Patents

Literature

406 results about "Tire rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire rotation is the practice of moving the wheels and tires of an automobile from one position to another, to ensure even tire wear. Even tire wear is desirable to extend the useful life of a set of tires.

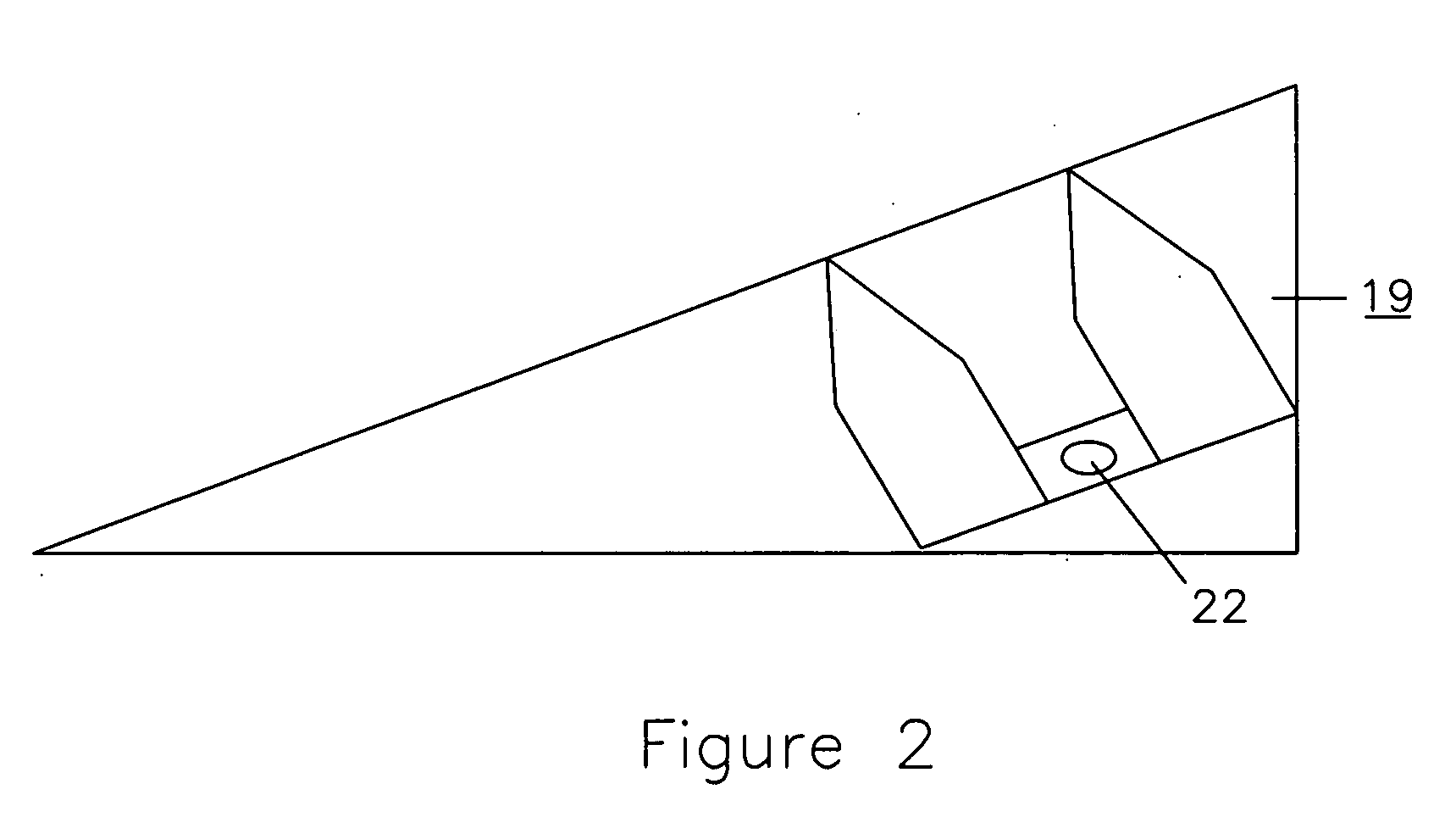

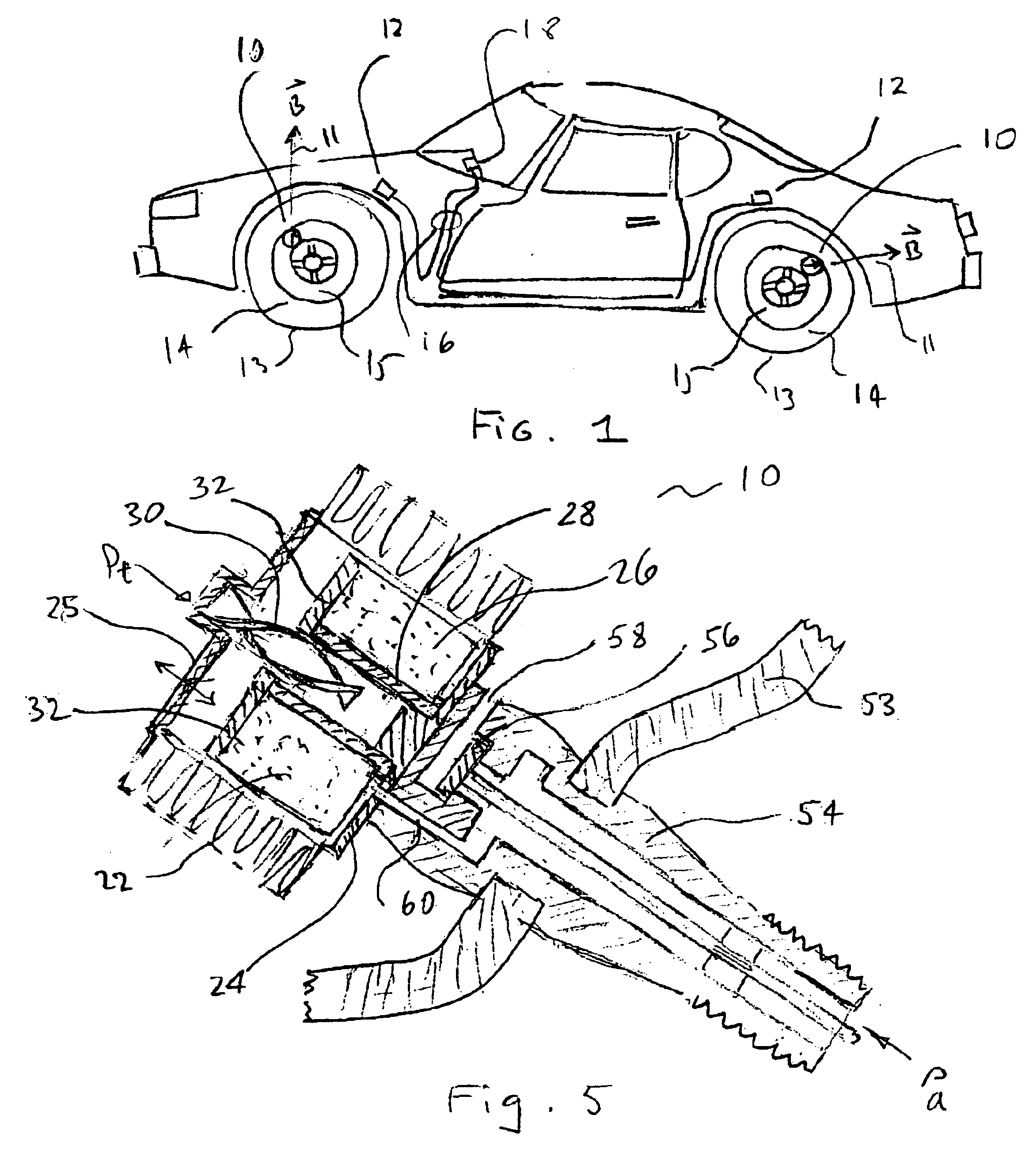

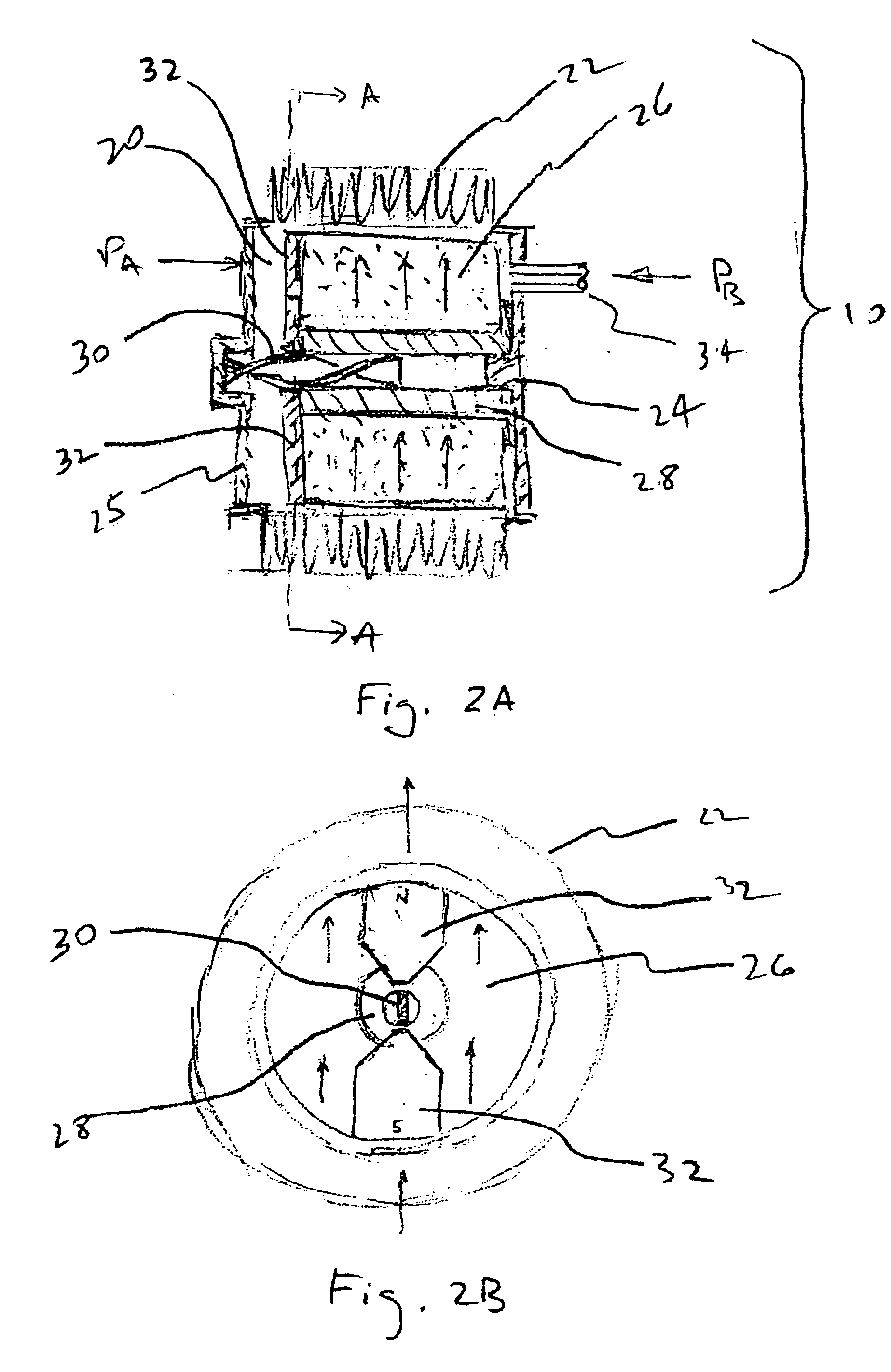

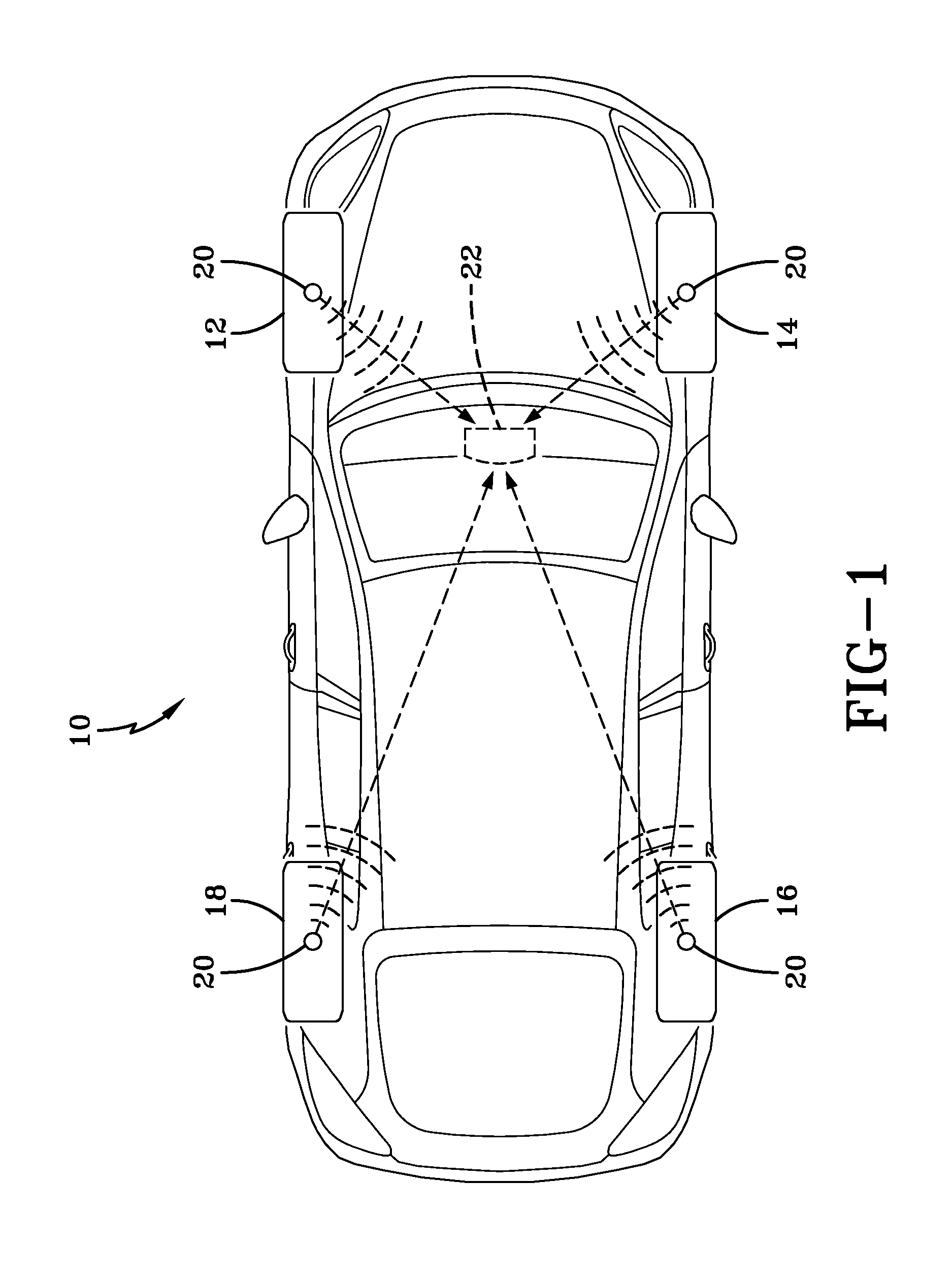

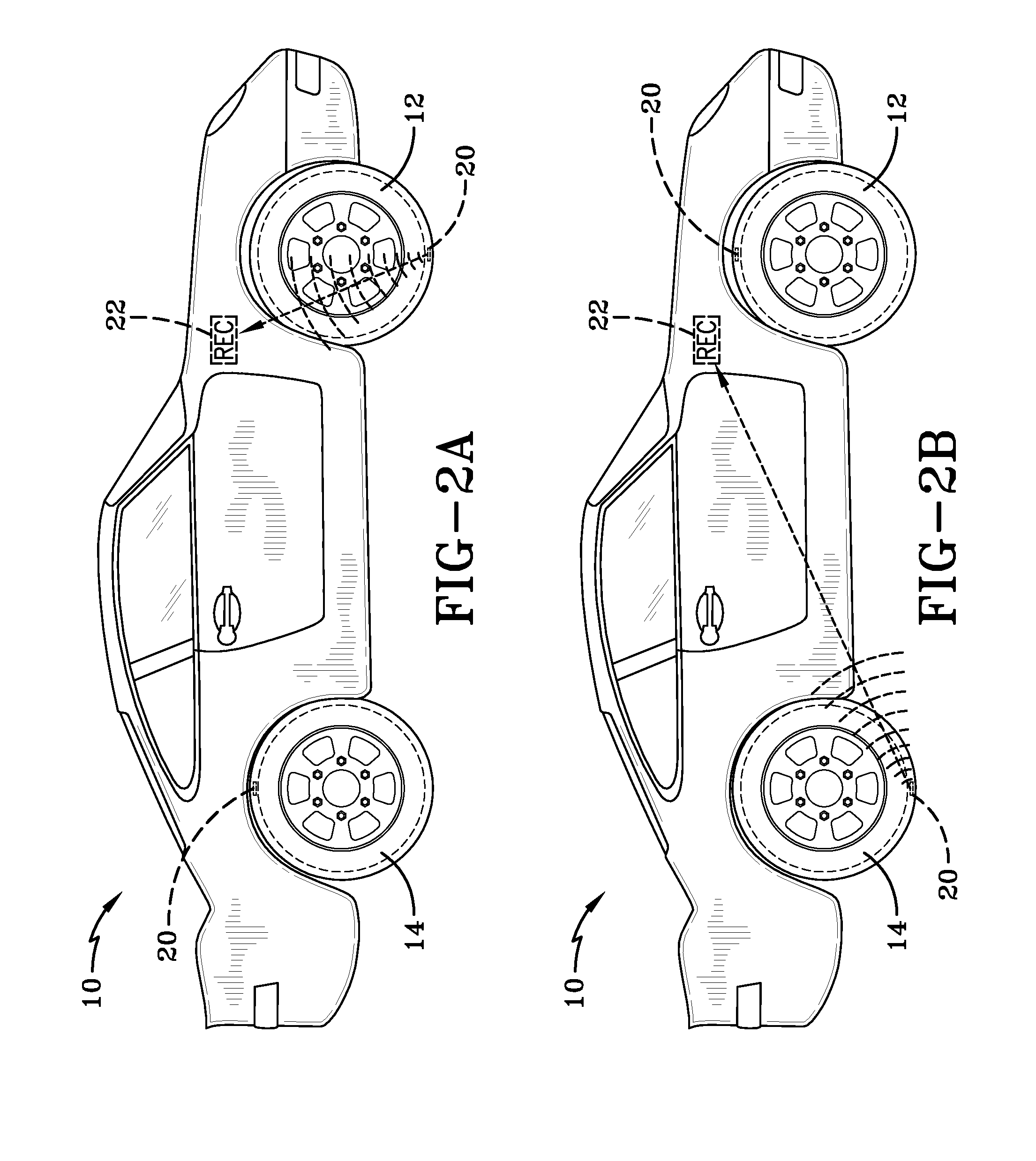

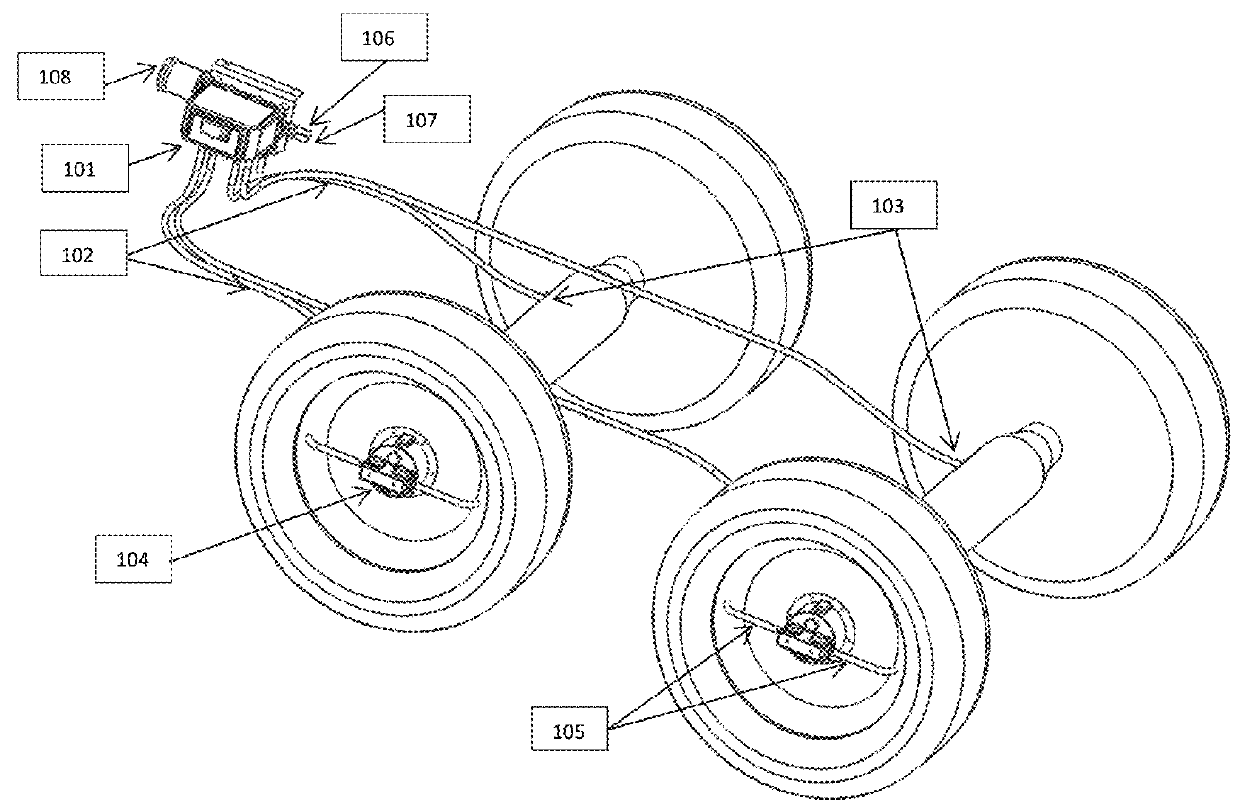

Method and apparatus for determining tire condition and location

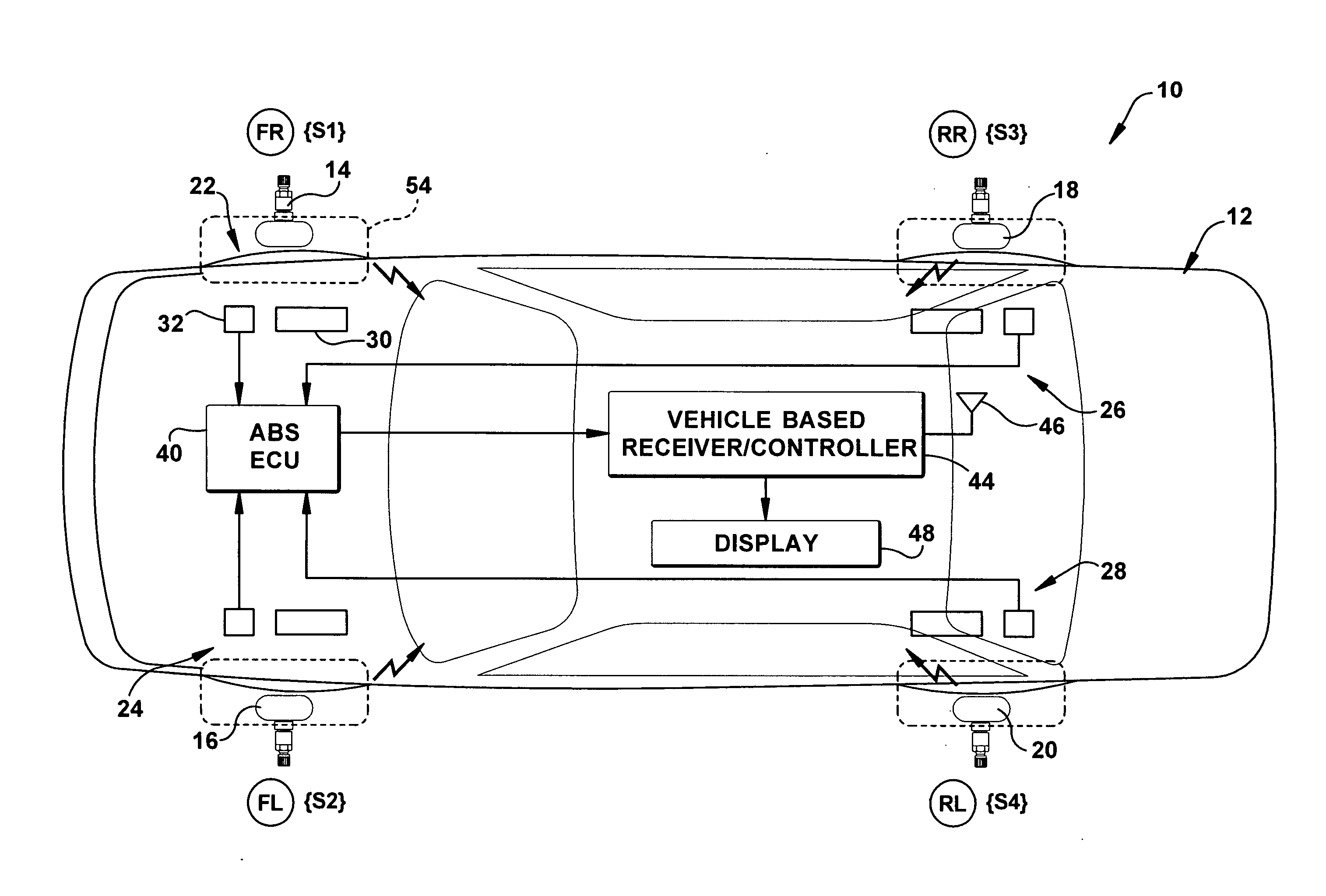

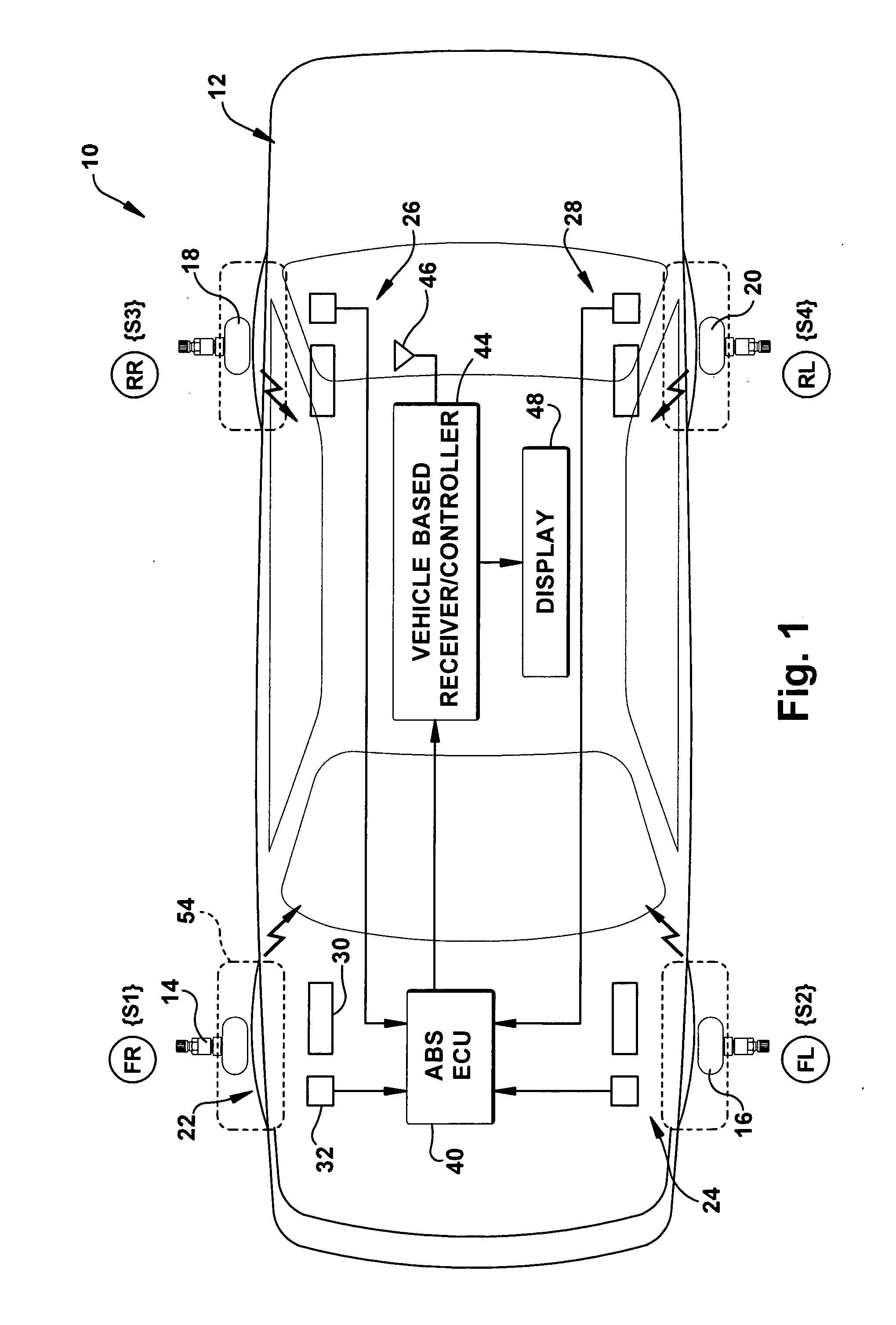

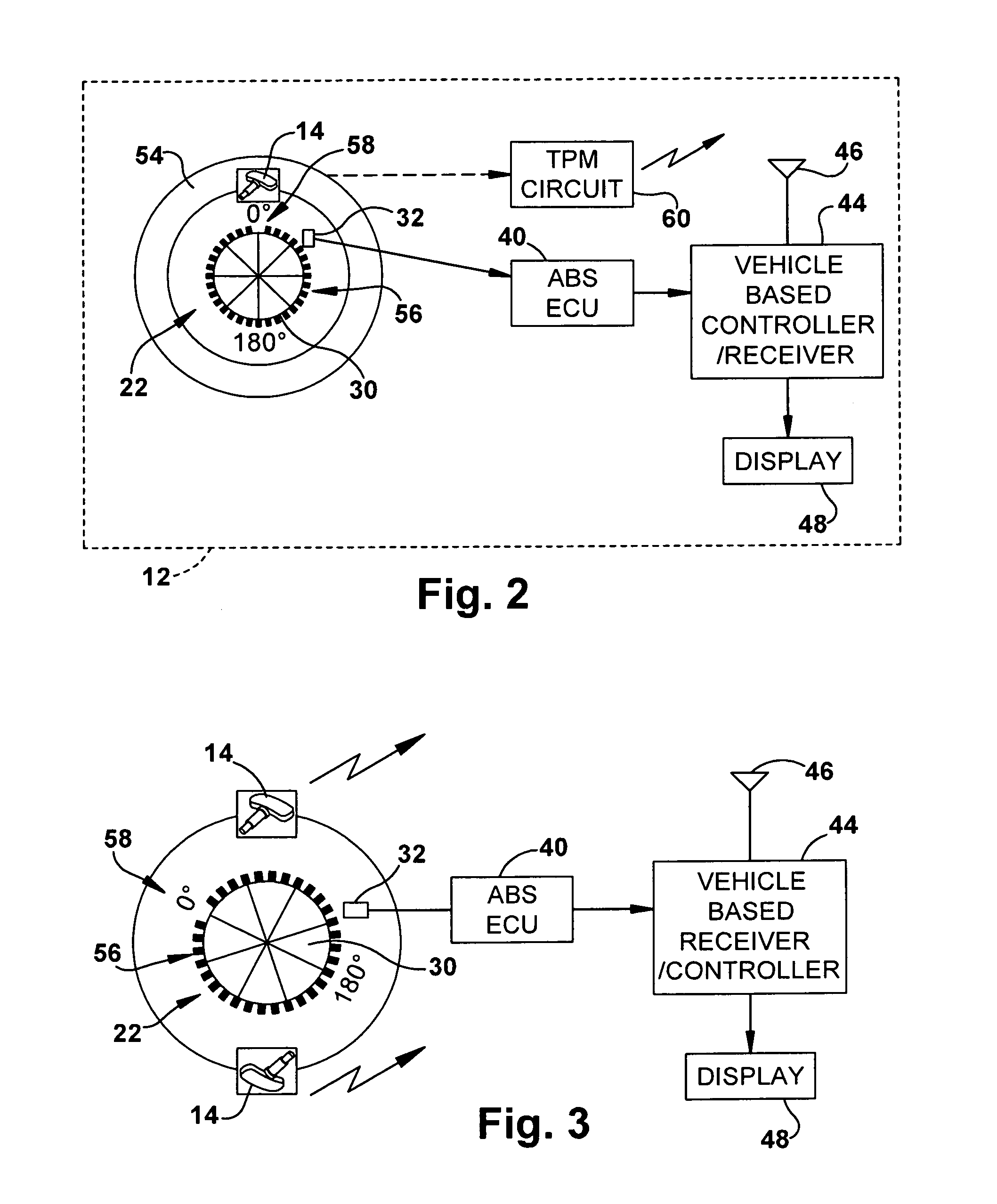

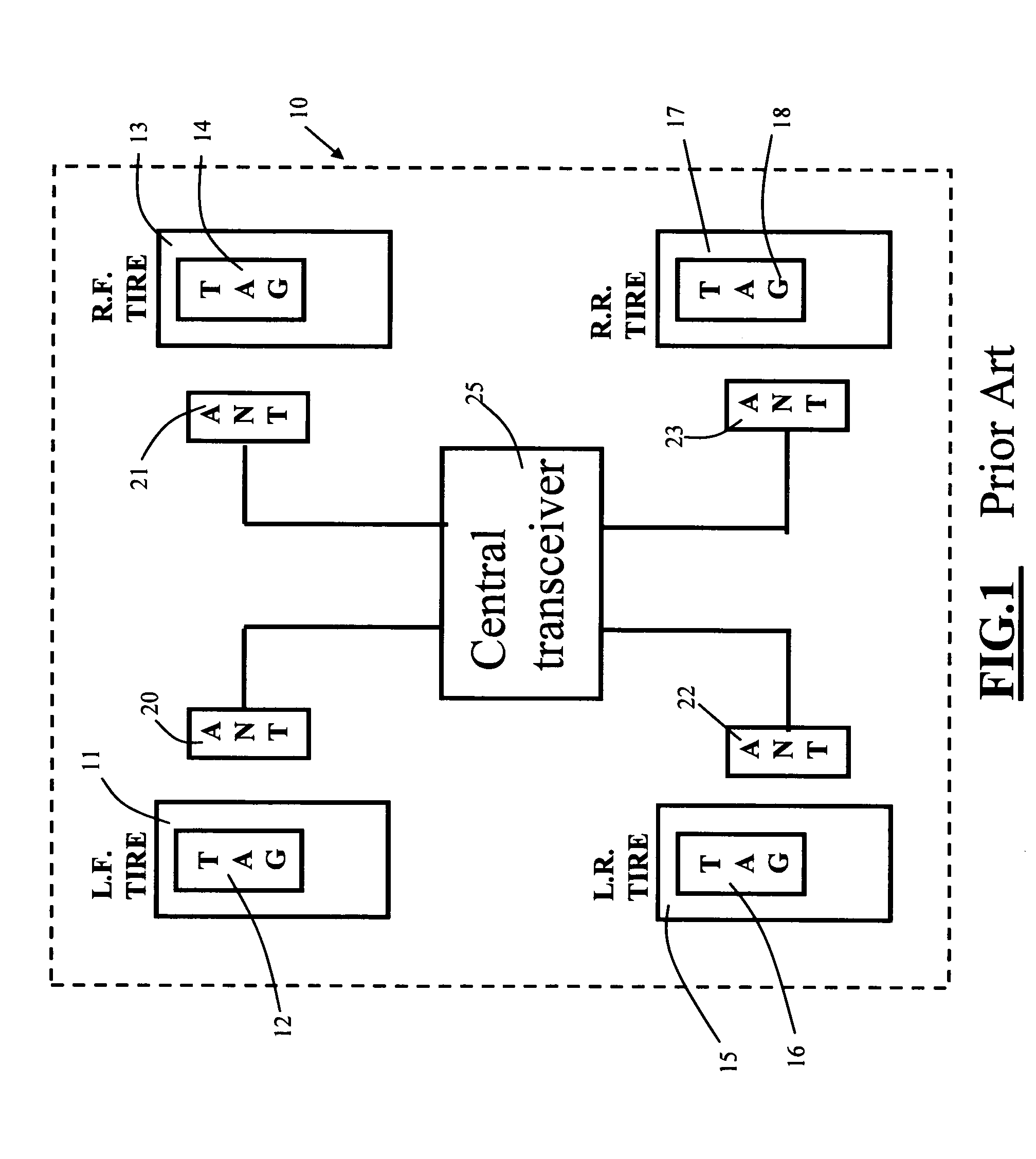

An apparatus (10) determines a tire condition and location on a vehicle (12) including a tire-based sensing unit (14), a plurality of tires (54) on the vehicle having an associated tire-based sensing unit, each tire-based sensing unit (14) including, a first tire rotation sensor (66) mounted for rotation with the tire (54) and for providing a first tire rotation signal (80) each time the tire passes one of at least two predetermined rotational positions during tire rotation, a tire condition sensor (82) for sensing a tire condition and for providing a tire condition signal indicative thereof and an unique tire identification indicator, a transmitter (86) for transmitting the tire condition signal and the unique tire identification indicator, and a controller for controlling the transmitter so that the transmission of the tire condition signal and the unique tire identification indicator occurs when the first tire rotation signal indicates the tire has reached one of the at least two predetermined rotational positions during tire rotation. The apparatus further includes a second tire rotation sensor (22) mounted external of the tire for sensing tire rotation and for providing a second tire rotation signal indicative of incremental angular position of the tire relative to a reference. A vehicle-based receiver (44) receives the transmitted tire condition signal, the unique tire identification indicator, and the second tire rotation signal and correlates reception of the tire condition signal with the second tire rotation signal so as to associate the unique tire identification indicator with a particular tire location on the vehicle.

Owner:TRW AUTOMOTIVE US LLC

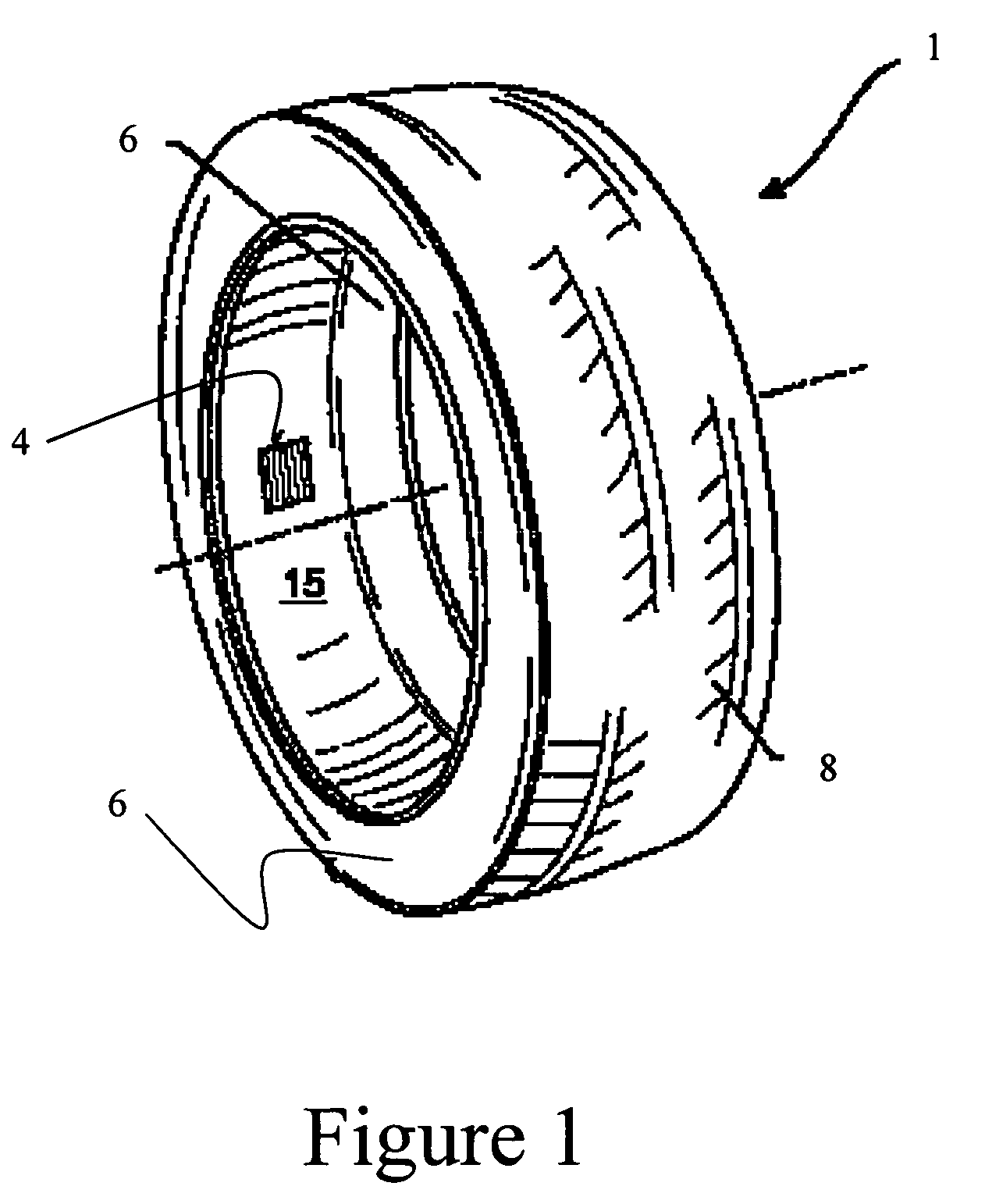

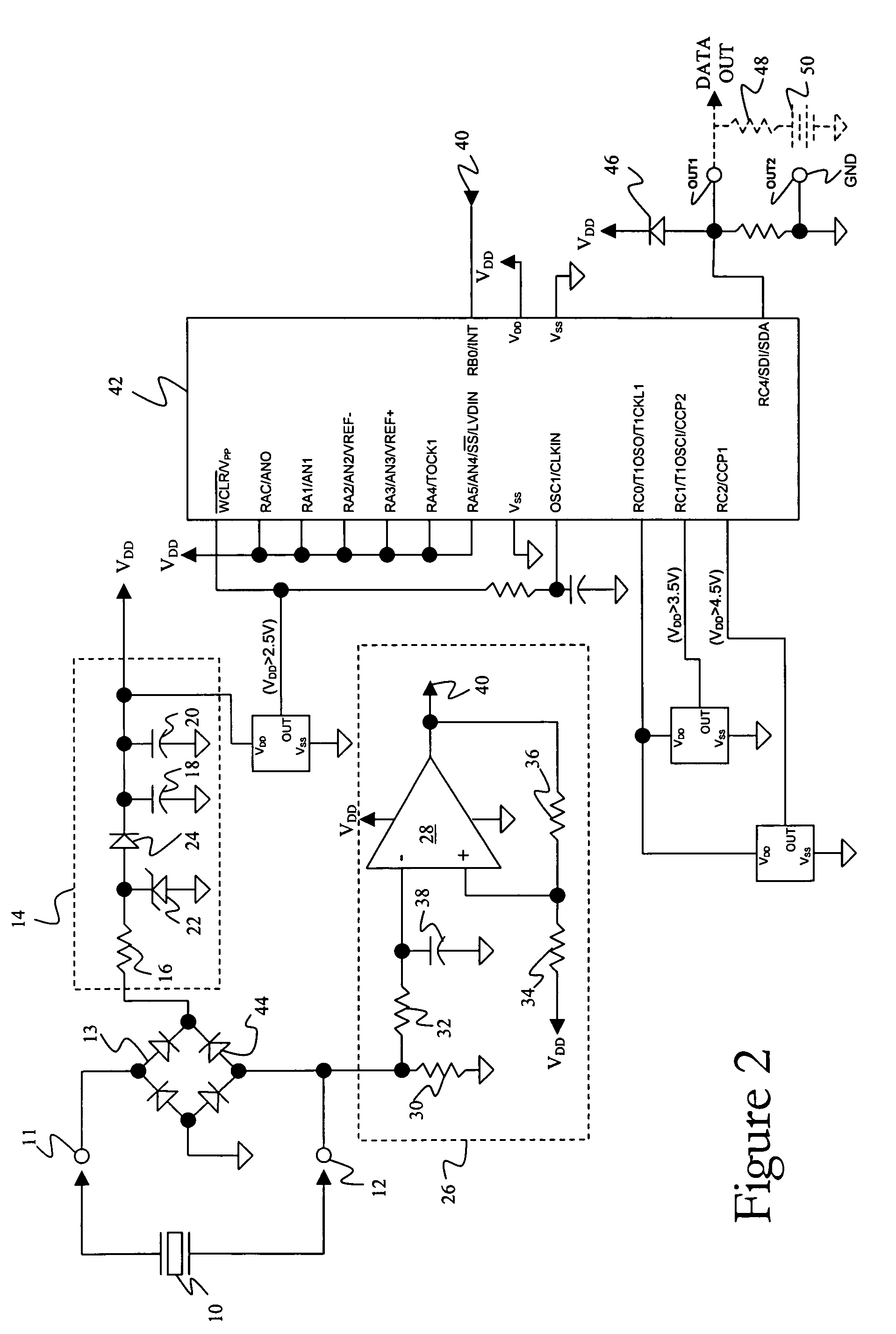

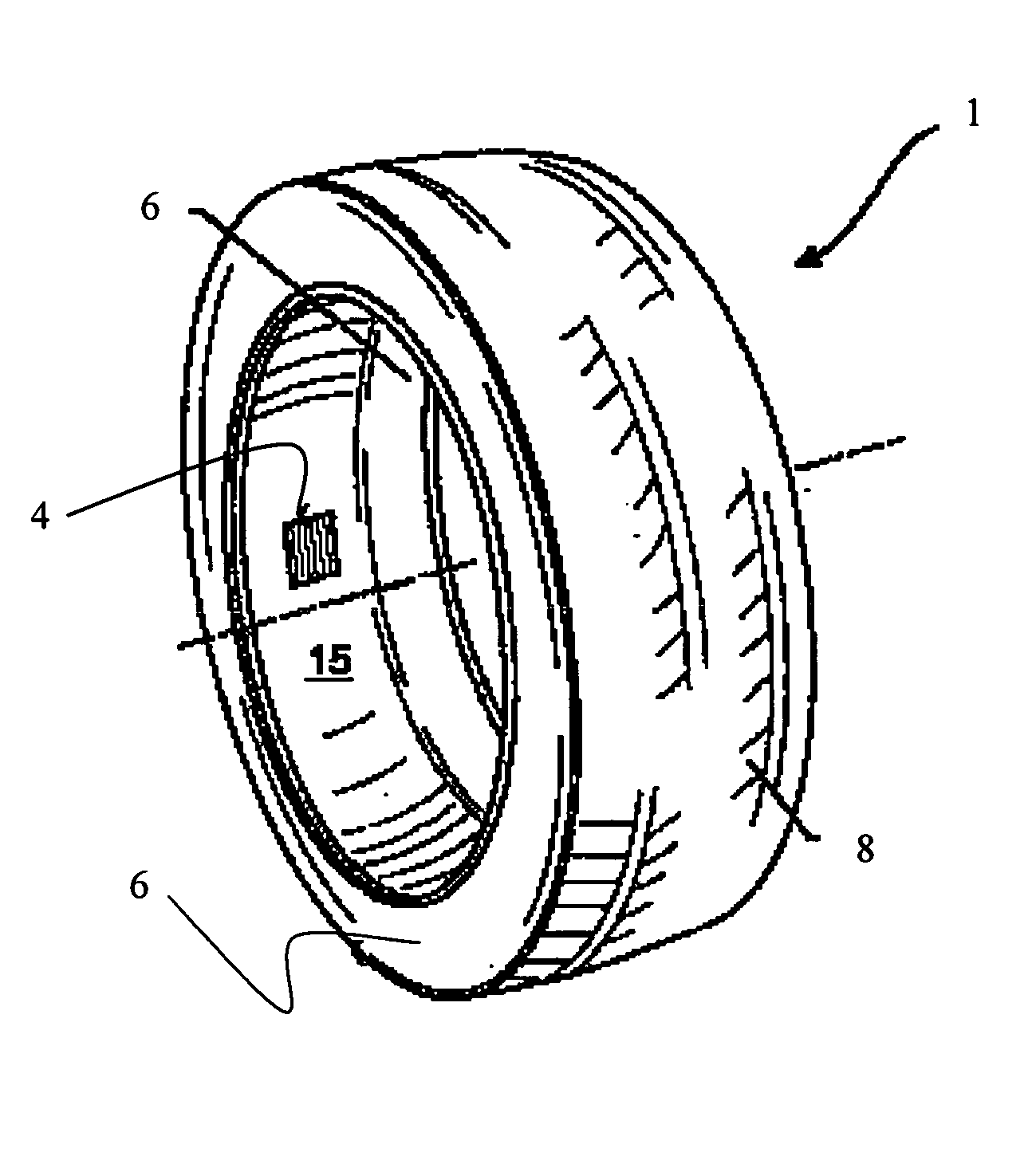

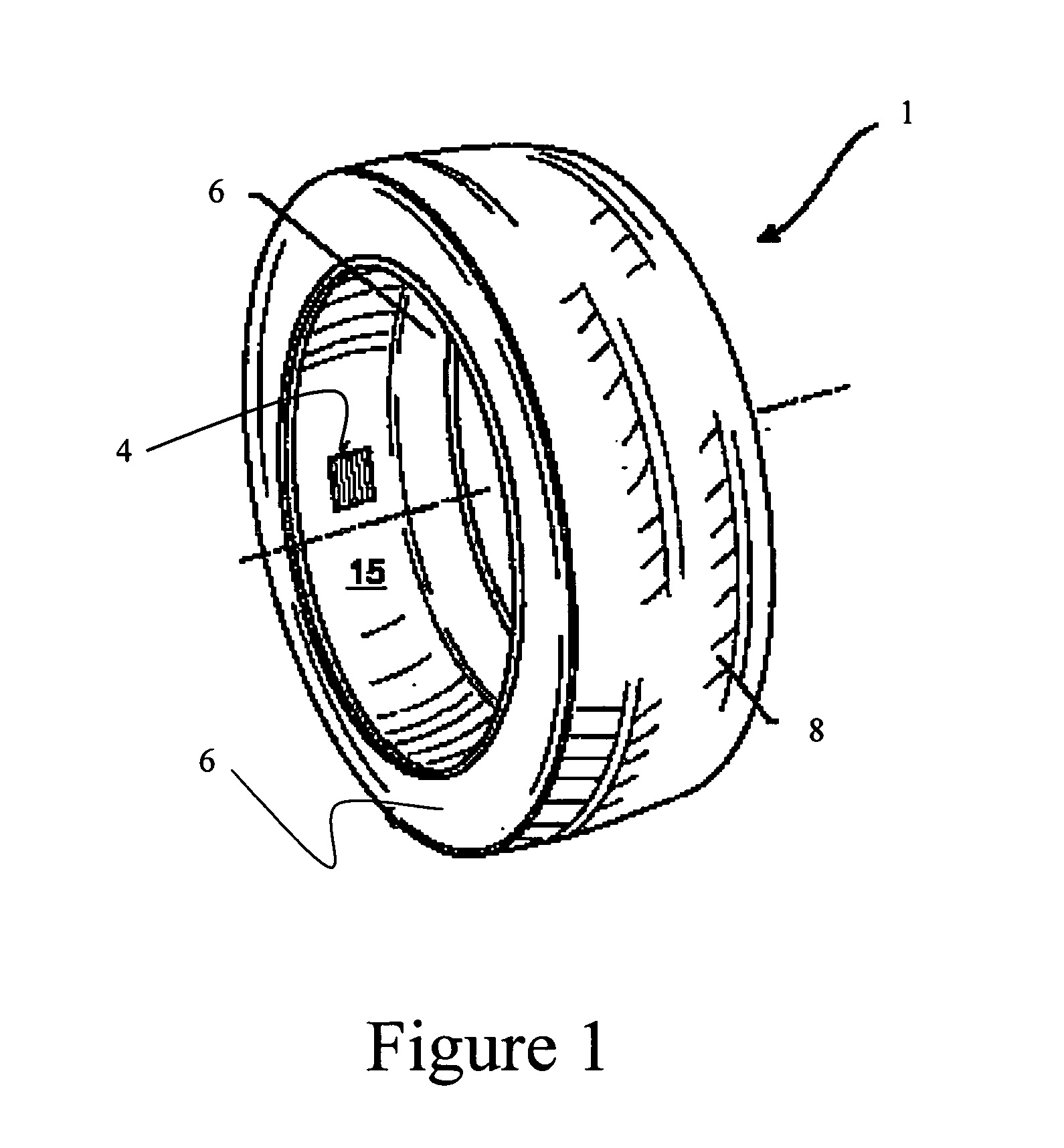

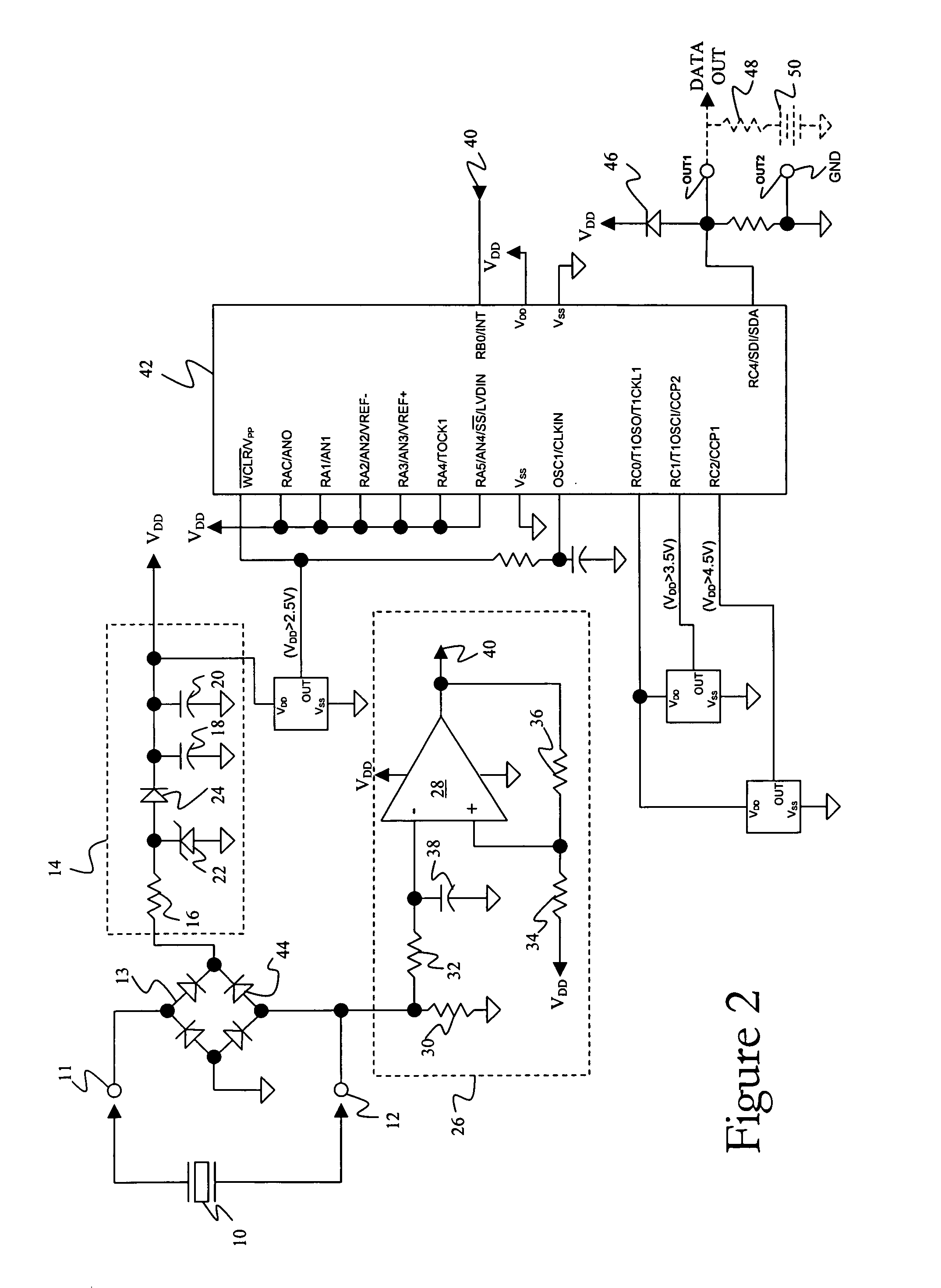

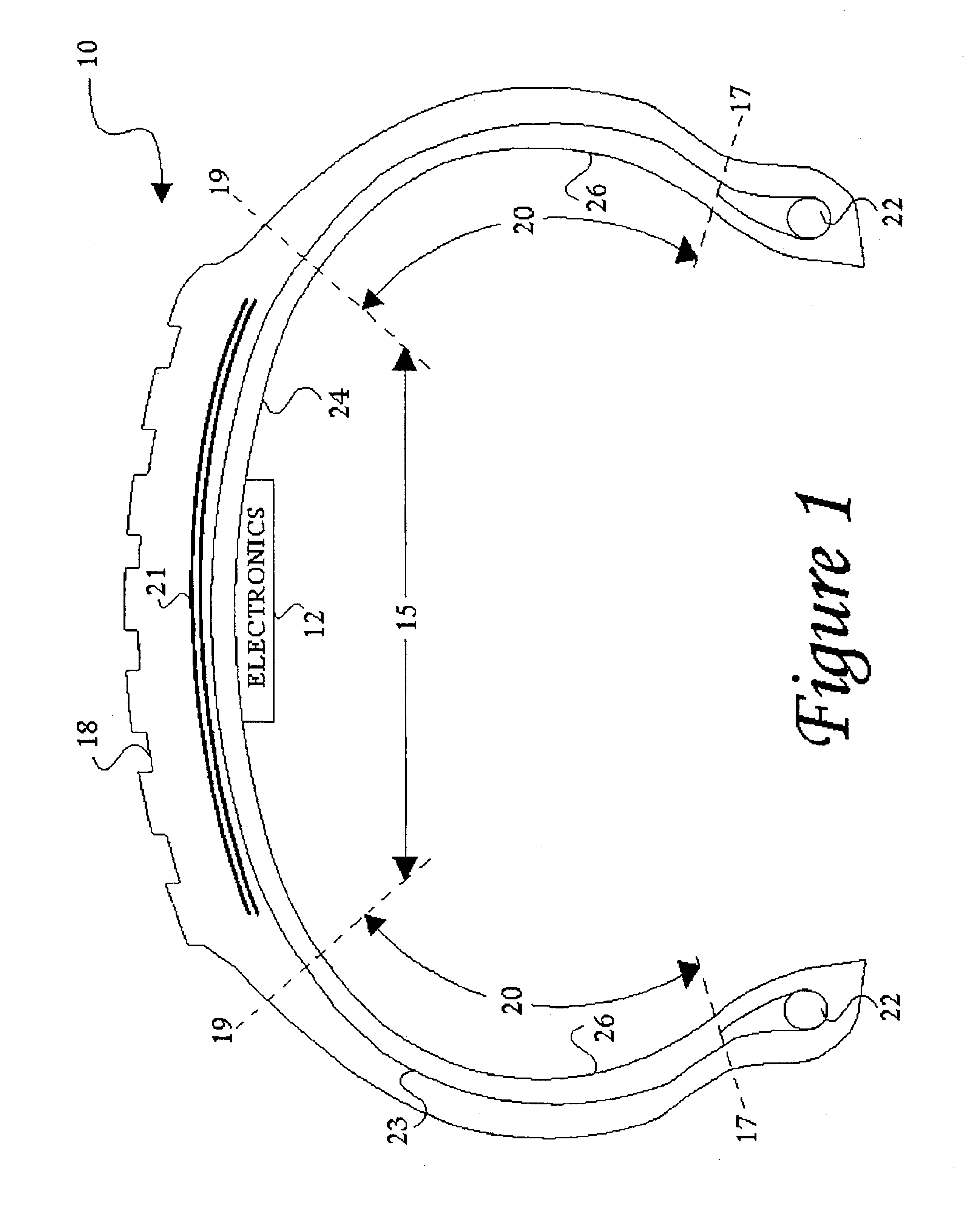

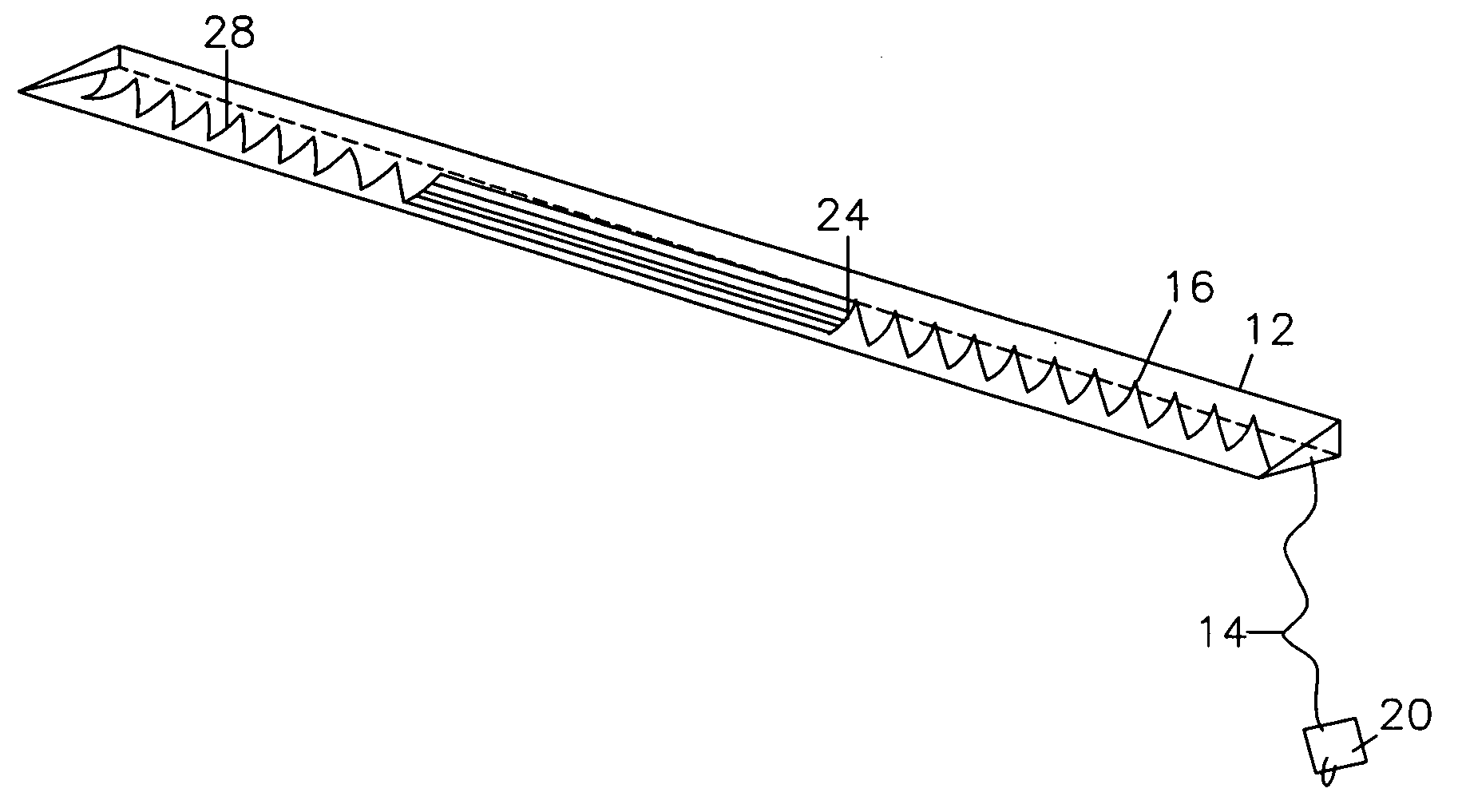

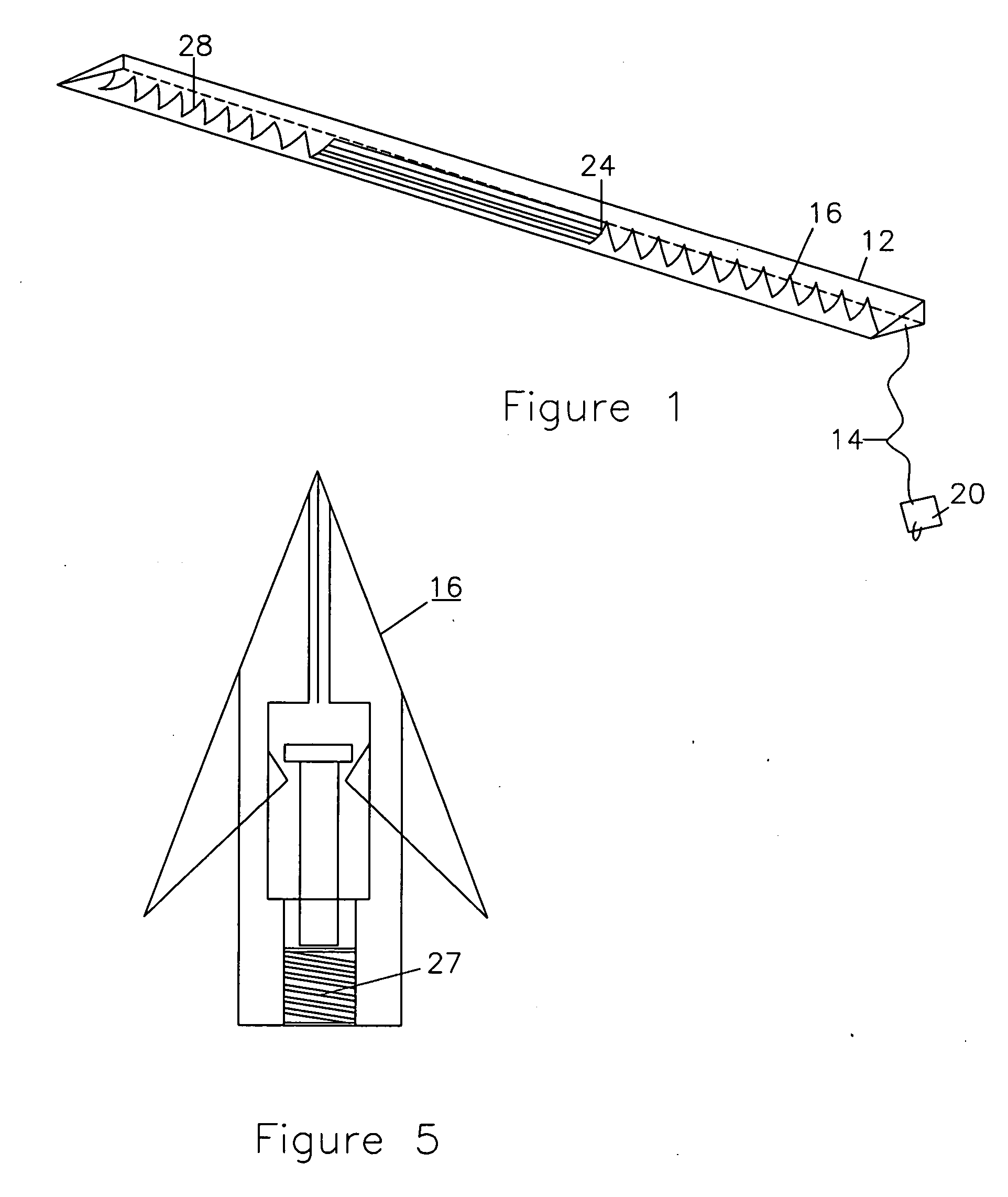

Integrated self-powered tire revolution counter

ActiveUS7132939B2Enhanced advantageAccurate countRegistering/indicating working of machinesNavigation instrumentsMicrocontrollerTire rotation

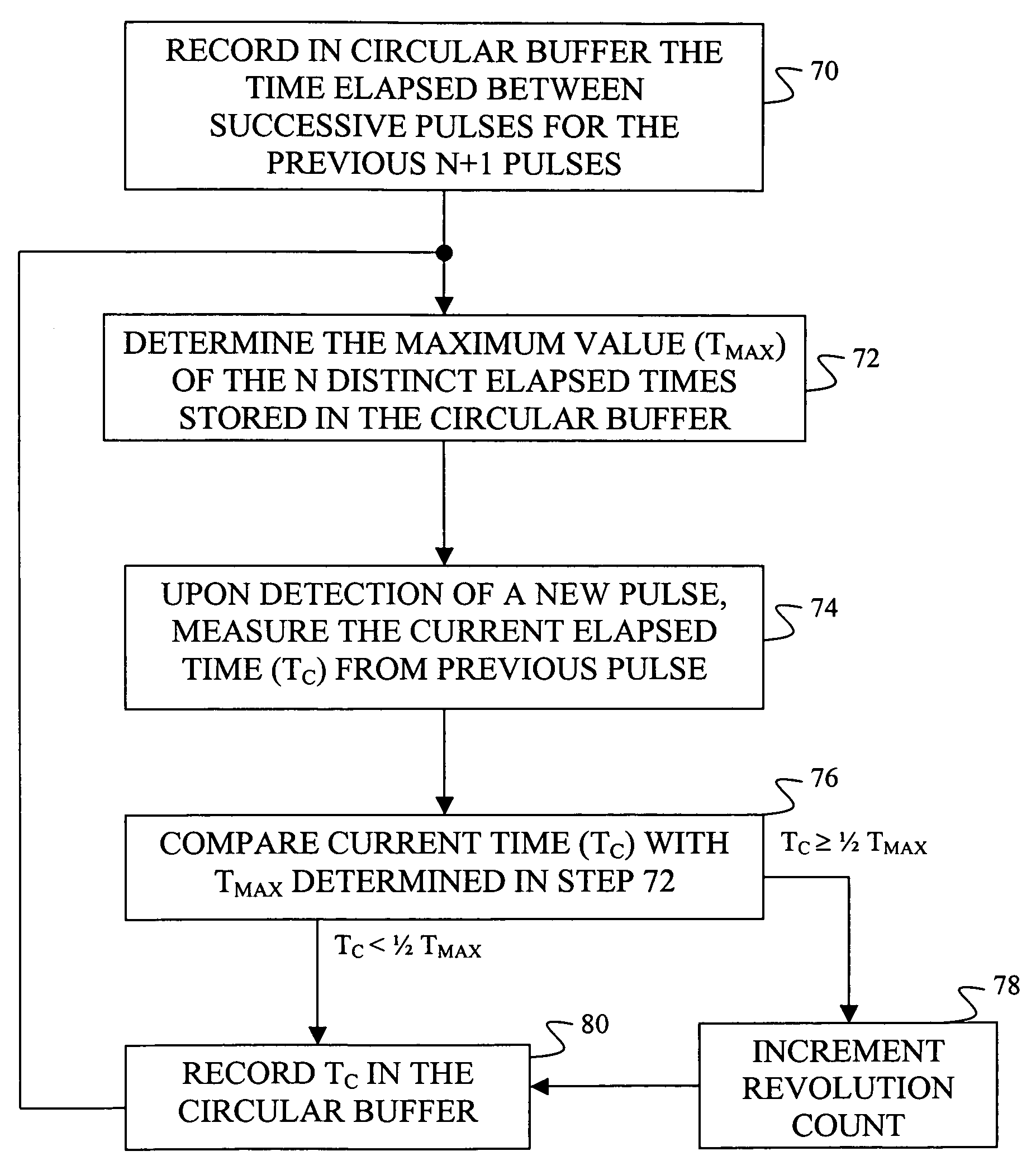

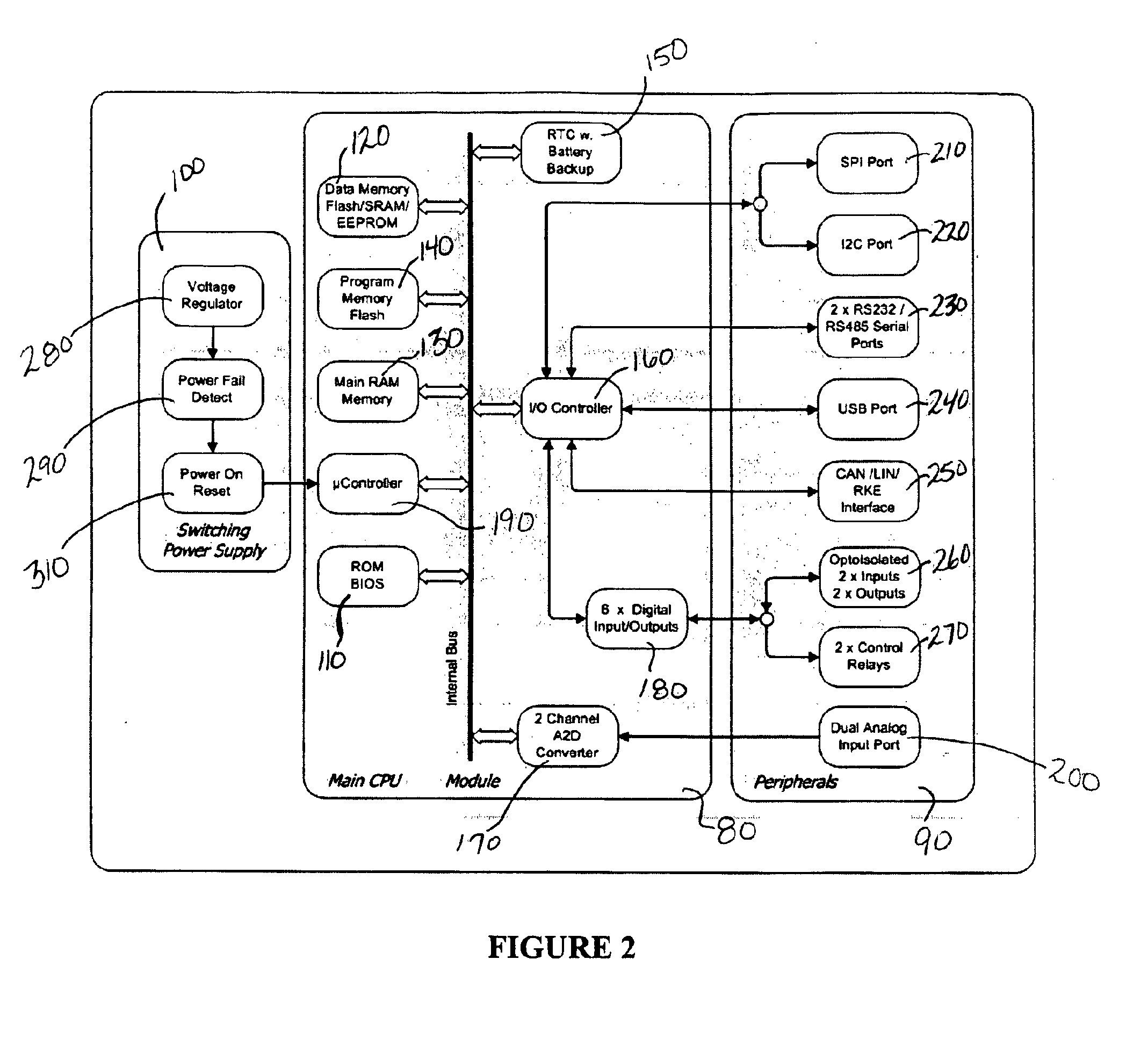

A self-powered tire revolution counter includes a motion sensitive power generation mechanism, a power conditioner, a pulse detector, a microcontroller, and, optionally, a radio frequency (RF) transmitting device. In one exemplary embodiment, the power generation mechanism corresponds to a piezoelectric patch that, during movement, provides both operating electrical power and pulsed signals indicative of tire rotation. The power conditioner receives a generator signal from the power generation mechanism and produces a conditioned output voltage that can be used to power associated electronic devices, including the microcontroller. The pulse detector receives the generator signal and produces a detection signal whenever the generator signal meets a predetermined condition. The microcontroller is programmed to determine current and lifetime-accumulated values of selected pulse indications in the detection signal that meet predetermined criteria. Data corresponding to tire environment related parameters such as temperature, pressure, tire deflection, and / or vehicle speed may be stored in the microcontroller at times during tire rotation as power is supplied from the power generation mechanism through the power conditioner. Additional data may be supplied to the microcontroller directly from an external source and read from the microcontroller either by direct electrical contact or via selective RF transmission.

Owner:MICHELIN RECH & TECH SA

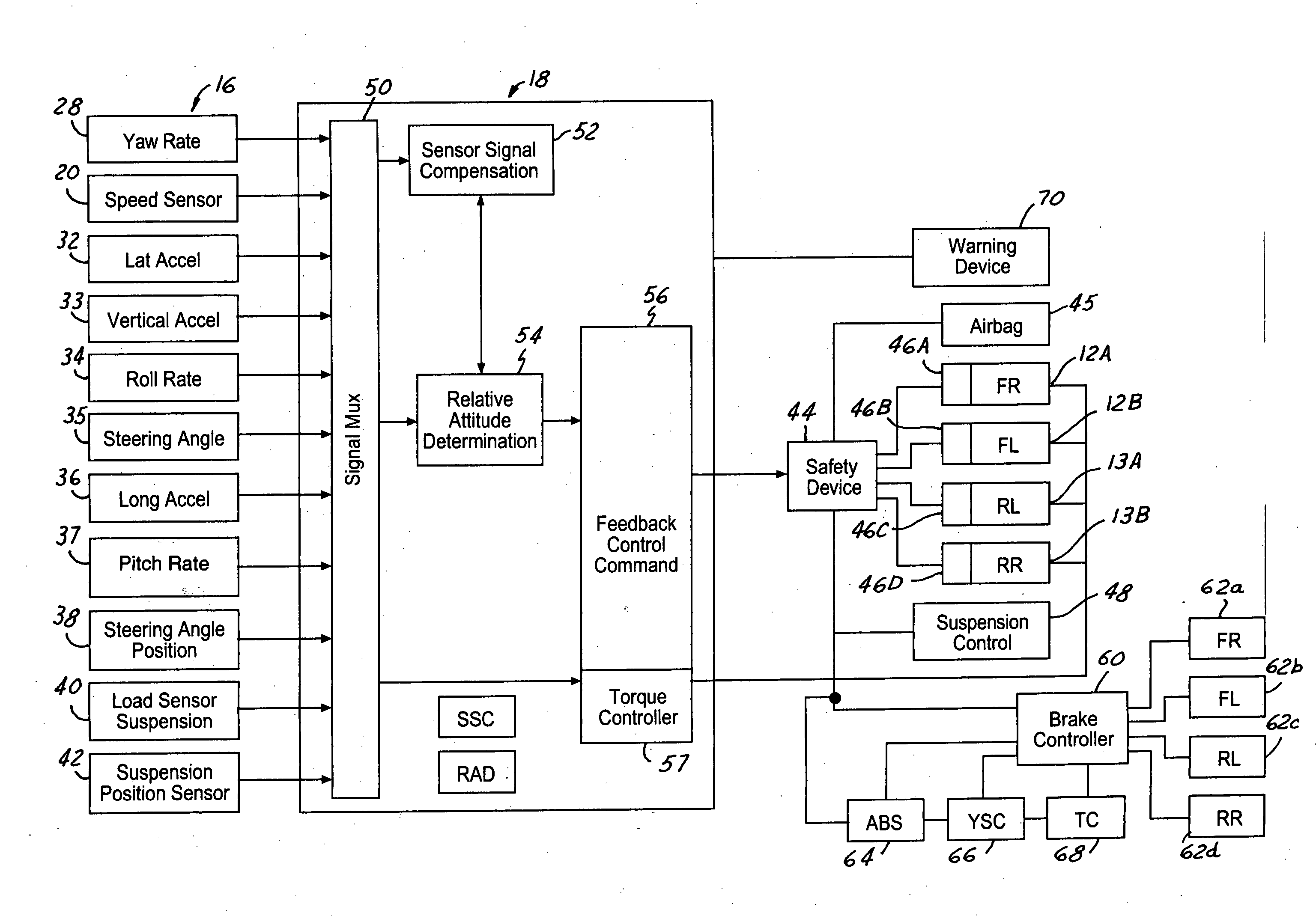

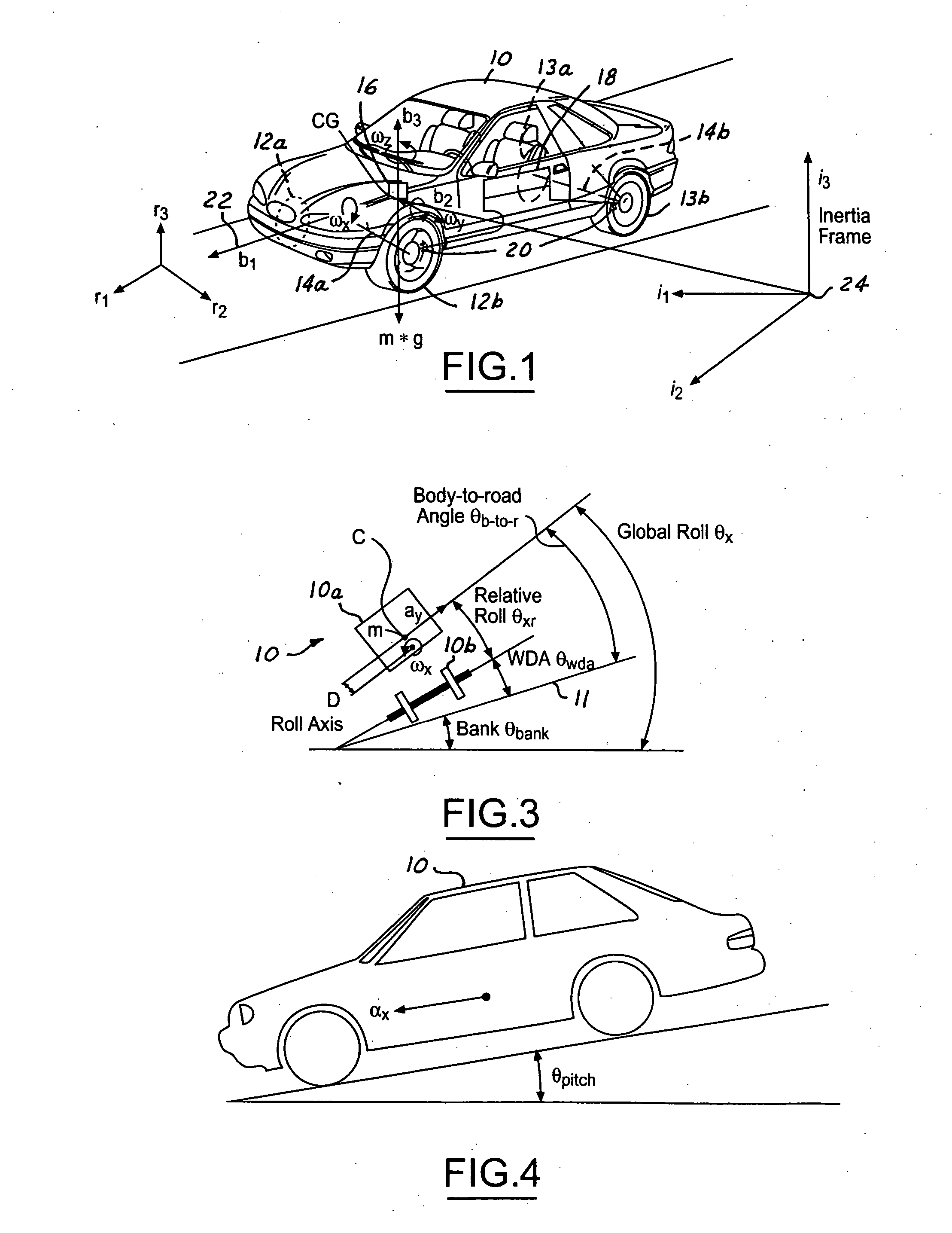

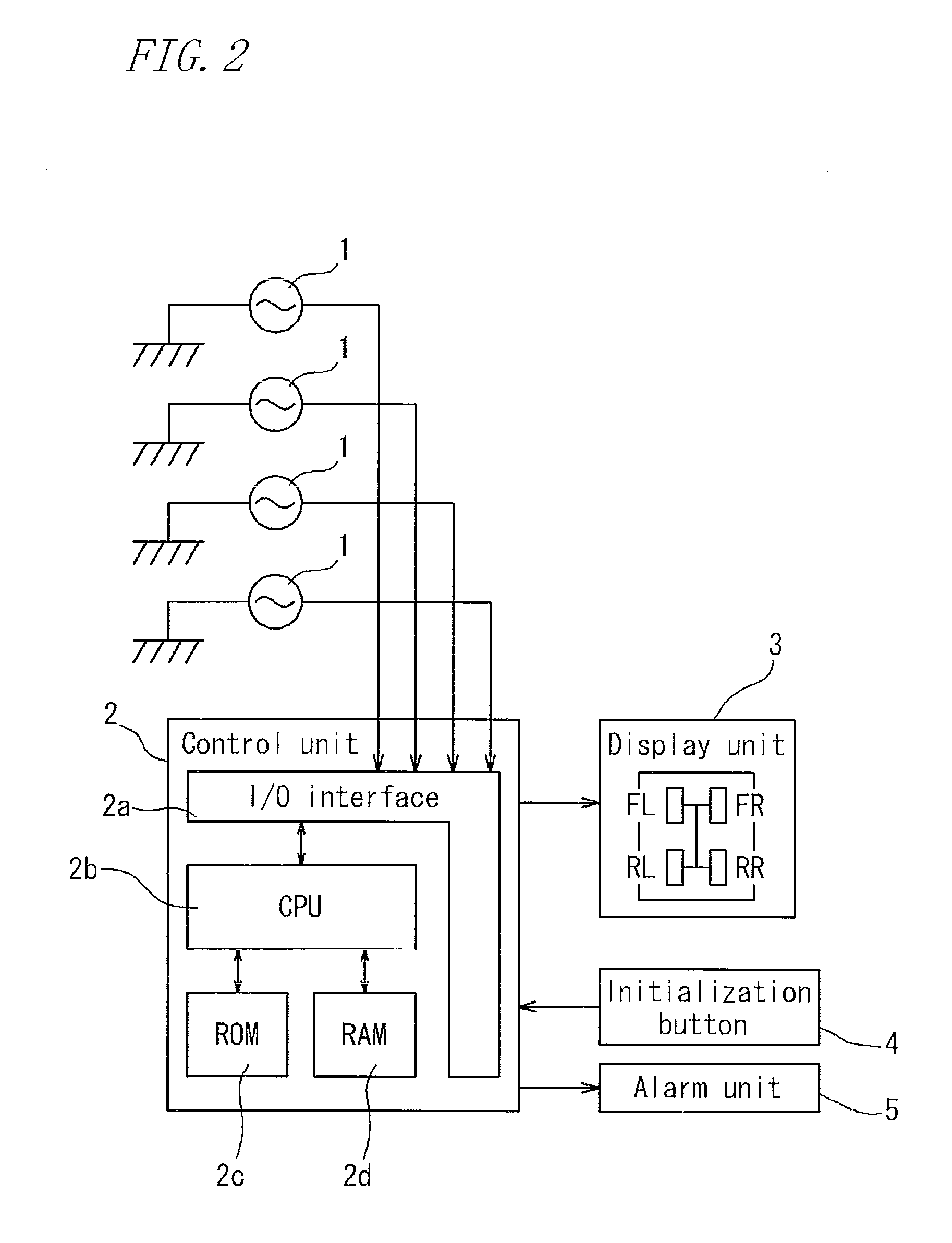

Tire abnormal state monitoring system for an automotive vehicle

InactiveUS20060267750A1Improve control effectOptical signallingTyre measurementsControl systemMonitoring system

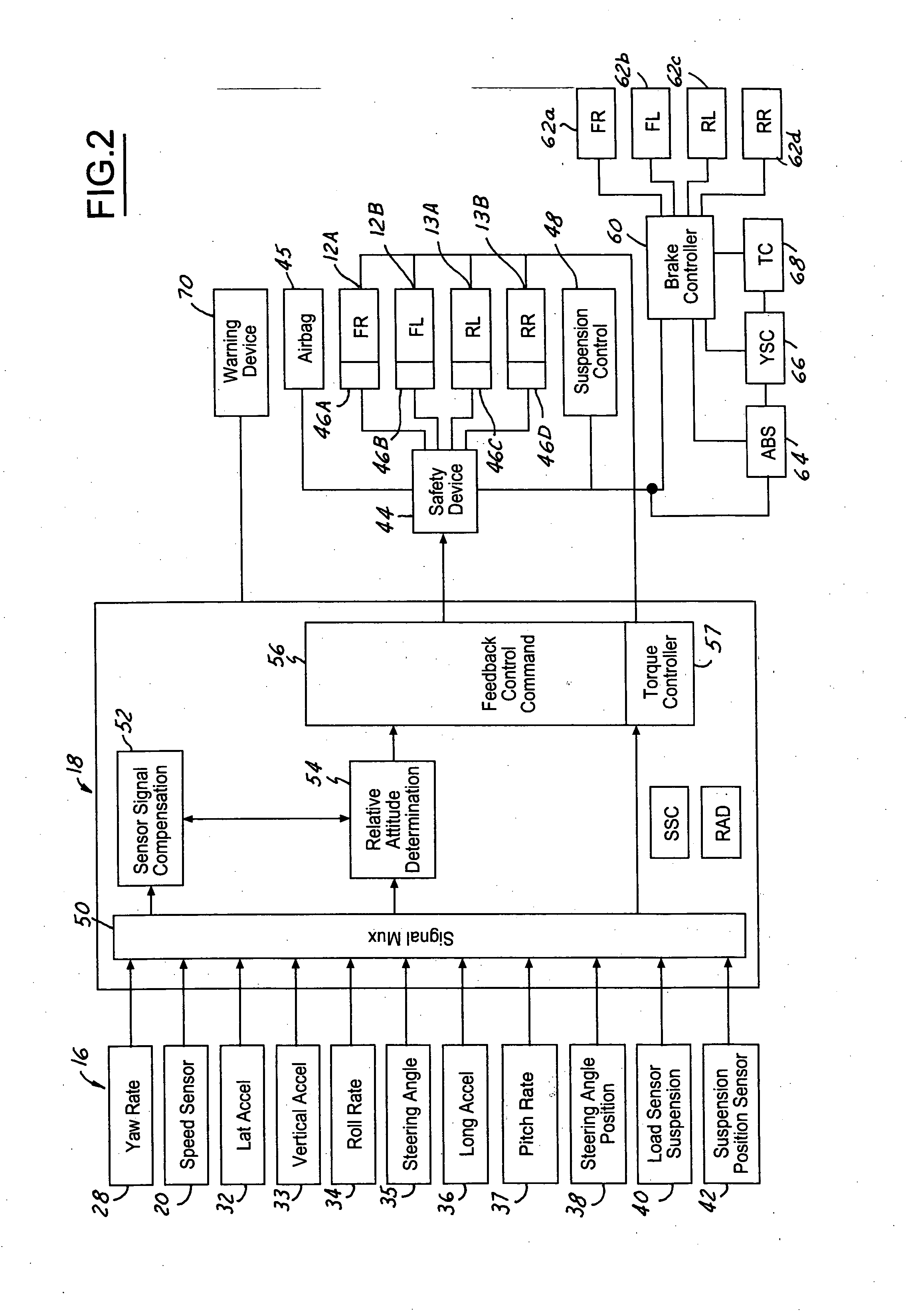

A control system for controlling an automotive vehicle (10) is set forth. Various tire parameters such as a rolling radius, a vertical spring rate, and a tire rotational spring rate may be used to determine a tire abnormal state. The vehicle (10) is controlled in response to the tire abnormal state. To control the vehicle various dynamic control systems such as anti-lock brakes, traction control, various sensors existing in the vehicle such as a yaw signal, roll signal and pitch signal may be used to determine a tire parameter.

Owner:FORD GLOBAL TECH LLC

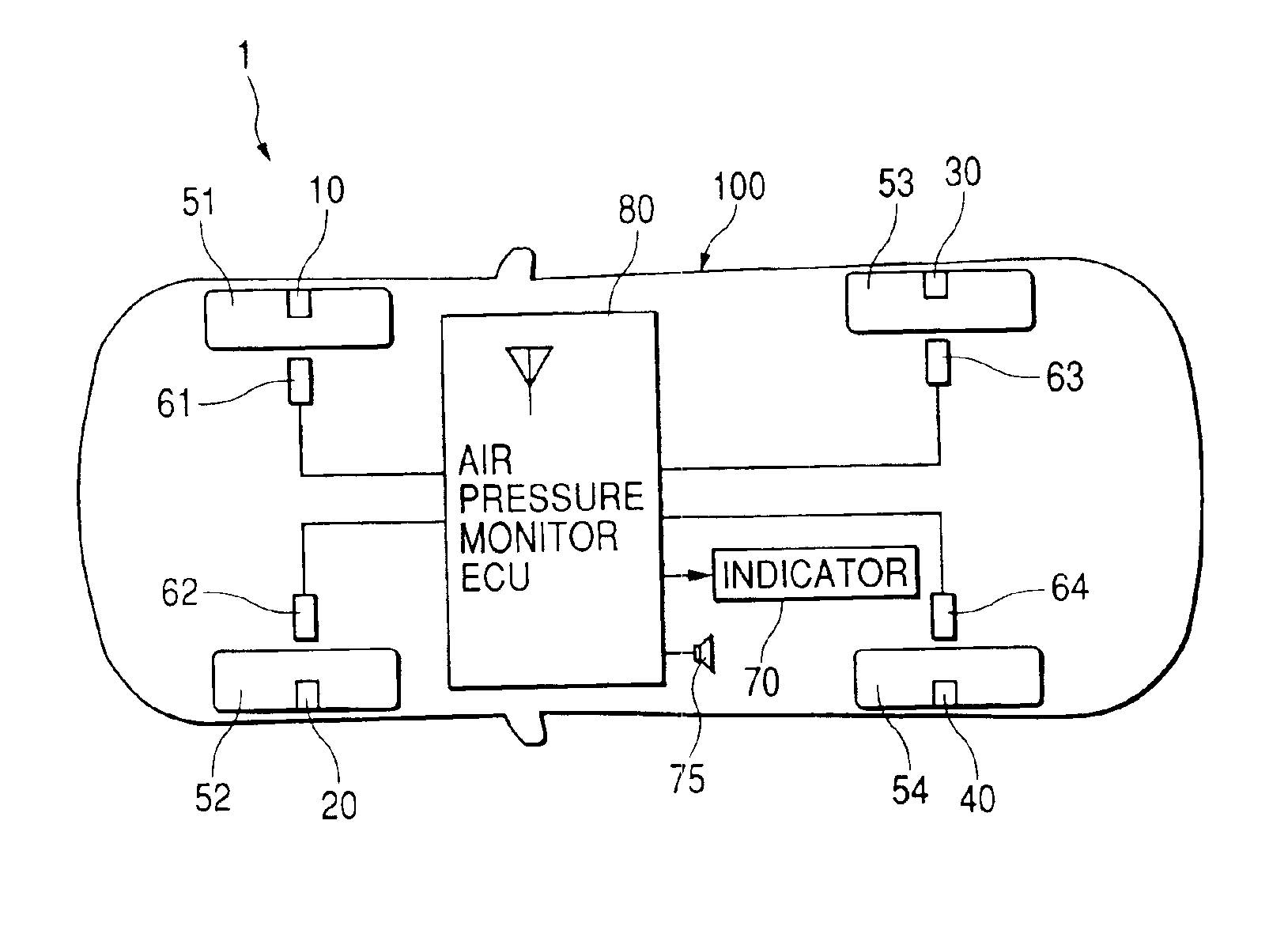

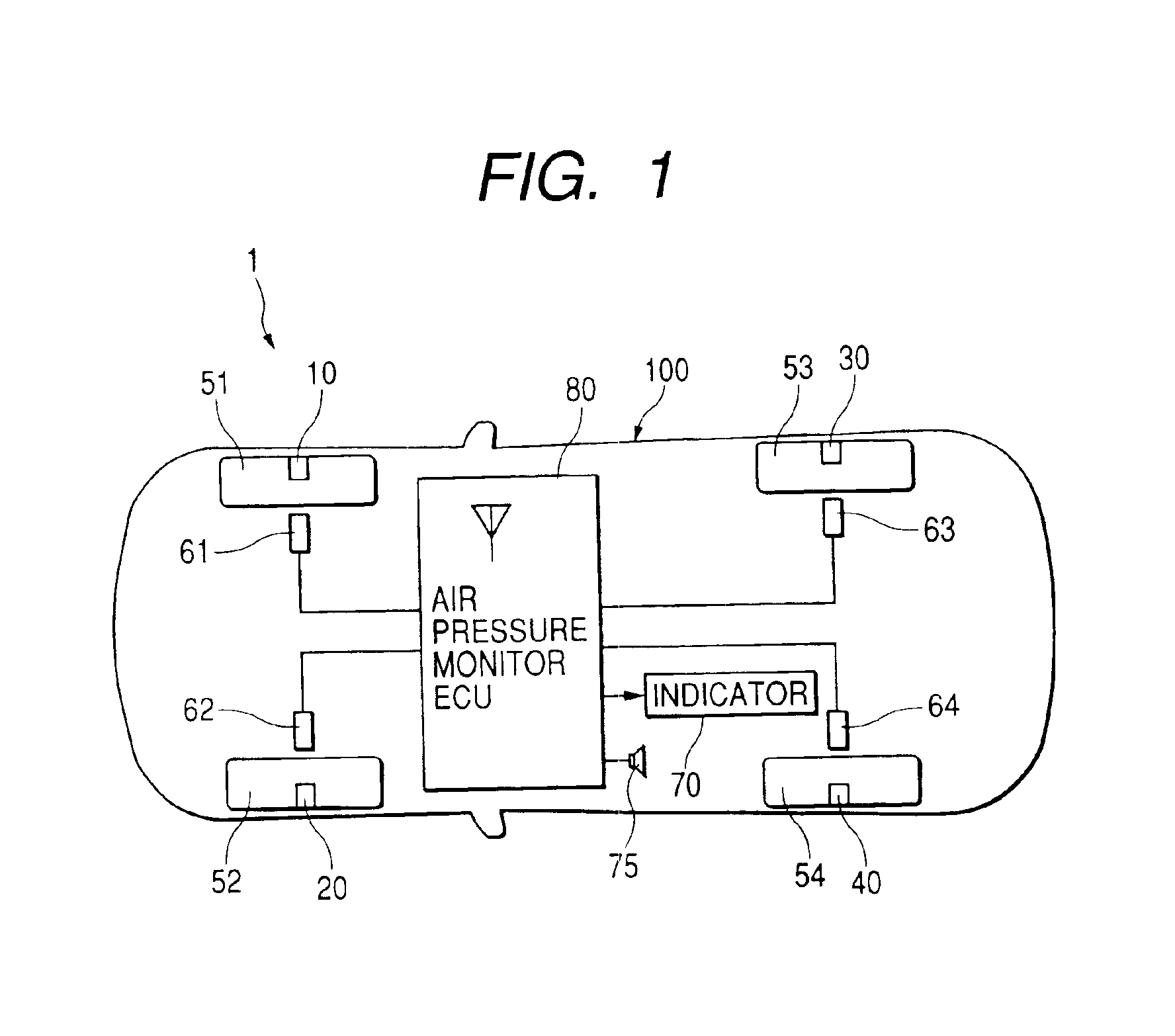

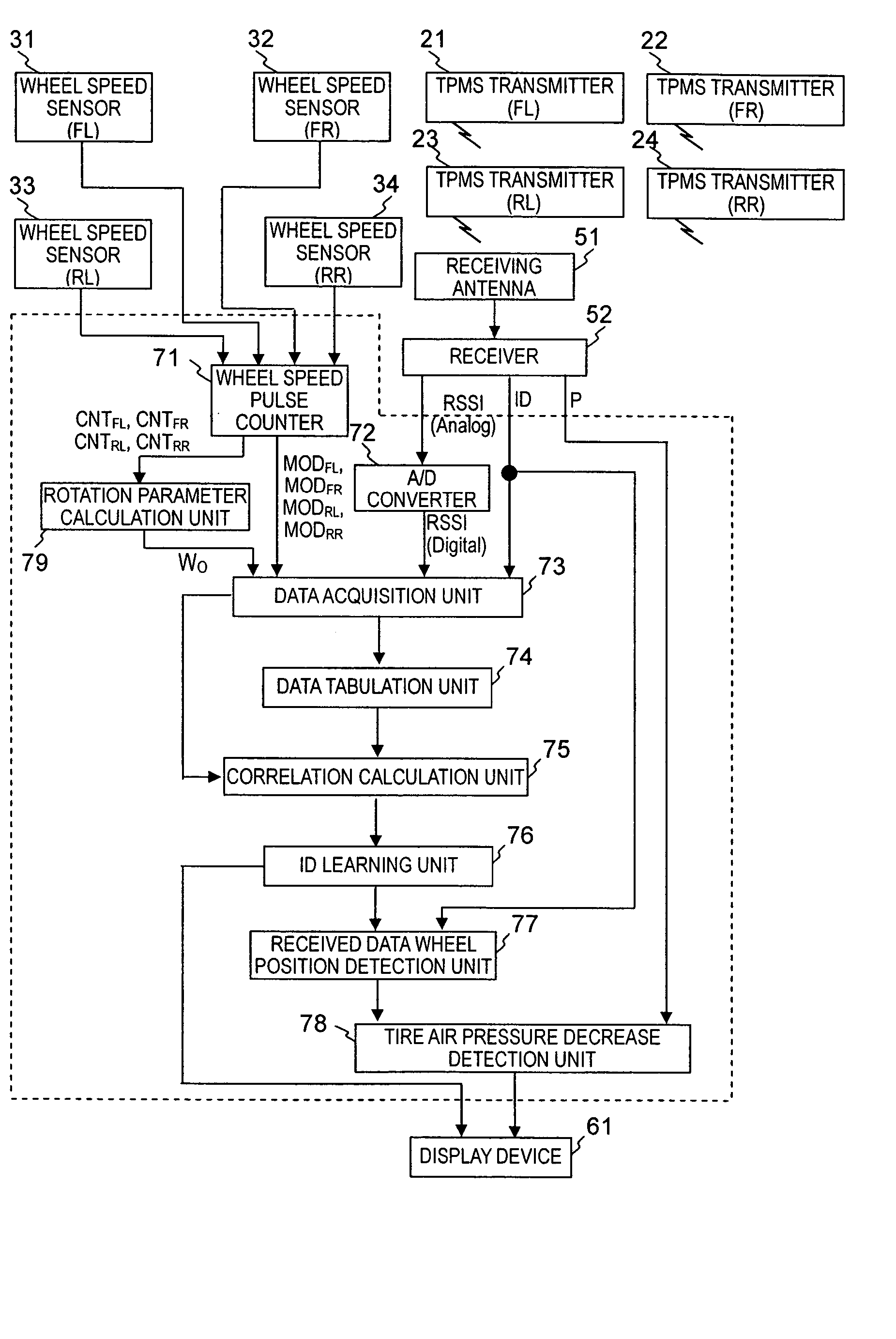

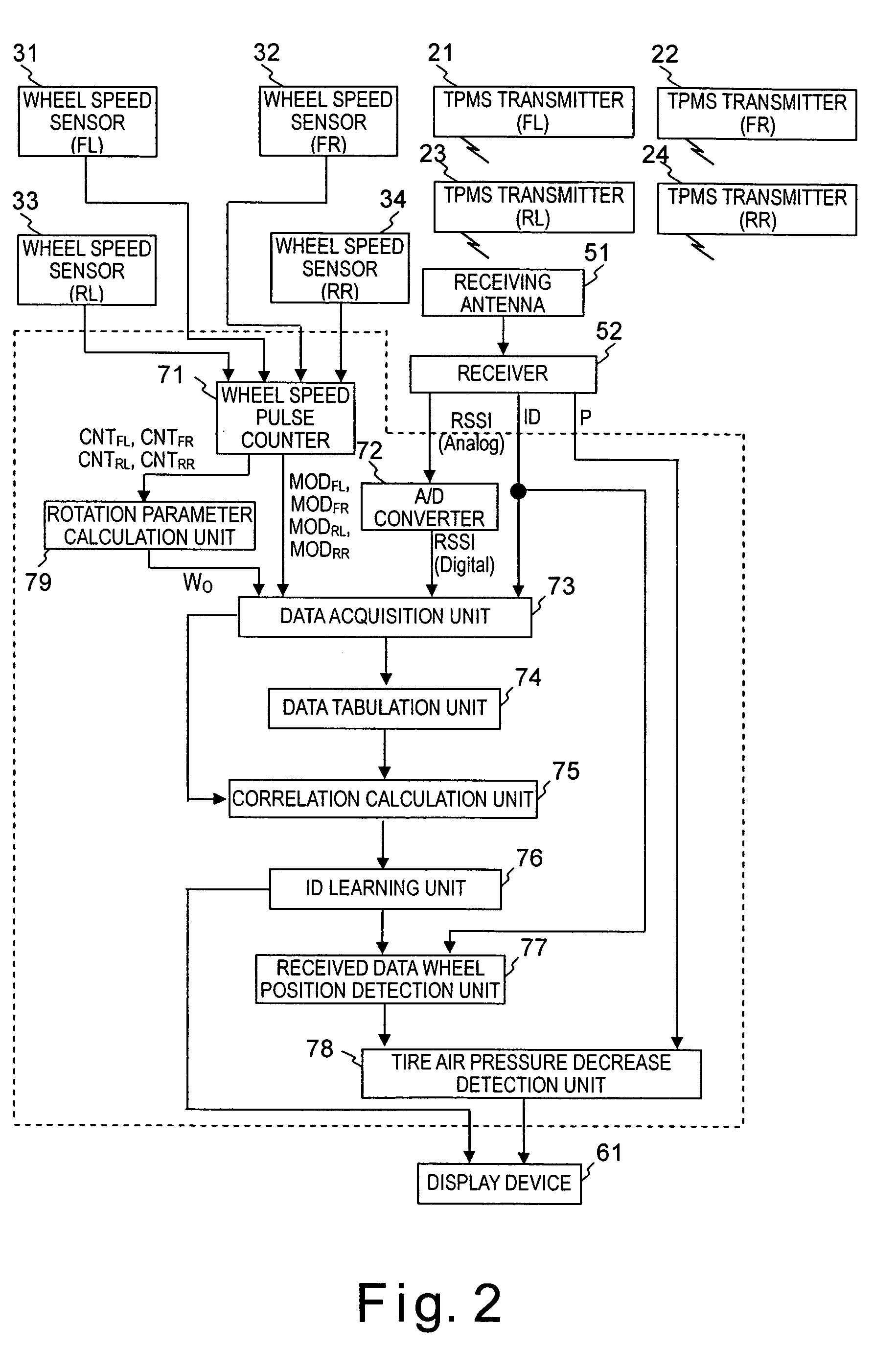

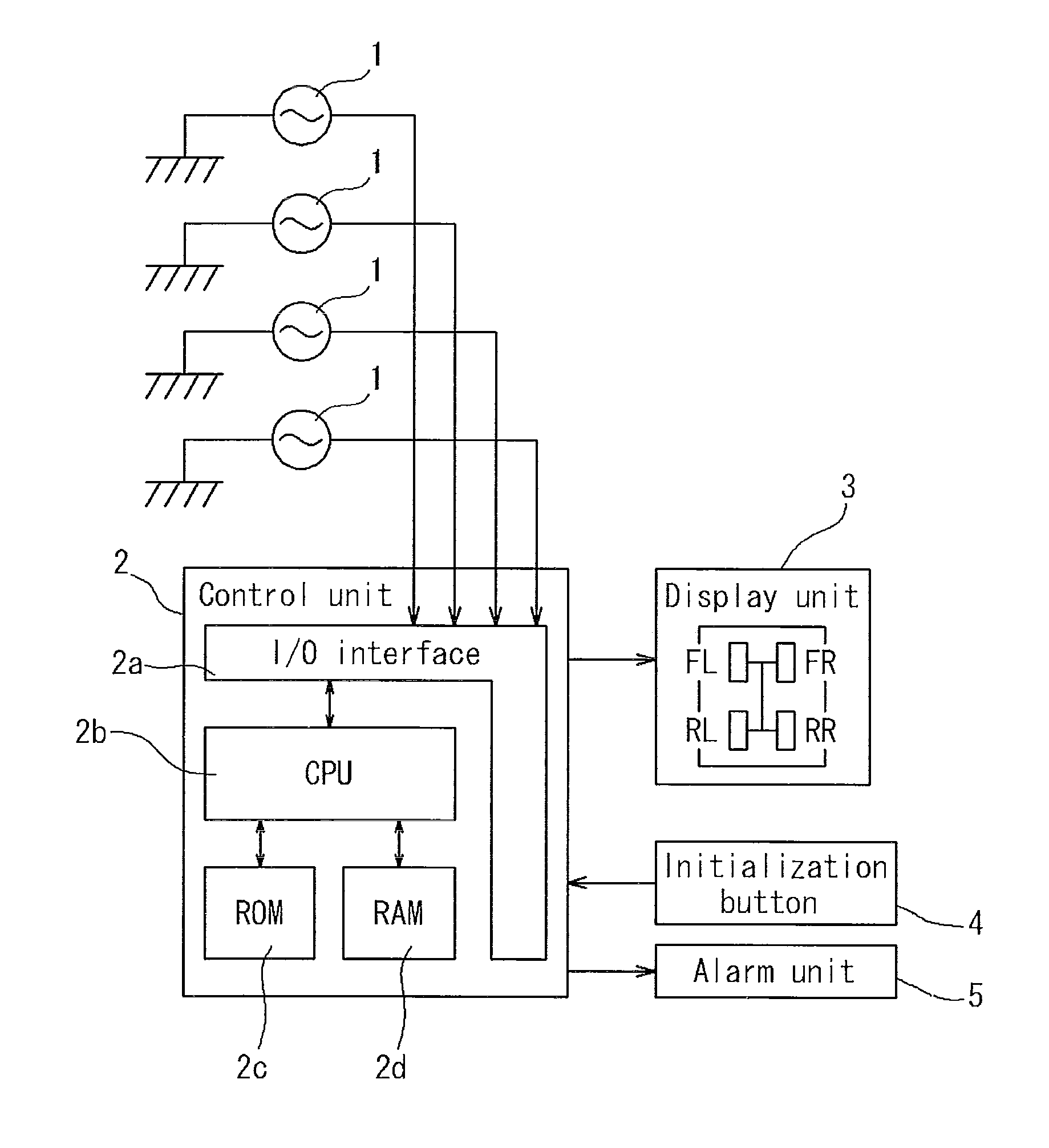

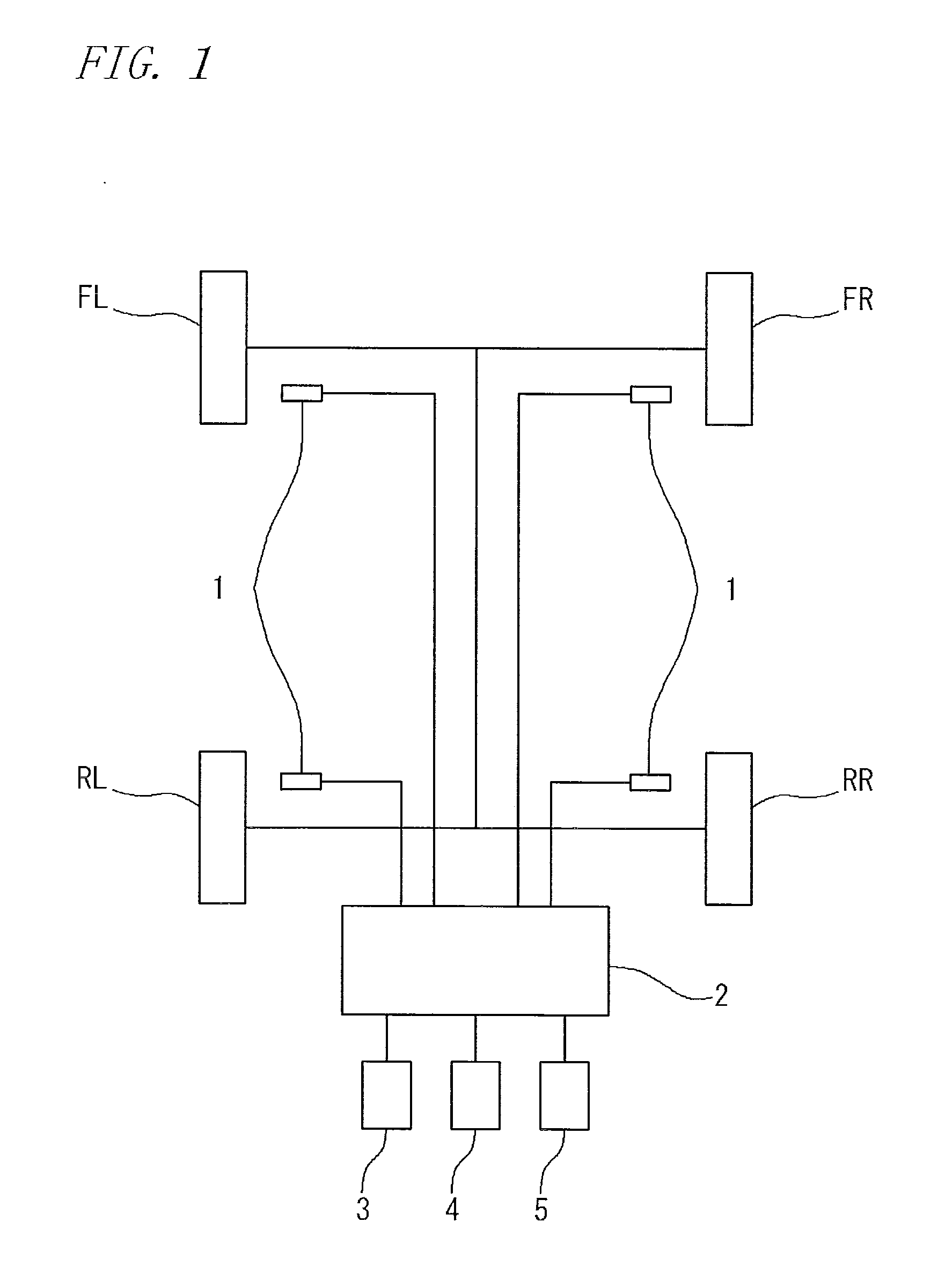

Tire air pressure monitoring system

ActiveUS6885293B2Reduce power consumptionInflated body pressure measurementTransmission systemsMonitoring systemTire rotation

Provided is a tire air pressure monitoring system capable of grasping the tire positions where there are sensor units even in the case of tire rotation. In the tire air pressure monitoring system, a trigger signal is transmitted from a transmission coil antenna to only the corresponding sensor unit in a manner such that a magnetic field is used as a medium and, upon receipt of the trigger signal, the sensor unit measures a tire air pressure and others and transmits a transmission signal including the measurement values to a monitoring unit. The monitoring unit makes a decision on the tire position where there is the sensor unit on the basis of the transmission signal from the sensor unit.

Owner:DENSO CORP

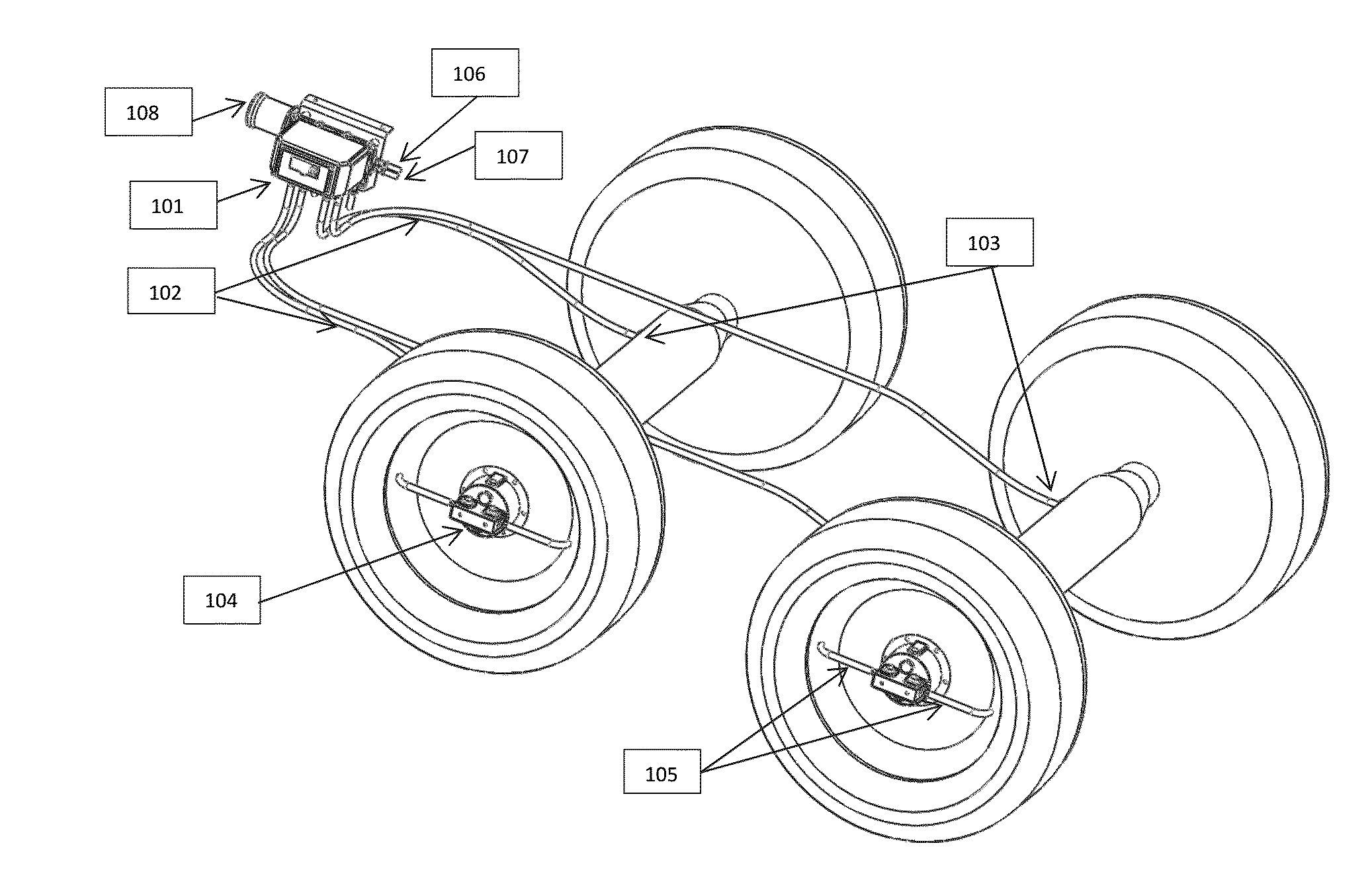

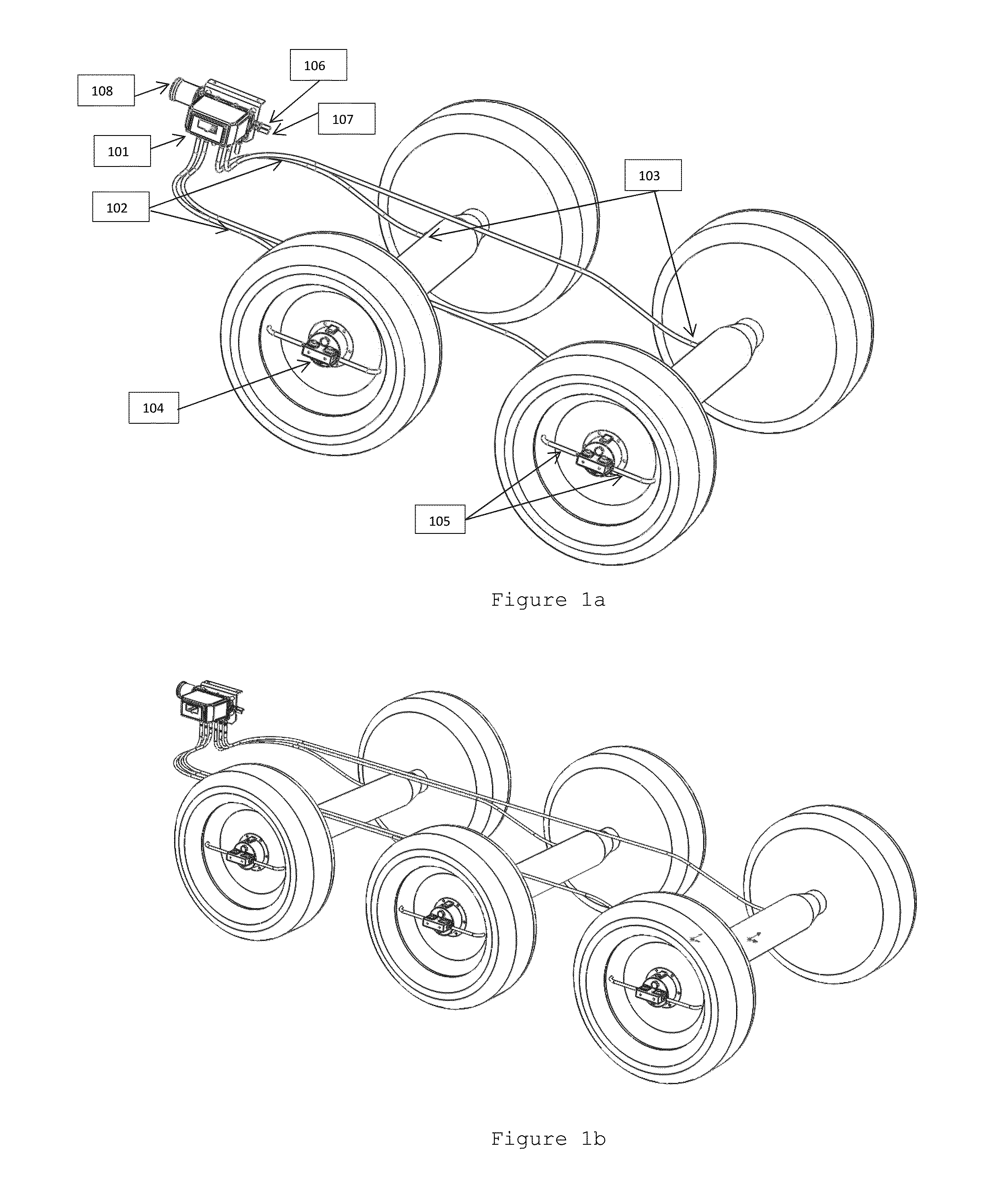

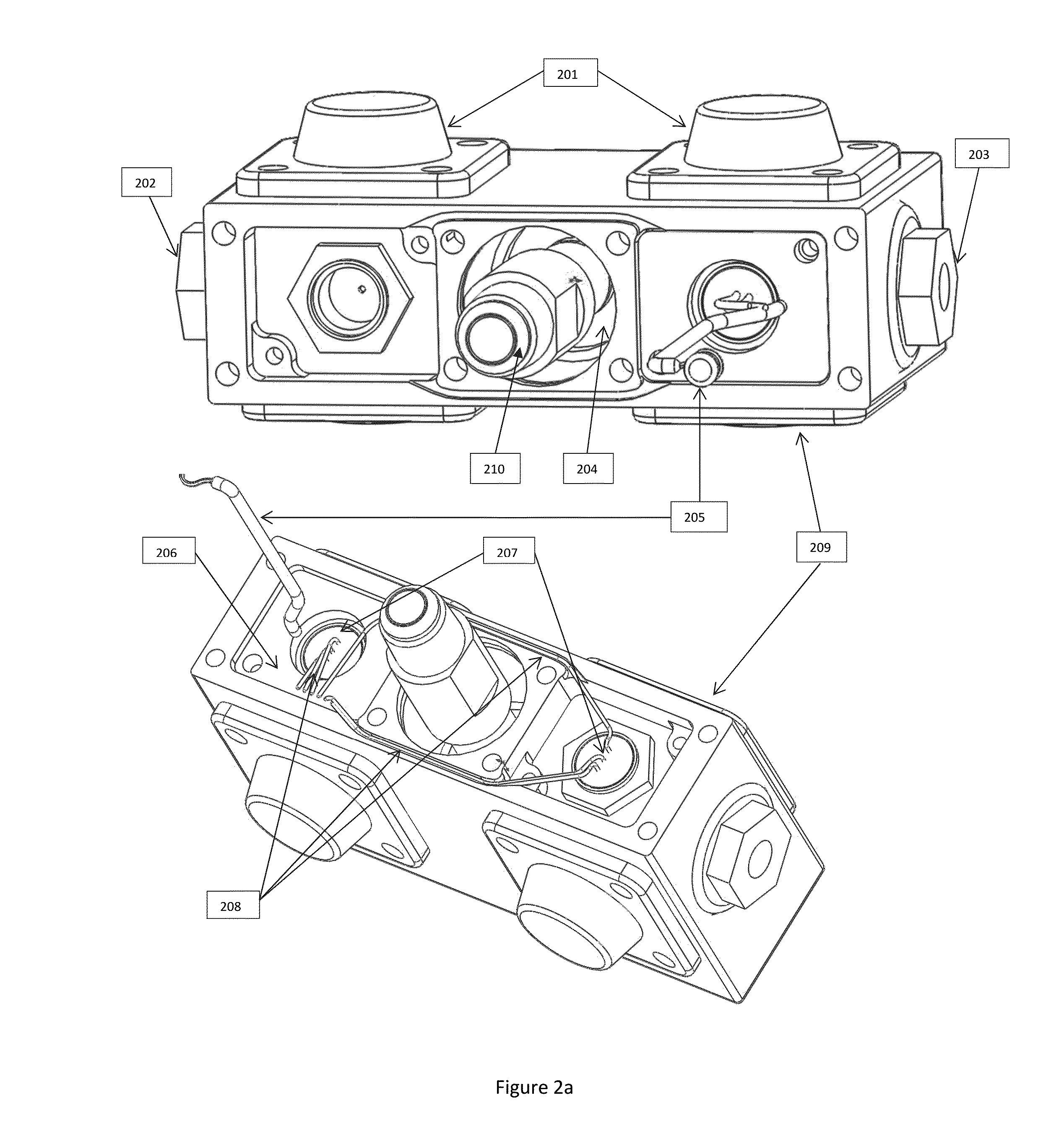

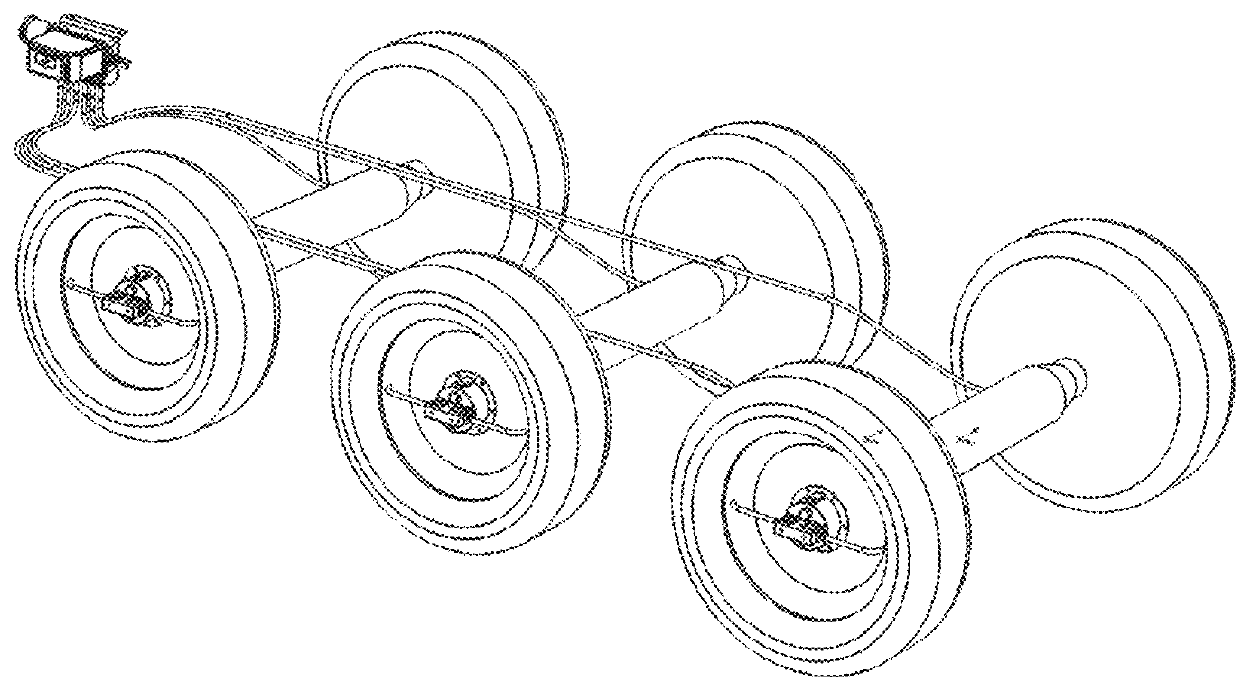

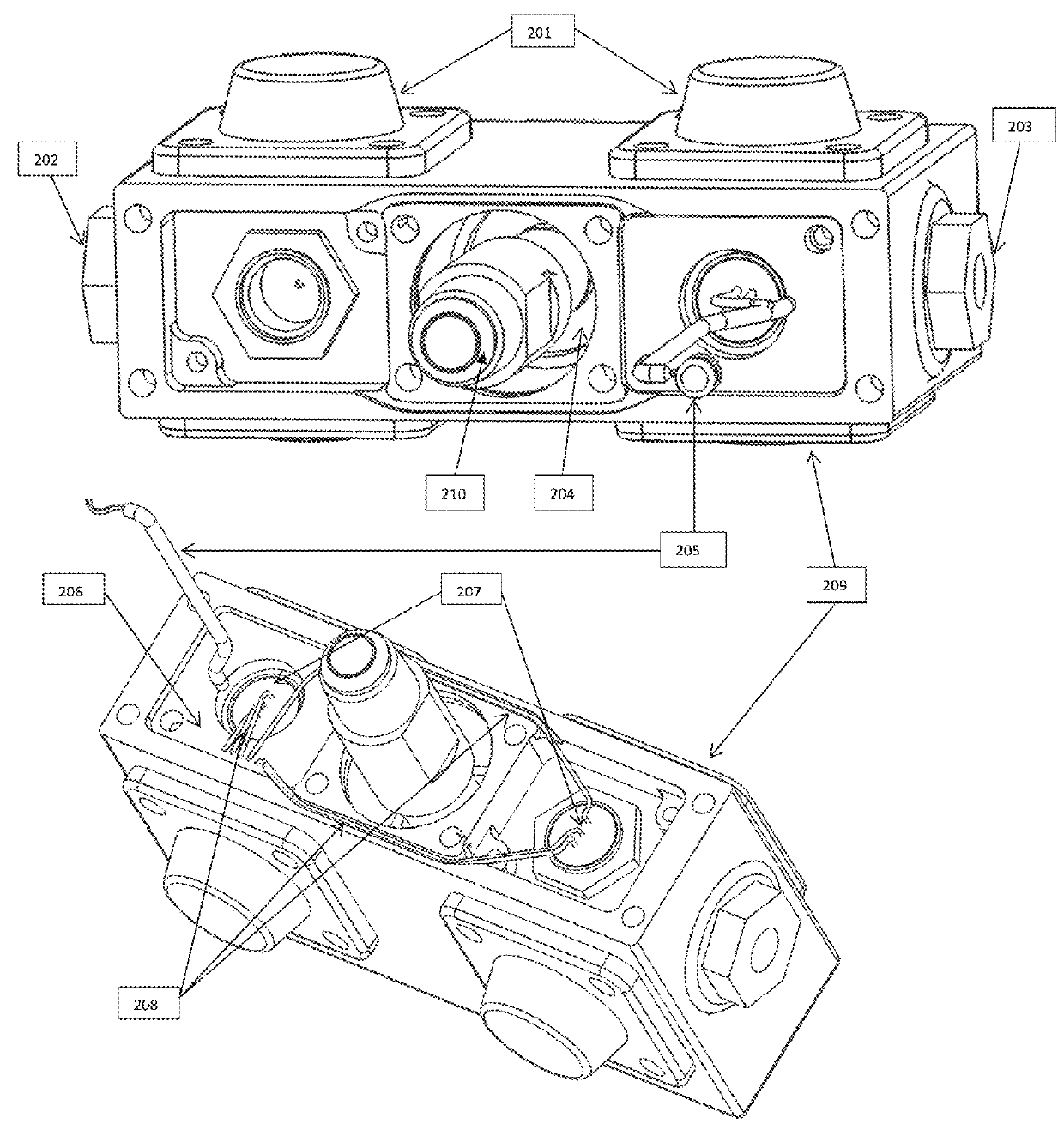

Intelligent Tire Inflation and Deflation System Apparatus

ActiveUS20150174972A1Sure easyFacilitating regular tire maintenanceTyre measurementsDistance measurementTire rotationTire-pressure monitoring system

An intelligent tire pressure management system capable of real-time tire pressure monitoring, vehicle load detection, and automatic tire inflation and deflation for maintaining optimal tire pressure in a commercial vehicle. Additional functions include counting tire rotations for calculating and recording distance travelled for each tire, and detecting wheel sliding due to locked-up tires. The system includes a chassis-mounted control box connecting to the vehicle air supply, a hubcap-mounted dual wheel valve apparatus integrated with a rotary union assembly that connects through the vehicle hollowed axles to the air tubes from the control box. The inflation / deflation supporting dual wheel valve apparatus has an embedded electronic unit that monitors individual tire pressure and temperature in real time, and communicates with the control box over the power line. Furthermore a load sensor integrated with the control box provides the system with the current vehicle load information. With readily available real time tire pressure data and current vehicle load information, this system can intelligently adjusts tire pressure to the desired level when necessary and, as a result, prolongs tire life, improves fuel economy, reduces the vehicle maintenance costs, and promptly alerts the driver of low, leaky or flat tire conditions for enabling the driver to take immediate corrective actions.

Owner:ZHOU JOE HUAYUE +1

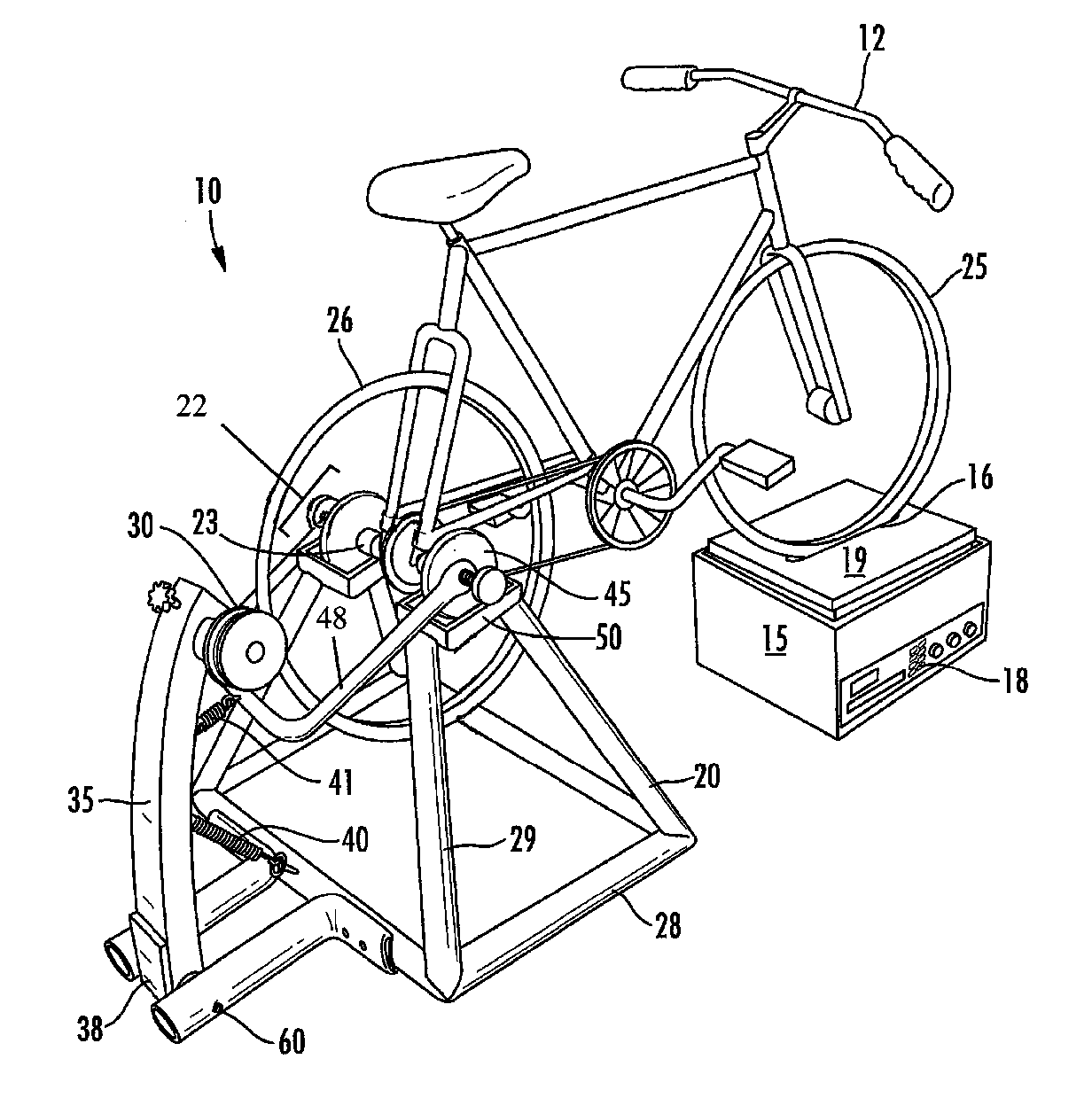

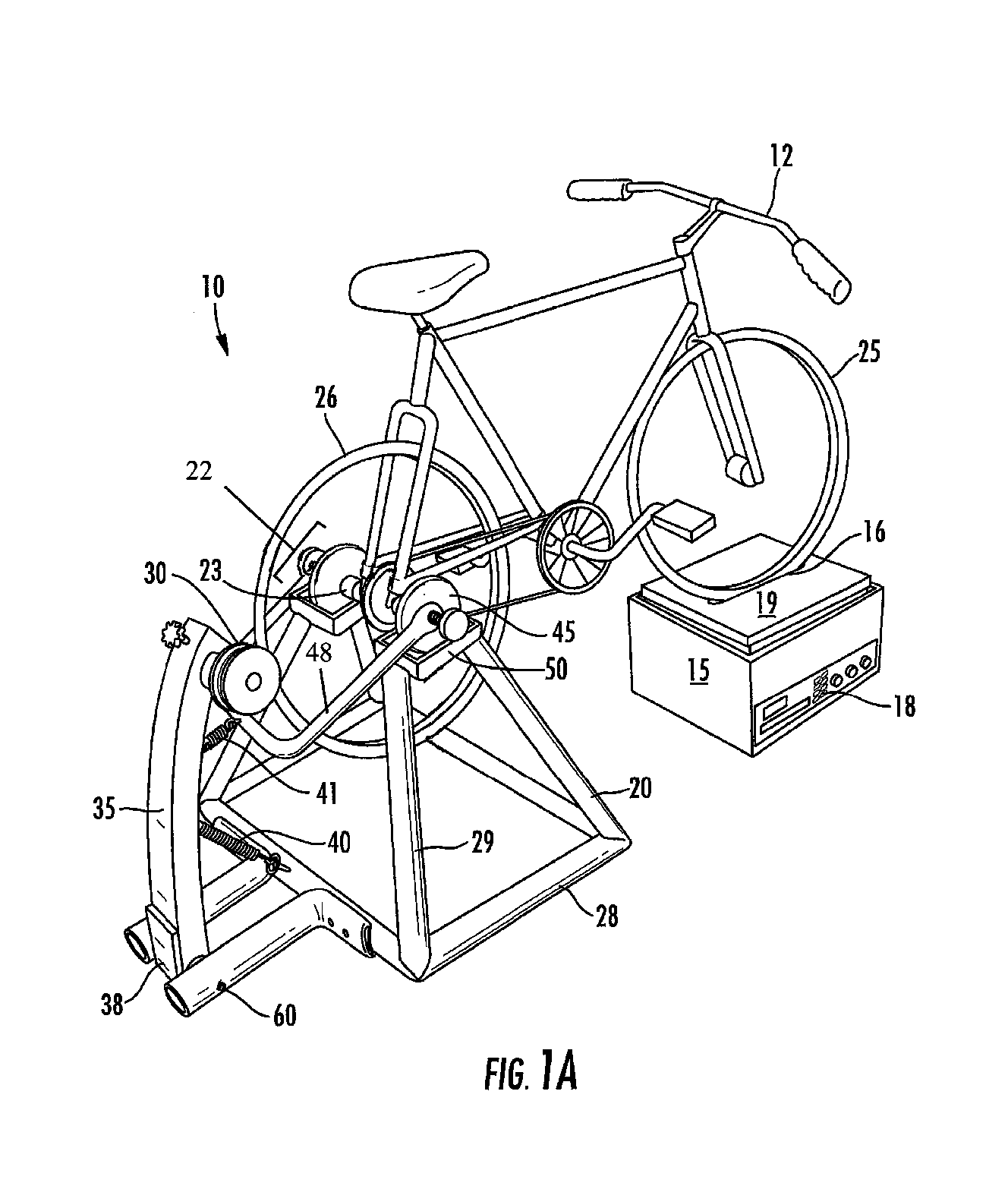

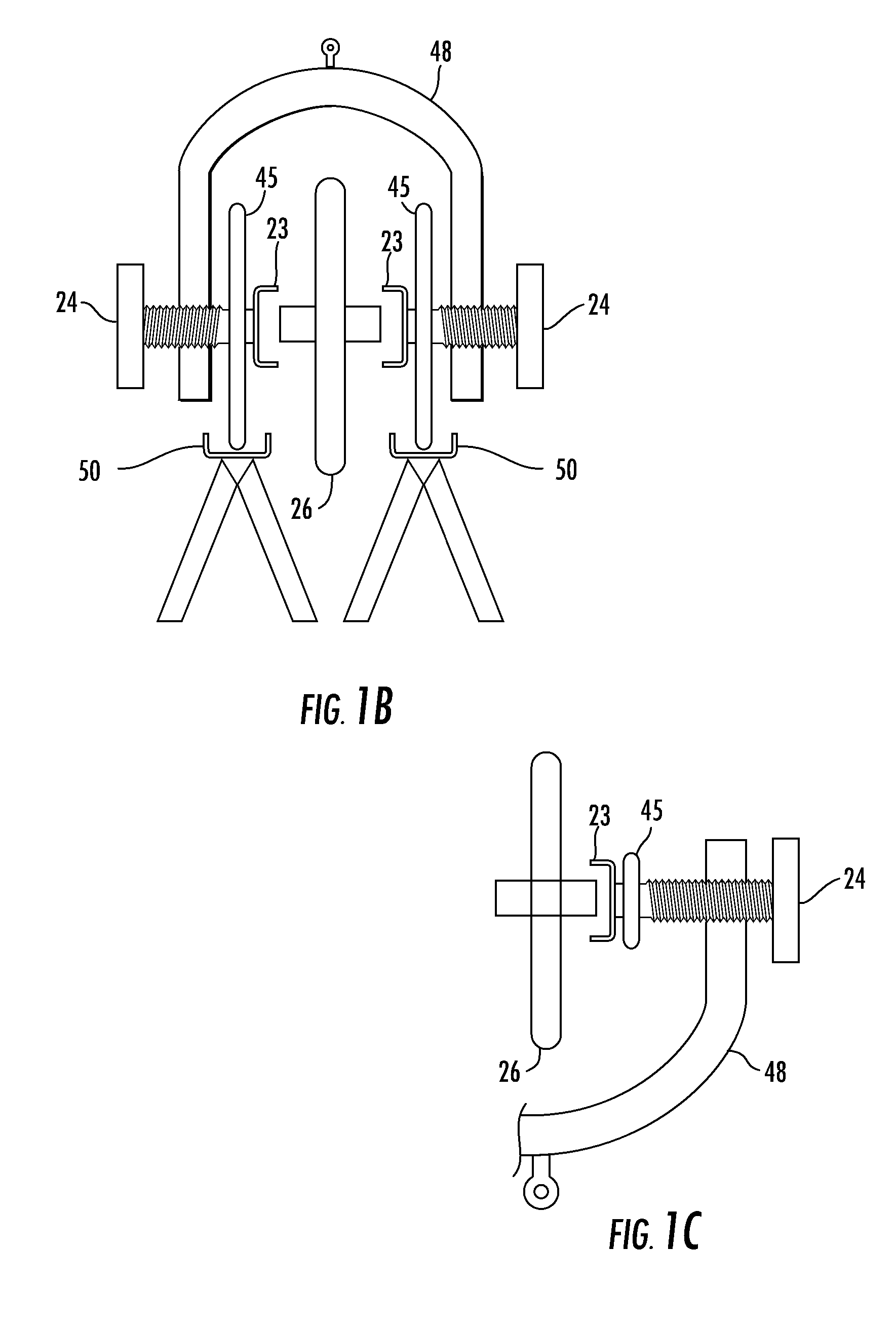

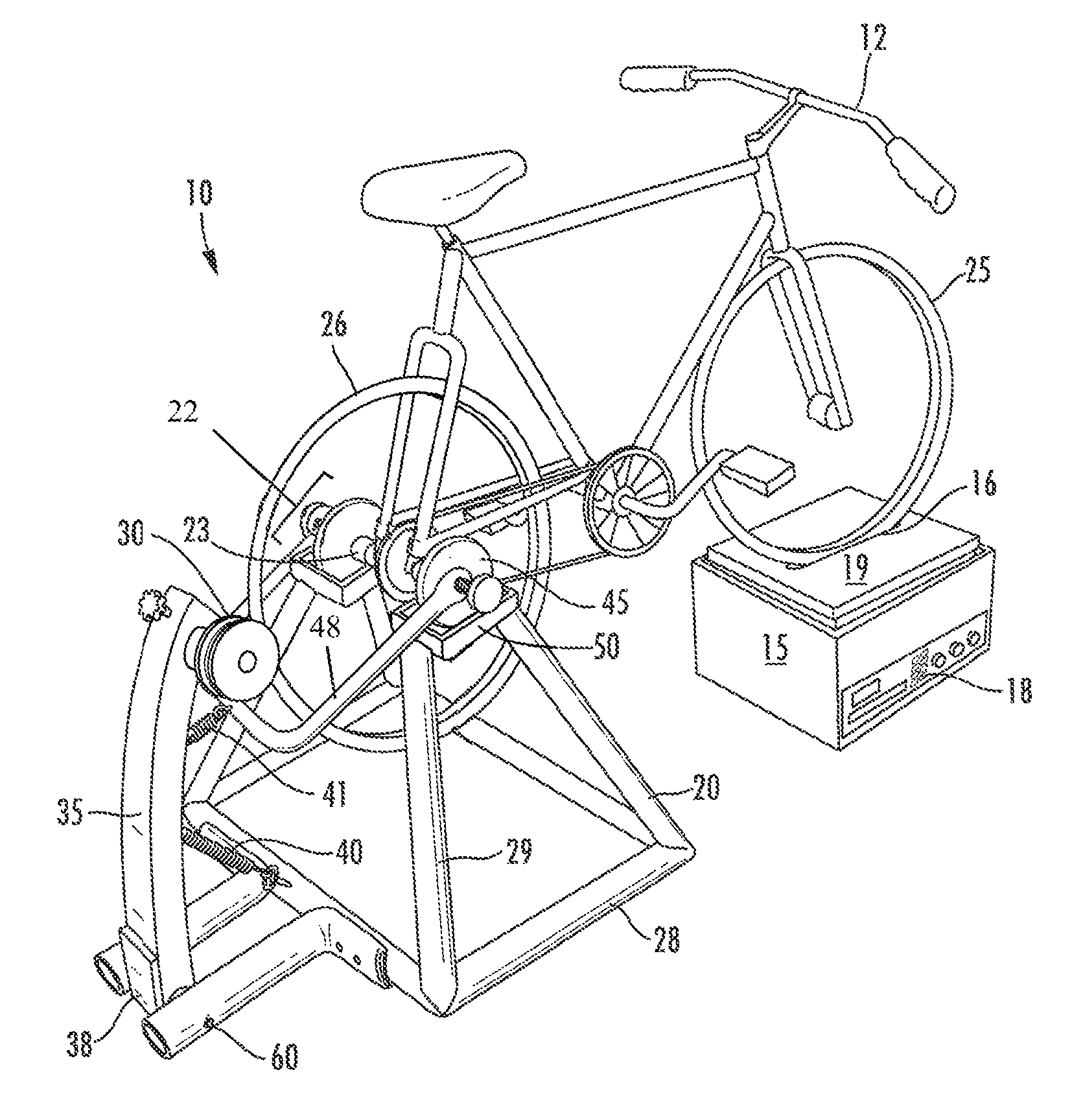

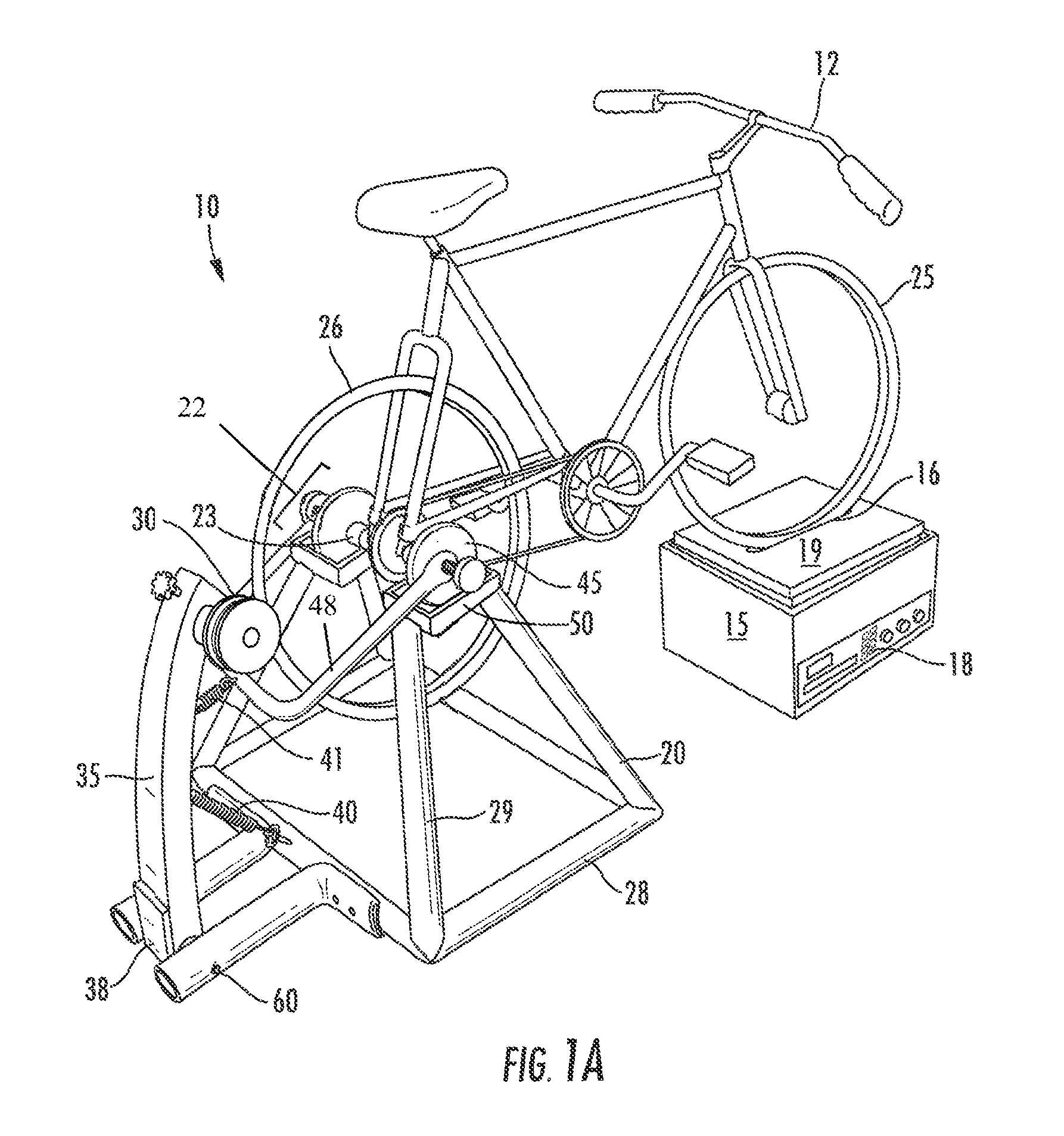

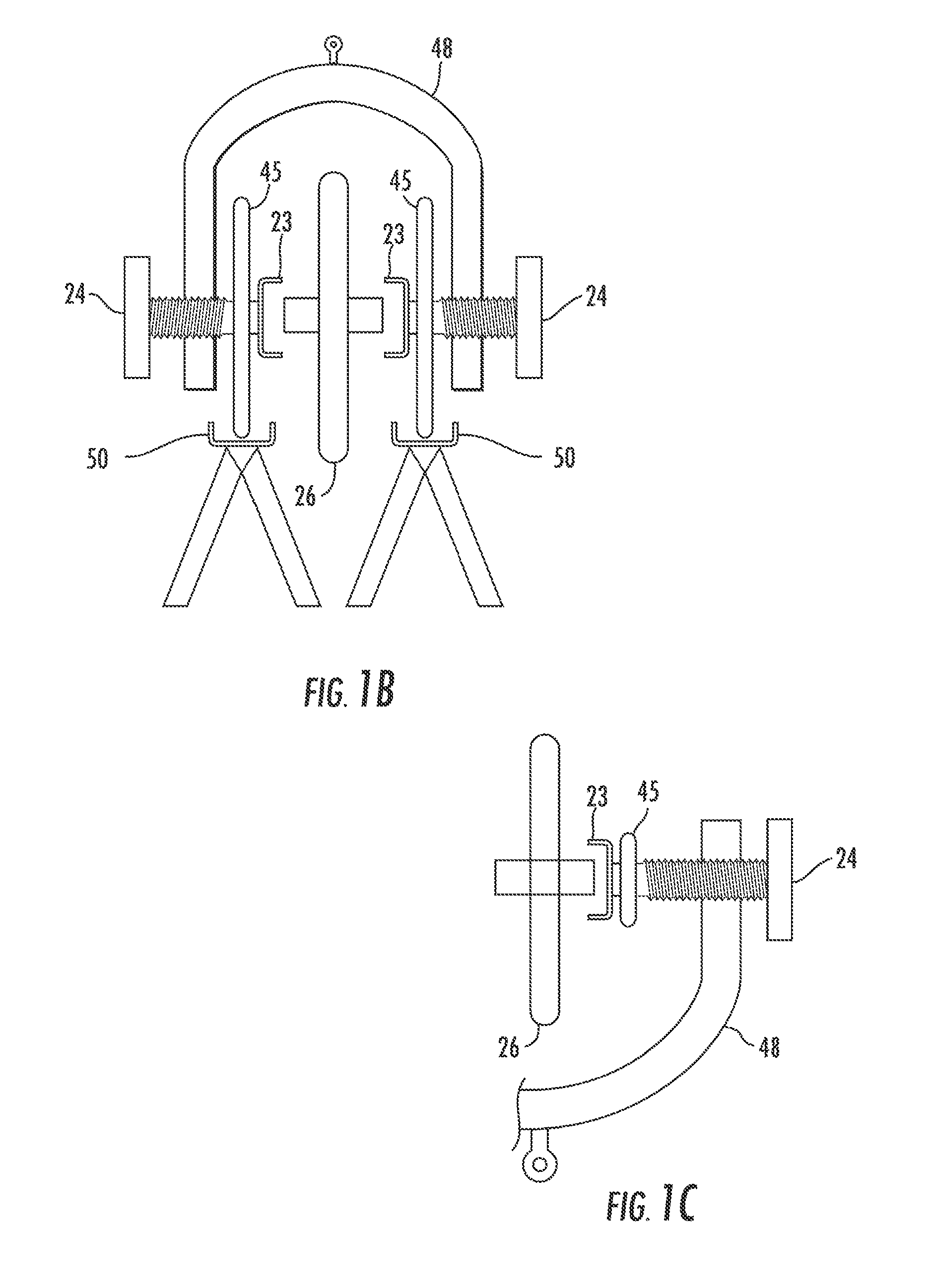

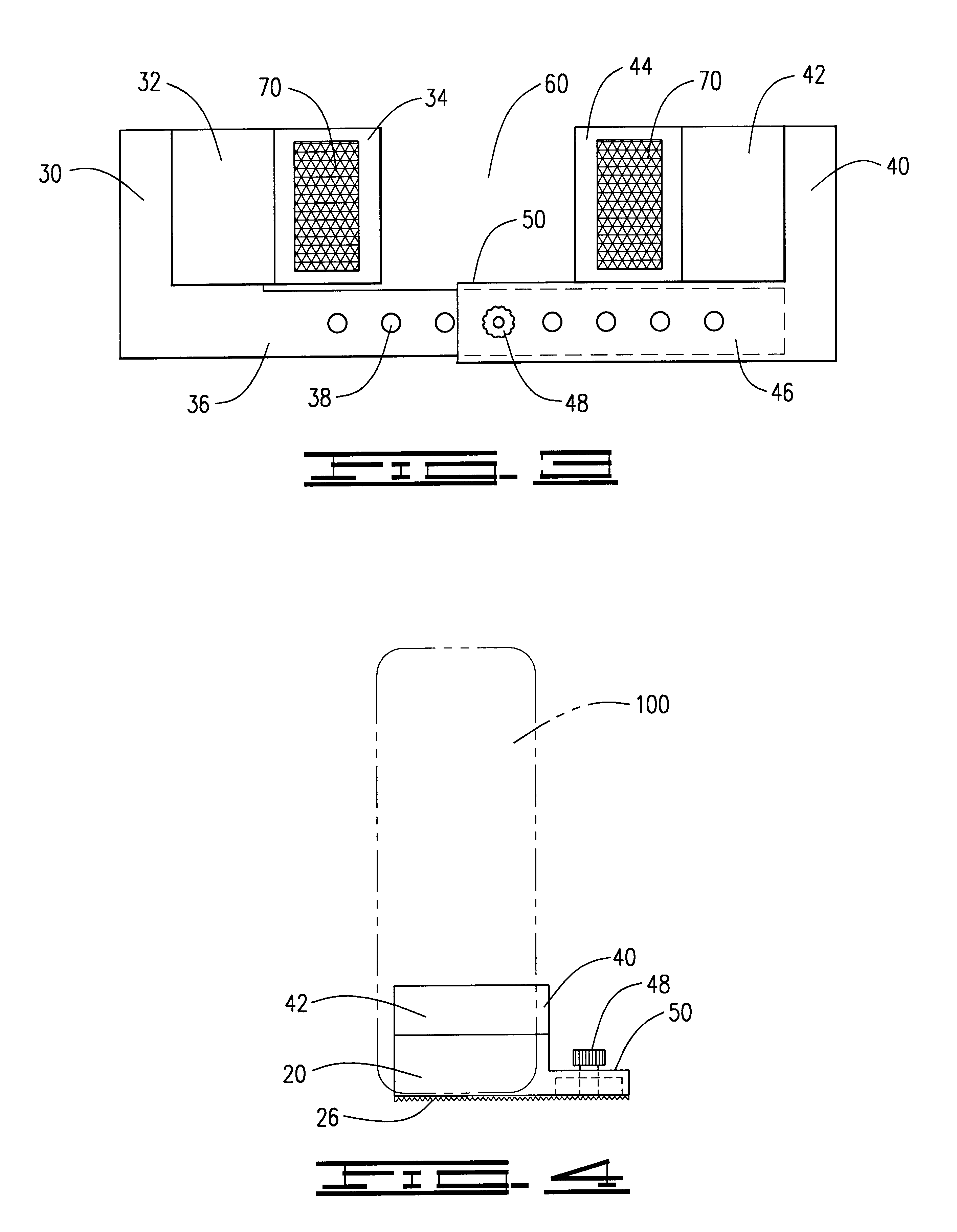

Bicycle trainer with variable resistance to pedaling

ActiveUS7766798B2Improve the ride experienceHigh densityCosmonautic condition simulationsFrictional force resistorsEngineeringTire rotation

Owner:MANIAC HLDG LLC

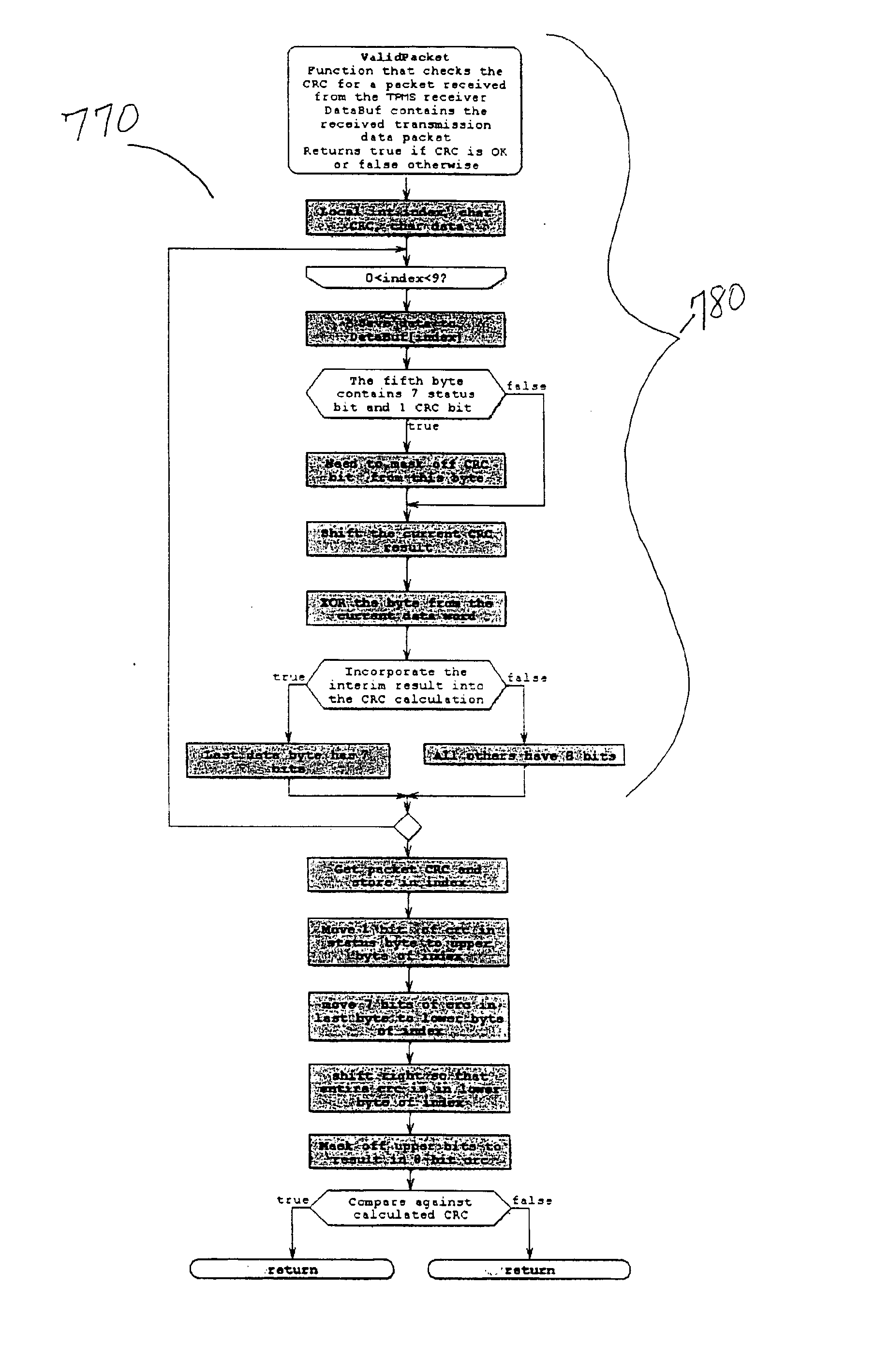

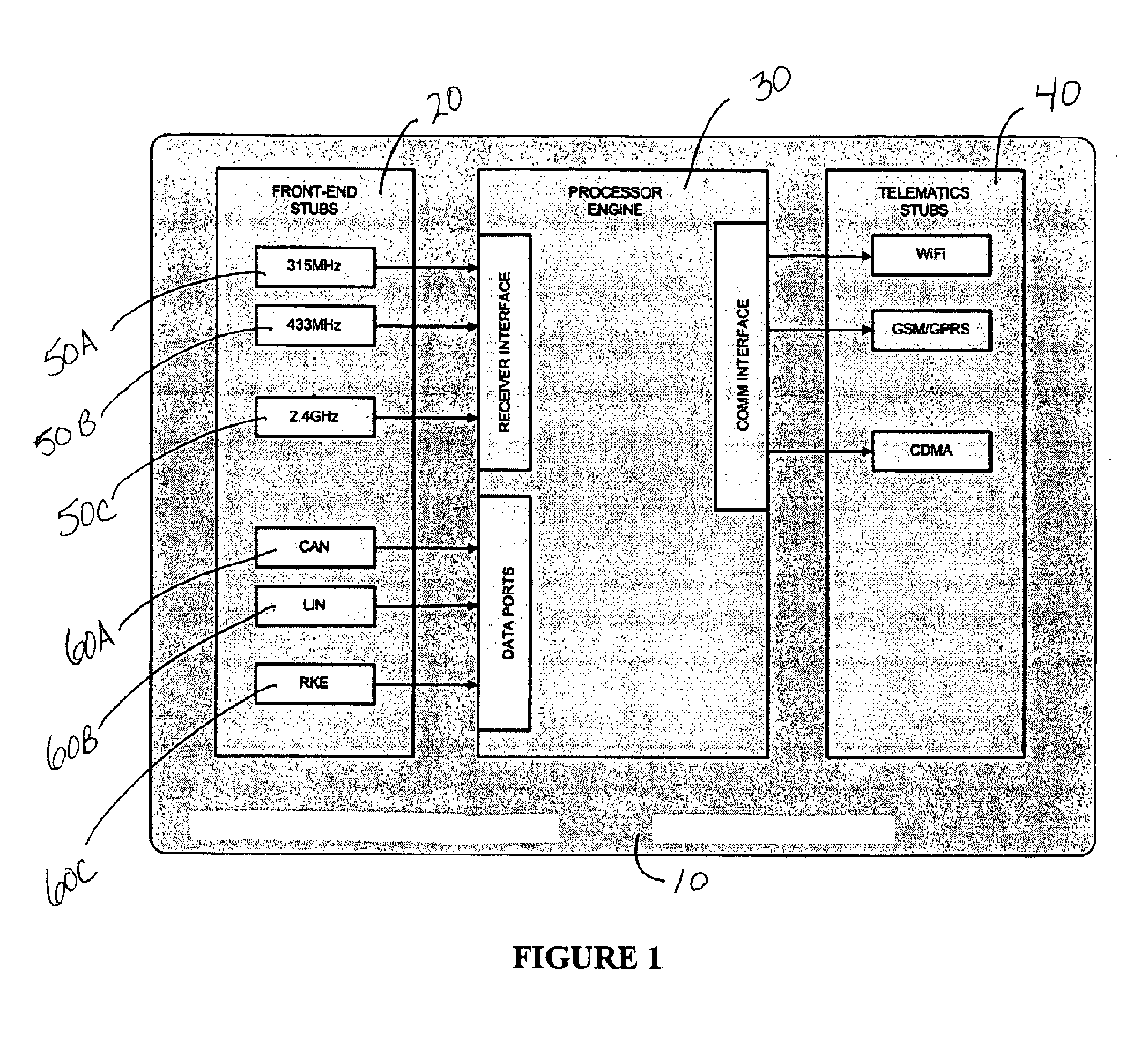

Universal Tire Pressure Monitoring System and Wireless Receiver

InactiveUS20080024287A1Easy to analyzeEfficient and optimized movement and transmissionVehicle testingRegistering/indicating working of vehiclesInformation processingEngineering

The present invention provides a universal receiver (OTR) device which functions within a vehicle in the “under-the-hood” (UTH) environment such that various types of tire pressure management system (TPMS) device, located within, upon or near a vehicle's tires can transmit tire information, such as the transmitter identification number (TIN), the tire unique identifier (TUID), the vehicle identification number (VIN), tire pressure, tire temperature, tire rotation, and other tire relevant data, to the OTR for further processing regardless of frequency, data transfer speed, or data format of the TPMS device. The OTR device in sequence: identifies the TPMS device, receives the tire information from the TPMS device, and processes the tire information into date records for efficient and optimized transmission of such data records for future analysis both within and off a vehicle. The OTR also interfaces with various types of telematics devices, regardless of the type of transmission or protocol used, by identifying the type of telematics device. The OTR also stores or retrieves information related to various telematics and TPMS devices in order to identify these devices. For example, an automotive manufacturer, dealership, or tire distributor would be able to select various manufacturers' TPMS and telematics devices for installation within the vehicle and with the OTR collect previously captured TPMS data for further analysis.

Owner:BOYLE SEAN ROBERT +2

Bicycle trainer with variable resistance to pedaling

ActiveUS8439808B2Improve the ride experienceHigh densityFrictional force resistorsMovement coordination devicesTire rotationVariable resistance

Owner:MANIAC HLDG LLC

Integrated self-powered tire revolution counter

ActiveUS20060006991A1Enhanced advantageAccurate countRegistering/indicating working of machinesNavigation instrumentsMicrocontrollerElectricity

A self-powered tire revolution counter includes a motion sensitive power generation mechanism, a power conditioner, a pulse detector, a microcontroller, and, optionally, a radio frequency (RF) transmitting device. In one exemplary embodiment, the power generation mechanism corresponds to a piezoelectric patch that, during movement, provides both operating electrical power and pulsed signals indicative of tire rotation. The power conditioner receives a generator signal from the power generation mechanism and produces a conditioned output voltage that can be used to power associated electronic devices, including the microcontroller. The pulse detector receives the generator signal and produces a detection signal whenever the generator signal meets a predetermined condition. The microcontroller is programmed to determine current and lifetime-accumulated values of selected pulse indications in the detection signal that meet predetermined criteria. Data corresponding to tire environment related parameters such as temperature, pressure, tire deflection, and / or vehicle speed may be stored in the microcontroller at times during tire rotation as power is supplied from the power generation mechanism through the power conditioner. Additional data may be supplied to the microcontroller directly from an external source and read from the microcontroller either by direct electrical contact or via selective RF transmission.

Owner:MICHELIN RECH & TECH SA

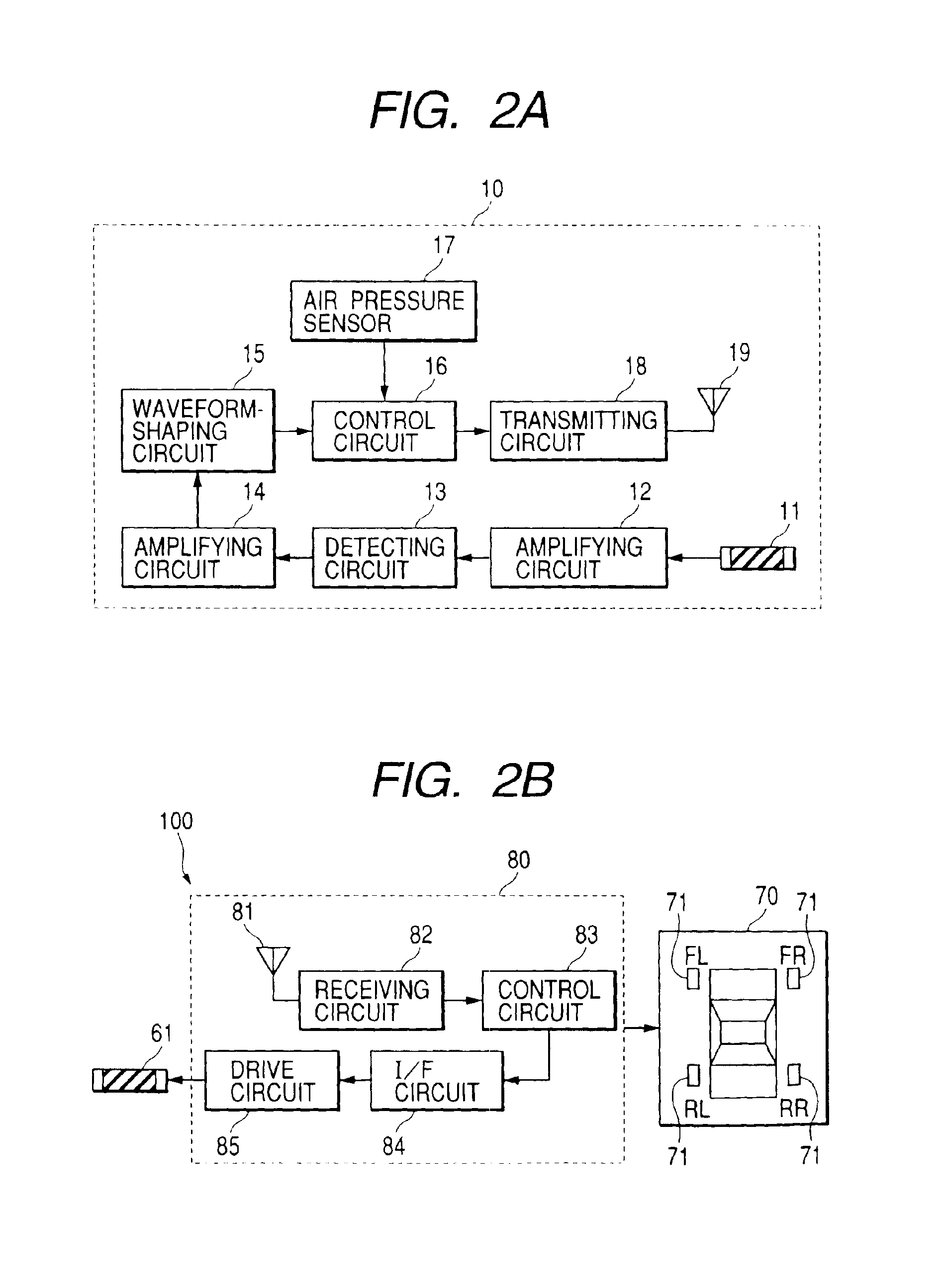

Tire air pressure monitoring system

InactiveUS20060012469A1Precise positioningTyre measurementsBurglar alarm by hand-portable articles removalTire rotationAtmospheric pressure

A tire air pressure monitoring system is provided that comprises a transmitting device, a receiving device, and a tire identification number registration device. The transmitting device is mounted on a wheel of a vehicle, and configured and arranged to wirelessly transmit a signal indicative of at least tire air pressure information of a tire coupled to the wheel and a tire identification number assigned to the wheel. The receiving device is mounted on the vehicle, and configured and arranged to receive the signal transmitted from the transmitting device. The tire identification number registration device is configured to estimate a position of the wheel with respect to the vehicle based on correlation information corresponding to an extent of a correlation between strength of the signal and a tire rotational angle of the wheel, and to register the tire identification number with the position of the wheel.

Owner:NISSAN MOTOR CO LTD

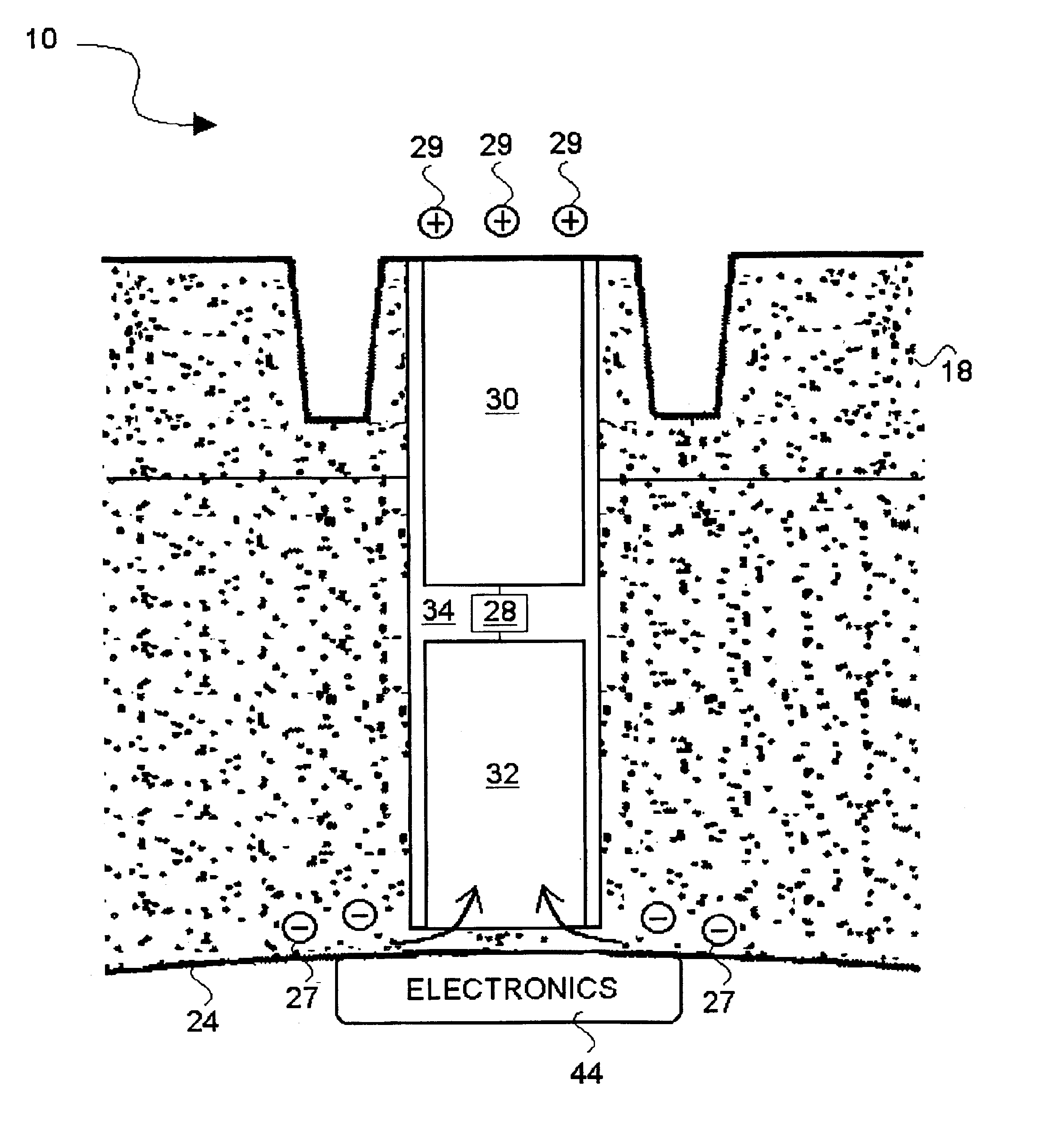

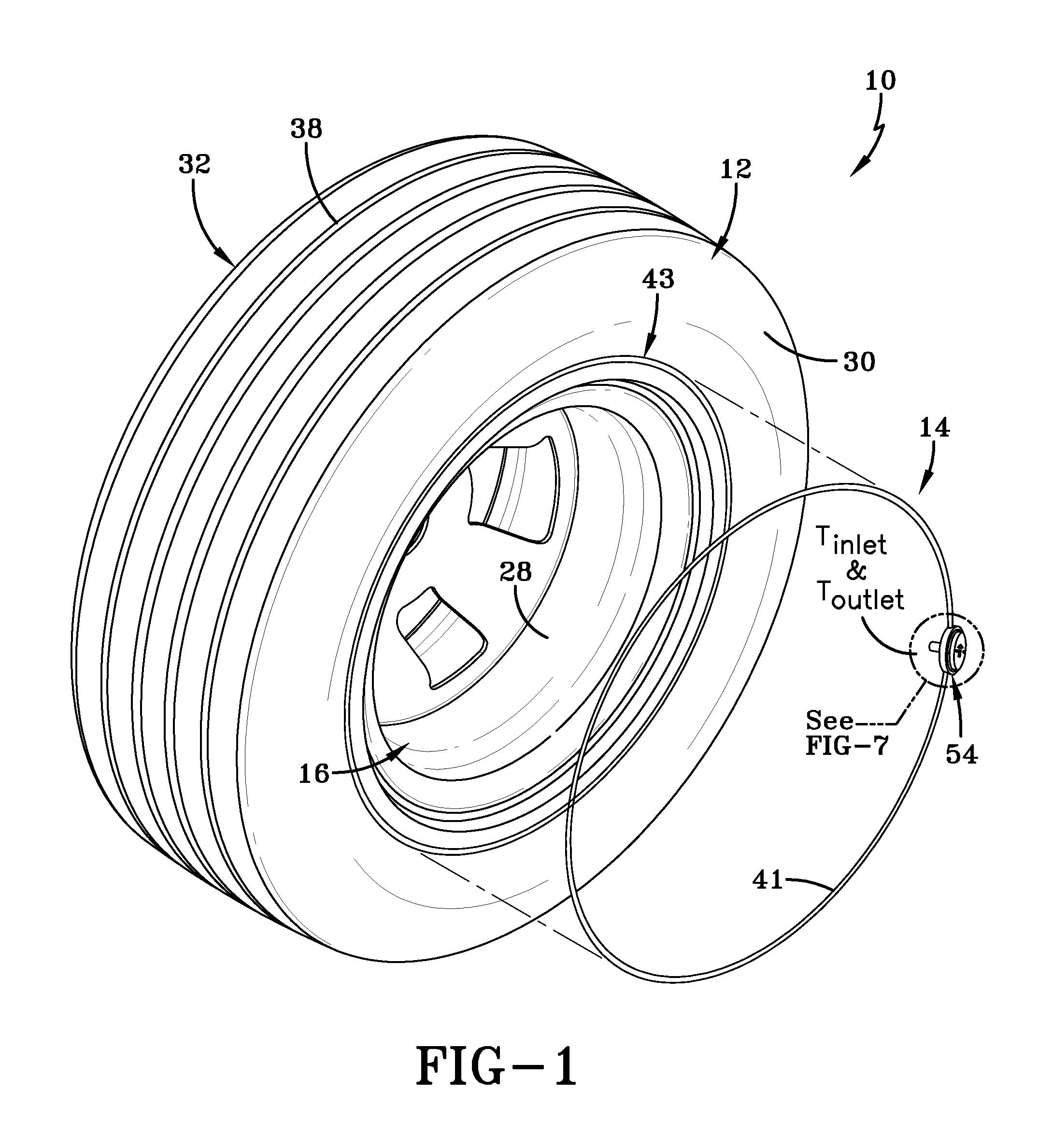

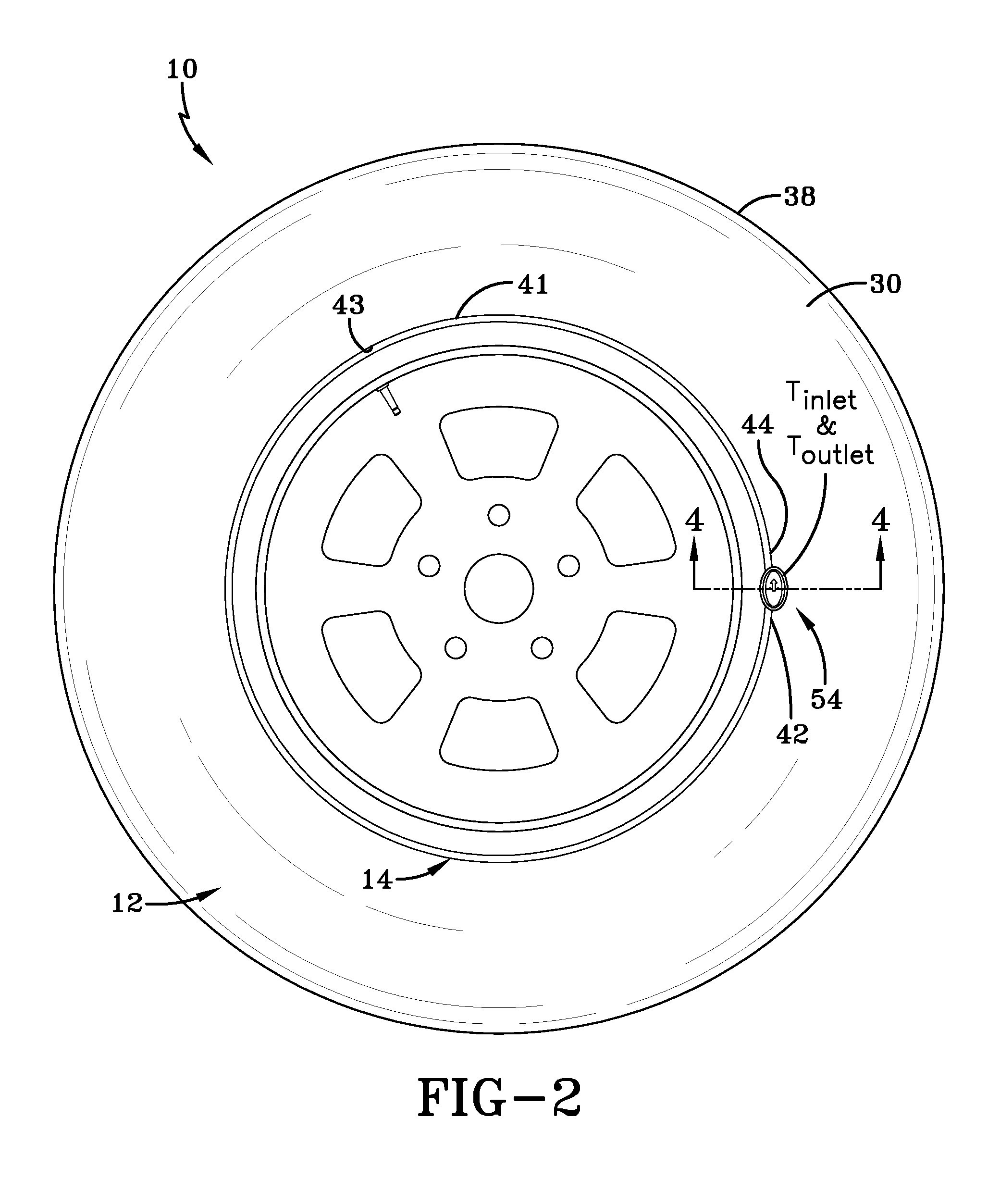

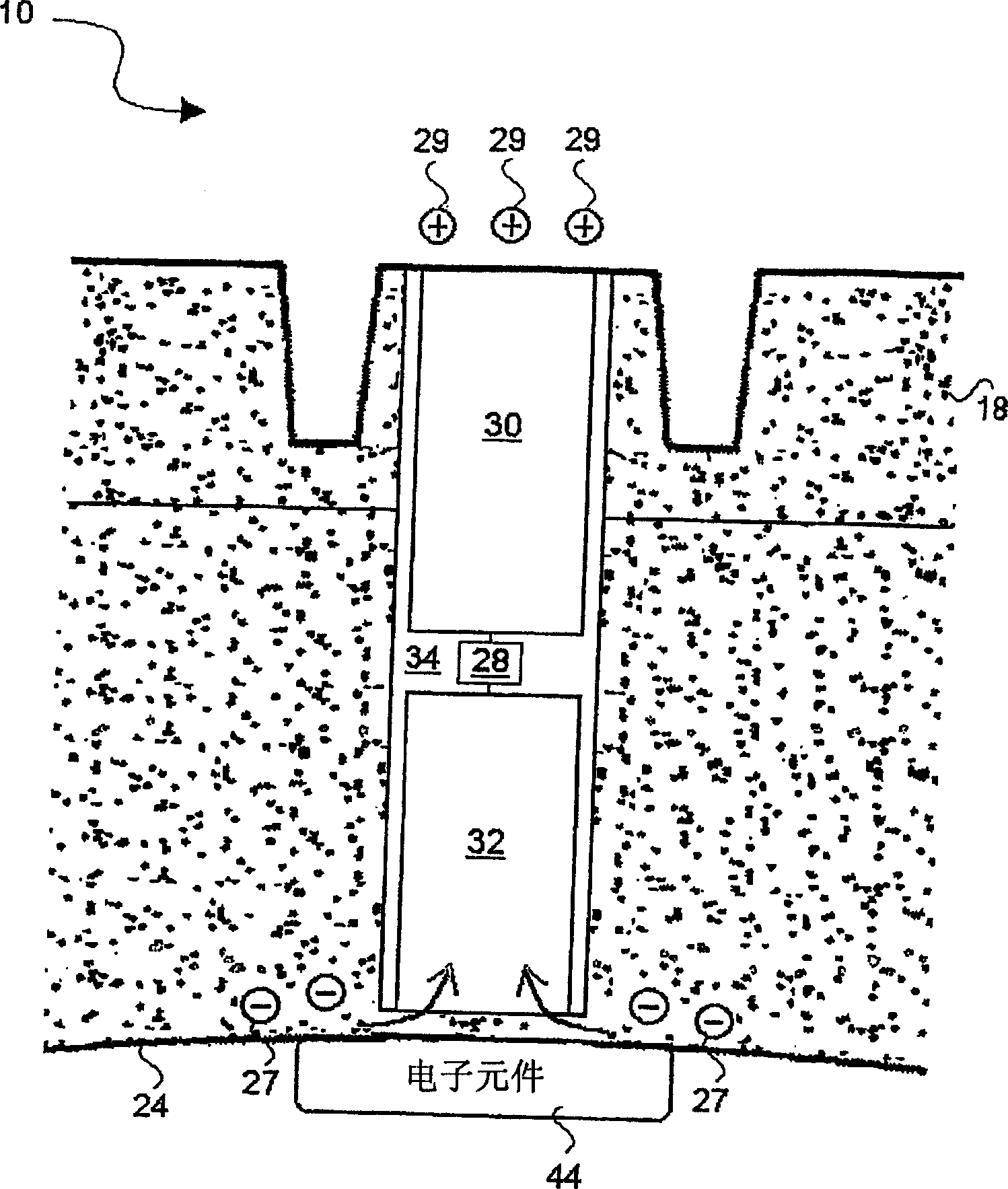

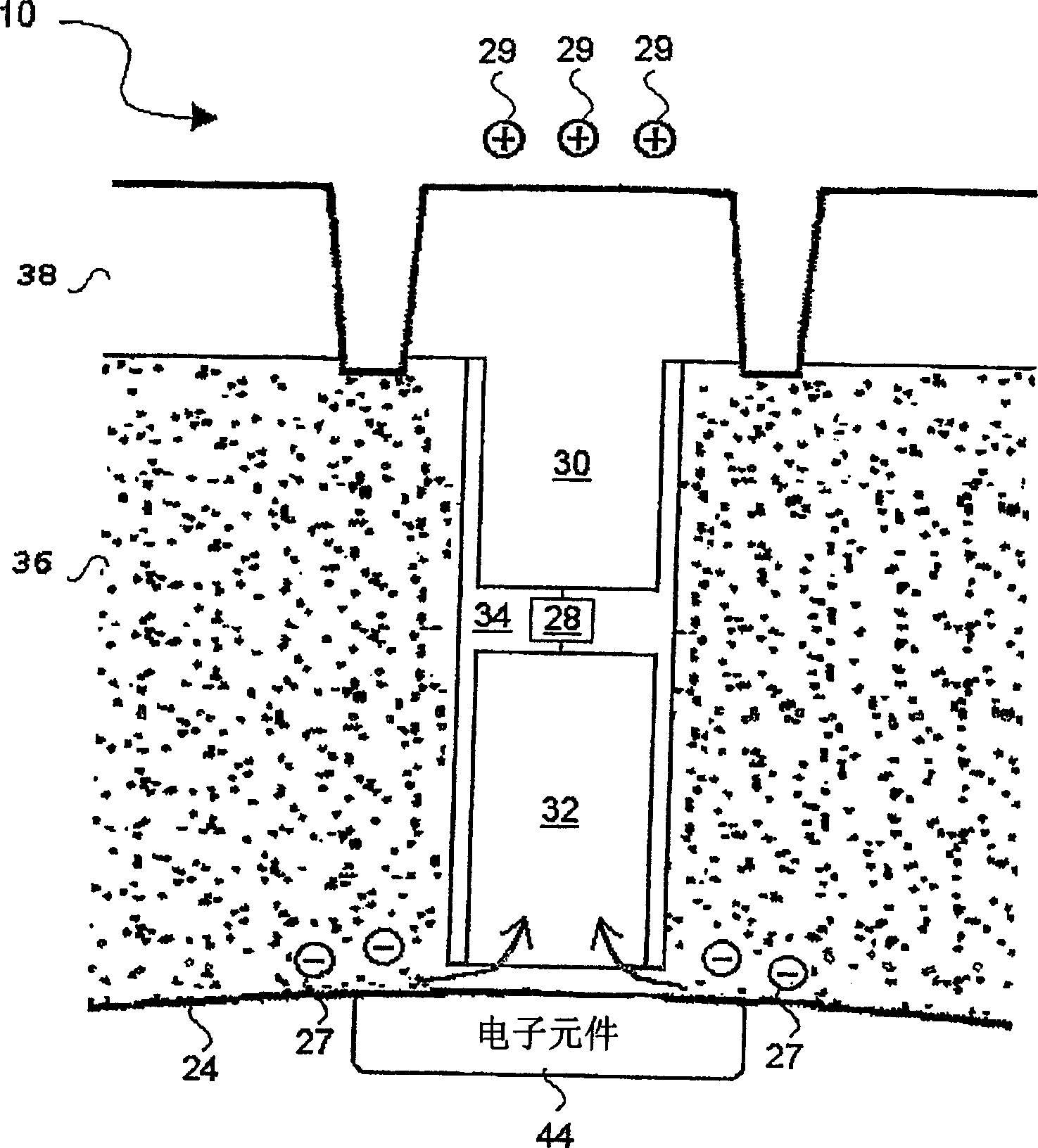

System and method for harvesting electric power from a rotating tire's static electricity

ActiveUS6847126B2Reduce amountFunction increaseTyresMachines/enginesElectric power systemElectrical battery

A power harvesting solution concerns a generally non-conductive tire structure that is formed with at least one defined conductivity path through which static electricity accumulated in the tire structure during tire rotation can dissipate to ground. Such conductivity path is formed from a portion of conductive material that may be partially surrounded by additional insulative material to restrict the flow of electric charge to ground. An energy storage device, such as a capacitor or rechargeable battery, is coupled with the conductivity path and configured to store selected amounts of the electric charge dissipating through the conductivity path. Various diode elements may be provided in combination with the energy storage device to prevent reverse discharging of and to provide voltage protection for the energy storage device. Sufficient accumulations of such harvested energy can then power tire electronic systems, including various condition-responsive devices (i.e., sensors, etc.) a revolution counter, a radio frequency (RF) device, a rechargeable battery or a lighting device.

Owner:MICHELIN RECH & TECH SA

Vehicle skidstop

A device for stopping a moving vehicle, a strip placed in front of the vehicle to be stopped, said strip having a plurality of spikes for entwining the tires, a cable attached to a spike which unwinds and entwines the axle of the wheel proximate to the tire for and stopping its rotation or otherwise impedes wheel or tire rotation as the cable anchors to the vehicle underside.

Owner:SHACKELFORD BRIAN +3

Magnetically coupled tire pressure sensing system

ActiveUS6854335B1Low costImprove securityFluid pressure measurement using inductance variationTyre measurementsTire rotationDual purpose

A tire pressure reporting and warning system employs low-cost passive magnetically coupled pressure senders within the tires. These senders employ permanent magnets that rotate in response to pressure and may conveniently be mounted on the valve stem. A sender comprises a high-permeability helical ribbon that translates in response to pressure and penetrates a magnetic circuit. The magnetic circuit rotates into alignment with the helical ribbon. A novel feature of this invention is the dual-purpose use of the magnet both as a means for producing rotation in response to pressure and simultaneously for producing the remotely sensed external magnetic field. The direction and strength of the external field depends both on the rotation of the magnet with respect to the tire and on the overall orbital motion as the tire rotates. Remote pressure readers at each wheel respond to the magnetic field components and interpret the response asymmetry in terms of tire pressure by continuously calculating response skew as the tires rotate. Analyzing skew obviates the need for tire rotation sensing and timing and eliminates magnetic strength effects. No special alignment is required between senders and readers, so the readers may be mounted rather arbitrarily nearby the vehicle wheels.

Owner:BURNS ALAN ALEXANDER

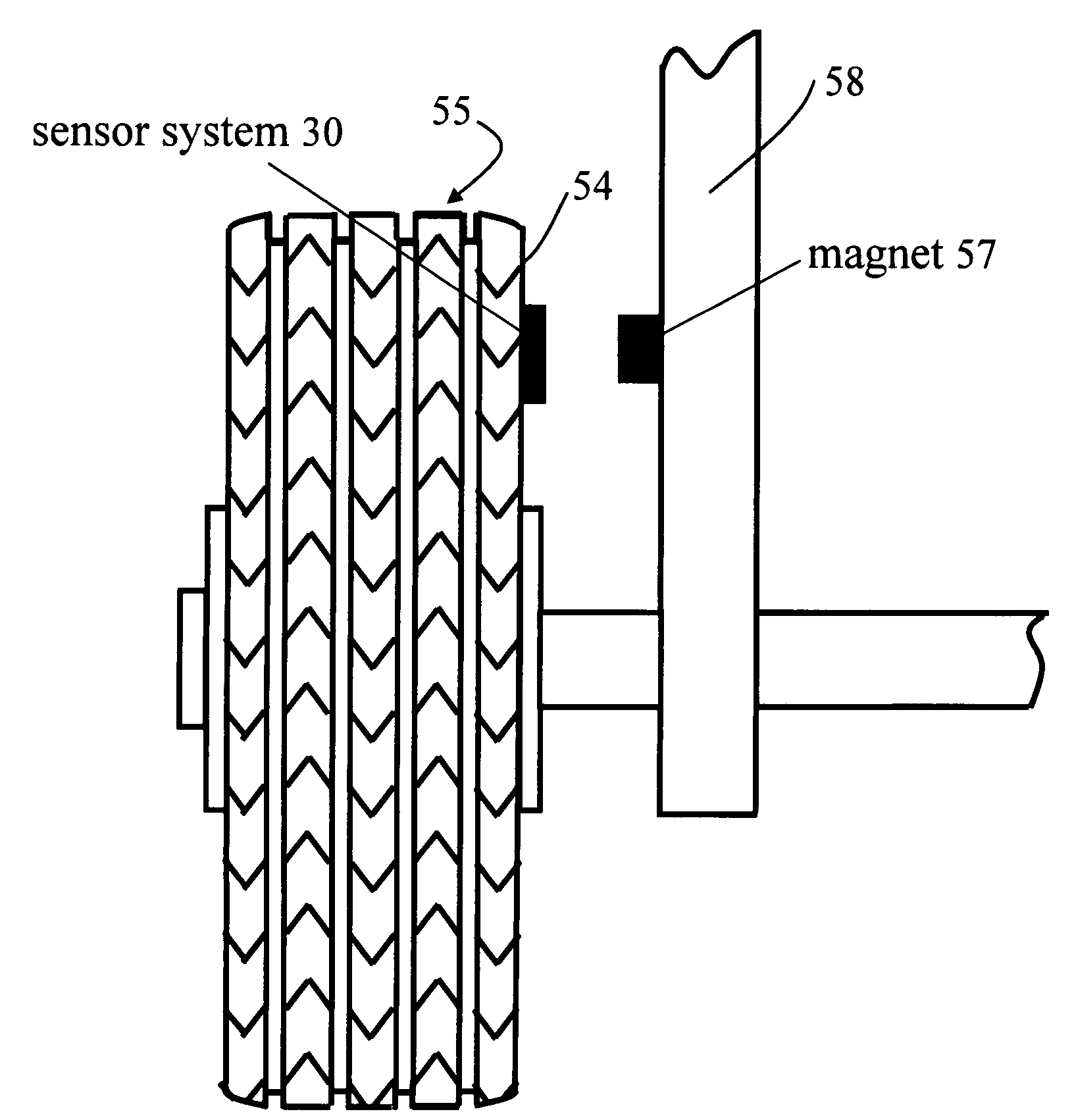

Tire parameter monitoring system with inductive power source

InactiveUS7363806B2Simple and inexpensive to implementEliminate needTyre measurementsRoads maintainenceVoltage multiplierMonitoring system

A battery-less tire parameter sensor system for monitoring a vehicle tire parameter such as pressure and temperature. A sensor assembly has a power system, a processor / transmitter, a sensor, and a power coil mounted on a substrate. This assembly is mounted on or in the side wall or tread wall of a tire. A magnet is mounted on the vehicle in proximity to the path of the power coil during tire rotation. The moving power coil passes through the magnetic field and generates operating voltage for the sensor assembly components. The power system includes a voltage multiplier, a voltage regulator, and a storage capacitor. Two or more sensor assemblies can be mounted on the same tire to monitor different parameters.

Owner:SILICON VALLEY MICRO C CORPORATION

Pneumatic radial tire including false dividing groove

A pneumatic radial tire for passenger car has a directional tread pattern (with respect to a rotating direction of tire) defined by a circumferential center groove, a plurality of directional slant grooves disposed at intervals in the circumferential direction of the tire, and a plurality of blocks formed at intervals in both circumferential and axial directions of the tire, in which these blocks form a pair of central block rows and a pair of side block rows, and surfaces of acute corner portions of blocks constituting the central block row and the side block row located outward and inward in the axial direction of the tire at given length, and chamfered acute corner portions of blocks constituting the central block row and the side block row are connected to each other at their chamfered shallowest tips.

Owner:BRIDGESTONE CORP

Tire stop lock

InactiveUS6725979B1Reduce the possibilityQuick installationBraking element arrangementsPortable braking systemTire rotationAutomotive engineering

The invention is a safety lock applied to a vehicle wheel during a road stop to prevent the vehicle from moving or being driven away during the stop. This safety lock would be applied to any tire on the vehicle by law enforcement or safety inspectors during the stop, the safety lock slid onto the tire from the outside of the tire, with friction enhanced chocks in front and in back of the tire, locking onto the tire to prevent the rotation of the tire, reducing the risk of injury or escape in the event an attempt is made to drive away during the road stop. It may also be used to secure a tire or wheel during maintenance or during an emergency roadside repair, the device compact enough to fit in the trunk of a car and light enough in weight to be carried by an average individual.

Owner:SNOOK KENNETH G

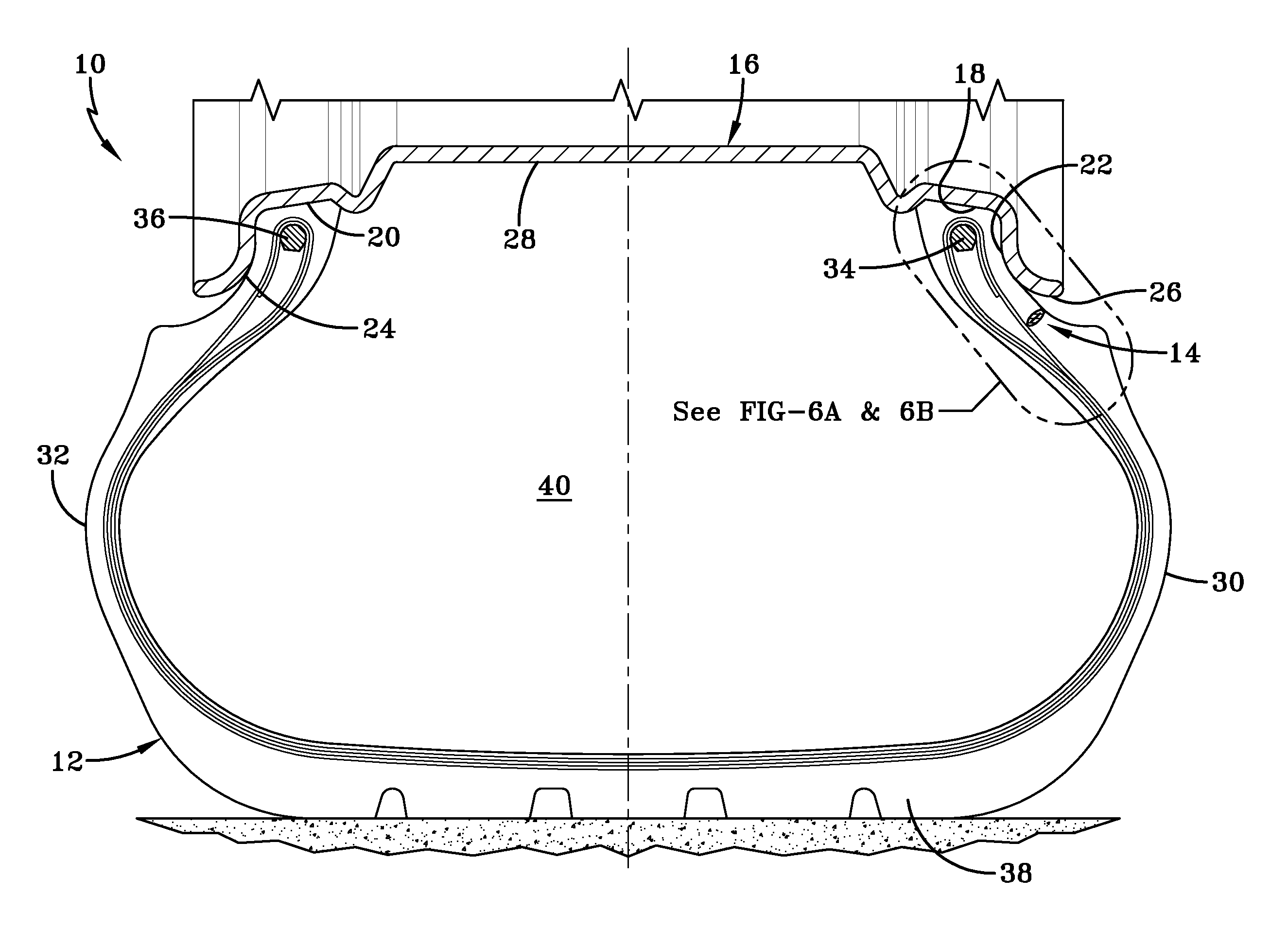

Self-inflating tire and pressure regulator

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to a regulator device. The regulator device regulates the inlet air flow to the air tube and the outlet air flow to the tire cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

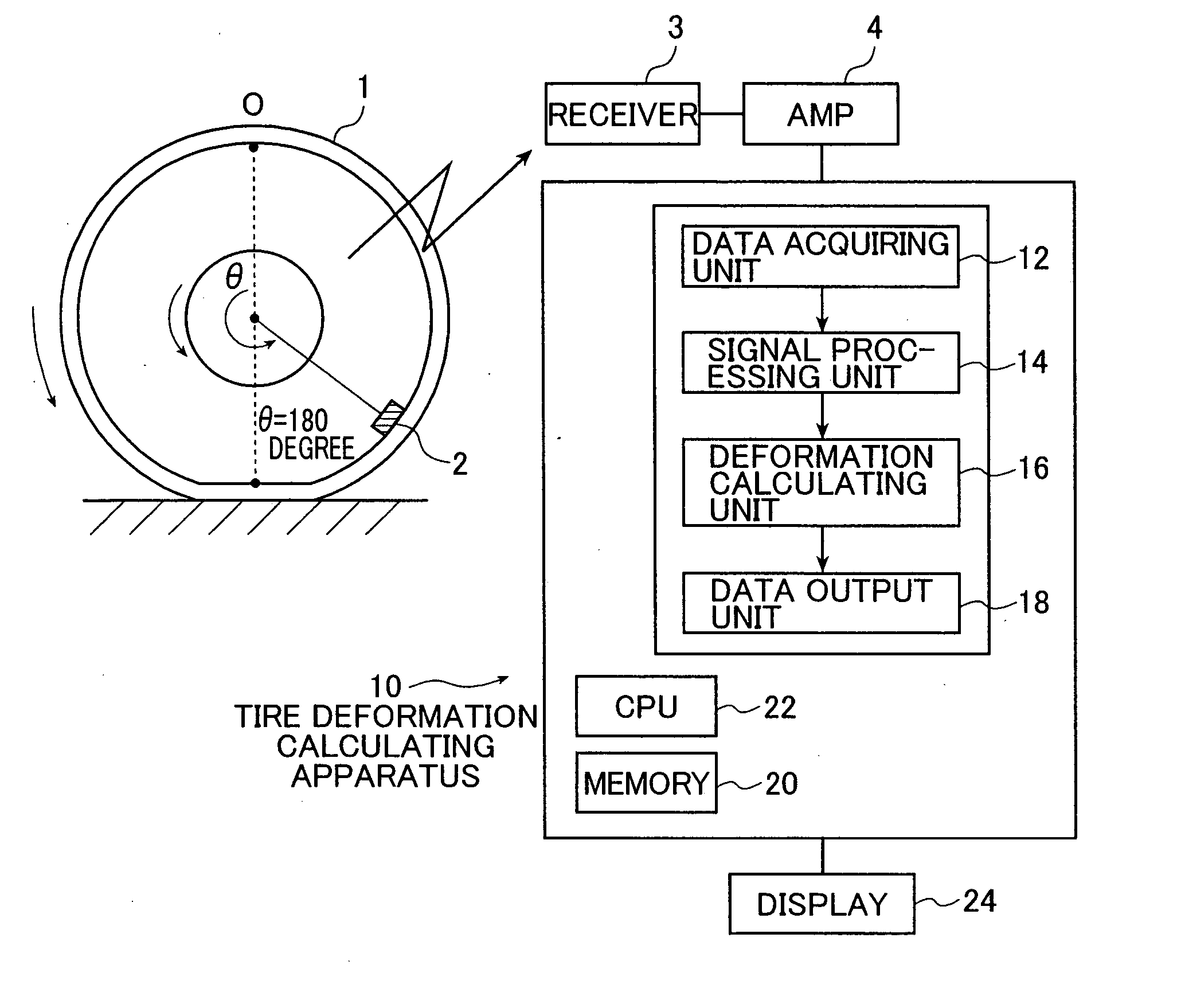

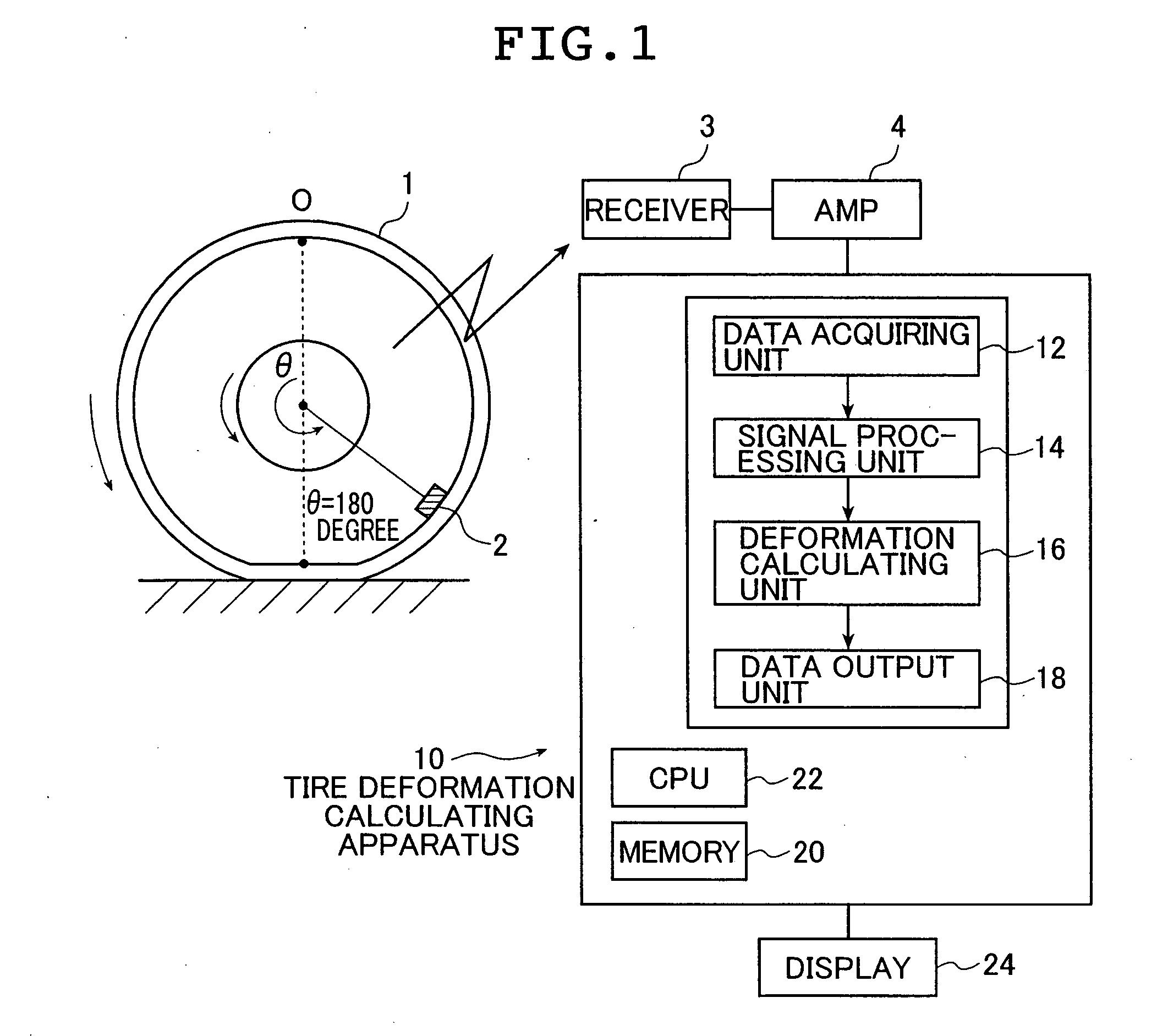

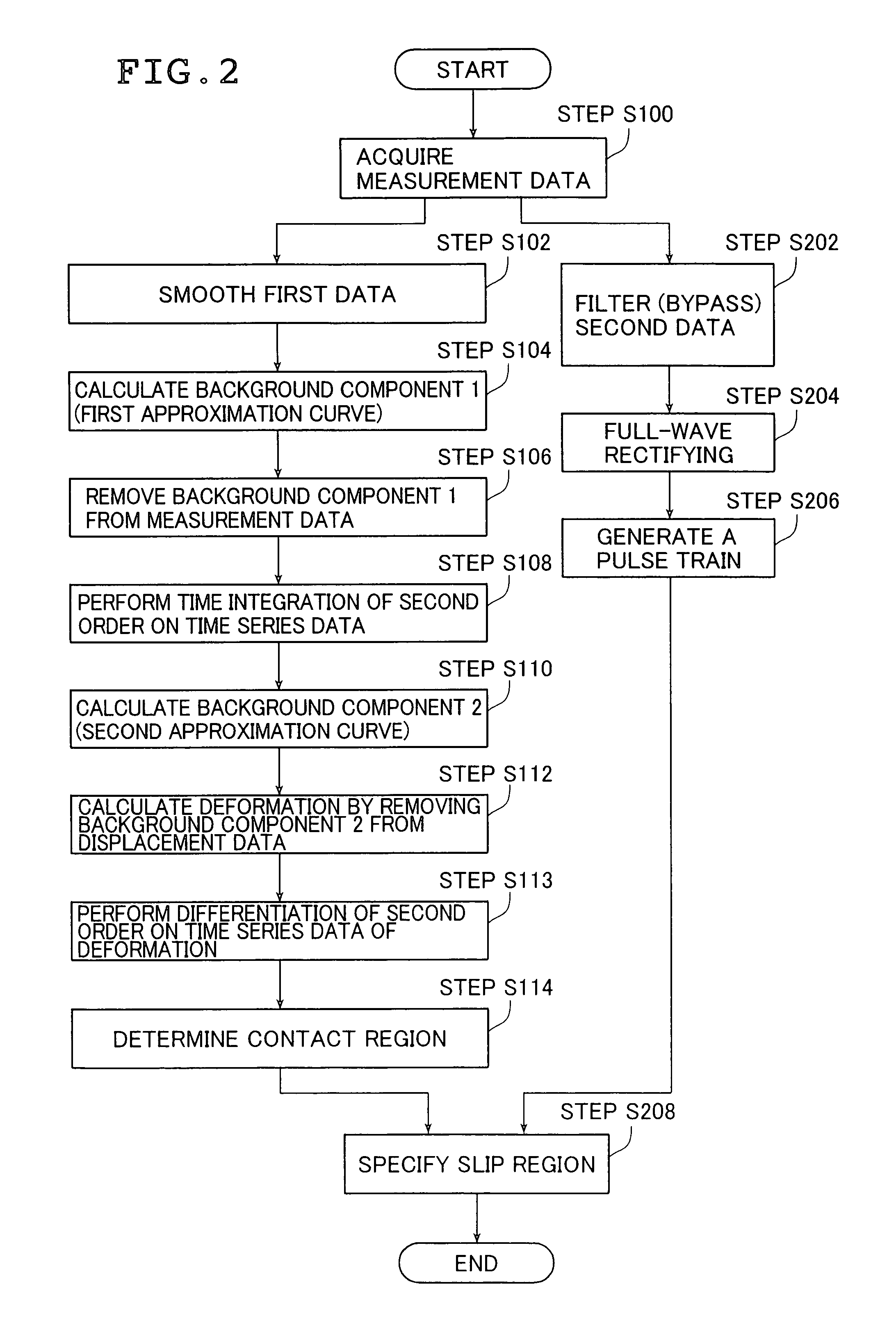

Tire Deformation Calculating Method And Tire Deformation Calculating Apparatus

InactiveUS20070213953A1Good coefficientImprove accuracyMeasurement arrangements for variableOptical signallingEngineeringRoad surface

A deformation of a rotating tire on a road surface is calculated the following. At first, time series data of acceleration extracted from measurement data of acceleration corresponding to one round of tire rotation is subjected to a time integration of second order to obtain displacement data so as to calculate the deformation at the tread portion. The time series data of acceleration and the displacement data in the non-contact region excluding a road surface contact region on the tire circumference at the tread portion are respectively approximated to calculate a first and a second approximation curves. The two approximation curves are subtracted respectively from the time series data of acceleration and the calculated displacement data, thereby extracting time series data of acceleration due to tire deformation and obtaining the deformation at the tread portion.

Owner:THE YOKOHAMA RUBBER CO LTD

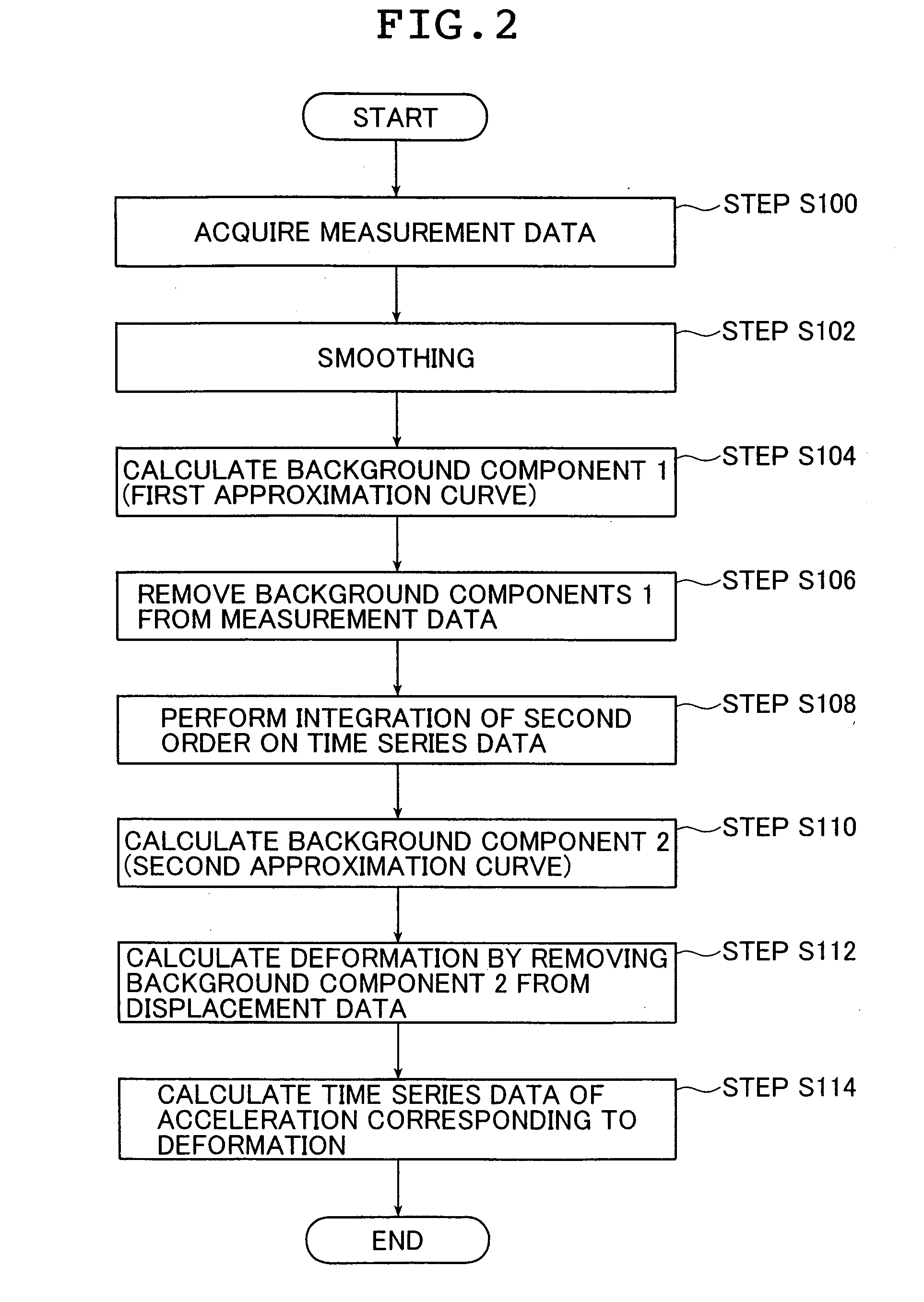

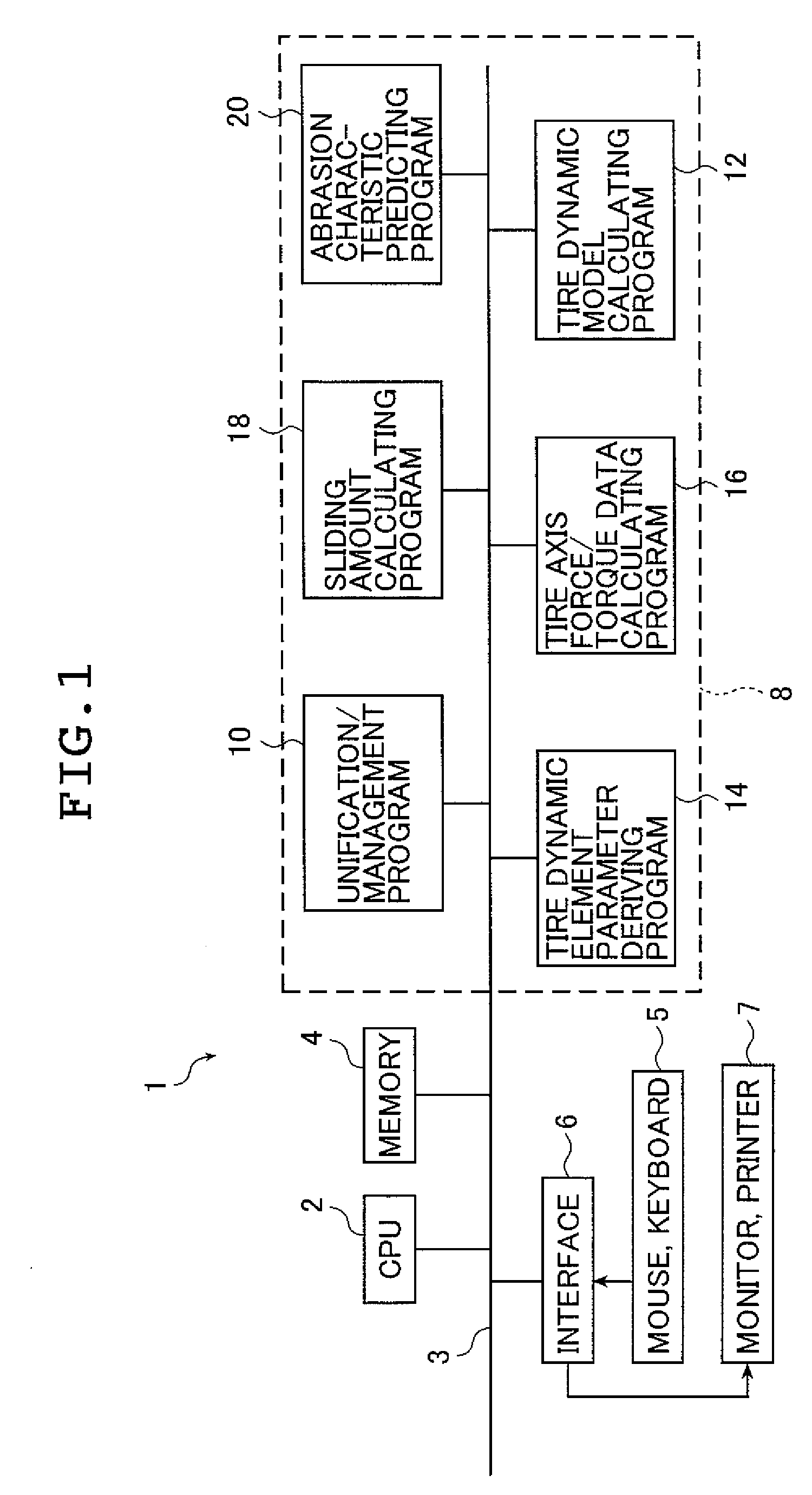

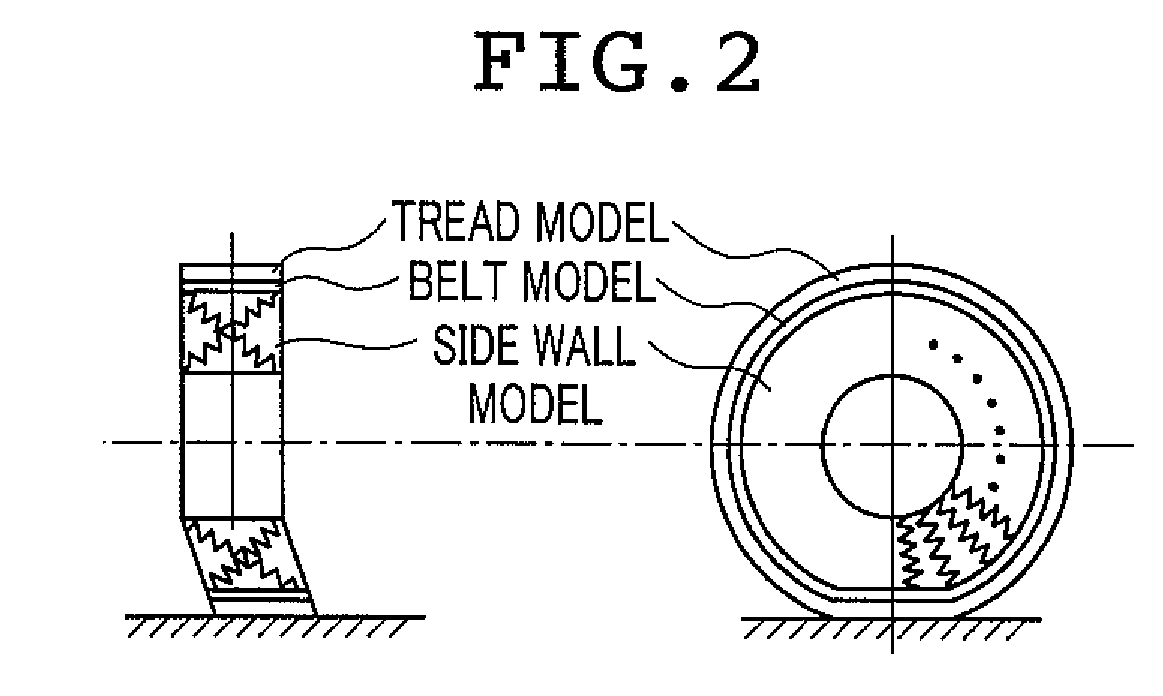

Tire Abrasion Predicting Method, Tire Designing Method, Tire Manufactring Method Tire Abrasion Predicting Sytem, and Program

ActiveUS20080228411A1Improve accuracyPlug gaugesAutomatic initiationsPredictive methodsDynamic models

In a prediction of abrasion characteristic of a tire, a characteristic curve of a tire axis force generated on a tire rotation axis at the slip ratio applied to the tire and changed depending upon the slip ratio is acquired. From the characteristic curve, values of tire dynamic element parameters determining the characteristic curve are derived based on a tire dynamic model constituted by the tire dynamic element parameters. Furthermore, a tire sliding amount based on a sliding region, the sliding region and an adhesive region formed on the contact patch of the tire at the applied slip ratio are calculated by applying the values of the tire dynamic element parameters to the model. Lastly, an abrasion characteristic of a tread part of the tire at the applied slip ratio is predicted by using the tire sliding amount with abrasion characteristic data of a tread rubber of the tread part. According to the prediction results, a tire is designed and produced.

Owner:YOKOHAMA RUBBER CO LTD

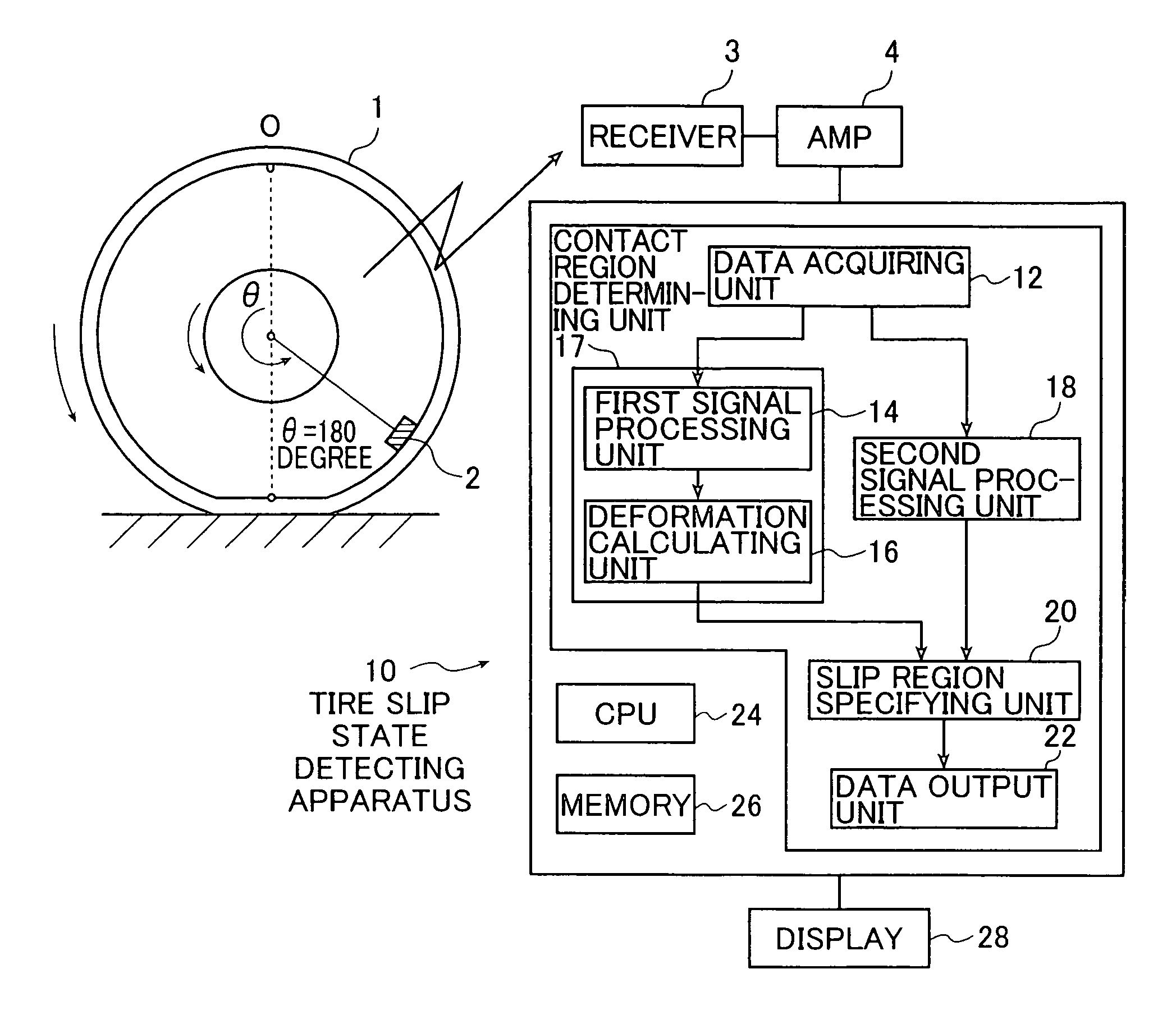

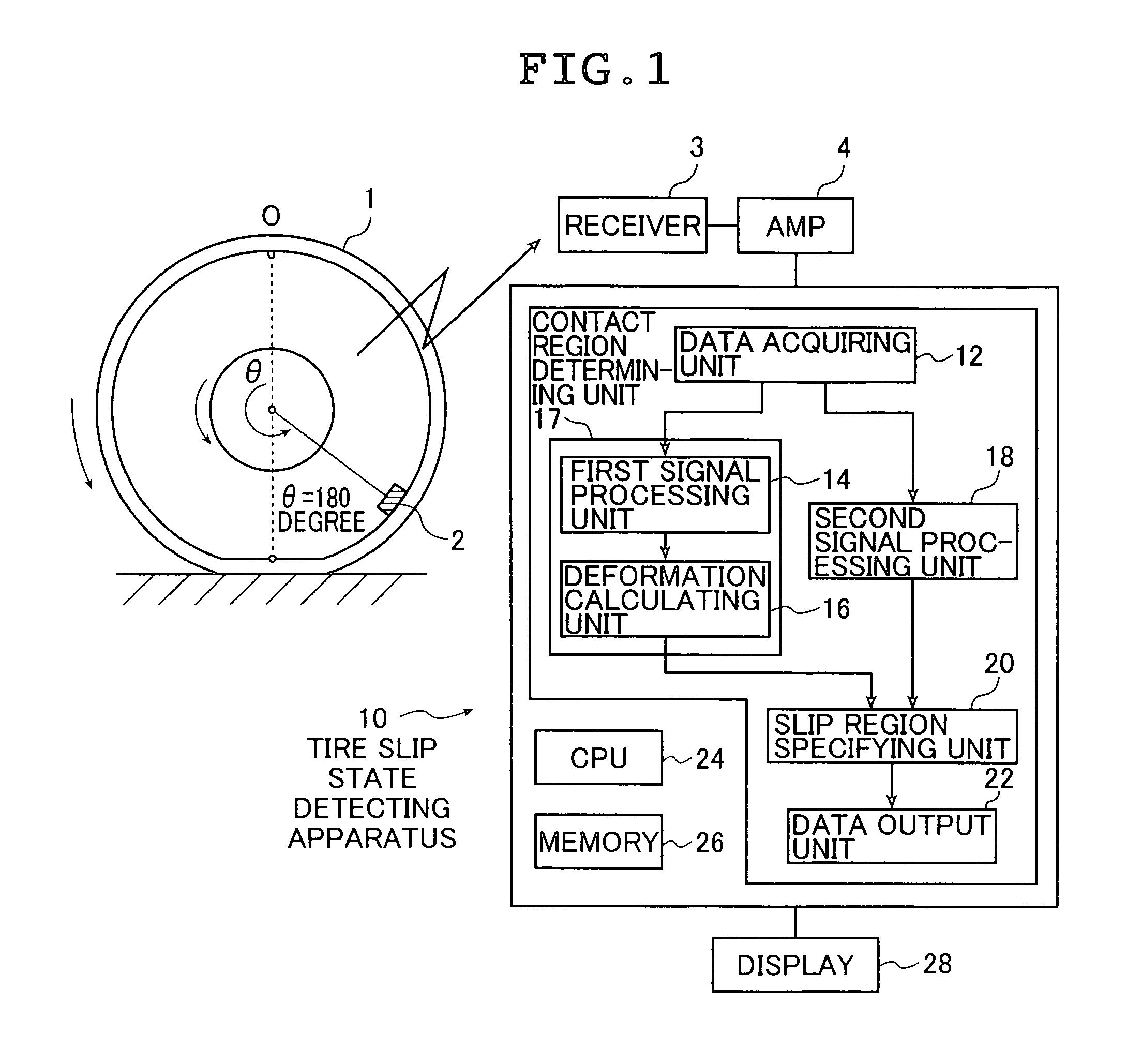

Tire Slip State Detecting Method And Tire Slip State Detecting Apparatus

ActiveUS20070205879A1Efficient identificationEfficient and accurate identificationSuspensionsOptical signallingEngineeringTire rotation

To detect a slip state in a contact region of a rotating tire on a road surface, first, the first radical direction data and the second width direction data of measurement data of acceleration at a tread portion of the rotating tire for a duration corresponding to one round of tire rotation are acquired. Second, time series data of acceleration due to tire deformation is extracted from the first radical direction data and displacement data is obtained by subjecting the time series data of acceleration due to tire deformation to a time integration of second order, thereby a deformation at the tread portion is calculated and a contact region of the rotating tire is determined from the calculated deformation. Next, from the second width direction data, a slip region within the determined contact region is specified based on vibration level of the second data.

Owner:THE YOKOHAMA RUBBER CO LTD

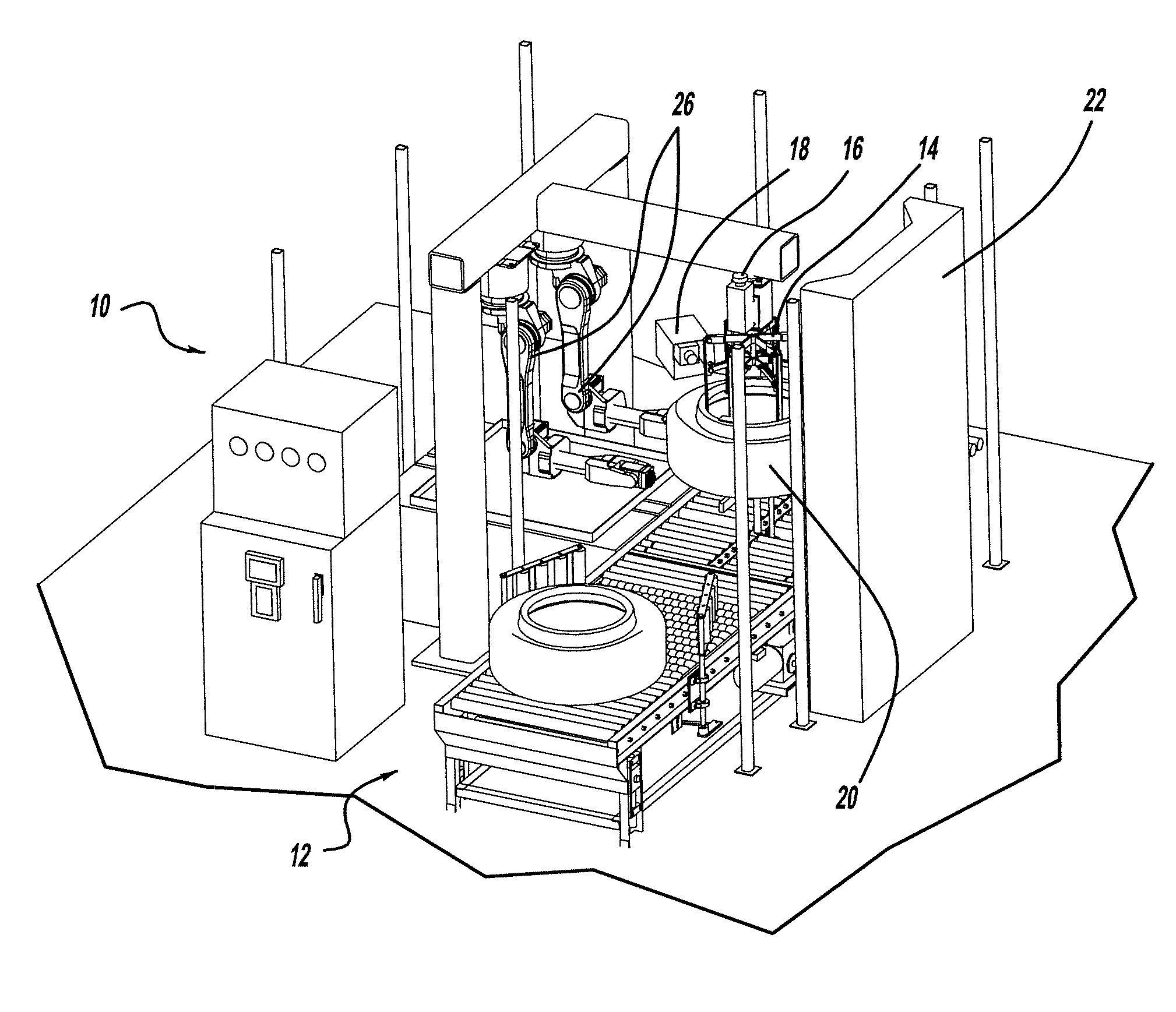

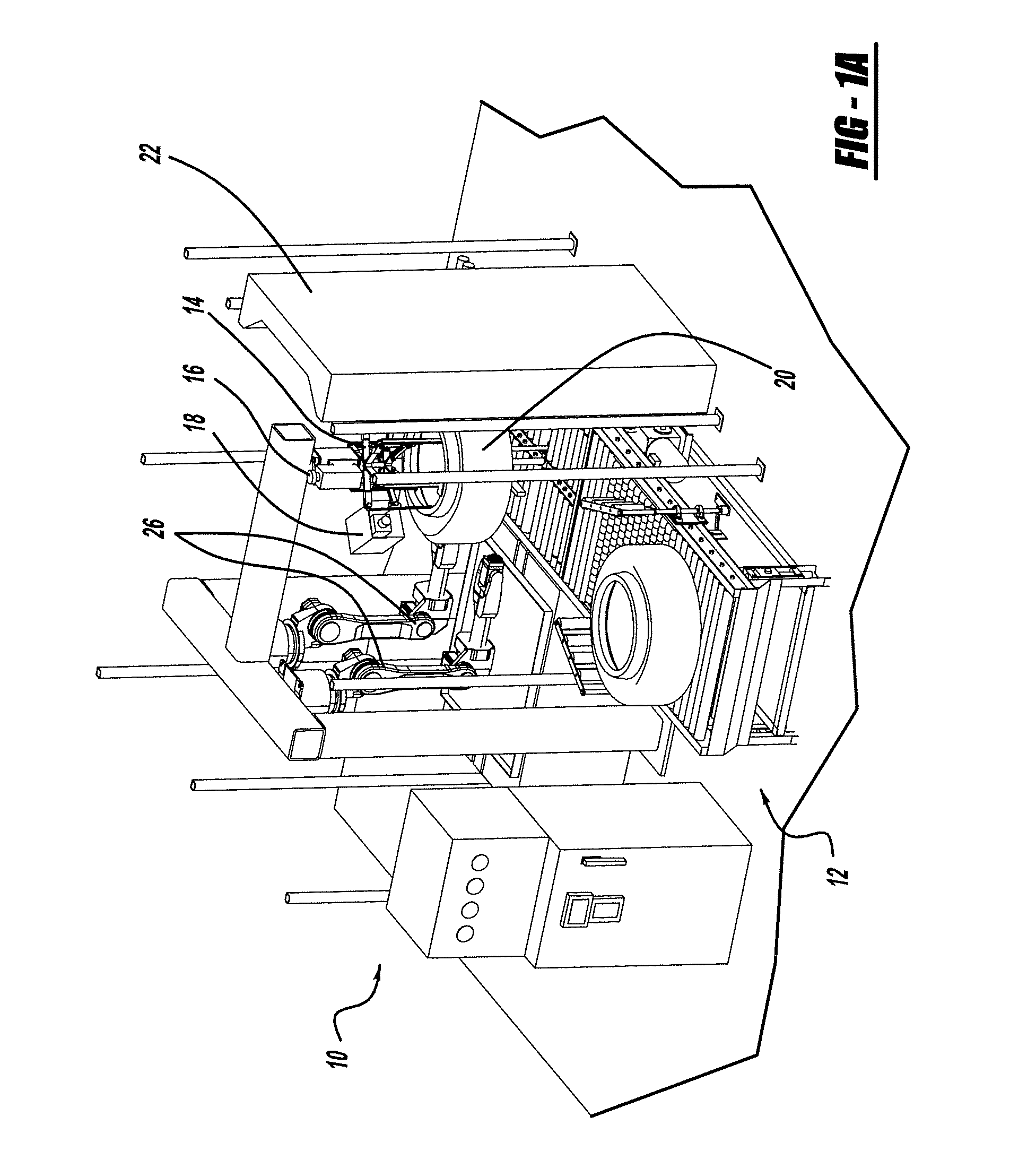

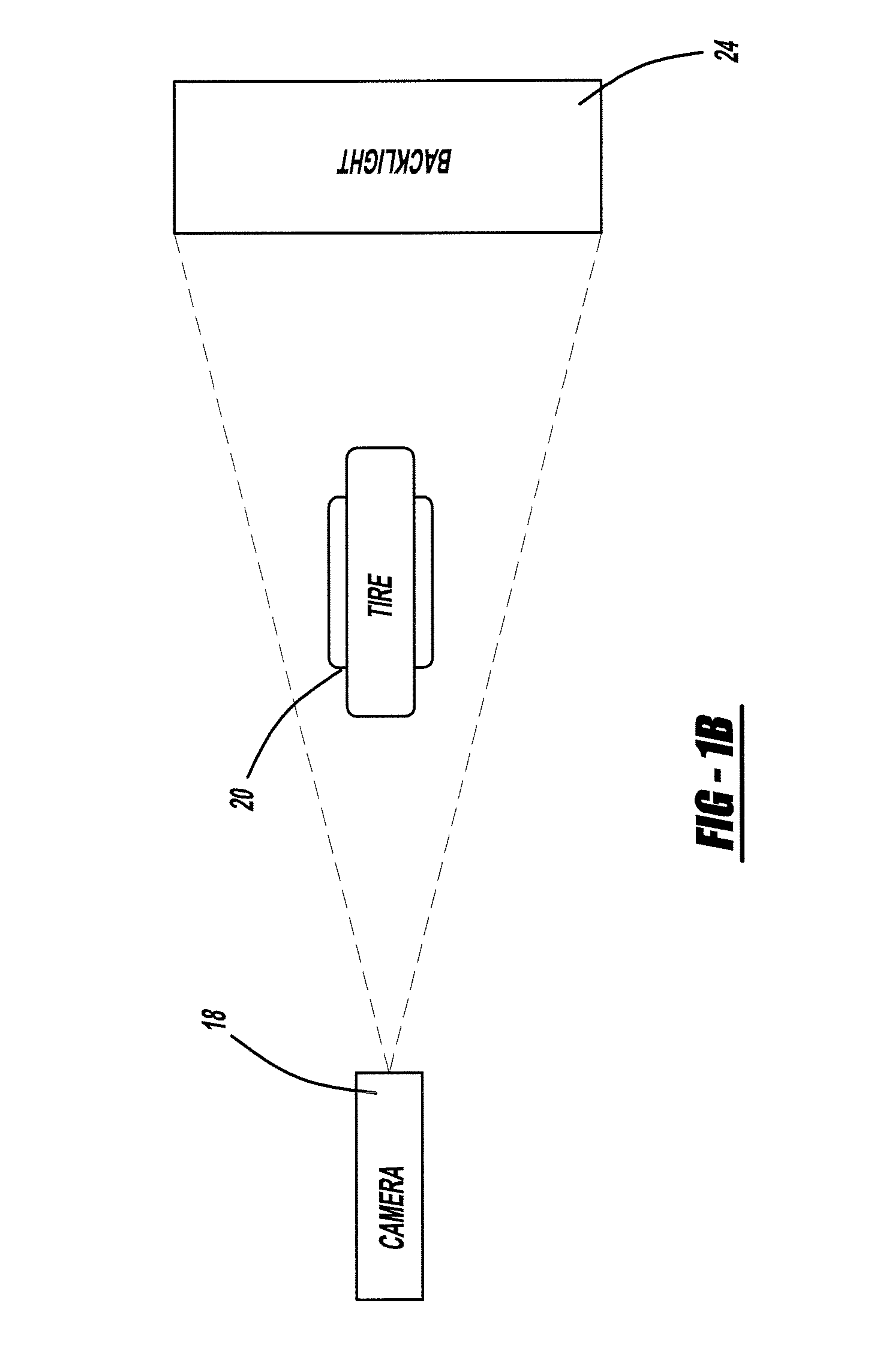

Robotic tire spraying system

ActiveUS20090061099A1Optimal spray coveragePrecision SprayingTyresLiquid/solution decomposition chemical coatingCamera imageRobot position

A robotic spray system is provided for accurately spraying mold release onto any size or shaped green tire. The system analyzes individual green tires using an integrated vision system. The system controls the robotic spray position, the fan, fluid, atomizing air, and tire rotation speed for optimal spray coverage on both the inside and outside of green tires. The system includes a conveyor, an overhead mounted camera located over an infeed station, and a second camera located perpendicular to the green tire's tread and several feet away from the center of the tire. Pictures of the green tire in the station are used to estimate the center and radius of the tire and locate the angle of the bar code with respect to the center of the tire. Reference points are provided from the camera images and robot positions are calculated to control the spraying.

Owner:PIONEER IND SYST

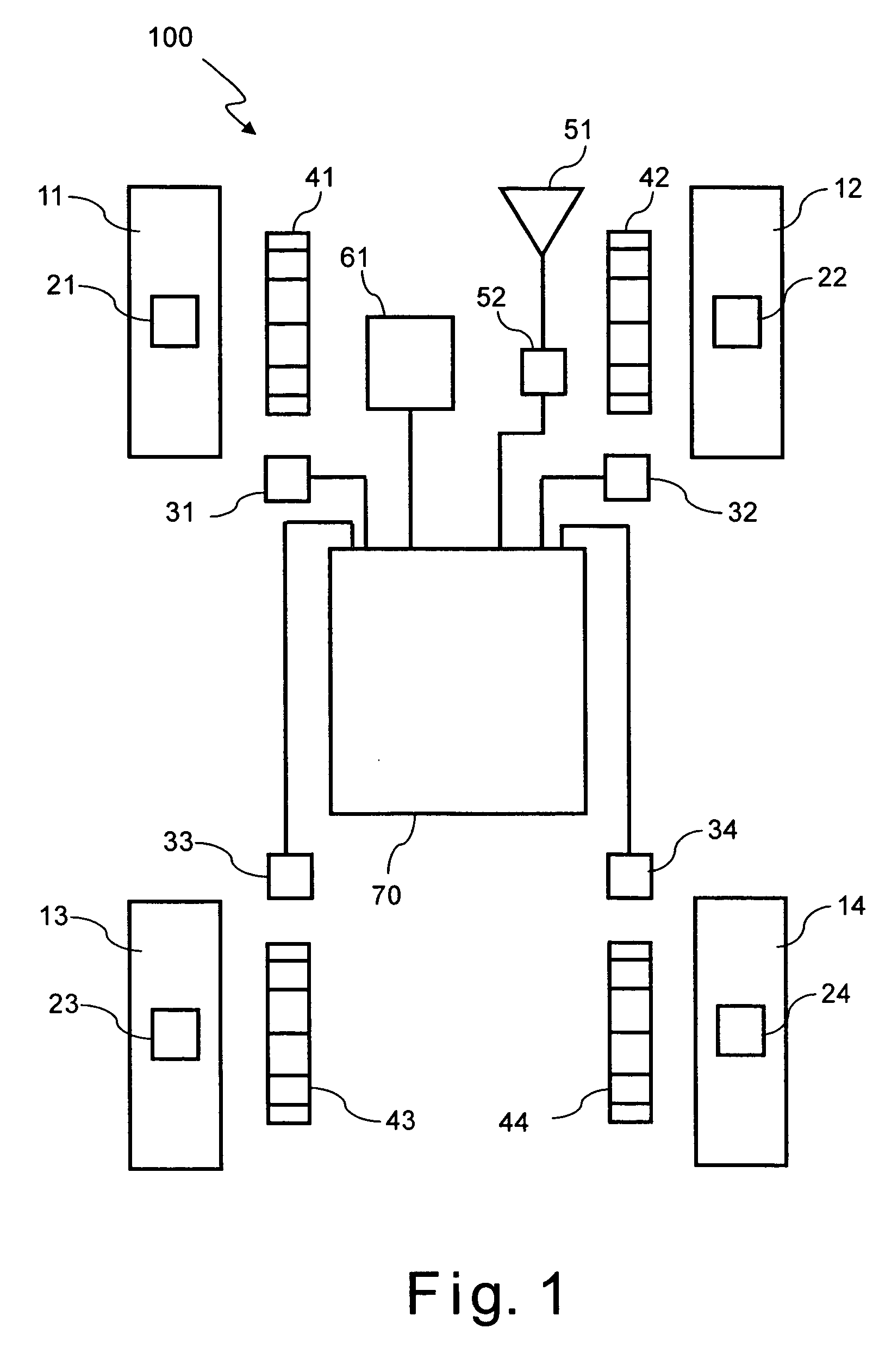

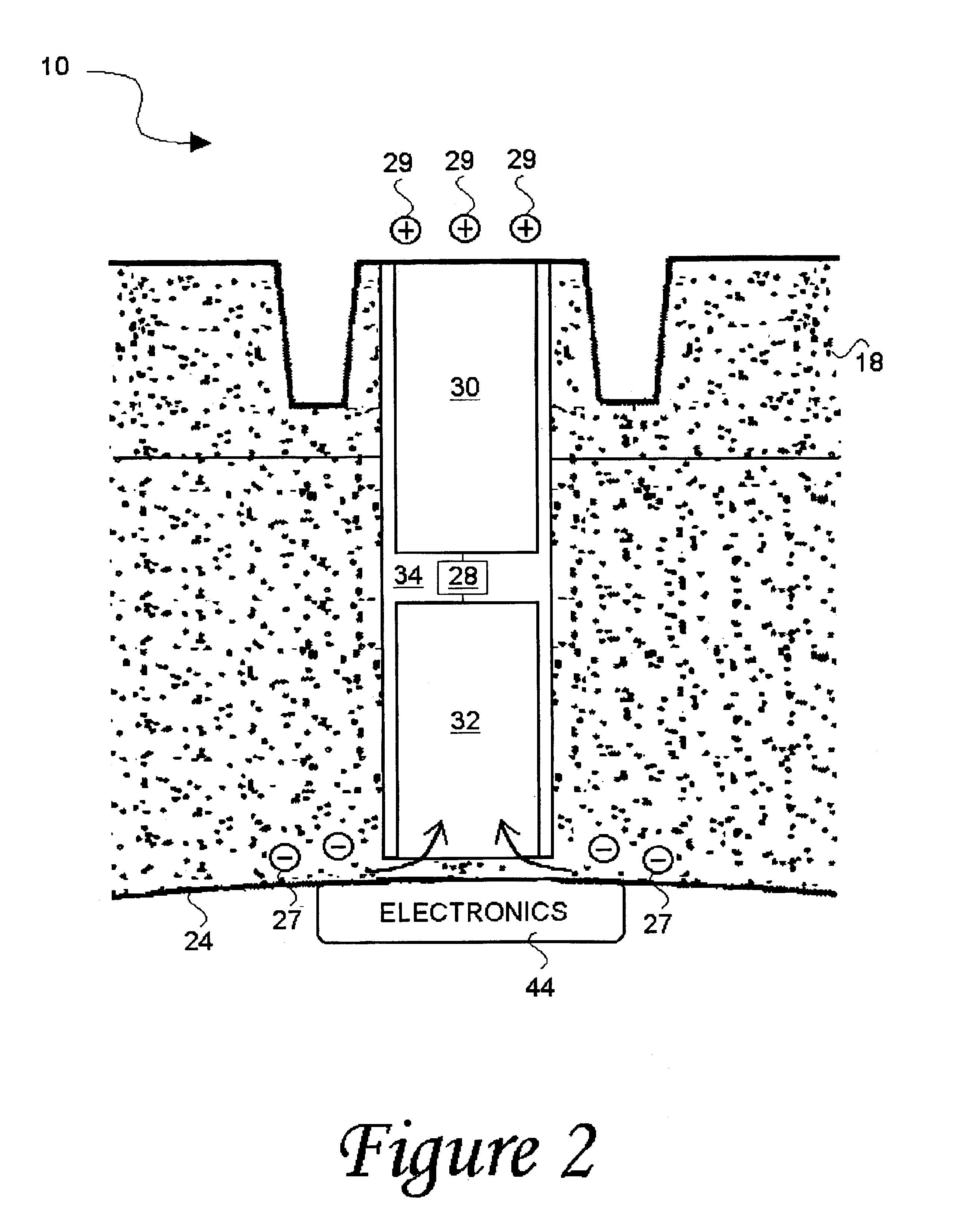

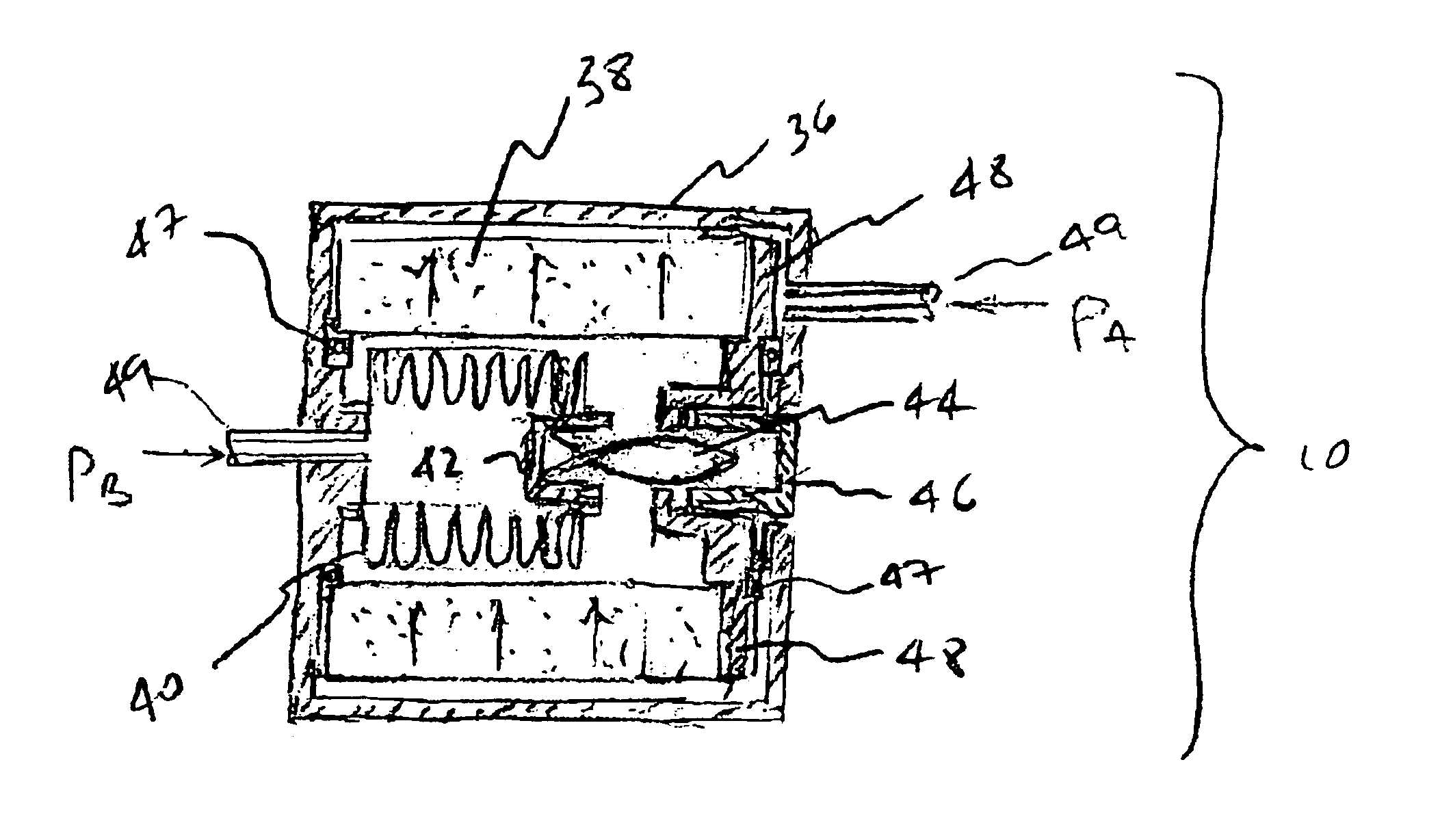

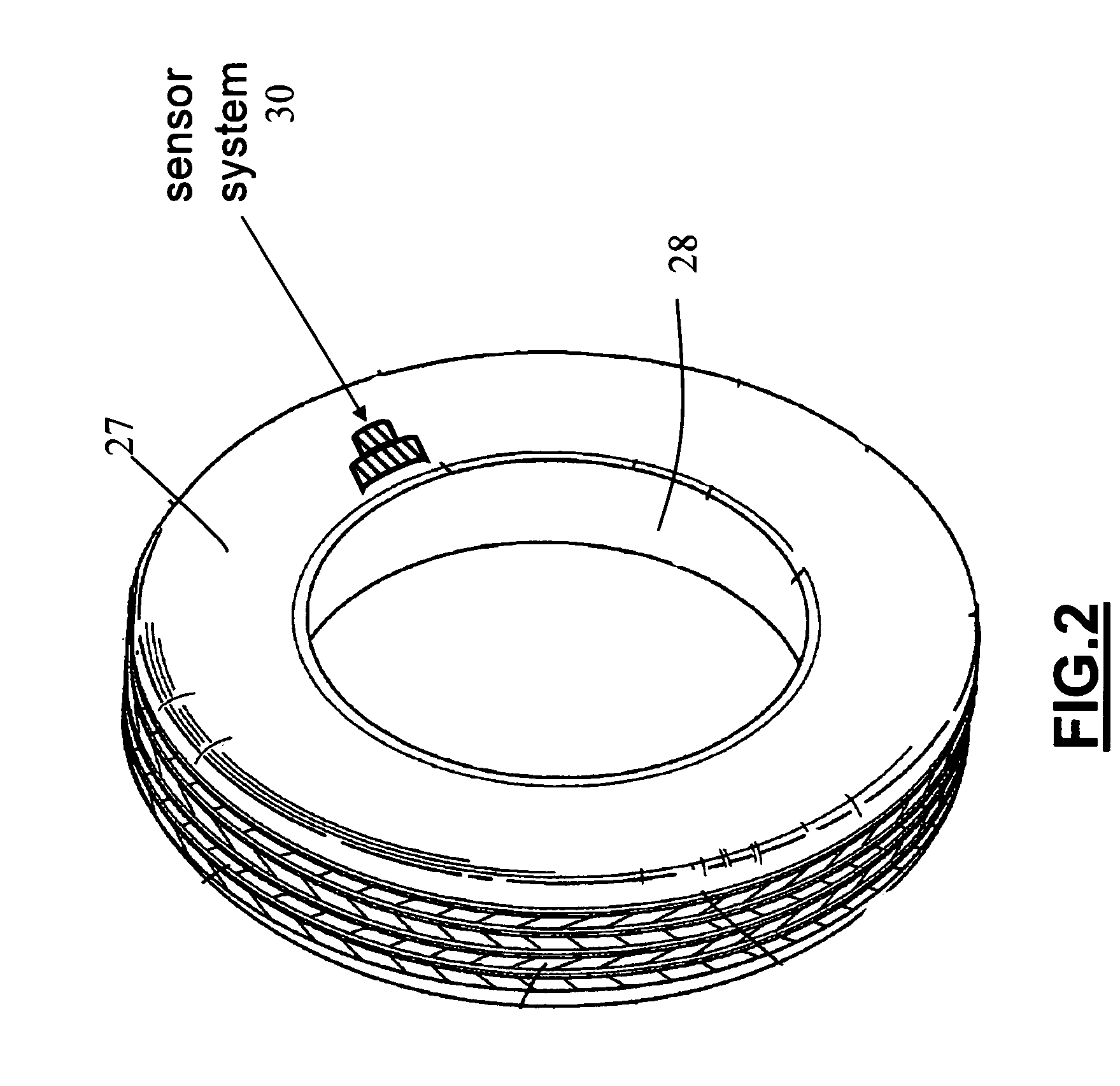

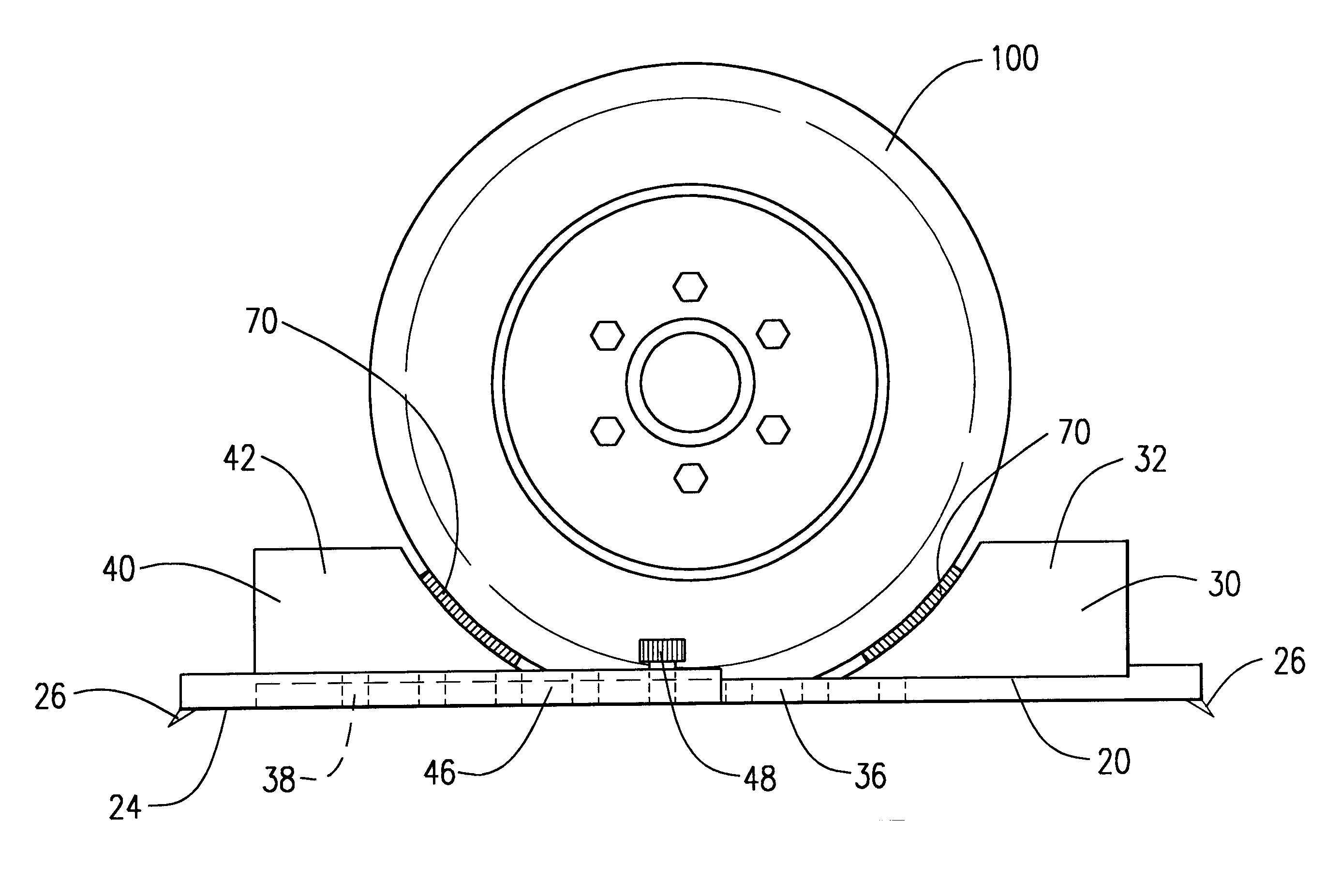

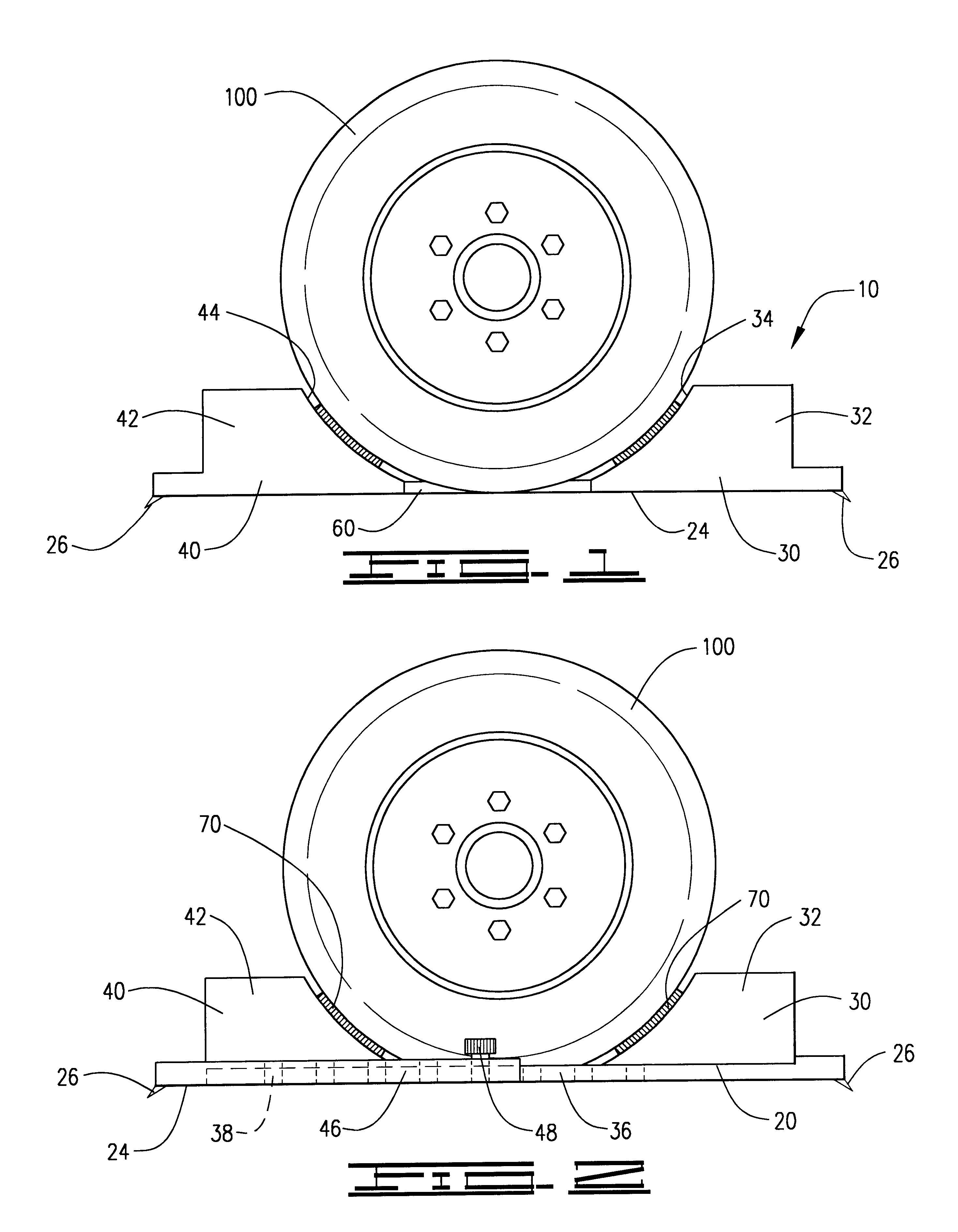

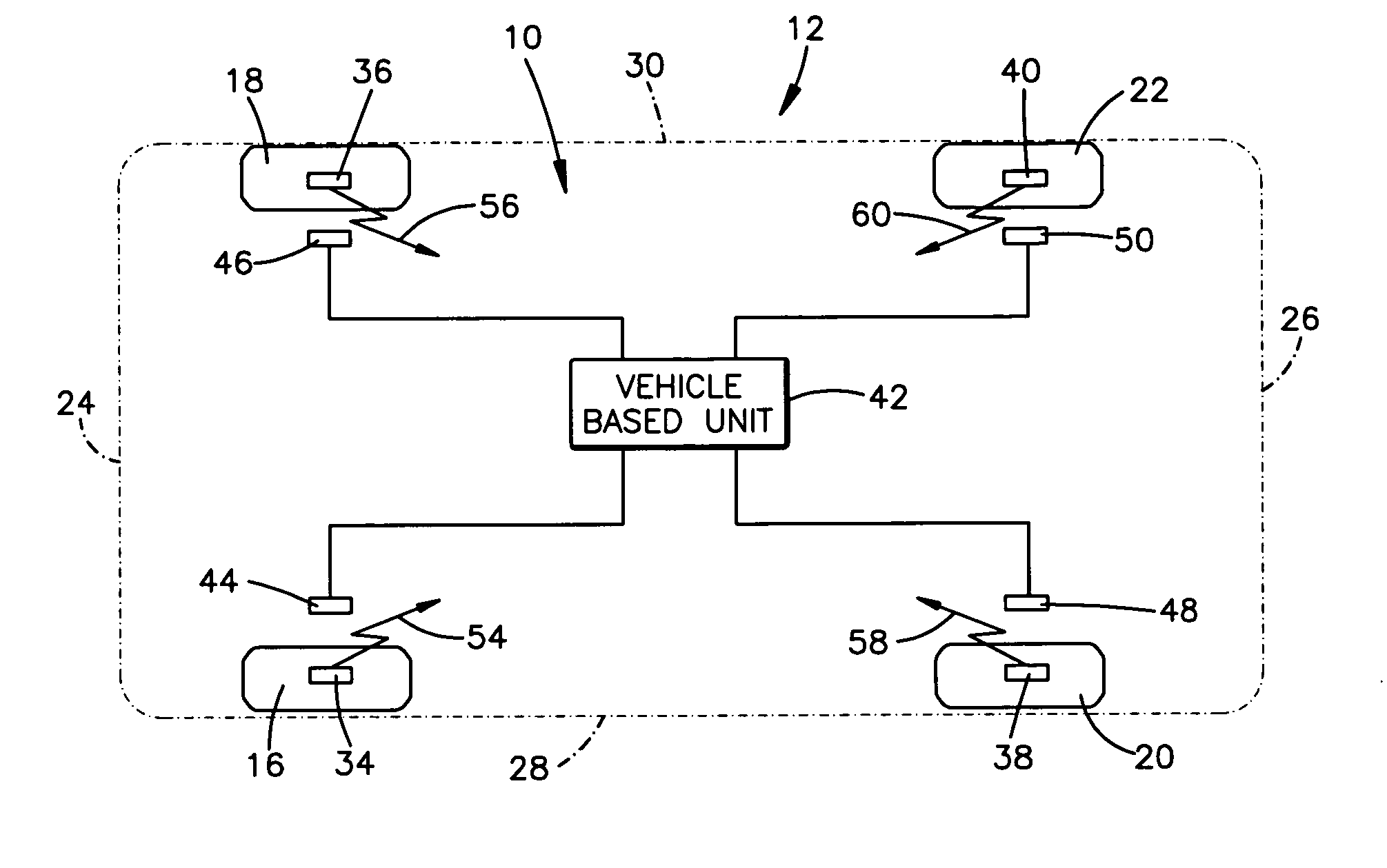

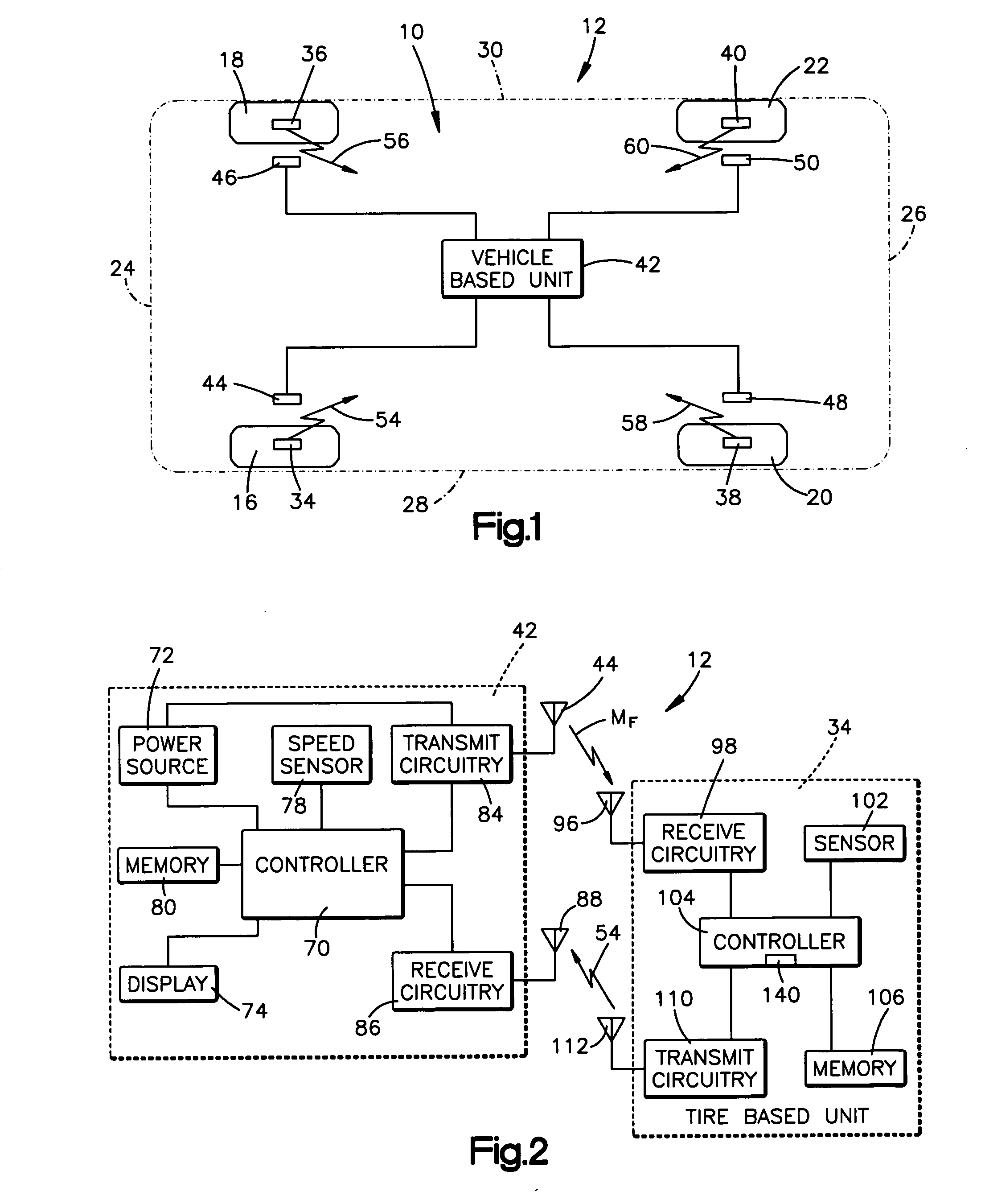

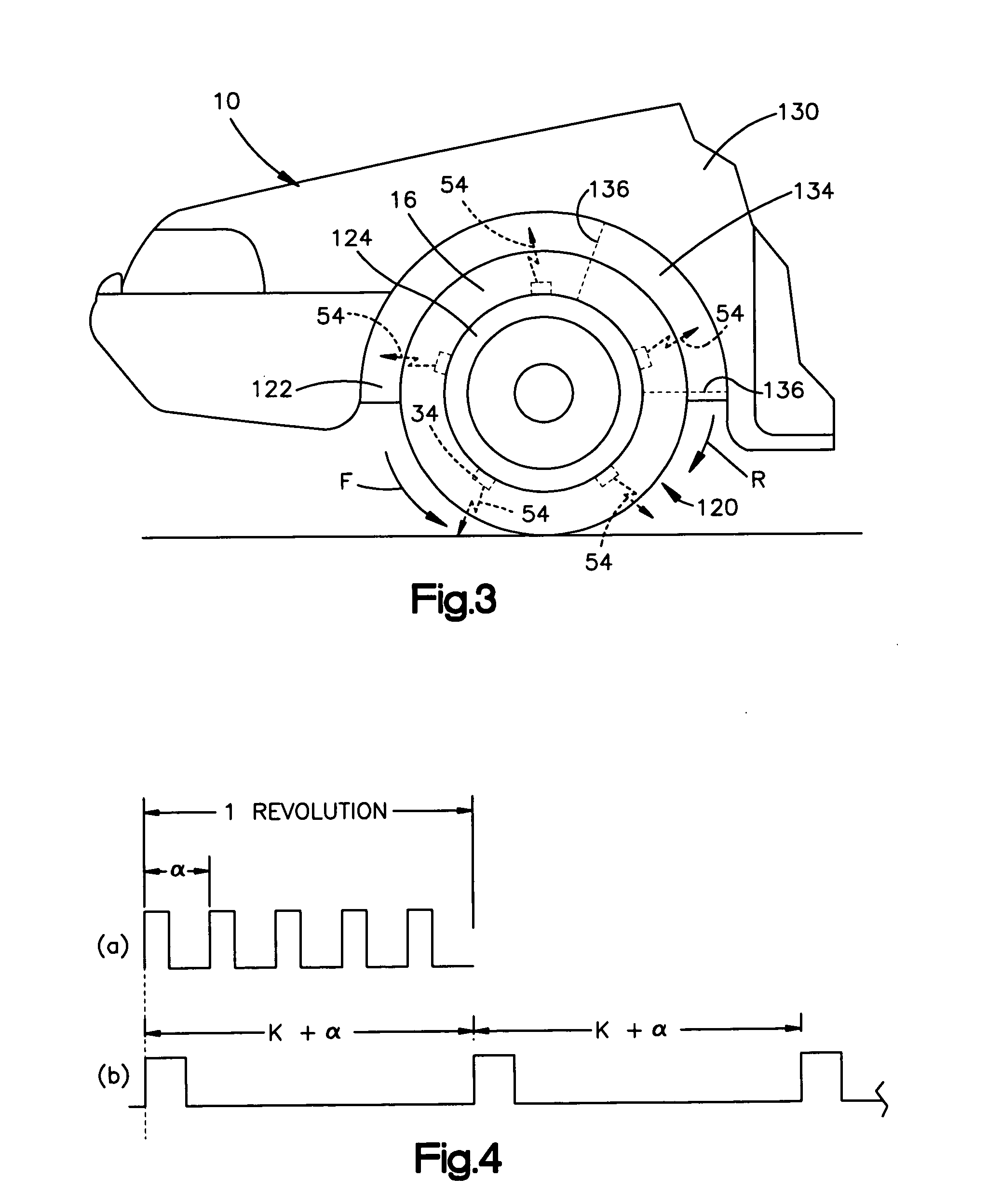

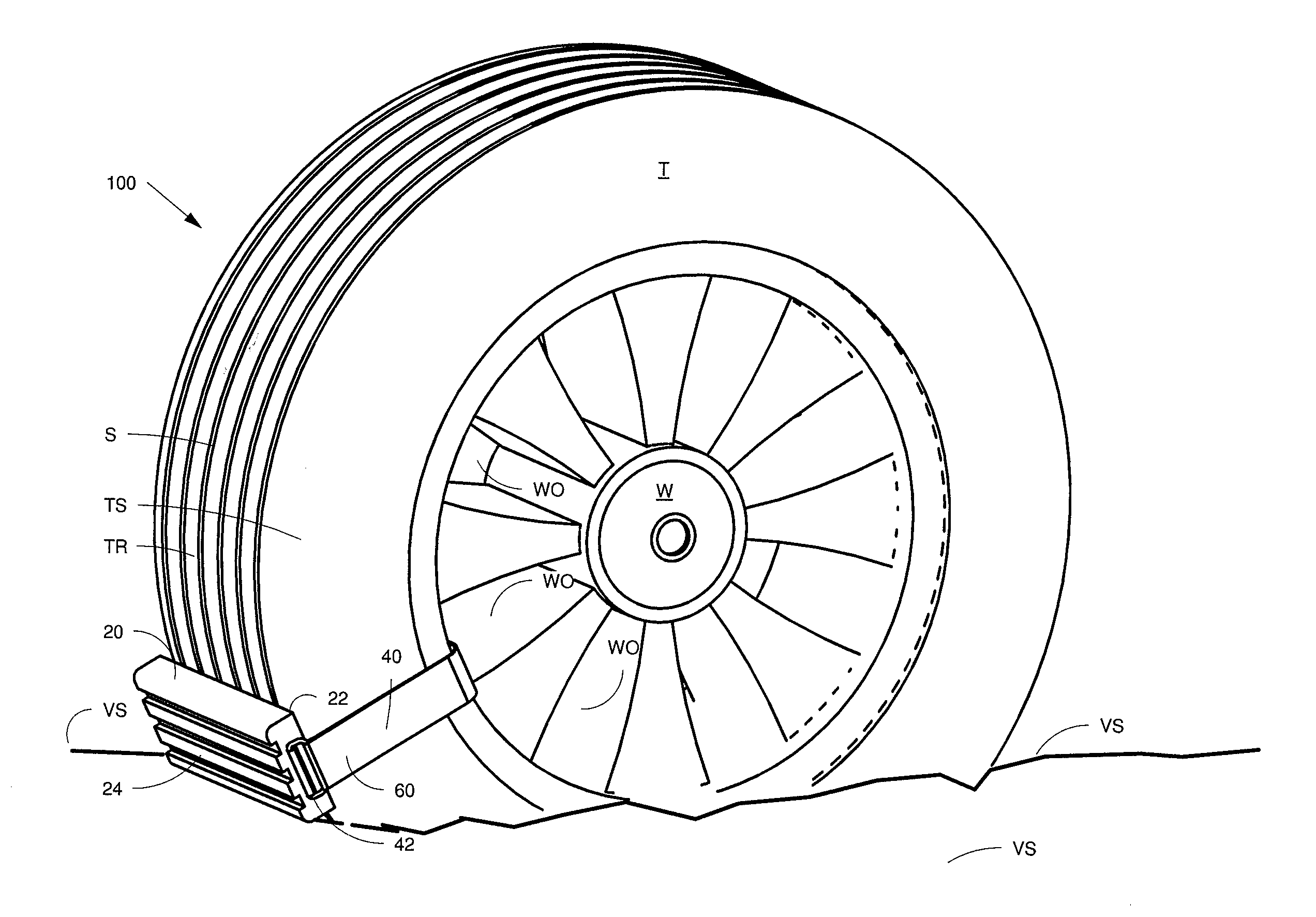

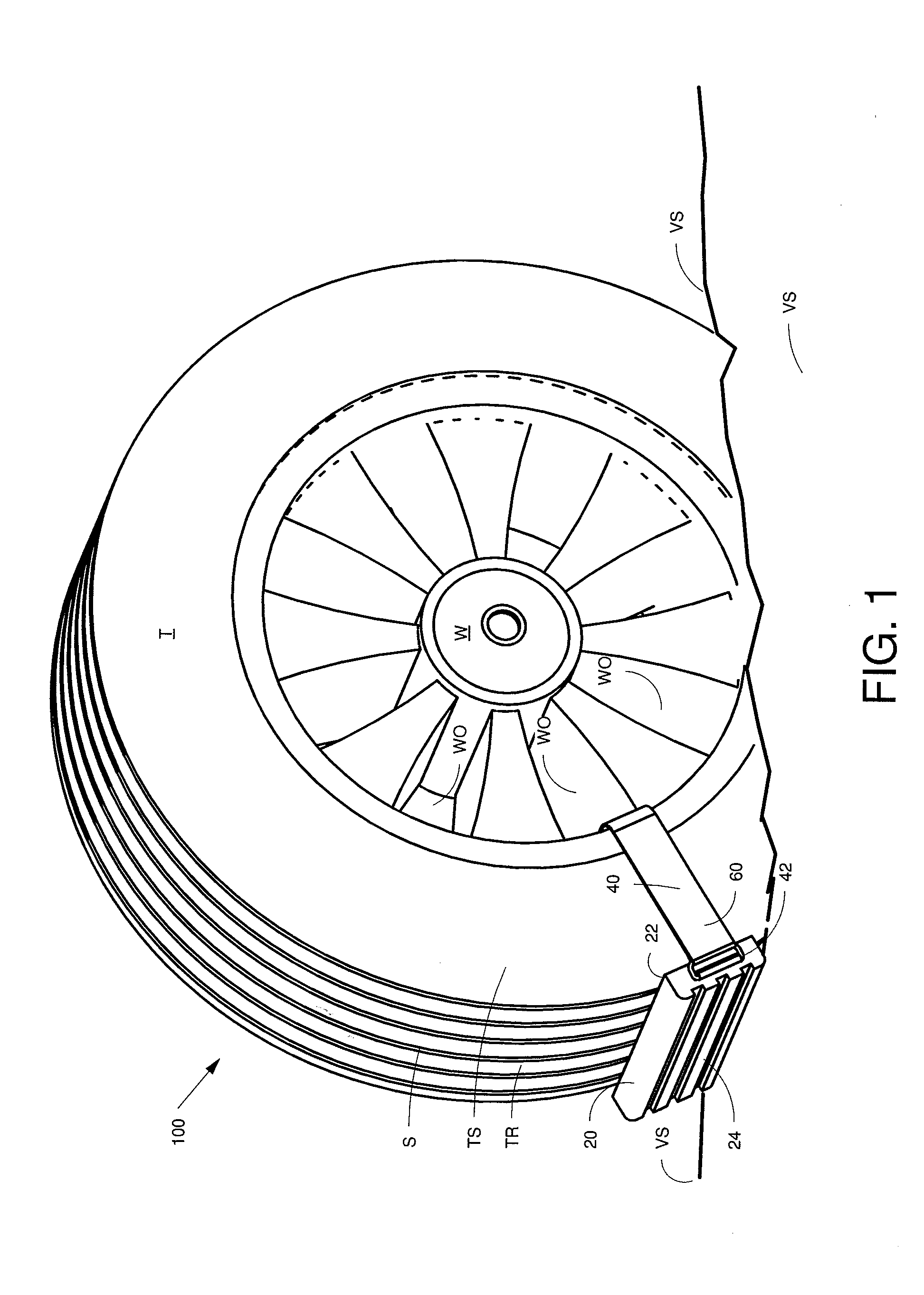

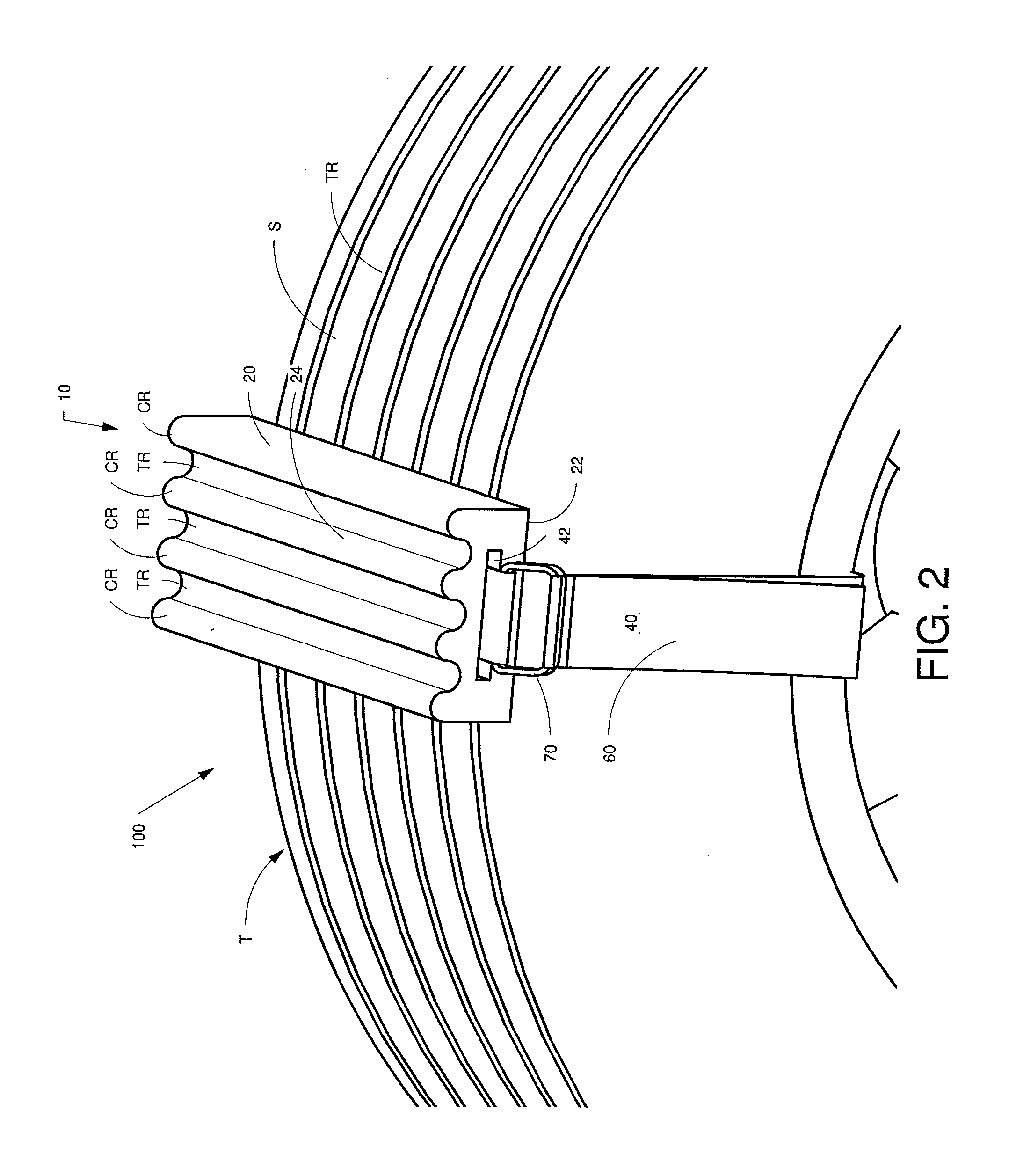

Tire parameter sensing system having a tire rotation dependent transmission scheme

A tire parameter sensing system (12) for a vehicle (10) comprises a vehicle-based unit (42) for receiving parameter signals. A tire-based unit (34) is associated with a tire (16) of the vehicle (10) and rotates with the tire (16). The tire-based unit (34) is located in a communication zone (134) for communicating with the vehicle-based unit (42) through only a portion of each rotation of the tire (16). The tire-based unit (34) is configured to sense a parameter of the tire (16) and to transmit a parameter signal (54) indicative thereof. The system (12) also comprises means (78) for monitoring the rotation of the tire and for providing rotation information indicative of the monitored tire rotation. The tire-based unit (34) is responsive to the rotation information for transmitting the parameter signal (54) while the tire-based unit (34) is located the communication zone (134).

Owner:TRW AUTOMOTIVE US LLC +1

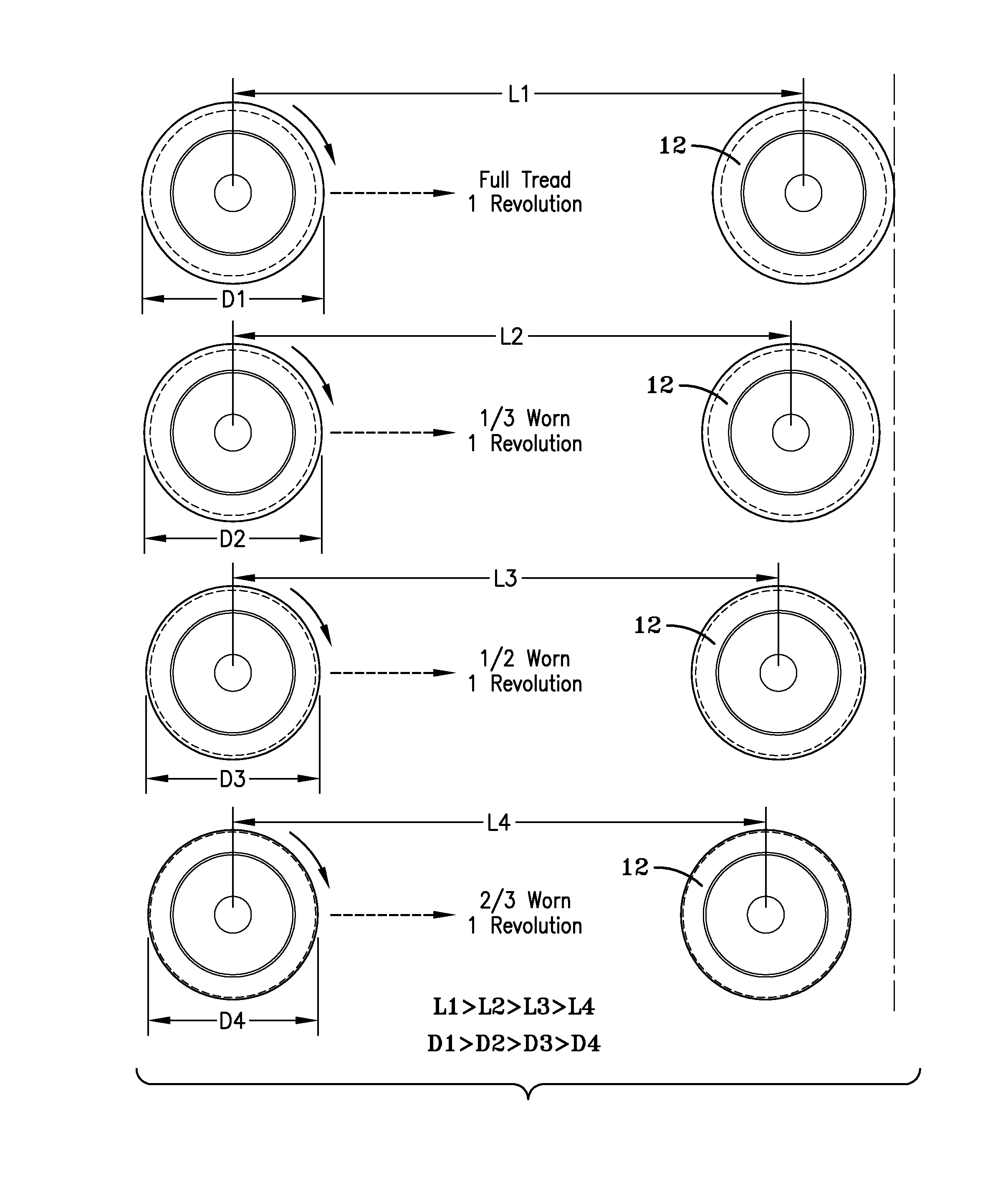

Tread wear estimation system and method

ActiveUS20170023441A1Great tractionError minimizationTyre measurementsTyre tread bands/patternsLow speedEffective radius

A tire wear state estimation system for a tire calculates tire effective radius during measured distance intervals travelled by the tire from vehicle speed and tire rotation counters. The system includes a filter for selecting slow-speed effective radius measuring intervals and an estimator for estimating the tire effective radius during only those intervals in which the vehicle is travelling below a threshold speed.

Owner:THE GOODYEAR TIRE & RUBBER CO

Apparatus, method, and program for detecting rotation speed information, and apparatus, method, and, program for detecting tire having decreased pressure

ActiveUS20100217542A1Accurate calculationReduce pressureInflated body pressure measurementDigital data processing detailsTime informationGear wheel

A rotation speed information detection apparatus, including: a wheel sensor for detecting passage of teeth of a gear provided in association with tires of a vehicle; a number-of-teeth calculation means for calculating the number of teeth of the gear passed per a sampling cycle set in advance; and a wheel speed calculation means for regularly calculating rotation speed information of the tire with using the number of teeth calculated. The number-of-teeth calculation means is configured to use a ratio between time information at the point and a remaining time until the time at which the next sampling cycle is started is reached to thereby calculate the number of remaining teeth to calculate the number of teeth passed during the sampling cycle. The wheel speed calculation means is configured to calculate tire rotation speed information based on an interval between neighboring teeth in the gear, the number of teeth passed during the sampling cycle, the number of remaining teeth calculated by the number-of-teeth-calculation means, and the sampling cycle.

Owner:SUMITOMO RUBBER IND LTD

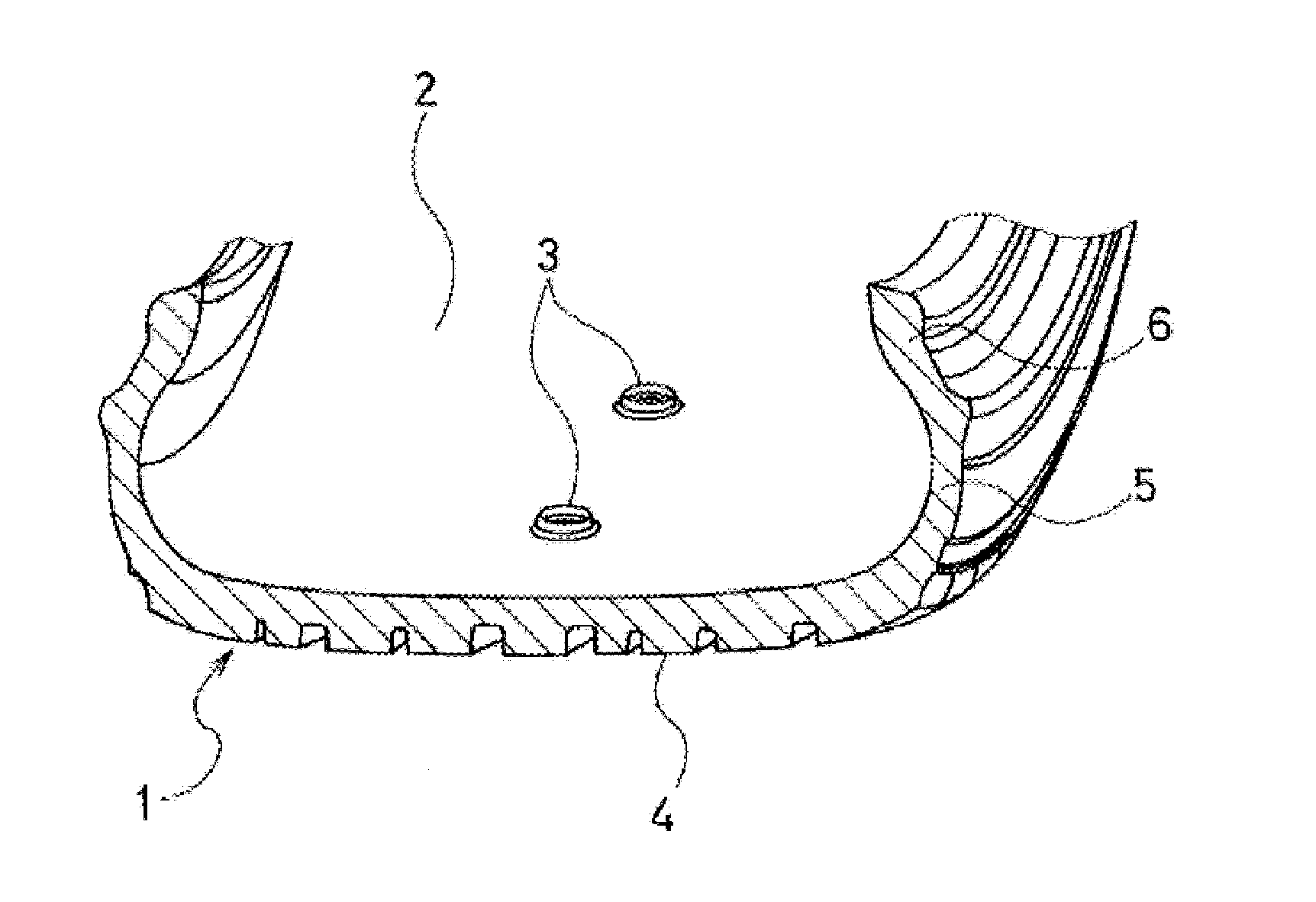

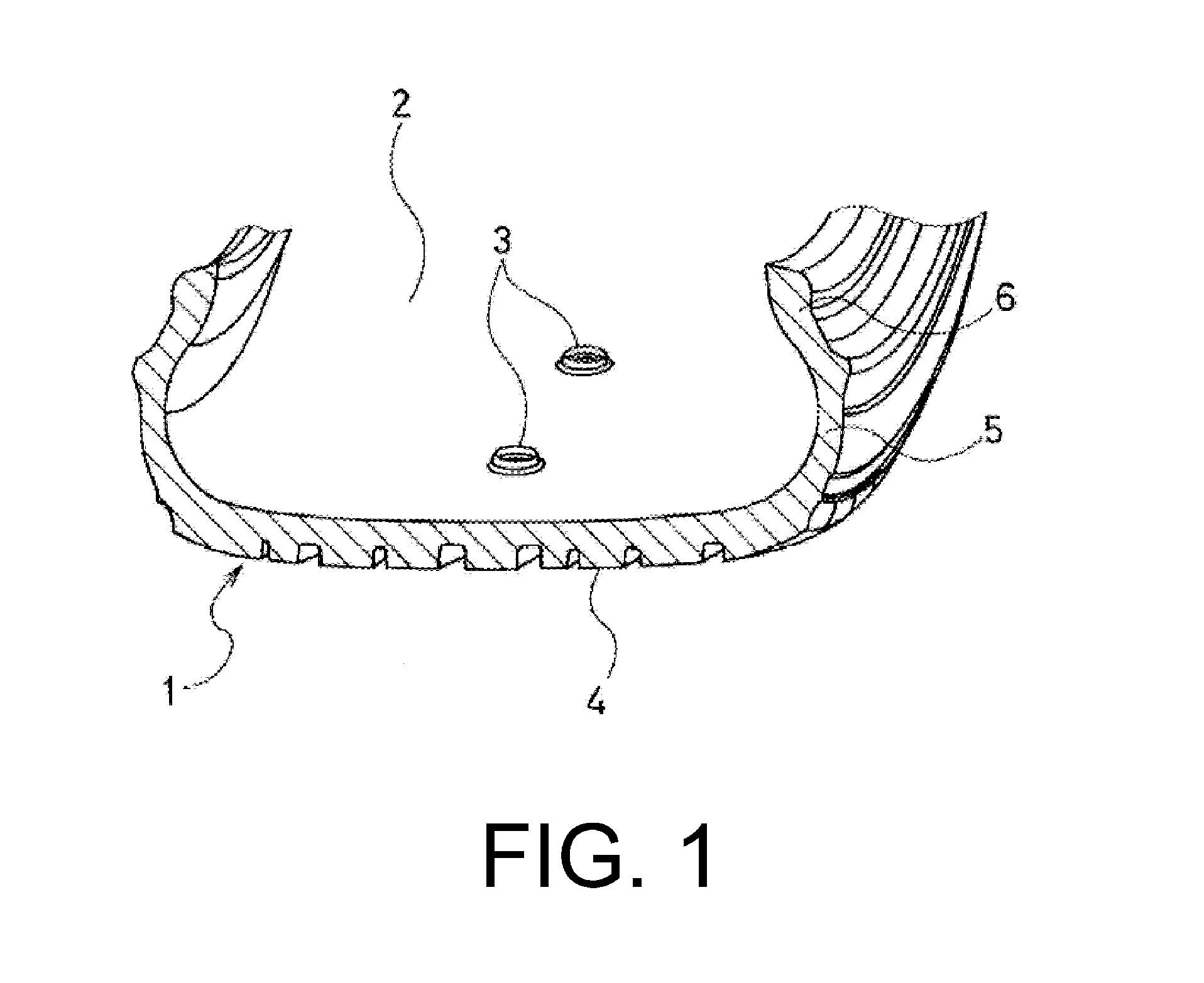

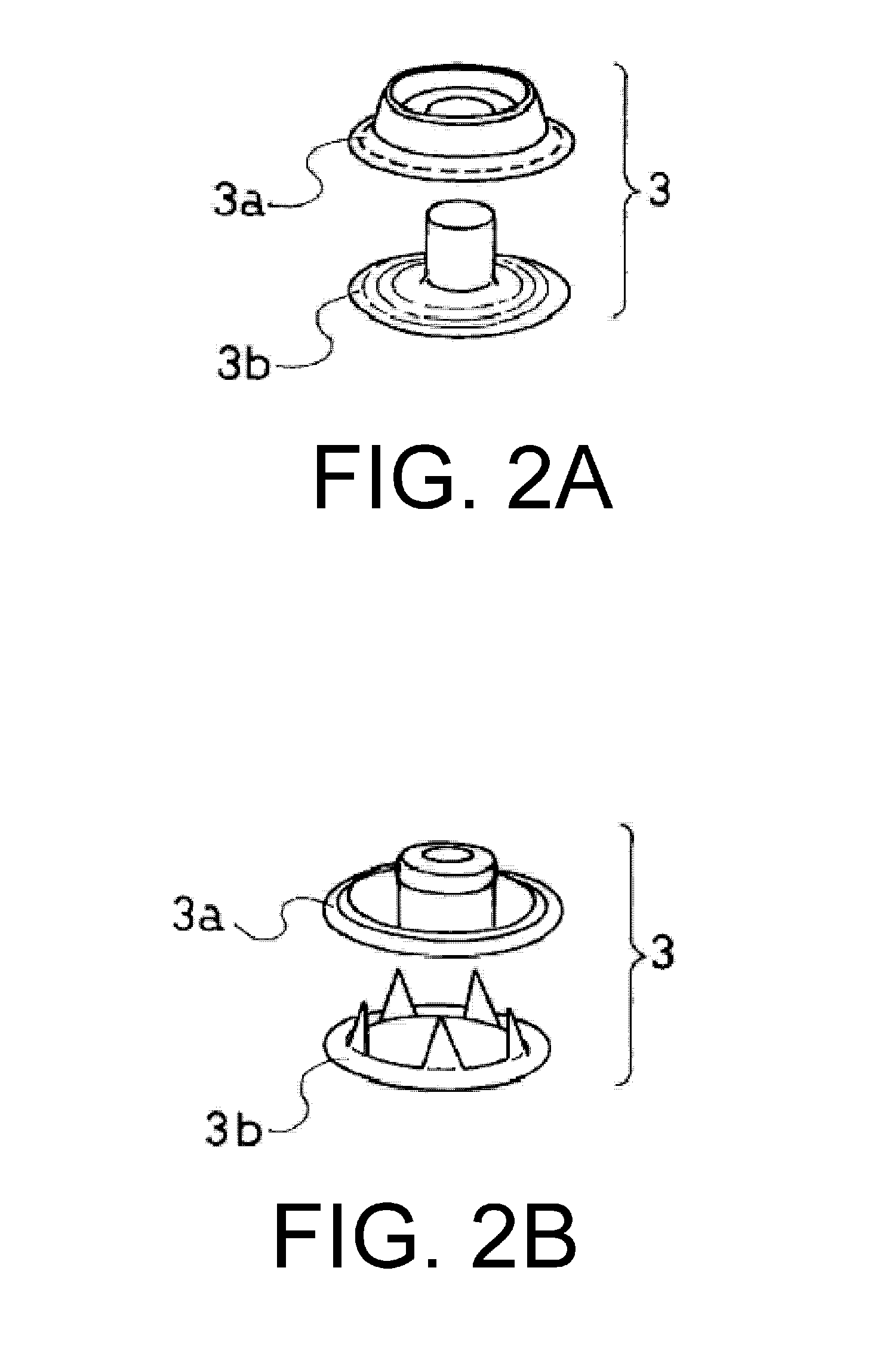

Pneumatic tire

ActiveUS20120024439A1Increased durabilityImprove stabilityRotating bodies balancingTyresTire rotationFastener

A pneumatic tire including a separatable pair of mechanical fasteners wherein a first fastener of the pair of mechanical fasteners is provided on a tire inner surface. In this pneumatic tire, the obtained engagement force of the pair of mechanical fasteners is great and is essentially free of variations (positional variation within the tire and variation from tire to tire); the engagement force deteriorates / declines minimally over time due to extreme usage conditions including repetitive deformation and compaction over an extended period of time caused by tire rotation at high speeds in a state of relatively elevated temperatures; and the desired engagement force can be maintained over an extended period of time.

Owner:YOKOHAMA RUBBER CO LTD

System an method for harvesting electric power from a rotating tire static electricity

ActiveCN1753796AReduce complexityLess signaling hardwareTyresTyre measurementsElectric power systemElectrical battery

A power harvesting solution concerns a generally non-conductive tire structure that is formed with at least one defined conductivity path through which static electricity accumulated in the tire structure during tire rotation can dissipate to ground. Such conductivity path is formed from a portion of conductive material that may be partially surrounded by additional insulative material to restrict the flow of electric charge to ground. An energy storage device, such as a capacitor or rechargeable battery, is coupled with the conductivity path and configured to store selected amounts of the electric charge to dissipating through the conductivity path. Various diode elements may be provided in combination with the energy storage device to prevent reverse discharging of and to provide voltage protection for the energy storage device. Sufficient accumulations of such harvested energy can then power tire electronic systems, including various condition-responsive devices (i.e., sensors, etc.) a revolution counter, a radio frequency (RF) device, a rechargeable battery or a lighting device.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

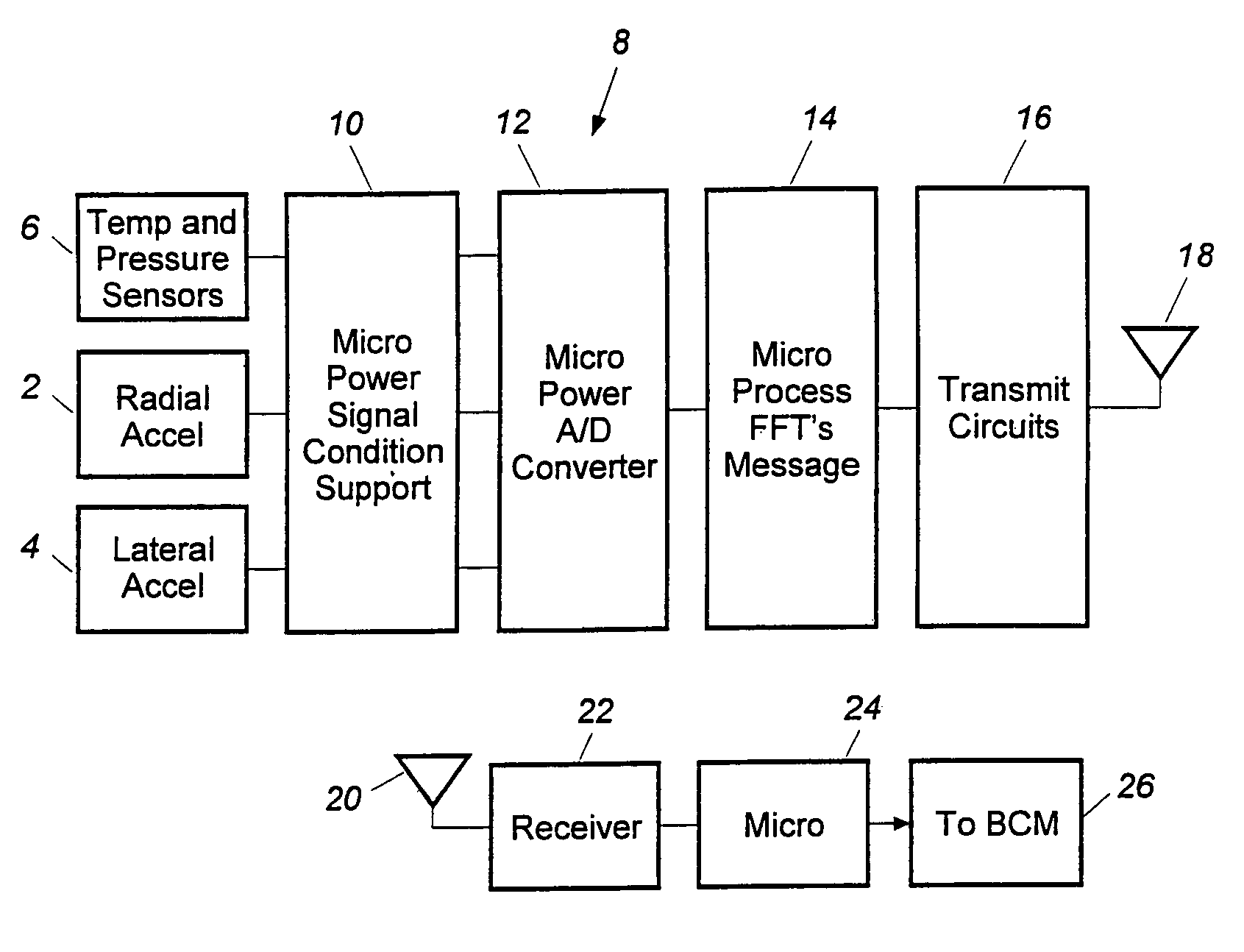

Tire and suspension warning and monitoring system

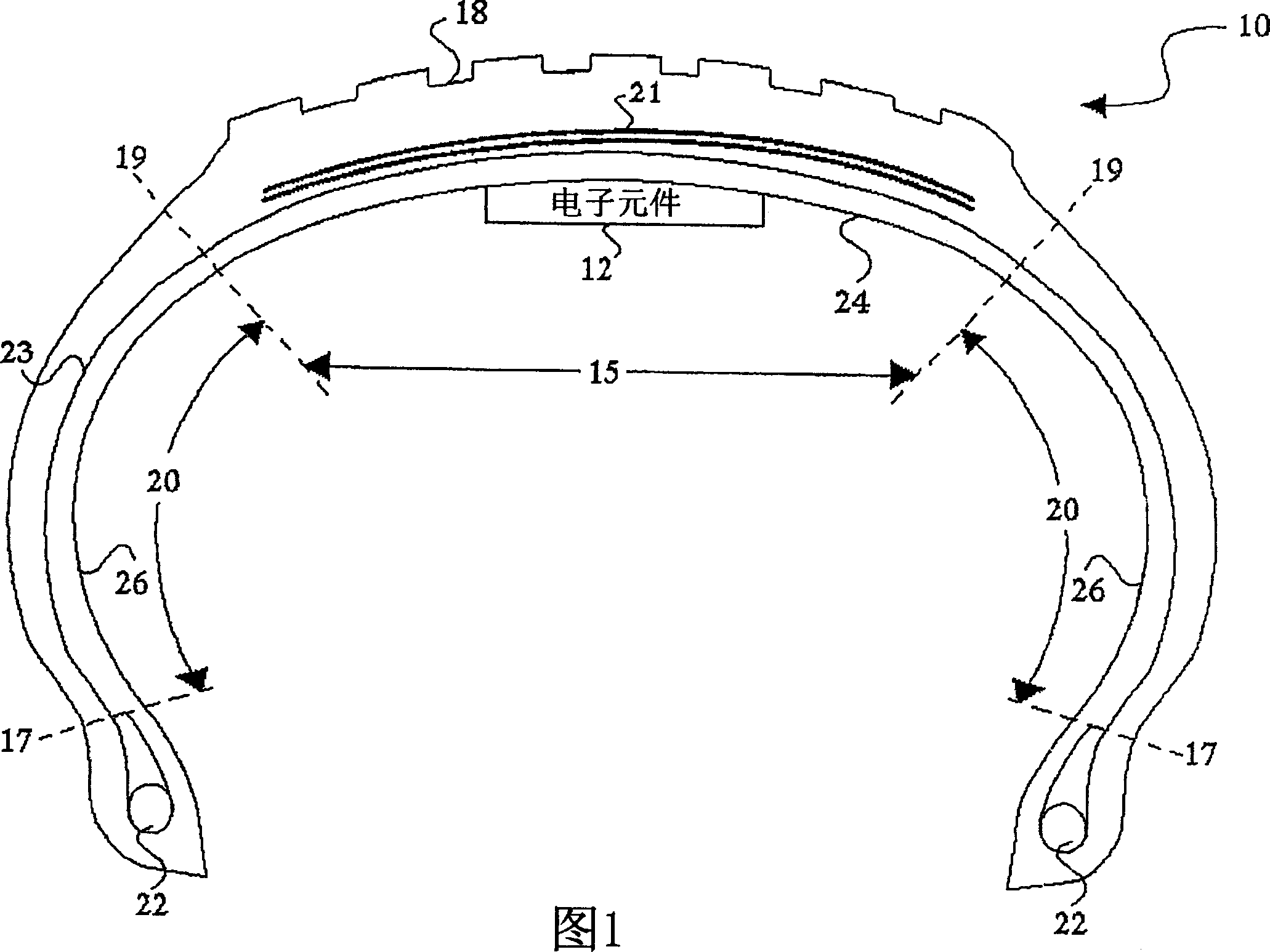

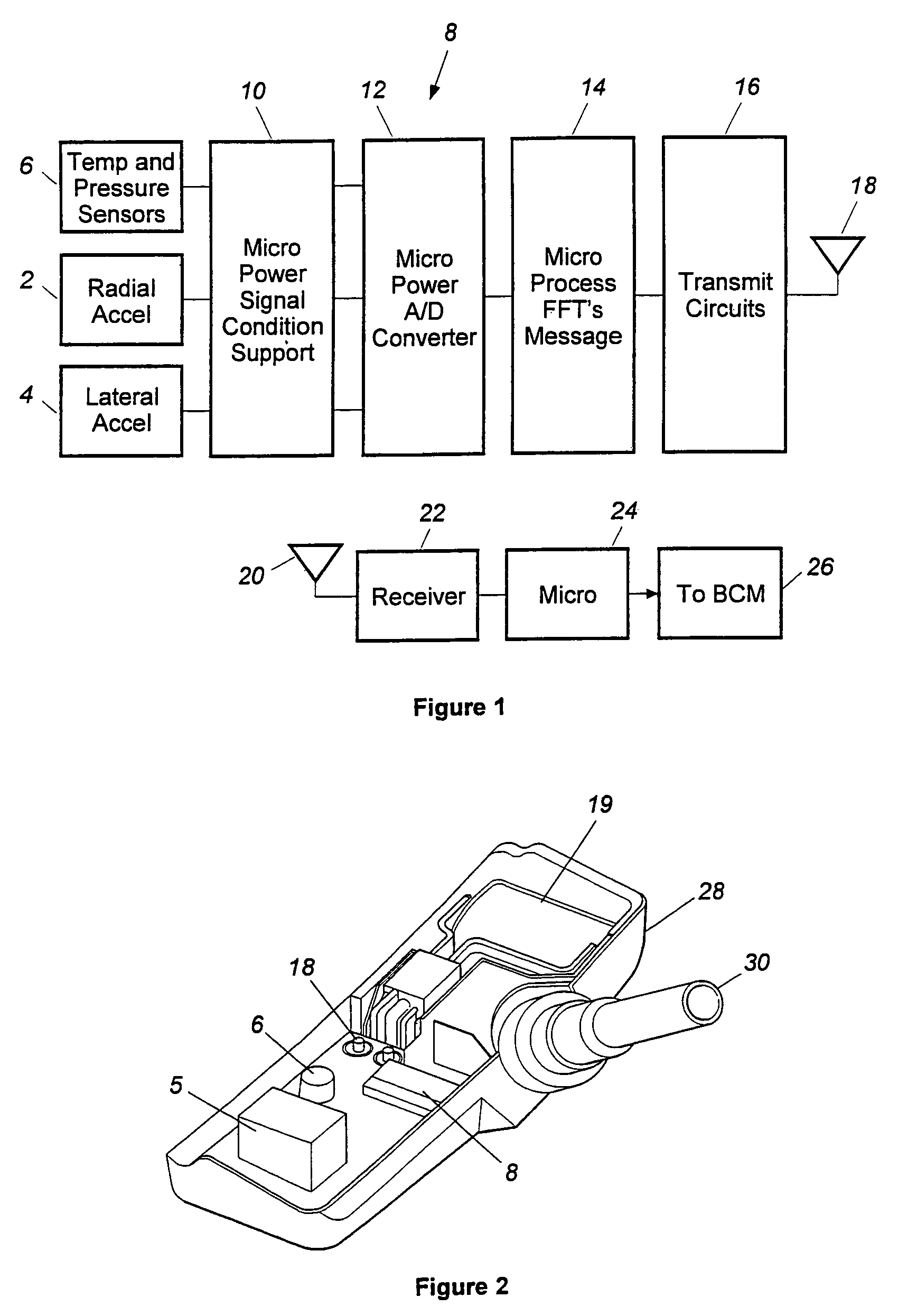

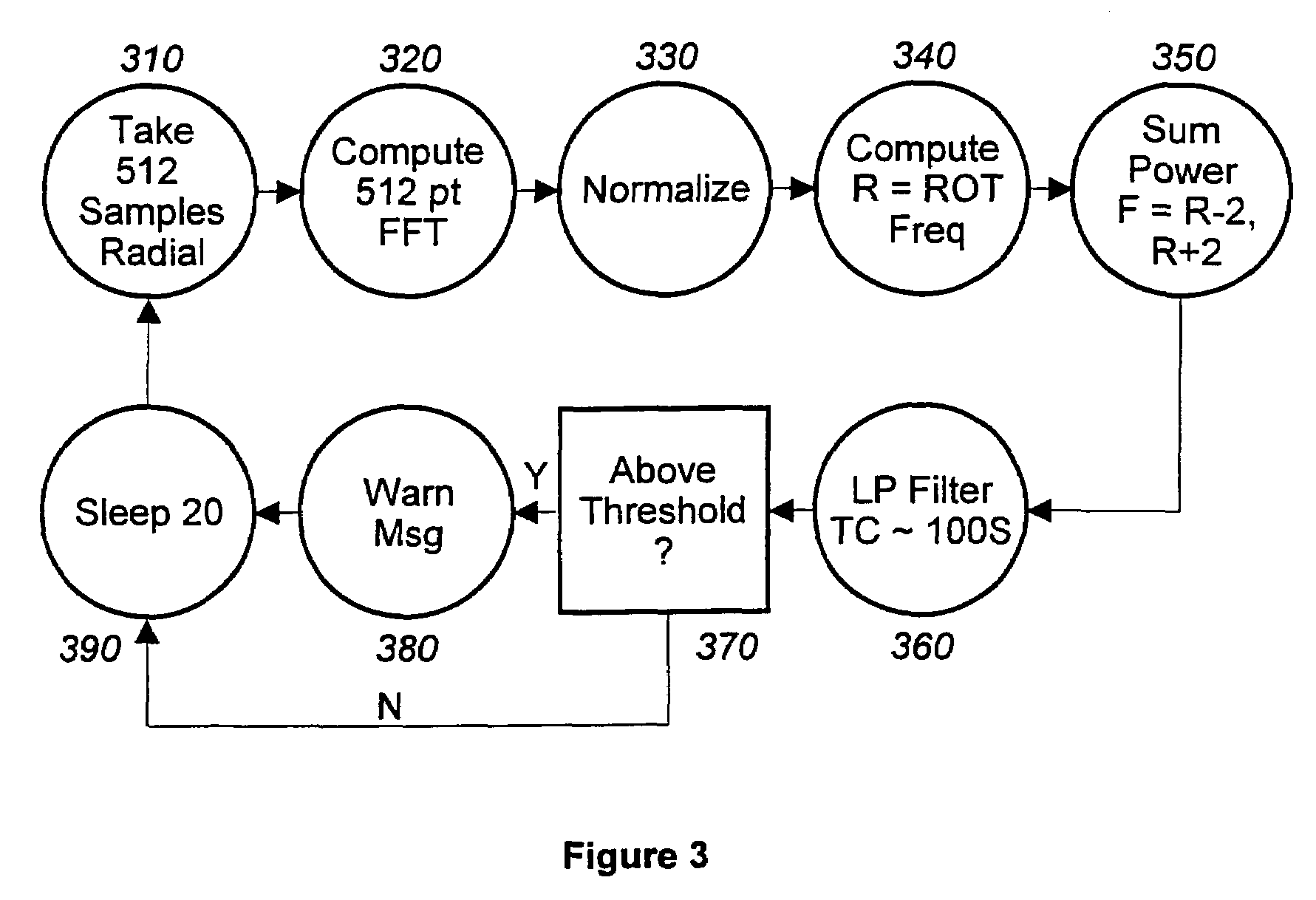

InactiveUS7443288B2Eliminate high order frequencyAcceleration measurement using interia forcesOptical signallingMonitoring systemTire rotation

A tire and suspension monitoring and warning system consisting of a set of multi-function sensors that monitor and warn of a failure mode. The system monitors and warns for tire imbalance, tire tread wear, and shock absorbers for a tire attached to a vehicle. The monitoring and warning system includes one axial, radial, and lateral acceleration measurement of the wheel to provide acceleration signal sample power. For tire imbalance, signal sample power in the second harmonic of the tire rotational frequency is compared to that of the first harmonic. For tire tread wear, average signal sample power within a second frequency range is compared to a previously stored baseline value. For shock absorber performance, a sum of all frequency components in a second predetermined frequency range is compared to a baseline value.

Owner:TRW AUTOMOTIVE US LLC

Vehicle wheel lifting block apparatus for climbing out of depression in viscous surfaces

ActiveUS20120119564A1Avoid insufficient lengthWheels with plate-like shoesNon-skid devicesTerrainTweel

A wheel lifting block apparatus includes a climbing block such as of rubber having a block abutting surface for placement against a tire tread and has a block traction surface facing outwardly from the tire tread; and block securing means for mounting the block on the circumferential tread surface of a tire after the tire has become embedded in a depression in a viscous surface to grip the viscous surface while lifting the tire relative to the viscous surface so that tire rotation causes the tire to climb out of the depression and advance to stable terrain. The block securing means preferably includes a strap slot extending through the block; and a strap having first and second strap ends and passing through the strap slot and having a length sufficient so that the first and second strap ends can wrap around a segment of a tire and through an opening in a vehicle wheel.

Owner:PERRY JAMES

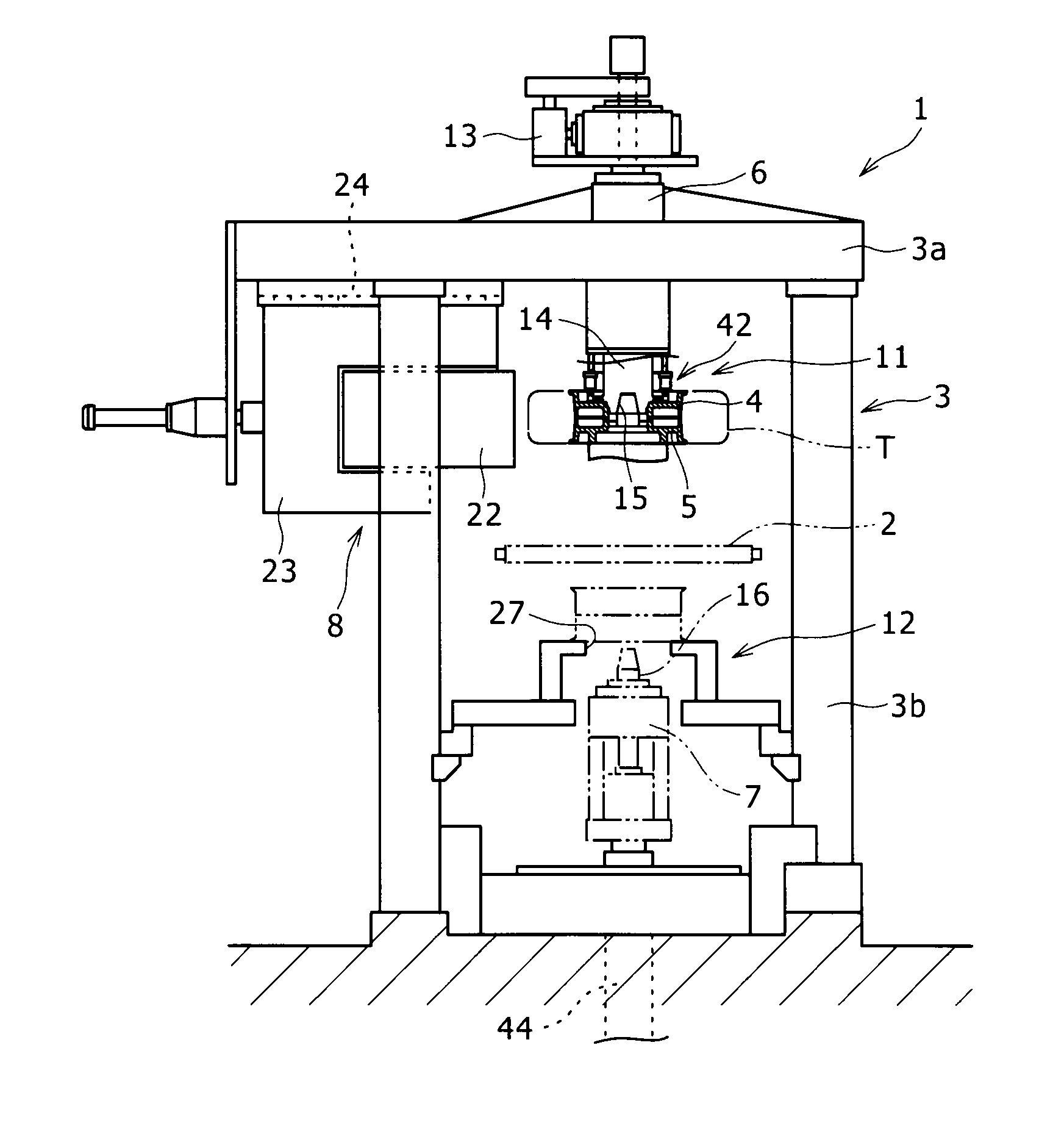

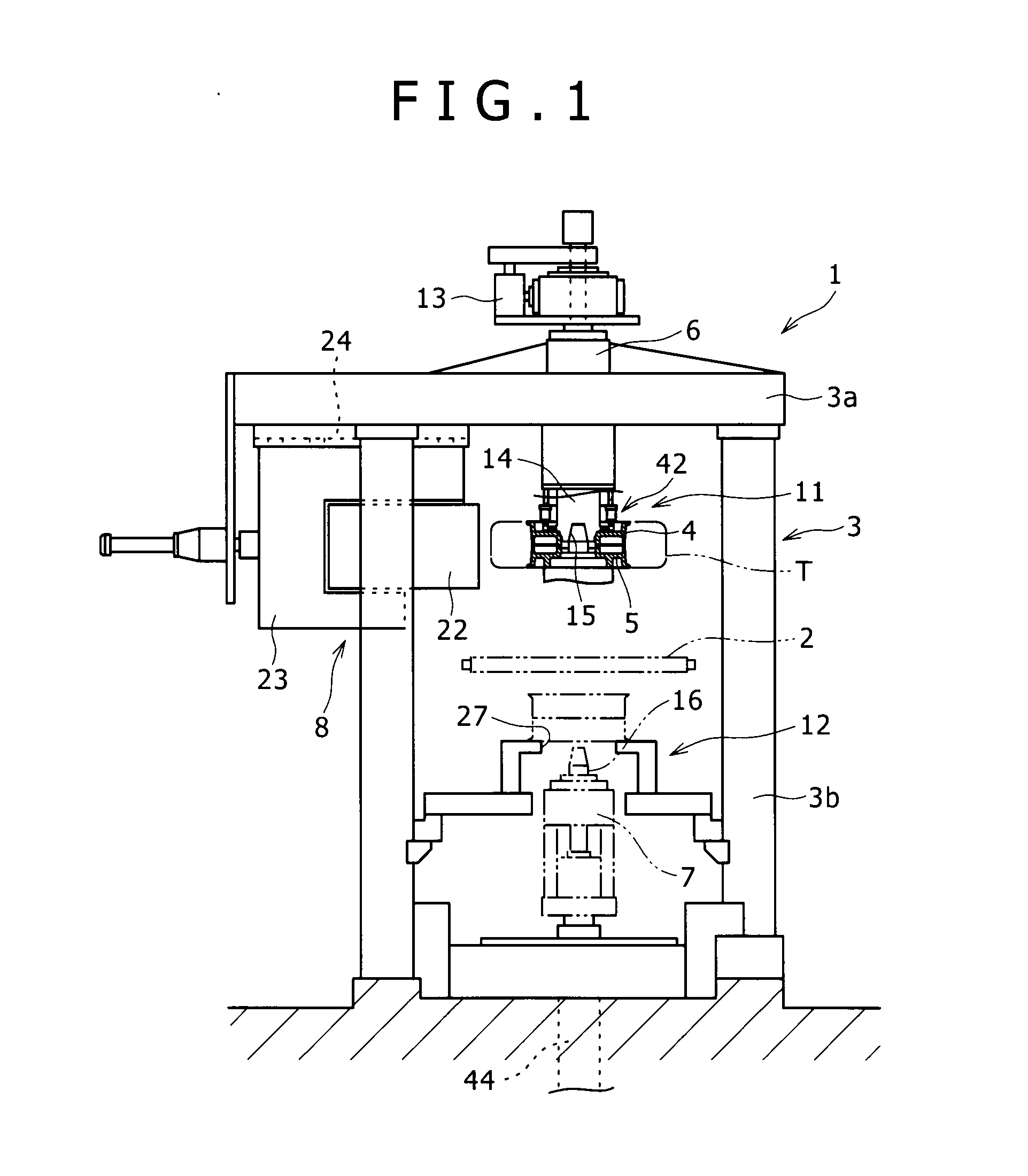

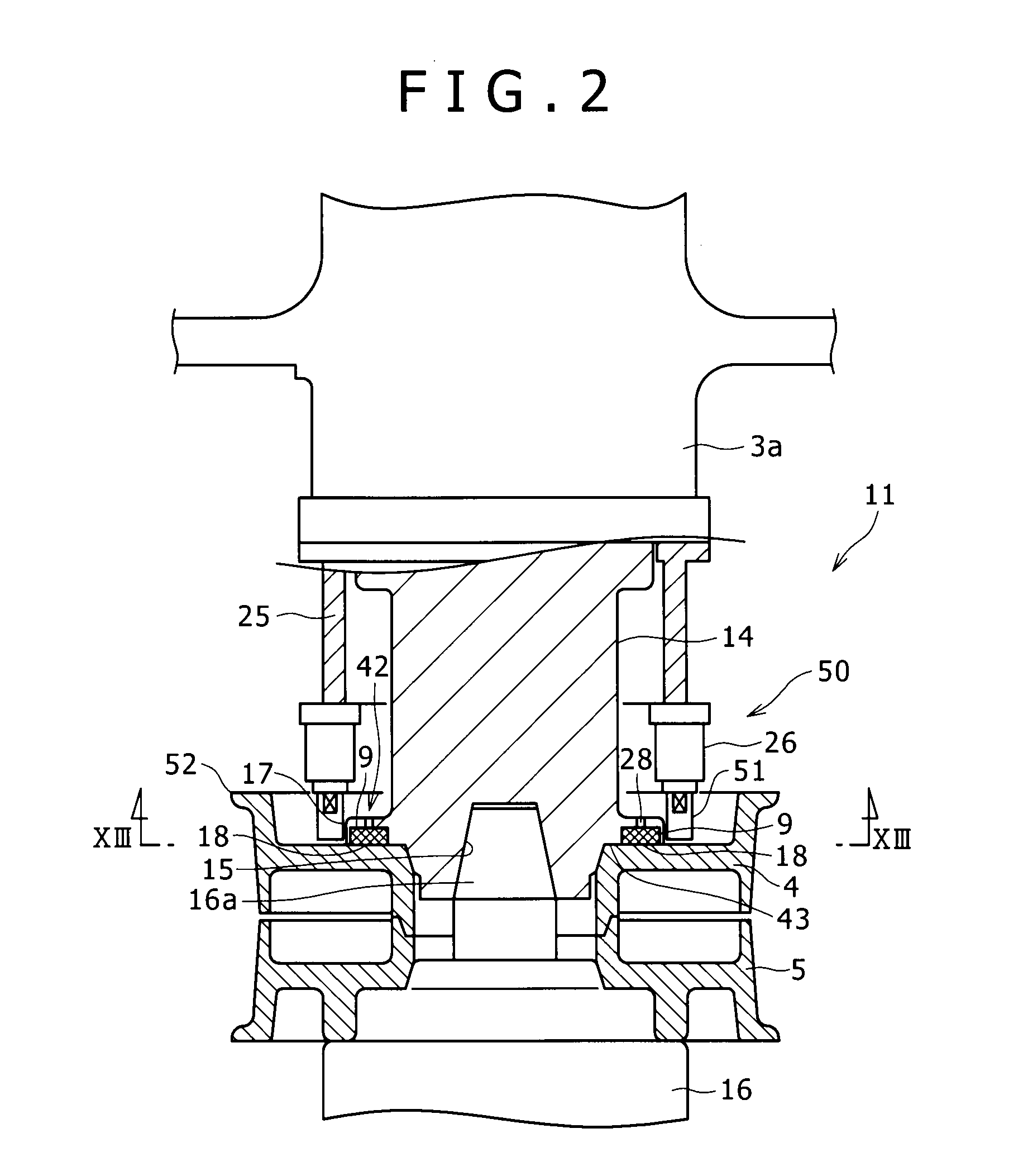

Rim mounting device for tire testing device, magnet mounting method, rim replacing device and tire testing device

ActiveUS20110226050A1Easy to fixEasy to separateRoads maintainenceVehicle tyre testingMagnetStructural engineering

A rim mounting device configured in such a manner that, even if a permanent magnet breaks due to impact produced during mounting thereof by magnetic attraction, the rim mounting device can be handled easily after the breakage of the permanent magnet. The rim mounting device is provided to a tire testing device having a spindle for rotating a tire and is adapted that a rim is mounted to the tip of the spindle. The rim mounting device is provided with: a rim mounting section provided to the tip of the spindle, having a rim mounting surface capable of making contact with the rim, and having mounting recesses formed in the rim mounting surface so as to be arranged side by side; permanent magnets inserted in the mounting recesses, respectively, and generating magnetic force for attracting the rim to the rim mounting surface; and scatter suppressing members. The scatter suppressing members are provided in the mounting recesses, respectively, and when the permanent magnet inserted in each mounting recess breaks, suppress scatter of fragments of the permanent magnet.

Owner:KOBE STEEL LTD

Intelligent tire inflation and deflation system apparatus

ActiveUS9248707B2Sure easyEasy maintenanceTyre measurementsDistance measurementTire rotationTire-pressure monitoring system

An intelligent tire pressure management system capable of real-time tire pressure monitoring, vehicle load detection, and automatic tire inflation and deflation for maintaining optimal tire pressure in a commercial vehicle. Additional functions include counting tire rotations for calculating and recording distance travelled for each tire, and detecting wheel sliding due to locked-up tires. The system includes a chassis-mounted control box connecting to the vehicle air supply, a hubcap-mounted dual wheel valve apparatus integrated with a rotary union assembly that connects through the vehicle hollowed axles to the air tubes from the control box. The inflation / deflation supporting dual wheel valve apparatus has an embedded electronic unit that monitors individual tire pressure and temperature in real time, and communicates with the control box over the power line. Furthermore a load sensor integrated with the control box provides the system with the current vehicle load information. With readily available real time tire pressure data and current vehicle load information, this system can intelligently adjusts tire pressure to the desired level when necessary and, as a result, prolongs tire life, improves fuel economy, reduces the vehicle maintenance costs, and promptly alerts the driver of low, leaky or flat tire conditions for enabling the driver to take immediate corrective actions.

Owner:ZHOU JOE HUAYUE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com