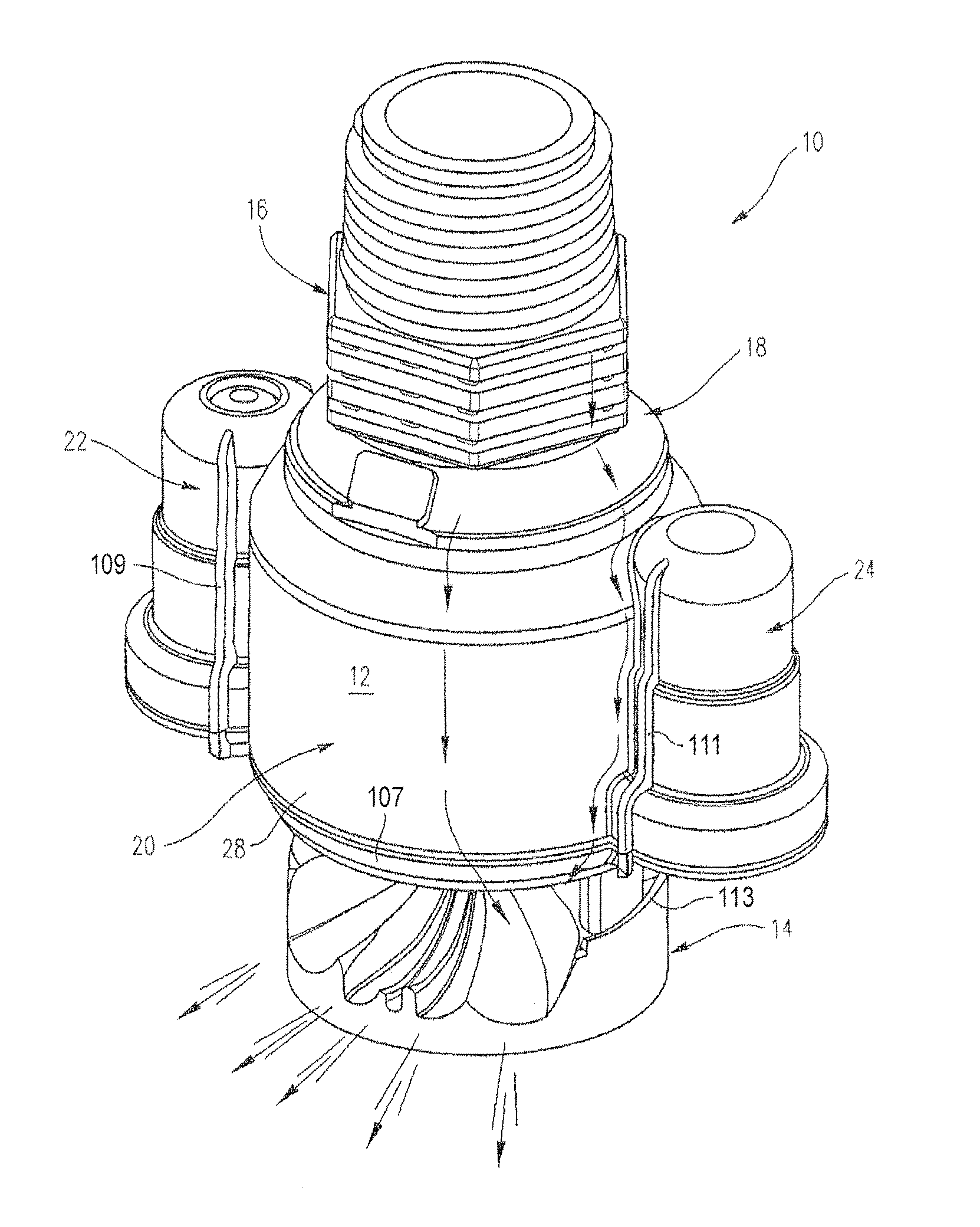

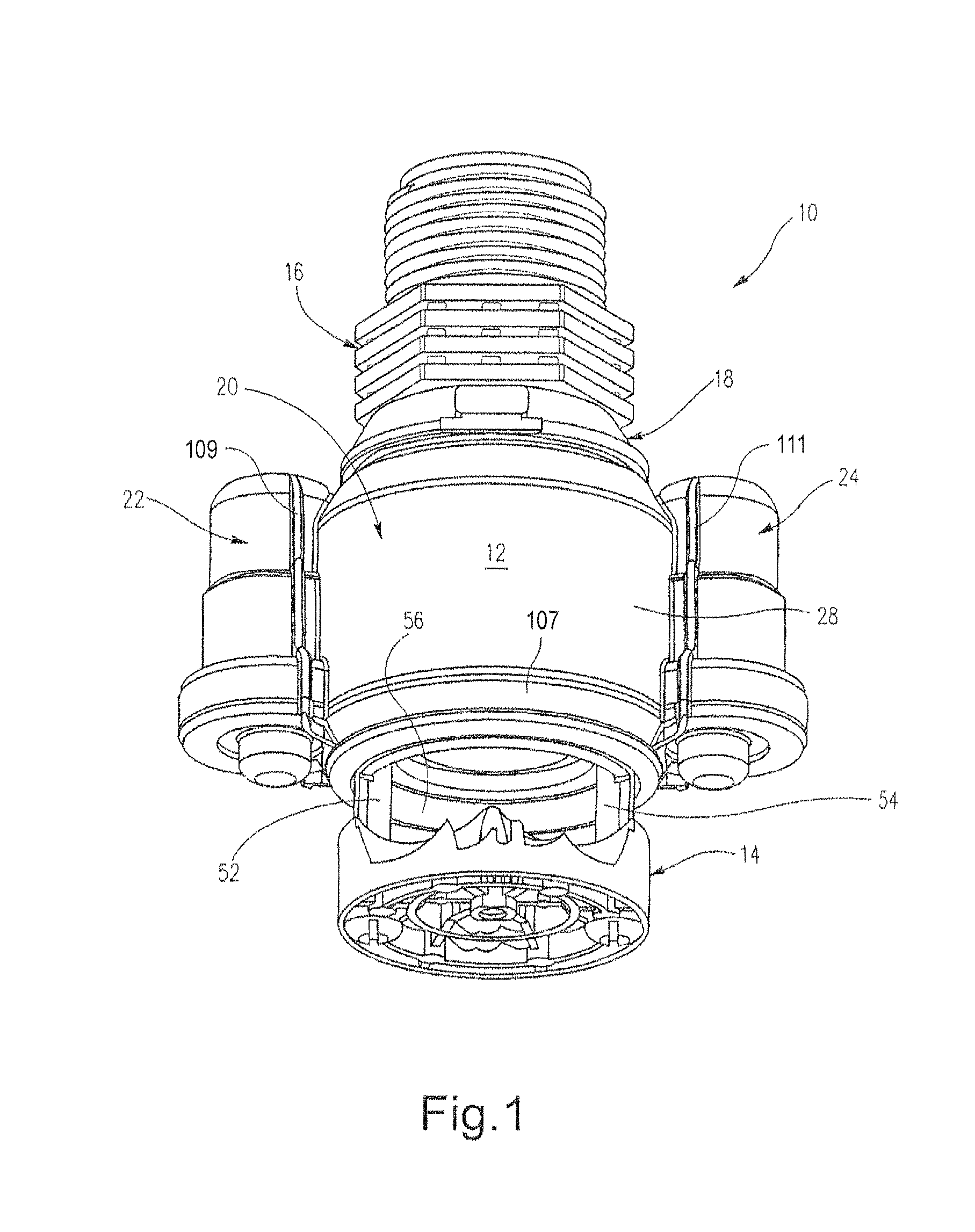

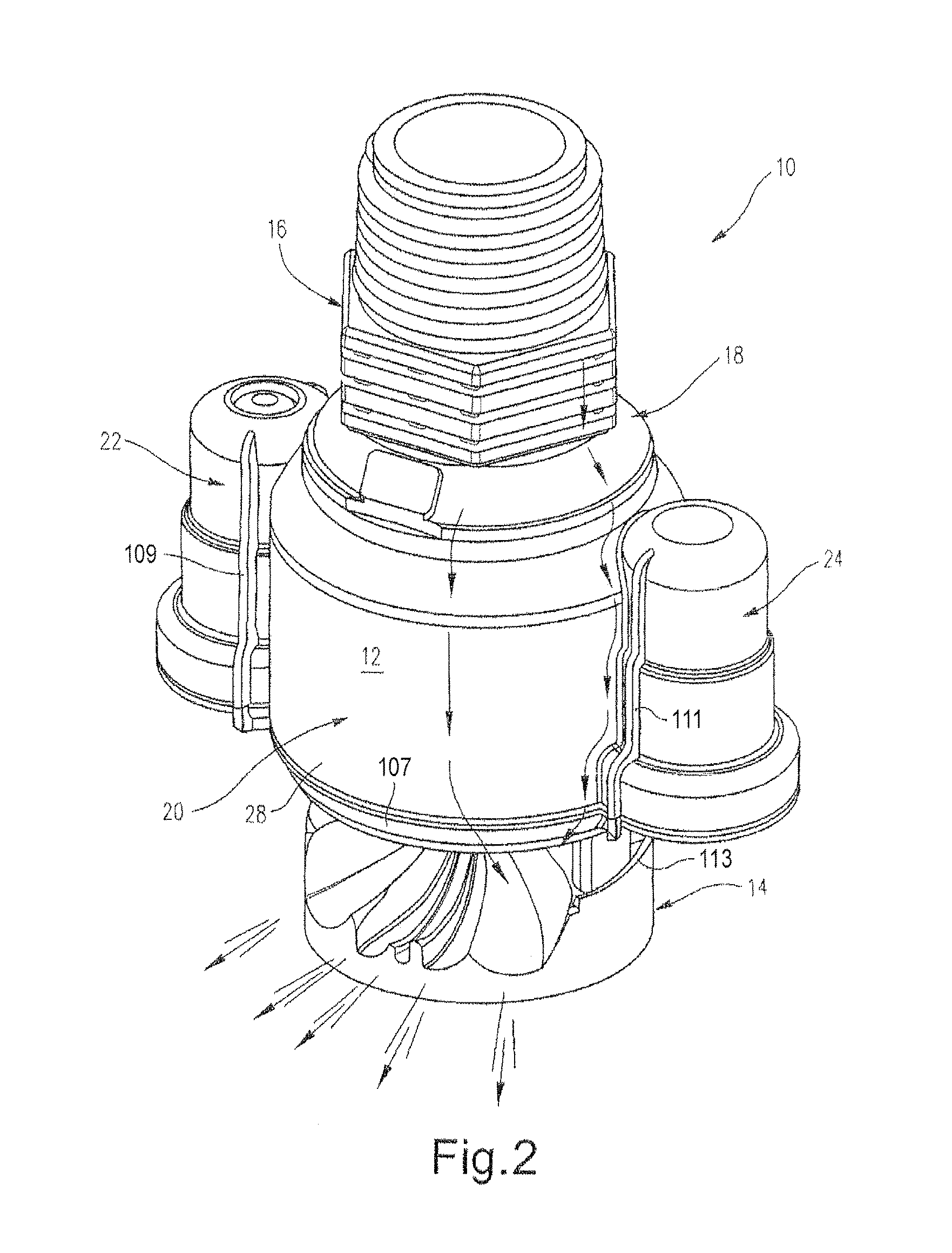

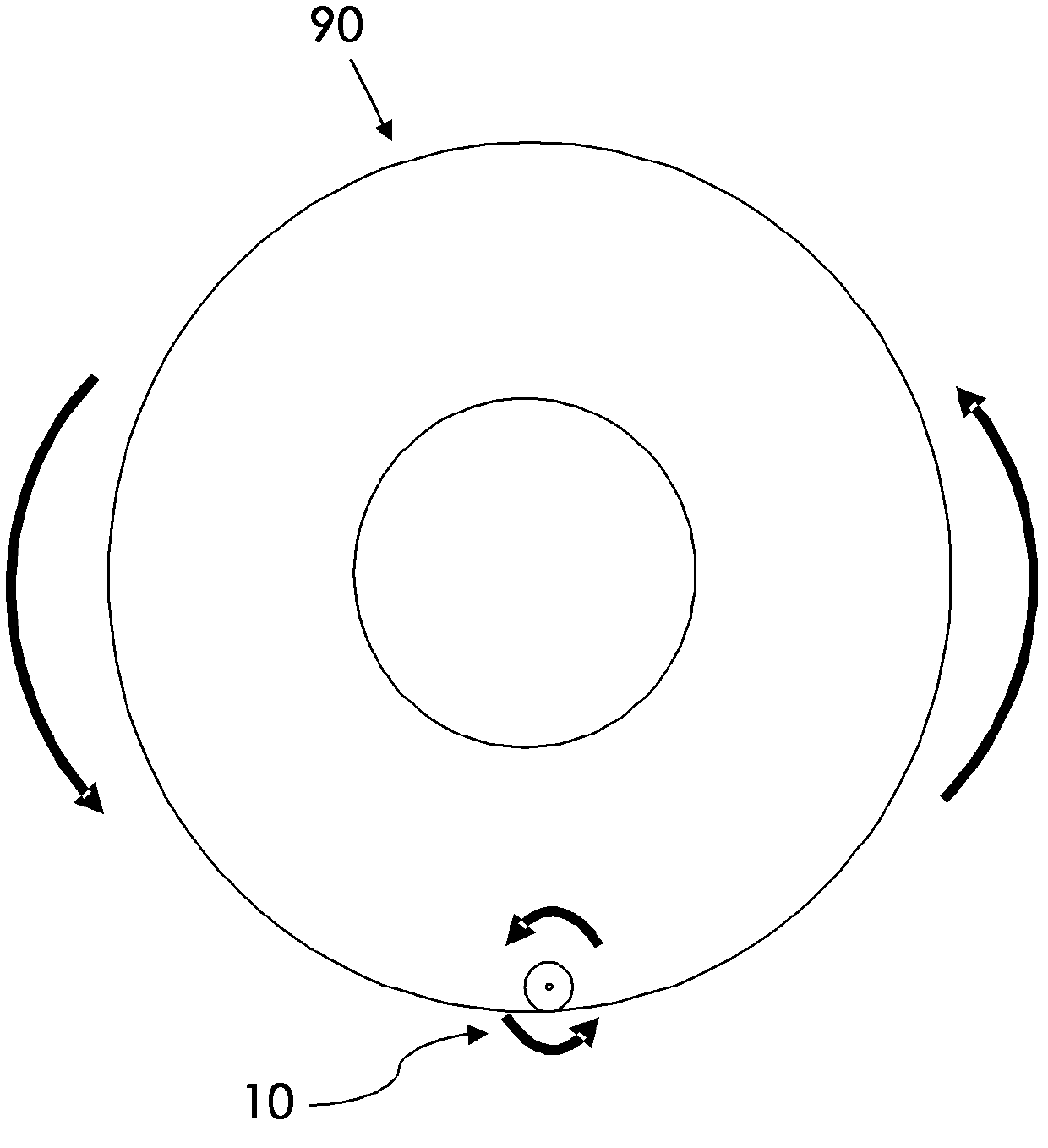

Sprinkler Head

A sprinkler device is provided comprising a central body, a deflector assembly and at least one vane, directly or indirectly connected to the deflector assembly. The central body incorporates a nozzle in communication with a water inlet which is directed towards the deflector assembly. The deflector assembly is loosely coupled to the body and located in use, on a path of the jet projecting from the nozzle to deflect the jet as a series of droplets. The deflector assembly also has one or more substantially radially extending spray grooves which are acted on by the jet to rotate and roll the deflector assembly causing the jet to be broken into droplets. The deflector assembly is also provided with one or more vanes connected to and extending in a direction having a radial component relative to the deflector assembly, whereby the one or more vanes interact with surrounding air when the deflector assembly rotates to slow rotation and fan the air outwardly to help propel the droplets.

Owner:HOLMES TONY

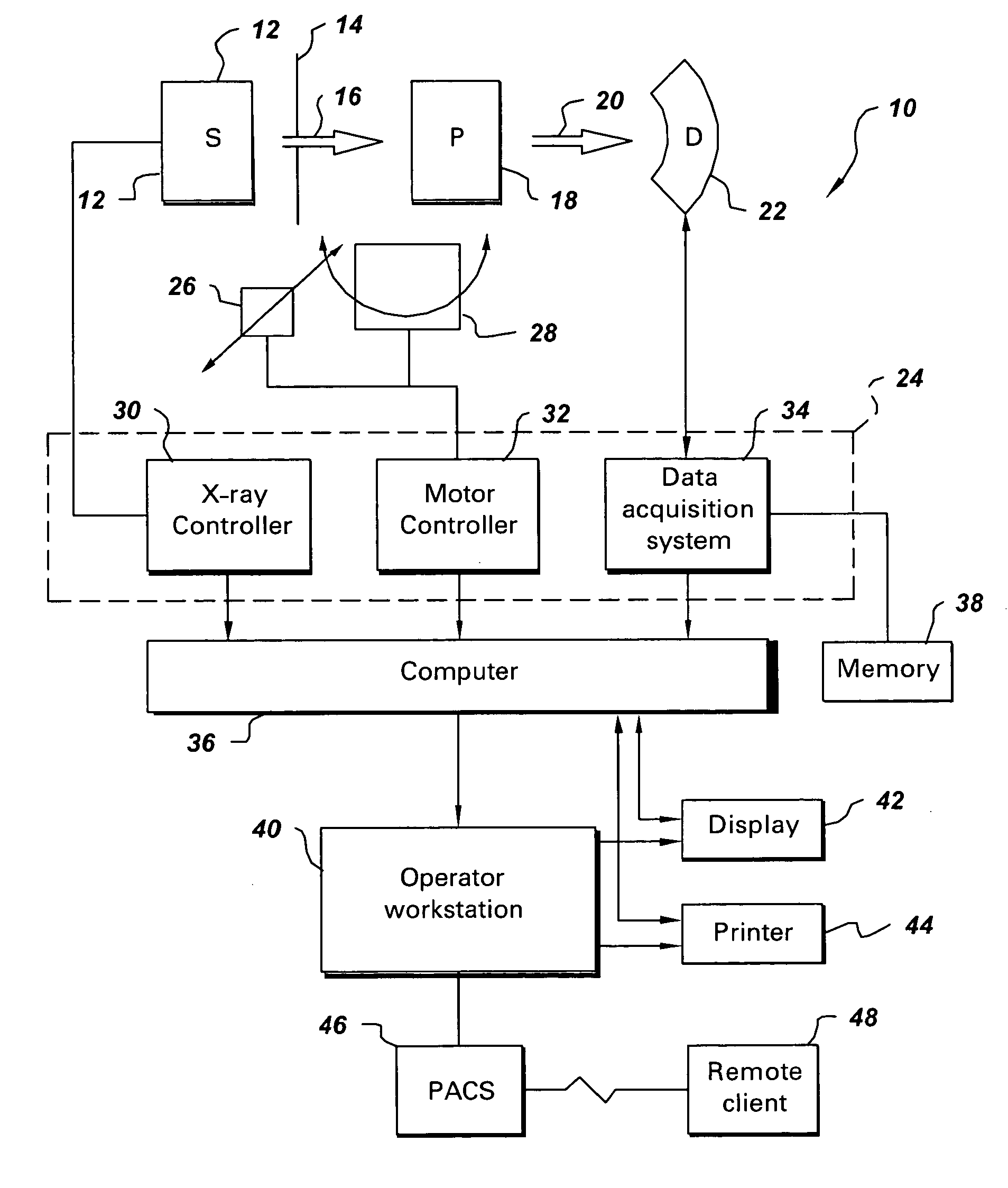

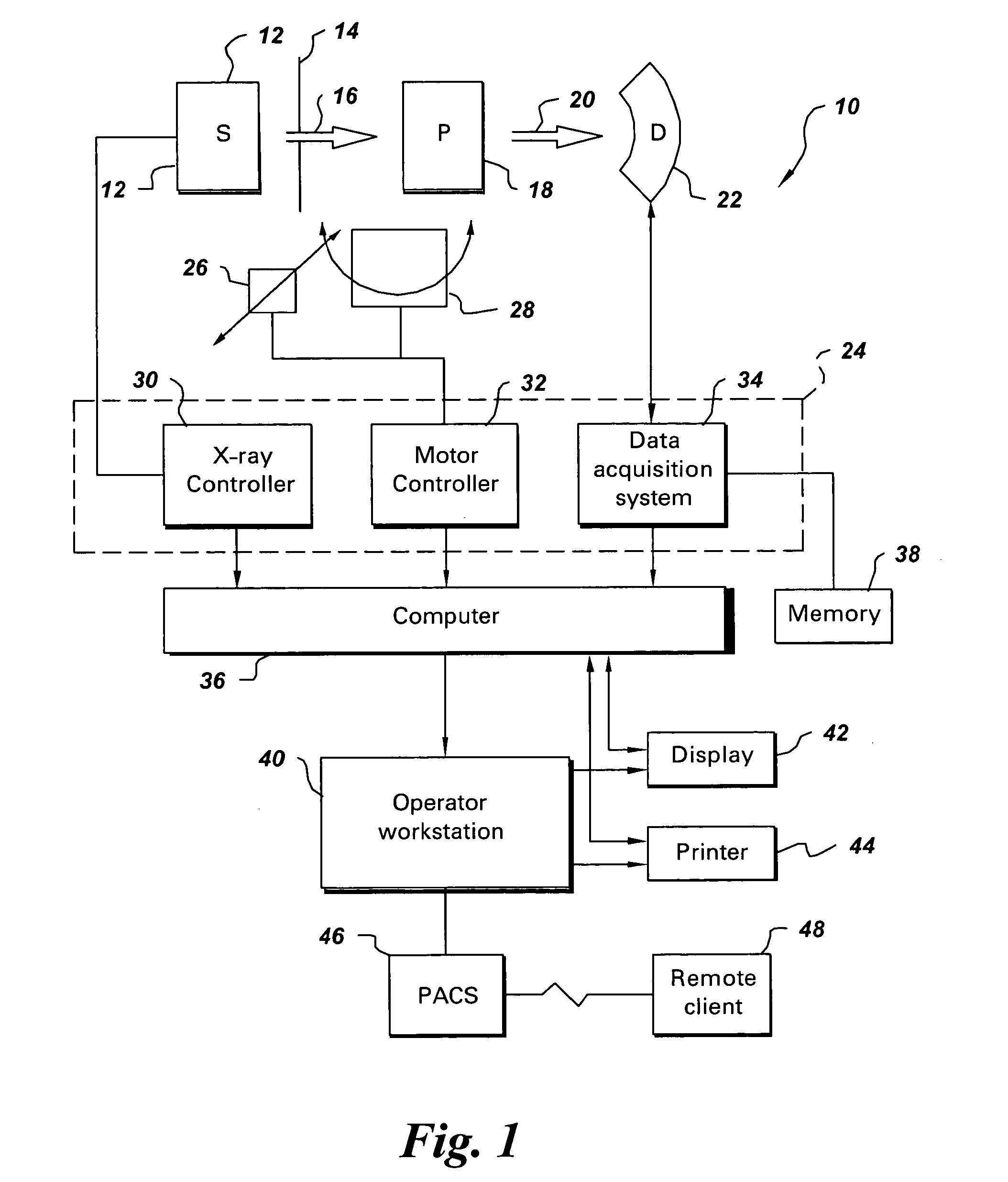

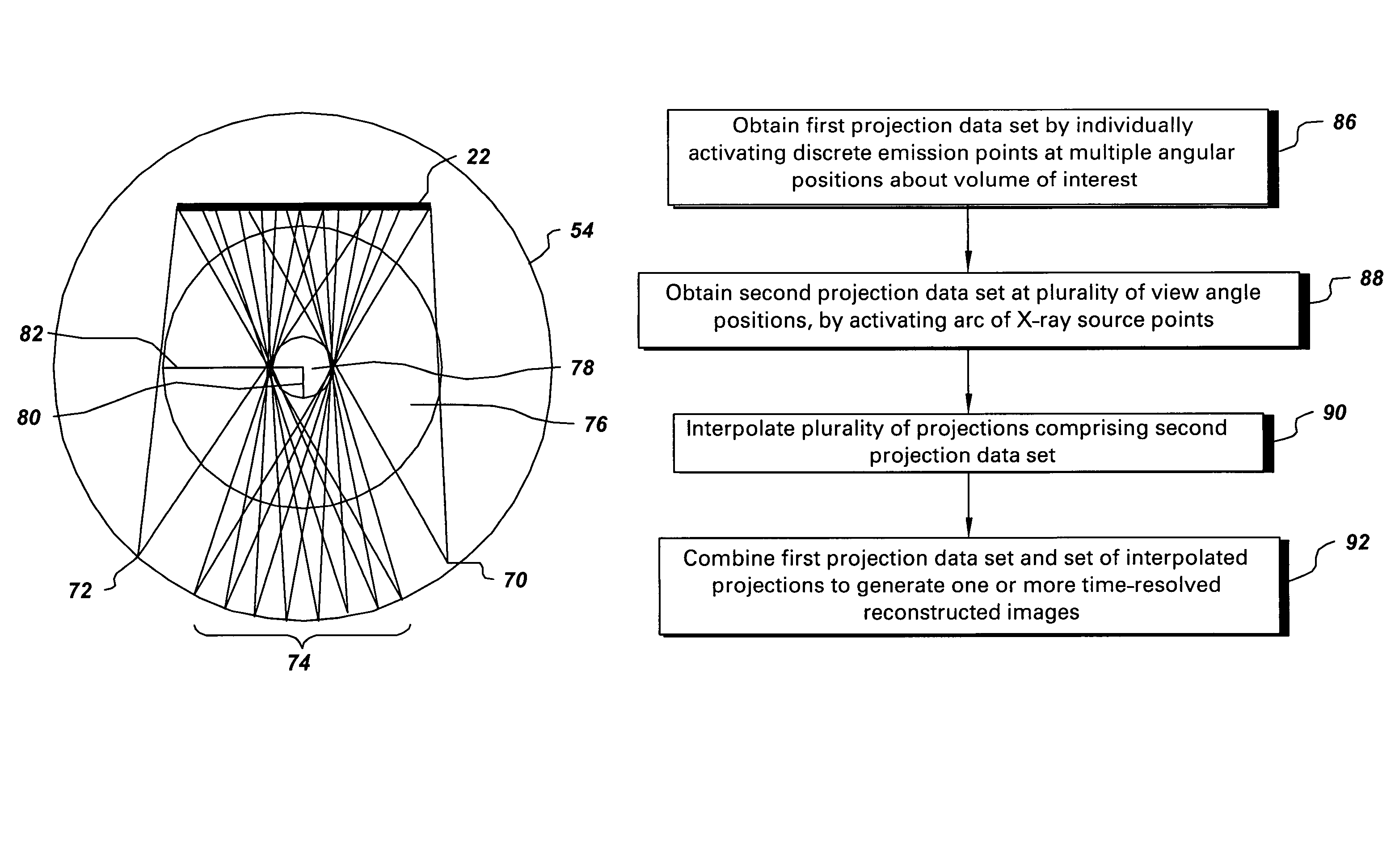

Method and system for CT imaging using a distributed X-ray source and interpolation based reconstruction

ActiveUS20060233295A1Material analysis using wave/particle radiationRadiation/particle handlingX-raySlow rotation

A method for Computed Tomography (CT) imaging is provided. The method comprises rotating a gantry at a substantially slow rotation speed about a volume of interest. The gantry comprises a combination of X-ray source points. The X-ray source points comprise one or more discrete emission points and an arc of discrete or continuous X-ray source points. The method then comprises obtaining projection data from the combination of X-ray source points and performing a suitable reconstruction based on the projection data obtained from the combination of X-ray source points, to generate one or more reconstructed images.

Owner:GENERAL ELECTRIC CO

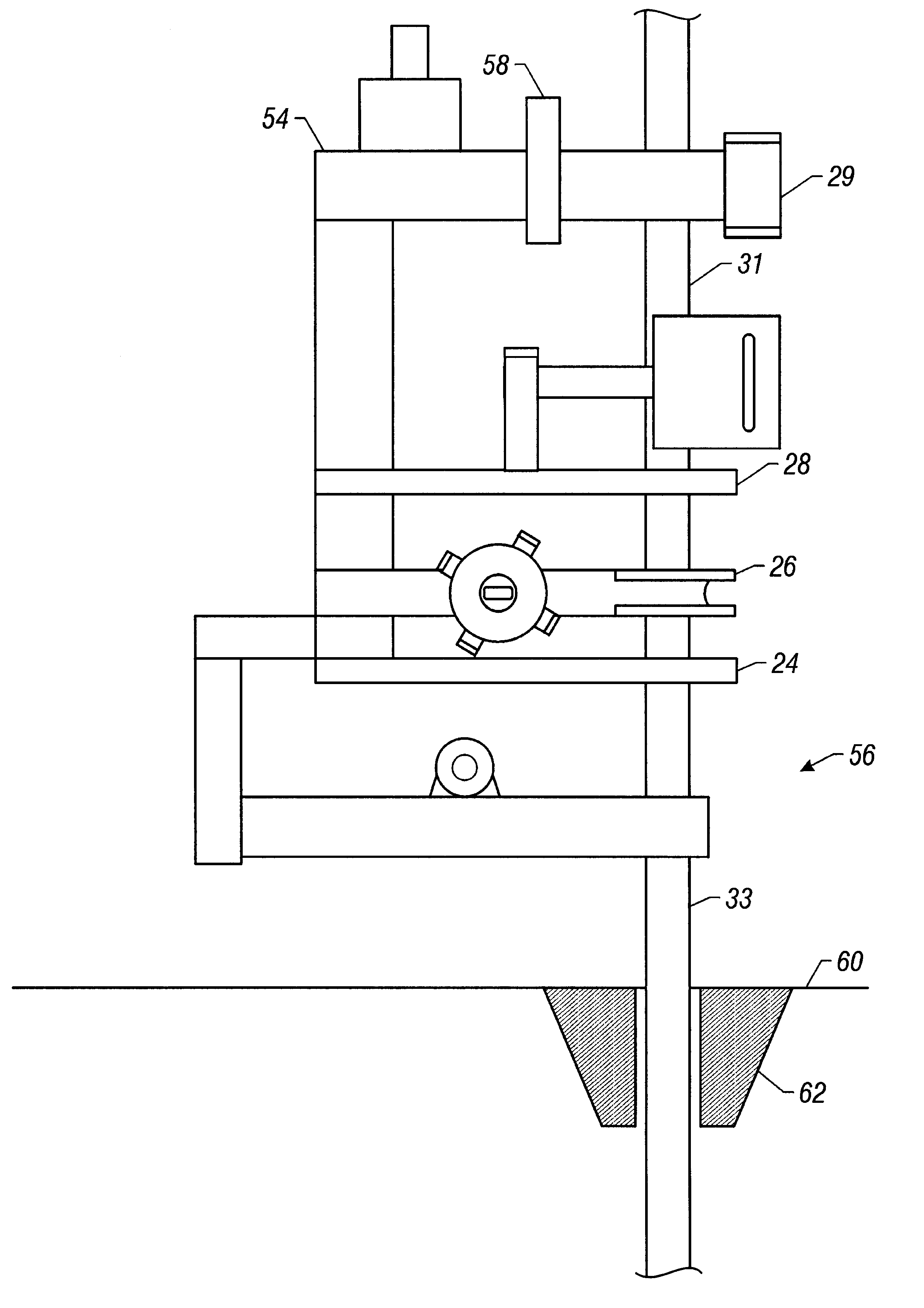

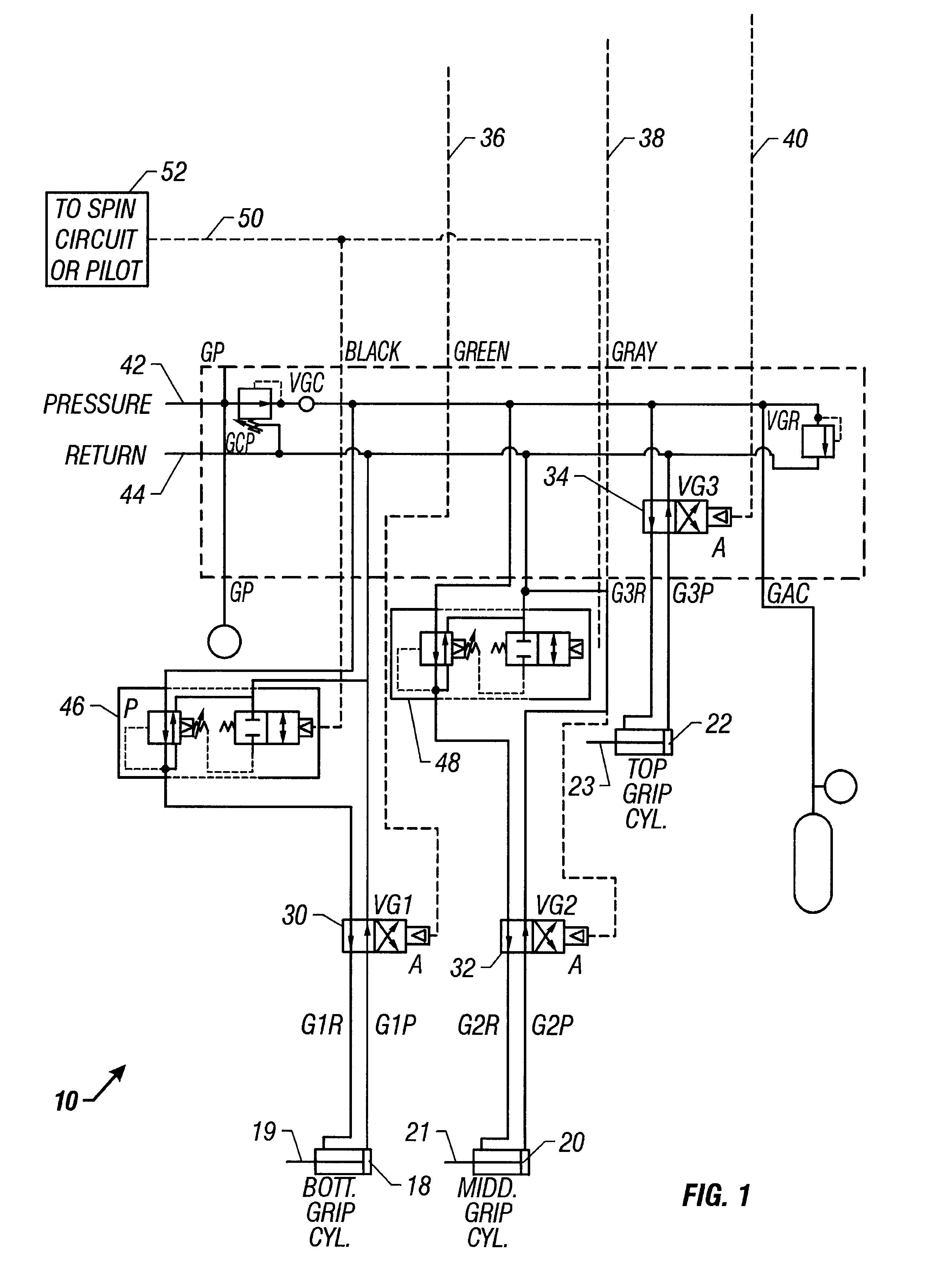

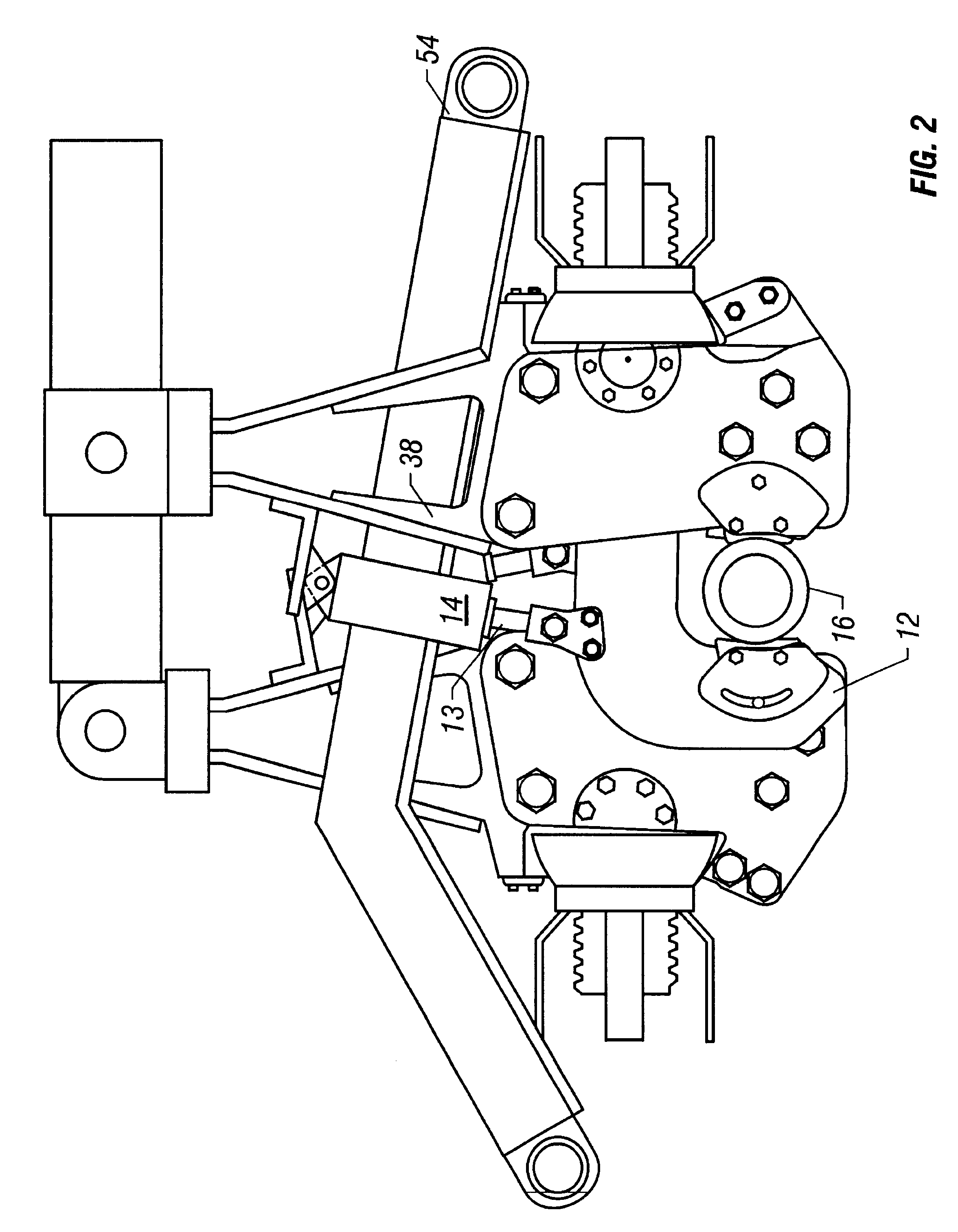

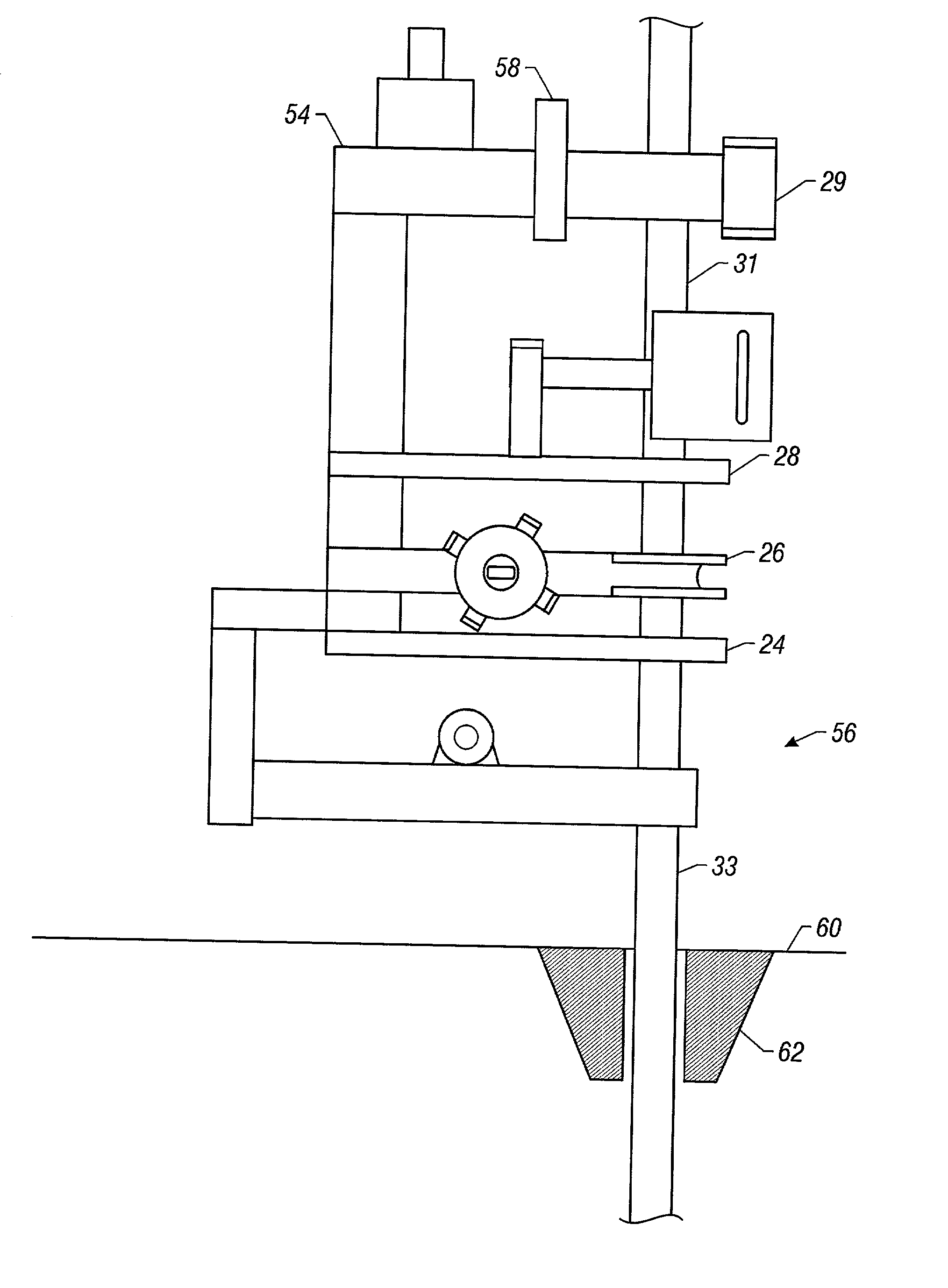

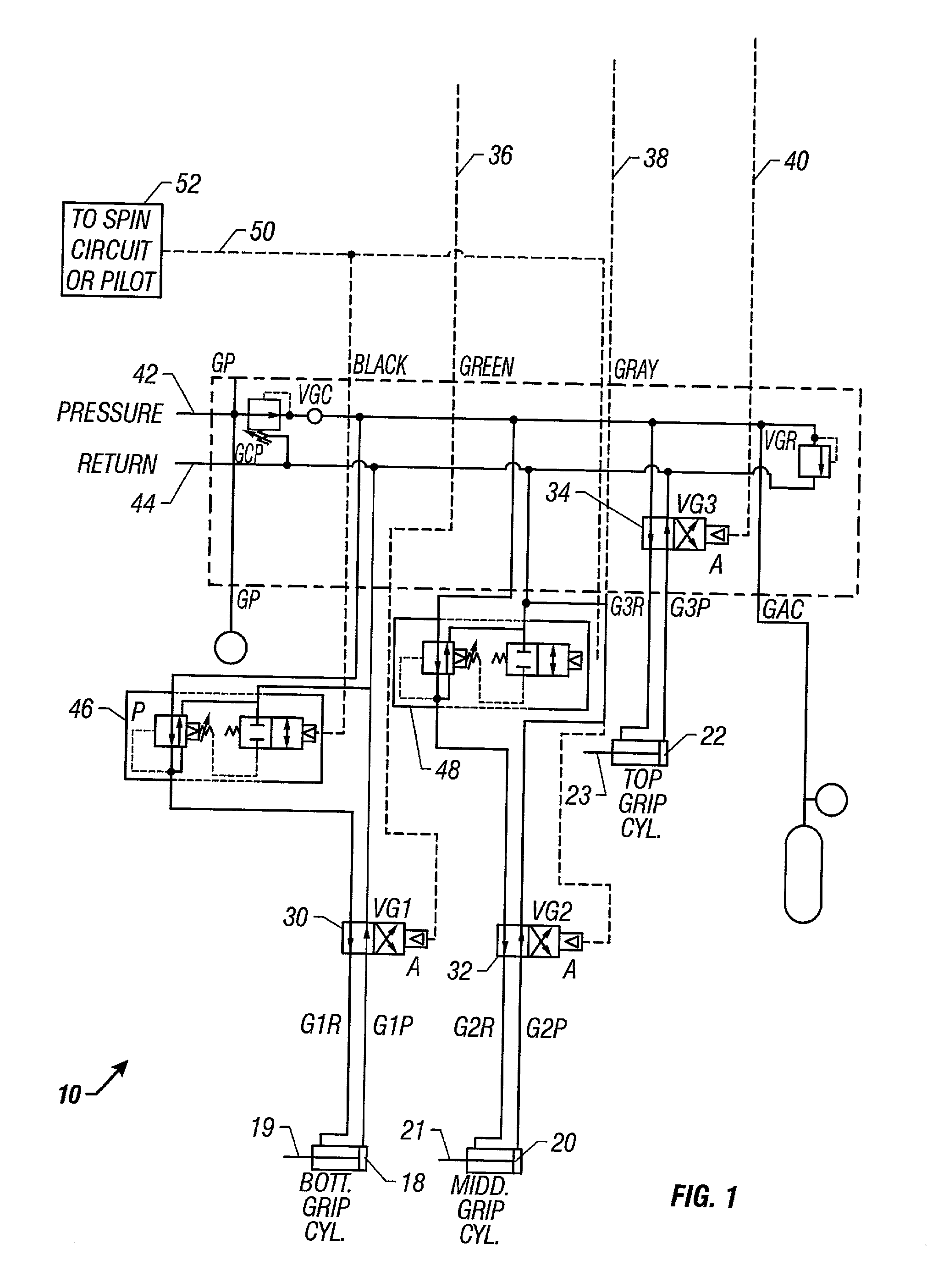

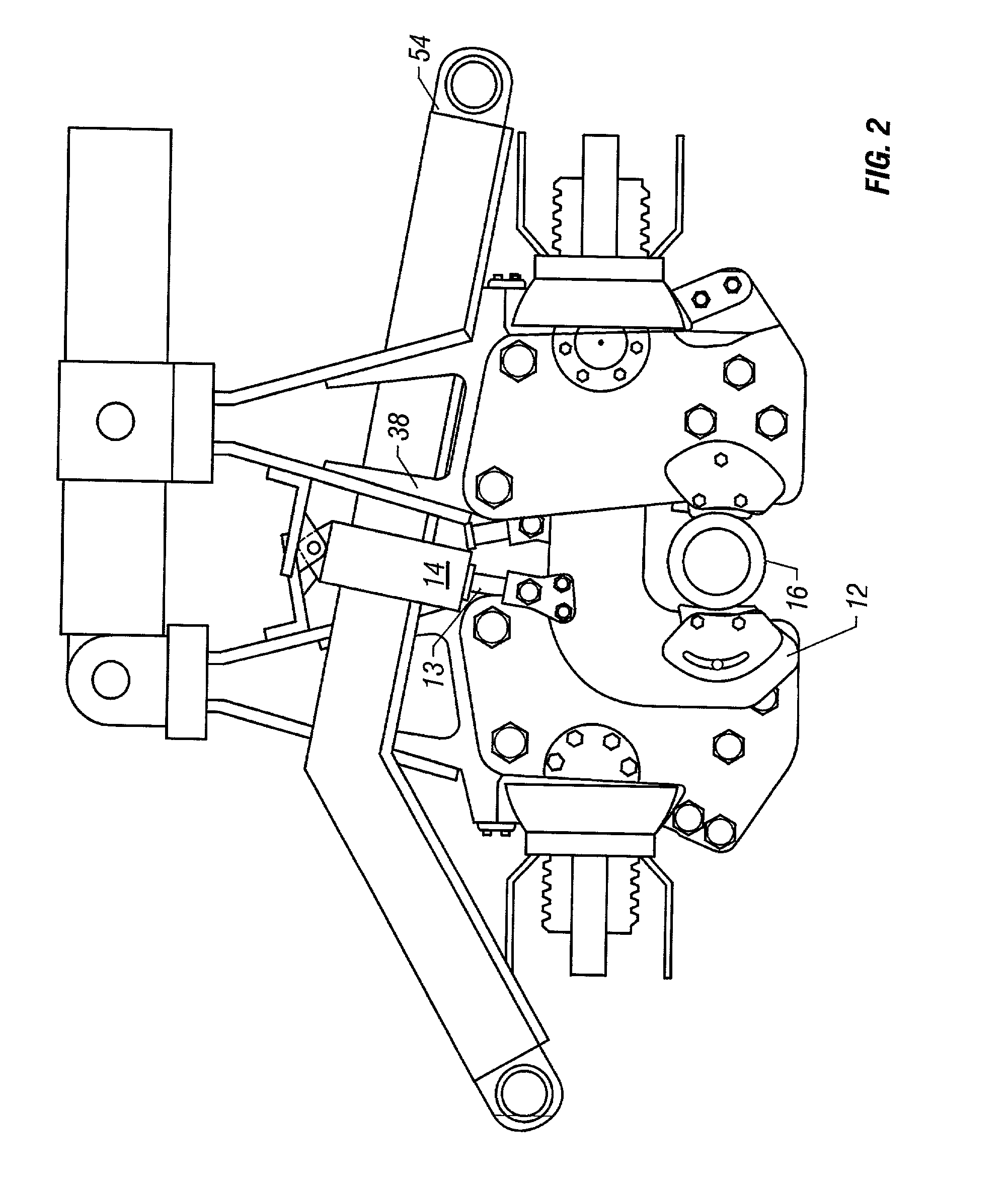

Apparatus and method for connecting wellbore tubulars

The present invention discloses an apparatus and method for controlling a power tong unit having a power spinner and, in a preferred embodiment, three power jaws. The control system controls grip pressure applied by a selected power jaw to a first wellbore tubular to provide a relatively reduced grip pressure when the power spinner is activated to thereby rotate a second wellbore tubular at a relatively high rotation speed but with a relatively low torque. The control system applies a relatively high grip pressure to two selected power jaws used for applying high torque but at a relatively slow rotation speed for final making up or initial breaking out of the wellbore tubulars with respect to each other.

Owner:FRANKS INT

Method and apparatus for correcting motion in image reconstruction

ActiveUS7782998B2Reconstruction from projectionMaterial analysis using wave/particle radiationProjection imageSlow rotation

A plurality of projection images are acquired over an angular range during the slow rotation of a C-arm gantry having a source and detector. Phase-specific reconstructions are generated from the plurality of projections, wherein each phase-specific reconstruction is generated generally from projections acquired at or near the respective phase. In one embodiment, a plurality of motion estimates are generated based upon the phase-specific reconstructions. One or more motion-corrected reconstructions may be generated using the respective motion estimates and projections. The motion-corrected reconstructions may be associated to form motion-corrected volume renderings.

Owner:GENERAL ELECTRIC CO

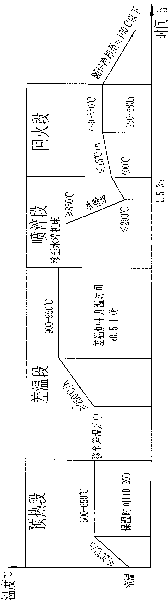

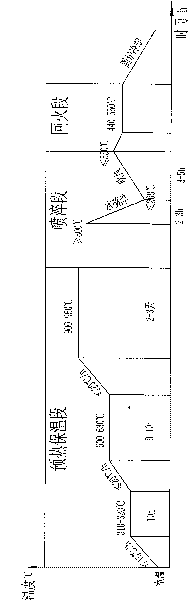

Quenching method for integral cast steel supporting roll

ActiveCN101698902ALow tensile strengthHigh hardnessFurnace typesHeat treatment process controlSlow rotationHardness

The invention relates to a quenching method of an integral cast steel supporting roll, which is an improvement of the quenching method of the working layer of the integral cast steel supporting roll, and the method is characterized in that the integral heating of the supporting roll comprises the following steps: first, heating the quenched and tempered supporting roll according to a heating rate of less than or equal to 20 DEG C / h to the temperature which is 50-100 DEG C below the cotectic curve temperature, and keeping temperature for 13D-20D; transferring the supporting roll into a differential heating furnace, quickly heating the supporting roll according to the heating rate of greater than or equal to 250 DEG C / h under slow rotation until the surface temperature is greater than or equal to the quenching temperature, and keeping temperature until the thermoosmosis thickness is greater than or equal to the required depth of the hardening layer; transferring the roll into a water quenching machine, carrying out rotating water spray quenching when the surface temperature is greater than or equal to 850 DEG C at the cooling rate of greater than or equal to 2 DEG C / s for the spray quenching of the roll, and stopping spraying water when the surface temperature is less than or equal to 220 DEG C; and transferring the roll into a heating furnace for tempering treatment to obtain the roll of which the surface hardness is 55-75HSD, the uniformity of the surface hardness is less than or equal to + / -1HSD, the radial hardness drop of the hardening layer is less than or equal to 0.5HSD / cm, and the tensile strength of the hardening layer is greater than or equal to 1200MPa. Compared with the prior art, the invention has high hardness of the working layer, good hardness uniformity, good hardening capacity, controllable depth of the hardening layer and small radial hardness drop.

Owner:JIANGSU GONGCHANG ROLL

Rotary strut sprinkler

ActiveUS20110031332A1Seal dragHigh seal dragBurnersMovable spraying apparatusSlow rotationEngineering

A rotary sprinkler includes a sprinkler body including a nozzle, a water-deflection plate supported for rotational movement relative to the sprinkler body, the water-deflection plate having one or more grooves configured to cause the water-deflection plate to rotate when impinged upon by a stream emitted from the nozzle; a first brake arranged to slow rotation of the water-deflection plate at all times; and a second brake arranged to further slow rotation of the water-deflection plate as a function of water pressure exerted on the water-deflection plate.

Owner:NELSON IRRIGATION

Method and system for CT imaging using a distributed X-ray source and interpolation based reconstruction

ActiveUS7227923B2Material analysis using wave/particle radiationRadiation/particle handlingX-raySlow rotation

A method for Computed Tomography (CT) imaging is provided. The method comprises rotating a gantry at a substantially slow rotation speed about a volume of interest. The gantry comprises a combination of X-ray source points. The X-ray source points comprise one or more discrete emission points and an arc of discrete or continuous X-ray source points. The method then comprises obtaining projection data from the combination of X-ray source points and performing a suitable reconstruction based on the projection data obtained from the combination of X-ray source points, to generate one or more reconstructed images.

Owner:GENERAL ELECTRIC CO

Electroplating using DC current interruption and variable rotation rate

A negative bias is applied to an integrated circuit wafer immersed in an electrolytic plating solution to generate a DC current. After about ten percent to sixty percent of the final layer thickness has formed in a first plating time, biasing is interrupted during short pauses during a second plating time to generate substantially zero DC current. The pauses are from about 2 milliseconds to 5 seconds long, and typically about 10 milliseconds to 500 milliseconds. Generally, about 2 pauses to 100 pauses are used, and typically about 3 pauses to 15 pauses. Generally, the DC current density during the second plating time is greater than the DC current density during the initial plating time. Typically, the integrated circuit wafer is rotated during electroplating. Preferably, the wafer is rotated at a slower rotation rate during the second plating time than during the first plating time.

Owner:NOVELLUS SYSTEMS

Rotary strut sprinkler

ActiveUS8567699B2Prevent rotationConstant speedBurnersMovable spraying apparatusSlow rotationEngineering

A rotary sprinkler includes a sprinkler body including a nozzle, a water-deflection plate supported for rotational movement relative to the sprinkler body, the water-deflection plate having one or more grooves configured to cause the water-deflection plate to rotate when impinged upon by a stream emitted from the nozzle; a first brake arranged to slow rotation of the water-deflection plate at all times; and a second brake arranged to further slow rotation of the water-deflection plate as a function of water pressure exerted on the water-deflection plate.

Owner:NELSON IRRIGATION

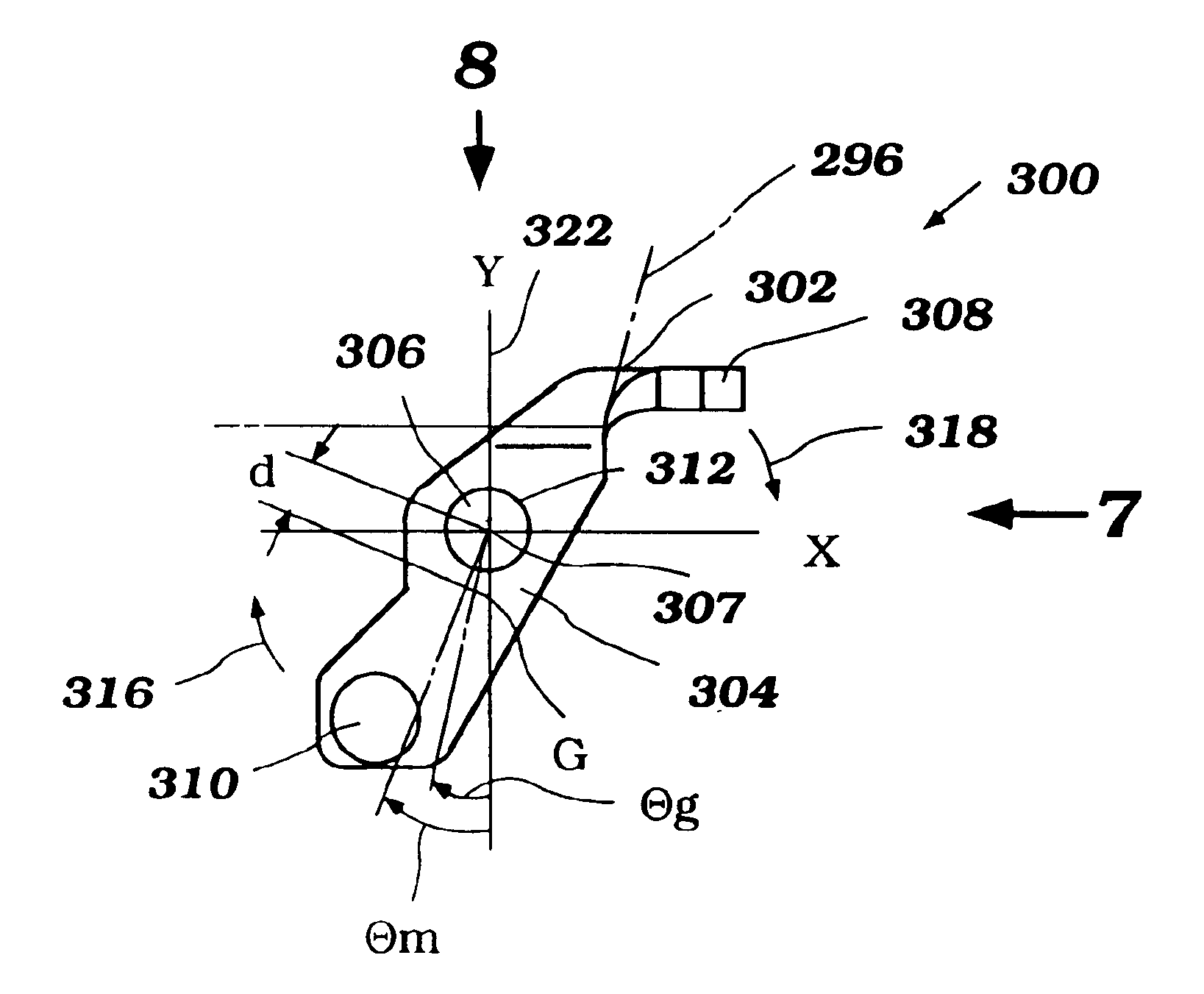

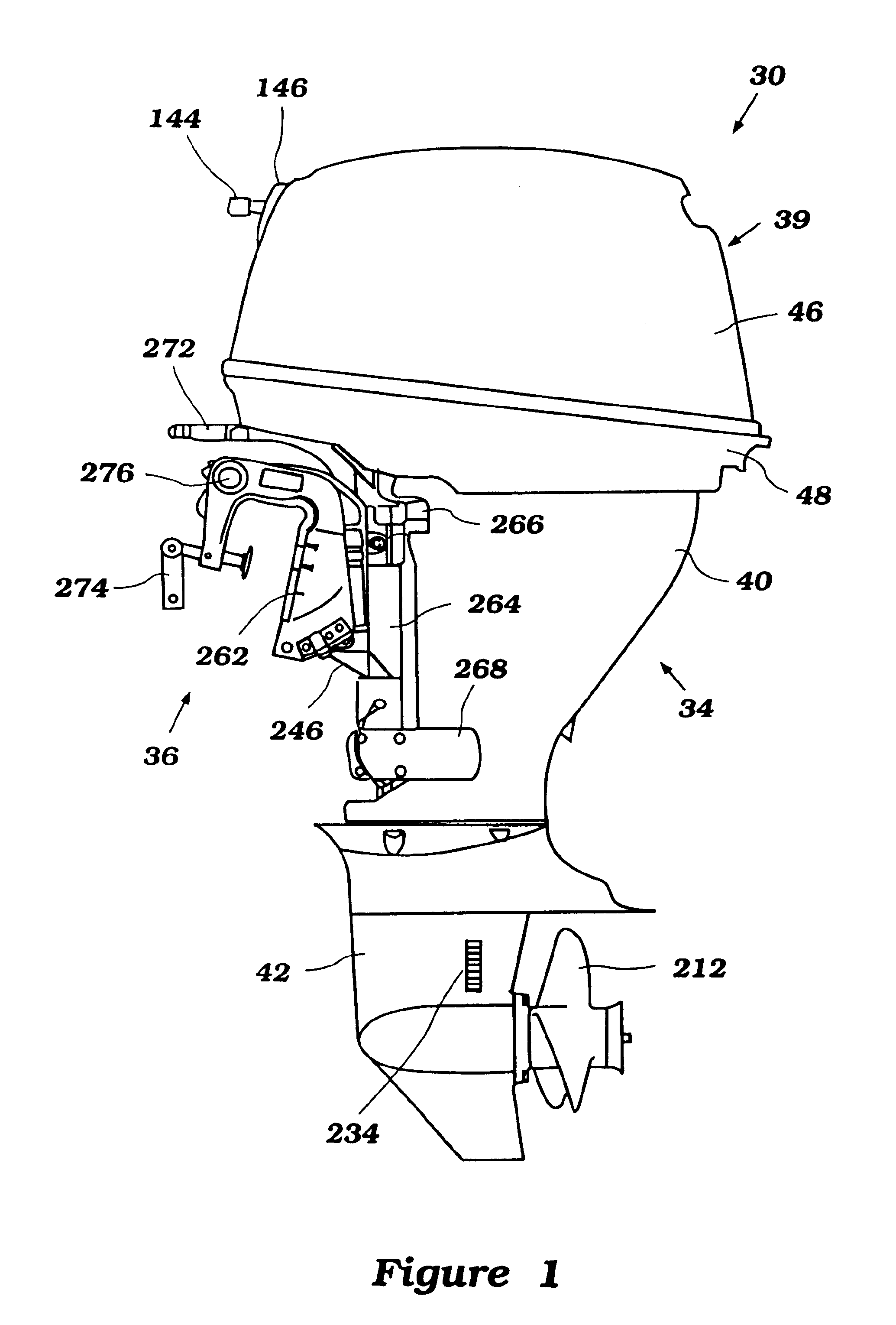

Engine decompression device

An engine decompression device includes an improved construction to release at an exceedingly slow engine speed. The engine has a camshaft that actuates at least one exhaust valve and extends generally vertically. The decompression device has an actuator mounted on the camshaft for pivotal movement about a pivot axis extending generally normal to an axis of the camshaft. The actuator includes a cam section that holds the exhaust valve in an open position and a sinker section that moves with centrifugal force produced by relatively slow rotation of the camshaft so as to release the cam section from holding the exhaust valve open.

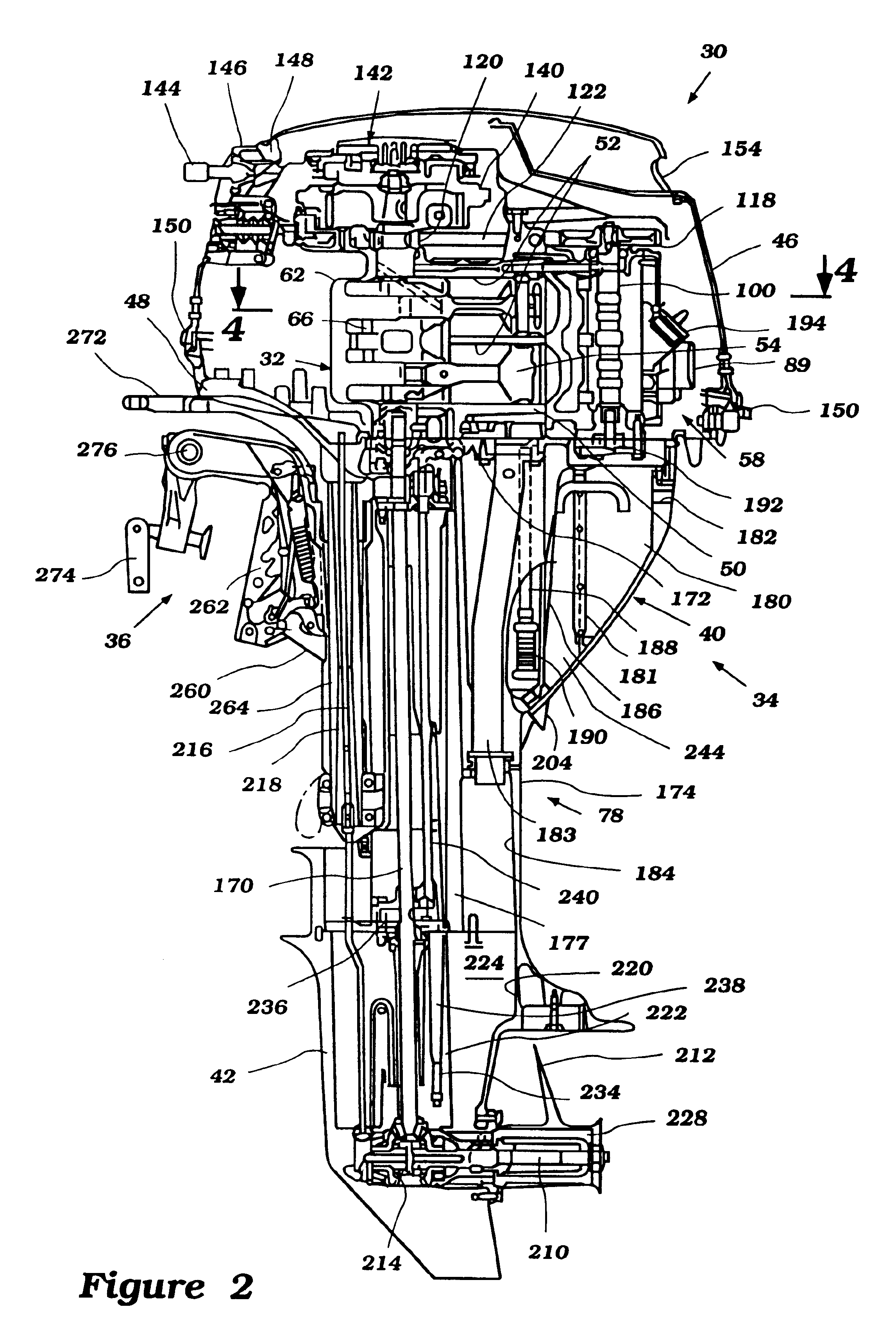

Owner:SANSHIN KOGYO CO LTD

Torque controller in an electric motor

ActiveUS20070001636A1DC motor speed/torque controlMotor control for very low speedsMaximum torqueSlow rotation

The torque of a motor operated by an inverter circuit is controlled to allow maximum torque in the motor when the motor is stalled or at low rotation speeds. Control is accomplished by providing a switching frequency to the motor at a first switching frequency, detecting a rotation speed of the motor, and switching the current to the motor to a second switching frequency when the rotation speed of the motor drops to a predetermined slow rotation speed. The second switching frequency is less than the first switching frequency.

Owner:DRS NETWORK & IMAGING SYST

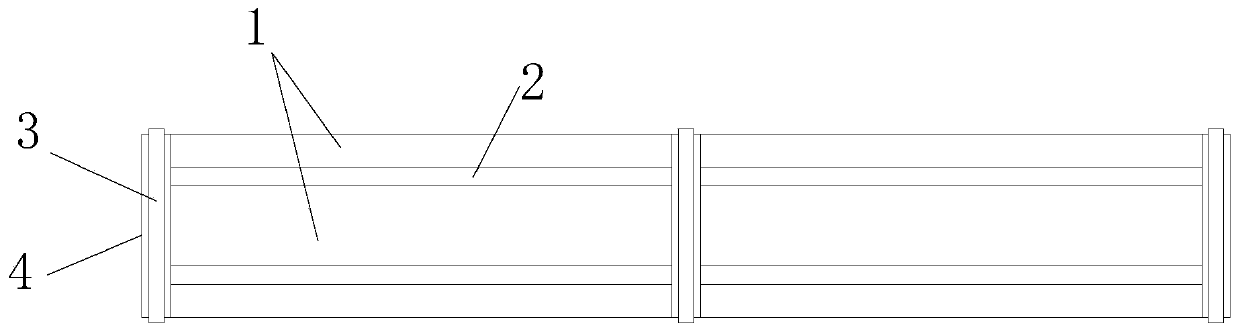

Fireproof composite cable

ActiveCN110111940AQuick breakQuickly turn offInsulated cablesInsulated conductorsHeat conductingSlow rotation

The invention discloses a fireproof composite cable, which comprises a cable body formed by splicing more than one outer sheath layer and more than one connecting pieces, wherein the connecting piecesare arranged between adjacent outer sheath layers; each outer sheath layer is in fixed contact with the end surfaces of the corresponding connecting pieces; more than one cavity is disposed on the outer sheath layer and surround the outer sheath layer; each cavity is filled with an expansion body; each expansion body is filled with an inert gas; the bottom of each expansion body is provided witha bottom plate layer; more than one compression spring is arranged at the bottom of each bottom plate layer; the bottom of each compression spring is fixedly connected with the bottom surface of the cavity; and the outer end side of each expansion body is provided with a heat conducting piece. The fireproof composite cable, by using a method of thermal expansion, jets out the inert gas and a partof a fire extinguishing agent when there is a fire source in order to quickly extinguish the flame on the outer sheath layer and the surrounding flame, and can achieve one-side jet to realize slow rotation in order to well stay away from the fire source and well extinguish the fire.

Owner:江西美园电缆集团有限公司

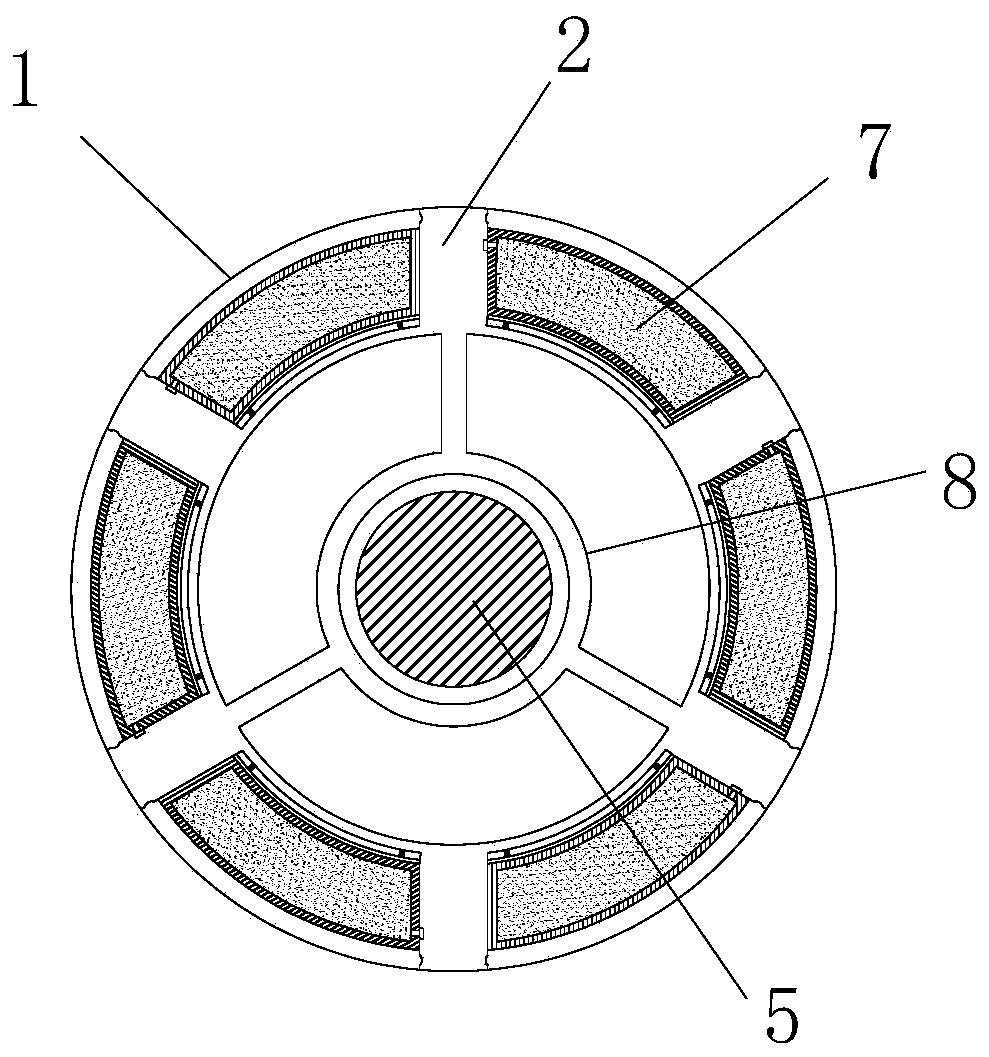

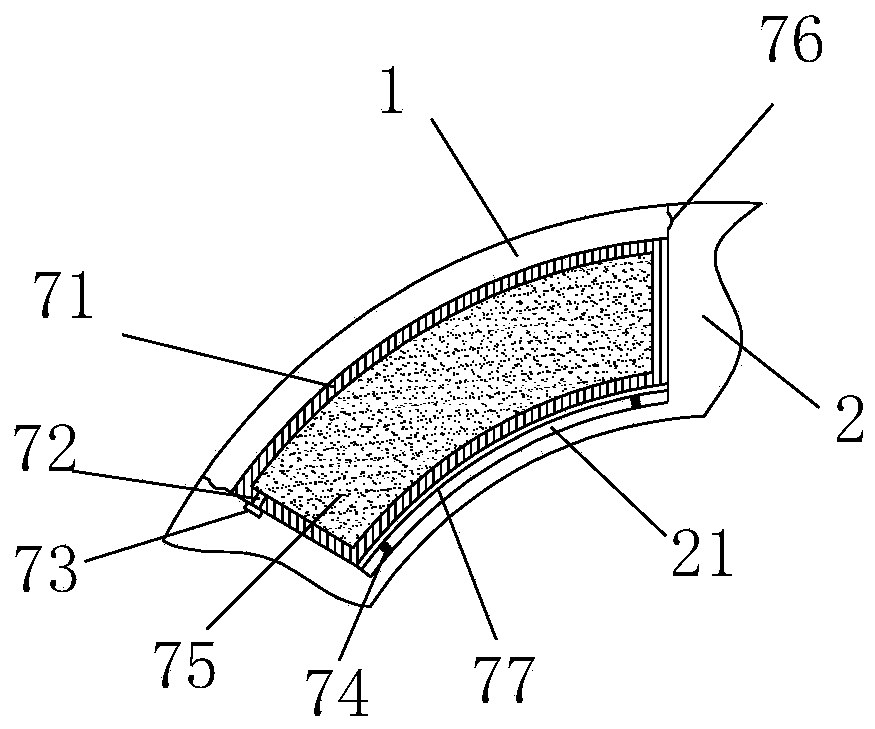

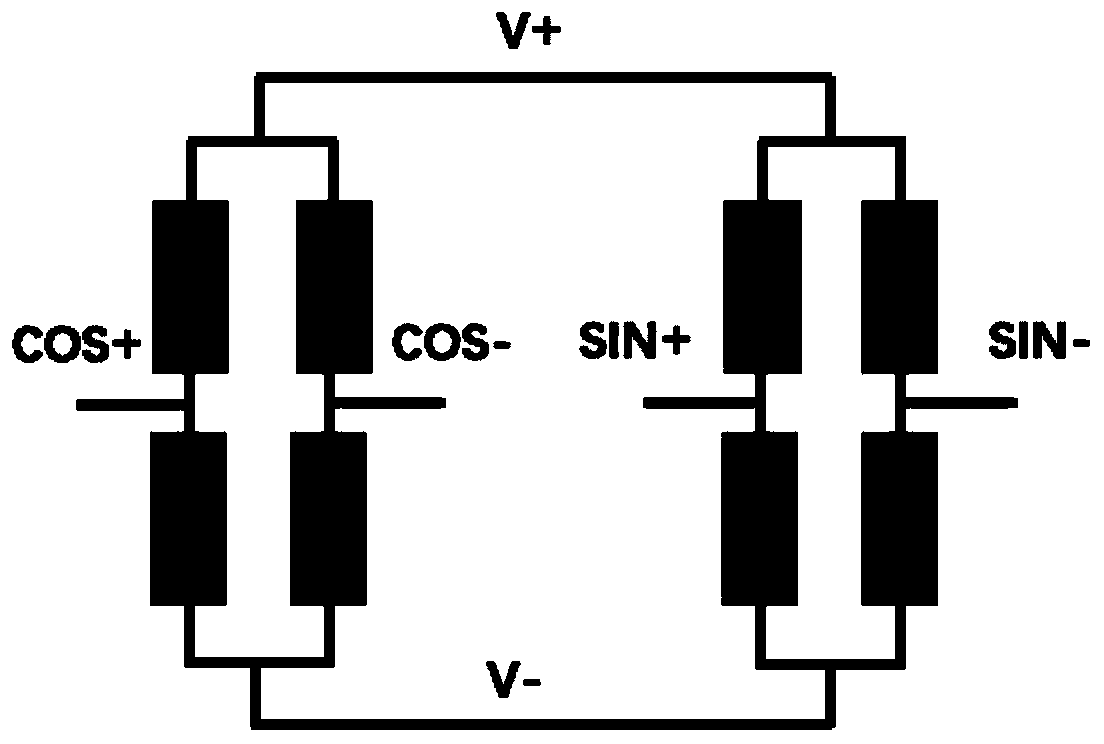

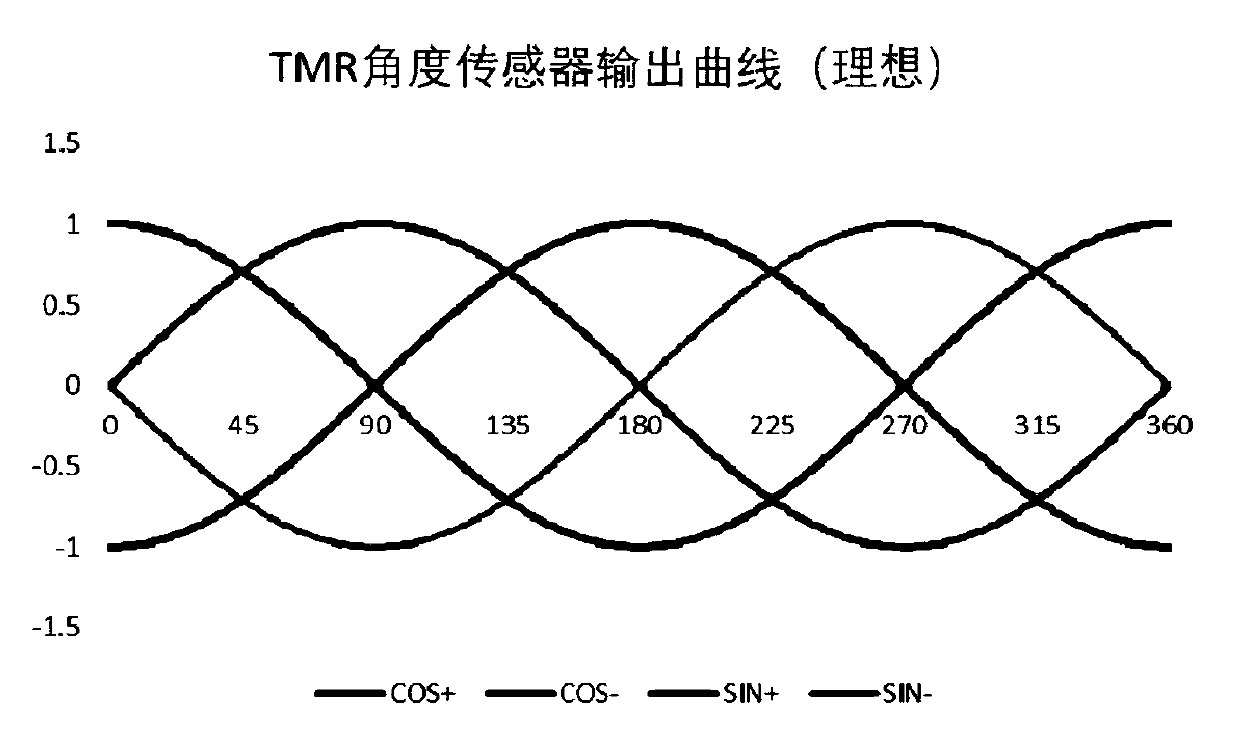

Magnetic angle sensor self-calibration method and device, magnetic angle sensor and system

ActiveCN109855668AReduce calibration timeIncrease productivityInstrumentsSlow rotationData treatment

The invention relates to the technical field of magnetic angle sensors, and particularly discloses a magnetic angle sensor self-calibration method. The magnetic angle sensor self-calibration method comprises the following steps: obtaining a first group of magnetic angle data; obtaining a second group of magnetic angle data; processing the first group of magnetic angle data and the second group ofmagnetic angle data to obtain an angle value to be calibrated; and calibrating the magnetic angle sensor; wherein obtaining the first group of magnetic angle data and obtaining the second group of magnetic angle data both include the following steps: obtaining the current two channels of magnetic angle signal values of the magnetic angle sensor; determining whether to output a slow rotation driving signal of the motor or not according to the relationship between the current two channels of magnetic angle signal values and a first threshold range; and determining whether to output the two channels of magnetic angle signal values or not according to the relationship between the current two channels of magnetic angle signal values and a second threshold range. The invention also discloses a magnetic angle sensor self-calibration device, a magnetic angle sensor and a magnetic angle sensor system. The magnetic angle sensor self-calibration method provided by the invention greatly reduces the calibration time and improves the production efficiency.

Owner:中电海康无锡科技有限公司

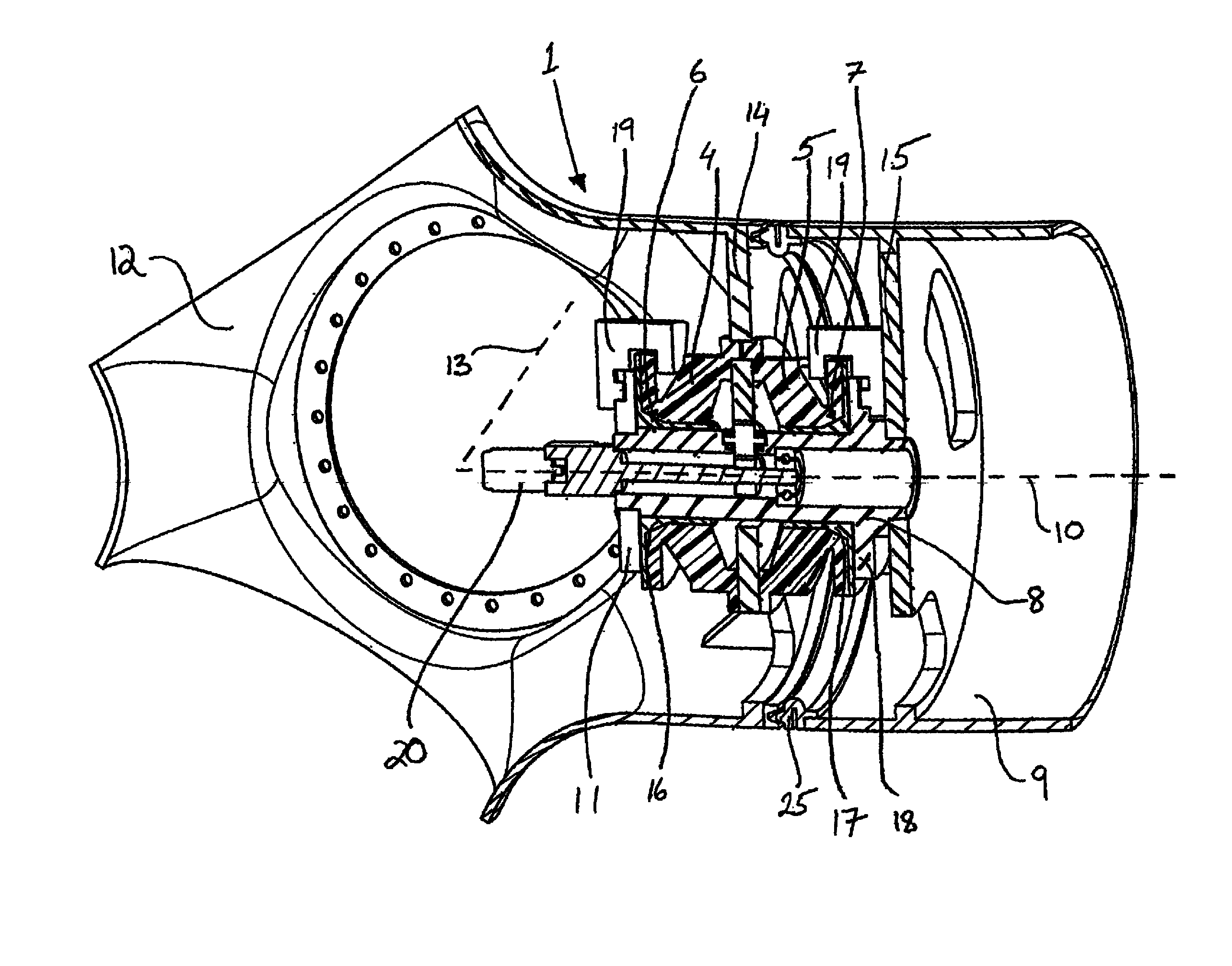

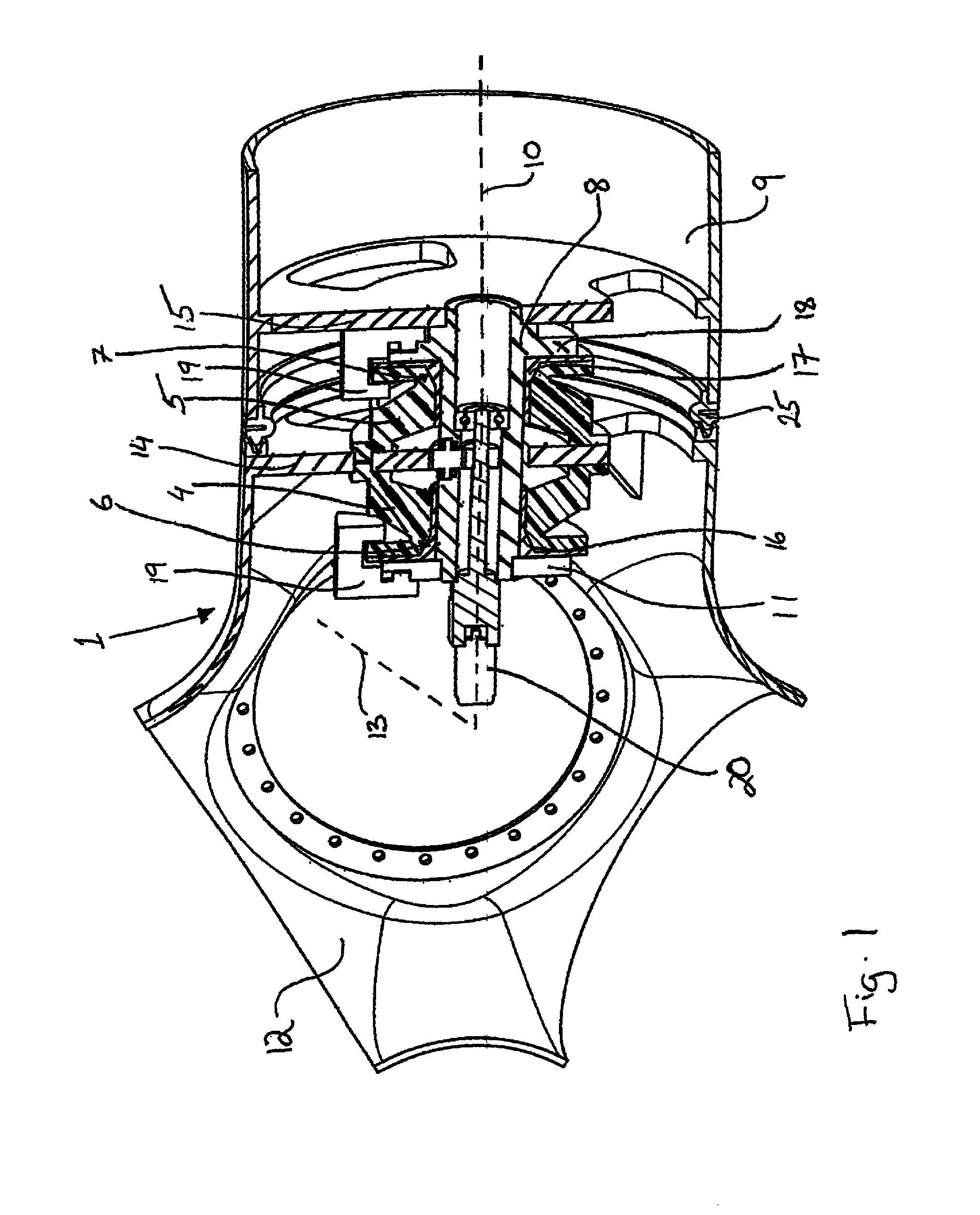

Hybrid wind turbine blade bearing

InactiveUS9011010B2Reduce maintenanceIncreased bending momentRolling contact bearingsWind motor controlTurbine bladeSlow rotation

Wind turbine blade pitch bearing device (1) adapted for rotational support of a turbine blade (9), having a first bearing unit (4, 5) and a second bearing unit (6, 7) coaxial to the first bearing unit. The first bearing unit (4, 5) and the second bearing unit (6, 7) are of different bearing types. By using two different bearing types, one bearing can be optimized for small and quick rotations and the other type can be optimized for larger and slower rotations.

Owner:AB SKF

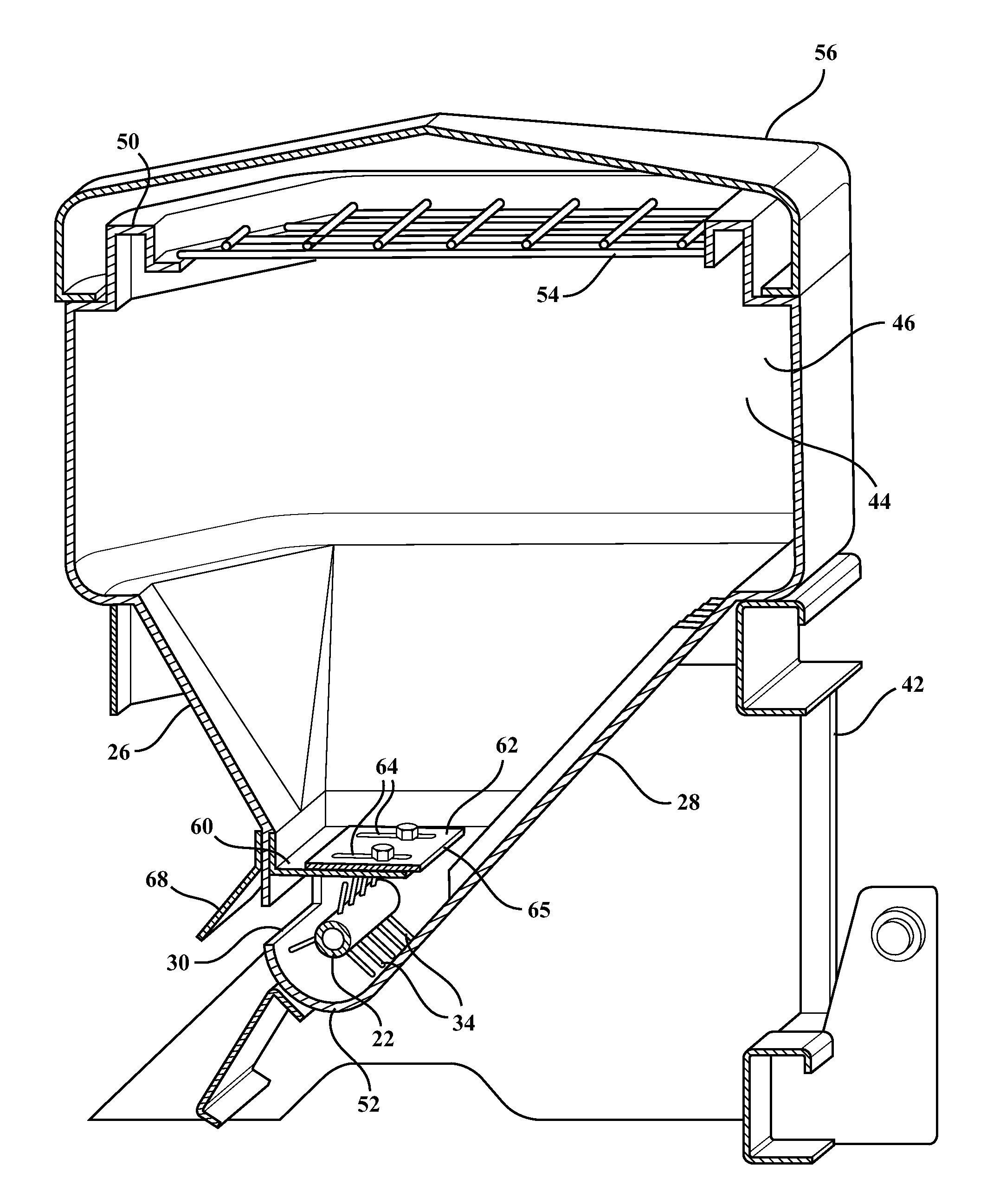

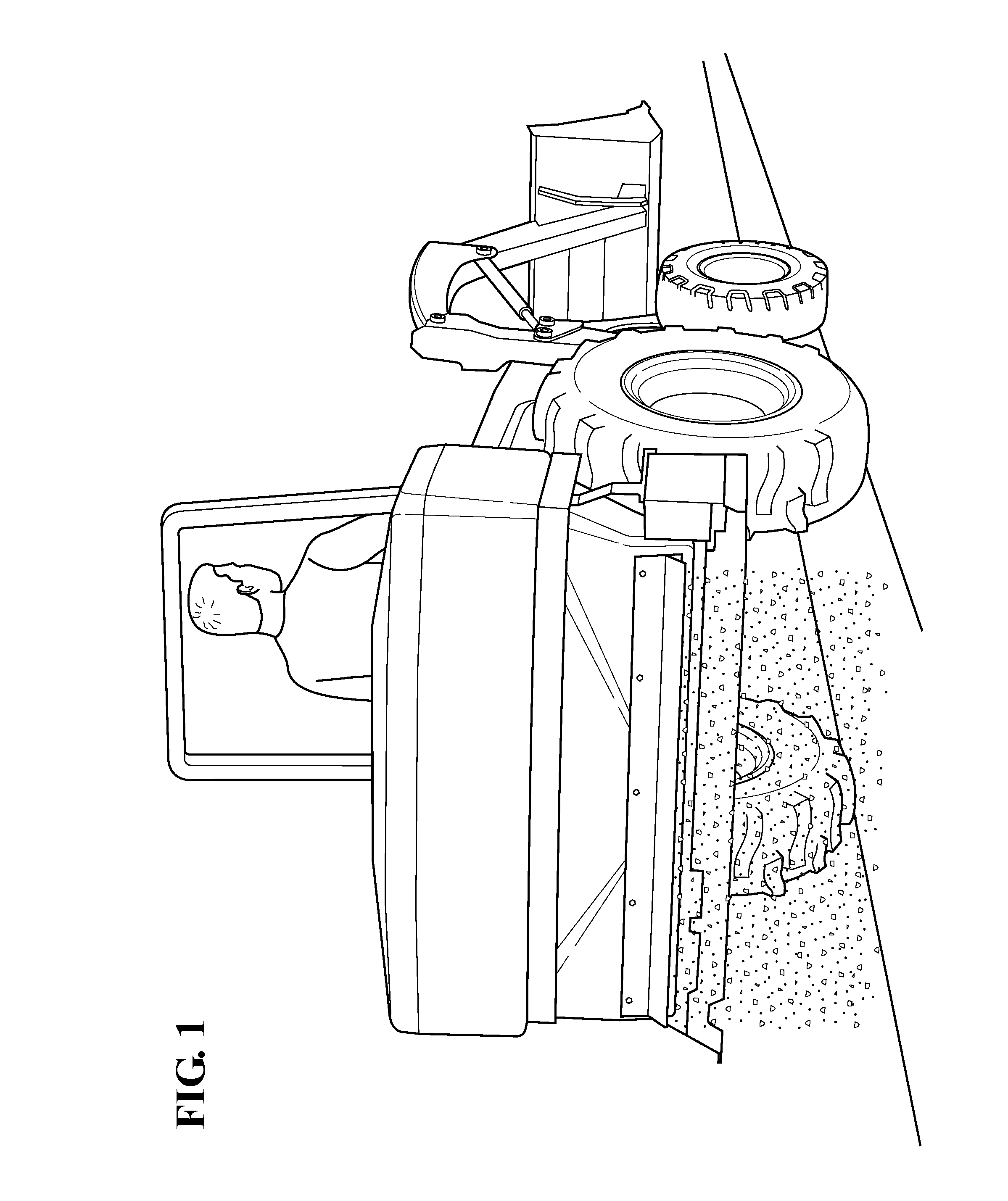

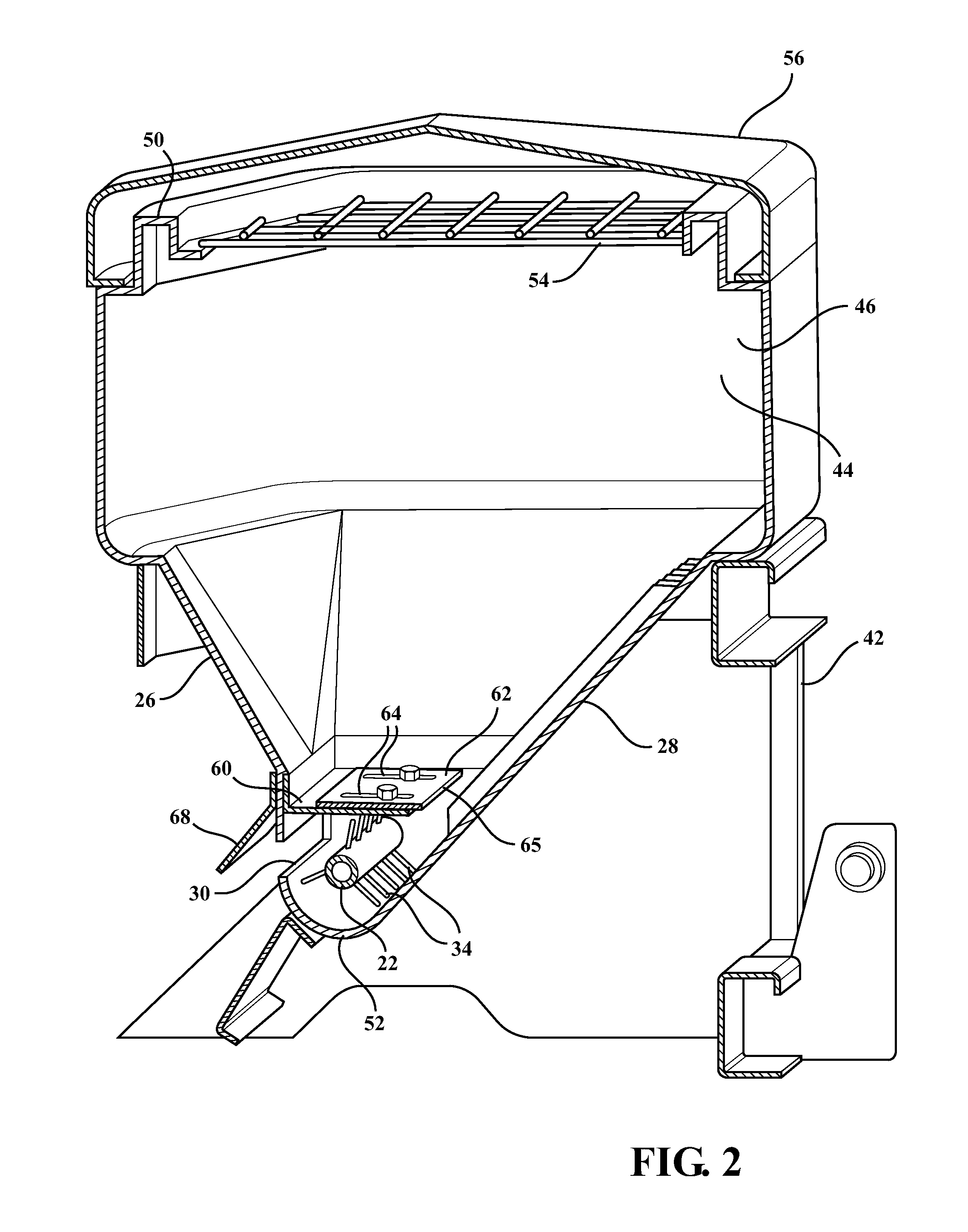

Spreader device

ActiveUS20140374515A1Spin easilyEasy to controlCentrifugal wheel fertilisersWay cleaningMotor speedSlow rotation

A material spreader having a beater bar that meters the supply of small quantities of material to the discharge opening of a material spreader hopper eliminating the need for a gate. The beater bar has one and preferably several paddles that rotate adjacent the discharge opening and as the paddle passes the opening, discharges only the amount of material on the paddle. The material spreader uses a high ratio transmission and low rpm motor to allow for extremely slow rotation of the beater bar. The motor speed can be controlled to allow very slow rotation and very small amounts of material to be discharged from the hopper. The spreader does not require a gate. The discharge of material is metered electronically.

Owner:DOUGLAS DYNAMICS

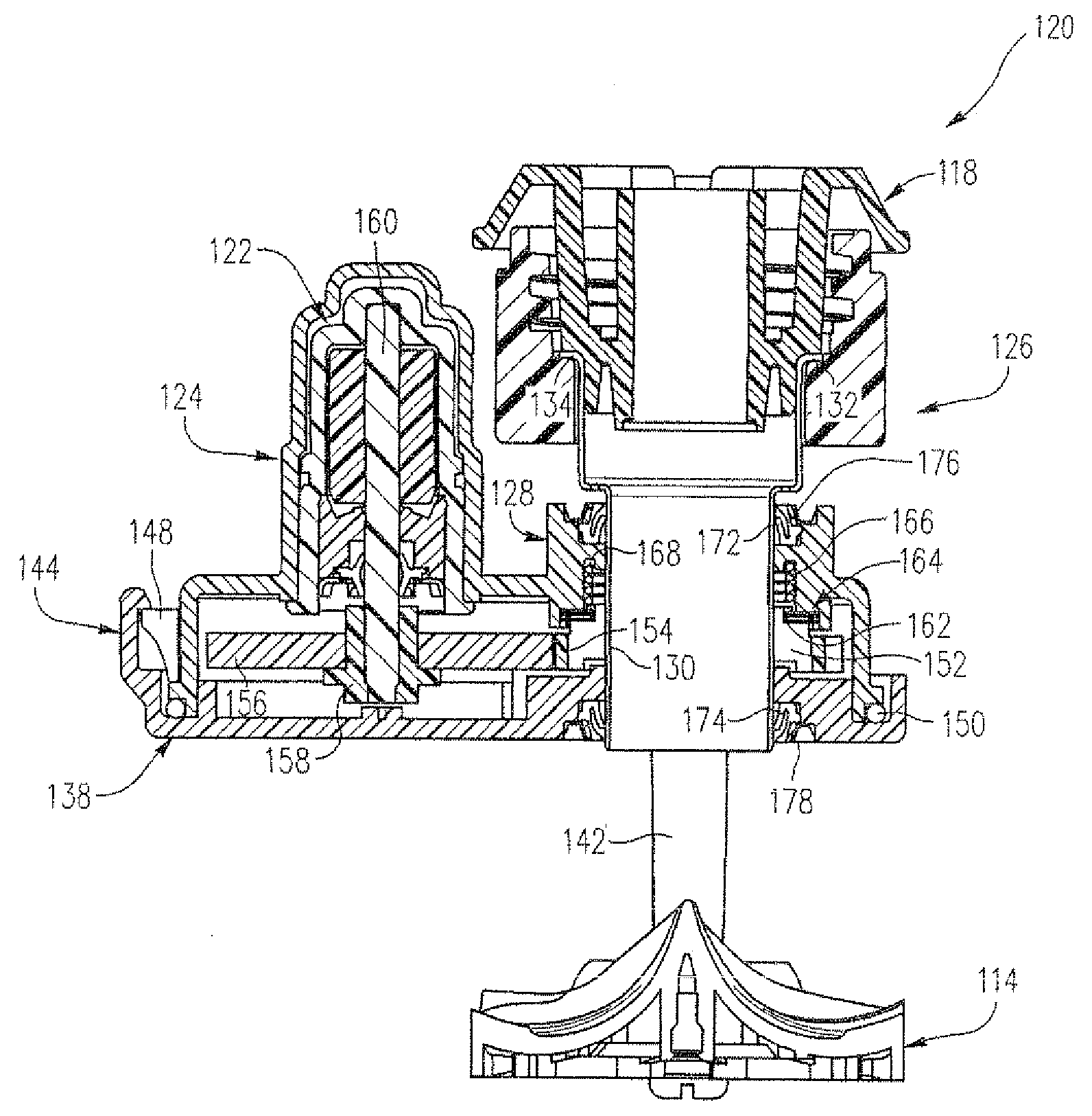

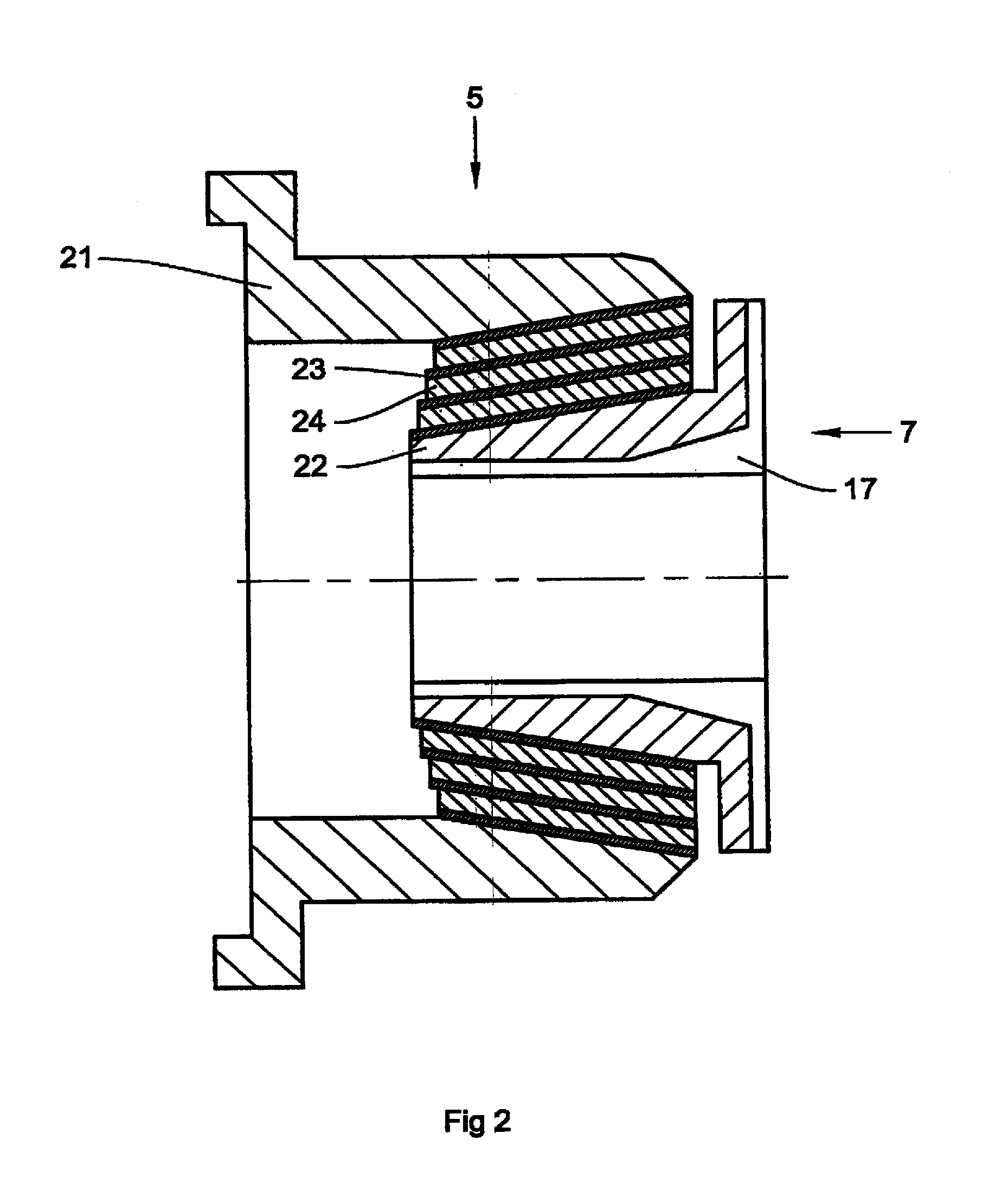

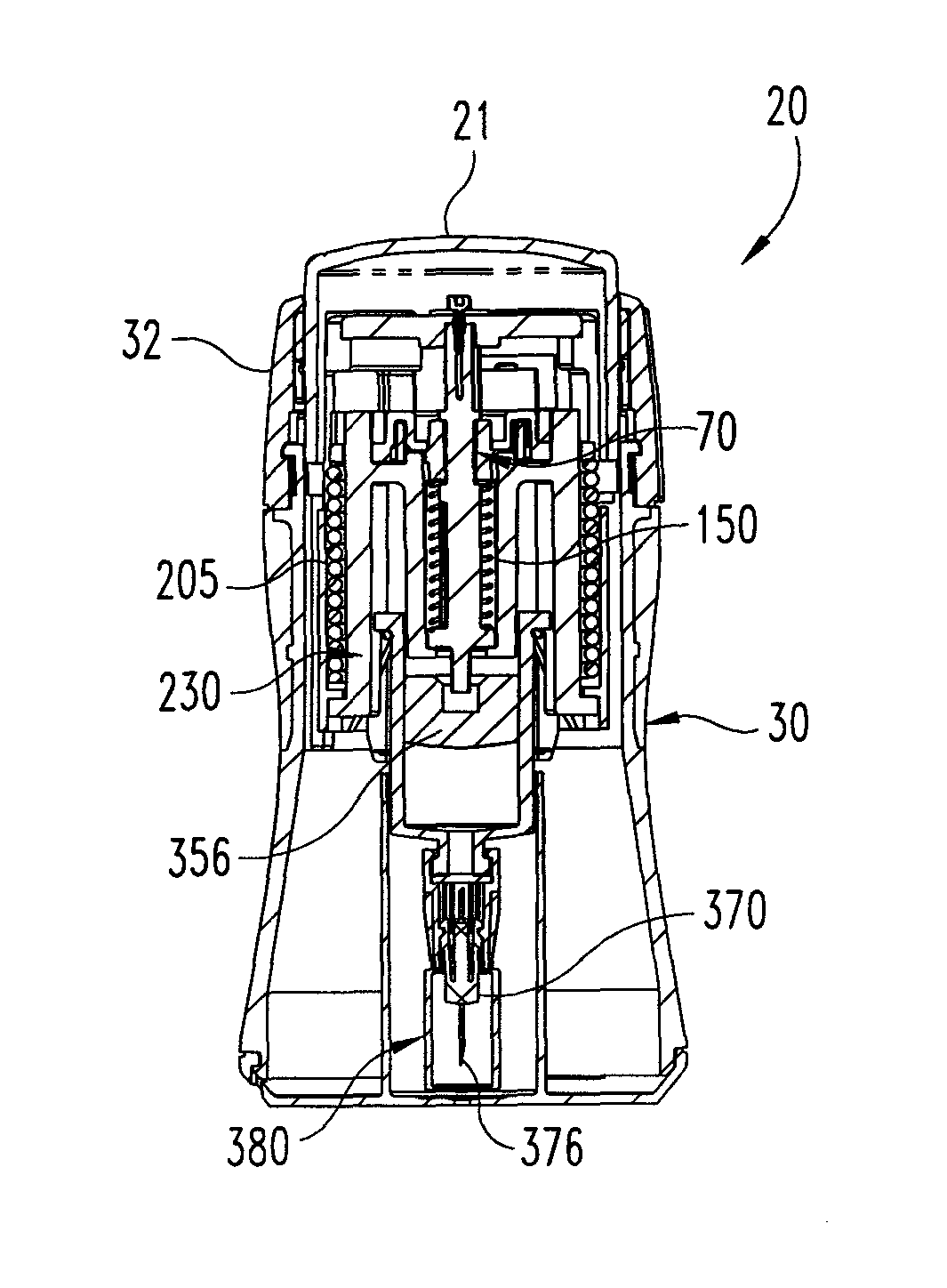

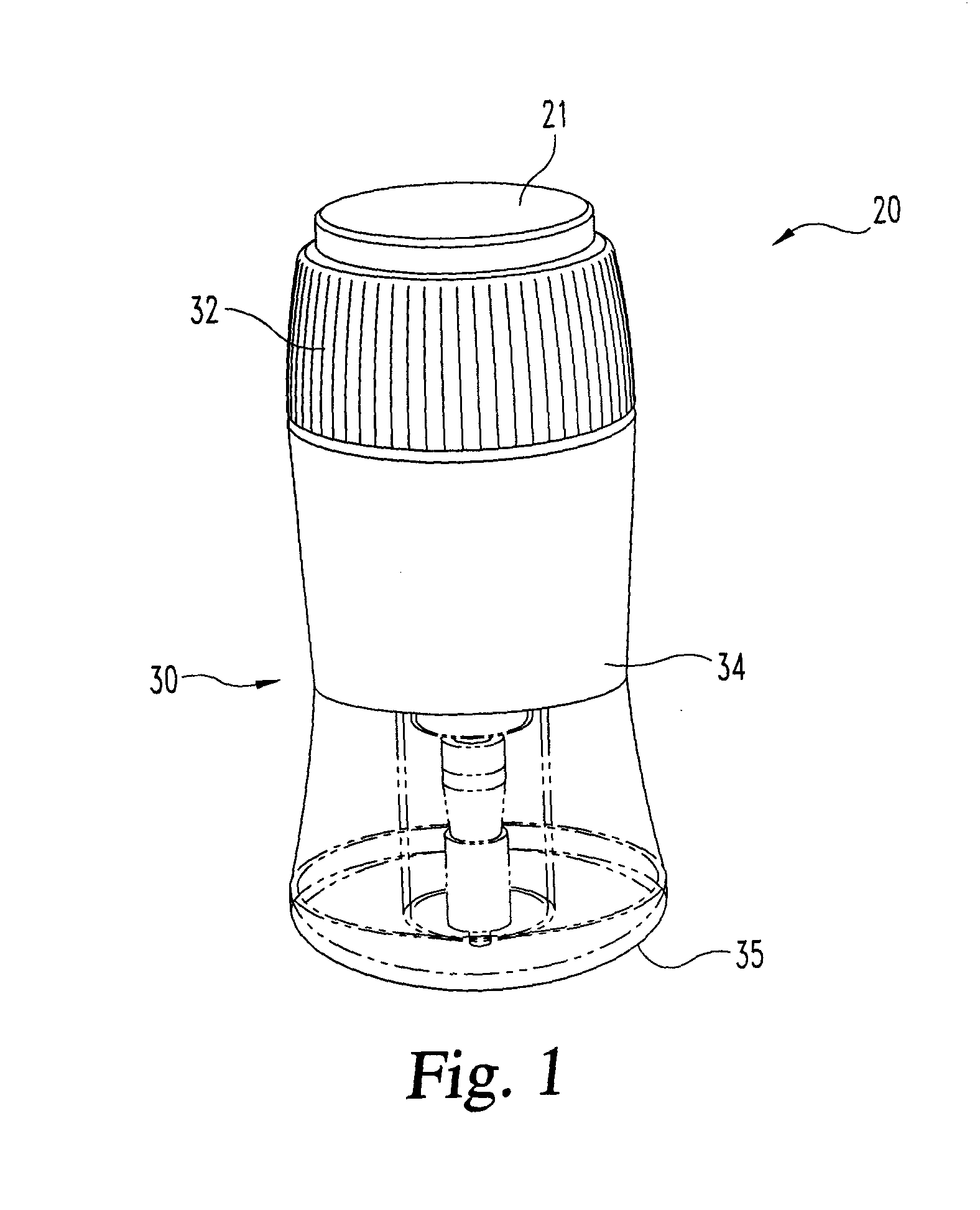

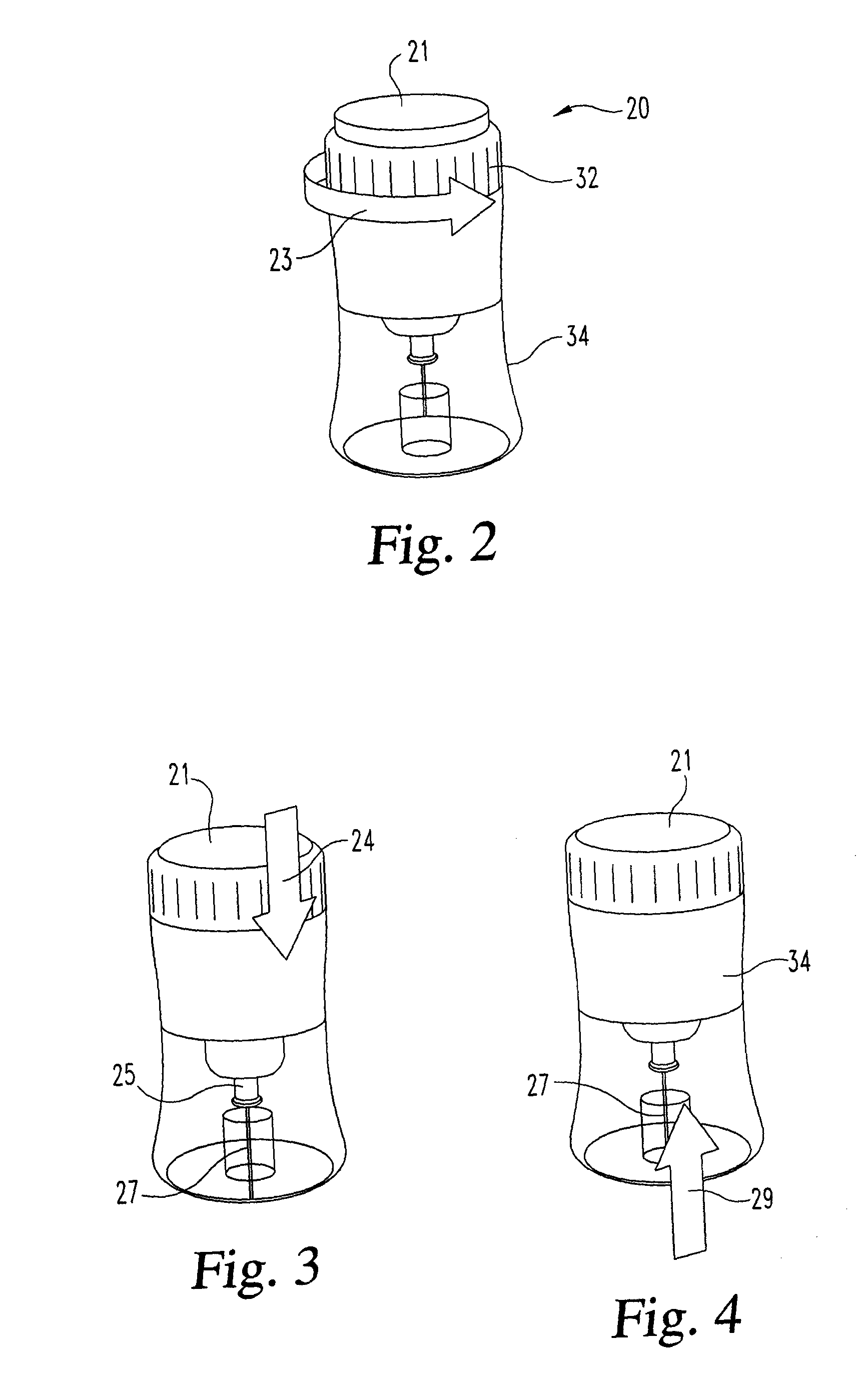

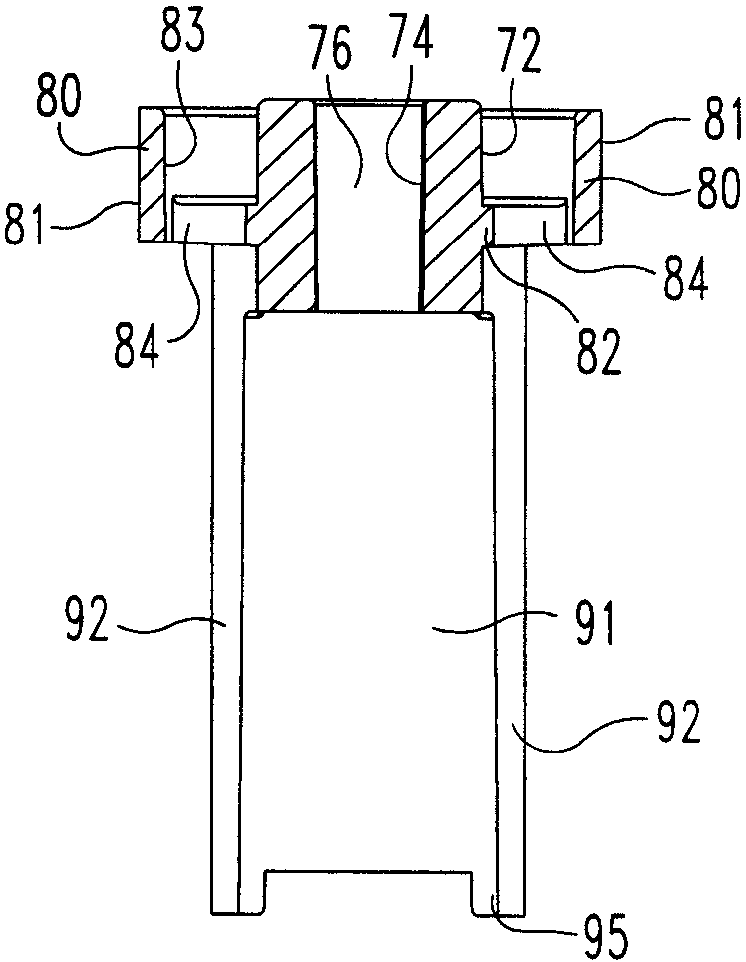

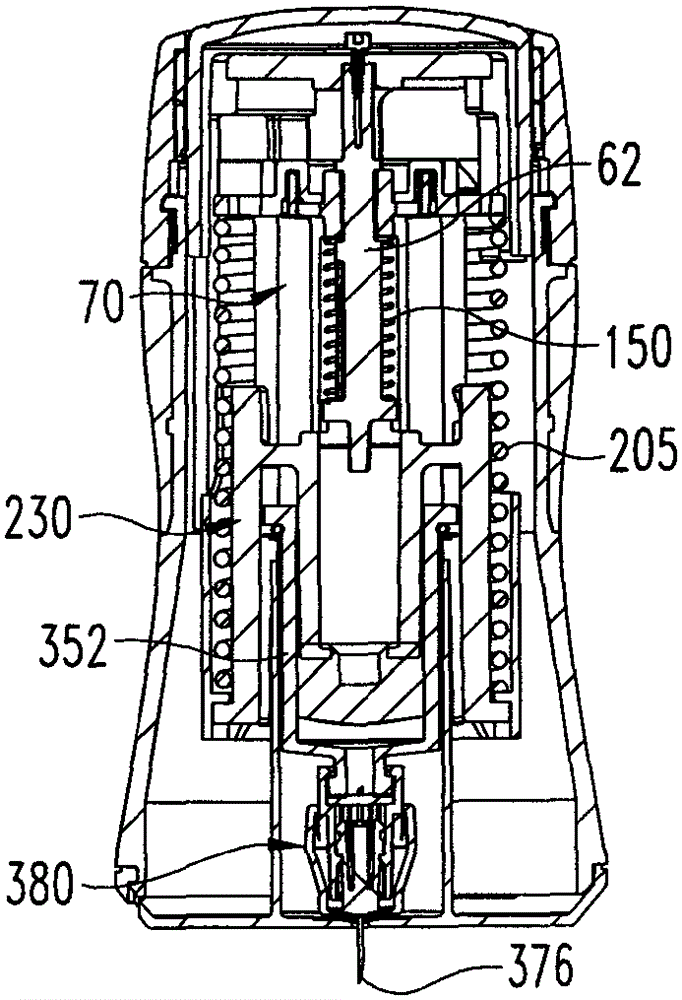

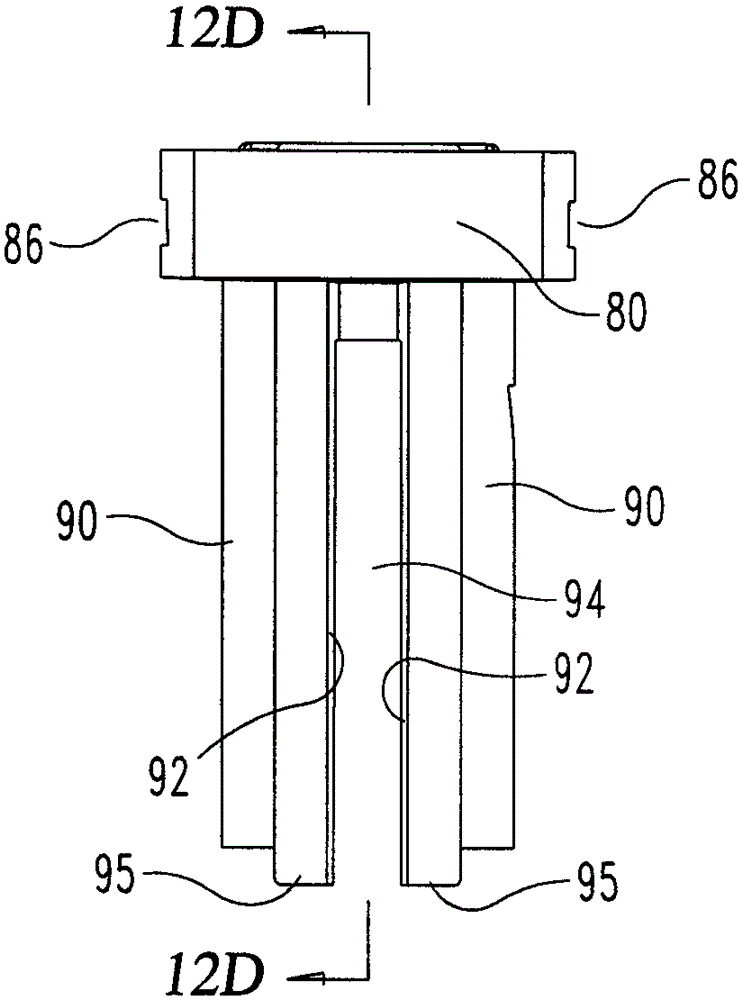

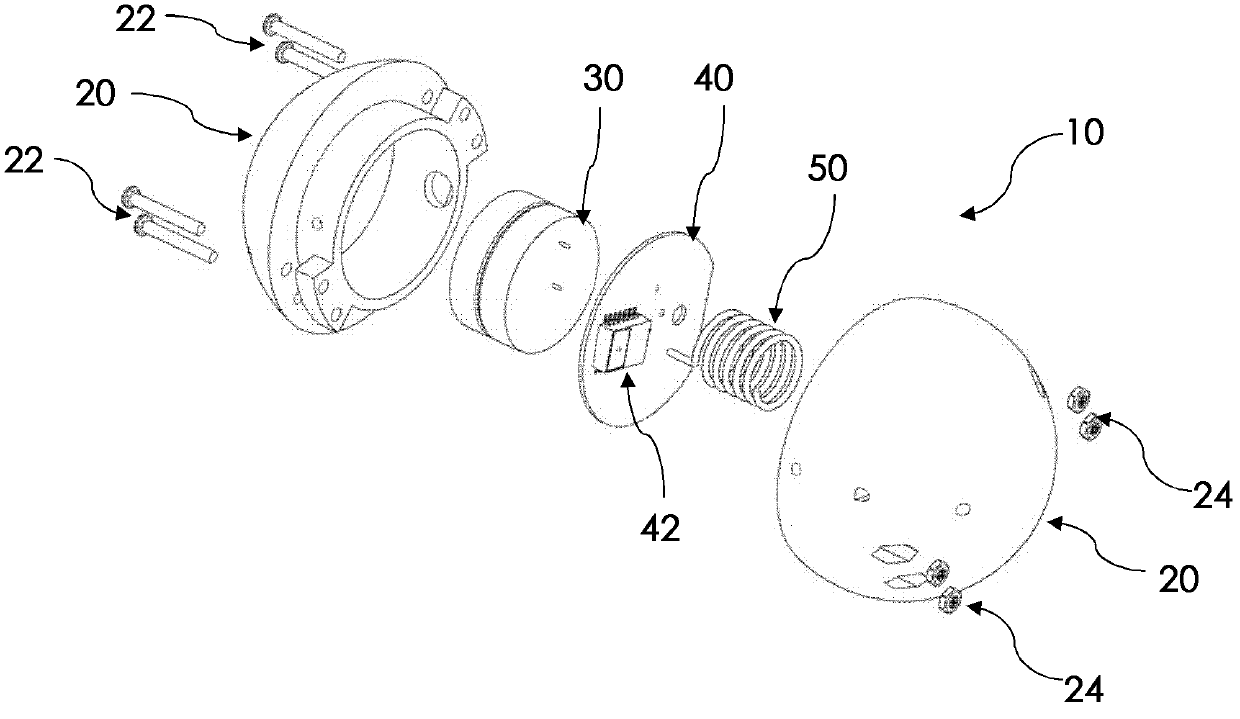

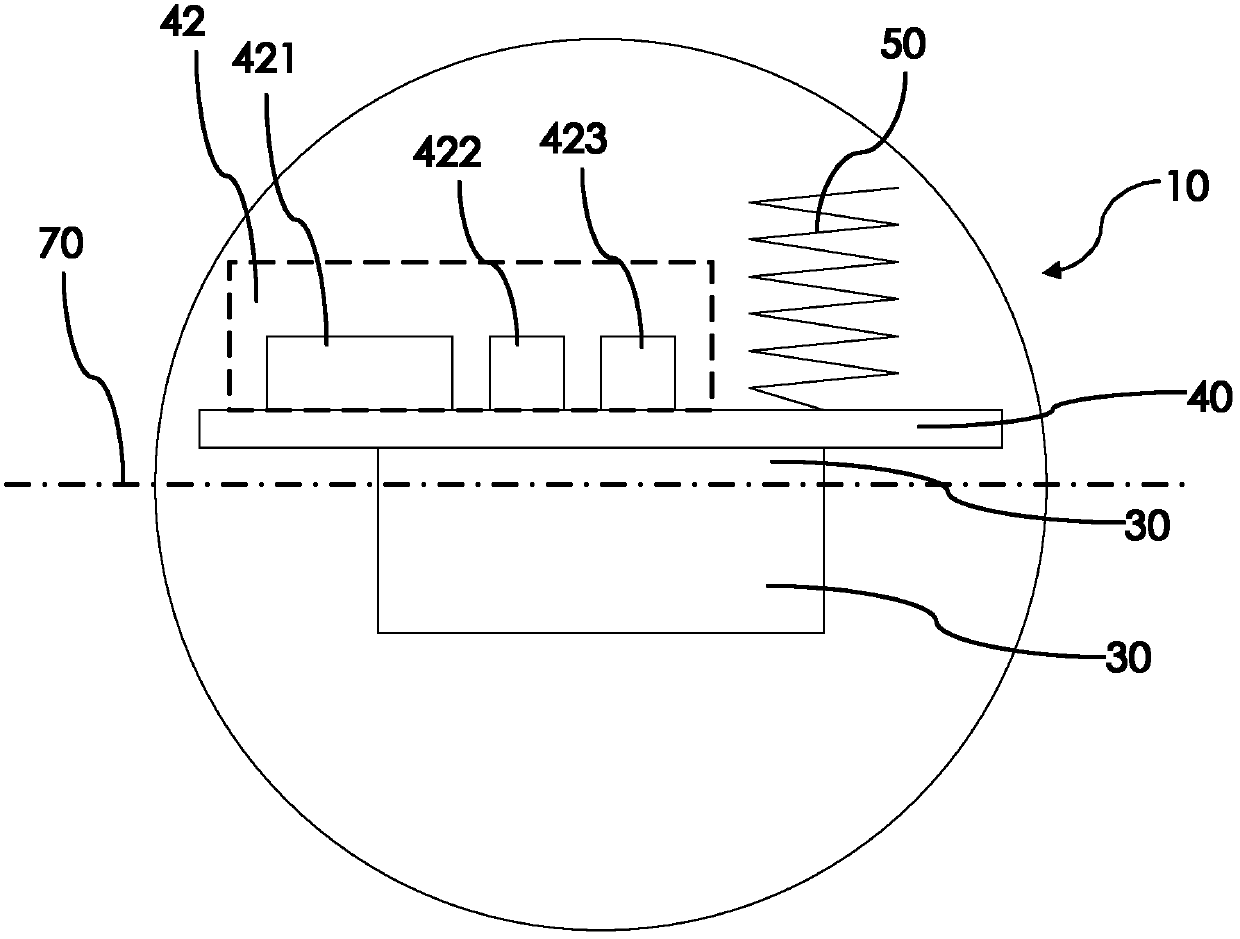

Delay mechanism suitable for compact automatic injection device

ActiveUS20160001004A1Compact designSecure retentionAutomatic syringesInfusion needlesSlow rotationSyringe needle

A delay mechanism for an automatic injection device having a housing and a medication filled syringe. The delay mechanism includes a shuttle, a follower, a damping compound, at least one biasing member, and a biased plunger element. When moved in the device housing from a first location to a second location, the biased plunger element is adapted to drive the syringe piston within syringe barrel to force medication through the syringe needle for an injection. The follower, when the plunger element is so moved, is freed to move, under urging of the at least one biasing member, from a first position on the housing toward a second position to thereby move the shuttle for retracting the syringe needle into the housing after injection. The damping compound dampens or slows rotation of the follower as the follower moves from the first position toward the second position.

Owner:ELI LILLY & CO

Delay mechanism suitable for compact automatic injection device

A delay mechanism for an automatic injection device having a housing and a medication filled syringe. The delay mechanism includes a shuttle, a follower, a damping compound, at least one biasing member, and a biased plunger element. When moved in the device housing from a first location to a second location, the biased plunger element is adapted to drive the syringe piston within syringe barrel to force medication through the syringe needle for an injection. The follower, when the plunger element is so moved, is freed to move, under urging of the at least one biasing member, from a first position on the housing toward a second position to thereby move the shuttle for retracting the syringe needle into the housing after injection. The damping compound dampens or slows rotation of the follower as the follower moves from the first position toward the second position.

Owner:ELI LILLY & CO

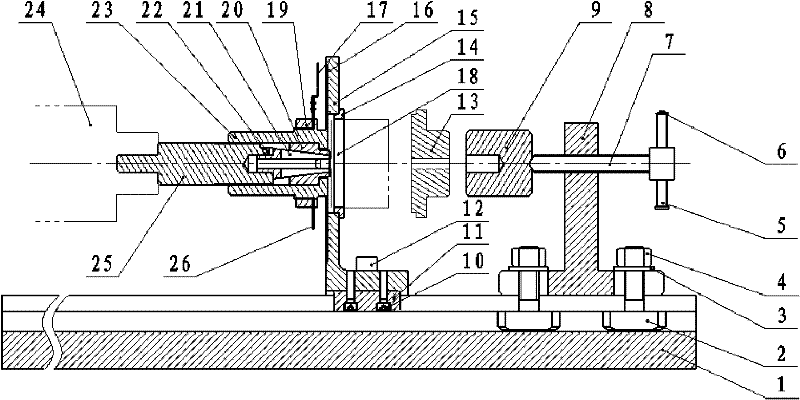

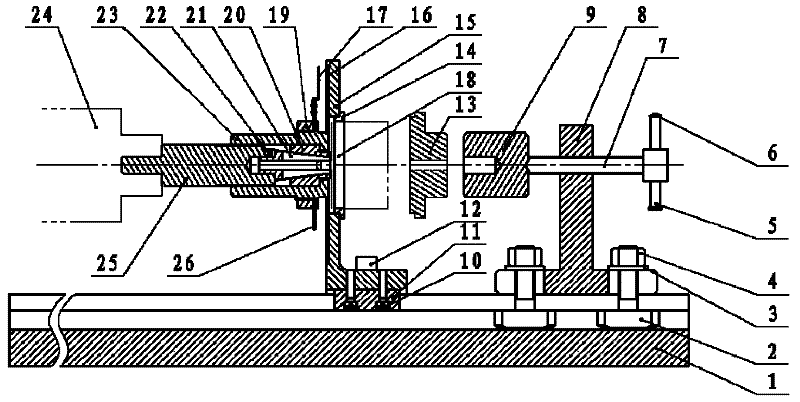

Linear tester and test method for potentiometers

The invention discloses a linear tester and test method for potentiometers. A potentiometer is fixed on an angle plate, and the angle plate is embedded with a meter dial. A mandrel is provided with an adjustable pointer, and after the potentiometer is connected with a power supply and an electric meter, an index head handle is stably and slowly rotated by hand, thereby realizing the stable and slow rotation of the potentiometer and measuring the change process of linear voltage values of the potentiometer. The tester and test method disclosed by the invention have the advantages that the situation that unqualified potentiometers are put into production is avoided, the unnecessary economic losses and the repeated operations of workers are reduced, and the linear test on purchased potentiometers can be performed firstly by inspection personnel.

Owner:XIAN KAITIAN RAILWAY ELECTRICAL

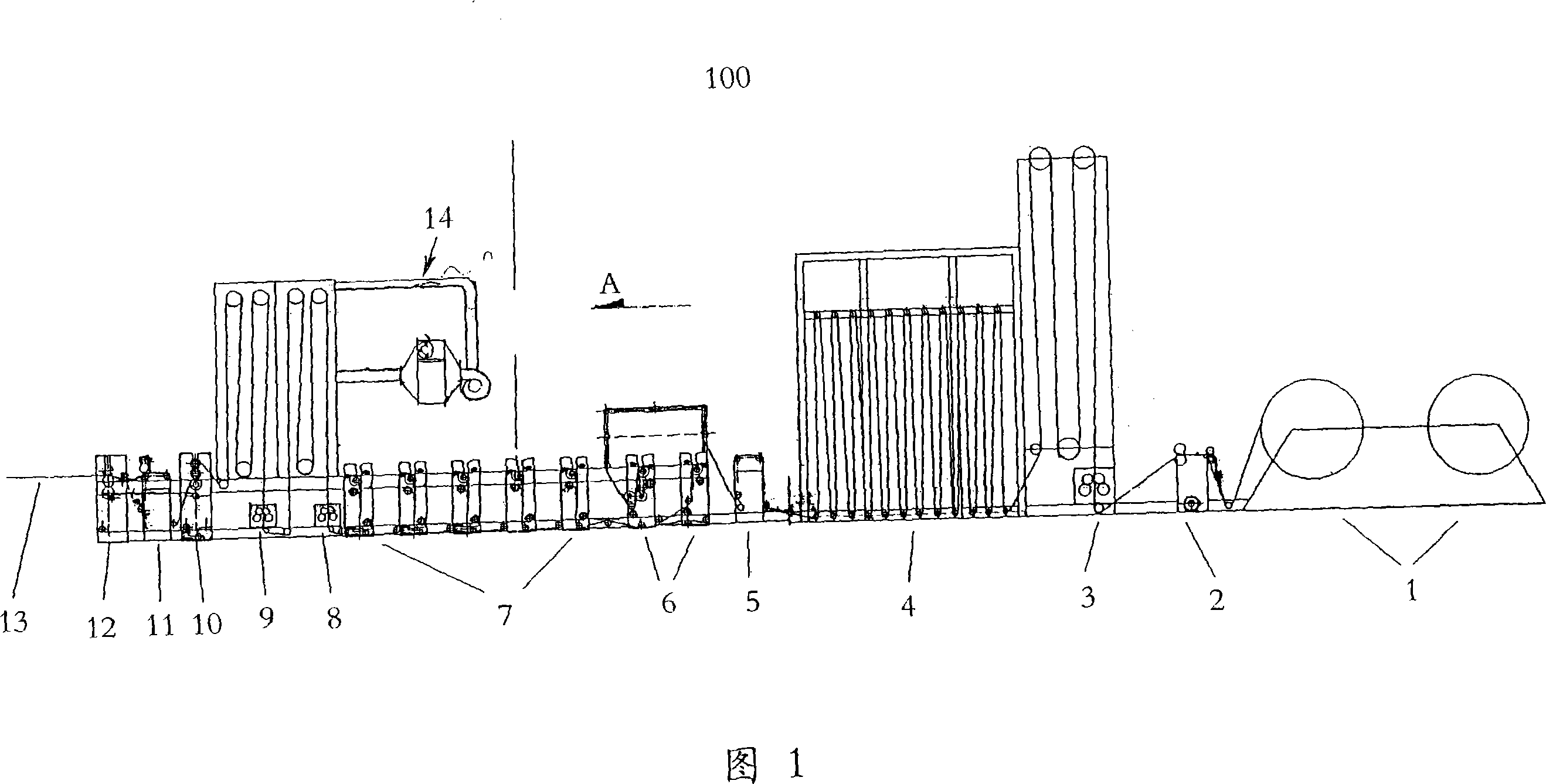

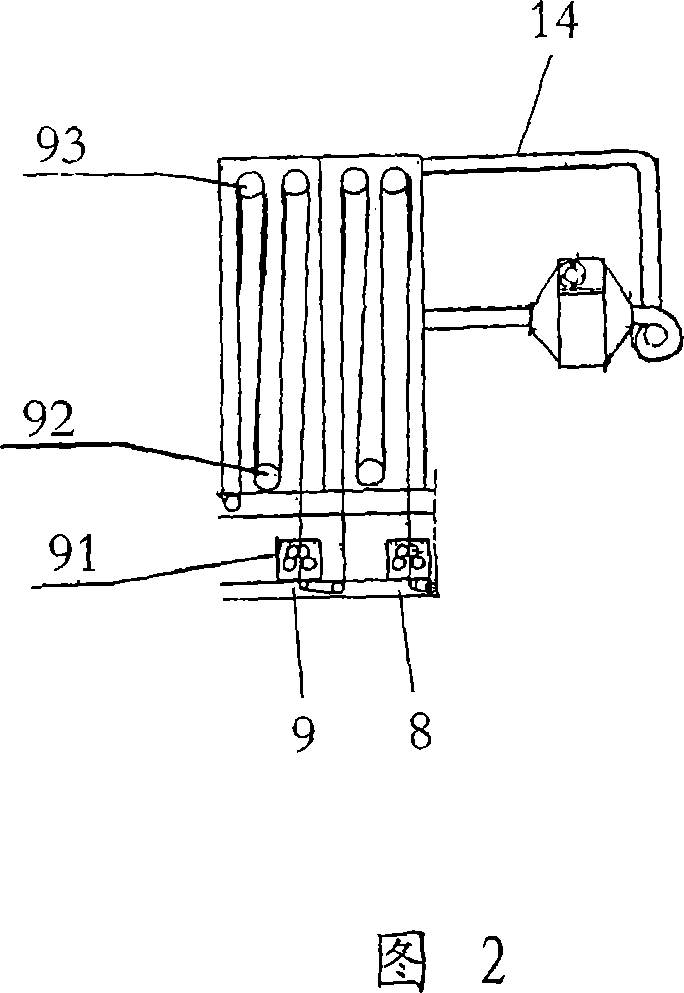

Vertical type reeled paper glazing device and the printing system thereof

ActiveCN101032881AFully automatedImprove printing qualityOffice printingPrinting press partsGear driveRolling paper

The vertical coil paper glazing machine includes one glazing head, a coil paper conveying and supporting roller and a stoving unit. The glazing head includes a frequency variable speed regulating motor with synchronous rotation with the printing unit during glazing operation and slowed rotation in no glazing operation, one driving gear driven with the motor, one glazing roller and one slurry roller driven with the driving gear, and one roller clutch driving unit. The present invention also discloses one kind of printing system with the vertical coil paper glazing machine. The present invention has raised printing quality, lowered production cost and other advantages.

Owner:浙江武义华东实业有限公司

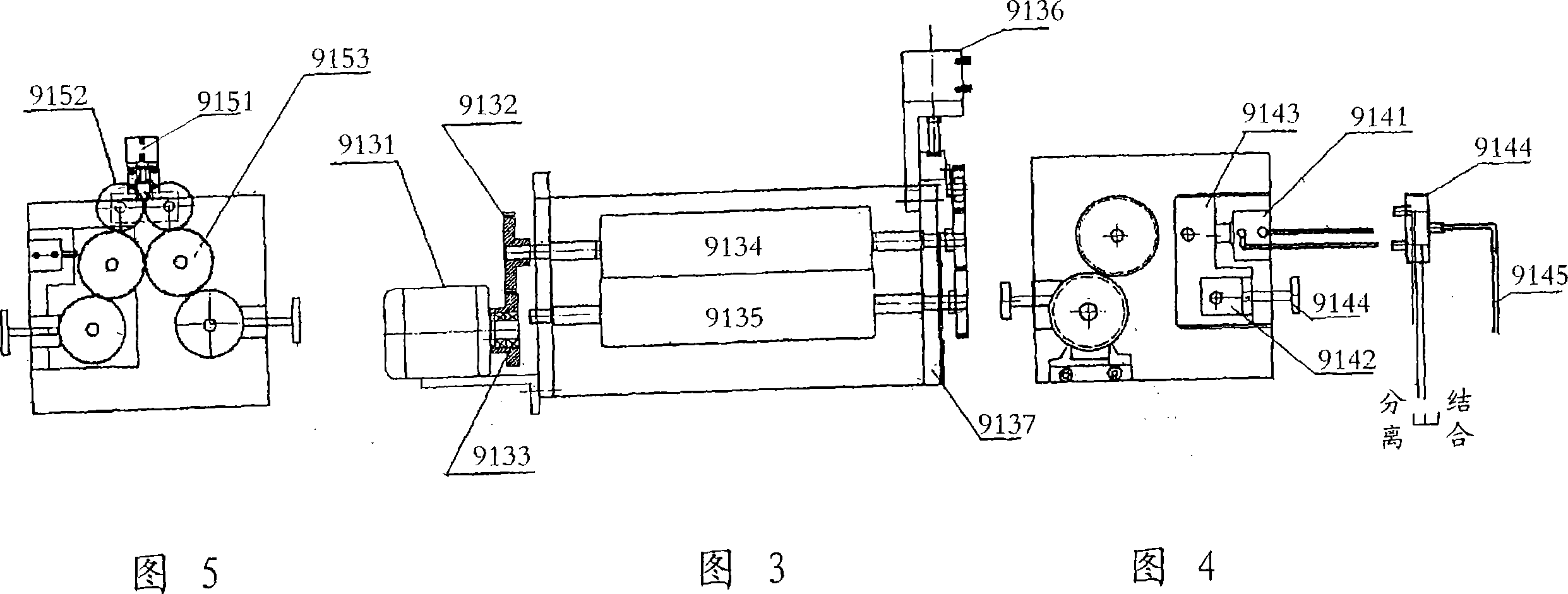

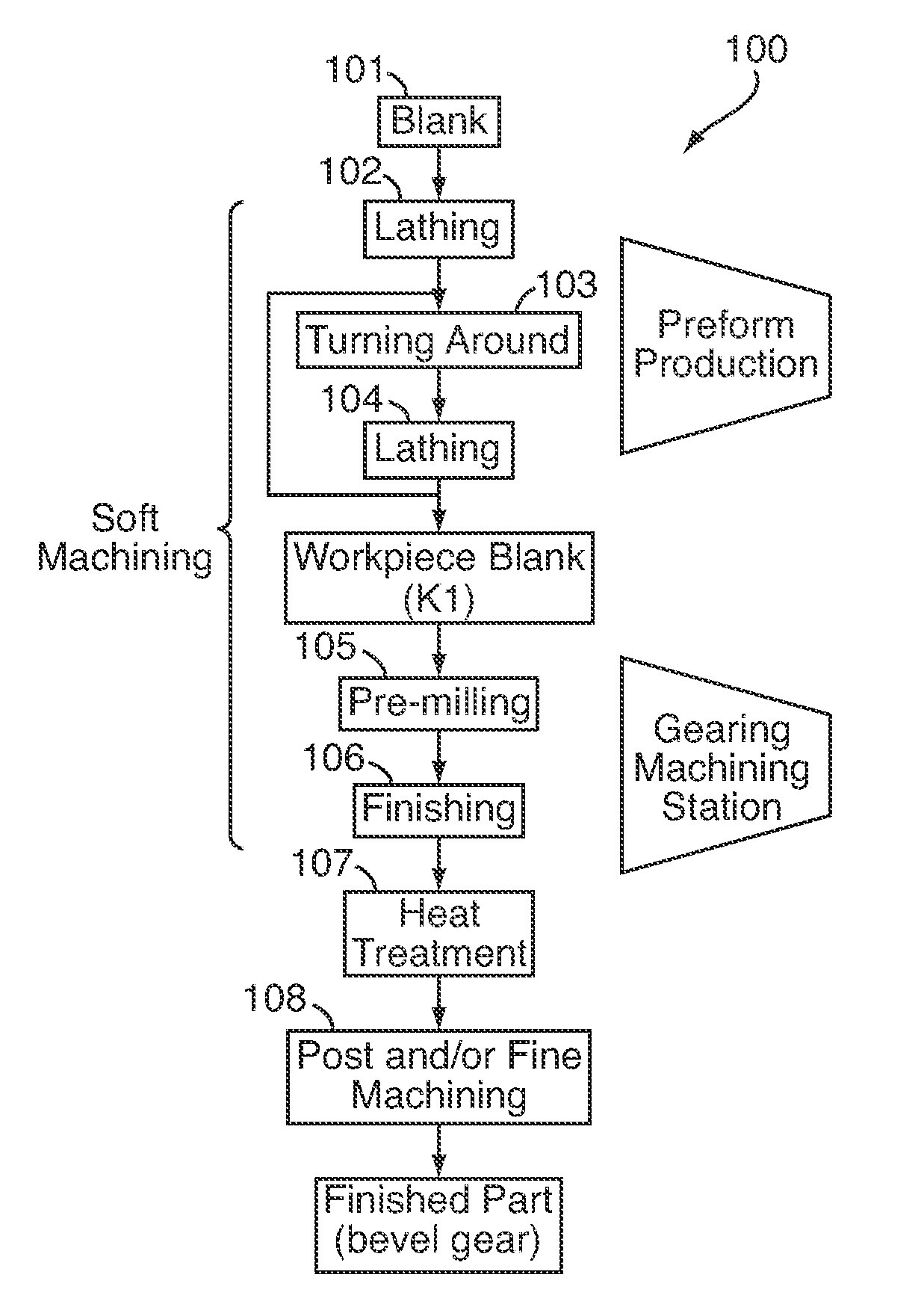

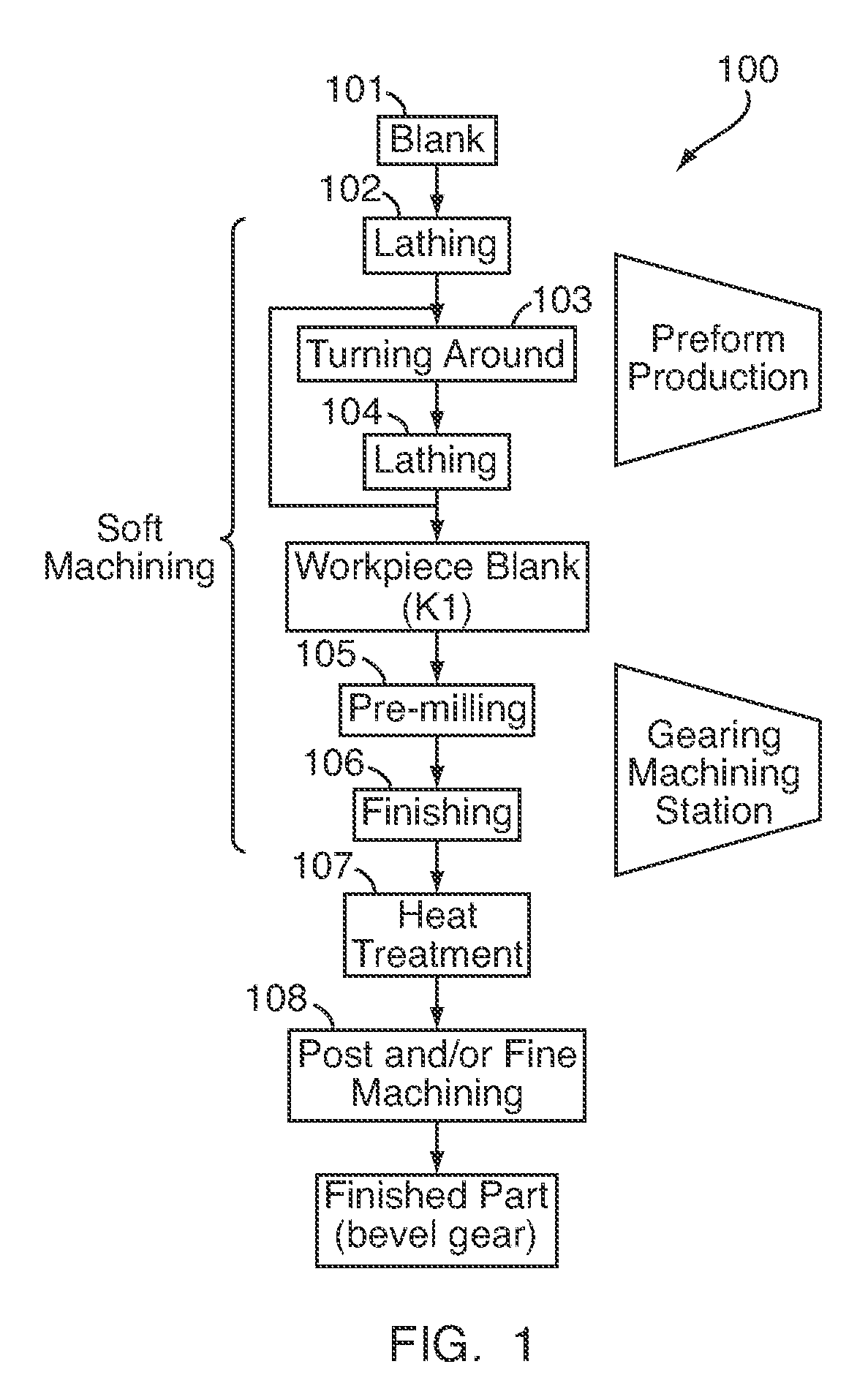

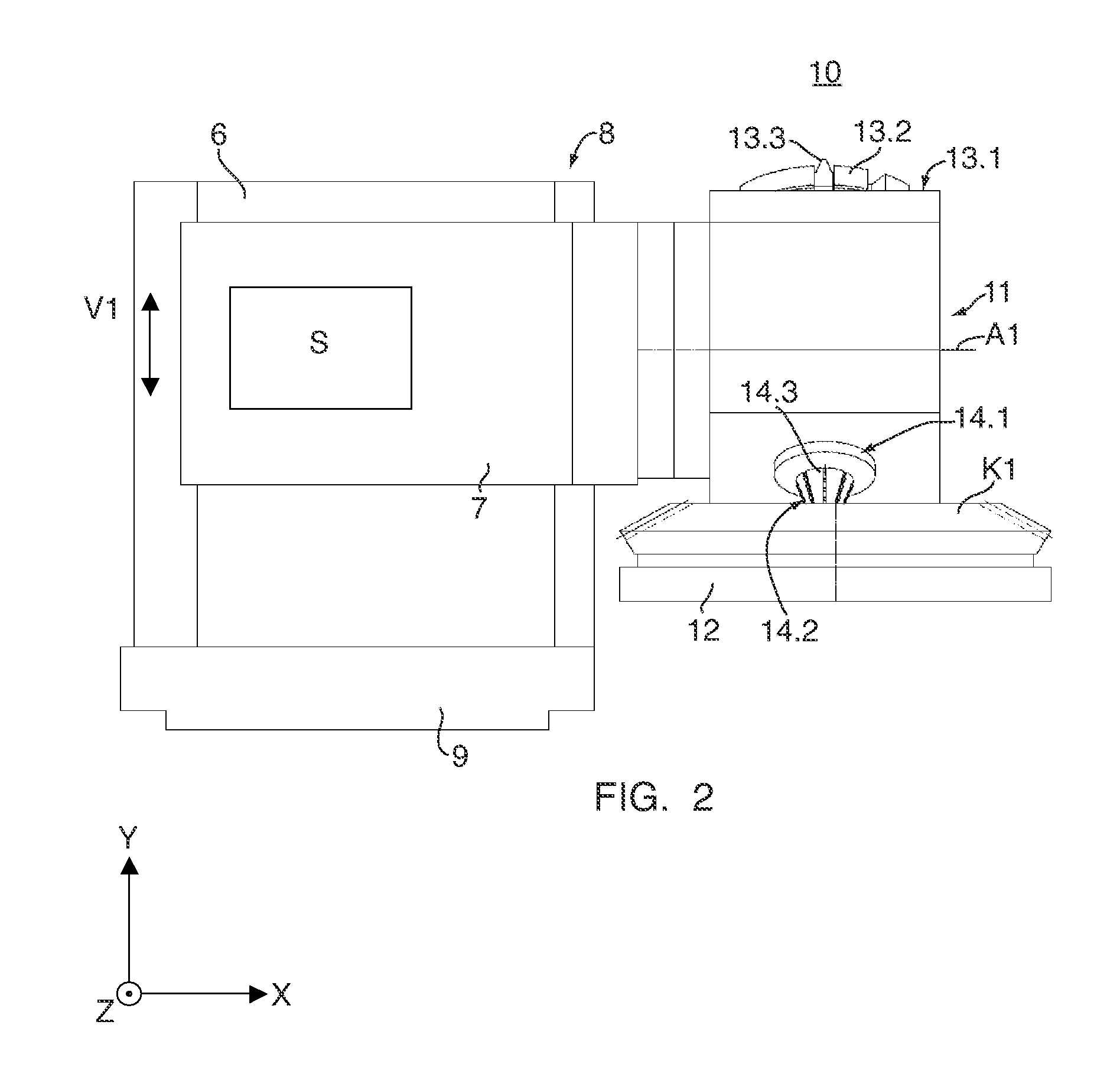

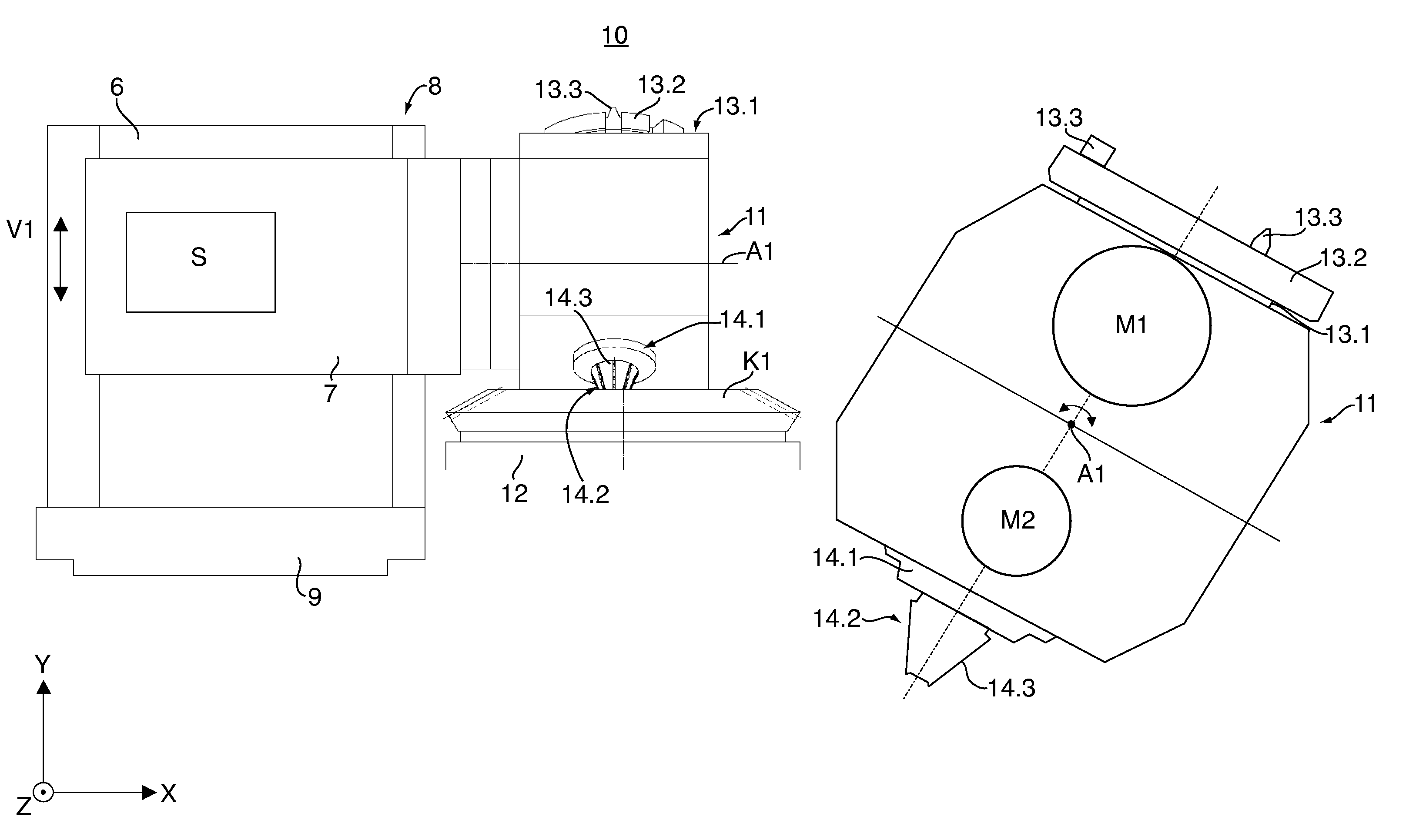

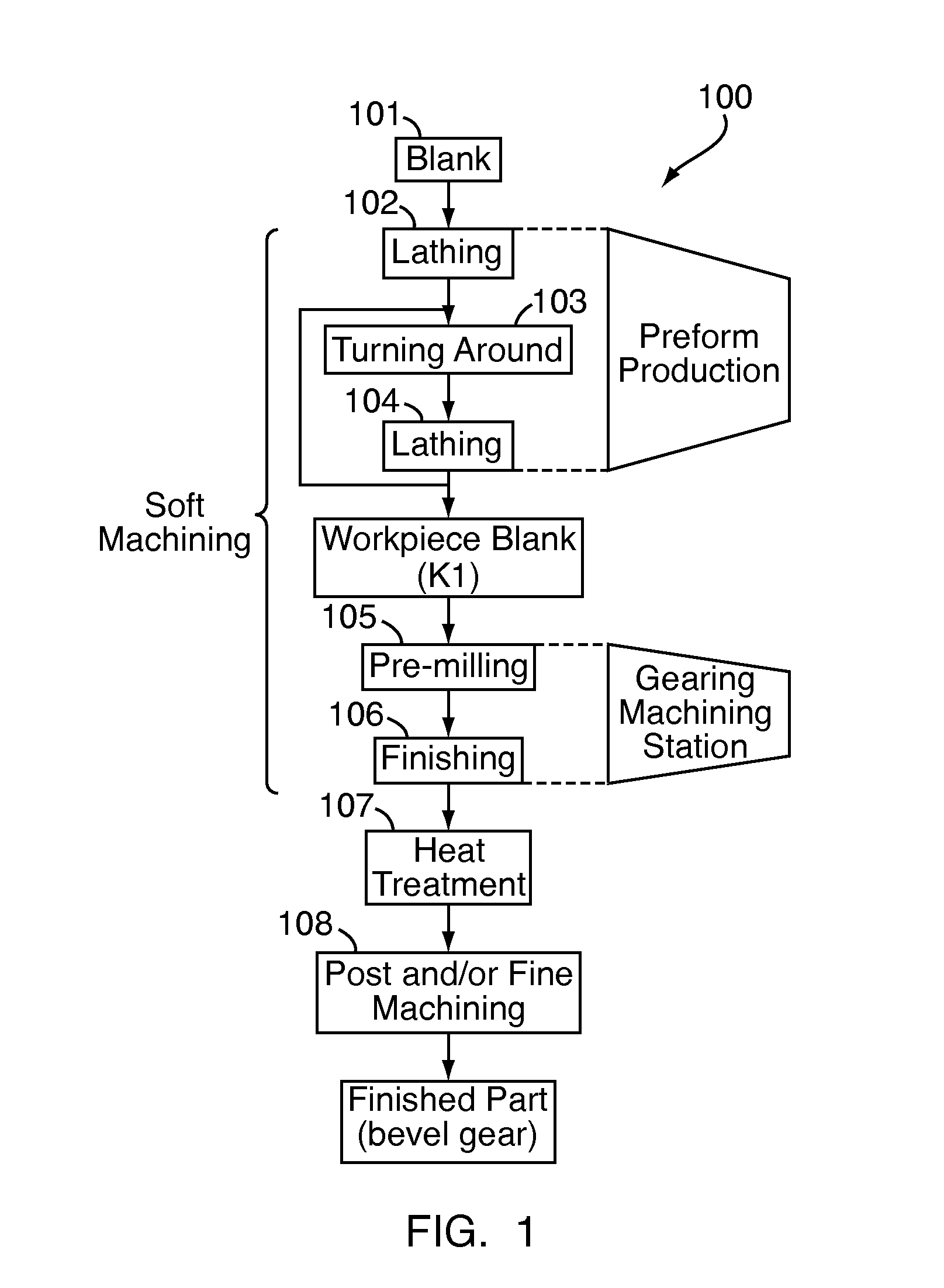

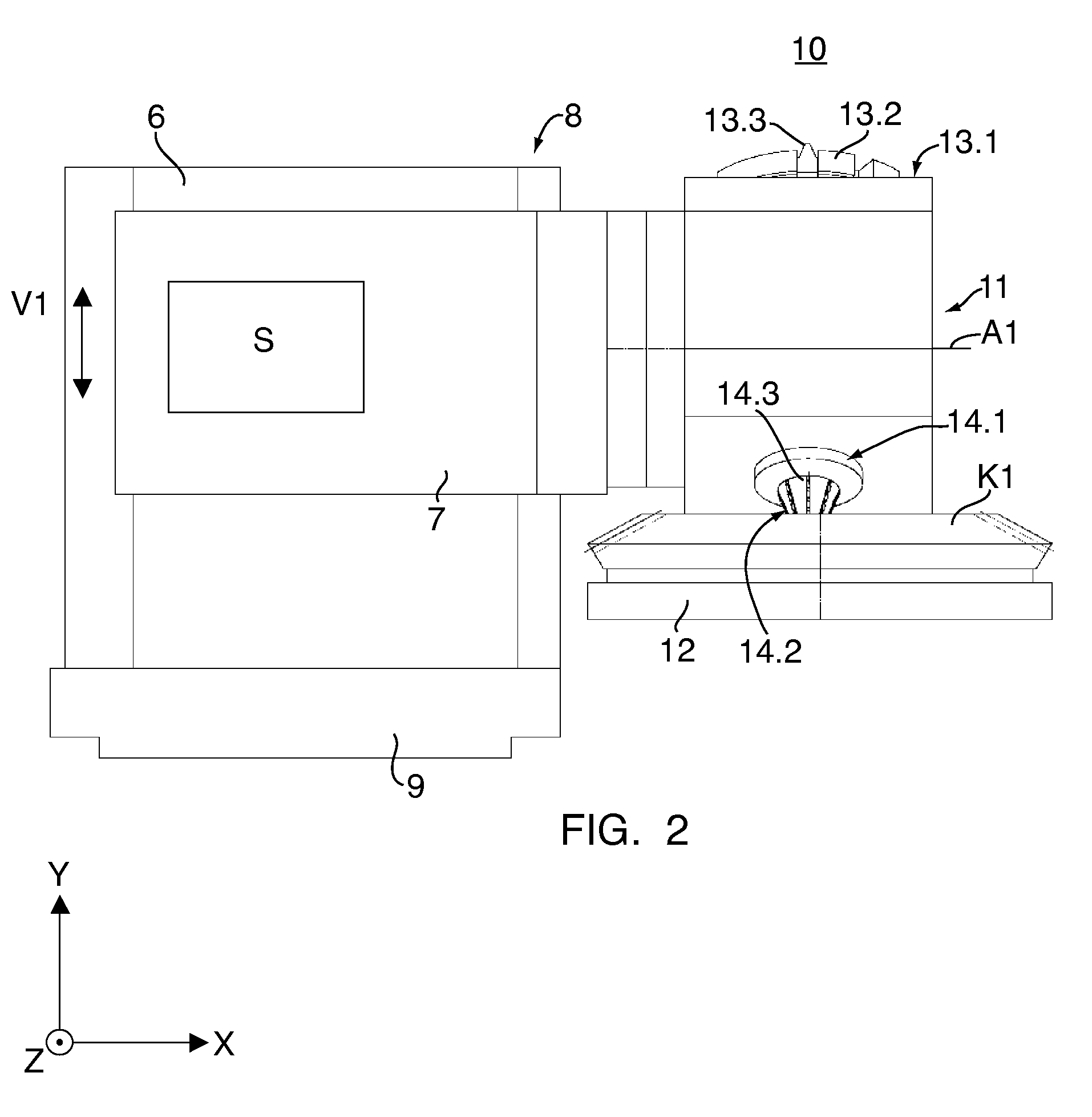

Device and method for soft machining of bevel gears and use of the device

InactiveUS20070283545A1Cost-effectiveAutomatic/semiautomatic turning machinesMilling machinesSlow rotationMachining process

A device (10) for soft machining of bevel gears, having a receptacle (12) for receiving a bevel gear blank (KI) and having a tool spindle (13.1) for receiving a cutter head (13.2). The device comprises a machining arm (11) having a pivot axis (Al) which has the tool spindle (13.1) for receiving the cutter head (13.2) on a first side and has a tool spindle (14.1) for receiving an end-milling cutter (14.2) on a second side. A CNC controller (S) puts the end-milling cutter (14.2) into rapid rotation to cut a predefined number of tooth gaps on the bevel gear blank (K1). After the machining arm (11) is pivoted, the cutter head used as the bevel gear finishing tool (13.2) is used. It is put into slower rotation to machining the bevel gear blank (K1) using the bevel gear finishing tool (13.2) in a post-machining process

Owner:KLINGELNBERG AG

Tire pressure monitoring system without requirement of assembly

The invention relates to a tire pressure monitoring system without requirement of assembly. According to the system, a tire pressure monitoring sensor capable of movement inside the tire comprises a housing, wherein a pressure sensing / sending unit, one or a plurality of batteries, and an antenna for sending a signal of an internal tire pressure instruction are accommodated in the housing. In one embodiment, components are assembled inside the housing, such that the centre of gravity and the geometric center of the housing are the same. During the tire rotation process, a monitor independently rotates inside the tire, and is particularly applicable for the tire with the characteristic of slow rotation, such as a tire used in a gantry system. Optionally the pressure monitoring components are assembled inside the housing, such that the centre of gravity deviates the geometric center of the housing. With the centripetal force generated during the tire rotation process, the monitor and the tire rotate together, and the monitor is applicable for the tire with the characteristic of rapid rotation, such as an automobile tire. The tire pressure monitoring system comprises the monitor and a receiver, wherein the receiver is positioned outside the tire, and is provided for receiving the monitoring signal.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Apparatus and method for connecting wellbore tubulars

The present invention discloses an apparatus and method for controlling a power tong unit having a power spinner and, in a preferred embodiment, three power jaws. The control system controls grip pressure applied by a selected power jaw to a first wellbore tubular to provide a relatively reduced grip pressure when the power spinner is activated to thereby rotate a second wellbore tubular at a relatively high rotation speed but with a relatively low torque. The control system applies a relatively high grip pressure to two selected power jaws used for applying high torque but at a relatively slow rotation speed for final making up or initial breaking out of the wellbore tubulars with respect to each other.

Owner:FRANKS INT

Device and method for soft machining of bevel gears and use of the device

InactiveUS7461441B2Cost-effectiveAutomatic/semiautomatic turning machinesMilling machinesSlow rotationEngineering

Owner:KLINGELNBERG AG

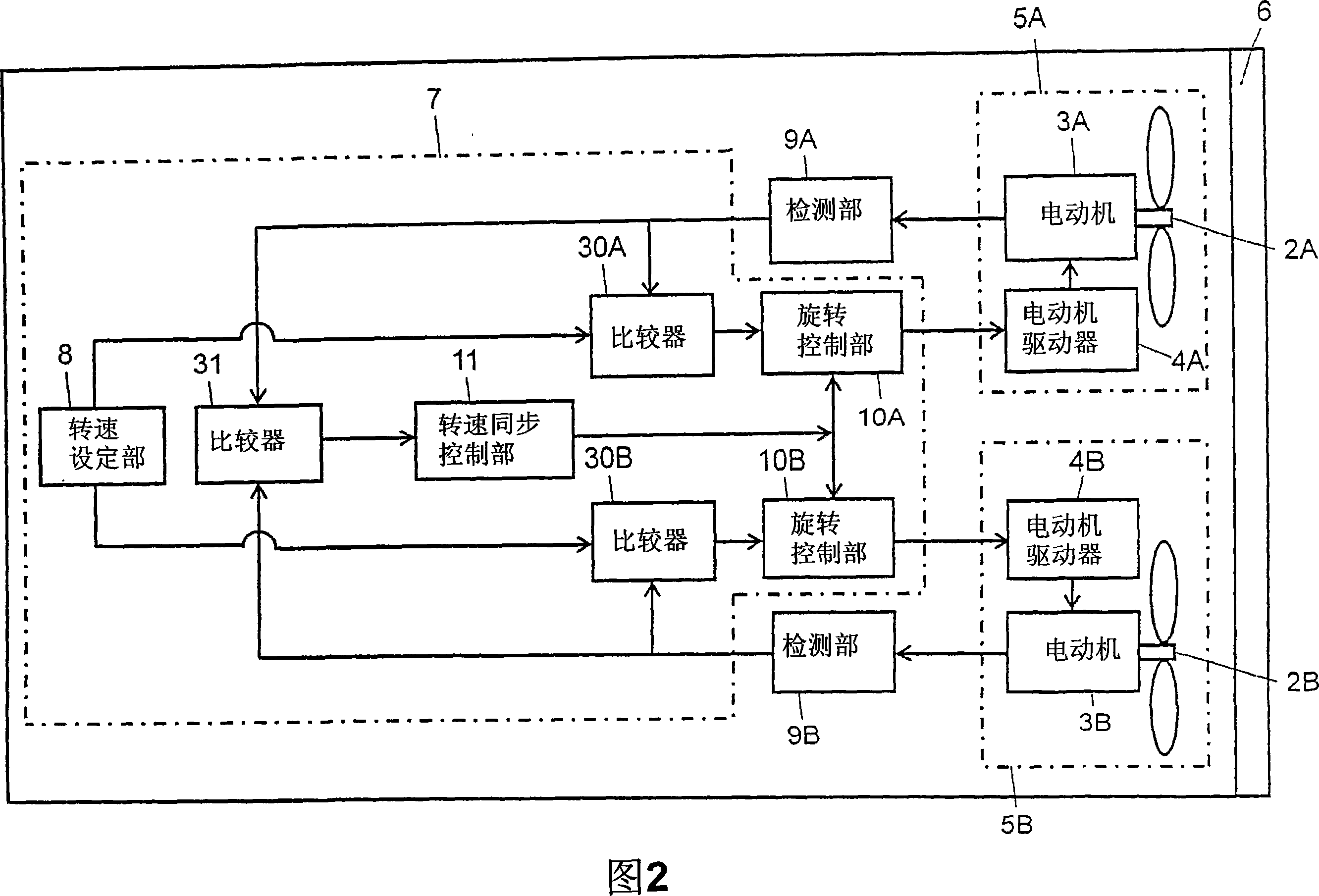

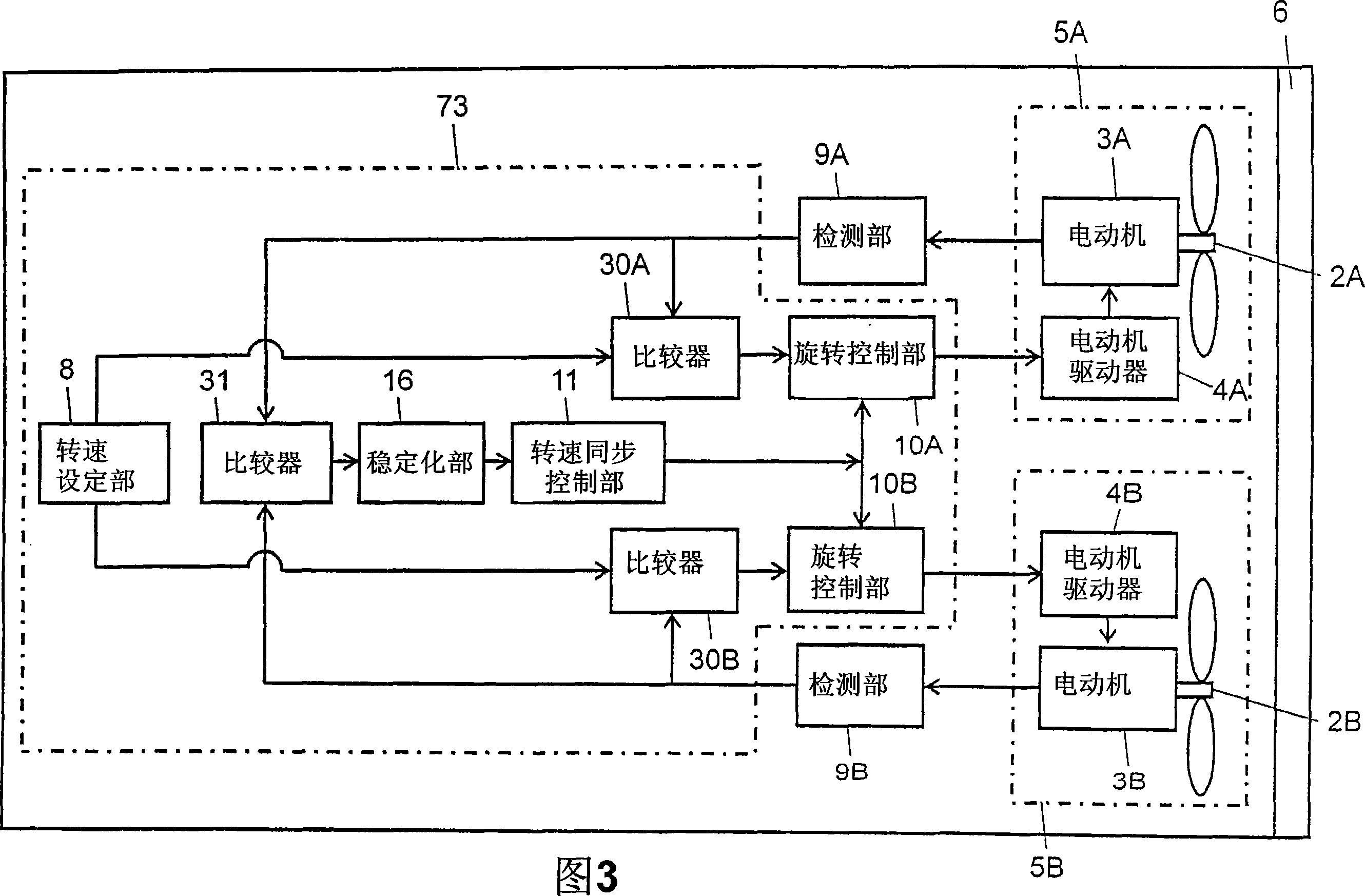

Fan filter unit

ActiveCN101107482ASuppress beepConsistent speedSpace heating and ventilation safety systemsLighting and heating apparatusSynchronous controlSlow rotation

A fan filter unit comprises a plurality of fan motors, a plurality of detecting sections, a body control section, and a filter. Each fan motor includes a fan and a motor. The body control section performs feedback control of each fan motor so that its detection rotation speed coincides with a set rotation speed based on a rotation speed detected at the detecting section. When a rotation speed detection value at any detecting section is smaller than that at other detecting sections, rotation speed synchronization control is carried out for matching the rotation speed of other fan motors to that of the fan motor of slow rotation speed.

Owner:PANASONIC CORP

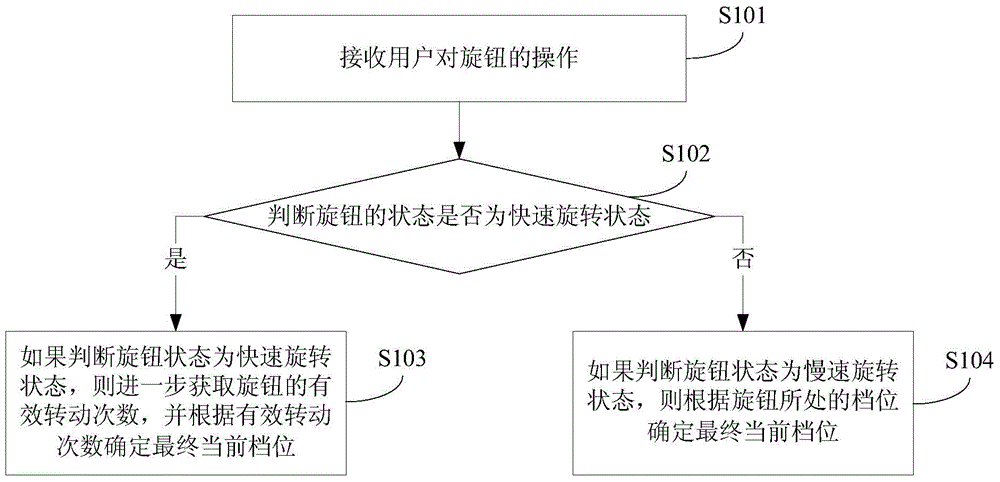

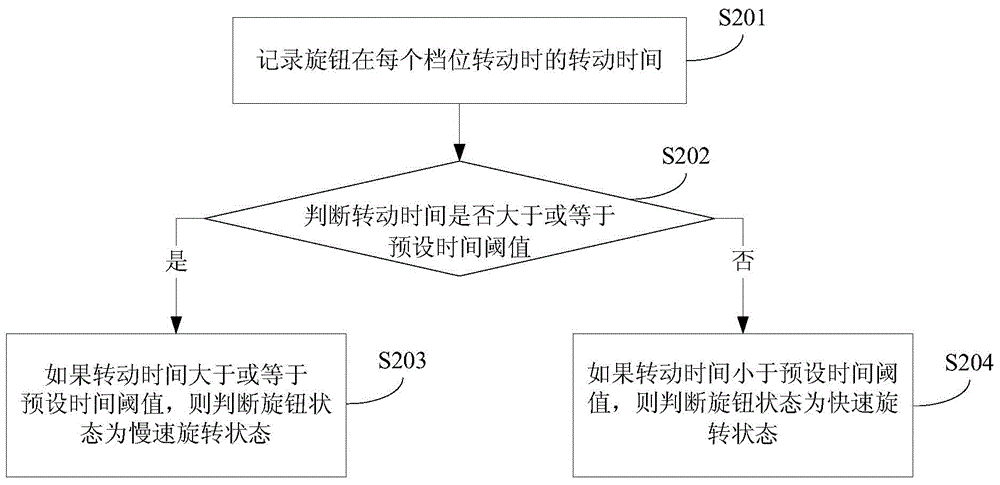

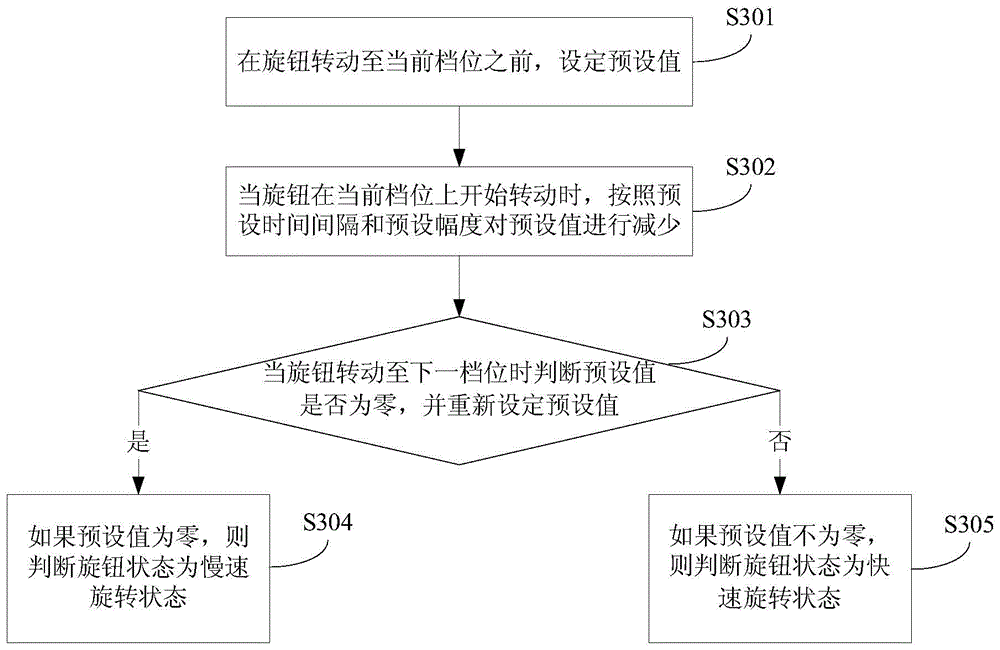

Turn button control method and device of household electrical appliance

The invention discloses a turn button control method and device of a household electrical appliance. The method comprises the following steps that operation of a turn button by a user is received; whether the turn button is in a rapid rotation state is determined; if yes, the effective rotation frequency of the turn button is further obtained, and a present shift is determined according to the effective rotation frequency; and if the turn button is in a slow rotation state, the present shift is determined according to the shift of the turn button. Thus, the response speed of the household electrical appliance when the turn button is turned rapidly is adjusted to the degree that can be accepted by human, and the operation experience of the household electrical appliance is greatly improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

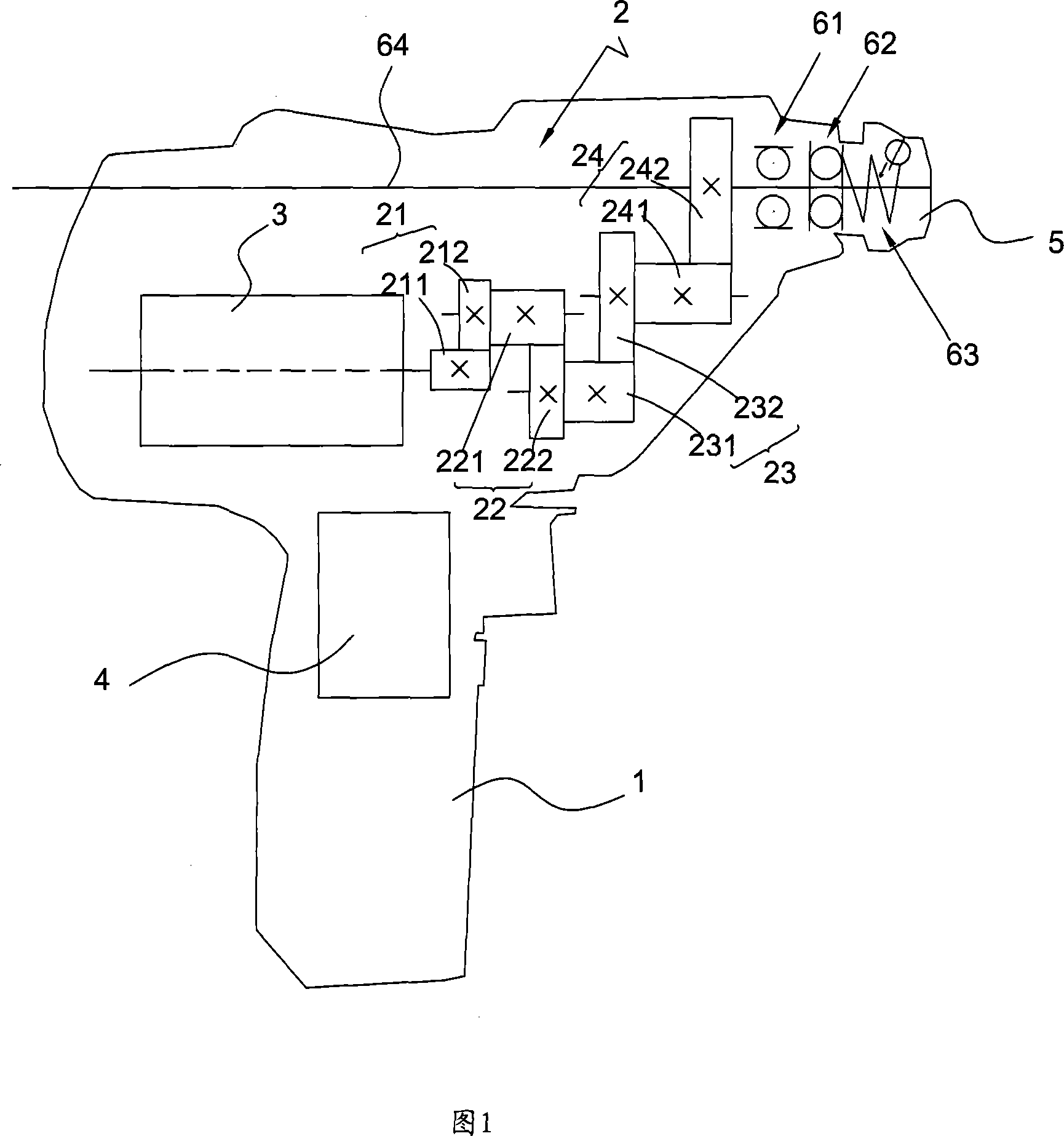

Medical electric drill

A medical electric drill with slow rotation speed is composed of a shell, a drill bit holder, a drive unit and an electric motor for driving said drill bit holder via said drive unit. Said drive unit is an N-stage gear-type speed reducer, which features hat the mutually engaged big and small gears in each stage are coaxial.

Owner:苏州华盛医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com