Patents

Literature

38results about How to "Prevent free rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

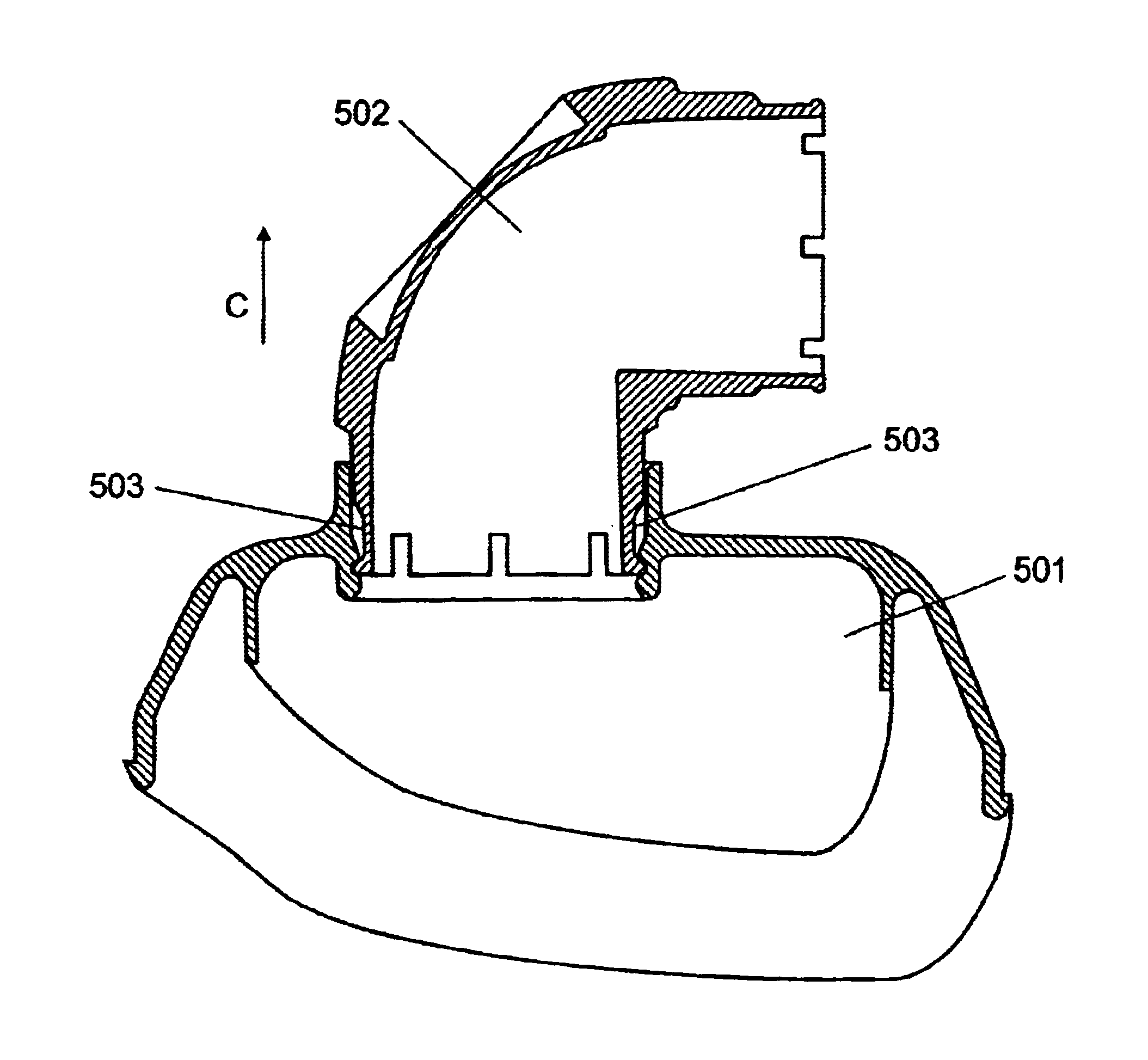

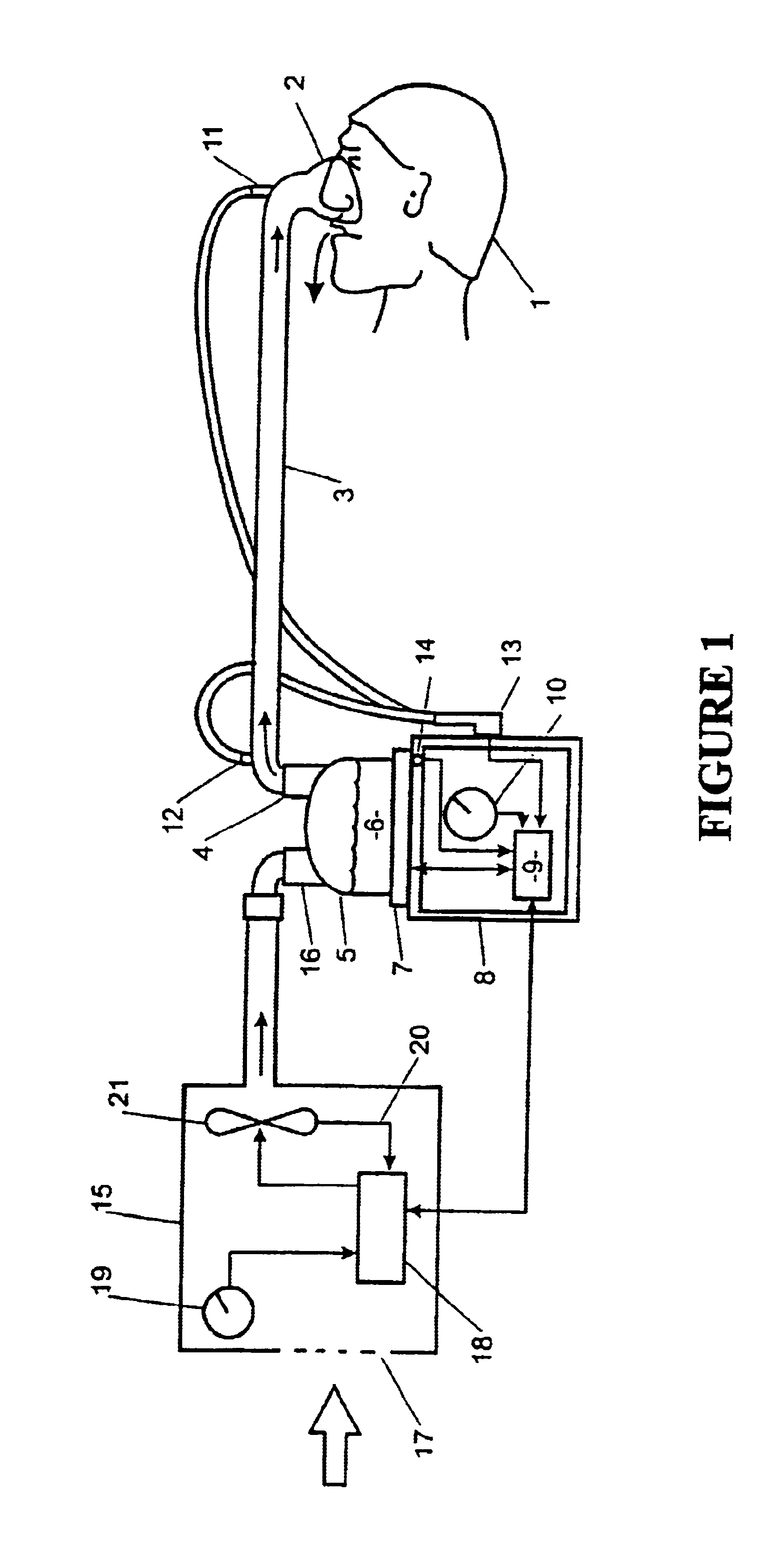

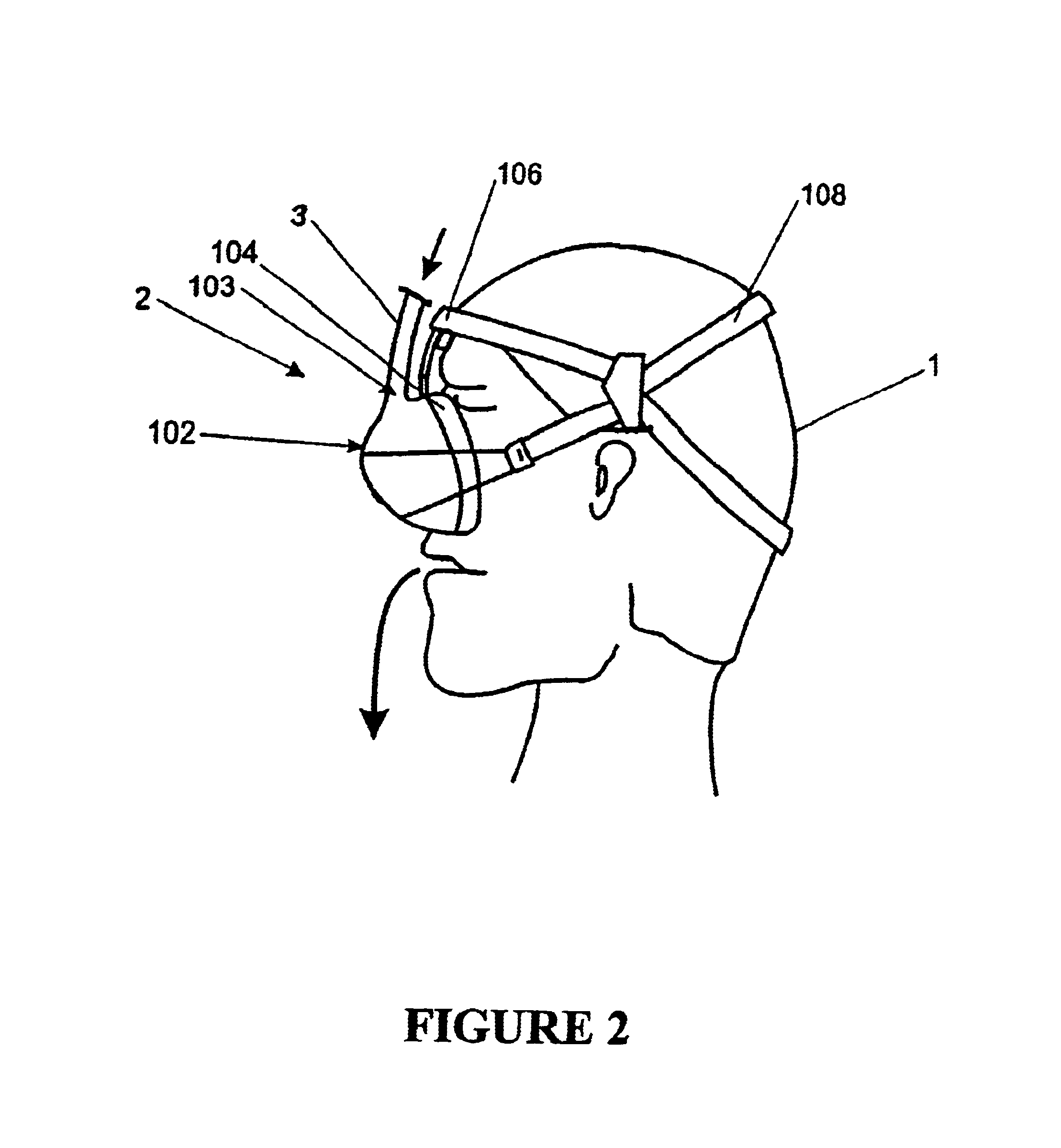

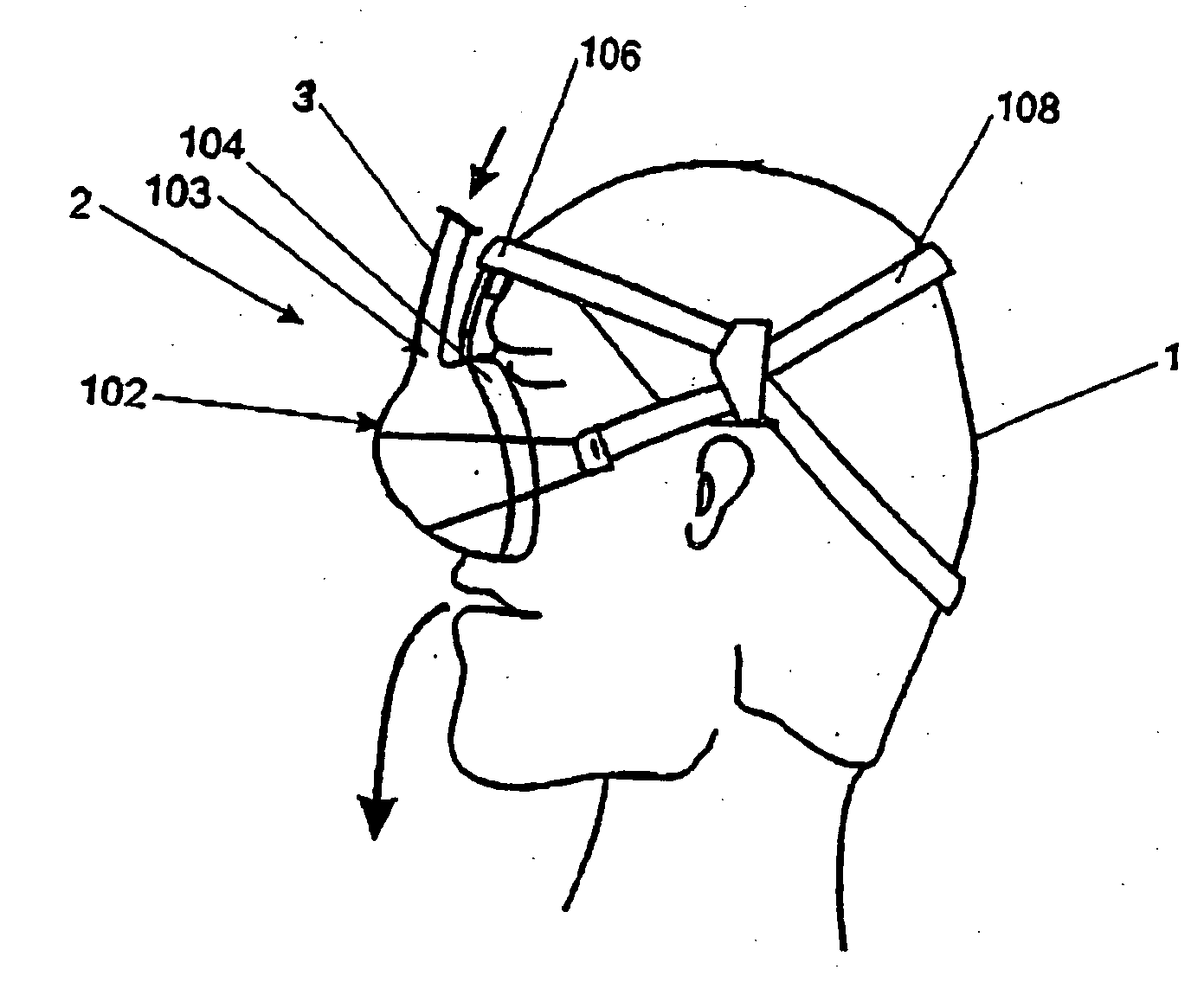

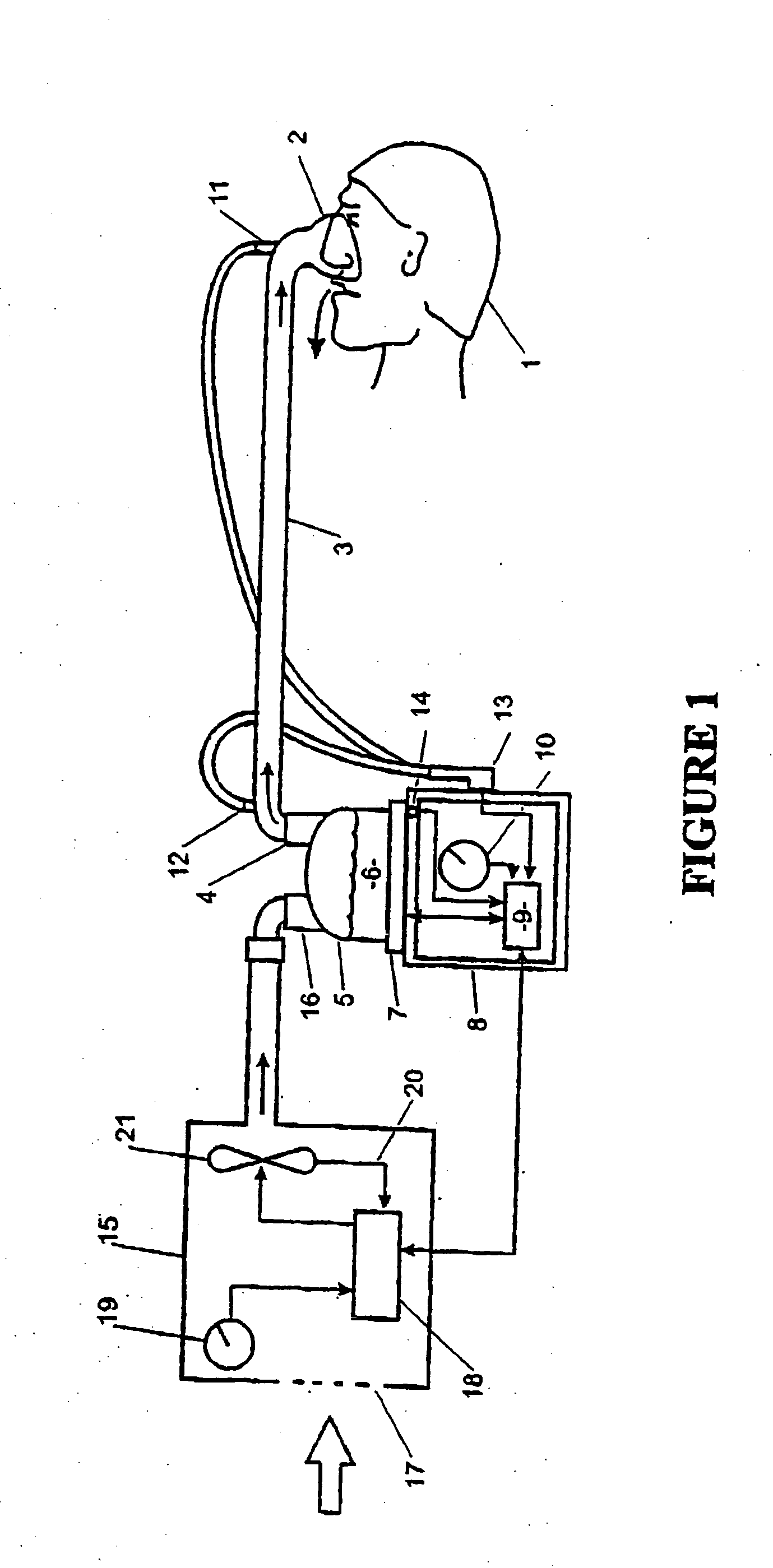

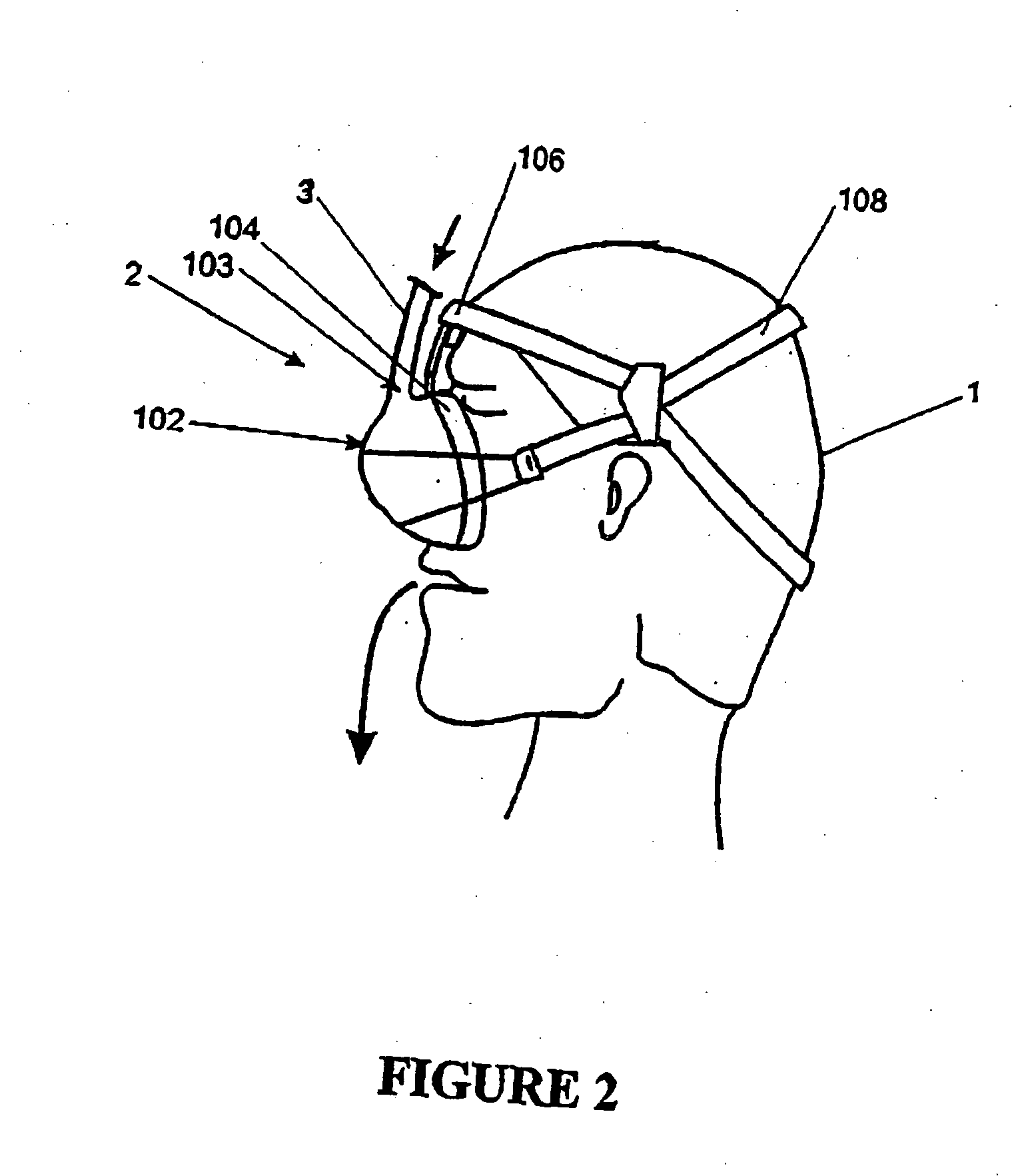

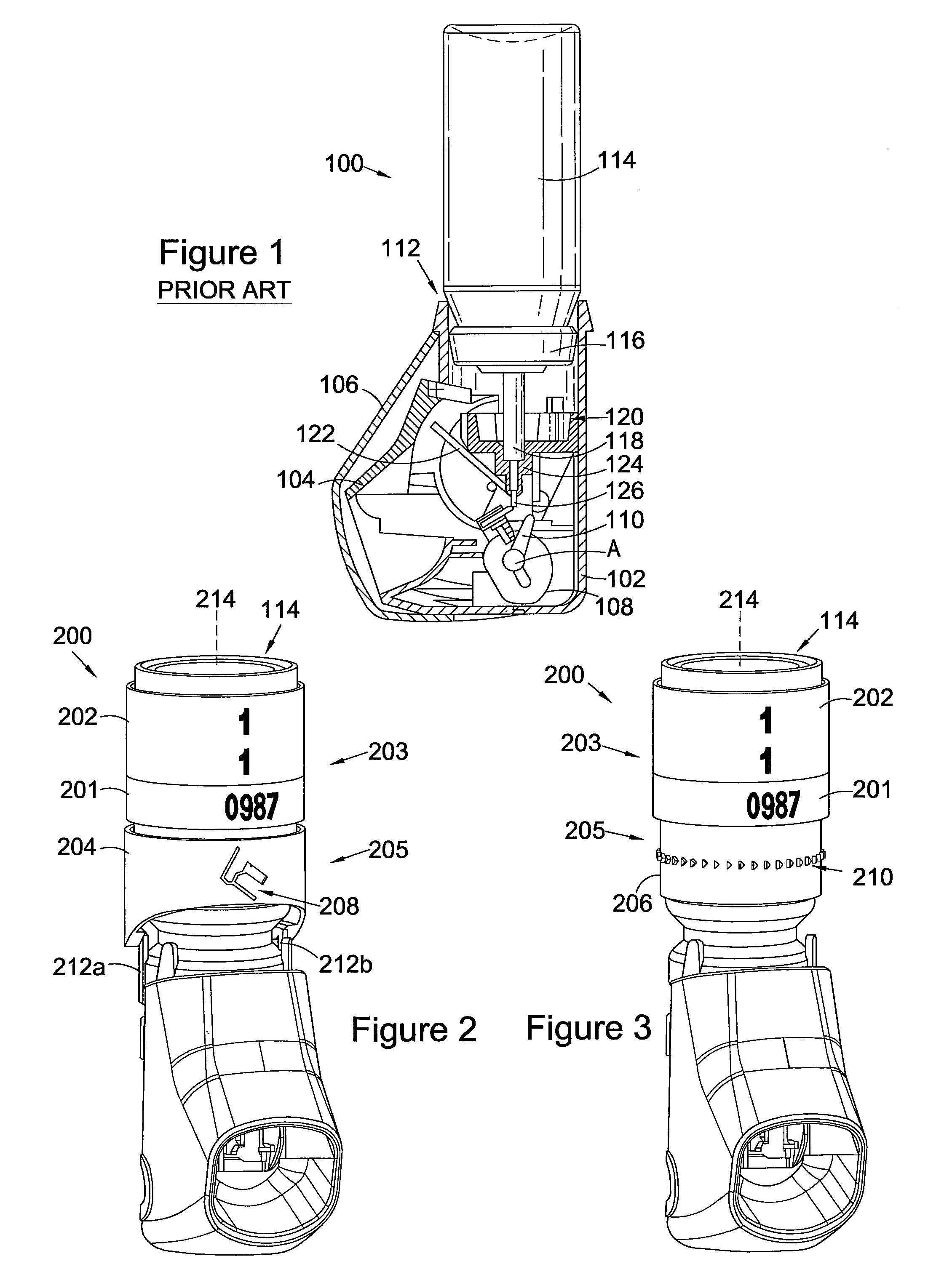

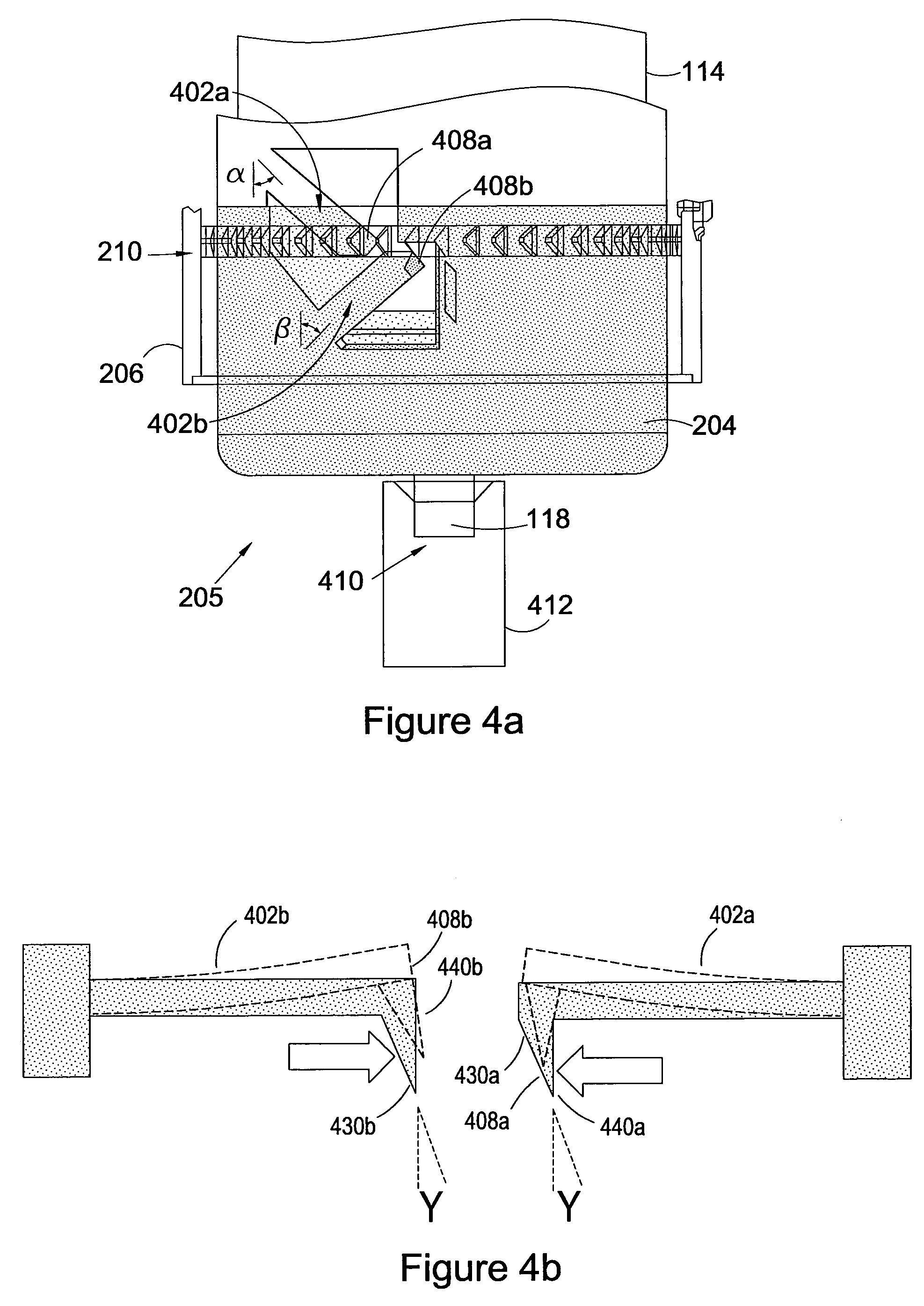

Patient interfaces

Owner:FISHER & PAYKEL HEALTHCARE LTD

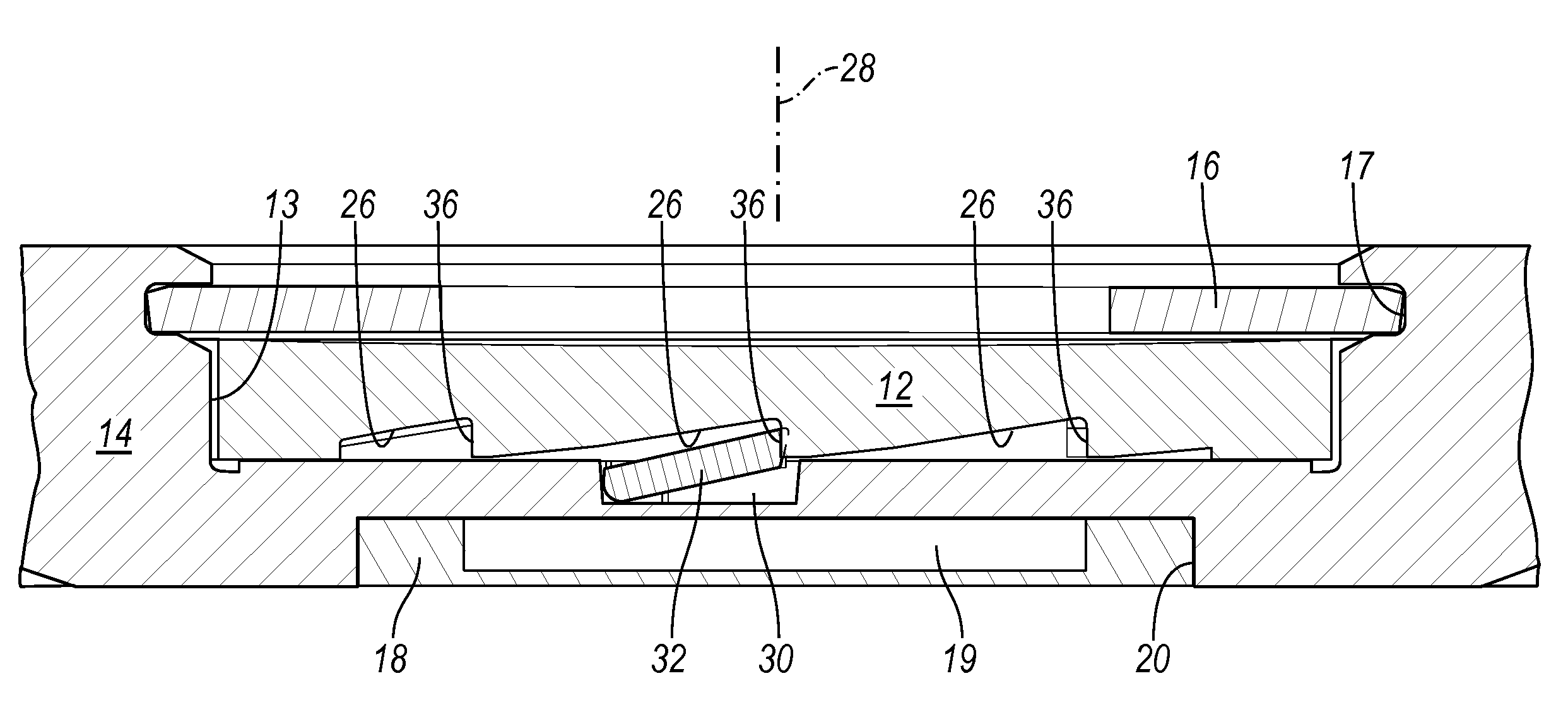

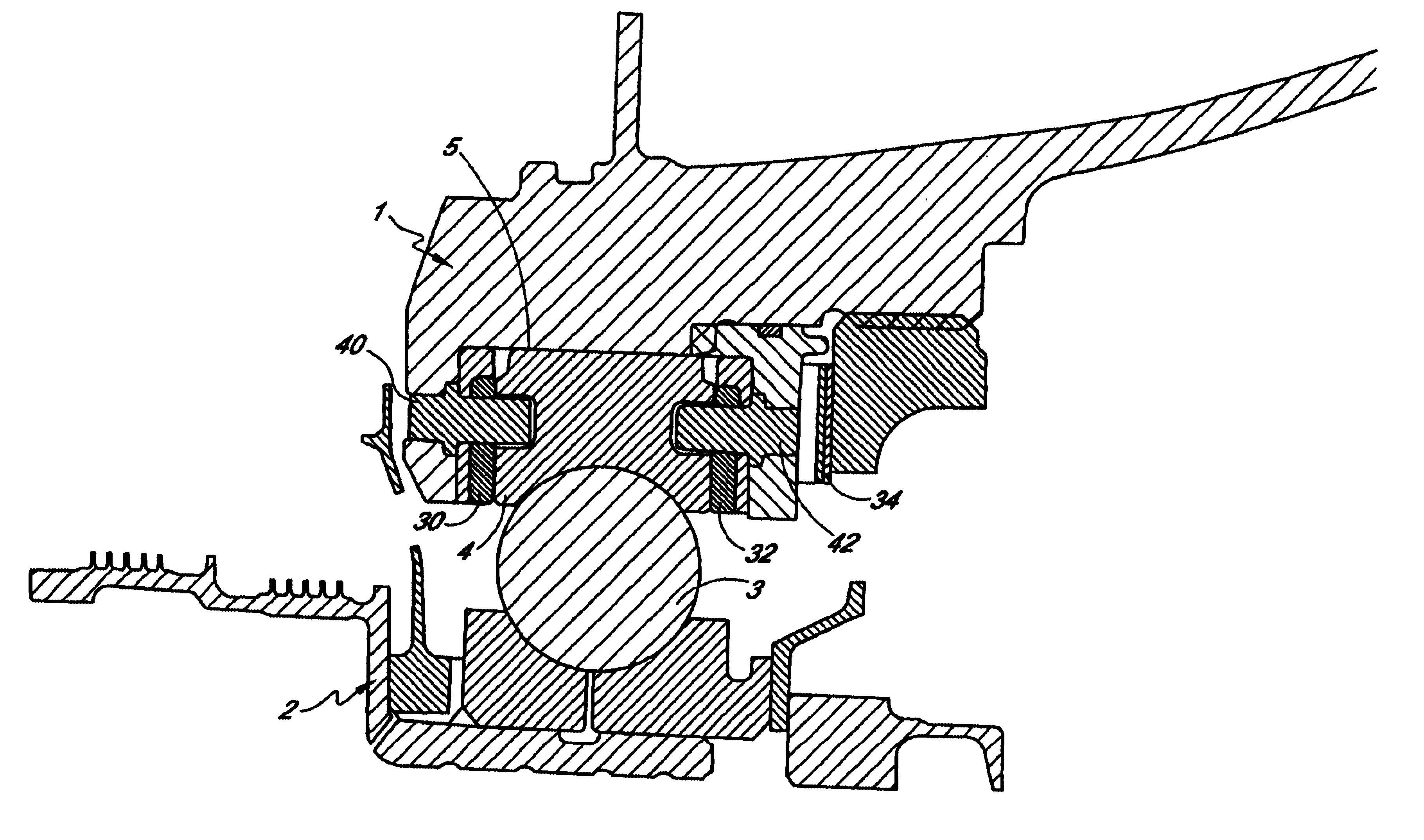

Magnetically actuated mechanical diode

A one-way clutch includes a first plate including cams distributed about an axis, a second plate axially facing the cams and including pockets, a coil located in one of the plates, struts, each strut supported in one of the pockets for pivoting axially relative to the cams in response to an electromagnetic field induced by current in the coil, and springs urging the struts to pivot opposite a pivot direction caused by energizing the coil.

Owner:FORD GLOBAL TECH LLC

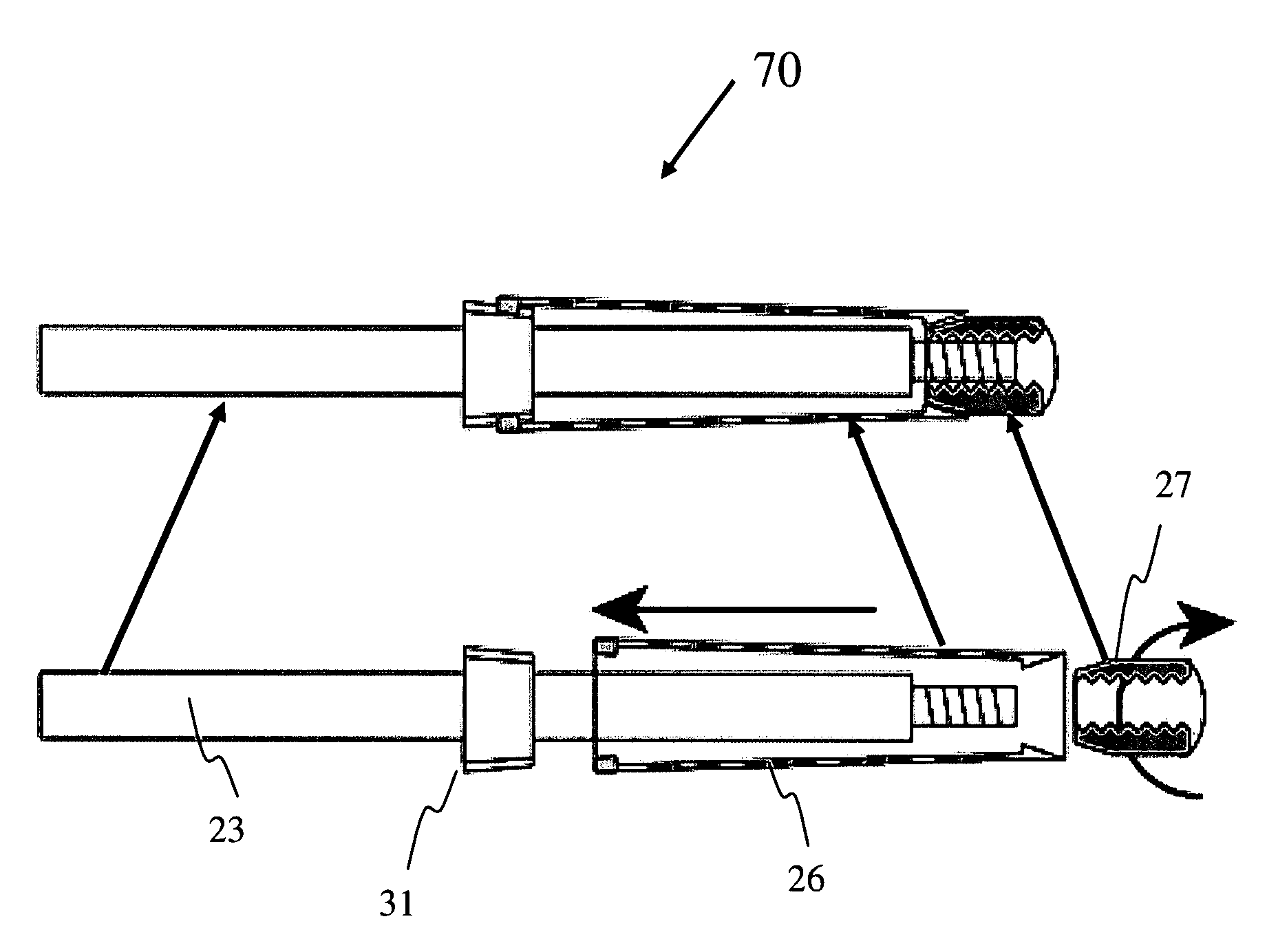

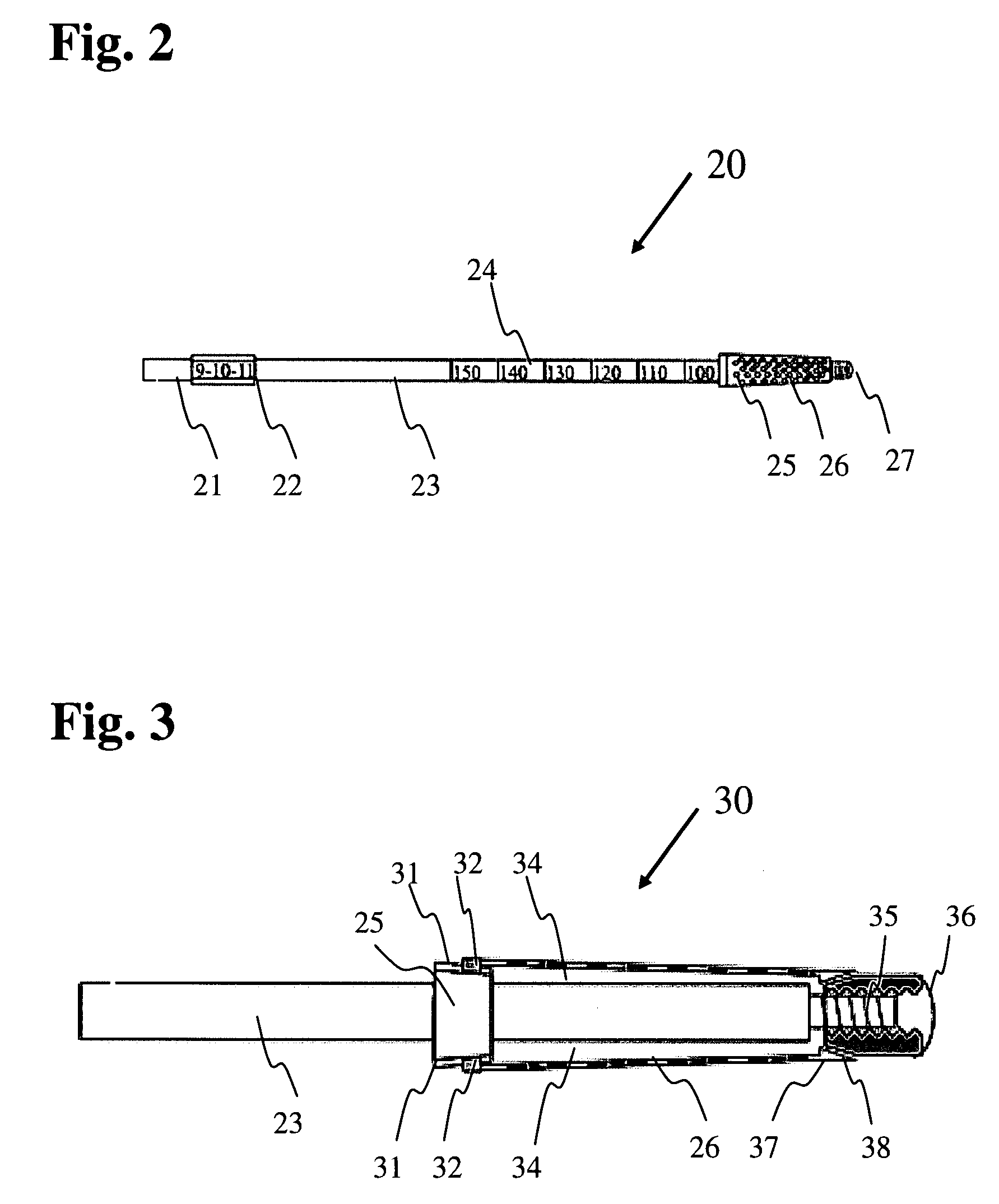

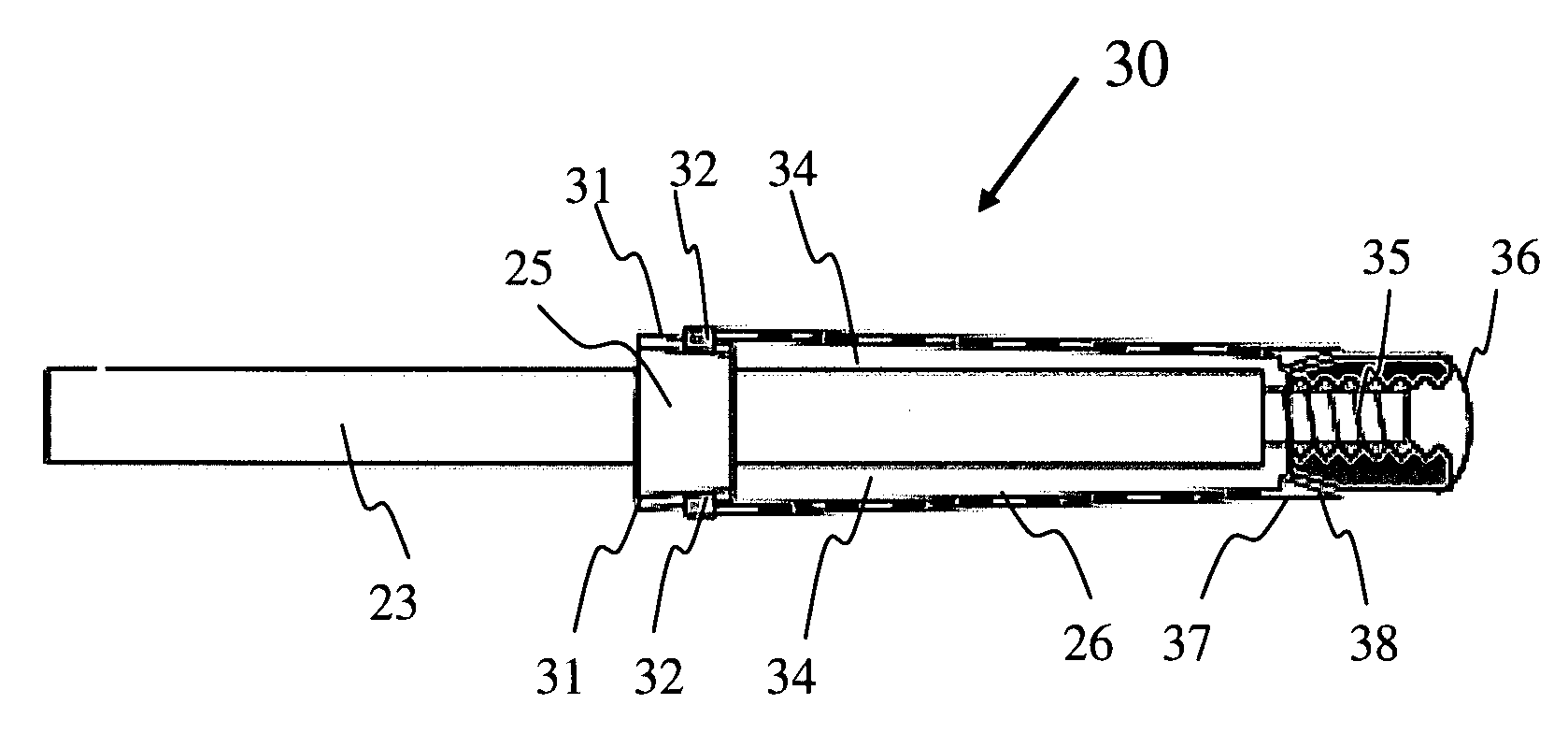

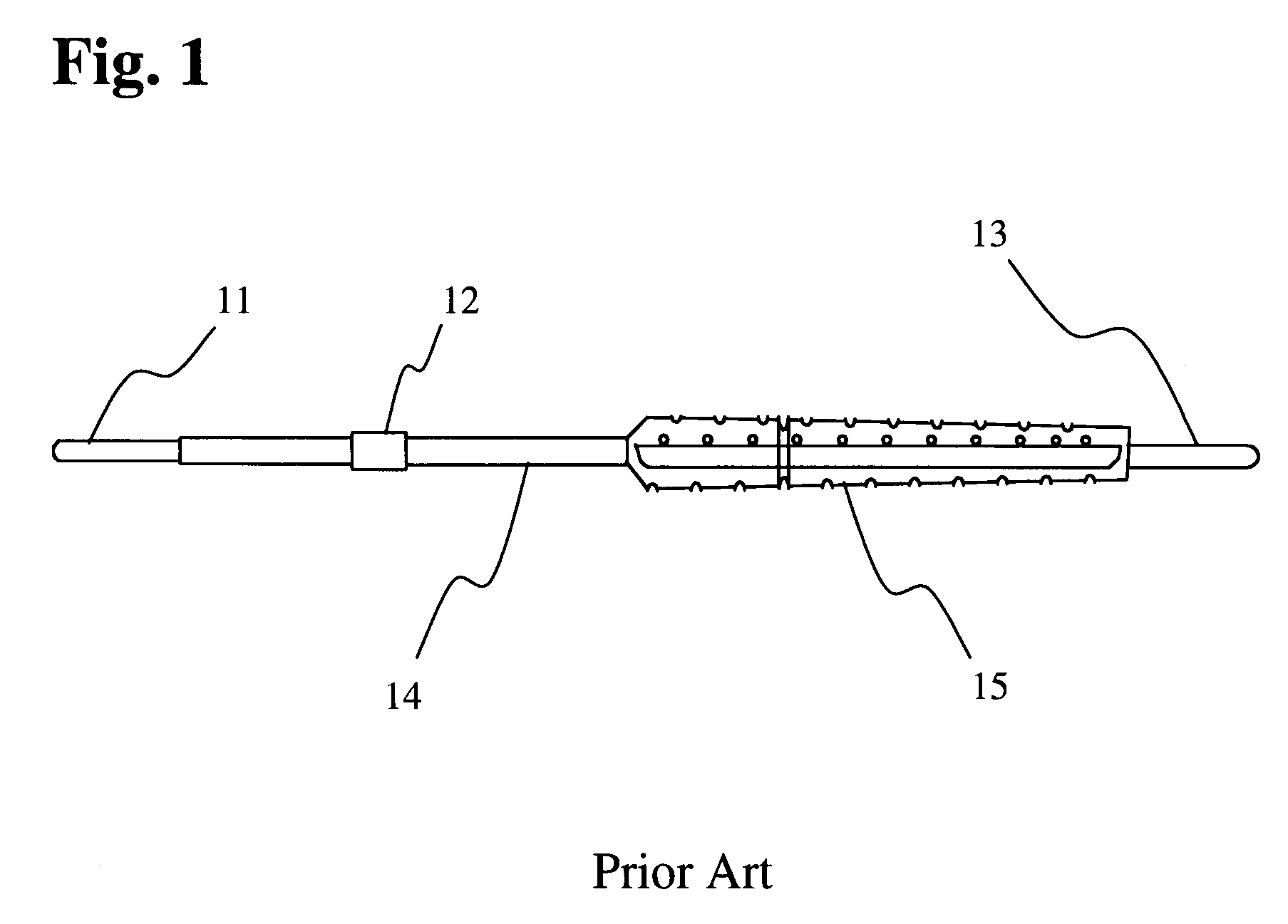

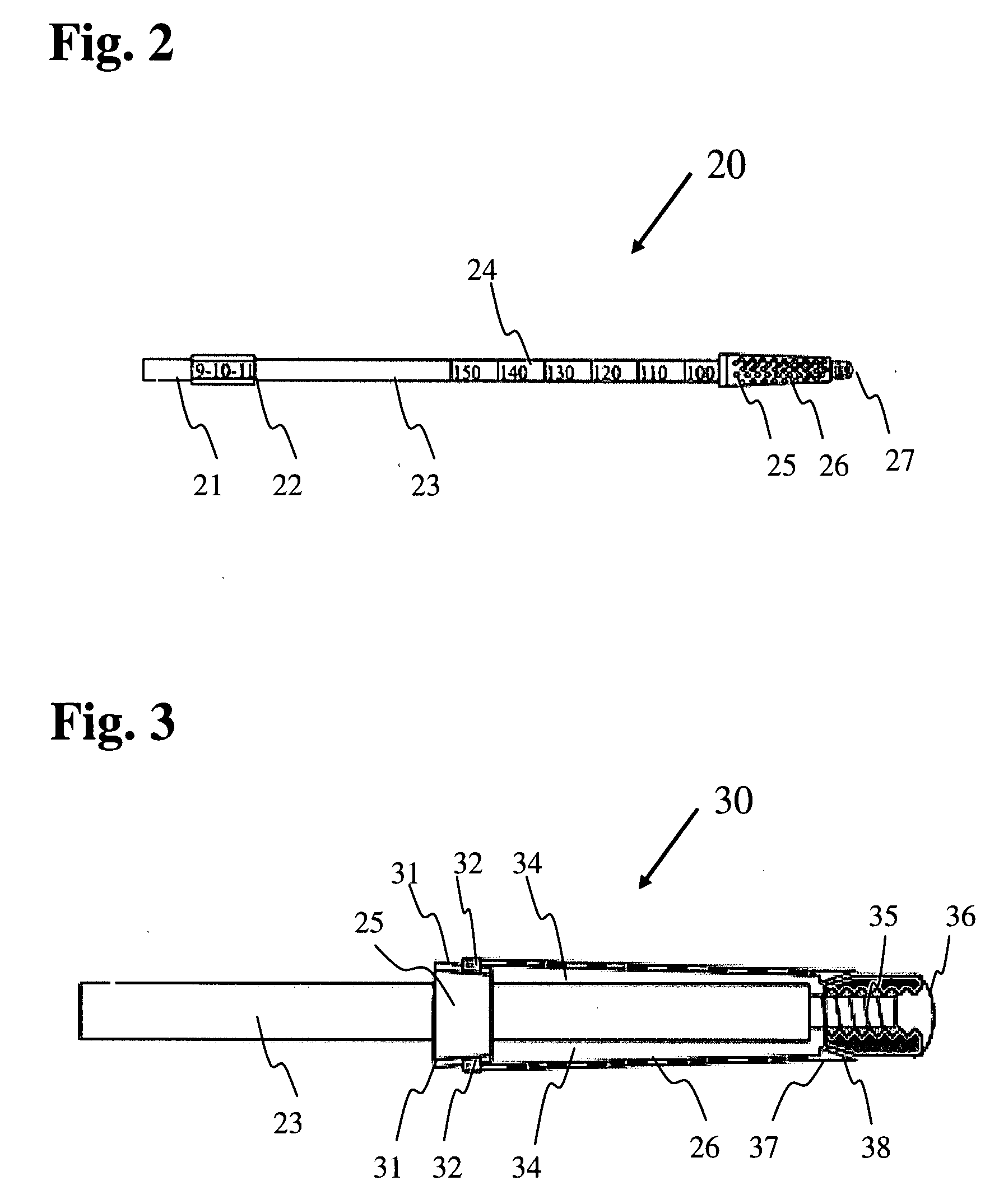

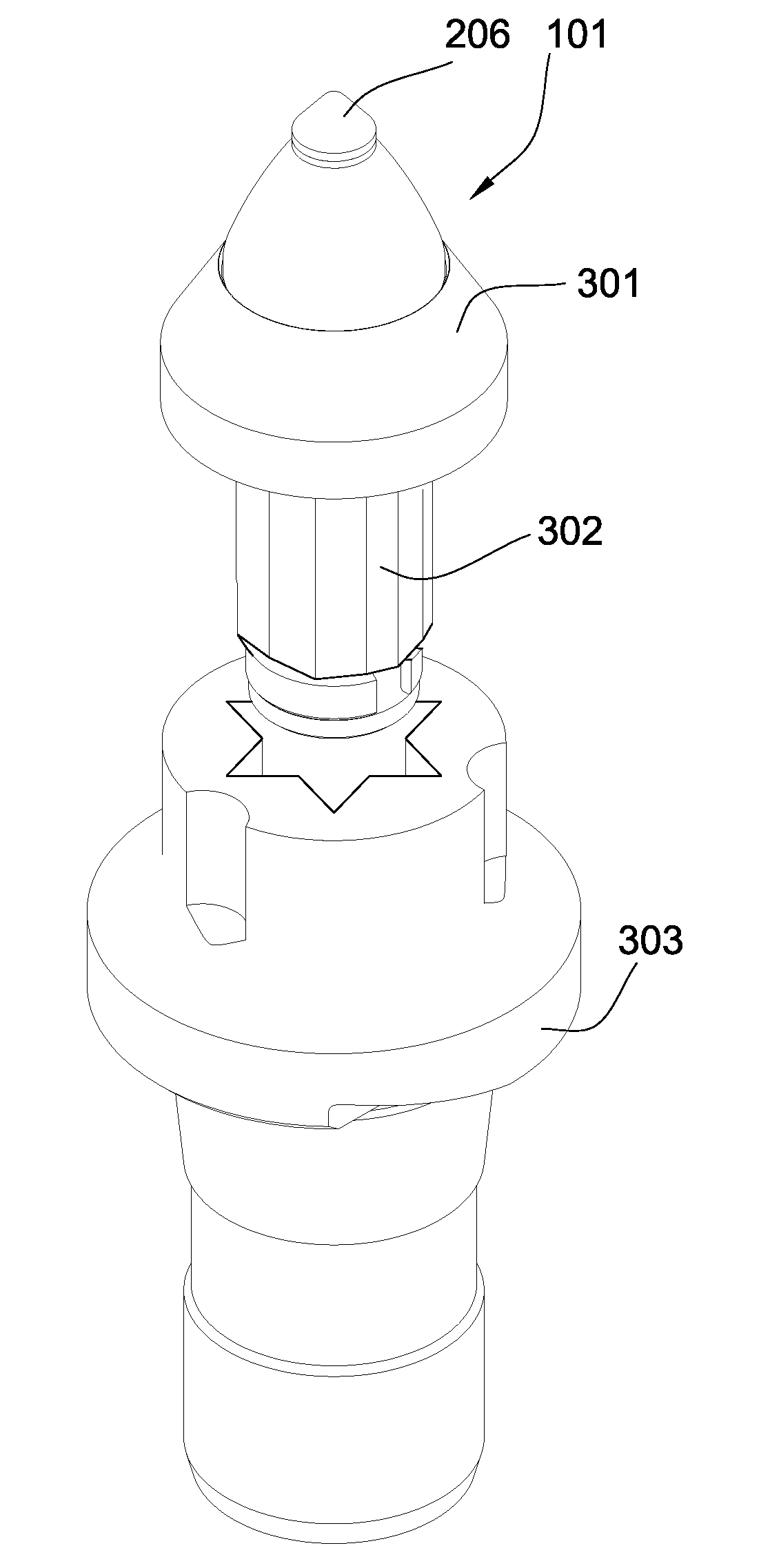

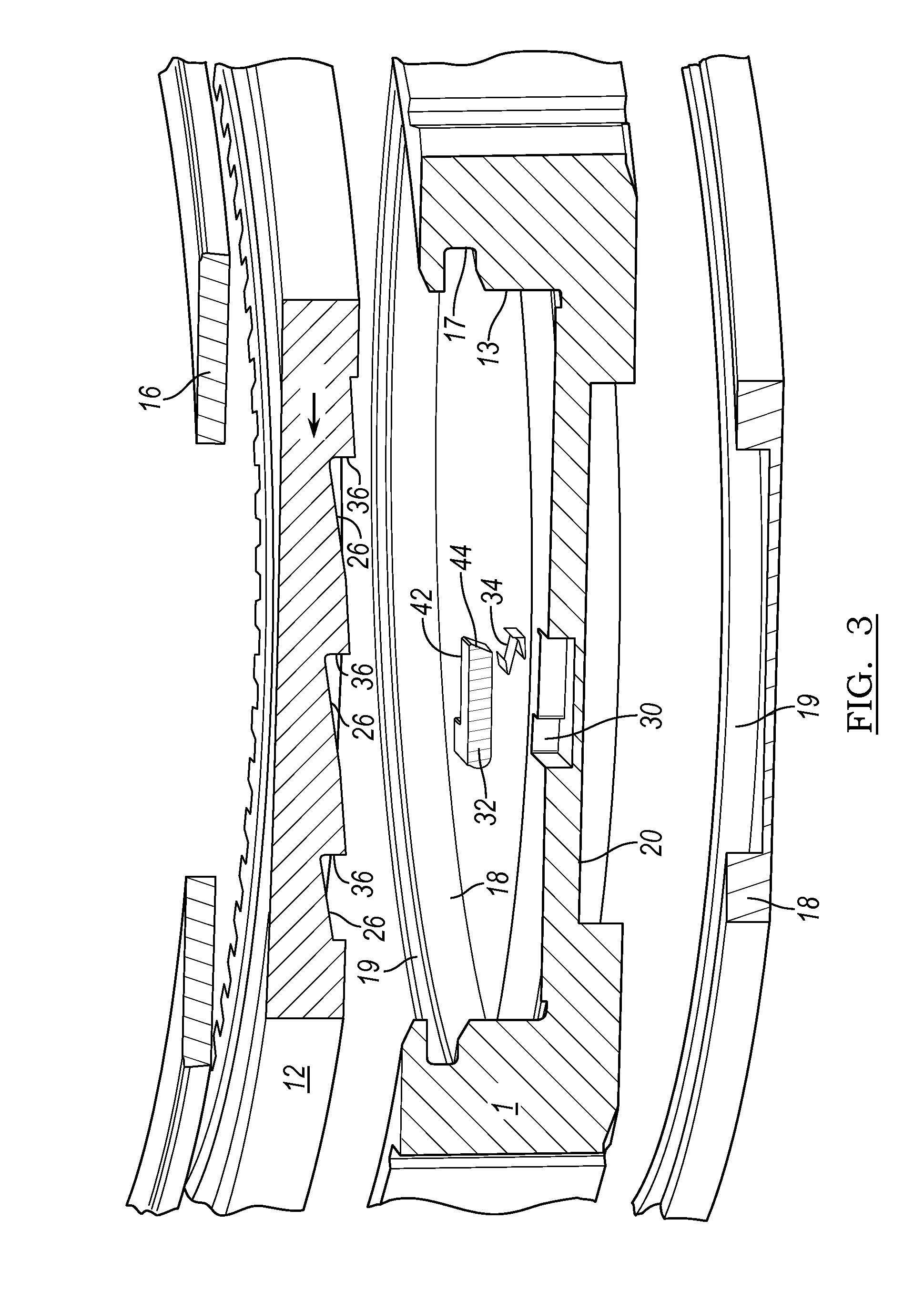

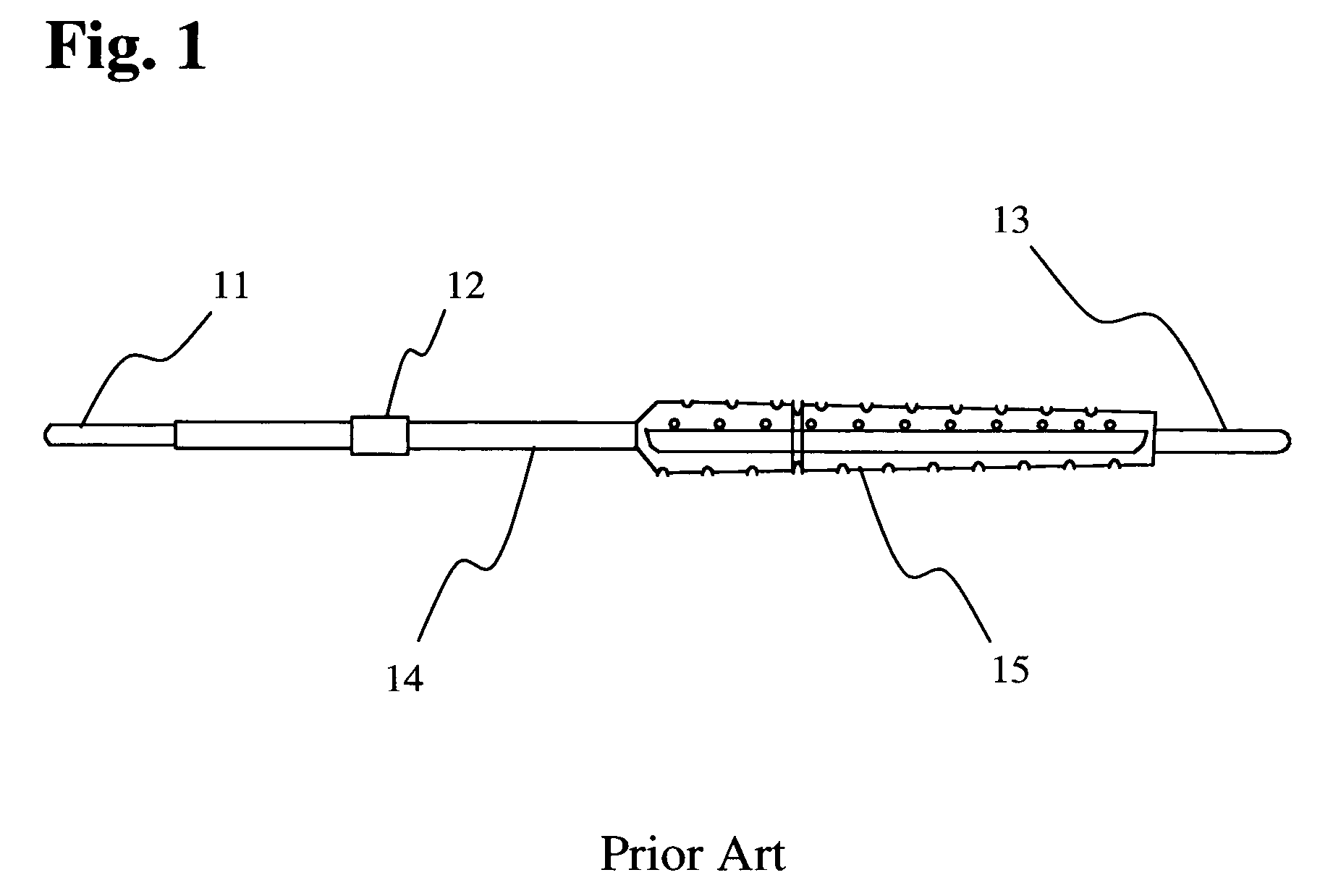

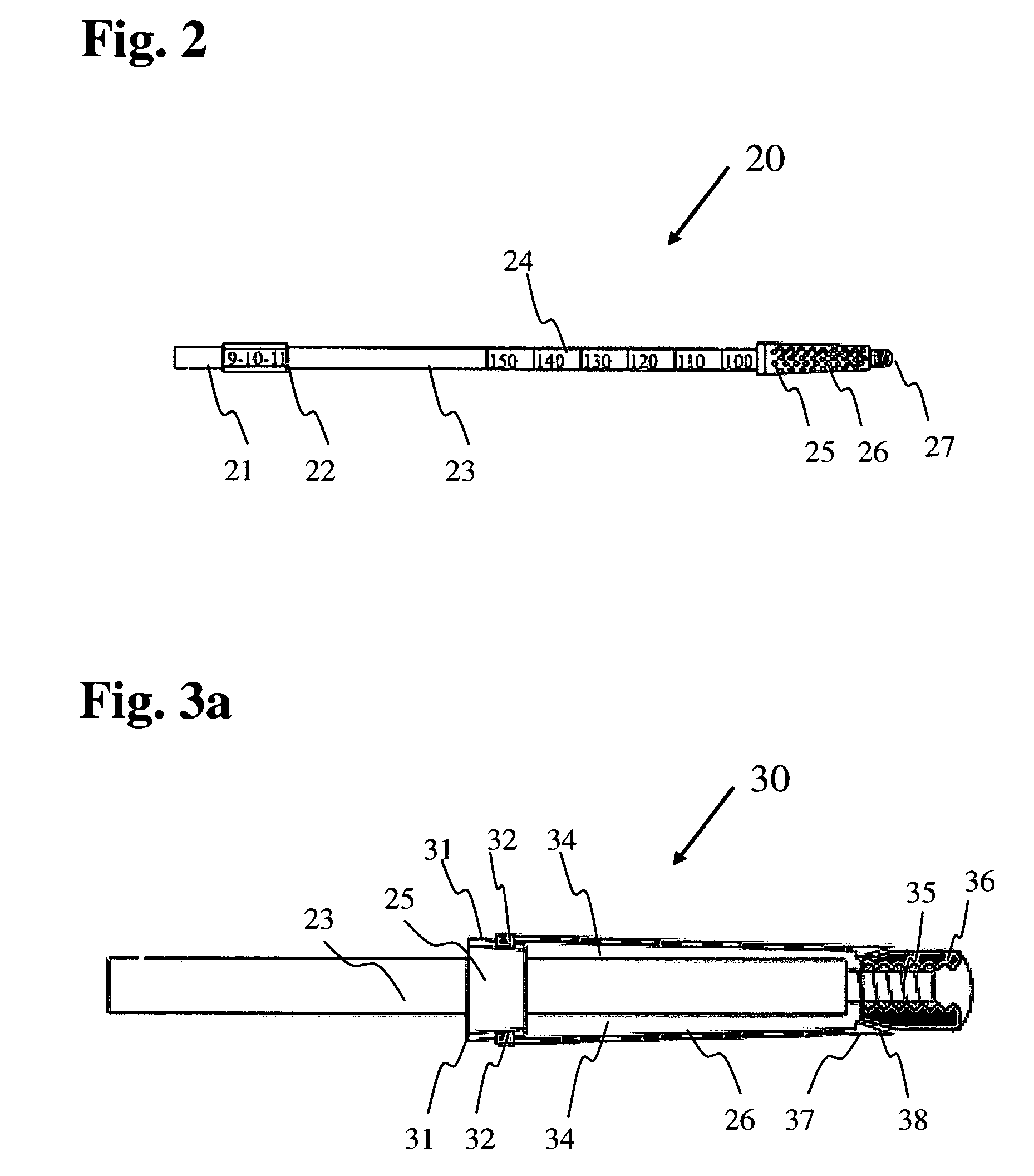

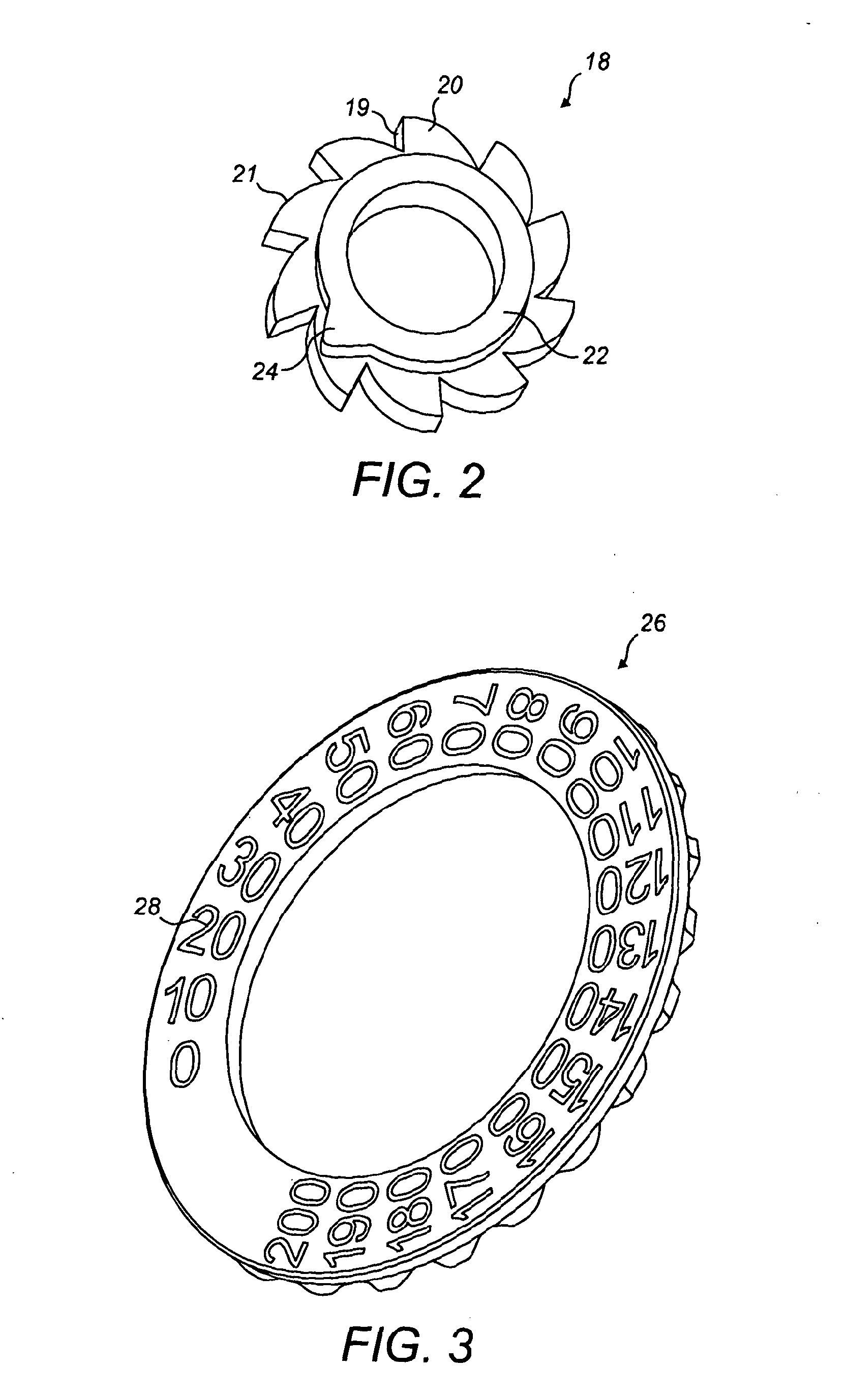

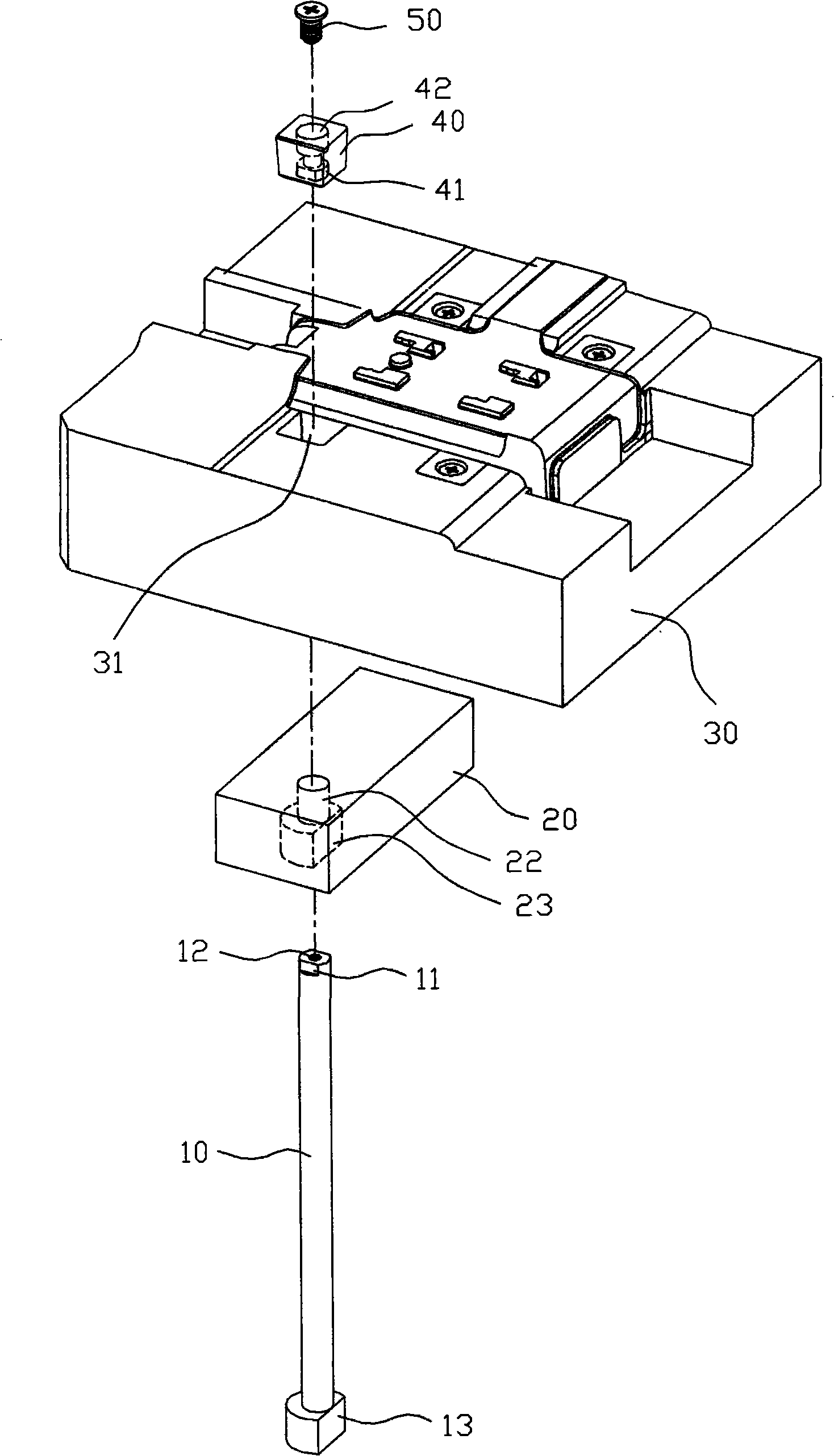

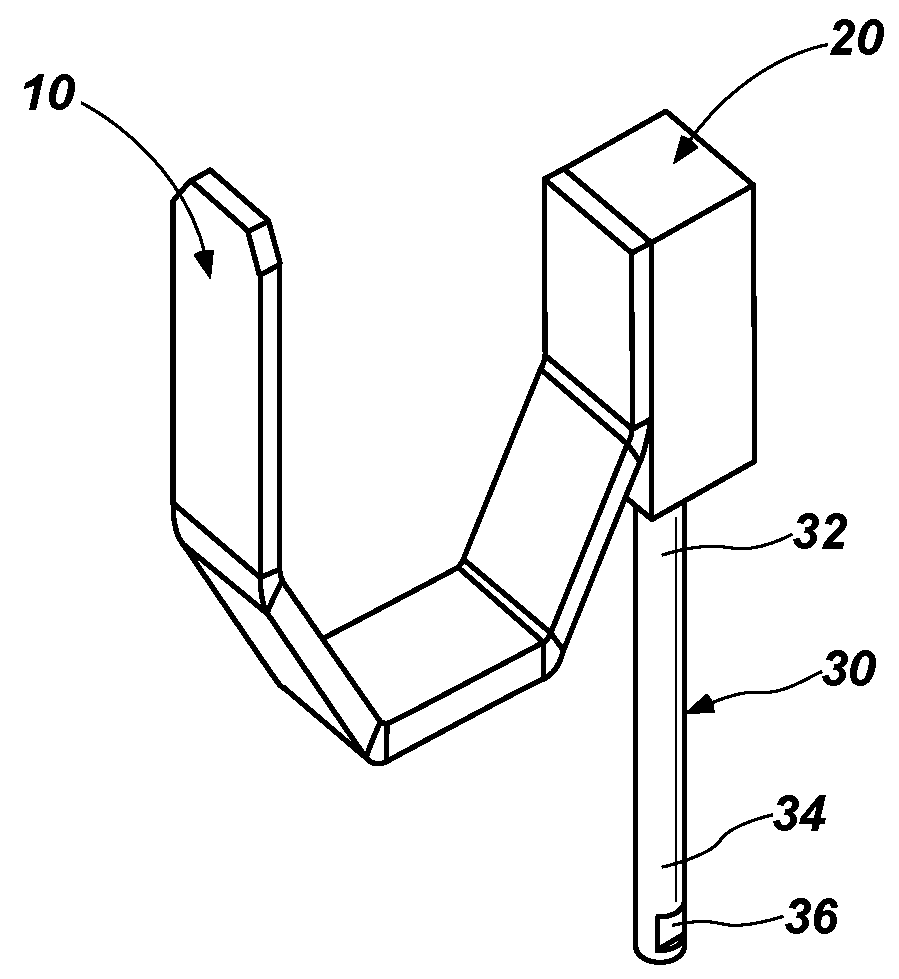

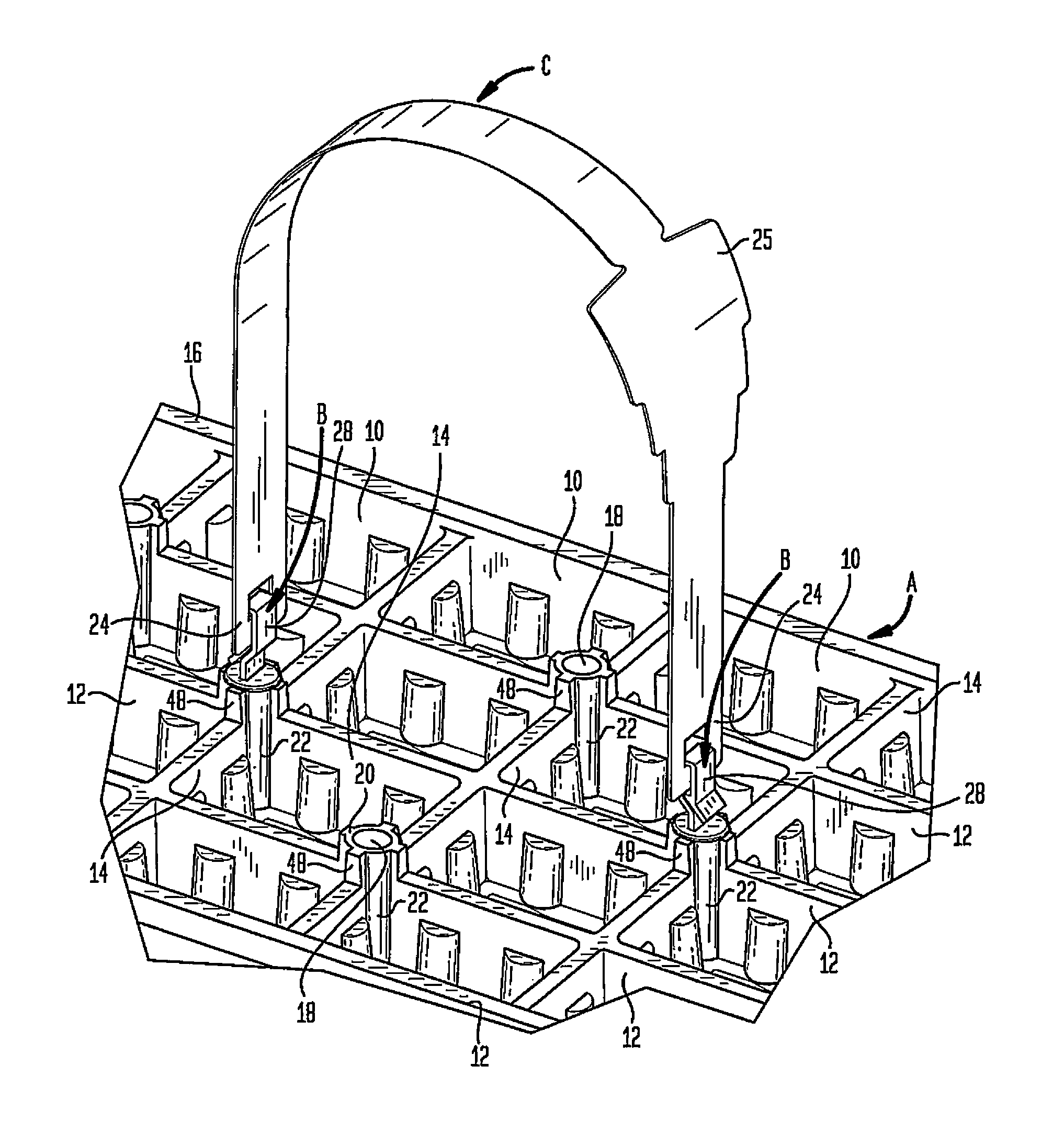

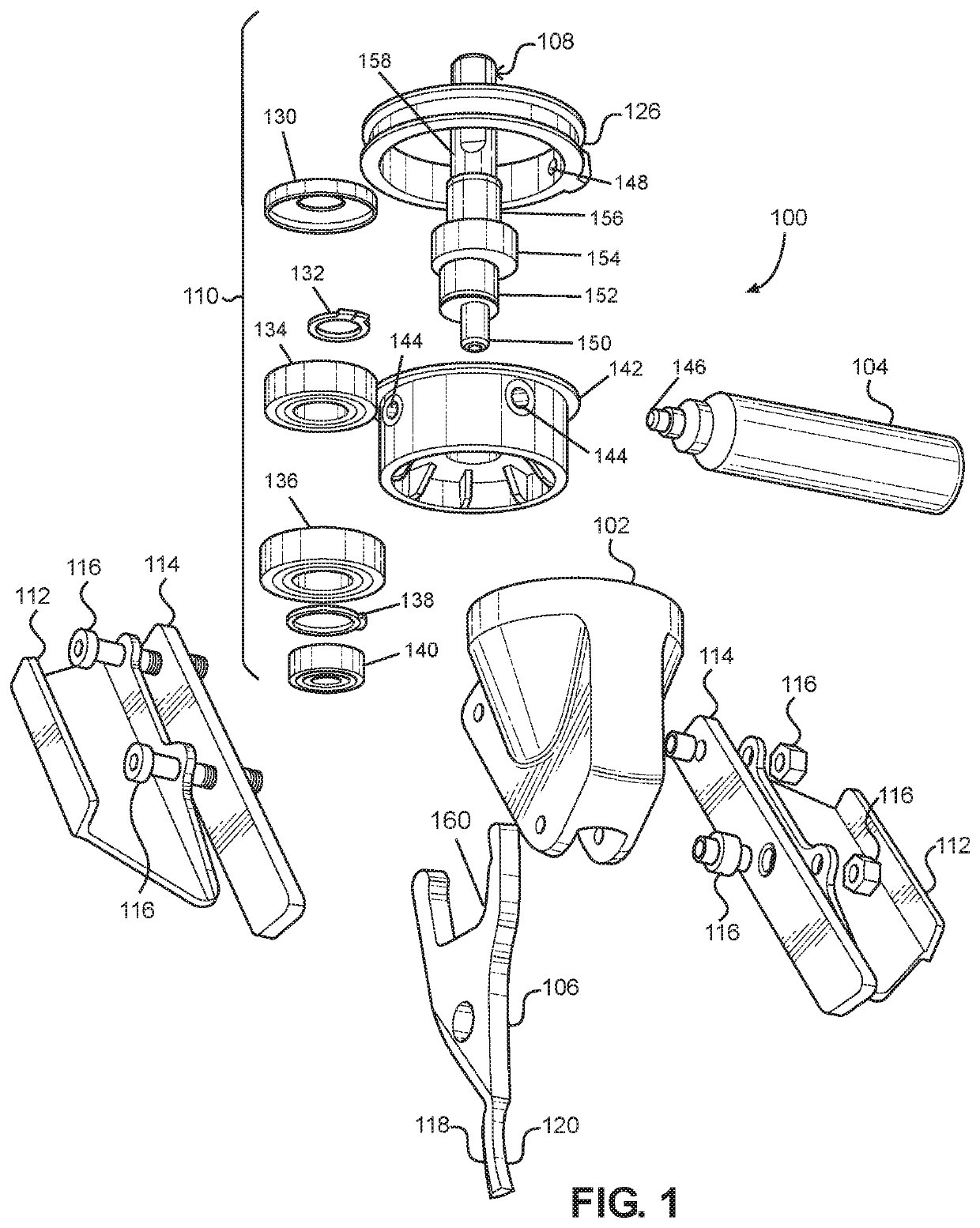

Modular tapered hollow reamer for medical applications

A reamer for medical applications comprising a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The reamer sleeve has attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable reaming torque in an efficient manner.

Owner:LRS SCI & TECH LLC

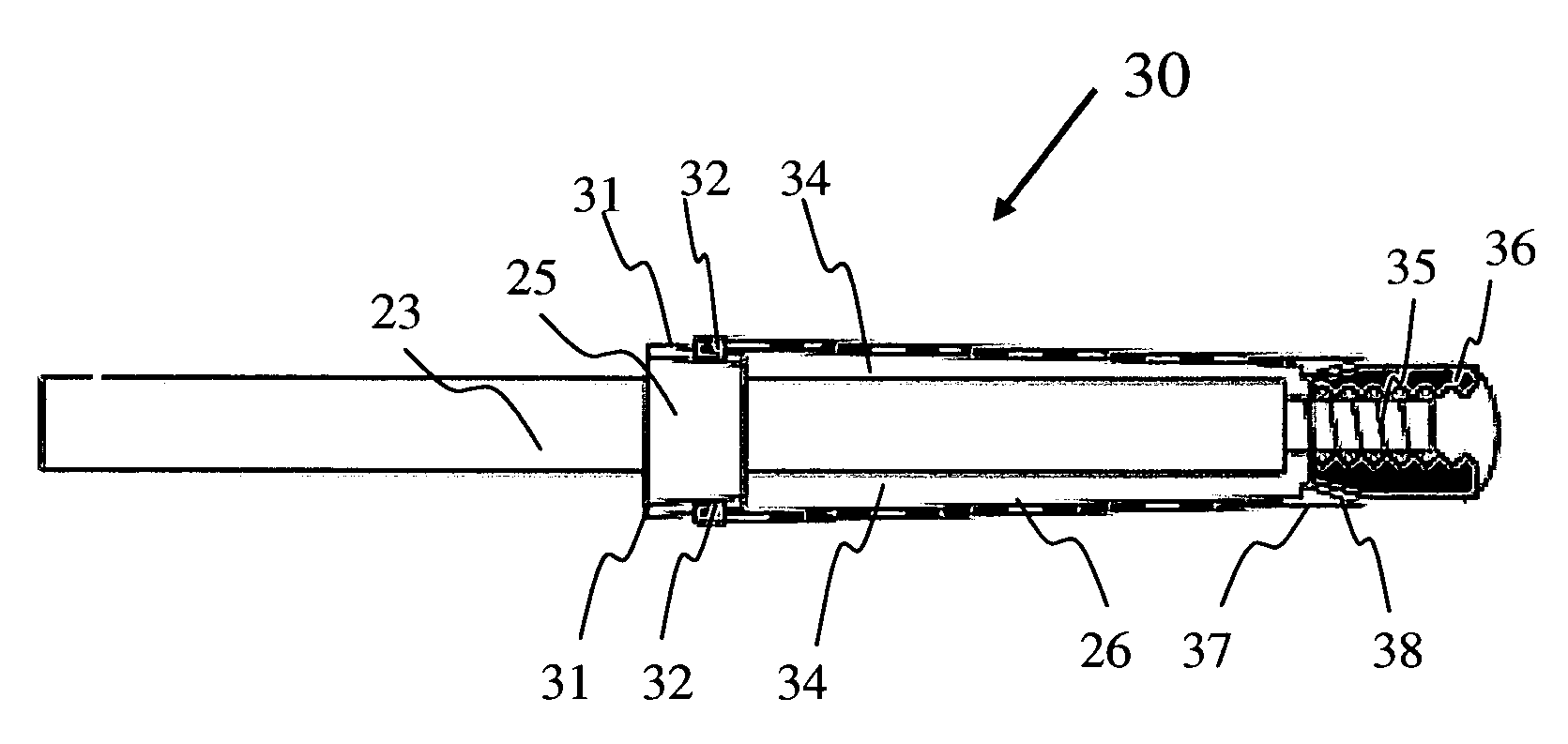

Modular tapered hollow reamer for medical applications

An easy-to-assemble reamer for medical applications includes a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The tapered hollow reamer sleeve has integrally attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft distal end engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable, wobble free, reaming torque in a highly efficient manner.

Owner:LRS SCI & TECH LLC

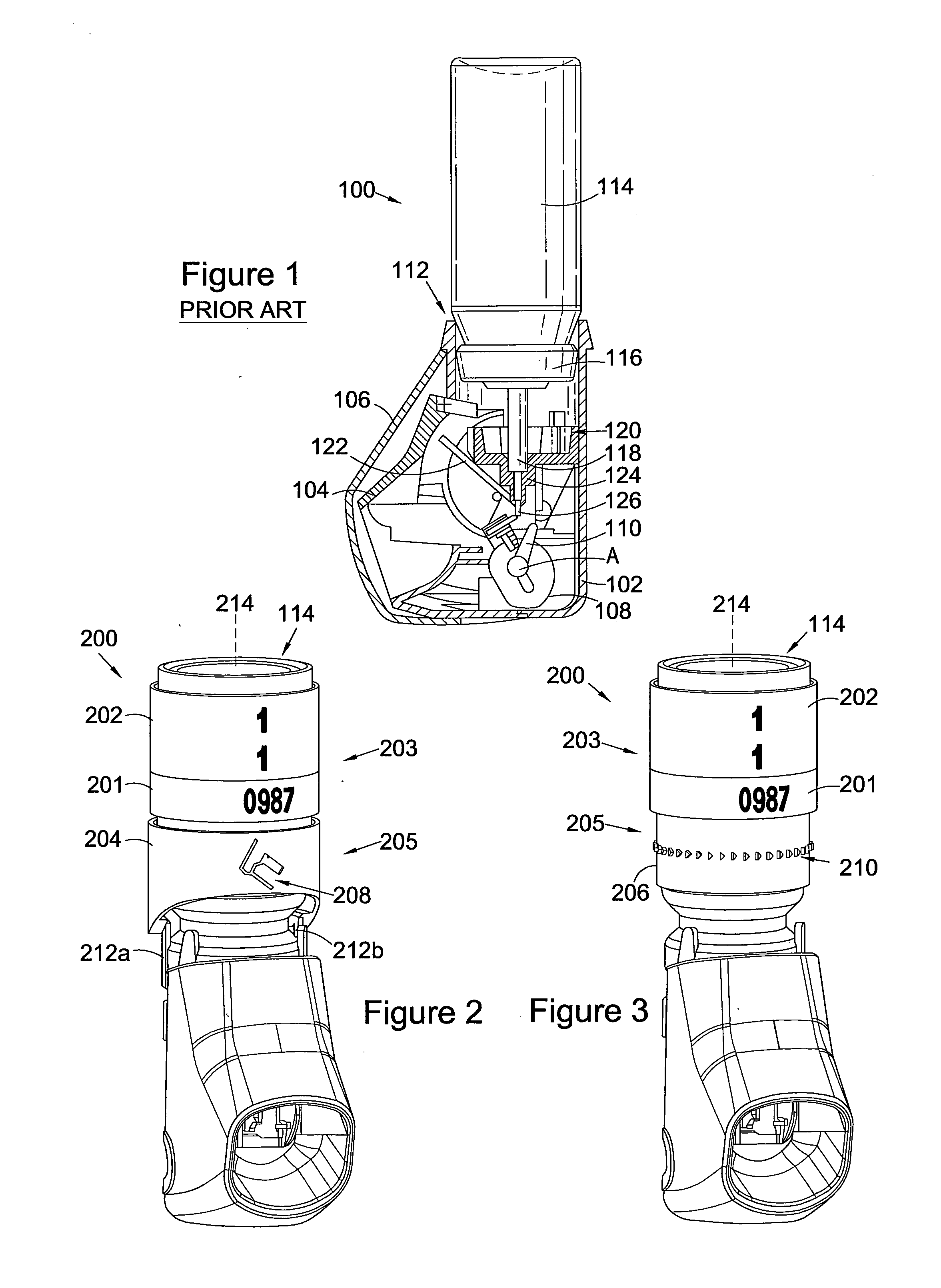

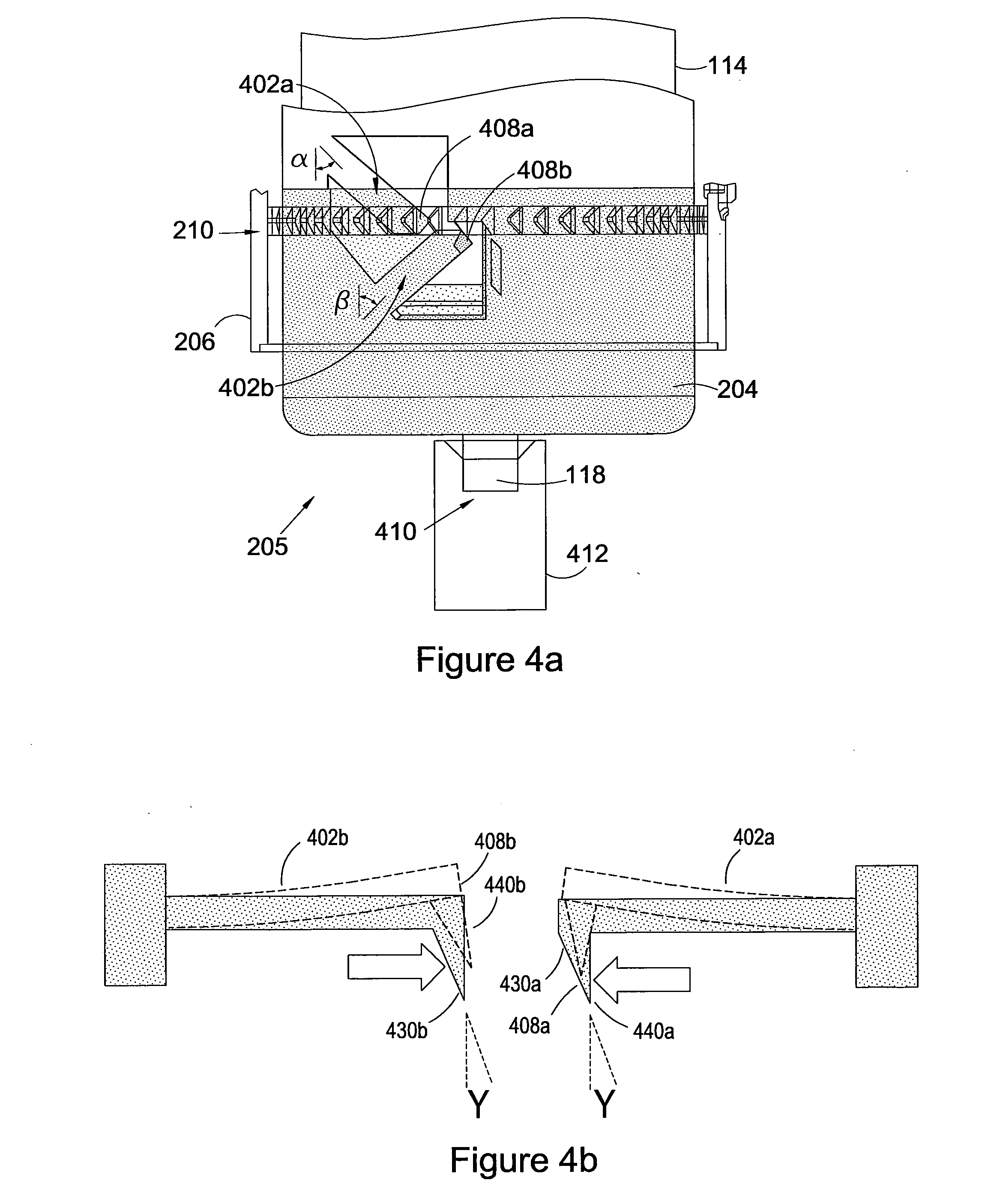

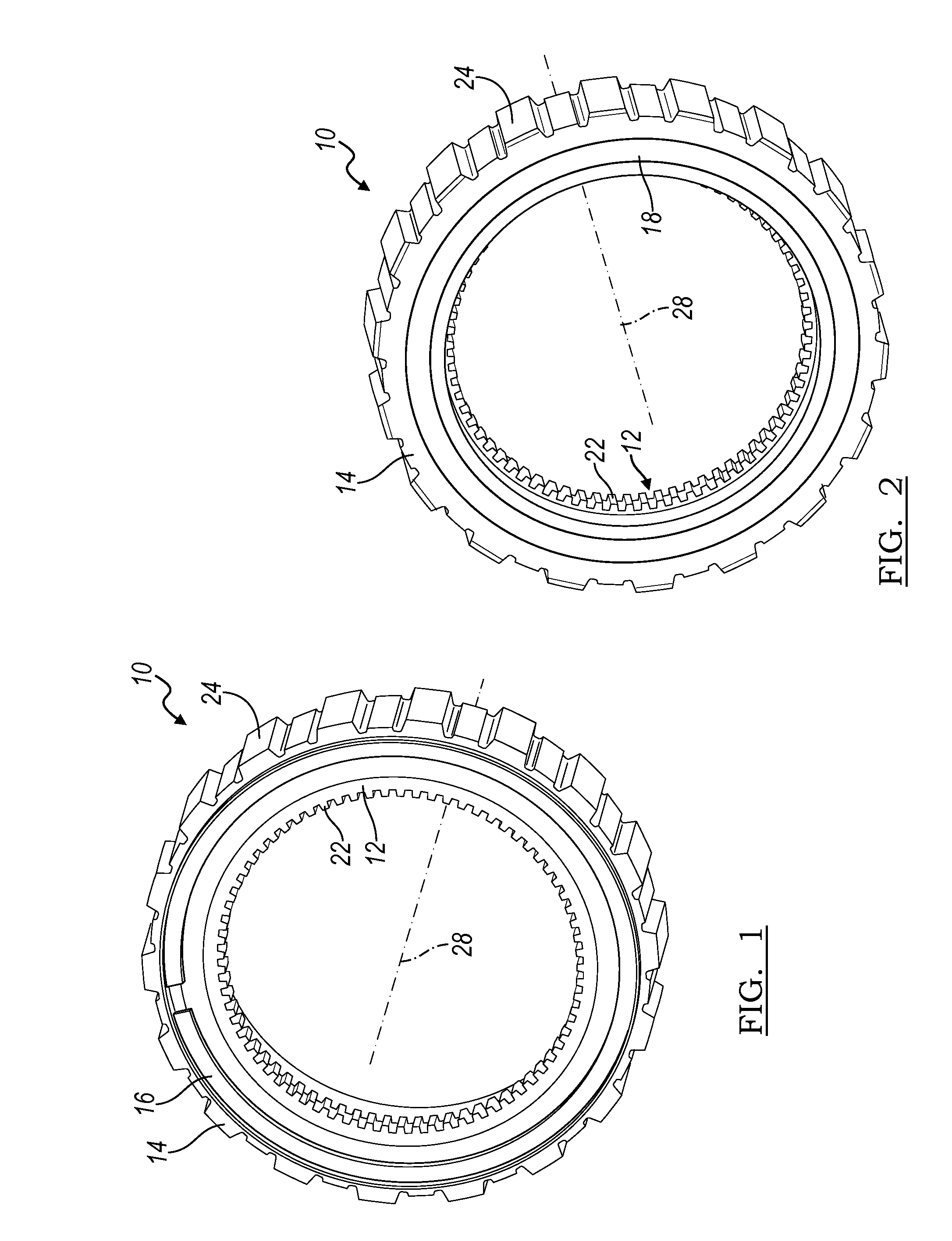

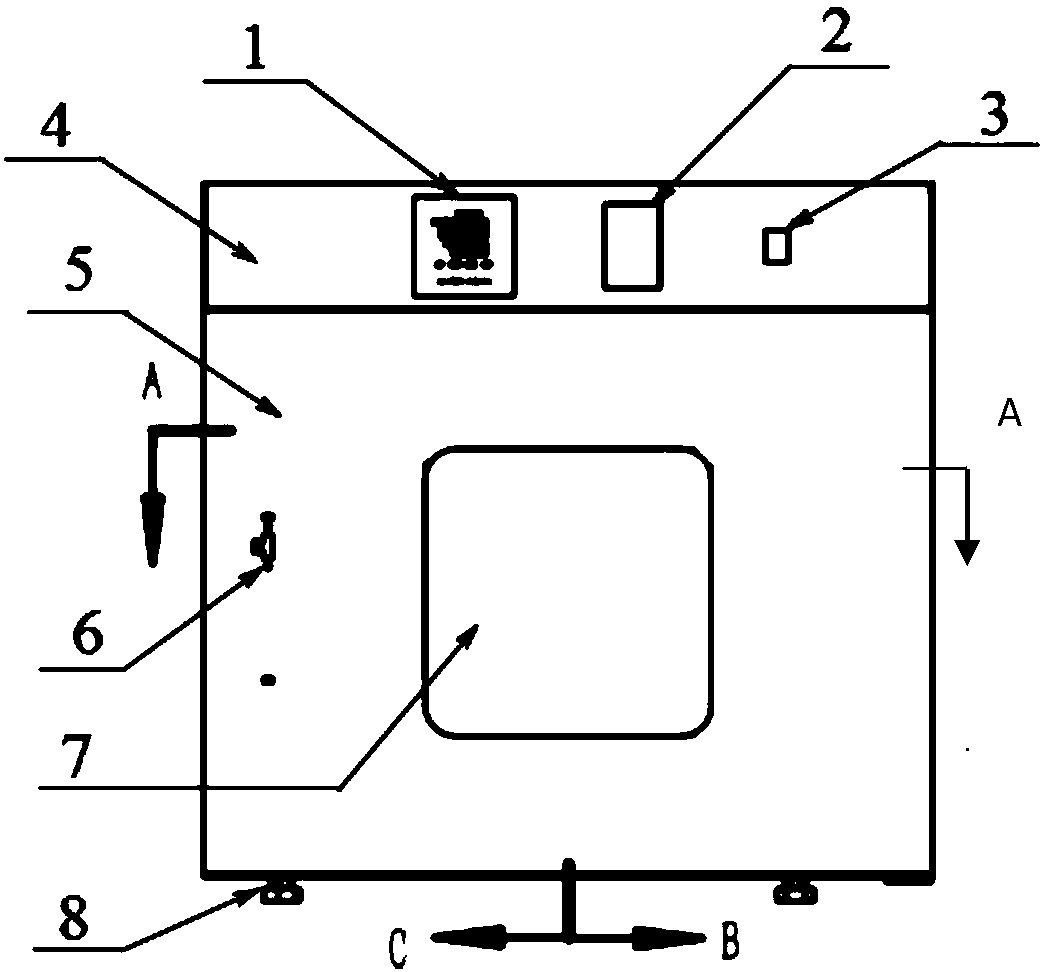

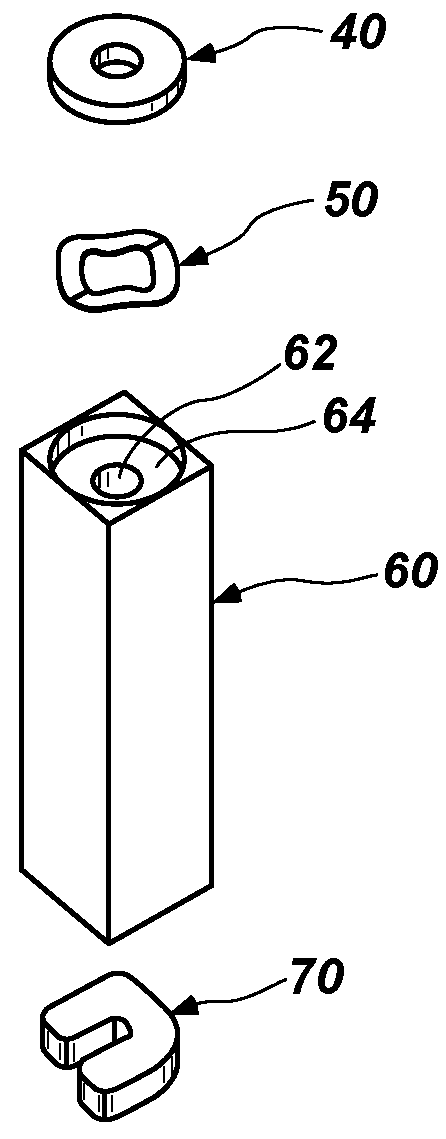

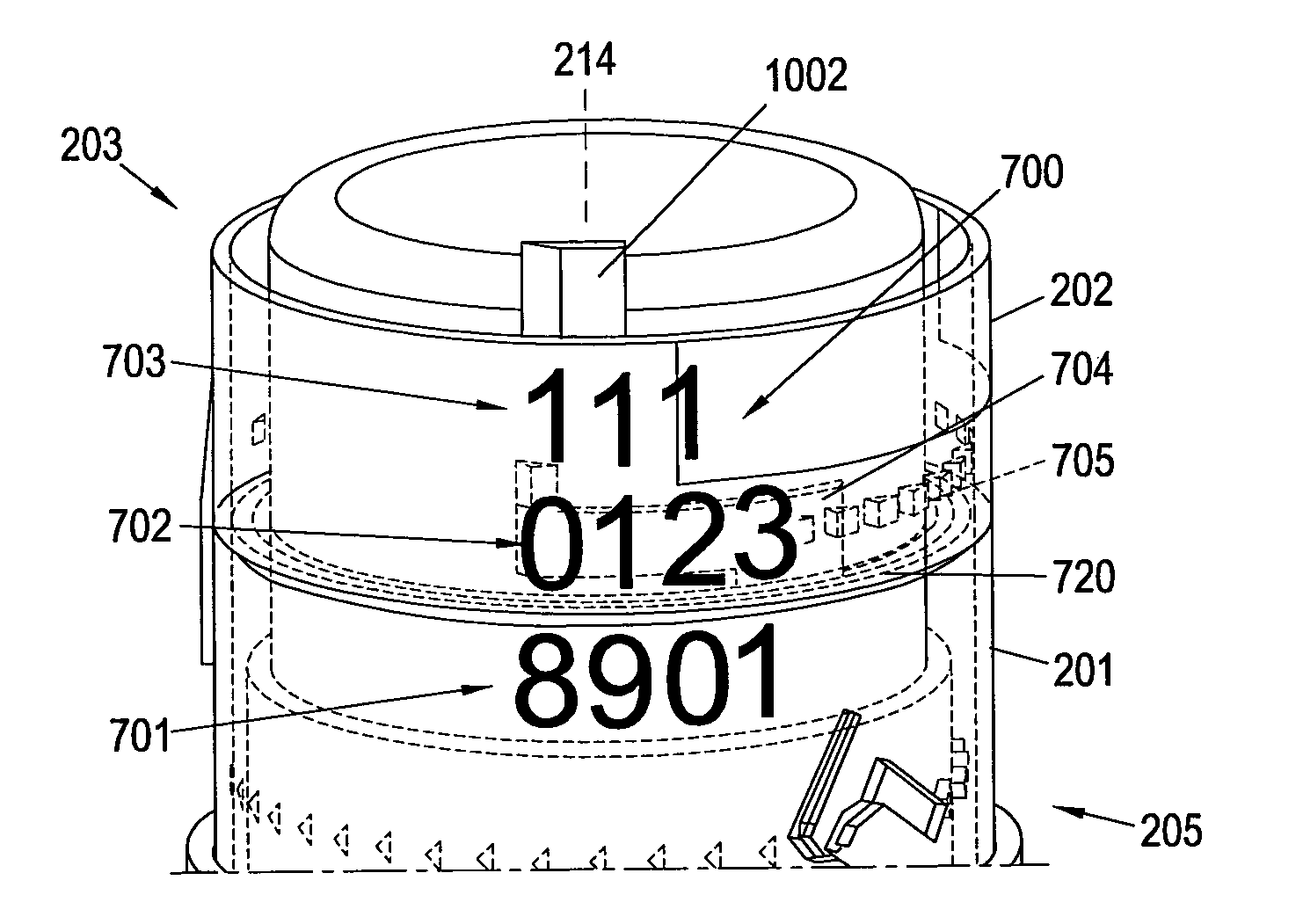

Counter

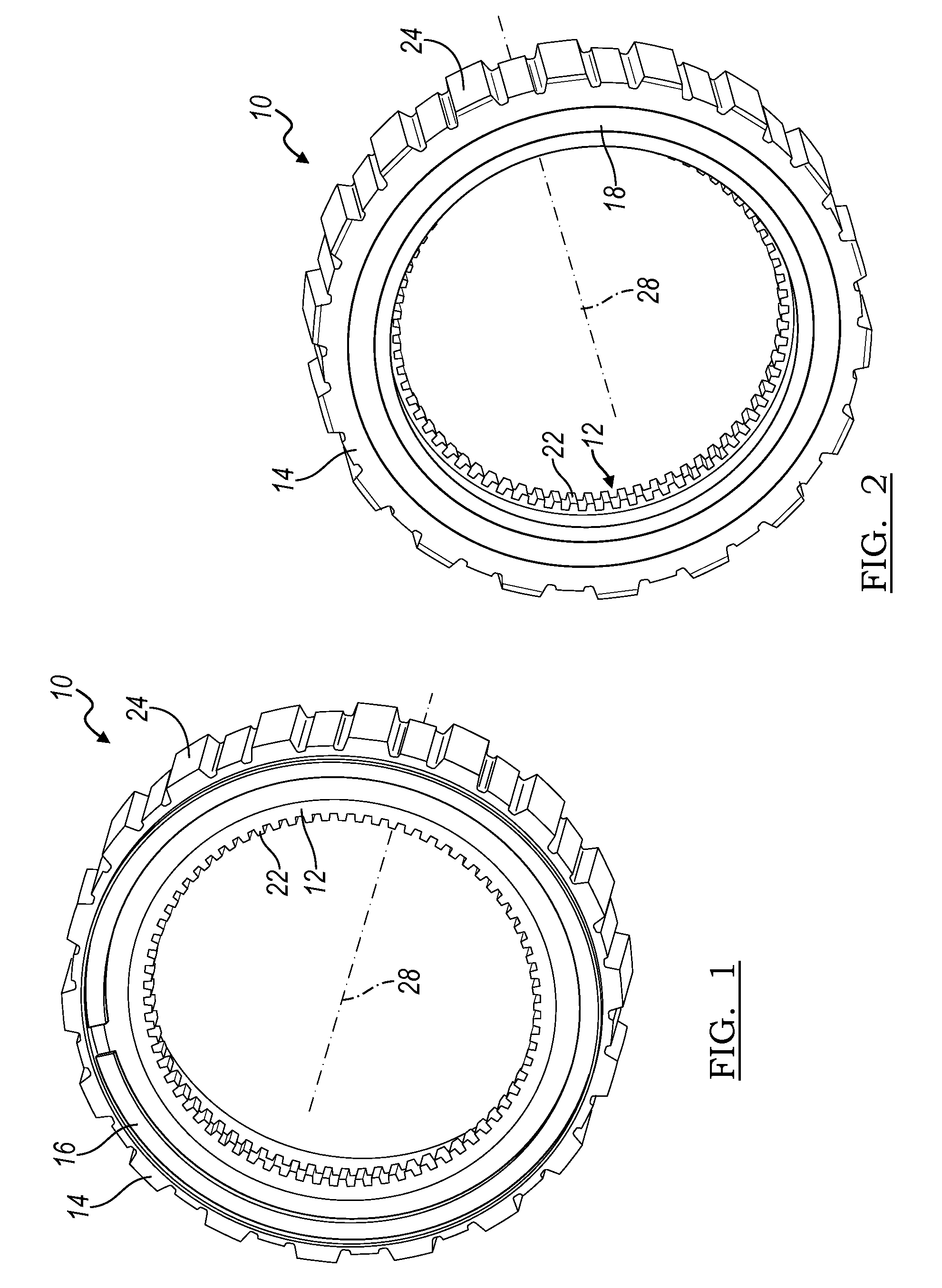

ActiveUS20120111323A1Prevent rotationAvoid excessive rotationRespiratorsCounting mechanisms/objectsMechanical engineeringEngineering

A counter comprising: a first ring member having first indicia and a second ring member having second indicia, each of said first and second ring members being rotatable in increments about a common axis, one or both of said first and second indicia indicating a count; a drive mechanism for rotating said first ring member; and a coupling mechanism for releasably coupling said first ring member to said second ring member, to allow said first and second ring members to rotate cooperatively when coupled and to allow independent rotating of said first ring member when not coupled; wherein said coupling mechanism comprises first and second engagement means, said first engagement means being movable radially outwardly and radially inwardly relative to said axis.

Owner:EURO-CELTIQUE SA

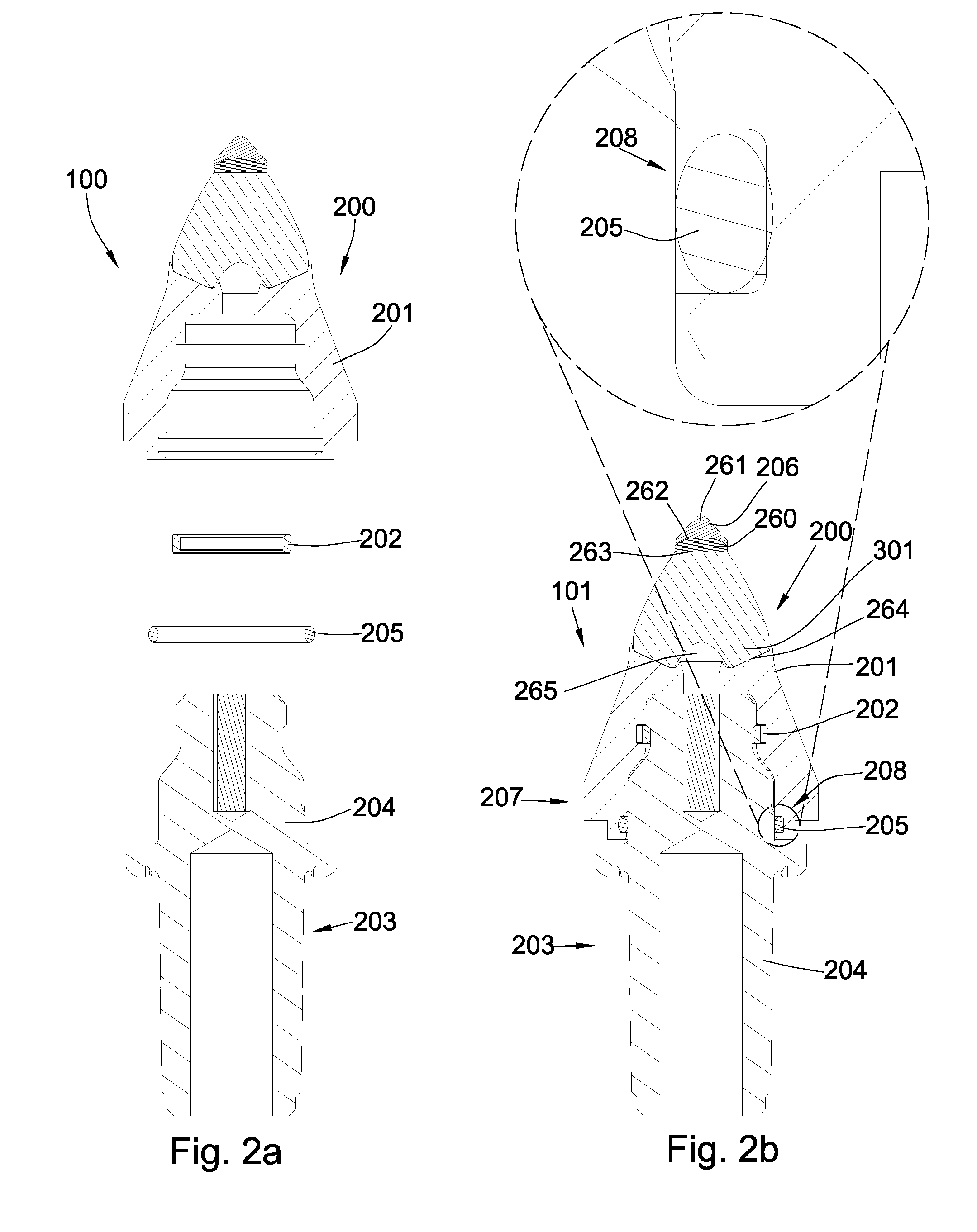

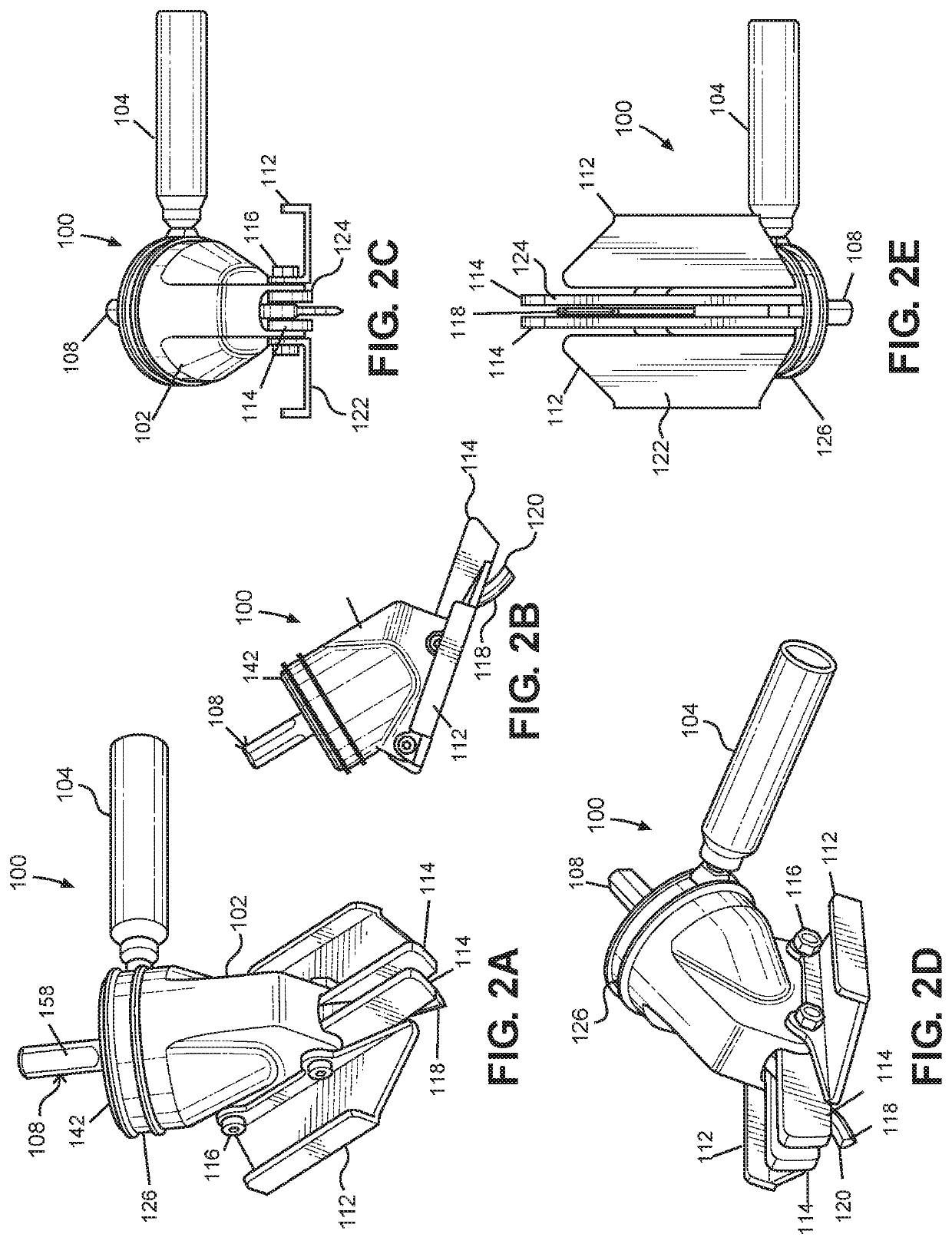

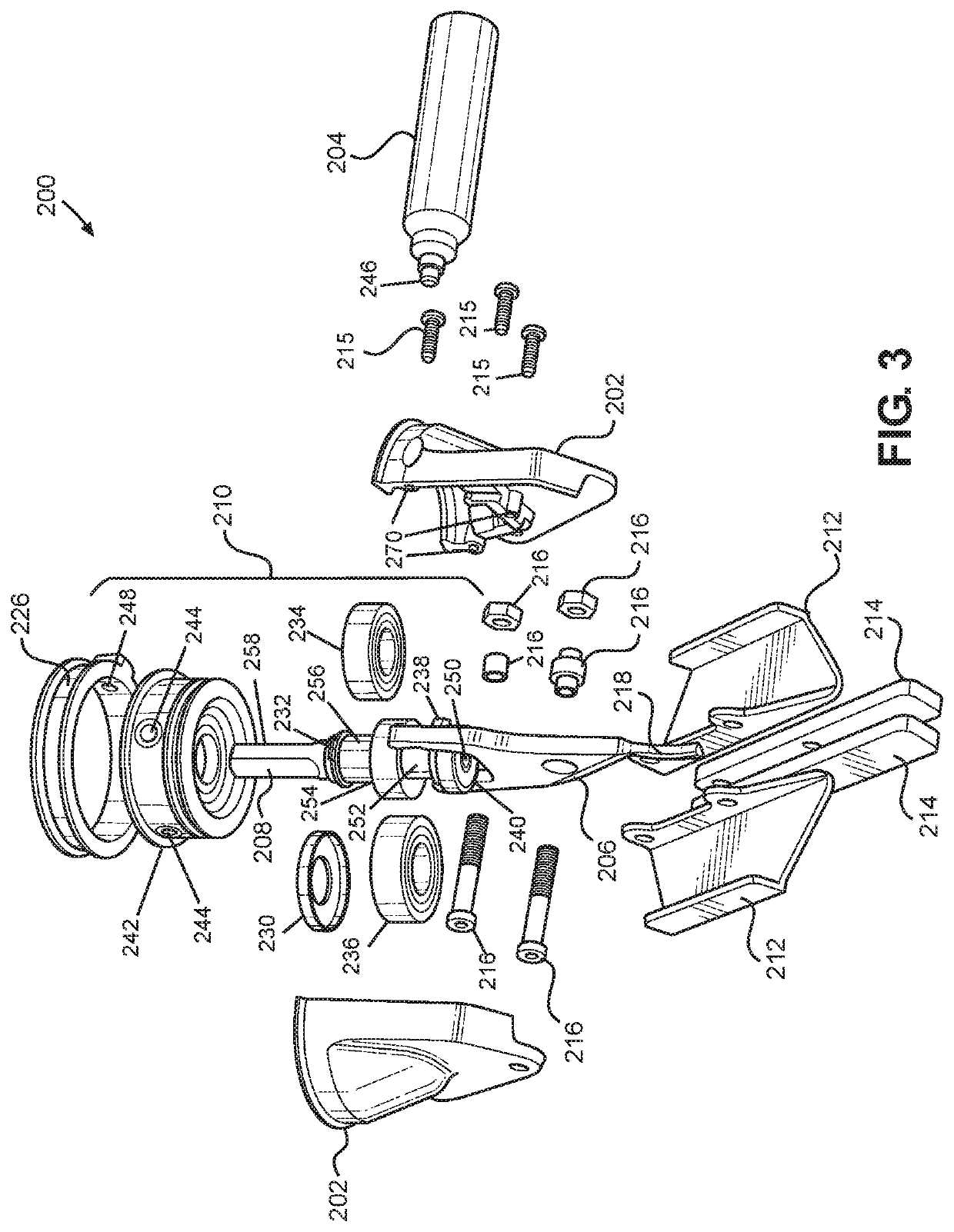

Manually Rotatable Tool

InactiveUS20090200855A1Limit such free rotationPrevent free rotationDisloding machinesUnderground miningFree rotationEngineering

In one aspect of the present invention, a tool assembly comprises a rotary portion and a stationary portion. The rotary portion comprises a bolster bonded to a diamond symmetric, substantially conically shaped tip. The stationary portion comprises a block mounted to a driving mechanism. A compressible element is disposed intermediate and in mechanical contact with both the rotary and stationary portions. The compressible element is compressed sufficiently to restrict free rotation during a degradation operation.

Owner:SCHLUMBERGER TECH CORP

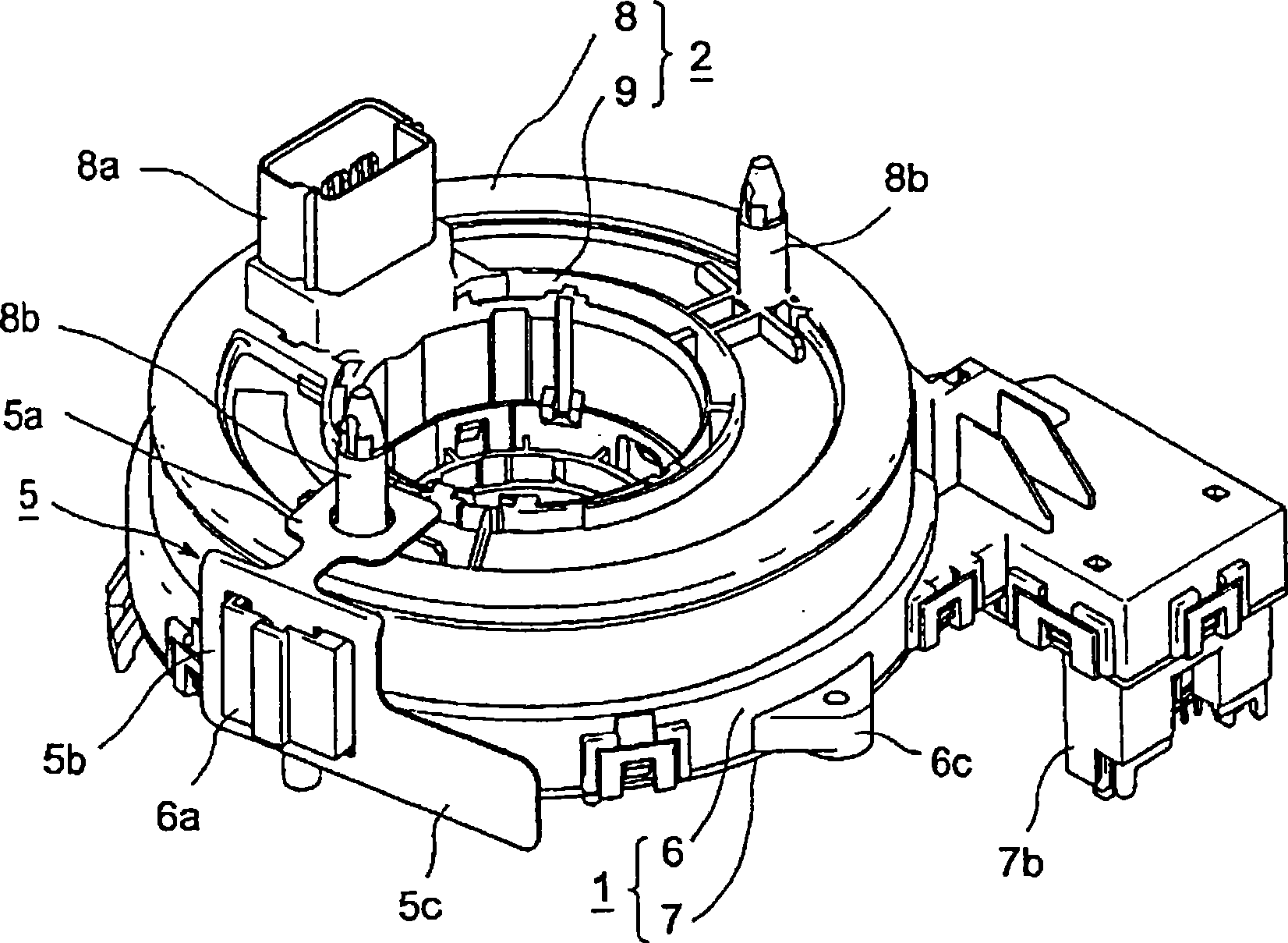

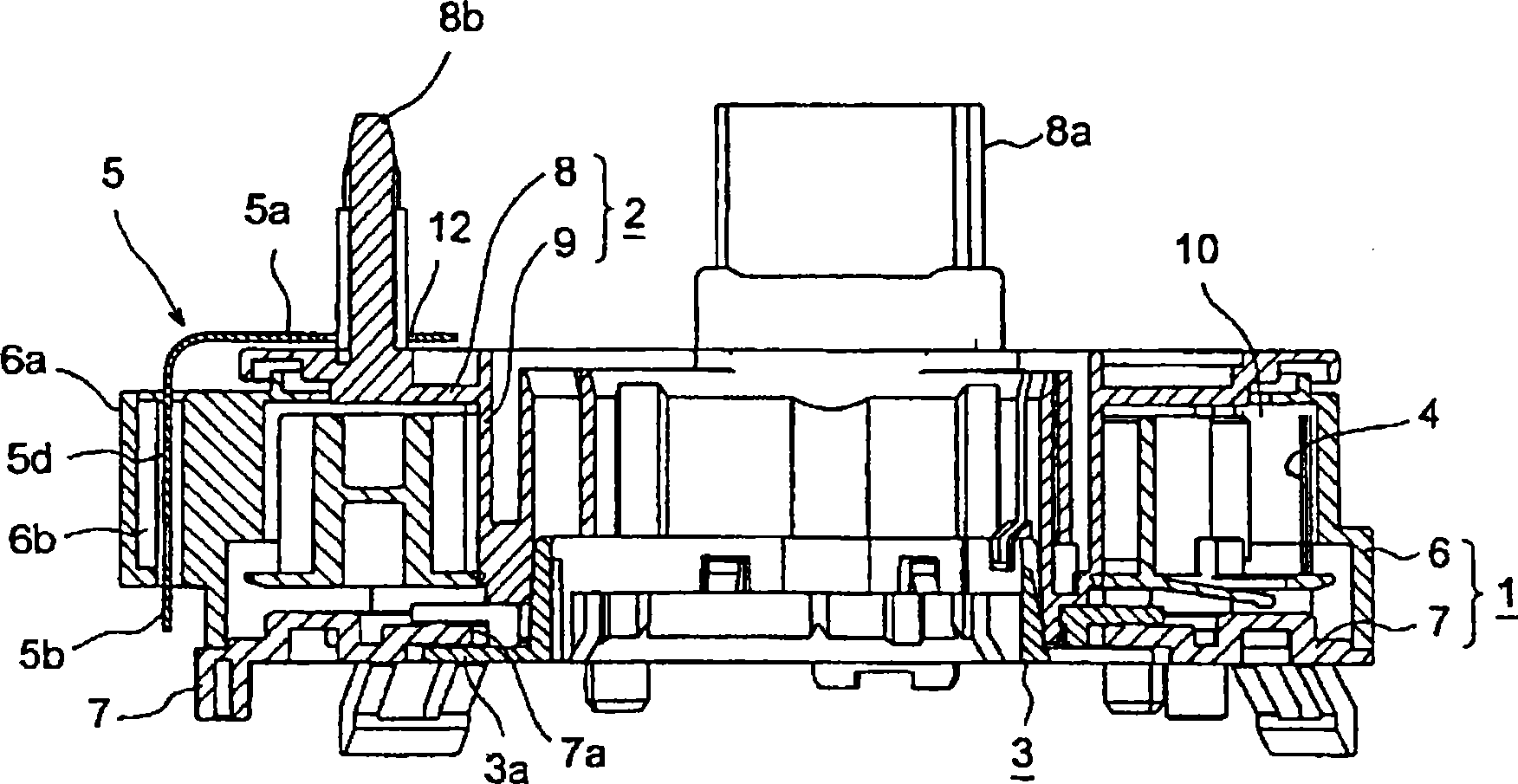

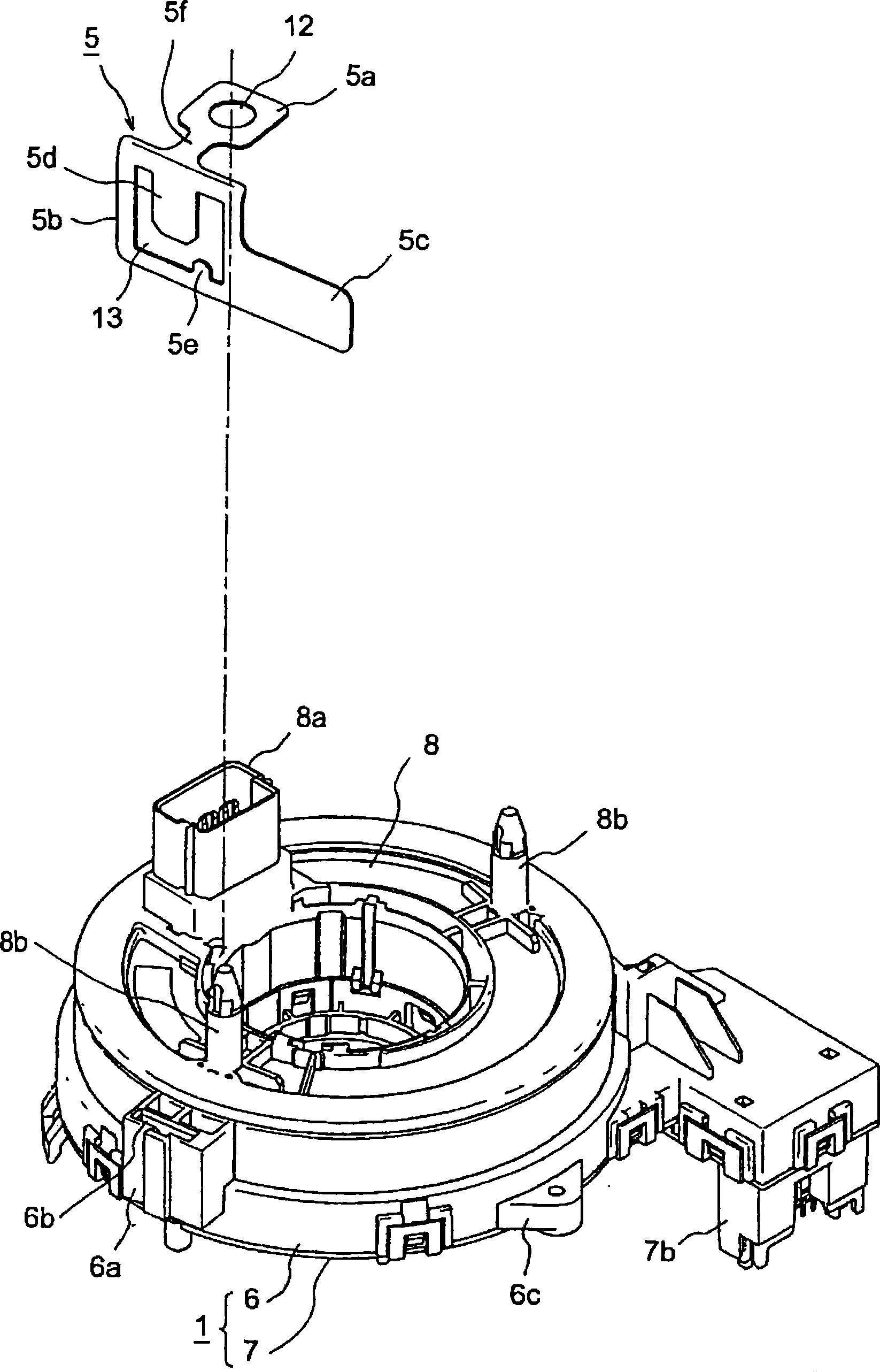

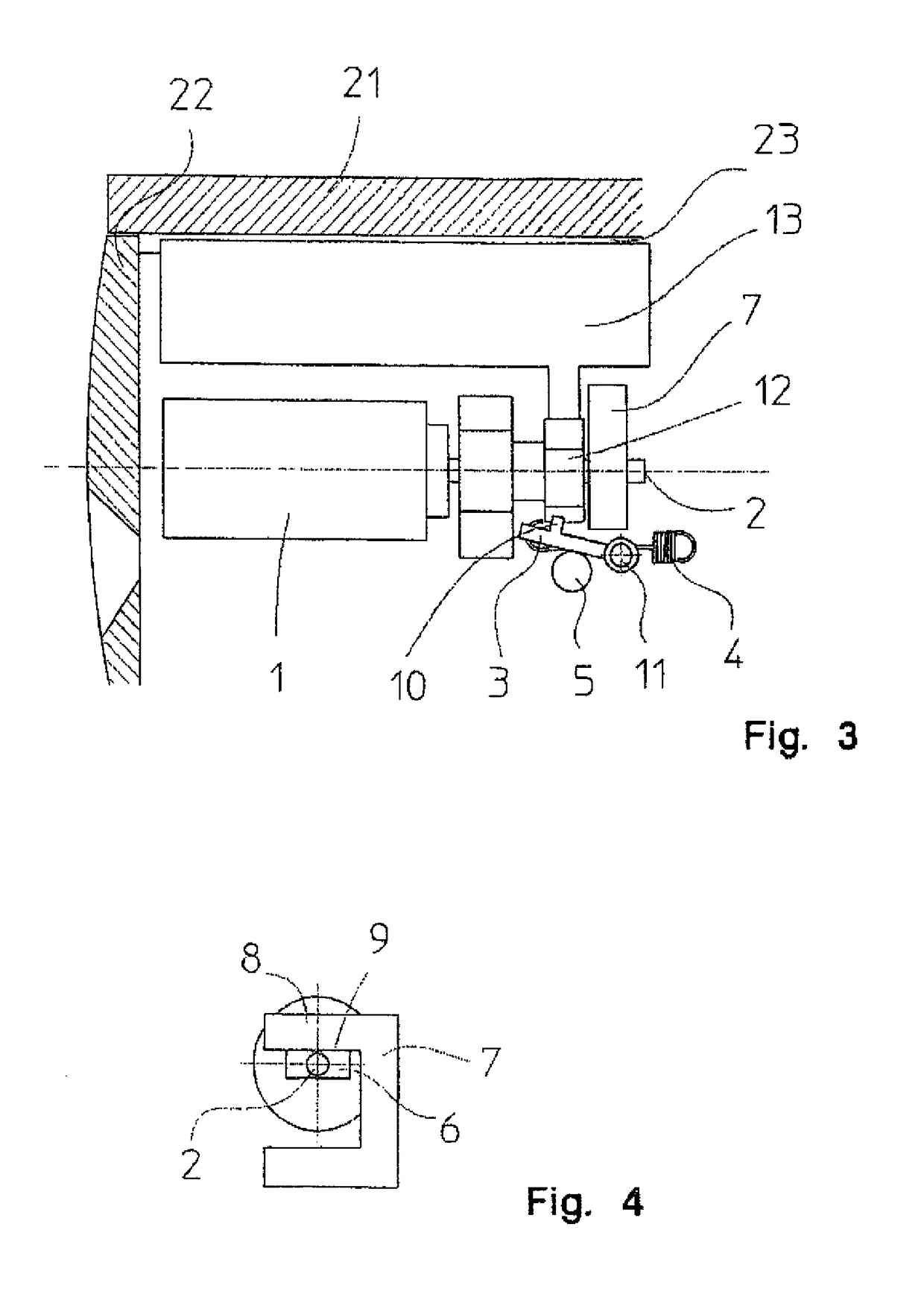

Rotary connector

InactiveCN101399423AEasy to lockPrevent free rotationElectric/fluid circuitFlexible/turnable line connectorsFree rotationEngineering

The present invention provides a rotation connector which can simply hold a rotor component at a rotation neutrality position with a fixing component that is detachably mounted in the period between assembling finishing and executing various examinations to the rotation connector. The fixing component (5) which is formed by PET film, etc. is integratedly formed with a first clamping part and a second clamping part (5a) and (5b). An insertion hole (12) which is formed on the second clamping part (5a) is inserted with a clamping column (8b) which is vertically installed on a top plate part (8) of rotor casing (2). A clamping projection (6a) which is provided on an outer cylinder part (6) of stator casing (1) with a projection mode is formed with a clamping hole (13) that is formed on the second clamping part (5b) through an external embedding mode. Thereby one part of tongues (5d) and (5e) which are formed on the second clamping part (5b) are inserted in the clearance (6b) of clamping projection (6a) from the upper direction and the lower direction. Therefore the free rotation of the rotor casing (2) relatively to the stator casing (1) is prevented and the rotation neutrality positon of rotation connector can be simply held in the period between assembling finishing and executing various examinations.

Owner:ALPS ALPINE CO LTD

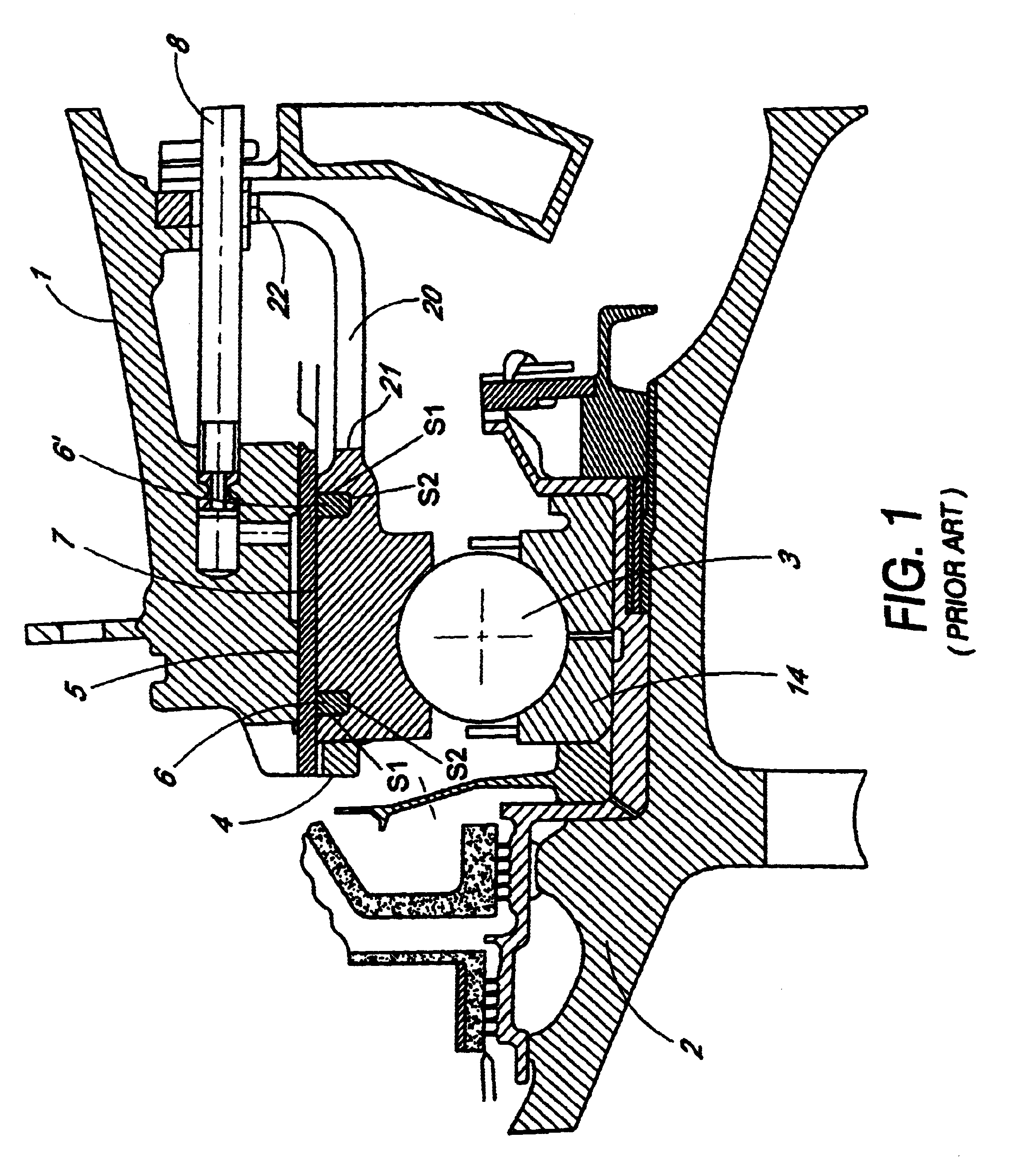

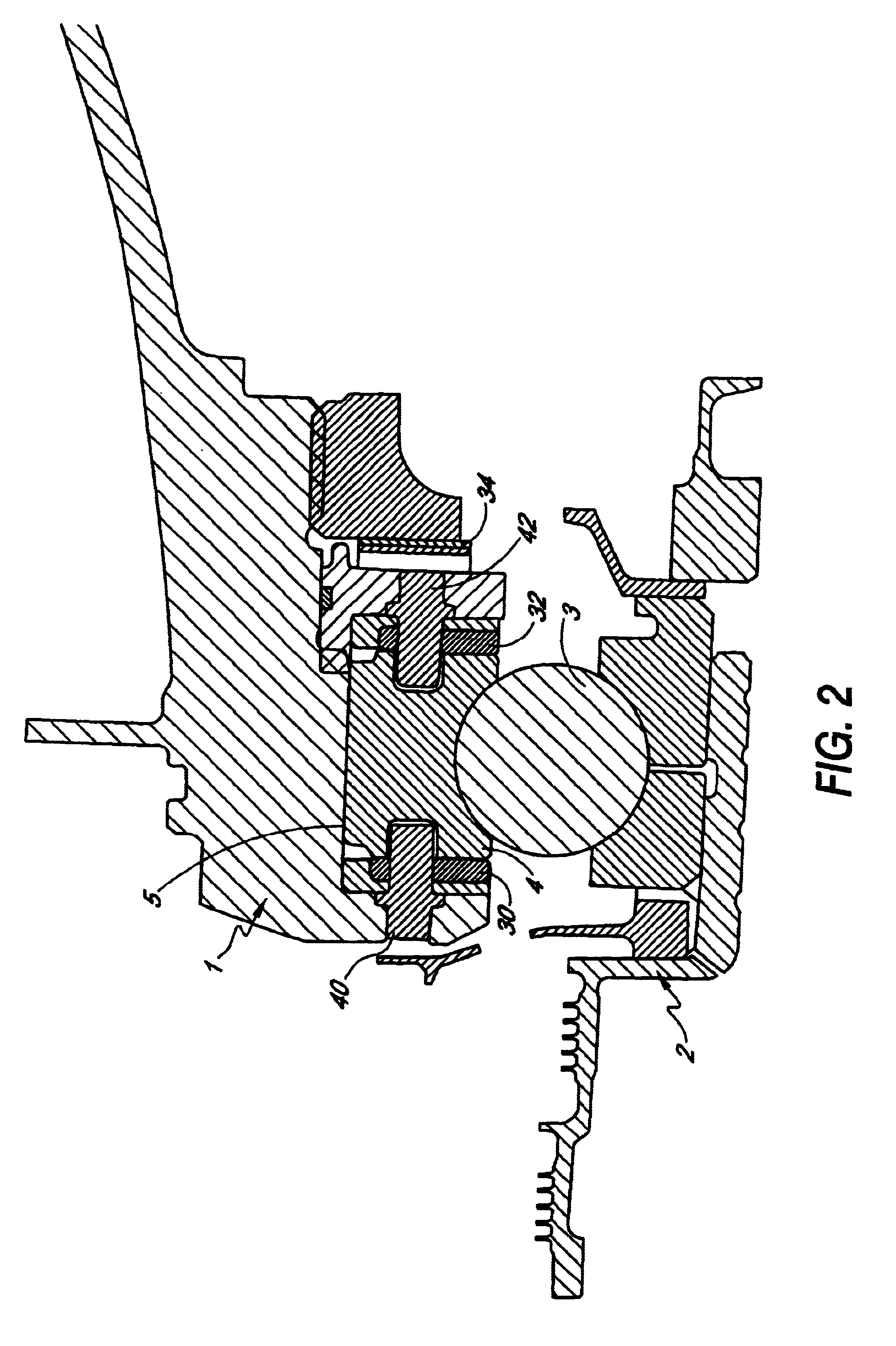

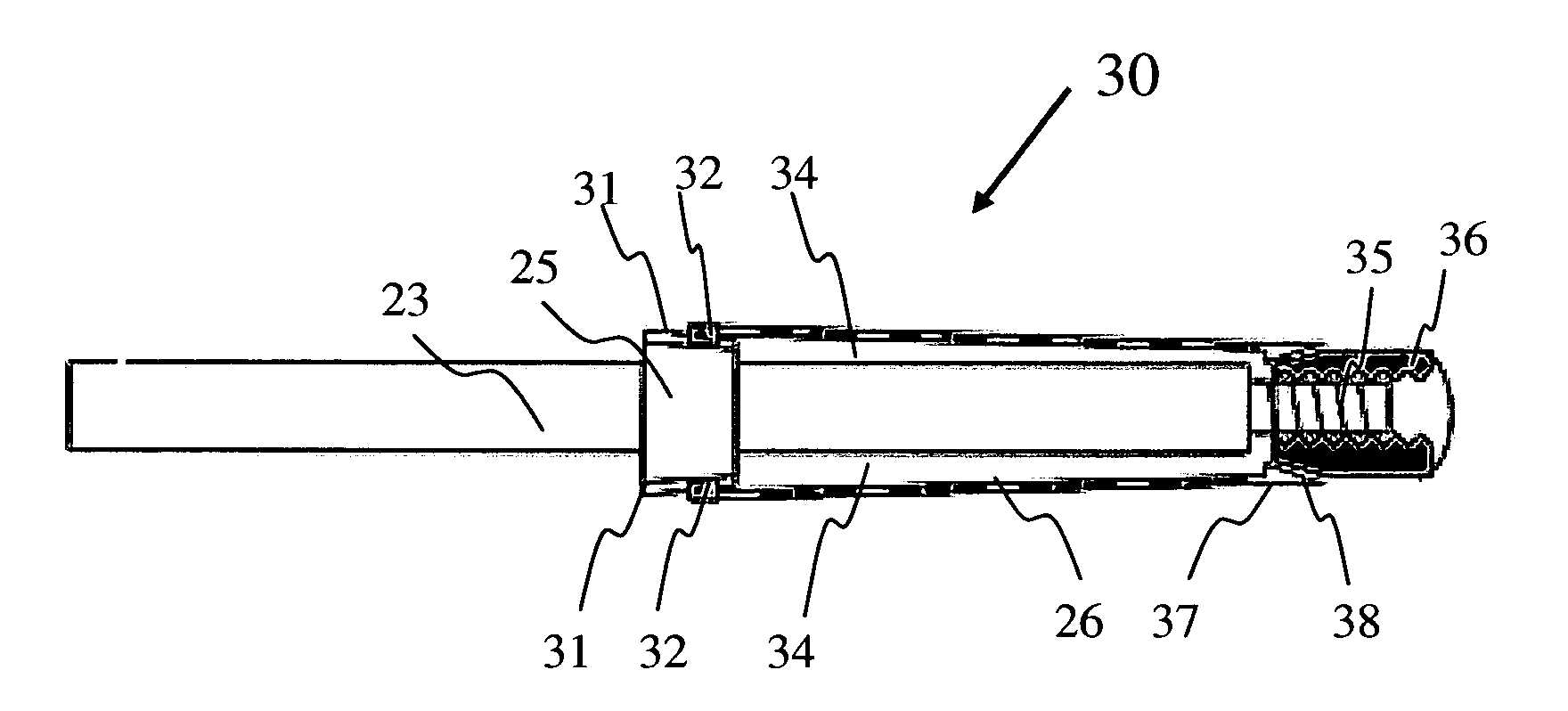

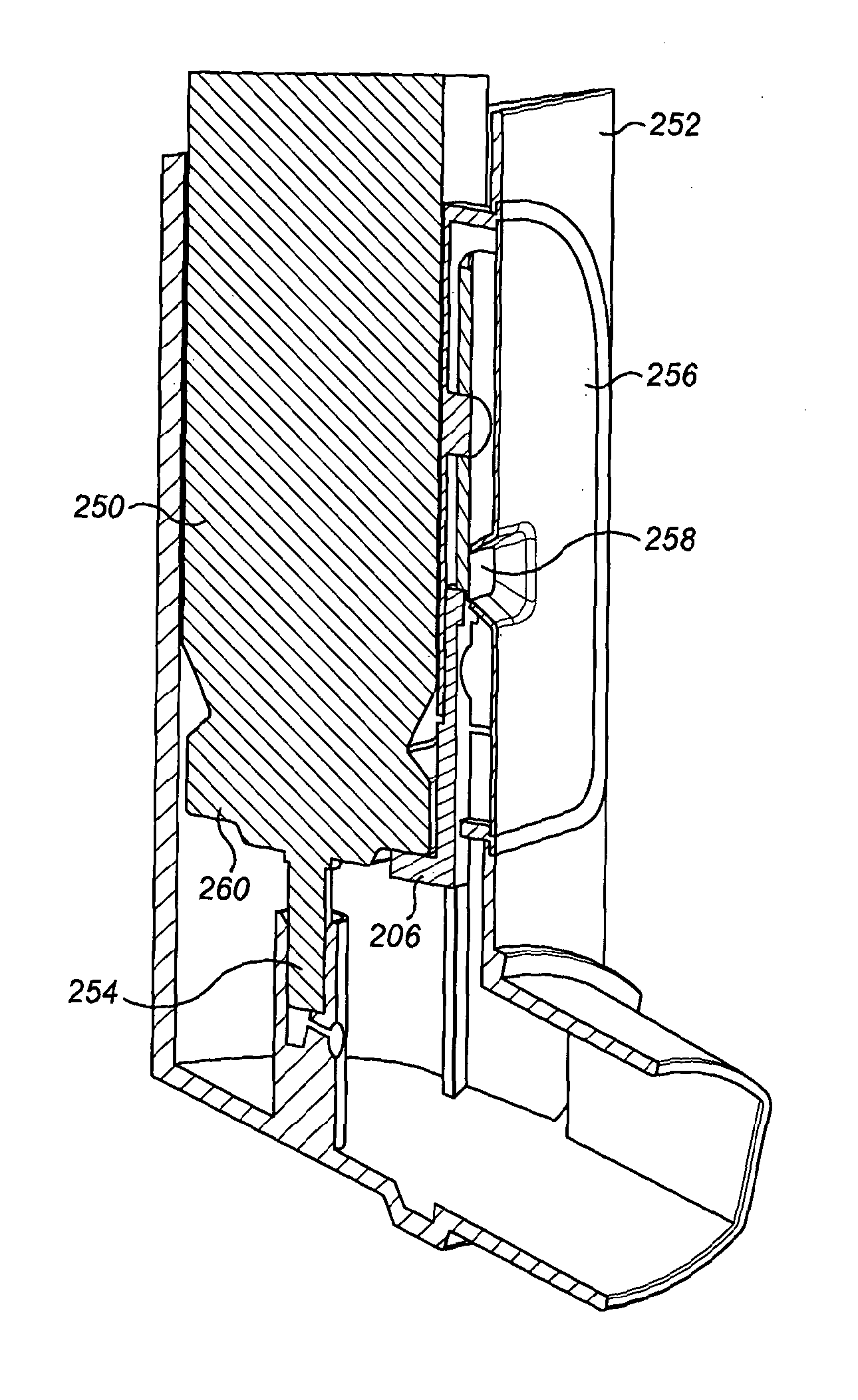

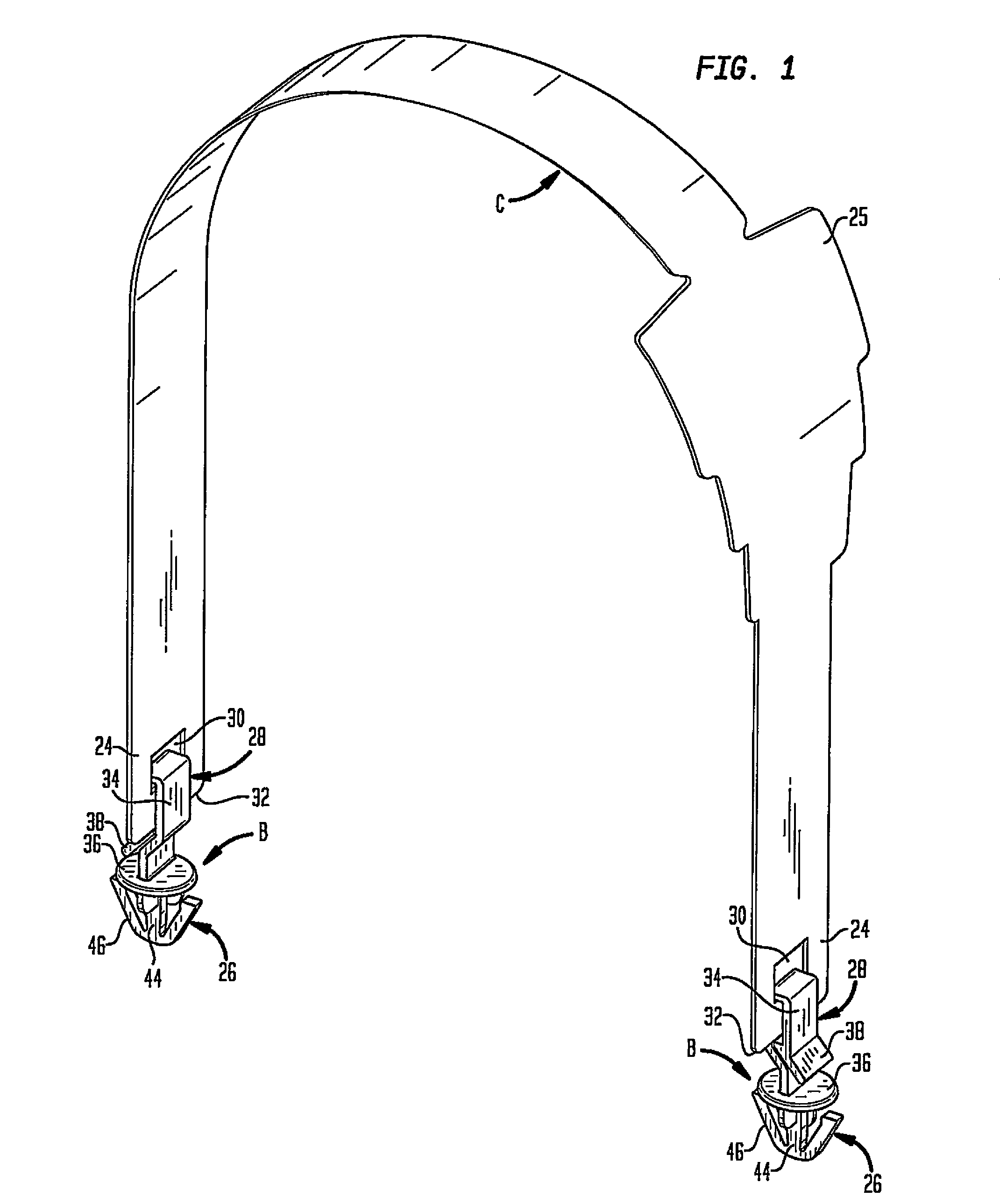

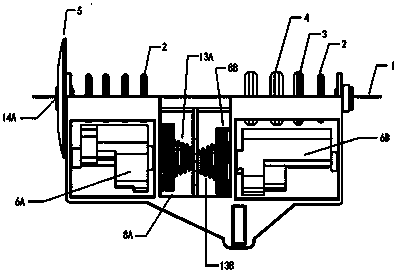

Patient interfaces

The present invention relates to a device for delivering a supply of gases to a patient. The device includes a patient interface and connecting member. The connecting member is preferably a L-shaped swivelled connector that is capable of being fixed into one of two positions, a first position where the connector is freely rotatable within the patient interface, and a second position where an interference between the interface and connector prevents the free rotation of the connector within the patient interface. The present invention further relates to a connector that has outlet means, which includes at least one outlet vent and a funnel, which in use directs and passes a substantial portion gases expired from the patient through the outlet vent or vents.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Magnetically Actuated Mechanical Diode

ActiveUS20120103746A1Prevent free rotationMagnetically actuated clutchesFriction clutchesPower flowEngineering

A one-way diode includes a first plate including a coil and cams distributed about an axis, a second plate axially facing the cams and including pockets and a second coil, and struts, each strut supported in one of the pockets for pivoting axially relative to the cams in response to an electromagnetic field induced by current in the coil and the second coil.

Owner:FORD GLOBAL TECH LLC

Squeeze film damping type bearing

The present invention is related to a bearing for maintaining an inner mobile structural component with a revolution symmetry, rotating inside an outer structural component, which is itself fixed or mobile, said bearing comprising a set of balls or rollers and at least an outer race which provides the mechanical contact between said balls or rollers and said outer structural component, said bearing also comprising a pressurized-oil damper known as a "squeeze film" damper, arranged at the annular contact surface between said outer race and the outer structural component, characterized in that each side surface of the outer race is in contact with a side seal having an annular form, said seals being securely fastened to the outer race by means of a series of anti-rotation fixing members.

Owner:TECHSPACE AERO

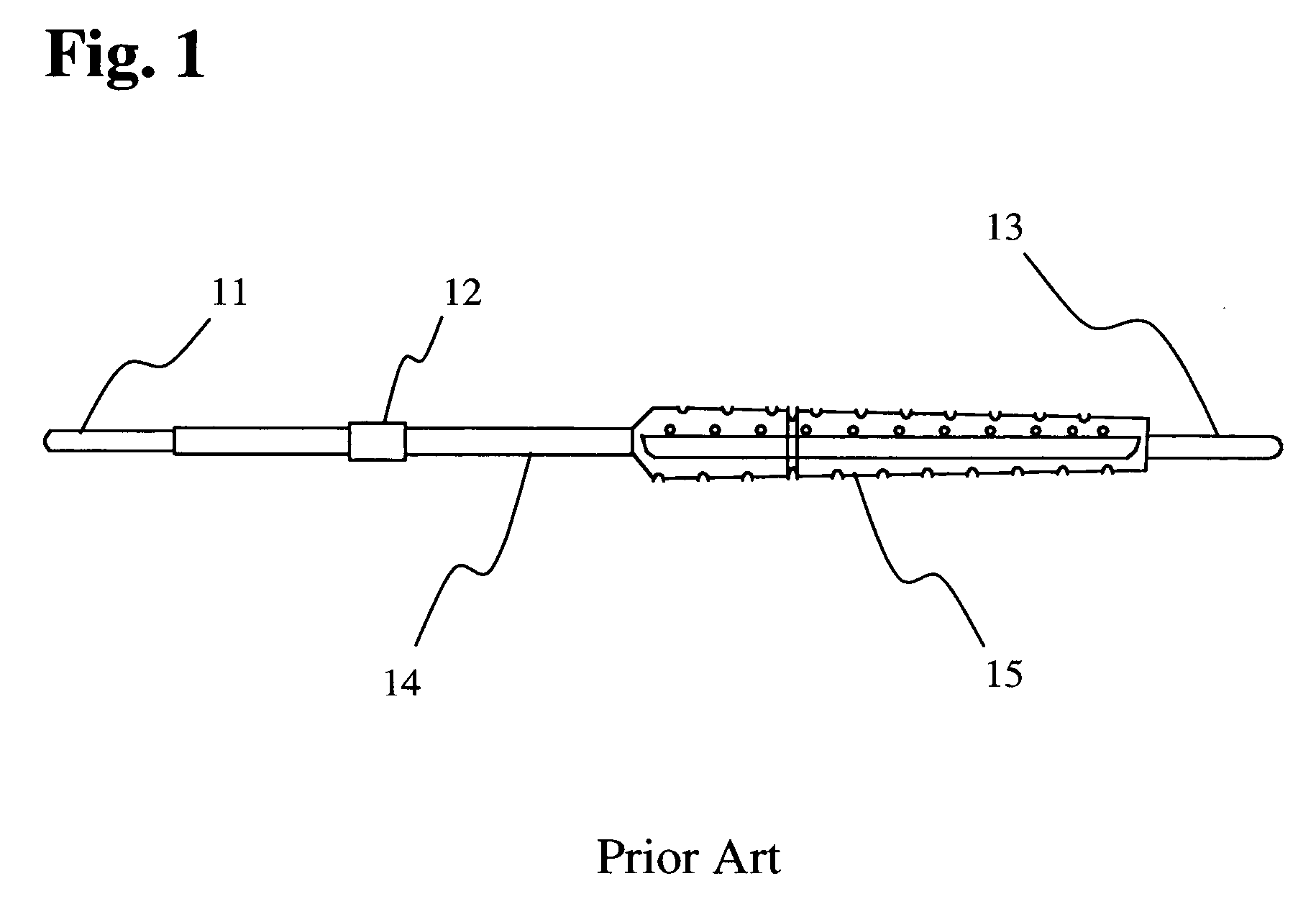

Modular tapered hollow reamer for medical applications

An easy-to-assemble reamer for medical applications includes a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The tapered hollow reamer sleeve has integrally attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft distal end engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable, wobble free, reaming torque in a highly efficient manner.

Owner:LRS SCI & TECH LLC

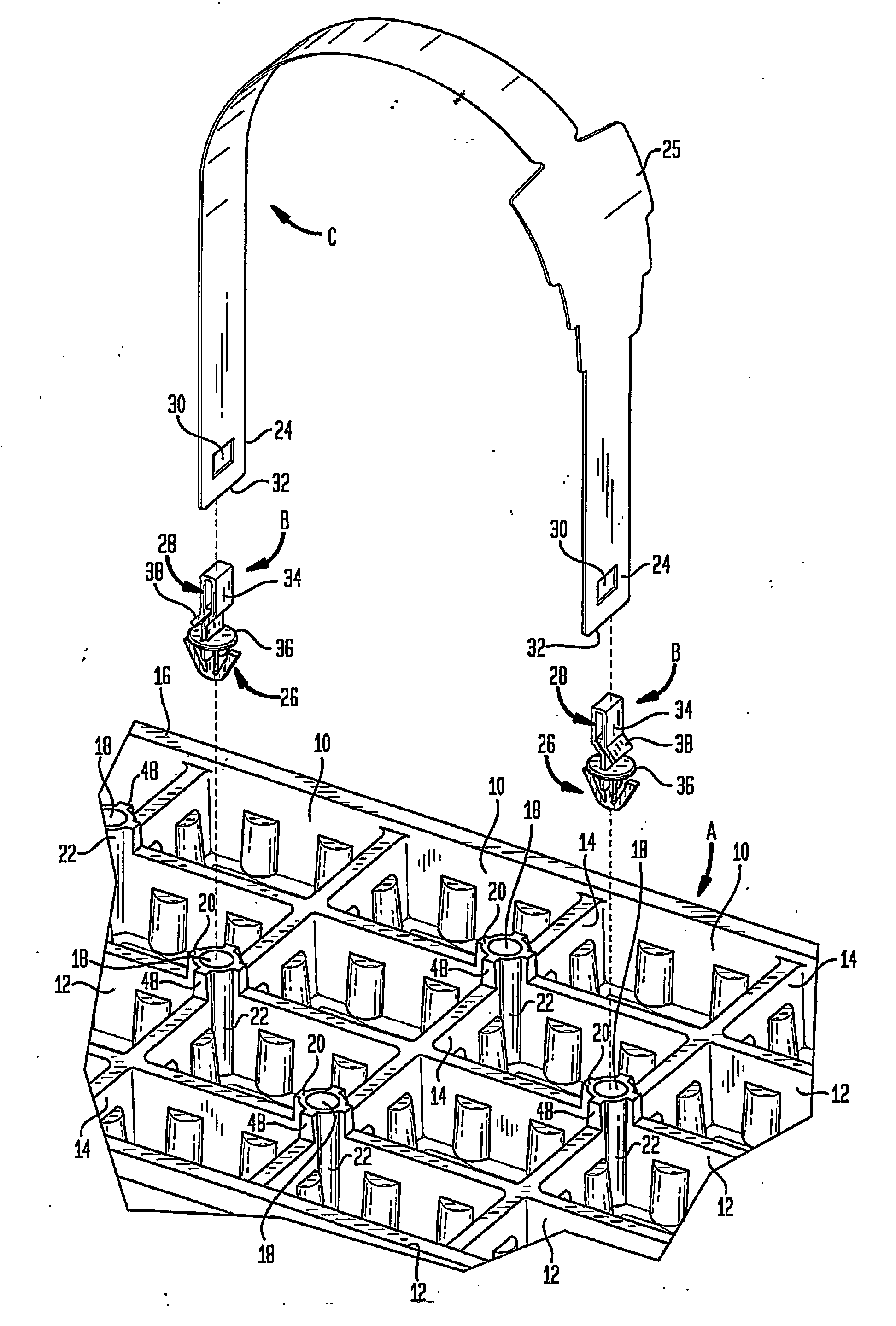

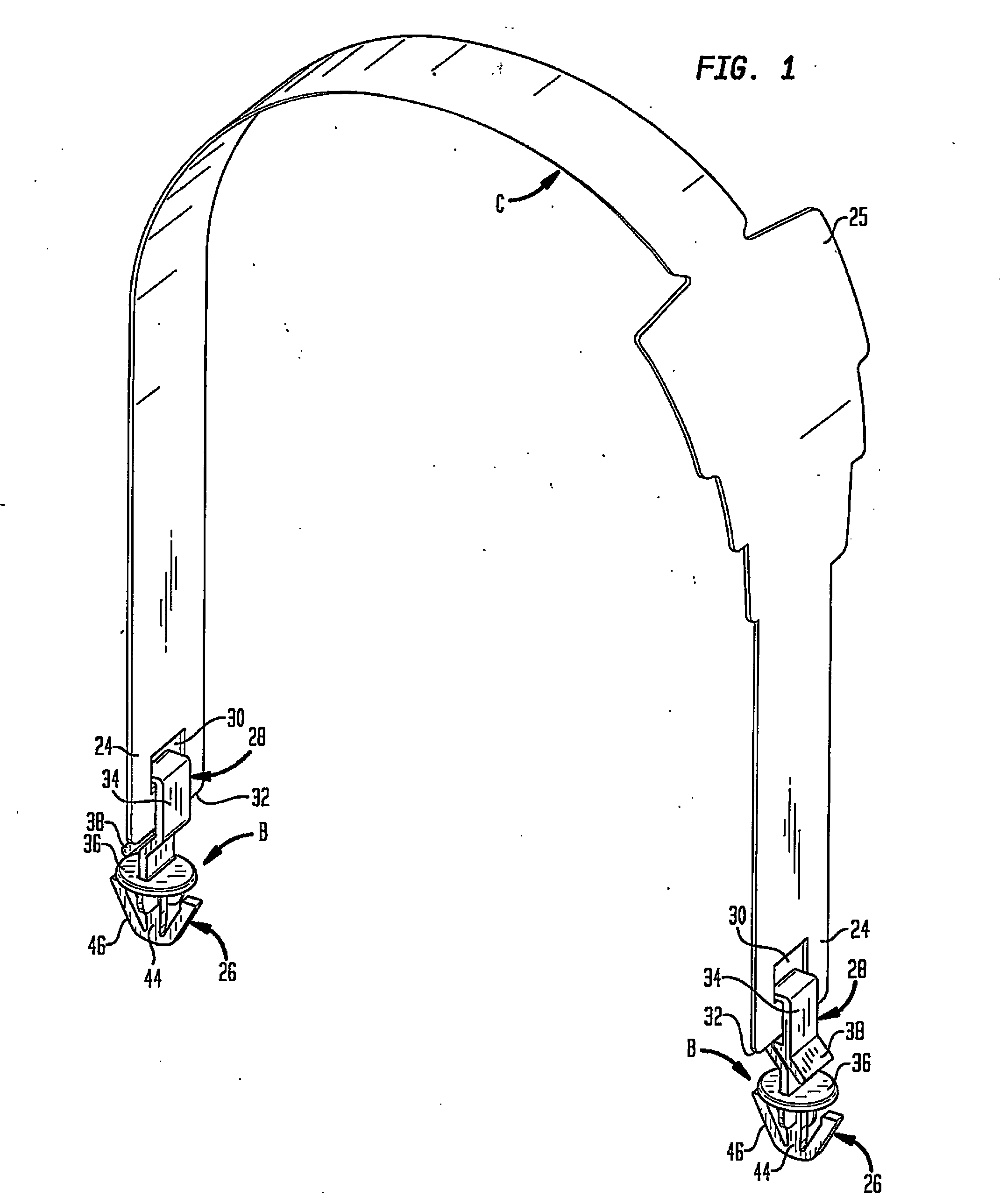

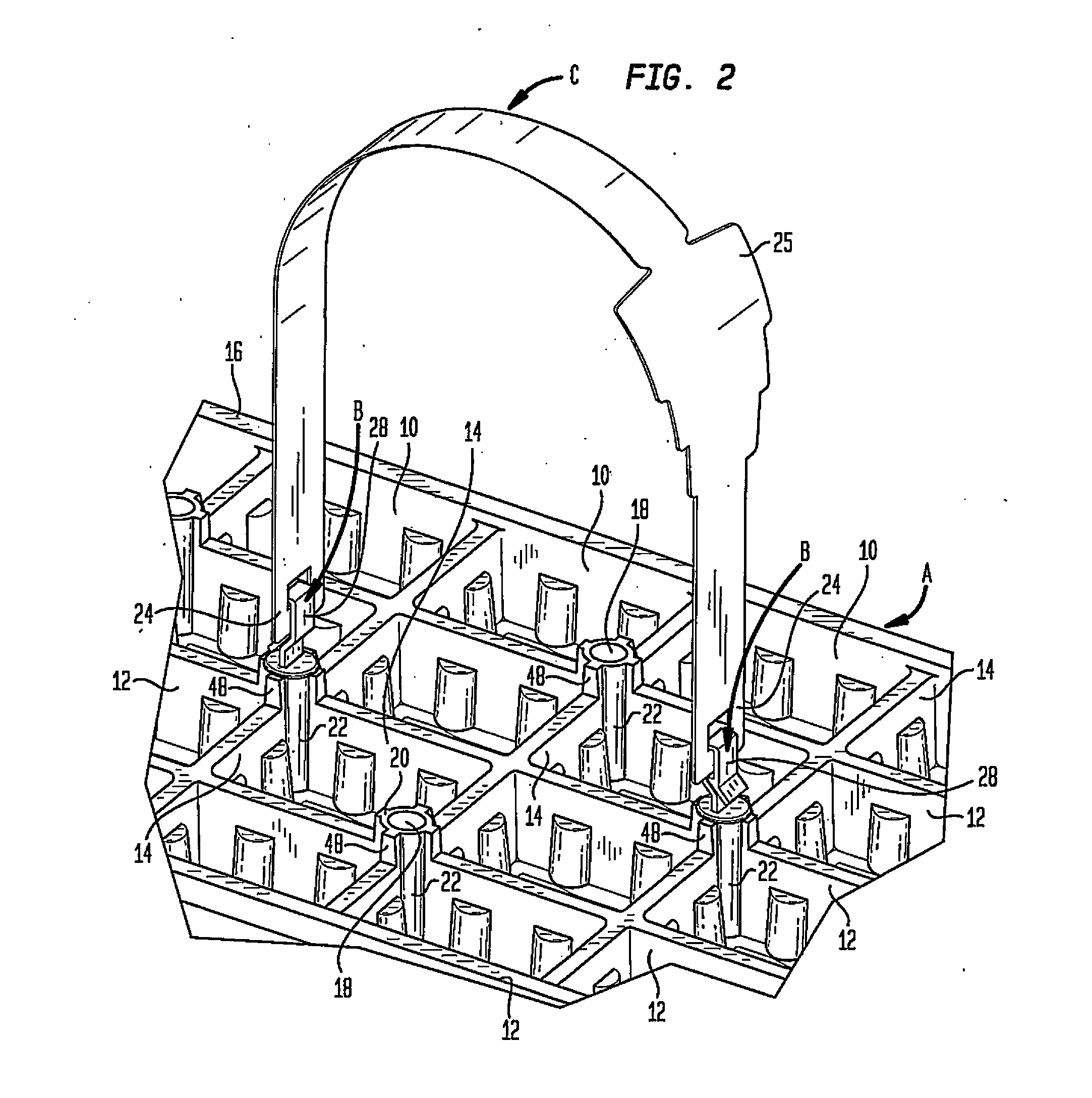

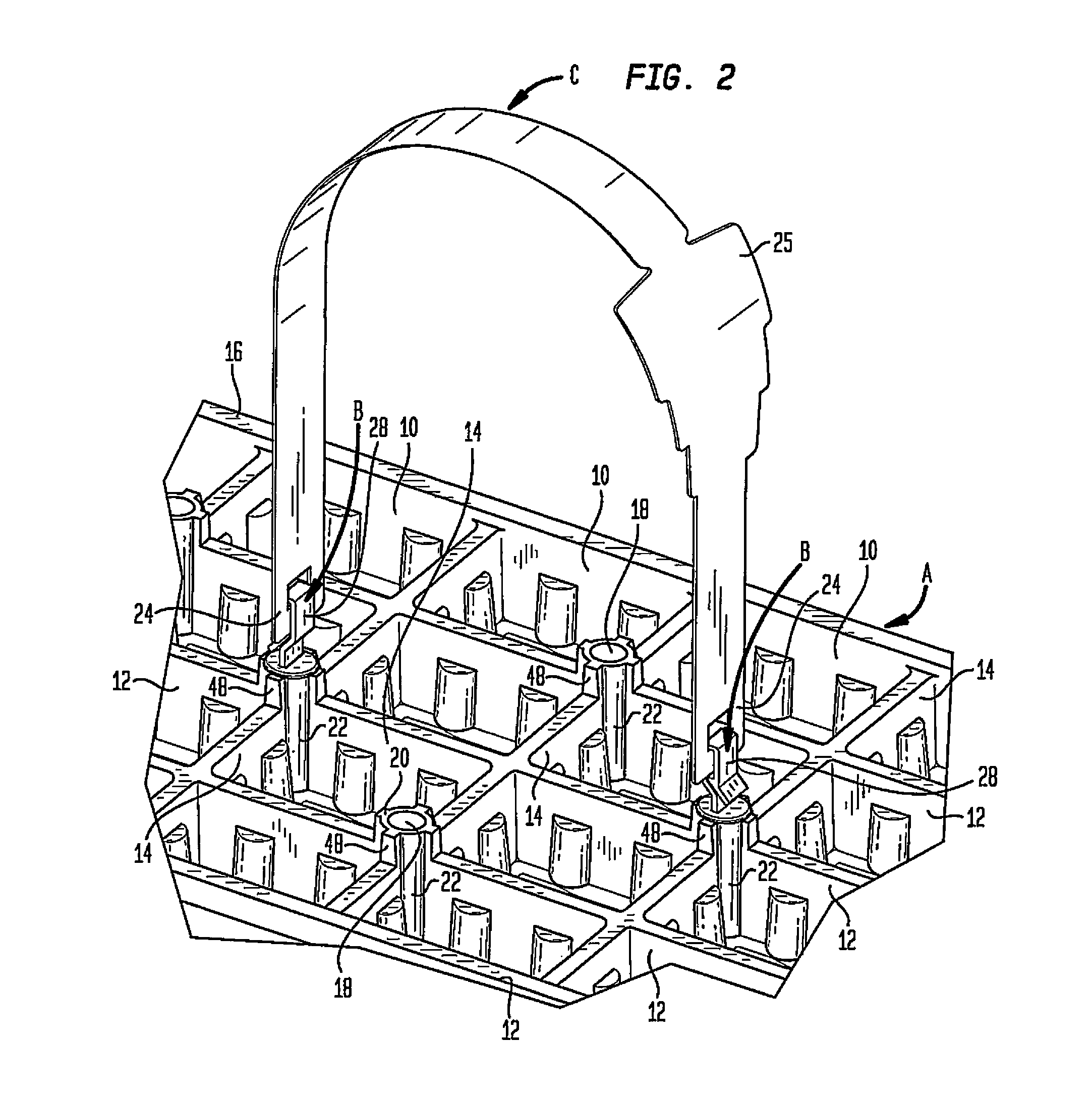

Two-part handle system for horticultural tray

InactiveUS20130277381A1Inhibit sheddingPrevent free rotationSnap fastenersSecuring devicesFree rotationHandling system

The handle end portions are attached to the tray by separate connectors. The tray has spaced openings to receive the connectors. Each connector has an anchor-shaped section which is received in a tray opening and a section which engages a handle end portion. The anchor-shaped section has arms which flex to permit the connector to be received in the tray opening and thereafter return to their extended position to cooperate with the tray to securely attach the connector to the tray and prevent free rotation of the connector. The handle engaging section includes a hook-shaped member which is received an opening in the handle end portion.

Owner:AFTEX ENTERPRISES

Modular tapered hollow reamer for medical applications

An easy-to-assemble reamer for medical applications includes a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The tapered hollow reamer sleeve has integrally attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft distal end engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable, wobble free, reaming torque in a highly efficient manner.

Owner:LRS SCI & TECH LLC

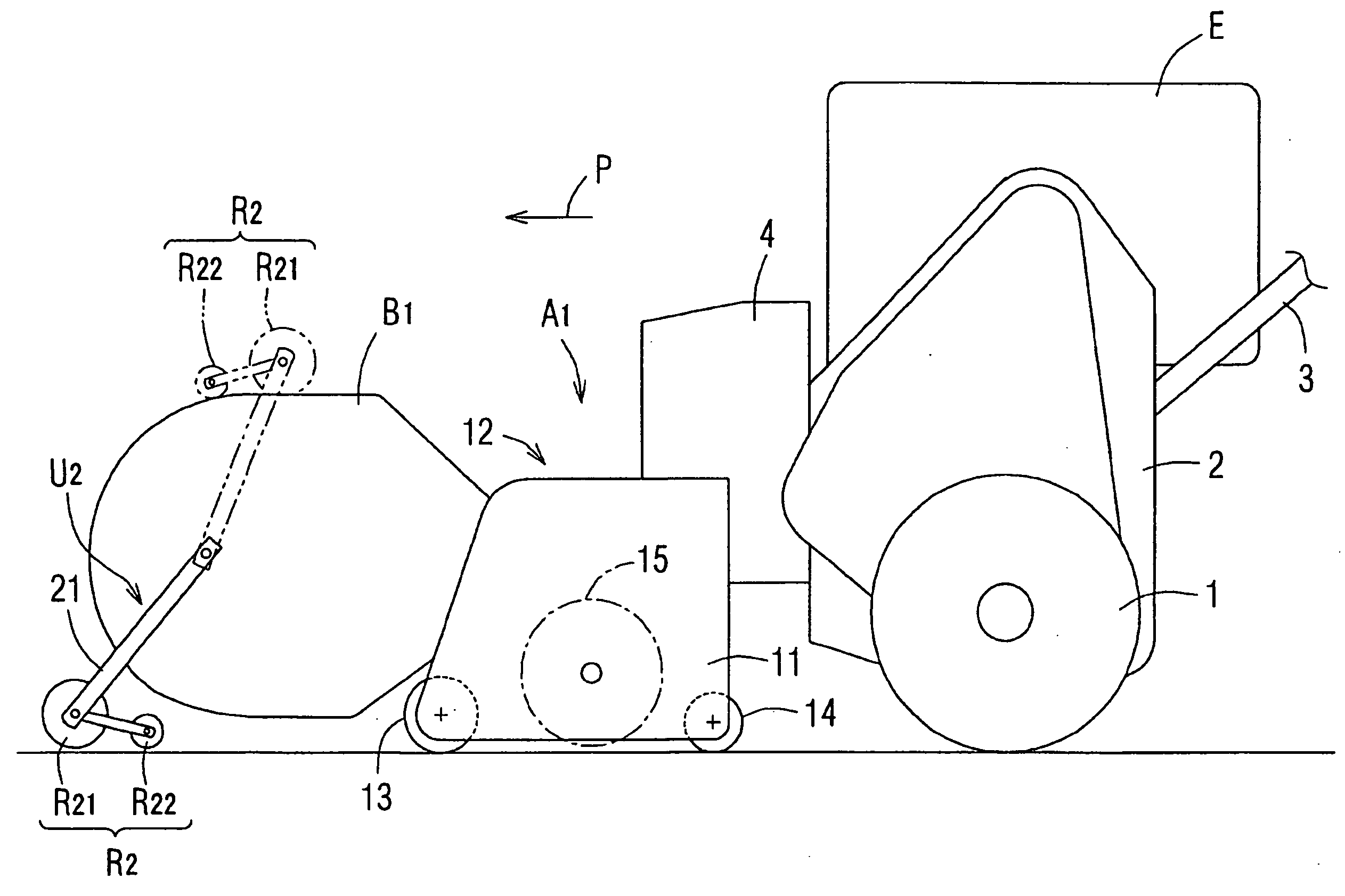

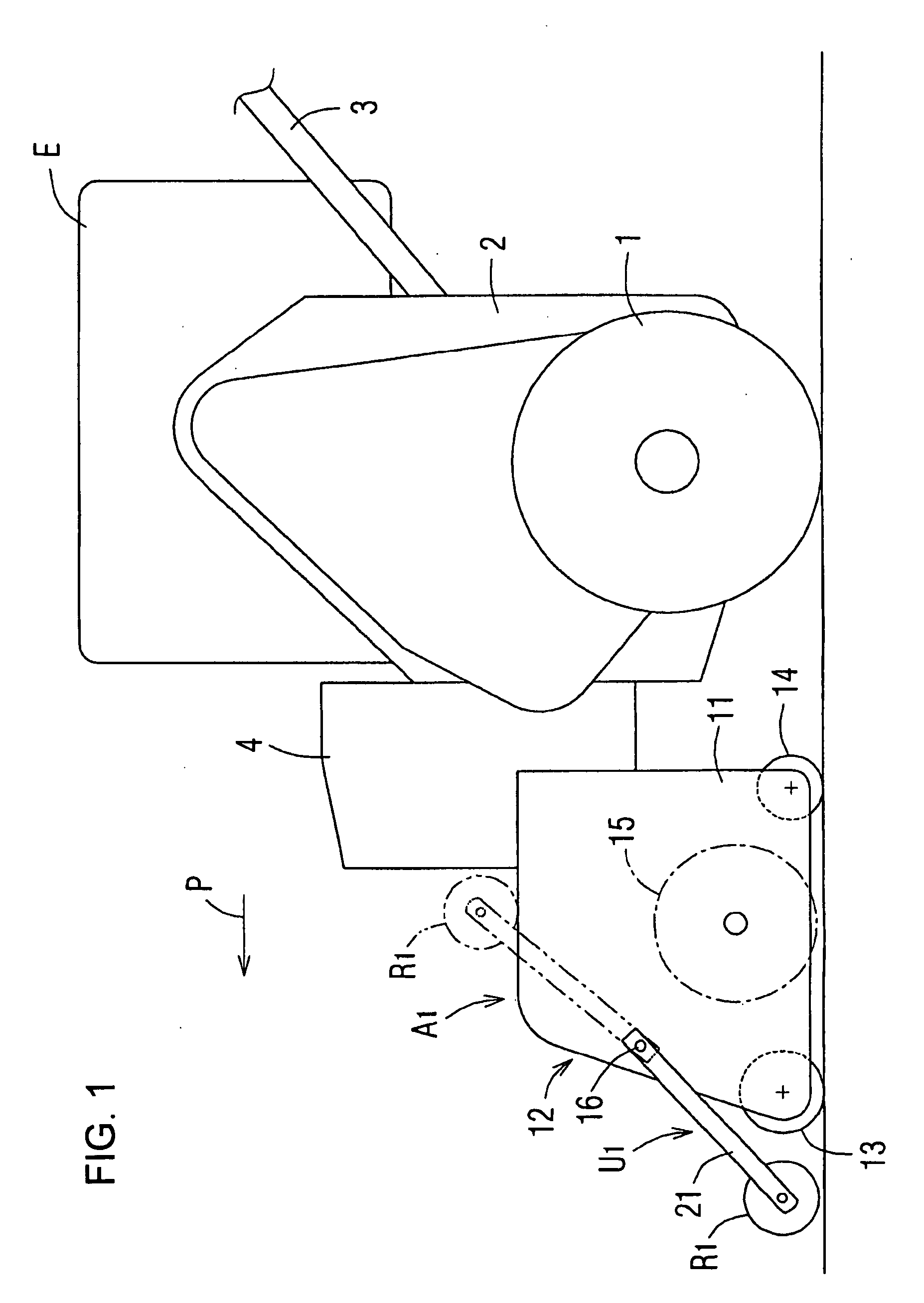

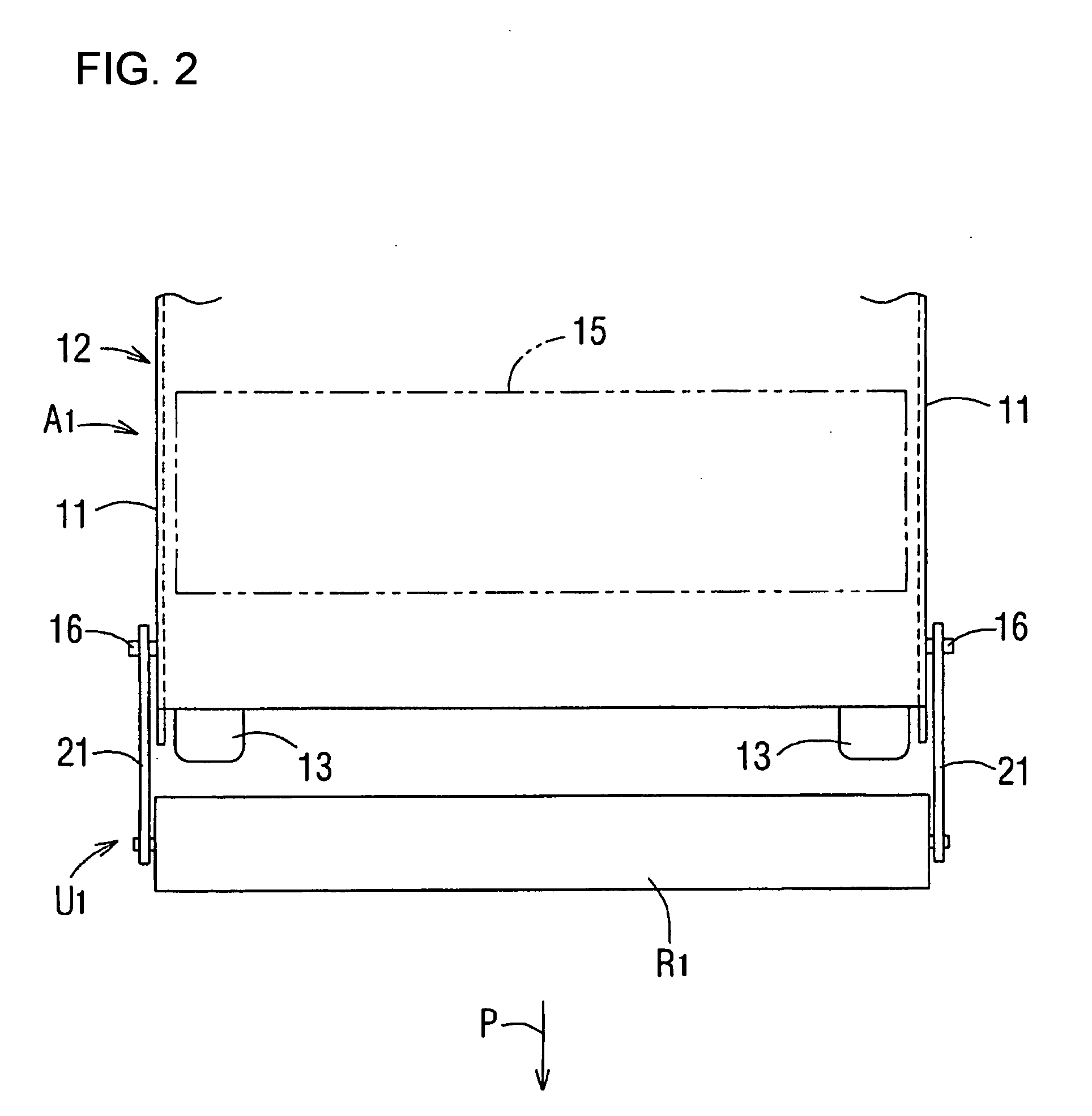

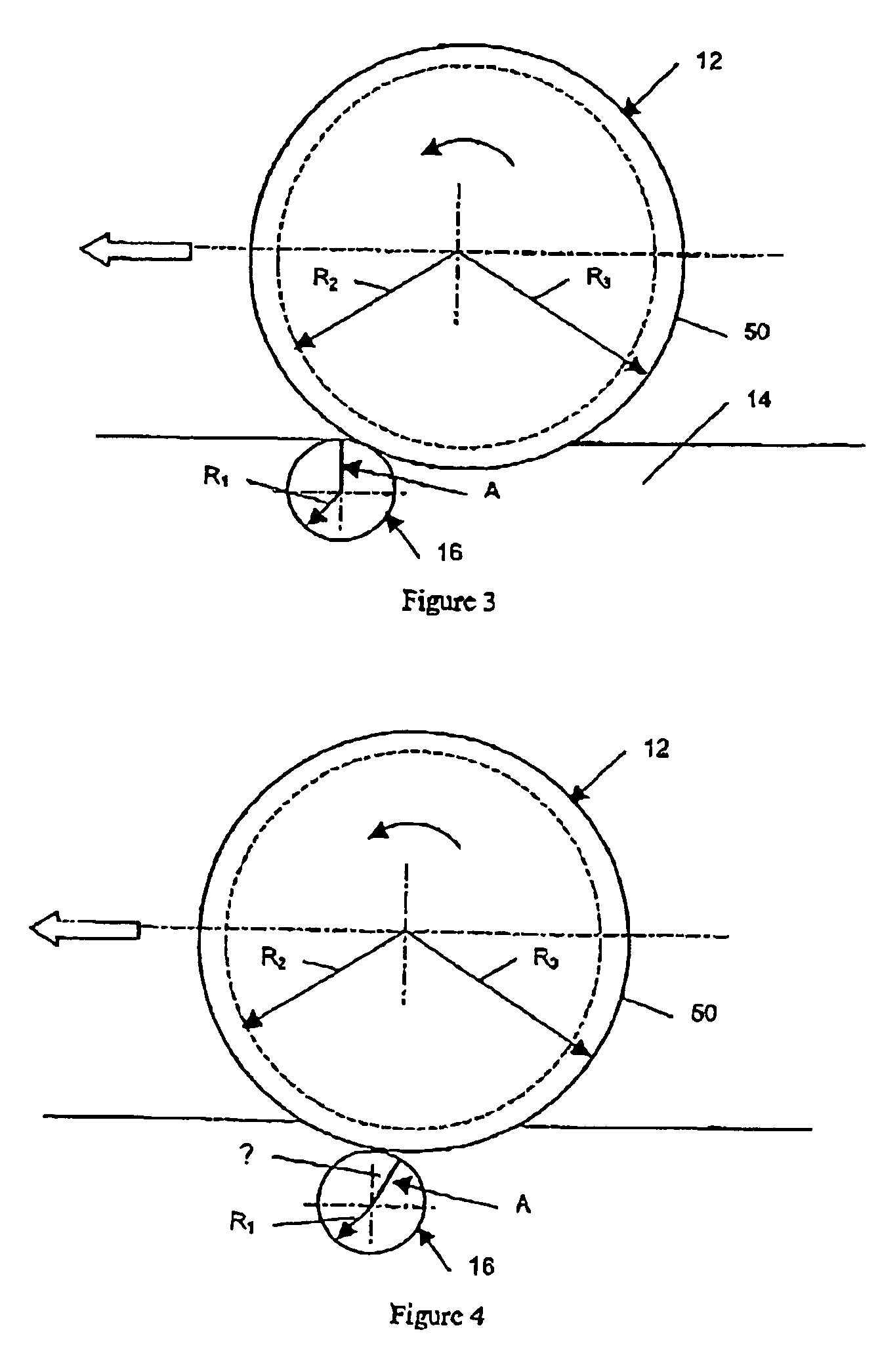

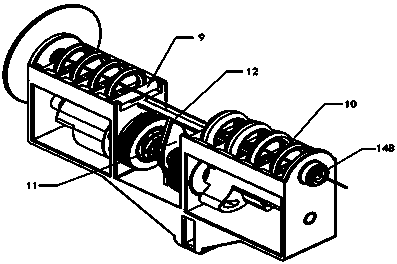

Lawn Mower and Droplet Wiping Roller Unit

A lawn mower comprising a reel cutter type lawn mowing unit (A1) for neatly mowing a lawn by wiping droplets adhered to the lawn without damaging the lawn to increase the mowing rate of the lawn. A pair of right and left arms (21) are rotatably supported on the front part of the housing (12) of the lawn mowing unit (A1), and a roller (R1) for wiping droplets is rotatably supported at the free end parts of the pair of arms (21). Accordingly, the roller (R1) for wiping droplets is disposed at the front of the lawn mowing unit (A1) when used, and when not in use, allowed to retreat to a retreated position at the upper part of the lawn mowing unit (A1) positioned on the diagonal rear upper side of a use position.

Owner:KYOEISHA

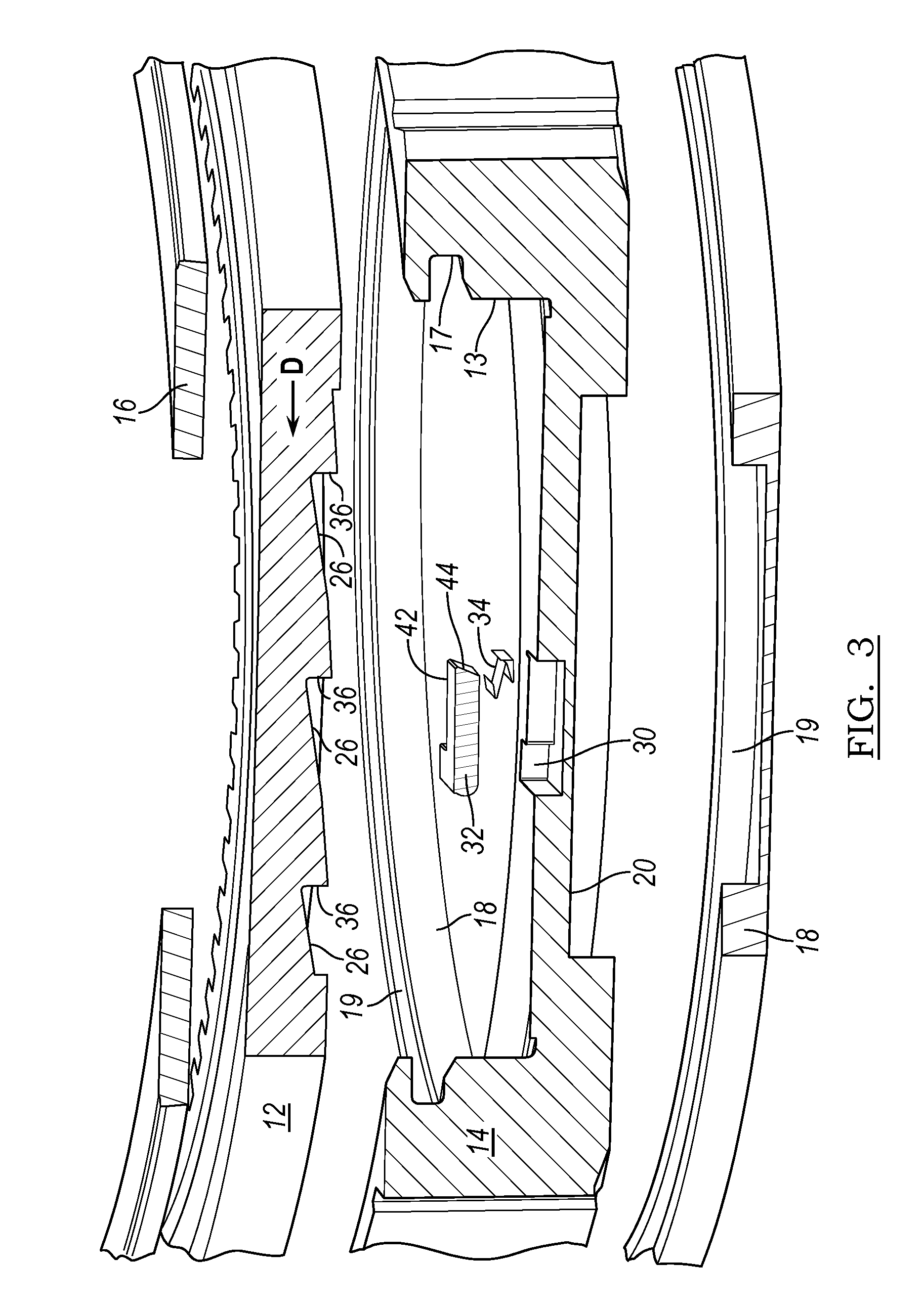

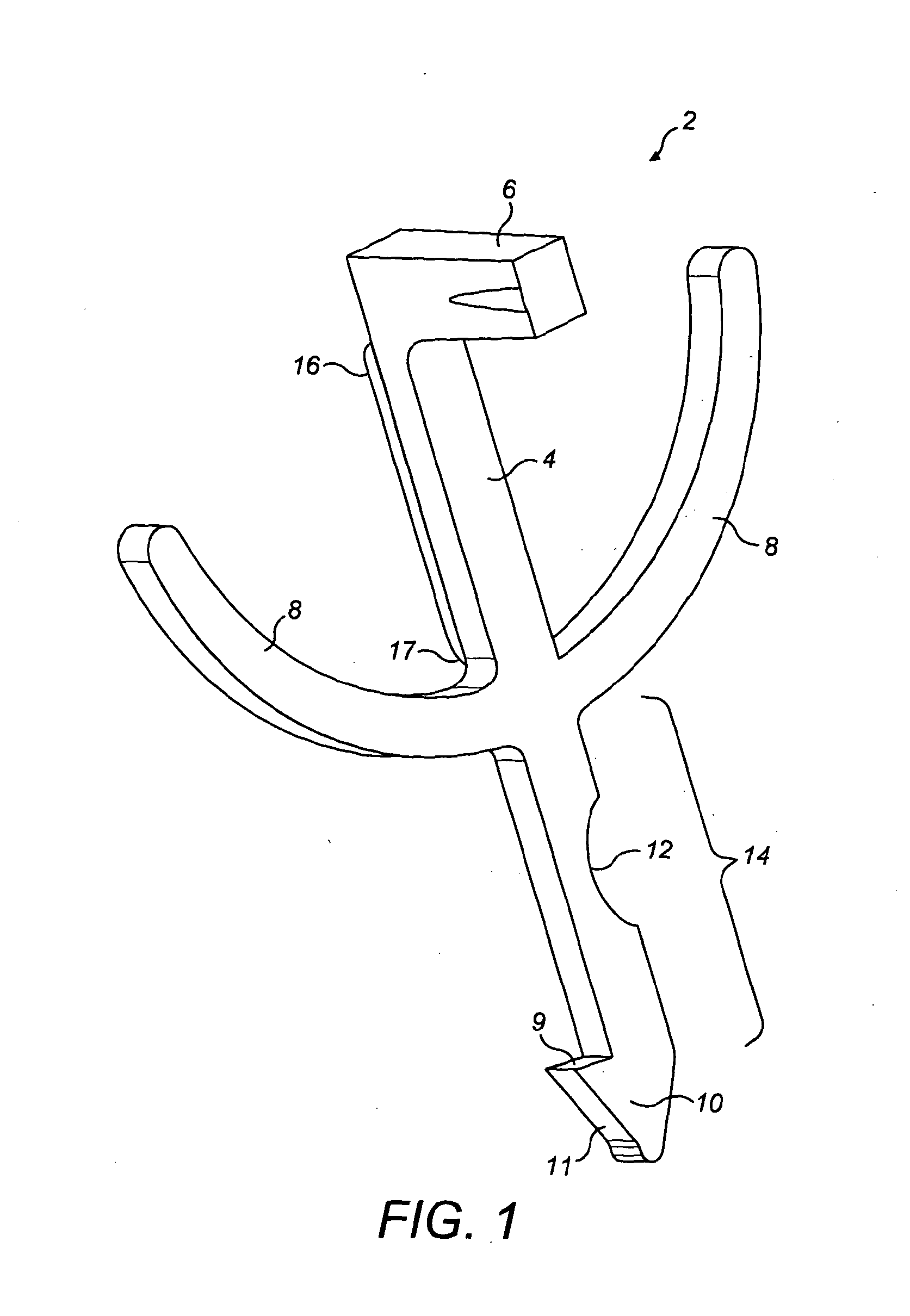

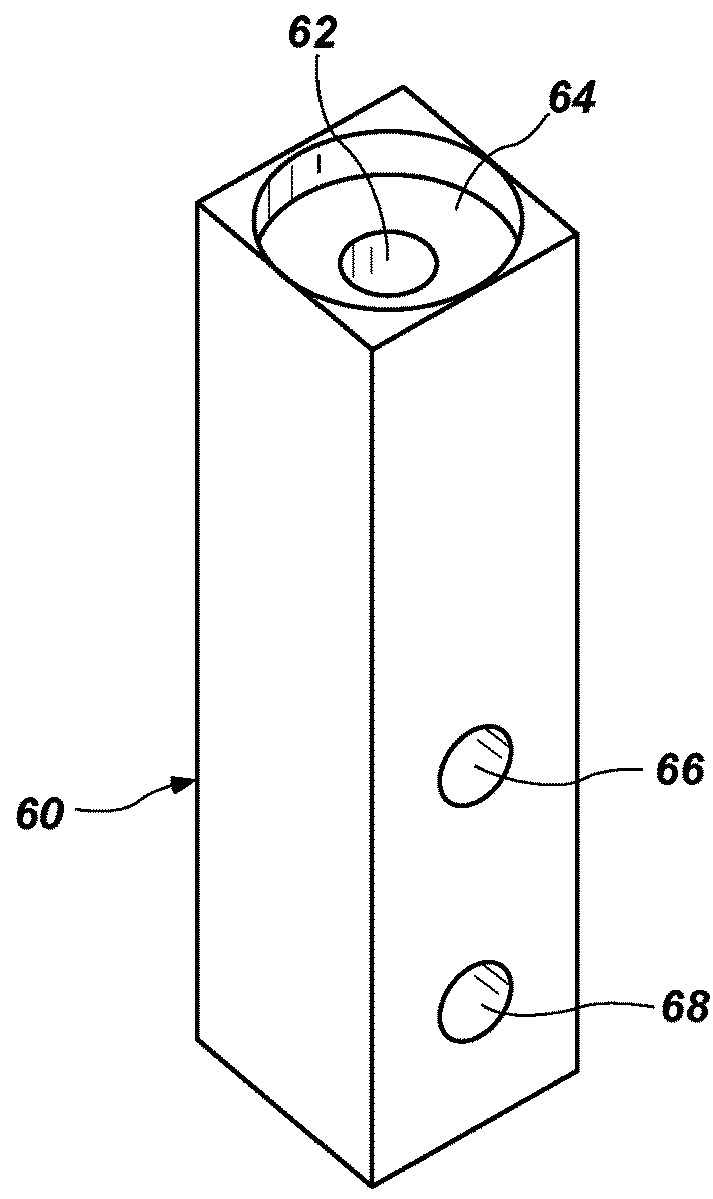

A Dose Counter

InactiveUS20140150778A1Easy to readPrevent rotationMedical devicesCounting mechanisms/objectsActuatorControl theory

The present invention relates to a dose counter. Particularly, but not exclusively, the invention relates to a dose counter for use with a Metered Dose Inhaler (MDI). The dose counter comprises a rotary counting element (26) and an actuator (2). The actuator (2) is movable relative to the rotary counting element (26) and comprises a shaped part (17) which can move into and out of engagement with a complementary feature (33) of the rotary counting element (26) when the actuator (2) moves between first and second positions. When the shaped part (17) of the actuator (2) is engaged with the complementary feature (33) of the rotary counter element (26), rotation of the rotary counter element (26) is resisted.

Owner:CIPLA LTD

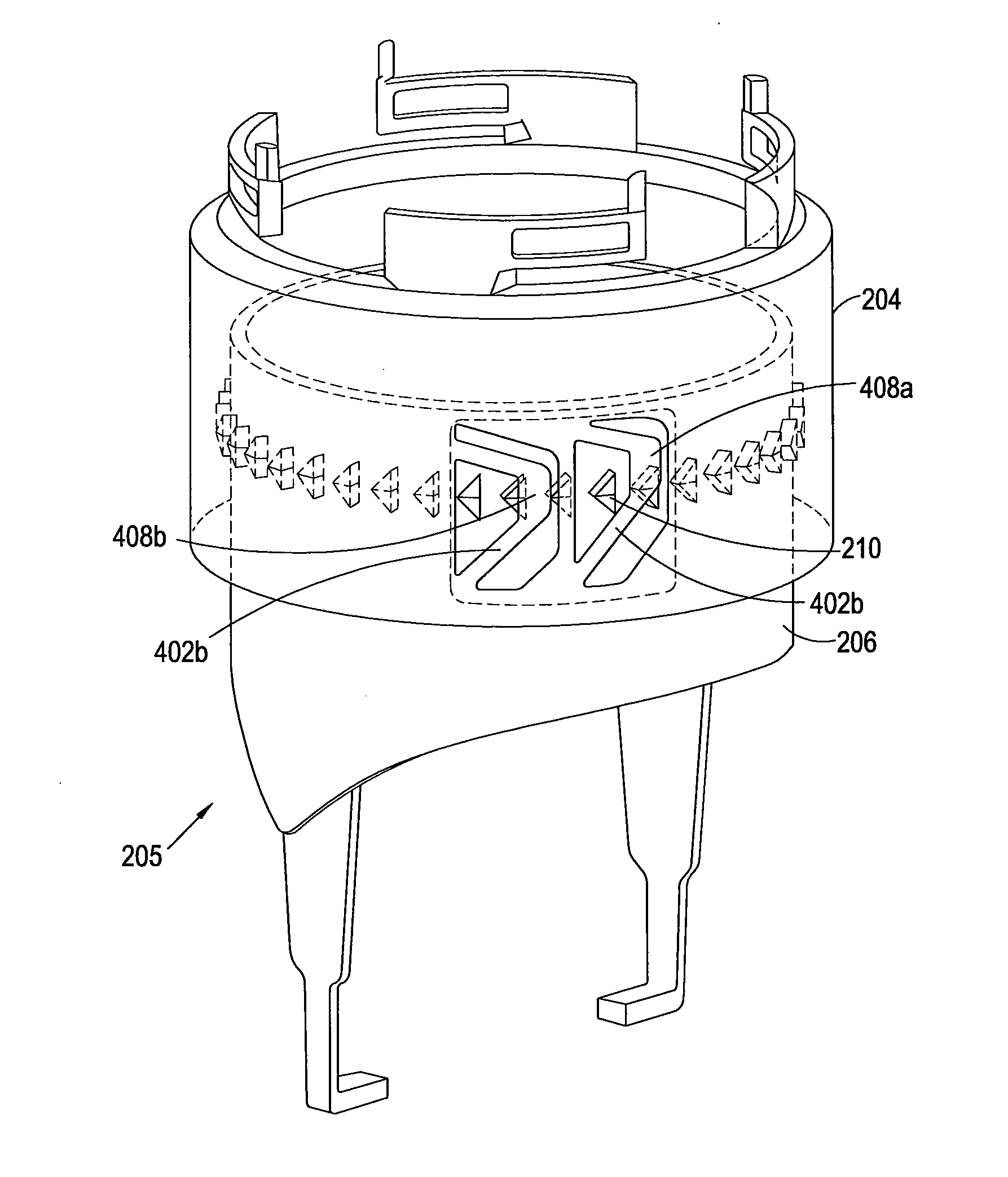

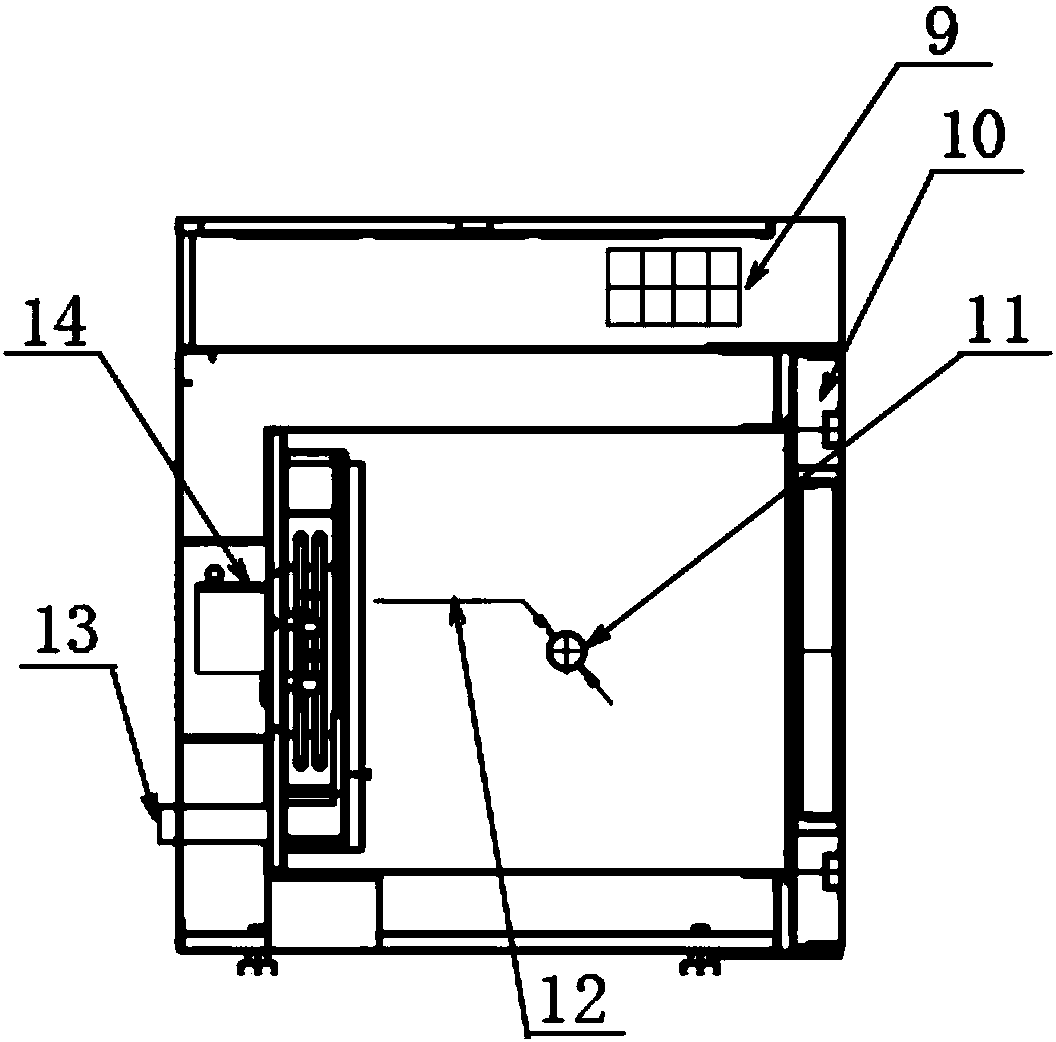

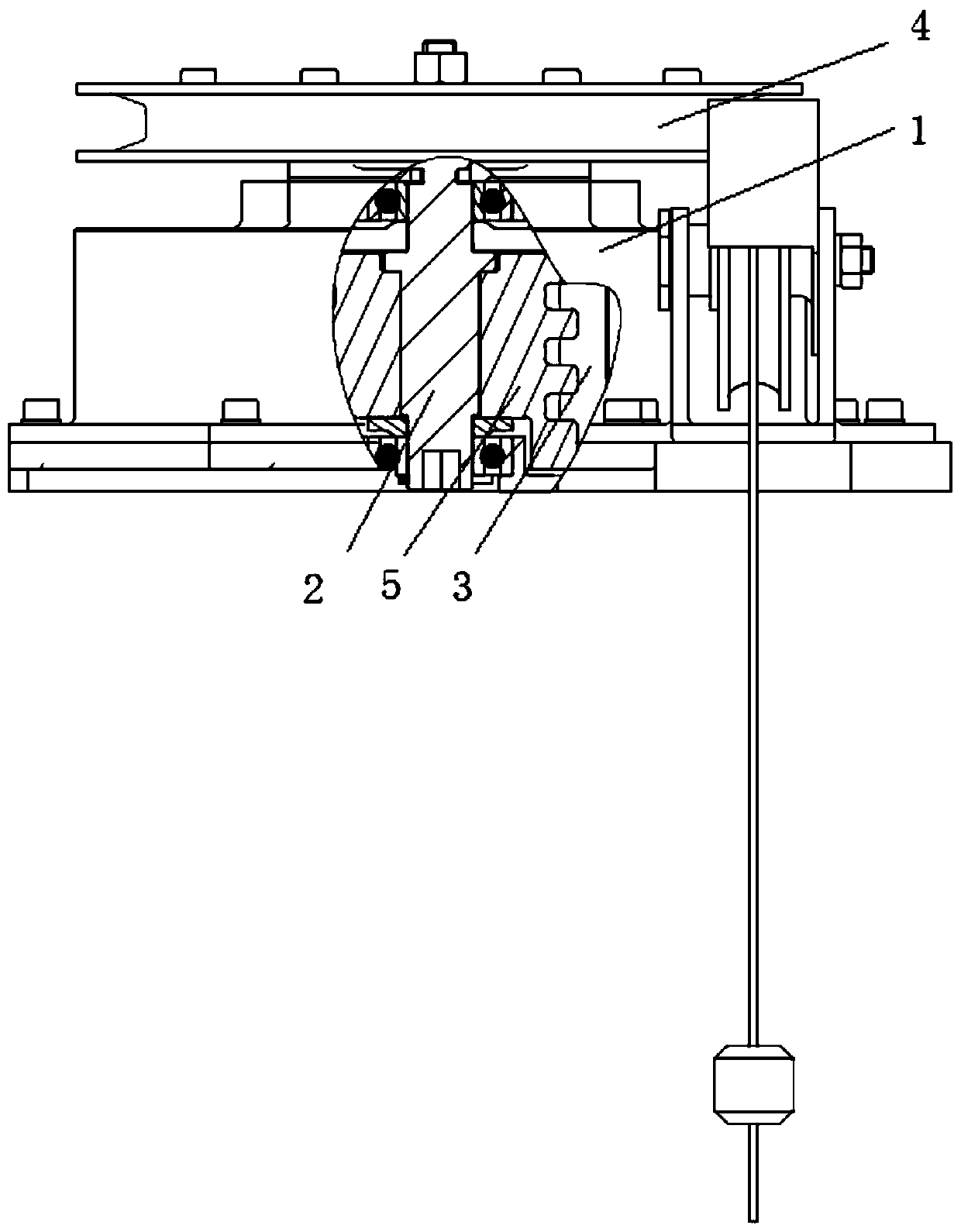

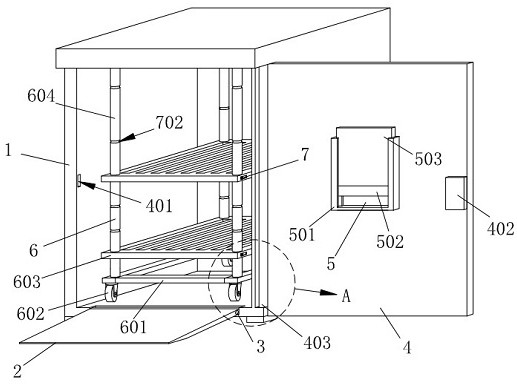

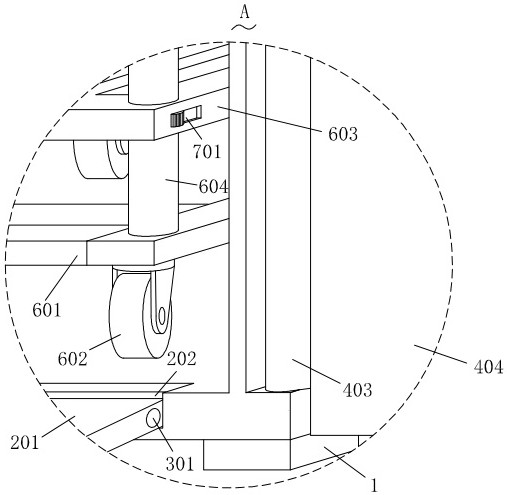

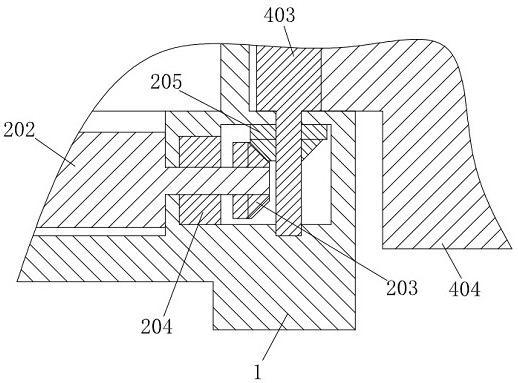

Internal rotation homogeneous reaction device with locating system

PendingCN108273467AStrong rust resistanceEasy to cleanChemical/physical/physico-chemical moving reactorsEngineeringGlass wool

The invention discloses an internal rotation homogeneous reaction device with a locating system. The internal rotation homogeneous reaction device comprises a box body, wherein an electrothermal air blasting heating device, a rotating device, a locating device and reacting kettles are arranged inside the box body; the rotating device consists of a rotating motor, a center rotating shaft, a rotating bracket and a plurality of size-adjustable clamping slots; the rotating motor is arranged on one side inside the box body; the rotating motor is connected with one end of the center rotating shaft;the center rotating shaft penetrates through the whole box body; the rotating bracket is arranged on the center rotating shaft; the multiple size-adjustable clamping slots are formed in the rotating bracket; and the reaction kettles are arranged in the clamping slots. The box body is made of high-quality cold-rolled steel plates, and the surface is coated with electrostatic powder to form a hard and firm coating layer which is extremely high in antirust capacity. A working chamber is a high-quality stainless steel plate which is in a fillet style, smooth, fluent and very easy to clean. A spacebetween the box body and the working chamber is filled with an ultrafine glass wool heat isolation material, so that high heat preservation performance is realized, and stability and accuracy of temperature in the box are effectively guaranteed.

Owner:NORTHWEST UNIV(CN)

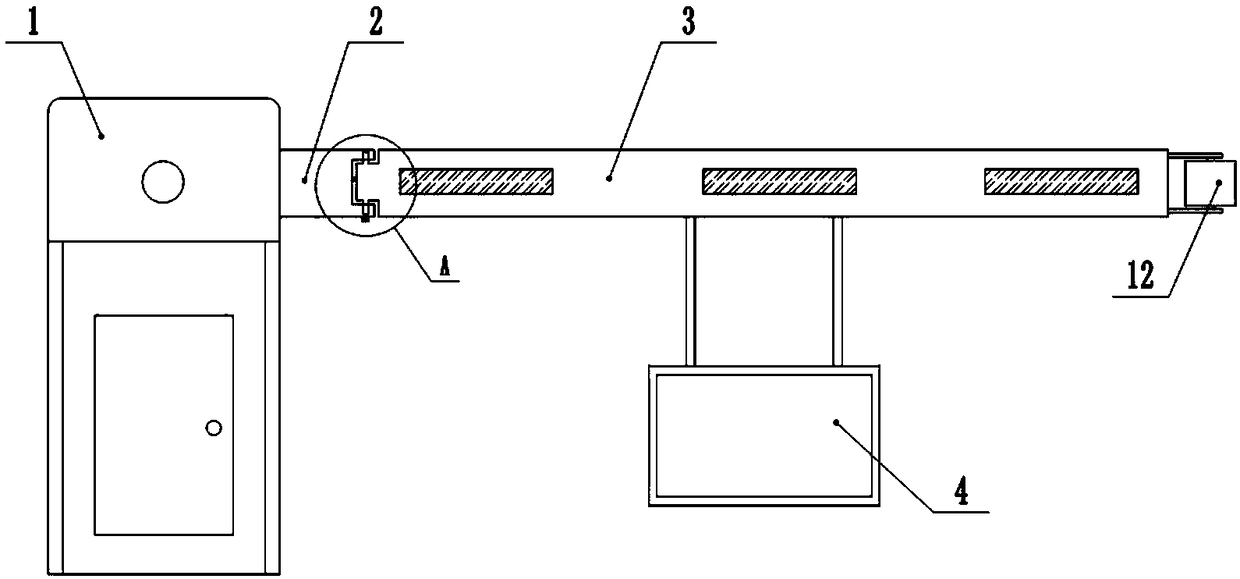

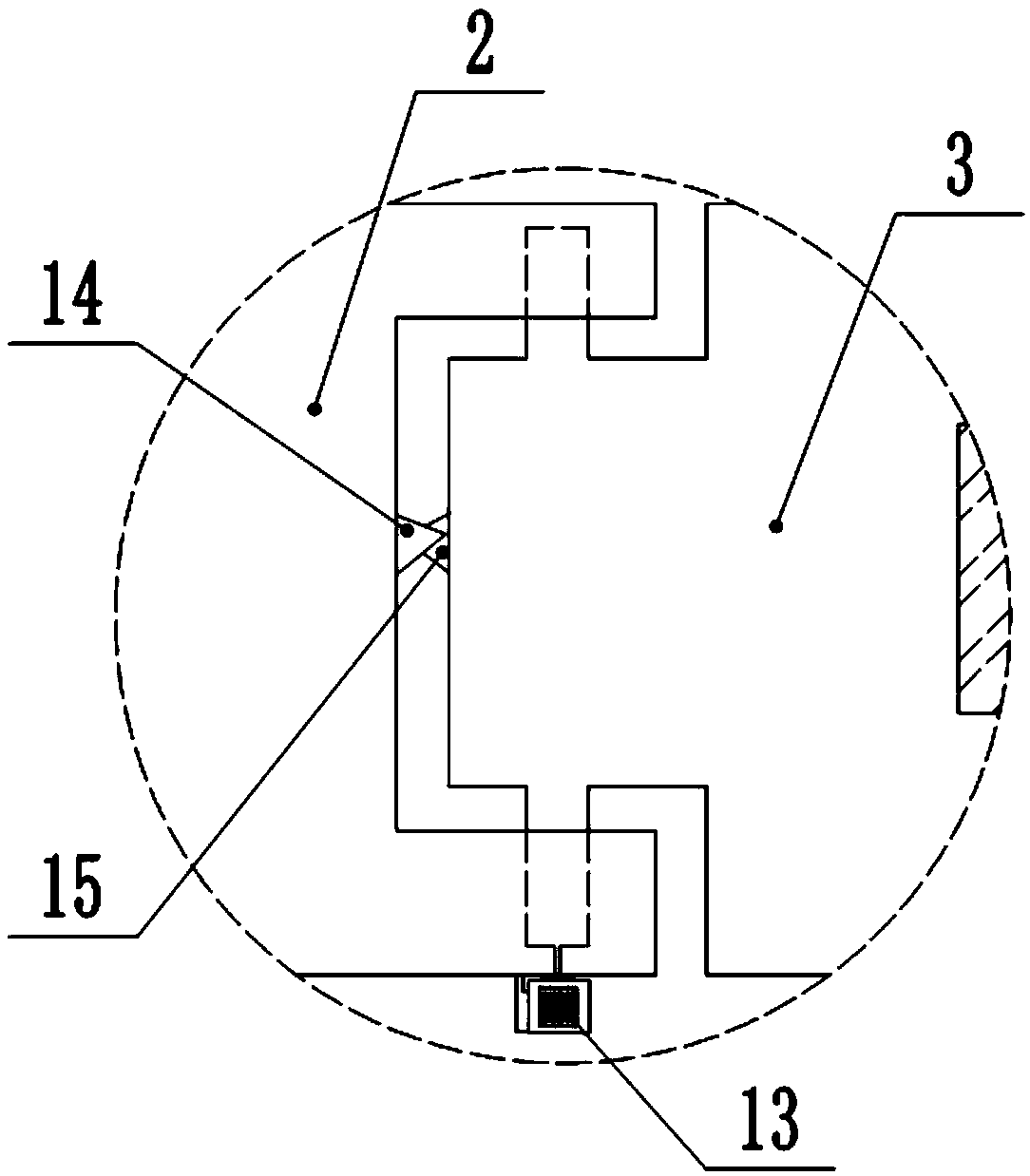

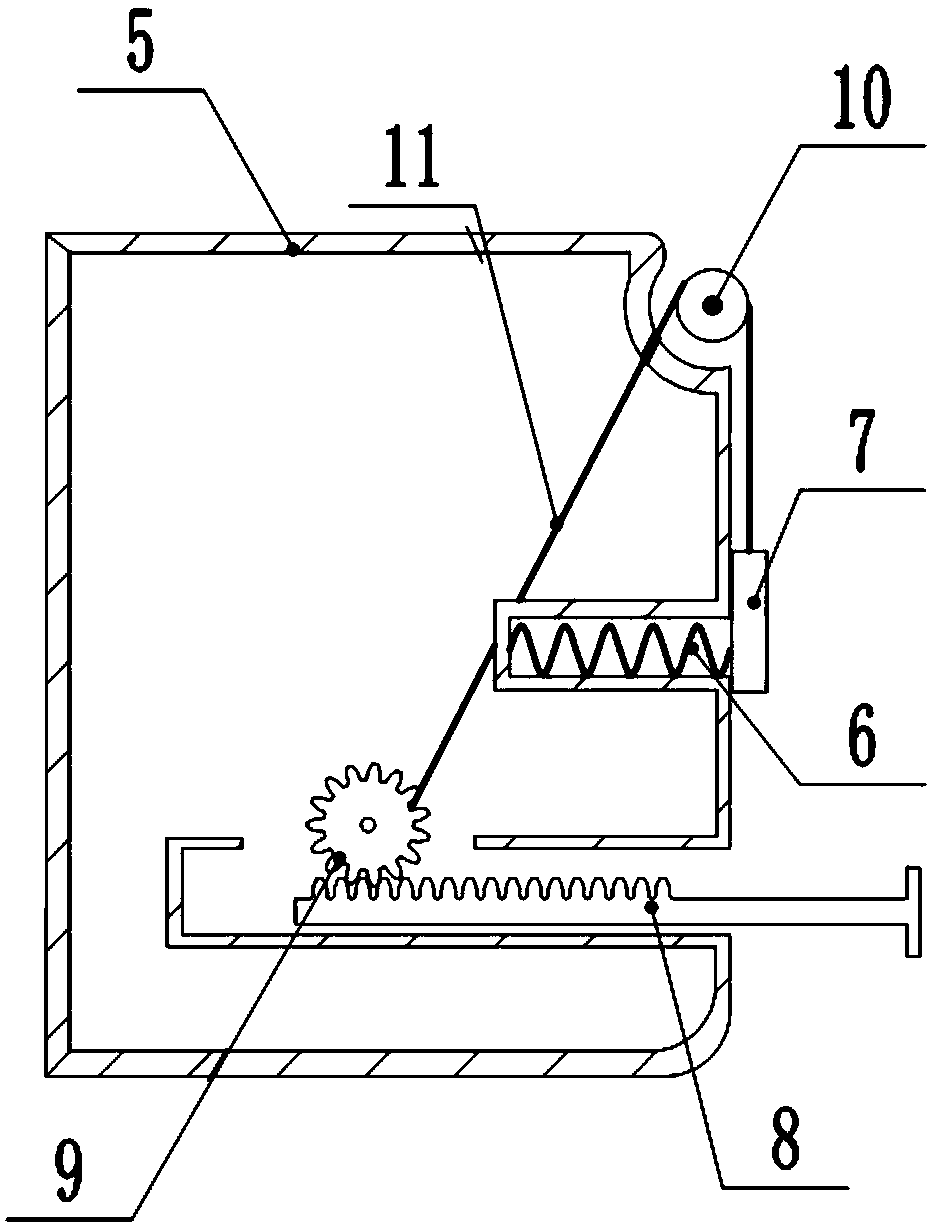

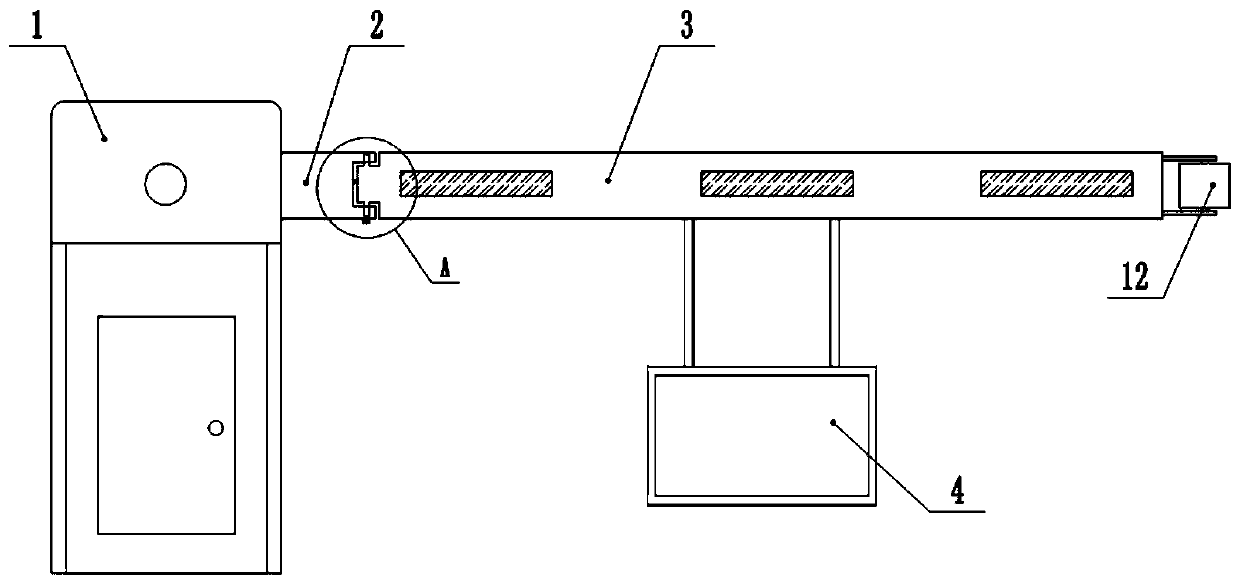

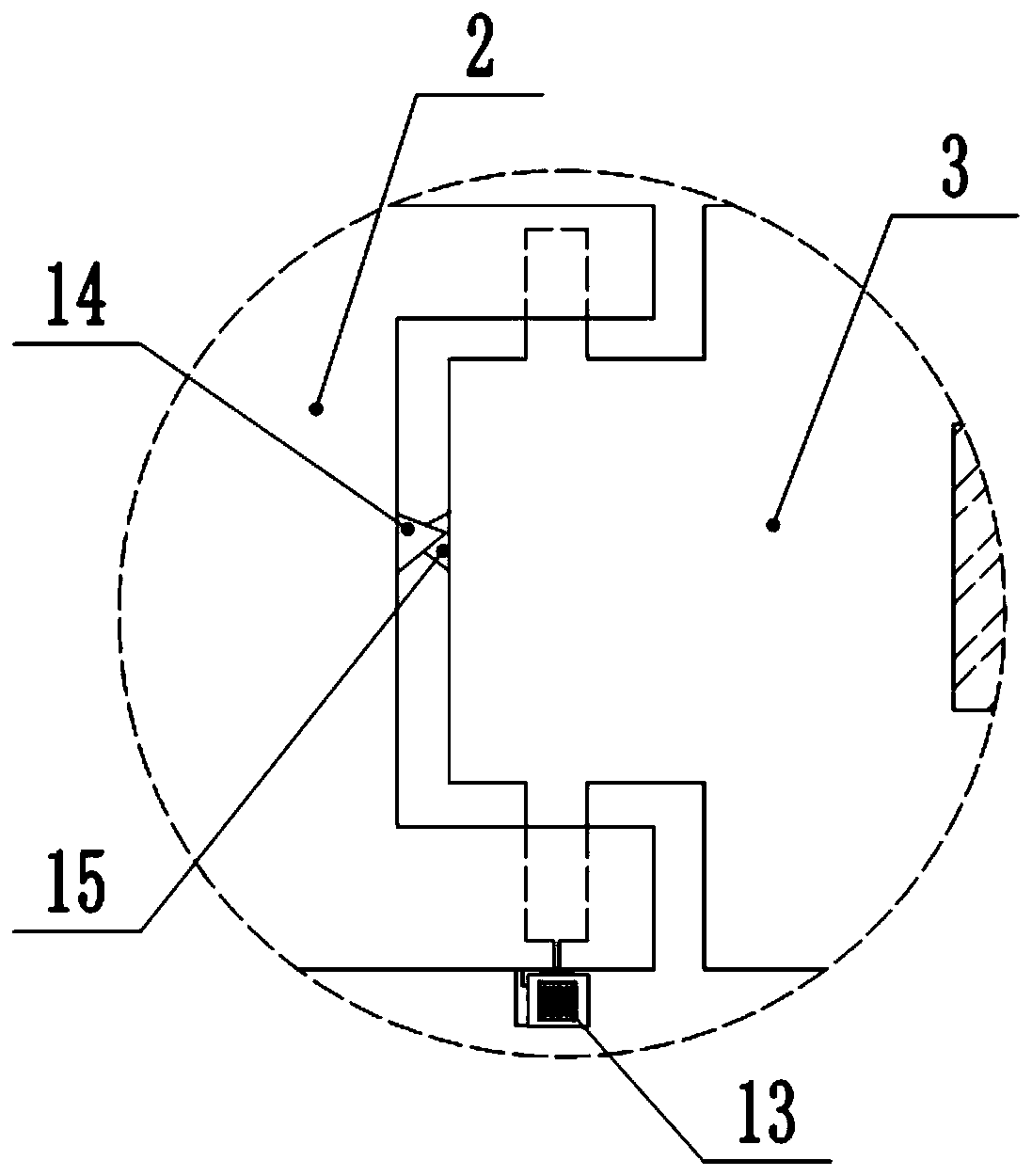

Residential entrance guard anti-collision gate

ActiveCN109112992AReduce labor costsAvoid scratching and bendingTraffic restrictionsPrinting inkEngineering

The invention relates to the technical field of gateways, in particular to a residential entrance guard anti-collision gate, comprising a gateway positioning seat and a lifting rail. The lifting railcomprises a driving rod, a limiting rod and a rubbing plate. The inner end of the driving rod is rotatably connected with the gate positioning seat; the mass of the outer end of the limiting rod is larger than the mass of the inner end, the inner end of the limiting rod is hinged with the outer end of the driving rod, and the limiting rod can be hinged as the axis and rotate in the horizontal direction; the rubbing plate is disposed under the limiting rod, and the rubbing plate and the limiting rod are fixedly connected by the connecting rod, and the surface of the rubbing plate is coated withthe printing ink. The technical proposal of the invention can solve the problems that the driver inadvertently collides with the lifting railing and causes the lifting railing to be scratched, bent and damaged, and meanwhile ensures the normal passage of the vehicles in the district when the lifting railing cannot be lifted and lowered normally.

Owner:云侠科技(苏州)有限公司

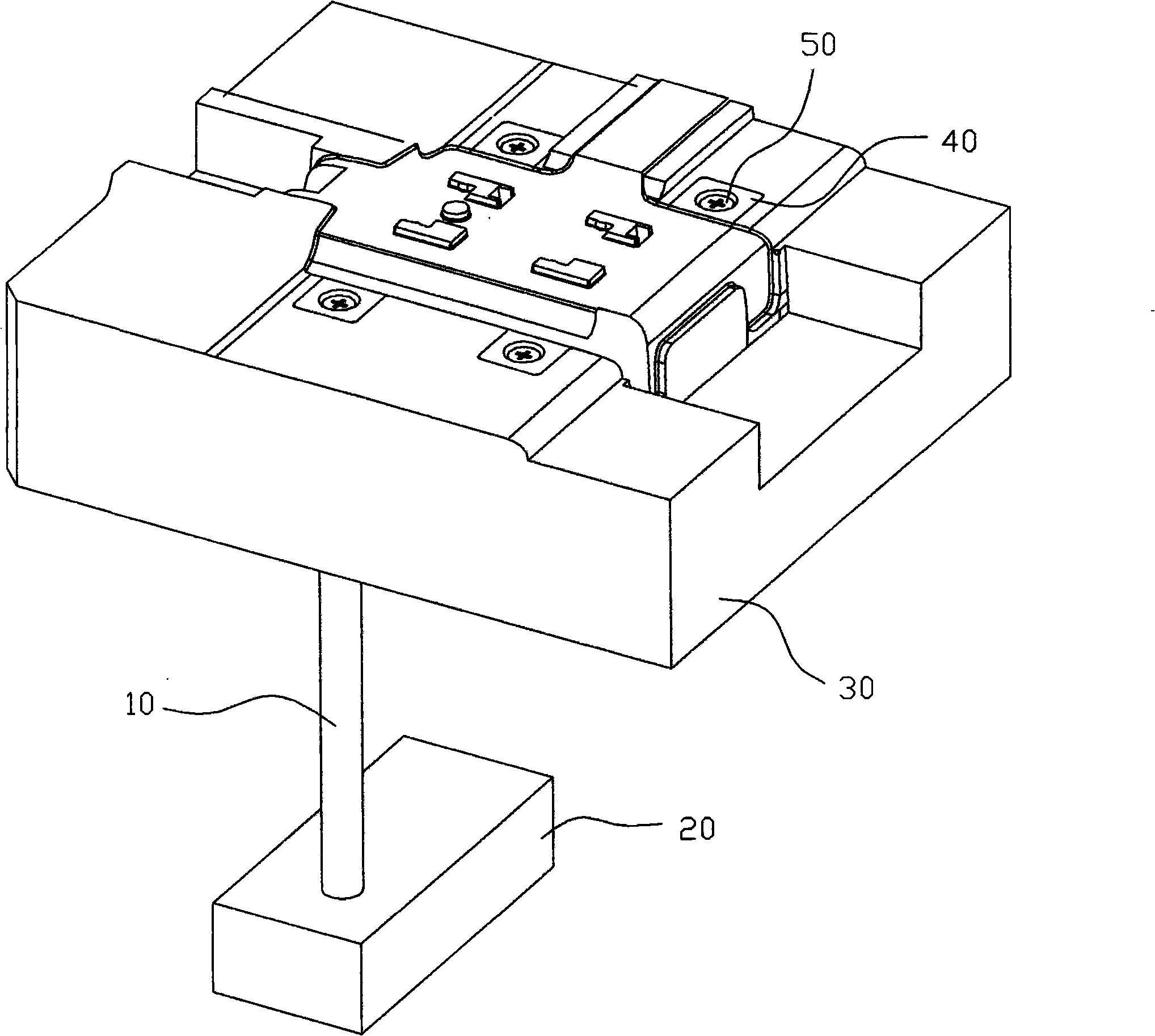

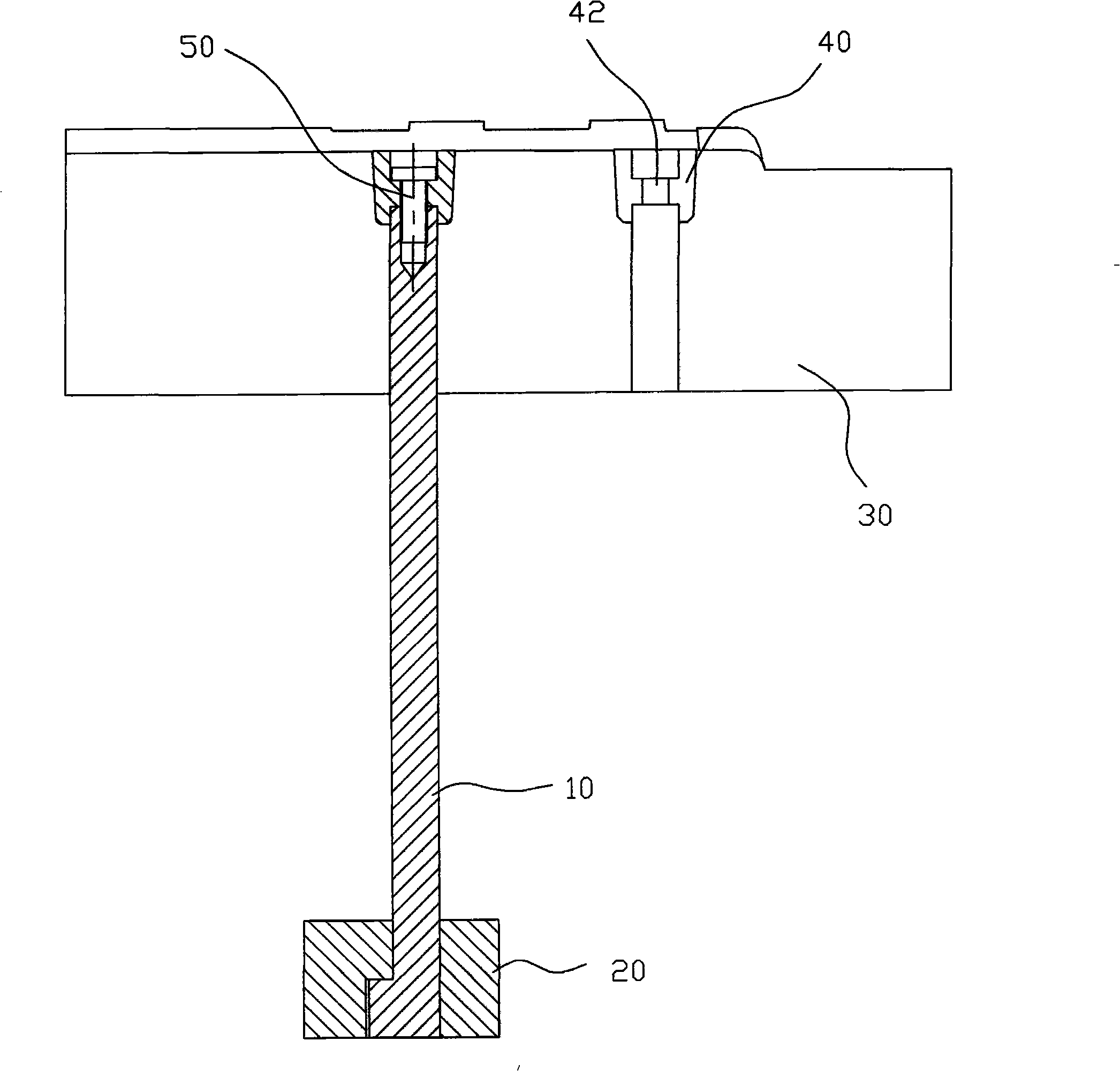

Ejecting rotation-proof assembly

The invention relates to an anti-rotation knockout combination which is suitable for a mould structure, wherein, the mould structure comprises a mould core that is provided with a knockout groove at the lateral margin of a mould area; the anti-rotation knockout combination comprises an ejector pin, one end of which is provided with an anti-rotation part, the anti-rotation part is internally provided with a locking-up hole; the outside of the ejector pin is sleeved with an ejector block that is held in the knockout groove, and the ejector block is internally provided with an anti-rotation holding groove which holds the anti-rotation part; the side at the interior of the ejector block where the anti-rotation holding groove is arranged is provided with a penetrating part which is communicated with the locking-up hole; the penetrating part is sleeved and provided with a locking-up piece which is fixed in the locking-up hole. Even though the locking-up piece looses, the anti-rotation coordination between the anti-rotation holding groove and the anti-rotation part can prevent the free rotation of the ejector block, thus avoiding damage of the mould core caused by collision between the ejector block and the mould core.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

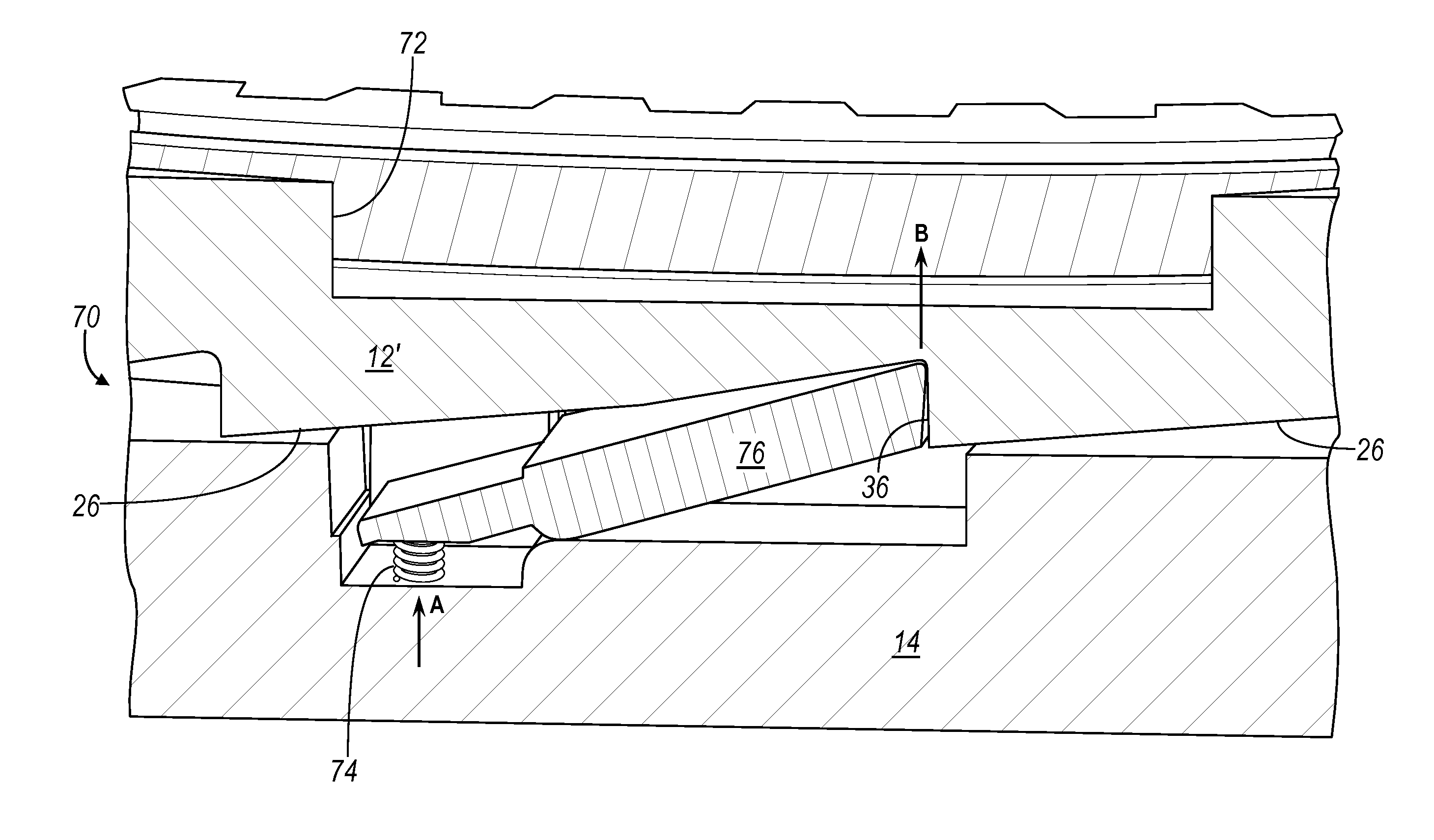

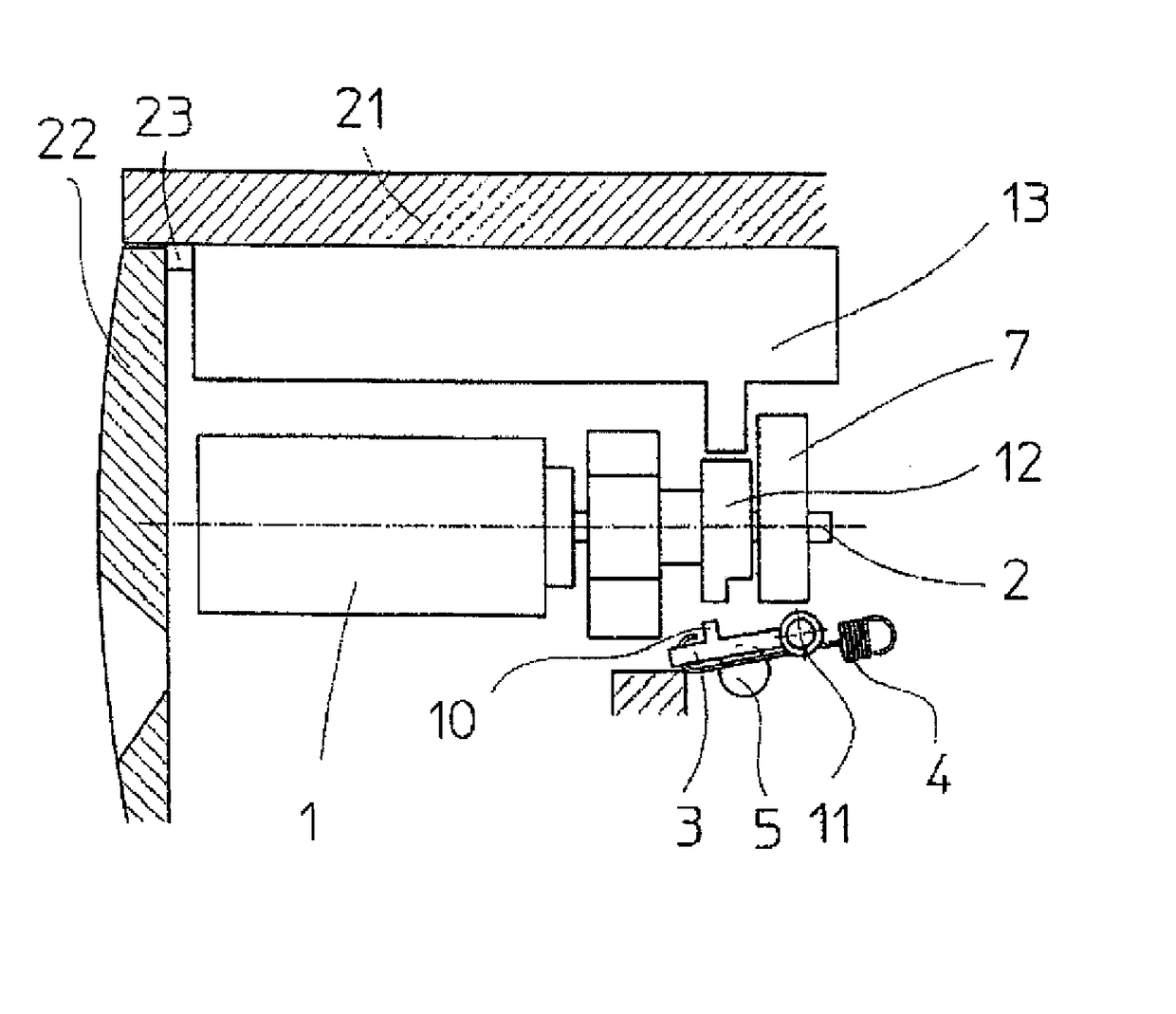

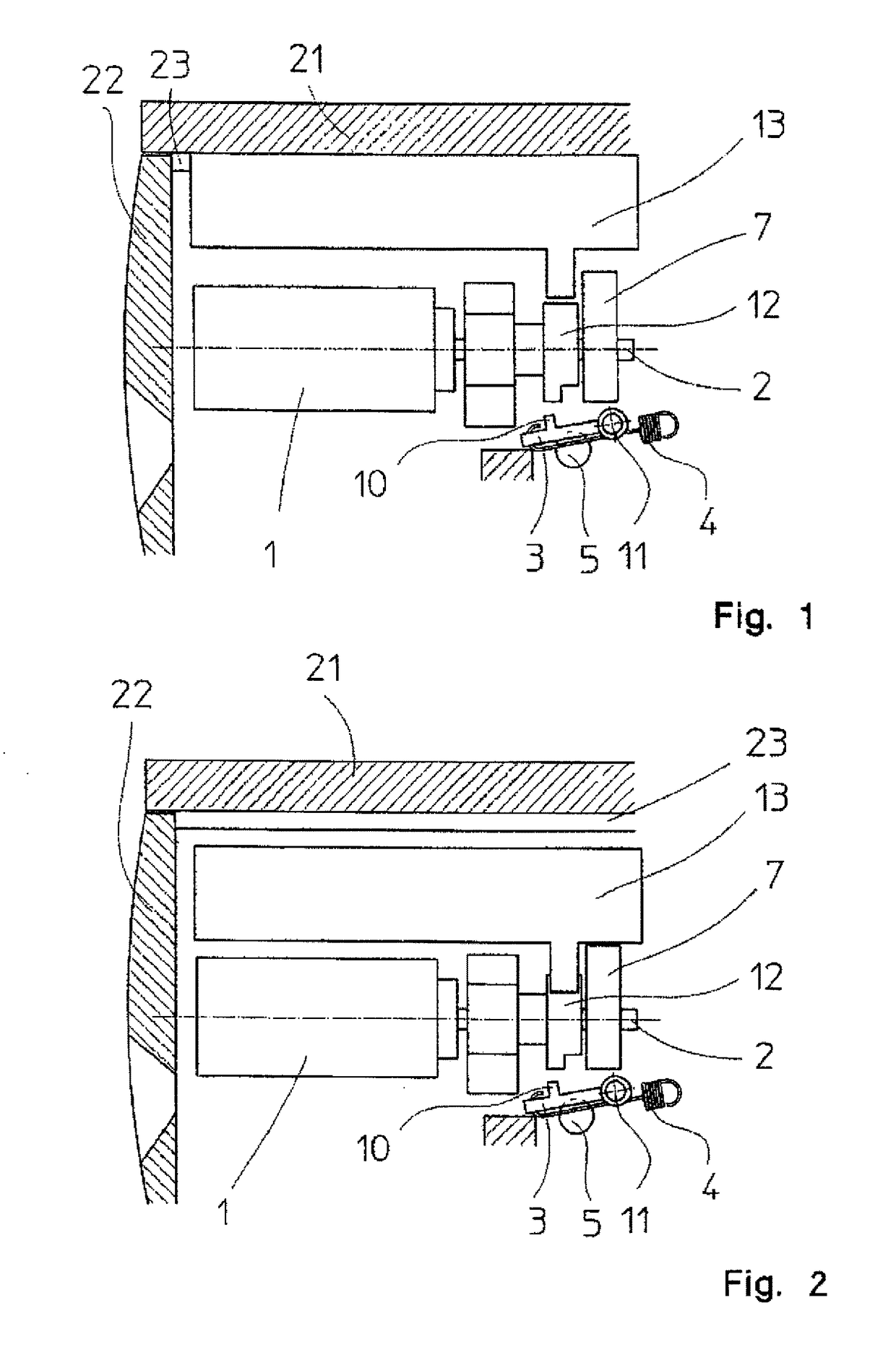

Movement lock for a locking element or an actuator in a locking system

InactiveUS9683389B2Prevent rotationPrevent free rotationNon-mechanical controlsElectric permutation locksEngineeringActuator

The invention relates to a movement lock for a locking element or an actuator in a locking system which can be operated in a mechanical or mechatronic manner. Provision is made here for the movement lock to have a blocking element which can be brought into engagement with the locking element or actuator by a system which is maintained under tension or caused to move and can be triggered as a result of an external pulse application on the locking system.

Owner:ASSA ABLOY SICHERHEITSTECHN

Hinge assembly with retaining ring cam

A rifle holder hinge mechanism comprising a rifle hook attached to a hinge block, the hinge block having a hinge block sleeve, with a hinge pin rotatable within the hinge block sleeve. A cam is provided connected to the hinge pin and configured to arrest rotation of the hinge pin, such that the hinge pin is rotatable from a first position to an approximately 90-degree second position. In some configurations, a retaining collar with a first detent and a second detent functions as the rotation limiting cam.

Owner:ACTION TARGET

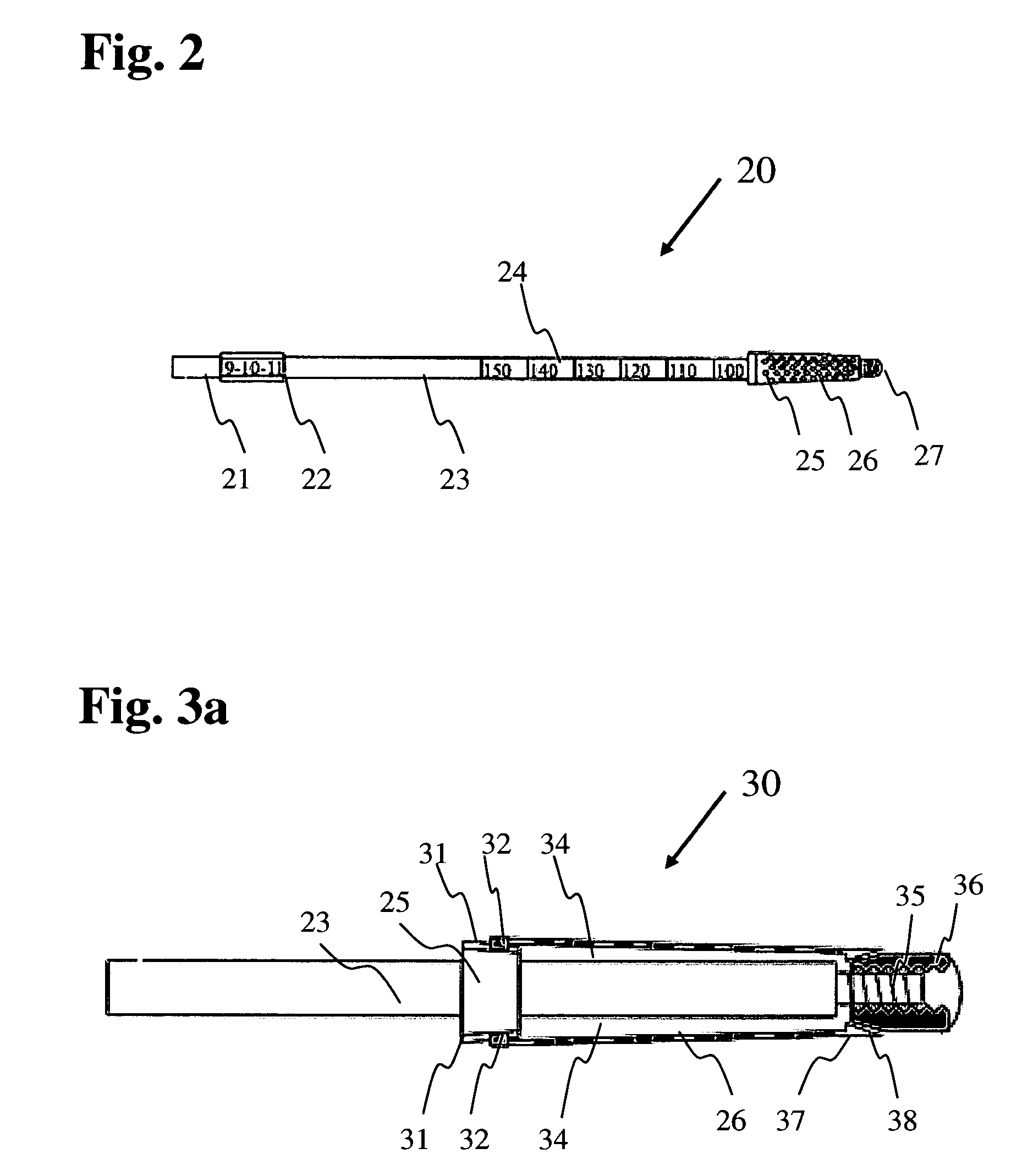

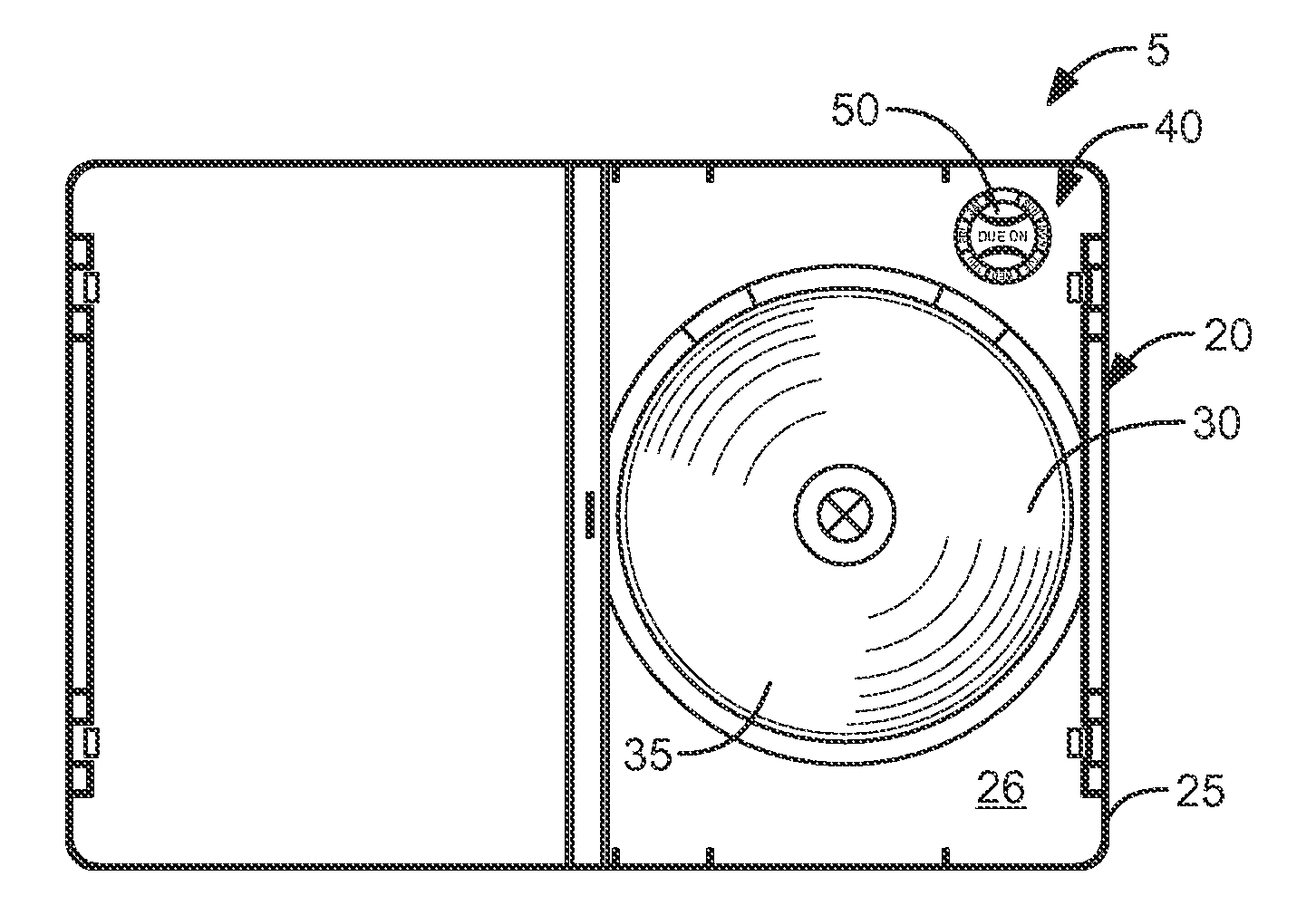

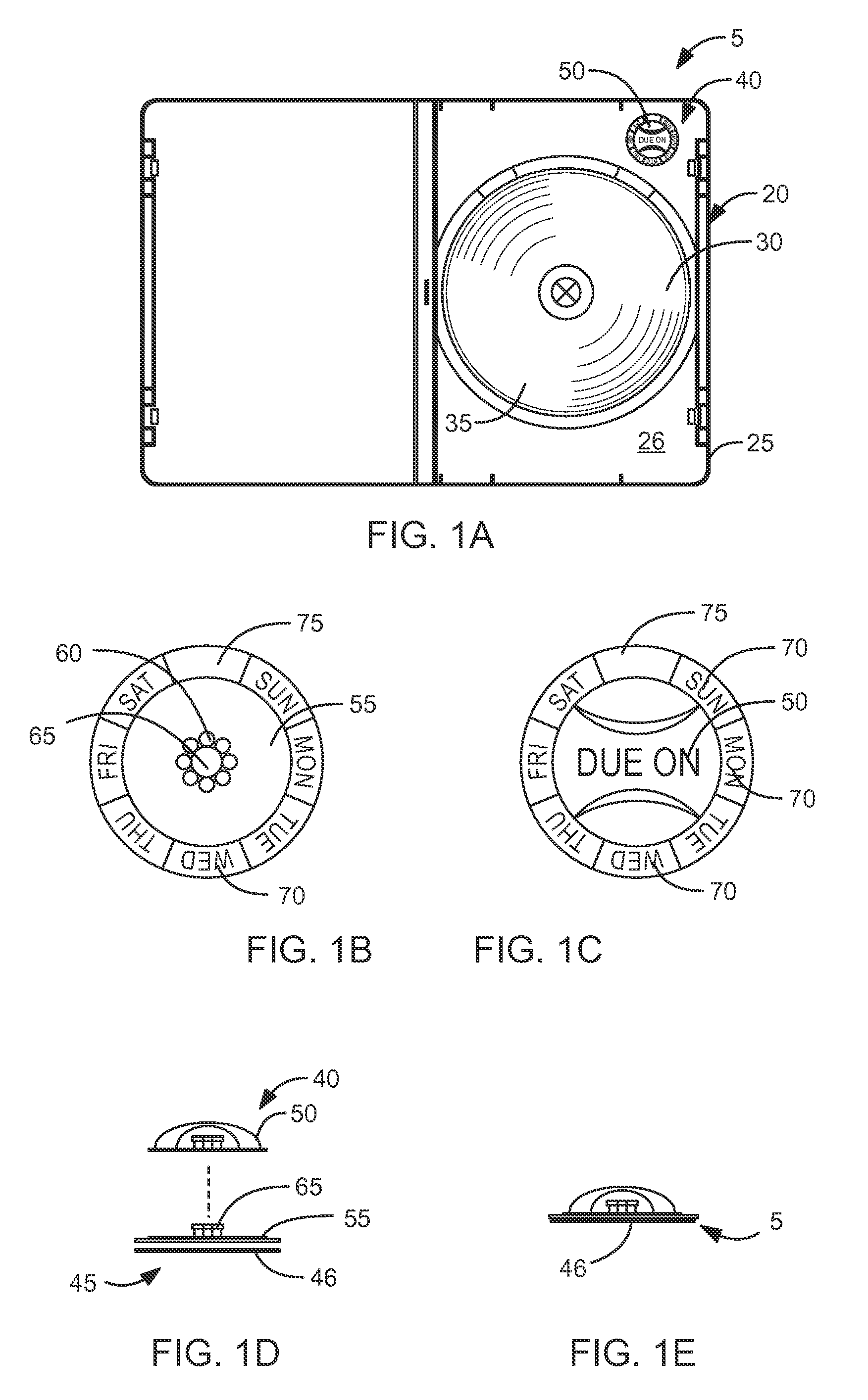

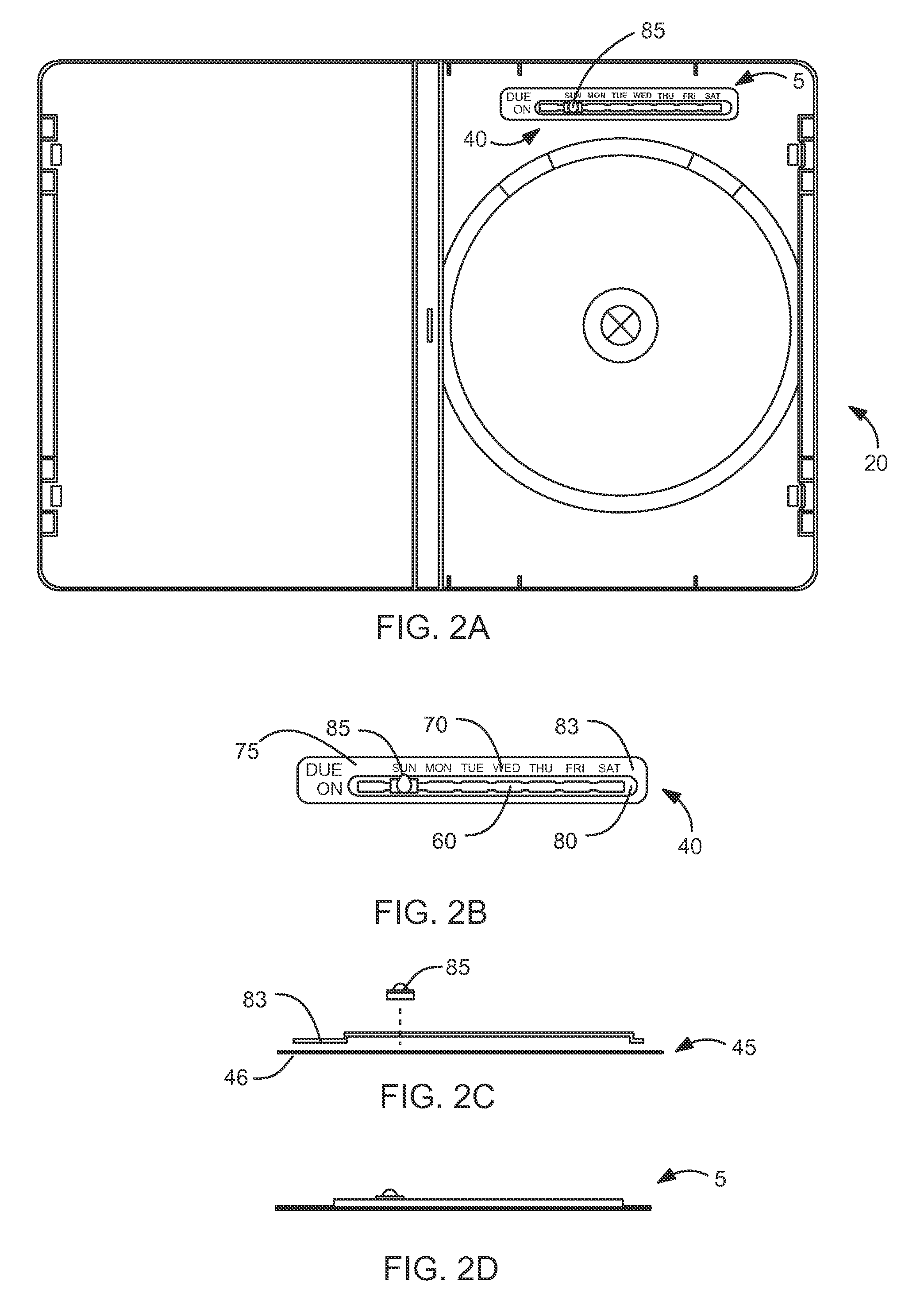

Media Case Date Indicator

InactiveUS20090109006A1Simple instructionsPrevent free rotationRecord information storageSignalling system detailsMechanical engineeringCalendar date

The present device relates to a media storage case mechanically adjustable time indicator for indicating the due date of media elements. One embodiment of the invention is an adjustable time indicator system for fixing to the media case. An alternate embodiment of the invention is an adjustable time indicator formed into the media case itself. The invention includes multiple embodiments of the time indicator including but not limited to a rotary dial embodiment, a slidable indicator embodiment, a peg hole indicator embodiment, and a deformable button embodiment.

Owner:HELMSTETTER GREG

Two-part handle system for horticultural tray

InactiveUS8827110B2Inhibit sheddingPrevent free rotationSnap fastenersSecuring devicesFree rotationEngineering

Owner:AFTEX ENTERPRISES

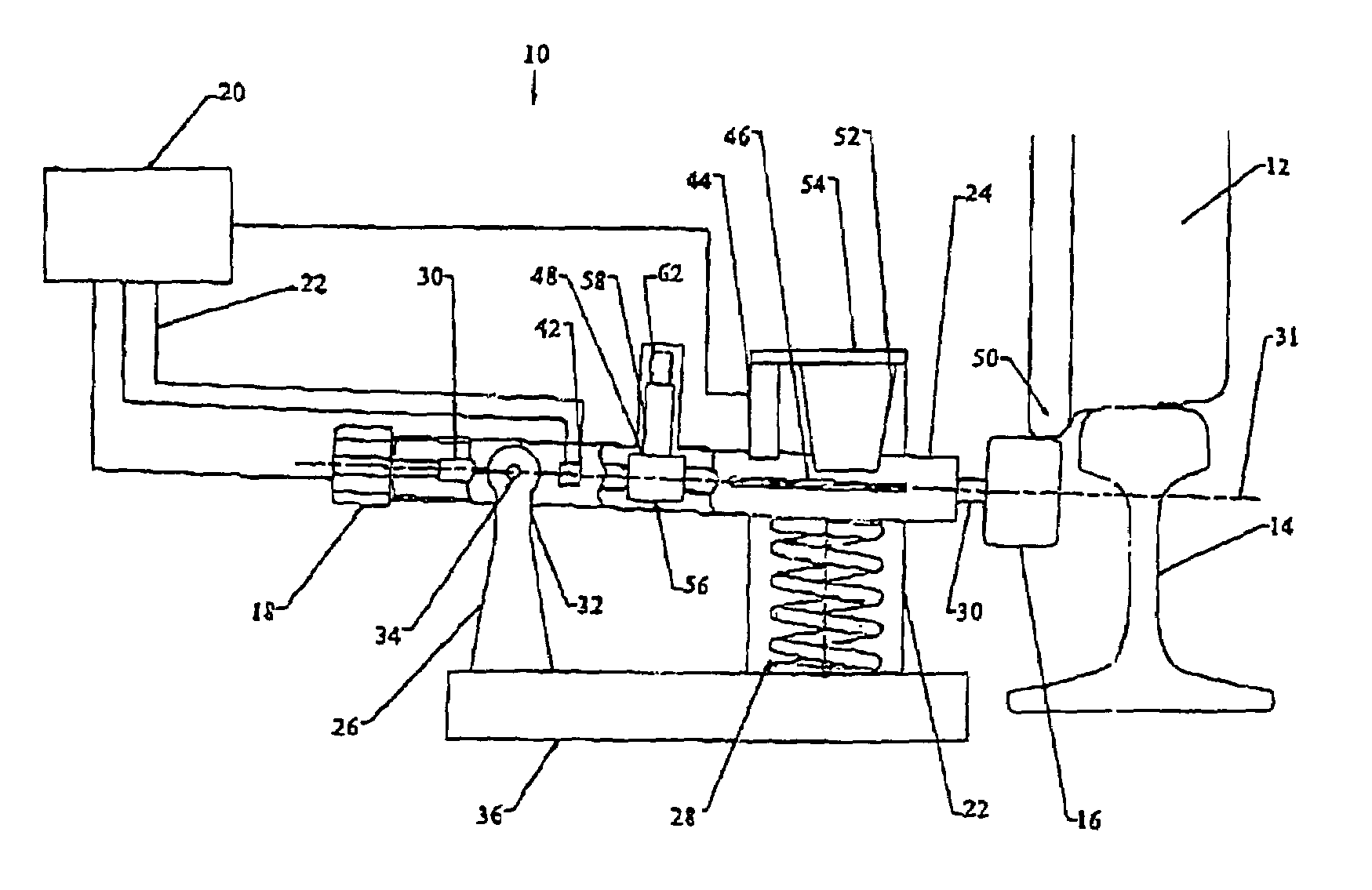

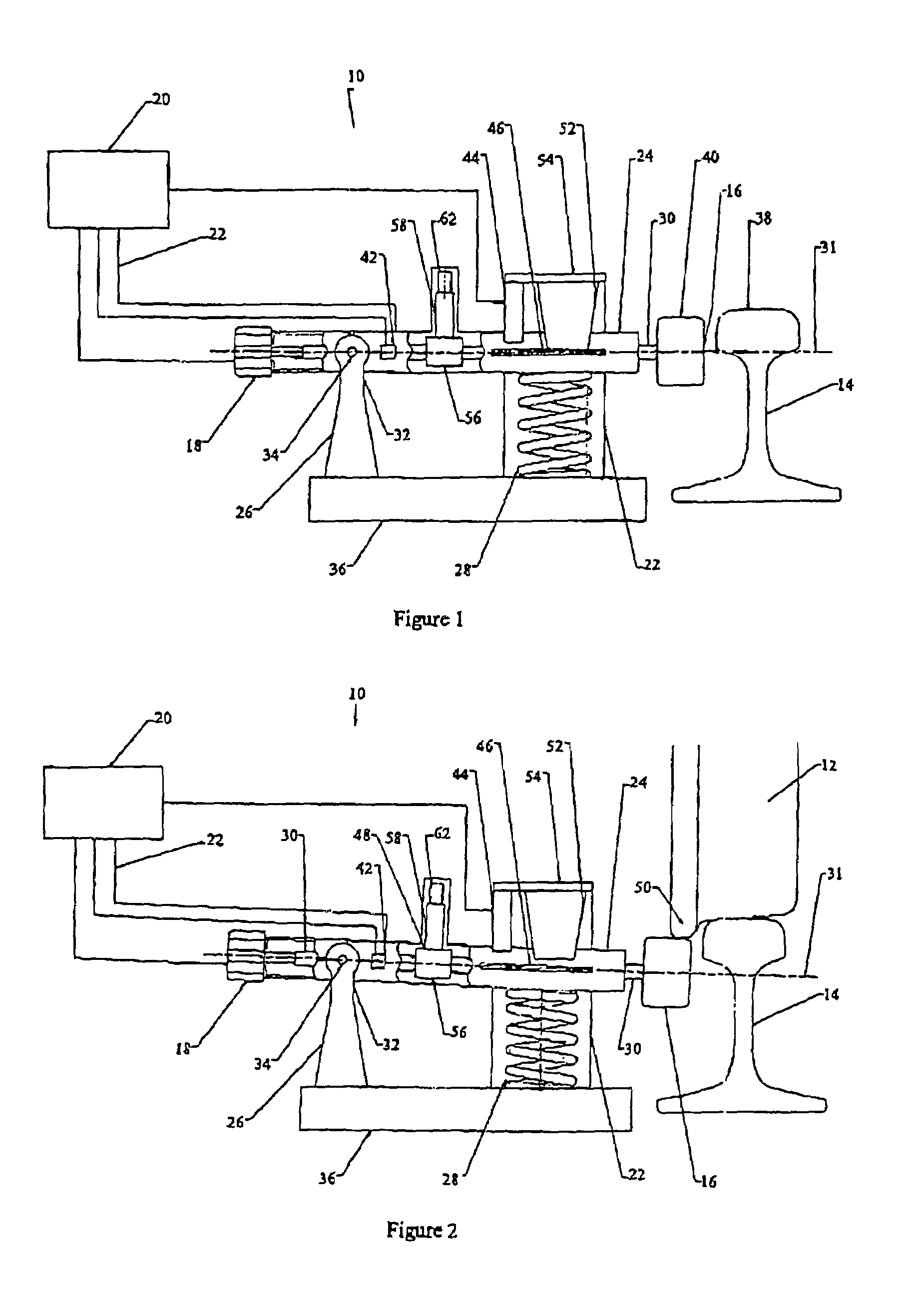

System for detecting sliding of a wheel travelling along a track

ActiveUS7043971B2Prevent slippingPrevent free rotationTelevision system detailsAnalogue computers for trafficEngineeringMechanical engineering

A system 10 for detecting sliding of a wheel 12 on a rail 14 includes a roller 16 disposed adjacent the rail 14 so that a wheel 12 travelling along the rail 14 can engage the roller 16, and a tachometer 18 coupled with the roller 16 for providing a rotation signal representative of the degree of rotation of the roller. The system 10 includes a computer 20 which receives the rotation signal from the tachometer 18 and by using an appropriate rotation algorithm calculates the degree of rotation of the roller 16. The computer 20 then compares the degree of rotation with a predetermined range of roller rotations and, if the calculated degree of rotation of the roller is less than predicted by analysis, the apparatus 10 provides a signal indicative of the wheel 12 sliding.

Owner:SIEMENS MOBILITY PTY LTD

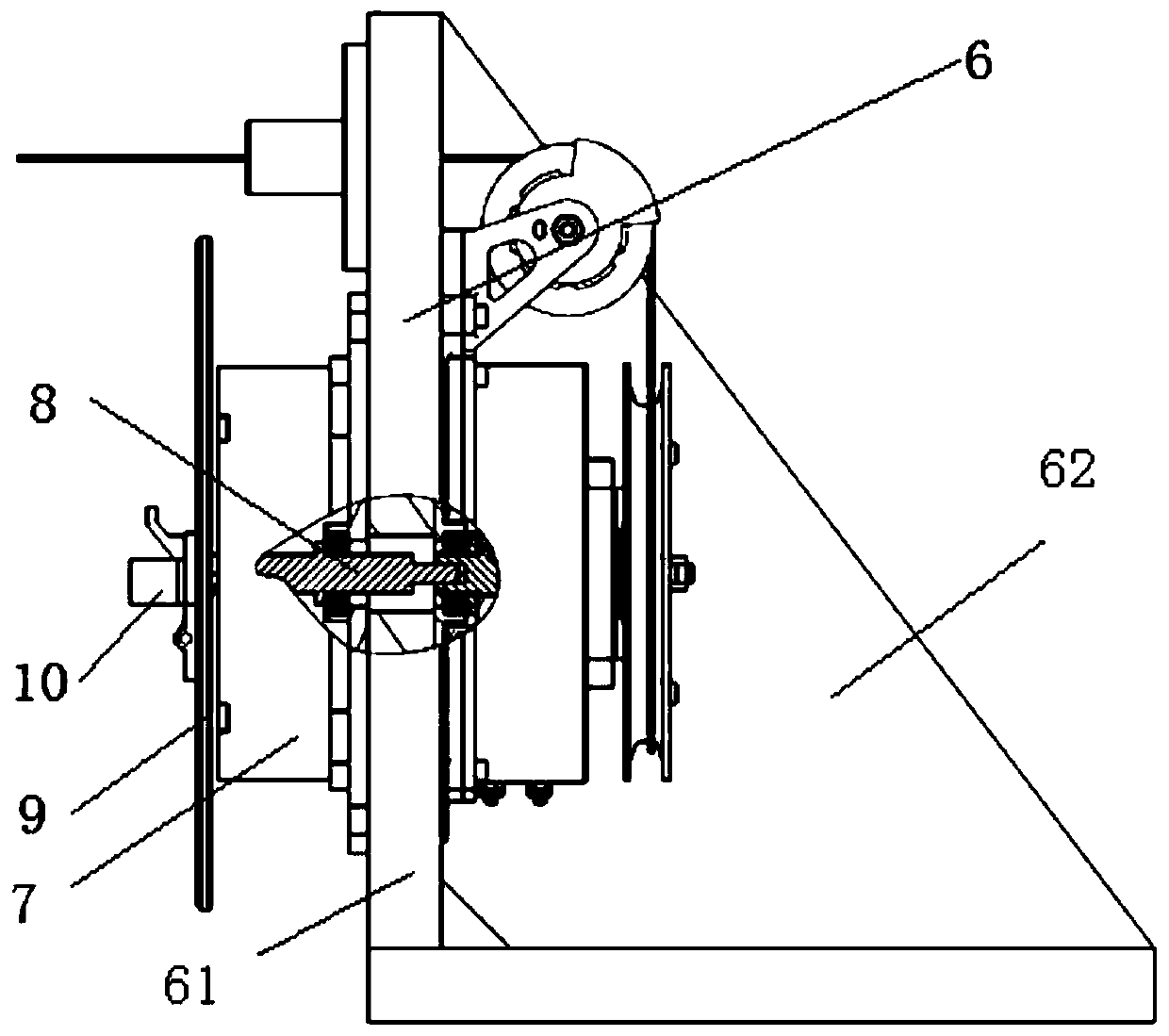

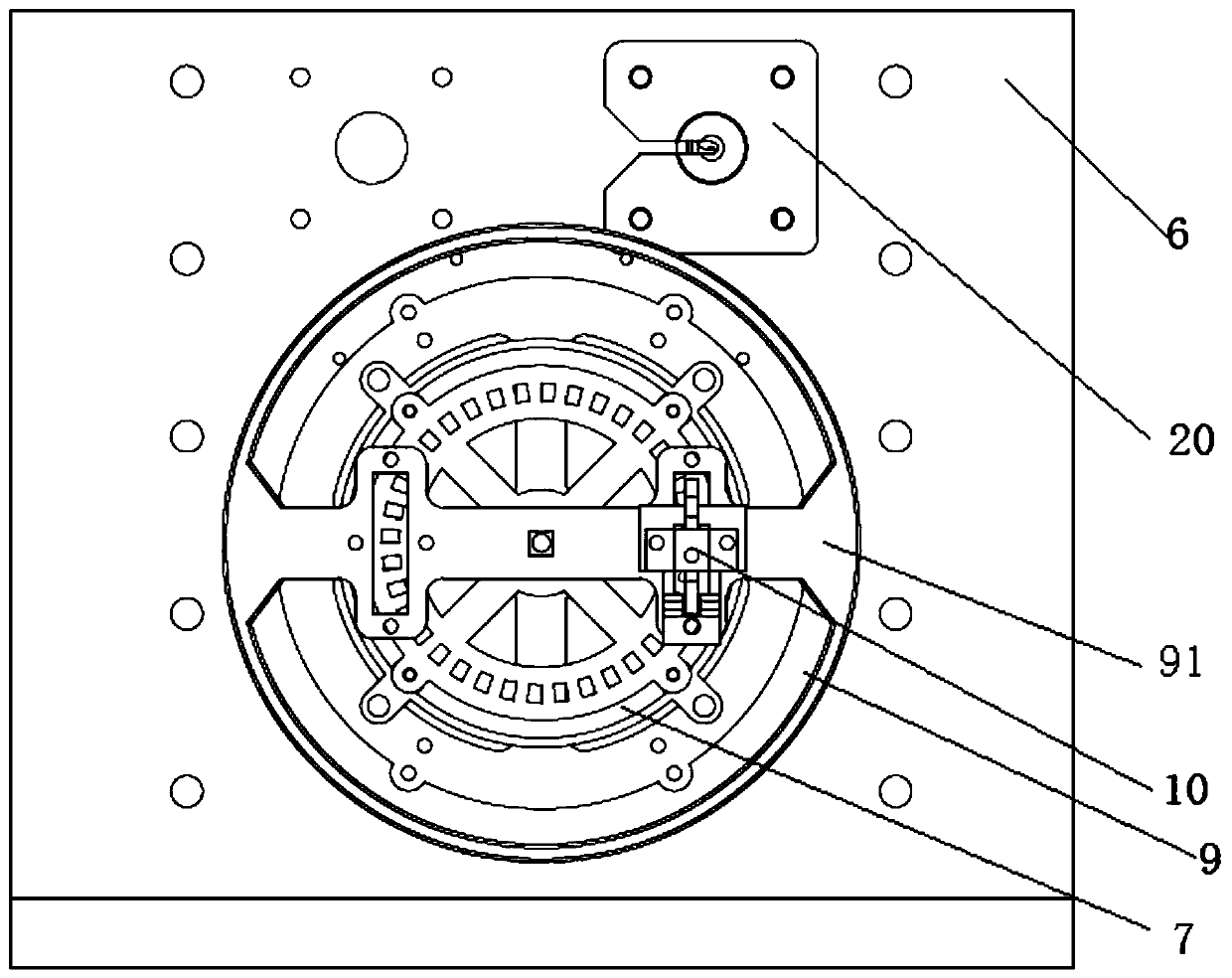

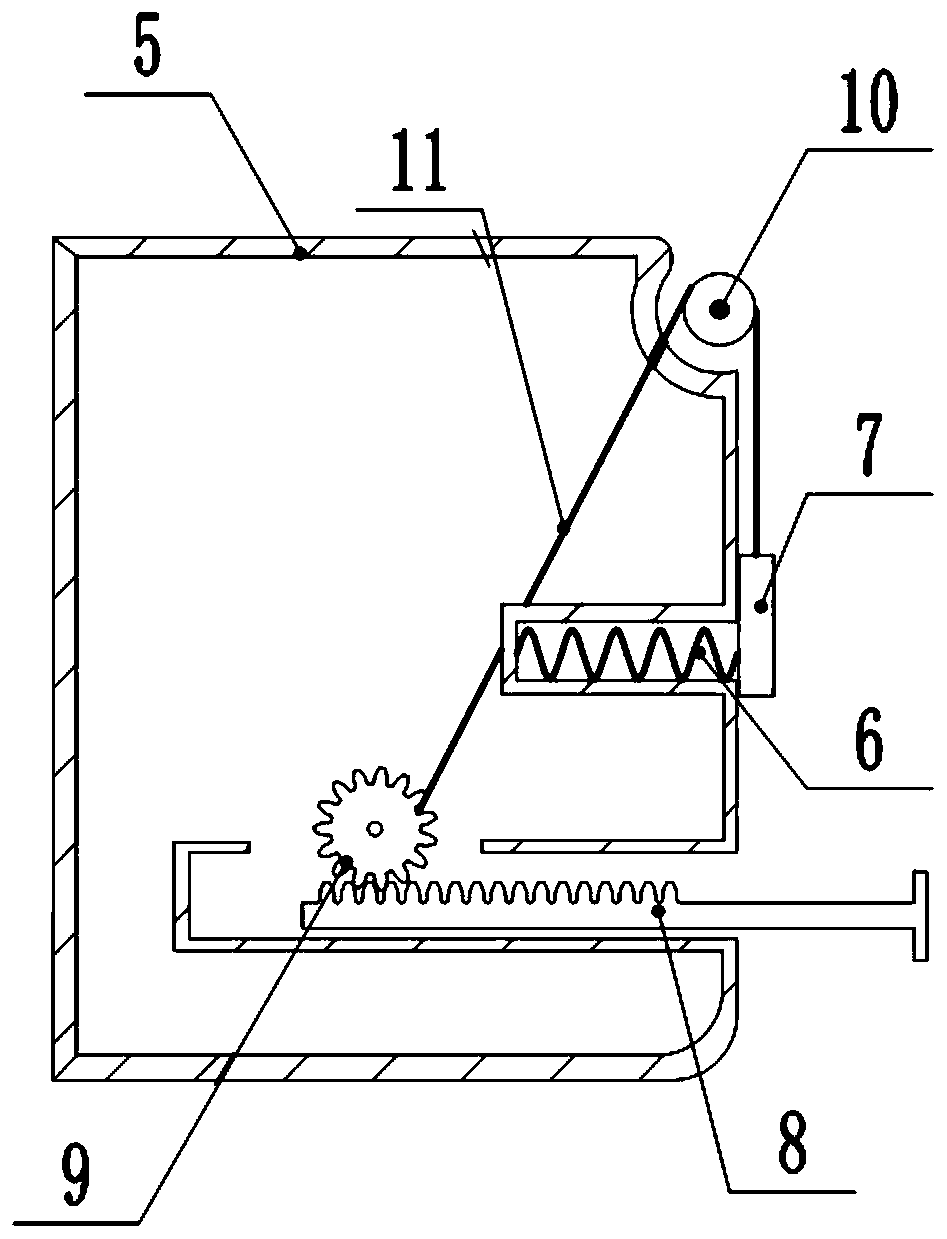

Pre-tightening force adjusting device and method of tension guiding mechanism

ActiveCN110119166AAvoid free turningImprove assembly efficiency and accuracyCosmonautic vehiclesCosmonautic partsEngineeringVolute spring

The invention provides a pre-tightening force adjusting device and method of a tension guiding mechanism, and belongs to the technical field of aerospace assembly. The to-be-adjusted tension guiding mechanism is fixed to one side of a fixing seat of the adjusting device, and thus a rotating shaft of the tension guiding mechanism and a rotating shaft of the adjusting device are fixedly connected; arotating wheel is rotated to drive a volute spring of the tension guiding mechanism to be tightly coiled or uncoiled; when the preset position is reached, braking is conducted through a brake, and the volute spring is always in the current state to achieve pre-tightening of the plane volute spring; torque is measured through a torque wrench, and by combining with the positions of clamping grooveswhich are evenly distributed in the circumference, the working position of the plane volute spring when a solar battery array is expanded can be accurately found; and the pre-twisting angle of the plane volute spring is precisely set to be + / - 5 degrees, the output torque is precisely controlled to be + / - 0.04 Nm, and the adjusting efficiency and accuracy of the tension guiding mechanism are improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

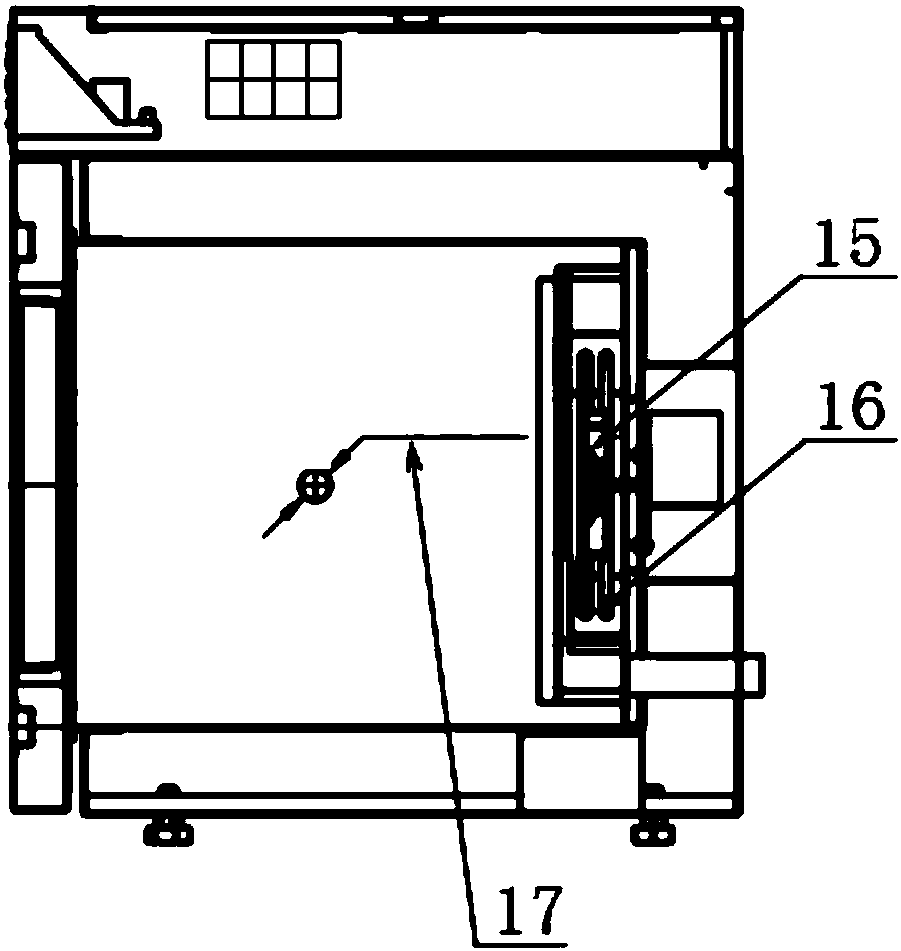

Preparation process of molybdenum oxide composite pressed balls and drying device of molybdenum oxide composite pressed balls

ActiveCN114440578AEasy to placeThe placement of the molybdenum oxide composite pressure ball is convenientDrying gas arrangementsDrying chambers/containersDry boxMolybdenum oxide

The invention relates to the technical field of blowing-type drying boxes, in particular to a molybdenum oxide composite press ball preparation process and a drying device thereof.The drying device comprises a blowing-type drying box main body, a placing structure is connected to the blowing-type drying box main body, and a limiting structure is connected to the placing structure; the blowing-type drying box main body is connected with a bearing structure, the bearing structure is connected with a splitting structure, the blowing-type drying box main body is connected with a protection structure, and the protection structure is connected with an observation structure; molybdenum oxide composite pressing balls can be conveniently placed through the placing structure, under the assistance of the limiting structure, the distances of different specifications can be conveniently adjusted, the placing structure can be conveniently and stably moved into the blowing-type drying box body through the bearing structure, the bearing structure can be disassembled through the disassembling structure when the bearing structure is not needed, and the structure is convenient to disassemble. The protection structure plays a closed protection role, and the interior of the blowing-type drying box body can be conveniently observed through the observation structure.

Owner:莱芜钢铁集团泰东实业有限公司

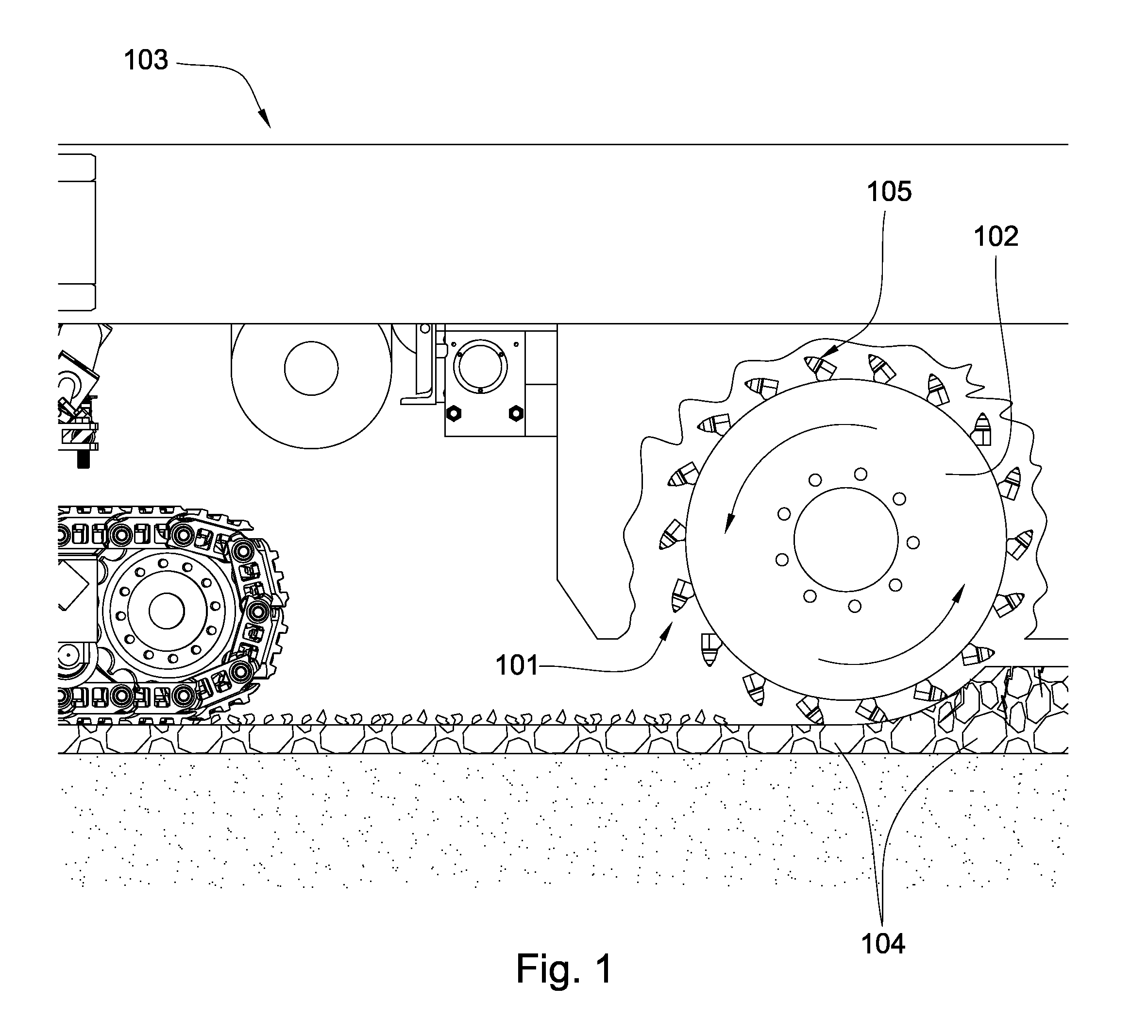

Tool attachment for cutting heavy duty substrate

PendingUS20220063006A1Prevent free rotationReduce chanceShearing machinesPortable power-driven toolsFree rotationStructural engineering

A cutting tool attachment for a power tool is freely rotatable about an end of the power tool. A fence provides a complementary flat surface area for the cutting tool attachment to rest against a surface of the material to be cut. The fence prevents free rotation of the cutting tool ttachment while in use. A handle allows a user to guide the attachment along the surface of the material, while also providing leverage to keep the attachment against the material surface close to the attachment, but at a safe position to reduce the chance of injury. A user can rotate the power tool relative to the cutting attachment to achieve a comfortable position or to help turn the attachment and power tool. The power tool is therefore positionable along a 360 arc of movement relative to the attachment while the attachment is positioned along the surface of a material.

Owner:GEN TOOLS & INSTR

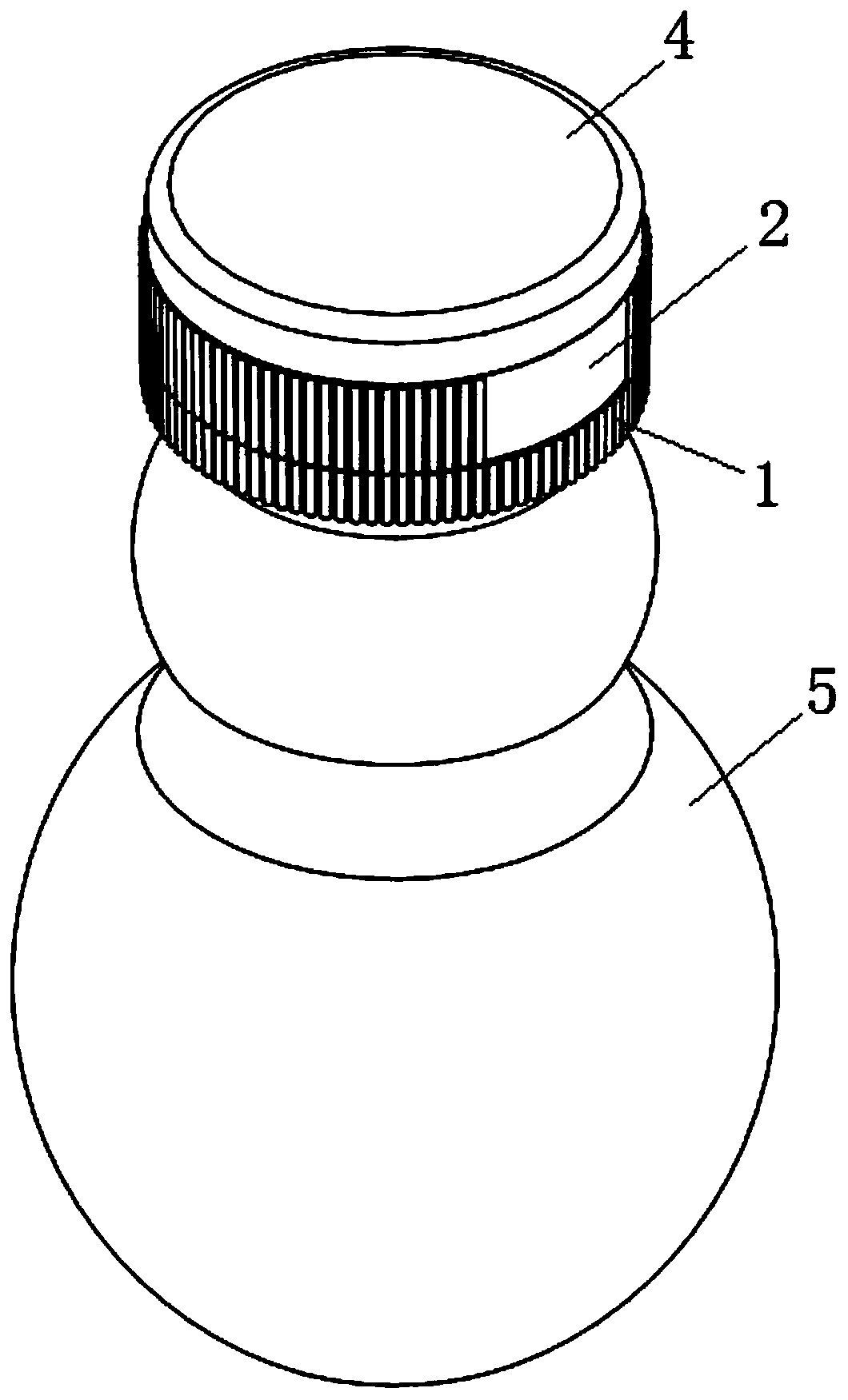

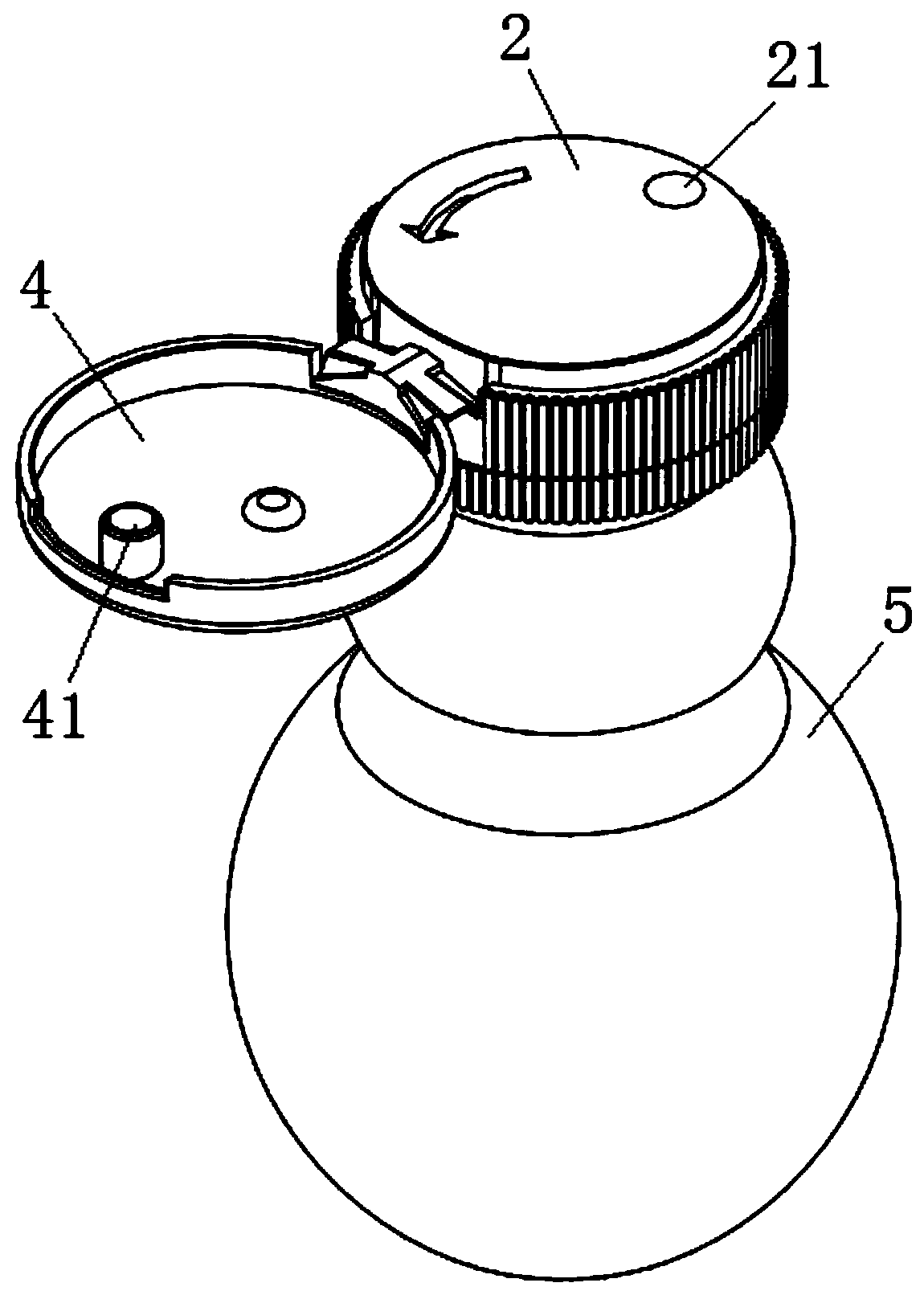

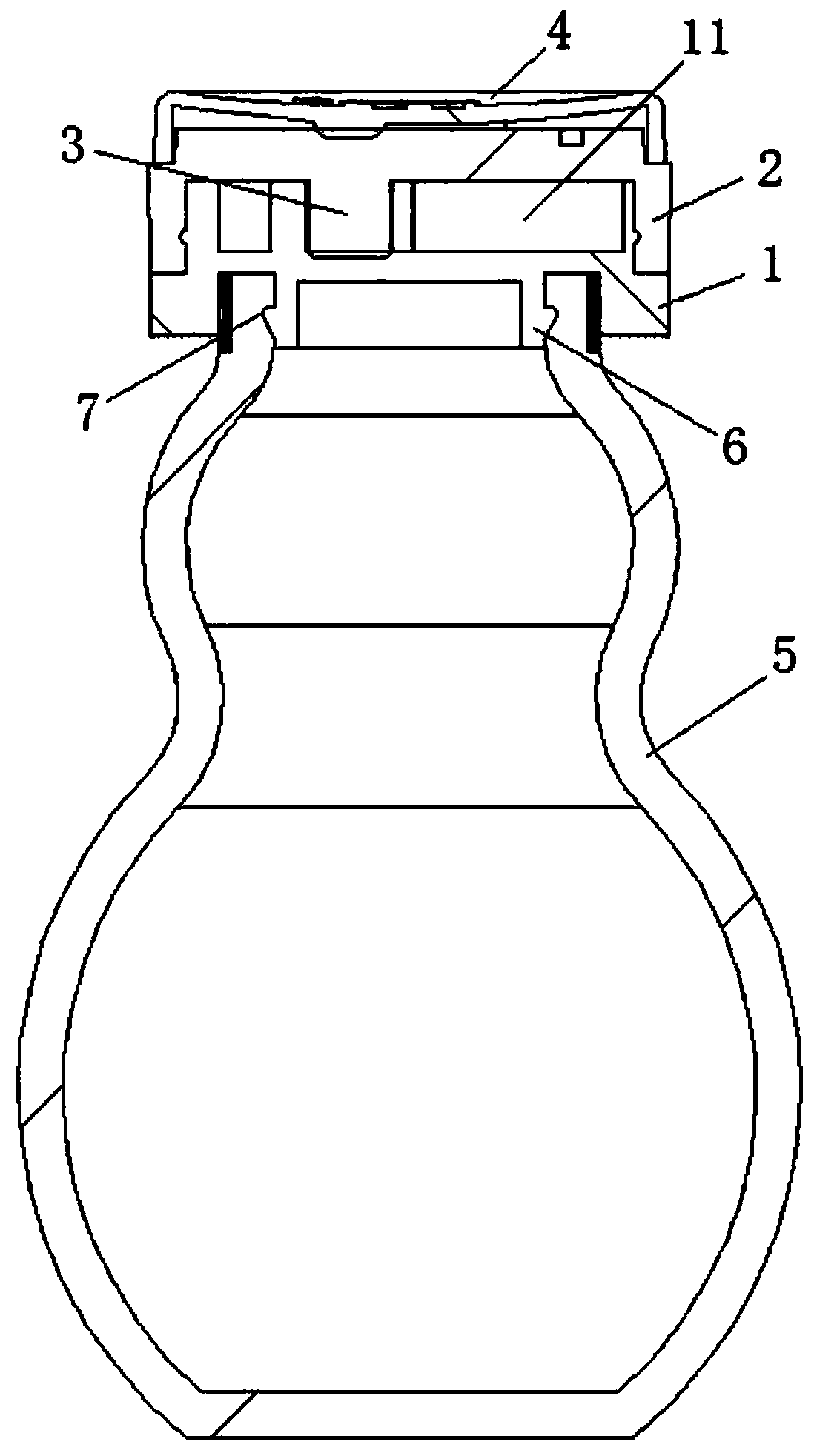

Bottle cap and medicine bottle with bottle cap

The invention provides a bottle cap and a medicine bottle with the bottle cap, and belongs to the technical field of containers for material storage. The bottle cap comprises a lower layer cover, a middle layer cover and a plugging structure, wherein the bottom part of the lower layer cover is suitable to be connected with a bottleneck; a temporary holding groove for holding the preset number of medicines is formed in the upper surface; a first medicine outlet hole communicating with the inner part of a bottle body is formed in the bottom of the temporary holding groove; and the medicines in the bottle body can enter the temporary holding groove through the first medicine outlet. According to the bottle cap provided by the invention, the number of the medicines stored in the bottle cap canbe decided according to the size of the temporary holding groove; when the medicines in the temporary holding groove are taken out, the first medicine outlet hole is sealed, so that the medicines inthe medicine bottle is prevented from contacting the outside; and all medicines in the temporary holding groove can be entirely taken out through a second medicine outlet hole, and during the process,the medicines in the temporary holding groove cannot slide along the middle layer cover, so that the medicines are prevented from being damaged.

Owner:JIANGSU HUA LAN PHARMA NEW MATERIALS LTD BY SHARE LTD

Residential access control anti-collision barrier

ActiveCN109112992BAvoid scratching and bendingPrevent crashTraffic restrictionsStructural engineeringPrinting ink

The invention relates to the technical field of gateways, in particular to a residential entrance guard anti-collision gate, comprising a gateway positioning seat and a lifting rail. The lifting railcomprises a driving rod, a limiting rod and a rubbing plate. The inner end of the driving rod is rotatably connected with the gate positioning seat; the mass of the outer end of the limiting rod is larger than the mass of the inner end, the inner end of the limiting rod is hinged with the outer end of the driving rod, and the limiting rod can be hinged as the axis and rotate in the horizontal direction; the rubbing plate is disposed under the limiting rod, and the rubbing plate and the limiting rod are fixedly connected by the connecting rod, and the surface of the rubbing plate is coated withthe printing ink. The technical proposal of the invention can solve the problems that the driver inadvertently collides with the lifting railing and causes the lifting railing to be scratched, bent and damaged, and meanwhile ensures the normal passage of the vehicles in the district when the lifting railing cannot be lifted and lowered normally.

Owner:云侠科技(苏州)有限公司

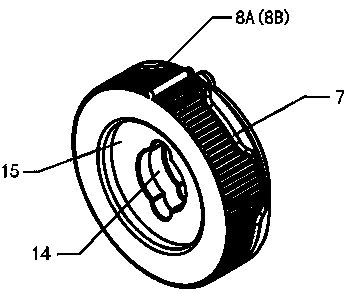

Knob-type yarn tension regulator

The present invention discloses a knob-type yarn tension regulator, comprising: a stand, a tension regulating knob, a cam group, a piercing rod, a tension rod, tensioning rings, a yarn inlet and a yarn outlet; the knob-type yarn tension regulator regulates the tension of a single yarn, the yarn firstly enters the knob-type yarn tension regulator from a magnetic hole at the middle of a tension plate of the yarn inlet, then passes through the first group of tensioning rings and the second group of tensioning rings, finally gets out from a magnetic hole of the yarn outlet; the cam group is drivento rotate by turning the tension regulating knob, thus realizing selection of different tensioning rings and achieving the goal of applying different specific tensions to yarns.

Owner:TIANHAI LACE CO LTD

Counter

InactiveUS9114221B2Reduce in quantityPrevent rotationRespiratorsCounting mechanisms/objectsEngineeringMechanical engineering

A counter containing: a first ring member having first indicia and a second ring member having second indicia, each of the first and second ring members being rotatable in increments about a common axis, one or both of the first and second indicia indicating a count; a drive mechanism for rotating the first ring member; and a coupling mechanism for releasably coupling the first ring member to the second ring member, to allow the first and second ring members to rotate cooperatively when coupled and to allow independent rotating of the first ring member when not coupled; wherein the coupling mechanism contains first and second engagement structures, the first engagement structures being movable radially outwardly and radially inwardly relative to the axis.

Owner:EURO-CELTIQUE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com