Patents

Literature

2983results about "Vehicle tyre testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

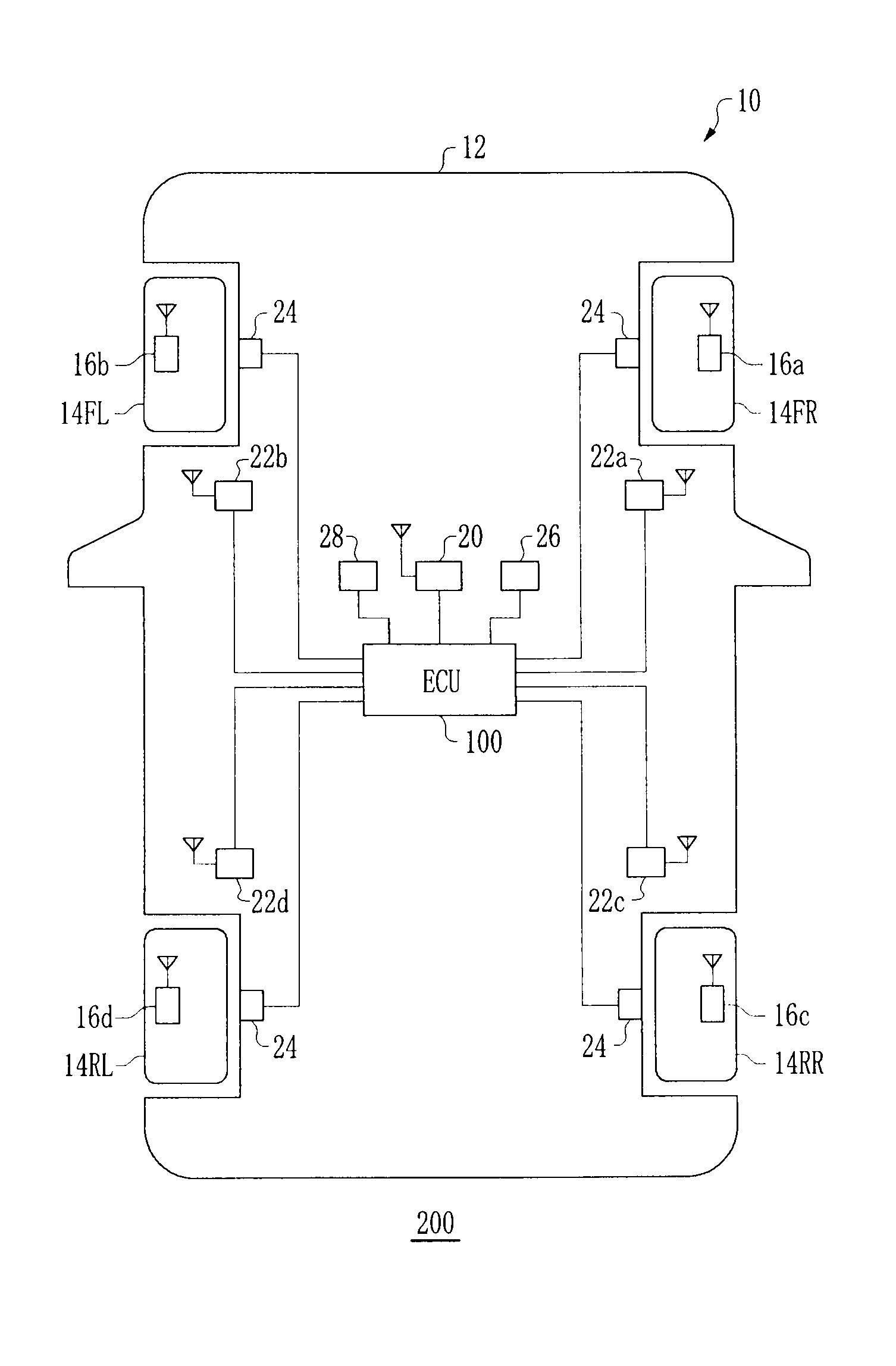

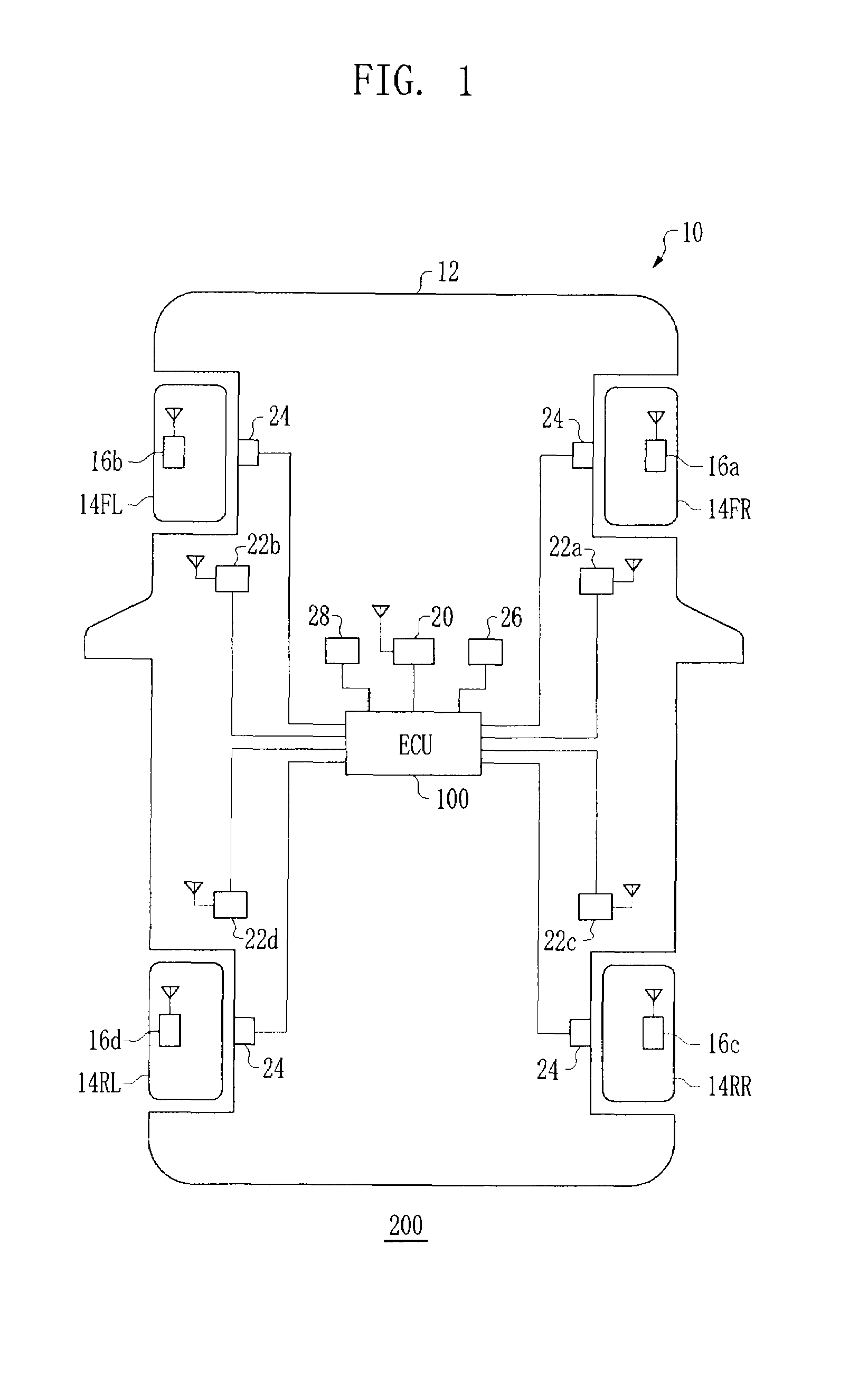

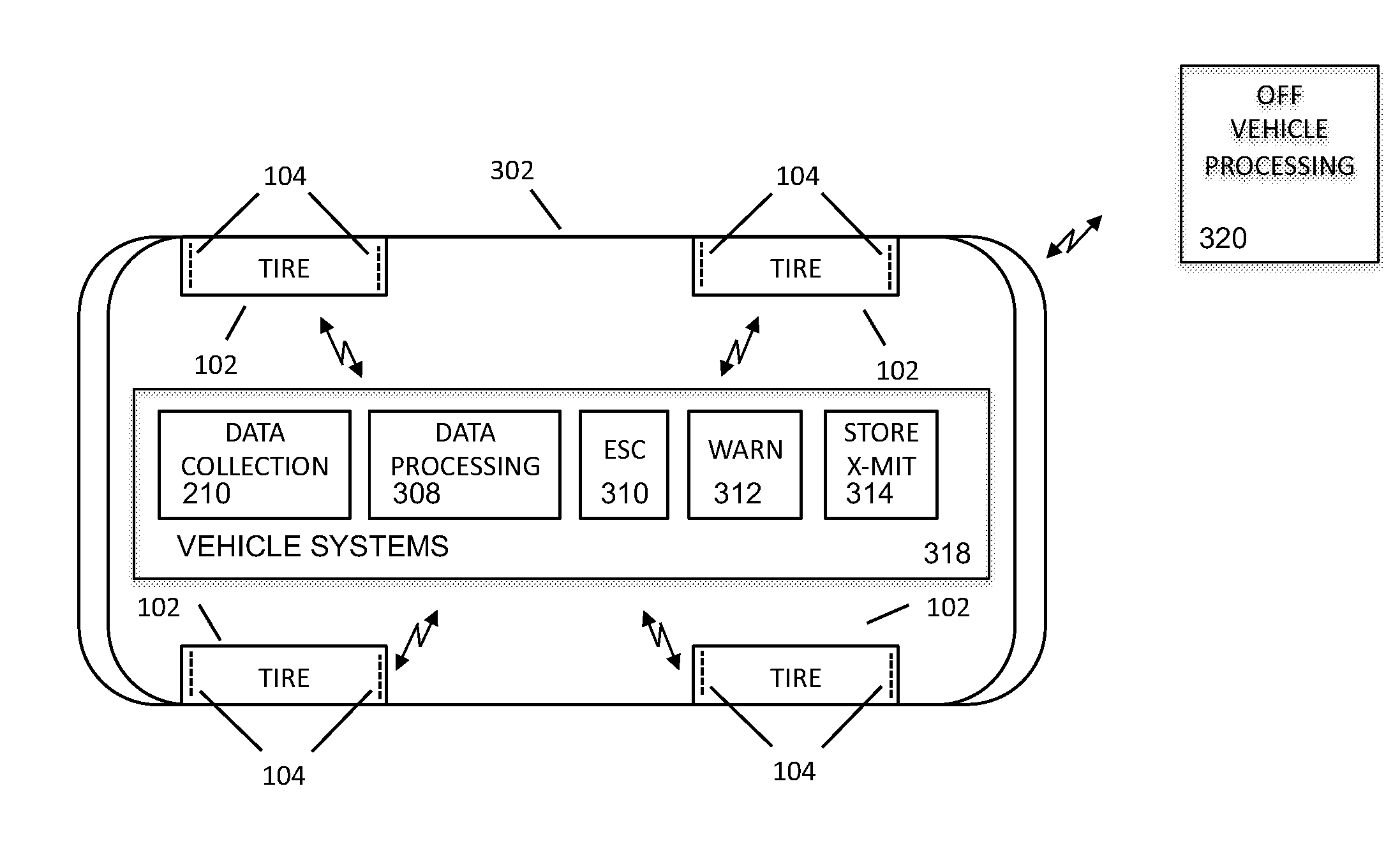

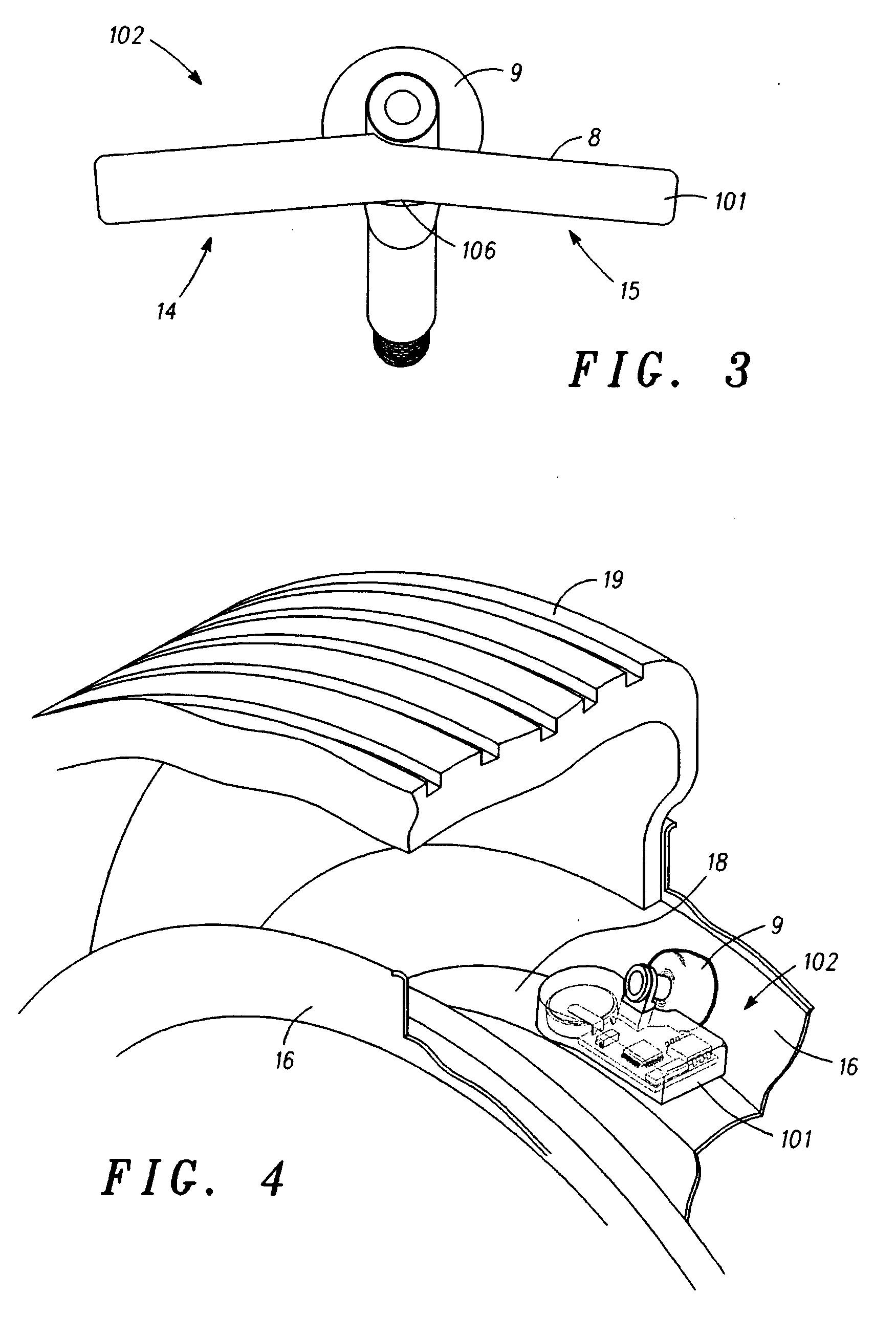

Wheel state monitoring system and wheel state detecting apparatus

InactiveUS7661299B2Tyre measurementsRoads maintainenceMonitoring systemTire-pressure monitoring system

A tire pressure monitoring system, that includes a plurality of the wheel state detection unit, provided at wheel of a vehicle, and that transmits detected wheel state information. A request signal transmitter transmits a request signal to request transmission of the detected wheel state information. When each wheel state detection unit receives the request signal, it transmits the detected wheel state together with the indication information indicating that the wheel state is detected in response to the transmission request signal. The ECU sets a determination threshold value for triggering an alert regarding tire pressure based on the detected wheel state information transmitted from the plurality of wheel state detection units.

Owner:TOYOTA JIDOSHA KK

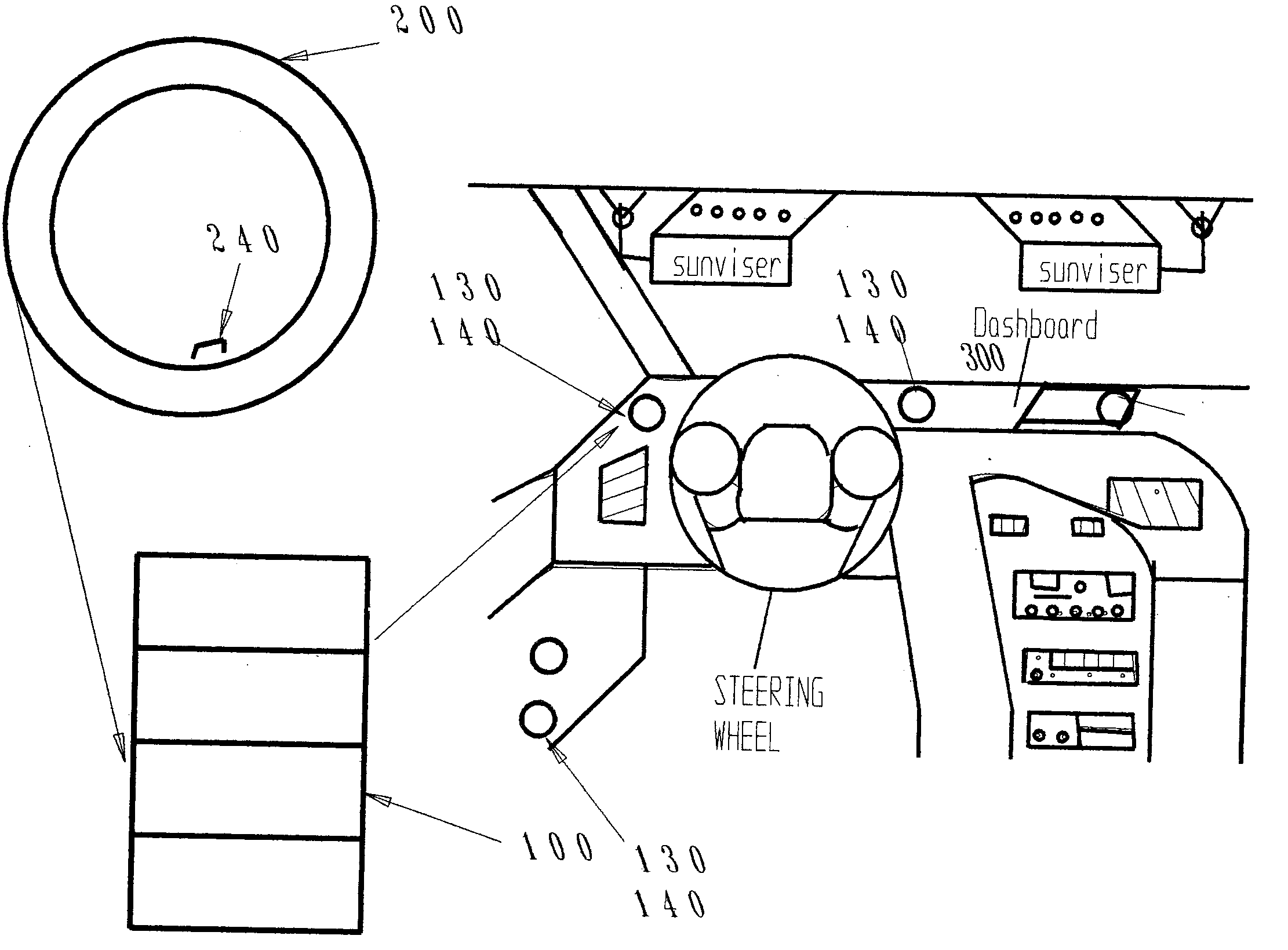

Vehicle interactive electronic wireless air pressure system's information: "VIEW A PSI"

InactiveUS20050179531A1Transmission easilyEasy to receiveTyre measurementsRoads maintainenceAcoustic energyIn vehicle

A vehicle tire communication and information system for viewing air psi and other characteristics that affects psi in a tire includes un-obstructive sensors embedded in a silicon substrate and etched in a re-enforced micro-fibered material to enable excellent detection platform, sensitivity, and selectivity within the detection environment. The embedded sensors facilitate detection and communication efficiency and transforms electrical energy into acoustic energy indicative of data transmission to a wireless electronic control module, allowing a nitride membrane to march the acoustic impedance of the air inside the tire to enable pressure waves indicative of the tire pressure.

Owner:TABE JOSEPH AKWO

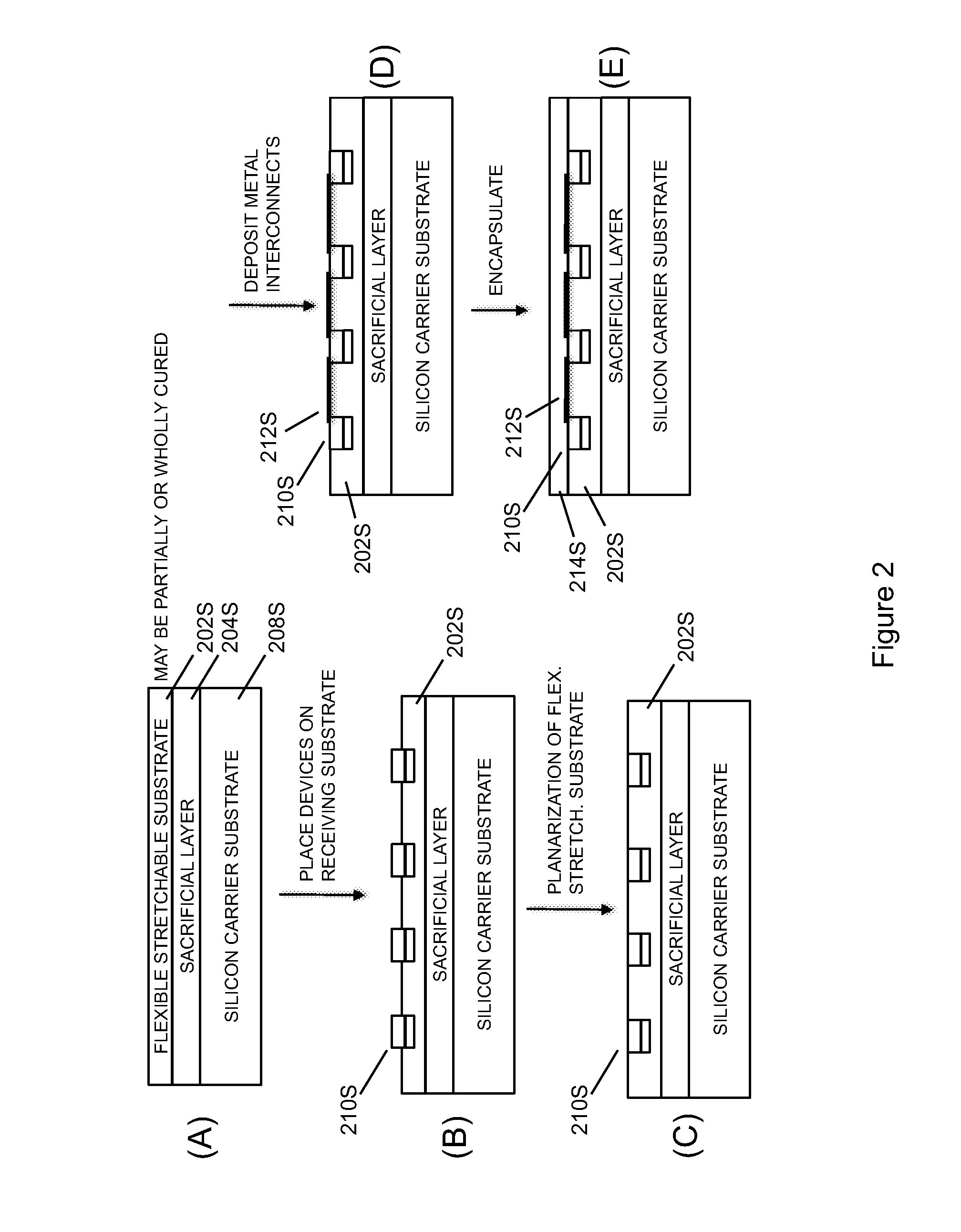

Systems, devices, and methods utilizing stretchable electronics to measure tire or road surface conditions

InactiveUS20100271191A1Improve performanceIncrease motivationTyre measurementsRoads maintainenceStretchable electronicsRoad surface

In embodiments, the present invention may comprise a sensor-based tire data collection facility integrated with the body of a vehicle tire, wherein the sensor-based tire data collection facility includes a stretchable electronics circuit and a wireless communications facility for communicating data collected by the sensor-based tire data collection facility to a vehicle data collection facility external to the body of the vehicle tire.

Owner:MC 10 INC

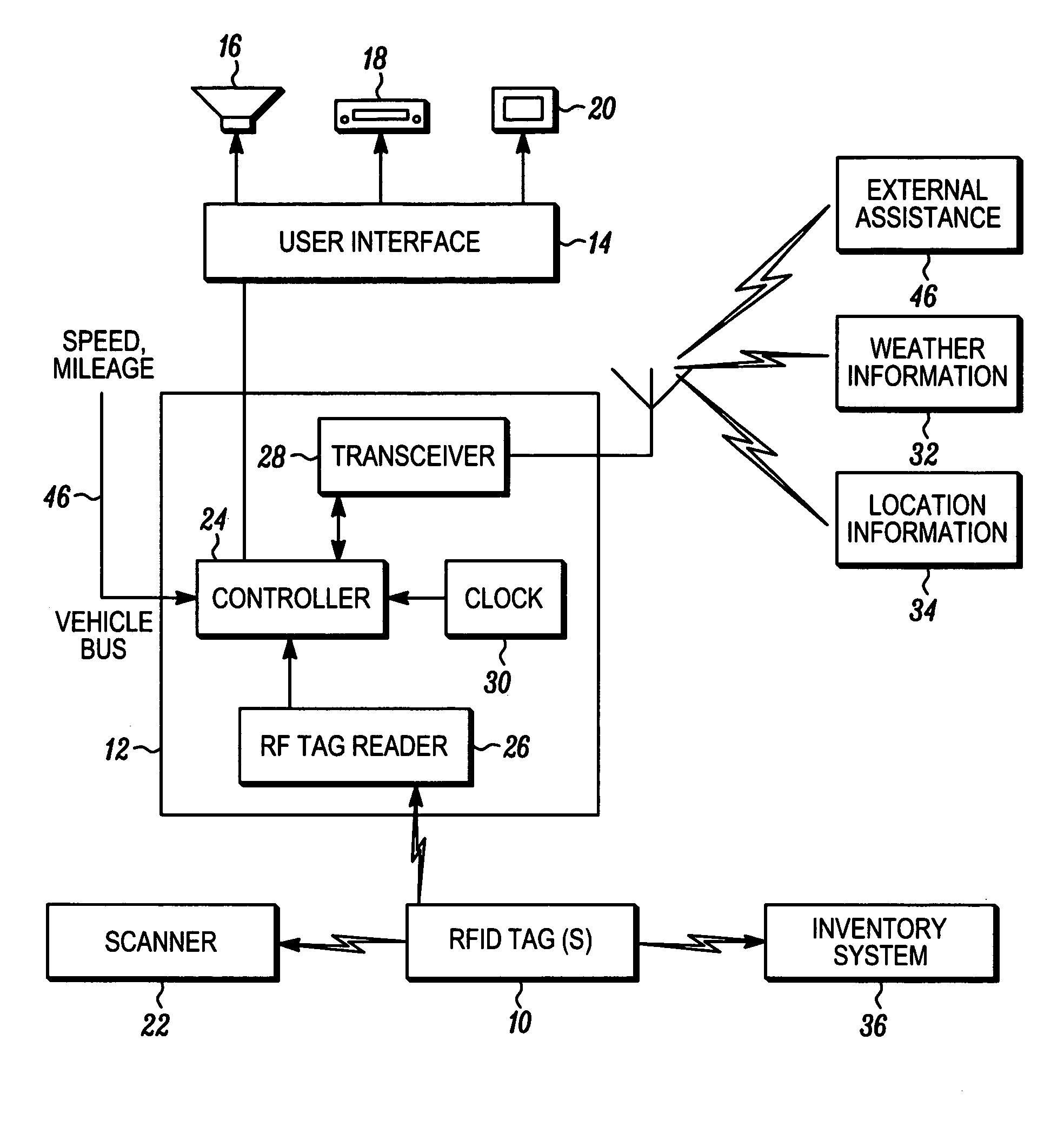

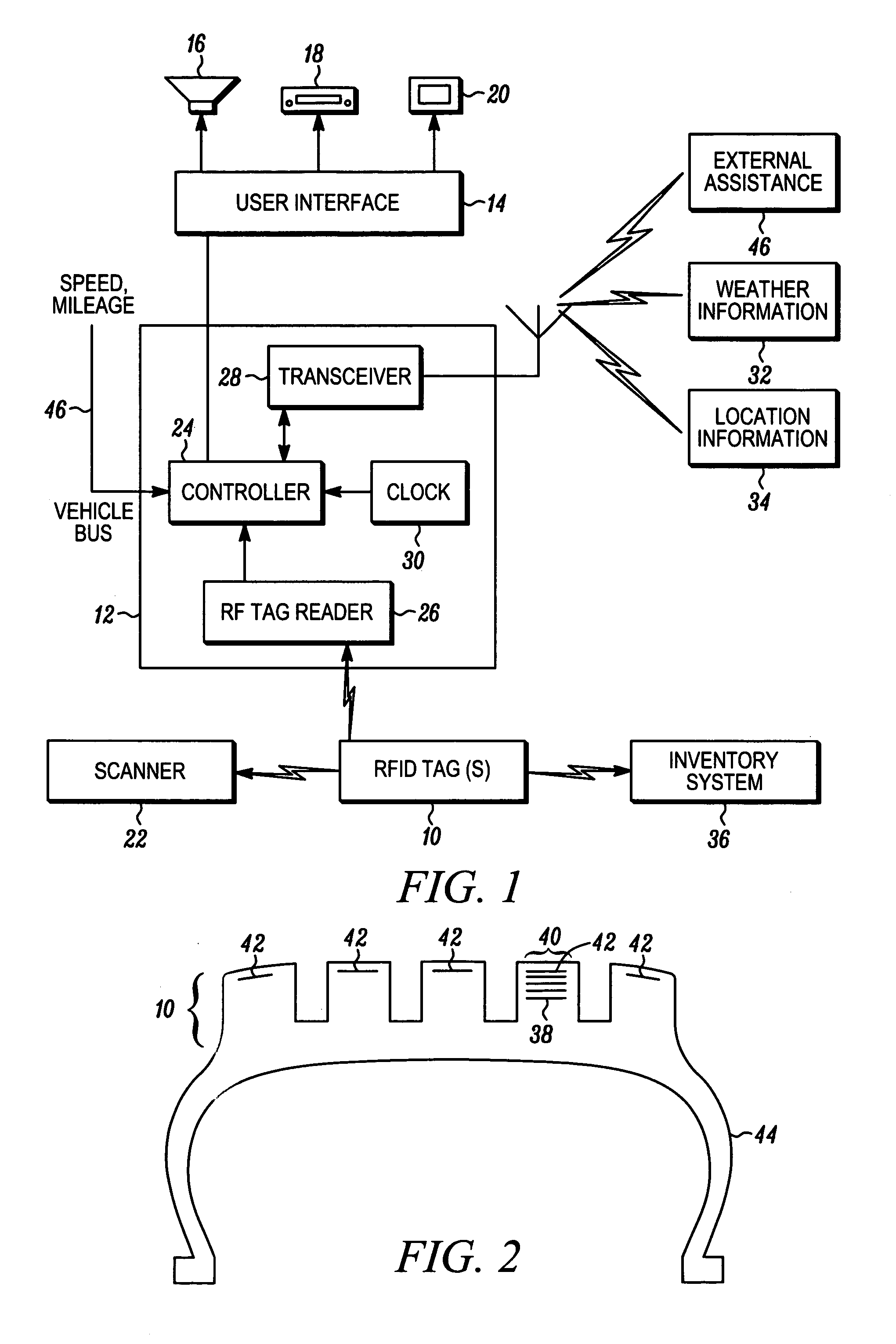

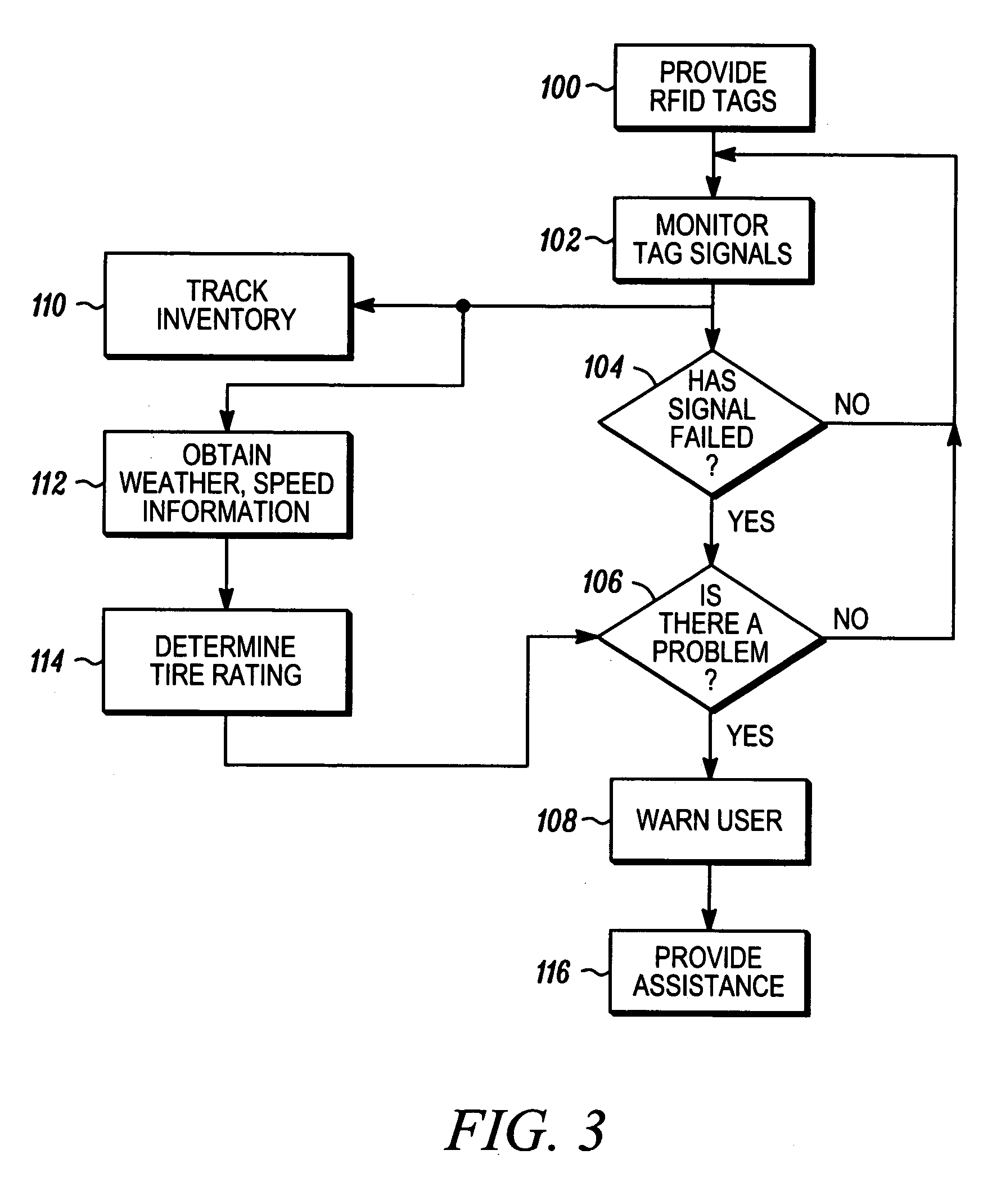

Tire tread wear sensor system

A system and method for monitoring belt wear or tread wear of a tire includes at least one radio frequency identification (RFID) tag with unique identification embedded in the belt or tread of the tire at one or more wear points. An RF tag reader periodically monitoring signals from the at least one RFID tag. If the RF tag reader fails to obtain any signals from the at least one RFID tag, indicating a destroyed RFID tag, the user can be warned about a wear problem of that belt or tire. RFID tags can be distributed at different depths of the tire(s), or across the tread at the same depth, of the tire(s) to determine different wear problems. The same RFID tag can also be used for inventory tracking purposes.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

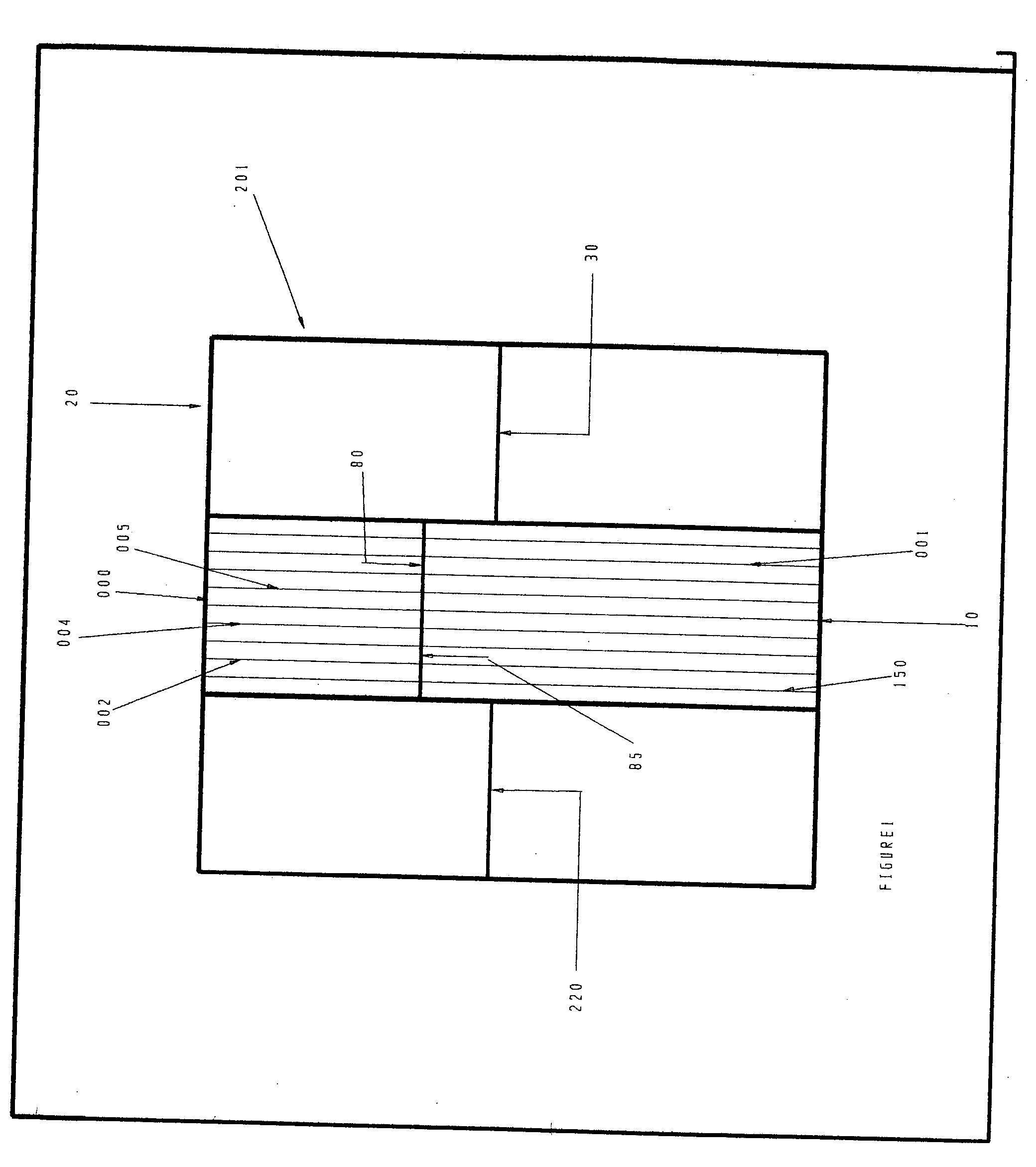

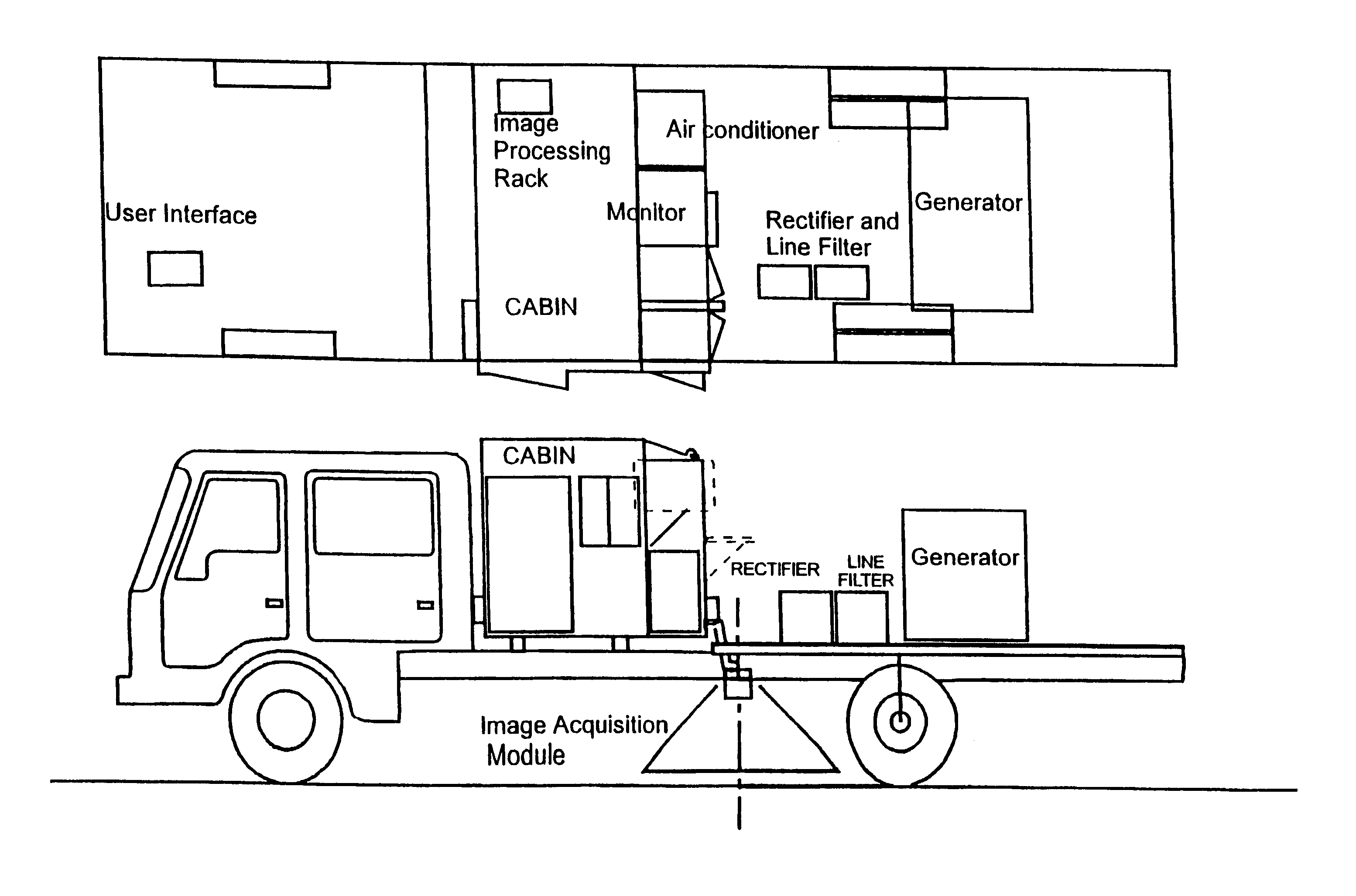

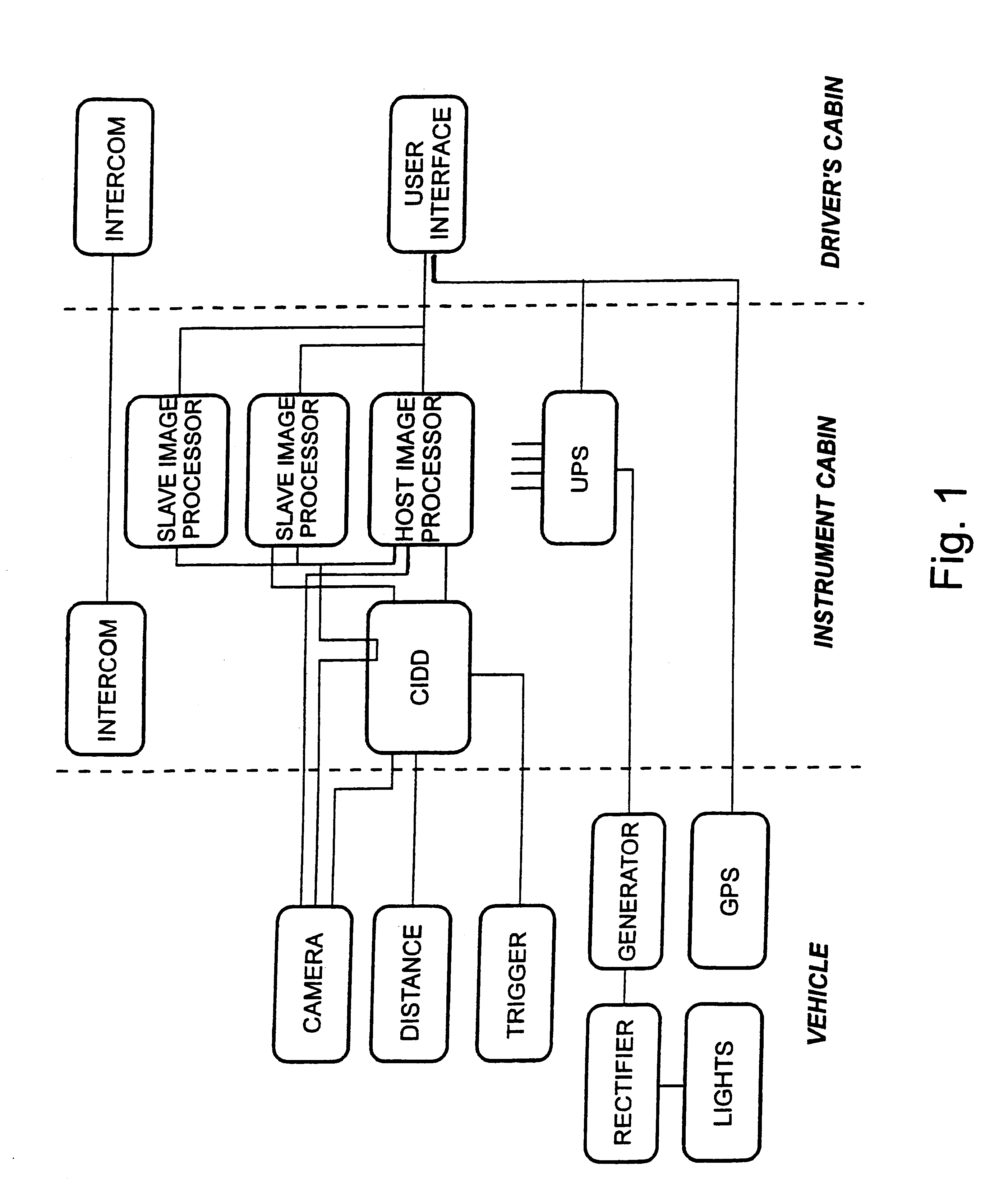

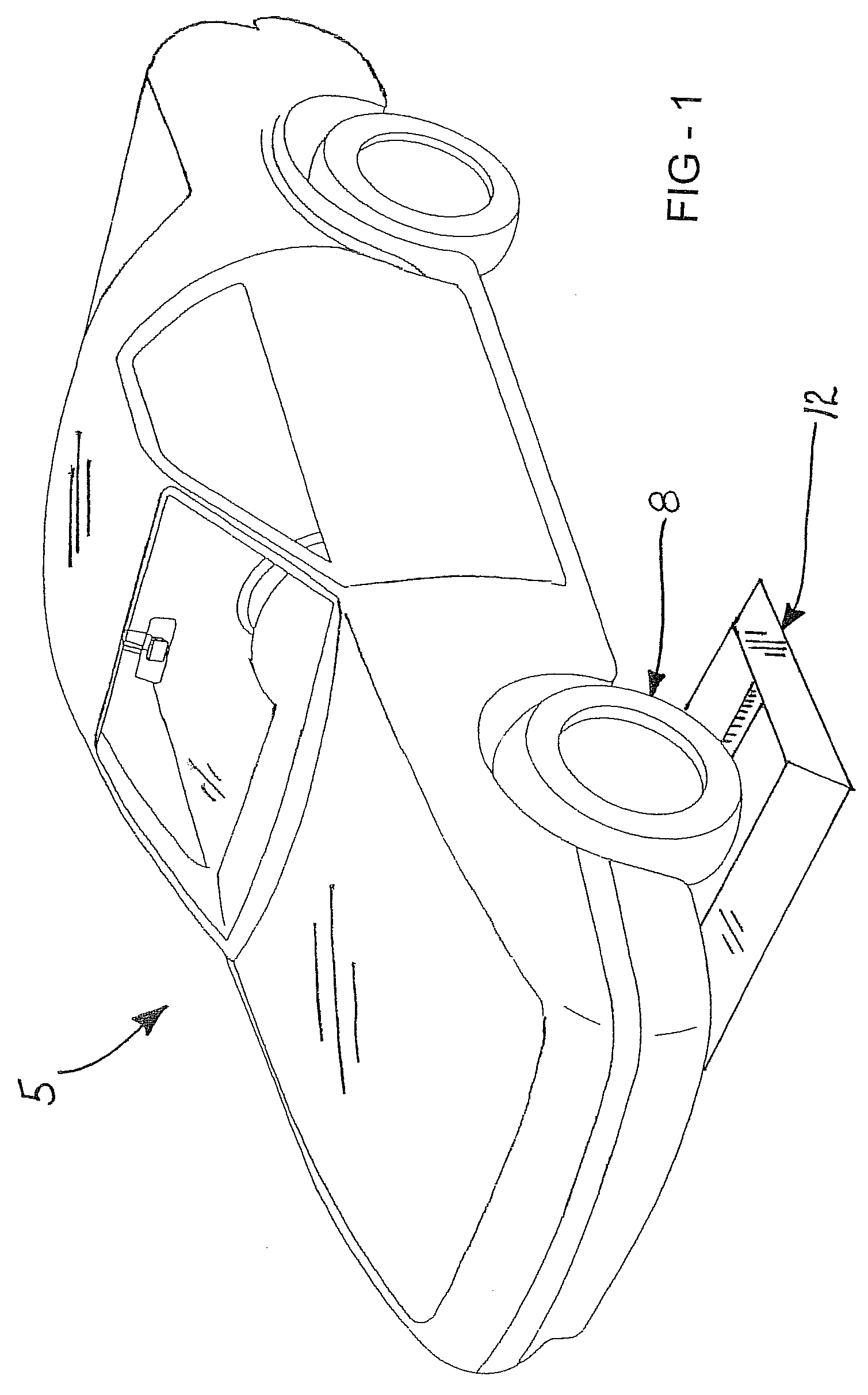

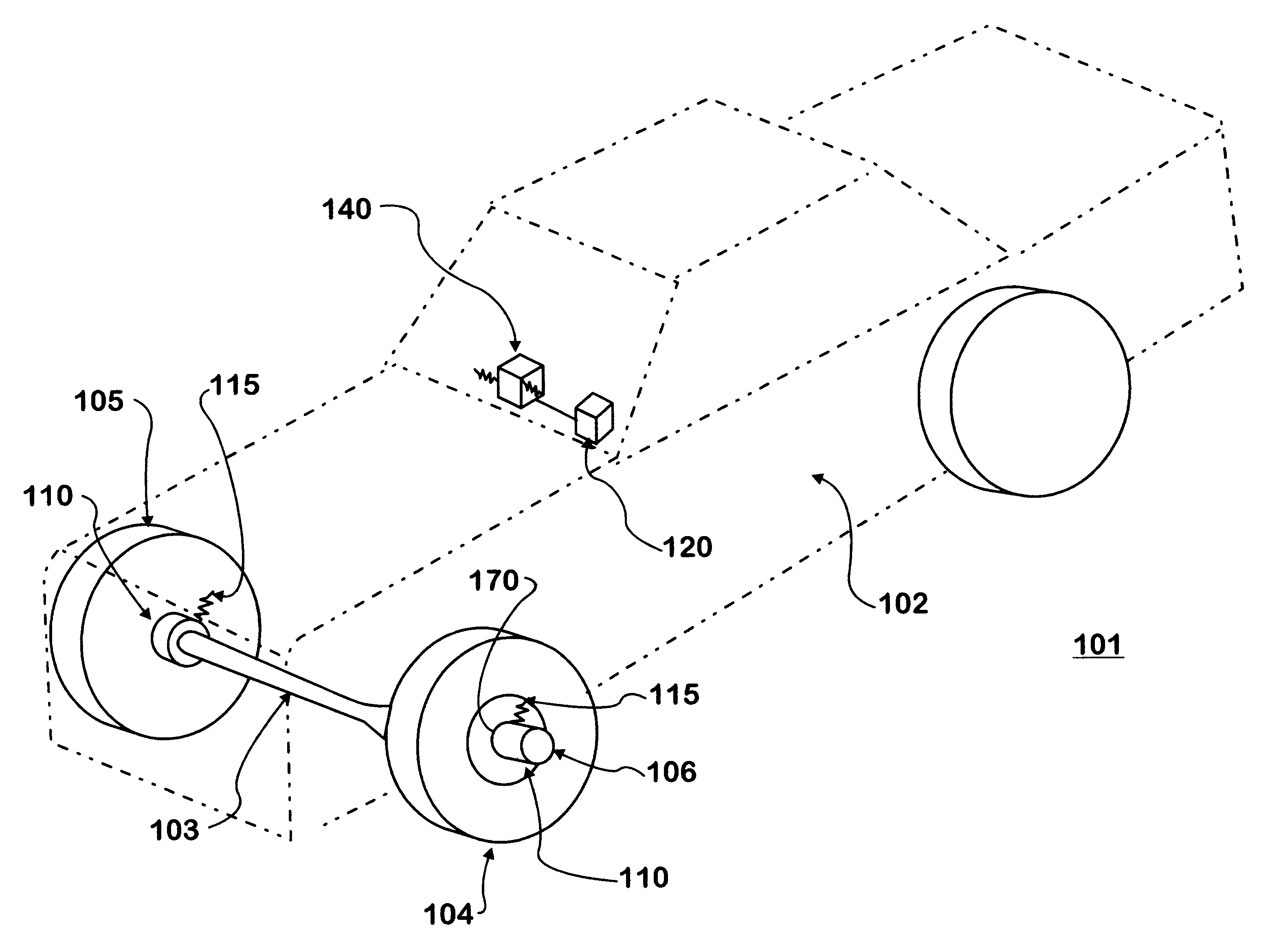

Road pavement deterioration inspection system

InactiveUS6615648B1Reduce the risk of injuryReduce transferDigital computer detailsMeasurement arrangements for variableRoad surfaceDigital camera

A system for acquiring, processing, storing, analyzing and reporting data relating to the condition of a road or other pavement surface (102) in real time. The system includes a digital camera (104) mounted on a vehicle and positioned relative to a pavement surface (102) so as to capture images of the pavement surface (102) while the camera (104) is moving relative to the surface (102). The system also includes an illumination assembly (100) to illuminate the region from which an image is taken and an interface between the digital camera (104) and at least one computer. The system also includes a processor in the computer for processing the images to detect and classify cracks and other pavement surface (102) features.

Owner:COMMONWEALTH SCI & IND RES ORG +1

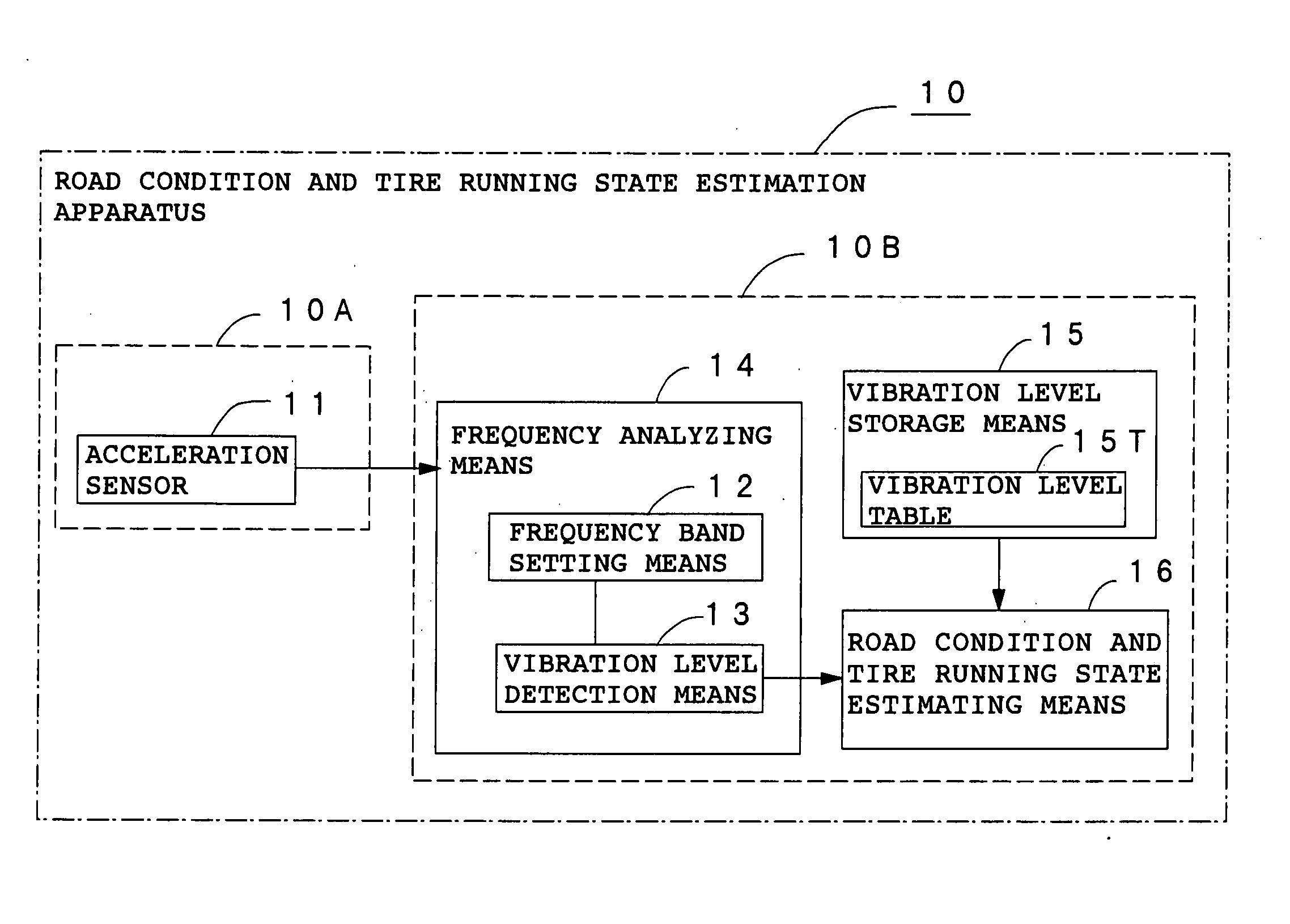

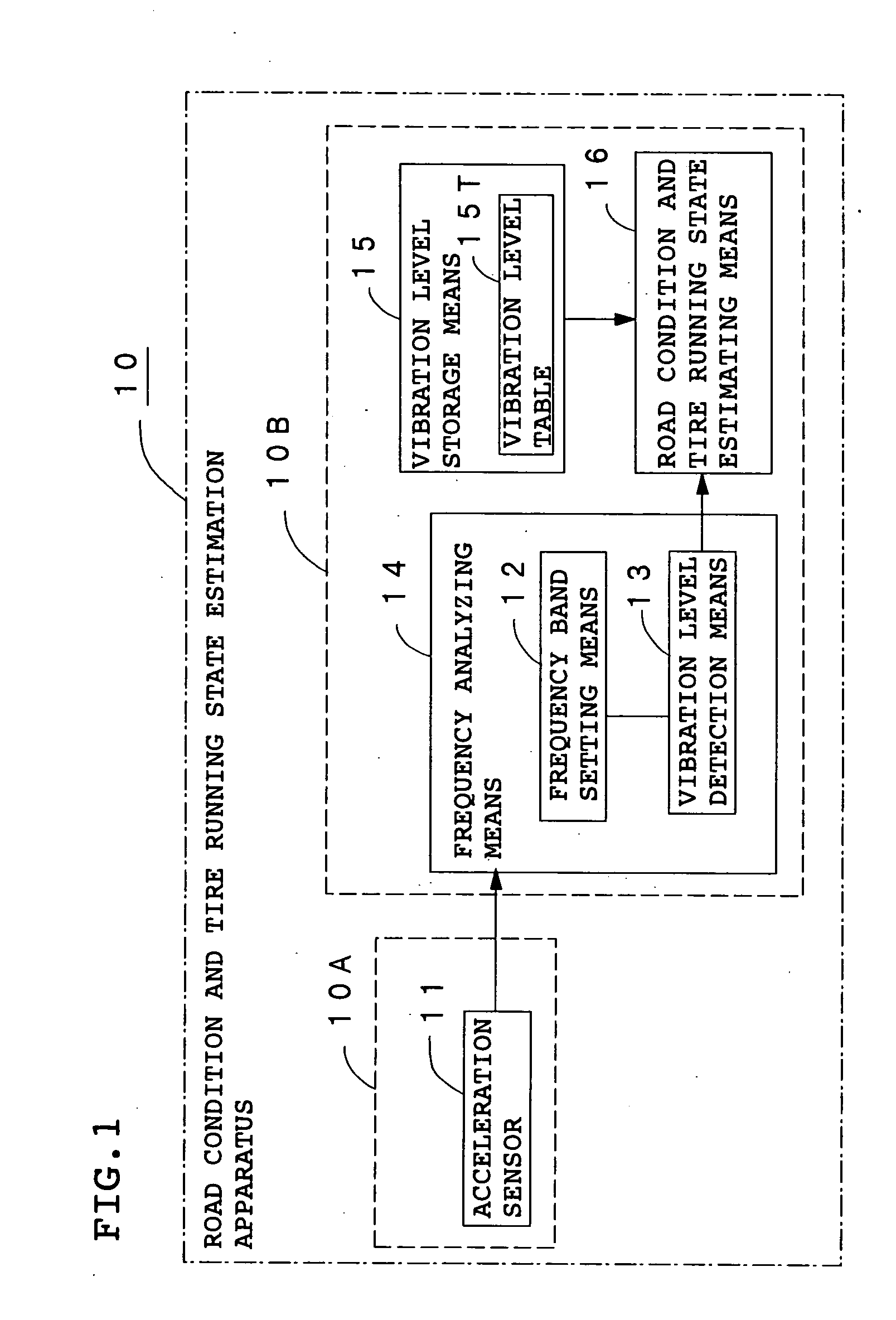

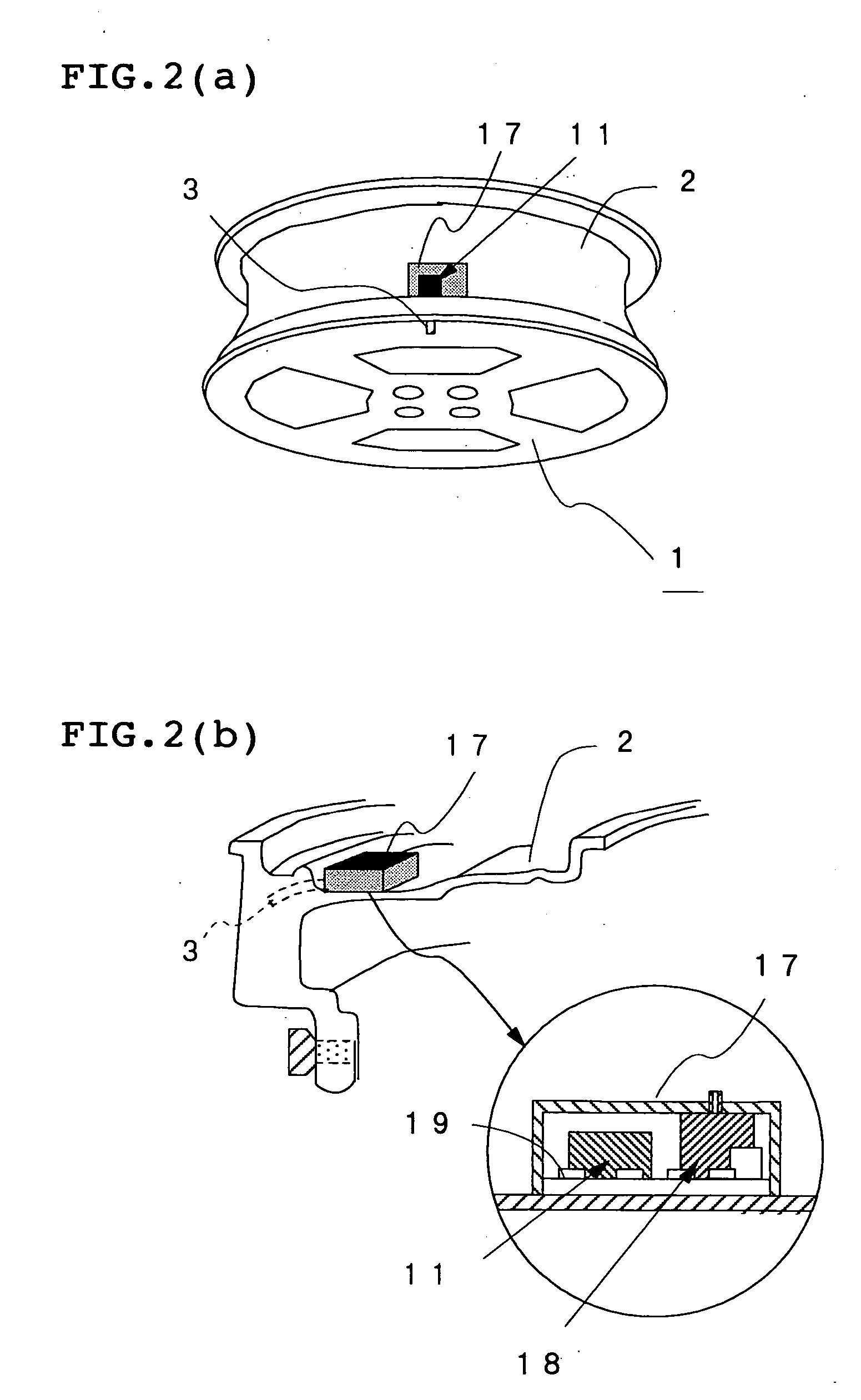

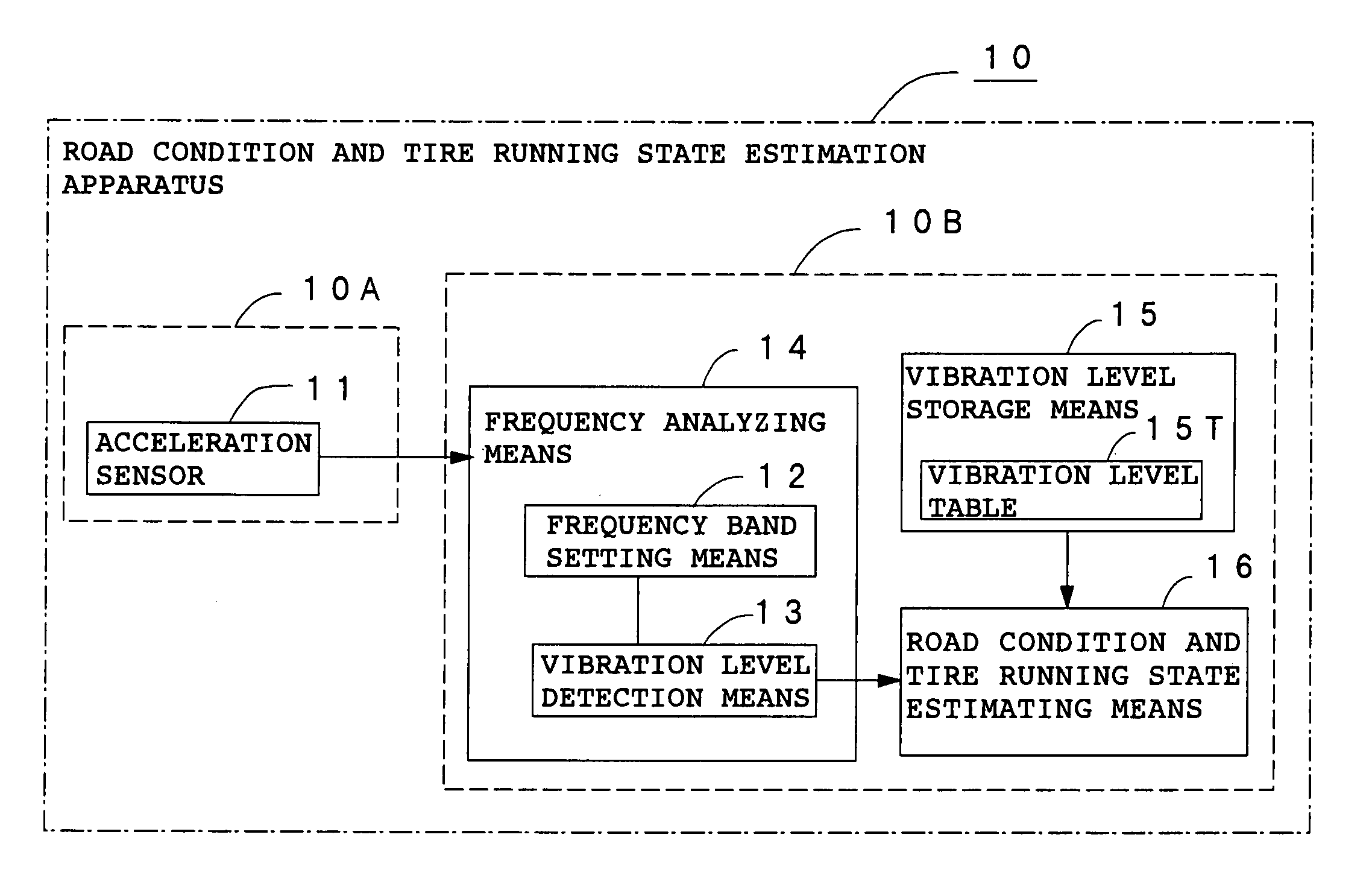

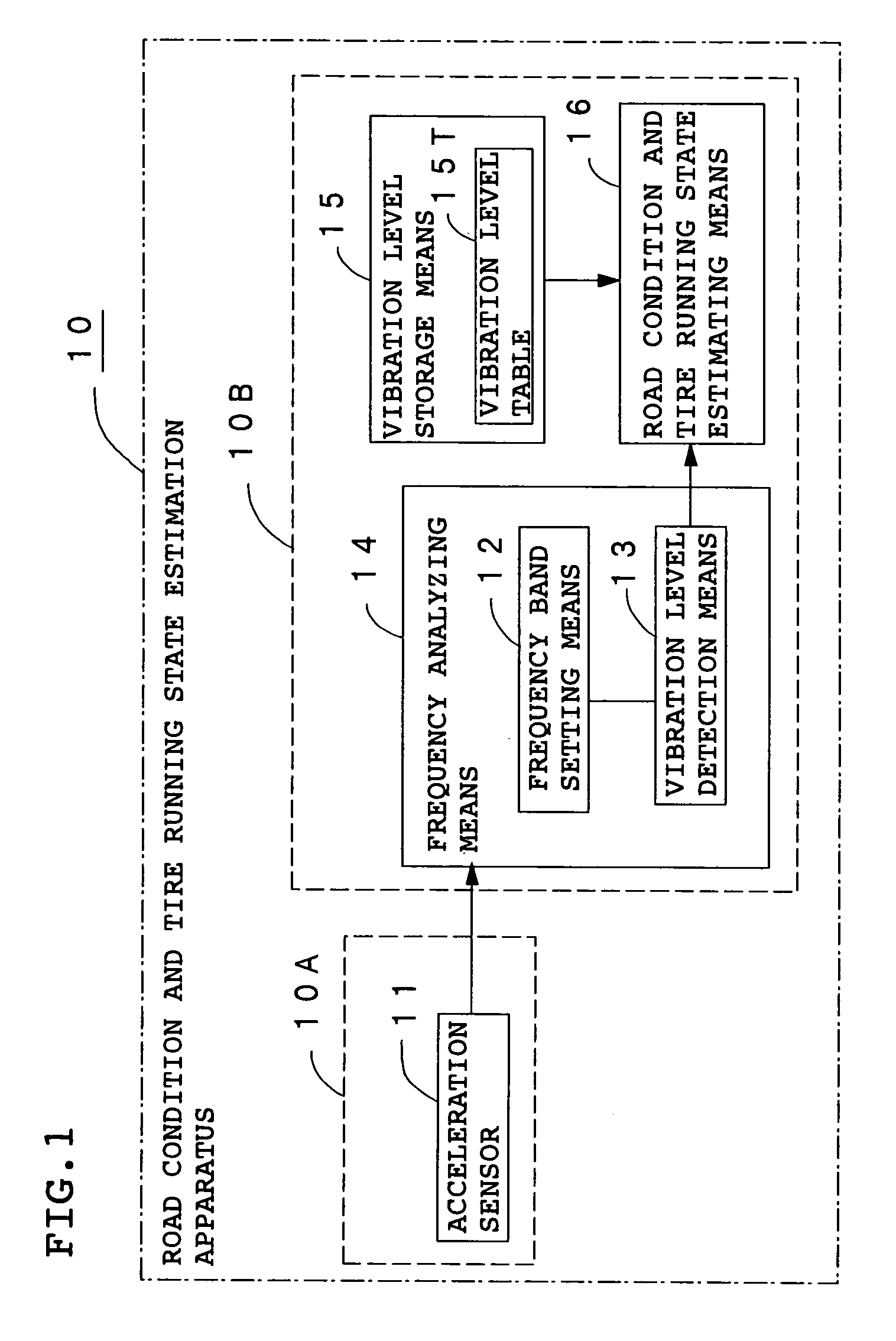

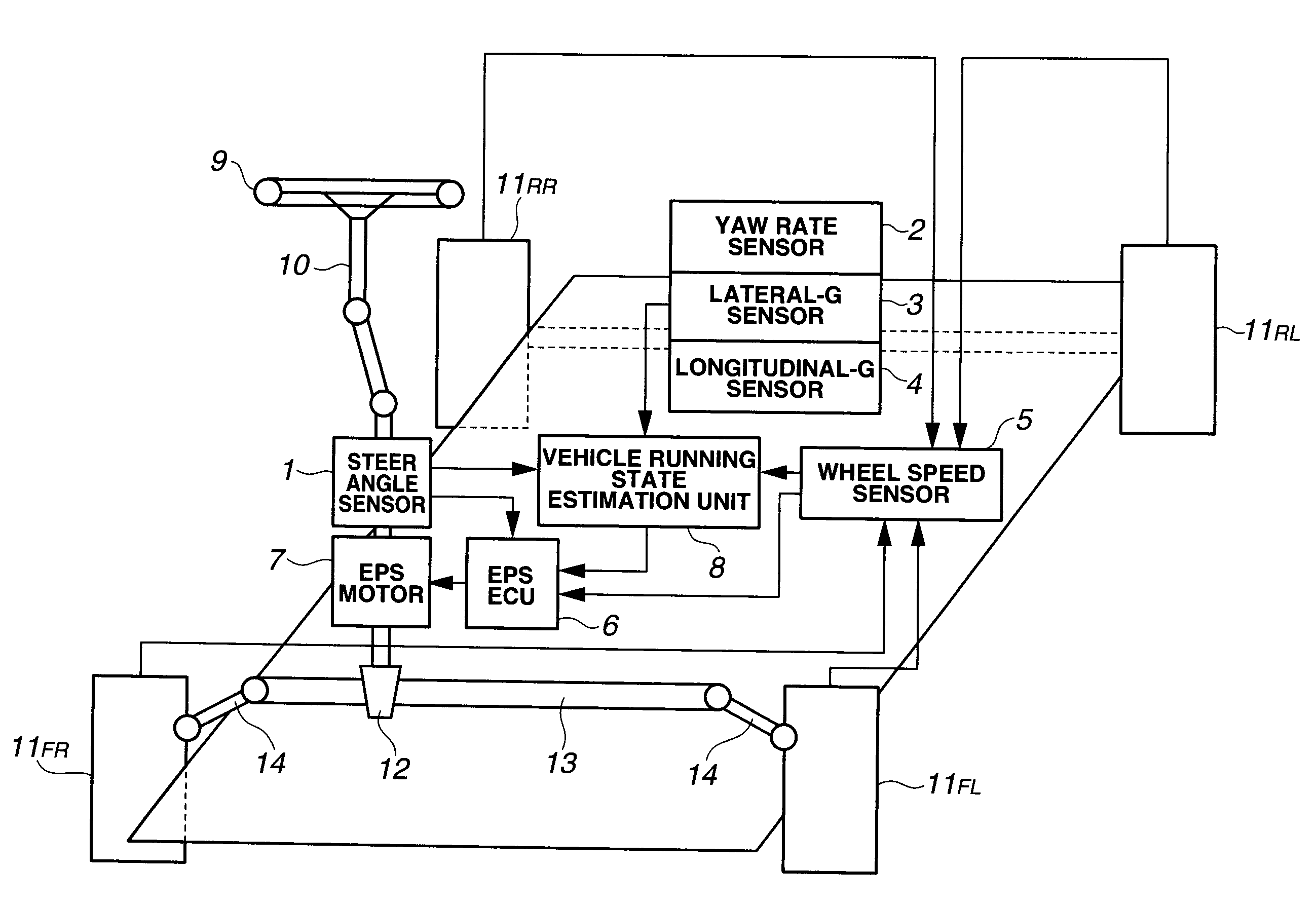

Method and apparatus for estimating road surface state and tire running state, abs and vehicle control using the same

InactiveUS20050085987A1Accurate estimateRegistering/indicating working of vehiclesDigital data processing detailsRoad surfaceVehicle control

The frequency of an information signal indicative of the vibration of a wheel detected by an acceleration sensor 11 mounted to a wheel 1 or the frequency of an information signal indicative of a change in the pressure of a gas in a tire detected by a pressure sensor 31 installed in the tire is analyzed by frequency analyzing means 14 (34), the band value of the obtained vibration spectrum or pressure change spectrum is detected, and a vibration level or pressure change level at the detected frequency band is compared with a vibration level table 15T showing the relationship between road friction coefficient μ and vibration level stored in vibration level storage means 15, or a pressure change level table 35T showing the relationship between road friction coefficient μ and pressure change level stored in pressure change level storage means 35 to estimate a road friction coefficient μ. Therefore, it is possible to estimate the value of road friction coefficient μ accurately and improve the safety of a car.

Owner:BRIDGESTONE CORP

Method and apparatus for estimating road surface state and tire running state, ABS and vehicle control using the same

InactiveUS7203579B2Accurate estimateRegistering/indicating working of vehiclesDigital data processing detailsRoad surfaceVehicle control

Owner:BRIDGESTONE CORP

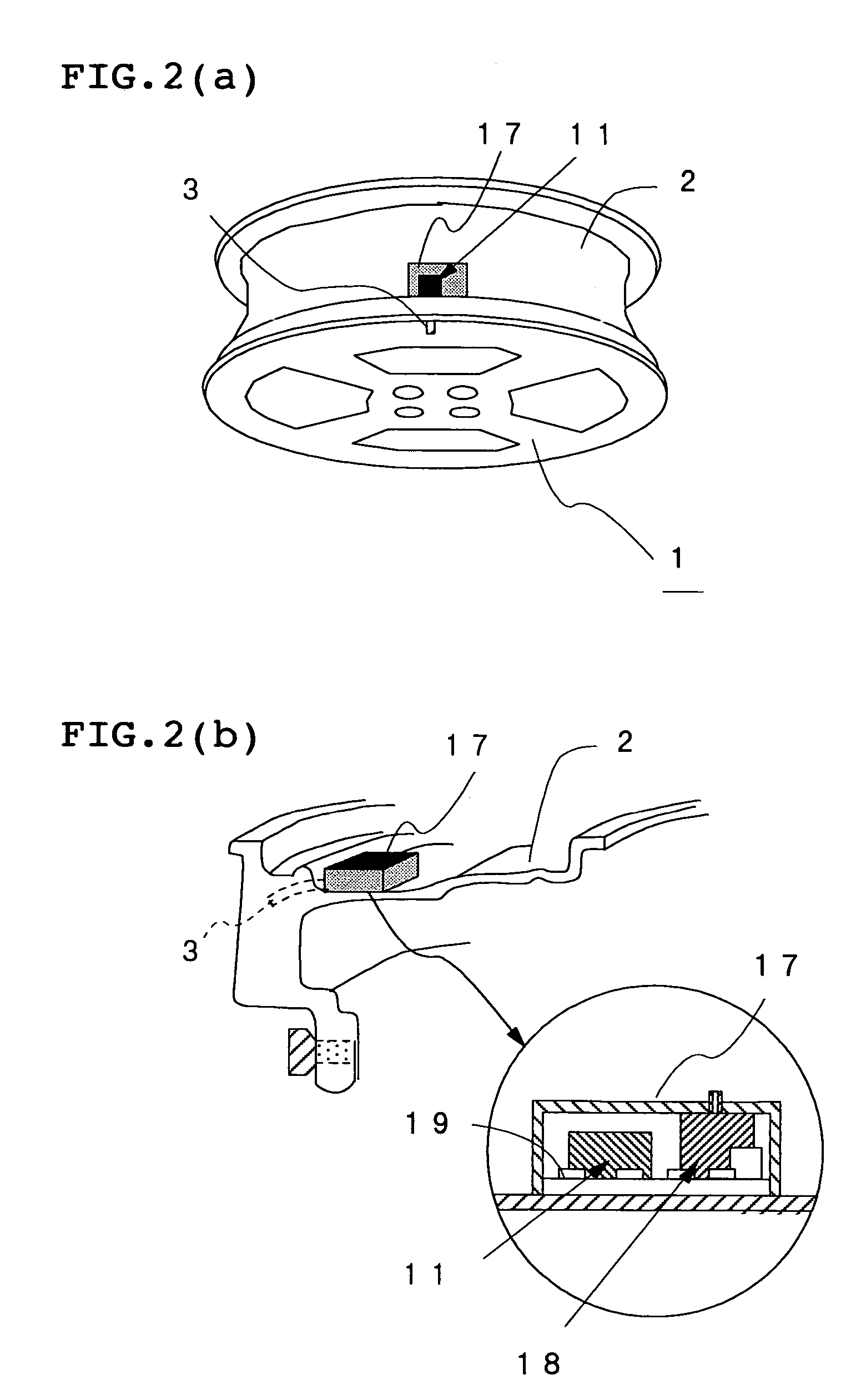

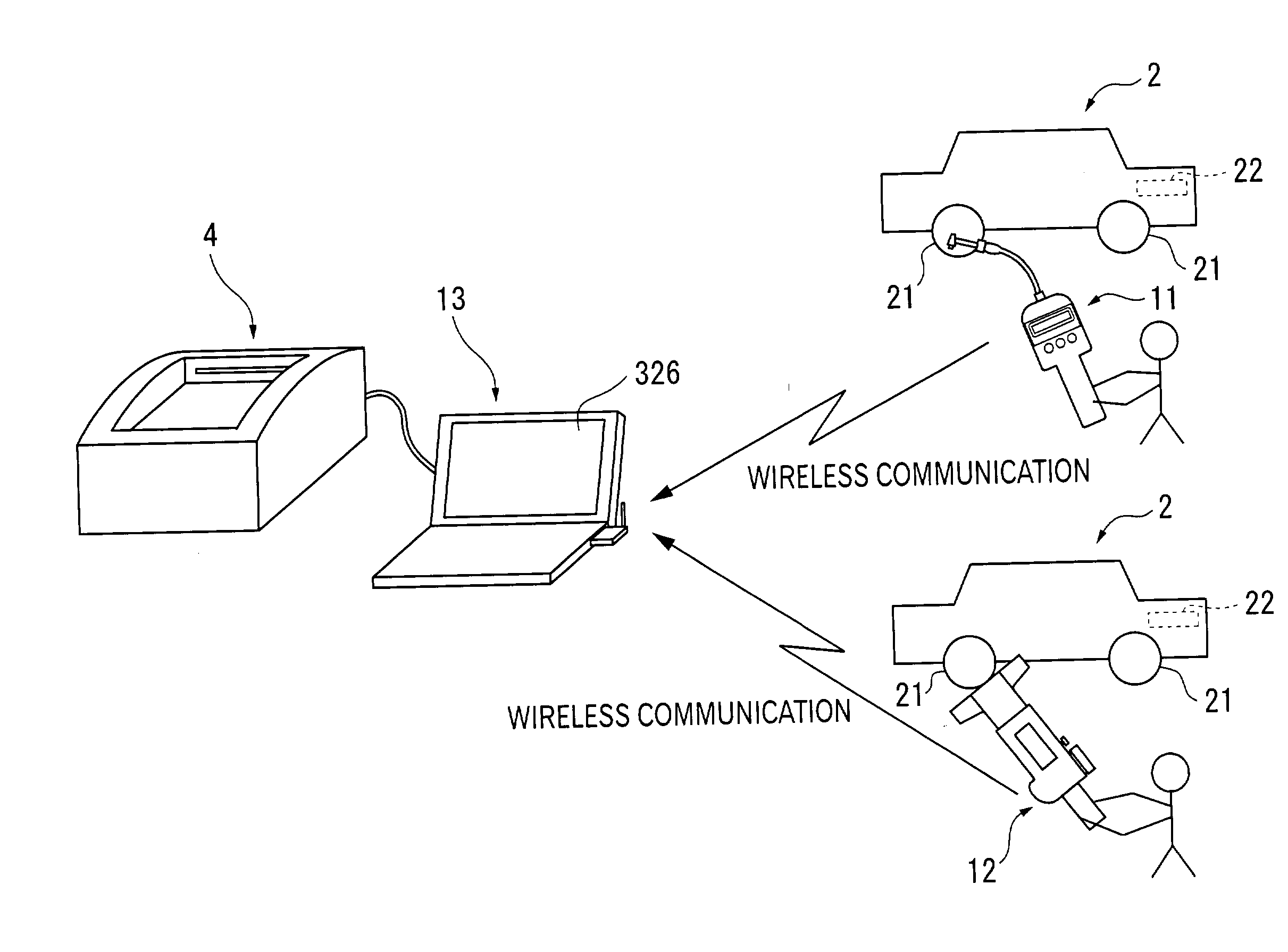

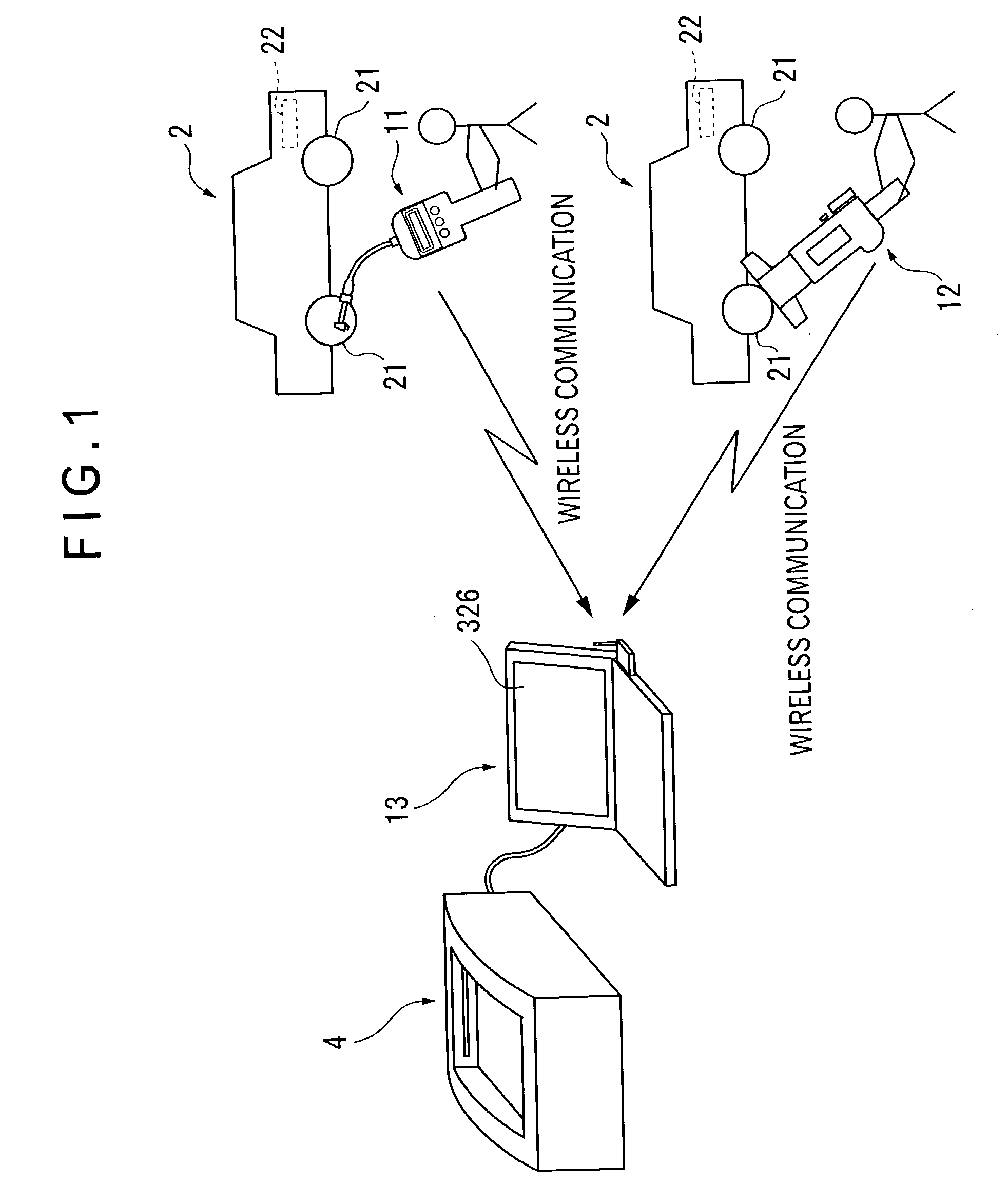

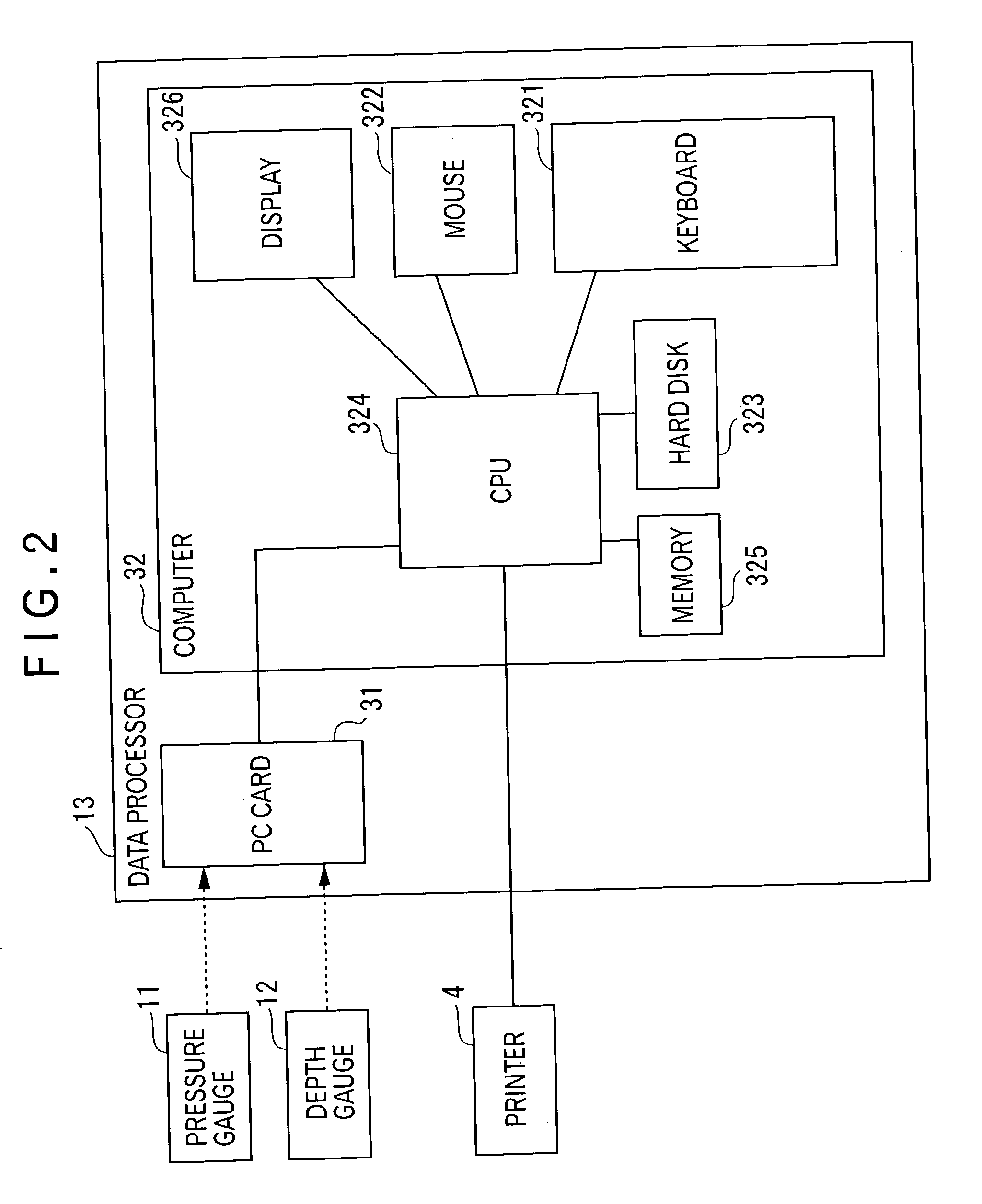

Wheel measuring system, wheel measuring method and wheel-related product sales method

InactiveUS20030187556A1Eliminate needBusiness can be proceeded more smoothlyInflated body pressure measurementTransmission systemsDisplay deviceEngineering

A data processor (13) has a receiver for receiving measurement data on tires (21, 22) attached to an automobile (2) from a tire gauge (11, 12), and a data displaying portion for processing and displaying the received measurement data on a display (326) in a predetermined form. The received measurement data includes pressure value and tread depth of the tires (21, 22). The tread depth is measured on three points of inside, middle and outside in width direction of a tread surface of the tire. The received data is displayed in graphic representing positions of the tires (21, 22) of the automobile (2) and in a graph coloured corresponding to the measurement value.

Owner:MITUTOYO CORP

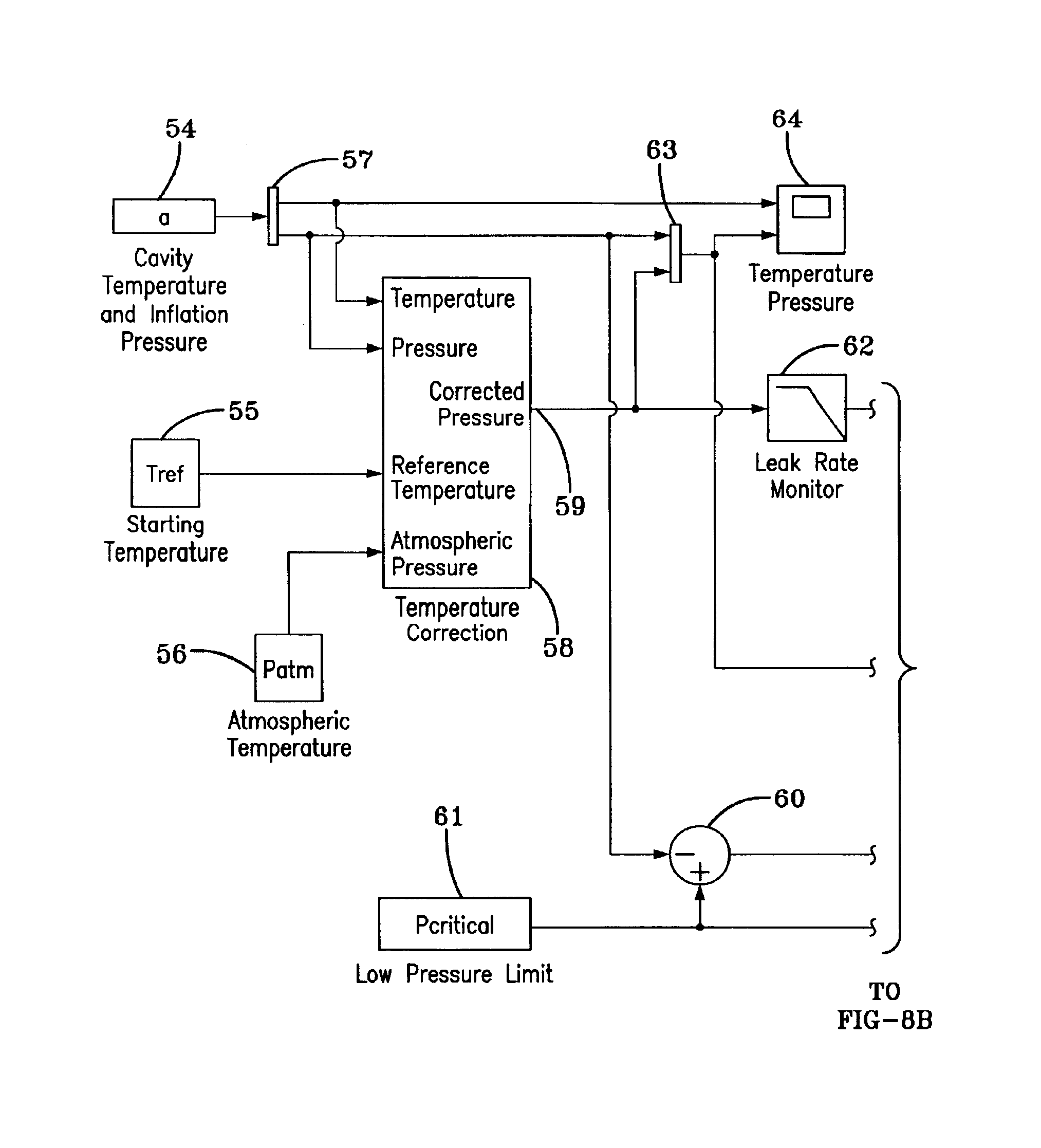

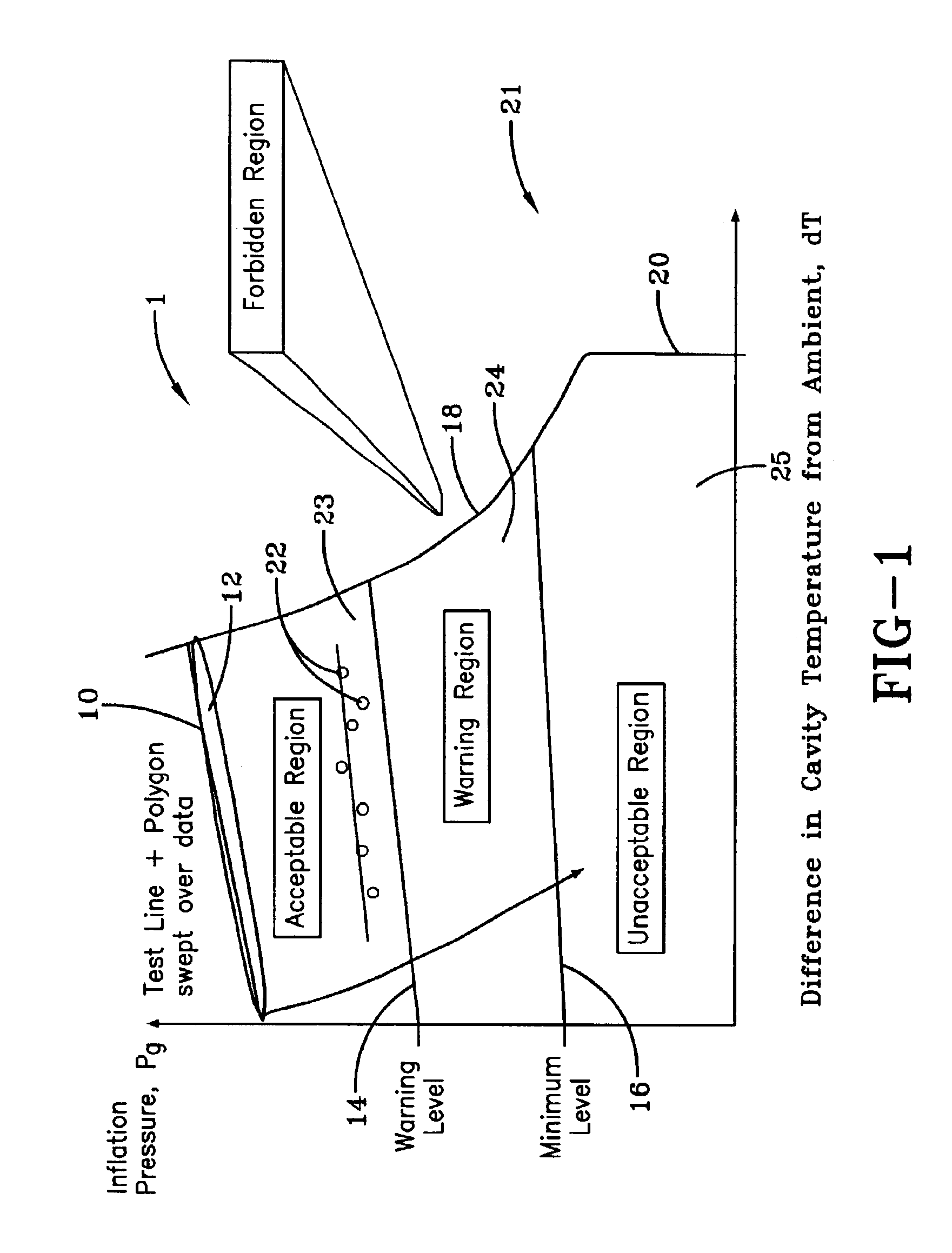

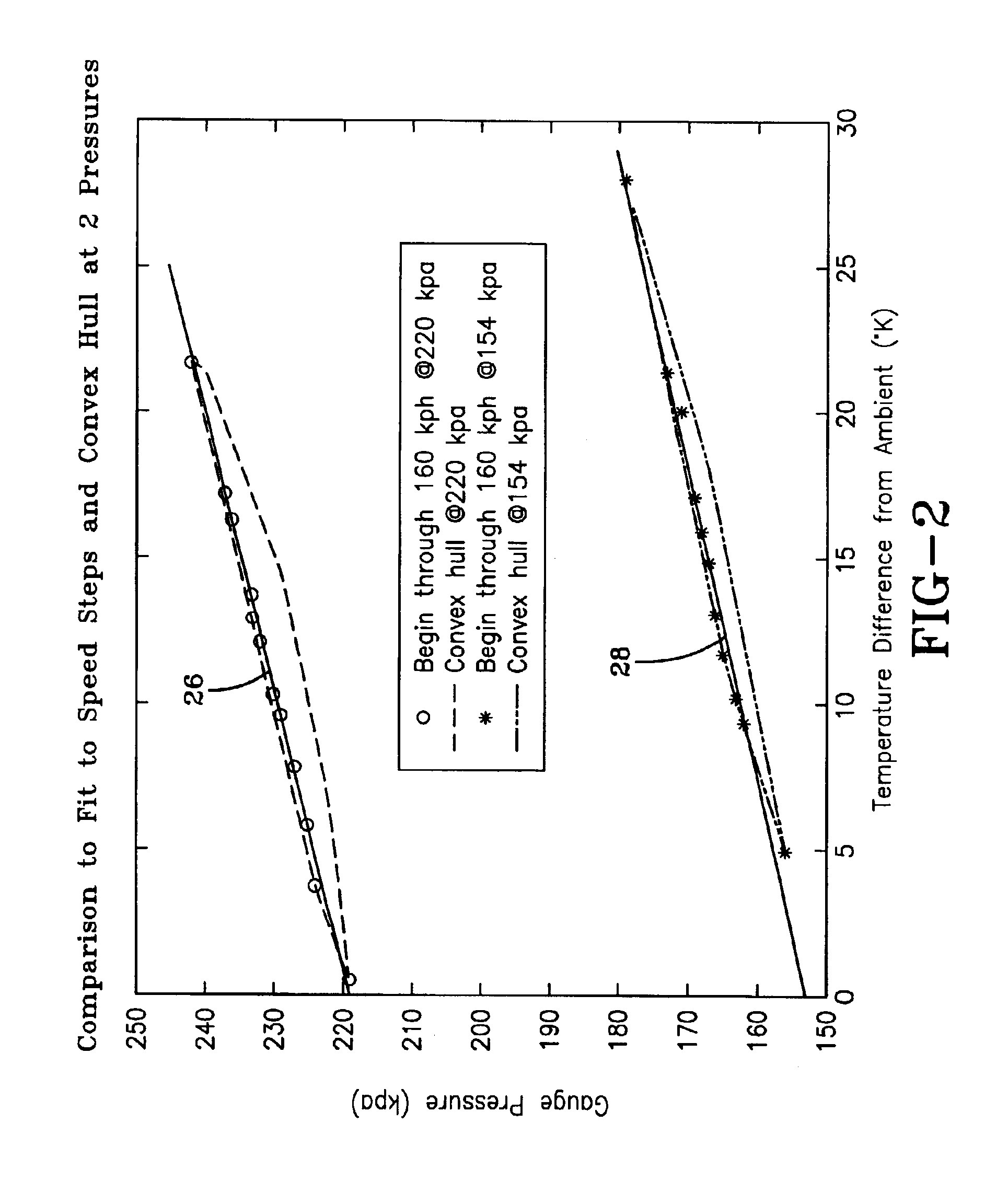

Method for processing information in a tire pressure monitoring system

InactiveUS6868358B2Improve utilizationAccurate detectionInflated body pressure measurementRegistering/indicating working of vehiclesEngineeringTire-pressure monitoring system

A method of processing information in a tire pressure monitoring system includes the steps of: establishing a reference temperature; determining a pressure warning threshold at the reference temperature; measuring gauge pressure and gauge temperature within a tire cavity; correcting the gauge pressure to a filtered pressure value at the reference temperature using the Ideal Gas Law; and comparing the filtered pressure value against the pressure warning threshold to determine the necessity for a warning signal. In an advanced form of the invention, the method includes determining a pressure leak rate; predicting the time interval that the filtered pressure value will cross the pressure warning threshold at the leak rate and generating progressive warnings to the driver over the time interval. Fuzzy logic is used to quantify the probability of a warning state for each data point, allow for measurement error; and report the state of maximum probability to minimize the occurrence of false warning. A warning utility function is derived based upon a combination of the filtered pressure and leak rate.

Owner:THE GOODYEAR TIRE & RUBBER CO

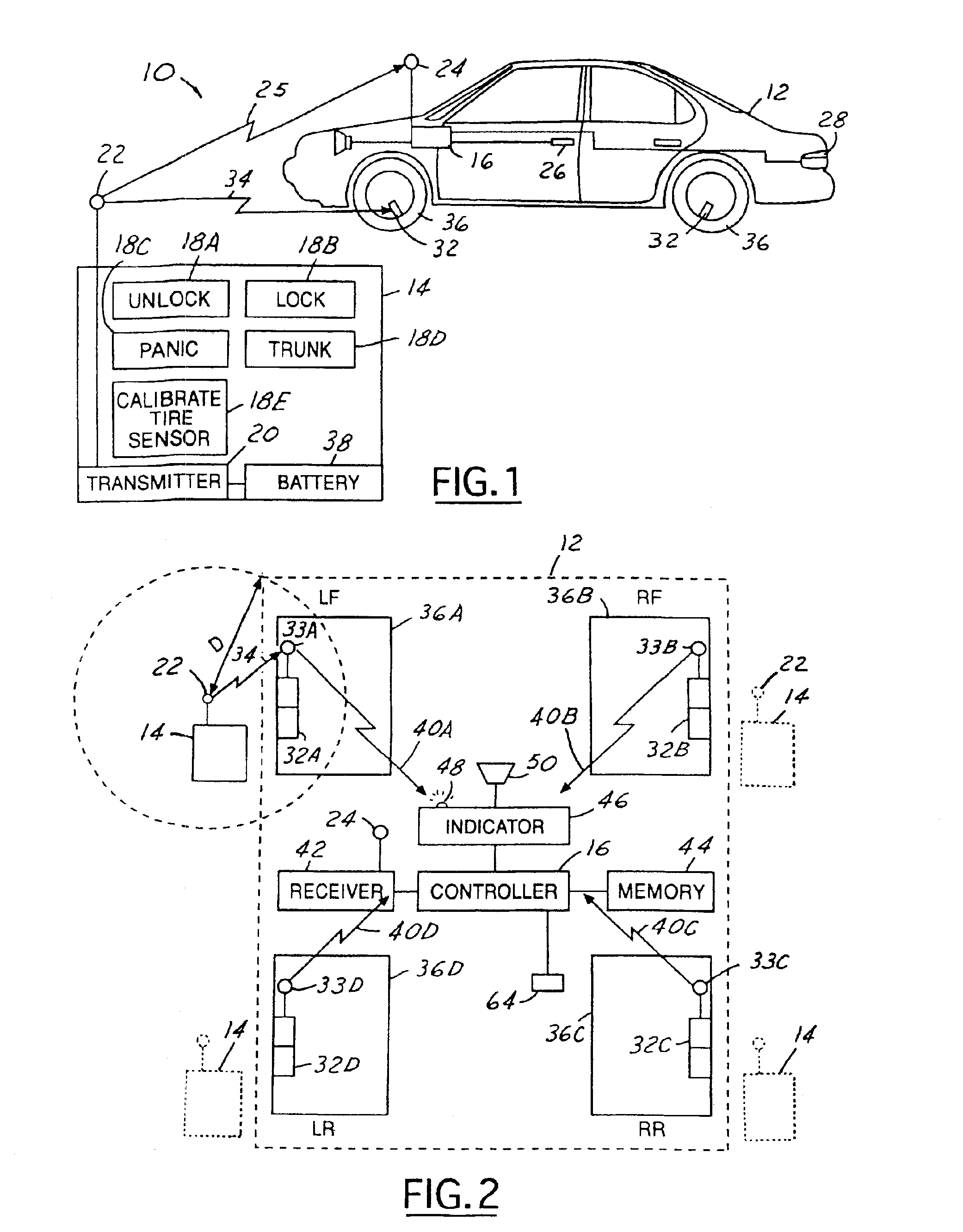

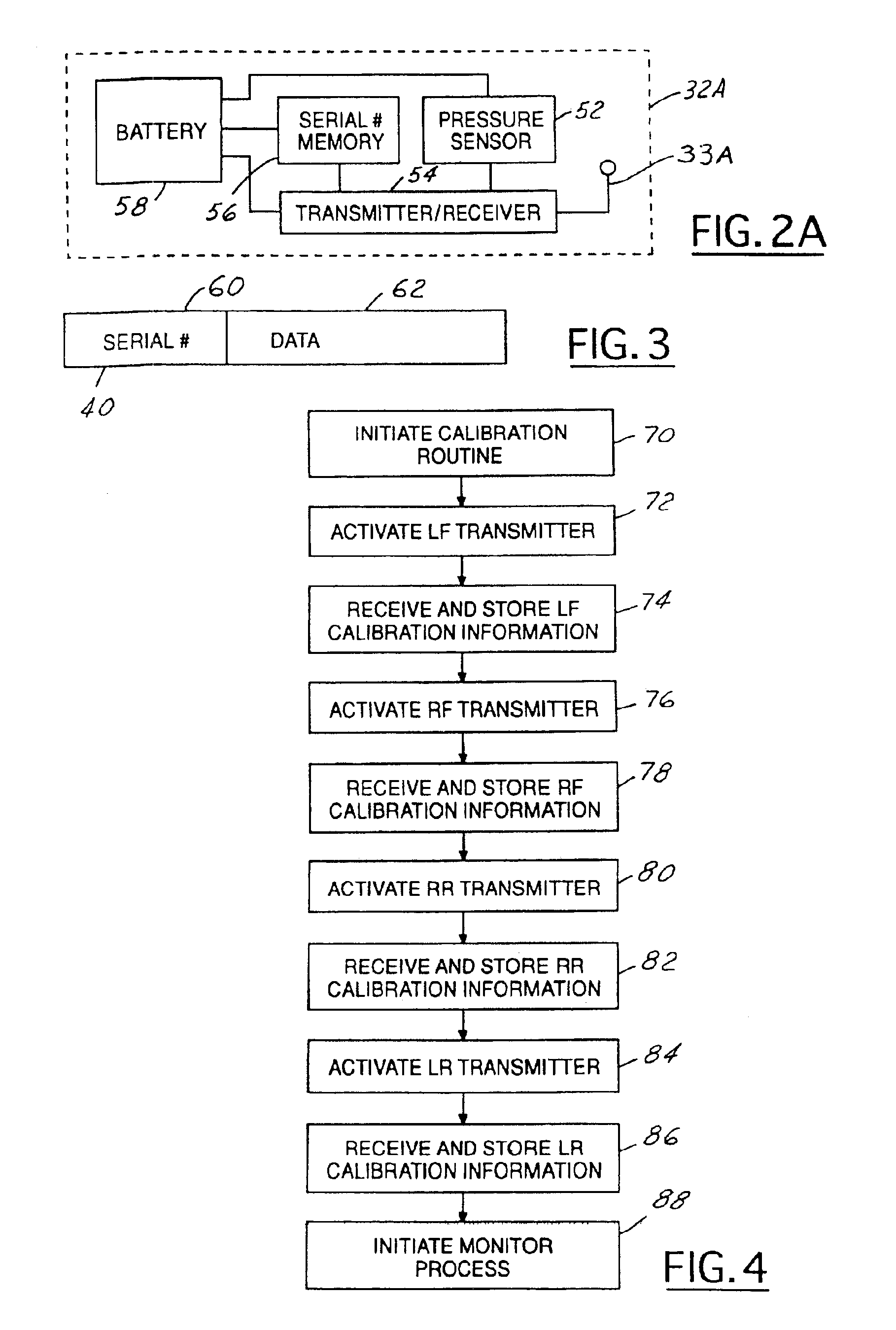

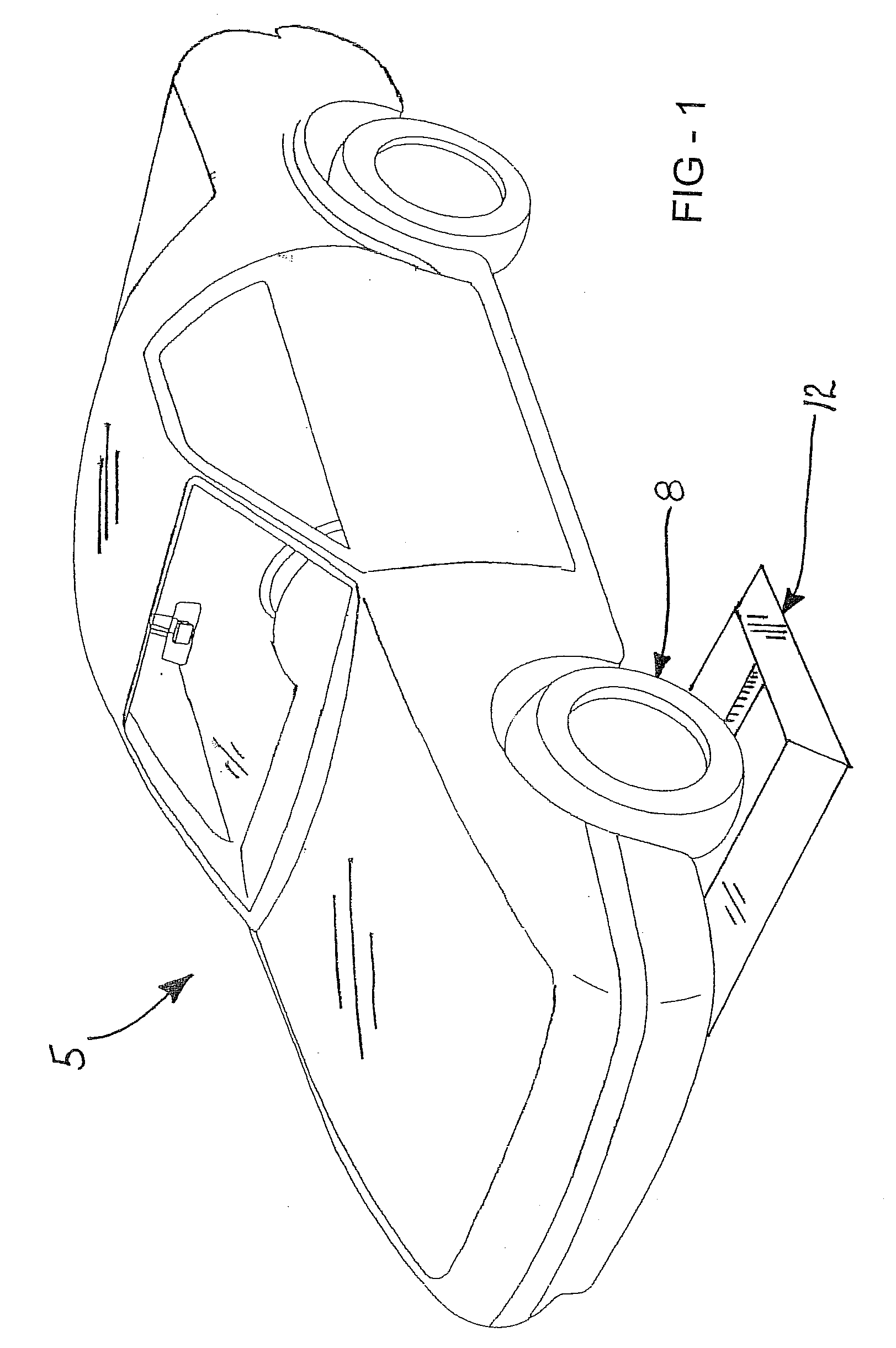

Method and system for calibrating a tire pressure sensing system for an automotive vehicle

InactiveUS6945087B2Eliminate the problemNot subject to easy lossFluid pressure measurementTyre measurementsMobile vehicleEm coupling

A system (10) and method is provided for calibrating a tire pressure monitoring system using an EM transmitter (14). The present invention includes a first pressure sensor coupled to a wheel of an automotive vehicle (12). The EM pressure transmitter (14) is coupled to the pressure sensor (32). The transmitter (14) has a serial number associated therewith. An EM calibration device has a transmitting range. The EM transmitter device has an actuator. When the actuator is activated, a calibration signal (34) is transmitted within the transmitting range. The calibration signal causes the EM pressure transmitter (32) to transmit a serial number. A controller (16) is EM coupled to the pressure transmitter. The controller (16) receives the serial number and associates the serial number with a tire location of the vehicle.

Owner:FORD GLOBAL TECH LLC

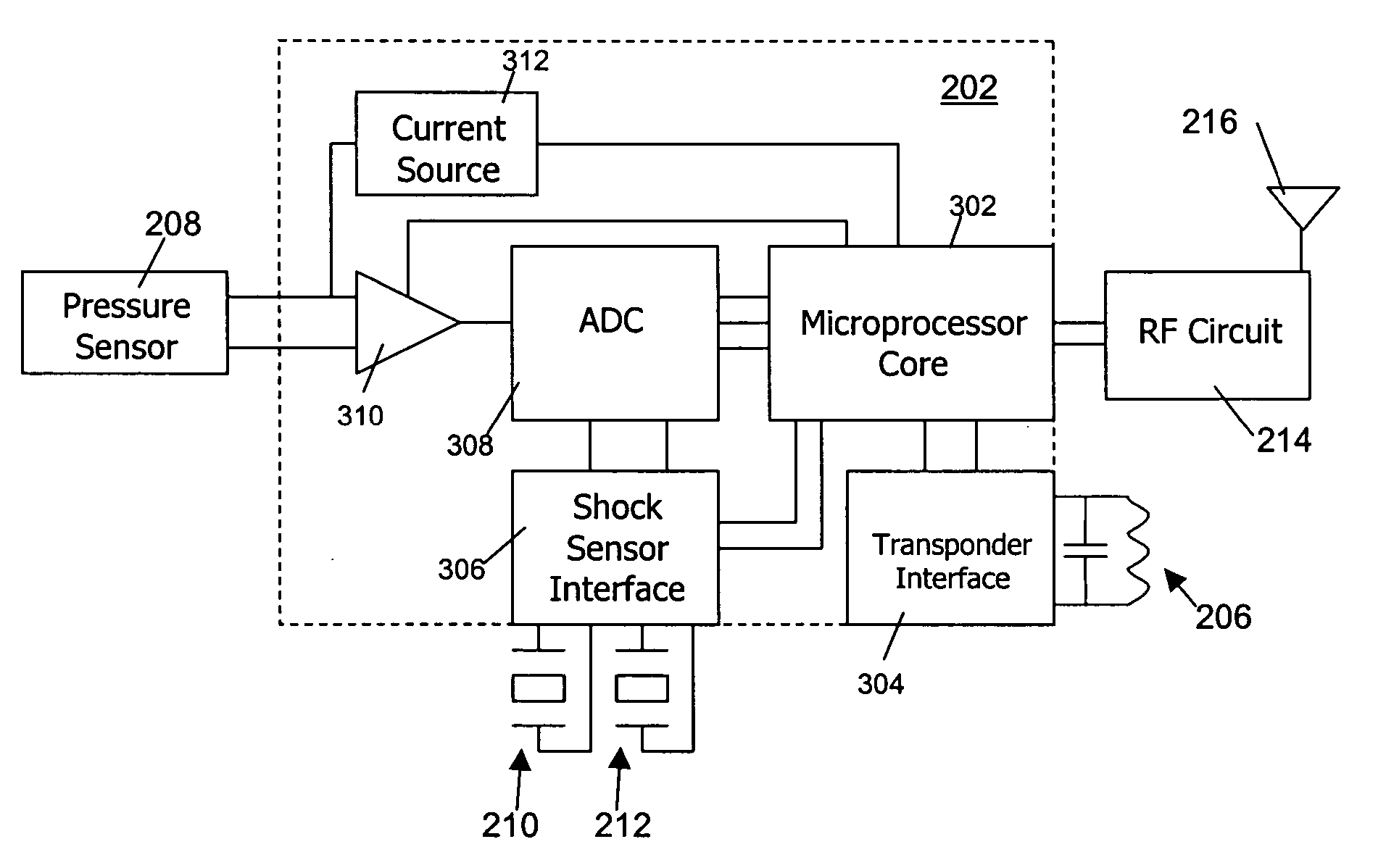

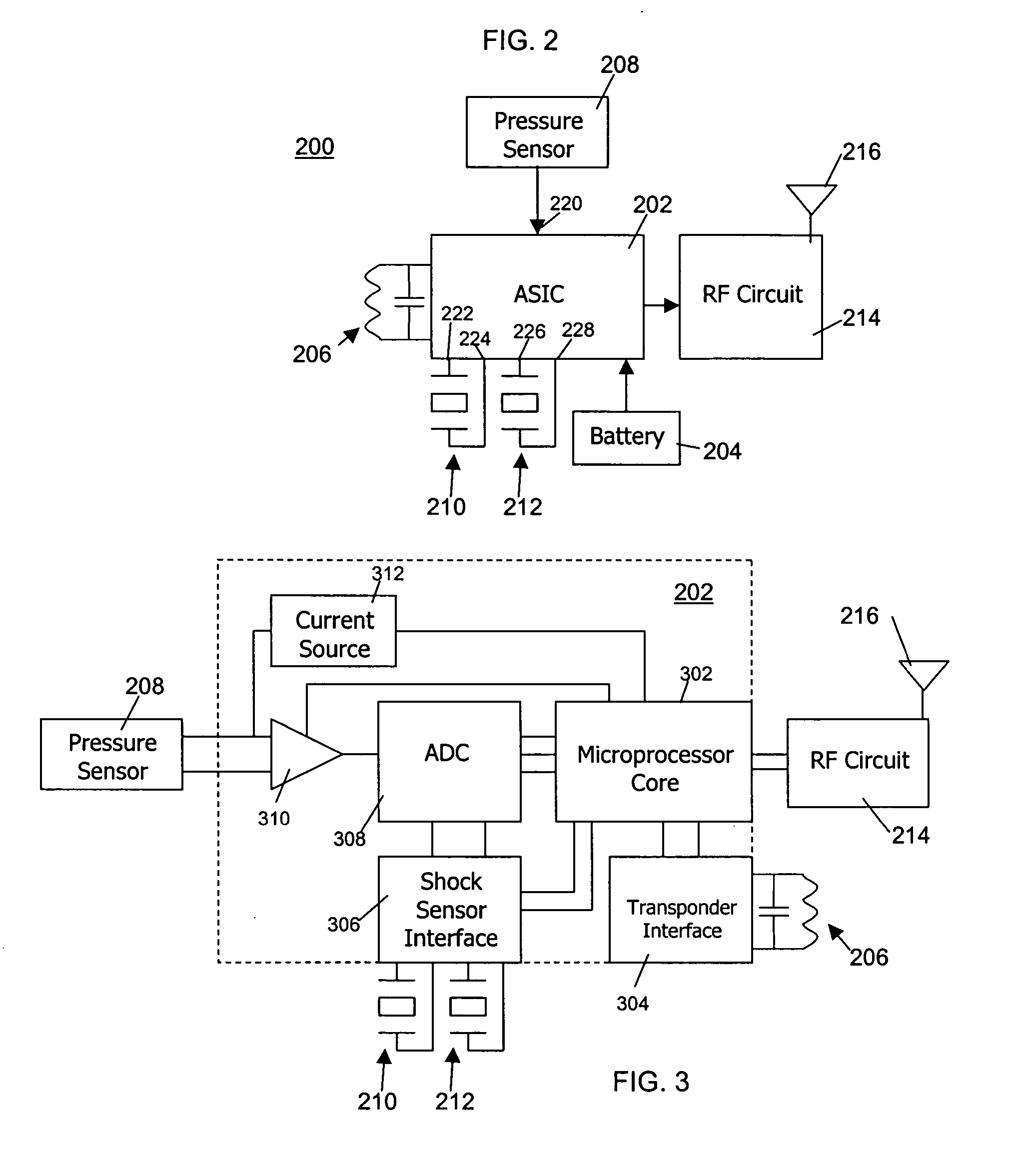

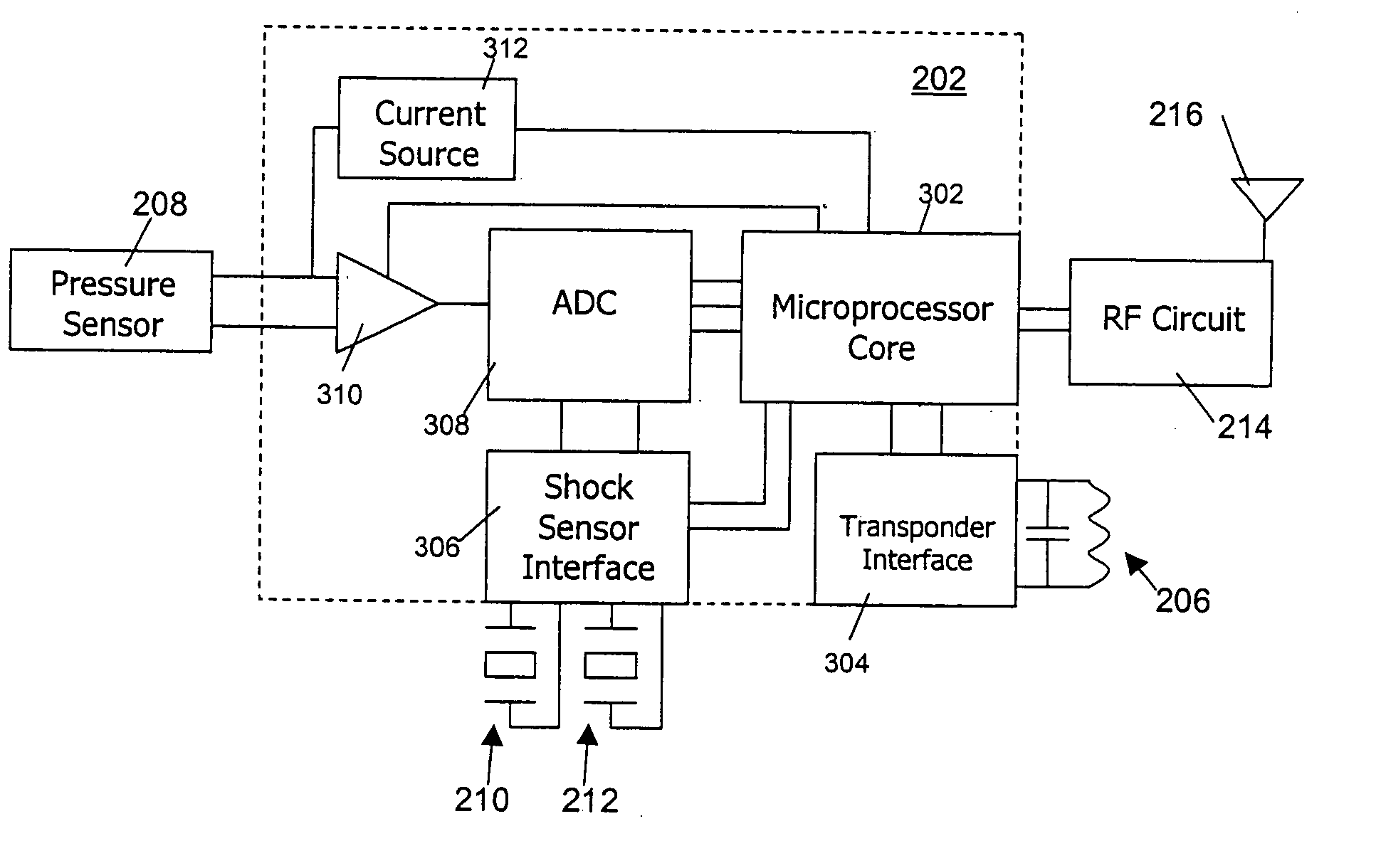

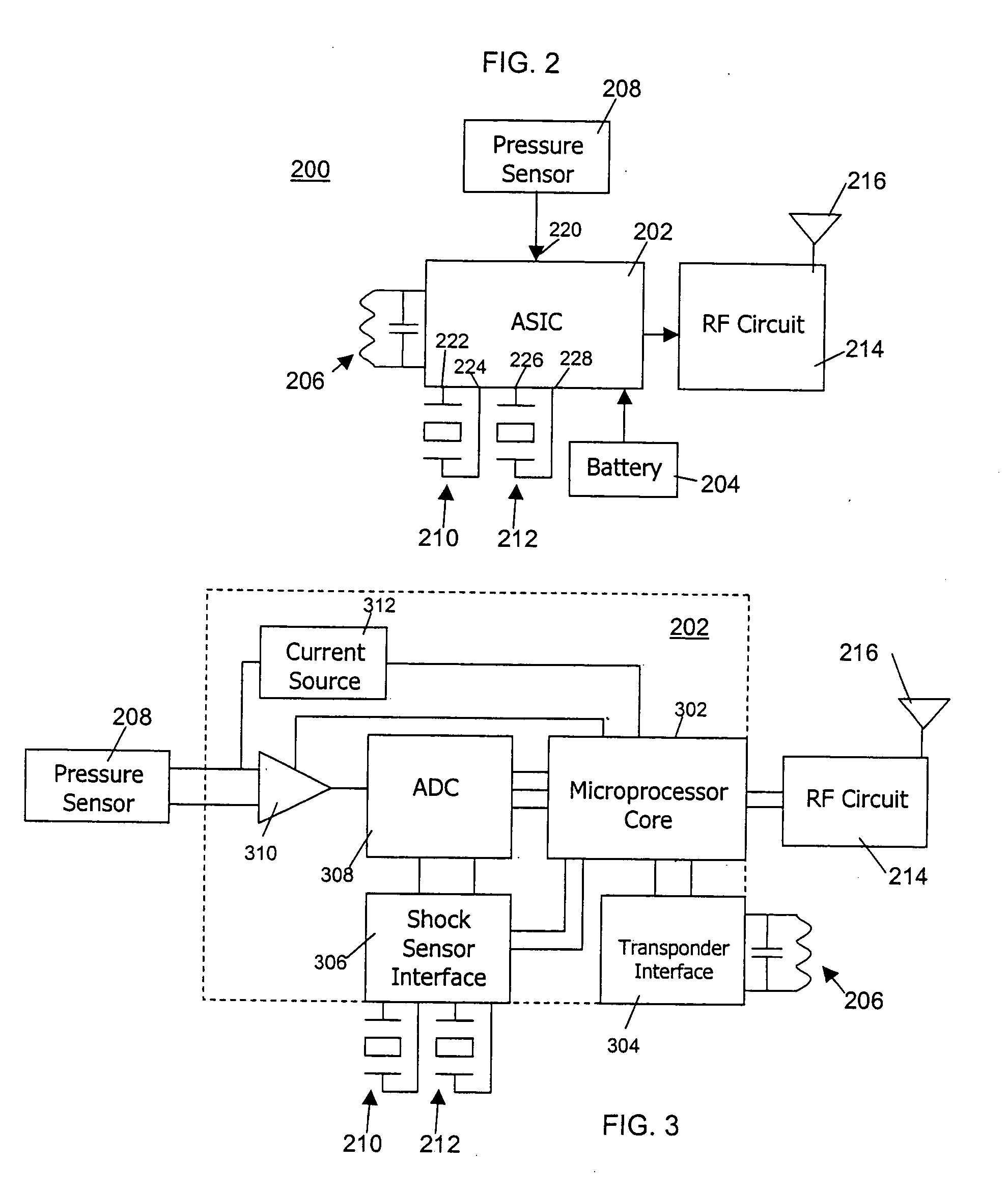

Motion detection using a shock sensor in a remote tire pressure monitoring system

ActiveUS20050156722A1Tyre measurementsRoads maintainenceMonitoring systemTire-pressure monitoring system

A tire monitor for mounting to a vehicle as part of a remote tire monitoring system includes a tire condition sensor to produce a tire condition signal, a controller coupled to the tire condition sensor to control operation of the tire monitor, and a radio circuit coupled to the controller to transmit radio signals based at least in part on the tire condition signal. A shock sensor is coupled to the controller of the tire monitor to produce a motion signal indicating motion of the tire monitor.

Owner:SENSATA TECHNOLOGIES INC

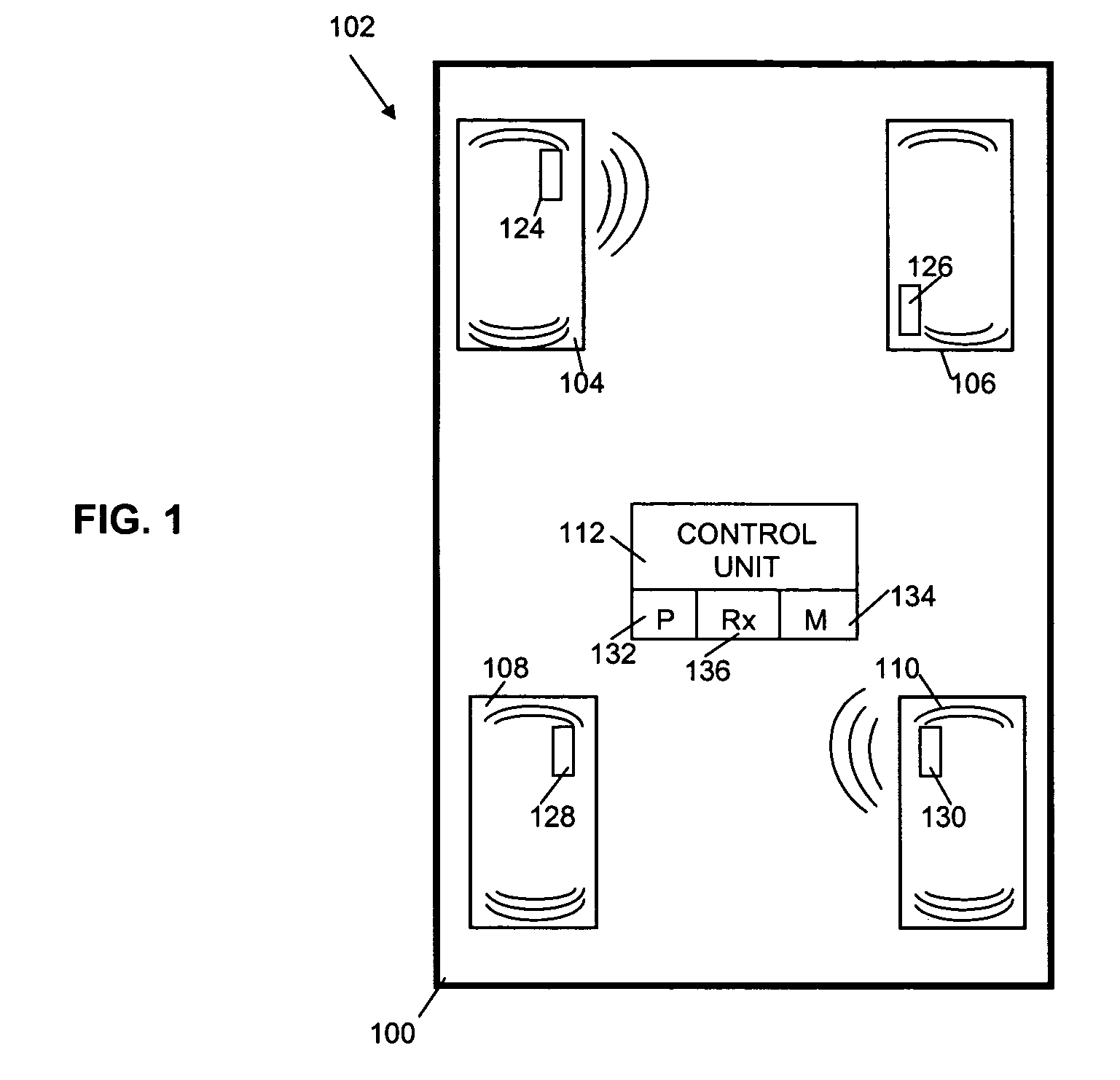

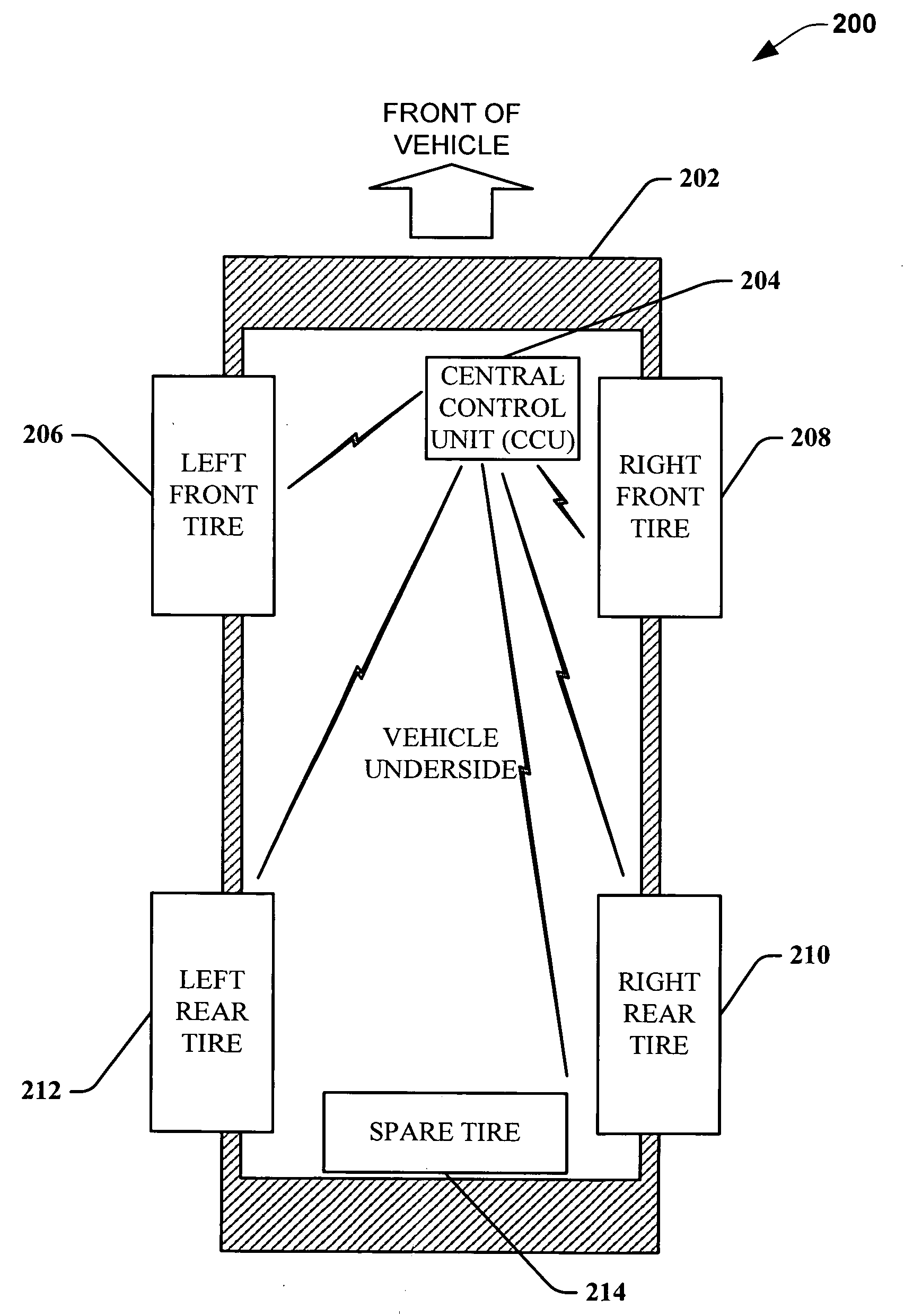

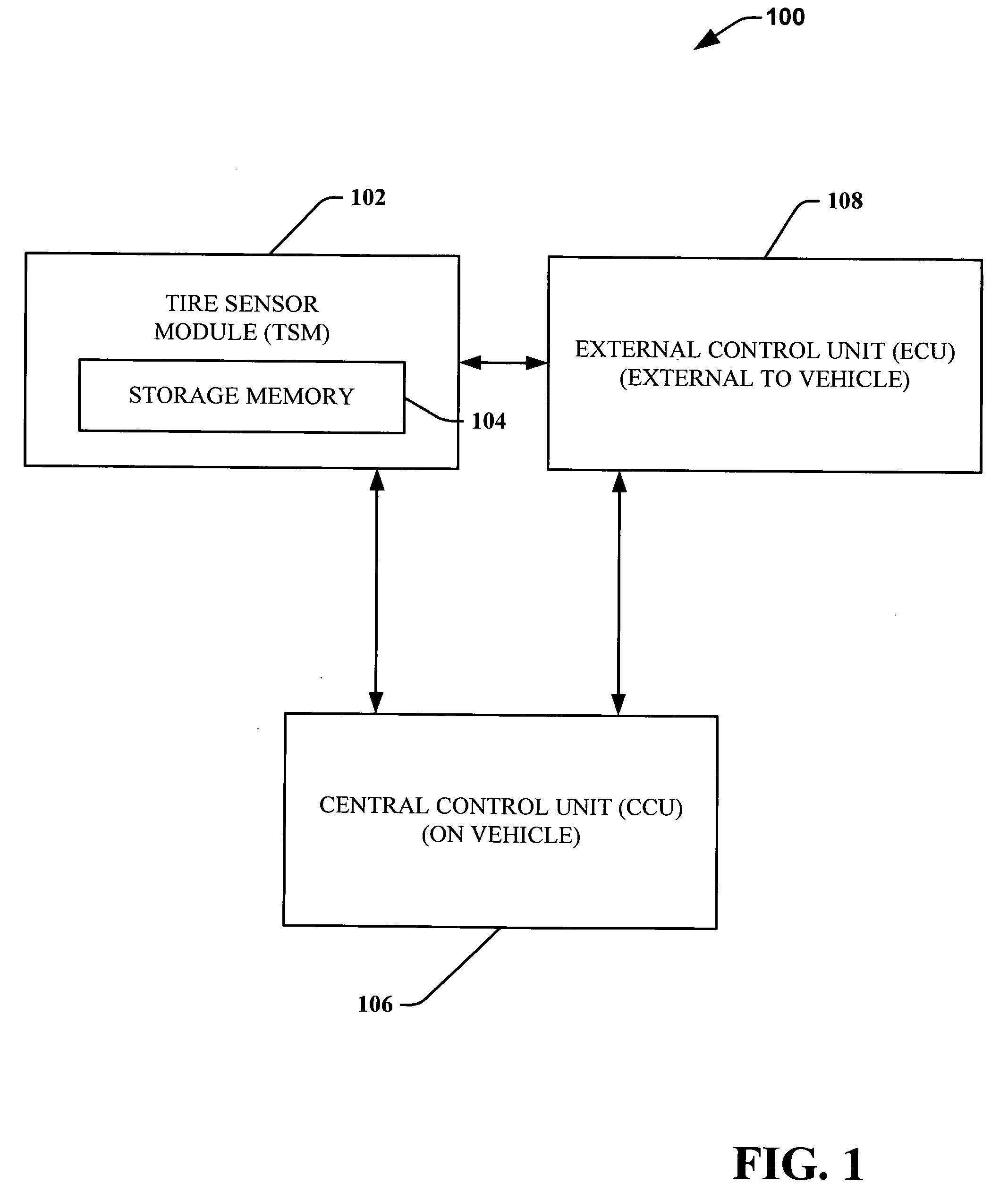

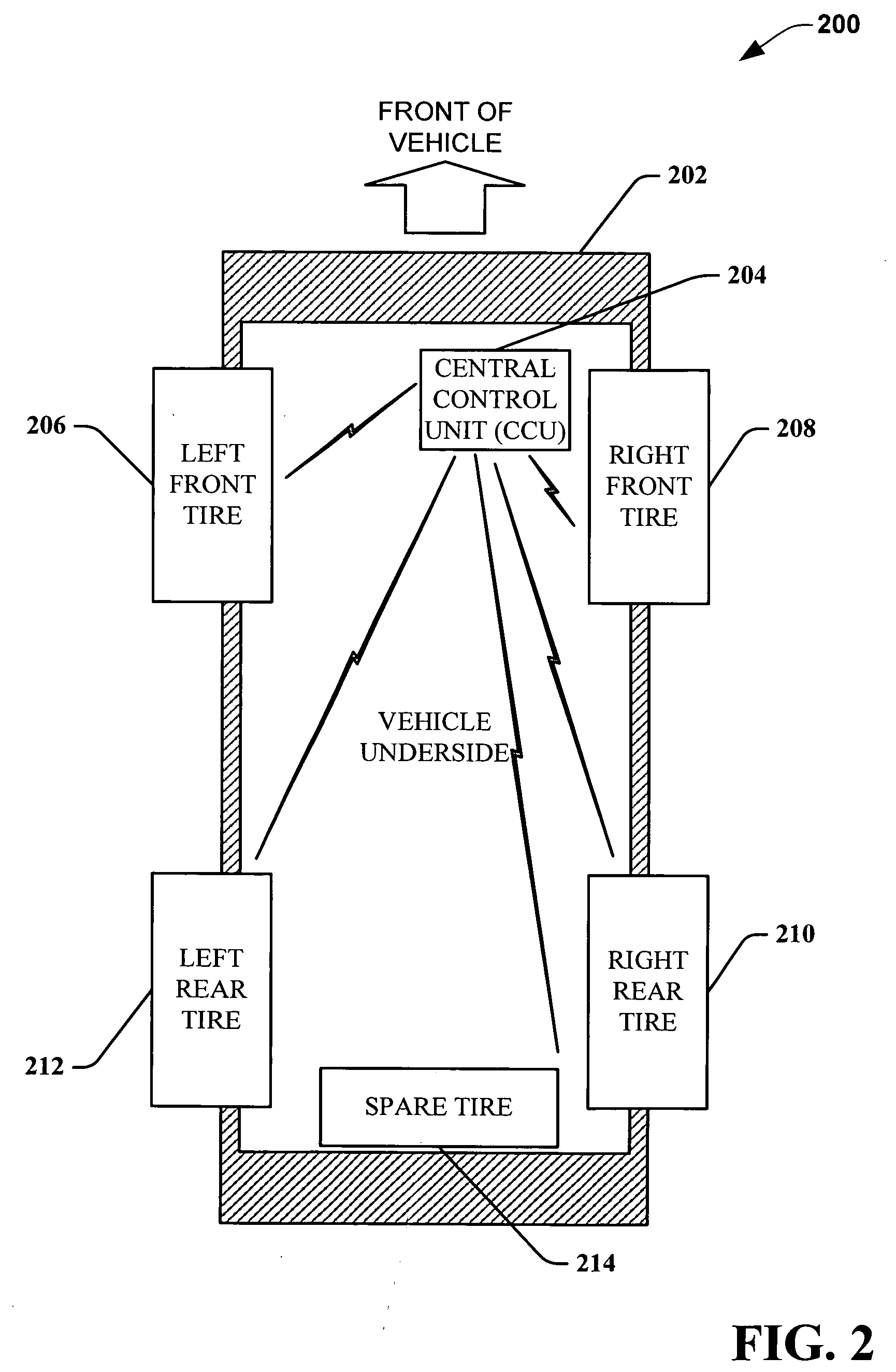

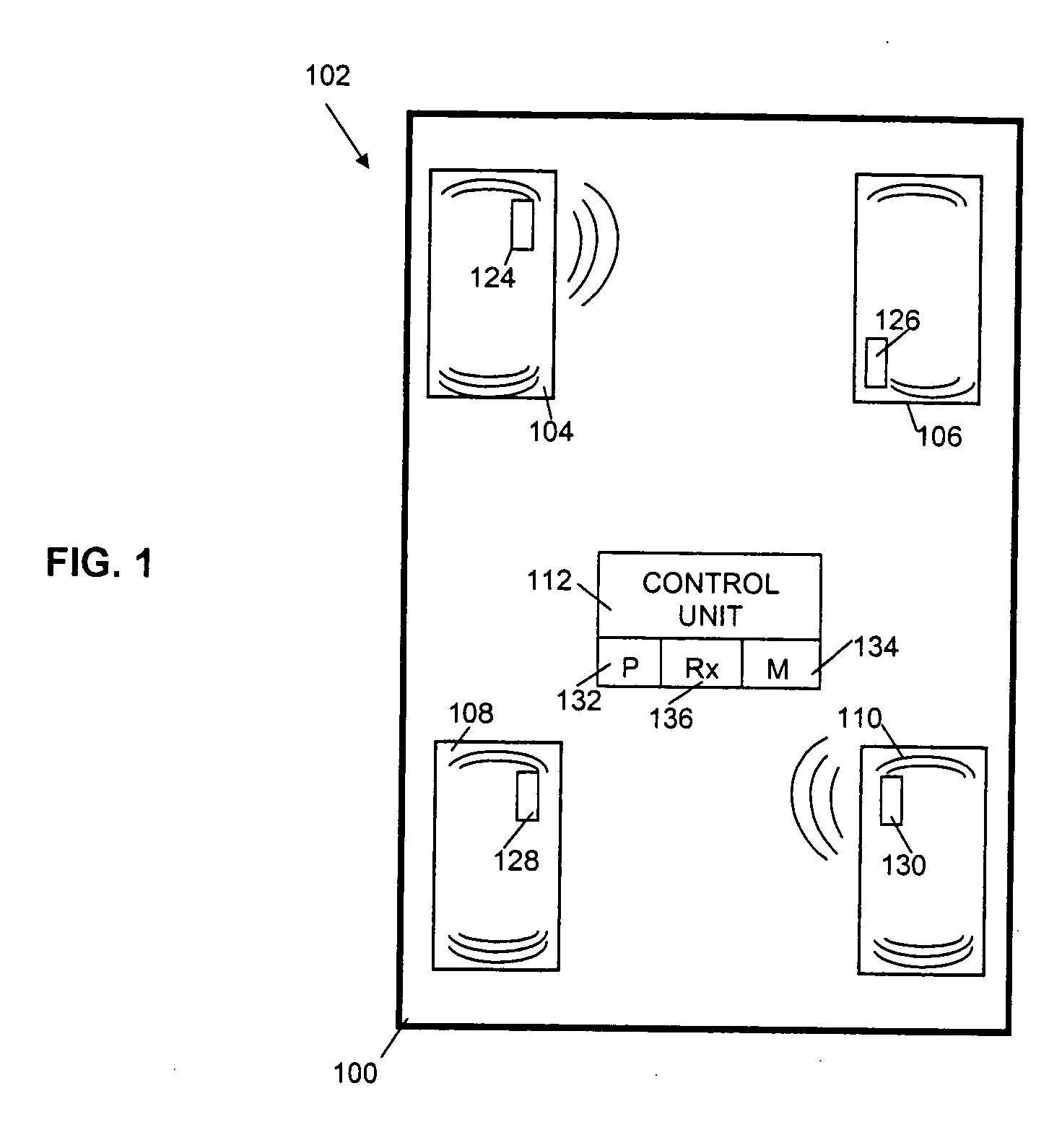

Contactless sensor systems and methods

InactiveUS20070279203A1Well formedDigital data processing detailsElectric testing/monitoringMonitoring systemControl unit

A tire monitoring system and associated method is disclosed. The tire monitoring system includes a plurality of tire sensor modules, employing contactless sensors, configured to transmit tire data at a predetermined time interval. The system also includes a central control unit that is configured to receive the tire data from the tire sensor modules, and is further configured with an external control unit that can communicate with the tire sensor modules, the central control units and outside sources.

Owner:INFINEON TECH AG

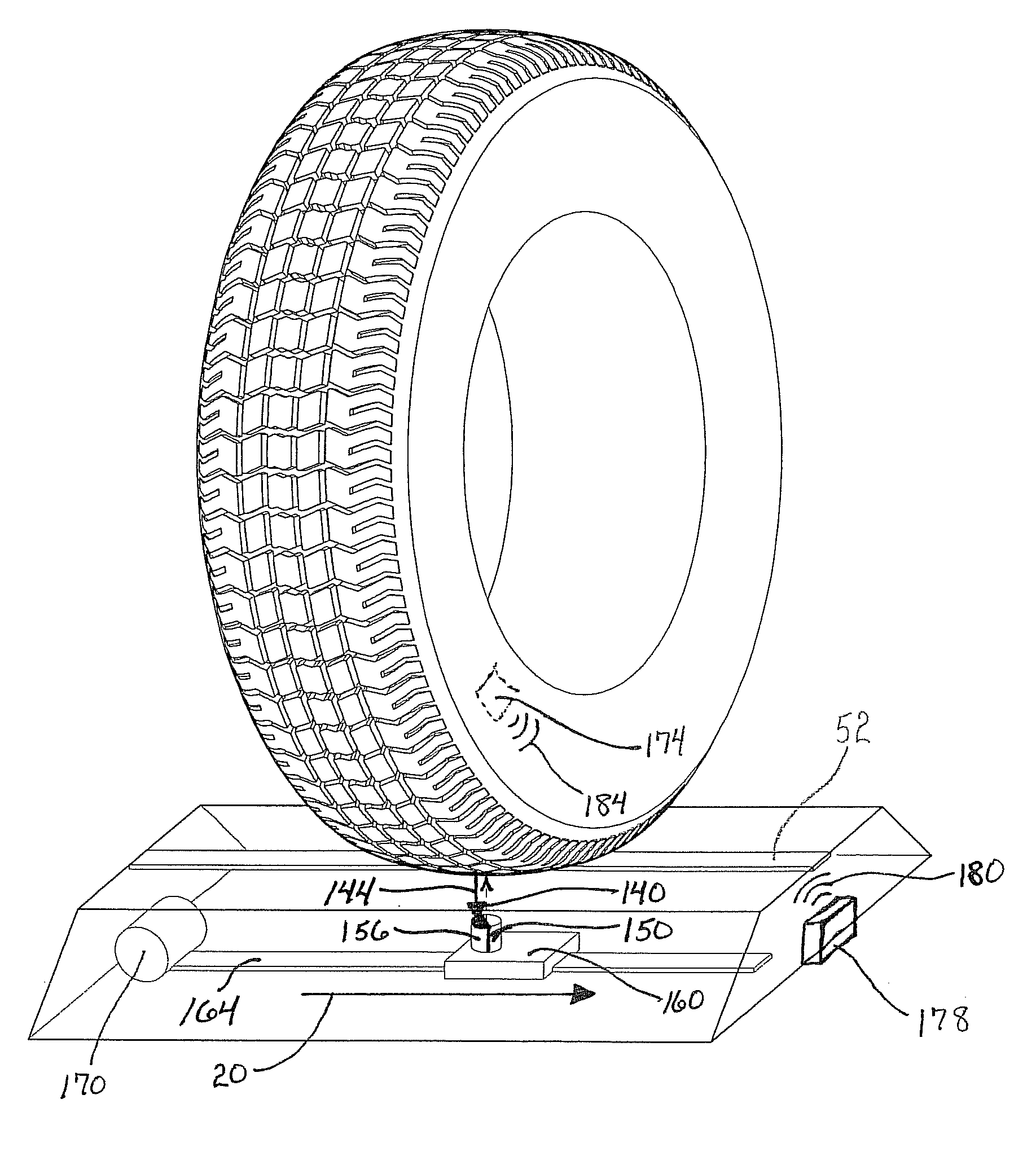

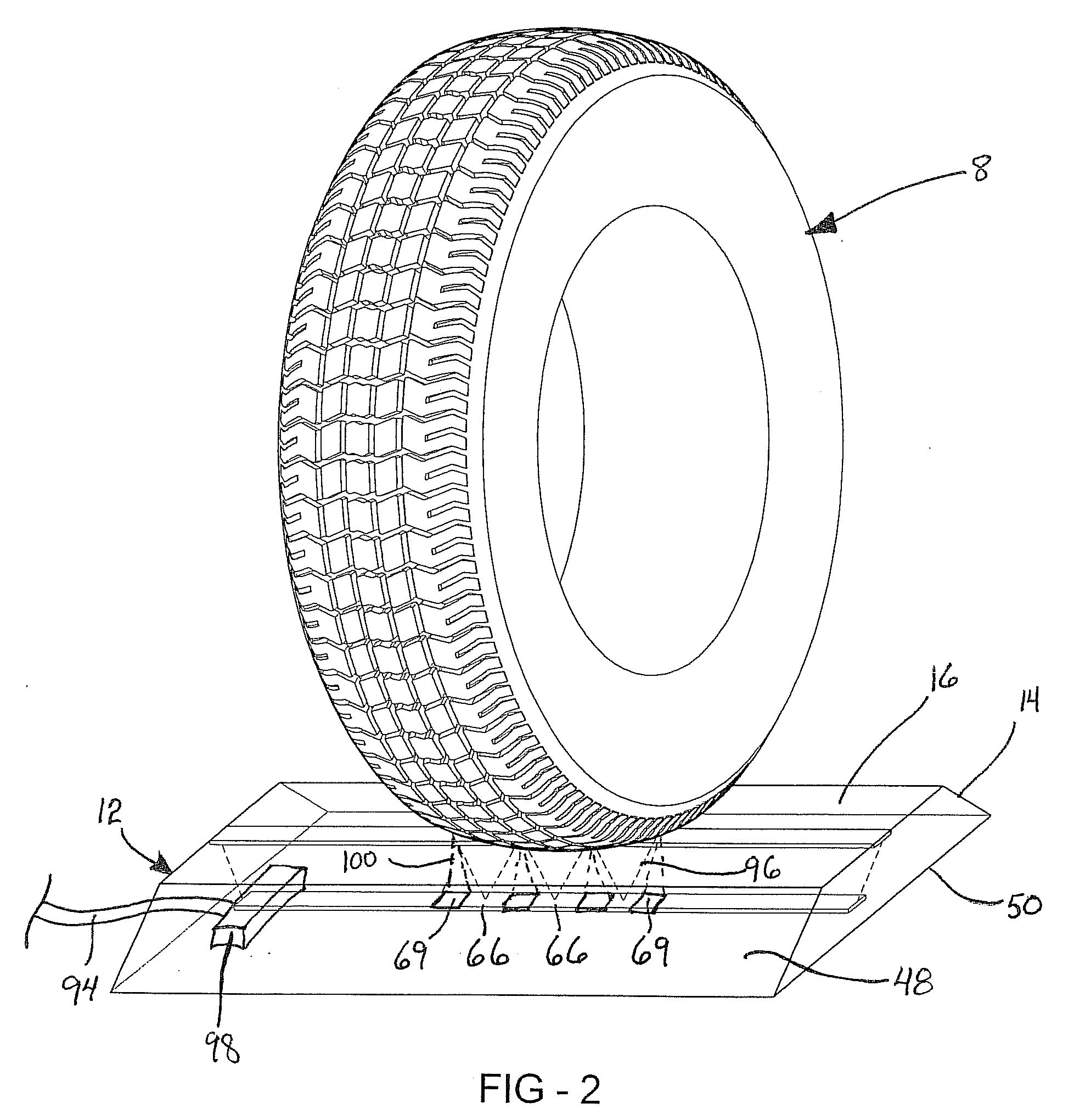

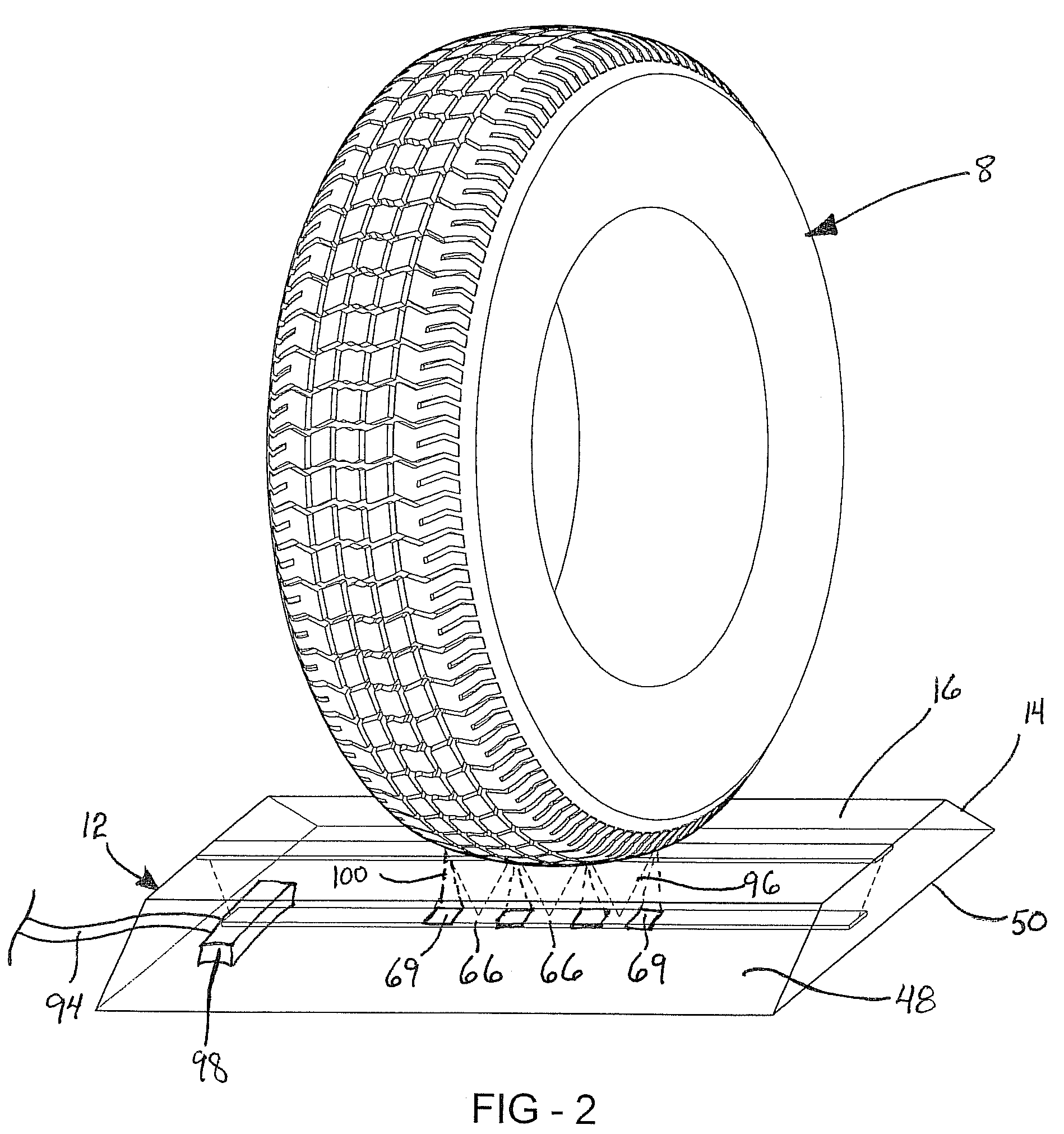

Tread depth sensing device and method for measuring same

A tread depth measurement system for measuring a depth of a tread provided to a tire on a vehicle. The system includes an energy source for emitting a wireless signal to be transmitted to the tire; a sensor for detecting a return wireless signal emitted from the tire to be transmitted in response to the wireless signal from the energy source; and a housing over which the tire is to roll while attached to the vehicle, said housing separating the sensor from the tire while the tread depth is being measured. A control unit is operatively coupled to the sensor for determining the depth of the tread as a function of at least the return wireless signal detected by the sensor.

Owner:THE GOODYEAR TIRE & RUBBER CO

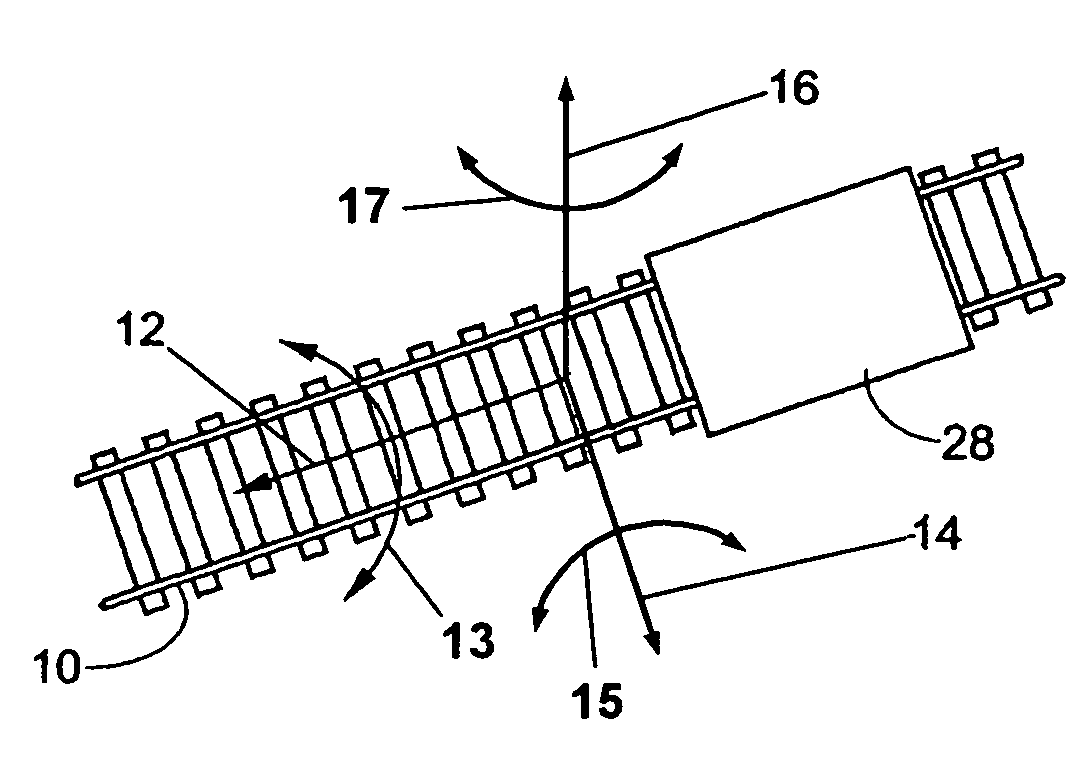

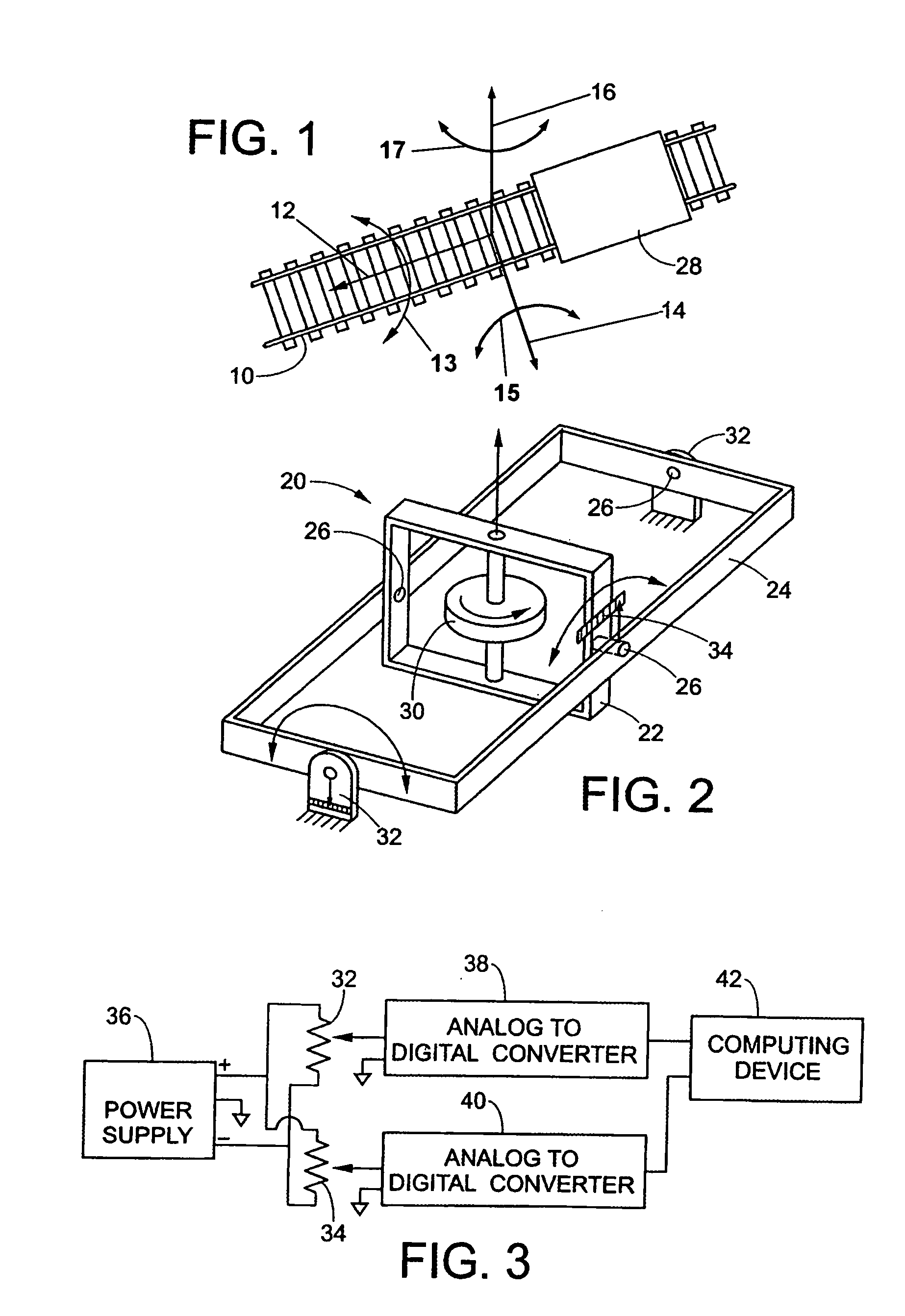

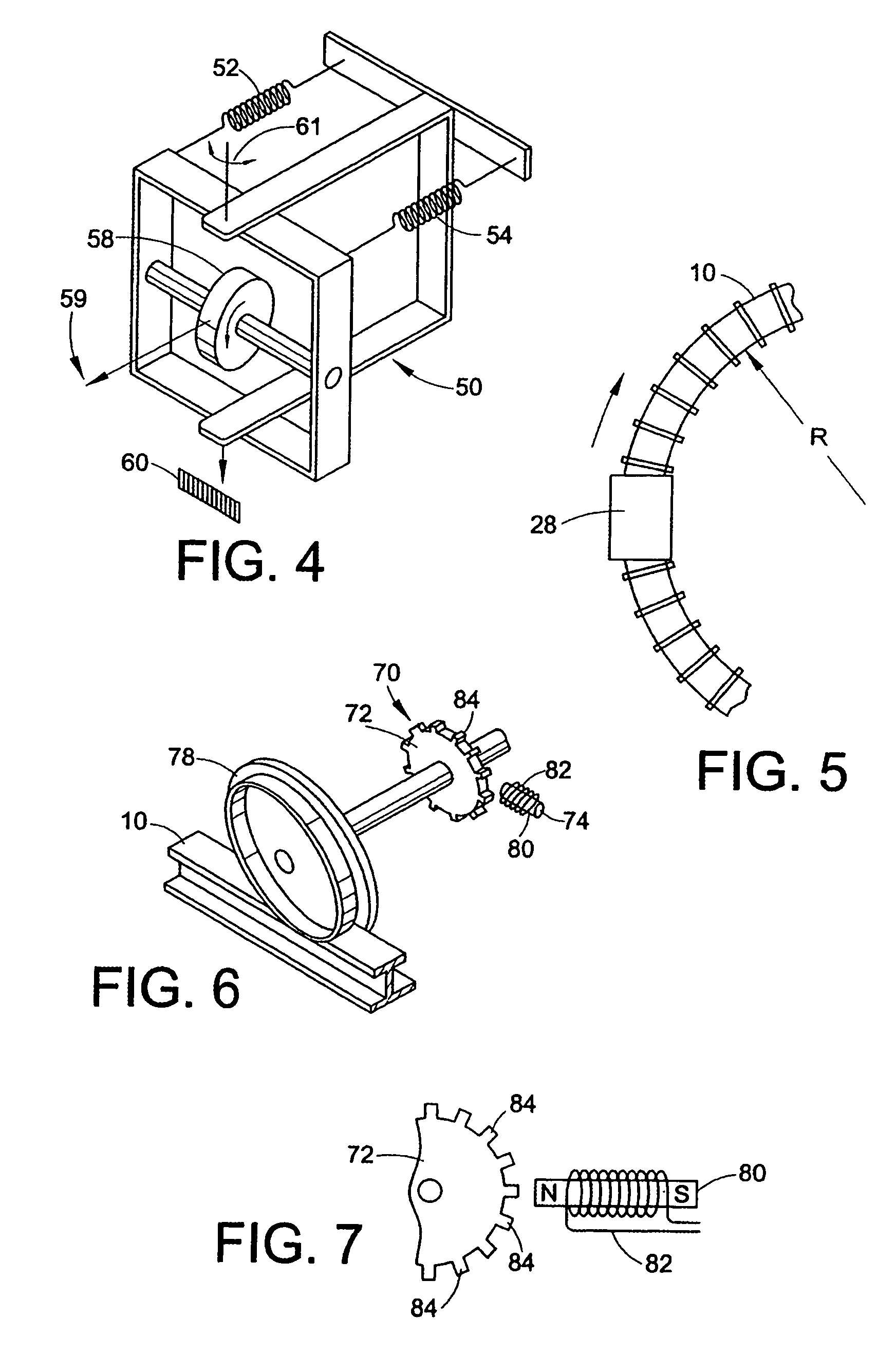

Geometric track and track/vehicle analyzers and methods for controlling railroad systems

InactiveUS7164975B2Reduce flanging forceIncreasing locomotive tractive forceDigital data processing detailsTrack side maintainanceReal time analysisVehicle detector

Track and track / vehicle analyzers for determining geometric parameters of tracks, determining the relation of tracks to vehicles and trains, analyzing the parameters in real-time, and communicating corrective measures to various control mechanisms are provided. In one embodiment, the track analyzer includes a track detector and a computing device. In another embodiment, the track / vehicle analyzer includes a track detector, a vehicle detector, and a computing device. In other embodiments, the track / vehicle detector also includes a communications device for communicating with locomotive control computers in lead units, locomotive control computers in helper units, and a centralized control office. Additionally, methods for determining and communicating optimized control, lubrication, and steering strategies are provided. The analyzers improve operational safety and overall efficiency, including fuel efficiency, vehicle wheel wear, and track wear, in railroad systems.

Owner:ANDIAN TECH

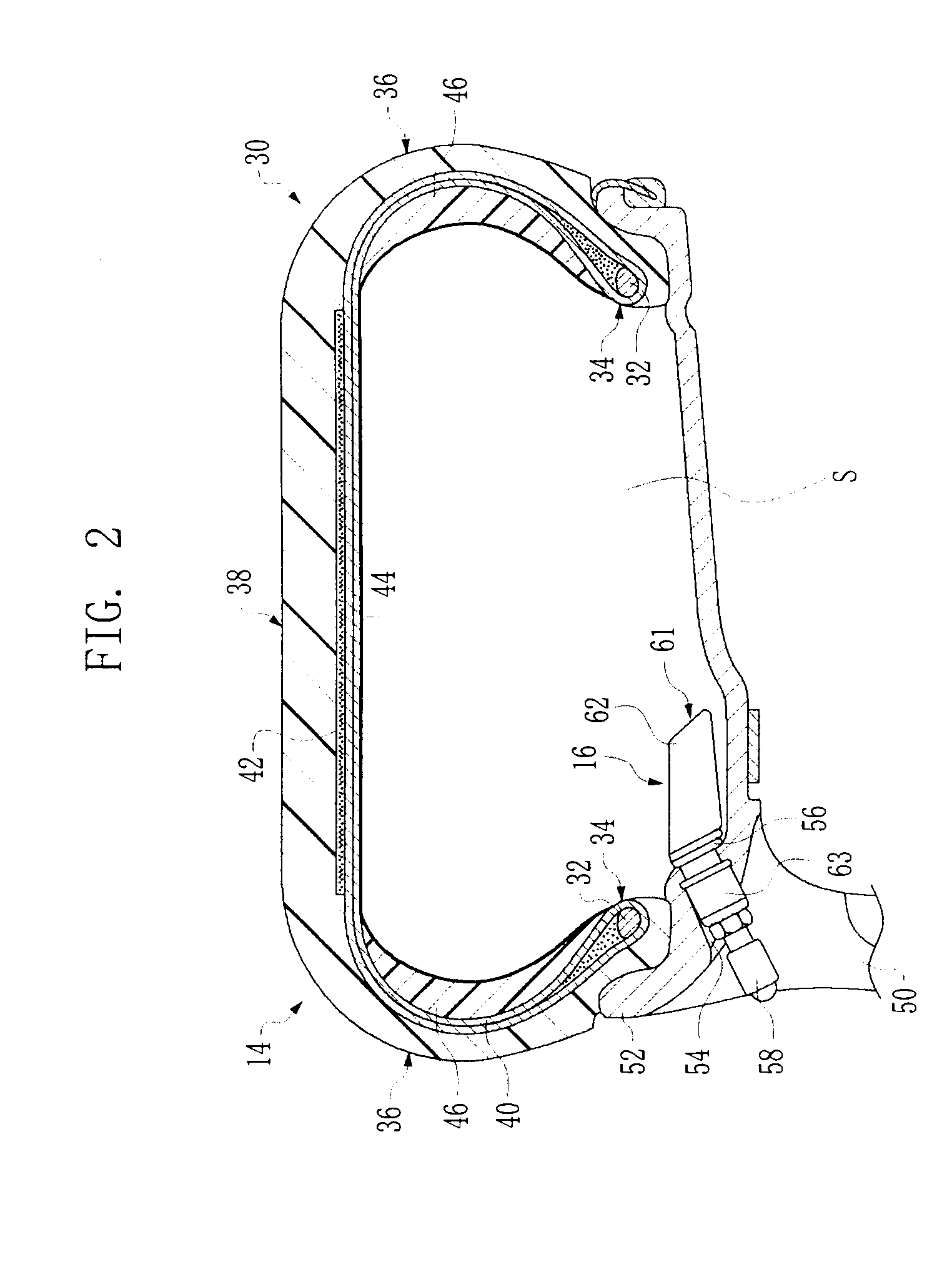

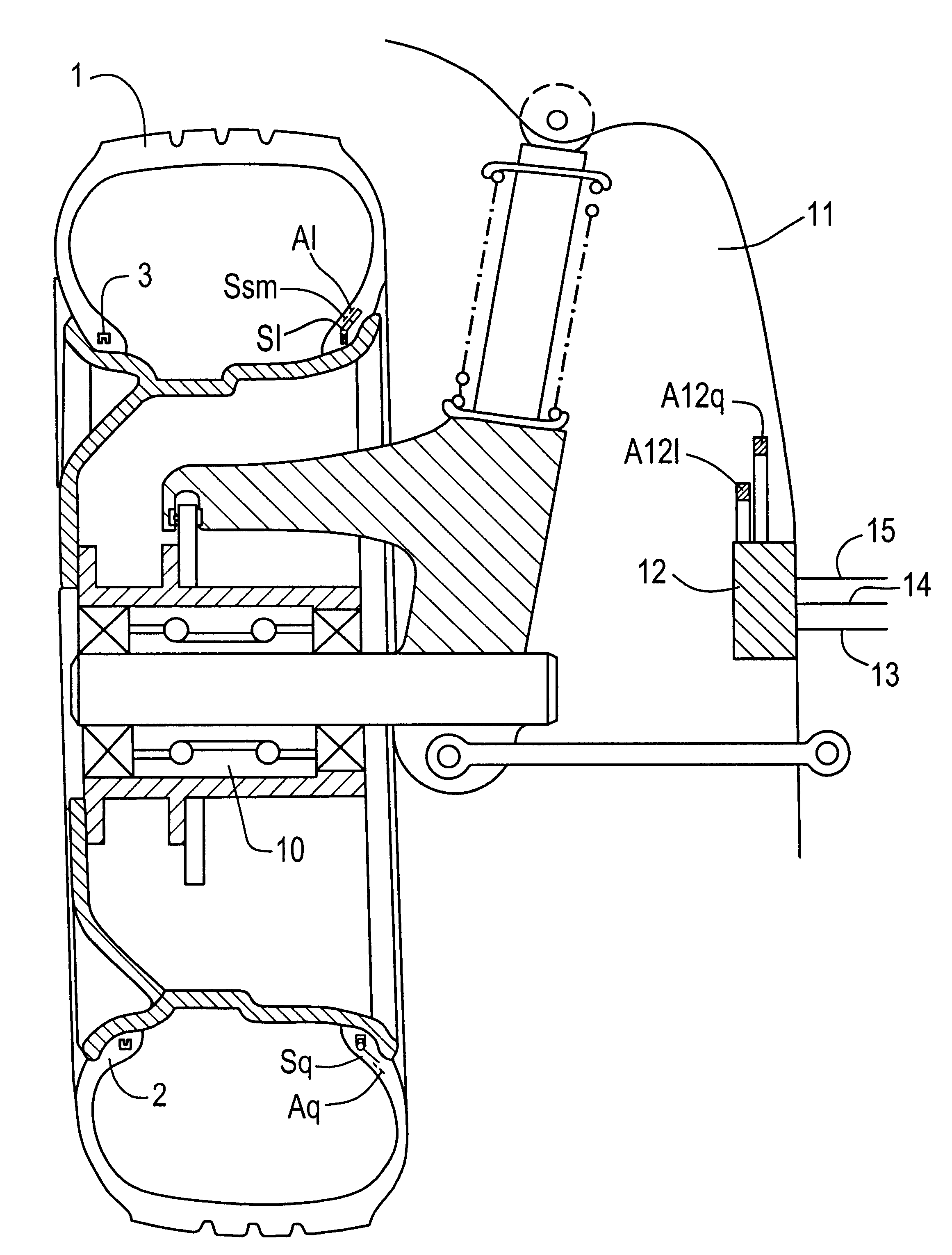

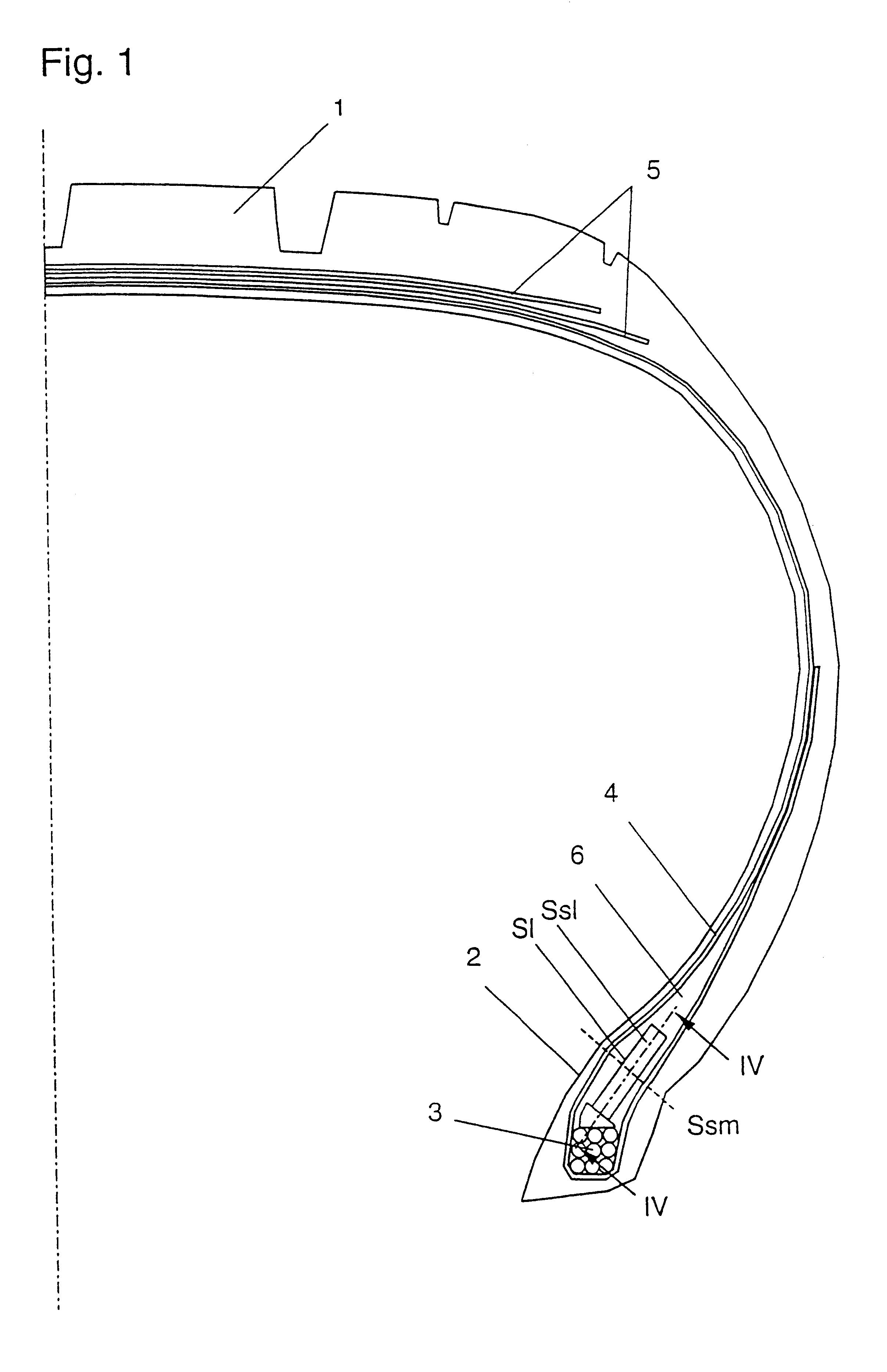

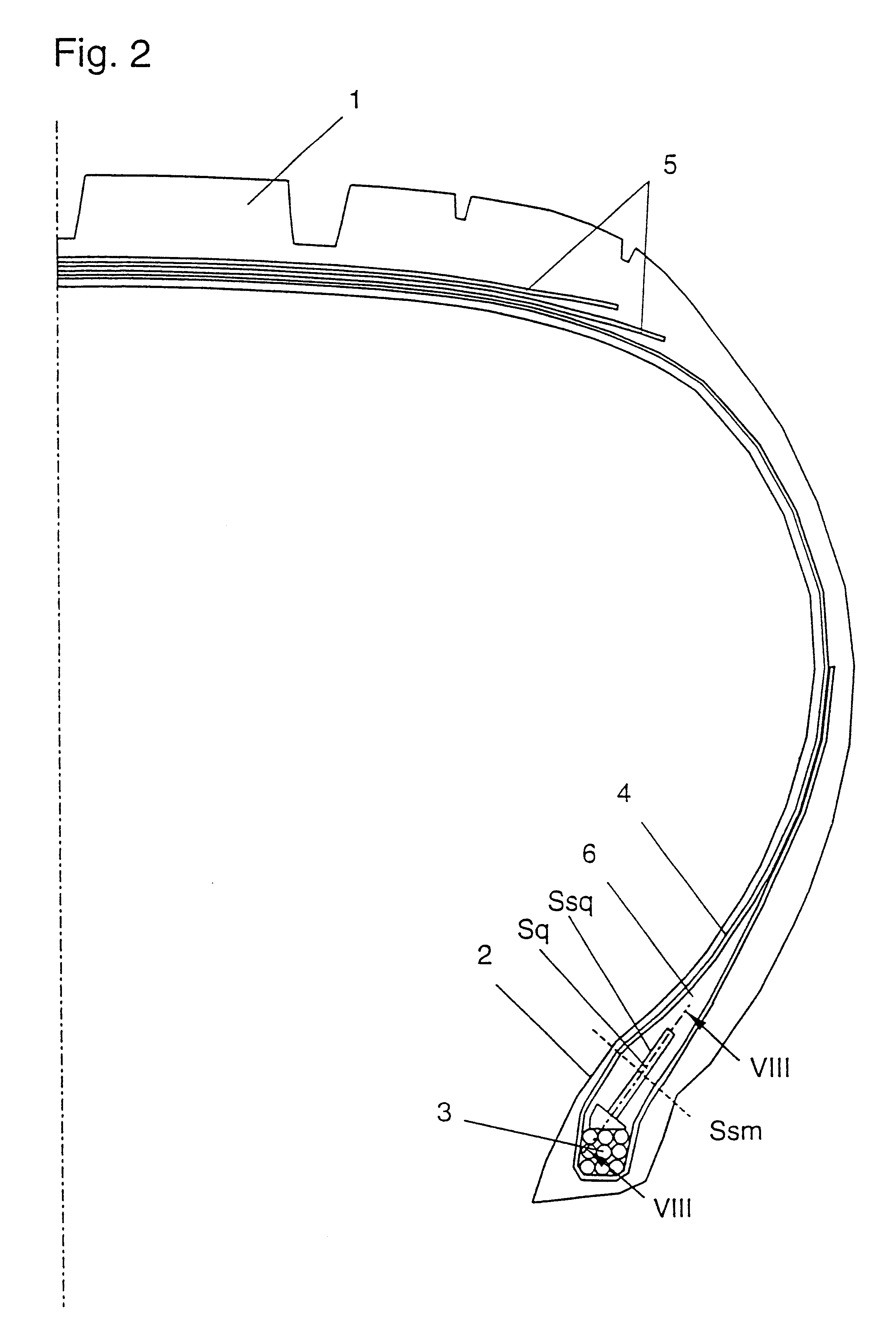

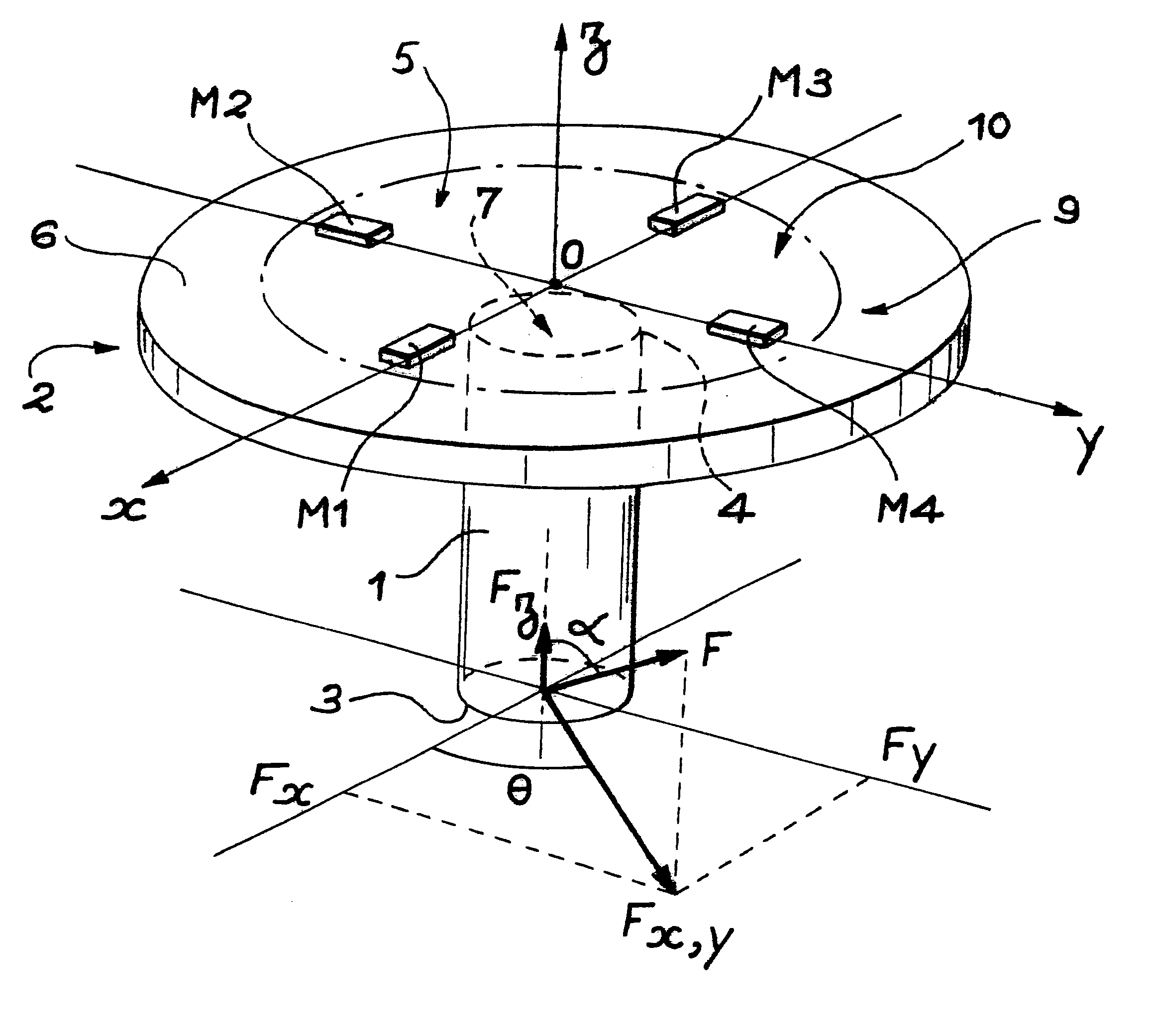

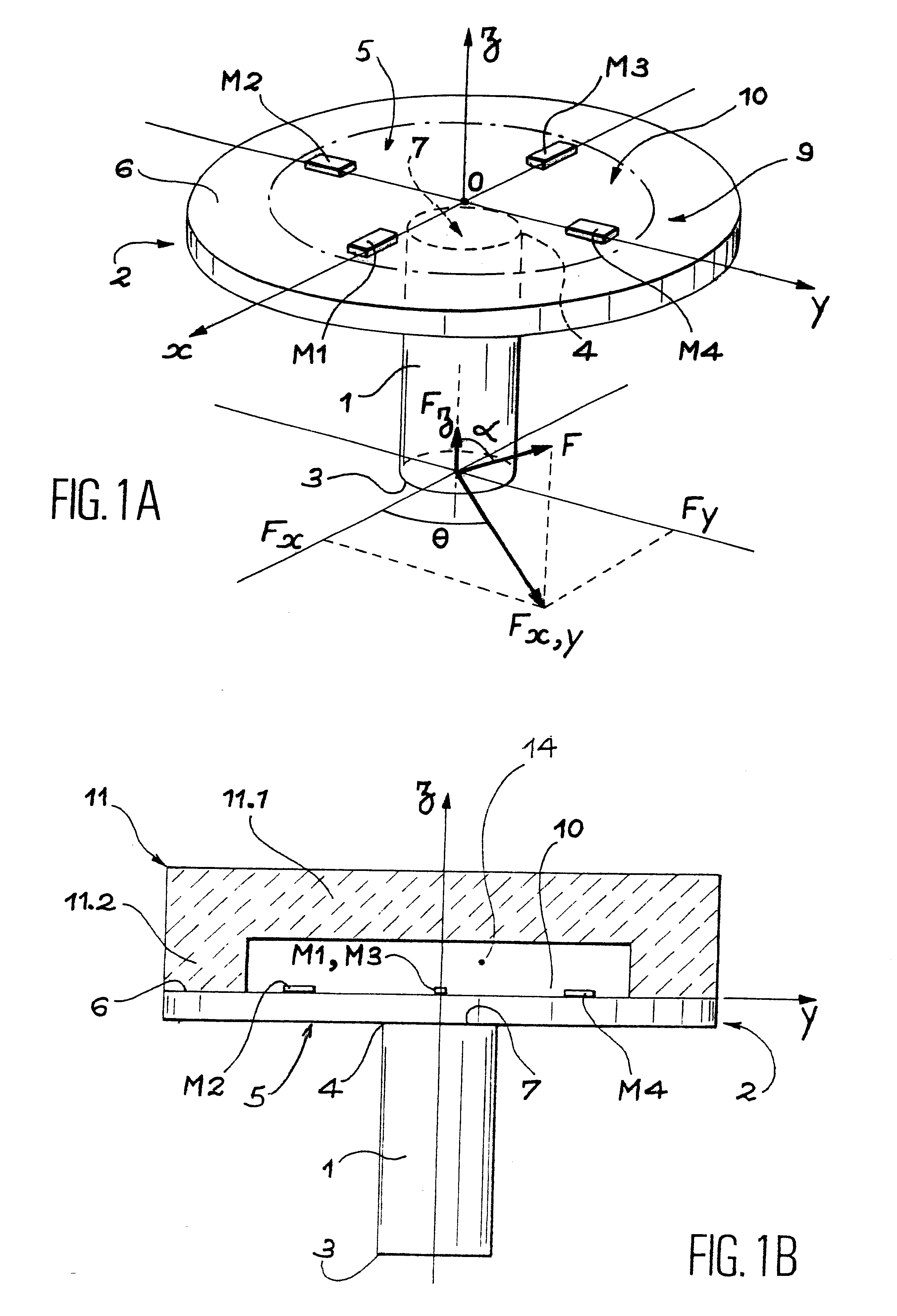

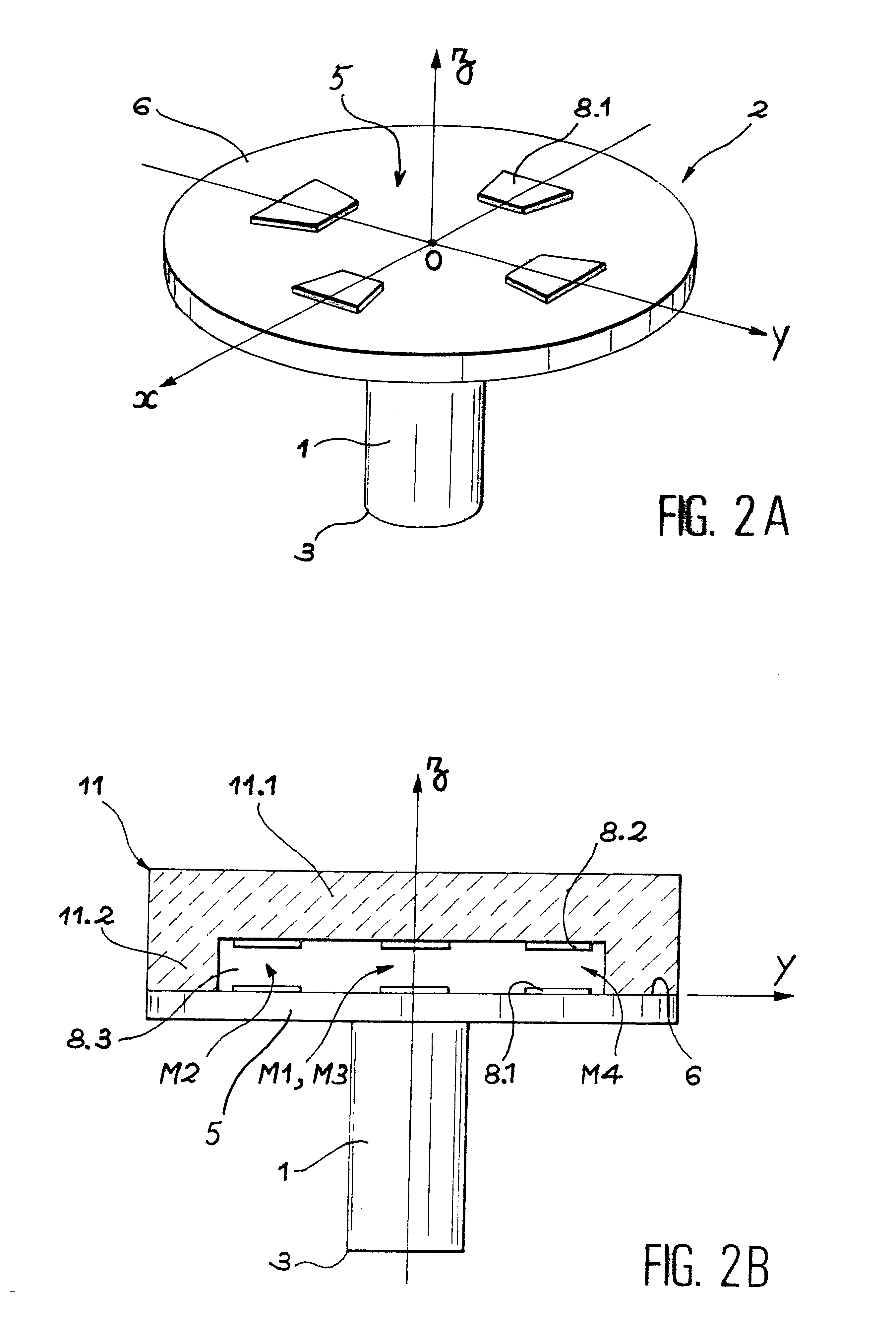

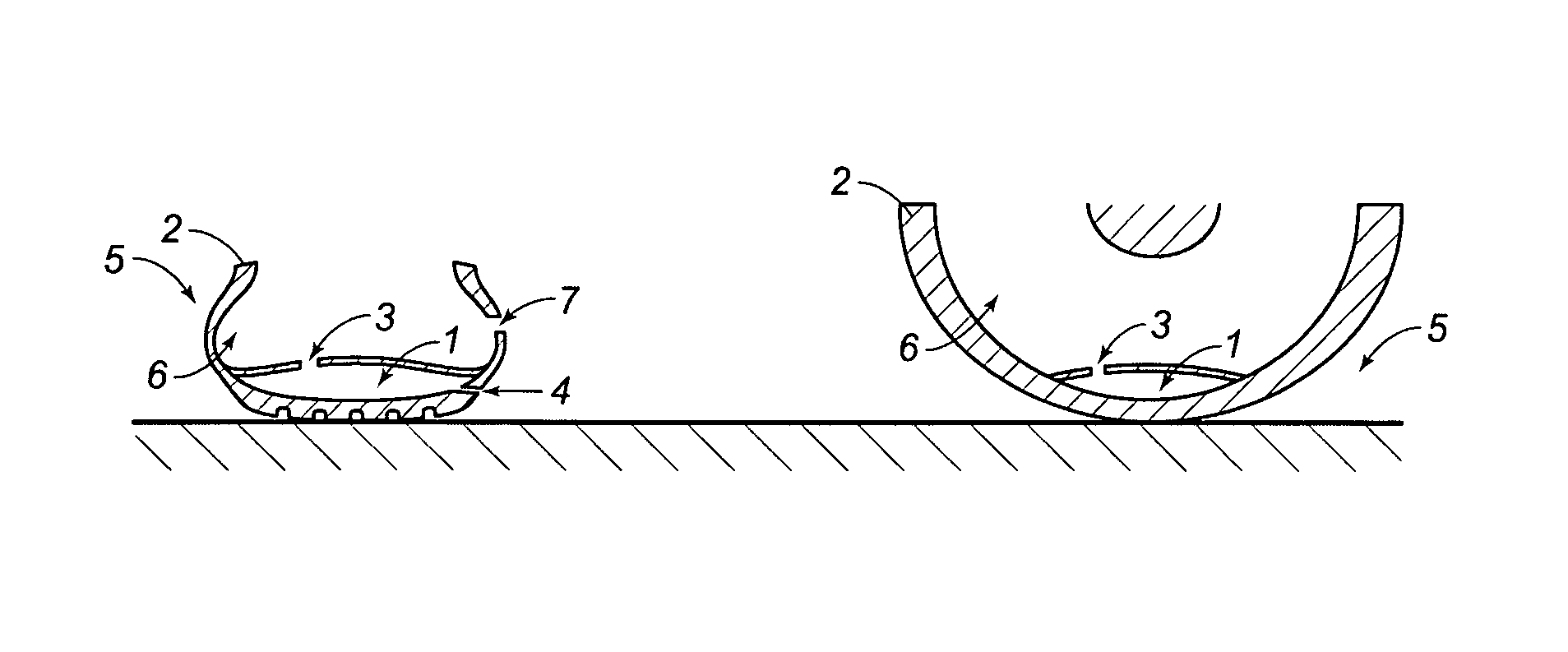

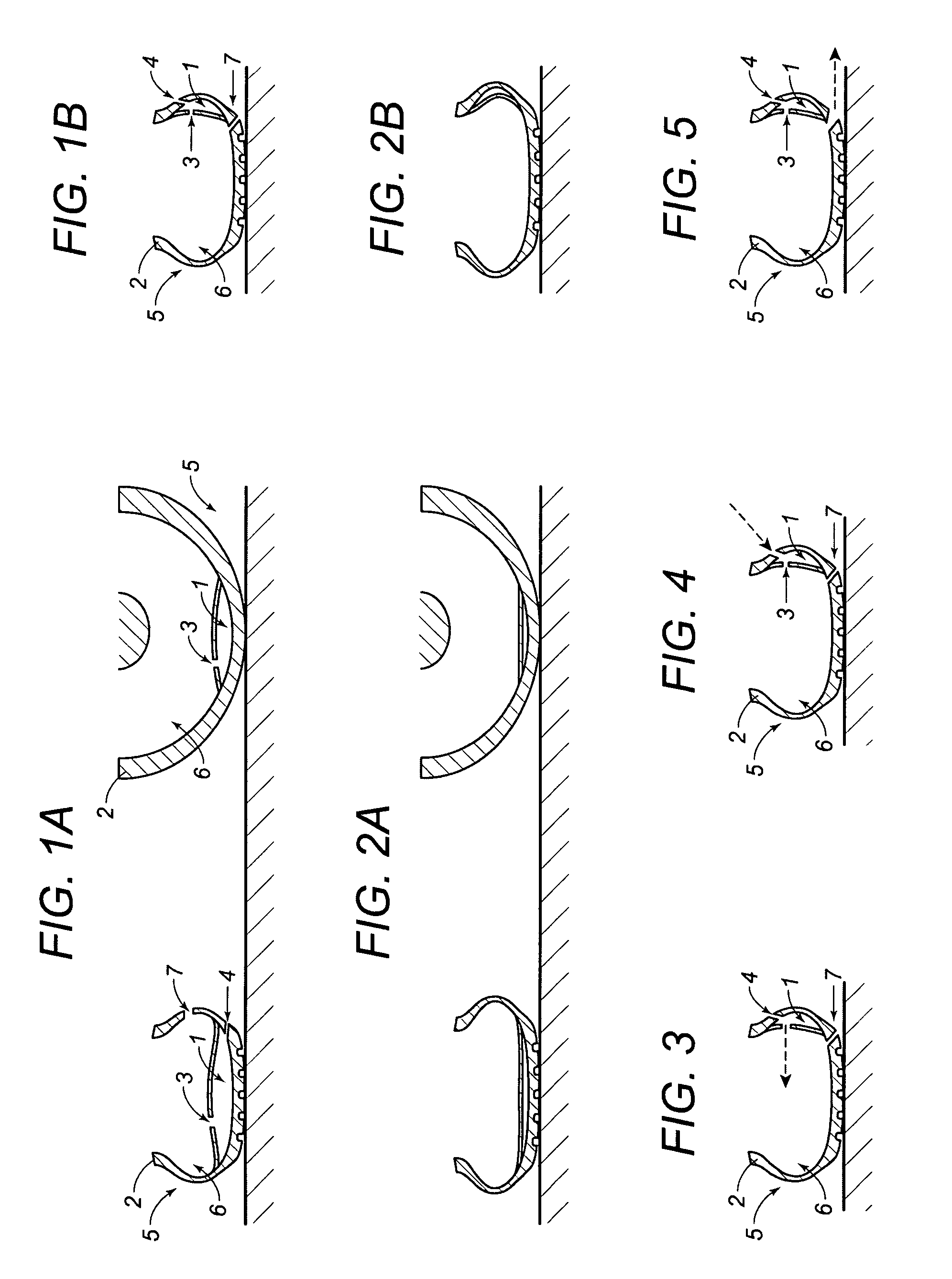

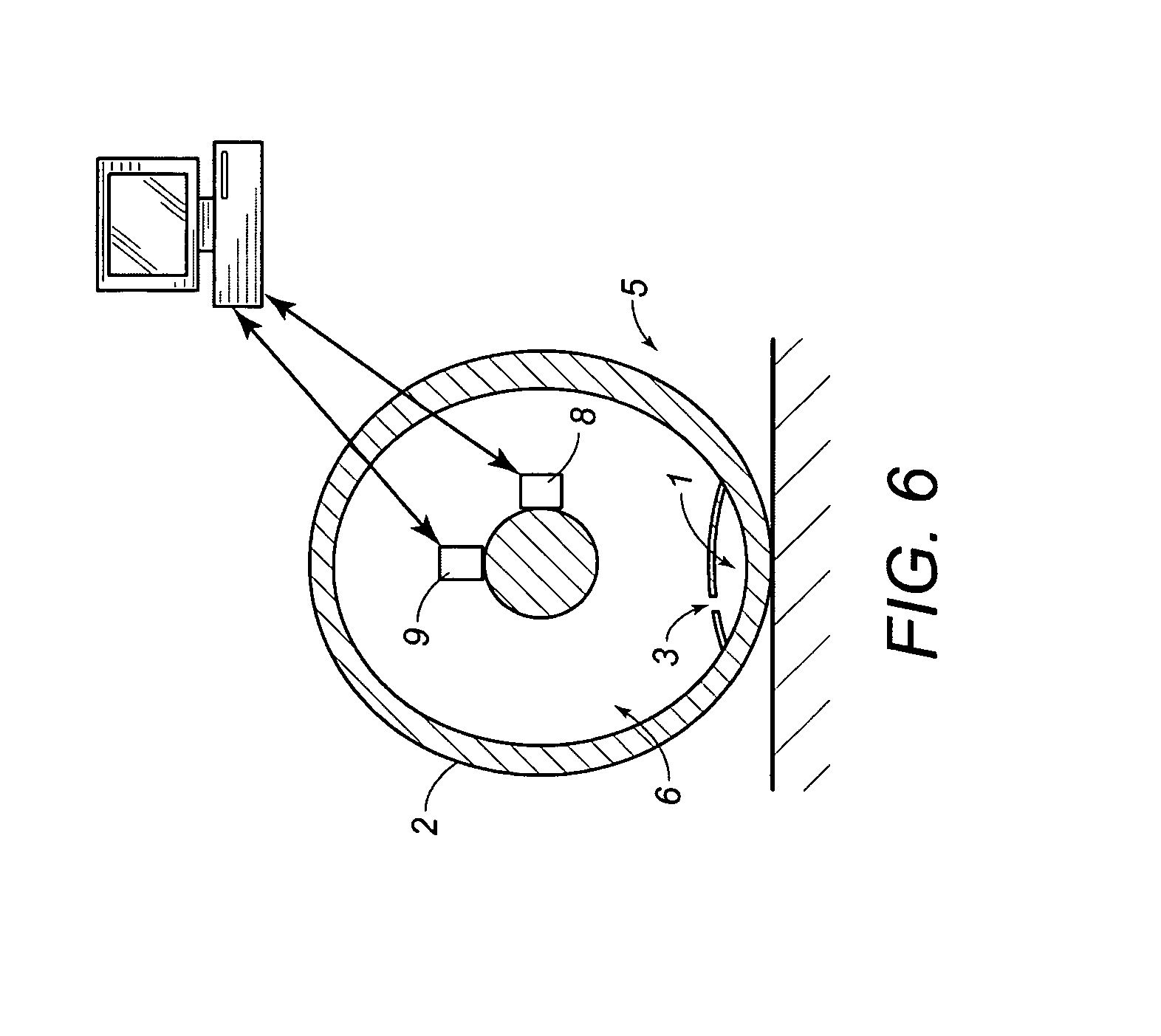

Pneumatic automobile tire with integrated sensors and traction control system

InactiveUS6339956B1Complicates of longitudinal forceReduce brake pressureForce measurement using piezo-electric devicesTyre beadsTire beadTraction control system

A pneumatic vehicle tire includes a carcass, a bead with a bead core arranged in the bead, and a first sensor located within the bead. The first sensor delivers signals which are correlated to frictional forces transmitted by the pneumatic vehicle tire during operation. This sensor has a first end and a second end, wherein the first end includes a heel attached to the bead core and the second end extends radially outward from the bead core within the tire. A plurality of such sensors can be included in each tire, some for measuring longitudinal forces in a circumferential direction of the tire and others for measuring lateral forces in an axial direction of the tire.

Owner:CONTINENTAL AG

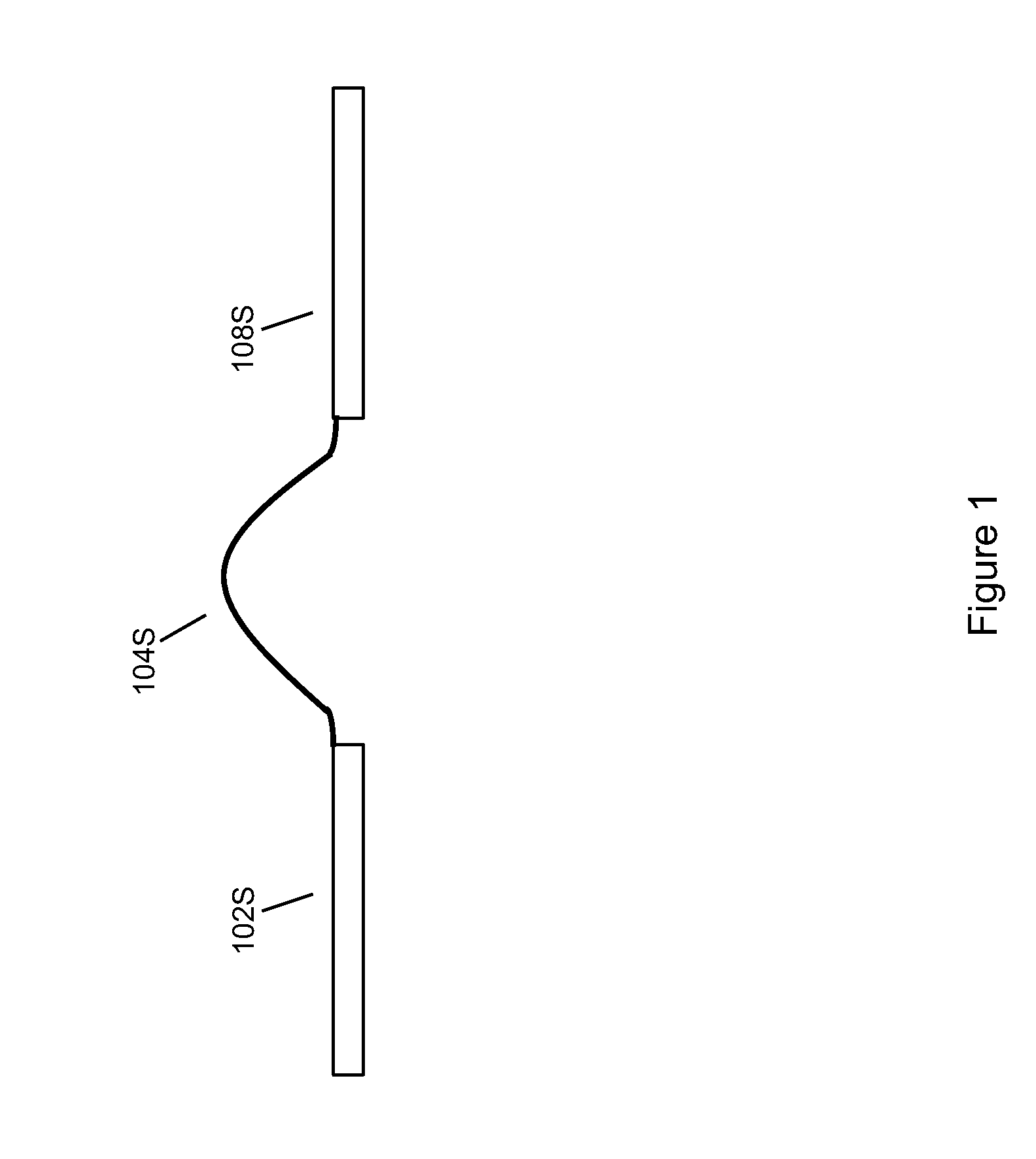

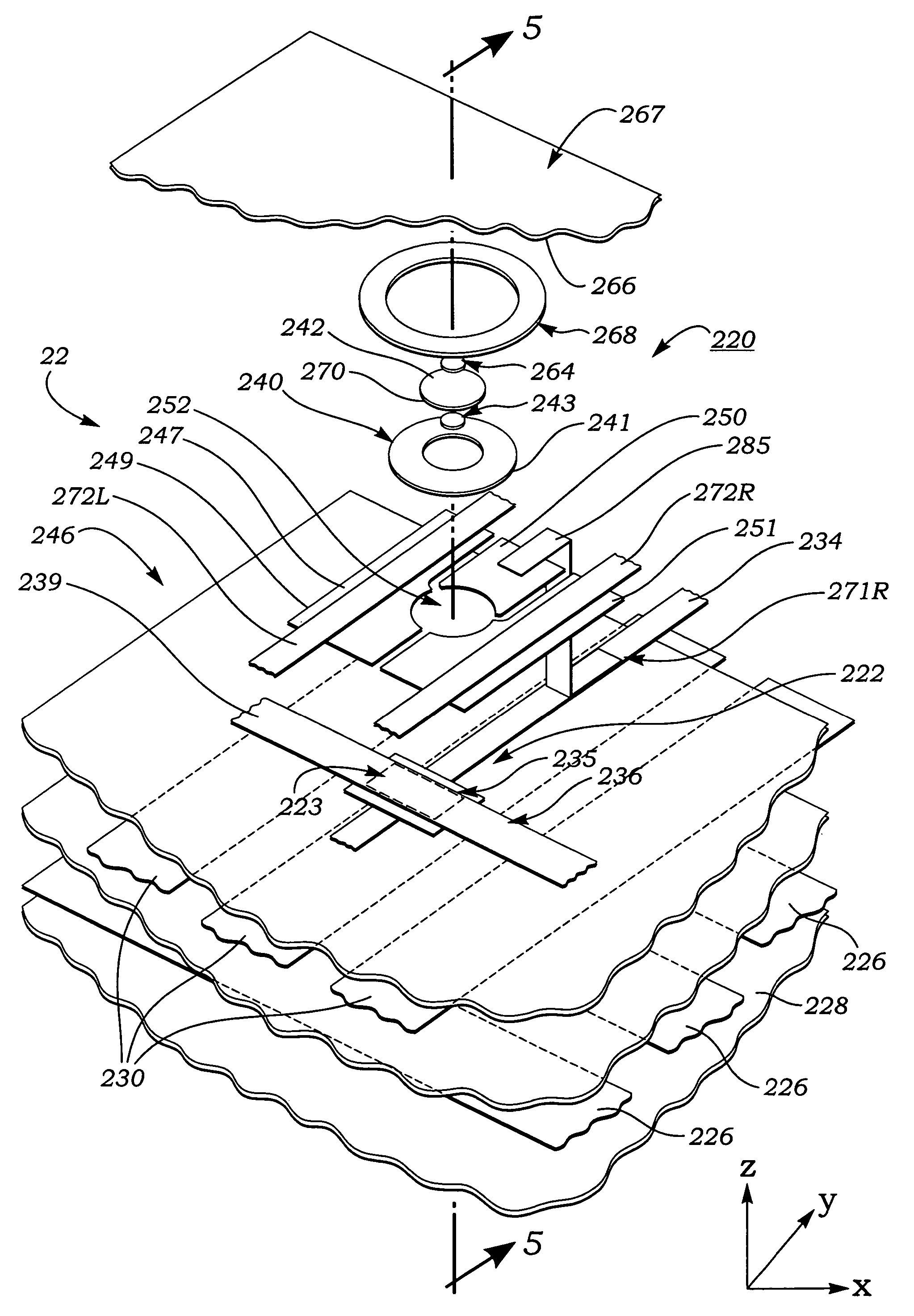

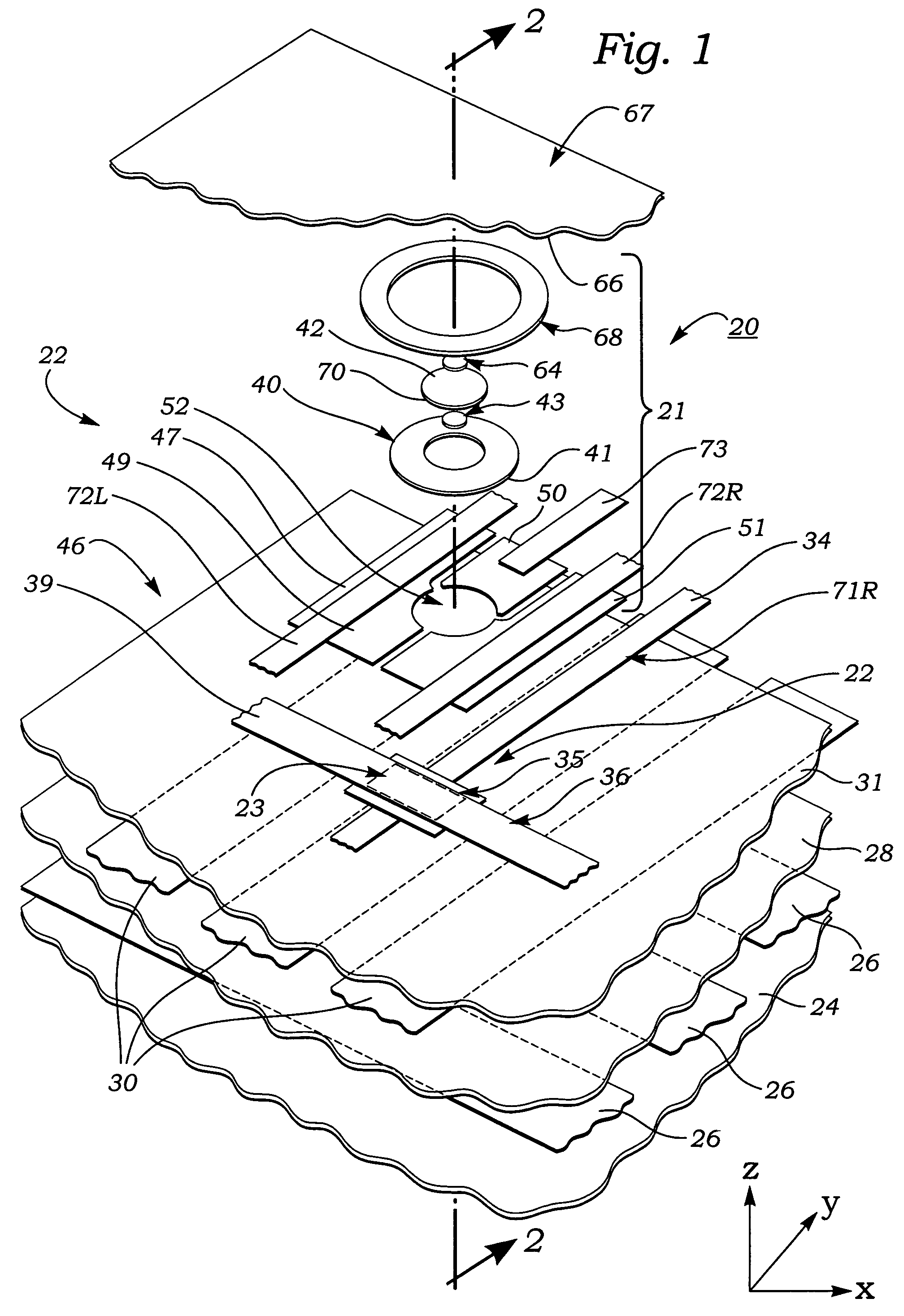

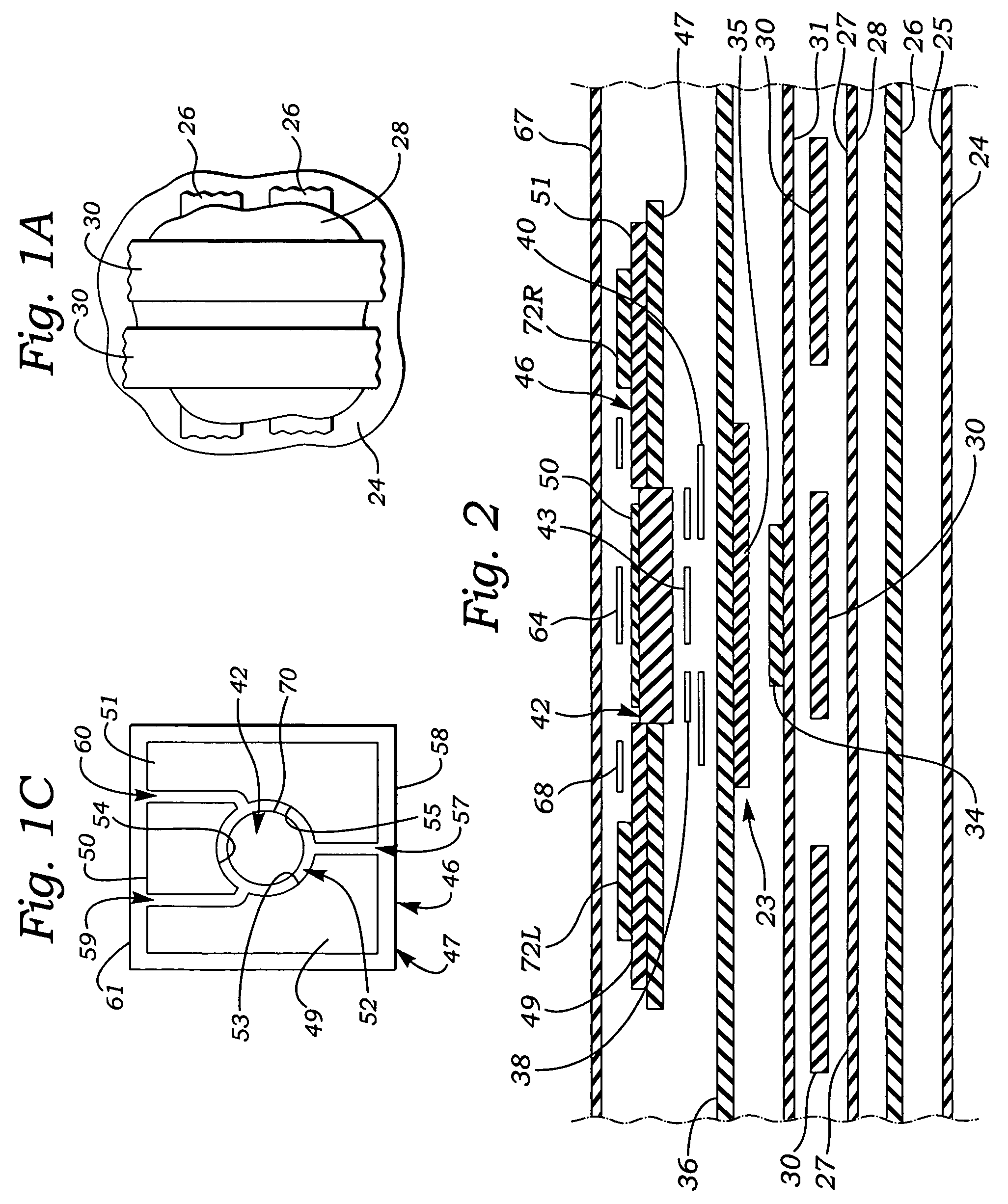

Normal force gradient/shear force sensors and method of measuring internal biological tissue stress

InactiveUS7201063B2Small sizeStretchable conformabilityForce measurementDiagnostic recording/measuringSensor arrayElectrical conductor

A normal force gradient / shear force sensor device and measurement method for measuring internal stresses in tissues of a person supported by a chair or bed includes a planar matrix array of peripheral normal force sensors radially spaced from central shear force sensors, comprising an electrically conductive disk located within a circular opening bordered by circumferentially spaced apart electrodes. The disk and electrodes are located between upper and lower cover sheets made of a stretchable material such as polyurethane; one cover sheet is adhered to the disk and the other sheet is adhered to a support sheet for the electrodes. Motion between the cover sheets in response to shear forces exerted on the array causes the disk to press more or less tightly against the electrodes varying electrical conductance between the disk and electrodes proportionally to the magnitude and direction of the shear force. Each normal force sensor includes an electrically conductive film pressed between row and column conductors. Measurements of conductance values of pairs of sensor, which vary proportionally to normal forces exerted on the sensor, are used to calculate a gradient vector of normal forces exerted by a body part on the sensor array, which is combined with the shear force vectors in an algorithm to calculate internal reaction shear forces, e.g., on flesh near a bony prominence.

Owner:VISTA MEDICAL

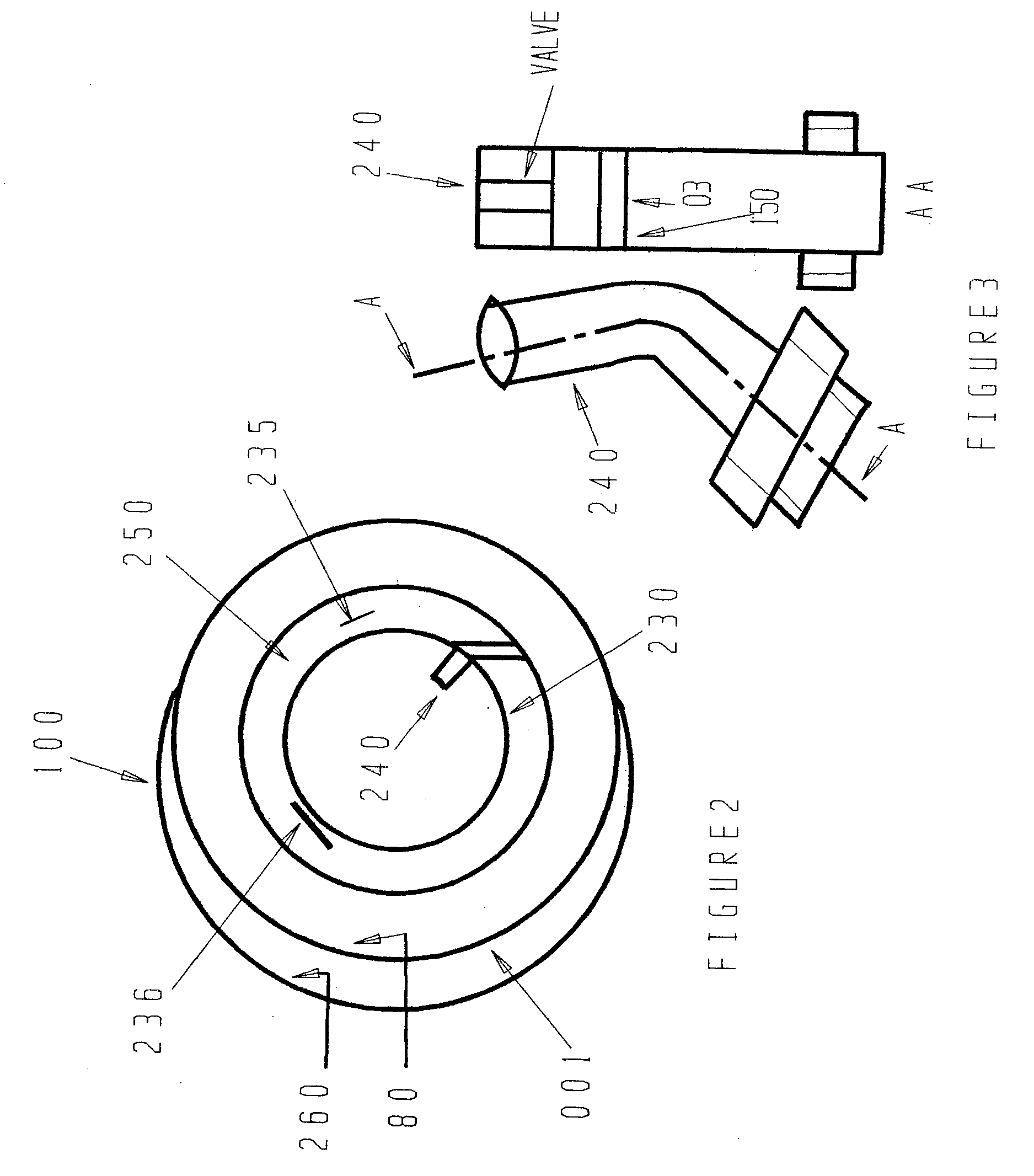

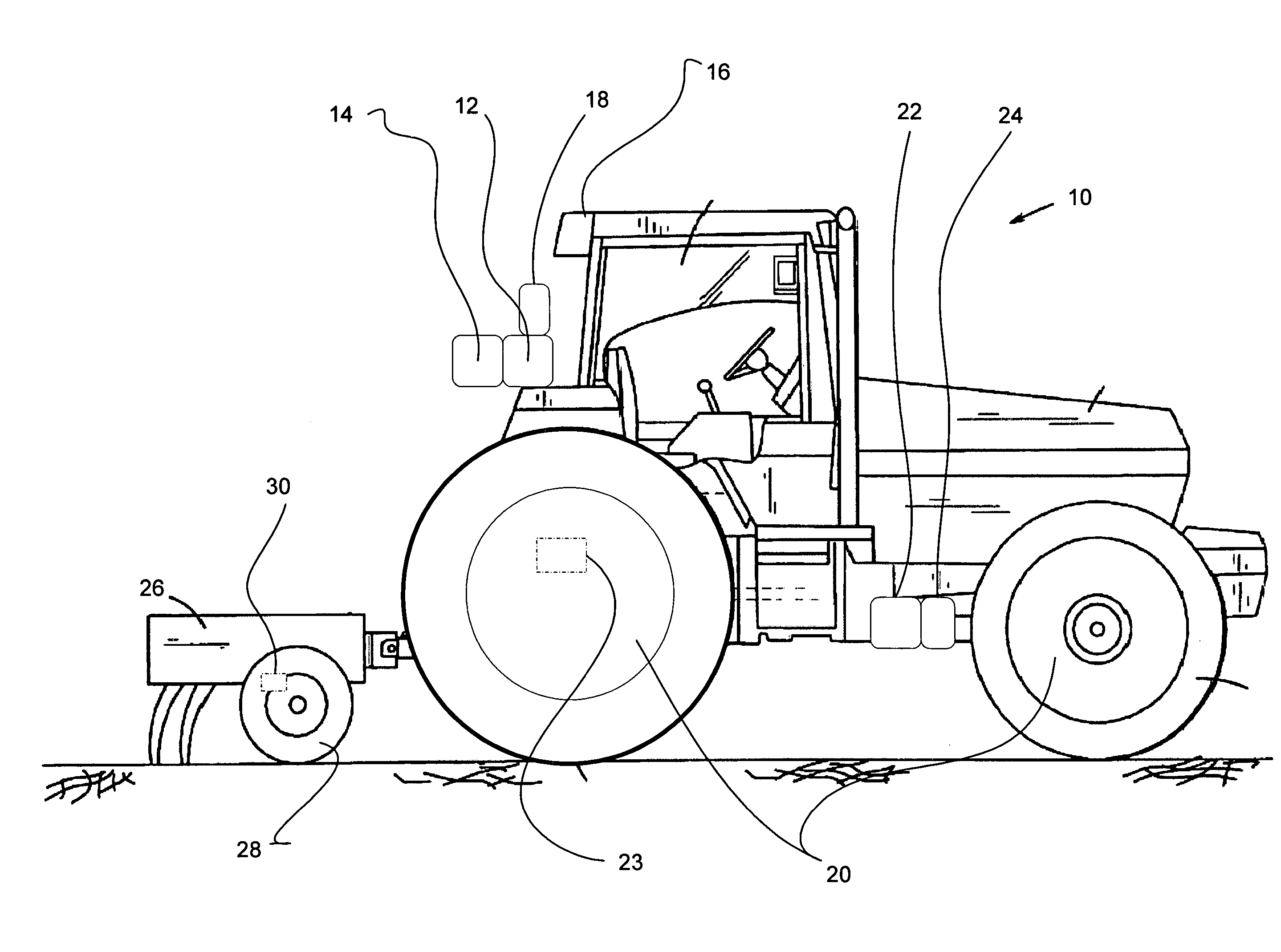

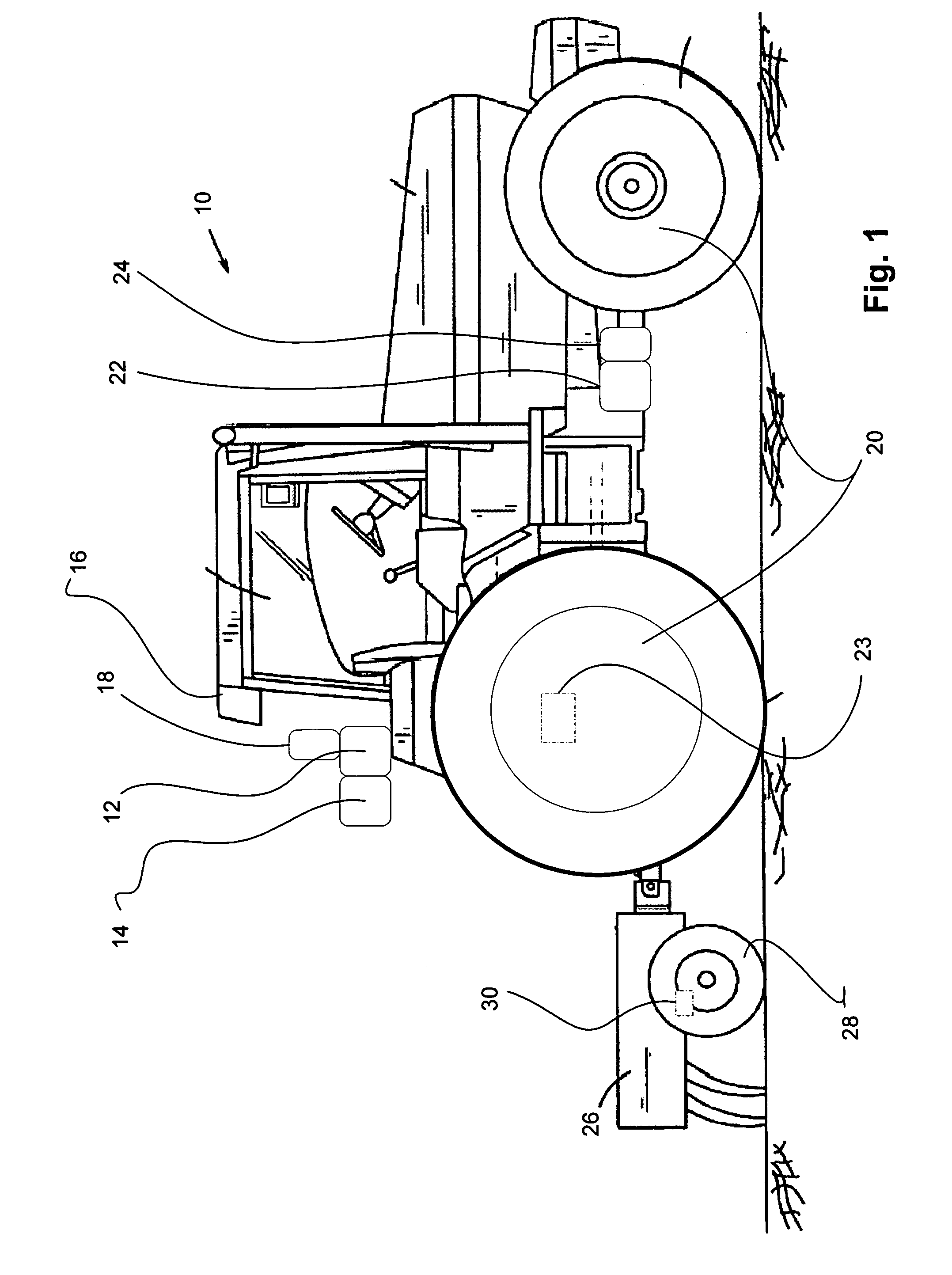

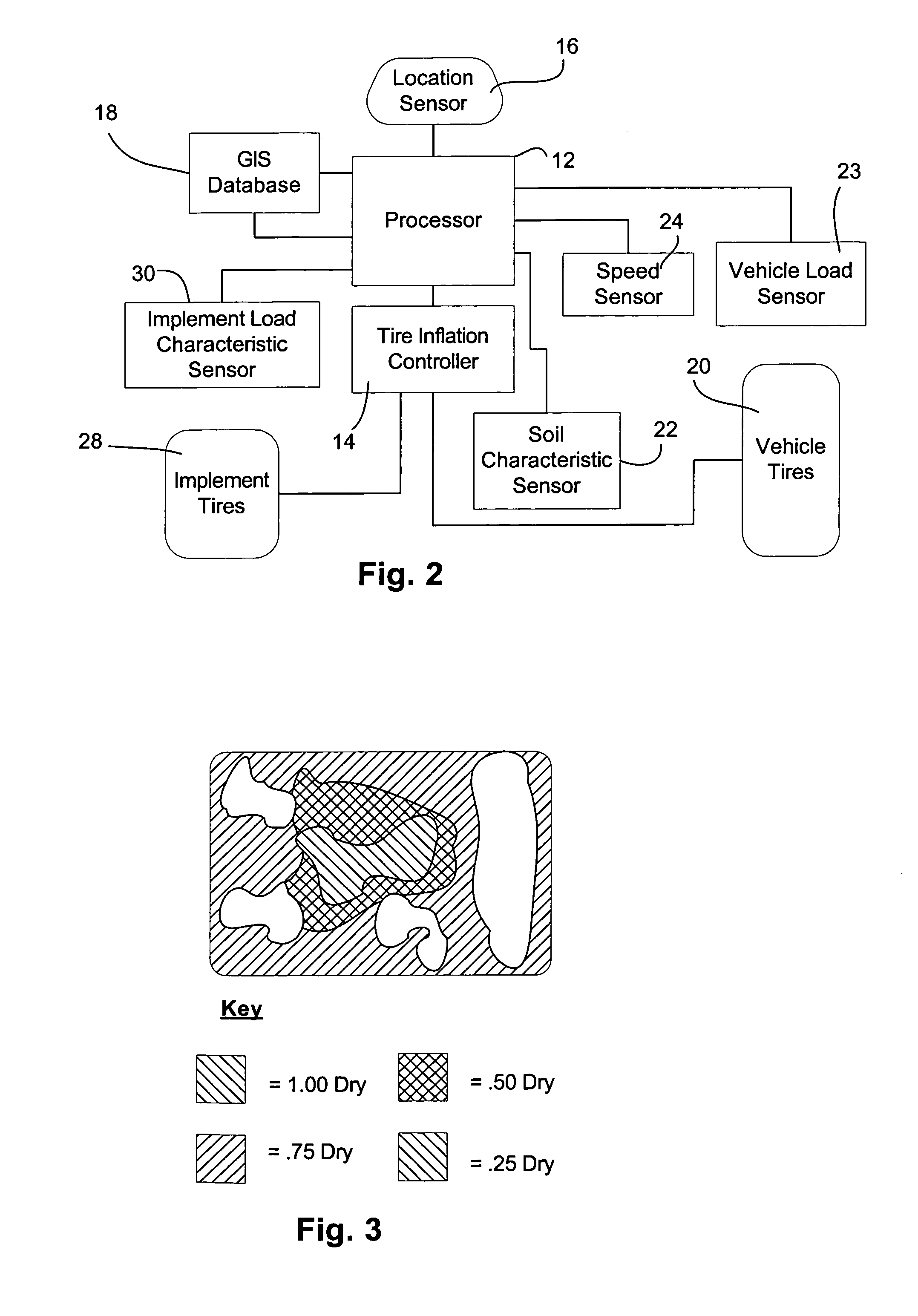

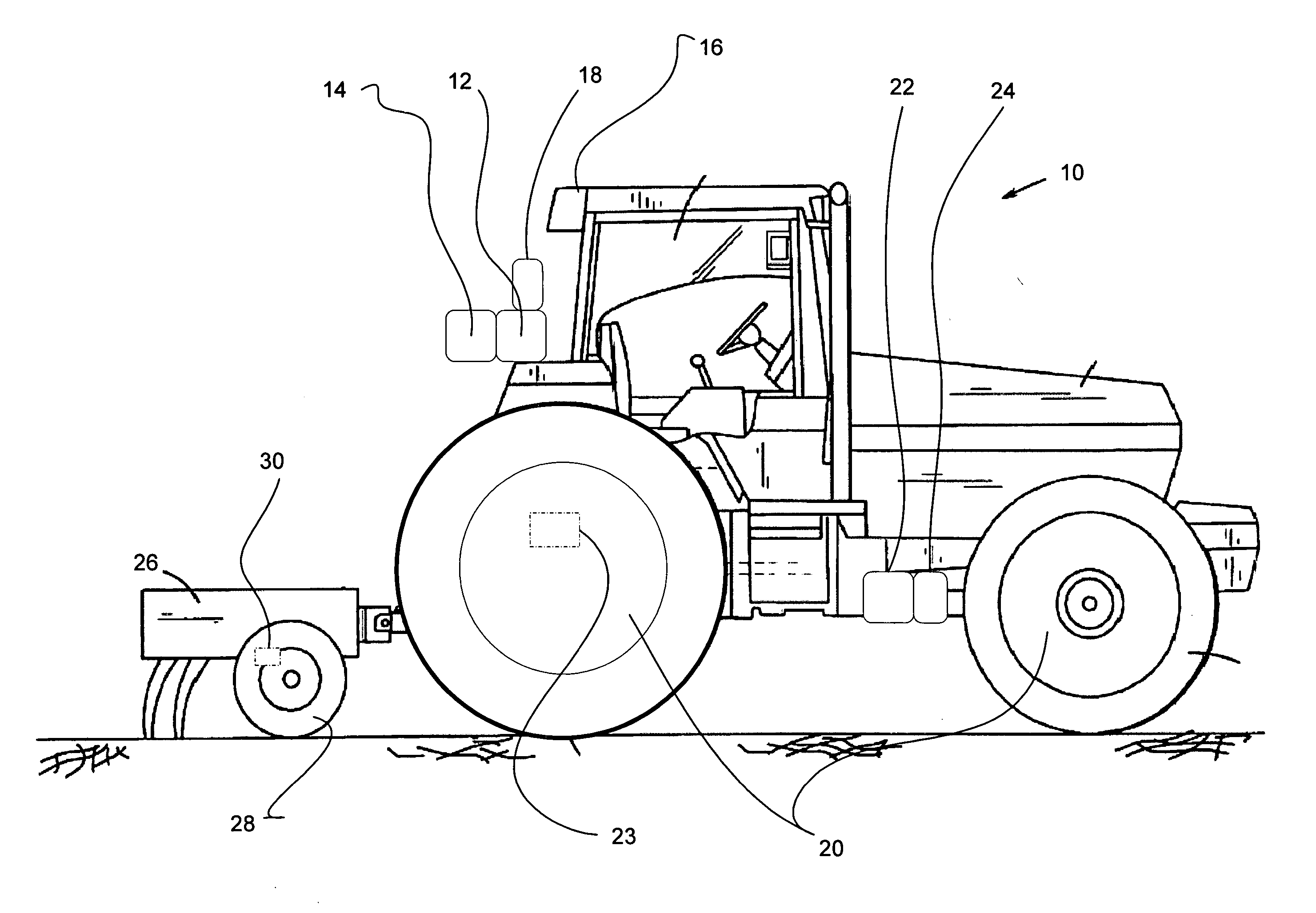

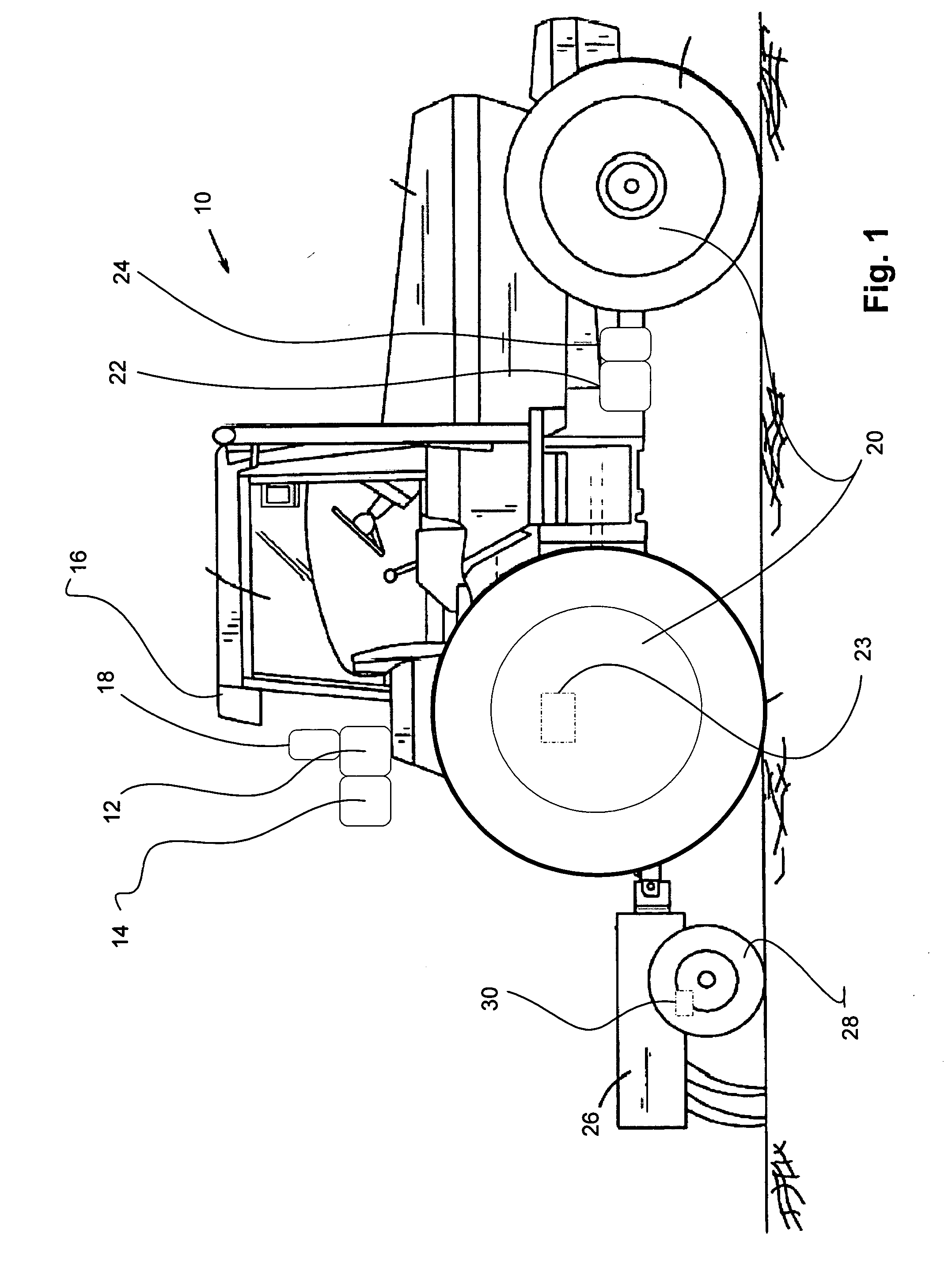

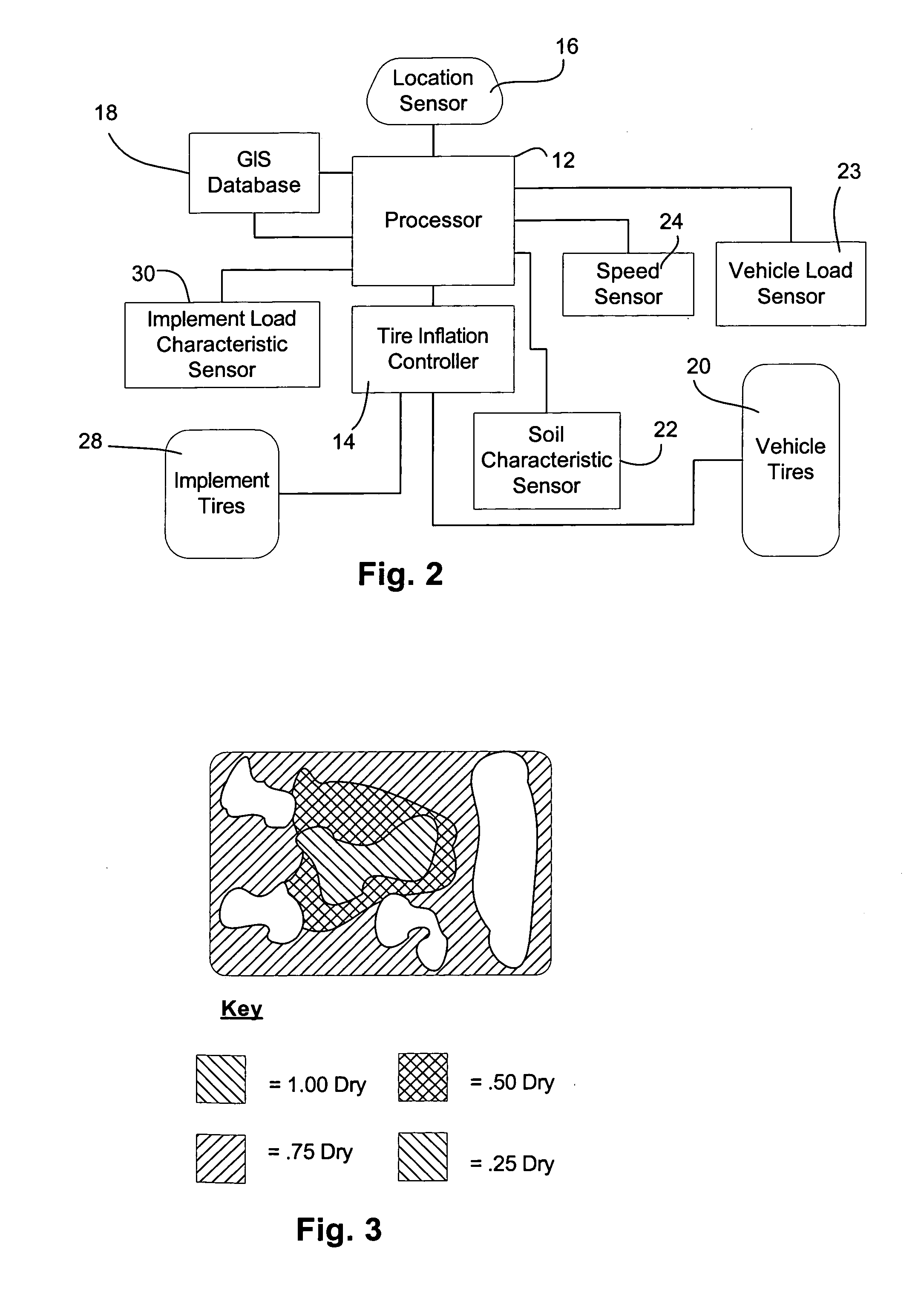

Tire inflation system for use with an agricultural implement

ActiveUS7302837B2Increase and decrease loadTyre measurementsRoads maintainenceCentral tire inflation systemLocation determination

Owner:BLUE LEAF I P INC

Tire inflation system for use with an agricultural implement

ActiveUS20070068238A1Increase and decrease loadTyre measurementsRoads maintainenceCentral tire inflation systemLocation determination

A central tire inflation system for an agricultural implement that is linked to a work vehicle for movement in a field. The central tire inflation system includes a database of soil conditions corresponding to location, an implement load sensor, a location determiner, a processor, and tire inflation controller. The processor determines the proper inflation of implement tires based on factors including the soil conditions and implement load.

Owner:BLUE LEAF I P INC

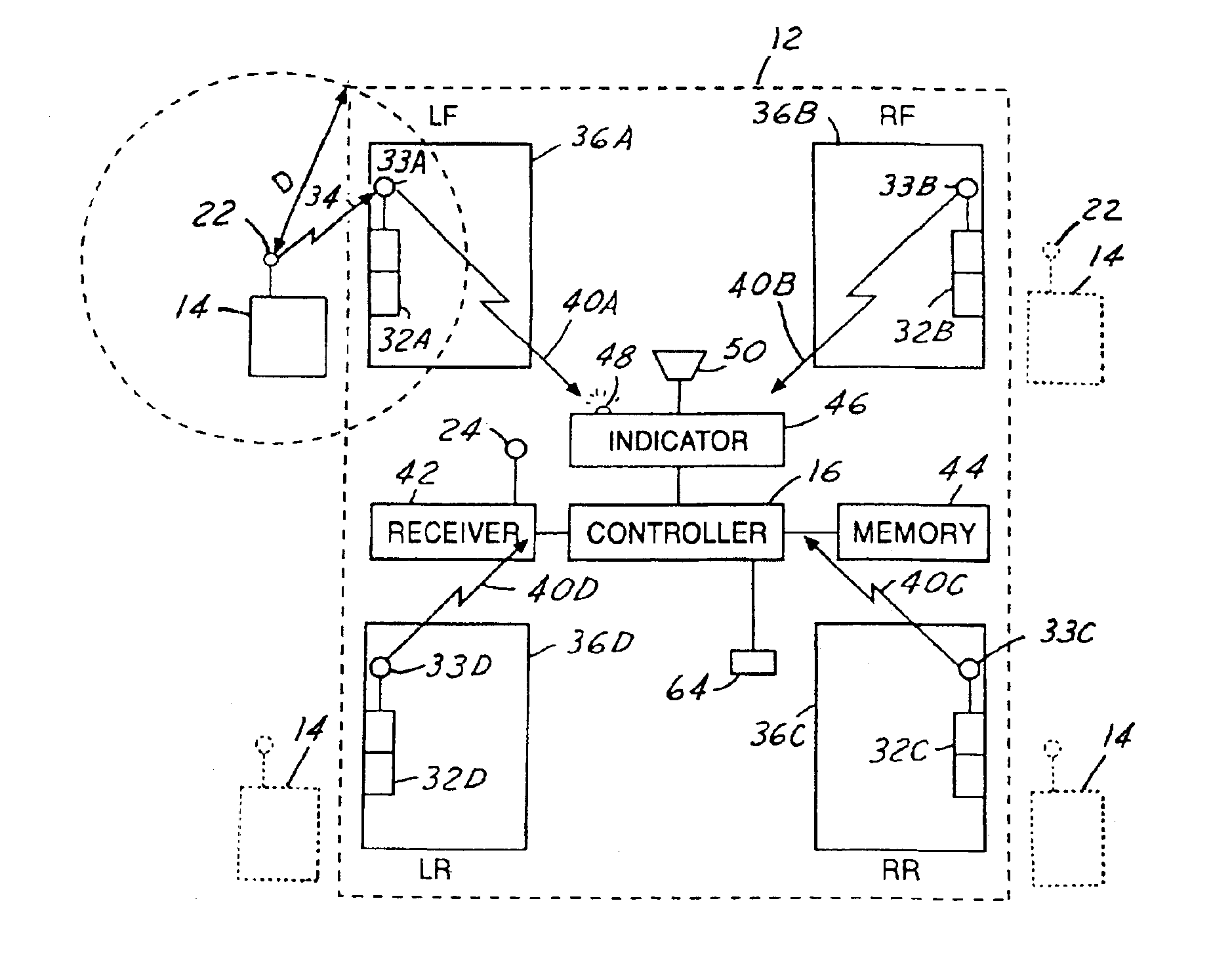

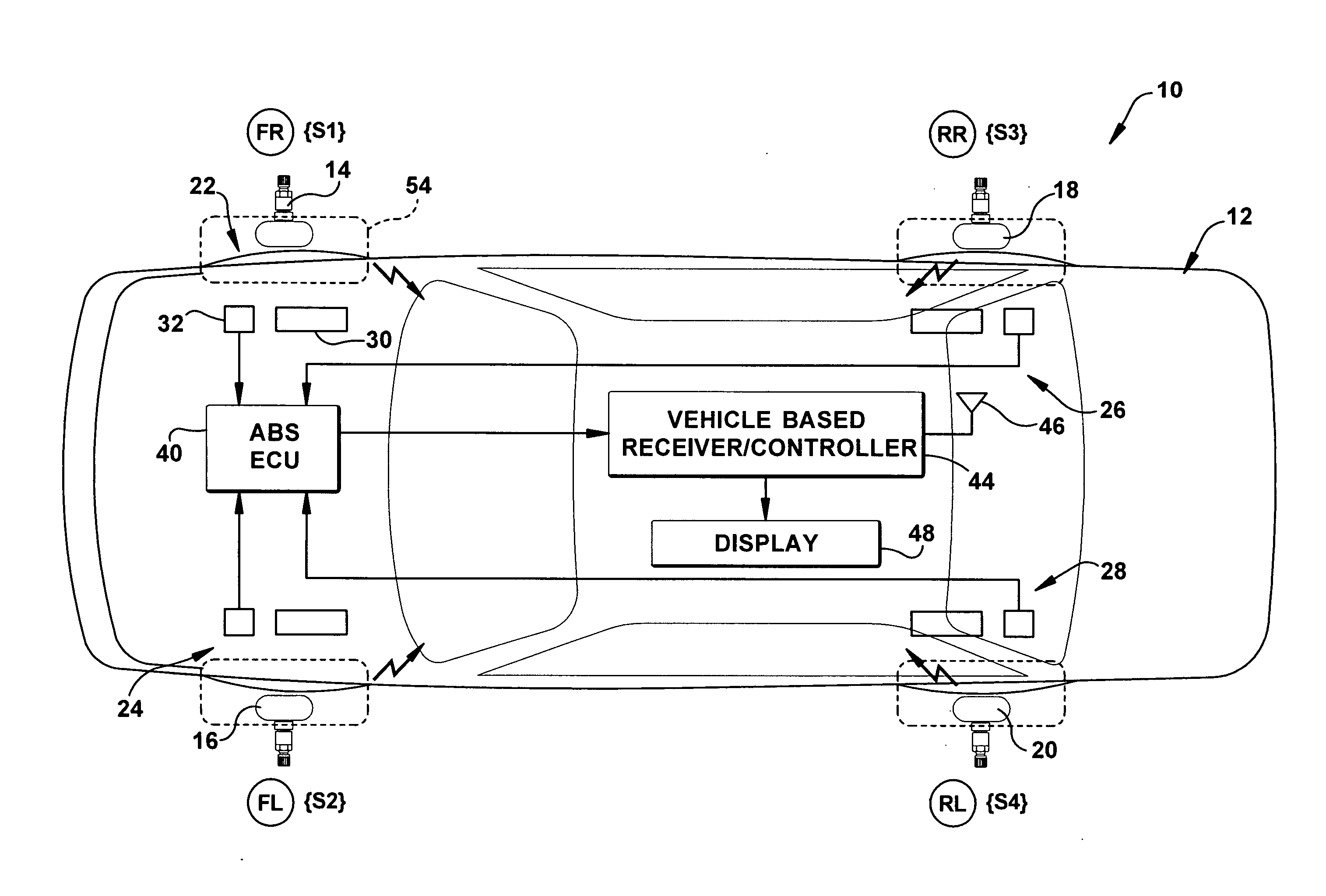

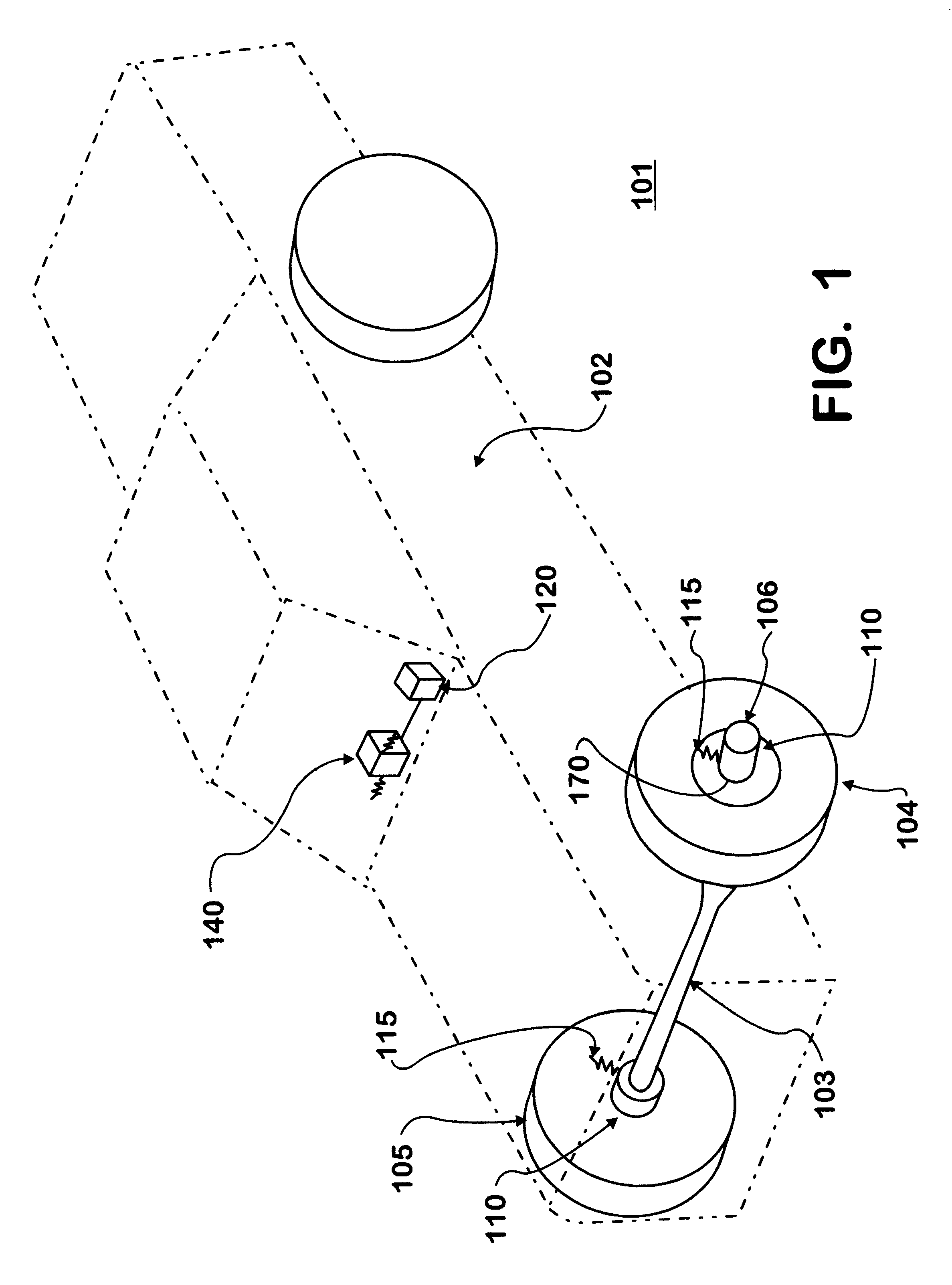

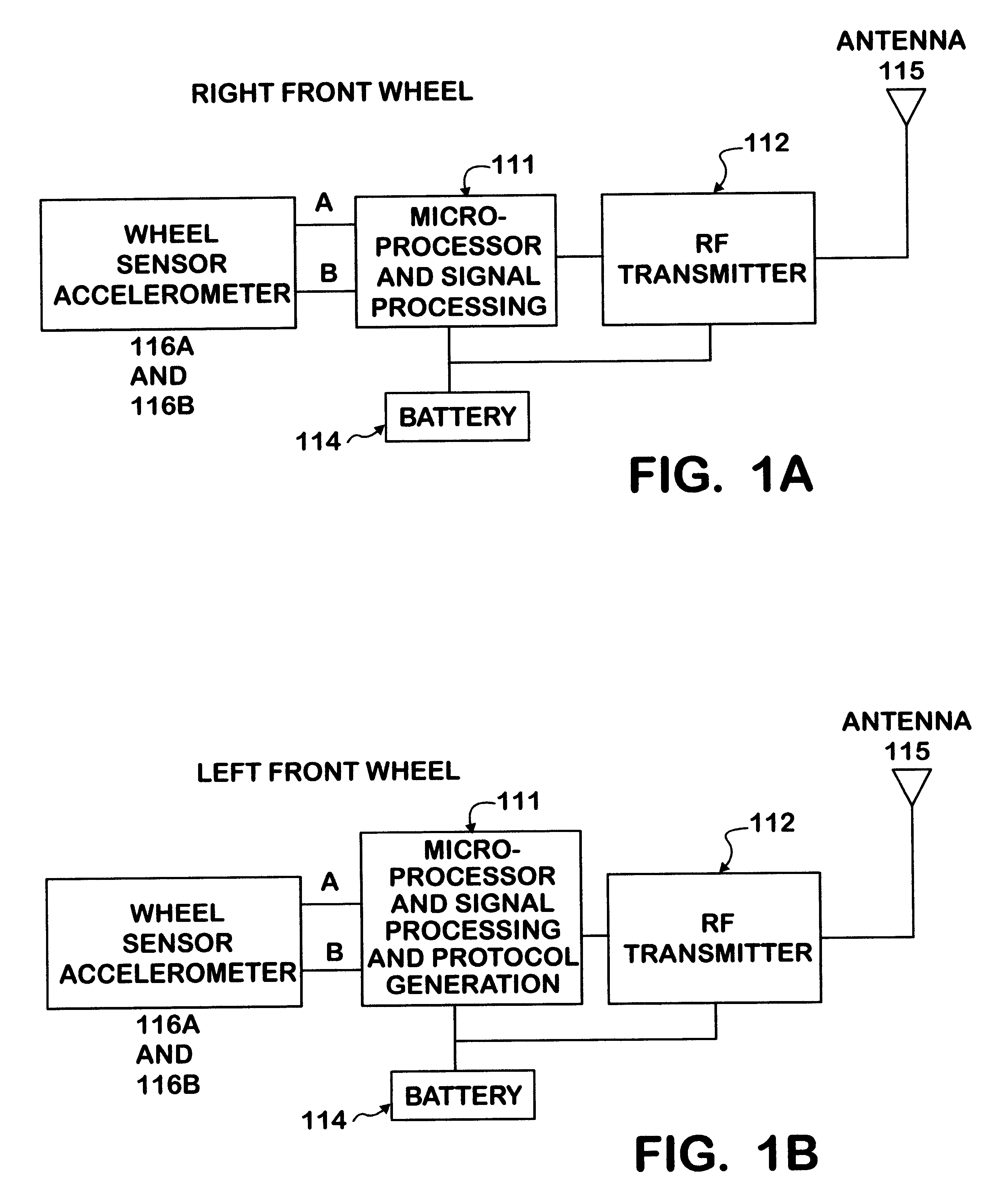

Determination of wheel sensor position using shock sensors and a wireless solution

A remote tire monitor system includes a control unit and a plurality of tire monitors mountable on respective wheels of a vehicle to transmit radio signals to the control unit. The tire monitors each include a pair of motion sensors such as shock sensors and a control circuit configured to determine position information for the respective tire monitor based on first and second shock sensor signals from the pair of shock sensors. The shock sensors produce an output voltage proportional to a change in applied force. Therefore, the offset created by centrifugal force in previously used accelerometers is absent, simplifying design of the tire monitors.

Owner:SENSATA TECHNOLOGIES INC

Tire comprising a measurement device

Owner:MICHELIN RECH & TECH SA

Device for monitoring maintenance and adjustment of pressure in a tire

InactiveUS7117731B2Reduce fuel consumptionExtend tire lifeTyre measurementsRoads maintainencePeristaltic pumpInterior space

Device for monitoring, maintenance and / or adjustment of pressure in a tire includes the chamber with shape memory deformable for the period of application of external mechanical forces when the tire rolls on the road surface, connected valve with the inside space of the tire and valve with the outside environment. At least one wall of the chamber is adjacent to the inside wall of the tire or is a part of the inside wall of the tire. Furthermore, the device operates on the peristaltic pump principle consisting of the chamber, which is deformable up to the zero cross section. At least one chamber with block with shape memory is freely open at one end and equipped with at least one valve at the other end or next to it. The minimum volume of the part of the chamber at the end equipped with the internal valve or external valve is from 1 to 80% of the total maximum volume of the chamber.

Owner:SITHOLD SRO

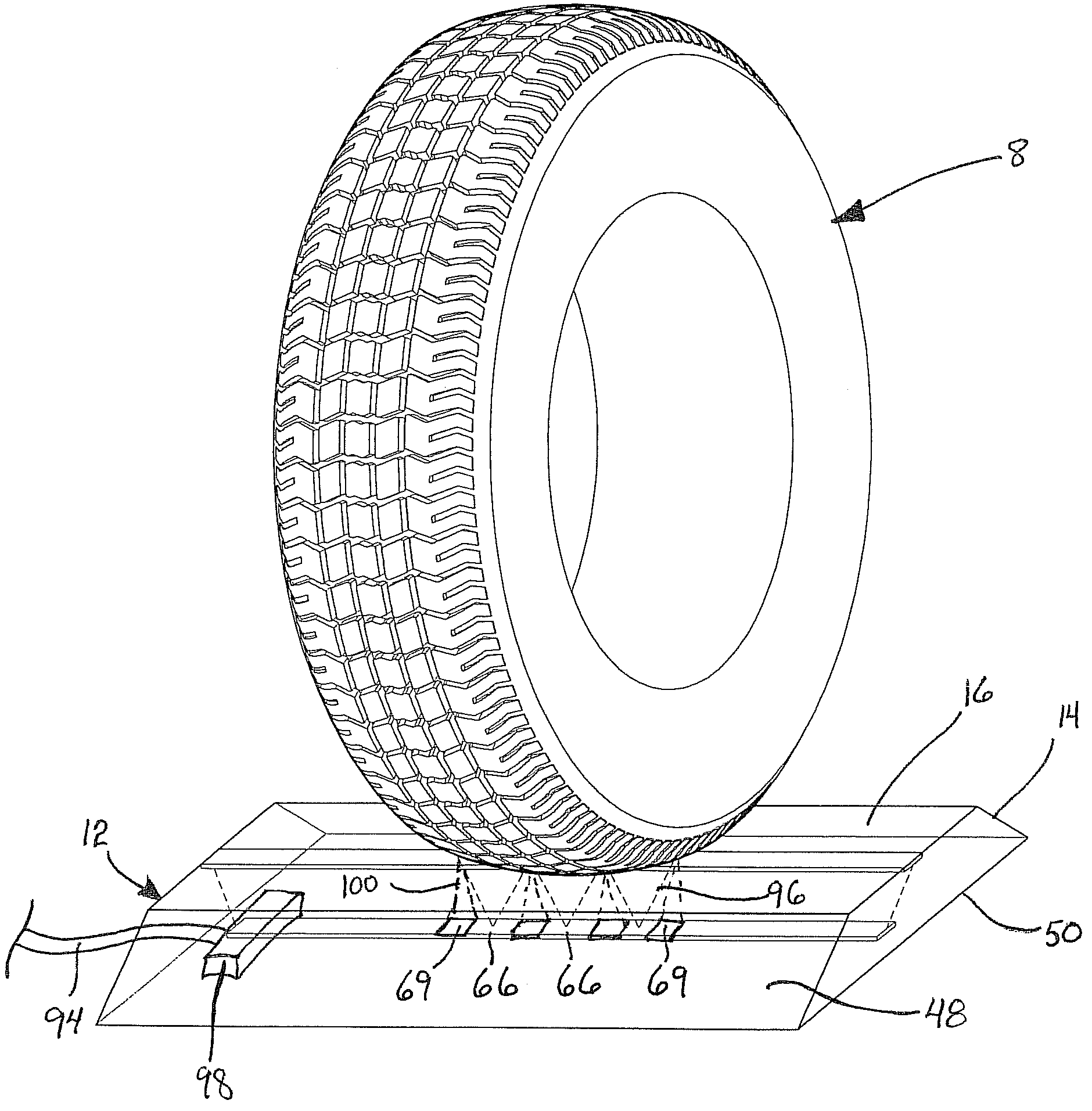

Tread depth sensing device and method for measuring same

A tread depth measurement system for measuring a depth of a tread provided to a tire on a vehicle. The system includes an energy source for emitting a wireless signal to be transmitted to the tire; a sensor for detecting a return wireless signal emitted from the tire to be transmitted in response to the wireless signal from the energy source; and a housing over which the tire is to roll while attached to the vehicle, said housing separating the sensor from the tire while the tread depth is being measured. A control unit is operatively coupled to the sensor for determining the depth of the tread as a function of at least the return wireless signal detected by the sensor.

Owner:THE GOODYEAR TIRE & RUBBER CO

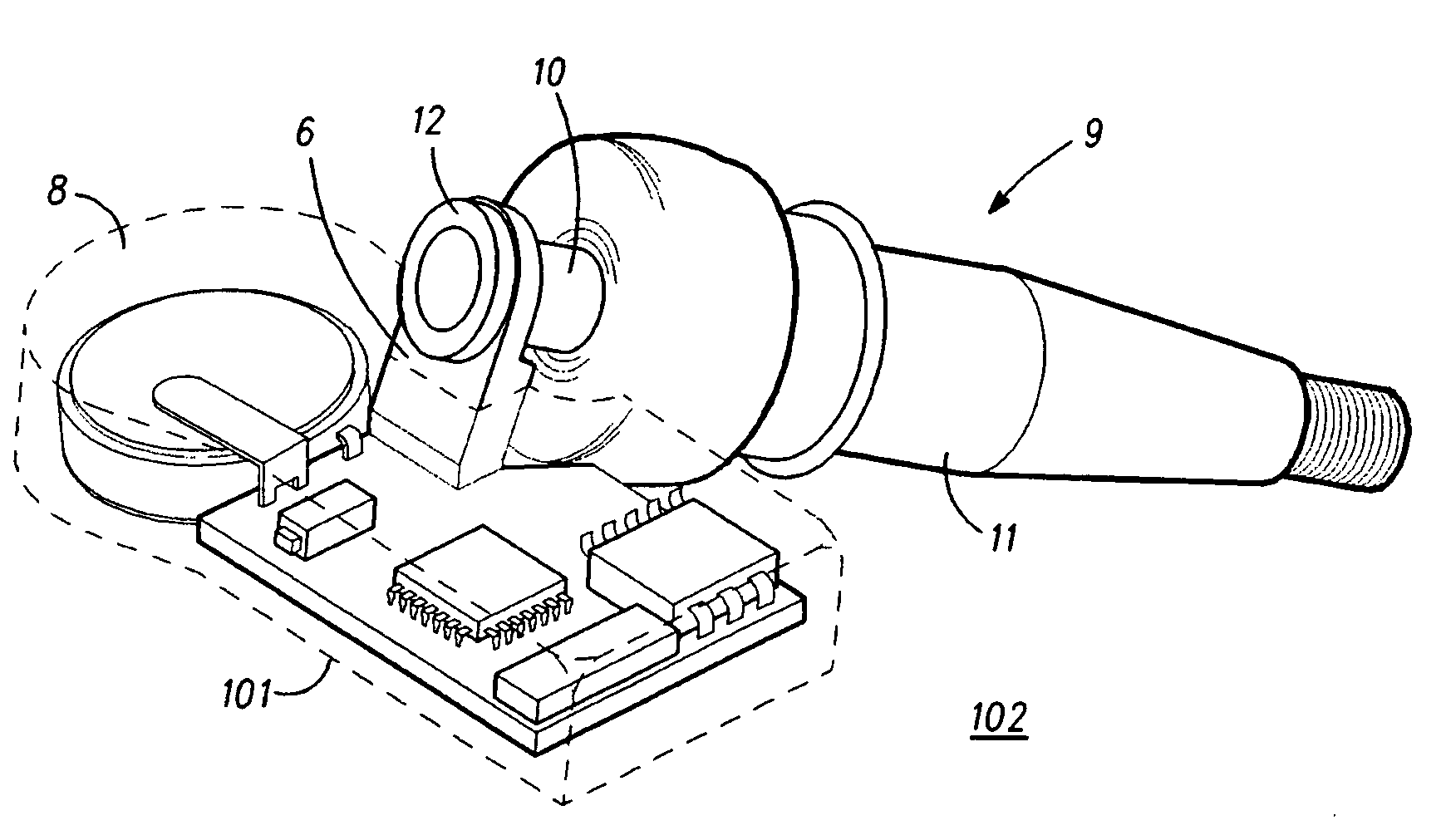

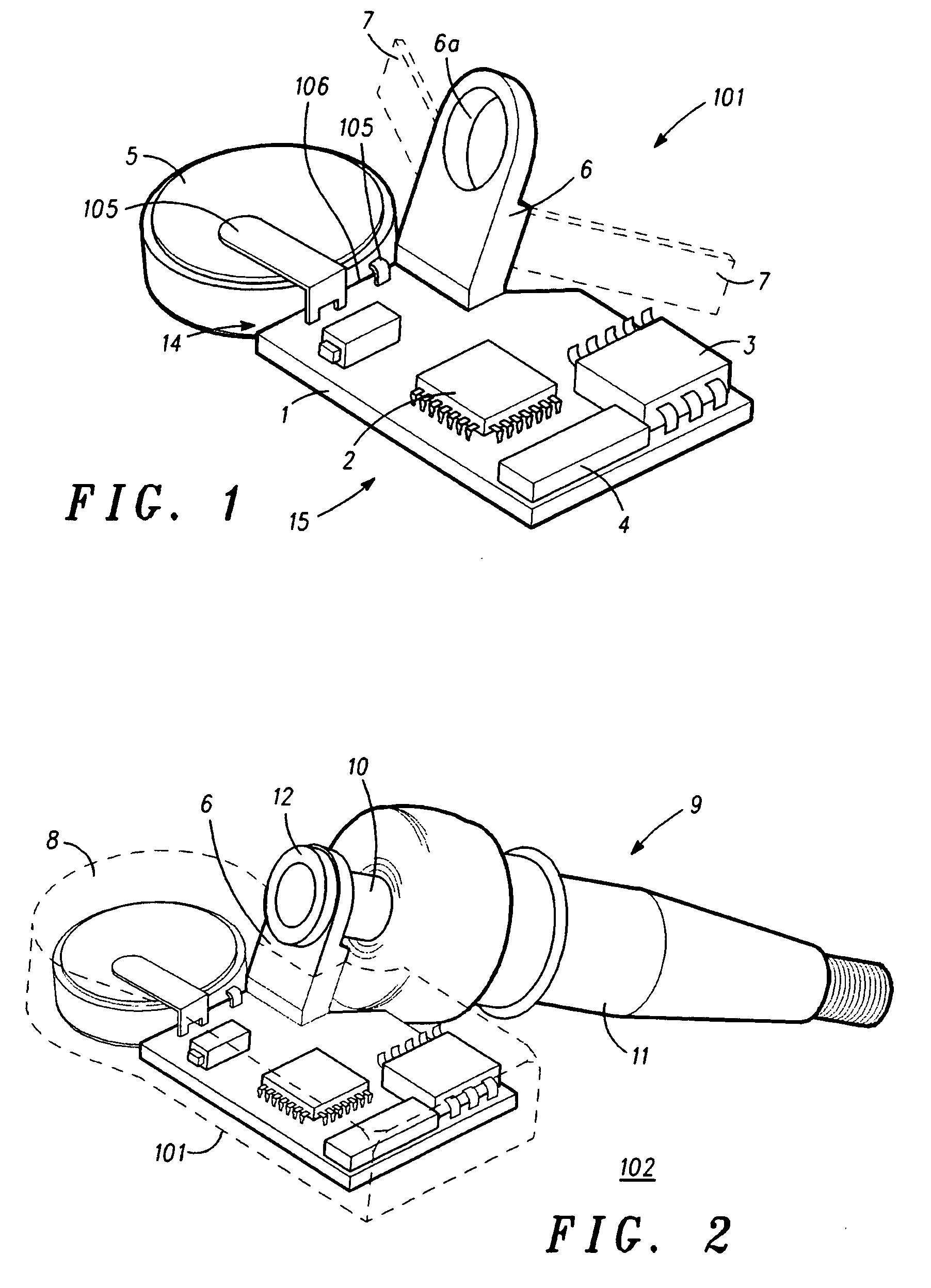

Tire pressure sensor assembly

The disclosure provides a tire pressure sensor assembly that includes a battery and a printed circuit board (PCB) configured with electronics to measure tire pressure and to transmit an electromagnetic signal related to the measured tire pressure. The PCB and battery are contained in a housing that allows the PCB and the battery to be angularly oriented with respect to each other. Such orientation permits the sensor to conform to the curved surface of the rim. An embodiment of the disclosed tire pressure sensor assembly is adapted to fasten to a valve stem via a metal terminal. The attachment configuration permits the valve stem assembly to deform as the valve stem is installed in a rim and also allows the valve stem to function as a portion of the antenna structure to facilitate transmitting the RF signal to a receiver.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

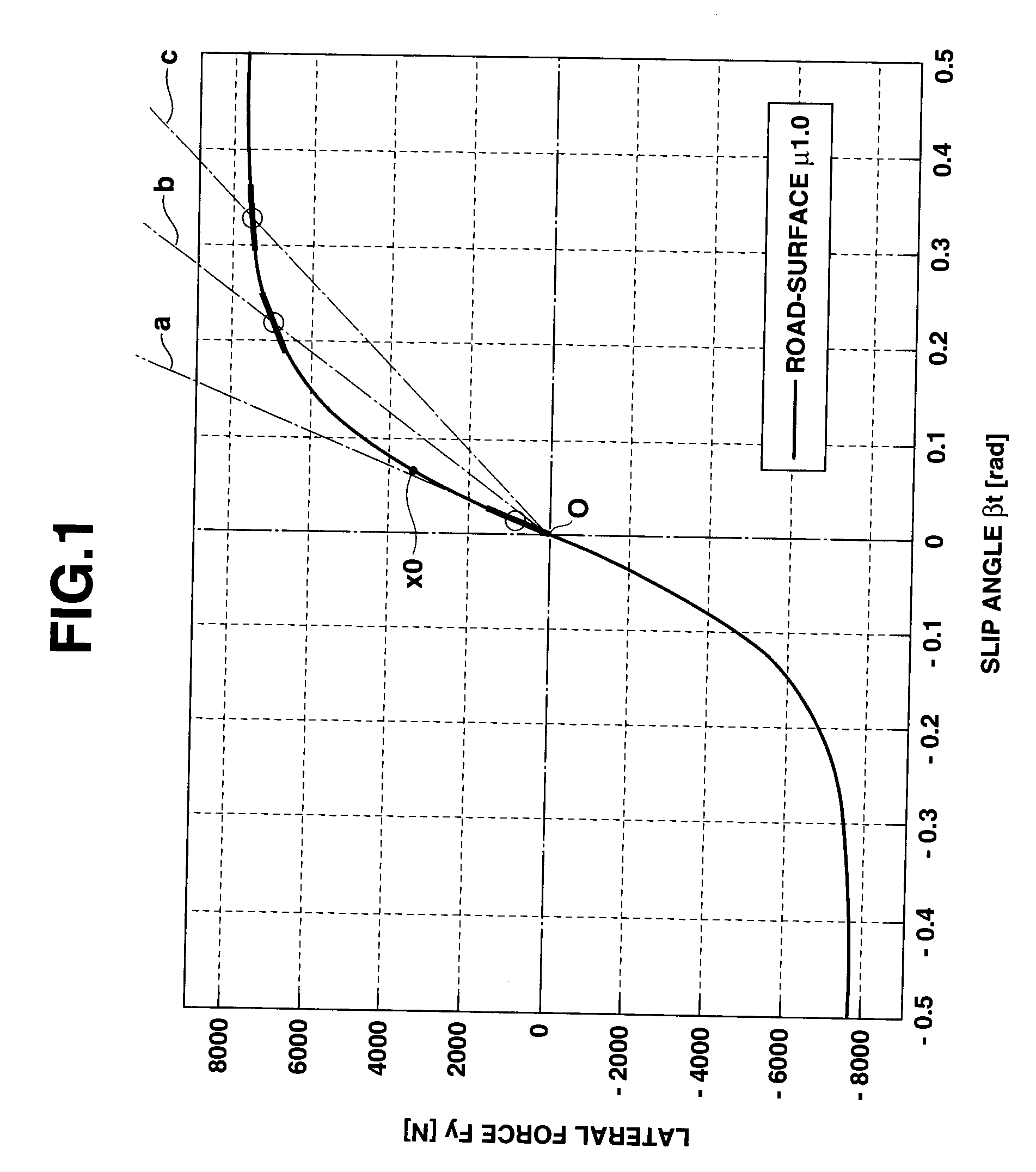

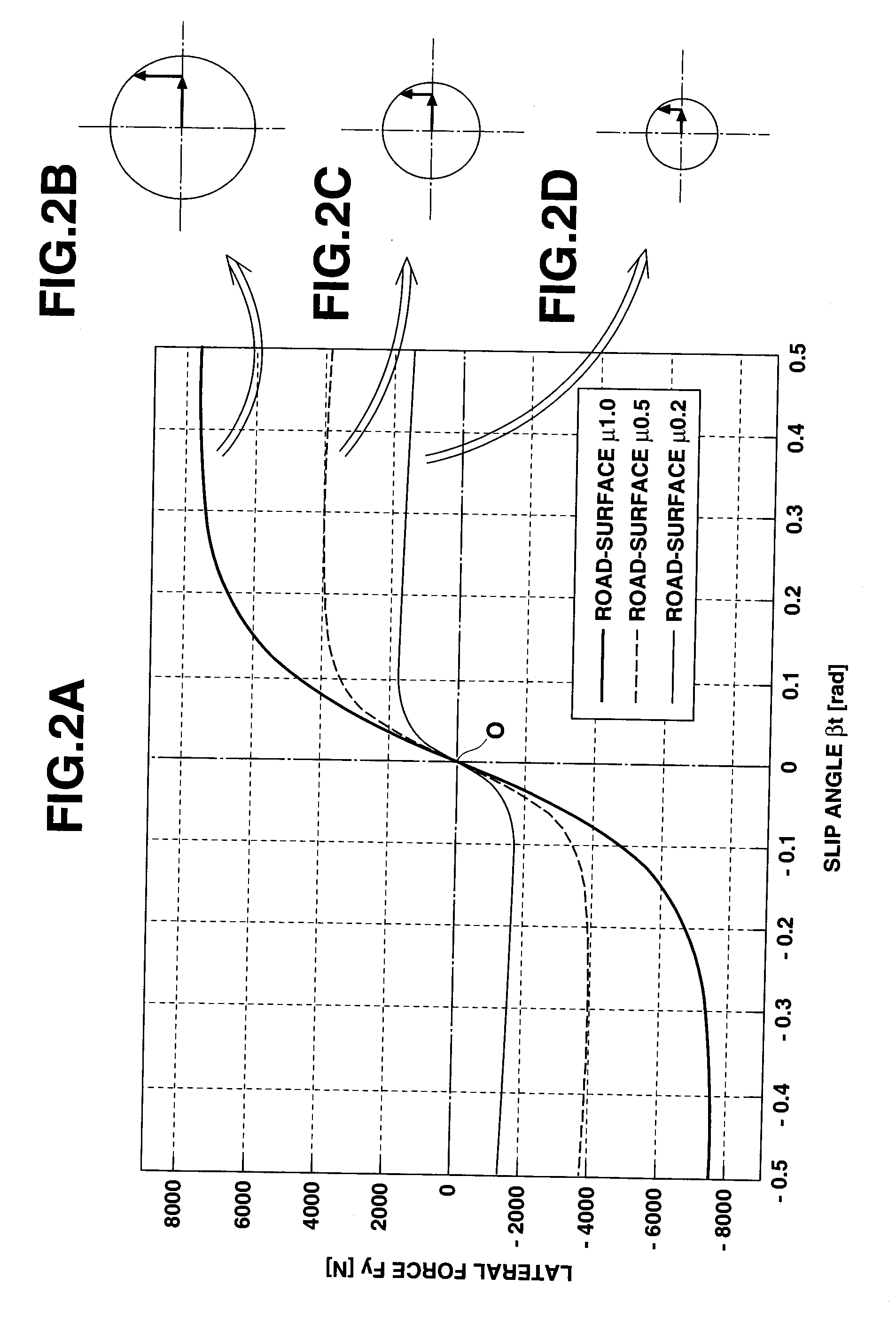

Device and method for estimating frictional condition of ground contact surface of wheel

InactiveUS20100114449A1Accurate detectionElectric devicesDigital data processing detailsGround contactAutomotive engineering

Apparatus for estimating a ground contact surface gripping characteristic of a vehicle wheel of a vehicle comprises an input section and an output section. The input section sets an input representing a ratio of a wheel force acting on the vehicle wheel in the ground contact surface, and a wheel slipping degree of the vehicle wheel. The output section determines, from the input, an output representing a grip characteristic parameter indicative of the gripping characteristic of the vehicle wheel.

Owner:NISSAN MOTOR CO LTD

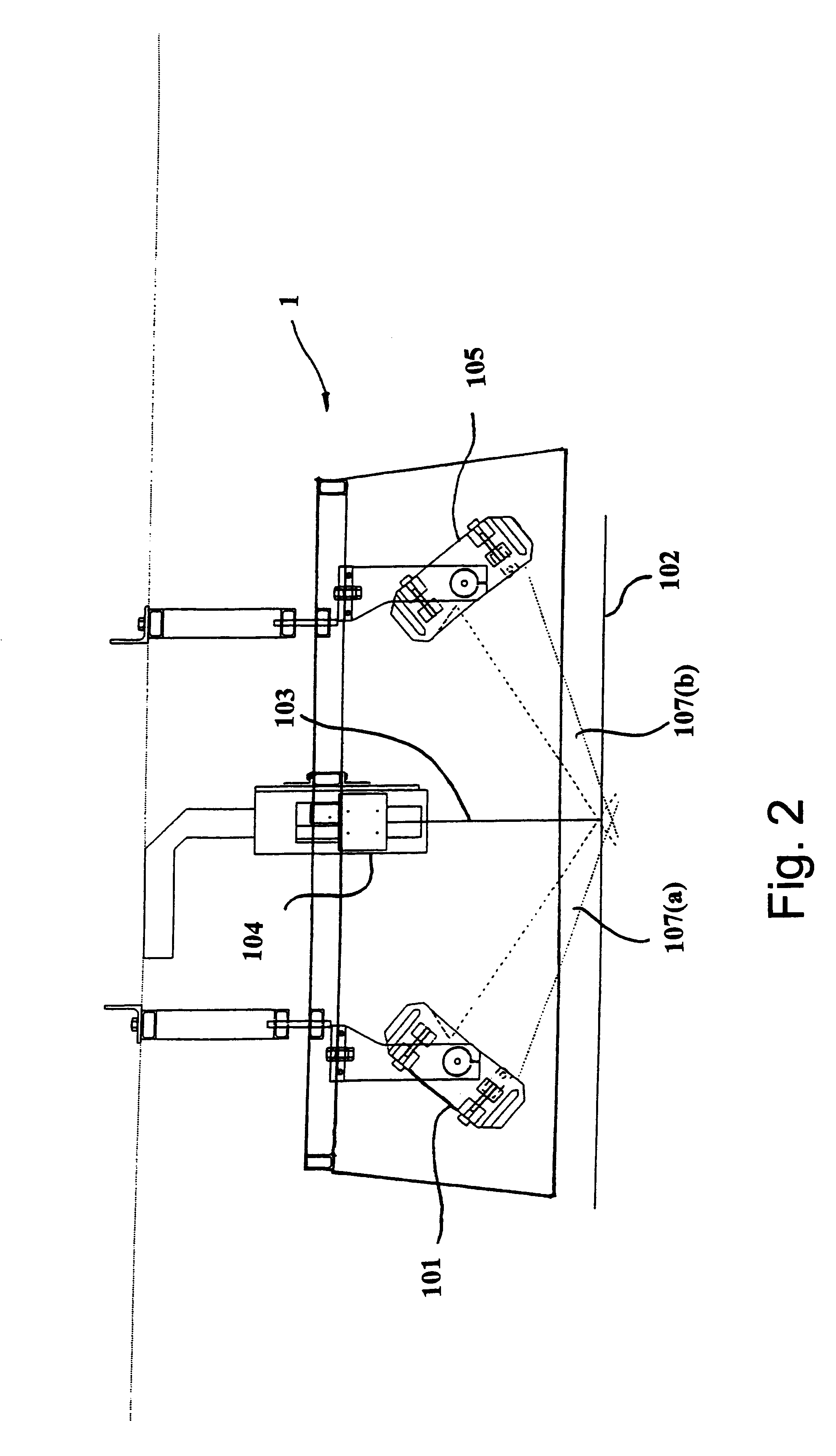

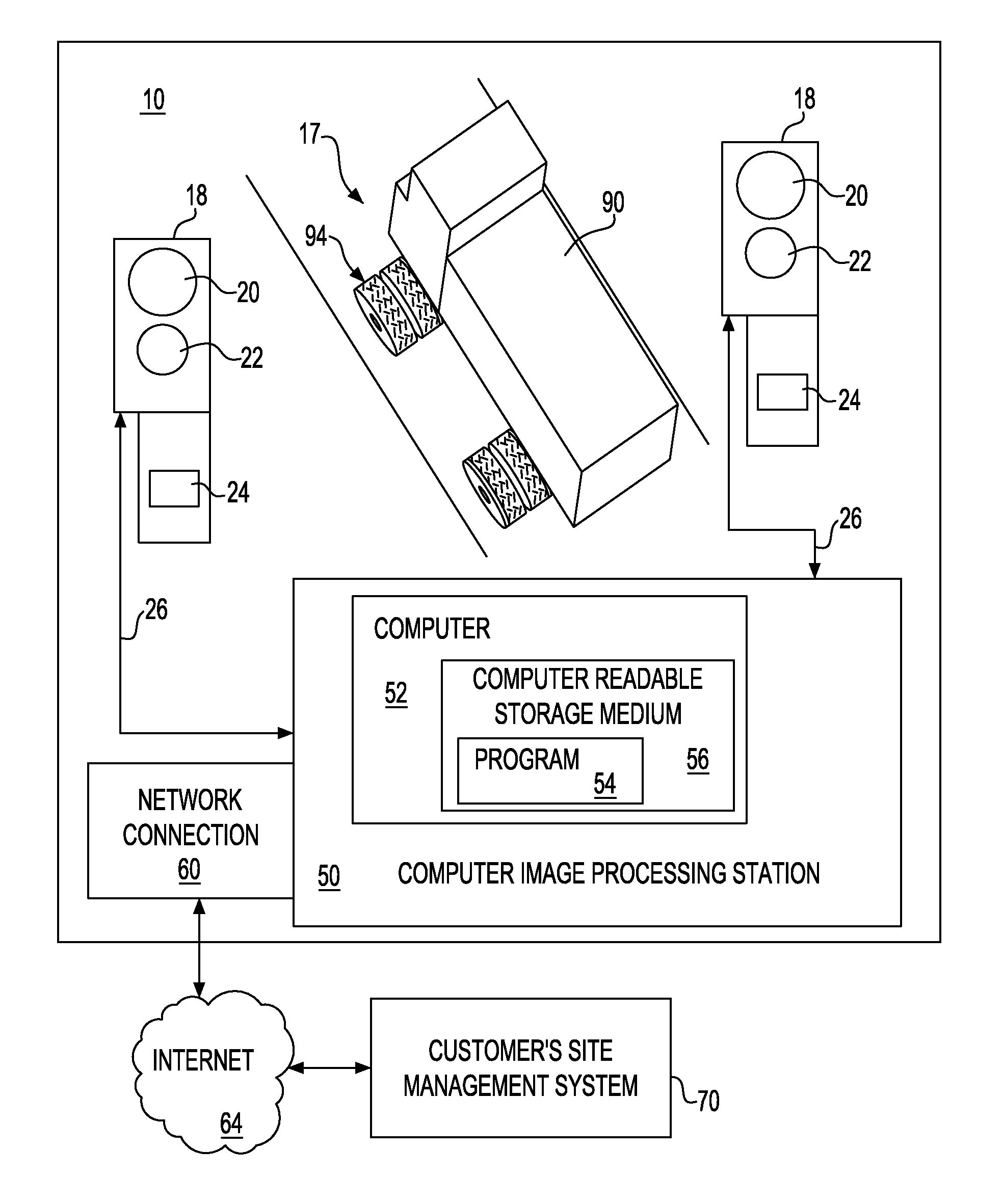

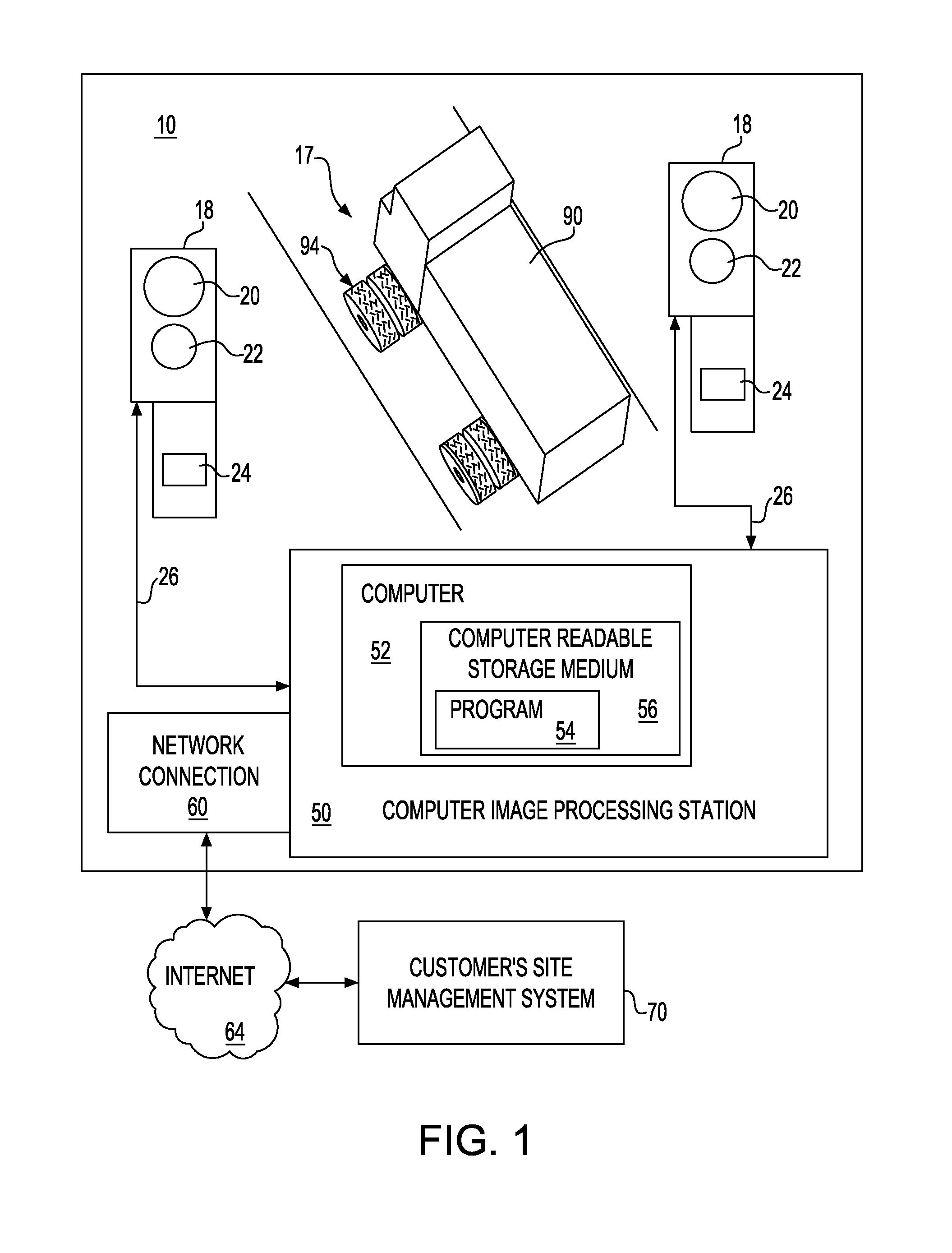

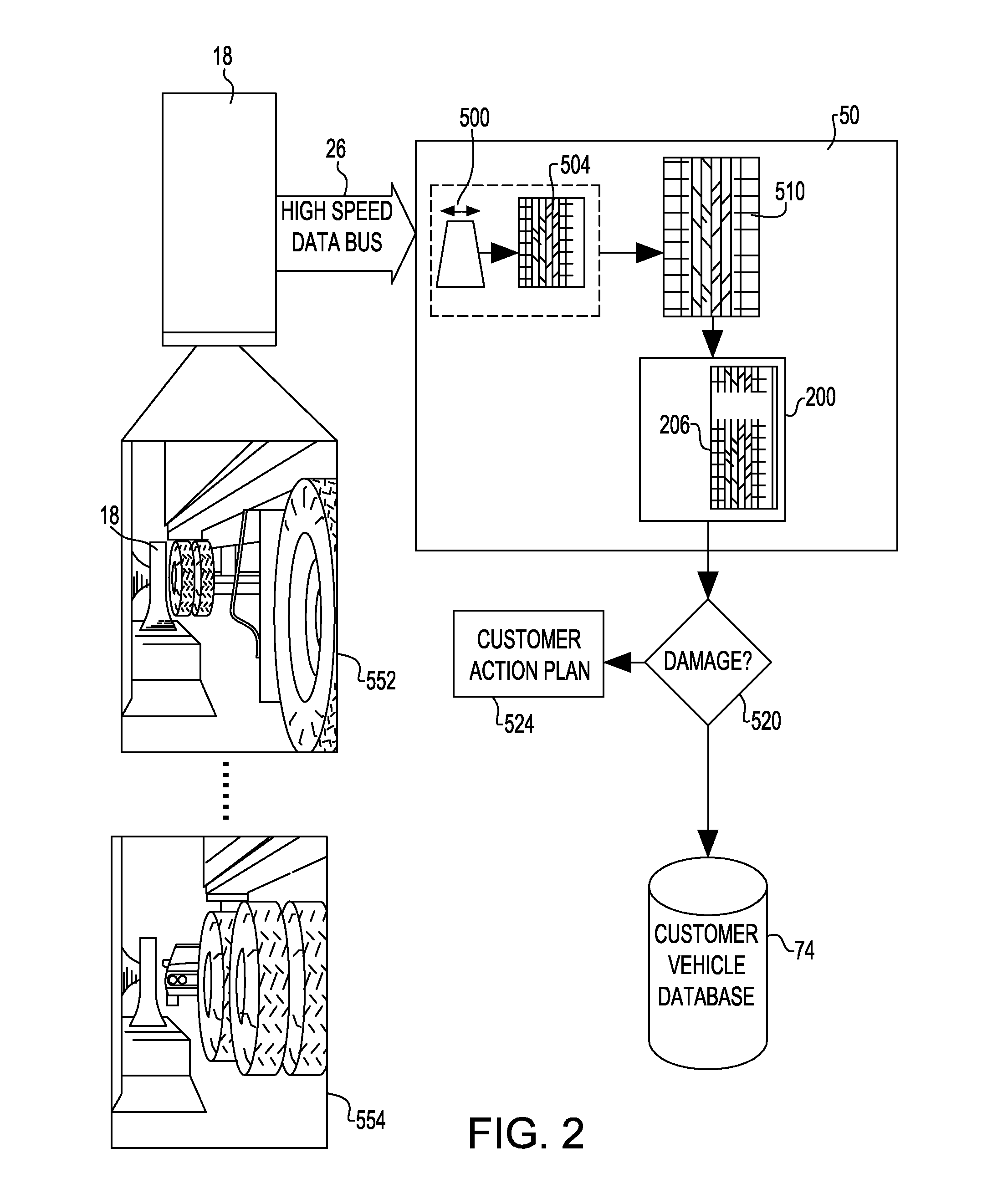

Computer vision aided automated tire inspection system for in-motion inspection of vehicle tires

A system and method related thereto, for automatically inspecting at least one tire of a moving vehicle. The system includes an image acquisition device including at least one camera. The camera acquires multiple real-time images of at least one tire of a moving vehicle. As the tire of the vehicle enters a field of view of the camera, the camera component is configured to photograph and transmit the multiple photographs of the at least one tire. A light source illuminates the at least one tire of the vehicle in the field of view of the camera, and the light application may be synchronous with the imaging performed by the camera. A computer image processing component receives the multiple images transmitted from the camera and analyzes the multiple images using a detection program. The computer imaging processing component analyzing the photographs and provides an inspection analysis of each at least one tire.

Owner:NASCENT TECH

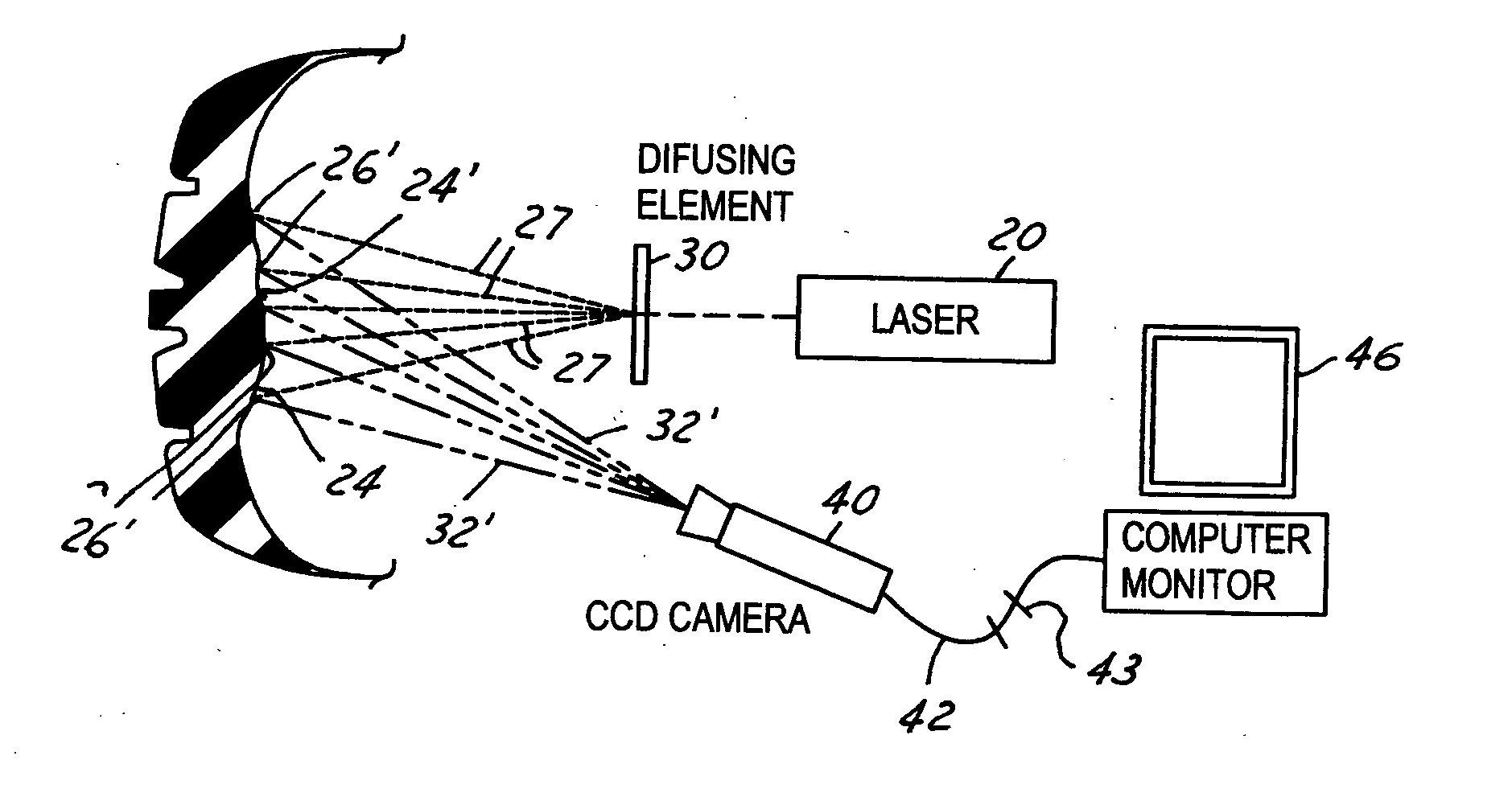

Tire inspection apparatus and method

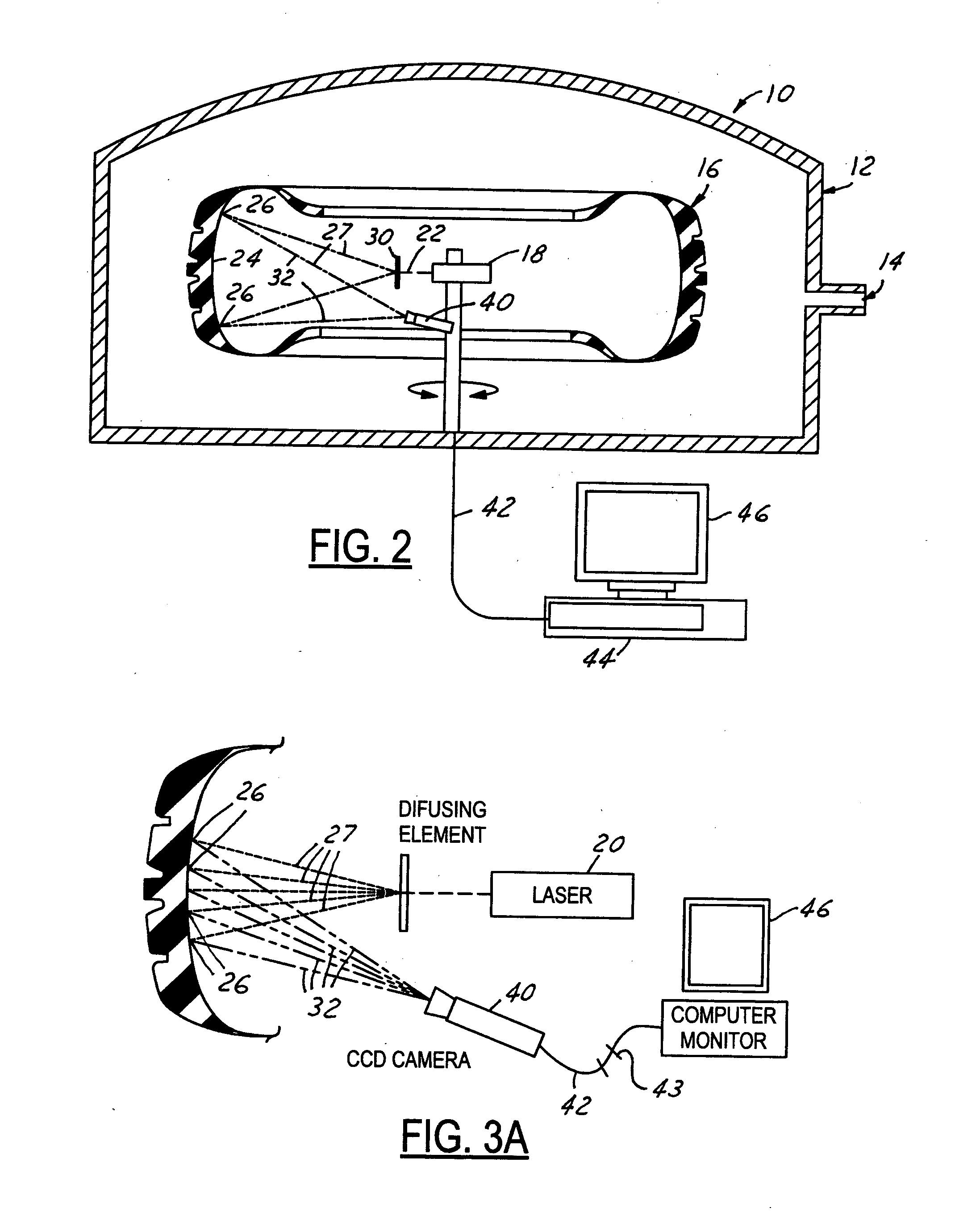

InactiveUS20050052637A1Inflated body pressure measurementForce measurement by measuring optical property variationAnomaly detectionOptics

Described is an anomaly detector apparatus 10 for detecting an anomaly in a tire comprising: a source of coherent light 18 to shine the light 27 directly onto the tire surface 24 and the light being reflected 32 from the tire; a stressing apparatus 12 which can stress the tire; a reflected light receiving apparatus 40 for receiving the light 32 reflected directly from the tire surface 24 when the tire is in a stressed and unstressed condition; a processor 44 which compares images of reflected light from the reflected light receiving apparatus 40 when the tire is stressed and unstressed thereby ascertaining an anomaly in the tire and generates an output from the comparison; and a display apparatus 46 electronically connected to the processor for displaying the output from the processor.

Owner:RAVEN ENG

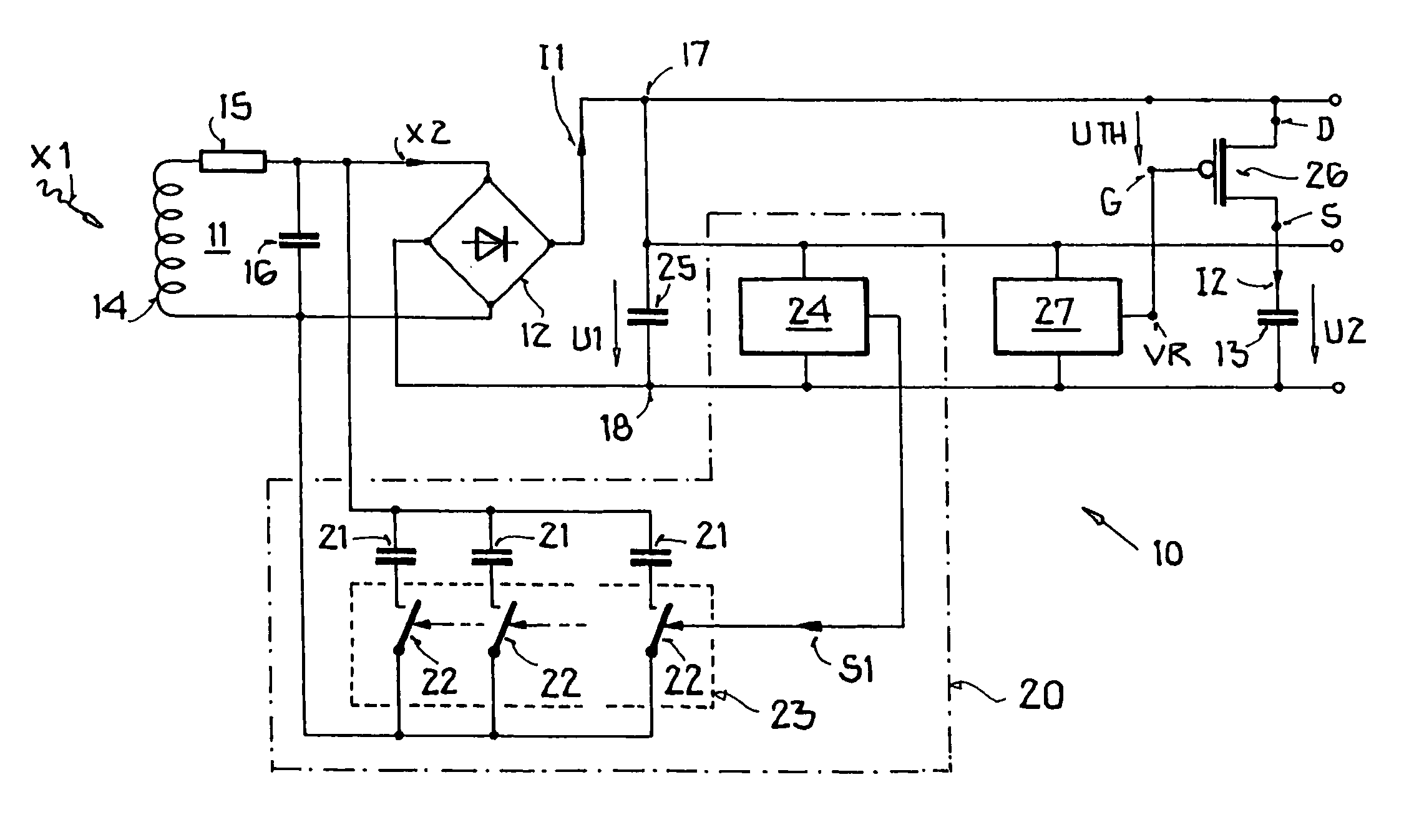

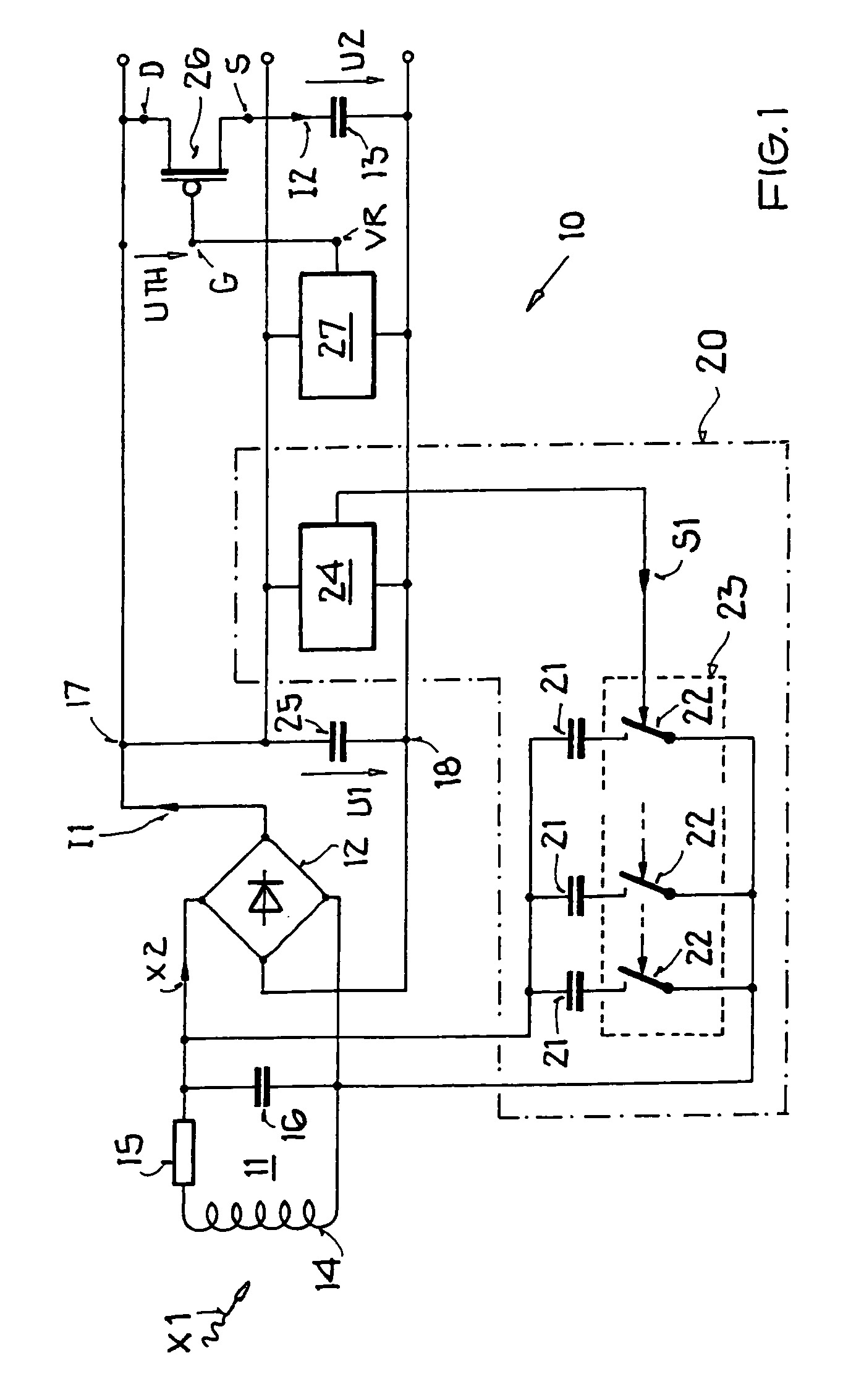

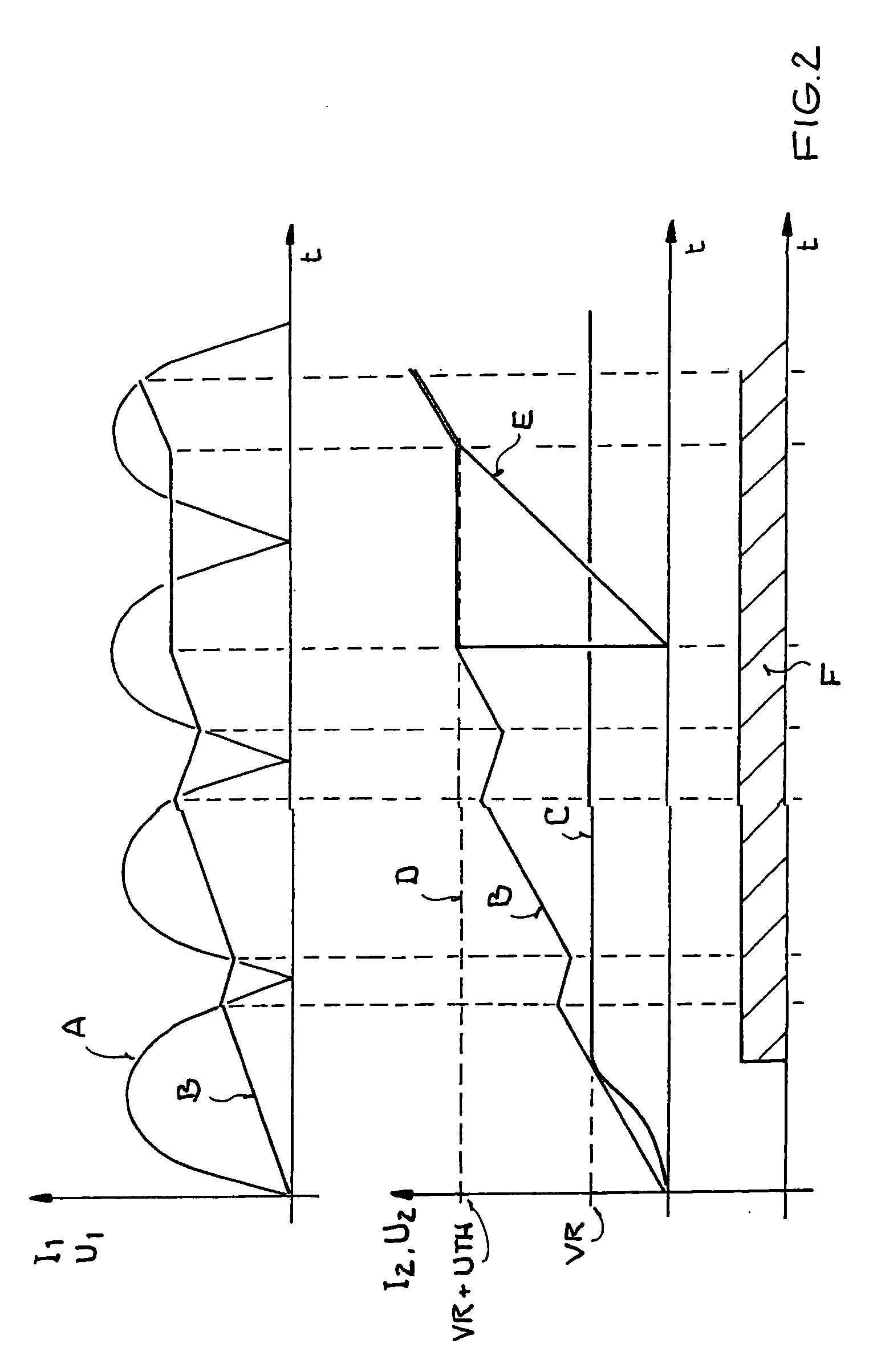

Circuit arrangement and method for supplying power to a transponder

ActiveUS20060187049A1Fast chargingMinimum charge timeTyre measurementsRoads maintainenceResonanceEngineering

A circuit arrangement is provided for a power supply to a transponder including an antenna resonant circuit and a downstream rectifier circuit for receiving and for rectifying an electromagnetic signal, a charging capacitor connected downstream on the output side of the rectifier circuit to provide a first supply voltage, with a tuning circuit for tuning the antenna resonant circuit to its resonance frequency, and with an auxiliary voltage source, which is designed to provide a second supply voltage, lower than the first supply voltage, for supplying the tuning circuit. A method is also provided for supplying power to a transponder with a first supply voltage, as well as a transponder having a circuit arrangement for a power supply.

Owner:ATMEL CORP

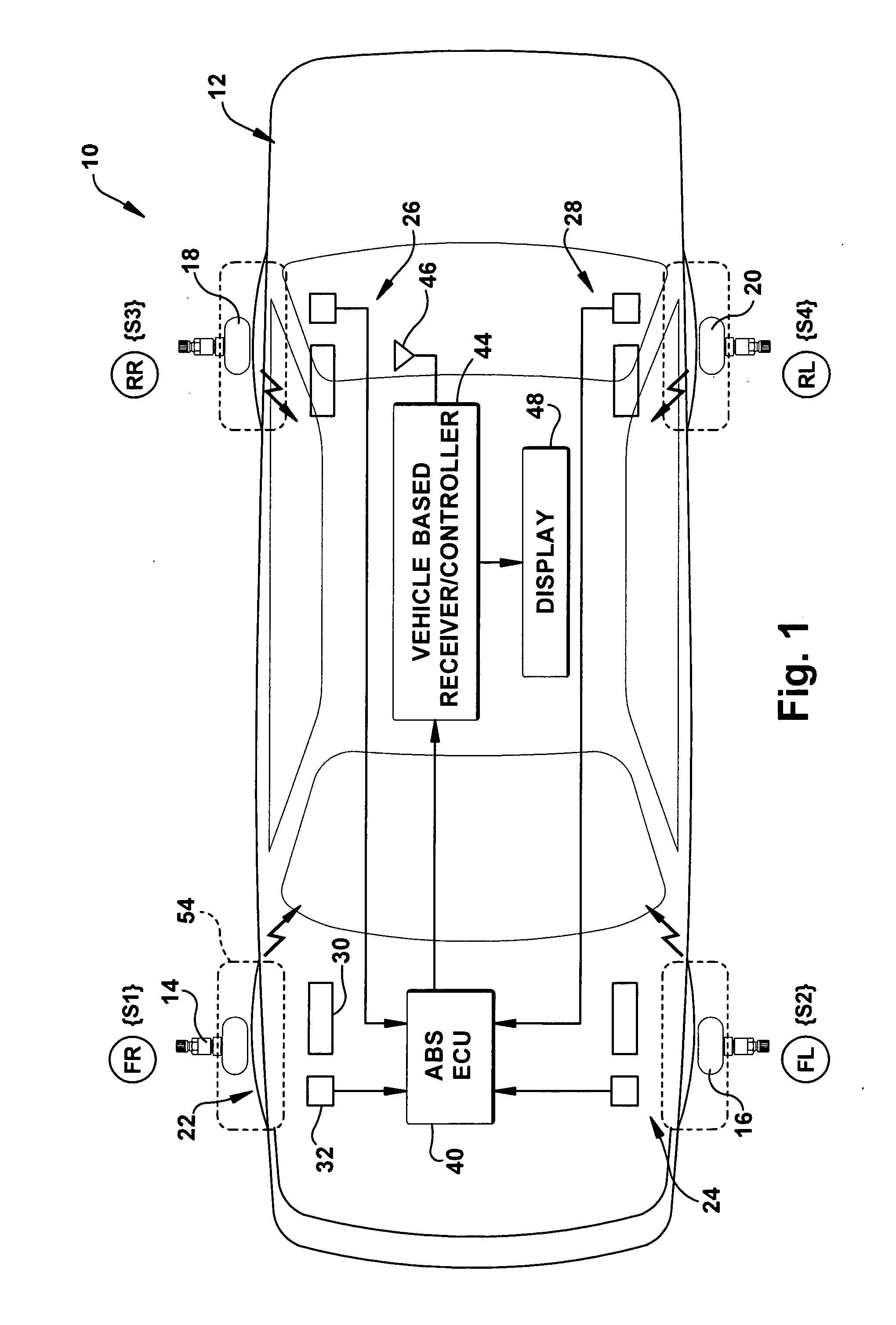

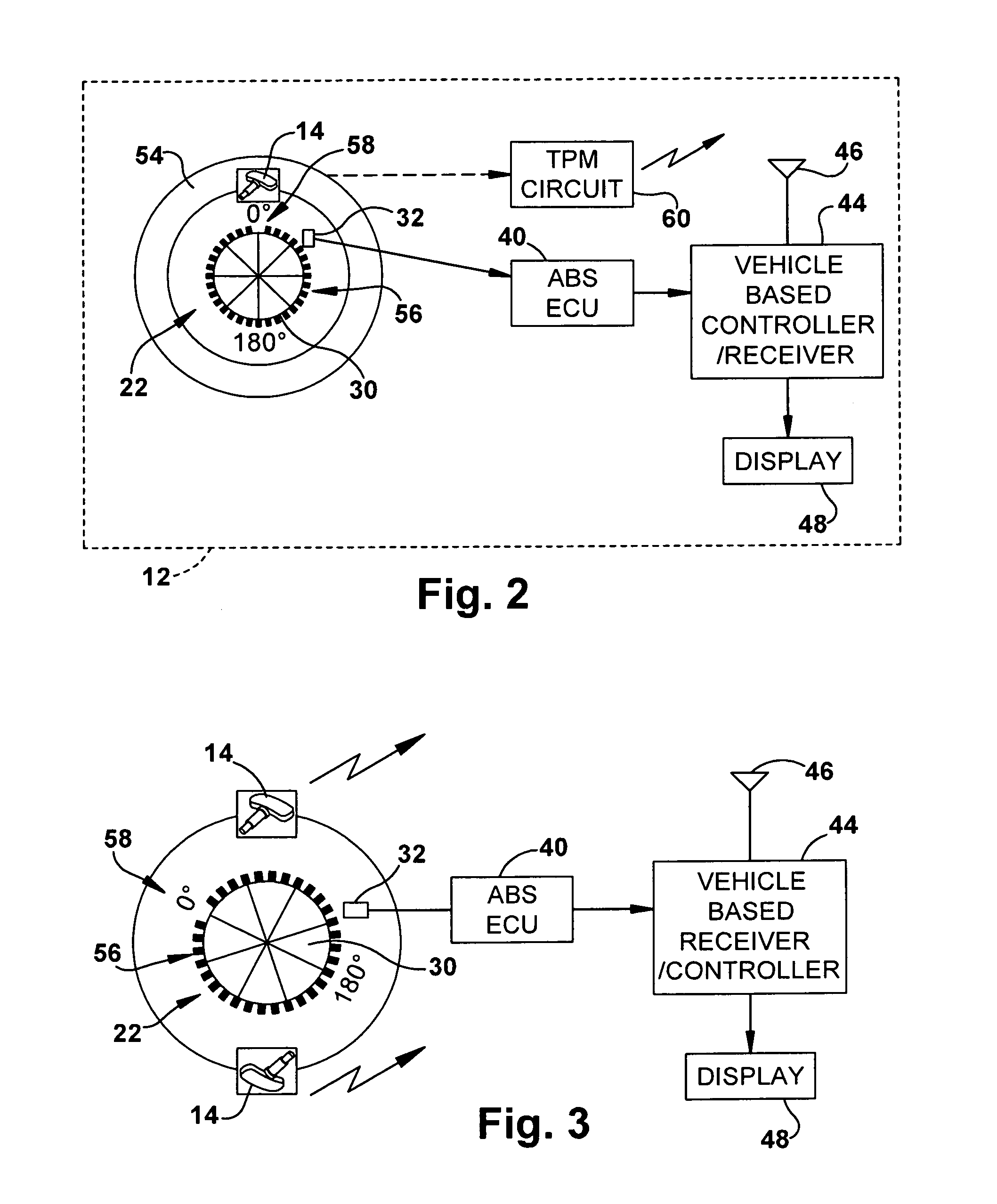

Method and apparatus for determining tire condition and location

An apparatus (10) determines a tire condition and location on a vehicle (12) including a tire-based sensing unit (14), a plurality of tires (54) on the vehicle having an associated tire-based sensing unit, each tire-based sensing unit (14) including, a first tire rotation sensor (66) mounted for rotation with the tire (54) and for providing a first tire rotation signal (80) each time the tire passes one of at least two predetermined rotational positions during tire rotation, a tire condition sensor (82) for sensing a tire condition and for providing a tire condition signal indicative thereof and an unique tire identification indicator, a transmitter (86) for transmitting the tire condition signal and the unique tire identification indicator, and a controller for controlling the transmitter so that the transmission of the tire condition signal and the unique tire identification indicator occurs when the first tire rotation signal indicates the tire has reached one of the at least two predetermined rotational positions during tire rotation. The apparatus further includes a second tire rotation sensor (22) mounted external of the tire for sensing tire rotation and for providing a second tire rotation signal indicative of incremental angular position of the tire relative to a reference. A vehicle-based receiver (44) receives the transmitted tire condition signal, the unique tire identification indicator, and the second tire rotation signal and correlates reception of the tire condition signal with the second tire rotation signal so as to associate the unique tire identification indicator with a particular tire location on the vehicle.

Owner:TRW AUTOMOTIVE US LLC

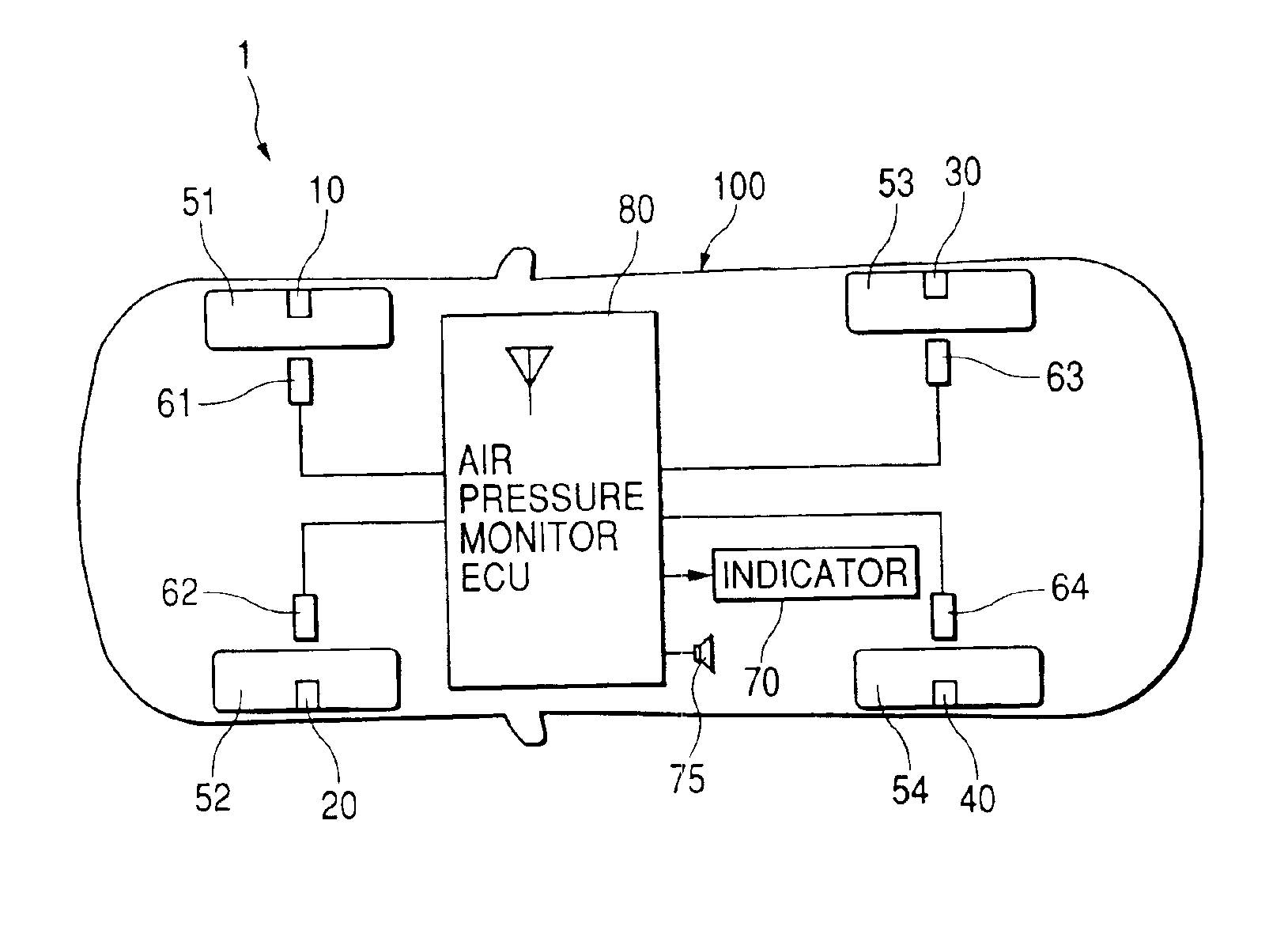

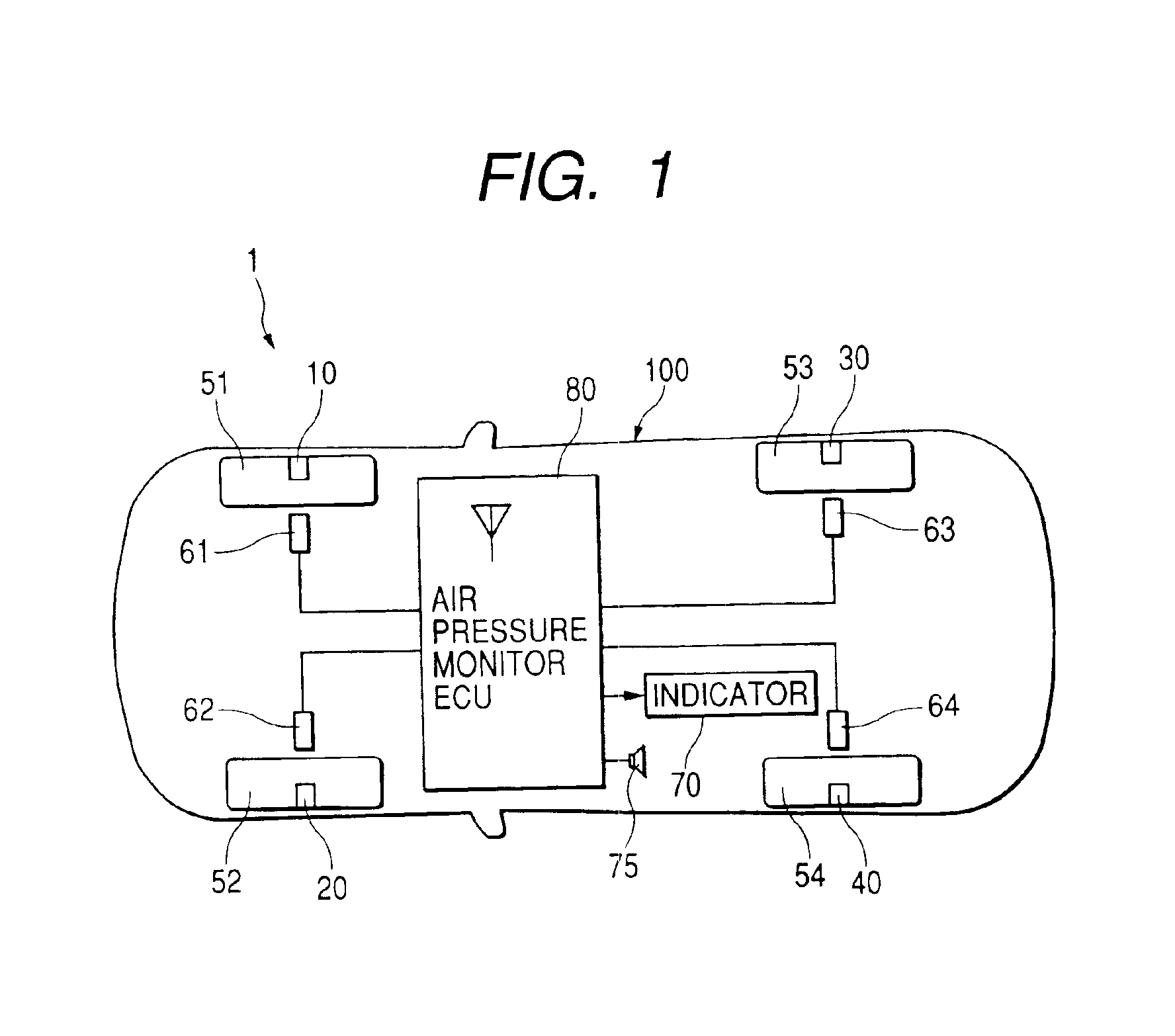

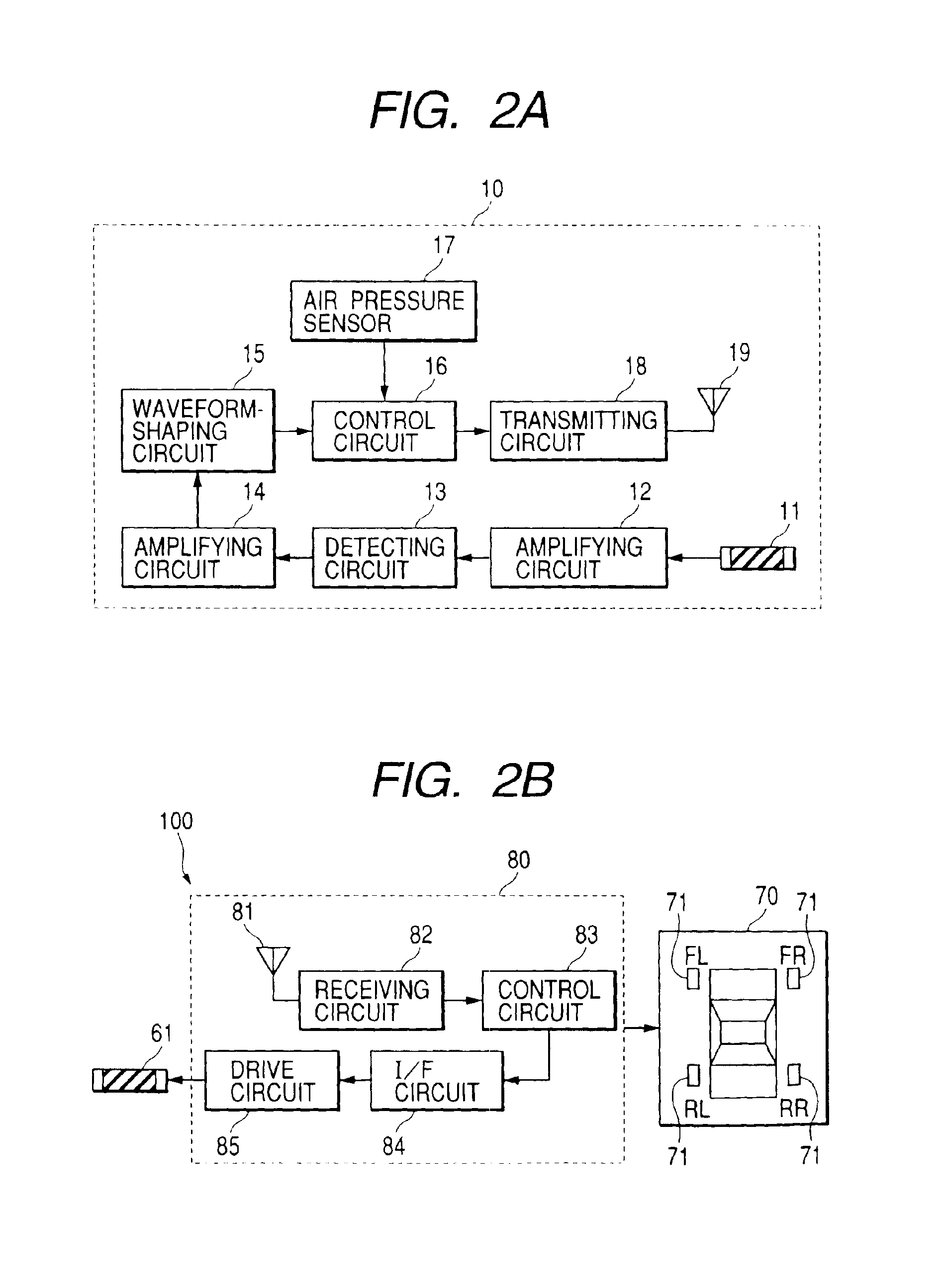

Tire air pressure monitoring system

ActiveUS6885293B2Reduce power consumptionInflated body pressure measurementTransmission systemsMonitoring systemTire rotation

Provided is a tire air pressure monitoring system capable of grasping the tire positions where there are sensor units even in the case of tire rotation. In the tire air pressure monitoring system, a trigger signal is transmitted from a transmission coil antenna to only the corresponding sensor unit in a manner such that a magnetic field is used as a medium and, upon receipt of the trigger signal, the sensor unit measures a tire air pressure and others and transmits a transmission signal including the measurement values to a monitoring unit. The monitoring unit makes a decision on the tire position where there is the sensor unit on the basis of the transmission signal from the sensor unit.

Owner:DENSO CORP

Gravimetric rotation sensors: dead reckoning, velocity, and heading sensor system for vehicle navigation systems

InactiveUS6466887B1Less importantHigh precisionInstruments for road network navigationAcceleration measurement using interia forcesAccelerometerIn vehicle

A rotational sensor for use with an in-vehicle navigation system , a navigation system that uses the sensor, and a vehicle with the sensor installed. The rotational sensor is created by placing two gravitational accelerometers configured at 90 degrees with respect to one another and mounted at the center of a vehicle wheel. As this resulting sensor is rotated, sine and cosine signals with a quadrature relationship are generated with respect to the earth's gravity vector, from which both rotation and direction of rotation can be determined. These signals may then allow the counting of the turns of the wheel, thus estimating the distance and the rate at which the vehicle has moved. A self-contained version of this device including a transmitter can relay this information to a receiving unit located within the vehicle. When one of these devices is located on each of the steerable wheels of the vehicle, the relative heading-direction of the vehicle may also be estimated.

Owner:WEINBRENNER RICHARD L

Popular searches

Burglar alarm by hand-portable articles removal Optically investigating flaws/contamination Counting objects with random distribution Electric digital data processing Profile tracing Hardware monitoring Automatic initiations Vehicle position/course/altitude control Special data processing applications Position/direction control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com