Tire pressure monitoring system without requirement of assembly

A technology of air pressure monitoring and tires, which is applied in tire measurement, tire parts, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

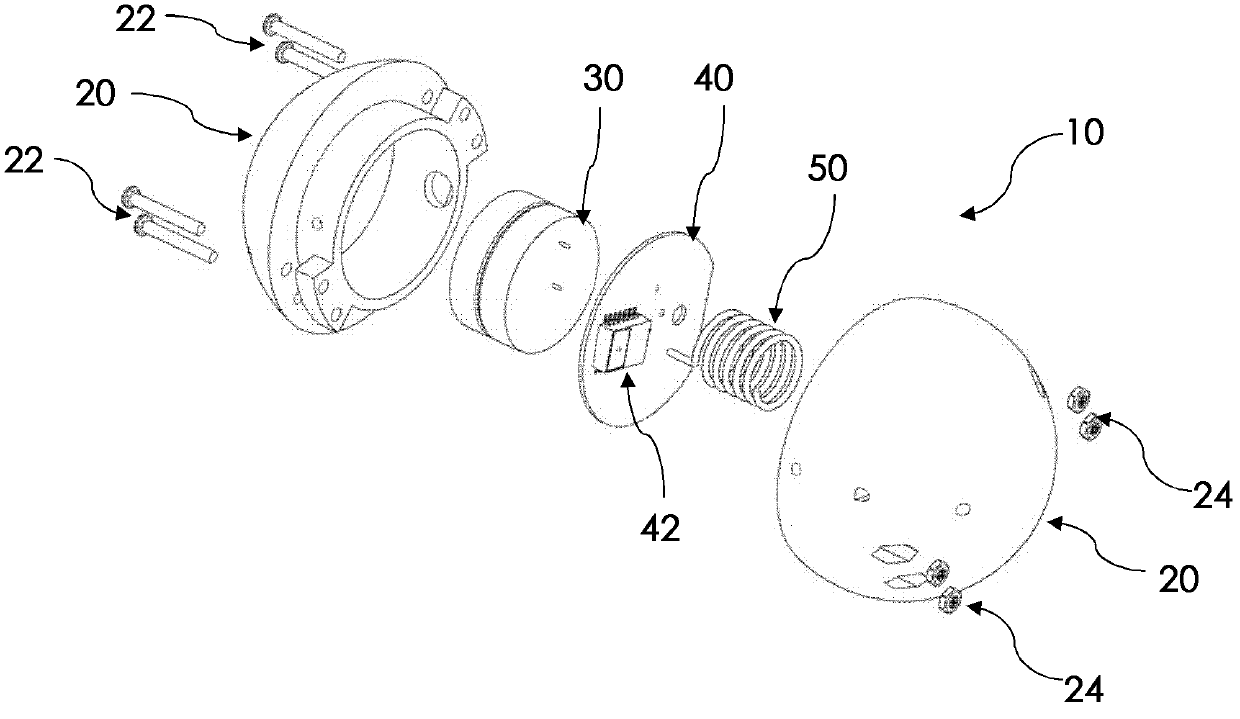

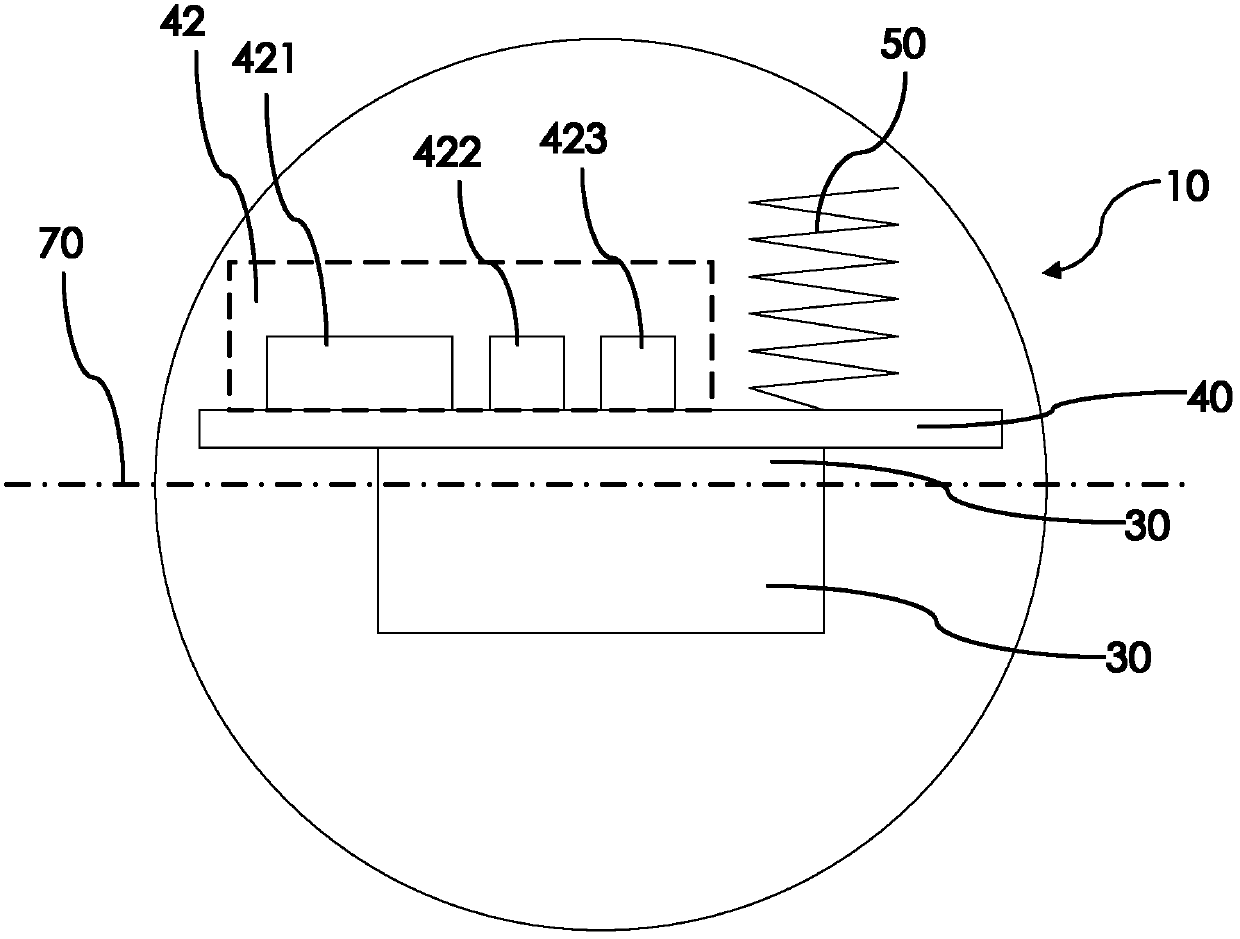

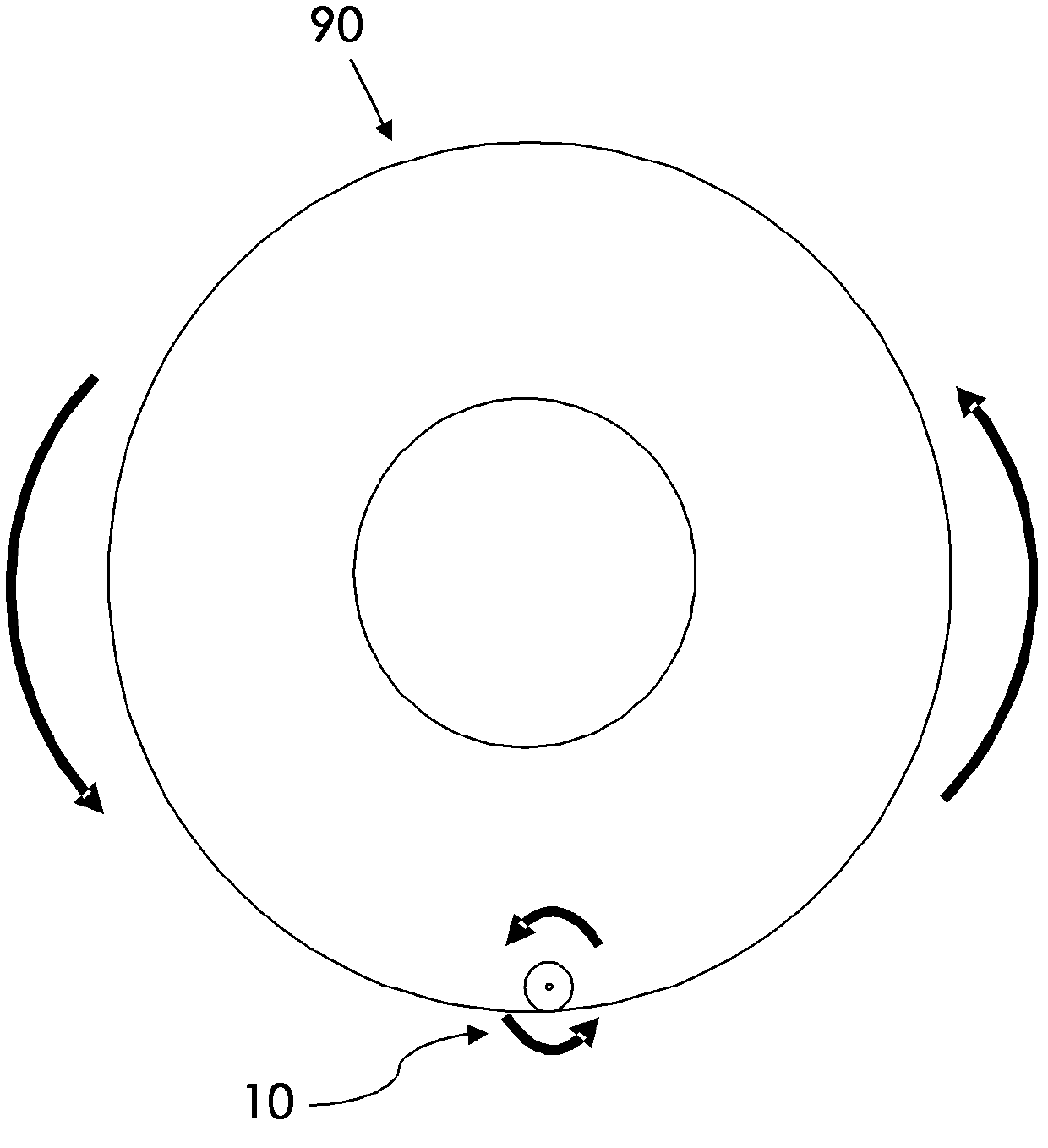

[0020] In particular, like reference numerals are shown in the figures to indicate identical or similar parts in each of the several views. figure 1 A tire pressure monitor 10 is described, configured to be movable inside the tire (either inside a tubeless tire or inside the inner tube of a tubed tyre), i.e. the sensor 10 need not be fixedly fitted to the edge of the tire or any part of the tire itself at a single location.

[0021] The sensor 10 includes a housing 20, such as figure 1 Shown are two parts of the housing fastened together by fasteners 22 . The fastener 22 is shown as a threaded fastener with a lock 24 . However, it should be understood that the portioning of the enclosure is not critical and that the enclosure is shown for ease of assembly, other configurations such as those with an opening at one end by a snap-hinged door, or any other configuration that allows insertion of components into the enclosure may For sensor 10.

[0022] Housing 20 includes at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com