Patents

Literature

232 results about "Wear Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

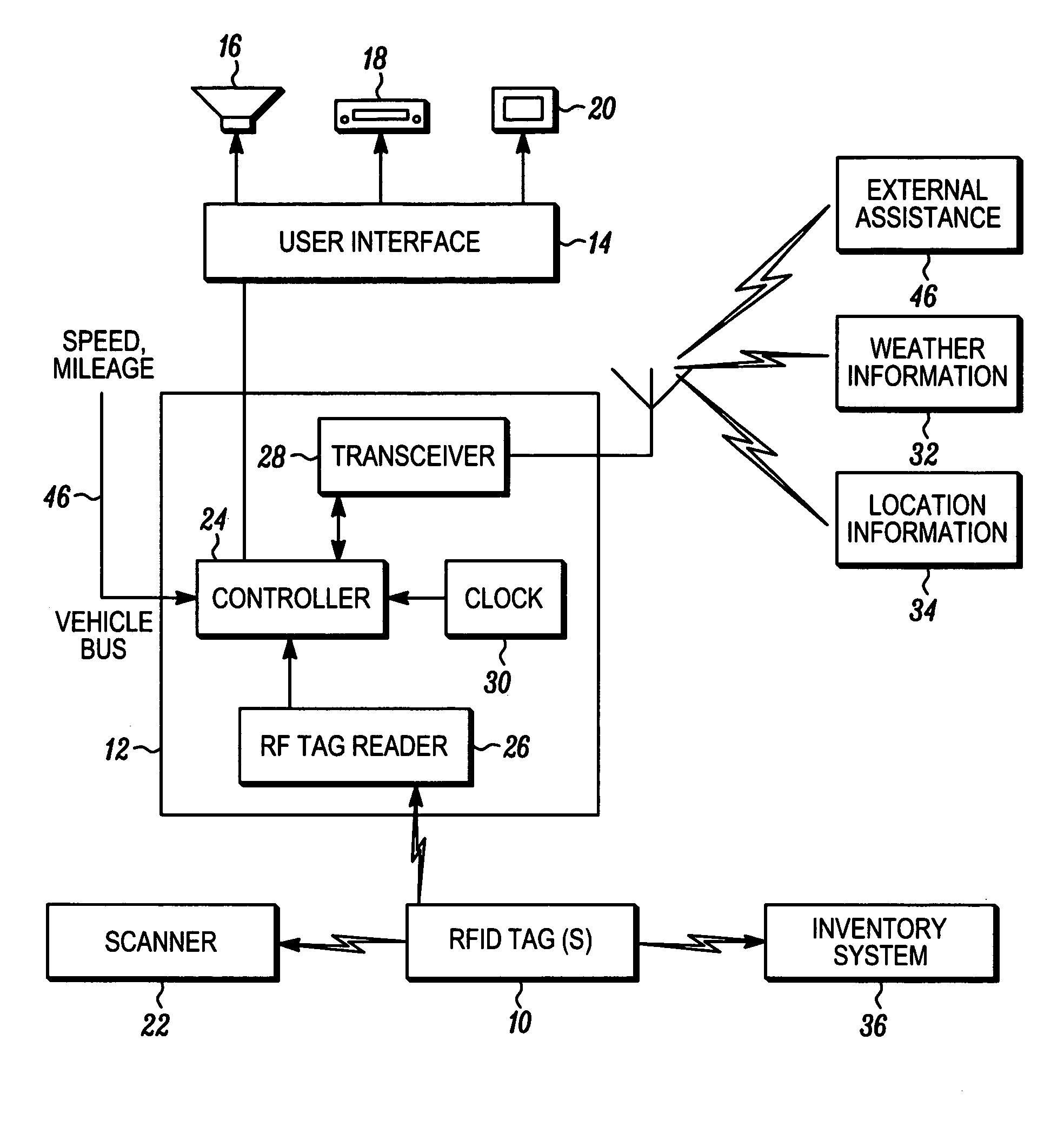

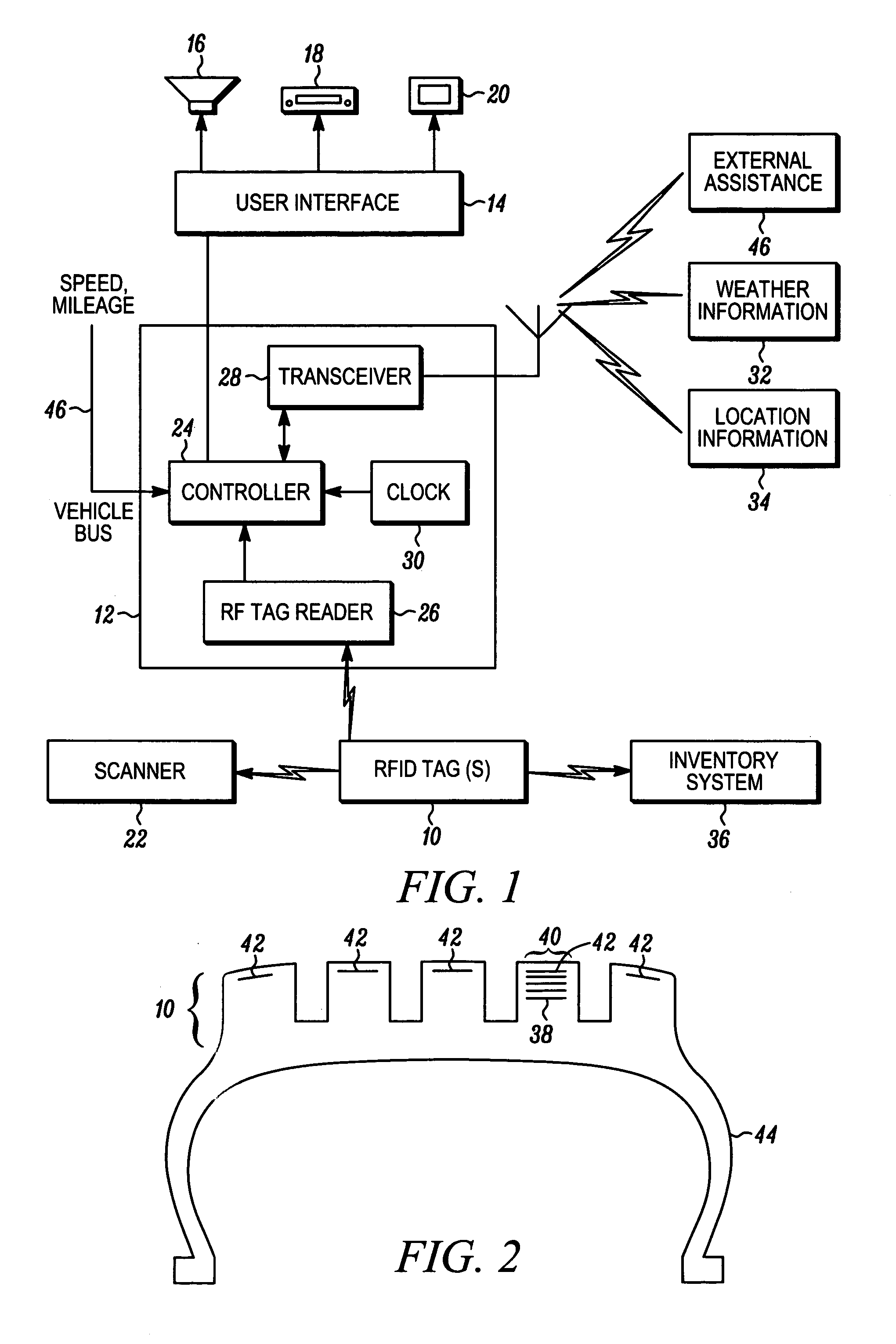

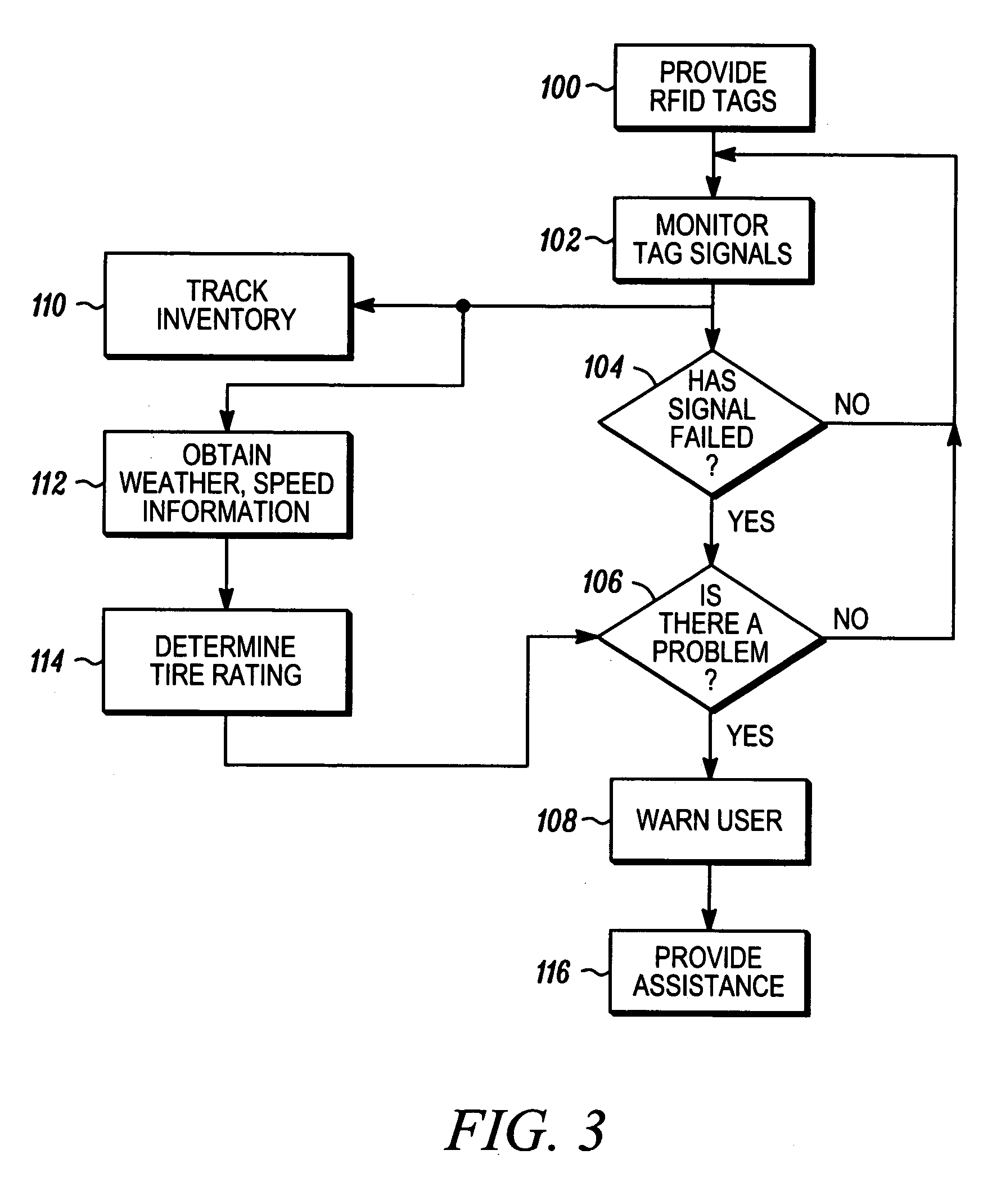

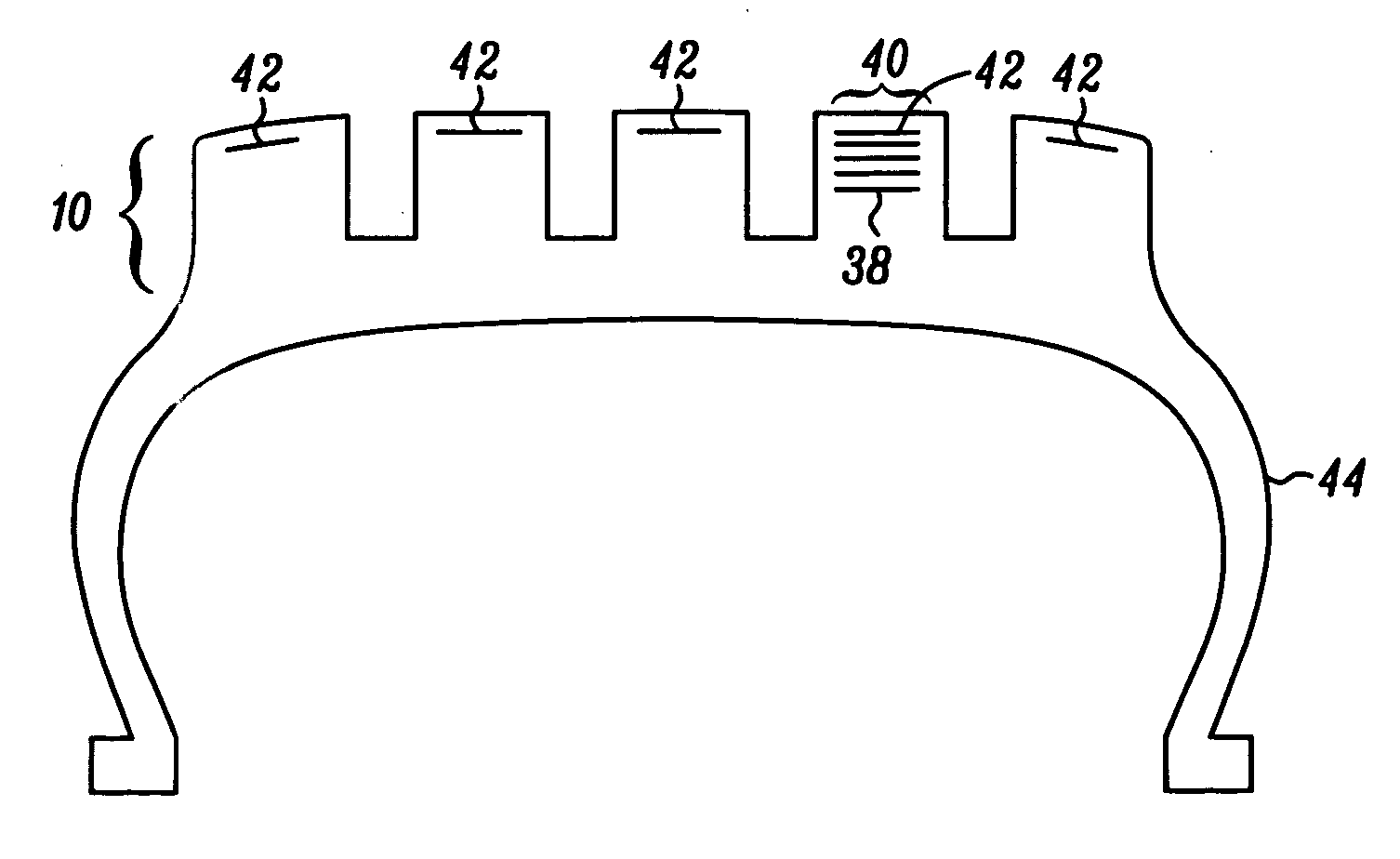

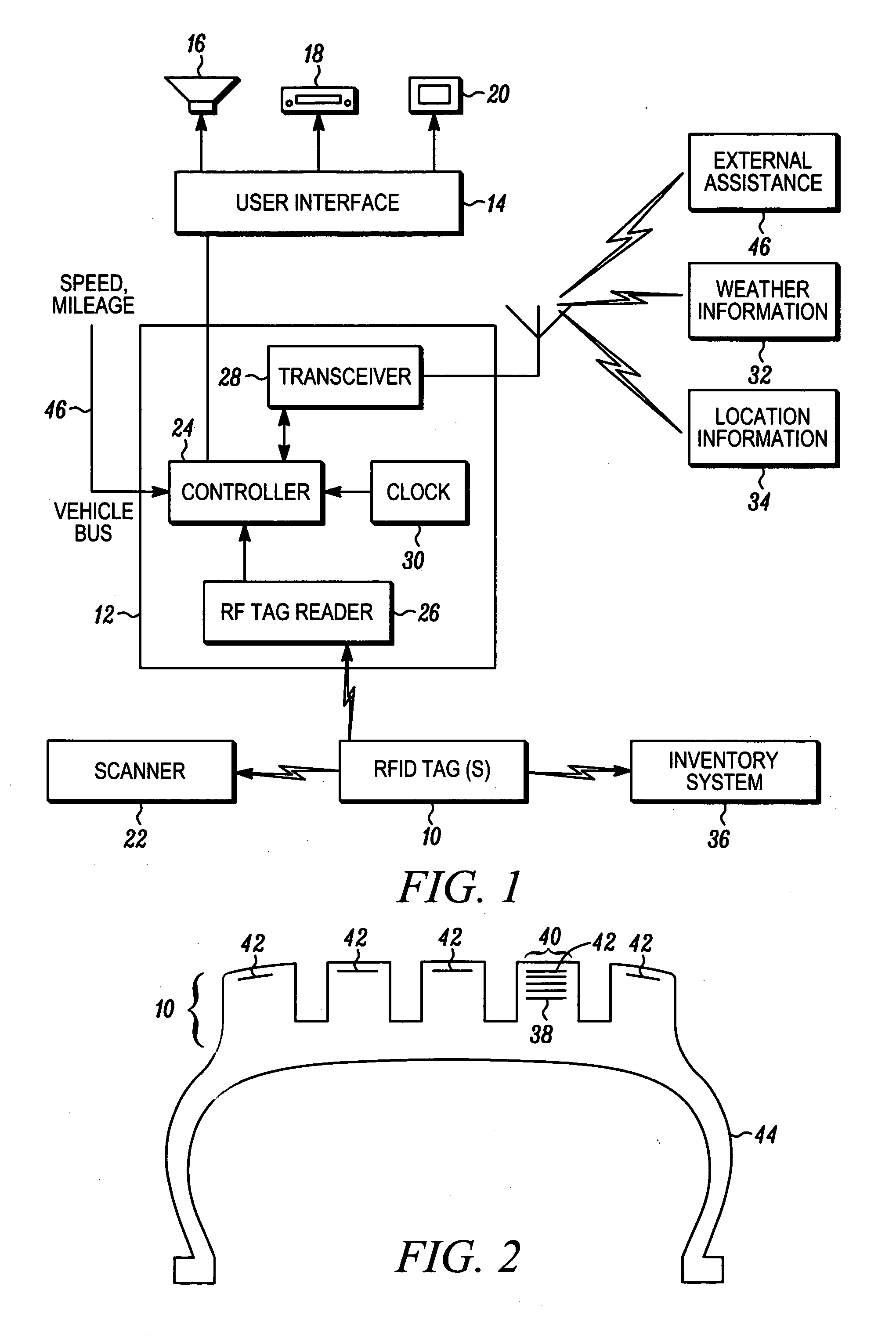

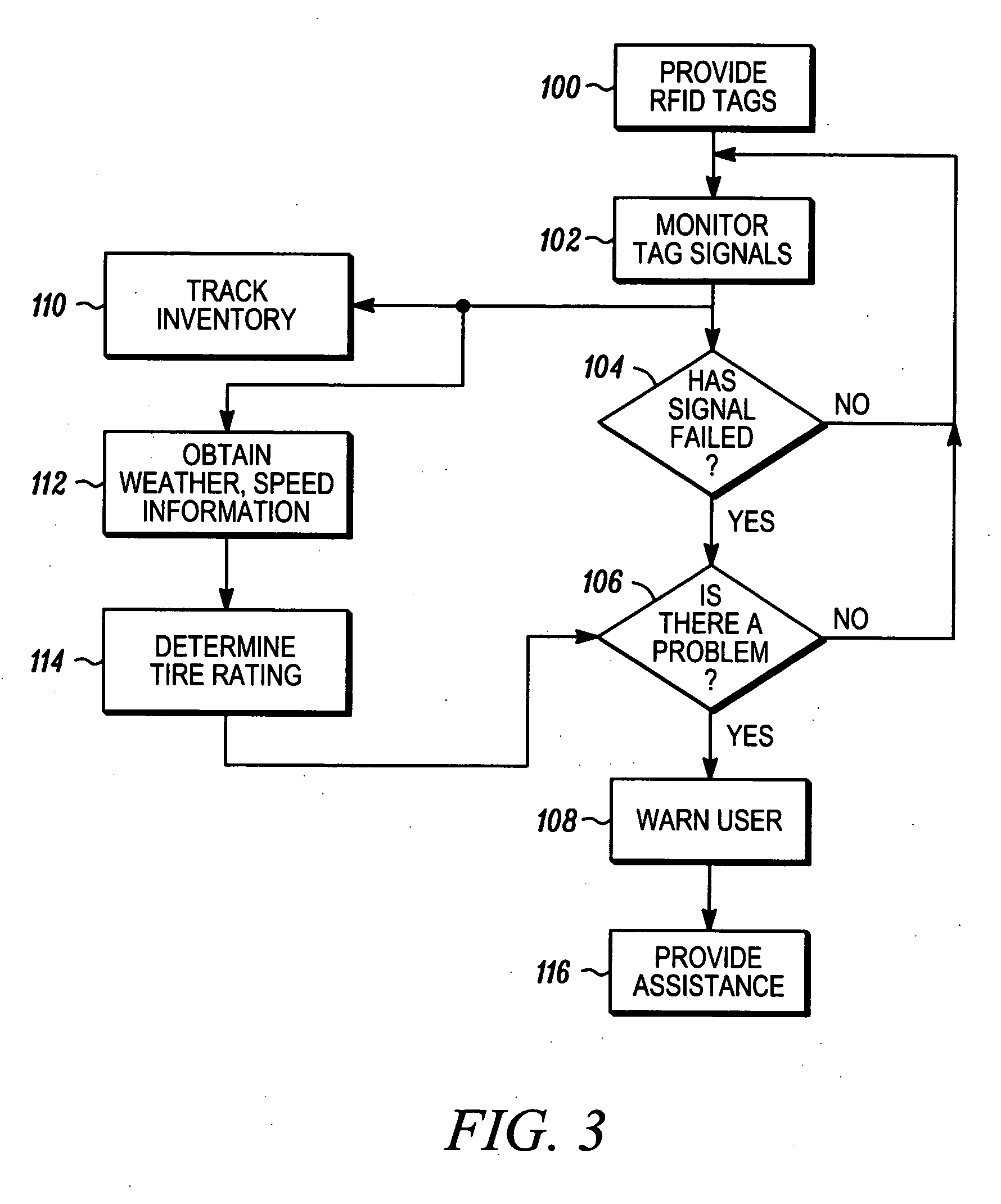

Tire tread wear sensor system

A system and method for monitoring belt wear or tread wear of a tire includes at least one radio frequency identification (RFID) tag with unique identification embedded in the belt or tread of the tire at one or more wear points. An RF tag reader periodically monitoring signals from the at least one RFID tag. If the RF tag reader fails to obtain any signals from the at least one RFID tag, indicating a destroyed RFID tag, the user can be warned about a wear problem of that belt or tire. RFID tags can be distributed at different depths of the tire(s), or across the tread at the same depth, of the tire(s) to determine different wear problems. The same RFID tag can also be used for inventory tracking purposes.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Tire tread wear sensor system

A system and method for monitoring belt wear or tread wear of a tire includes at least one radio frequency identification (RFID) tag with unique identification embedded in the belt or tread of the tire at one or more wear points. An RF tag reader periodically monitoring signals from the at least one RFID tag. If the RF tag reader fails to obtain any signals from the at least one RFID tag, indicating a destroyed RFID tag, the user can be warned about a wear problem of that belt or tire. RFID tags can be distributed at different depths of the tire(s), or across the tread at the same depth, of the tire(s) to determine different wear problems. The same RFID tag can also be used for inventory tracking purposes.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

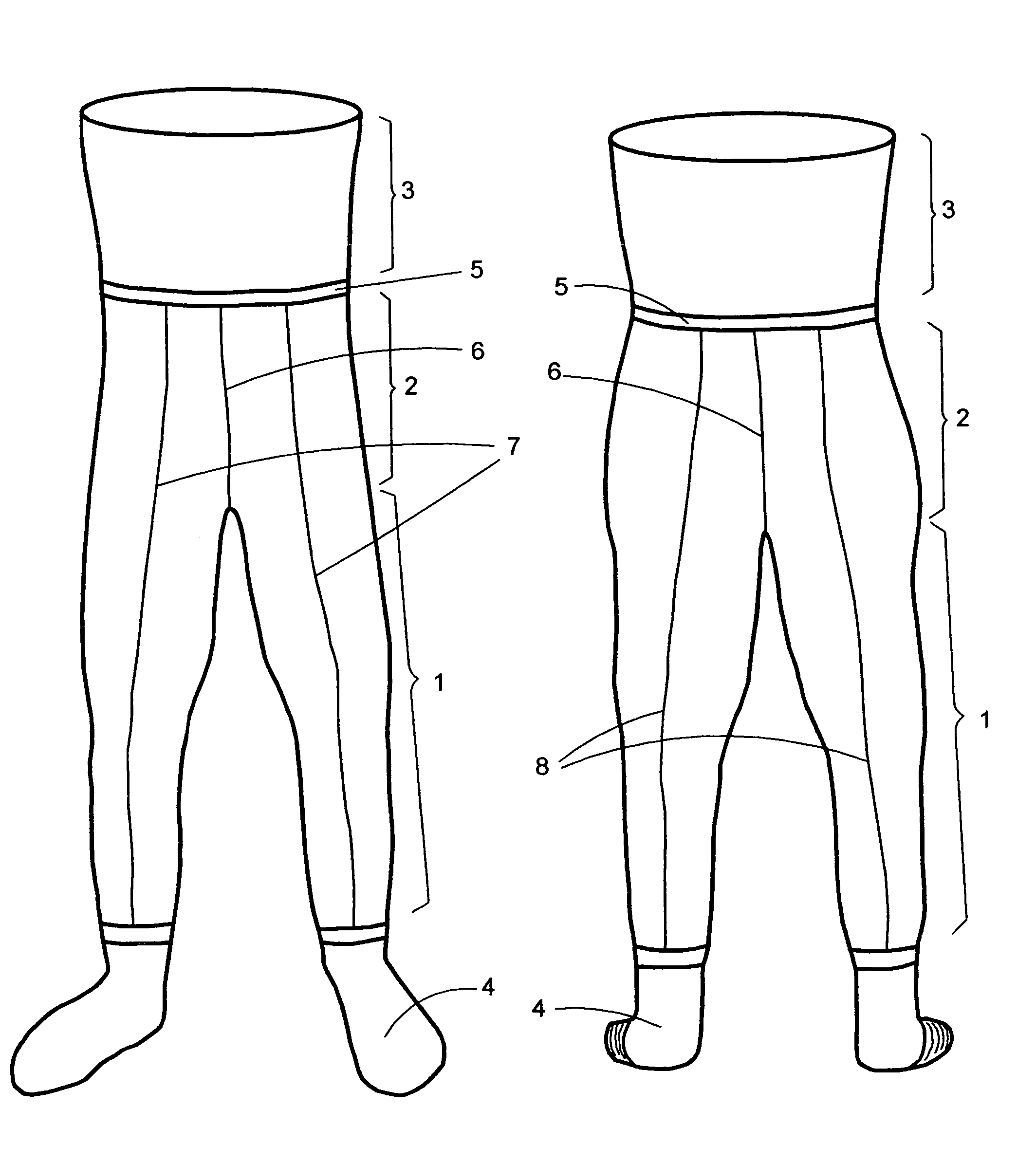

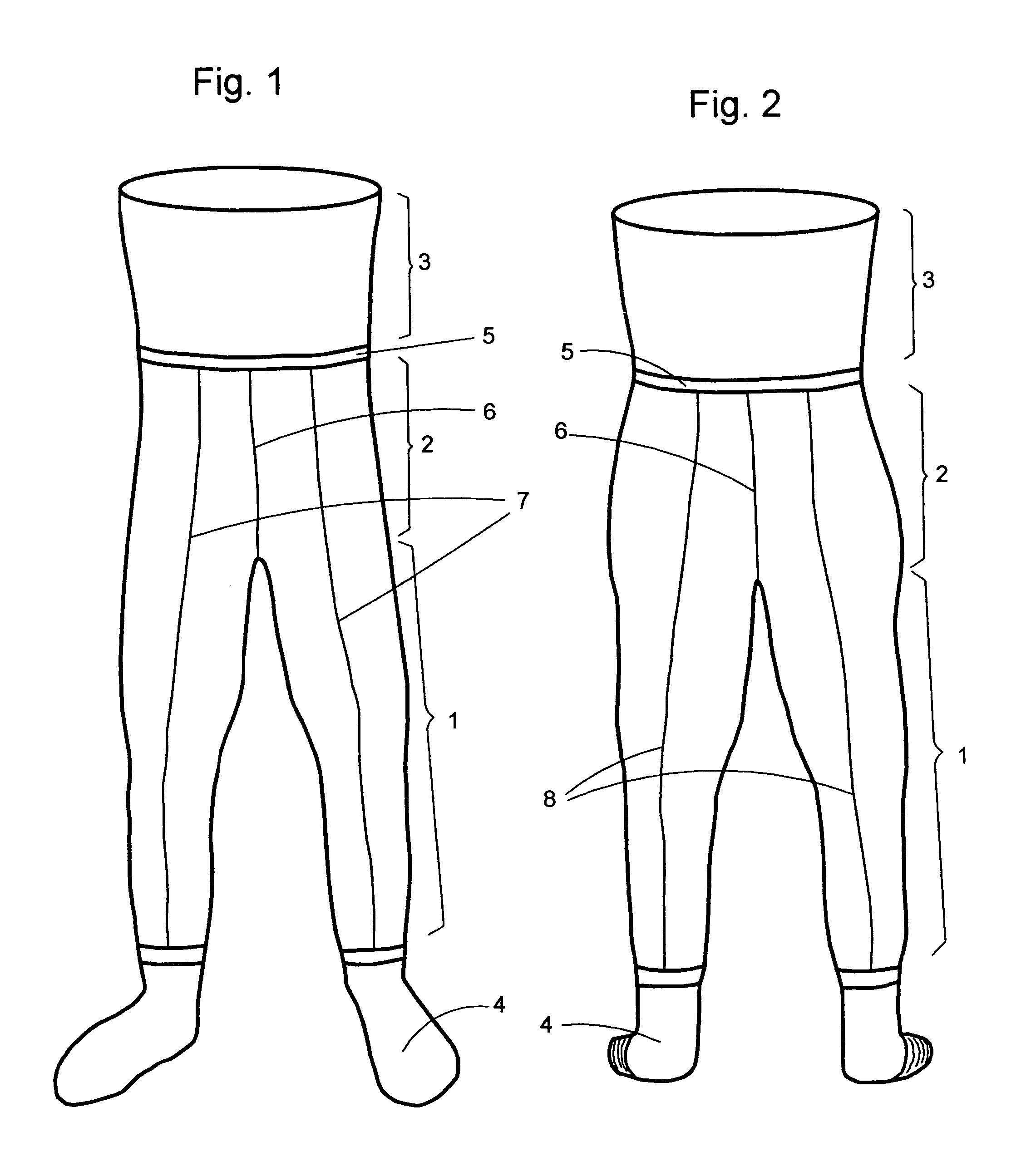

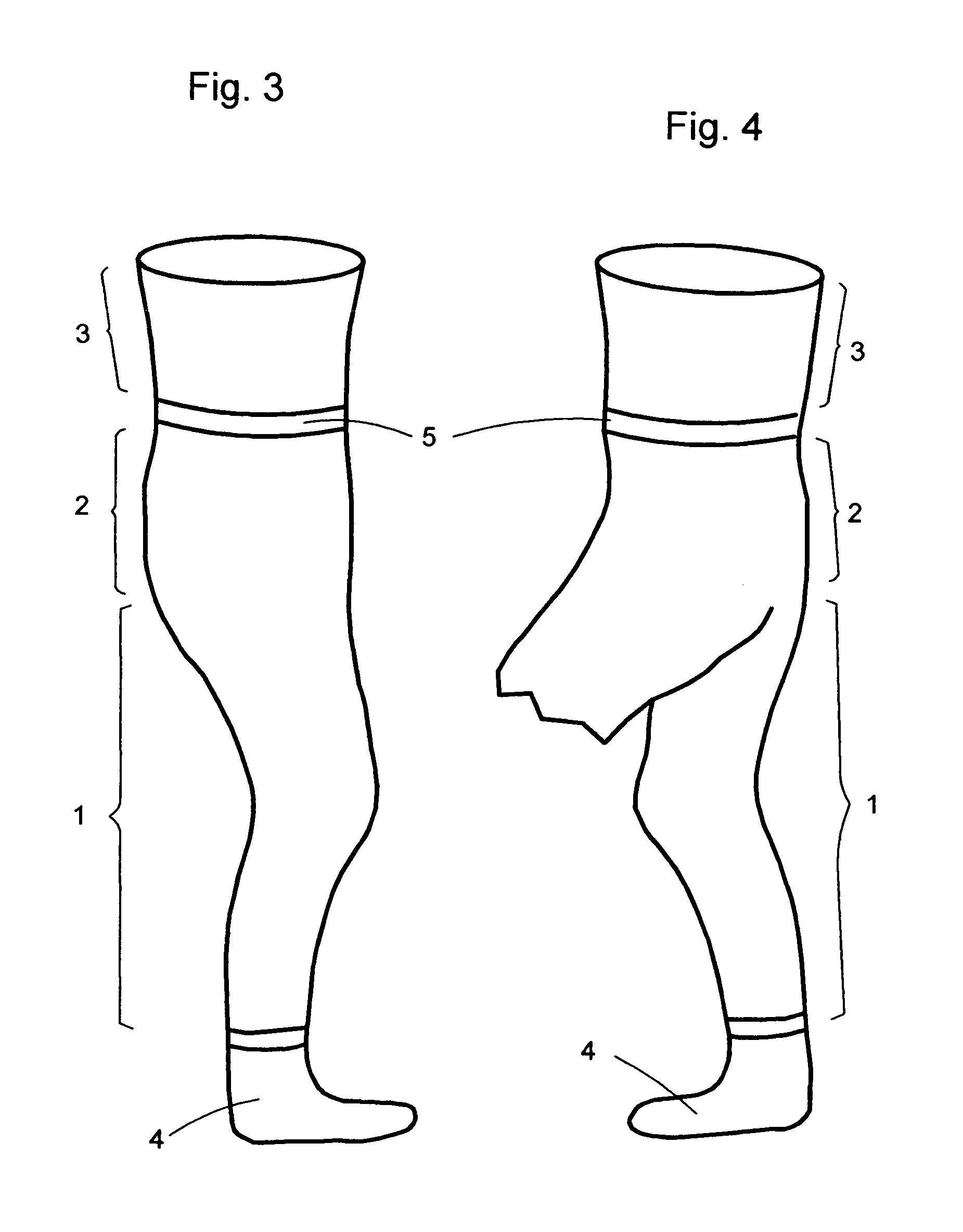

Pre-curved wader with front and back seams

A wader that is shaped to allow for ease of movement in the hip and knee areas and that has seams running vertically on the anterior and posterior sides of the leg portions. The wader is designed to alleviate discomfort caused by stiff seams and to address the problem of seam abrasion. The wader is made of breathable fabric, and the seams are sewn and sealed. The wader can include, optionally, a foot-covering device and a cinching device. In the preferred embodiment, the seams are sealed with a thermoplastic adhesive tape. A method of manufacturing the wader described above.

Owner:M BLENKARN DESIGN

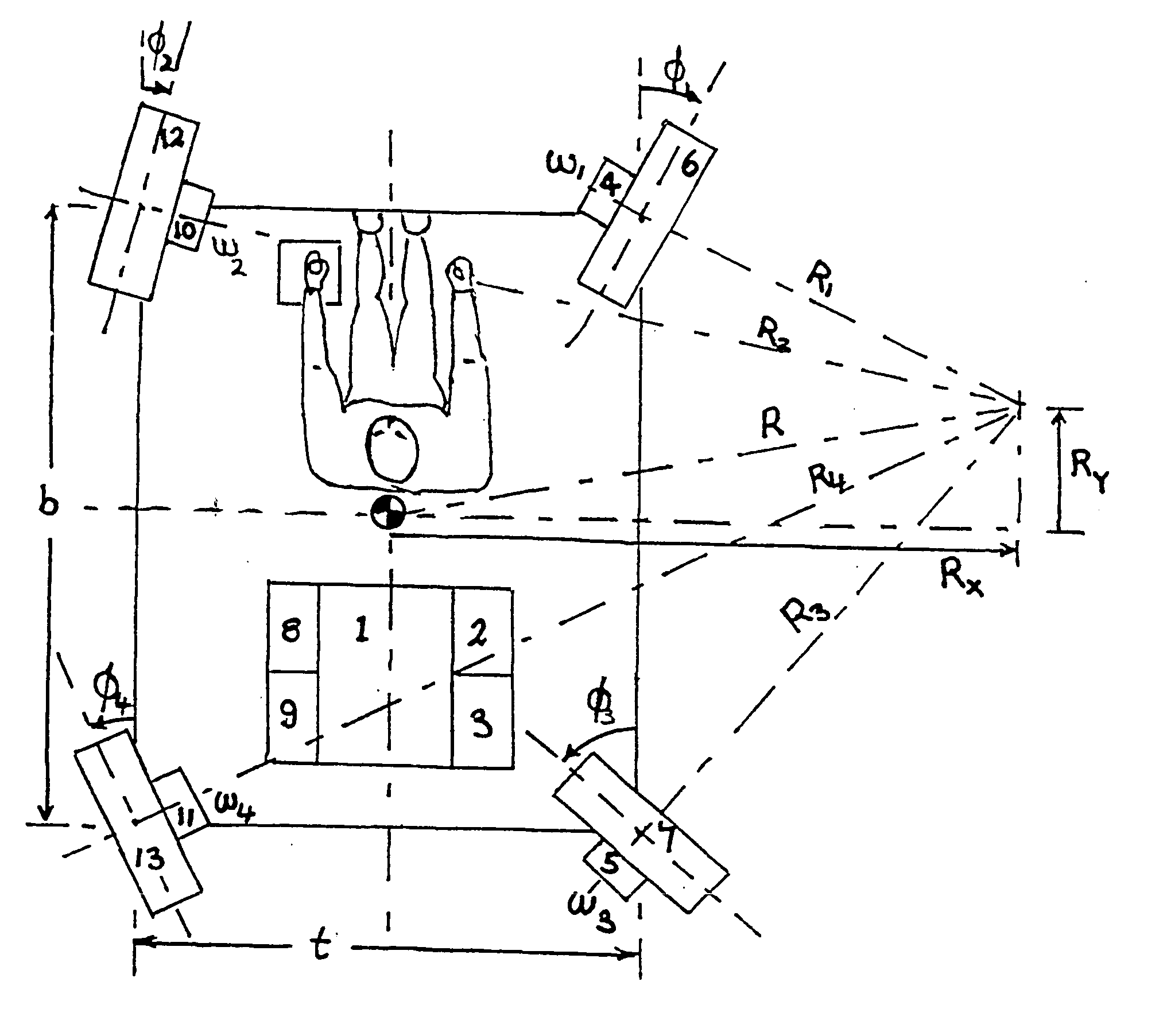

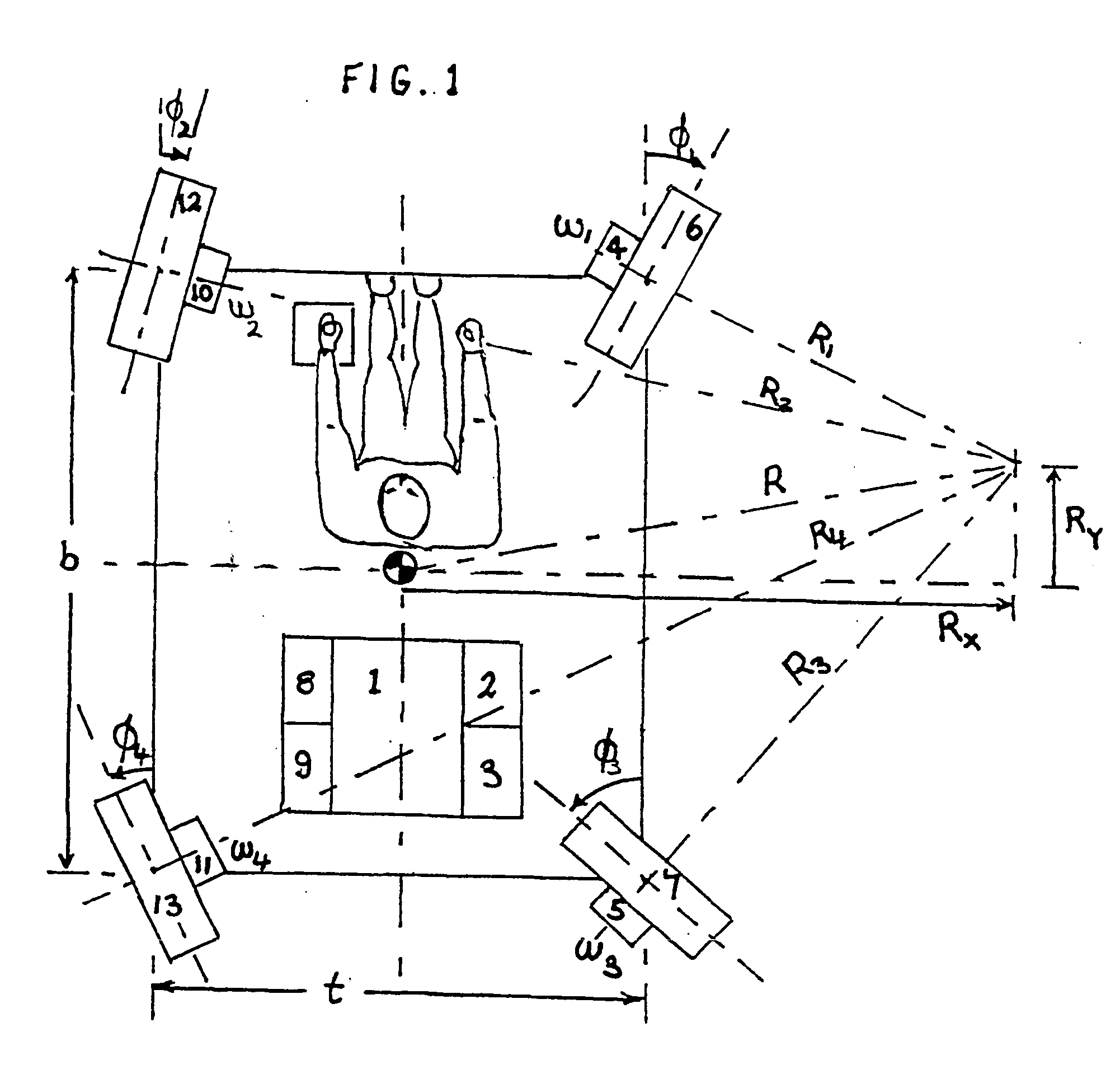

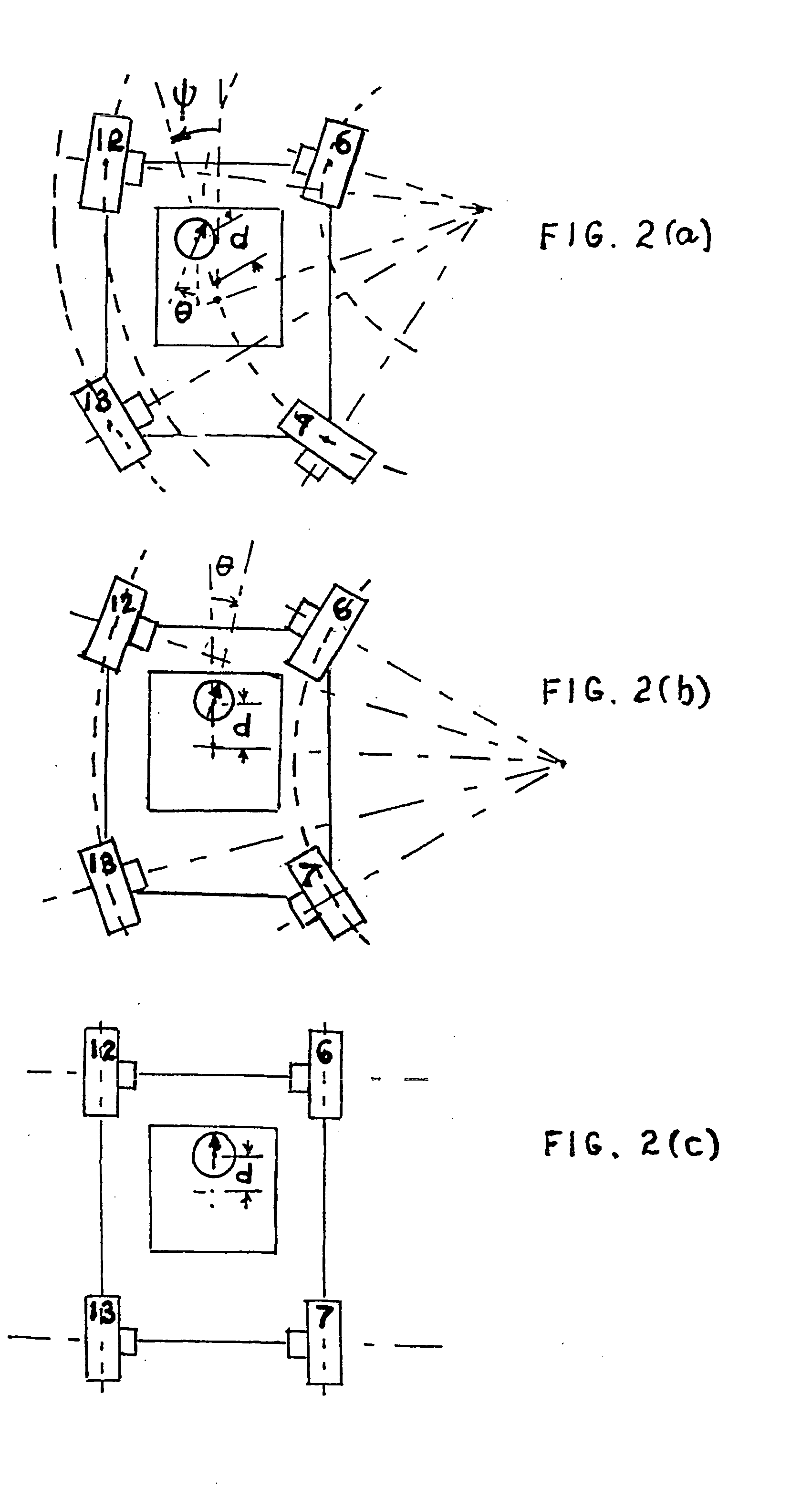

Off road vehicle

InactiveUS20040195013A1Maximises manoeuvrabilitySpeed controllerSteering linkagesEngineeringFood consumption

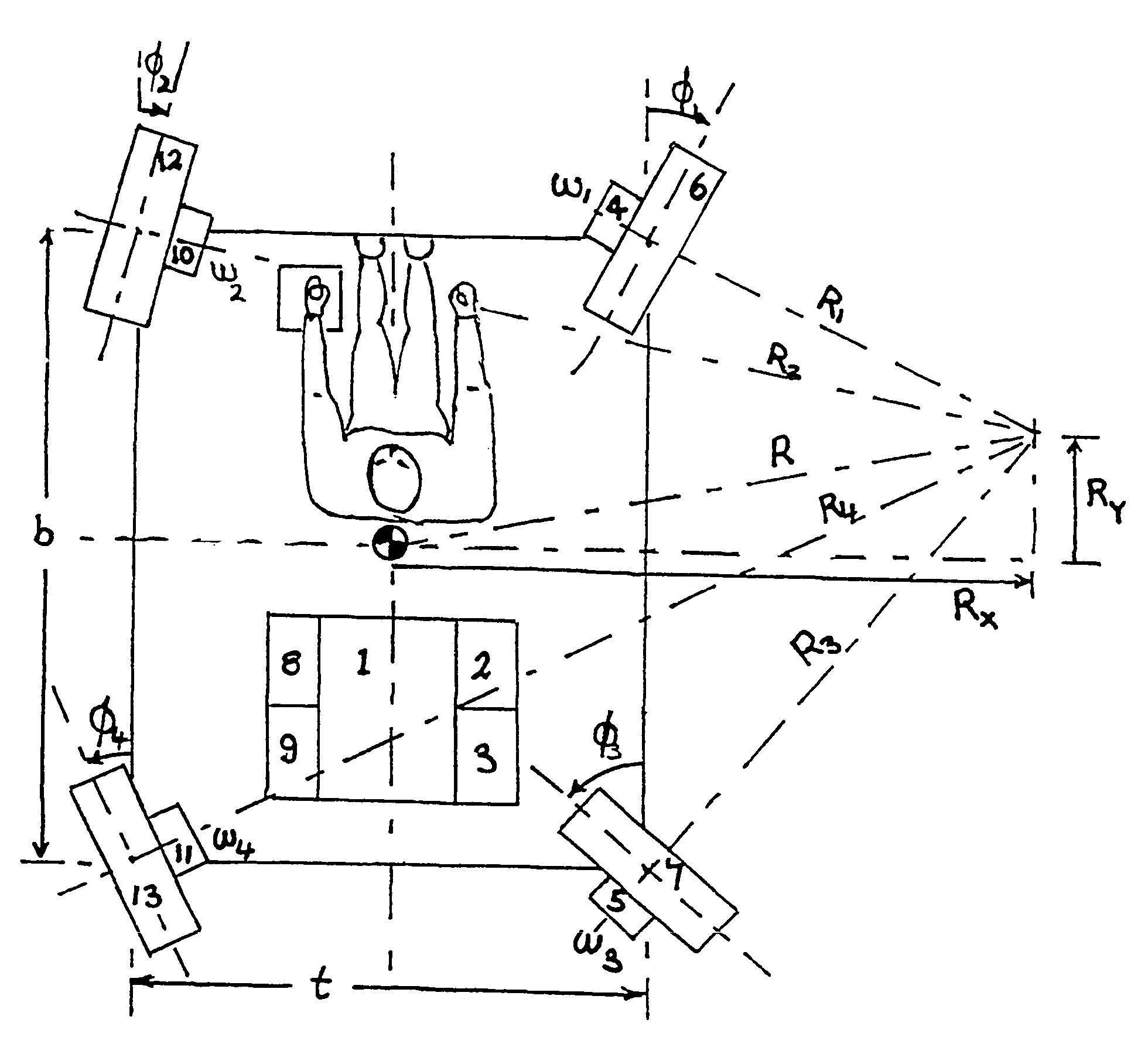

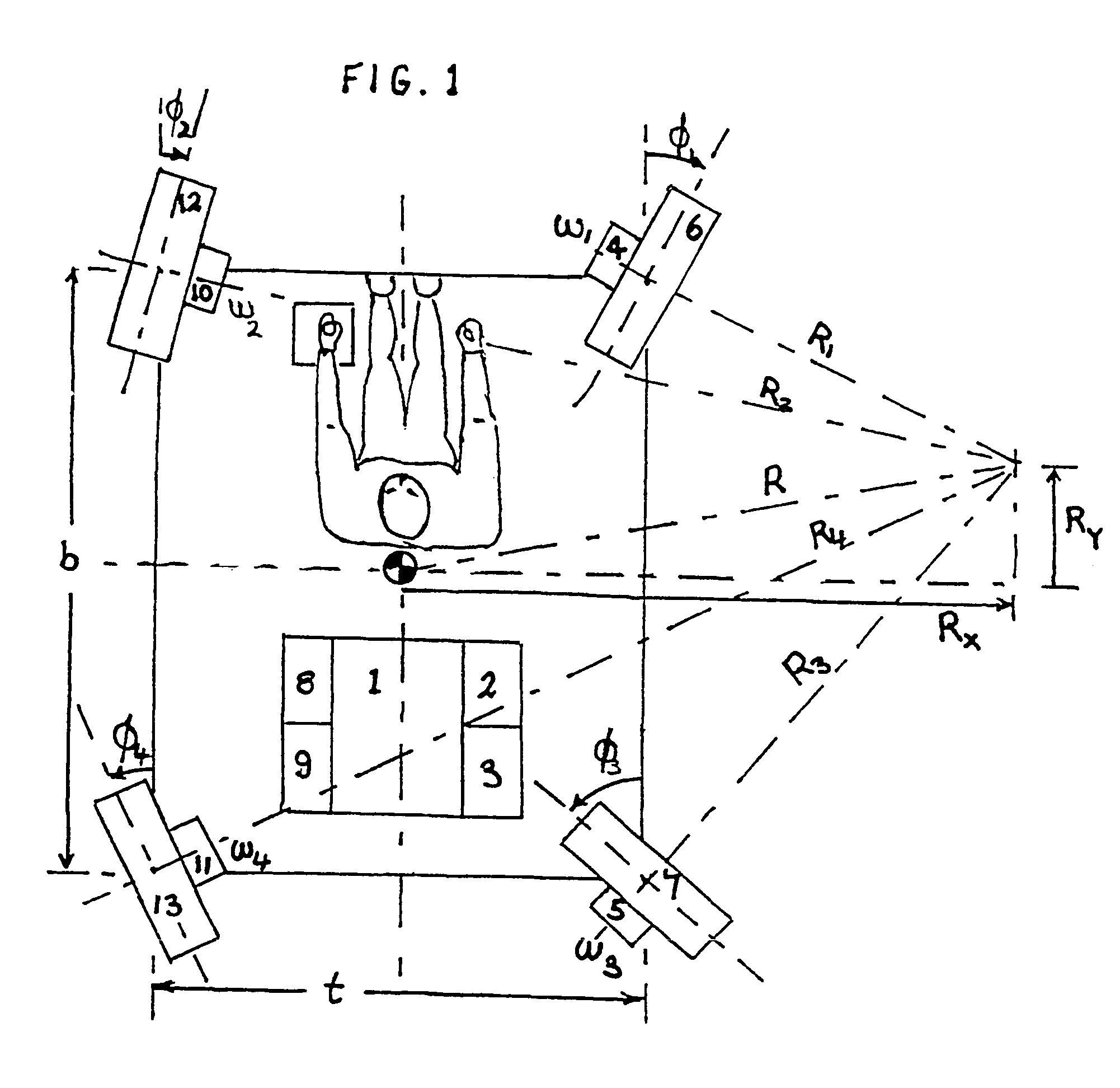

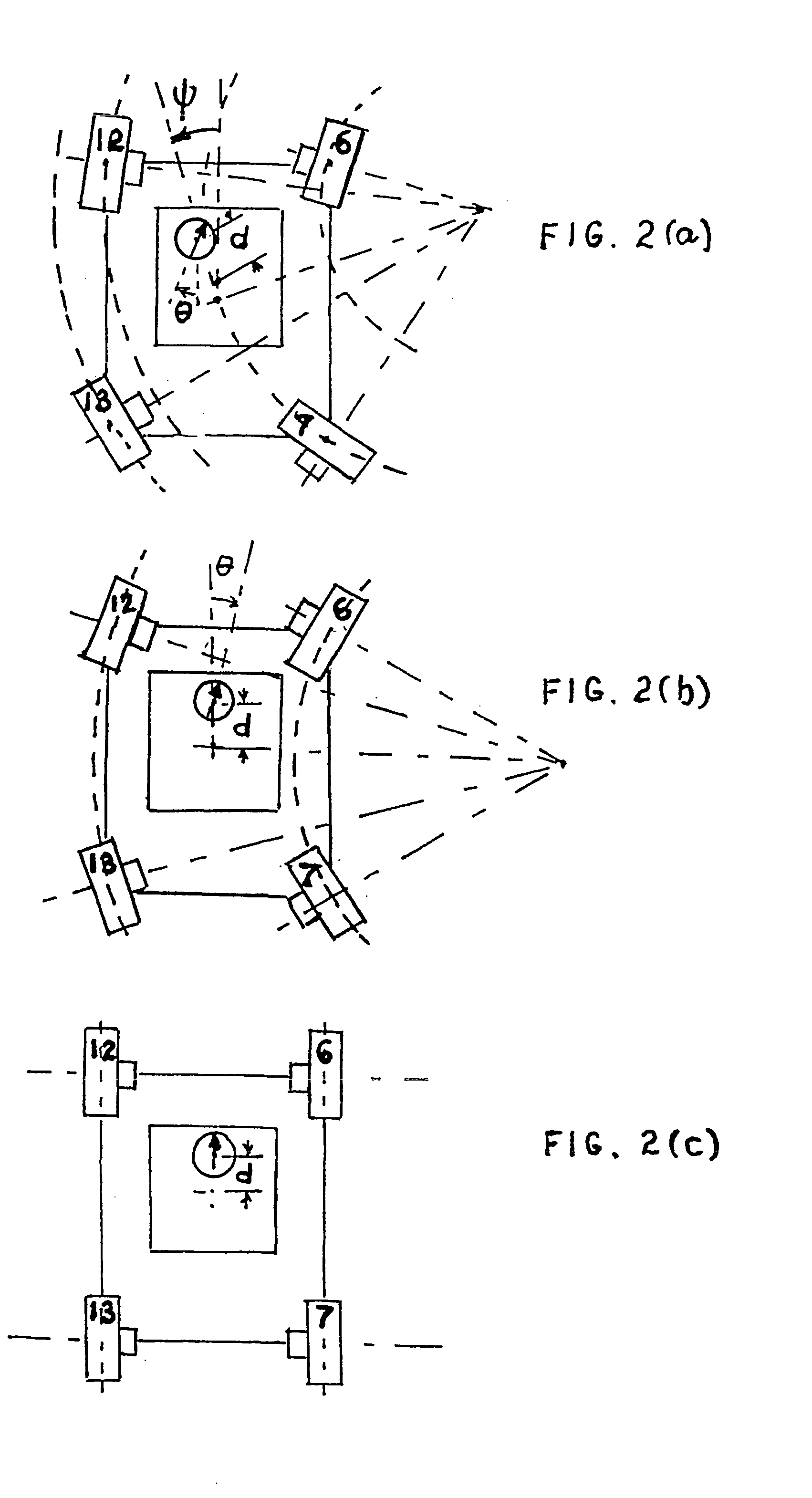

There are two basic methods of steering a wheeled vehicle. One method is to turn one or more steerable wheels. The other is to drive one or more left hand wheels independently of one or more right hand wheels. Traditional vehicles address the potential conflict between to two steering systems by either disabling one system or by causing one to overpower the other. This leads to skidding or scuffing problems respectively. In the present invention both steering systems are enabled but are integrated by means of an on board computer so that they always act in unison. This mutual reinforcement will allow the invention to operate safely on steep or slippery slopes while minimising fuel consumption and ground damage. The invention will also be more manoeuvrable than traditional vehicles since it is capable of both pure rotation and pure translation or any combination of rotation and translation.

Owner:SPARK IAN JAMES

Off road vehicle

InactiveUS7191865B2Maximises manoeuvrabilitySpeed controllerSteering linkagesEngineeringFood consumption

There are two basic methods of steering a wheeled vehicle. One method is to turn one or more steerable wheels. The other is to drive one or more left hand wheels independently of one or more right hand wheels. Traditional vehicles address the potential conflict between the two steering systems by either disabling one system or by causing one to overpower the other. This leads to skidding or scuffing problems respectively. In the present invention both steering systems are enabled but are integrated by means of an on board computer so that they always act in unison. This mutual reinforcement will allow the invention to operate safely on steep or slippery slopes while minimizing fuel consumption and ground damage. The invention will also be more maneuverable than traditional vehicles since it is capable of both pure rotation and pure translation or any combination of rotation and translation.

Owner:SPARK IAN JAMES

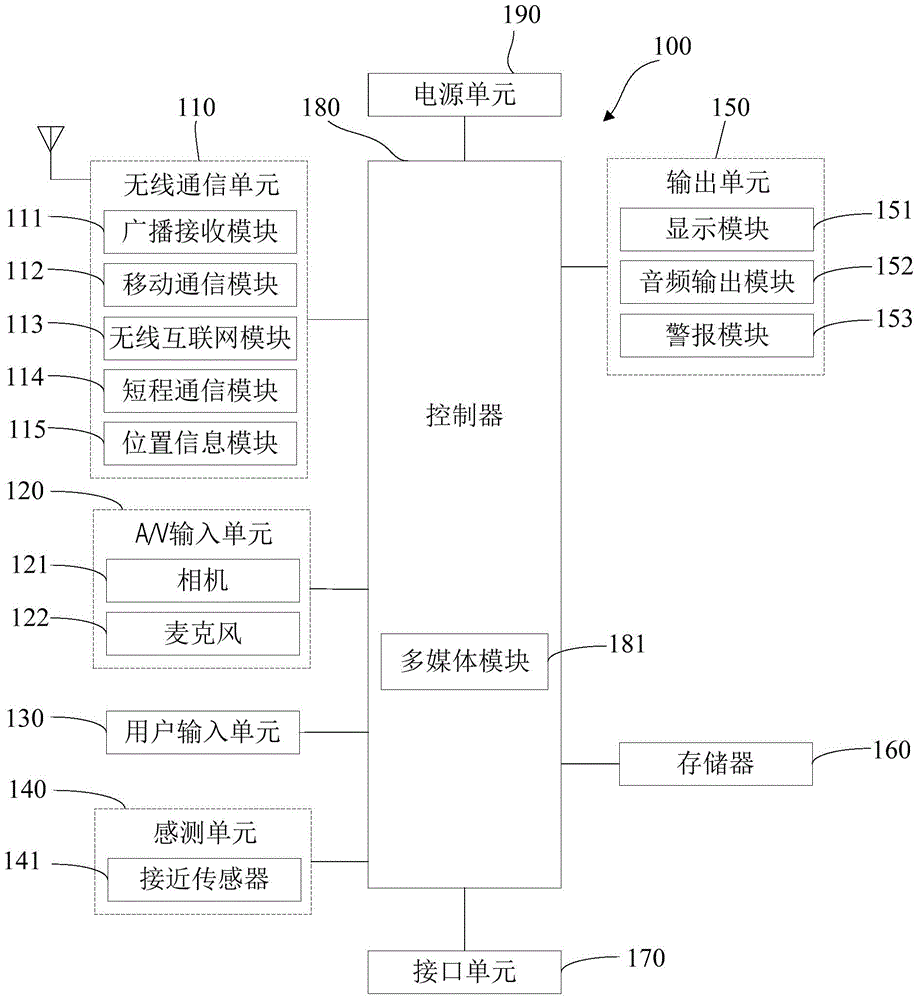

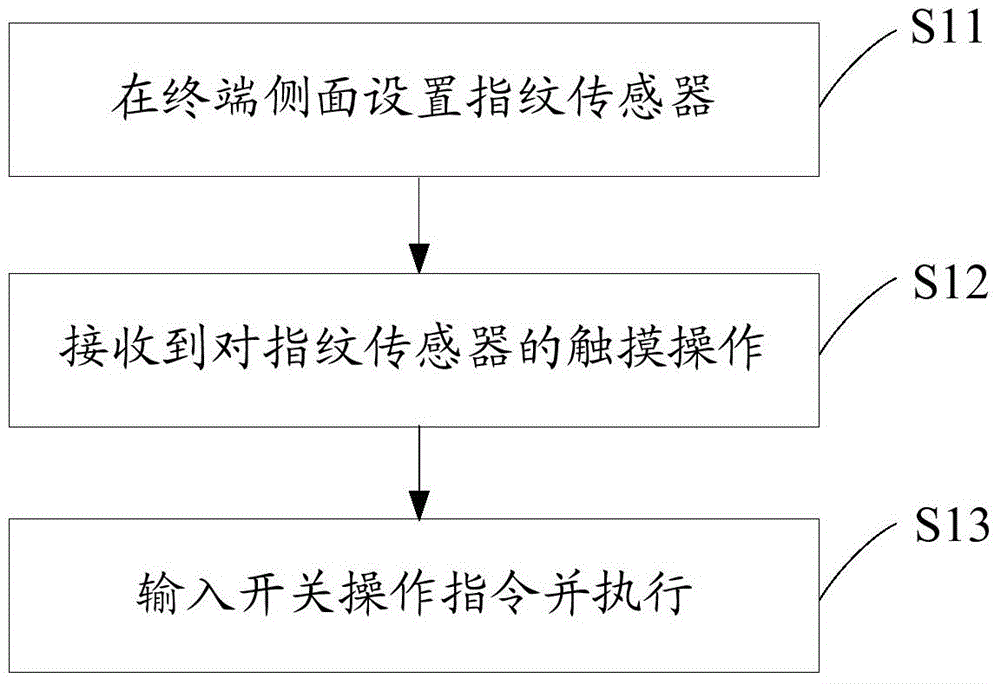

Touch operation method and apparatus

InactiveCN104866223AReduce design difficultyLow costInput/output processes for data processingKey pressingFingerprint

The present invention discloses a touch operation method and apparatus, the method applies to a terminal, and a side surface of the terminal is provided with a fingerprint sensor. The method comprises steps of: receiving a touch operation by using the fingerprint sensor and inputting a corresponding operation instruction; and executing the operation instruction. The side surface of the terminal is provided with the fingerprint sensor, and a touch operation is received by using the fingerprint sensor, so that a conventional power button or / and volume button are simulated, to replace conventional physical buttons based on mechanical contacts, thereby reducing costs, making the terminal simpler and more elegant, meanwhile eliminating the wear problem of mechanical buttons, improving aesthetics and durability, and resulting in a more sensitive and comfortable operation.

Owner:NUBIA TECHNOLOGY CO LTD

Synthetic fiber containing powders with the shape of hollow sphere

Disclosed is a synthetic fiber, including hollow sphere-shaped particles each formed of any one selected from among an inorganic material, an organic material, or combinations thereof, which is advantageous in terms of a low specific gravity, thereby effectively solving conventional wearing problems.

Owner:SEOK MI SOO

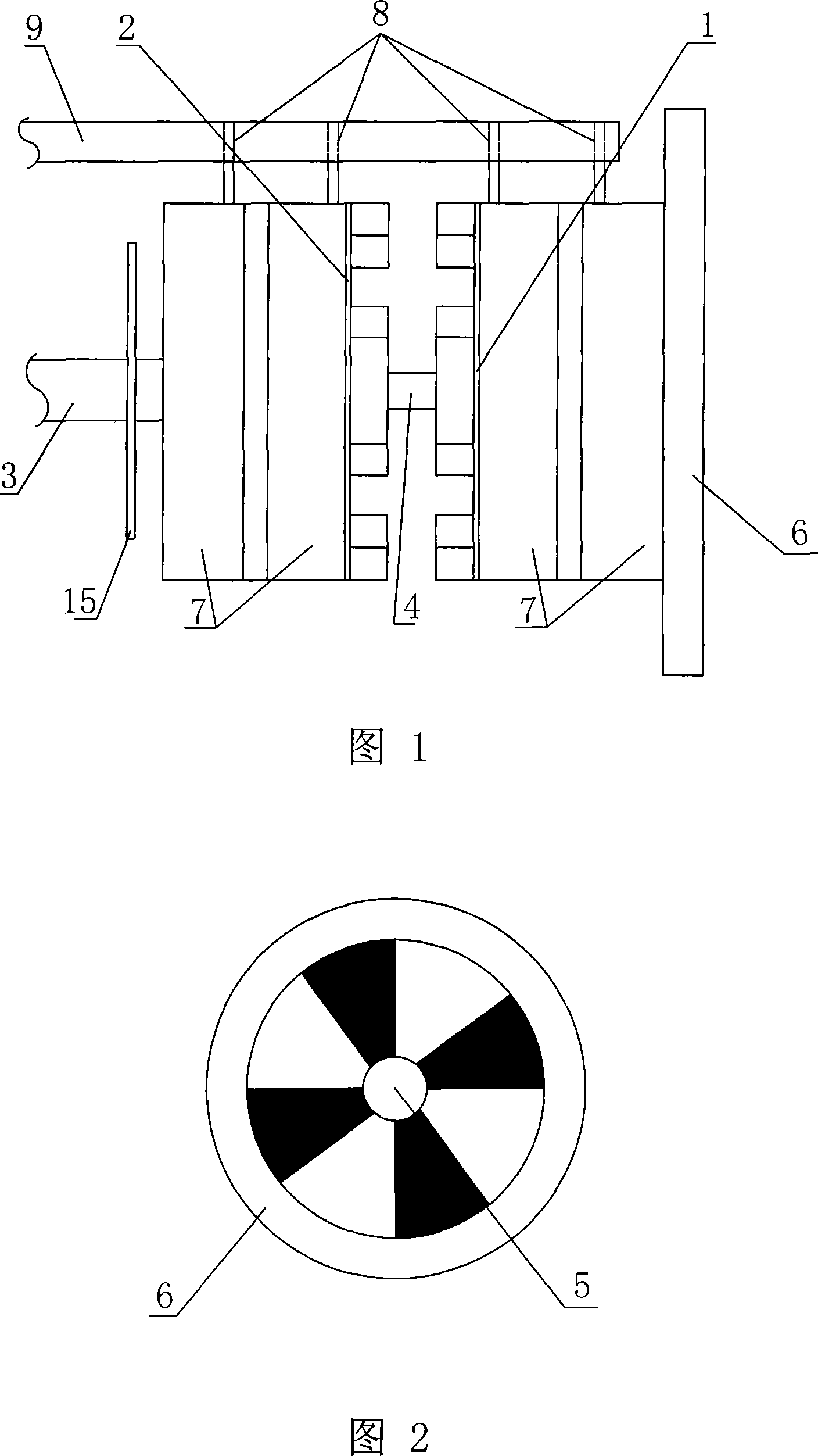

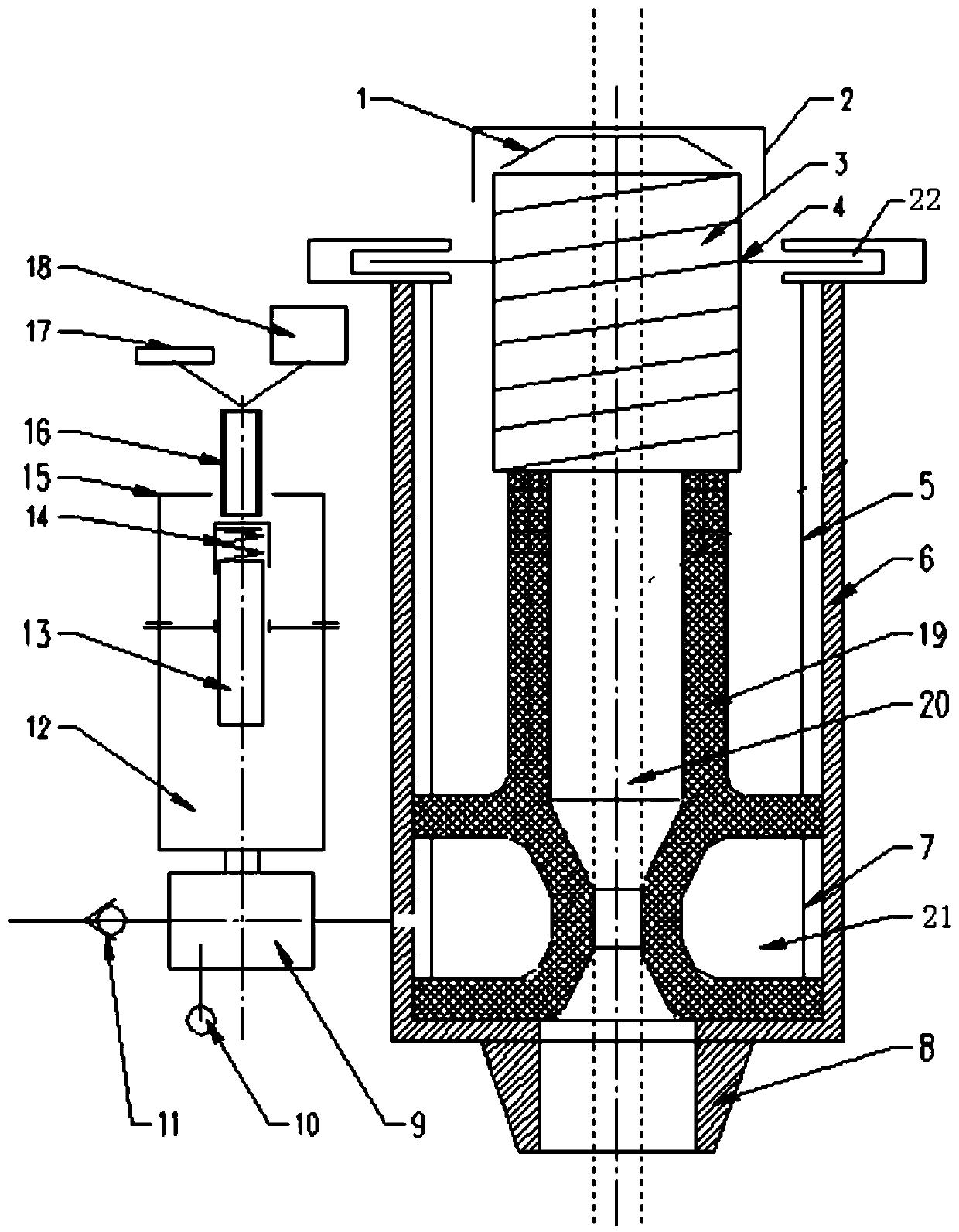

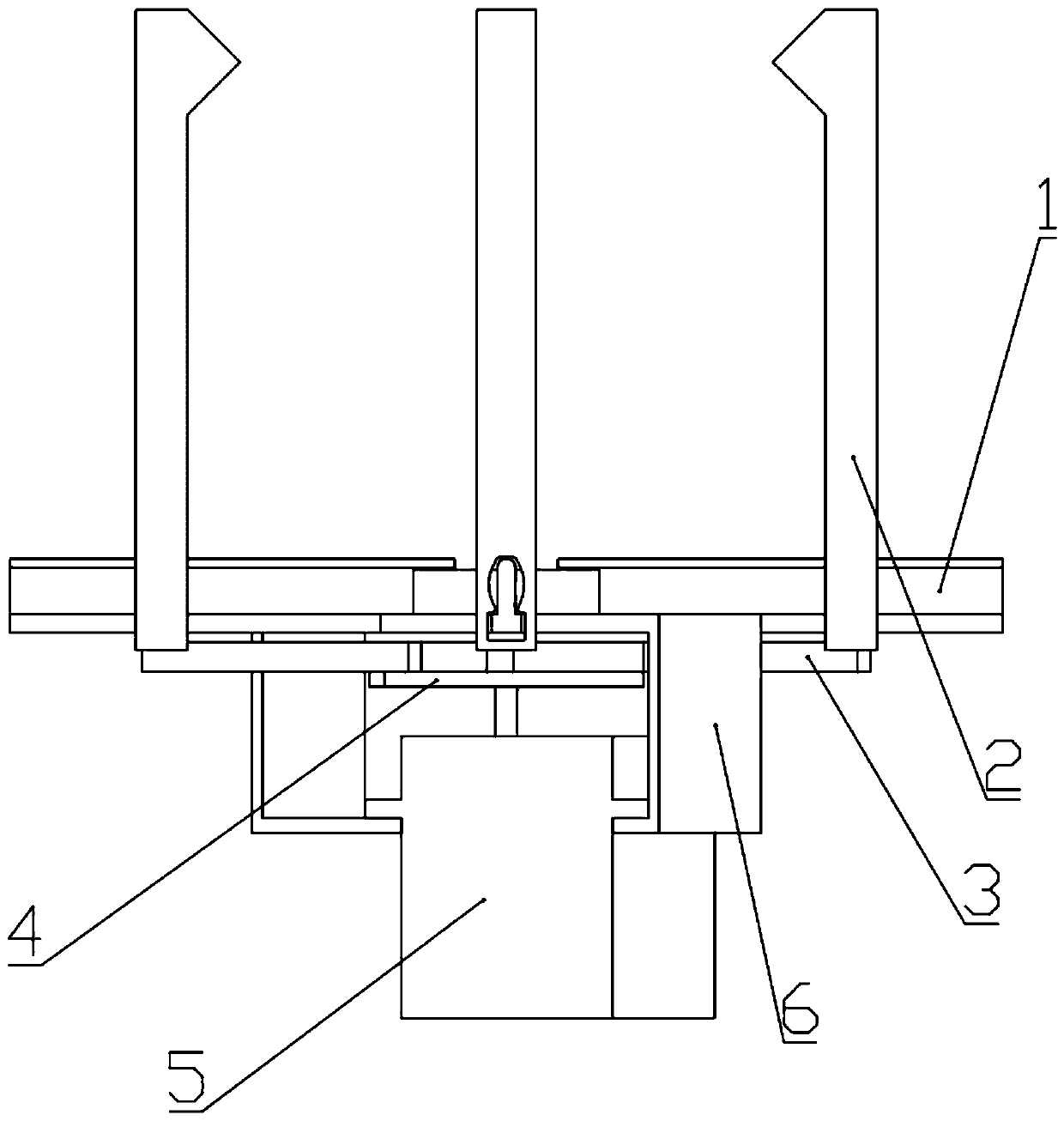

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

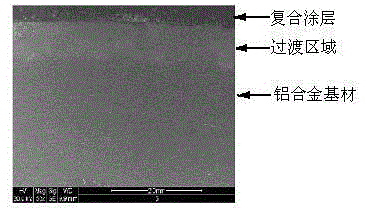

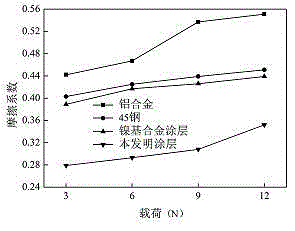

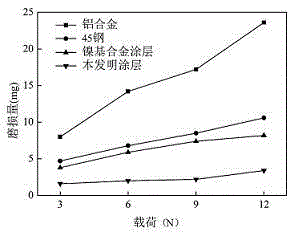

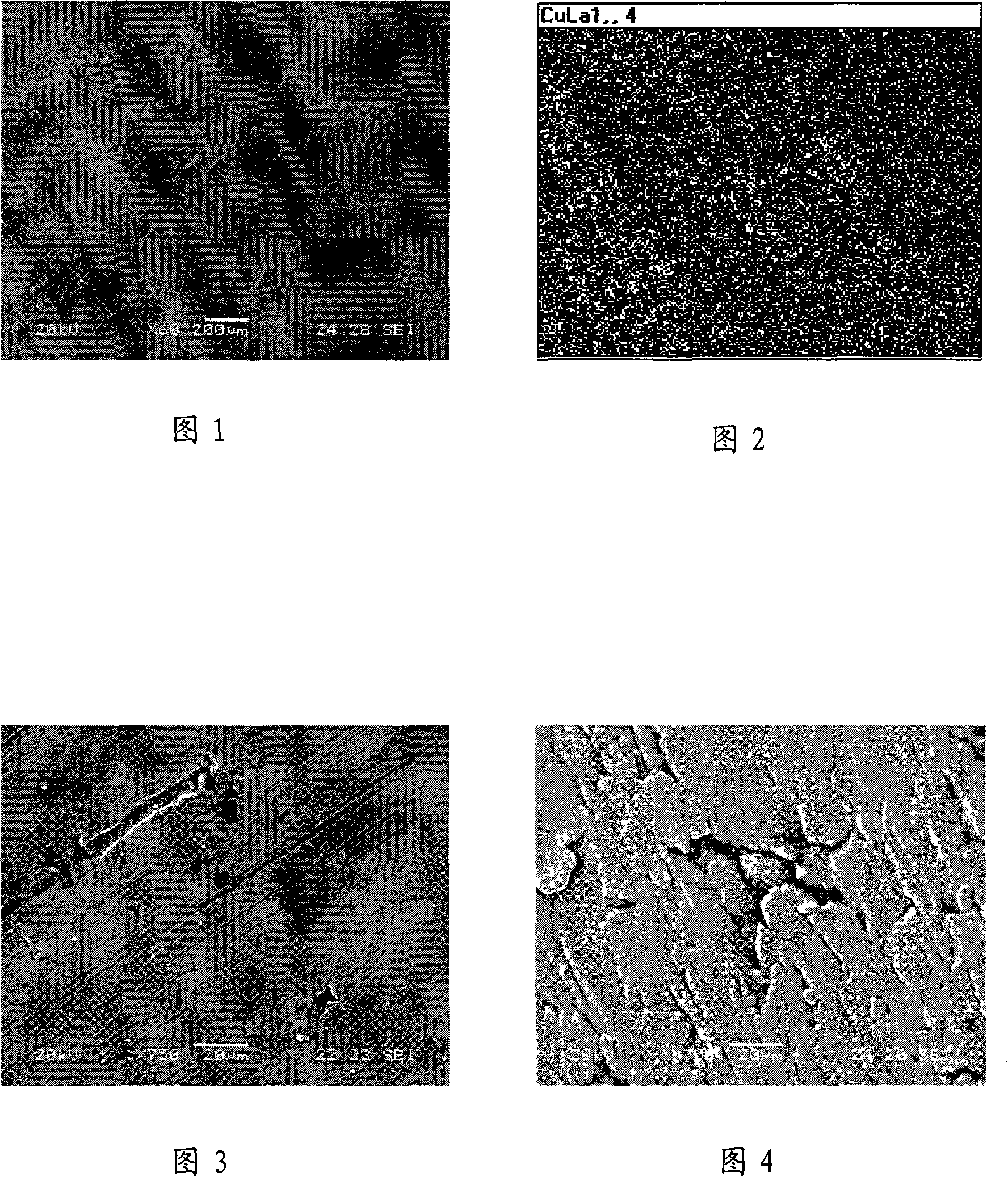

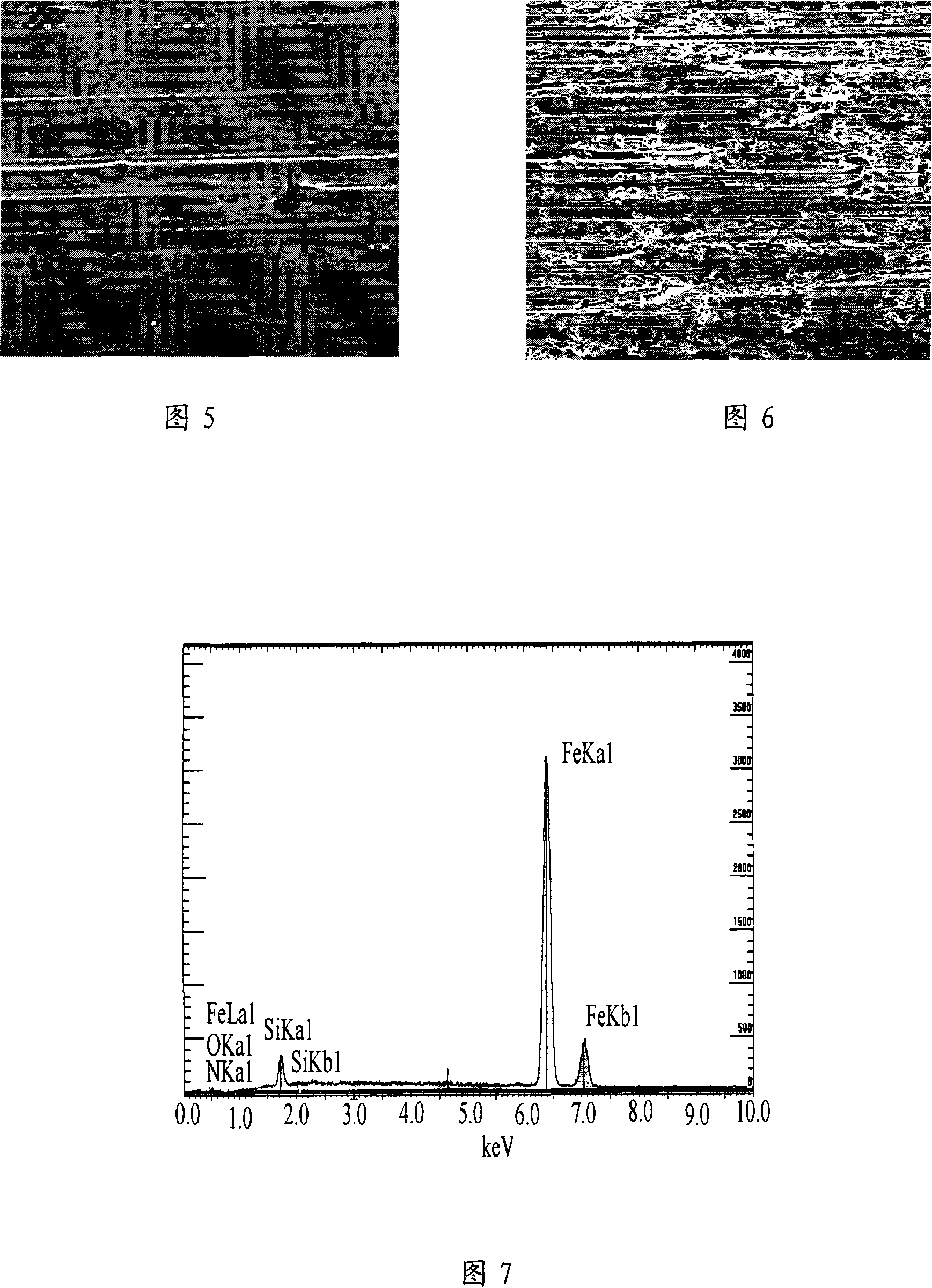

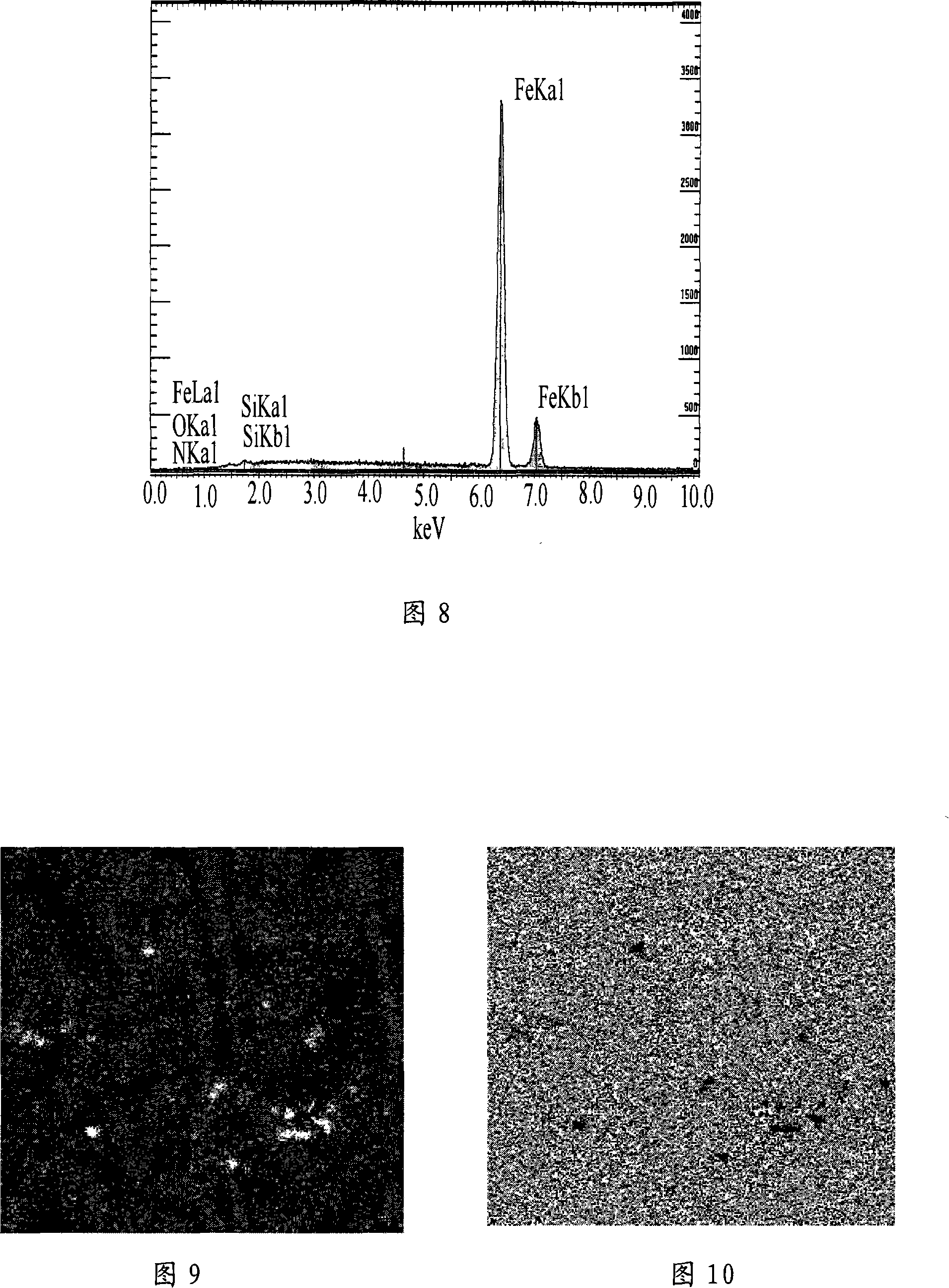

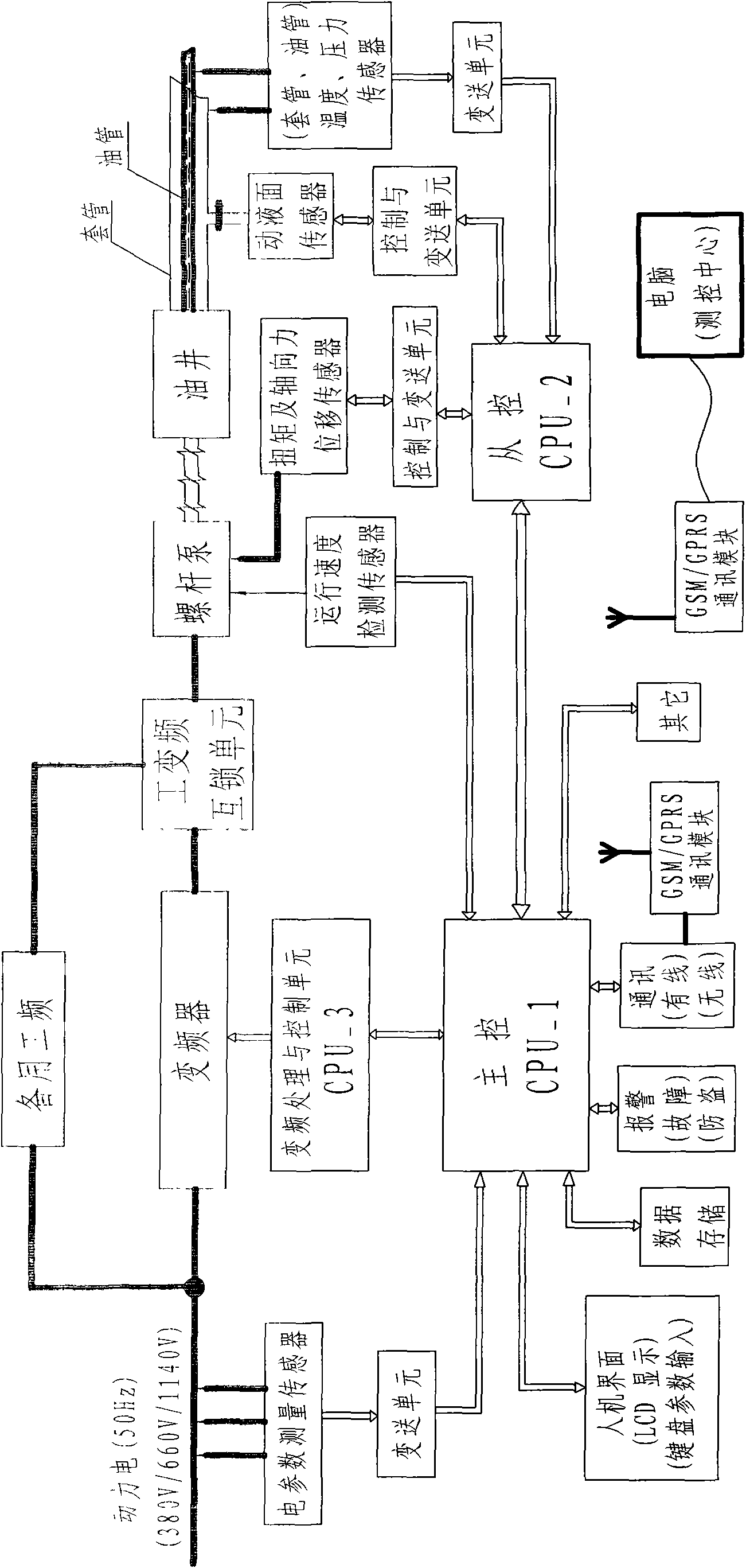

Wear-resistant and antifriction composite coating for aluminum alloy component surfaces and preparation method thereof

InactiveCN105624670AImprove microstructureReduce coefficient of frictionMetallic material coating processesAdhesiveWear resistance

The invention relates to a wear-resistant and antifriction composite coating for aluminum alloy component surfaces. The coating is composed of, by weight, 13-15% of tungsten carbide powder, 18-20% of titanium diboride powder, 2.0-4.0% of cerium oxide powder, 3.0-5.0% of nickel-coated molybdenum disulfide powder and the balance nickel-base alloy powder, wherein the components are blended through adhesives and then are arranged on the aluminum alloy component surfaces in a laser cladding mode for forming the coating; in the nickel-coated molybdenum disulfide powder, the coating ratio of nickel is 71-73%; nickel-base alloy is composed of, by weight, 0.75-0.85% of C, 15-16% of Cr, 3.5-4.5% of Si, 3.0-4.0% of B, 14.5-15.5% of Fe and the balance Ni. The coating is high in wear resistance and low in friction coefficient and solves the friction and wear problems of aluminum alloy used for friction members of mechanical equipment at high loads or impact loads, the service life is prolonged, and the friction energy consumption is lowered.

Owner:中国人民解放军理工大学野战工程学院

Nano lubricating oil additive

InactiveCN101148628AReduce fuel consumptionReduce fuel consumption by 5-15%, reduce noiseAdditivesOil additiveOxidation stability

The present invention discloses one kind of nanometer lubricating oil additive, which consists of liposoluble nanometer copper or copper alloy and liposoluble nanometer silica. The nanometer lubricating oil additive of the present invention can realize the self repair of the worn part, and possesses the functions of saving oil, resisting abrasion, reducing noise, decreasing carbon deposit, raising power performance, etc. It has high dispersivity in lubricating oil, high oxidation stability and long term stability, and is favorable to solving different friction and wear problems in different work conditions.

Owner:BEIJING SIBNANO TECH

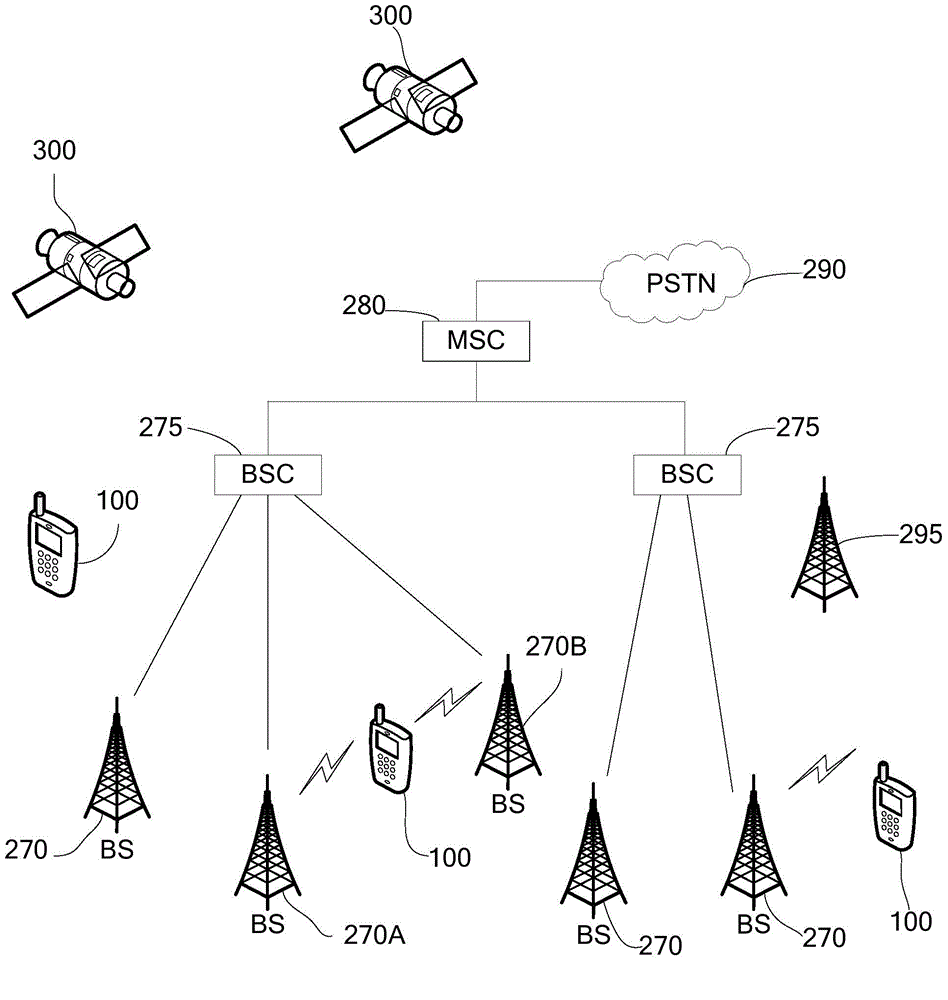

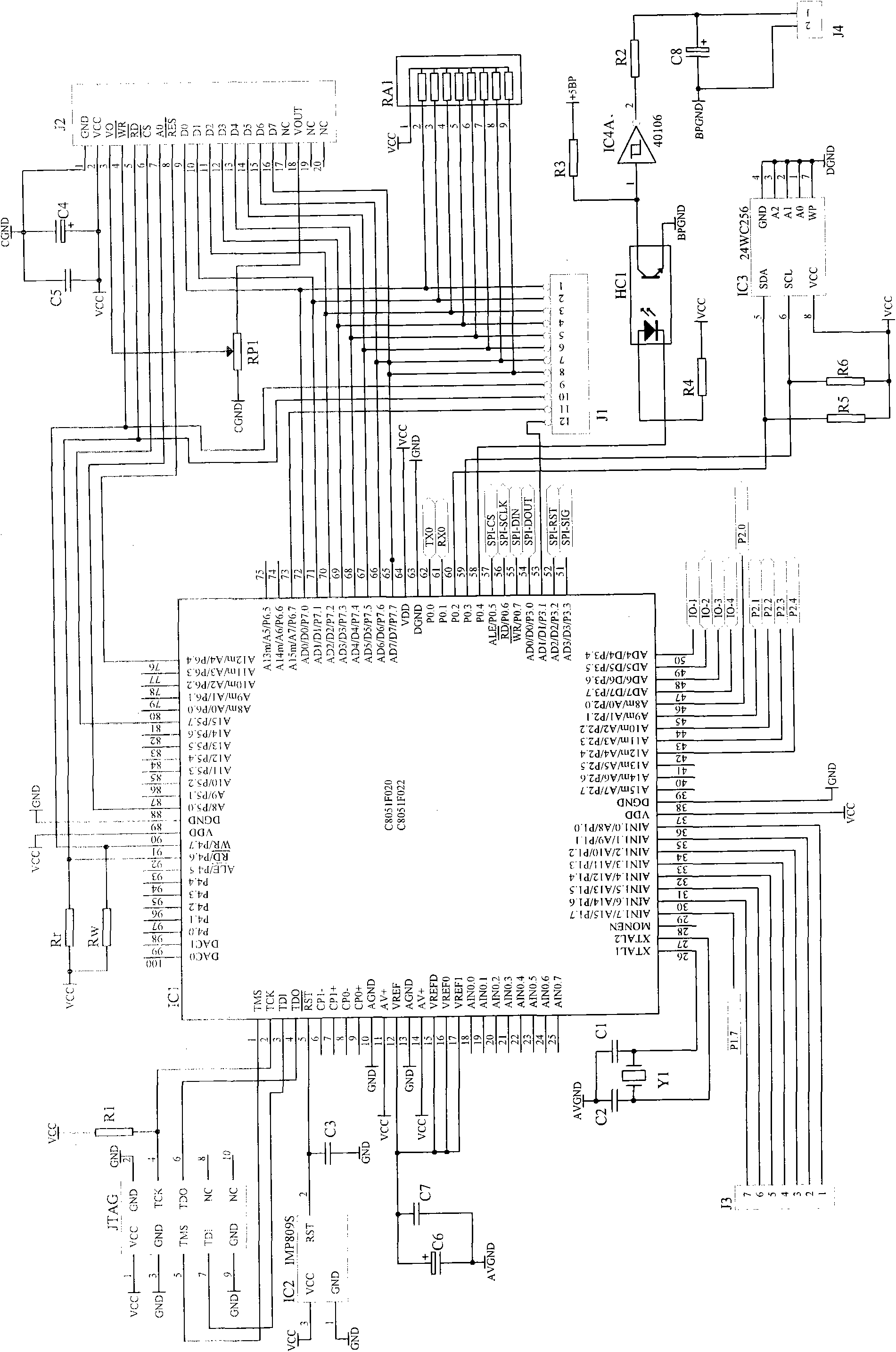

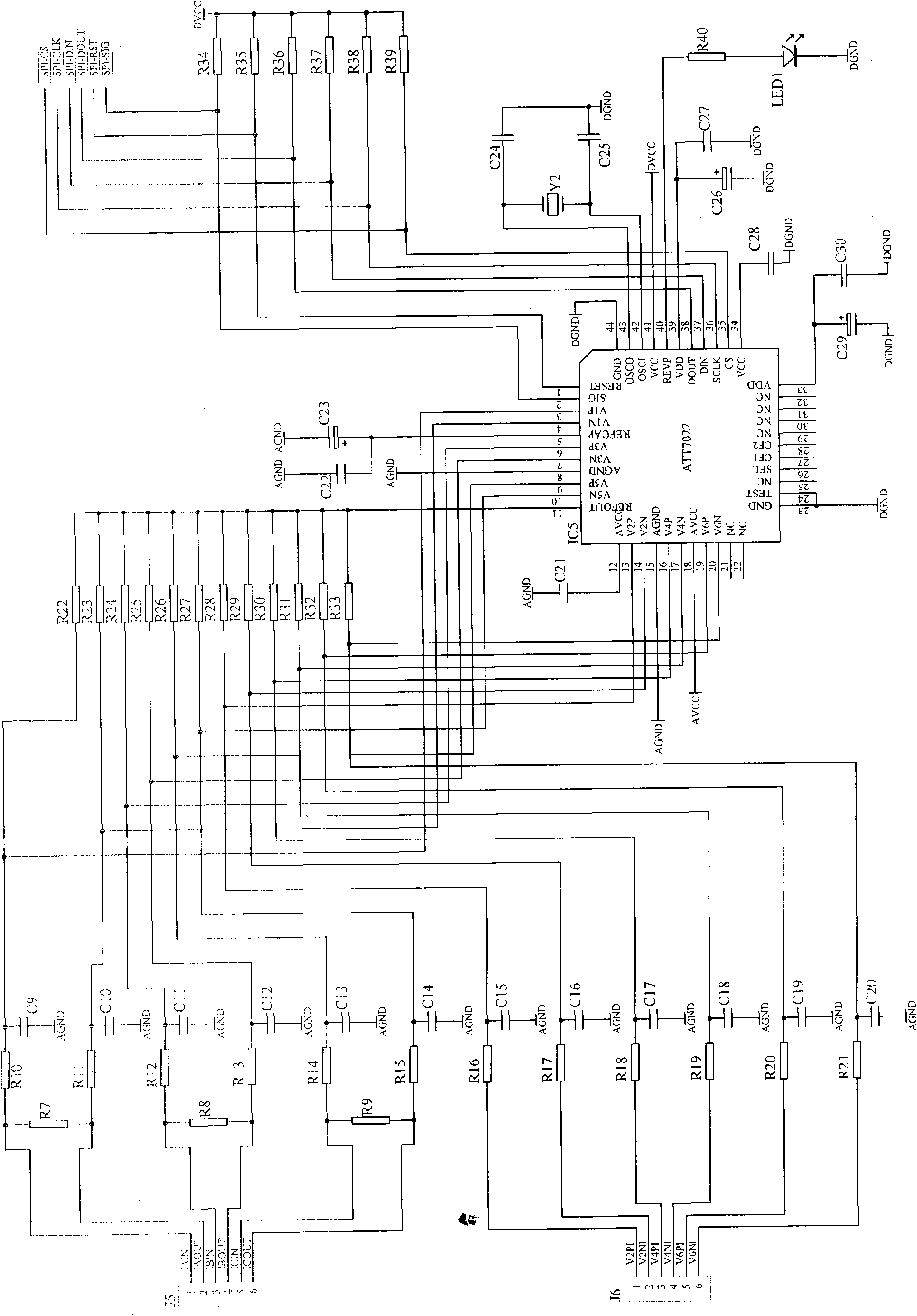

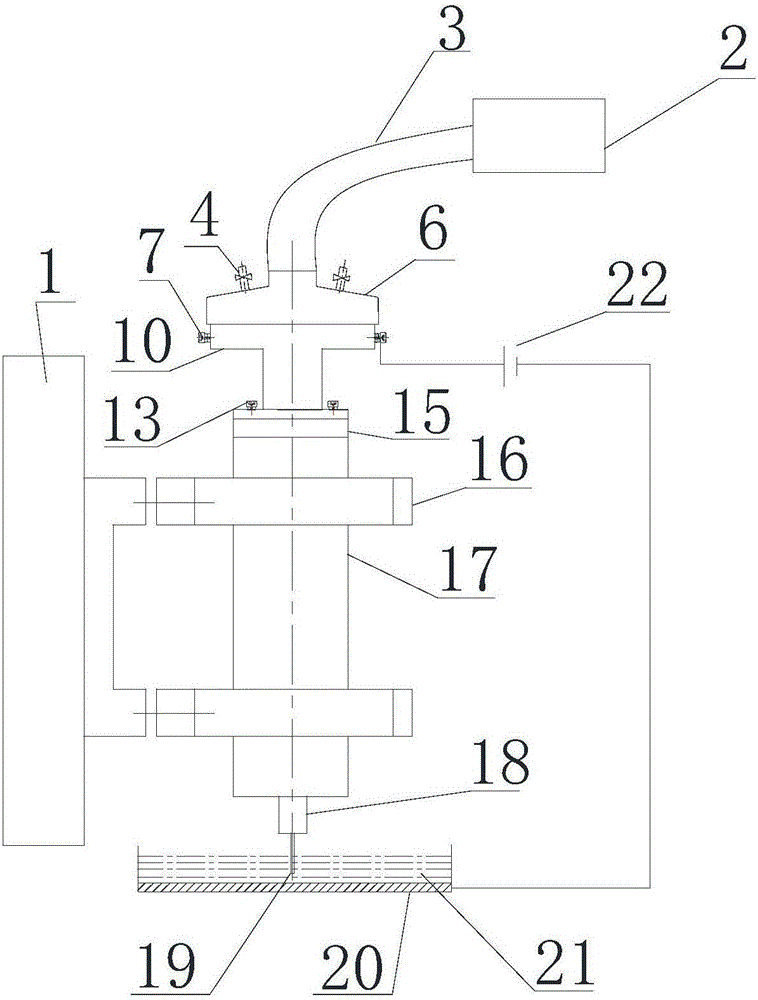

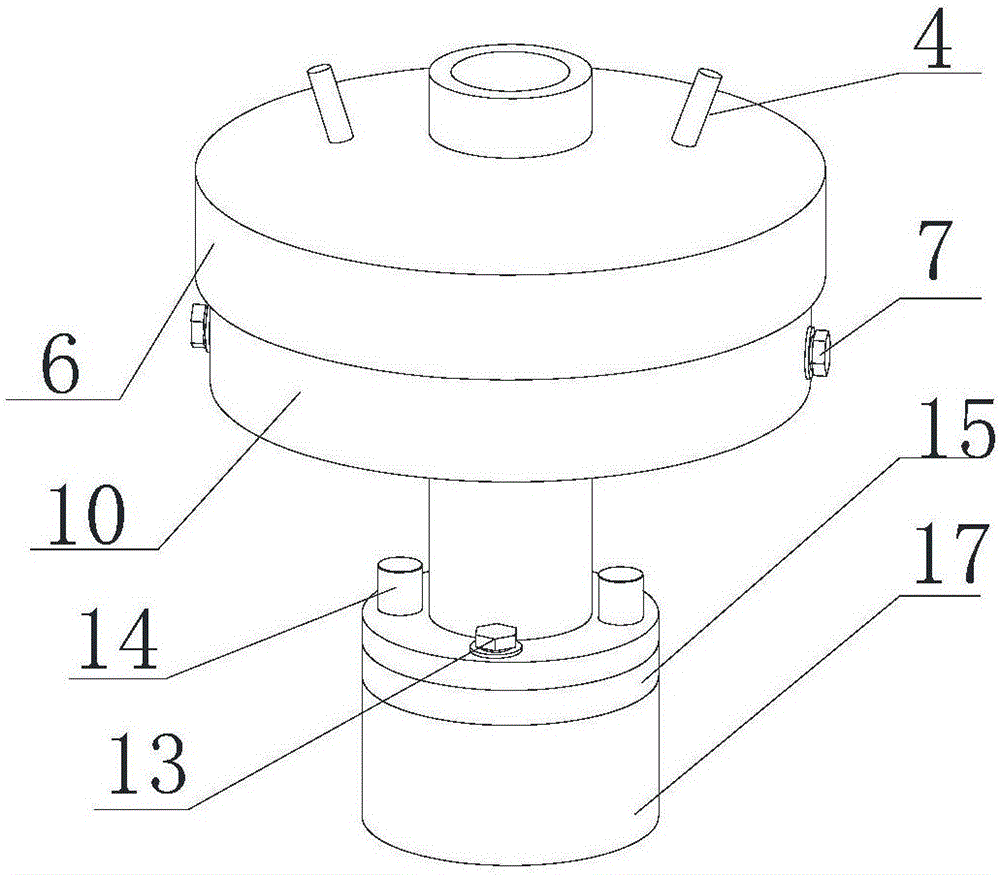

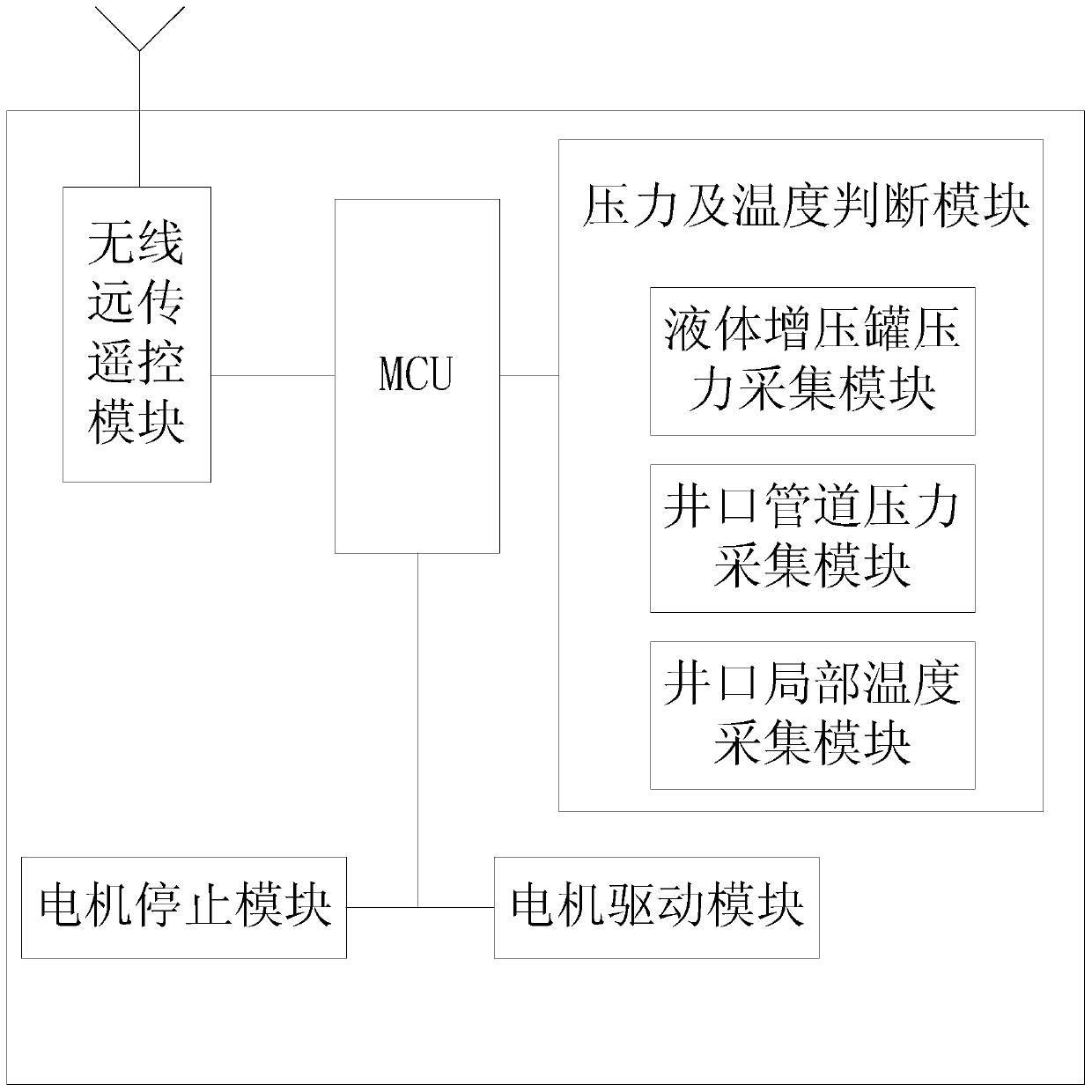

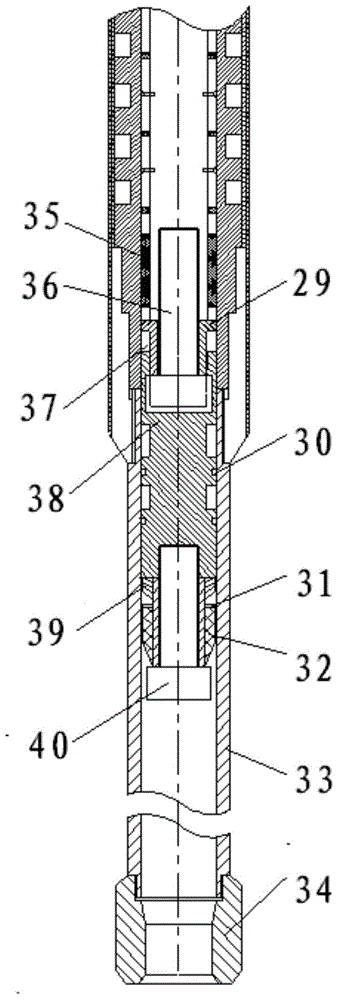

Intelligent monitoring device for screw pump well

InactiveCN101539135AMonitor work dataExtended service lifeFlexible member pumpsElectric controllersClosed loopEngineering

The invention relates to an intelligent monitoring device for a screw pump well, which is a high-performance industrial control device combined with optical, mechanical and electronic integration and electronic information and communication technology, and is mainly used for intelligently monitoring oil extraction of the screw pump well in oil field. The intelligent monitoring device mainly comprises a light current part and a strong current part, and is characterized in that the intelligent monitoring device takes connection of parts such as a sensor capable of measuring dynamic liquid level of the screw pump well on line, a sensor capable of measuring the torque and axial force of the screw pump well on line, a sensor capable of measuring electricity using parameters such as running current constantly and a remote wireless communication device and the like with a CPU as a core to realize the effective measurement and intelligent closed-loop control of the screw pump well. The intelligent monitoring device can avoid pump burning phenomenon of a screw pump caused by evacuation through accurate measurement and effective monitoring and dispatching, scientifically make a hot washing system according to wax deposition cause and the like to avoid phenomena such as rod breakage and the like, find eccentric wear problem in time to prolong pump detection cycle, and optimize design of the screw pump well to reasonably determine working parameters and reduce potential safety hazard and the like.

Owner:王洪亮 +1

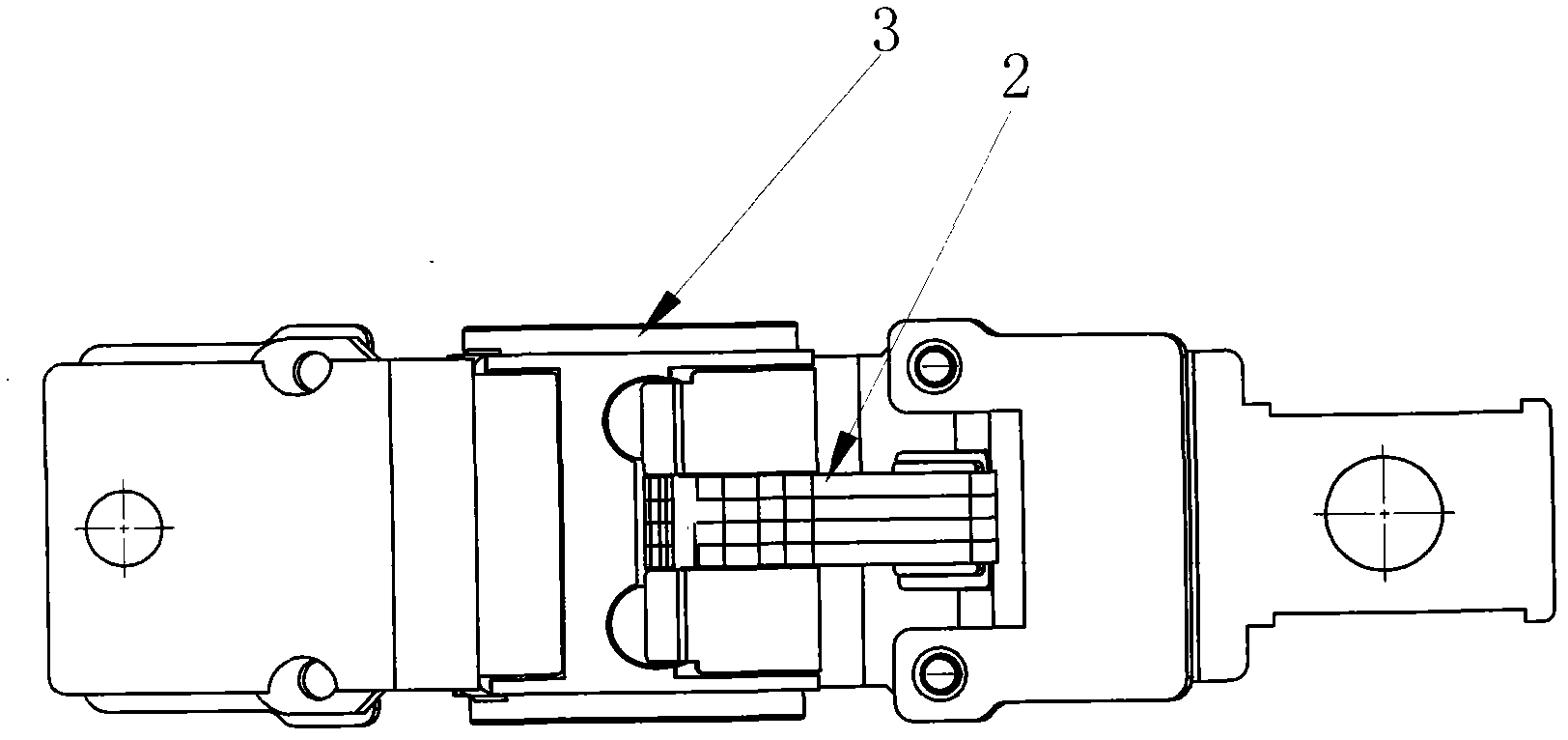

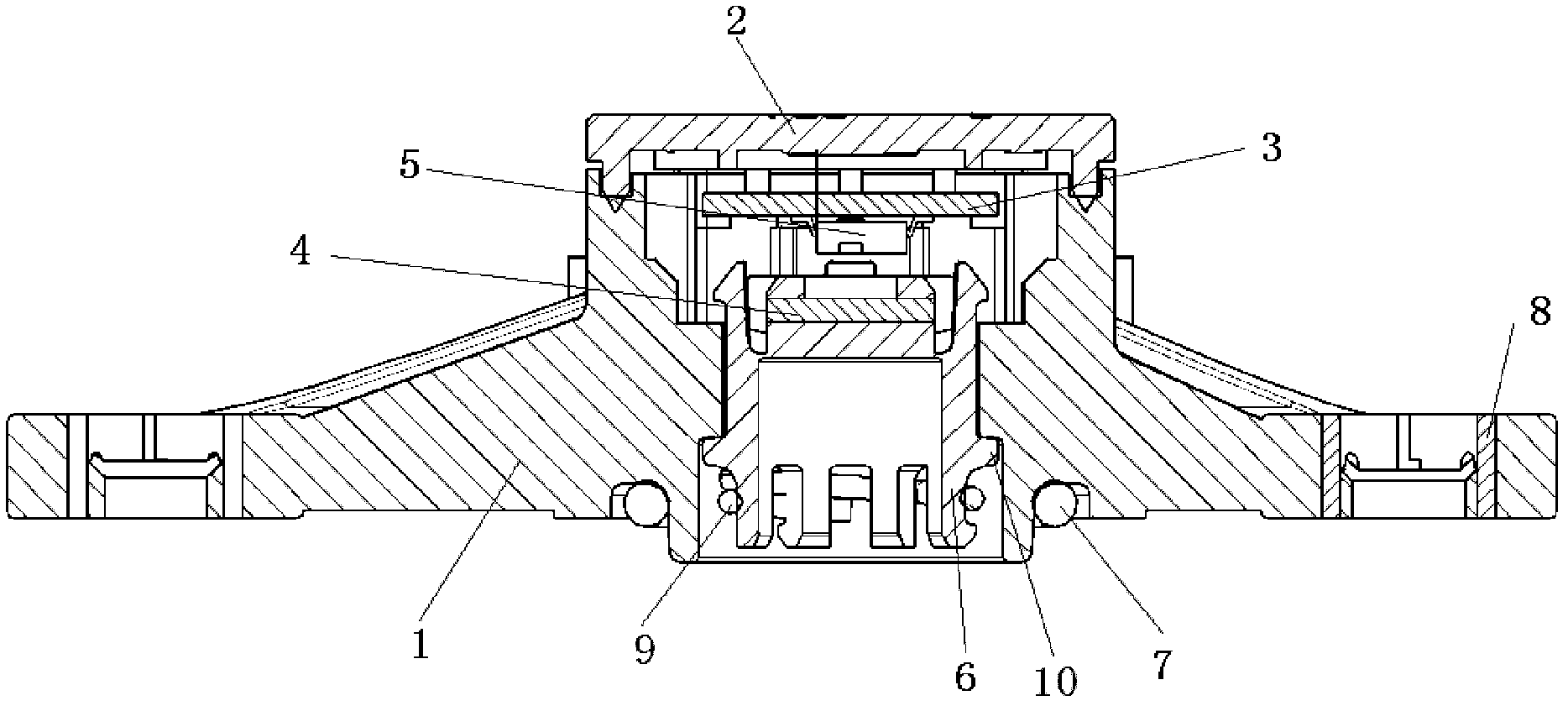

Contact system of low-voltage circuit breaker

InactiveCN102024632AExtended service lifeSmall contact forceContact engagementsCircuit-breaking switch contactsLow voltage circuitsRolling resistance

The invention relates to a contact system of a low-voltage circuit breaker. In the contact system, a first sliding shaft is a hollow tube, the connecting ends matched with the first sliding shaft, of a first spring and a second spring separately form a rotating supporting shaft; the both ends of the first sliding shaft are sleeved on the rotating supporting shafts respectively to constitute hinged connections; and the first sliding shaft fits with the first cam-shaped surface of the main body in a rolling friction manner. As the sliding shaft is hinged with the first spring and the second spring, the sliding shaft can rotate along the rotating supporting shaft; when the moving contact moves, the sliding shaft does not perform rigid friction, but rolling friction with the moving contact and the contact force is small, thus the rolling time is greatly shortened, namely the rejection time of the moving contact is shortened; and as the wear problem does not exist, the service life of the sliding shaft can be prolonged and the service life of the entire contact system is increased.

Owner:CHZHETSZJAN DADA ELEKTRIKAL KO

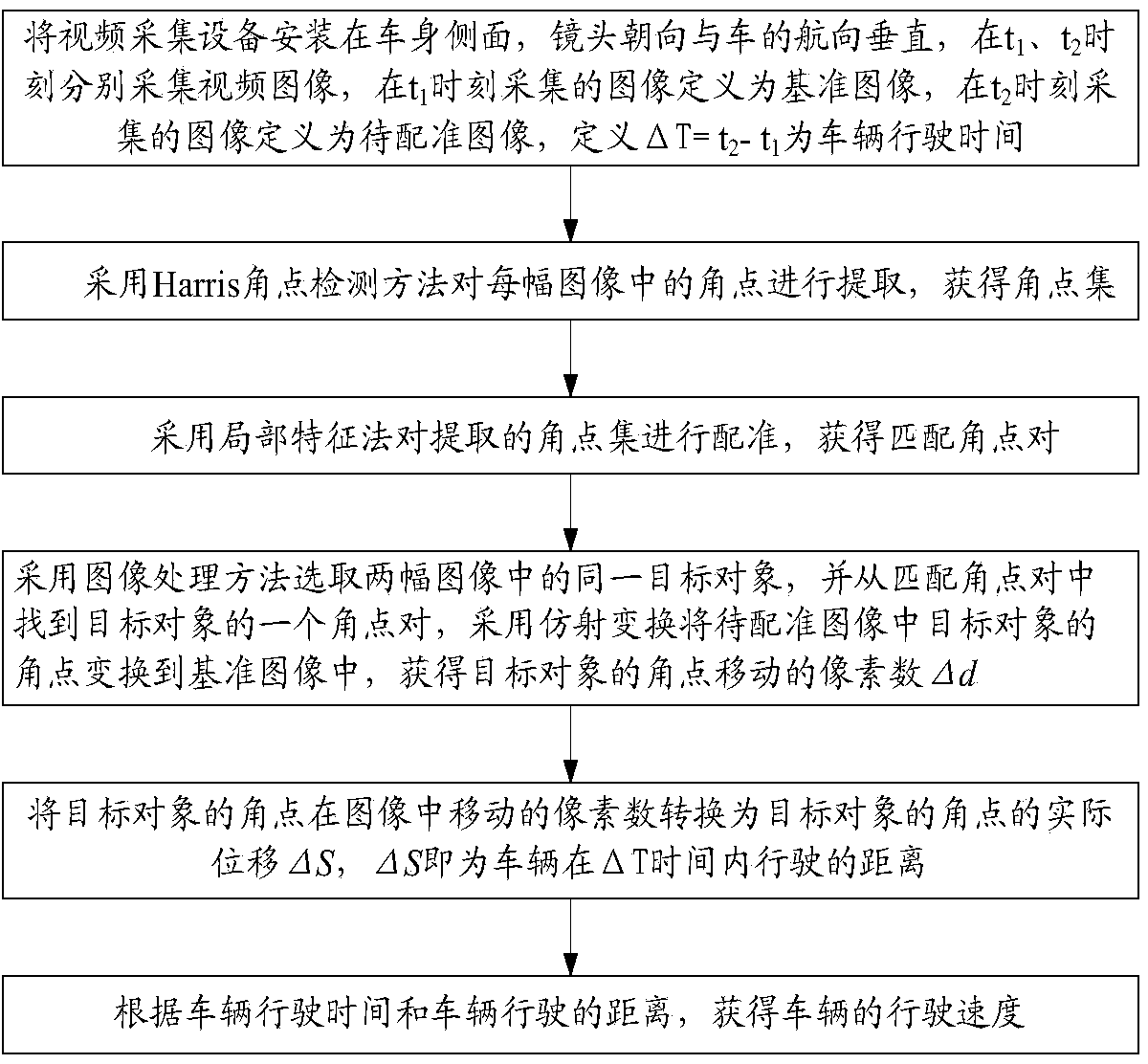

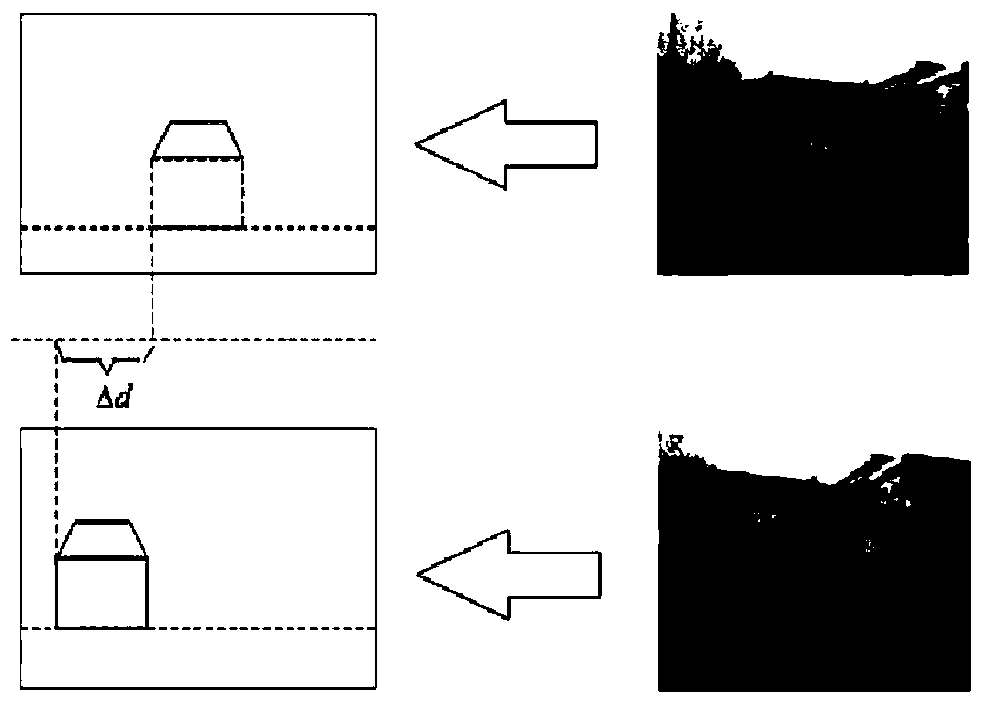

Real-time speed measurement method based on vehicle-mounted sensor video streaming matching

InactiveCN103686083ANot affected by disturbanceImage analysisRoad vehicles traffic controlWear ProblemVideo streaming

The invention discloses a real-time speed measurement method based on vehicle-mounted sensor video streaming matching. The method includes the steps that the number of movement pixels of one corner point of the same target object in two images shot by a vehicle-mounted camera is utilized to conduct reverse derivation on driving displacement of a vehicle within the time interval of the two images, the driving speed of the vehicle is acquired, and then real-time speed information is provided for a driver. By the utilization of the method, the vehicle speed can be monitored only by installing one vehicle-mounted camera, the influences of manufacturing and assembly errors of the vehicle and tire wear problems on vehicle speed measurement do not exist, and the method is convenient to conduct and feasible.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

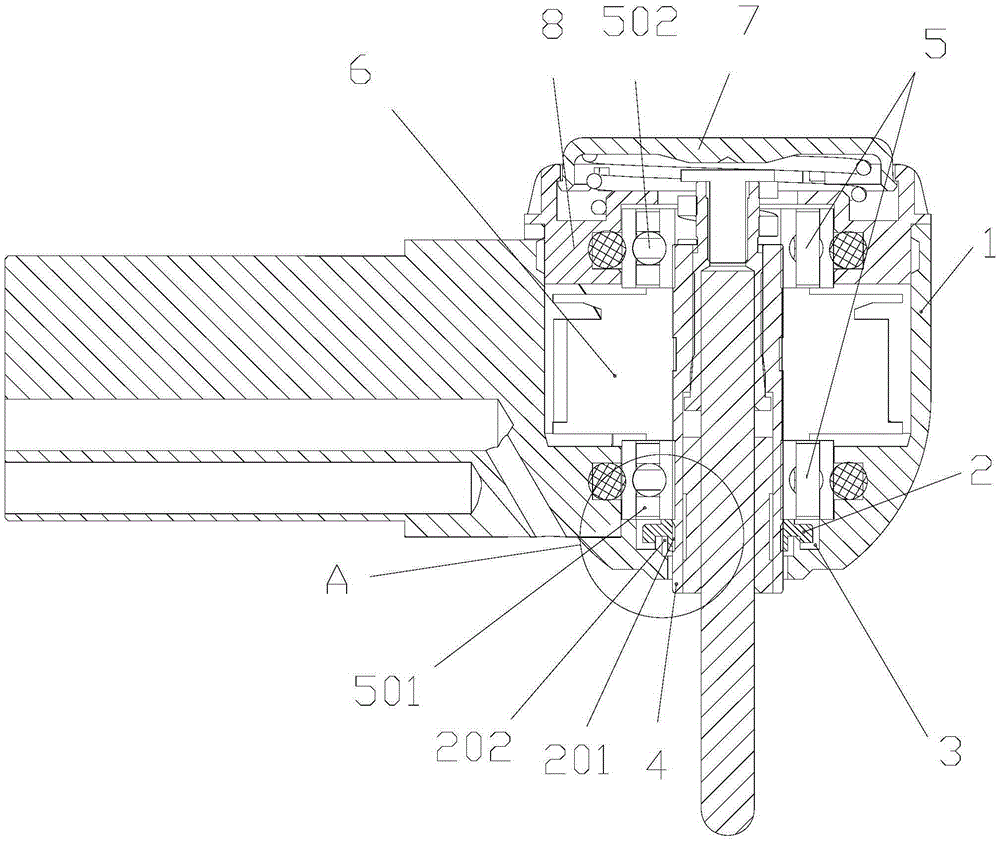

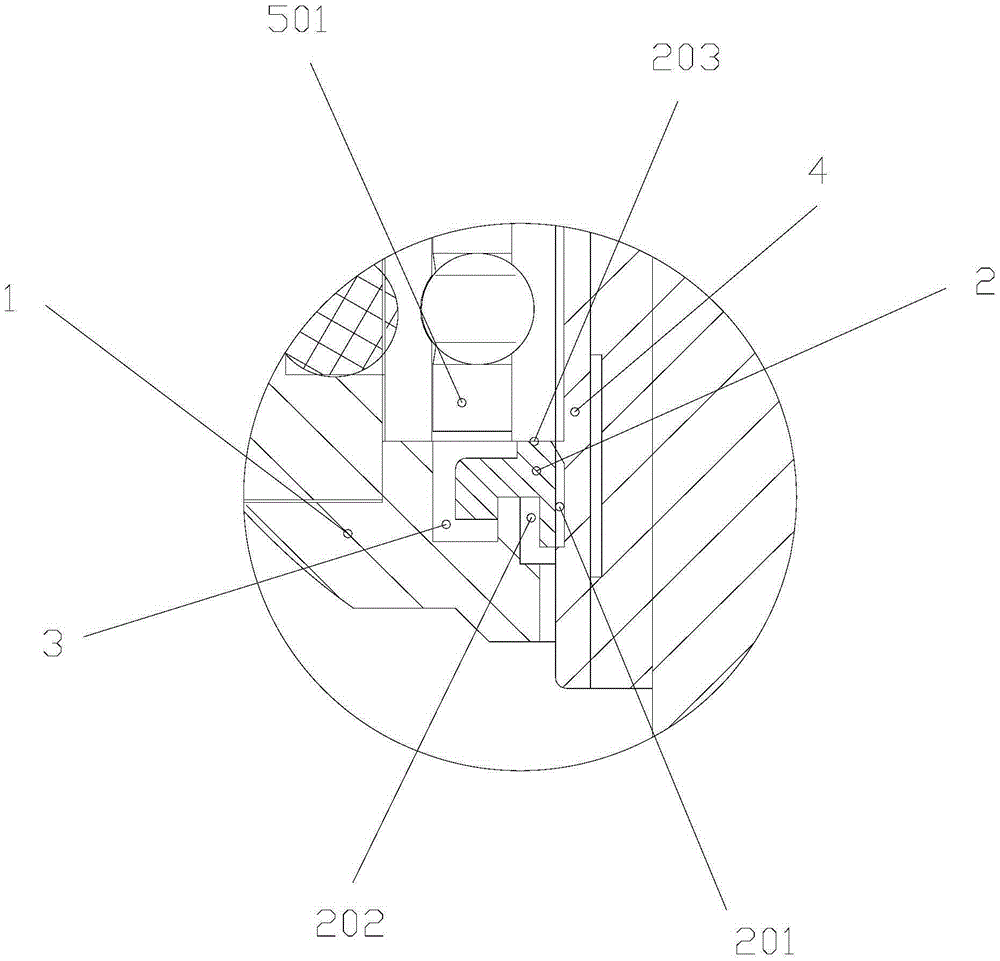

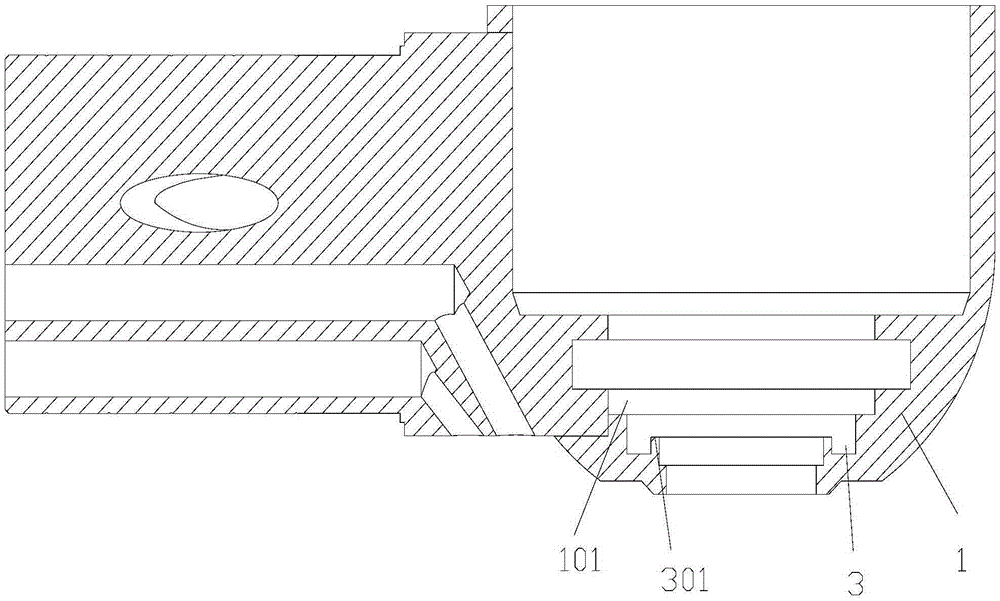

Tool electrode high-speed rotation electromachining electric conduction device

ActiveCN106475647ANo health hazardNo pollution in the processElectric circuitsElectricityEngineering

The invention discloses a tool electrode high-speed rotation electromachining electric conduction device. The device comprises an air pump, a rubber tube, an upper end cover, a reducing valve, a revolution joint, a conducting solution, a fixed joint and an electric conduction screw. By the adoption of the device, the abrasion problem of an electric brush in a traditional electric conduction mode can be solved, and the advantages of being safe, green and free of pollution are achieved compared with a mercury electric conduction mode. Meanwhile, compared with a wireless electric conduction mode, the device is simple and easy to implement, the process difficulty and cost are low, and the practicability is good.

Owner:颍上县祥盛建设管理有限公司

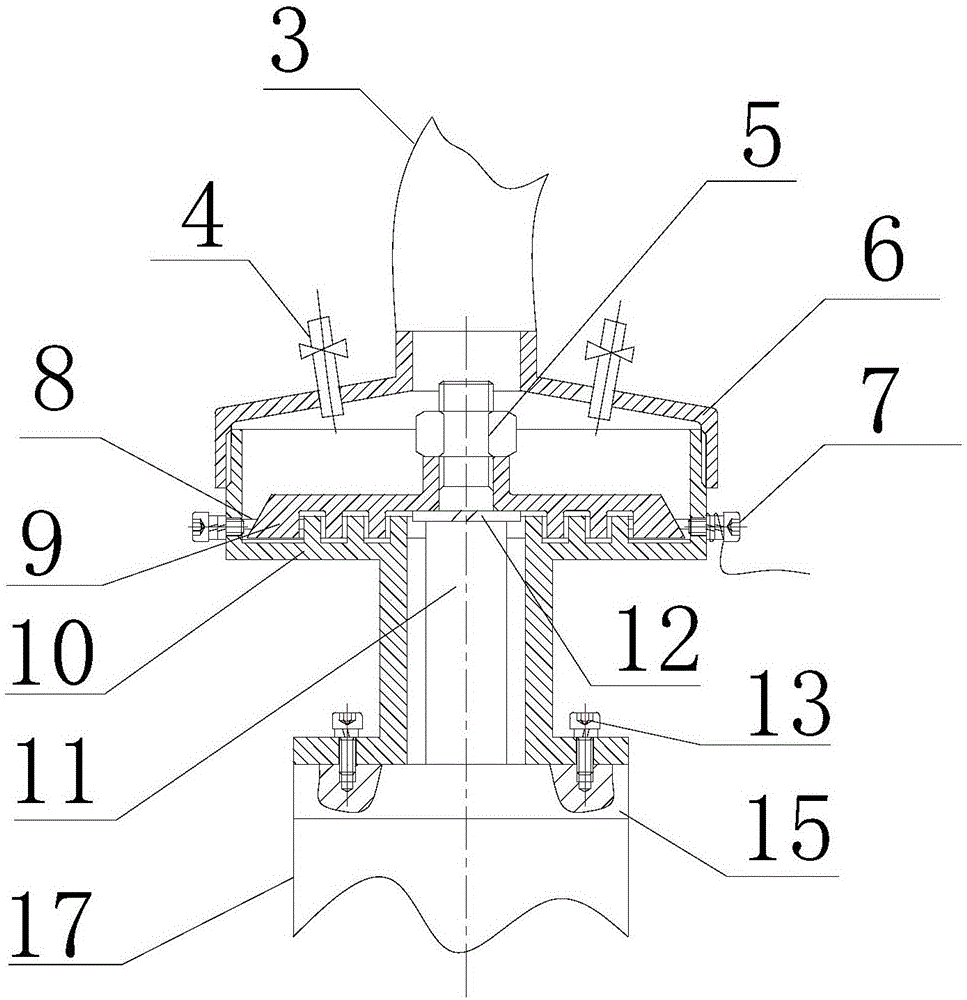

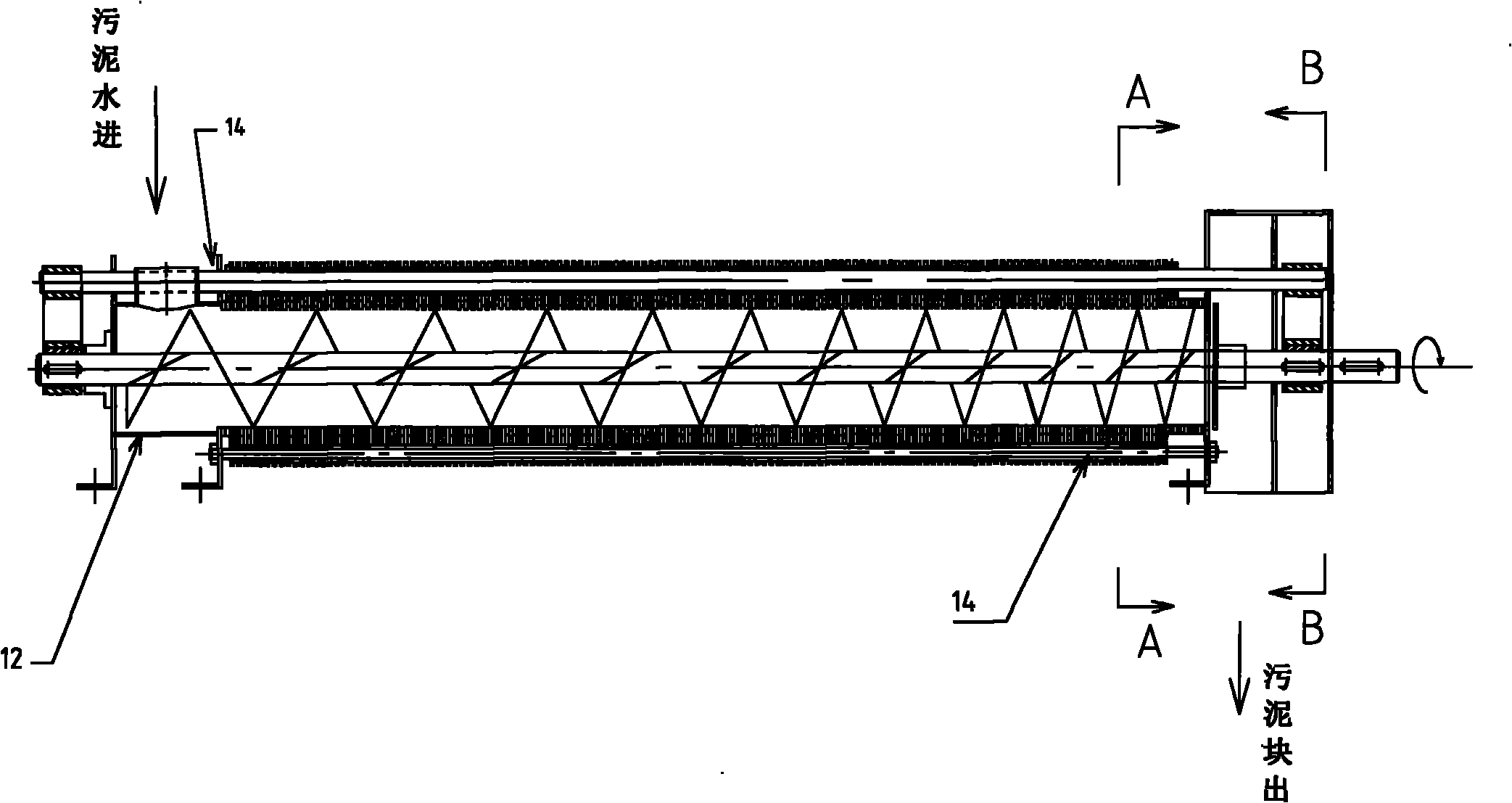

Screw type solid-liquid separator

InactiveCN101905098AEasy to separateEasy dischargePressesStationary filtering element filtersLinear motionPulp and paper industry

The invention relates to the solid-liquid separating technology, particularly belonging to a filtering device of environmental protection sewage field. The invention more particularly discloses a screw type solid-liquid separator which comprises a fixed ring, a movable ring and a spiral shaft, wherein the spiral shaft is provided with the fixed ring and the movable ring which are arranged in a staggered way along the radial direction; the movable ring is connected with a guide rod which is connected with a connecting rod; the two ends of the spiral shaft are provided with eccentric sections; the connecting rod is sheathed and connected with the eccentric sections; the spiral shaft drives the eccentric sections to rotate so as to further drive the connecting rod to make eccentric motion; and the guide rod is driven to make linear motion in a guide rail by the eccentric motion of the connecting rod, so that the movable ring is driven to move. The motion of the movable ring of a filtering body is realized by the eccentric motion of the connecting rod and the guide rod driven by the eccentric sections, so that the problem of abrasion between the movable ring and a spiral shaft blade can be fundamentally solved, and the durability and the practicability of the separator can be greatly improved. The screw type solid-liquid separator is applicable to large, medium and small-sized sewage treatment plants.

Owner:上海日鹤环保设备技术有限公司

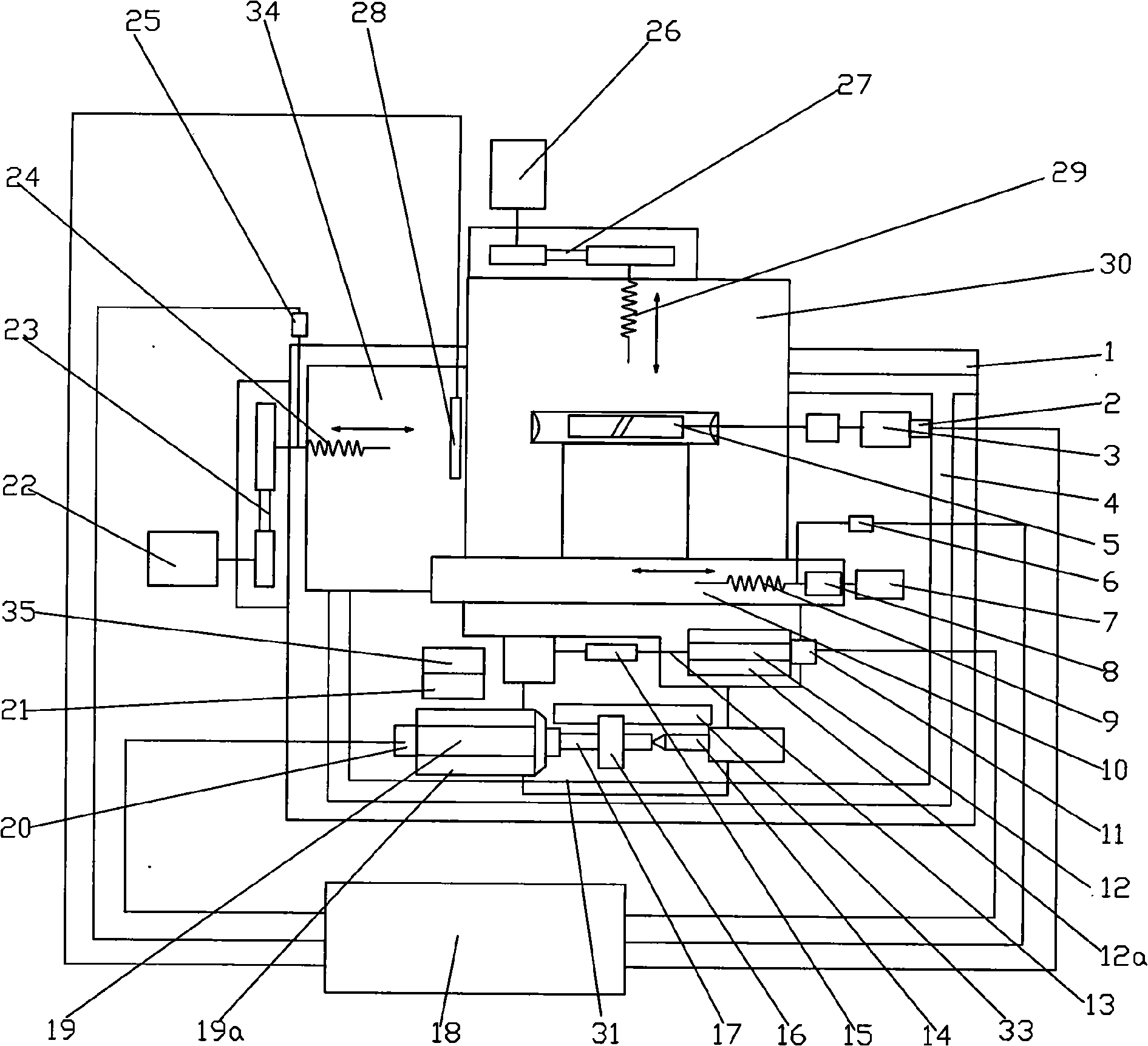

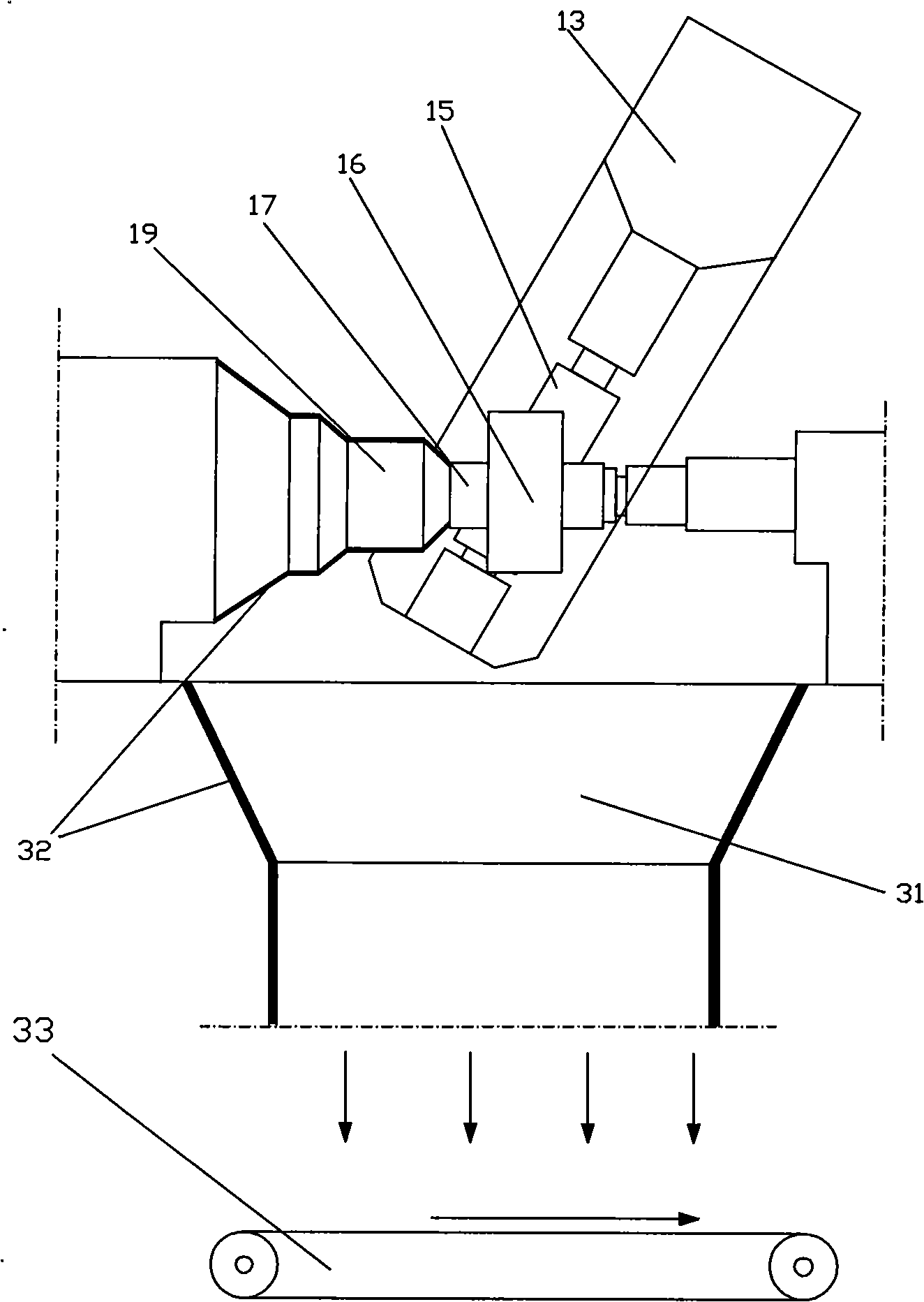

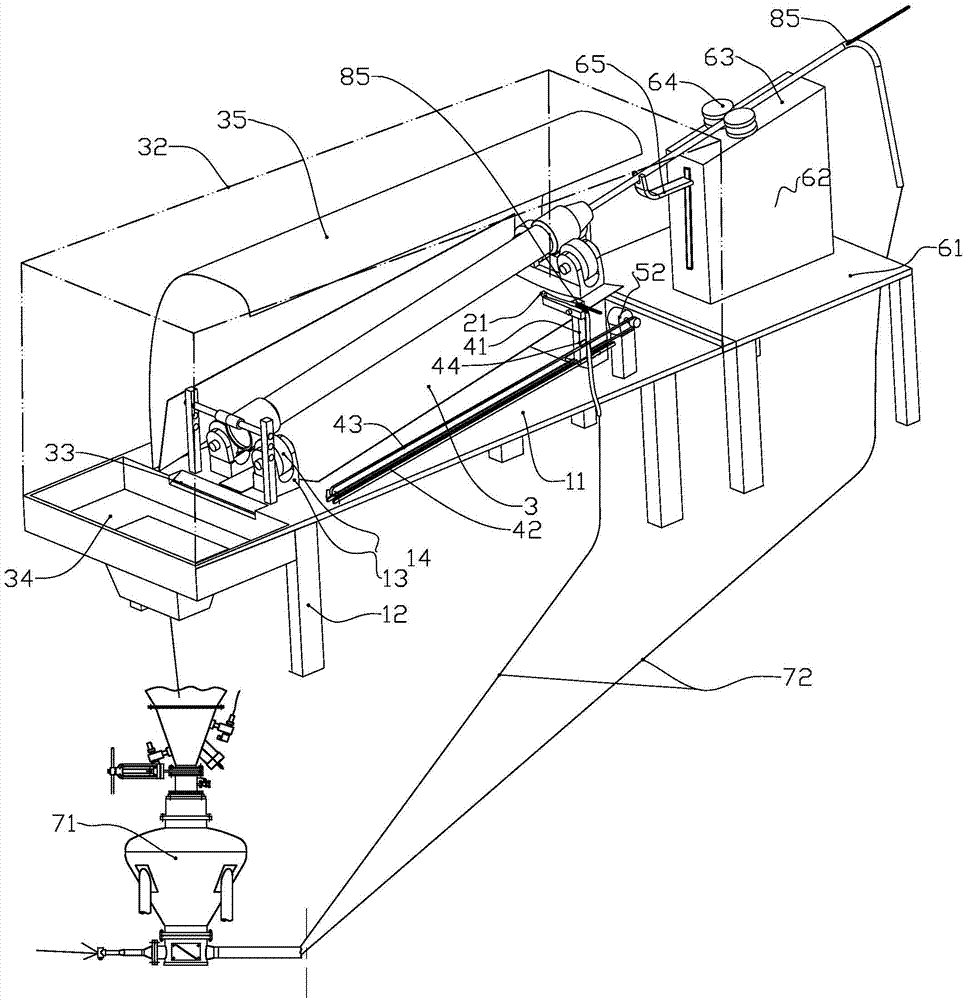

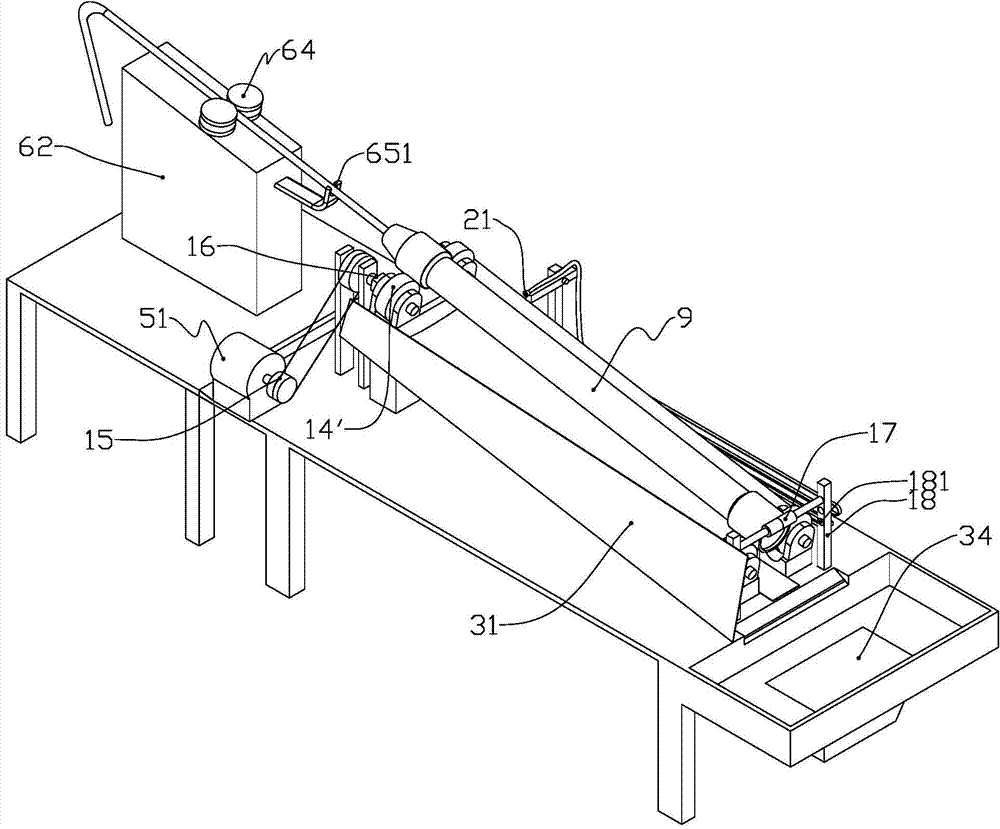

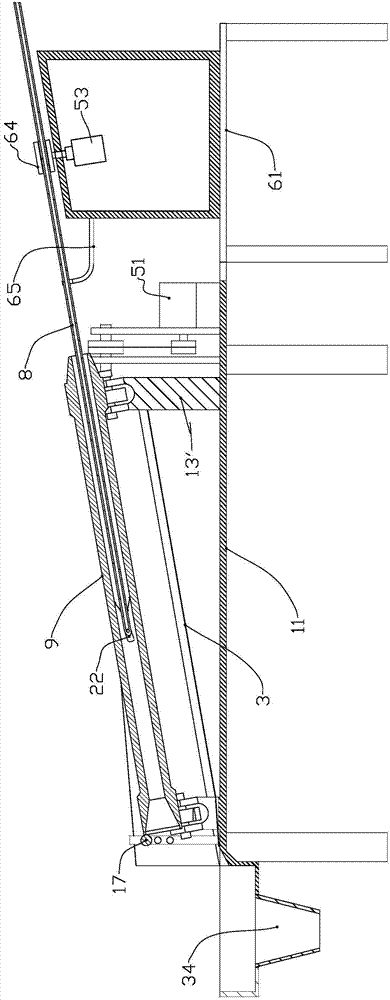

Shot-blasting intensifying and cleaning device for inner and outer walls of petroleum drilling rod

ActiveCN104493727AAchieve cleaning effectAchieve reinforcementAbrasive machine appurtenancesAbrasive blasting machinesDrive wheelCoupling

The invention discloses a shot-blasting intensifying and cleaning device for inner and outer walls of a petroleum drilling rod. The device comprises a supporting part, a driving power part and a pneumatic shot-blasting part, wherein supporting legs are arranged at four corners of a platform; two mounting seats are fixedly arranged on the platform; the height of each mounting seat is larger than the height of the other mounting seat; the tops of one of the two mounting seats are inclined; a pair of supporting wheels which can support one drilling rod is arranged on the top of each mounting seat; the drilling rod is in an inclined state; one supporting wheel is connected to a belt pulley by virtue of a universal coupling; the belt pulley is driven by a first motor by virtue of belt drive; a rubber layer covers the surface of the supporting wheel serving as a driving wheel; and the first motor, a second motor and a third motor form a driving part. The inner wall of the drilling rod is cleaned and intensified, so that the wear resistance and strength of the inner wall are effectively improved, and the wear problem generated in the process of contacting the inner wall of the traditional drilling rod and sand is solved.

Owner:山东阳谷天岳钻具有限公司

End-engaging clutch

The present invention discloses a torque transfer clutch engagement End, including fixed meshing plate,mesh with the fixed-line activities face meshing disk and control activities along the axial meshing engagement with the fixed-combination and separation circuit control devices, fixed mesh disk and disk activity relative meshing surface-installed with the mesh face each other tooth Face or trough, fixed disk and meshing engagement activities on the site coaxial circular wound by a circuit-control meshing surface in a magnetic coil, a fixed mesh at the same magnetic disk and disk activity meshing separation, have the opposite when the fixed mesh magnetic disk Meshing and activities set of suction. The invention sovles the traditional friction clutch slipping easily and wear problems, and convenient manipulation, simple structure with high reliability.

Owner:李卫华

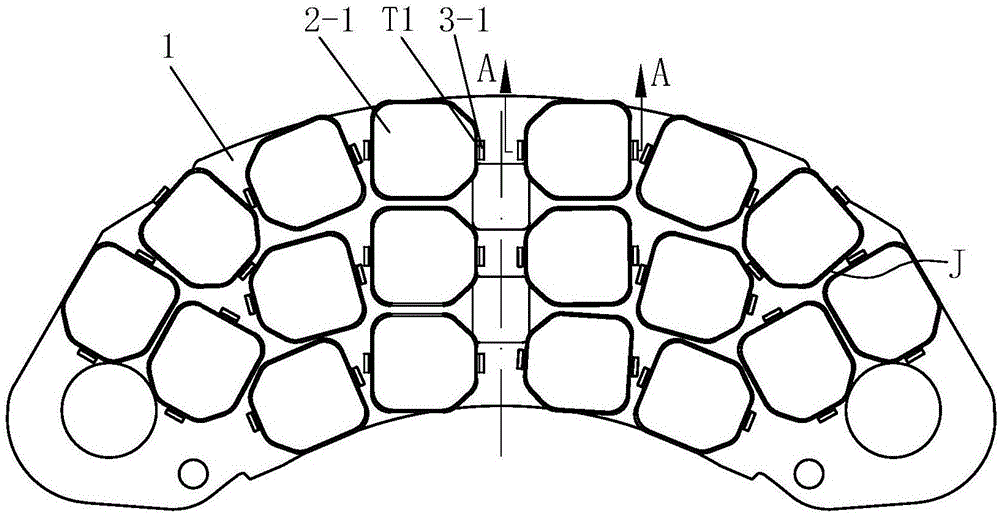

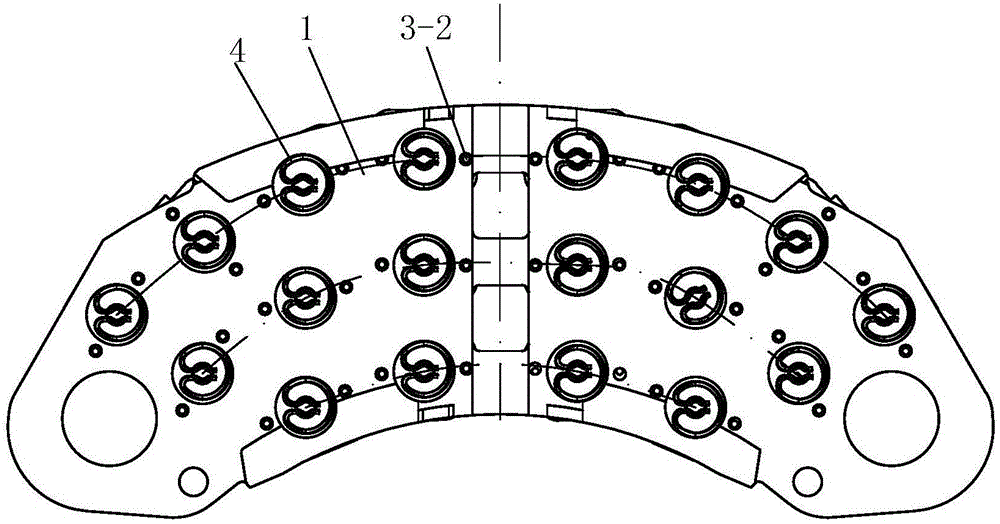

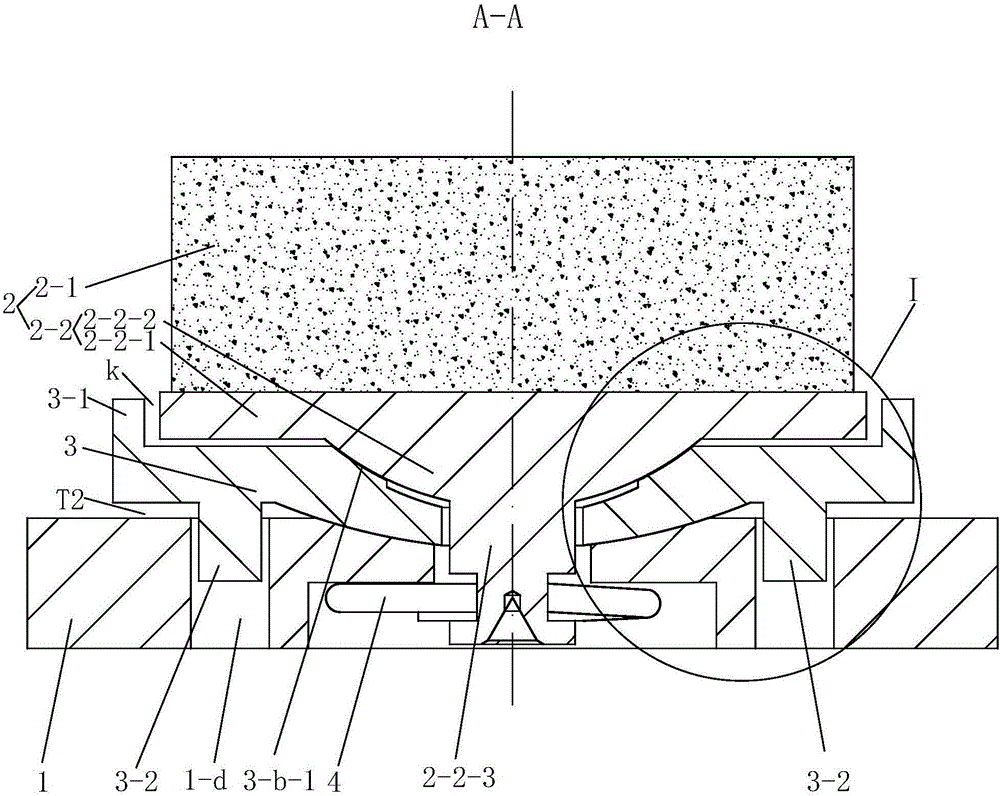

Train brake pad

ActiveCN106763330ARealize multi-dimensional adjustmentSolve partial wearBraking elementsFriction liningTwo stepBrake pad

The invention discloses a train brake pad; a plurality of friction blocks are arranged on a back plate; each friction block comprises a friction body and a support body; each support body consists of a plate body, a table body and a pin body; a downward convex spherical face is formed in the middle of the bottom surface of each adjustment seat; each adjustment seat is provided with a middle hole; the upper part of each middle hole is expanded around to form a two-step-shaped spherical face; the friction blocks sit on upper-step spherical faces of the middle holes through the table bodies of the support bodies; a gap is formed between one support body and the top surface of one adjustment seat correspondingly; pin bodies pass through the middle holes in a loosening manner; the upper part of each mounting hole is expanded around to form a concave spherical face; the adjustment seats sit on the concave spherical faces of a mounting seat through the downward convex spherical faces; two locating pins of each adjustment seat are inserted into two corresponding locating holes in the back plate in a loosening manner; a gap is formed between the peripheral edge of the bottom surface of each adjustment seat and the top surface of the mounting seat; spring clamp rings are arranged at the lower parts of the pin bodies; and the friction blocks, the adjustment seats and the back plate are connected in a floating manner by the spring clamp rings. Multidimensional adjustment on the friction blocks is realized, a situation that the surfaces of the friction blocks are in 100% contact with the surface of the train brake pad all the time is ensured, and the eccentric wear problem of train brake pad is solved.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

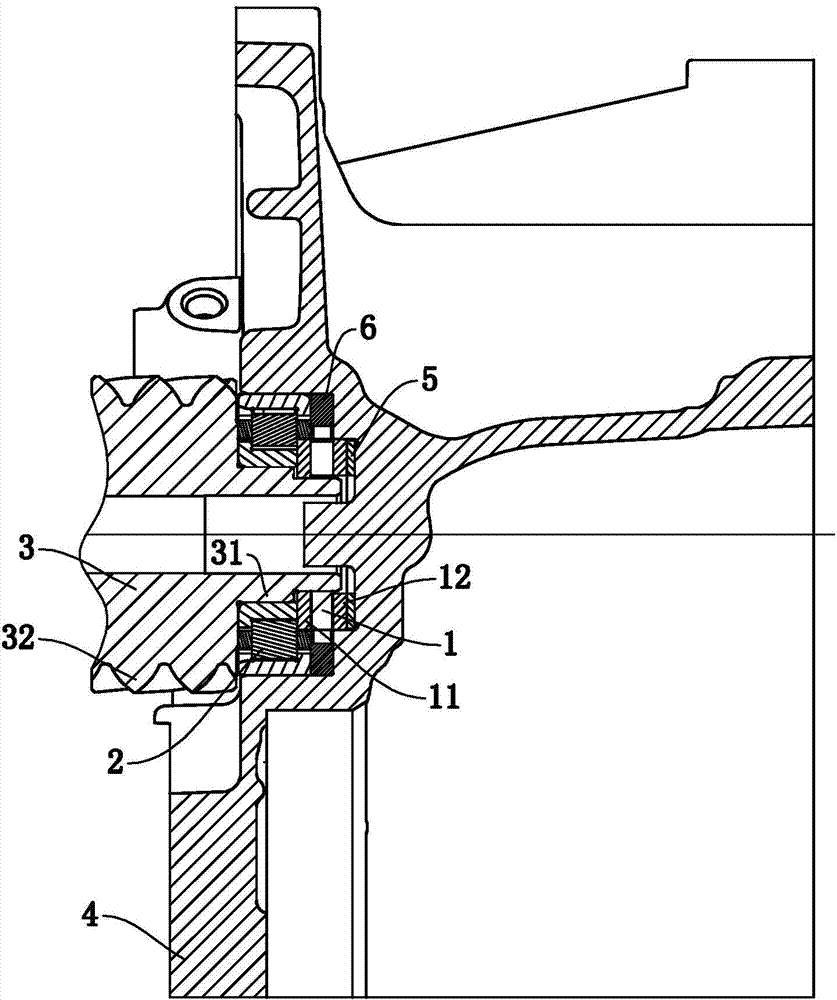

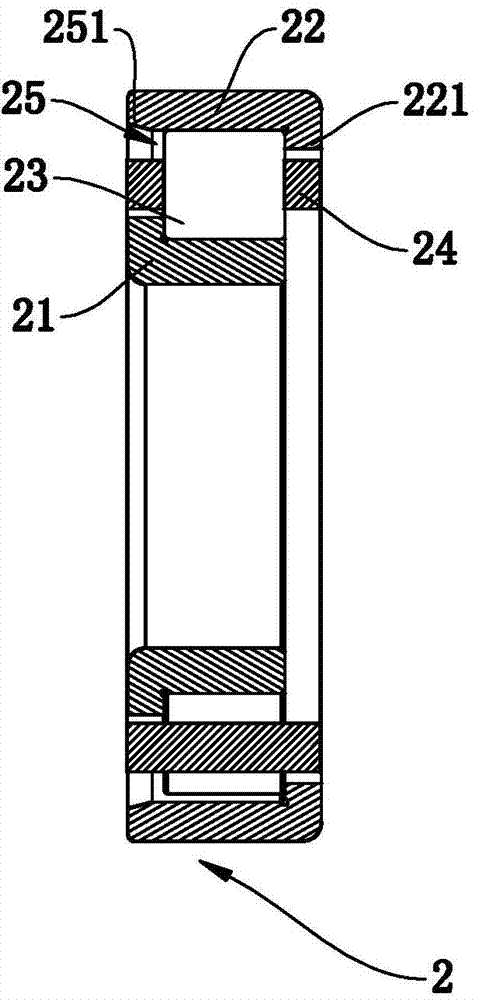

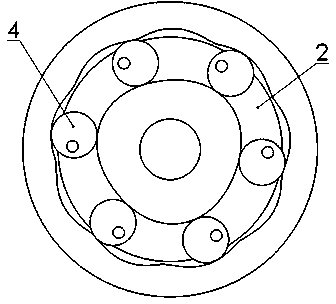

Output shaft support device for automatic gearbox

The invention discloses an output shaft support device for an automatic gearbox, and belongs to the technical field of the automatic gearbox. The output shaft support device for the automatic gearbox comprises an anti-thrust bearing and a radial bearing; an adjusting shim is installed between the ring of the anti-thrust bearing and the shell of the gearbox; the inner ring of the radial bearing is sleeved on the shaft shoulder of the output shaft; the outer side of the inner ring of the radial bearing bears against the output gear of the output shaft, and the inner side of the inner ring bears against the shaft ring of the anti-thrust bearing; the inner side of the outer ring of the radial bearing is provided with a flange; a spacer is installed between the flange and the shell of the gearbox; the outer ring of the radial bearing is fixedly installed with the shell of the gearbox; and the outer side of the outer ring of the radial bearing is provided with an opening. The output shaft support device for the automatic gearbox is capable of, through designing the radial bearing as the separated structure, solving the wearing problem of the gearbox shell, and solving the assembling problem of the radial bearing.

Owner:SHENGRUI TRANSMISSION

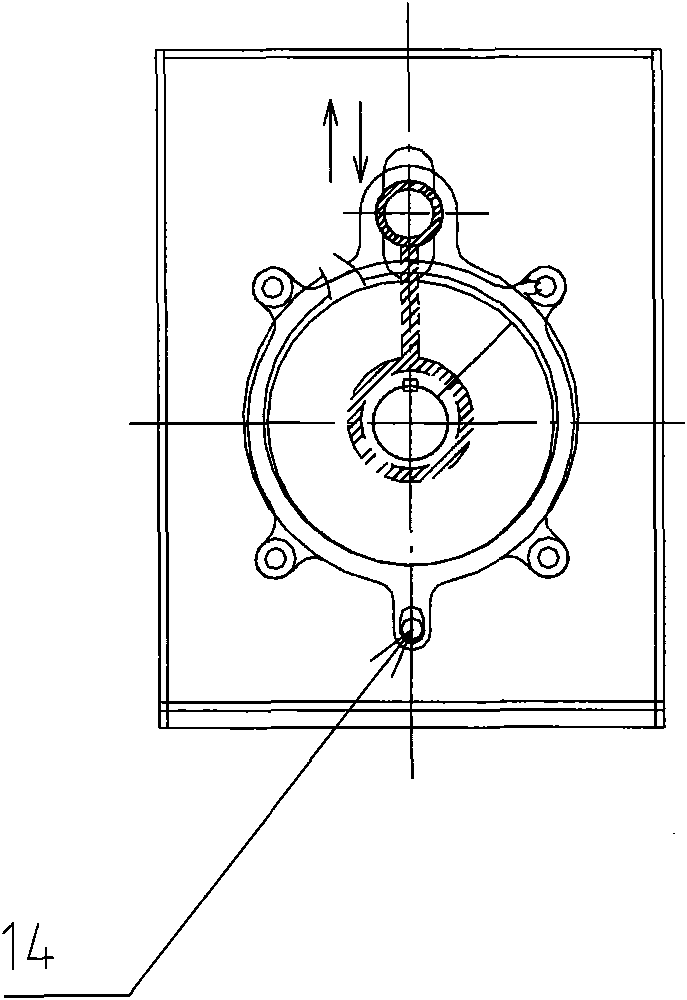

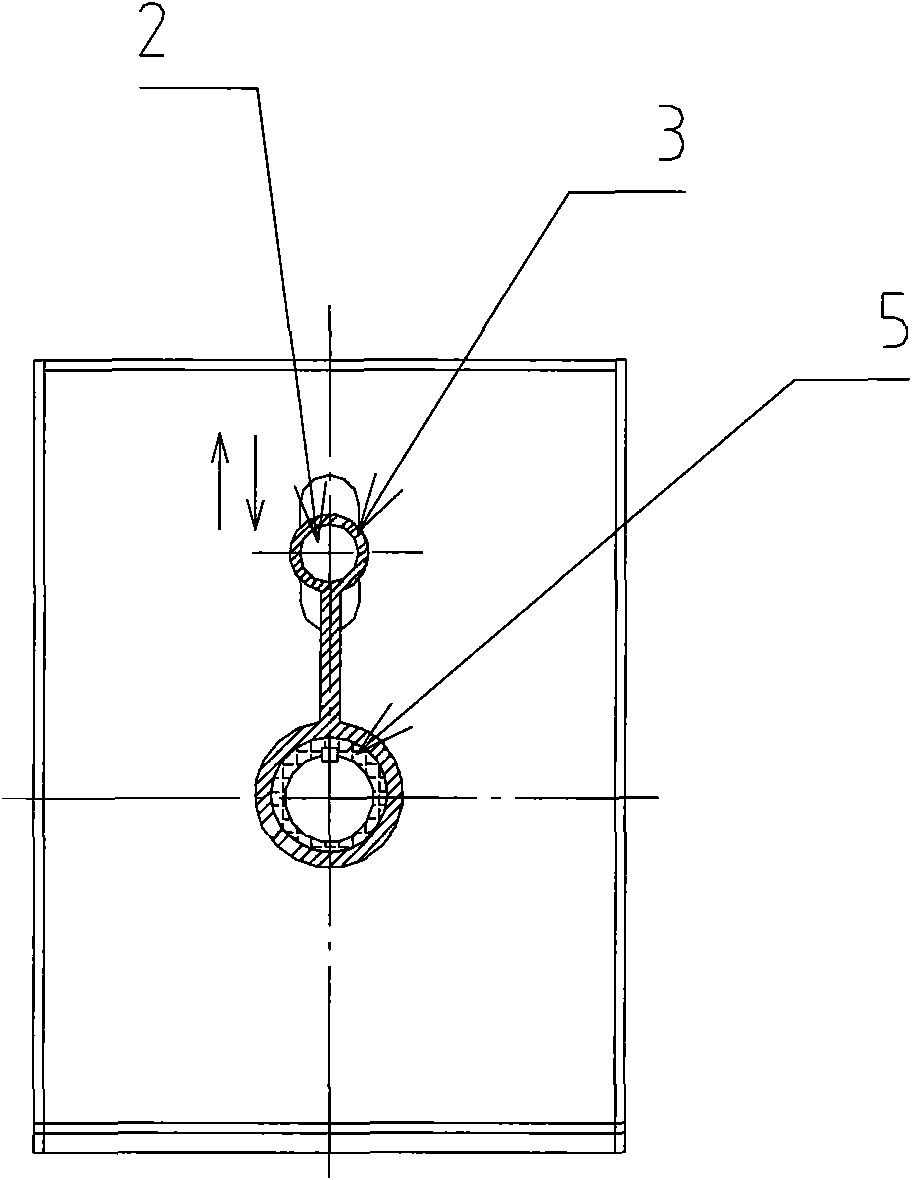

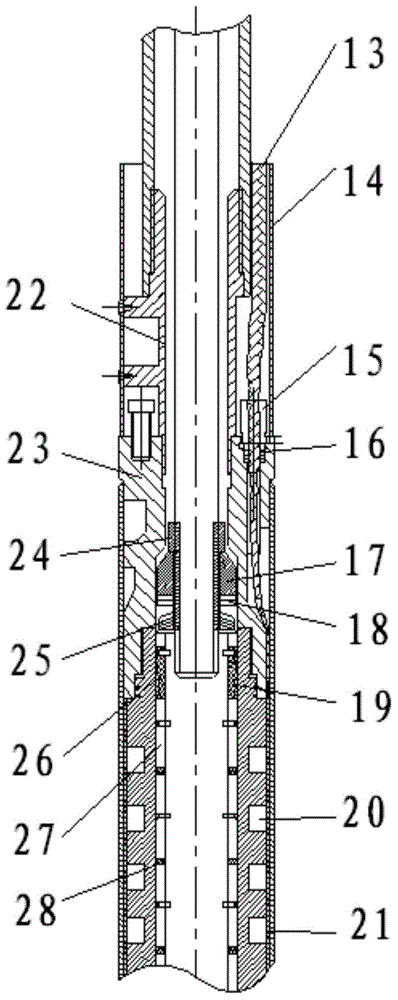

Intelligent wellhead sealing device

PendingCN109736739ASolve the sealing problemEnsure safe productionSurveyConstructionsEngineeringHigh pressure

The invention discloses an intelligent wellhead sealing device. The device comprises a floating double-sealing device and a set of hydraulic energy storage and reinforcement system capable of compensating pressure; the floating double-sealing device comprises a shell and an annular sealing sleeve; a 360-degree sliding groove is formed in the top end of the shell; an annular sealing sleeve is fixedly installed in an inner cavity of the shell through a first supporting ring and a second supporting ring; the annular sealing sleeve is composed of a straight cylinder connecting sleeve and at leastone annular high-pressure sealing cavity; a floating packing box capable of horizontally floating in a sliding groove in the top end of the shell is installed at the upper end of the straight cylinderconnecting sleeve on the upper portion of the annular sealing sleeve; packing is installed in the floating packing box; an elastic pressing plate and a packing locking cap are installed on the packing; a polished rod of an oil pumping unit is installed in the annular sealing sleeve; the upper end of the polished rod of the oil pumping unit sequentially penetrates through the floating packing box,the packing, the elastic pressing plate and the packing locking cap; and the lower portion of the shell is connected with the hydraulic energy storage reinforcement system communicating with the high-pressure sealing cavity. An eccentric wear problem generated in 90% or more of oil wells is solved, and the service life of the oil pumping unit is prolonged.

Owner:刘胜益

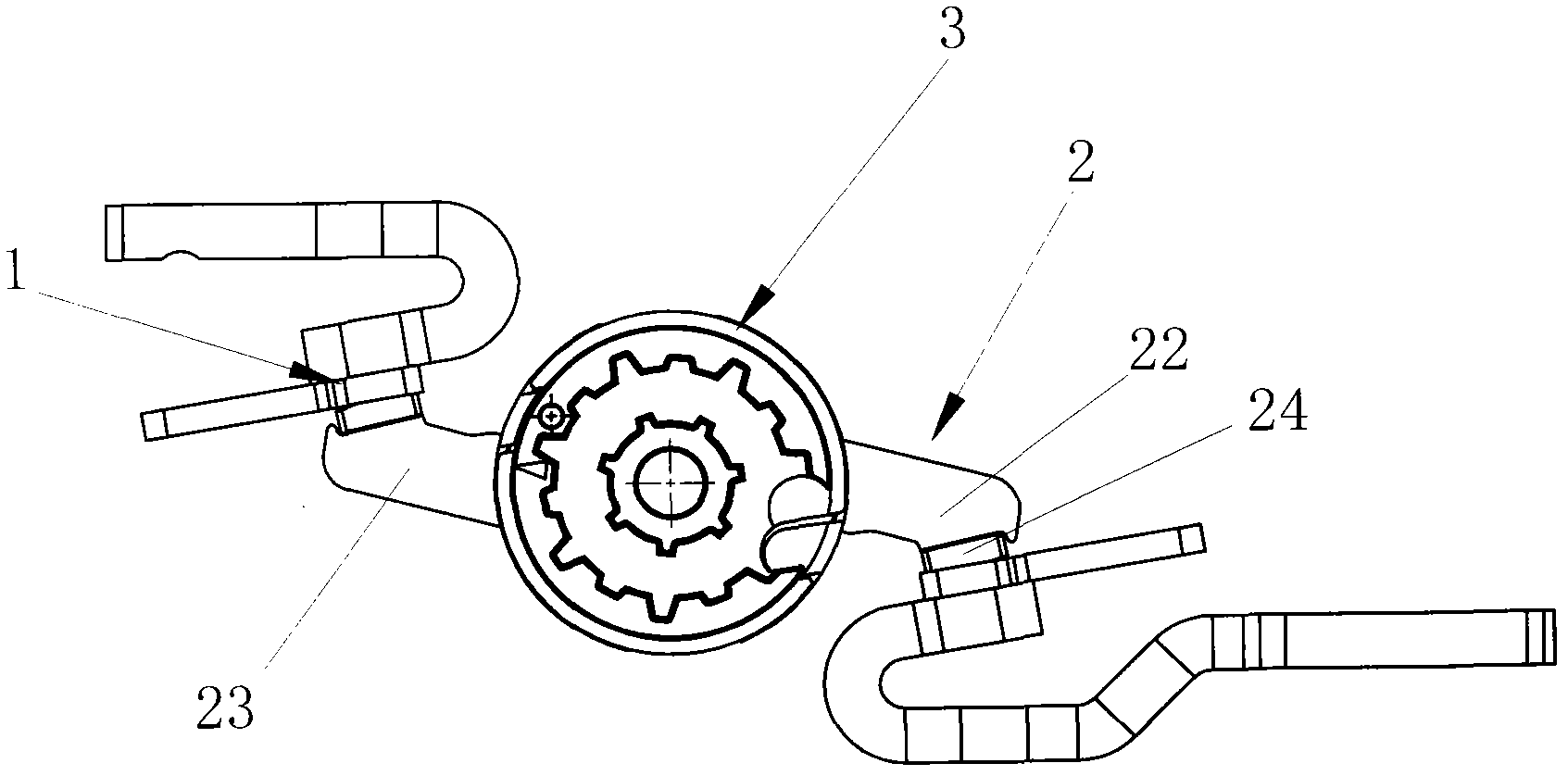

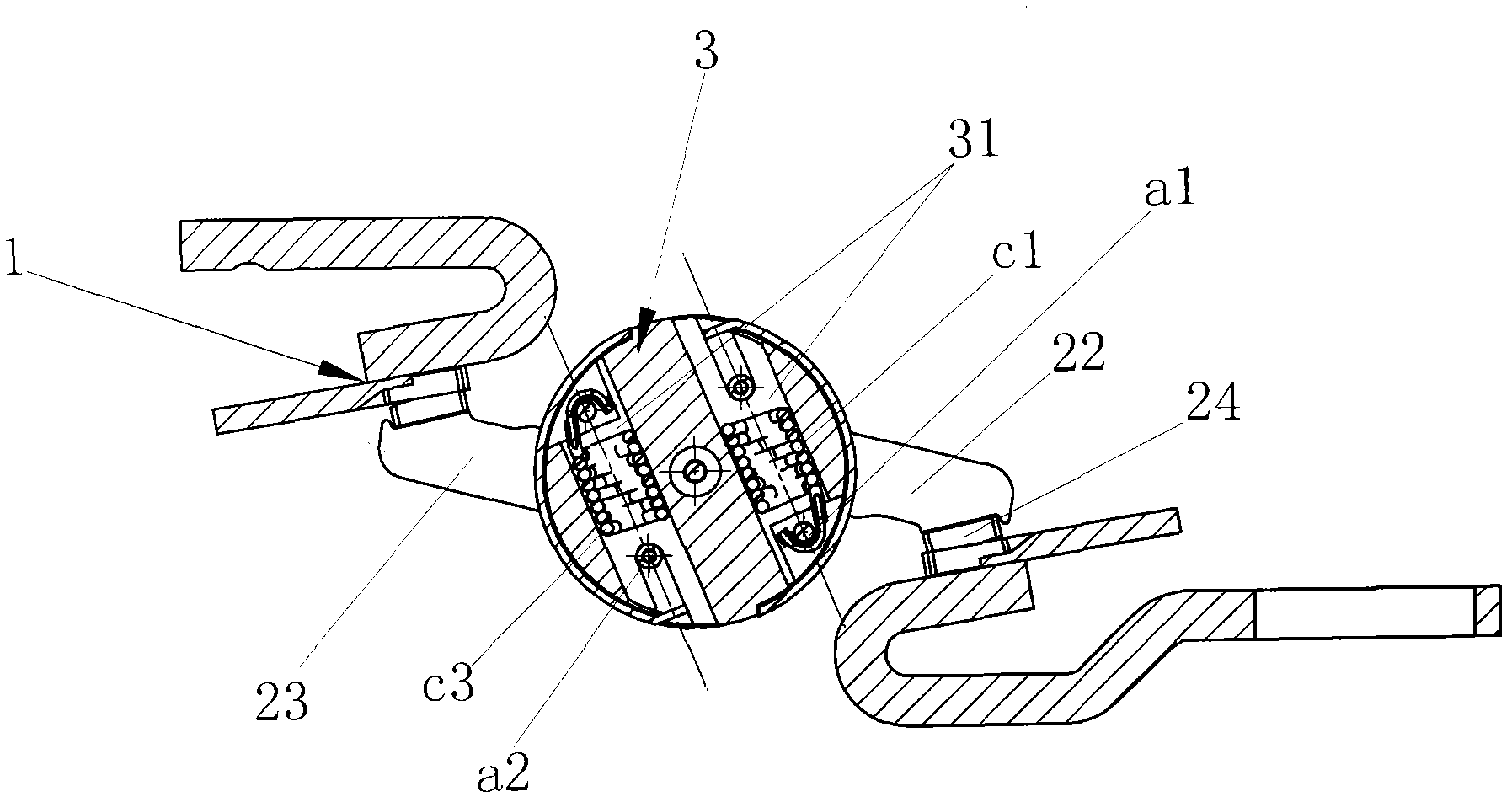

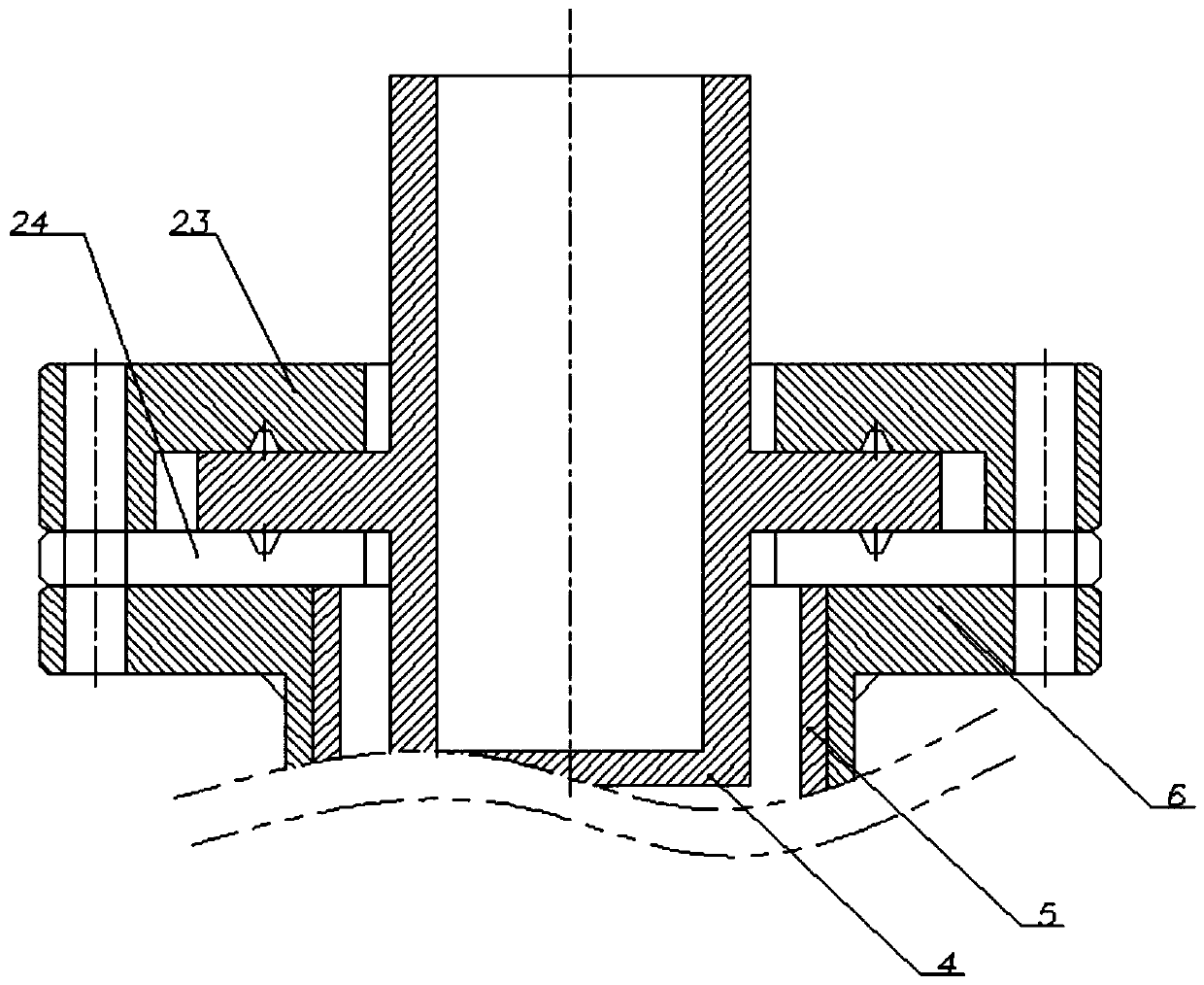

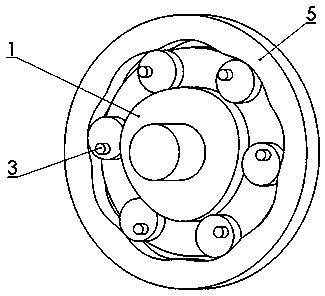

Cosine shock wave swing movable teeth transmission device

The invention relates to a cosine shock wave swing movable teeth transmission device which is characterized in that an input shaft shock wave generator is installed coaxially with an output shaft rack and a central internal gear; the central inner gear is fixedly connected with a machine body base; movable teeth pins are arranged on the output shaft rack; swing movable teeth are sleeved on the movable teeth pins and simultaneously in contact with the tooth profile of the input shaft shock wave generator and the tooth profile of the central internal gear; the tooth profile of the input shaft shock wave generator is a cosine tooth profile in which a cosine curve or an equidistant curve of the cosine curve serves as a profile contour curve and a cosine teeth profile conjugate curve, or the equidistant curve of the cosine curve serves as the profile contour curve. The cosine shock wave swing movable teeth transmission device fundamentally solves a wearing problem of a movable teeth engagement pair, so that the processing technology difficulty is greatly lowered, the size and the accuracy are well guaranteed, the stability in transmission is also guaranteed by the smooth curvature characteristic of a cosine shock wave, and the cosine shock wave swing movable teeth become transmission elements with an excellent transmission performance due to the characteristics.

Owner:HUNAN HENGZHI ROCK DRILLING TECH

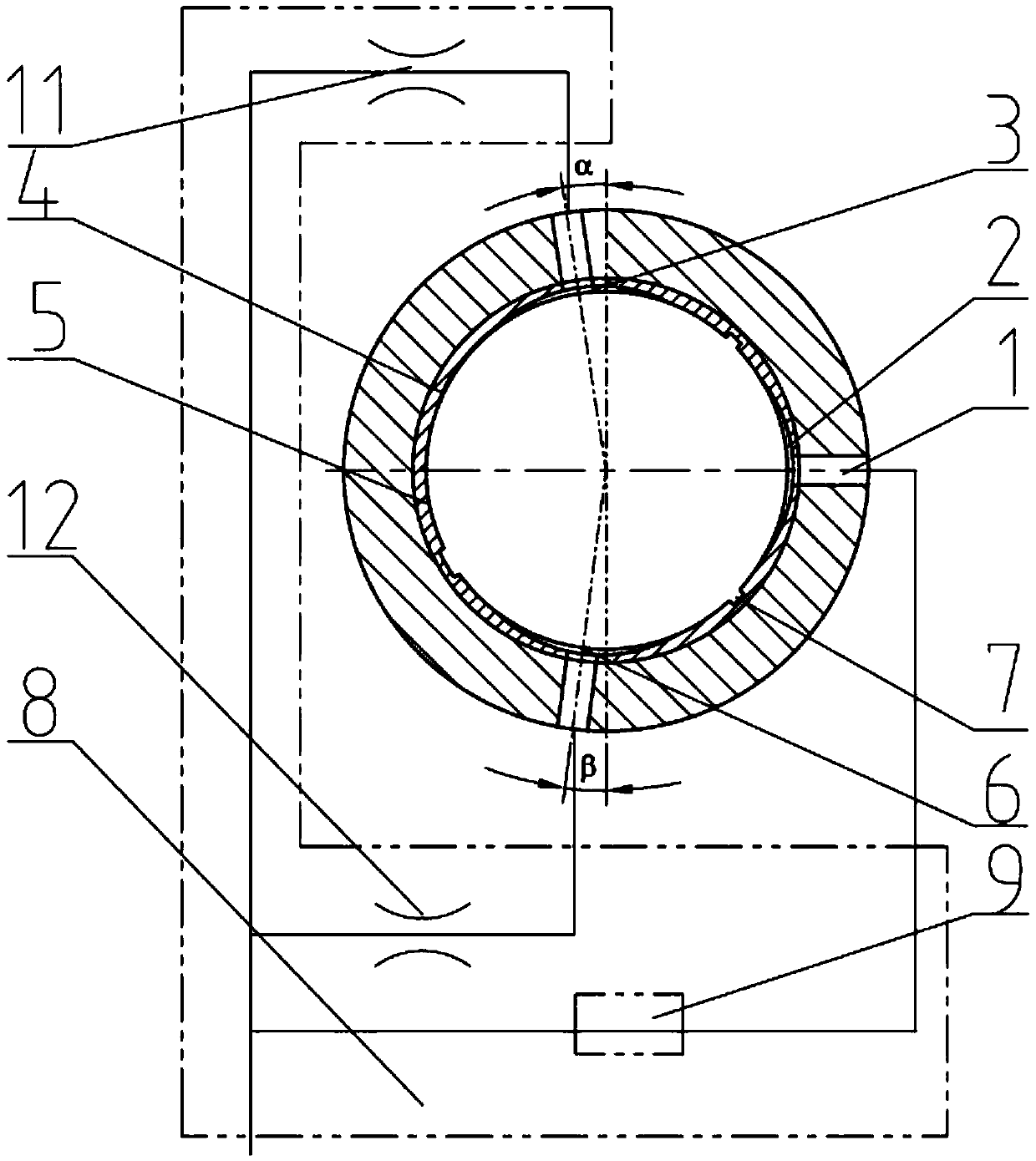

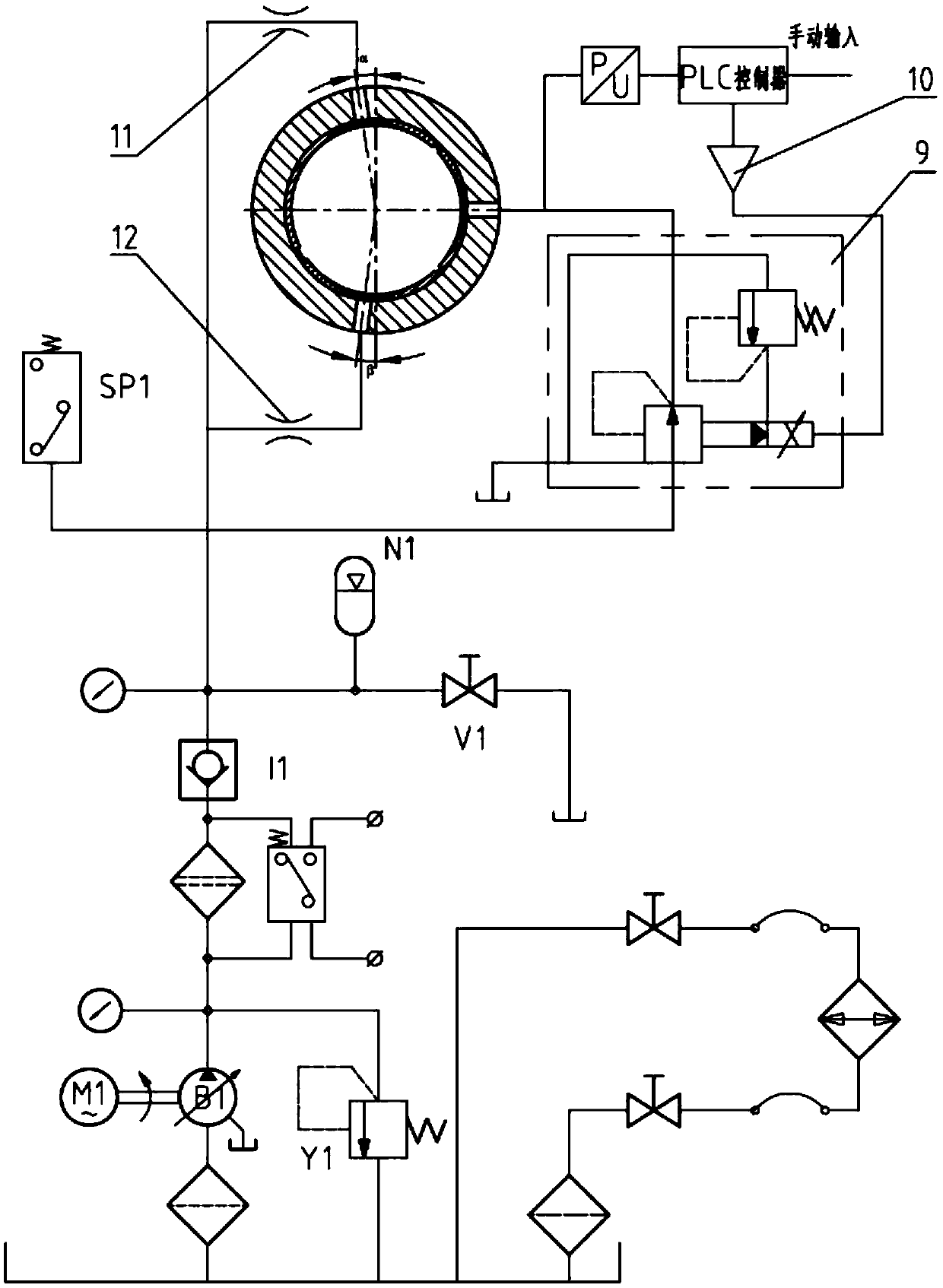

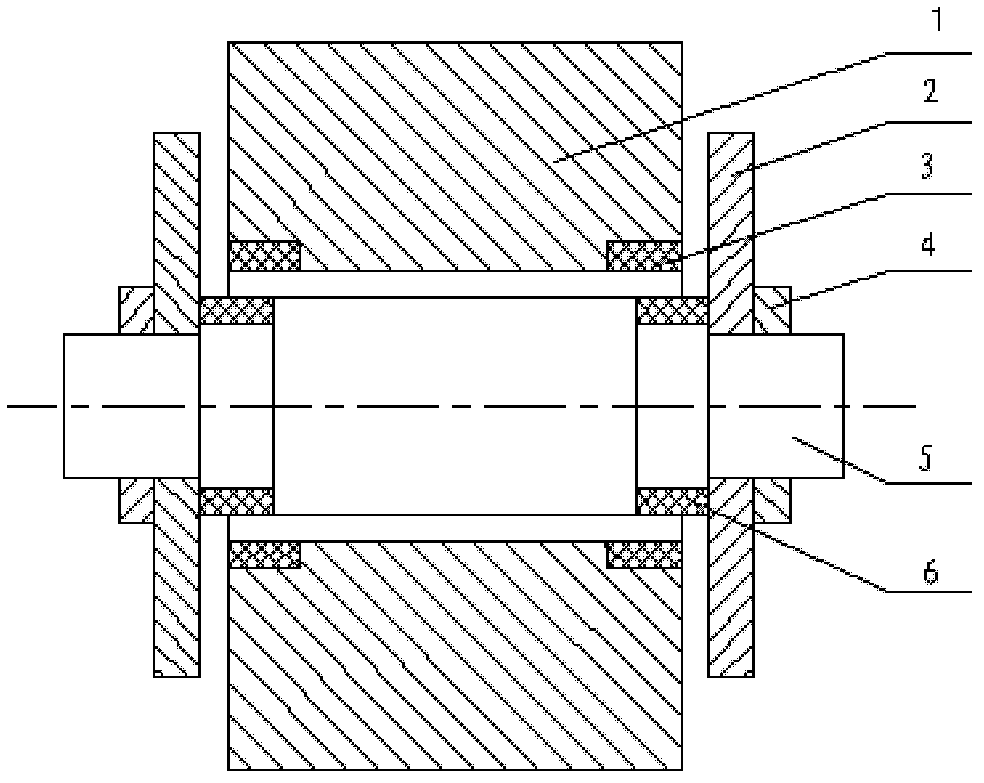

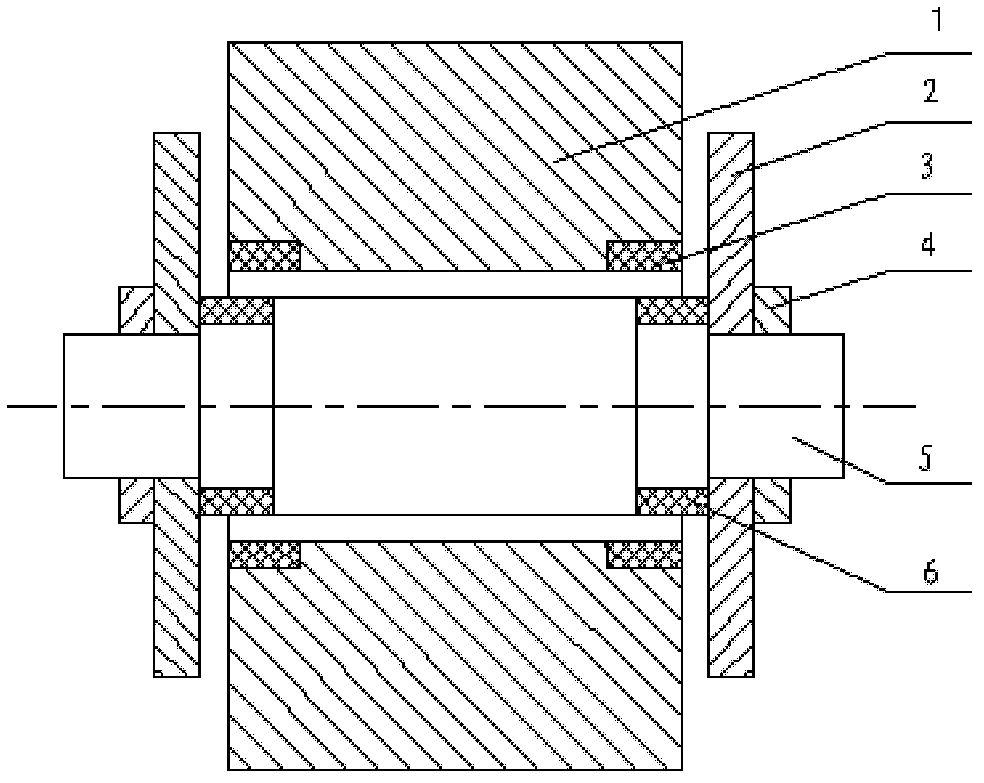

Oil film rigidity-adjustable fluid dynamic and static pressure slide bearing

ActiveCN105508426AEnhance the dynamic pressure effectAdjust oil film rigidityShaftsLiquid cushion bearingsDynamic pressurePetroleum engineering

The invention relates to an oil film rigidity-adjustable fluid dynamic and static pressure slide bearing. The bearing comprises a front static pressure oil cavity, an upper static pressure oil cavity, a lower static pressure oil cavity, a dynamic pressure cavity, three oil inlet holes, three axial oil return grooves and an oil supply system; the three oil inlet holes are respectively communicated with the front static pressure oil cavity, the upper static pressure oil cavity and the lower static pressure oil cavity, and are connected with the oil supply system; a wedged cavity is formed between the upper static pressure oil cavity and the dynamic pressure cavity; and the section of the wedged cavity is an Archimedes spiral oil cavity molded surface. The bearing overcomes and makes up the defects of other dynamic and static pressure slide bearings, preferably solves the wear problem caused by friction contact with the dynamic and static pressure bearing during starting of a main shaft, has the prominent characteristic of adjustability of oil film rigidity, and facilitates guarantee of revolving precision of a main shaft system and prolonging of service life.

Owner:SHANGHAI MACHINE TOOL WORK +1

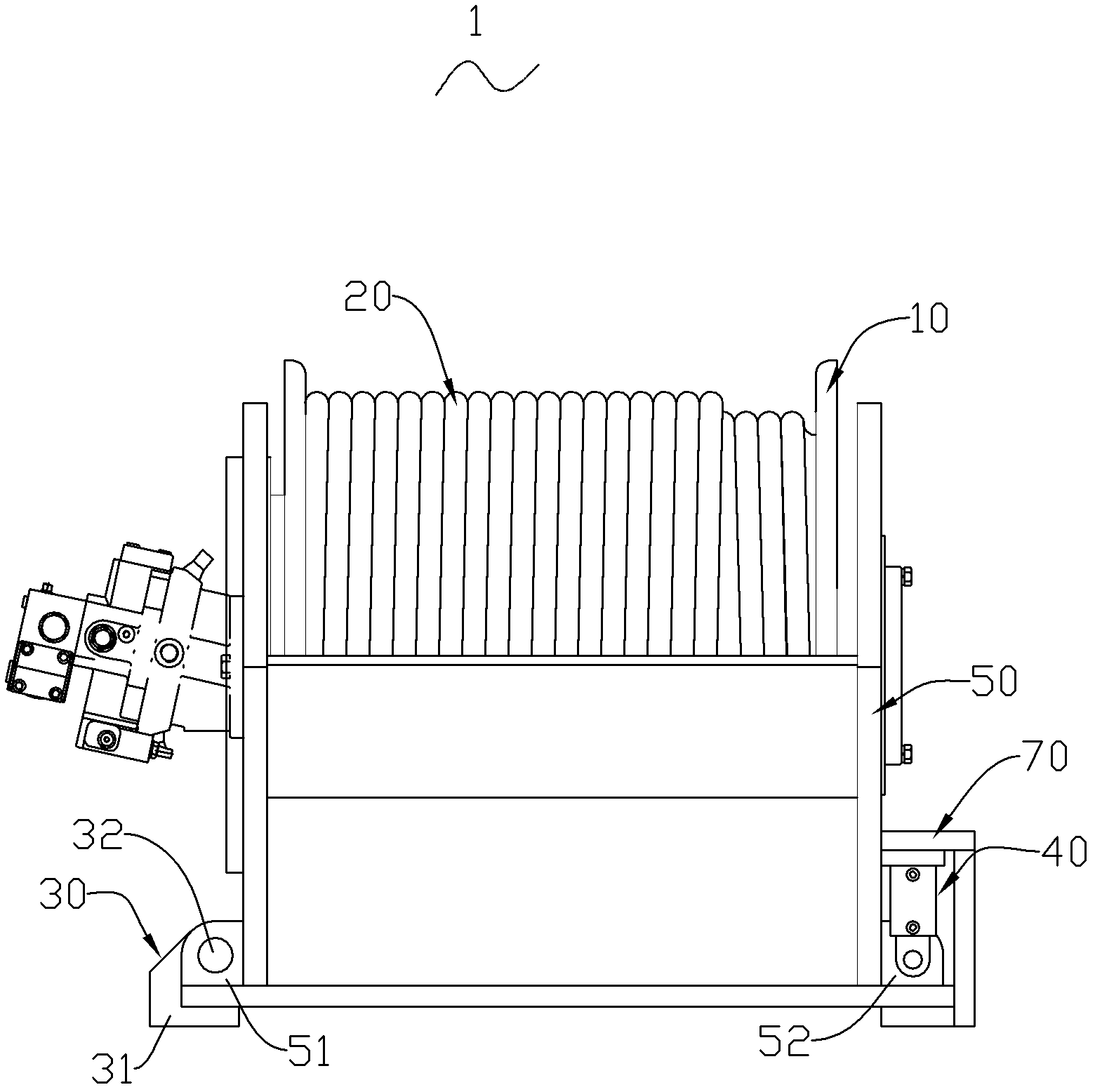

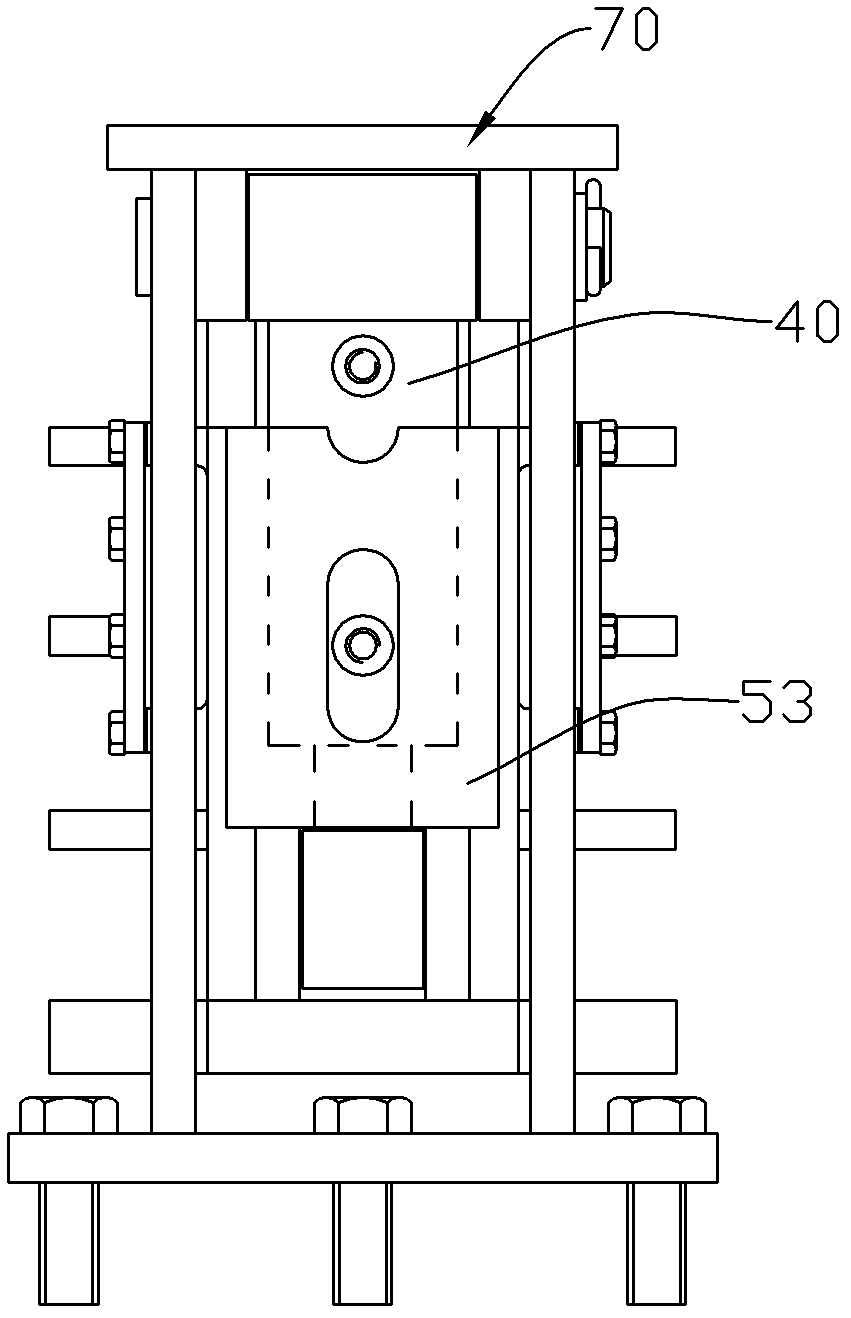

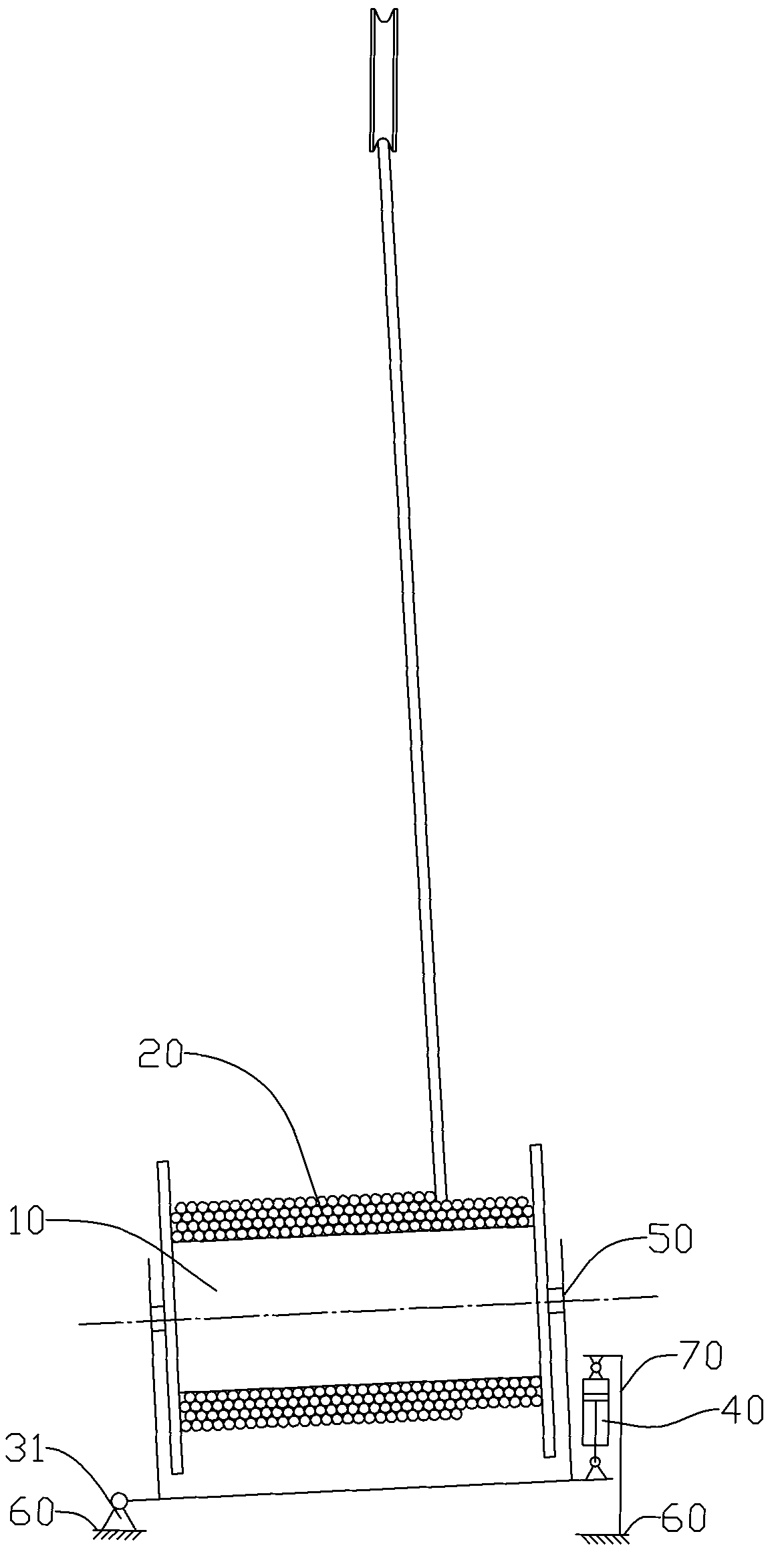

Winch with angle-adjustable winding drum axis

ActiveCN102515048AExtended service lifeSolve serious wear and tear problemsWinding mechanismsVertical planeEngineering

The invention provides a winch with an angle-adjustable winding drum axis, which comprises a winding drum, a frame and a steel wire rope. One end of the frame is hinged to a carrier supporting the winch, and the other end of the frame is connected with the carrier supporting the winch through an adjusting oil cylinder. When the winch works, a declination angle between the frame and a winding drum vertical plane can be adjusted correspondingly along with the steel wire rope coiling in and coiling out of the drum under driving of the adjusting oil cylinder, and the declination angle between the steel wire rope and the winding drum vertical plane is reduced. The winch greatly reduces abrasion between the inlet and outlet steel wire rope and an adjacent rope ring, prolongs service life of the steel wire rope, is simple and reasonable in structure, strong in bearing load and easy and convenient to install, solves the problem that relevant technology can not solve the problem of severe abrasion of the steel wire rope of the winch fundamentally, and fills a gap in the technical field. The winch is especially applicable to machines with winches for long-time heavy-load operation, such as rotary excavating drilling machines, and is also widely suitable for other machinery using winches.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

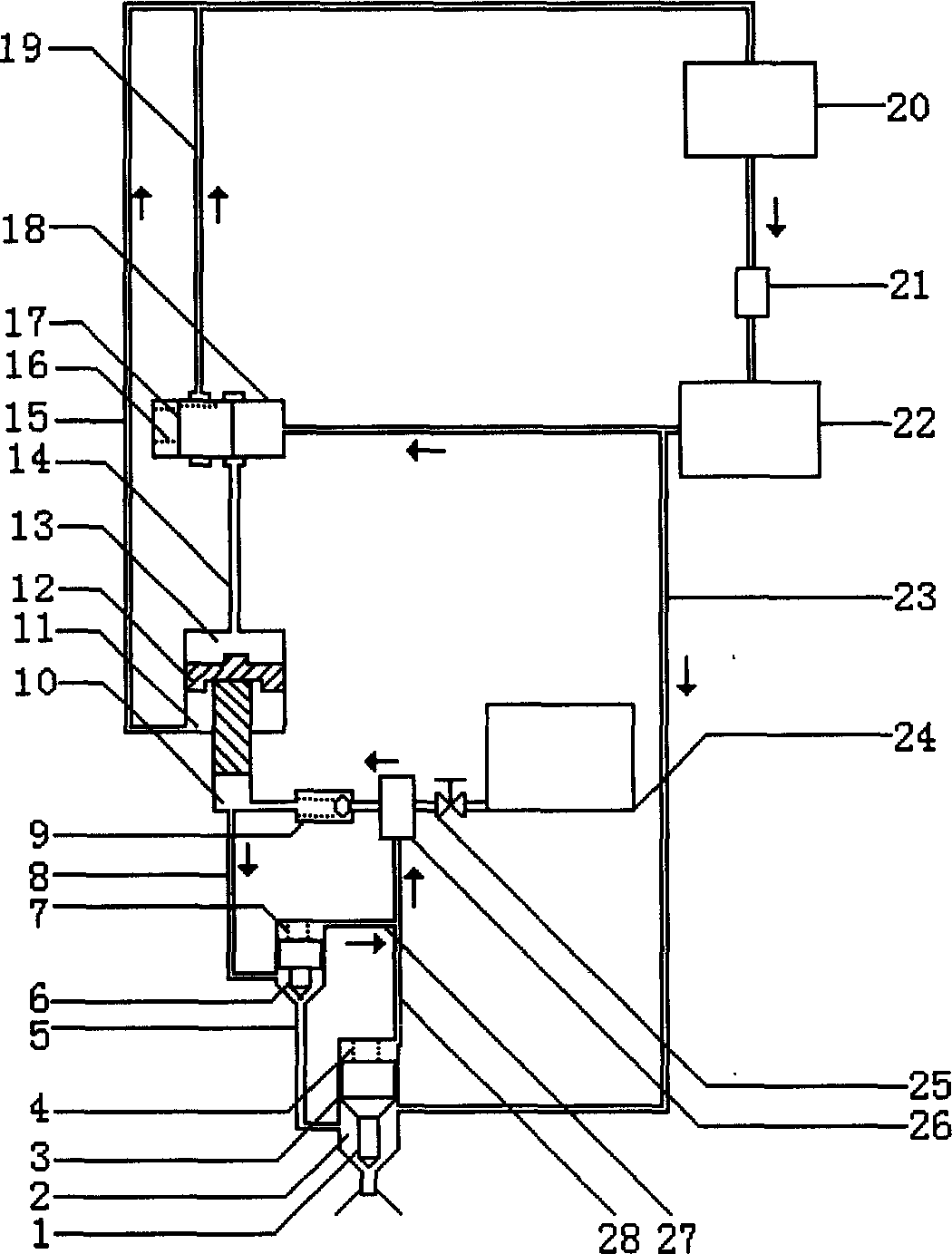

Diesel, dimethylether mixed injection system

InactiveCN1556319ASolve wear and tearMinor changesInternal combustion piston enginesHigh pressure gas fuel injectionHigh pressureCheck valve

The system includes fuel injector, dimethyl ether needle valve, dimethyl ether, check valve, compression cavity for dimethyl ether, drive piston, drive cavity, slide valve, diesel oil pump, storage tank for dimethyl ether etc. Diesel oil pump through slide valve is connected to drive cavity so as to form system for driving dimethyl ether. Diesel oil pump provides diesel oil for fuel injector. Dimethyl ether from storage tank through check valve and needle valve is provided for fuel injector. Refluent diesel oil on upper part of the fuel injector reenters into spraying system for playing lubrication. In the invention, diesel oil supply system provides diesel oil and as a driving system for dimethyl ether. Mixed fuel is formed inside fuel injector. Dimethyl ether is not needed to pass through oil pump, and high-pressure nitrogen tank is also not needed. Wear problem is also solved in the invention.

Owner:SHANGHAI JIAO TONG UNIV

Gas-magnetic hybrid bearing for gyro motor use

ActiveCN102434586AExtended service lifeSolve friction and wear problemsBearingsMagnetic bearingSystem stability

The invention relates to a gas-magnetic hybrid bearing for gyro motor use. The bearing comprises a shaft sleeve, a shaft, thrust plates, inner magnet rings, outer magnet rings and nuts. The shaft piercing through the shaft sleeve is coaxial installed inside the shaft sleeve, and two ends of the shaft are coaxially provided with thrust plates that are fastened by nuts. Tiny gaps are kept between the shaft and the shaft sleeve as well as between the thrust plates. A group of outer magnet rings are coaxially arranged on the inner surface of the shaft sleeve, and a group of inner magnet rings corresponding to the outer magnet rings in positions are coaxially mounted on the outer surface of the shaft. And the inner round faces of the outer magnet rings and the outer round faces of the inner magnet rings are of the same polarity, so that the function of a permanent magnetic bearing can be realized. The gas-magnetic hybrid bearing for gyro motor use in the invention has simple structure, scientific design, safety and reliability, and strong practicality. The bearing provided in the invention integrates the advantages of aerodynamic bearings and permanent magnetic bearings, overcomes the friction and wear problems during motor starting and stop in aerodynamic bearings, and also solves the problems of poor system stability and small rigidity in permanent magnetic bearings.

Owner:TIANJIN NAVIGATION INSTR RES INST

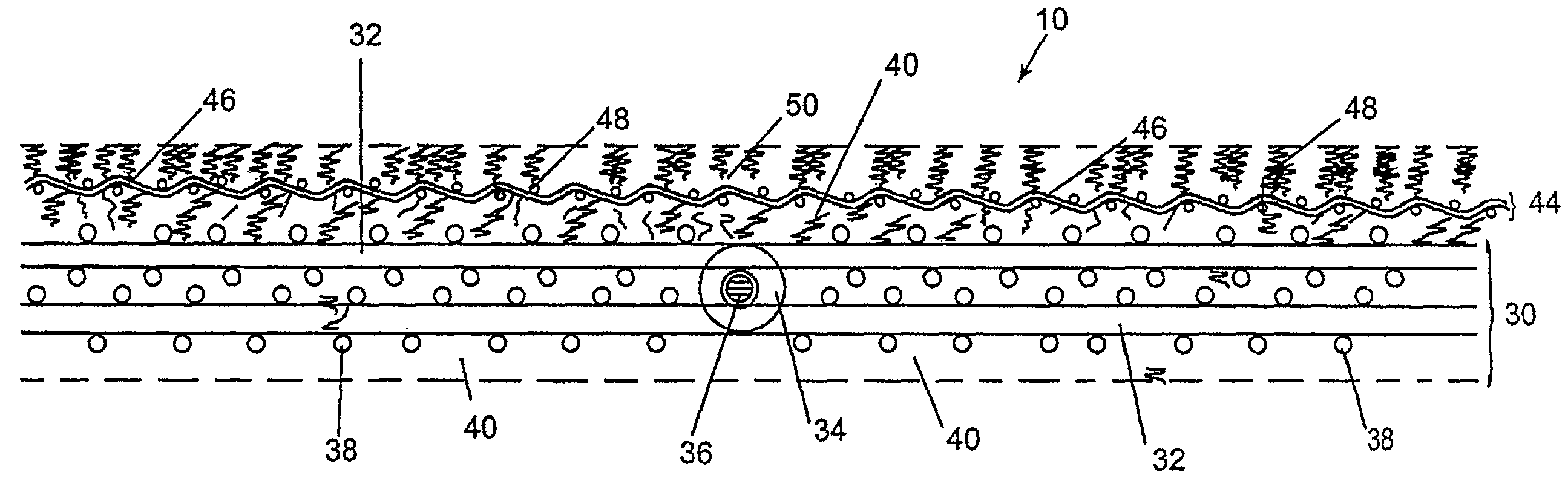

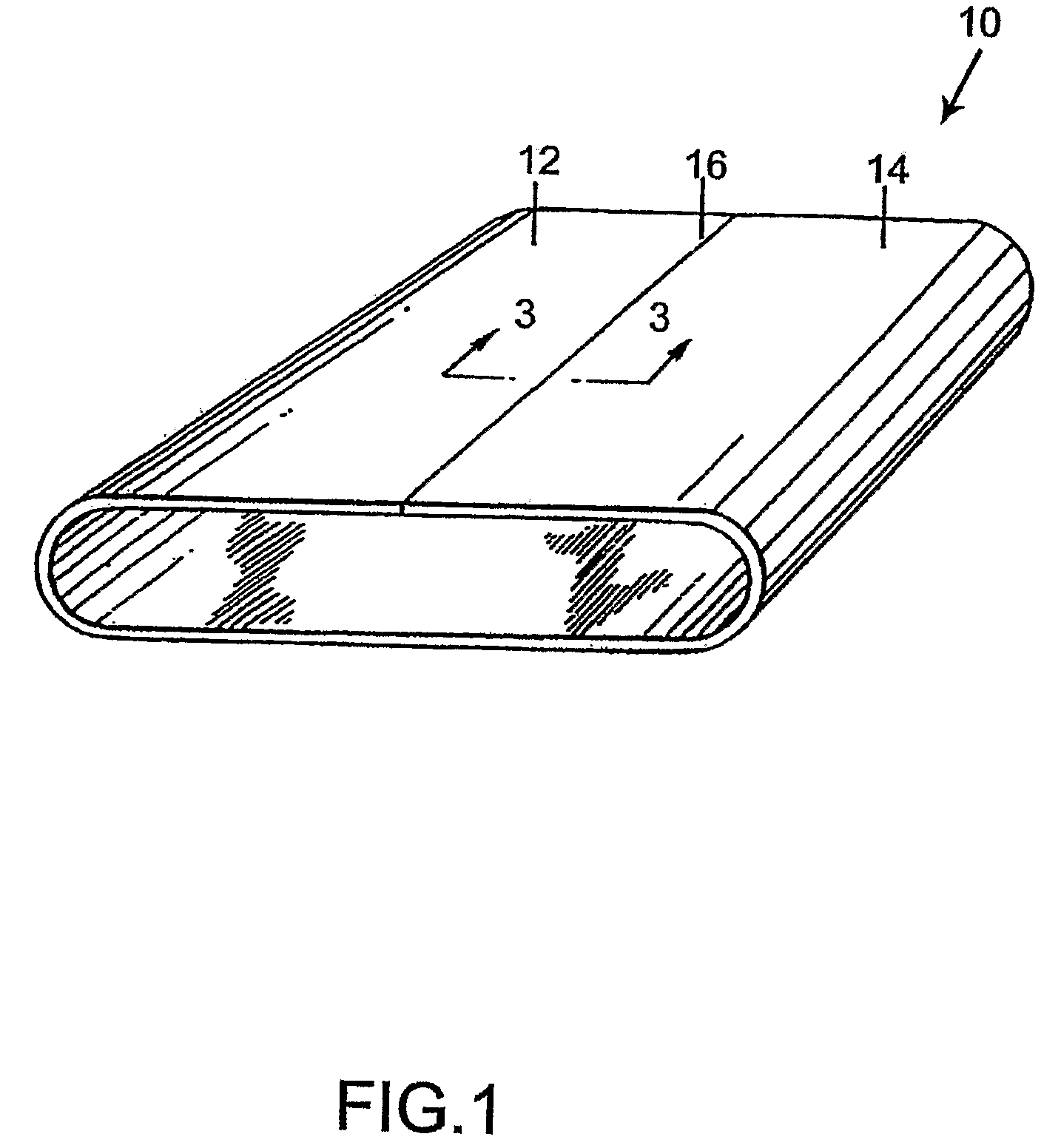

Passive sensor system for detection of wear problems in paper machine clothing

A stratified press fabric for the press section of a paper machine having a passive sensor system for detecting wear in the press fabric. The lower (non-surface) layer(s) of the stratified press fabric are produced using colored staple fiber batt material. As the surface of the fabric is worn away through use, the colored batt material is exposed to provide a visual indication of the wear. This visual indication allows the customer to readily determine the appropriate time to replace the press fabric.

Owner:ALBANY INT CORP

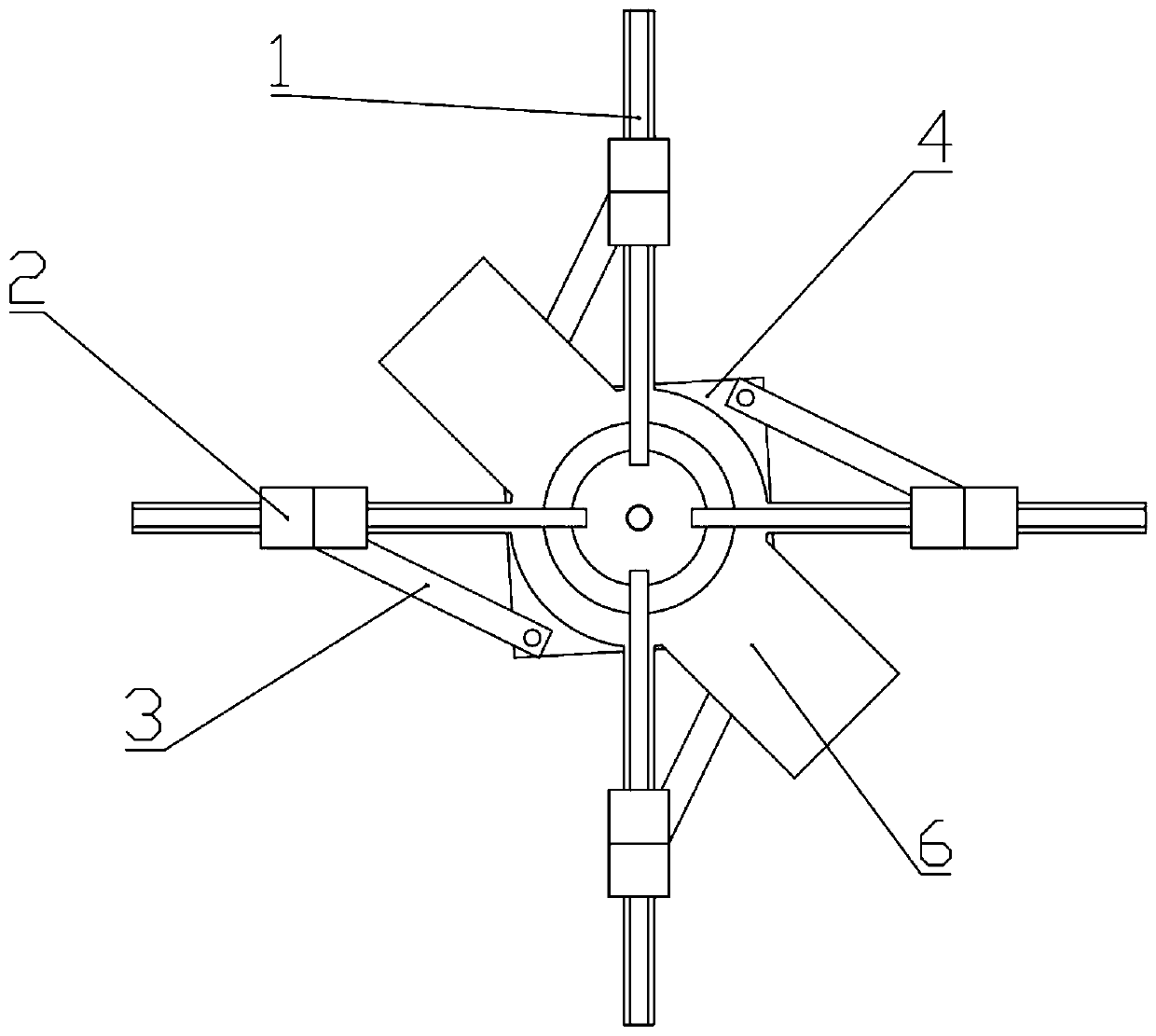

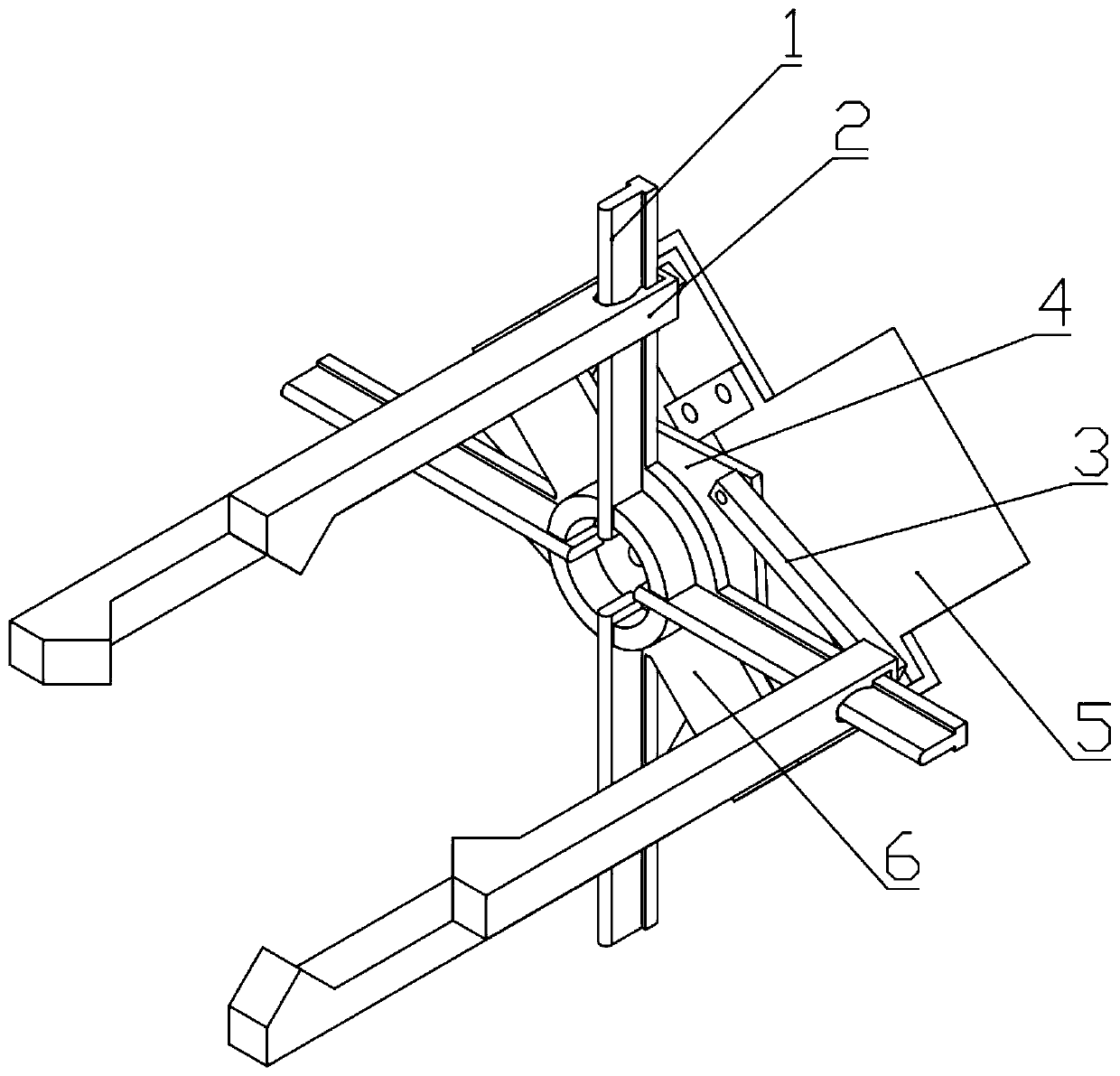

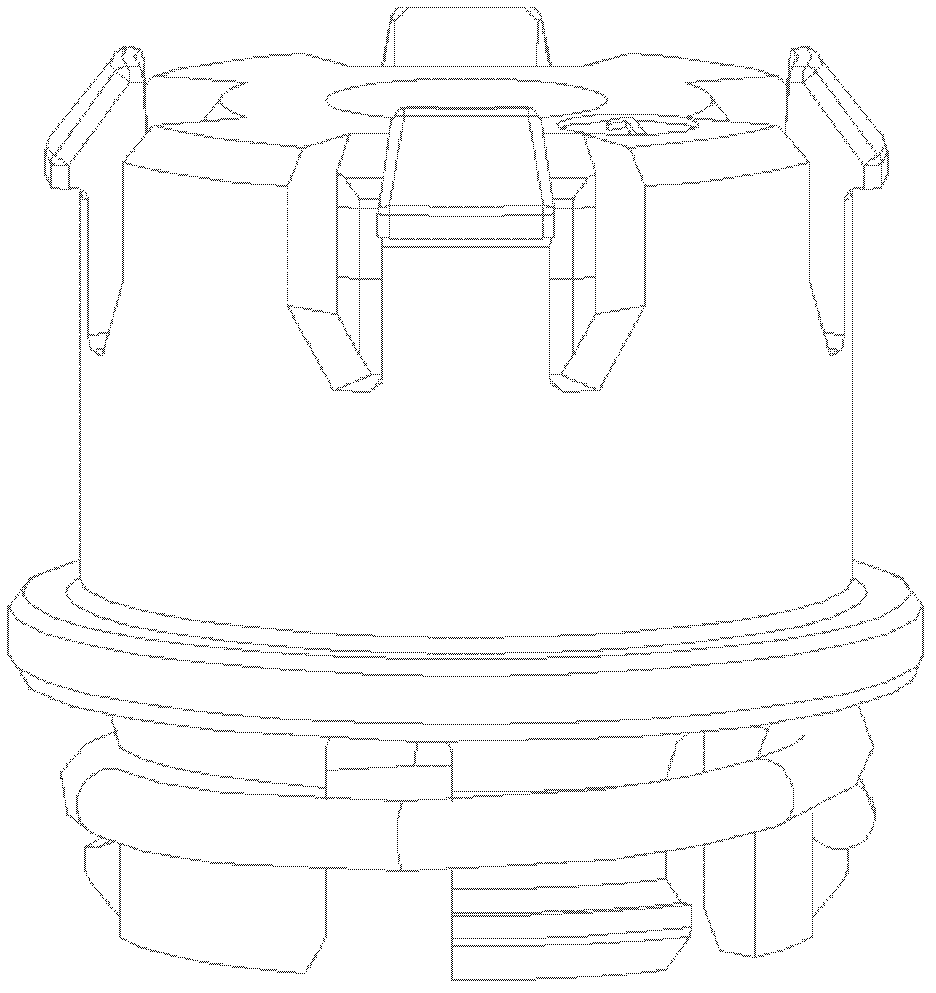

Centripetal closing type clamp mechanical gripper

The invention discloses a centripetal closing type clamp mechanical gripper. The centripetal closing type clamp mechanical gripper can achieve automatic gripping through autonomous control or parameter setting. The centripetal closing type clamp mechanical gripper comprises fixing machine frame guide rails. The lower ends of the fixing machine frame guide rails are coaxially and fixedly connectedwith a steering plate. The steering plate is coaxially and fixedly connected with a steering gear output shaft. The steering gear is connected with the fixing machine frame guide rails. The four corners of the steering plate are each hinged to one end of a connection rod. The other ends of the connection rods are hinged to four gripping jaws. The gripping jaws are connected to the guide rails. Thefour gripping jaws are arranged in four directions of the steering gear output shaft at equal intervals. The centripetal closing type clamp mechanical gripper is simple in structure, simple in control method and high in transportability. By controlling the flare angle, a spherical object can be stably gripped, and the shape of the object is not changed. During design of the centripetal closing type clamp mechanical gripper, the part wear problem is taken into full consideration, and parts are convenient to replace.

Owner:NANJING UNIV OF SCI & TECH

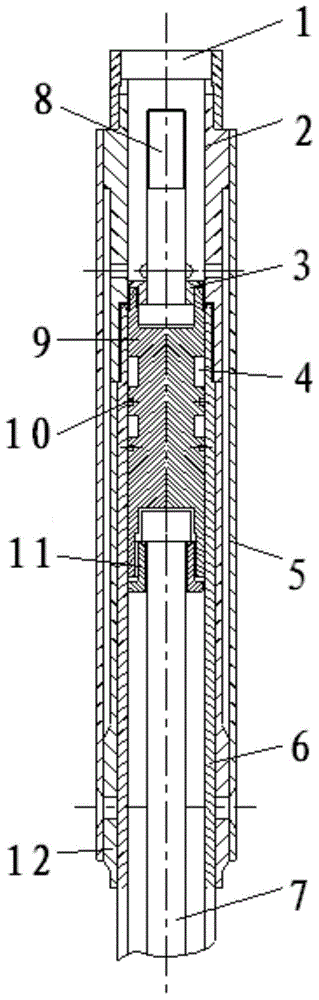

Rodless oil extraction device driven by underground permanent magnet linear motor

ActiveCN104632139ARealize "zero transmissionSolve partial wearFlexible member pumpsFluid removalDirectional wellPressure difference

The invention relates to a rodless oil extraction system driven by an underground permanent magnet linear motor. The rodless oil extraction system is composed of a front piston pipe, magnetic steel and a tail pipe. The front piston pipe is located at the uppermost end of the system and plays the roles of balancing pressure difference and preventing sand; the magnetic steel is located in the middle of the system, and the magnetic steel is powered by a cable to generate magnetic pumping so as to drive a rotor to linearly move in a reciprocating mode; the tail pipe is located at the lower end of the system and plays the roles of limiting the rotor and preventing sand for the motor; a pull-down oil well pump barrel is connected with the front piston pipe in a threaded mode, a pull-down oil well pump plunger and a motor pull rod are connected through a conversion connector with a pin, a pull-down oil well pump upper coupling is connected with an oil tube, an electronic rotor drives the pull-down oil well pump plunger to pump oil, and crude oil enters the oil tube from the pump barrel. According to the rodless oil extraction system, oil extraction without a pumping rod is achieved, and the rod pipe eccentric wear problem which can not be solved in a directional well is solved fundamentally; zero transmission from the motor to an oil well pump is achieved, stroke loss is eliminated, pumping efficiency of the oil well pump and system efficiency are improved, and operation safety risks are reduced.

Owner:PETROCHINA CO LTD

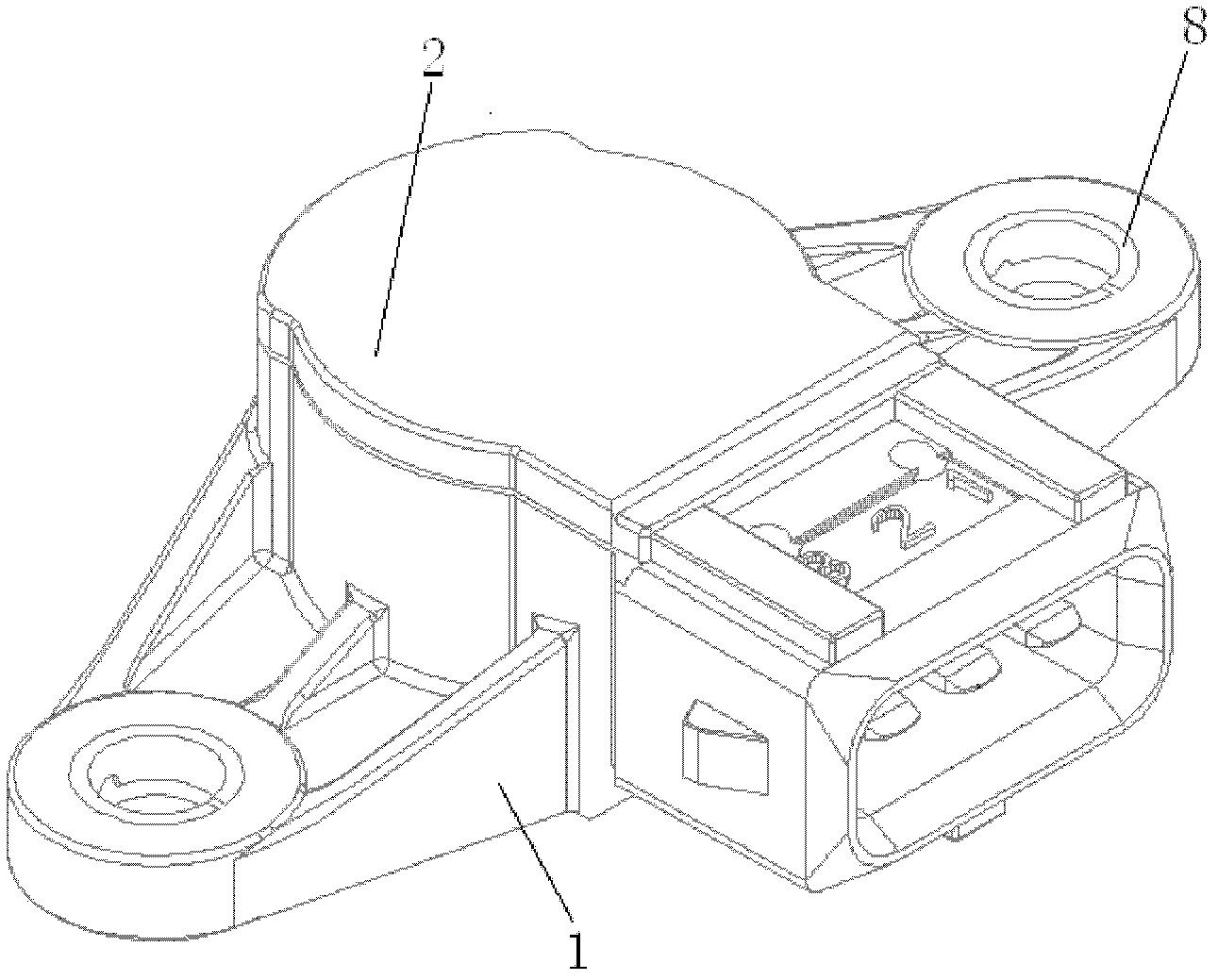

Non-contact throttle position sensor

InactiveCN103017797ASolve wear and tearExtended service lifeMeasurement apparatus componentsConverting sensor output electrically/magneticallyHall elementEngineering

The invention discloses a non-contact throttle position sensor which is mounted on a throttle body. The sensor comprises a shell, a cover board, a circuit board, a hall element, a magnetic element and a rotor, wherein the circuit board, the hall element, the magnetic element and the rotor are arranged in the shell, the rotor is tightly connected with a shaft of the throttle by a snap spring, the magnetic element is fixedly mounted on the rotor, the circuit board is installed on the shell and is fixedly connected with the hall element, a gap is formed between the hall element and the magnetic element, and the upper end of the rotor is provided with a plurality of buckles which can be buckled on a flange of the inner wall of the shell. According to the invention, the wearing problem caused by long-term running of the conventional throttle position sensor is effectively solved, the service life of the sensor is prolonged, the output precision of the sensor is higher, the stability of the sensor in a high-temperature environment is higher, and thus the application scope of the sensor is wider.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

Dust prevention structure for dental handpiece

ActiveCN105380718ASimple structureNo significant increase in manufacturing costsBoring toolsEngineeringTurbine

The invention provides a dust prevention structure for a dental handpiece. The dust prevention structure comprises a handpiece shell. A handpiece core is arranged in the handpiece shell and mainly comprises a handpiece core turbine and a handpiece-core large shaft driven by the handpiece core turbine to rotate. The handpiece-core large shaft is supported into the handpiece shell through a bearing piece, and the bearing piece comprises a front end bearing and a back end bearing; a first groove is formed in the handpiece shell and formed below the front end bearing, a dust prevention cover is arranged in the first groove and is a hollow columnar piece, and the hollow inner wall of the dust prevention cover is in close fit with the outer wall of the handpiece-core large shaft; a second groove which is provided with a downward opening and is used for changing a sucking path is formed in the outer portion of the dust prevention cover. The dust prevention structure is simple in structure and easy to achieve, and the pollution problem and the wear problem of the front end bearing are solved through the dust prevention cover and the first groove; compared with the prior art, the dust prevention structure has more stable and durable characteristics, and the service life of the handpiece is objectively prolonged.

Owner:SINOL MEDICAL EQUIP GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com