End-engaging clutch

A clutch and end face technology, applied in the field of clutches, can solve the problems of inconvenient maintenance, wear of the pressure plate and friction plate, short service life, etc., and achieve the effects of high bonding reliability, overcoming easy slippage, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

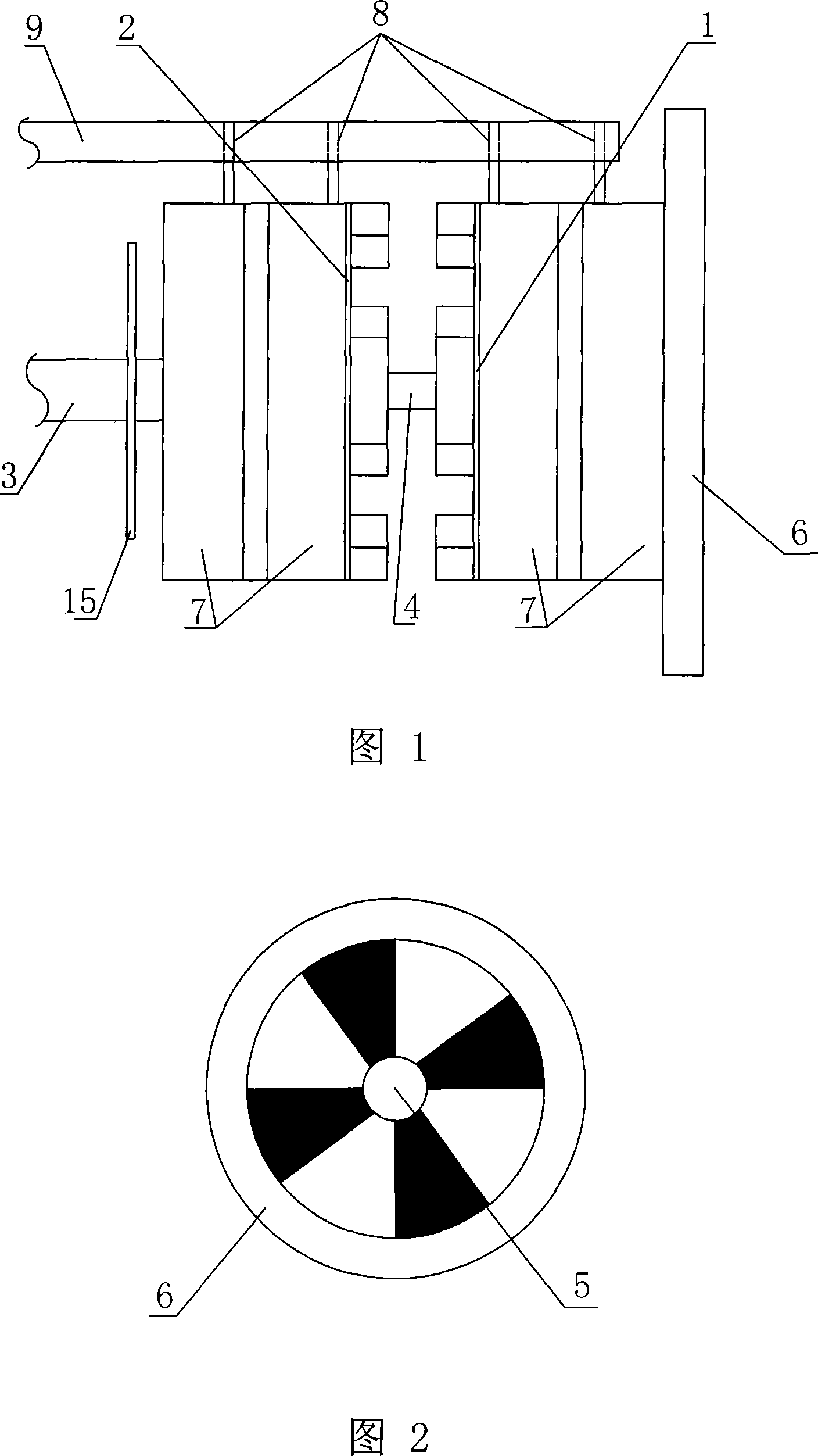

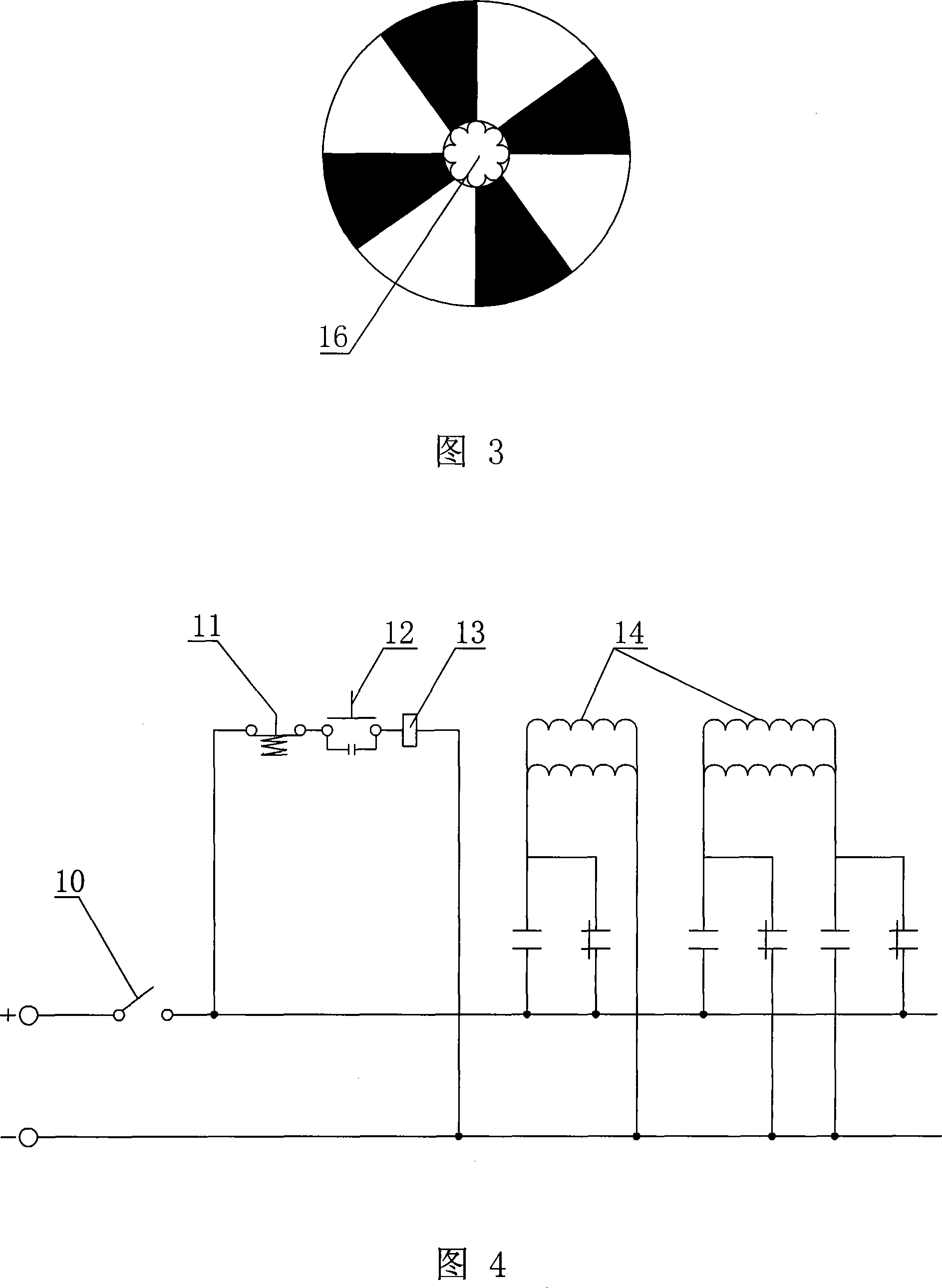

[0022] In the embodiment of the present invention shown in Figure 1, the two main parts of the end face clutch are a circular steel fixed meshing disc 1 and a movable meshing disc 2, the central shaft hole of the movable meshing disc 2 is a spline groove 16, and the movable meshing The spline groove 16 of disc 2 is movable set with the spline output shaft 3 of the gearbox that is arranged horizontally, and the output shaft 3 shaft ends are also coaxially lathed with positioning pin 4. The fixed meshing disk 1 and the movable meshing disk 2 are set facing each other. The center of the fixed meshing disk 1 is provided with a positioning hole 5. The positioning pin 4 of the output shaft 3 is installed in cooperation with the positioning hole 5 of the fixed meshing disk 1. After installation, the movable meshing disk 2 is axially concentric with the fixed meshing disc 1 .

[0023] As shown in Figure 1 and Figure 2, the face of the movable meshing disk 2 facing the fixed meshing di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com