Patents

Literature

2767results about "Magnetically actuated clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

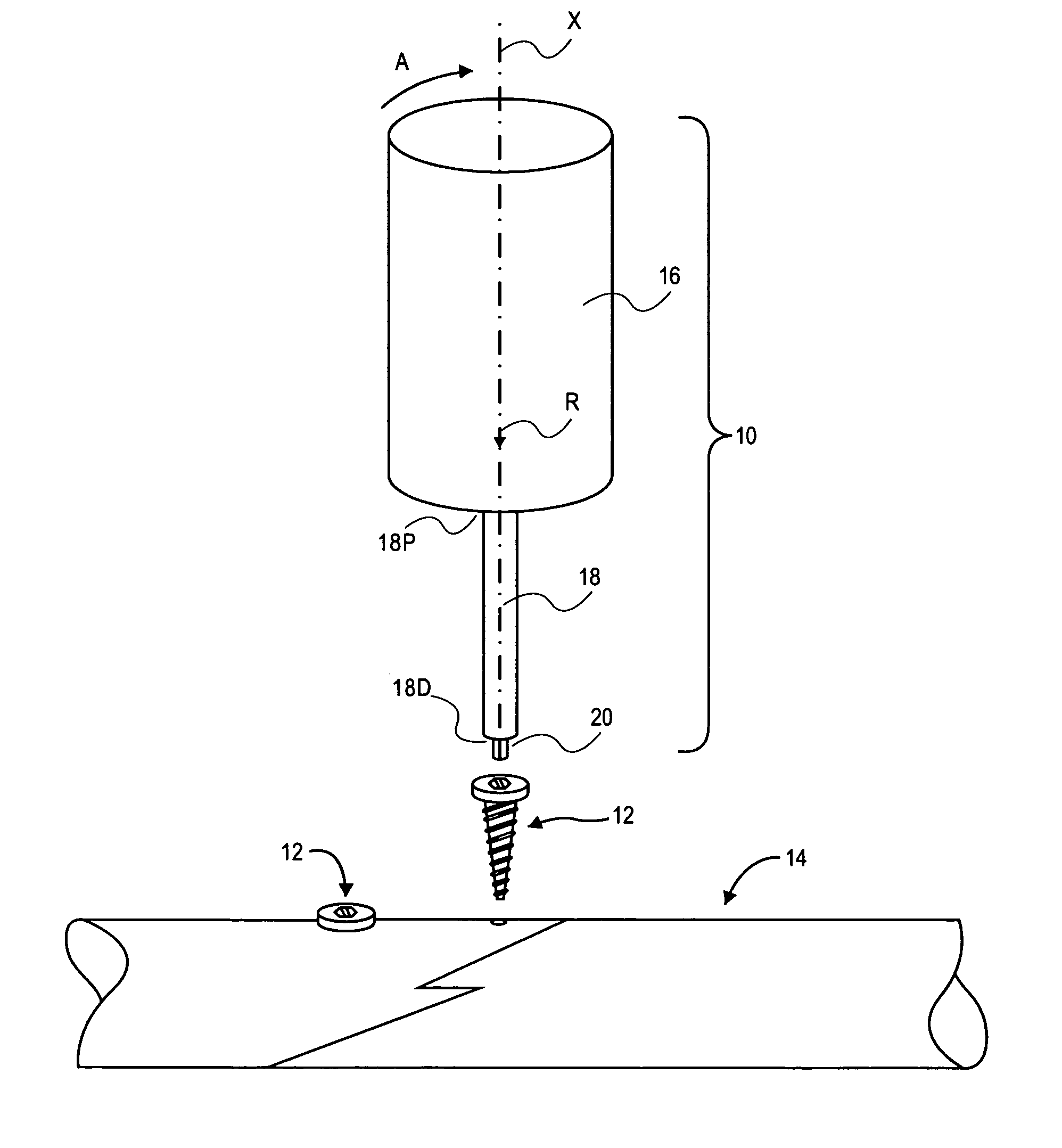

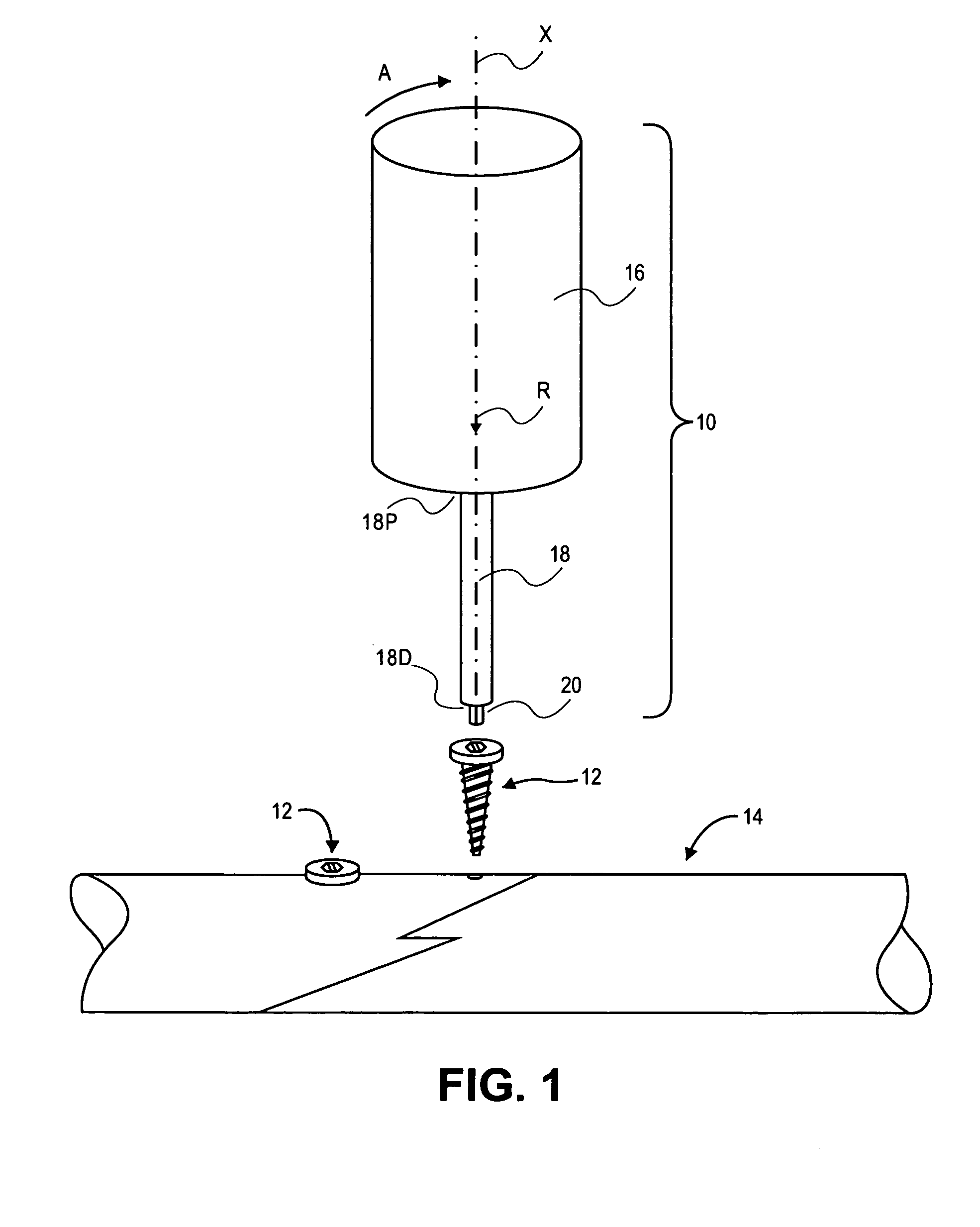

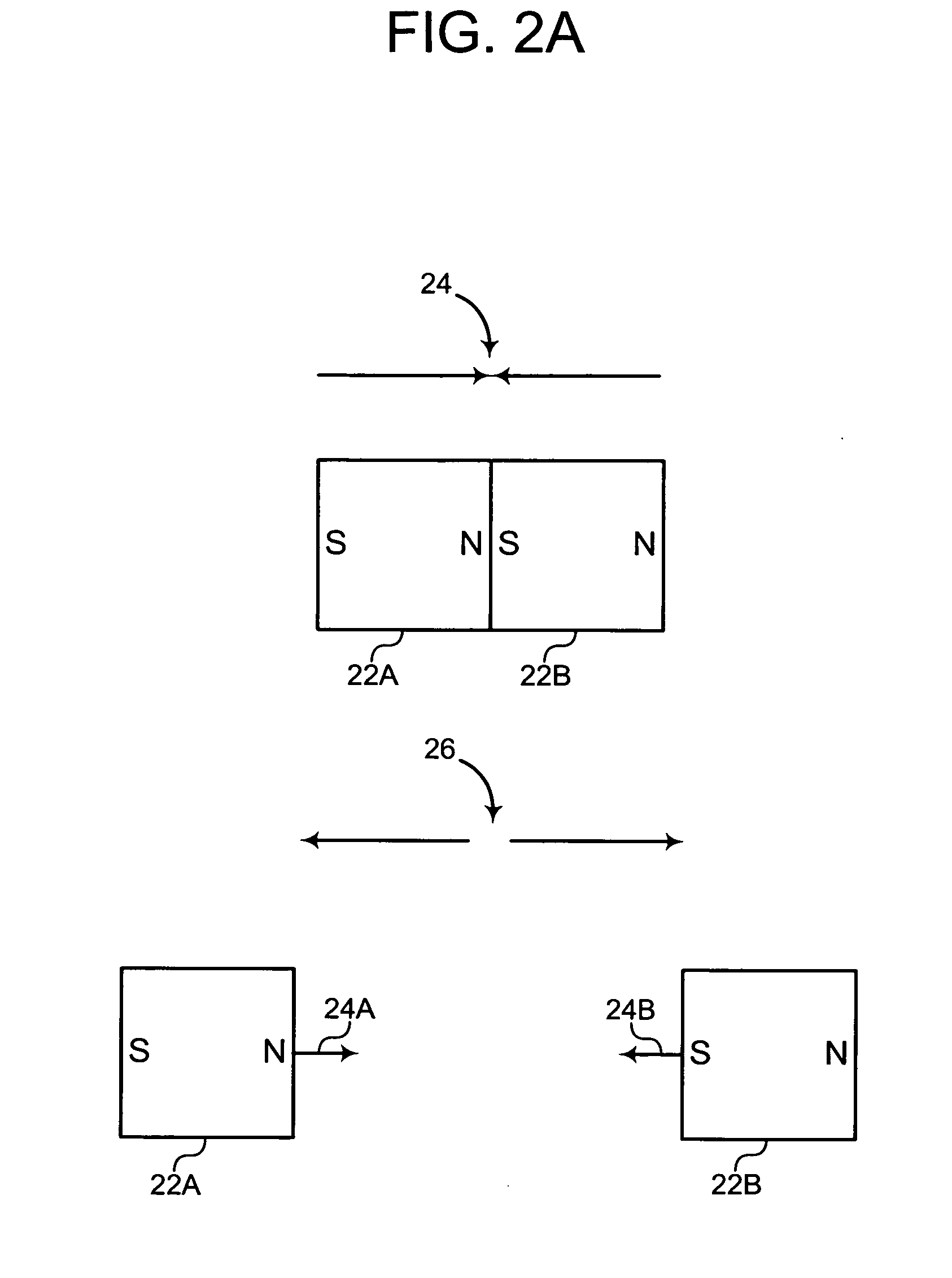

Magnetic torque-limiting device and method

In a torque-limiting device, a first end engages a fastener, a second end receives an applied torque, and a magnetic torque limiter transmits the applied torque from the second end to the first end to rotate the first end in conjunction with the second end when the applied torque is less than a predetermined limit.

Owner:PILLING WECK INC

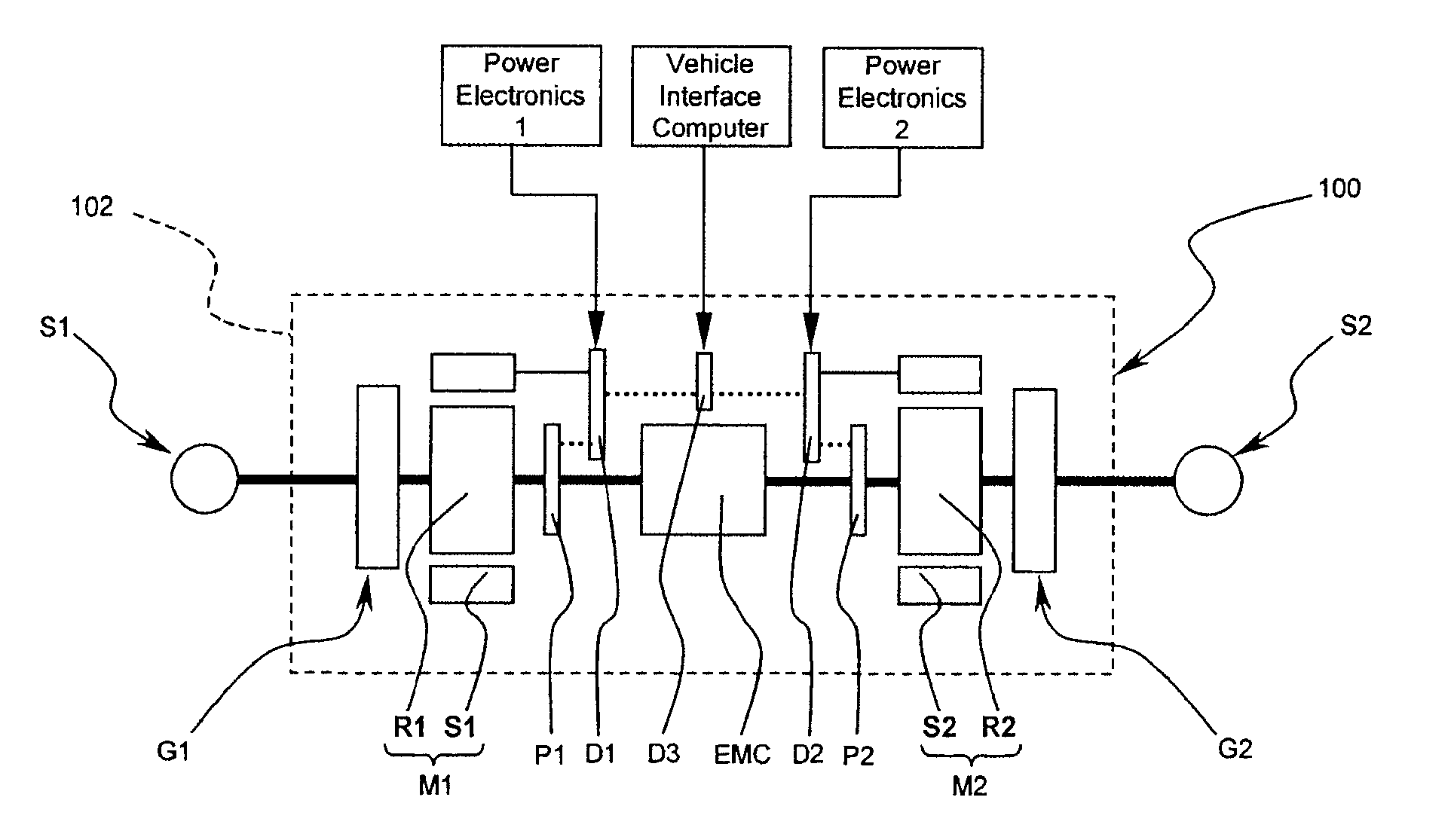

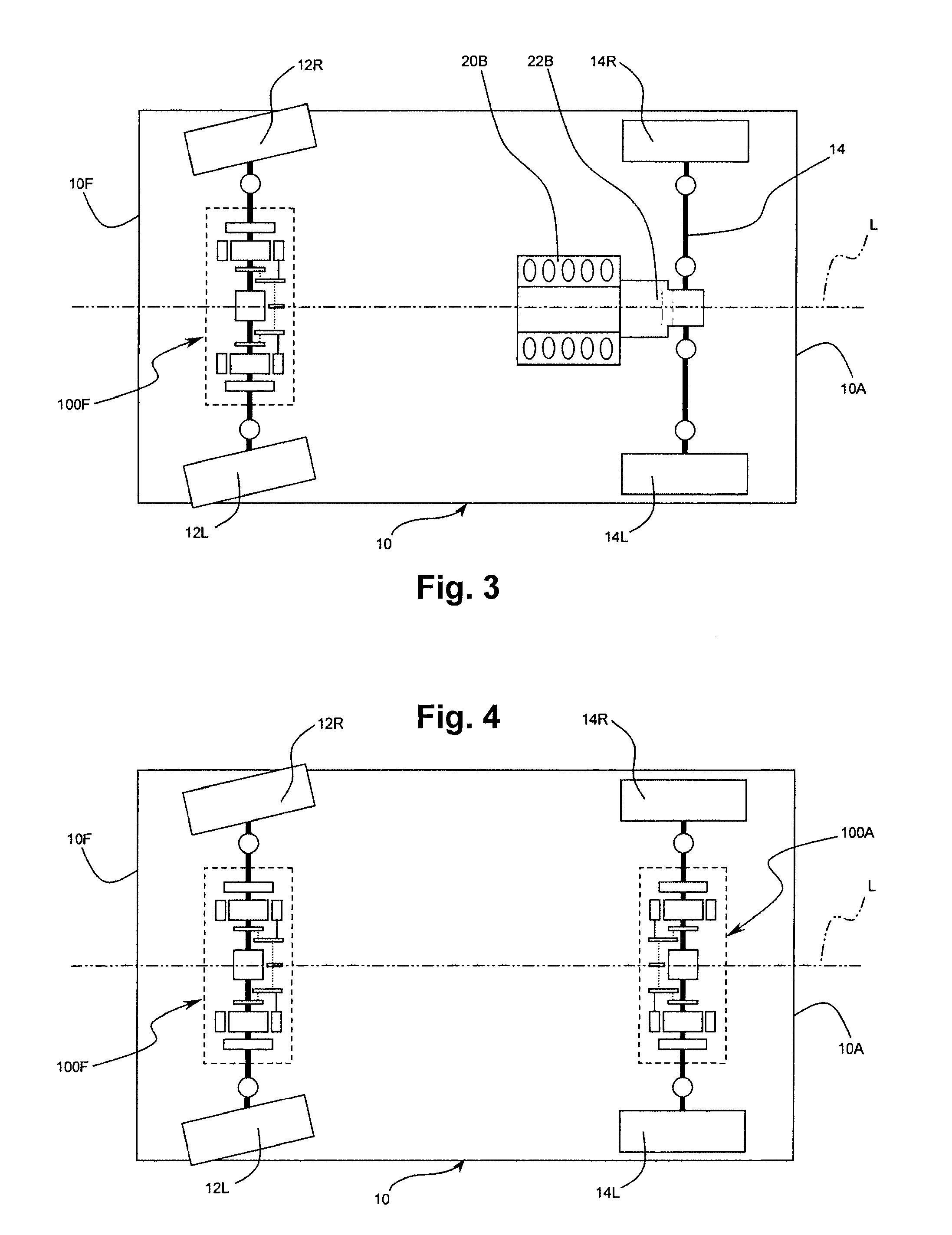

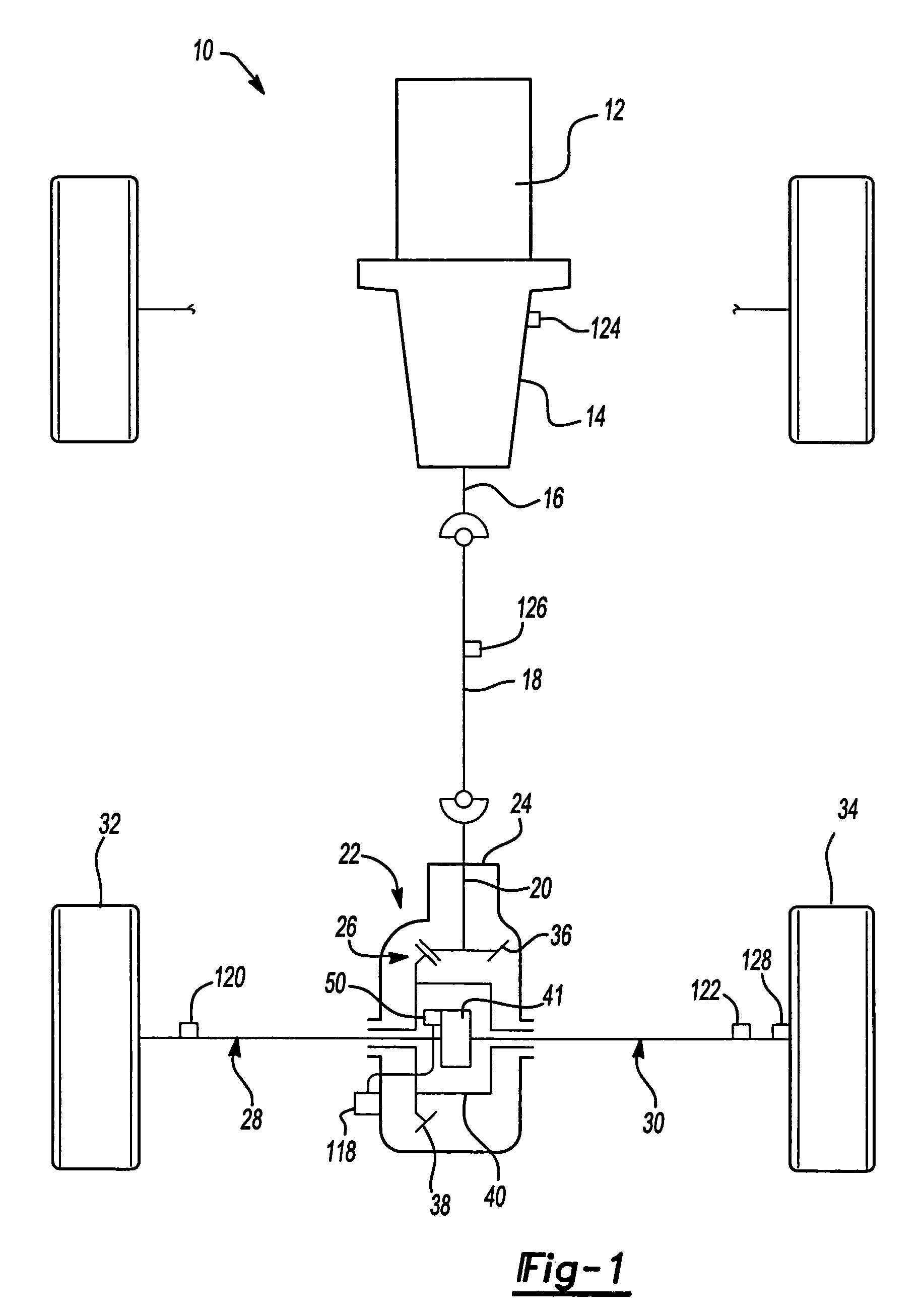

Electric propulsion system

InactiveUS20100025131A1Minimal modificationIncrease supplyDigital data processing detailsUnderstructuresElectric powerMotive power

The present invention relates to a motive power device for a vehicle, which is preferably retrofittable as front or rear axle. In a first embodiment, the device comprises a chassis (301) supporting at least one electric motor (318) and attached to the vehicle suspension fixtures with mounts (302, 304). Wheel hubs (377) are suspended from the chassis (301) and driven by the at least one motor (318). Further independent claims are included for a motive power device having a controller providing launch assist and / or stability control, a motive power device having at least two motors and a clutch therebetween, a vehicle provided with these various motive power devices, a method of making a vehicle, a clutch per se and an acceleration controller.

Owner:BLUWAV SYST LLC

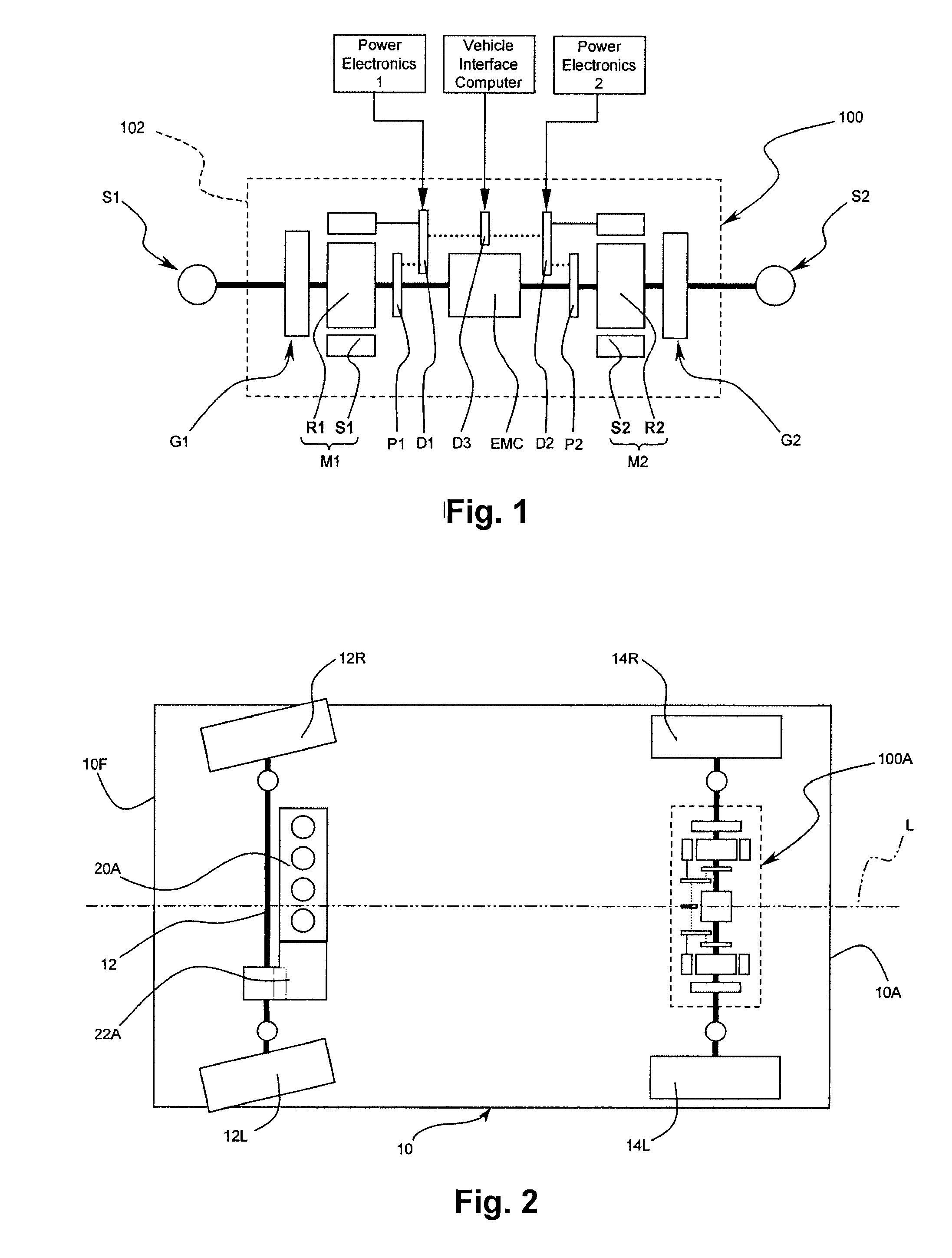

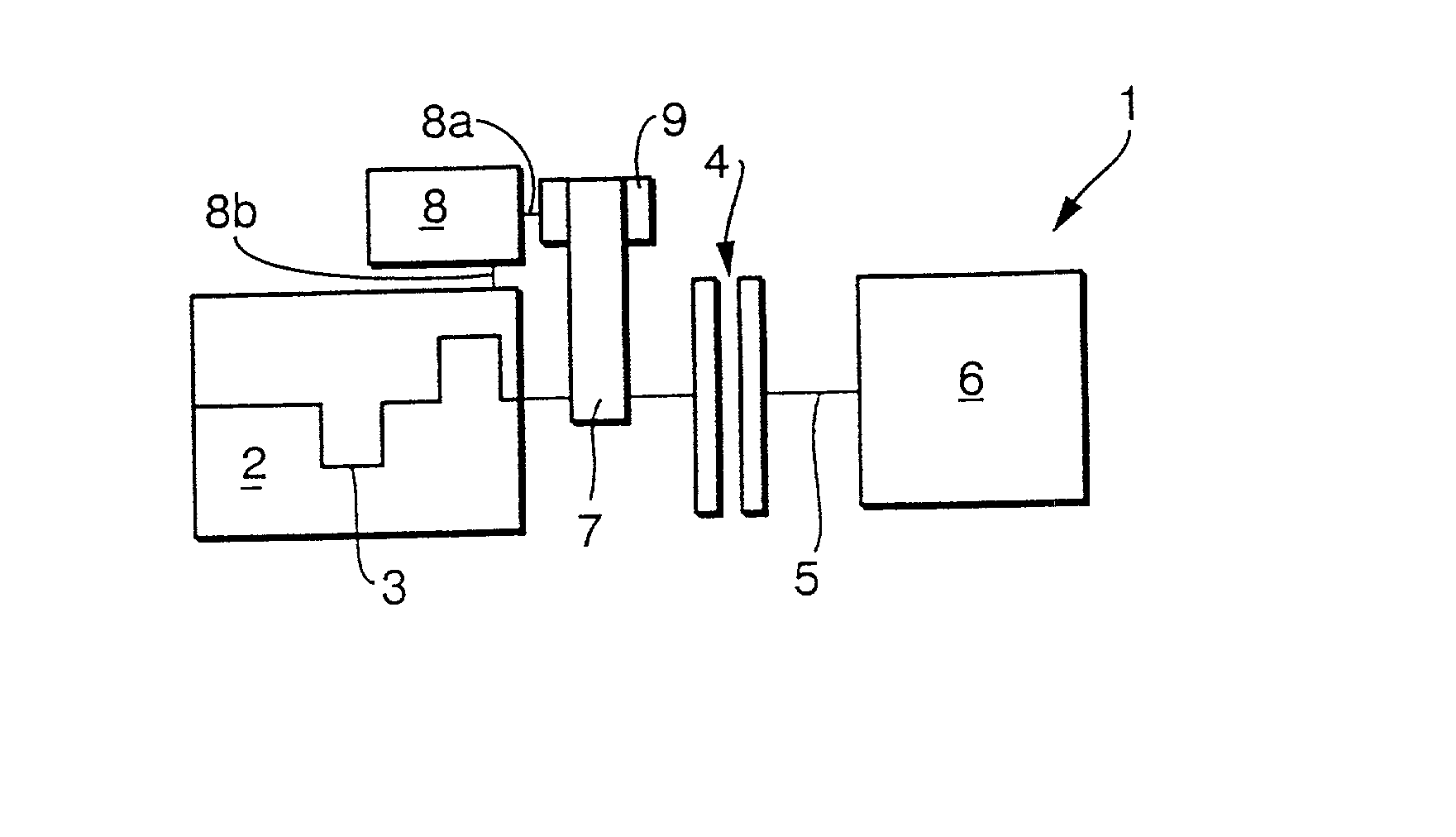

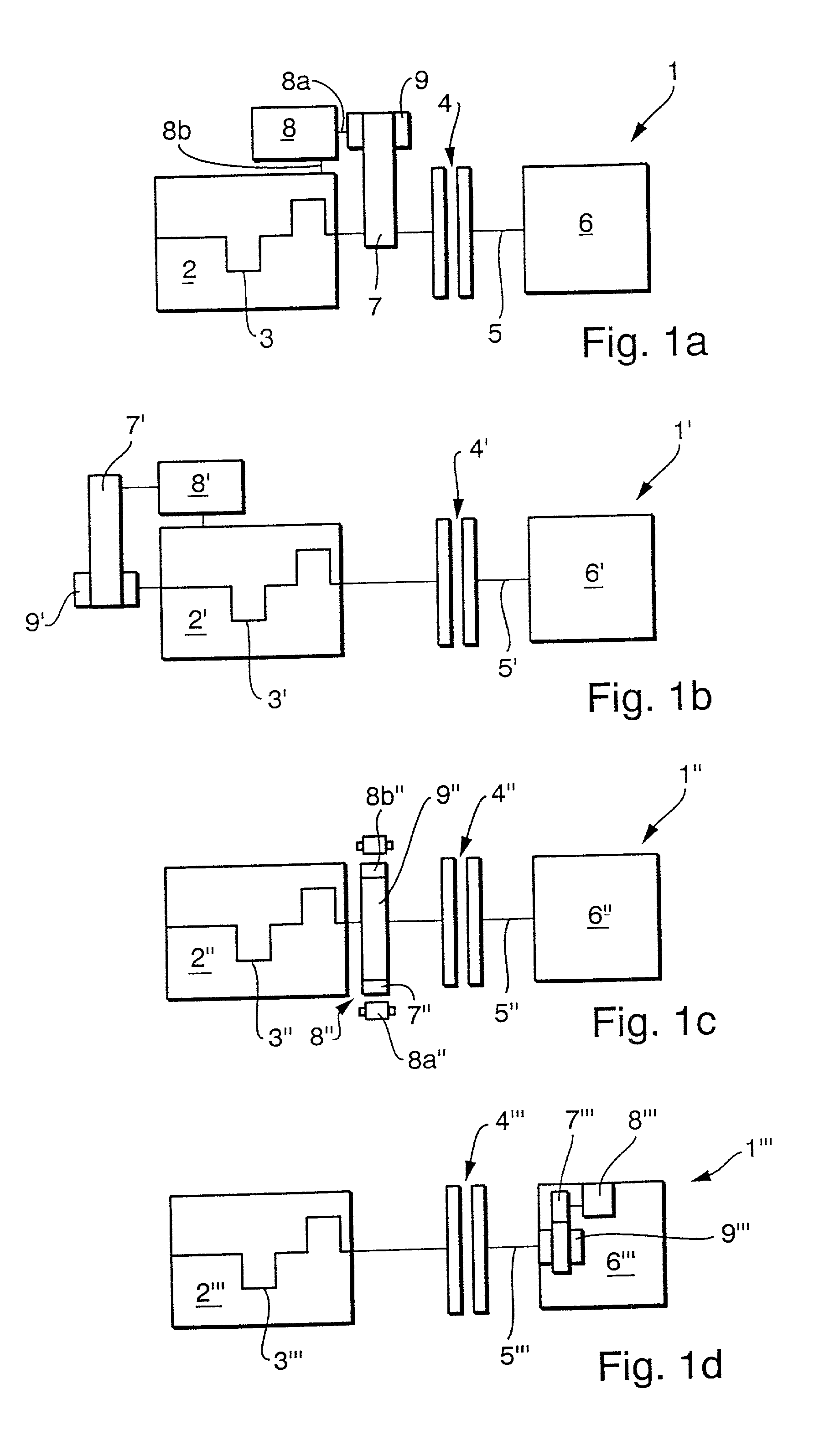

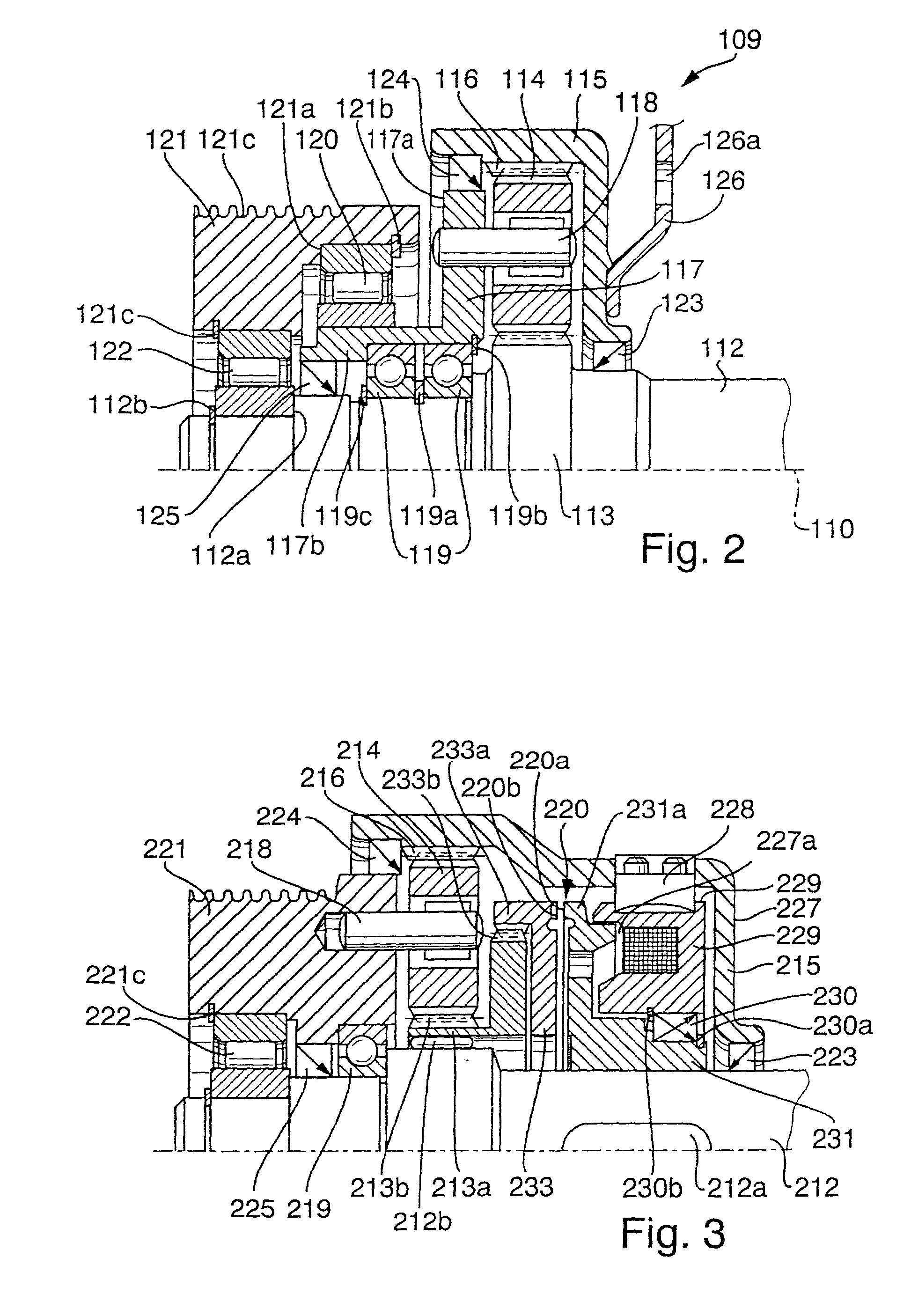

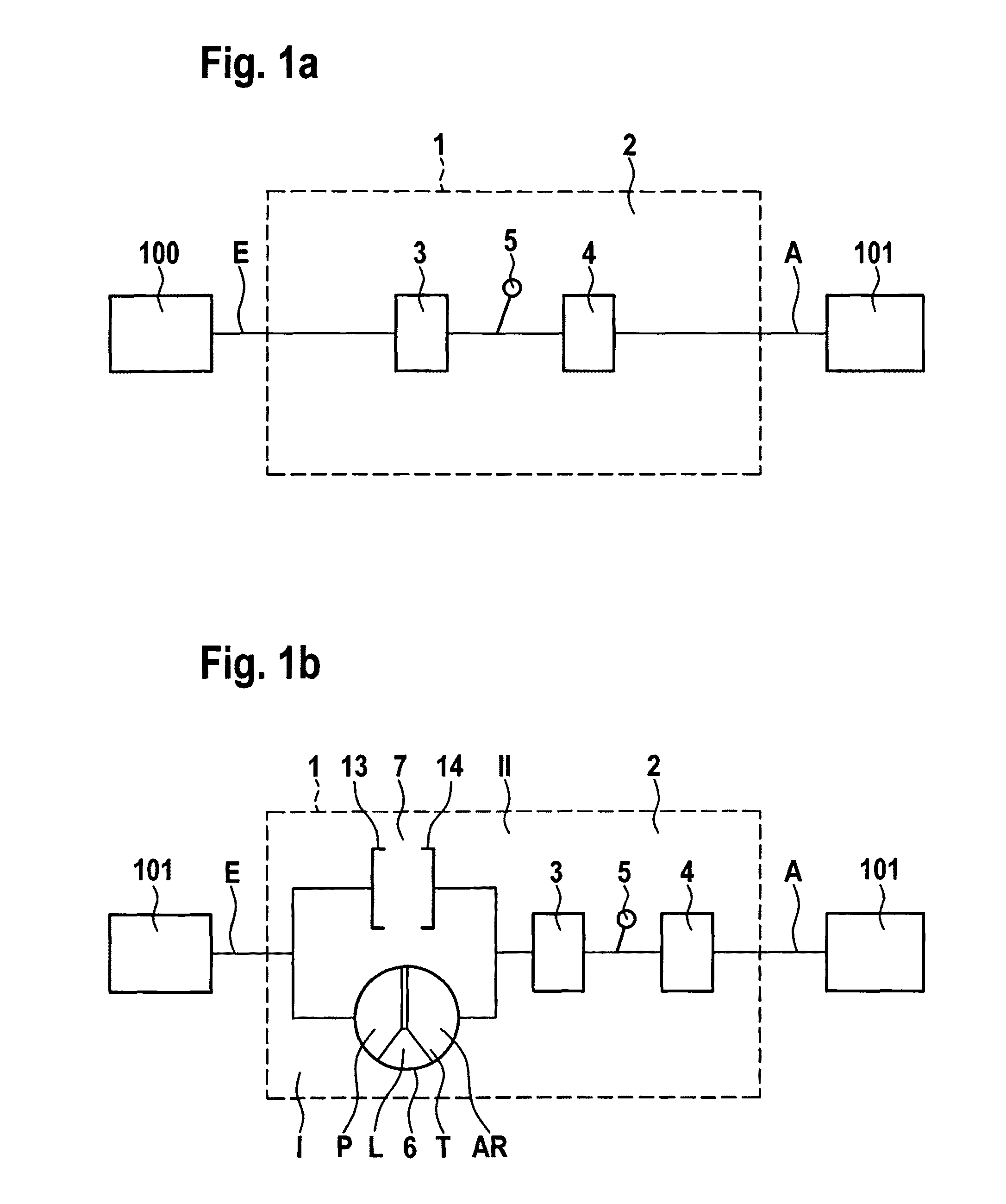

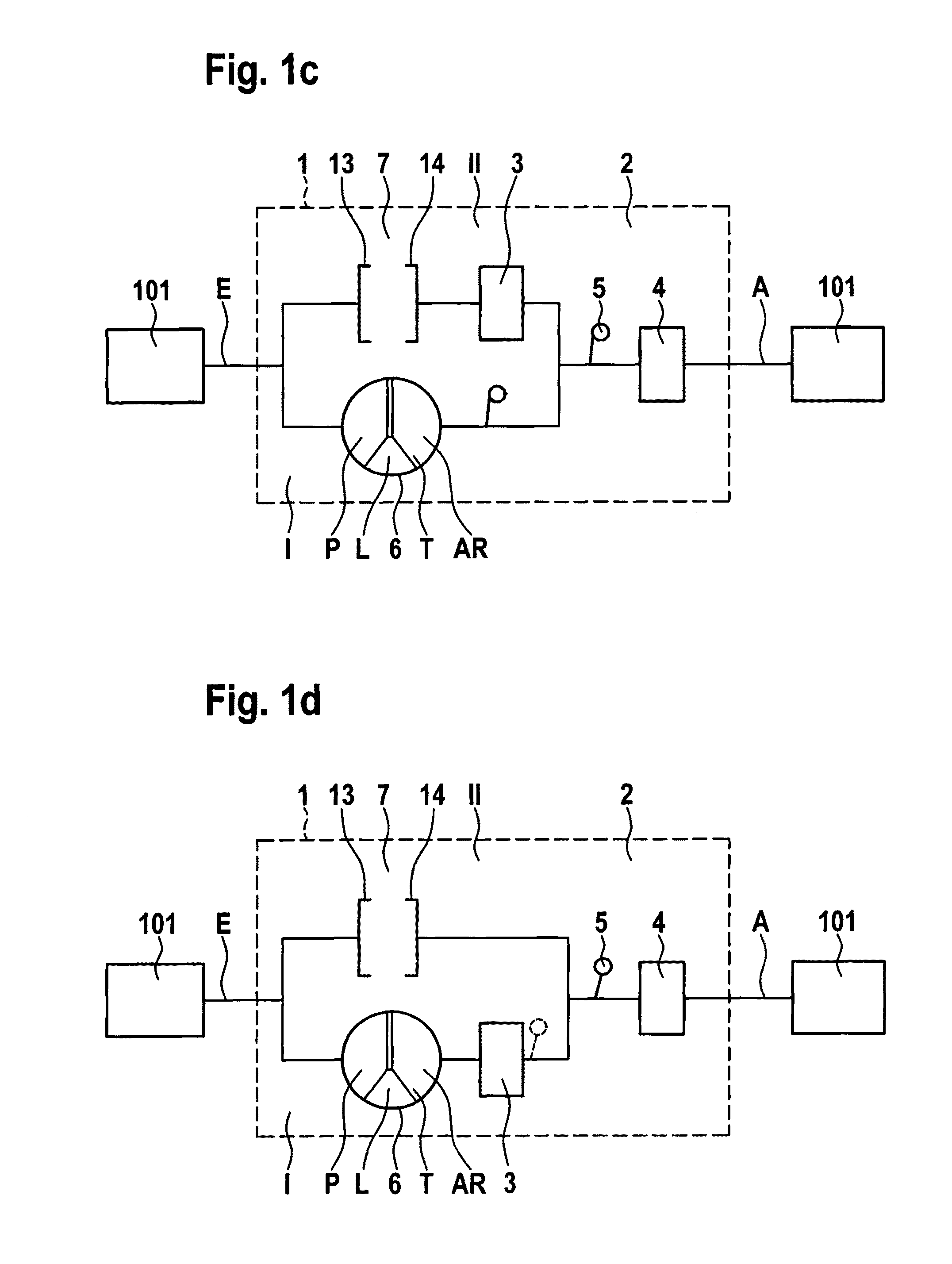

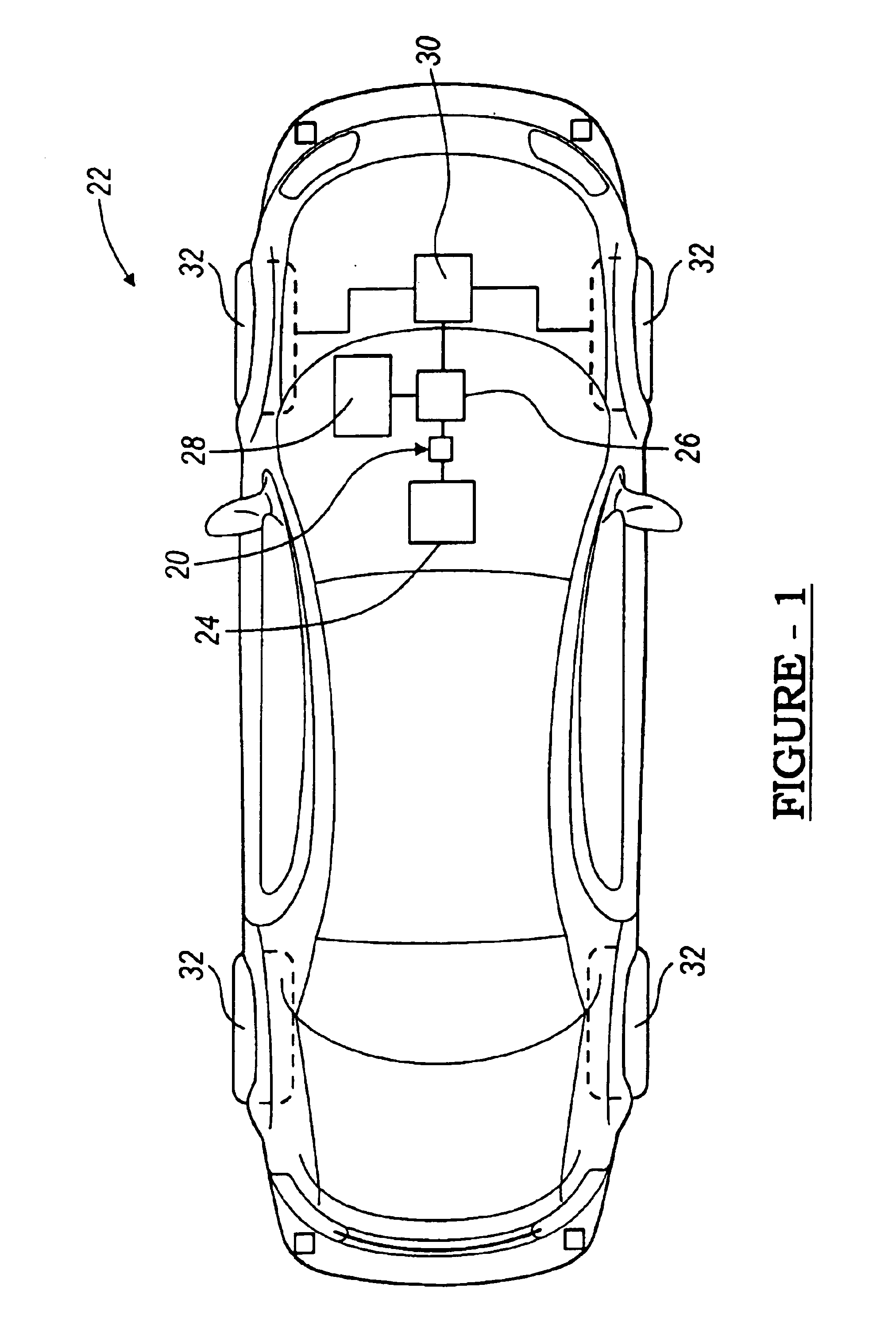

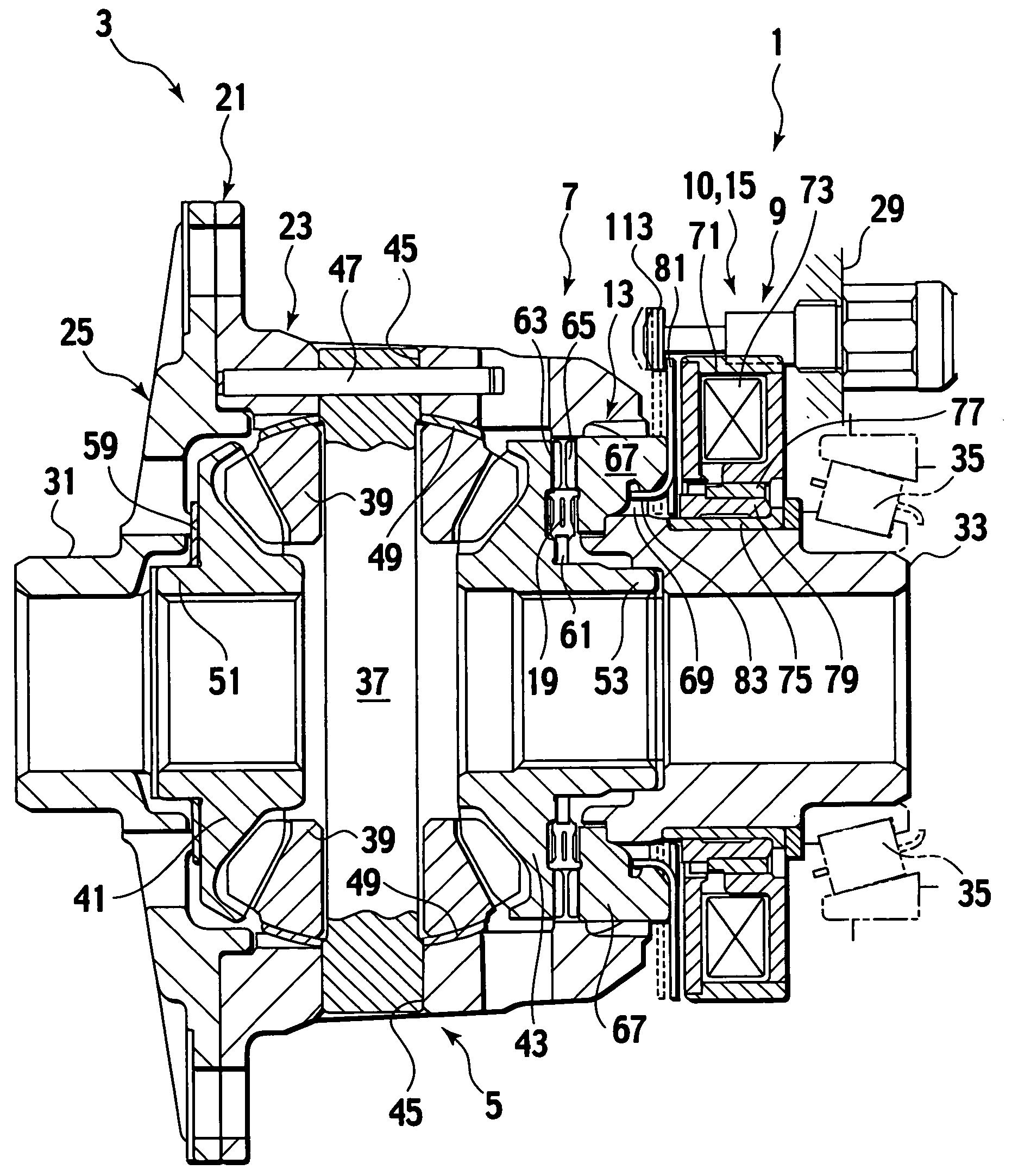

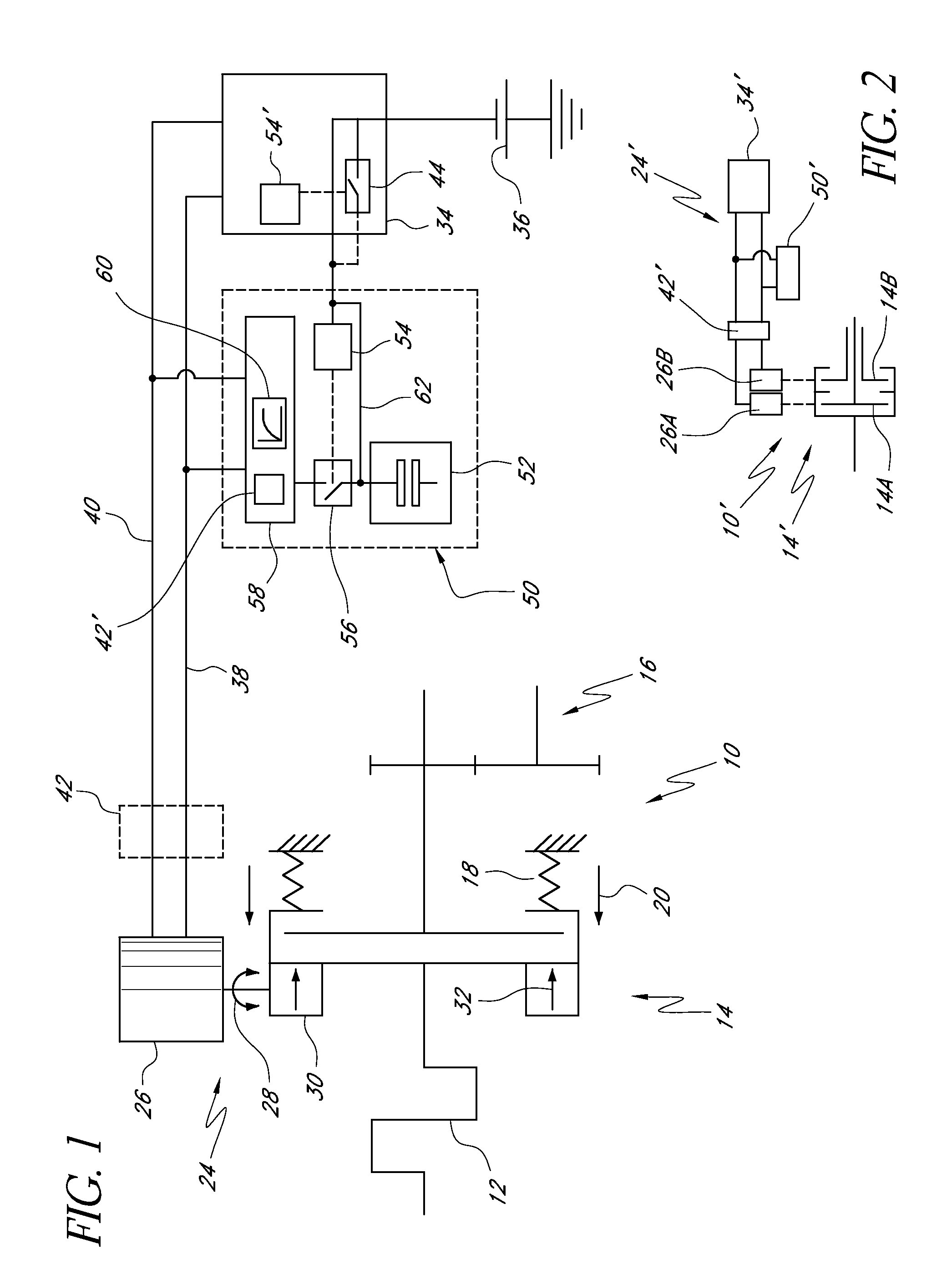

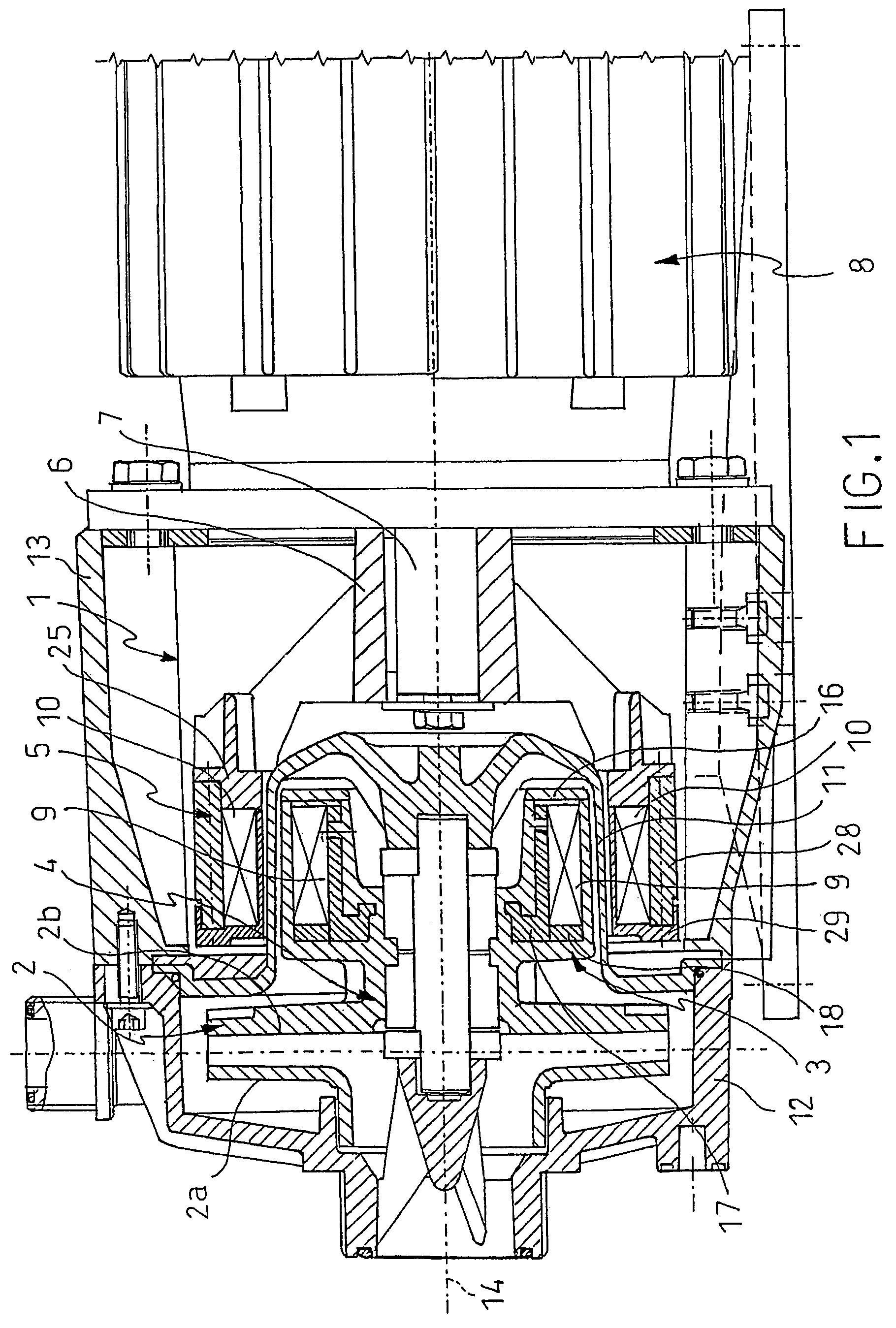

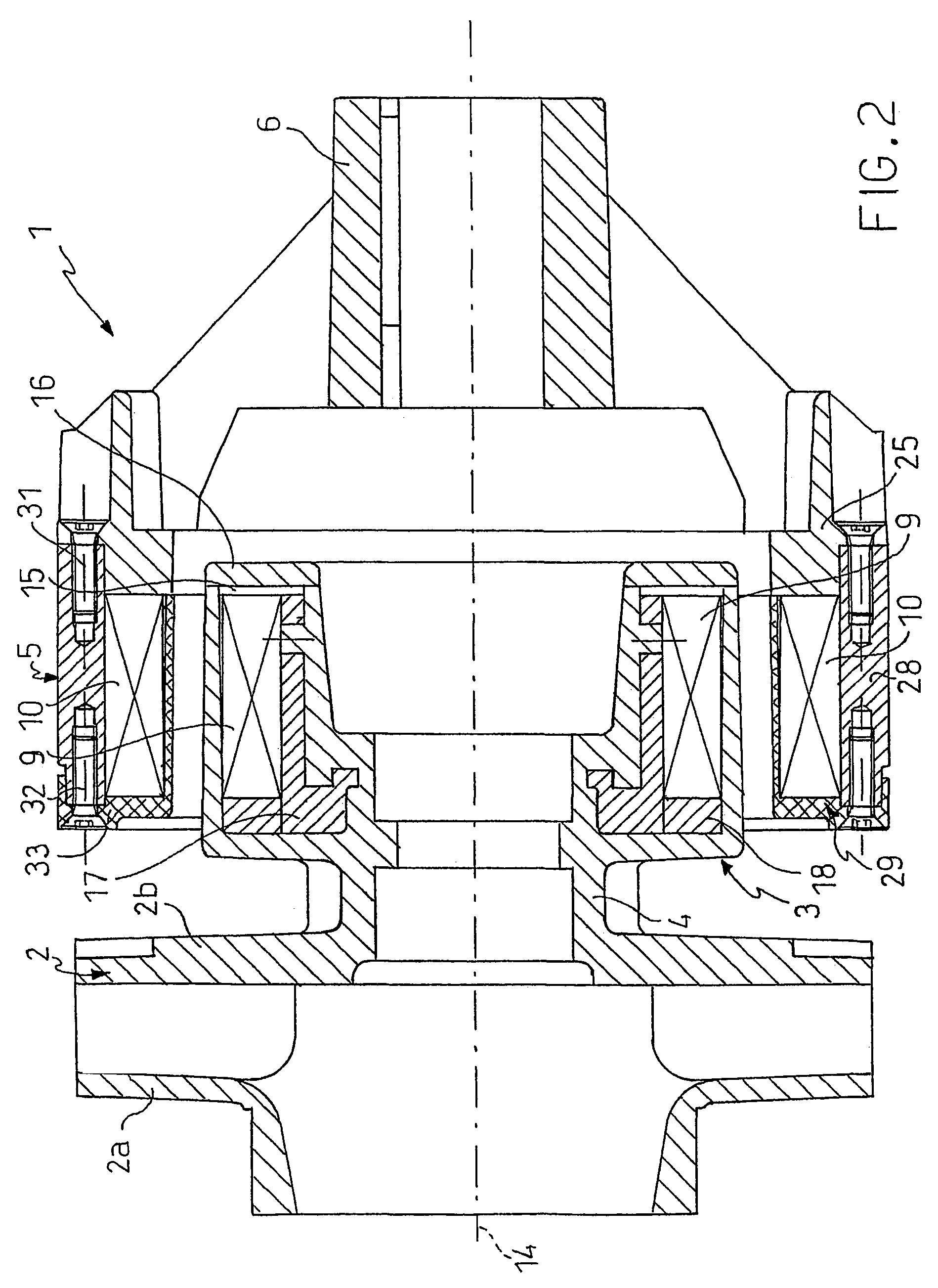

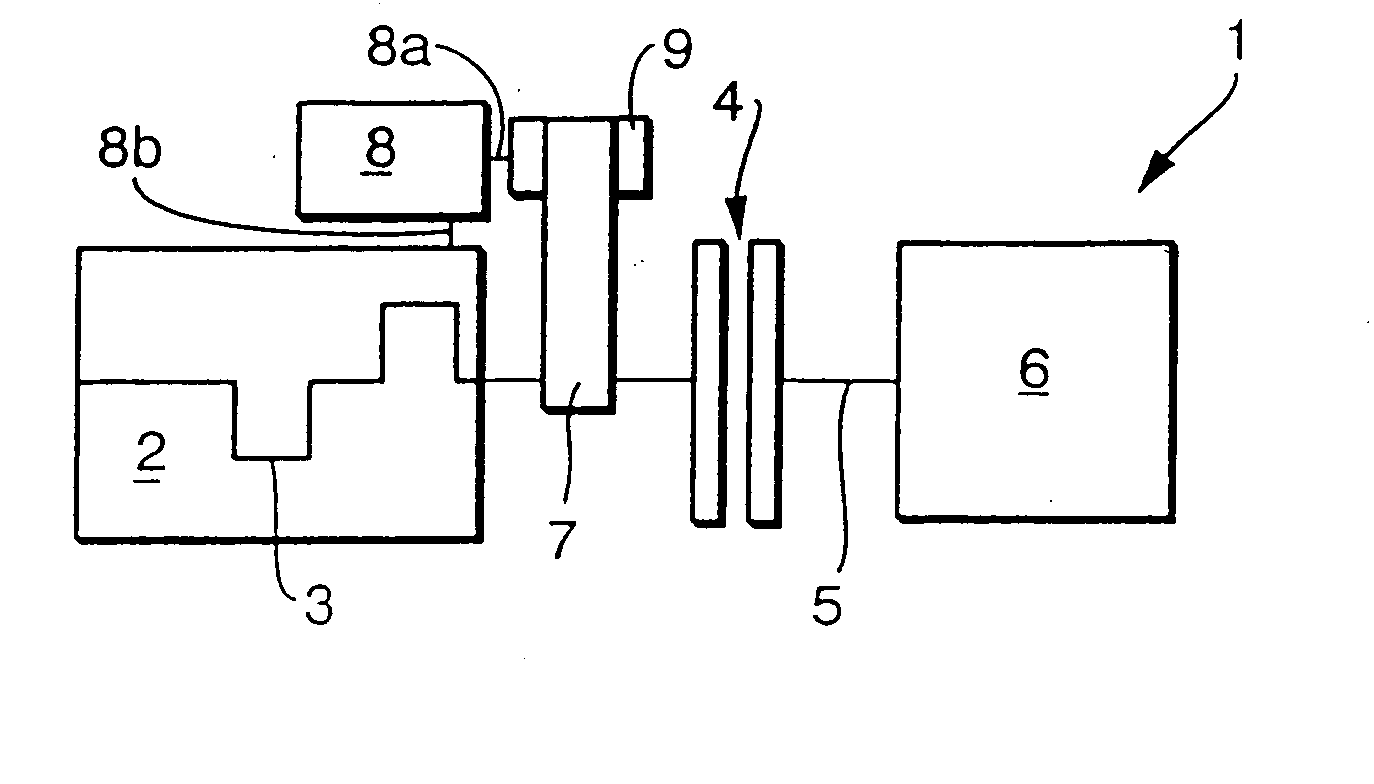

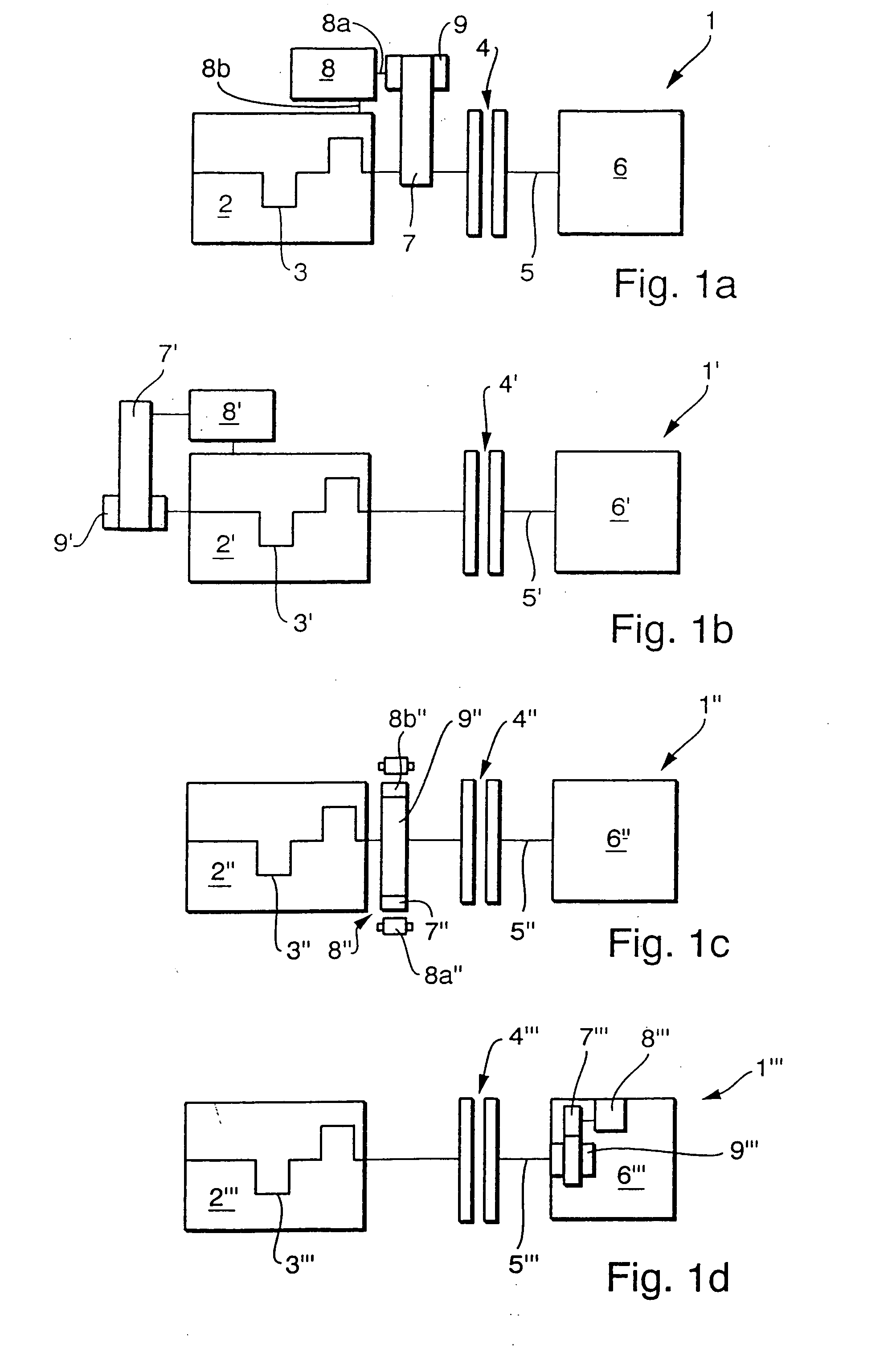

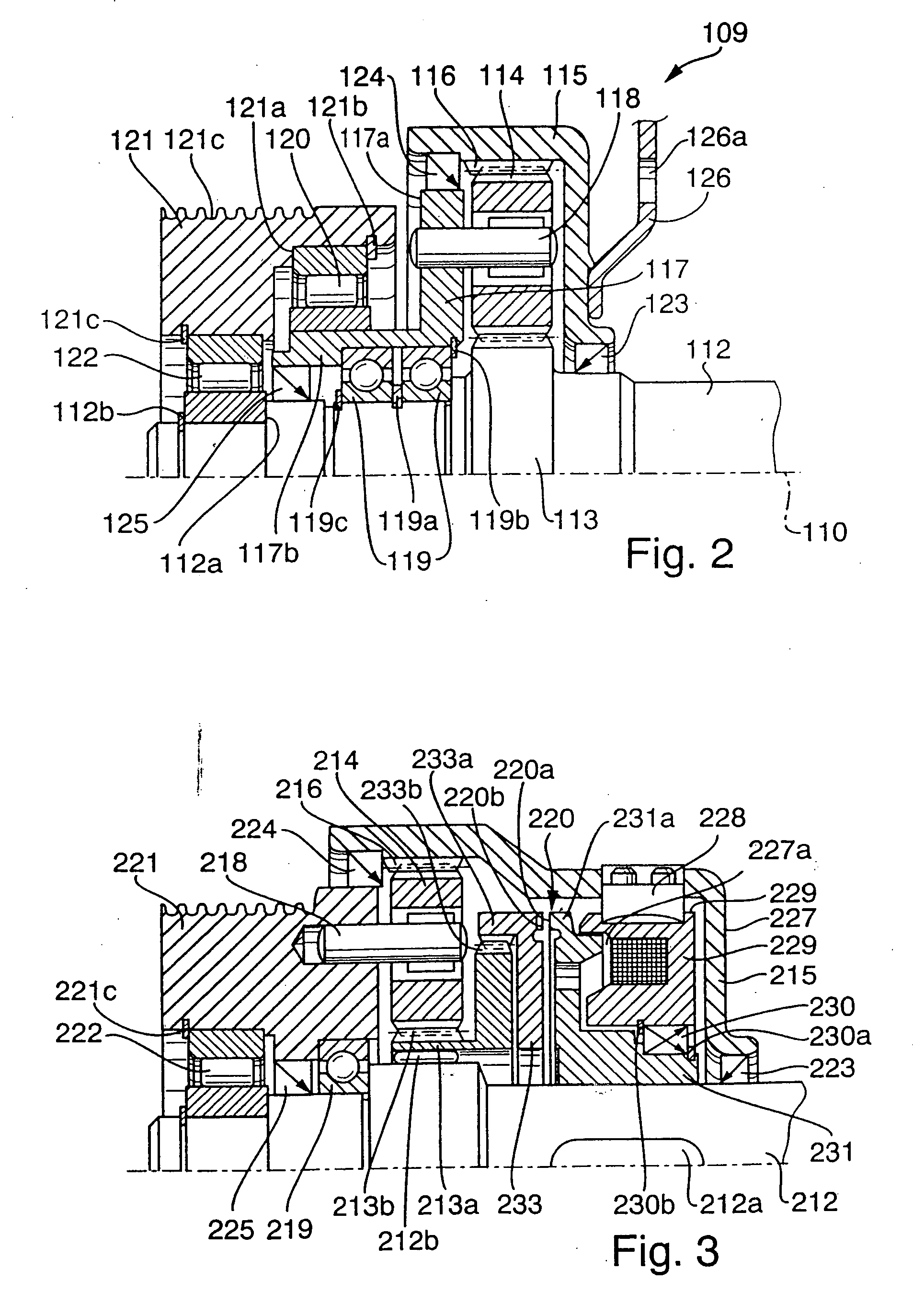

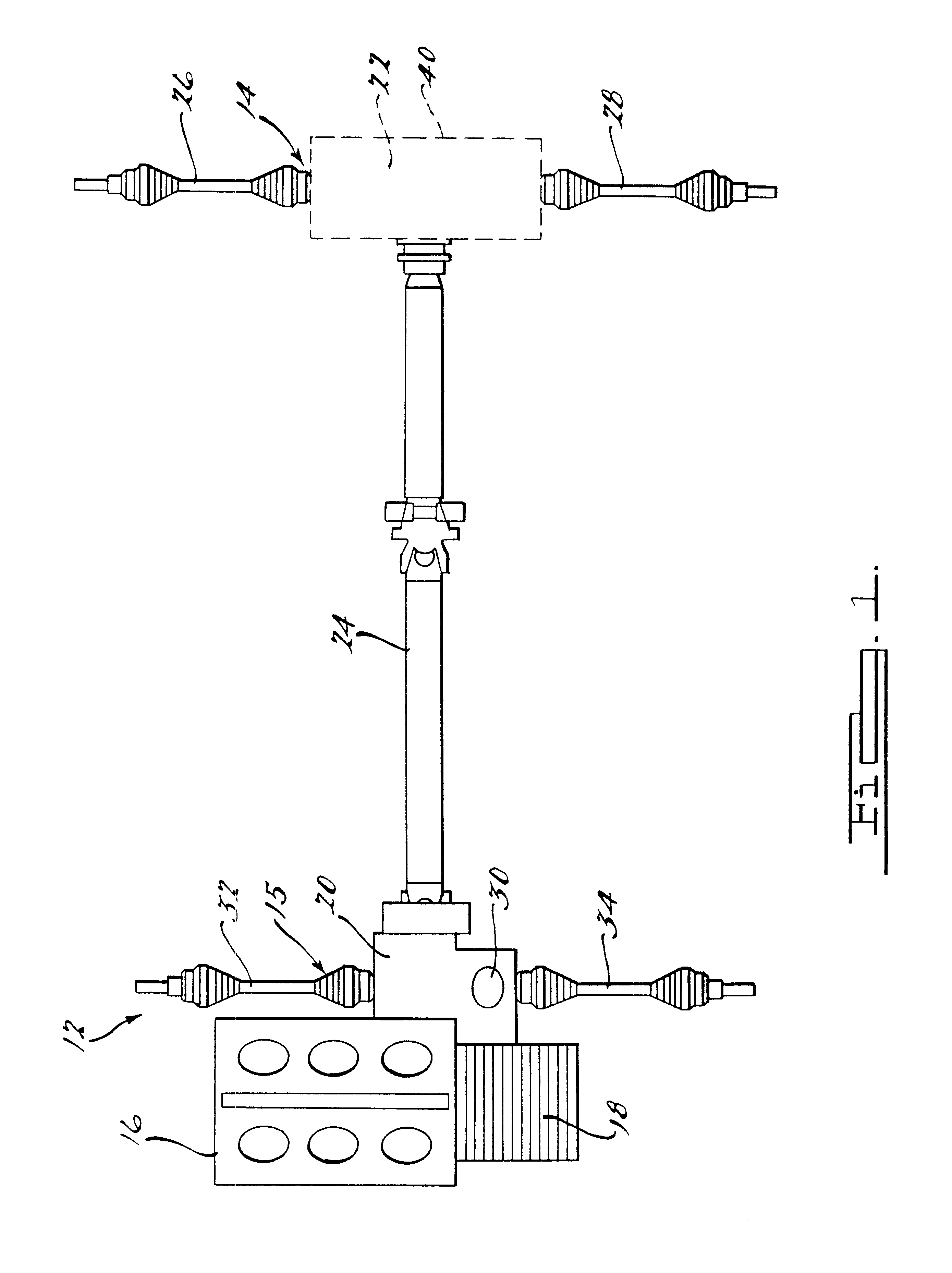

Power train for a motor vehicle

InactiveUS20020117860A1Easy to handleIncreased operating lifePropulsion using engine-driven generatorsMagnetically actuated clutchesMobile vehicleCombustion

A power train for a motor vehicle includes a combustion engine, a clutch or other torque-coupling device, a transmission, and an electro-mechanical energy converter that is operable at least as a motor and as a generator. The electro-mechanical energy converter is coupled to the output shaft of the combustion engine through a torque transfer device with at least two rpm ratios that automatically set themselves according to whether the vehicle is operating in a start-up mode or in a driving mode.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

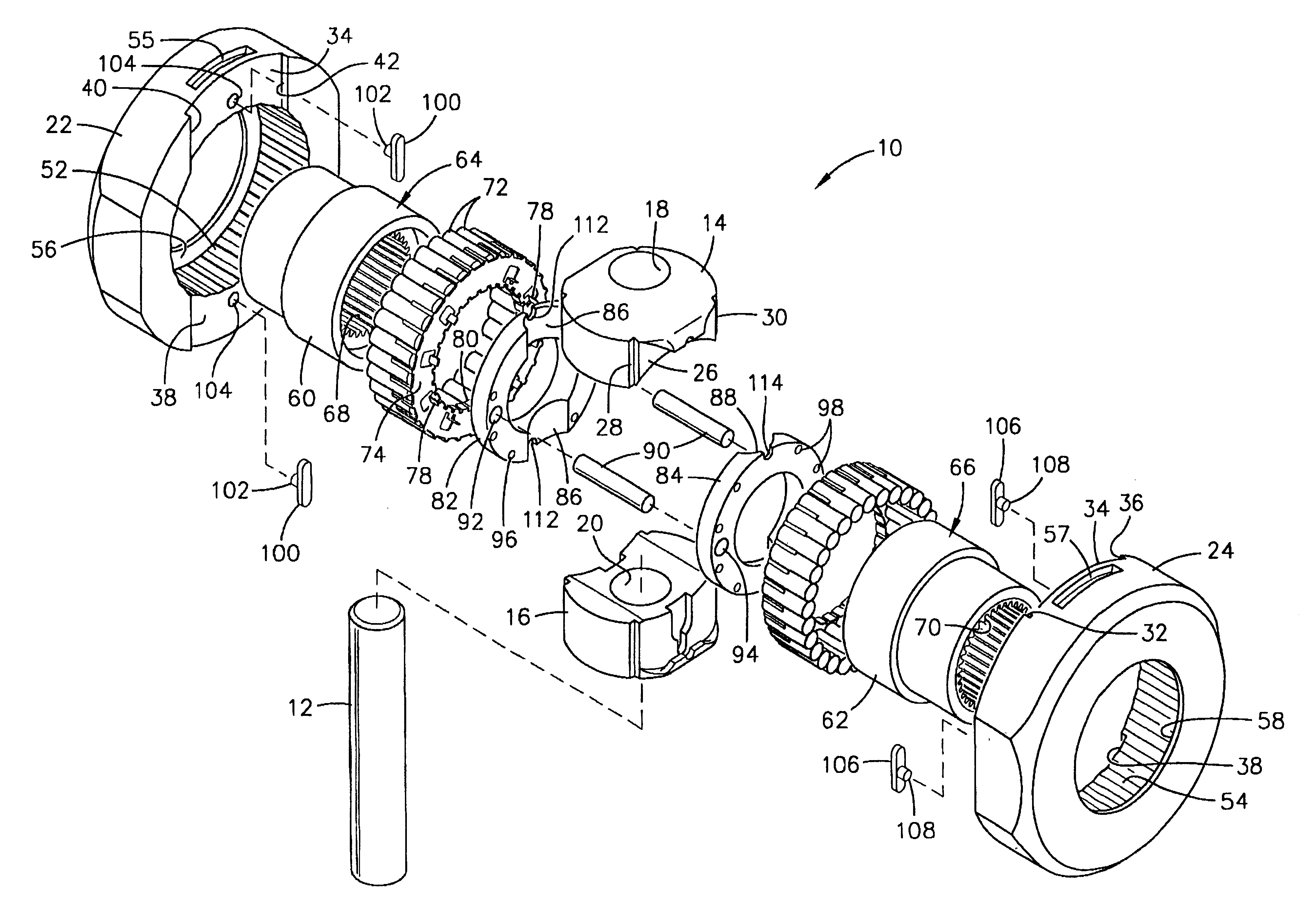

Automotive full locking differential

InactiveUS6269712B1Simple and effective and smooth in its operationMagnetically actuated clutchesDifferential gearingsCouplingEngineering

A full-locking differential drive mechanism, comprised of an input drive which is composed of a pair of opposed spaced drive races, each having an inner diameter, a coupling block disposed between the races for coupling them to drive together, output driven means comprising a pair of co-axially disposed coupler members, each having an outer diameter disposed within the drive races inner diameters, which produces a bi-directional roller clutch disposed between the inner diameters and the outer diameters and operative to couple the drive races to the coupler members enabling driving engagement therebetween.

Owner:ZENTMYER JOHN

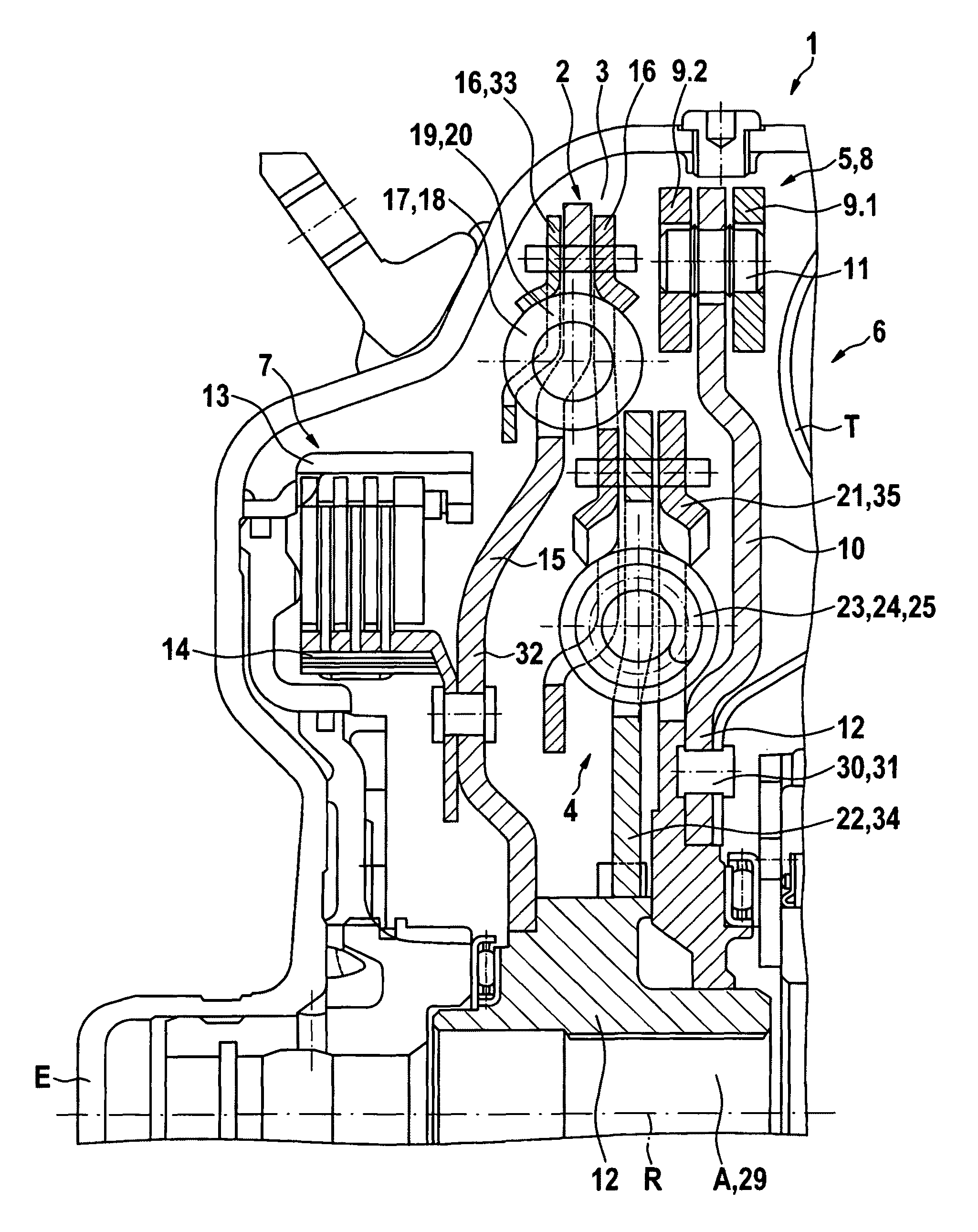

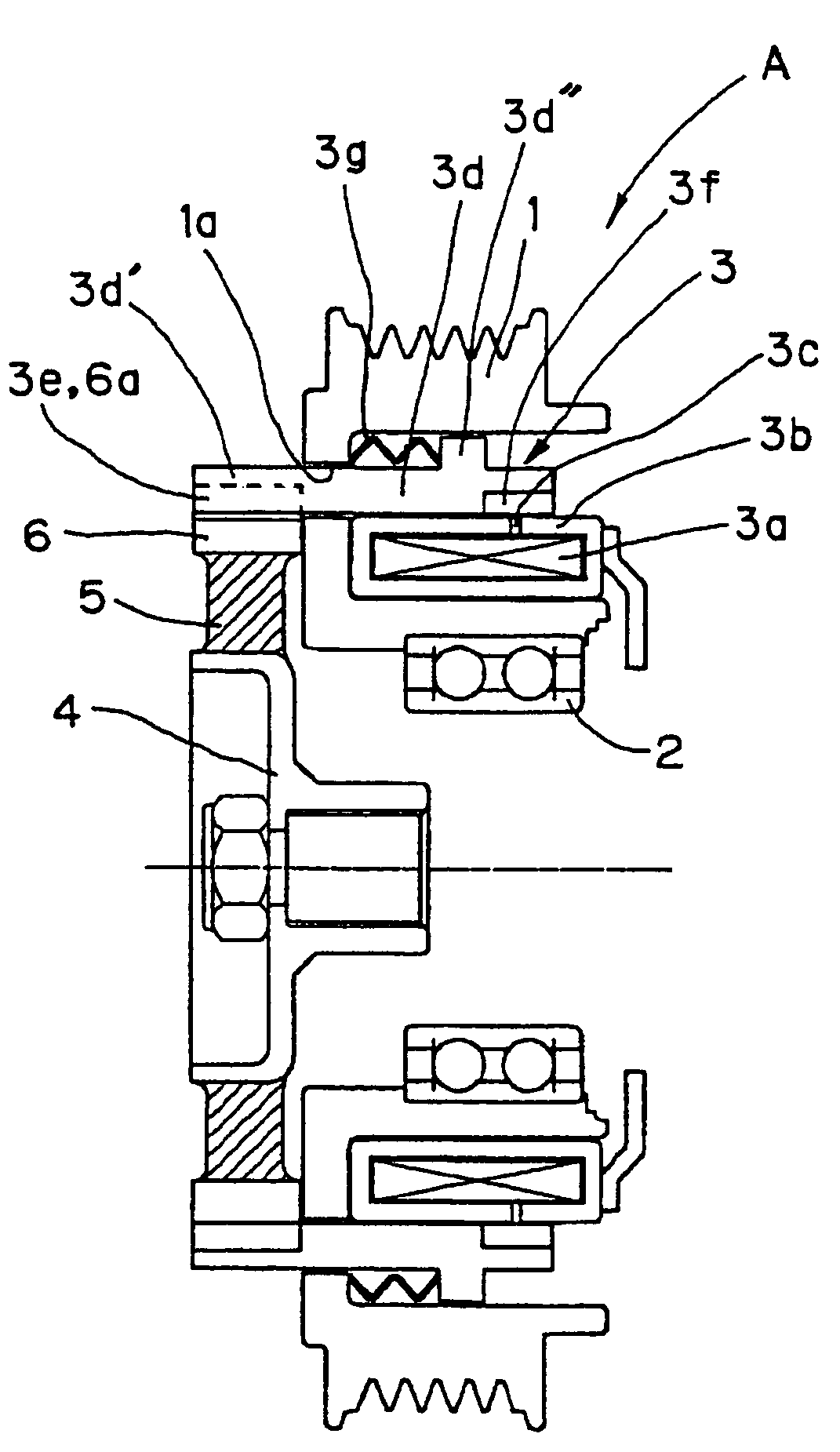

Force transmission device in particular for power transmission between a drive engine and an output

ActiveUS8161739B2Reduce variationEliminate variationRotating vibration suppressionYielding couplingTuned mass damperSelf adaptive

A force transmission device, in particular or power transmission between a drive engine and an output, comprising a damper assembly with at least two dampers, which can be connected in series, and a rotational speed adaptive absorber, wherein the rotational speed adaptive tuned mass damper is disposed between the dampers at least in one force flow direction through the force transmission device.

Owner:SCHAEFFLER TECH AG & CO KG

Series drive clutch

InactiveUS6846257B2Prevent rotationPlural diverse prime-mover propulsion mountingFluid clutchesCombustionEngineering

A clutch mechanism is disclosed for use with a hybrid electric vehicle wherein the electric motor-generator and engine are arranged in a series configuration. The clutch mechanism is positioned between and in communication with the electric motor-generator and engine to allow for either direct drive or a predetermined gear ratio between the electric motor-generator and engine. The electric motor-generator is preferably an integrated electric motor and generator. The engine is preferably a combustion engine.

Owner:NTN CORP

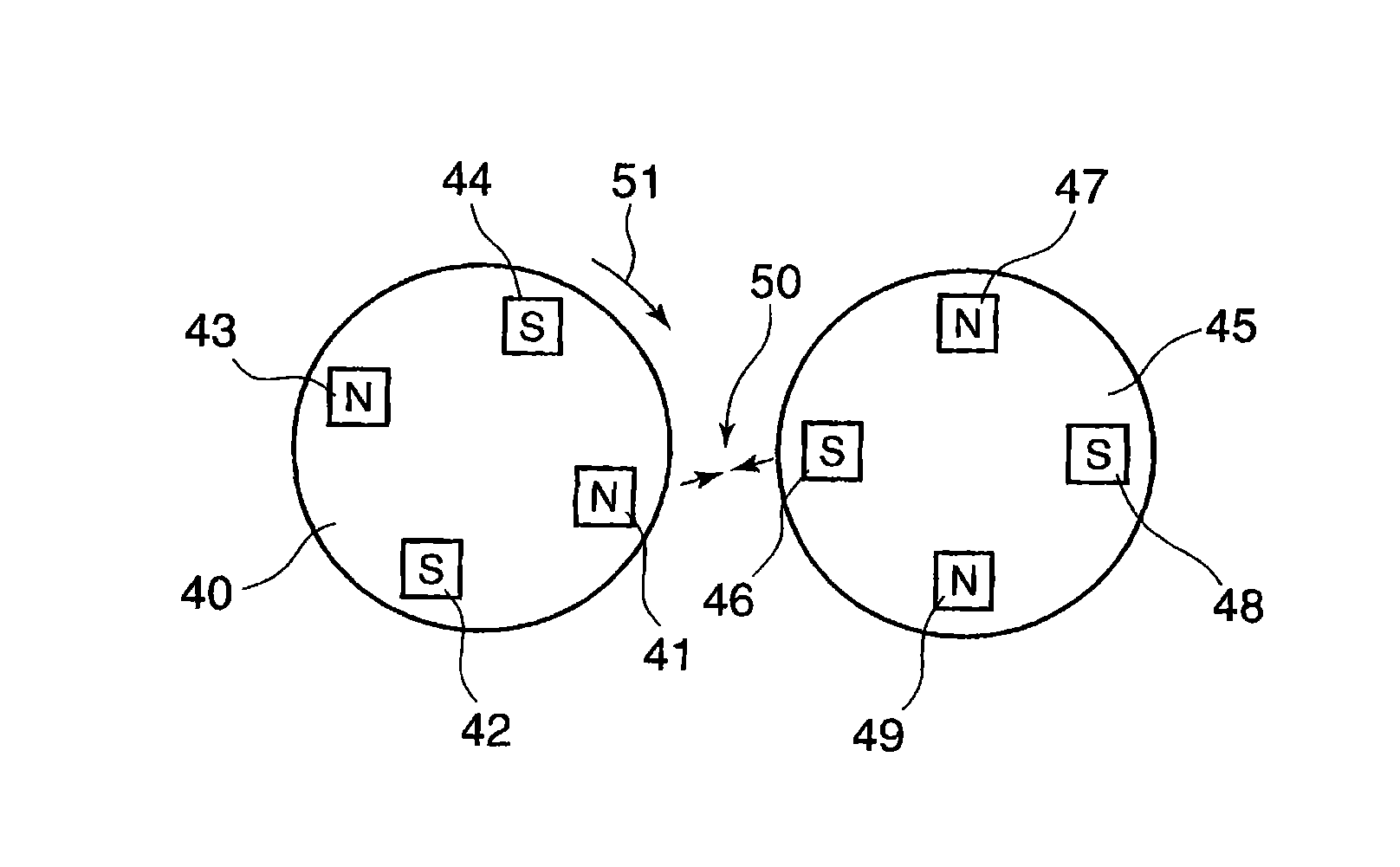

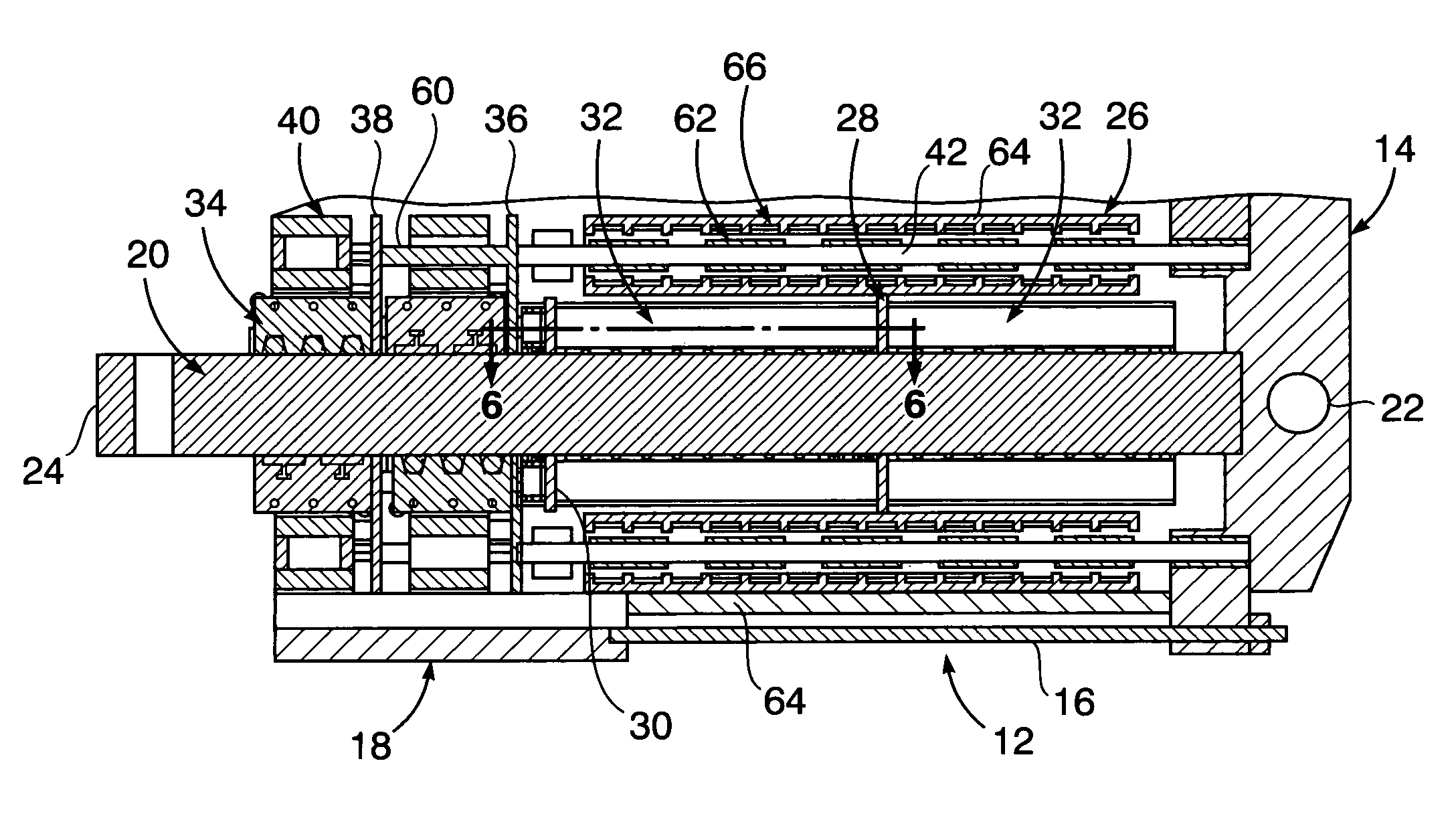

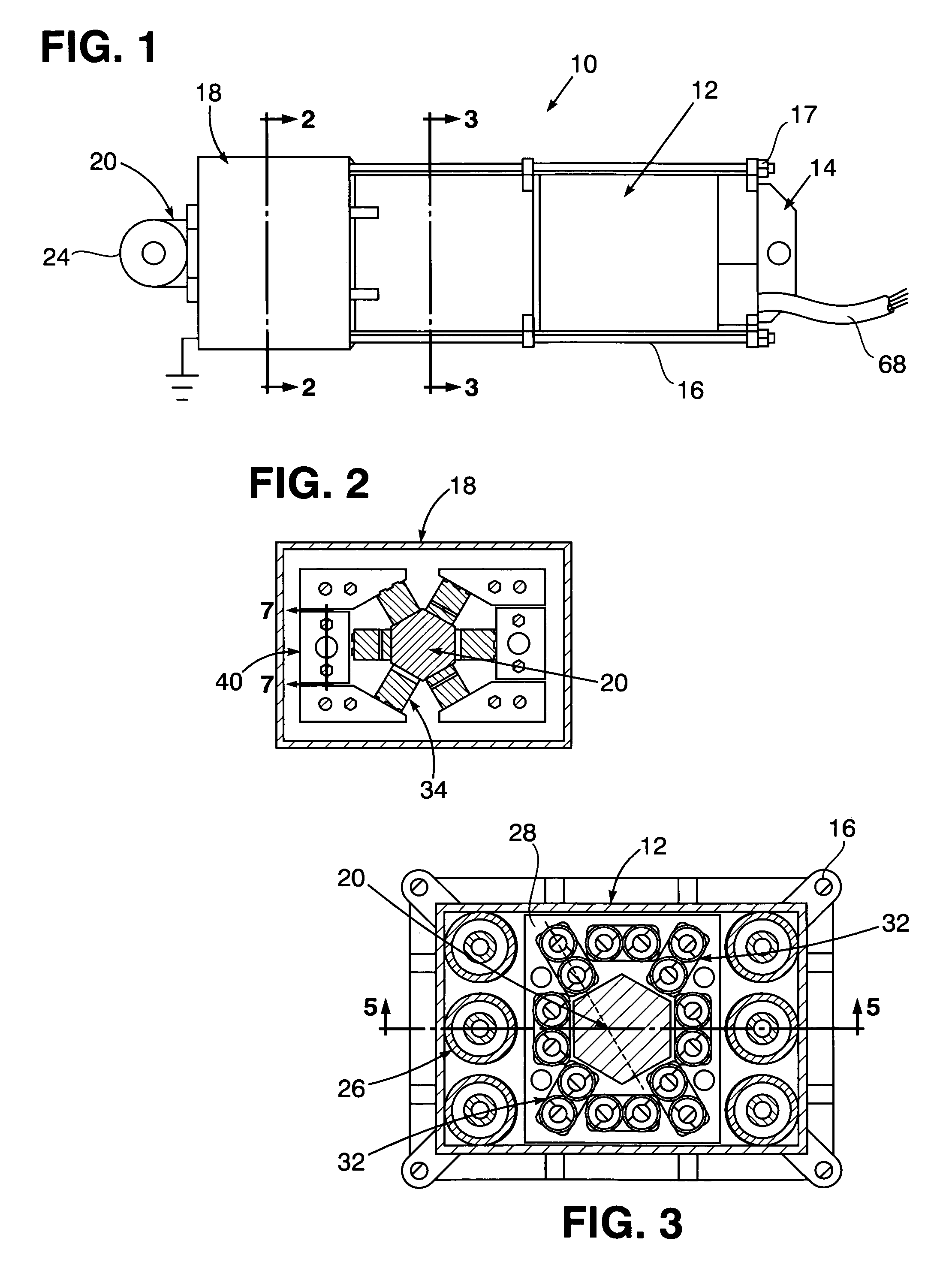

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

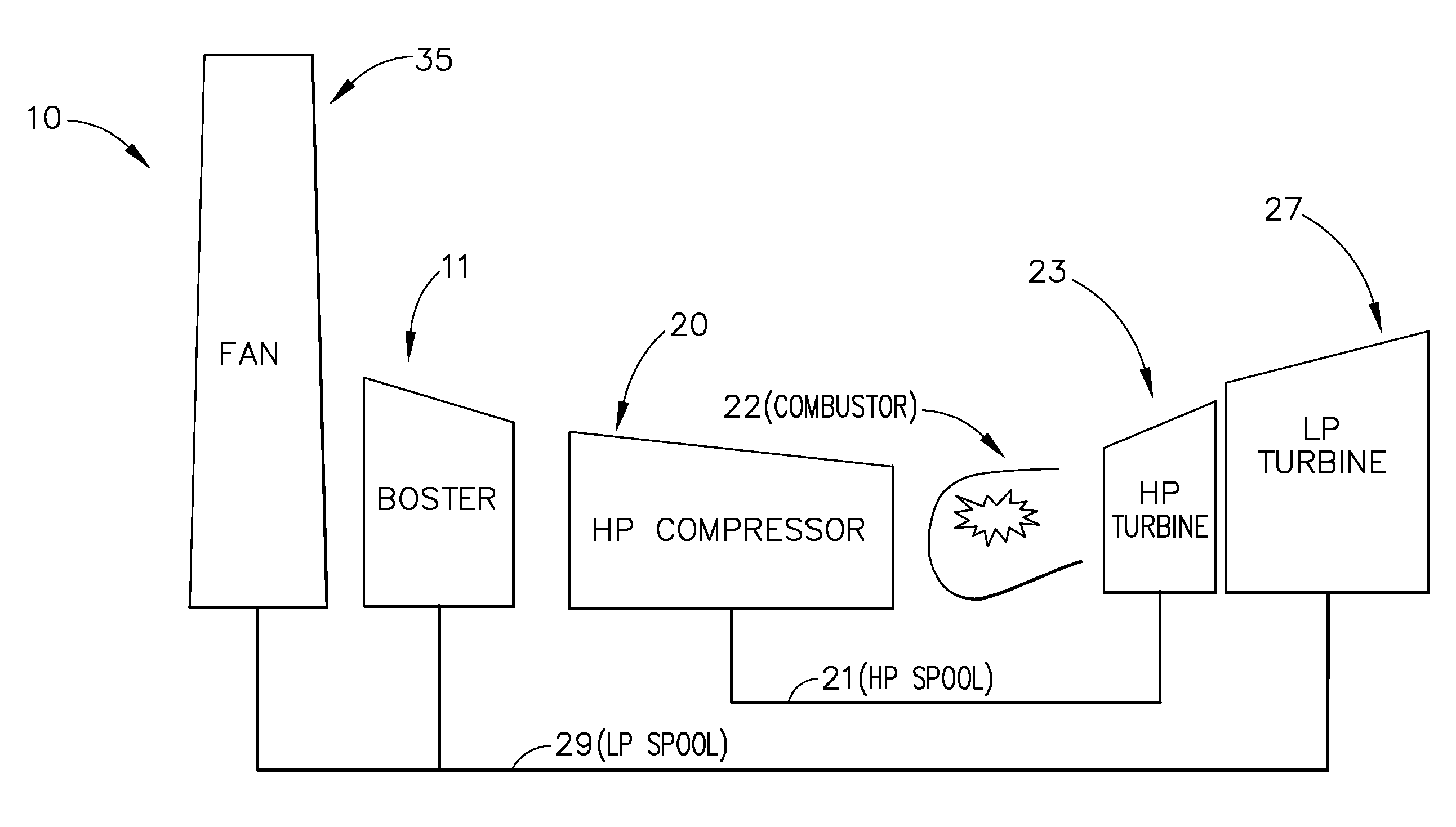

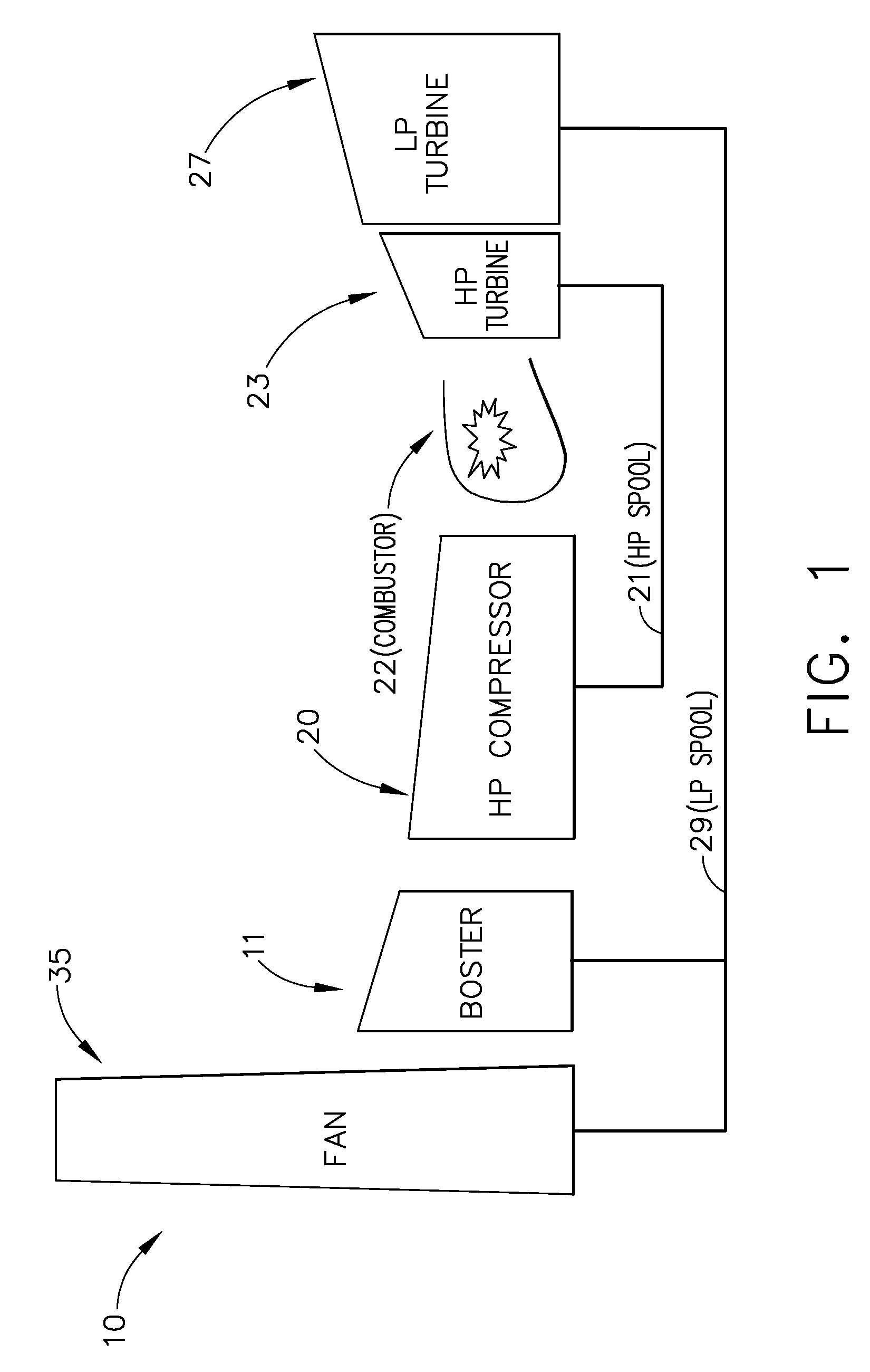

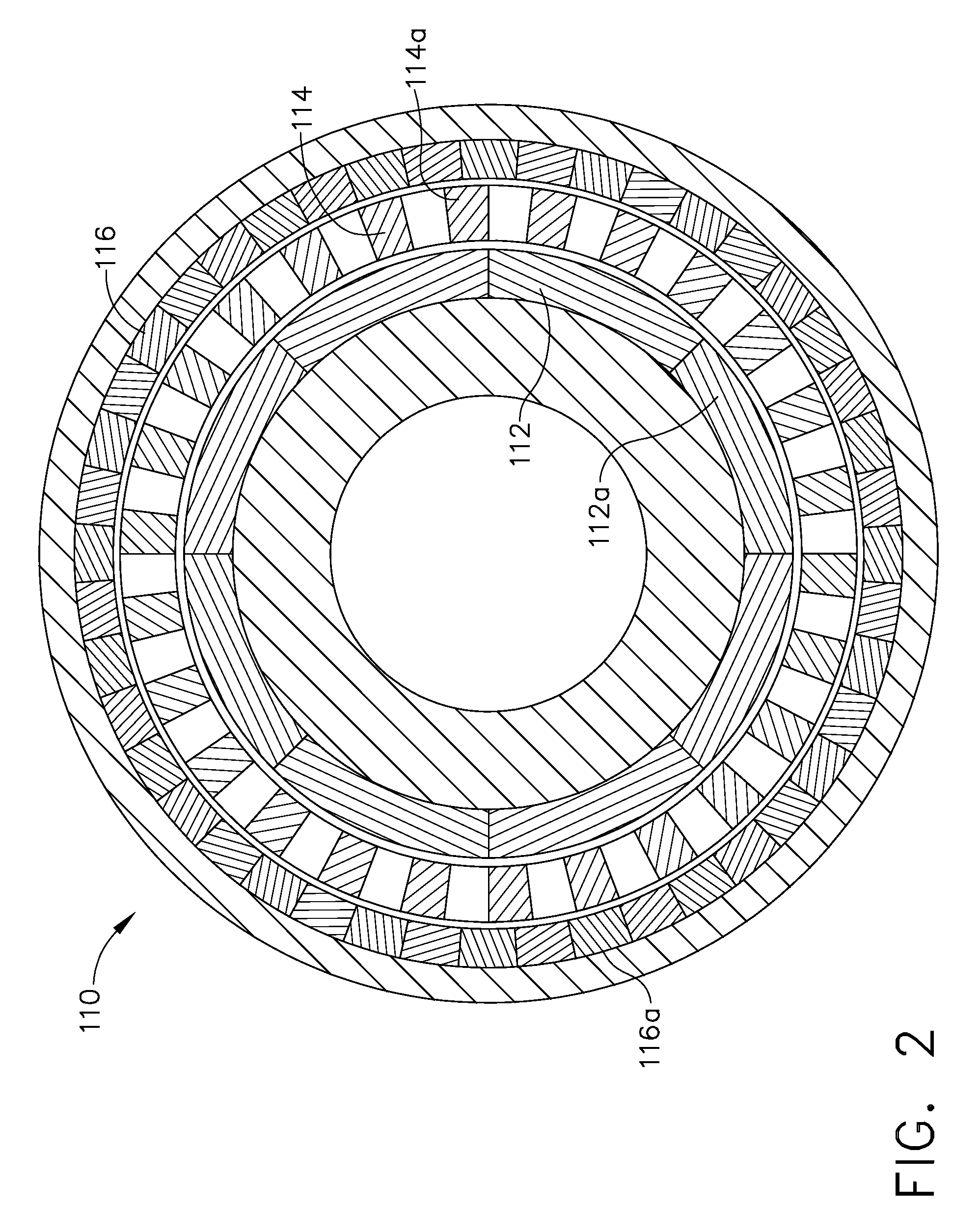

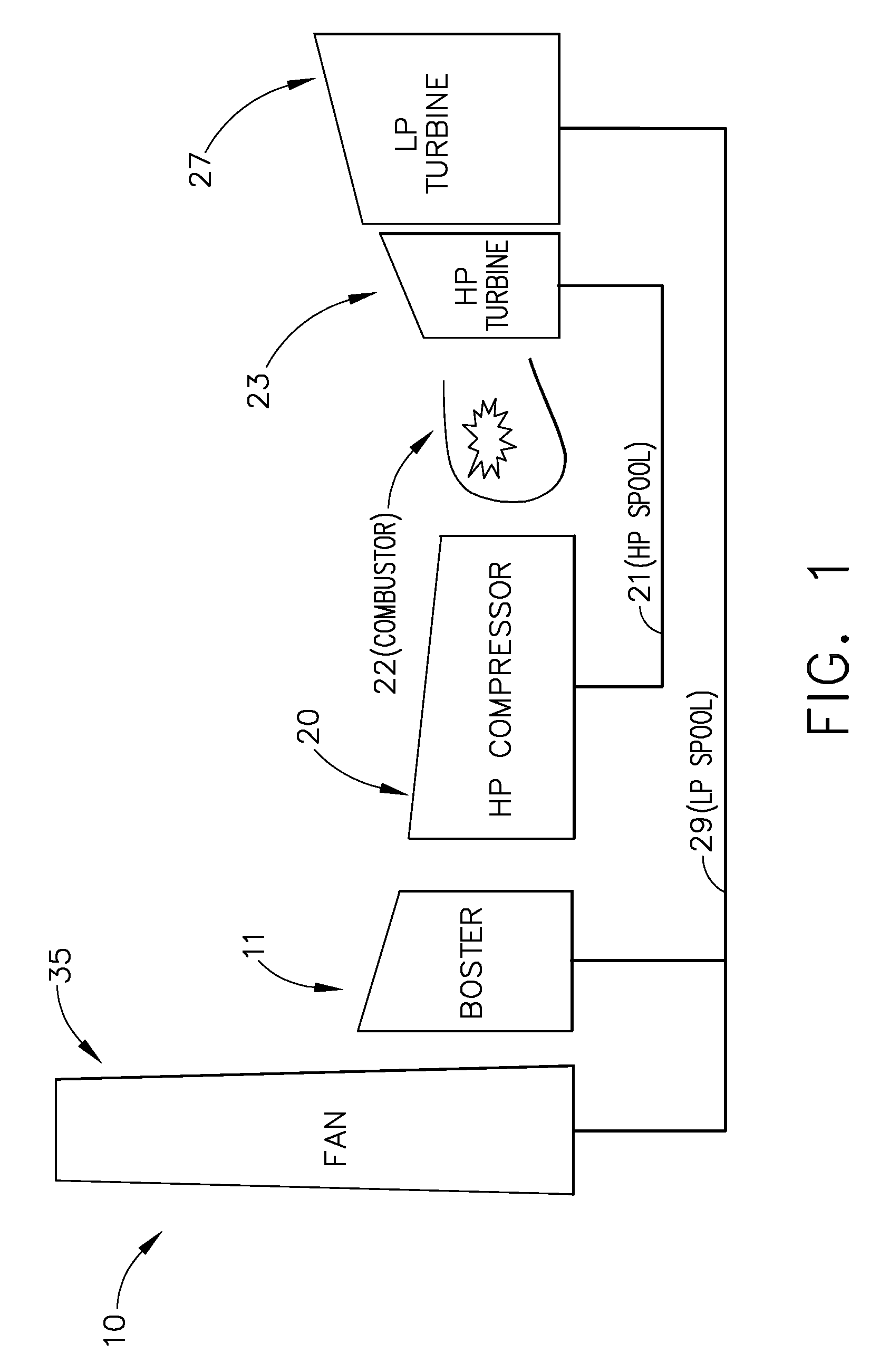

Variable Magnetic Coupling of Rotating Machinery

ActiveUS20080149445A1Reduce vibration transmissionMechanical actuated clutchesEngine fuctionsCouplingEngineering

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

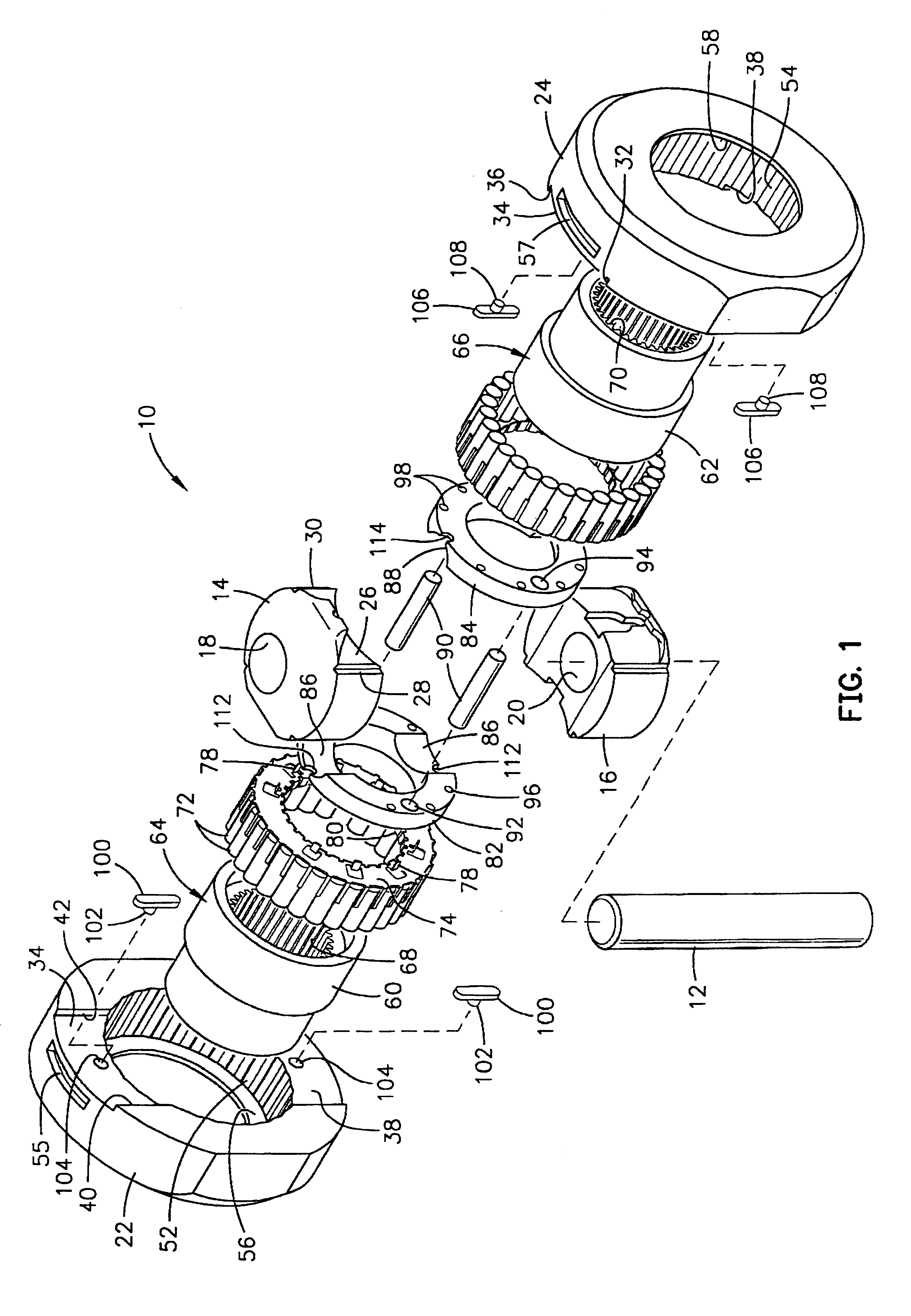

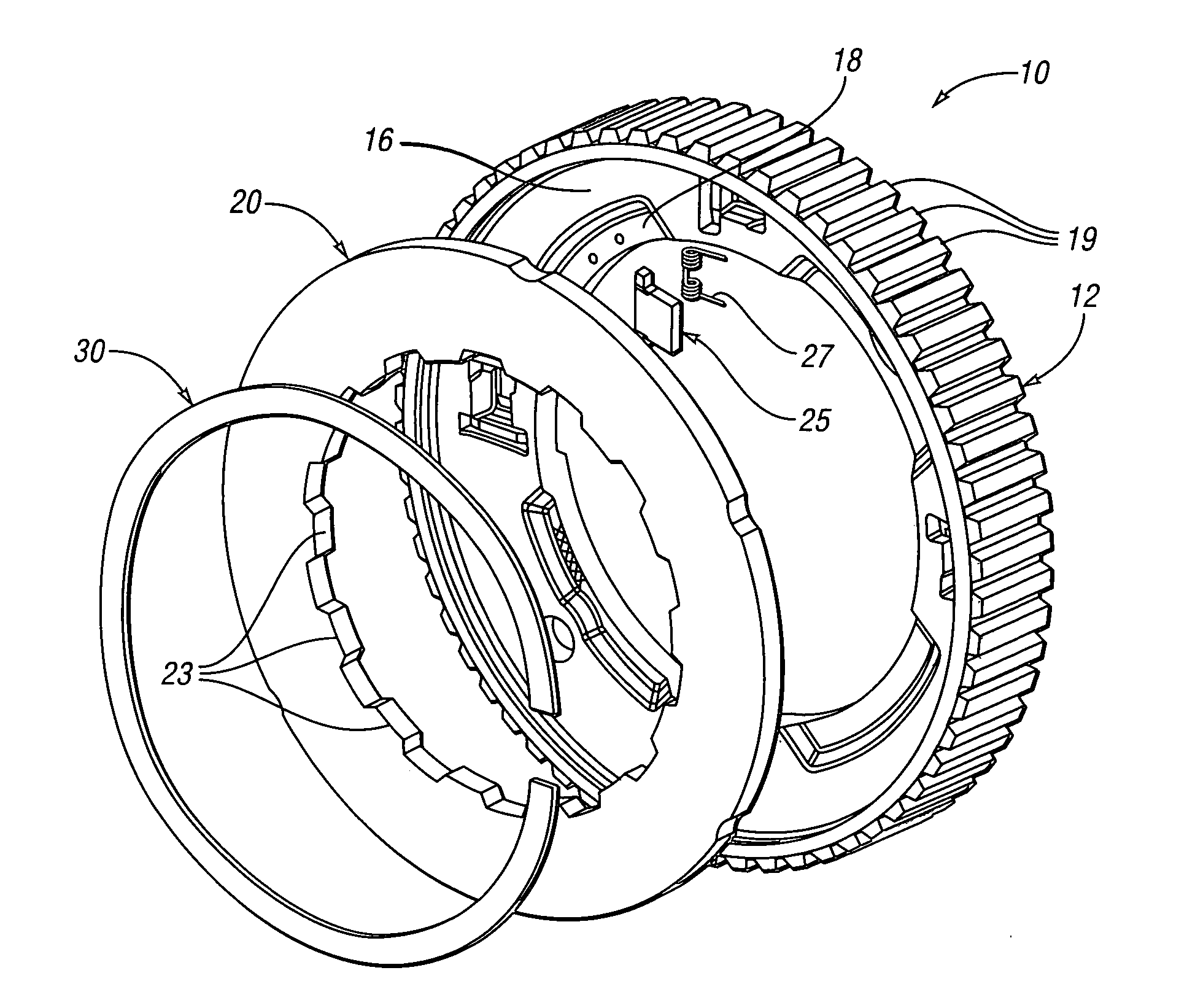

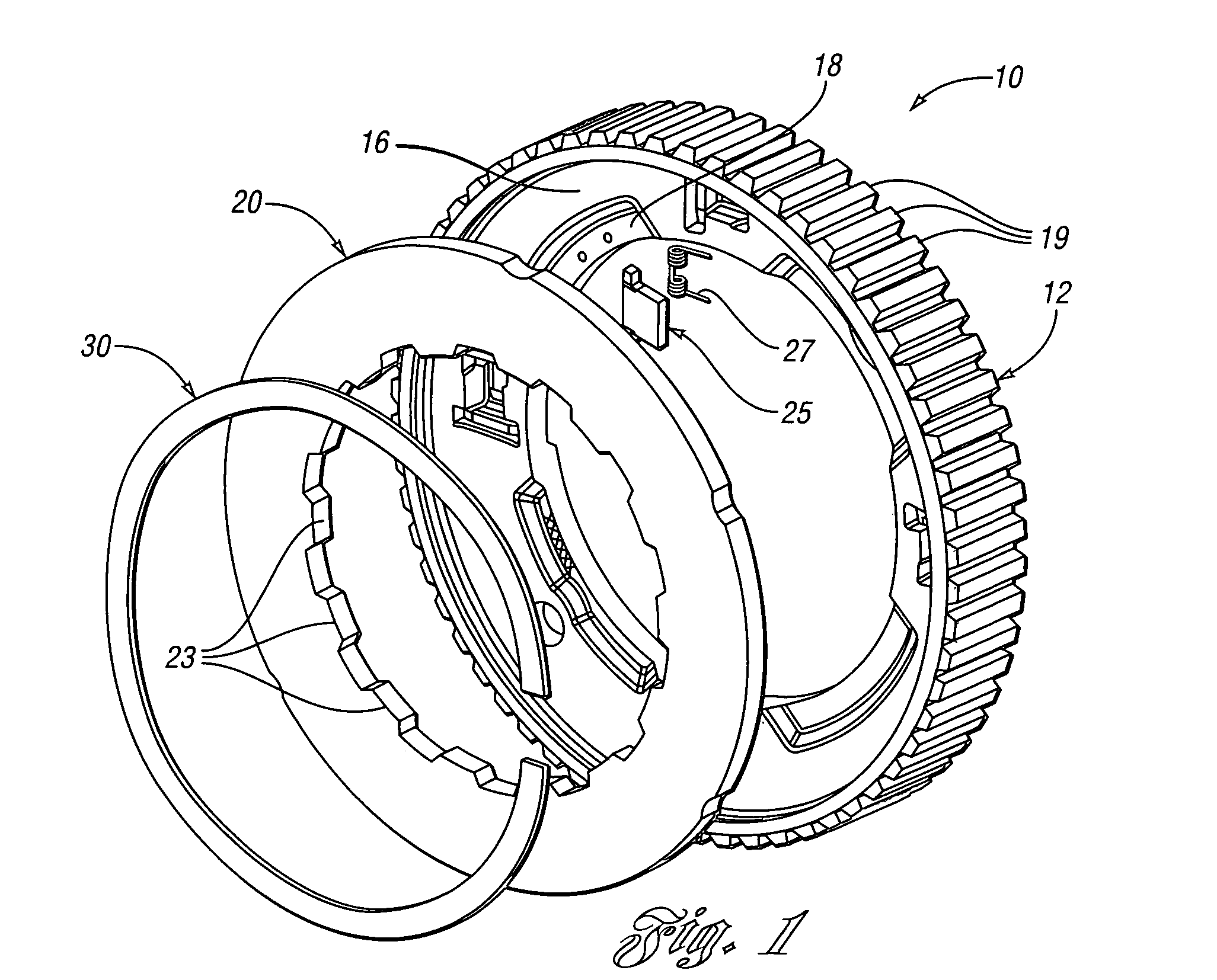

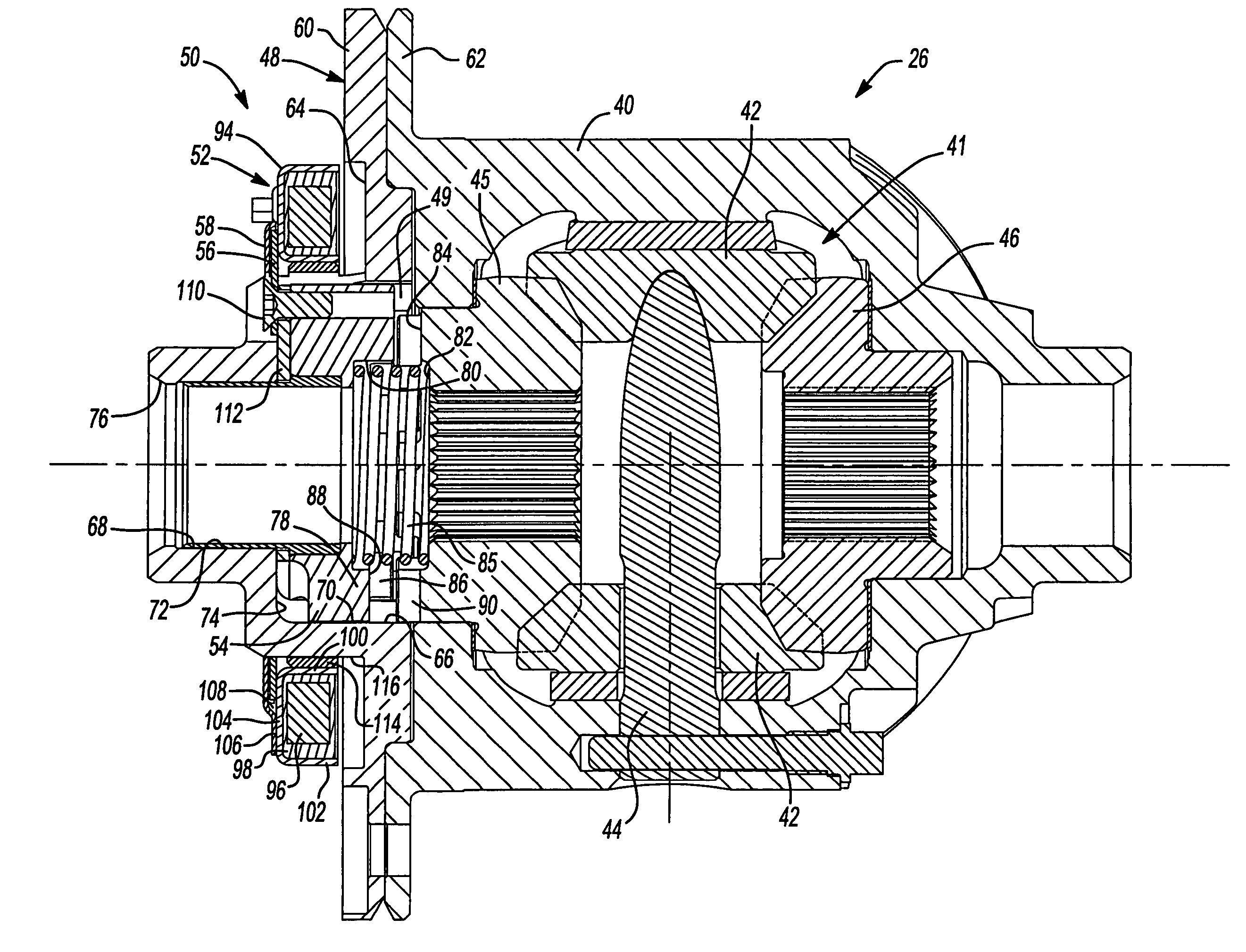

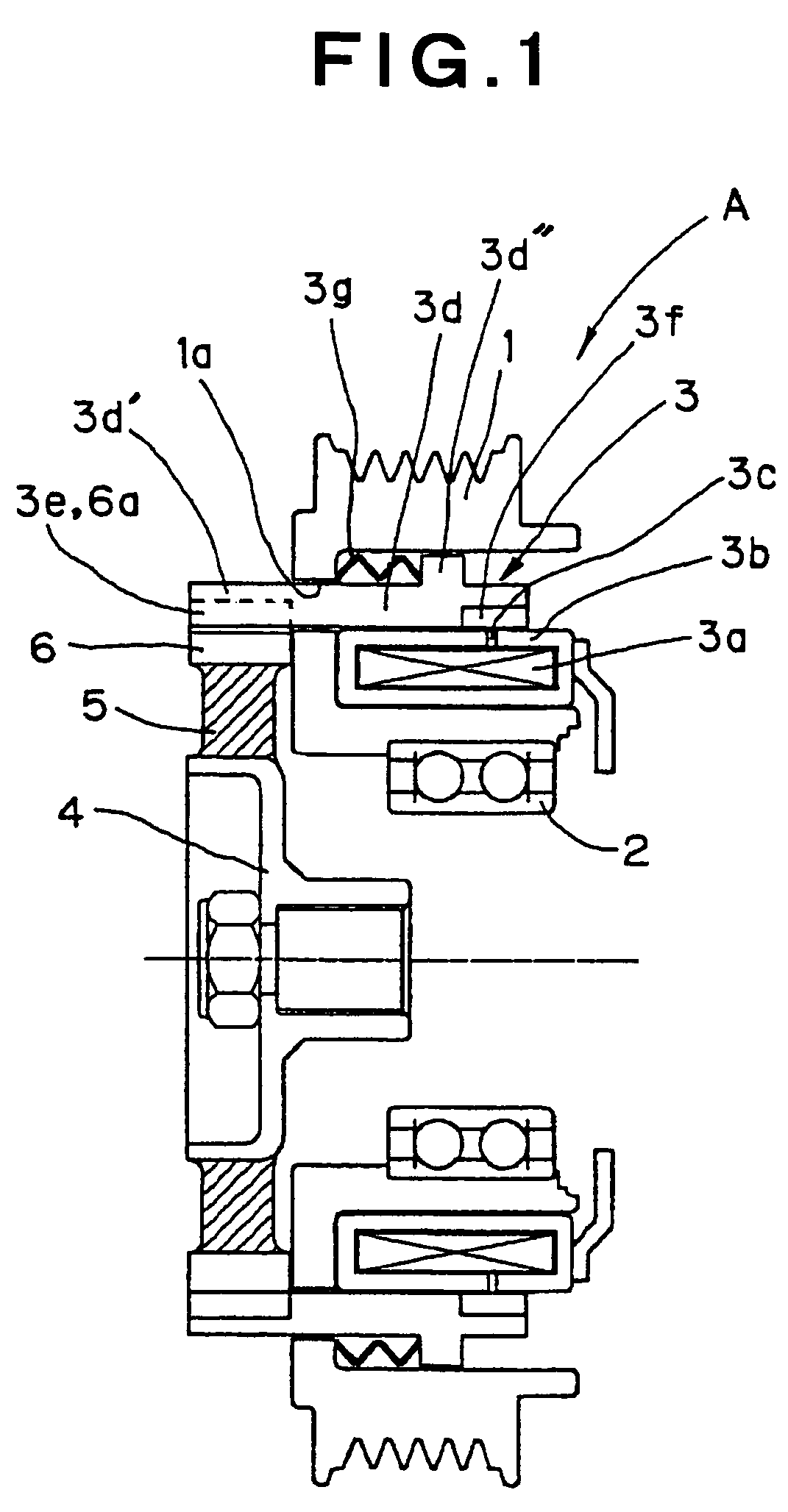

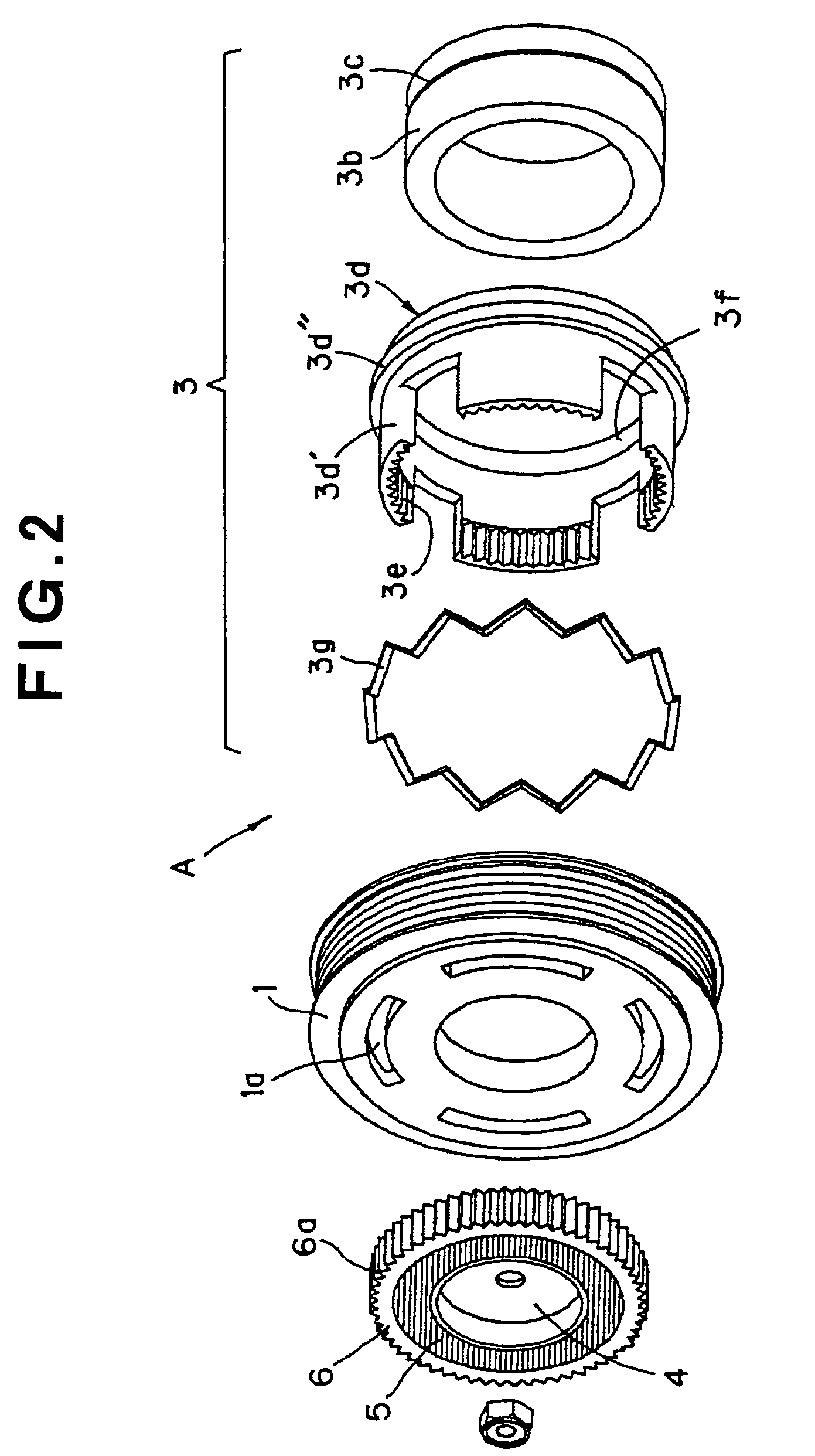

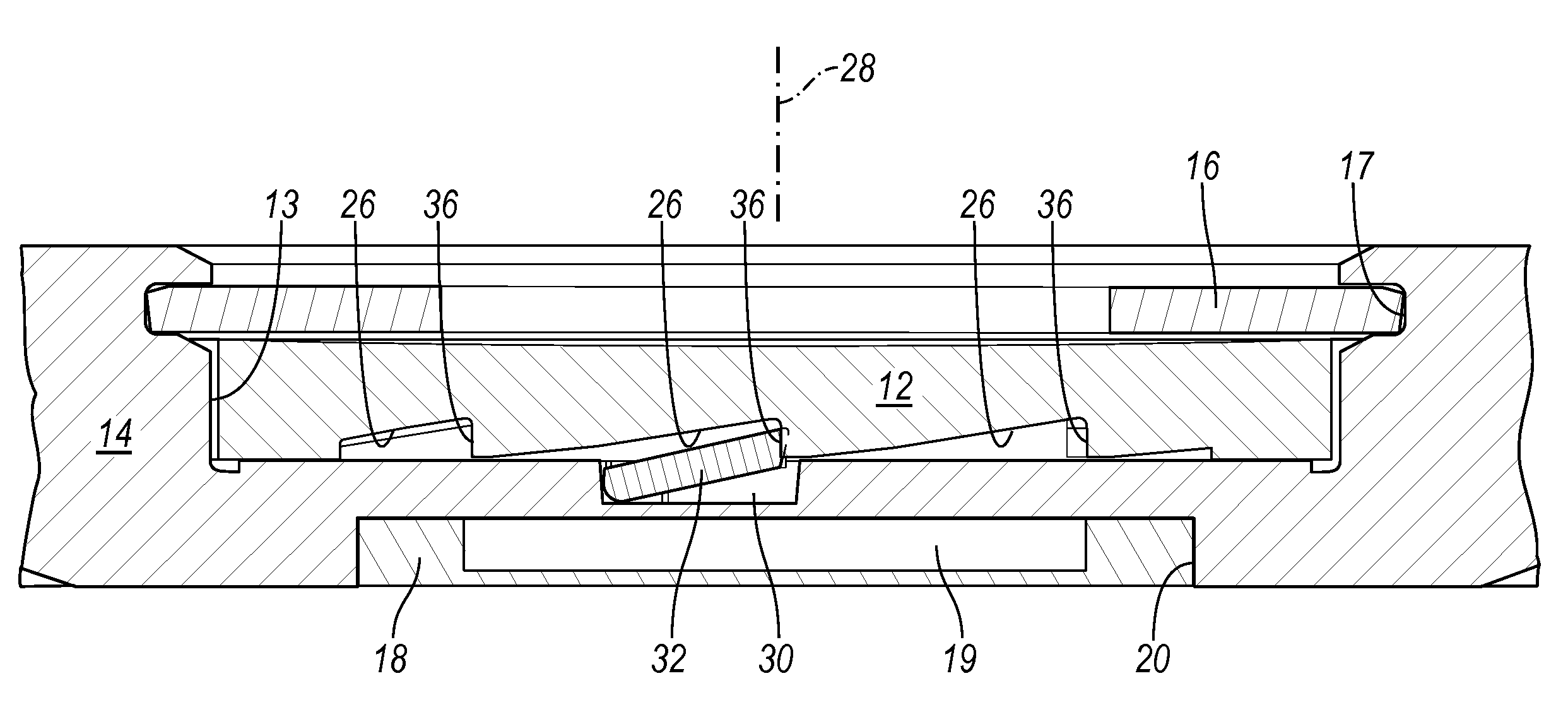

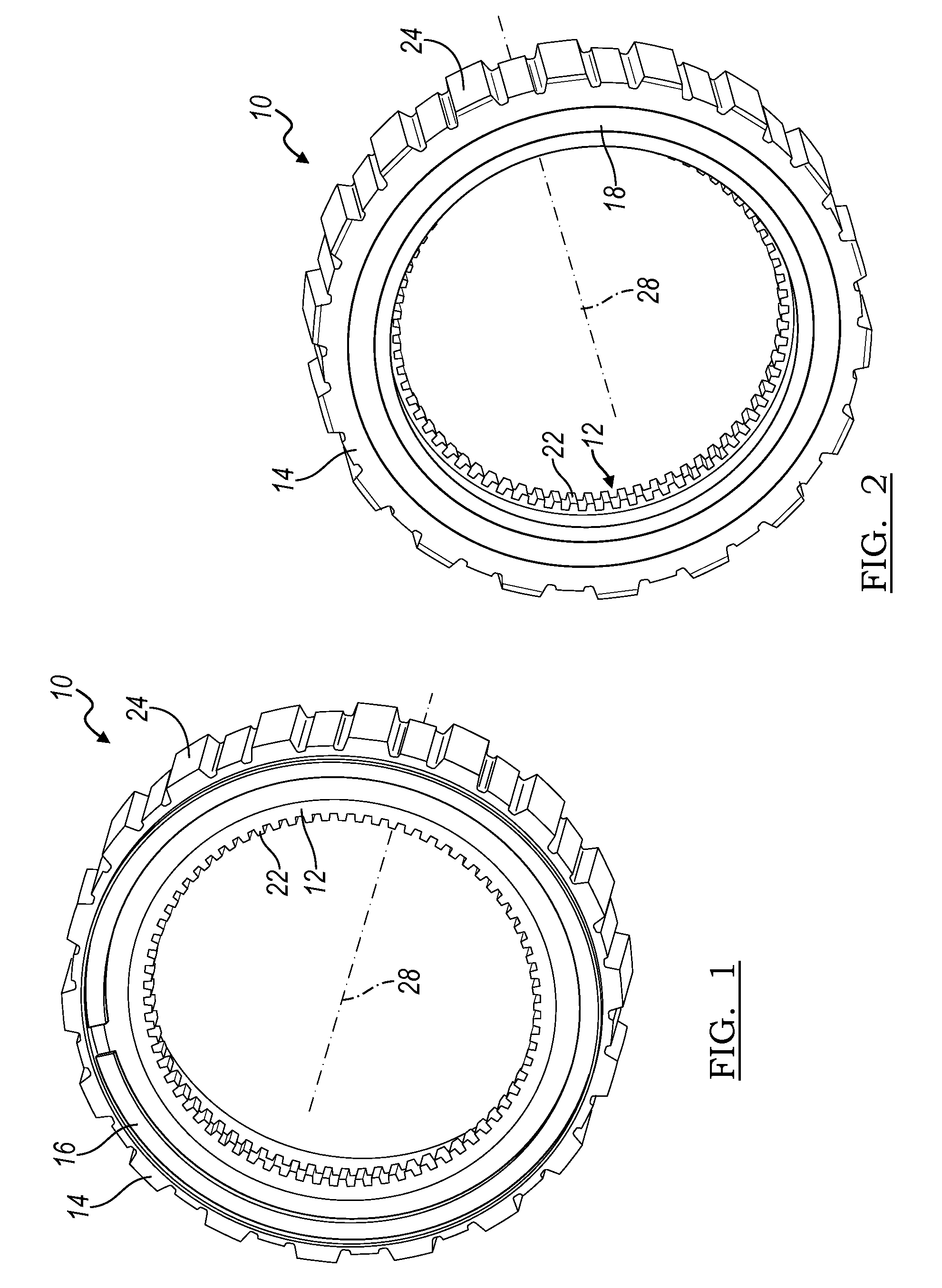

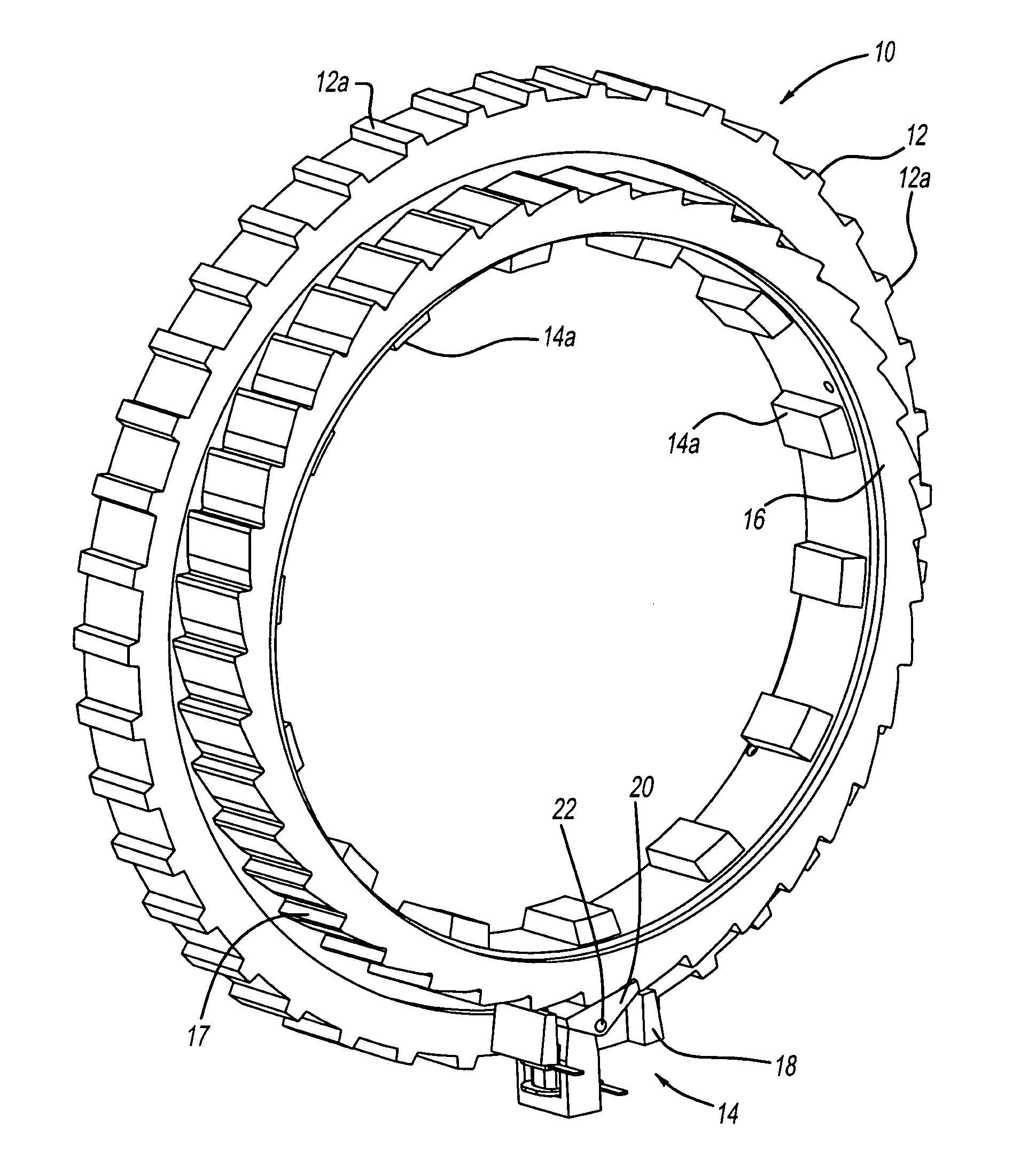

Overrunning coupling assembly having improved shift feel and/or noise reduction

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

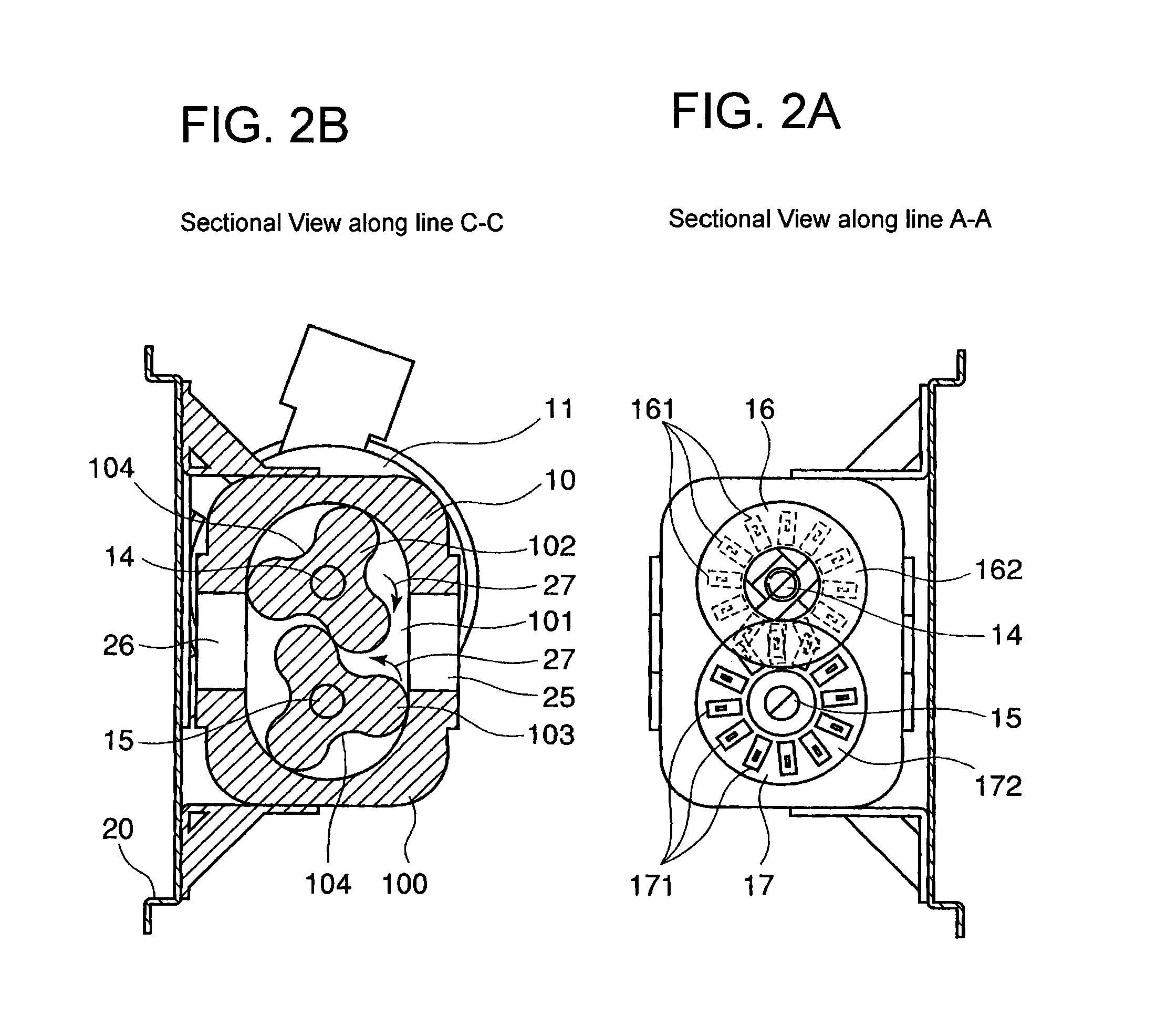

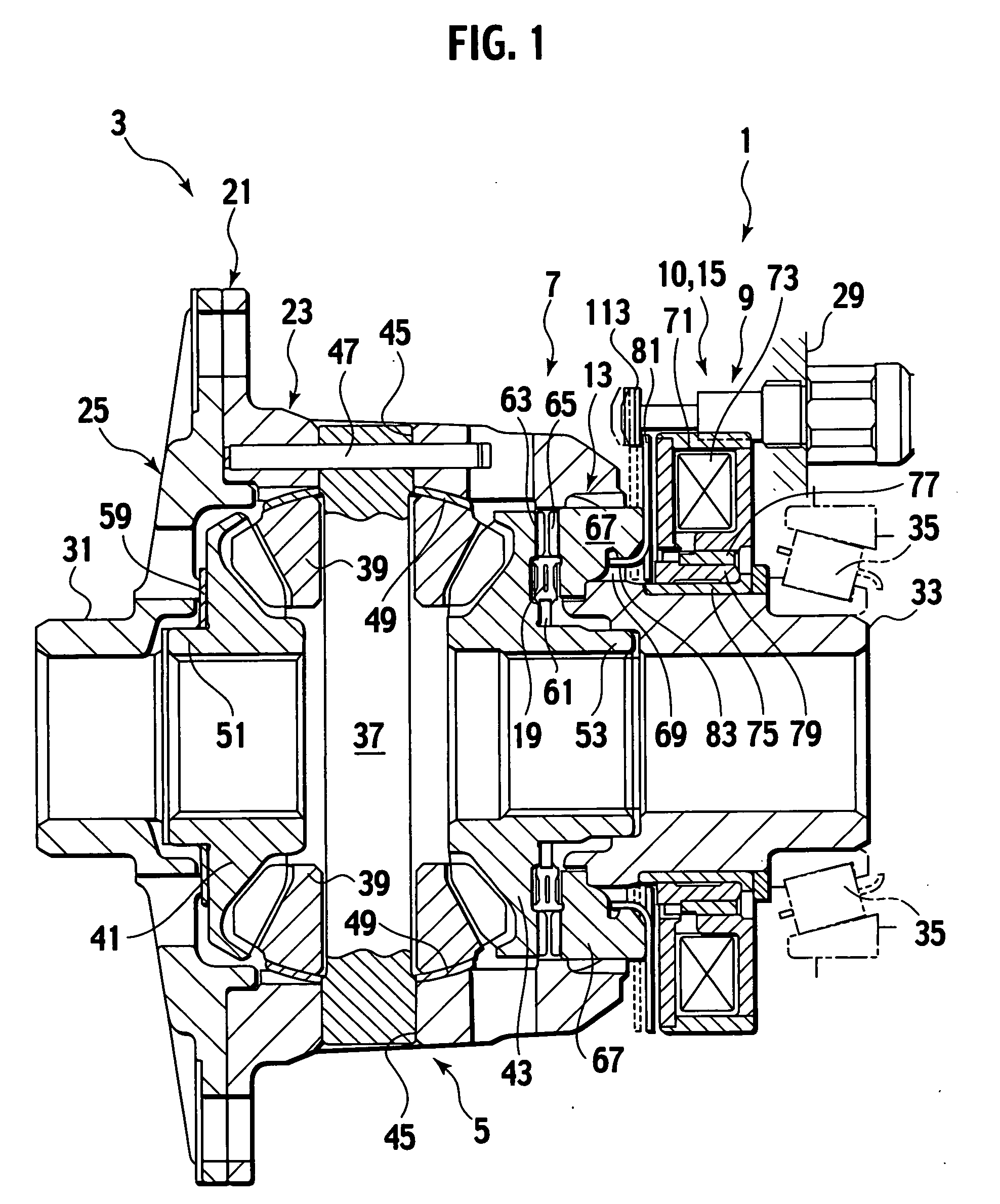

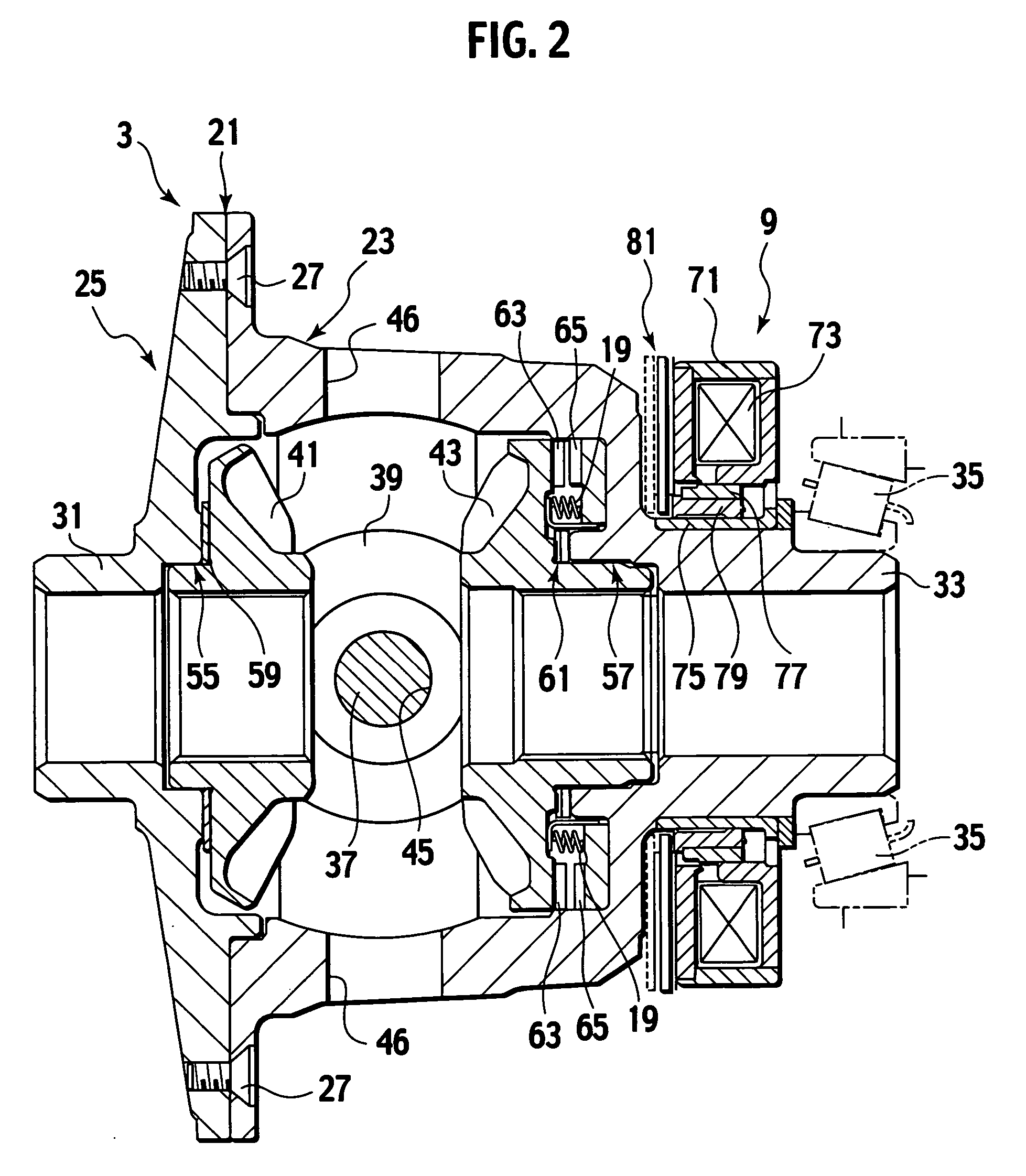

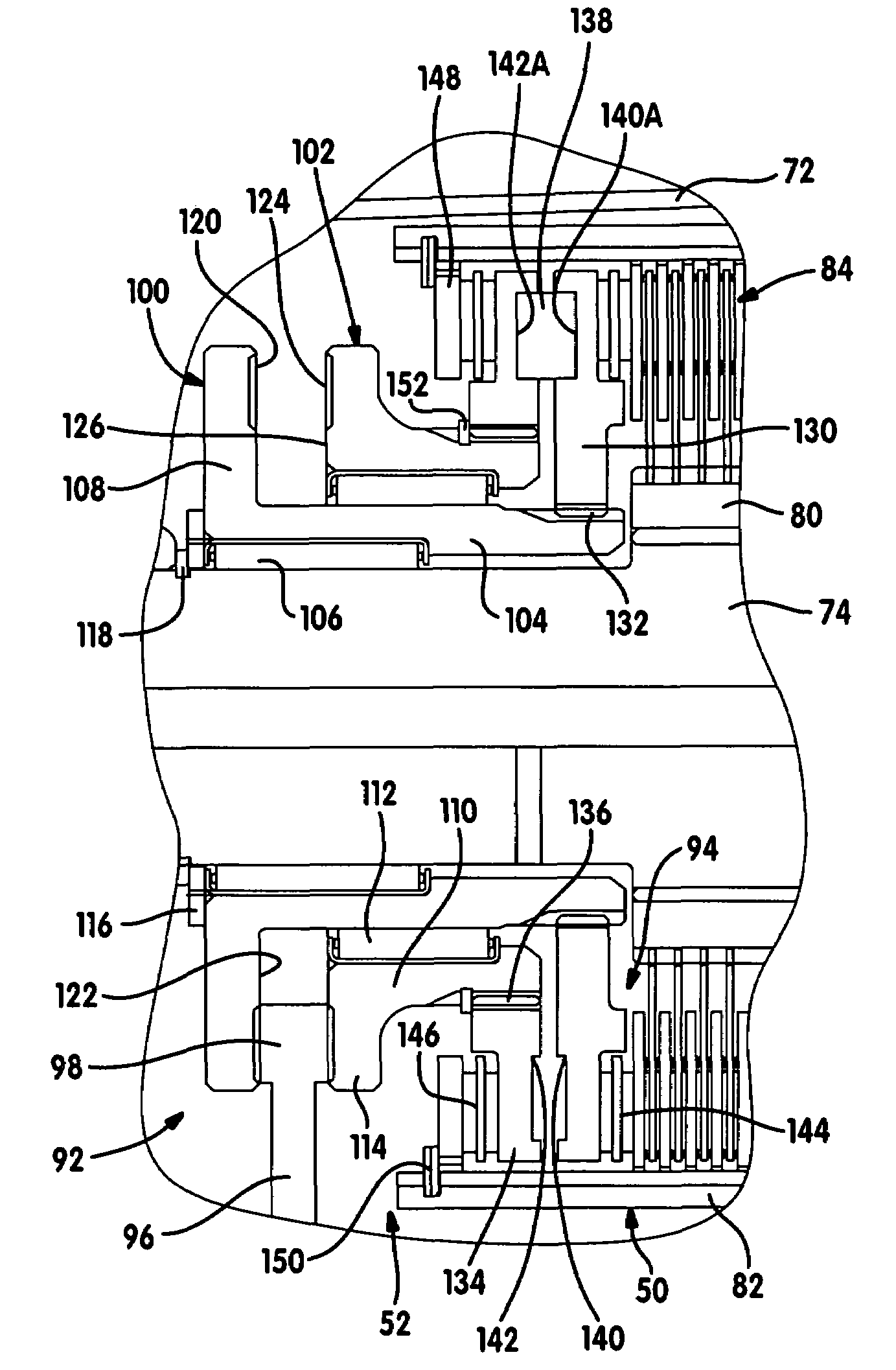

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS20050279607A1Inhibit heat generationSuppress power consumptionMechanical actuated clutchesFluid actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

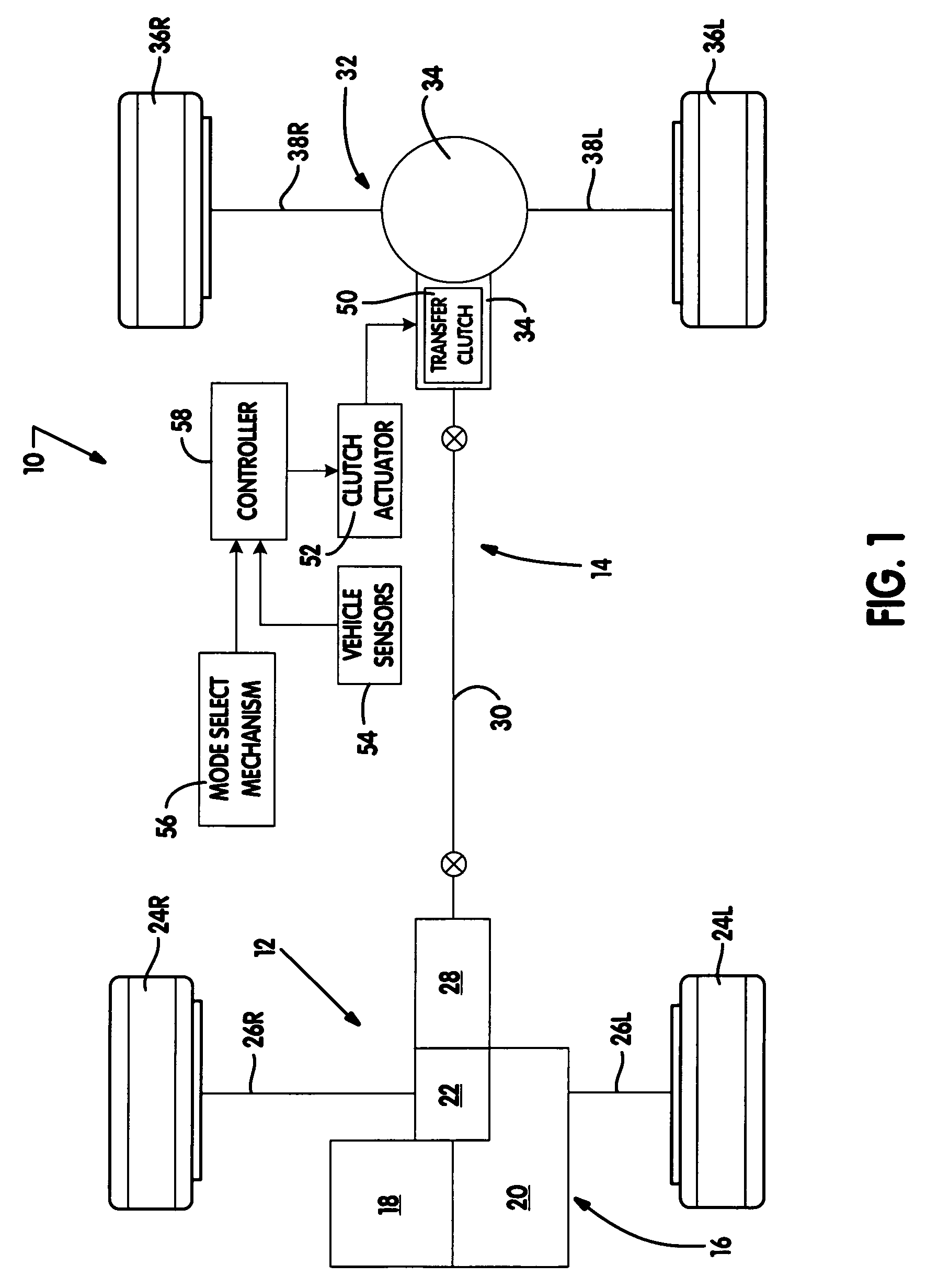

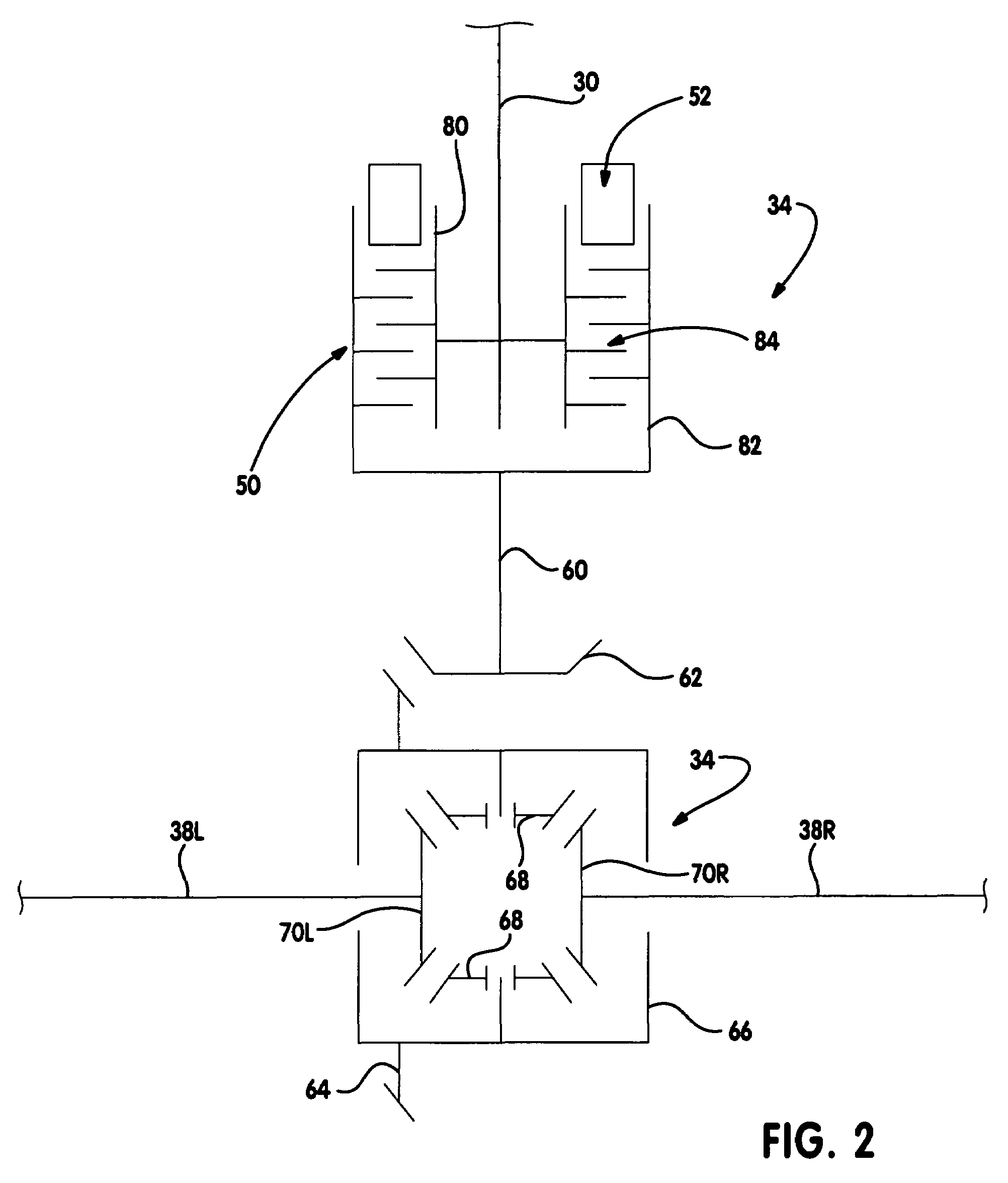

Bi-directional overrunning clutch

InactiveUSRE38012E1Prevent rotationYielding couplingFluid couplingsElectronic control systemDrive shaft

A bi-directional overrunning clutch is disclosed for controlling torque transmission between a secondary drive shaft and secondary driven shafts. The overrunning clutch includes a pinion input shaft in a differential housing that engages with a clutch housing rotatably disposed within the differential housing. At least one race is located adjacent to the clutch housing and is engaged with an output shaft. A cage is located between the race and the clutch housing. The cage is movable with respect to the clutch housing. A <DEL-S DATE="20030304" ID="DEL-S-00001" / >first<DEL-E ID="DEL-S-00001" / > coil is mounted within the differential housing adjacent to the cage and is adapted to produce an electromagnetic field when energized which causes the cage to drag with respect to the clutch housing. The dragging of the cage with respect to the clutch housing positions <INS-S DATE="20030304" ID="INS-S-00001" / >rolls within <INS-E ID="INS-S-00001" / >the cage to engage the clutch housing with the race when wheels on a primary drive shaft lose traction. <DEL-S DATE="20030304" ID="DEL-S-00002" / >A<DEL-E ID="DEL-S-00002" / > <INS-S DATE="20030304" ID="INS-S-00002" / >If desired a <INS-E ID="INS-S-00002" / >second coil <DEL-S DATE="20030304" ID="DEL-S-00003" / >is<DEL-E ID="DEL-S-00003" / > <INS-S DATE="20030304" ID="INS-S-00003" / >may be <INS-E ID="INS-S-00003" / >mounted within the differential housing adjacent <DEL-S DATE="20030304" ID="DEL-S-00004" / >adjacent<DEL-E ID="DEL-S-00004" / > to the cage. The second coil is adapted to produce an electromagnetic field when energized which advances cage with respect to the clutch housing causing the clutch housing to engage with the races. When the second coil is activated, the output shaft drives the pinion input shaft producing engine braking. An electronic control system is utilized to control the energizing of the coils.

Owner:HILLIARD

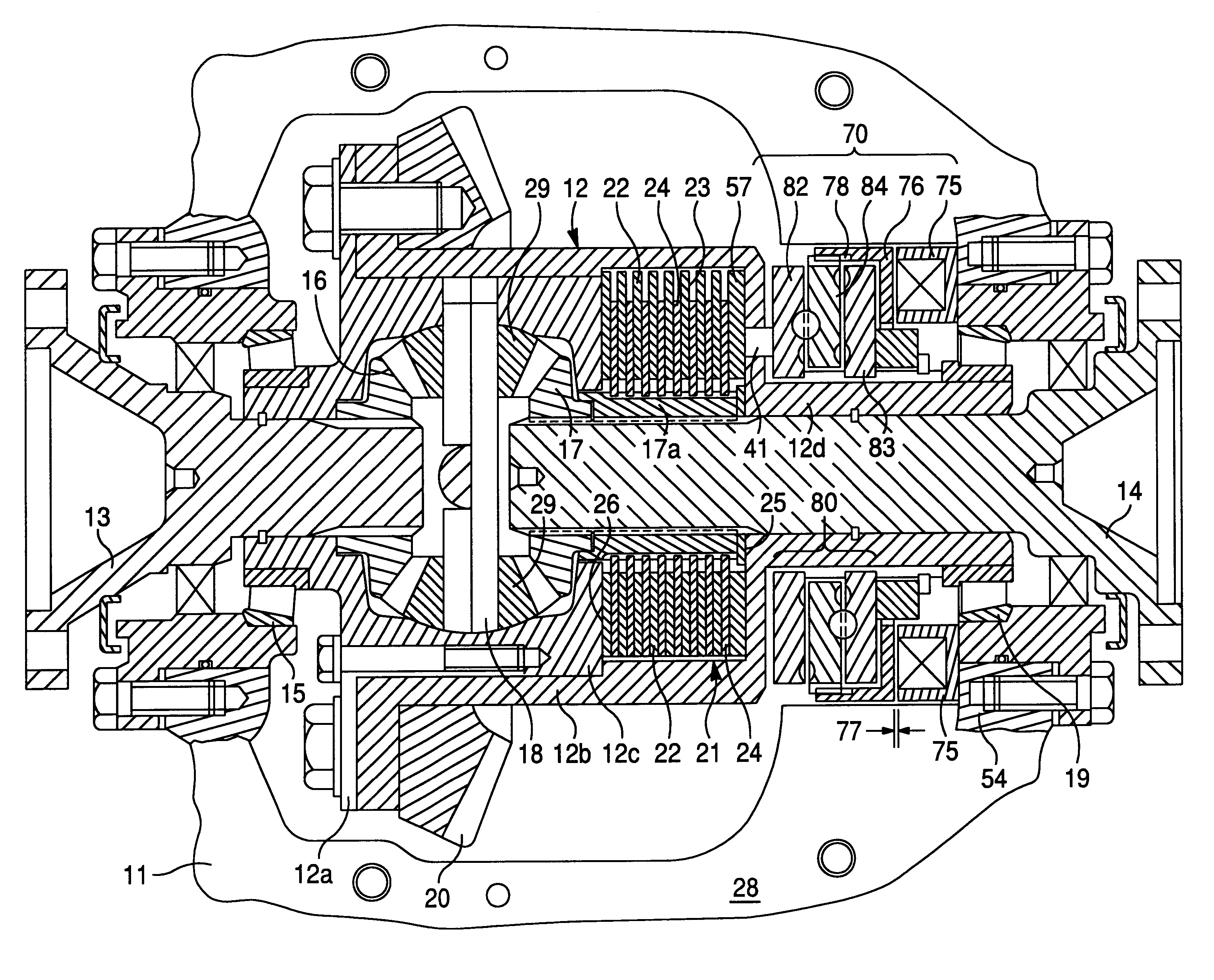

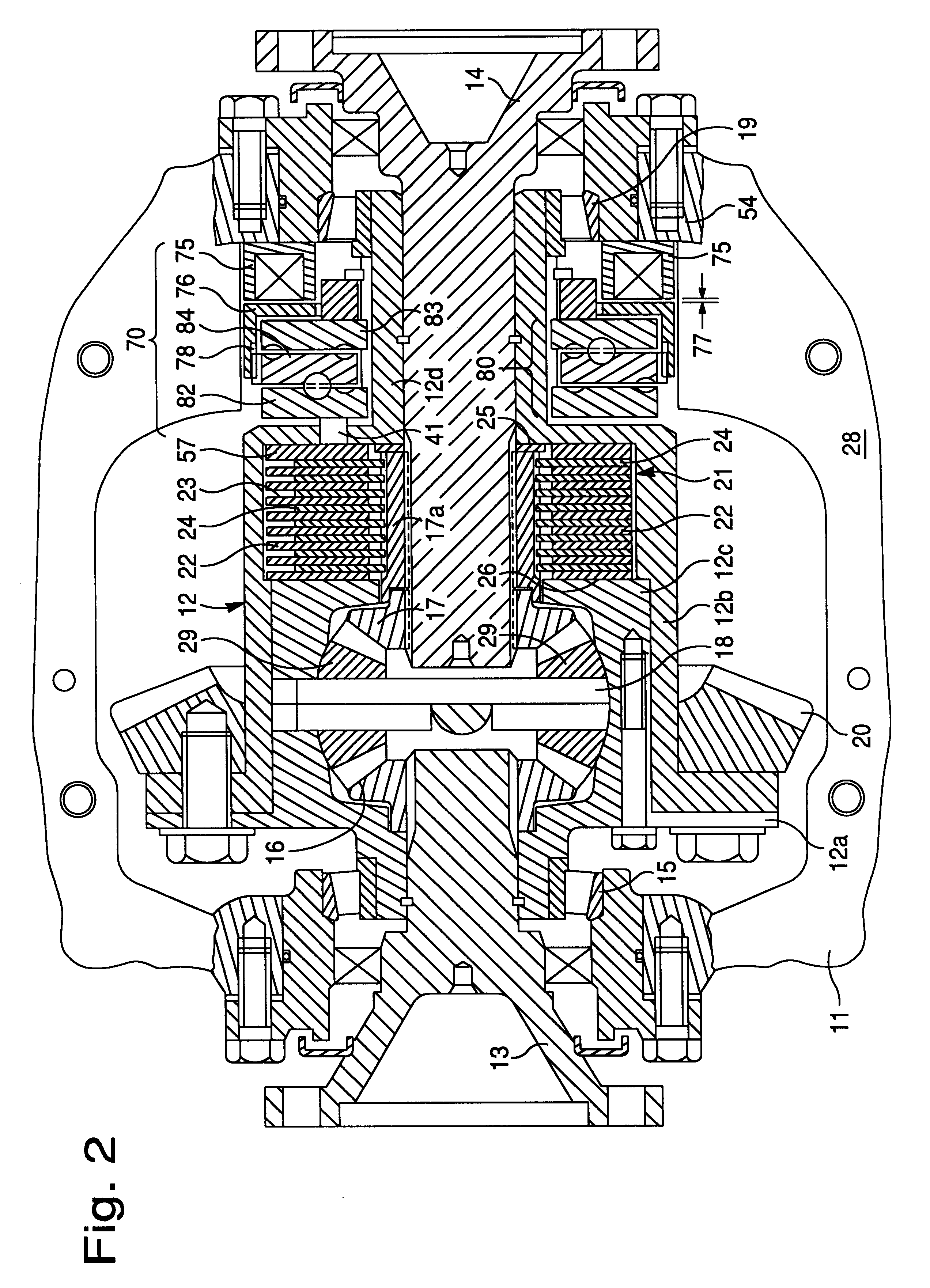

Electro-mechanical automatic transmission having dual input shafts

InactiveUS6044719APrevent rollbackImprove efficiencyRoad transportGear lubrication/coolingAutomatic transmissionEngineering

An electro-mechanical automatic transmission is provided including a first input shaft and a second input shaft concentric with the first input shaft. A plurality of drive gears are rotatably mounted to each input shaft and are provided with synchronizer devices for selectively engaging the drive gears to the input shafts. A driver shaft is provided with a plurality of driven gears in meshing engagement with the drive gears. The electro-mechanical automatic transmission is provided with a pair of electro-mechanical clutch actuators for selectively disengaging dual clutches which transmit engine torque to the input shafts, as well as an electro-mechanical shift actuator system which operatively engage the synchronizer devices for selectively engaging the drive gears.

Owner:FCA US

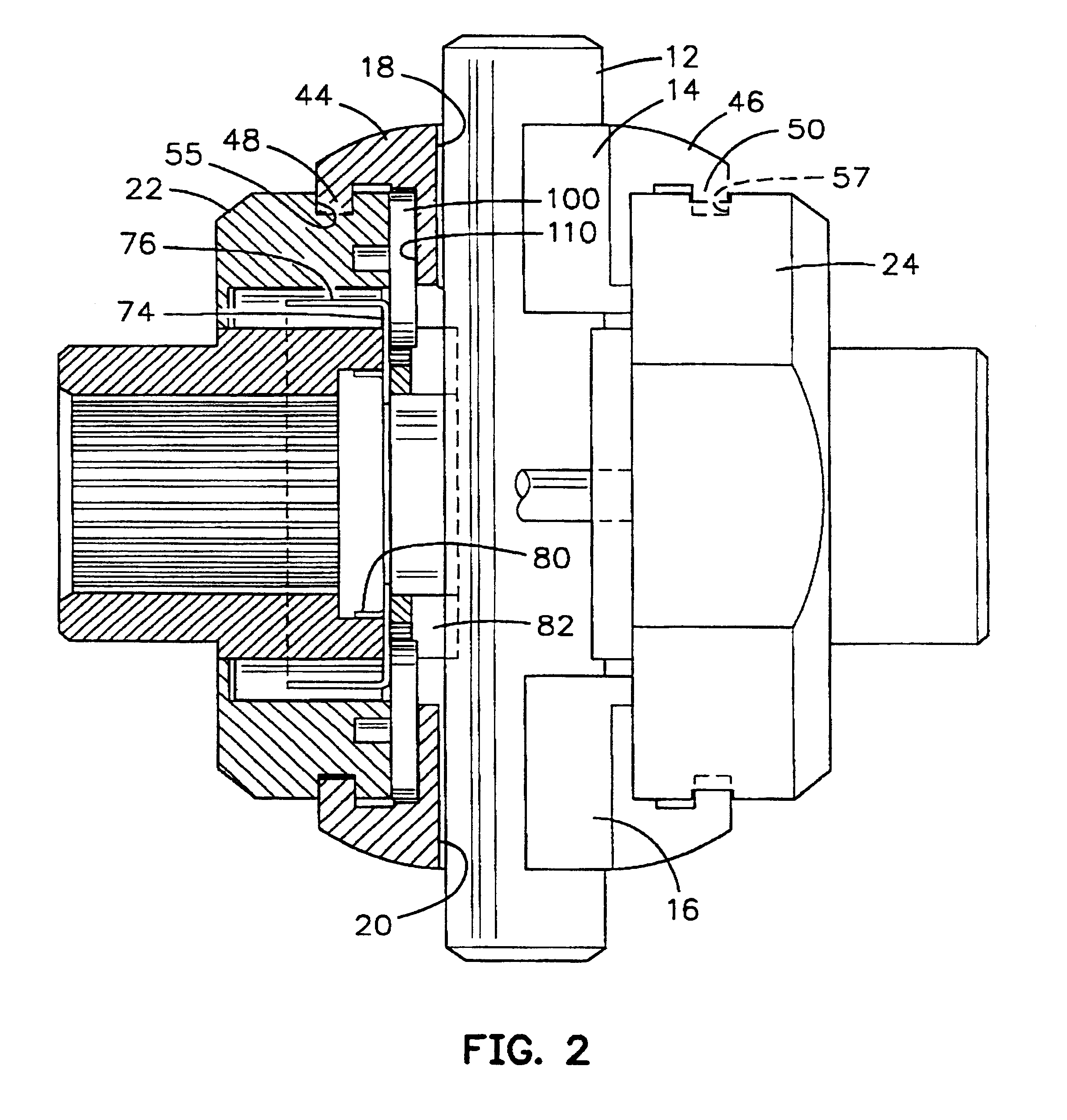

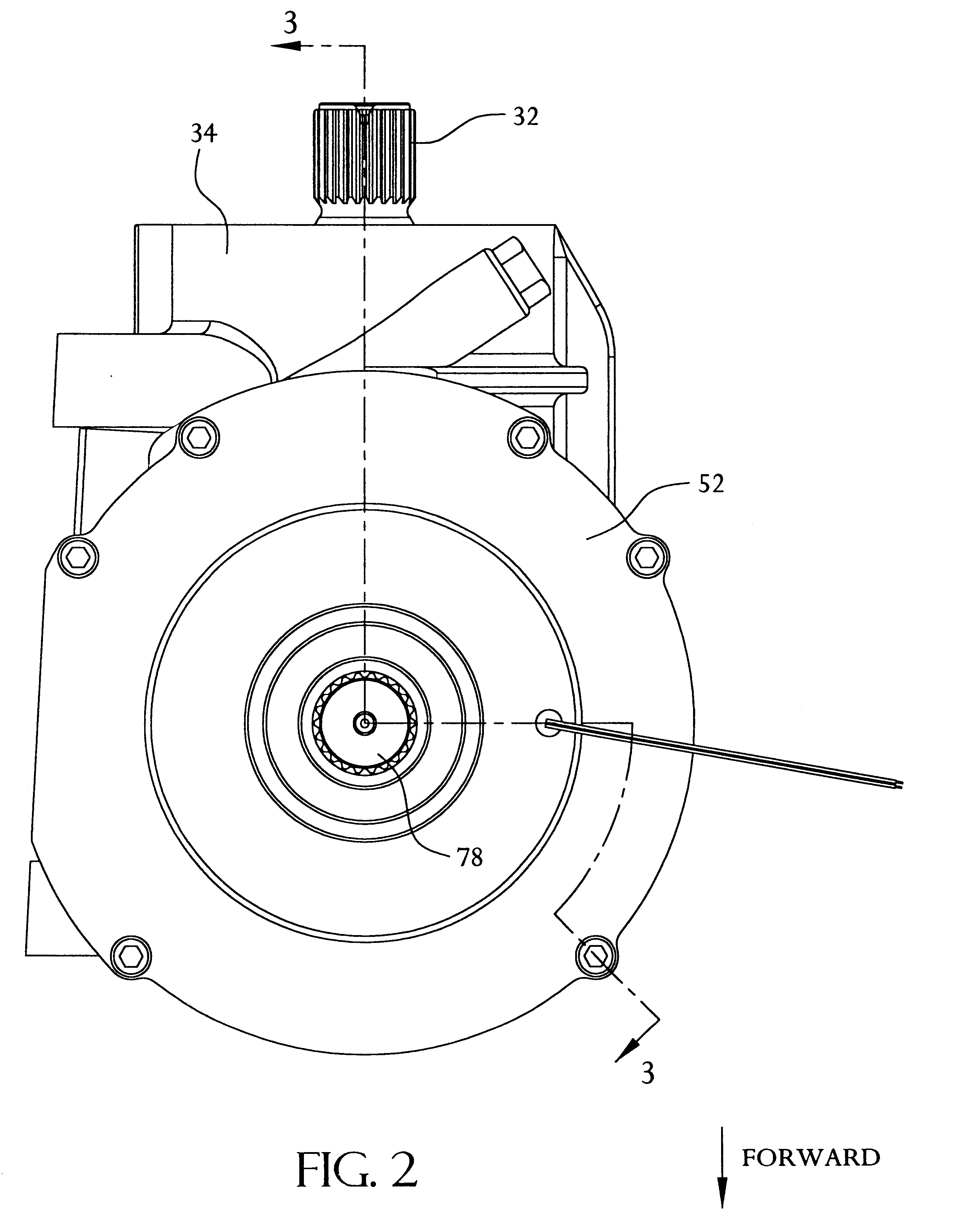

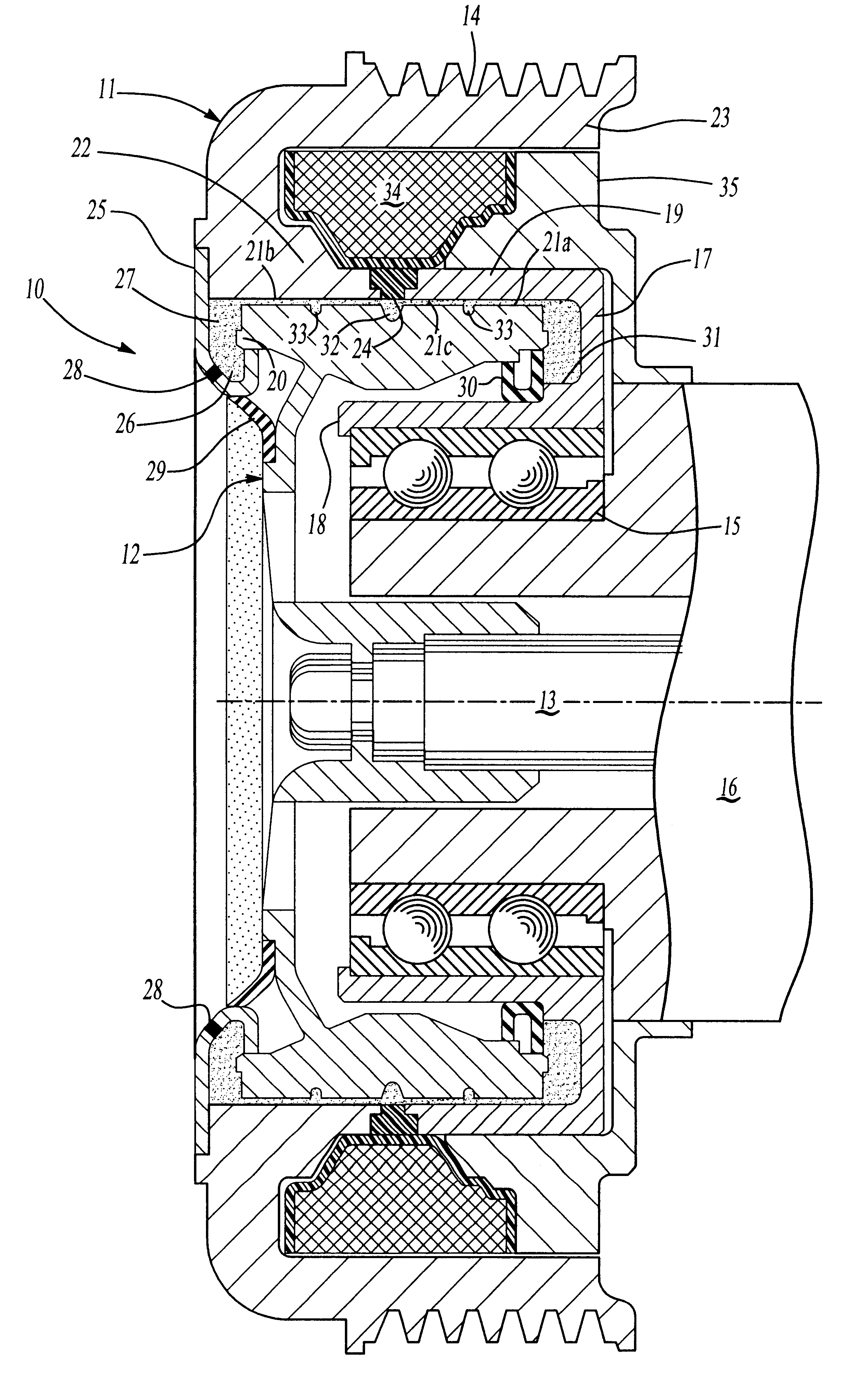

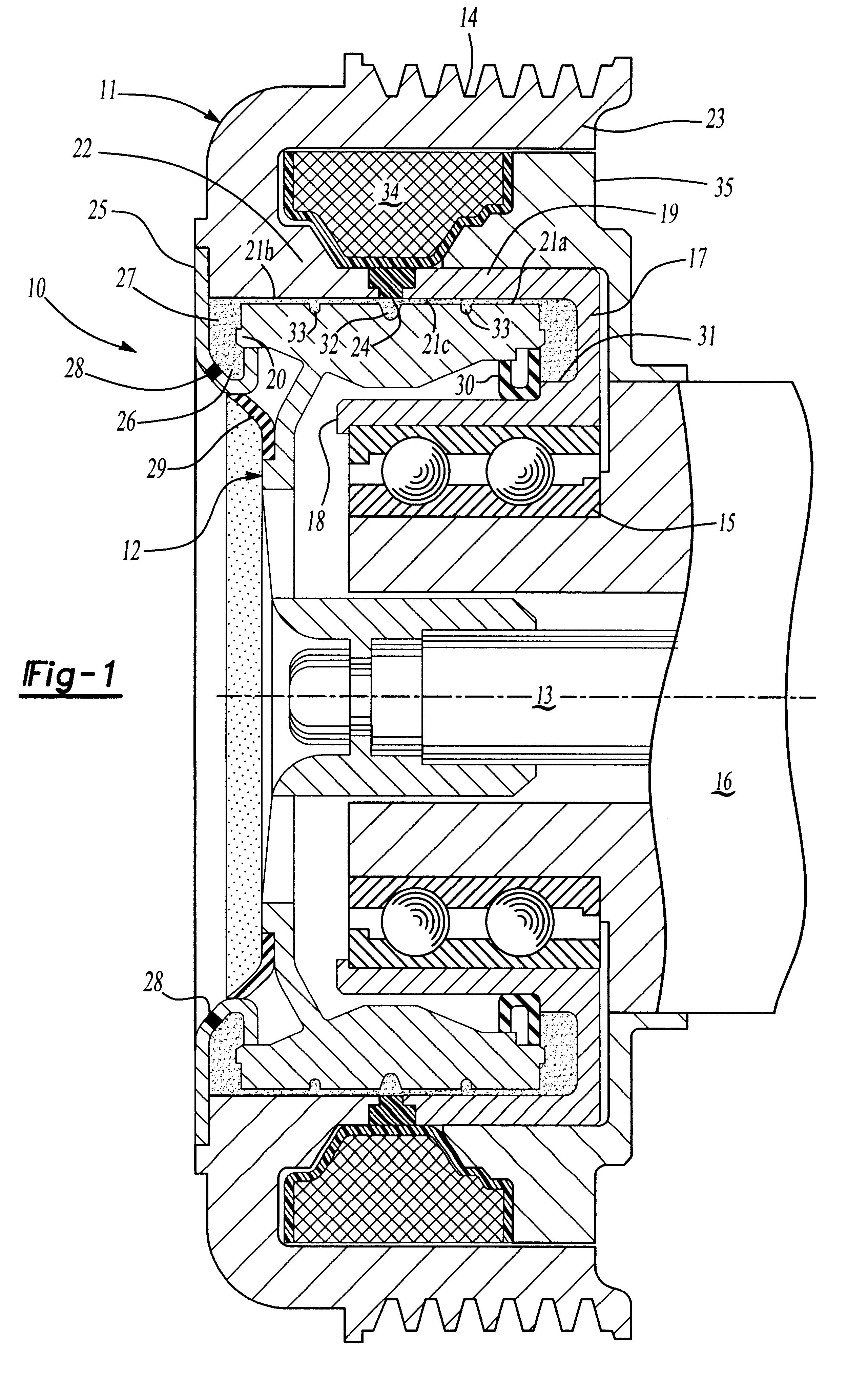

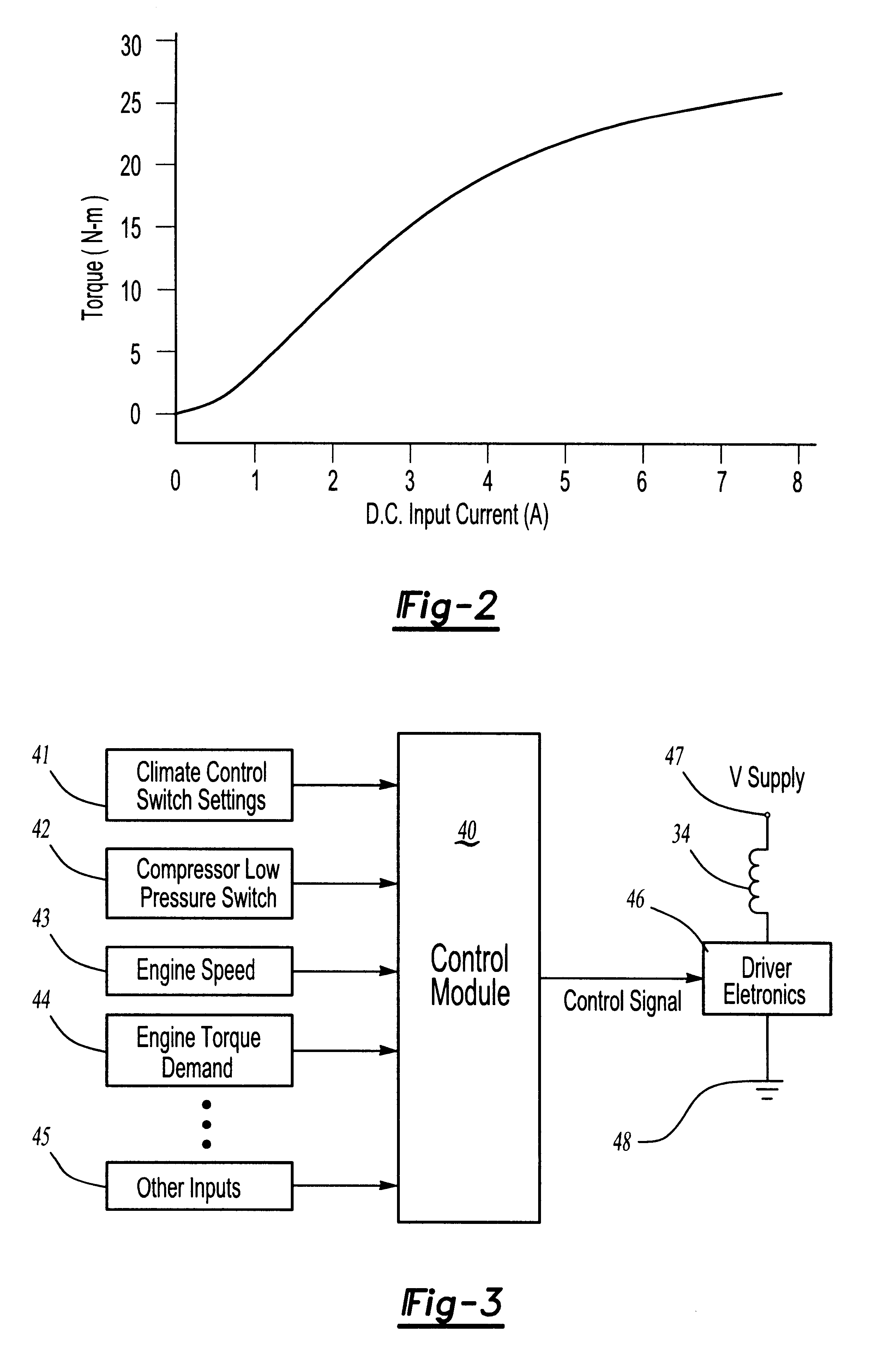

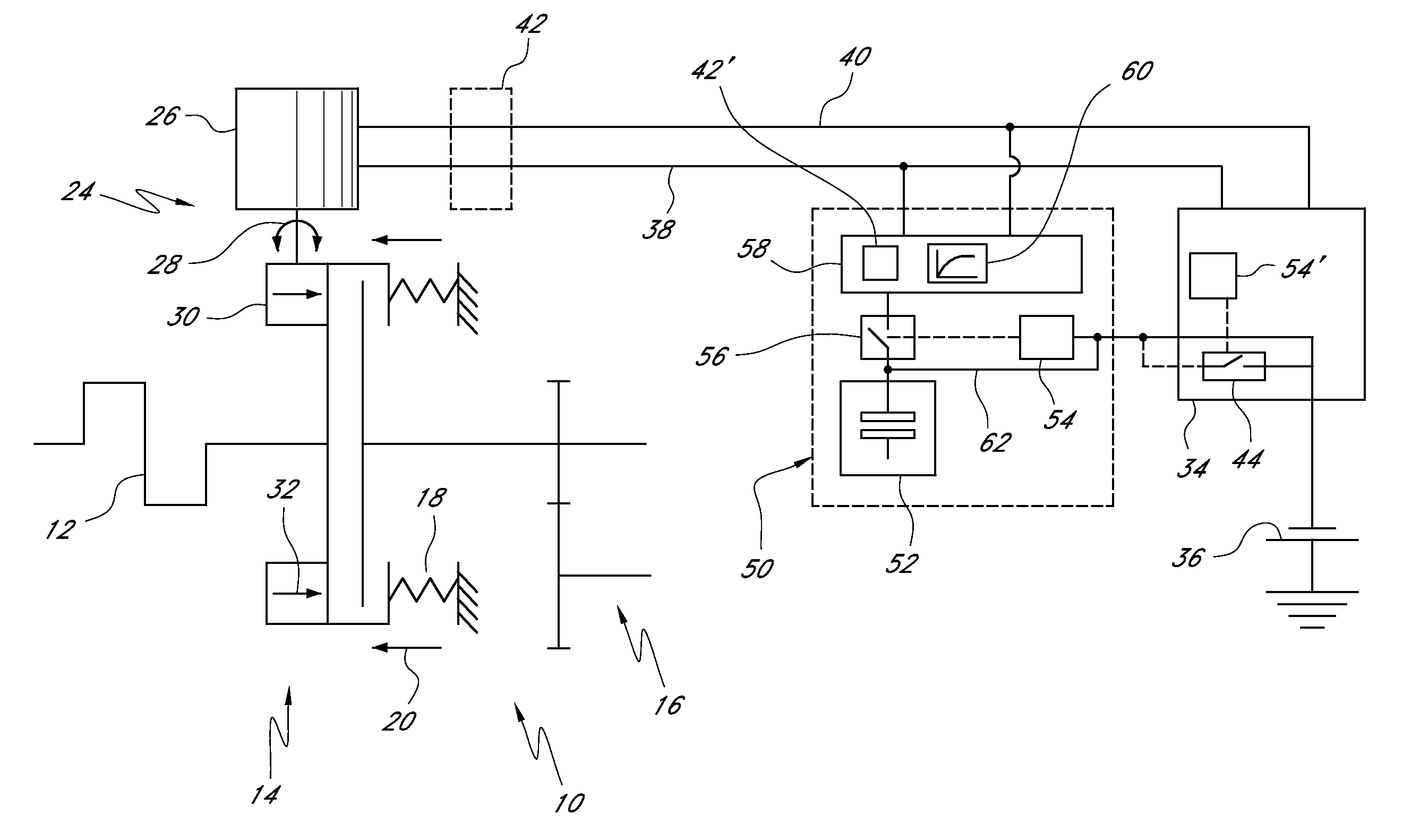

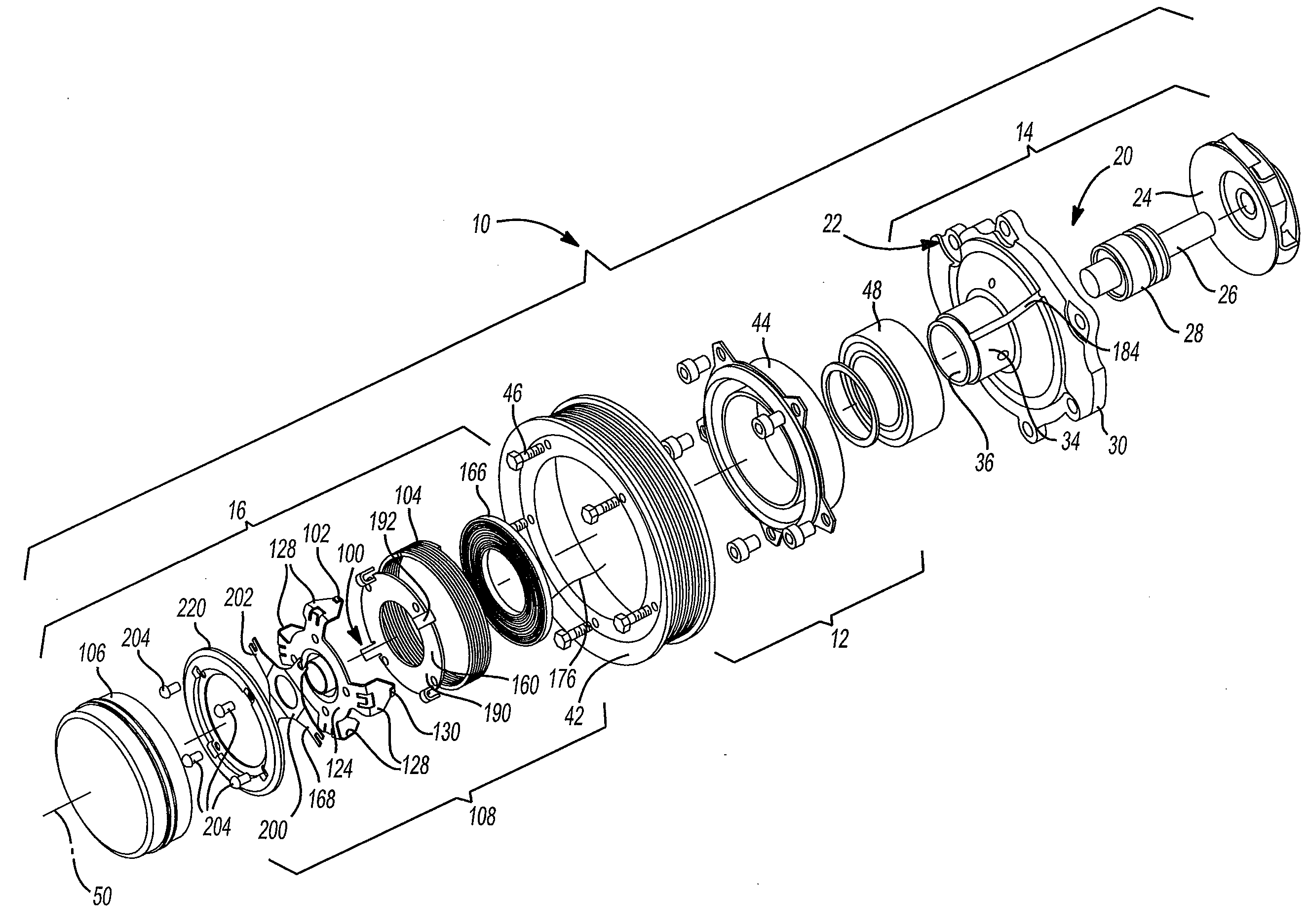

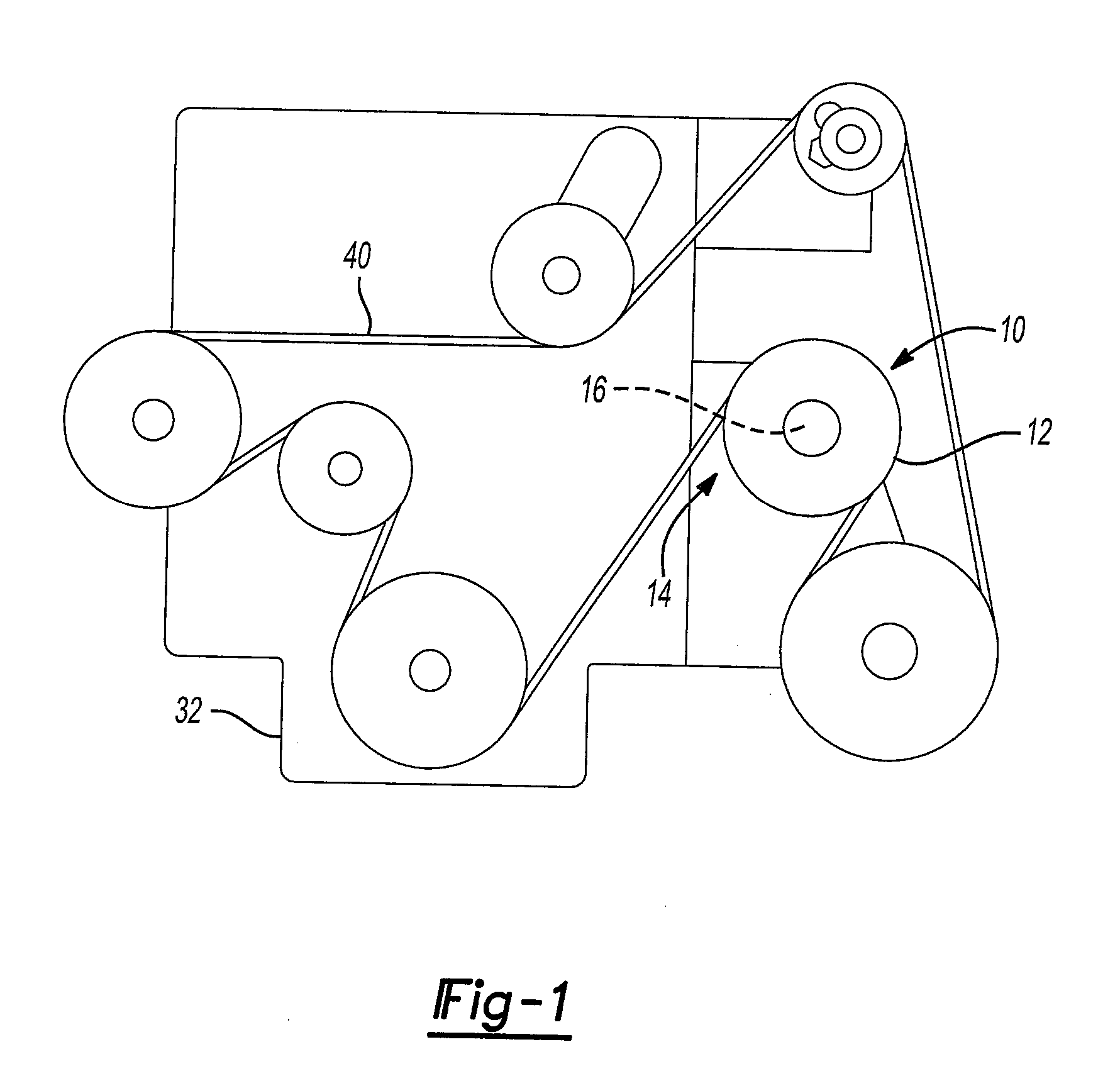

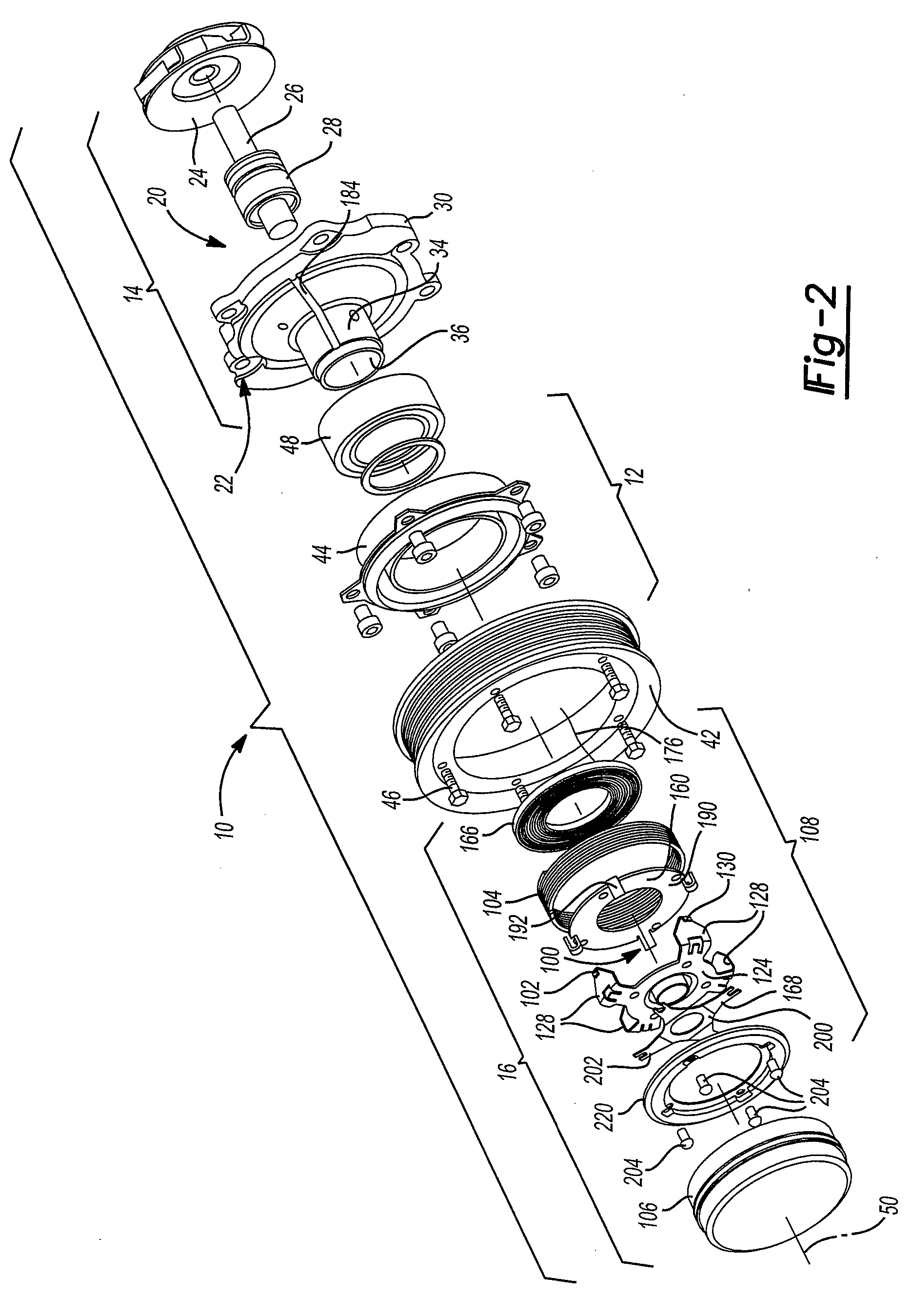

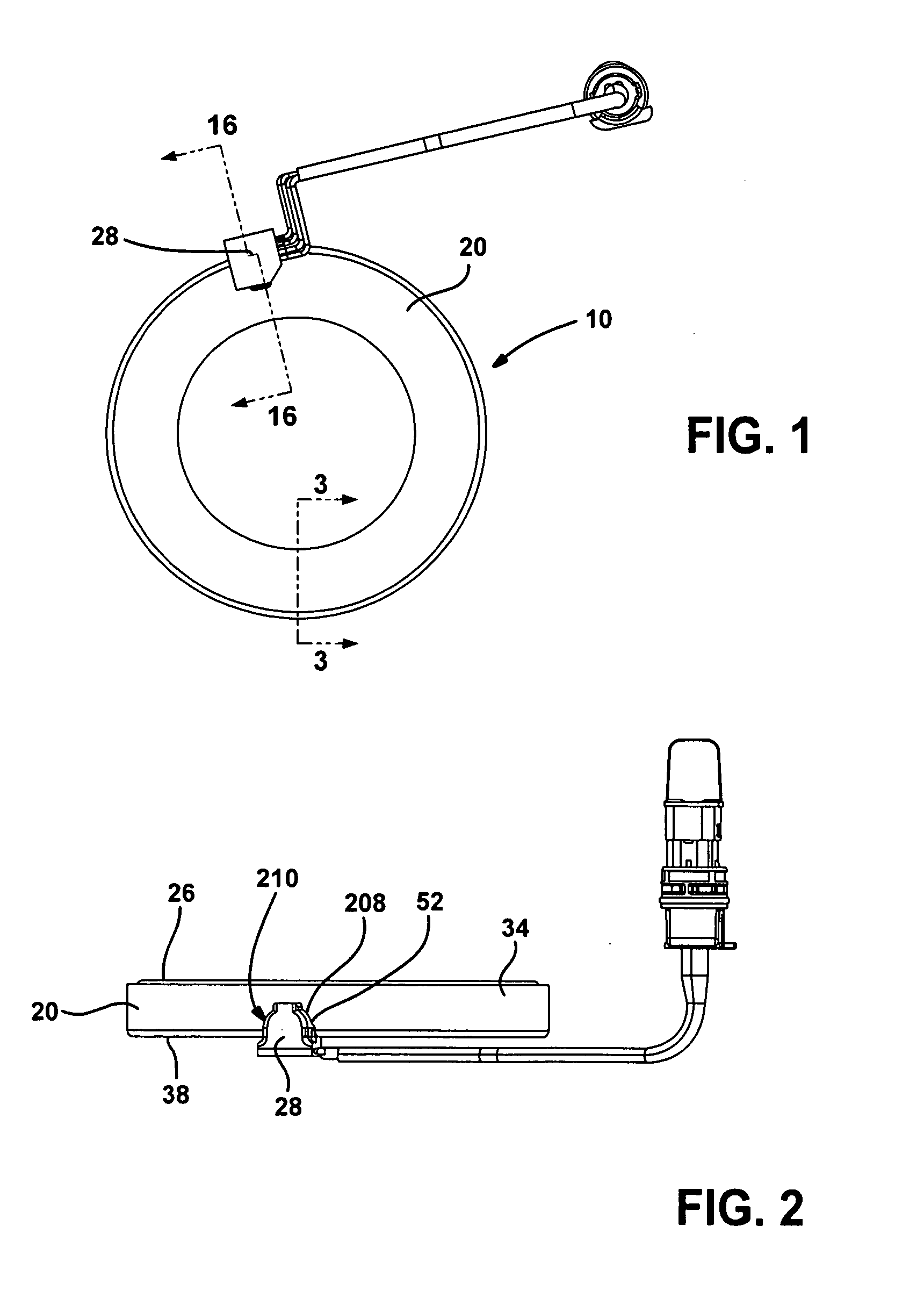

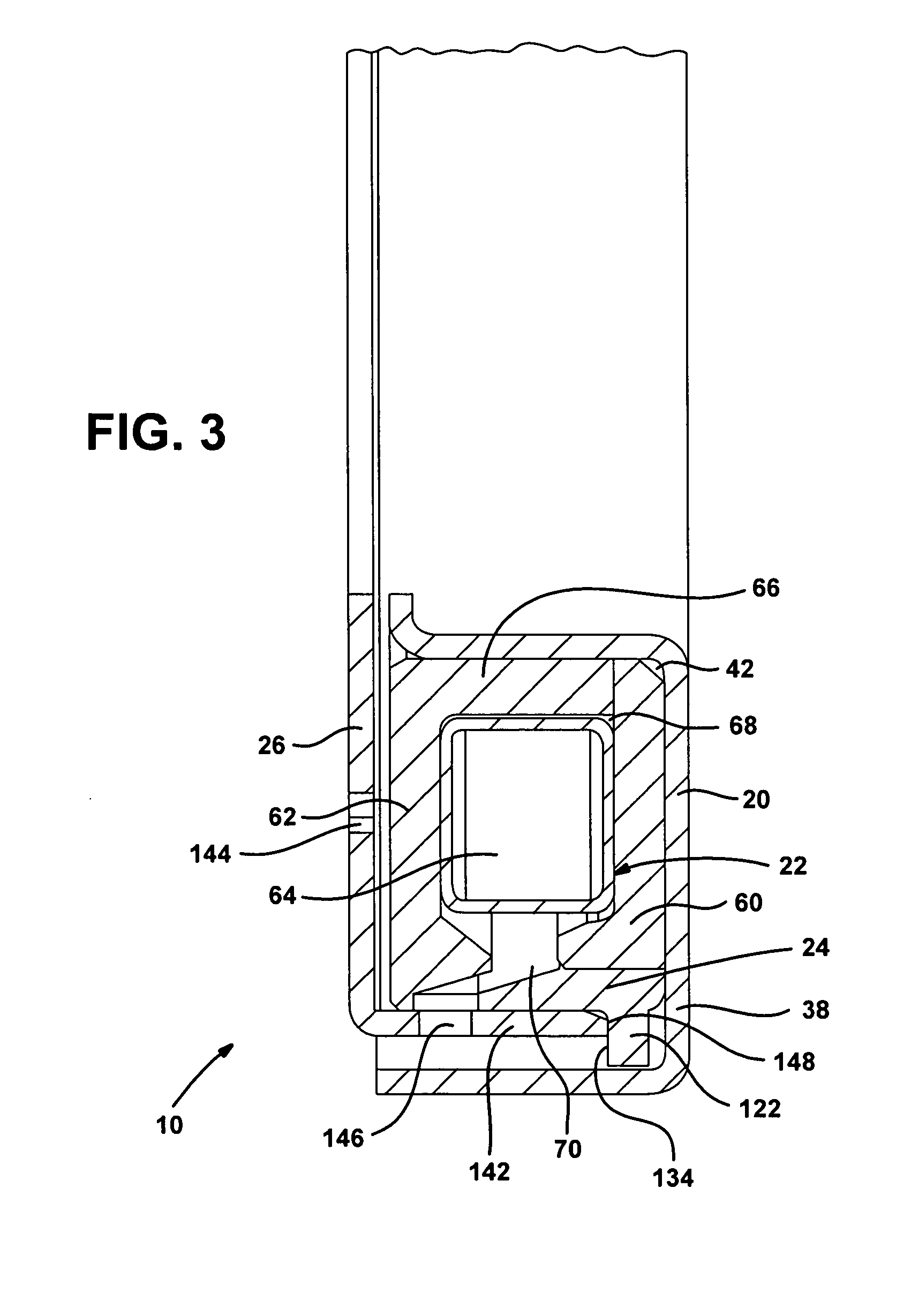

Soft start compressor clutch

InactiveUS6290043B1Start softLess objectionable noiseMagnetically actuated clutchesInterengaging clutchesElectromagnetic clutchEngineering

An electromagnetic clutch (10) for an air conditioning compressor includes a generally cylindrical pulley (11) rotatably mounted on a compressor housing (16) and having an annular friction surface (21b), a driven member (12) mounted on a compressor shaft (13) and having an annular friction surface (21a) positioned radially adjacent the first friction surface to form an annular space (21c) therebetween. A quantity of flowable magnetic material (27) is provided in the annular space (21c) and a magnetic coil (34) is fixed on the housing adjacent thereto. A control (40,46,46') connected to the magnetic coil (34) supplies electrical power from a power supply (47) to energize the magnetic coil and create magnetic flux in the annular space (21c) polarizing the magnetic material and frictionally coupling the first and second friction surfaces (21a,21b) to cause the pulley (11) to rotate the driven member (12). The control (40,46,46') can pulse width modulate or ramp the supplied power for "soft" starting and / or stopping of the compressor.

Owner:VISTEON GLOBAL TECH INC +1

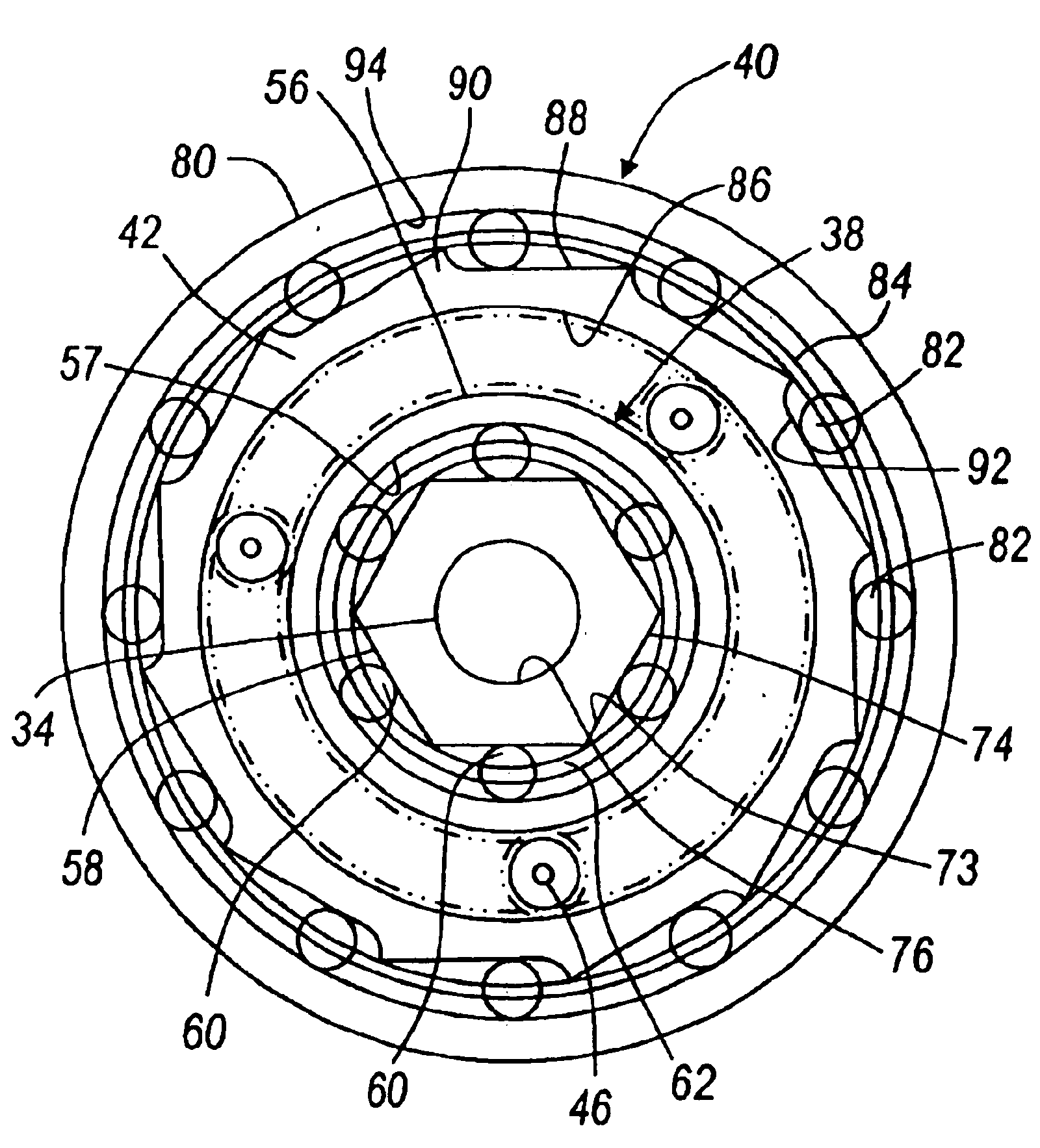

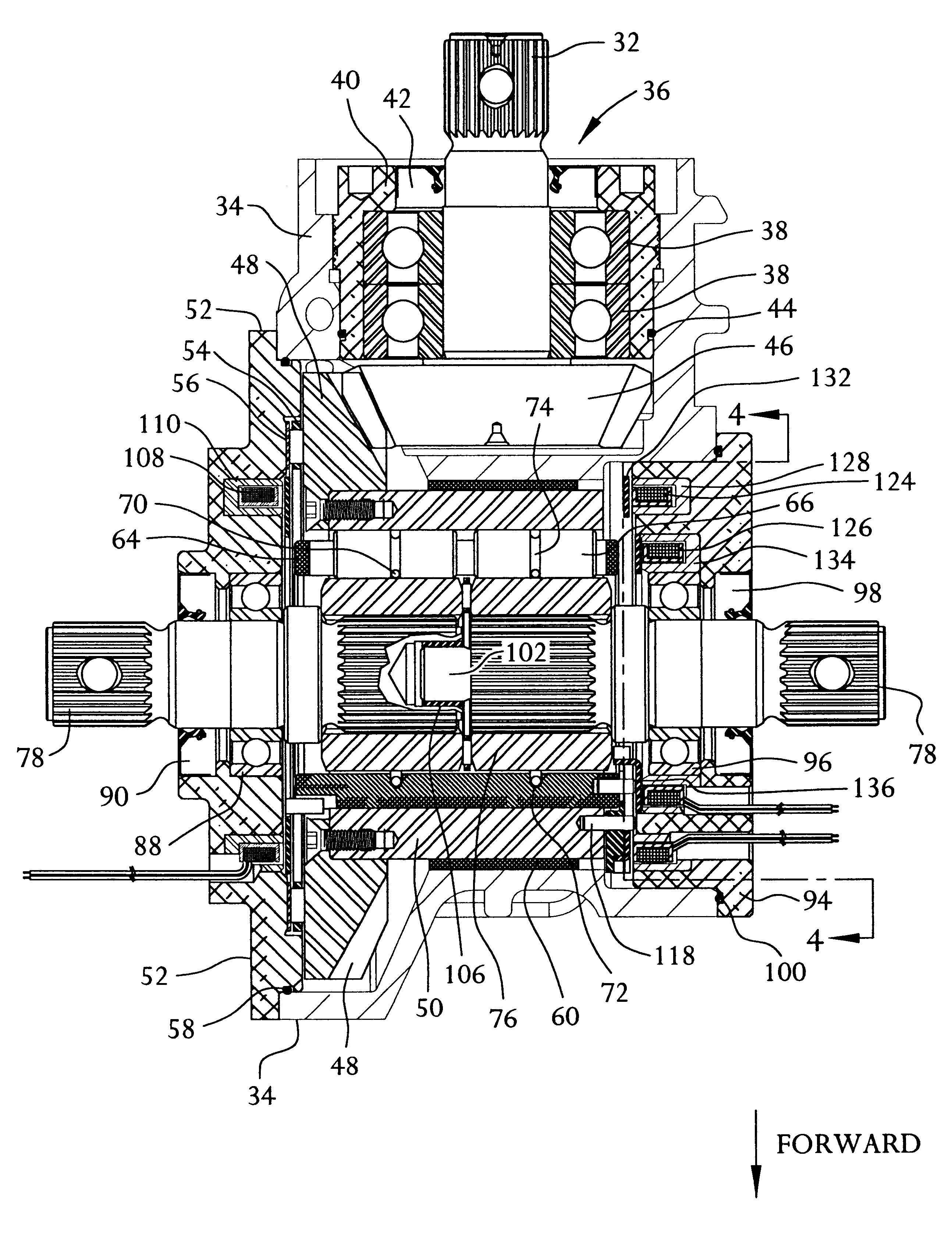

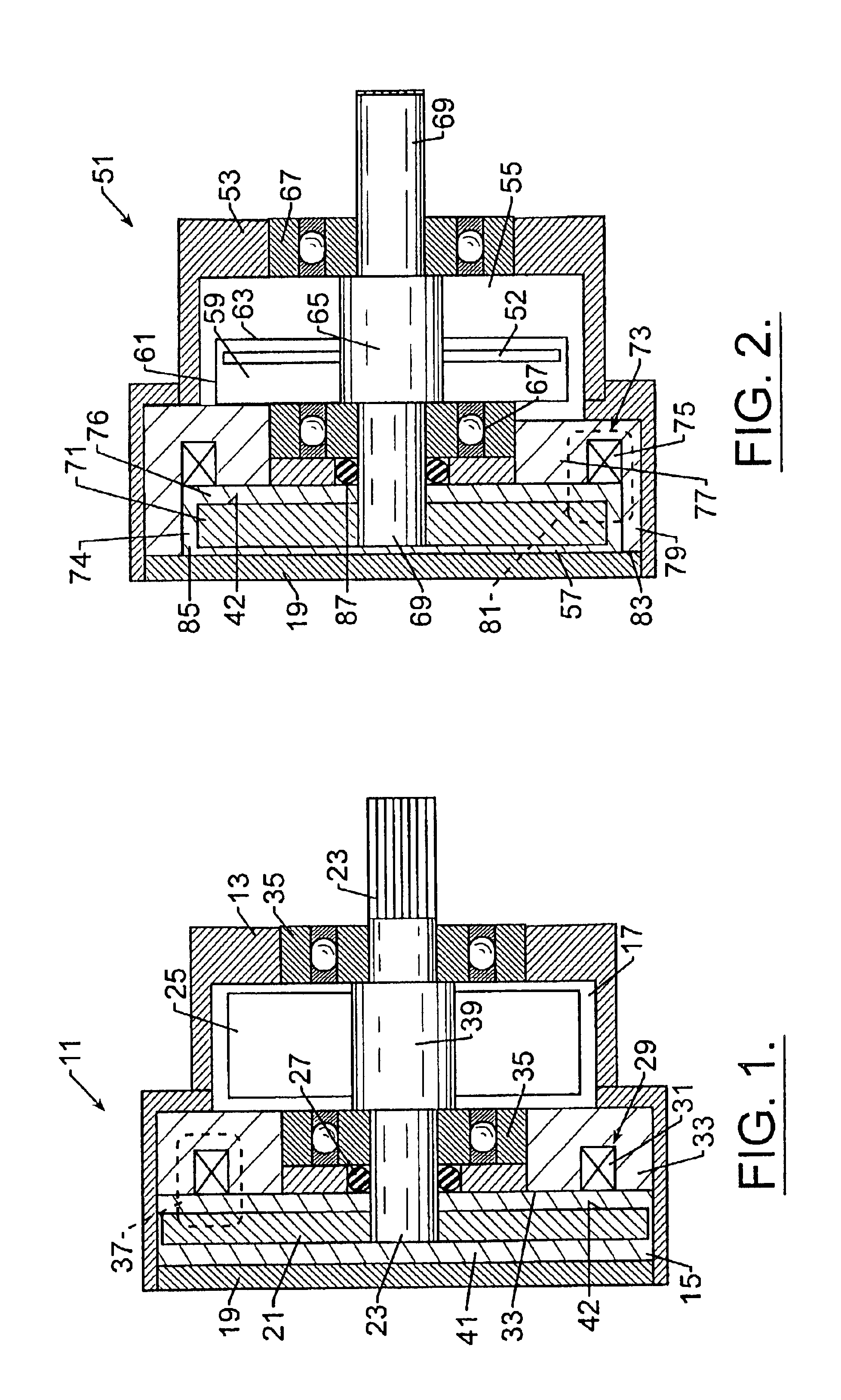

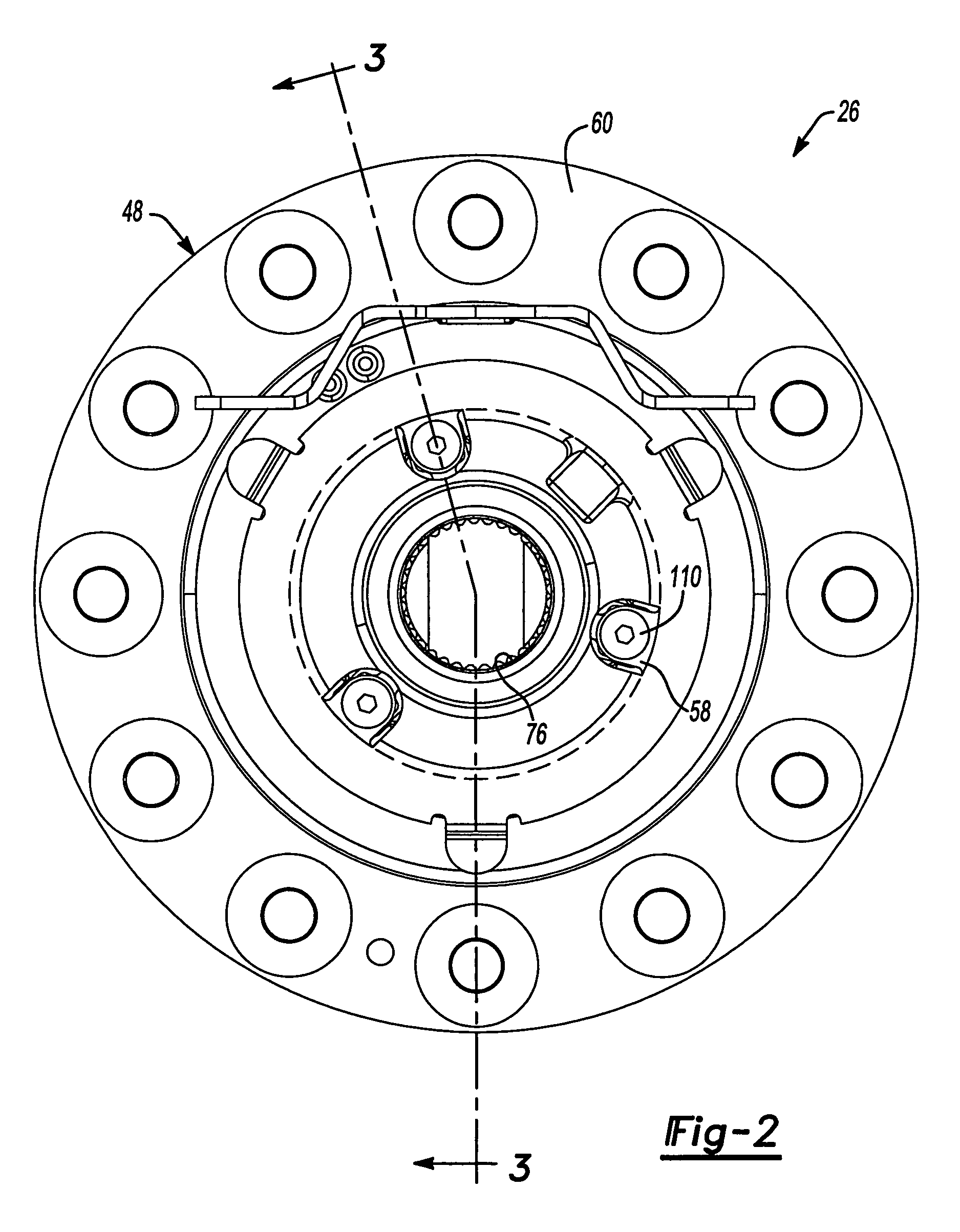

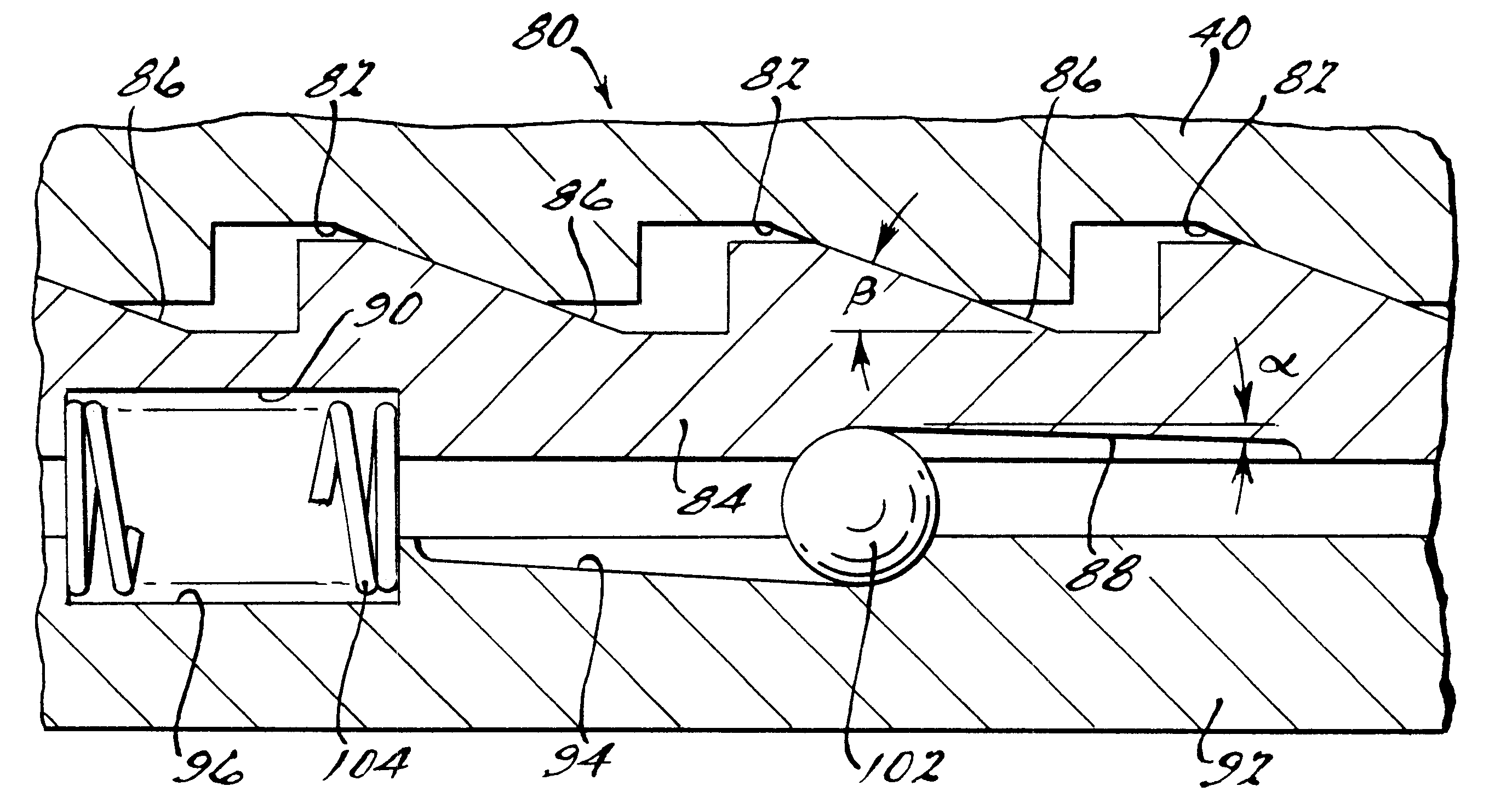

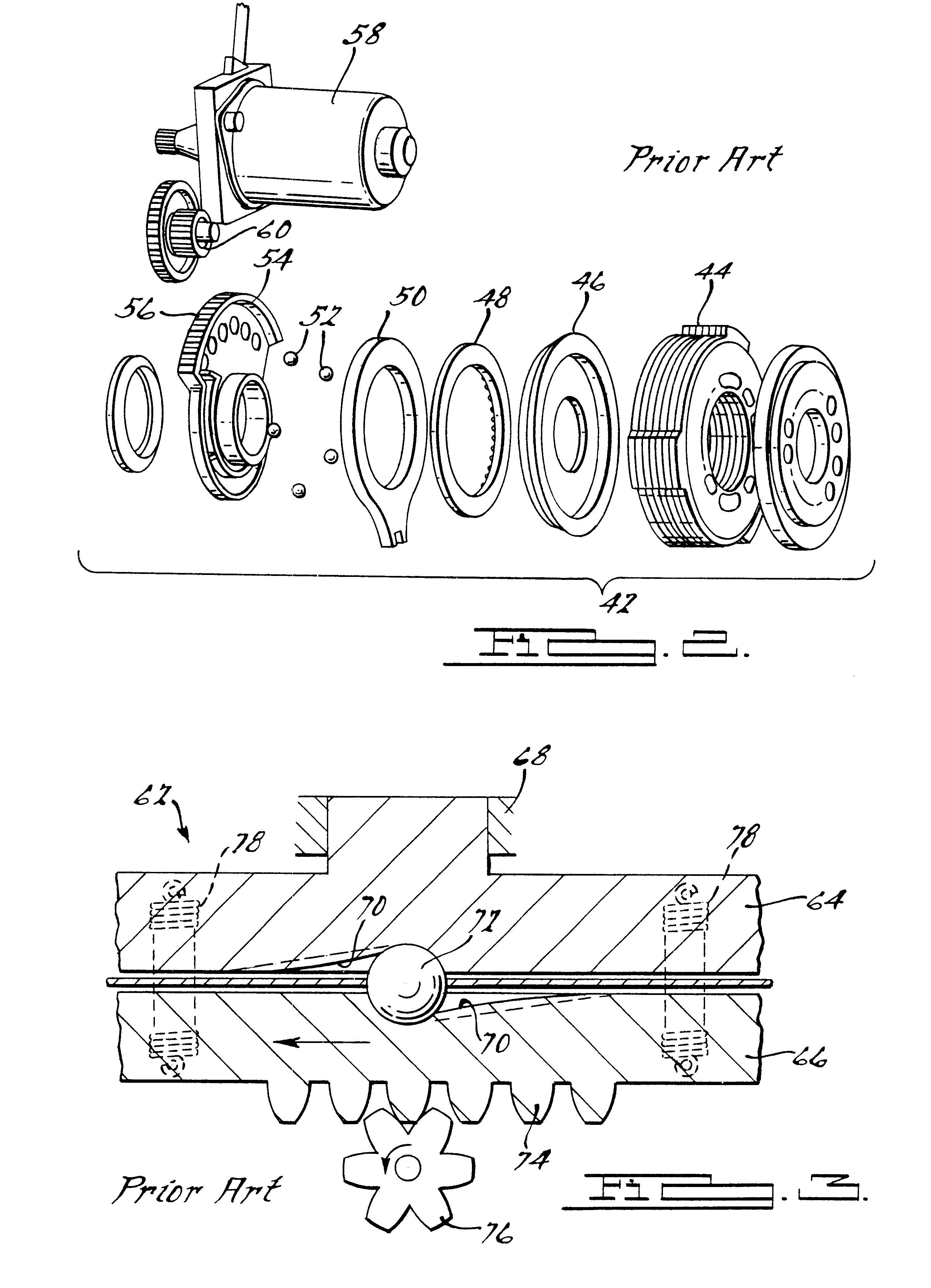

Dual ball ramp actuator for locking differential

A dual ball ramp actuator having a control ring acting with a pressure plates to supply an axial clutch clamping force to a differential clutch assembly where the ball ramp paths follow overlapping eccentric grooves that can be actuated in both the forward and reverse directions. The dual ramp feature doubles the effectiveness and sensitivity when compared to a single ramp system. The overlapping eccentric ball ramps increase (effectively double) the angular travel distance while reducing the ramp angle (in half). The forward and reverse feature provides clutch actuation in both the forward and reverse directions. The dual ramp, 3-piece sandwich construction permits the central control ring to roll up on two sets of balls on each side. This structure doubles the axial travel available to compress a disc pack and lock up the differential with the same ball ramp angle when compared to a single ramp system involving only two ramp plates.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Brake with field responsive material

InactiveUS6854573B2Prevent rotationSome backlashLiquid resistance brakesSpringsEngineeringMechanical engineering

A controllable brake includes a rotor supported on one shaft end. The rotor is housed within a chamber containing a field controllable material which is acted upon by a magnetic field generator to change the rheology of the material and thereby impede movement of the rotor. The shaft is supported by two bearings which, in combination with the housing define a second housing chamber adapted to enclose means for monitoring and / or controlling the brake and in this way, an integrated, compact controllable brake is provided.

Owner:LORD CORP

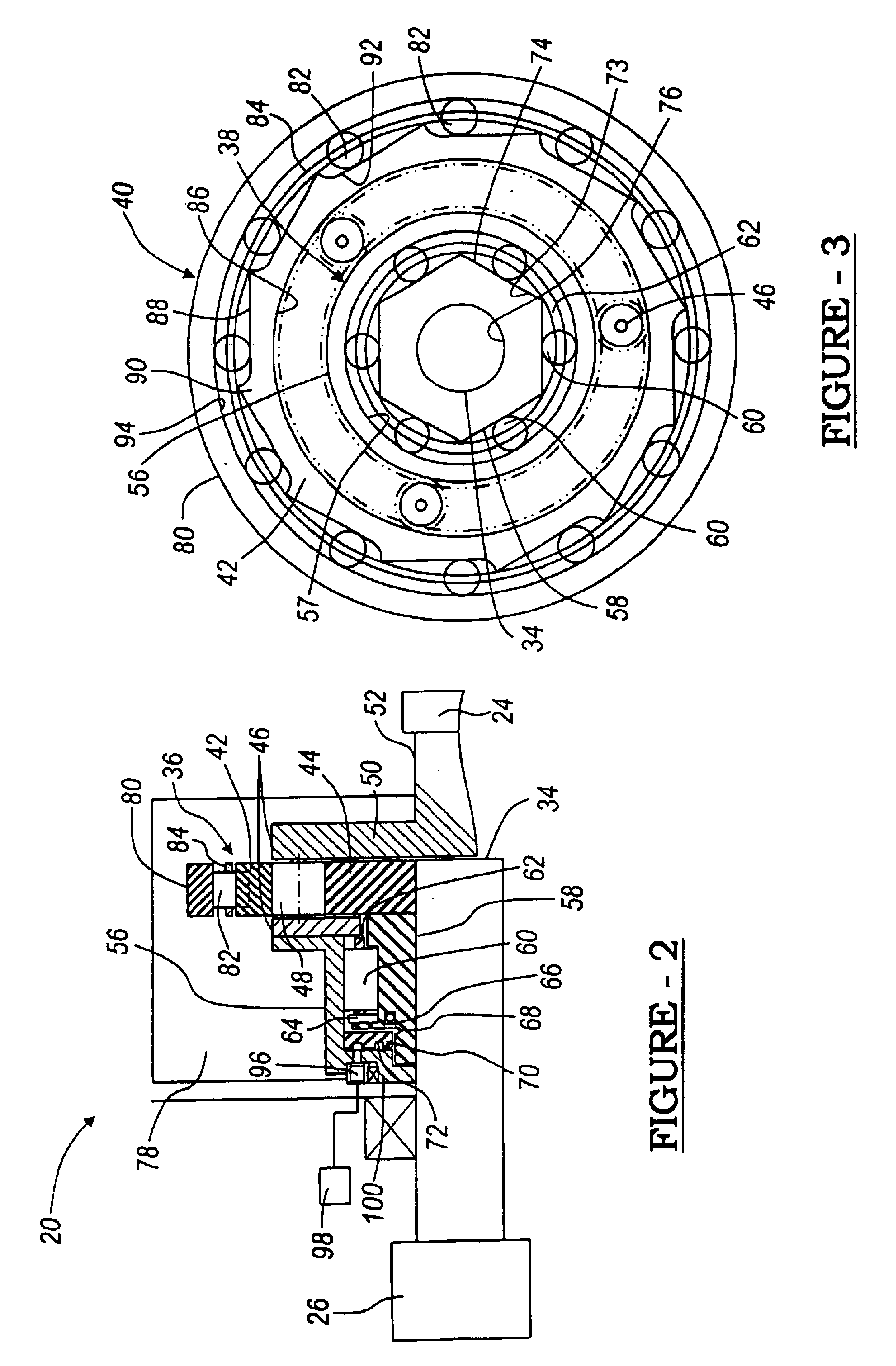

Electromagnetic locking differential assembly

InactiveUS6958030B2Mechanical actuated clutchesElectrodynamic brake systemsGear wheelElectromagnetic lock

Owner:AMERICAN AXLE & MFG

Actuator arrangement for a motor vehicle clutch

ActiveUS20090255773A1Shorten activation timeOpen the clutch/clutches very quicklyMagnetically actuated clutchesGearing controlMobile vehicleActuator

An actuator arrangement for a clutch of a drive train for motor vehicles. The clutch is prestressed into an opened position and can be activated electromechanically. An electric motor can be coupled to the clutch in order to activate it. A control unit actuates the electric motor. The actuator arrangement has a safety device which is connected to the electric motor parallel to the control unit. The safety device is configured, in the case of a fault state, to supply electrical power to the electric motor independently of the control unit in order to open the clutch.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

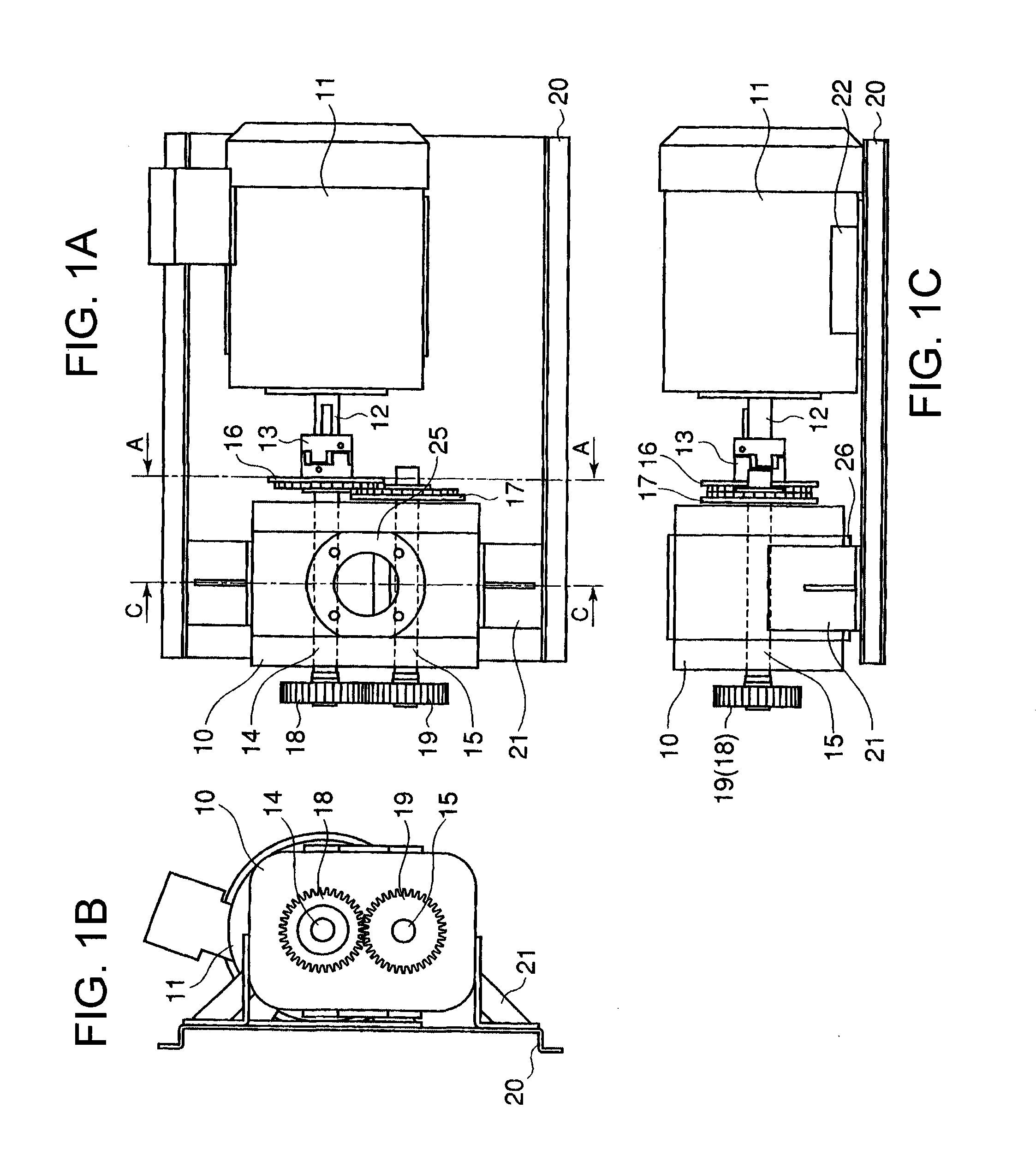

Power transmission

InactiveUS7153228B2Smooth motionReduce and eliminate likelihMechanical actuated clutchesChain/belt transmissionElectric power transmissionTorque transmission

A power transmission includes a first rotating member driven by an external drive source, an electromagnetic solenoid provided to the first rotating member, a second rotating member fixed to a main shaft of a rotary apparatus, and an mechanism for engaging and disengaging a plunger of the electromagnetic solenoid from the second rotating member. When the rotary apparatus is not used, the energy of the external drive source may be prevented from being wasted by interrupting the torque transmission from the first rotating member to the second rotating member by the operation of the mechanism for engaging and disengaging.

Owner:SANDEN CORP

Hybrid electric linear actuator

InactiveUS6982502B1Piezoelectric/electrostriction/magnetostriction machinesMechanical actuated clutchesElectric machinePermanent magnet synchronous motor

A hybrid linear actuator features a central load shaft on which a plurality of solid-state magnetostrictive thrusters are positioned in operative relation to electric motors of a permanent magnet synchronous type to impart linear thrust force to the load shaft through clutch units also positioned thereon and under control of force and stroke amplification of output force from motor shafts projecting from the motors.

Owner:TOYOTA JIDOSHA KK +1

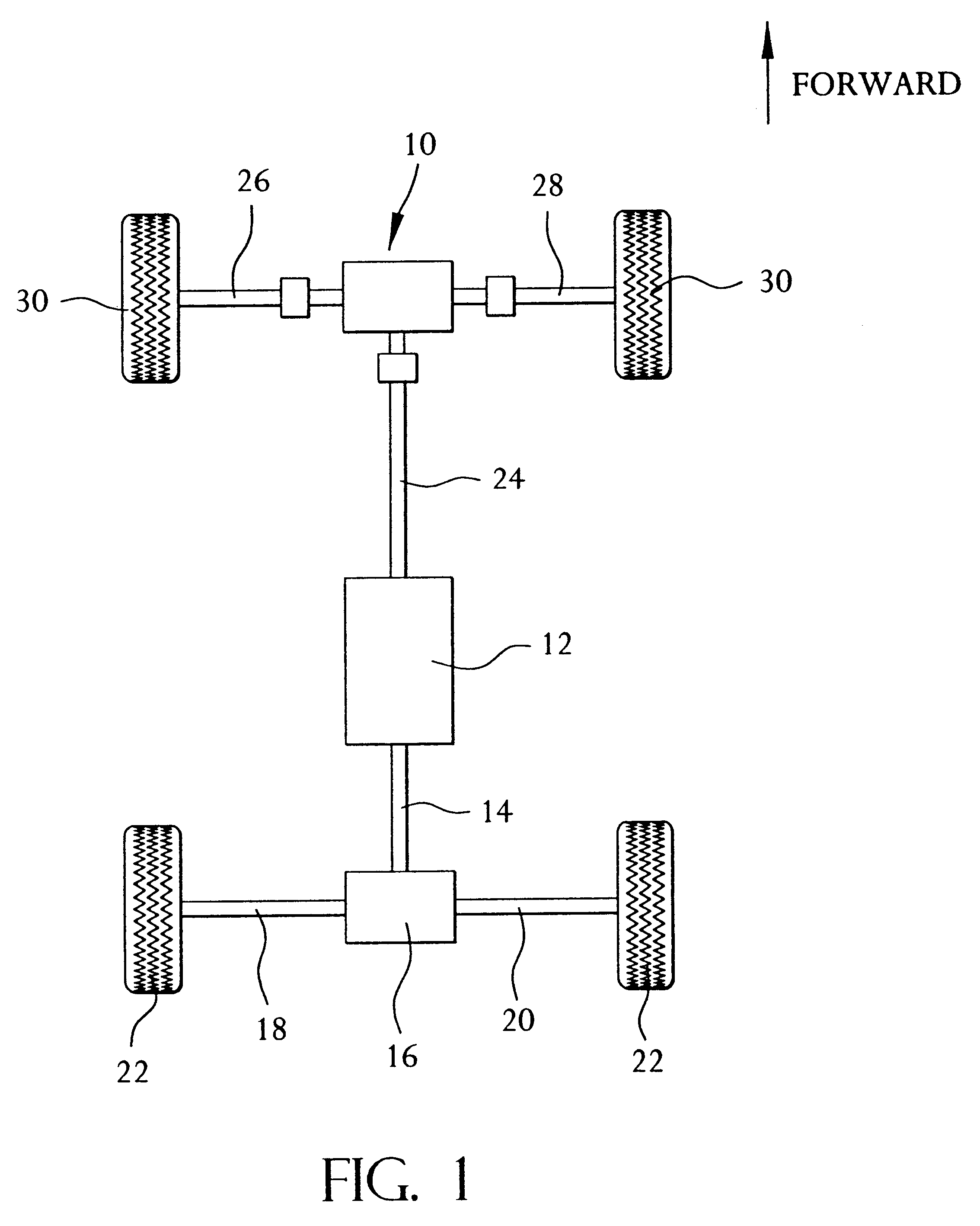

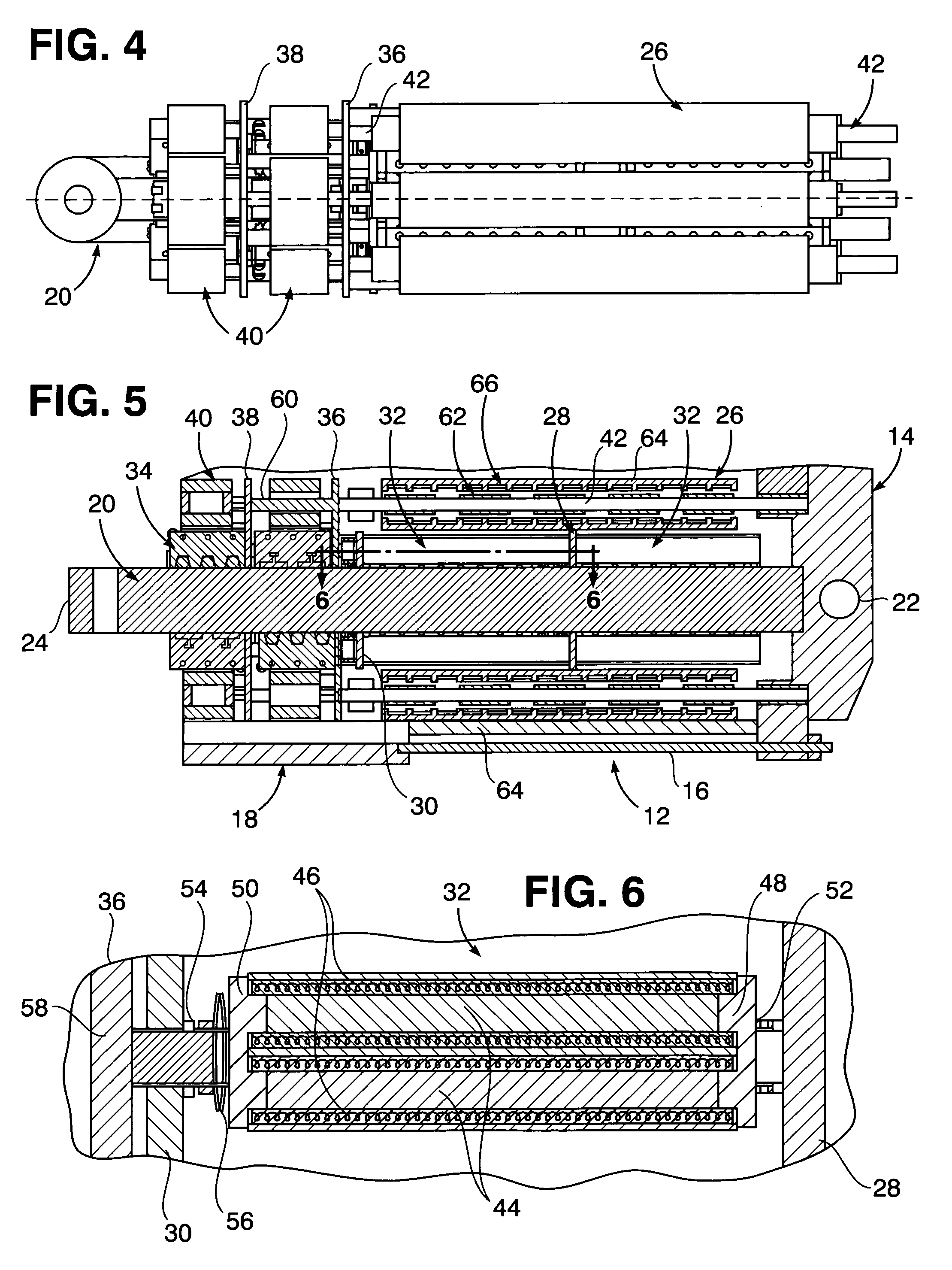

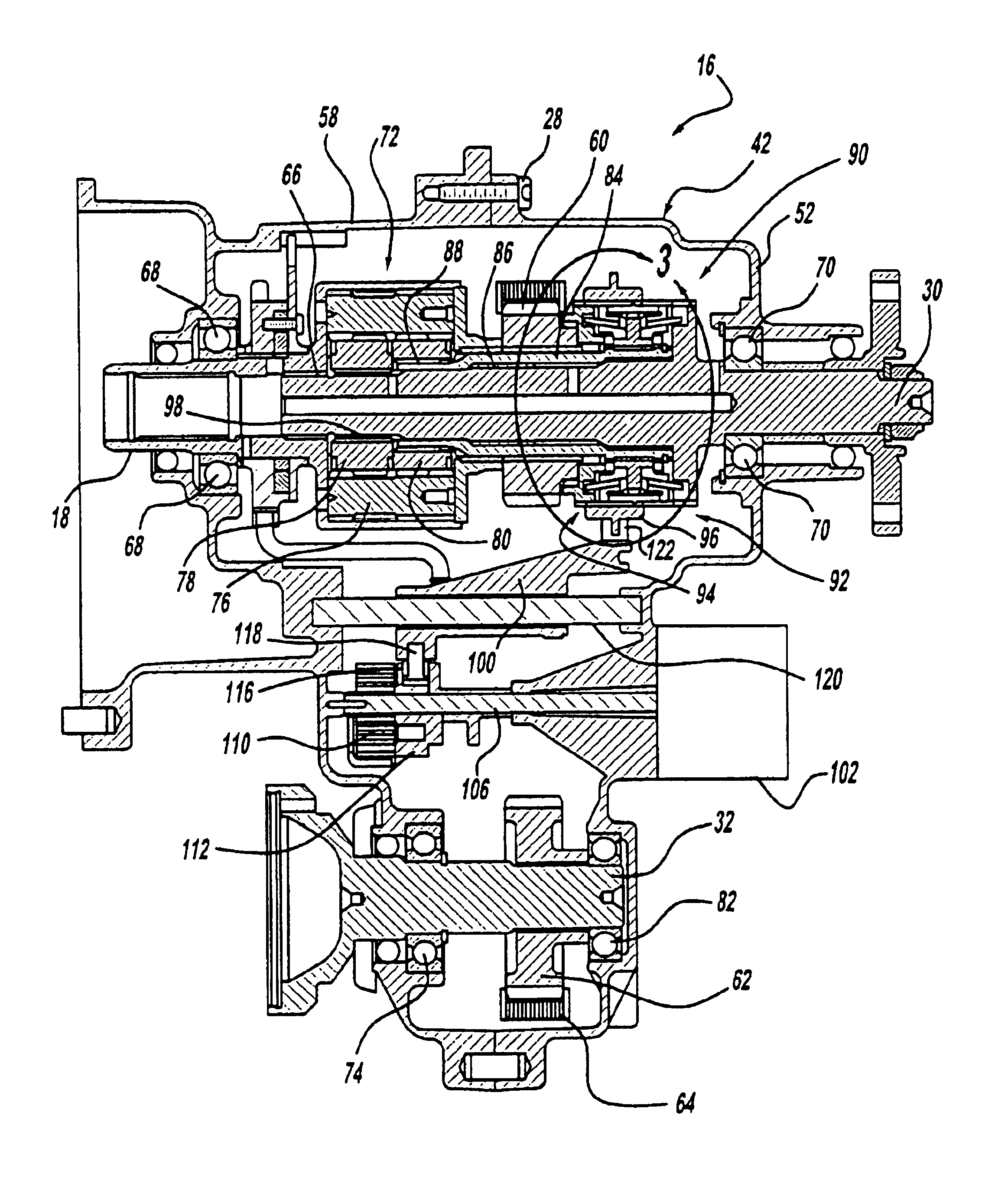

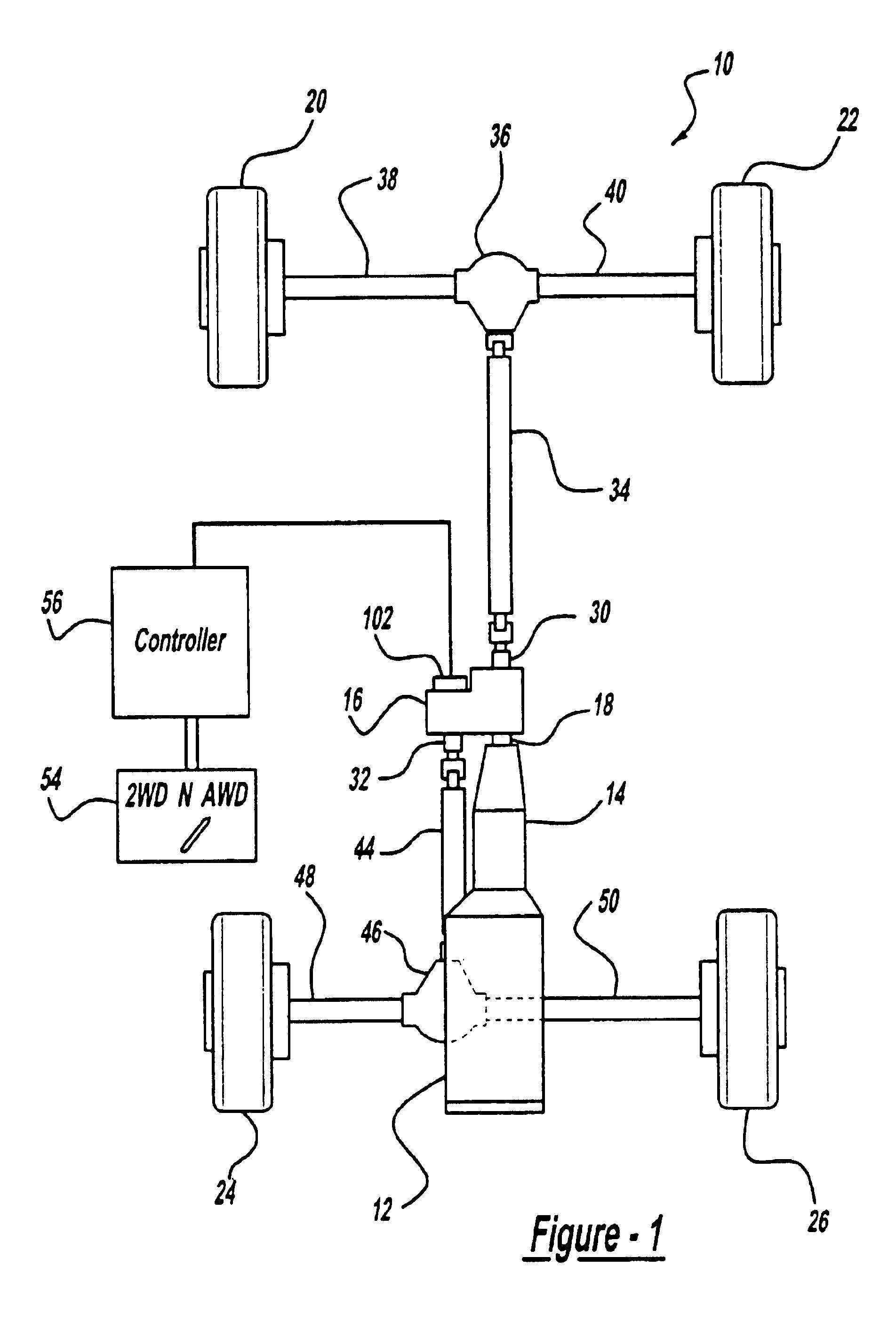

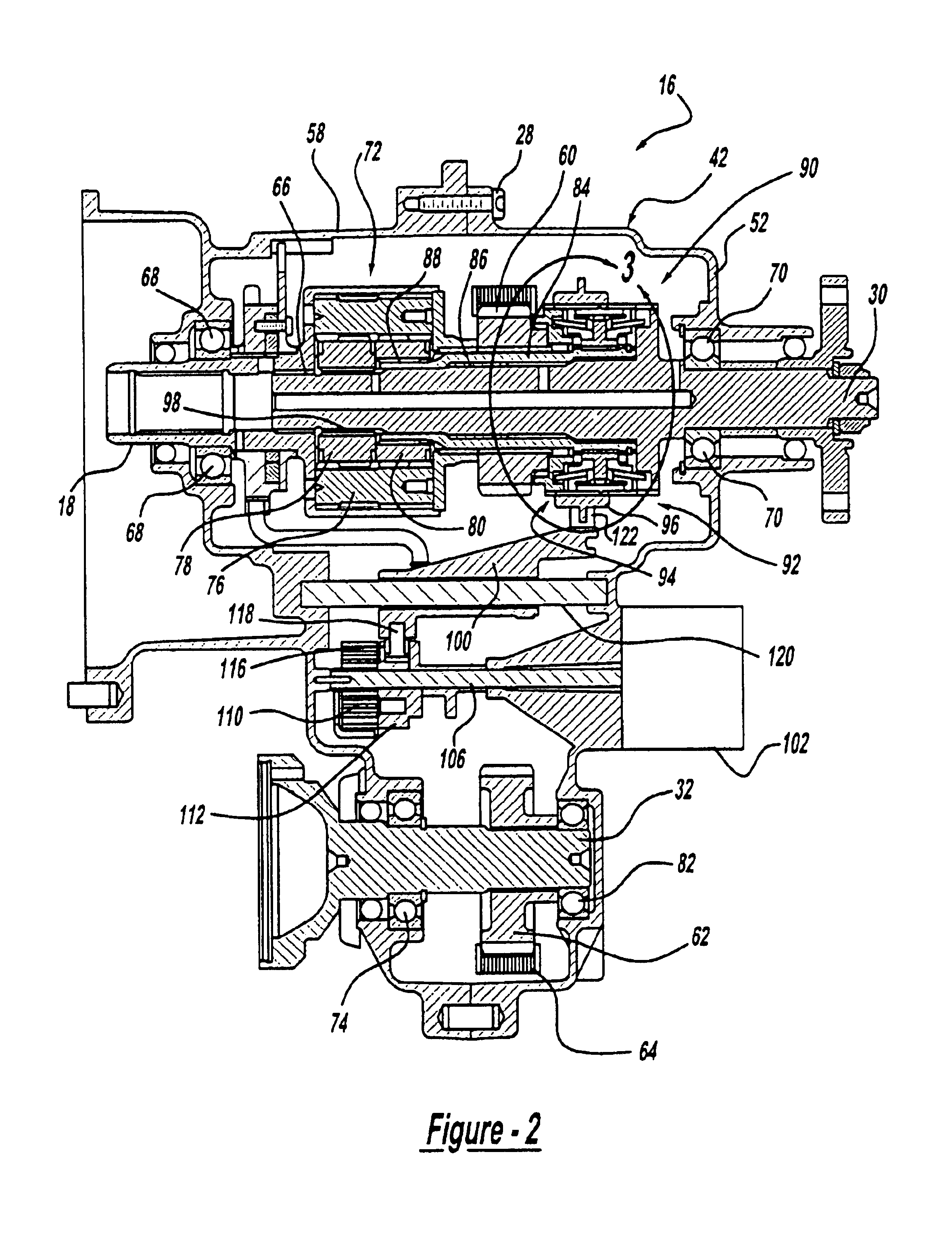

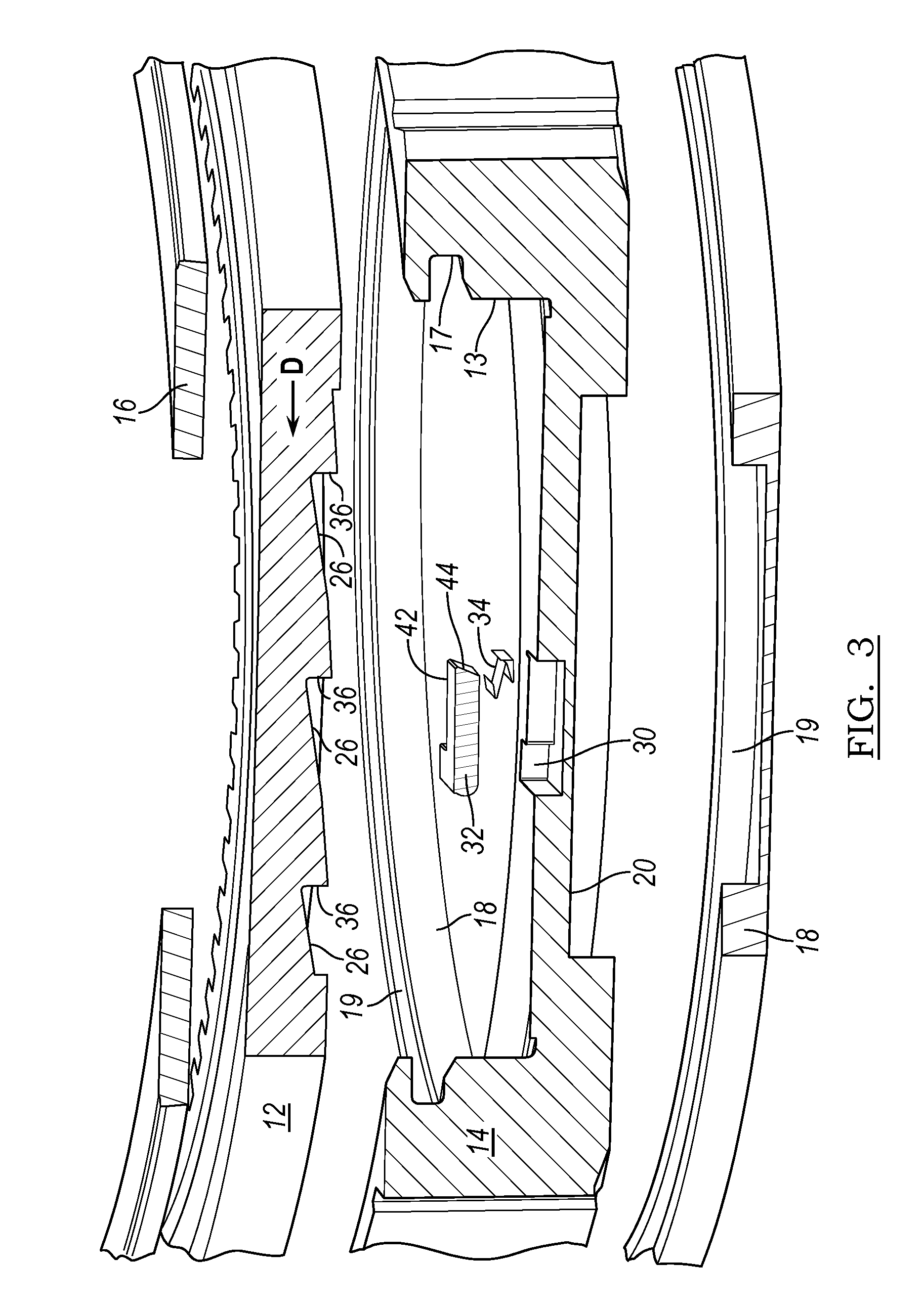

Transfer case with synchronizer clutch

InactiveUS6814682B2Mechanical actuated clutchesMagnetically actuated clutchesTransfer caseDrive shaft

A transfer case for a vehicle that allows shifting between AWD and two-wheel drive at any vehicle speed. The transfer case includes a center differential employing pinion and sun gears that allow a front drive shaft and a rear drive shaft to turn at different speeds to provide the all-wheel drive function. The transfer case further includes an electrically actuated synchronizer assembly that allows the speed of the front drive shaft to be synchronized to the speed of the rear drive shaft when shifting from two-wheel drive to all-wheel drive to provide the shift on the fly function. The synchronizer assembly also includes a neutral position where both the front drive shaft and the rear drive shaft are not engaged to the vehicle transmission to allow for vehicle towing.

Owner:BORGWARNER INC

Driven accessory with low-power clutch for activating or de-activating same

ActiveUS20100122882A1Reduce and eliminate residual magnetismRoad transportMagnetically actuated clutchesEngineeringMoment of inertia

A driven accessory having a clutch that permits selective operation of an accessory portion. The clutch employs rotational inertia to control driving engagement of a wrap spring to an interior clutch surface on a drive member and / or driving disengagement of the wrap spring from the interior clutch surface.

Owner:LITENS AUTOMOTIVE INC

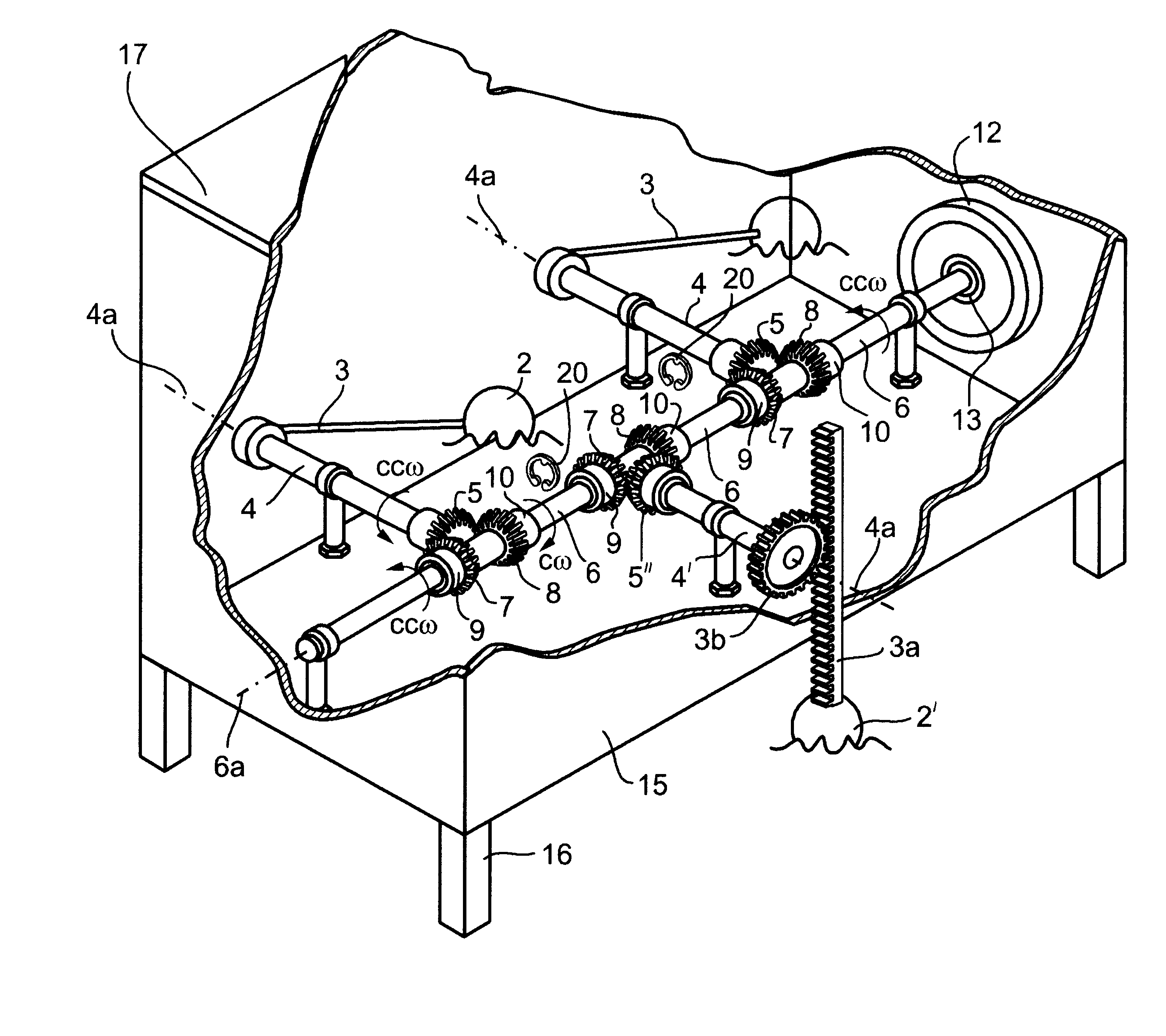

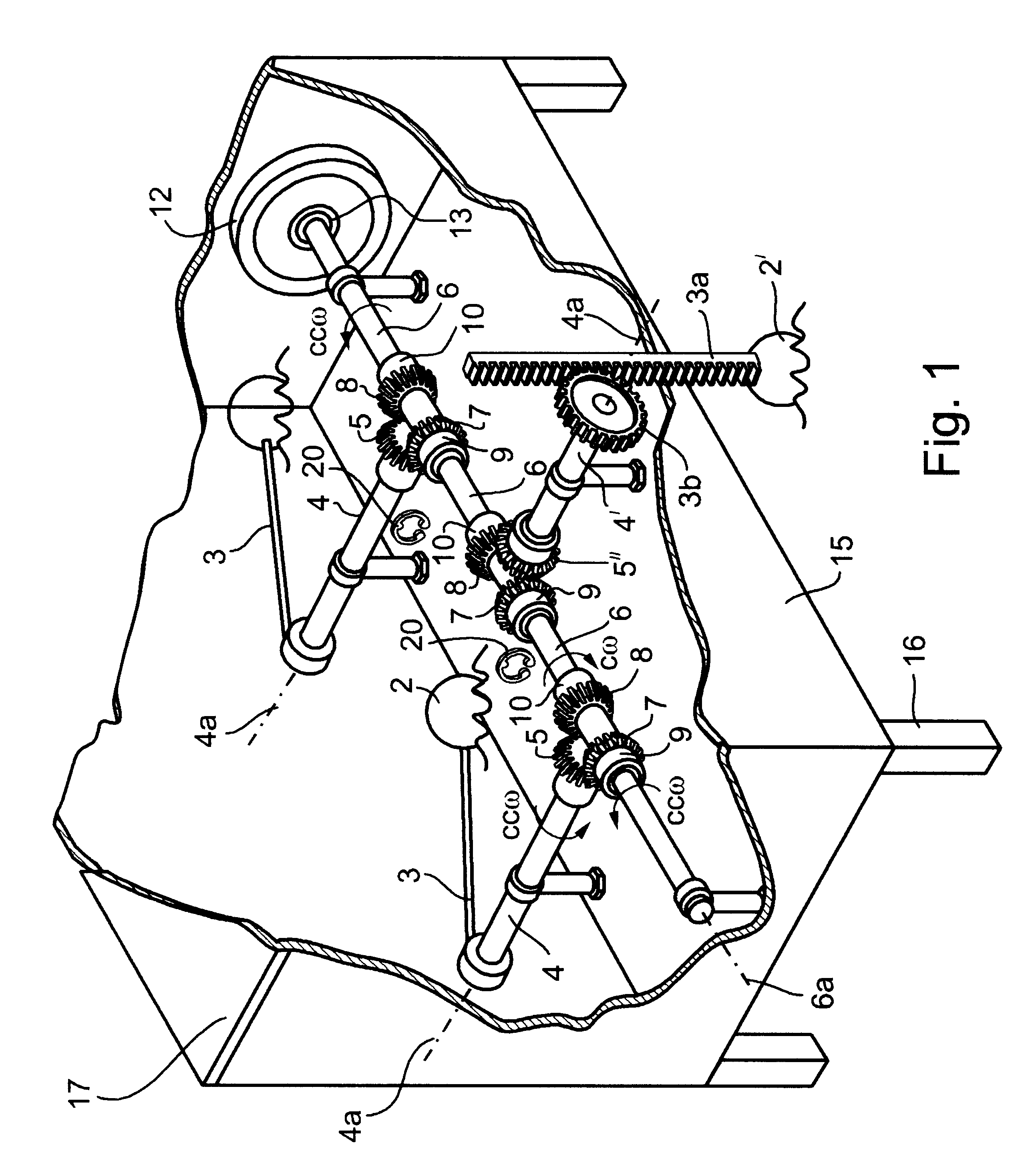

Bidirectional rotary motion-converter, wave motors, and various other applications thereof

Motion-converter apparatus for converting bidirectional rotary movements to unidirectional rotary movements includes: an input shaft for inputting the bidirectional rotary movements; an output shaft for outputting the unidirectional rotary movements, the output shaft having a longitudinal axis perpendicular to the longitudinal axis of the input shaft; a drive bevel gear coaxial with, and driven bidirectionally by, the input shaft; a pair of driven bevel gears coaxial with the output shaft and meshing with the drive bevel gear on opposite sides of the axis of the drive bevel gear so as to be driven bidirectionally thereby but in opposite directions with respect to the output shaft; and a pair of one-way clutches coupling the driven bevel gears to the output shaft such that both one-way clutches are effective to drive the output shaft only in one direction. Various applications of such apparatus are also described, including wave and tide motors, wind turbines and bidirectional-movement measuring devices.

Owner:WORLDWIDE SOLUTIONS

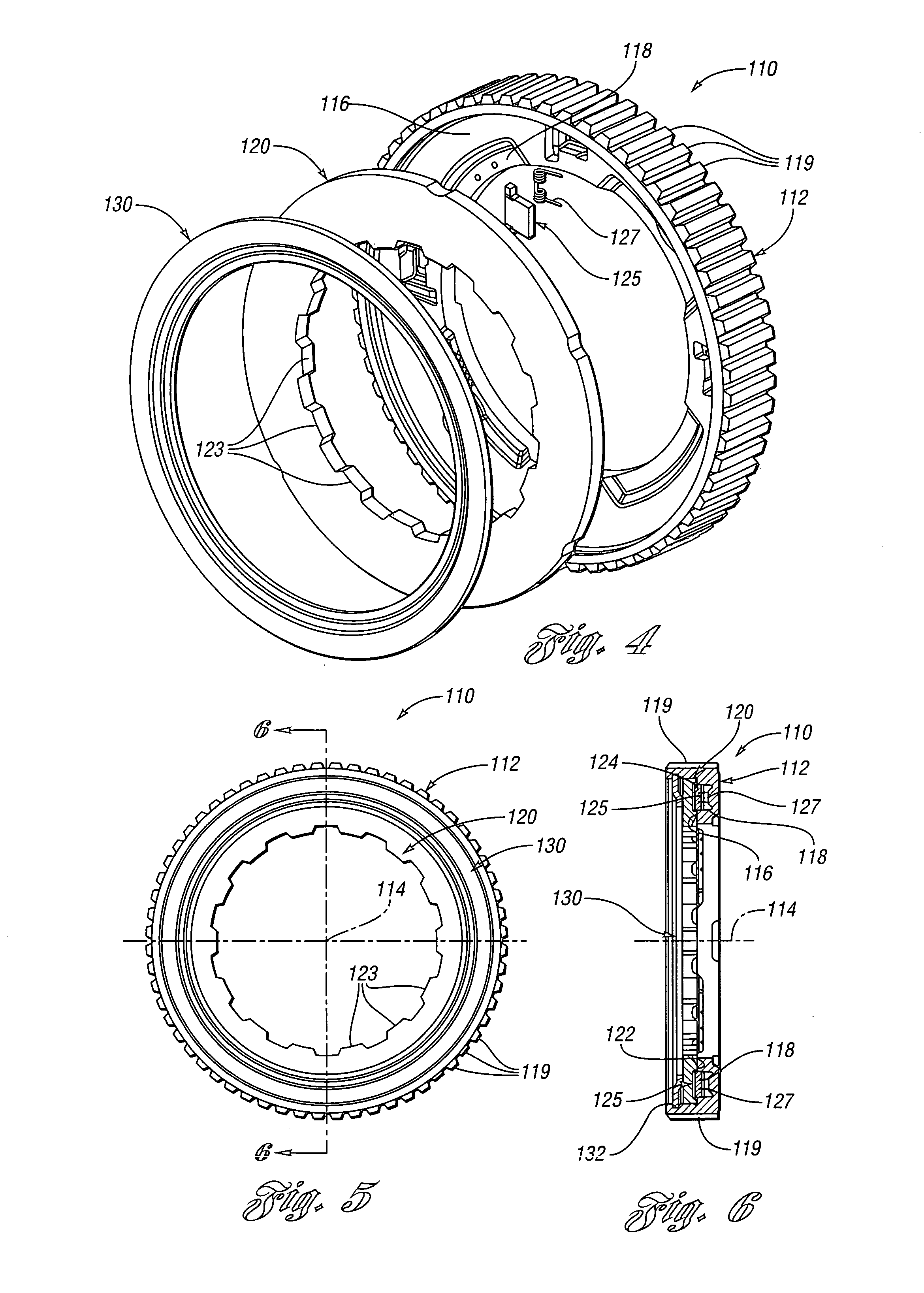

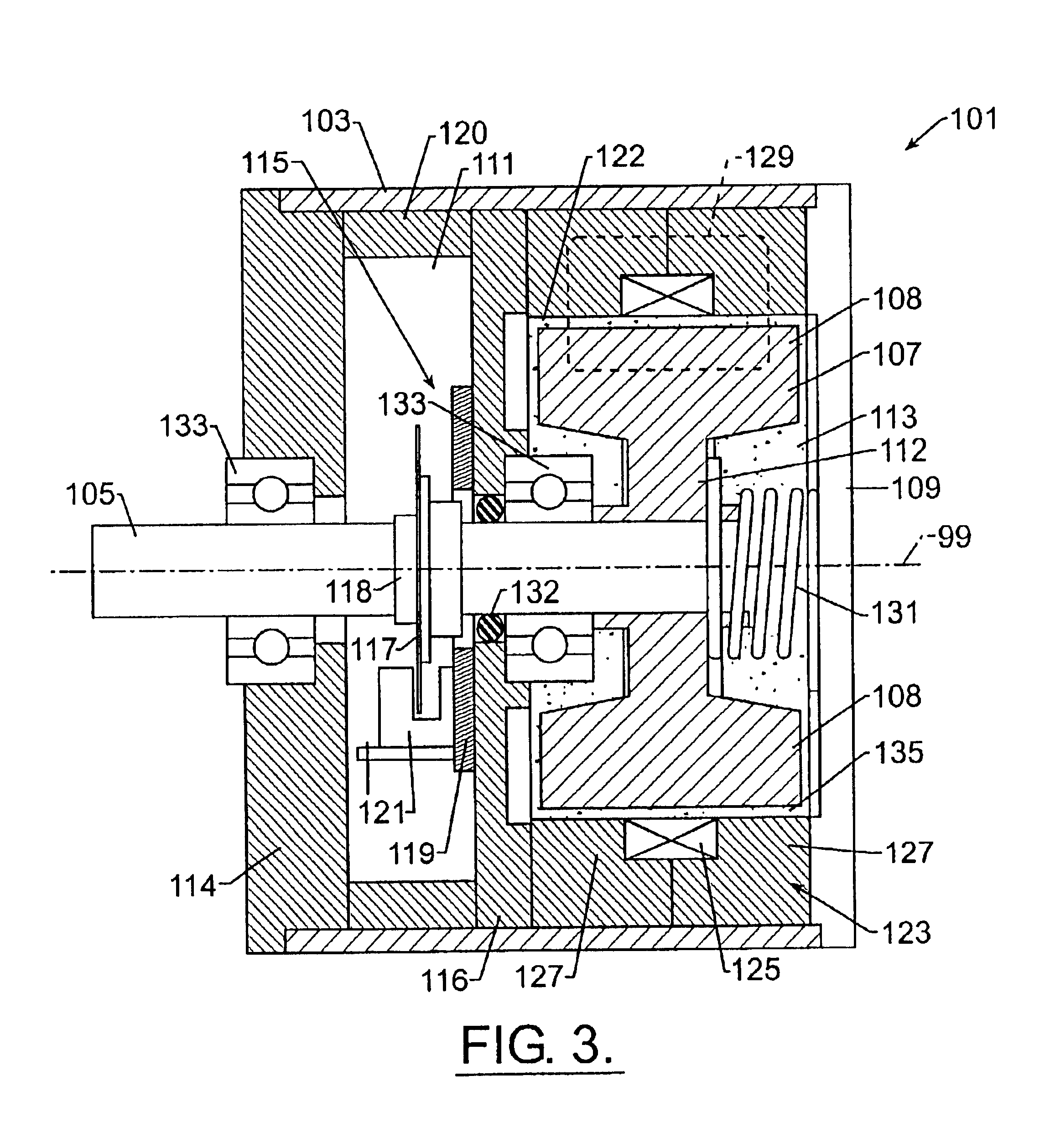

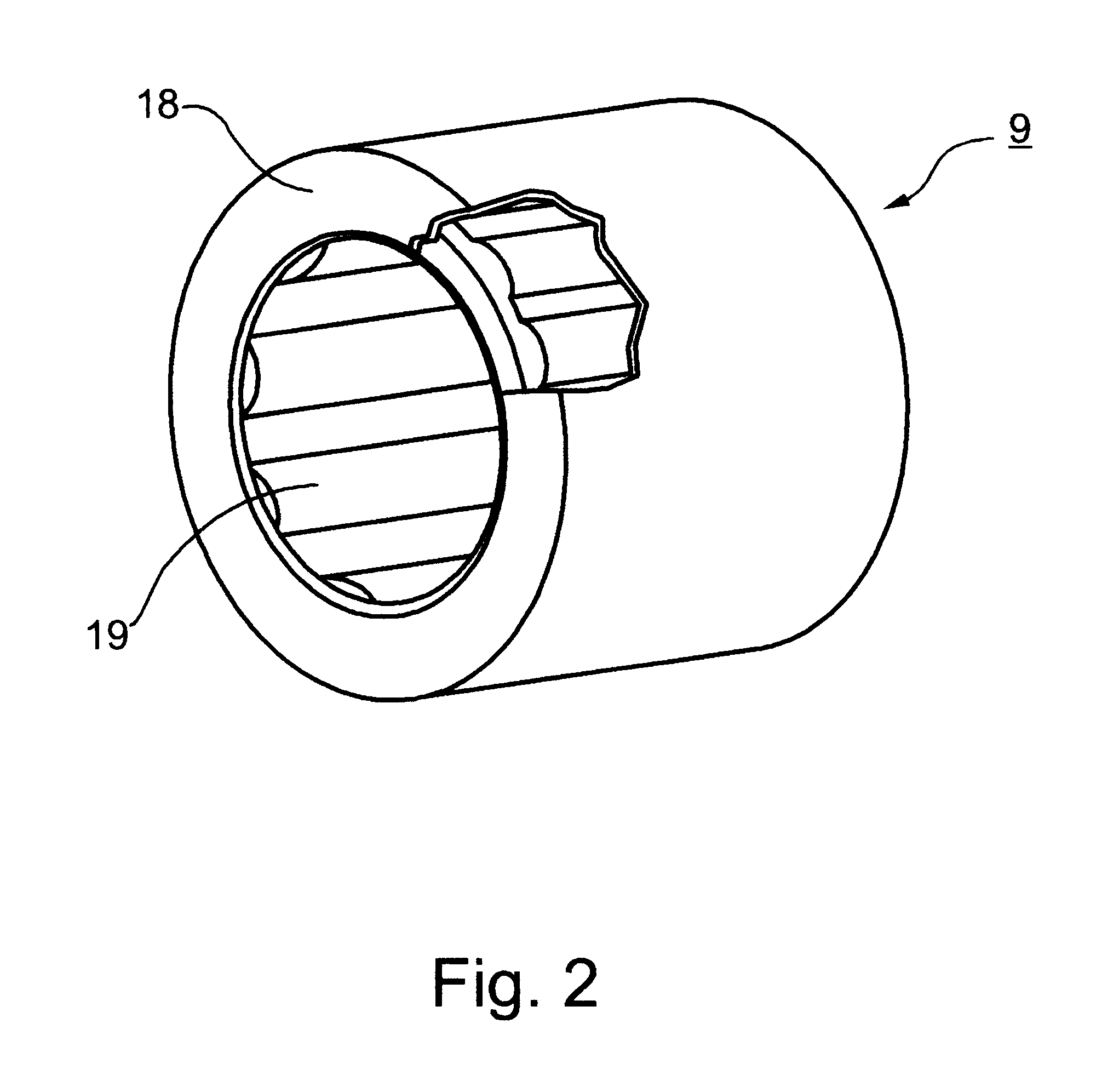

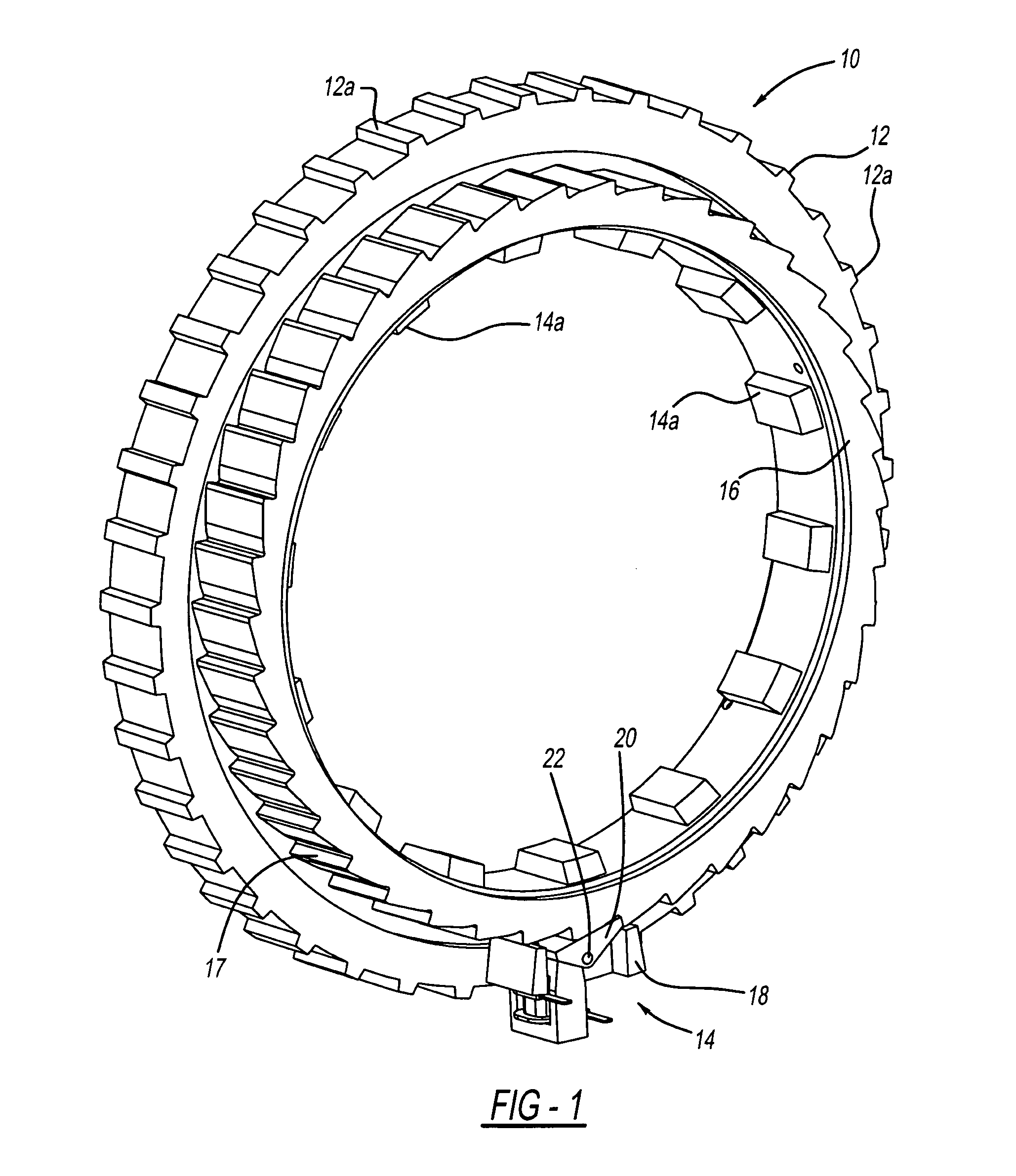

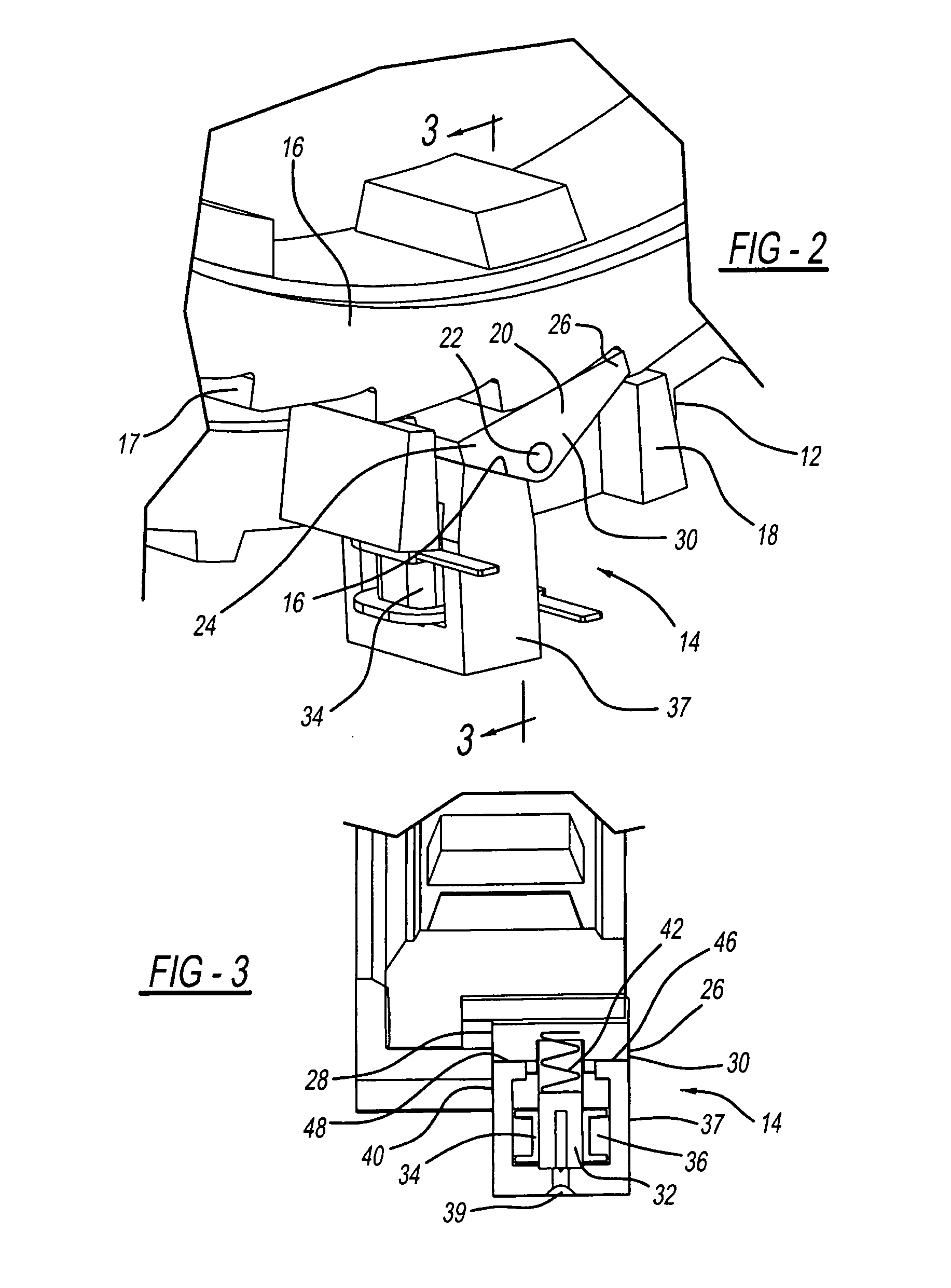

Magnetically actuated mechanical diode

A one-way clutch includes a first plate including cams distributed about an axis, a second plate axially facing the cams and including pockets, a coil located in one of the plates, struts, each strut supported in one of the pockets for pivoting axially relative to the cams in response to an electromagnetic field induced by current in the coil, and springs urging the struts to pivot opposite a pivot direction caused by energizing the coil.

Owner:FORD GLOBAL TECH LLC

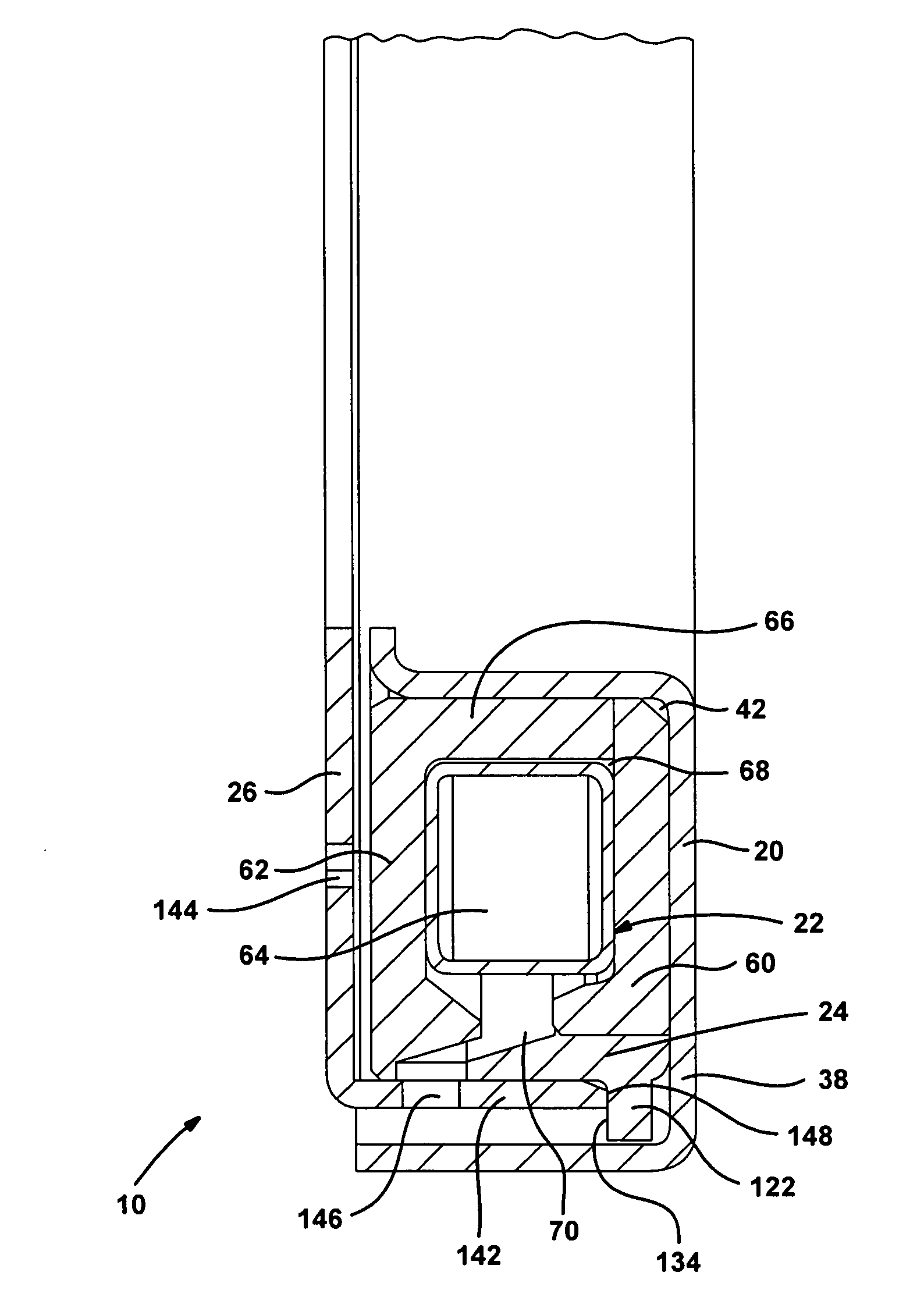

Power-operated clutch actuator for torque transfer mechanisms

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a power-operated face gear clutch actuator for generating and applying a clutch engagement force on the clutch assembly.

Owner:MAGNA POWERTRIAN INC (US)

Electronically actuated apparatus using solenoid actuator with integrated sensor

An electromagnetic actuator assembly that includes an annular frame, a coil assembly, an annular armature, a plunger and a sensor. The coil assembly is coupled to the frame and includes an annular core and an annular coil. The annular armature is received in the frame and abutted against the plunger. A sensor target can be coupled to the armature or the plunger and includes a radially outwardly extending sensor target. The sensor is coupled to the frame and configured to sense a position of the sensor target. A method for operating an electromagnetic actuator is also provided.

Owner:AMERICAN AXLE & MFG

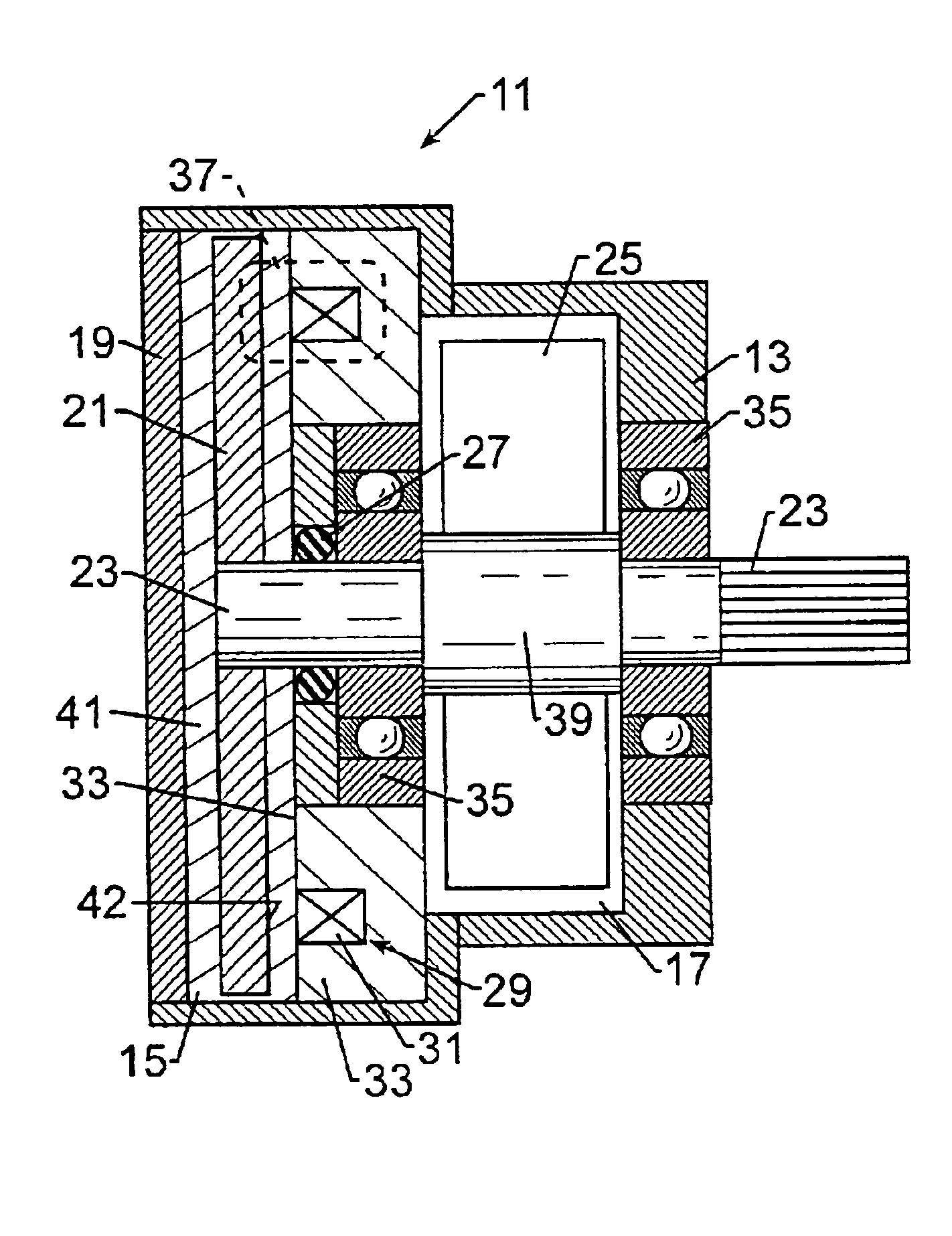

Electric actuator module for selectable clutch

ActiveUS20140102844A1StrongImprove accuracyMechanical actuated clutchesMagnetically actuated clutchesBobbinComputer module

A clutch module which includes a first rotating member including at least one strut actuation module and a second engaged member including cam surfaces thereon for engagement by said strut actuation module. The strut actuation module includes a frame with a strut pivotally movable with respect to the frame. The strut includes an engagement end and a base end including a first side and a second side thereof. A pin or post portion extends from the frame and has an insulated bobbin with an energizable coil surrounding the bobbin. A U-shaped member including a pair of actuation legs is attached to the pin member and forms a magnetic gap between the base end of the strut and peripheral ends of the legs, such that when the coil is energized the peripheral ends of the legs are polarized in a first polarity and the frame and the strut are polarized with an opposite polarity thereby biasing the strut toward the peripheral ends and pivoting the actuation end into engagement with a cam surface of the engagement member.

Owner:MAGNA POWERTRAIN OF AMERICA

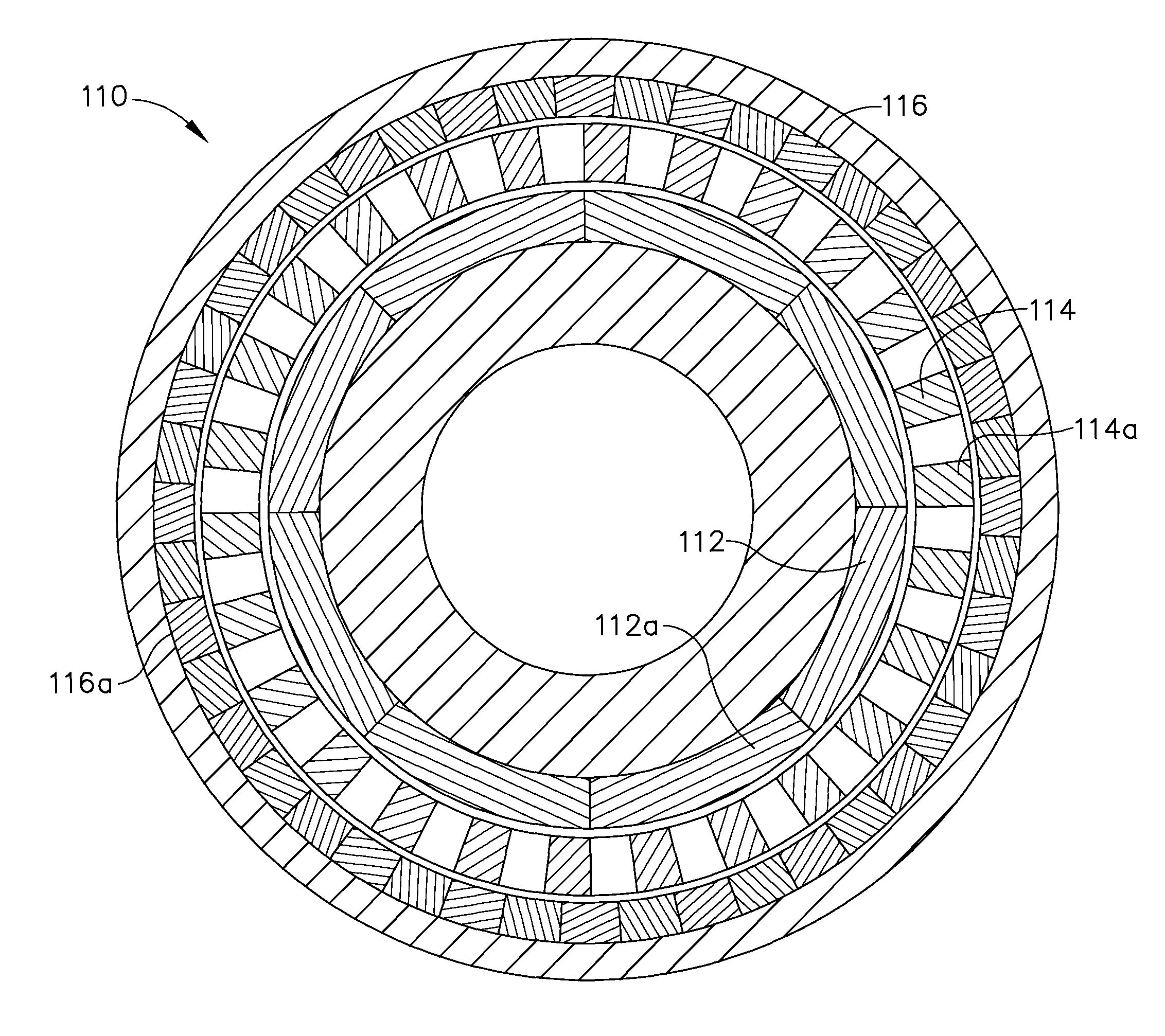

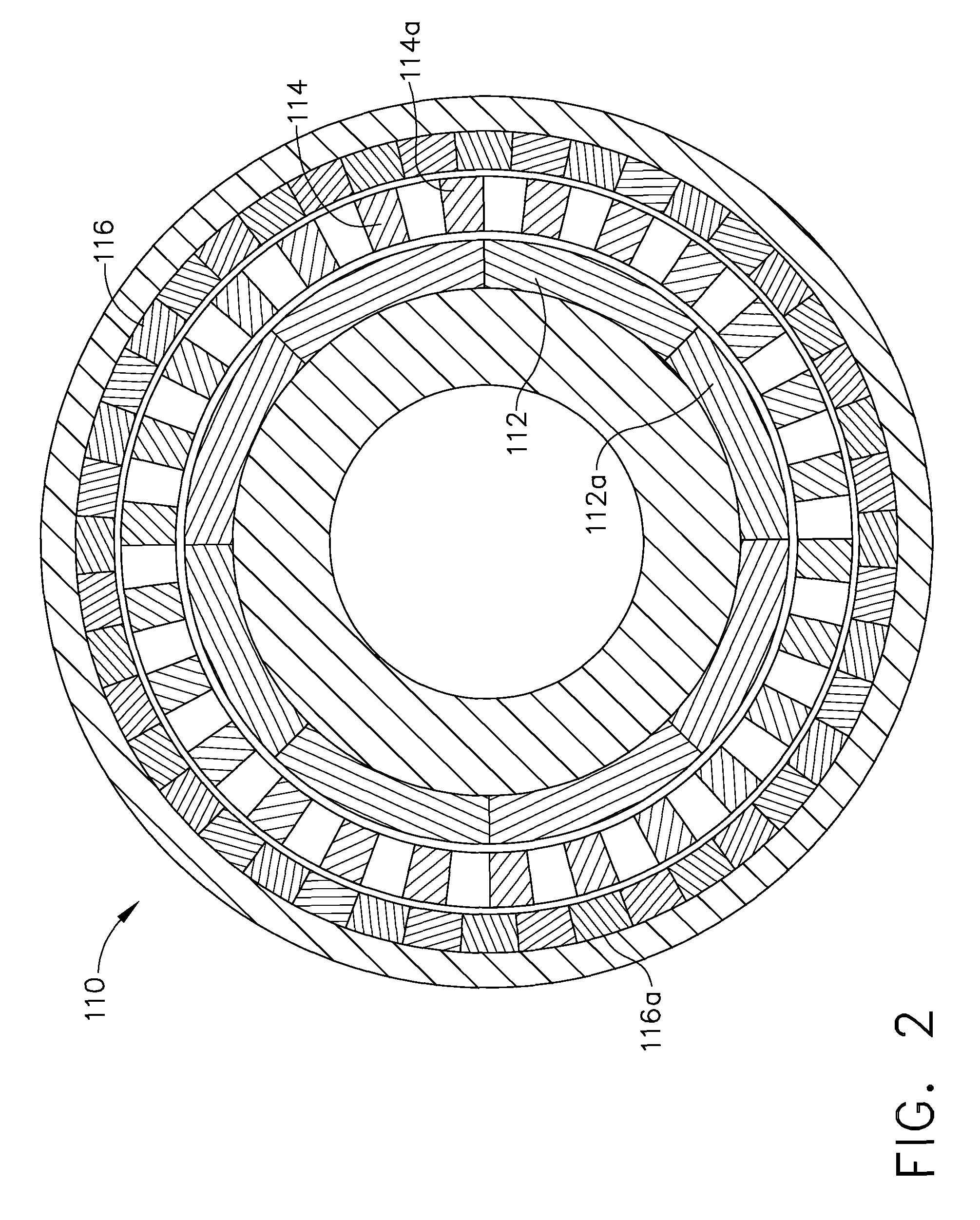

Variable magnetic coupling of rotating machinery

ActiveUS7791235B2Reduce vibration transmissionDynamo-electric brakes/clutchesMechanical actuated clutchesCouplingEngineering

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

Mechanical drive system operating by magnetic force

InactiveUS7057320B2Magnetic circuit rotating partsMagnetically actuated clutchesMagnetic tension forceDrive shaft

A mechanical drive system operating by magnetic force, to be fitted on a pump, comprises a basic structure on which a drive shaft, which extends along a longitudinal axis, is supported rotatably. A driving element operatively connected to the drive shaft is provided with driving magnets arranged in a ring. A driven element provided with driven magnets arranged in a ring is also mounted on the basic structure. A bell is inserted between the driving element and the driven element and isolates the environment containing the driven element. The driving element and the driven element comprise respective cages each having seats for housing the respective driving magnets or driven magnets.

Owner:C D R POMPE

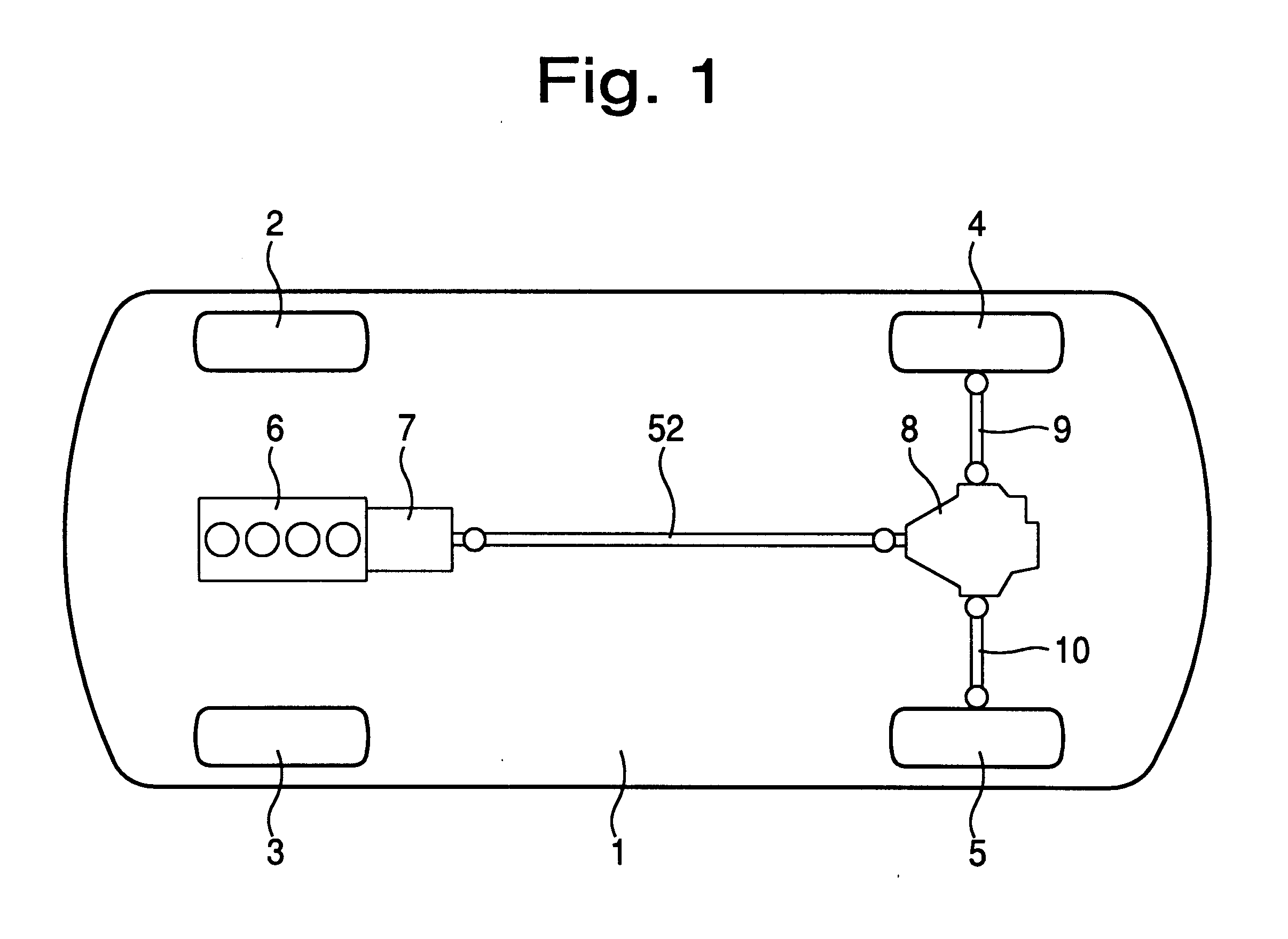

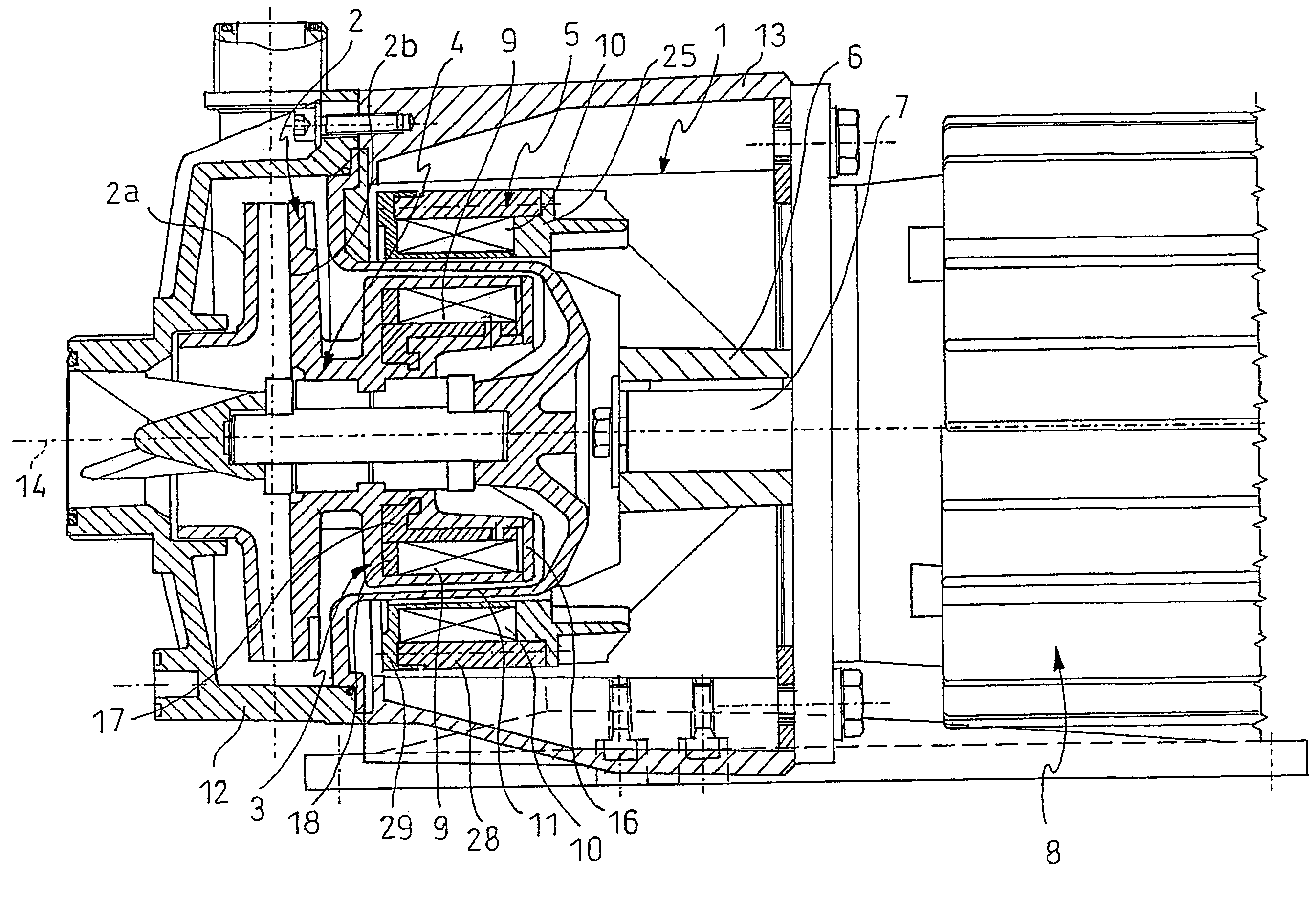

Power train for use in motor vehicles and the like

InactiveUS20040173393A1Increased operating lifeEasy to installGas pressure propulsion mountingMagnetically actuated clutchesMobile vehicleCombustion

A power train for a motor vehicle includes a combustion engine, a clutch or other torque-coupling device, a transmission, and an electro-mechanical energy converter that is operable at least as a motor and as a generator. The electro-mechanical energy converter is coupled to the output shaft of the combustion engine through a torque transfer device with at least two rpm ratios that automatically set themselves according to whether the vehicle is operating in a start-up mode or in a driving mode.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Engagement mechanism with two stage ramp angle

InactiveUS6571928B1Minimizes the required angular rotation and torque necessaryMaximizing engagementMagnetically actuated clutchesFriction clutchesDrivetrainEngineering

An engagement mechanism for use in a vehicle includes a housing. The engagement mechanism also includes a first ball ramp disc engaging the housing on one side. The first ball ramp disc includes a first ramp on the side engaging the housing. The first ball ramp disc also includes a second ramp having a predetermined angle on the side opposite of the side engaging the housing. The engagement mechanism further includes a ball ramp disc adjacent to the first ball ramp disc on a side opposite of the side engaging the housing which is rotatably driven. The engagement mechanism also includes a spring element arranged between the first ball ramp disc and the second ball ramp disc. The engagement mechanism is used to engage a friction clutch pack of a vehicle drivetrain system.

Owner:GKN DRIVELINE NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com